Die-cutter

A die-cutting machine and frame technology, applied in metal processing, etc., can solve the problems of excessive waste, unfavorable production and processing, and increased production costs, so as to reduce labor intensity, improve precision and quality, and increase feeding speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

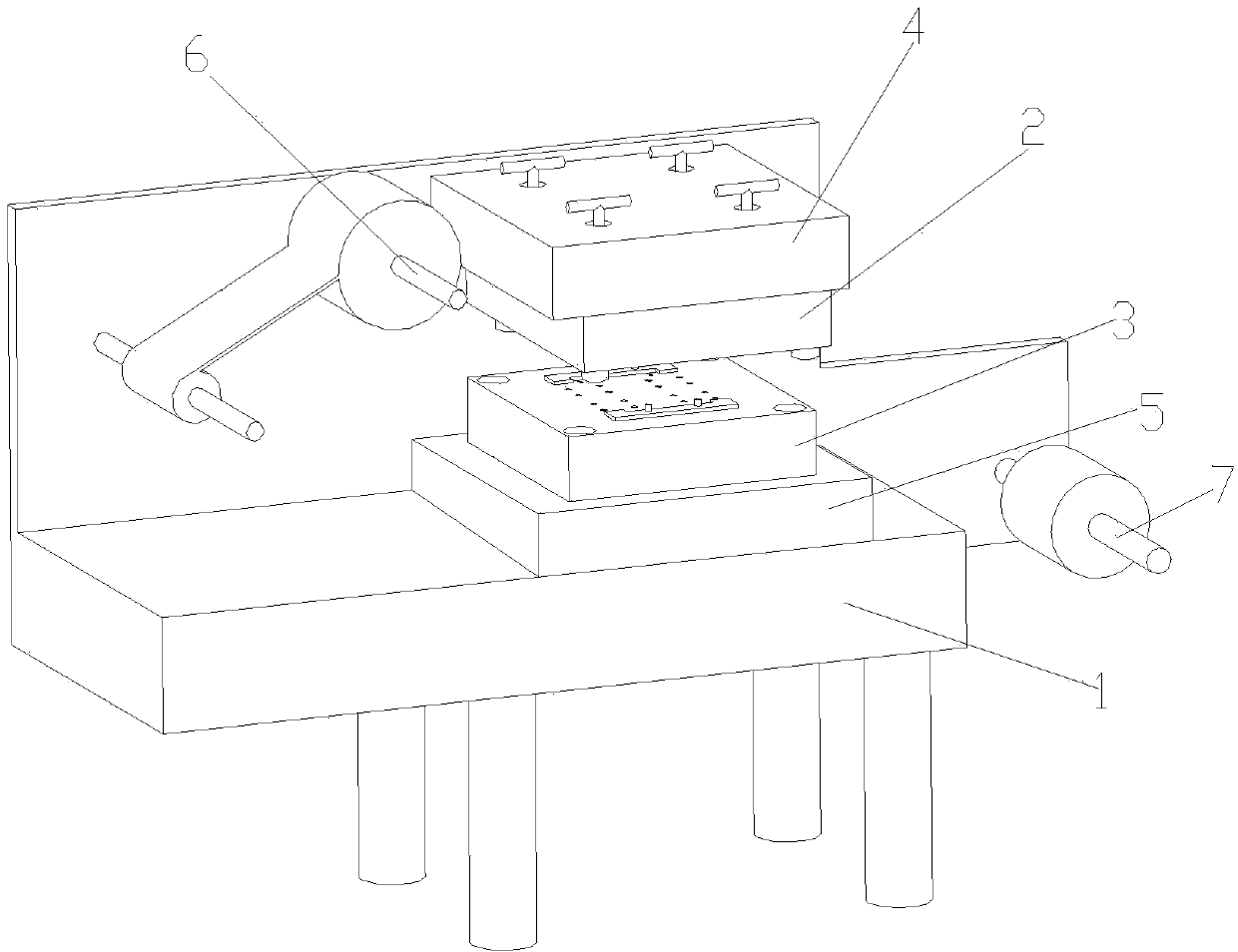

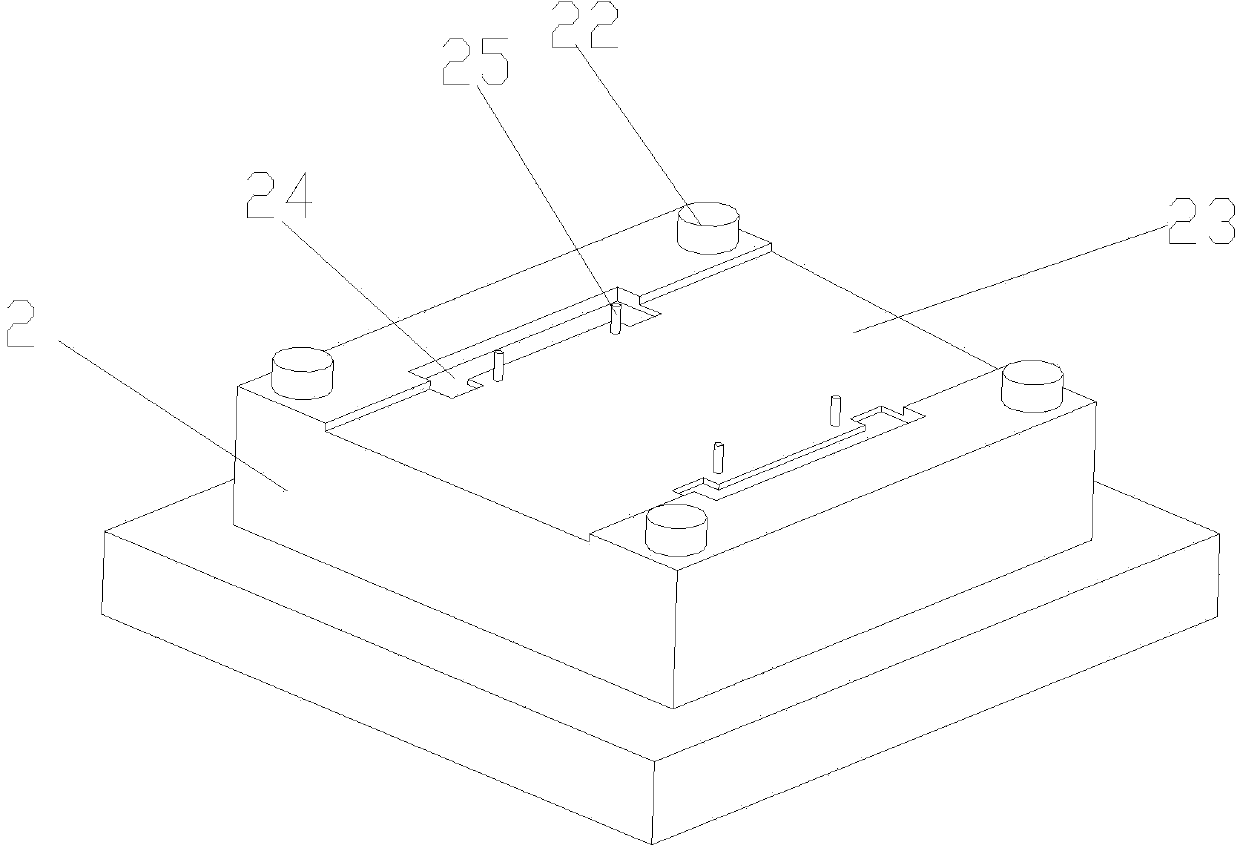

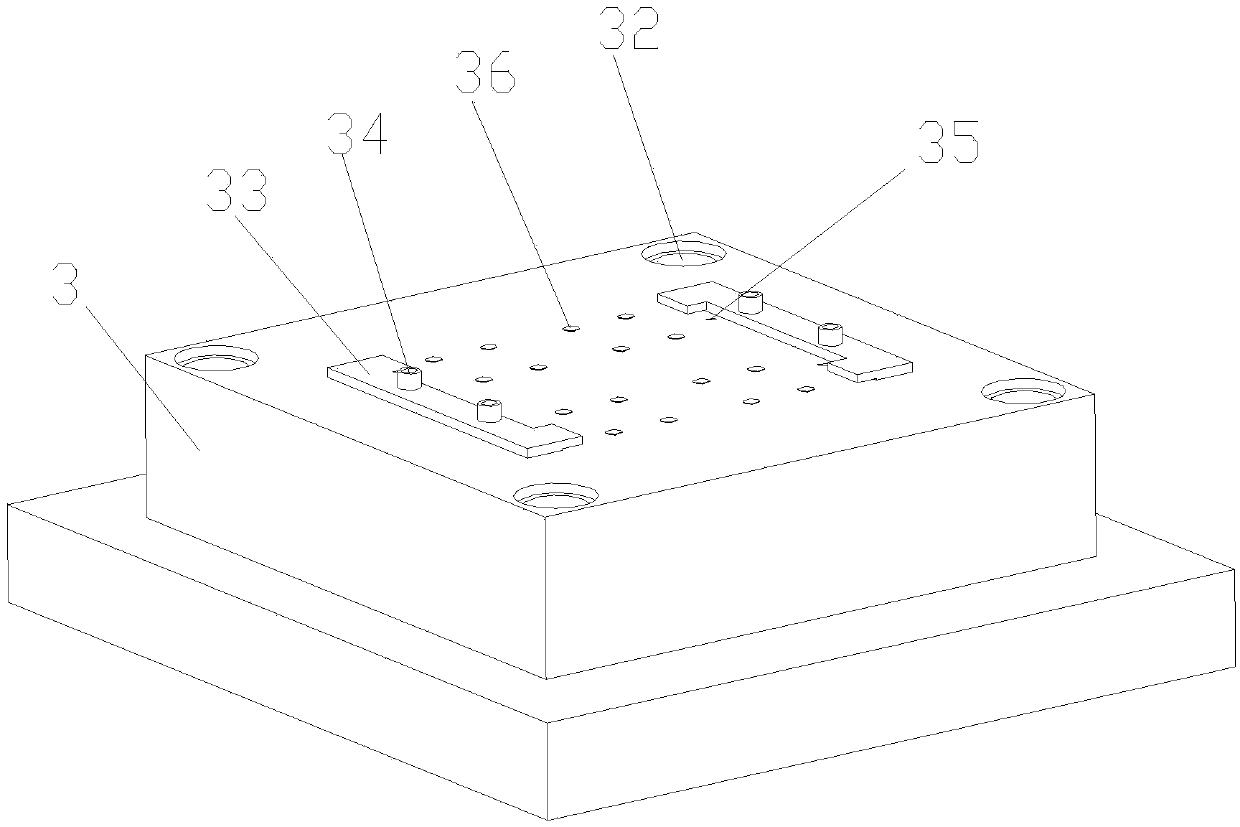

[0014] attached Figure 1-3 Be a kind of die-cutting machine described in the present invention, comprise frame 1, mould, upper fixed plate 4, lower fixed plate 5, feeding device 6 and receiving device 7; Described upper and lower fixed plate 4,5 are installed on On the frame 1; the feeding device 6 and the receiving device 7 are respectively arranged on the front and rear sides of the frame 1; the mold includes an upper mold 2 and a lower mold 3; the upper mold 2 is fixed on the upper fixed plate 4; The lower mold 3 is fixed on the lower fixing plate 5; the four corners of the upper mold 2 are provided with positioning columns 22; the middle part of the upper mold 2 is a concave step 23; the two sides of the concave step 23 are also provided with clamping grooves 24; the upper mold 2 inside the clamp groove 24 is provided with a positioning thimble 25; the four corners of the lower mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com