Patents

Literature

1244results about How to "Increase the feeding speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

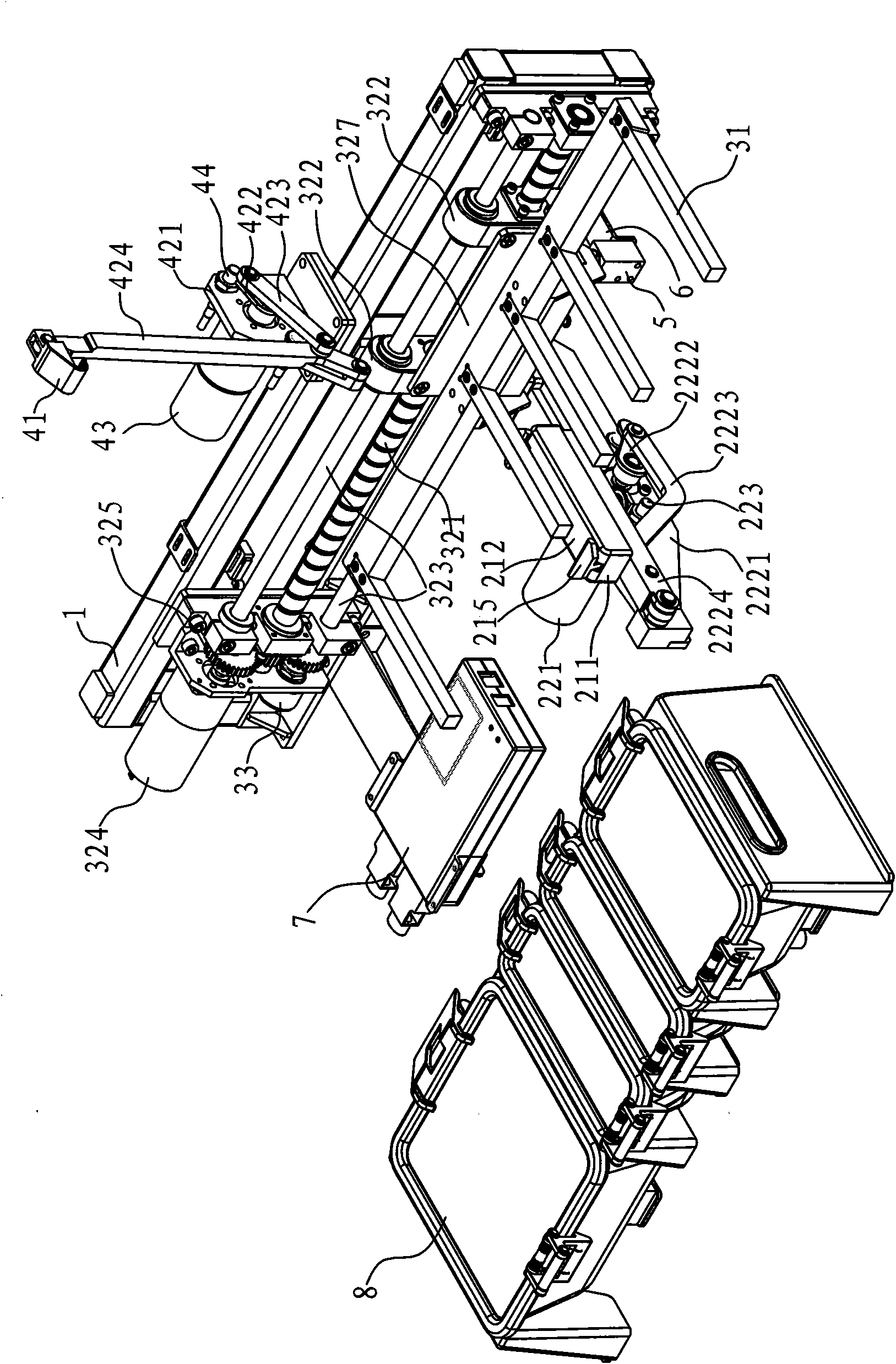

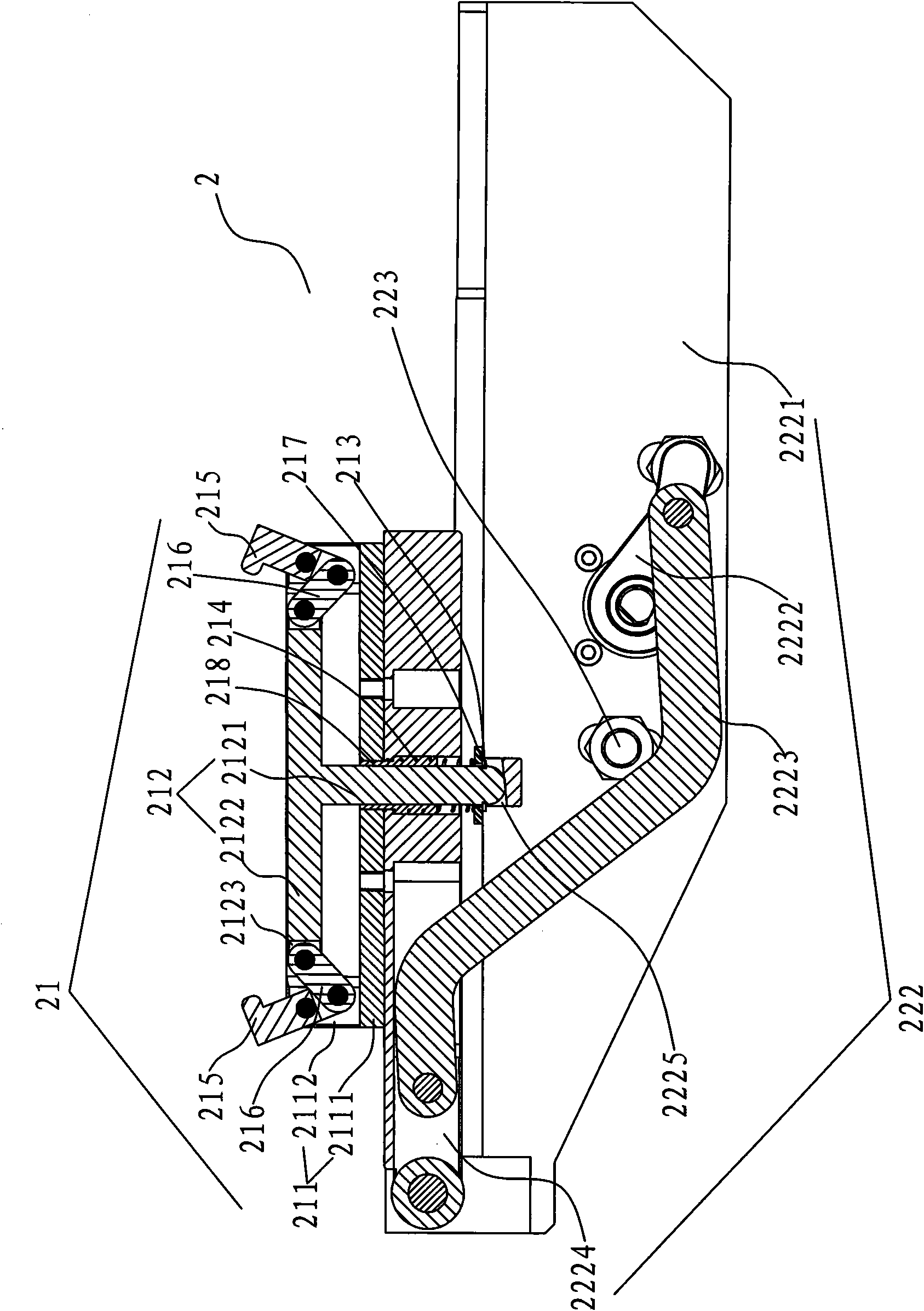

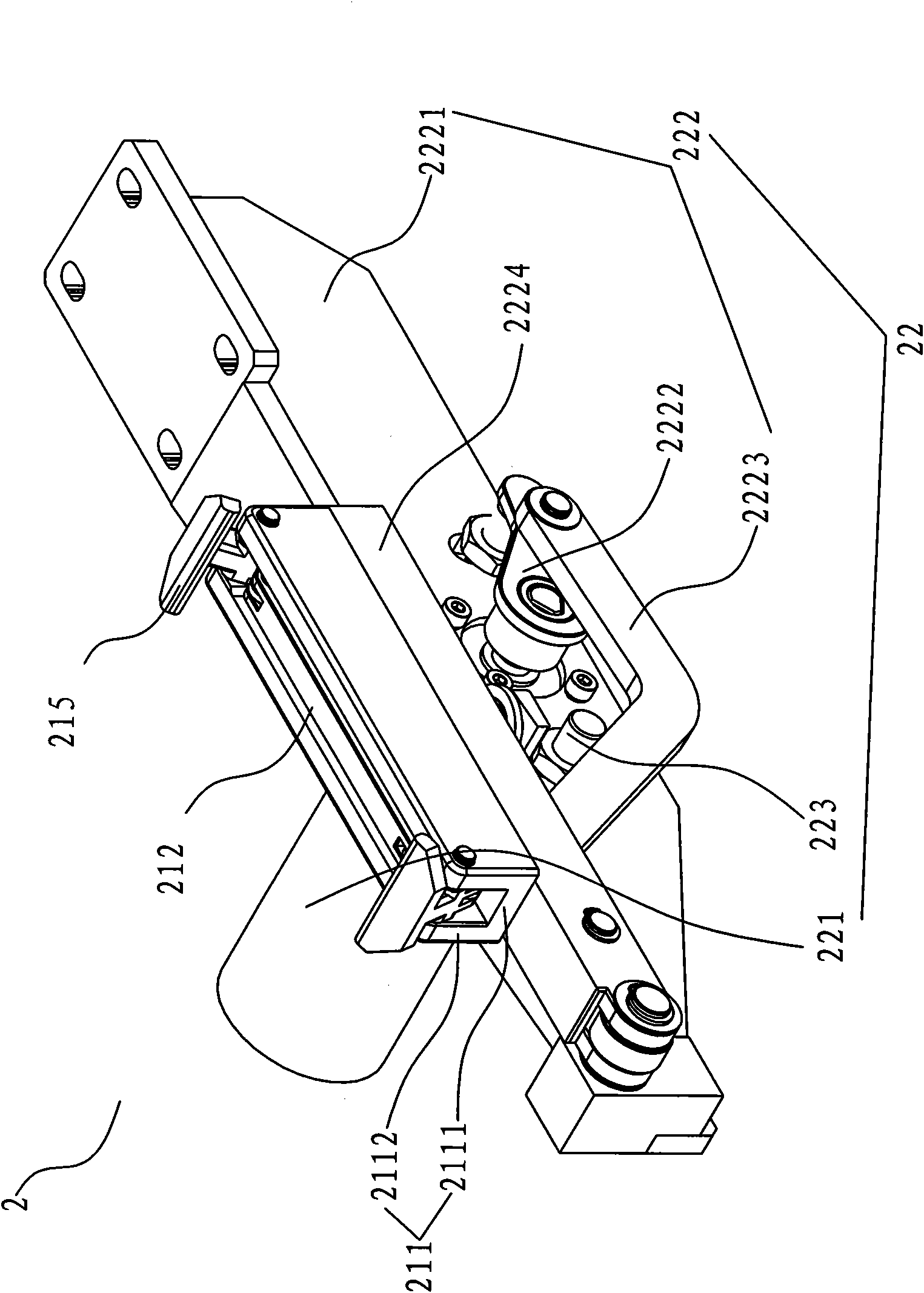

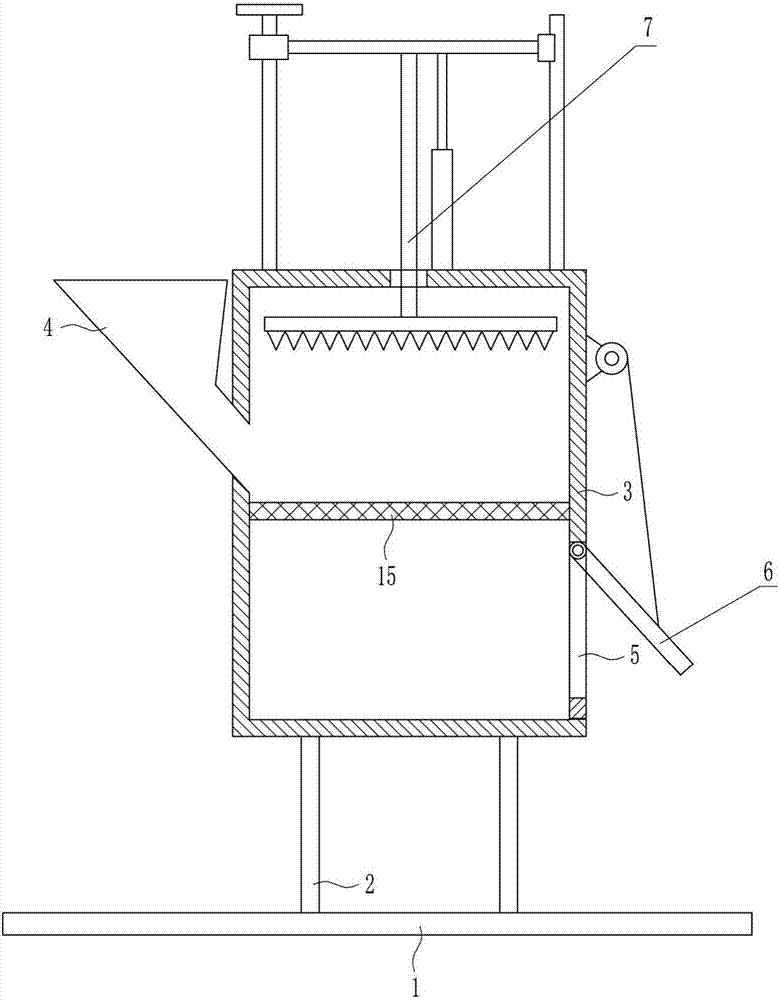

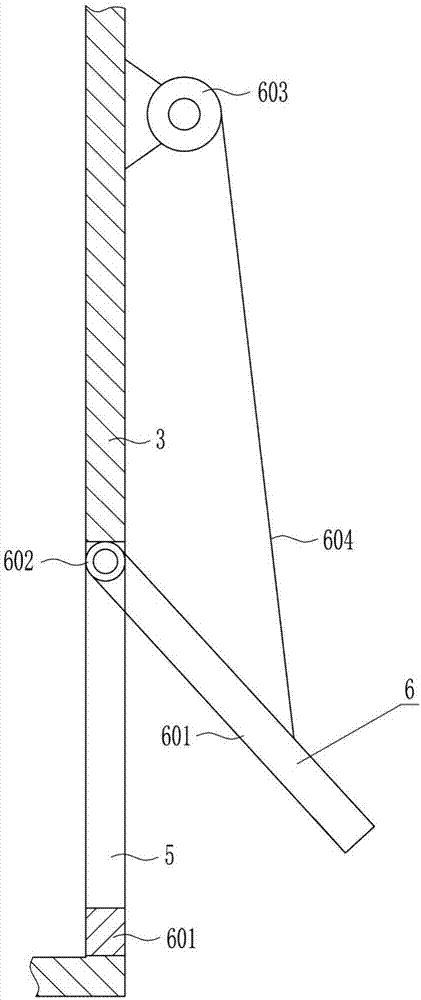

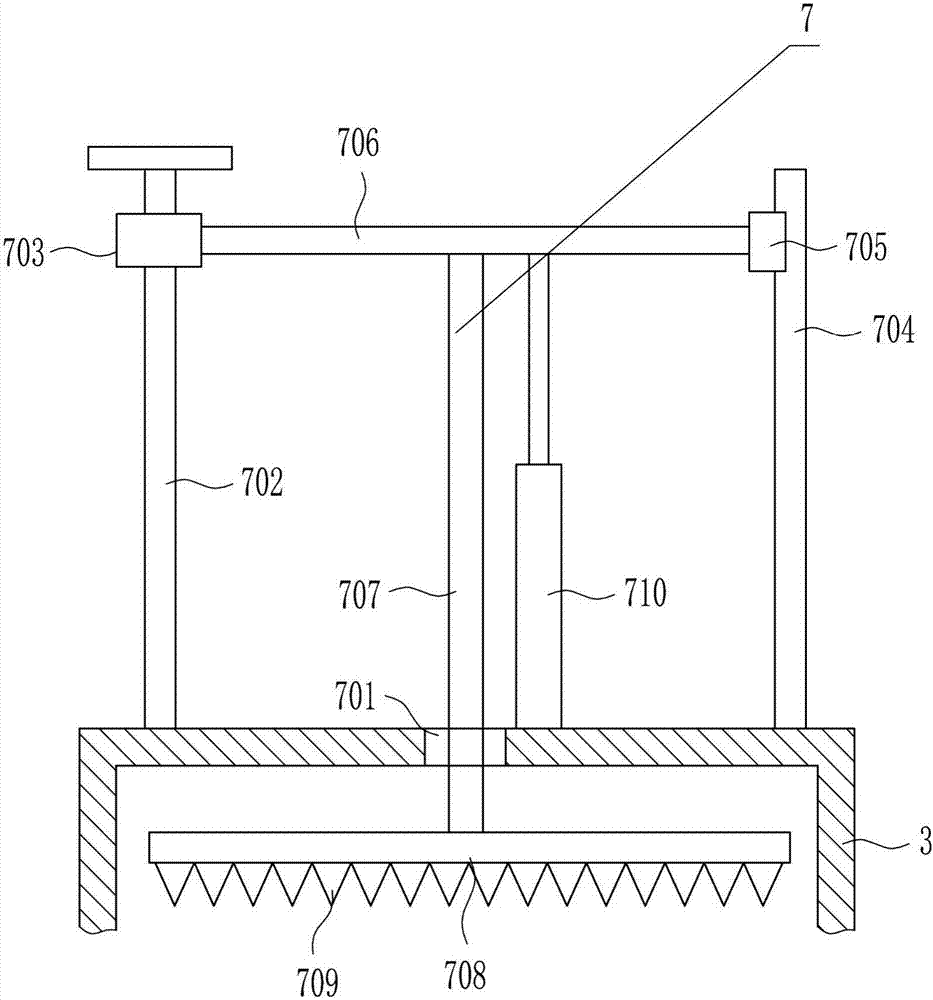

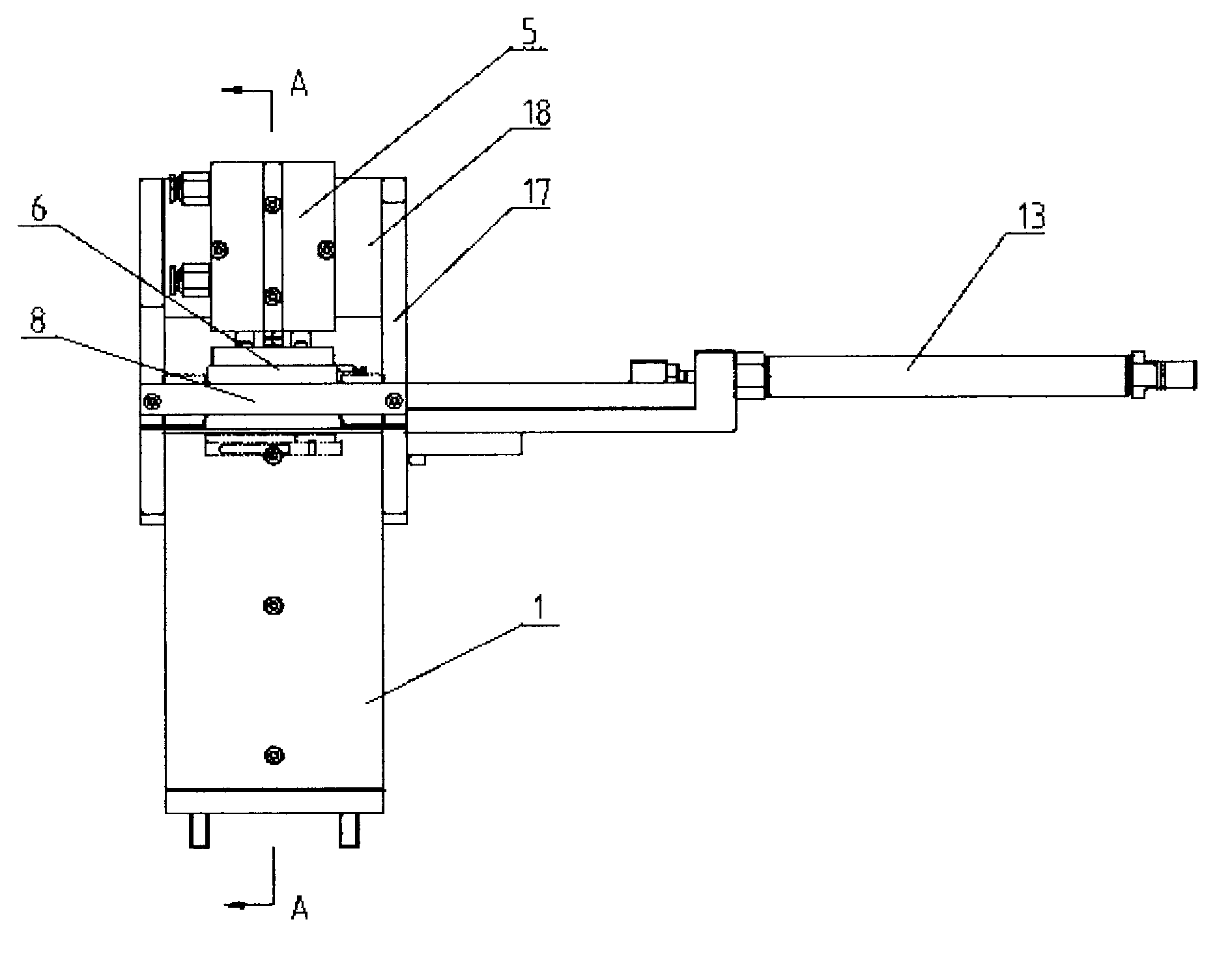

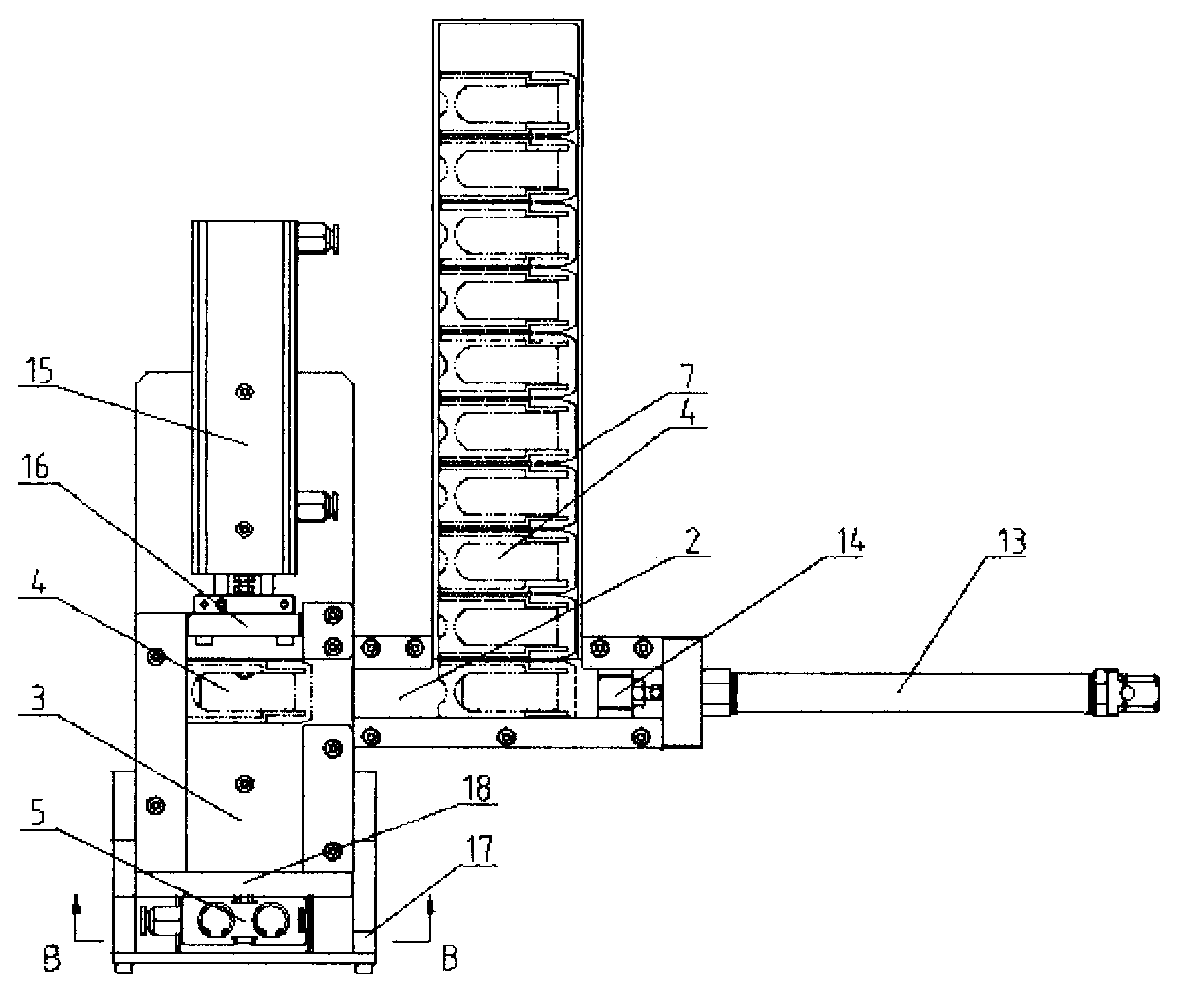

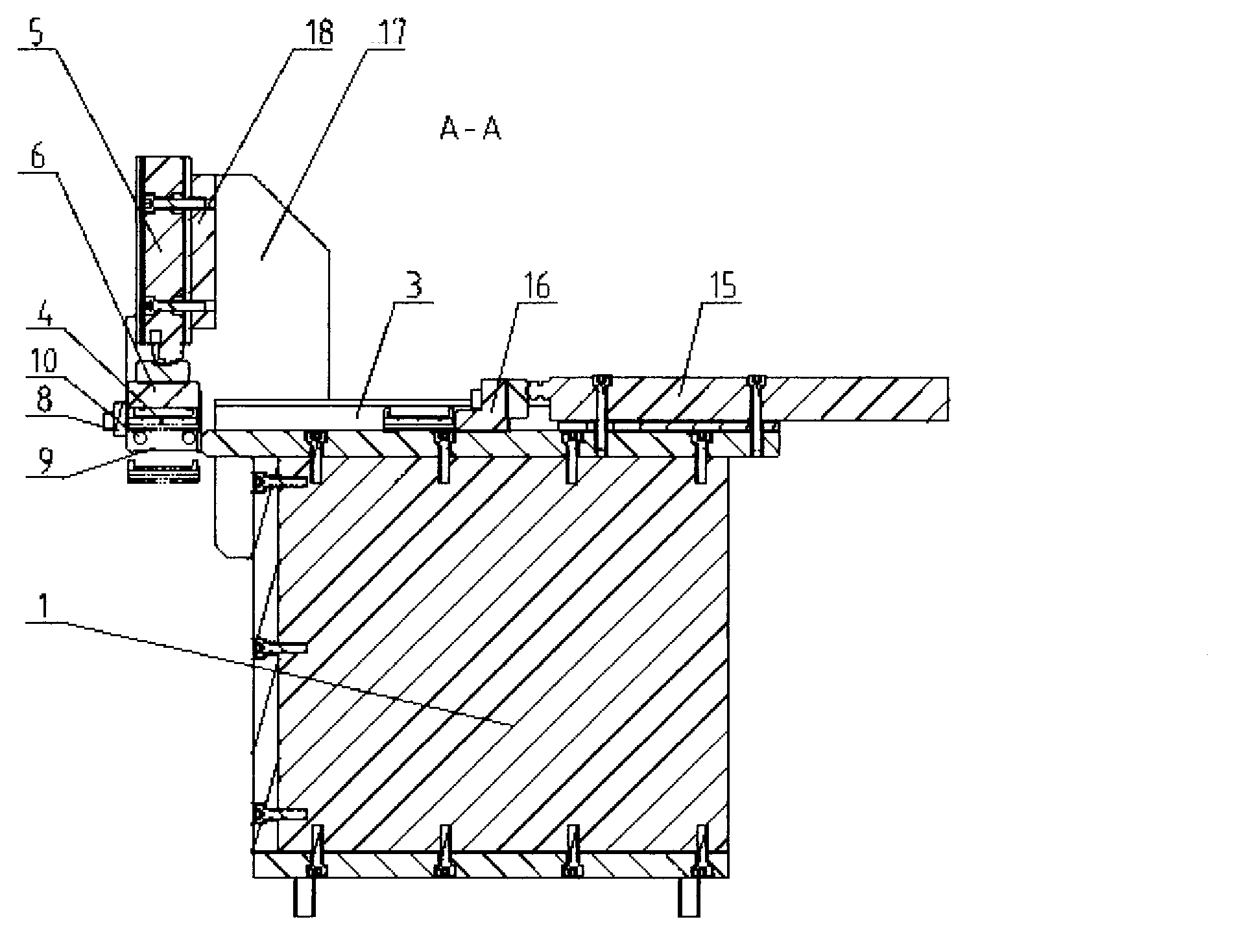

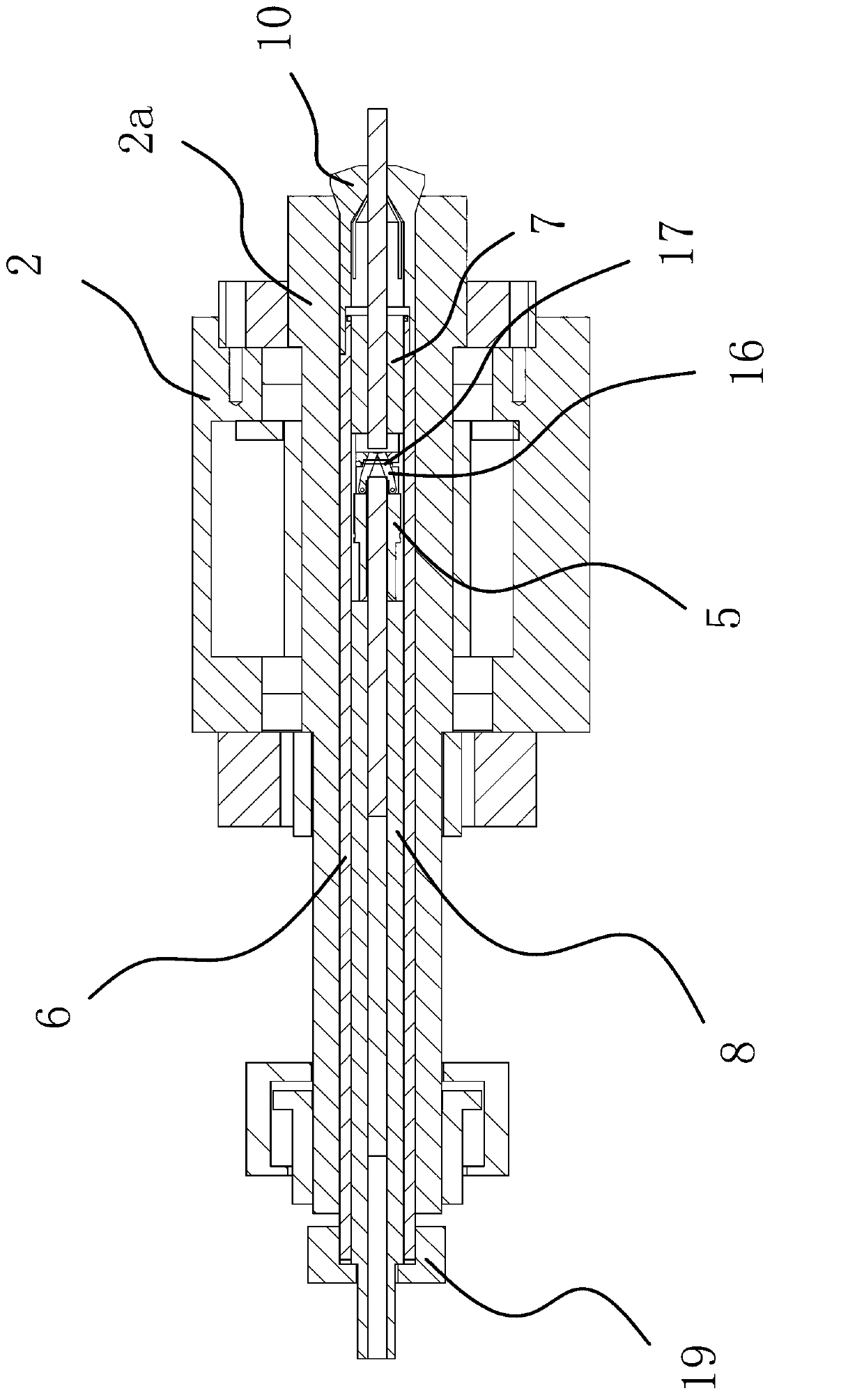

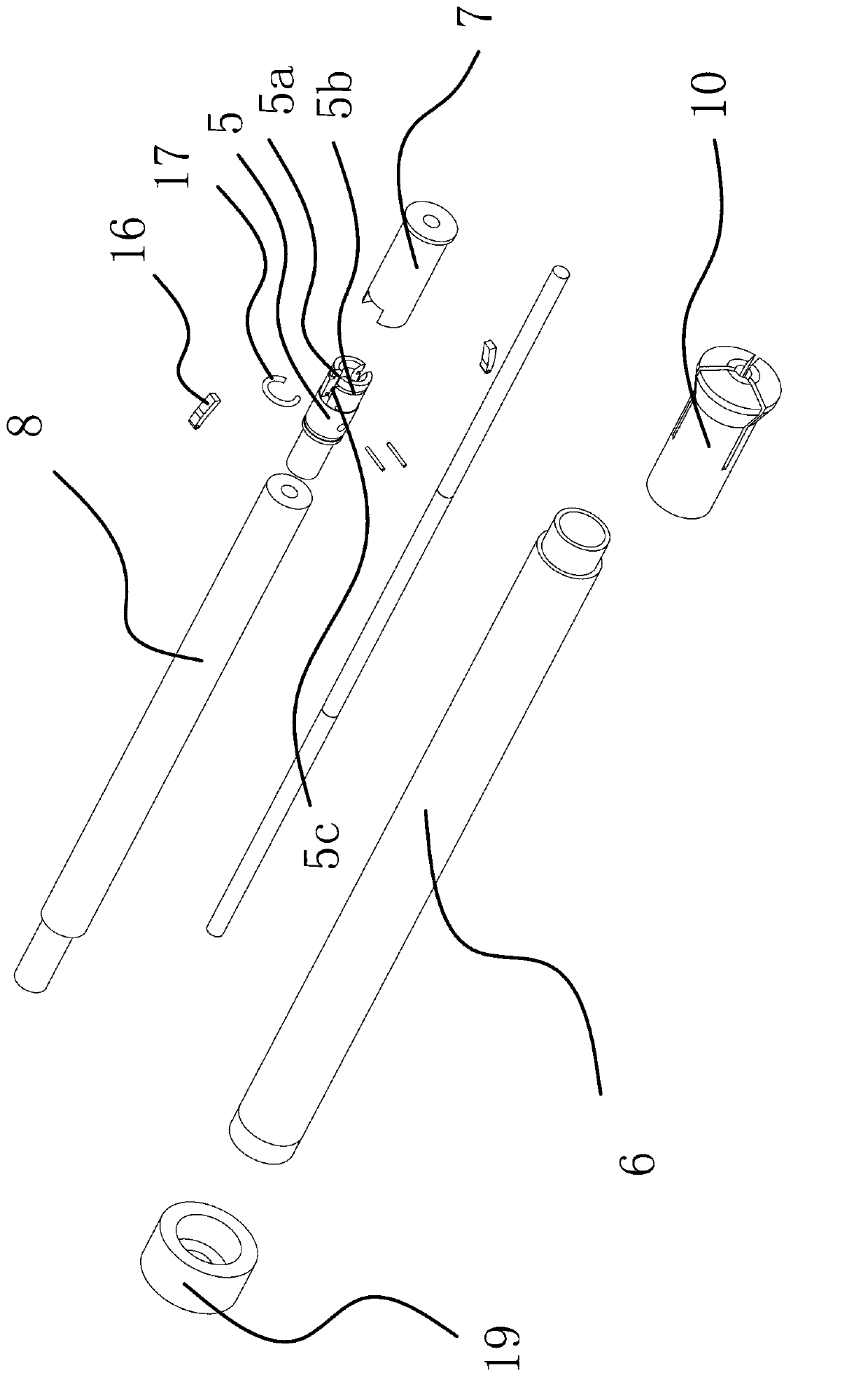

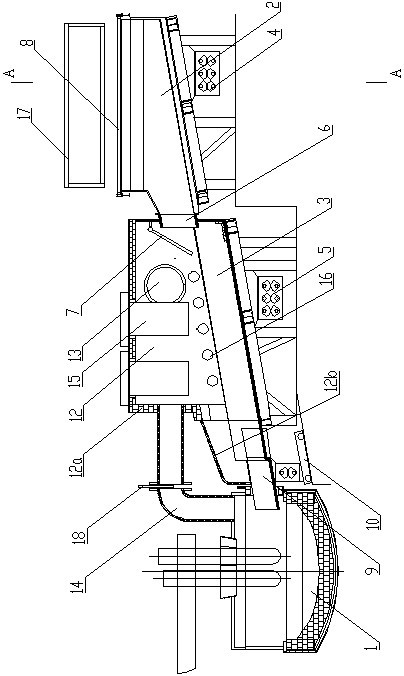

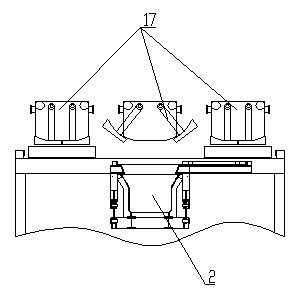

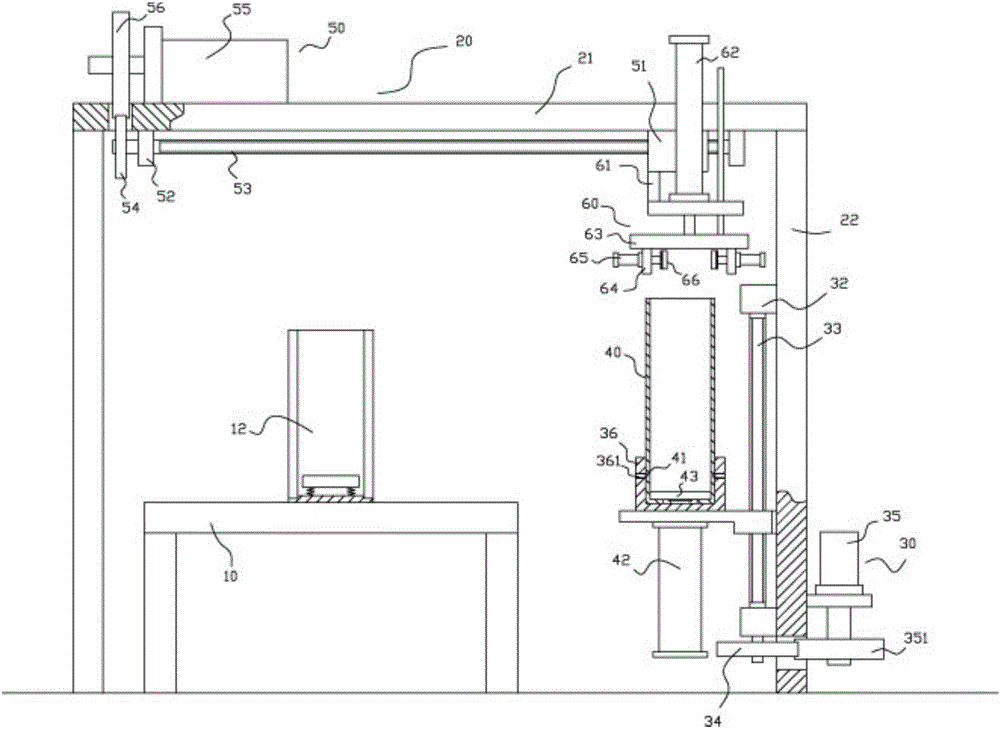

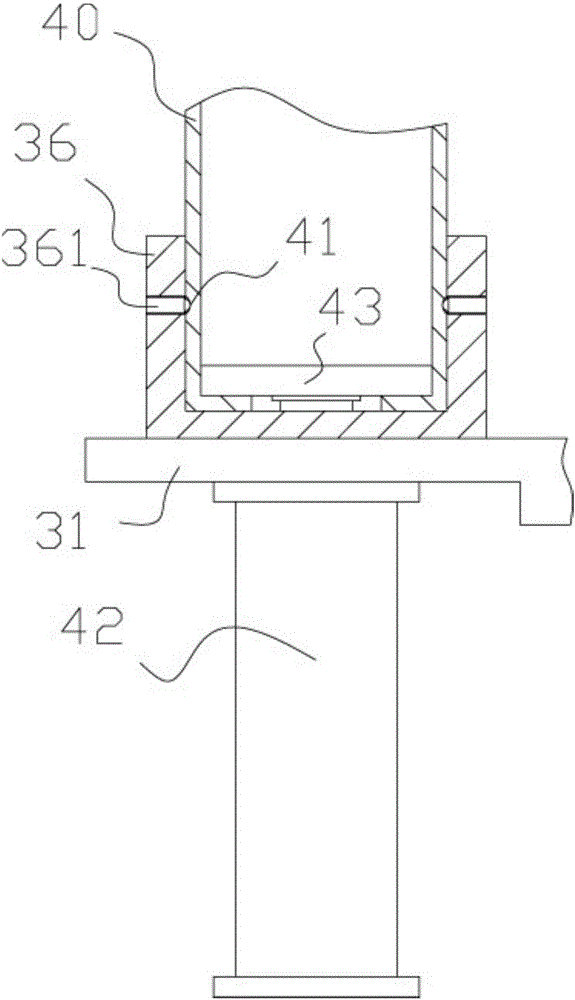

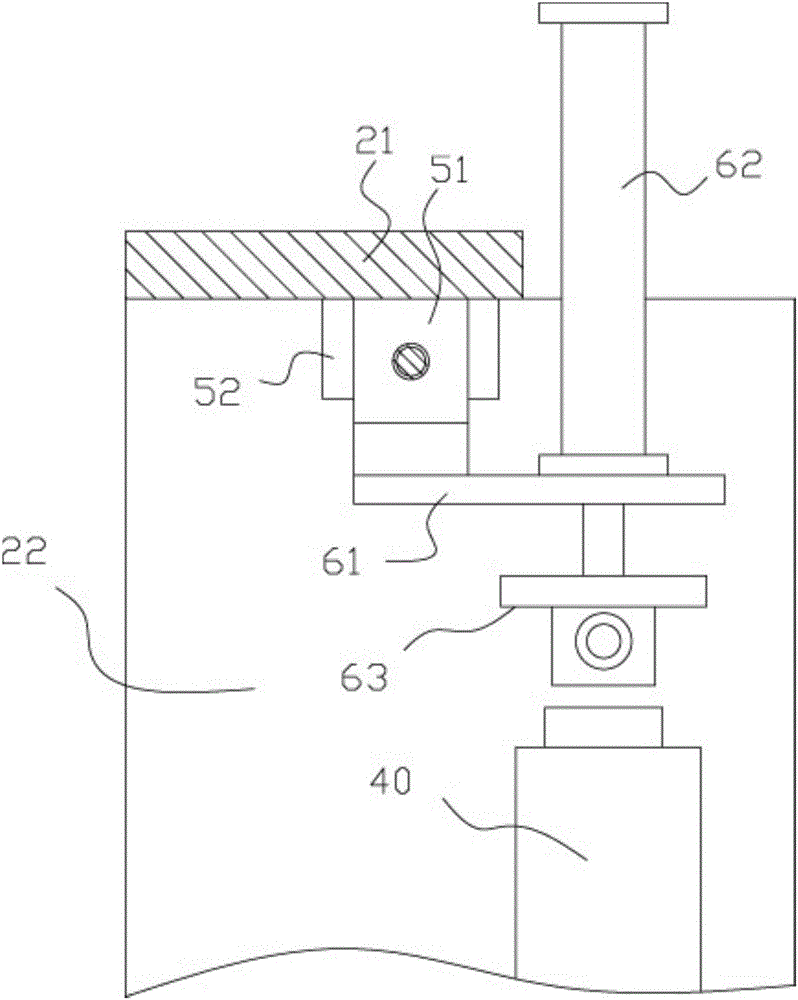

Automatic feeding device and automatic cooking device thereof

ActiveCN101637357ALow costIncrease the feeding speedCooking vesselsMechanical engineeringEngineering

Owner:AIC ROBOTICS TECH

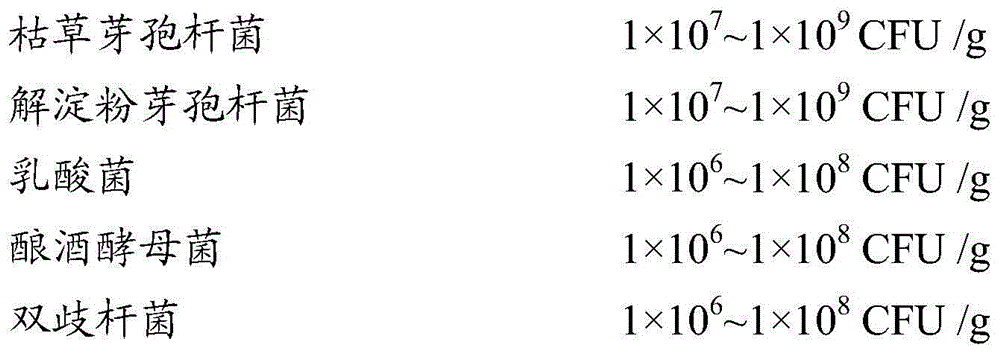

Novel efficient and natural attractant

ActiveCN102217713APromote secretionEliminate gasFood processingAnimal feeding stuffAquatic animalFeed additive

The invention relates to natural attractants, belonging to the field of feed additives. One natural attractant is mainly composed of a dried tangerine peel crushed substance, a hawthorn crushed substance, a cinnamon crushed substance, a mugwort leaf crushed substance, and composite microbial powder. The other natural attractant is mainly composed of a dried tangerine peel extractive, a hawthorn extractive, a cinnamon extractive, a mugwort leaf extractive, and composite microbial powder. The attractants provided by the invention has the advantages of promoting the ingestion of livestock, poultry and aquatic animals, increasing the ingestion speed and feed intake of the livestock, poultry and aquatic animals, avoiding the indigestion caused by overfeeding, increasing the feed intake and digestibility of the animals to the feeds hard to digest, expanding the application range and usage amount of unconventional feed materials, enhancing the immunity and anti-stress capability of the animals, resisting diseases, promoting growth, decreasing the production cost of the animal feeds and increasing the production benefits; the attractants contain no antibiotic and chemical medicine as well as drug residue, can be used for a long time without causing drug resistance, and have safety and high efficiency.

Owner:BEIJING KEEPYOUNG TECH

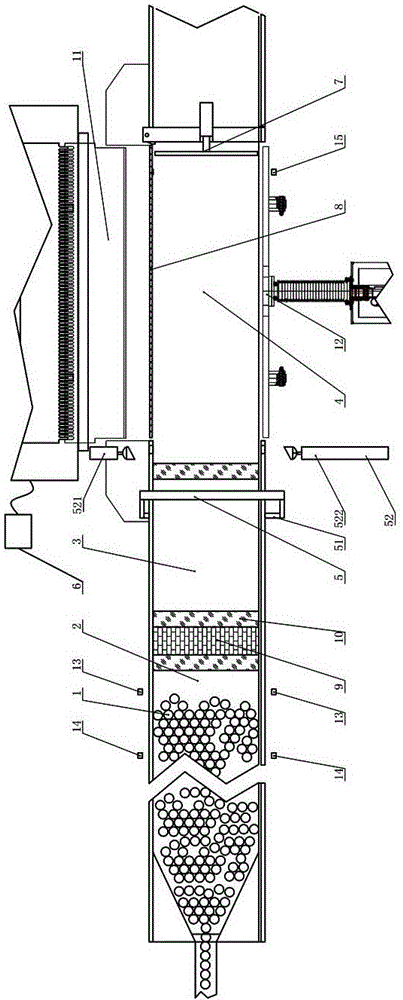

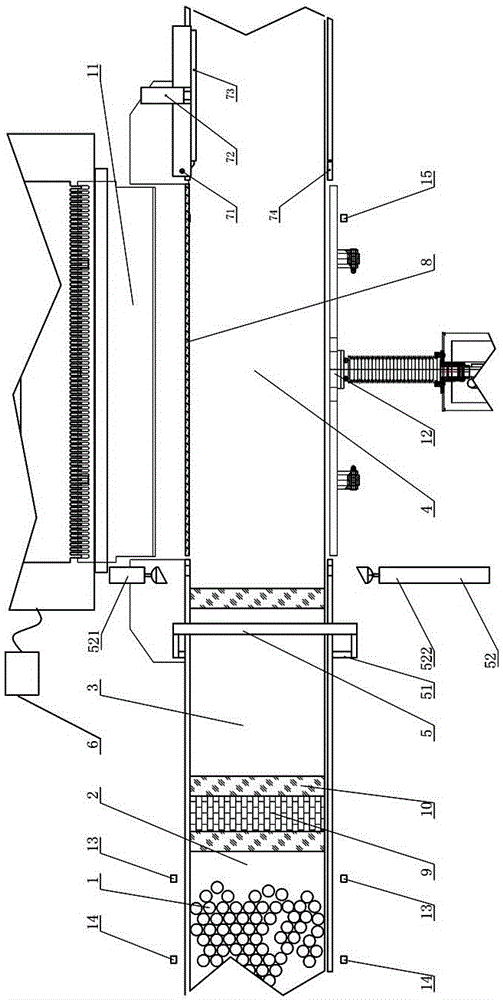

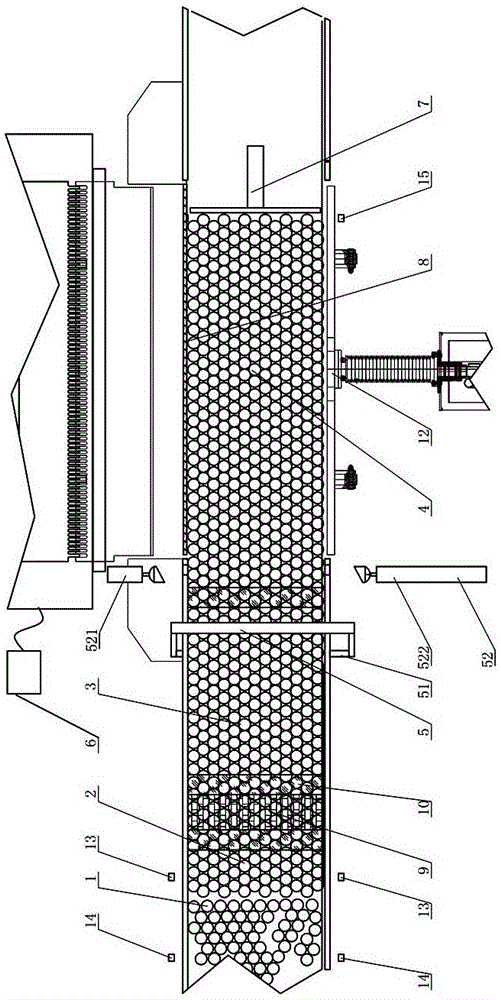

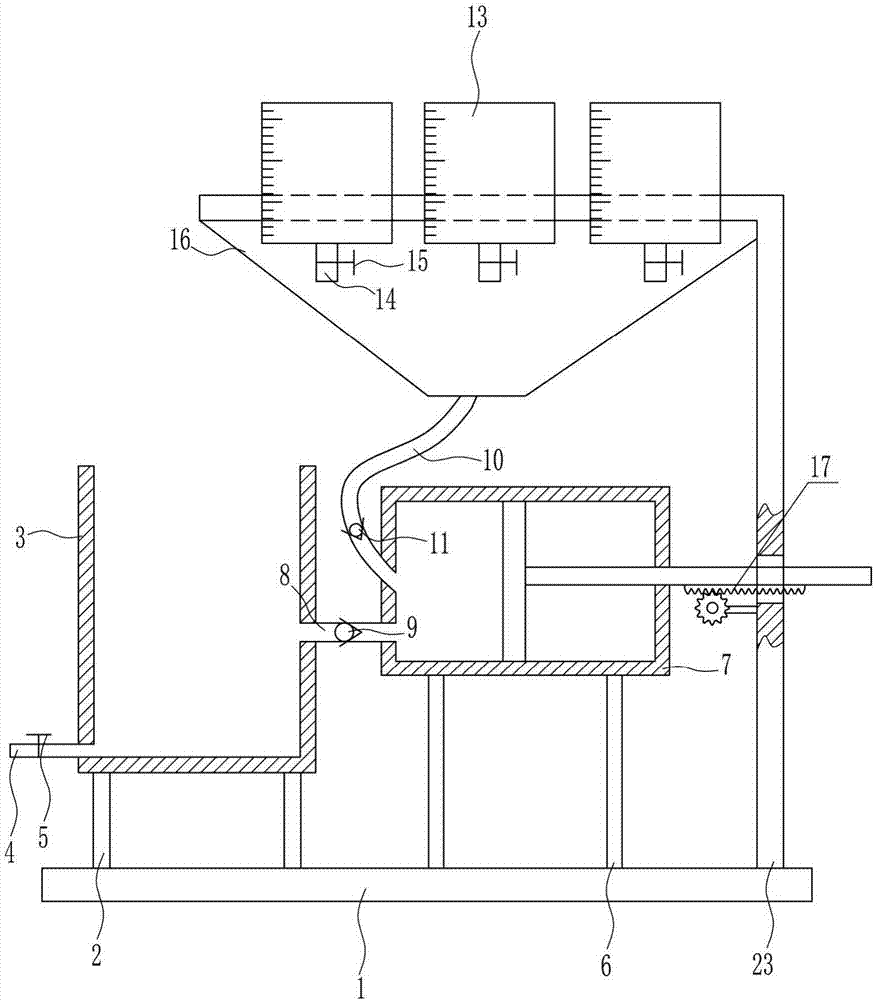

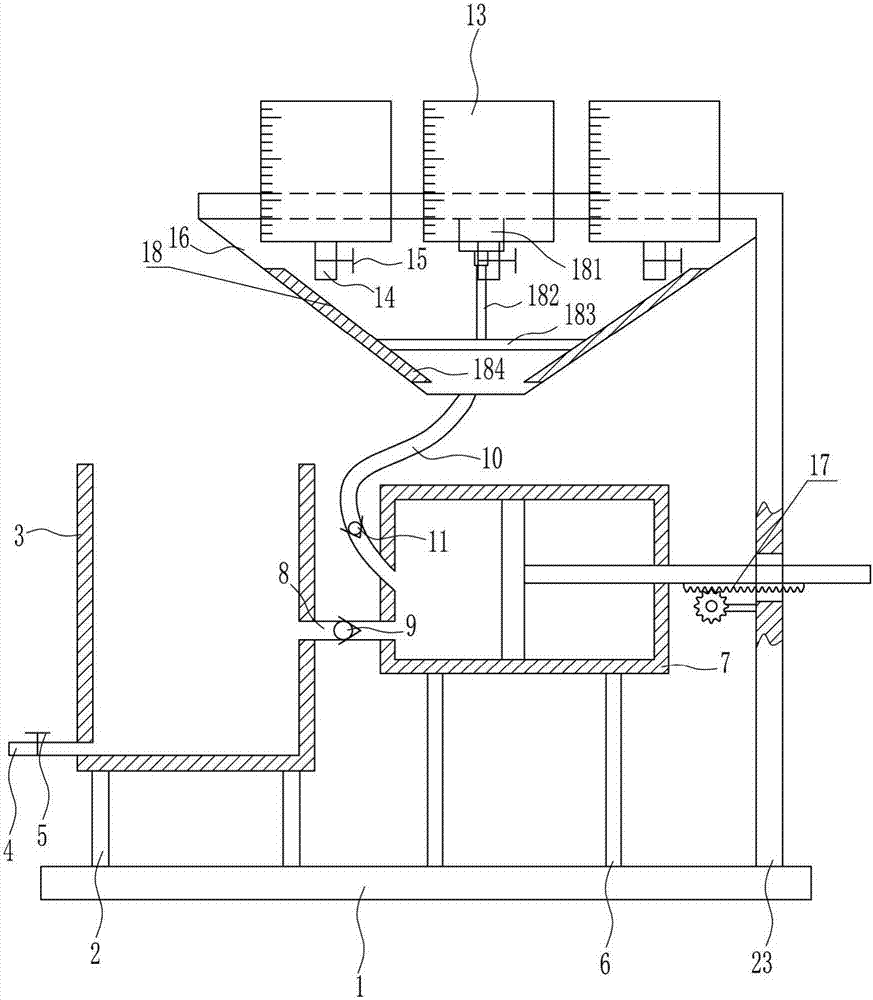

Food waste treatment device

InactiveCN106944177APrevent self-movingSmall footprintPlastic recyclingGrain treatmentsFood wastePlastic bag

The invention relates to a rubbish treatment device, in particular to a food waste treatment device and aims at achieving the technical purpose of providing the food waste treatment device which can reduce the waste floor space, save time and labor and improve the treatment efficiency. To achieve the technical purpose, the food waste treatment device is provided and comprises a bottom plate and the like. The top of the bottom plate is vertically connected with two first support plates through bolts, the two first support plates are symmetrical left and right, and the tops of the two first support plates are connected with a treatment box through bolts. The upper portion of the left side of the treatment box is connected with a feeding hopper through a bolt, the part, below the feeding hopper, of the treatment box is internally connected with a net plate through bolts, and a discharging opening is formed in the right side of the part, below the net plate, of the treatment box. According to the food waste treatment device, smashing teeth move up and down constantly to crush abandoned foam boxes, plastic bags and other waste, and therefore the waste floor space can be reduced, and time and labor can be saved.

Owner:湖州风雷餐饮管理有限公司

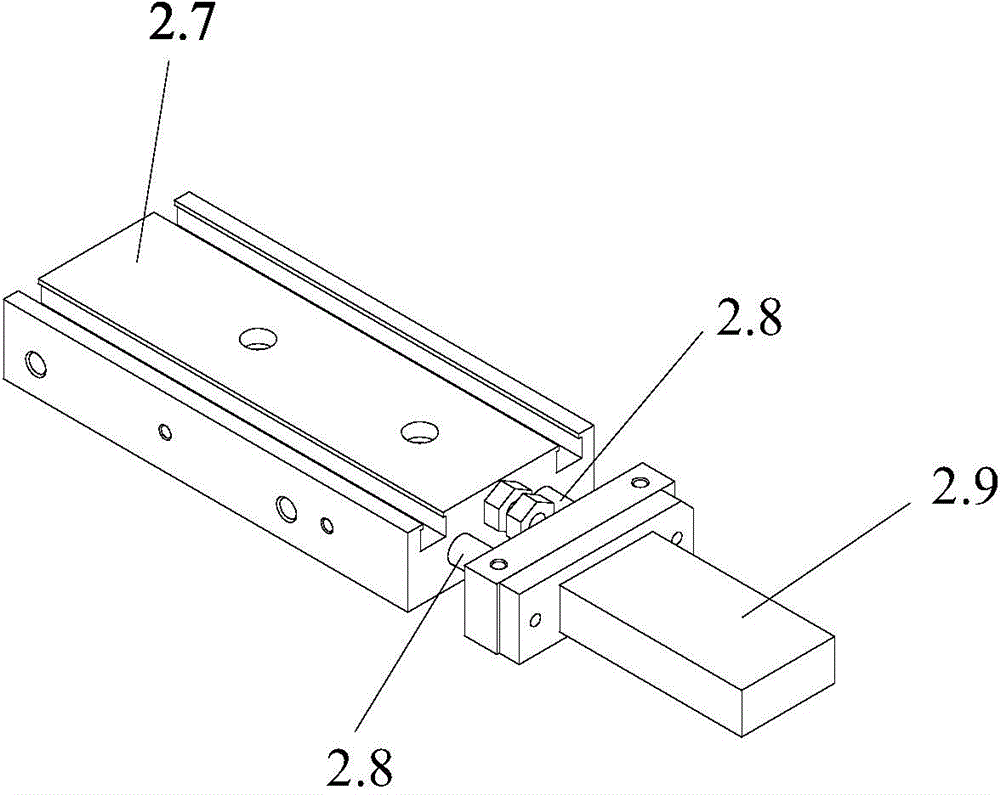

Shell feeding device of lockset spring assembly assembling machine

ActiveCN102794630ARealize mechanized operationImprove assembly qualityAssembly machinesMetal working apparatusEngineeringMechanical engineering

The invention discloses a shell feeding device of a lockset spring assembly assembling machine. The shell feeding device comprises a rack and a material pressing mechanism, wherein the rack is provided with a feeding rail and a material pushing rail; the tail end of the feeding rail is communicated with the front end of the material pushing rail; the front end of the material pushing rail is located below the material pressing mechanism, and the tail end of the feeding rail is provided with a feeding mechanism capable of conveying a shell into the material pushing rail; the tail end of the material pushing rail is provided with a material pushing mechanism capable of conveying the shell to be below the material pressing mechanism; the material pressing mechanism comprises a material pressing cylinder fixed on the rack and a material pressing plate fixed on the material pressing cylinder; and the rack is further provided with a fixing mechanism capable of fixing the shell which is conveyed to be below the material pressing plate. The shell feeding device disclosed by the invention has a high mechanical degree, can replace artificial assembling and has a high feeding speed, and can improve the assembling quality and stability of a lockset spring assembly.

Owner:CHANGZHOU INST OF NUMERICAL CONTROL TECH +1

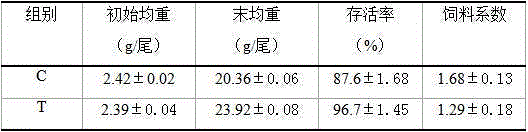

Australia crayfish breeding expanded sunken cooperation fodder and production process thereof

InactiveCN105010883AImprove Gut HealthEnhance disease resistanceAnimal feeding stuffAstaxanthinDigestion

The invention relates to Australia crayfish breeding expanded sunken cooperation fodder and a production process thereof and belongs to the technical field of shrimp expanded fodder. The fodder comprises 10-18 parts of fish meal, 5-10 parts of dried-powder of housefly larvae, 10-16 parts of shrimp meal, 4-8 parts of fermented soybean meal, 14-16 parts of soybean meal, 5-15 parts of peanut meal, 12-14 parts of strong flour, 2-4 parts of yeast autolysis powder, 2-5 parts of squid liver, 2-3 parts of shrimp shell meal, 2-5 parts of dried earthworm powder, 1-2 parts of fish oil, 2-3 parts of phosphatide oil, 1.5-2 parts of monocalcium phosphate, 1.66-2.63 parts of bentonite, 0.1-0.2 part of choline chloride, 0.04-0.08 part of calcium bisbutyrate, 0.1-0.2 part of unshell agents, 0.05-0.1 part of astaxanthin, 0.06-0.1 part of synbiotics, 0.2-0.3 part of compound vitamin premix and 0.3-0.5 part of compound trace element premix. By means of the fodder, the intestinal health of Australia crayfish can be substantially improved, the disease resistant capacity of the Australia crayfish is enhanced, the fodder digestion rate is improved, the growth performance is improved, and great social value and economic value are created.

Owner:TONGWEI

Formulation and preparing method of expanded assorted feed for ophiocephalidae

InactiveCN101040668APromote rapid growthImprove digestion and absorption rateFood processingClimate change adaptationYeastWater quality

The invention relates to a formula of compound puffed feed for snakehead mullet and process for preparation, wherein the constituents in the formula comprise (by mass ratio): fish meal 35-50%, fermented soybean waste 10-20%, meat and bones meal 0-12%, silkworm chrysalis powder 0-5%, blood powder 0-5%, brewer's yeast 2-5%, shrimp grease 0-6%, fish oil 1.0-3%, high grade flour 10-20%, liquid phosphatide 1-2%, calcium dihydrogenphoshate 0.5-1.5%, composite vitamin 0.5-1%, compound minerals 0.5-1%, choline chloride 0.3-0.5%. The preparing process consists of proportioning constituents, mixing homogeneously, disintegrating, modulating, palletizing and drying.

Owner:GUANGDONG HENGXING GROUP

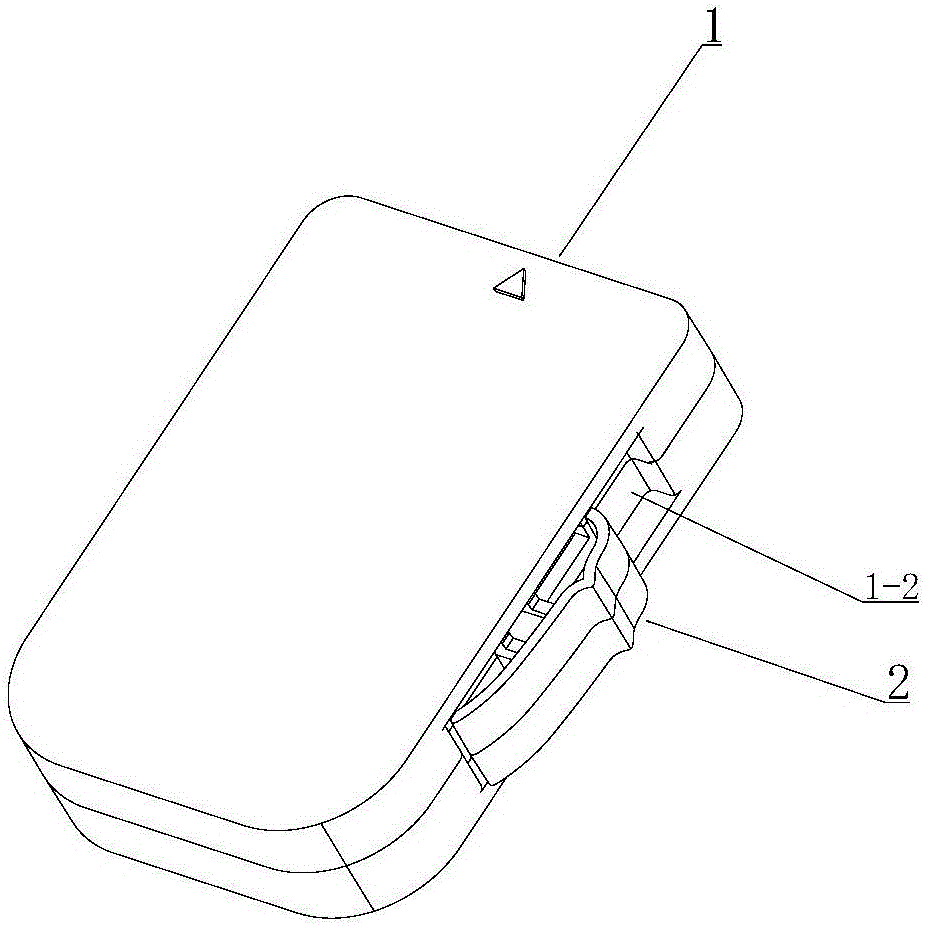

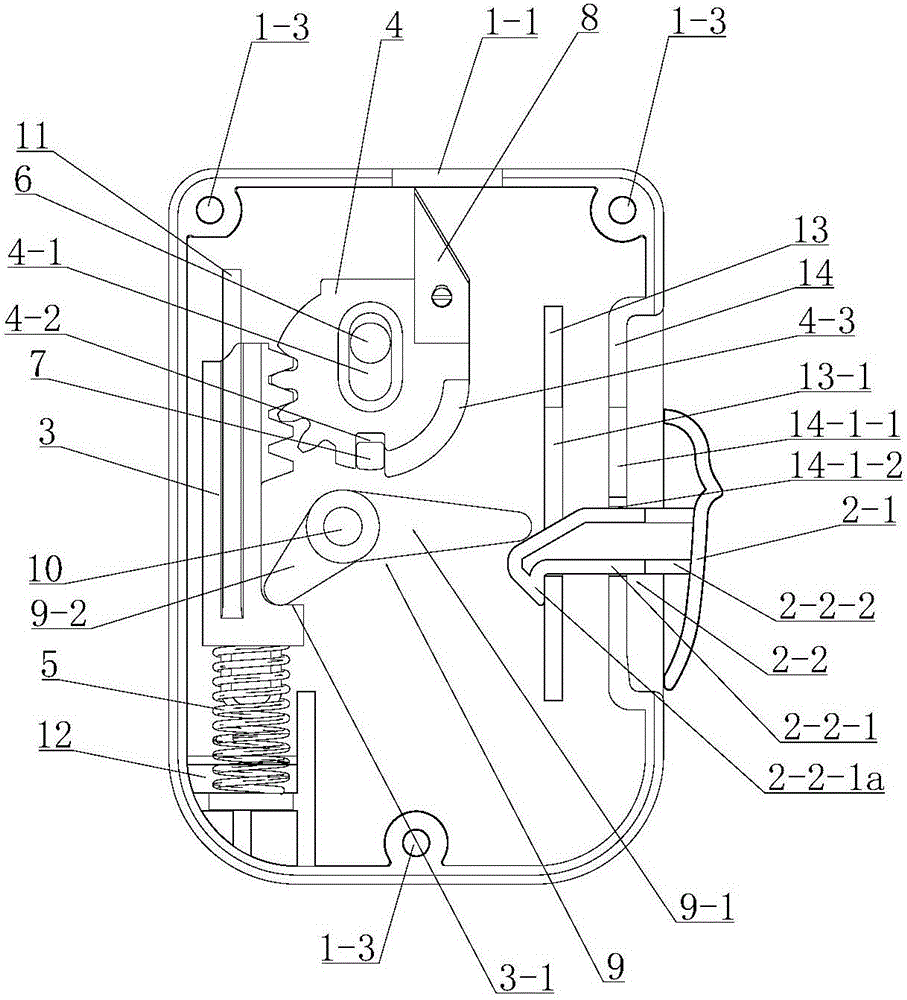

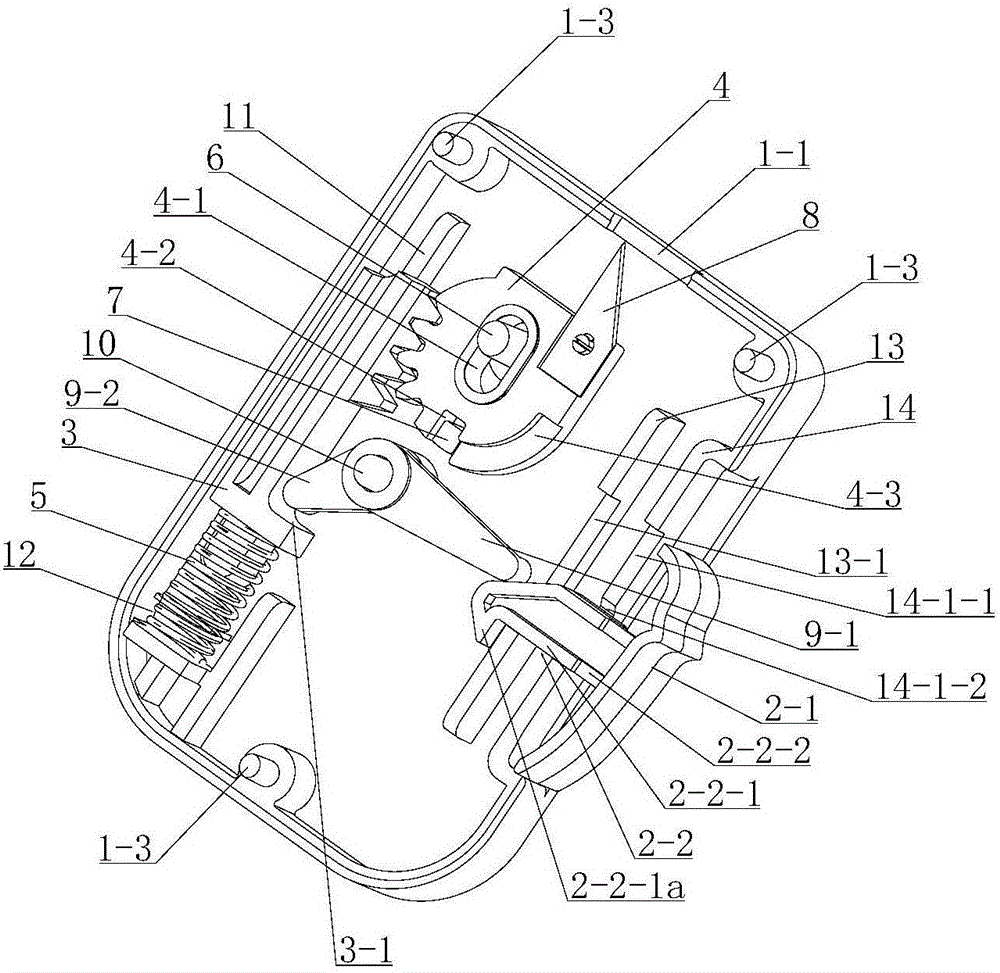

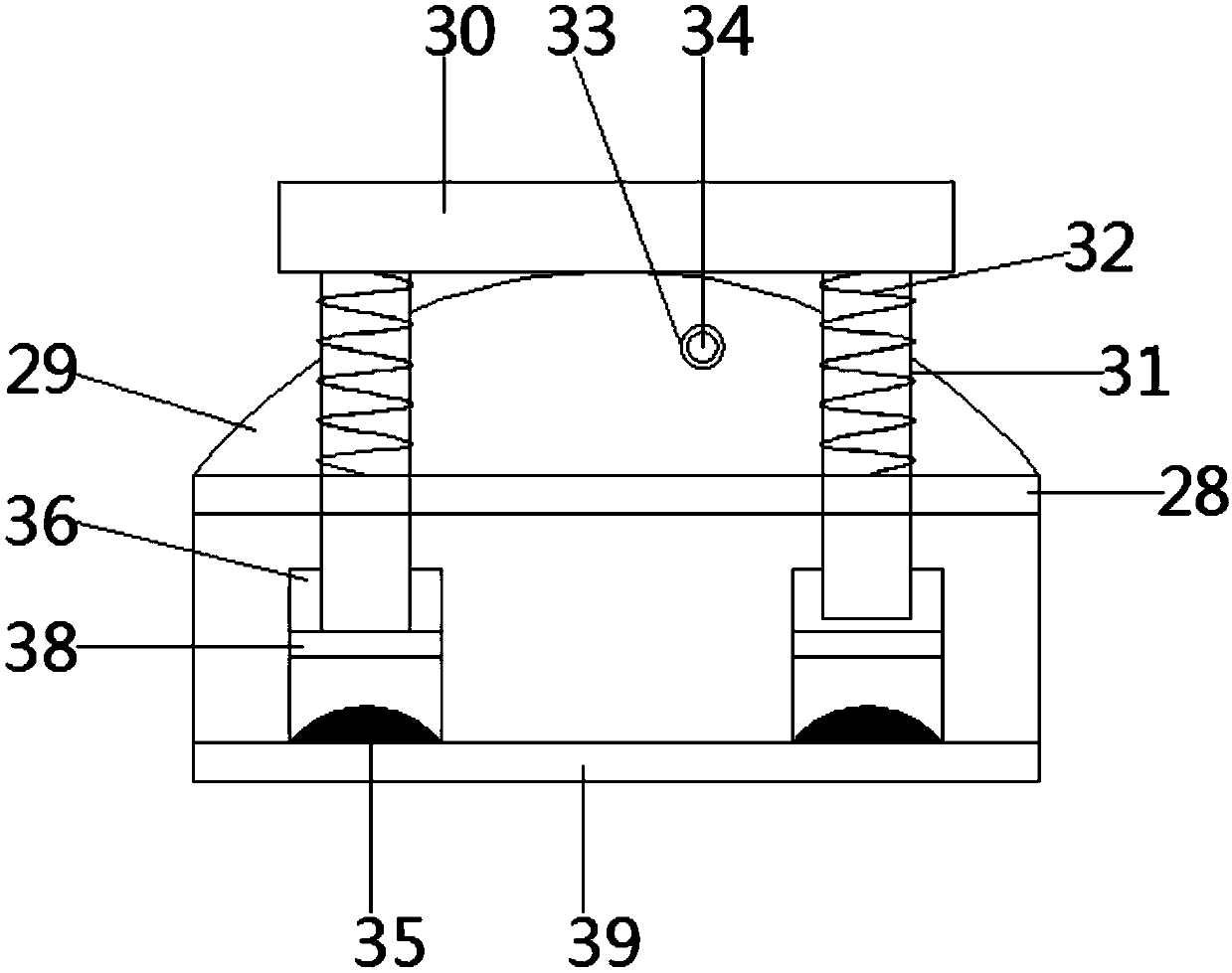

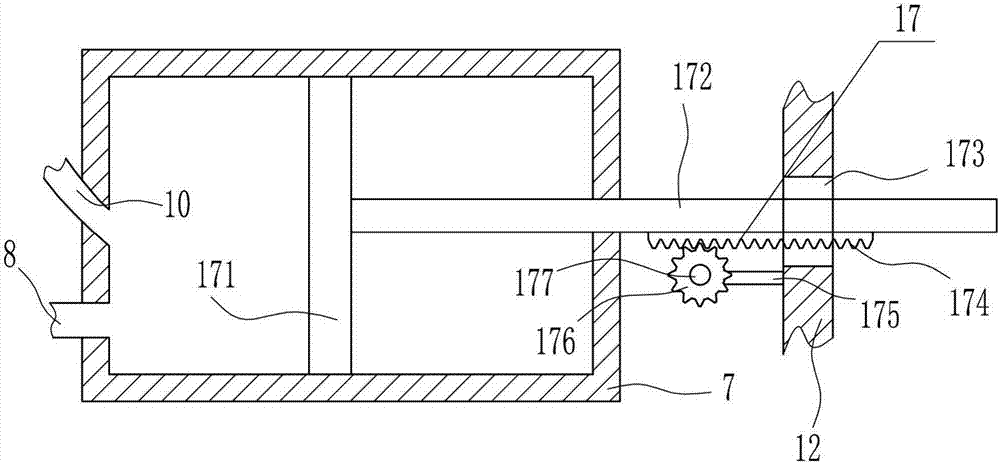

Heel blood sampler

InactiveCN106236112AEasy to operateIncrease the feeding speedDiagnostic recording/measuringSensorsDemarcation pointGear wheel

The invention discloses a heel blood sampler. The heel blood sampler comprises a shell, a trigger piece installed on an installing port, a rack, a trigger gear and a trigger control swing arm, wherein a blade outlet is formed in the front end of the shell, and the installing port is formed in one side of the shell; the trigger piece is connected with the shell in the mode of moving inwards and forwards; the rack and the trigger gear are connected in a meshed mode, the rack is installed in the shell in the mode of sliding forwards and backwards, a trigger spring is connected to the rear end of the rack, the rear end of the trigger spring is connected with a spring fixing structure arranged in the shell, the trigger gear is connected with a first supporting shaft fixed into the shell through a connecting long hole, a limit opening is formed in the rear end of the trigger gear, a limit insertion block is arranged in the shell, and a blade is installed at the front end of the trigger gear; the trigger control swing arm is rotationally installed on a second supporting shaft arranged in the shell and is composed of a first arm segment and a second arm segment with the second supporting shaft being the demarcation point. The heel blood sampler has the advantages that operation is convenient, blade feeding speed is high, and the painful feeling is light in the blood sampling process.

Owner:TIANJIN HUAHONG TECH

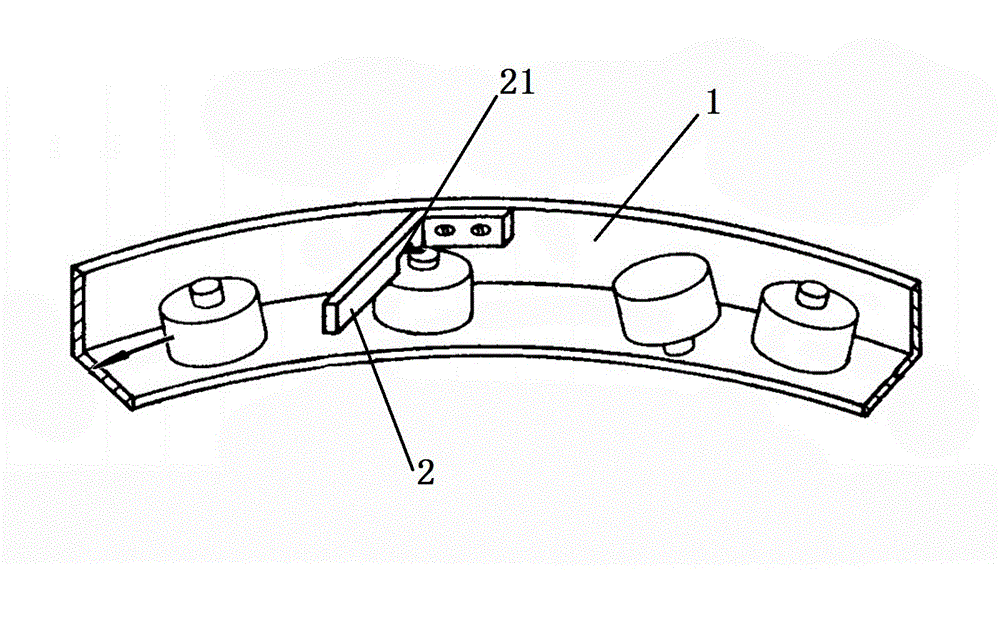

Tenon workpiece array trail

InactiveCN102942048ASimple structureImprove screening efficiencyConveyor partsEngineeringSupport surface

Owner:CHONGQING TIANZHIDAO SCI & TECH DEV

High-speed feeding and discharging system and method

ActiveCN105059911AFast feeding speedImprove efficiencyControl devices for conveyorsBottles/feedBottle

The invention discloses a high-speed feeding and discharging system, which comprises a control assembly, a bottle collecting net belt, a target platform and a bottle pushing assembly, wherein the target platform and the bottle pushing assembly are respectively located at two sides of the bottle collecting net belt; a bottle feeding end of the bottle collecting net belt is in butt joint with a bottle feeding net belt; the bottle feeding end is provided with a bottle feeding assembly; a bottle stopping assembly is arranged at one end, opposite to the bottle feeding end, of the bottle collecting net belt; the bottle collecting net belt is provided with a detection assembly used for detecting the length of a bottle queue on the bottle collecting net belt; and the detection assembly is connected with the control assembly. The invention also discloses a high-speed feeding and discharging method. When a condition that the length of the bottle queue on the bottle collecting net belt is identical with the length of the target platform is detected, the control assembly stops the transmission of the bottle collecting net belt and the bottle feeding net belt, and the bottle queue on the bottle collecting net belt is pushed towards the bottle stopping assembly, so that after the bottle queue between the bottle feeding assembly and the bottle stopping assembly is in butt joint with a bottle feeding end of the target platform, the bottle queue is pushed onto the target platform by the bottle pushing assembly. The system and the method have the advantage that the feeding speed is improved.

Owner:TRUKING TECH LTD

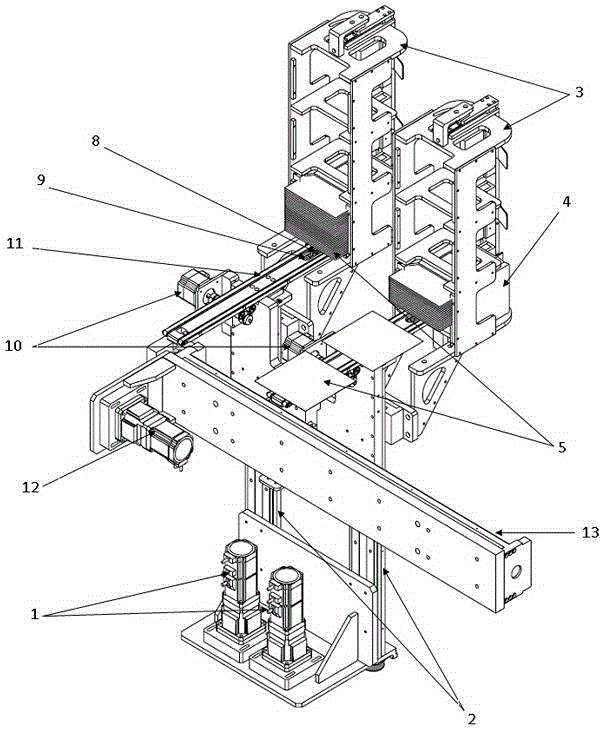

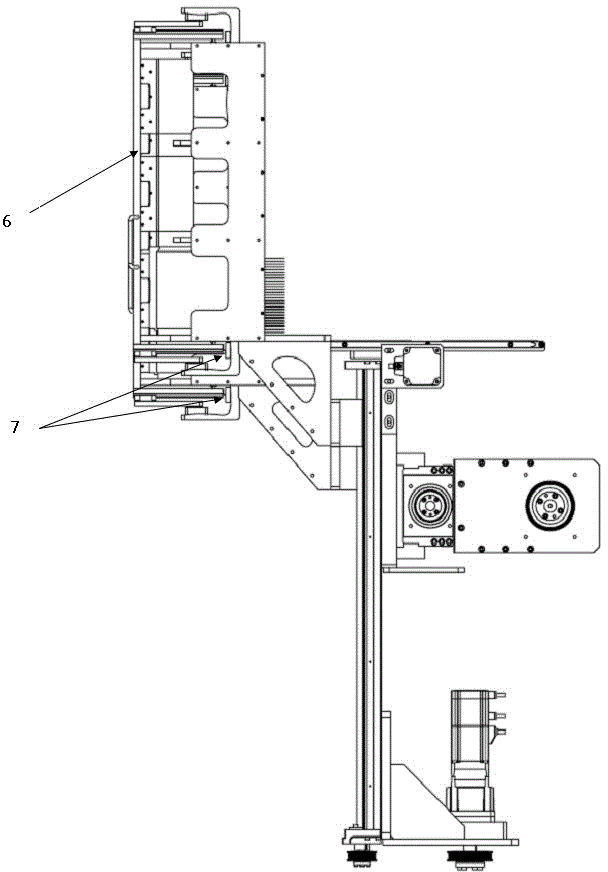

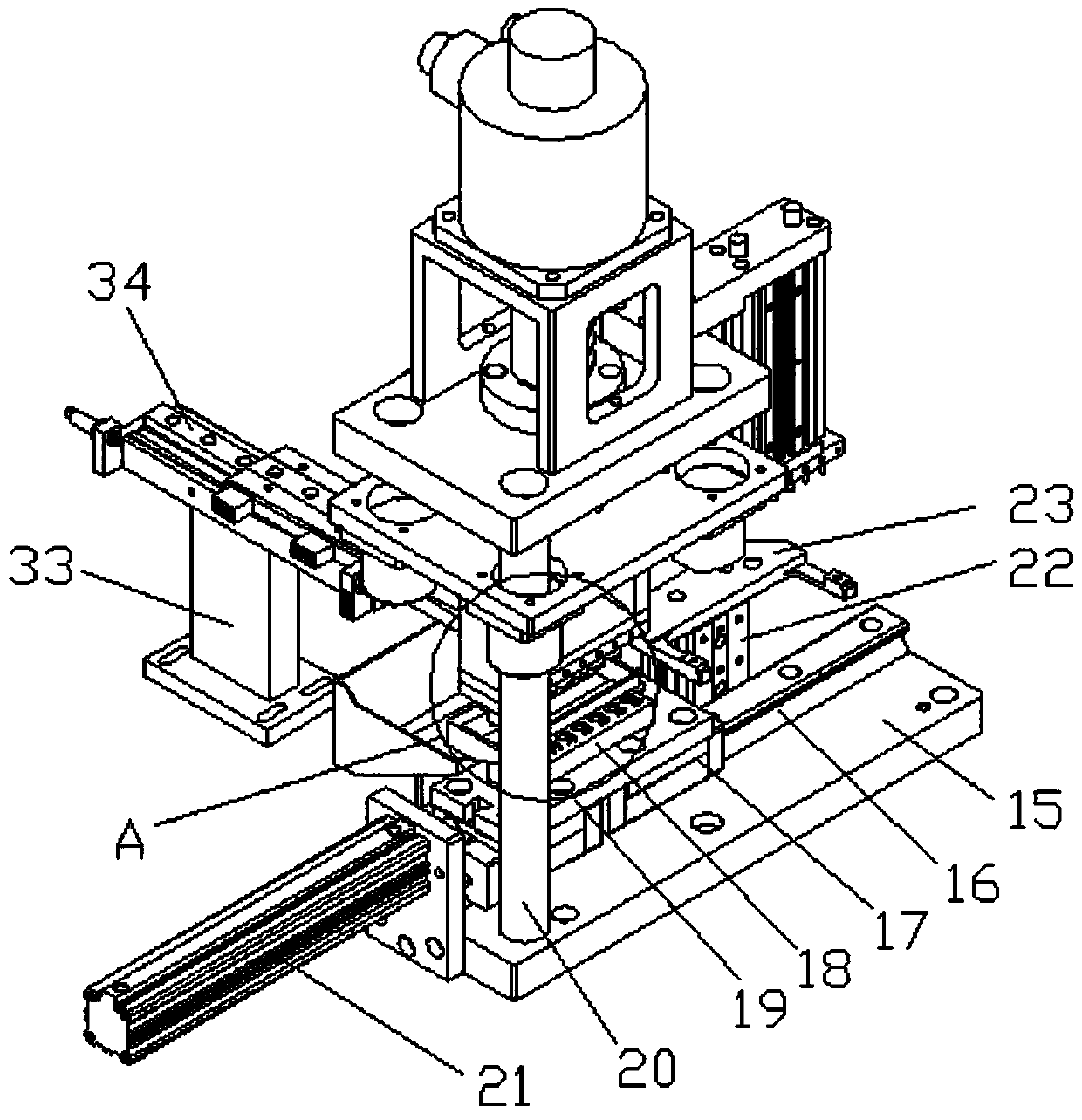

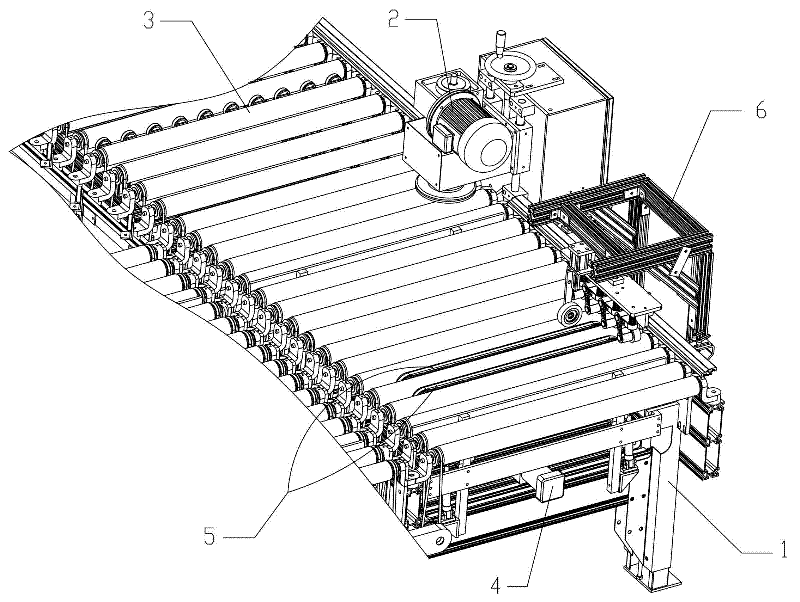

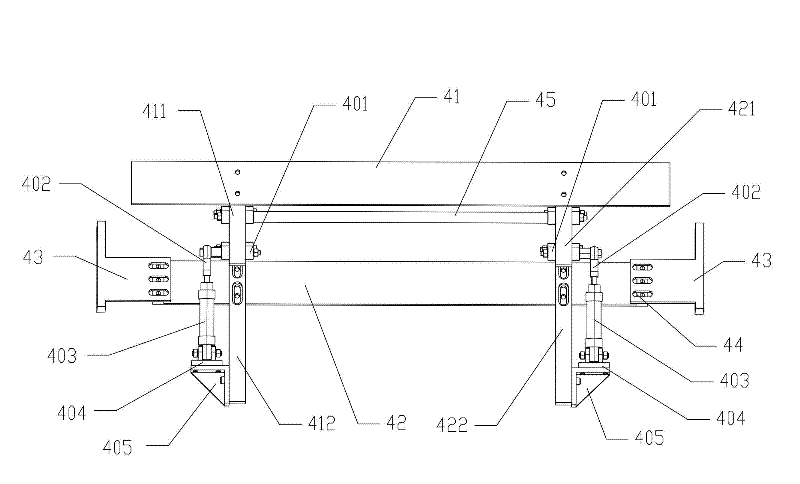

Full-automatic numerically-controlled machine tool for shafts

ActiveCN103273366APrecise positioningImprove work efficiencyMetal working apparatusNumerical controlEngineering

The invention provides a full-automatic numerically-controlled machine tool for shafts, and belongs to the technical field of machinery. The full-automatic numerically-controlled machine tool for the shafts solves the problems that an existing numerically-controlled machine tool for the shafts is low in efficiency because feeding is low in speed, and feeding and blanking are separately carried out. The full-automatic numerically-controlled machine tool for the shafts comprises a working platform, a main machine, a front rack and a rear rack, wherein a material box is installed on the upper side portion of the front rack, a material conveying channel is formed in the front rack, a feeding device is installed on the front rack, a material receiving device is installed on the rear rack, a clamping stay tube is arranged in a spindle, a collet is installed at the front end of the clamping stay tube, a material leading base is installed on the working platform, a double-arm mechanical claw is arranged on the material leading base, a material leading device is arranged between the material leading base and the material receiving device, the material leading device and the spindle are arranged on the same axis line, a locating base is installed in the clamping stay tube, a locating mechanism is installed in the locating base, and a shaft arranged in the locating base can only pass through the locating mechanism under the action of external force. The full-automatic numerically-controlled machine tool for the shafts has the advantages that working efficiency is high, location is accurate, and feeding and blanking are synchronously carried out.

Owner:宁波宫铁智能科技有限公司

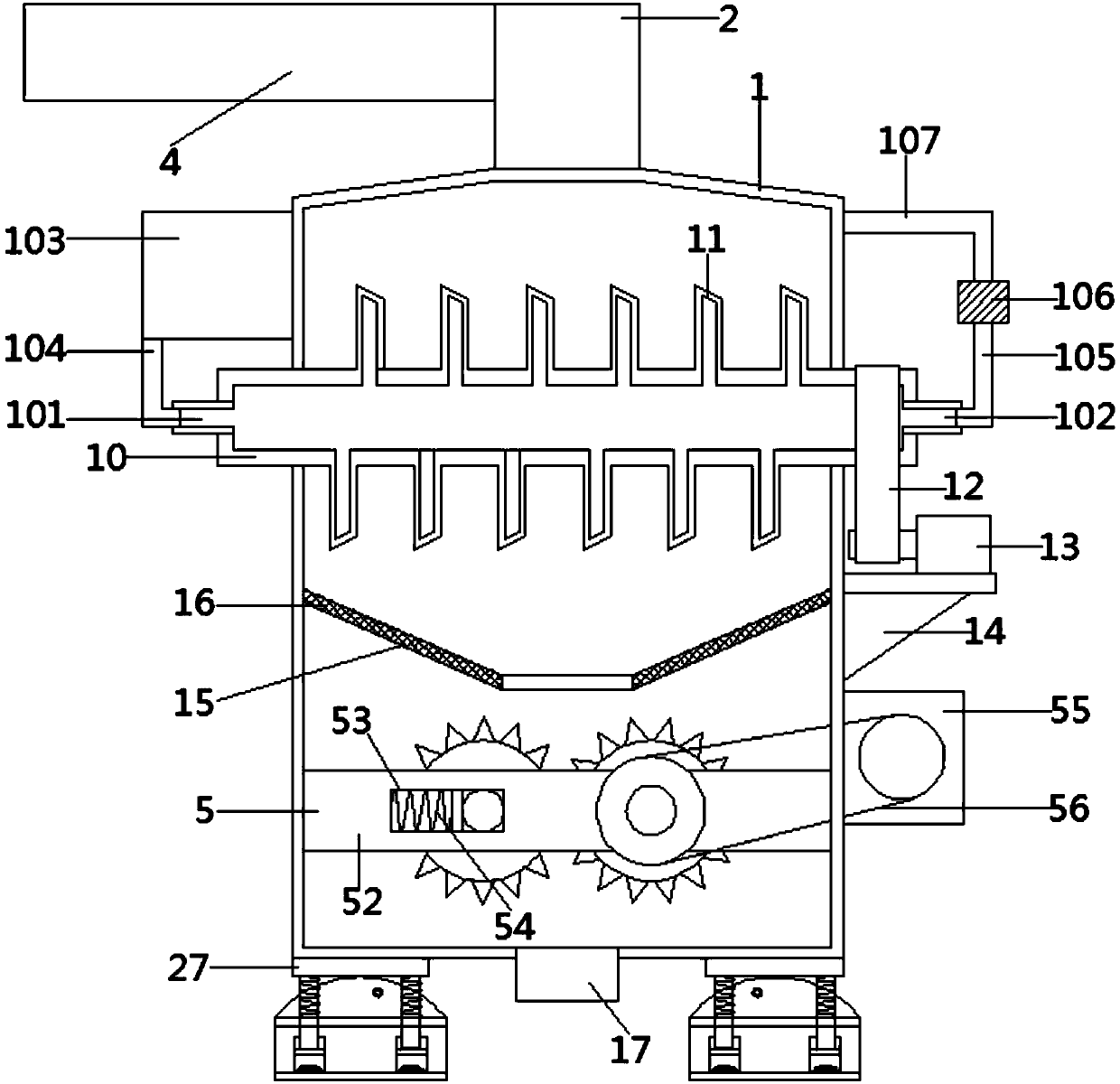

Differential motion airtight feeding electric furnace smelting device and feeding method thereof

ActiveCN102181601AShorten the lengthIncrease the feeding speedCharge manipulationElectric furnaceEngineeringHeat losses

The invention discloses a differential motion airtight feeding electric furnace smelting device and a feeding method thereof. The device comprises an electric furnace and a charging device, wherein the charging device comprises a cold receiving conveying trough and a heat conveying trough; the lower sides of the cold receiving conveying trough and the heat conveying trough are provided with an independently-controlled excitation device respectively; the outlet of the cold receiving conveying trough is provided with a conveying throat opening which is extended into the heat conveying trough; and the distance between the conveying throat opening and the bottom of the heat conveying trough is greater than or equal to the depth of the heat conveying trough. By the feeding method, shock excitation at different frequencies is applied to the two conveying troughs to realize the differential motion conveying of raw materials, so that a thicker material layer can be laid on the cold receiving conveying trough, and the material loading speed is increased; simultaneously, a shorter cold receiving conveying trough and a shorter material-conveying bottom elongated slot can be designed, so that the device and the method make project implementation convenient. In addition, due to the adoption of the throat opening and a sealed door structure, the possibility of material blocking and the air leakage rate are greatly reduced, and the device has low heat loss and a good dedusting effect, and is high-efficient, energy-saving and environment-friendly during smelting.

Owner:CISDI ENG CO LTD

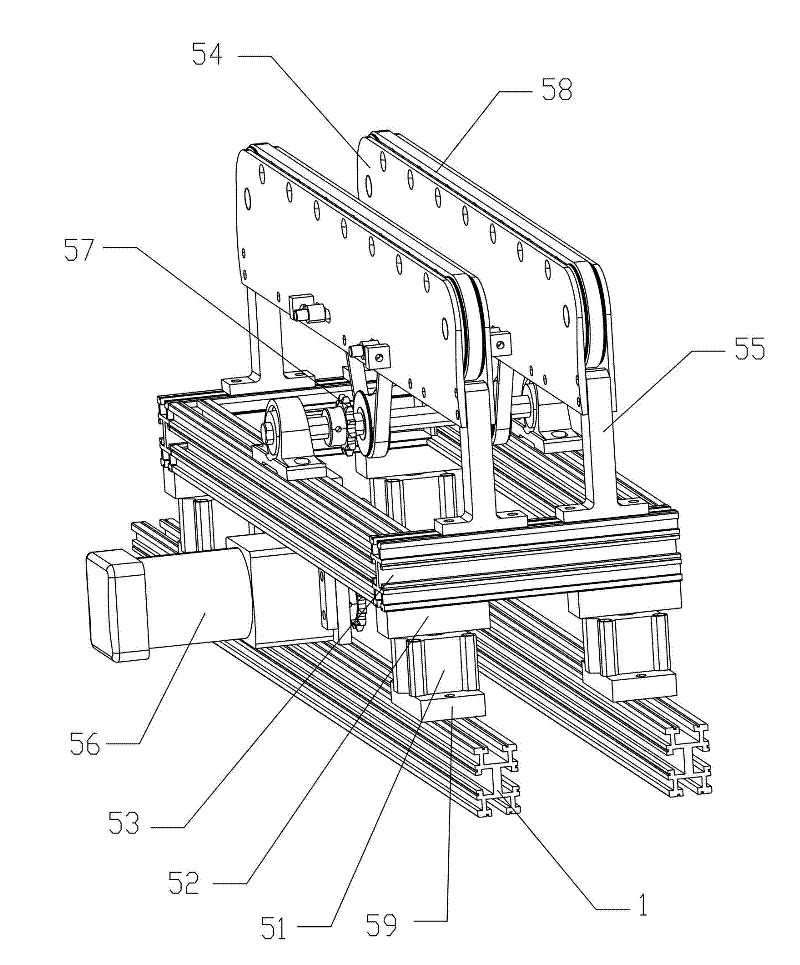

Automatic loading and moving mechanism of plastic sleeves

ActiveCN106003221AIncrease the feeding speedImprove efficiencyMetal working apparatusEngineeringMechanical engineering

The invention discloses an automatic loading and moving mechanism of plastic sleeves. The mechanism comprises a frame and a loading frame; a sleeve body is fixed on a top plate of the frame; the loading frame includes an upper flat plate; side support plates are fixed on the bottom surfaces of two ends of the upper flat plate; the frame is positioned below the upper flat plate and between the two side support plates; a hoisting mechanism is arranged on the side support plate on the right side of the loading frame; a loading barrel is fixed on a hoisting plate of the hoisting mechanism; a transverse moving mechanism is arranged on the upper flat plate; a grabbing mechanism is fixed on a transverse moving block of the transverse moving mechanism, and is corresponding to the loading barrel and the sleeve body; the hoisting mechanism includes two hoisting support blocks arranged up and down; the hoisting support blocks are fixed on the side support plate on the right side; two ends of a vertical screw rod are hinged to two hoisting support blocks; and the lower end of the vertical screw rod downwards extends out of the hoisting support blocks, and is fixed with a hoisting gear. The mechanism can automatically grab the plastic sleeves for automatic loading, and is fast in loading speed and high in efficiency.

Owner:FOSHAN LIANZHI XINCHUANG TECH CO LTD

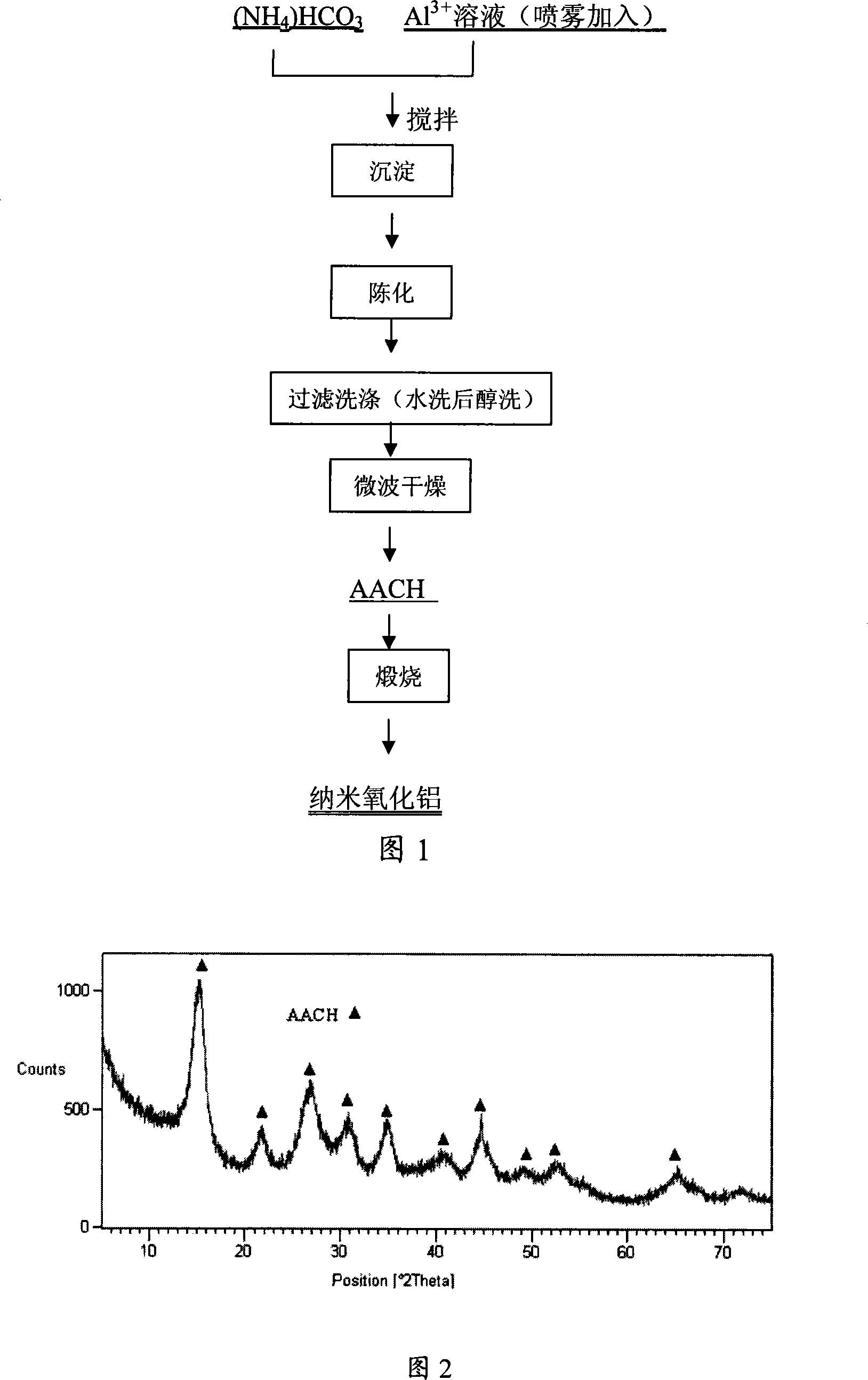

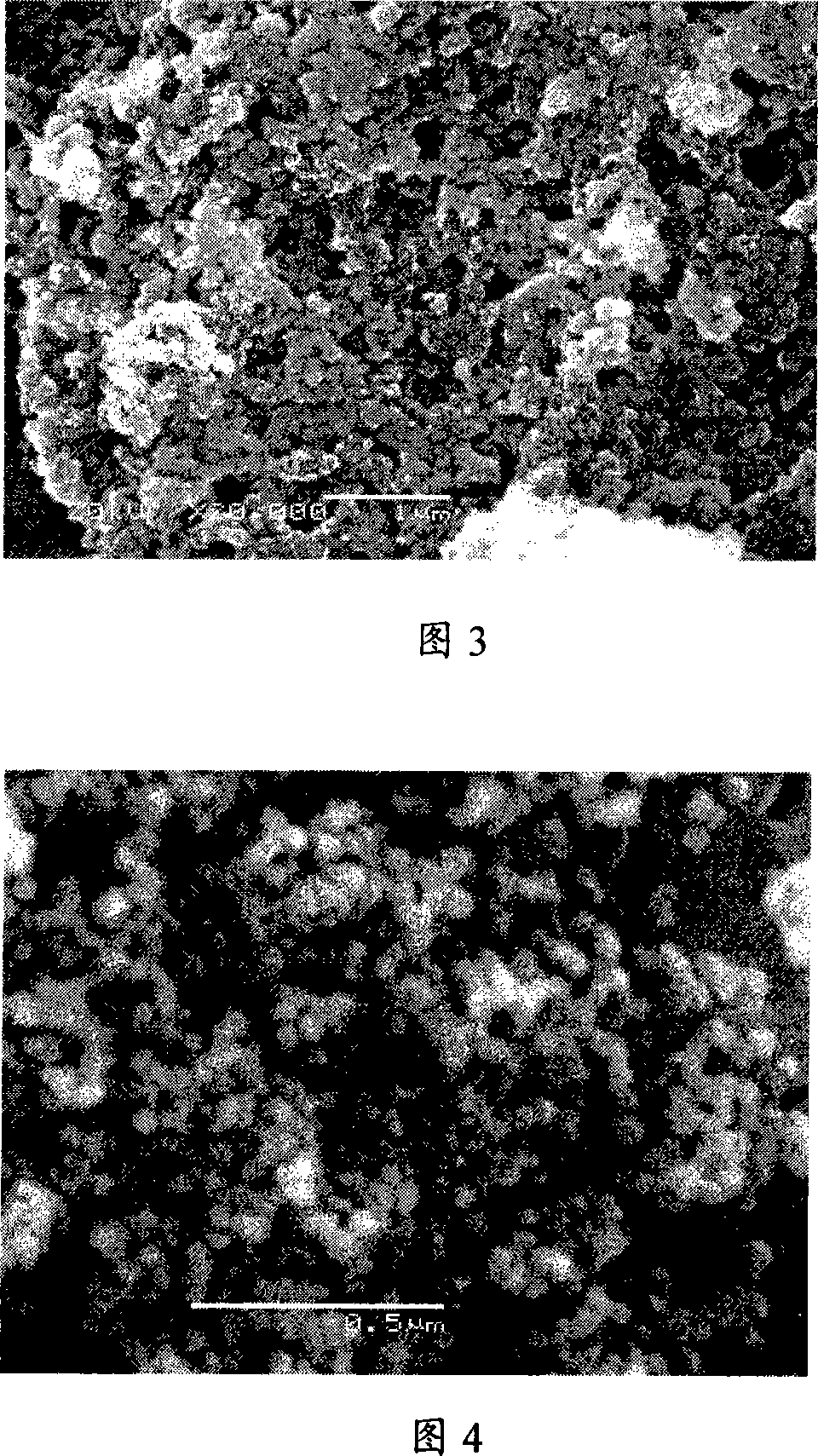

Method for preparing nano aluminum oxide powder

InactiveCN101186325AWell mixedEvenly dispersedNanostructure manufactureAluminium oxide/hydroxide preparationMicrowaveFiltration

The invention relates to a preparation method of nano-alumina powder, and is characterized in that a preparation process embodies that aluminum salt solution atomized by spraying is first sprayed into ammonium bicarbonate solution in a stirred state, then reacting with surfactant added; the mixture obtained is next treated with microwave drying after precipitation, aging, filtration and washing, calcined to obtain the nano-alumina powder. In addition, the dried AACH prepared by the preparation method of the invention can be calcined to obtain nano Gamma-Al2O3 with less conglobation and uniform particle size.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

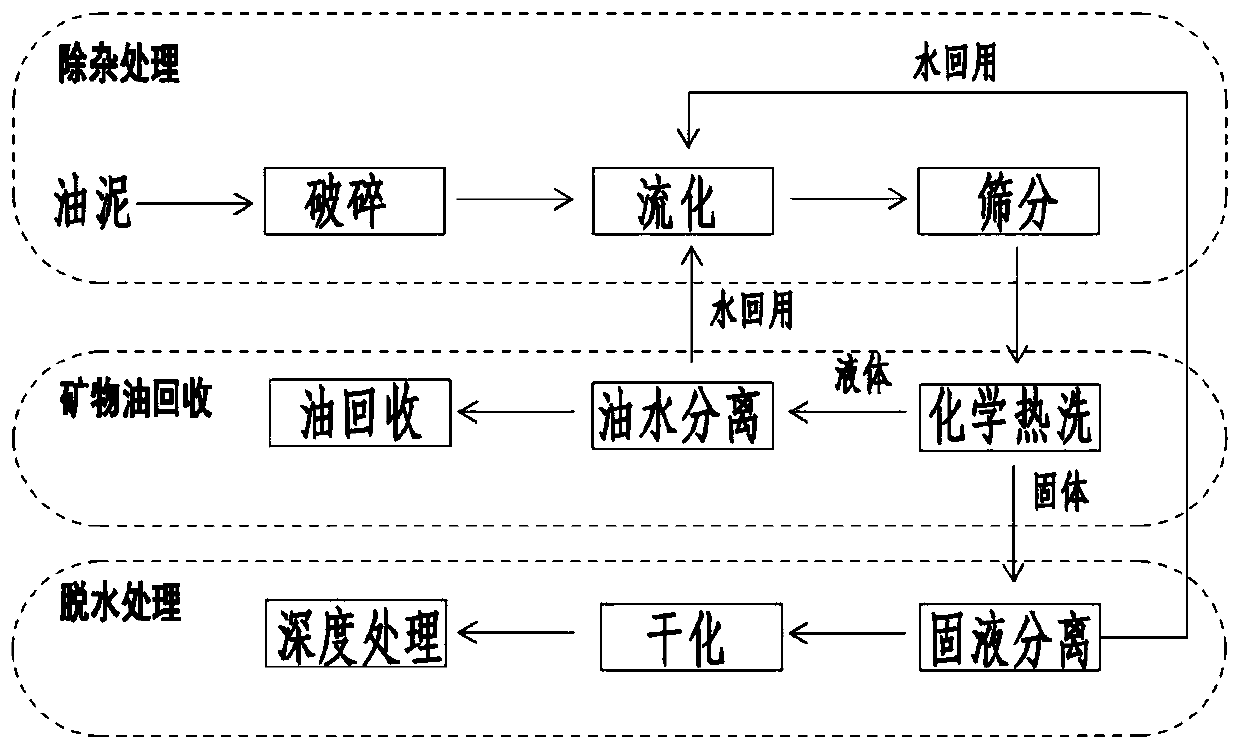

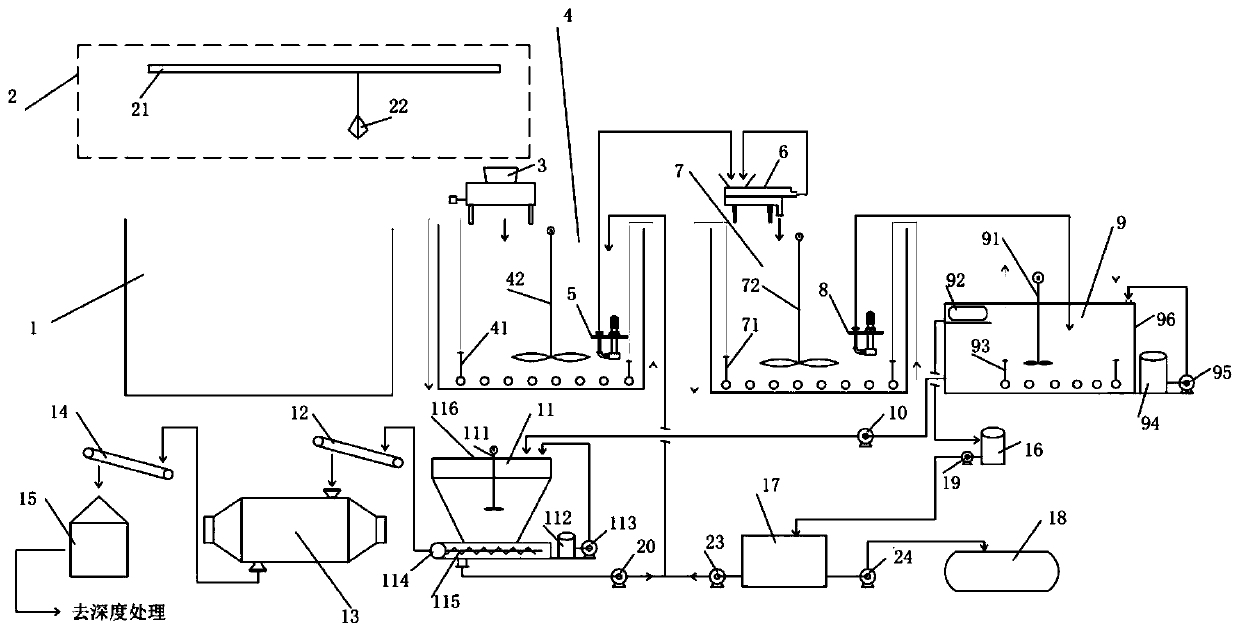

Oily sludge recycling and reduction treatment method and system

InactiveCN110606633AImplement resourcesAchieve reductionSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesReduction treatmentSlag

The invention discloses an oily sludge recycling and reduction treatment method and system. The treatment method comprises the steps of crushing, fluidization, screening and impurity removal, chemicalhot washing, solid-liquid separation, drying, deep treatment and the like. The treatment system mainly comprises an oily sludge storage tank, a feeding device, an impurity removal system, an oil recovery system and a dehydration system which are connected in sequence, wherein oily sludge in the oily sludge storage tank is conveyed to the impurity removal system through the feeding device to be subjected to crushing, fluidization and screening treatment, then the oil sludge treated by the impurity removal system is conveyed to the oil recovery system to collect crude oil, and isolated slag slurry is conveyed to the dehydration system to be subjected to solid-liquid separation, drying treatment and harmless deep treatment. By adopting the method and the treatment system provided by the invention, more than 80% of mineral oil in the oily sludge can be recycled, and meanwhile, the moisture content in the sludge is reduced to 30% or below, so that recycling and reduction of the oily sludgeare realized.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

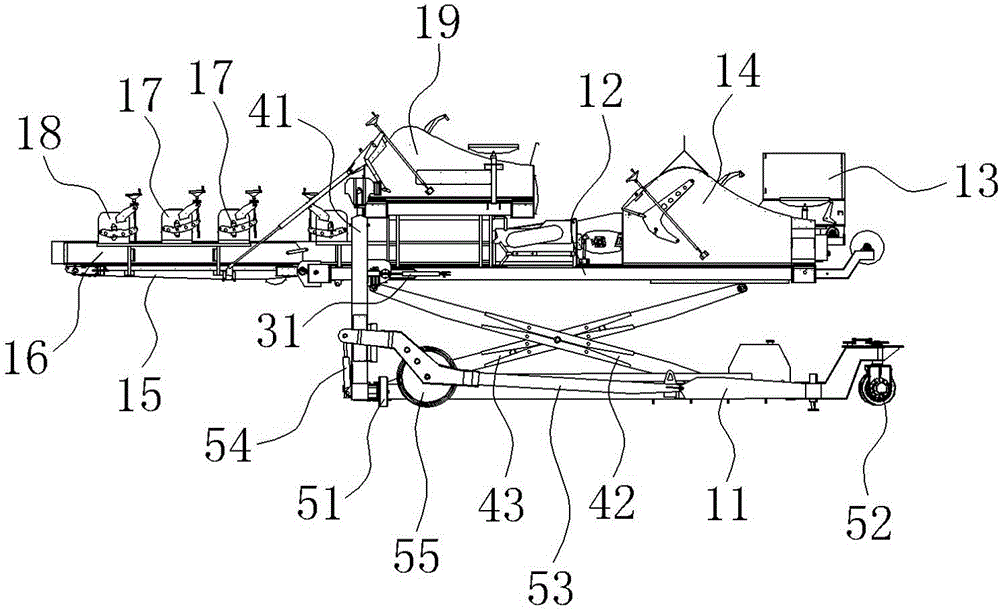

Garbage treatment apparatus for environmental protection engineering

InactiveCN107755038AIncrease workloadIncrease the feeding speedNon-rotating vibration suppressionGrain treatmentsEnvironmental resistanceDrive shaft

The invention discloses a garbage treatment apparatus for environmental protection engineering. The garbage treatment apparatus comprises a machine body, wherein the upper side of the machine body isprovided with a material inlet, the water inlet is connected with a material inlet pipe, the left side of the material inlet pipe is connected with a belt loading apparatus, and the belt loading apparatus comprises frame bodies as well as a driving roller, a driving shaft, three supporting rollers and a tension roller which are arranged between the frame bodies by virtue of a bearing seat frame from left to right. By adopting the belt loading apparatus to automatically load materials, the working efficiency is increased; moreover, the automatic discharging can be realized; by arranging an upper crushing mechanism and a lower crushing mechanism, and the crushing effect is ensured, the crushing efficiency is increased; water circularly flowing inside a rotating shaft can bring away the heatgenerated by the friction, the cooling can be performed without stopping, the crushing machine can work continuously, the excessive feeding can be prevented from damaging the rolling rollers, and theservice life is prolonged; the vibration of the machine body can be greatly reduced, and the stability is improved.

Owner:邓雨佳

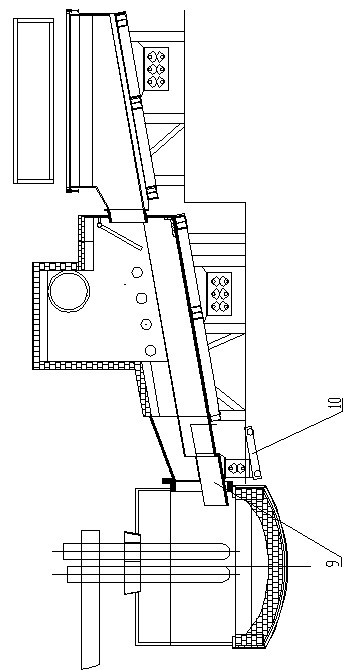

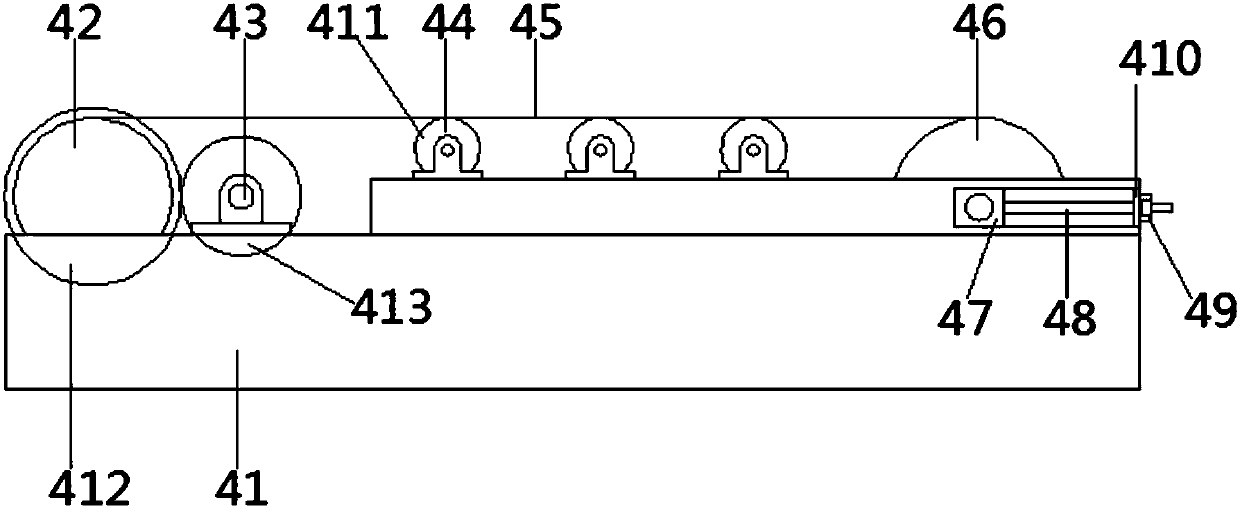

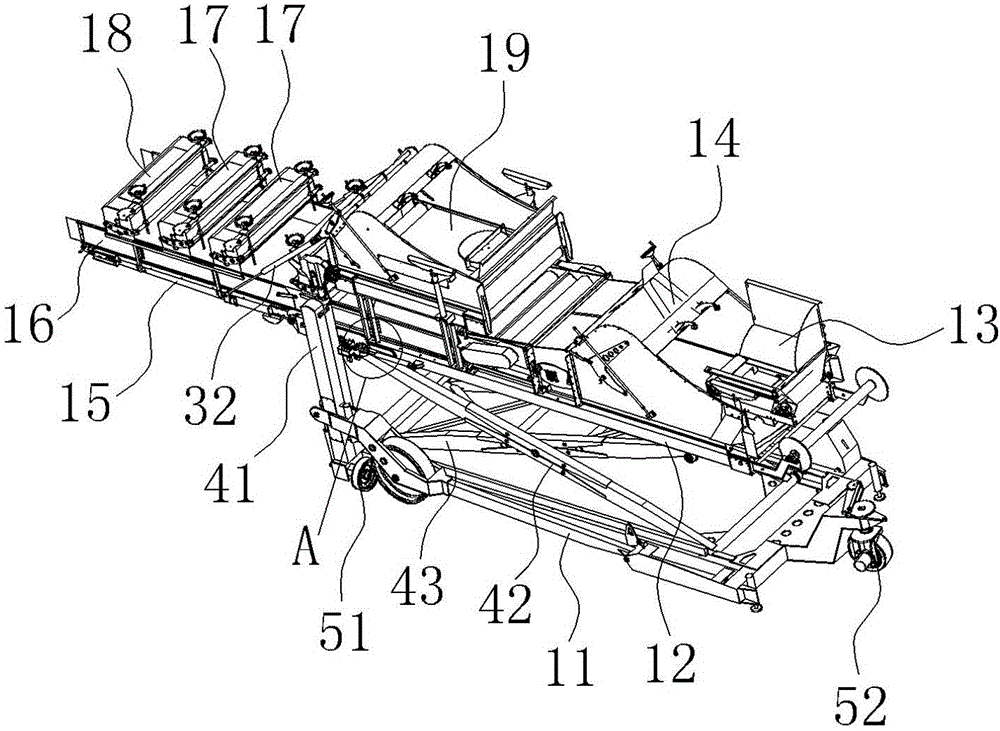

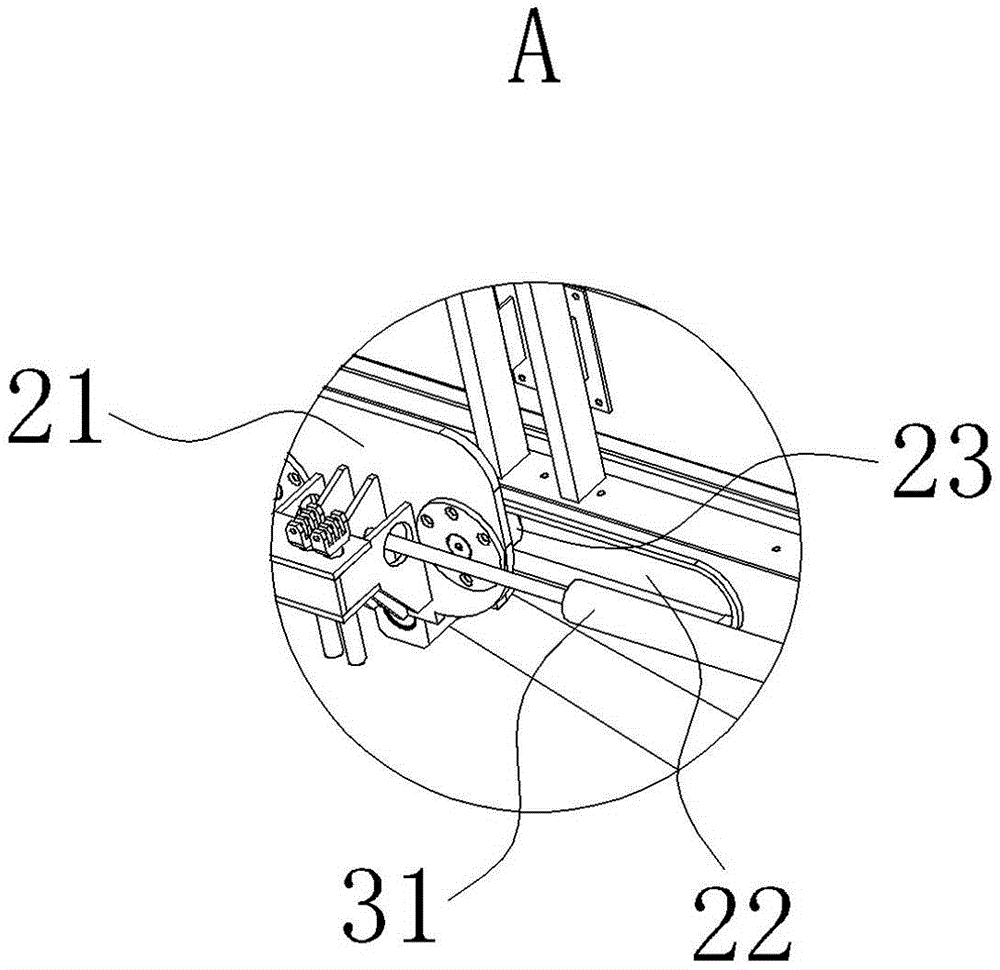

Mushroom bed feeder

The invention provides a mushroom bed feeder, belongs to the technical field of machinery, and solves the problems of low work efficiency as a forklift and manual operation need to be matched when the existing mushroom bed is used for feeding. The mushroom bed feeder comprises a moving frame, a worktable arranged above the moving frame and a lifting mechanism arranged between the moving frame and the worktable for driving the worktable to lift; a conveyor belt is arranged on the worktable; a feeding hopper and a poking flattening unit, which are positioned above the conveyor belt, are sequentially arranged on the worktable along the conveying direction of the conveyor belt; a swing head for supporting the conveyor belt and a support structure for supporting the swing head are arranged at the front part of the worktable; an adjusting structure for adjusting the horizontal distance, relative to the worktable, of the swing head is also arranged on the worktable. The mushroom feeder has the advantages of good feeding effect, high feeding efficiency, broad feeding range and the like.

Owner:ZHEJIANG HONGYE EQUIP TECH

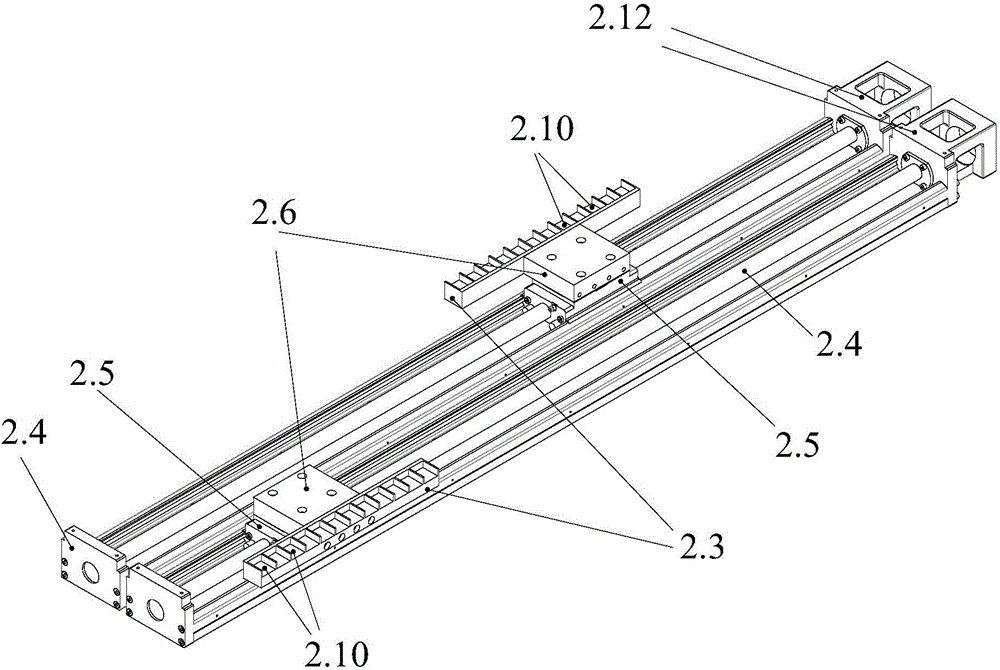

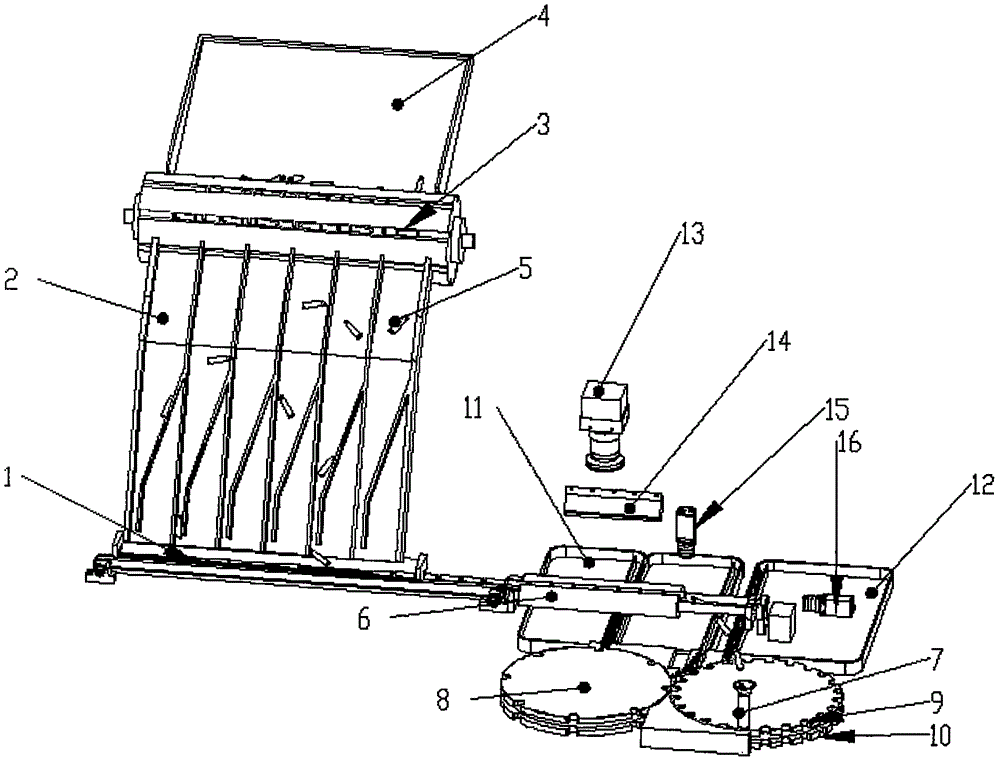

Feeding system and feeding method for silicon chip quality sorting equipment

ActiveCN104307759ARealize uninterrupted feedingIncrease the feeding speedSortingButt jointEngineering

The invention discloses a feeding system for silicon chip quality sorting equipment. The feeding system mainly comprises multiple feeding units with the same structure. Each one of the feeding units comprises a vertical guide rail, the vertical guide rail is provided with a feeding box, a basket case is installed in the feeding box, a side of the vertical guide rail is provided with a horizontal transmission mechanism, the horizontal transmission mechanism is used for transmitting silicon chips in the basket case to a downstream station, an output end of the horizontal transmission mechanism is provided with a horizontal guide rail, and the multiple horizontal transmission mechanisms can horizontally move reciprocatingly so that butt joint of the corresponding horizontal transmission mechanism and the downstream station is switched and thus when the feeding box in the multiple feeding units carries out feeding, the rest of the feeding boxes carry out loading. The multiple feeding units are installed on the horizontal guide rail capable of horizontally moving so that left-to-right switching of the multiple feeding units is realized. When one of the feeding units carries out a feeding process, the rest of the feeding units carry out basket case loading so that uninterrupted feeding is realized.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

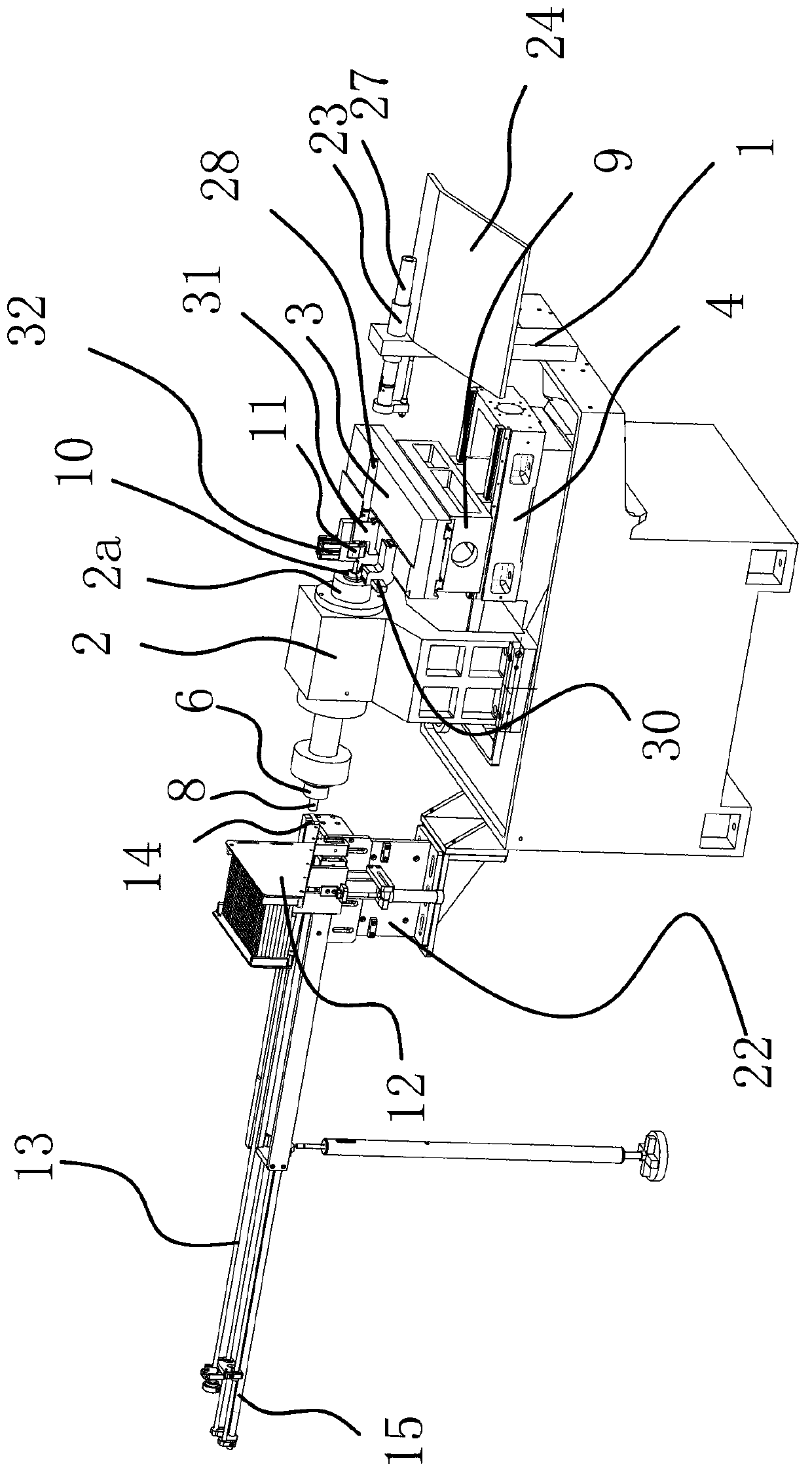

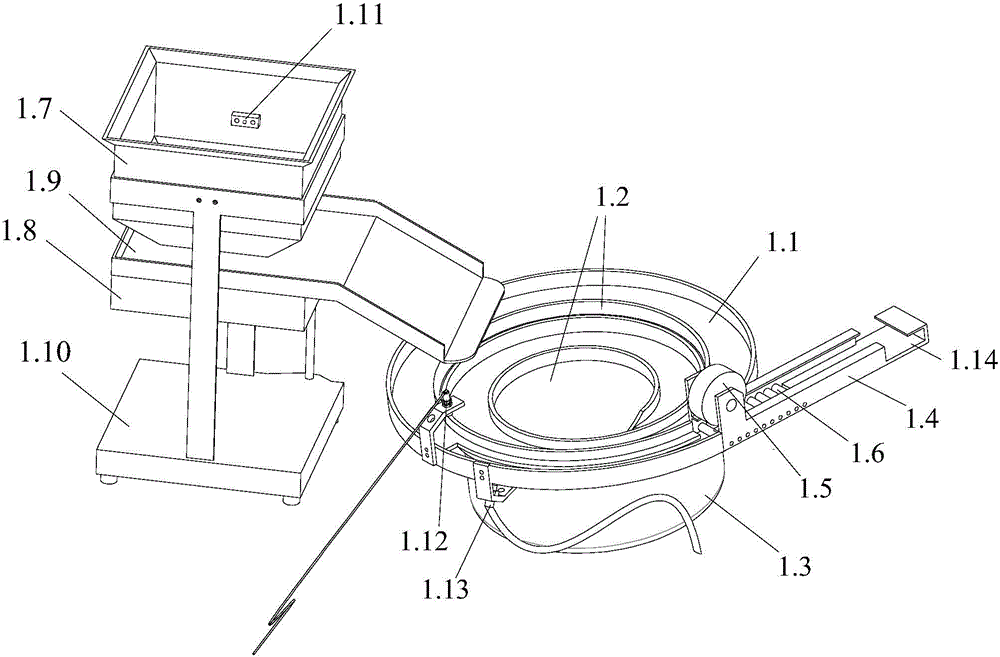

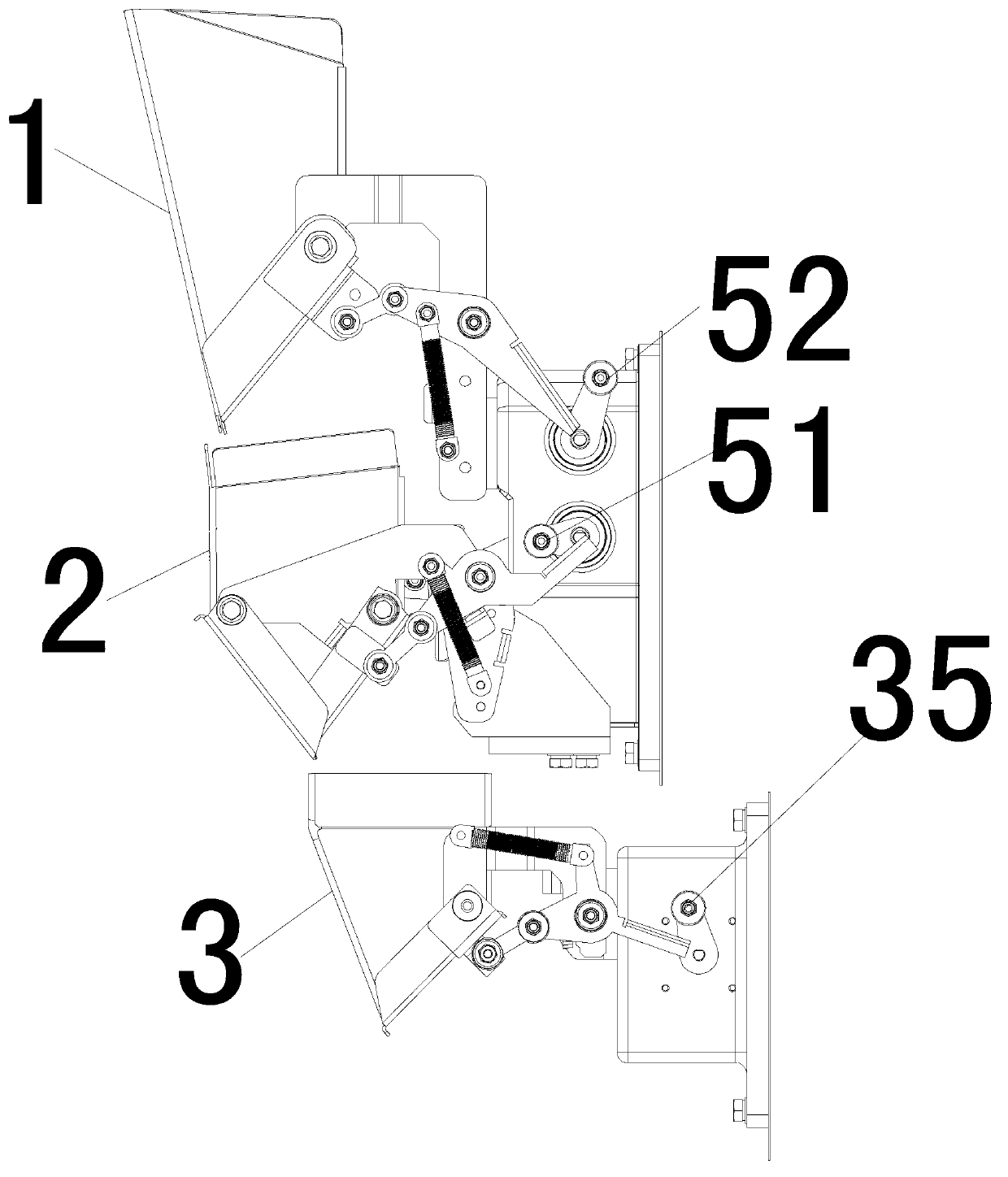

Automatic single-color mosaic-particle lay-up device and lay-up method thereof

ActiveCN104085241AImprove laying efficiencyHigh speedOrnamental structuresConveyor partsEngineeringAutomatic testing

The invention provides an automatic single-color mosaic-particle lay-up device and a lay-up method of the automatic single-color mosaic-particle lay-up device. The automatic single-color mosaic-particle lay-up device comprises a stander, a mosaic forming die which is arranged on the stander, at least one automatic mosaic-particle single-track lay-up unit, a loading device and a controller, wherein each automatic mosaic-particle single-track lay-up unit is used for gradually collecting mosaic particles one by one after transporting the mosaic particles one by one, arranging the mosaic particles into rows / columns according to a preset rule and then driving the entire row / column of mosaic particles to enter a loading procedure; the loading device is connected with the stander and used for sequentially transporting and loading the well-arranged entire row / column of mosaic particles in each automatic mosaic-particle single-track lay-up unit into the mosaic forming die; the controller is respectively connected with each automatic mosaic-particle single-track lay-up unit and the feeding device by signals. The automatic single-color mosaic-particle lay-up device is high in lay-up stability, high in lay-up speed and capable of effectively improving the lay-up efficiency and lay-up accuracy of the mosaic particles. The automatic lay-up method is used for substituting the traditional manual lay-up process, so that the problems that the current mosaic industry is low in automation degree and low in production efficiency can be solved.

Owner:FOSHAN UNIVERSITY

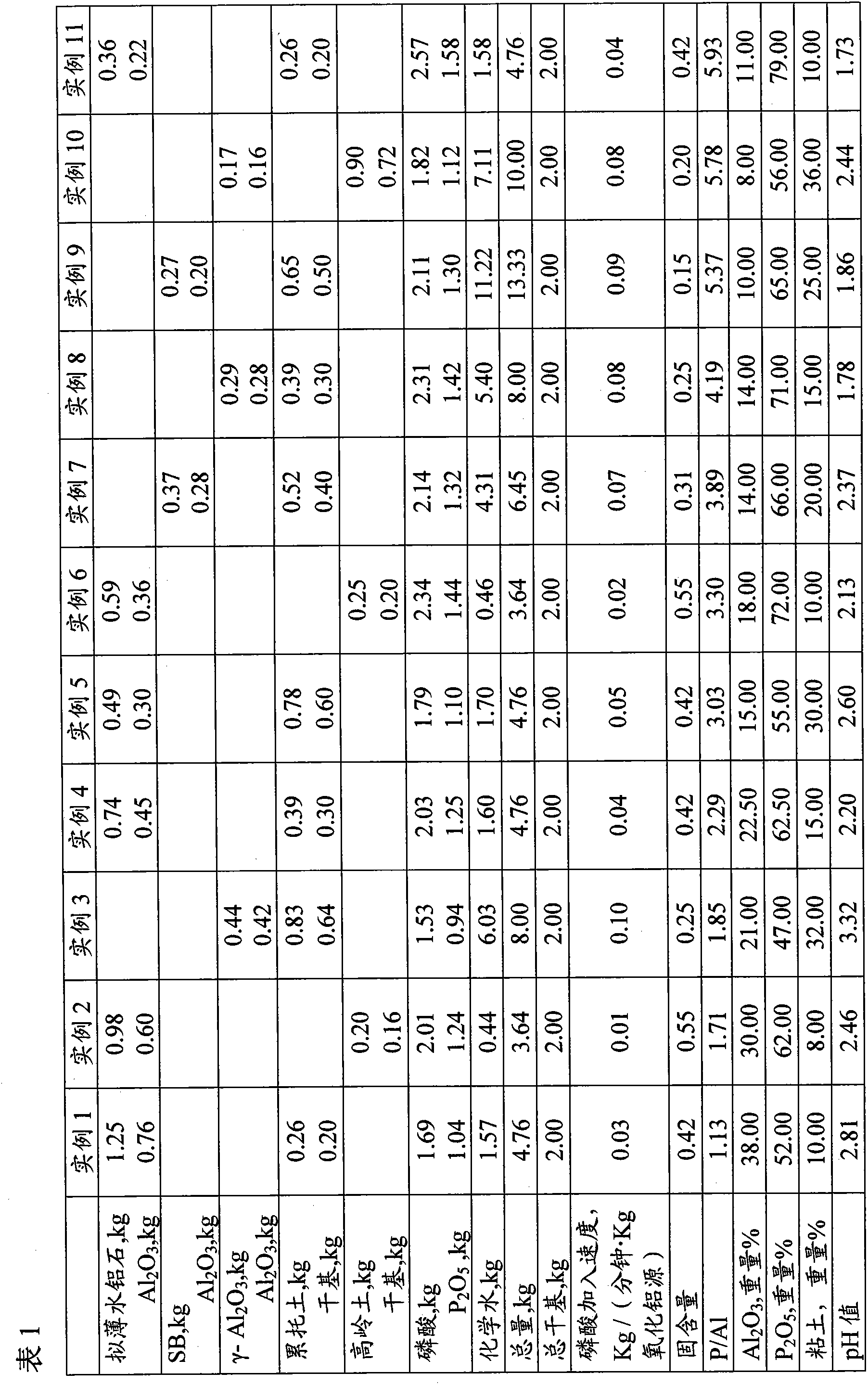

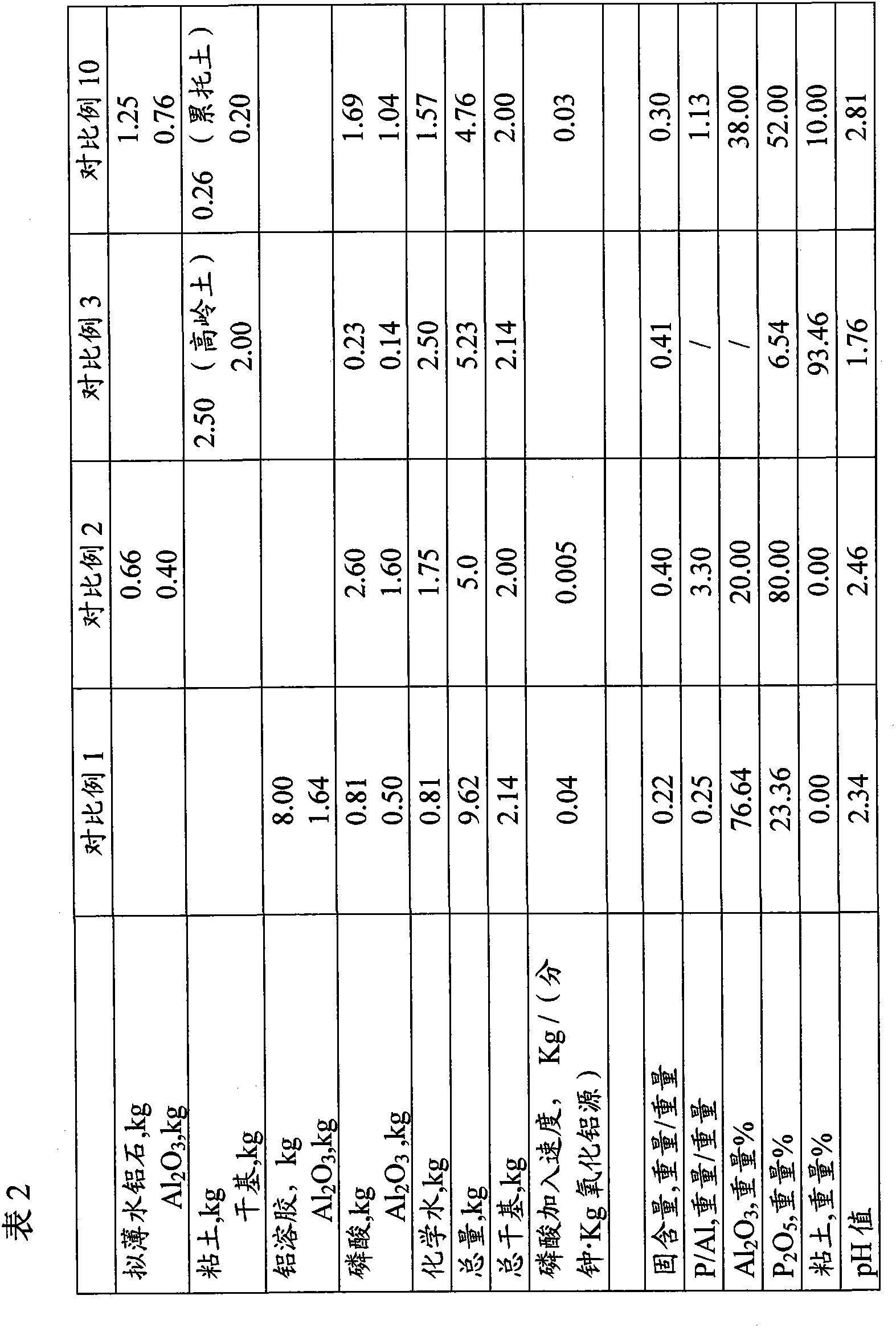

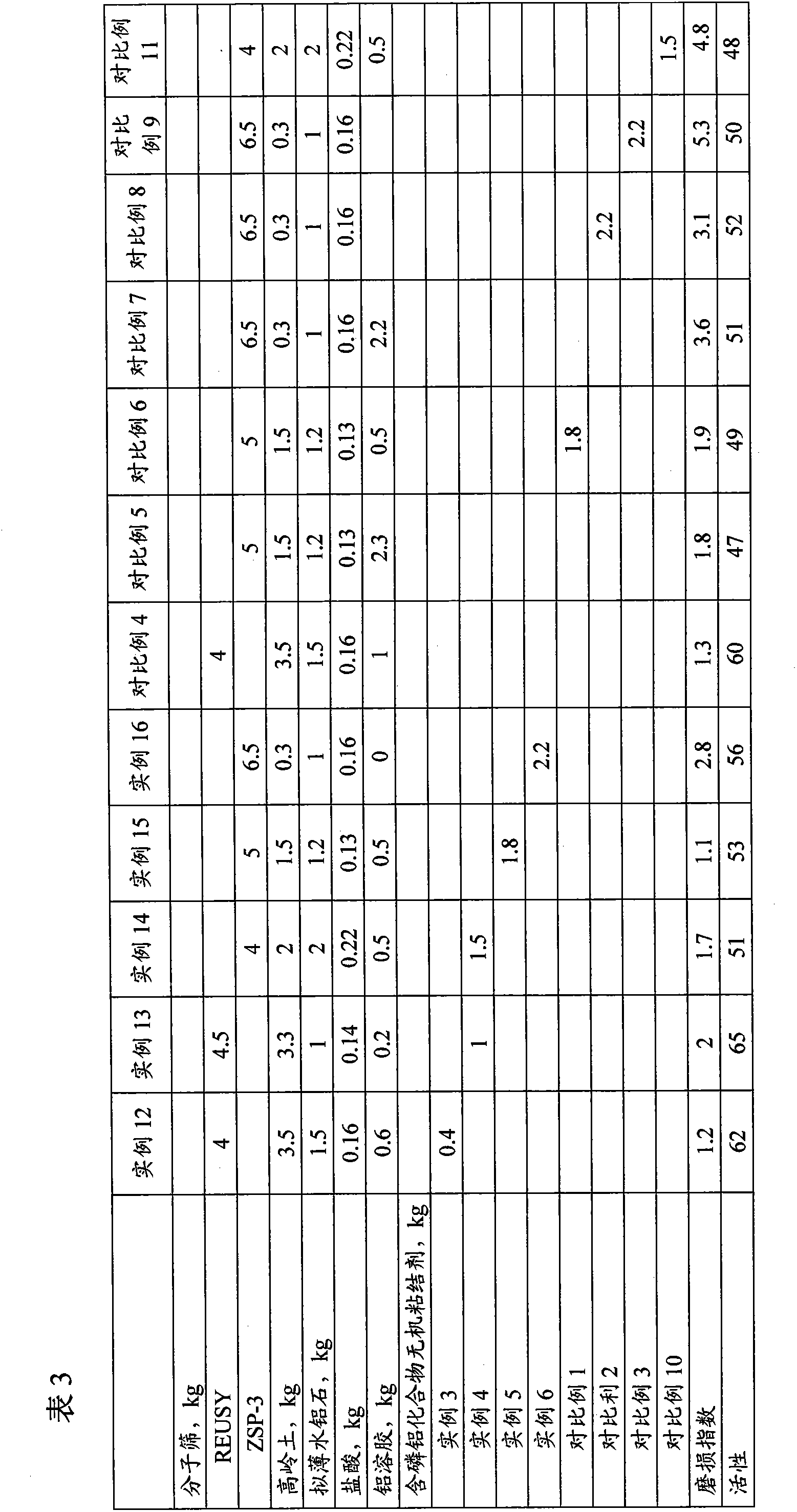

Inorganic binder containing phosphorus and aluminum compounds

ActiveCN102847547APrevent curingIncrease the feeding speedCatalytic crackingMolecular sieve catalystsAluminium hydroxidePhosphoric acid

The inventive inorganic binder containing phosphorus and aluminum compounds comprises (by weight percentages) alumina 15-40, phosphorus pentoxide 45-80, and clay 1-40. The binder has P / Al weight ratio of 1-6, pH of 1-3, and solid content of 15-60 wt%. The preparation method includes mixing acid-soluble aluminum hydroxide and / or alumina, clay and deionized water; pulping into pulp having solid content of 15-45%; adding concentrated phosphoric acid into the pulp under stirring at P / Al weight ratio of 1-6; and reacting at 50-99 DEG C for 15-90 min. The preparation method can avoid binder solidification due to overheat caused by heat release of non-uniform local instantaneous intensive reaction of materials. The binder can improve wear resistance, activity and selectivity of FCC catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

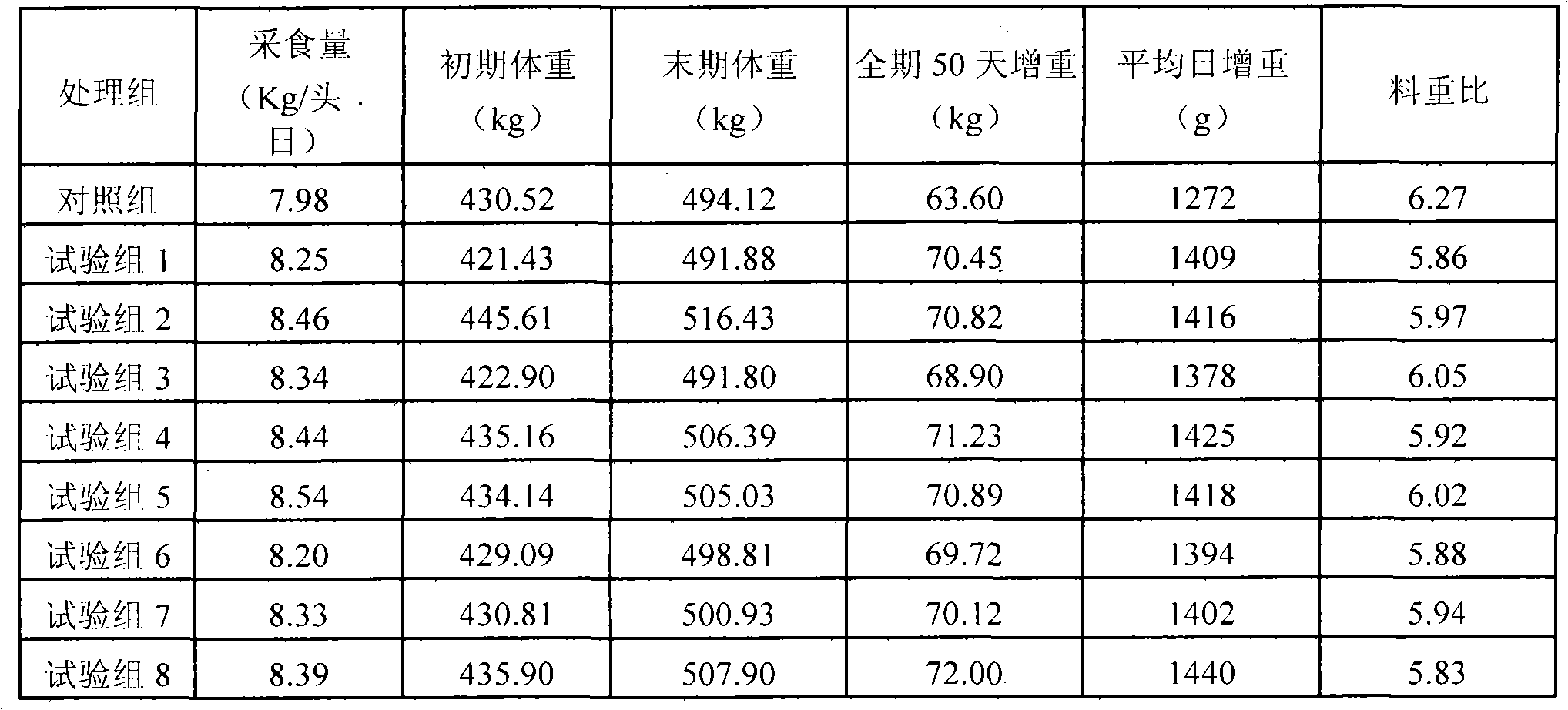

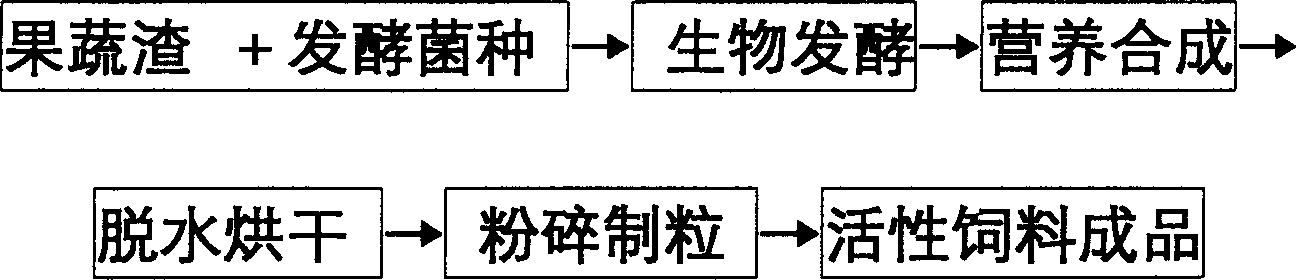

Process of fodder with bioactivity

InactiveCN1504102AImprove palatabilityIncrease the feeding speedFood processingAnimal feeding stuffBuffering agentFodder

The invention discloses a process for manufacturing biologically active fodder which mainly includes a fermentation procedure, wherein 0.1-5% zymogeneous bacteria, 0.5-5% buffering agent, and 0.1-10% Yishengyuan are added into the slag of fruits and vegetables under the condition of pH 5-7, temperature 30-42 deg.C, stacking the fruit and vegetable slag to a thickness of 20-100cm, fermentation 20-40 hrs, and a nourishment synthesis procedure. The invention realizes the utilization of industrial and agricultural waste resource.

Owner:SHANGHAI JIUCHUAN SCI & TECH DEV

Nylon affinity membrane preparing method and use

InactiveCN1935339AHigh purification factorSmall pressure dropSemi-permeable membranesHydrolasesCibacron Blue F3GABiological macromolecule

The present invention discloses a preparation method of nylon affinity membrane. Said method includes the following steps:(1) on the nylon membrane chemically-bonding chitosan so as to obtain the chitosan modified nylon membrane; and (2) bonding the chitosan modified nylon membrane and affinity dye Cibacron Blue F3GA so as to obtain the described nylon affinity membrane which can be used for separating and purifying papain.

Owner:DONGHUA UNIV

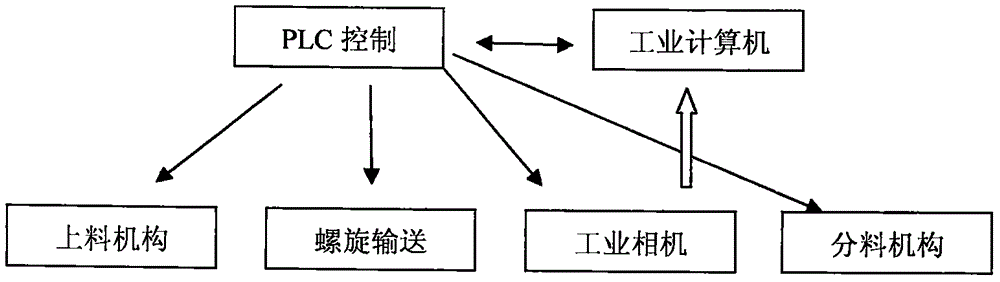

Vision detection system for cartridge case

InactiveCN106248691AImprove accuracyReduce the outflow of defective cartridge casesOptically investigating flaws/contaminationConveyor partsIndustrial PCSignal lines

Owner:QINGDAO SMARTEYE TECH

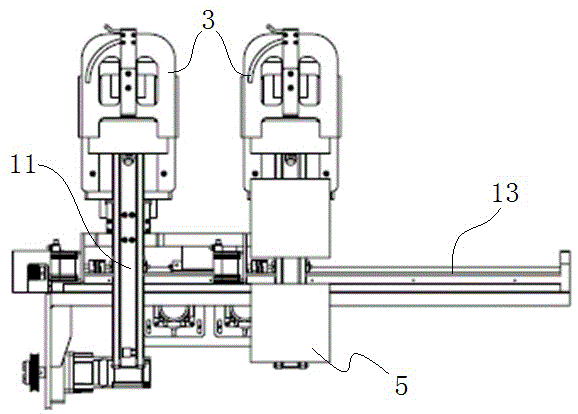

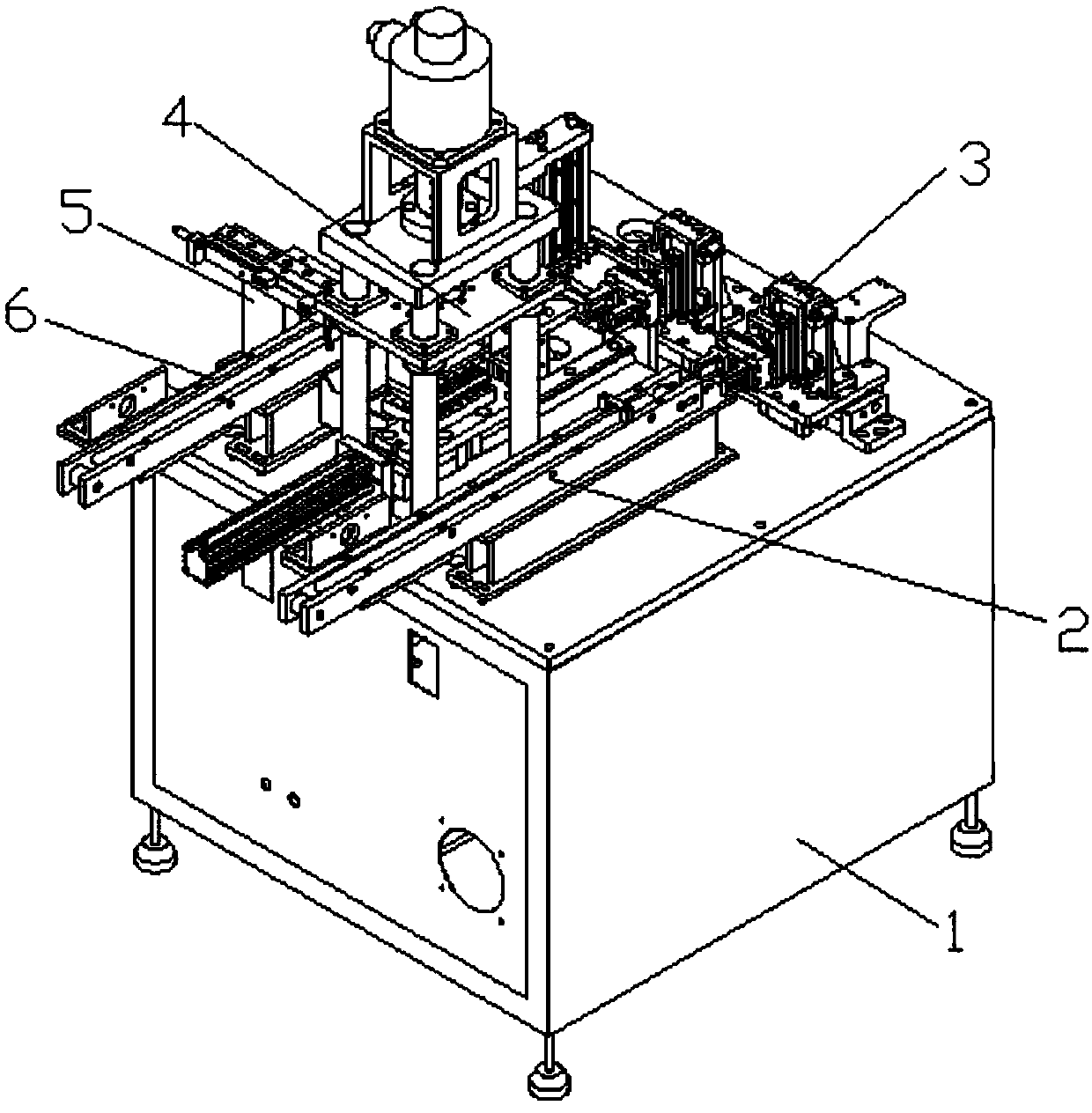

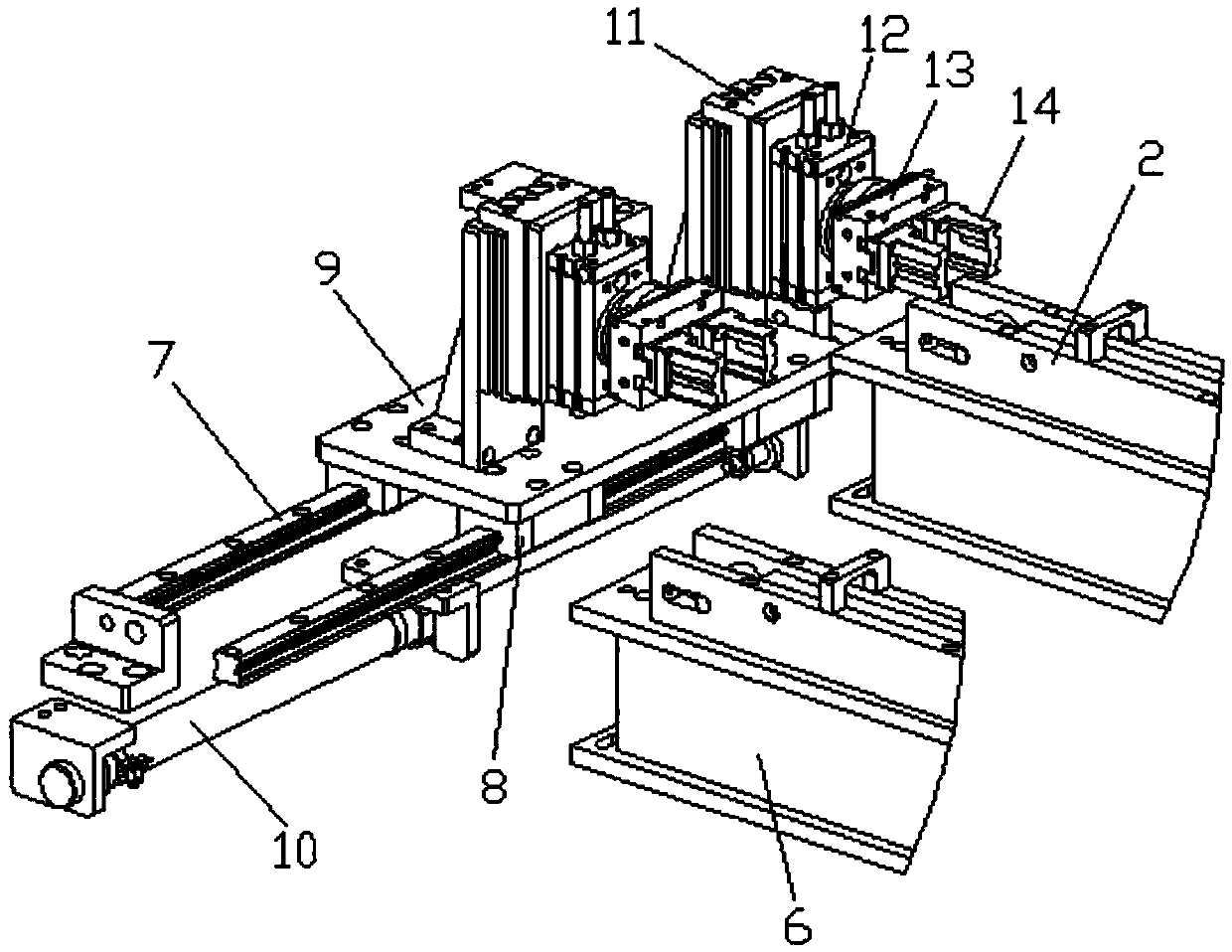

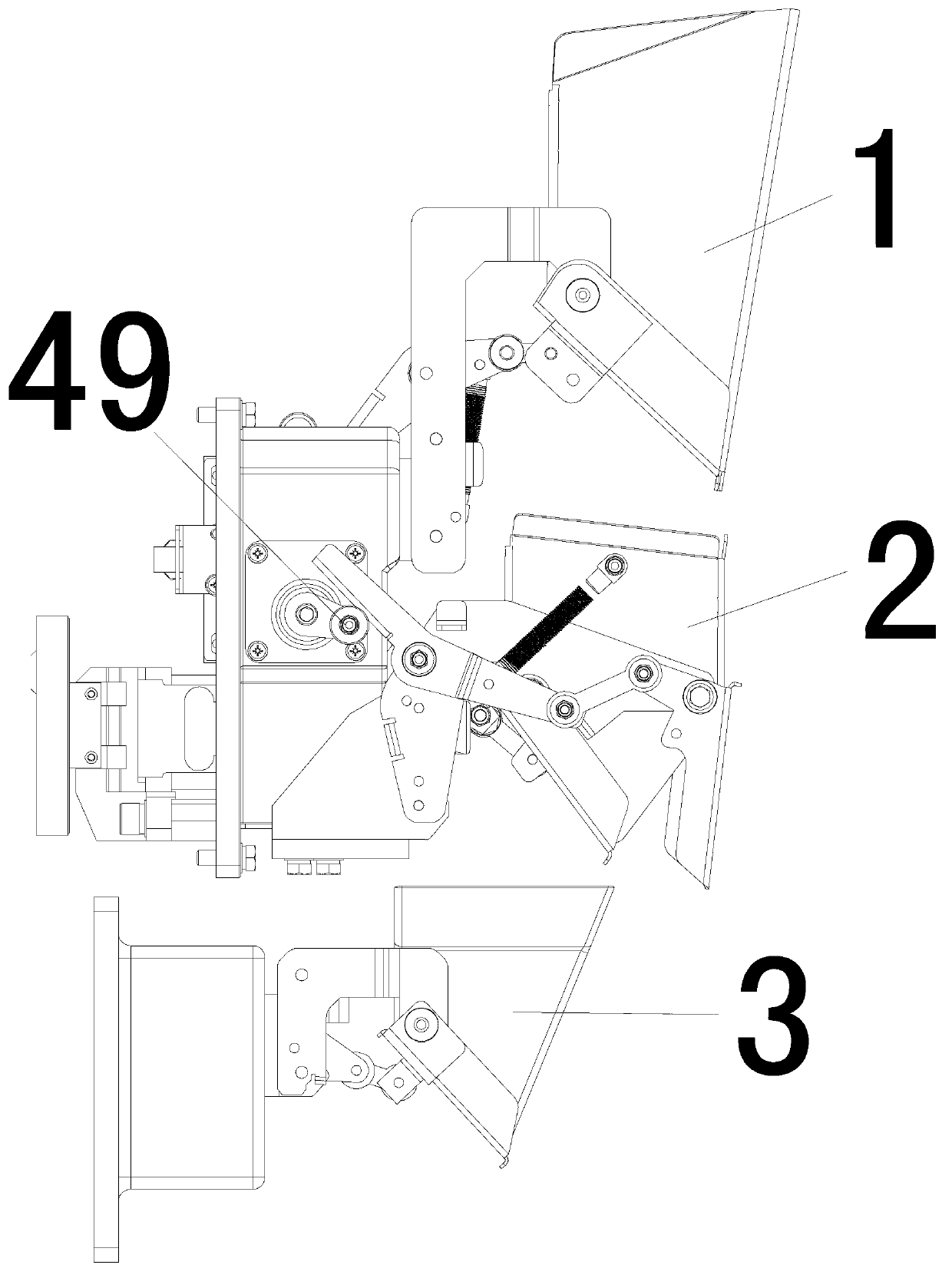

Automatic press-fitting machine of button motor

InactiveCN107803640ARealize automatic nestingIncrease productivityMetal working apparatusConveyor partsEngineeringMechanical engineering

The invention relates to a button motor automatic pressing machine, which includes a frame, on which a feeding mechanism and a pressing mechanism that cooperate with each other are arranged, and the feeding mechanism includes an upper cover arranged on the frame in front of the pressing mechanism The feeding track and the feeding and conveying device set on the right side of the pressing mechanism to cooperate with the feeding track of the upper cover, the feeding carrier of the upper cover is placed on the feeding track of the upper cover, and the right side of the pressing mechanism is provided. Pressing device, the pressing device includes a pressing lifting cylinder vertically arranged on the pressing mechanism, the lower end of the push rod of the pressing lifting cylinder is connected with a pressing seat, and the lower part of the pressing seat is vertically arranged to cooperate with the feeding carrier of the upper cover. The pressing rod of the press-fitting servo motor drives the press-fit lifting seat to slide up and down, and the press-fit lifting seat drives the shell pressing device to cooperate with the carrier, and the upper cover and the bottom shell of the button motor are pressed tightly together. Realize the automatic pressing of the button motor, improve the stability of the product, and improve the production efficiency.

Owner:DONGGUAN UNIV OF TECH

Special feed for mandarin fish fries

InactiveCN105394452AConvenient foragingImprove digestion and absorption rateFood processingClimate change adaptationPrawnCerium

The invention discloses special feed for mandarin fish fries. The special feed comprises raw materials in parts by weight as follows: 20-80 parts of fish meal, 30-80 parts of prawn powder, 15-35 parts of blood worm powder, 2-8 parts of cod-liver oil, 1-3 parts of palm oil, 1-4 parts of citrus oil, 10-30 parts of bone meal, 20-30 parts of sweet corn protein powder, 8-14 parts of corn germ meal, 2-10 parts of bean pulp, 10-30 parts of fermented bioprotein, 5-15 parts of black sesame powder, 8-14 parts of bloodworms, 0.5-3 parts of aloe powder, 0.5-3 parts of lotus leaf powder, 0.1-0.8 parts of cerium citrate, 1-3 parts of methionine, 1-3 parts of threonine, 0.01-0.07 parts of a complex enzyme, 0.01-0.09 parts of microelements, 1-3 parts of Chinese herbal medicines, 2-10 parts of an attractant and 0.5-1.5 parts of multivitamins. With the adoption of the special feed, even if under the condition of manual high-density culture, the fatality rate of the mandarin fish fries is very low, the feed is good in palatability and high in nutritional value, the ratio is reasonable, the cost is low, and fish is delicious.

Owner:全椒县鮰鱼养殖专业合作社

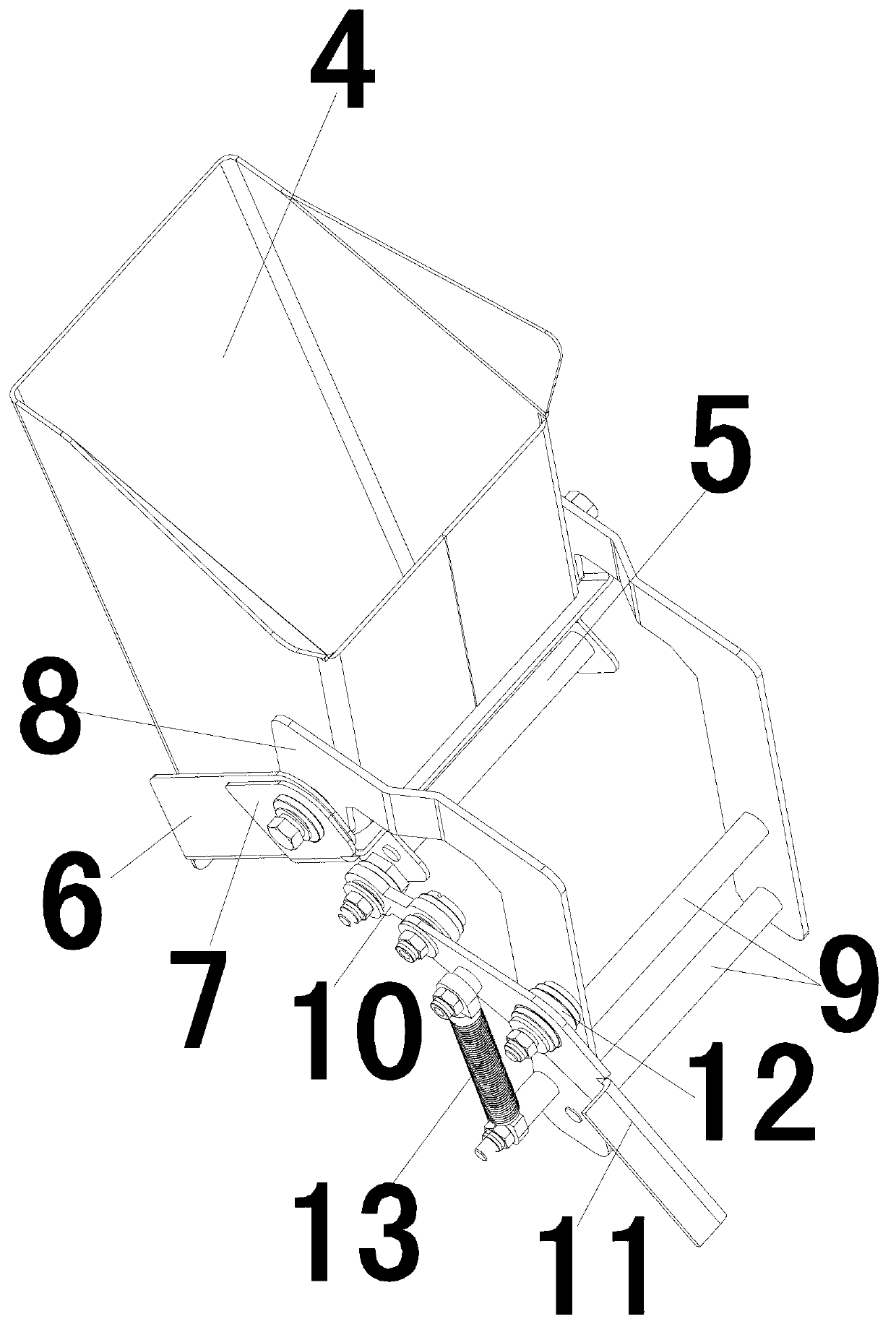

Weighing device with memory function and for combination scale and achieving method thereof

ActiveCN102997982ASimple structureIncrease the feeding speedWeighing indication devicesSpecial purpose weighing apparatusQuality controlEngineering

The invention discloses a weighing device with a memory function and for a combination scale. The weighing device comprises a buffer hopper, a weighing hopper and a memory hopper used for storing materials delivered by the weighing hopper. The buffer hopper and the weighing hopper are connected with a first driving aluminum box from top to bottom, the memory hopper is connected with a second driving aluminum box, the first driving aluminum box and the second driving aluminum box are arranged on a frame, and the first driving aluminum box and the second driving aluminum box are connected with a controller respectively. An achieving method of the weighing device with the memory function and for the combination scale is further disclosed. The weighing device and the method effectively resolve the problems of large consumption power, high manufacture process requirement and cost, easily-damaged structure, large shock, inaccurate weighing, difficulty in quality control and the like, and have the advantages of being simple in structure, high in feeding and discharging speed, small in consumption power, small in vibration, small in noise, high in weighing accuracy, convenient to process and the like.

Owner:GUANGODNG HIGH DREAM INTELLECTUALIZED MACHINERY

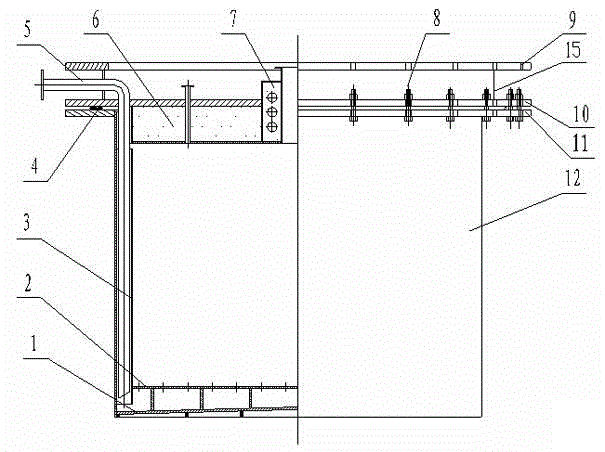

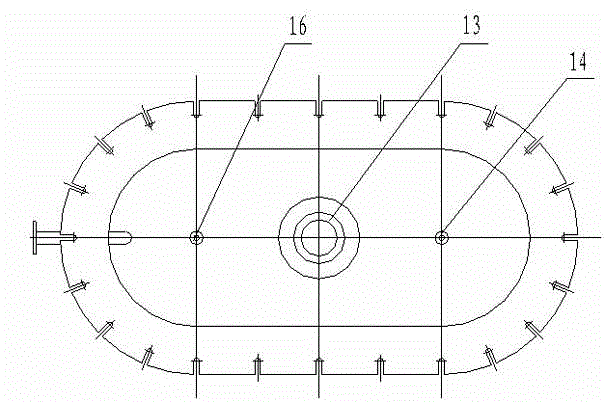

Sponge titanium reduction distillation reactor and production technique thereof

The invention relates to a sponge titanium reduction distillation reactor which is formed by connecting a tank body and a large cover through a flange rubber cushion and a bolt set, wherein the tank body comprises a bottom plate, a sieve plate, a magnesium chloride discharge casing, a tank body flange and a waist-type cylinder; the large cover comprises a magnesium chloride discharge pipe, a thermal insulation layer, an internal heating device, a large cover upper flange, a large cover lower flange, a central pipe, a charging casing 1, a short cylinder and a charging casing 2; the integral reactor is in a stereoscopic waist circular structure; and the bottom plate is a sloping plate positioned on the lowest part of the whole reactor, and is matched with the waist-type cylinder to form an open stereoscopic waist-type tank body. The integral effective width of the reactor is 1.2-1.5 meters, the height is 1.5-2.5 times of the width, and the length is 2-3 times of the width. The reactor for producing sponge titanium can change the sponge titanium structure, solve the problem of compactness, greatly enhance the overall charging rate, simplify the distillation process and greatly shorten the period.

Owner:罗时雨

Auxiliary feeding device for side-stepping and board-trimming in carpentry

InactiveCN102229153AIntegrity guaranteedConducive to long-term developmentFeeding devicesEngineeringWoodworking

The invention discloses an auxiliary feeding device for side-stepping and board-trimming in carpentry. The auxiliary feeding device comprises a machine frame, a drive device mounted on the machine frame, and a roller platform consisting of a plurality of rollers. In addition, a pneumatic baffle plate device, a translating side-stepping device and a board-trimming pressing device are additionally arranged on the machine frame, wherein the pneumatic baffle plate device is used for preventing boards from being continuously conveyed, the translating side-stepping device is used for translating the boards to step to a side, and the board-trimming pressing device is used for stably conveying the boards to a next working procedure; and through the structural cooperation among the devices to makethe devices in compact connection, the automatic operation of the auxiliary feeding device per se is strengthened, the boards are ensured to be stably conveyed in a side-stepping manner, and the speed and the accuracy for feeding are greatly increased, the production efficiency is improved, meanwhile, the completeness of the boards is ensured.

Owner:广东科豪木工机械有限公司

Color matching device for producing and printing medicine package

InactiveCN106943934AImprove work efficiencyIncrease the feeding speedShaking/oscillating/vibrating mixersTransportation and packagingEngineeringCheck valve

The invention relates to a color matching device and particularly relates to a color matching device for producing and printing a medicine package. Aiming at solving the technical problems, the invention provides the color matching device for producing and printing the medicine package, which has an excellent matching effect, saves time and labor and has high working efficiency. In order to solve the technical problems, the color matching device for producing and printing the medicine package, provided by the invention, comprises a bottom plate, first supporting rods, a collection box, a first discharging pipe, a first valve, a second supporting rod, a cylinder body, a second discharging pipe, a first check valve, a feeding pipe and the like; first supporting rods are symmetrically welded left and right on tops of the bottom plate; the collection box is welded at the tops of the first supporting rods; the first discharging pipe is welded at the lower part of the left side of the collection box; and the first valve is arranged on the first discharging pipe. According to the color matching device for producing and printing the medicine package, a left-right movement device moves leftward and rightward and a pigment is matched; and the blended pigment is stirred and mixed through a stirring device and the working efficiency is improved.

Owner:滁州钰禾文具制品有限公司

Aquatic animal attractant and preparation method thereof

InactiveCN102771633AIncrease the feeding speedReduce lossAnimal feeding stuffAquaculture industryAquatic animal

The invention relates to the field of aquaculture industries, and more particularly relates to an aquatic animal attractant. The aquatic animal attractant is composed of the following components in parts by weight: 50-100 parts of allicin, 50-300 parts of trimethylamine oxide, 100-300 parts of dimethyl-beta-dimethylpropiothetin, 100-200 parts of zeolite powder and 100-700 parts of starch. A preparation method of the aquatic animal attractant comprises the following steps of: weighing the components in parts by weight; and grinding the weighed components into powders, and uniformly mixing the powders to obtain the aquatic animal attractant. The aquatic animal attractant disclosed by the invention has the beneficial effects of being capable of increasing the ingestion speed of aquaculture animals, effectively reducing the loss of baits, decreasing breeding costs, and improving water quality and reducing environmental pollution on water bodies while increasing breeding benefits.

Owner:TIANJIN SHENGJI GRP CO LTD

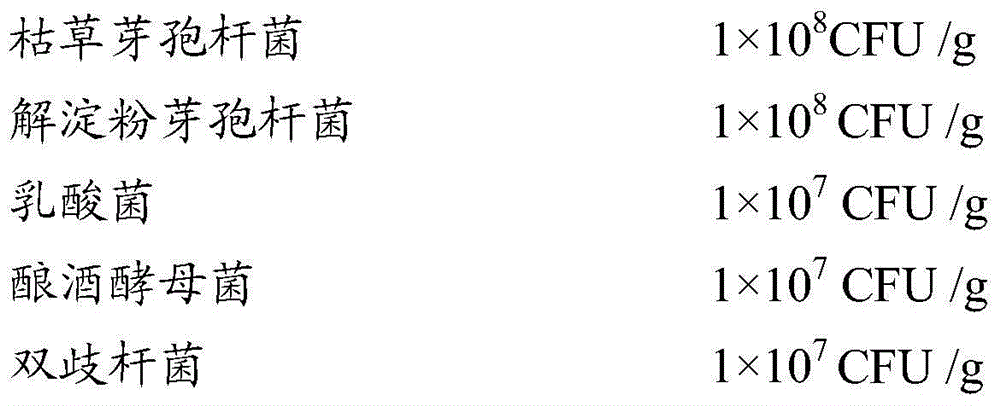

Straw feed

InactiveCN104855744AHigh in nutrientsImprove qualityAnimal feeding stuffAgriculture gas emission reductionBiotechnologyFermentation

The invention relates to the technical field of feeds, in particular to a straw feed. A preparation method for the straw feed comprises the step of fermenting straws with a fermentation composition to obtain the straw feed; the fermentation composition comprises complex bacteria and complex enzymes; the complex bacteria comprise bacillus subtilis, bacillus amyloliquefaciesaccharomyces cerevisiae bifidobacteria, and bifidobacterium; the complex enzymes comprise cellulase and diastase. Through the adoption of the straw feed, the quality of livestock products can be improved; meanwhile, the methane emission from ruminants can be greatly reduced, the loss of methane energy is reduced, the energy digestibility of diets and the feed net energy are increased, and the pollution of livestock breeding to the environment is reduced.

Owner:吉林省福一农业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com