Patents

Literature

1571results about "Feeding devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

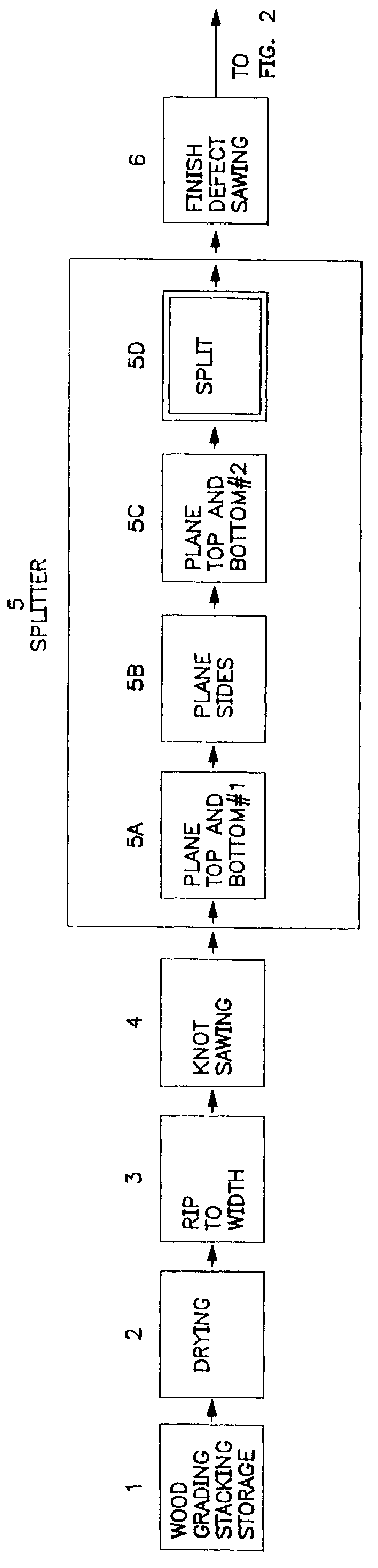

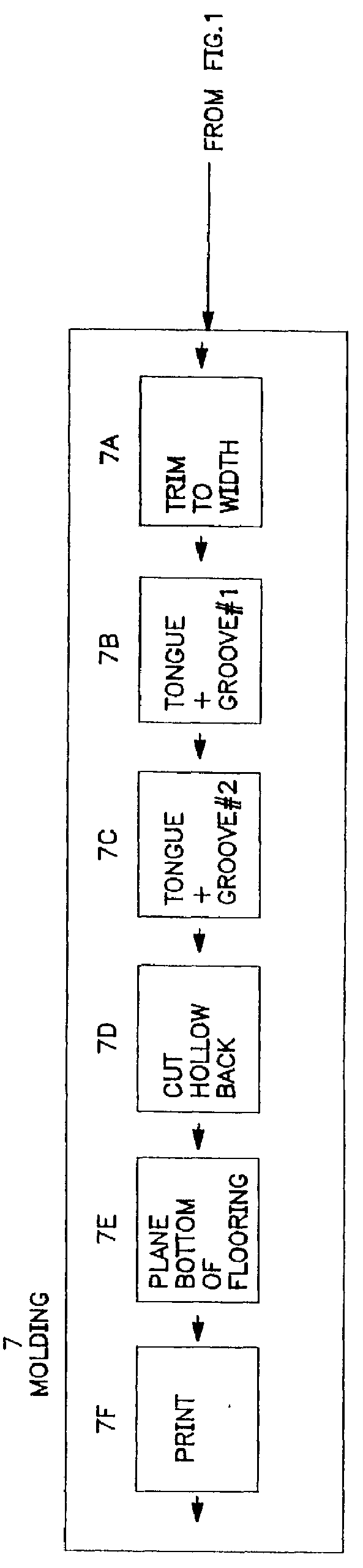

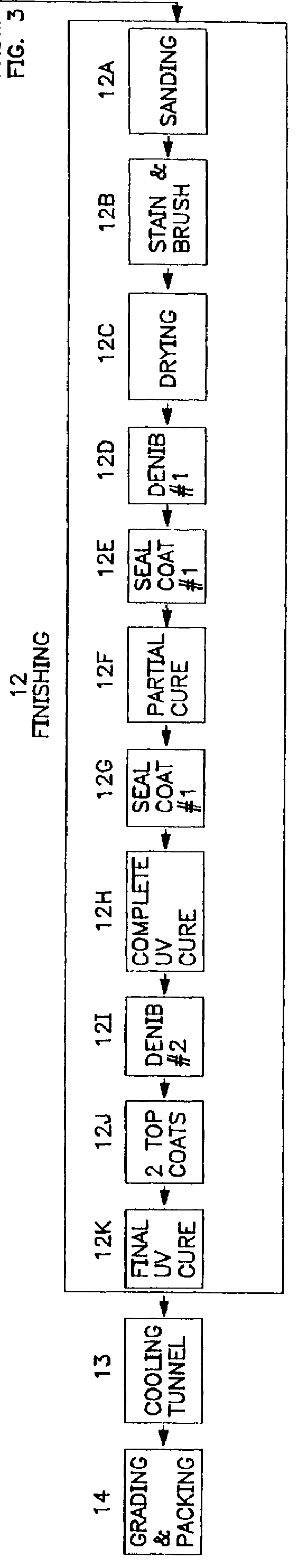

Low profile hardwood flooring strip and method of manufacture

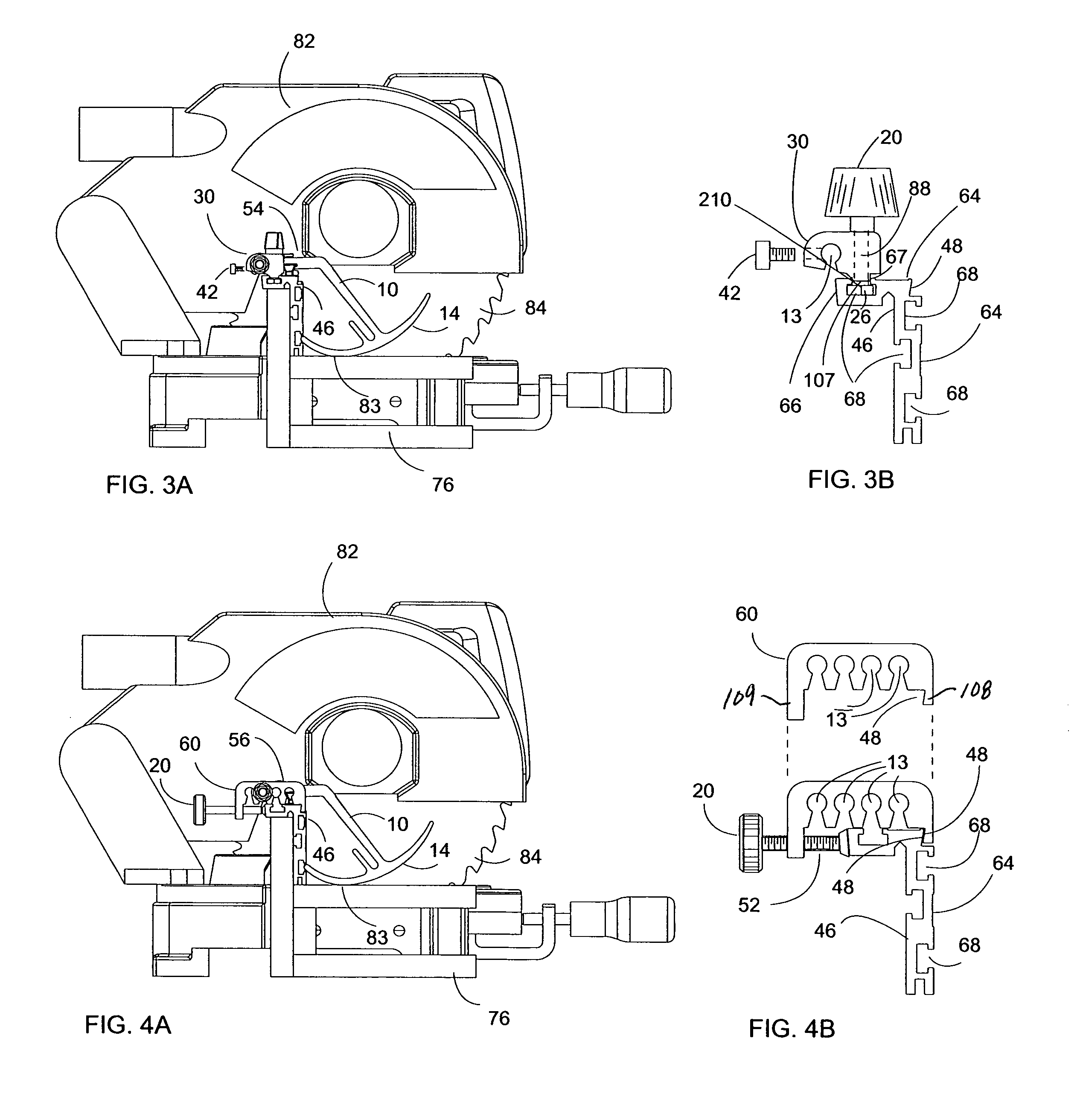

InactiveUS6148884AConsiderable quantityImprove rigidityDovetailed workMulti-purpose machinesCircular sawTongue and groove

A method of producing a hardwood flooring product, including the steps of processing a strip of raw wood into a blank having a predetermined thickness and width, and top and bottom surfaces defining parallel planes relative to each other, and splitting the blank along the width of the blank from one side to the other to form two low profile flooring strips having the same width as the blank and a thickness less than one-half the thickness of the blank. The splitting step includes the steps of providing first and second circular saw blades mounted on spaced-apart vertical axes for rotation in a single plane intermediate and parallel to the planes of the top and bottom surfaces of the blank and positioning the blank on conveying means upstream from the saw blades with the plane of rotation of the saw blades intermediate and parallel to the planes of the top and bottom surfaces of the blank for movement of the blank from an upstream position to a downstream position relative to the saw blades. The blank is moved downstream into the plane of rotation of the saw blades during rotation of the saw blades thereby horizontally splitting the blank to form first and second low-profile flooring strips. Interlocking members, such as molded, mating tongue and groove members, are molded into first and second longitudinally-extending side edges of the flooring strips for securing together the flooring strips when placed side-to-side to form a floor.

Owner:ARMSTRONG HARDWOOD FLOORING CO +2

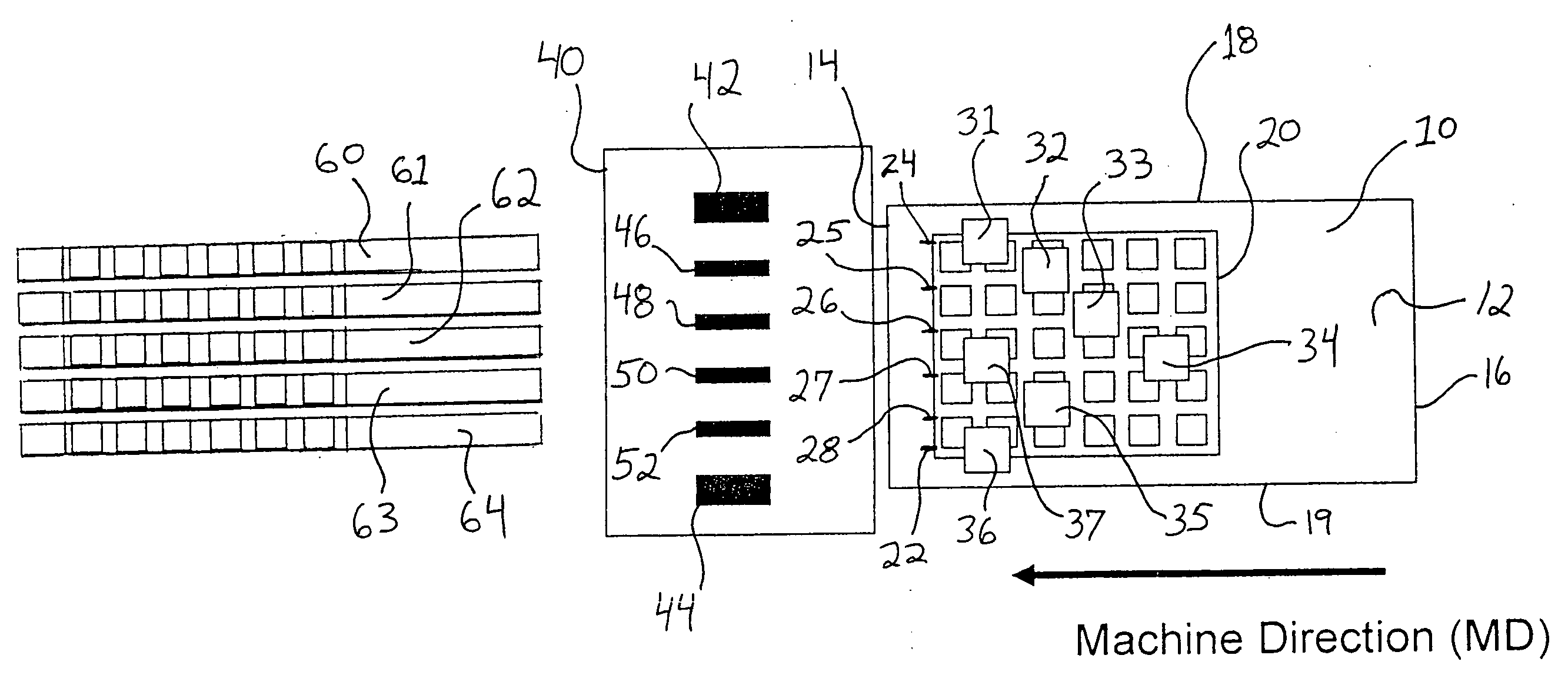

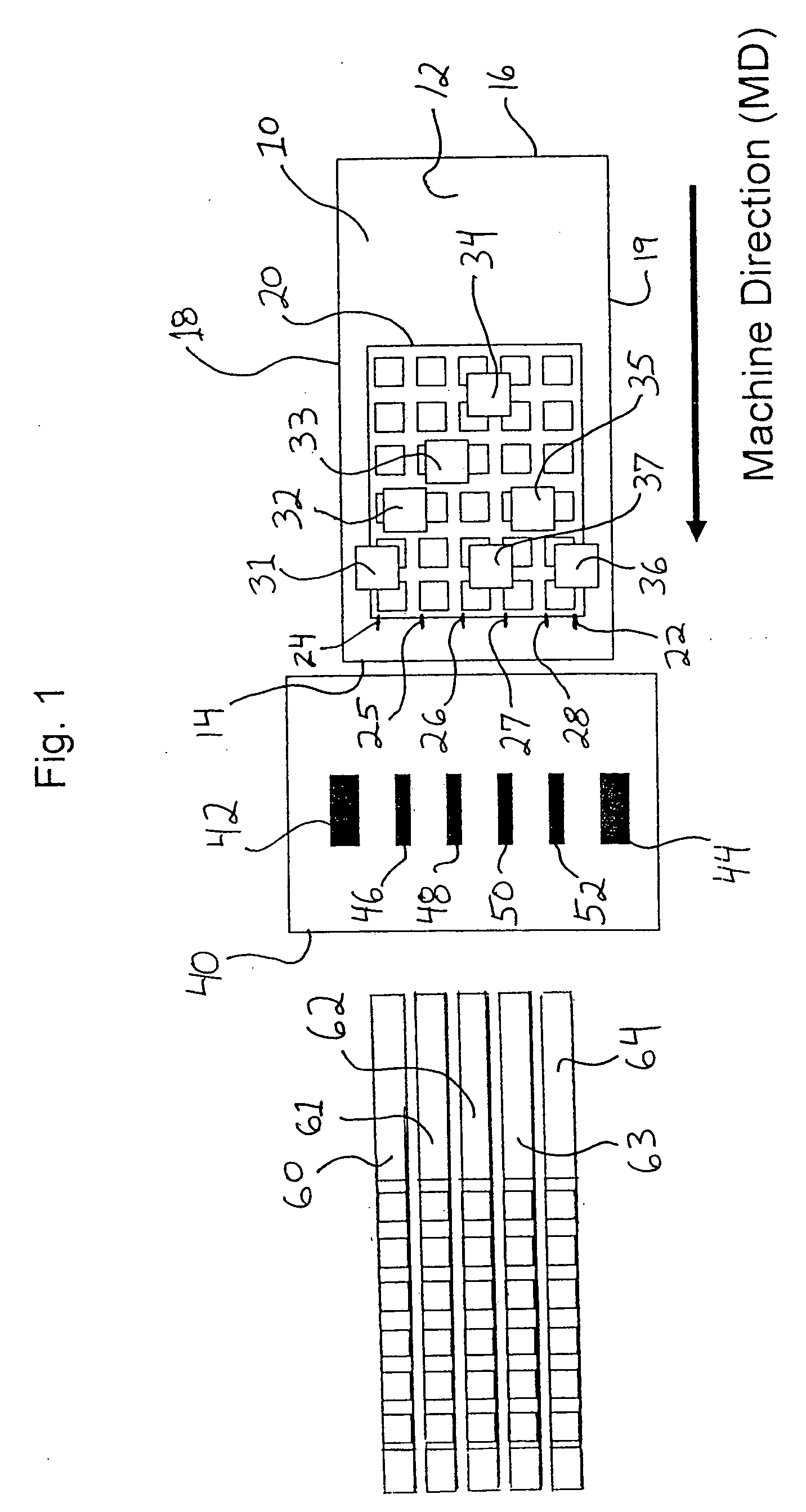

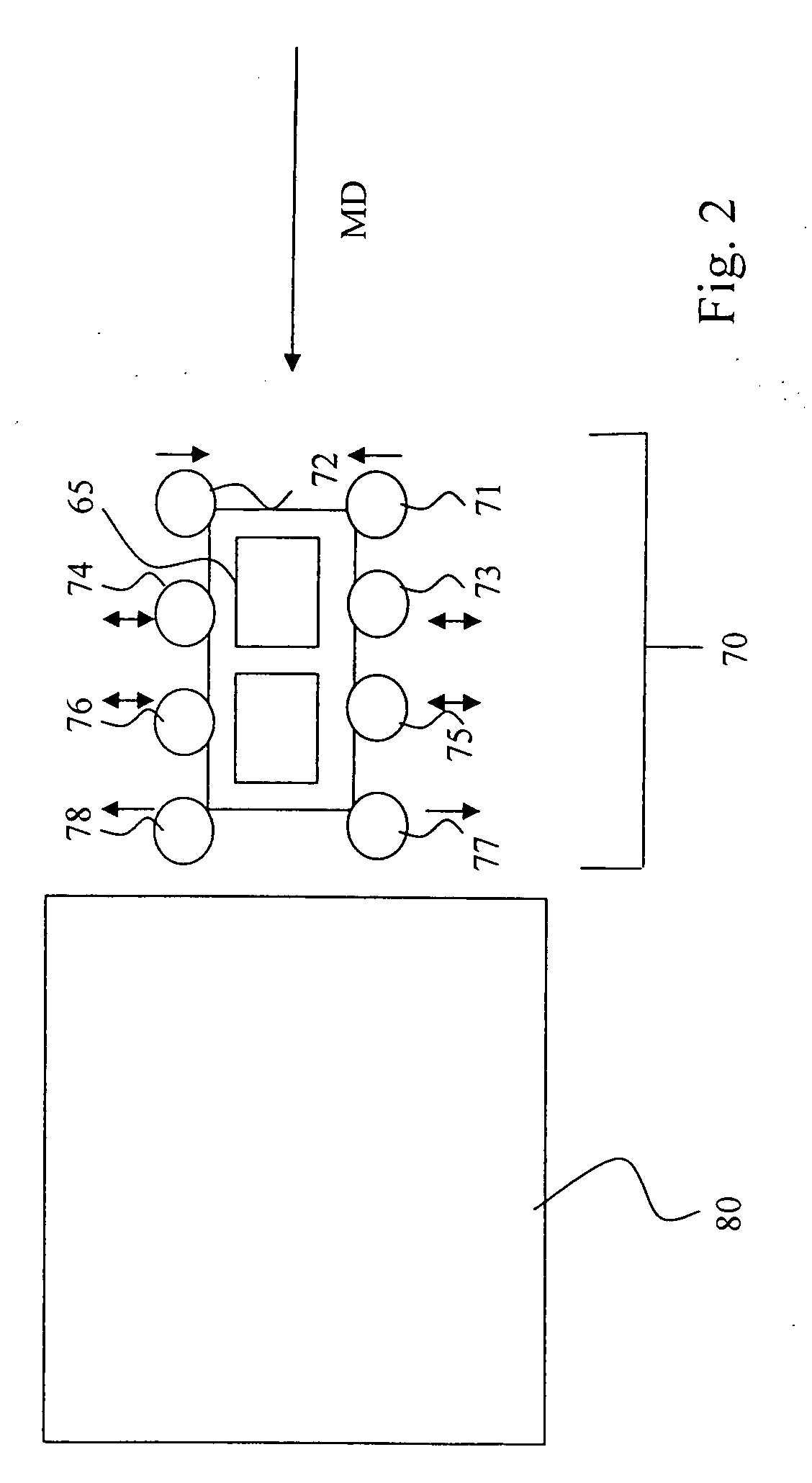

Process and system for sub-dividing a laminated flooring substrate

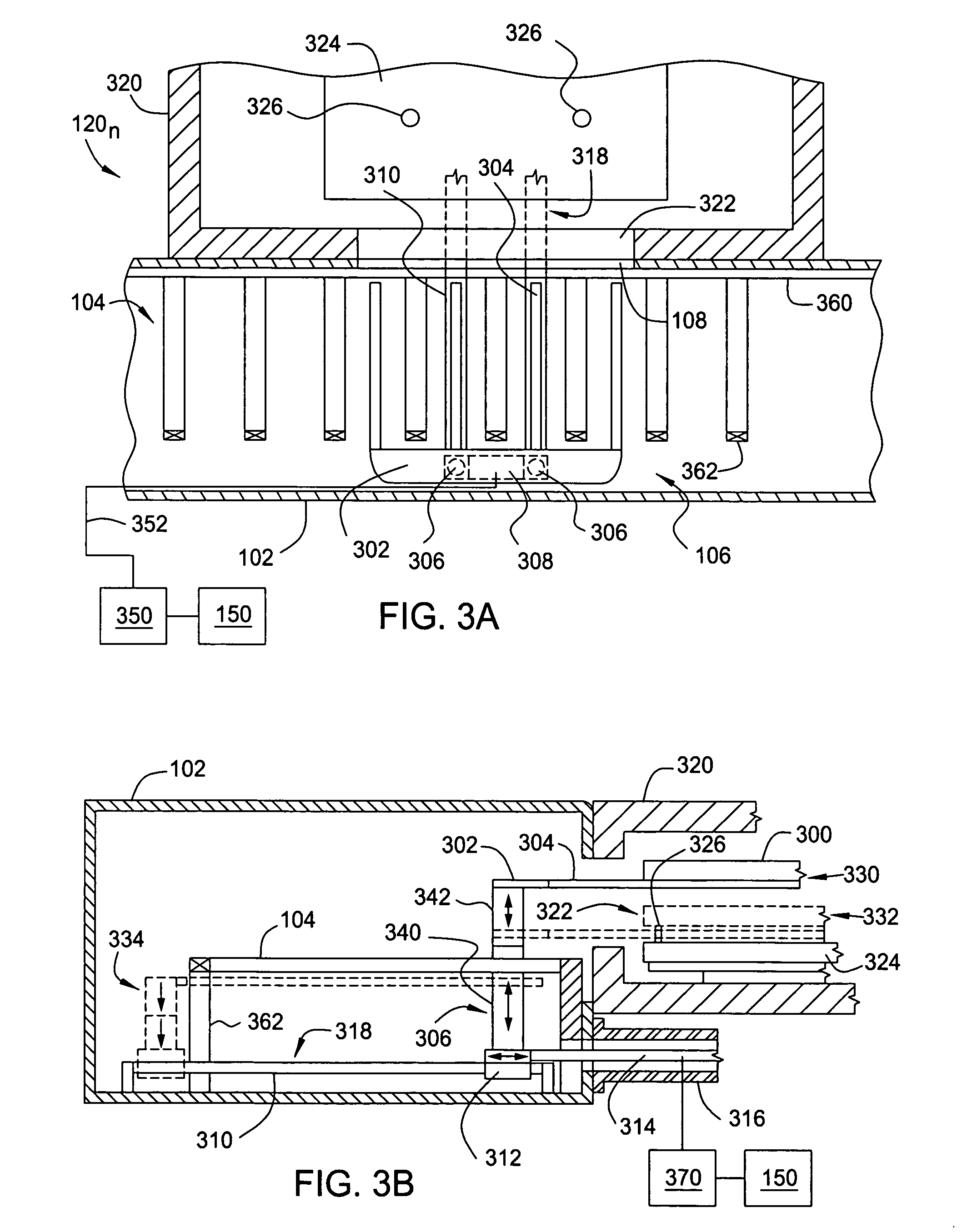

ActiveUS20070209736A1Good for healthAvoid mistakesMulti-purpose machinesAdjusting equipmentEngineeringControl unit

A process for sub-dividing a laminated flooring substrate into a plurality of laminated flooring planks and a system therefore are described. The process can include providing a laminated flooring substrate having a decorative pattern on a core wherein the decorative pattern can include a plurality of indicators, and independently detecting the indicators with a plurality of detecting devices, each assigned a respective indicator. The detecting devices can individually obtain the position of the detected indicators and a control unit can align a separate saw blade per each position detected. The system includes a cutting unit with individually adjustable saws or an alignment device configured to align the laminated flooring substrate with the saws, to cut the laminated flooring substrate along positions relative to the detected indicators, for example, in the center thereof or off-set therefrom.

Owner:MANNINGTON MILLS

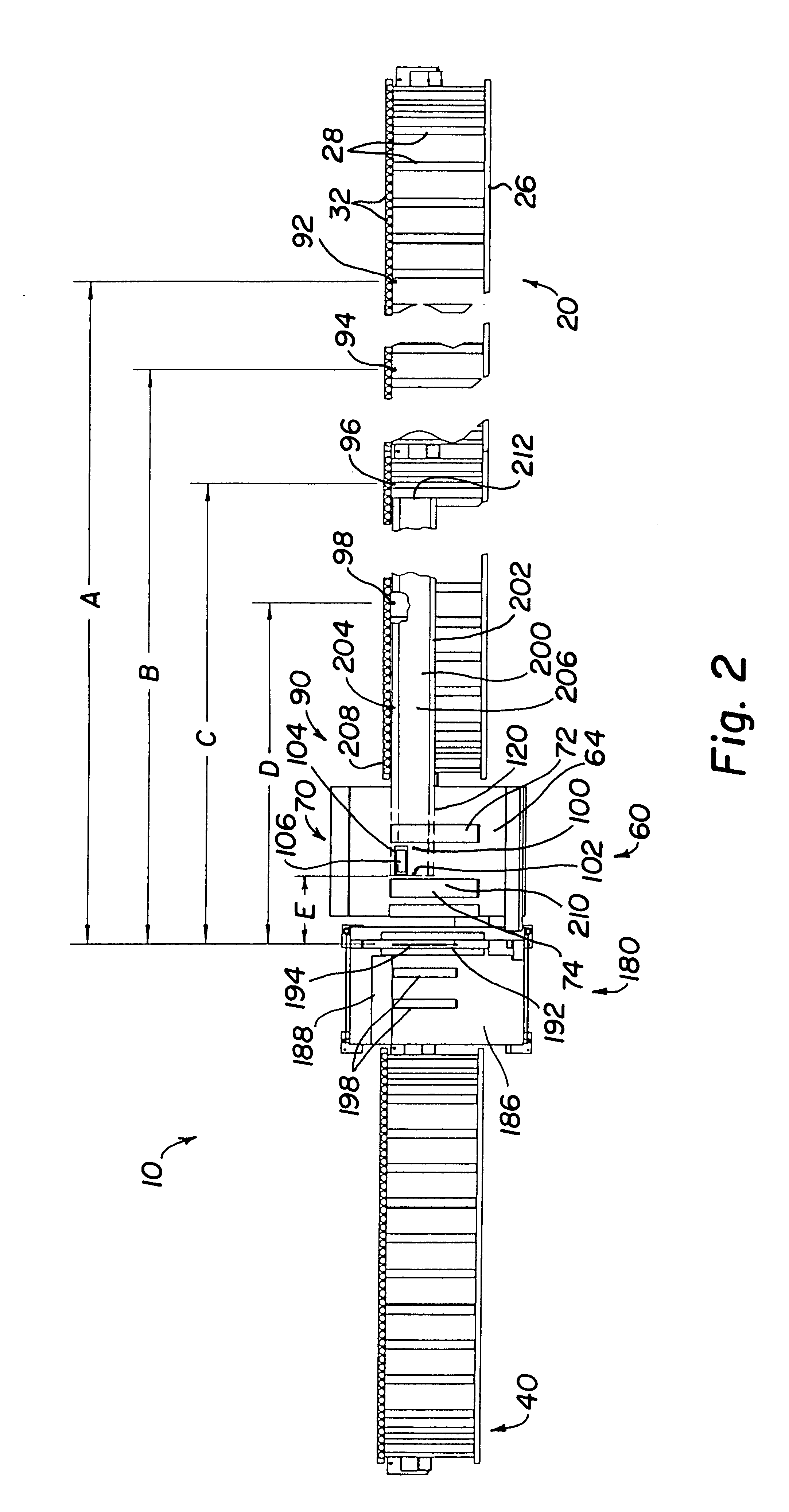

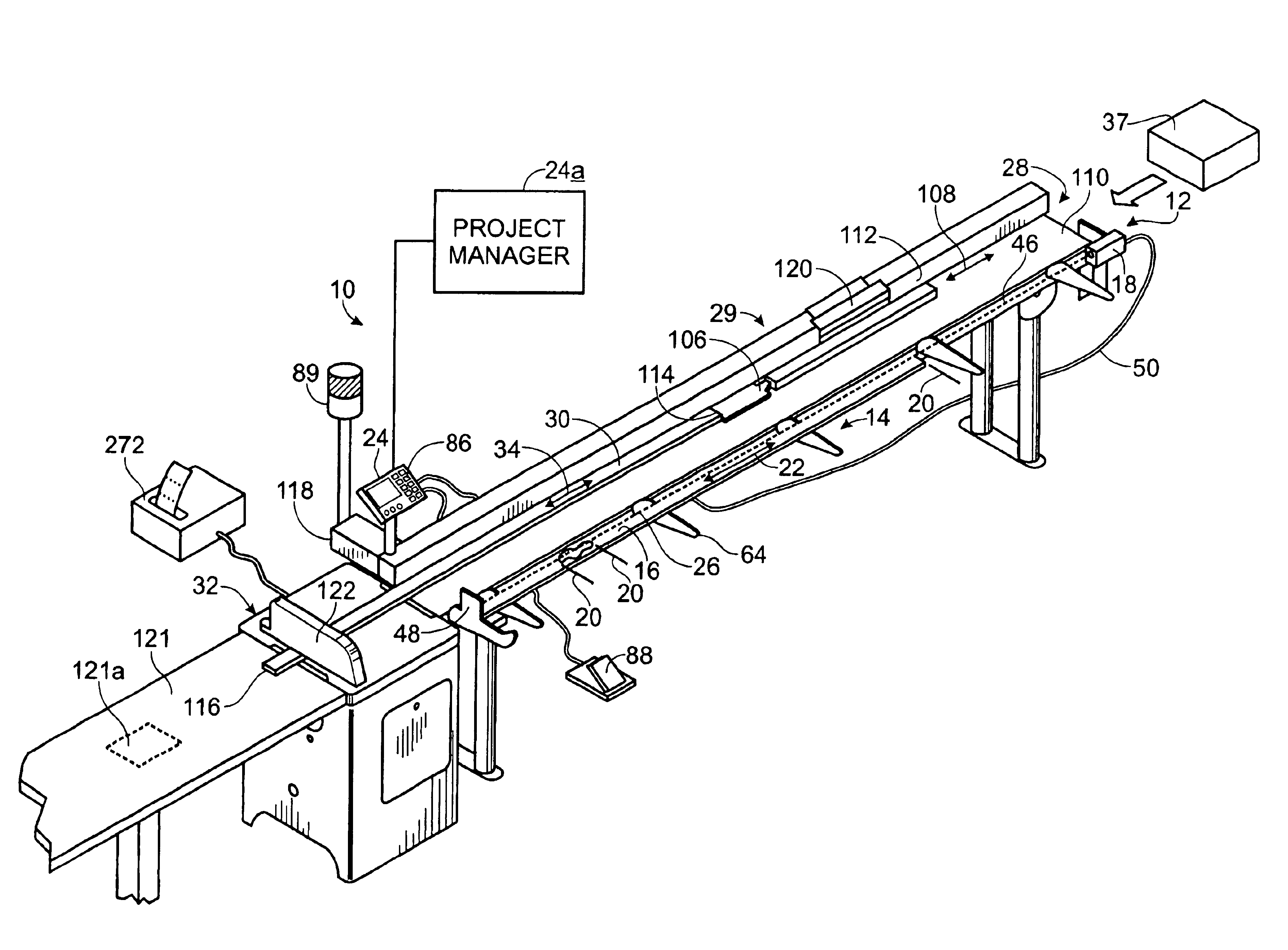

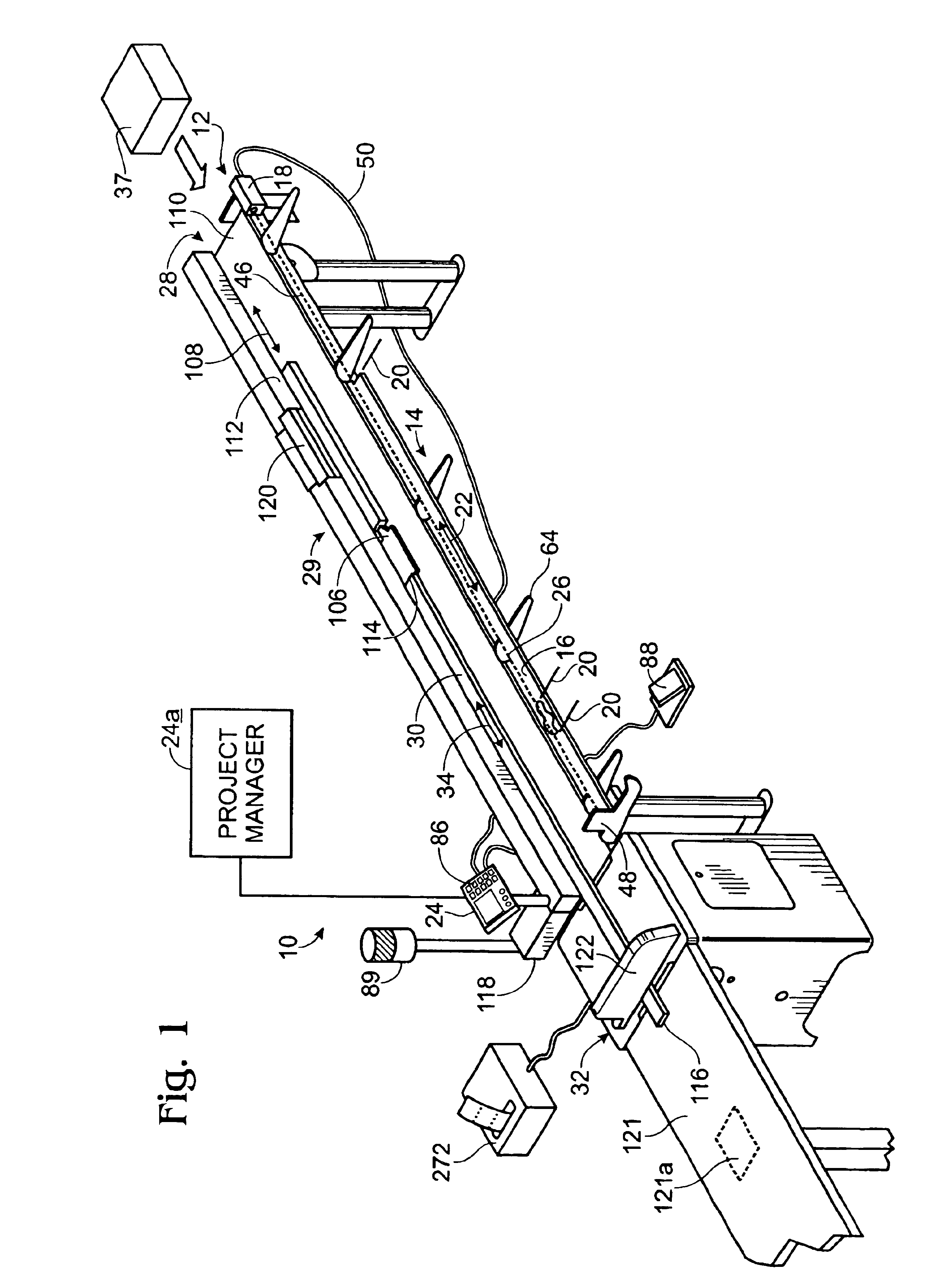

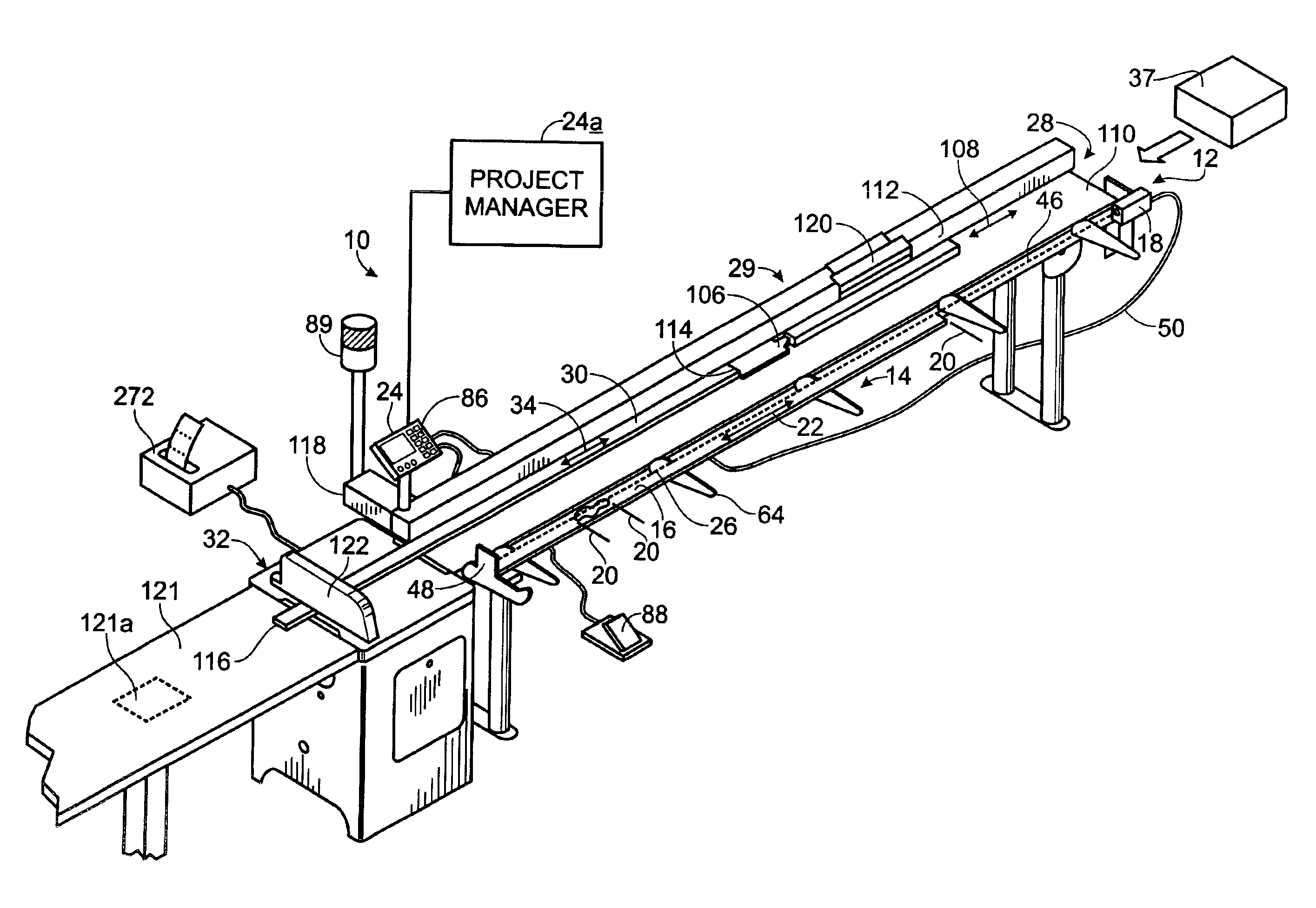

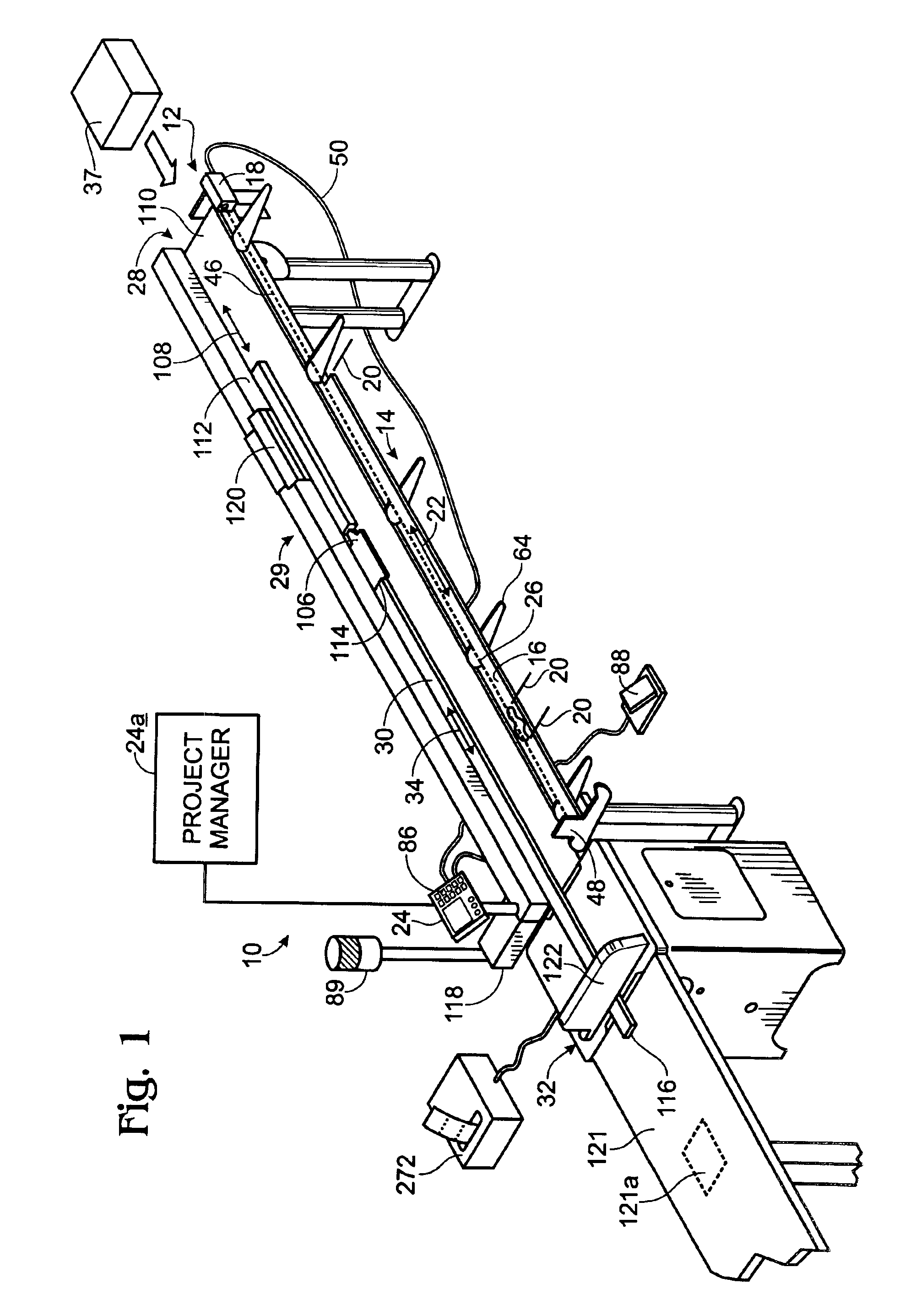

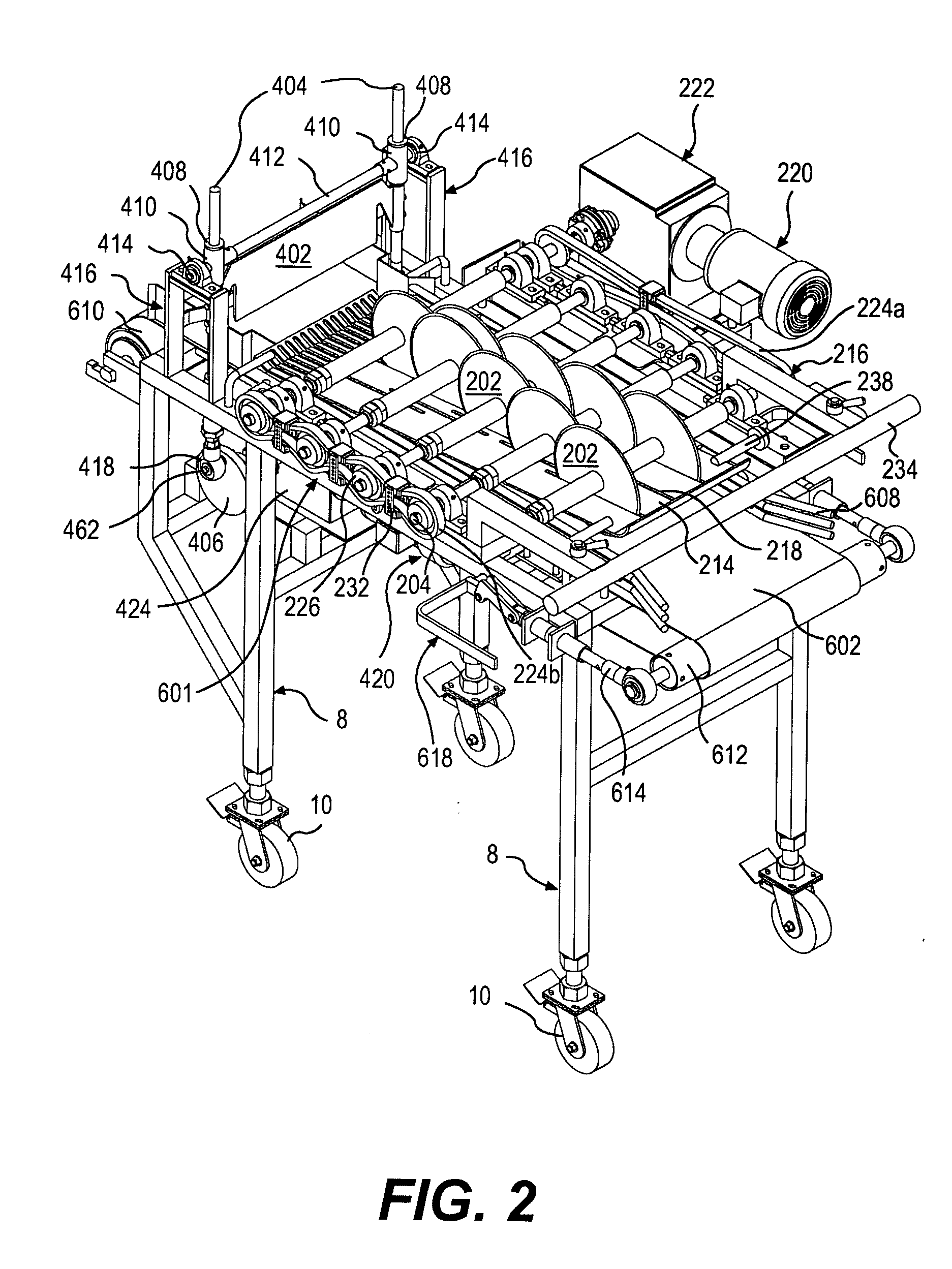

Engineered wood products cutting method and apparatus

InactiveUS6263773B1Automatic control devicesPrecision positioning equipmentEngineeringEngineered wood

The invention is a method and apparatus for processing an Engine Wood Product member. The member is moved to a home position in a driving unit and the length of the EWP member is automatically measured by moving the EWP member from the home position while engaging the EWP member with a measuring assembly including a measuring wheel having a smooth hard facing, the facing contacting the EWP member. The member is moved to a first cutting position and cut to a predetermined length. Activating one or more position sensor devices, at least one of the position sensor devices positioned such that the EWP member engages the position sensor device while the member is in the home position, the length of the member is determined as it is moved from the home position. Moving the EWP member is accomplished by clamping the EWP member between at least one driver roller and at least one pressure roller, each driver roller aligned with a corresponding pressure roller, and rotating the at least one driver roller to move the EWP member. First and second driver rollers may be spaced apart and positioned on opposite sides of the measuring wheel. An outfeed table and infeed table with angled rollers may further be employed.

Owner:ILLINOIS TOOL WORKS INC

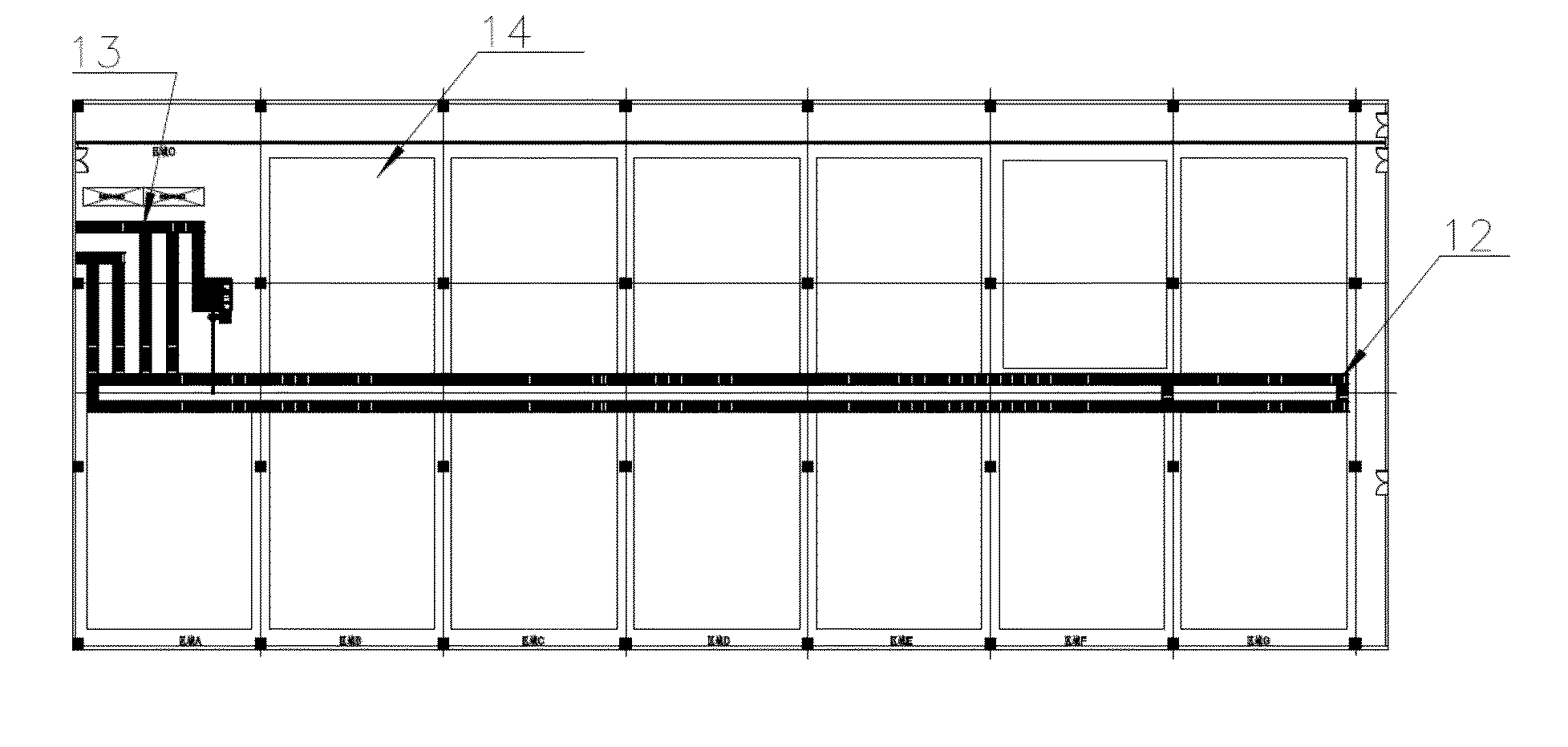

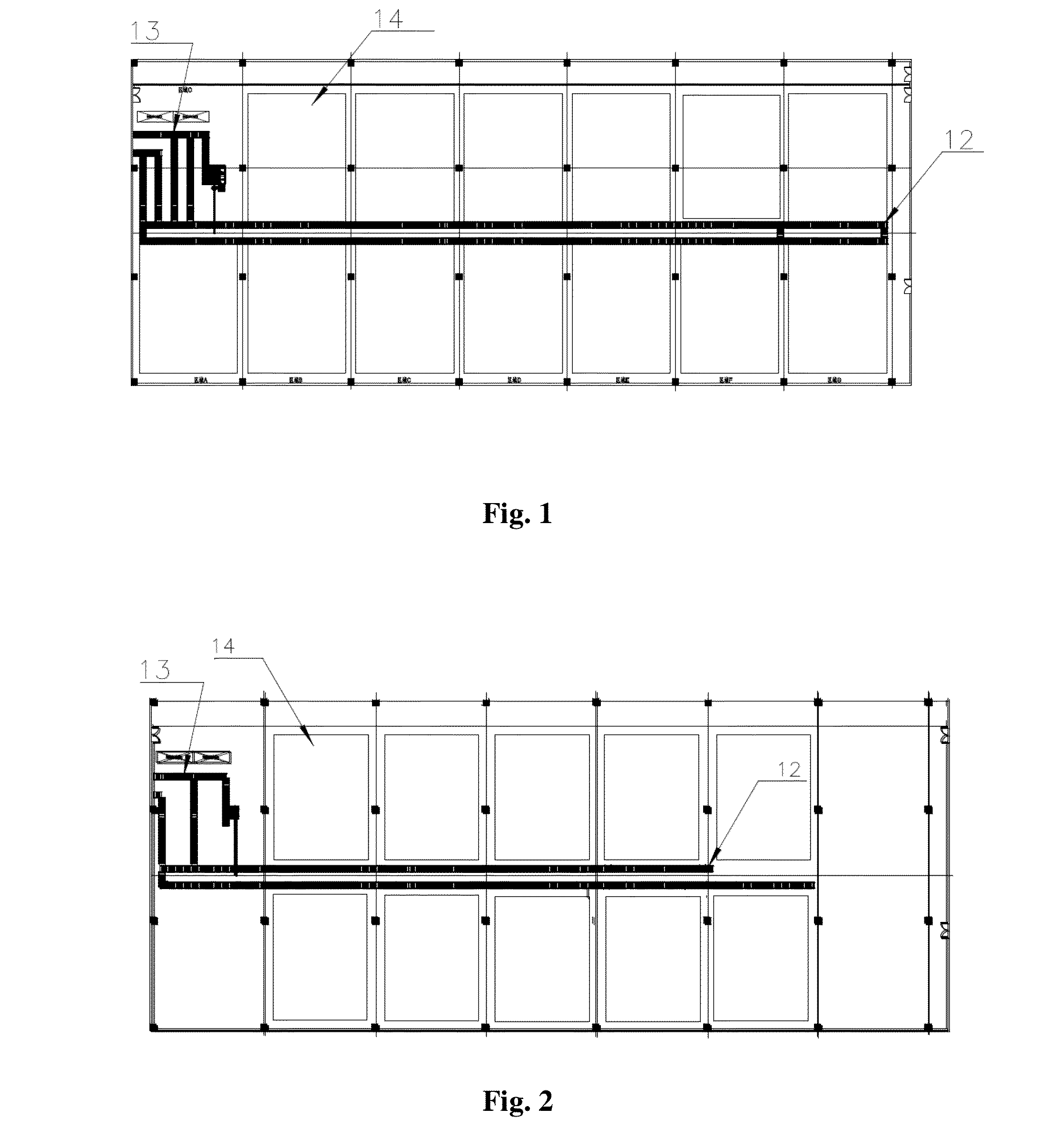

Fully-automatic verification system for intelligent electric energy meters

ActiveUS20130299306A1High operating requirementsLow production costMetal sawing devicesFeeding devicesVerification systemFully automatic

A fully-automatic verification system for intelligent electric energy meters comprises a plurality of verification units for automatic verification of the electric energy meters, main transport lines for connecting the verification units, and a verification management system for coordinating the work of the verification units. The main transport lines comprise upper transport lines for transporting boxes carrying electric energy meters to be verified to the verification units and lower transport lines for transporting the boxes carrying the electric energy meters back to the warehouse. The verification system for electric energy meters can implement fully-automatic verification, thus enhancing the efficiency and the verification accuracy.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER

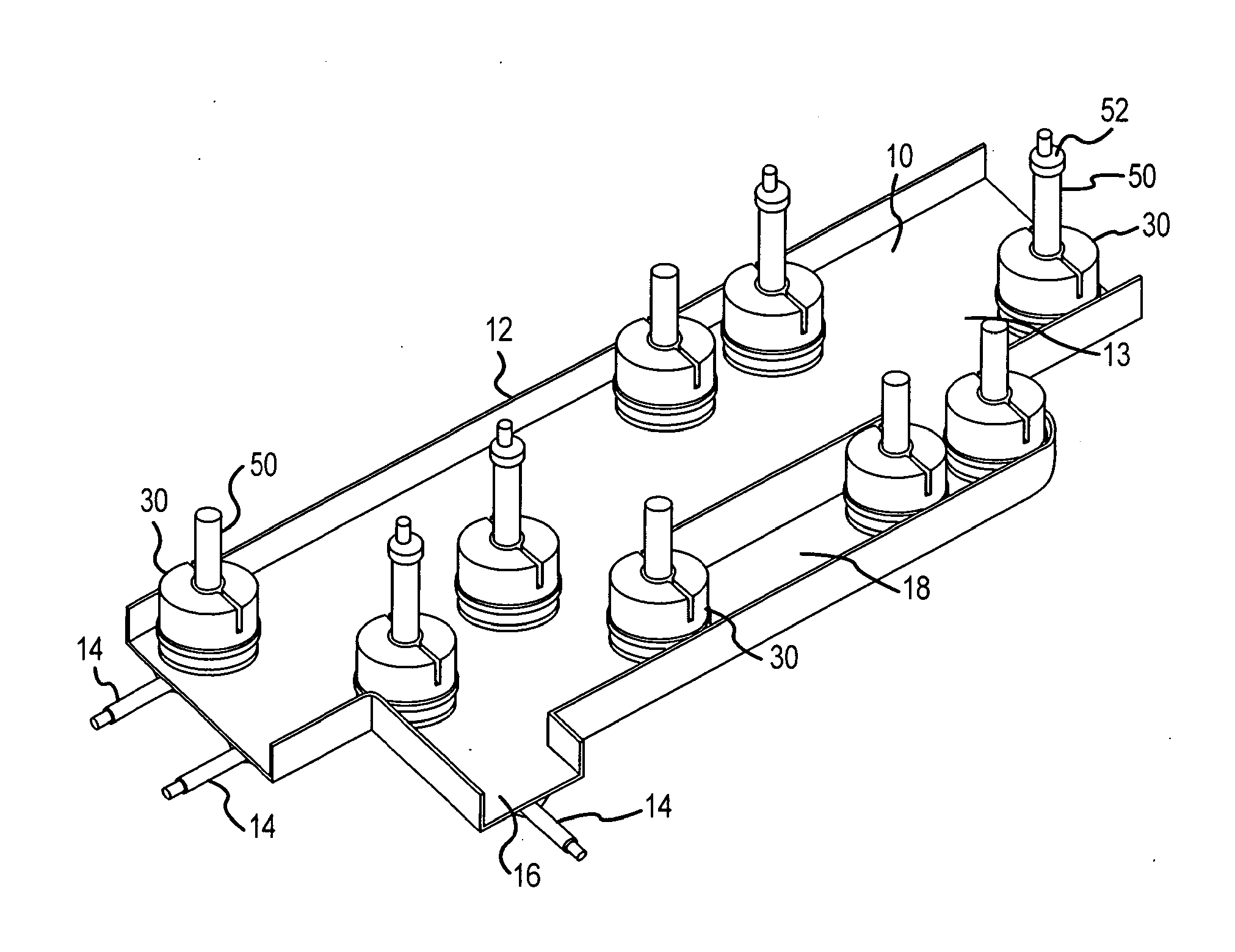

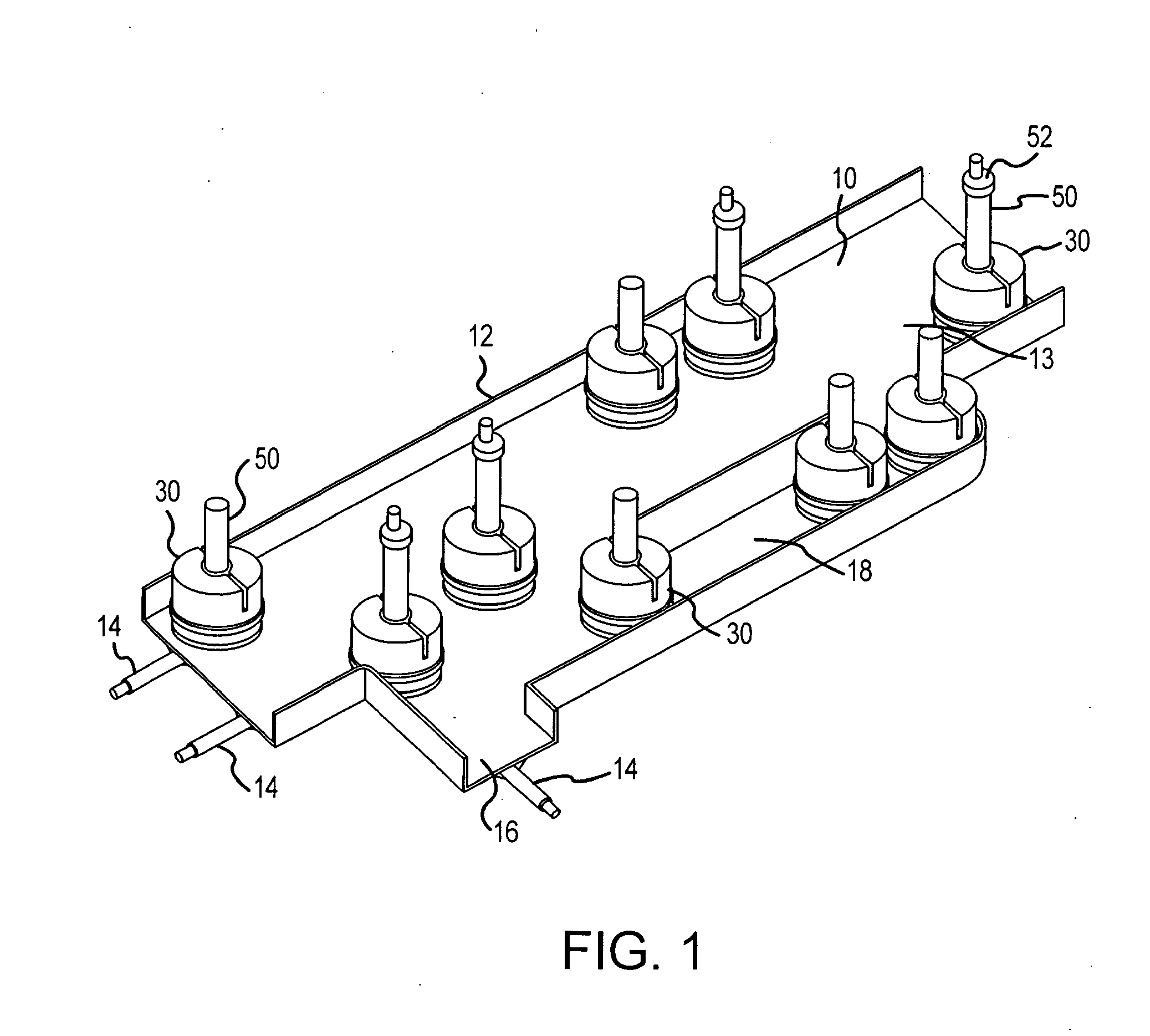

System and method including laboratory product transport element

The invention concerns a laboratory product transport element for a laboratory transport system with an energy receiver and / or energy accumulator to provide drive power, at least one signal receiver to receive control signals, a control unit to generate drive signals as a function of at least one control signal obtained from the at least one signal receiver, movement devices for independent movement of the laboratory product transport element on a transfer path as a function of the drive signals of the control unit, in which the drive devices are driven by the drive power and at least one holder to hold a laboratory product being transported. The invention also concerns a laboratory transport system with at least one laboratory product transport element according to an embodiment of the invention and a transfer path arrangement. The invention also concerns methods for operation of laboratory transport systems according to an embodiment of the invention.

Owner:BECKMAN COULTER INC

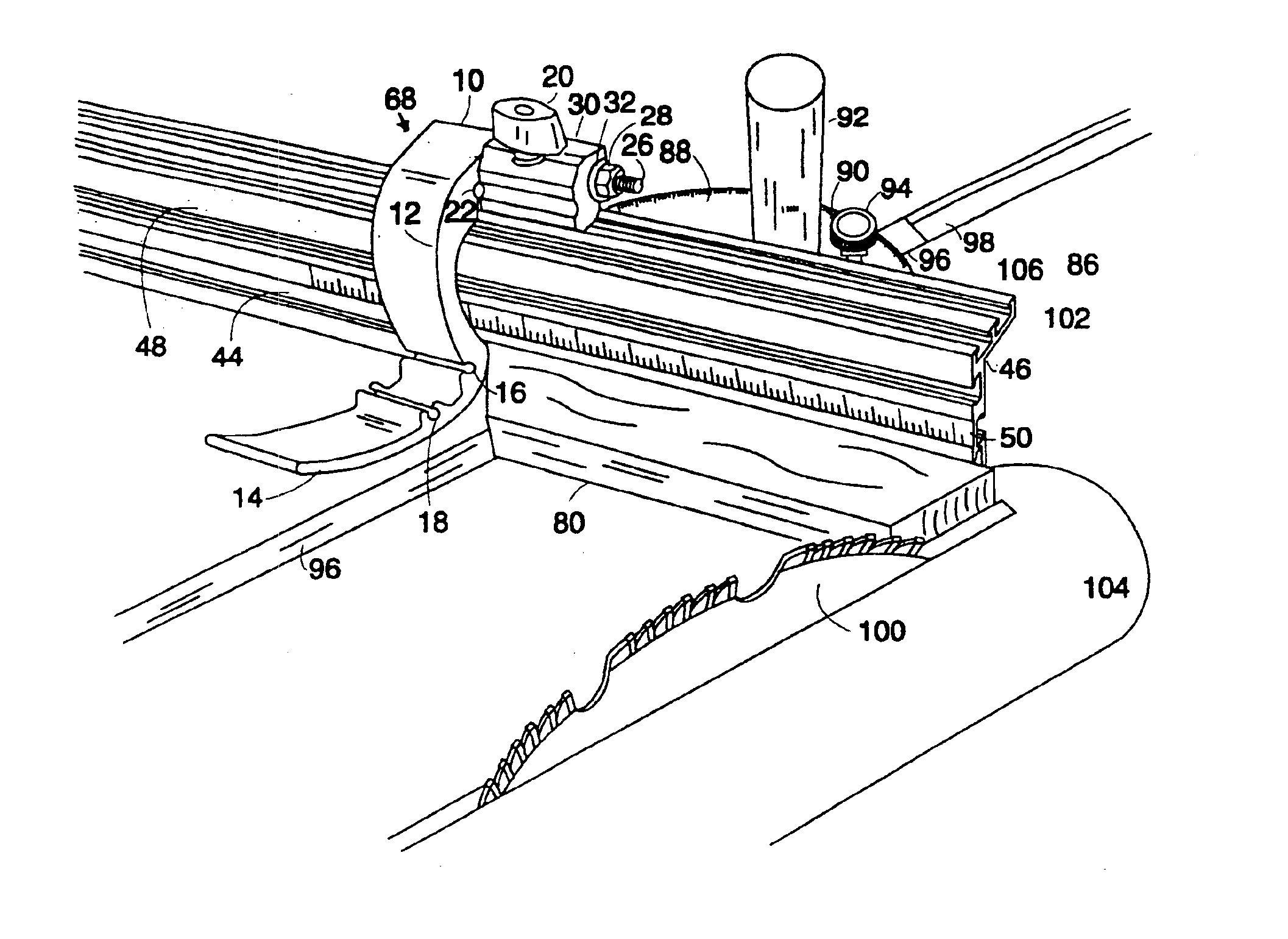

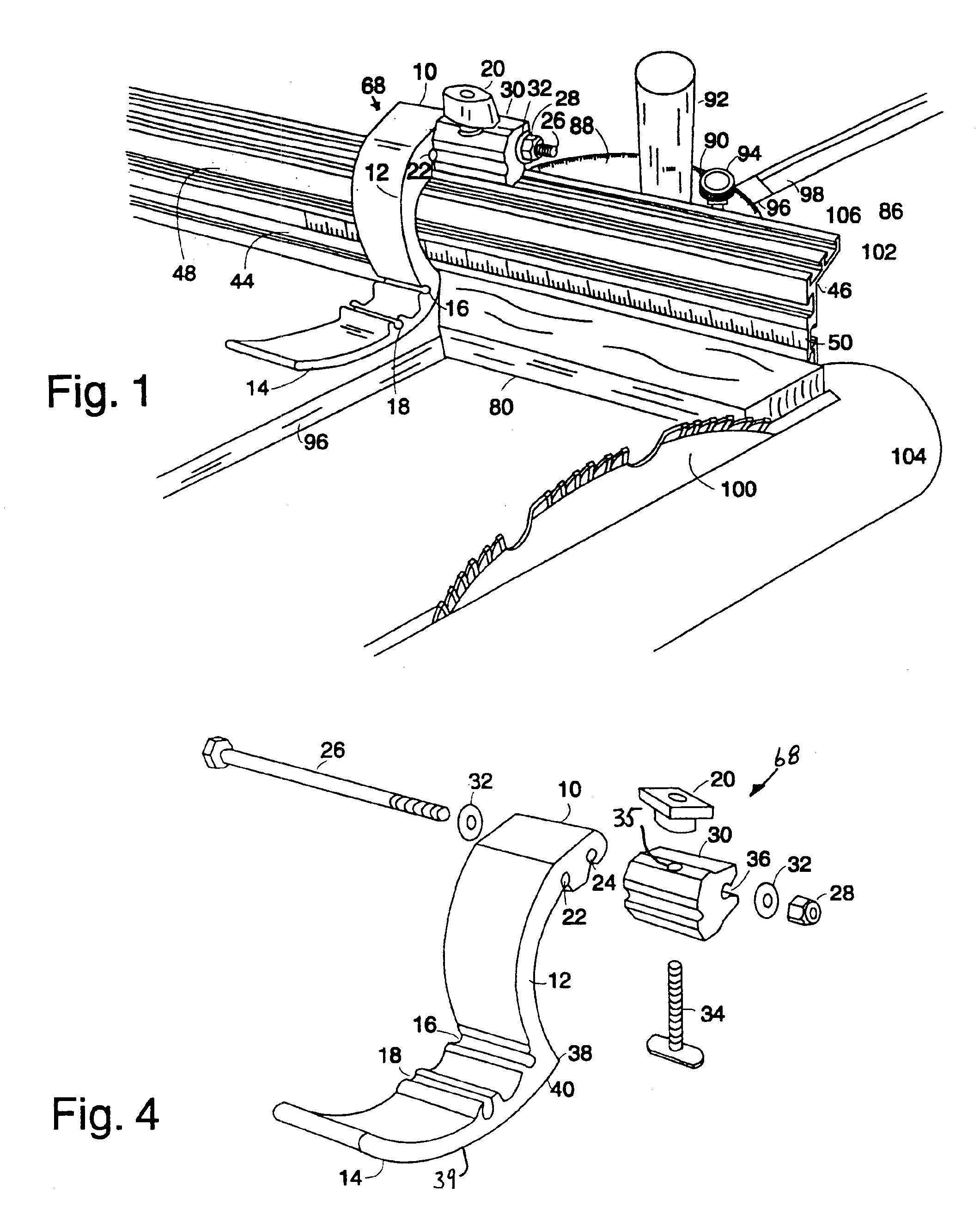

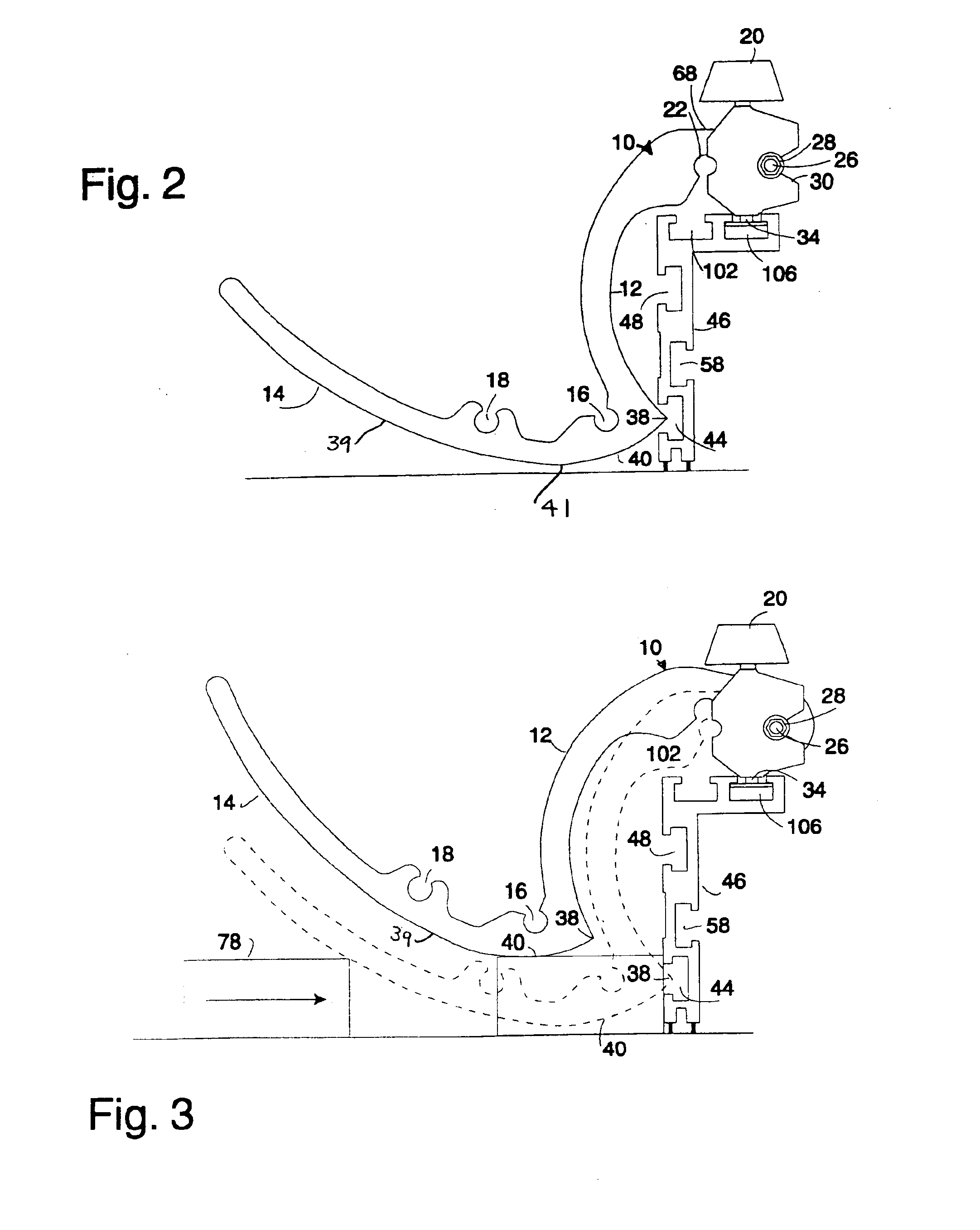

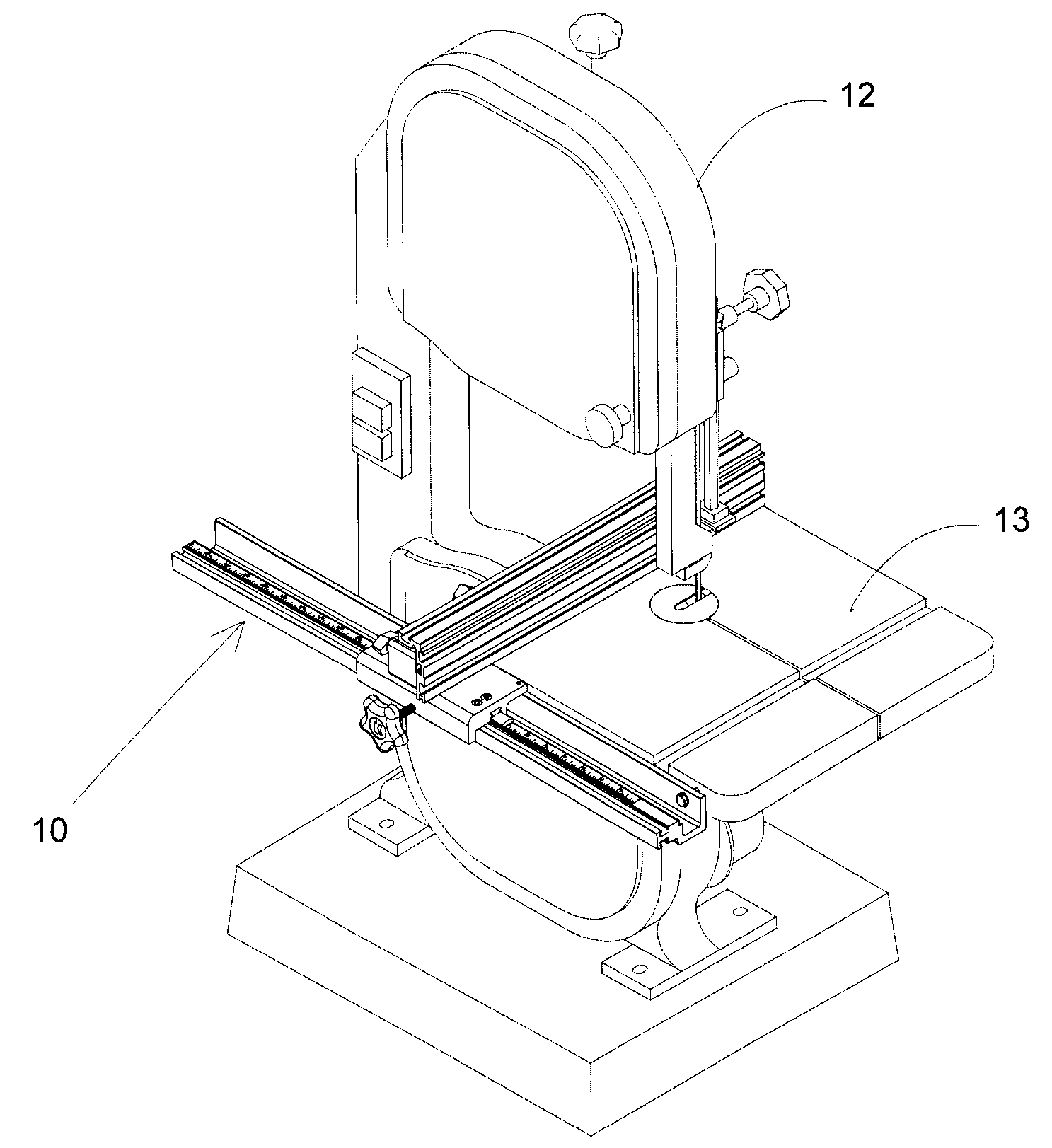

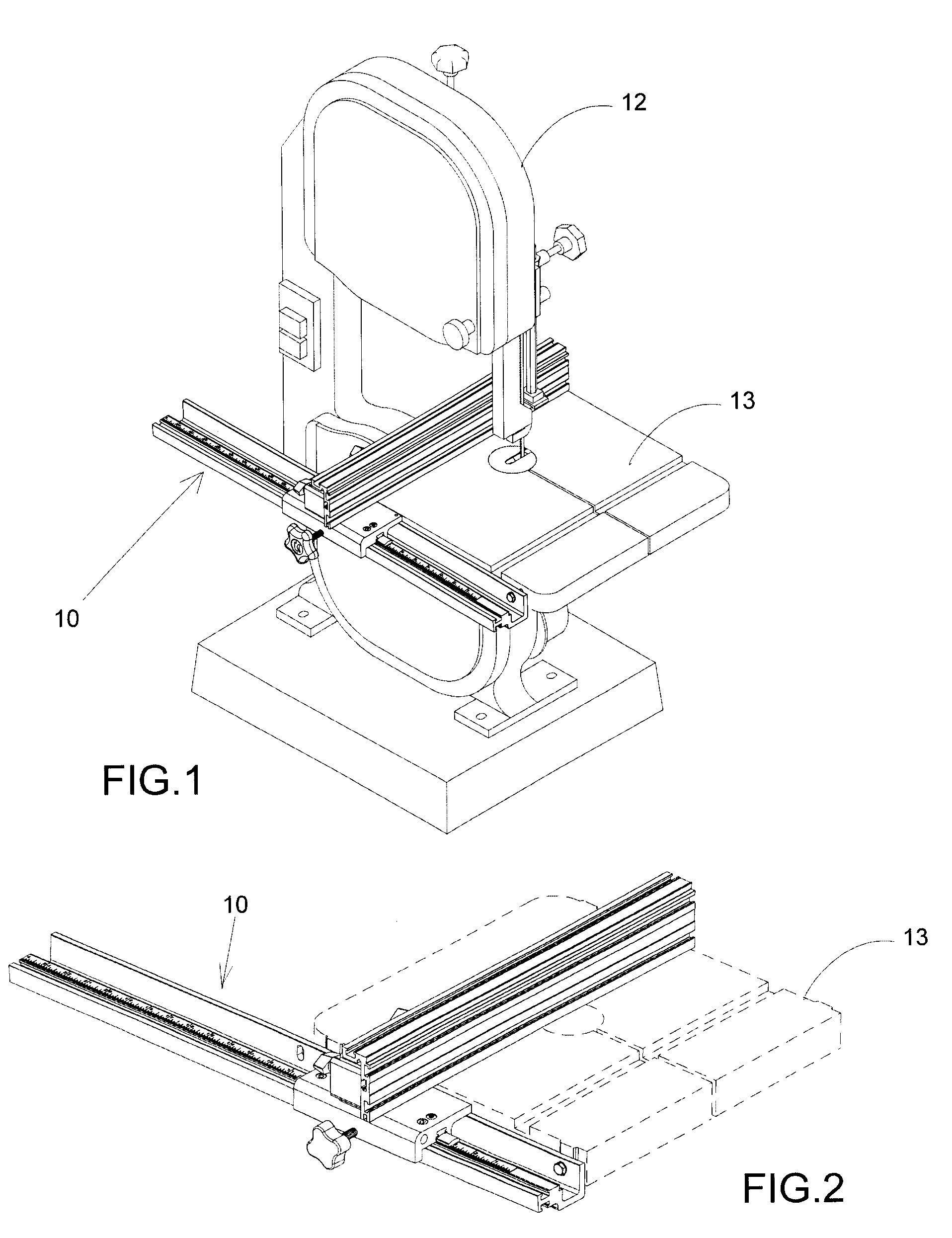

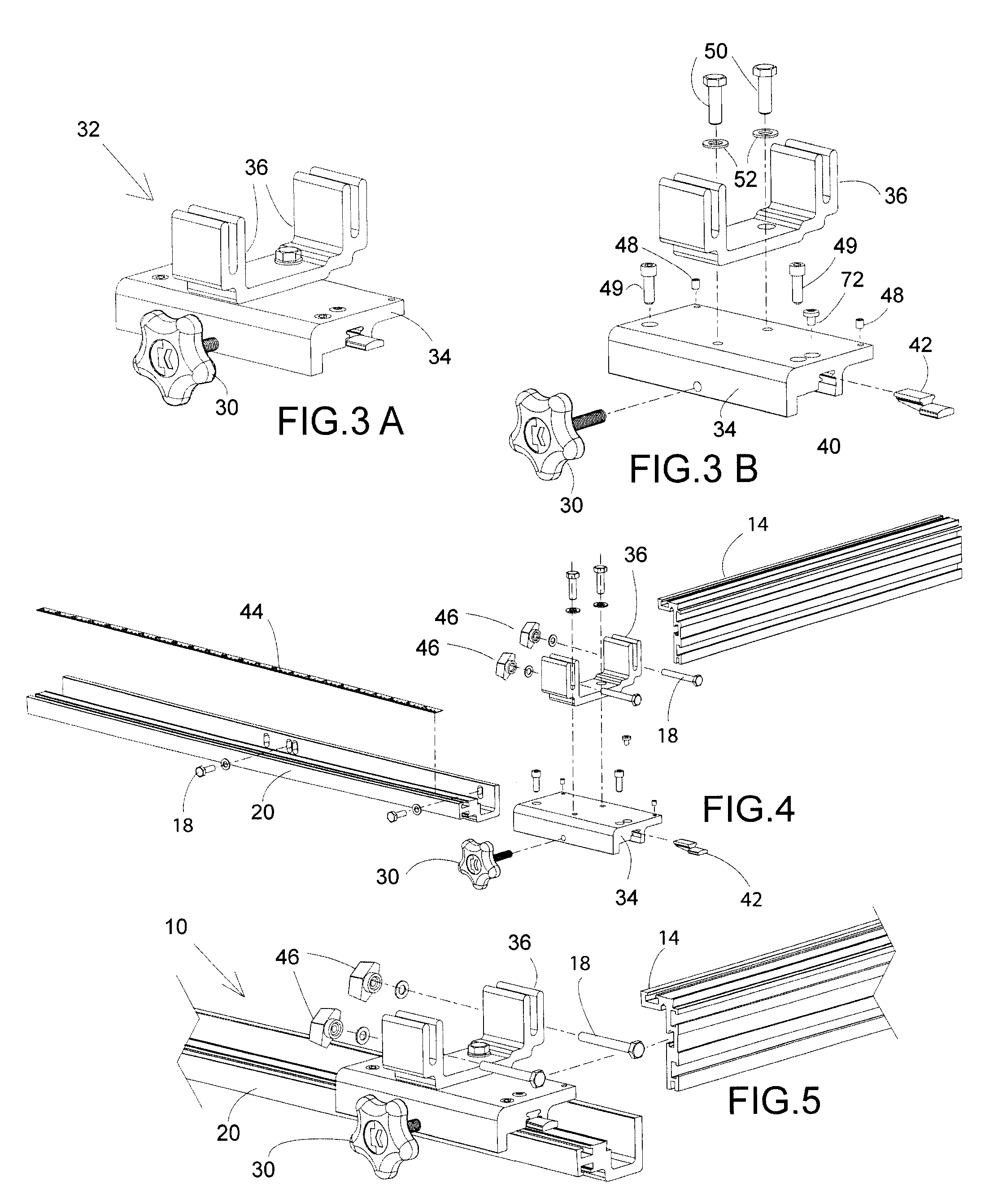

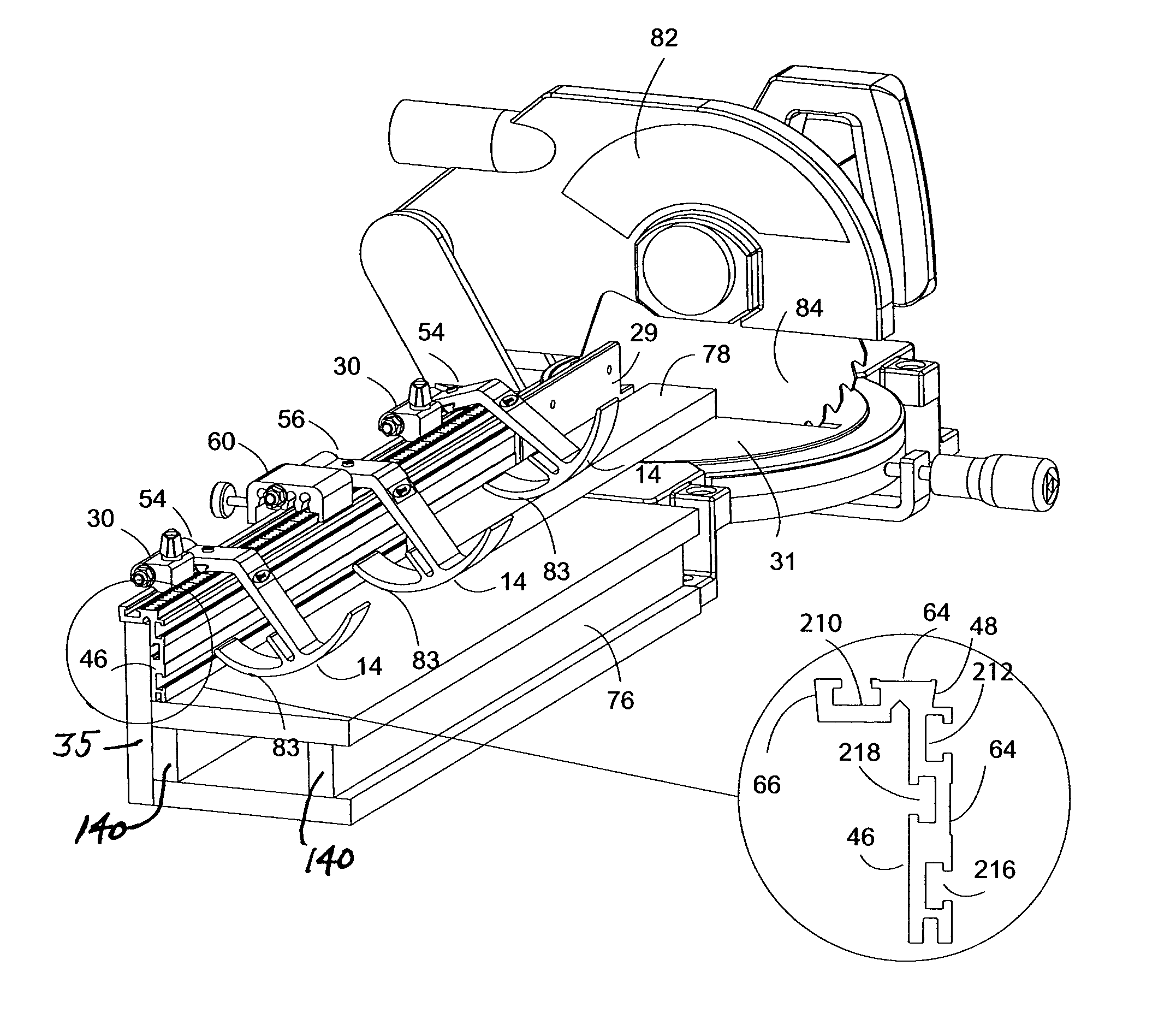

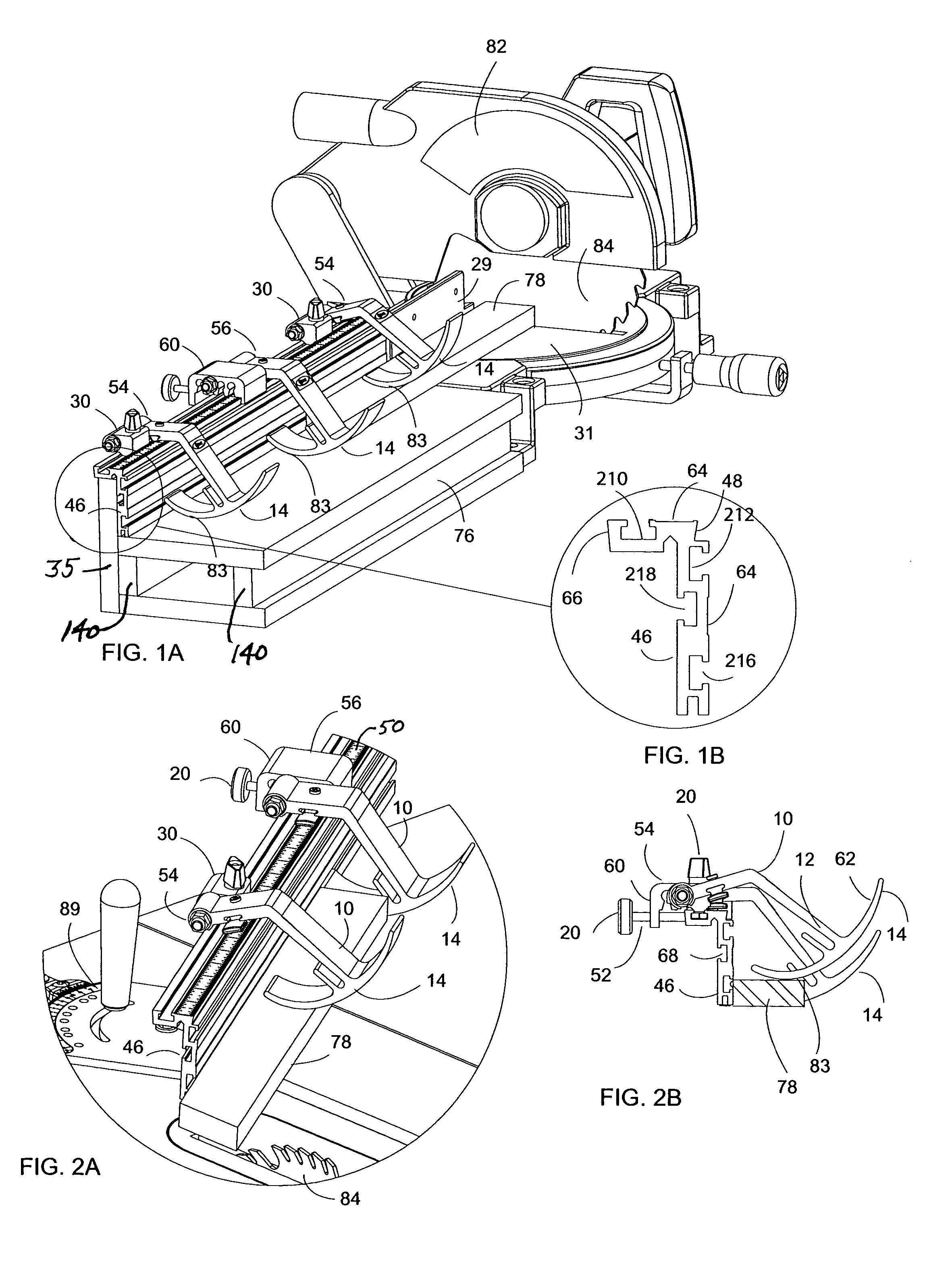

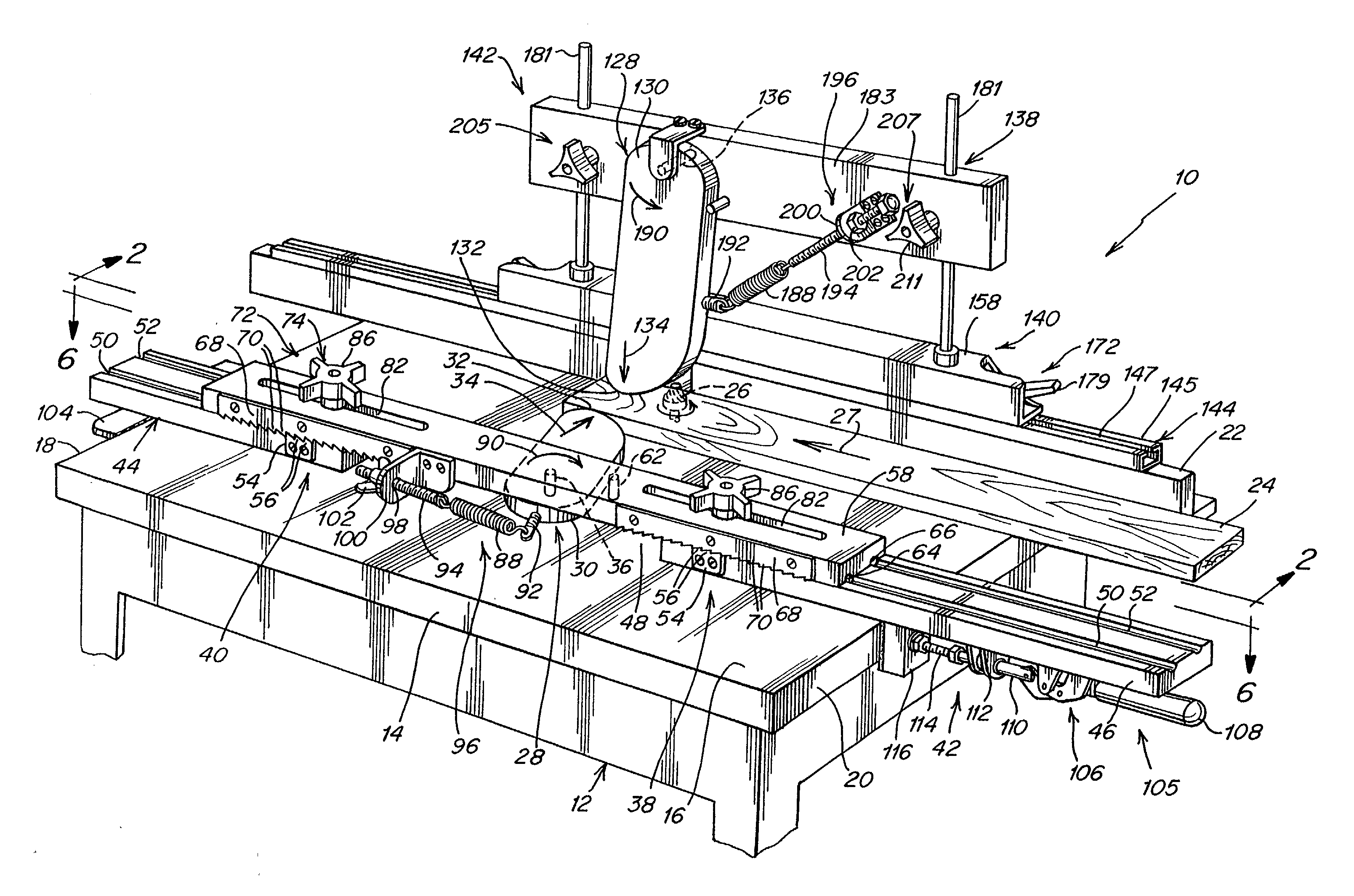

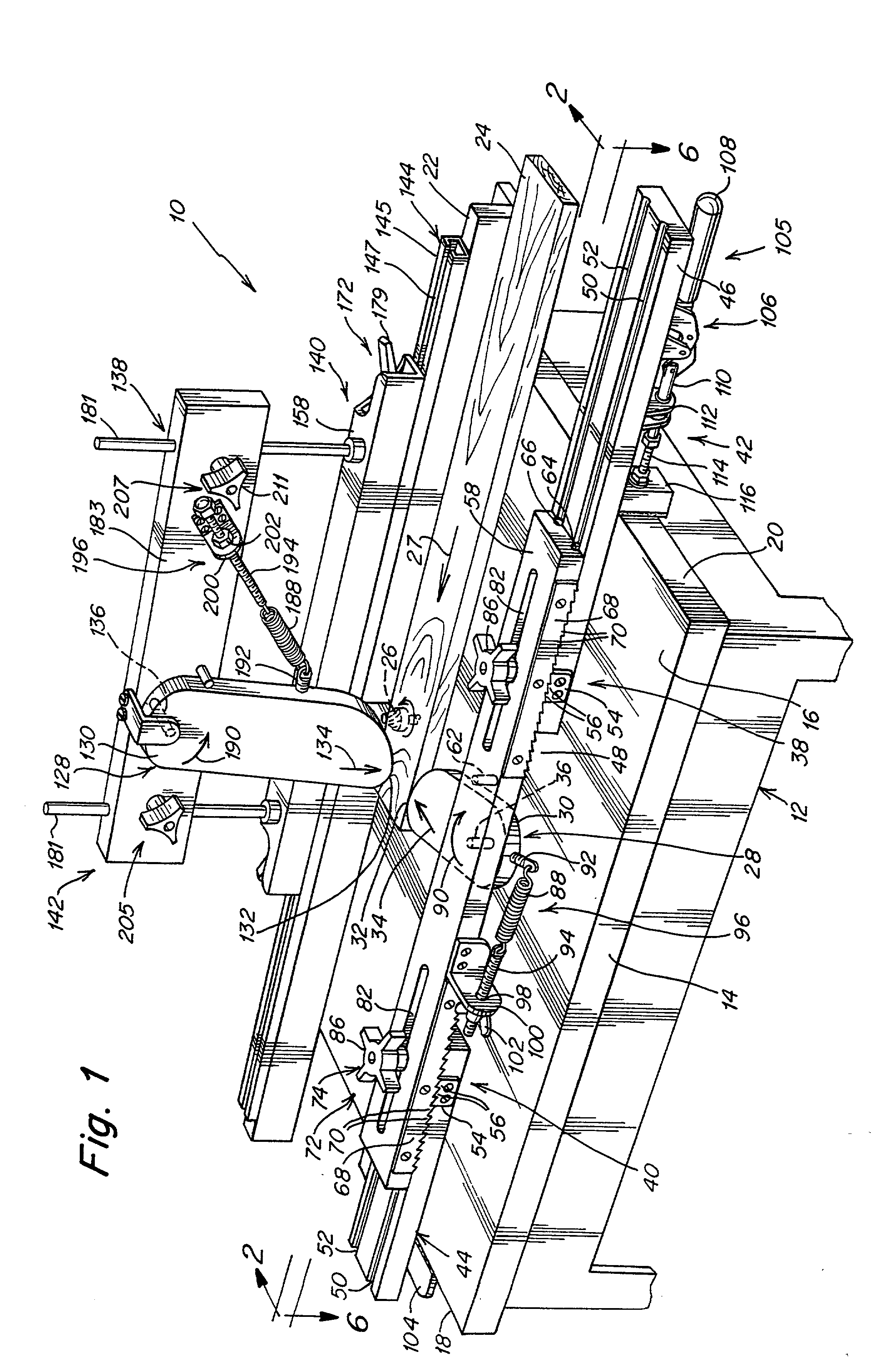

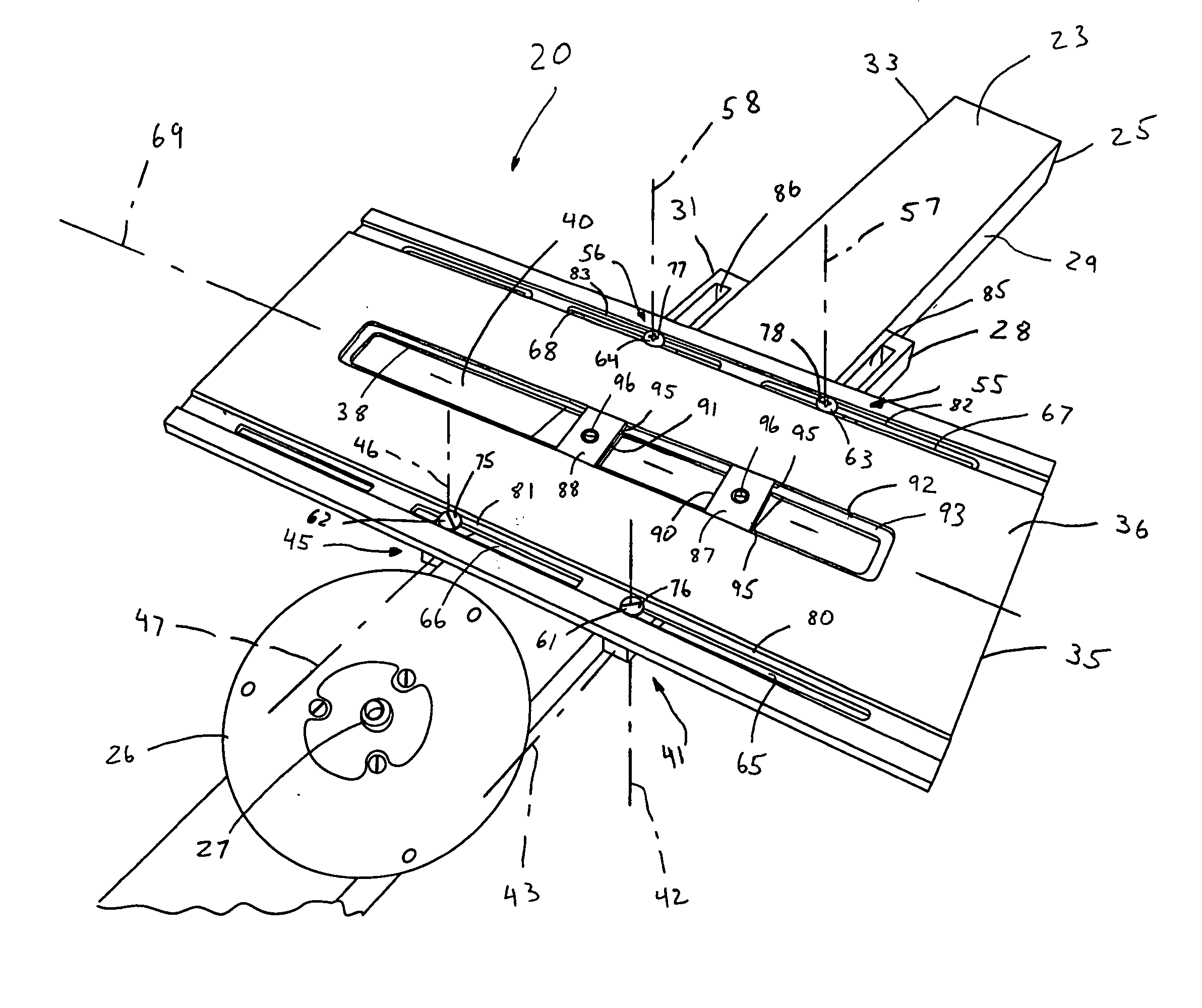

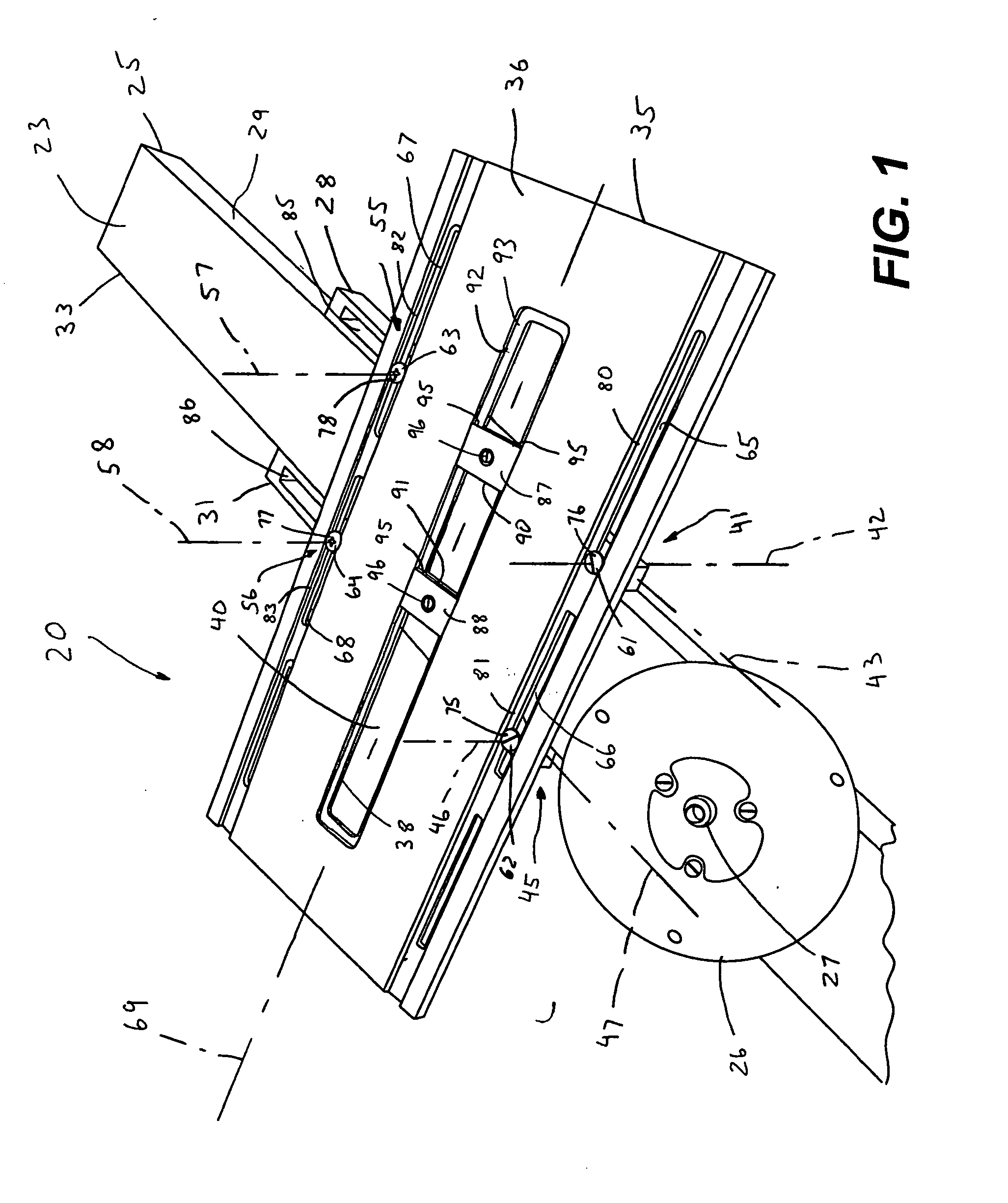

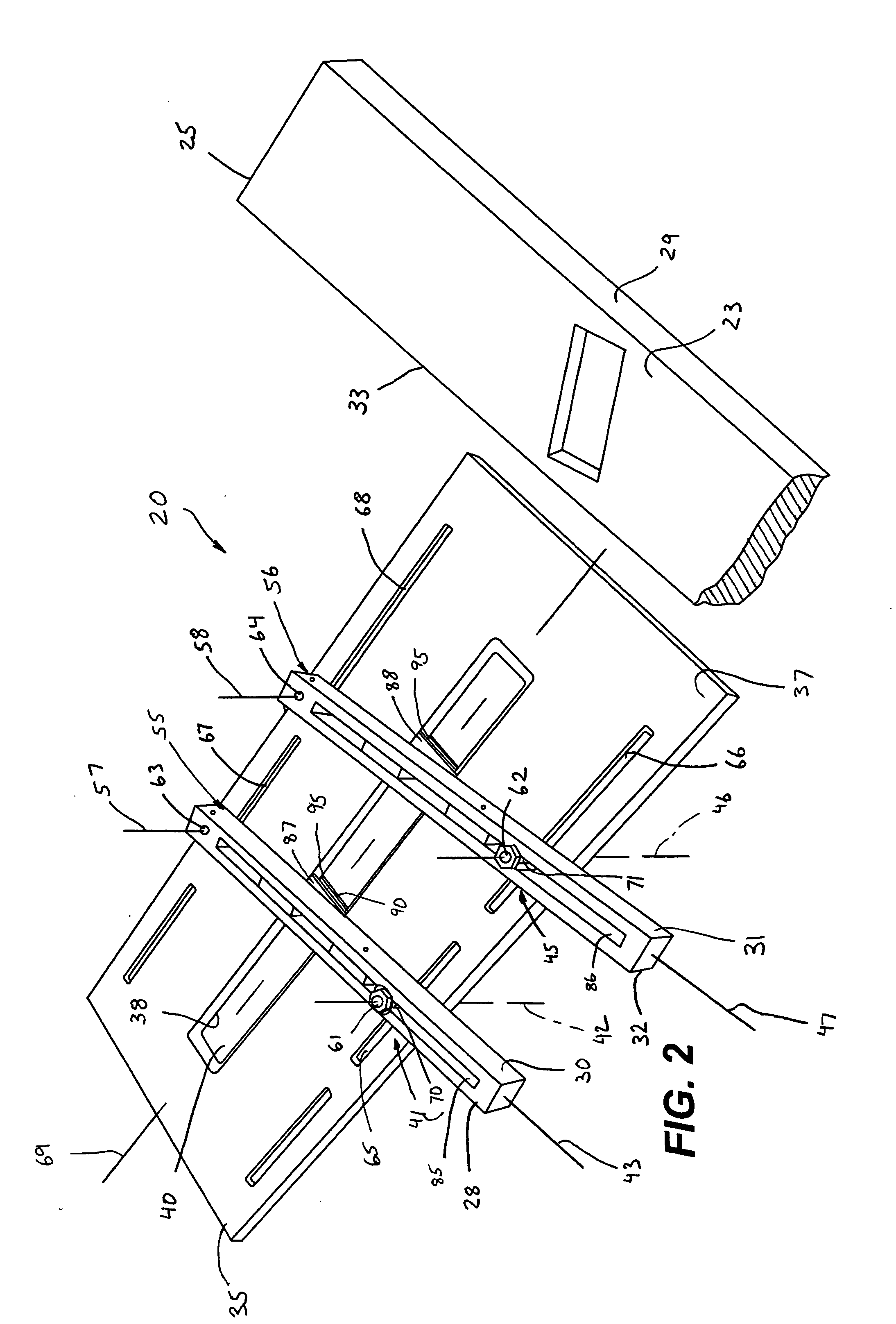

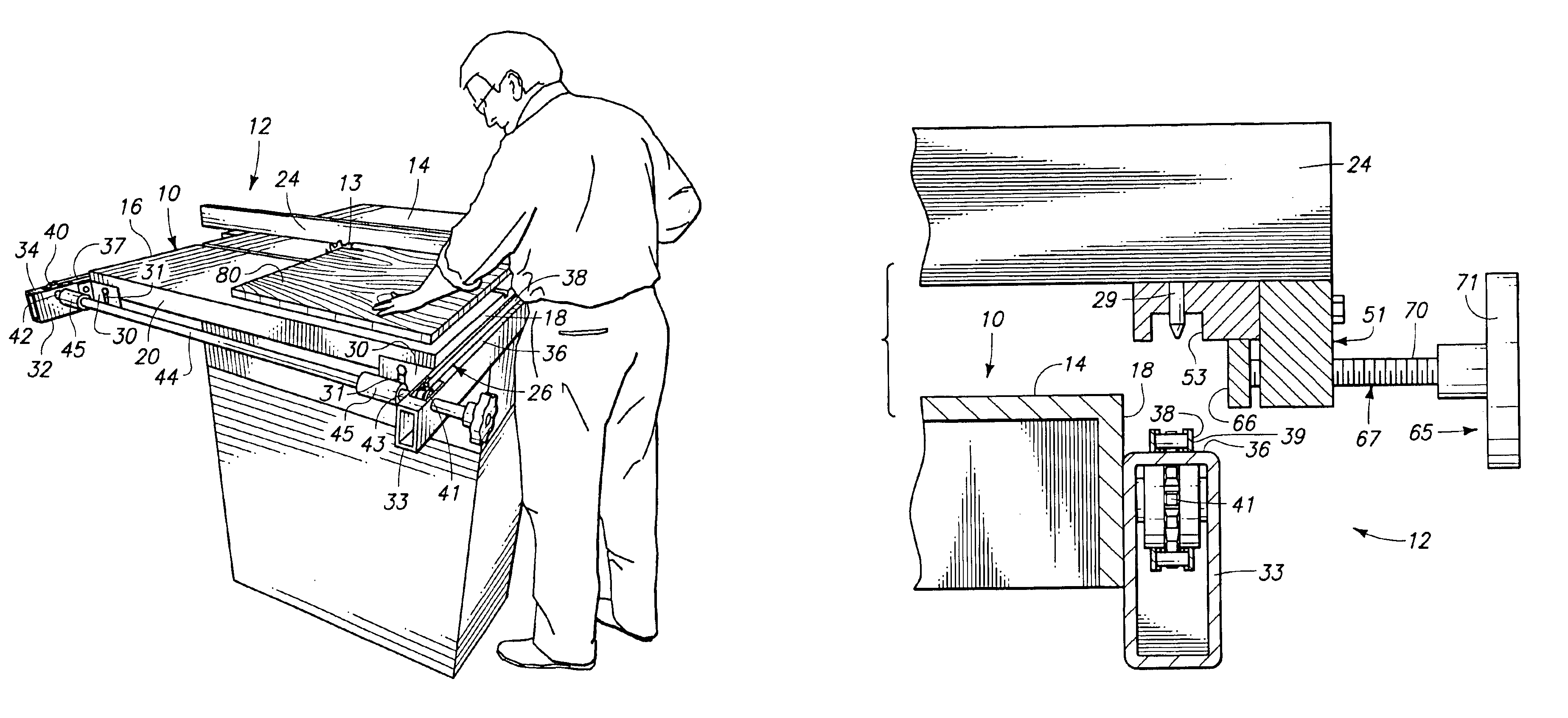

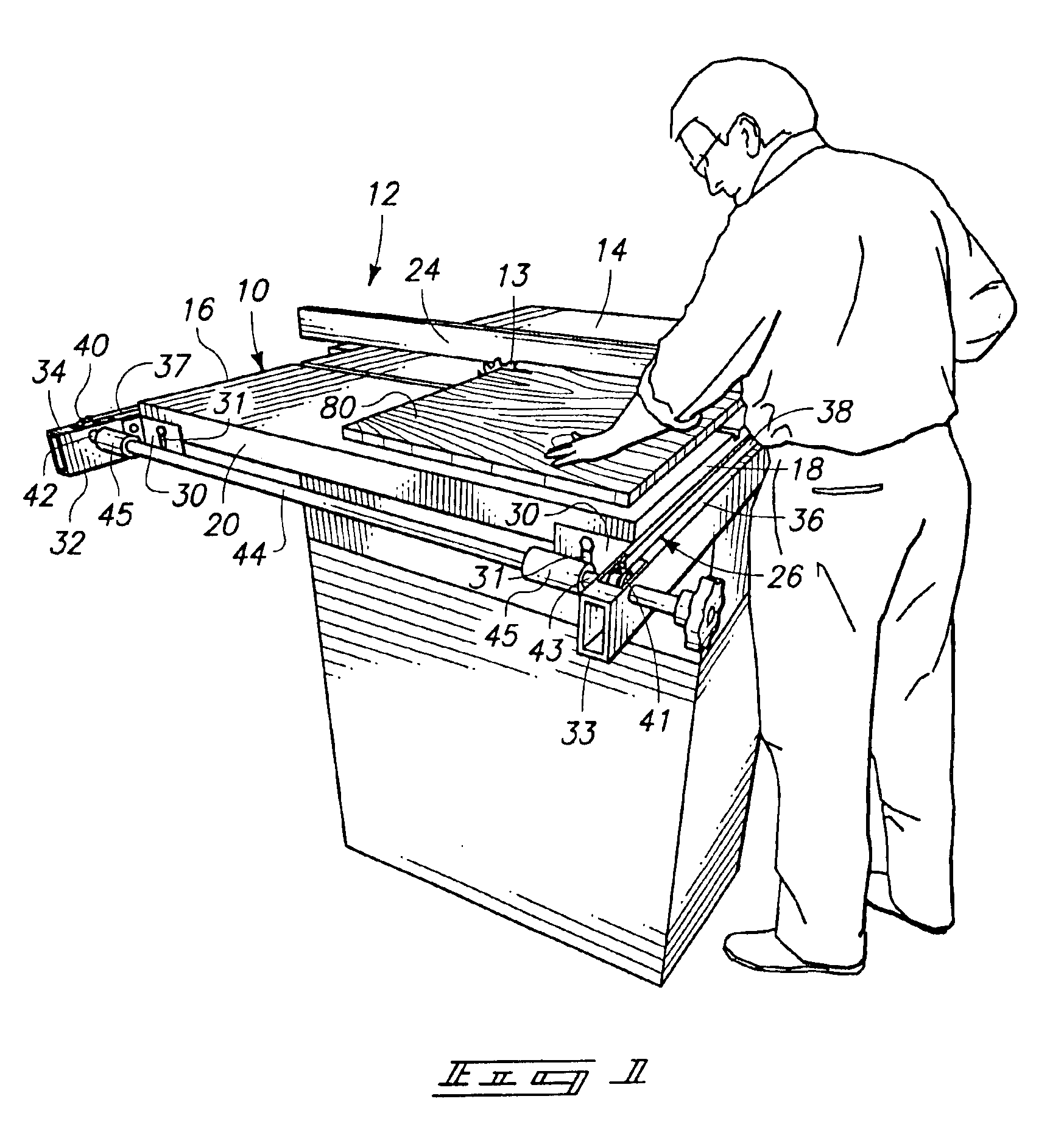

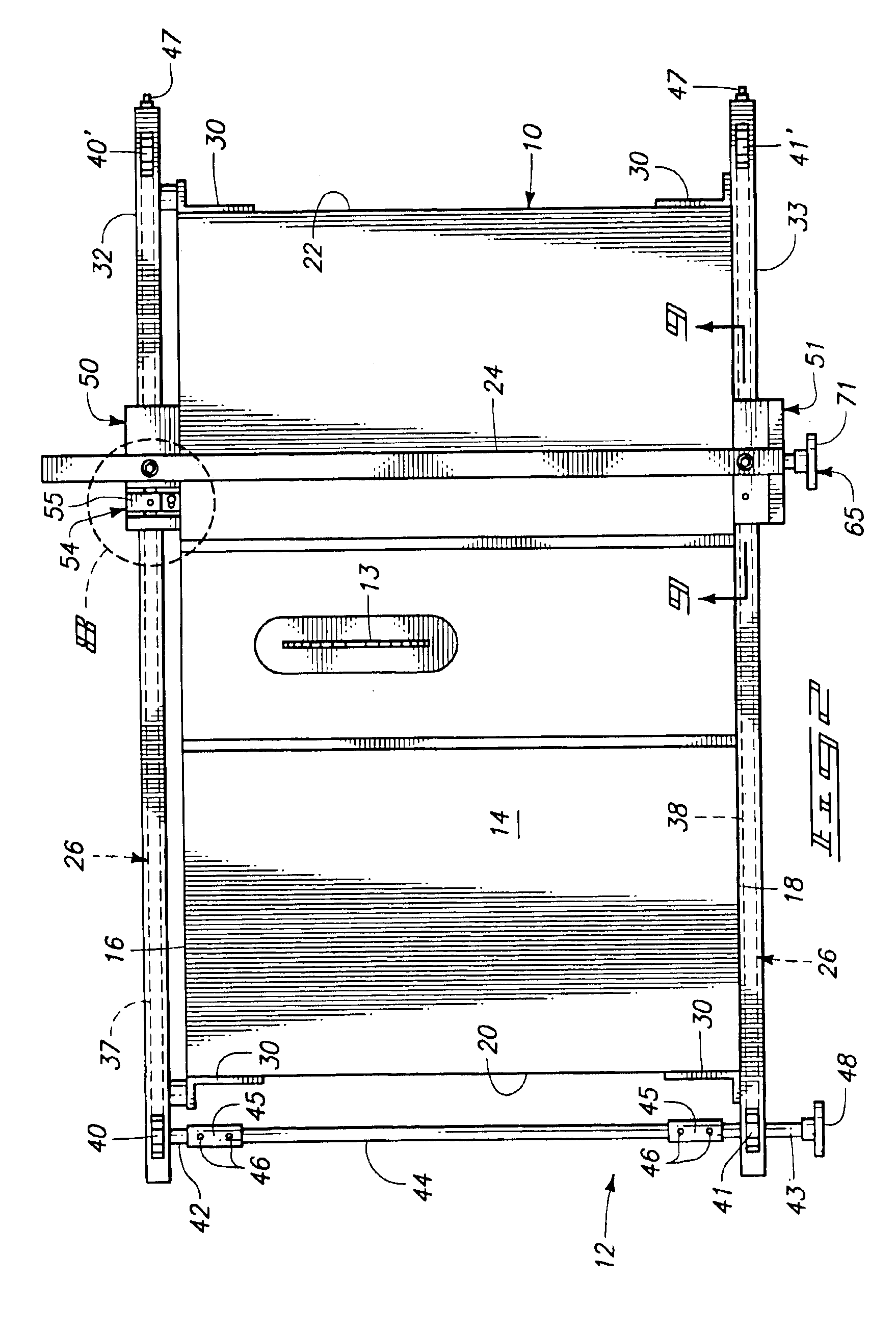

Woodworking machinery jig and fixture system

A woodworking machinery jig and fixture system includes a track which is or may be attached to a fence, a convex-concave curved flip stop and a base which mounts the stop to the track. The stop has a projecting portion which penetrates the plane of the fence so the stop isn't lifted by the point of a mitered board. The stop also has a lower convex surface which faces the work support surface and curves up at both ends. The top leg of the stop is concave toward the fence to allow clearance for a zero-clearance board and make the stop adaptable to different track and fence configurations. The base has opposite sides of different widths bordered by steps on one side and a ramp on the other side so the base can be used in a large range of T-track slot widths. The arm mounting hole of the base is offset from the base mounting so as to provide an offset to accommodate a ¾″ zero clearance board by turning the base a half turn relative to the slot. A two slot track is provided in which one of the slots can mount a sliding measurement tape or a base, and the other slot can also mount a base. In another track, a sidewall flange is provided which can be filed to accurately fit into a miter gauge slot of a cutting tool table.

Owner:KREG ENTERPRISES

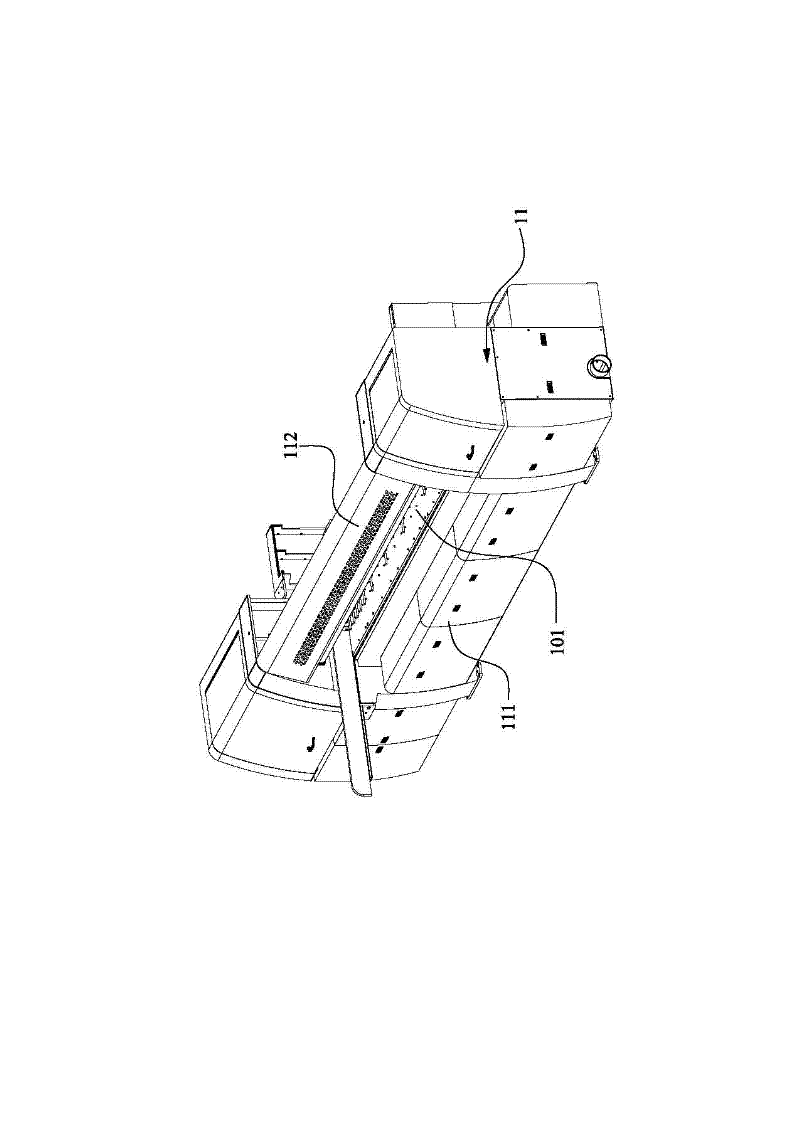

Back loading high-speed computer panel saw

ActiveCN102390063AGuaranteed cutting accuracyConducive to survivalFeeding devicesCircular sawsComputer control systemEngineering

The invention discloses a back loading high-speed computer panel saw comprising a machine station main body, a material feeding unit and a computer control system, wherein the machine station main body comprises a worktable, a material pressing device and a cutting device; the material pressing device and the cutting device are both arranged on the worktable; the material feeding unit is arranged at the back side of the machine station main body; the material feeding unit comprises a material feeding device and a material loading device; the material feeding device is arranged between the machine station main body and the material loading device; the material feeding device comprises a material feeding bracket and a first propulsion mechanism; the material loading device comprises a material loading bracket, a lifting table and a second propulsion mechanism; the computer control system controls the work of the material pressing device, the cutting device, the material feeding device and the material loading device, thereby realizing automation operation in the overall process of panel cutting, being favorable for ensuring the cutting precision of panel material, improving the work efficiency effectively, reducing the number of operation personnel and reducing the work strength for workers, thus reducing the production cost for an enterprise and being beneficial to the survival of the enterprise.

Owner:NANXING MACHINERY CO LTD

Improved Universal Machinery Fence System

A universal machinery fence system includes an L-shaped fence or a box shaped fence and clamp block which clamps to a rail extrusion with a half dovetail on the front on the edge of a table saw, band saw, shaper, router table, mortiser, or other woodworking or metal working machines. A U-shaped front rail is provided for attaching the fence to the cast iron table of a table saw, shaper, or band saw. The band saw fence U-shaped rail is predrilled to fit the table fence mounting holes of the most popular 14″ band saws. Optional extruded front rails are also provided for attaching the fence to shop made 0.750″ tables such as used on a drill press. Also provided is a fence rail extrusion for mounting the fence on the front and back of the popular 1.125″ size router table. An optional extruded front rail which is adjustable in height is also provided for attaching the fence to shop made tables between 0.750″ and 1.5″ in thickness. A re-saw guide fitted to the fence extrusion has a convex surface for supporting a workpiece on edge allowing the operator to easily adjust for blade drift. An optional micro-adjuster allows the fence to move accurately in small increments. A router table with holes and slots allows the fence to be used to guide the workpiece in the router table mode and then be used to guide the router or a saw on top of the workpiece.

Owner:KREG ENTERPRISES

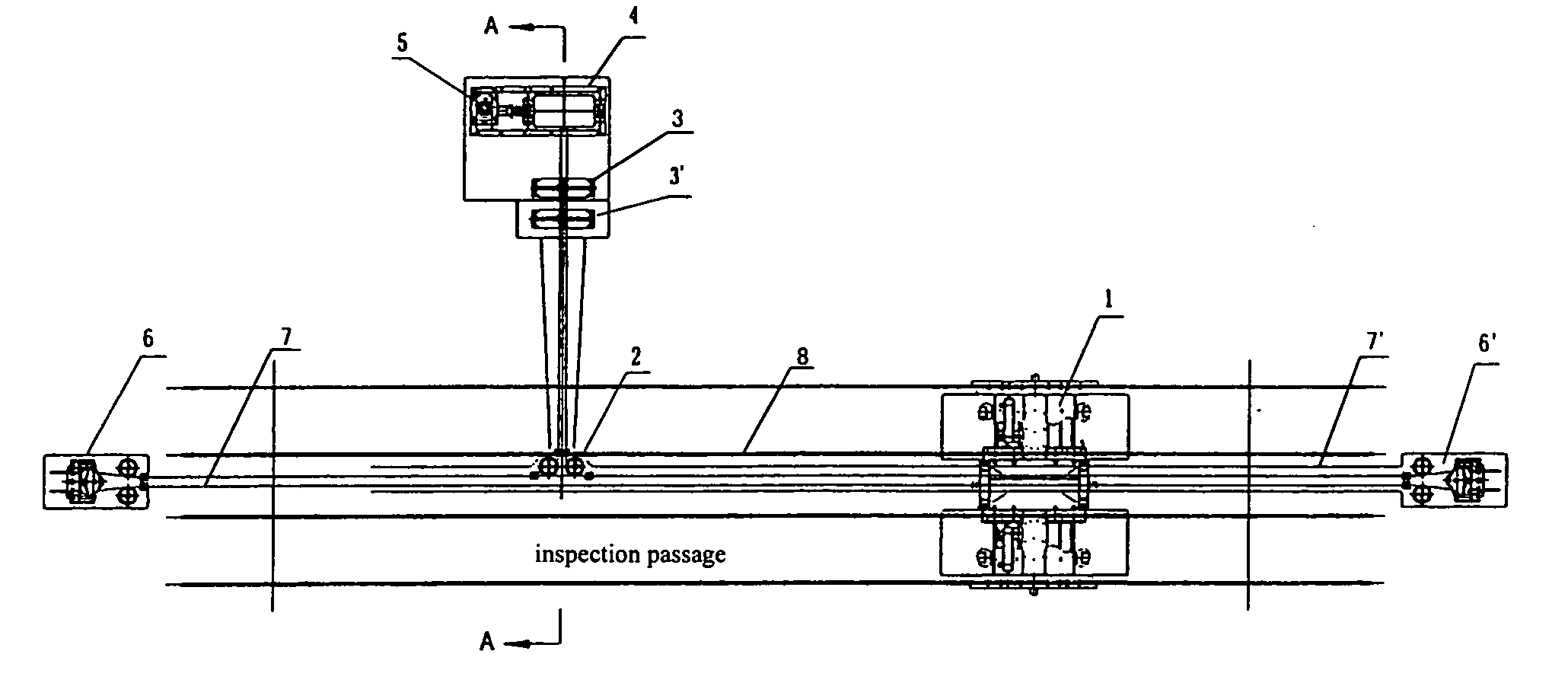

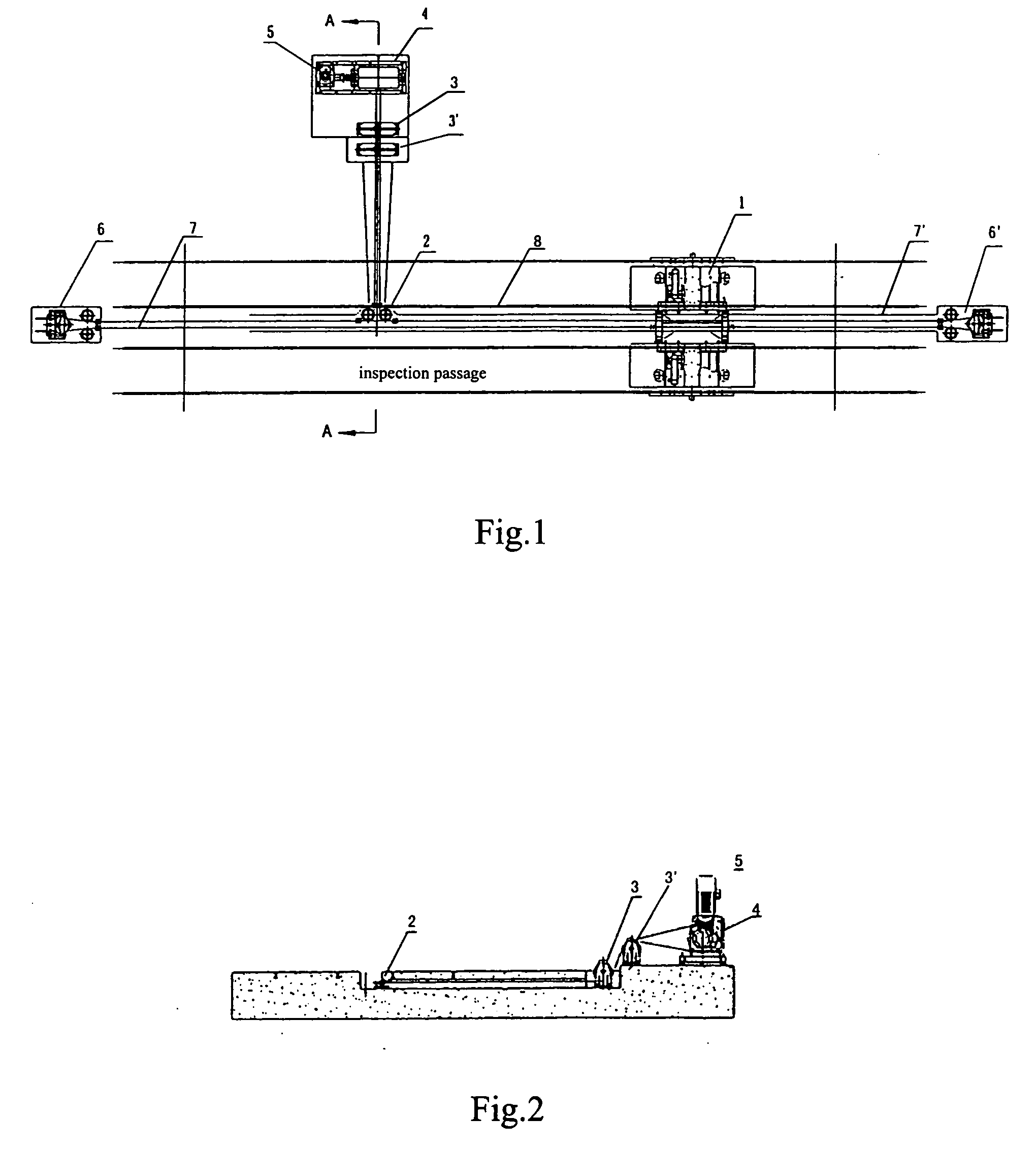

Pulling device for container inspection system

InactiveUS20060113163A1Reduce investmentReduced footprintMetal sawing devicesFeeding devicesWire tensionEngineering

The present invention discloses a pulling device for a container inspection system including a pulling vehicle (1) arranged inside an inspection passage, a winch (5) and wire tension mechanisms (6,6′). Front and rear ends of the pulling vehicle are connected to a wire rope so as to drive the pulling vehicle to move back and forth inside the inspection passage. The wire rope connected to front and rear ends of the pulling vehicle is wound around a wire tension mechanism arranged at front and rear ends of the inspection passage and is turned around by a swerving pulley (2) which is positioned at the same horizontal plane as that of the wire rope, the pulling vehicle, and the wire tension mechanisms, then the wire rope passes through the vertical pulley block, and finally it is connected to a single winding drum (4) of the winch (5) and wound around the single winding drum (4) respectively. Compared with the prior arts, the present invention is advantageous in reduction in equipment investment and decrease in area occupied by the pulling device. Further, the inspection operation can be carried out more reliably and safely.

Owner:NUCTECH CO LTD +1

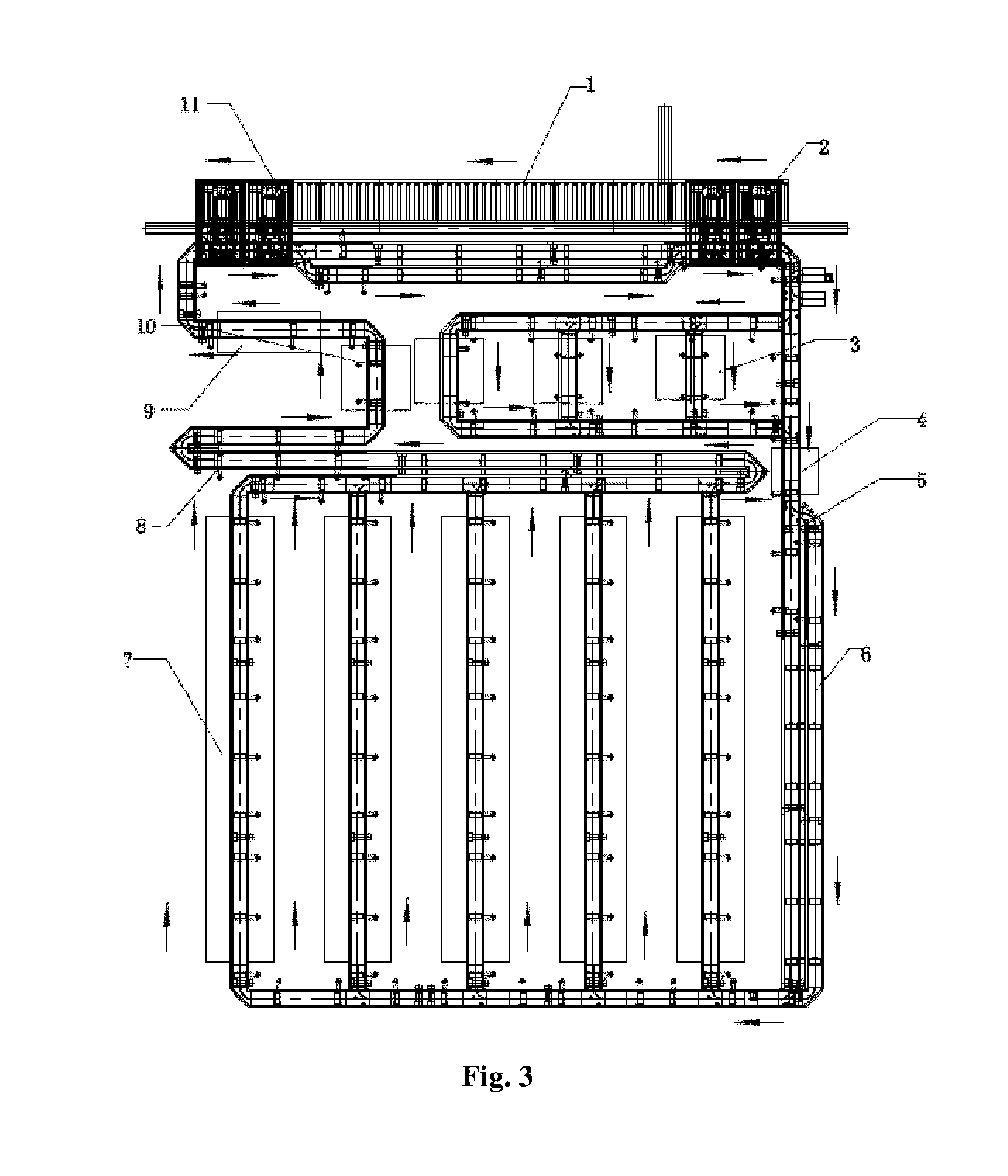

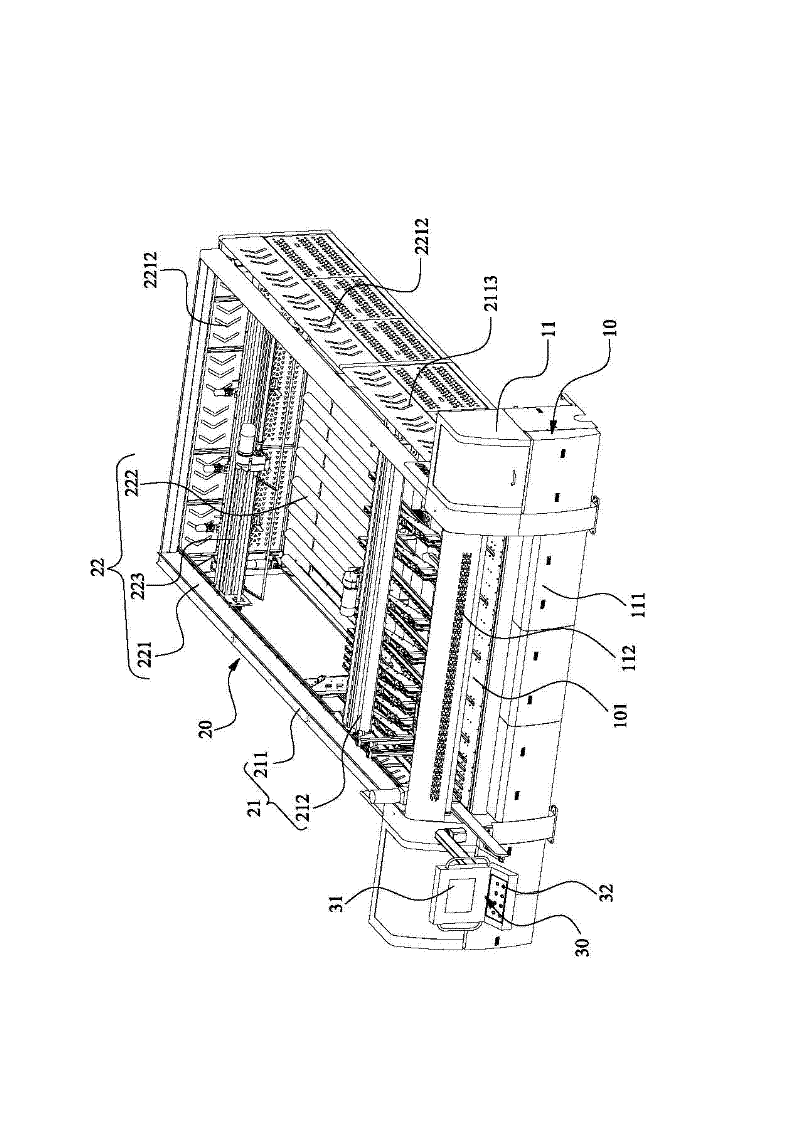

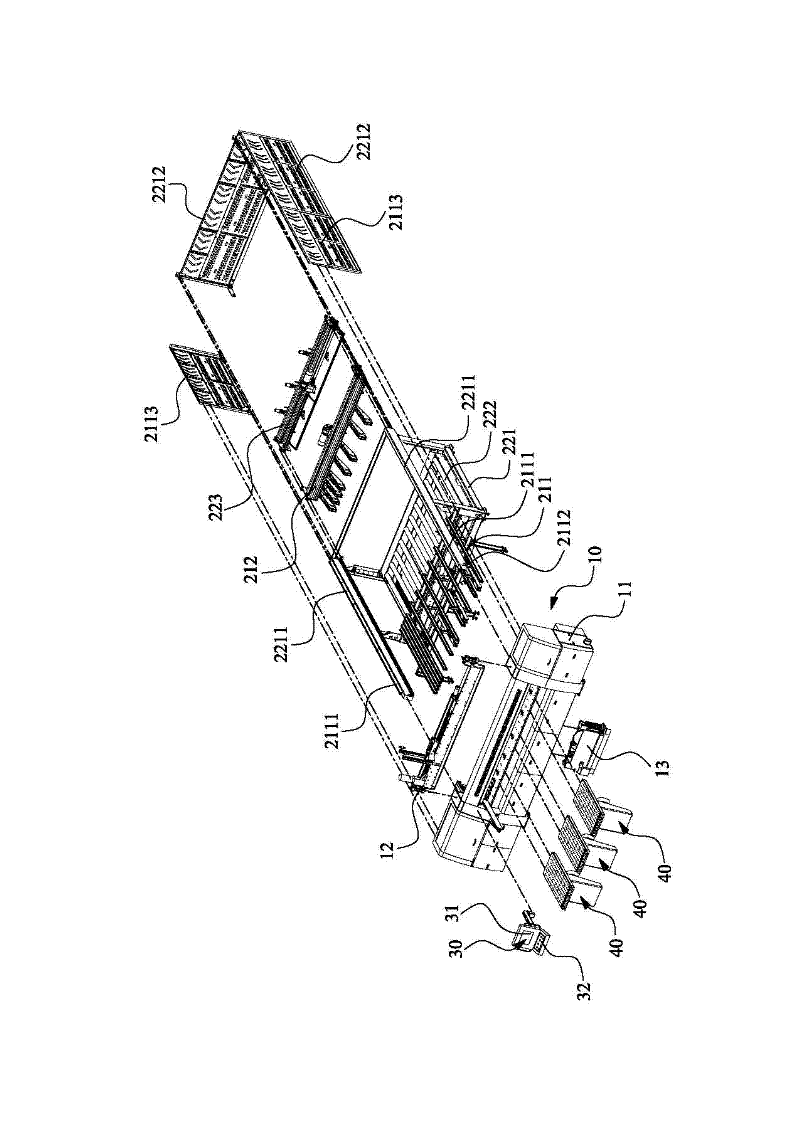

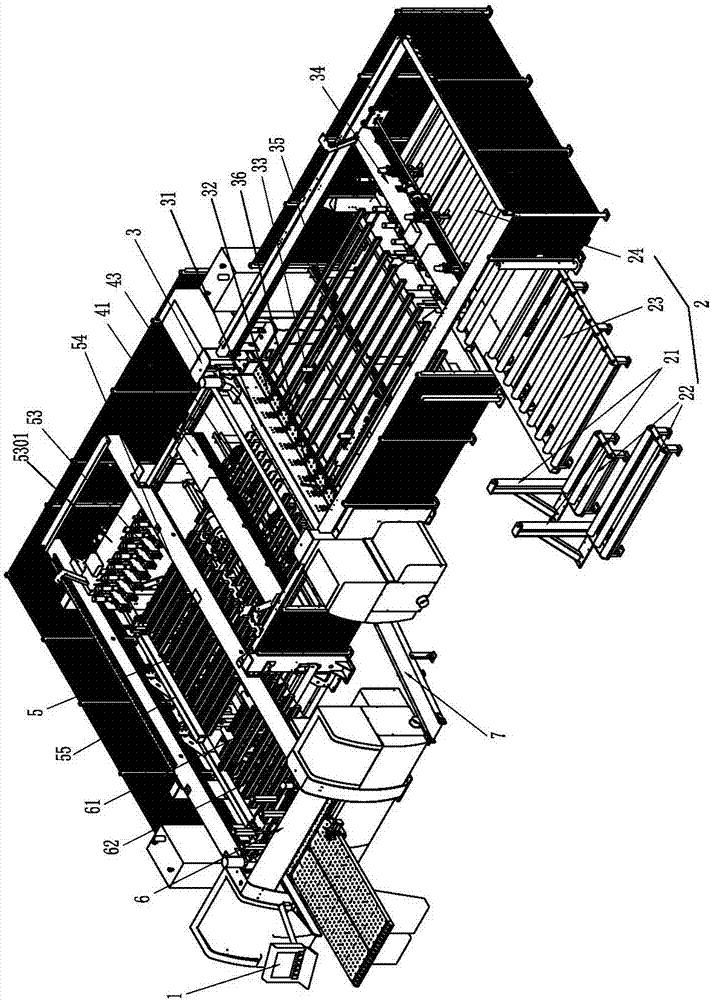

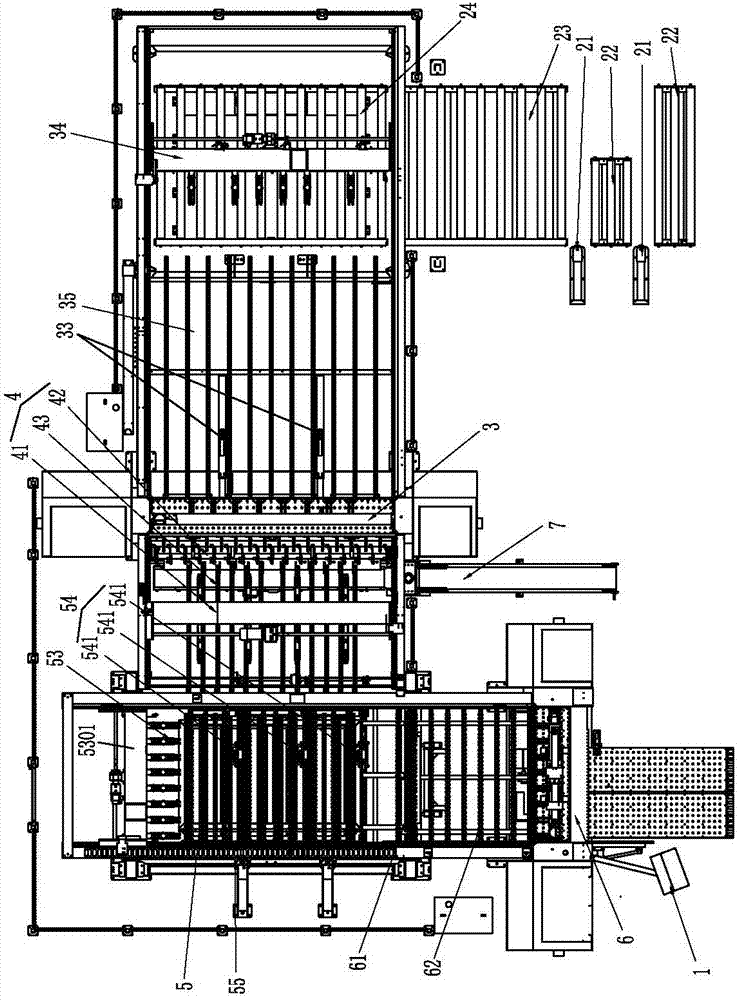

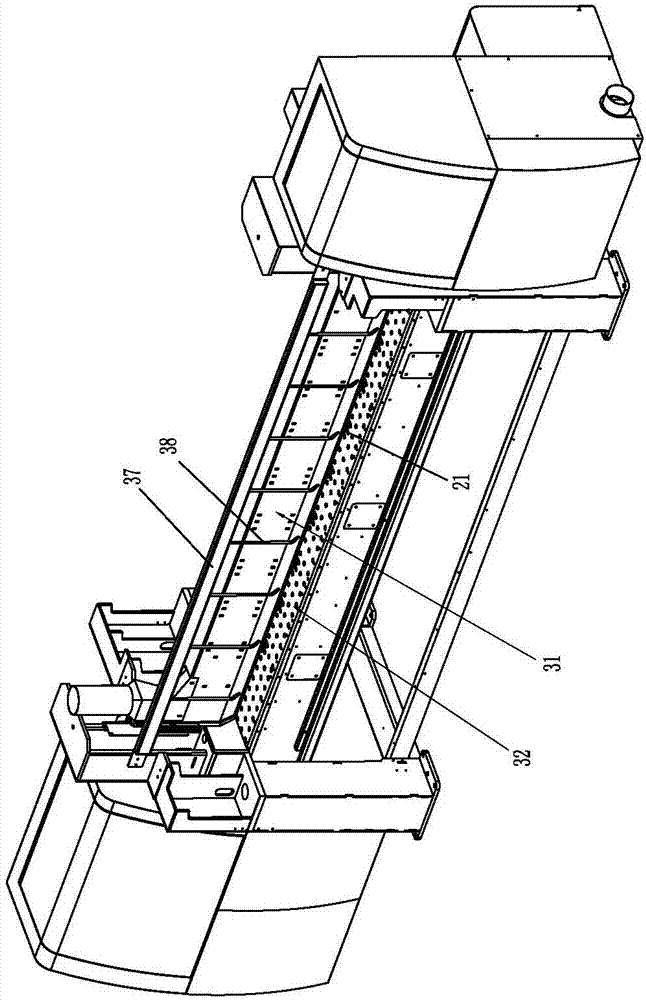

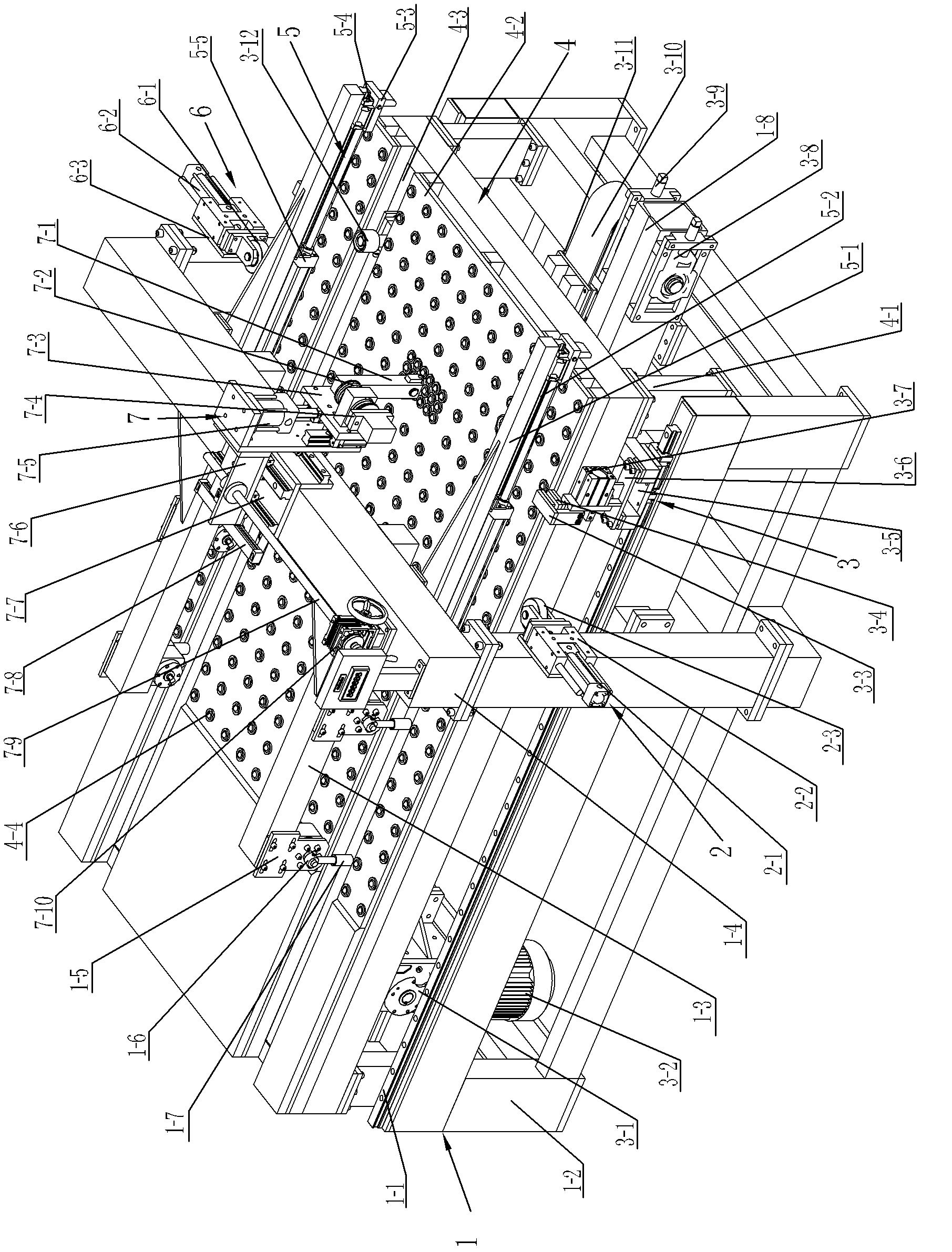

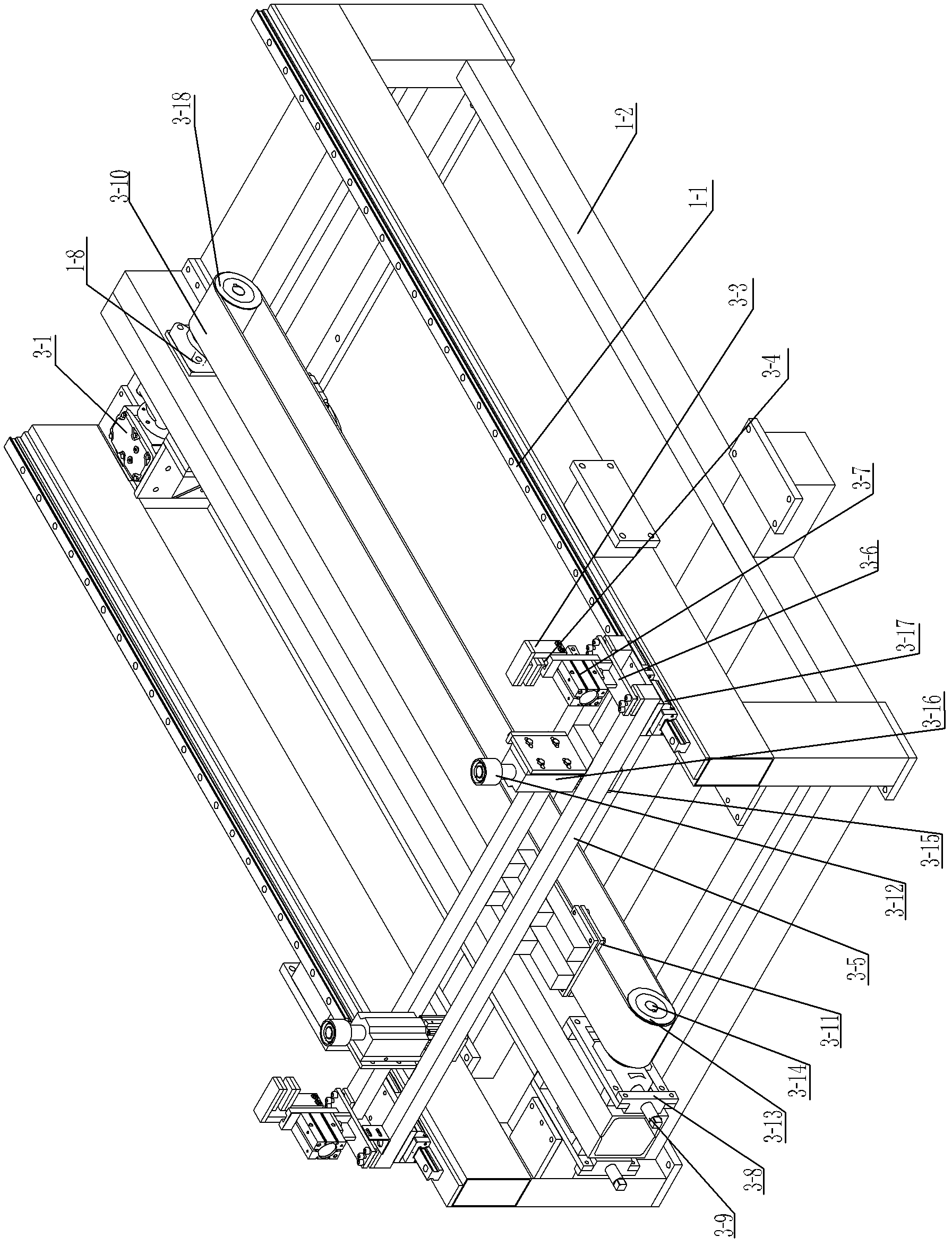

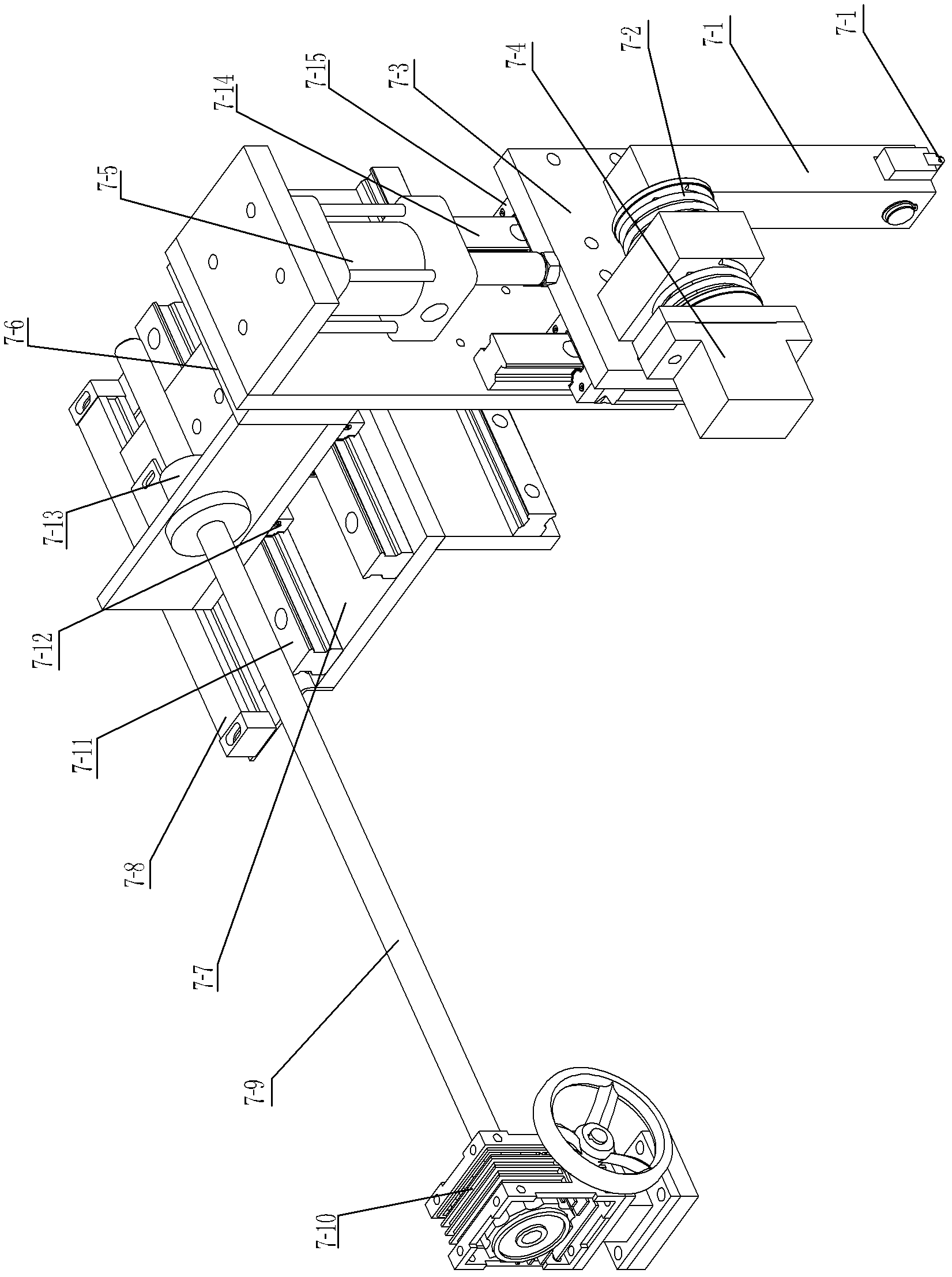

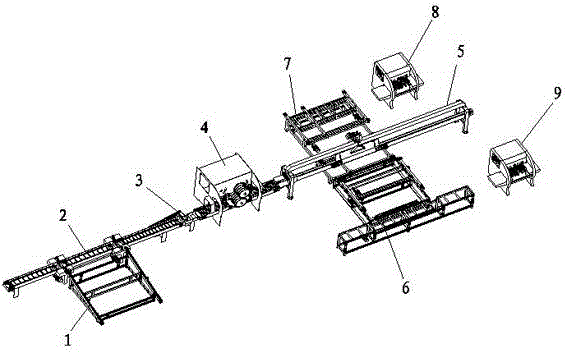

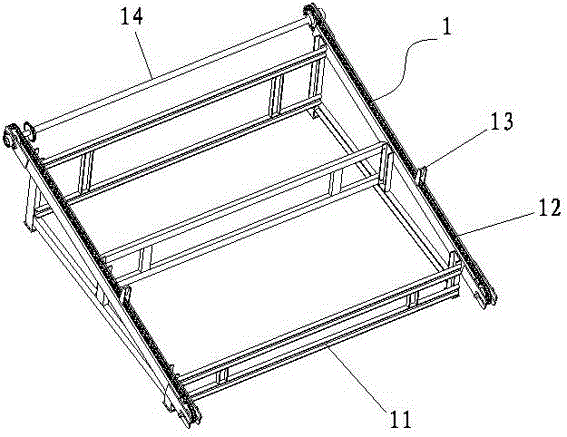

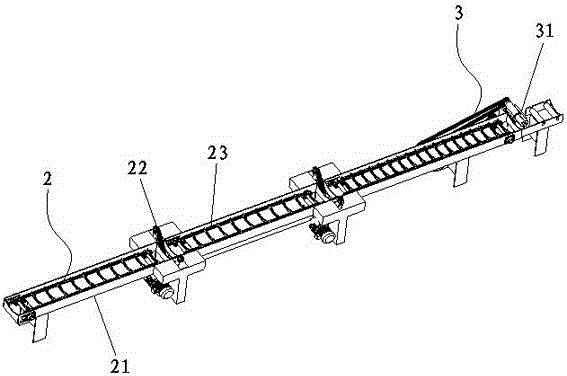

Longitudinal and transverse cutting computer cut-to-size saw equipment

ActiveCN106965261ARealize automatic feeding processImprove processing efficiencyFeeding devicesBark-zones/chip/dust/waste removalEngineeringWaste treatment

The invention discloses longitudinal and transverse cutting computer cut-to-size saw equipment which comprises a control unit, a feed unit, a longitudinal sawing unit, a transition feed unit, a lift type longitudinal and transverse bidirectional conveying platform, a transverse sawing unit and an excess material and waste treatment unit. The longitudinal sawing unit comprises a longitudinal sawing main machine rack, a longitudinal sawing saw carriage, a longitudinal sawing pressure cross beam, a longitudinal sawing plate front alignment device, a longitudinal sawing feed pushing rod cross beam assembly and a first conveying platform. The transition feed unit comprises a feed hooking hand mechanism, an excess material discharge mechanism and a second conveying platform. The lift type longitudinal and transverse bidirectional conveying platform comprises a transverse conveying unit and a longitudinal conveying unit which are arranged in a staggered mode. The transverse sawing unit comprises a transverse sawing main machine rack, a transverse sawing saw carriage, a transverse sawing pressure cross beam, a transverse sawing plate front alignment device and a third conveying platform. By adoption of the longitudinal and transverse cutting computer cut-to-size saw equipment, plate automatic feeding, automatic longitudinal cutting and automatic transverse cutting are achieved, trimming excess materials can be automatically treated, processing efficiency is greatly improved, and labor force is saved.

Owner:NANXING MACHINERY CO LTD

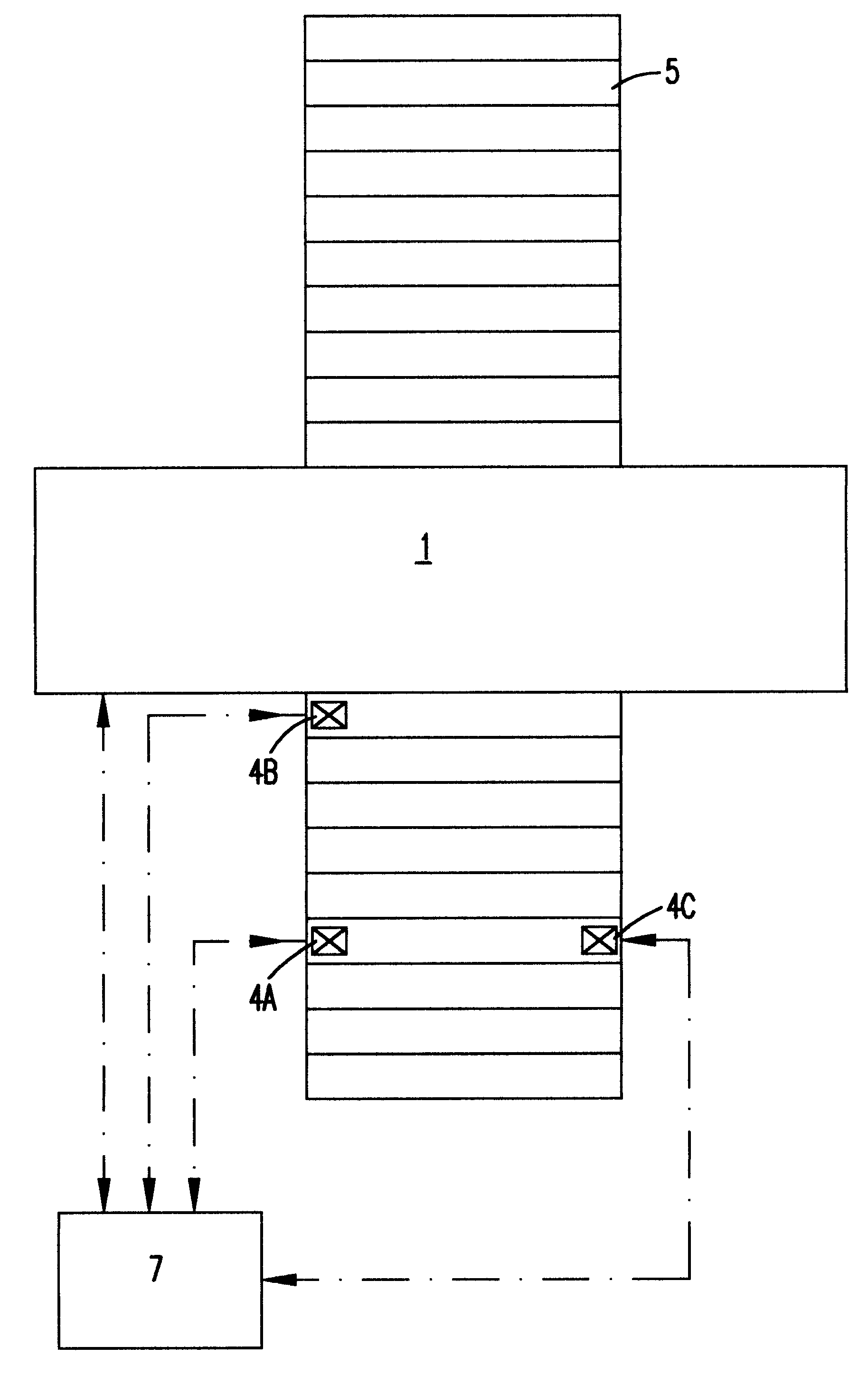

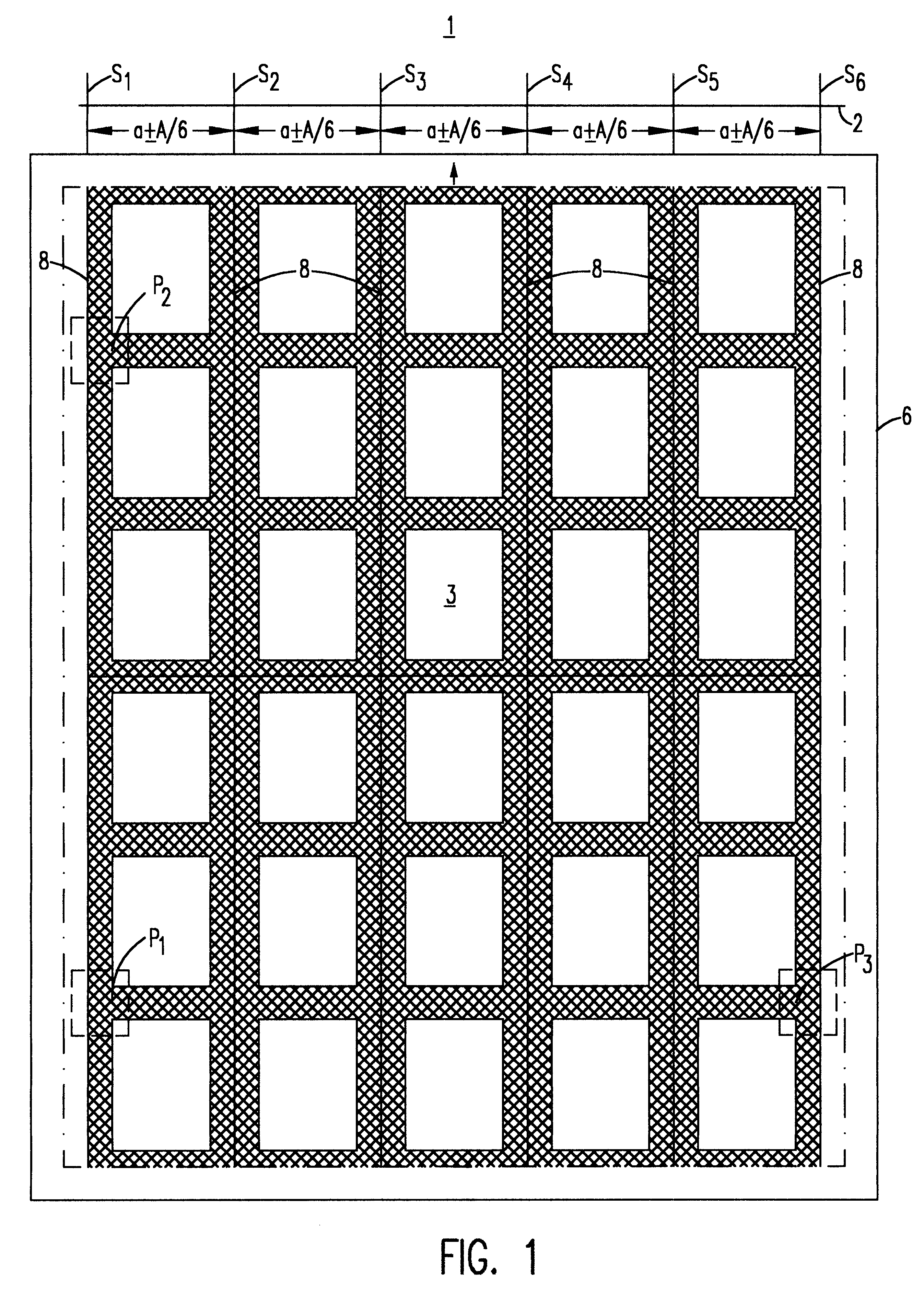

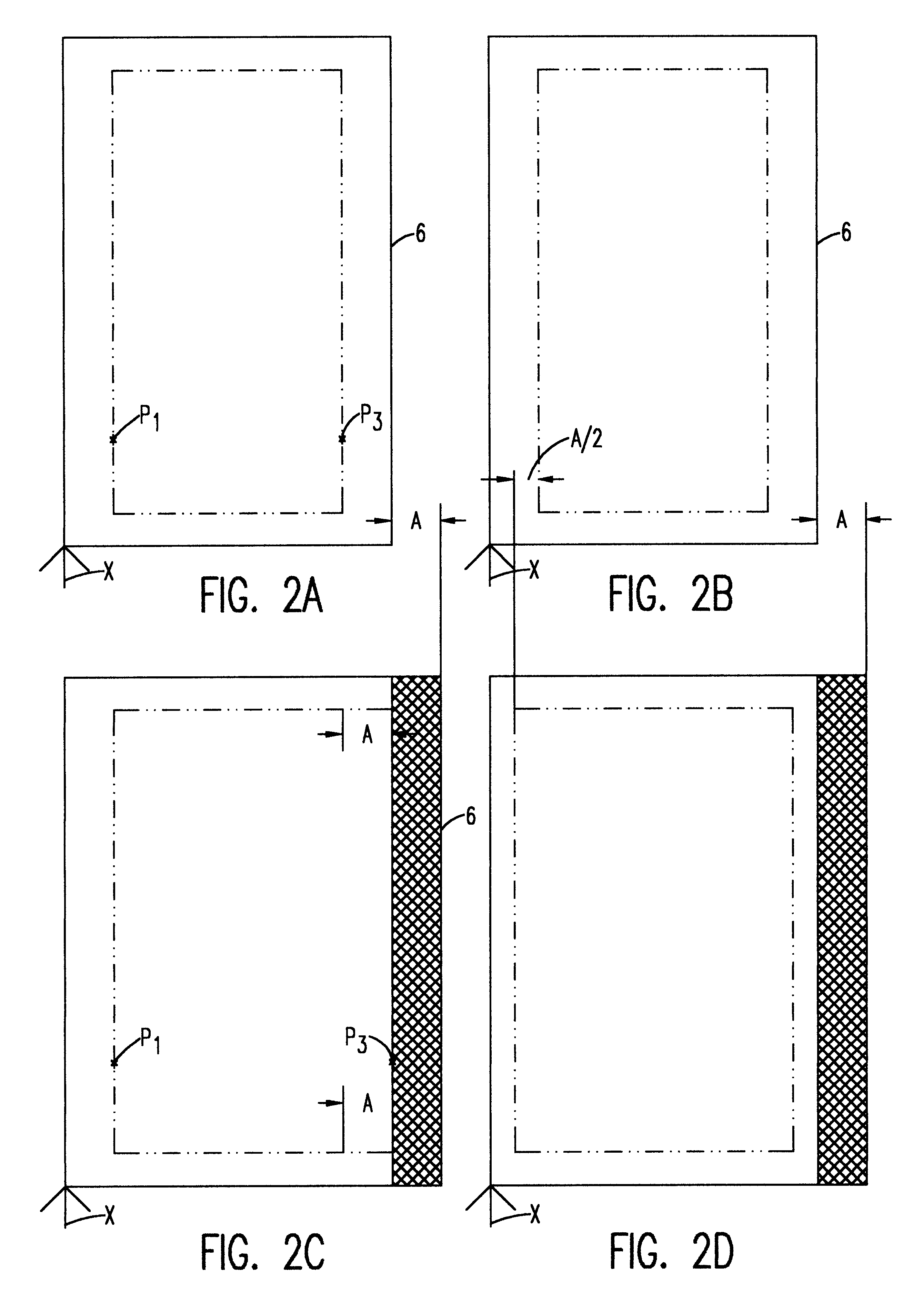

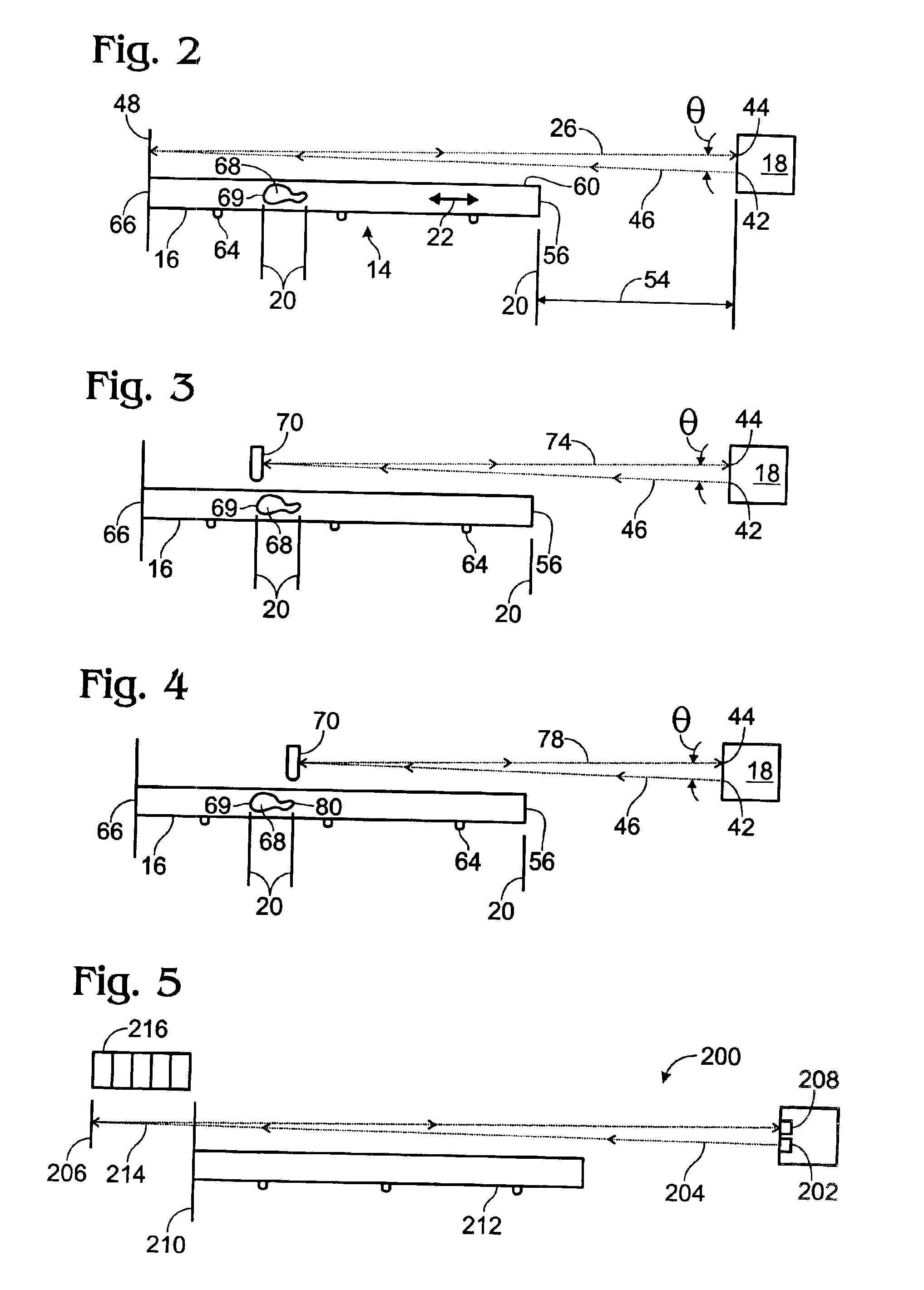

Process for cutting out panels or the like

InactiveUS6569272B2Quality improvementAutomatic control devicesLamination ancillary operationsWood fibreEngineering

A wood fiber board (6) which is provided with a decorative layer (3) of paper or similar material, and where the length or width value of the decorative layer (3) deviates from its original value after it is applied to the wood fiber board (6), is cut into uniform panels using a board-dividing apparatus that compensates for these deviations. The board-dividing apparatus has a saw (1) that preferably has a plurality of saw blades (S1, S2, . . . Sn) which are adjustably spaced in parallel fashion. The board-dividing apparatus is equipped with a number of cameras and with controller which utilizes deviation measurement information to adjust the spacing of the saw blades. The wood fiber board (6) is first aligned with at least one initial camera (4a) at a point P1. Then, predetermined points (P1 and P2) in the decorative layer (3) are recorded by the first camera (4a) and a second camera (4b). A distance (L) between the points (P1 and P2) is determined, and thee discrepancy in the width or length value is determined by comparison of the actual position and the desired position of the points (P1 and P2). Then, the value of the determined discrepancy (A) is placed in relation to the number (n) of the saw blades (Sn), and the parallel spacing (a) of the saw blades (Sn) is modified by the value of the ratio of the discrepancy to the number of saw blades (A / n). The orientation of the wood fiber board (6) to the saw (1) is displaced to one side in the amount of one half the determined discrepancy (A), and then the wood fiber board (6) is transported toward the saw (1) for cutting out the panels.

Owner:KRONOTEC

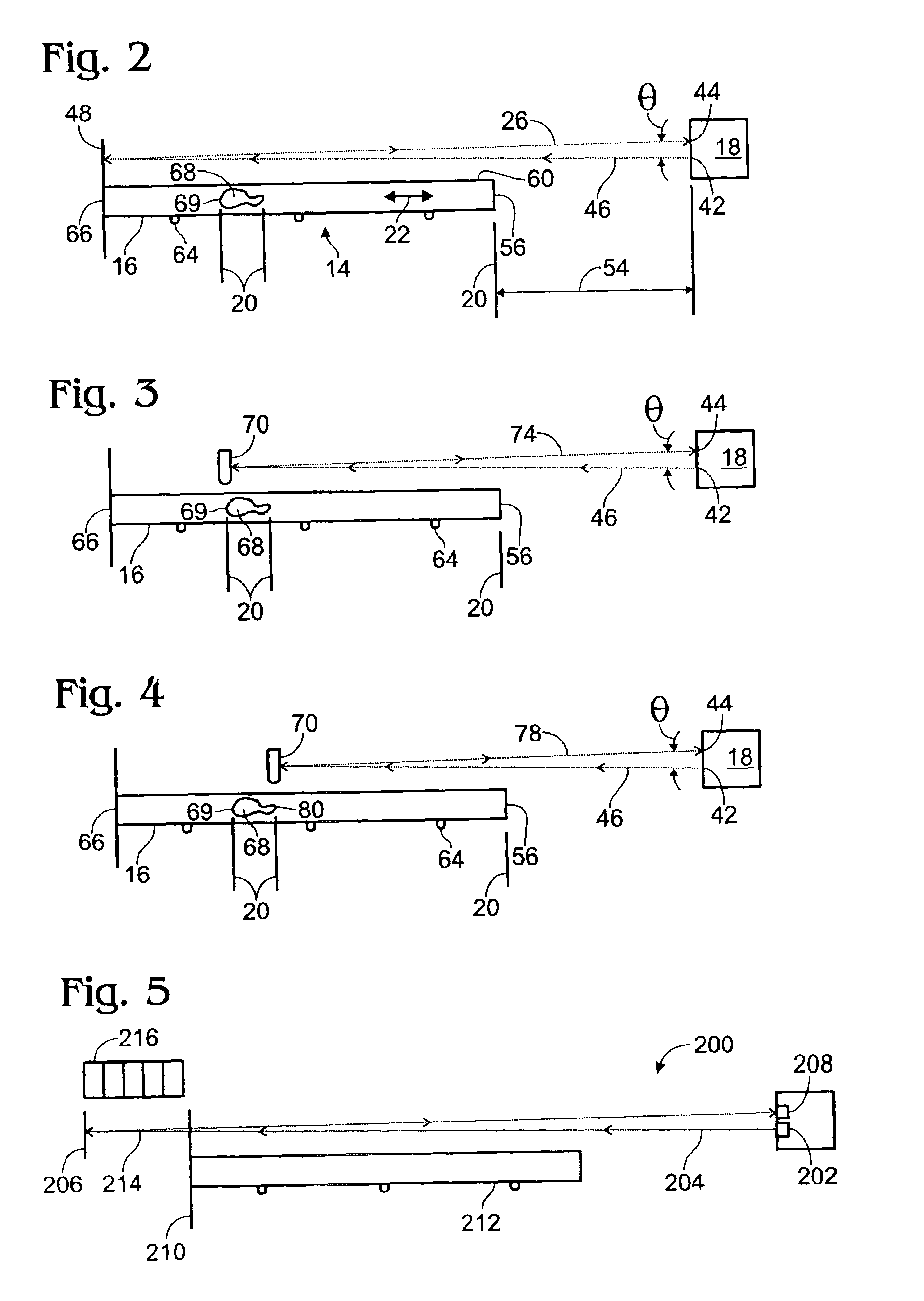

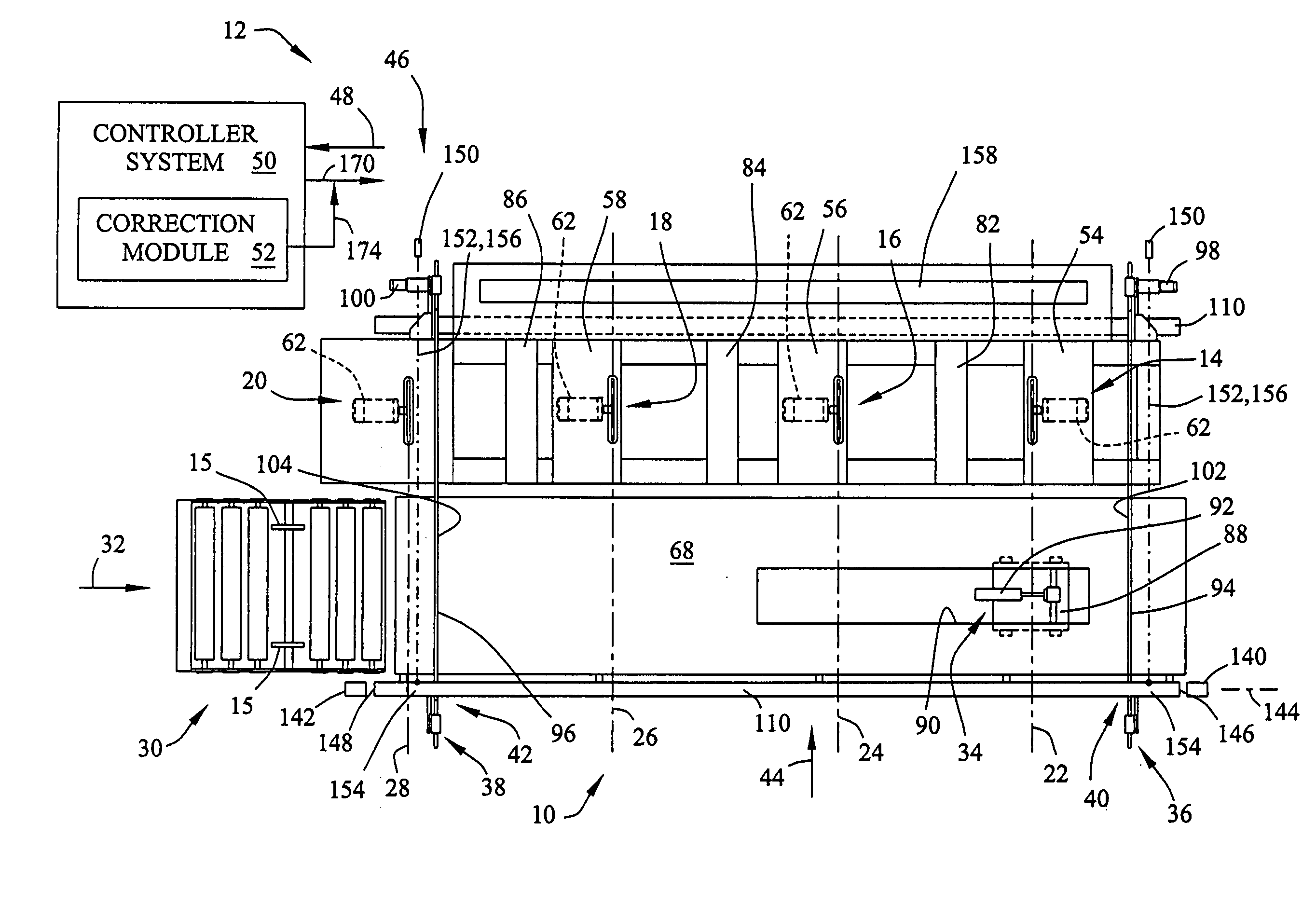

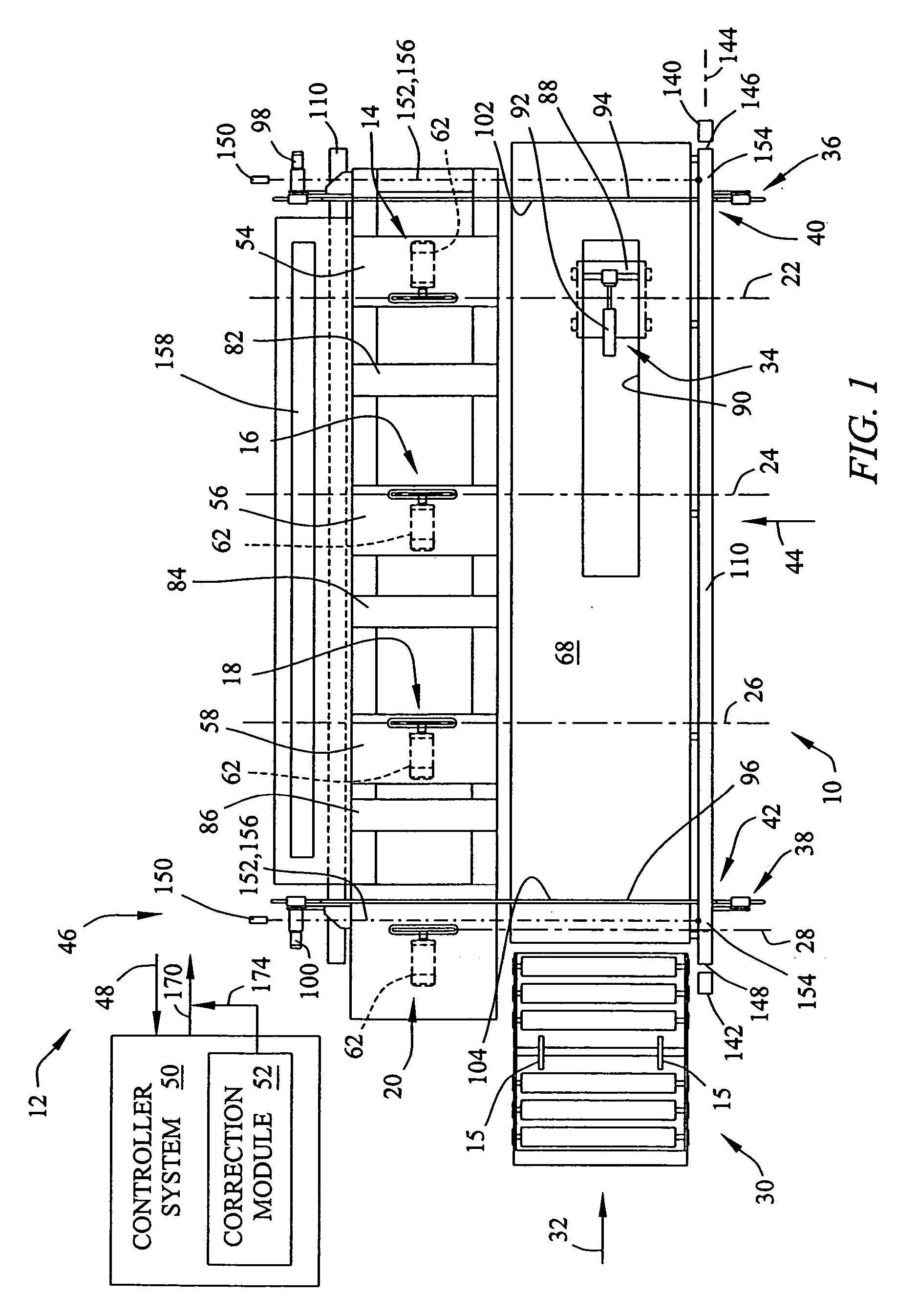

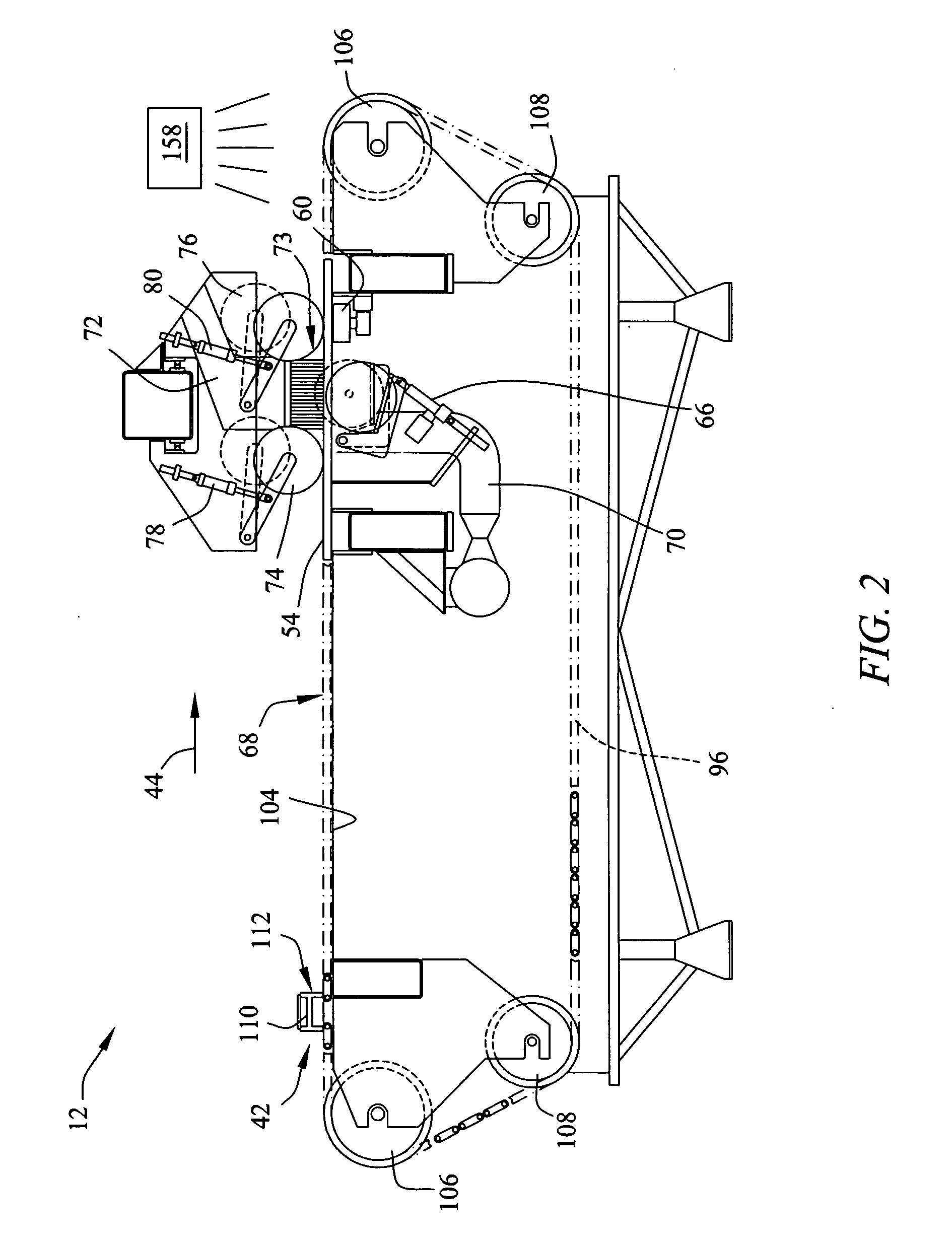

Systems and methods of processing materials

System, including apparatus and method, for processing a material involves automatically measuring the length of a work piece and calculating an optimal plan for cutting the work piece to fulfill cut list requirements.

Owner:PRECISION AUTOMATION

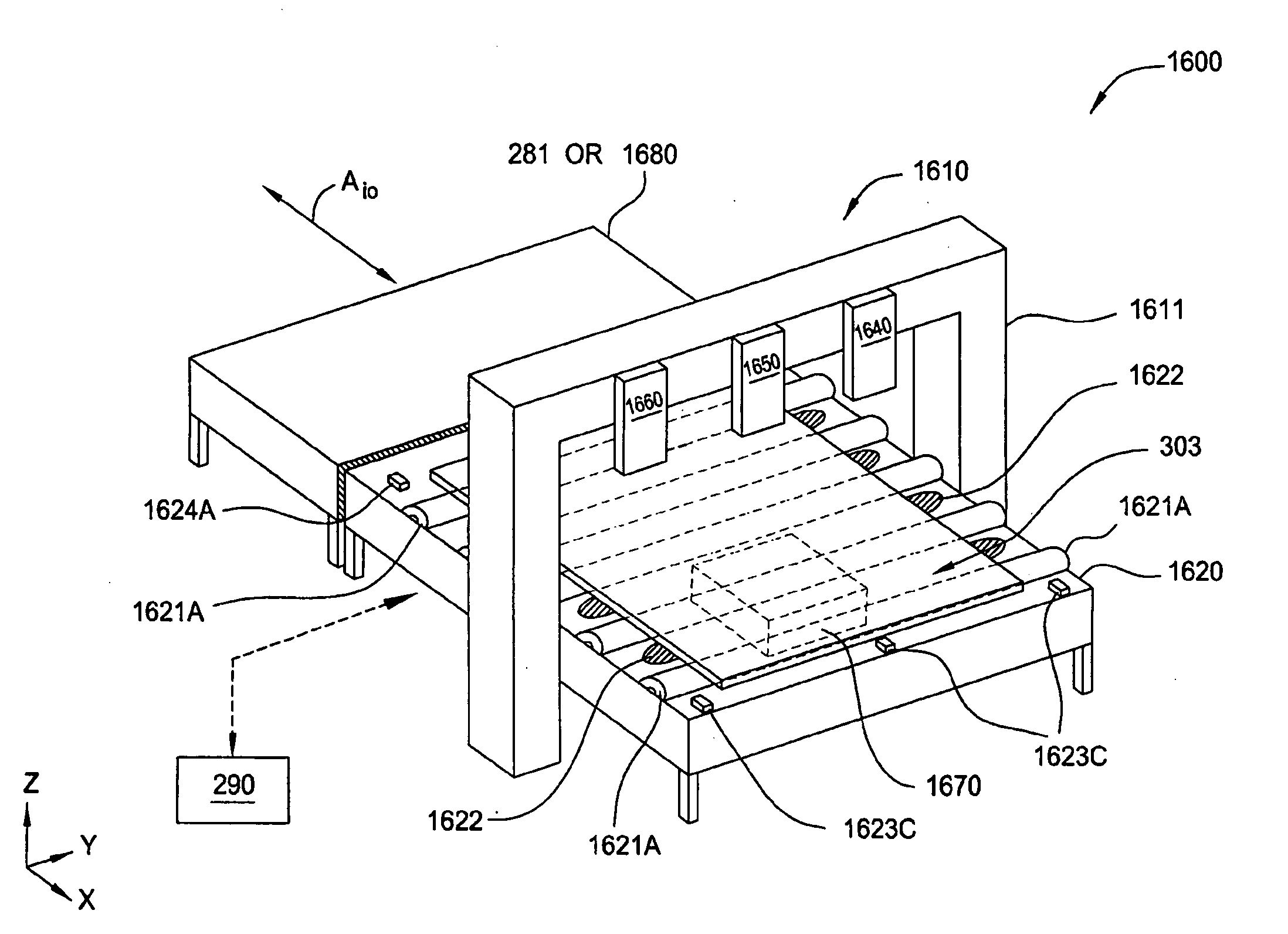

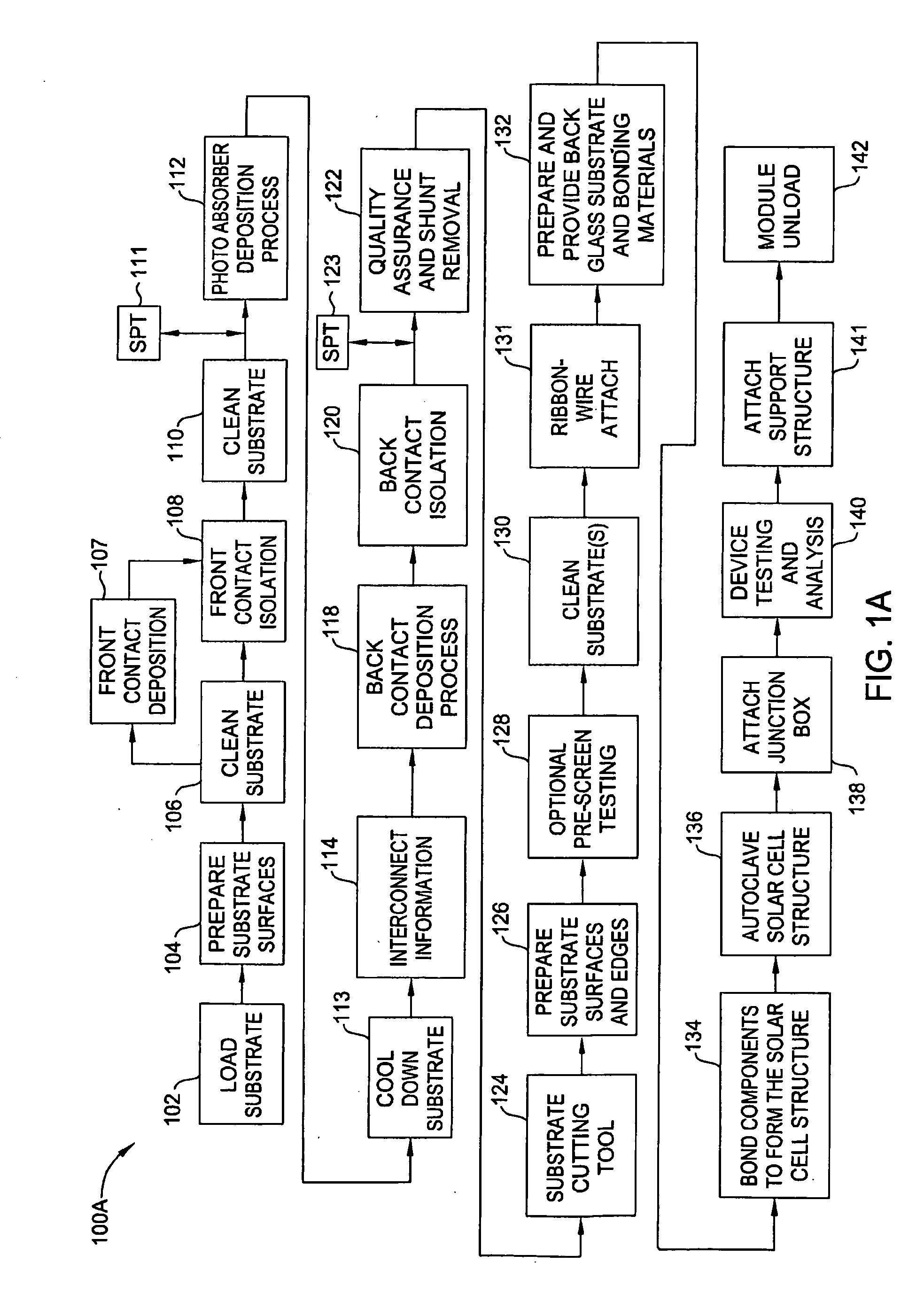

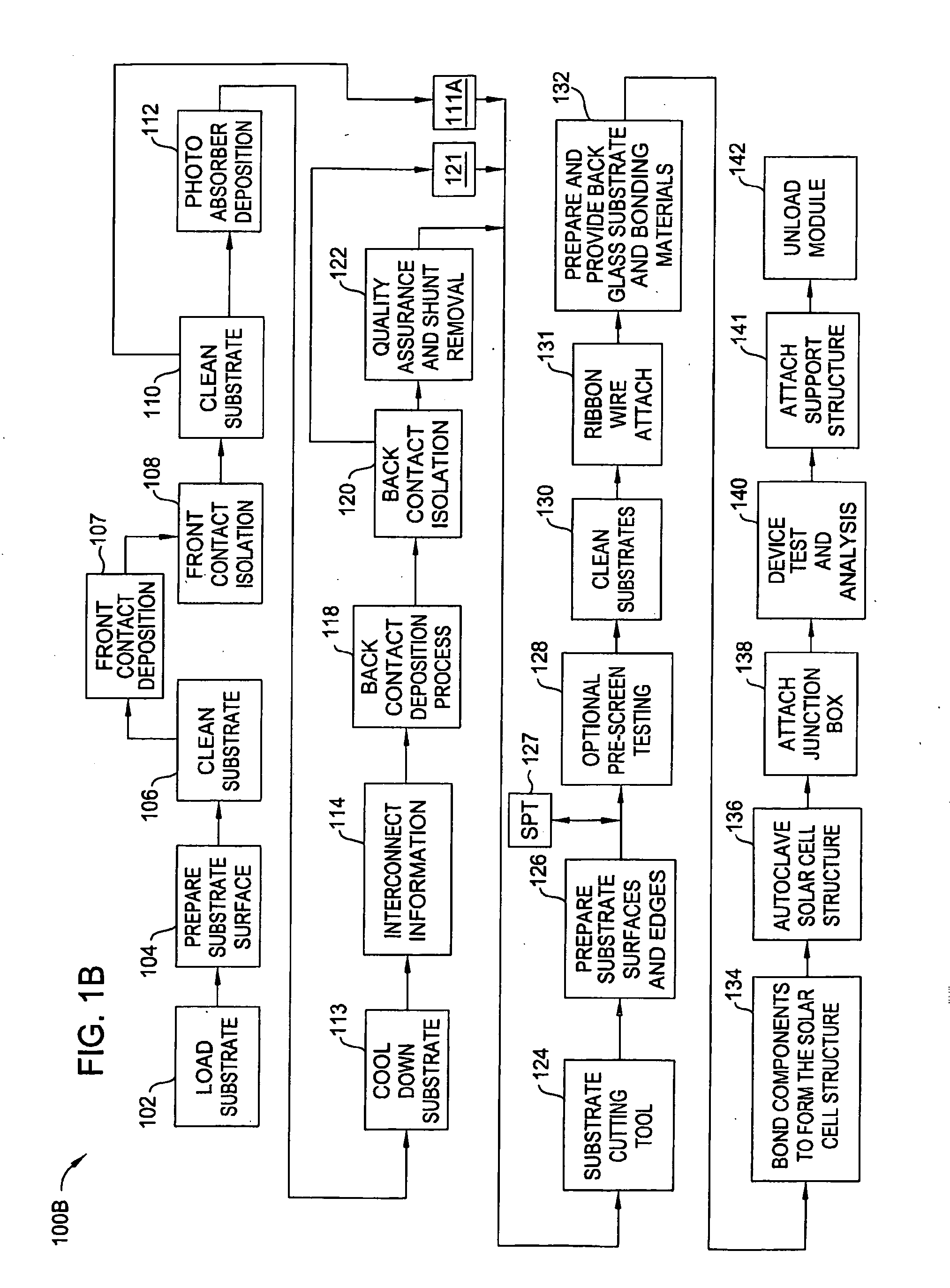

Solar parametric testing module and processes

Embodiments of the present invention generally relate to a module that can test and analyze various regions of a solar cell device in an automated or manual fashion after one or more steps have been completed in the solar cell formation process. The module used to perform the automated testing and analysis processes can also be adapted to test a partially formed solar cell at various stages of the solar cell formation process within an automated solar cell production line. The automated solar cell production line is generally an arrangement of automated processing modules and automation equipment that is used to form solar cell devices.

Owner:APPLIED MATERIALS INC

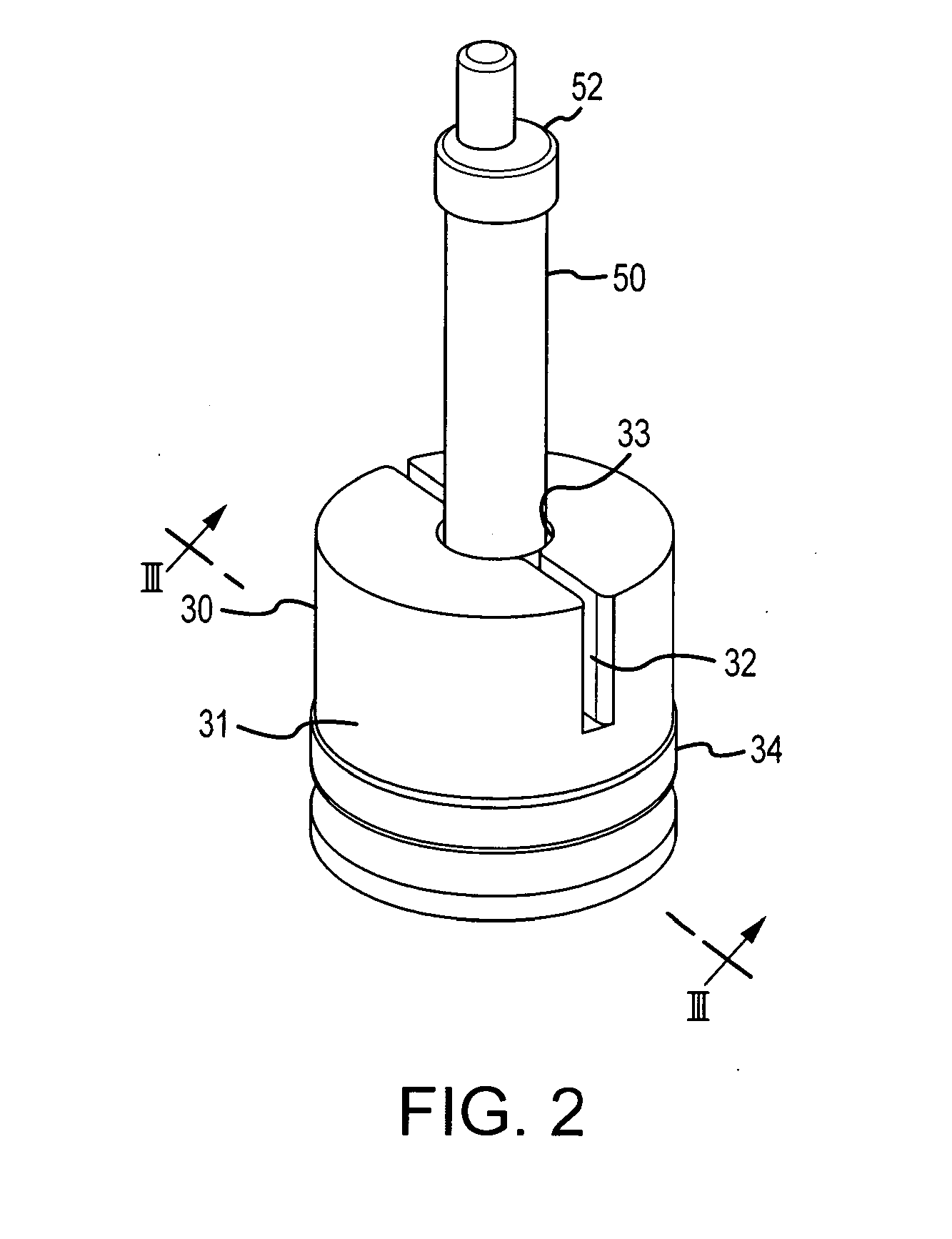

Woodworking machinery stop and track system

Owner:KREG ENTERPRISES

Labeling methods and apparatus

System, including apparatus and method, for processing a material involves automatically printing labels for pieces cut pursuant to a cut list.

Owner:PRECISION AUTOMATION

Horizontal hold down jig

InactiveUS7341081B1Uniform pressureEasy to useWood feeding arangementsFeeding devicesCompressive strengthMechanical engineering

A horizontal rotary hold down jig for use in horizontally guiding a piece of wood to be cut on one of a portable table saw and a portable router table comprising a spring biased rotatable wheel that can be secured to the table. The spring biasing can be adjusted to provide uniform or enhanced pressure through use of a plurality of substitutable compression springs of varying compressive strength characteristics to laterally stabilize a piece of wood of varying consistency, wood grain angle, feed cutting speed, width, and thickness or depth of cut.

Owner:VILLIGER ERIC J

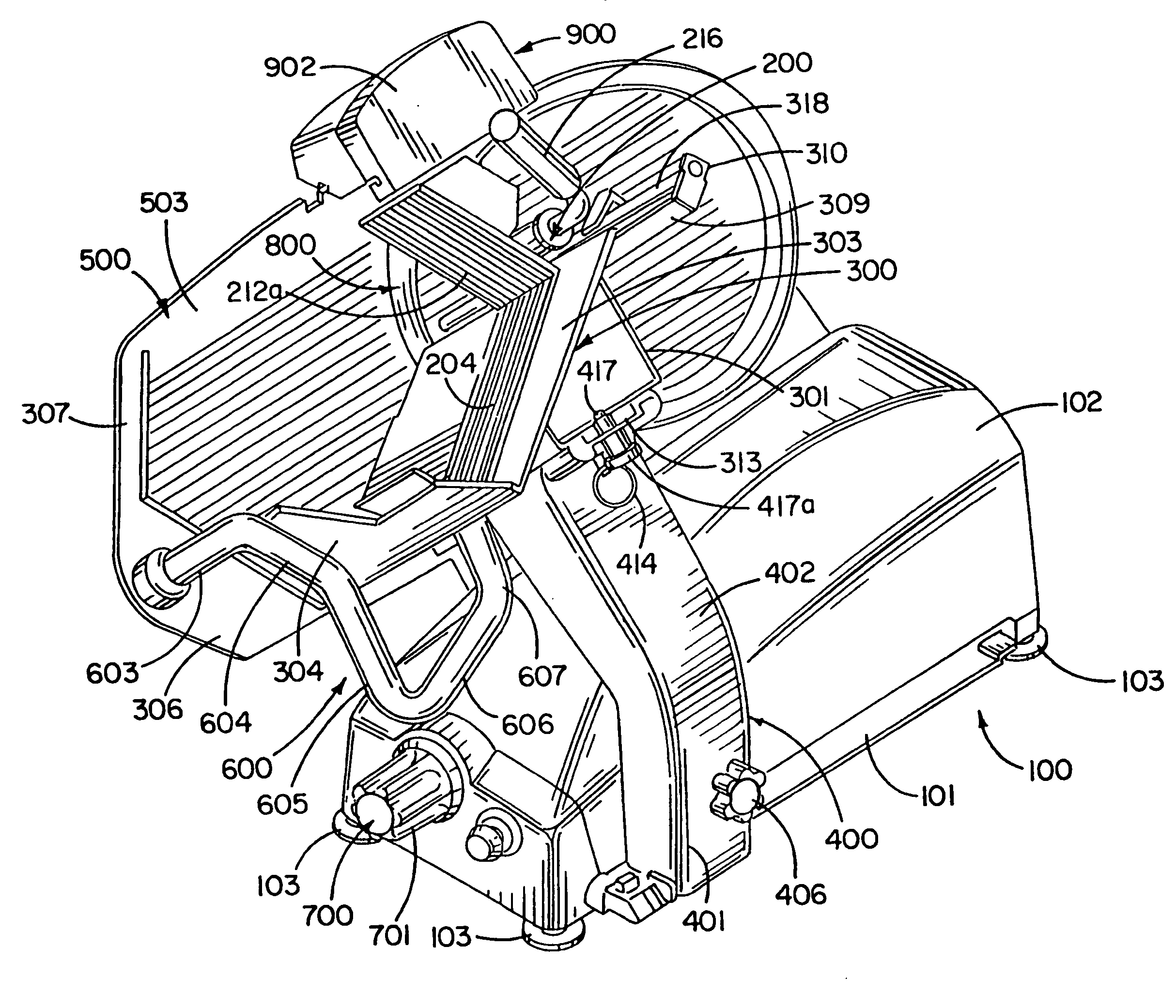

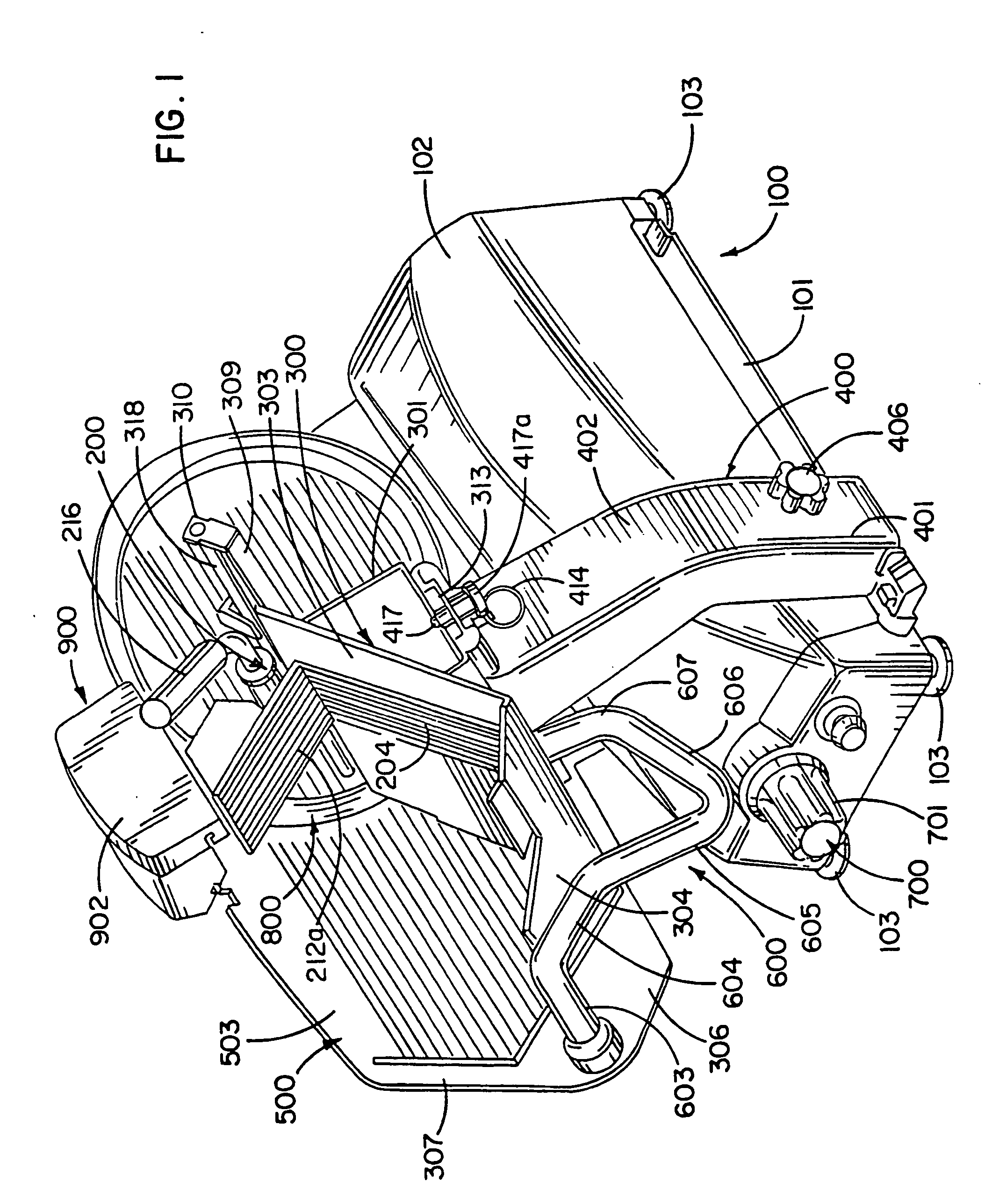

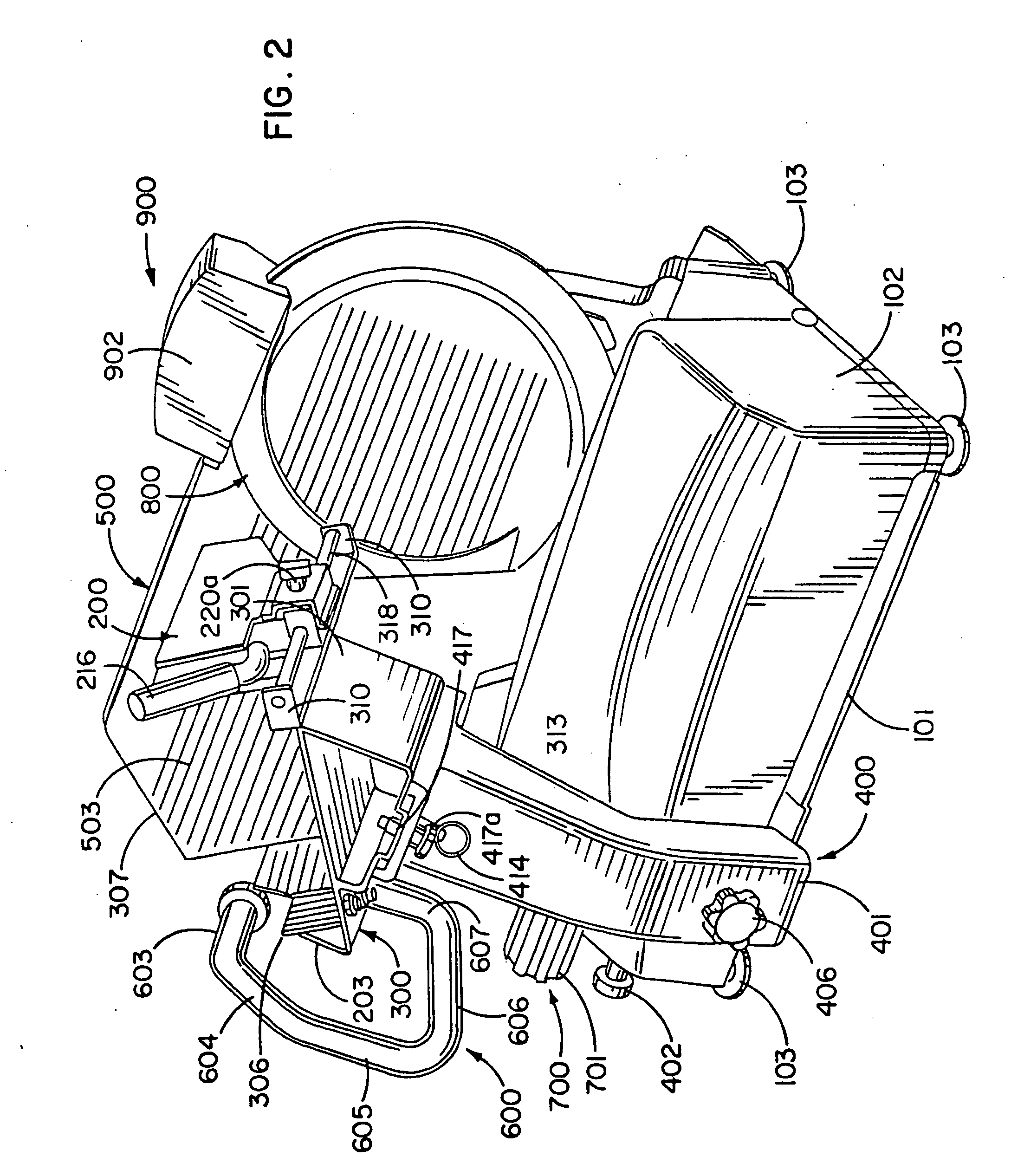

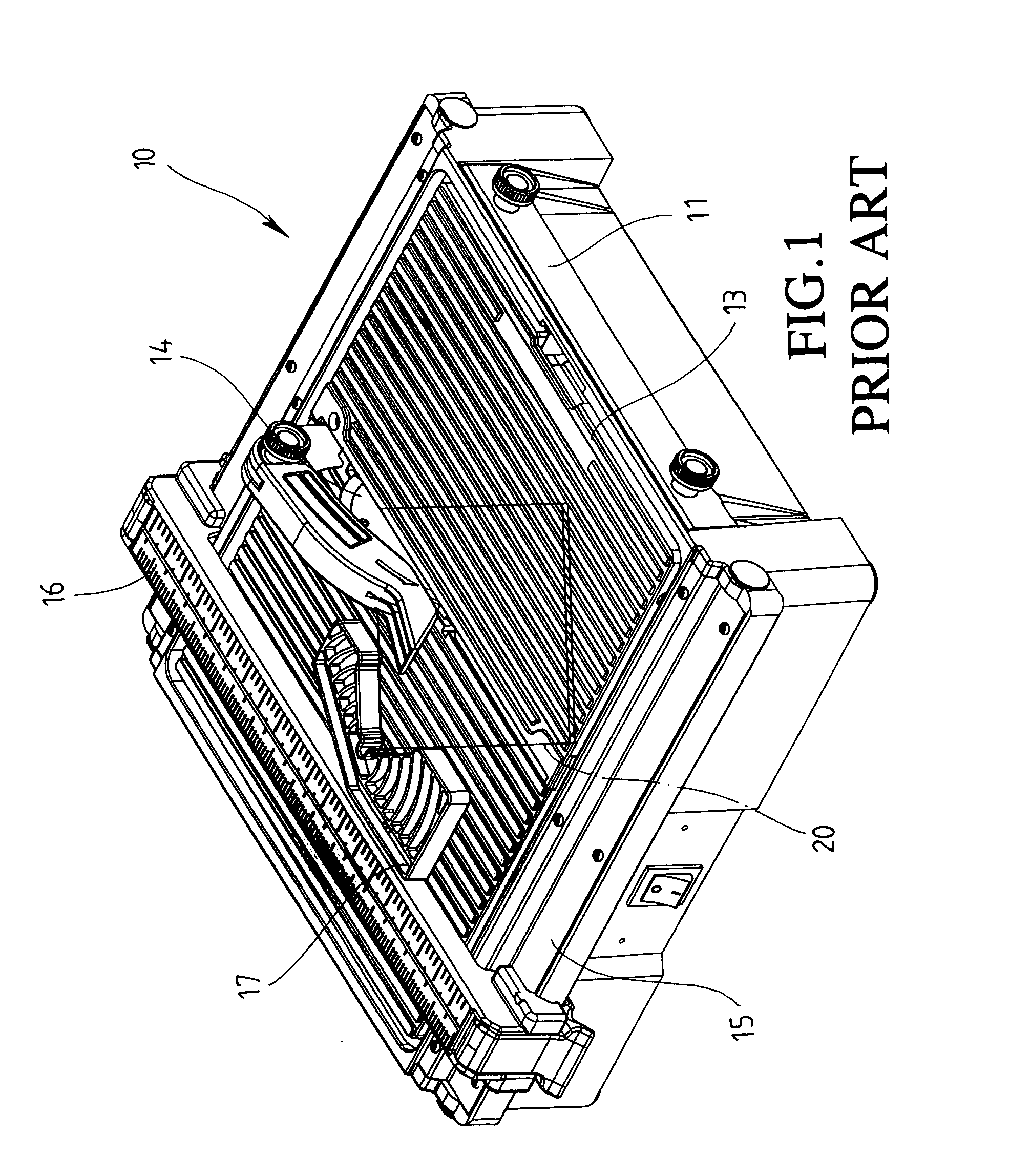

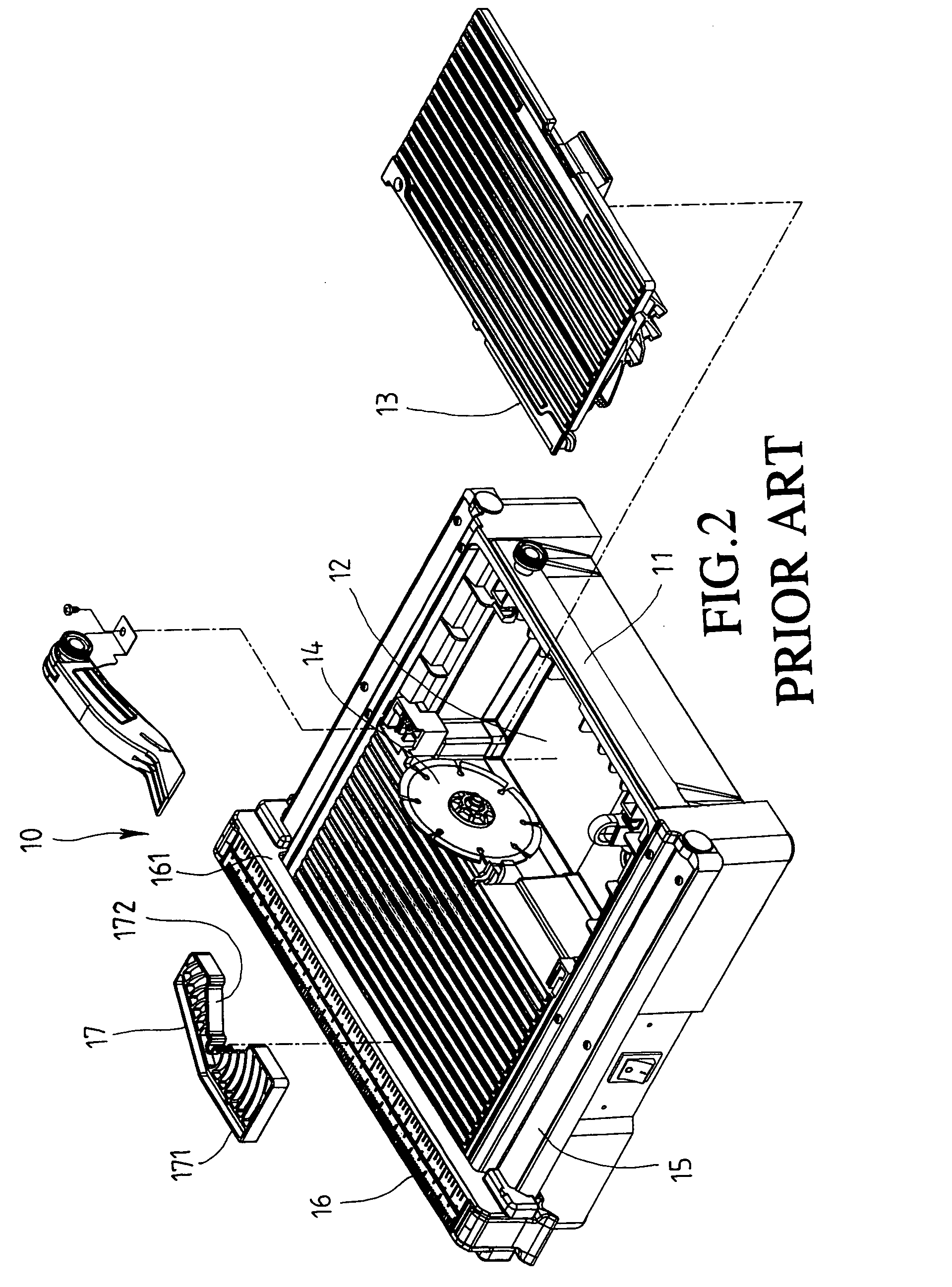

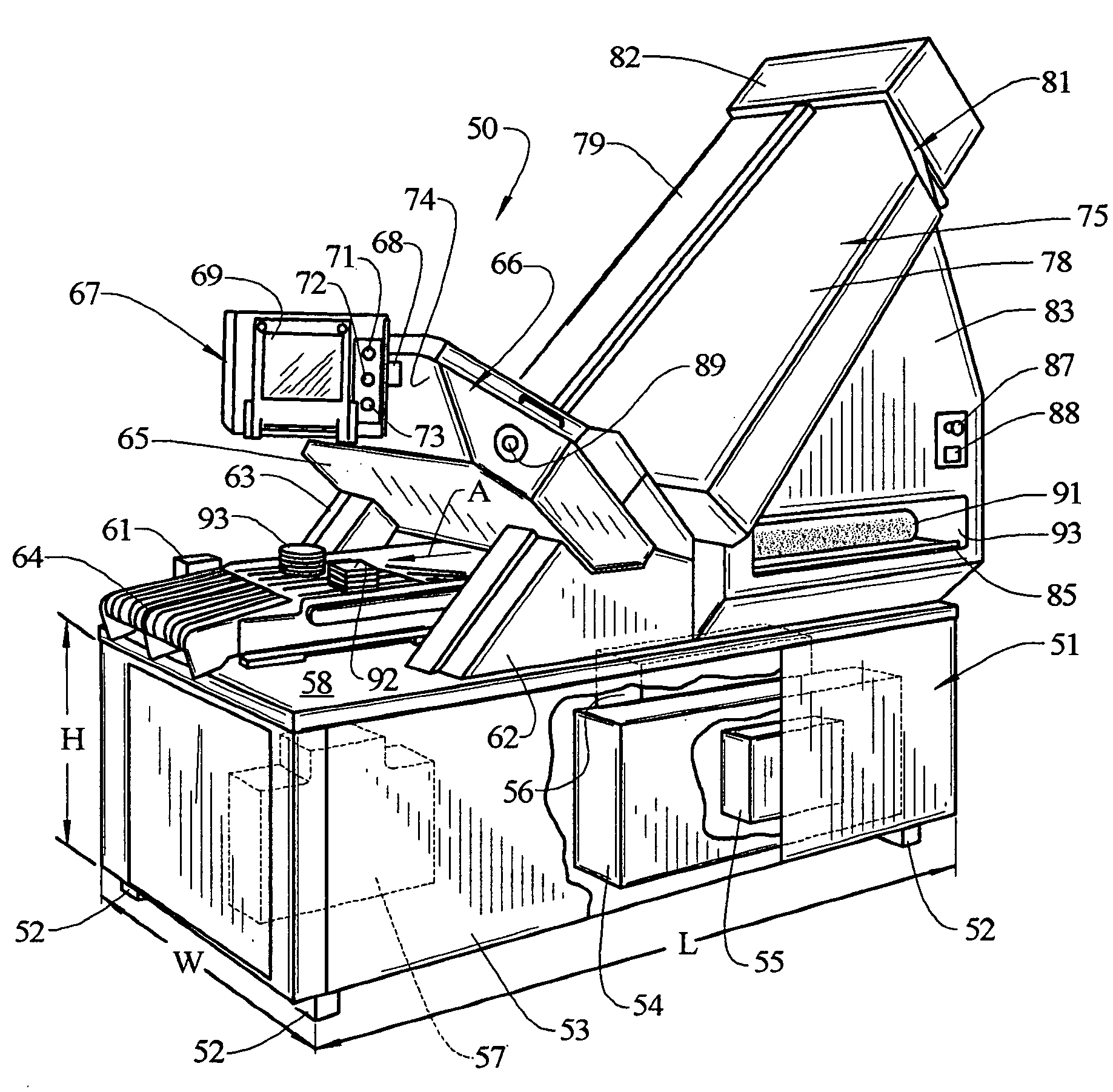

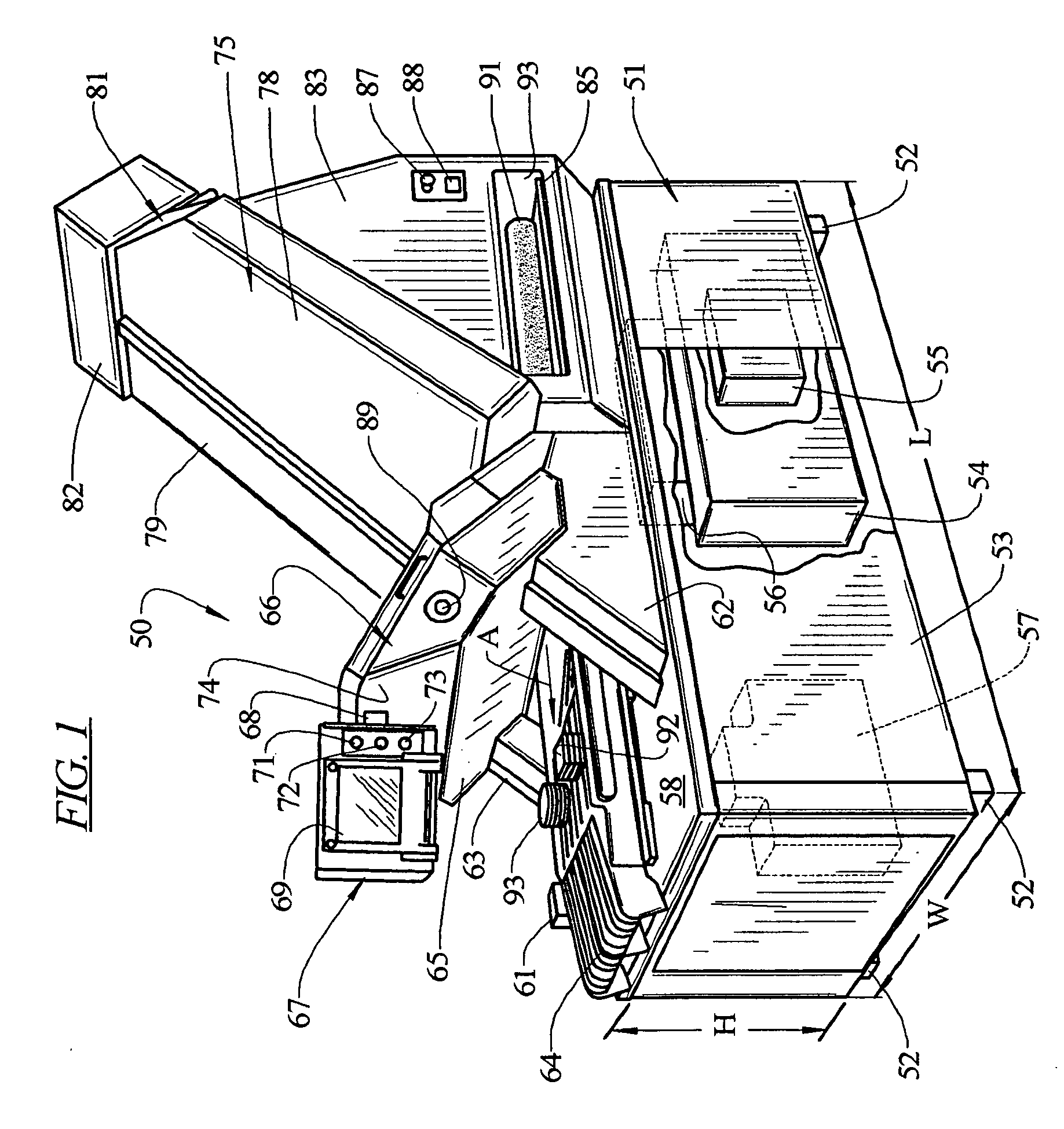

Slicing machine, method of use and components thereof

InactiveUS20060150791A1Quality improvementEasy to operateMetal sawing devicesFeeding devicesRisk strokeMechanical engineering

An ergonomically designed food slicing machine including a rotatable blade (800, 2800) for slicing bulk food product, a motor (1400, 3400) operably connected to the rotating blade (800, 2800), and a base (100) portion located below the rotatable blade (800, 2800) which defines a food slice receiving area. The machine may be provided with a sliced food receptable operably connected to a scale (3900), a visible indicia (3502) correlating to the distance between the gauge plate (2500) and rotatable blade (2800), a blade sharpening assembly (900, 2900), a sled (200) for securing the food product and an operator adjusted optimum stroke setting system for automatic operation of the slicing machine.

Owner:BERKEL & CONTRACTORS +1

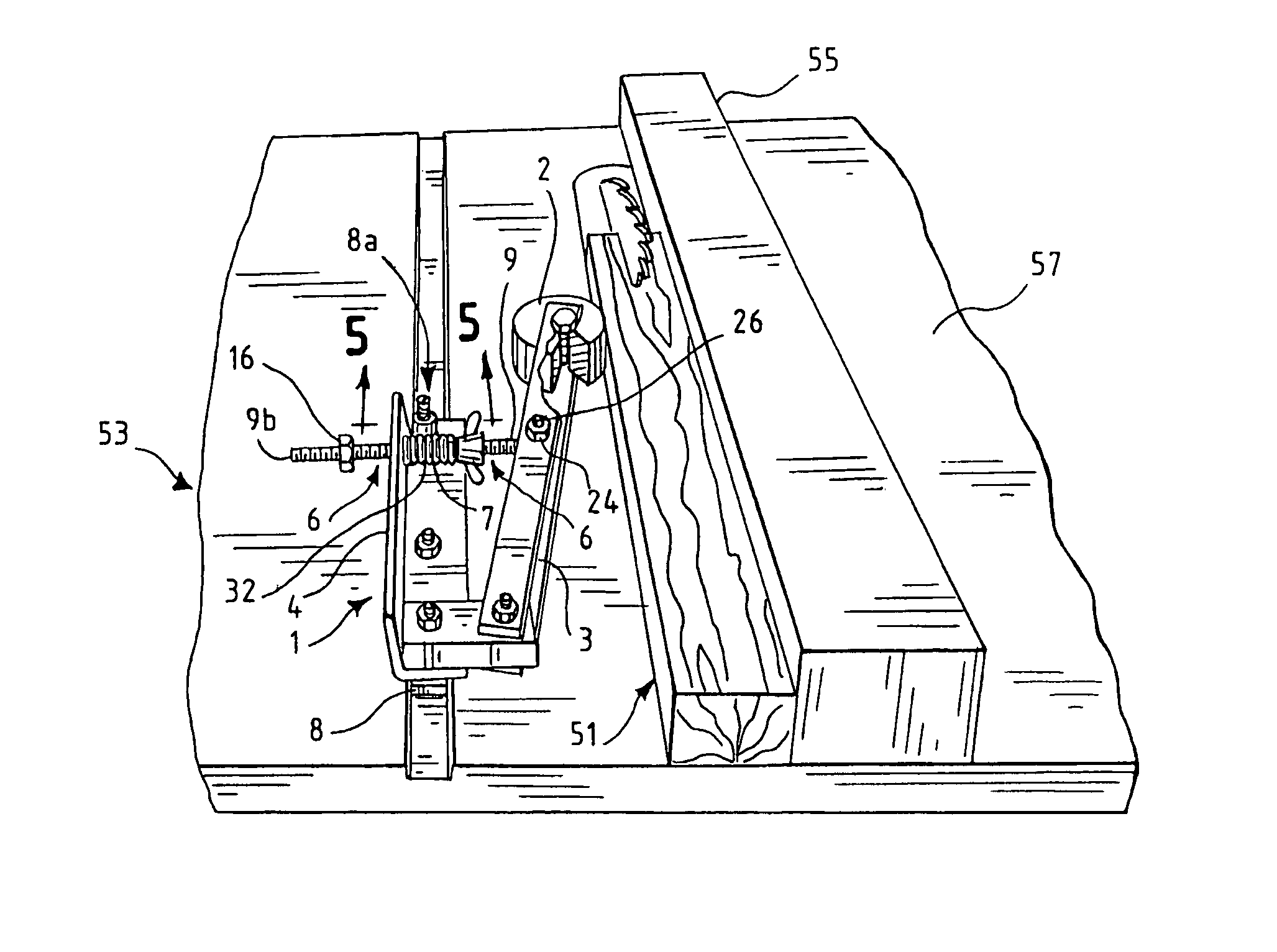

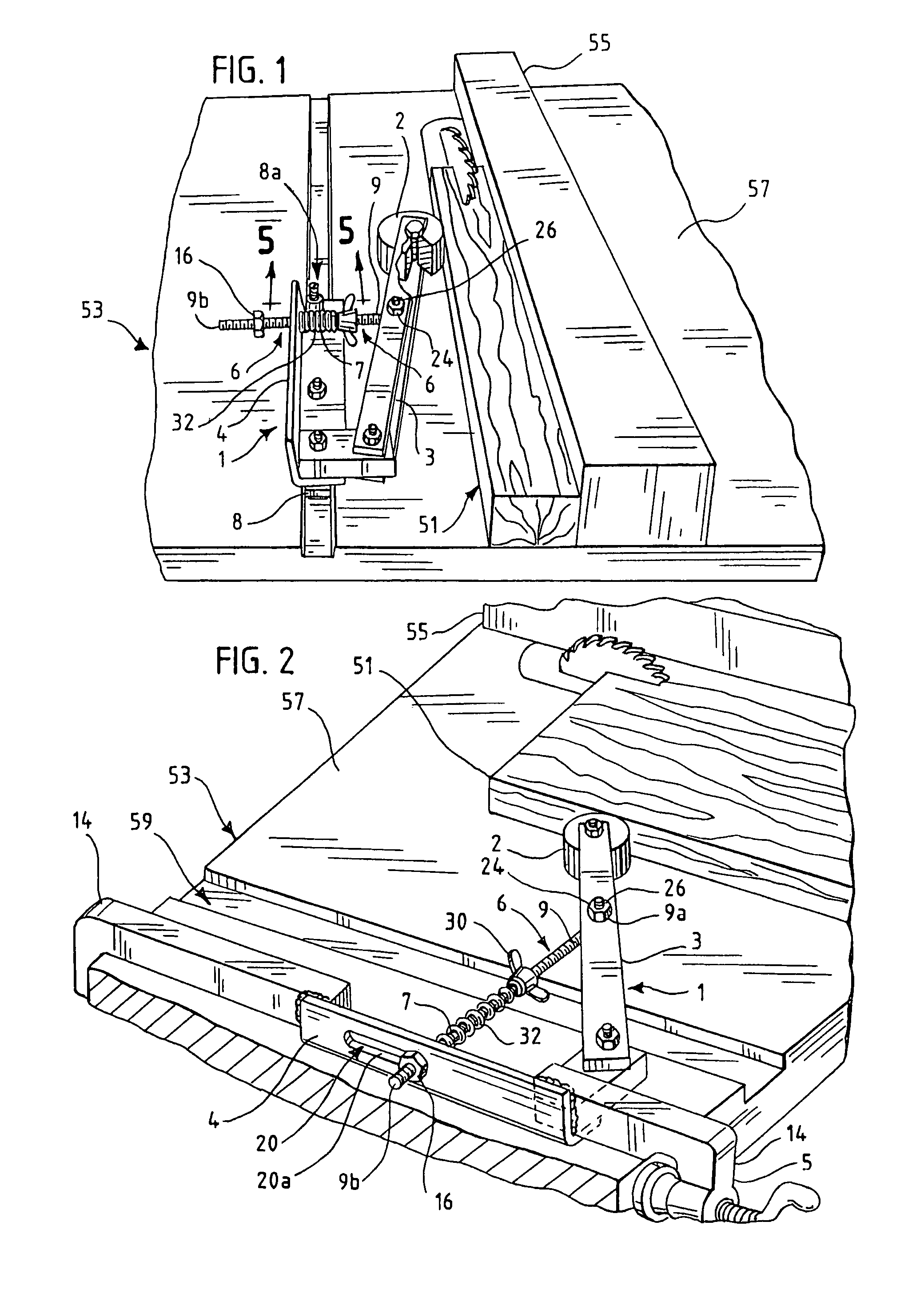

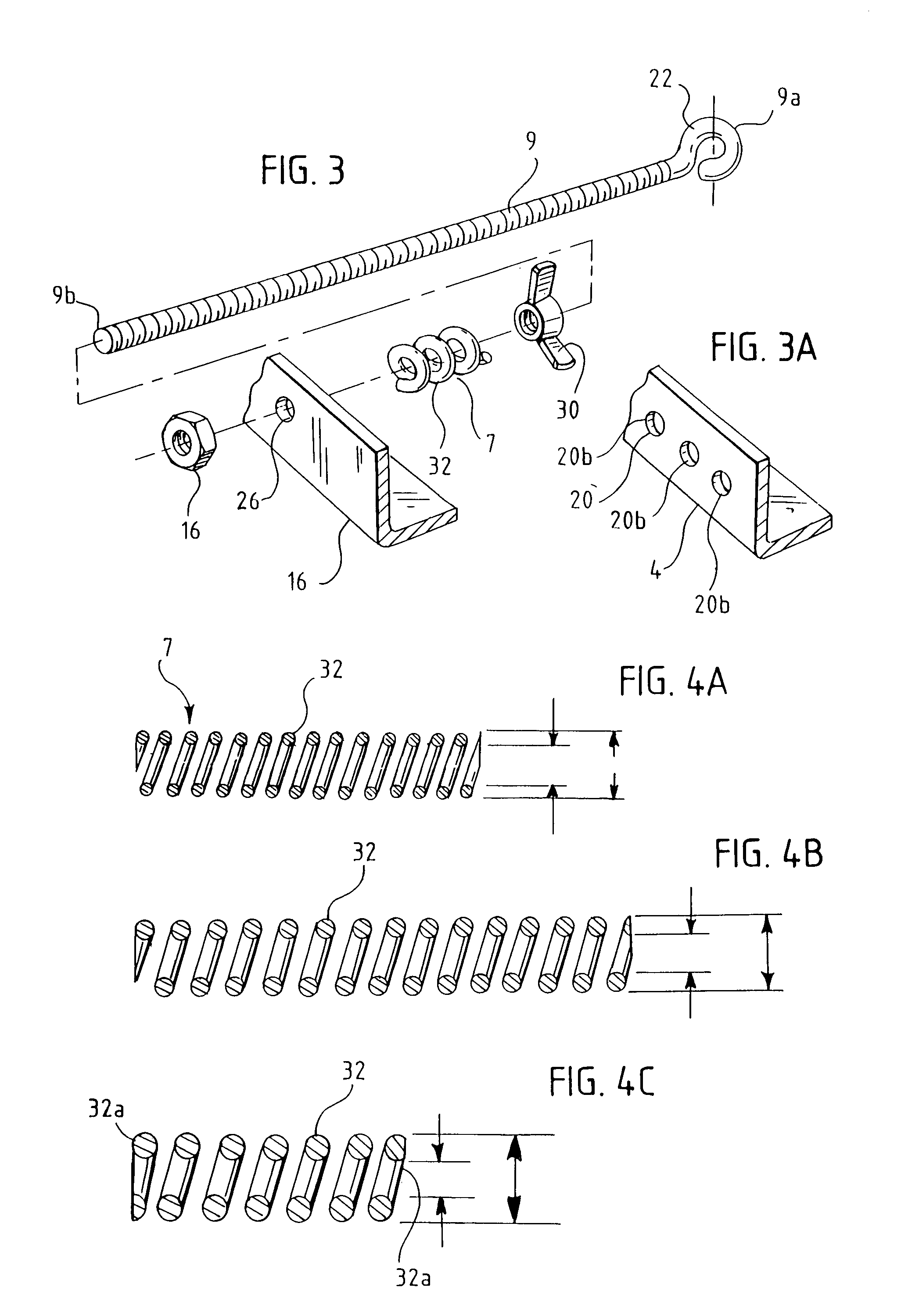

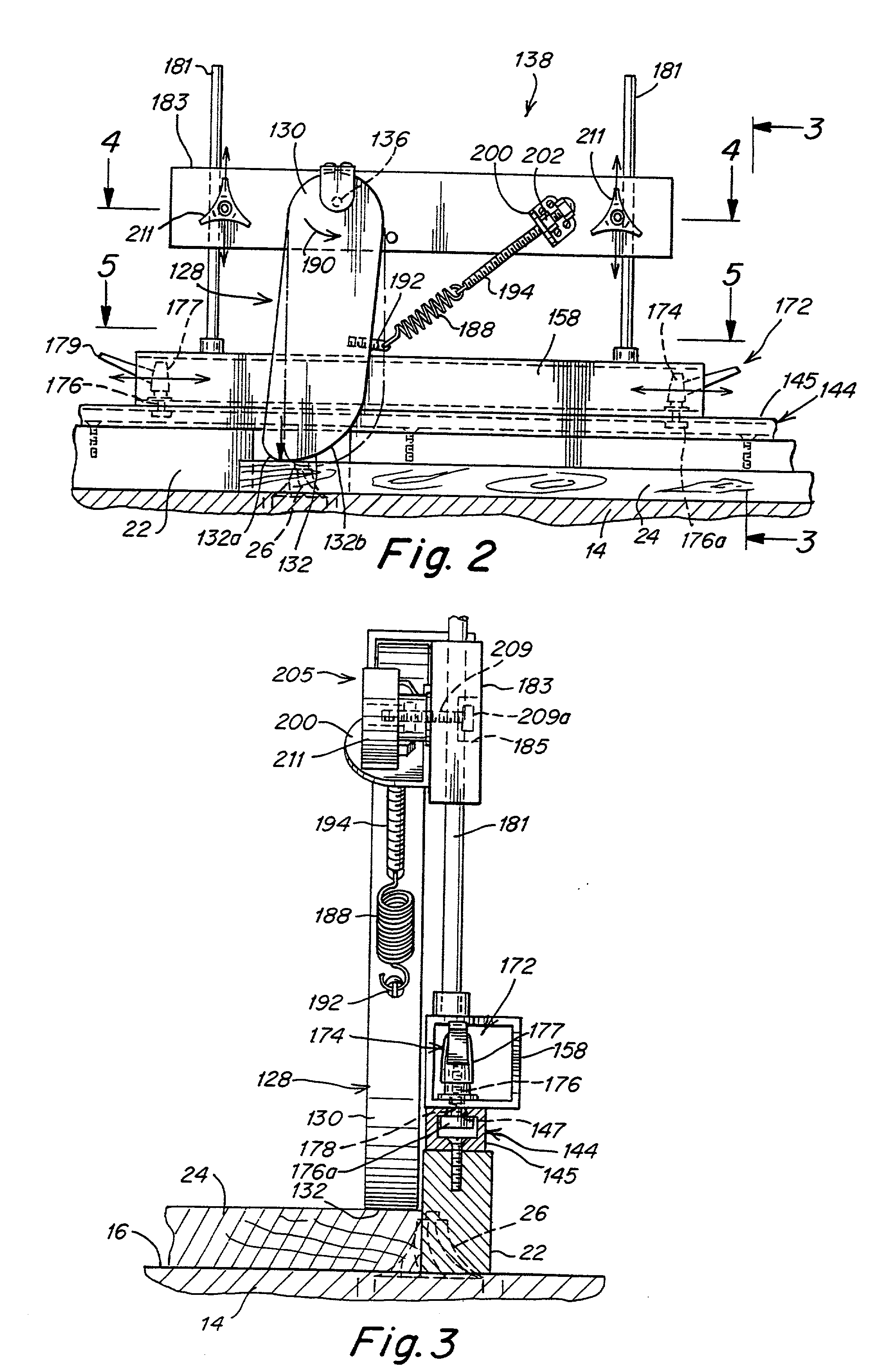

Combination workpiece positioning/hold-down and anti-kickback device for a work table

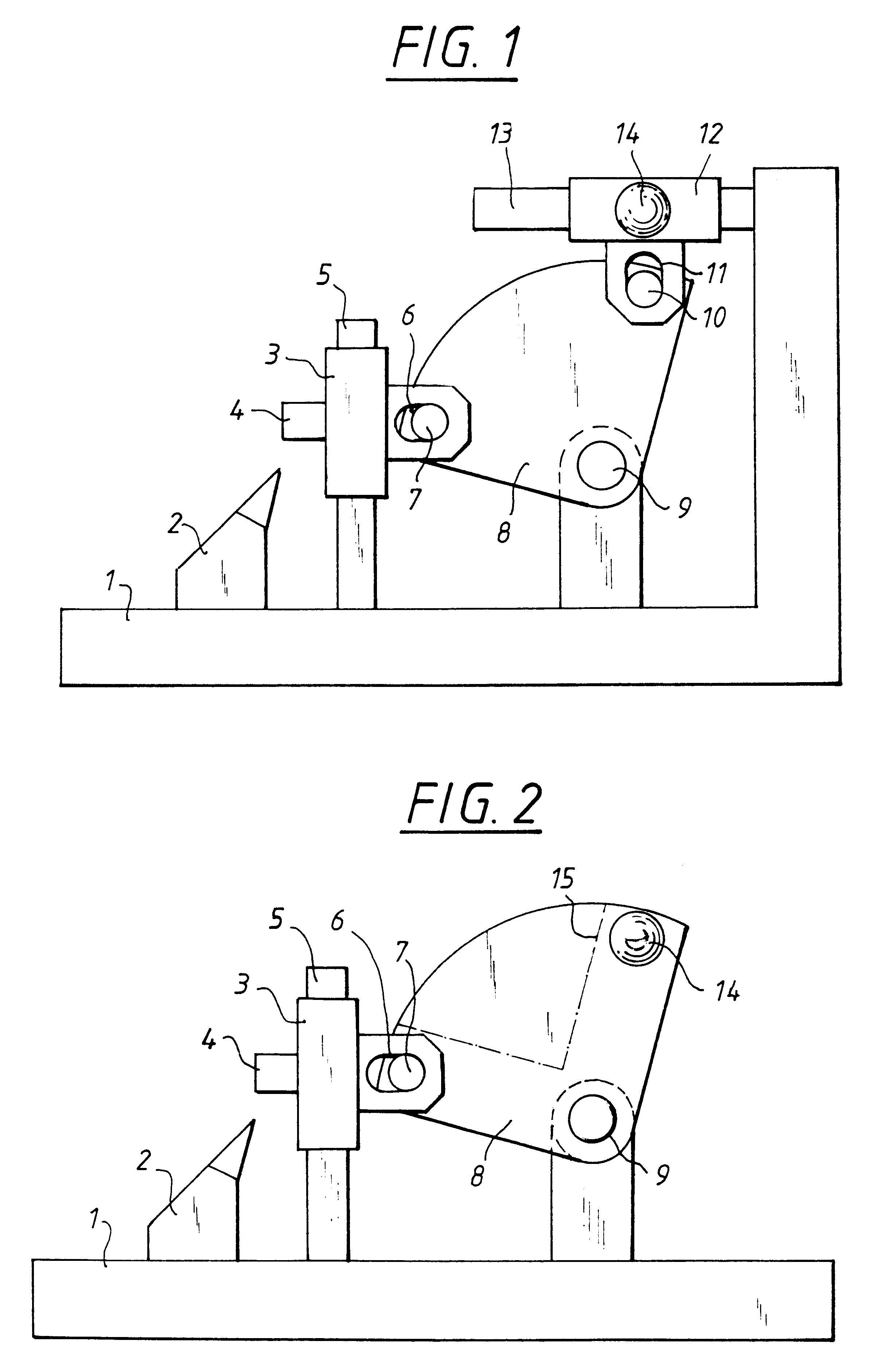

InactiveUS20020029822A1Preventing kick-backInherent disadvantageMetal sawing devicesWood feeding arangementsEngineeringCam

A combination workpiece positioning, hold-down and anti-kickback device for a work table having a fence against which a workpiece is guided, includes a non-rotatable positioning member having an arcuate cam surface at one edge for engaging a side surface of a workpiece on the work table; an adjustment device for moving the positioning member in lengthwise and transverse directions relative to the workpiece and for locking the same thereat; a pivot pivotally mounting the positioning member to the adjustment device; a spring connected between the positioning member and the adjustment device for biasing the positioning member in a pivot direction into engagement with the side surface of the workpiece; a variable tensioning device for variably adjusting the biasing force of the spring; a non-rotatable hold-down member having a second arcuate cam surface at one edge for engaging an upper surface of the workpiece; an adjustment device for moving the hold-down member in lengthwise and vertical directions relative to the workpiece, and for locking the same thereat; a pivot pivotally mounting the hold-down member to the second adjustment device; a second spring connected between the hold-down member and the adjustment device for biasing the hold-down member in a second pivot direction into engagement with the upper surface of the workpiece; and a second variable tensioning device for variably adjusting the biasing force of the second spring.

Owner:JUKOFF PETER

Adjustable router guide template assembly

InactiveUS20050236069A1Easy to operateEasily interchangeableWood feeding arangementsFeeding devicesInterconnectionEngineering

An adjustable guide assembly to guide a cutter bit of a tool device about a cutting surface of a workpiece. The guide assembly includes an elongated first guide rail having a first abutting surface adapted to abut a first side wall of the workpiece, and a second guide rail spaced-apart from the first guide rail, and having a second abutting surface adapted to abut a second side wall of the workpiece. A base member is positioned over the first and second guide rails, and includes a tool support surface and an opposed workpiece support surface. The base member includes a contacting wall defining a bit passage therethrough. A first and second interconnection assembly is configured to releasably lock the first and second guide rail, respectively, to the base member in a manner enabling the first guide rail to pivot about a first axis substantially perpendicular to a longitudinal axis of the first guide rail, and the second guide rail to pivot about a second axis substantially perpendicular to a longitudinal axis of the second guide rail, respectively. Further, the first interconnection assembly and the second interconnection assembly enable the first guide rail and the second guide rail to slide along the base member along respective paths adjacent to the bit passage. The first guide rail and the second guide rail are adjusted to abut the workpiece first side wall and the workpiece second side wall in a manner releasably positioning a targeted cutting region of the workpiece cutting surface in the bit passage.

Owner:OBRIEN VINCENT E

Cutting table fence

A fence is described for attachment to a cutting table or in combination with a cutting table. The fence includes pair of elongated guide rails with brackets configured to be mounted to the cutting table. An endless chain is provided on each guide rail, trained about sprockets rotatably mounted on the guide rail. Each chain includes a working flight that extends along the associated guide rail. Each chain further includes sprocket tooth receiving spaces. A shaft interconnects, one of the sprockets on one guide rail with one of the sprockets on the remaining guide rail such that rotation of the shaft will result in all the sprockets rotating in unison, causing uniform and equal movement of the chain. An elongated cutting guide is provided with aligning lugs that are releasably received within selected tooth receiving spaces of the chains in such a manner that the cutting guide may be selectively engaged with the chains and lifted from the chains. A locking mechanism is configured to secure the cutting guide in a selected position along the working flights of the chains.

Owner:KENNELLY JOHN P

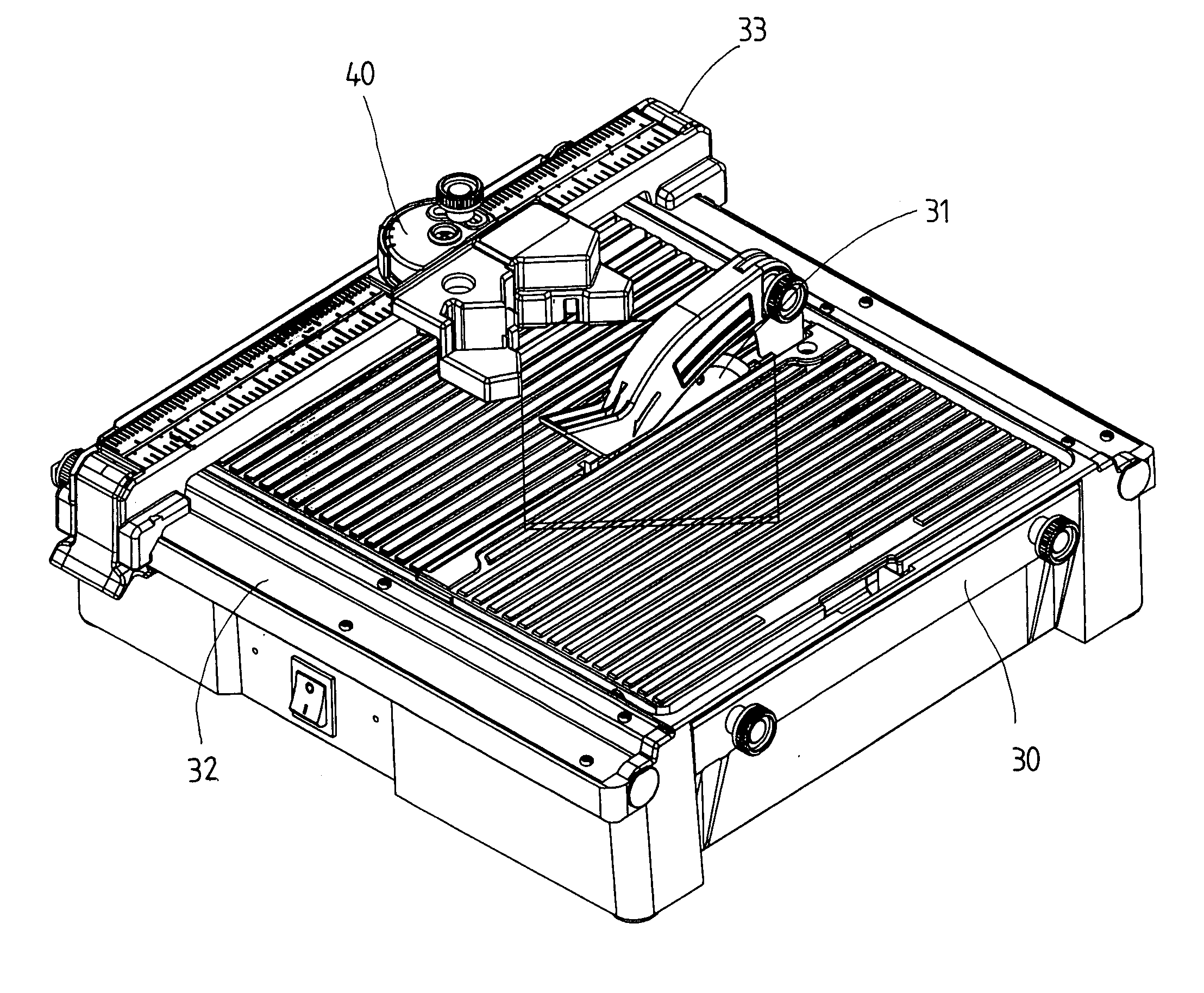

Tile positioning device for a tile cutting machine

A tile positioning device of a tile cutting machine includes a first piece slidably engaged with the gauge and a second piece is pivotably connected to the first piece. The second piece includes two protrusions and a right angle is defined between two surfaces of the two protrusions for clamping two sides of a tile and the tile can be rotated relative to the blade of the cutting machine by rotating the second piece. A third piece is optionally and pivotably connected to one of the two protrusions for adjusting the positioning of the tile.

Owner:MOTOMAX ELECTRIC

Apparatus and process for dicing a deformable product

ActiveUS20050005745A1Reduce in quantityMore productiveGuide fencesFeeding devicesEngineeringMovement pattern

An apparatus for cutting a product includes a conveyor assembly and a slitter assembly. The conveyor assembly conveys the product in a feed direction and defines a conveyance surface, on which the product is conveyed. The slitter assembly slits the product into strips as the product is conveyed in the feed direction. The slitter assembly comprises a plurality of cutting elements arranged in a V shape and overlapping one another in the feed direction, as viewed in a direction substantially normal to the conveyance surface. A chopping assembly is positioned downstream of the slitter assembly. The chopping assembly comprises an elongated blade, which moves in an elliptical cutting motion, such that it has a component in the downward direction to sever the strips of product, and a component in the feed direction to toss the severed pieces of product in the feed direction.

Owner:LEPRINO FOODS

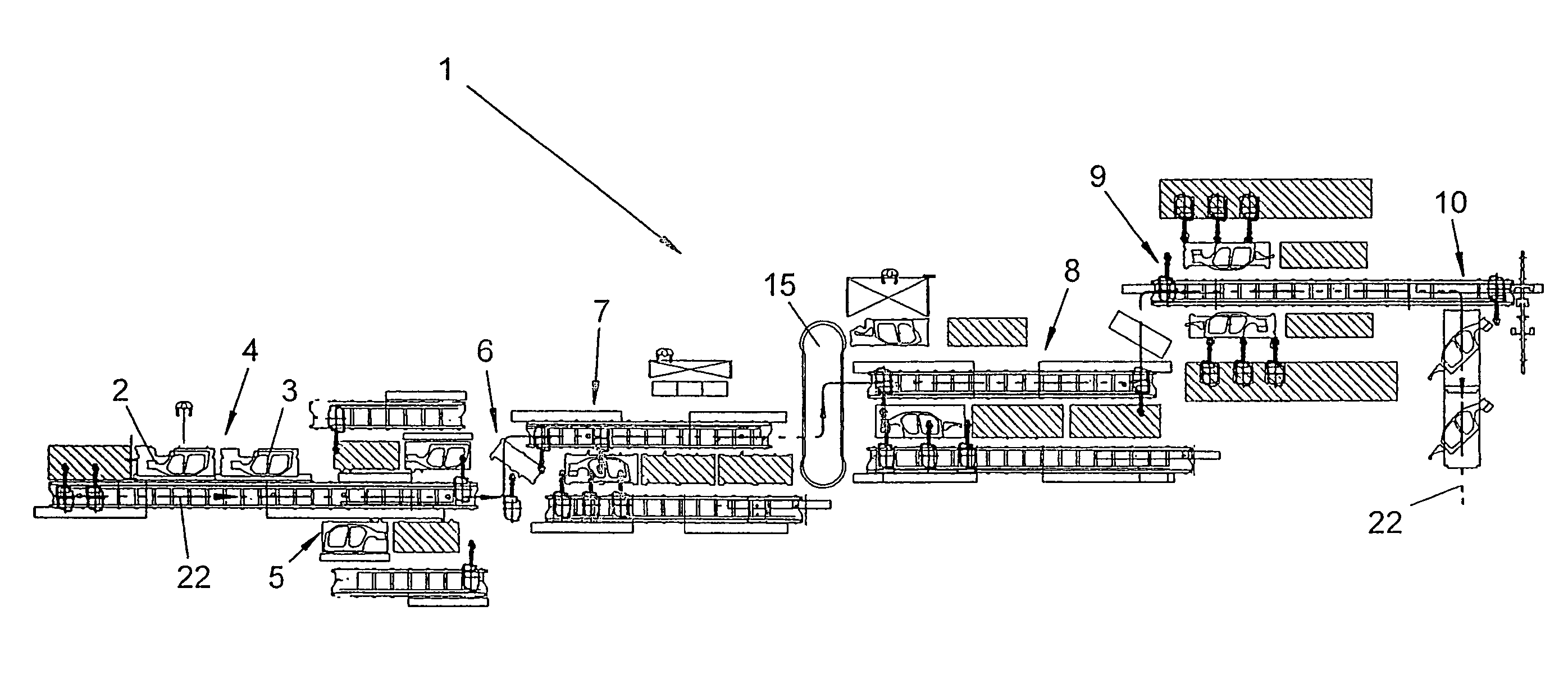

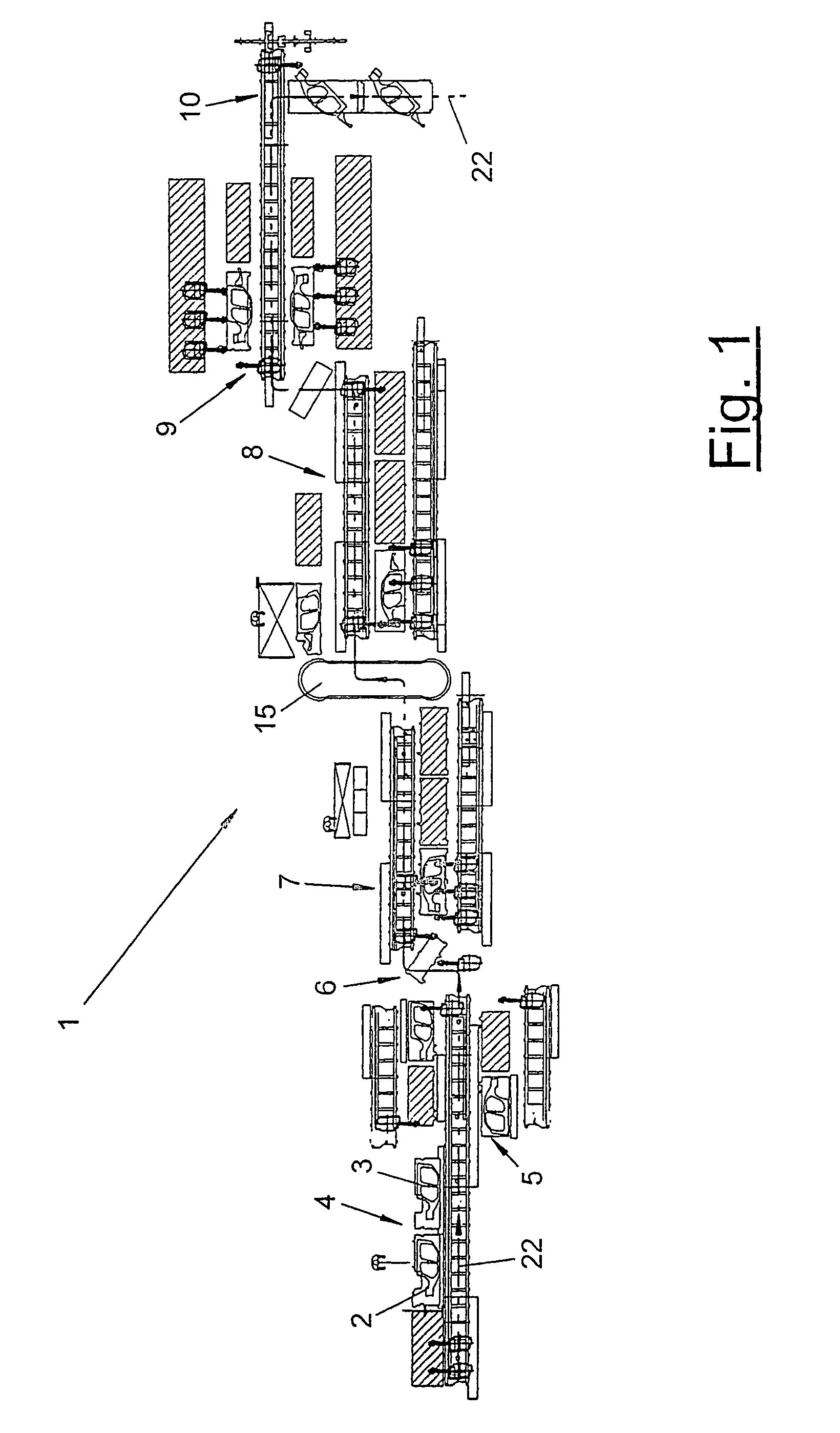

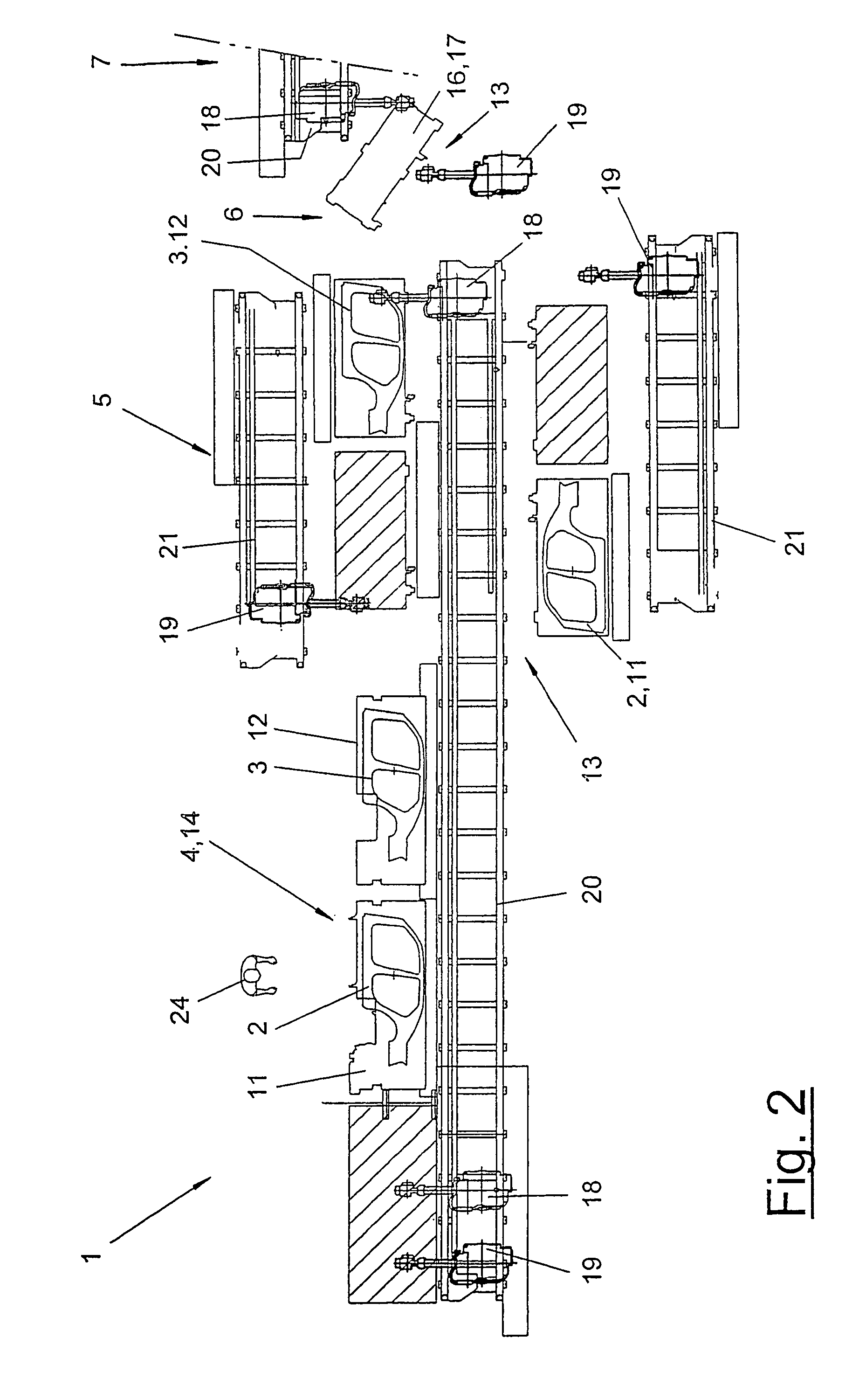

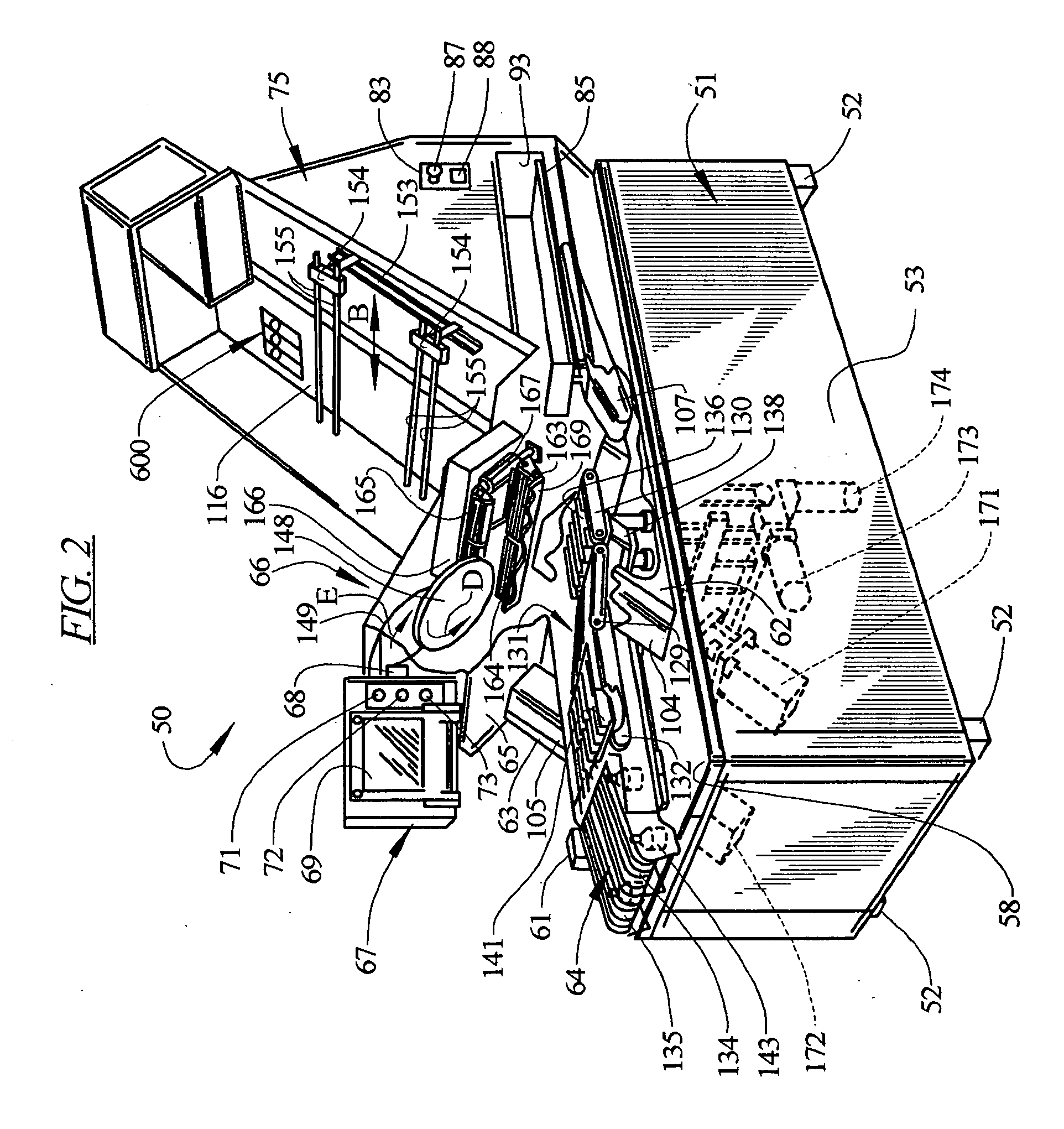

Manufacturing plant for parts, particularly vehicle body parts

InactiveUS7331439B2Expand the scope of workEasy to operateWelding/cutting auxillary devicesAssembly machinesTransfer lineWork site

A manufacturing plant (1) is provided for vehicle body parts (2, 3). The manufacturing plant includes a number of processing stations (4, 5, 6, 7, 8, 9, 10), which are situated one behind the other along a transfer line (22), and of a number of multiaxial robots (18, 19). In at least one processing station (4, 5, 6, 7, 8, 9, 10), one or more handling robots (18) for transporting parts is / are arranged on at least one axis of travel (20, 21). Next to the handling robot (18), one or more processing robots (19) is / are displaceably arranged on the same axis of travel (20). Working locations (11, 12) are arranged on both sides of a common axis of travel (20), whereby another common axis of travel can be provided on the rear side of the working locations.

Owner:KUKA SYSTEMS

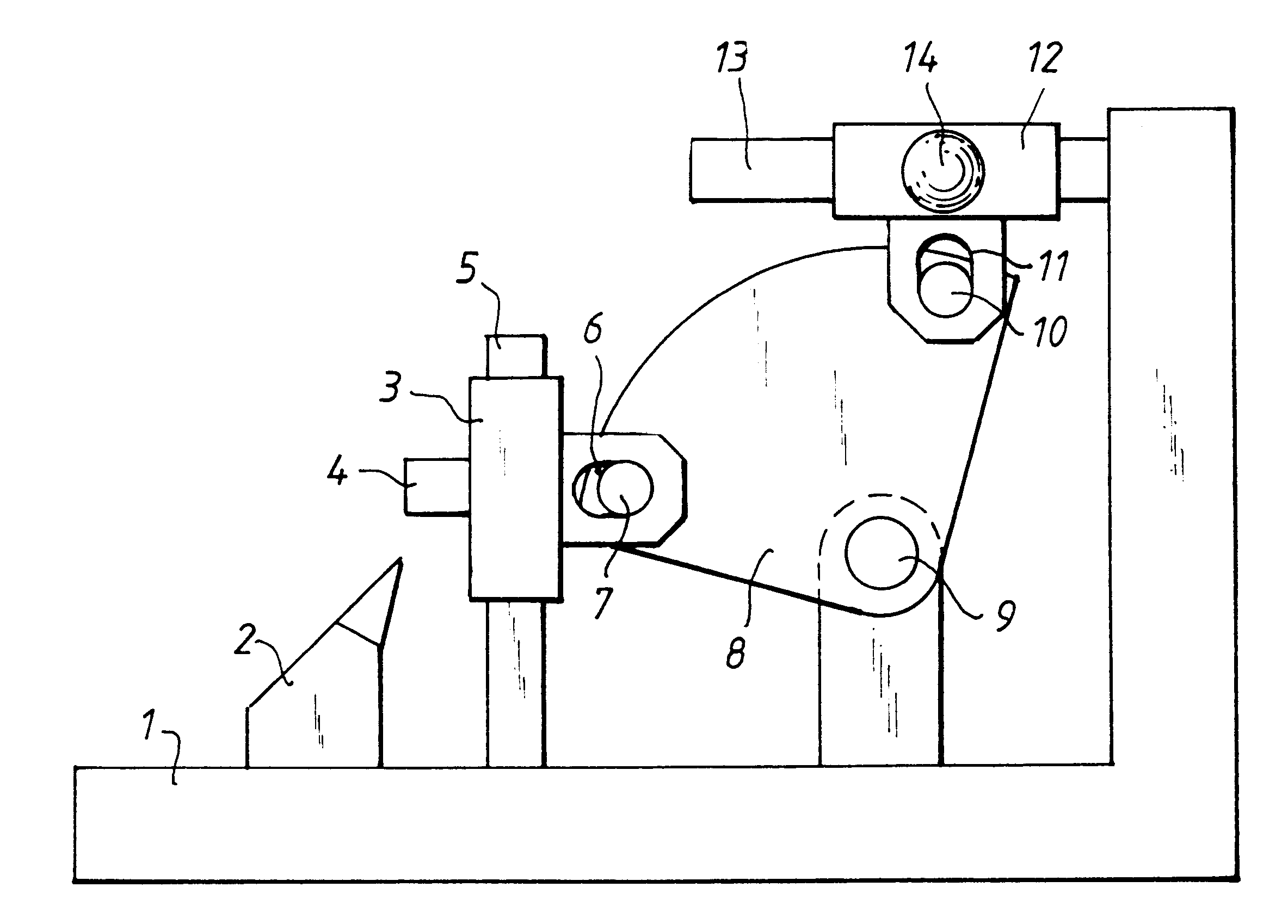

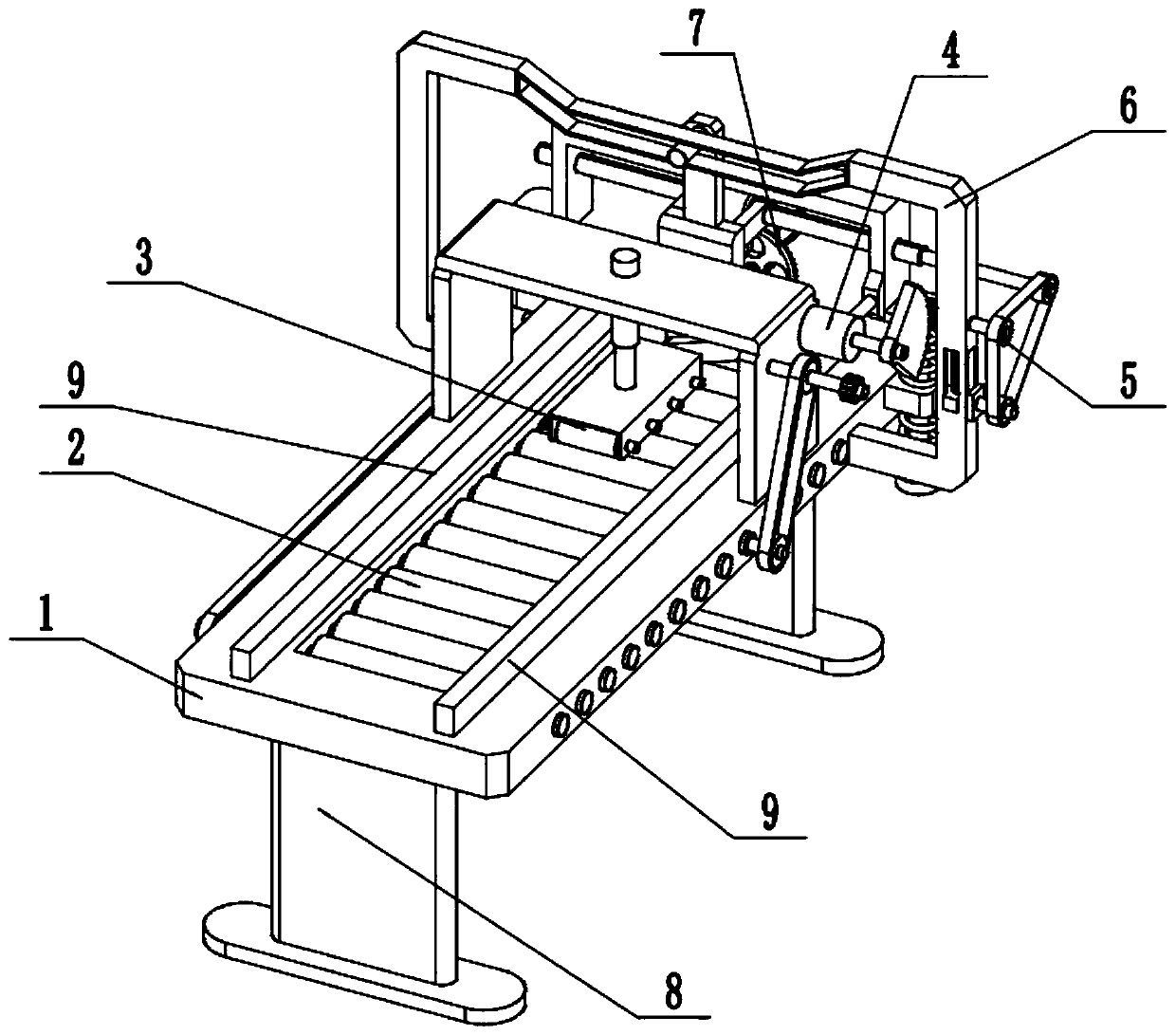

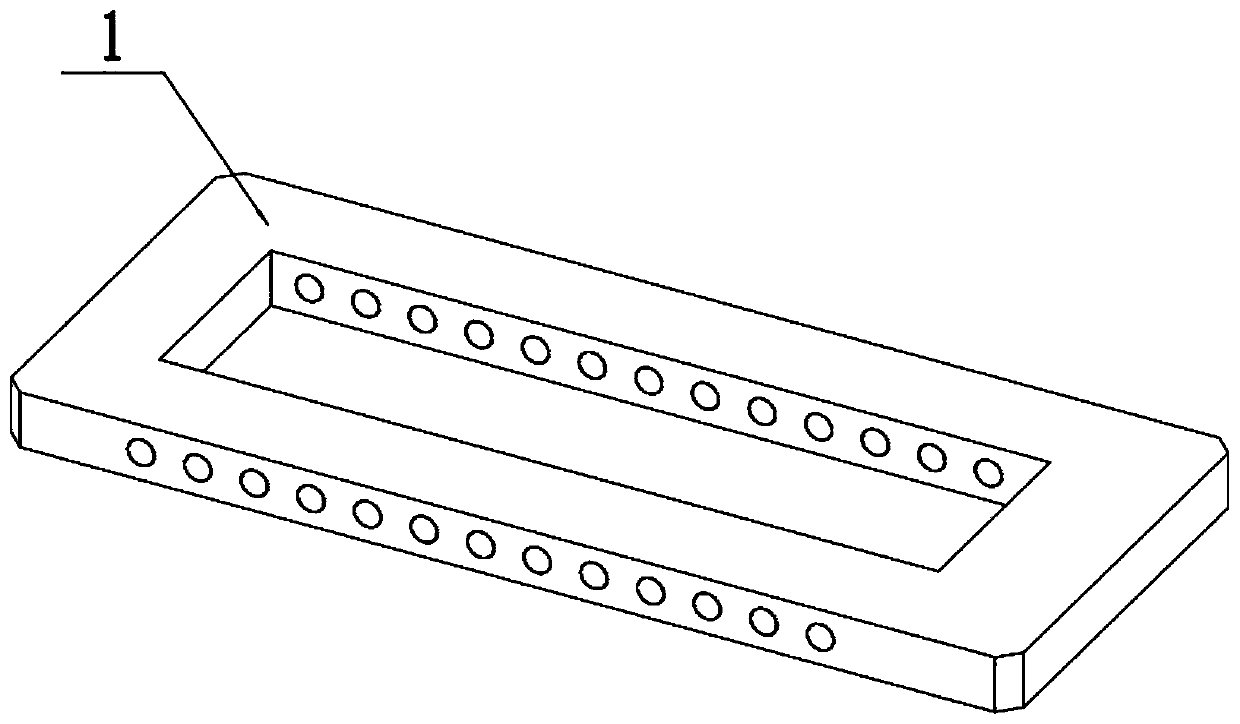

Feed pre-positioning method and device for molded plate

InactiveCN102350715AThe effect of accurate automatic positioningHigh degree of automationFeeding devicesClassical mechanicsStructural engineering

The invention relates to a feed pre-positioning device for a molded plate. The device comprises a frame mechanism, a working table, two pulling plate mechanisms, a lateral limiting mechanism, a lateral pushing mechanism, a vibration positioning mechanism and a supporting plate driving mechanism, wherein the frame mechanism comprises a supporting frame, a gantry frame and two upper longitudinal beams; the supporting frame has a framework structure; longitudinal driving guide rails are fixedly arranged on two sides of the top of the supporting frame respectively; the gantry frame is arranged across the supporting frame; the working table is fixedly arranged on the supporting frame; the two upper longitudinal beams are connected with the gantry frame; each upper longitudinal beam is longitudinally provided with at least two rotary cylinders in the backward and forward direction; the rotary cylinders are provided with rotary arms; a cross beam of the gantry frame is provided with at leasttwo pulling plate mechanisms and the vibration positioning mechanism; and the lateral limiting mechanism and the lateral pushing mechanism are arranged on two side beams of the gantry frame respectively. The device has the characteristics of rational structure, accurate positioning in a slot sheet, capability of increasing cutting yield, high universality and capability of clamping the sheet and driving the sheet to advance.

Owner:CHANGZHOU HUAWANG MECHANIC MFG CO LTD

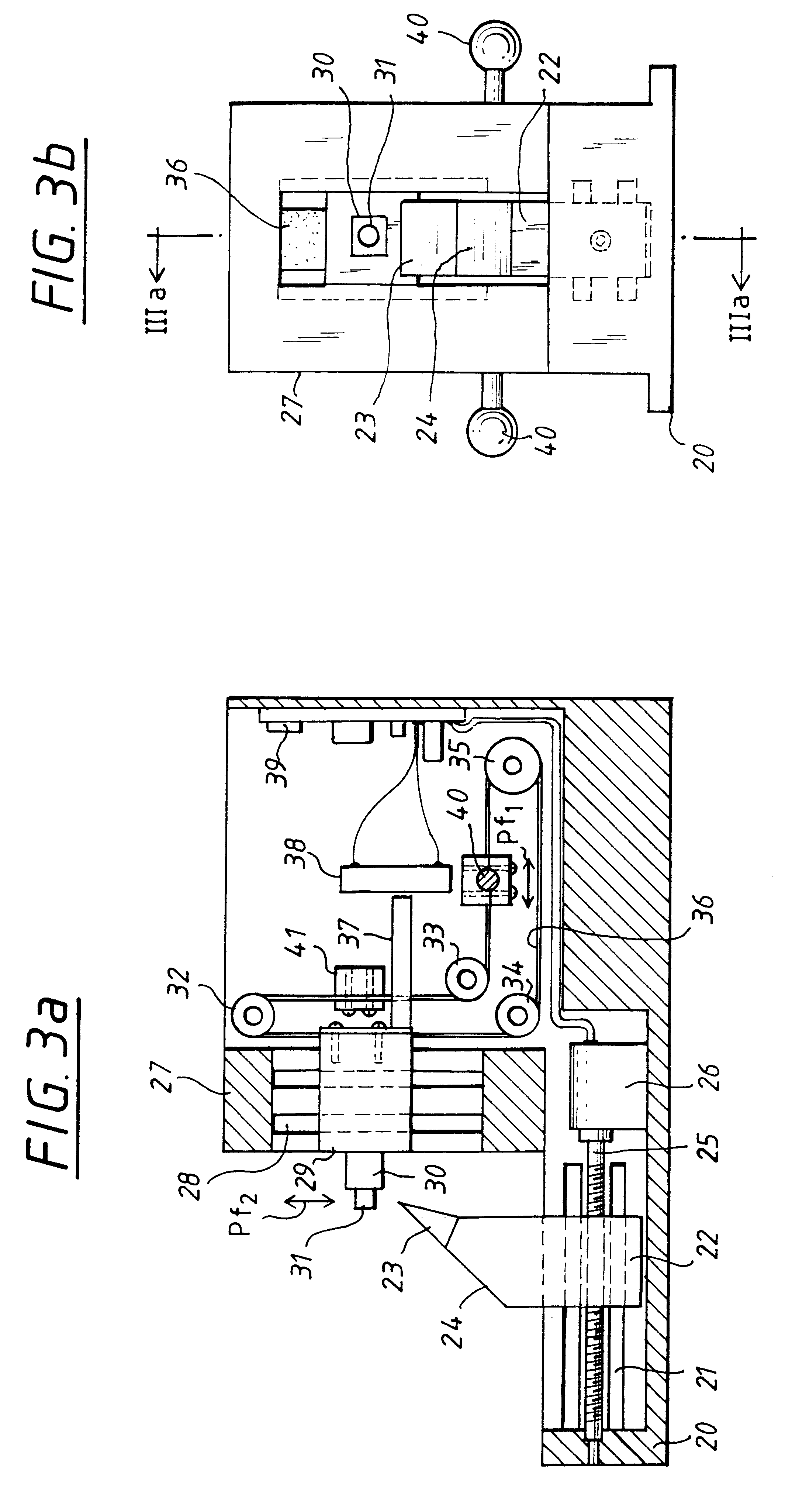

Microtome

The microtome has a sample carrier movable along a first linear guide and a hand drive movable along a substantially linear path of motion that is substantially perpendicular to the direction of motion of the sample carrier. A deflecting device is provided to deflect the motion of the hand drive into a motion in the direction of the linear guide of the sample carrier. By deflection of the paths of motion between the hand drive and the sample holder, the motion of the hand drive can take place substantially horizontally forward and backward and convert the motion of the hand drive into a motion of the sample carrier which is substantially perpendicular to the motion of the hand drive. The cutting motion takes place in a substantially vertical direction, so that the sections can be removed or washed away from the inclined back surface of the cutting knife or knife carrier.

Owner:MICROM INT

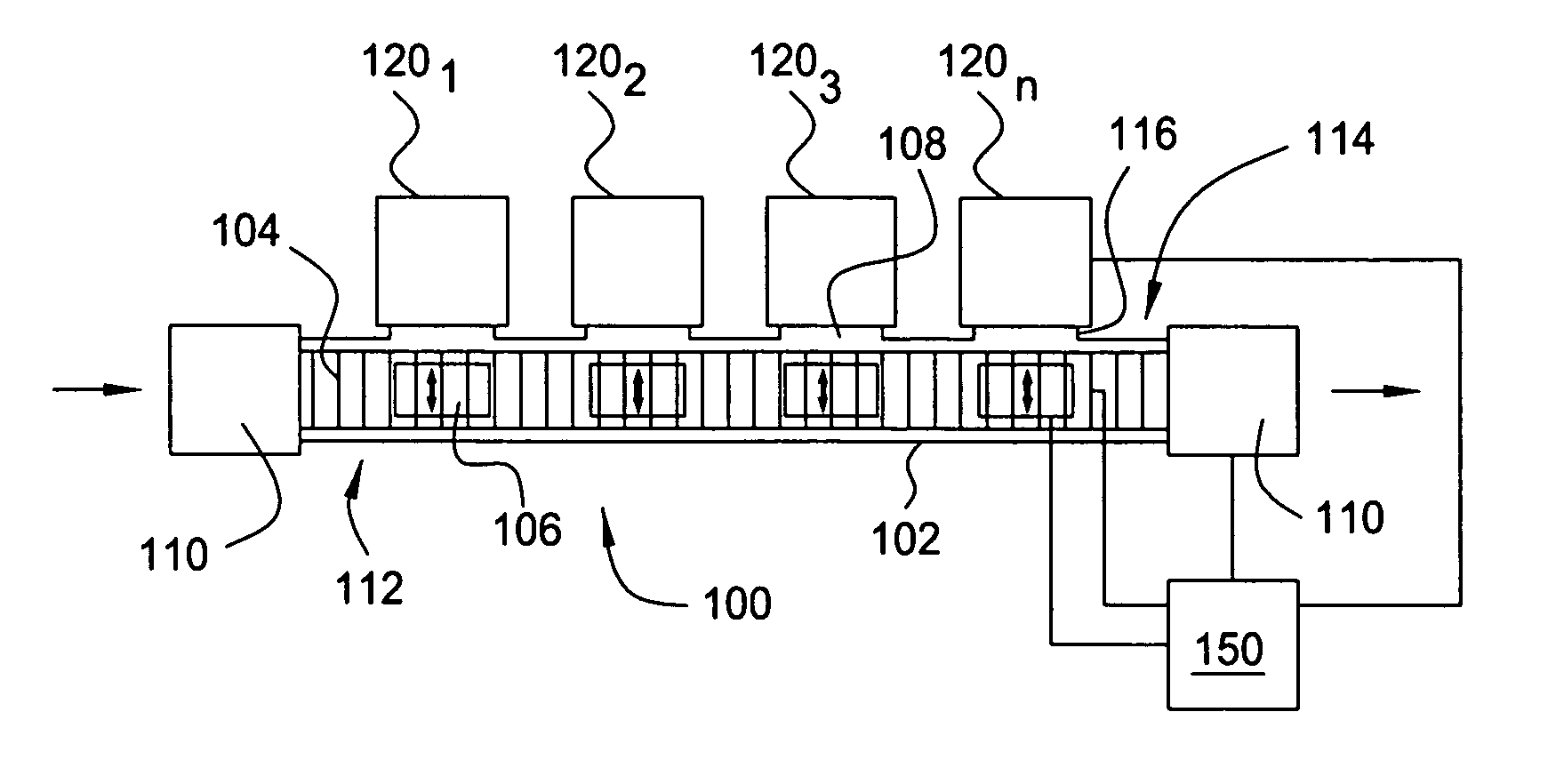

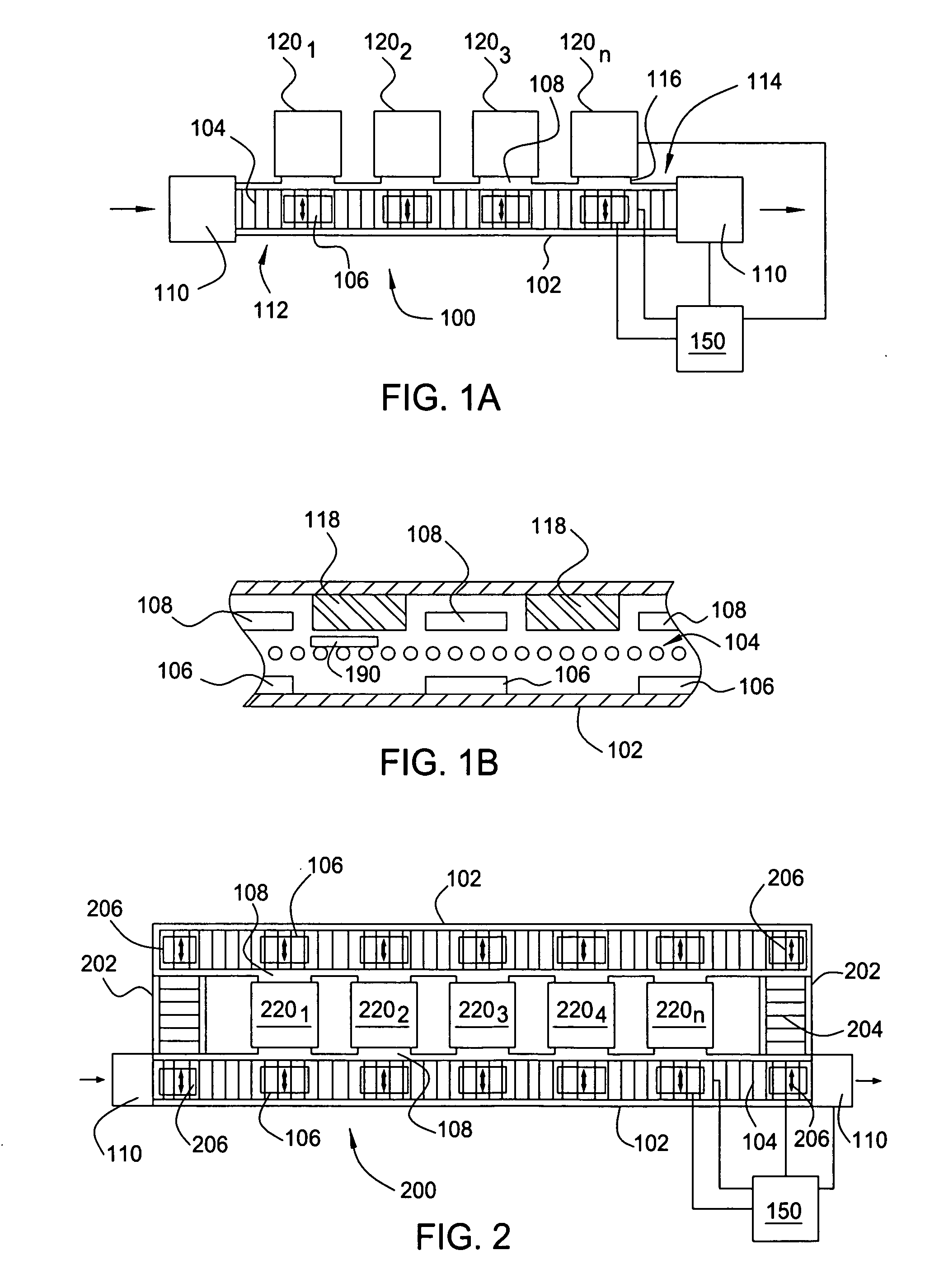

Linear vacuum deposition system

InactiveUS20060278497A1Vacuum evaporation coatingSemiconductor/solid-state device manufacturingLeading edgeEngineering

Embodiments of a vacuum conveyor system are provided herein. In one embodiment a vacuum conveyor system includes a first vacuum sleeve having a plurality of rollers that support and move substrates through the first vacuum sleeve. A port is provided for sealably coupling the first vacuum sleeve to a process chamber. A first substrate handler is disposed proximate the port. Multiple ports may be provided for sealably coupling the first vacuum sleeve to a plurality of process chambers. A dedicated substrate handler is provided for each process chamber. A second vacuum sleeve may be sealably coupled to an opposing side of the process chambers. The vacuum conveyor system may be modular with independent modules linked via load lock chambers. The plurality of rollers may compensate for any sag of the leading edge of a substrate being transported thereupon.

Owner:APPLIED MATERIALS INC

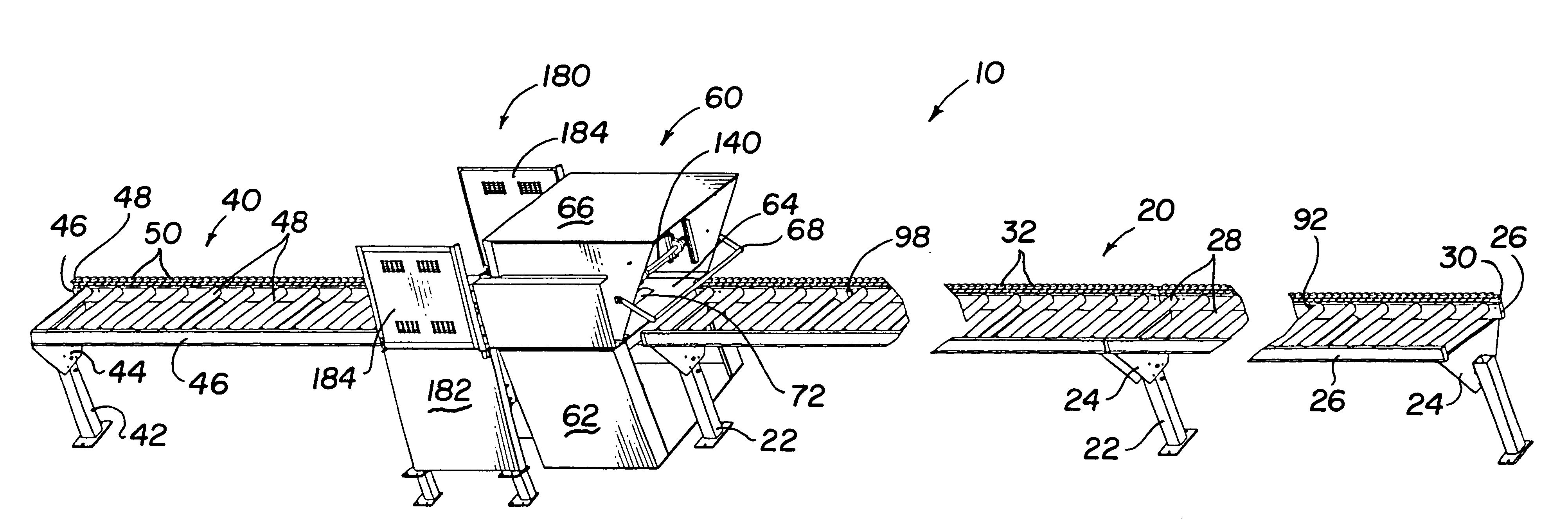

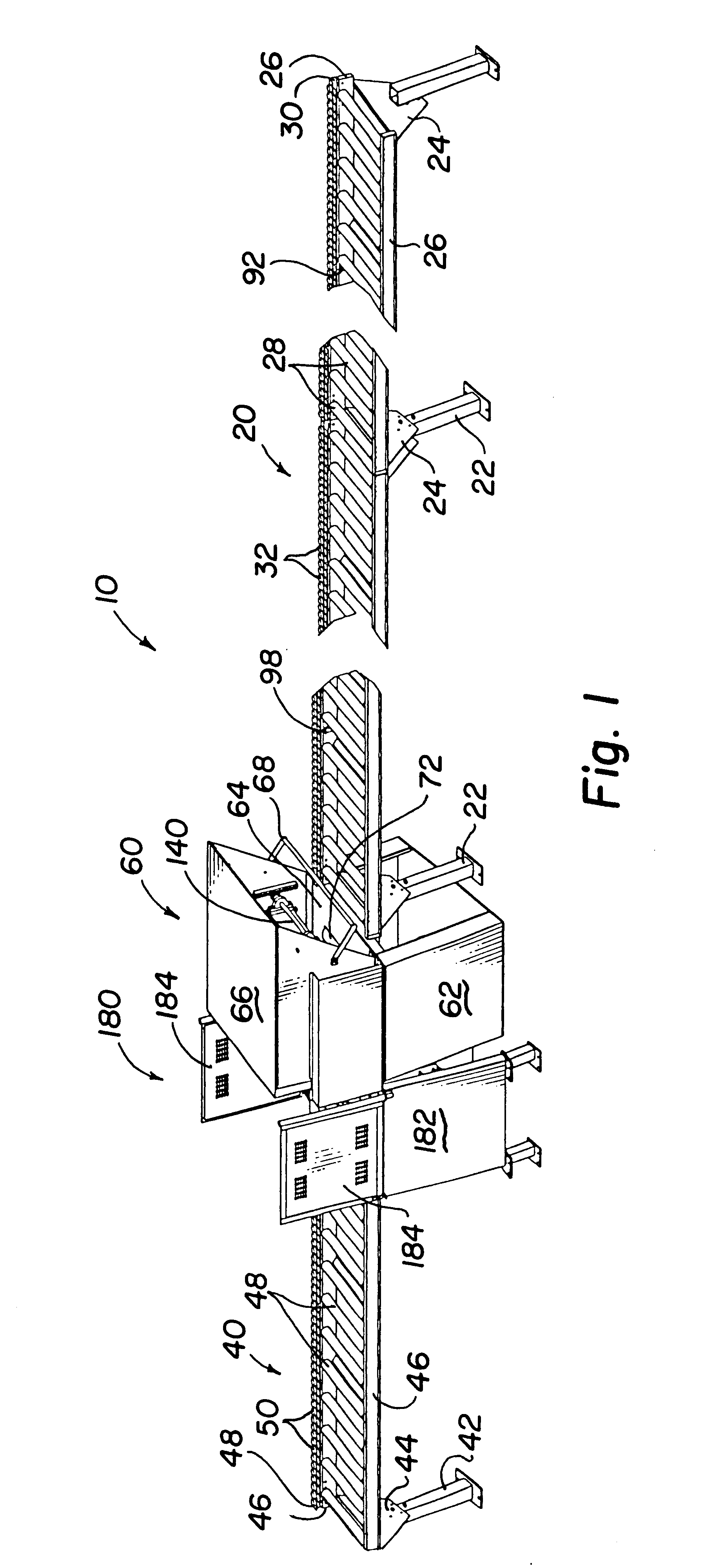

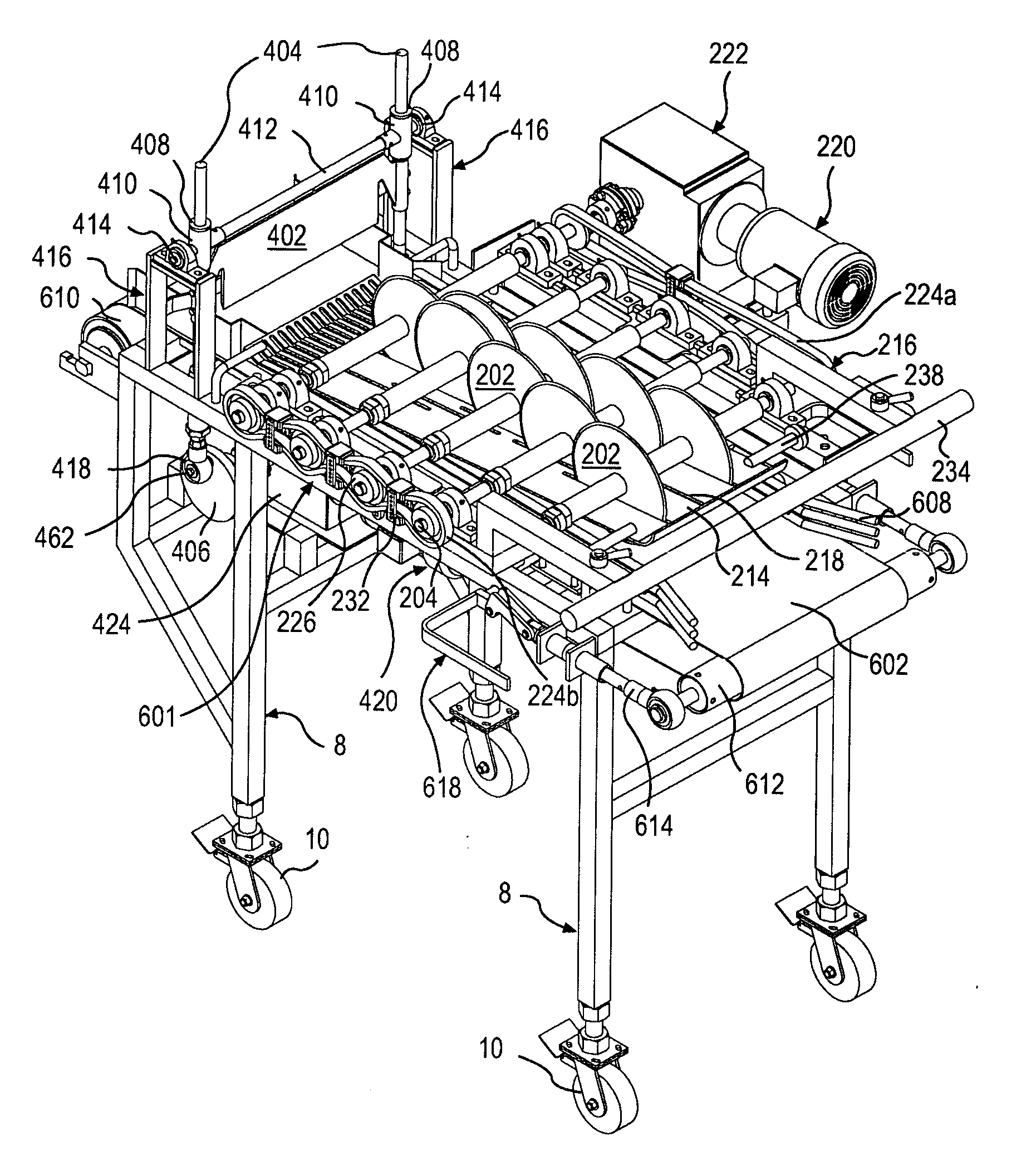

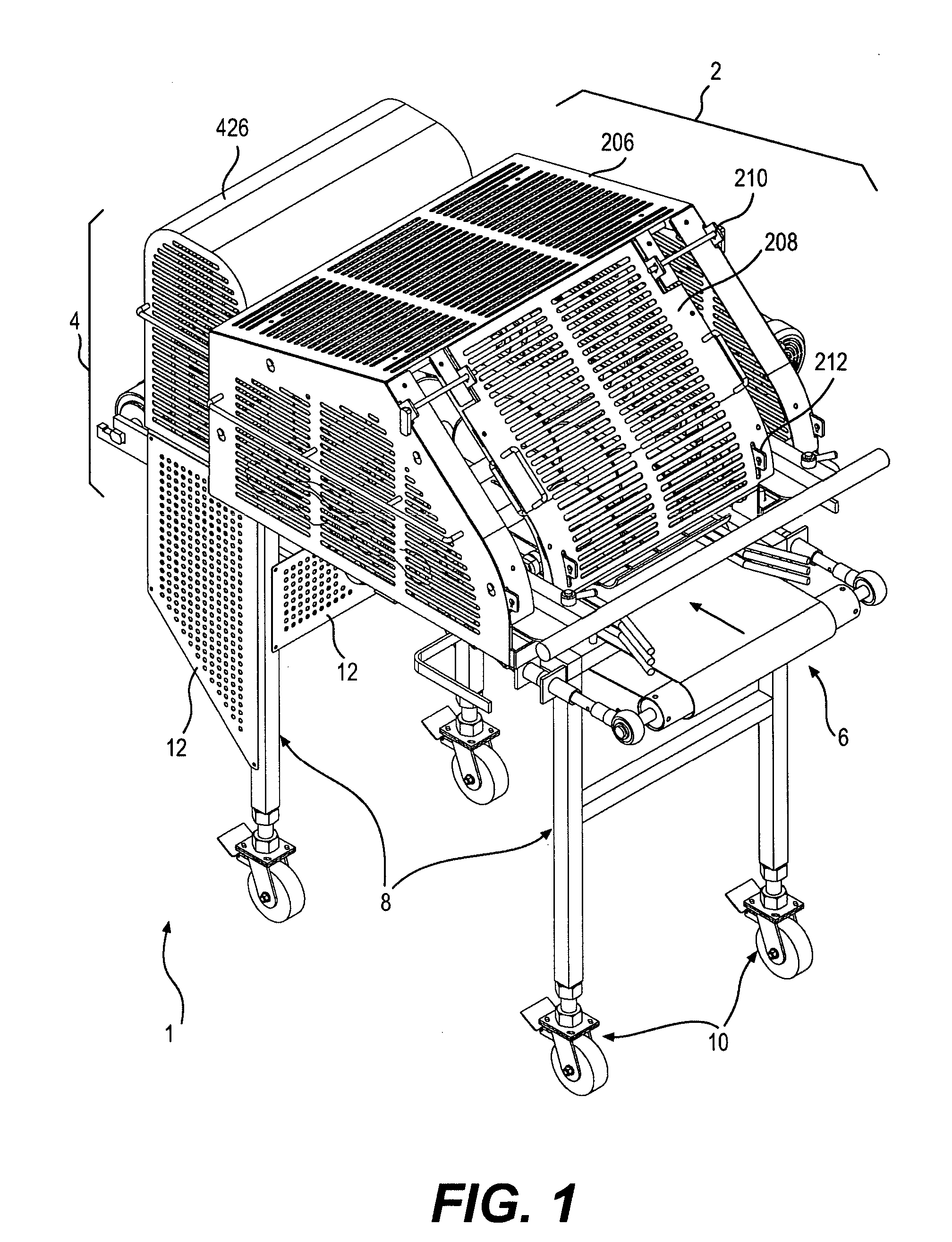

Systems and methods for end squaring and dividing elongated materials

ActiveUS20050189040A1Reduce maintenance costsReducing machine down timeFeeding apparatusCircular sawsEngineering

Owner:GLOBE MACHINE MFG

Processing line for round timber

ActiveCN104526771AReduce in quantityIncrease productivityFeeding devicesFlat surfacing machinesEngineeringMechanical engineering

The invention relates to a processing line for round timber. The processing line comprises a conveying device used for feeding, an overturning device used for centering the round timber in a rotating mode, a bottom bark planing device used for planing the bottom of the round timber to form a plane, a round timber slicing saw used for slicing the round timber in the axial direction of the round timber and a sheet sorting device used for sorting middle sheets and edge sheets of the round timber, wherein the conveying device, the overturning device, the bottom bark planing device, the round timber slicing saw and the sheet sorting device are sequentially arranged in the round timber processing advancing direction. The sheet sorting device comprises a first automatic conveying device used for conveying the middle sheets and a second automatic conveying device used for conveying the edge sheets, wherein the first automatic conveying device and the second automatic conveying device are arranged on the two sides of the sheet sorting device, and square timber slicing saws used for slicing the sheets again are arranged at the outlet of the first automatic conveying device and the outlet of the second automatic conveying device respectively. The processing line is simple in structure, low in manufacturing cost, easy to manufacture and complete in function, greatly improves the round timber working efficiency and lowers the production cost.

Owner:FUJIAN YUAN CHUANG ELECTRICAL & MECHANICAL CO LTD

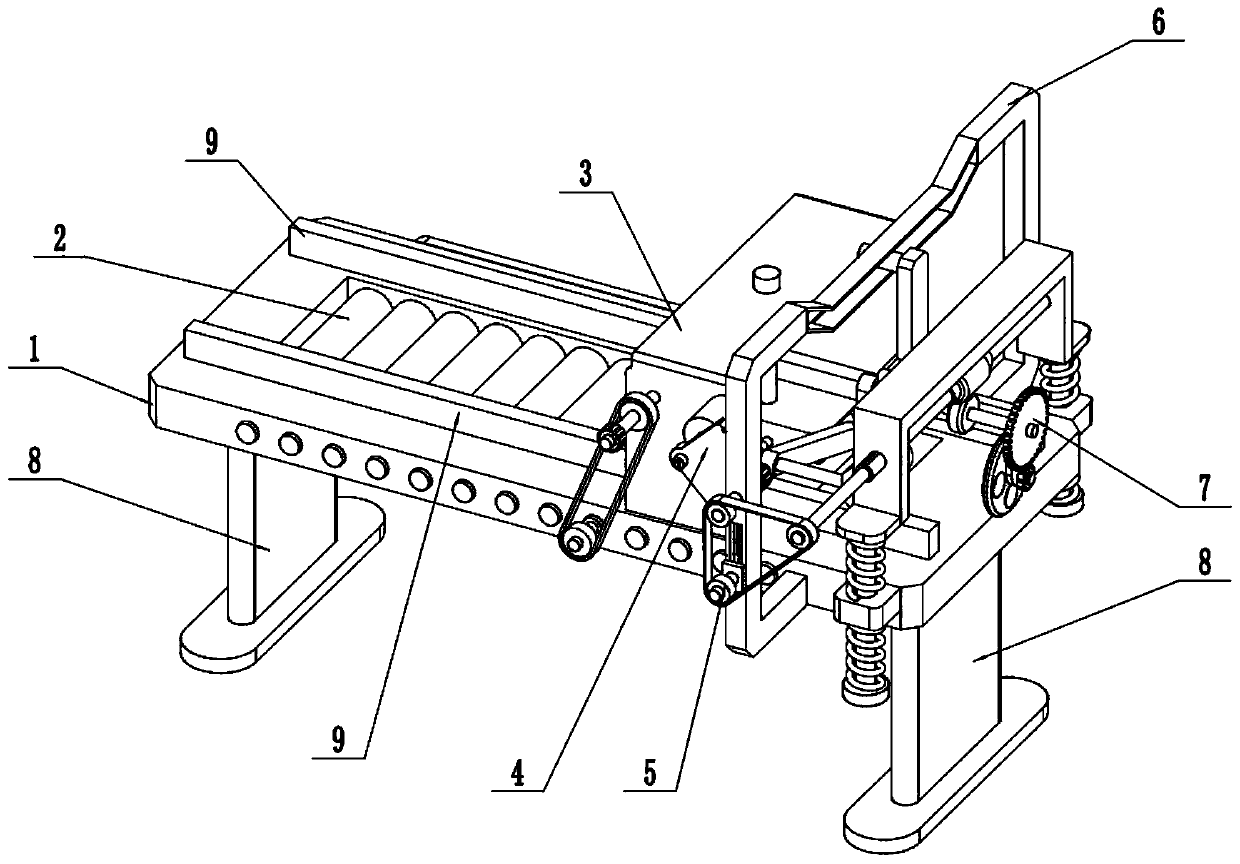

Wood board fixed-length cutting device

InactiveCN110238914AImprove cutting efficiencyImprove stabilityFeeding devicesGripping devicesEngineeringFixed length

The invention relates to the field of wood processing, in particular to a wood board fixed-length cutting device. The wood board fixed-length cutting device comprises a rack, a board conveying roller assembly, a pressure roller, a driving mechanism, a tensioning linkage wheel, a guide frame, a cutting mechanism, supporting legs and side baffles; the supporting legs are fixed at the front end and the rear end of the bottom face of the rack separately; the side baffles are fixed at the left end and the right end of the top face of the rack separately; the board conveying roller assembly is connected in an installation groove in the top face of the rack; the board conveying roller assembly is located between the two side baffles; the pressure roller is arranged at the front end of the top face of the rack; and the board conveying roller assembly is connected to the side end of the pressure roller. According to the wood board fixed-length cutting device, continuous fixed-length cutting is carried out on a wood board by adopting an automatic feeding and fixed length cutting mode, the cutting efficiency is high, and the labor force is low.

Owner:李锋

Loaf seam synchronization device for continuous loaf feed slicing machine

A mechanism and method is provided for controllably loading multiple food loaves into the slicing station of a continuous slicing machine. The parallel loaves that are engaged by a common loaf feed drive or side-by-side, independent loaf feed drives are engaged by the loaf feed drive or drives simultaneously such that the interface or seam between a preceding loaf and a trailing loaf in different loaf feed paths are located substantially at the same location during slicing of two side-by-side loaf streams. A clamp device is provided that clamps multiple food loaves when loaded to move along the parallel food loaf paths together, wherein the clamp device can be released once the multiple food loaves are simultaneously engaged by the loaf feed drive.

Owner:PROVISUR TECHNOLOGIES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com