Patents

Literature

105results about "Adjusting equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

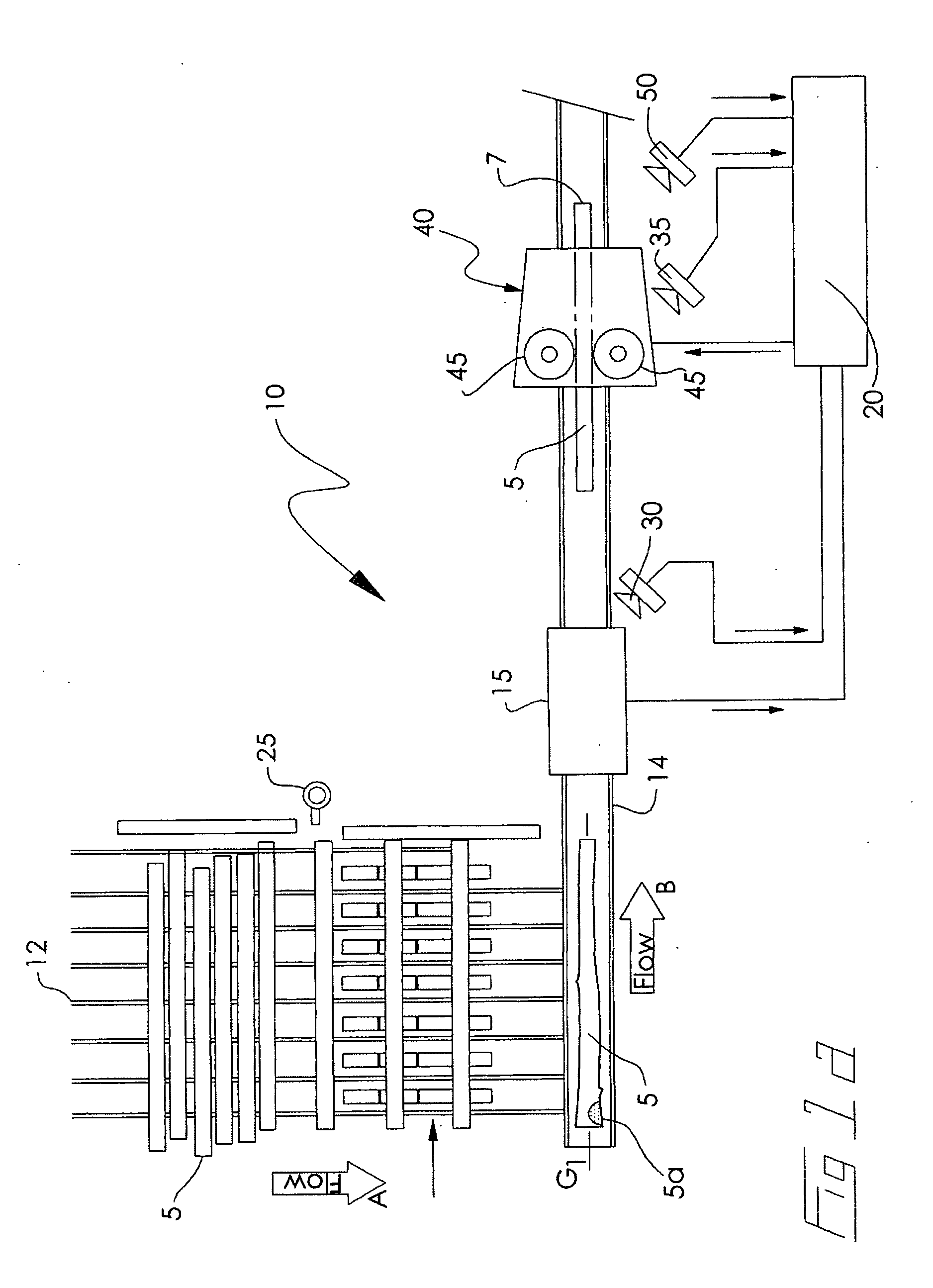

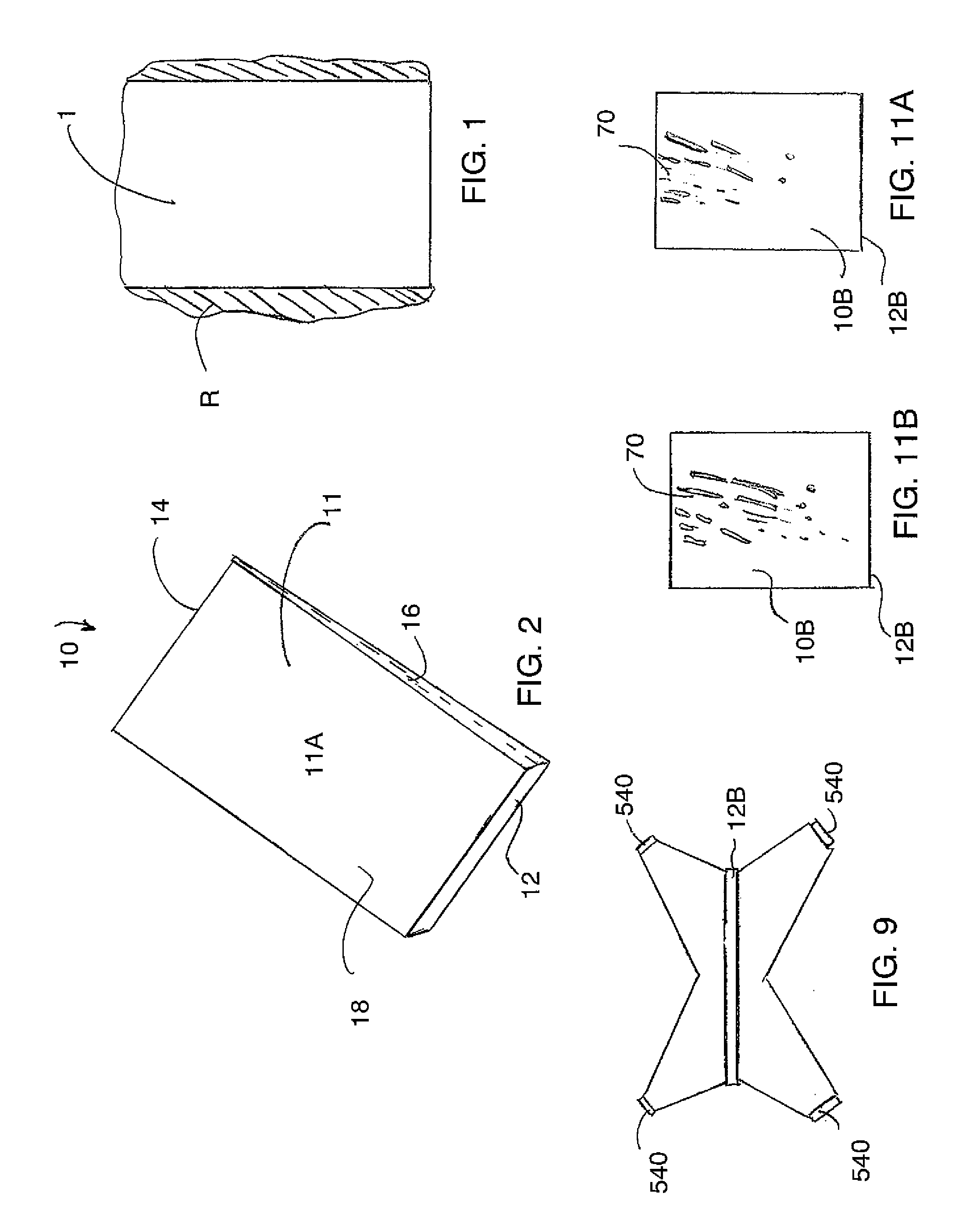

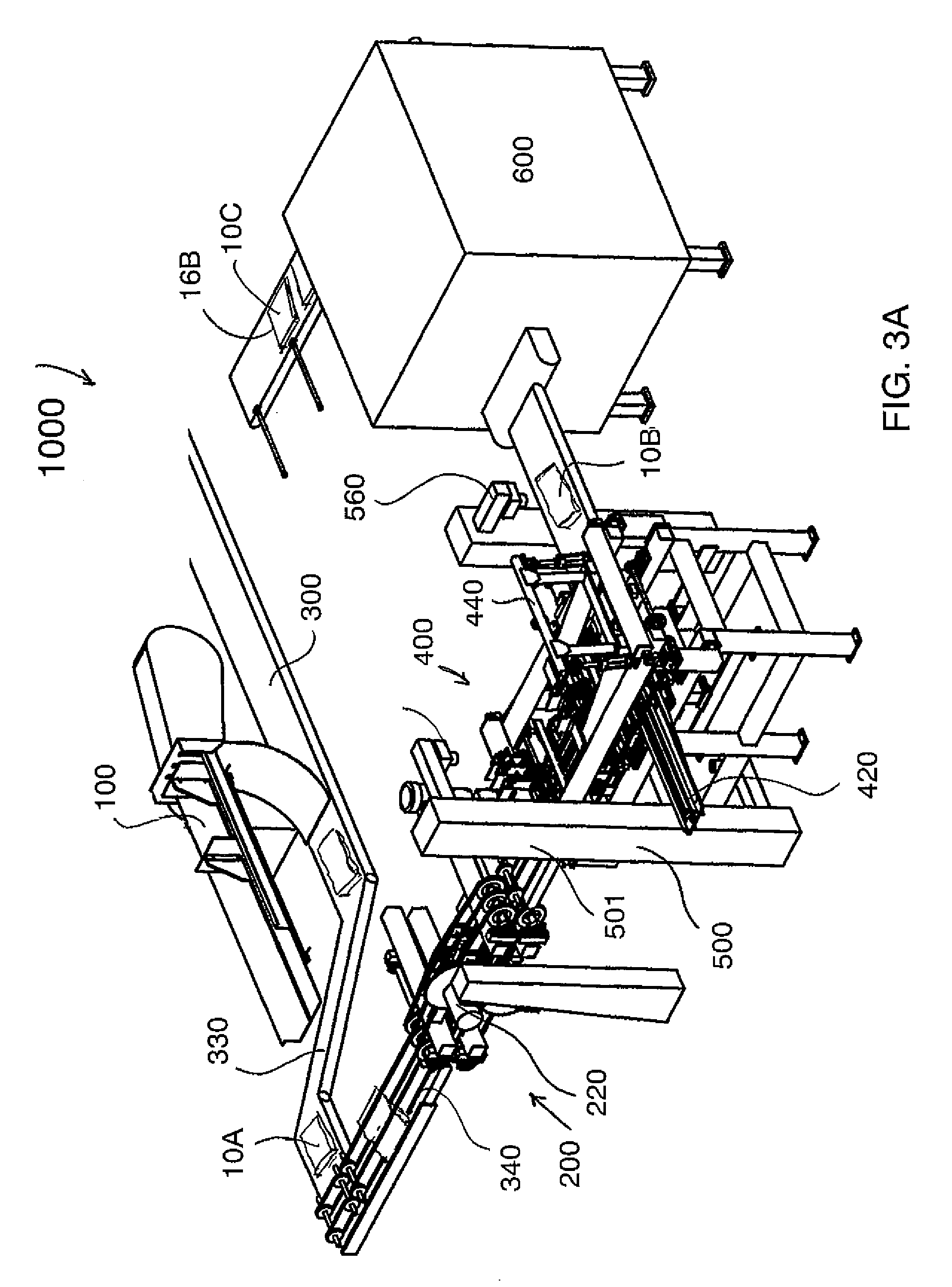

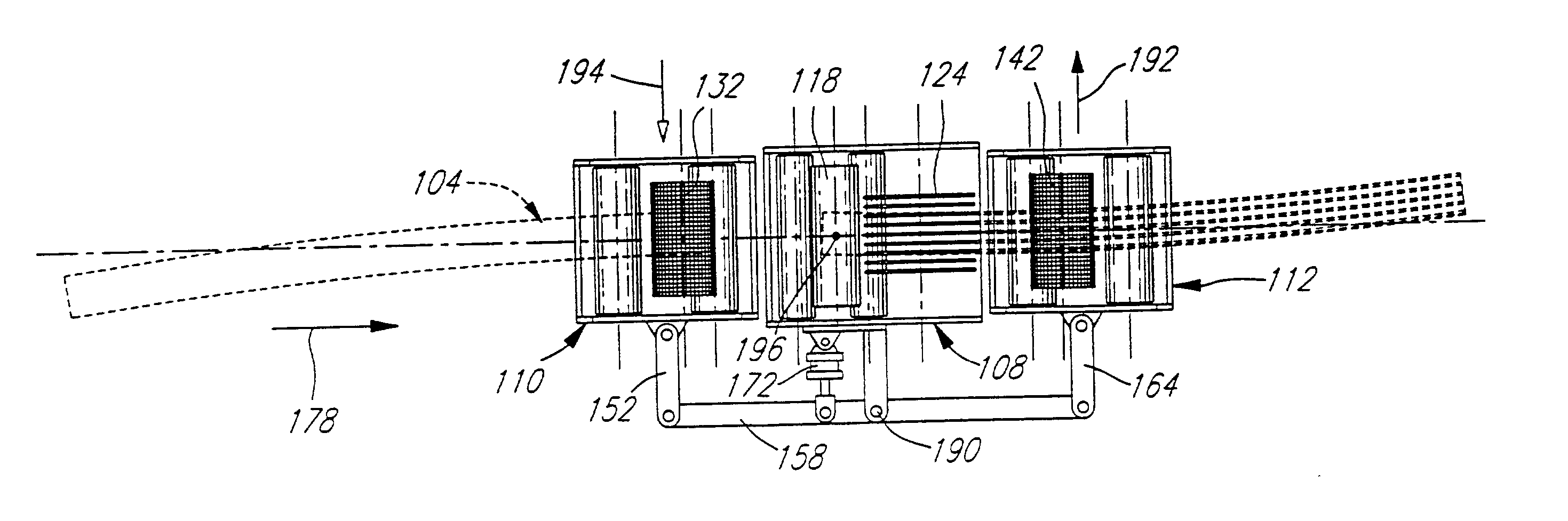

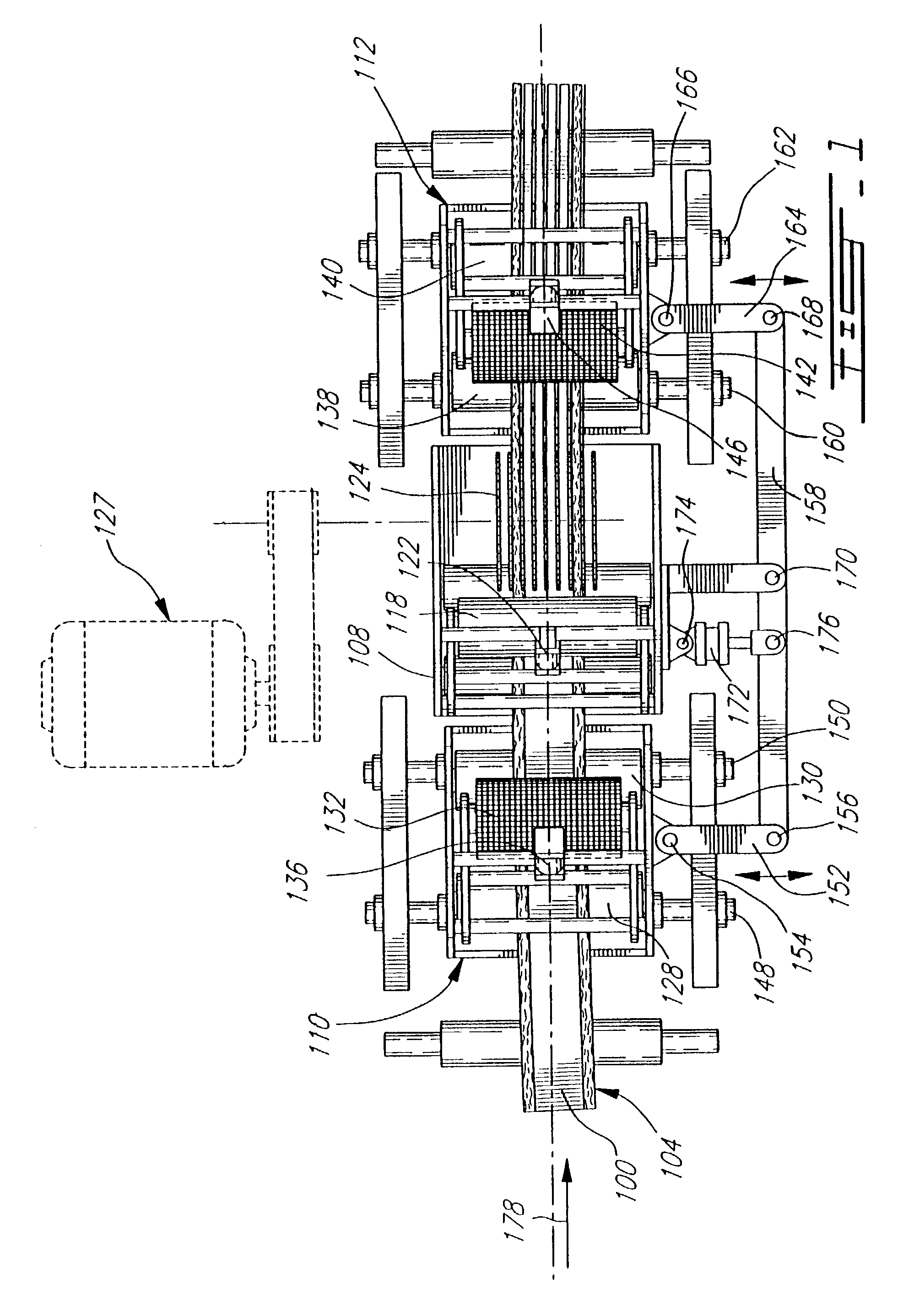

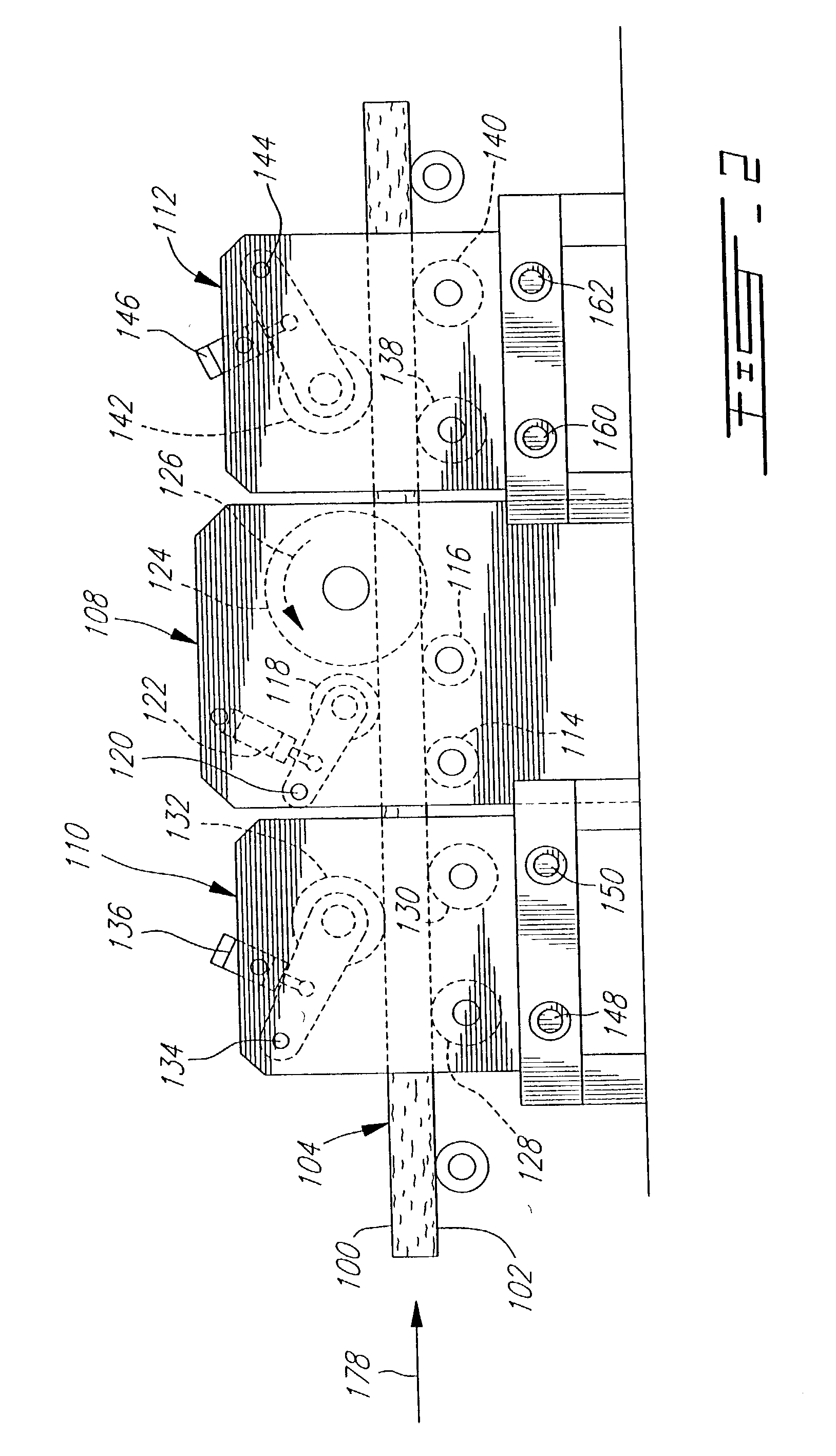

Process and system for sub-dividing a laminated flooring substrate

ActiveUS20070209736A1Good for healthAvoid mistakesMulti-purpose machinesAdjusting equipmentEngineeringControl unit

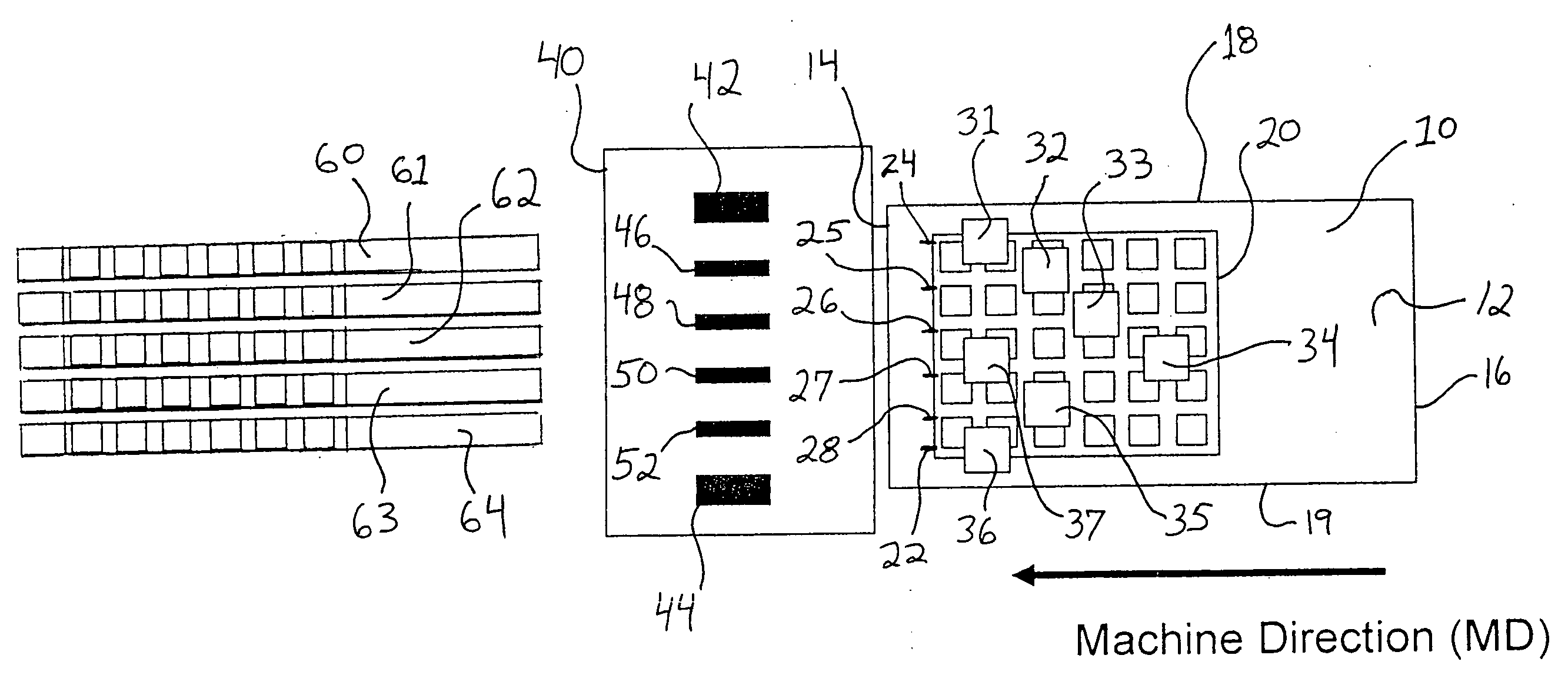

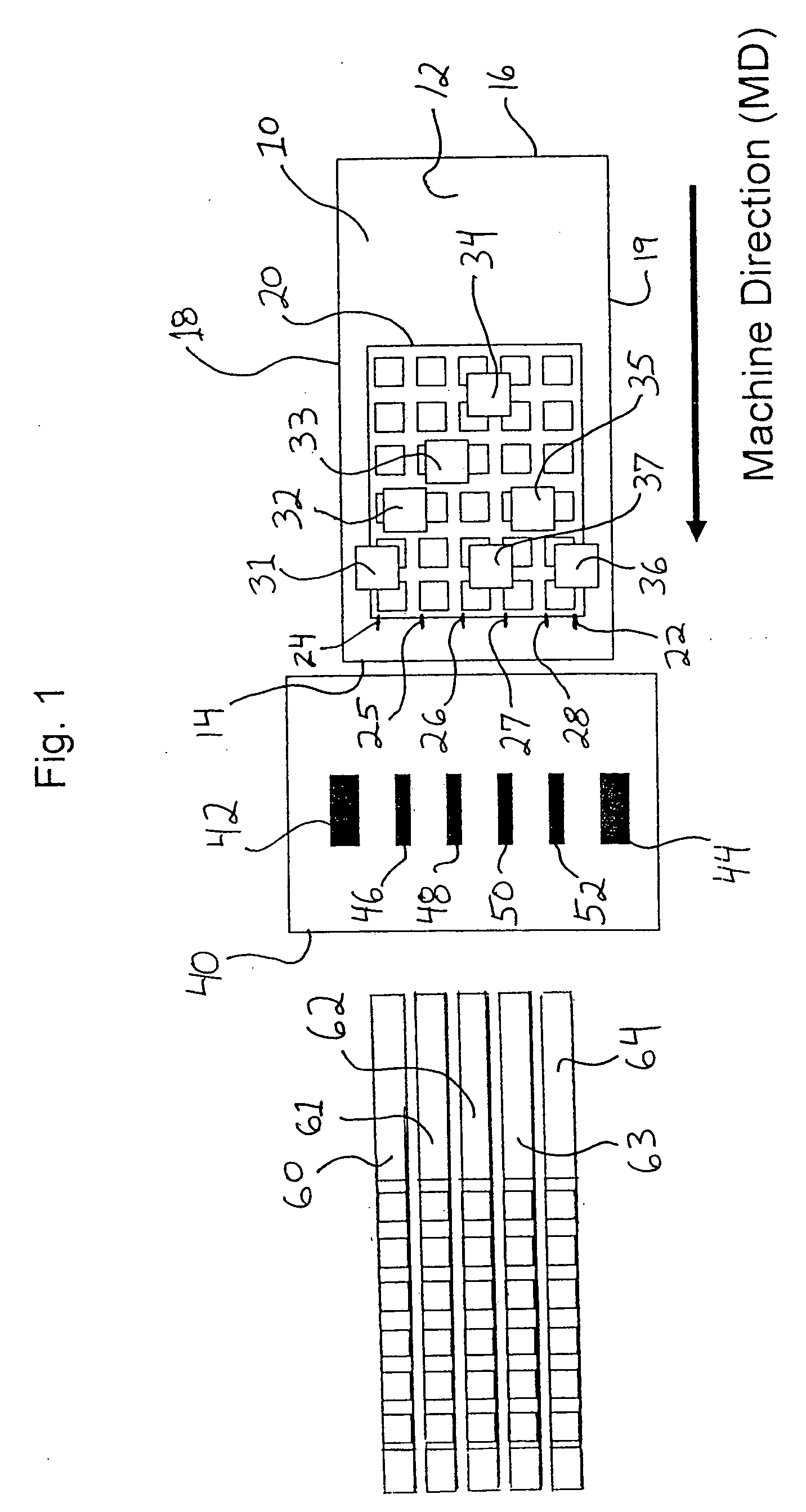

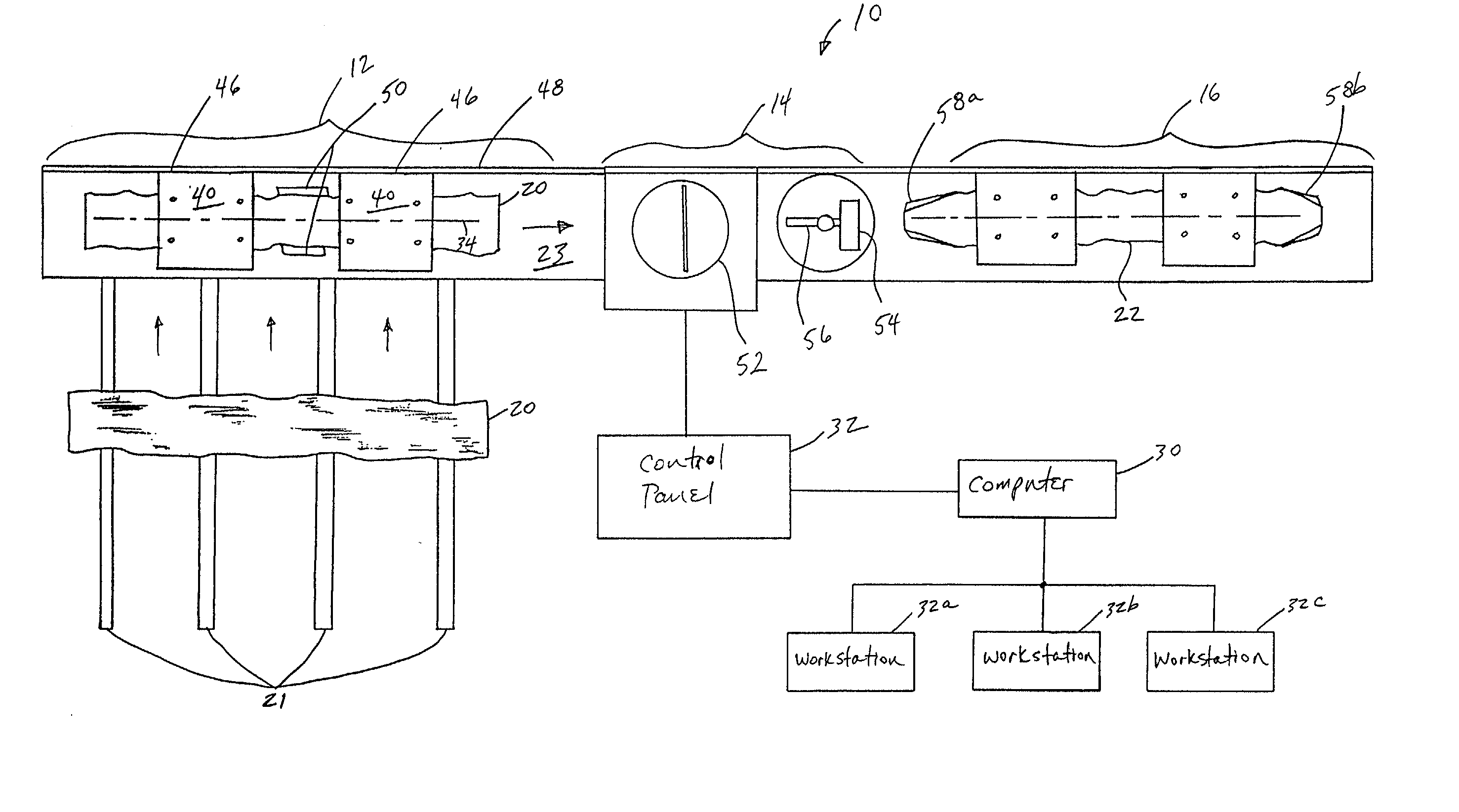

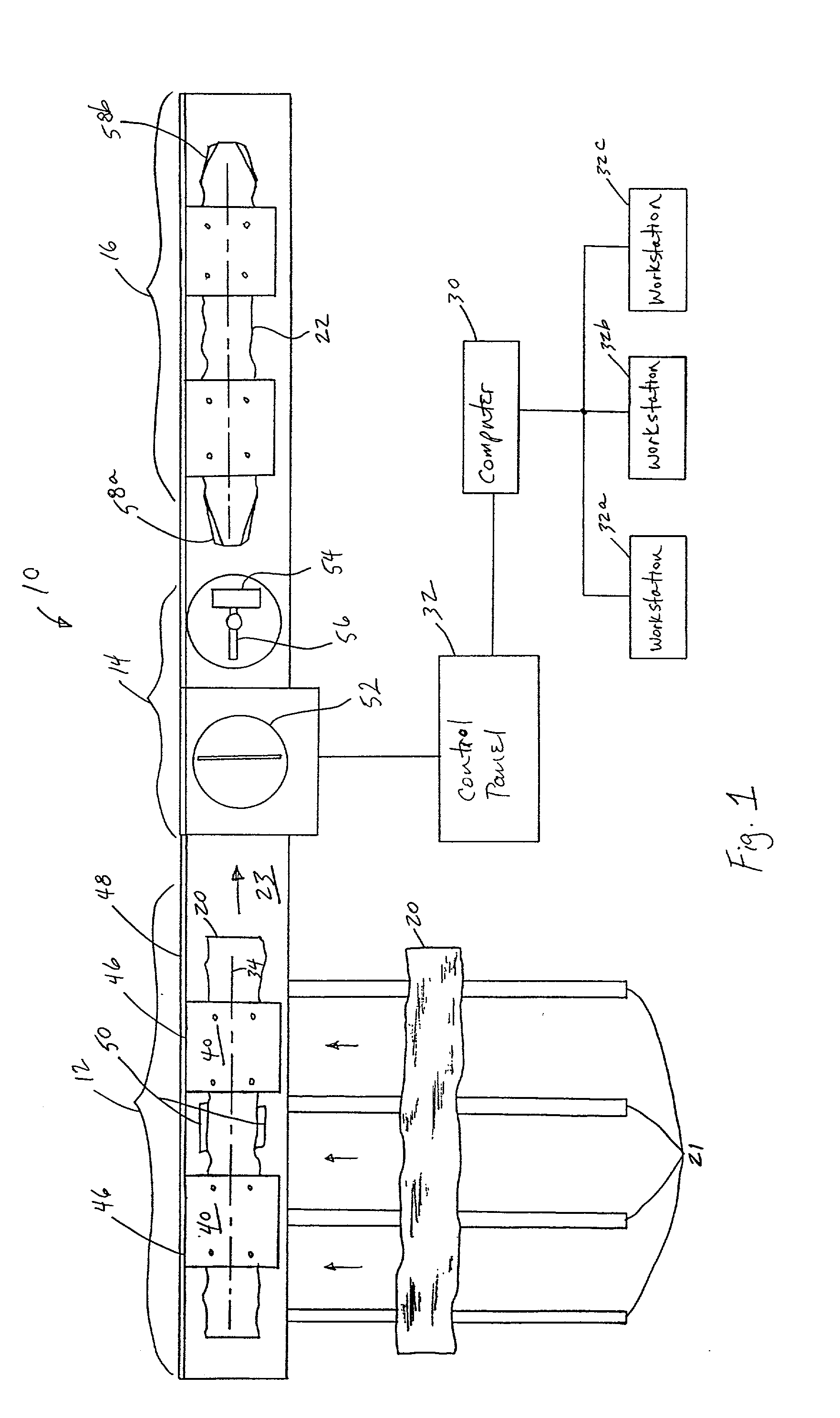

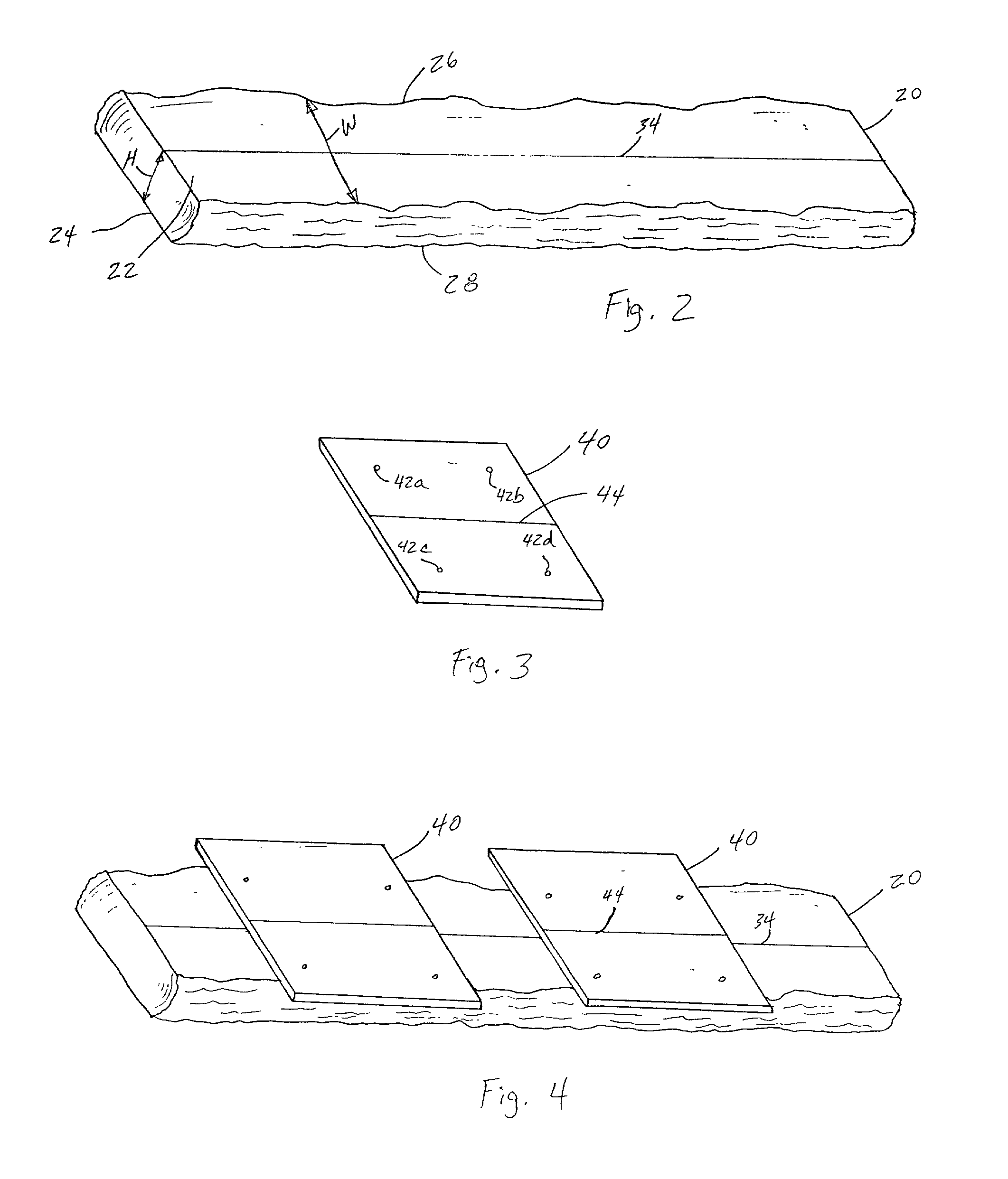

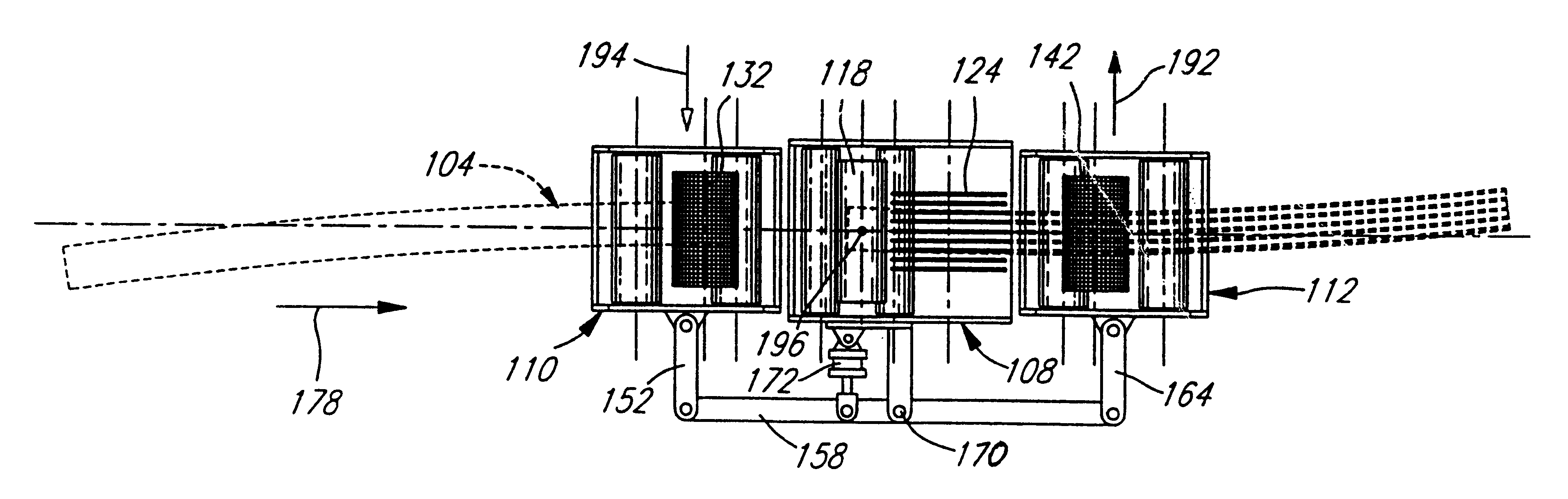

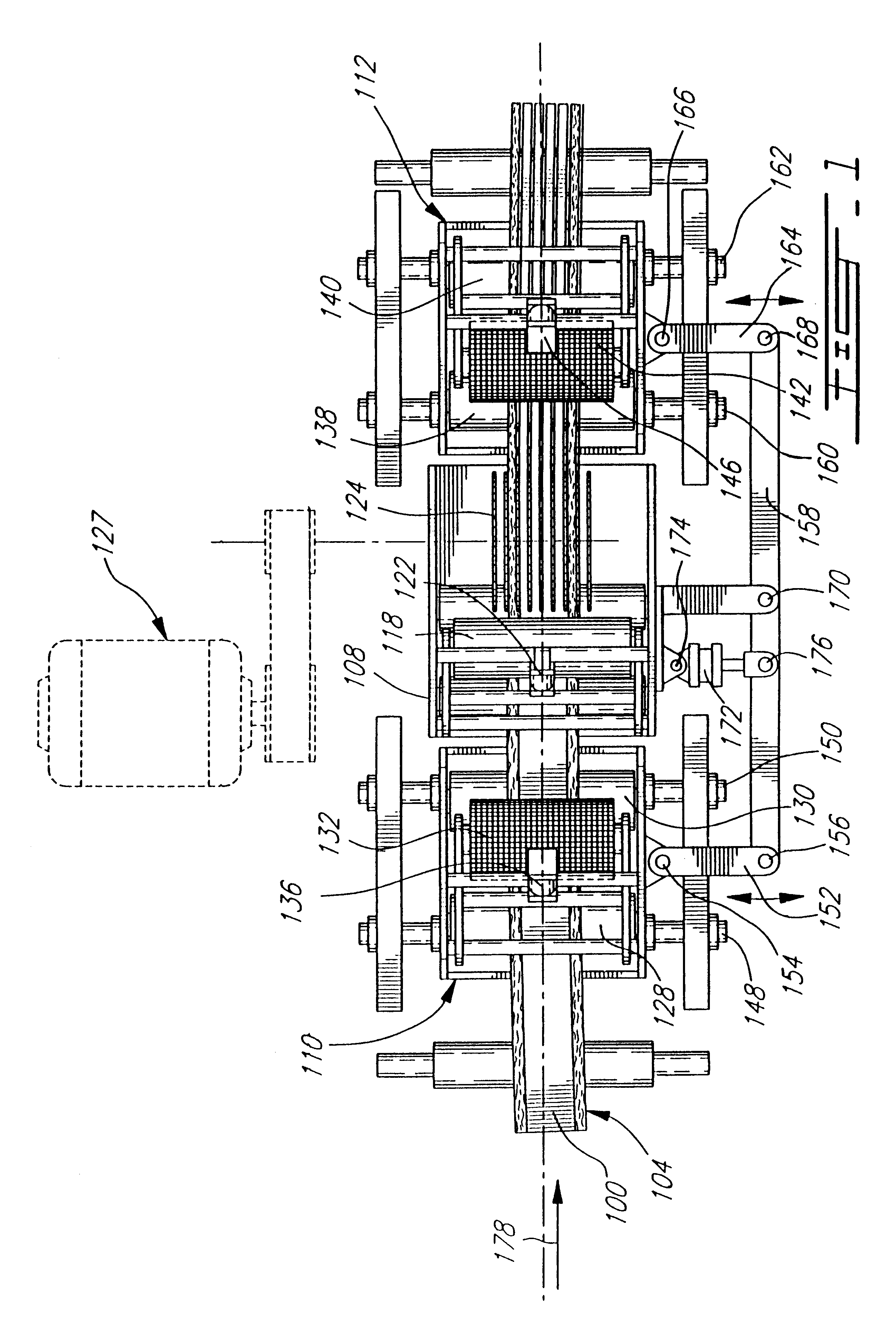

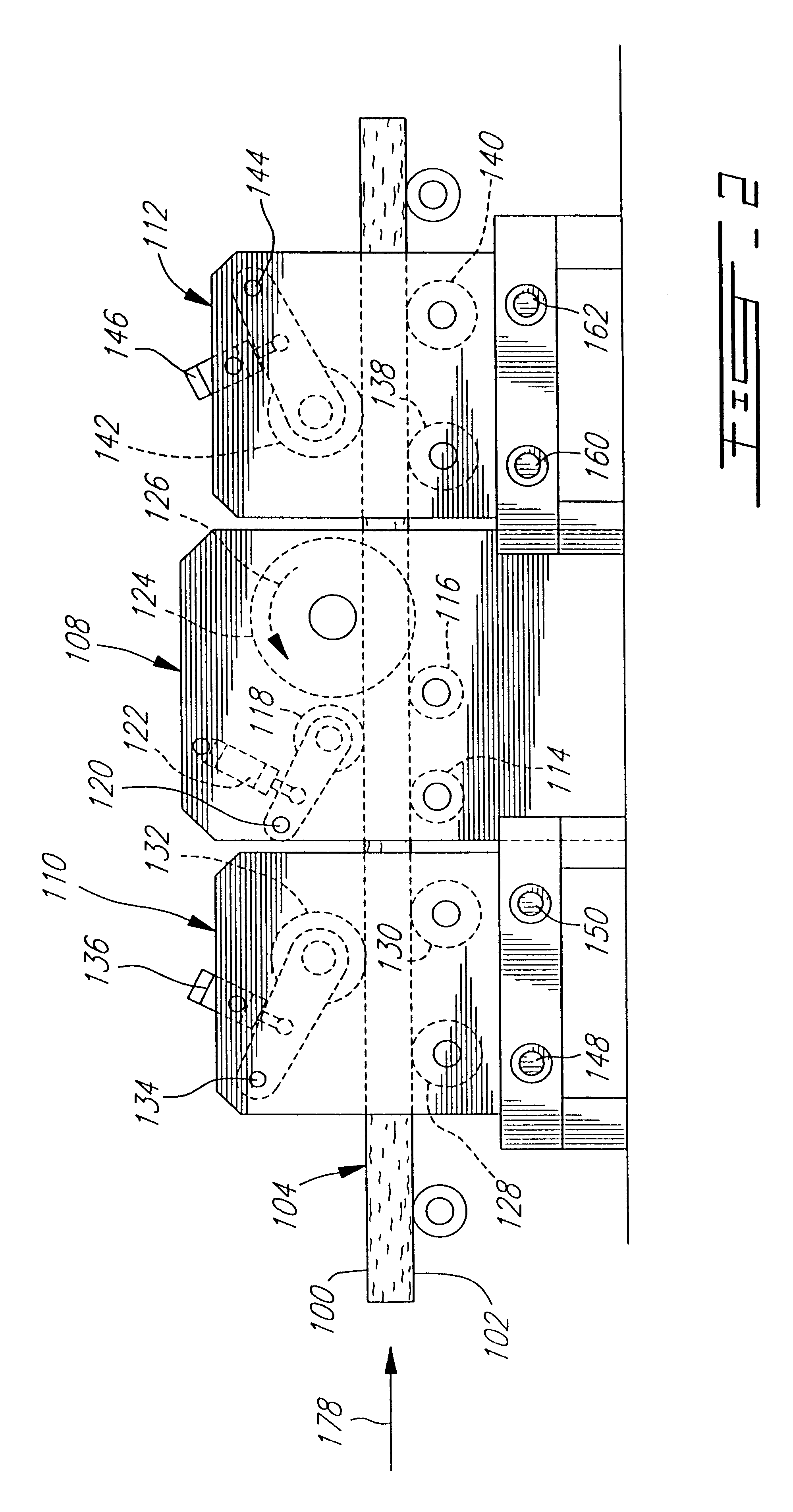

A process for sub-dividing a laminated flooring substrate into a plurality of laminated flooring planks and a system therefore are described. The process can include providing a laminated flooring substrate having a decorative pattern on a core wherein the decorative pattern can include a plurality of indicators, and independently detecting the indicators with a plurality of detecting devices, each assigned a respective indicator. The detecting devices can individually obtain the position of the detected indicators and a control unit can align a separate saw blade per each position detected. The system includes a cutting unit with individually adjustable saws or an alignment device configured to align the laminated flooring substrate with the saws, to cut the laminated flooring substrate along positions relative to the detected indicators, for example, in the center thereof or off-set therefrom.

Owner:MANNINGTON MILLS

Precision laser cutting guide

InactiveUS20030010173A1Precise processMetal sawing devicesMetal sawing accessoriesLaser cuttingEngineering

The invention is an attachment for a stationary power saw, attaching to an operationally non-moving base or frame member of the power saw, as opposed to the retractable saw blade portion of the power saw, providing a fully adjustable laser cutting guide for designating the strike point of the rotating saw blade on the material being cut by the saw blade.

Owner:HAYDEN JAMES ALAN

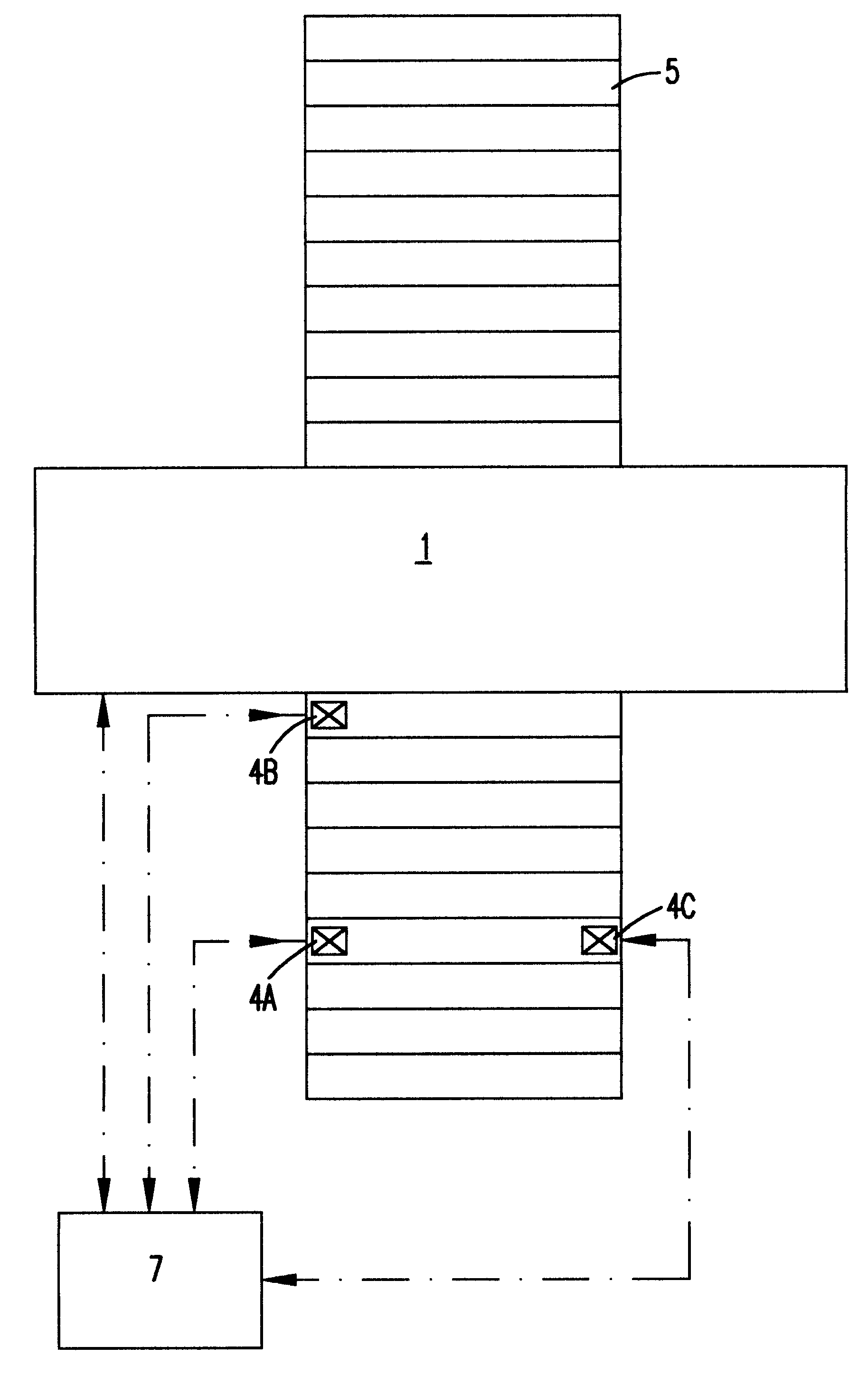

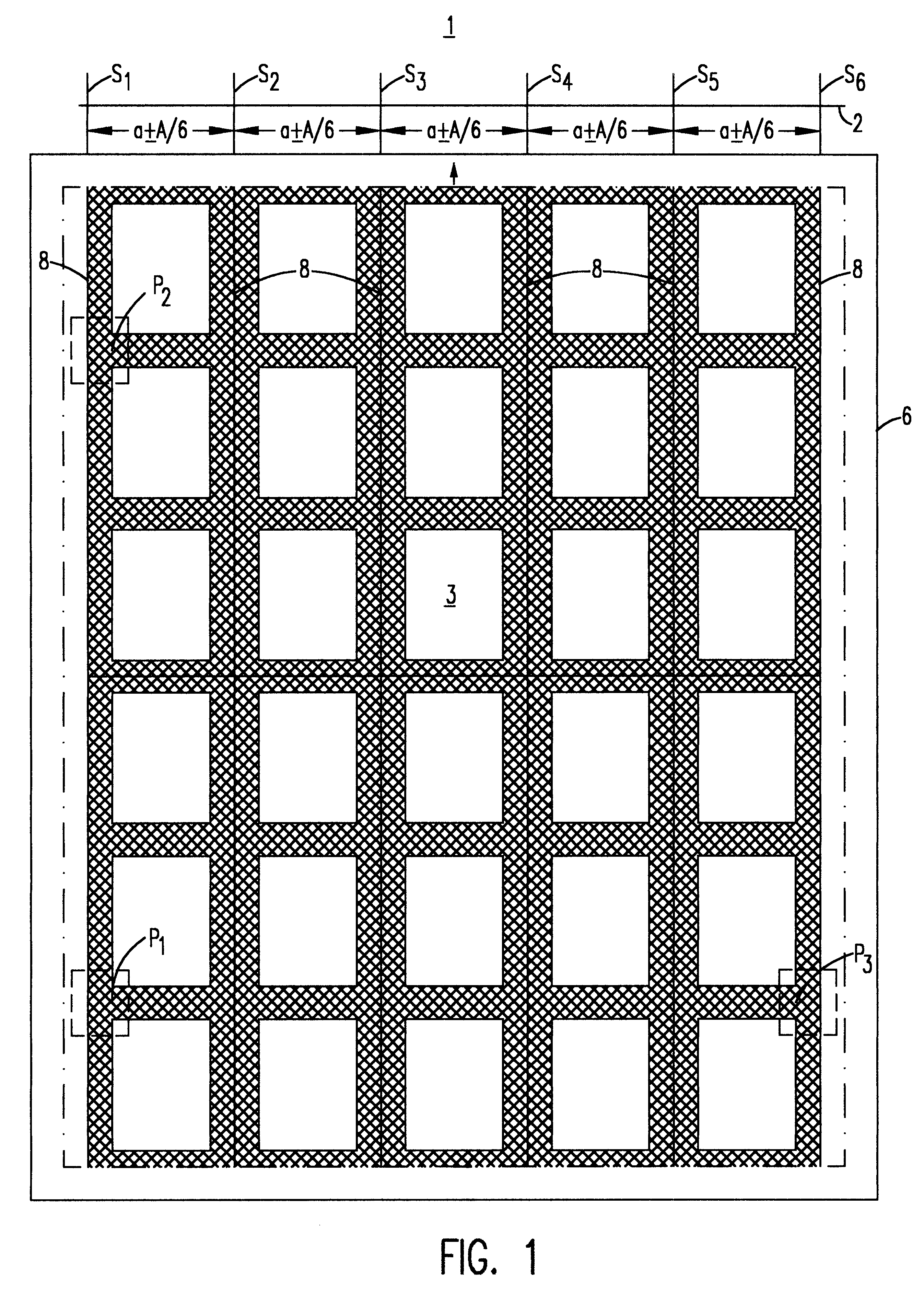

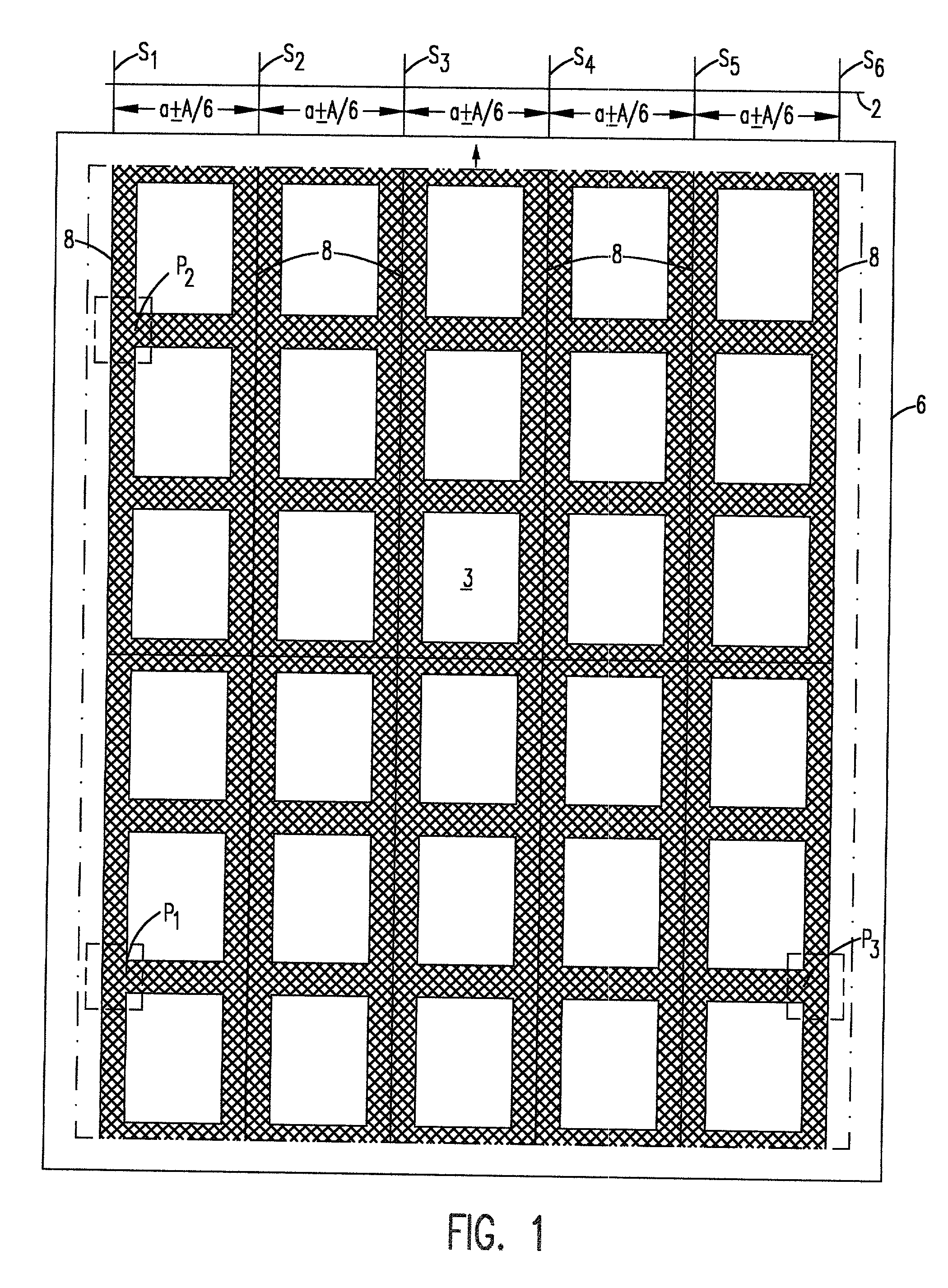

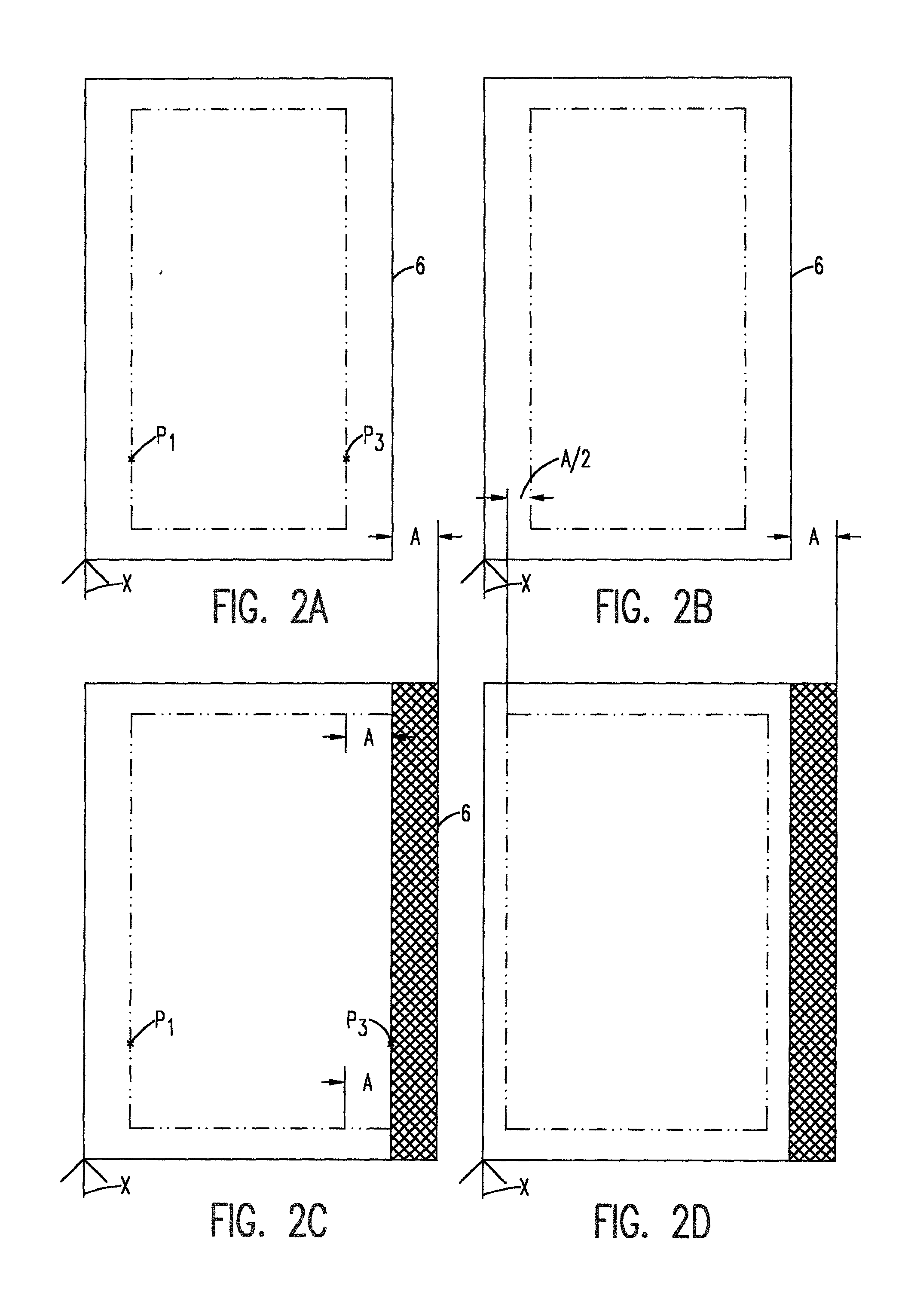

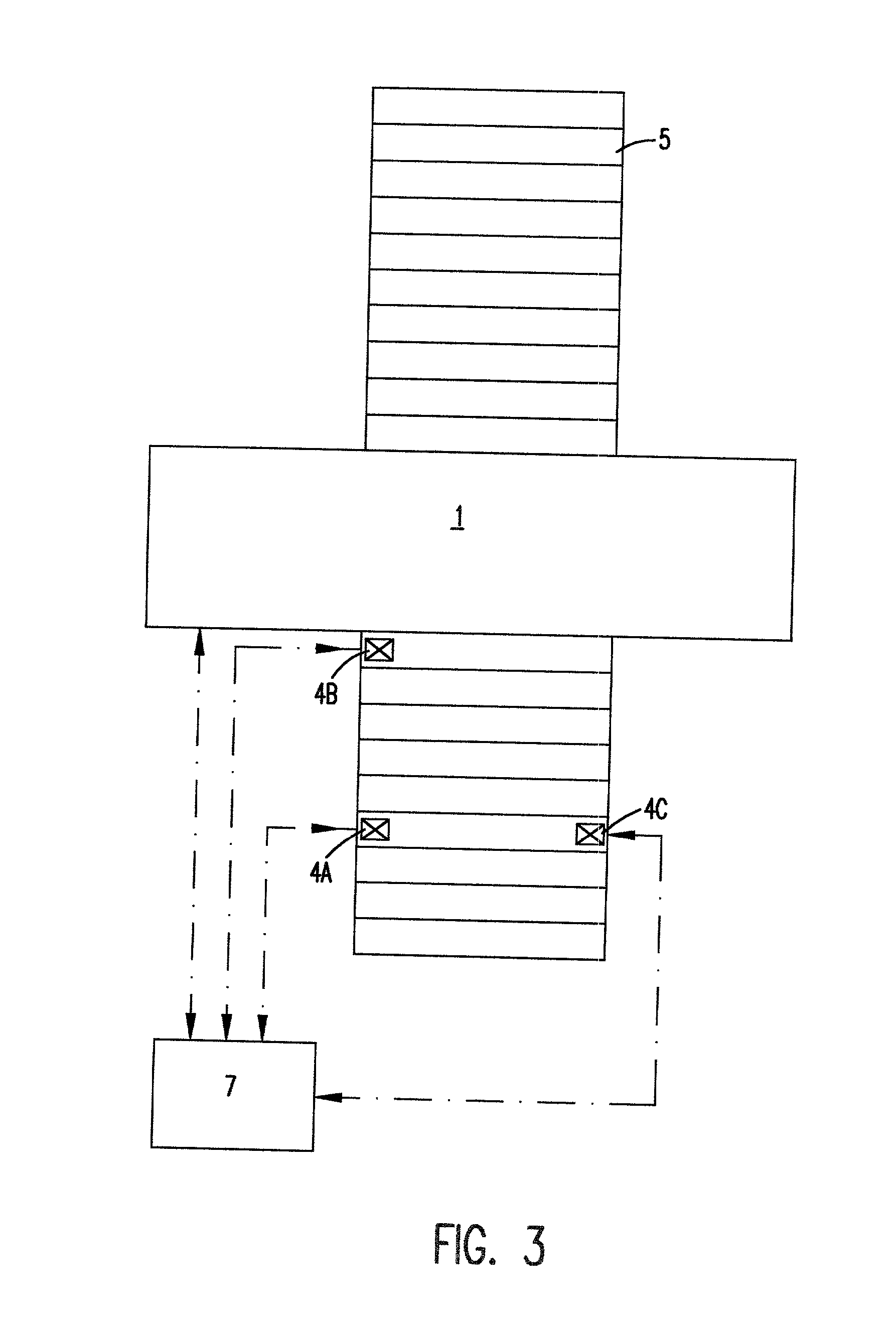

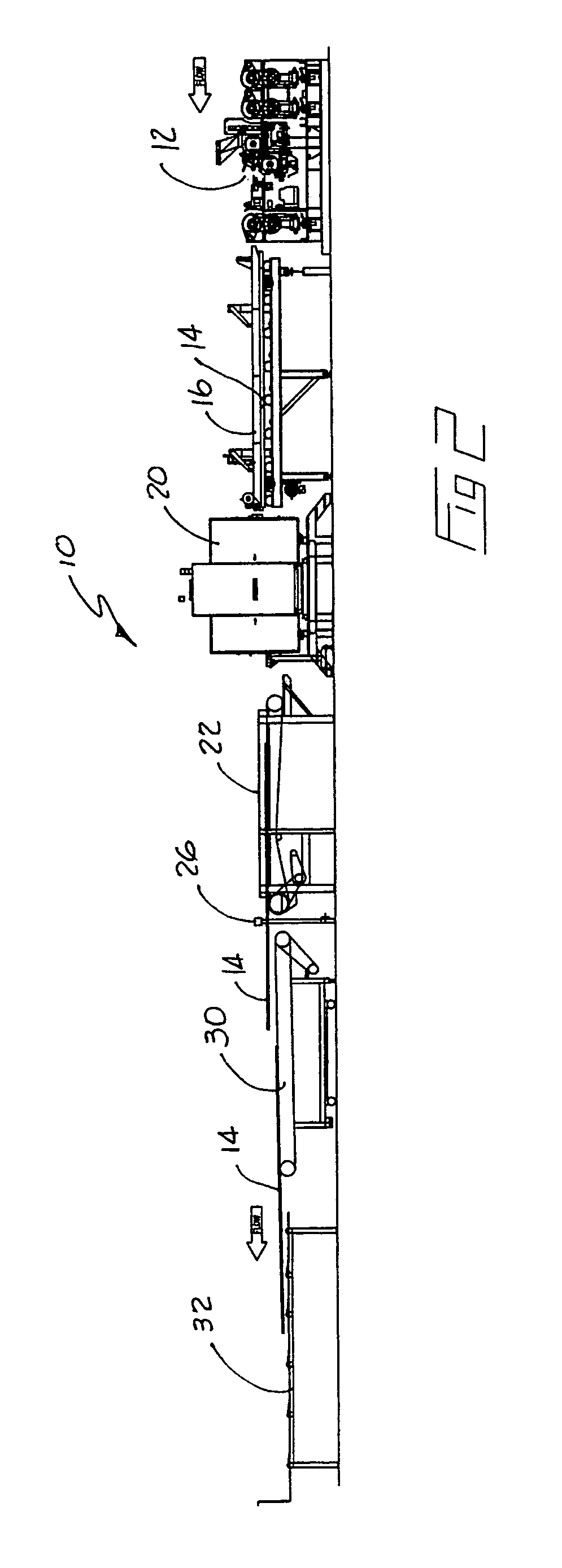

Process for cutting out panels or the like

InactiveUS6569272B2Quality improvementAutomatic control devicesLamination ancillary operationsWood fibreEngineering

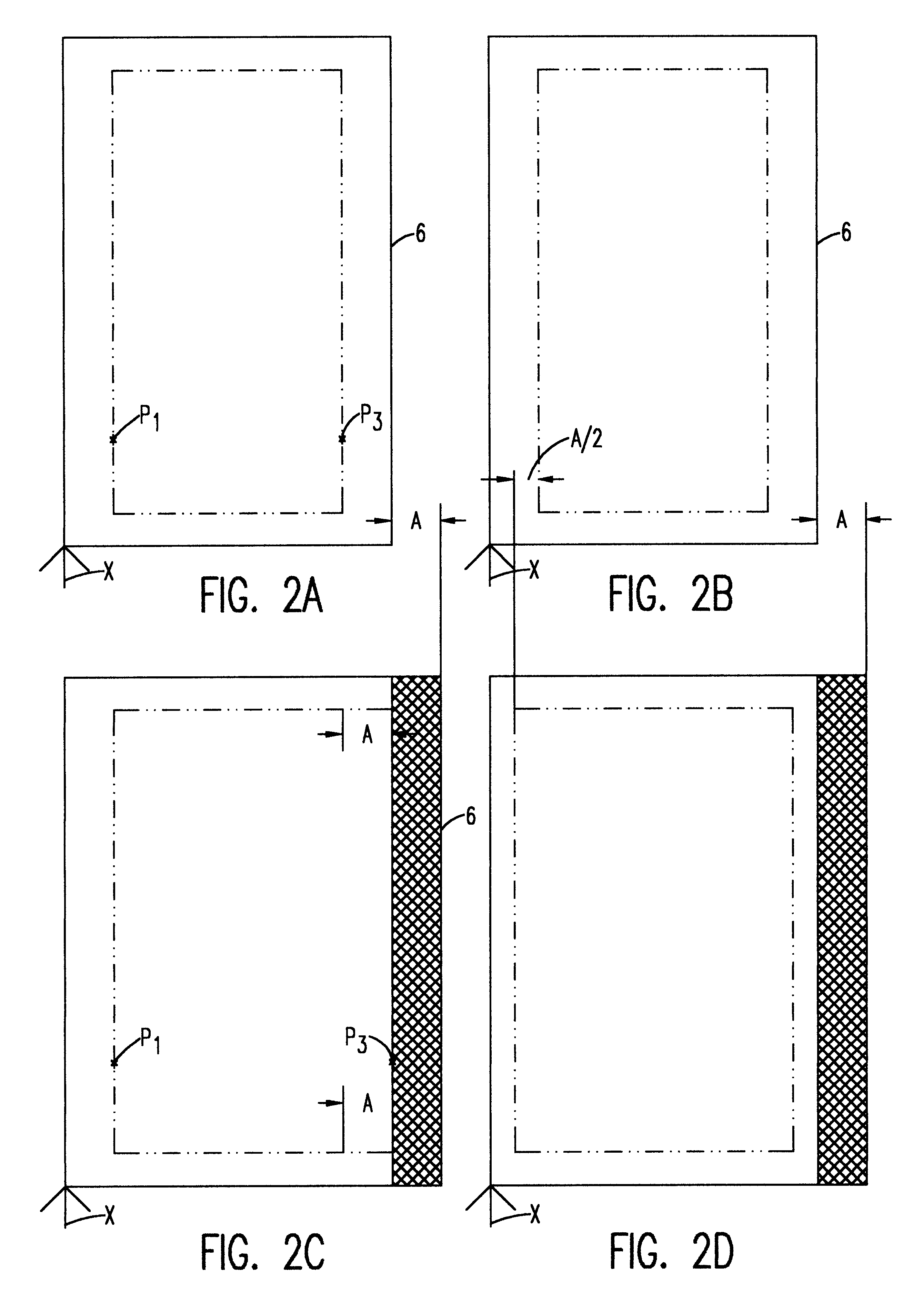

A wood fiber board (6) which is provided with a decorative layer (3) of paper or similar material, and where the length or width value of the decorative layer (3) deviates from its original value after it is applied to the wood fiber board (6), is cut into uniform panels using a board-dividing apparatus that compensates for these deviations. The board-dividing apparatus has a saw (1) that preferably has a plurality of saw blades (S1, S2, . . . Sn) which are adjustably spaced in parallel fashion. The board-dividing apparatus is equipped with a number of cameras and with controller which utilizes deviation measurement information to adjust the spacing of the saw blades. The wood fiber board (6) is first aligned with at least one initial camera (4a) at a point P1. Then, predetermined points (P1 and P2) in the decorative layer (3) are recorded by the first camera (4a) and a second camera (4b). A distance (L) between the points (P1 and P2) is determined, and thee discrepancy in the width or length value is determined by comparison of the actual position and the desired position of the points (P1 and P2). Then, the value of the determined discrepancy (A) is placed in relation to the number (n) of the saw blades (Sn), and the parallel spacing (a) of the saw blades (Sn) is modified by the value of the ratio of the discrepancy to the number of saw blades (A / n). The orientation of the wood fiber board (6) to the saw (1) is displaced to one side in the amount of one half the determined discrepancy (A), and then the wood fiber board (6) is transported toward the saw (1) for cutting out the panels.

Owner:KRONOTEC

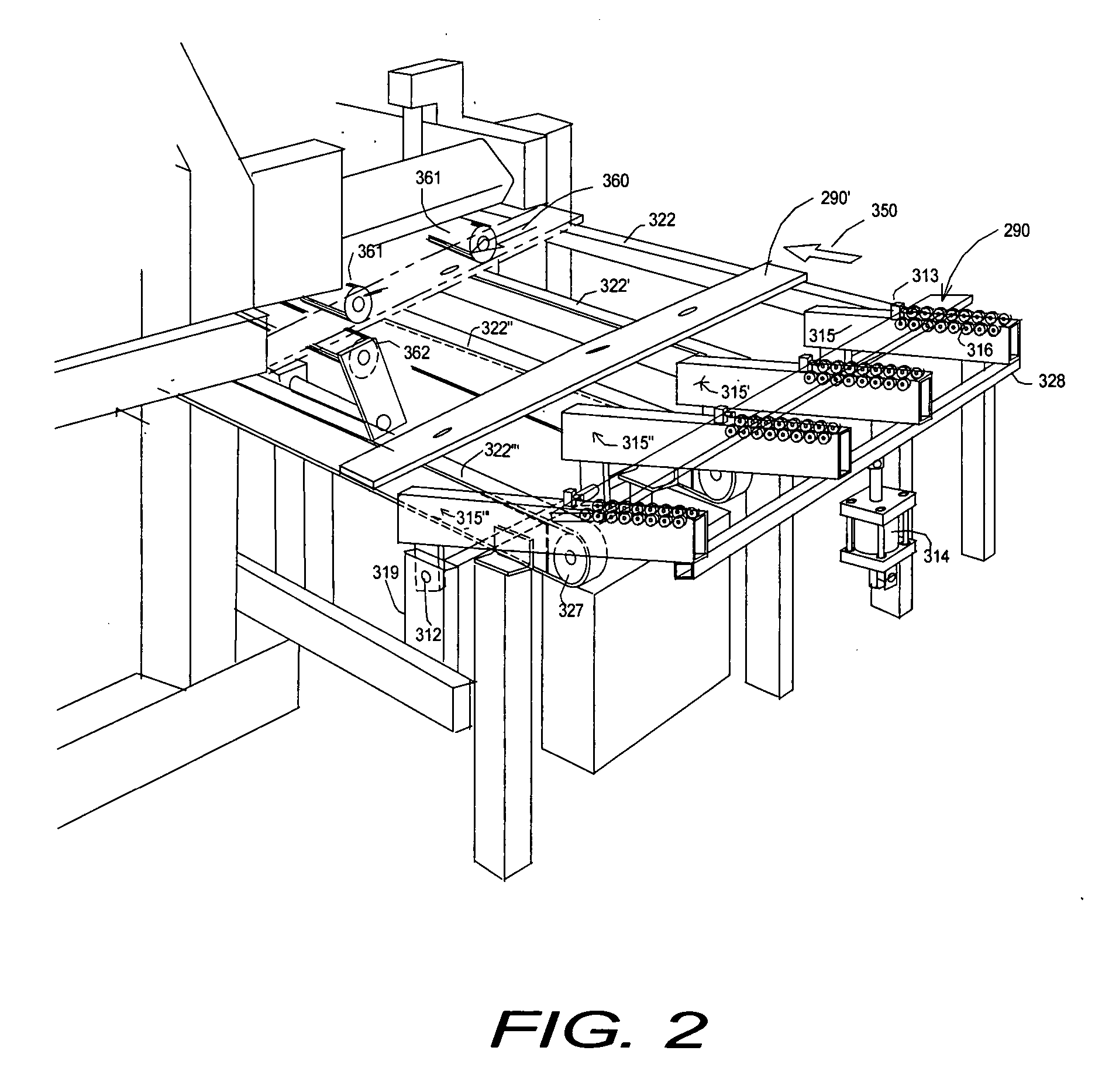

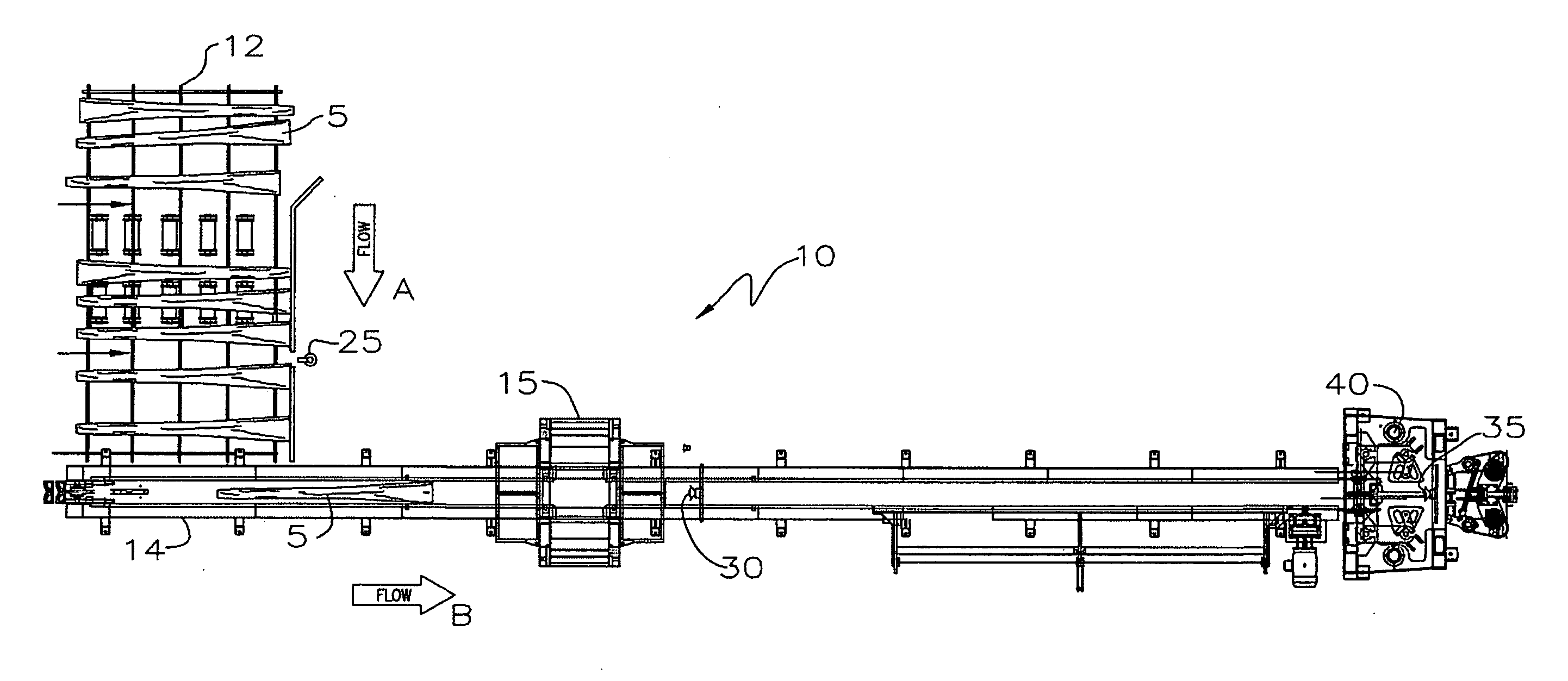

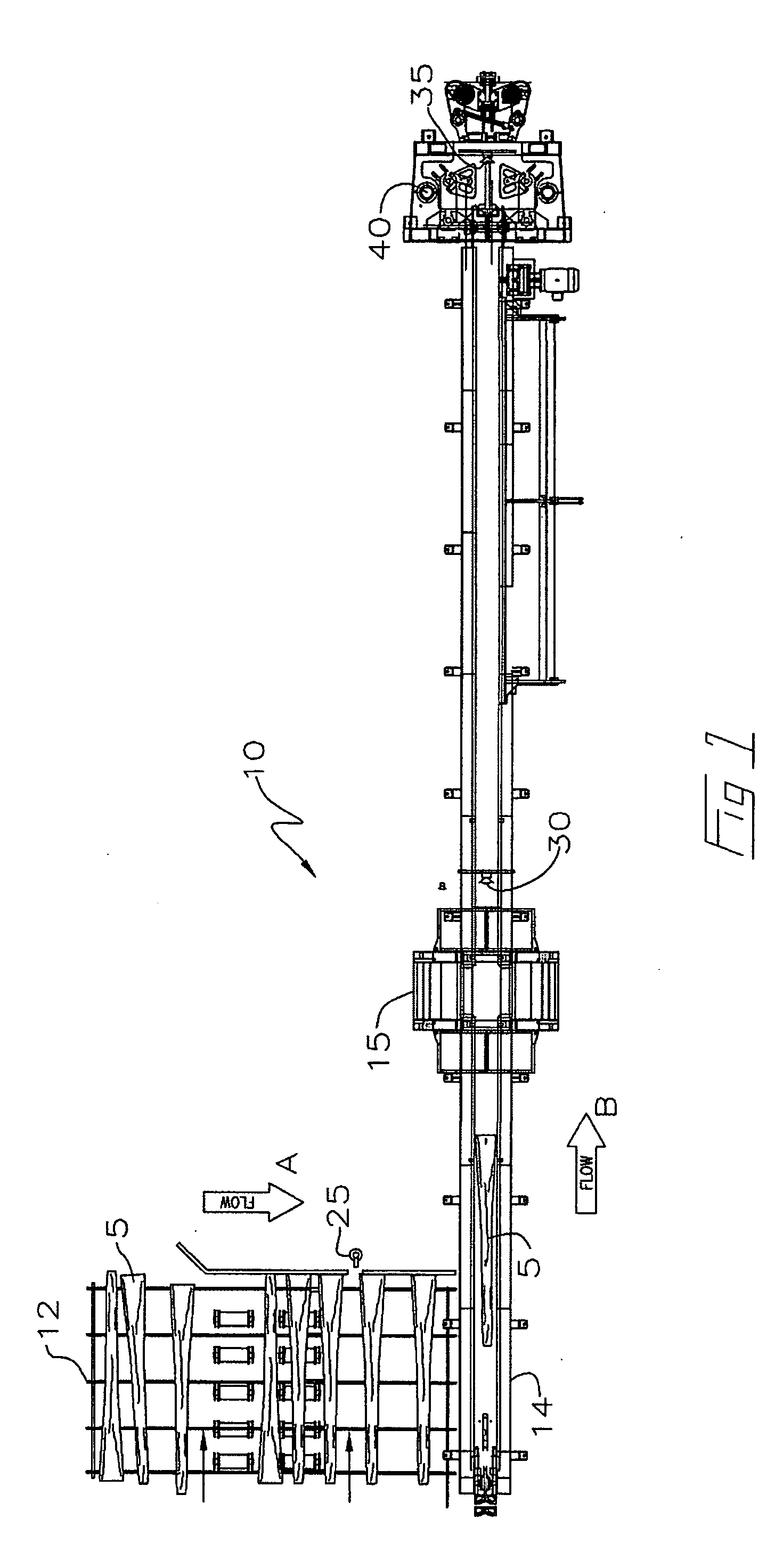

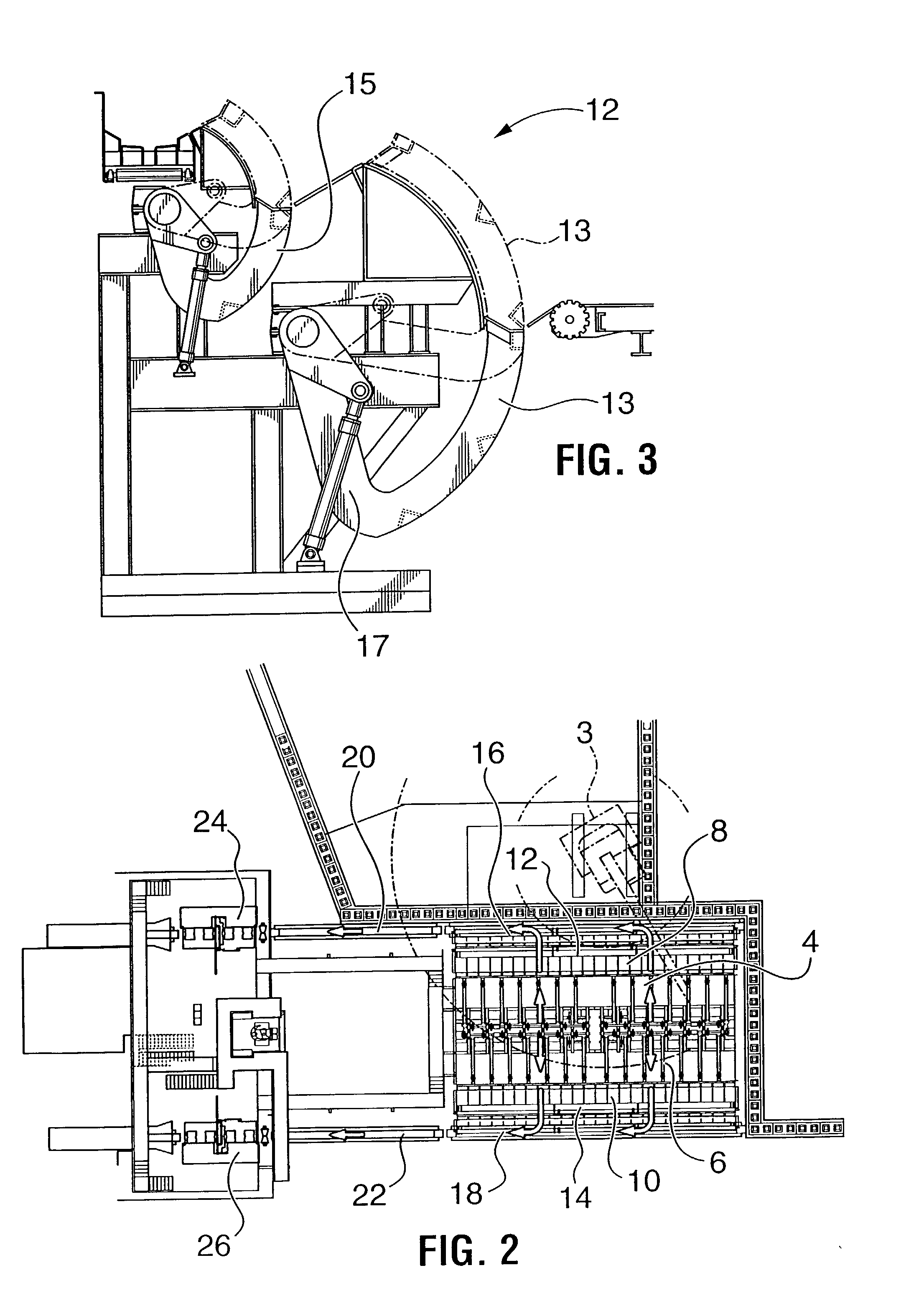

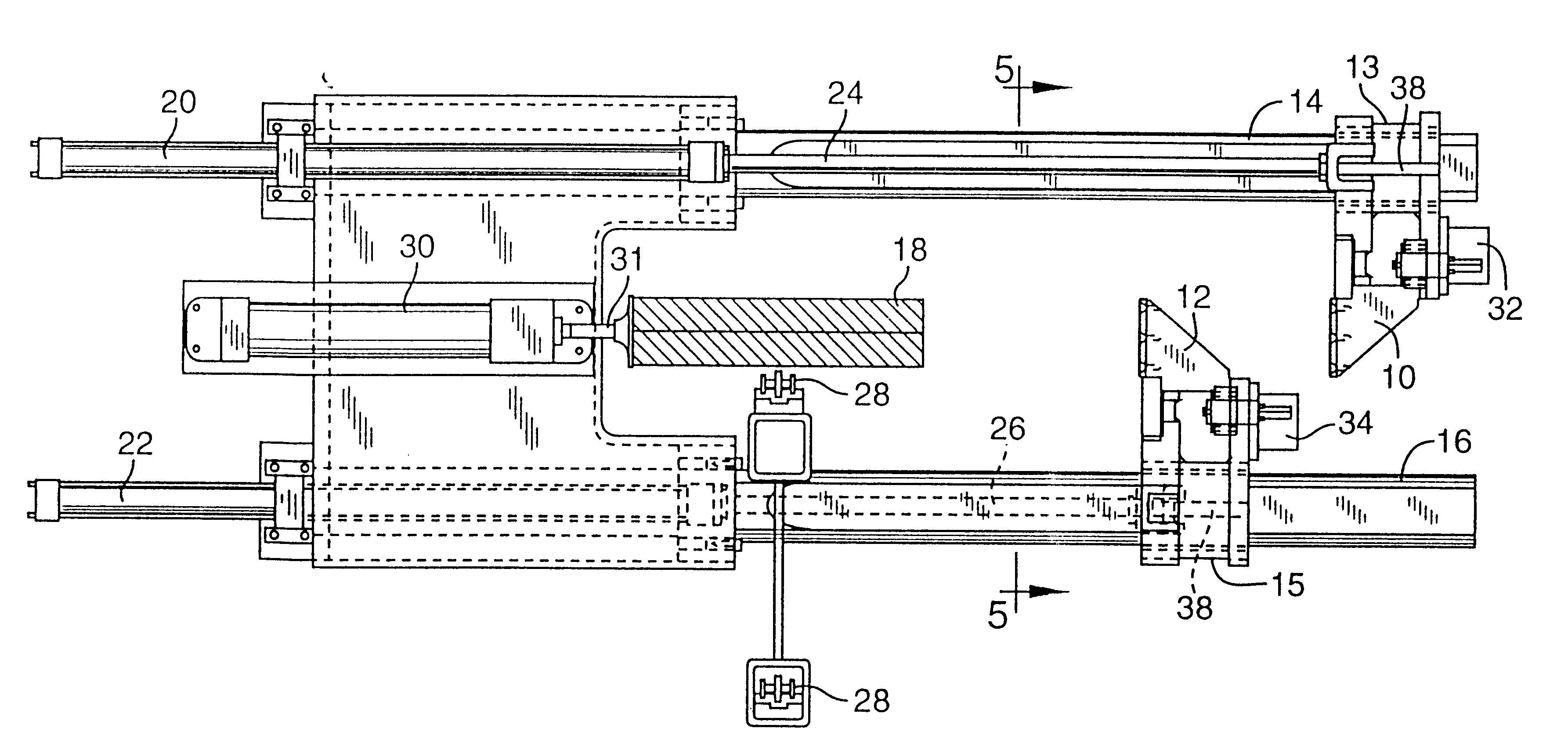

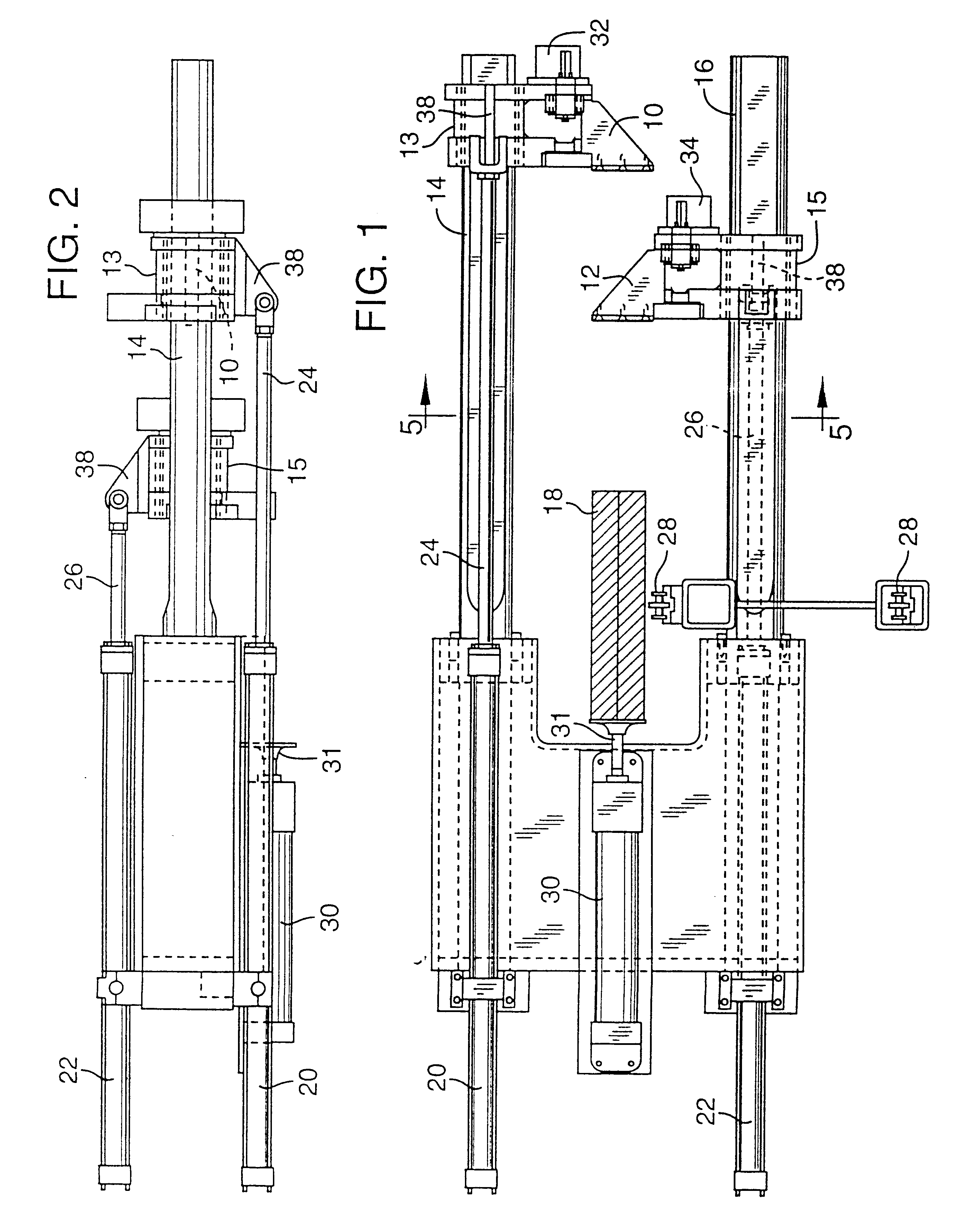

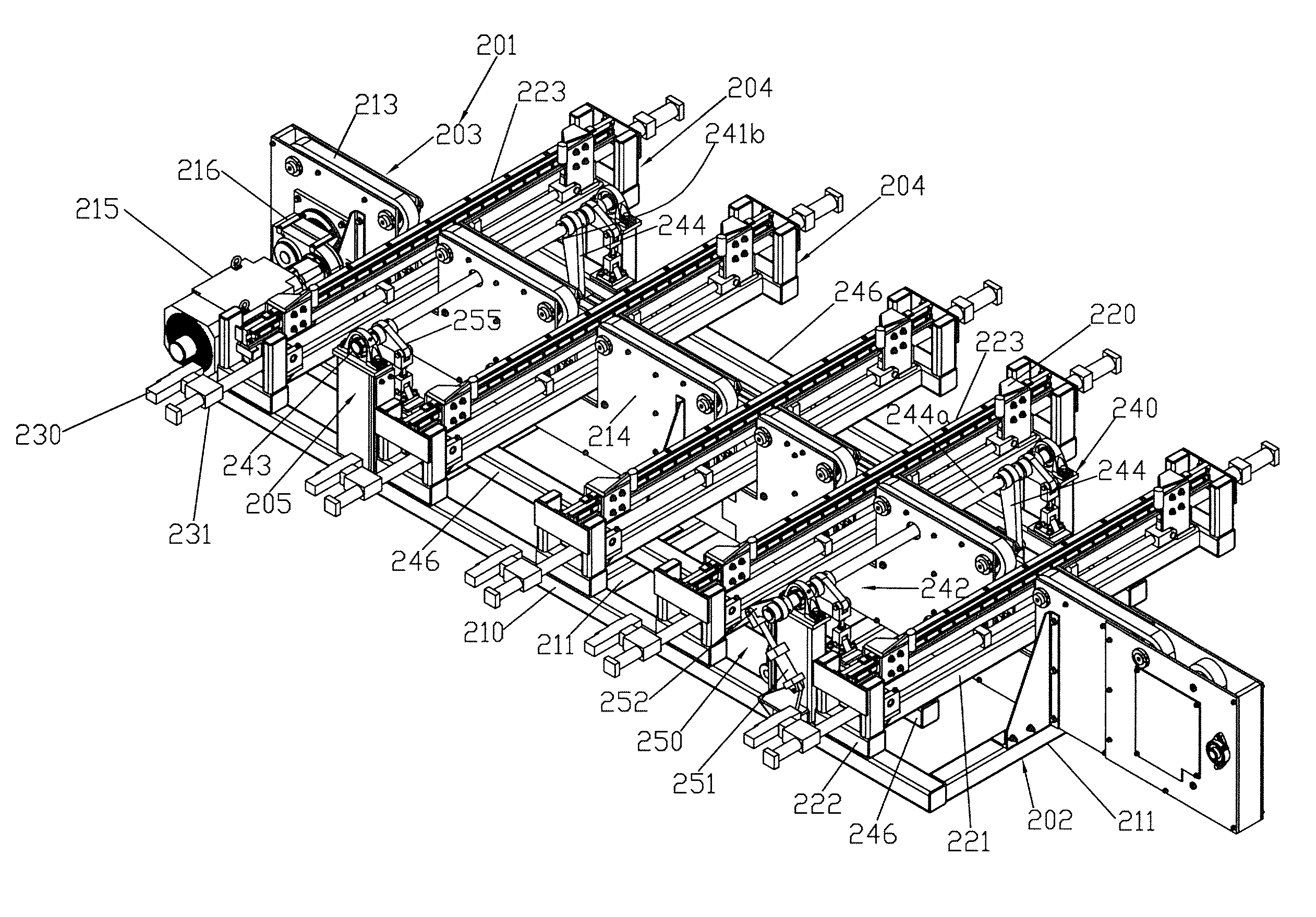

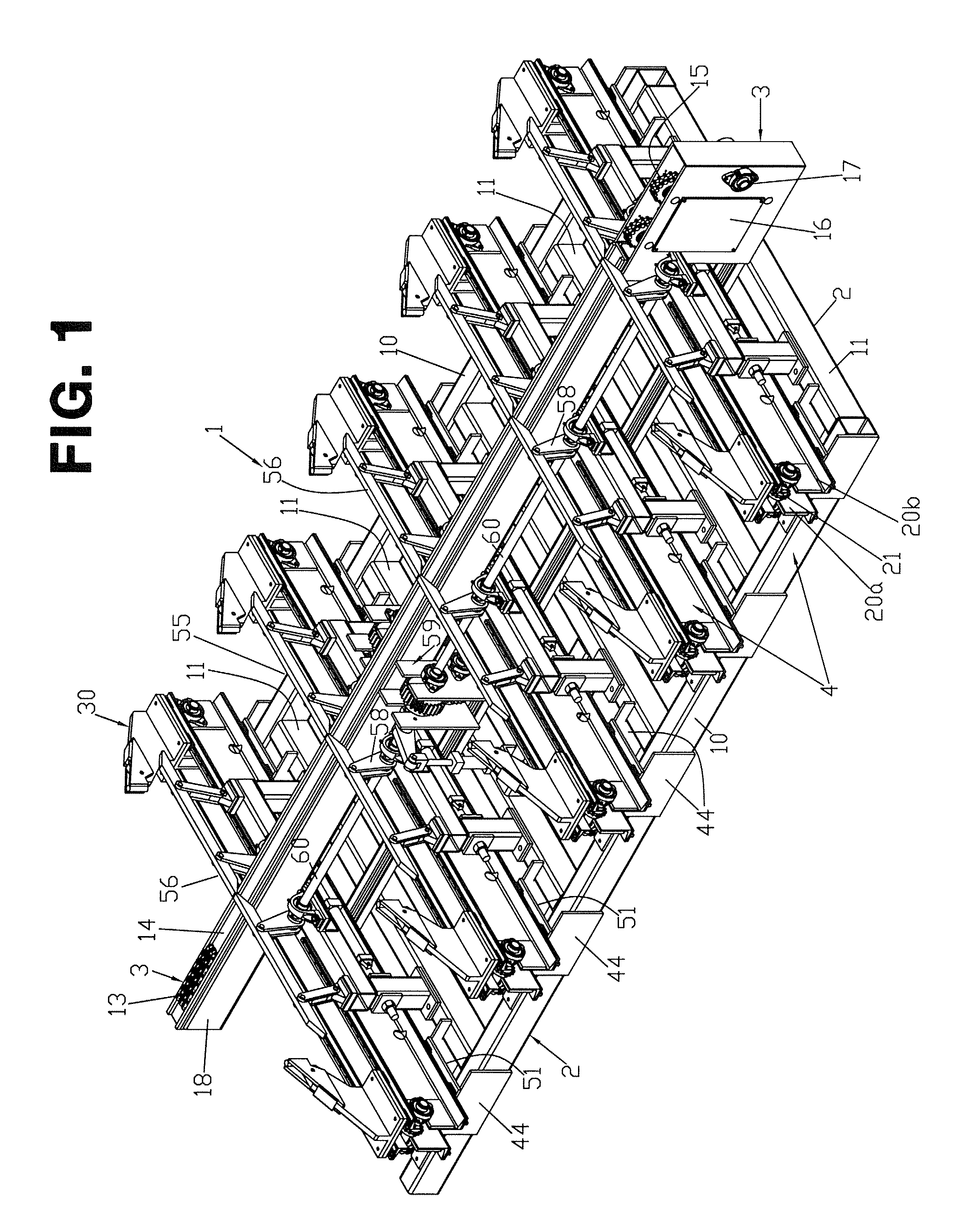

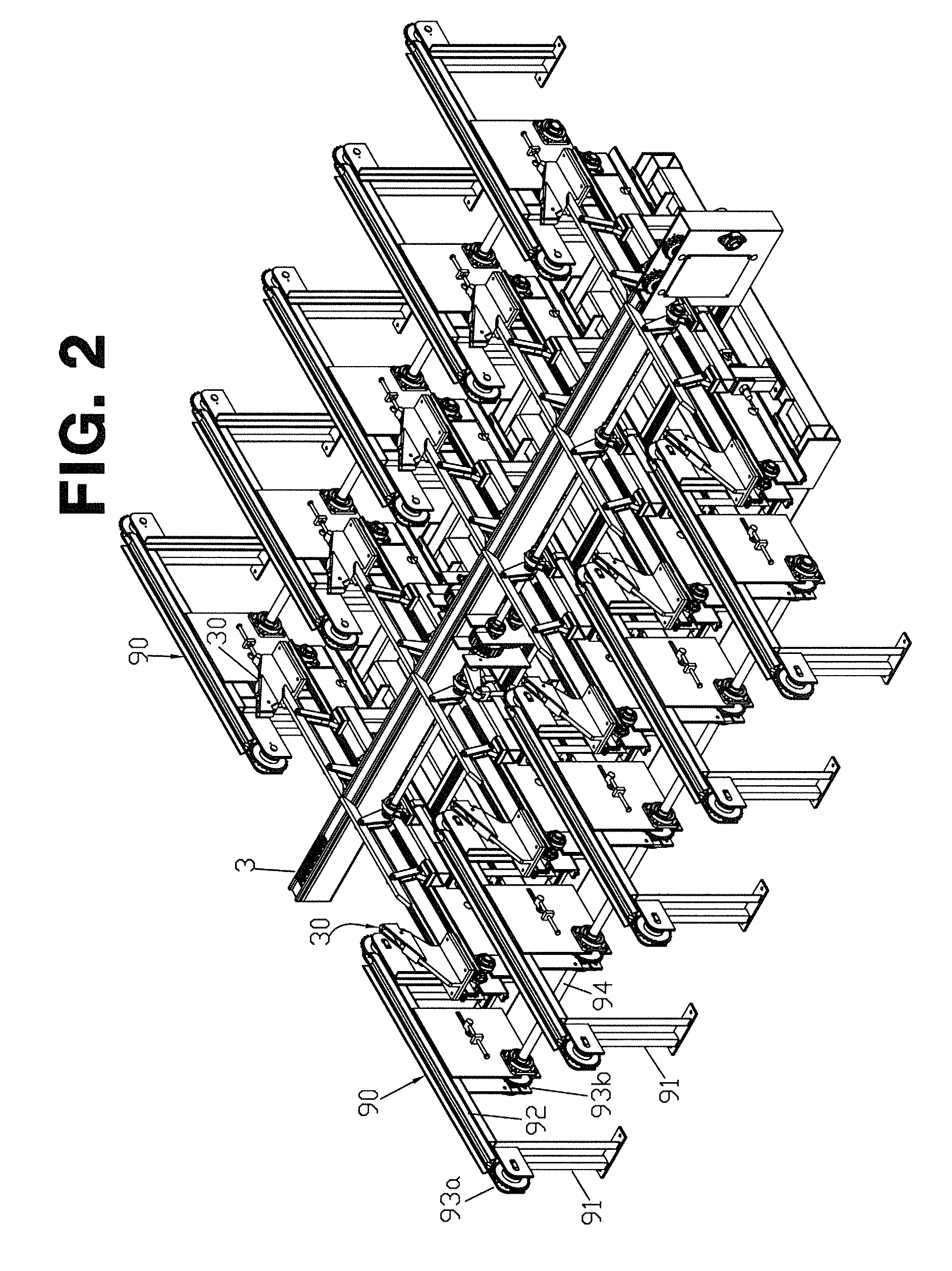

Automated board processing apparatus

InactiveUS20050120840A1Accurate and reliable operationEasy to controlAutomatic control devicesMetal sawing accessoriesOrder formIndustrial engineering

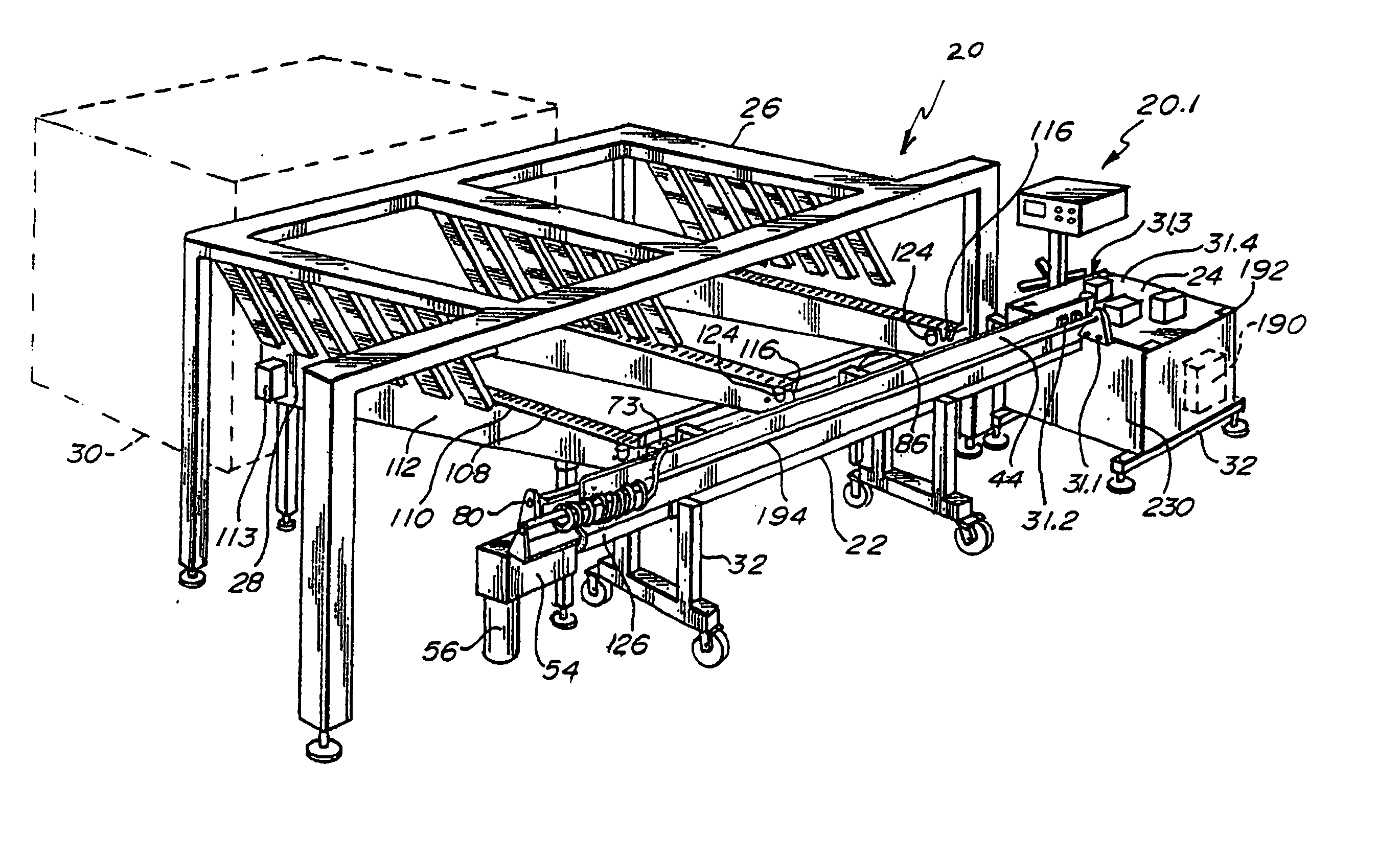

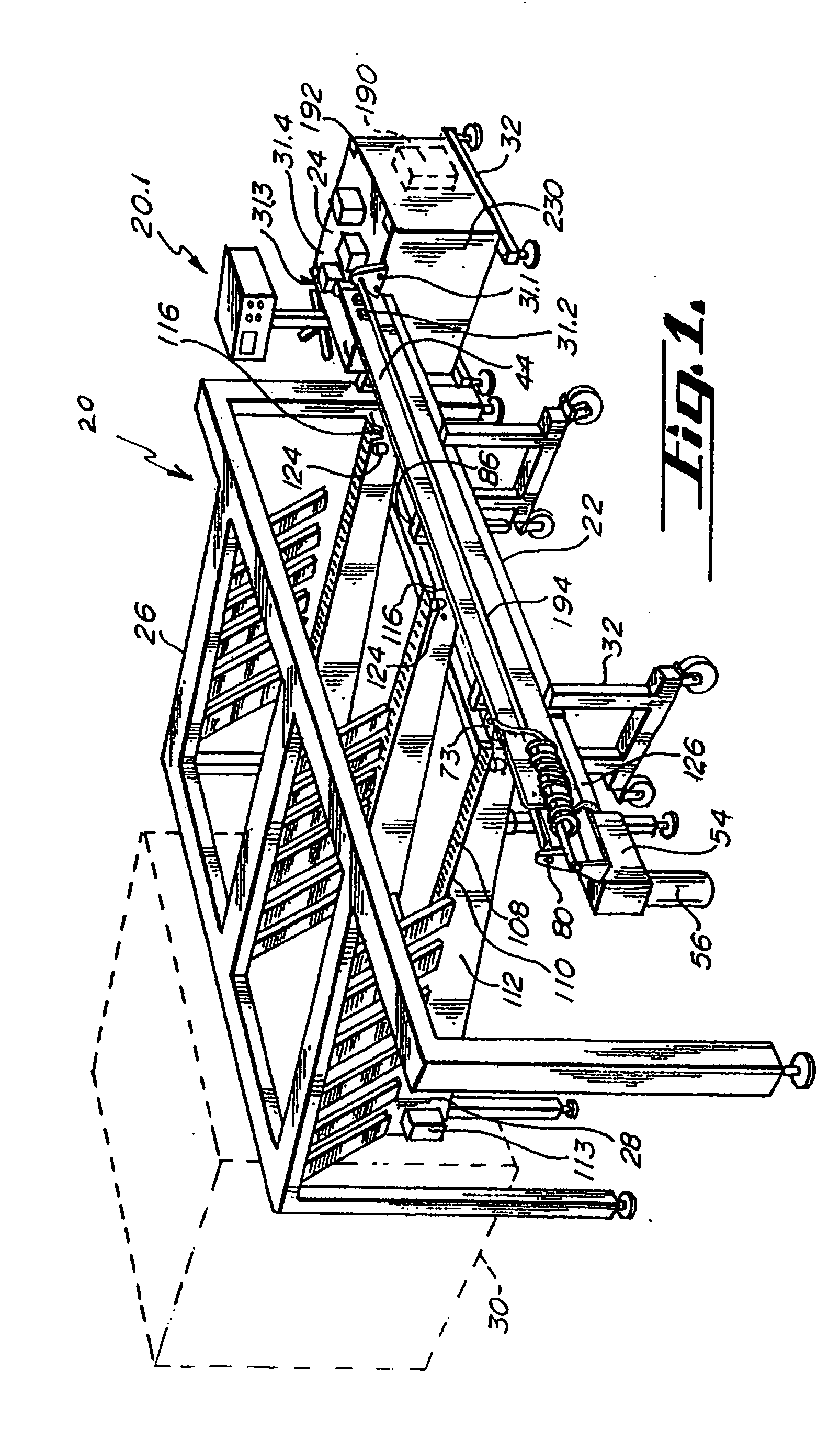

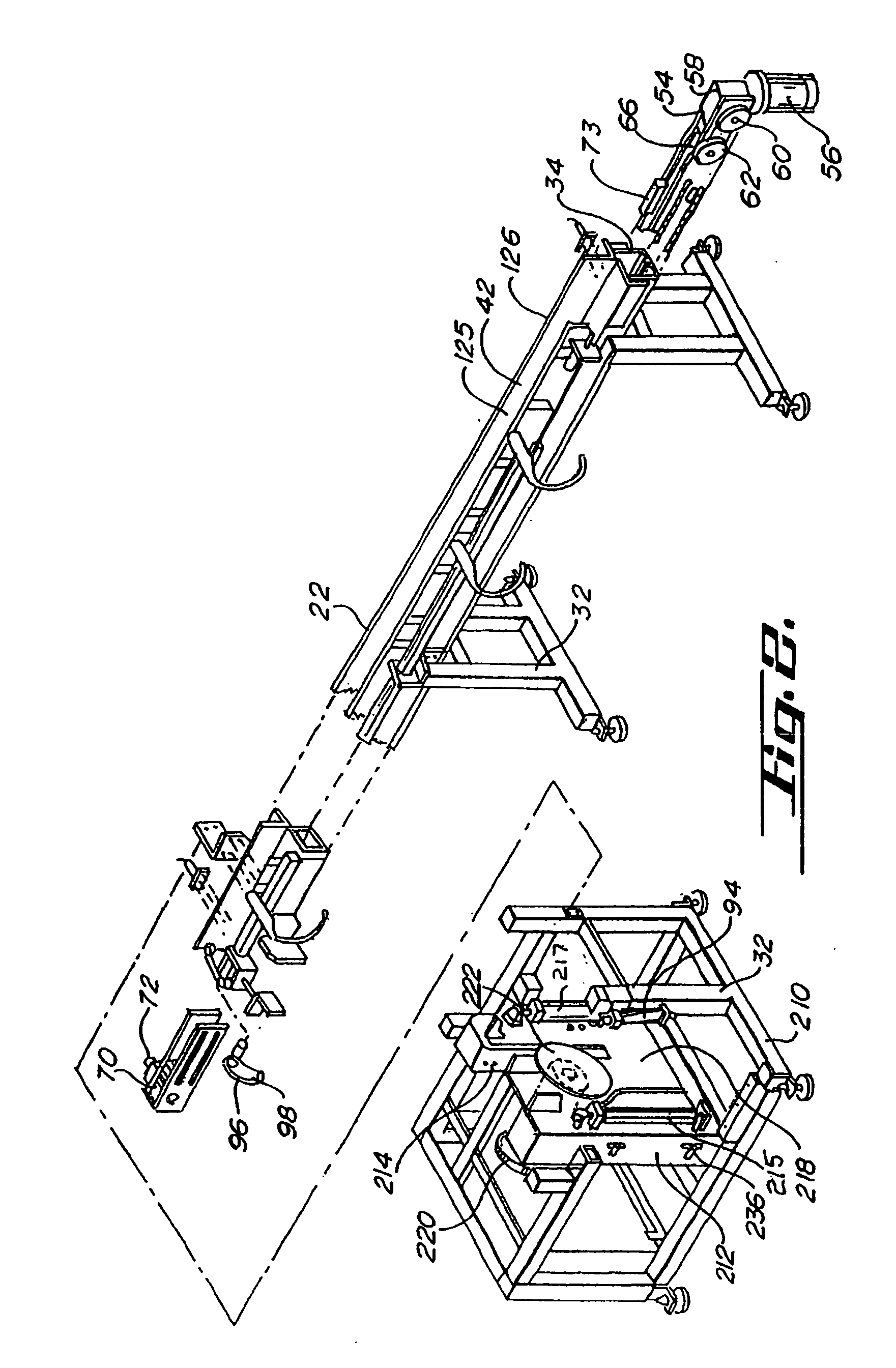

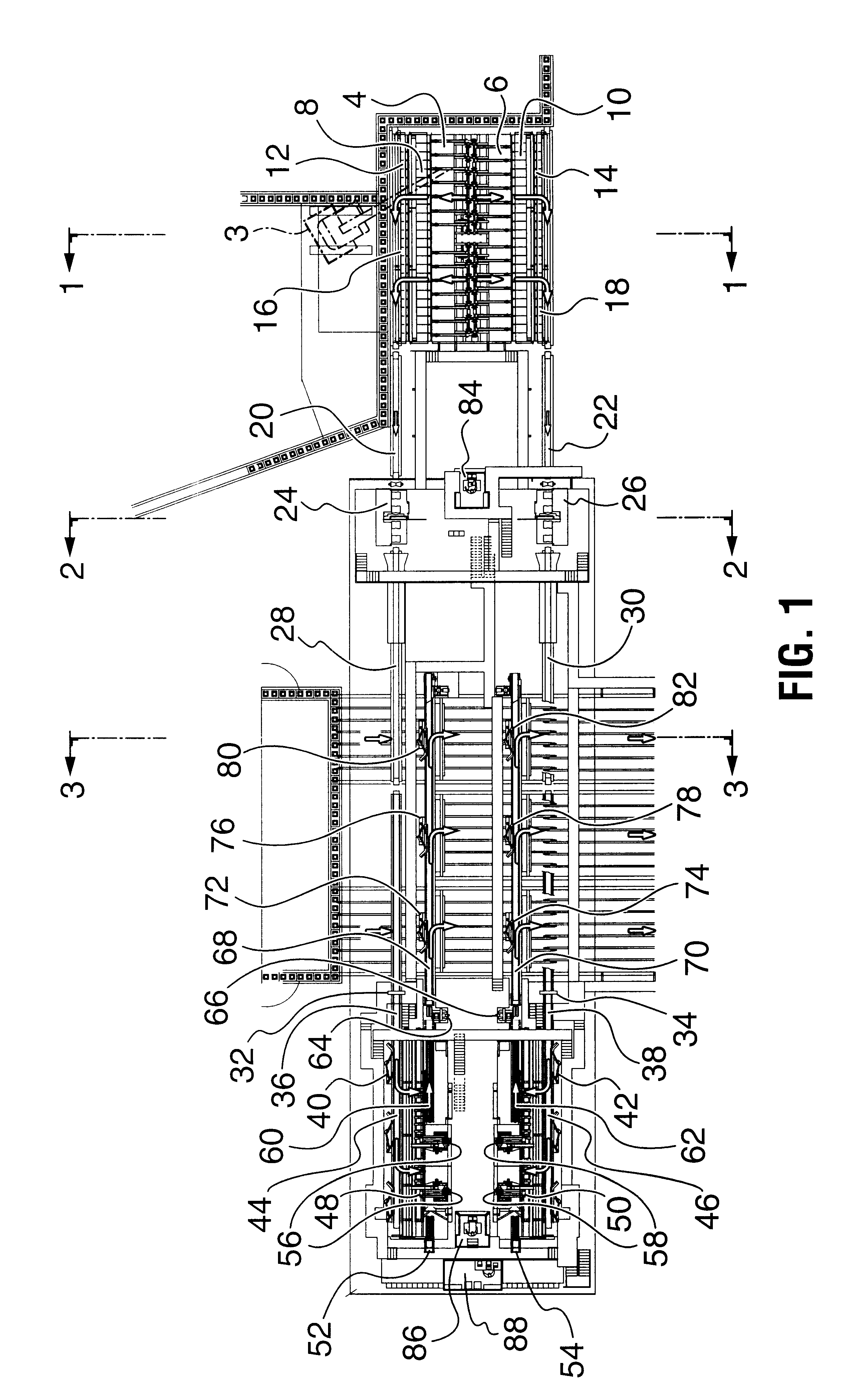

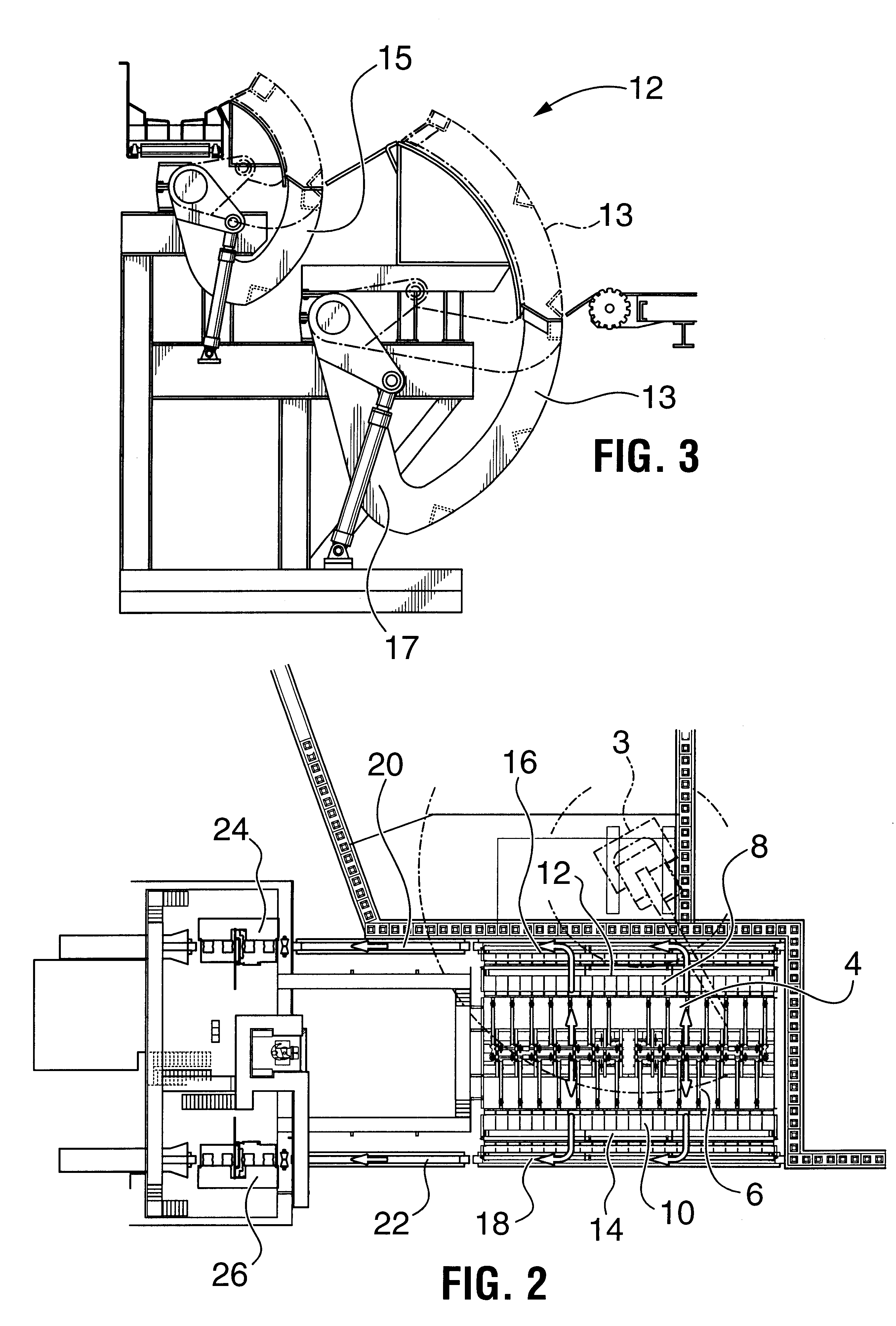

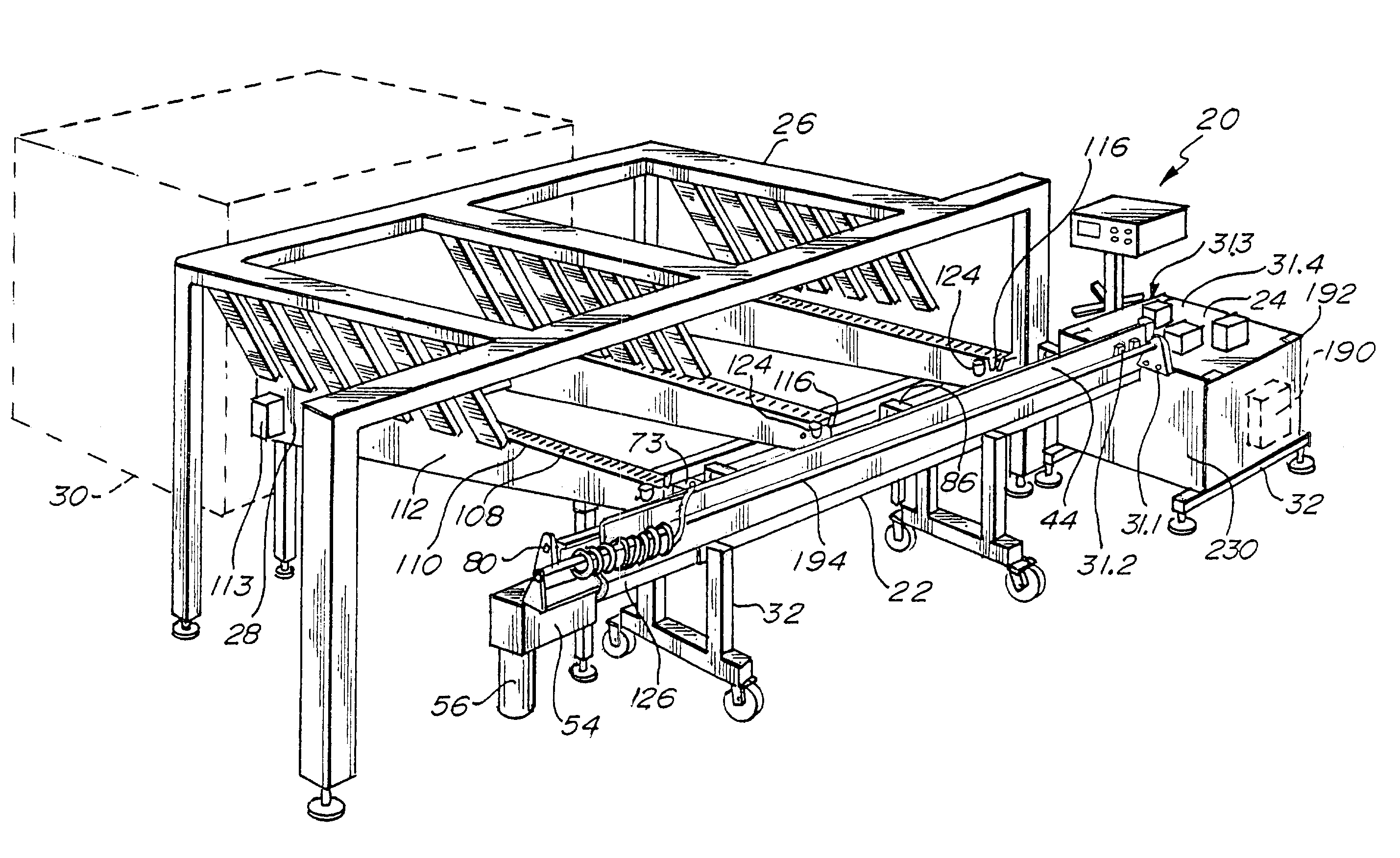

An automated board processing system and the corresponding processes that receives job orders comprising a needed set of specifically sized boards cut to specified lengths for assembly into components such as wall structures, roof trusses or other trusses. The system and processes expediently processes a series of boards from board feeding portion comprising individually selected magazines or other board sources to convey, measure, mark and / or saw same with optimal mechanical simplicity and efficiency thereby completing the job order. A control processor receives the job order and controls operation of the plurality of magazines or other board sources, the conveying, the measuring, the marking, the sawing, and the replenishment of the board sources in the board feeding portion.

Owner:MITEK HLDG INC

Timber selecting and chopping method and selection chopping saw therefor

InactiveCN1827319AIncrease productivityImprove operating rateLoading equipmentAdjusting equipmentComputer science

The invention discloses a timber optimized truncate method and relative optimized truncate saw. First, inputting the saw data list which comprises target saw length and quality parameters into the computer; when the sawed timber that longitudinally supplied passes the position relative to the detecting device, the detecting device reads the information of sawed timber into the computer, and the computer according to the input saw data list and said information to select the optimized sawing method; the saw machine according to said method processes truncating on the timber. Two sides of said truncate machine individually have a feeding platform and a finished product classifying platform; wherein, said feeding platform has a detecting device; said finished product classifying platform has a finished product classifying device; and a waste removing device is arranged between them.

Owner:JIANGSU JIANGJIA MACHINERY

Method and apparatus for singulating, debarking, scanning and automatically sawing and sorting logs into lengths

InactiveUS6539993B1Reduce stepsMinimize travelMulti-purpose machinesAdjusting equipmentComputer hardwareAlgorithm

Owner:WEYERHAEUSER CO

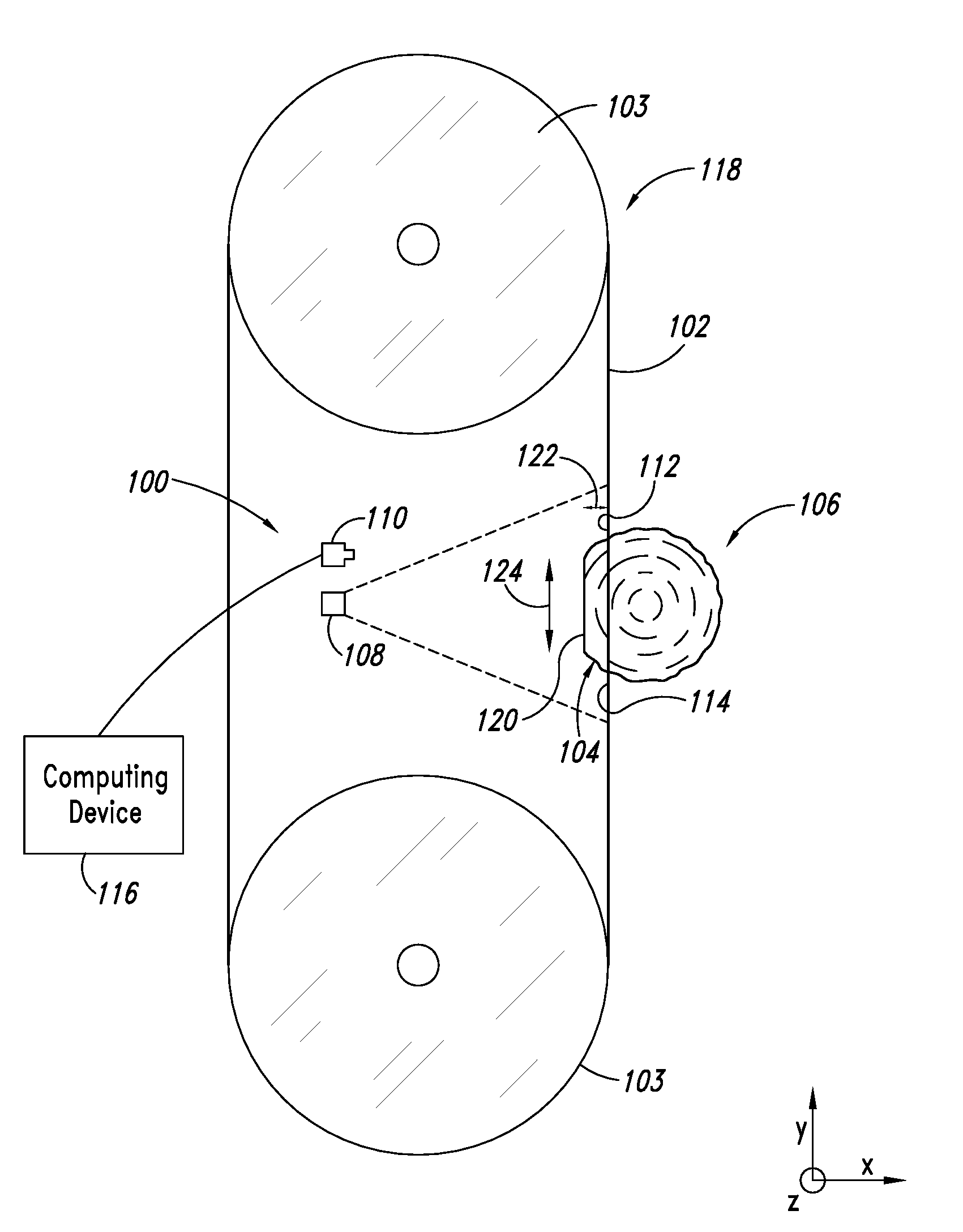

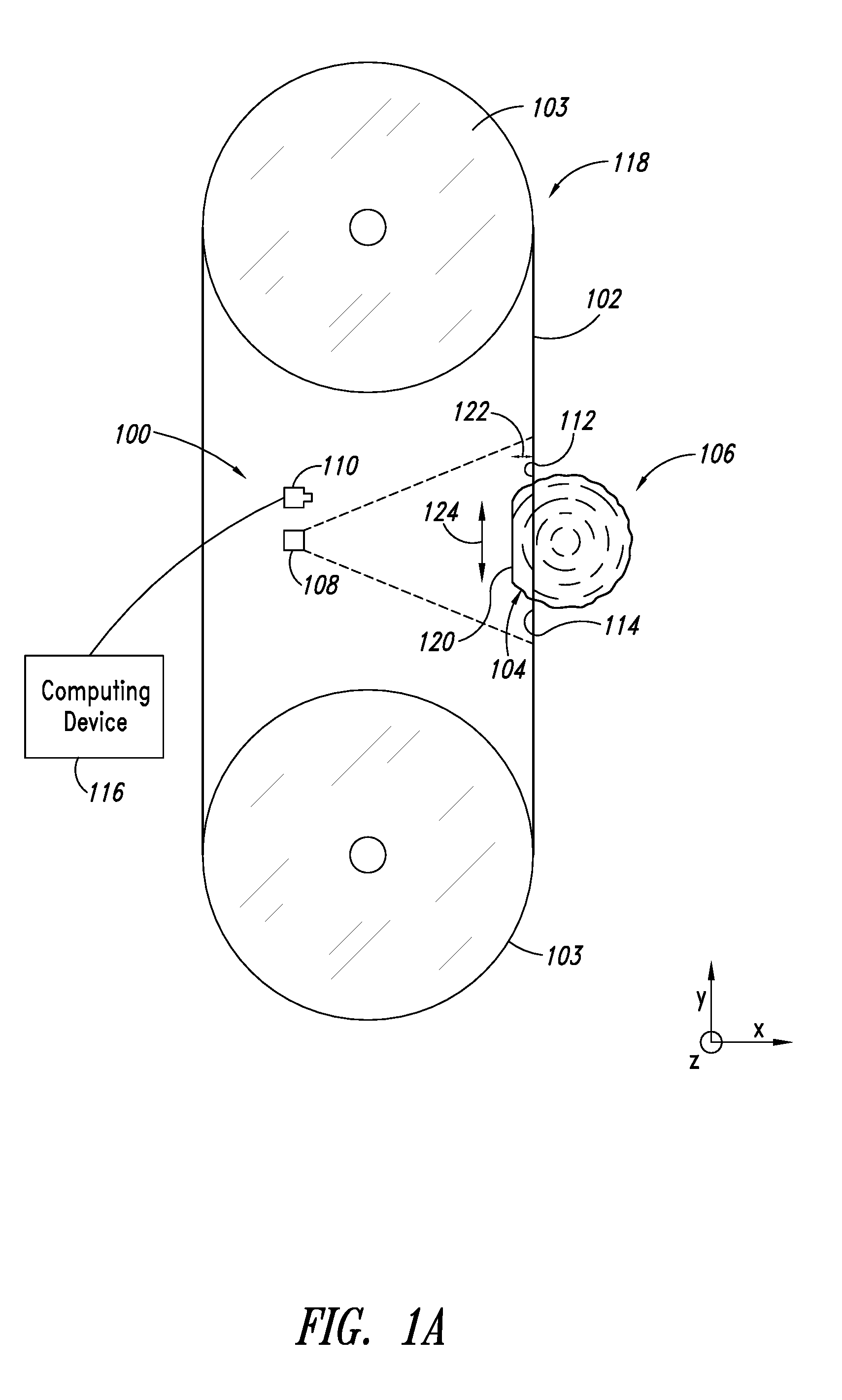

Systems and methods for monitoring a saw blade during sawing

ActiveUS20090095378A1Improve abilitiesProgramme controlAutomatic control devicesSingle imageMechanical engineering

A light source is used to illuminate a sawn portion of a piece of wood and exposed surfaces of the saw blade on both sides of the sawn portion. The sawn portion and the exposed surfaces of the saw blade are then imaged substantially concurrently using a single image generator. At least one geometric characteristic of the sawn portion and at least one geometric characteristic of the saw blade are determined based on the imaging.

Owner:WEYERHAEUSER NR CO

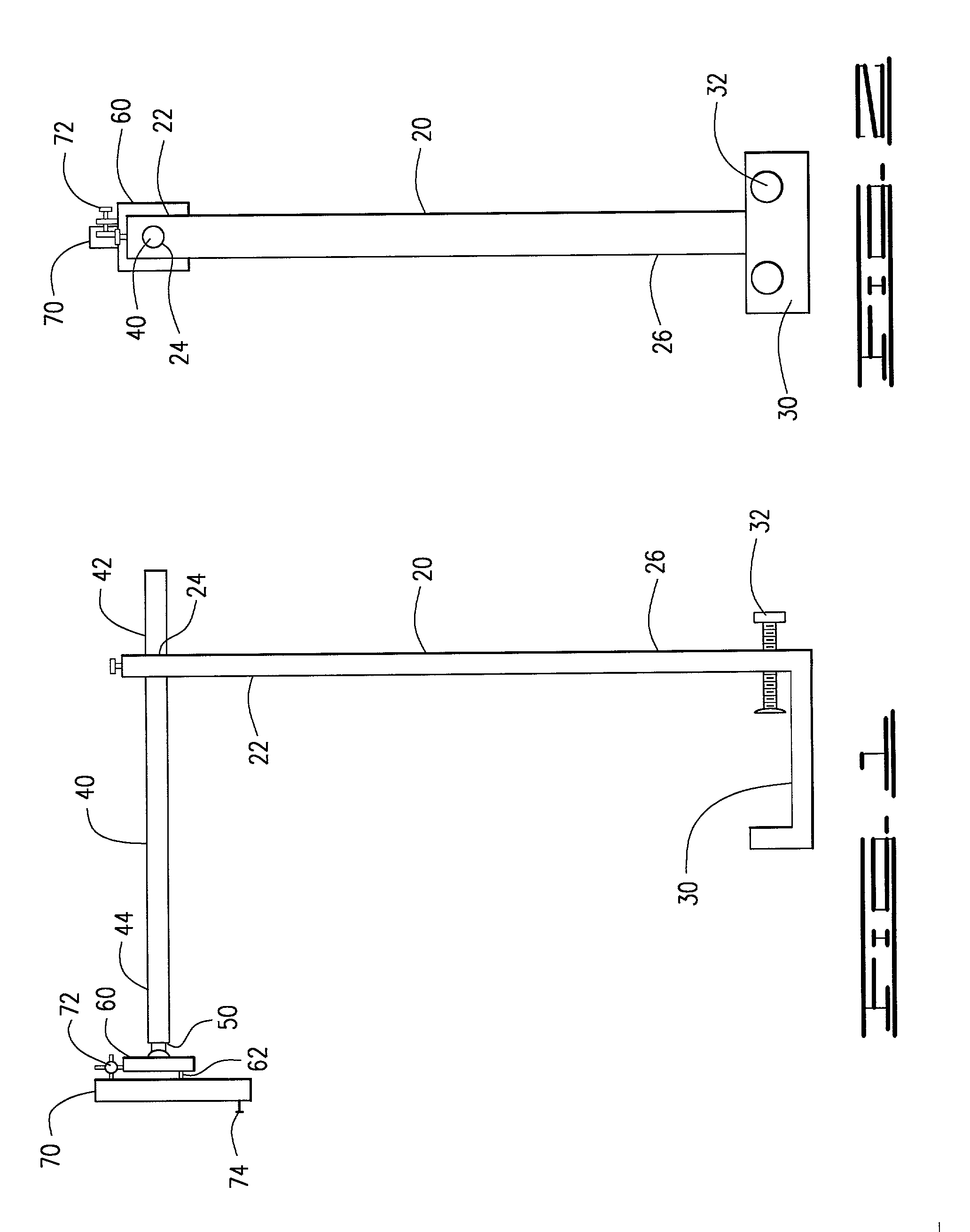

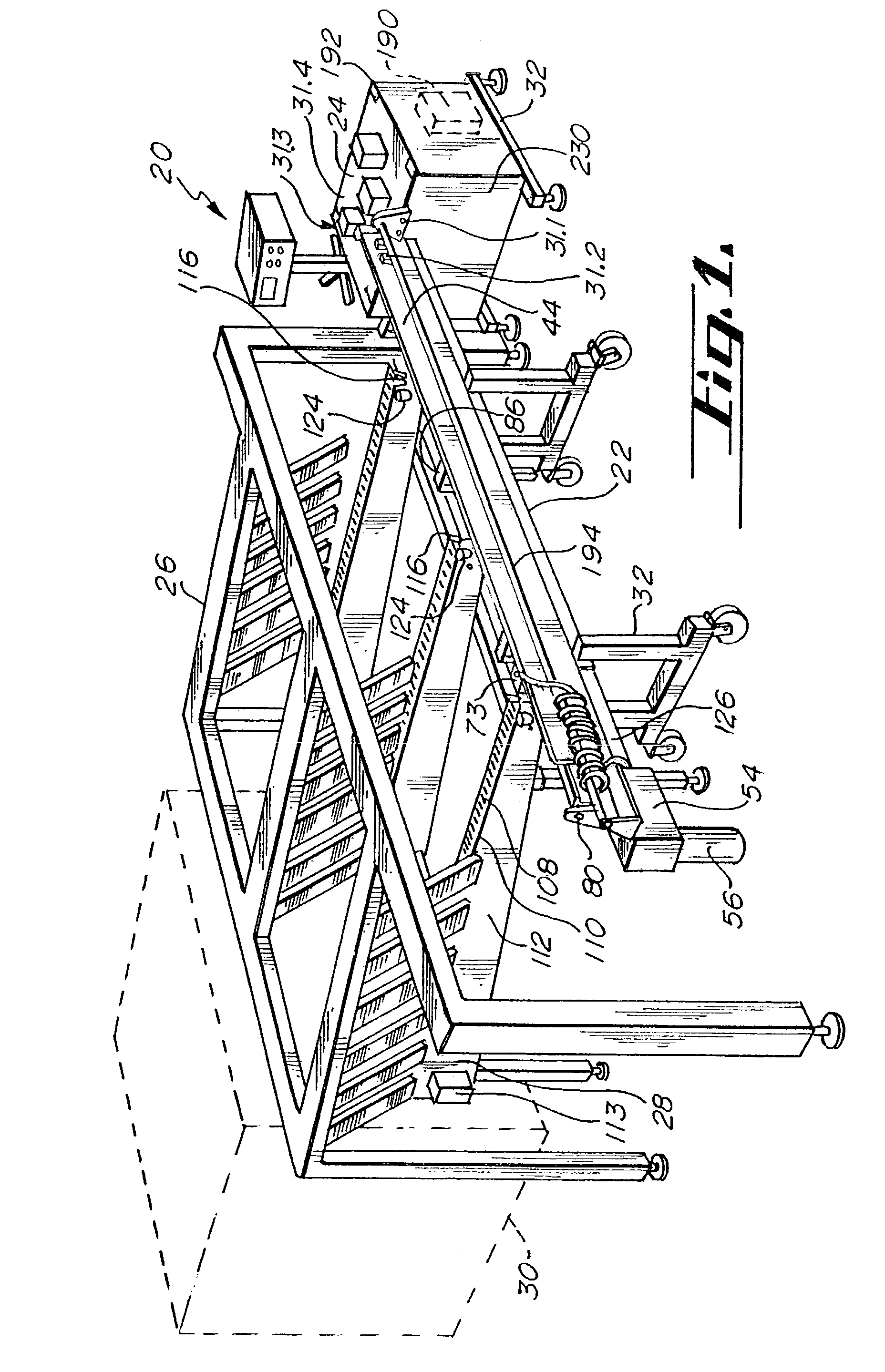

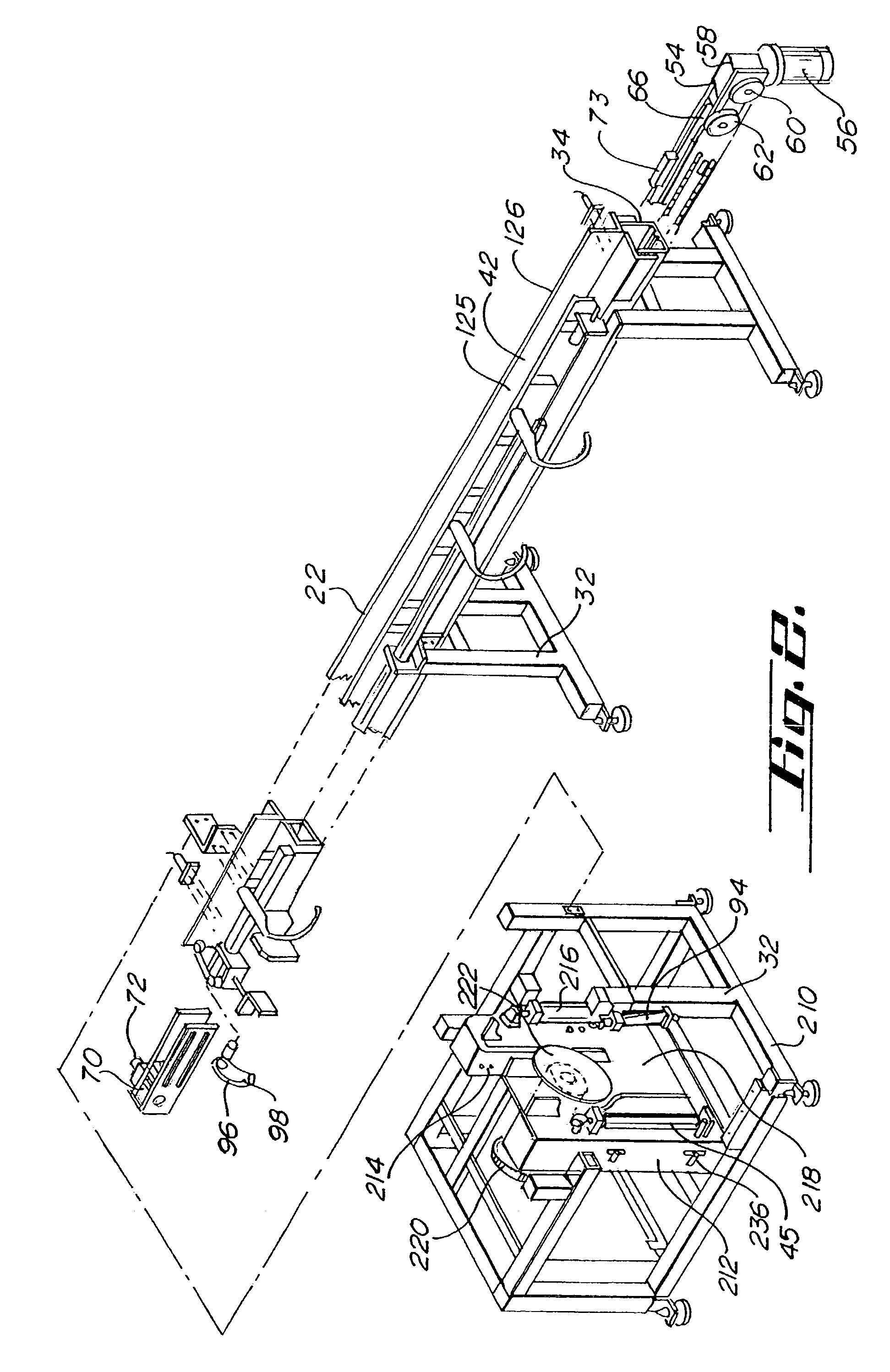

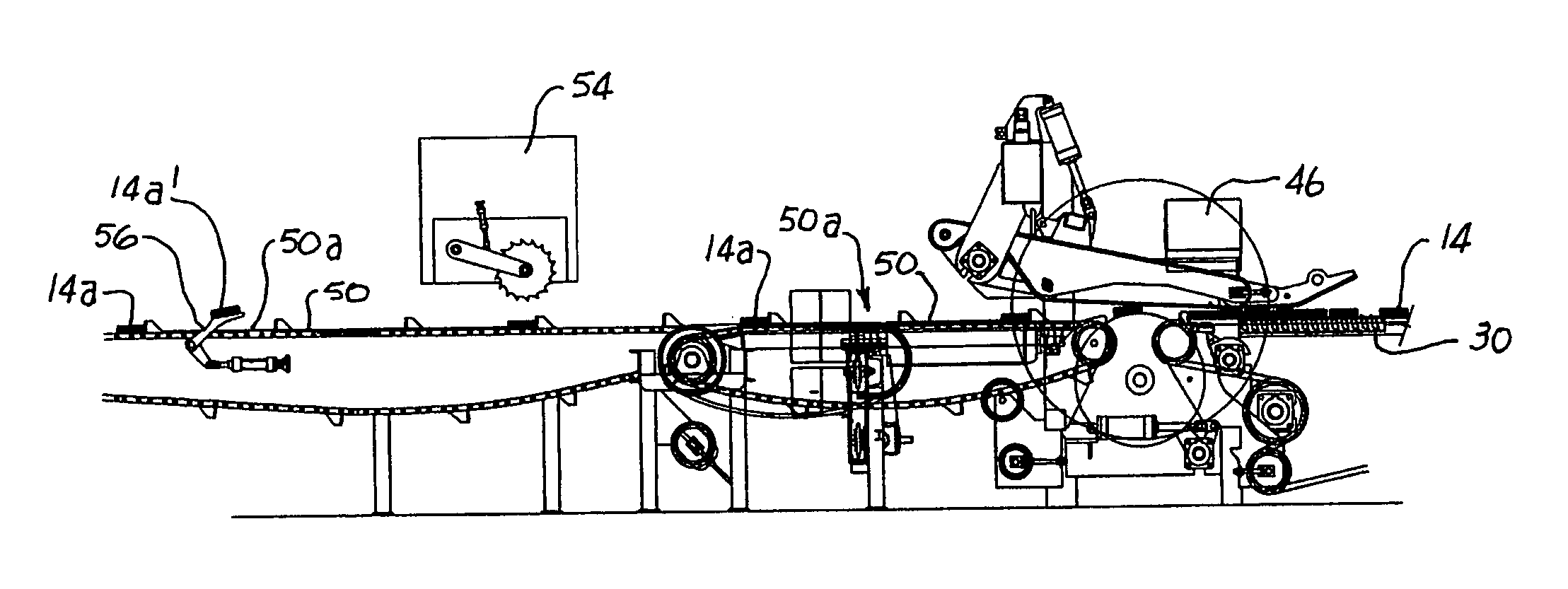

Saw infeed system

InactiveUS20070039664A1Ergonomically effectiveReduce labor costsAutomatic control devicesPrecision positioning equipmentEngineeringMechanical engineering

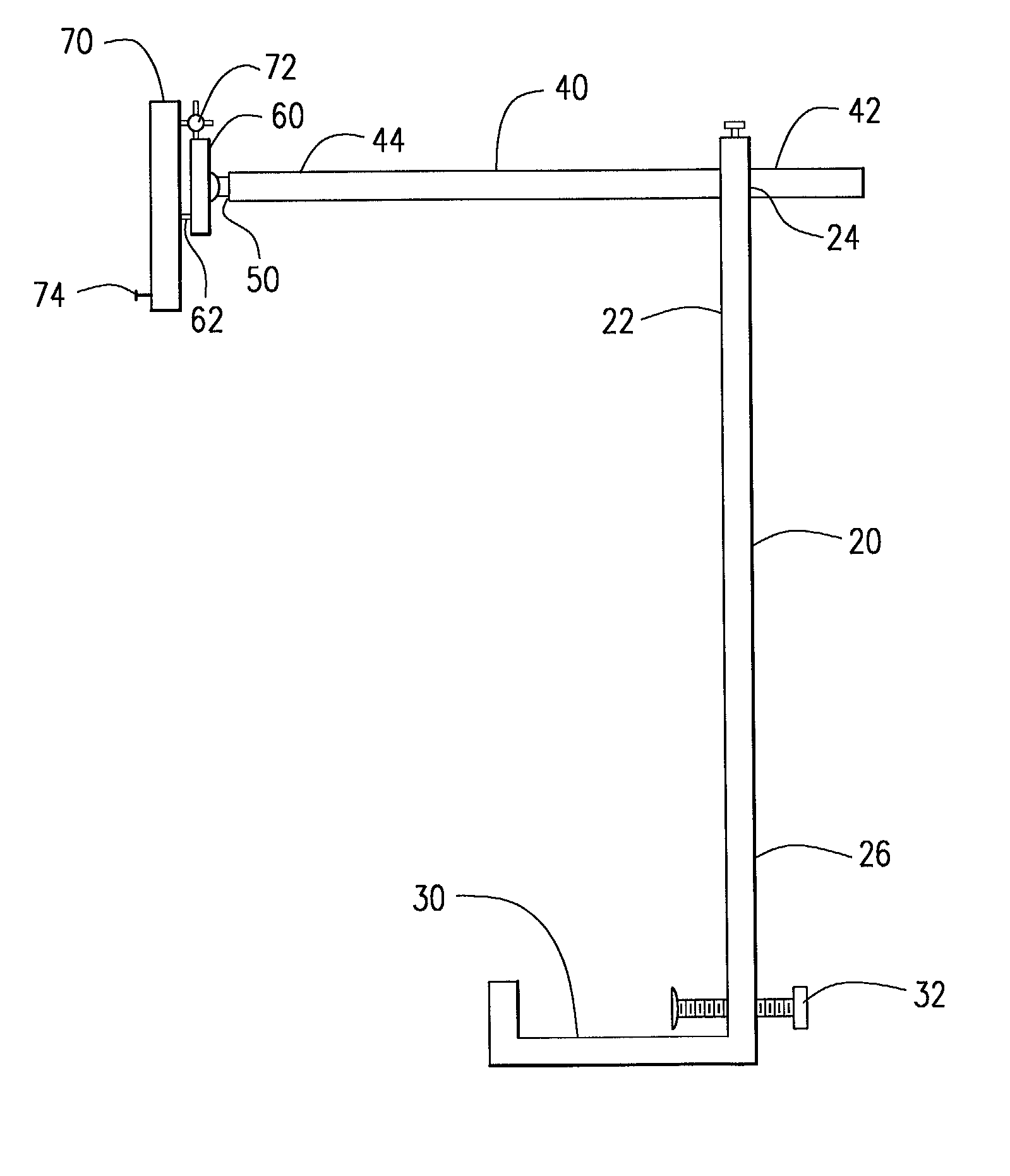

An apparatus and method for a single operator to load and control the automatic infeeding of workpieces to a saw including the loading of a first workpiece from a nearby supply and placing it onto a moveable structure that that is raised to form a ramp and lowered to release the workpiece. The workpiece moves down the ramp and stops against a stop member located on the top surface of the moveable structure positioned above a first conveyor. The operator controls the lowering of the ramp structure thereupon releasing the workpiece to the first conveyor moving the workpiece transversely past a scanner, which discerns dimensional characteristics of the workpiece. A second conveyor feeds the workpiece into the saw.

Owner:JAMES L TAYLOR MFG

Systems and methods for tracking lumber in a sawmill

ActiveUS20090255607A1Fast and immediate feedbackAutomatic control devicesWood splittingStructural engineeringMechanical engineering

Owner:WEYERHAEUSER NR CO

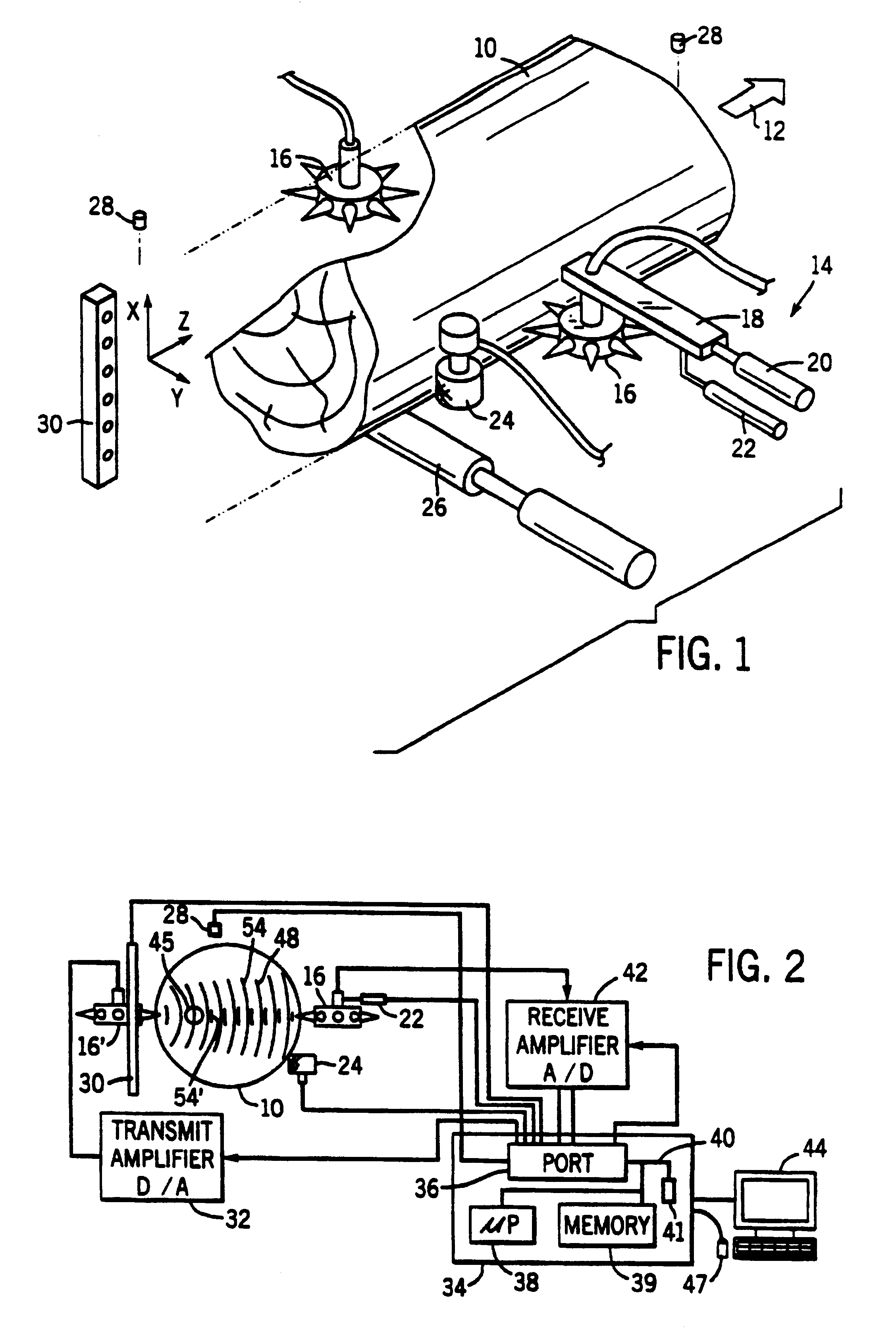

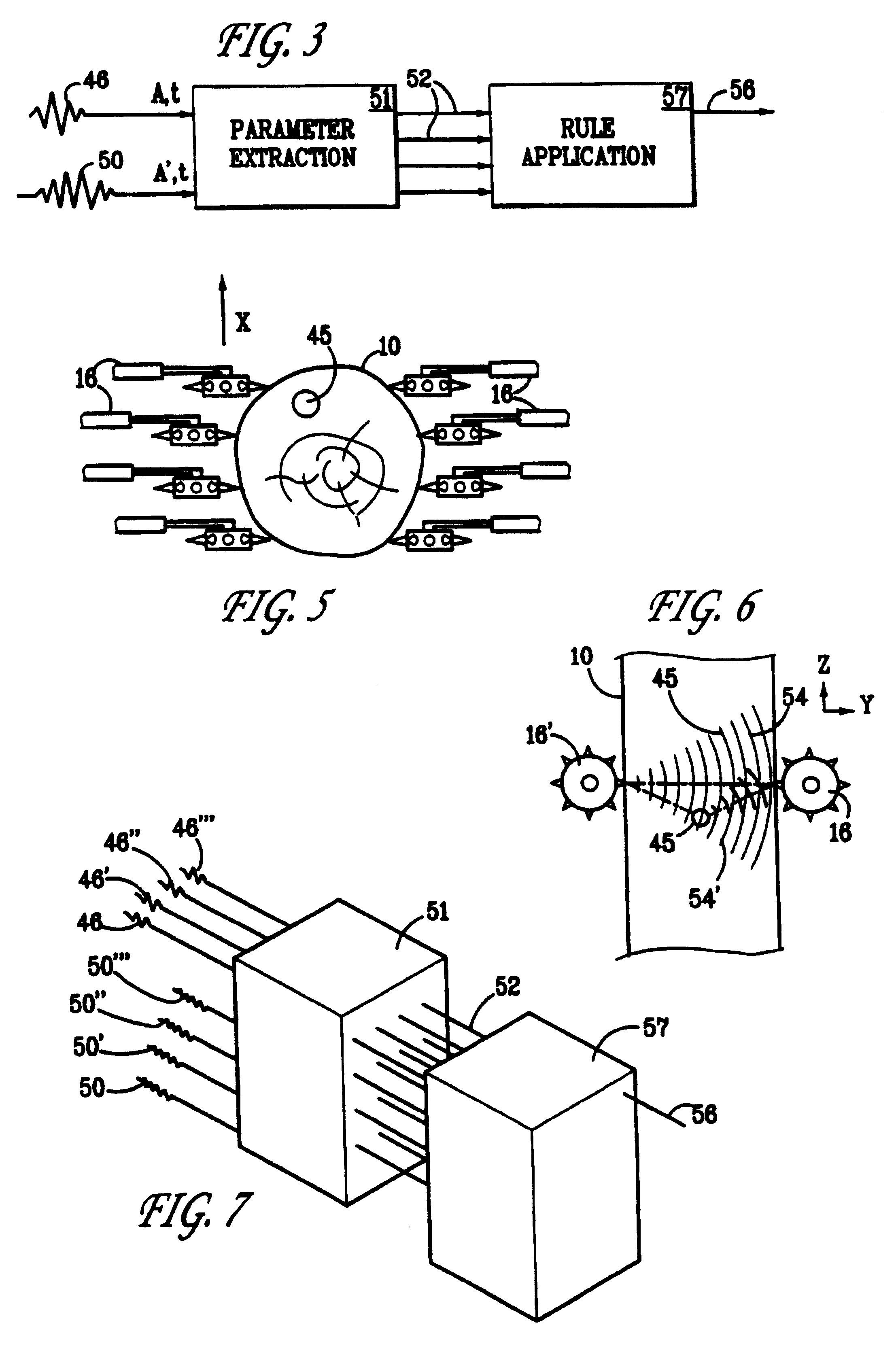

Method and apparatus for on-line monitoring of log sawing

InactiveUS6295907B1Simple and inexpensivePermit in selectingAutomatic control devicesMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineering

Ultrasonic techniques are applied to the measurement of wooden members to detect splitting during sawing operations and thereby allow modification of sawing technique or change in saw cut placement.

Owner:UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF AGRI THE +1

Systems and methods for tracking lumber in a sawmill

ActiveUS20090095377A1Fast and immediate feedbackAutomatic control devicesWood splittingStructural engineeringMechanical engineering

Owner:WEYERHAEUSER NR CO

Process for cutting out panels or the like

InactiveUS20010047702A1Quality improvementAutomatic control devicesLamination ancillary operationsWood fibreEngineering

A wood fiber board (6) which is provided with a decorative layer (3) of paper or similar material, and where the length or width value of the decorative layer (3) deviates from its original value after it is applied to the wood fiber board (6), is cut into uniform panels using a board-dividing apparatus that compensates for these deviations. The board-dividing apparatus has a saw (1) that preferably has a plurality of saw blades (S1, S2, . . . Sn) which are adjustably spaced in parallel fashion. The board-dividing apparatus is equipped with a number of cameras and with controller which utilizes deviation measurement information to adjust the spacing of the saw blades. The wood fiber board (6) is first aligned with at least one initial camera (4a) at a point P1. Then, predetermined points (P1 and P2) in the decorative layer (3) are recorded by the first camera (4a) and a second camera (4b). A distance (L) between the points (P1 and P2) is determined, and thee discrepancy in the width or length value is determined by comparison of the actual position and the desired position of the points (P1 and P2). Then, the value of the determined discrepancy (A) is placed in relation to the number (n) of the saw blades (Sn), and the parallel spacing (a) of the saw blades (Sn) is modified by the value of the ratio of the discrepancy to the number of saw blades (A / n). The orientation of the wood fiber board (6) to the saw (1) is displaced to one side in the amount of one half the determined discrepancy (A), and then the wood fiber board (6) is transported toward the saw (1) for cutting out the panels.

Owner:KRONOTEC

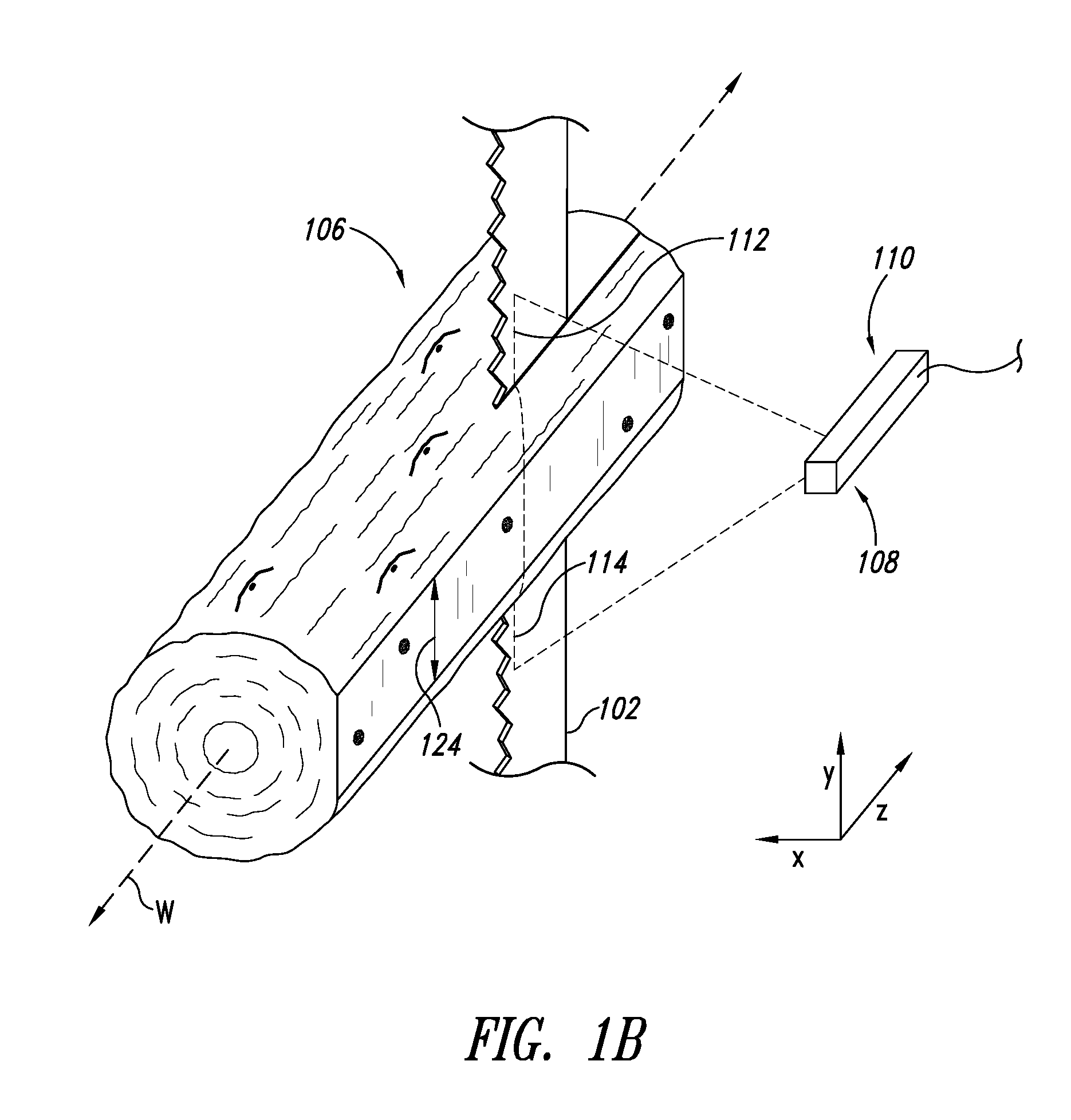

Log home fabrication process and associate log cutting machine

InactiveUS20030041919A1Tongue/grooves making apparatusMulti-purpose machinesComputer scienceComputer control

A log processing machine and associate method employs one or more log guides to make joinery cuts in a processed log which has at opposed edges of the processed log the raw log's natural external contour. In a preferred embodiment of the invention, each log guide includes a straight edge and is attached to the processed log to create an artificial straight edge for guiding the processed log through the joinery machine. Prior to attachment, centerlines are marked on the log guide and the processed log, and the centerlines are aligned when the log guide is attached to the processed log. The processed log, with the log guide attached, is then moved through the machine with the aid of computer control while the straight edge of the log guide follows a fence. In this manner, the position of the processed log and its centerline are always known so that the computer can make the programmed joinery cuts with high precision. An alternate embodiment of the invention employs one or more fence extensions as log guides. The fence extensions are positionable in guide channels formed in the contoured edges of the processed log. A further embodiment of the invention employs an opposed pair of clamping / alignment elements which are controlled by a computer to align and guide the log through the joinery machine.

Owner:HEARTHSTONE

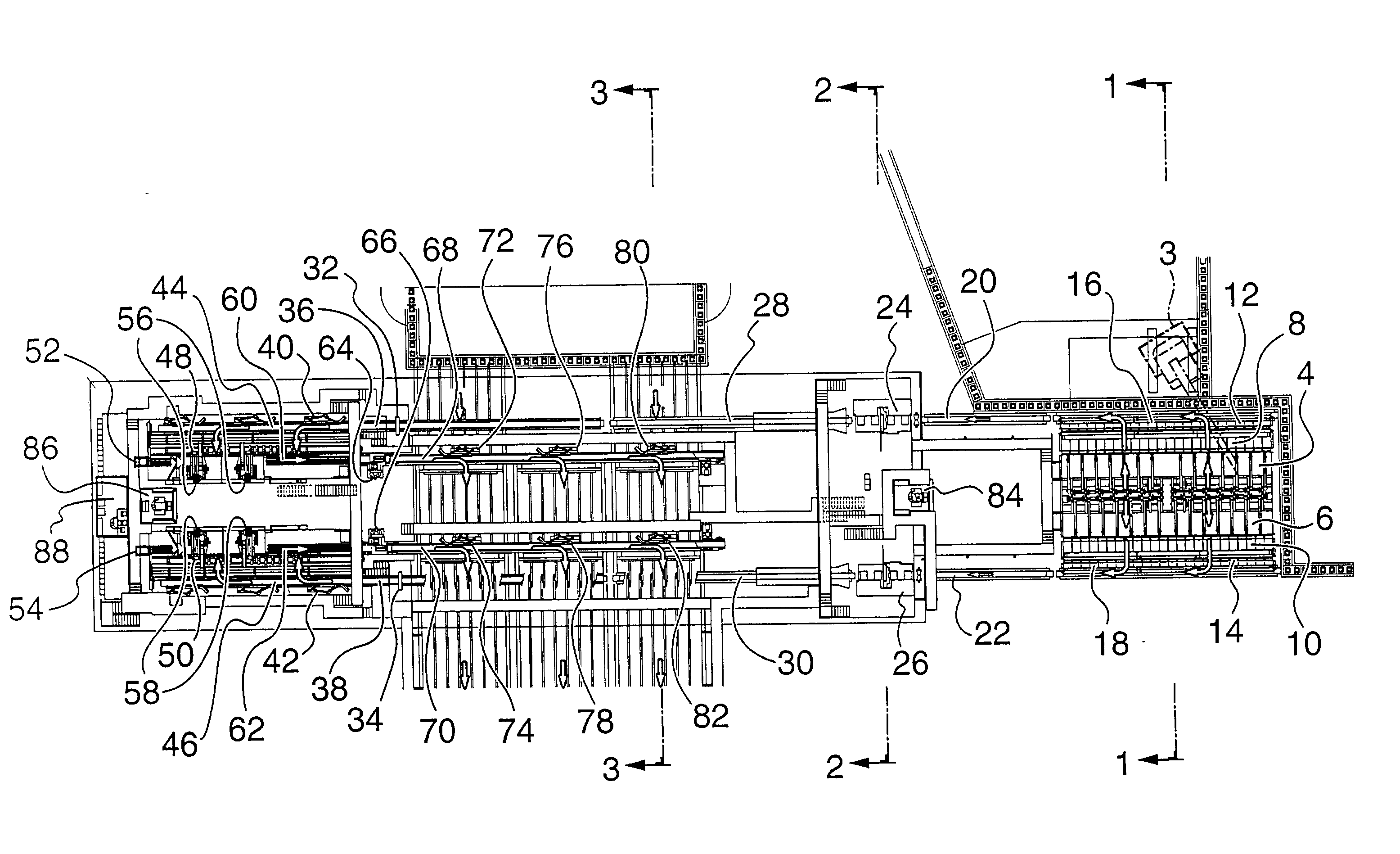

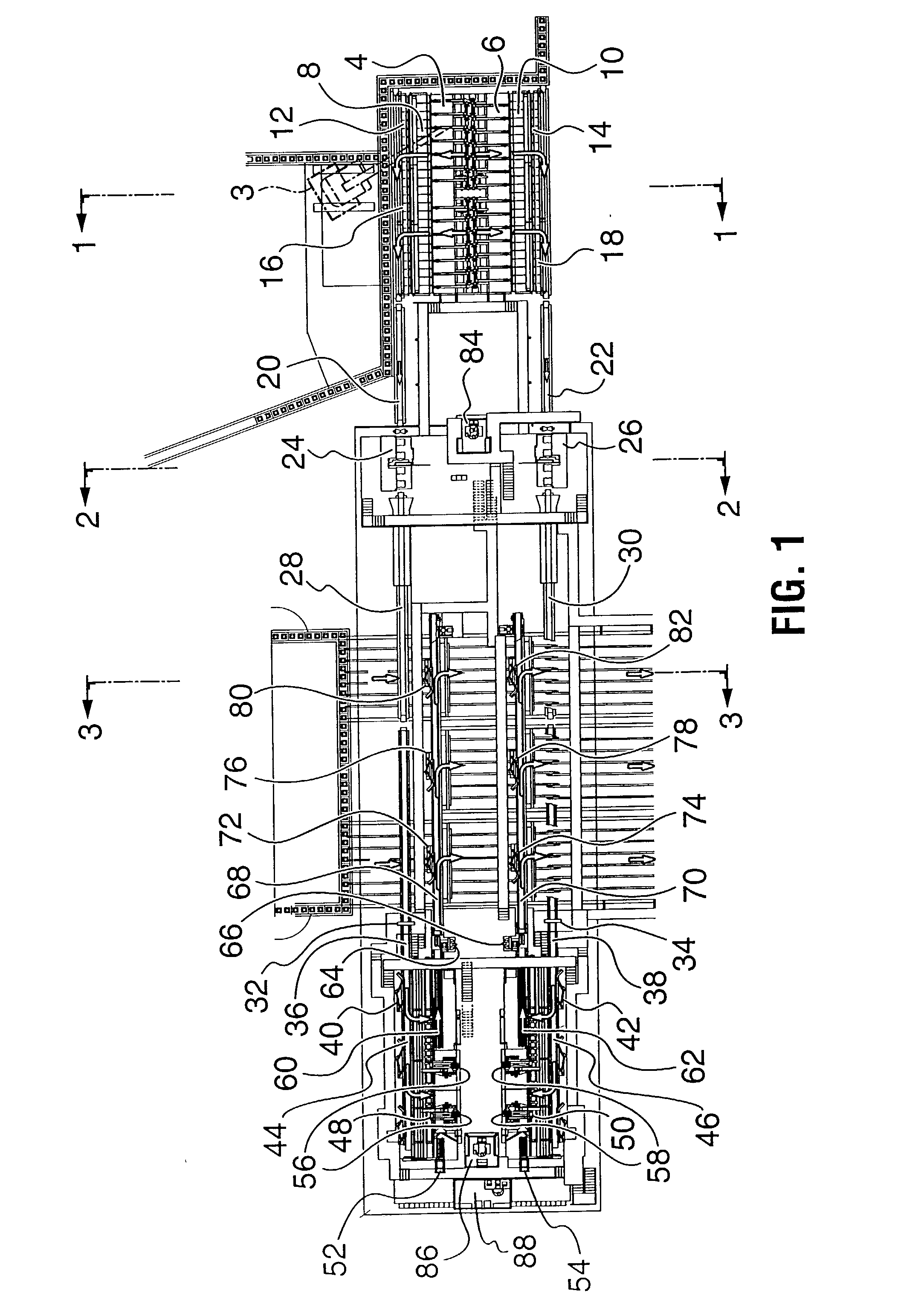

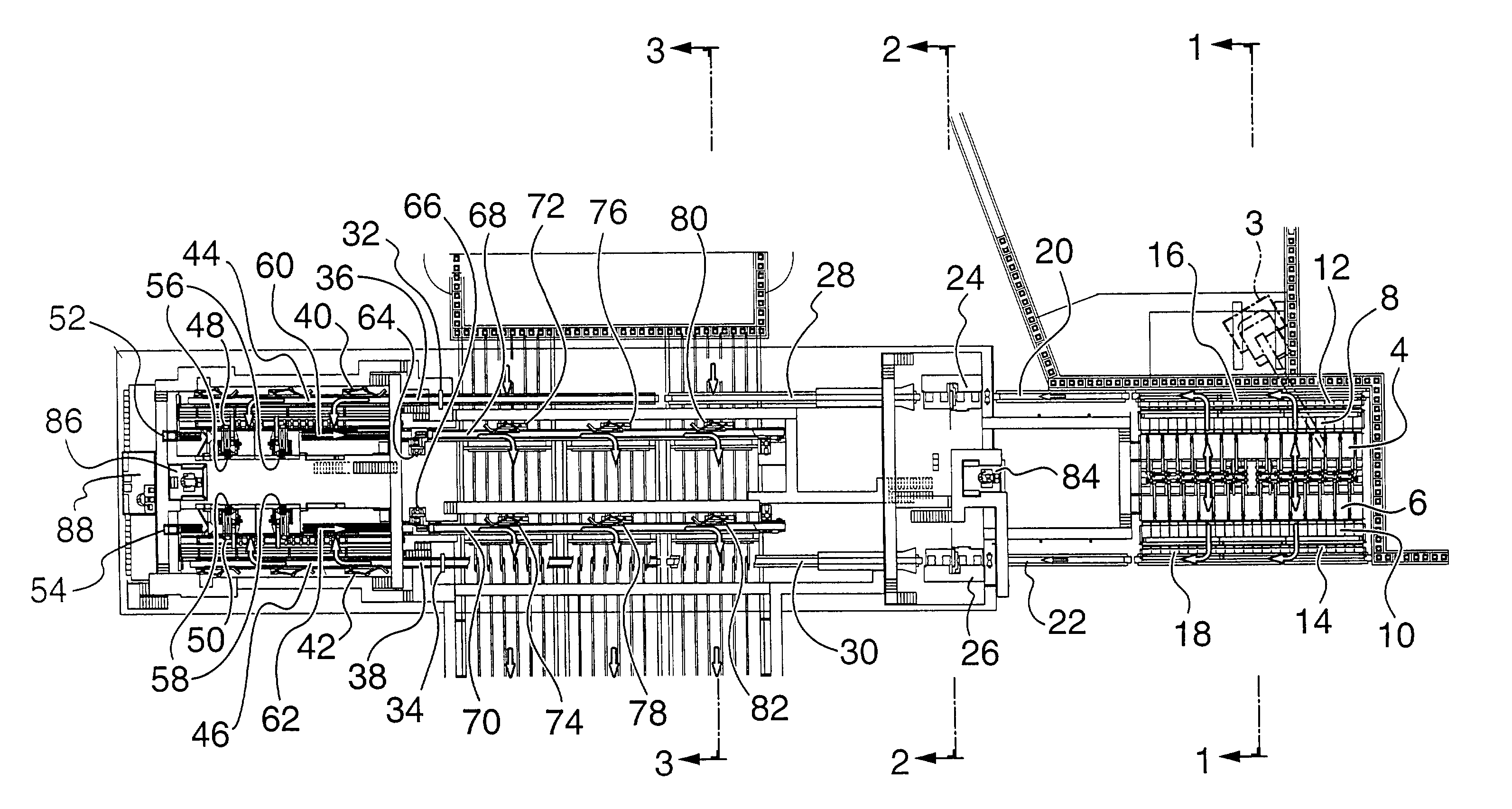

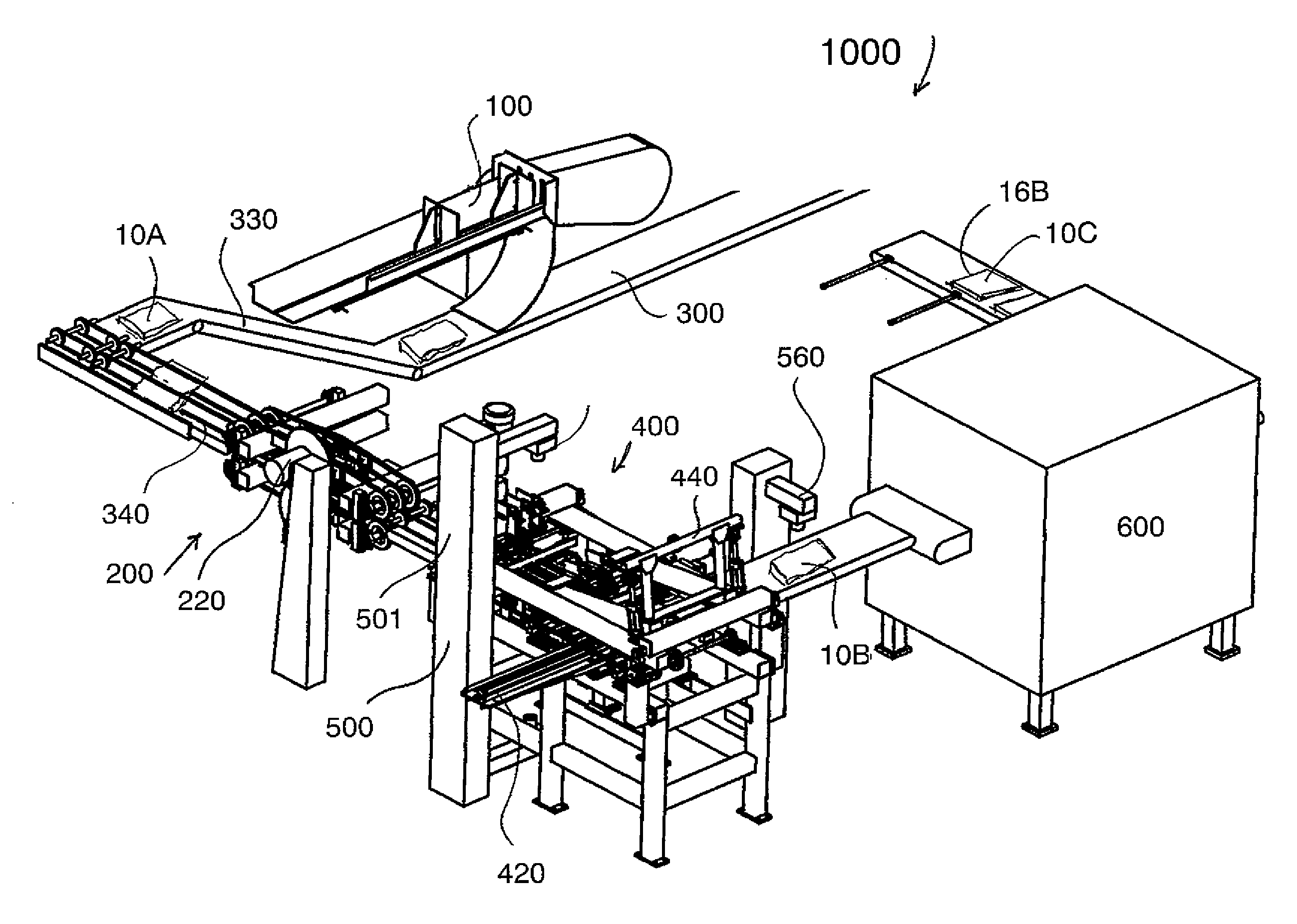

Automated board processing apparatus

InactiveUS7011006B2Accurate and reliable operationEasy to controlDigital data processing detailsShearing machinesEngineeringProcess control

In preferred embodiments the invention includes a transverse board conveyor, a board extrusion portion, a marking station, a sawing portion, and a plurality of board feeding portions, all of which are controlled by a process controller. In such preferred embodiments, a bunk feeder and magazines feed boards serially onto the transverse board conveyor and are conveyed in a direction transverse to the length of the boards. The boards are individually deposited into an elongate receiver of a board extrusion portion to be conveyed longitudinally. A carriage in the receiver transports the boards past an end detection station, past a marking station, and to a sawing station. The marking station prints desired indicia at selected positions on the board such as by an ink jet printer without physical contact of the printing mechanism with the board and while the board is moving.

Owner:MITEK HLDG INC

System for positioning a workpiece

ActiveUS20060048853A1Optimize locationPromote recoveryProgramme controlAutomatic control devicesEngineeringMechanical engineering

A system for positioning a workpiece in an optimized position. In one embodiment a marking device places a mark on the workpiece prior to the workpiece passing through a scanner cooperating with an optimizer. The optimizer determines the optimized position of the workpiece. The orientation of the workpiece is identified by a first camera. The mark may be used as a point of reference such that the workpiece may be positioned in the optimized position by rotating the workpiece relative to the orientation of the mark. A turning mechanism rotates the workpiece to position it in the optimized position. A further camera identifies the orientation of the mark while the workpiece is being rotated. A processor compares in real time the orientation of the workpiece with the optimized position to determine if the workpiece is in the optimized position.

Owner:USNRKOCKUMS CANCAR

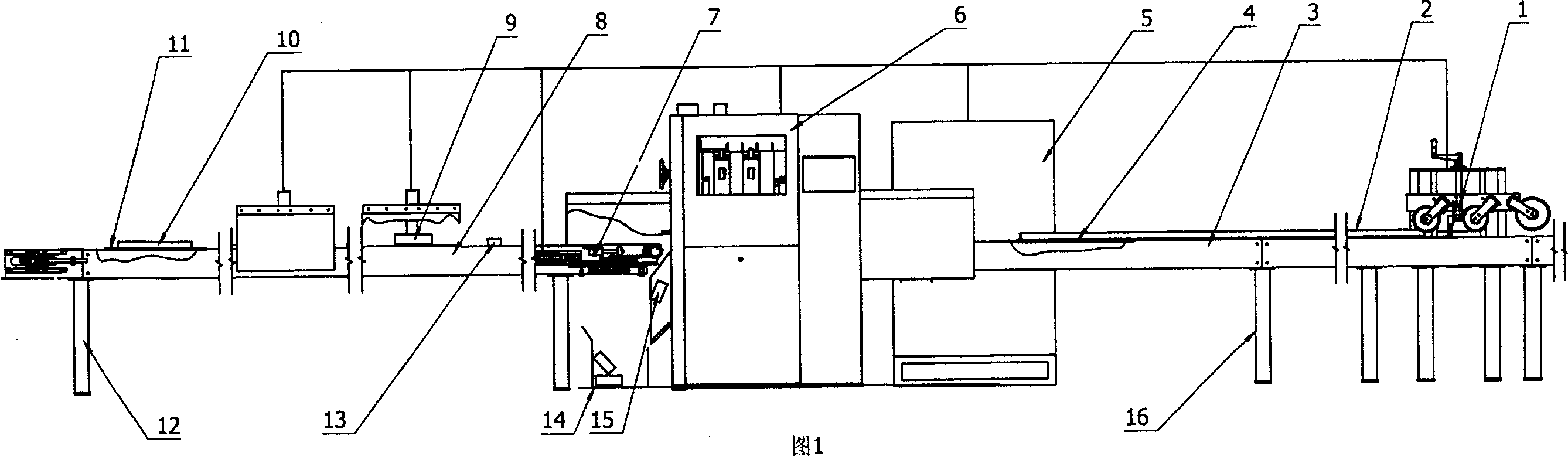

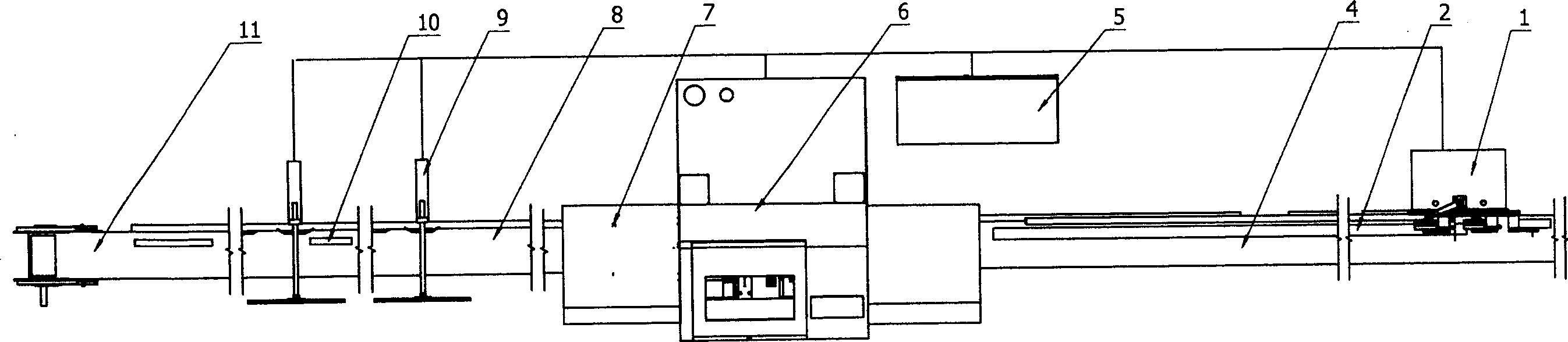

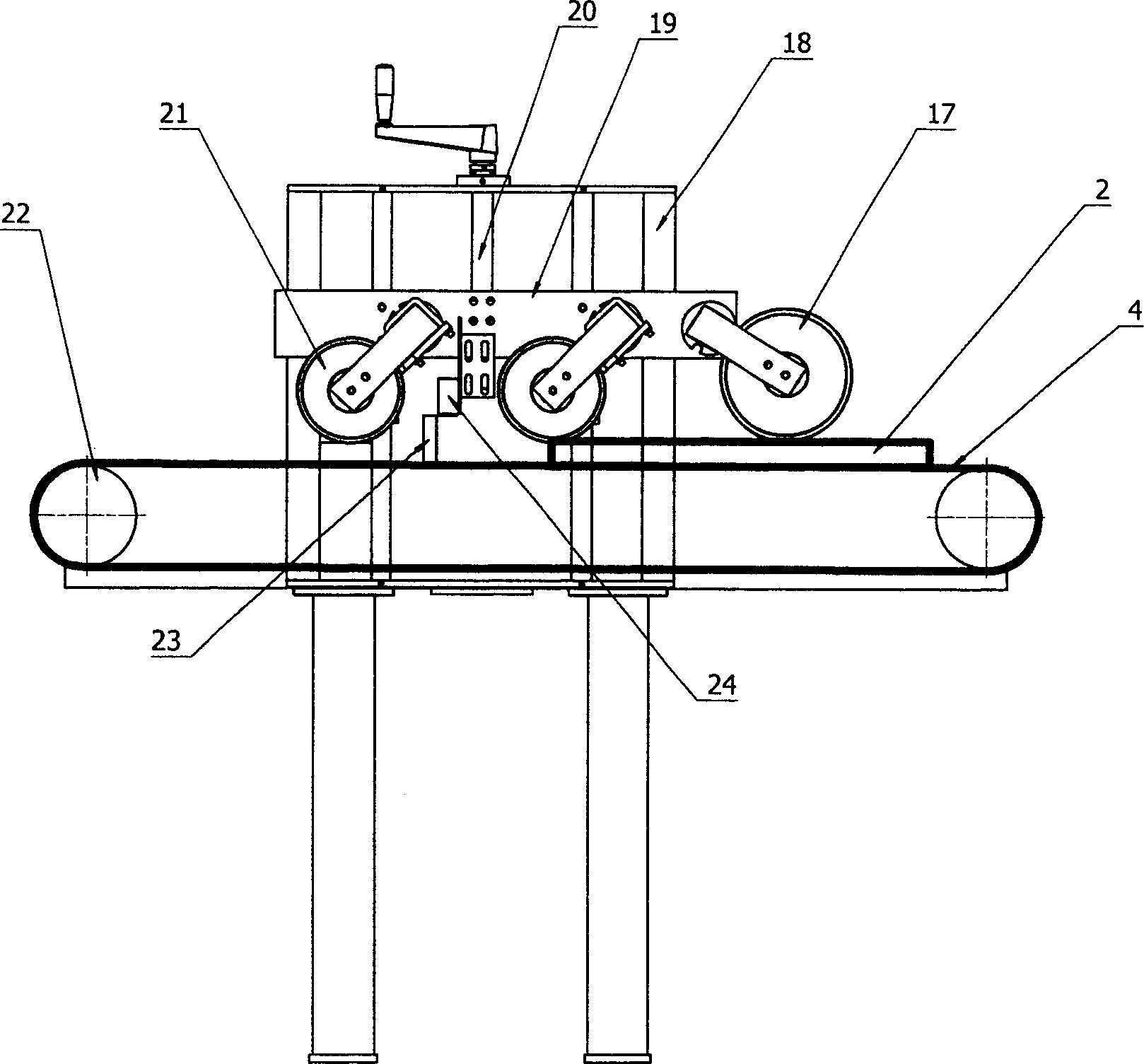

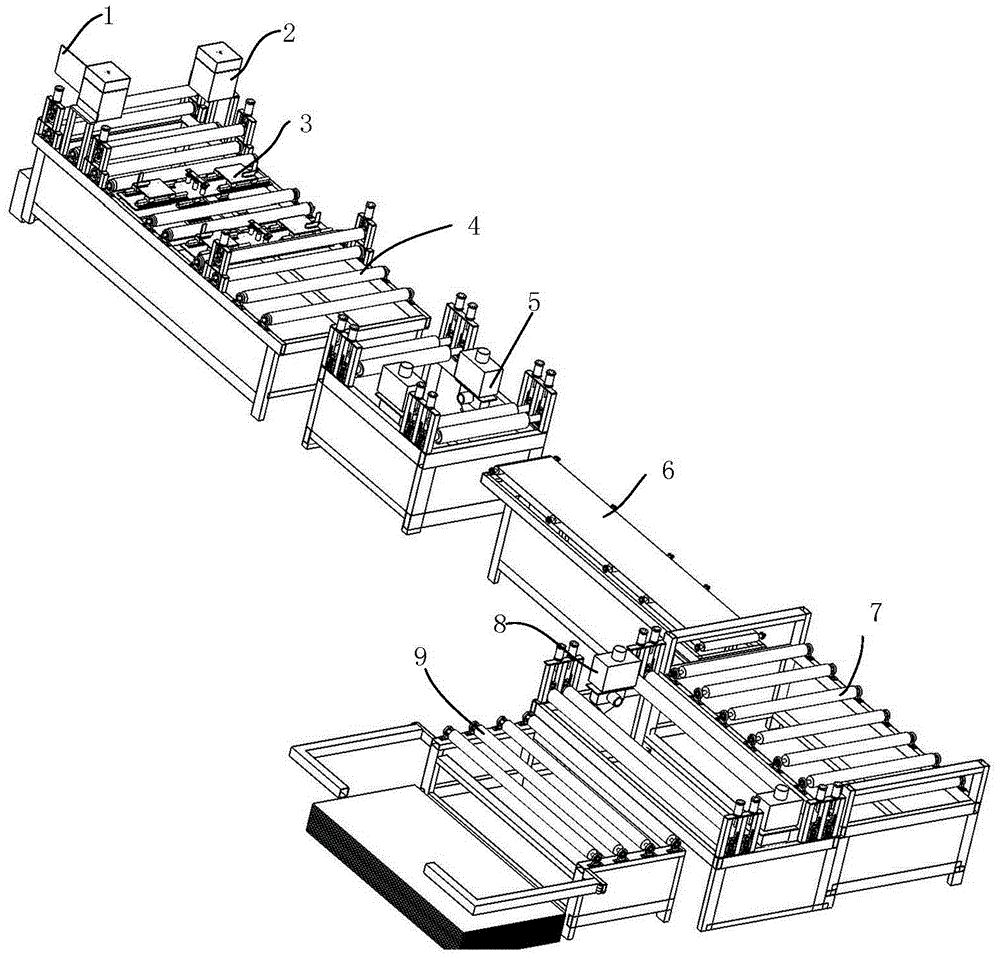

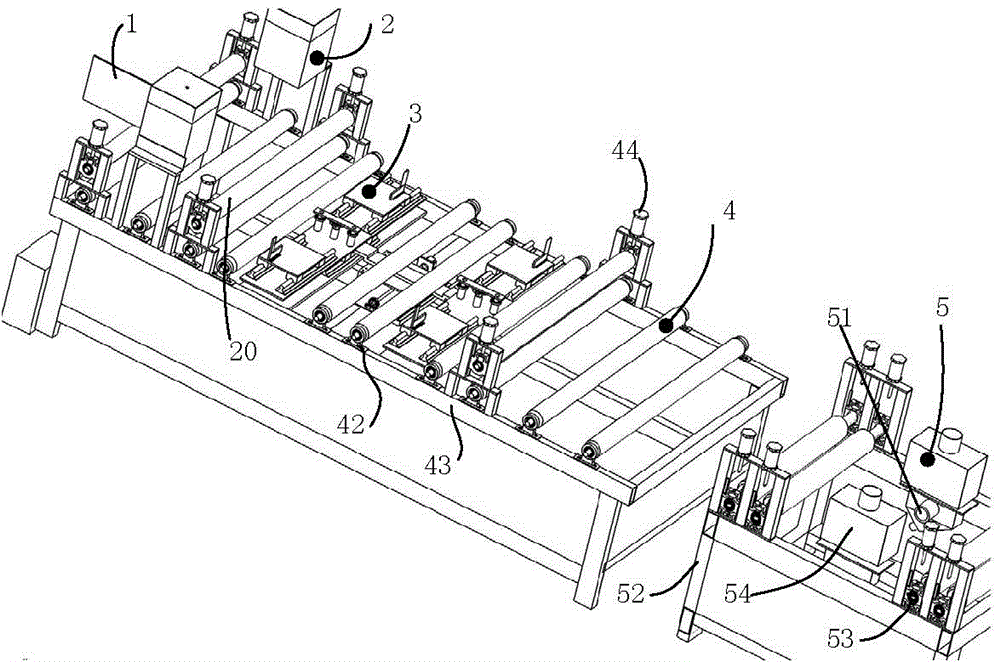

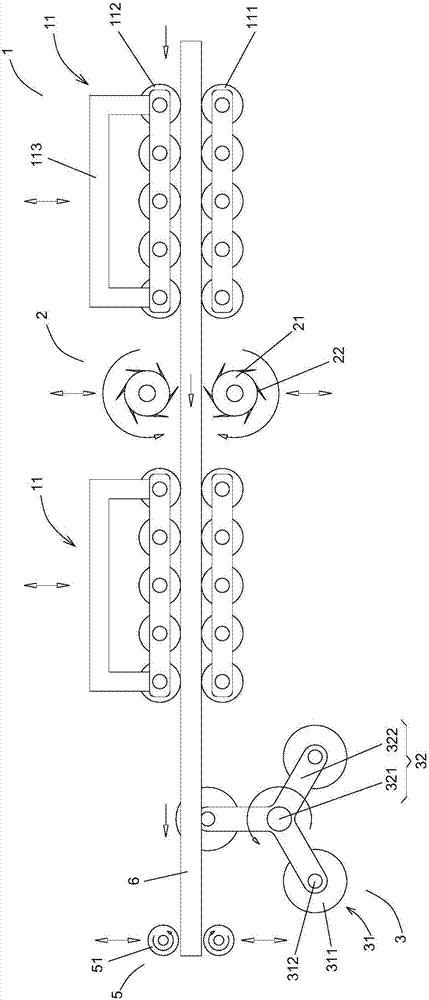

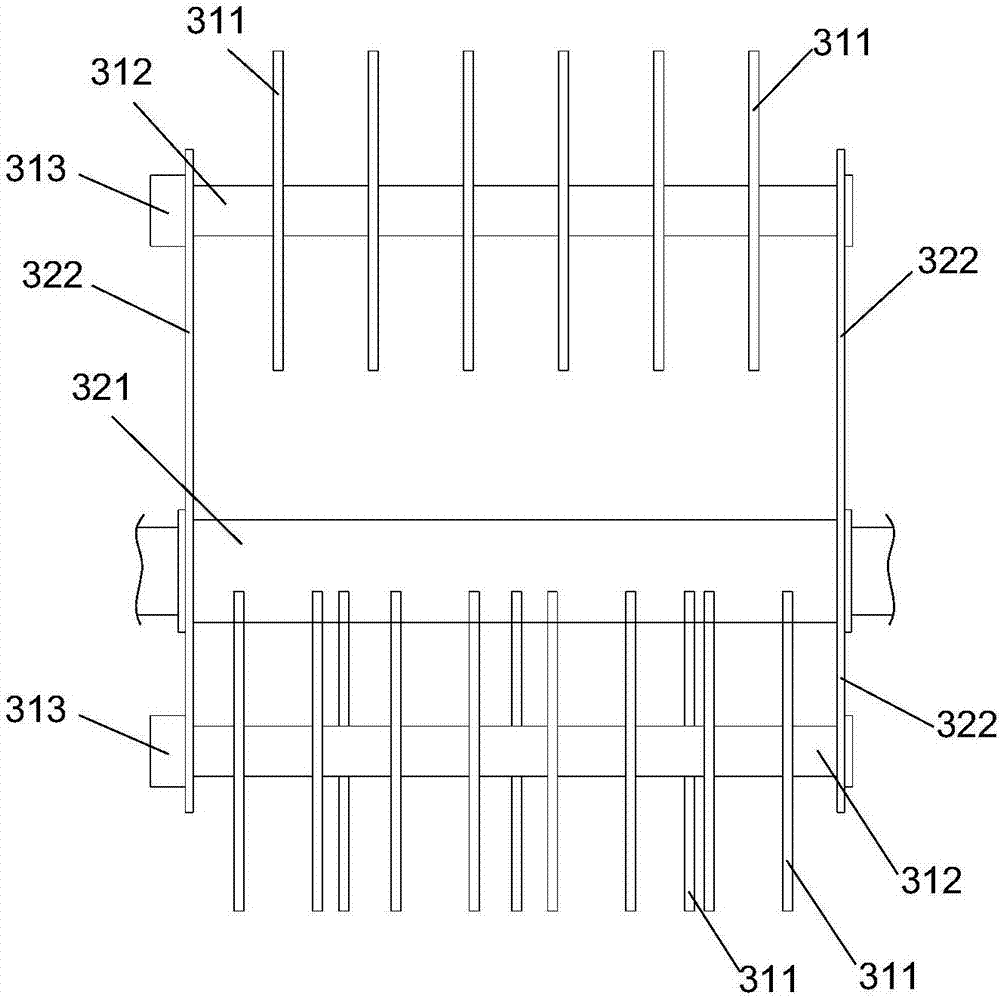

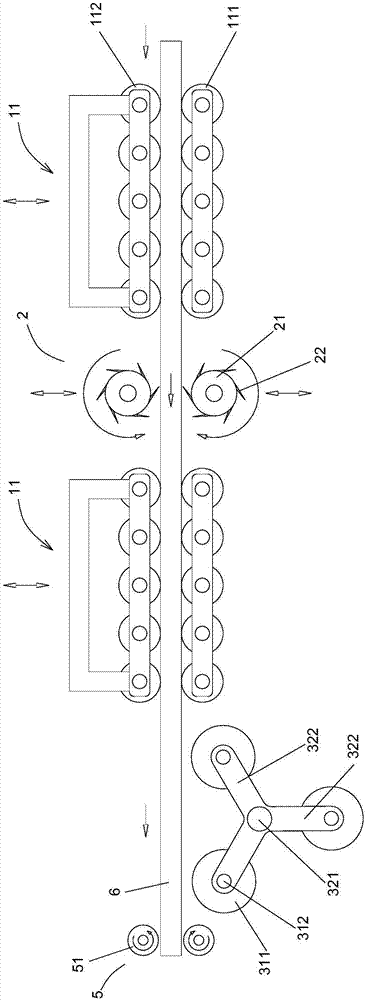

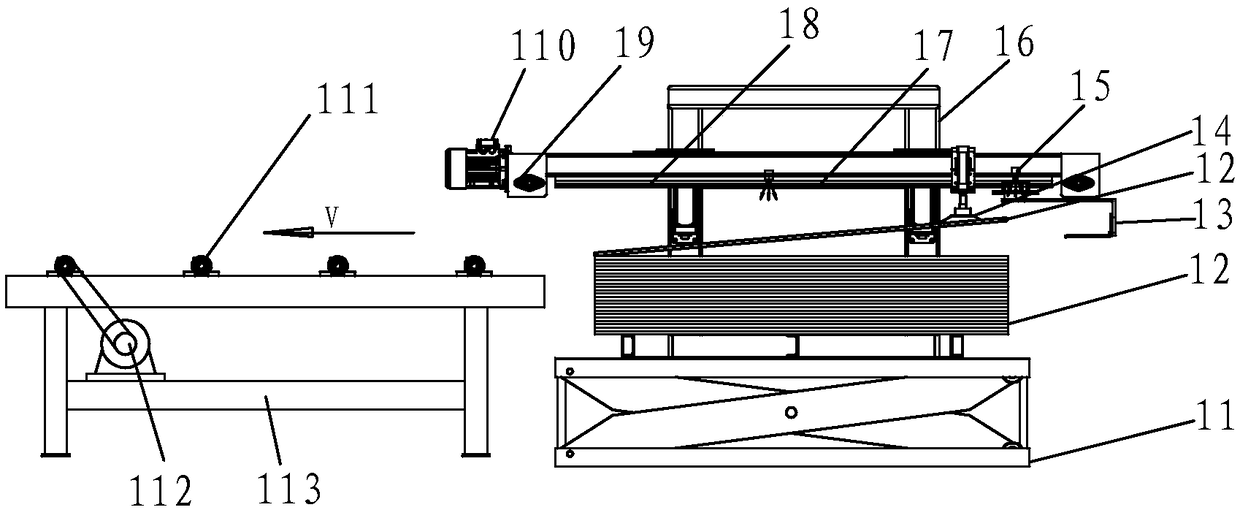

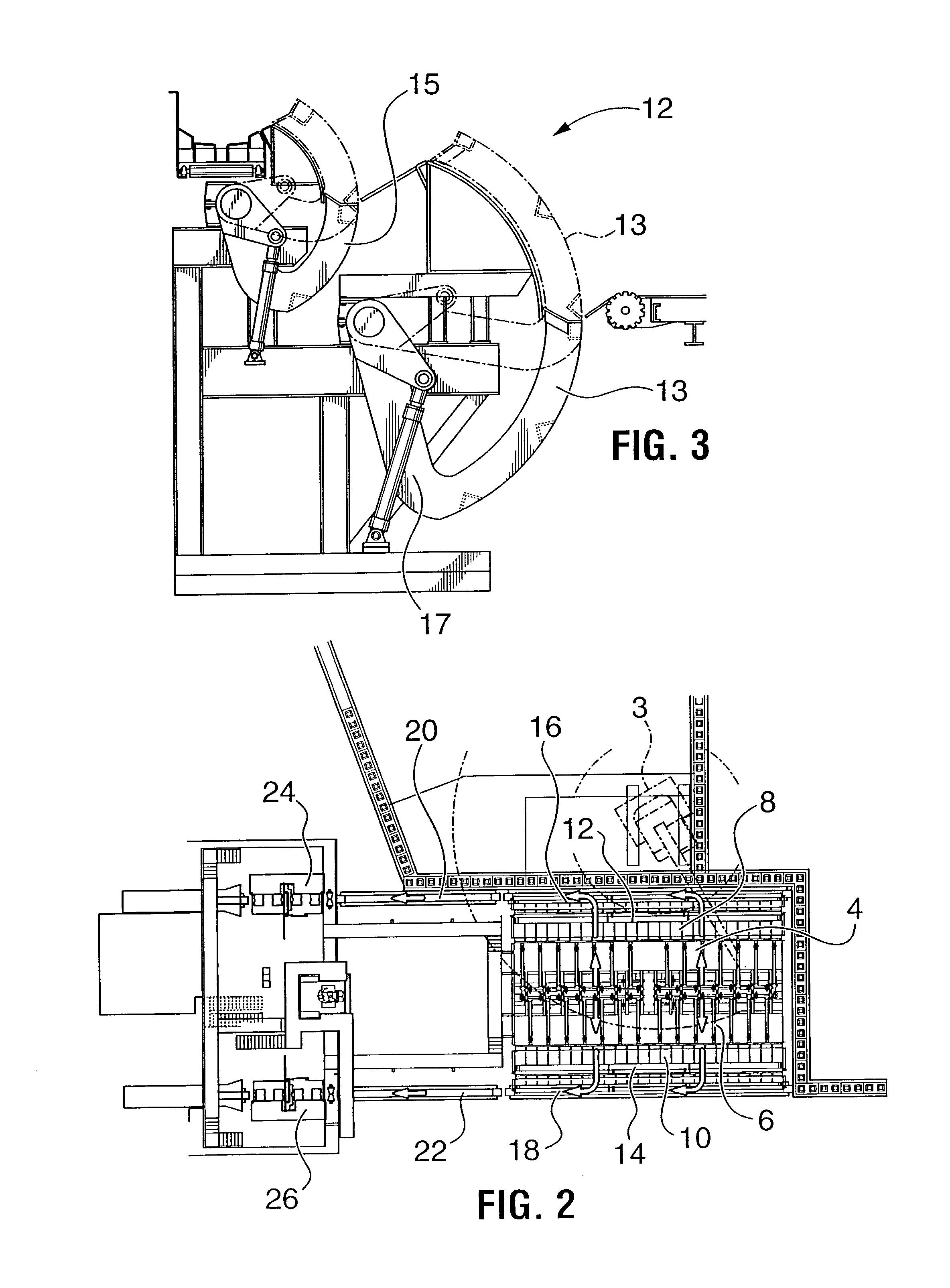

Intelligent deviation adjusting type artificial board longitudinal and transverse edge trimming production line and method

ActiveCN105710930AImprove cut qualityIncrease profitOptically investigating flaws/contaminationAdjusting equipmentProduction lineEngineering

The invention relates to an intelligent deviation adjusting type artificial board longitudinal and transverse edge trimming production line and a method. The production line comprises a board edge visual identification system 2, a board transverse deviation adjusting system 3, a conveying mechanism 4, a board longitudinal edge trimming system 5, a conveying mechanism 6, a board longitudinal centering mechanism 7, a board transverse edge trimming system 8 and a stacking mechanism 9. The deviation adjusting method comprises the following steps: adopting the board edge visual identification system 2 to collect and extract the transverse edge and longitudinal edge outlines of the board and the breadth flaw feature image information; calculating the finished board dimension and the offset and the offset direction of an artificial board; transferring the offset and the offset direction to the board transverse deviation adjusting system 3, adopting a servo motor 31 to drive a deviation adjusting sliding table 35 to move to realize automatic deviation adjustment of the board; and comparing the dimension of the finished board with the specification of a standard board, calculating intervals between longitudinal saws and between transverse saws, and automatically adjusting the intervals of saw blades of the board longitudinal edge trimming system 5 and the board transverse edge trimming system 8, thus realizing self-adaption of wide board cutting.

Owner:临沂金轮热压机械有限公司 +1

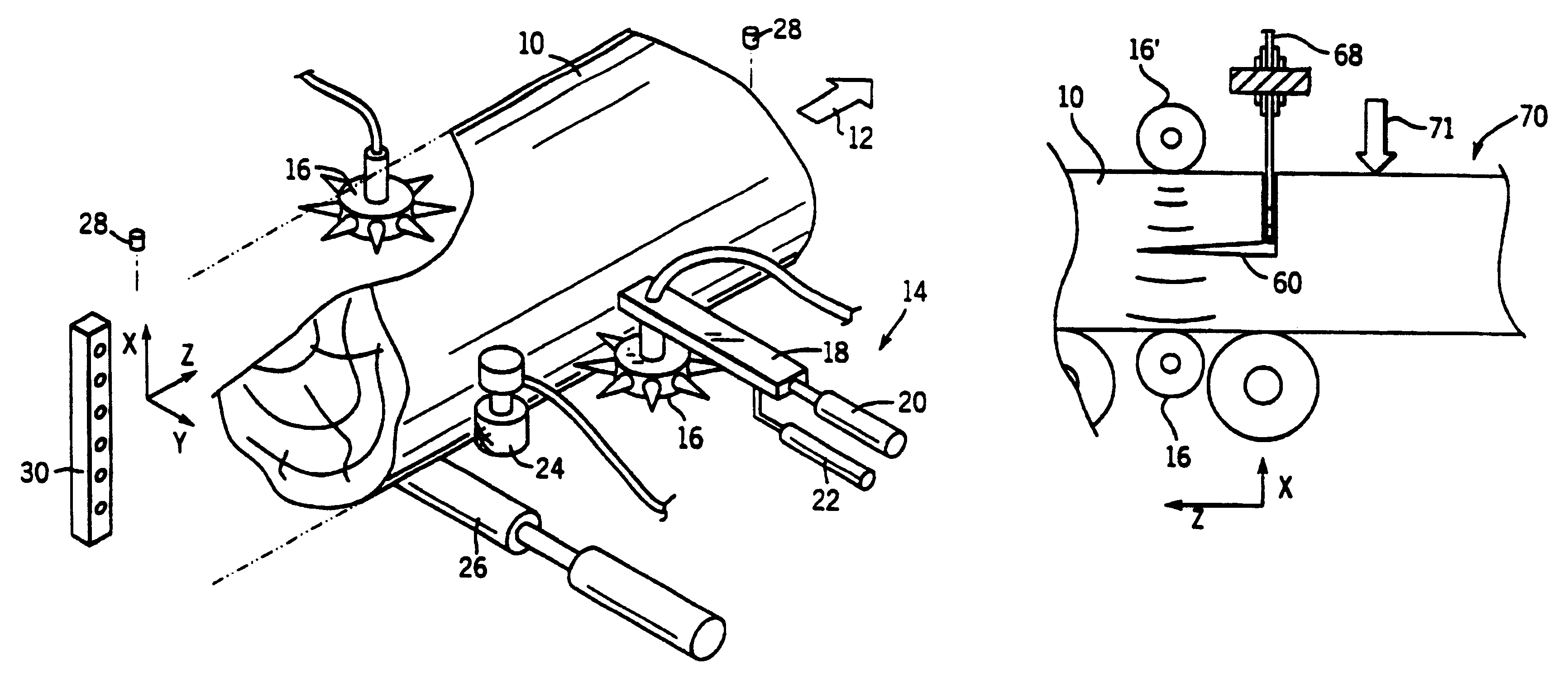

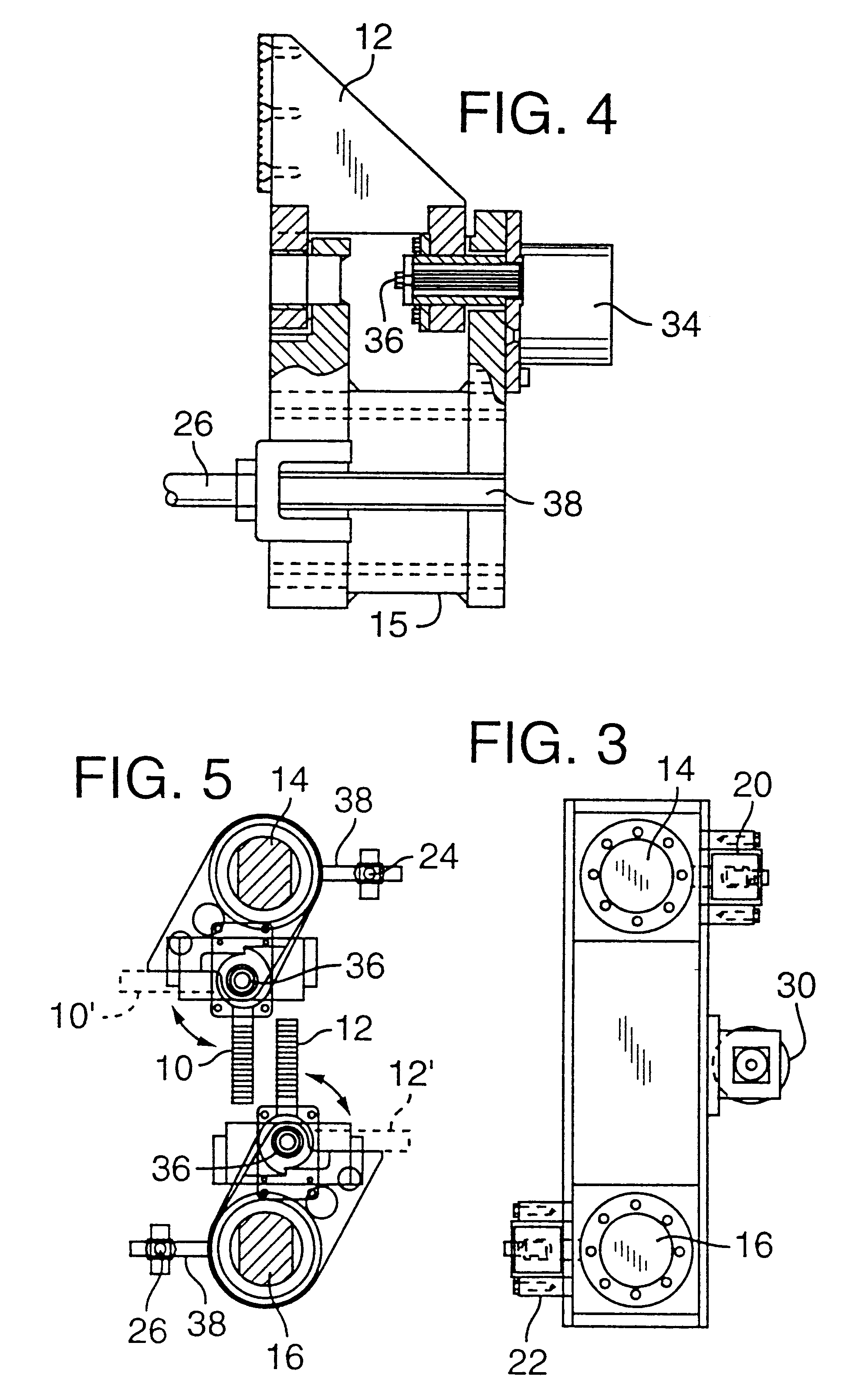

Apparatus for controlled curved sawing or cutting of two-faced cants

InactiveUS6494240B1Minimize lateral stressReduce side thrustAutomatic control devicesWood feeding arangementsEngineeringMechanical engineering

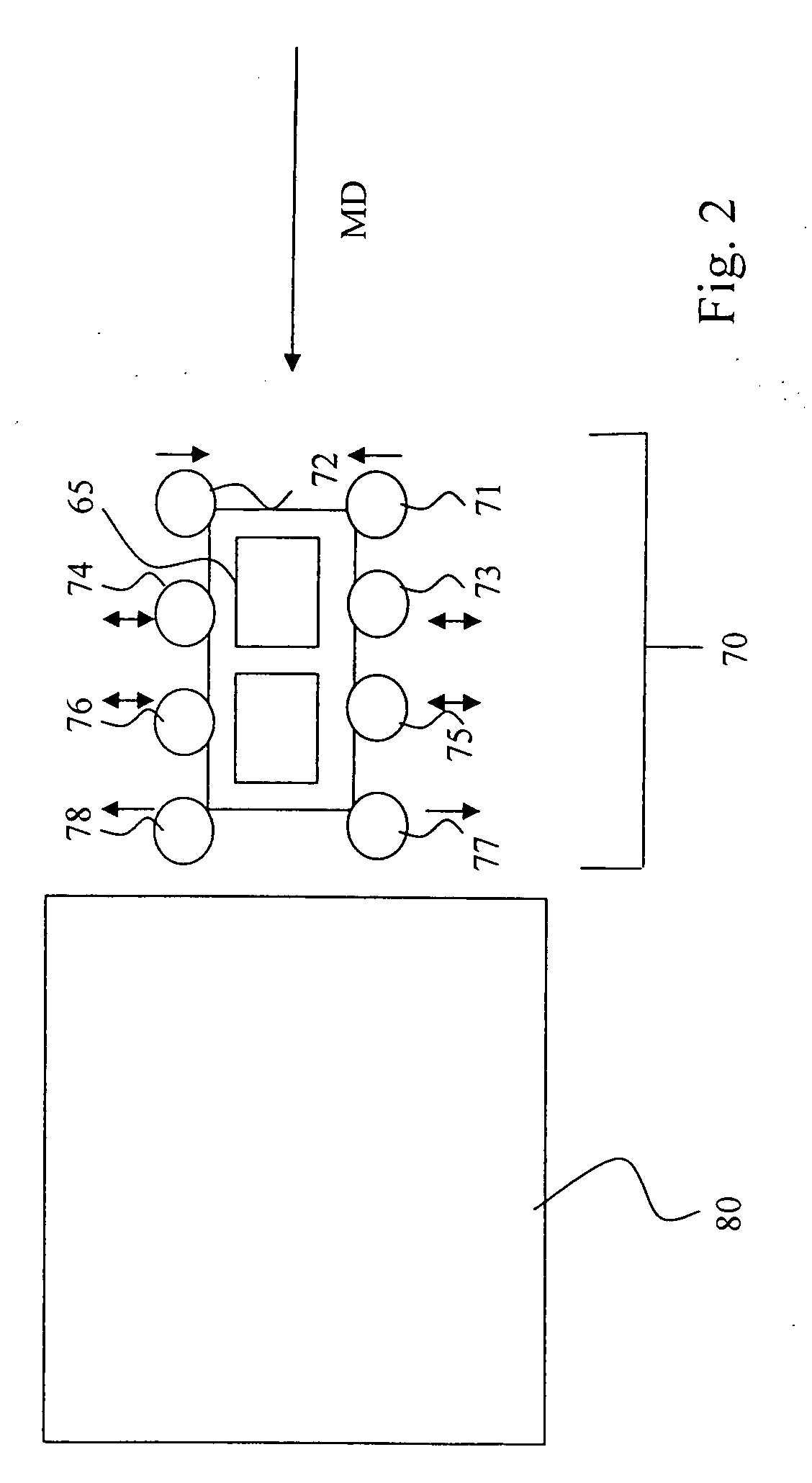

In combination with a cant sawing or cutting unit, a system for guiding two-faced cants through the cut along the line of their natural curvature which includes at the infeed and outfeed ends of the unit, laterally moveable rollers for clamping upon parallel planar faces of the cant and imparting to it a pivotal movement in the horizontal plane while it is moving forward through the cut, so that the saws or cutters follow along a controlled curve in relation to the natural curvature of the cant.

Owner:EQUIP COMACT INC COMACT EQUIP +1

Three-axis automatic planing and sawing combination machine

ActiveCN107053364AQuick conversionImprove versatilityFeeding devicesMulti-purpose machinesLong axisEngineering

The invention provides a three-axis automatic planing and sawing combination machine. The three-axis automatic planing and sawing combination machine comprises a conveying unit, a planing unit, a cutting unit, a lateral adjusting unit and a polishing unit. The lateral adjusting unit is arranged on the outer side face of a conveying path. The cutting unit comprises at least two saw blade sets, a conversion support capable of switching the two saw blade sets, and a saw blade driving mechanism. The saw blade sets are connected with the corresponding conversion supports. Each saw blade set comprises a plurality of saw blades and a saw blade rotating shaft used for connecting the saw blades in series. The saw blades are evenly distributed in the direction parallel to the long axis of each saw blade rotating shaft. The long axis of each saw blade rotating shaft is perpendicular to the front-back direction. The three-axis automatic planing and sawing combination machine can process panels of different widths. Due to arrangement of the cutting unit with the saw blade sets capable of being switched, the cutting distances of the saw blade sets can be switched quickly, there is no need to dismount original saw blade sets and mount new saw blade sets, equipment universality is enhanced, the planing, cutting and polishing technologies of the panels are achieved on one piece of equipment, space usage is small, production efficiency is high, and production cost can be better reduced.

Owner:QINGDAO KAISHUO MACHINERY TECH CO LTD

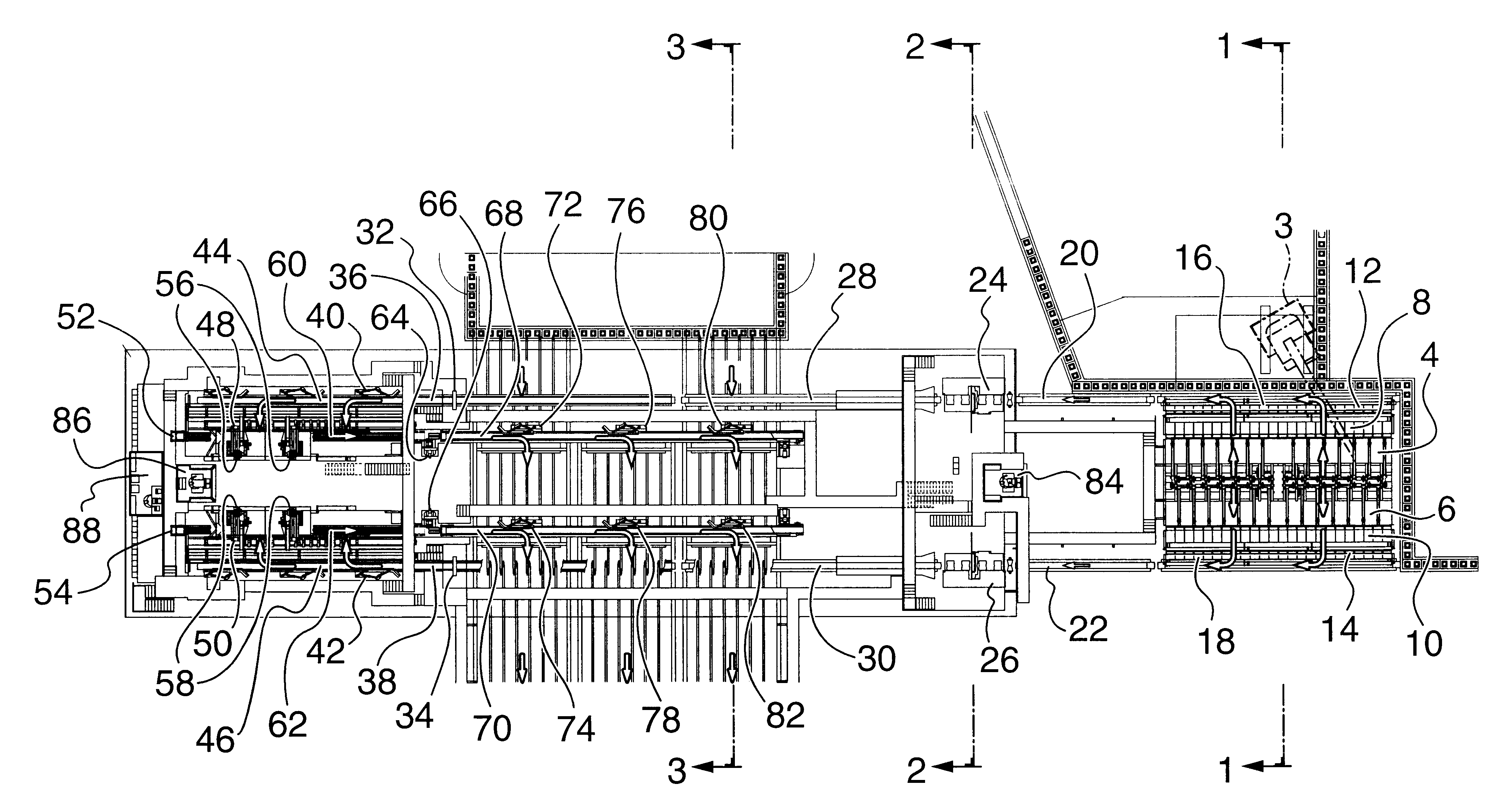

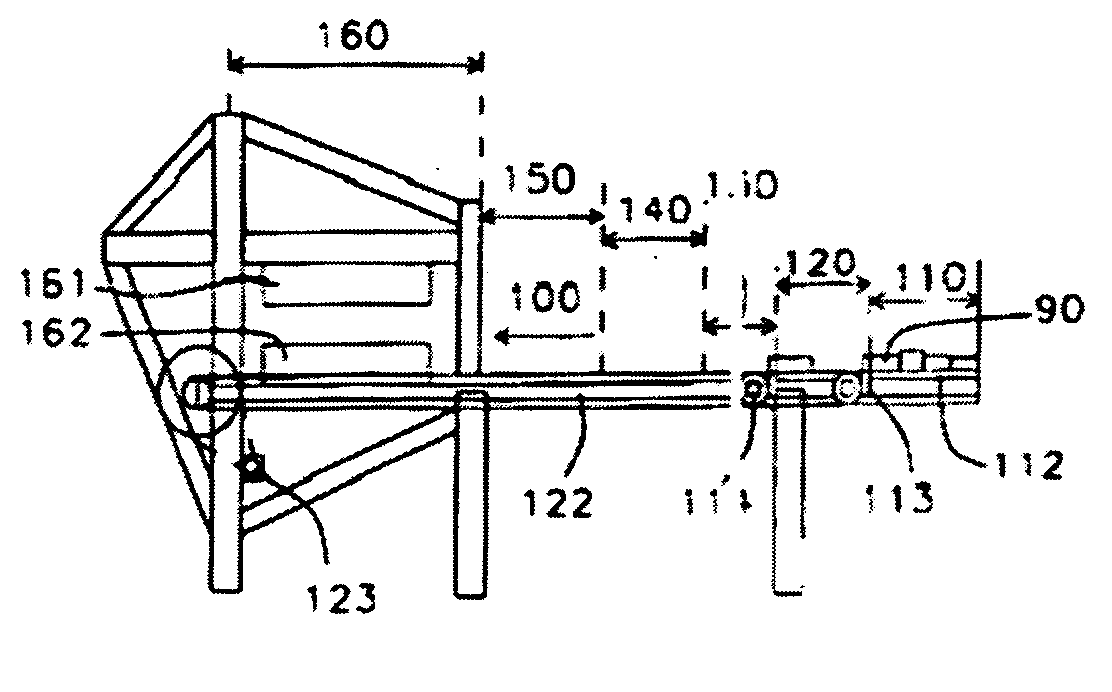

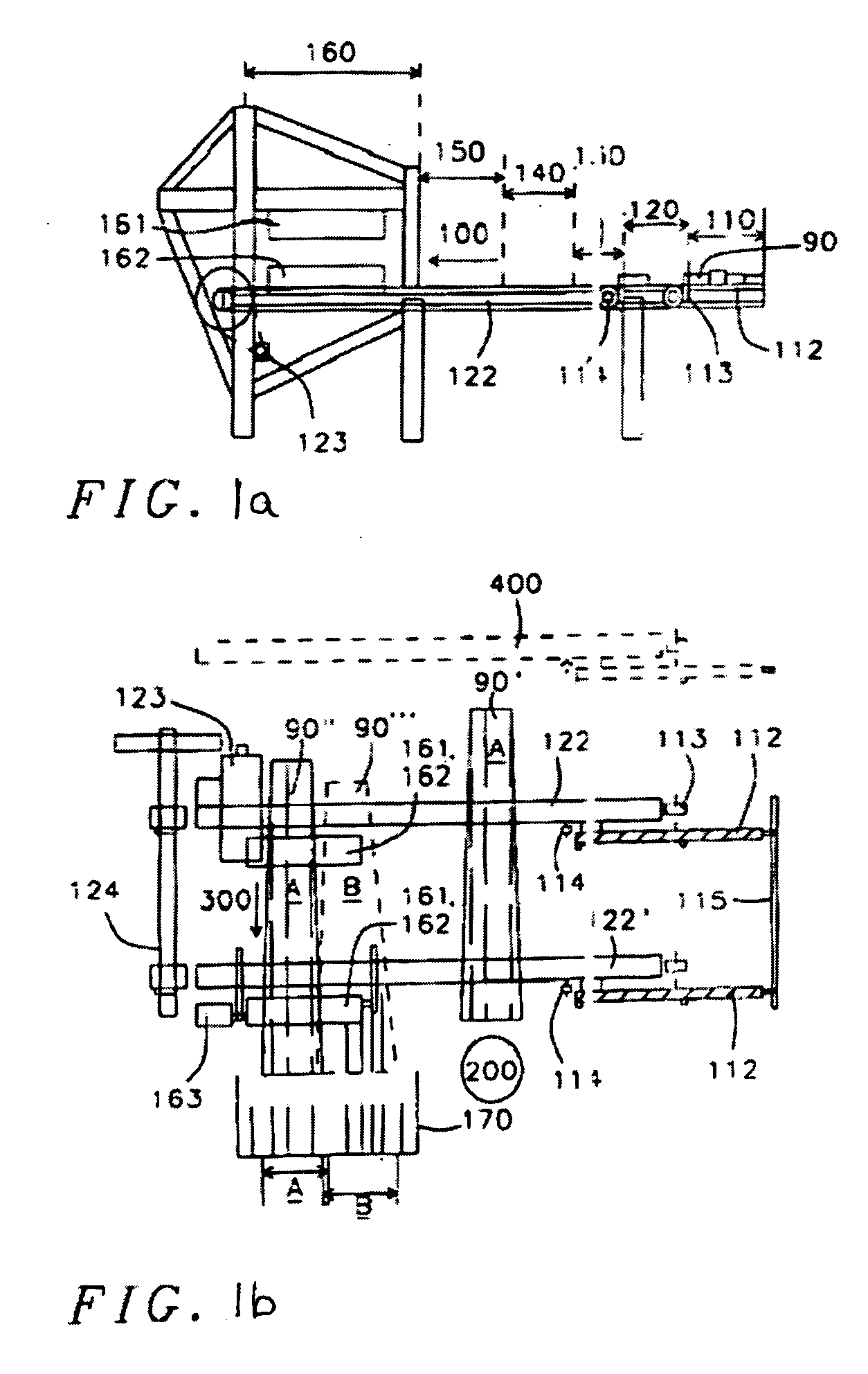

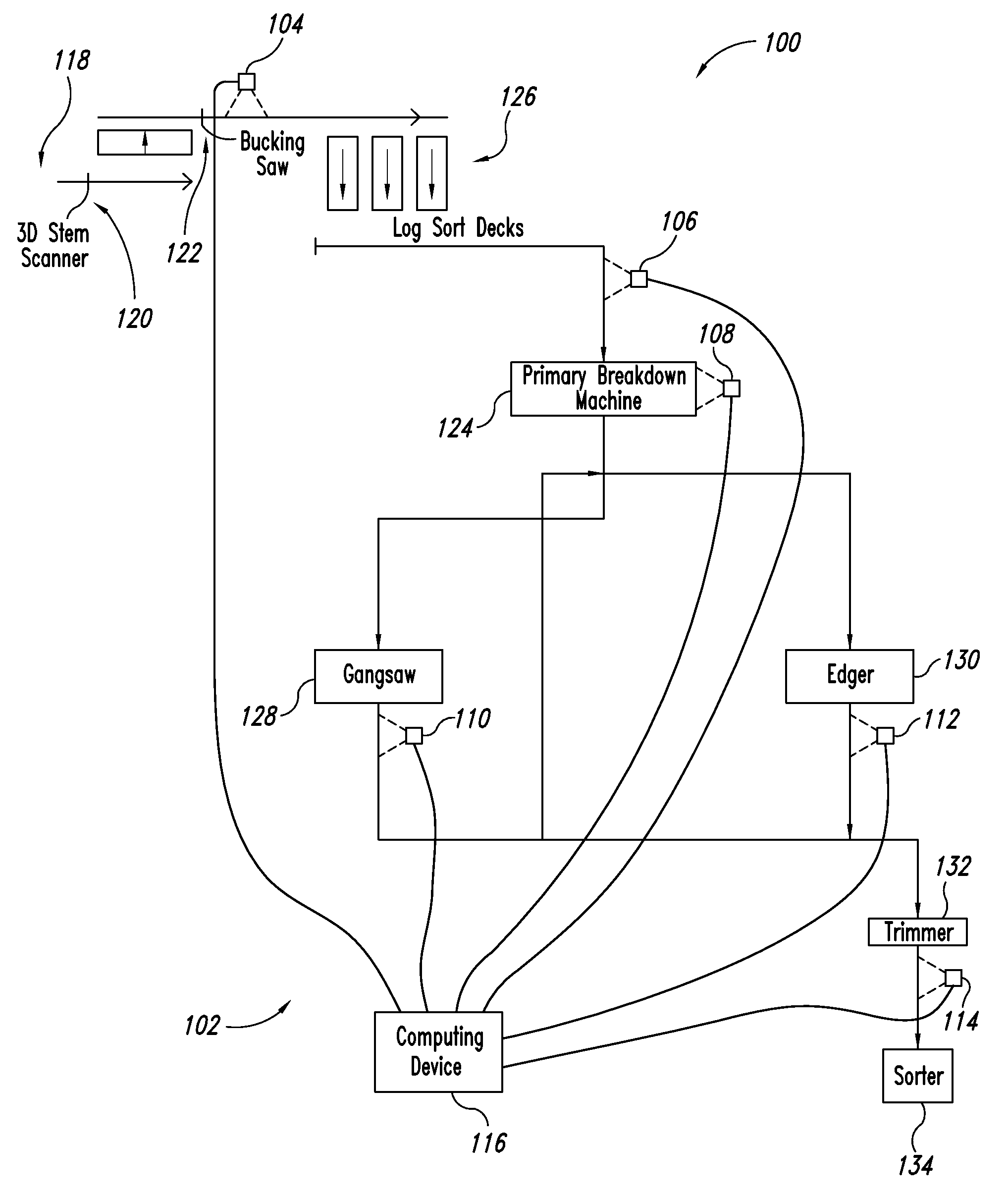

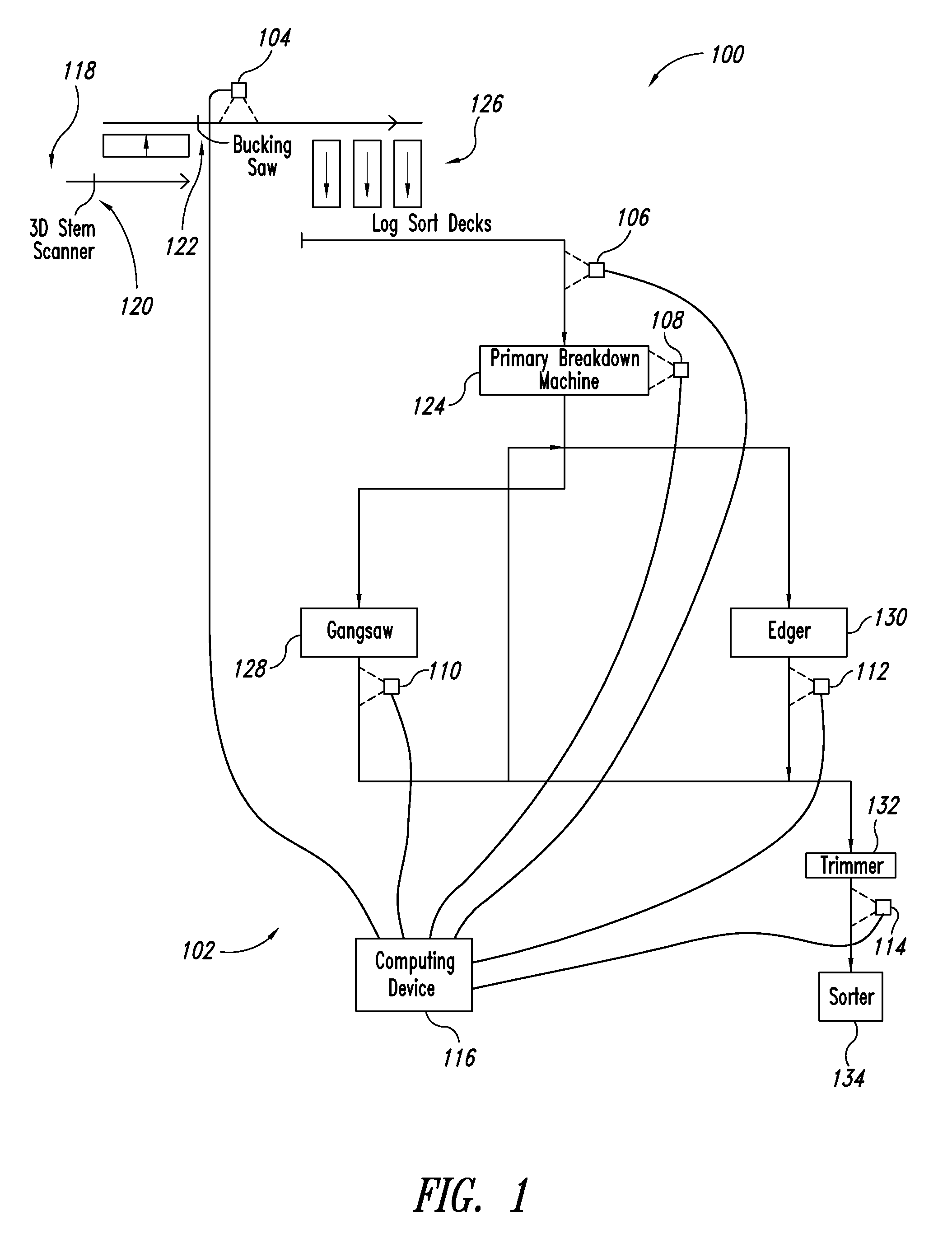

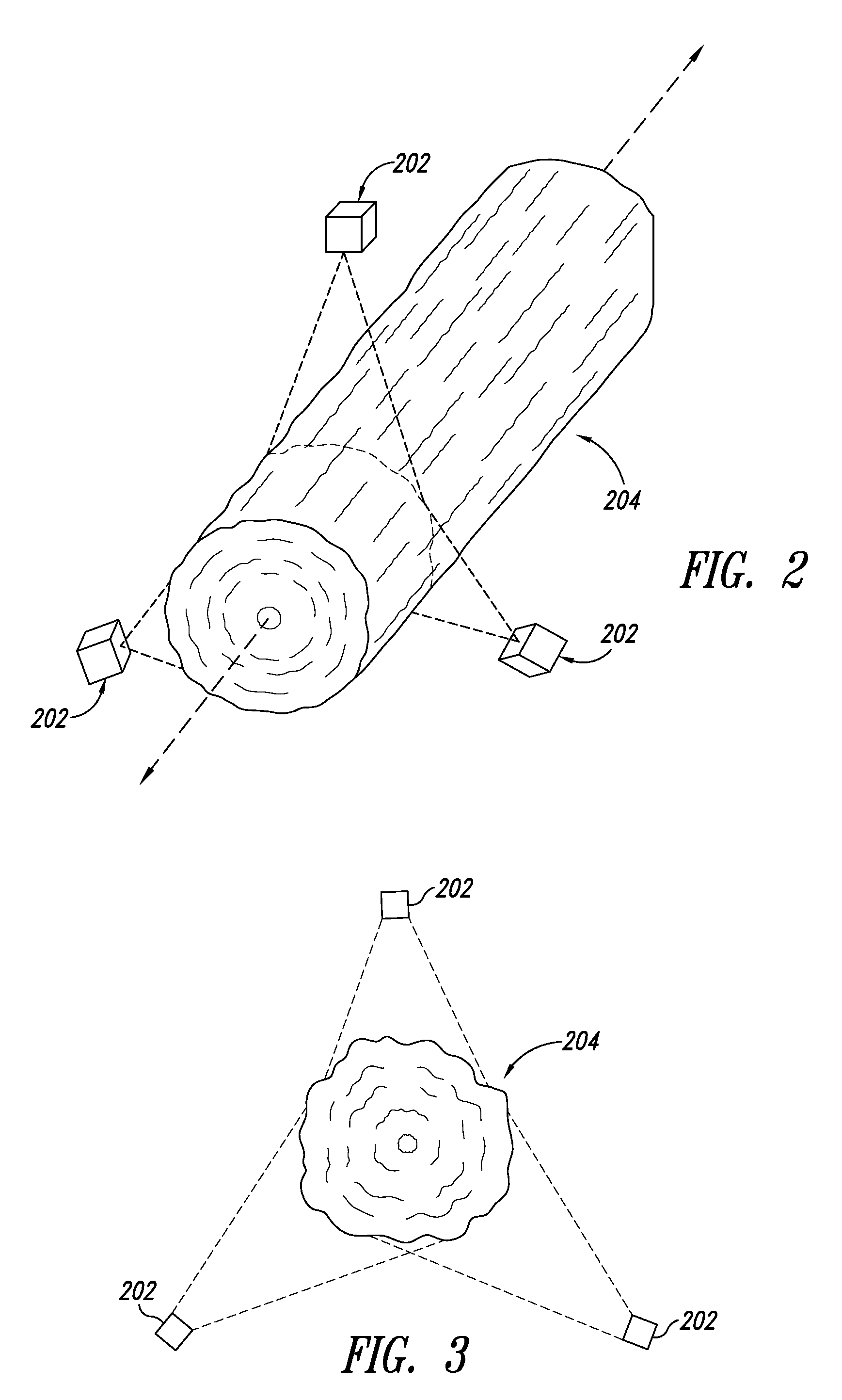

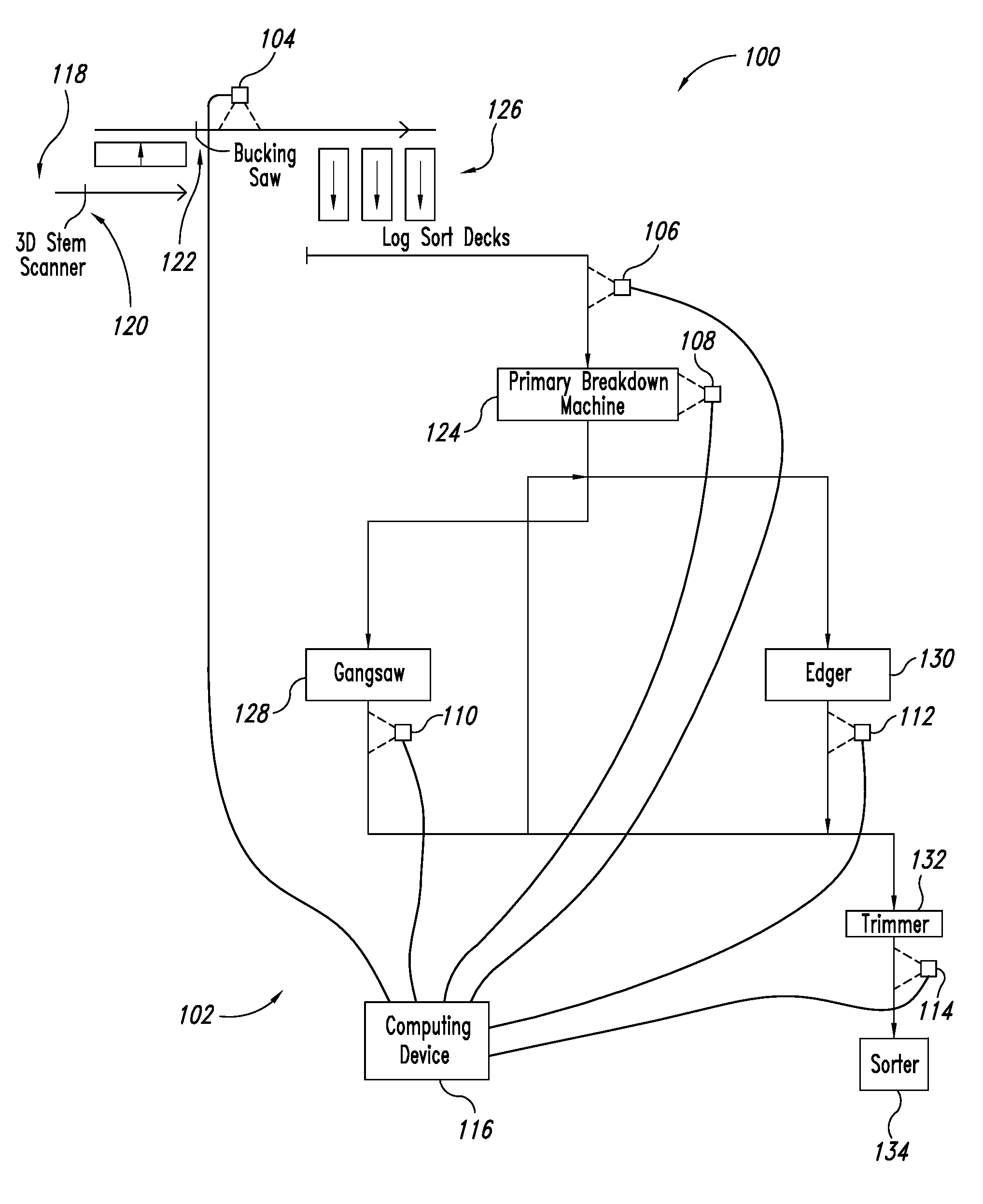

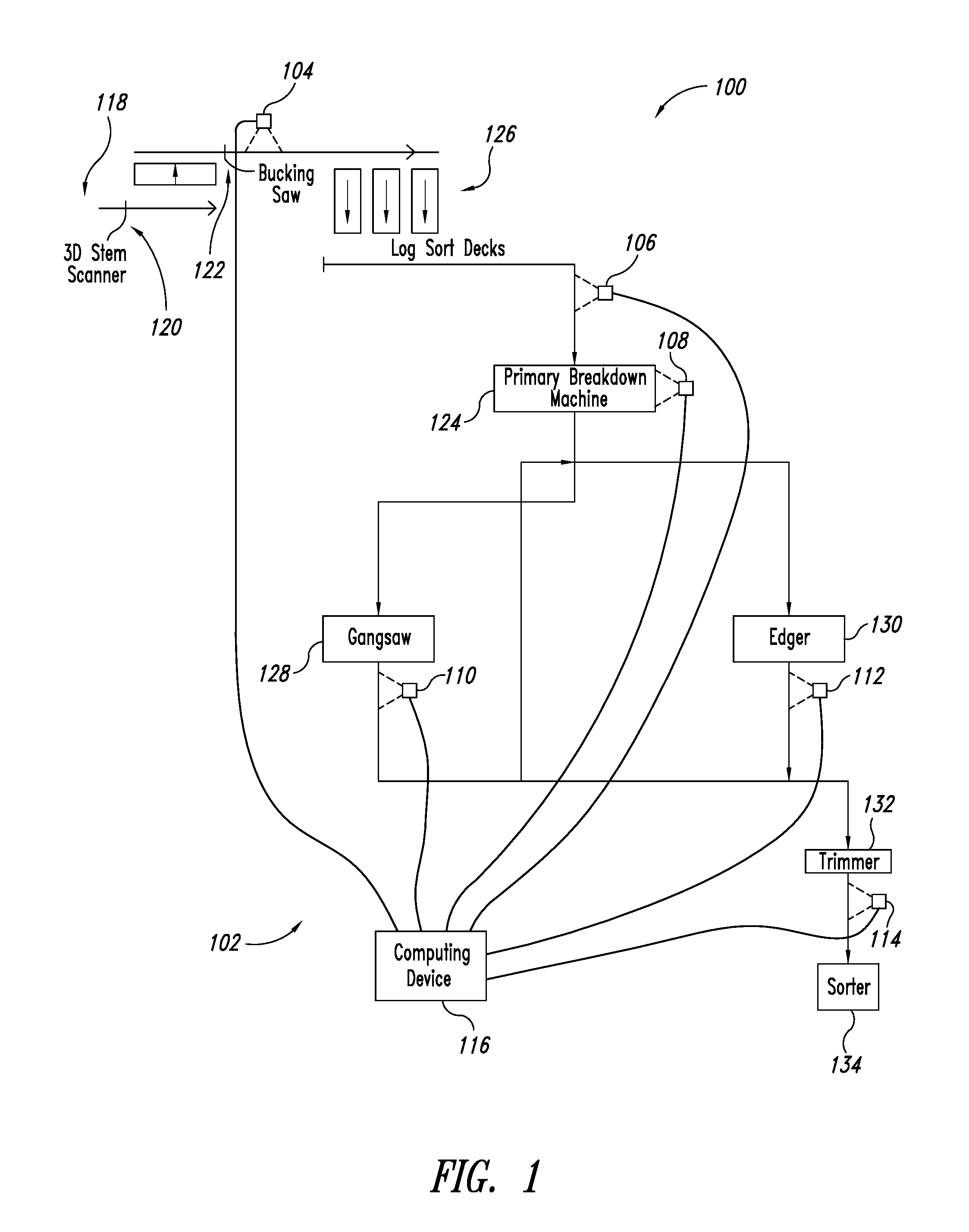

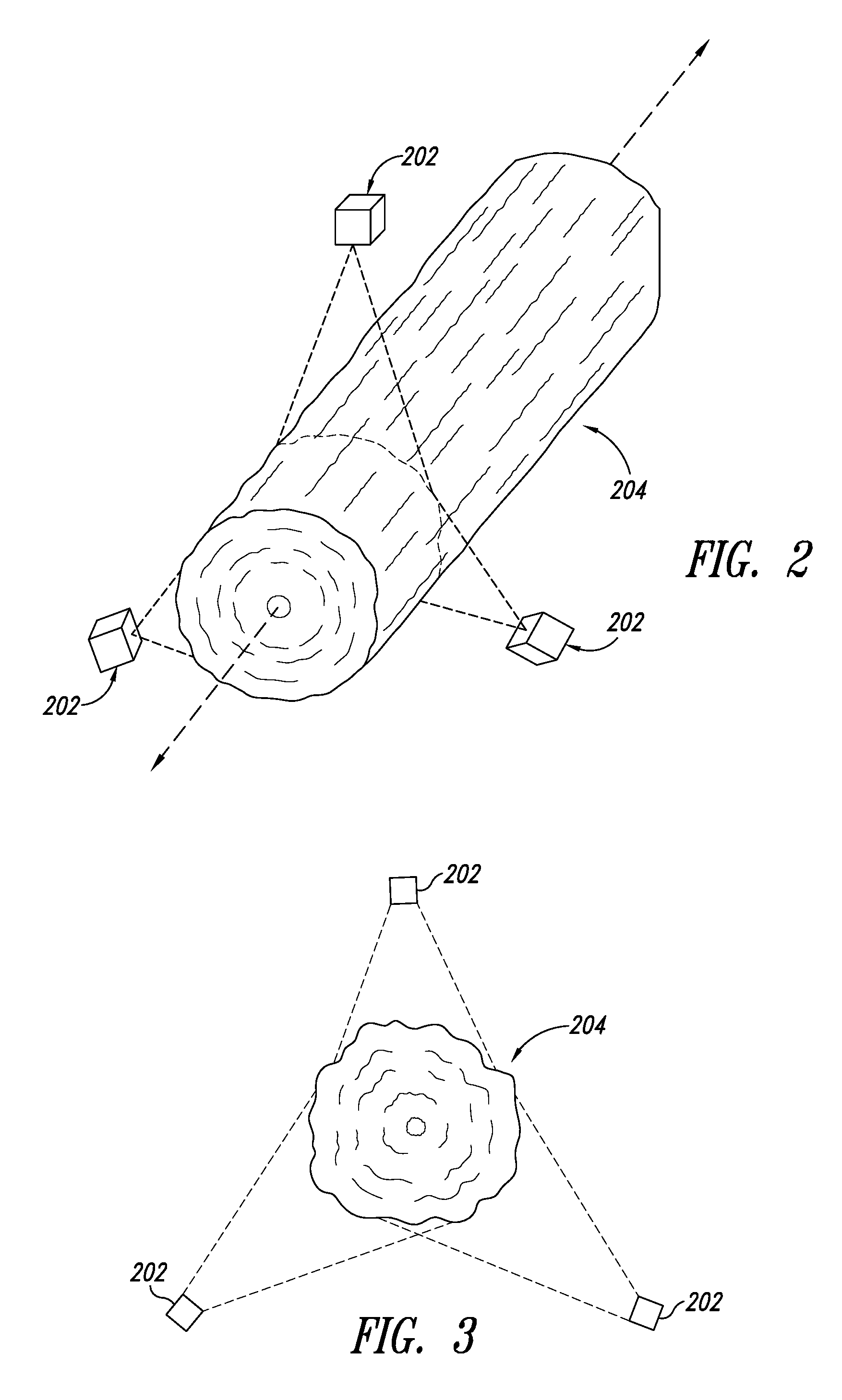

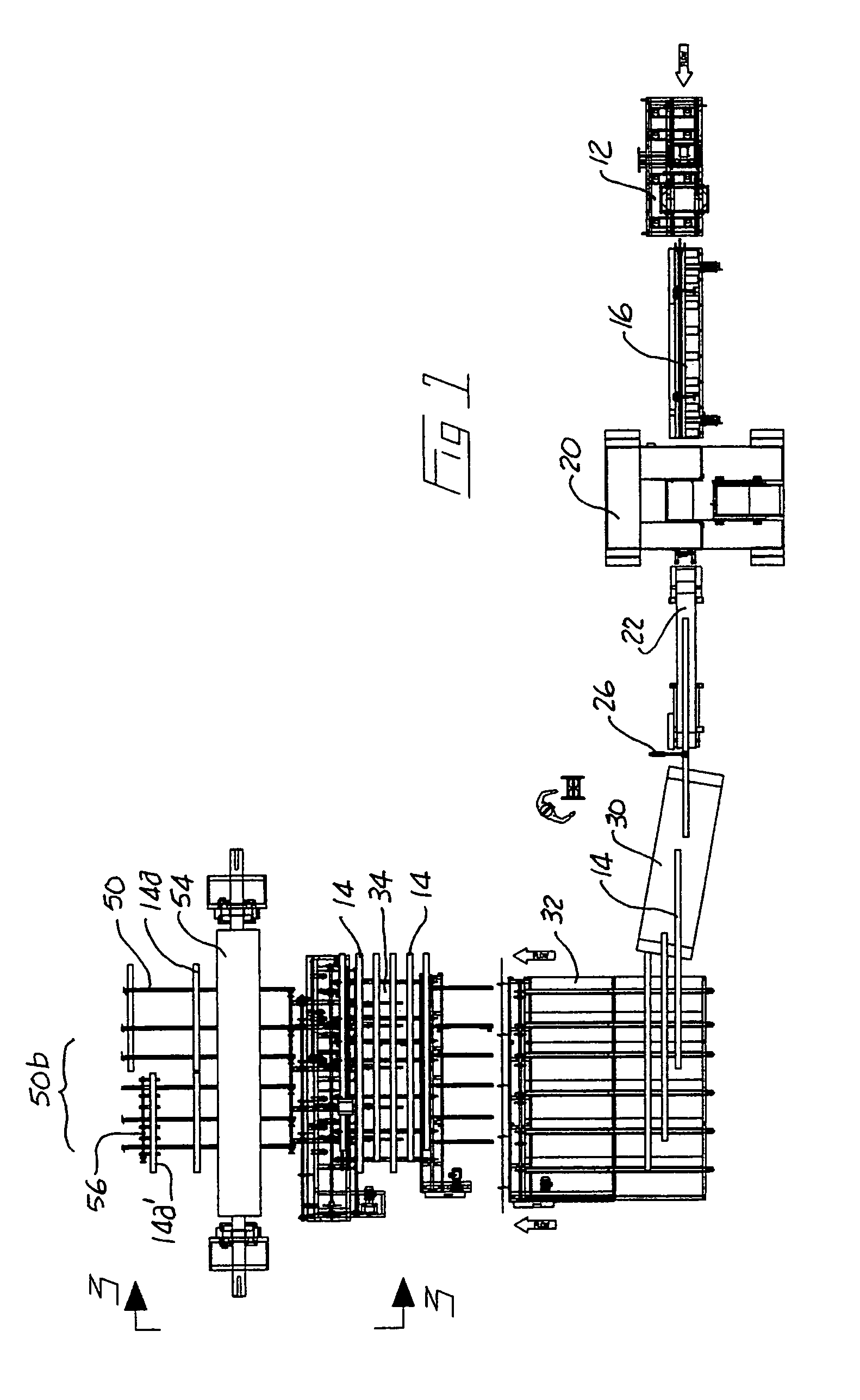

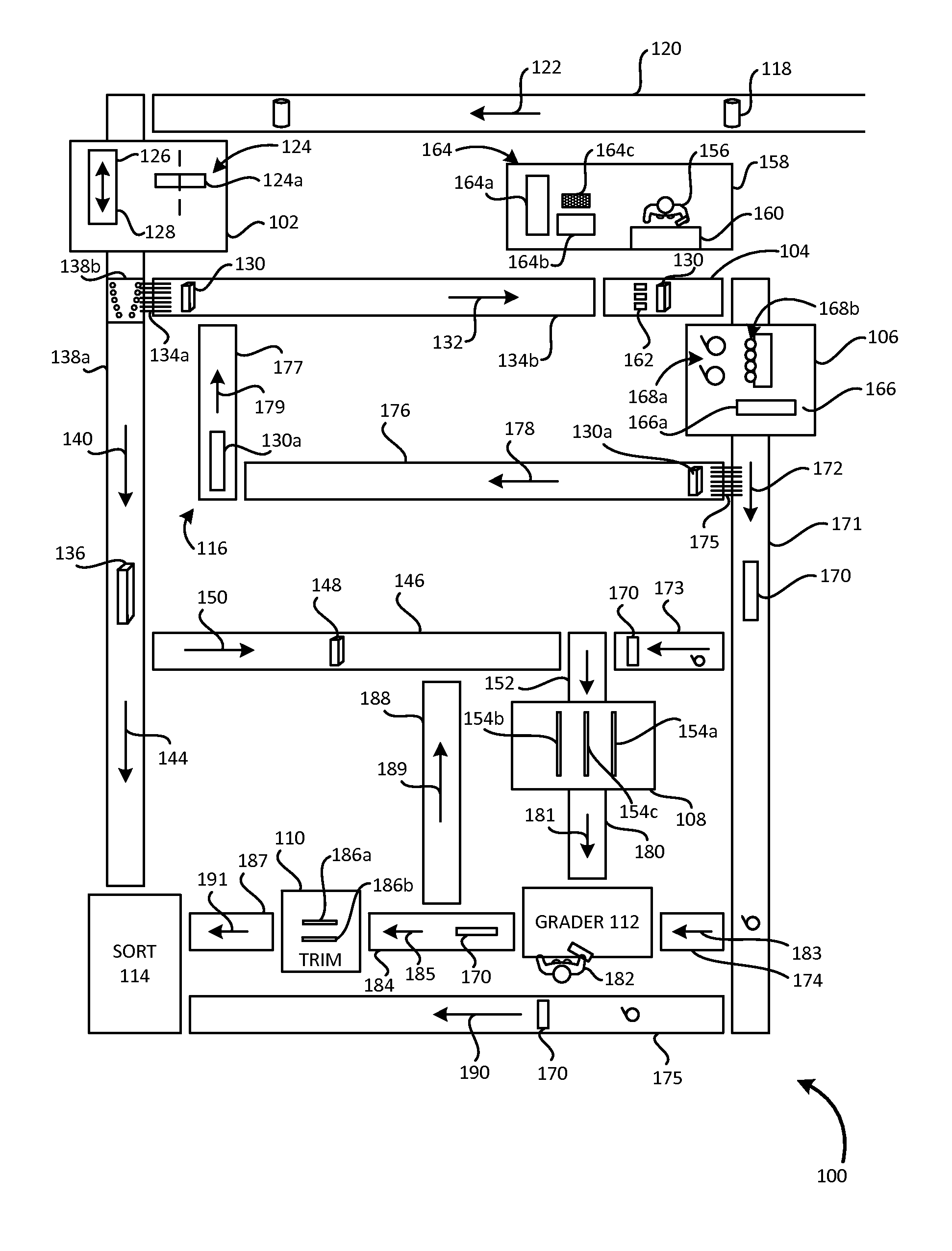

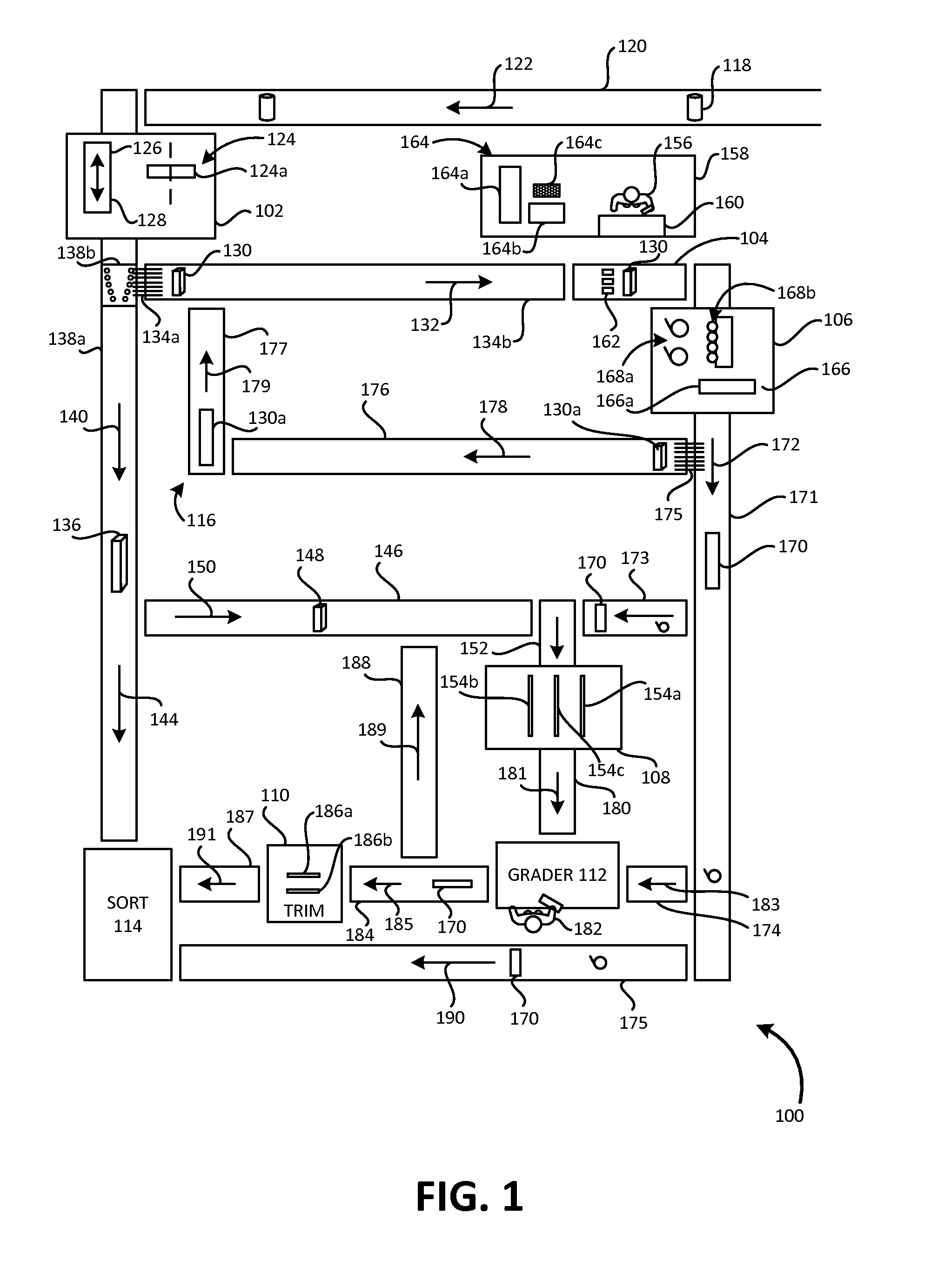

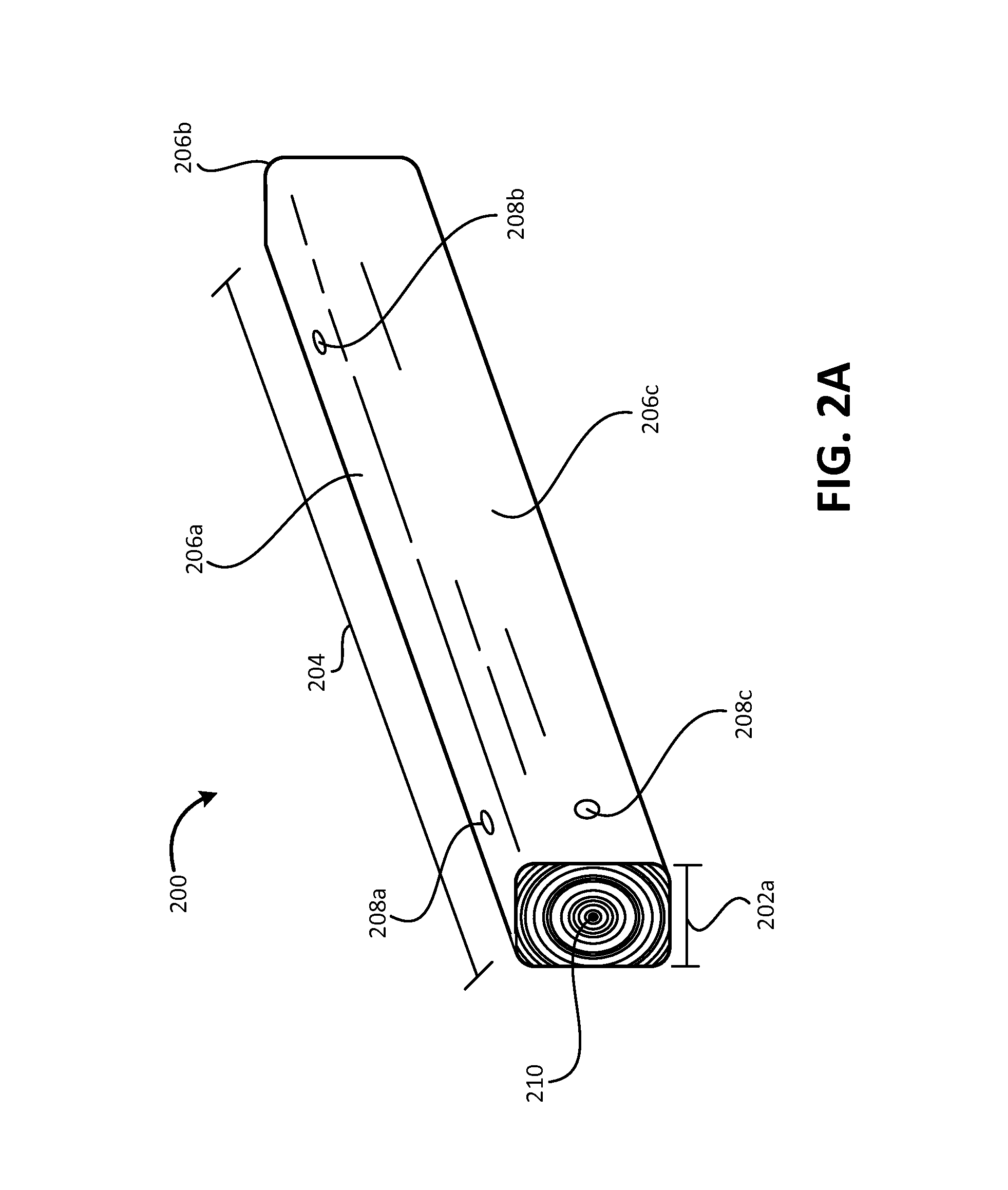

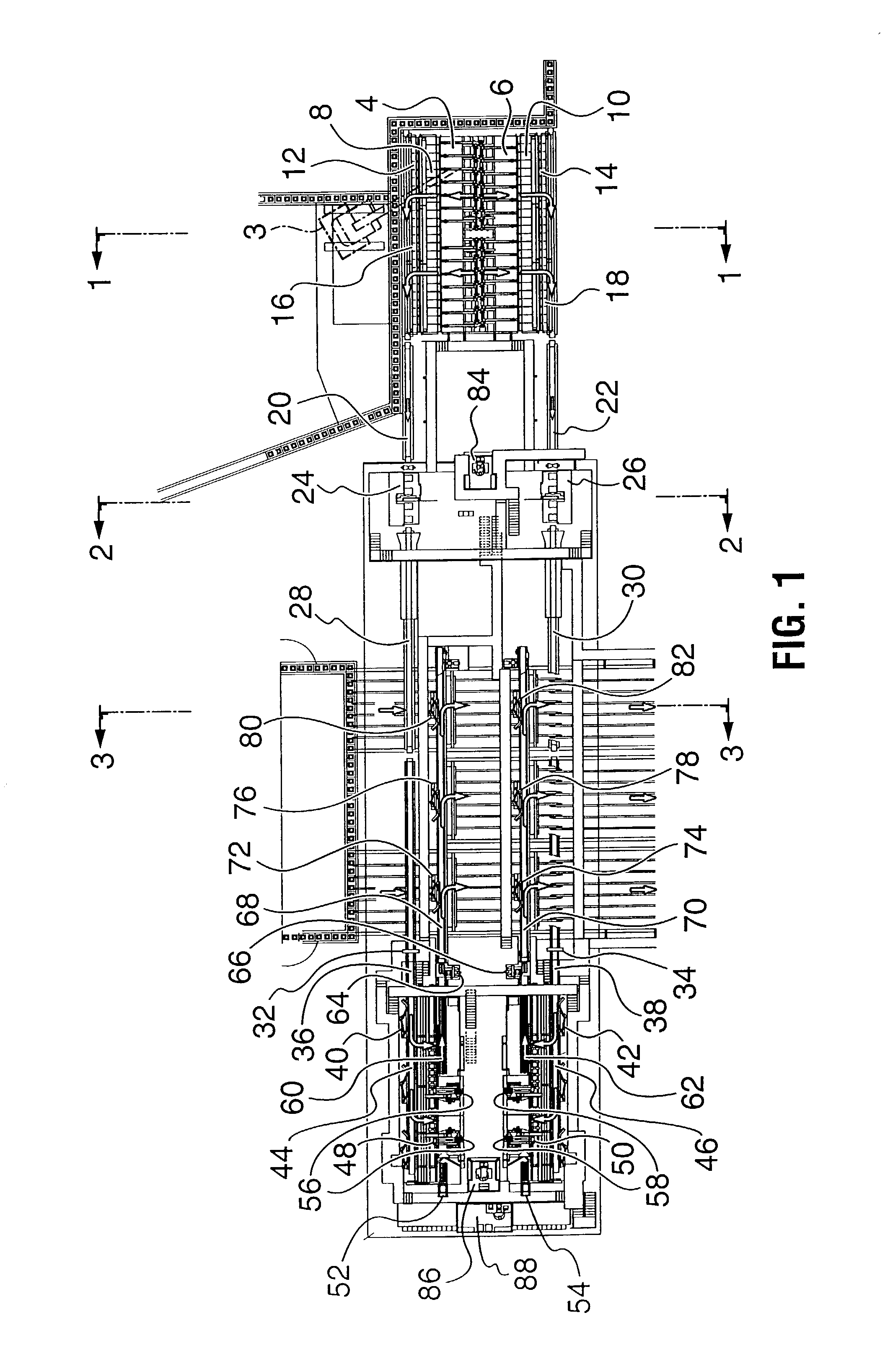

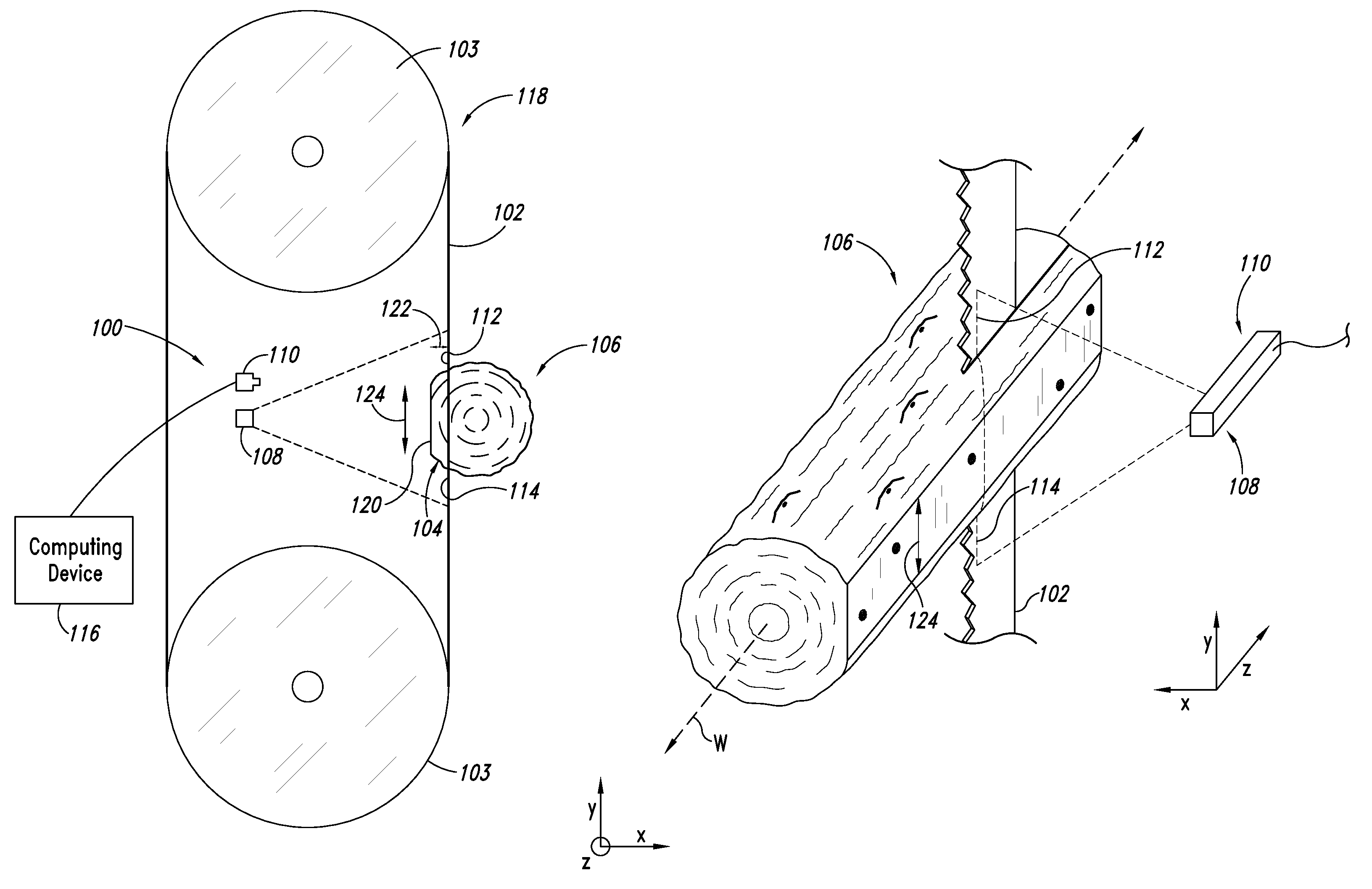

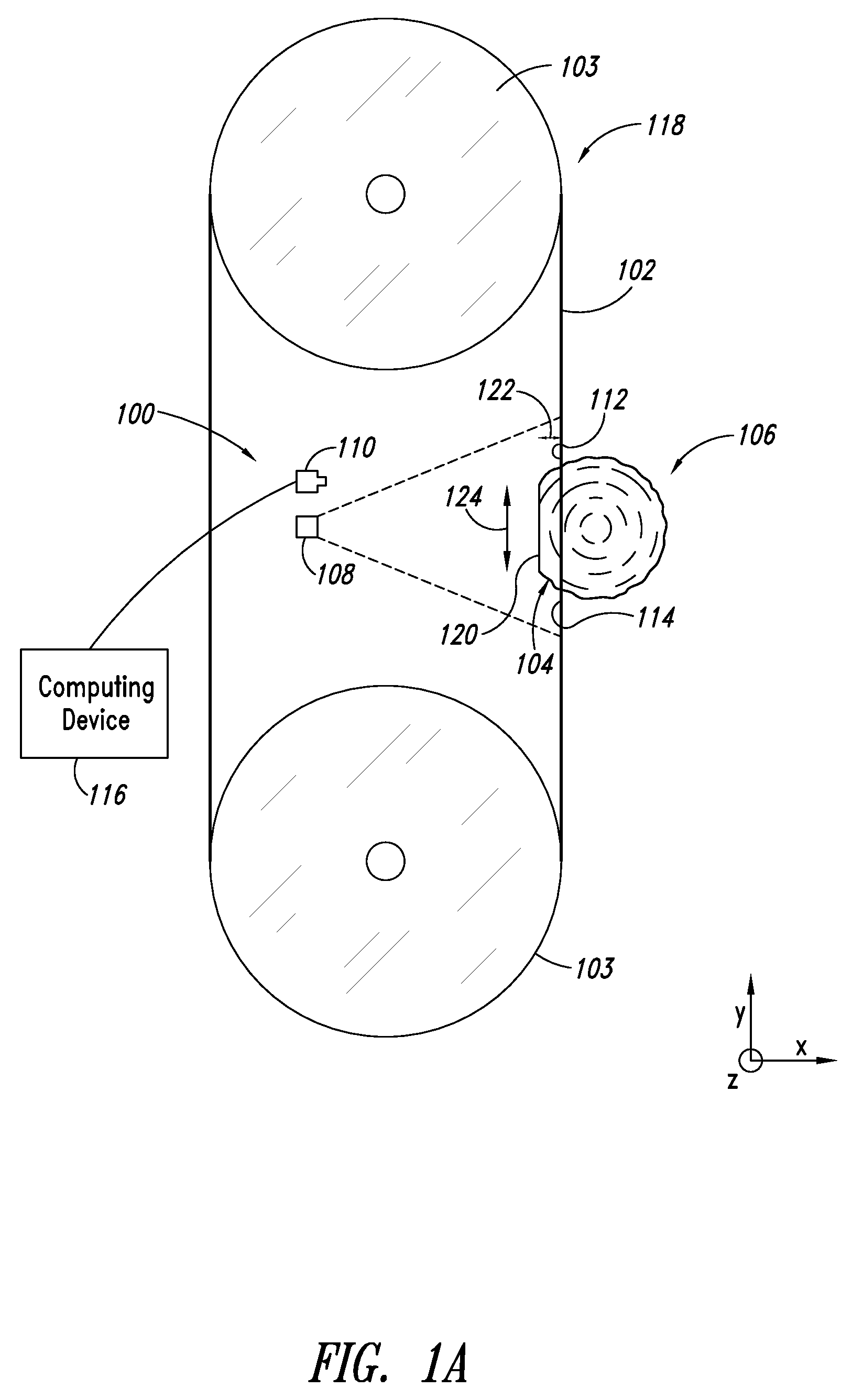

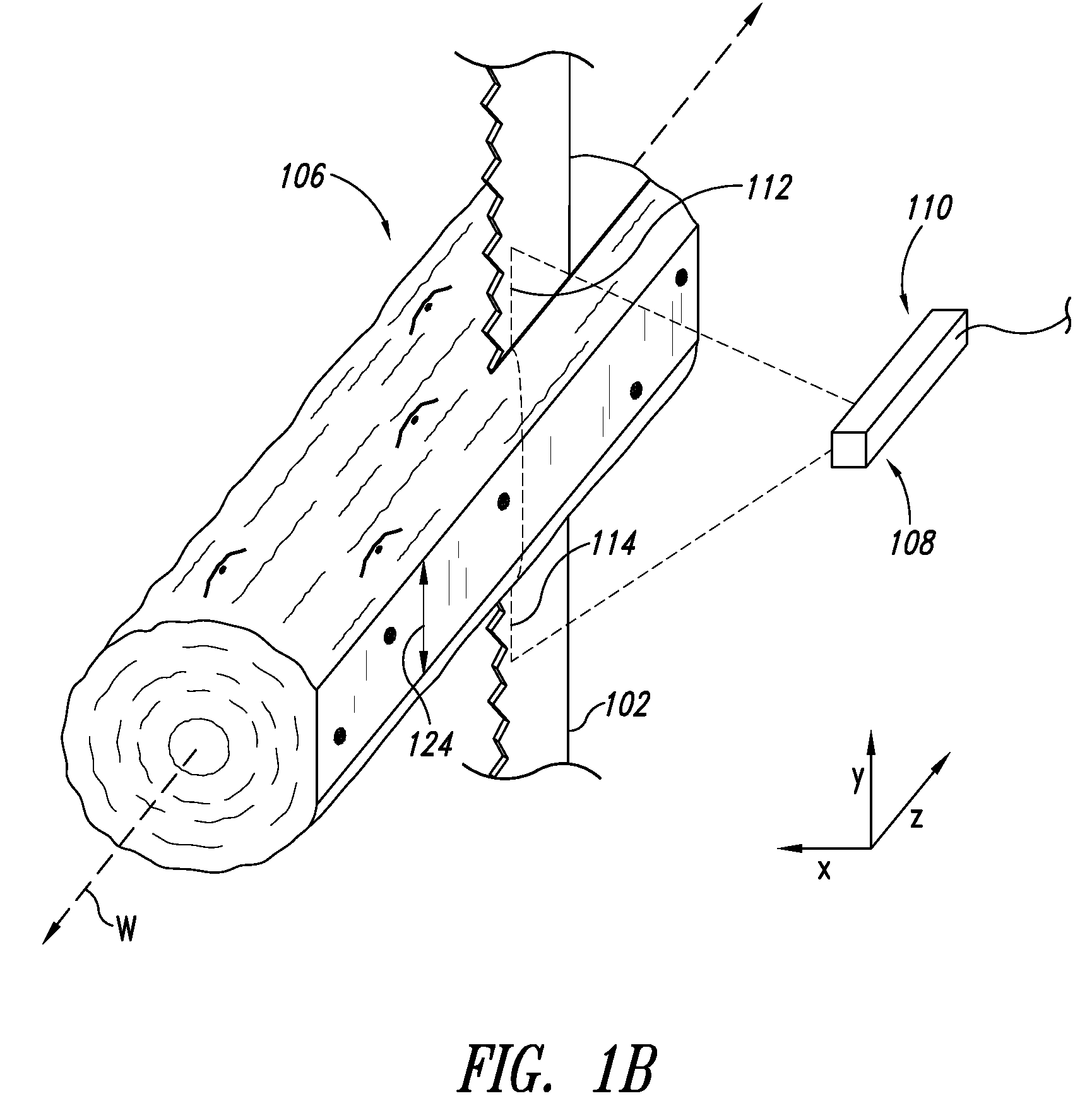

Method and apparatus for singulating, debarking, scanning and automatically sawing and sorting logs into lengths

InactiveUS20030029519A1Reduce stepsMinimize travelAdjusting equipmentFeeding apparatusFiberEngineering

A log handling and cutting system which cuts logs into lengths, and allows for maximum use of fiber. The system includes equipment for singulating the logs, optimally removing the bark from the logs, scanning the true log image, cutting the logs to length, and sorting the cut logs arranged in a sequence of coupled operations. The logs are singulated using a dual quadrant singulation system to provide maximum singulation reliability, thereby allowing a single operator to attend to this process. Once singulated, the logs are fed automatically into a debarker where the diameter and volume are scanned and debarker-operating parameters are set for optimum bark removal. The log is then scanned, tree length, using a unique scanning system, which determines the true image of the log. This enables the determination by computer of the optimum bucking solution of the log as well as a proper sorting of the optimum random lengths. The saws are adjusted in response to the computer solution and the log is positioned by a positioner according to a computer generated reference datum. This results in the log being positioned for cutting to the optimum random lengths. A command signal is sent from the computer to the log sorting system, which tracks the position of the random lengths and allows them to be sorted to the appropriate sort storage bin.

Owner:WEYERHAEUSER CO

Process and apparatus for identifying, tracking and handling lumber to be cut-in-two

ActiveUS7134465B2Automatic control devicesPrecision positioning equipmentIdentification deviceEngineering

Owner:USNRKOCKUMS CANCAR

Systems and methods of orienting a cant in lumber mills

InactiveUS20140238546A1Automatic control devicesPrecision positioning equipmentEngineeringHuman operator

Processing of a cant may include determining a rotational orientation about a longitudinal axis of the cant that optimizes a recovery from the cant from subsequent sawing operations. Such may include optimizing a width of a board that will be produced dependent on the particular rotational longitudinal orientation. Such may include determining a surface area of a board which would be produced, a thickness of a board that would be produced, and / or a volume of a board that would be produced. Such may include accounting for any premium associated with various width categories in which a board that would be produced would fit. Such may account for any premium associated with grade or quality of a board that would be produced. A corresponding signal may provide information to a human operator and / or automated machinery to orient the cant in an optimized orientation.

Owner:WEYERHAEUSER NR CO

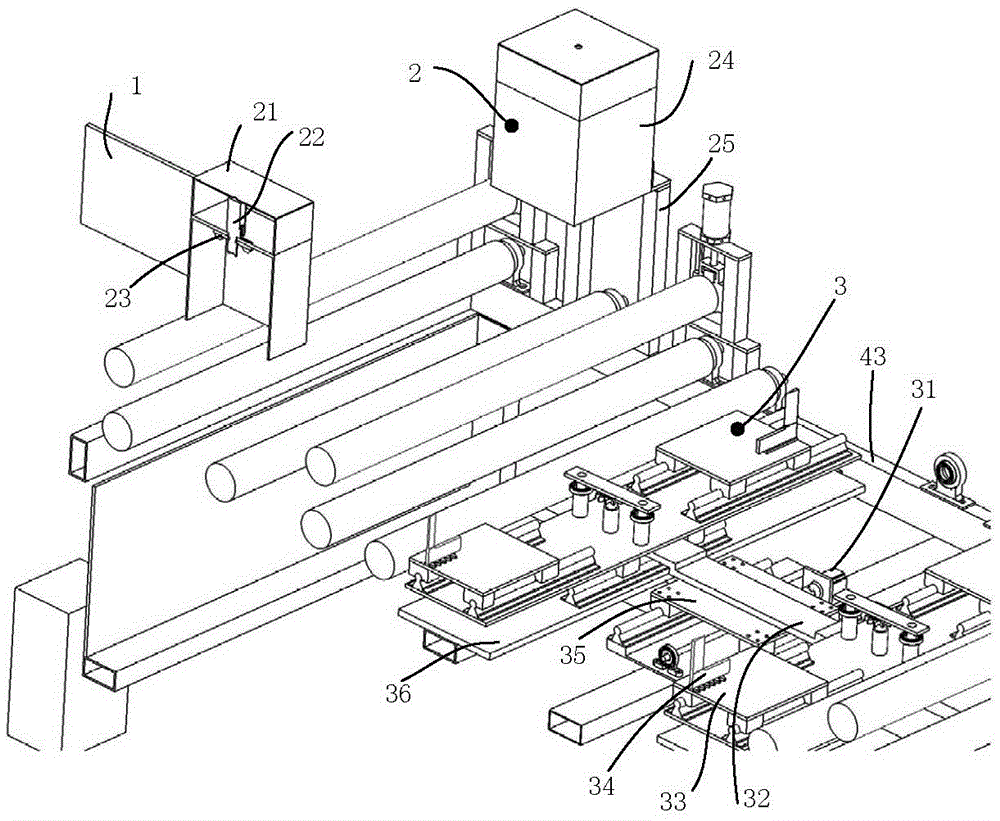

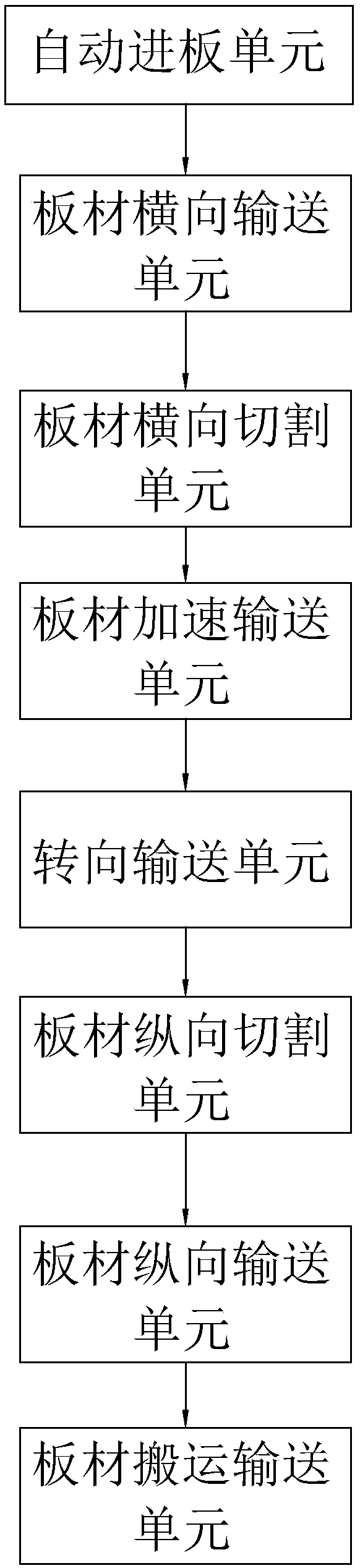

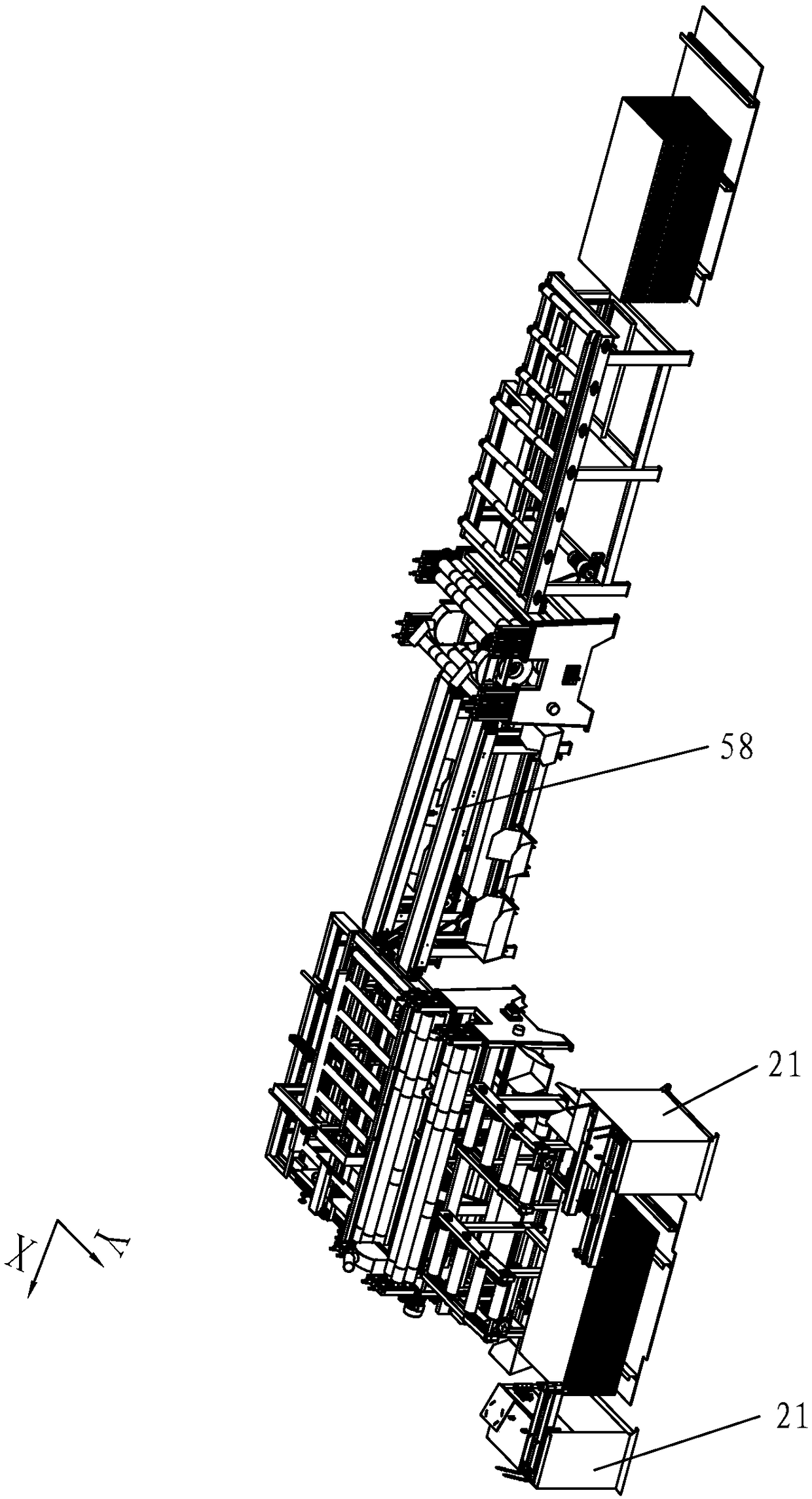

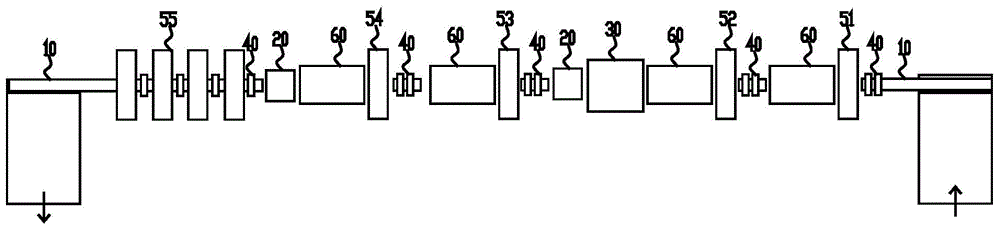

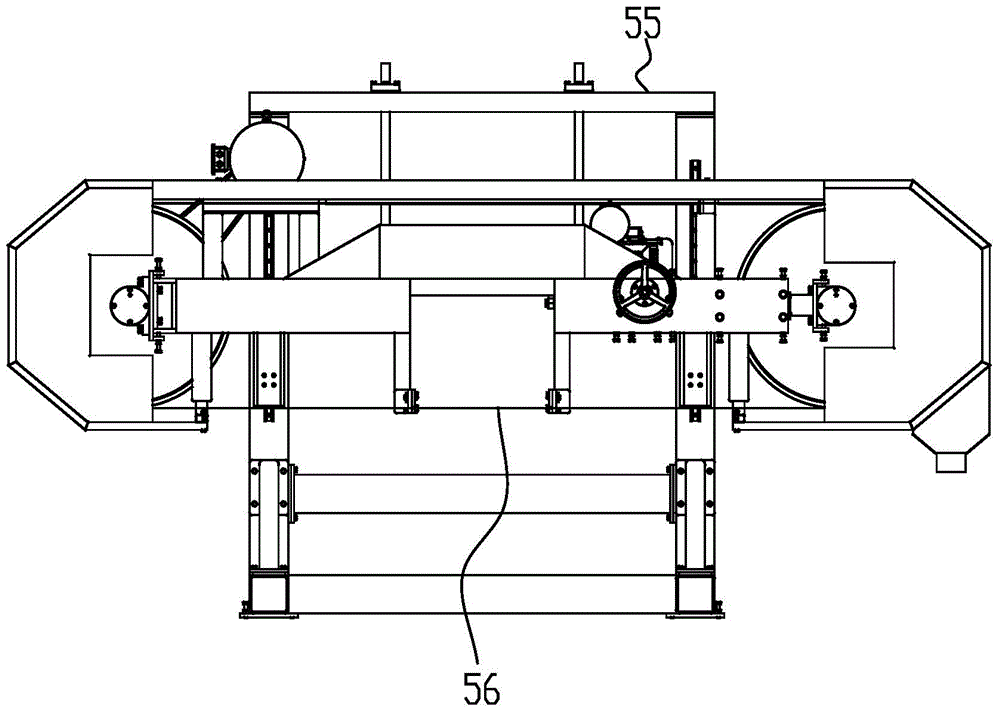

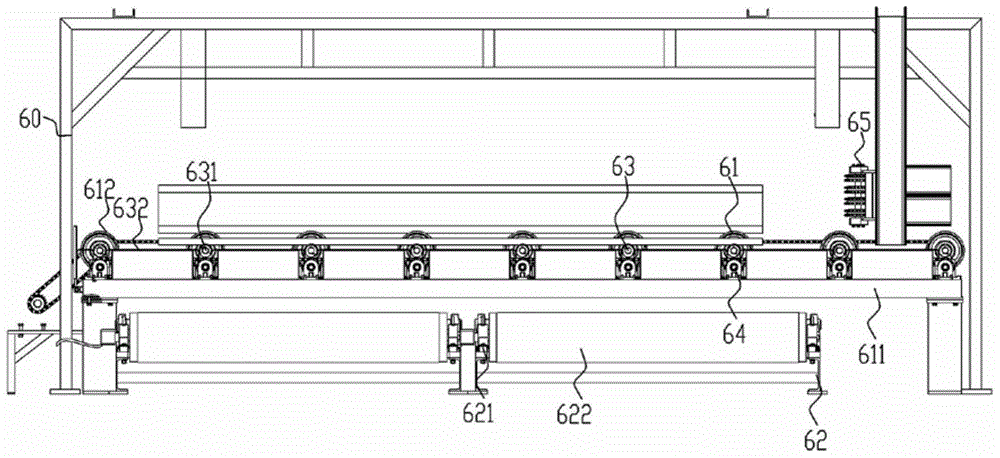

Board processing production line for highly automatically conveying boards

PendingCN109129724ACut Rate Improvement TuningImprove processing efficiencyFeeding devicesLoading equipmentProduction lineDischarge rate

The invention discloses a board processing production line for highly automatically conveying boards. The board processing production line comprises an automatic board feeding unit, a transverse boardcutting unit, a longitudinal board conveying unit and a board carrying and conveying unit; the automatic board feeding unit comprises a board feeding device with a feeding frame; the board carrying and conveying unit comprises positioning stack aligners and a carriage assembly; a transport frame is arranged on the carriage assembly; the feeding frame is connected with the transverse board conveying unit; the transport frame is connected with the longitudinal board conveying unit; and the two positioning stack aligners are arranged on two sides of the transport frame. Both board feeding beforecutting and board discharging after cutting are conducted automatically, safety is achieved, the automatic board feeding unit and the board conveying unit are located on the initial point and the stop point of the whole production line respectively, the board feeding rate and the board discharging rate are both improved, the cutting rate of the production line is improved and adjusted, and thus the processing efficiency of the whole production line is improved.

Owner:福建兴恒机械科技有限公司

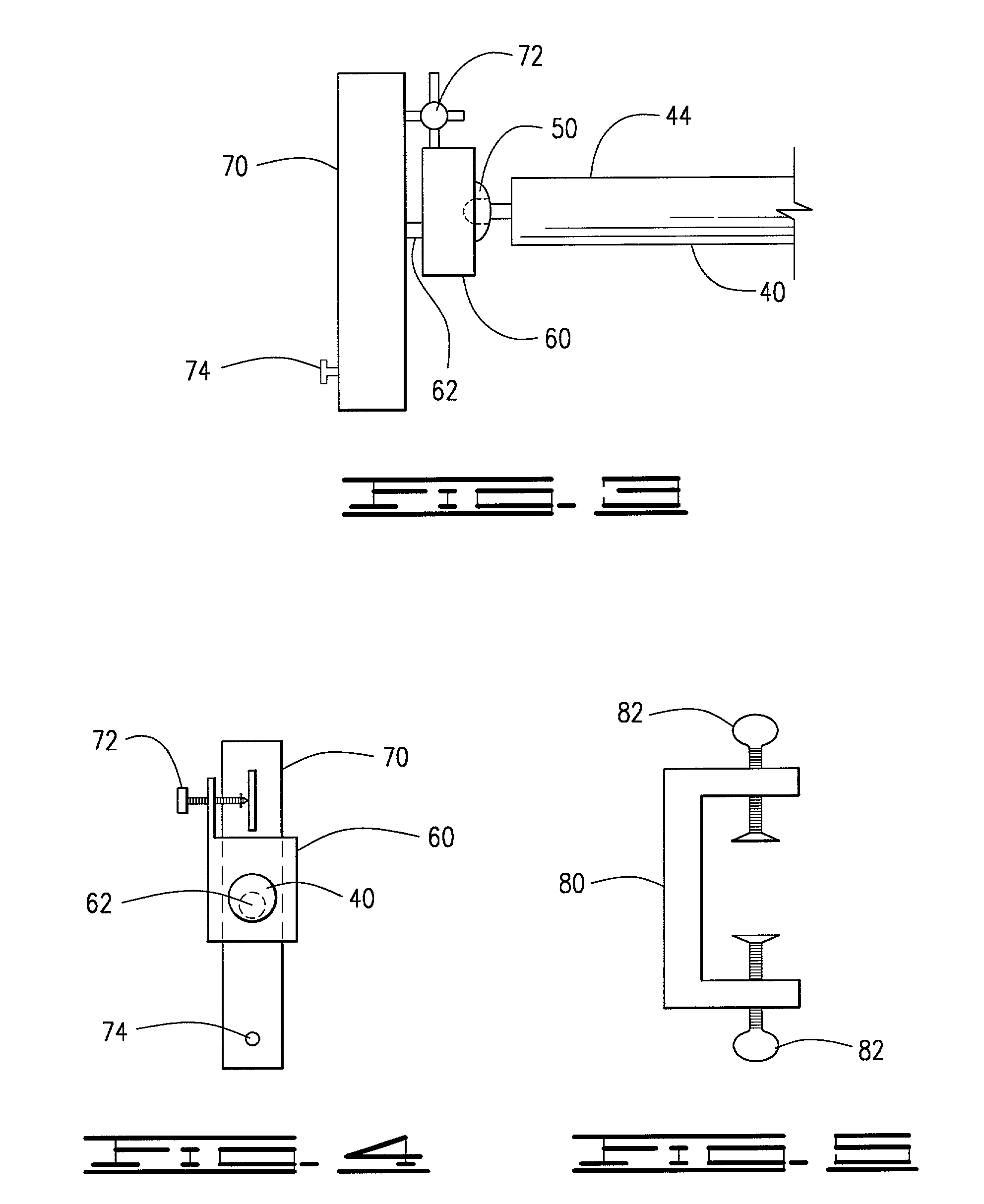

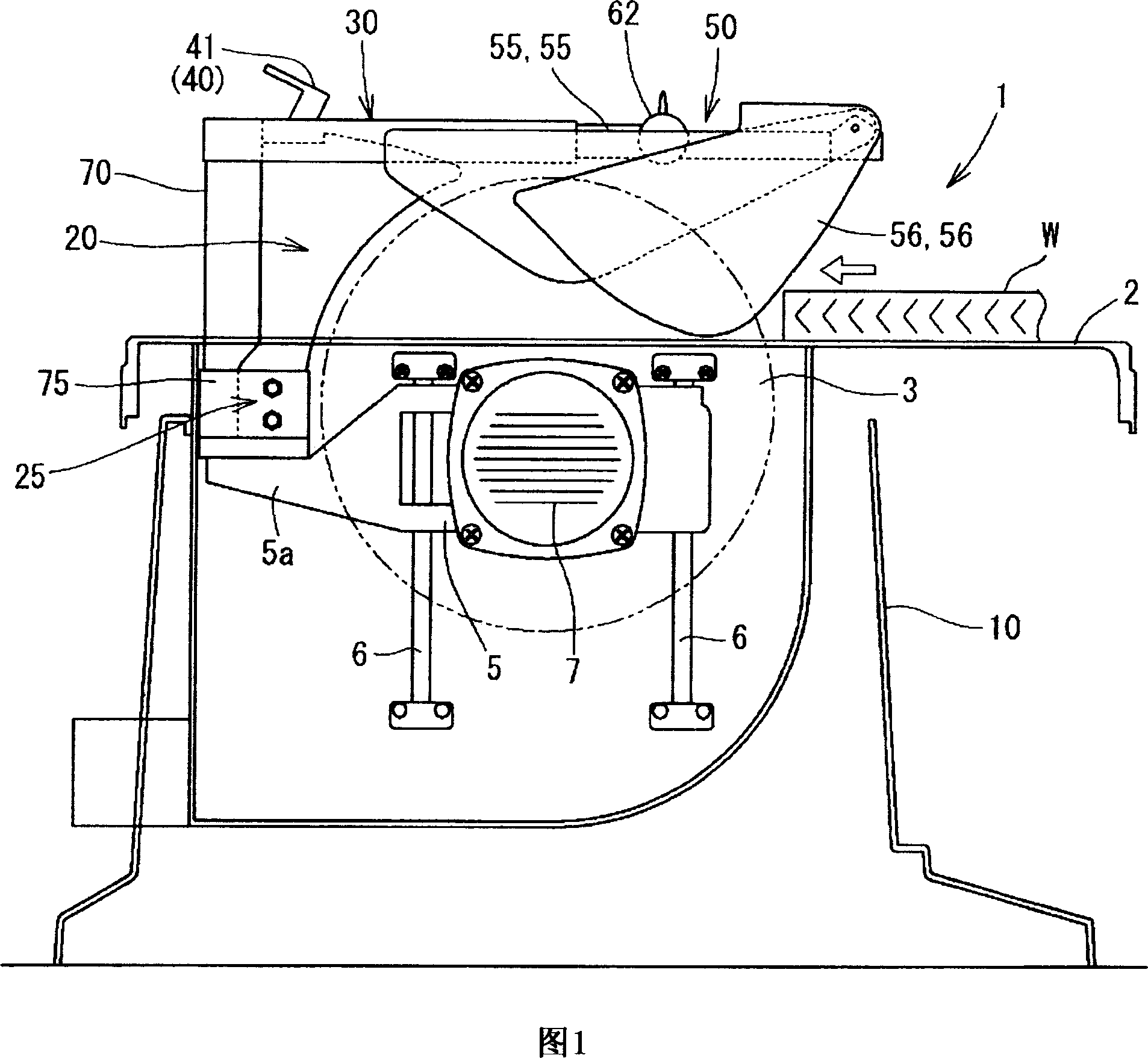

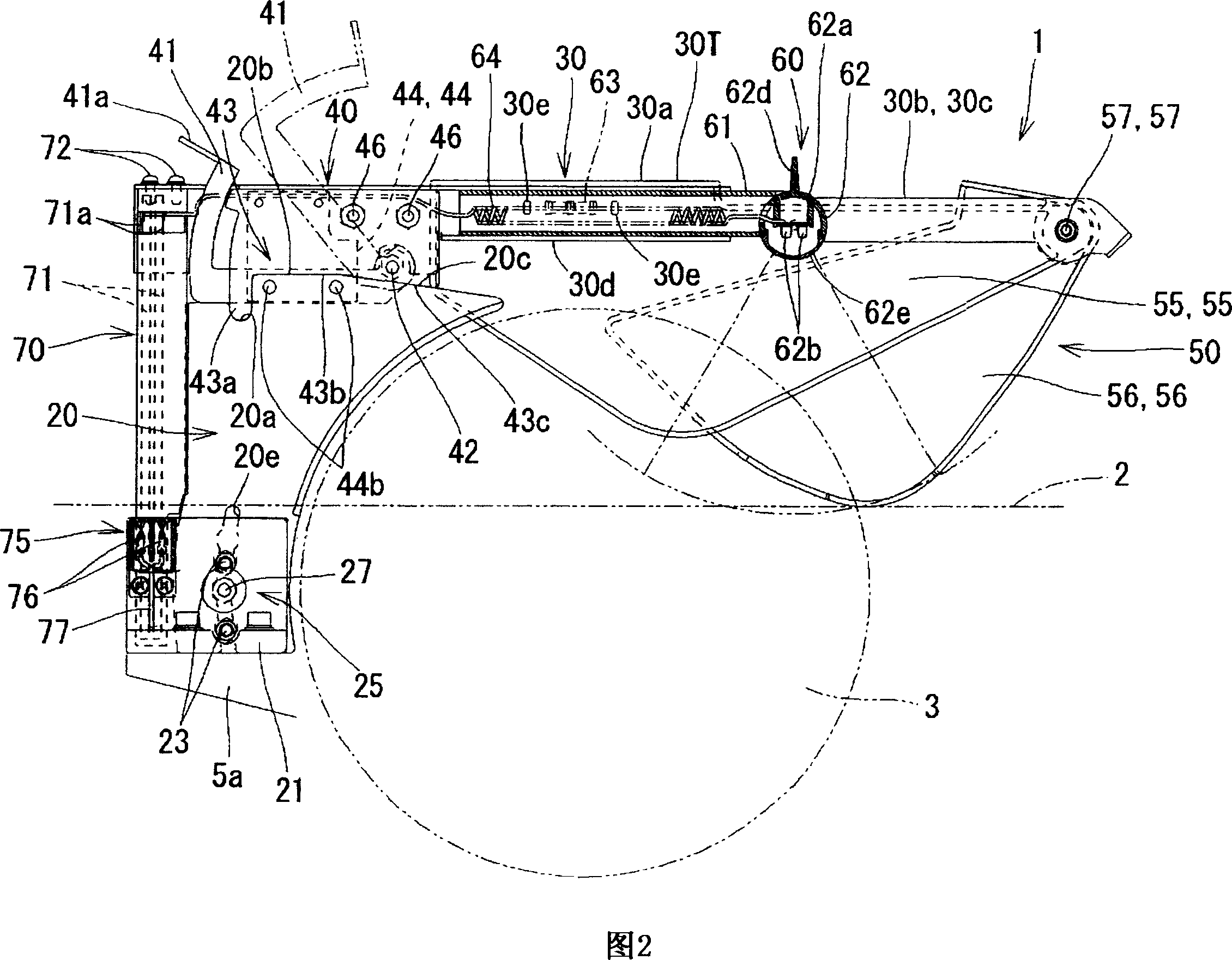

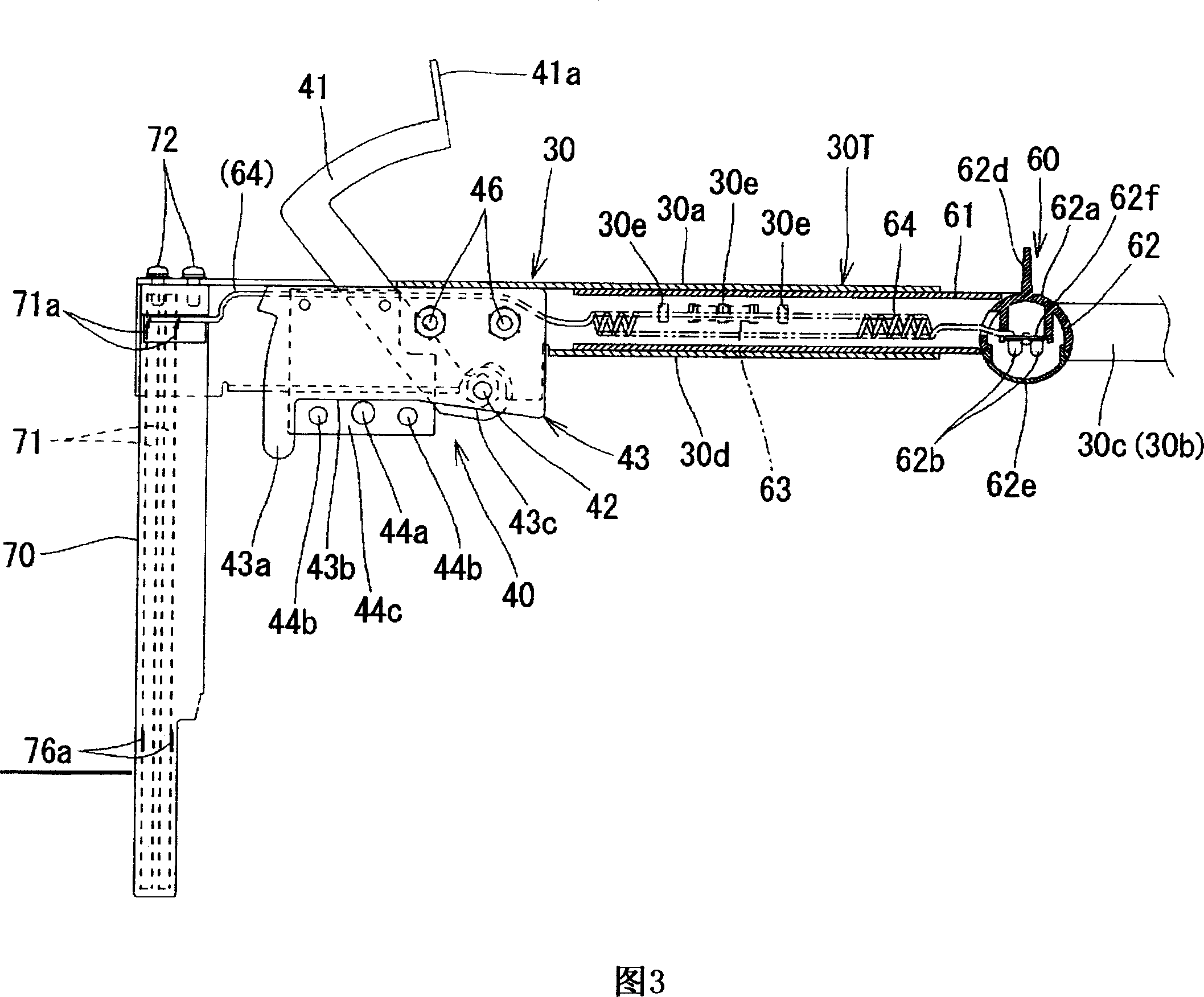

Cutting machine

InactiveCN1958204AEasy alignmentHigh Efficiency Cutting OperationMetal sawing devicesMetal sawing accessoriesEngineeringWorkbench

The purpose of the present invention is to provide a cutting machine that performs cutting work by moving the cutting material on the upper workbench protruding from the saw blade, even in a dark place, the cutting material can be easily carried out relative to the saw The ink line alignment work of the sheet. The guard (50) covering the upper part of the saw blade (3) protruding from the upper surface of the workbench (2) is supported on the mounting frame (30) mounted on the riving knife (20), and on this mounting An illuminating device (60) is arranged on the frame (30) to illuminate the cutting site from above.

Owner:MAKITA CORP

Method and apparatus for singulating, debarking, scanning and automatically sawing and sorting logs into lengths

InactiveUS20030029518A1Reduce disadvantagesReduce stepsAutomatic control devicesPrecision positioning equipmentFiberEngineering

A log handling and cutting system which cuts logs into lengths, and allows for maximum use of fiber. The system includes equipment for singulating the logs, optimally removing the bark from the logs, scanning the true log image, cutting the logs to length, and sorting the cut logs arranged in a sequence of coupled operations. The logs are singulated using a dual quadrant singulation system to provide maximum singulation reliability, thereby allowing a single operator to attend to this process. Once singulated, the logs are fed automatically into a debarker where the diameter and volume are scanned and debarker-operating parameters are set for optimum bark removal. The log is then scanned, tree length, using a unique scanning system, which determines the true image of the log. This enables the determination by computer of the optimum bucking solution of the log as well as a proper sorting of the optimum random lengths. The saws are adjusted in response to the computer solution and the log is positioned by a positioner according to a computer generated reference datum. This results in the log being positioned for cutting to the optimum random lengths. A command signal is sent from the computer to the log sorting system, which tracks the position of the random lengths and allows them to be sorted to the appropriate sort storage bin.

Owner:WEYERHAEUSER CO

Automatic log treatment system

ActiveCN104308903AFully automated processingImprove processing efficiencyFeeding devicesAdjusting equipmentAutomatic controlPrimary treatment

The invention provides an automatic log treatment system, which comprises a conveyer belt for conveying logs among devices, a primary treatment device for removing peripheral round edges of the logs, and a joint cutting device for cutting the logs in a centralized way. According to the automatic log treatment system, multiple horizontal type saws are combined and are used for accurately cutting the side edges of the logs; under the circumstance of removing edge materials, available log base materials are kept maximally, the primary log treatment accuracy is improved, and full-automatic control is realized. The logs subjected to primary processing are automatically cut in sequence by the joint cutting device via the multiple horizontal type saws, and are cut into multiple needed plates in one step, the log treatment efficiency is improved, and plate cutting and quick and automatic treatment are realized. The automatic log treatment system can be used for improving the log treatment efficiency, reducing the waste and lowering the labor intensity of workers.

Owner:HEBEI RUIFUXIANG MACHINERY MFG

Automated shingle milling system

Saw mill for machine vision detection of undesirable features in the wood in shingles being cut from billets and automated optimized saw operation are disclosed. The saw mill includes a transport system that carries the billet through a butt-trimming saw, past a machine vision station, into an transition station for changing direction of travel of the billet and aligning the billet for travel into the subsequent gang rip saw station. The machine vision station determines any defects in the billet, grades the billet according to order-specific parameters, determines the optimal saw cut to maximize the value of the shingle, and sends control data to the gang rip saw controller, to position the saw blades for the optimal saw cut(s) for the shingle. A sorting system receives instructions from the visual imaging system and automatically shunts the product coming from the gang rip saw station into the appropriate container.

Owner:LONGFELLOW JAMES L

Dual alternating transverse feeding mechanism for lumber edgers

InactiveUS6308756B1Fast and efficient and accurate mannerEasy to produceMulti-purpose machinesShearing machinesControl signalElectrical control

A lumber feeding mechanism for feeding lumber pieces laterally on a supply conveyor after scanning them with a light scanner to determine a reference axis for the optimum yield of boards. The lumber pieces are fed by dogs from a start position to a feed position in alignment with a feed conveyor which feeds such pieces longitudinally through a lumber edger with adjustable cutting saws. The feeding mechanism includes alternating sets of first and second dogs which are pivoted between a raised position for engagement with the rear edges of the lumber pieces to push such pieces from the start position to the feed position and a retracted position to enable the dogs to be returned to the start position passing on opposite sides or on the same side of the piece. Electrical actuation motors or fluid cylinder actuation motors with rotating output gears are used to pivot the dogs in response to a control signal produced by an electrical control system. The dogs are moved between the start position and the feed position along guides by drive cylinders and the lumber pieces are engaged by air stop cylinders as the pieces are moved toward the feed position to accurately position such pieces at the feed position where they are engaged by hold-down rolls and fed by the feed conveyor through the lumber edger.

Owner:USNR

Apparatus for controlled curved sawing or cutting of two-faced cants

InactiveUS20030034090A1Preventing undue saw stressEliminate needAutomatic control devicesPrecision positioning equipmentMechanical engineeringControl curve

In combination with a cant sawing or cutting unit, a system for guiding two-faced cants through the cut along the line of their natural curvature. The system comprises, at the infeed and outfeed ends of the unit, laterally moveable roller means for clamping upon parallel planar faces of the cant and imparting to it a pivotal movement in the horizontal plane while it is moving forward through the cut, thereby causing the saws or cutters to follow along a controlled curve in relation to the natural curvature of said cant.

Owner:BID GRP TECH LTD +1

Systems and methods for monitoring a saw blade during sawing

ActiveUS7886642B2Improve abilitiesAutomatic control devicesPrecision positioning equipmentSingle imageEngineering

A light source is used to illuminate a sawn portion of a piece of wood and exposed surfaces of the saw blade on both sides of the sawn portion. The sawn portion and the exposed surfaces of the saw blade are then imaged substantially concurrently using a single image generator. At least one geometric characteristic of the sawn portion and at least one geometric characteristic of the saw blade are determined based on the imaging.

Owner:WEYERHAEUSER NR CO

Econo-optimized board edger

ActiveUS8105009B1Automatic control devicesPrecision positioning equipmentEngineeringMechanical engineering

A method of positioning lumber in a given orientation in a handling apparatus having a base frame, a longitudinal transport assembly, and at least two gripper arm support platforms with a pair of gripper arms positioned on each of the support platforms. A work piece is gripped with the gripper arms without the work piece engaging the longitudinal transport assembly. The gripper arms are adjusted on at least one of the support platforms in a direction generally perpendicular to the longitudinal transport assembly in order to selectively position the work piece. The work piece is then brought into engagement with the transport assembly and the gripper arms are released from the work piece.

Owner:WPS INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com