Patents

Literature

77results about How to "Accurate and reliable operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

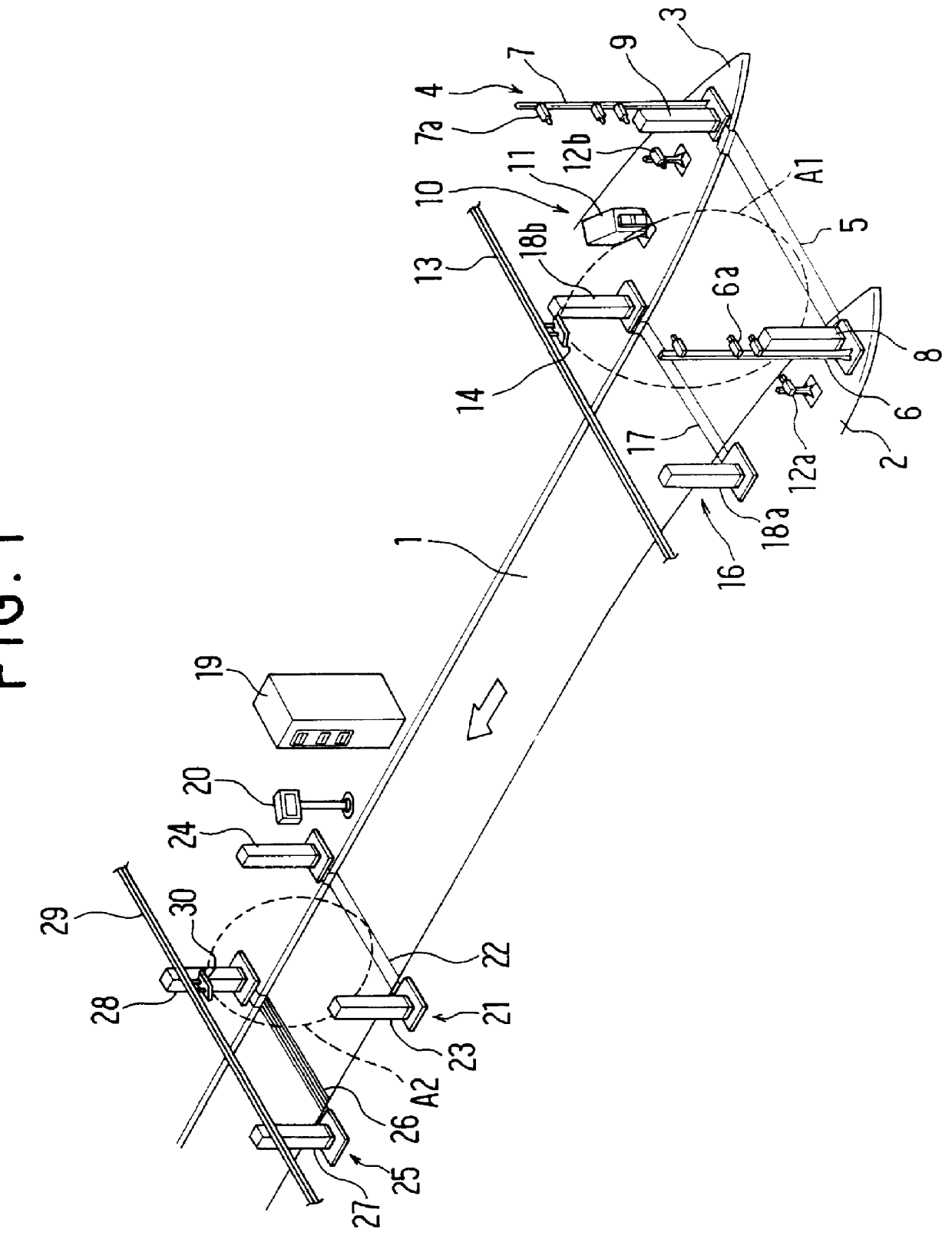

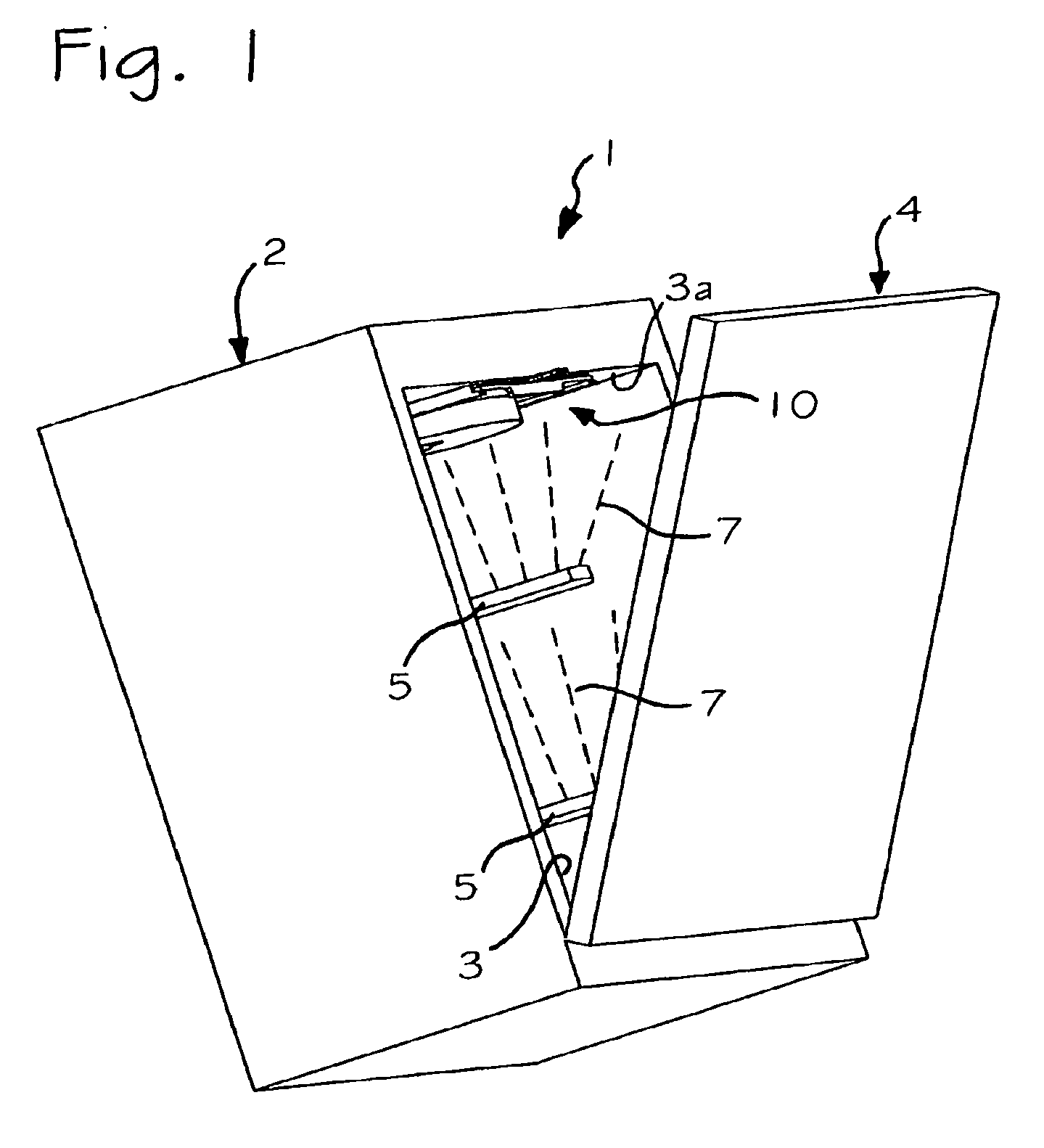

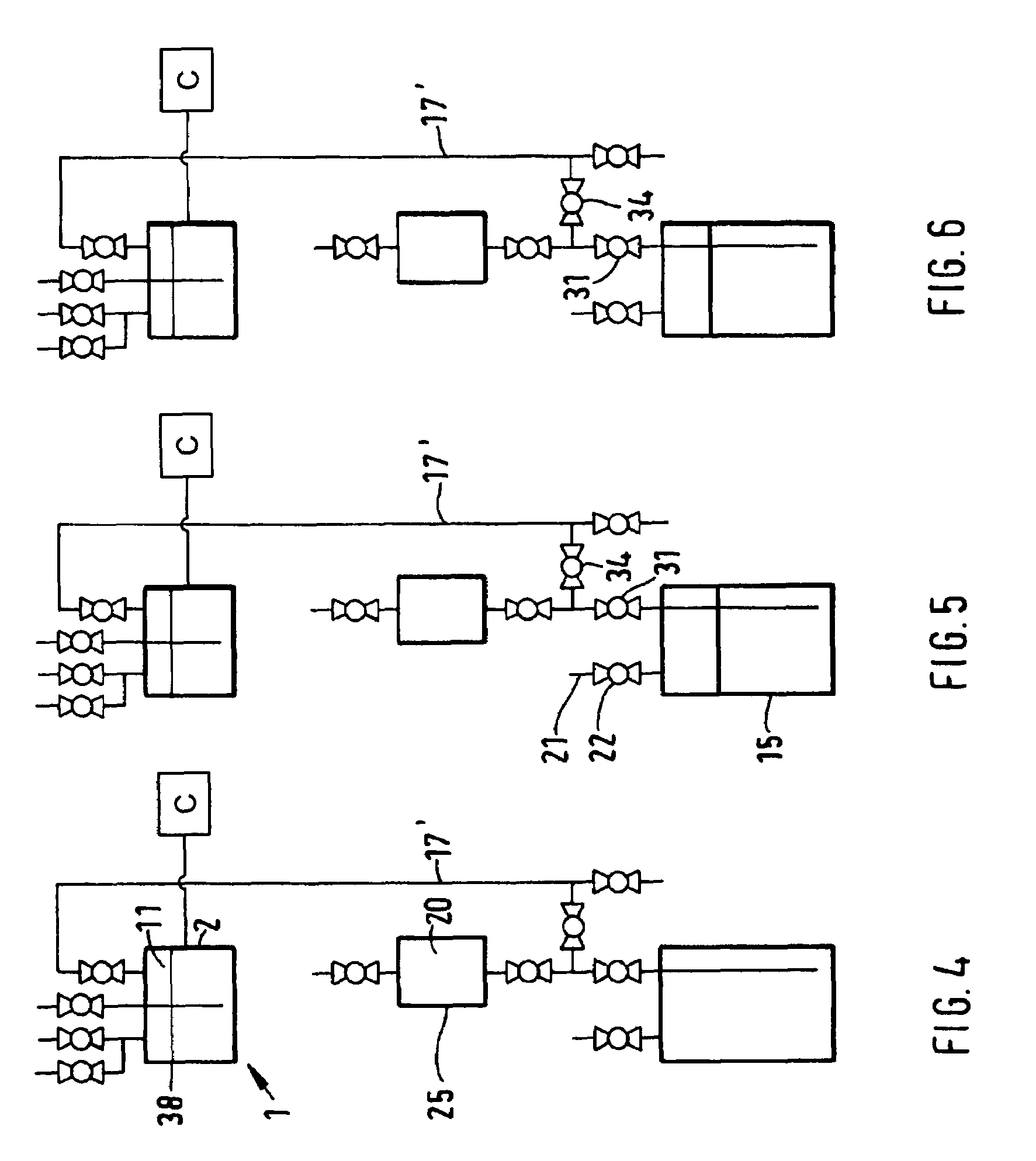

Toll collection system of toll road and in-vehicle unit for the same

InactiveUS6042008AAccurate and reliable operationEasy to passTicket-issuing apparatusDetection of traffic movementDiscriminatorToll road

To ensure the toll collection of a vehicle carrying an in-vehicle unit without stopping the vehicle at an entrance toll gate or an exit toll gate, an entrance toll gate lane is equipped sequentially from the entrance with a vehicle class discriminator, an entrance vehicle number reader, a first antenna, a vehicle detector, a ticket issuer, a display unit, a vehicle detector, a second antenna and a start detector. The first antenna communicates with an in-vehicle unit of a coming vehicle to write the entrance toll gate data. The display unit is caused, when the communication succeeds, to permit the passage of the vehicle therethrough. When the communication fails, the display unit is caused to stop the vehicle, and the ticket issuer issues the ticket. The second antenna writes the vehicle class data and the registered number data, as detected by the vehicle class discriminator and the vehicle number reader, in an in-vehicle unit. Thus, the existing facilities can be used as they are.

Owner:DENSO CORP

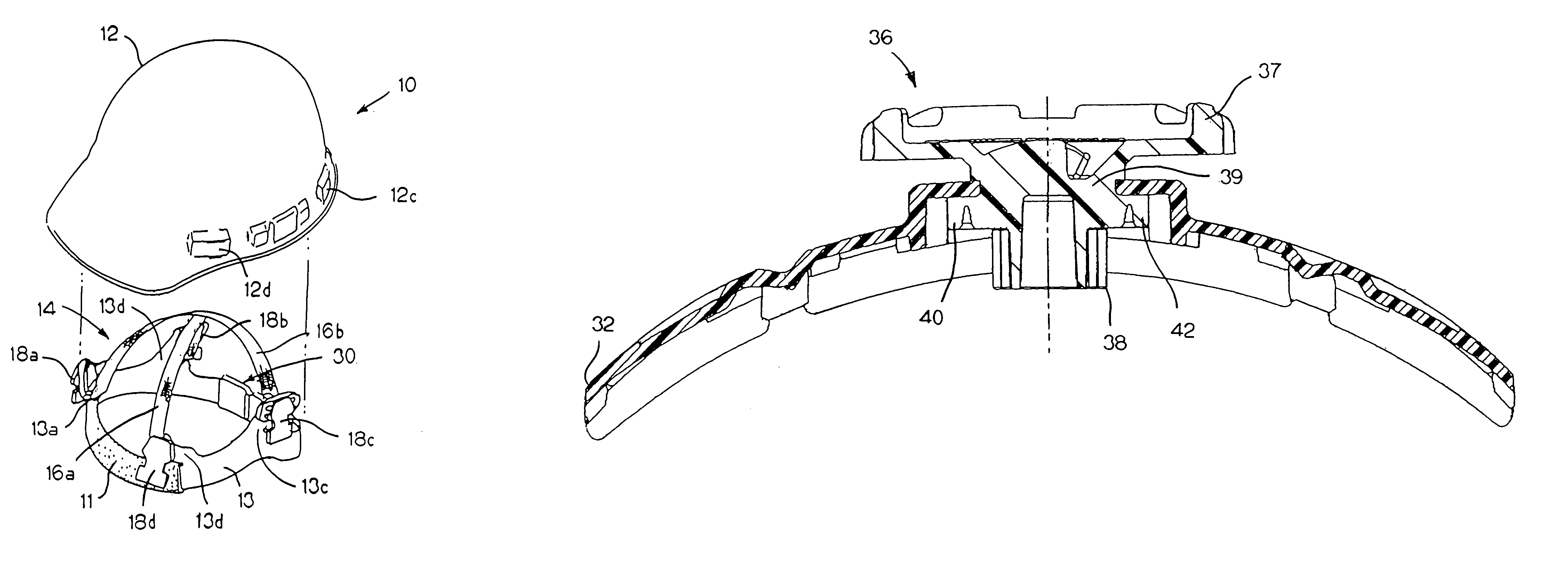

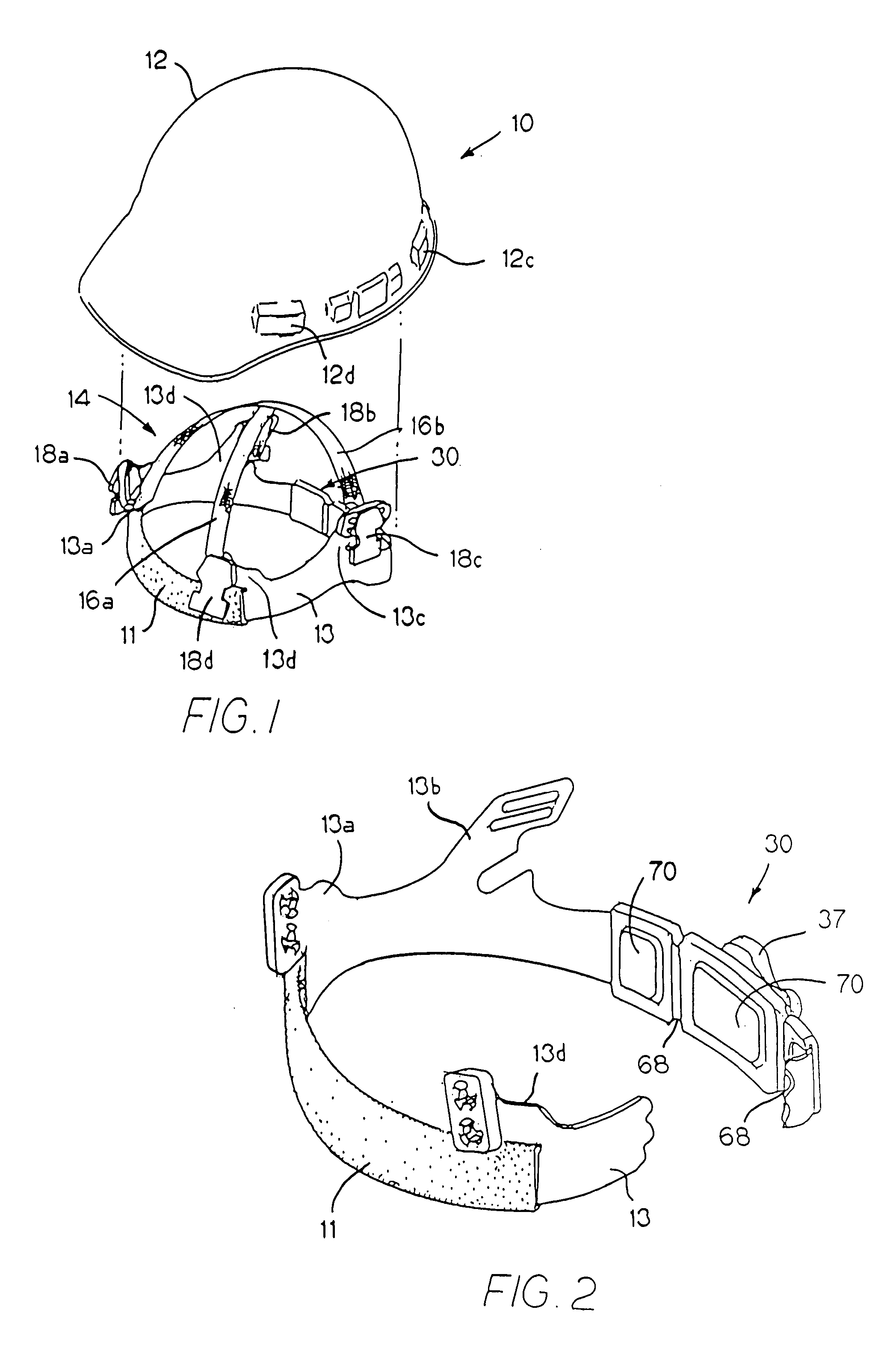

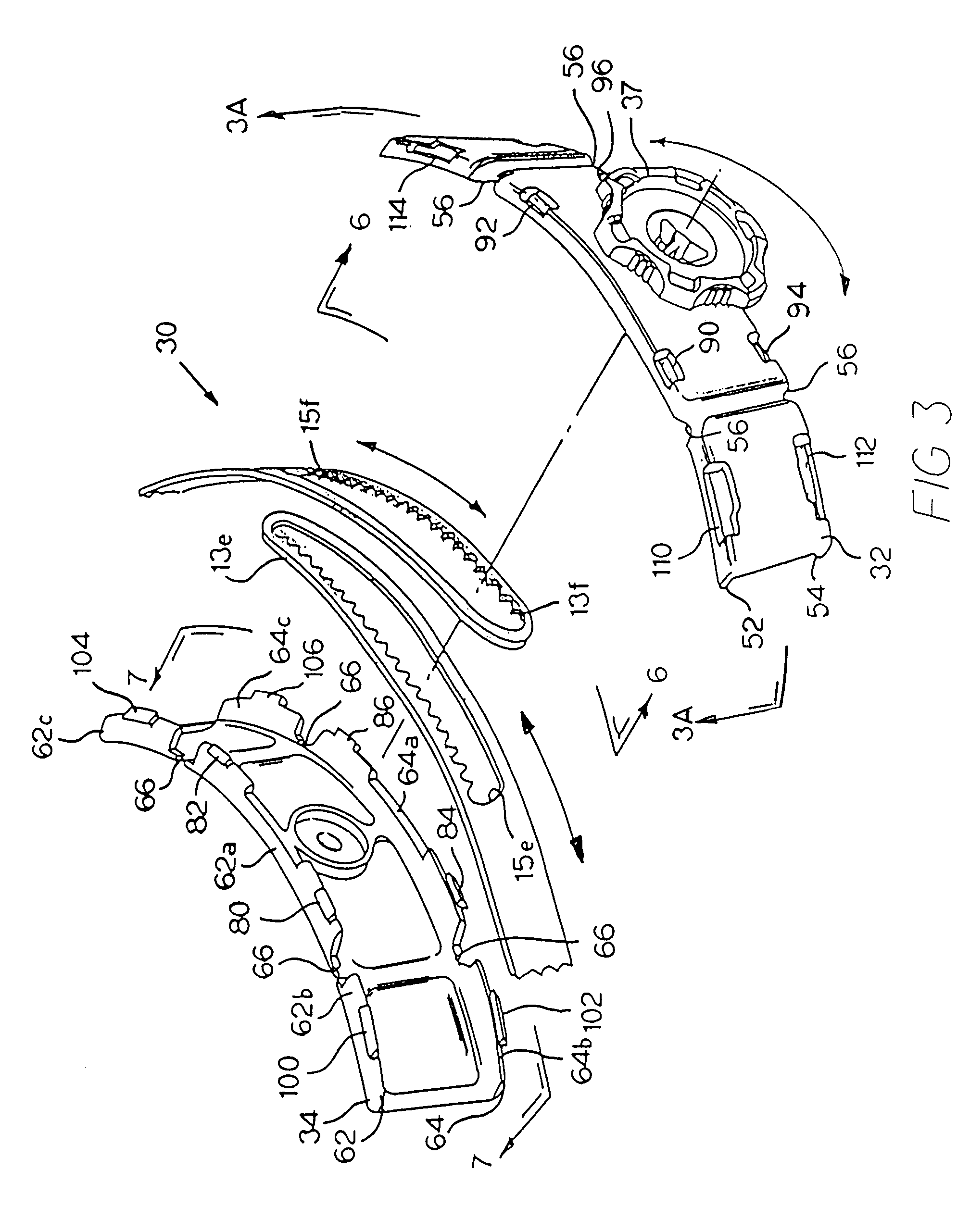

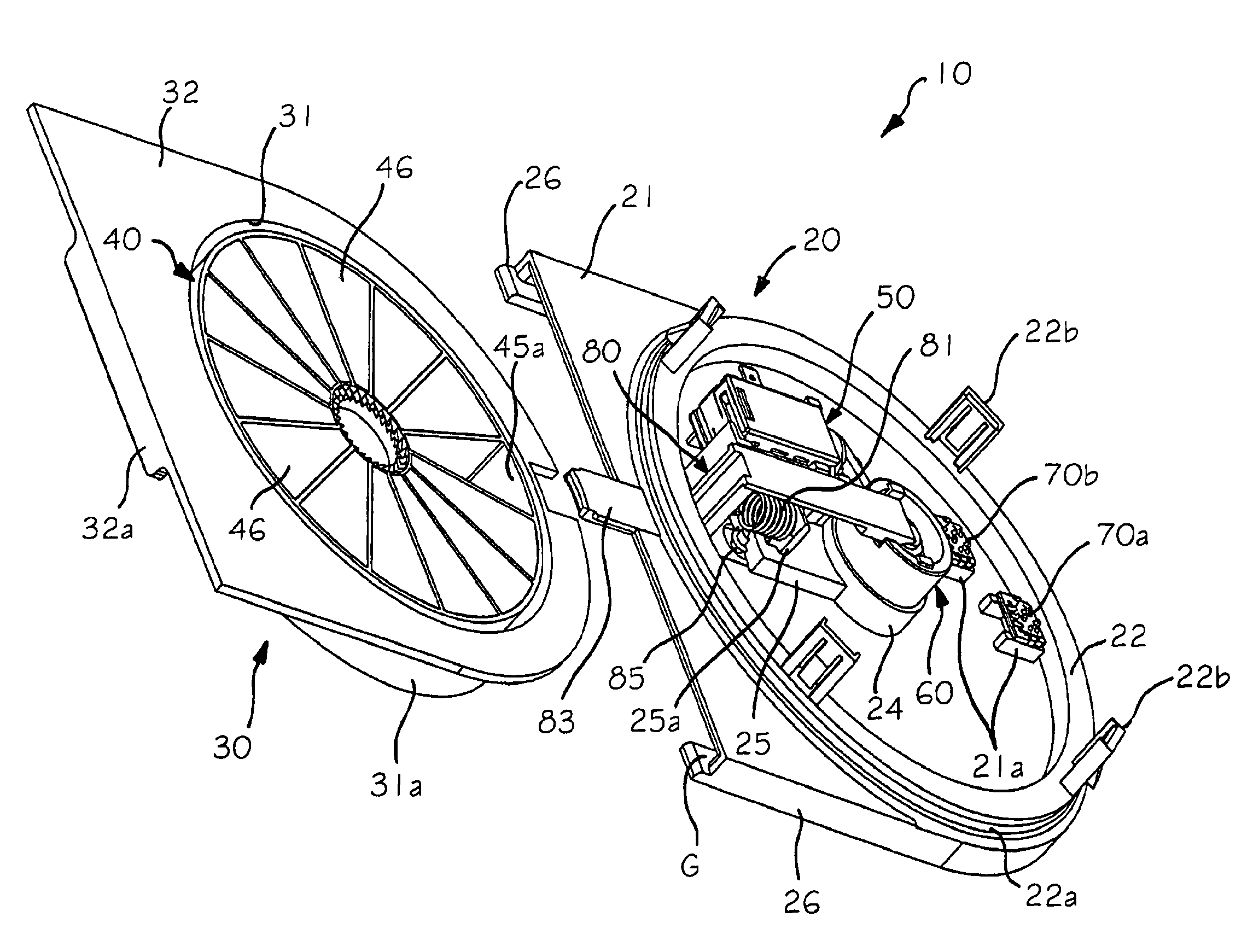

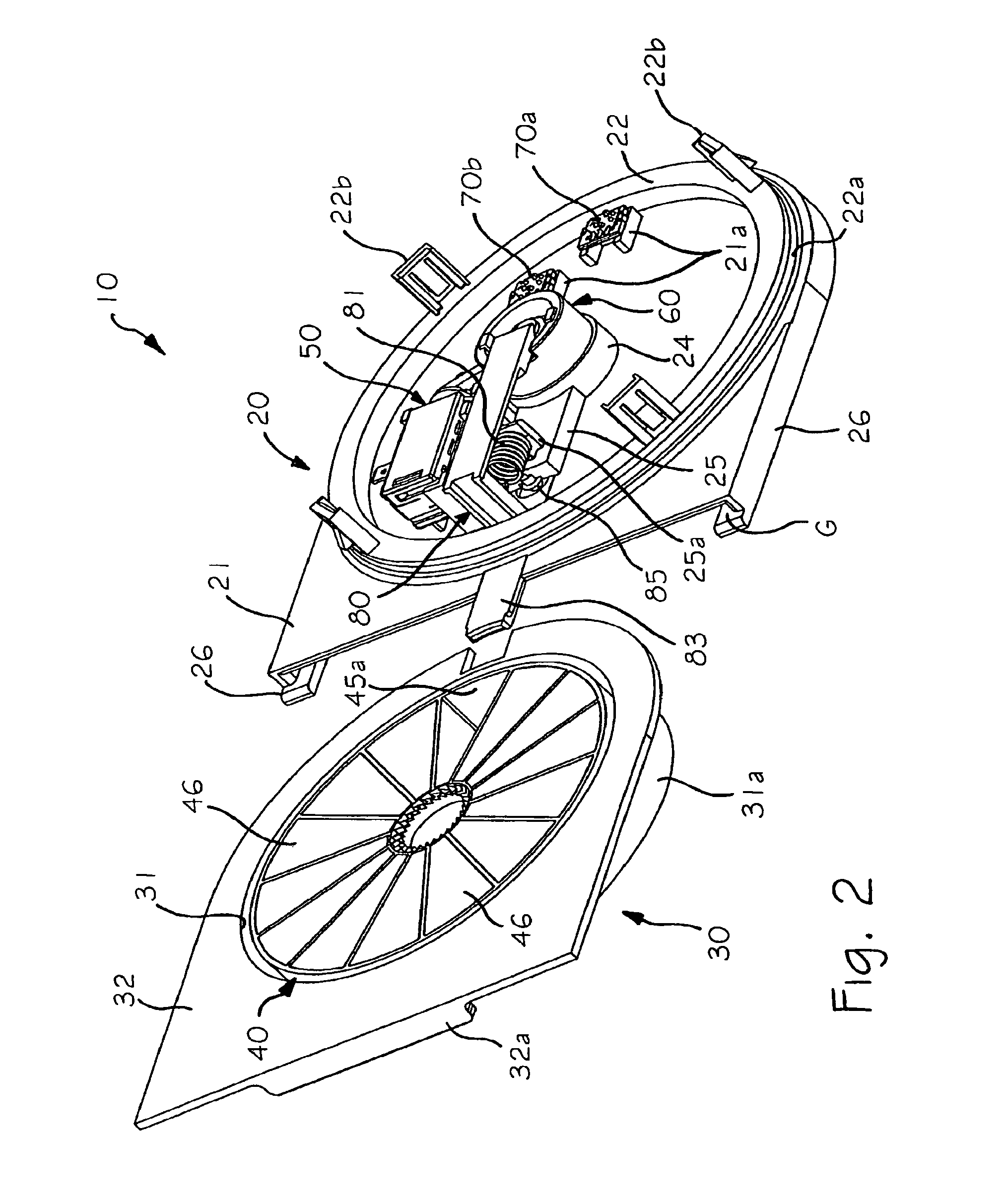

Ratchet mechanism with unitary knob and pinion construction

ActiveUS7043772B2Minimizes numberAccurate and reliable operationHatsHeadwear capsGear wheelEngineering

Owner:E D BULLARD

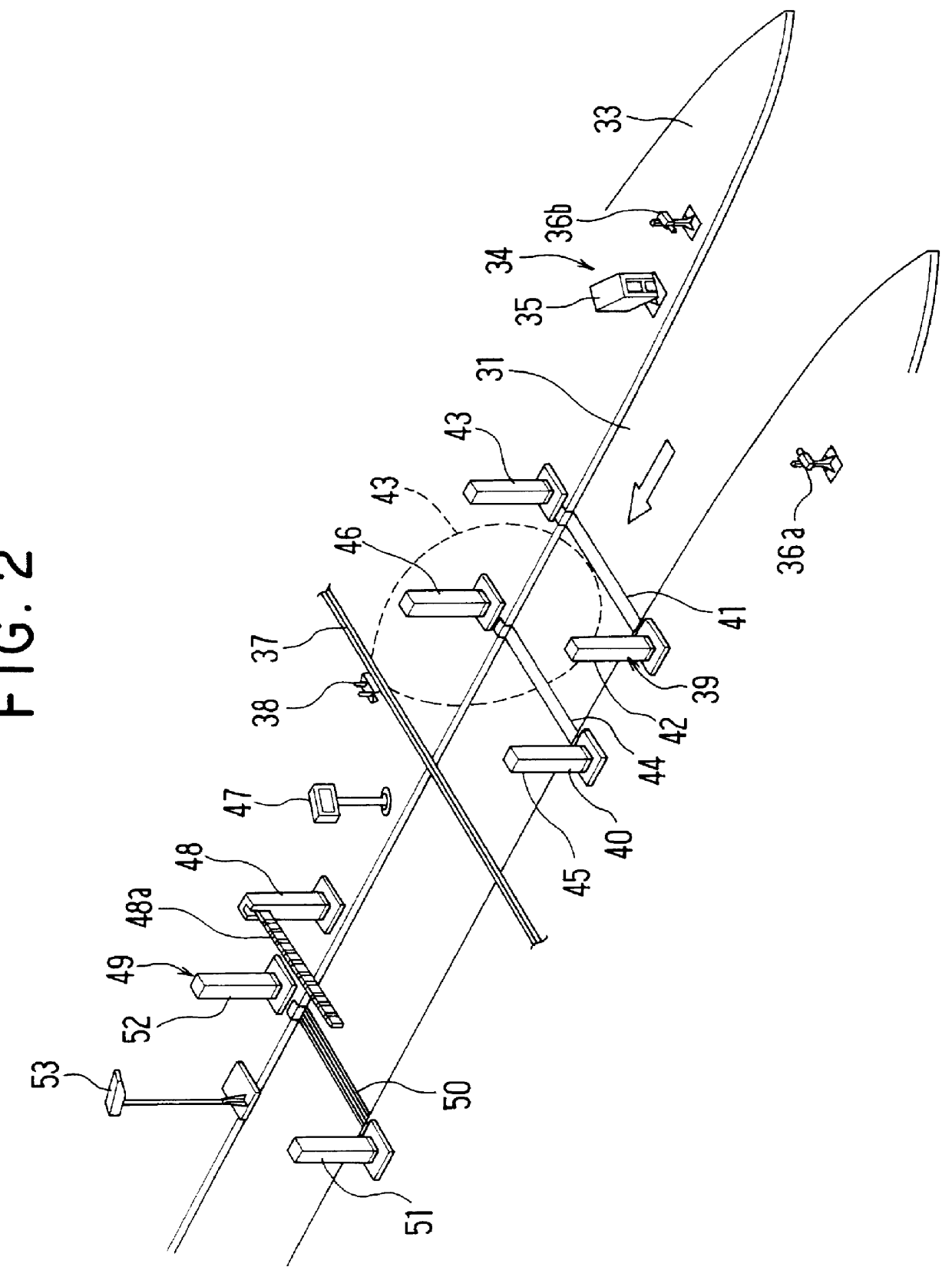

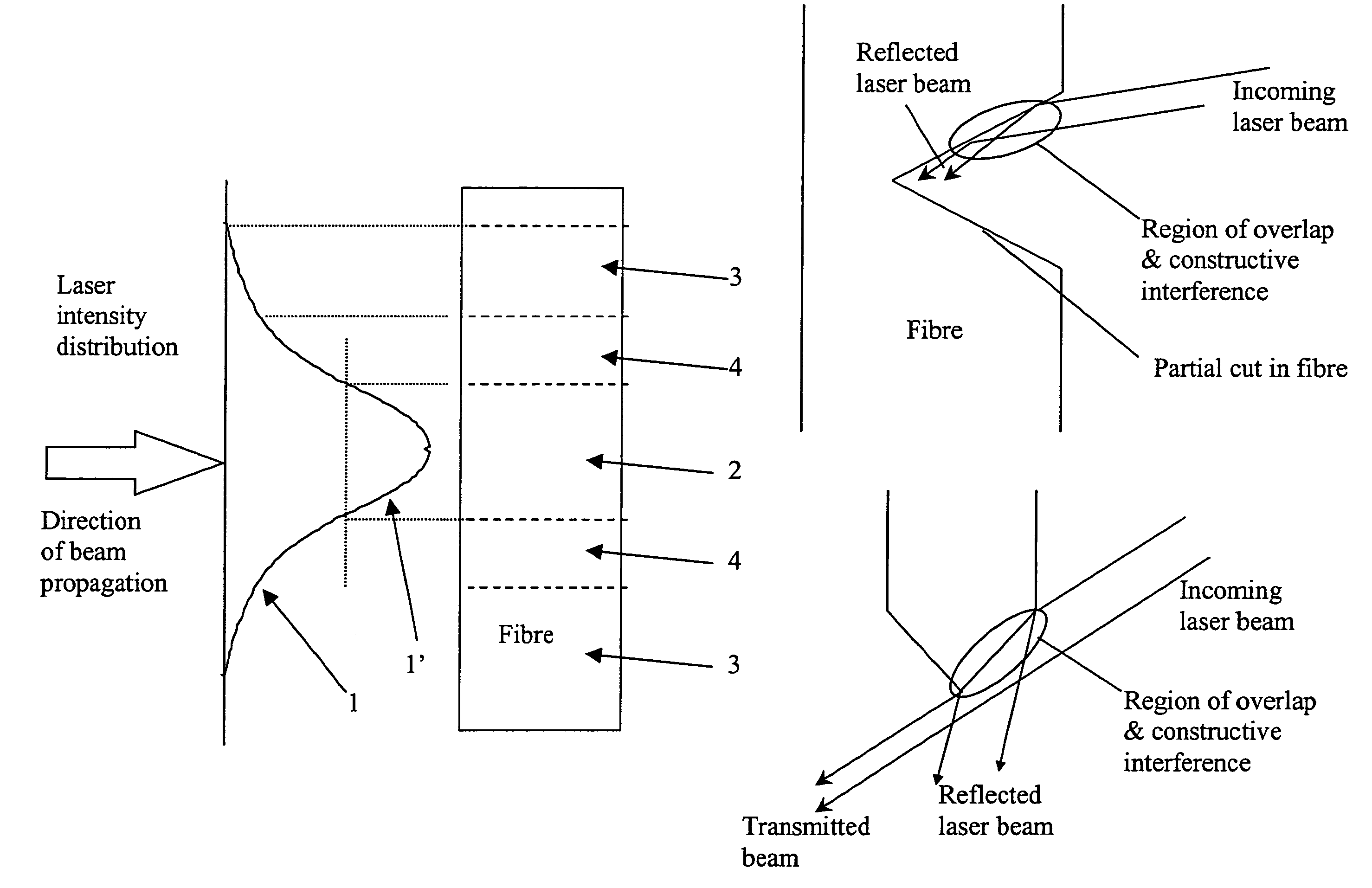

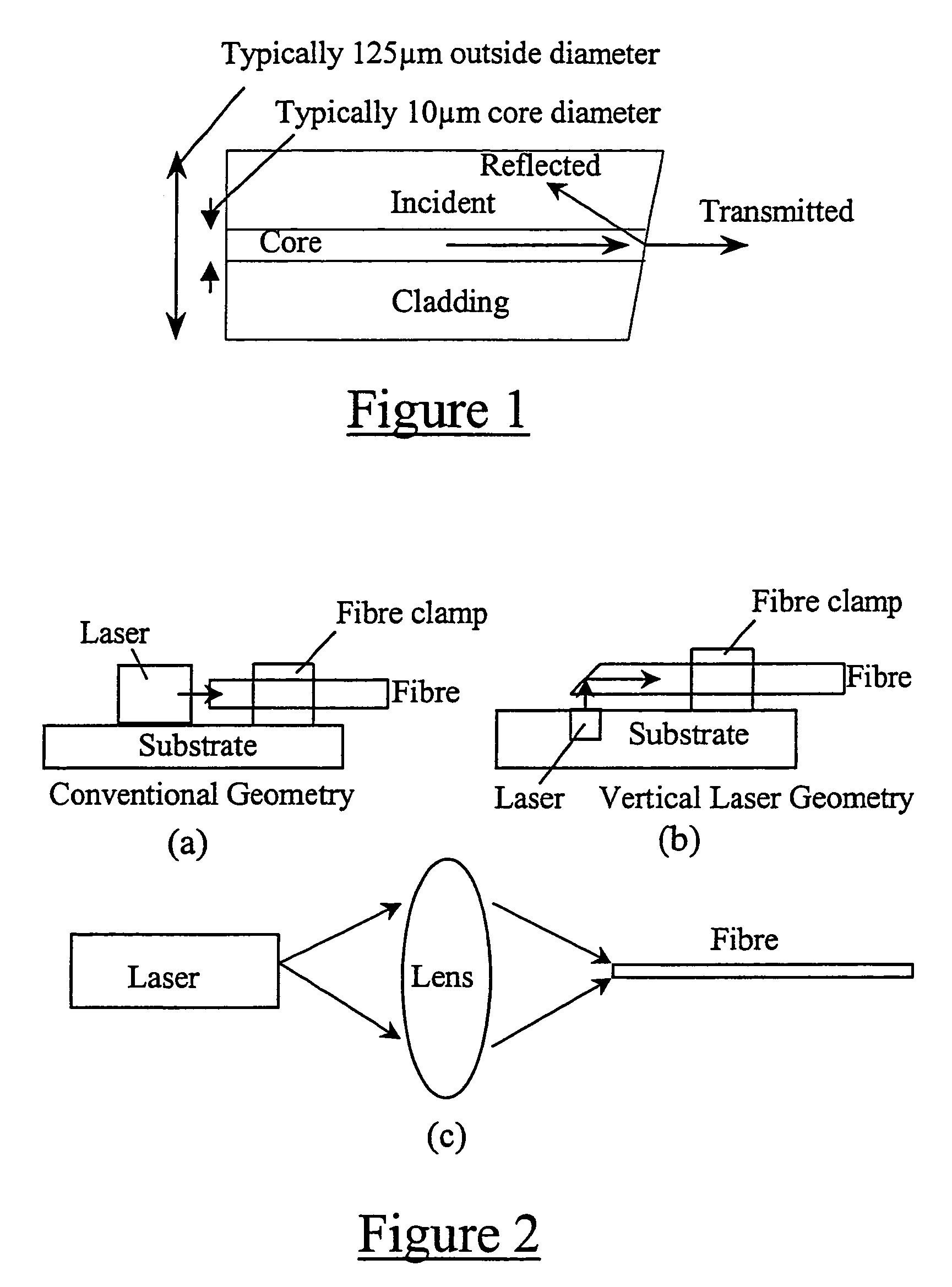

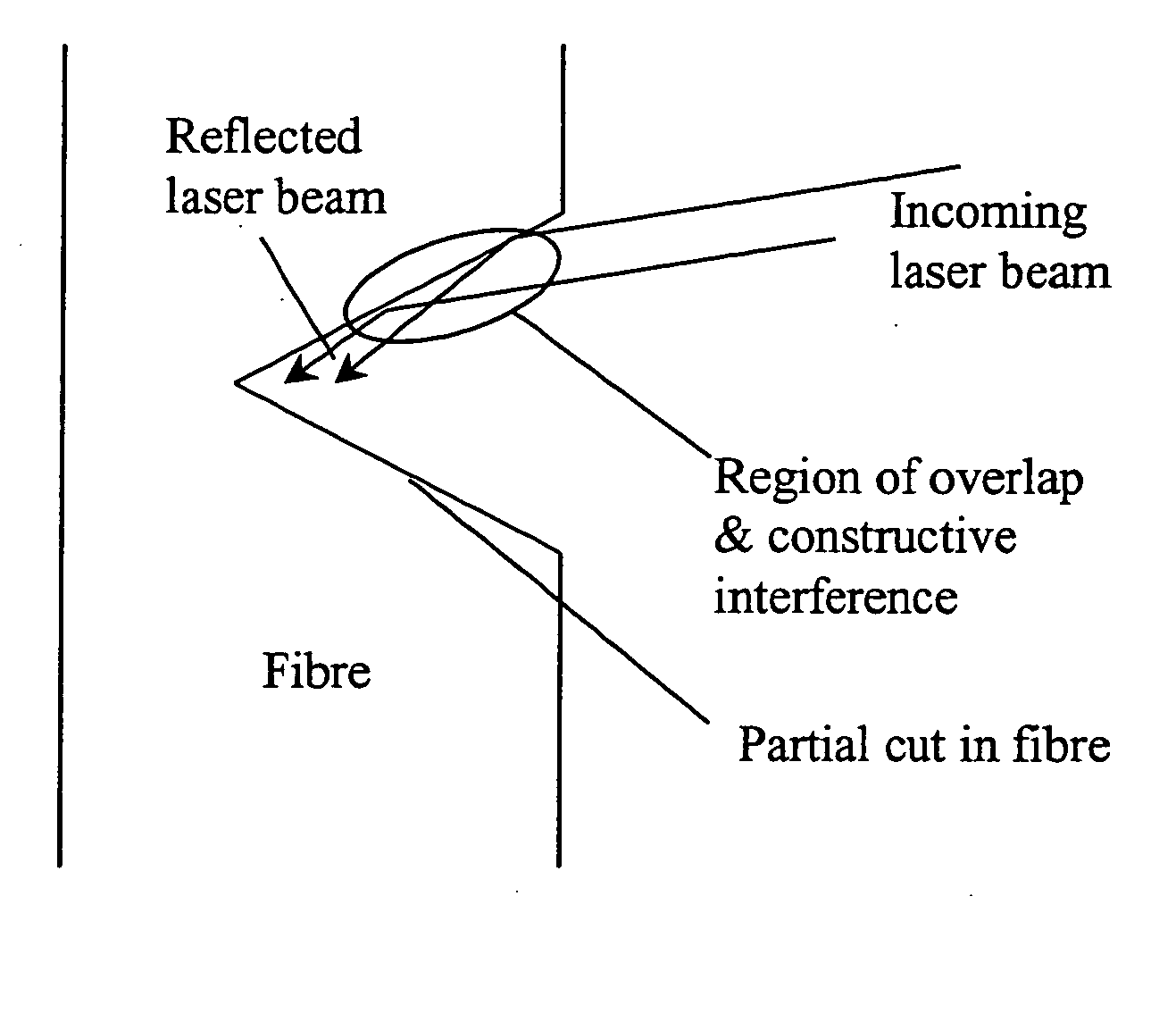

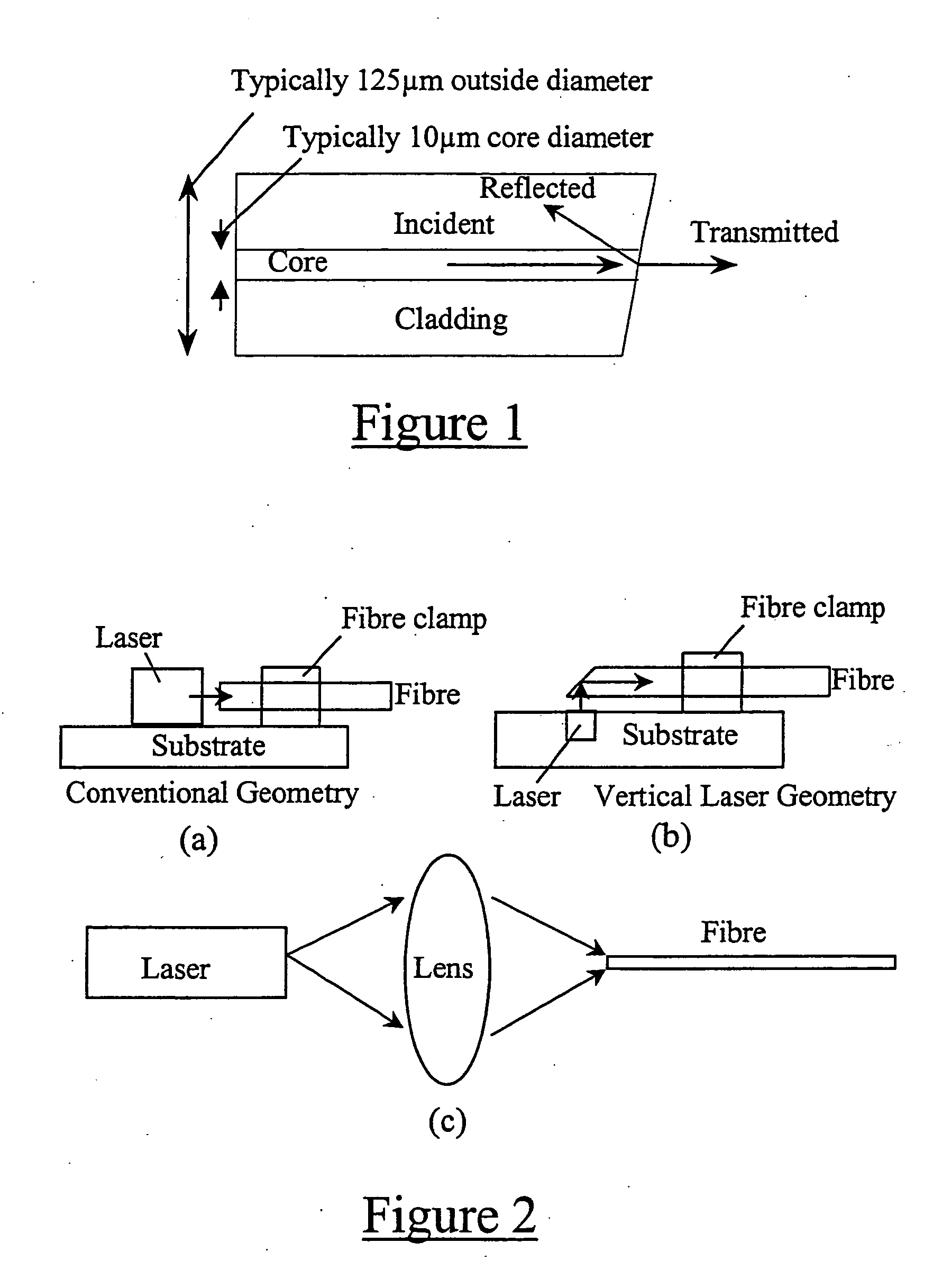

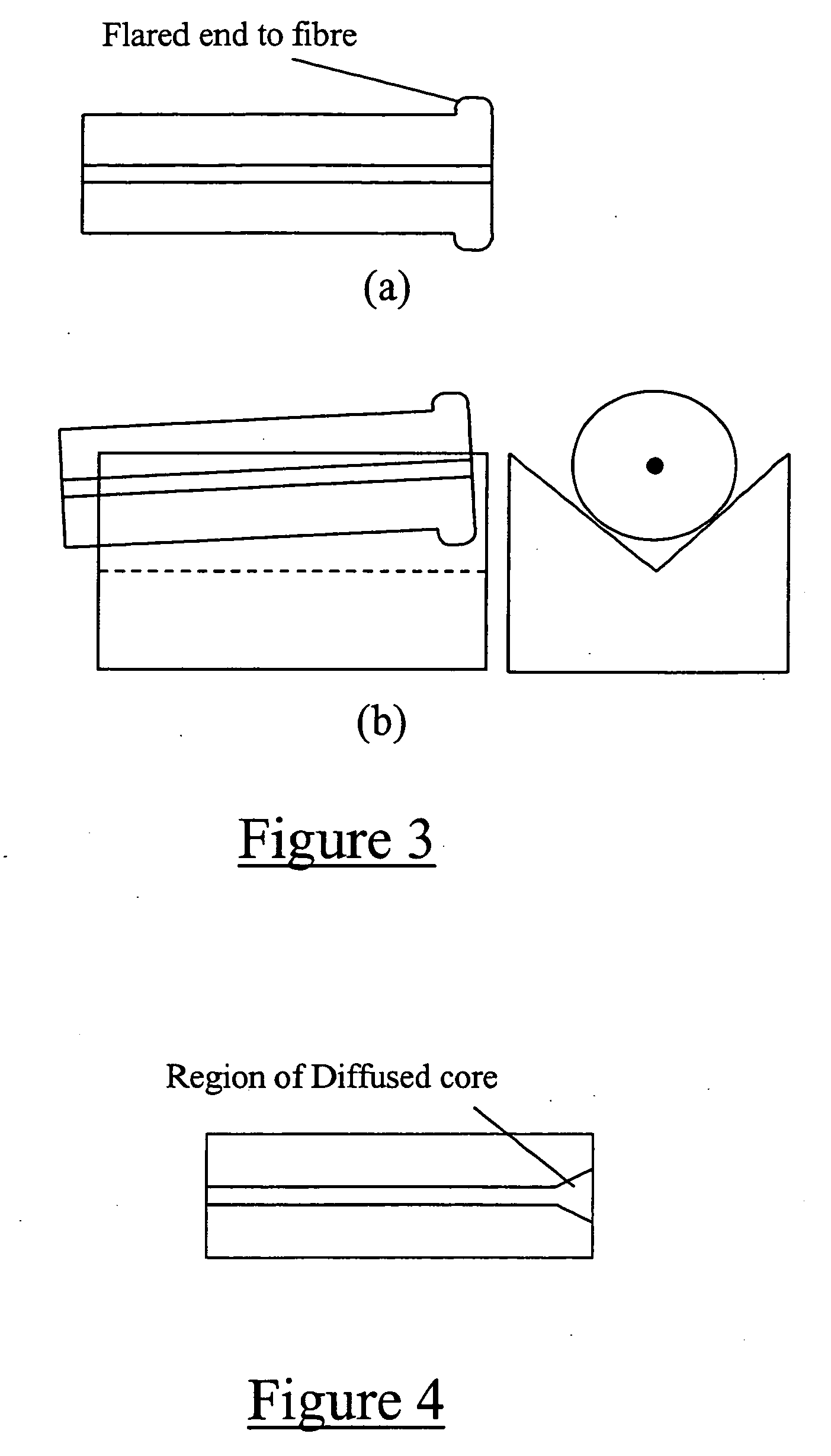

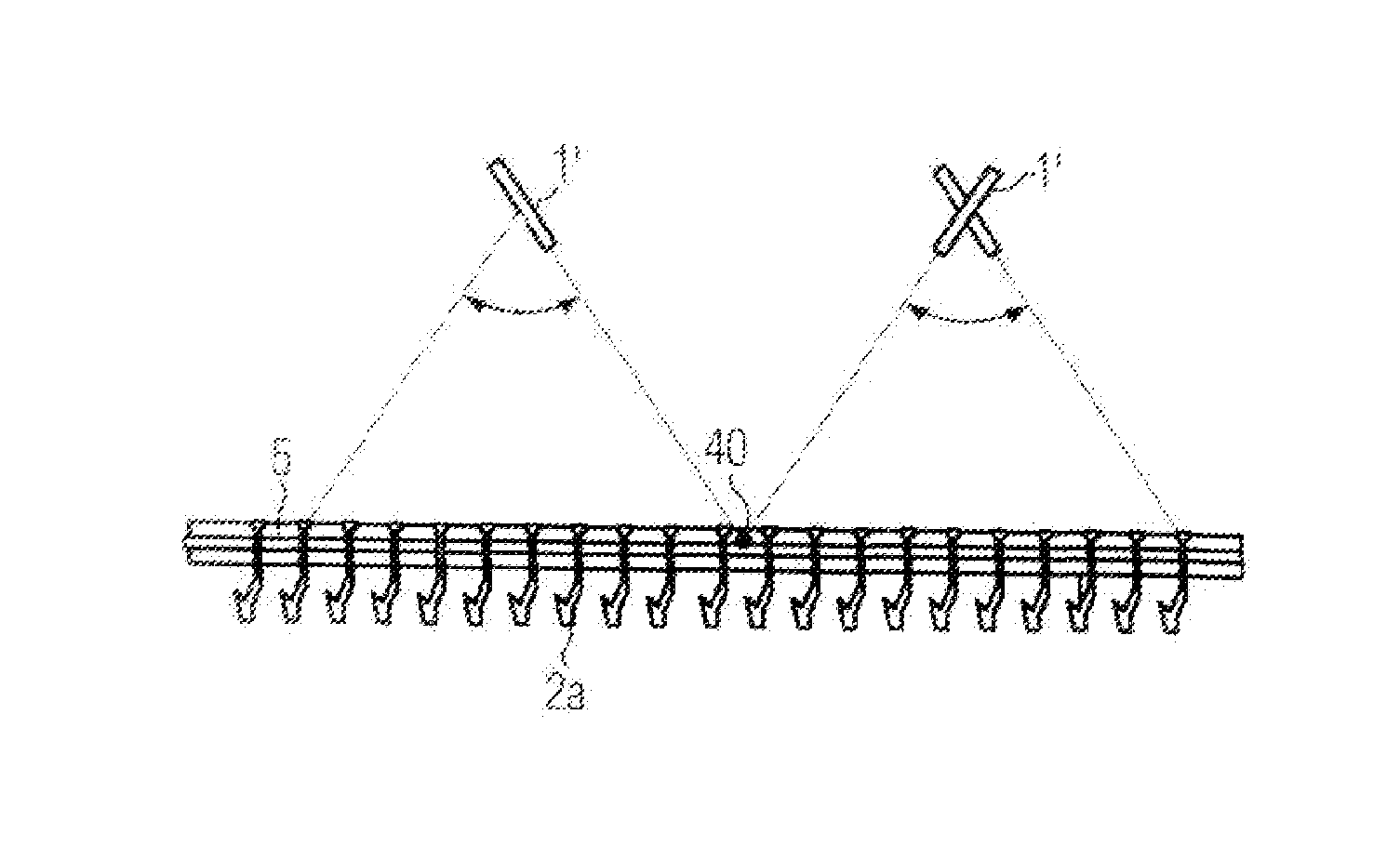

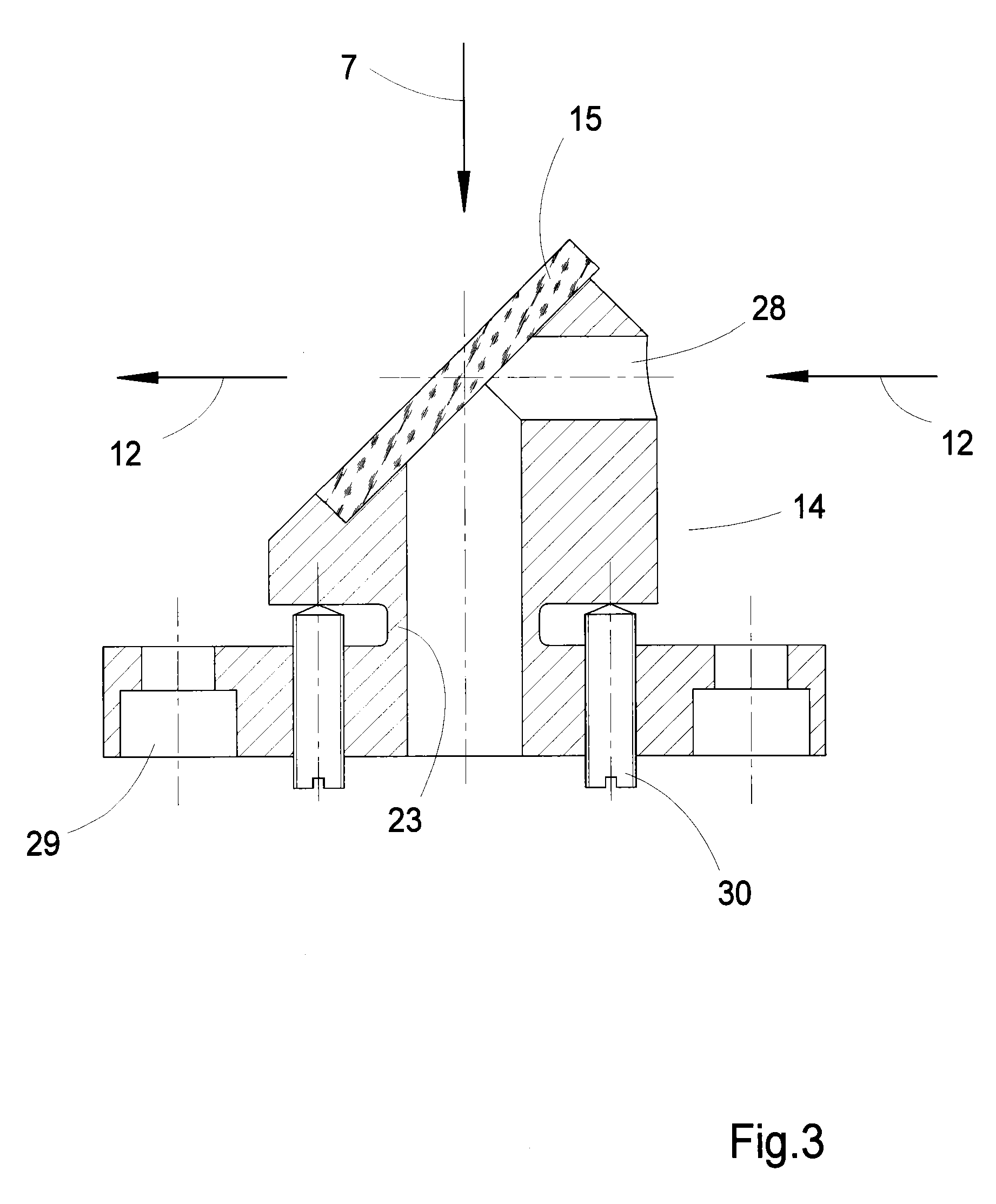

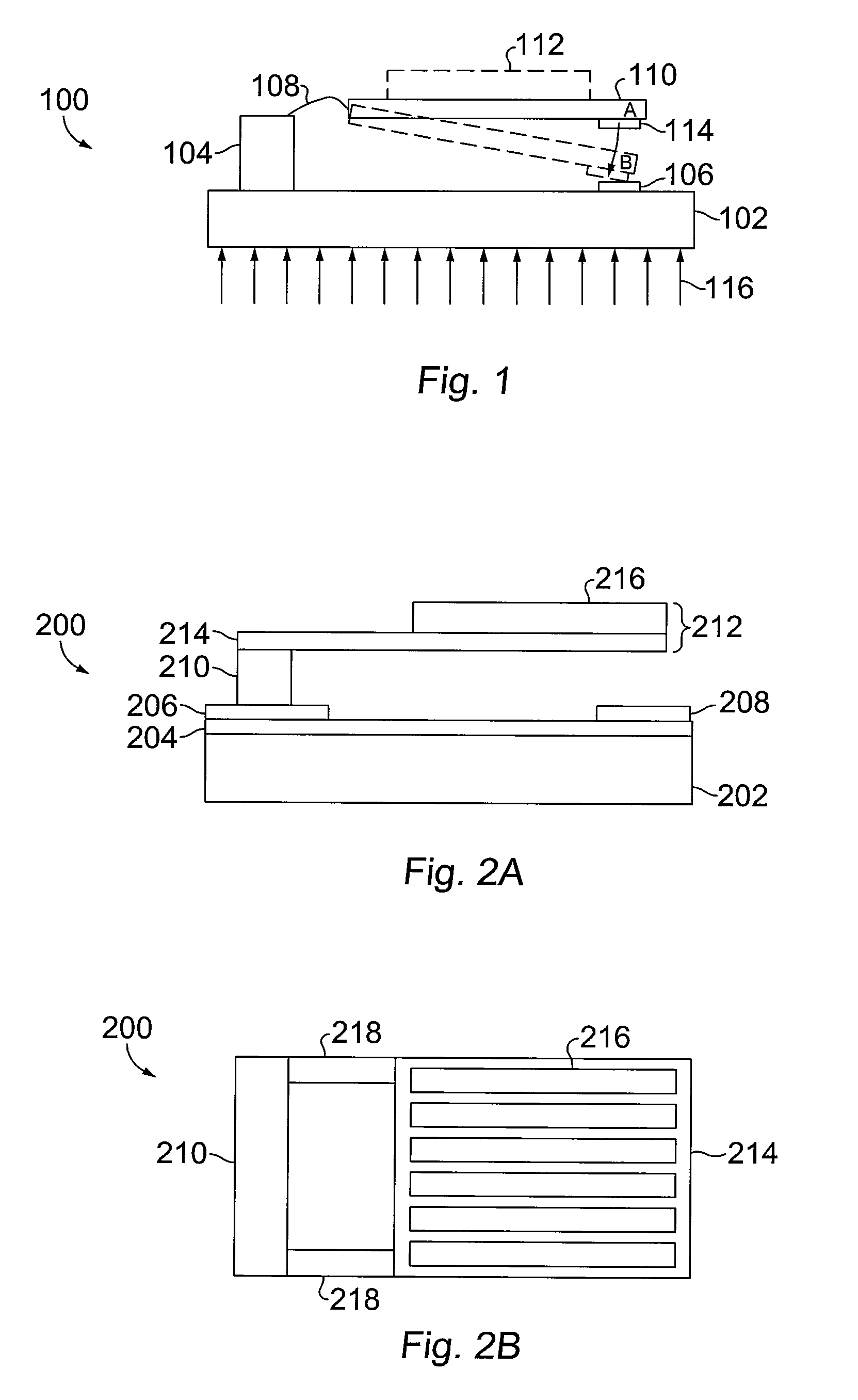

Laser cutting method and apparatus for optical fibres or waveguides

InactiveUS7142741B2Accurate and reliable operationReduce undesirable thermal effectGlass making apparatusCoupling light guidesLight beamLaser cutting

A cutting method and apparatus are provided to cut a portion of an optical fibre or waveguide with a laser beam. The proposed cutting action takes advantage of the sharp cutting edge of a laser beam generated so as to have a predetermined asymmetric intensity distribution. In operation, a prescribed amount of the beam distribution is impinged on the fibre or waveguide portion and causes the portion to ablate or vaporise so as to effect a cut at the portion in dependence upon the impingement. No translation of the laser beam across the fibre or waveguide is effected during cutting. The proposed cutting action bears definite advantages over conventional cutting techniques and finds utility for many optical fibre or waveguide applications. For example, the proposed cutting action can produce a substantially flat optical fibre or waveguide surface or a lens of enhanced quality at the end of the fibre or waveguide portion.

Owner:IRUVIS LTD

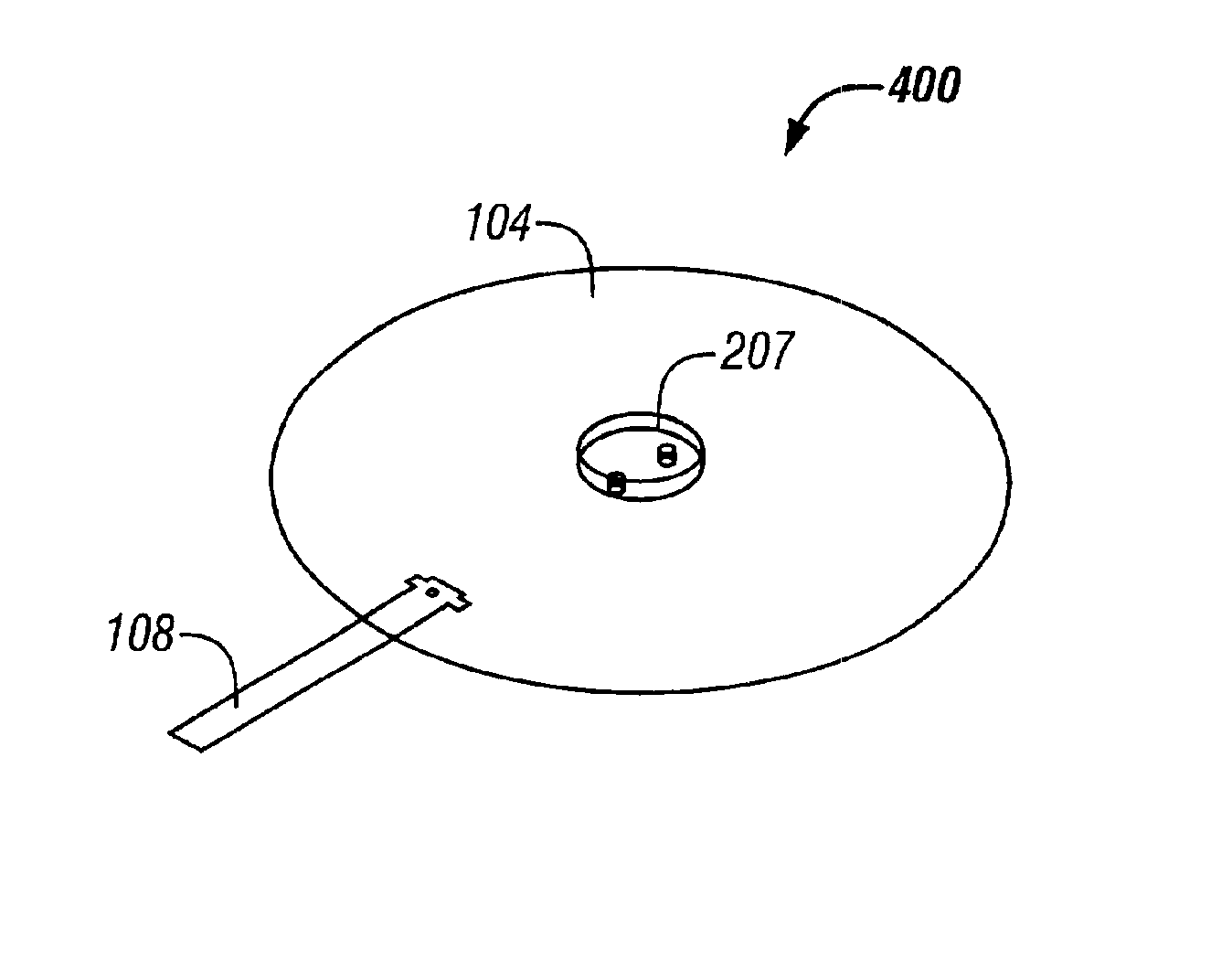

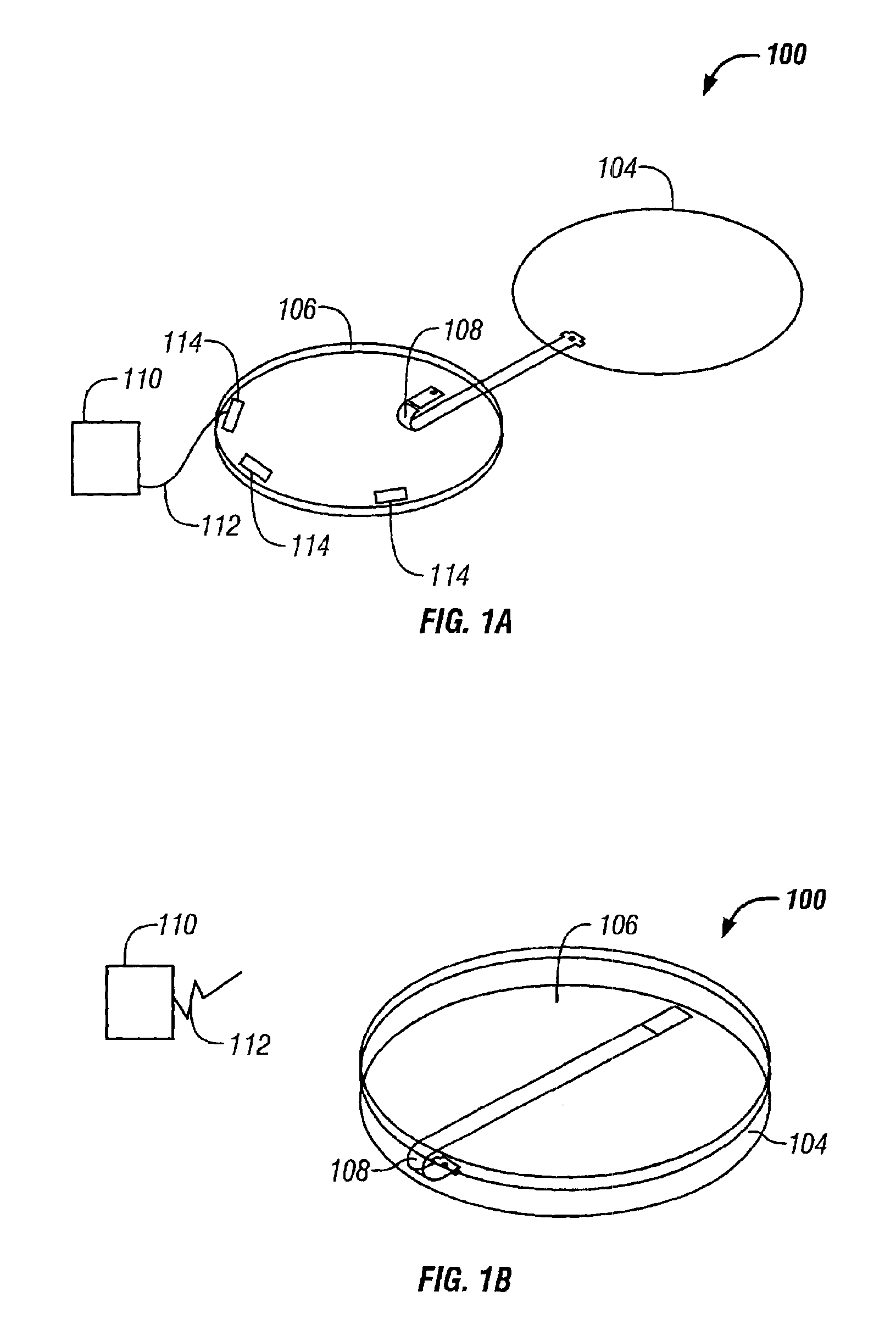

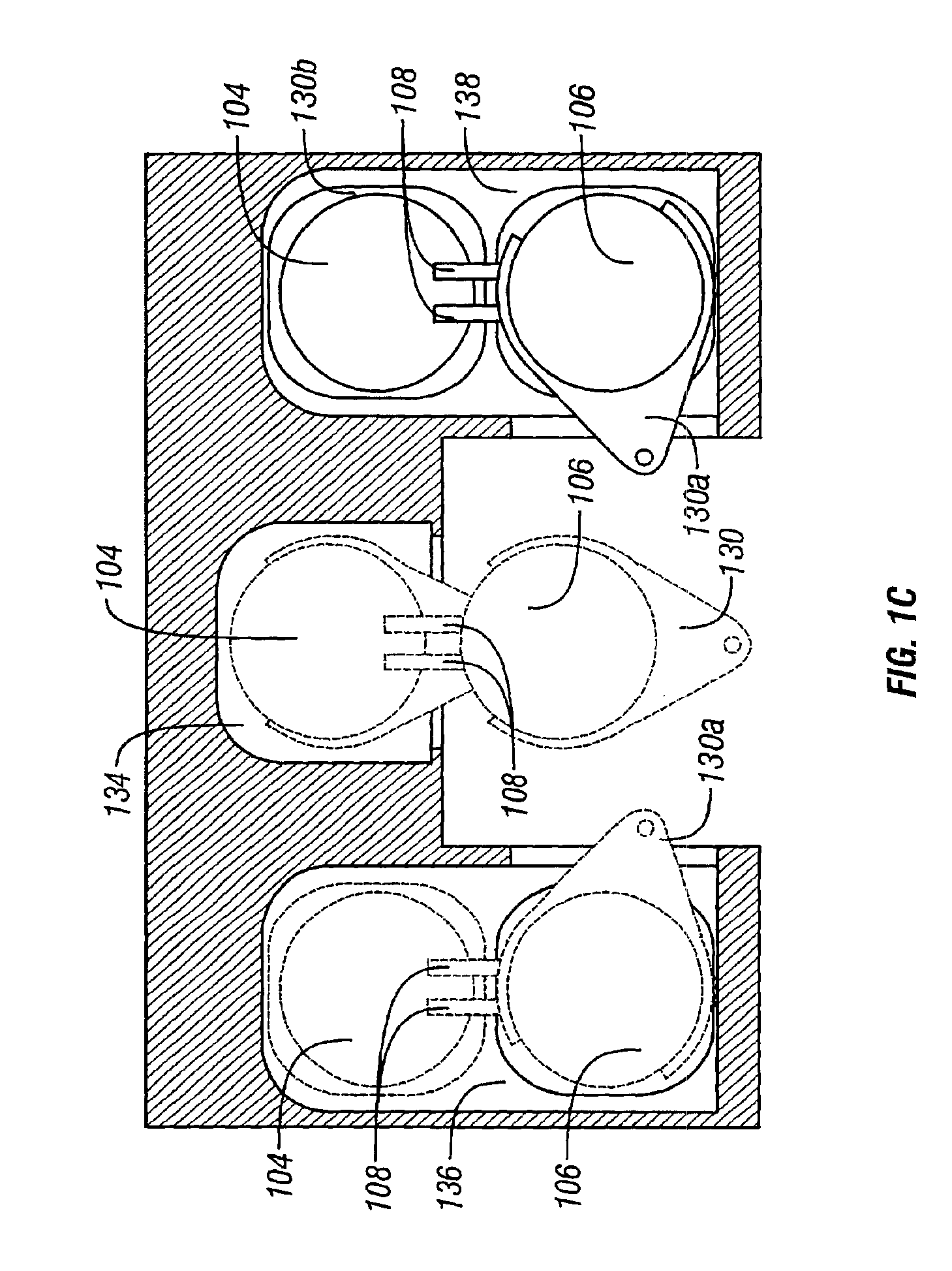

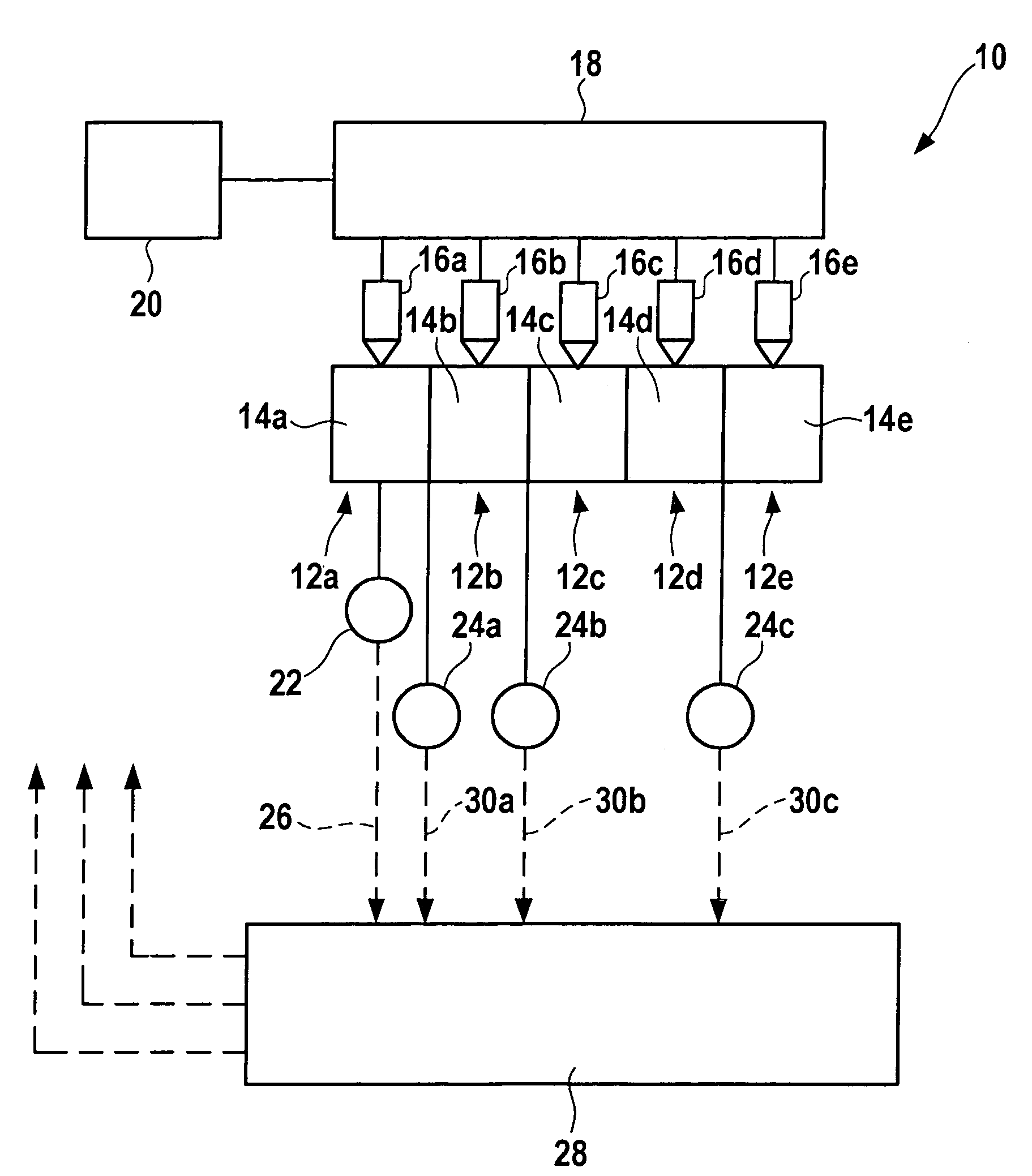

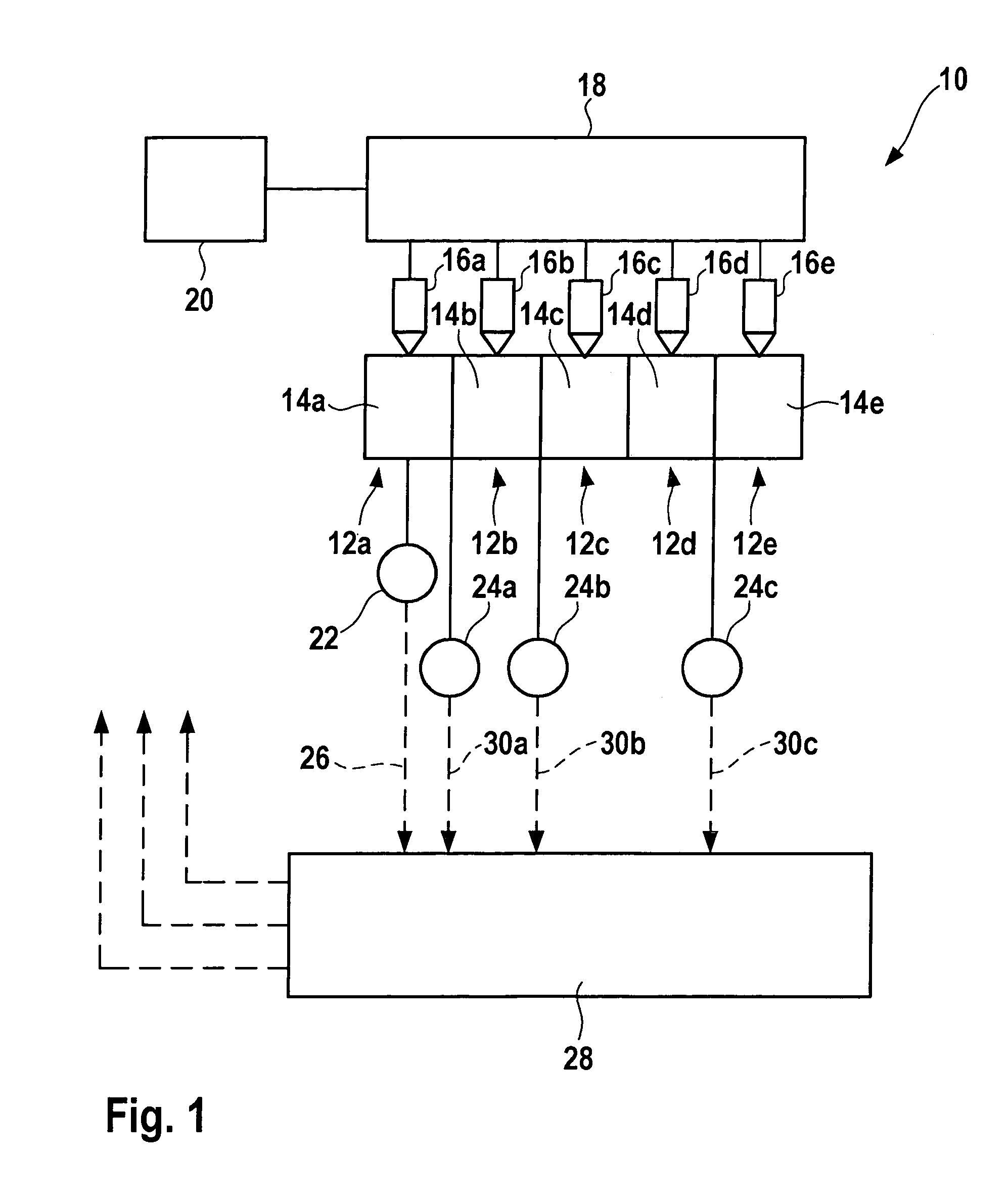

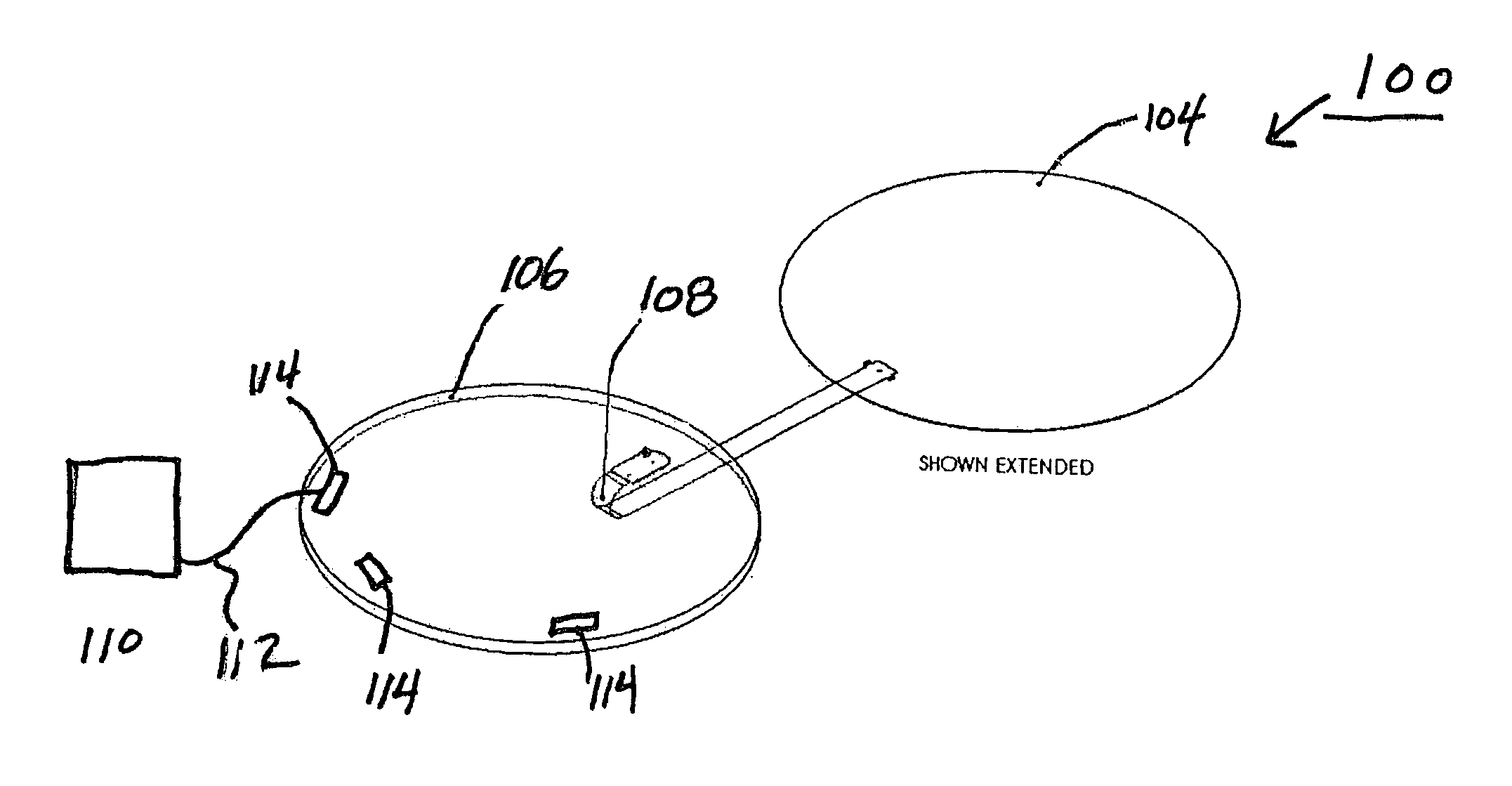

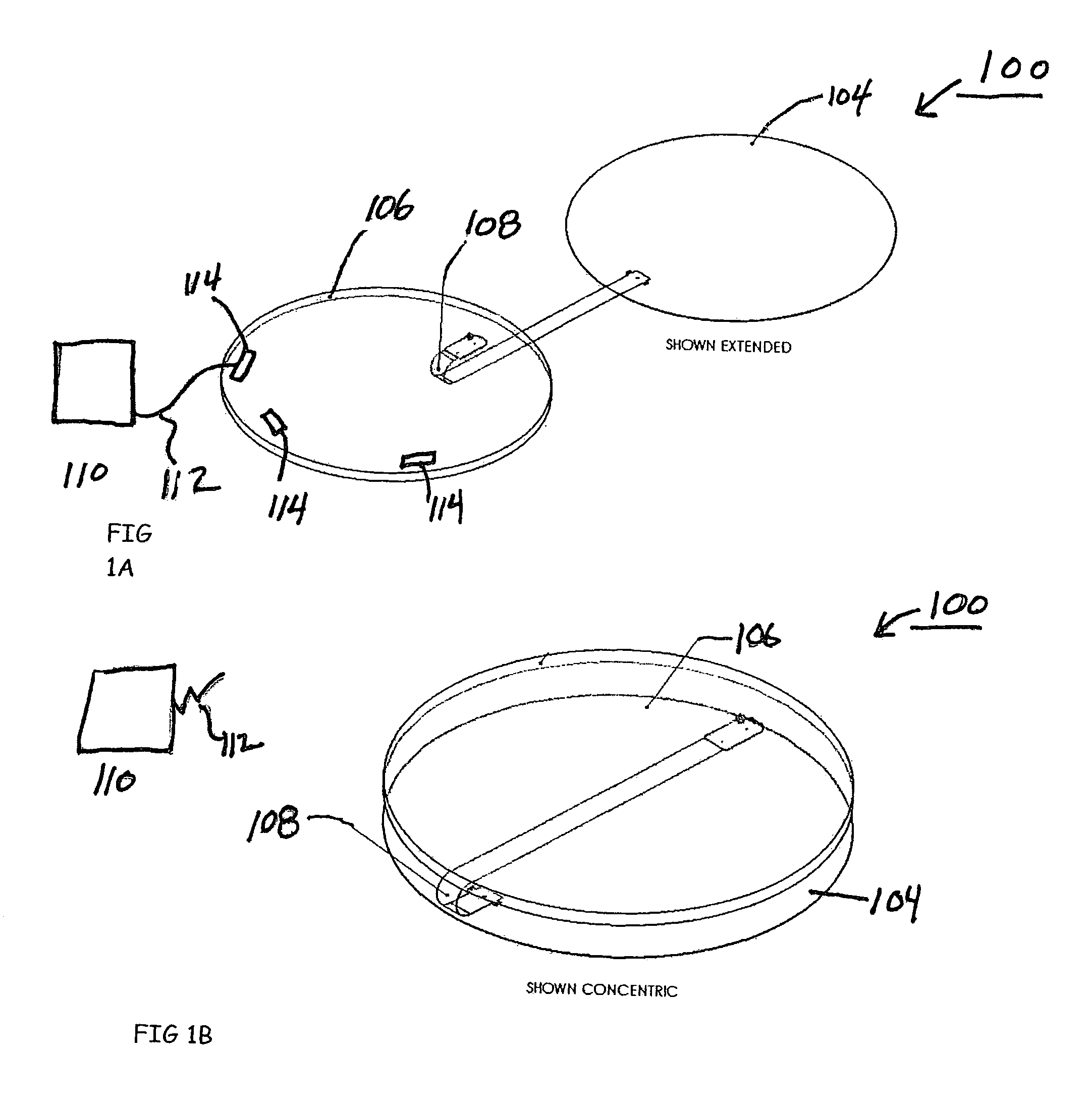

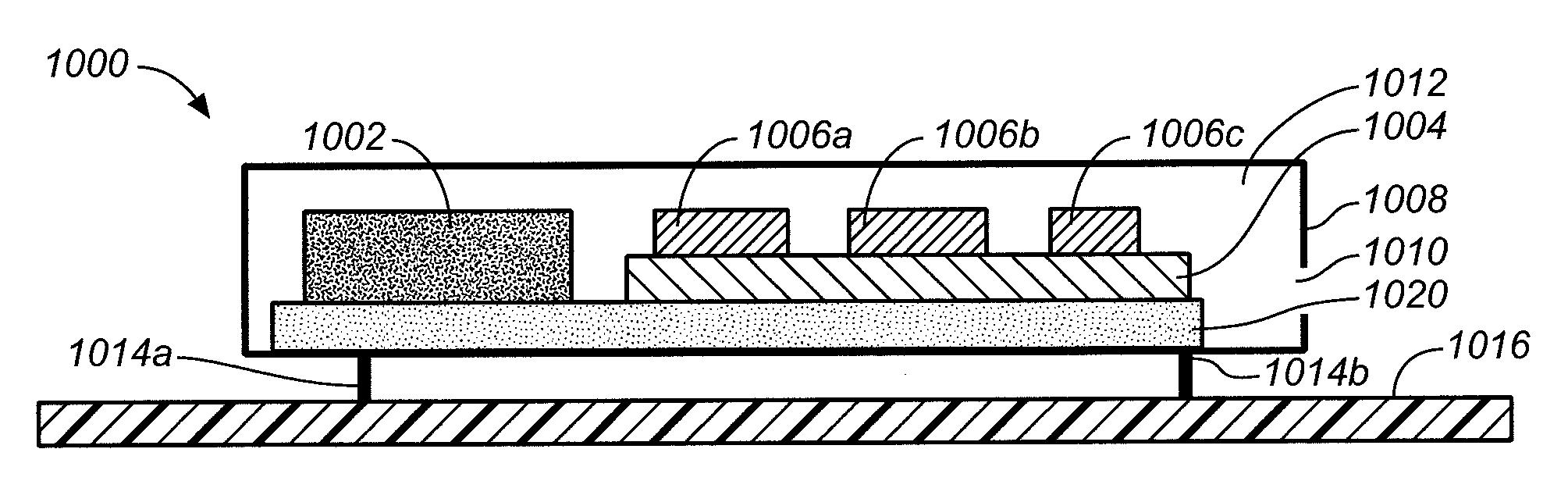

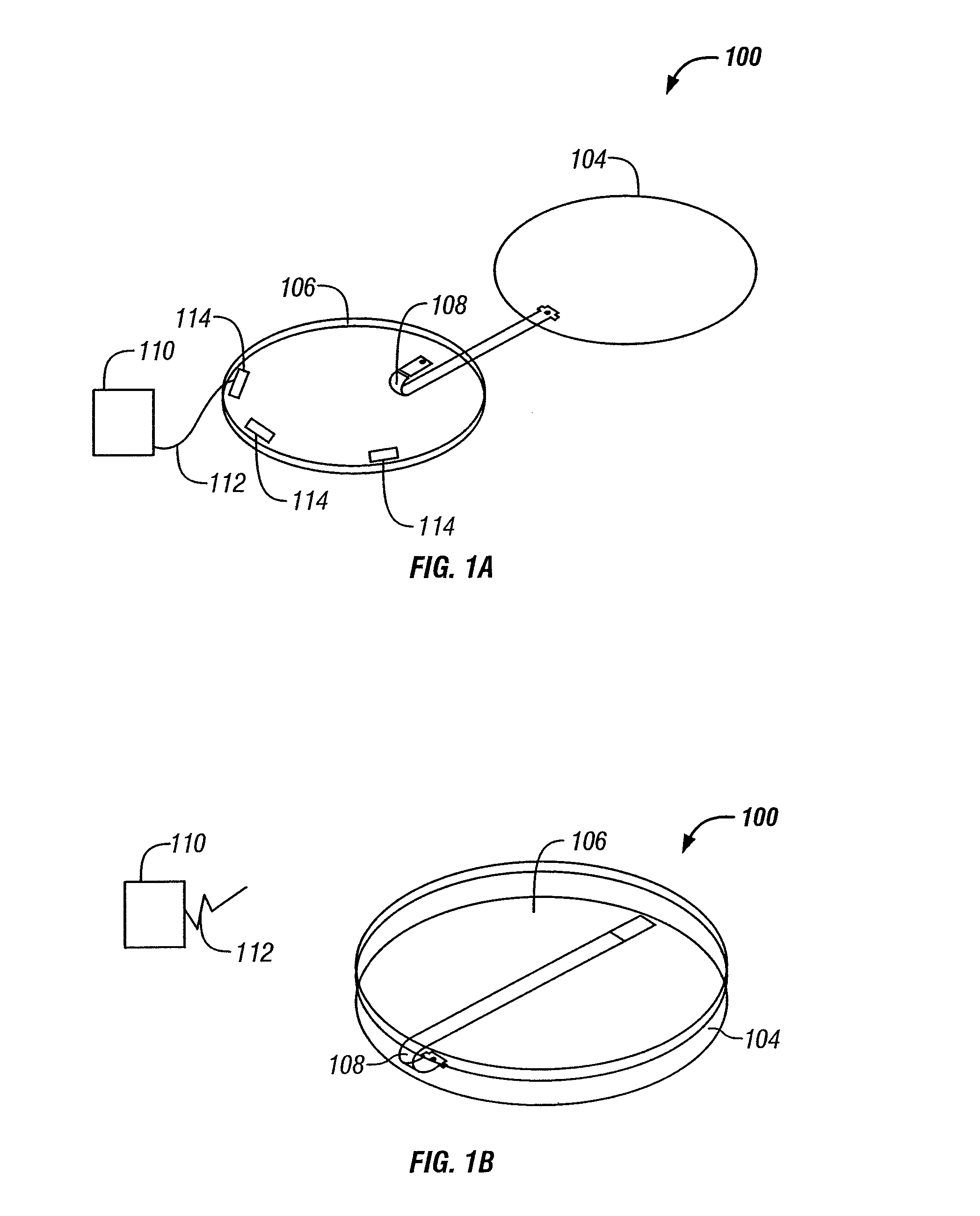

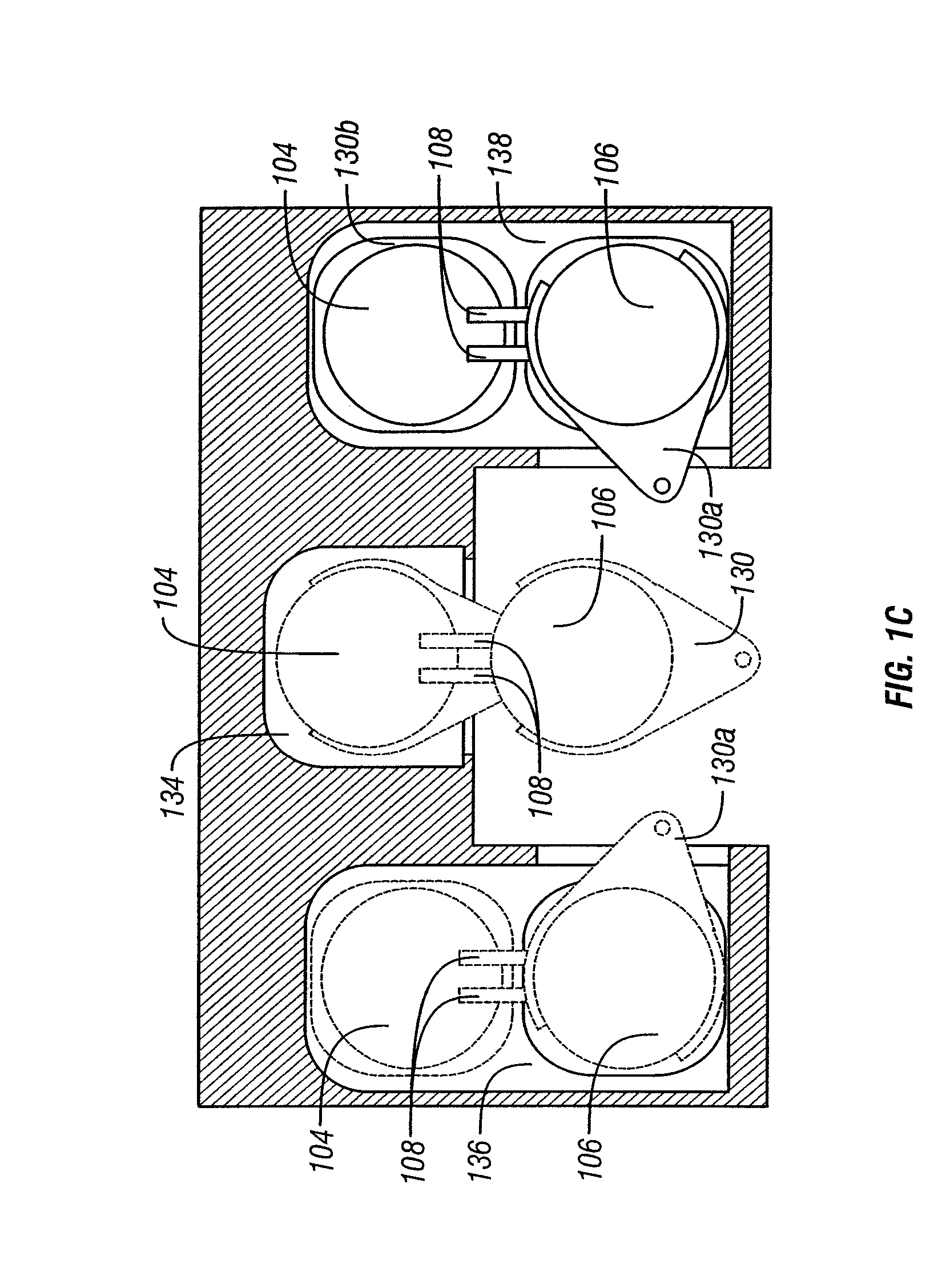

Process condition sensing wafer and data analysis system

InactiveUS6889568B2Accurate readingWide range of operationsElectric signal transmission systemsTesting/calibration apparatusMeasurement deviceEngineering

A measuring device incorporating a substrate with sensors that measure the processing conditions that a wafer may undergo during manufacturing. The substrate can be inserted into a processing chamber by a robot head and the measuring device can transmit the conditions in real time or store the conditions for subsequent analysis. Sensitive electronic components of the device can be distanced or isolated from the most deleterious processing conditions in order increase the accuracy, operating range, and reliability of the device.

Owner:KLA CORP

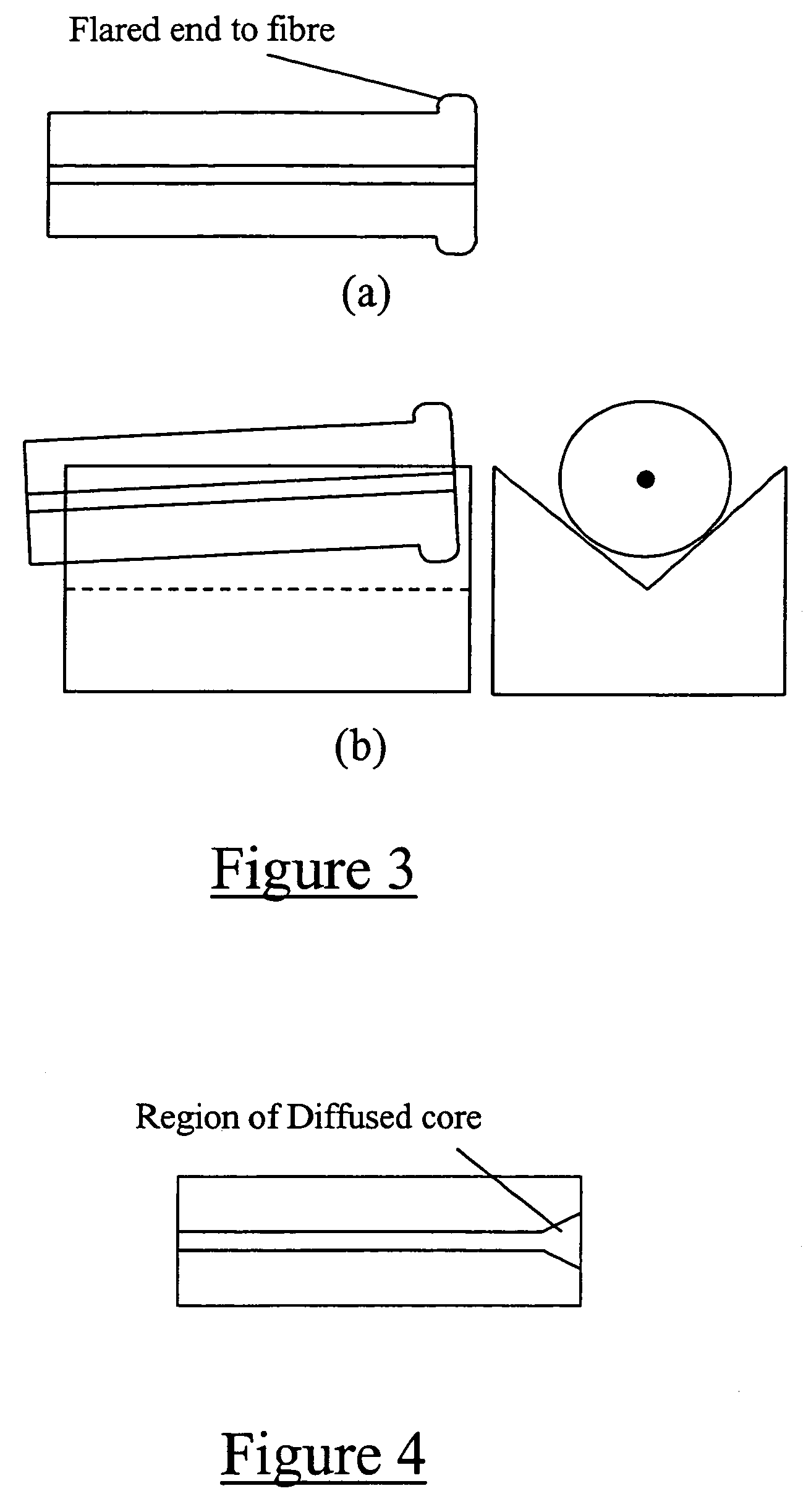

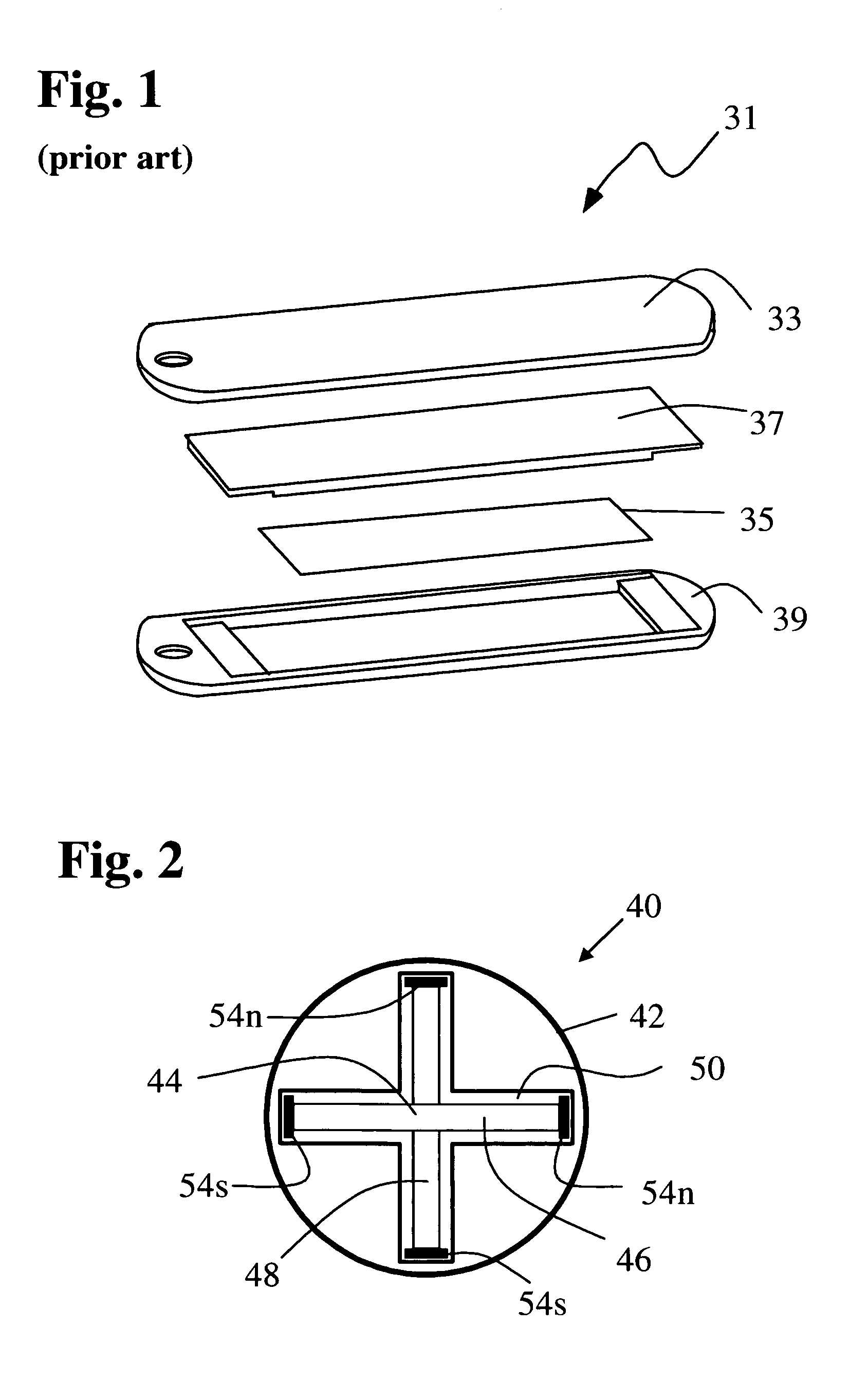

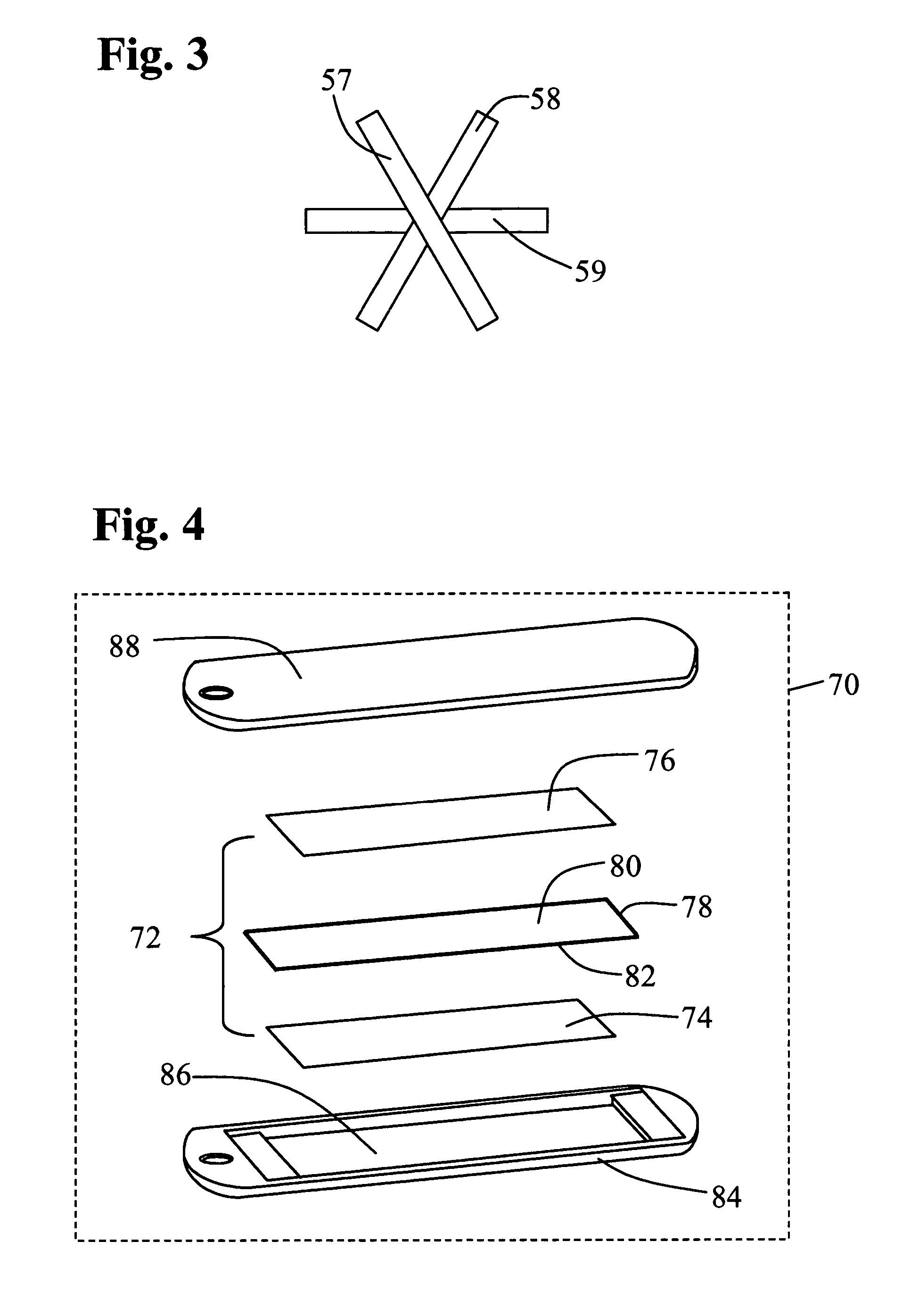

Miniature magnetomechanical tag for detecting surgical sponges and implements

InactiveUS7464713B2Serious consequenceEasy to operateDiagnosticsSurgeryEngineeringMechanical resonance

Externally detectable electronic article surveillance markers are attached to surgical implements, such as sponges and surgical instruments, appointed for use in a surgical wound. The attachment mechanism facilitates detection by an external interrogating field before the wound has been closed and the patient has left the operating table. The markers are responsive to the imposition of an interrogating field produced by an electronic article surveillance system. Markers contain one or more magnetomechanically responsive elements that are urged into mechanical resonance by the interrogating field. The ring-down of the resonance and the associated dipolar electromagnetic field provide a signal-identifying characteristic detected by a detection system. Upon detection, an audible or visible signal is triggered to alert relevant medical personnel to the need for follow-up care and removal of the offending item. The resonance occurs at a frequency ranging from about 70 to 300 kHz. Misadventures during operative procedures—especially those wherein implements remain undiscovered at the time of surgery and are retained indefinitely within the surgical cavity, often entailing dire consequences to the patient—are virtually eliminated. The attachment mechanism and markers assure that surgical implements are reliably detected and removed before completion of the surgical procedure.

Owner:FABIAN CARL E +2

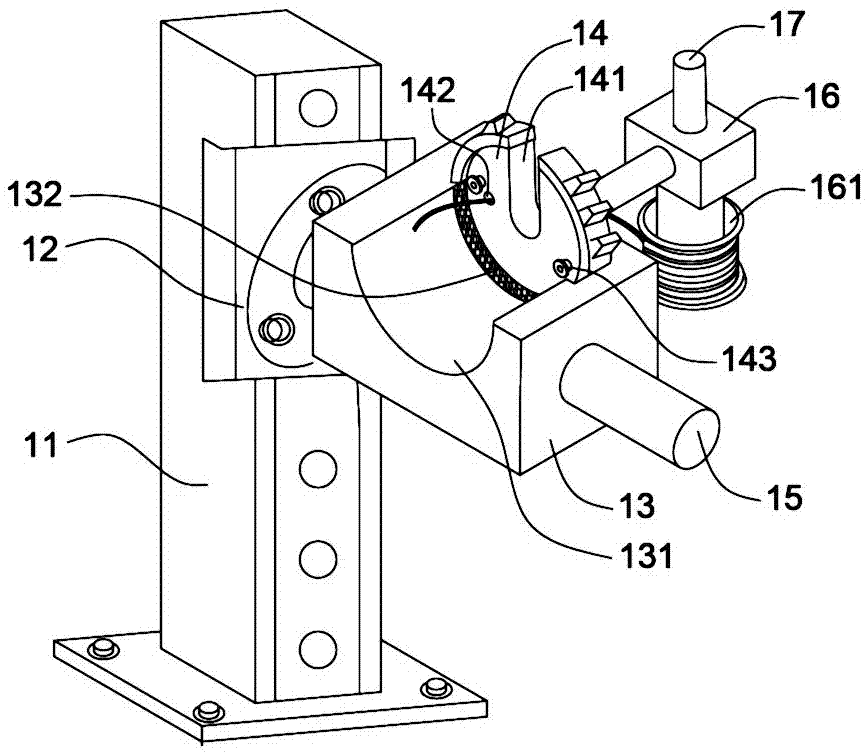

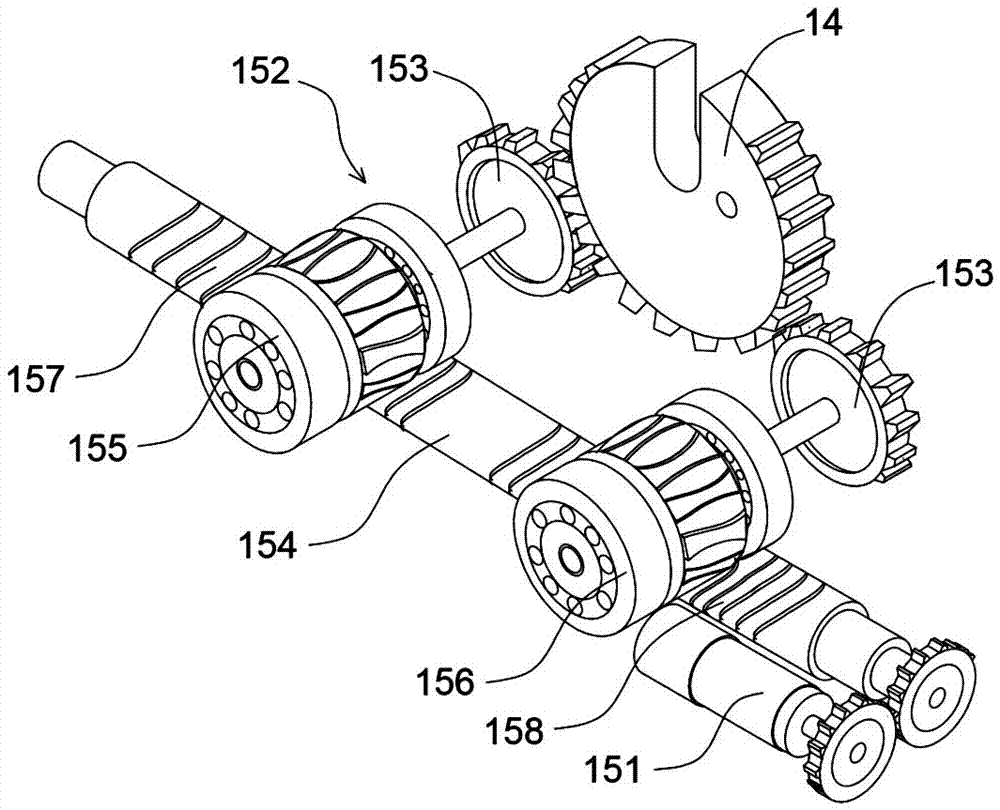

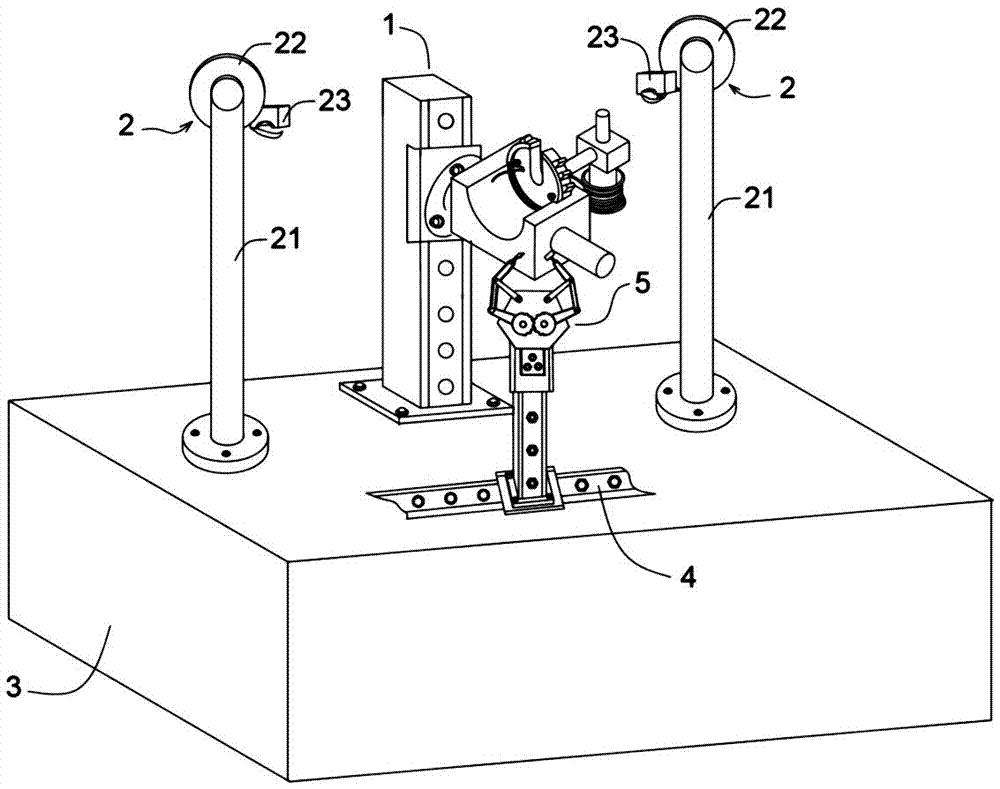

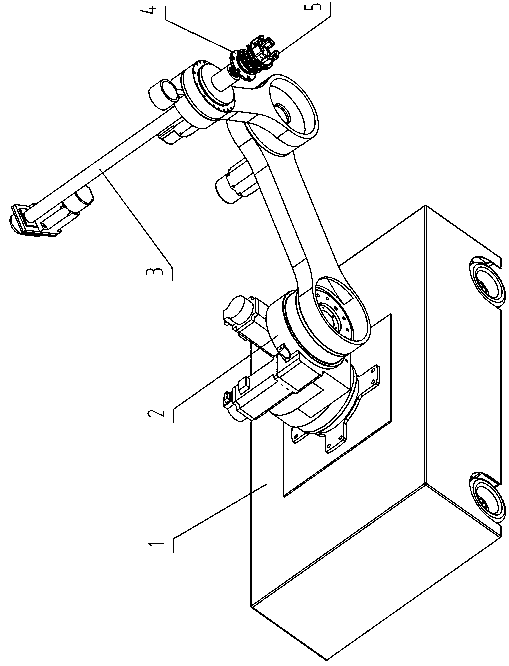

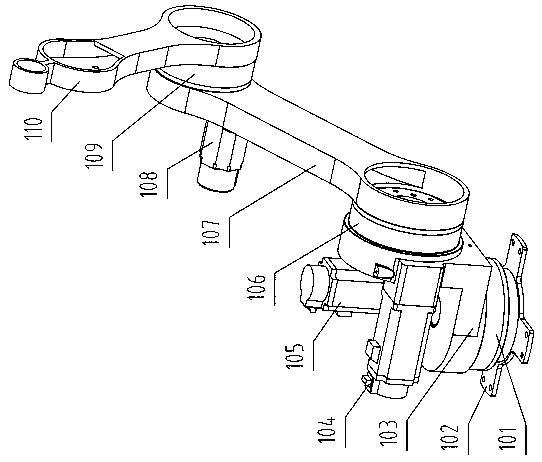

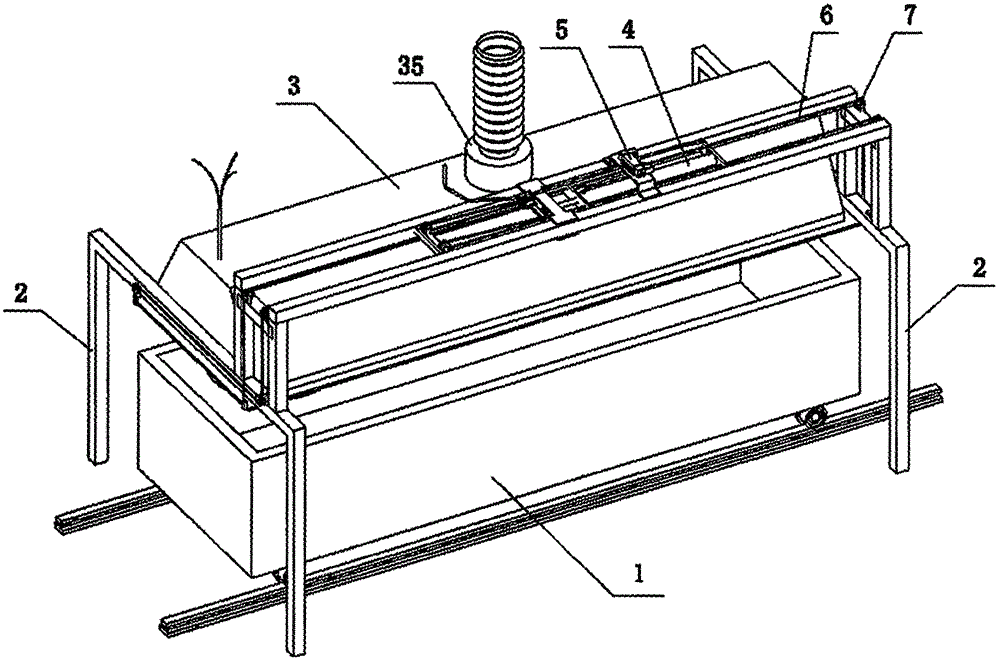

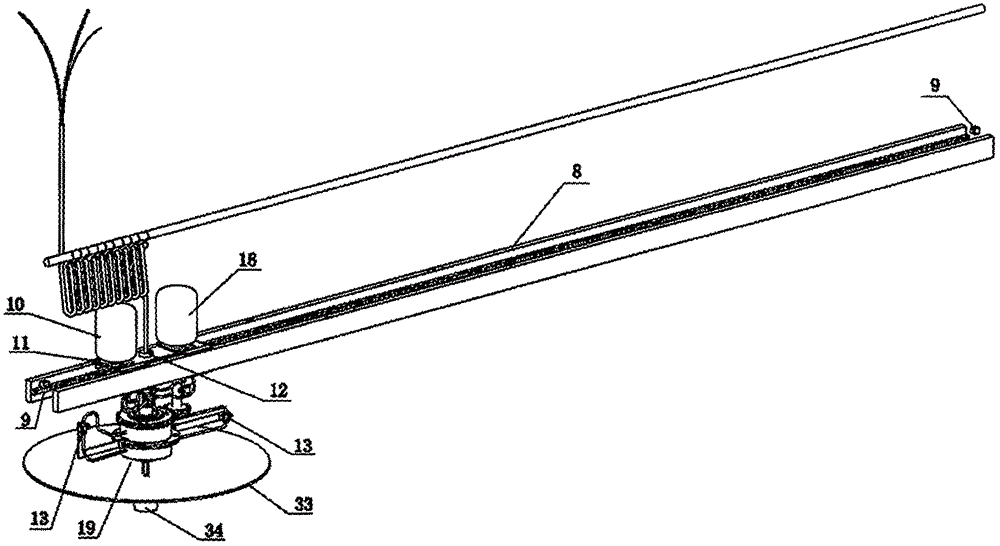

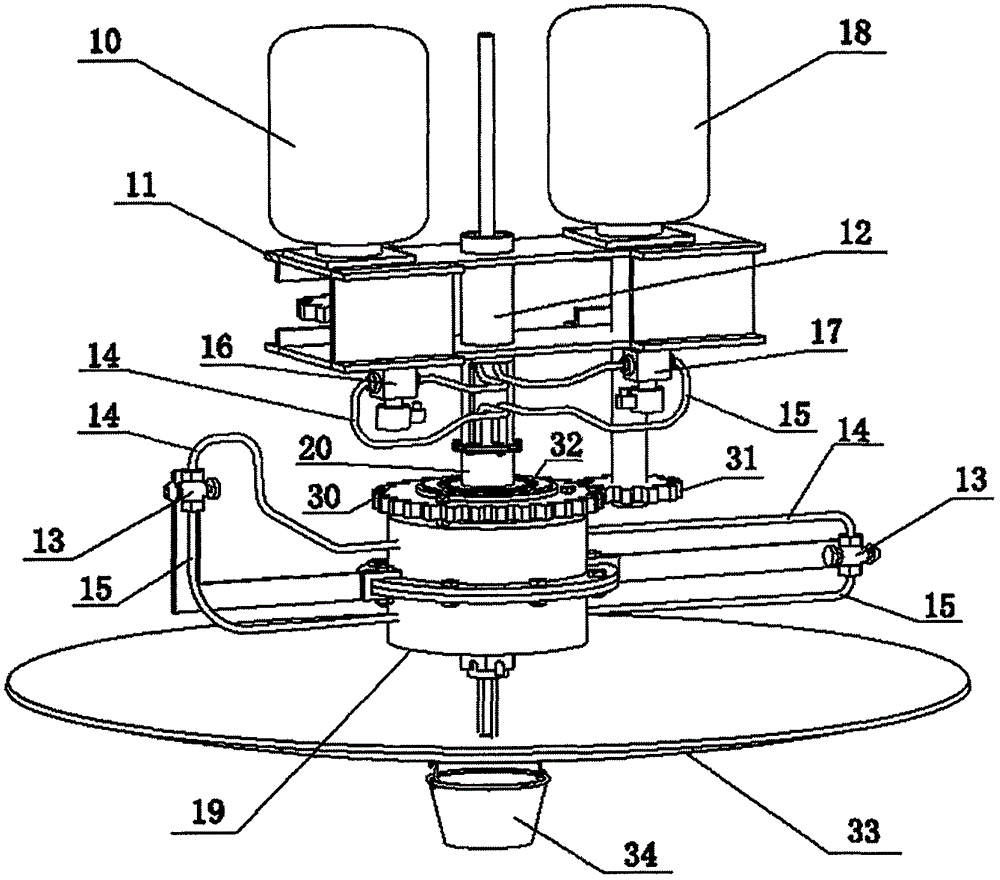

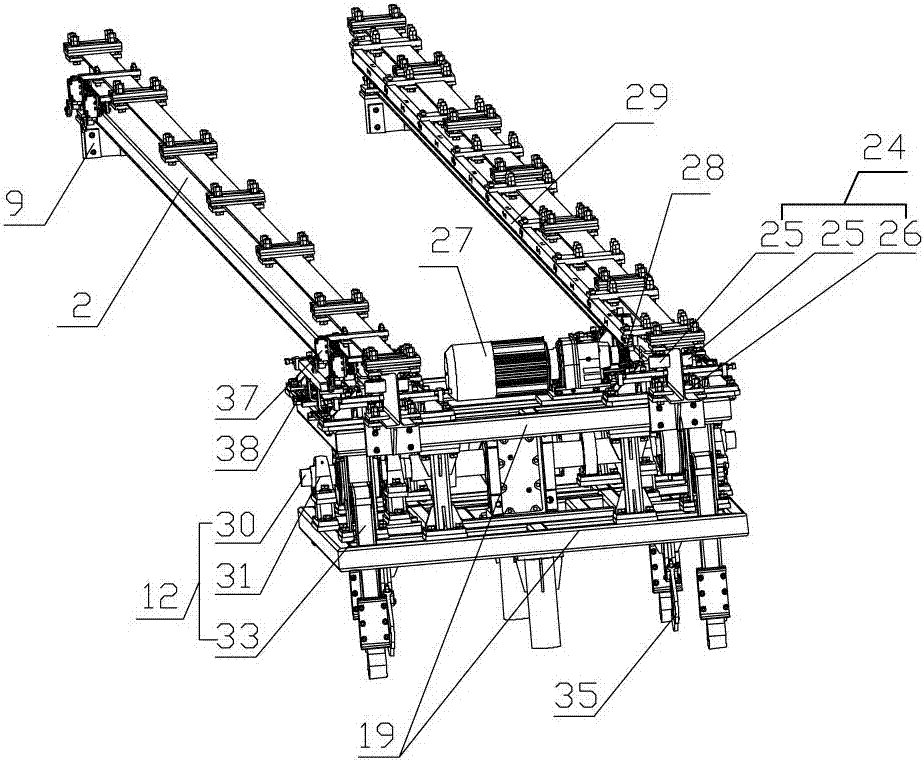

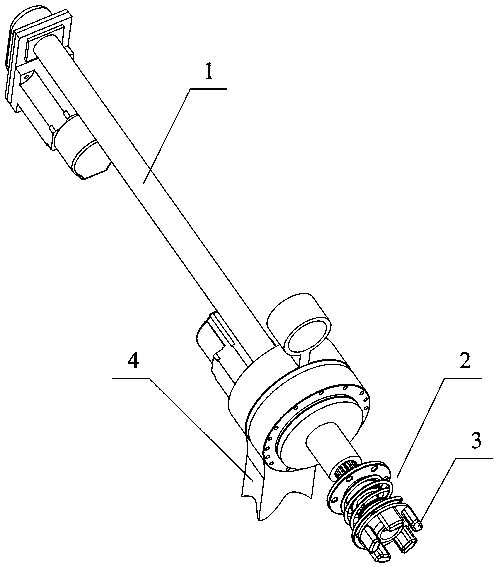

Power transmission line conductor repairing and winding device, robot and conductor repairing method

ActiveCN107196235AImprove work efficiencyReduce labor intensityApparatus for overhead lines/cablesEngineeringRepair method

The invention discloses a power transmission line conductor repairing and winding device, a robot and a conductor repairing method. The power transmission line conductor repairing and winding device comprises a support lifting arm, a connection base and a driving base; a spur gear with a line clamping groove is arranged on the driving base; furthermore, a threading hole is arranged on the spur gear; a winding driving mechanism is arranged in the driving base; a bracket is also arranged on the driving base; a winding roller and a releasing motor are arranged on the bracket; the power transmission line conductor repairing robot comprises a robot body with a camera and a walking positioning mechanism; a linear guideway and the power transmission line conductor repairing and winding device are arranged on the robot body; a conductor clamping jaw component is arranged on the linear guideway; and the conductor repairing method is used for repairing by winding an aluminium wire on a split conductor by using the power transmission line conductor repairing robot. By means of the power transmission line conductor repairing and winding device, the robot and the conductor repairing method disclosed by the invention, the current transmission capability of a power transmission conductor can be improved; therefore, the conductor repairing working efficiency can be greatly increased; the labour intensity can be reduced; and the conductor repairing security can be improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Laser cutting method and apparatus for optical fibres or waveguides

InactiveUS20040047587A1Accurate and reliable operationReduce heat loadCoupling light guidesLaser beam welding apparatusLight beamLaser cutting

A cutting method and apparatus are provided to cut a portion of an optical fibre or waveguide with a laser beam. The proposed cutting action takes advantage of the sharp cutting edge of a laser beam generated so as to have a predetermined asymmetric intensity distribution. In operation, a prescribed amount of the beam distribution is impinged on the fibre or waveguide portion and causes the portion to ablate or vaporise so as to effect a cut at the portion in dependence upon the impingement. No translation of the laser beam across the fibre or waveguide is effected during cutting. The proposed cutting action bears definite advantages over conventional cutting techniques and finds utility for many optical fibre or waveguide applications. For example, the proposed cutting action can produce a substantially flat optical fibre or waveguide surface or a lens of enhanced quality at the end of the fibre or waveguide portion.

Owner:IRUVIS LTD

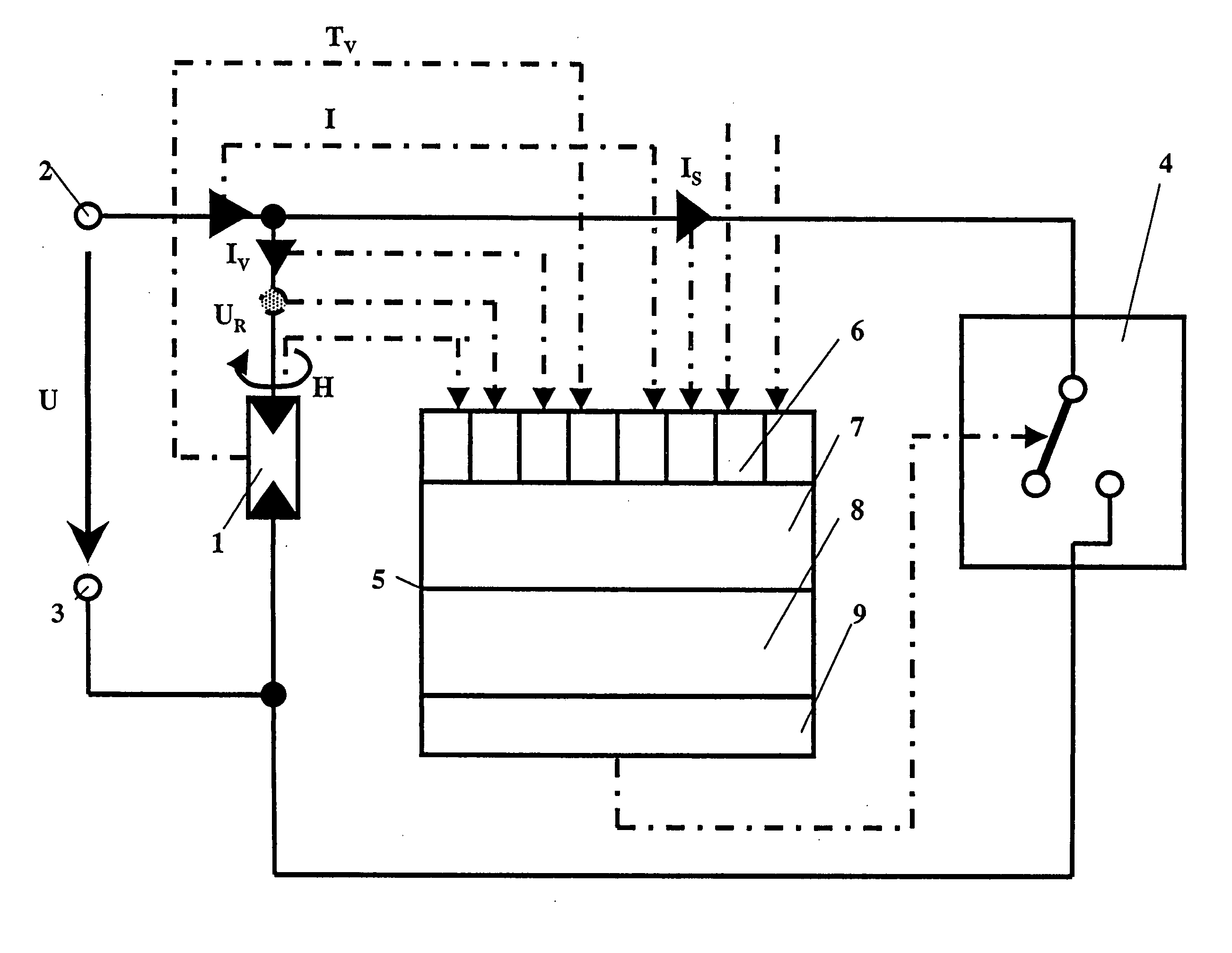

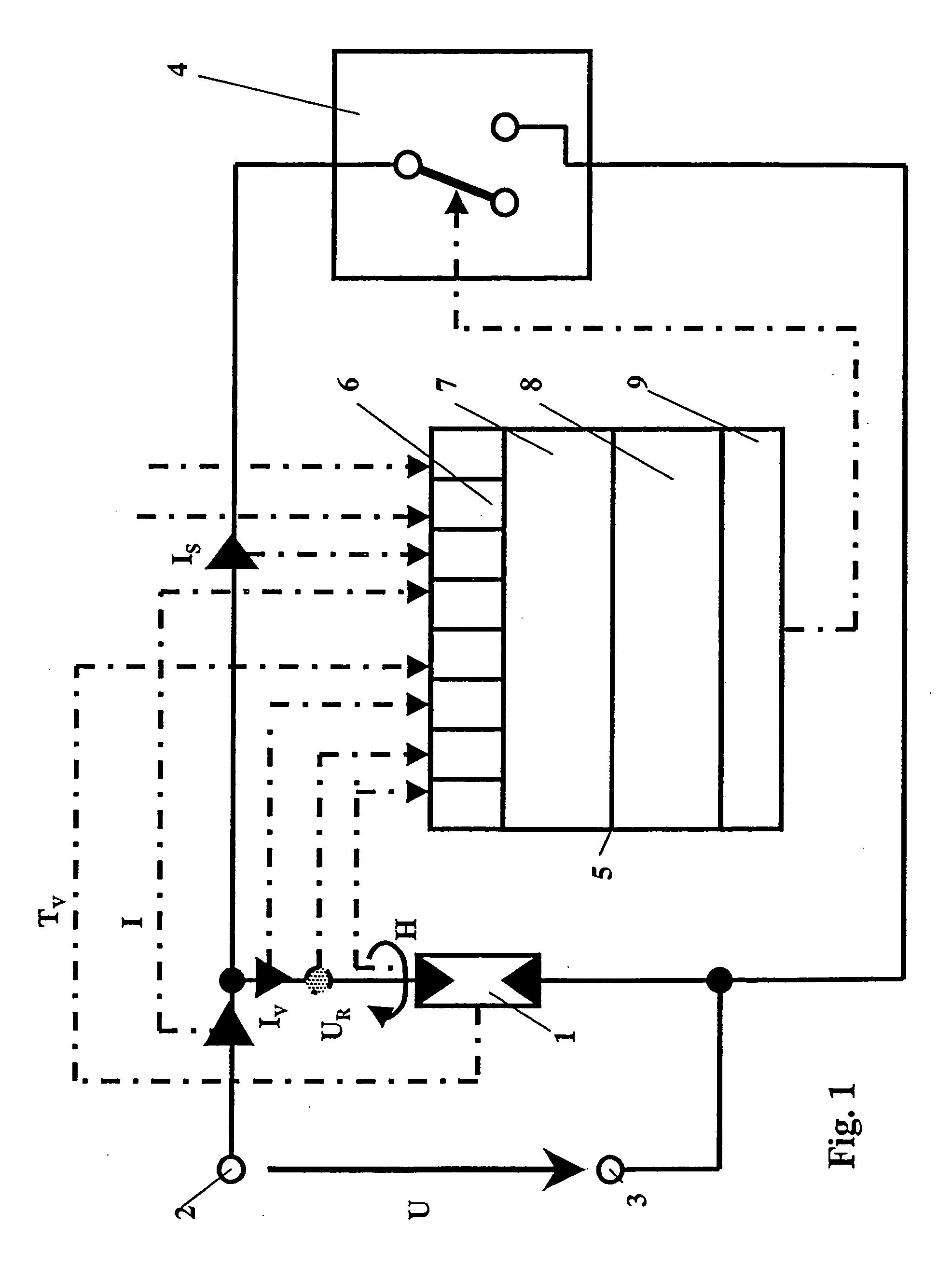

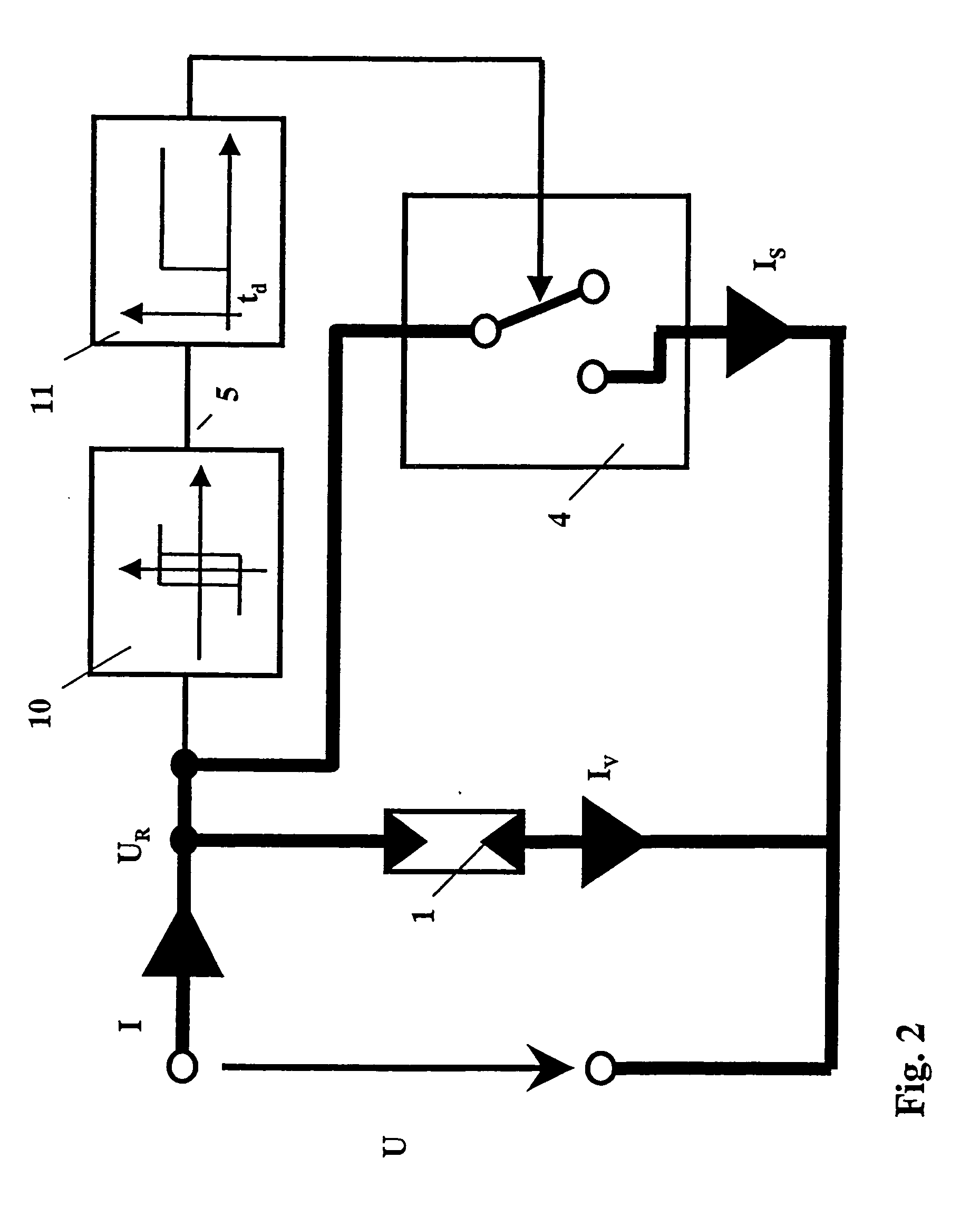

Voltage limiter

InactiveUS20040257742A1Improve electromagnetic compatibilitySwitch accuratelyMagnetic/electric field screeningResistor electrostatic/electromagnetic shieldingOperating variablesVaristor

The voltage limiter is used to effectively limit short-term and long-term overvoltages. Said voltage limiter has a varistor (1) and a discharge path which can be connected in parallel with the varistor. The discharge path contains a switching point (4), which is preferably in the form of a semiconductor switch and can be loaded with an uninterrupted current, and which can be closed above a limit value of a signal which is dependent on an operating variable of the varistor (1). The varistor (1) is arranged in a first area (24) and the switching point (4) is arranged in a second area (26) of two areas (24, 26, 28) which are at an axial distance from one another in the direction of an axis of symmetry (20). Means (5) for operating the switching point (4) are accommodated in a third area (28), which is at a defined potential. The arrangement of the components (1, 4, 5) of the voltage limiter in separate areas (24, 26, 28) results in a compact, modular construction, and those components of the voltage limiter which are subject to power loading, namely the varistor (1) and the switching point (5), are physically separated from one another, so that they can be cooled independently of one another. Since the operating means (5), which generally operate electronically, are accommodated in an electromagnetically shielded area (28), the operational reliability of the voltage limiter is at the same time improved, and, in particular, undesirable high-energy electromagnetic interference is kept away from this area (28).

Owner:ABB (SCHWEIZ) AG

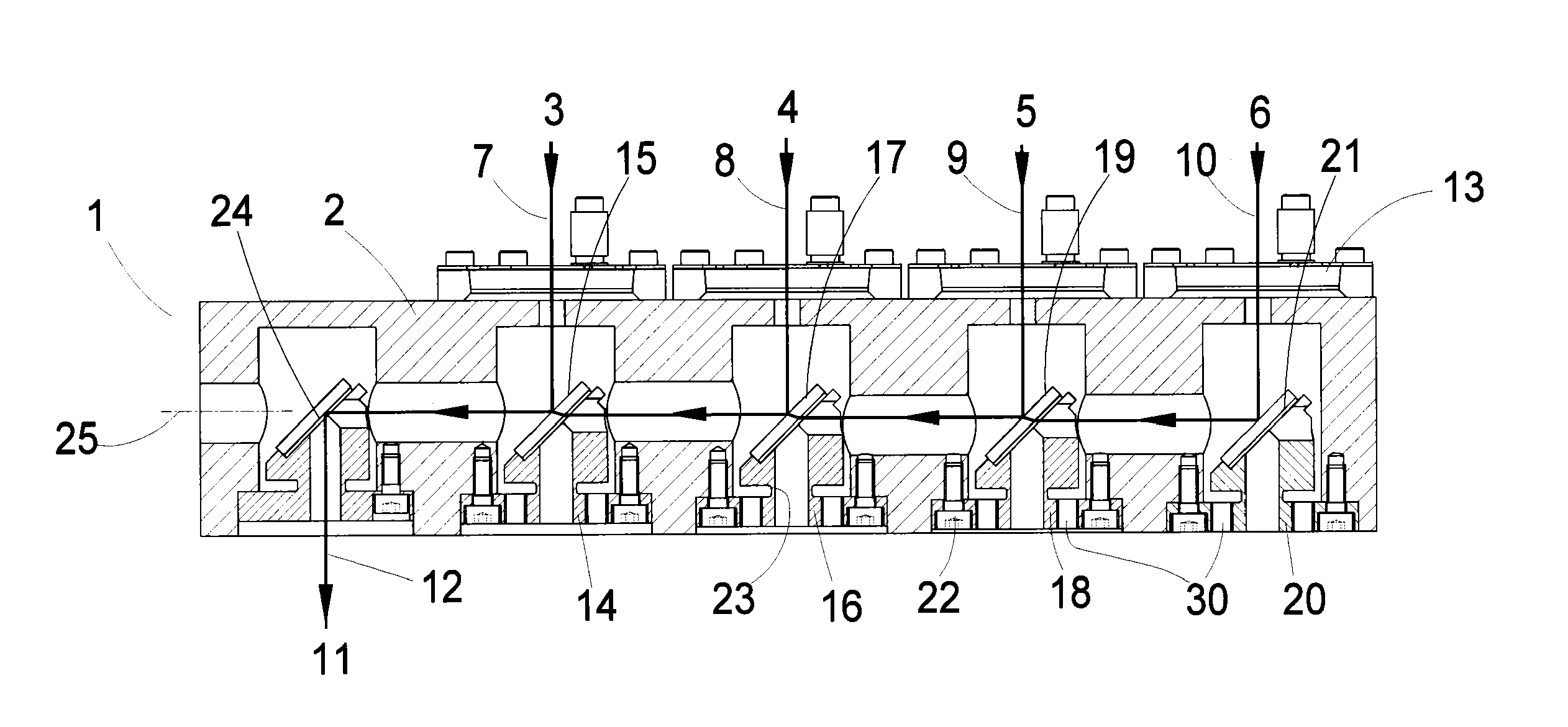

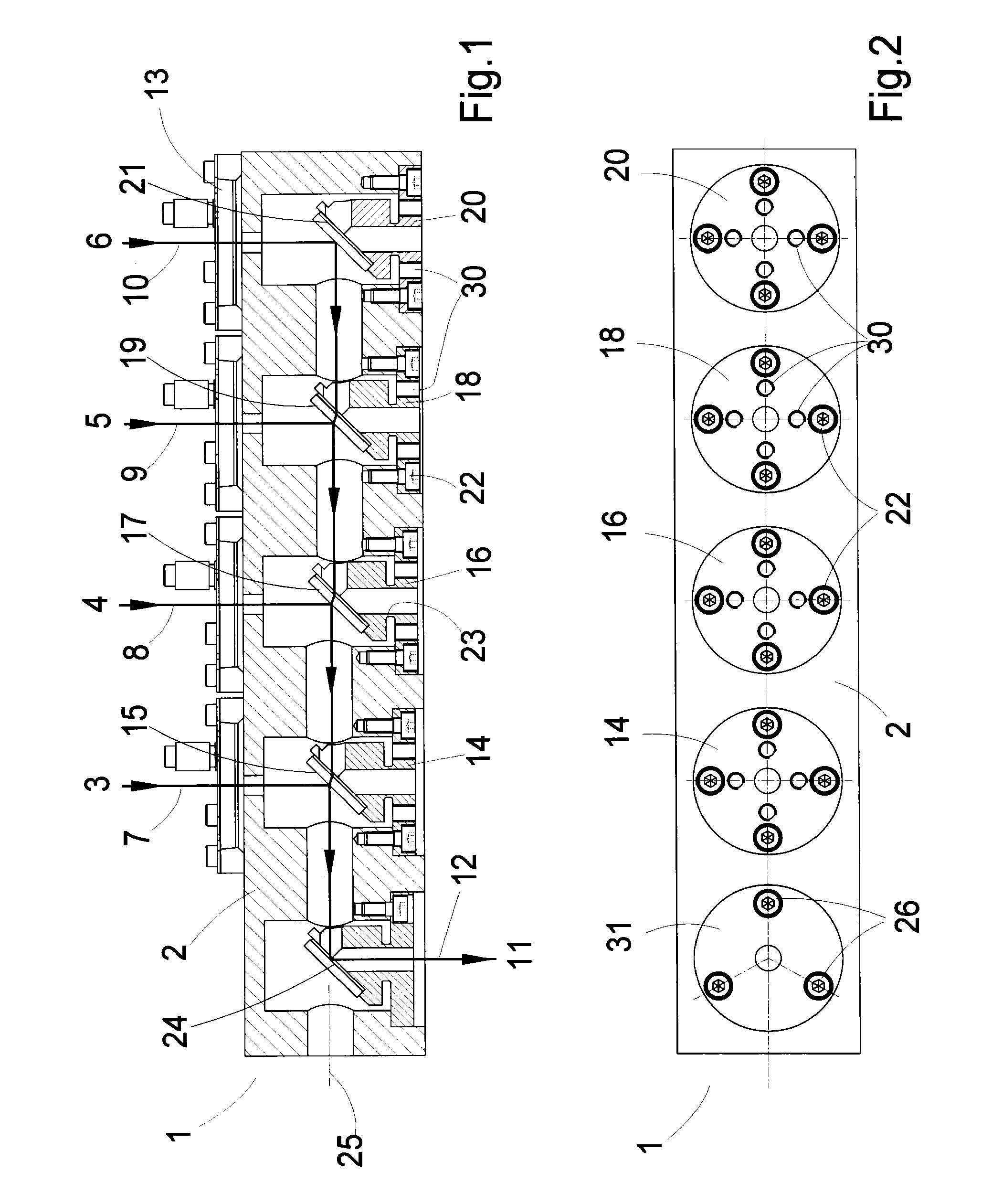

Dispensing device, particularly for domestic appliances

ActiveUS8651336B2Simple and relatively compact structureAccurate and reliable operationPower operated devicesHand rubbing apparatusElectricityEngineering

A long-life substance dispensing device for a washing machine, particularly a dishwasher, comprises: —a body (20′, 30′) designed to be sealingly fixed to a structure of the washing machine, —a support means (40) adapted to contain a total amount of a substance sufficient for performing a plurality of washing cycles, —an actuation system (47′, 50″, 61″) which is electrically controllable for causing delivery of at least one dose of the substance contained in the support means (40). The actuation system (47′, 50″, 61″) comprises at least one drive element and one driven element (47′) capable of cooperating to obtain the delivery. The actuation system (47′, 50″, 61″) is arranged for being able to take on an operative condition, wherein the drive element (61″) is operatively coupled with the driven element (47′), and an inoperative condition, wherein the drive element (61″) is decoupled from the driven element (47′).

Owner:ELTEK

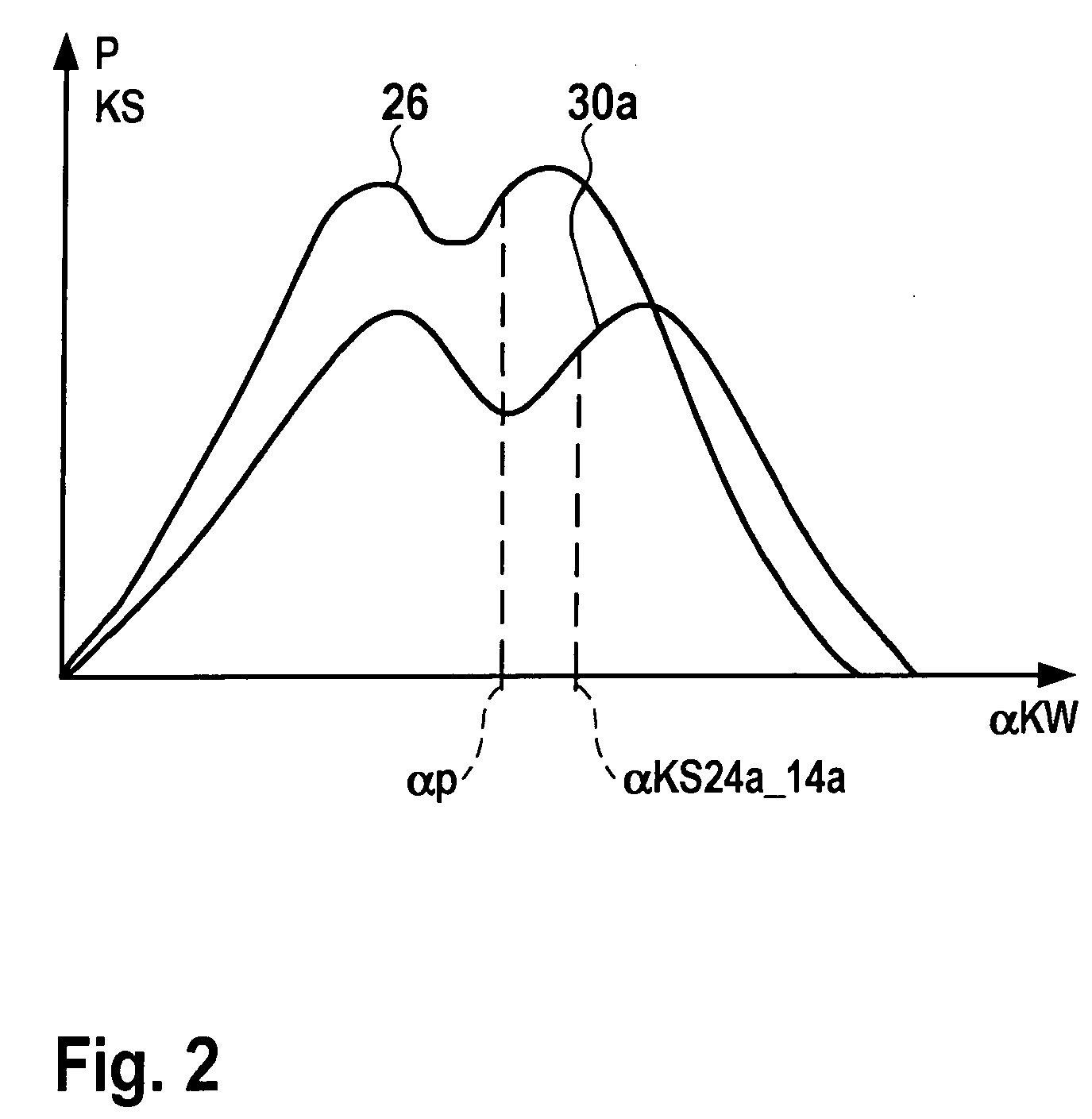

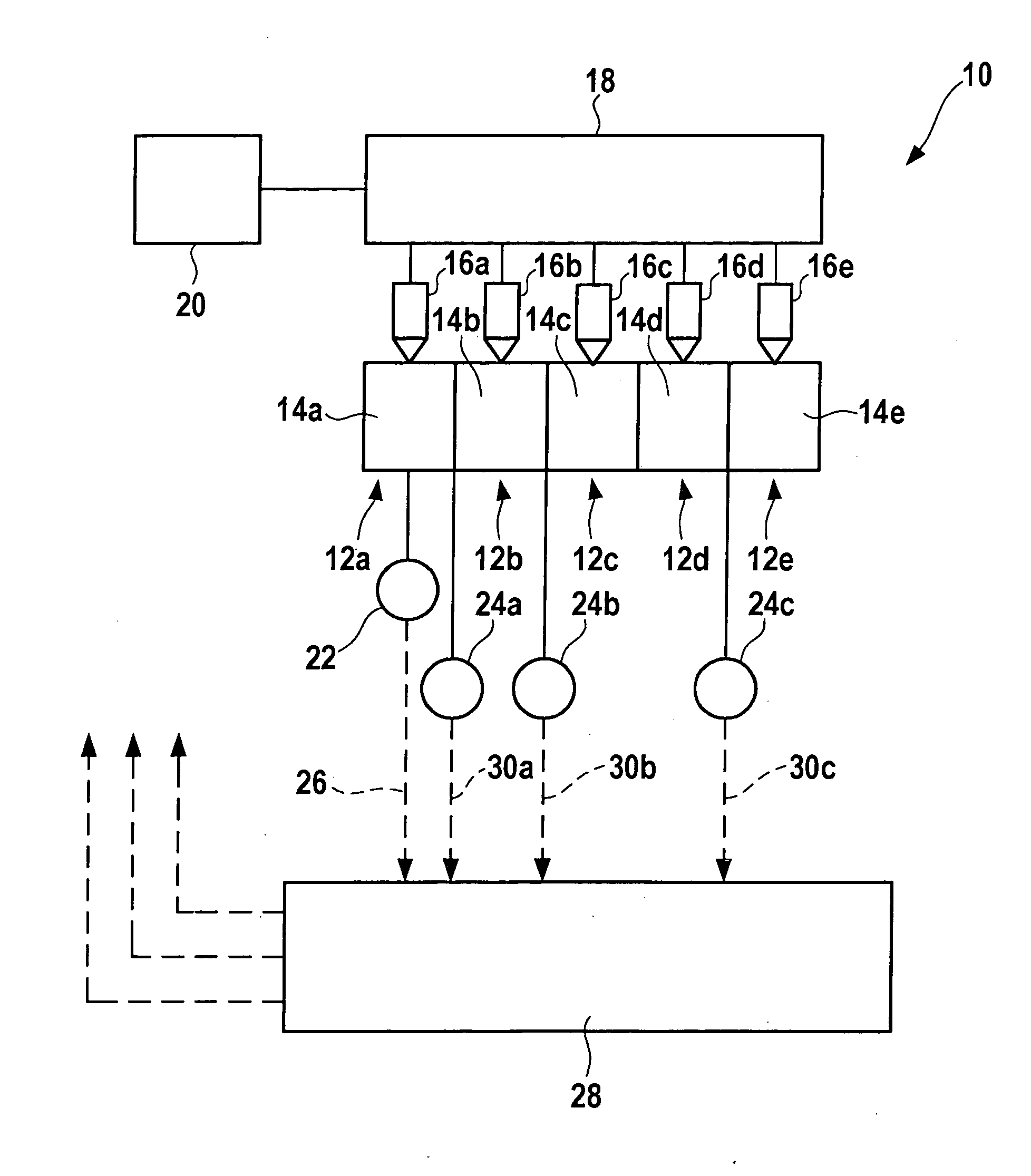

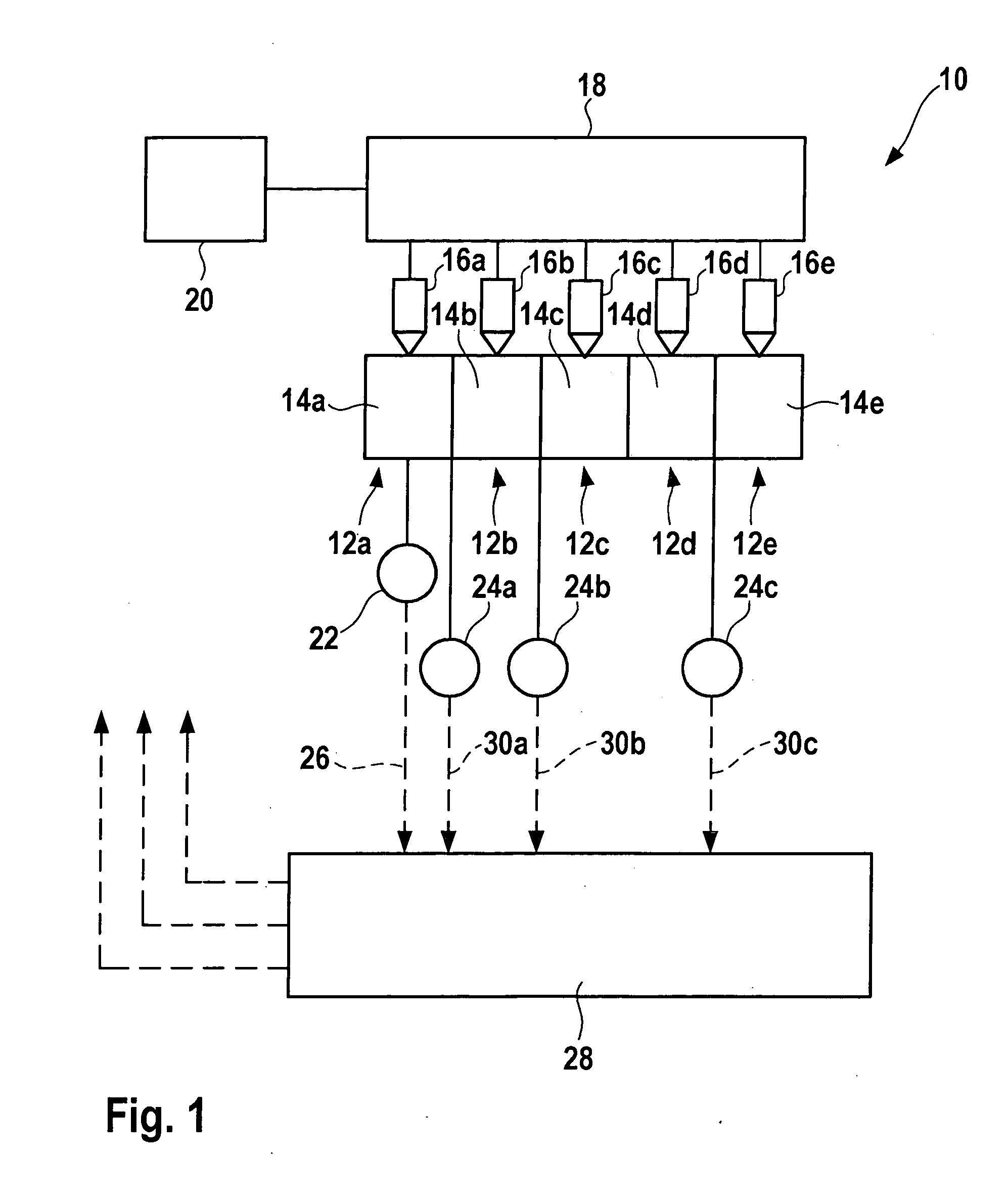

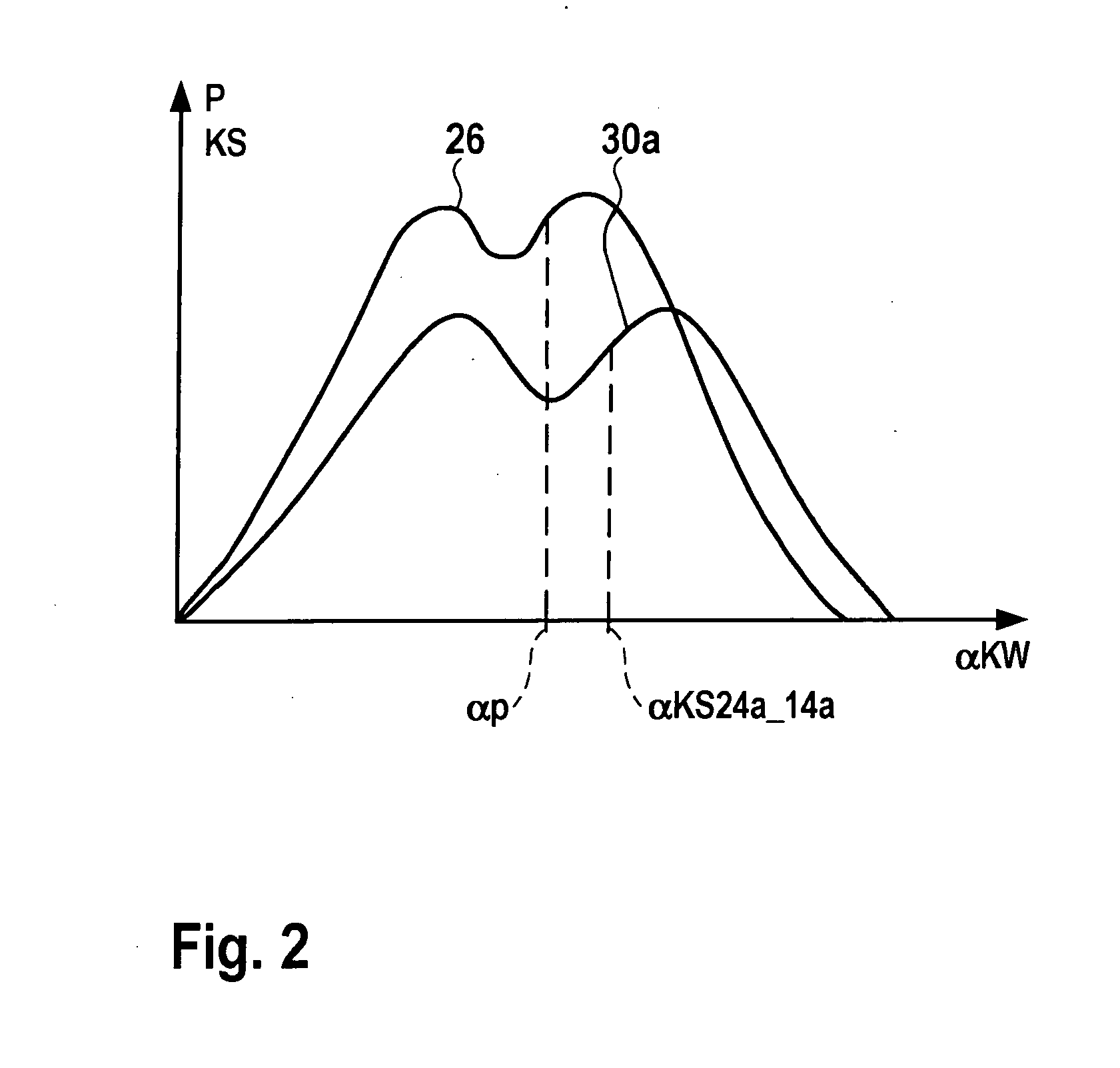

Method for operating an internal combustion engine

ActiveUS7260469B2Low accuracyGreatAnalogue computers for vehiclesElectrical controlCombustion chamberEngineering

In a method for operating an internal combustion engine, a first data quantity is derived based on a signal of a first sensor which detects the pressure in a first combustion chamber of a plurality of combustion chambers, and a second data quantity is derived based on a signal of a second sensor, which second data quantity is a function of the pressure variation in at least one of the plurality of combustion chambers. The first data quantity and the second data quantity are functions of the pressure variation in the same combustion chamber, and a drift of the second sensor is ascertained from a change over time in the second data quantity with respect to the first data quantity.

Owner:ROBERT BOSCH GMBH

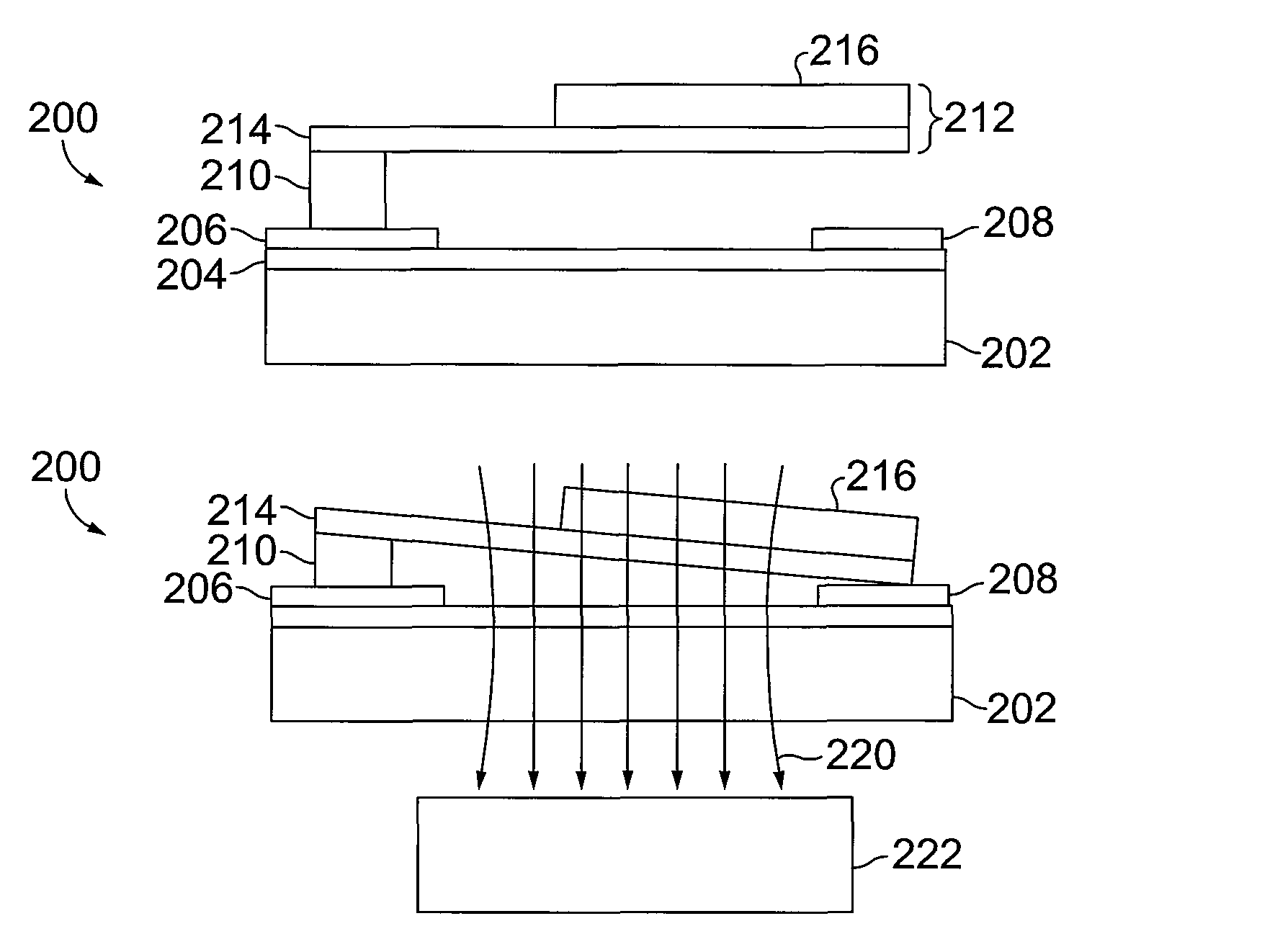

Process condition sensing wafer and data analysis system

InactiveUS7360463B2Accurate readingWide range of operationsSemiconductor/solid-state device testing/measurementTransmission systemsMeasurement deviceData analysis system

A measuring device incorporating a substrate with sensors that measure the processing conditions that a wafer may undergo during manufacturing. The substrate can be inserted into a processing chamber by a robot head and the measuring device can transmit the conditions in real time or store the conditions for subsequent analysis. Sensitive electronic components of the device can be distanced or isolated from the most deleterious processing conditions in order increase the accuracy, operating range, and reliability of the device.

Owner:SENSARRAY CORP

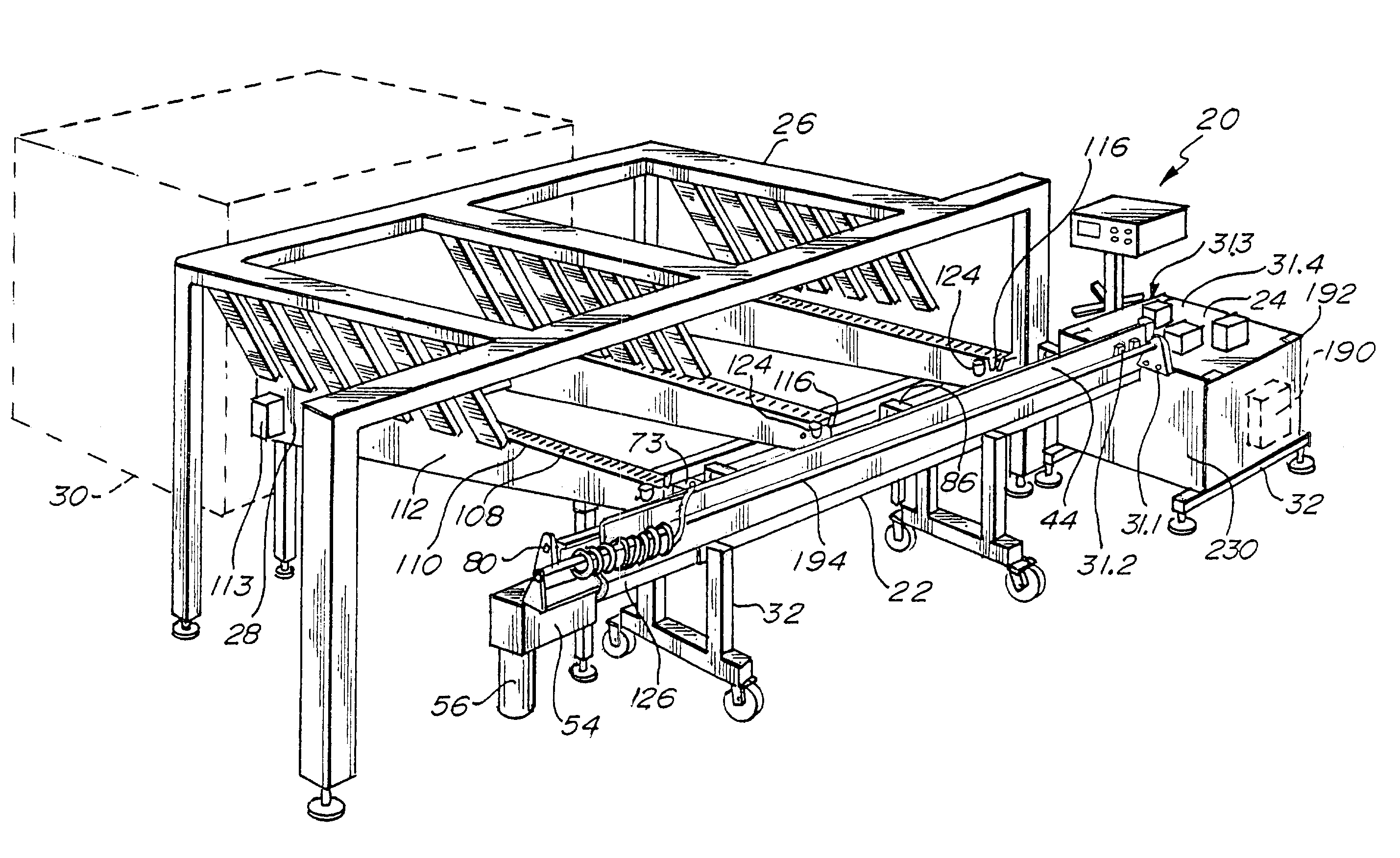

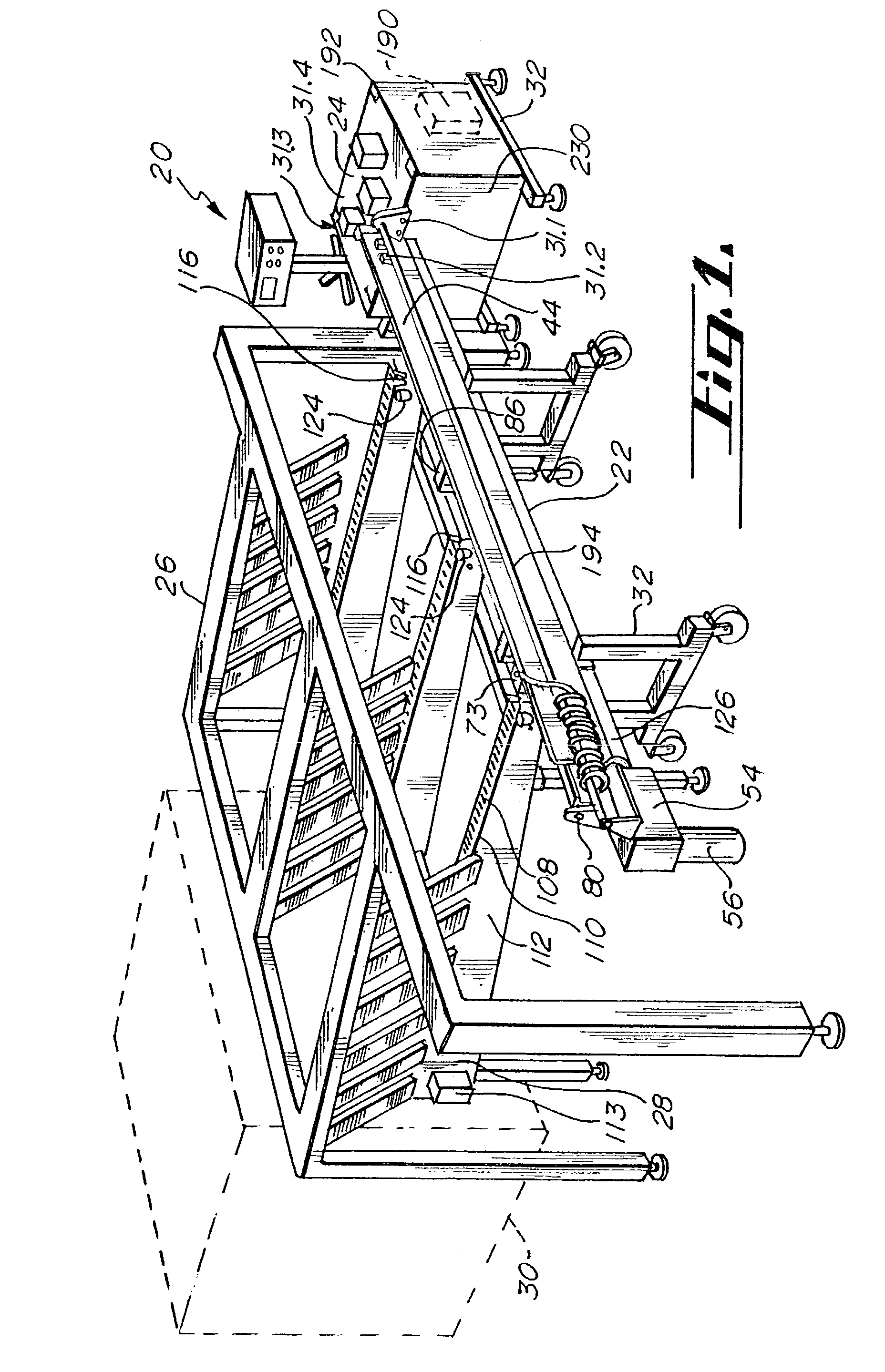

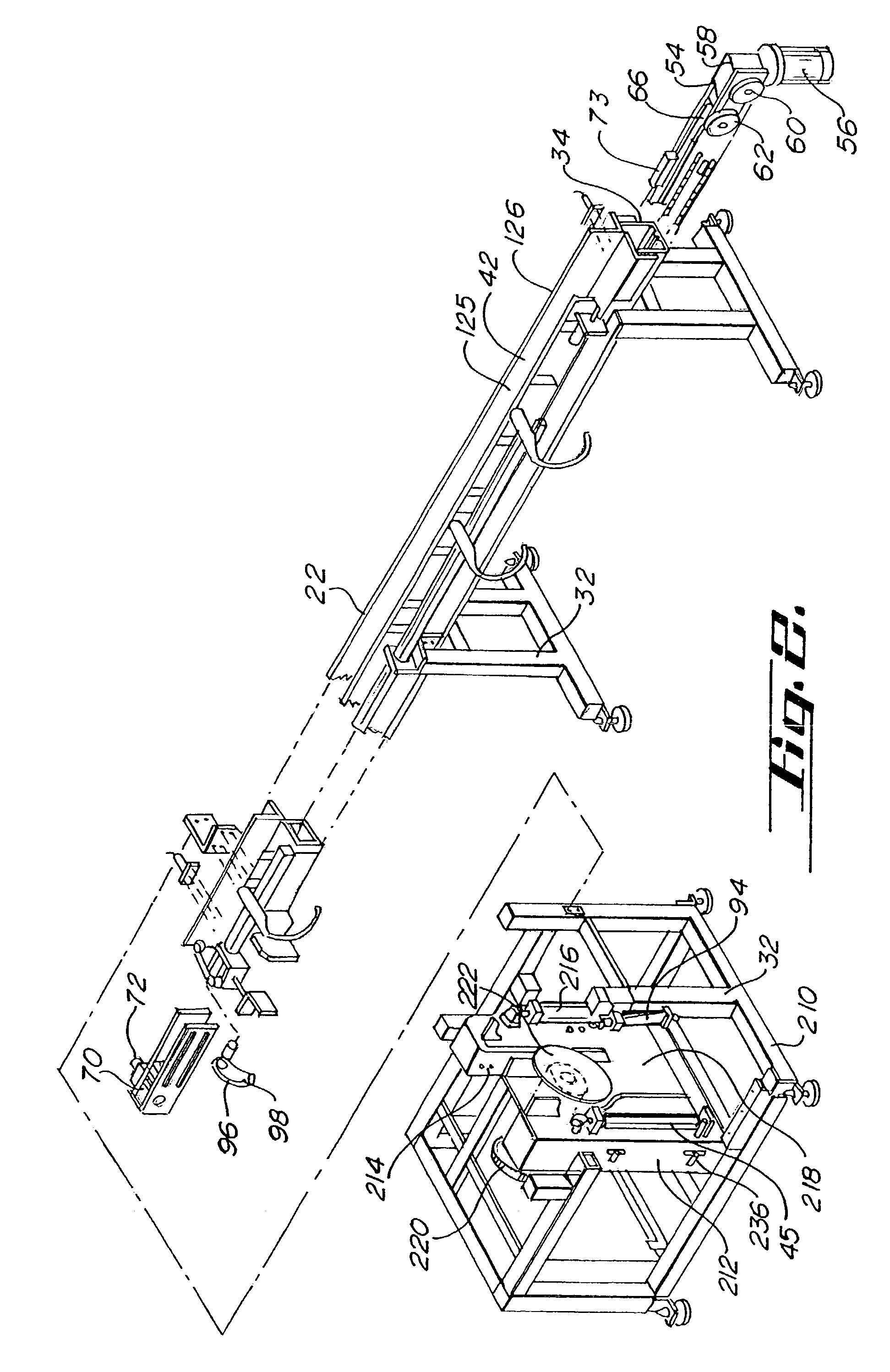

Automated board processing apparatus

InactiveUS7011006B2Accurate and reliable operationEasy to controlDigital data processing detailsShearing machinesEngineeringProcess control

In preferred embodiments the invention includes a transverse board conveyor, a board extrusion portion, a marking station, a sawing portion, and a plurality of board feeding portions, all of which are controlled by a process controller. In such preferred embodiments, a bunk feeder and magazines feed boards serially onto the transverse board conveyor and are conveyed in a direction transverse to the length of the boards. The boards are individually deposited into an elongate receiver of a board extrusion portion to be conveyed longitudinally. A carriage in the receiver transports the boards past an end detection station, past a marking station, and to a sawing station. The marking station prints desired indicia at selected positions on the board such as by an ink jet printer without physical contact of the printing mechanism with the board and while the board is moving.

Owner:MITEK HLDG INC

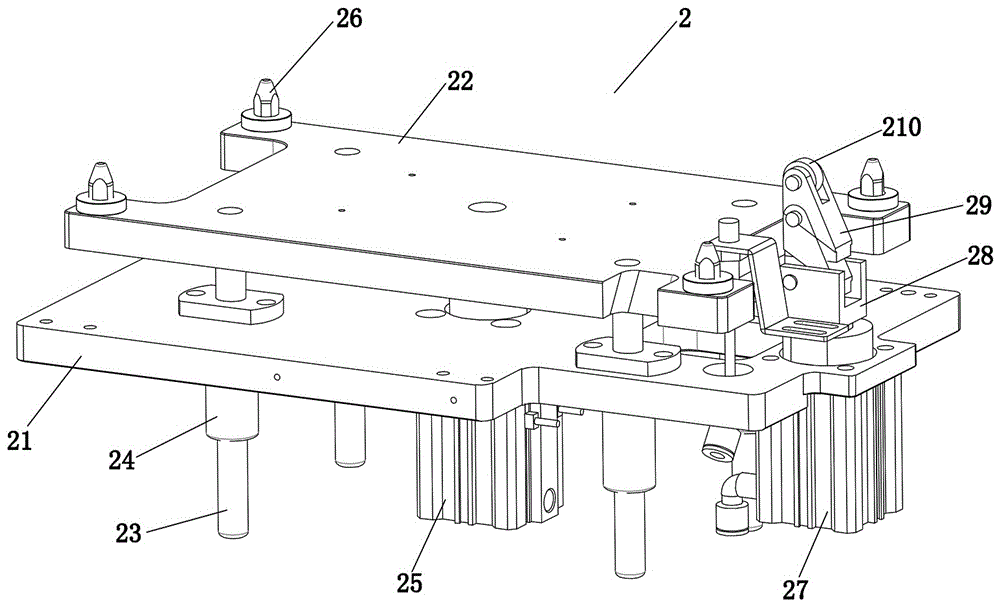

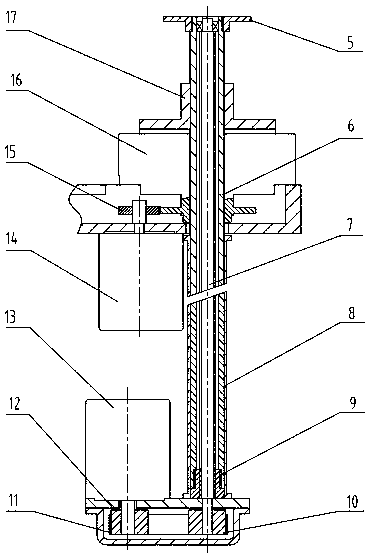

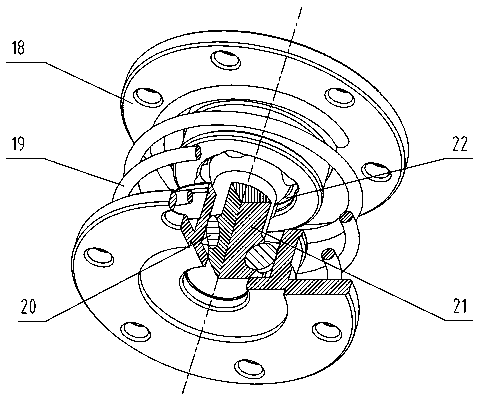

Operating device for densely-installed valves

PendingCN109578663AReasonable structural designSimple and safe operationOperating means/releasing devices for valvesSelf limitingReducer

The invention discloses an operating device for densely-installed valves. The problem that for dense valve tree using occasions, the operating space of an existing valve operating device is limited issolved. The operating device comprises a moving chassis, a multi-axis driving mechanism assembled on the moving chassis, and a self-limiting valve opening-closing device, and is characterized in thatthe self-limiting valve opening-closing device comprises a valve opening-closing transmission mechanism, a limiting compensator and a wrench which is of a clamping claw structure, the multi-axis driving mechanism is fixedly connected with a connection flange of the moving chassis through a base of a first RV speed reducer and orderly moves along with the moving chassis; and the valve opening-closing transmission mechanism composed of a telescopic rotation driving mechanism and a barrel body drives the wrench of the clamping claw structure through the limiting compensator, rotating is conducted while axial sliding is carried out, and valve opening, closing and adjusting are completed. The operating device is reasonable in structural design, safe, easy and convenient to operate, and quick and stable in operating, the operating enveloping space is not limited, manual valve operating can be effectively replaced, operating is more precise and reliable, and the operating efficiency is remarkably improved.

Owner:深圳中科捷飞科技有限公司

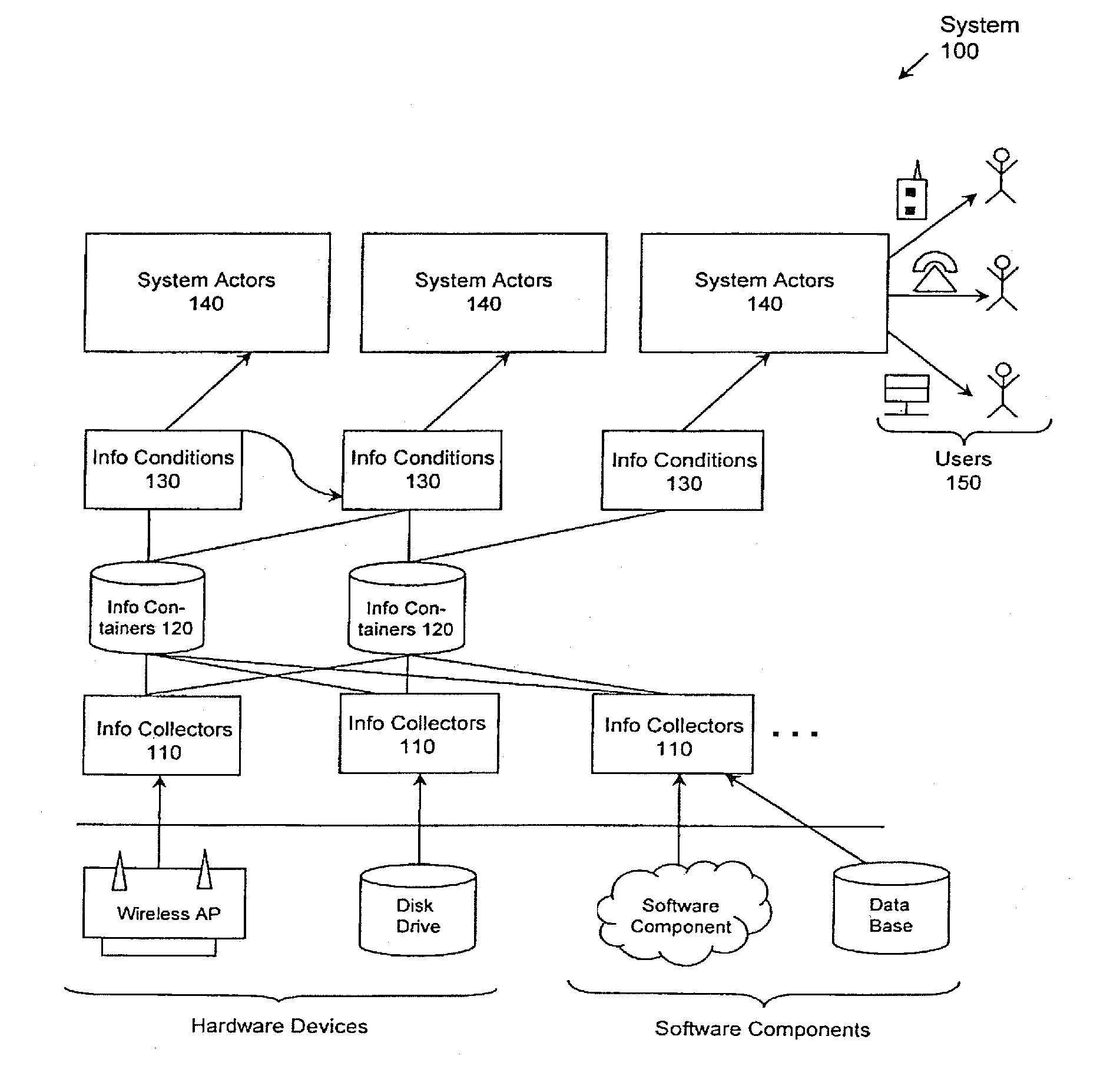

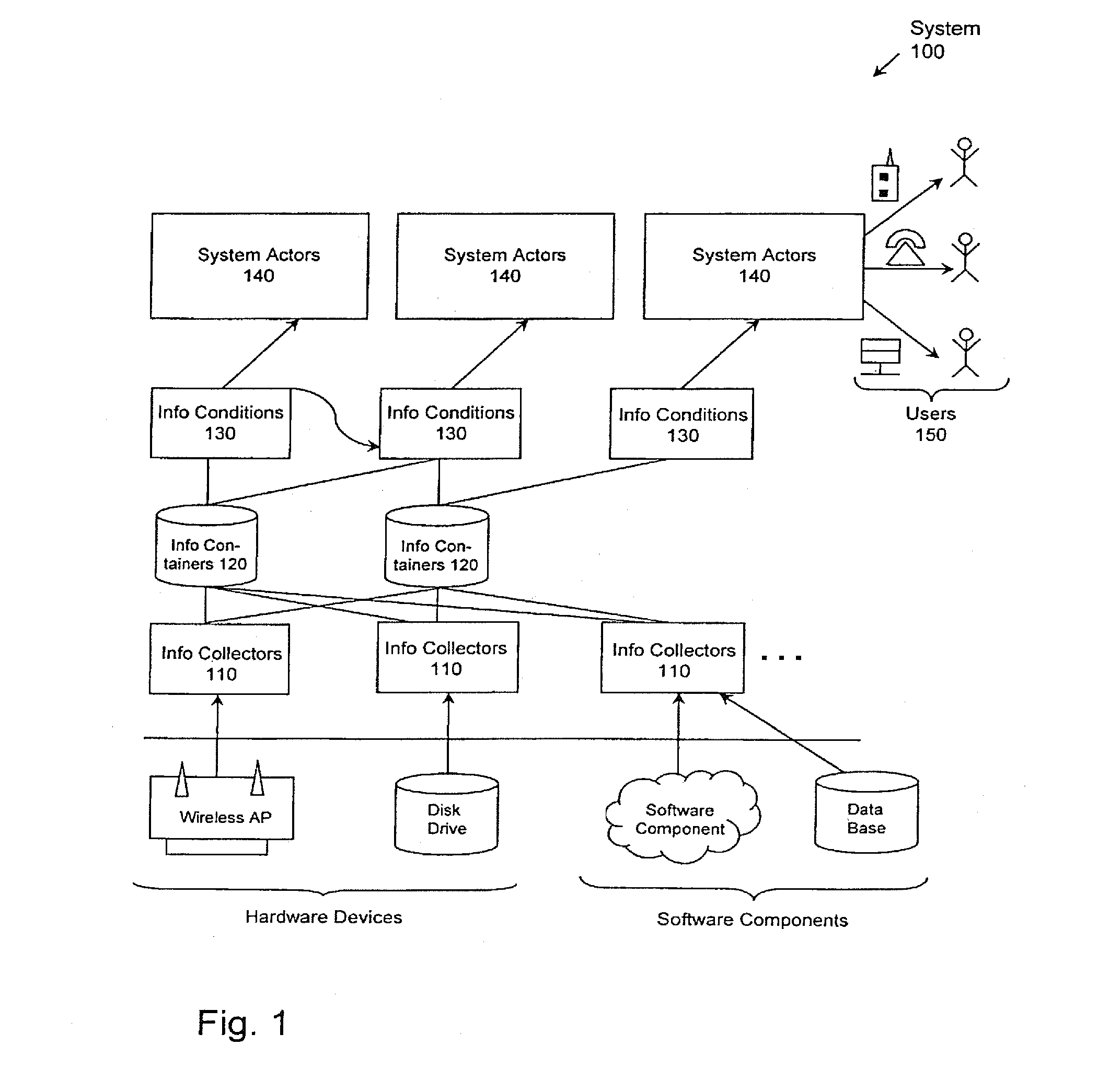

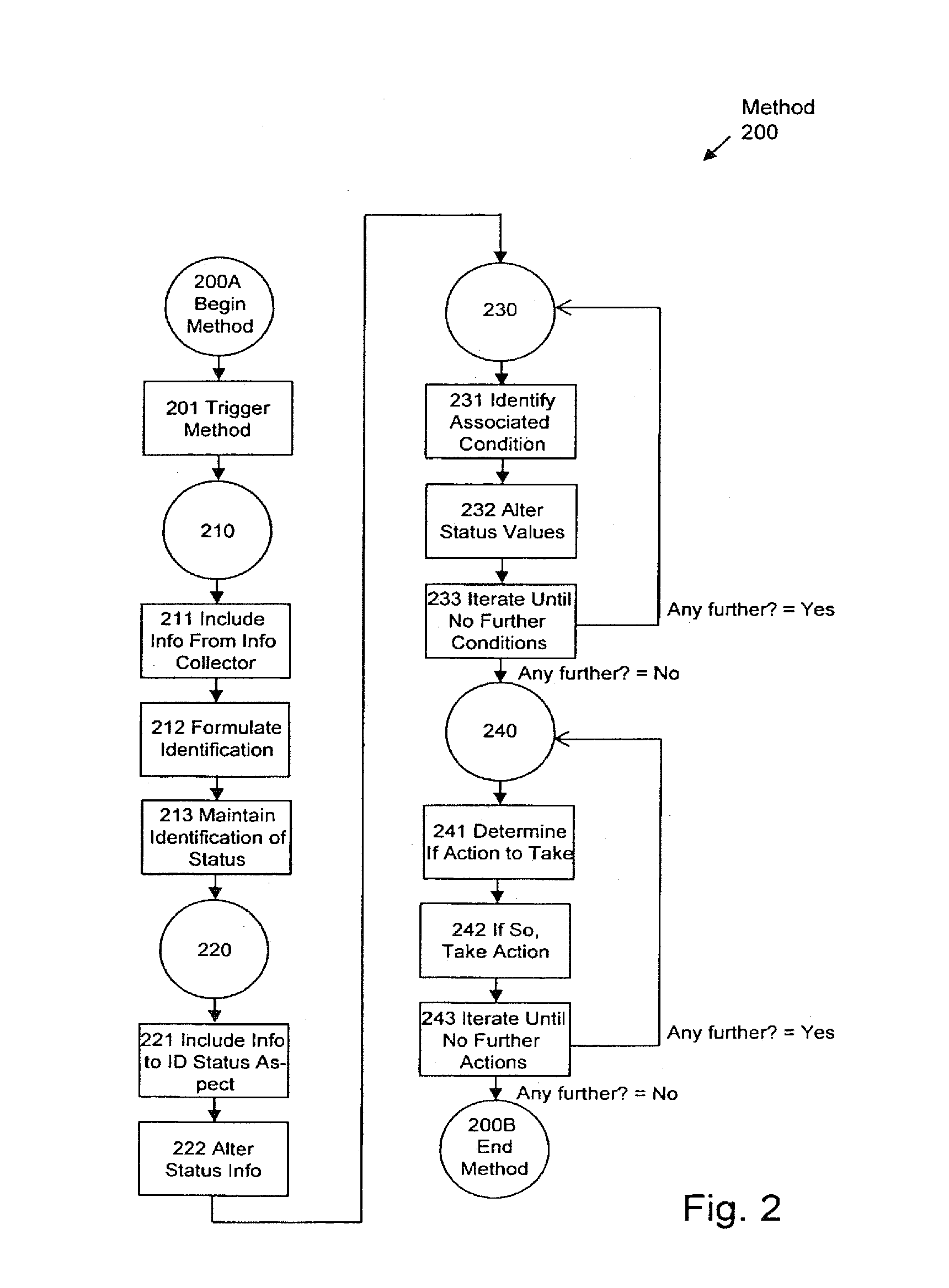

Condition detection and reporting in complex systems

ActiveUS8639971B1Maintain consistencyAccurate and reliable operationDigital data processing detailsNon-redundant fault processingOperational systemEngineering

Maintaining consistency and freshness of information about an operational system, assuring consistent actions by system actors, assuring that system elements use only a single global status of the system for any particular status time, assuring that each pair of elements acts only upon consistent status values, assuring that system elements operate only with status values measured sufficiently recently to be reliable. Information collectors respond to status values. Information containers respond to information collectors, maintaining status values and metadata indicating whether those status values are reliable, or are consistent with respect to known correct values. Information conditions respond to information collectors or information containers, maintaining logical consistency with a unified global status. System actors respond to information containers or information conditions, acting logically consistent with that global status. System actors might include those which notify monitors or operators, and those which modify the system to detect and correct operation gone awry.

Owner:SCALE COMPUTING

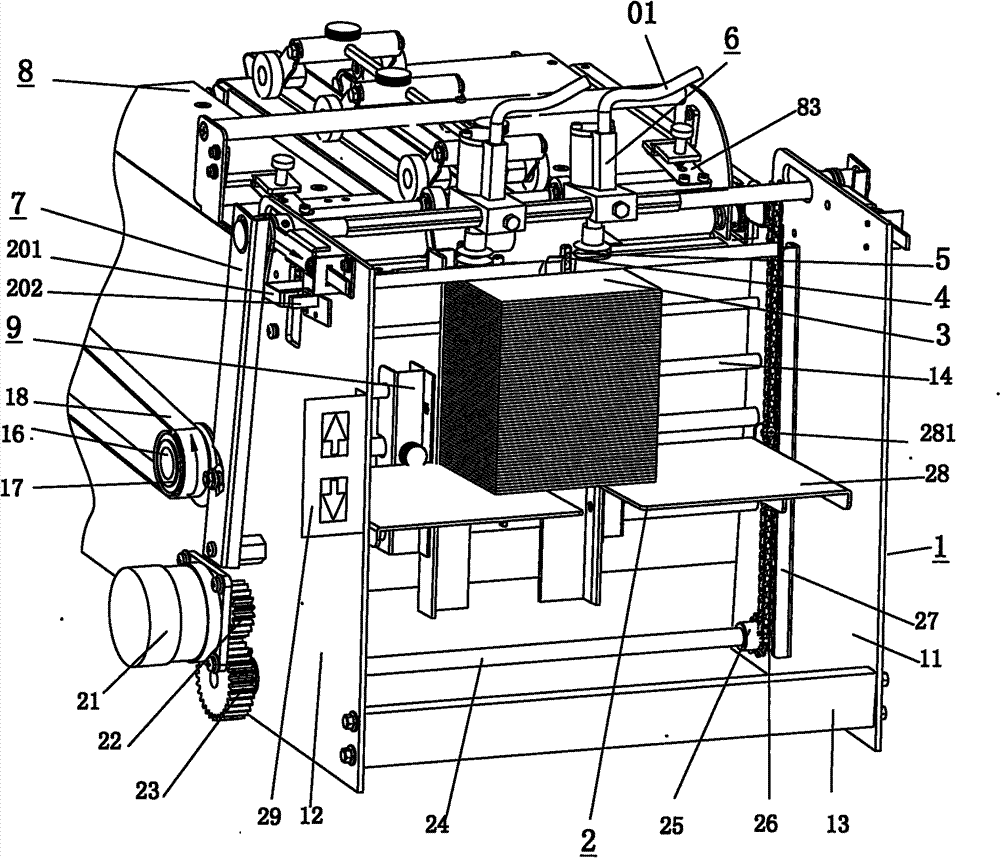

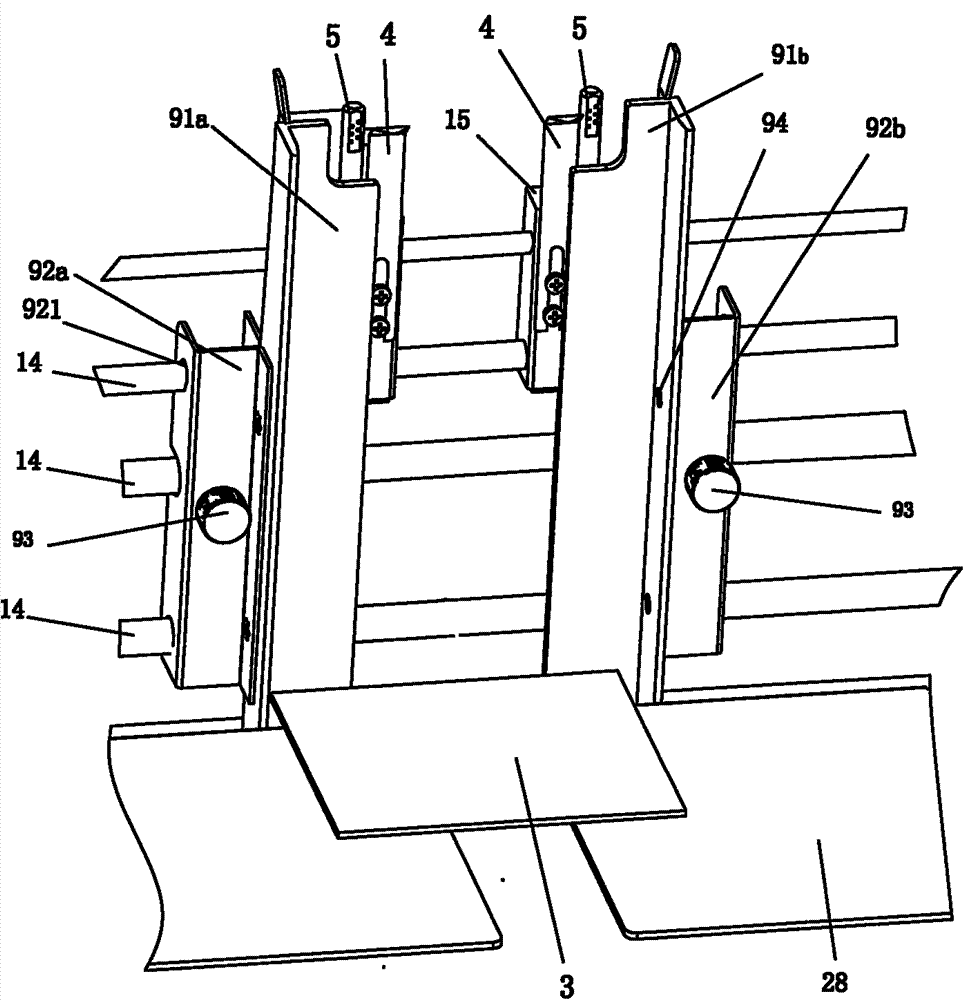

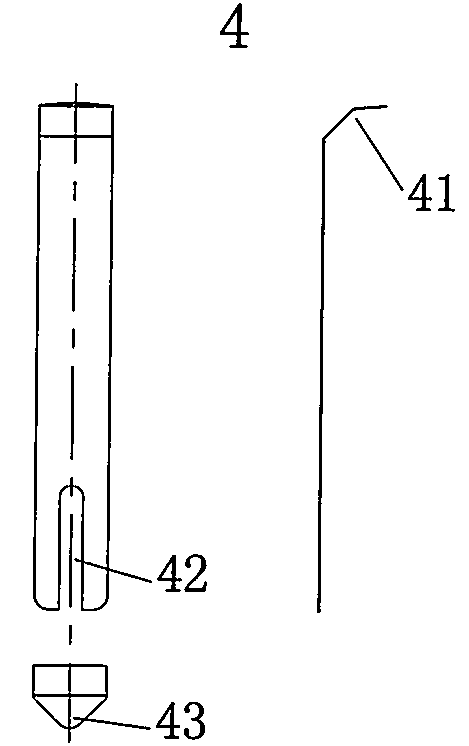

Vacuum-sucking paper feeding mechanism for offset press

The invention discloses a vacuum-sucking paper feeding mechanism for an offset press. The vacuum-sucking paper feeding mechanism comprises an automatic ascending-descending paper stacking table, paper guide rails, paper distributing claws, blowing pipes, vacuum sucking tube components, movable parts, a paper feeding platform, a vacuum suction pipe and a discharge pipe, wherein air suction and discharge are delivered by a vacuum pump. The automatic ascending-descending paper stacking table is provided with a transmission part which includes a pair of gears, a transmission shaft, chain wheels, chains, guide rails, a paper stacking table and a paper pressing plate, and provided with an electric button and a positioning photoelectric sensor to control operating of the motor, and paper on the paper stacking table is fed to the specified position. Suckers in the vacuum sucking tube components suck paper to the paper feeding platform; the movable parts on two sides are matched with transmission cams so as to support forward and backward moving of the vacuum sucking tube components, the paper feeding platform is provided with a front wheel pressure-flexible-adjustment component and a paper feed belt to convey paper backwards, and front wheels adjust pressure through leaf springs by the aid of adjusting screws. The vacuum-sucking paper feeding mechanism is quick and accurate and has no damage on paper, and clean and clear paper products can be printed smoothly.

Owner:何小午

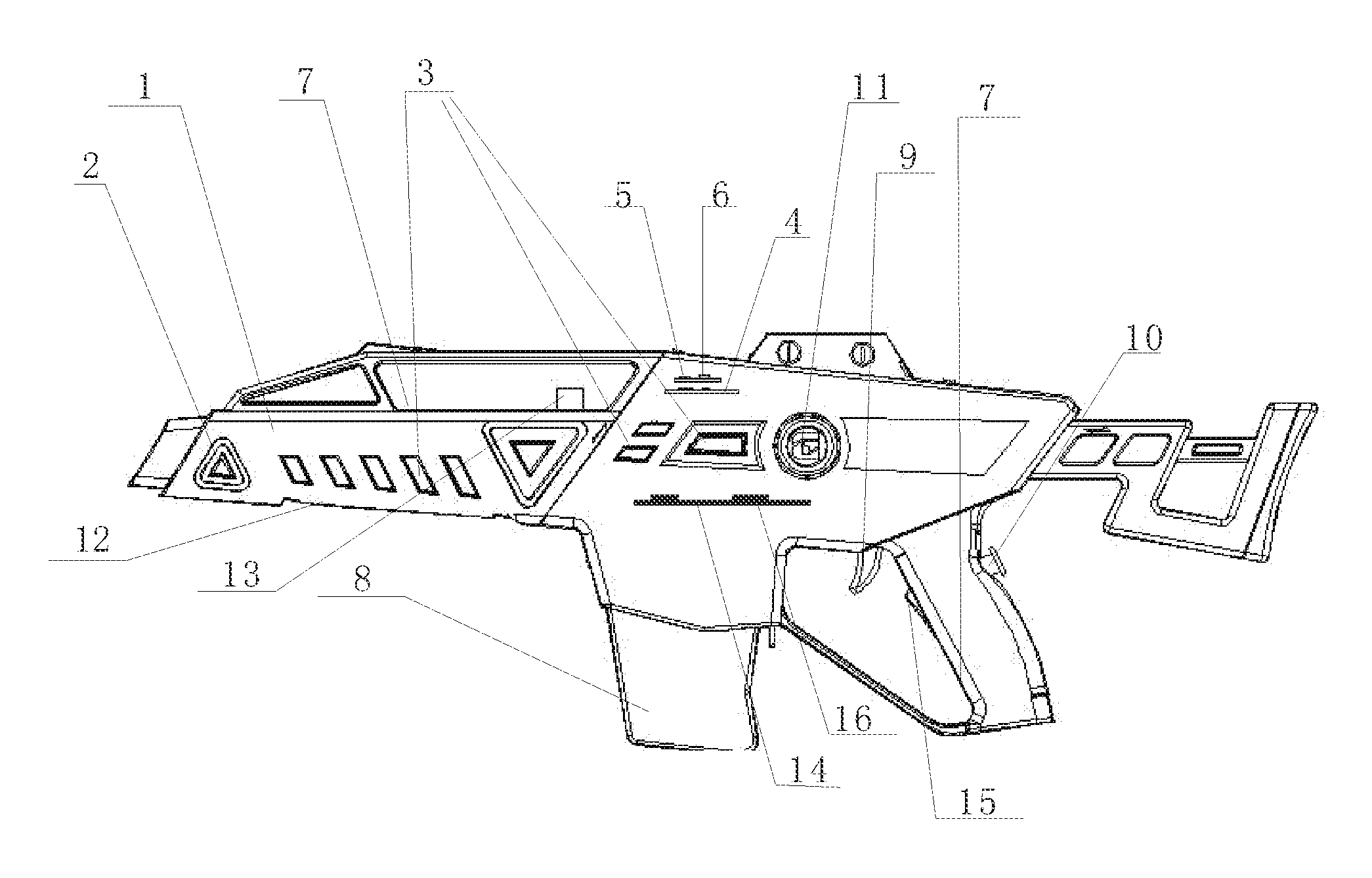

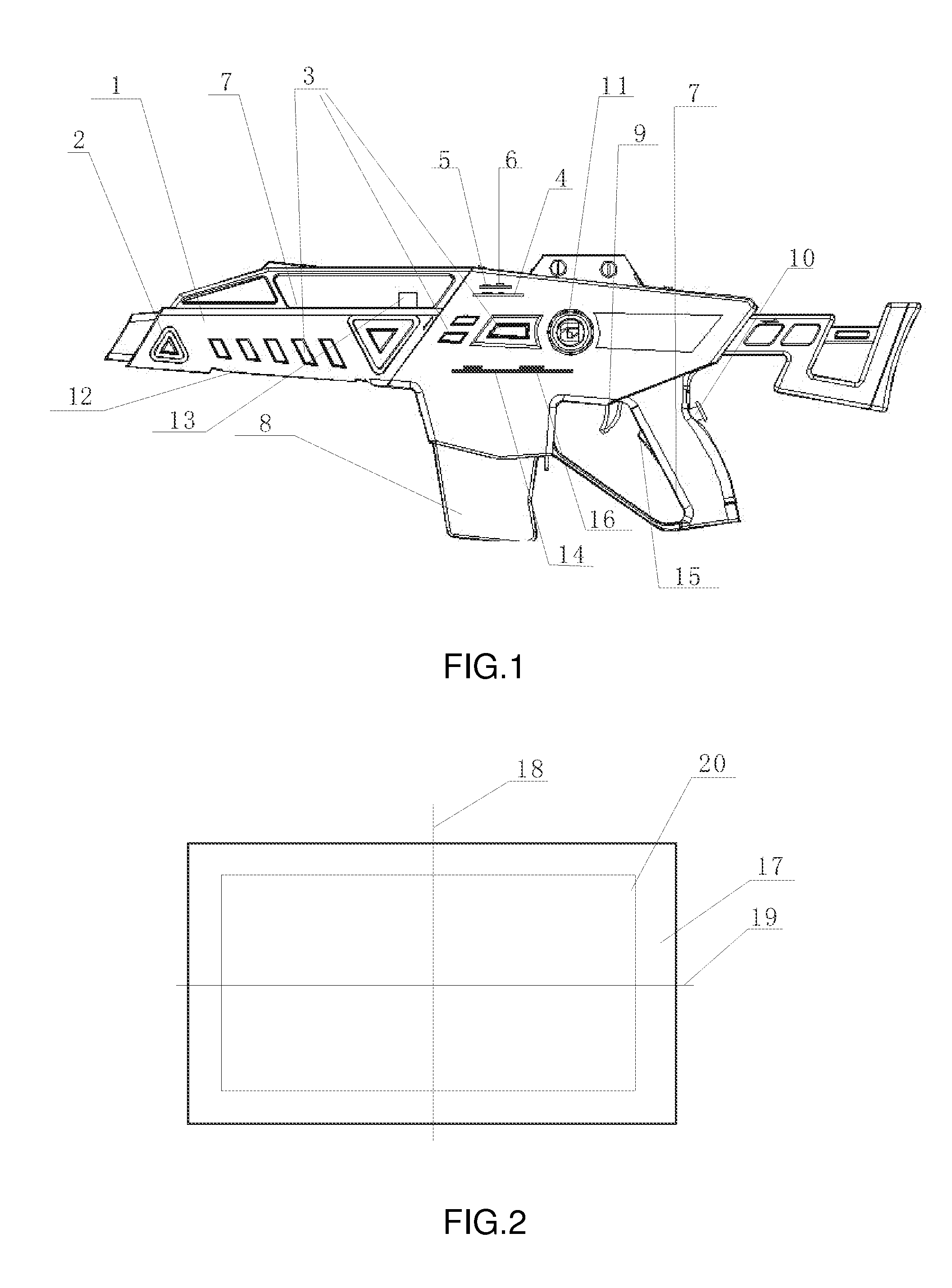

Gun-shaped game controller

InactiveUS20130029764A1Operation faster and convenient and flexiblePrecise and flexible spatial positioningVideo gamesSpecial data processing applicationsSpatial positioningGyroscope

A gun shaped game controller includes a gun shell, a calibration key, self-defined function keys, a two-axis gyroscope chip, a two-axis geomagnetic chip, a three-axis gravity acceleration chip, a human body capacitive touch chip, a battery compartment, a trigger, an arrow key, a cancel key, an infrared sensor, an angle adjustment knob and a main control circuit board. The two-axis gyroscope chip, the two-axis geomagnetic chip and the three-axis gravity acceleration chip achieve 3D spatial positioning of a “virtual potentiometer” via spatial geometrical mathematical modeling algorithm to meet predetermined objectives.

Owner:WANG YI ZHONG

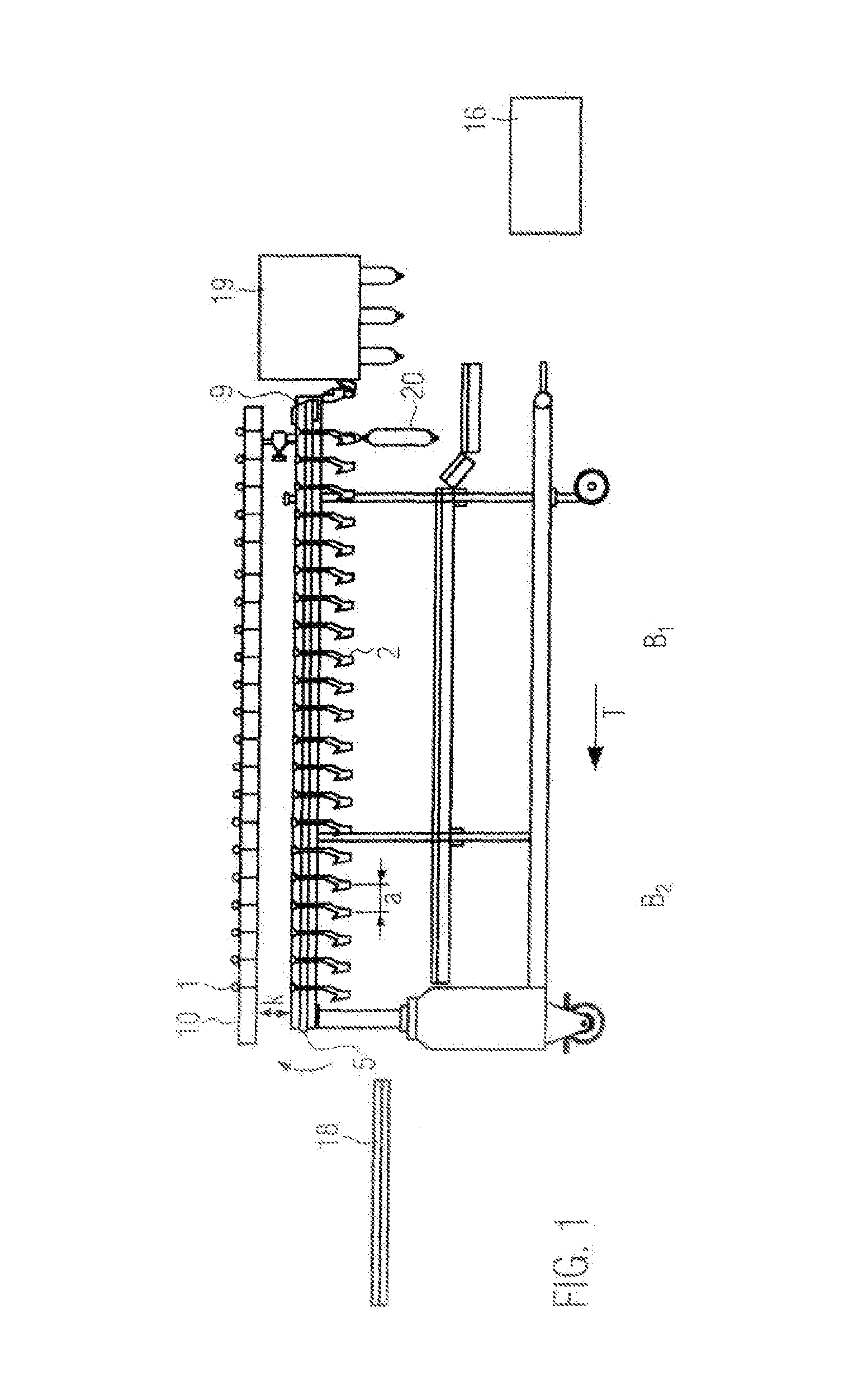

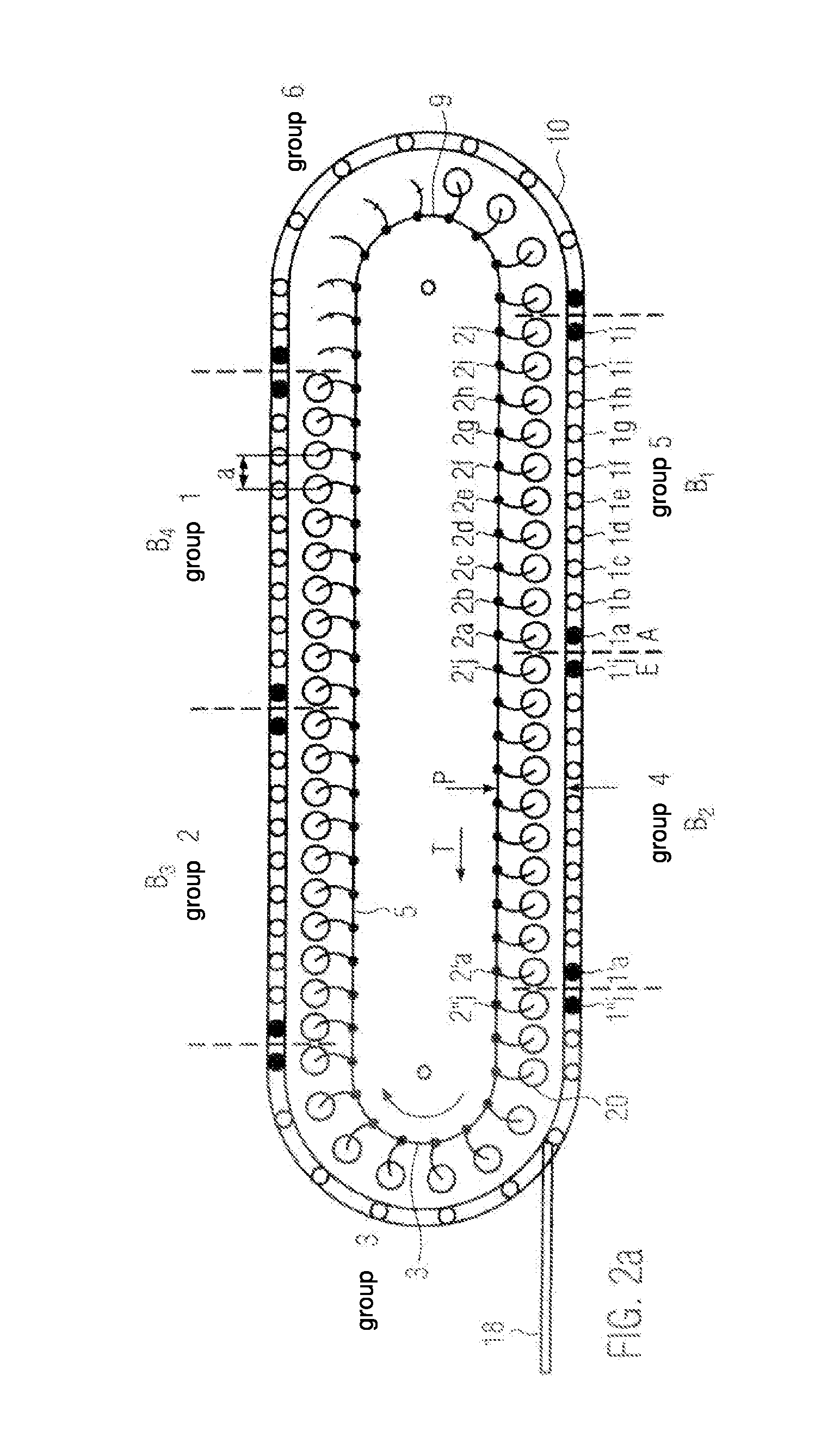

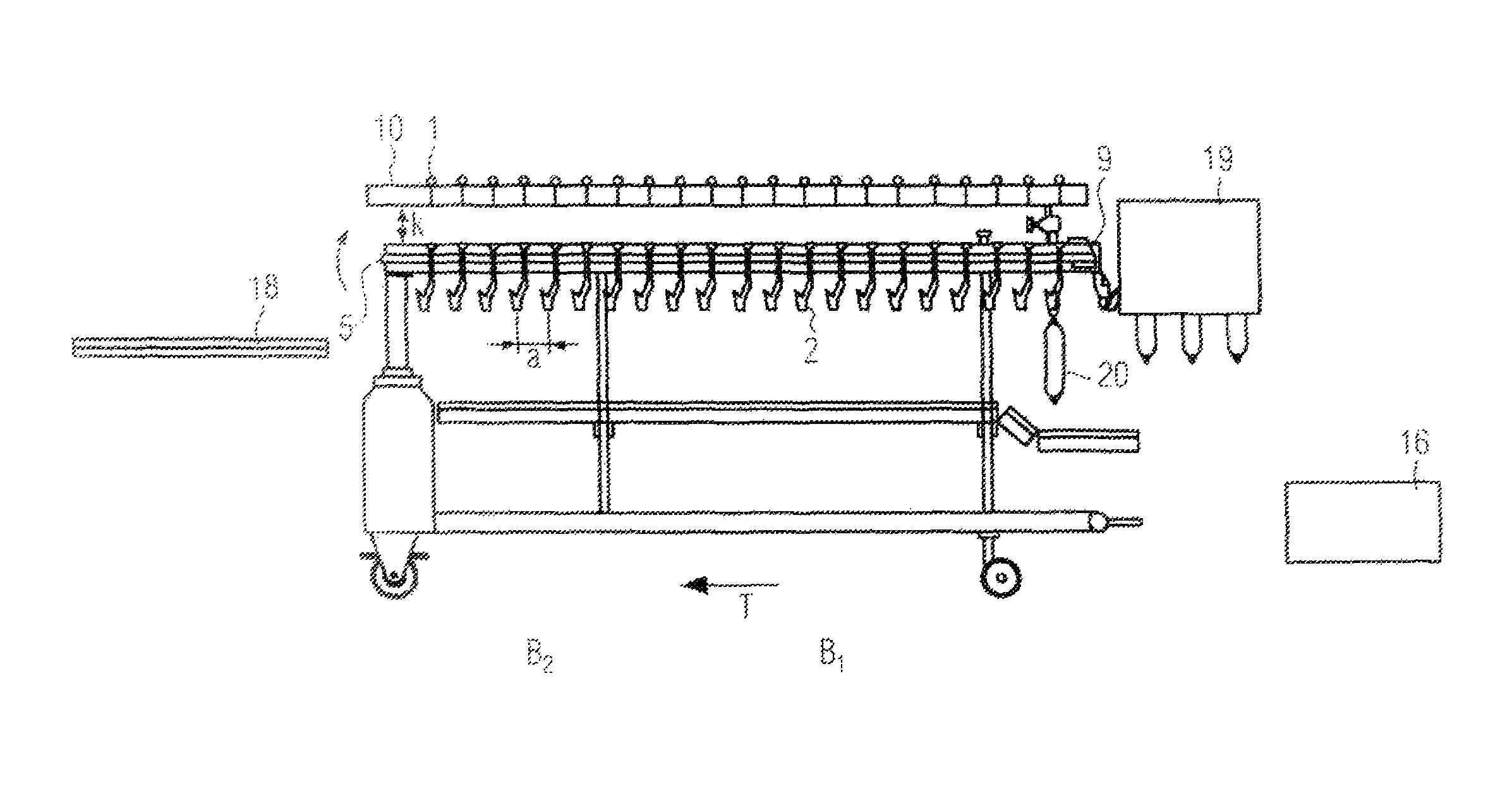

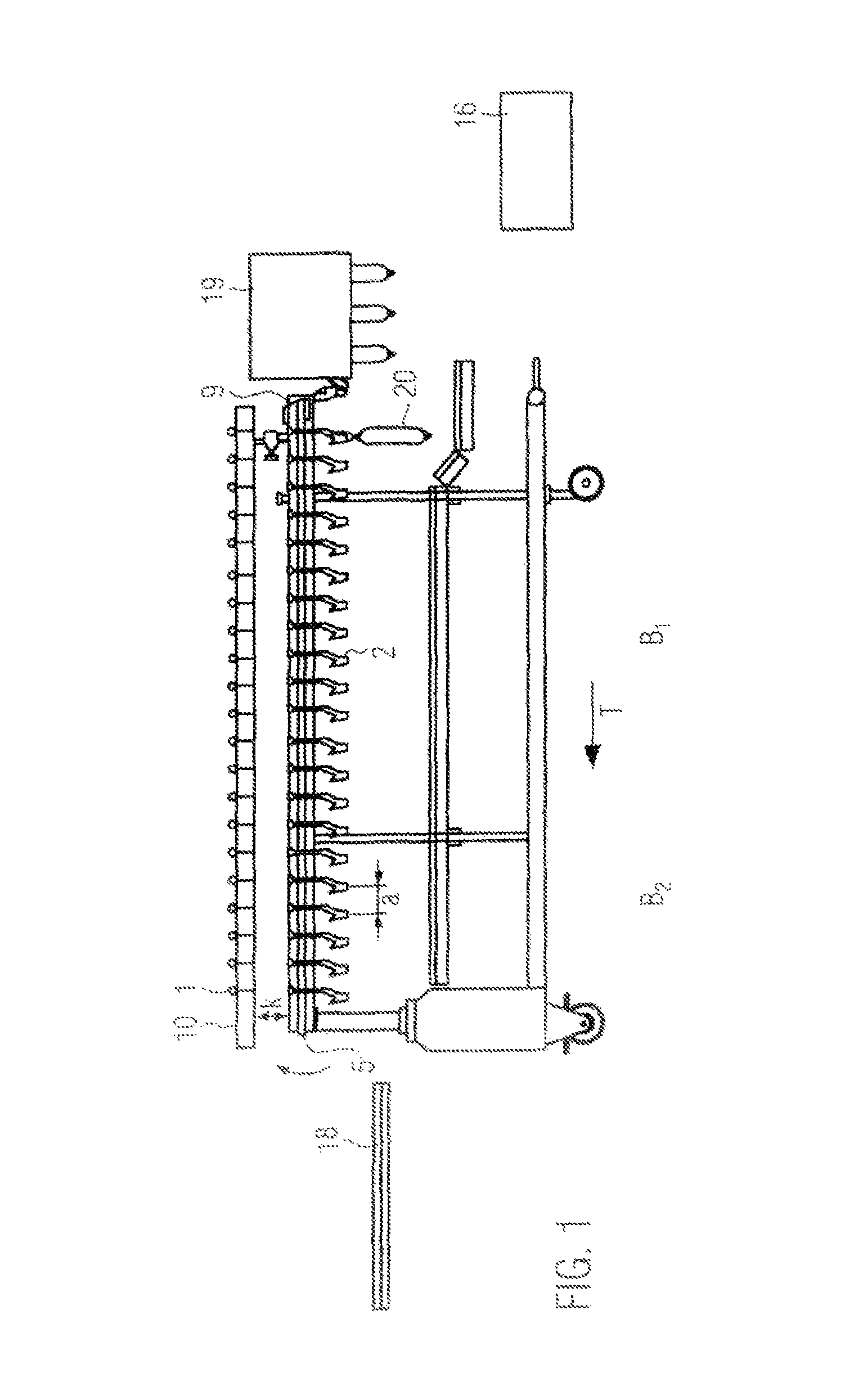

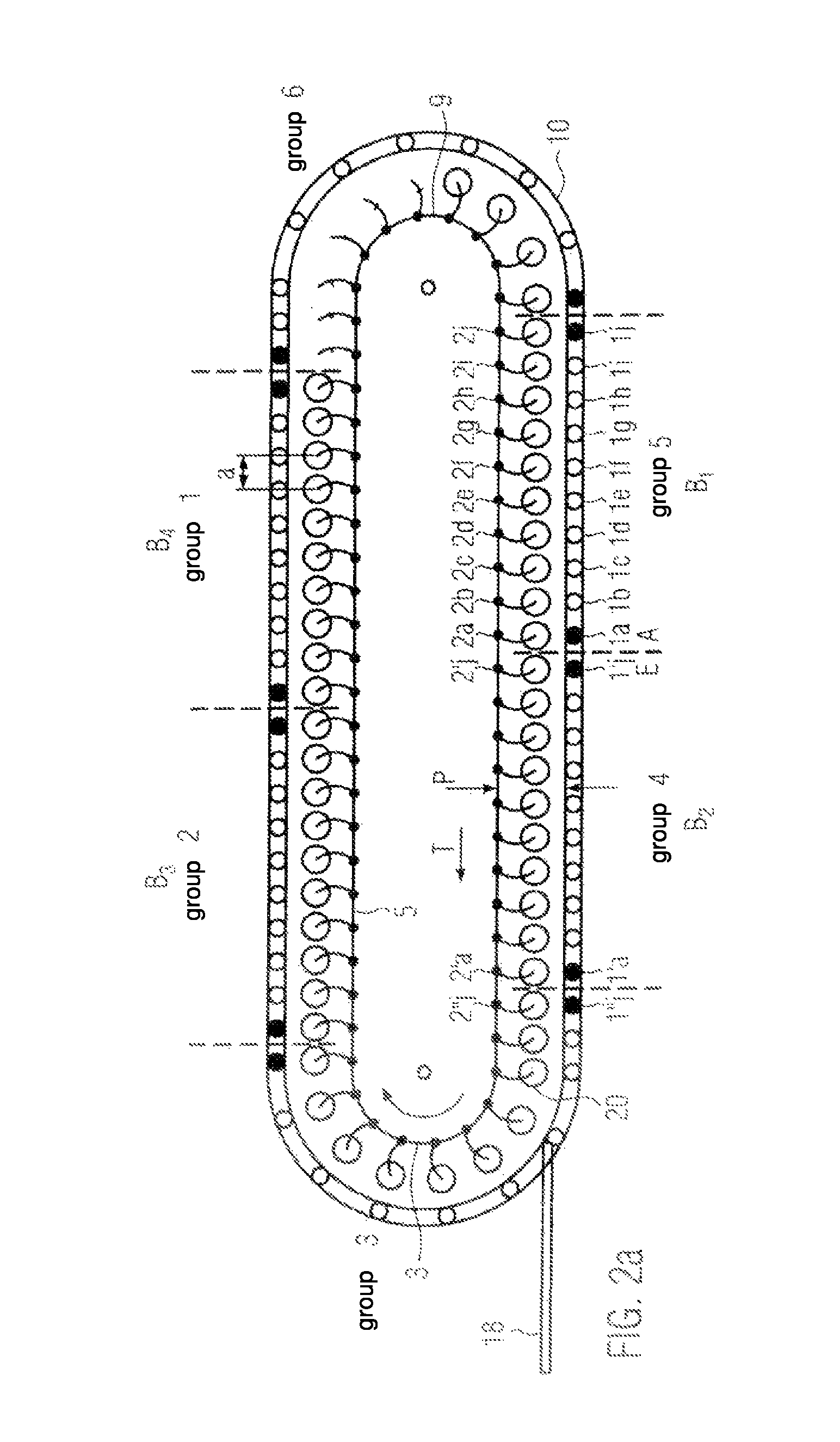

Suspension apparatus and method for suspending sausages, in particular sausage chains

ActiveUS20140073231A1Accurate operationEasily identifiableMeat/sausage hanging-upLinked sausage separationEngineering

Owner:ALBERT HANDTMANN MASCHFABRICK

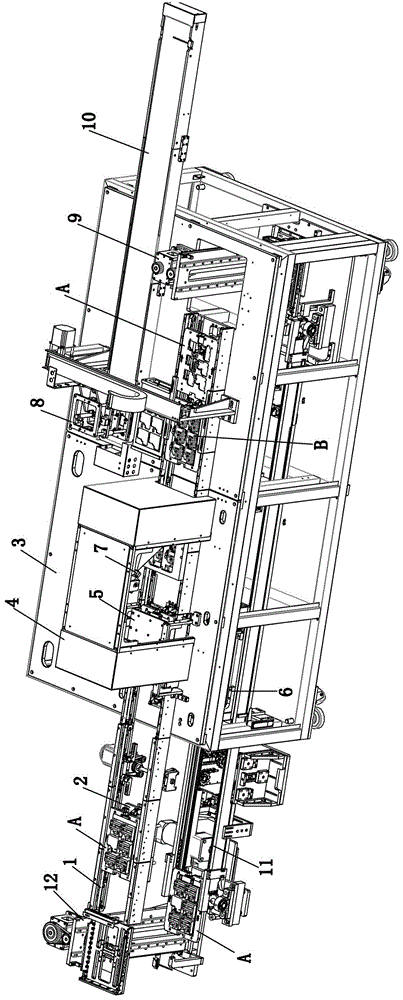

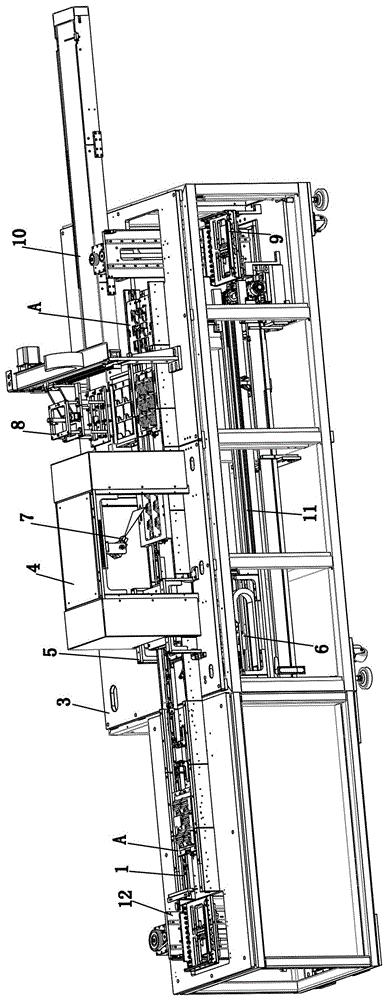

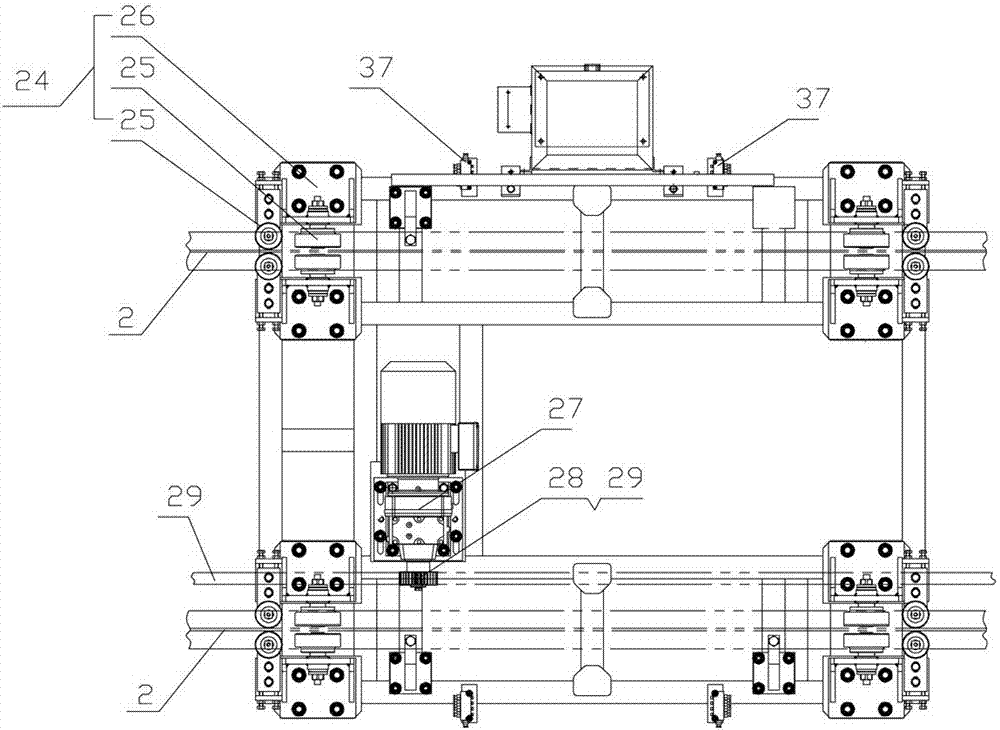

Element pin measurement machine and measurement process thereof

ActiveCN105979764AHigh degree of automationAccurate and reliable operationElectrical componentsMachineIndustrial engineering

The invention discloses an element pin measurement machine and a measurement process thereof. The e element pin measurement machine comprises an upper-layer material band, a frame lower measurement mechanism, an upper measurement mechanism, a product carrying mechanism, a discharging band, a tool elevating mechanism and a lower-layer material band, wherein the upper-layer material band and the lower-layer material band are respectively disposed above and below a frame; the tool elevating mechanism comprises a front tool elevating mechanism and a rear tool elevating mechanism, a tool drives a product to transmit the product backwards via the upper-layer material band to the lower measurement mechanism and the upper measurement mechanism for element pin and element measurement; and the product carrying mechanism is arranged above the rear end of the upper-layer material band, the product measurement mechanism carries the product after measurement to a discharging band at the side portion of the upper-layer material band, the product is discharged via the discharging band, the empty tool flows into the rear elevating mechanism, the rear elevating mechanism drives the tool to descend and pushes the tool into the lower-layer material band, the tool flows back to the front elevating mechanism along with the lower-layer material band, is driven to ascend via the front elevating mechanism, and slides into the upper-layer material band, and thus through cyclic flow, the product is continuously automatically conveyed.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

Process condition sensing wafer and data analysis system

InactiveUS7757574B2Accurate readingWide range of operationsSemiconductor/solid-state device testing/measurementSolid-state devicesMeasurement deviceEngineering

A measuring device incorporating a substrate with sensors that measure the processing conditions that a wafer may undergo during manufacturing. The substrate can be inserted into a processing chamber by a robot head and the measuring device can transmit the conditions in real time or store the conditions for subsequent analysis. Sensitive electronic components of the device can be distanced or isolated from the most deleterious processing conditions in order increase the accuracy, operating range, and reliability of the device. Isolation may be provided by vacuum or suitable material and phase change material may be located adjacent to electronics to maintain a low temperature.

Owner:KLA CORP

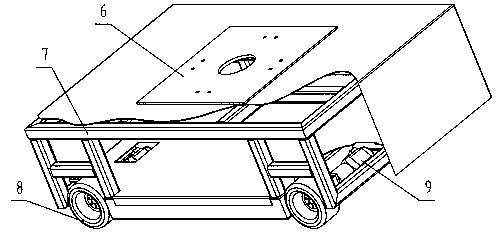

Automatic oil spraying device for aerated brick die vehicle

The invention discloses an automatic oil spraying device for an aerated brick die vehicle. The automatic oil spraying device comprises an oil spraying support erected above a die vehicle track, an oil spraying cover hoisted on the oil spraying support through a lifting mechanism and an oil spraying mechanism arranged at the lower portion of the oil spraying cover; the lifting mechanism comprises a double-way air cylinder, a solenoid directional valve, a steel wire rope and a sliding wheel; the oil spraying mechanism comprises a sliding rail, a limiting switch and an oil spraying trolley driven by a reciprocated motor to do reciprocated transverse movement along the sliding rail, the oil spraying trolley is provided with an oil spraying vertical shaft extending downwards, a double-fluid atomizing nozzle is arranged at the lower end of the oil spraying vertical shaft, and the oil supply hose and an air source hose are communicated with the double-fluid atomizing nozzle through an oil way solenoid valve and a gas way solenoid valve correspondingly. The automatic oil spraying device has the beneficial effects of being high in automatic degree, even in die removal oil smearing, safe, convenient, free of pollution and the like.

Owner:CHIFENG XINHAI ENERGY SAVING BUILDING MATERIAL

Apparatus for combining individual light beams of different wavelengths to form a coaxial light bundle

An apparatus for combining individual light beams to form a coaxial light bundle. The apparatus has a plurality of coupling-in positions, the number of which corresponds to the number of light beams, and also at least one coupling-out position. It is suitable for generating a collimated beam bundle as a multicolour source for use in digital image generation. The apparatus includes an apparatus base body with the coupling-in positions for the light beams and with a coupling-out position for the light bundle and adjusting devices for coaxially orienting the individual light beams relative to the beam direction of the light bundle. The coaxial light bundle can optionally emerge as free beam at the coupling-out position or into an optical waveguide via connecting elements.

Owner:LASOS LASERTECHN

Method for operating an internal combustion engine

ActiveUS20070050124A1Low accuracyCost-effective and simple to installAnalogue computers for vehiclesElectrical controlCombustion chamberEngineering

In a method for operating an internal combustion engine, a first data quantity is derived based on a signal of a first sensor which detects the pressure in a first combustion chamber of a plurality of combustion chambers, and a second data quantity is derived based on a signal of a second sensor, which second data quantity is a function of the pressure variation in at least one of the plurality of combustion chambers. The first data quantity and the second data quantity are functions of the pressure variation in the same combustion chamber, and a drift of the second sensor is ascertained from a change over time in the second data quantity with respect to the first data quantity.

Owner:ROBERT BOSCH GMBH

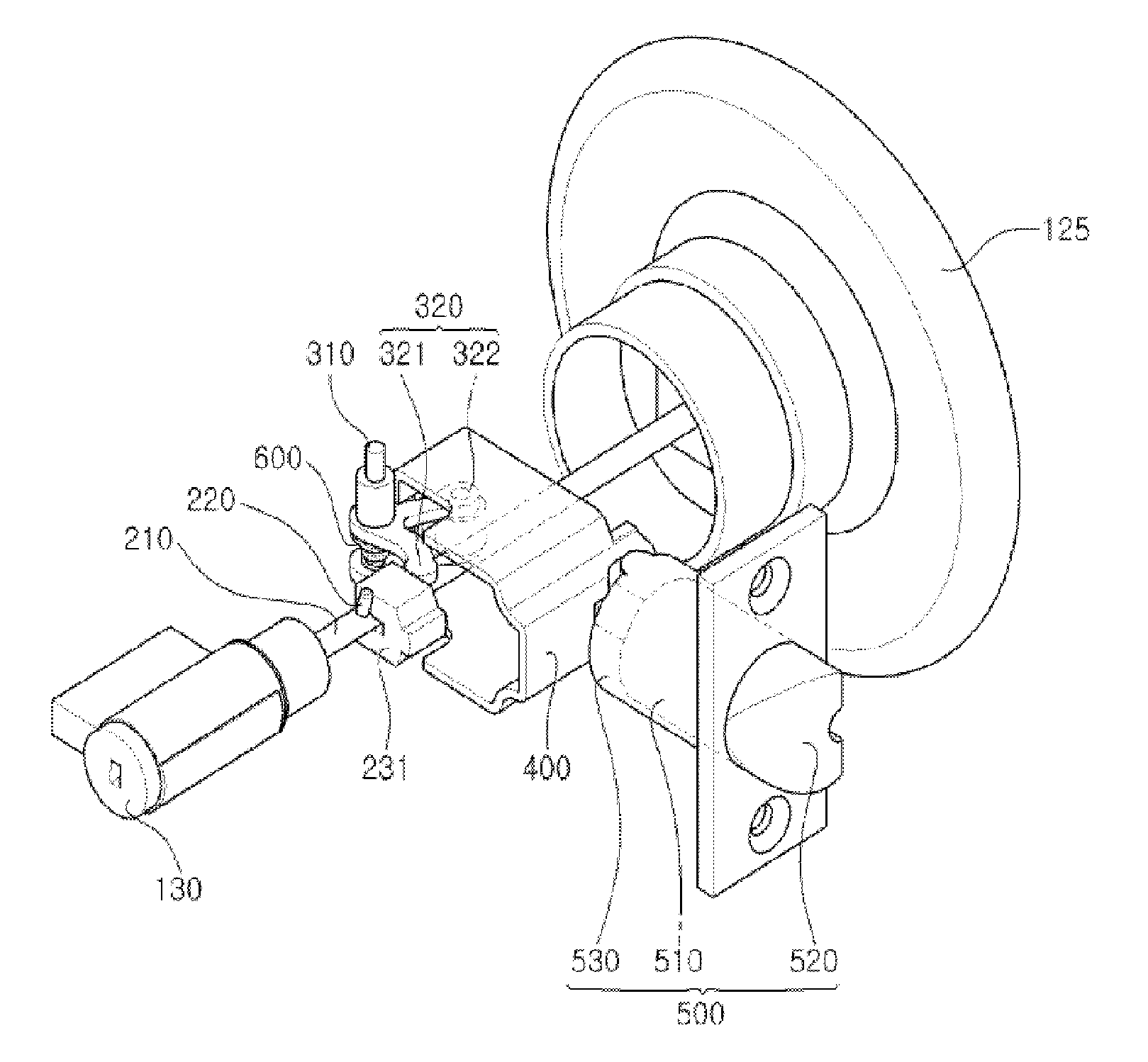

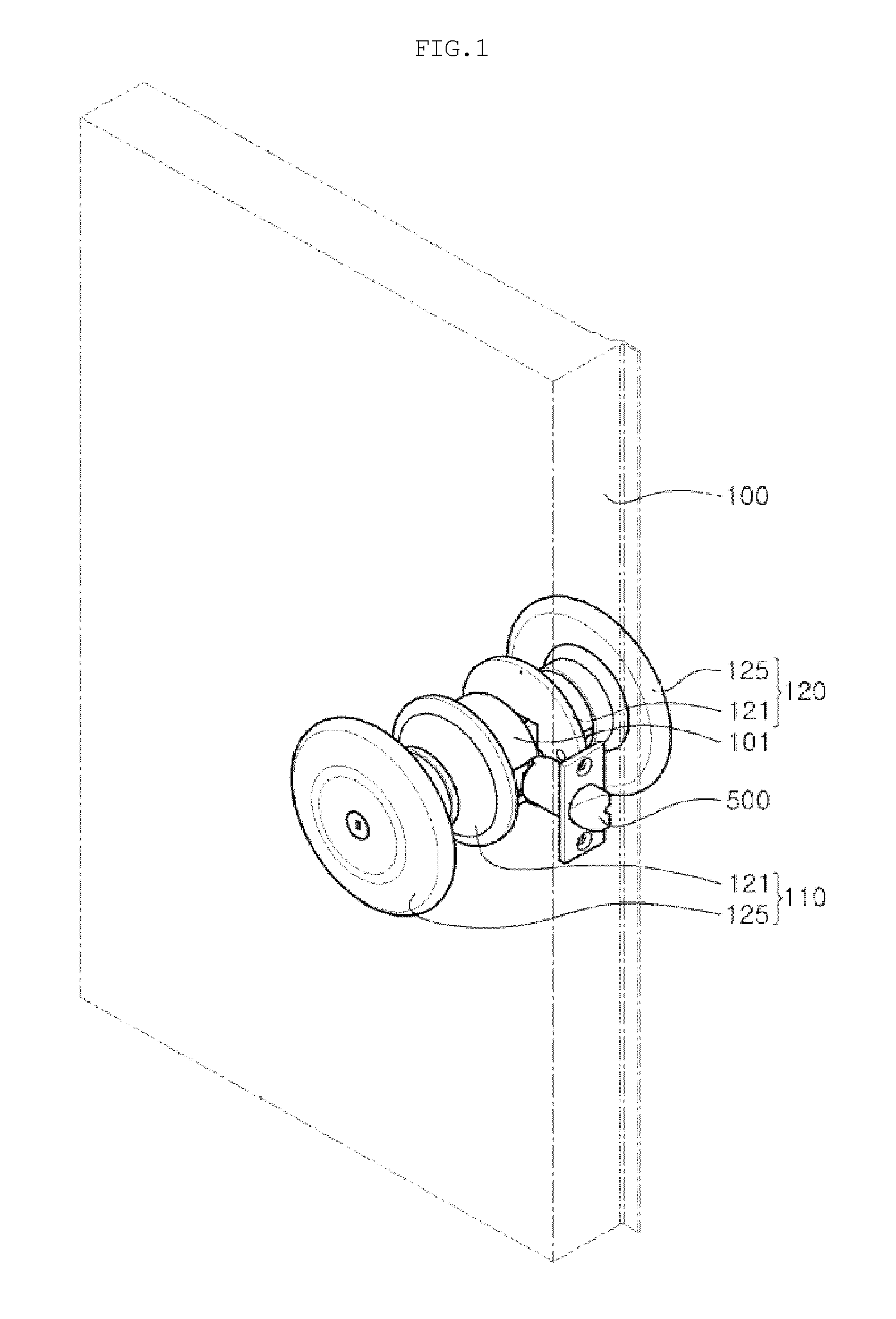

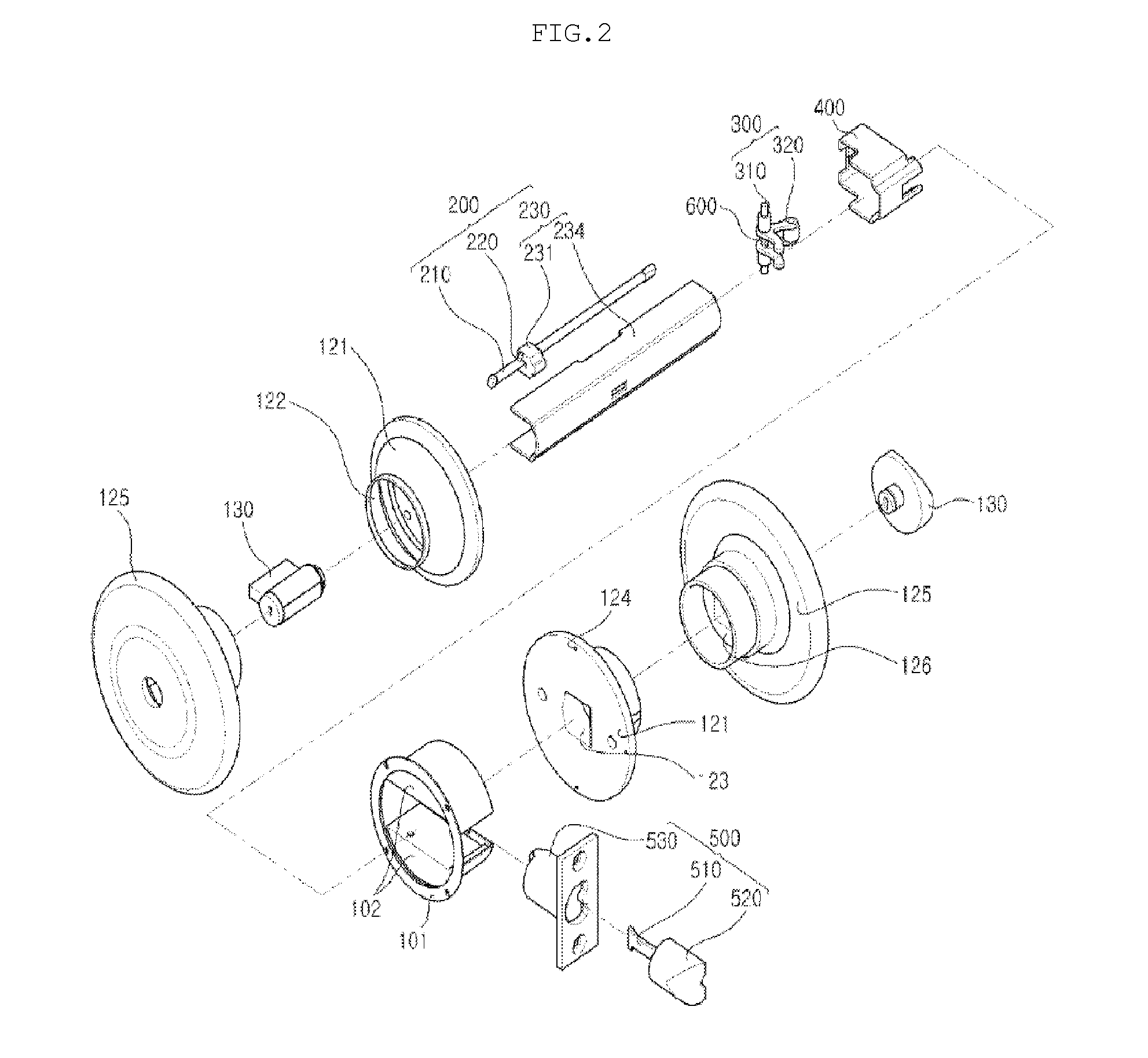

Apparatus for opening and closing entrance

InactiveUS9556644B2Simple structureImprove convenienceWing handlesKeyhole guardsEngineeringMechanical engineering

Owner:YOON BYUNGMAN +2

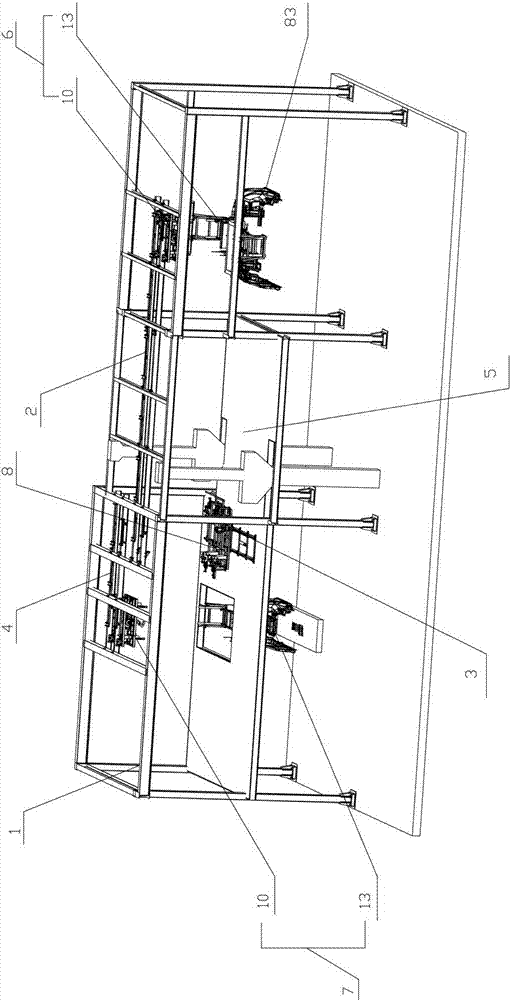

Full-automatic automobile side wall conveying system with high positioning precision

ActiveCN107310908AReduce waiting timeMeet production requirementsMechanical conveyorsEngineeringMechanical engineering

The invention relates to the technical field of automobile production auxiliary equipment, in particular to a full-automatic automobile side wall conveying system with high positioning precision. The full-automatic automobile side wall conveying system with high positioning precision is provided with a steel structure frame, and is characterized in that piece loading railways, piece receiving railways and piece unloading railways are respectively mounted in the steel structure frame; the piece loading railways and the piece unloading railways are arranged parallel to each other; the piece receiving railways are positioned below the piece loading railways and the piece unloading railways, and the piece loading railways and the piece unloading railways are arranged perpendicular to each other; a piece loading trolley is hoisted on the piece loading railways; a piece unloading trolley is hoisted on the piece loading railways; a piece receiving trolley which is connected with the piece loading railways and the piece unloading railways for transferring is mounted on the piece receiving railways. According to the full-automatic automobile side wall conveying system with high positioning precision, the operating time and the occupied area of side wall conveying equipment are reduced; the production efficiency and the production tempo are improved; the labour intensity of a worker and the environmental pollution of the equipment are reduced; the service life of the side wall conveying equipment is prolonged; the accuracy of operating and lifting in place of the side wall conveying equipment is improved; the full-automatic automobile side wall conveying system with high positioning precision has a good popularization prospect.

Owner:黄石鼎信机电有限公司

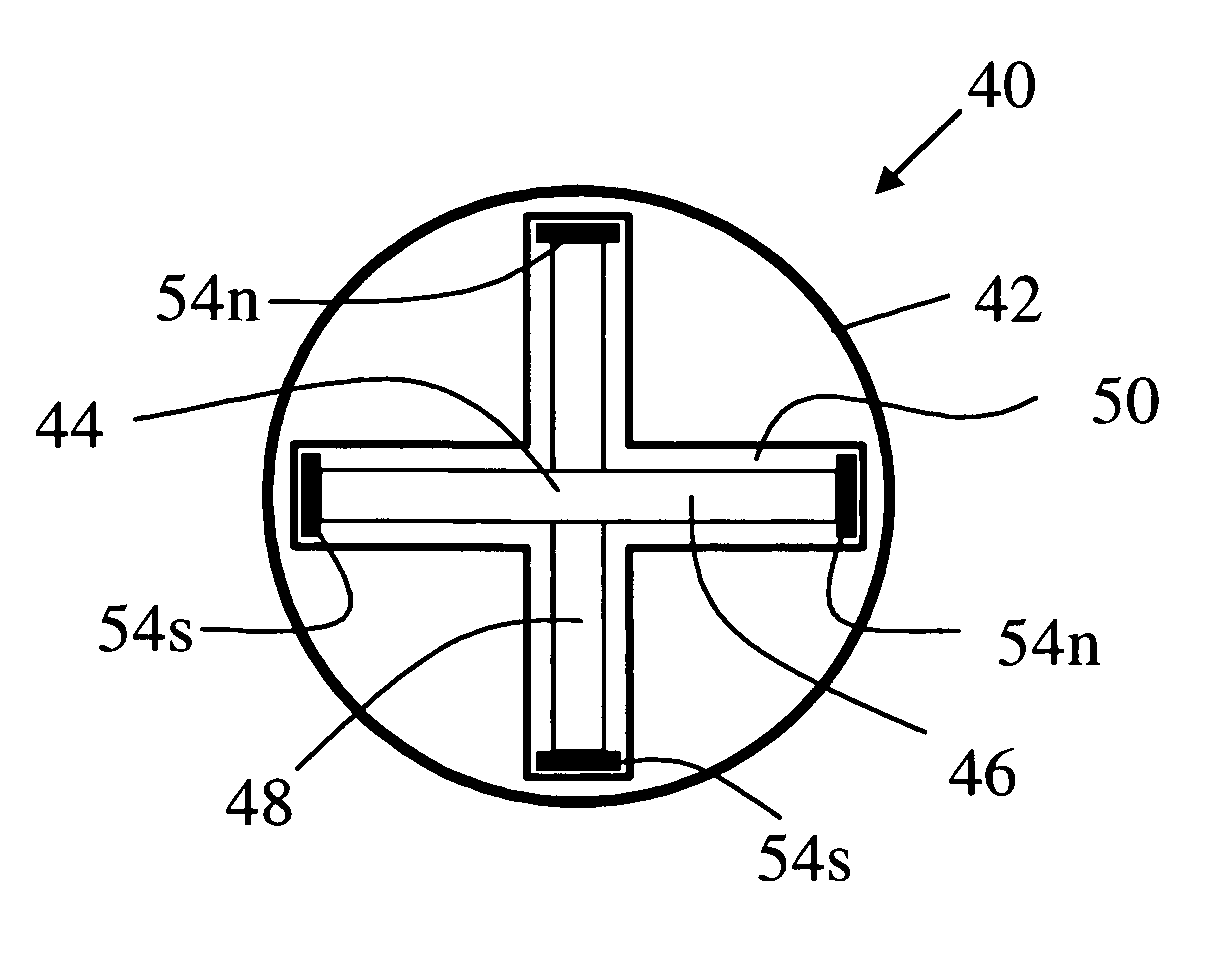

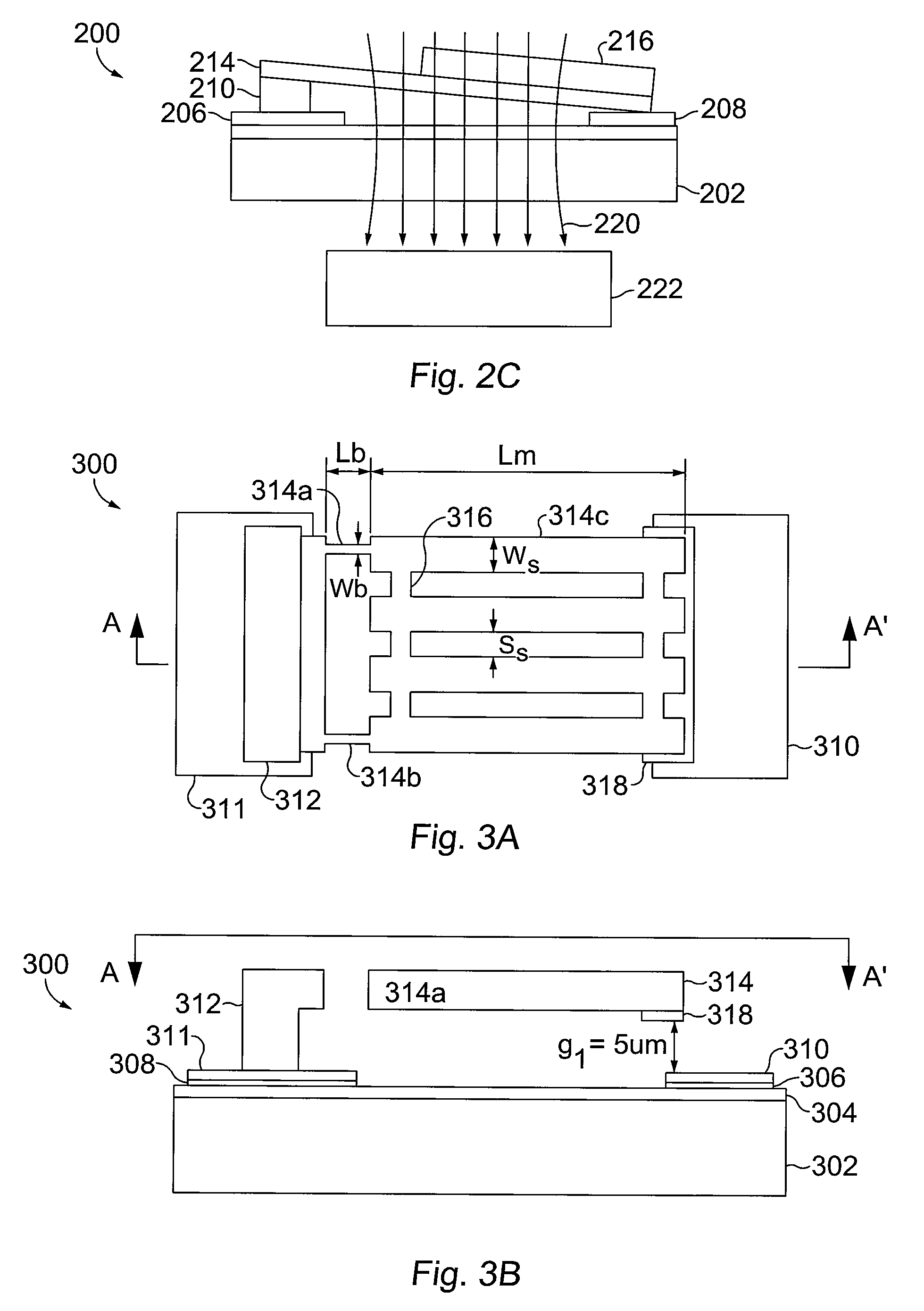

Microelectromechanical system

ActiveUS8174342B2Accurate and reliable operationElectromagnetic relay detailsMagnetostrictive relaysMagnetic actuationMicroelectromechanical systems

The invention relates to microelectromechanical systems (MEMS), and more particularly, to MEMS switches using magnetic actuation. The MEMS switch may be actuated with no internal power consumption. The switch is formed in an integrated solid state MEMS technology. The MEMS switch is micron and / or nanoscale, very reliable and accurate. The MEMS switch can be designed into various architectures, e.g., a cantilever architecture and torsion architecture. The torsion architecture is more efficient than a cantilever architecture.

Owner:STMICROELECTRONICS INT NV

Suspension apparatus and method for suspending sausages, in particular sausage chains

ActiveUS8795038B2Easily identifiableAccurate and reliable operationMeat/sausage hanging-upLinked sausage separationEngineeringMechanical engineering

Owner:ALBERT HANDTMANN MASCHFABRICK

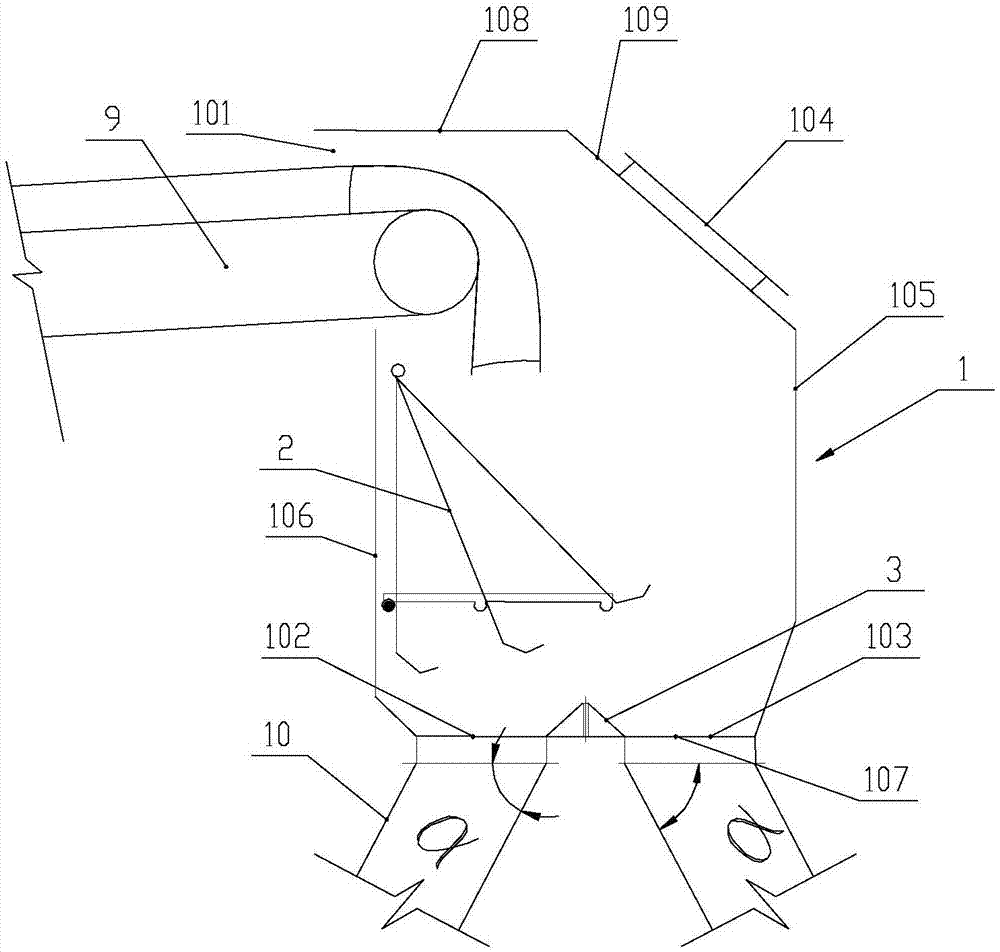

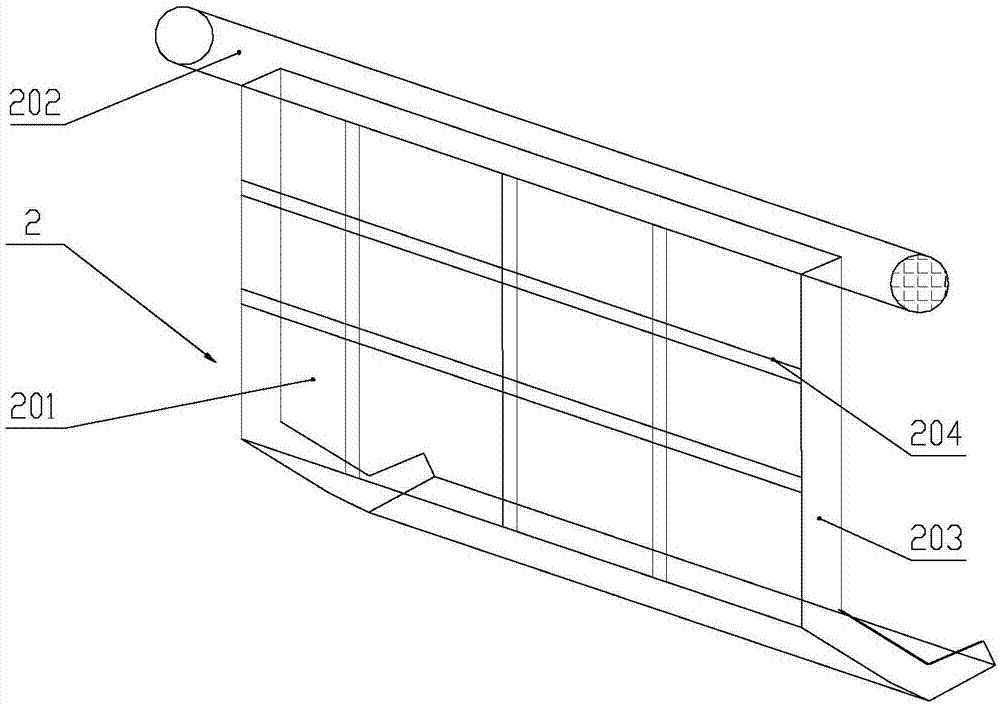

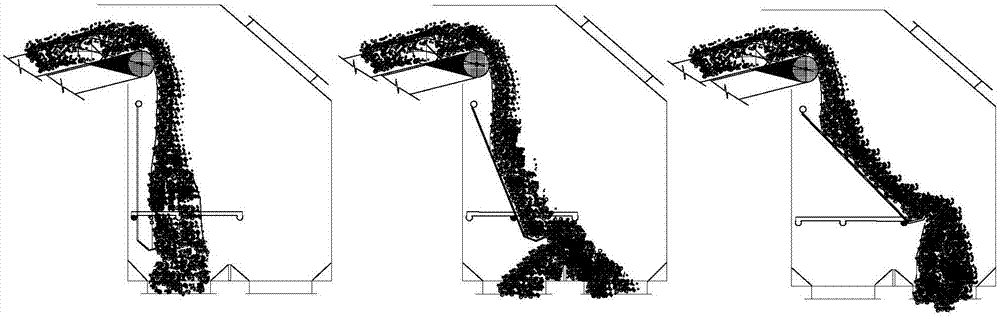

Funnel device with distributing and material guiding functions

PendingCN107010330AIncrease the cross-sectional areaLess investment in equipmentLarge containersConveyor partsEngineeringElectrical and Electronics engineering

The invention discloses a funnel device with the function of diverting and guiding materials, which comprises a funnel with an upper material inlet and two left and right symmetrical lower outlets, and a material guiding device located in the funnel for adjusting the flow direction of materials. In the funnel, there is a dividing plate between the two lower discharge ports; the material guide device is located below the feed port, one end of the material guide device is fixed in the funnel, and the material guide device can rotate around the fixed end to the The first station corresponding to the lower left outlet, the second station corresponding to the partition plate, and the third station corresponding to the lower right outlet. The funnel device uses the funnel and the material guide device to realize the combination of the three functions of diversion, material guide and storage and transportation, which increases the cross-sectional area of the material in the funnel, saves equipment investment, reduces the occupation of the factory building, and improves the space utilization rate of the factory building.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

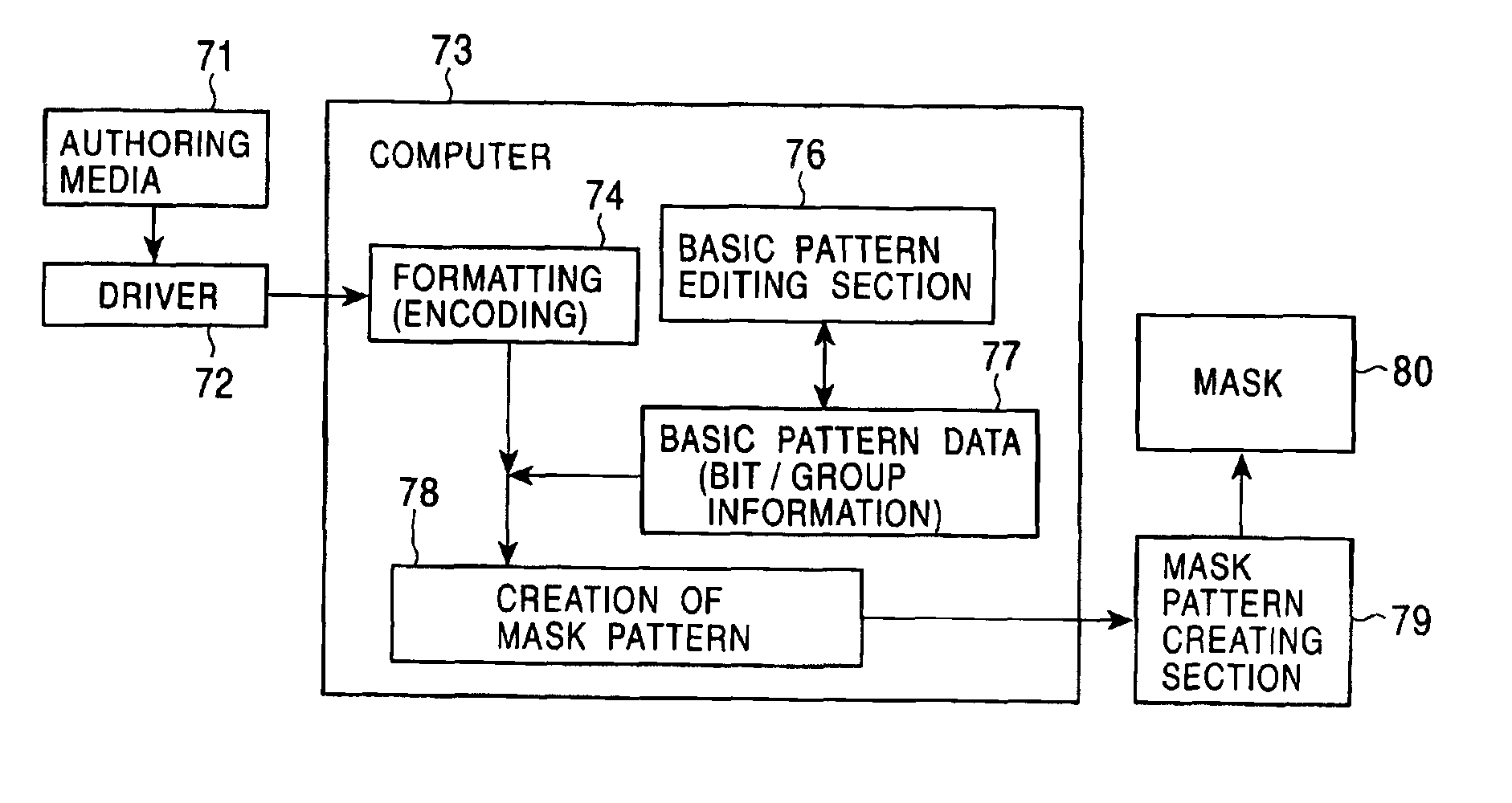

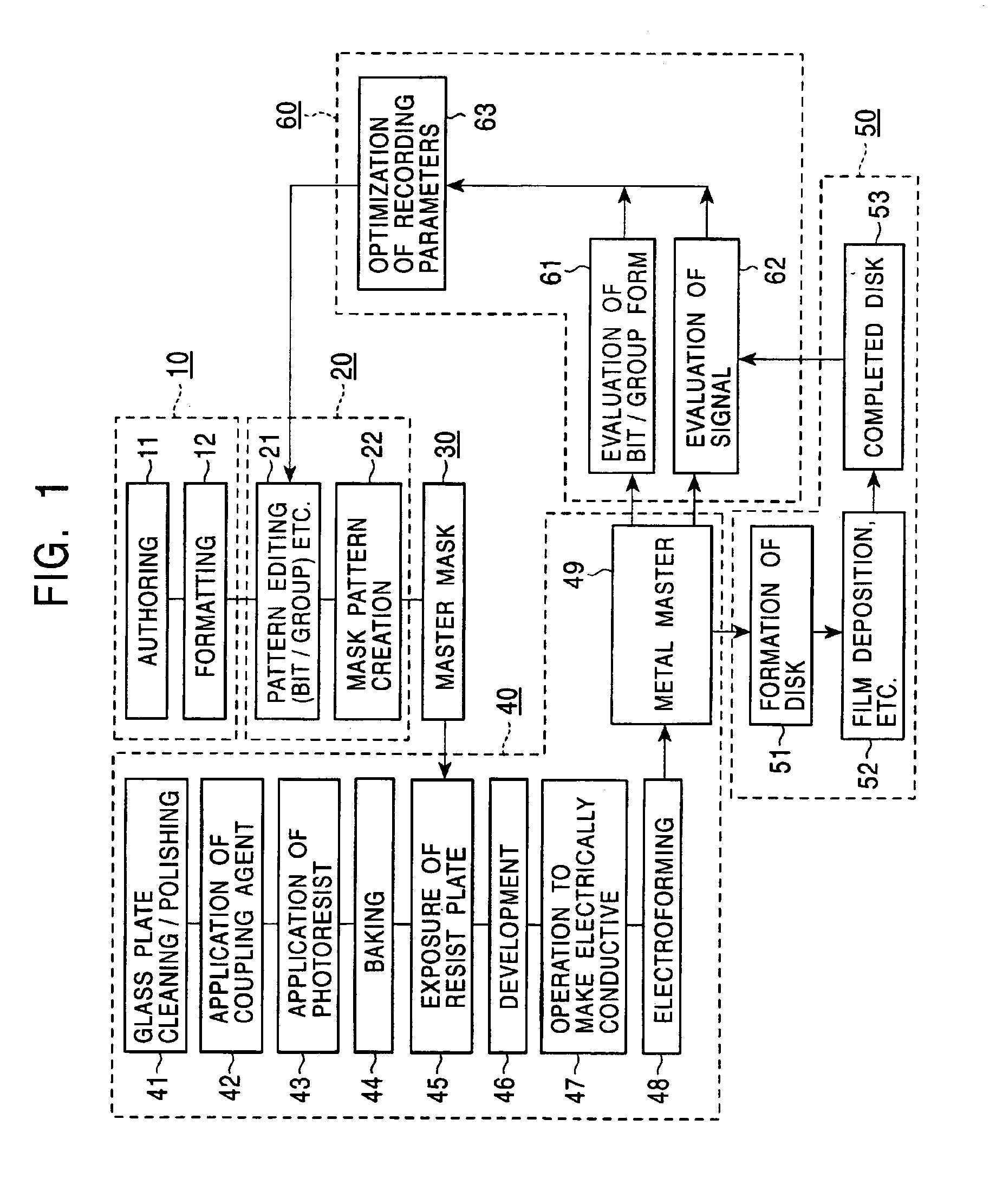

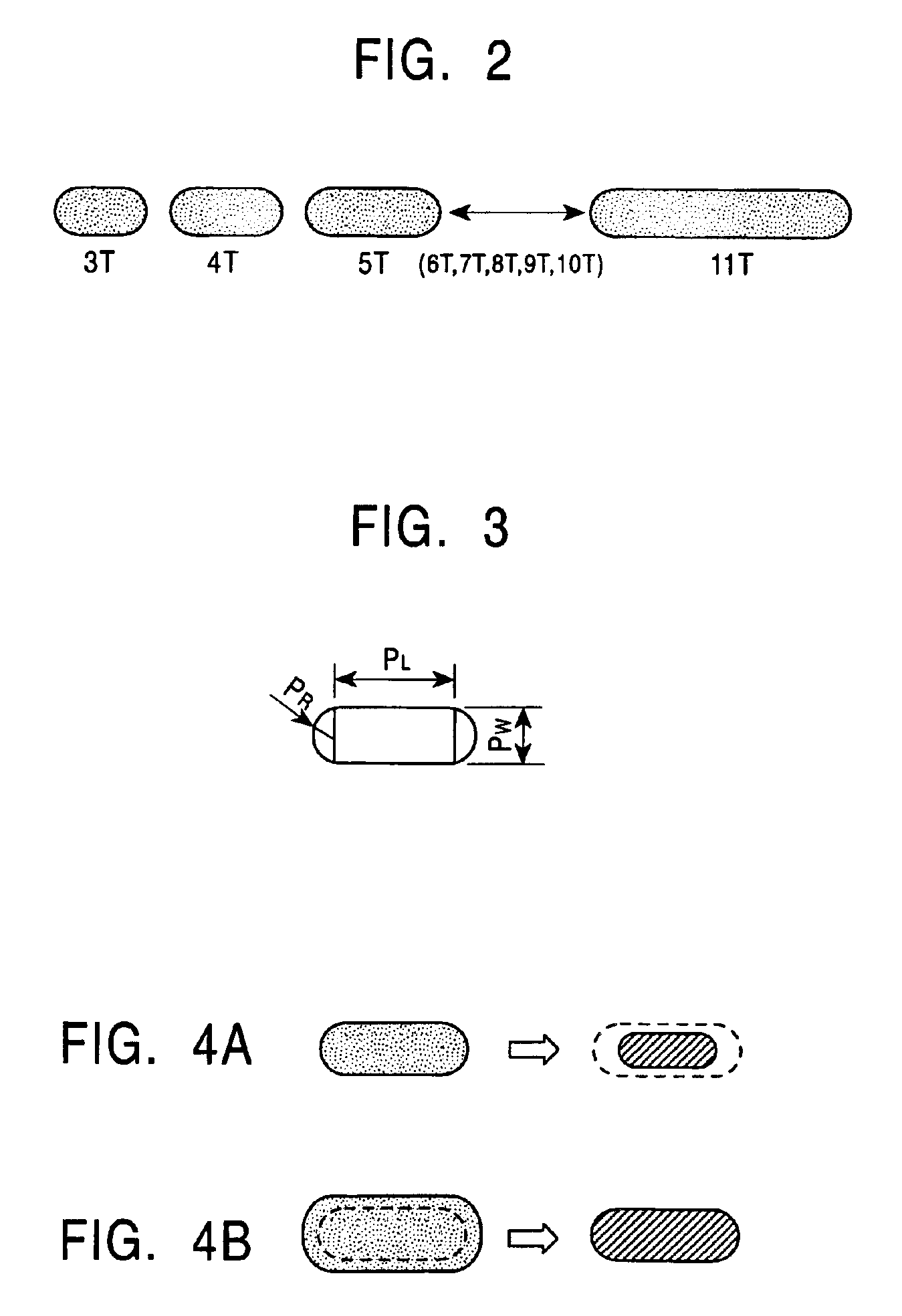

Mask pattern forming method and device, and method of producing optical disk

InactiveUS7038992B1Accurate and reliable operationShort timeTelevision system detailsRecord information storageComputer scienceOptical disc

A method of forming a mask pattern includes a formatting step for formatting authoring data in accordance with formats of specified media either by a fixed amount at a time or continuously. The authoring data is obtained by an authoring operation in which base information, such as image information or audio information, is edited. The method of forming a mask pattern also includes a mask pattern generating step in which basic pattern information is generated from basic signal pattern data necessary for various types of optical disks as a result of carrying out a pattern editing operation, and the basic pattern information is used to generate a mask pattern by carrying out a mask pattern generating operation. In the steps of a conventional method, it is necessary to carefully determine the conditions which allow disks produced after a plurality of later operations of the method have been carried out to satisfy standards. In addition, it is necessary to carefully observe at all times that these conditions are maintained during the long time required to produce the disks.

Owner:SONY CORP

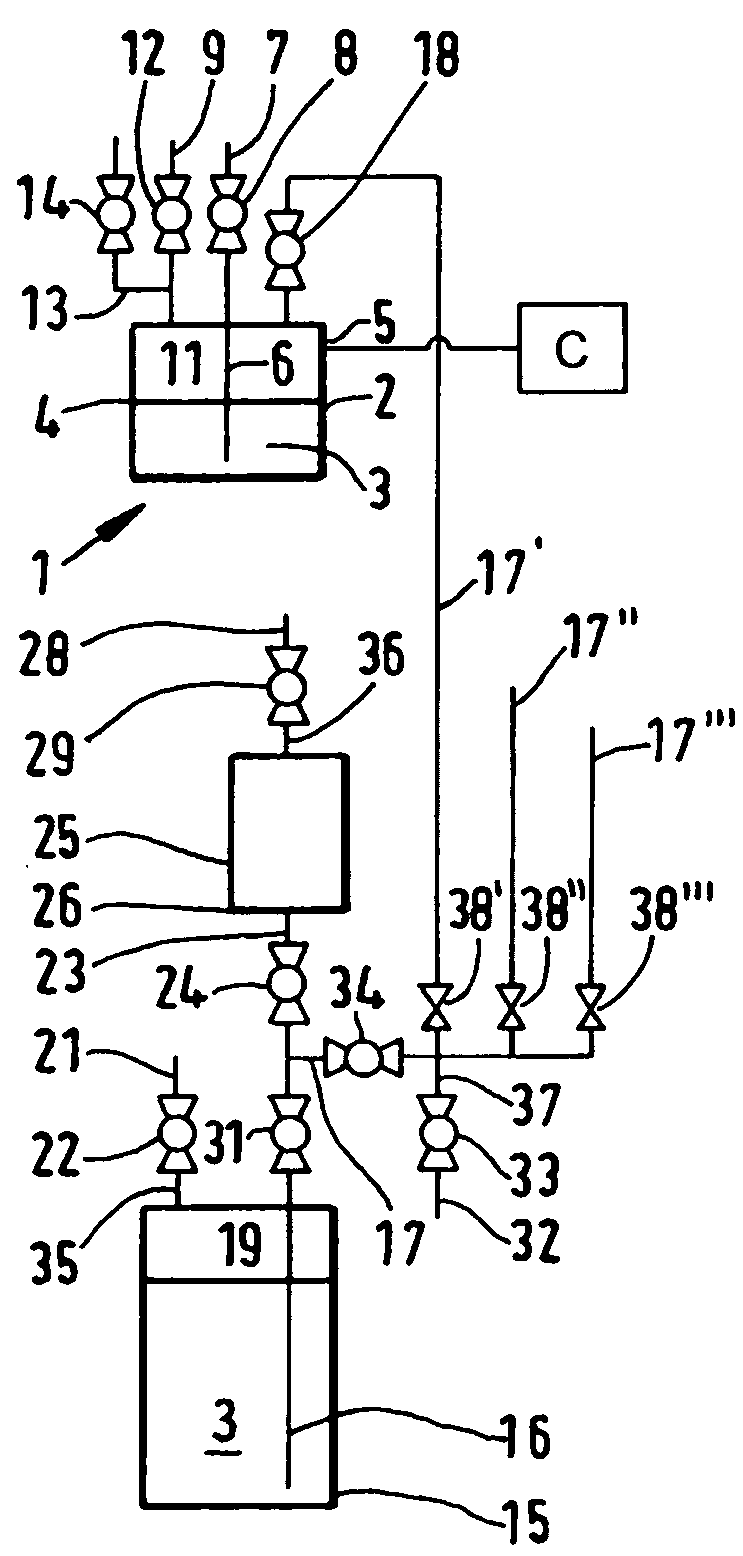

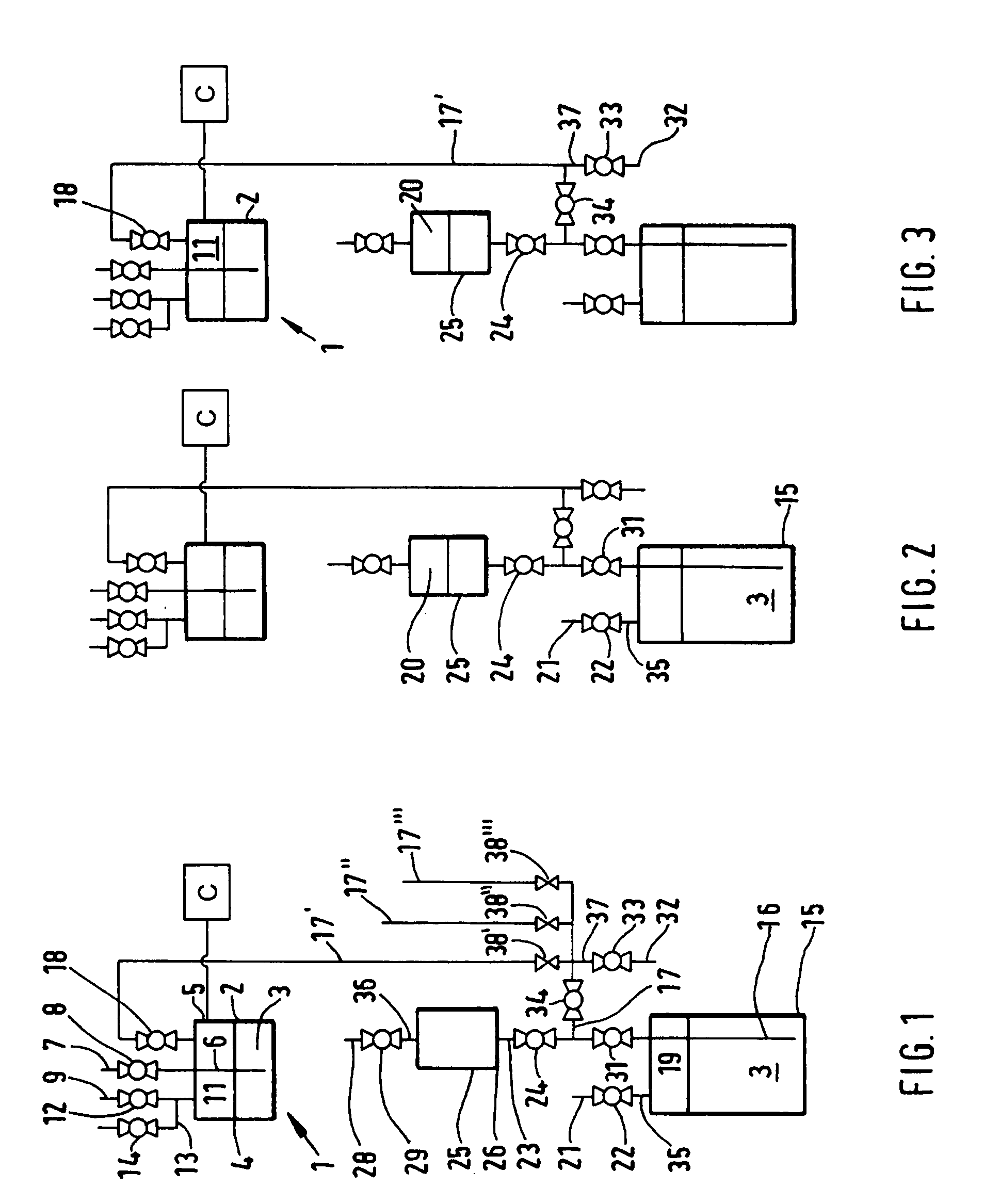

Apparatus and process for refilling a bubbler

ActiveUS7278438B2Simple refillSimple refillingLevel controlSpace heating and ventilationEngineeringInert gas

In order to evaporate a liquid substance (3) and convey it to a user, a bubbler (1) is provided, into which a carrier gas (7) is conveyed. When a minimum level (4) has been reached, an exact quantity of the substance (3) is refilled from a reservoir tank (15). For this purpose, an intermediate tank (25) is provided, which is filled with an inert gas up to a pressure P1. An inert gas (21) is applied to the reservoir tank (15) at a pressure P2, higher than P1. The intermediate tank (25) is connected with the reservoir tank (15), as a result of which a specific quantity of the substance (3) flows into the intermediate tank (25) and is conveyed via a connection line (17) to the bubbler (1), with inert gas (32) first having been applied to the connection line (17) at a pressure P3, lower than P2.

Owner:CSK INC

Self-limiting valve opening and closing device

PendingCN109519587AReasonable structural designSimple and safe operationOperating means/releasing devices for valvesMulti-valveSelf limiting

The invention discloses a self-limiting valve opening and closing device, and solves the problem of a traditional mechanical transmission mechanism incapable of extending front and back and adjustingleft and right in the center line direction of a valve mandrel of a valve hand wheel in multi-valve use places. The self-limiting valve opening and closing device comprises a valve opening and closingtransmission mechanism, a limiting compensator and a spanner, wherein the valve opening and closing transmission mechanism consists of an extension driving mechanism, a rotary driving mechanism, anda cylinder supported between the extension driving mechanism and the rotary driving mechanism; under driving by an extension motor and a rotary motor, when a hollow spline shaft penetrating through atransmission shaft of a rotary RV speed reducer axially slides in the cylinder, the hollow spline shaft is synchronously rotated around a center line parallel to a rotary shaft; and the spanner with aclamping jaw structure is driven through the limiting compensator, and is rotated during axially sliding to finish opening, closing and adjustment of a valve. The self-limiting valve opening and closing device is simple in structure, reasonable in design, convenient to operate and stable in operation, can effectively replace manual adjustment of the valve, is precise, fast and safe in operation,and prominently improves the operation efficiency.

Owner:深圳中科捷飞科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com