Patents

Literature

1233results about How to "Improve detection reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Human detection and tracking for security applications

InactiveUS20090041297A1Improve detection reliabilityTelevision system detailsImage enhancementContent analyticsApplication software

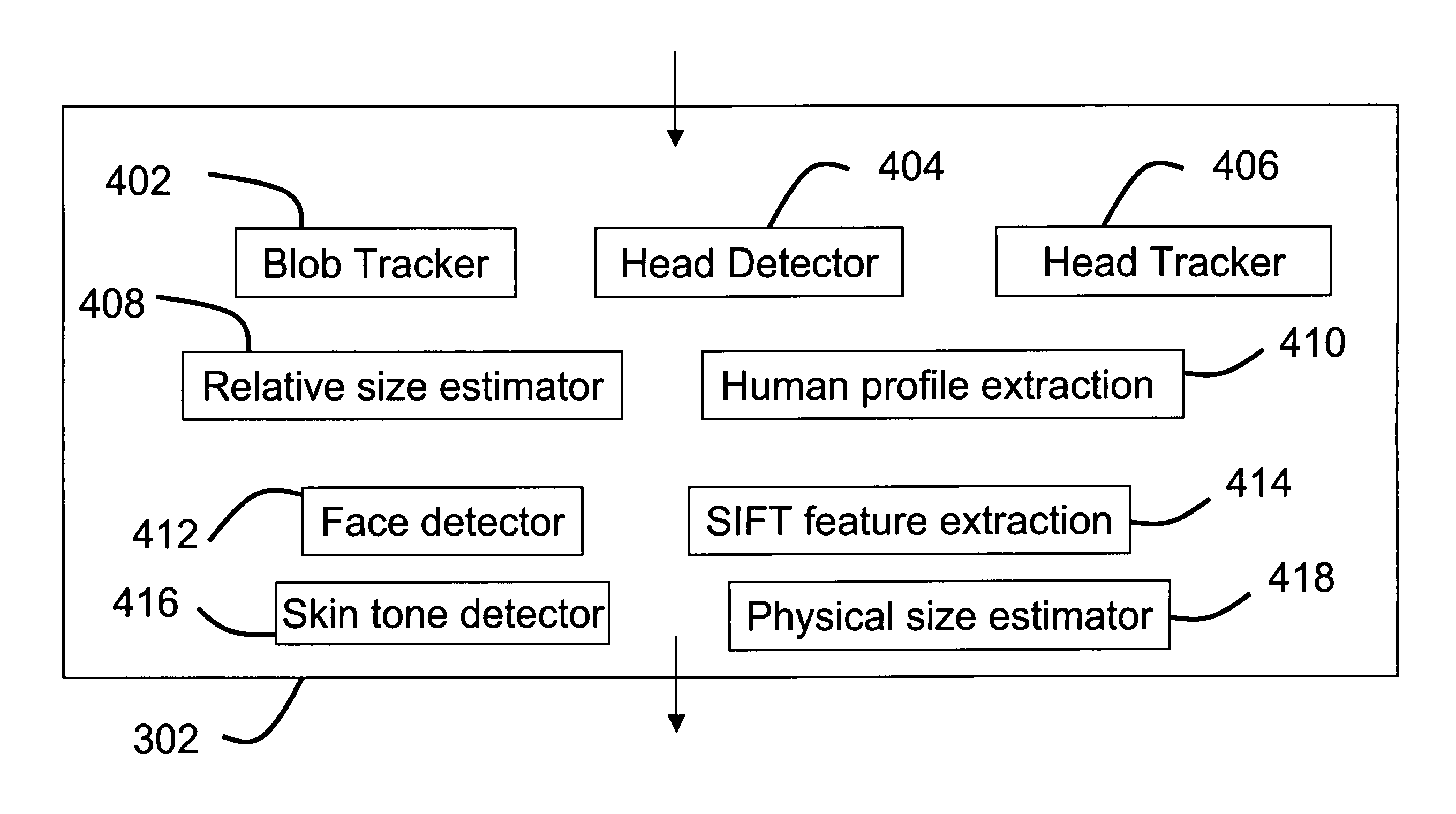

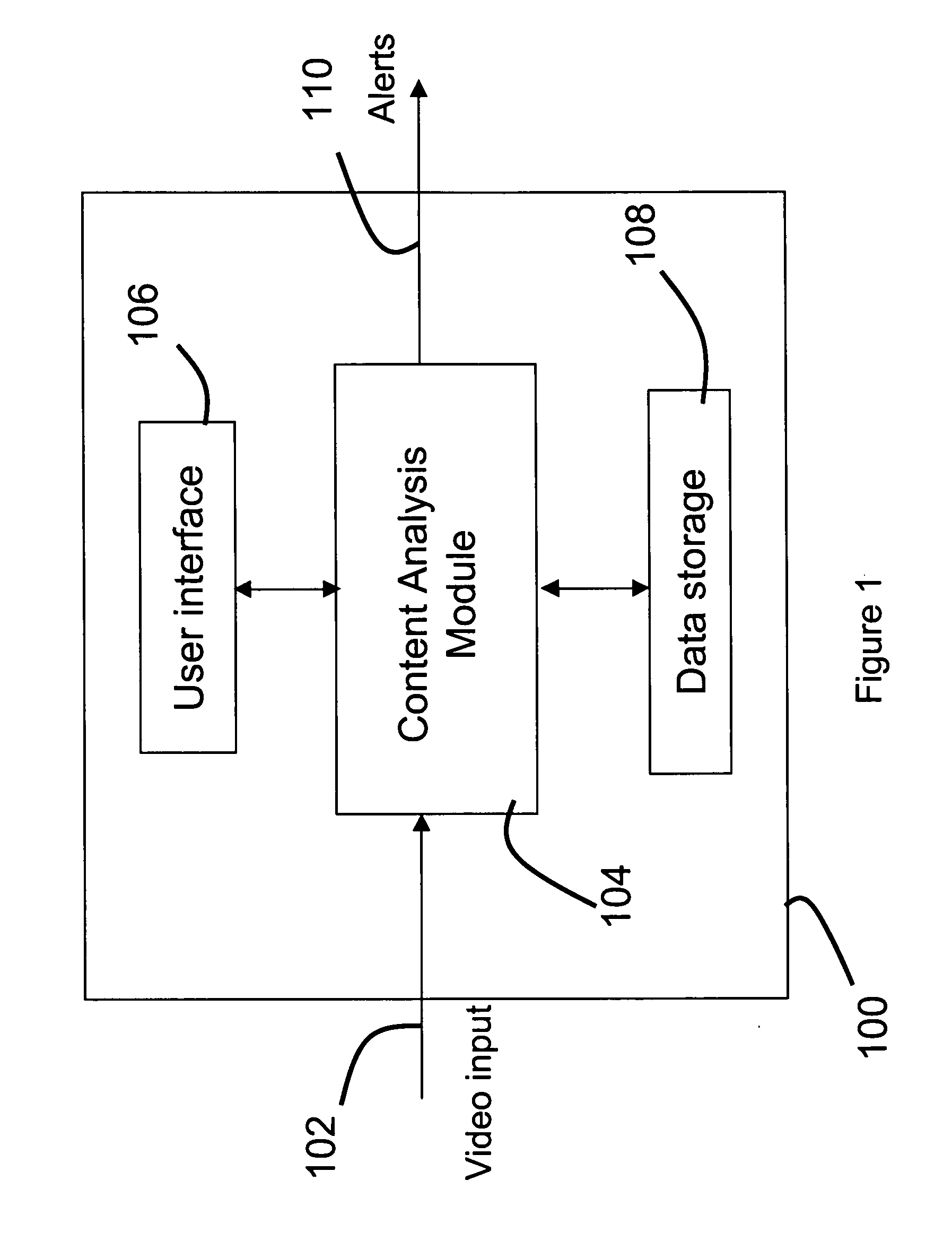

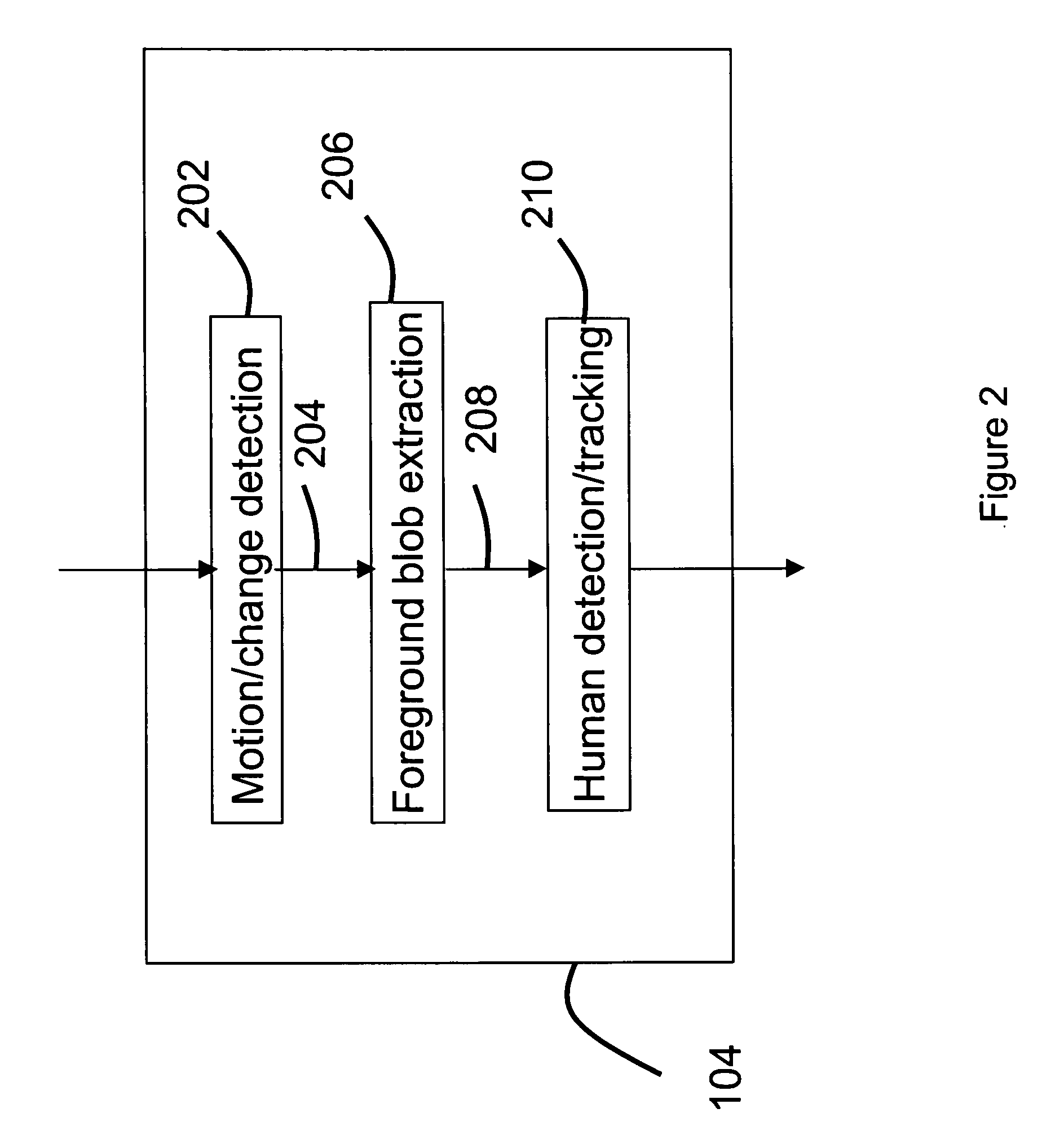

A computer-based system for performing scene content analysis for human detection and tracking may include a video input to receive a video signal; a content analysis module, coupled to the video input, to receive the video signal from the video input, and analyze scene content from the video signal and determine an event from one or more objects visible in the video signal; a data storage module to store the video signal, data related to the event, or data related to configuration and operation of the system; and a user interface module, coupled to the content analysis module, to allow a user to configure the content analysis module to provide an alert for the event, wherein, upon recognition of the event, the content analysis module produces the alert.

Owner:OBJECTVIDEO

Voice recognition system

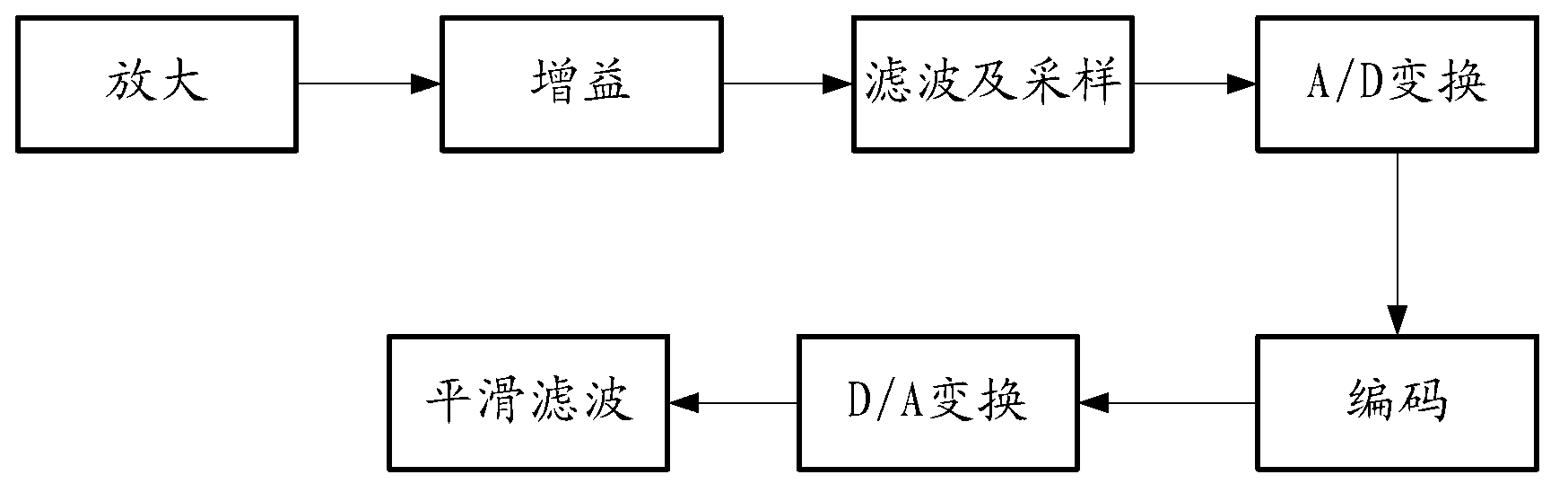

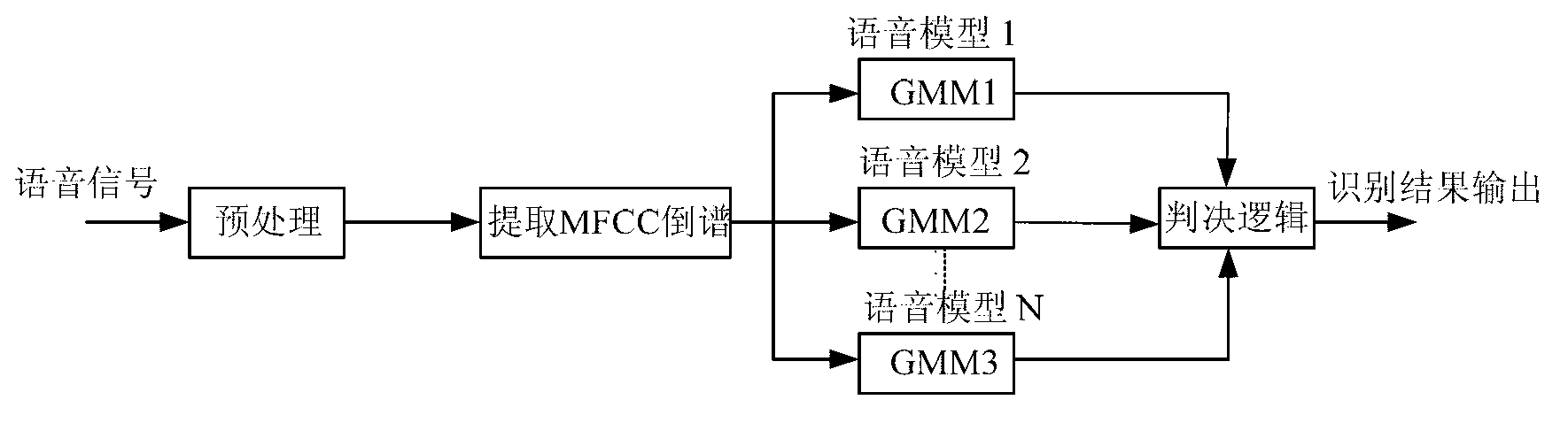

ActiveCN103236260AImprove detection reliabilityRealize the recognition functionSpeech recognitionMel-frequency cepstrumPattern matching

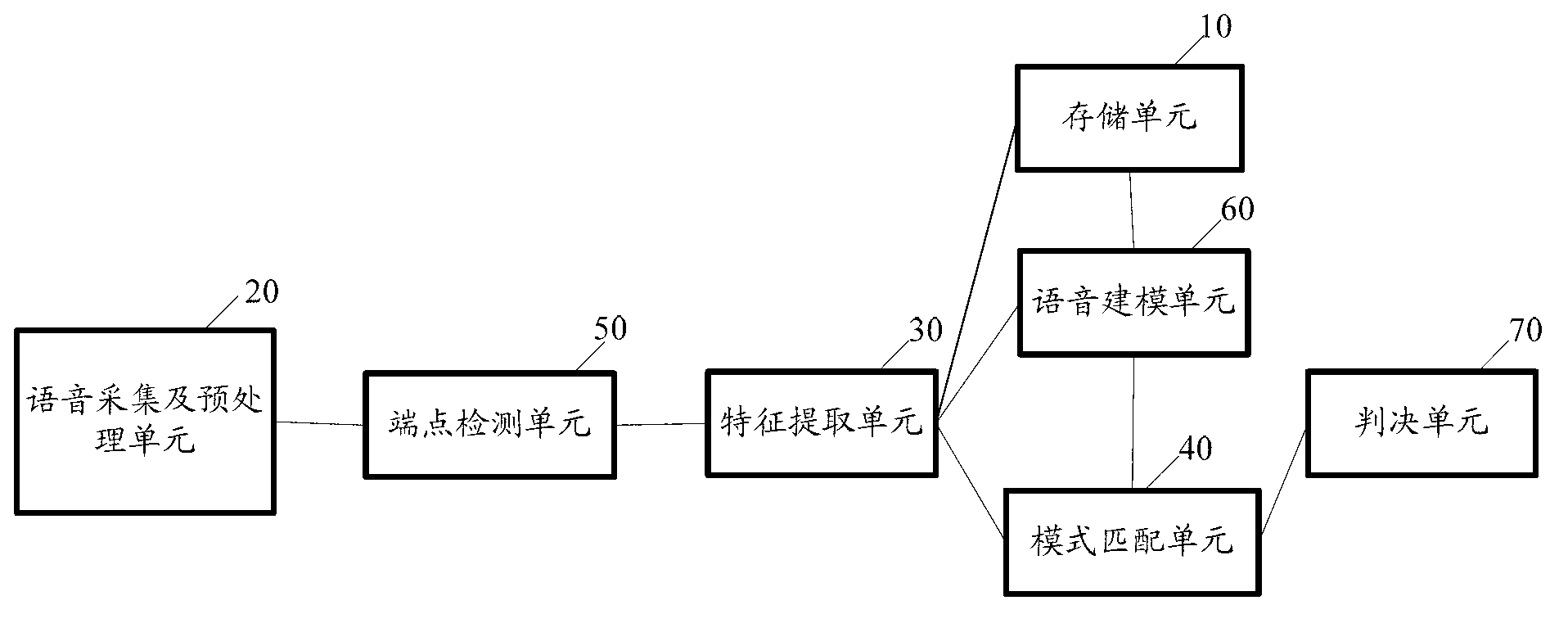

The invention provides a voice recognition system comprising a storage unit, a voice acquisition and pre-processing unit, a feature extraction unit and a pattern matching unit, wherein the storage unit is used for storing at least one user's voice model; the voice acquisition and pre-processing unit is used for acquiring a to-be-identified voice signal, transforming the format of the to-be-identified voice signal and encoding the to-be-identified voice signal; the feature extraction unit is used for extracting voice feature parameters from the encoded to-be-identified voice signal; and the pattern matching unit is used for matching the extracted voice feature parameters with at least one voice model so that the user to which the to-be-identified voice signal belongs is identified. Based on the voice generation principle, voice features are analyzed, MFCC (mel frequency cepstrum coefficient) parameters are used, a speaker voice feature model is established, and speaker feature recognition algorithms are achieved, and thus, the purpose to improve speaker detection reliability can be achieved, and the speaker identification function can be finally realized on an electronic product.

Owner:BOE TECH GRP CO LTD +1

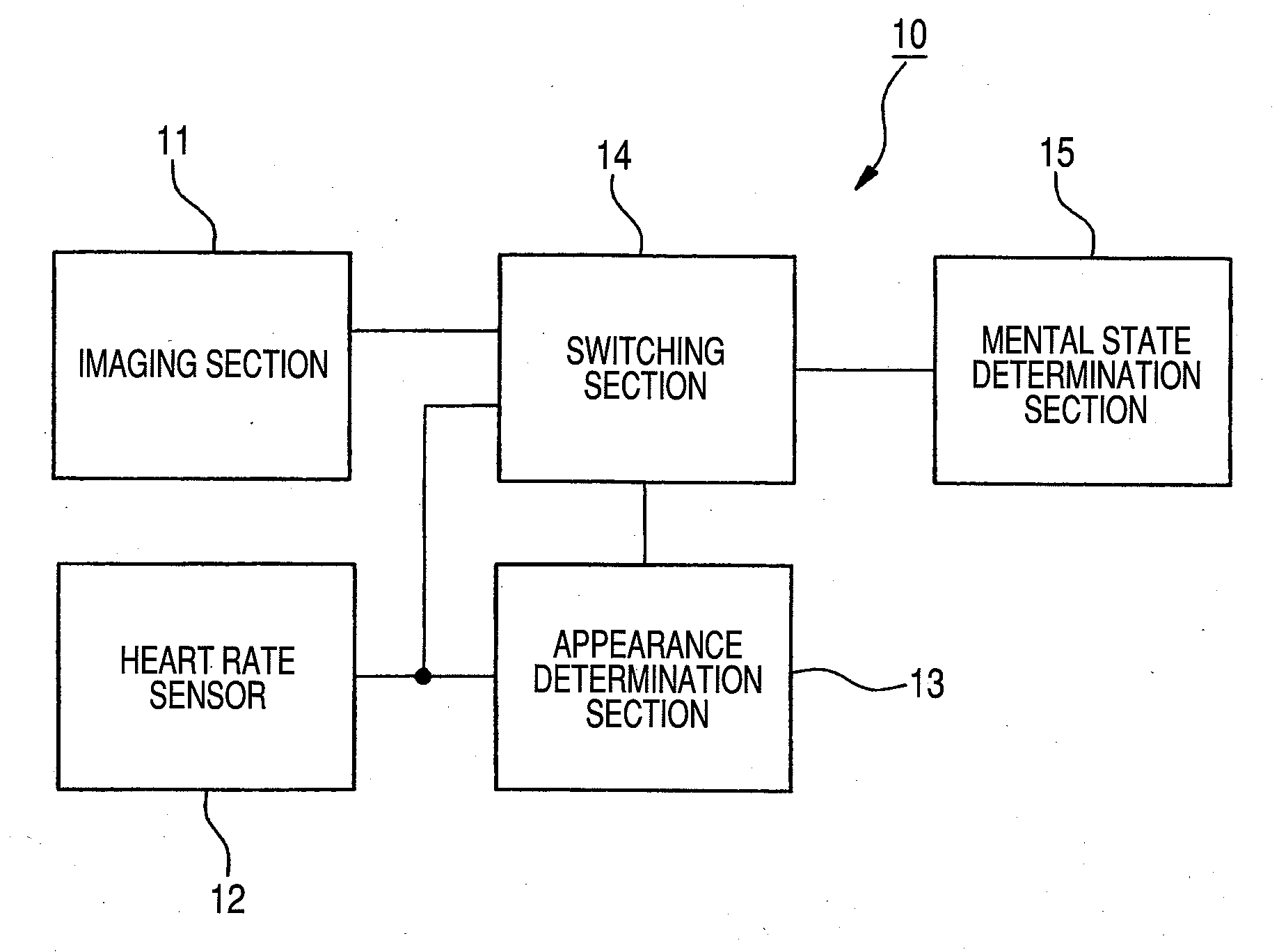

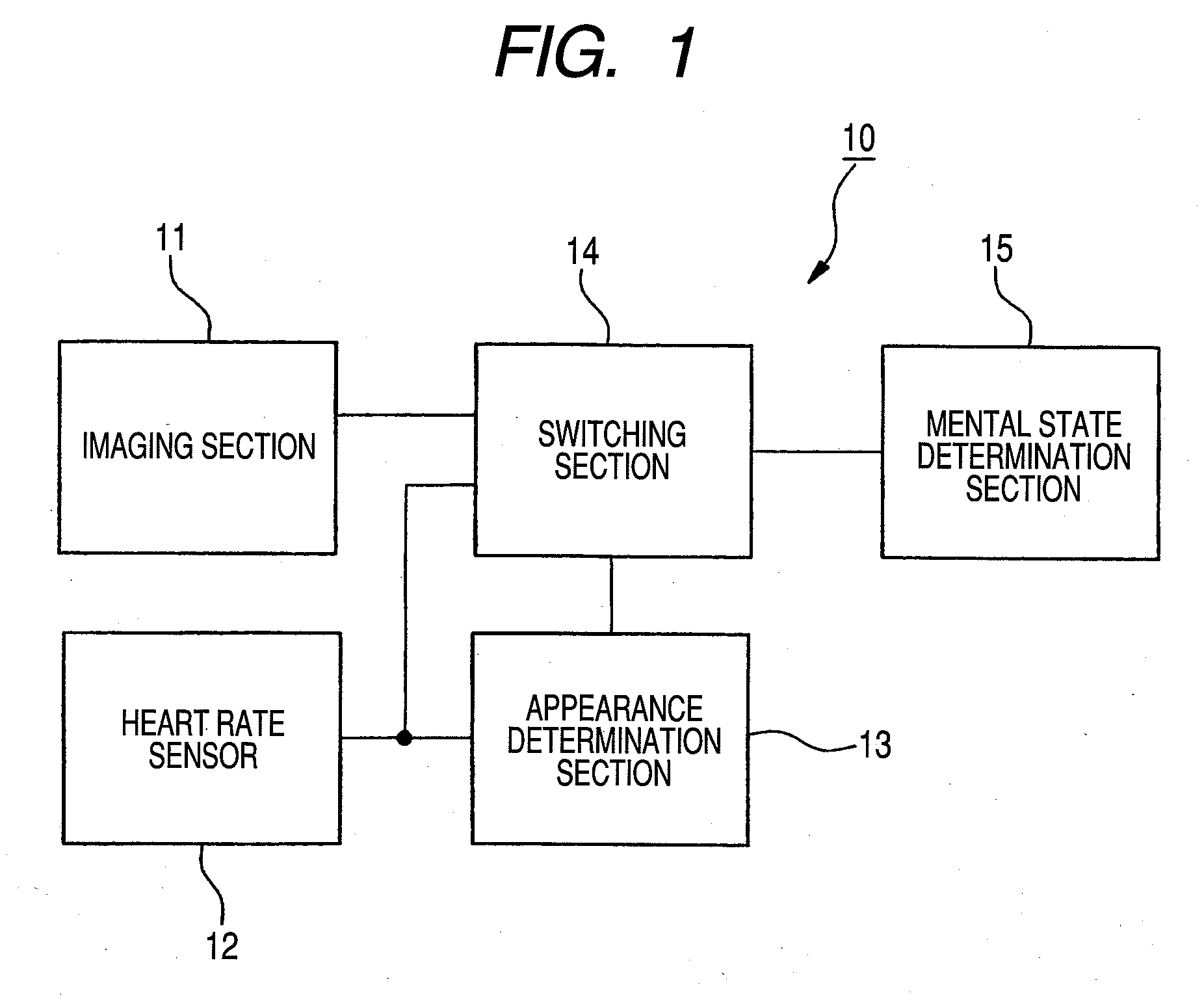

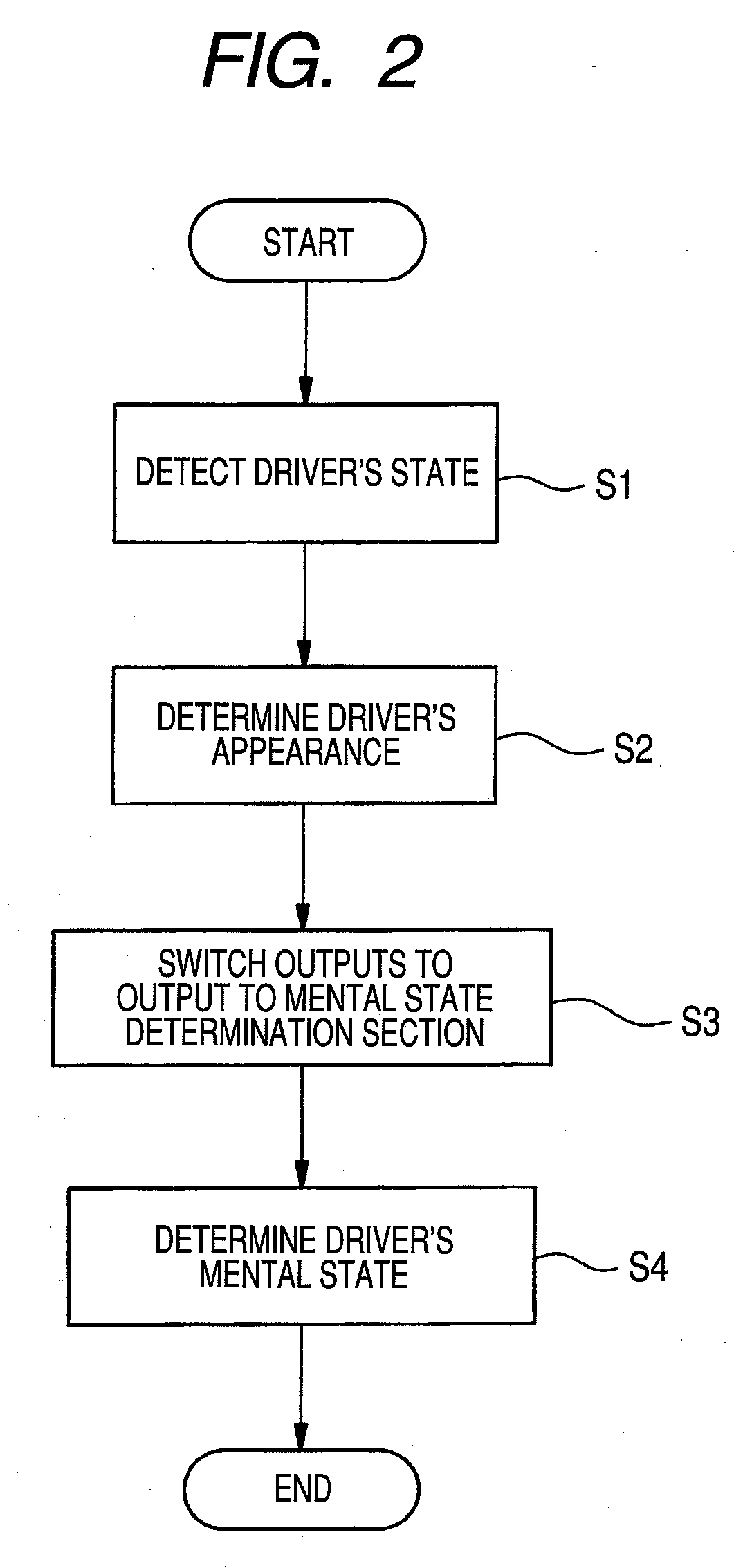

Apparatus for detecting driver's mental state and method for detecting mental state

InactiveUS20090209829A1Improve detection reliabilityDiagnostic recording/measuringSensorsMental stateDriver/operator

The reliability of detection of a driver's mental state in a vehicle in a driving state is enhanced without impairing operation stability of driving action of the vehicle.There are provided an imaging section 11 and a heart rate sensor 12 that serve as a plurality of detection means for detecting a driver's state; an appearance determination section 13 for determining a driver's appearance from detection results from the imaging section 11 and the heart rate sensor 12; and a mental state determination section 15 for determining a driver's mental state from the detection results from the imaging section 11 and the heart rate sensor 12. A switching section 14 switches the outputs from the imaging section 11 and the heart rate sensor 12 to an output from the mental state determination section 15 on the basis of a determination result from the appearance determination section 13.

Owner:PIONEER CORP

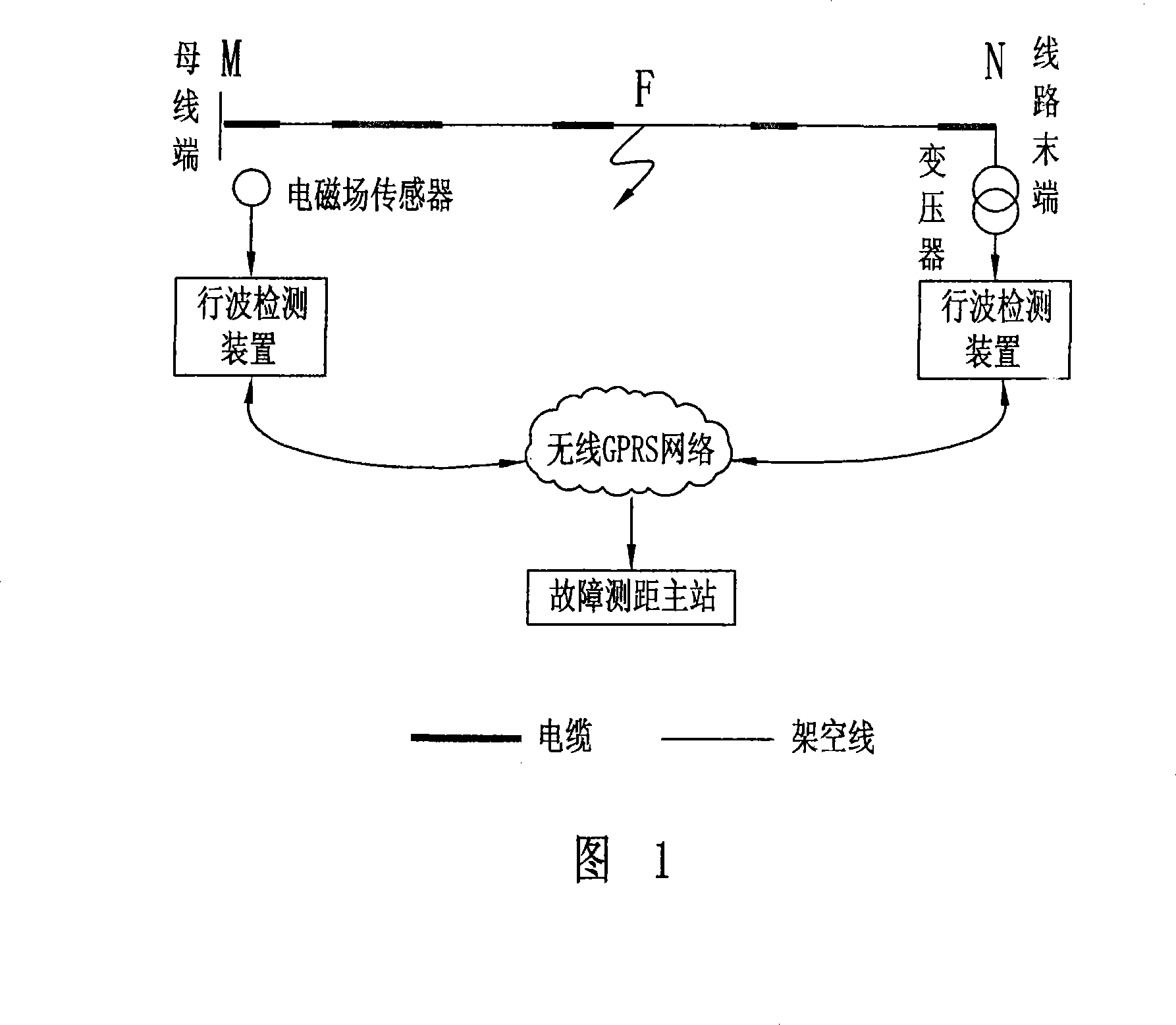

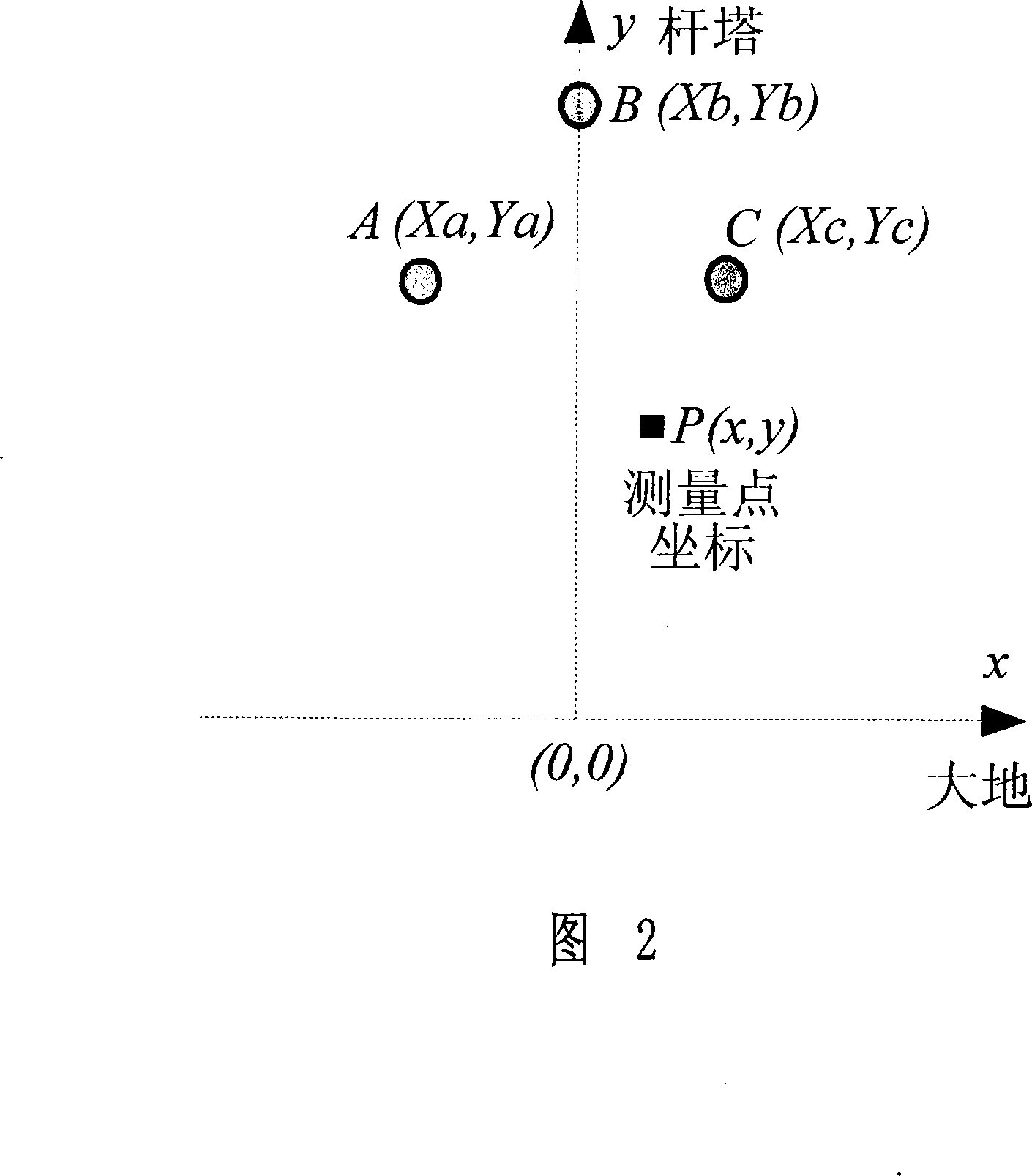

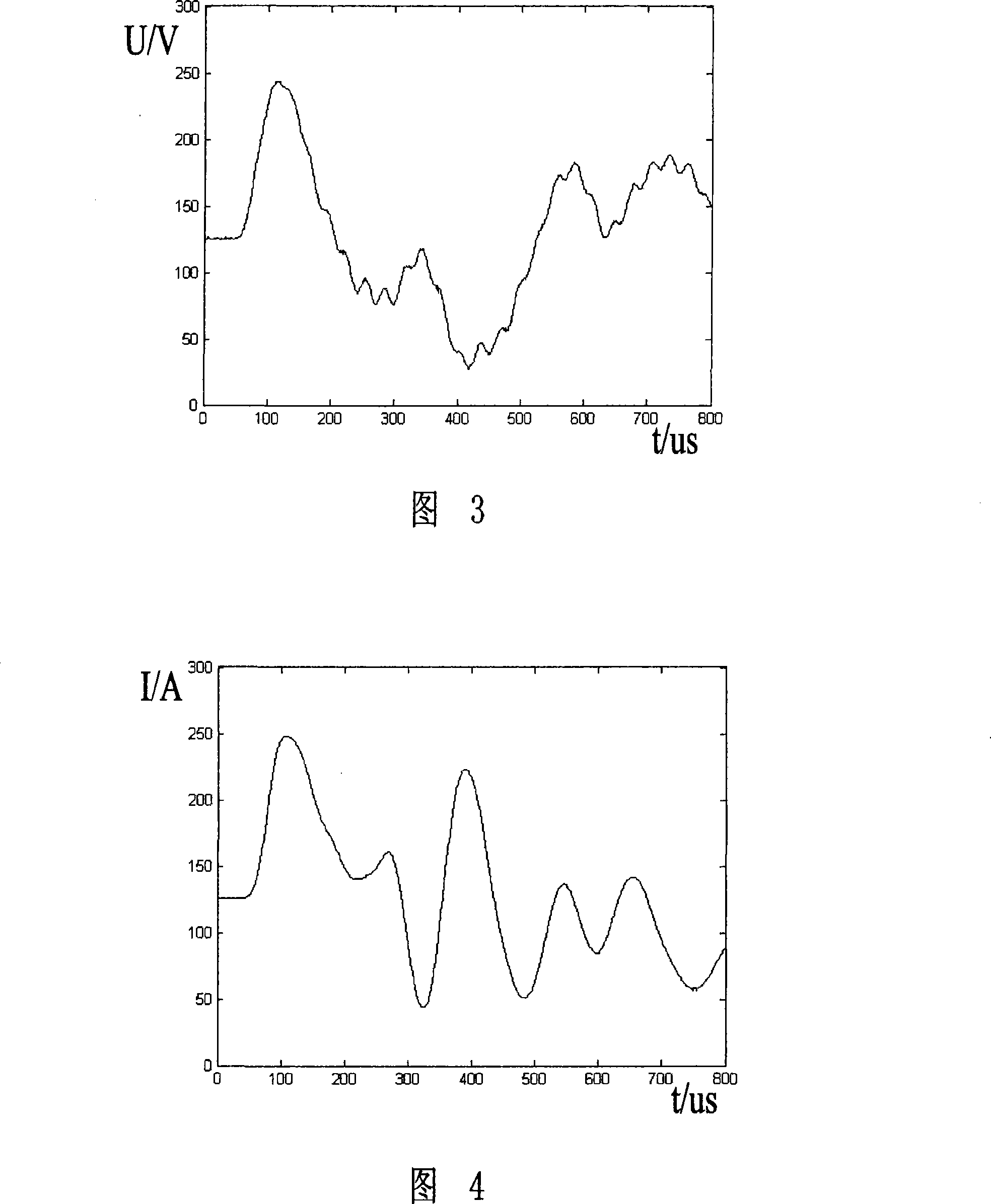

Non-effective earthing distribution system fault locating method based on neutral point of transient traveling wave

InactiveCN101232176ASolve hard-to-reach puzzlesFix speed inconsistenciesEmergency protective circuit arrangementsFault locationTransient stateDistribution transformer

The invention discloses a method for locating fault of power distribution system with ineffectively grounded neutral point based on transient traveling wave, which can acquire required traveling wave signals and relatively higher detection reliability by arranging equipment only on both sides of circuit. According to the actual site condition, a non-contact electromagnetic field sensor is arranged in a transformer substation to acquire transient voltage and current traveling wave, a power distribution transformer arranged on the tail end of the circuit transmits voltage-variable traveling wave to solve the problem in acquisition of tail-end voltage traveling wave signals, and the type of the fault of the circuit can be rapidly recognized according to the amplitude and the polarity characteristics of a fault traveling wave recorded by the secondary side of the transformer. The invention provides a new fault search algorithm based on the midpoint of time to solve the problem of noncontinuous wave speed of aerial wire and cable. Accordingly, the proposal can achieve the assembly and the operation of the equipment without adding extra primary equipment of the system and powering off the circuit, thus saving the cost and reducing the complex degree of the project. Practical operation shows that the method can locate a fault within a range of plus or minus 100 m.

Owner:WEIFANG UNIVERSITY

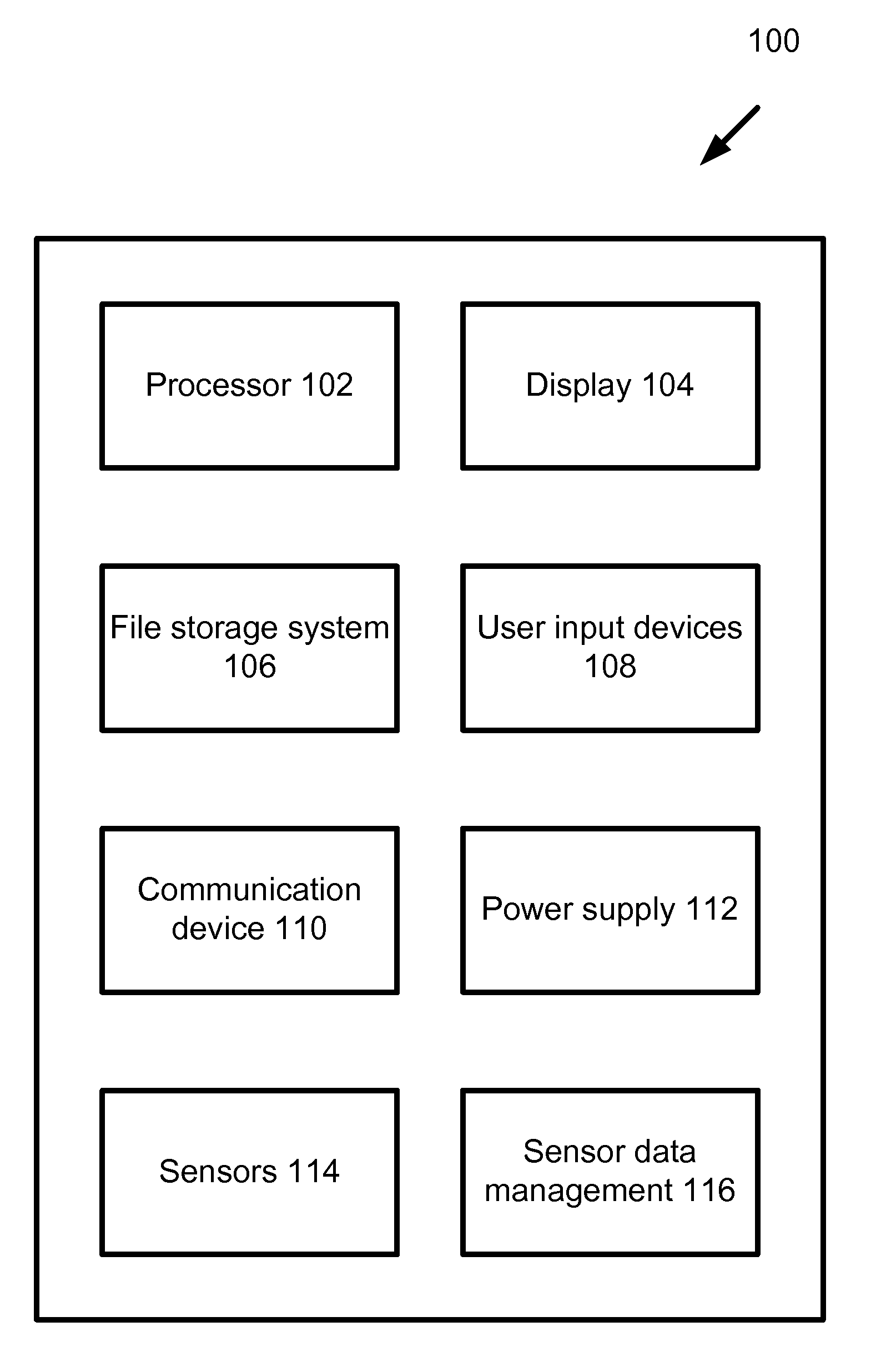

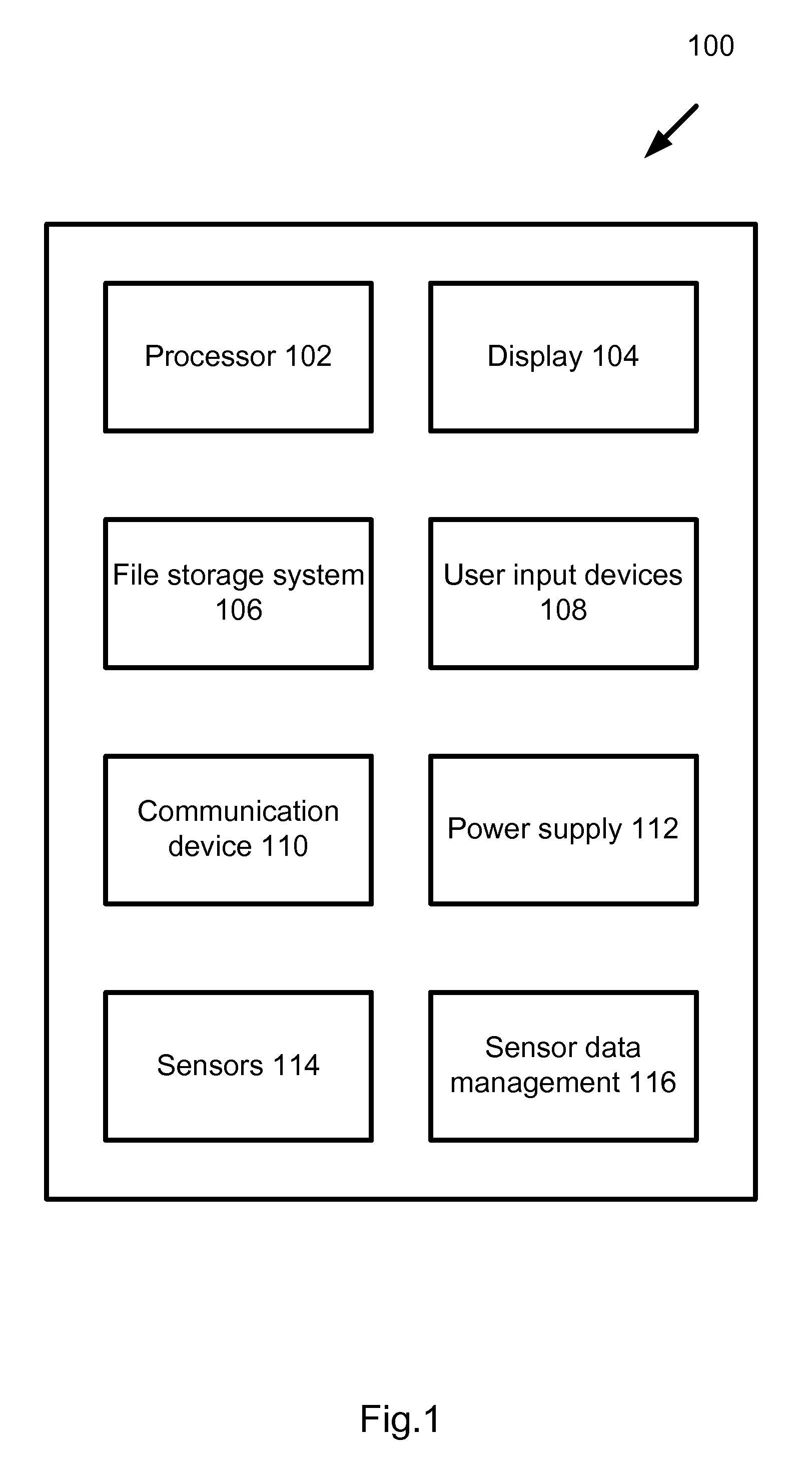

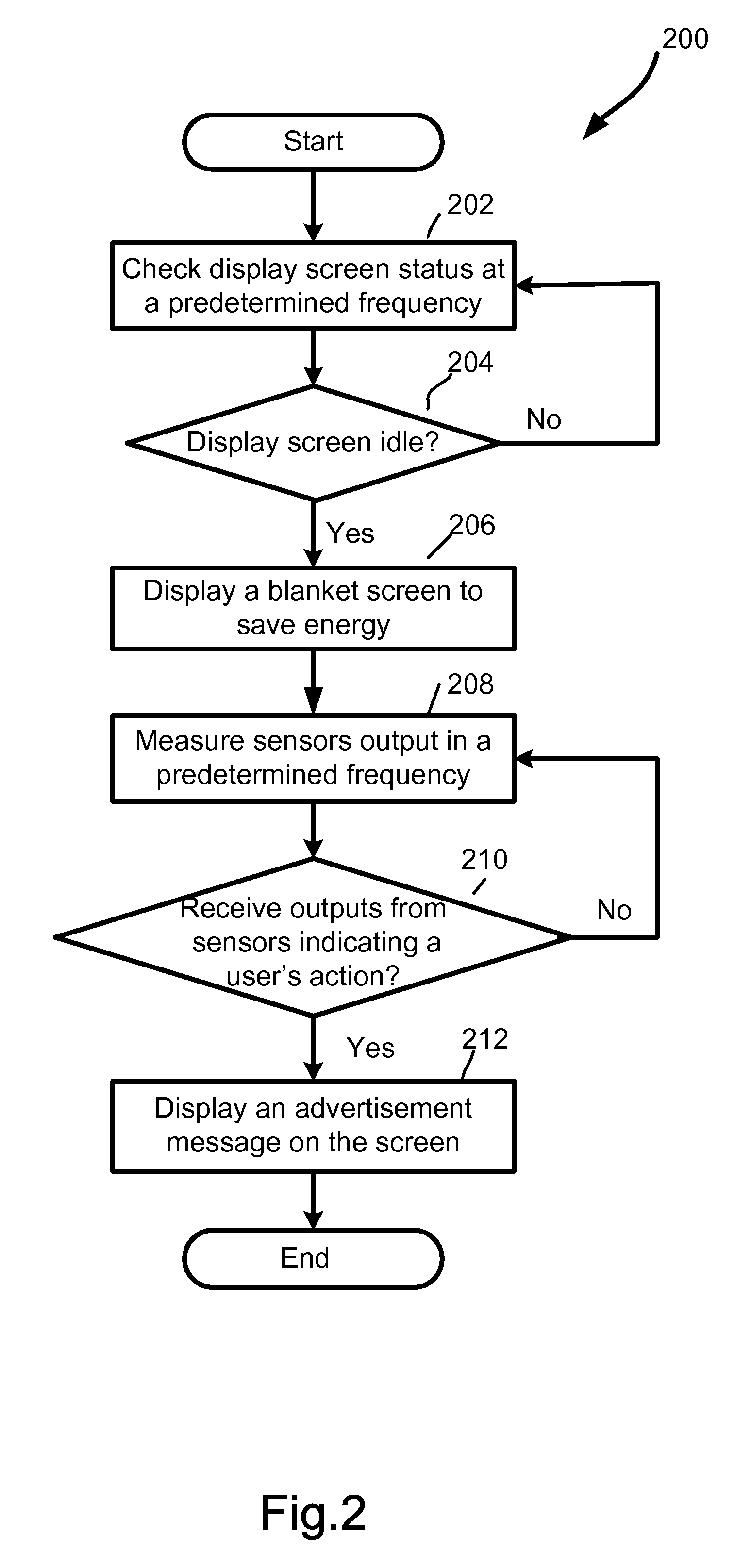

Delivering Advertisement Messages to a User by the Use of Idle Screens of Mobile Devices with Integrated Sensors

InactiveUS20100035656A1Improve reliabilityAdditional power consumptionEnergy efficient ICTDigital data processing detailsPressure sensorBlanket

A method is disclosed by the use of an idle display screen of a mobile device to present an advertisement message. An idle screen, which is taken as a blanket screen in the exemplary case for the illustration, is displayed while the device is idling. A plurality of sensors is integrated with the mobile device. The sensors are used to detect the user's action for holding and positioning the device before user's input actions. A message can then be displayed a short period of time before user's input actions to the device. The system requires a minimum amount of additional power consumption for delivering advertisement messages to the user. It allows that multimedia messages are delivered with acceptable power consumption when utilizing of the idle screens. One embodiment employs pressure sensors, which are placed in selected locations on the sidewalls and / or on the surface of the backside of the device. The locations are selected to match the locations on the surface of the device that a user's hand is in touch with when holding the device for a user's input action. Another embodiment employs touch-screen type of sensors to sense a human hand in touch with the device. Further, accelerator-meters and photo-sensors can be placed in or onto the device to detect changes of physical parameters associated with the interaction actions from the user before an advertisement message is displayed.

Owner:FUJI ELECTRIC CO LTD

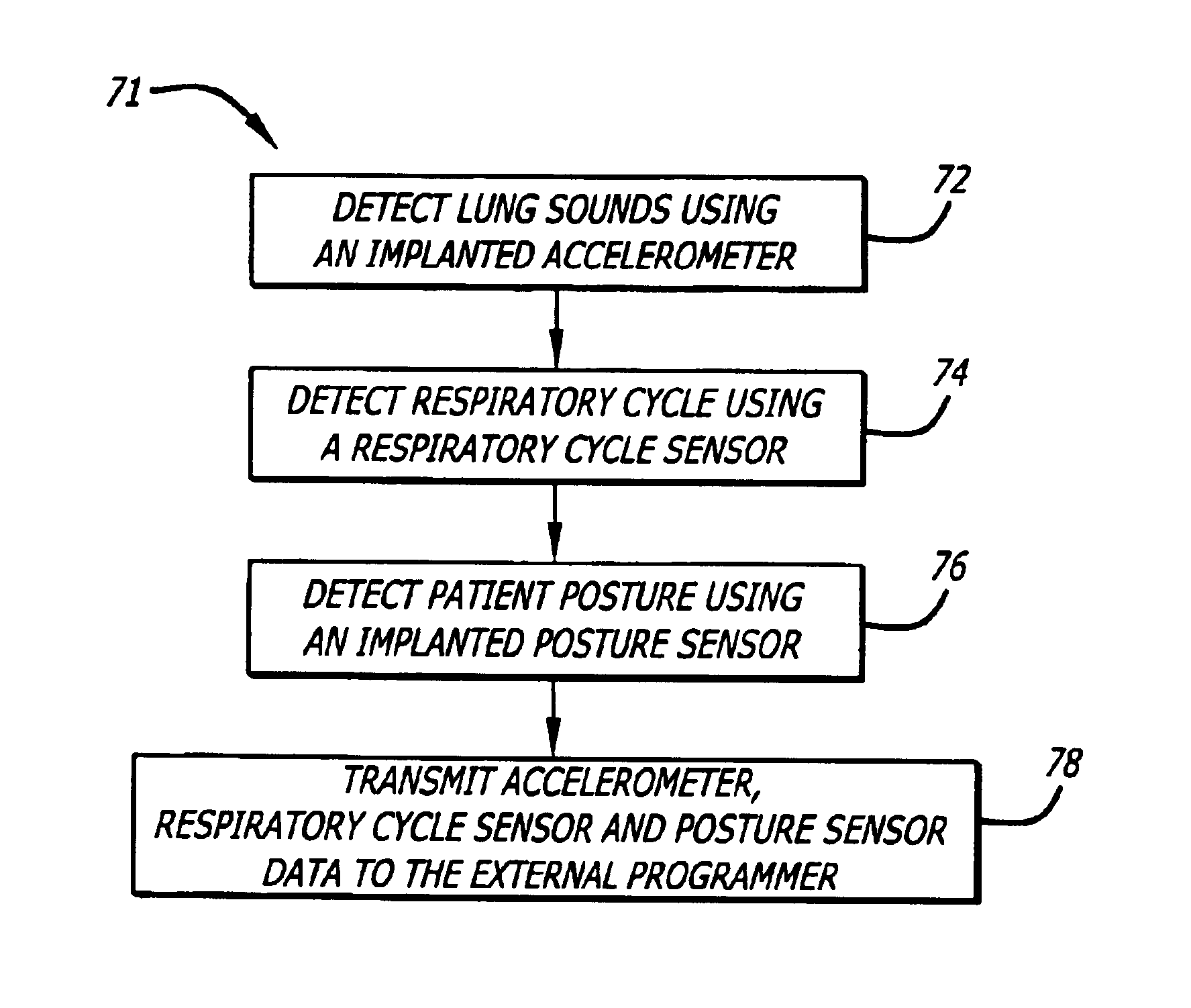

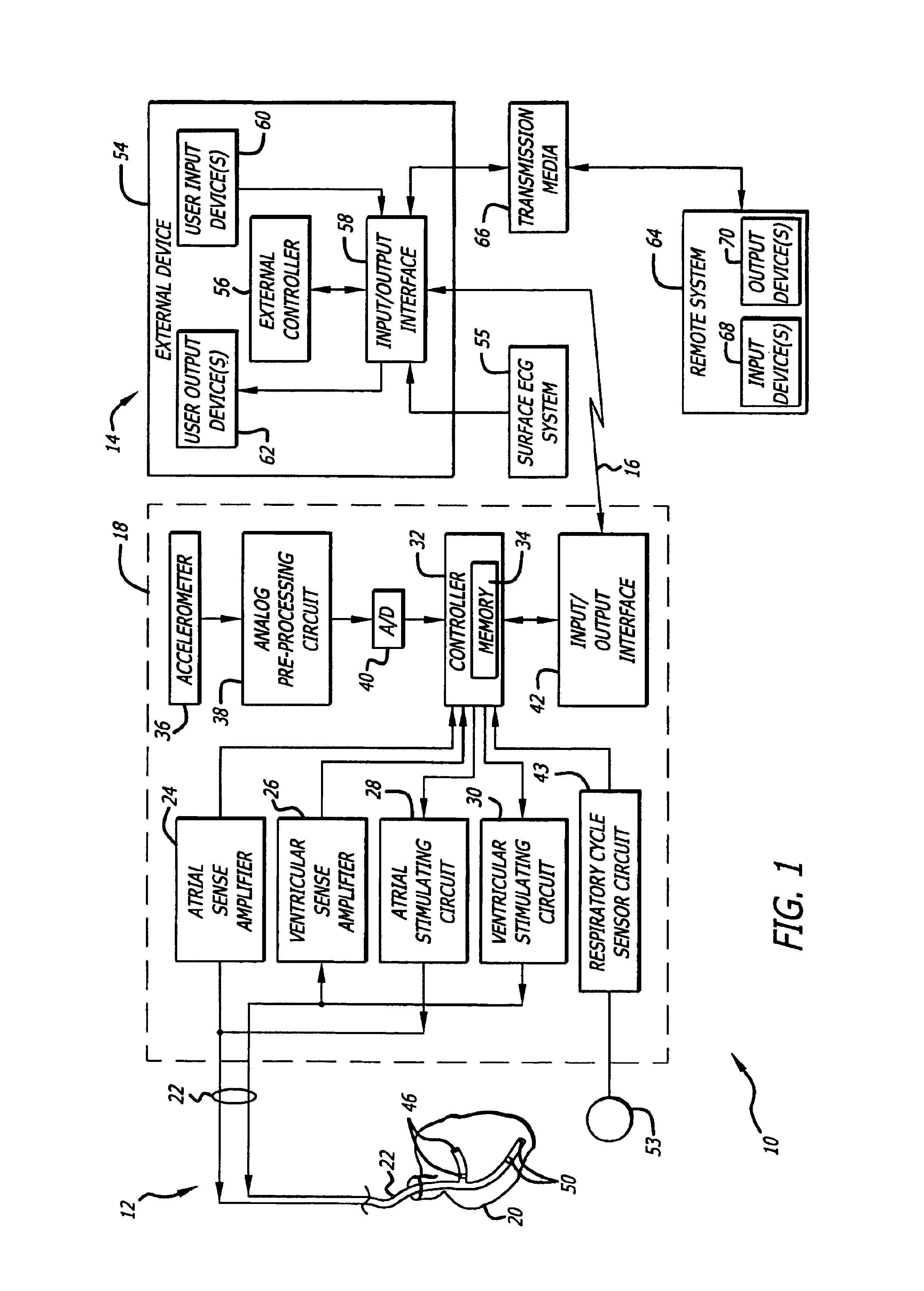

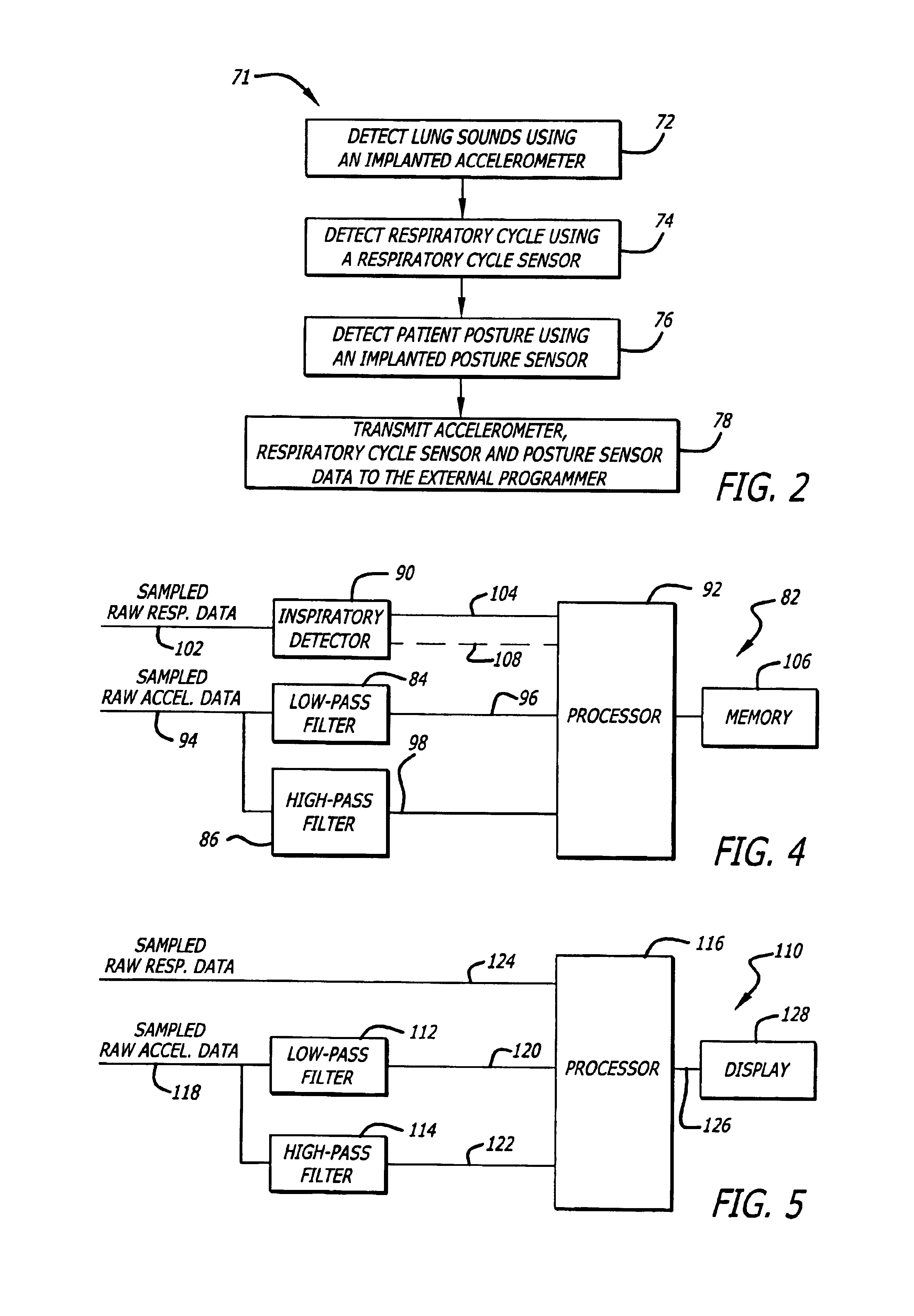

Apparatus and method for detecting lung sounds using an implanted device

InactiveUS6949075B2Reliably detects presenceImprove detection reliabilityAuscultation instrumentsRespiratory organ evaluationMedicineImplanted device

Adventitious lung sounds indicative of lung congestion are detected using an implantable sensor. The sensor is adapted to be positioned adjacent to a pulmonary system and to output signals indicative of lung sounds in response to pulmonary system activity. A controller receives the signals and processes the signals to detect the presence of adventitious lung sounds. A respiratory cycle sensor operating in conjunction with the lung-sound sensor enables classification of an adventitious lung sound according to its time occurrence within the respiratory cycle. Posture sensing in conjunction with lung-sound sensing provides valuable additional information as to the severity of the lung congestion.

Owner:CARDIAC PACEMAKERS INC

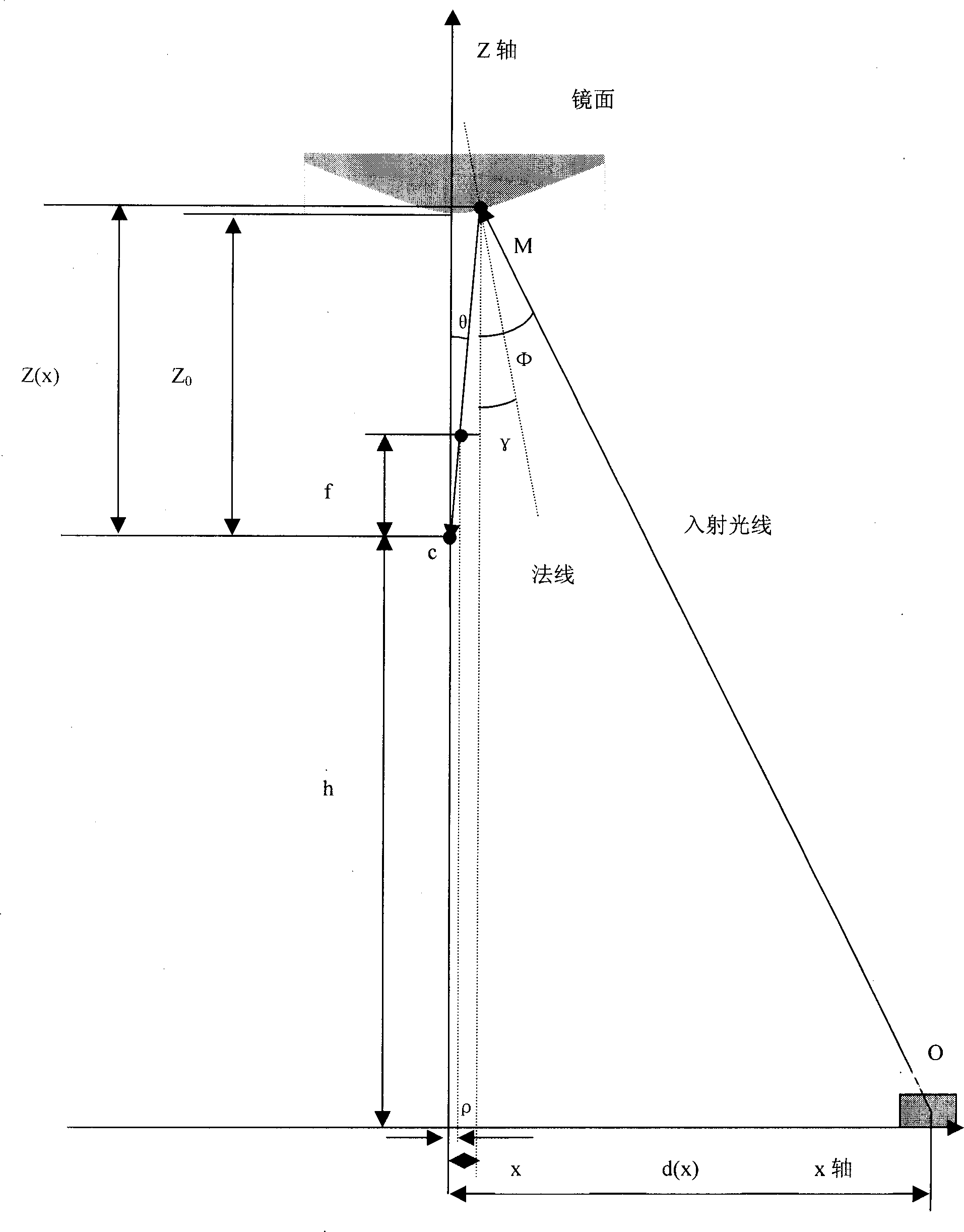

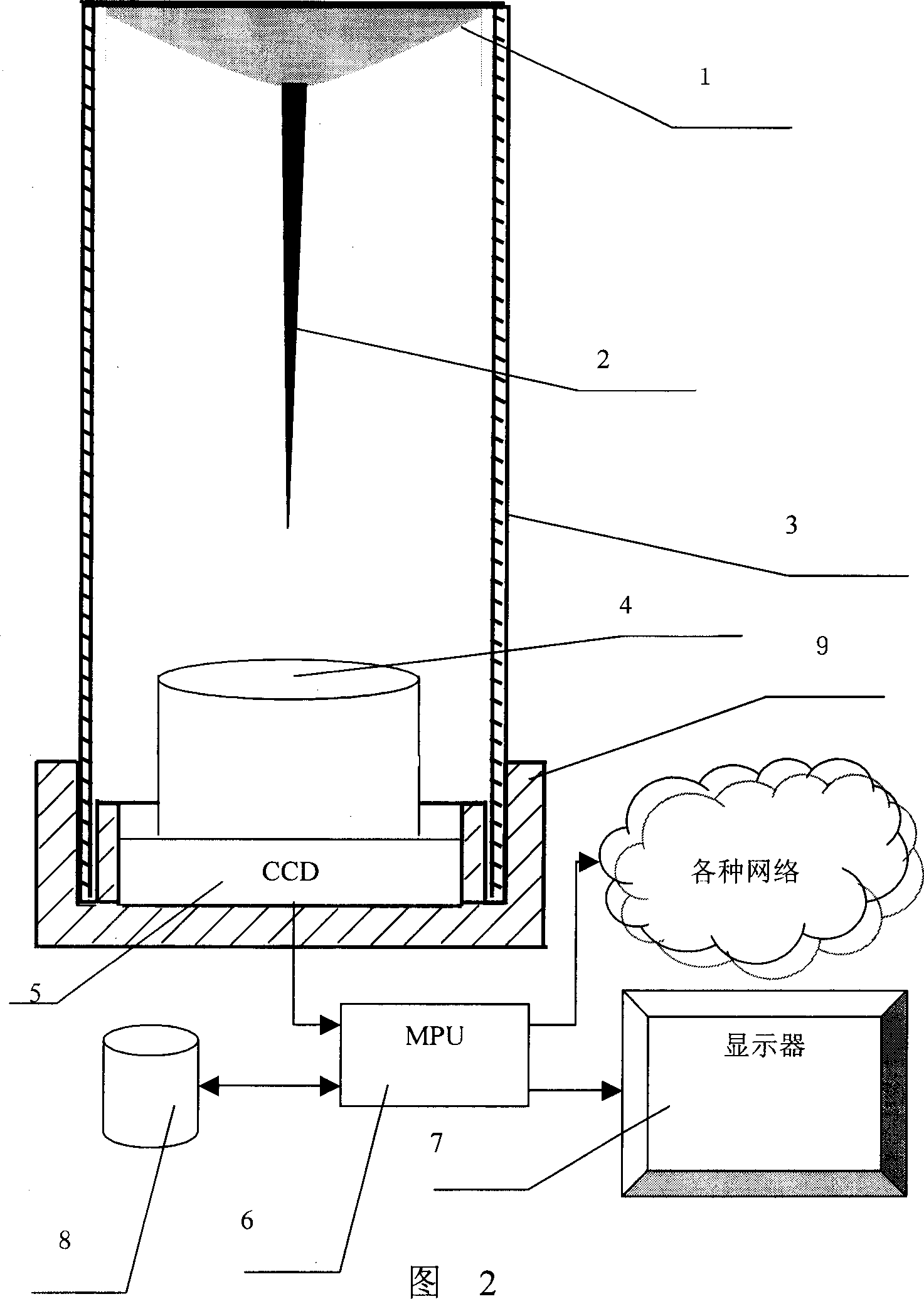

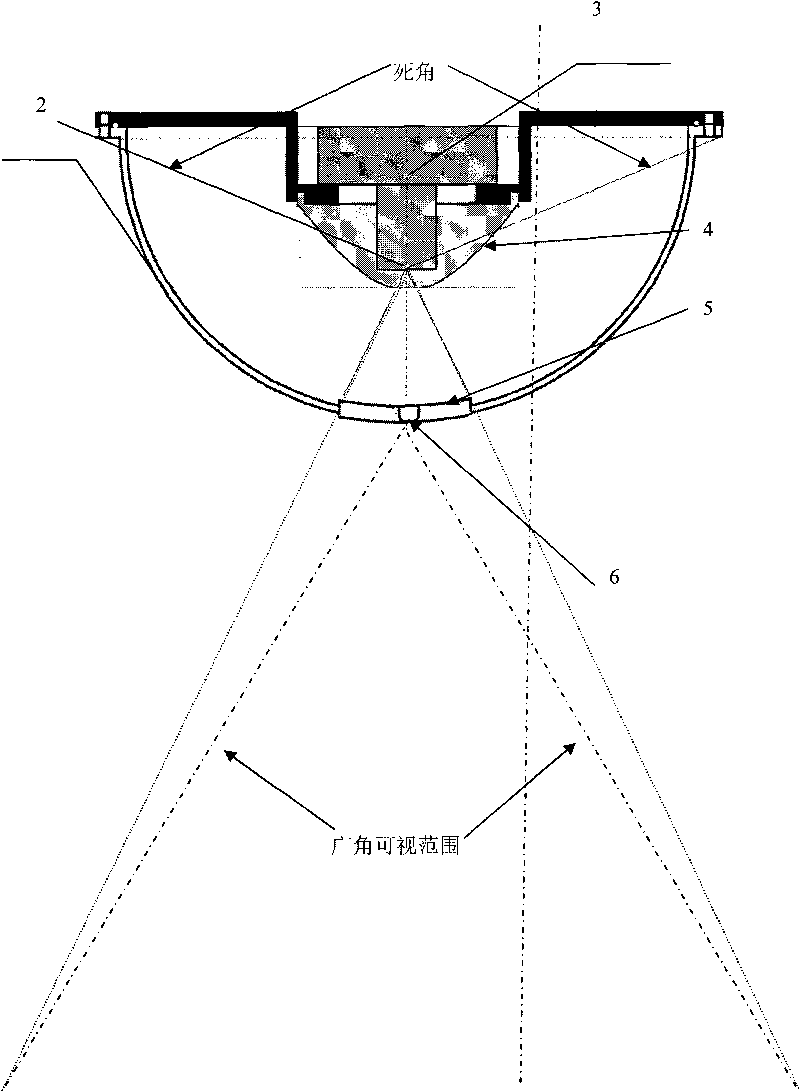

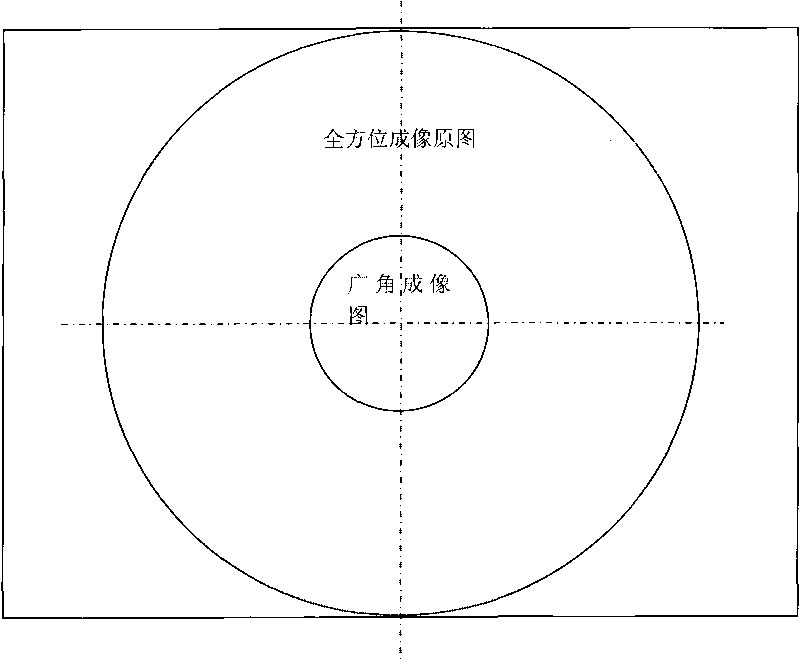

Intelligent tunnel safety monitoring apparatus based on omnibearing computer vision

InactiveCN1852428ACarry out the function of monitoringLow maintenanceImage analysisClosed circuit television systemsDisplay deviceVision sensor

The monitoring equipment includes microprocessor, video sensor in use for monitoring site of tunnel, and communication module for communication outside. Microproceesor includes following modules: reading module for image dada in use for reading information of video image transferred from video sensor; file storage module in use for storing data collected by video sensor to storage device; real time playing module on site connected to external display device is in use for playing monitored image on site in real time. Output of the video sensor is connected to microprocessor through communication. Using all directional computer vision sensor monitors tunnel site, processes and analyzes images. Using detected variation character for fire flame in early phase, the invention finds early fire in tunnel as well as obtains traffic data including vehicle flowrate, and occupancy ratio, speed, and traffic accident etc.

Owner:ZHEJIANG UNIV OF TECH

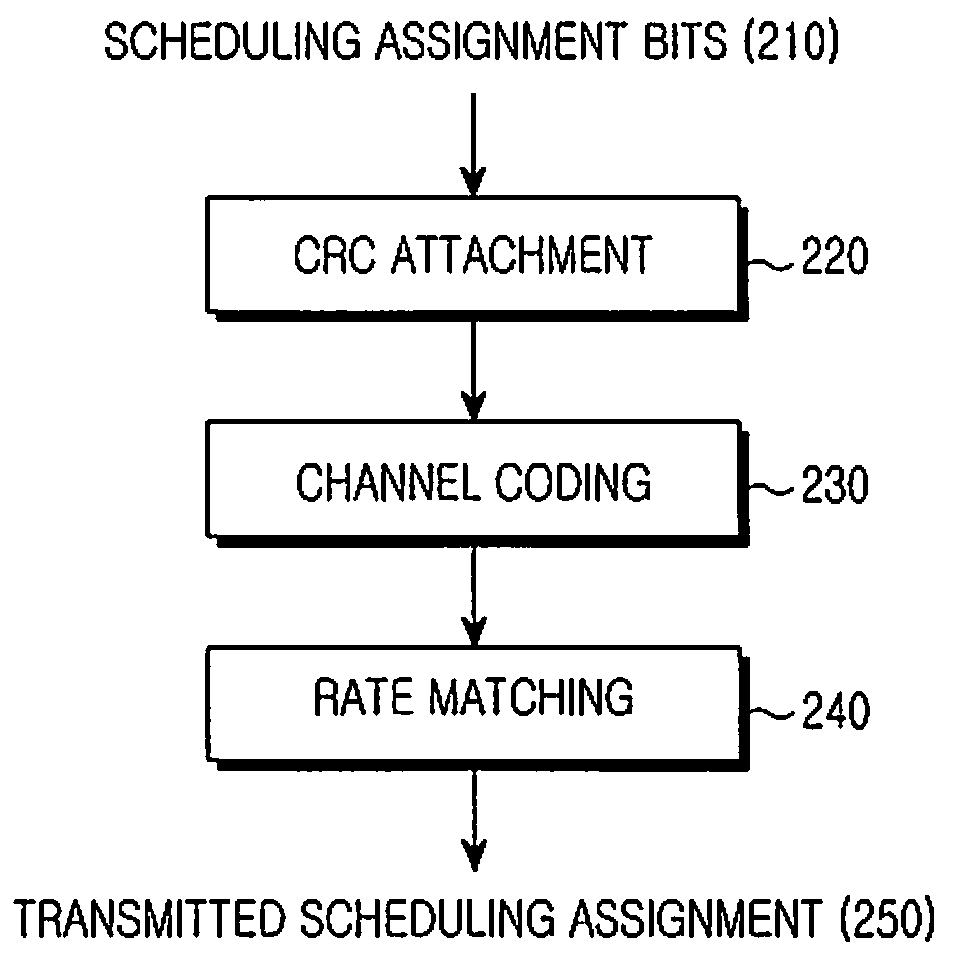

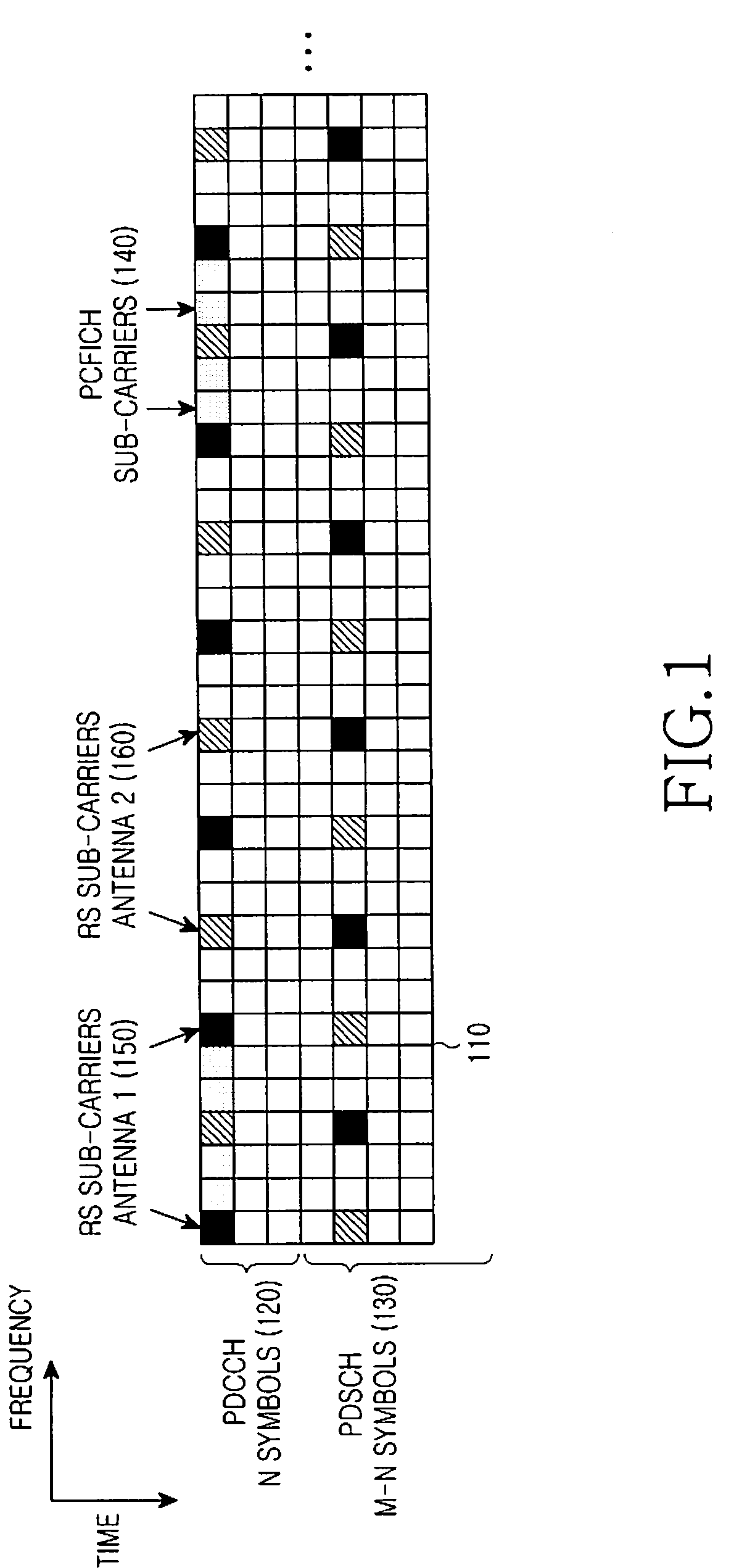

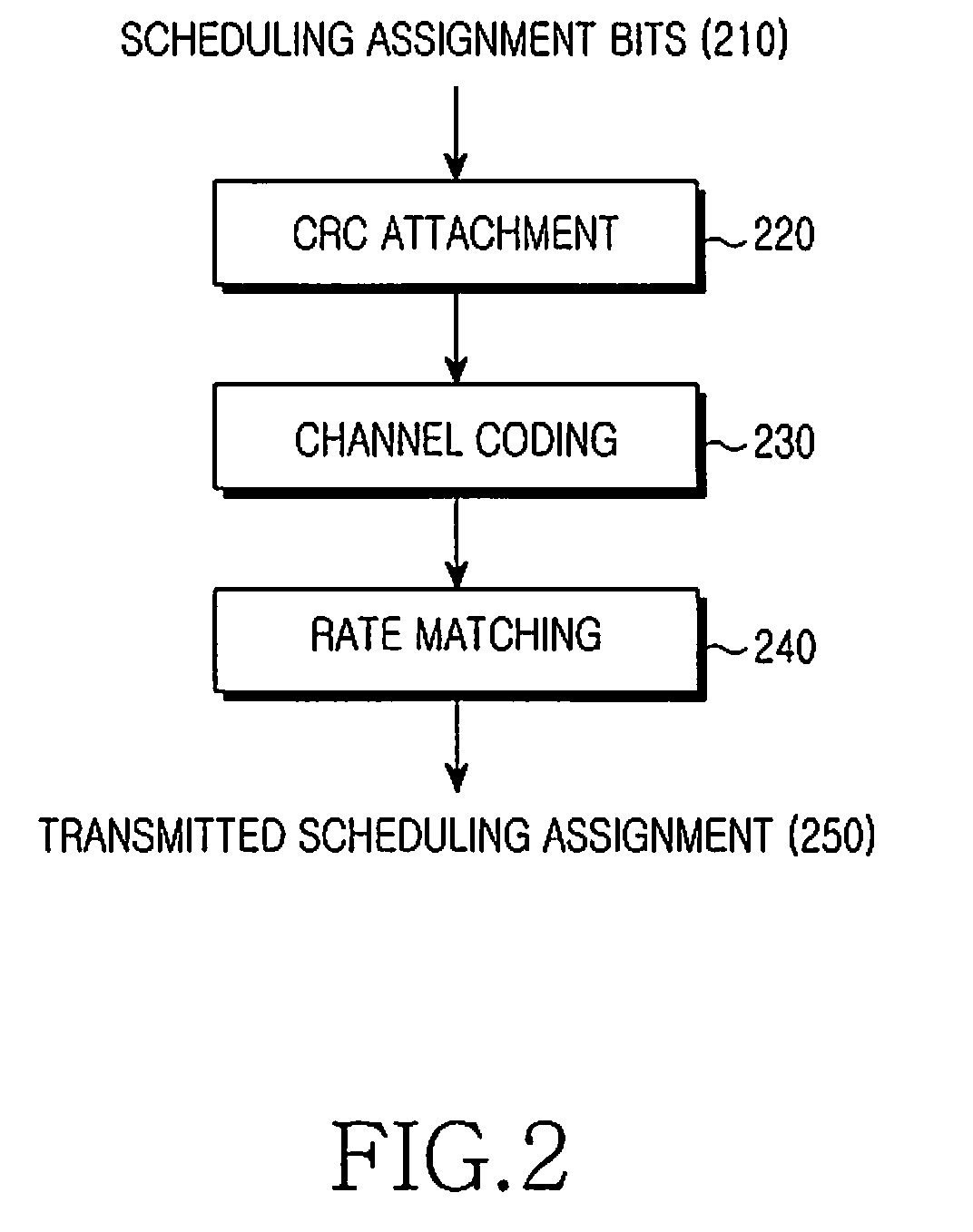

Transmission of scheduling assignments in multiple operating bandwidths

ActiveUS20100135237A1Simplify and reduce SA decoding operationImprove detection reliabilityTransmission path divisionSignal allocationCommunications systemCarrier signal

Methods and apparatuses are described for the transmission of Scheduling Assignments (SAs) from a base station to User Equipments (UEs) for data reception in the downlink or data transmission in the uplink of a communication system consisting of multiple Component Carriers (CCs). The SAs are separately coded and transmitted using elementary units (Control Channel Elements or CCEs). Locations of CCEs determine whether an SA is intended for a first CC or for a second CC. Further, the location of CCEs for an SA intended for a first CC is used to determine locations of CCEs for an SA intended for a second CC.

Owner:SAMSUNG ELECTRONICS CO LTD

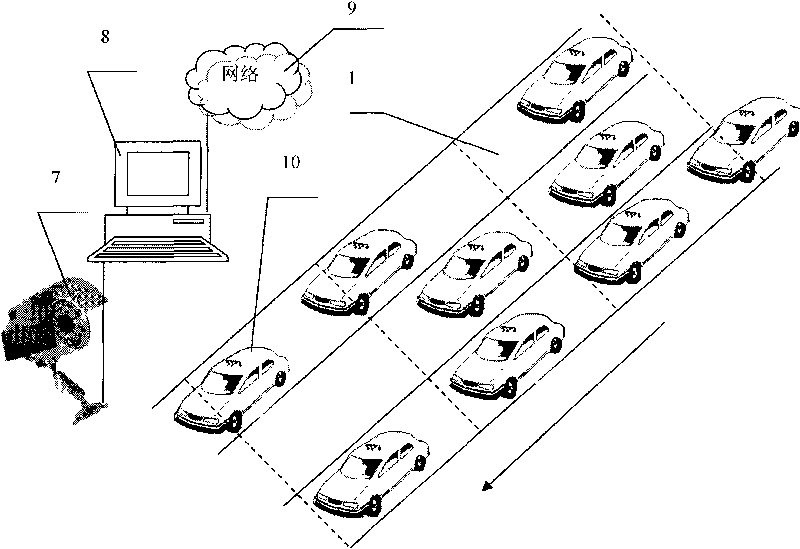

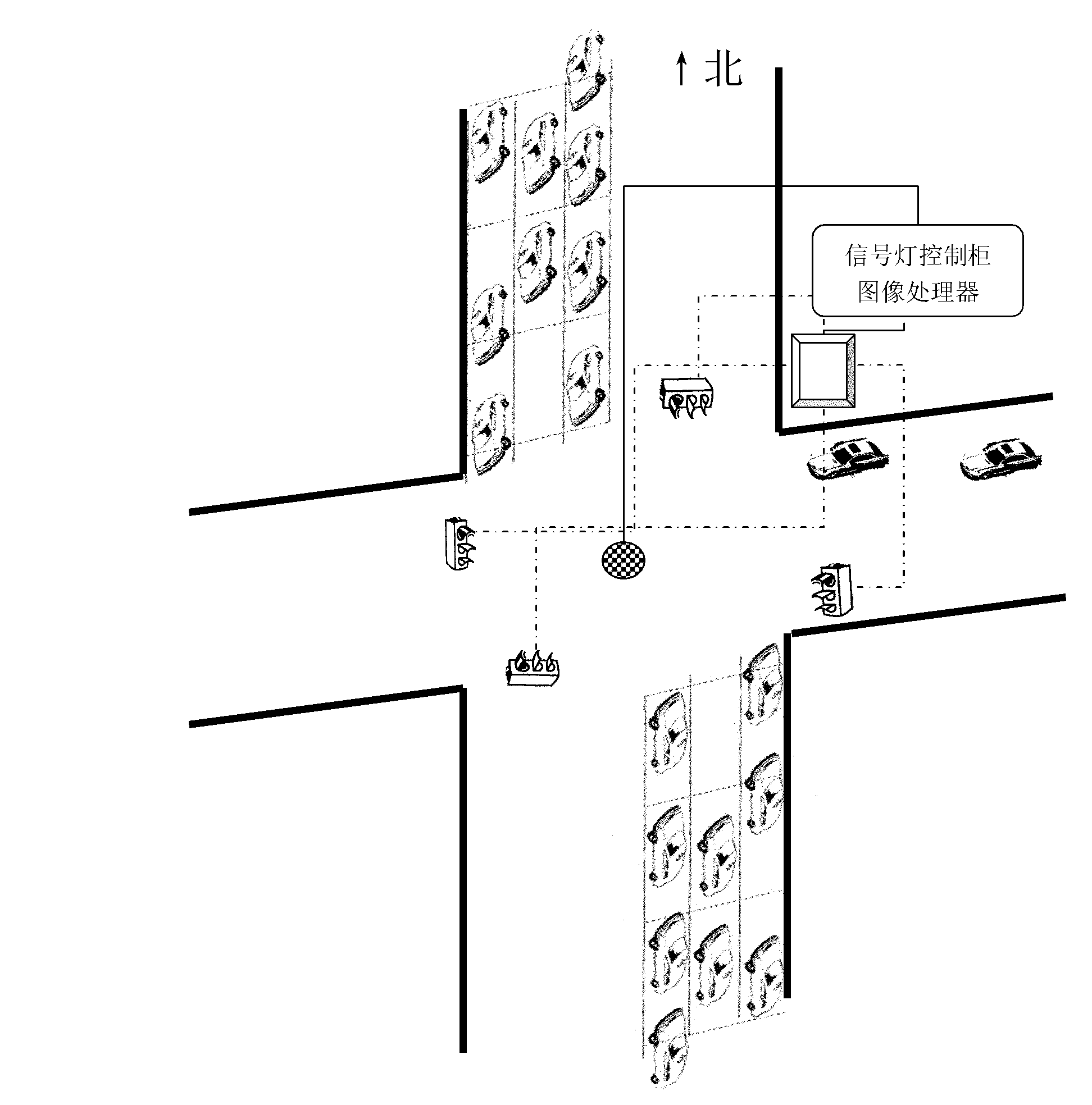

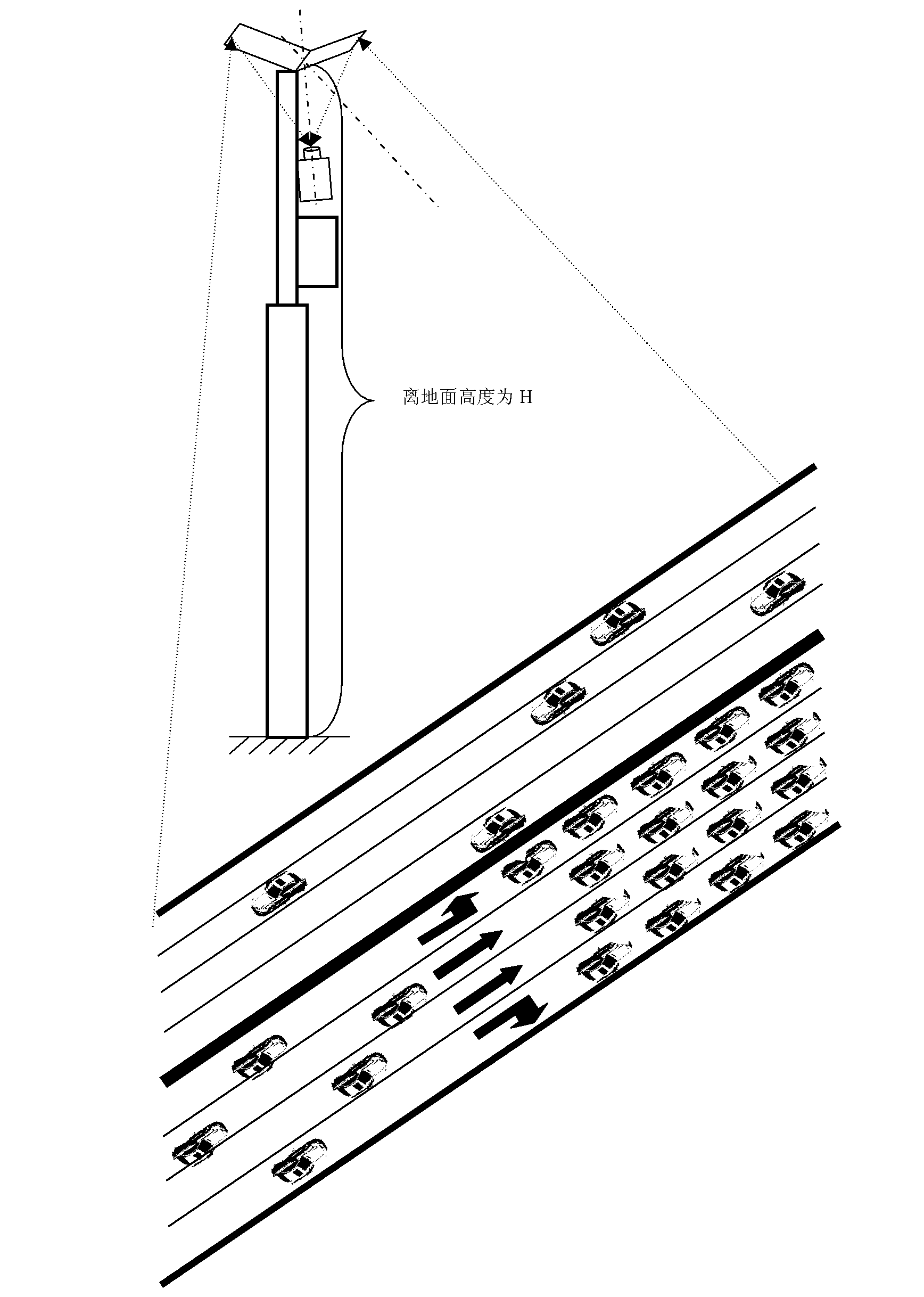

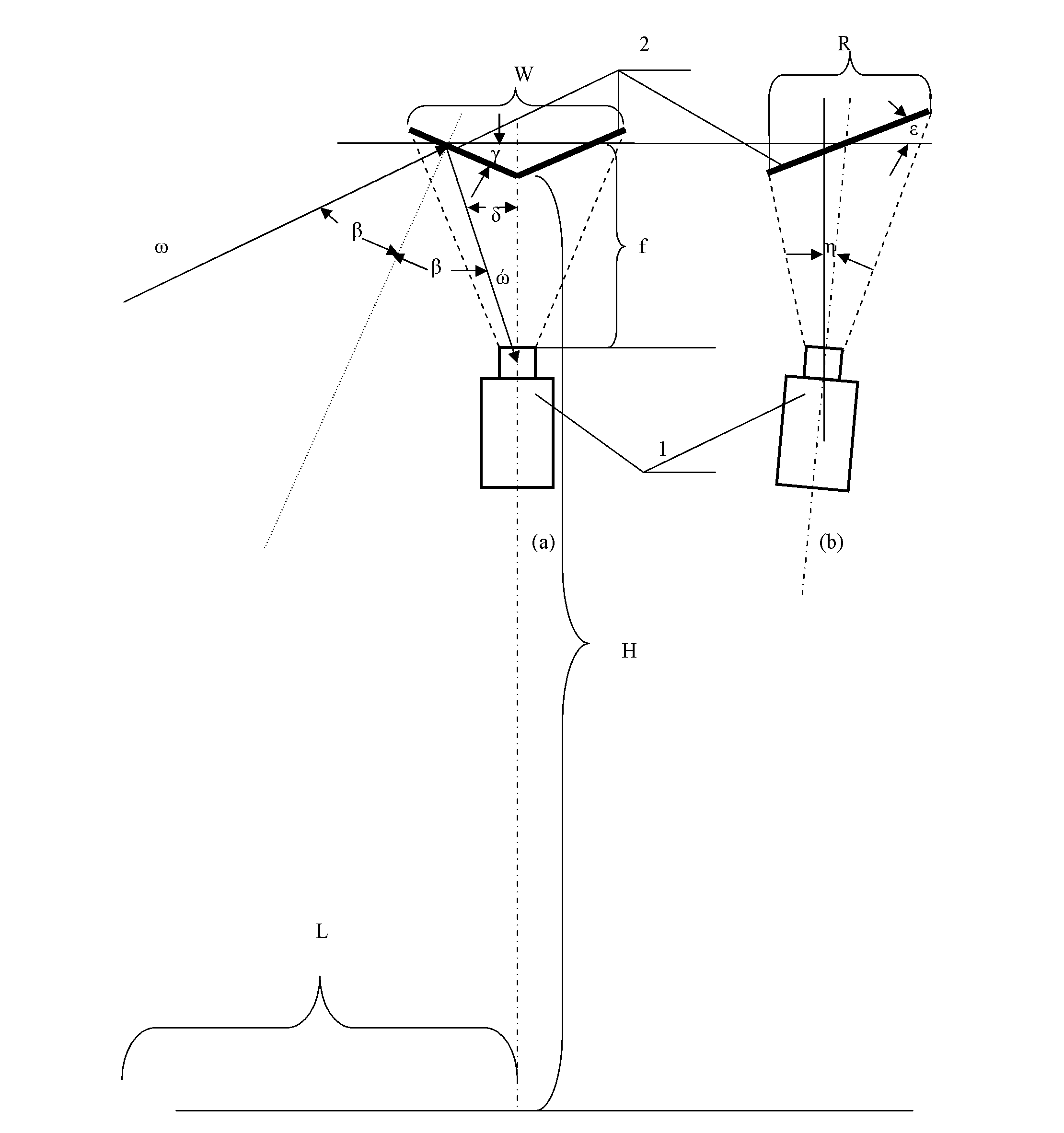

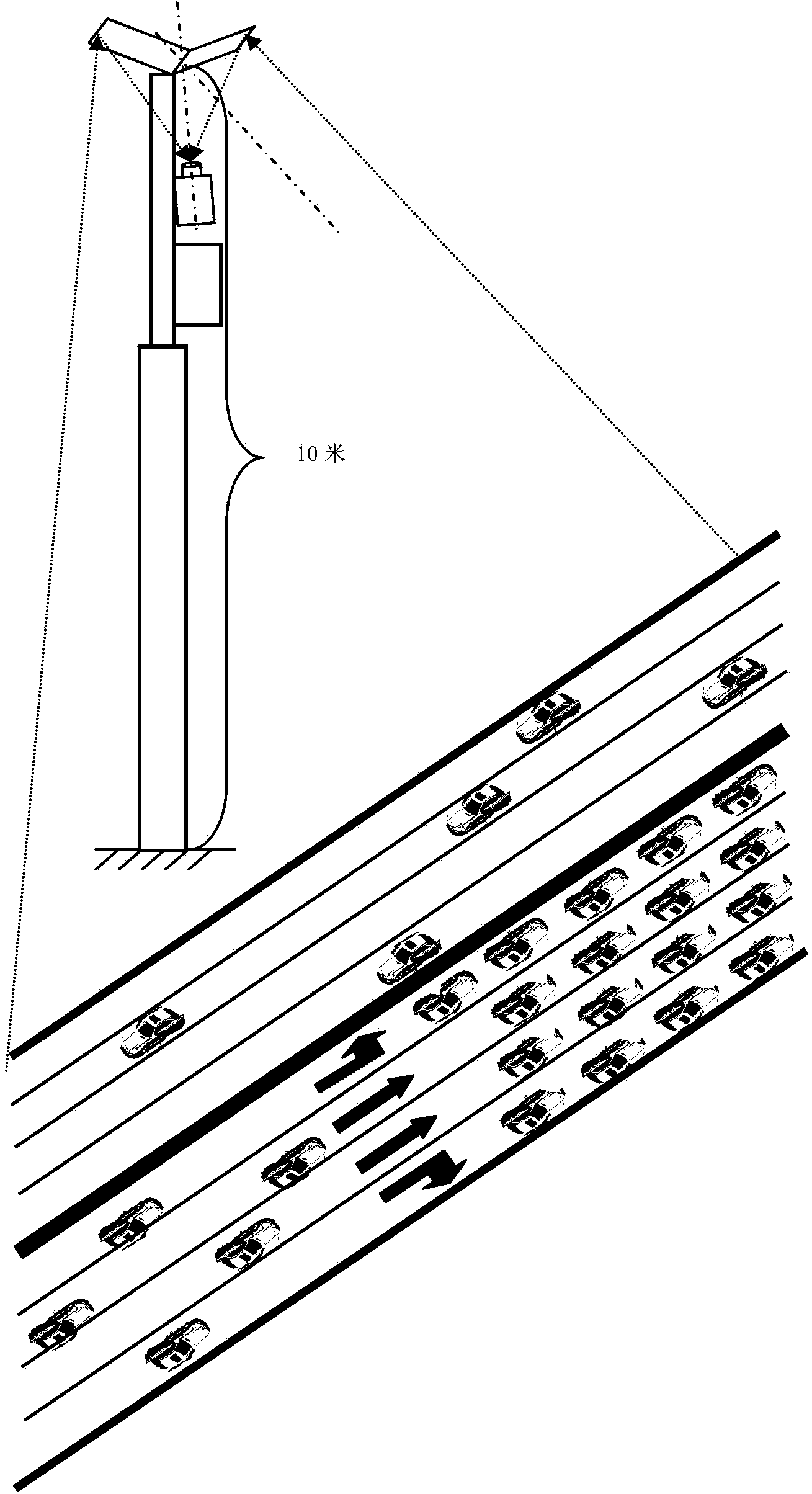

Road traffic state detecting device based on omnibearing computer vision

InactiveCN101710448AWill not affect trafficEasy to implementDetection of traffic movementLearning unitMeasurement point

The invention relates to a road traffic state detecting device based on omnibearing computer vision, comprising shooting devices and a microprocessor, wherein the shooting devices are installed on all measuring points in all roads in a road network; the microprocessor is used for evaluating the road traffic state according to the video data of the shooting devices and comprises a full-view image obtaining unit, a road service capability customizing unit, a road service level self-learning unit, a road service level judging unit, a detecting data processing unit and an artificial checking unit. The road traffic state detecting device based on omnibearing computer vision has wide detecting range, high detecting precision, good detecting instantaneity, convenient application, visual and clear detecting result, subjective sensitivity index data and objective evaluation index data and is convenient for all grades of road networks of a city to carry out comprehensive evaluation on the road traffic state in time and space.

Owner:ZHEJIANG UNIV OF TECH

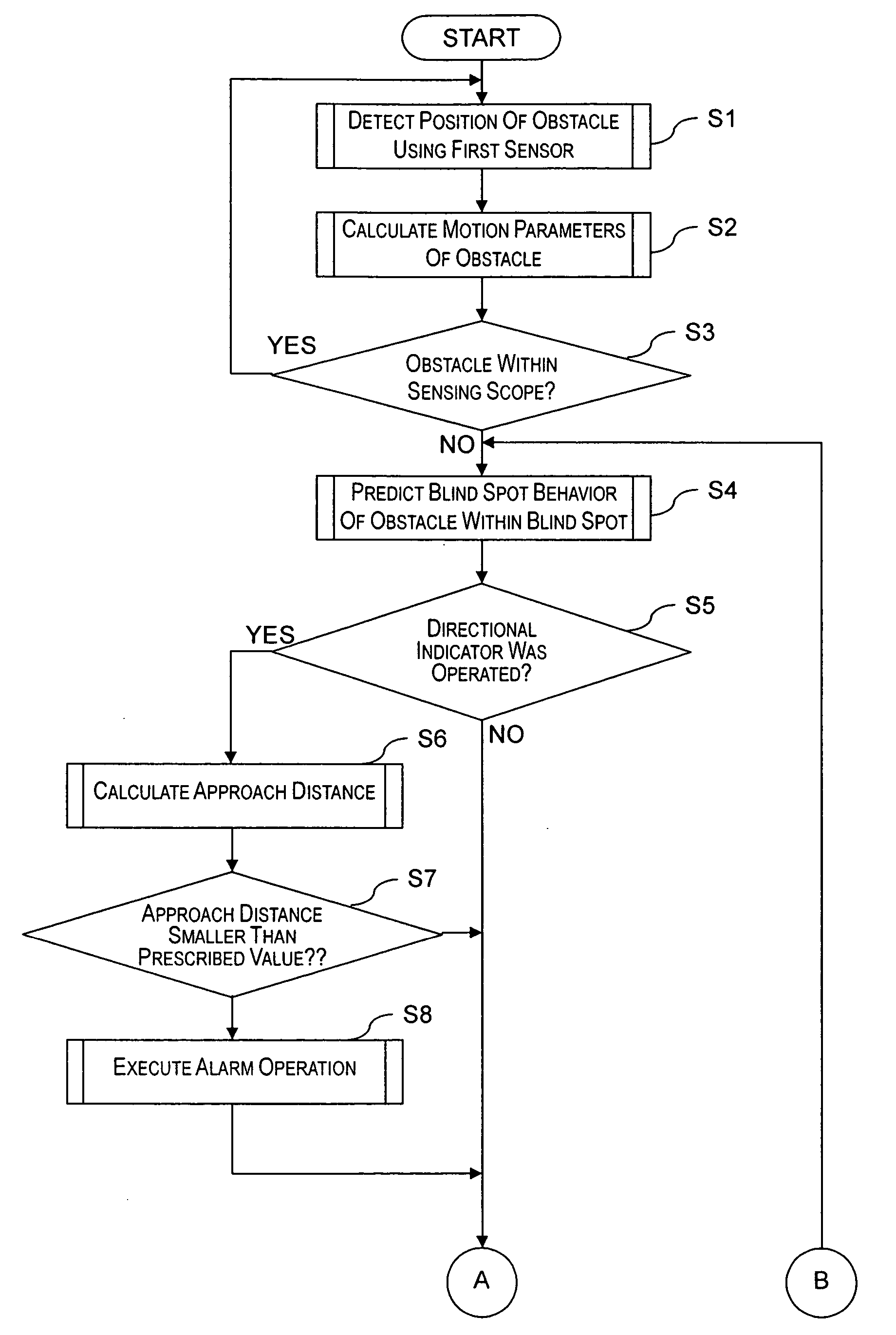

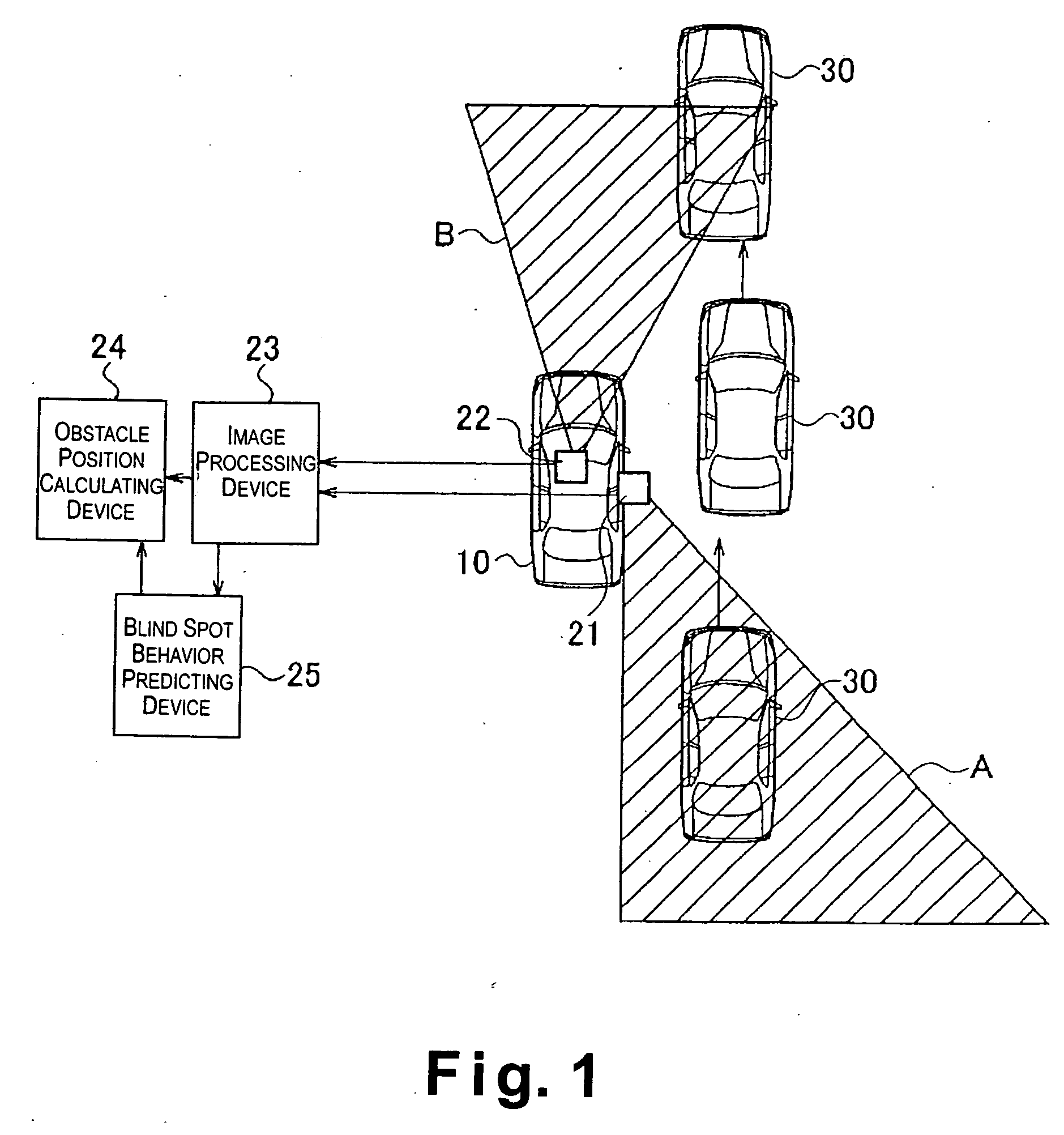

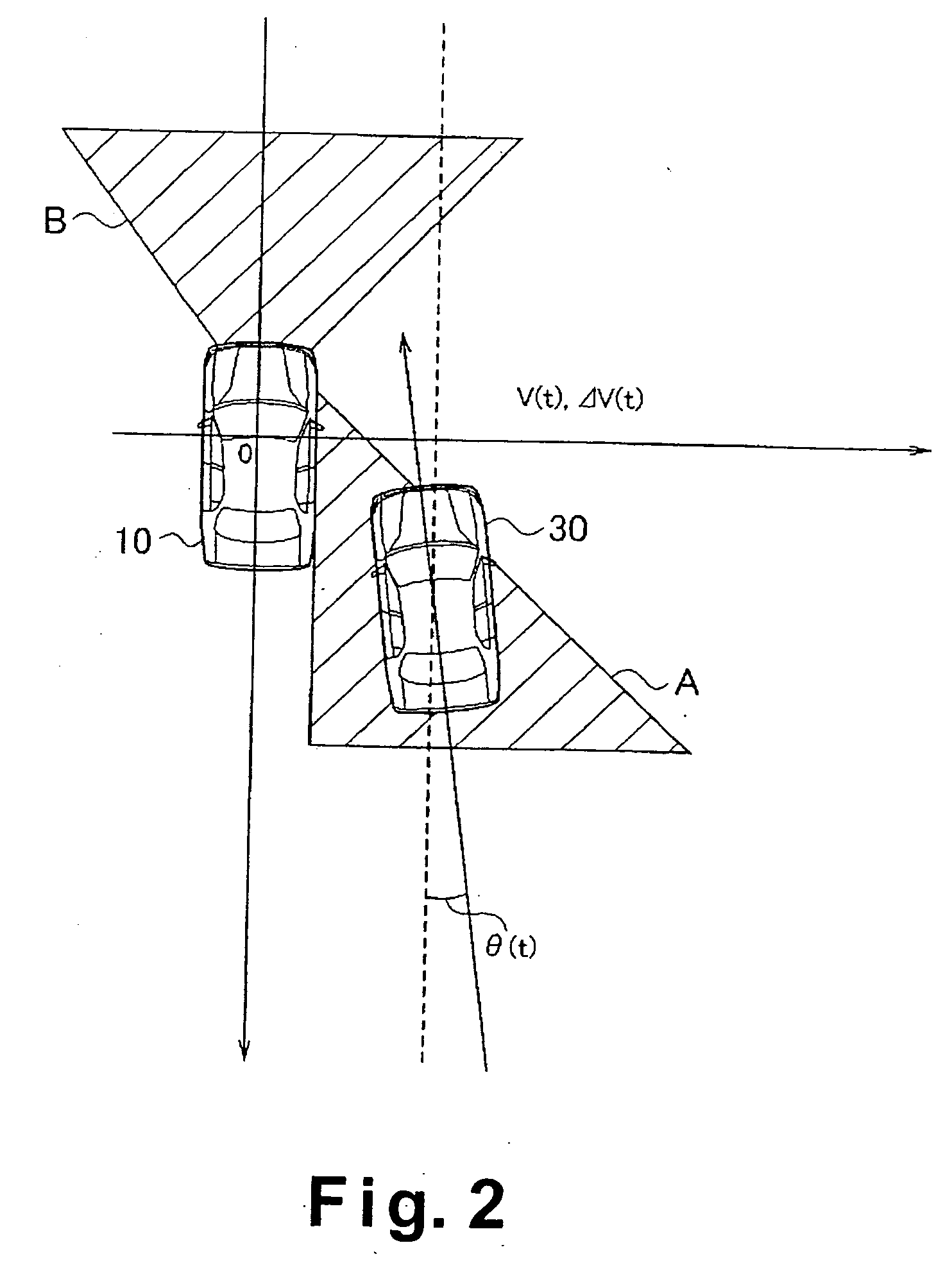

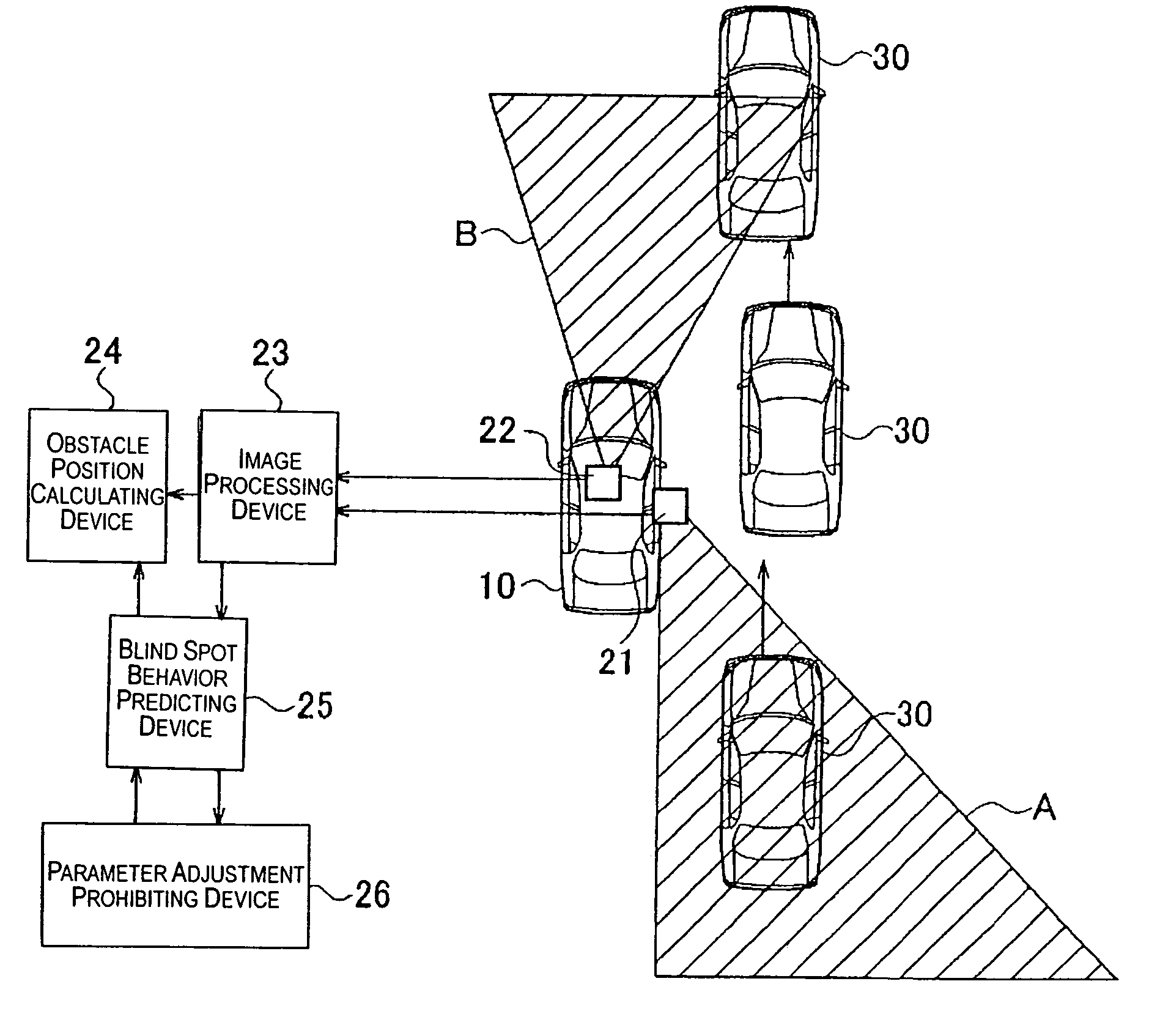

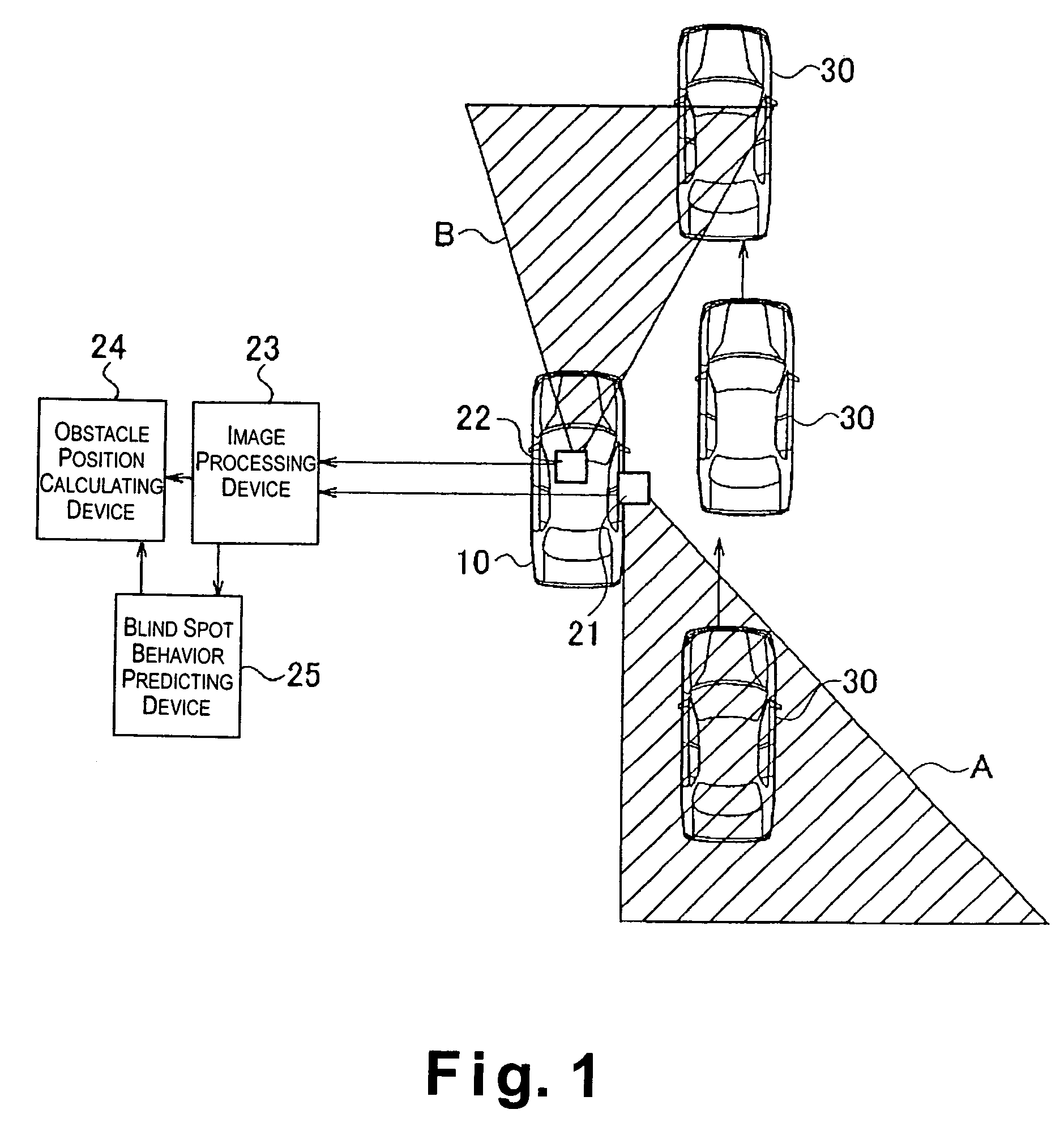

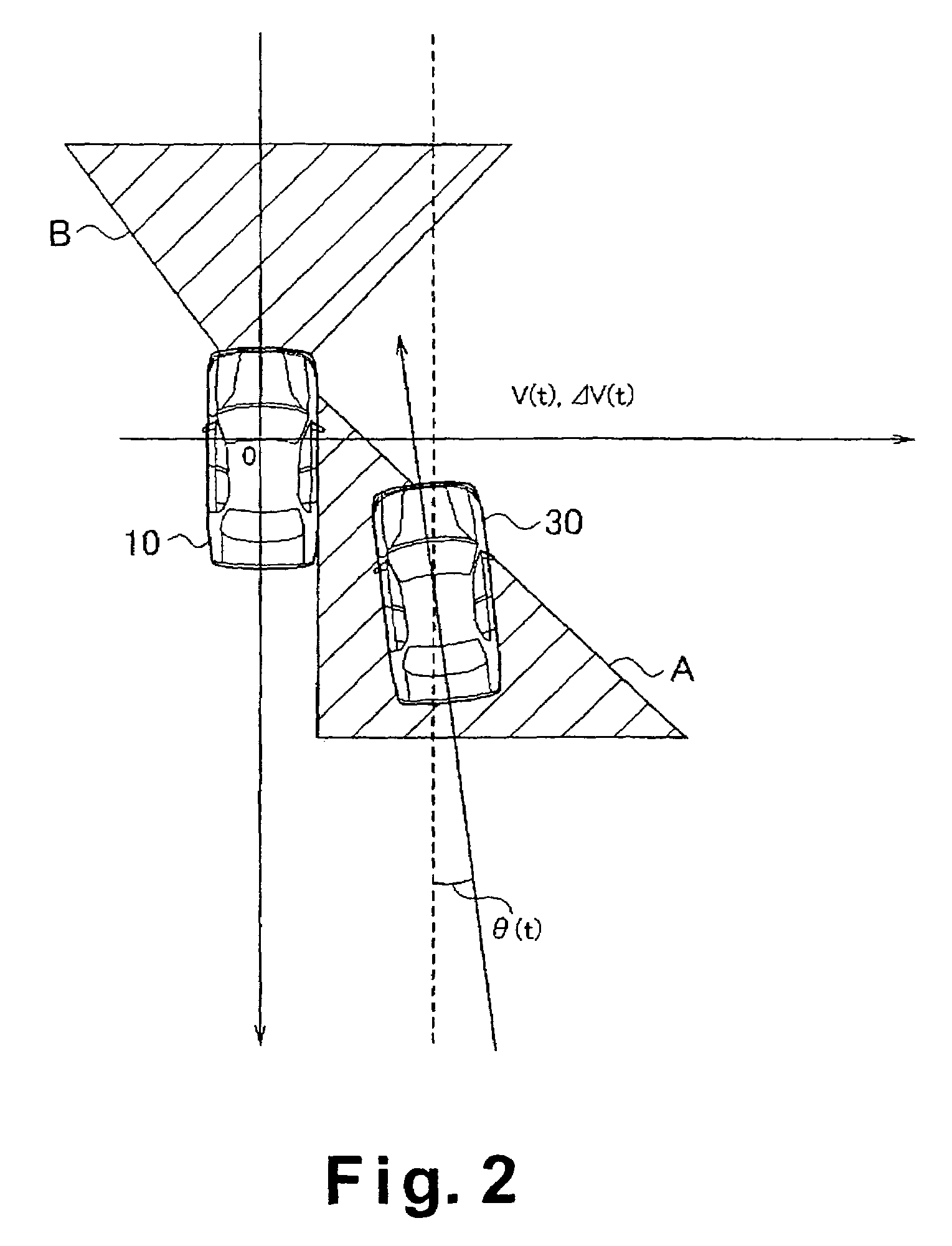

Vehicle obstacle detecting device

ActiveUS20050012604A1Improve detection reliabilityEfficient use ofPedestrian/occupant safety arrangementAnti-collision systemsEngineering

The vehicle obstacle detecting device improves safety of the vehicle by utilizing information detected by a plurality of sensors to appropriately handle situations in which an obstacle exists in a blind spot of the sensors. The vehicle obstacle detecting device includes at least first and second sensors arranged such that sensing scopes of the first and second sensors do not substantially overlap. The vehicle obstacle detecting device is configured to observe the behavior of an obstacle existing within the sensing scope of one of the first and second sensors and predict the blind spot behavior of the obstacle in a blind spot between the sensing scopes of the first and second sensors based on the observed behavior of the obstacle. Thus, the vehicle obstacle detecting device is configured to predict the existence of an obstacle in the blind spot where the first and second sensors cannot actually detect the obstacle.

Owner:NISSAN MOTOR CO LTD

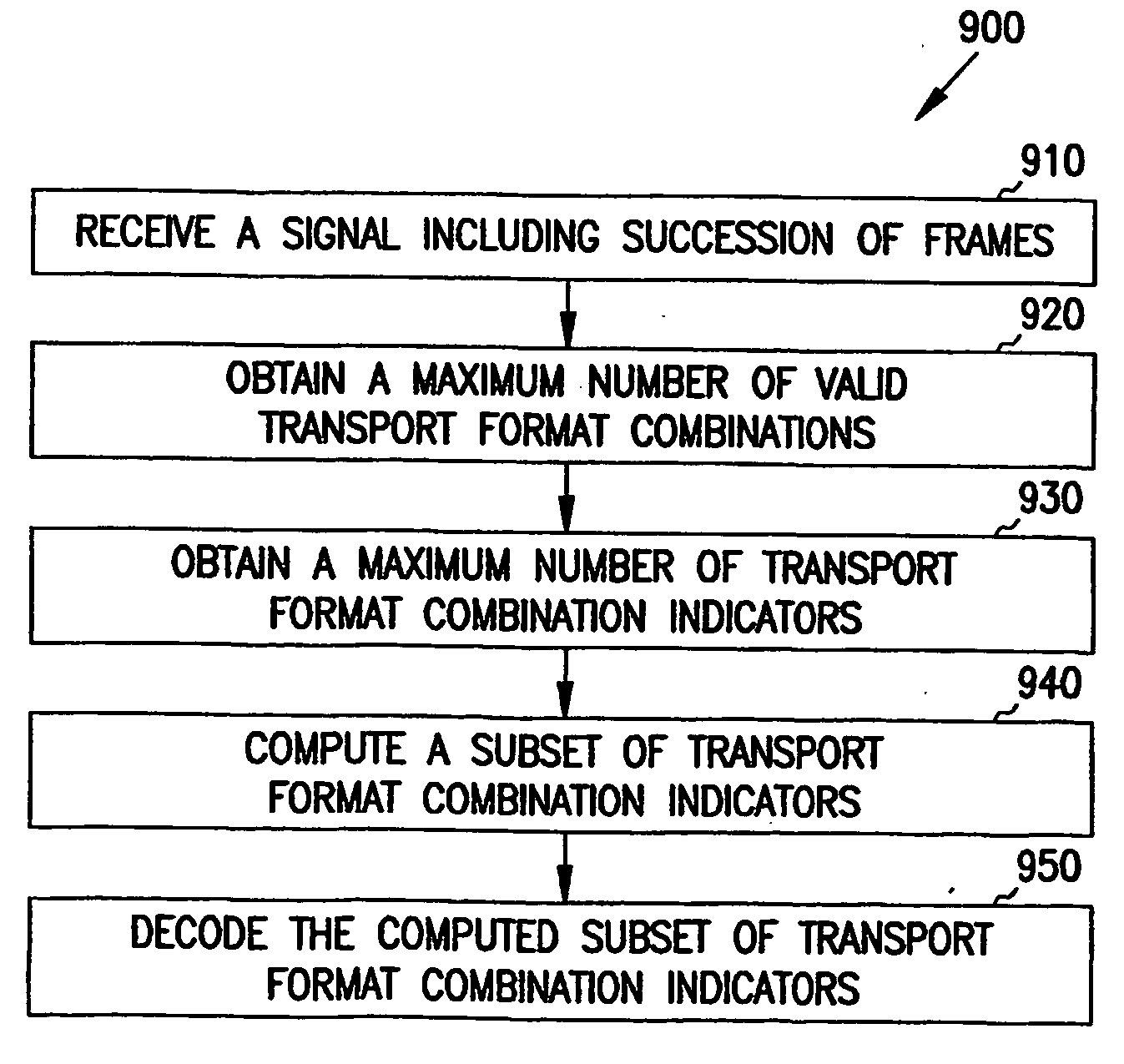

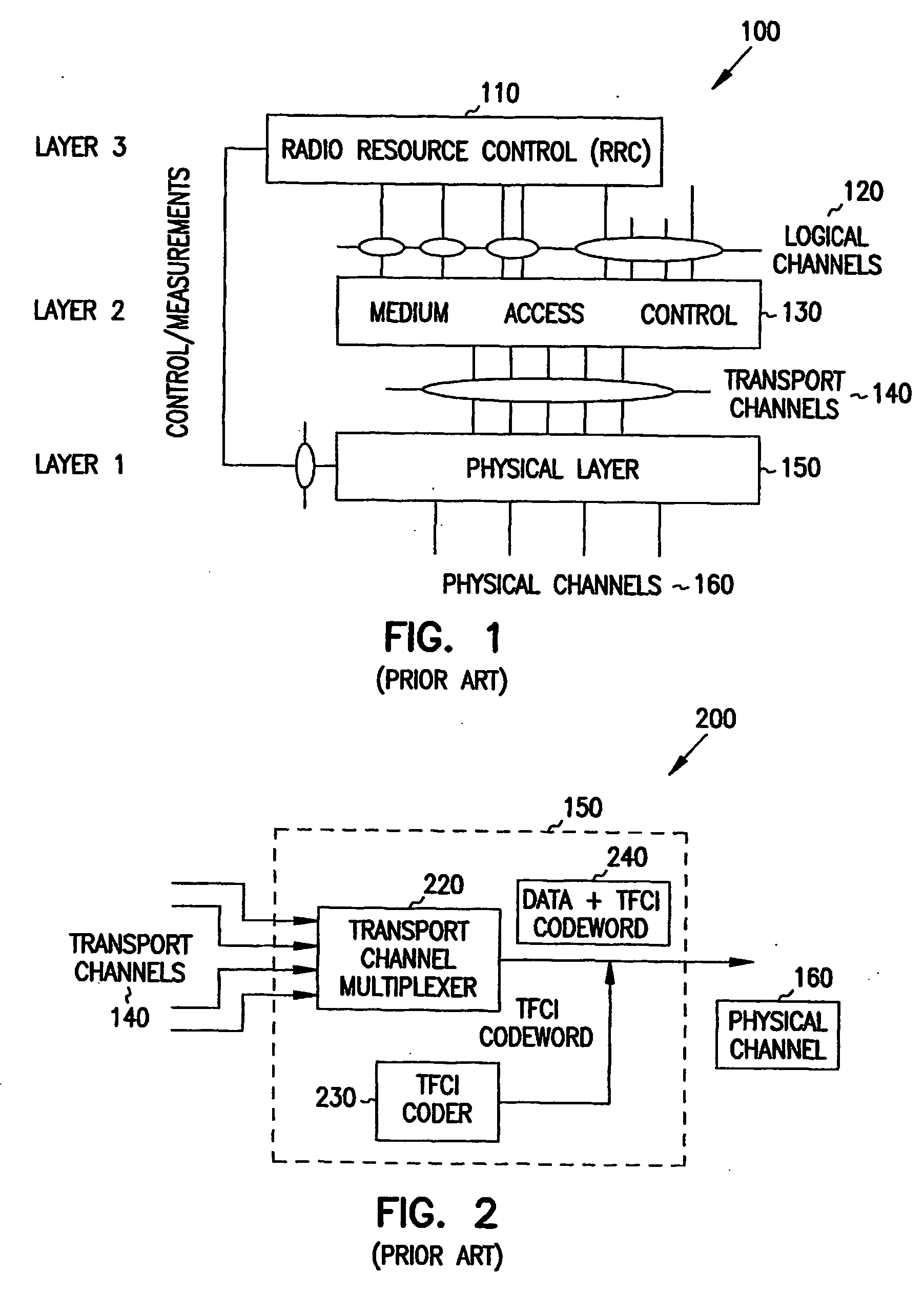

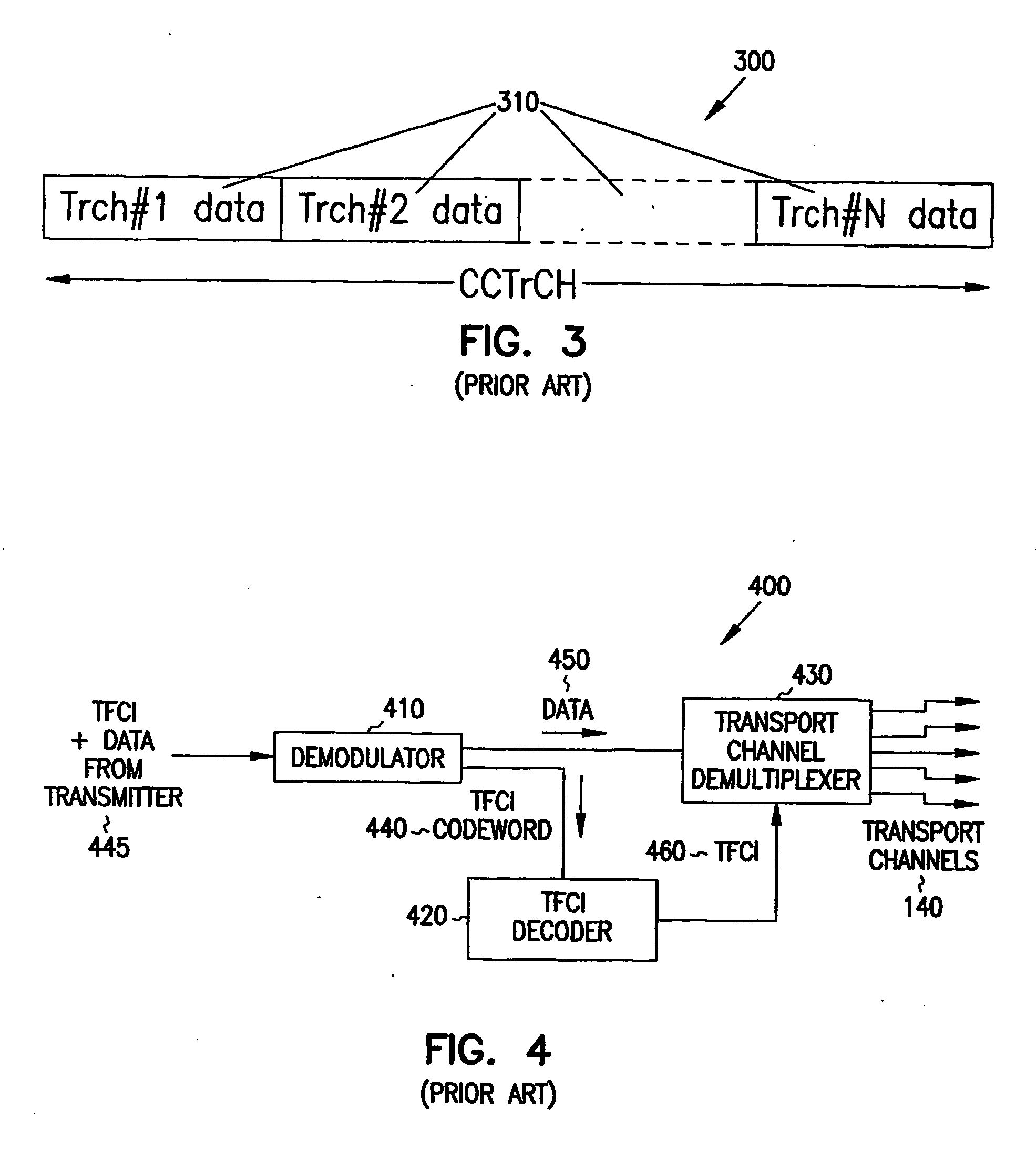

Data-rate detection in cdma systems

ActiveUS20050018614A1Reduce calculationImprove data-rate detection reliabilityTransmission systemsFrequency-division multiplex detailsCellular radioCommunications system

The present invention provides an improved receiver for data-rate detection in a signal received from a transmitter of a cellular radio communication system including multiple transport channels supporting variable data-rate transmissions. This is accomplished by a computationally efficient technique for data-rate detection. The improved receiver receives data and TFCI associated with each of the multiple transport channels. The receiver then obtains a maximum number of valid transport format combinations and a maximum number of TFCIs that can be formed. The receiver then computes a subset of TFCIs using the obtained maximum number of valid transport format combinations and the maximum number of TFCIs, and decodes from the computed subset of TFCIs within the frame to reduce computation during decoding and to improve data-rate detection reliability.

Owner:SASKEN COMMUNICATION TECHNOLOGIES

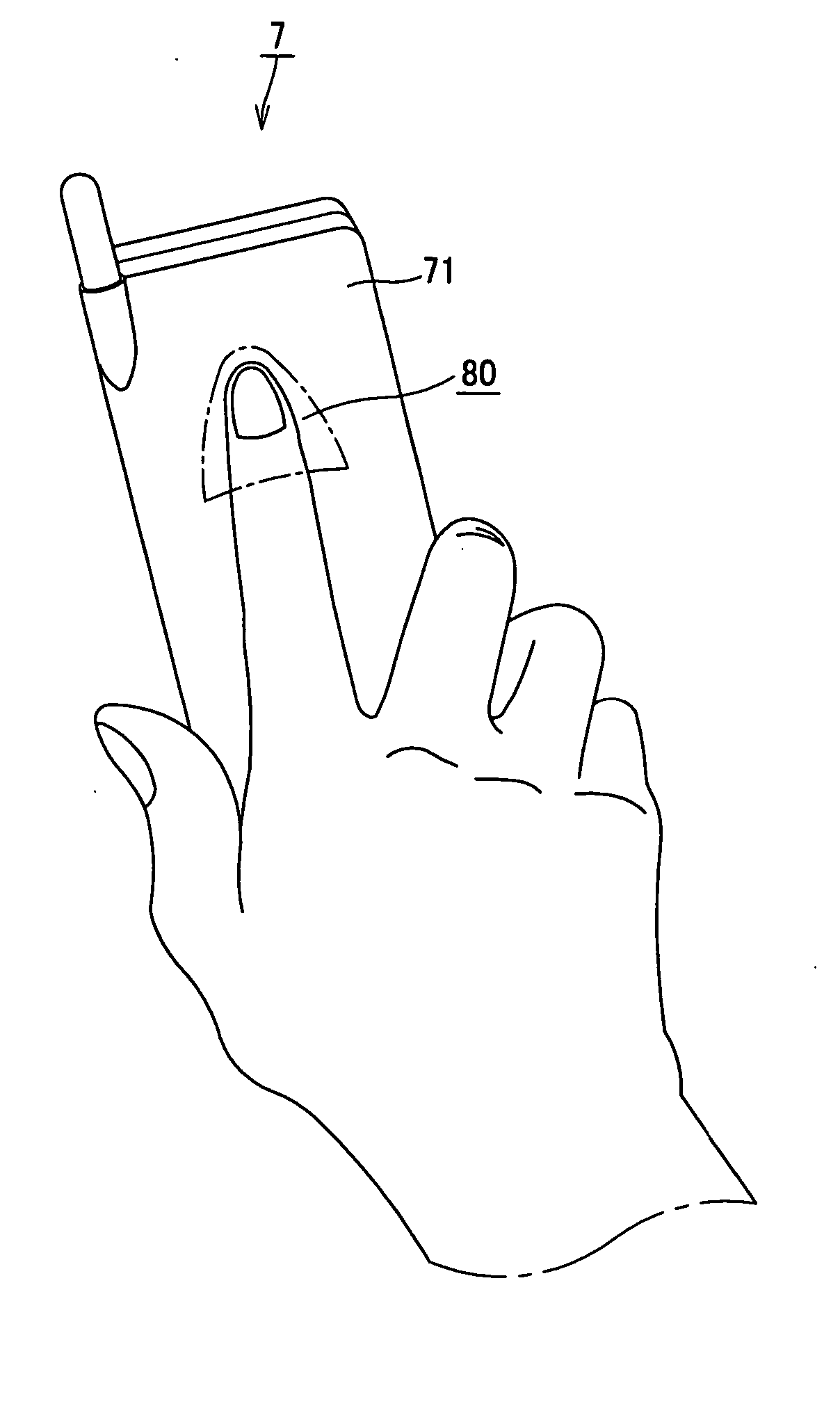

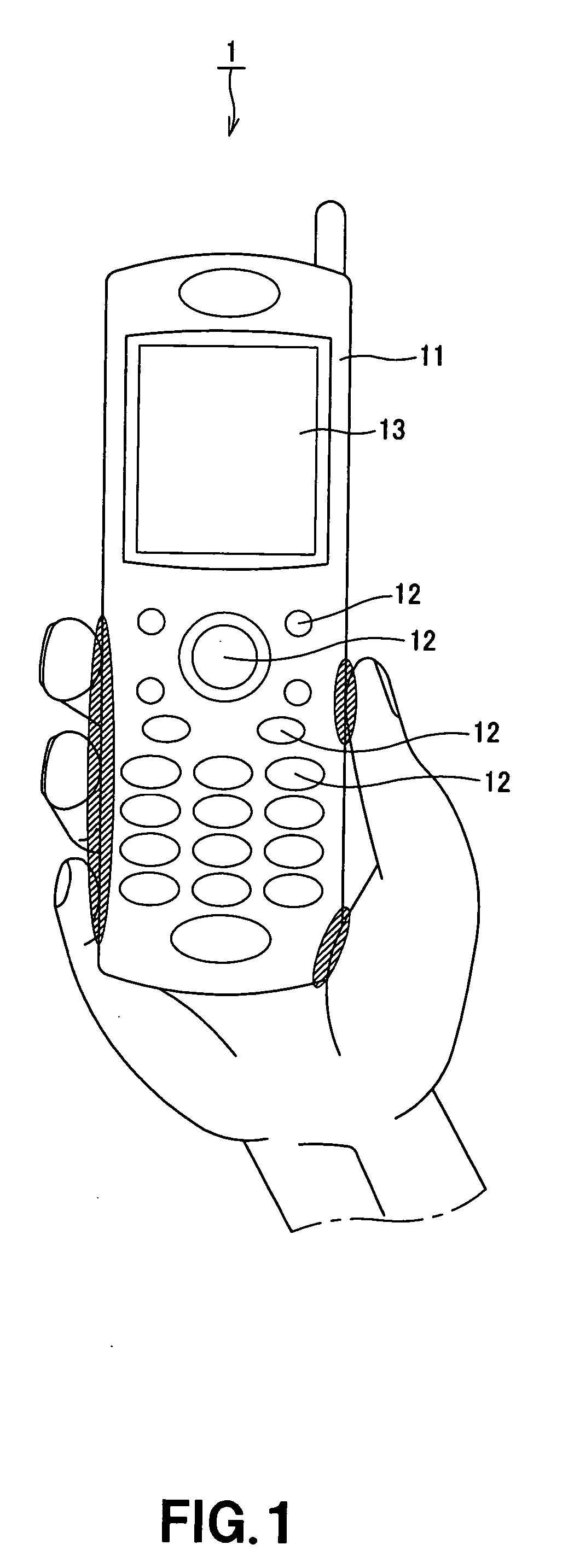

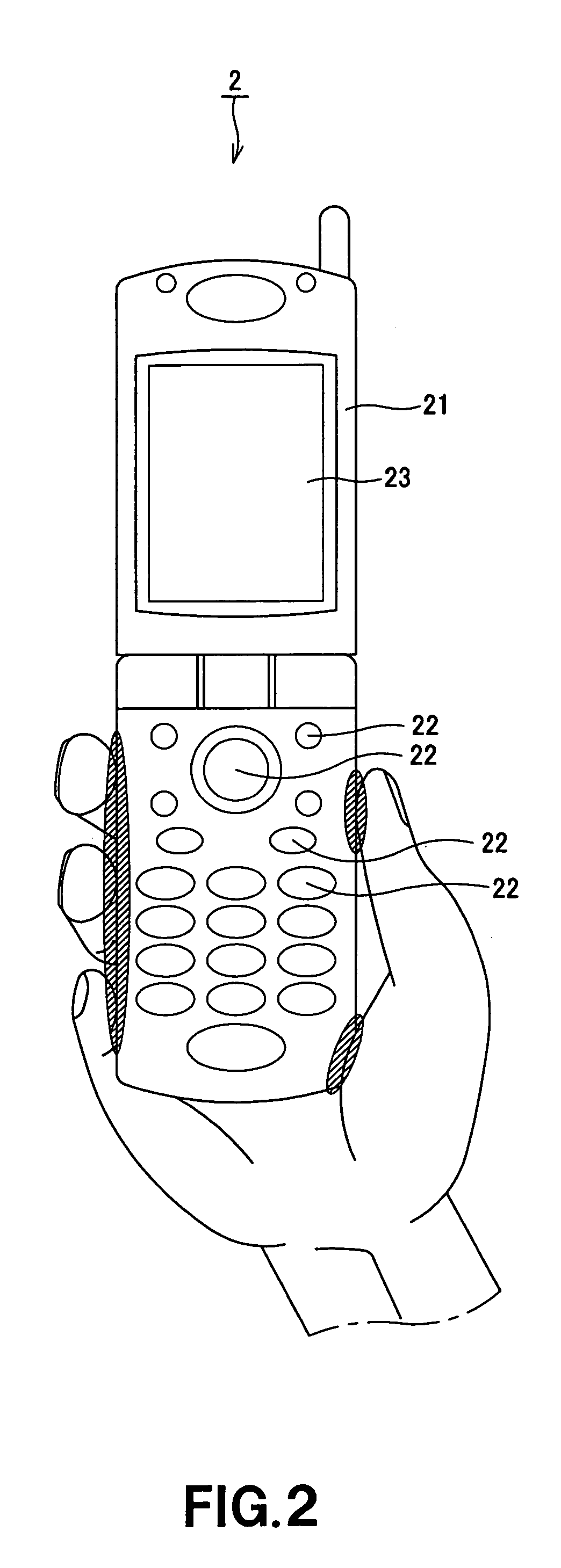

Input Device, Input Method, And Electronic Device

InactiveUS20070299322A1Eliminate the problemStablyPerson identificationDevices with sensorContinuous measurementData processing

The present invention is directed to a mobile telephone capable of successively acquiring bioindices. When plane surface where display screen serving to display guide display for operation and information is provided is caused to be casing front face as a position where bioindices can be successively measured without performing explicit acquiring operation if user uses the mobile telephone by ordinary way of use at the time of operation such as calling or mail input, etc., GSR sensors are provided at the side surface portion of the outer peripheral surface side, the corner portion and / or operation surface of operation input buttons of the telephone. In a non-foldable mobile telephone (1), GSR sensors (50a) are provided at side surface portions (14) of the outer peripheral surface side of the casing, and GSR sensors (50b) are provided at corner portions (15) of the outer peripheral surface side of the casing. Further, GSR sensors (50c) are provided on the operation surfaces of operation input buttons (12). In addition, the mobile telephone further comprises data processing sections for processing detection values which have been detected by respective biosensors, whereby a detection value judgment section (105) serves to select an optimum value from detection values which have been processed at the data processing sections.

Owner:SONY CORP

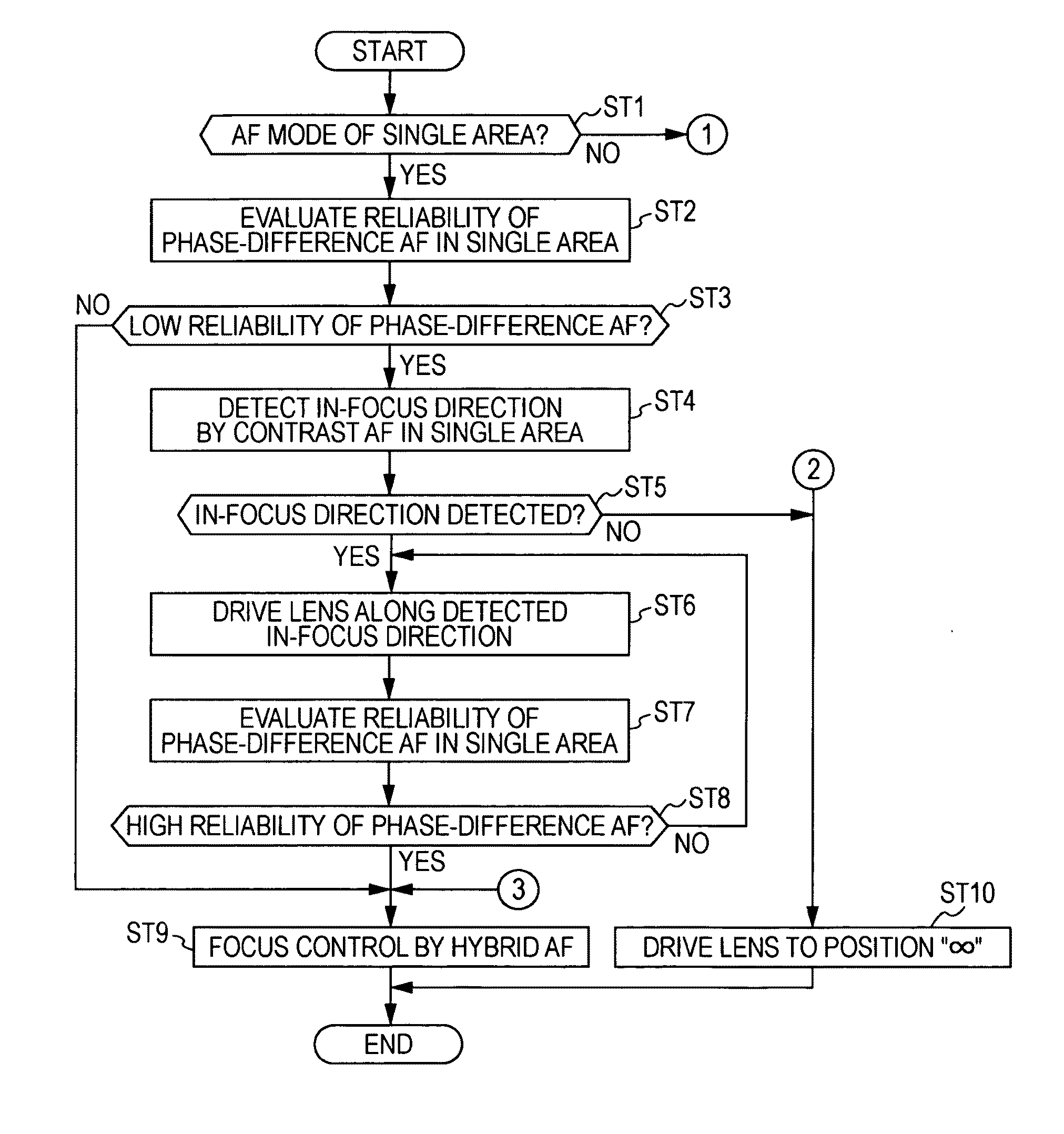

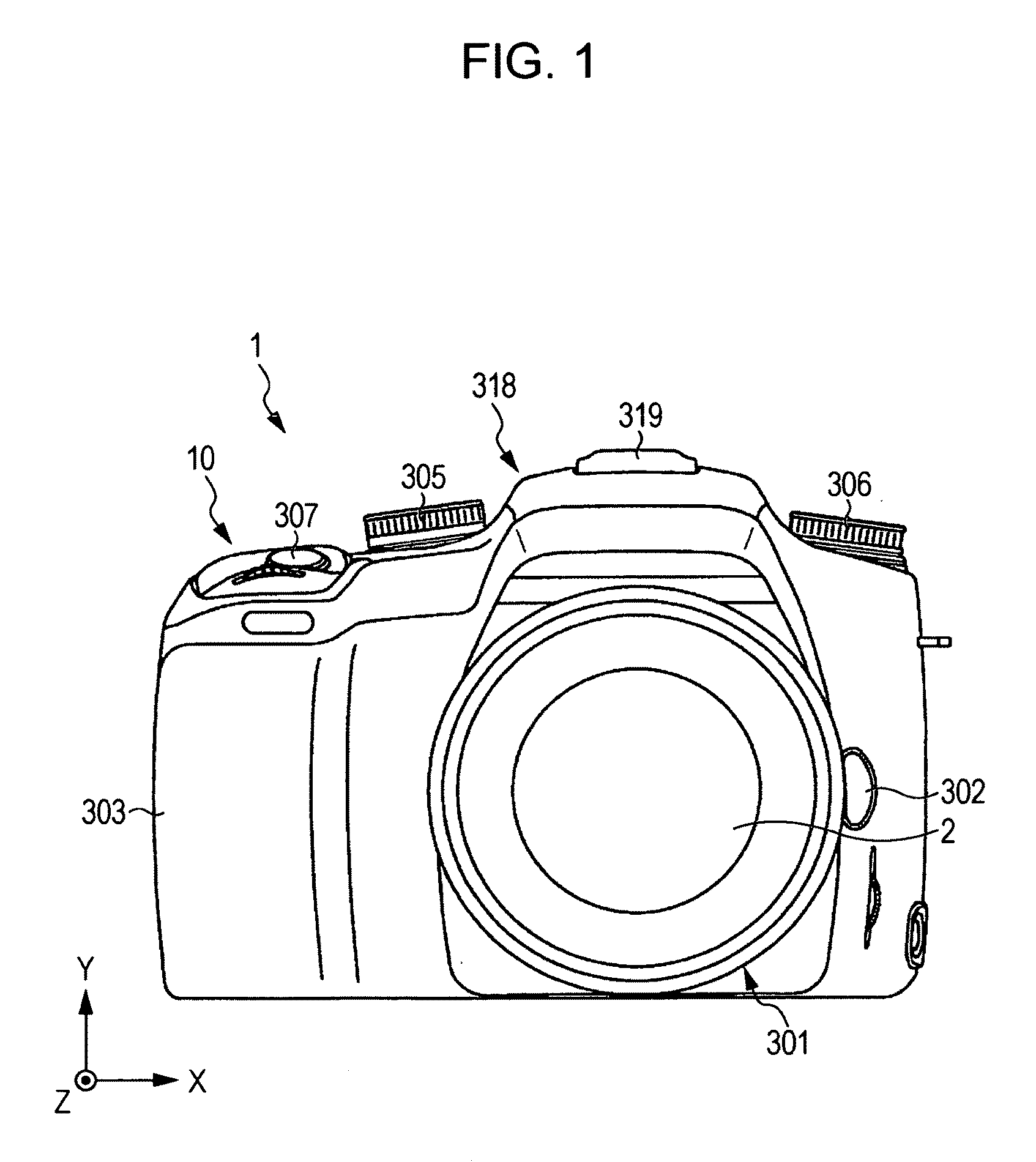

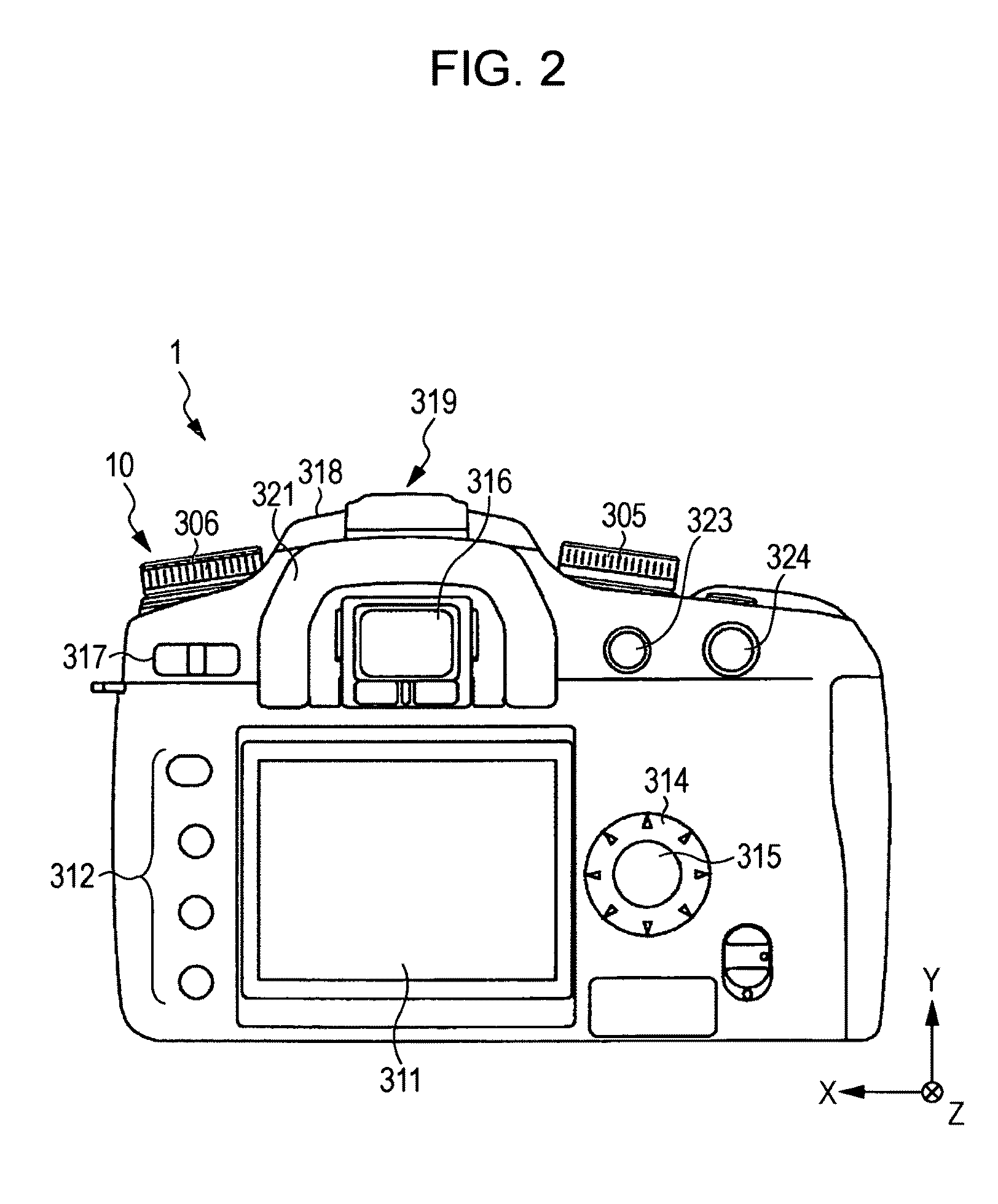

Image Pickup apparatus and focus control method

ActiveUS20100150538A1Improve detection reliabilityDetection reliability is lowProjector focusing arrangementCamera focusing arrangementPhase differencePupil

An image pickup apparatus includes an imaging element having a group of AF pixel pairs that realizes a pupil-dividing function and a group of normal pixels without such a pupil-dividing function. The image pickup apparatus performs focus control for driving a focus lens toward an in-focus position detected by phase different AF based on a pixel signal generated from the group of AF pixel pairs when it is determined that the reliability of the phase difference AF is high based on the pixel signal. The image pickup apparatus performs focus control for driving a focus lens in an in-focus direction detected by contrast AF based on a pixel signal generated from the group of normal pixels when it is determined that the reliability of the phase difference AF is low.

Owner:SONY CORP

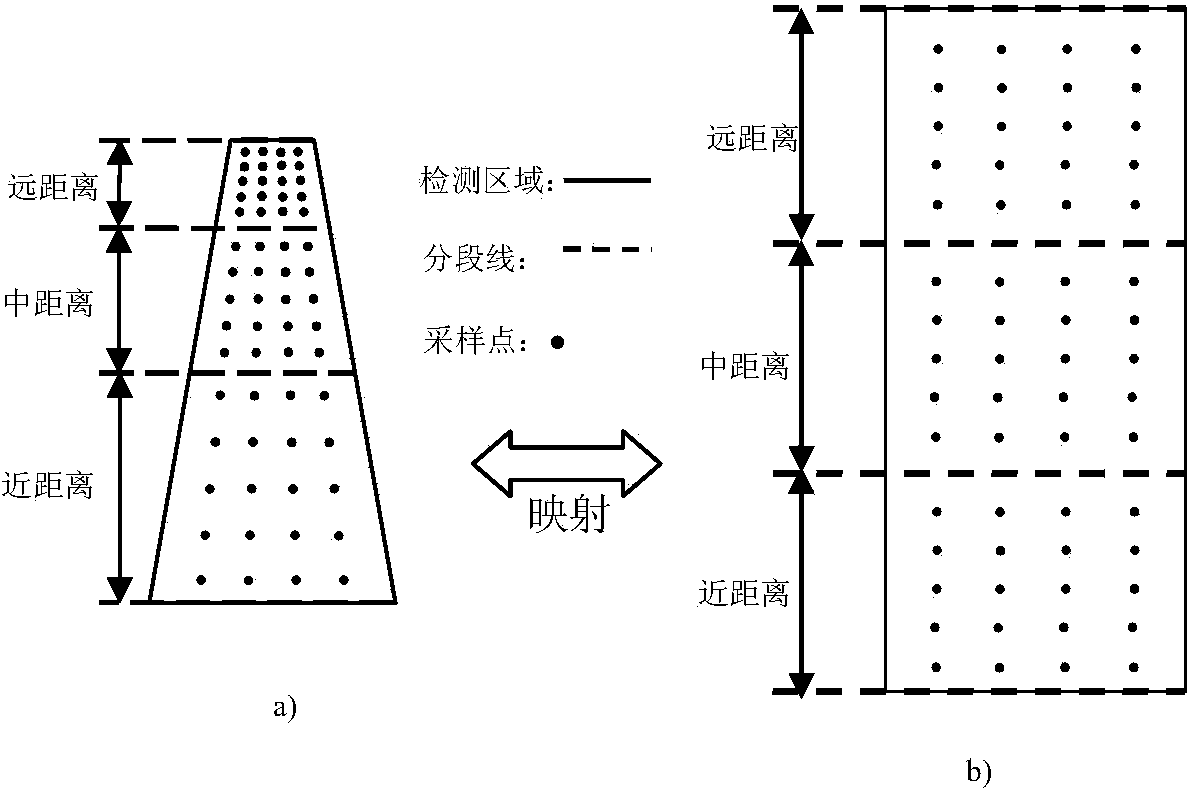

Road traffic condition detection device based on panorama computer vision

ActiveCN102136194AWill not affect trafficEasy to implementControlling traffic signalsImage analysisMeasurement pointRoad networks

The invention discloses a road traffic condition detection device based on panorama computer vision, comprising a camera device of each measuring point and a microprocessor, wherein the camera device is installed on each road on a road network; the microprocessor is used for evaluating road traffic condition according to the panorama video data of the camera device; and the microprocessor comprises a panorama image acquisition unit, a sampling point, a lane, a lane driving direction customization module, a road congestion state detection module and a road service level judgement module. The invention provides a road traffic condition detection device based on panorama computer vision, which has the advantages of wide detection range, high detection precision, good detection instantaneity and intuitional and clear detection result, is convenient to implement and is convenient to realize on an embedded system; in addition, the road traffic condition detection device has subjective perceptibility index data and objective perceptibility congestion data, and is convenient for each level of road network of a city to comprehensively evaluate the road traffic condition on the aspect of time and space.

Owner:ZHEJIANG UNIV OF TECH

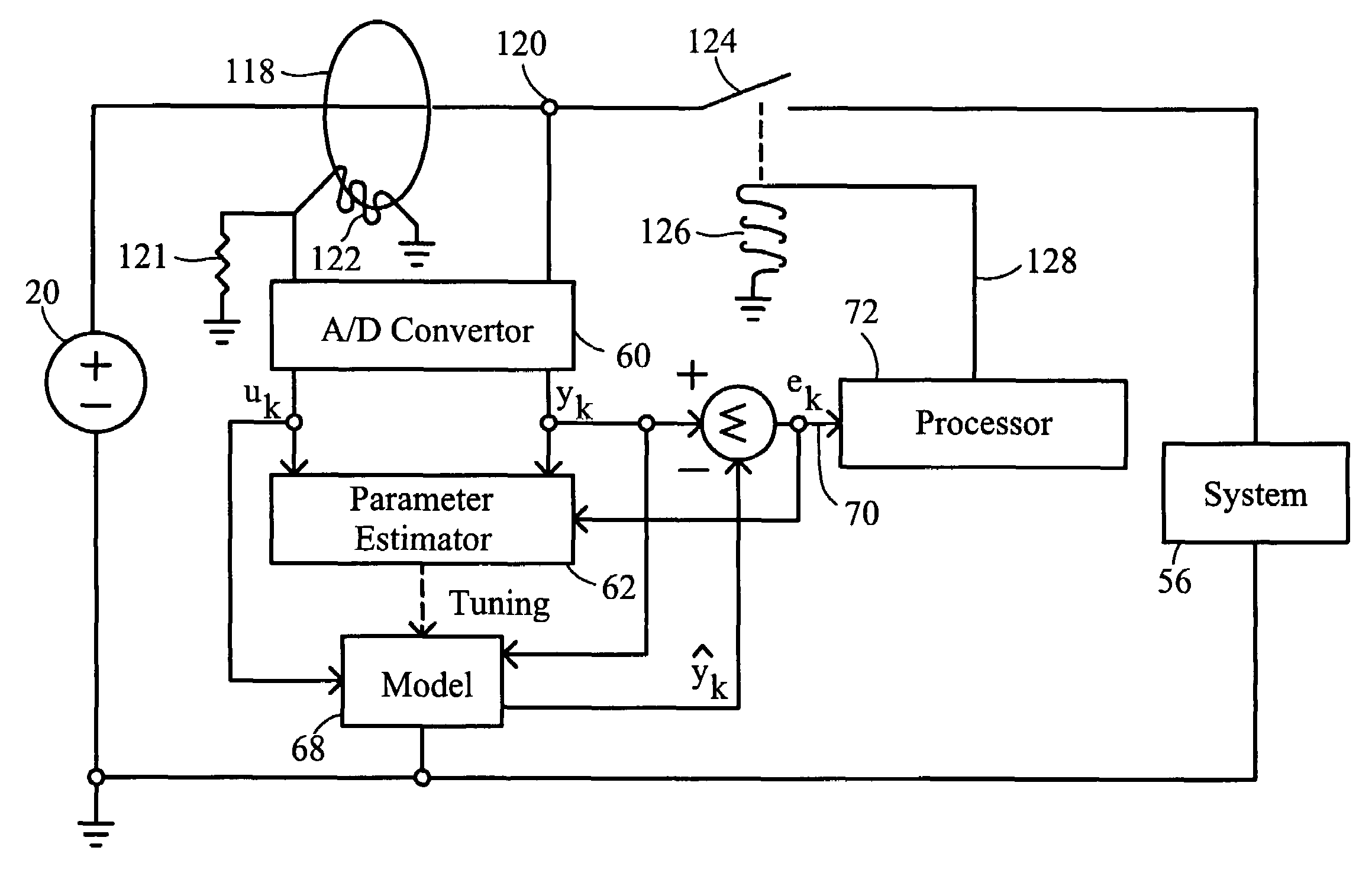

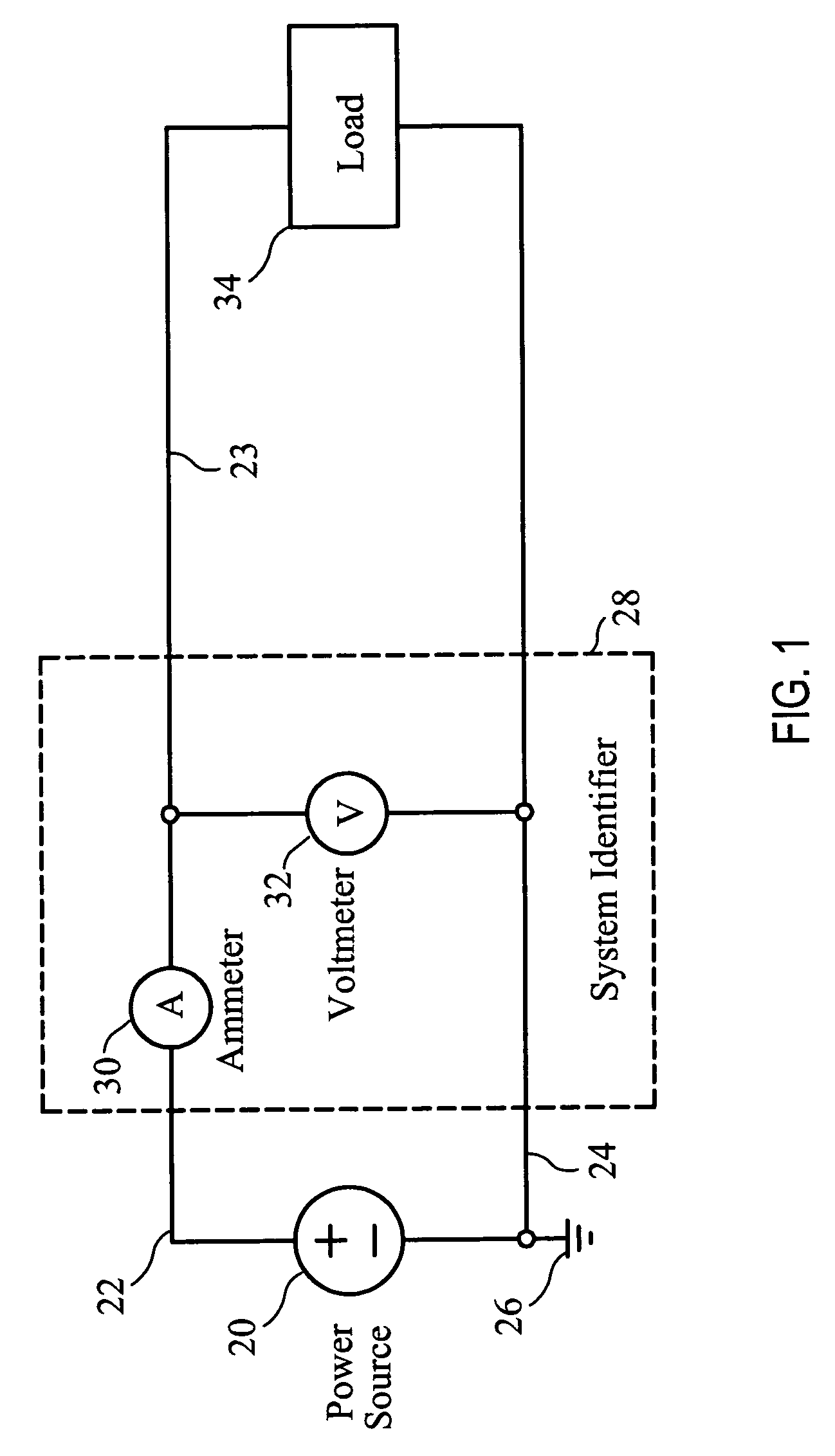

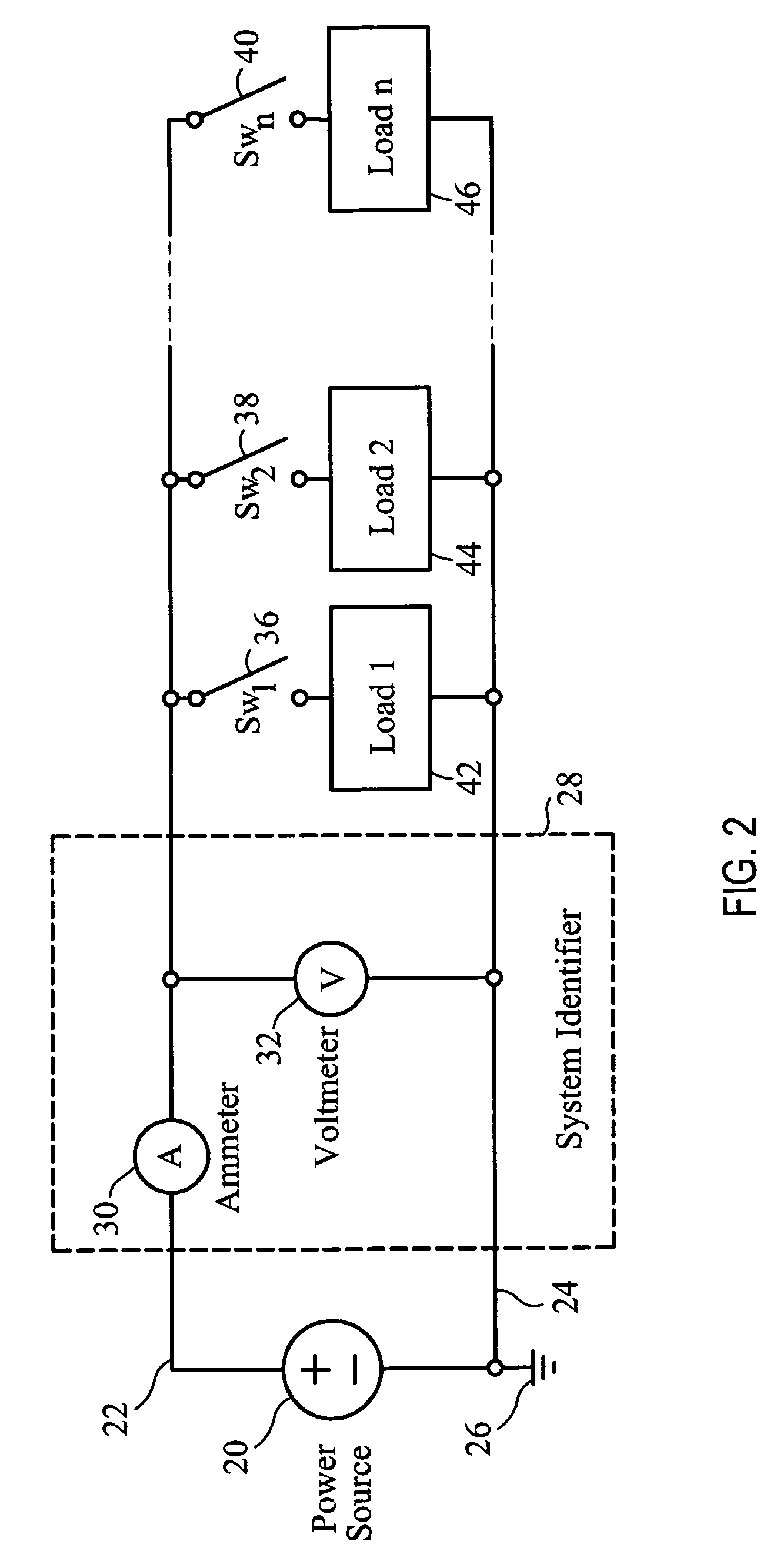

Arc fault identification using model reference estimation

ActiveUS7366622B1RobustnessImprove detection reliabilityElectrical testingNuclear monitoringElectricityPower grid

An apparatus and method for the identification of arcing phenomena in a faulted electrical network. By continually updating a model for the load on an electrical branch, an estimate of the behavior of that load may be calculated. Since electrical arcing faults result in a chaotic behavior that is difficult to describe, when arcing occurs, the model will be unable to adequately describe the arcing behavior and this inability indicates a fault condition, in response to which, power may be removed in full or in part from the faulted electrical network. In some embodiments, a current shunt is used to distinguish between source side and load side arcing. Some embodiments utilize a solid state switch as both current shunt and interruption means.

Owner:X L SYNERGY

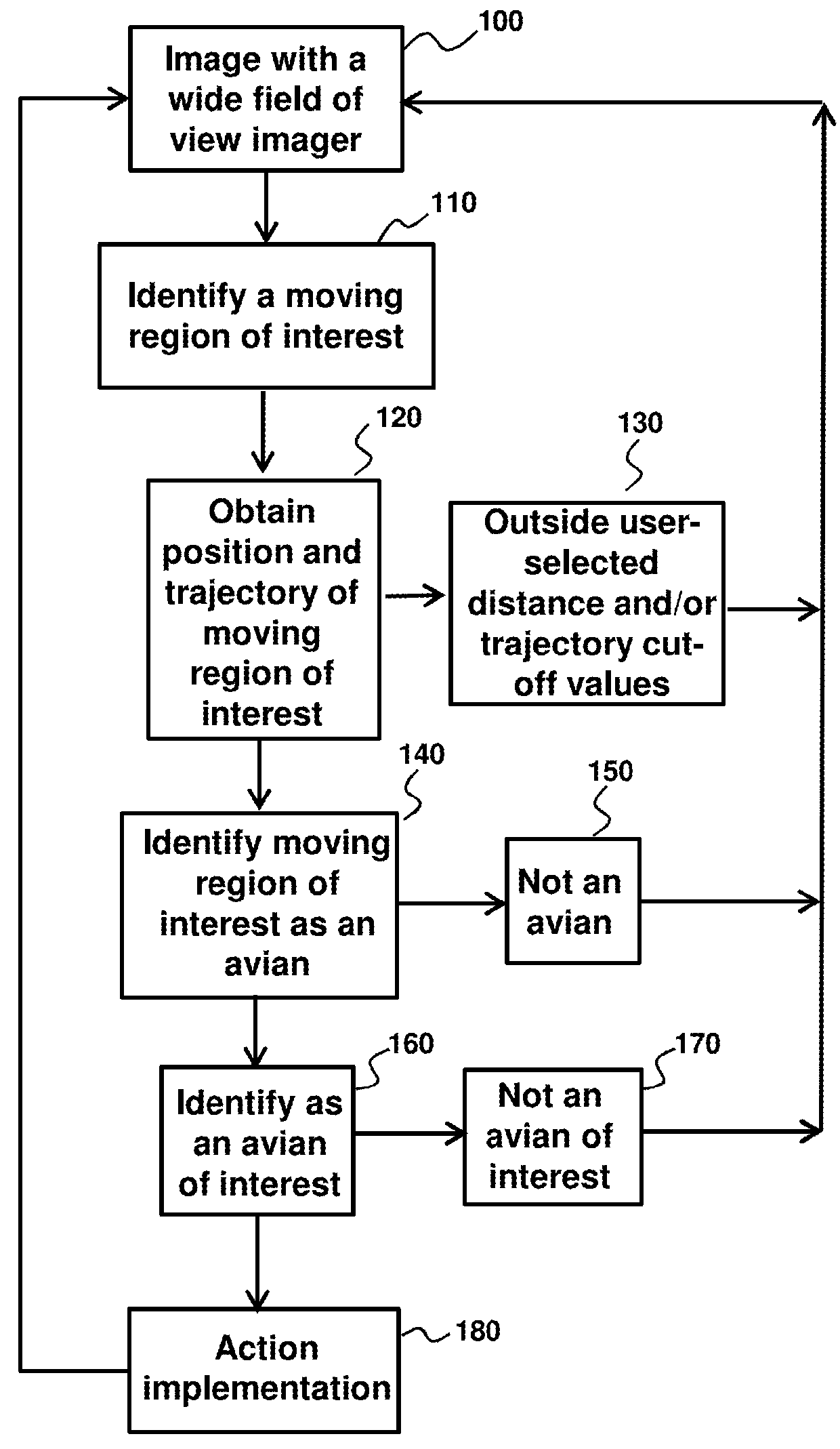

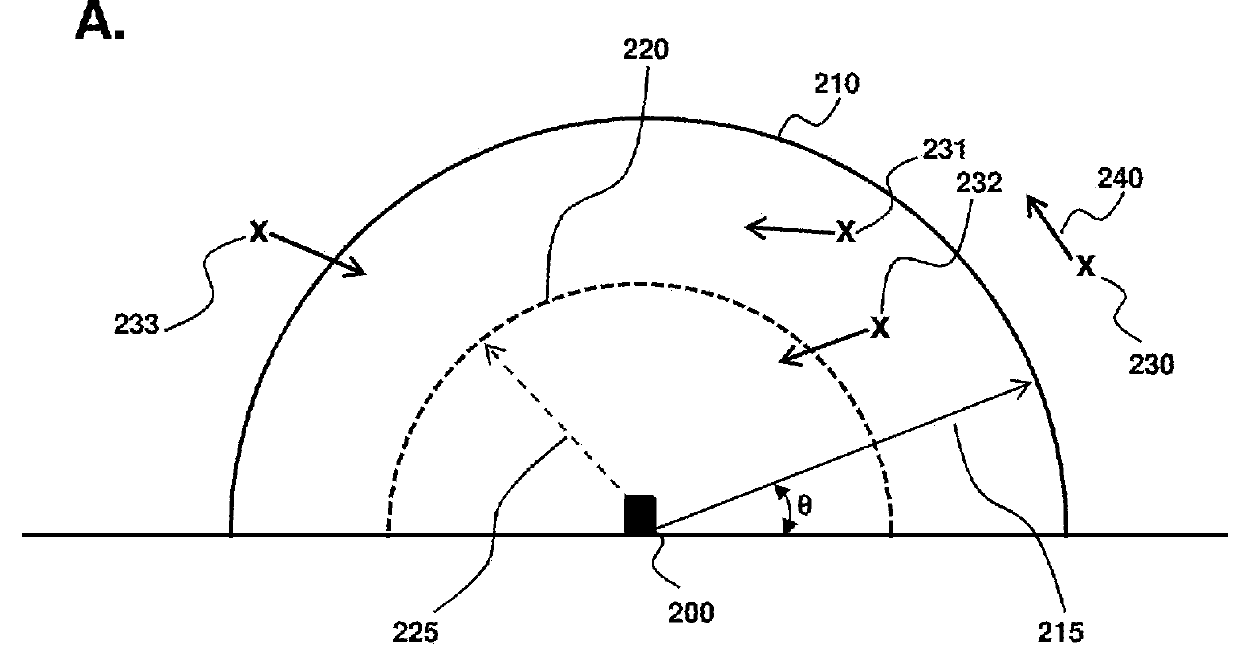

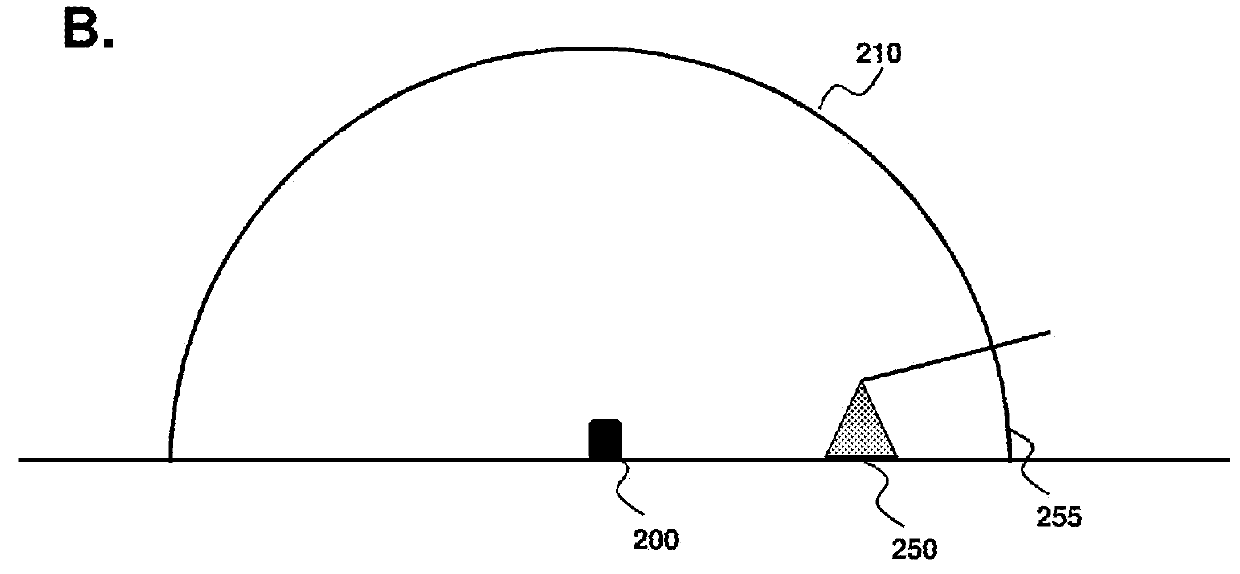

Avian detection systems and methods

ActiveUS20160055400A1Fast and accurate determinationCost-effective and reliableTelevision system detailsImage enhancementMicrochiropteraTurbine blade

Provided herein are detection systems and related for detecting moving objects in an airspace surrounding the detection system. In an aspect, the moving object is a flying animal and the detection system comprises a first imager and a second imager that determines position of the moving object and for moving objects within a user selected distance from the system the system determines whether the moving object is a flying animal, such as a bird or bat. The systems and methods are compatible with wind turbines to identify avian(s) of interest in airspace around wind turbines and, if necessary, take action to minimize avian strike by a wind turbine blade.

Owner:IDENTIFLIGHT INT LLC

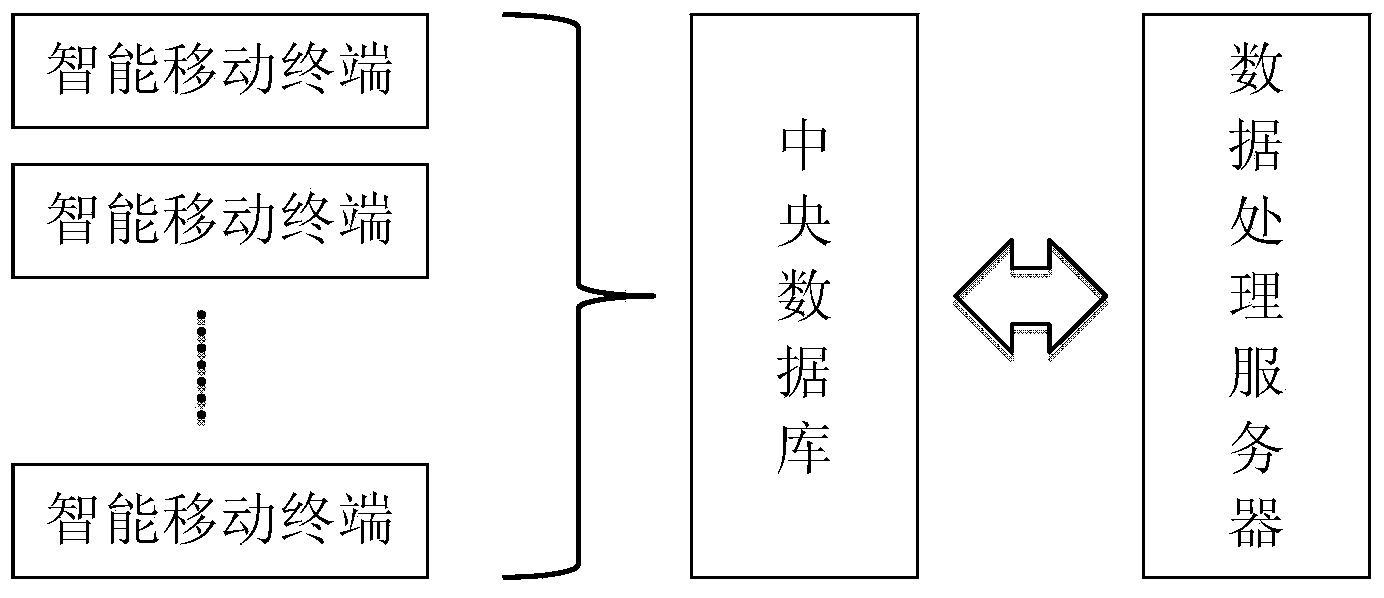

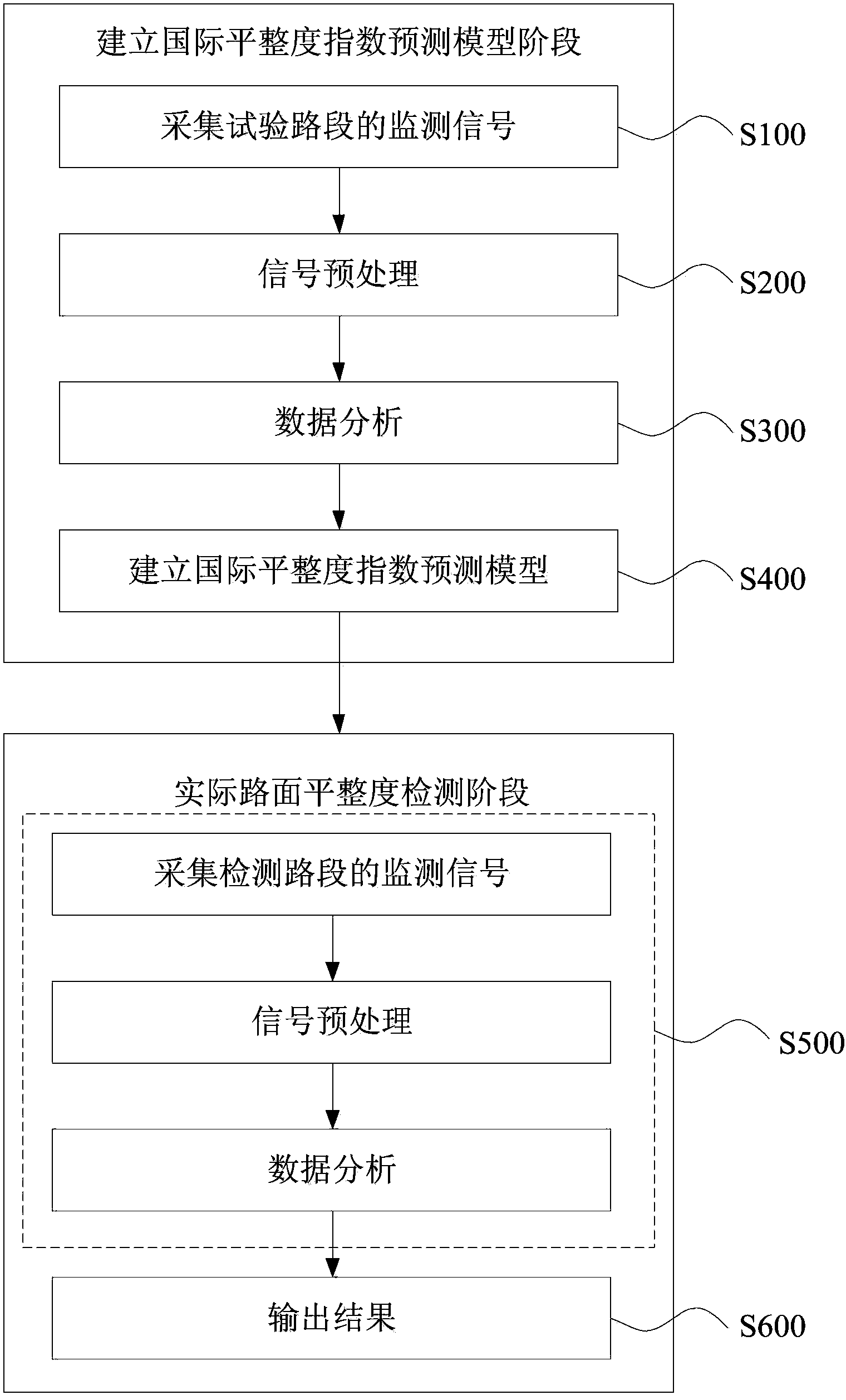

Pavement smoothness detection method based on mobile terminal and intelligent pavement information real-time monitoring system

ActiveCN104164829AImprove detection accuracy and reliabilityReduce testing costsRoads maintainenceRegression analysisData processing

The invention relates to a pavement smoothness detection method based on a mobile terminal and an intelligent pavement information real-time monitoring system. The method comprises the following steps: collecting vibration information as well as running state information of a driving vehicle through a smart phone and uploading to a central database of the intelligent pavement information real-time monitoring system; analyzing through a data processing server to obtain a cumulative displacement index of a tested pavement based on an acceleration signal, and establishing an international smoothness index prediction model through statistical regression analysis on tested pavement damping information, tested pavement environmental information and the cumulative displacement index of the tested pavement; collecting and calculating the cumulative displacement index of the detected pavement through the steps, and thus obtaining an international smoothness index of the detected pavement depending on the obtained international smoothness index prediction model, the detected pavement damping information, the detected pavement environmental information and the cumulative displacement index of the detected pavement. Through the detection method disclosed by the invention, pavement smoothness detection cost is greatly reduced and a detection cycle is shortened to the greatest extent.

Owner:田雨

Light-weight holographic road traffic state visual inspection device

ActiveCN103985250AAccurate and efficient background update methodNo errorsDetection of traffic movementMeasurement pointSimulation

The invention discloses a light-weight holographic road traffic state visual inspection device comprising visual sensors installed at measuring points in each road on a road network, and a microprocessor for analyzing and evaluating the road traffic state according to video image data of the visual sensors. According to the invention, a point replacing surface type video image detection method is adopted to reduce spatial redundancy; an accurate background update strategy based on sampling points is adopted to realize a light-weight, accurate and efficient background update method; and at the same time, the detection of road traffic jam and the detection of various of traffic basic parameters can be completed.

Owner:ZHEJIANG UNIV OF TECH

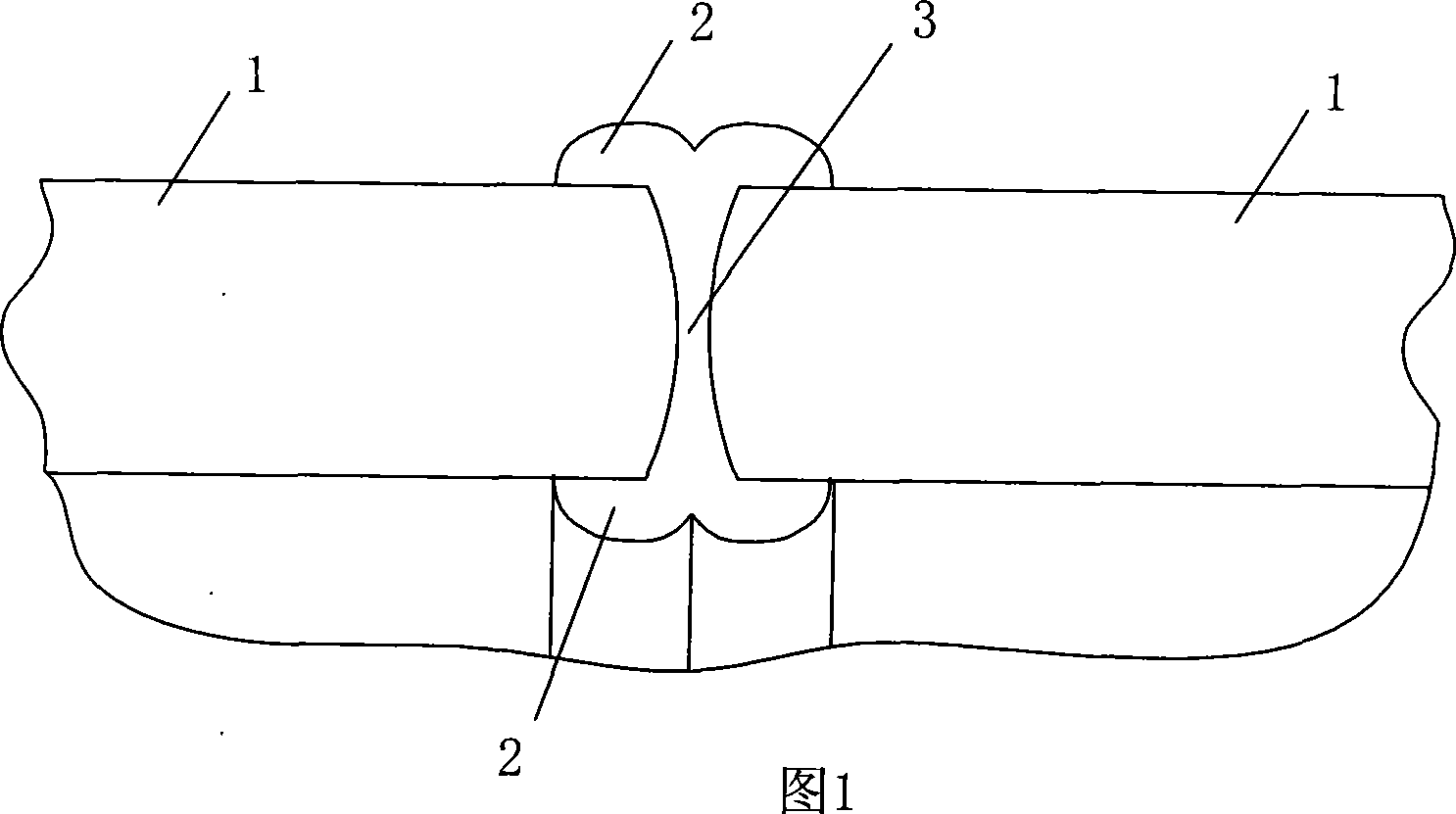

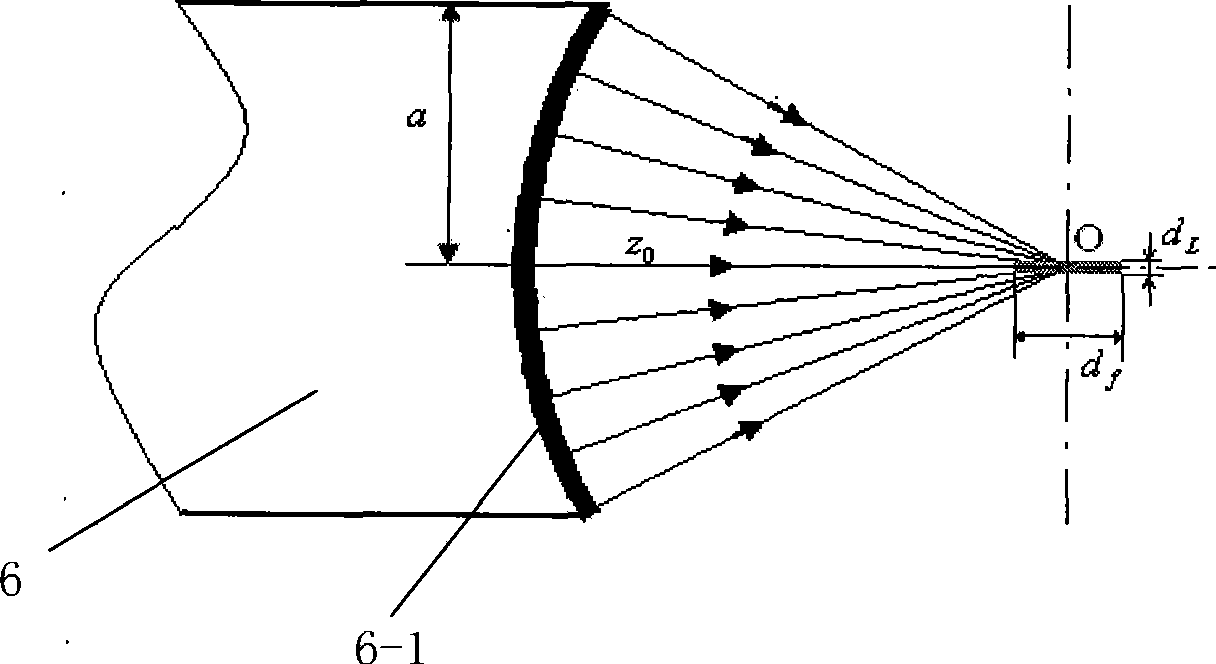

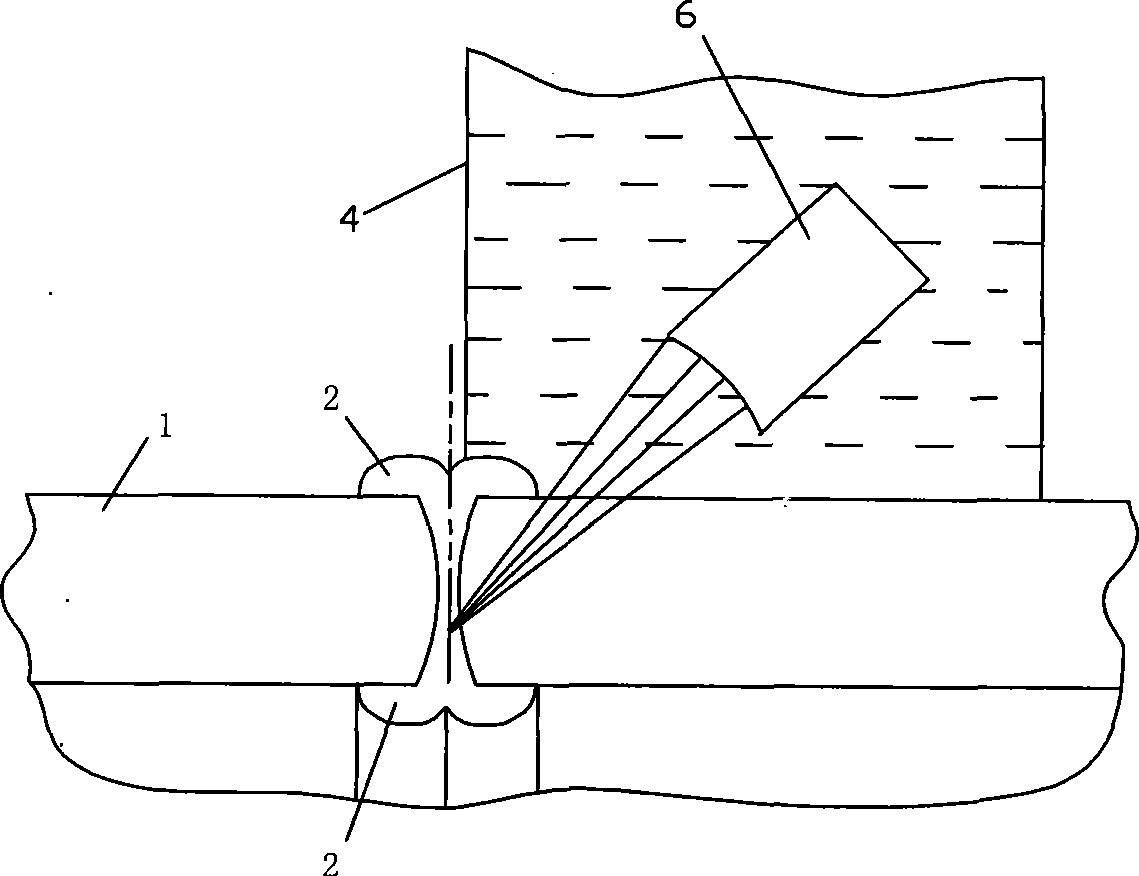

Coupling and focusing ultrasonic detection method and detection device for polyethylene pipe hot melt butt joint

ActiveCN101393170AHigh detection sensitivityImprove detection sensitivityAnalysing solids using sonic/ultrasonic/infrasonic wavesMiddle lineSonication

The invention relates to a method for detecting the welding quality of a hot-melt even joint of a polyethylene pipeline and a detection device thereof. The aim of the invention is that the provided detection method and the detection device have the characteristics of high sensitivity, high detection precision, high reliability, high detection efficiency and low misoperation rate. The technical proposal is a method for the coupling focusing ultrasonic detection of the hot-melt even joint of the polyethylene pipeline, which comprises the following steps: (1) a coupling agent liquid is positioned on the outer surface of a pipeline joint fusion region; (2) an ultrasonic probe adopting a spherical curved wafer is immersed into the coupling agent liquid in order that the focus is positioned in the centerline of the pipeline joint fusion region; and (3) the ultrasonic probe does linear scanning motion along the diameter direction of the pipeline and does uniform scanning motion along the circumferential direction of the pipeline; and obtained signal data is processed by a computer to form a C scanning picture. The ultrasonic detection device comprises a coupling receiving device, the ultrasonic probe adopting the spherical curved wafer, a mechanical scanning device, a signal processing and controlling system, and the computer.

Owner:ZHEJIANG PROVINCIAL SPECIAL EQUIP INSPECTION & RES INST +1

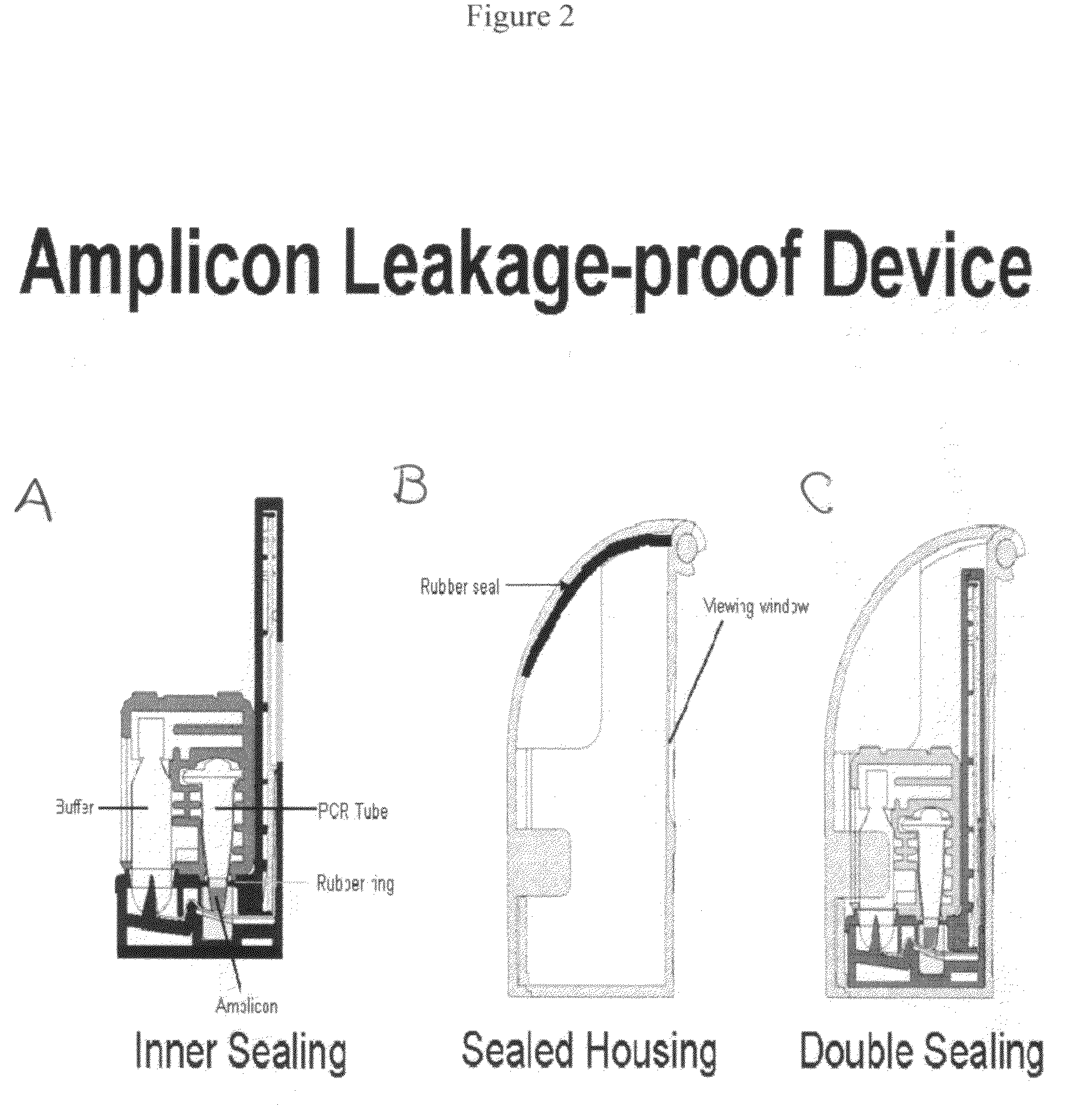

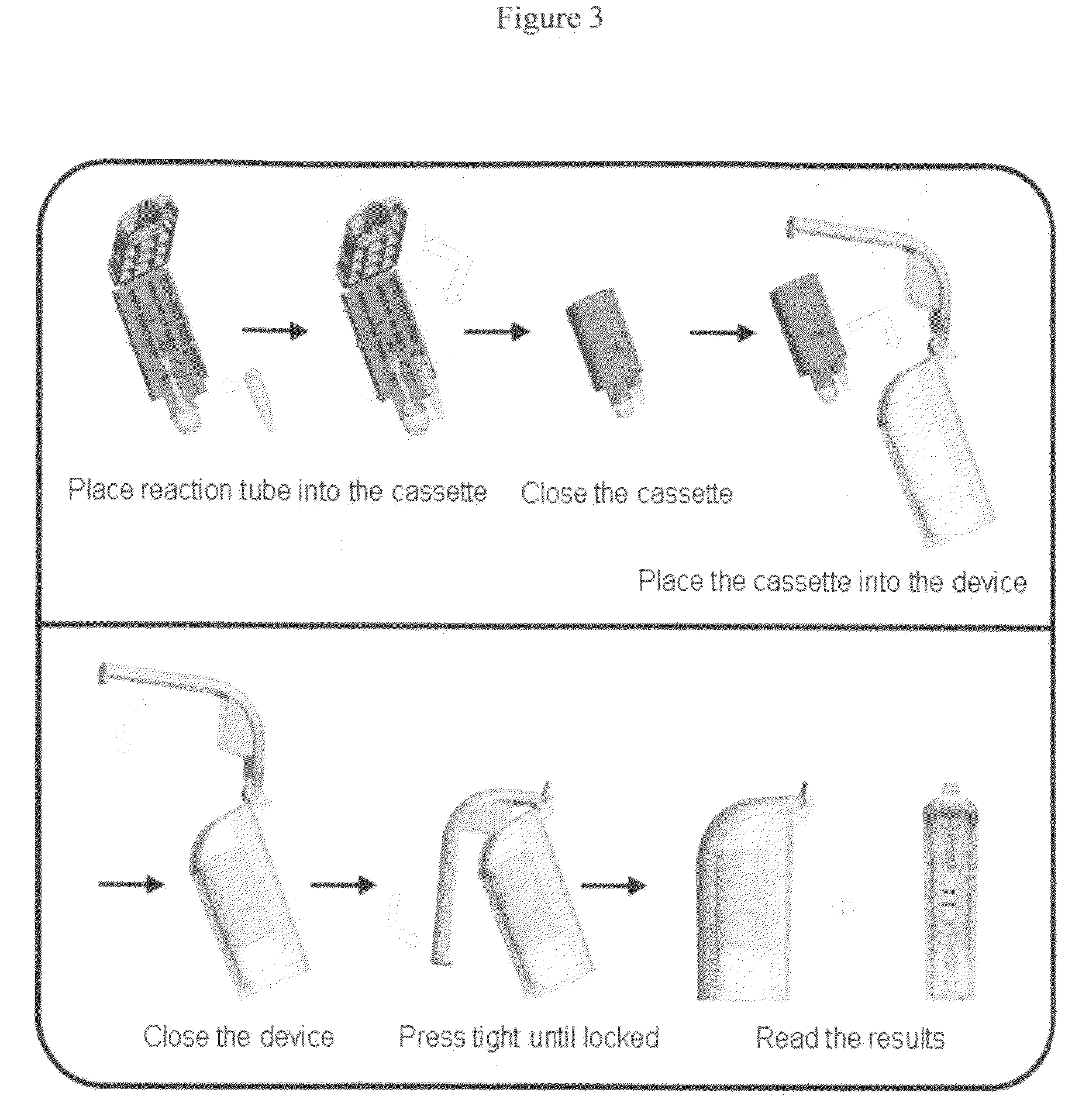

Enclosed unit for rapid detection of a target nucleic acid amplification product

ActiveUS20090181388A1Quick checkSimple and rapid in operationBioreactor/fermenter combinationsBiological substance pretreatmentsFood industryQuarantine

The invention relates to a method for rapid detection of a target nucleic acid amplification product while preventing cross-contamination between target nucleic acid amplification products and avoiding false positives, comprising the steps of: a) leaving the reaction tube unopened after the amplification reaction is finished, so as to prevent the target nucleic acid amplification product from leaking out and resulting in contamination; b) placing the unopened reaction tube inside an enclosed unit, making the target nucleic acid amplification product be transferred to a test strip from the reaction tube in a physically enclosed environment; c) performing detection in a visual read-out manner, and determining the result; d) discarding the enclosed unit in a safety place as a whole without opening it after the detection. The invention also relates to a totally enclosed unit for detecting a target nucleic acid amplification product, and still relates to applications of the totally enclosed rapid detection unit in detection of infectious pathogens, food industry, agriculture, livestock husbandry, customs quarantine control, and determination of DNA.

Owner:YOU QIMIN +3

Automated dispenser with sensor arrangement

InactiveUS7795584B2Easy to detectImprove detection reliabilityRadiation pyrometrySolid-state devicesValue setControl system

Owner:SCA HYGIENE PROD AB

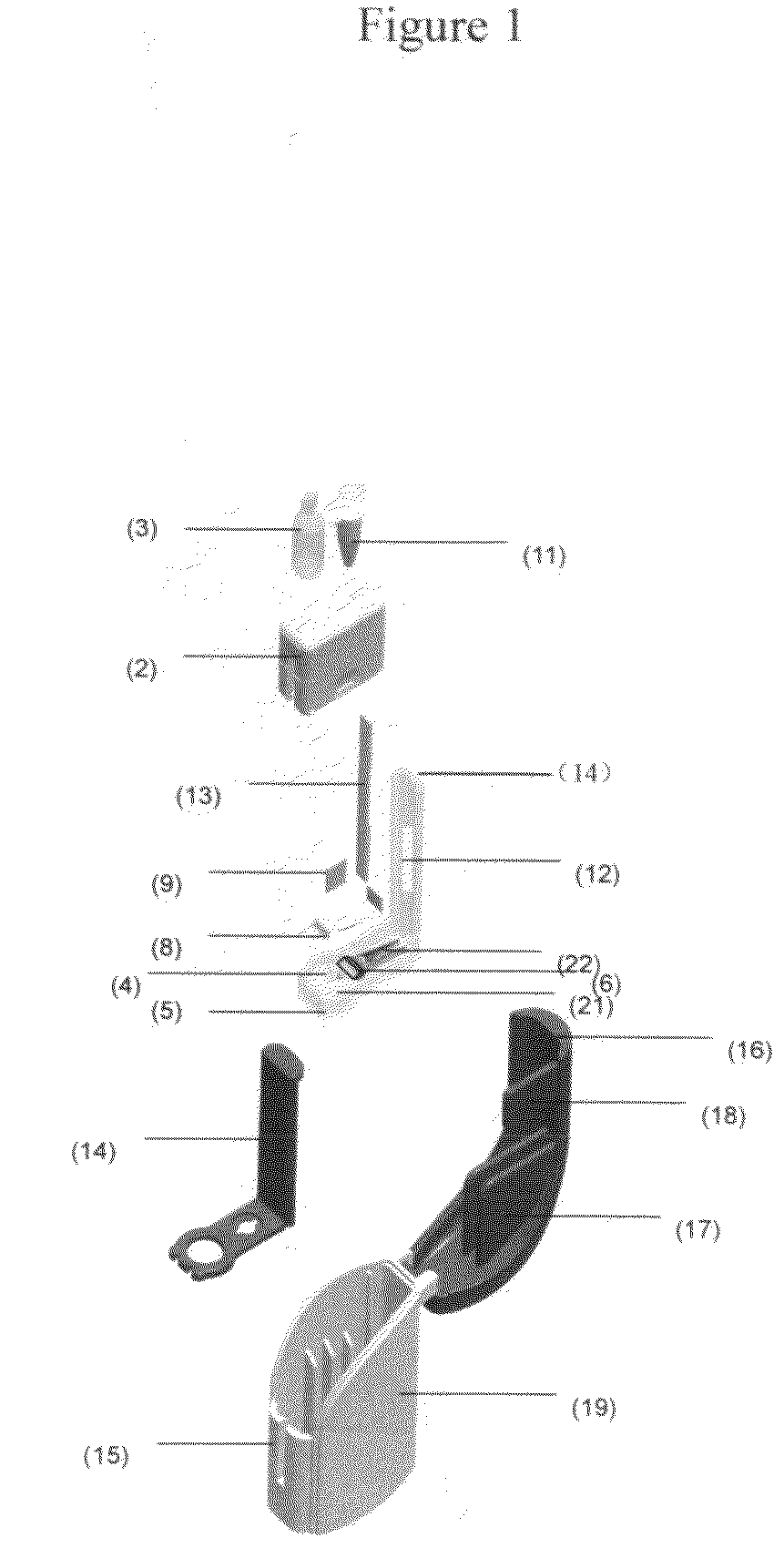

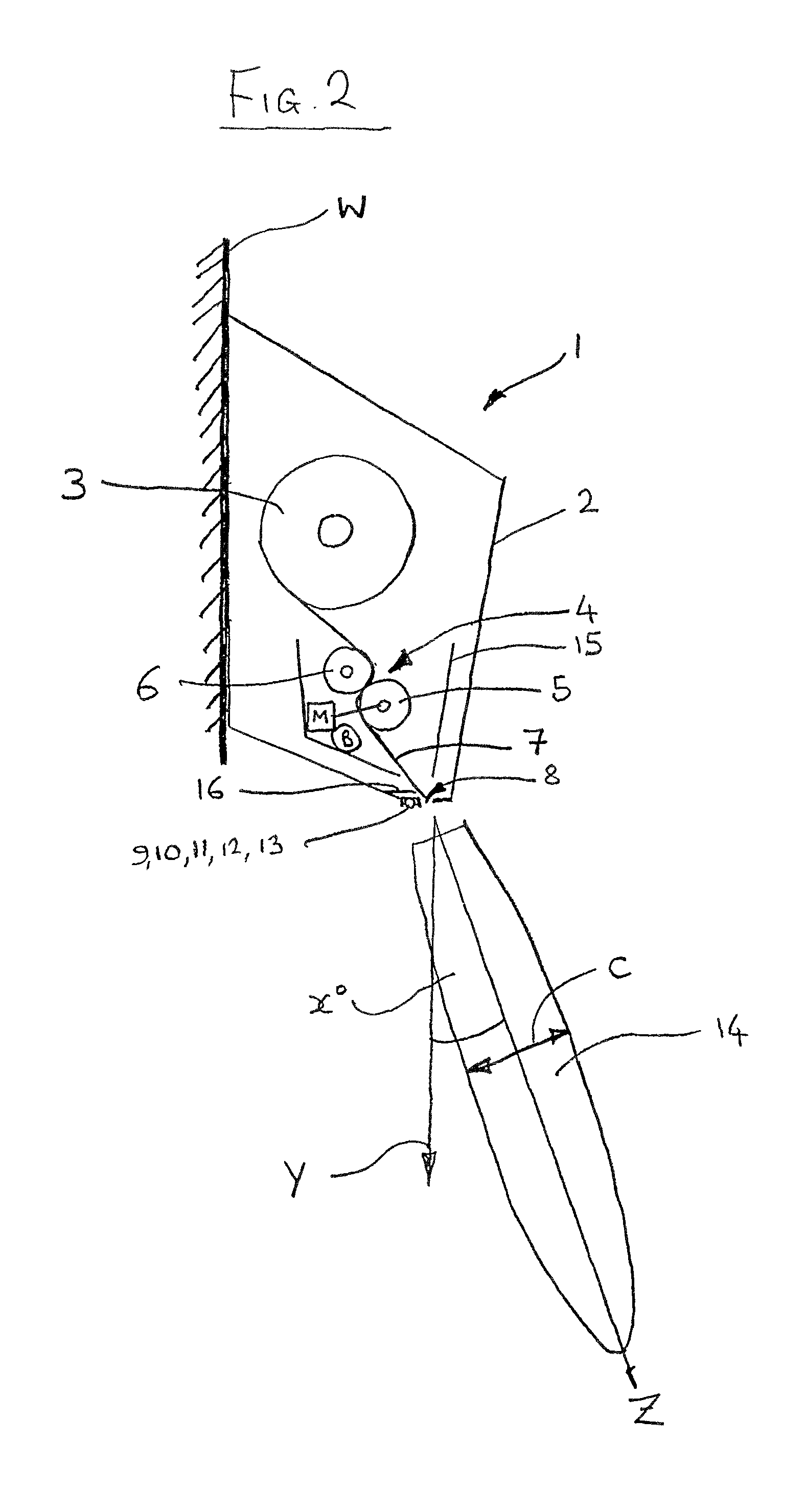

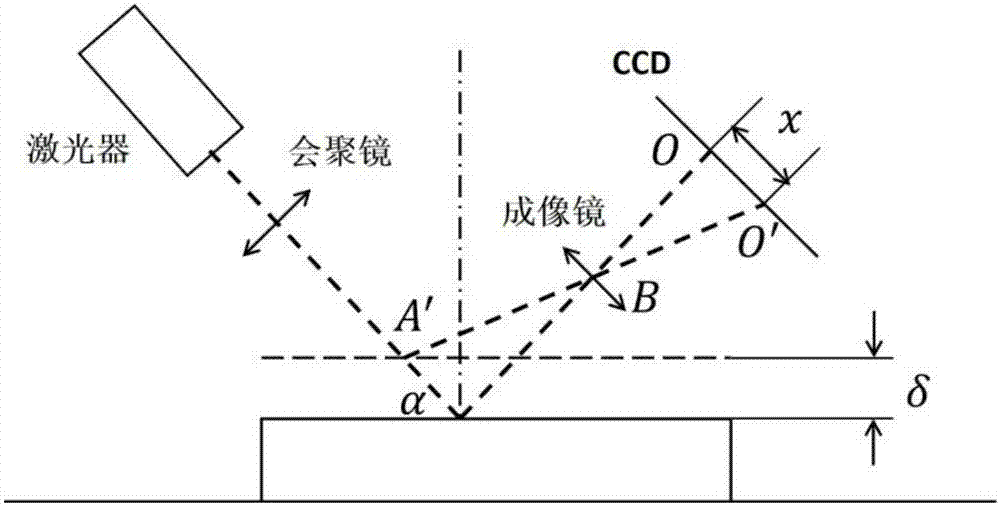

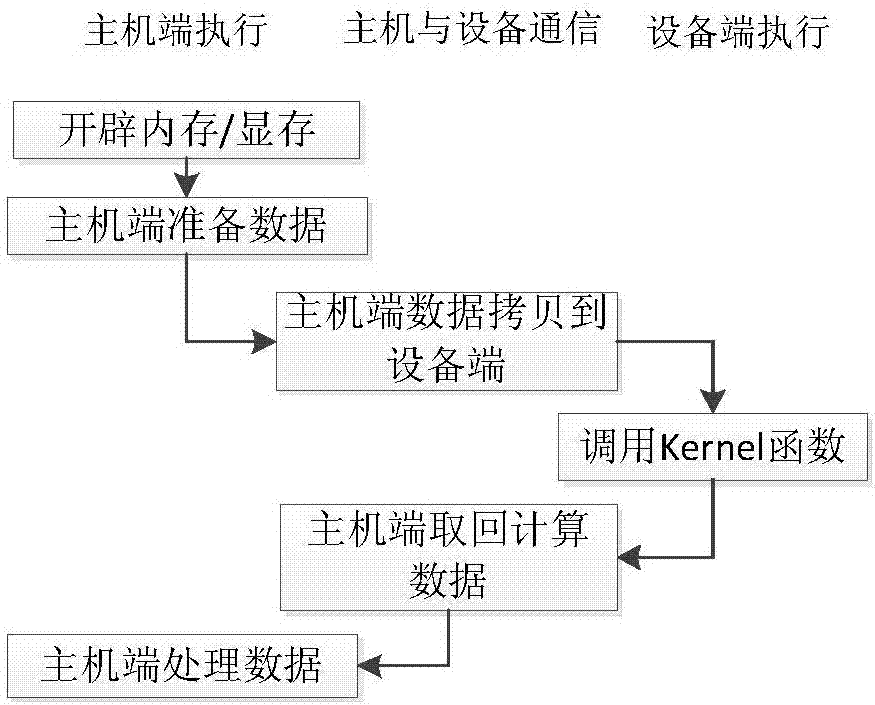

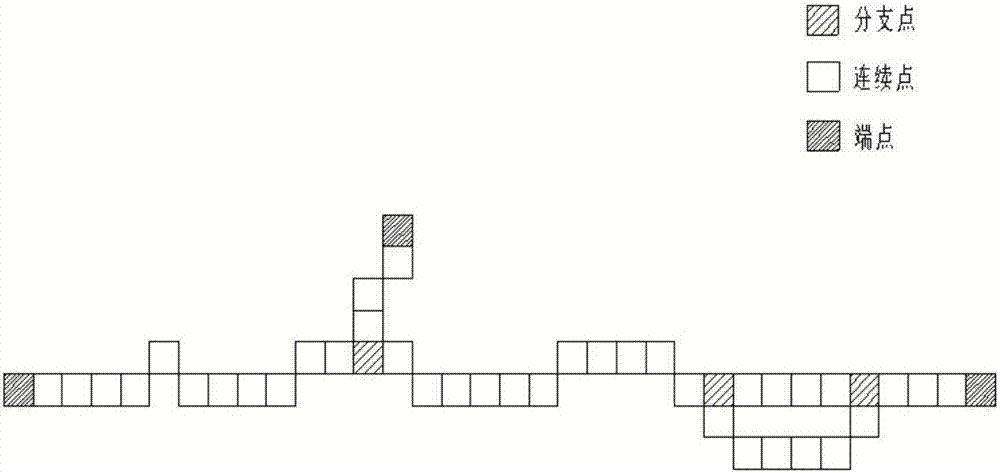

Three-dimensional detection and welding seam inflection point identifying method for multilayer multiple welding seams of robot

ActiveCN107876970AGuaranteed accuracy requirementsEnsure real-time requirementsProgramme-controlled manipulatorLaser beam welding apparatusFeature vectorThree dimensional morphology

The invention discloses a three-dimensional morphology detection and welding seam inflection point identifying method for multilayer multiple welding seams of a robot. The three-dimensional detectionand welding seam inflection point identifying method comprises the following steps that 1, a camera, line structural light and the robot are calibrated; 2, a welding seam structure light image is obtained and processed; and 3, the three-dimensional spatial morphology of the multilayer multiple welding seams is obtained, and inflection point characteristics are identified, specifically, the processcomprises the following steps that 3.1, the eigenvector of a calculated hessian matrix during extraction of a center line is recorded; 3.2, according to the direction of the eigenvector, the threshold value of the eigenvector difference is set to identify inflection points of the multilayer multiple welding seams; and 3.3, according to model data calculated in the step 1, the sub-pixel coordinatevalue of the center line under a camera coordinate system is converted to be under a robot coordinate system and serves as the three-dimensional data of the welding seam surface for being used for robot welding. According to the three-dimensional detection and welding seam inflection point identifying method for the multilayer multiple welding seams of the robot, the precision is high, the reliability is high, and real-time performance is good.

Owner:ZHEJIANG UNIV OF TECH

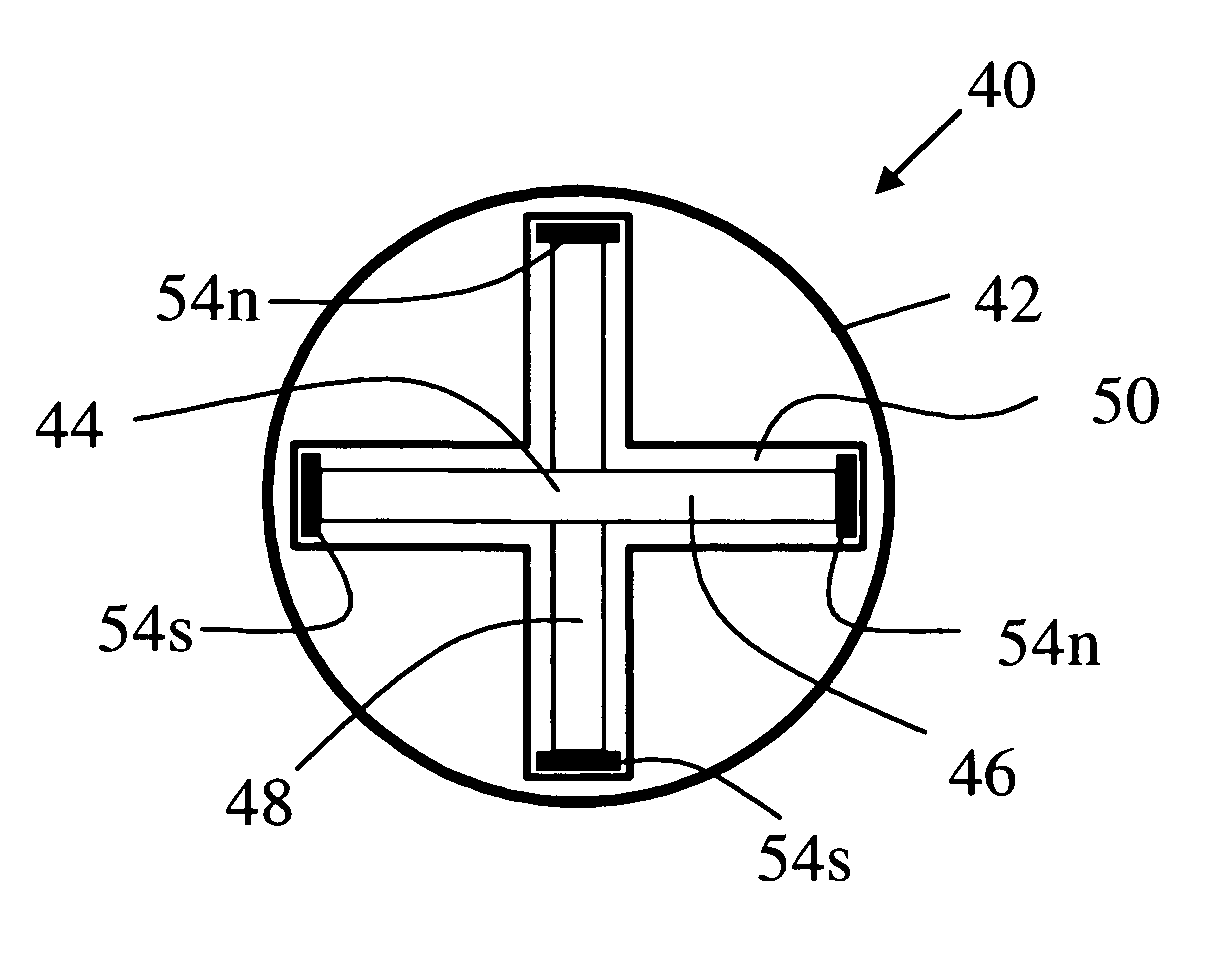

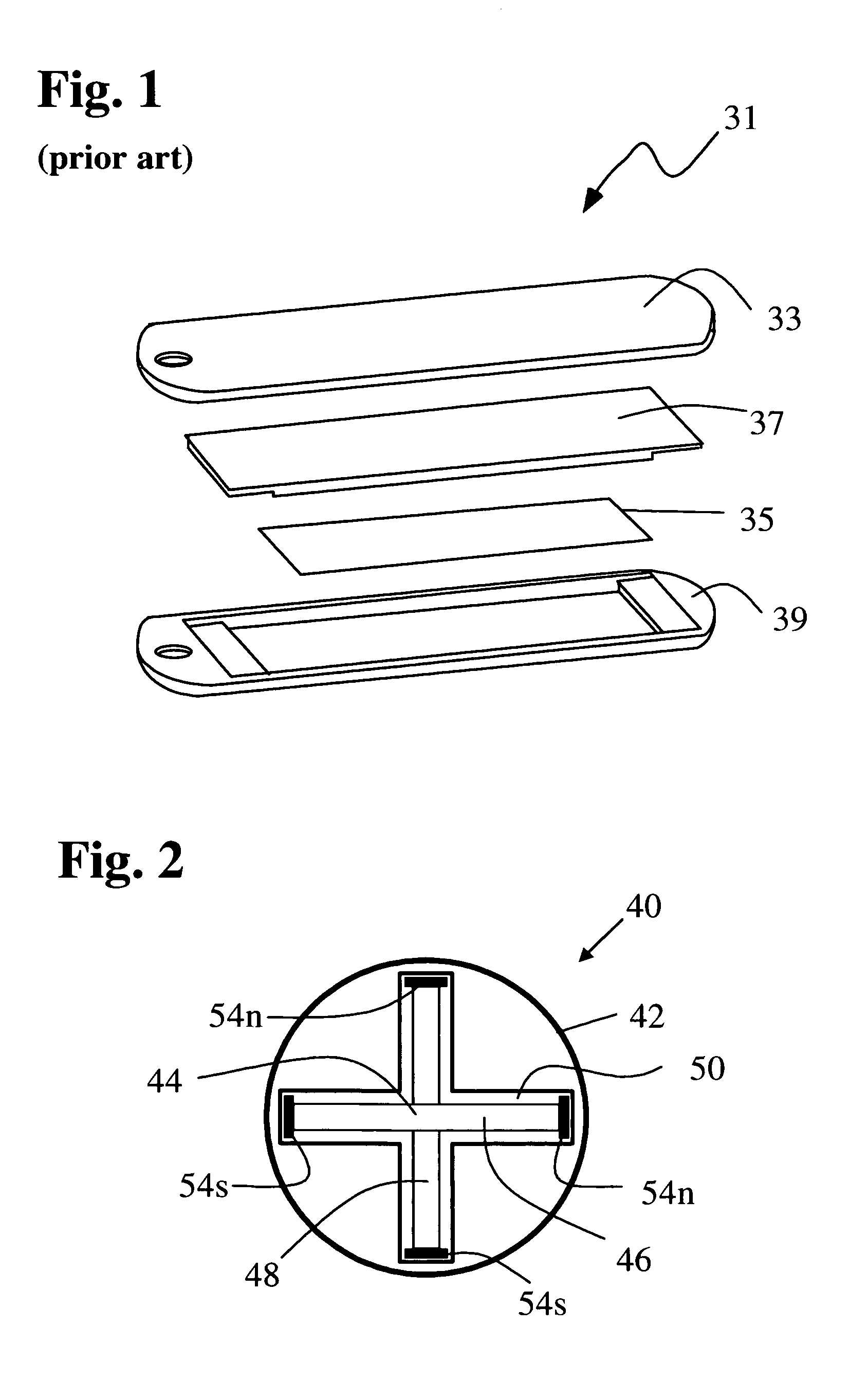

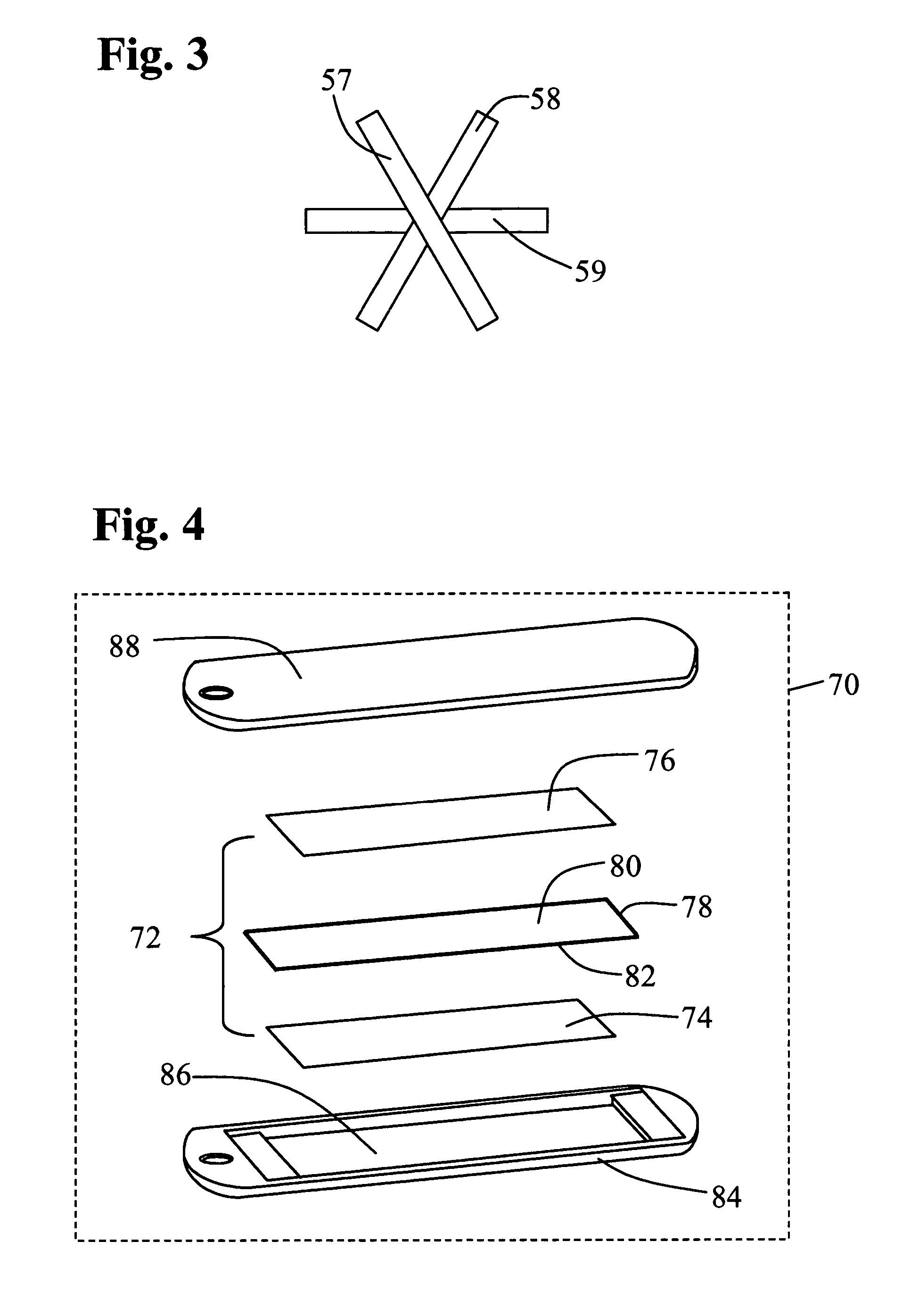

Miniature magnetomechanical tag for detecting surgical sponges and implements

InactiveUS7464713B2Serious consequenceEasy to operateDiagnosticsSurgeryEngineeringMechanical resonance

Externally detectable electronic article surveillance markers are attached to surgical implements, such as sponges and surgical instruments, appointed for use in a surgical wound. The attachment mechanism facilitates detection by an external interrogating field before the wound has been closed and the patient has left the operating table. The markers are responsive to the imposition of an interrogating field produced by an electronic article surveillance system. Markers contain one or more magnetomechanically responsive elements that are urged into mechanical resonance by the interrogating field. The ring-down of the resonance and the associated dipolar electromagnetic field provide a signal-identifying characteristic detected by a detection system. Upon detection, an audible or visible signal is triggered to alert relevant medical personnel to the need for follow-up care and removal of the offending item. The resonance occurs at a frequency ranging from about 70 to 300 kHz. Misadventures during operative procedures—especially those wherein implements remain undiscovered at the time of surgery and are retained indefinitely within the surgical cavity, often entailing dire consequences to the patient—are virtually eliminated. The attachment mechanism and markers assure that surgical implements are reliably detected and removed before completion of the surgical procedure.

Owner:FABIAN CARL E +2

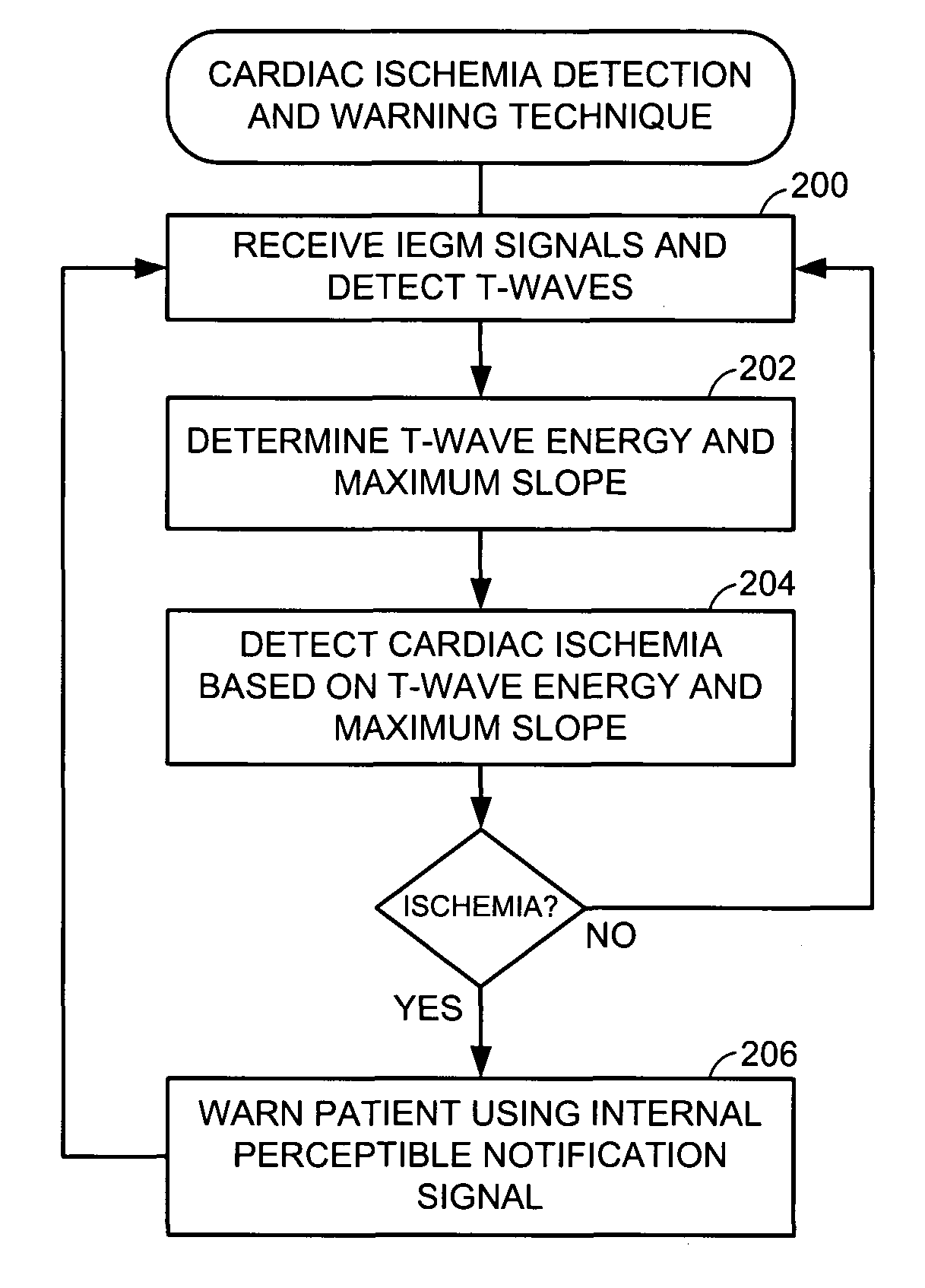

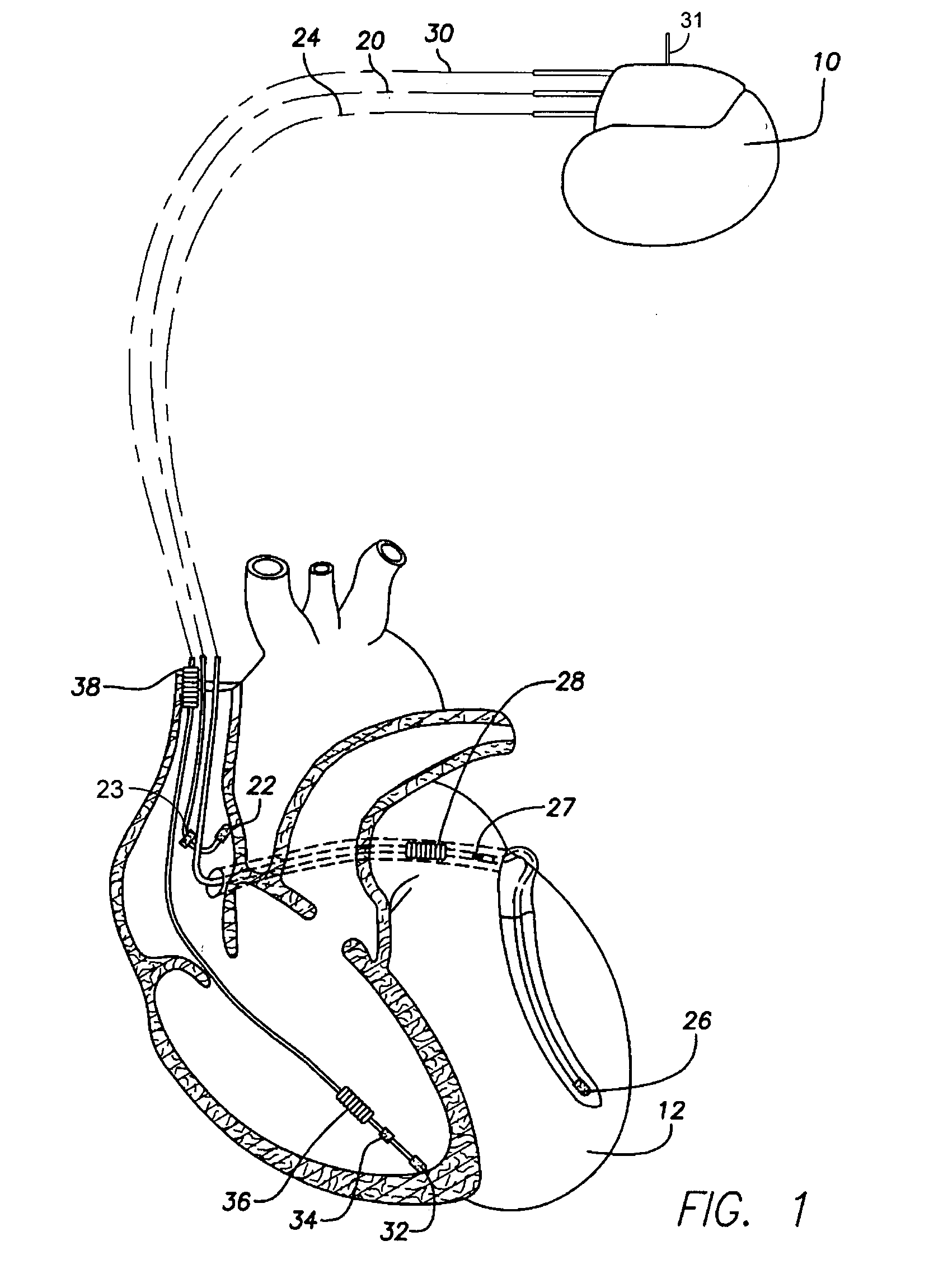

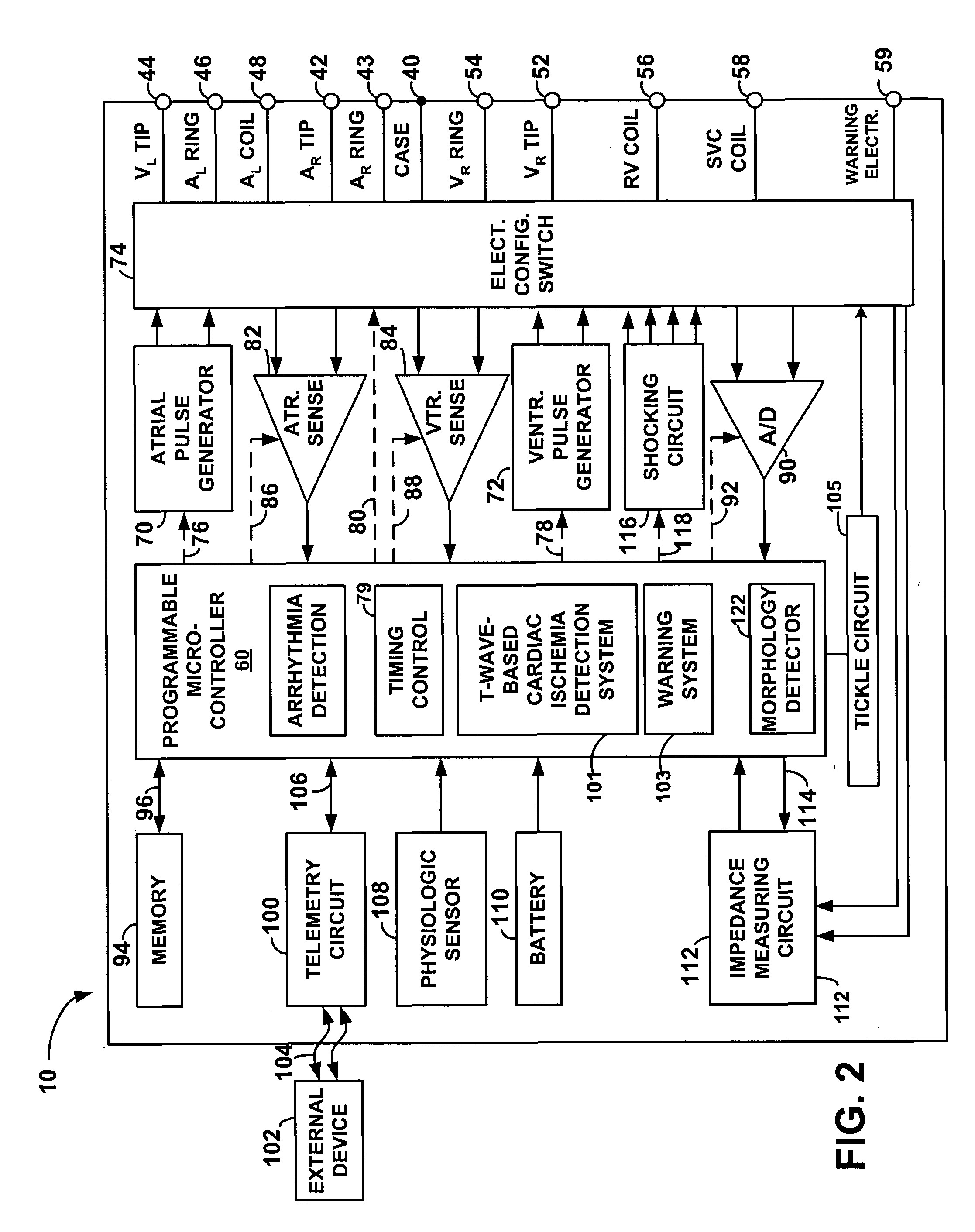

System and method for detecting cardiac ischemia based on T-waves using an implantable medical device

ActiveUS7225015B1Reliable detectionSimple technologyElectrocardiographyHeart stimulatorsP-waveCombined use

A technique is provided for detecting episodes of cardiac ischemia based on an examination of the total energy of T-waves. Since cardiac ischemia is often a precursor to acute myocardial infarction (AMI) or ventricular fibrillation (VF), the technique thereby provides a method for predicting the possible onset of AMI or VF. Briefly, the technique integrates internal electrical cardiac signals occurring during T-waves and then compares the result against a running average. If the result exceeds the average by some predetermined amount, ischemia is thereby detected and a warning signal is provided to the patient. The maximum slope of the T-wave is also exploited. Techniques are also set forth herein for reliably detecting T-waves, which help prevent P-waves from being misinterpreted as T-waves on unipolar sensing channels. The T-wave detection technique may be used in conjunction with ischemia detection or for other purposes.

Owner:PACESETTER INC

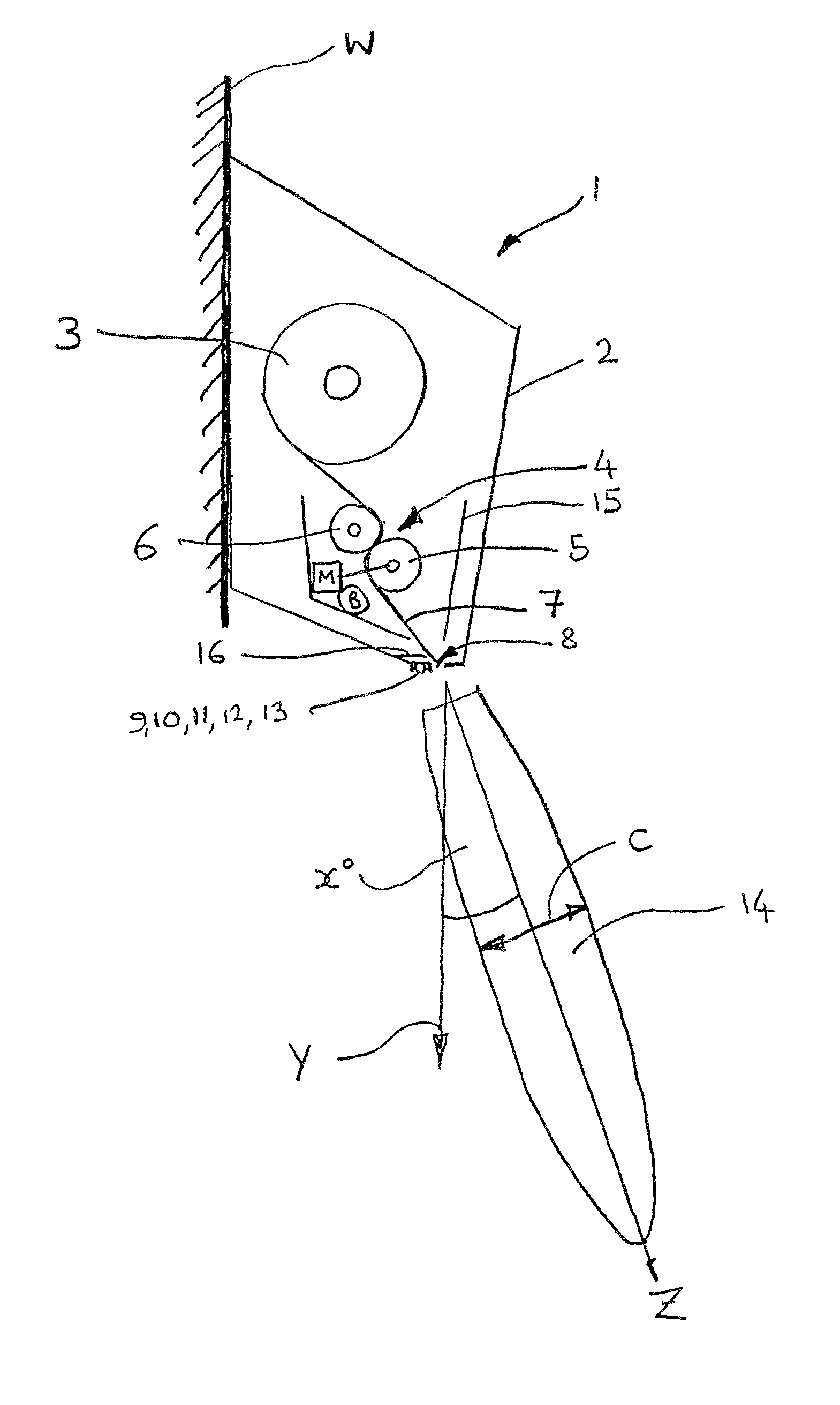

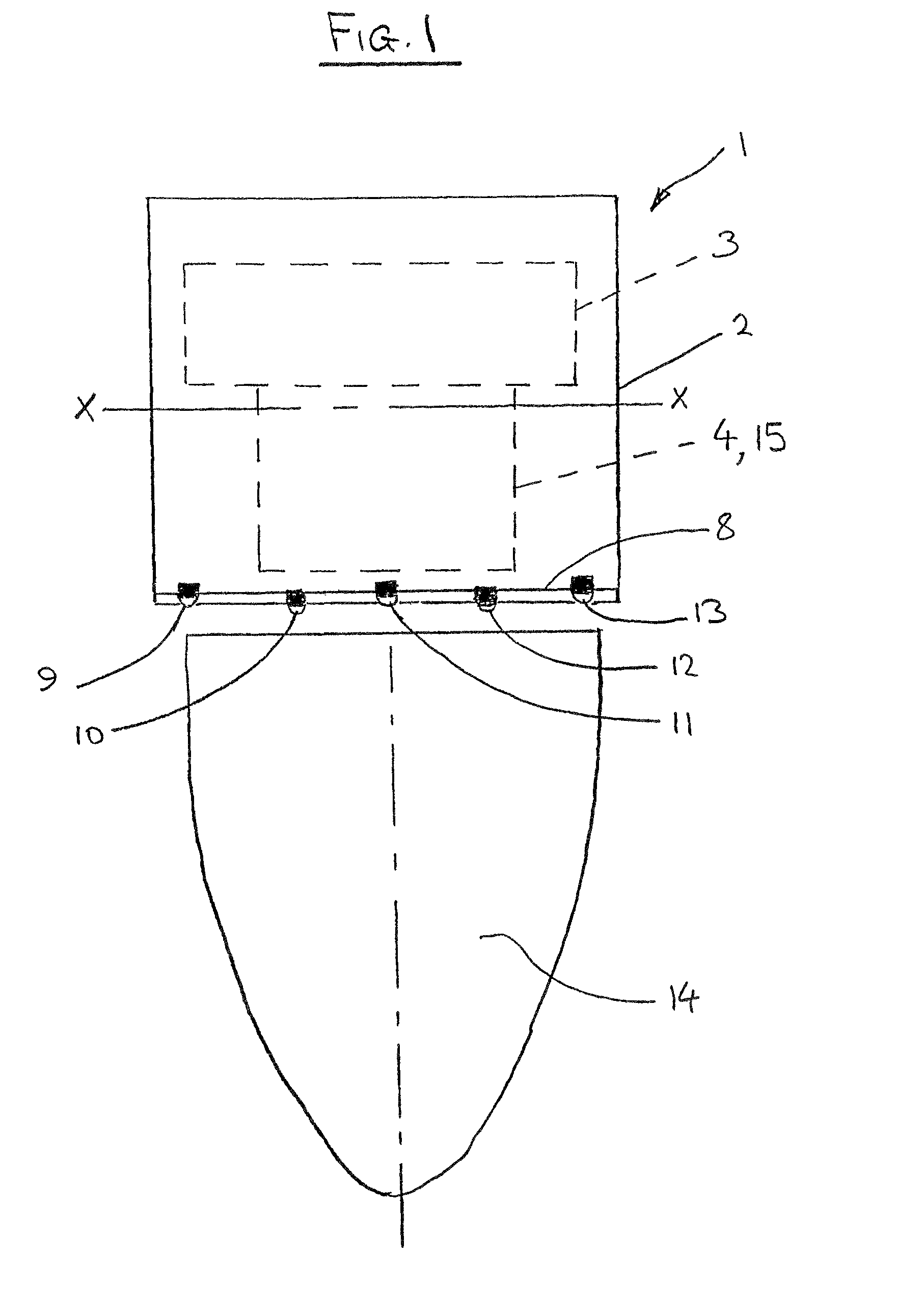

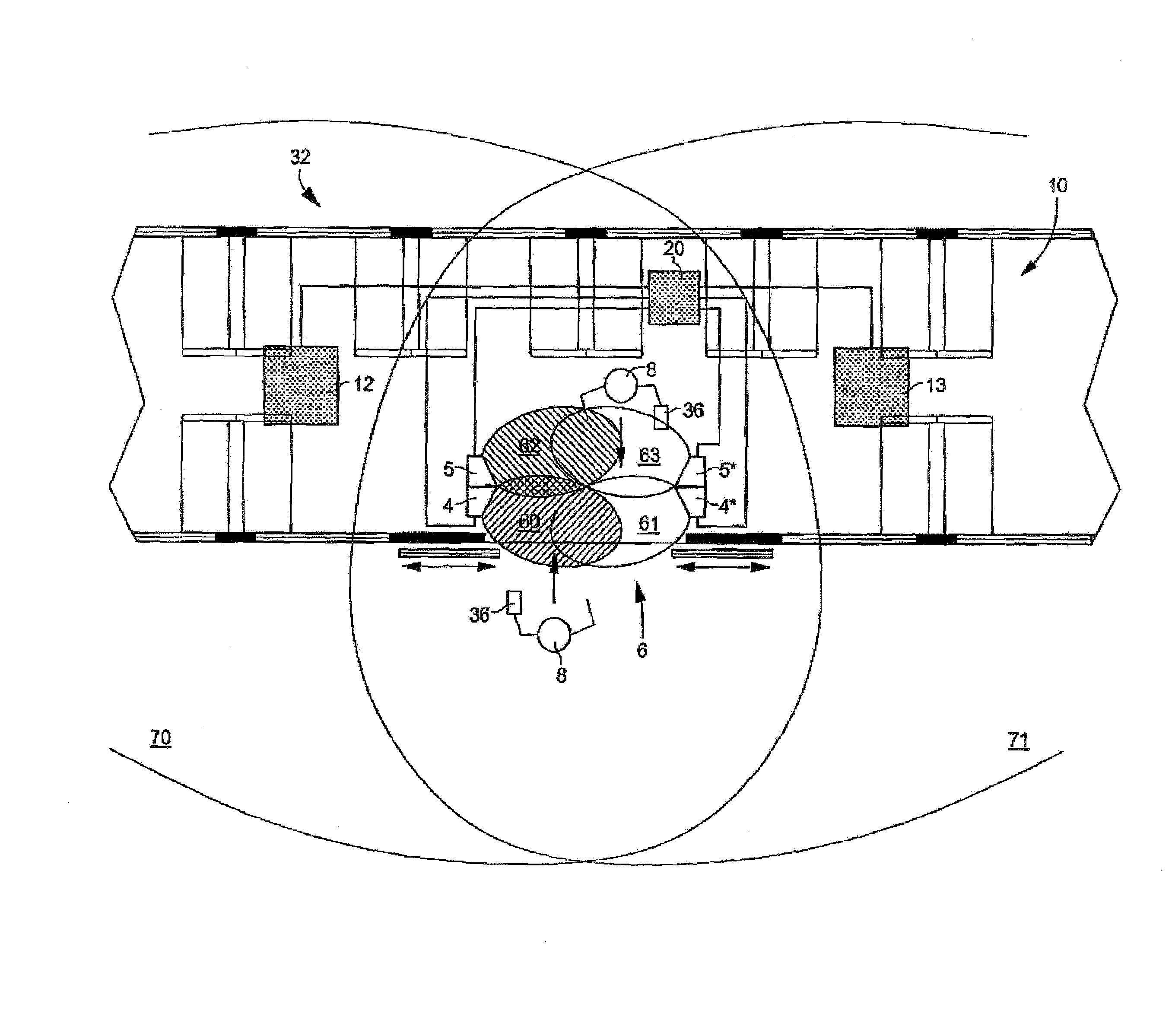

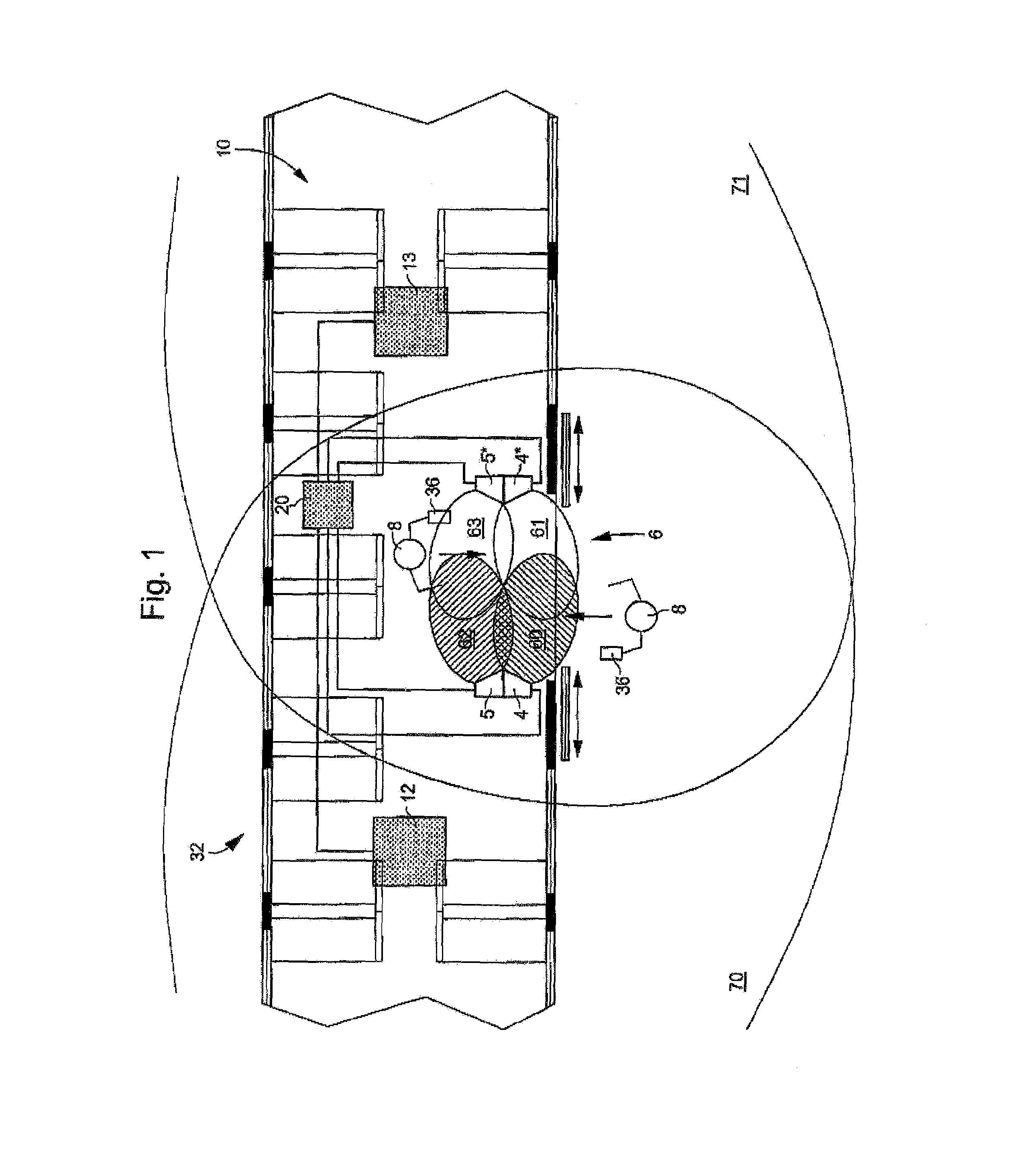

System and method for detecting persons or objects in definite areas provided each with at least an entrance

InactiveUS7325723B2Correction errorImprove detection reliabilityTransfer mechanismsSensing record carriersOperation modeComputer science

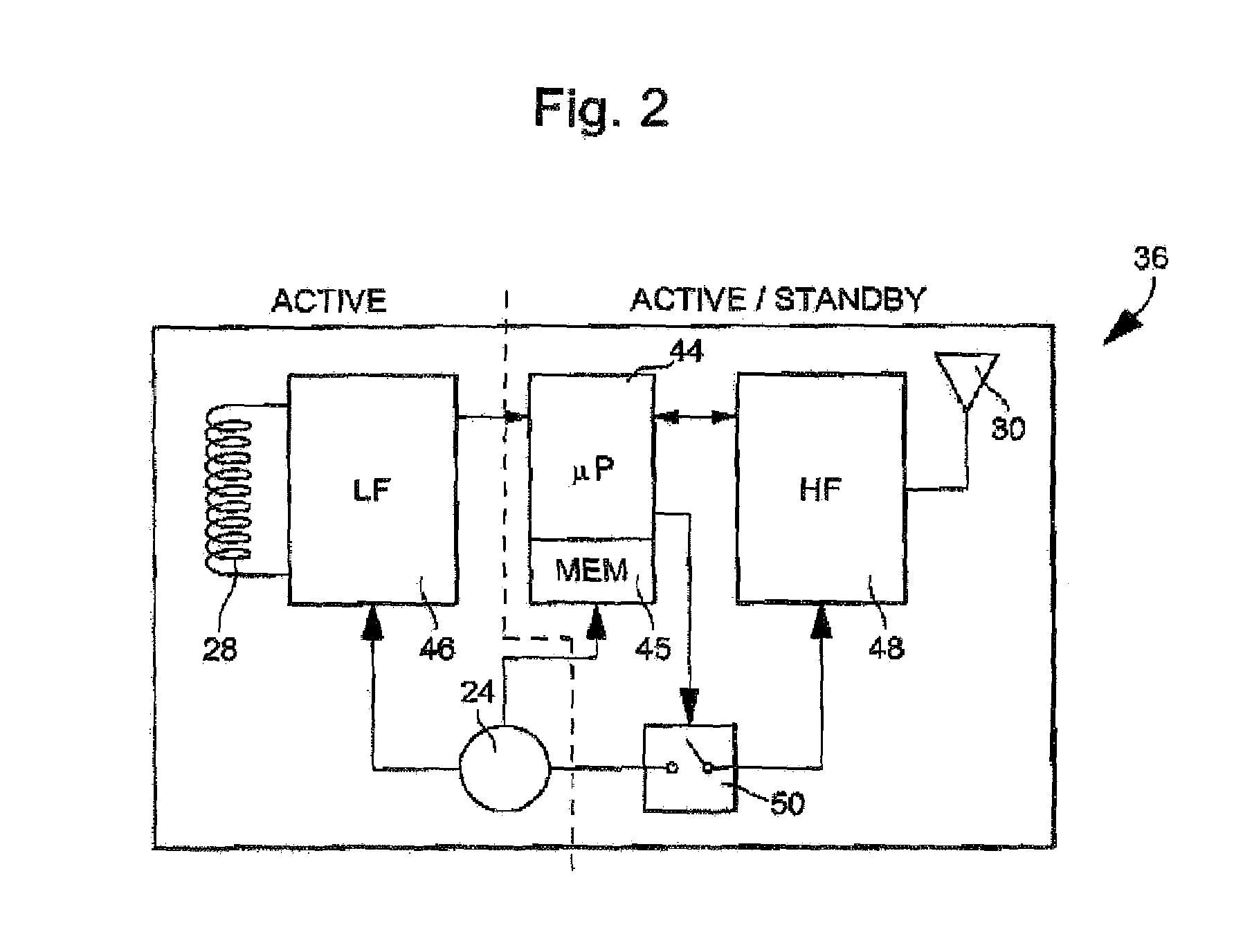

A system and a method are described for detection of individuals (8) or objects in a plurality of delimited spaces (10), each having at least one entrance (6). The detection system comprises LF transmission means (4, 4*, 5, 5*) located at the entrance, for transmitting a LF electromagnetic signal, HF transmission-reception means (12, 13) for transmitting-receiving a HF electromagnetic signal (C, ACK), cards or portable electronic units (36) equipping each individual or object, for receiving the LF signal and for transmitting and receiving the HF signal, and a central processing unit (20) for recording data relating to the entry and exit of the portable electronic units. The system can operate according to at least two distinct modes of operation and the LF signal comprises selection information (SELECT) indicating which of the two modes of operation should be used by the electronic units during their passage through the entrance. The system is preferably configured to pass, at least temporarily, in one of the said delimited spaces, from one mode of operation to the other.

Owner:EM MICROELECTRONIC-MARIN

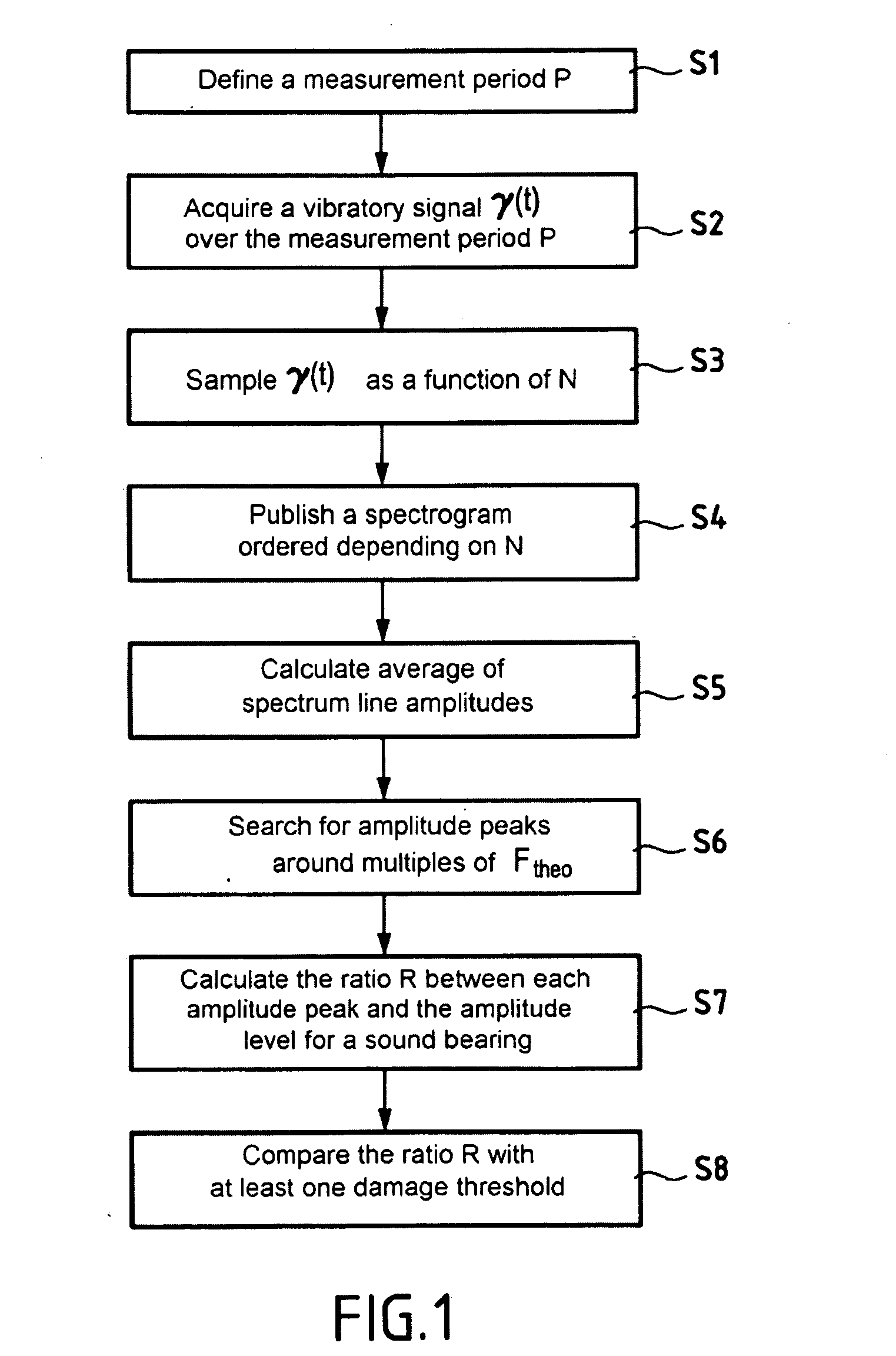

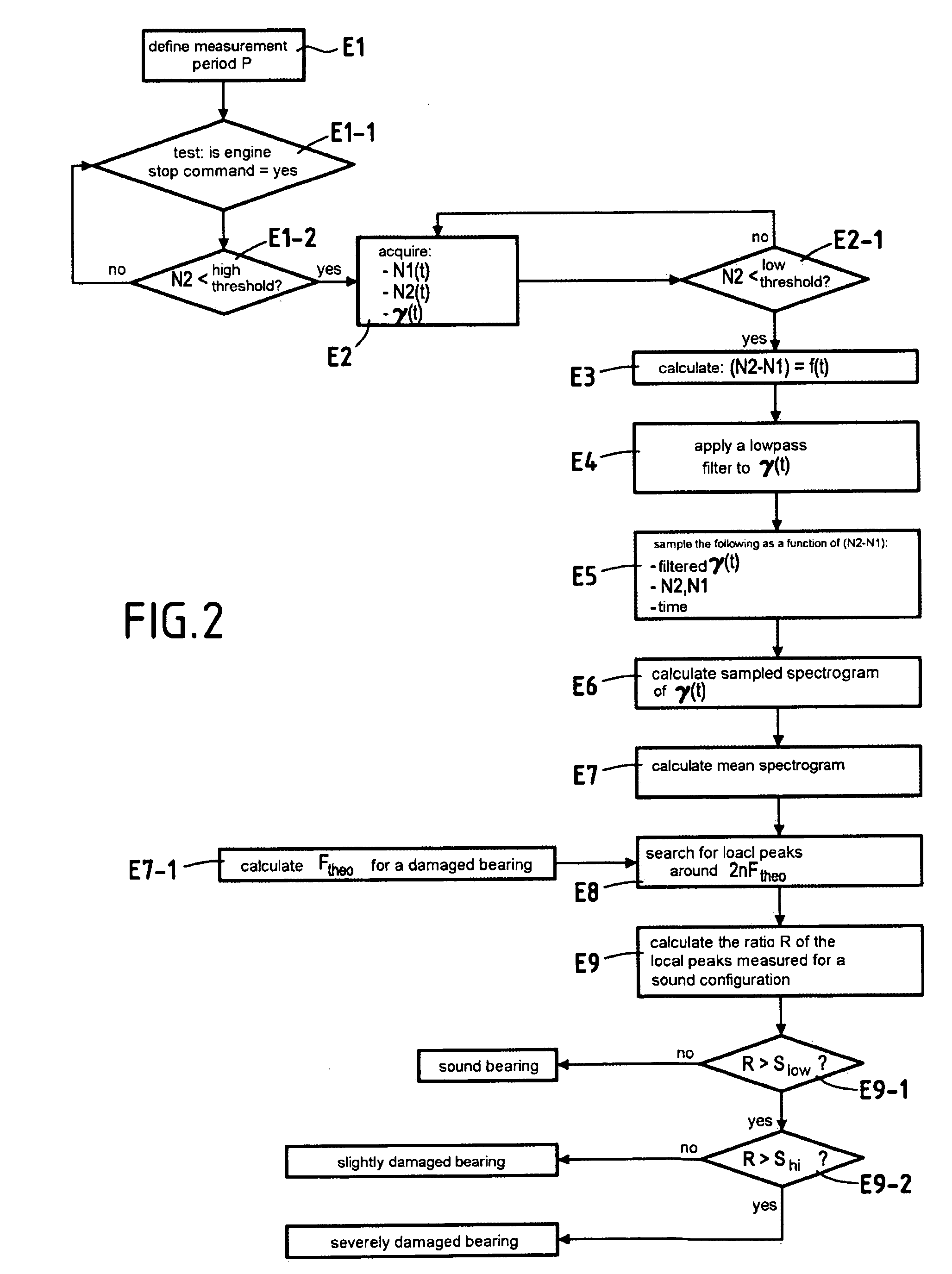

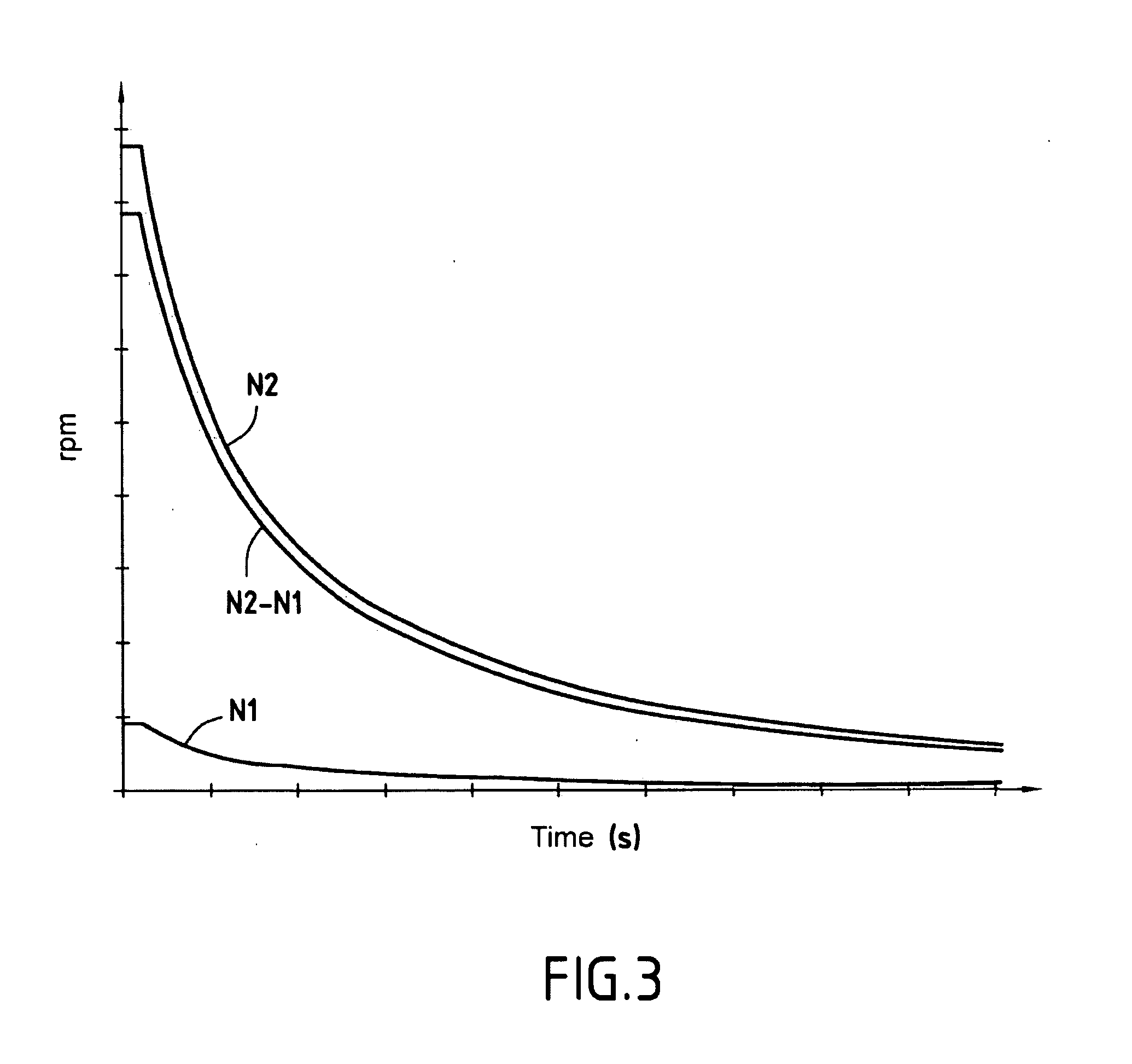

Method of detecting damage to an engine bearing

ActiveUS20080223135A1Mitigate such drawbackLess polluted by noiseVibration measurement in solidsMachine part testingLow speedFrequency spectrum

The invention relates to a method of detecting damage in a bearing supporting at least one rotary shaft of an engine in rotation, the method consisting in: defining a measurement period corresponding to a range of speeds of rotation of the shaft during renewable activity at low speeds of operation of the engine; acquiring over the entire measurement period a vibratory signal representative of acceleration of components of the engine; sampling the vibratory signal as a function of the speed of rotation of the shaft during the measurement period; transforming the sampled vibratory signal into a frequency signal to obtain frequency spectrum lines as a function of the speed of rotation of the shaft; calculating the mean of the amplitudes of the spectrum lines; determining amplitude peaks around multiples of the theoretical frequency of a damaged roller; calculating the ratio between each amplitude peak and the amplitude level determined for a sound bearing; and comparing the ratio that is obtained with at least one predetermined damage threshold.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

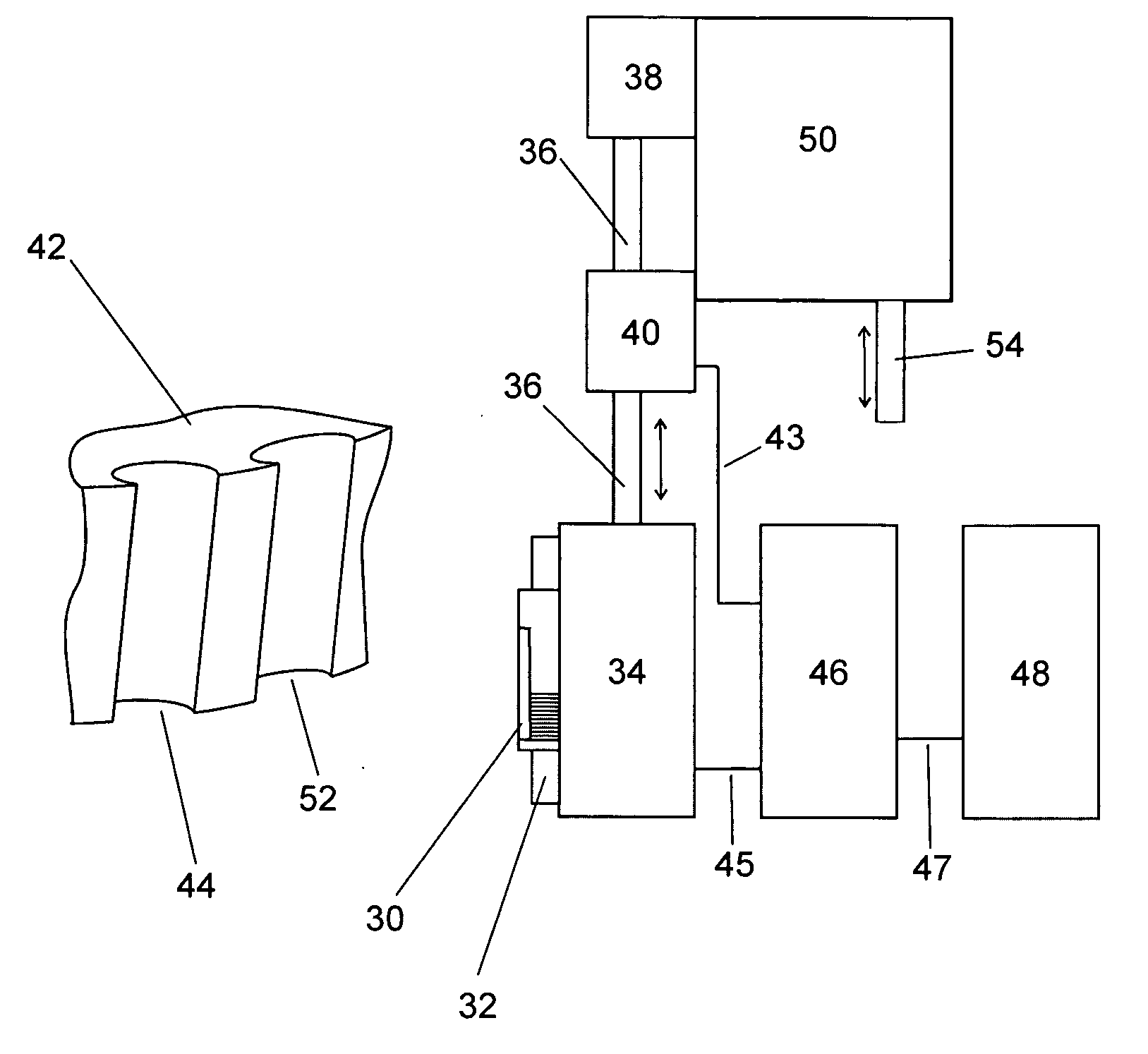

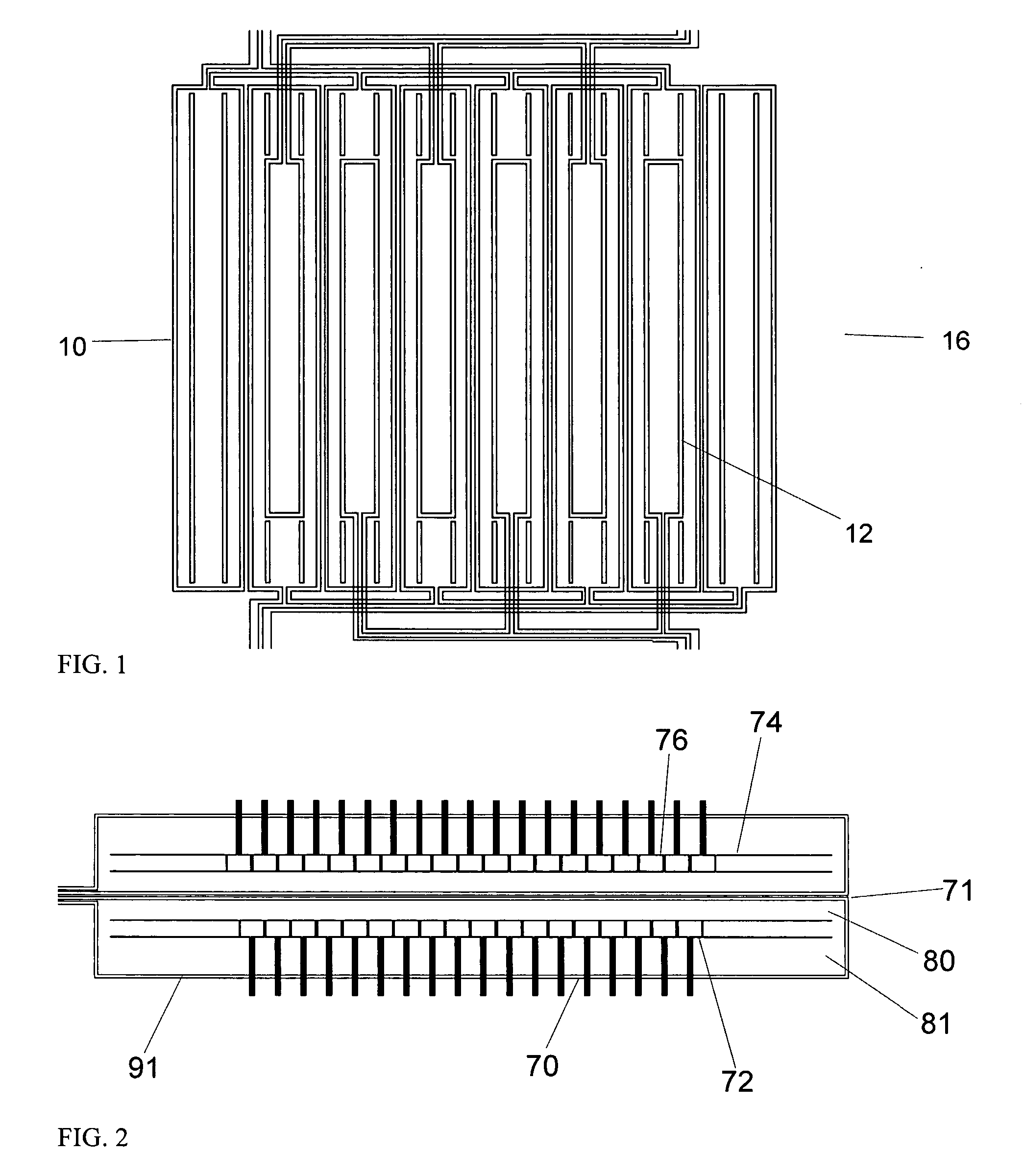

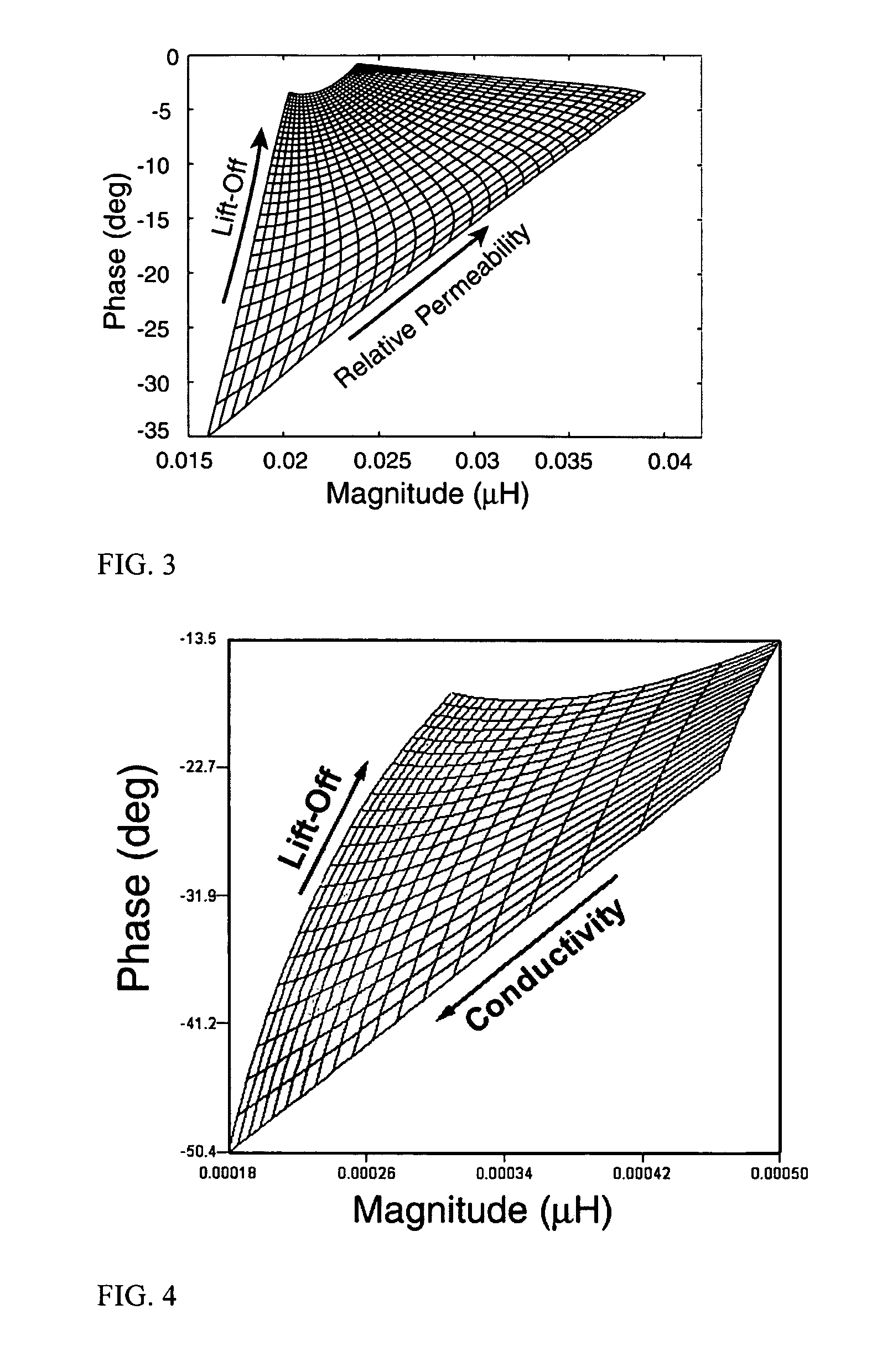

Material characterization with model based sensors

InactiveUS20070069720A1Improve crack detection reliabilityImprove reliabilityMaterial magnetic variablesSensor arrayElectric field sensor

Nondestructive material condition monitoring and assessment is accomplished by placing, mounting, or scanning magnetic and electric field sensors and sensor arrays over material surfaces. The material condition can be inferred directly from material property estimates, such as the magnetic permeability, dielectric permittivity, electrical property, or thickness, or from a correlation with these properties. Hidden cracks in multiple layer structures in the presence of fasteners are detected by combining multiple frequency magnetic field measurements and comparing the result to characteristic signature responses. The threshold value for indicating a crack is adjusted based on a high frequency measurement that accounts for fastener type. The condition of engine disk slot is determined without removal of the disk from the engine by placing near the disk a fixture that contains a sensor for scanning through the slot and means for recording position within the slot. Inflatable support structures can be placed behind the sensor to improve and a guide can be used to align sensor with the slot and for rotating the disk. The condition of an interface between a conducting substrate and a coating is assessed by placing a magnetic field sensor on the opposite side of the substrate from the coating and monitoring at least one model parameter for the material system, with the model parameter correlated to the interfacial condition. The model parameter is typically a magnetic permeability that reflects the residual stress at the interface. Sensors embedded between material layers are protected from damage by placing shims on the faying surface. After determining the areas to be monitored and the areas likely to cause sensor damage, a shim thickness is determined and is then placed in at least one area not being monitored by a sensor. The condition of a test fluid is assessed through a dielectric sensor containing a contaminant-sensitive material layer. The properties of the layer are monitored with the dielectric sensor and correlated to contaminant level.

Owner:JENTEK SENSORS

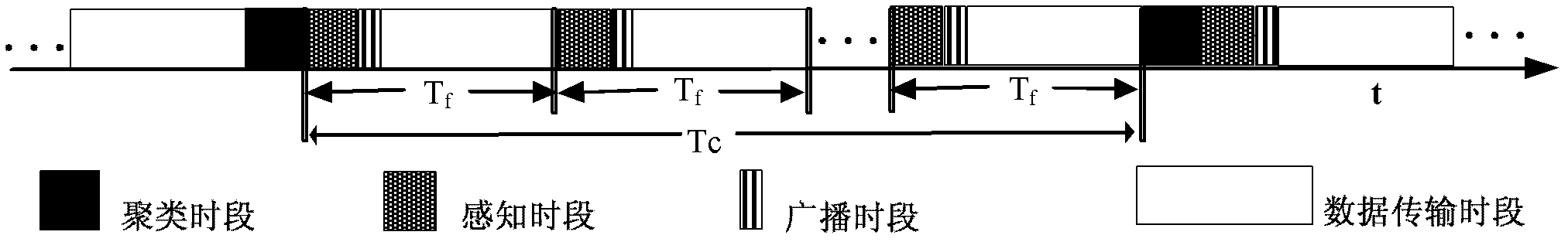

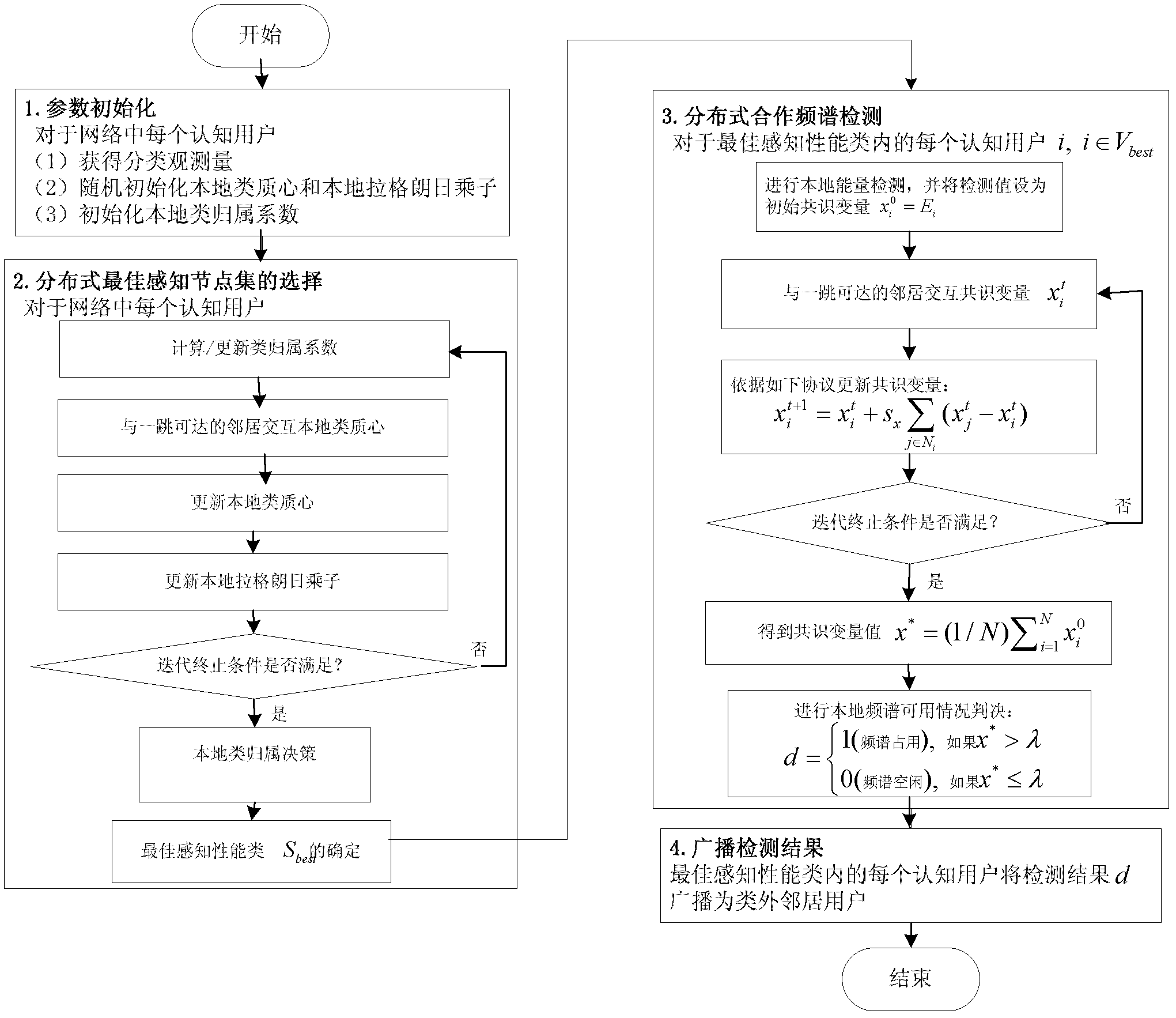

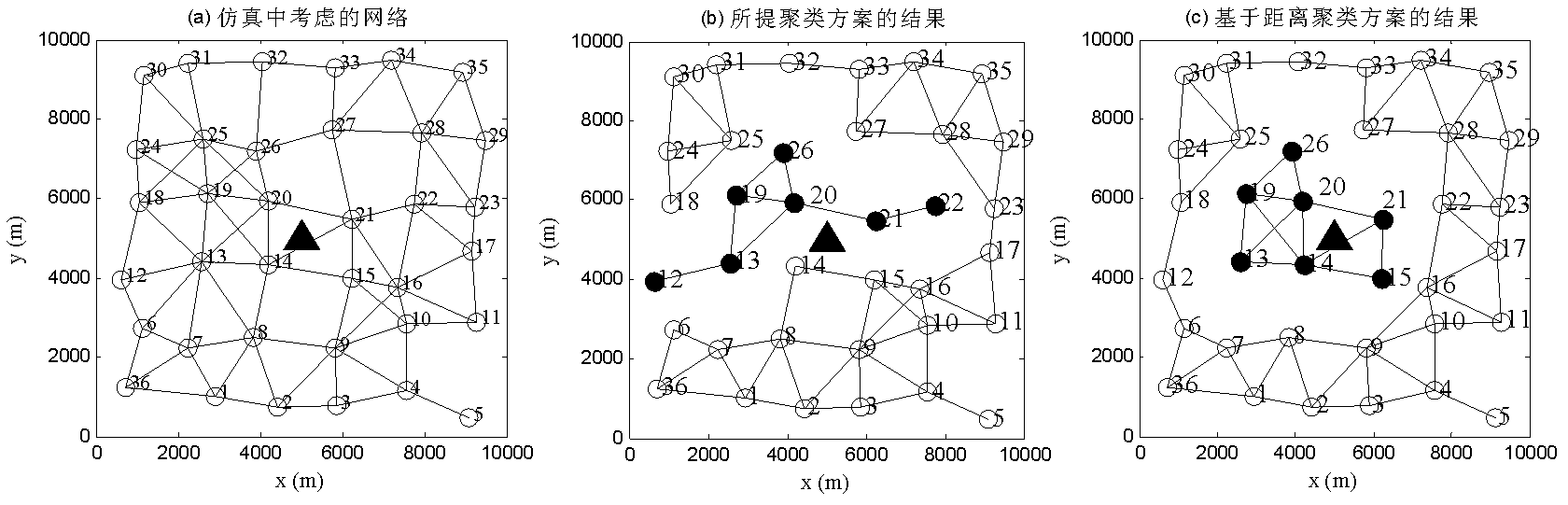

Non-supervision clustering-based distributed cooperative spectrum sensing method for cognitive self-organizing network

ActiveCN102546059AImprove scalabilityReduce overheadTransmission monitoringWireless communicationSignal-to-noise ratio (imaging)Frequency spectrum

A non-supervision clustering-based distributed cooperative spectrum sensing method for a cognitive self-organizing network relates to the field of cognitive radio in wireless communication technology. Aiming at solving the problems of difficult distributed cooperation of the cognitive self-organizing network and large overhead of whole-network cooperation, the method adopts the latest achievements of a non-supervision clustering theory and a co-recognition theory to achieve fully-distributed, steady and reliable distributed cooperative spectrum sensing under the condition of simplifying the overhead of network sensing; and users with potential optimal detection performance spontaneously gather only via information interaction between neighbors, further the users carry out cooperation spectrum sensing by utilizing an average co-recognition protocol, and a sensing result is broadcast to the whole network users. The method does not require local users to receive apriori information of noise-signal ratio, and does not need any central controllers, thereby greatly lowering sensing overhead and acquiring detection performances similar to optimal soft combination solution.

Owner:PLA UNIV OF SCI & TECH

Vehicle obstacle detecting device

ActiveUS7061373B2Improve detection reliabilityEfficient use ofPedestrian/occupant safety arrangementAnti-collision systemsEngineering

The vehicle obstacle detecting device improves safety of the vehicle by utilizing information detected by a plurality of sensors to appropriately handle situations in which an obstacle exists in a blind spot of the sensors. The vehicle obstacle detecting device includes at least first and second sensors arranged such that sensing scopes of the first and second sensors do not substantially overlap. The vehicle obstacle detecting device is configured to observe the behavior of an obstacle existing within the sensing scope of one of the first and second sensors and predict the blind spot behavior of the obstacle in a blind spot between the sensing scopes of the first and second sensors based on the observed behavior of the obstacle. Thus, the vehicle obstacle detecting device is configured to predict the existence of an obstacle in the blind spot where the first and second sensors cannot actually detect the obstacle.

Owner:NISSAN MOTOR CO LTD

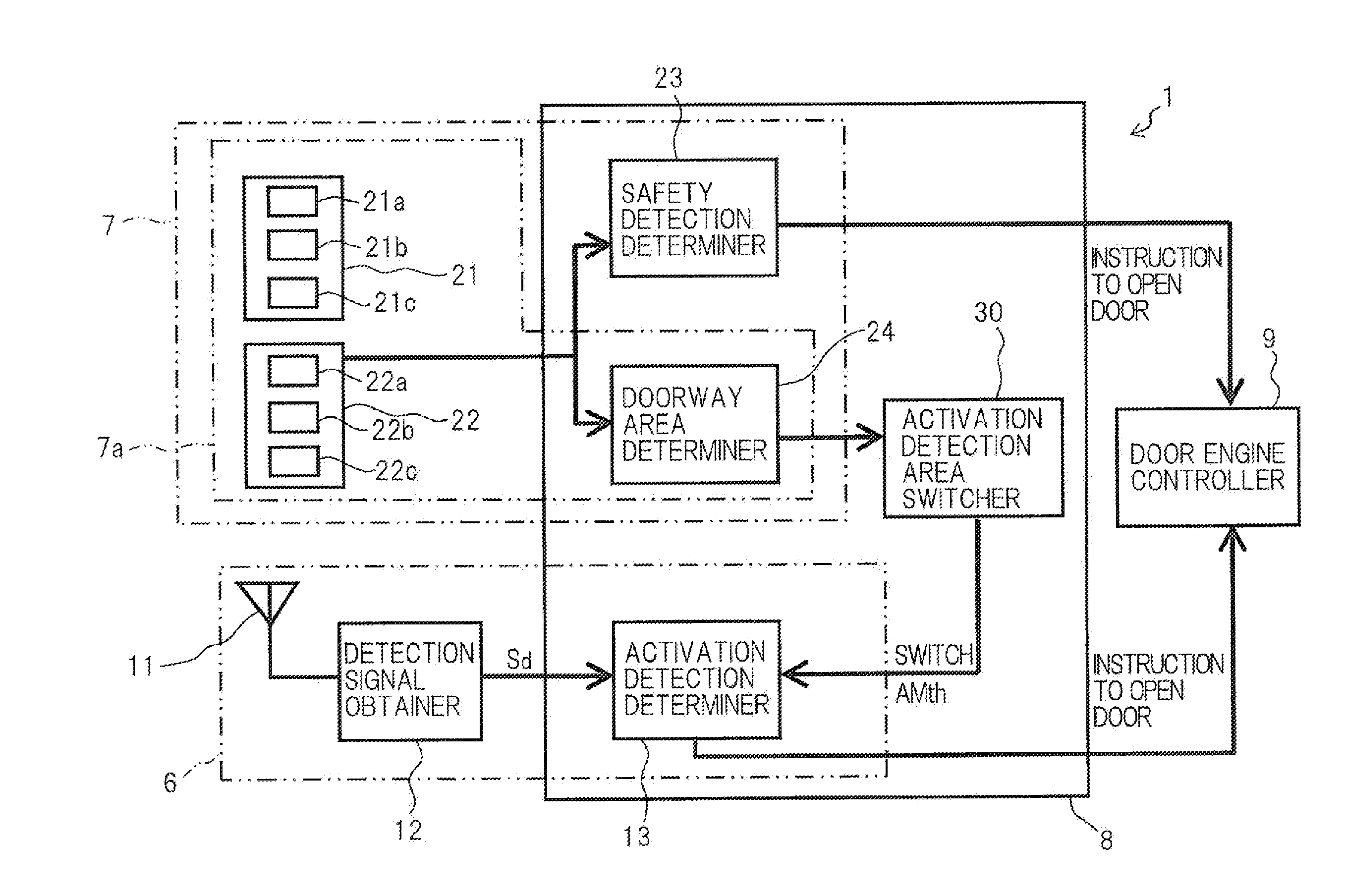

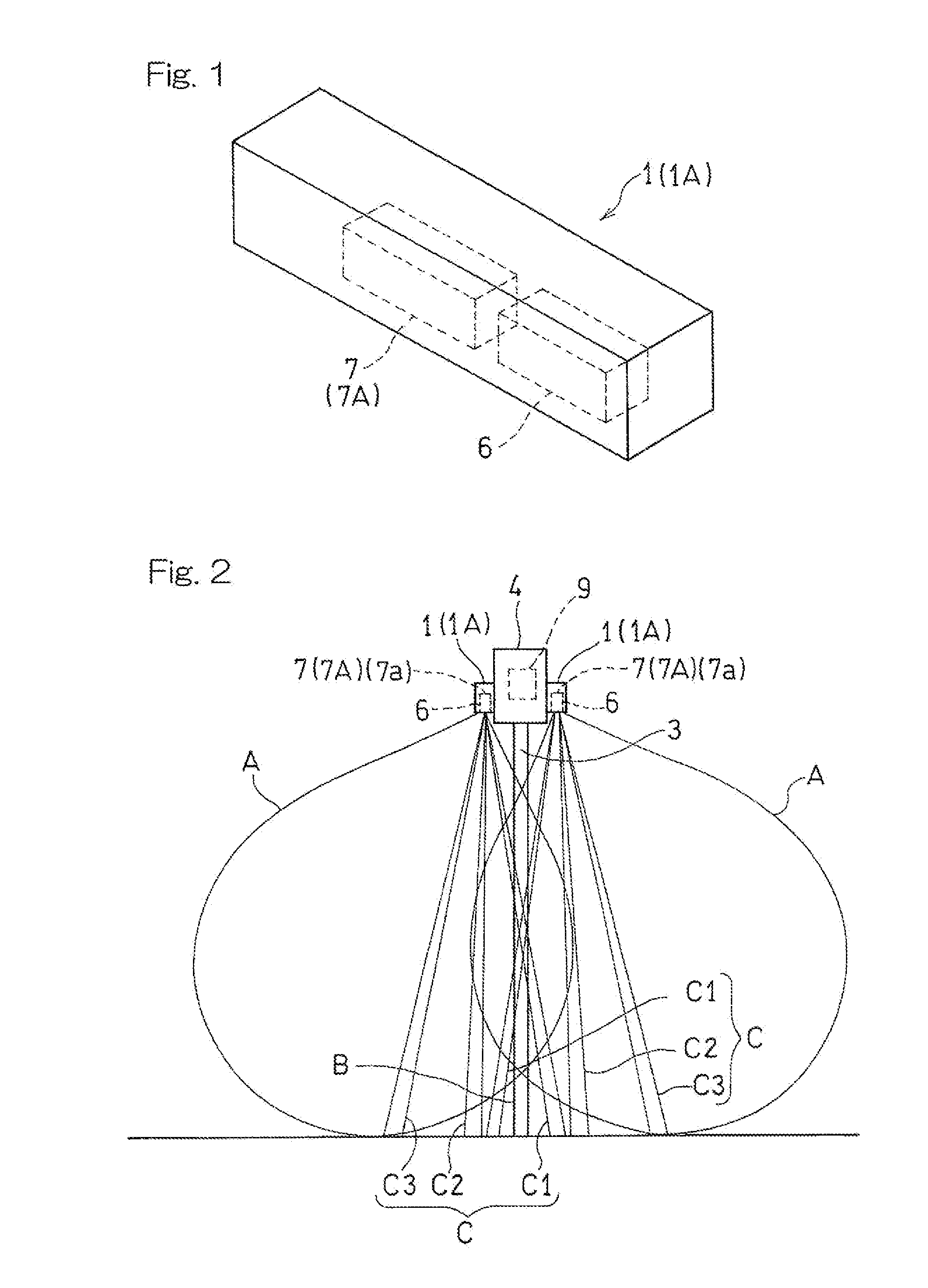

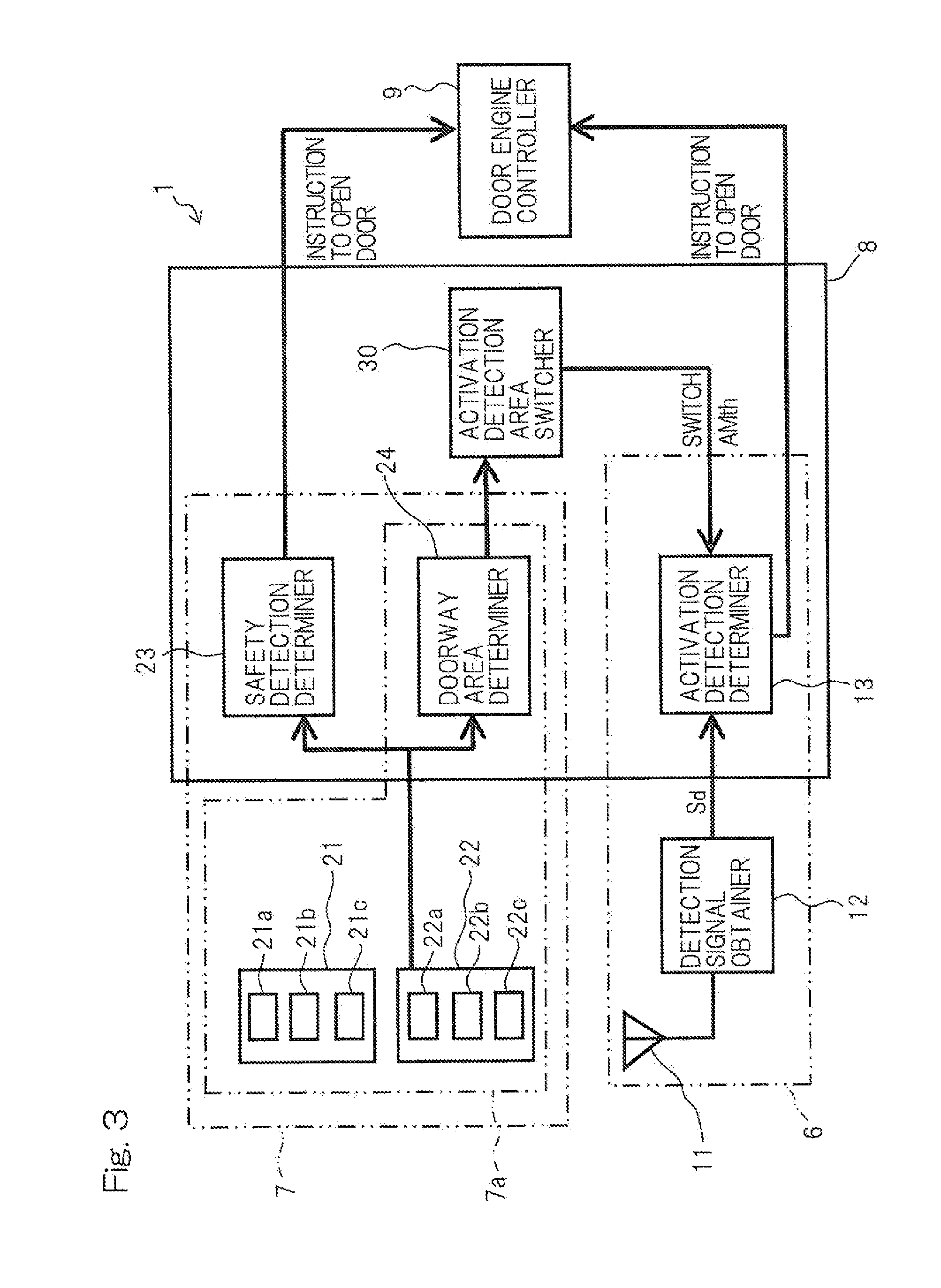

Automatic door sensor device

ActiveUS20150059248A1Prevent false detectionImprove detection reliabilityDoors/windowsPower-operated mechanismEngineering

Owner:OPTEX CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com