Three-dimensional detection and welding seam inflection point identifying method for multilayer multiple welding seams of robot

A multi-layer, multi-channel, identification method technology, applied in the field of weld detection of robot automatic welding, can solve the problems of low precision, poor real-time performance, low reliability, etc., and meet the requirements of ensuring accuracy, removing influence, and efficient denoising processing method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

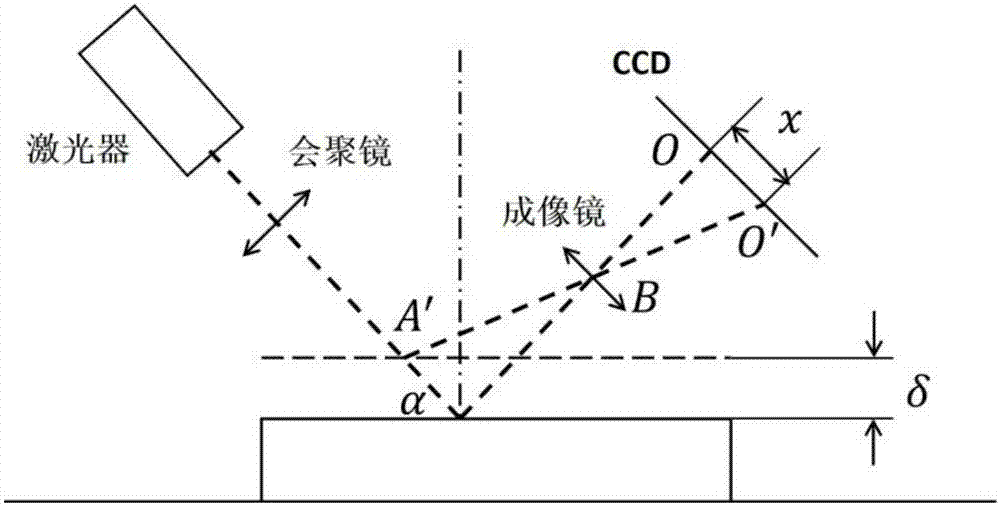

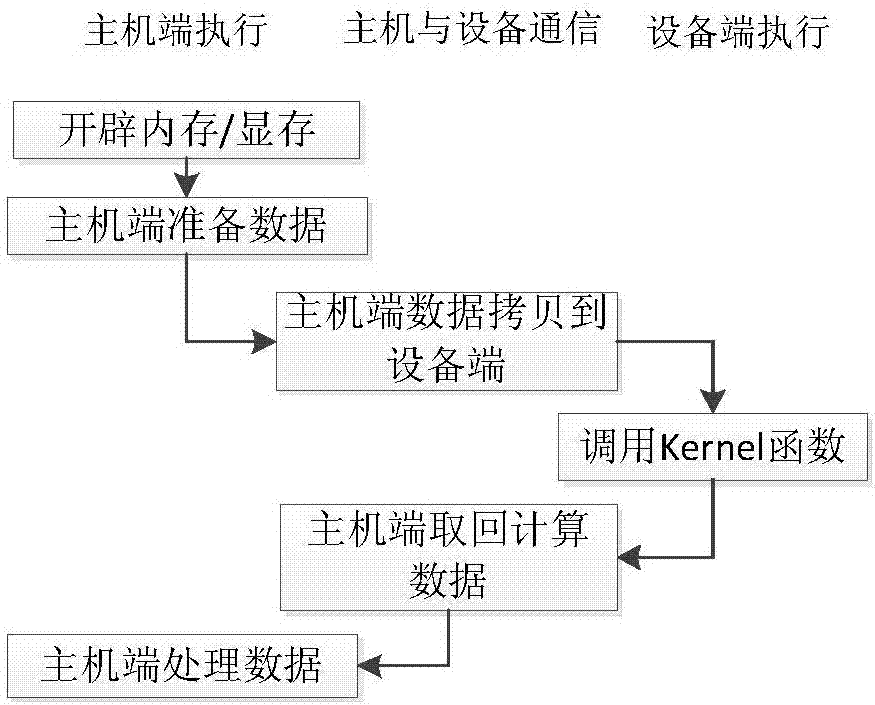

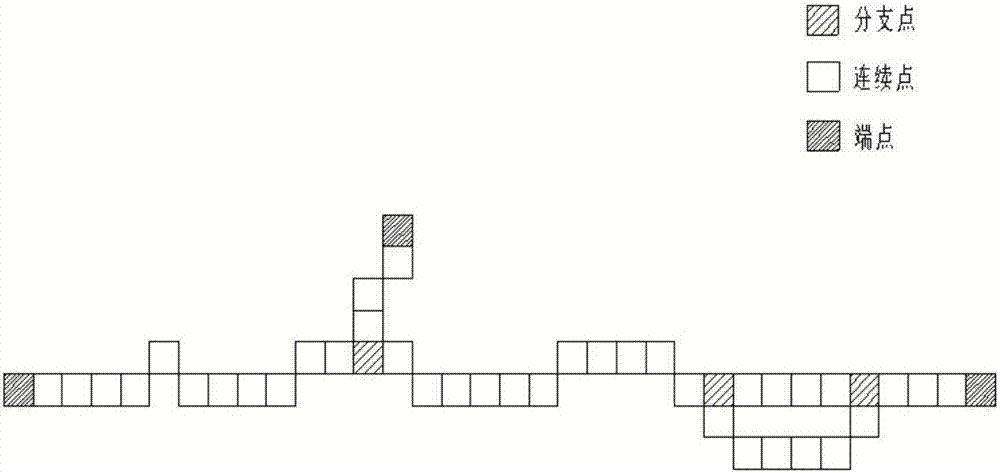

Method used

Image

Examples

example 1

[0147] Example 1: First, calibrate the single-line structured light and the camera, and then calibrate the camera and the robot. Any common calibration method can be used for calibration. In this embodiment 1, the plane template calibration method of Professor Zhang Zhengyou was used to calibrate the camera. The calibration results are shown in Table 1:

[0148]

[0149] Table 1

[0150] At the same time, the points of the line structured light on the plane template are obtained, and the light plane equation is fitted by the SVD method to obtain the parameters of the structured light plane. The light plane is as follows Figure 6 shown.

[0151] Finally, use the "two-step method" to obtain the pose relationship between the camera and the end effector of the robot, as follows:

[0152]

[0153] After the calibration, use the camera to obtain the structured light fringe image on the weld surface, such as Figure 7 As shown, then use the method described above for denois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com