Patents

Literature

87results about How to "Compact space layout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

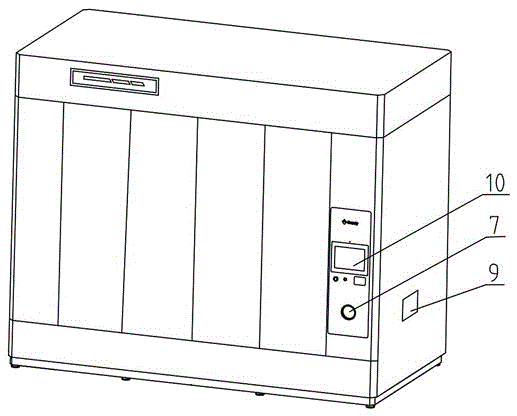

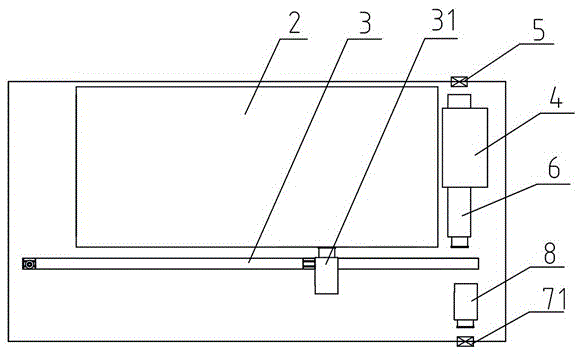

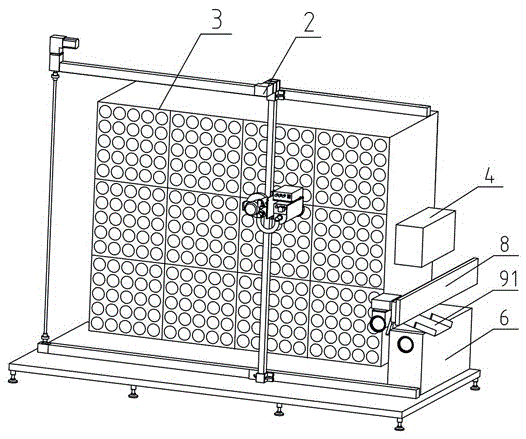

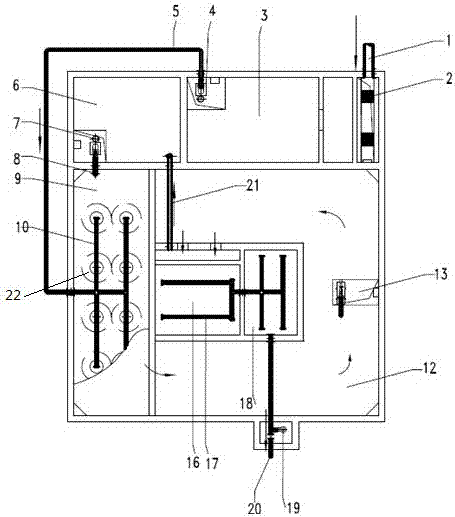

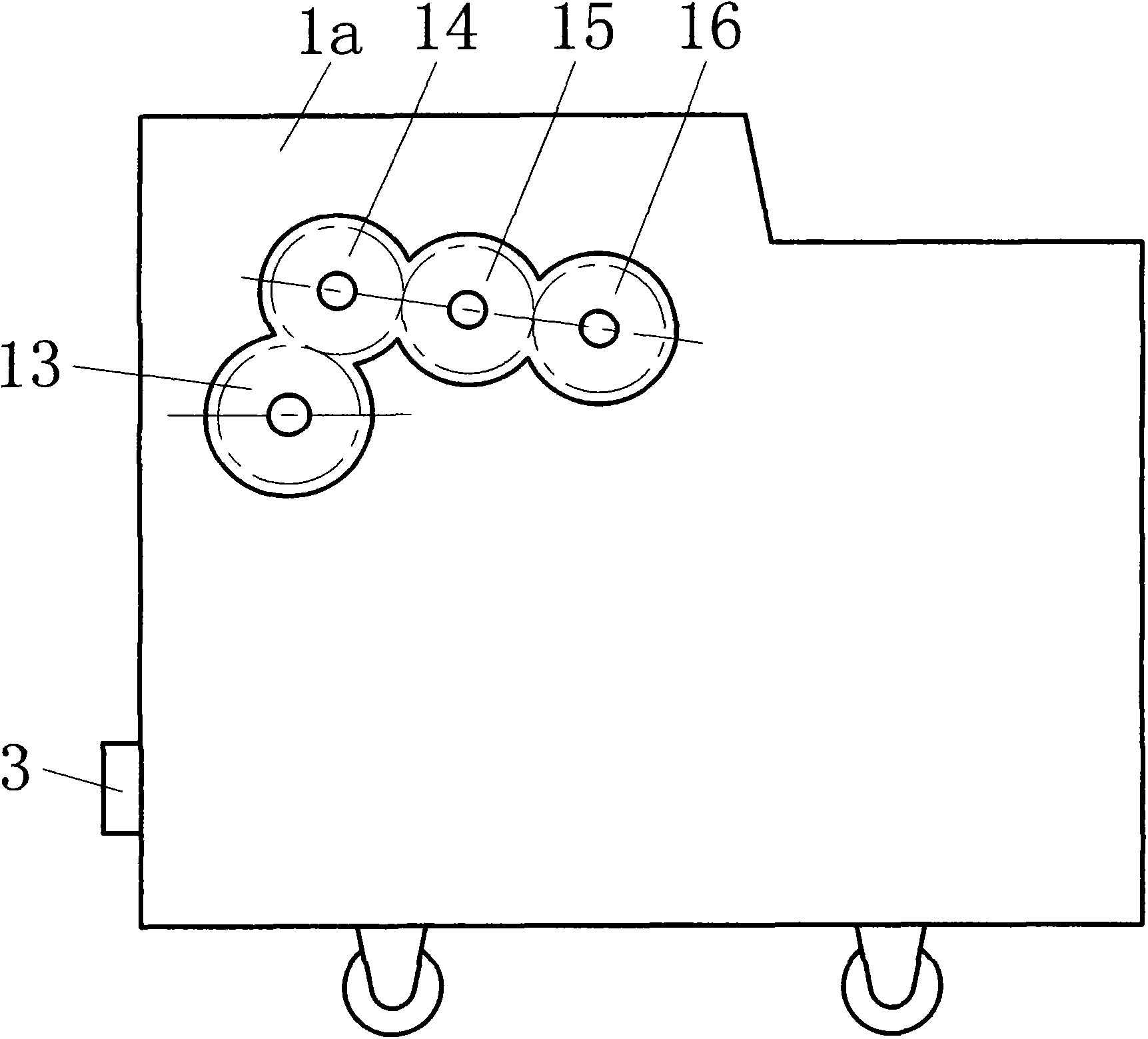

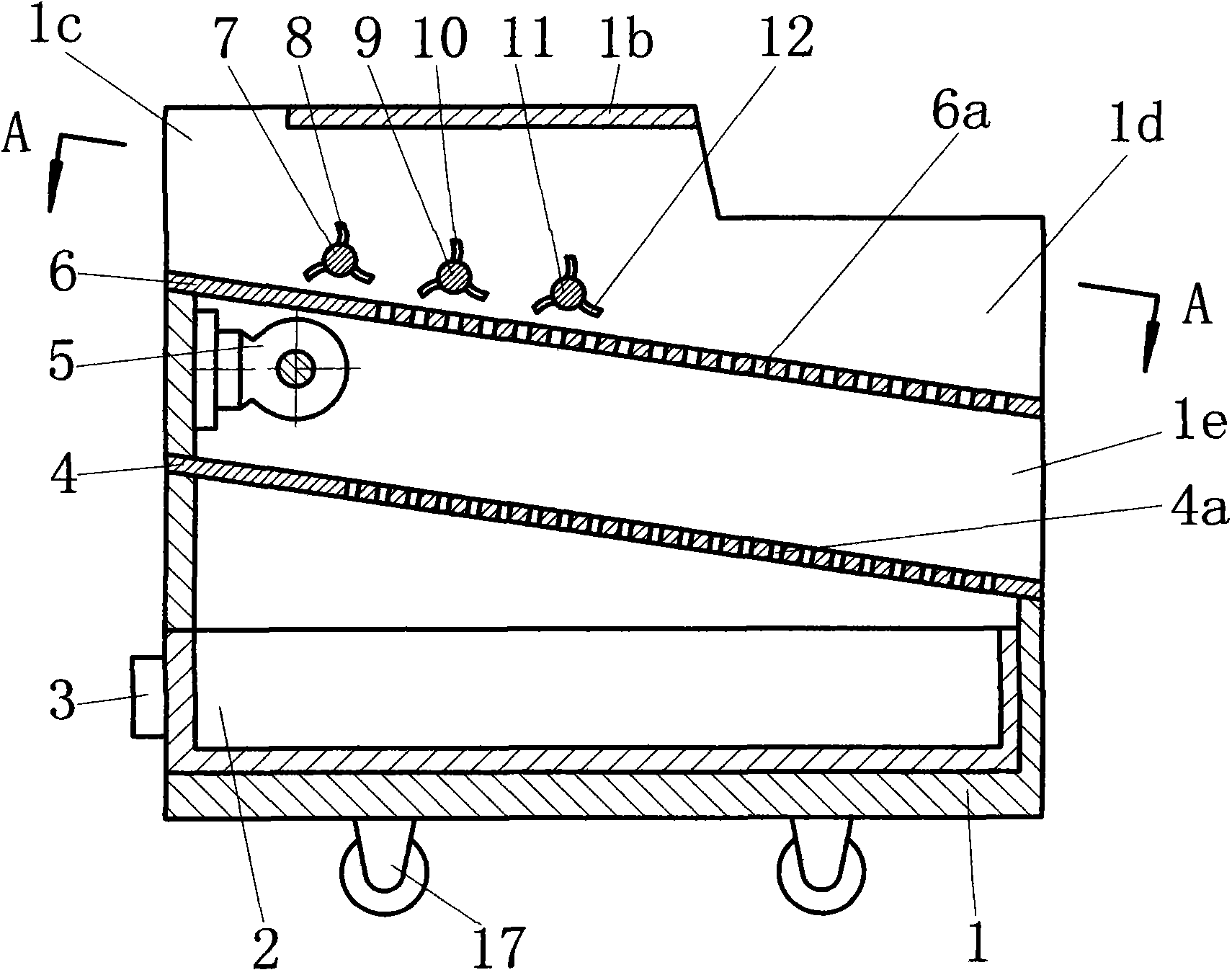

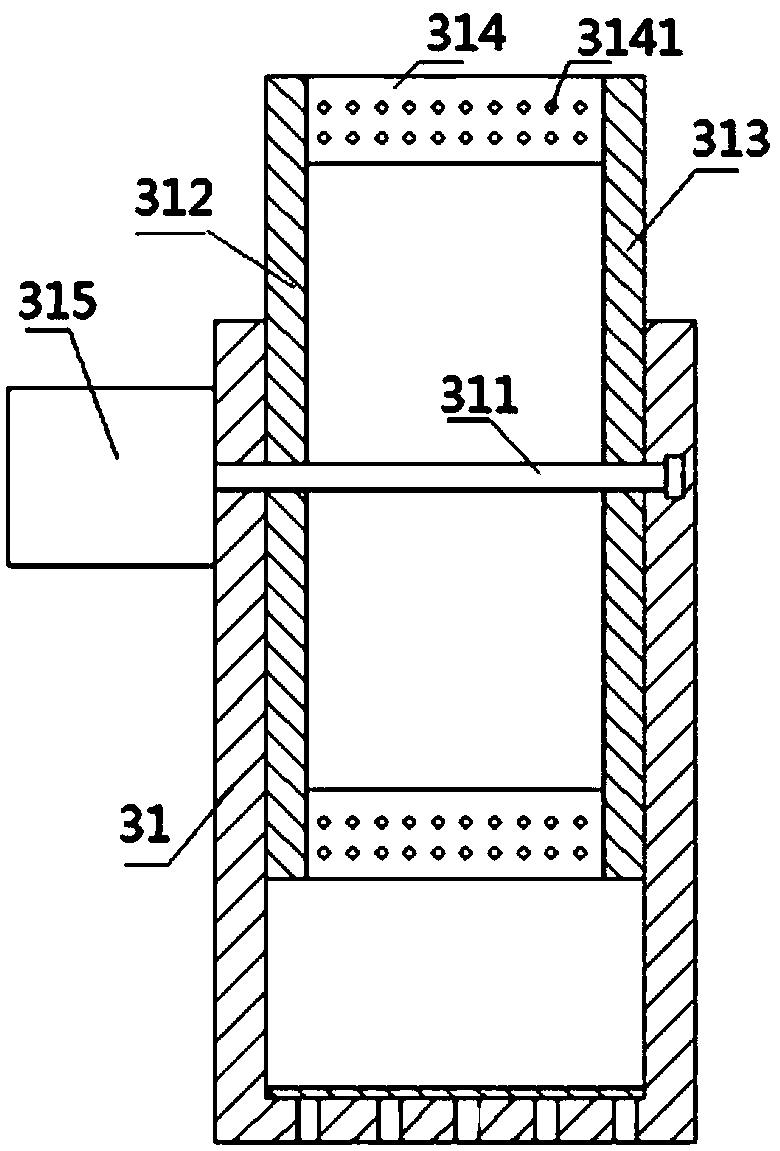

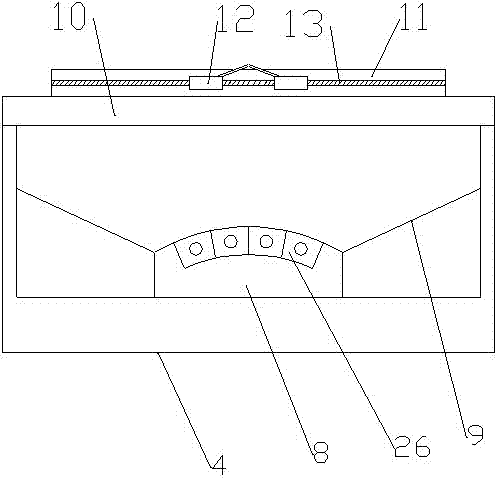

Intelligent sample storage cabinet system

InactiveCN105620994ACompact space layoutImprove storage space utilizationStorage devicesManipulatorIntelligent control

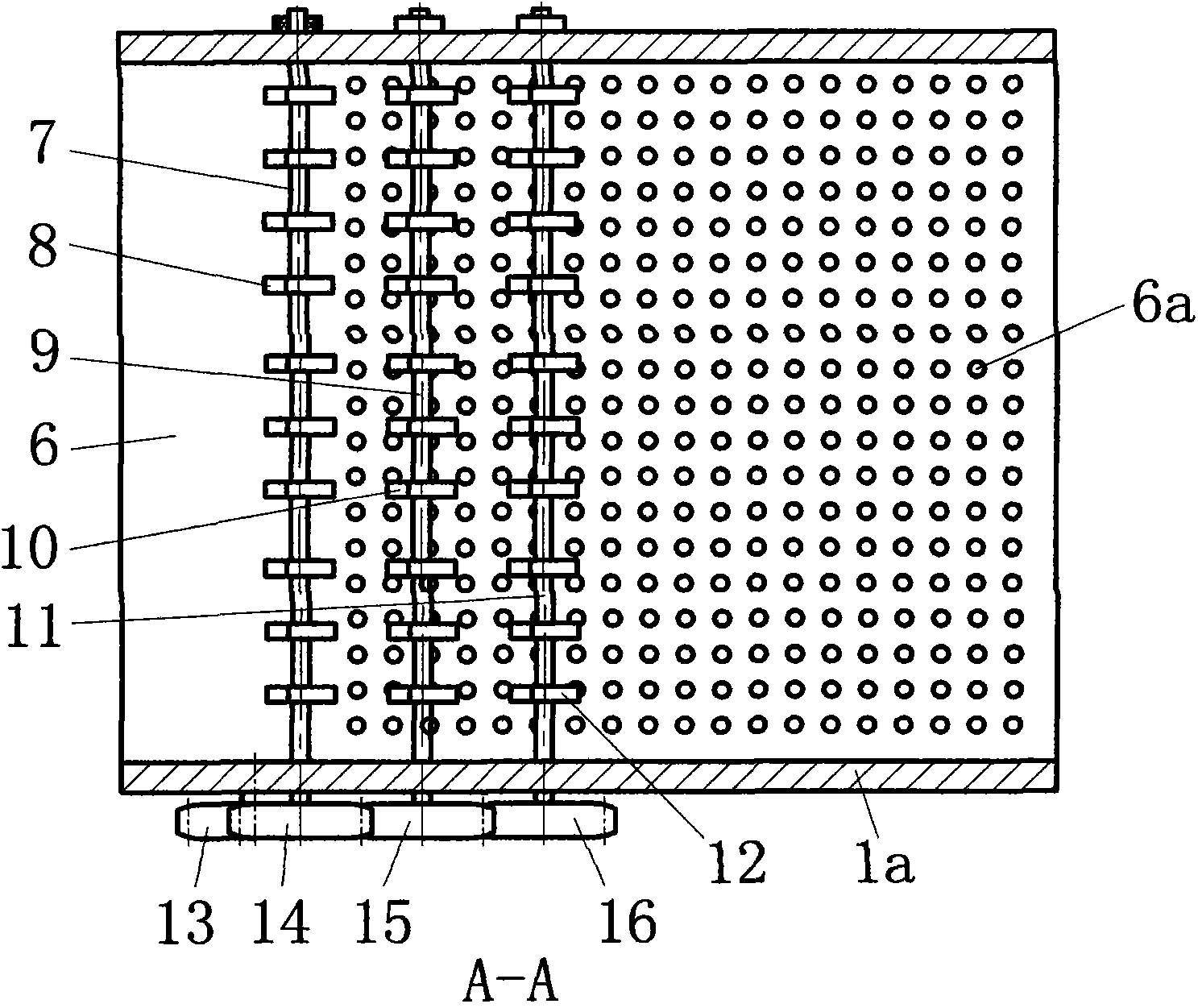

The invention discloses an intelligent sample storage cabinet system. The system comprises a sample storage unit for storing samples, a sample storage / taking movement unit for shifting the samples, and an intelligent control unit; the sample storage unit includes multiple storage bins arranged in an array form; the sample storage / taking movement unit includes a pneumatic manipulator mechanism; the pneumatic manipulator mechanism is provided with a storage cavity and a negative-pressure production component; and after an opening end of the storage cavity is tightly connected with opening ends of the storage bins, the negative-pressure production component extracts air in the storage cavity and the storage bins to form vacuum negative pressure so as to suck the samples in the storage bins to the storage cavity. The system has the advantages of high space utilization rate, high intelligent modular degree, capability of synchronously storing and taking one or more samples and safe and efficient sample storage and taking.

Owner:HUNAN SUNDY SCI & TECH DEV

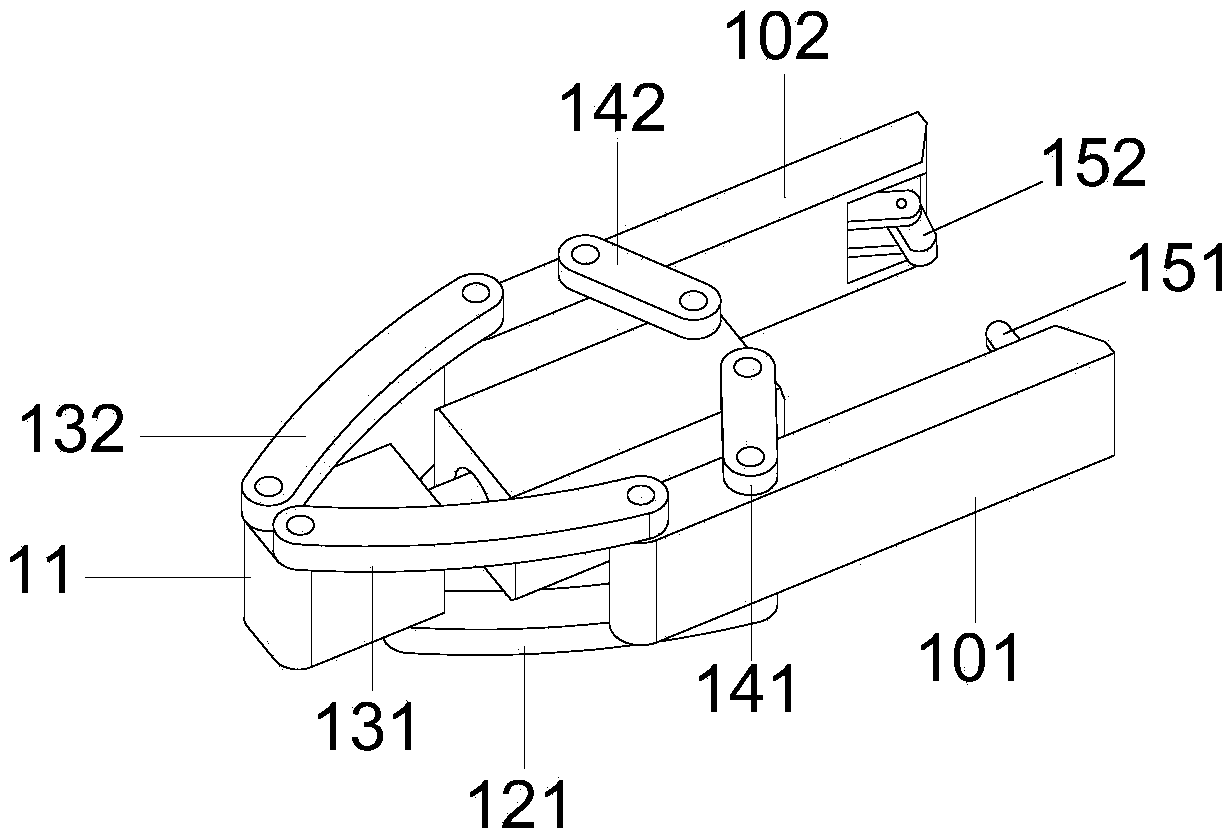

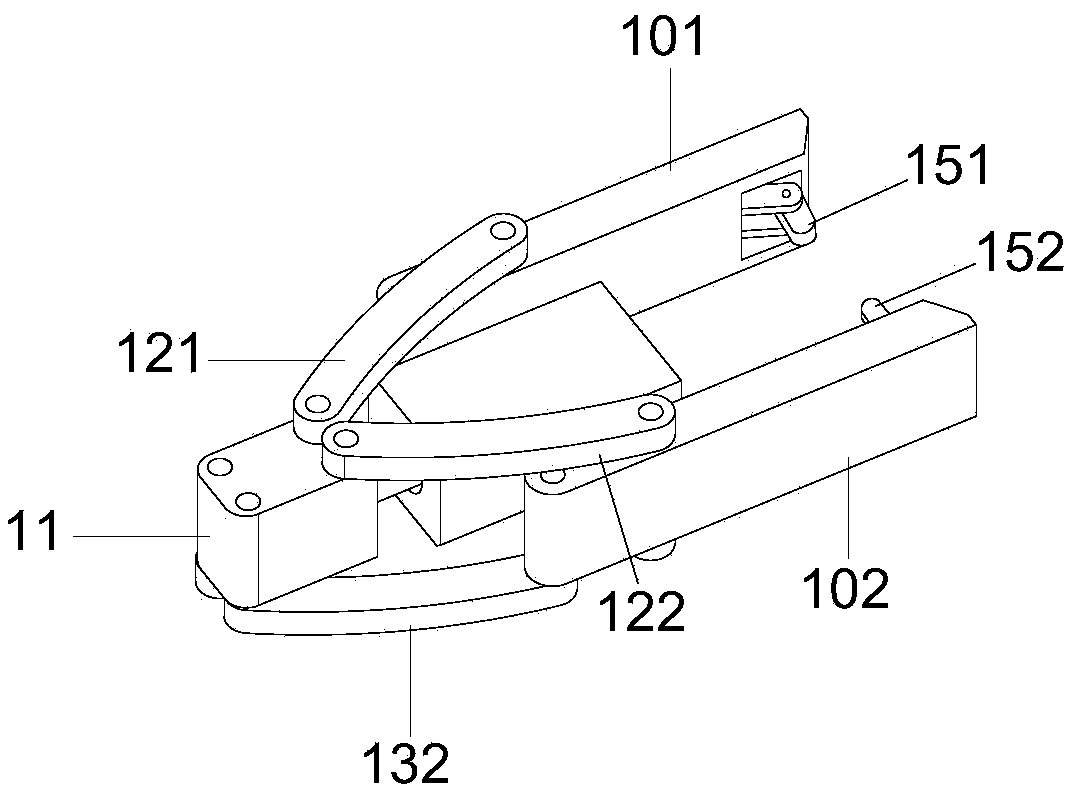

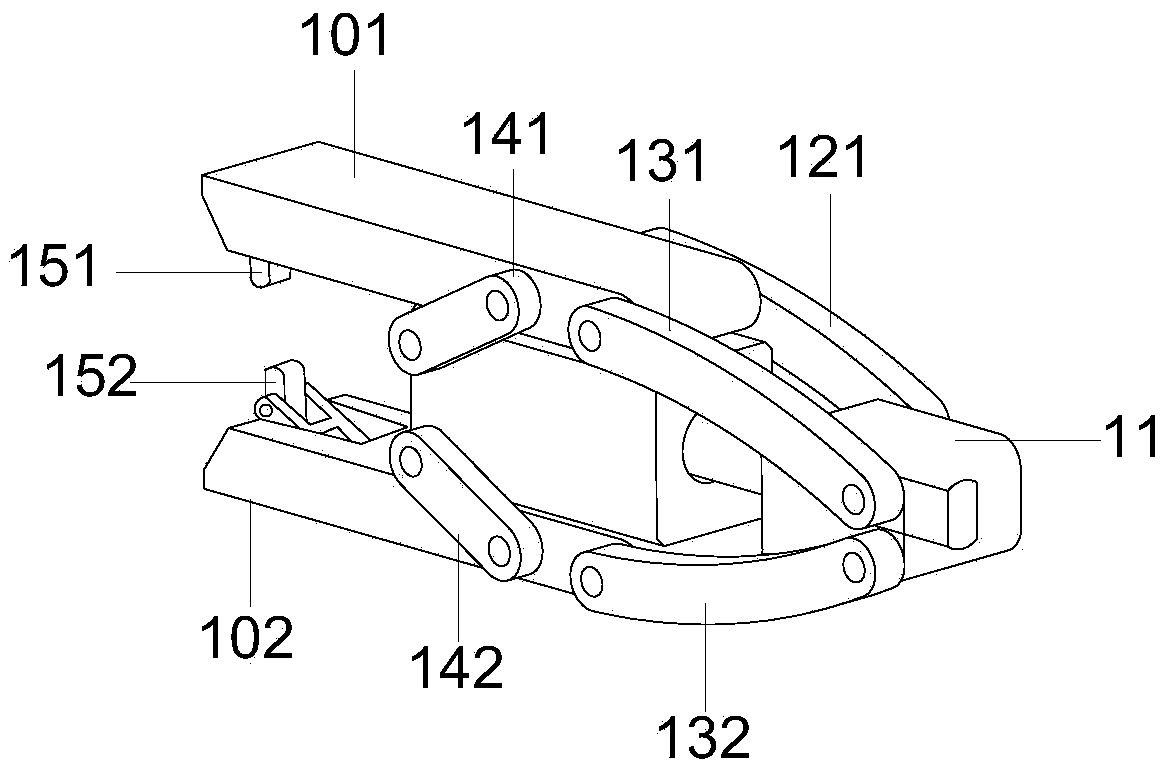

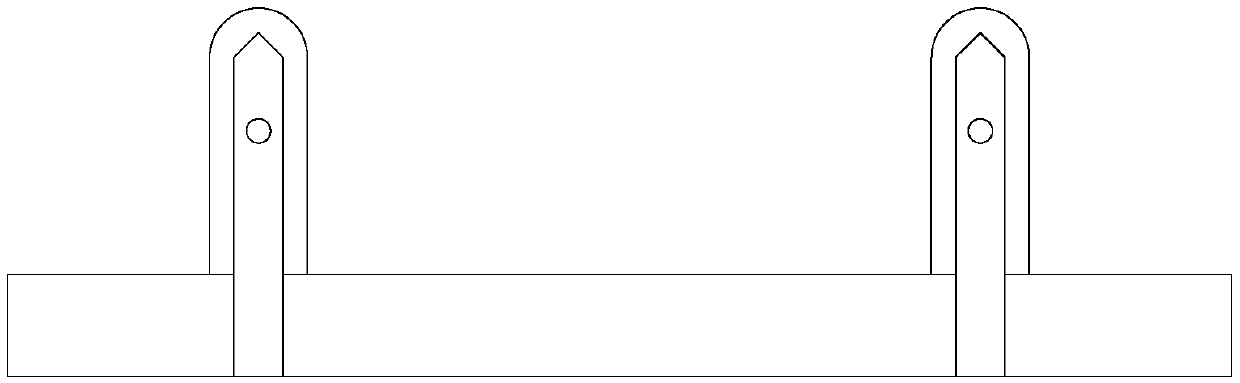

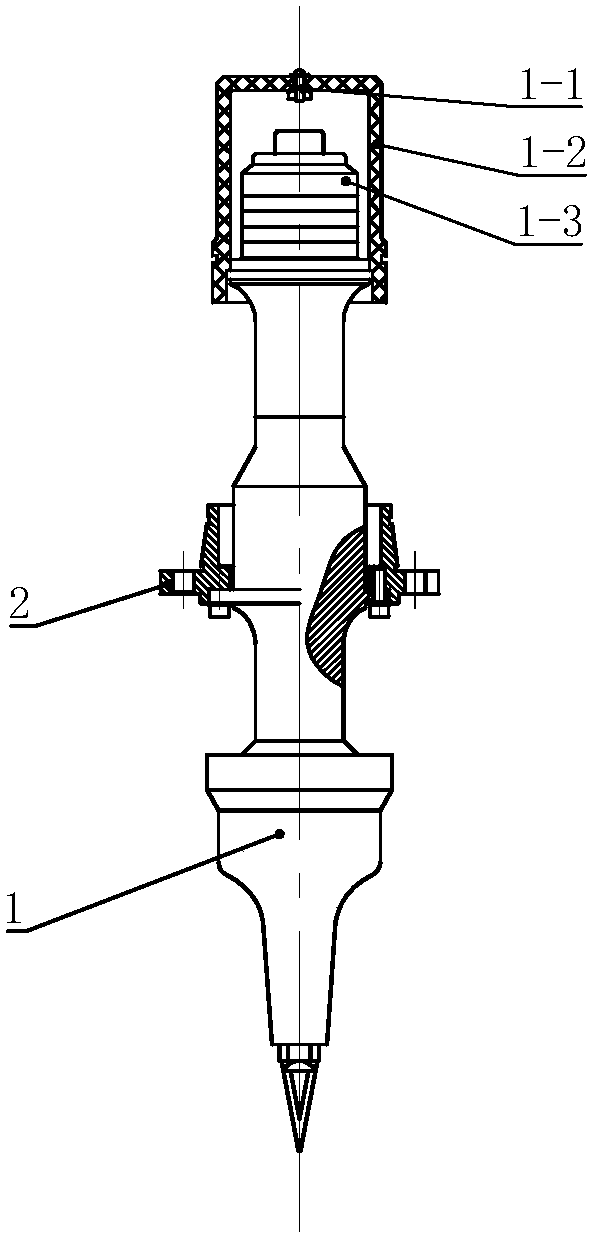

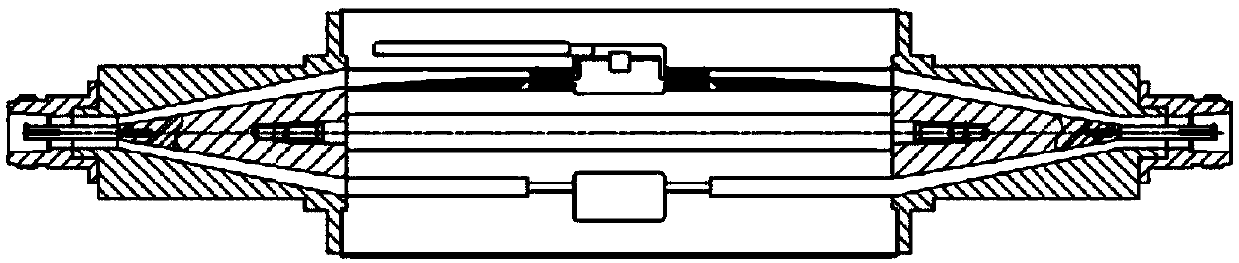

Petroleum drilling and production equipment, drilling table surface manipulator and pipe column support mechanism

ActiveCN105370226ASimple structureCompact space layoutDrilling rodsDrilling casingsManipulatorPetroleum

The invention discloses petroleum drilling and production equipment, a drilling table surface manipulator and a pipe column support mechanism. The invention discloses the pipe column support mechanism, comprising a first grabbing rod, a second grabbing rod and a telescopic driving piece, wherein a first connecting rod and a second connecting rod are hinged between the first grabbing rod and a first end of the telescopic driving piece; a third connecting rod and a fourth connecting rod are hinged between the second grabbing rod and the first end of the telescopic driving piece; a fifth connecting rod is hinged between the first grabbing rod and a second end of the telescopic driving piece; a sixth connecting rod is hinged between the second grabbing rod and the second end of the telescopic driving piece; the first grabbing rod, the first connecting rod, the second connecting rod and the telescopic driving piece are formed to a parallelogram mechanism; and the second grabbing rod, the third connecting rod, the fourth connecting rod and the telescopic driving piece are formed to a parallelogram mechanism. The pipe column support mechanism is simple in structure, compact in space layout, accurate and quick in positioning in pipe grabbing and excellent in working reliability.

Owner:SANY GRP

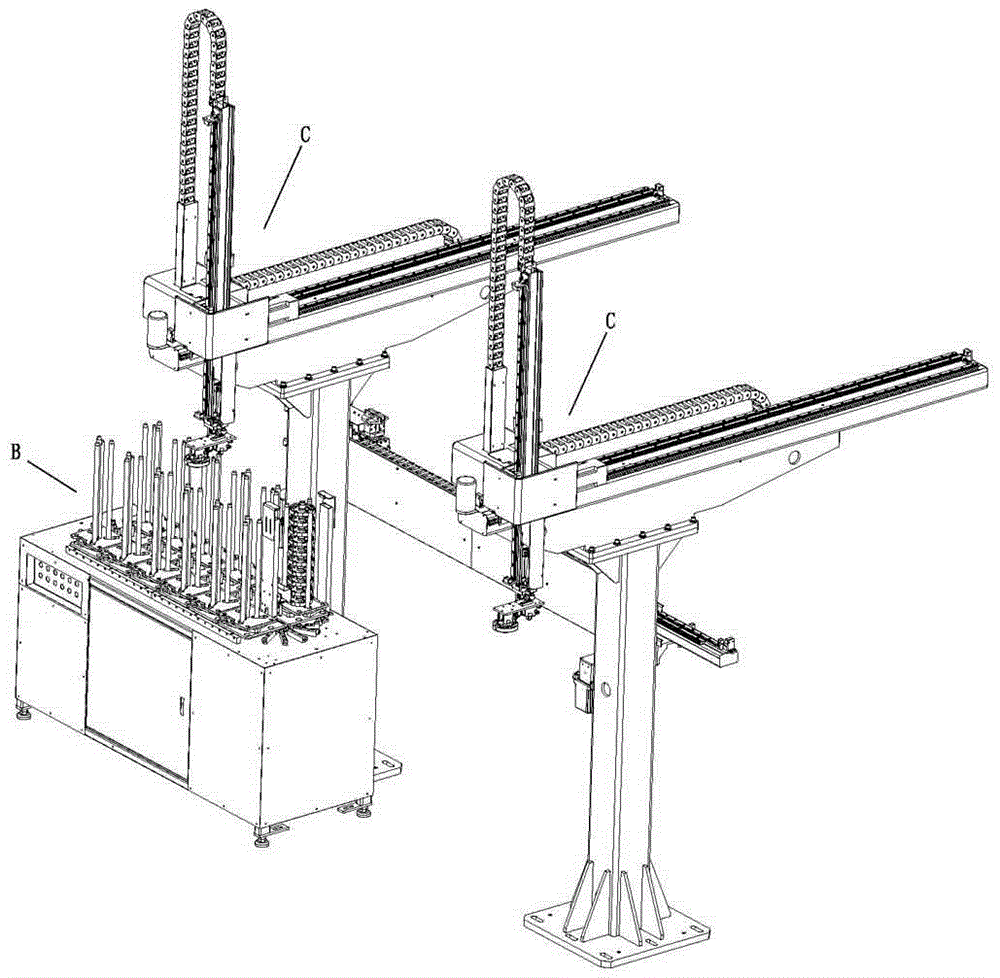

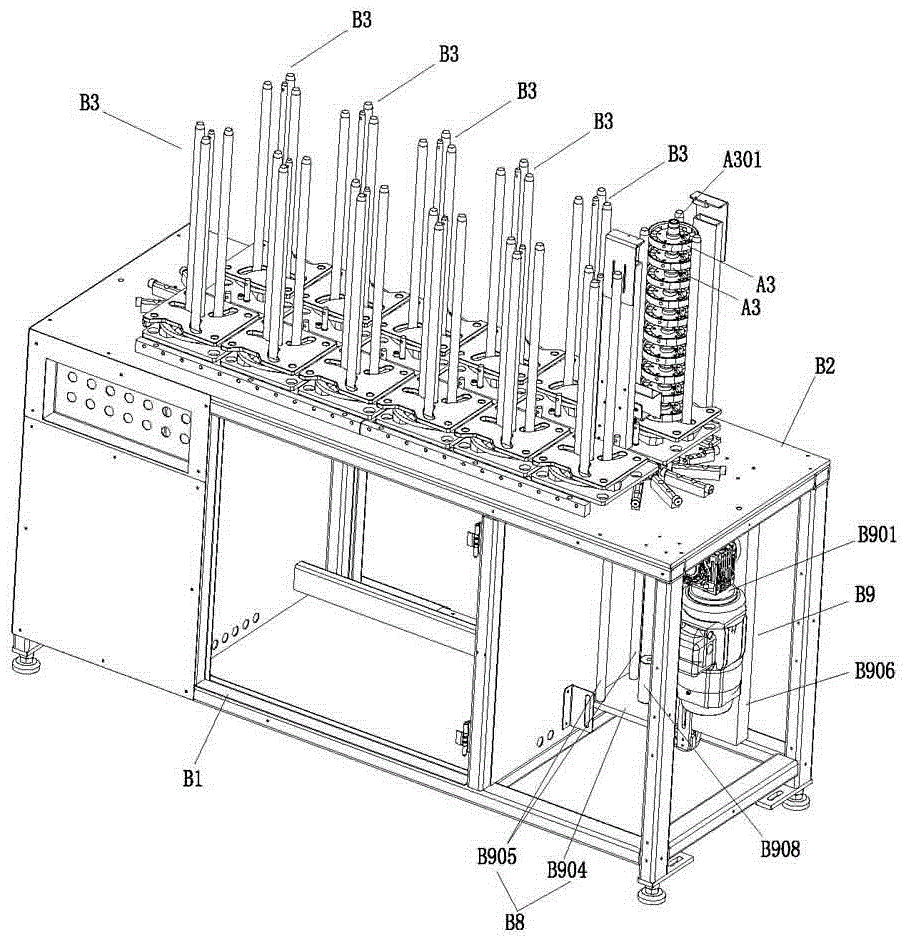

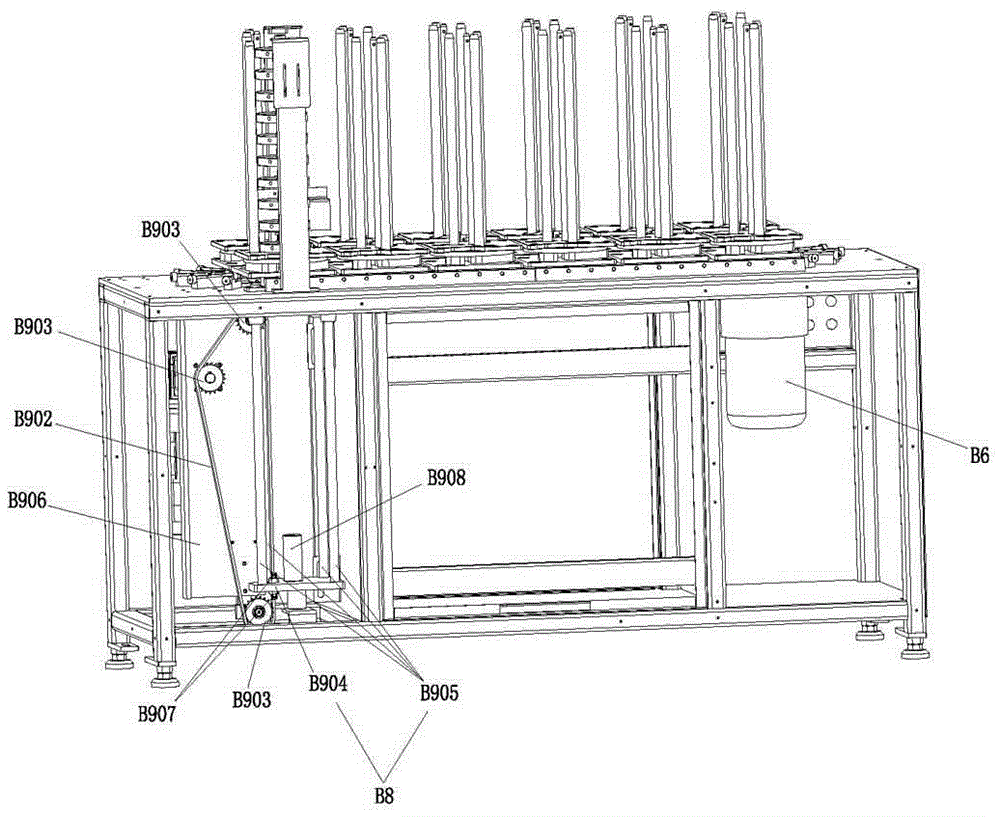

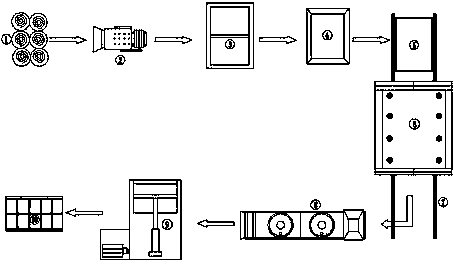

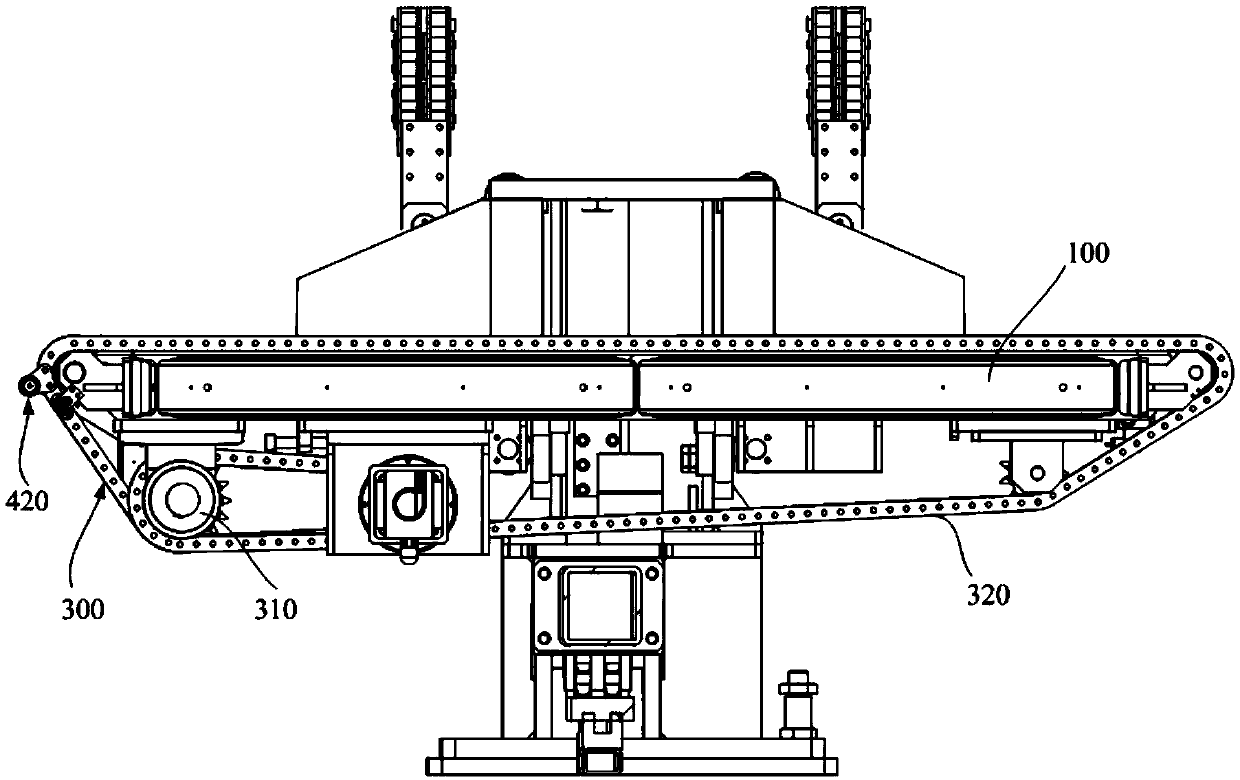

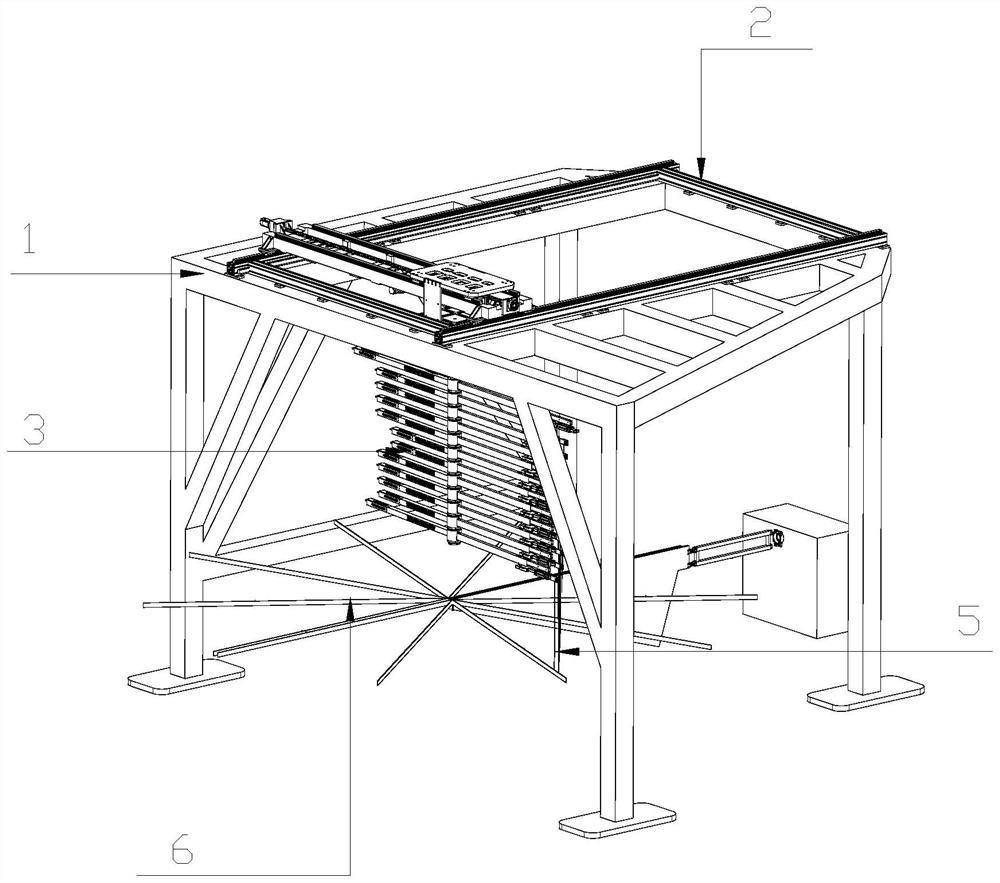

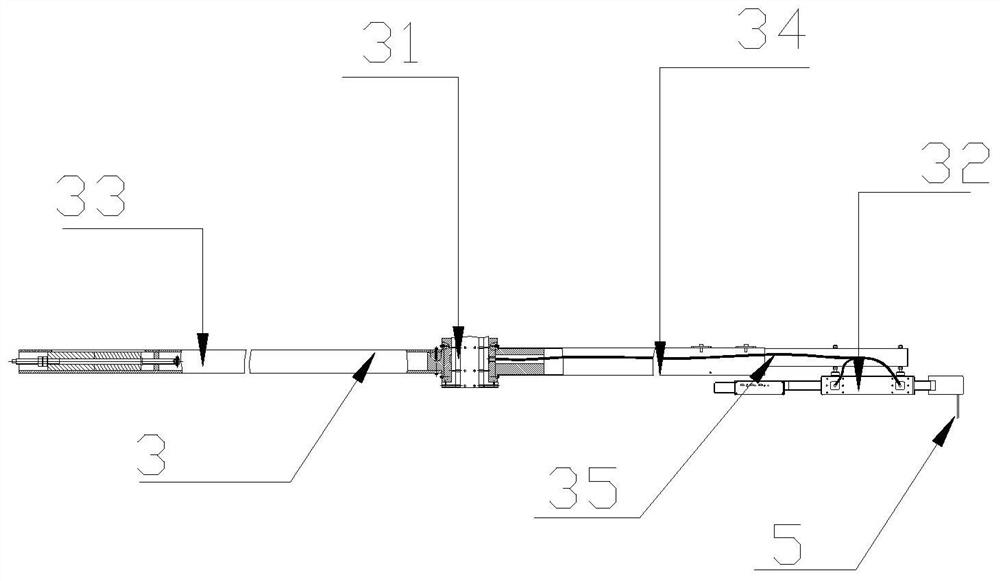

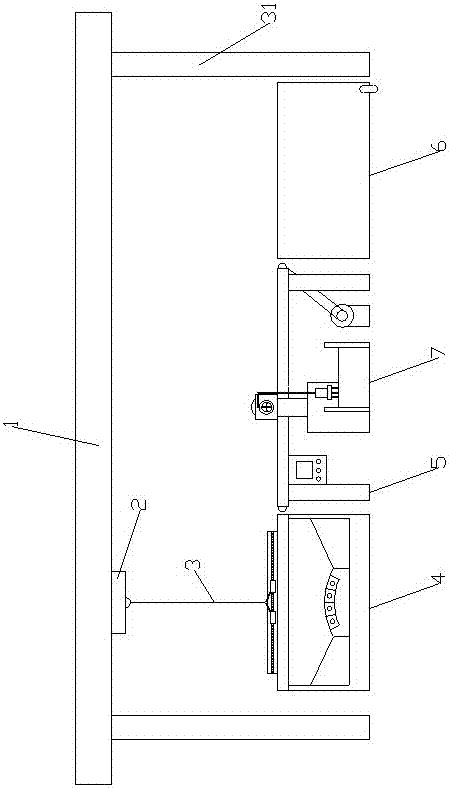

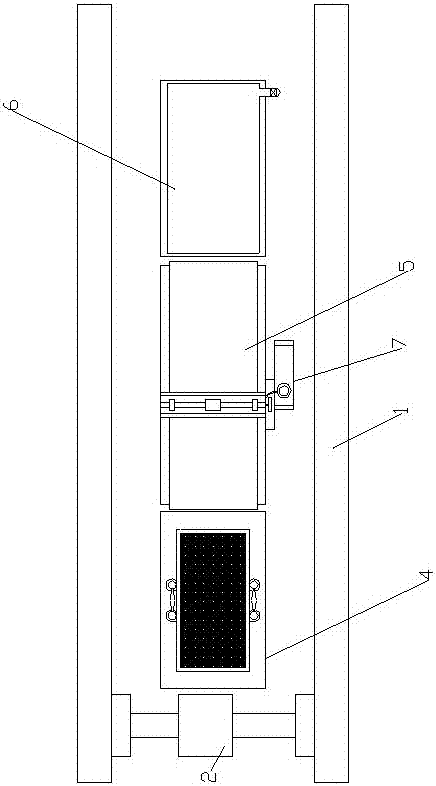

Automatic feeding and taking equipment with u-turning device

The invention relates to automatic feeding and taking equipment with a u-turning device. The automatic feeding and taking equipment comprises a rotary type material bin and two two-shaft mechanical arms and a u-turning transferring device; the rotary type material bin comprises a material bin base, a working table is arranged at the top of the material bin base, a plurality of material storage frames are installed on the working table, and a plurality of workpieces are stacked on each material storage frame; two transmission chain wheels are arranged on the two sides of the working table correspondingly, the two transmission chain wheels are connected through a transmission chain, and one of the transmission chain wheels is driven by a transmission chain wheel motor; the multiple material storage frames are arranged in the layout extending direction of the transmission chain, each material storage frame is in connected fit with the transmission chain through a connecting assembly, and each material storage frame achieves movement along with transmission of the transmission chain; a lifting frame is installed in the material bin base and is driven by a lifting assembly, so that the lifting frame penetrates the working table to upwards lift the workpieces; and the multiple material storage frames are all arranged to be capable of moving along with the transmission chain, rotary workpiece conveying is formed, the storage capacity of the workpieces is effectively increased, and the machining efficiency is effectively improved.

Owner:广东圣特斯数控设备有限公司

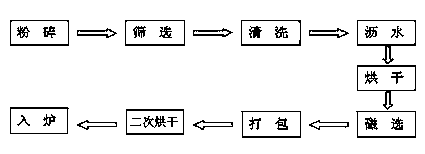

Titanium scrap recycling and remelting technology

ActiveCN103966465AImprove qualityImprove compactnessProcess efficiency improvementTitanium metalIngot casting

The invention relates to a processing technology for a great deal of titanium scraps produced from the processes of surface planing and milling and end surface cutting off of unpolished ingots produced from the casting of titanium ingots. The titanium scrap processing technology is a titanium scrap recycling and remelting technology which is characterized by comprising the following steps: pulverizing, screening, washing, water drainaging, drying, magnetic separating, packing, secondary drying and putting into the furnace. The titanium scrap recycling and remelting technology provides a set of processing scheme of high safety, reliability, practicability and efficiency and low cost for secondary recycling casting of the titanium scraps produced from the processes of surface planing and milling and end surface cutting off of the unpolished ingots produced from the casting of titanium, and the whole titanium scrap recycling and remelting technology is low in labor and time consumption; meanwhile, the space arrangement of devices is compact and reasonable, the process is coherent, the operation is convenient, the processing result is radical, and the general requirements to recycle, remelt and process titanium scraps of titanium ingot casting manufacturers can be met.

Owner:QINGHAI JUNENG TITANIUM IND CO LTD

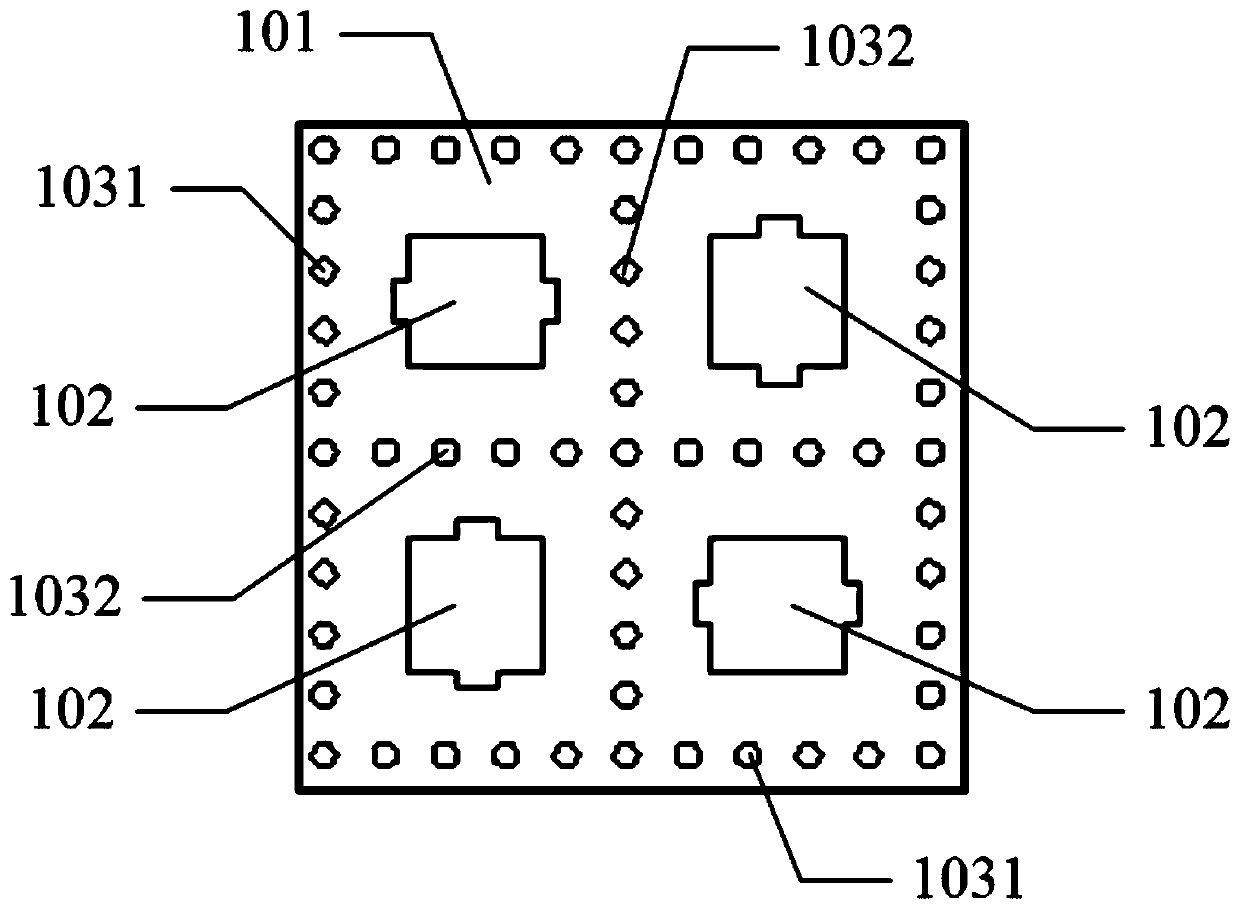

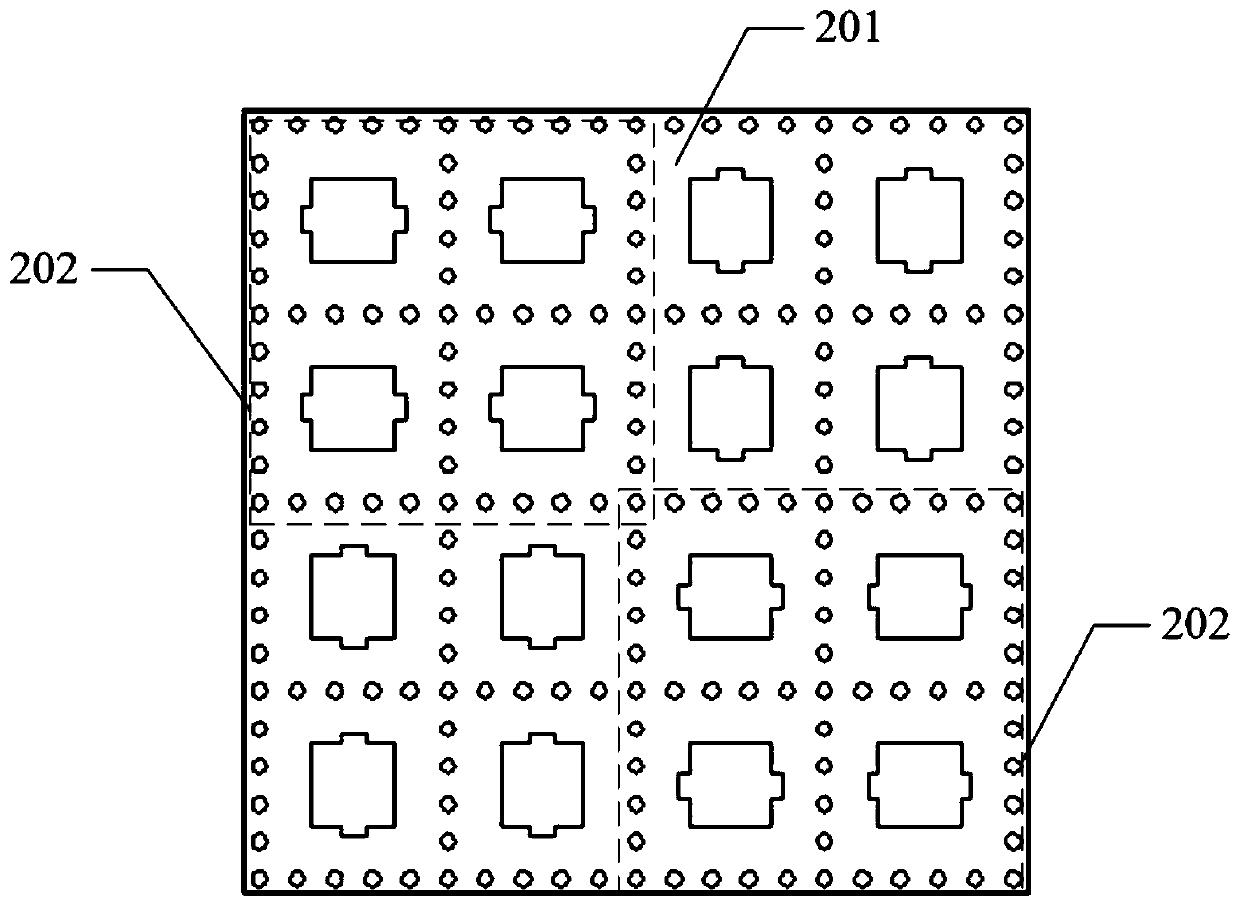

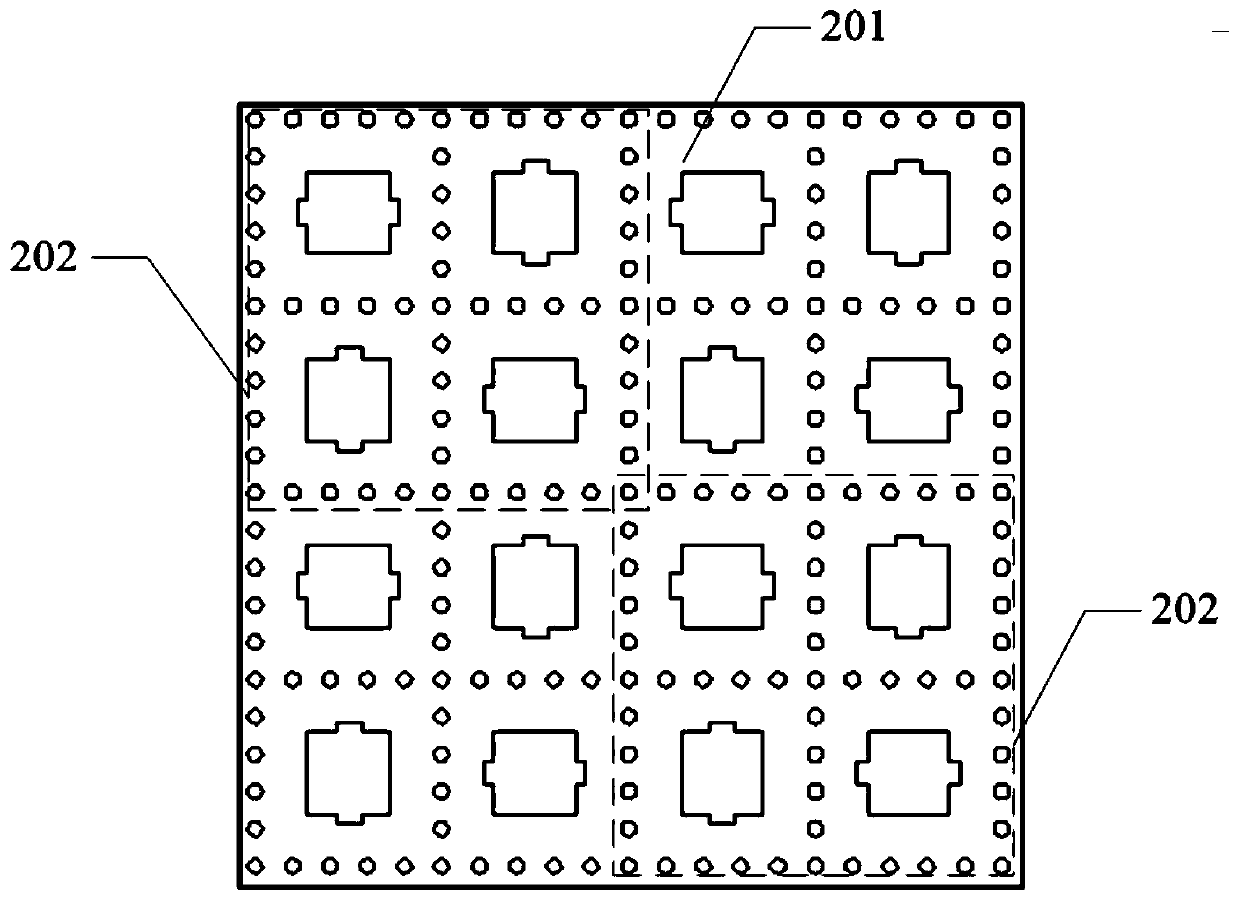

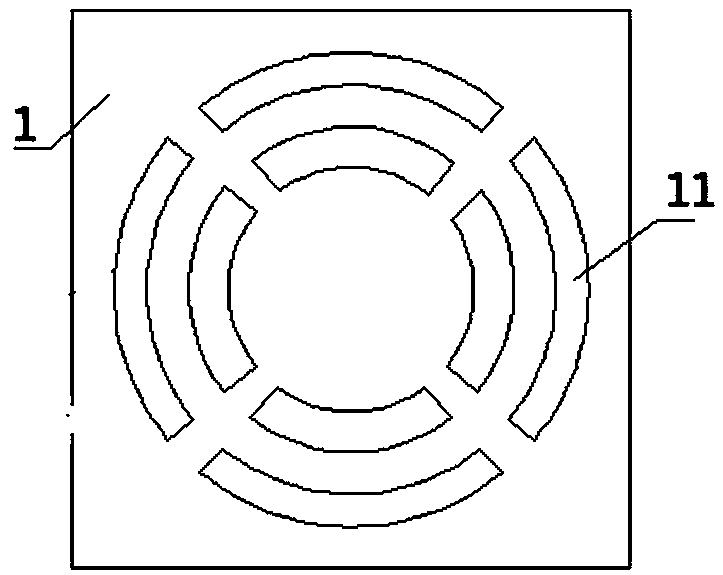

Array antenna subarray, array antenna module and array antenna

PendingCN110459871AImprove isolationImprove electrical performanceRadiating elements structural formsIndividually energised antenna arraysDielectric substrateElectrical performance

The invention discloses an array antenna subarray, an array antenna module and an array antenna. At least two unit antennas are arranged on the surface of a dielectric substrate, the at least two unitantennas surround a first center of the surface of the dielectric substrate, and the rotation angle difference between adjacent unit antennas is 360 degrees / N. Meanwhile, each unit antenna is the same, and the distance between each antenna unit and the first center is the same. The antenna subarray arranged by adopting the above mode has very compact spatial arrangement after being assembled intoa phased array antenna, and a better circular polarization function can be achieved. In addition, metal vias can also be arranged around each unit antenna and between two adjacent unit antennas, so that the isolation of the whole phased array antenna is improved on the basis of improving the isolation between the unit antennas, thereby having the technical effects of improving the overall electrical performance of the phased array antenna and improving the wide-angle scanning ability of the phased array antenna.

Owner:CHENGDU T-RAY TECH CO LTD

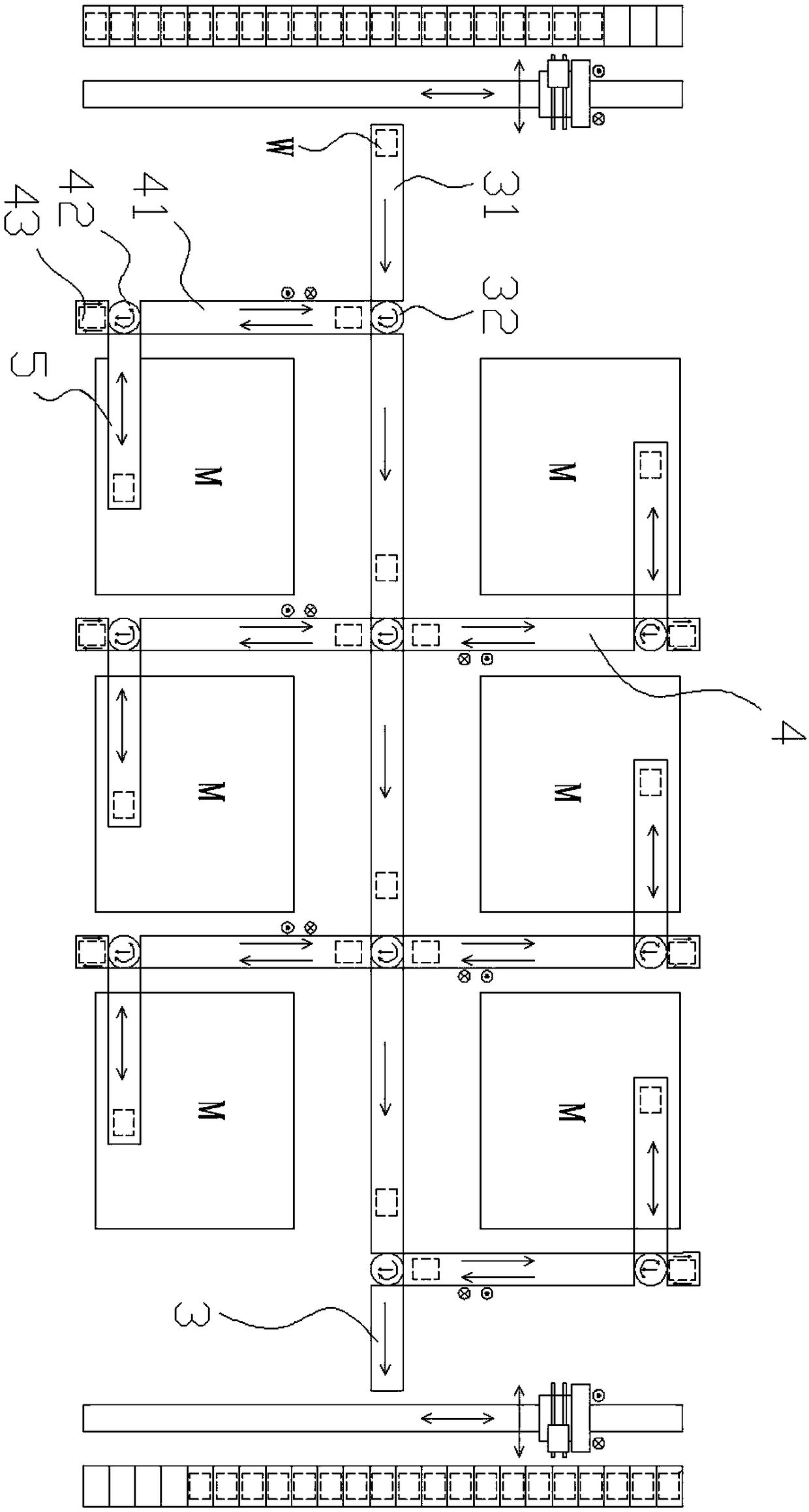

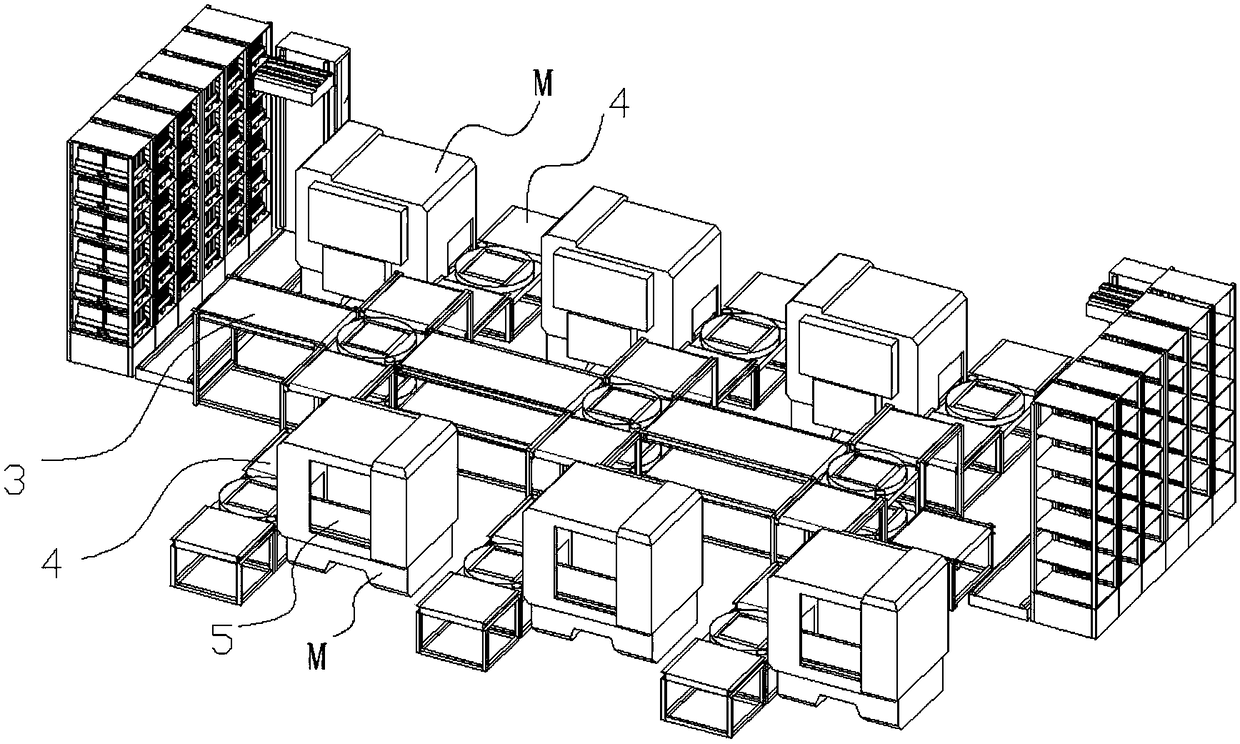

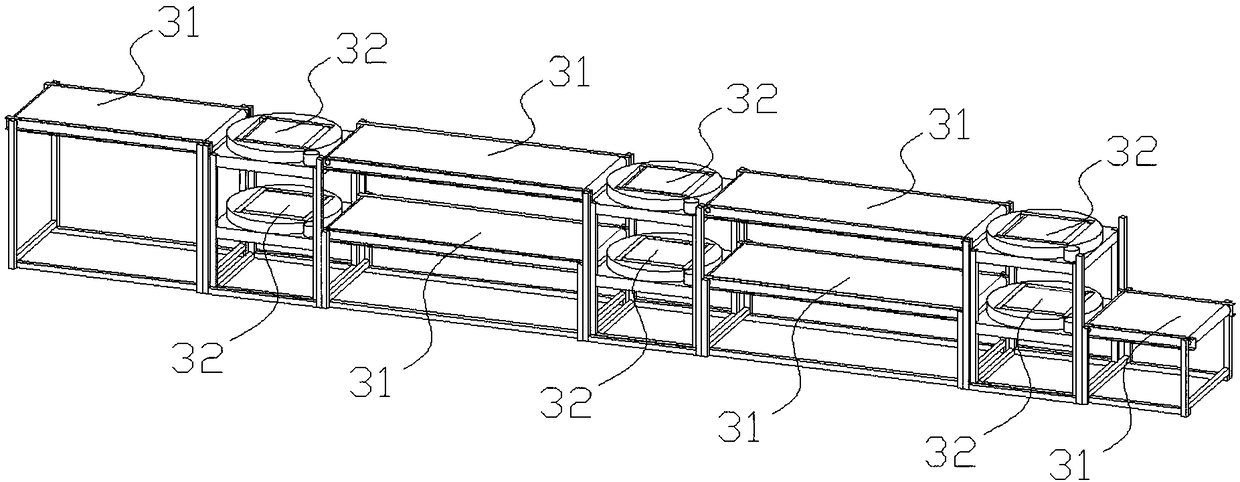

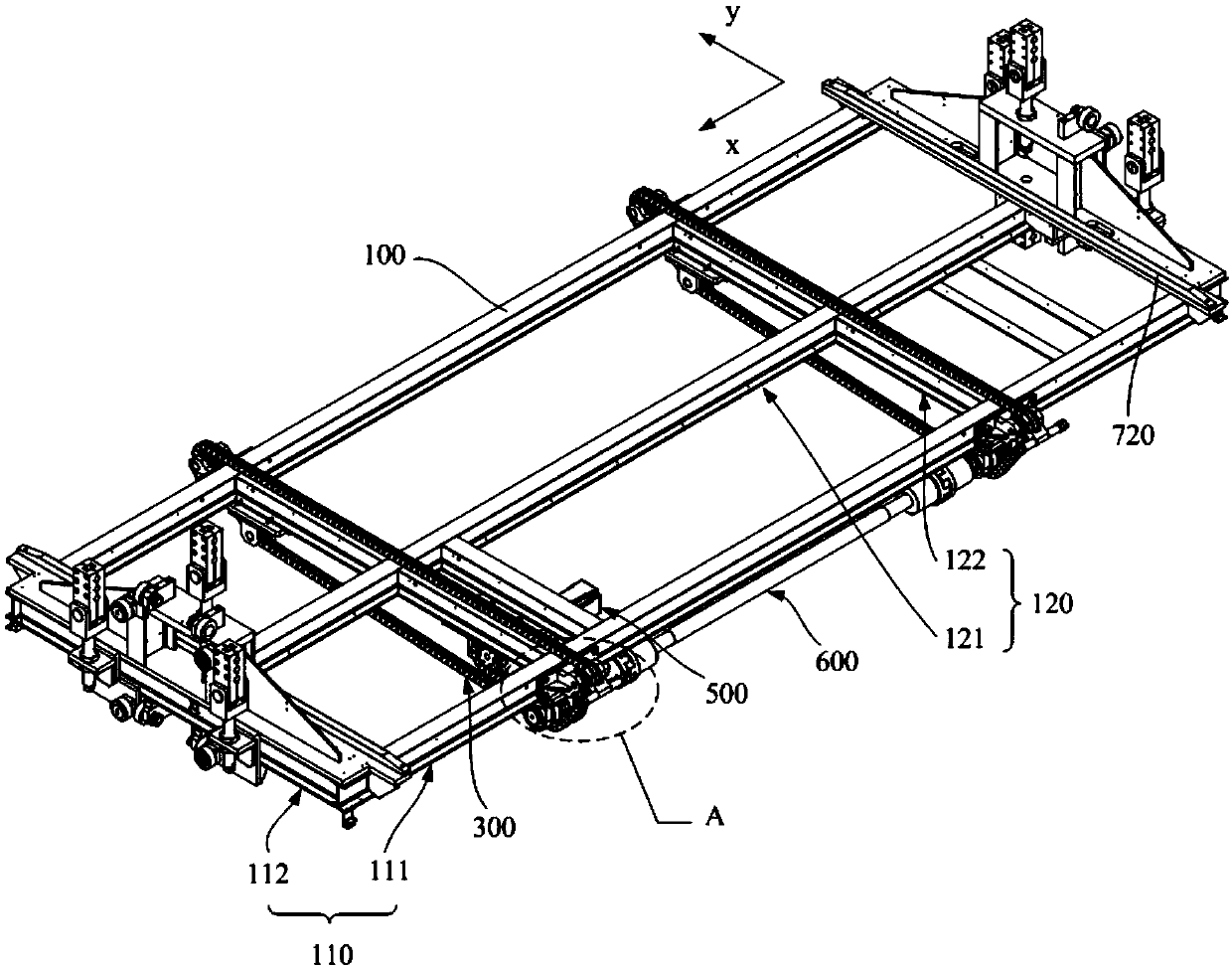

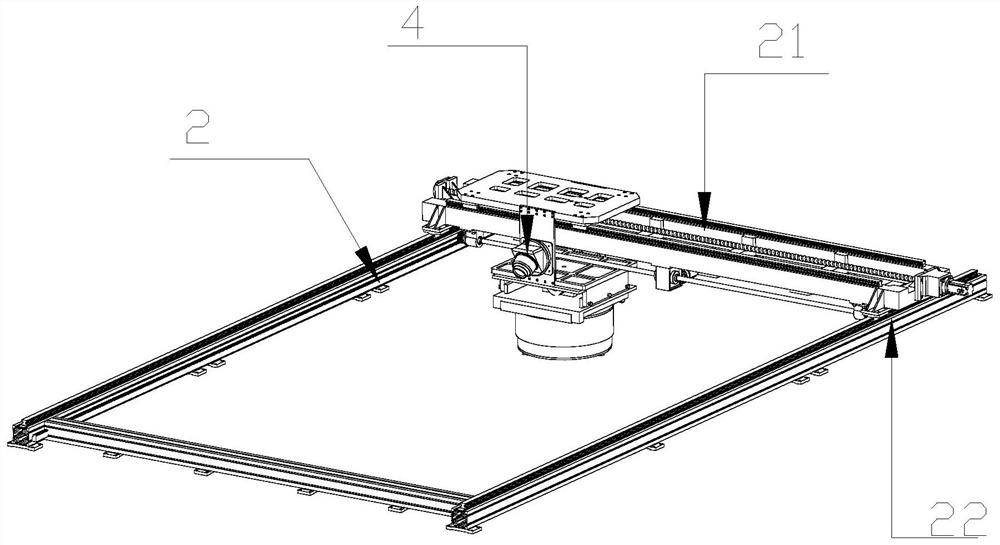

Flexible workpiece transferring system with temporary storage function

ActiveCN108190462ASmall footprintUnmanned automatic operationConveyor partsContinuous/uninterruptedTransfer system

A flexible workpiece transferring system with a temporary storage function comprises a transferring line and a machining center. The transferring line is used for transferring workpieces to the machining center or transferring the workpieces from the machining center. The flexible workpiece transferring system with the temporary storage function is characterized in that the transferring line comprises a temporary storage transferring line, the temporary storage transferring line is arranged adjacent to the machining center, and one machining center is correspondingly provided with one temporary storage transferring line. Due to the fact that the transferring line is used for transferring the workpieces, the situation that a complex robot in the prior art is used is avoided, the flexible workpiece transferring system is simple and economical, less space is occupied, unmanned automatic operation can be achieved through the whole system, the whole system is provided with a relatively short conveying path, fewest robots are applied, a compact space layout and continuous uninterrupted high-efficiency machining are achieved, the flexibility of adjusting the conveying path on line is achieved, and the flexible workpiece transferring system with the temporary storage function is extremely economical and practical.

Owner:江西衡源智能装备股份有限公司

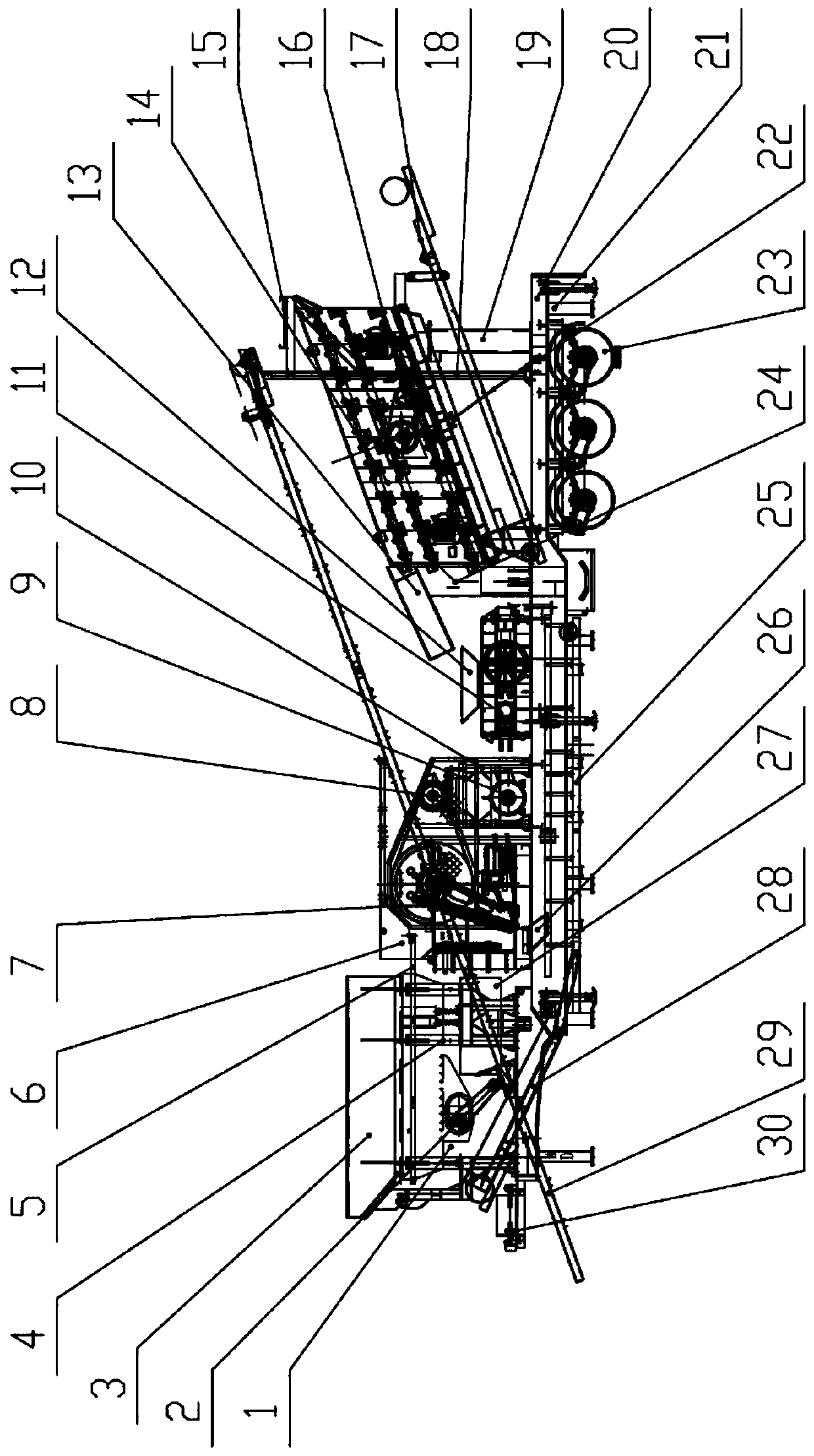

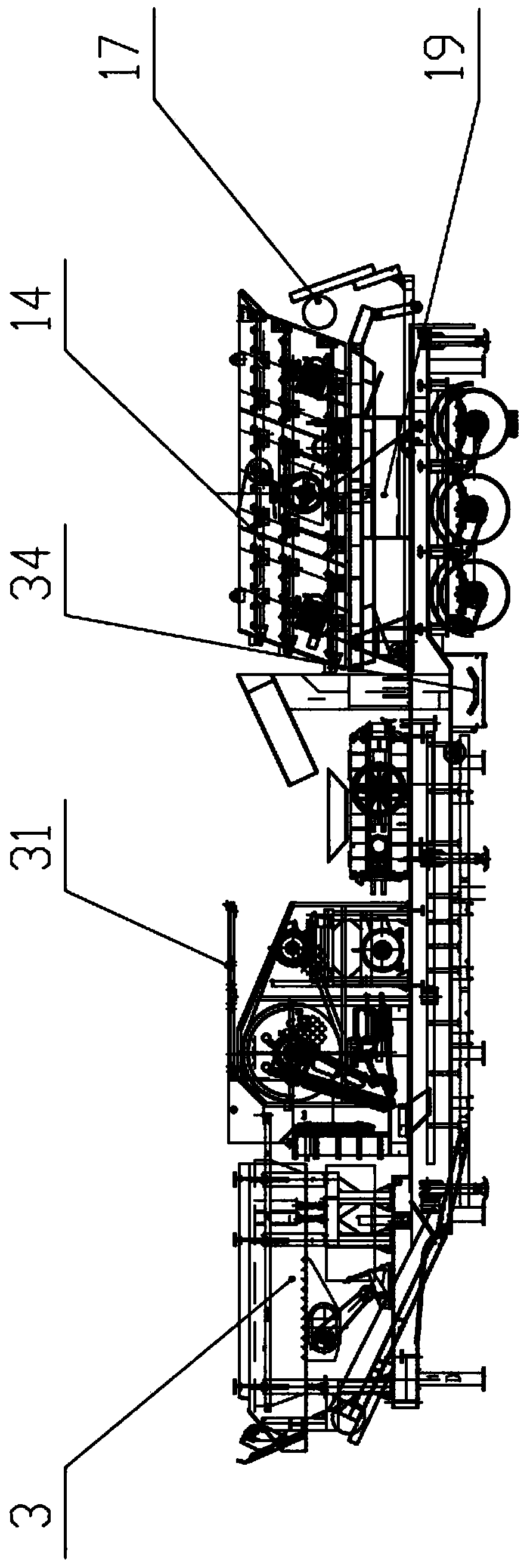

Environment-friendly aggregate series mobile crushing station

InactiveCN103752394AReduce man-hour consumptionCompact and reasonable space layoutGrain treatmentsLand resourcesBelt conveyor

The invention relates to an environment-friendly aggregate series mobile crushing station which is applicable to materials in various rigidities, as well as coarse crushing, intermediate crushing and fine crushing tasks in different fields. The station comprises vibratory feeding equipment, primary crushing equipment, secondary crushing equipment and vibratory screening equipment which are arranged from the front to the back, wherein a discharge port of the vibratory feeding equipment corresponds to a feed hopper of the primary crushing equipment; an unfinished product discharge hopper of the vibratory screening equipment corresponds to a feed hopper of the secondary crushing equipment; a first belt conveyor is arranged at discharge ports of the primary crushing equipment and the secondary crushing equipment in a penetrating manner; the first belt conveyor and a subsequent belt conveyor connected with the first belt conveyor are further connected to a feed port of the vibratory screening equipment; and a finished product discharge port of the vibratory screening equipment corresponds to a finished product belt. The station adopts an integrated complete unit, is reasonable and compact in spatial arrangement, optimizes a working site to the greatest extent, saves the land resources, can be combined flexibly according to different crushing technological requirements, is high in adaptability, reduces space occupation, saves cost, and is reliable and safe in performance and convenient to service.

Owner:上海建冶路桥机器设备有限公司

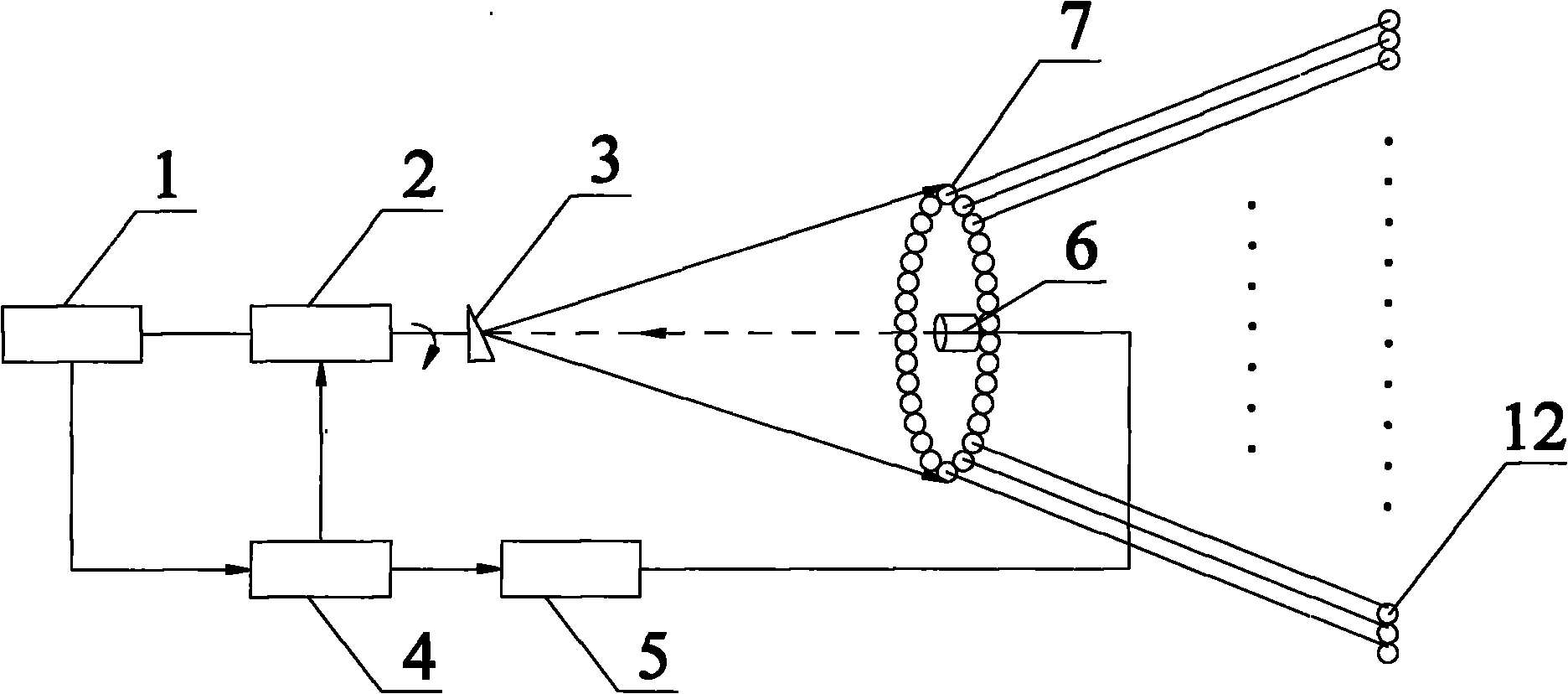

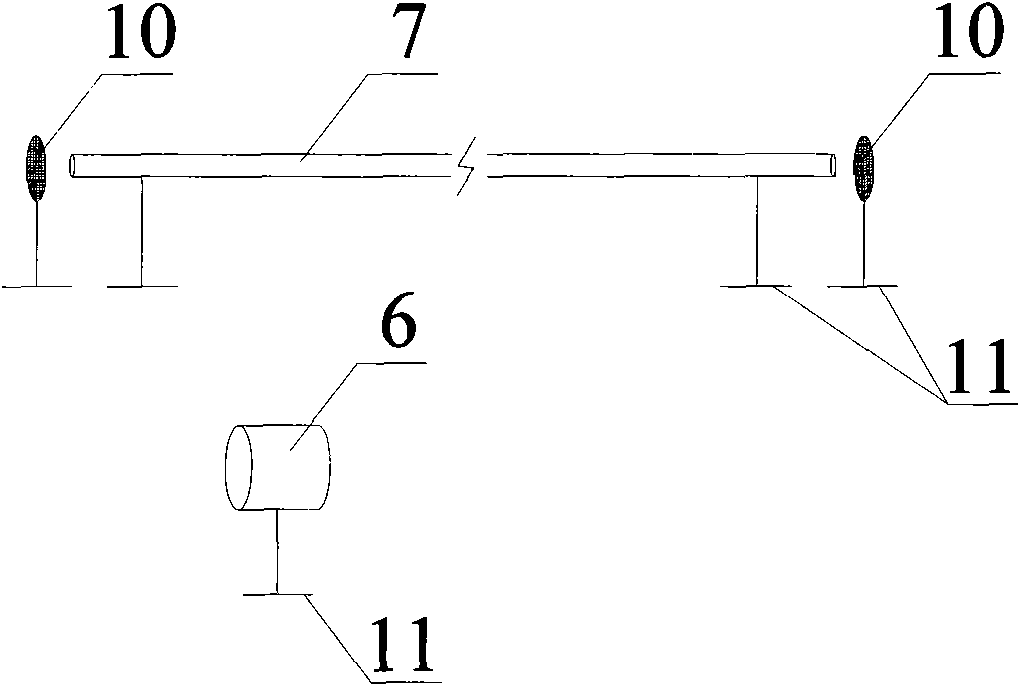

Laser radar launcher based on laser scanning fiber coupling system

InactiveCN101819270AThe principle is simpleExtend the scan rangeWave based measurement systemsLaser scanningOptoelectronics

The invention relates to a laser radar launcher based on a laser scanning fiber coupling system. A photoelectric encoder and a reflector are respectively connected to the rotating shaft of a brushless DC motor; a collimator in the same axis with the rotating shaft is connected to the tail fiber of a pulse fiber laser device; the end surfaces of one ends of energy transmission fibers are arranged into a circle around the axis and are fixed, and the end surfaces of the other ends of the energy transmission fibers are arranged side by side and fixed to form a fiber panel; a control subsystem is respectively connected with the pulse fiber laser device, the brushless DC motor and the photoelectric encoder; and the control subsystem comprises a motor diver with a Hall sensor, and a FRGA (Field Programmable Gate Array). The invention has the benefits of simple principle, large scanning scope which is not less than + / -16 degrees, compact spatial distribution, easy assembly, high earthquake resistance and high comprehensive efficiency, wherein the overall efficiency of the laser device from transmission to an optical system is 0.81.

Owner:DONGYING CITY JIAWEN OPTOELECTRONICS

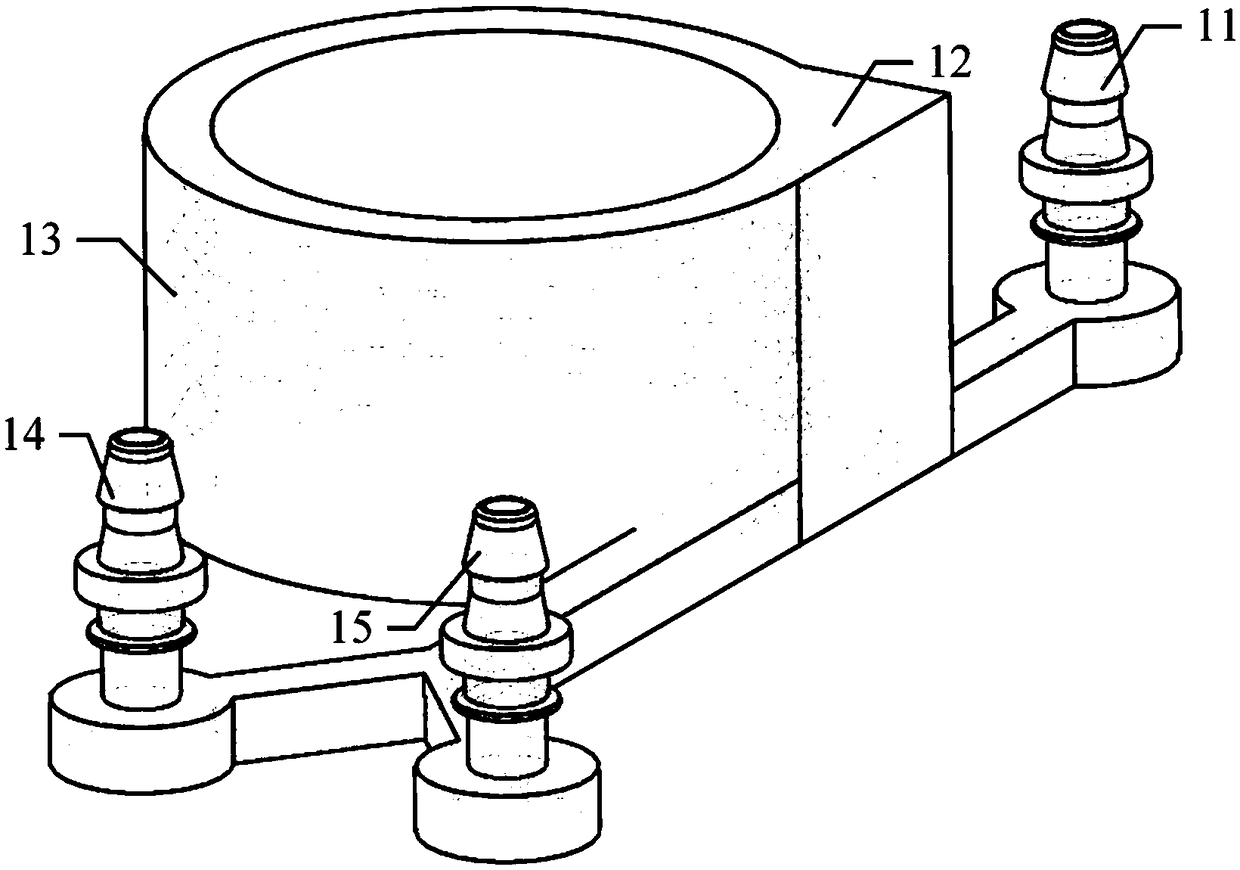

Microfluidic device for precise cell control

ActiveCN108715794AGuaranteed coupled inertial flow actionStable Coupled Inertial Flow ActionBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid storage tankEngineering

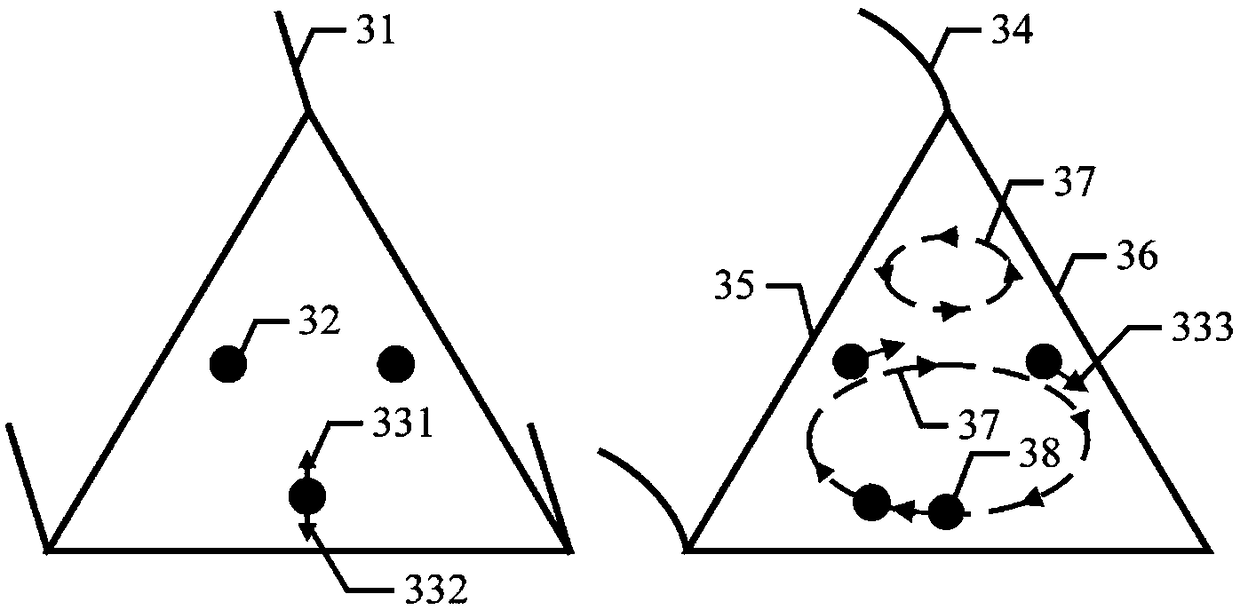

The invention provides a microfluidic device for precise cell control. The microfluidic device for precise cell control comprises an inlet end, a microfluidic device main body and an outlet end whichare sequentially connected, wherein the microfluidic device main body comprises a spatial spiral flow channel with a specially-shaped section; the two ends of the spatial spiral flow channel with thespecially-shaped section are communicated with the inlet end and the outlet end respectively; the cross section of the spatial spiral flow channel with the specially-shaped section is an isosceles triangle or a semicircle; the spatial spiral flow channel with the specially-shaped section adopts a spiral structure from top to bottom; the spiral structure has equal curvature radius; the inlet end comprises a sample inlet, a first liquid storage tank, a sample introducing flow channel and a connecting flow channel which are sequentially connected; the connecting flow channel is communicated withthe spatial spiral flow channel with specially-shaped section.

Owner:苏州中芯启恒科学仪器有限公司

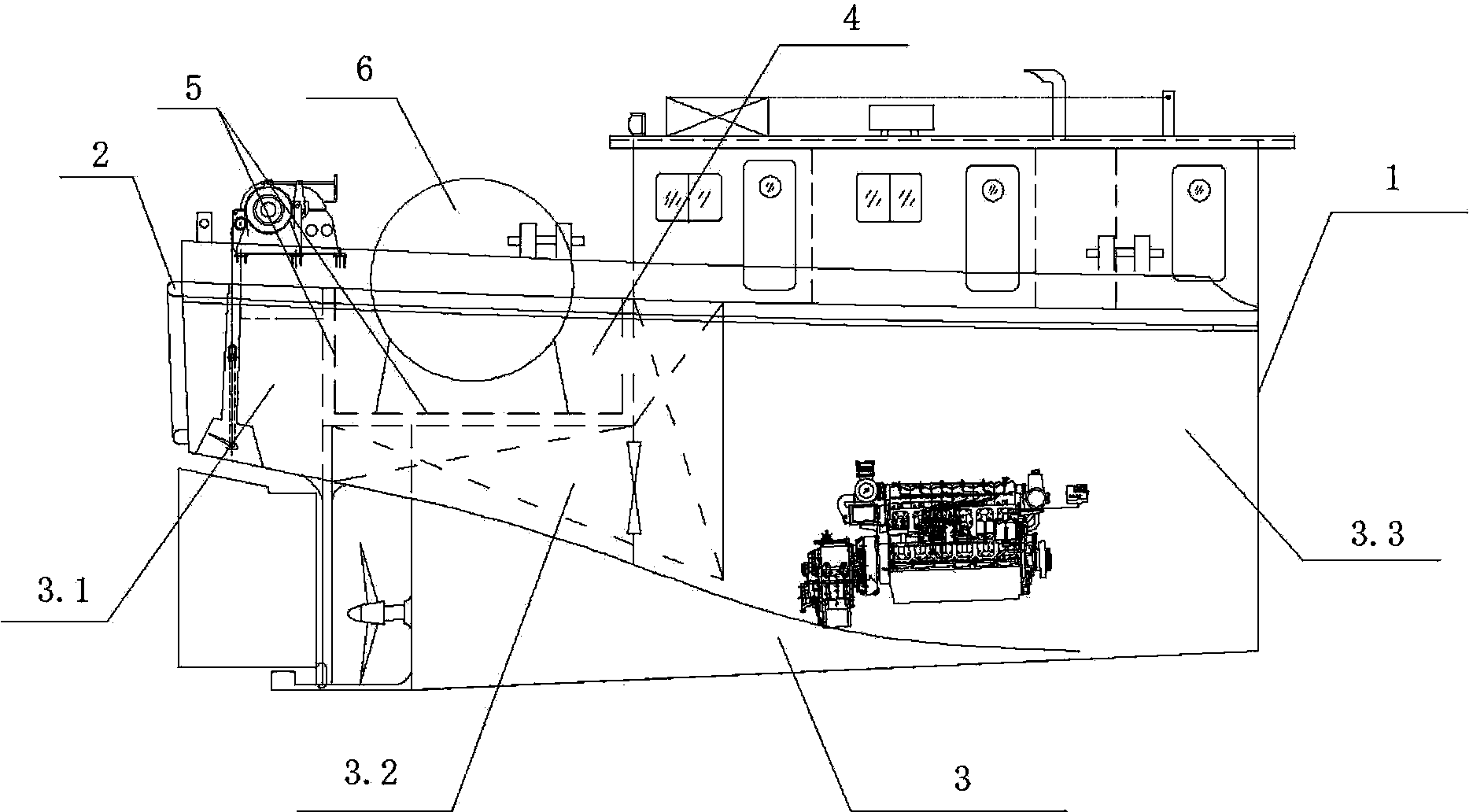

Gas storage tank bearing device for LNG (liquefied natural gas) single-fuel ship

InactiveCN104044697ASimple structureEasy to useHull interior subdivisionSpatial structureEnvironmental engineering

The invention provides a gas storage tank bearing device for an LNG (liquefied natural gas) single-fuel ship, which structurally comprises a hull. The hull is separated into an open-air part and a cabin part by a deck, wherein the cabin part comprises an afterpeak, a water ballast space and an engine room in sequence from the stern; a gas storage tank cabin connected with the deck is arranged between the water ballast space and the deck; the gas storage tank cabin is connected into a cuboid box shape through a supporting plate; a gas storage tank is arranged on the bottom of the gas storage tank cabin. Compared with the prior art, the gas storage tank bearing device for the LNG single-fuel ship has the advantages that the whole space structure layout is compact, the additionally arranged gas storage tank does not occupy too much space, the practicability is high, the application scope is wide, and promotion is easy.

Owner:SHANDONG HANGYU SHIPPING IND GRP

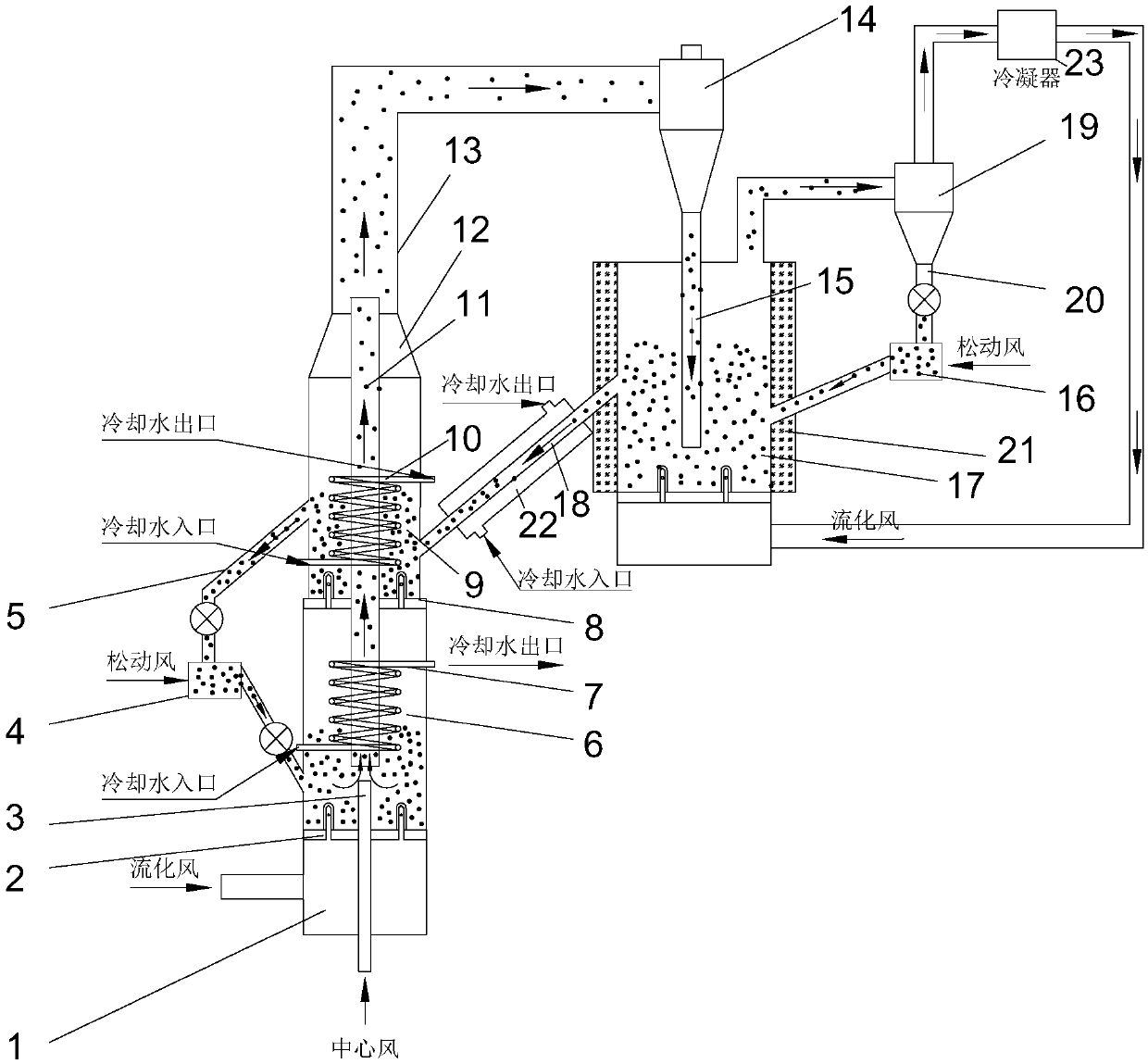

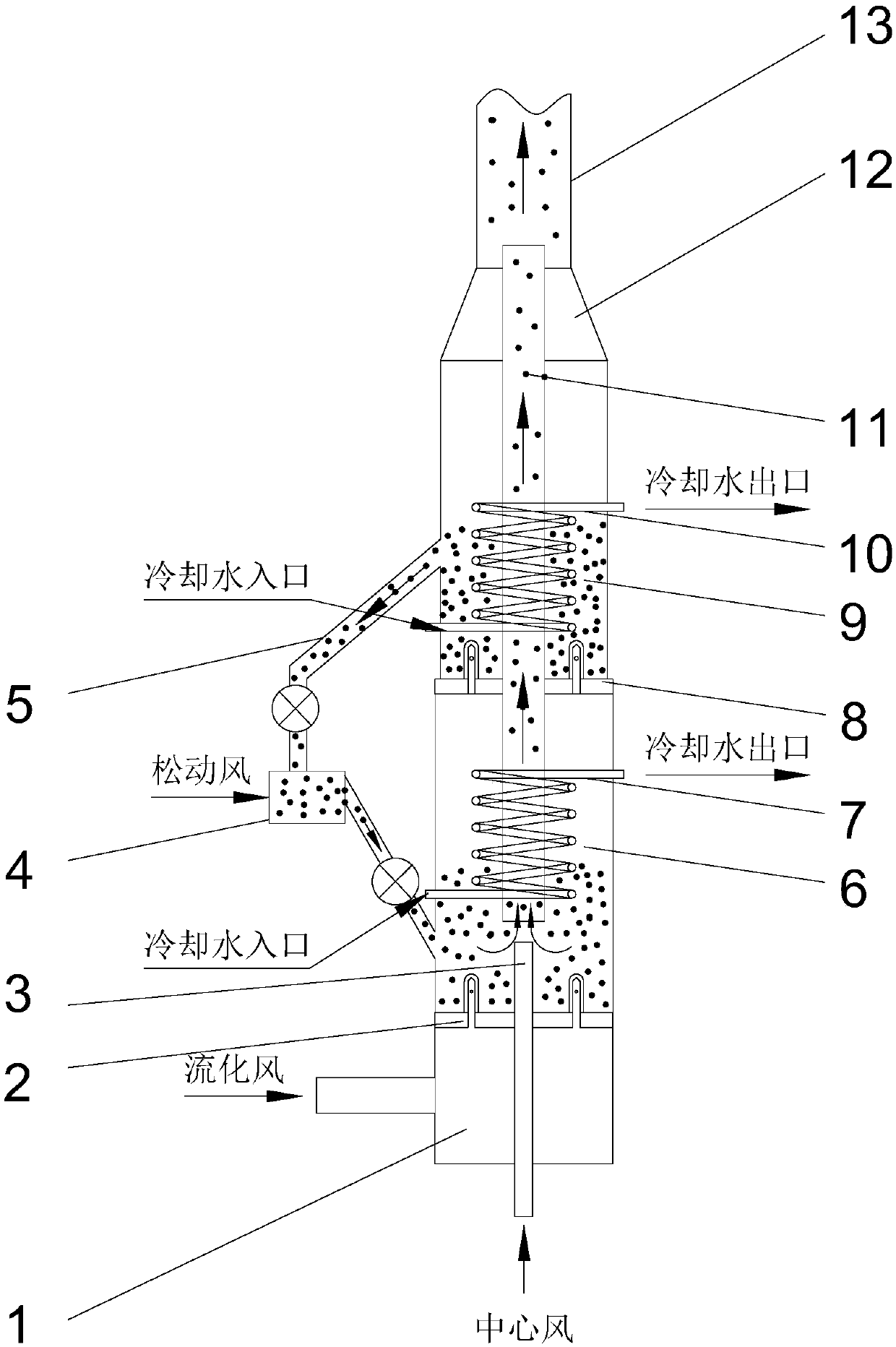

Multi-stage serial bubbling bed-transporting bed superimposed CO2 adsorption reactor and method thereof

InactiveCN109647134AIncrease flexibilityImprove universalityGas treatmentDispersed particle separationContact timeSorbent

The invention relates to a multi-stage serial bubbling bed-transporting bed superimposed CO2 adsorption reactor and a method thereof. The reactor comprises a wind chamber, a central air duct, a riser,bubbling beds and a transport bed. Several layers of bubbling beds are coaxially arranged above the wind chamber, and the caliber of the upper bubbling beds is smaller than the caliber of the lower bubbling beds. The topmost bubbling bed is connected to the transport bed. The bubbling bed comprises an air distributor, on which a CO2 adsorbent is arranged. The central air duct passes through the middle part of the bottom layer of air distributors, and the riser passes through the rest of air distributors. The riser and the central air duct are coaxially arranged and there is a gap between theair outlet of the central air duct and an inlet of the riser. Adjacent two bubbling beds are communicated through an overflow pipe, which is provided with a return valve. The gas-solid contact time can be controlled, and circulating rate of the adsorbent also can be adjusted. Meanwhile, the gas-solid countercurrent back-mixing is effectively inhibited, the carbonation difference of the adsorbent is reduced, and efficient and stable operation of the decarbonization system is guaranteed.

Owner:SOUTHEAST UNIV

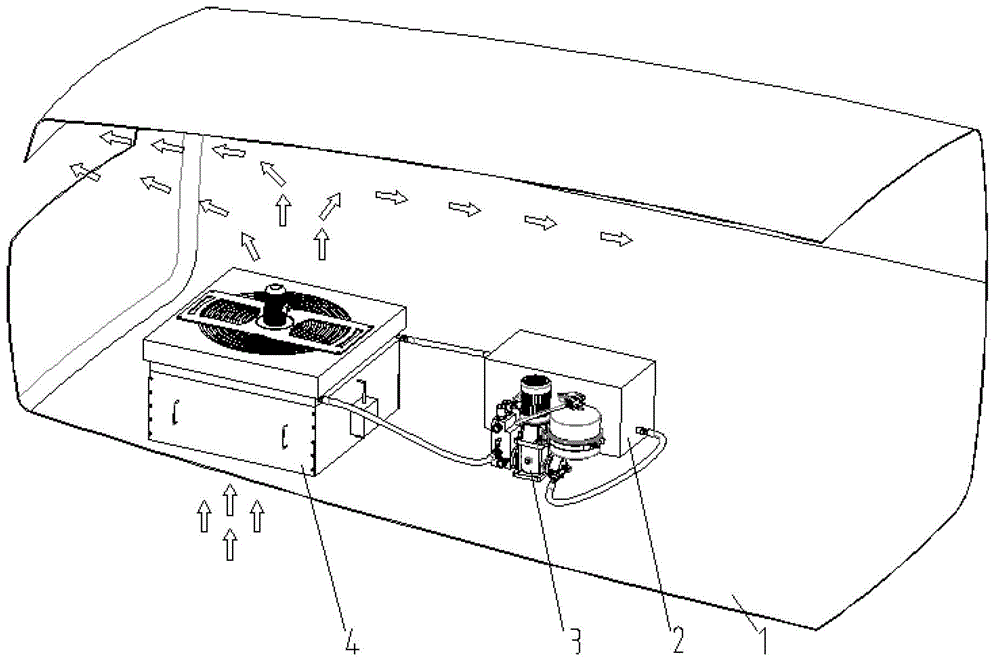

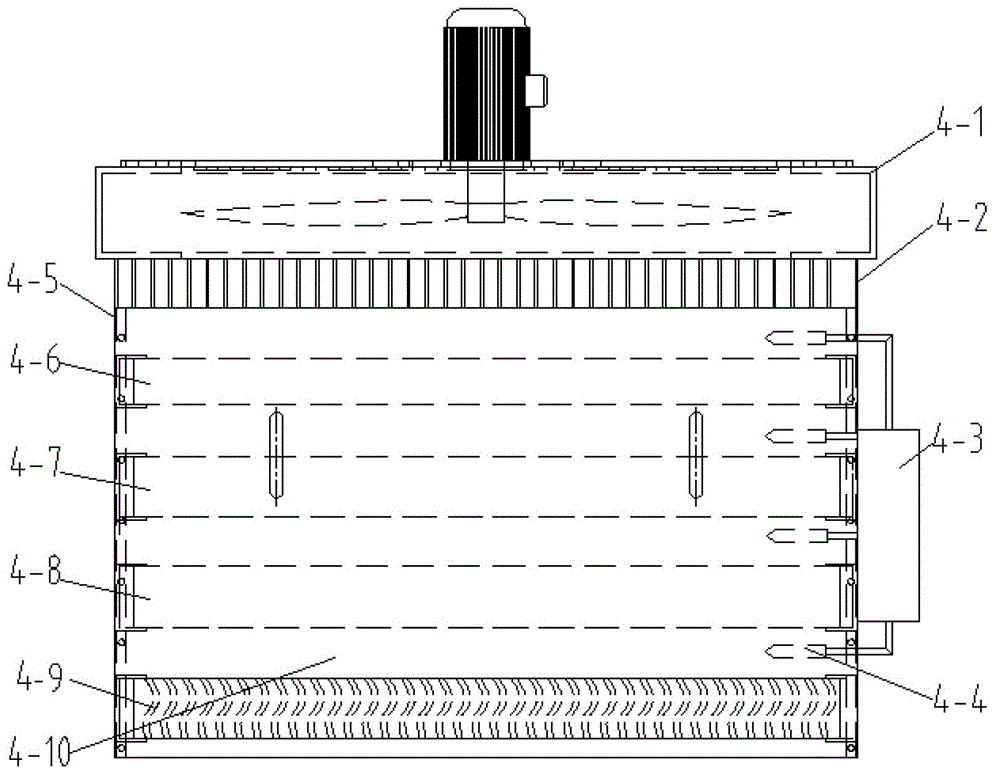

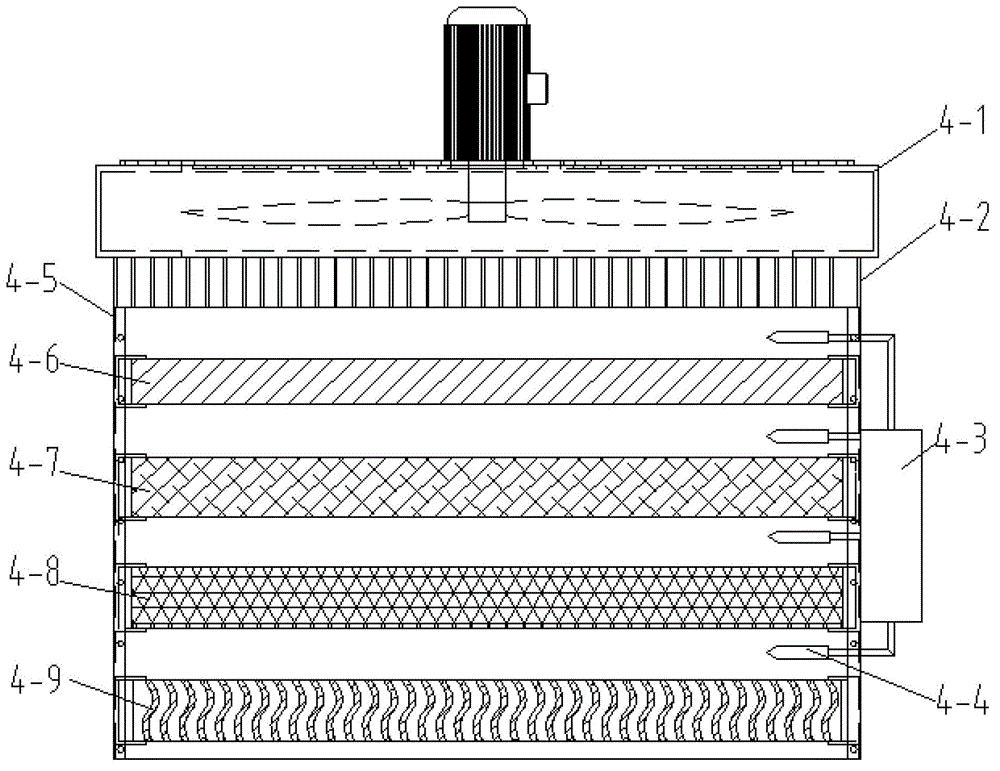

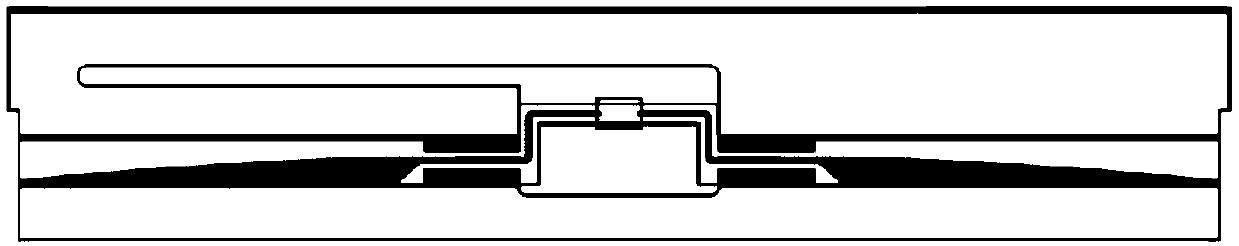

Ventilating and filtering heat exchange device and method of offshore wind driven generator set

InactiveCN102748244ACompact space layoutImprove cleanlinessCorrosion preventionMachines/enginesWind drivenPositive pressure

The invention discloses a ventilating and filtering heat exchange device and method of an offshore wind driven generator set, wherein the device is arranged in a cabin cover of the wind driven generator set, and comprises a heat exchanger and a filtering box body; the heat exchanger comprises a draught fan and a heat radiating structure; the heat radiating structure is connected with a heating device through a pump set so as to form enclosed-type circulation of a heat exchange medium; the inlet of the filtering box body is provided with a steam water separator; an air filtering core body is arranged behind the steam water separator; the filtering box body is arranged at the air cooling inlet side of the heat radiating structure of the heat exchanger; the draught fan is arranged at the other side of the heat radiating structure; and the cabin cover is provided with an open pore. According to the invention, air of offshore environment is introduced to the filtering box body through the draught fan, steam and water are separated, the air is filtered and purified, air after purification enters the heat exchanger so as to cool down the heat exchange medium, the air after heat exchange enters the cabin and is mixed with the original environment, the air is discharged from the open pore on the cabin cover, and the positive pressure effect in the cabin is ensured; and the device can simplify the structure, can enable the space to be compact, and can improve the integral environment quality in the cabin.

Owner:GUODIAN UNITED POWER TECH

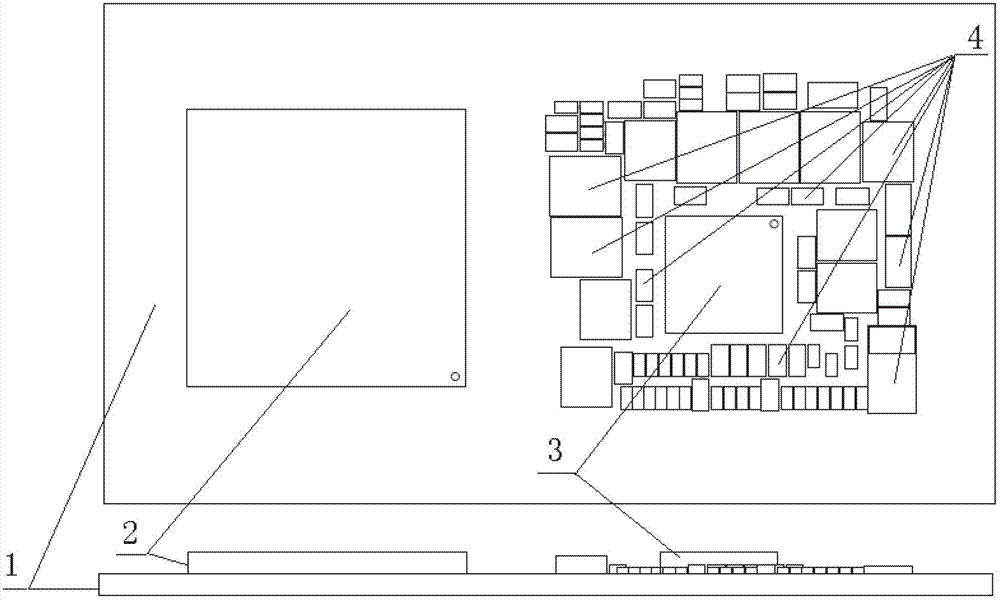

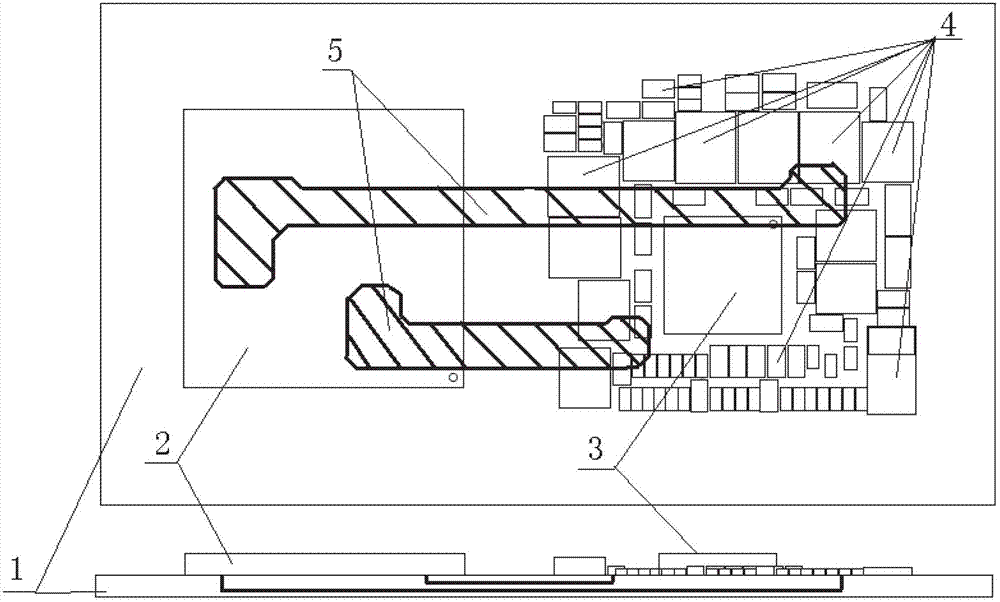

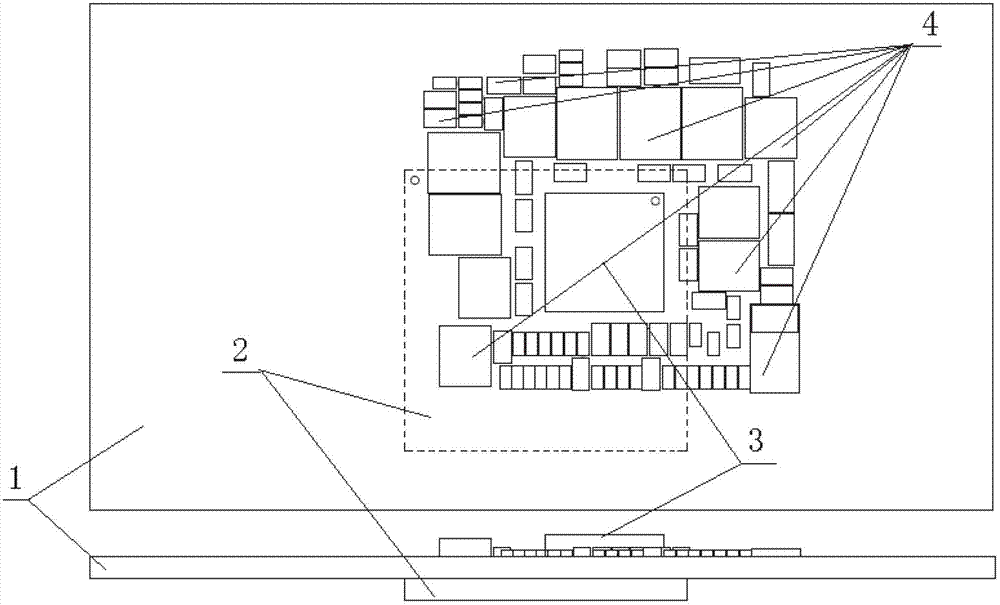

Printed circuit board (PCB) chip layout structure and electronic terminal using the same

InactiveCN103037621AReduce DC internal resistanceReduce AC internal resistancePrinted circuit non-printed electric components associationPower Management UnitEngineering

The invention discloses a printed circuit board (PCB) chip layout structure and an electronic terminal using the PCB chip layout structure. The PCB chip layout structure comprises a PCB, a central processing unit (CPU) and a power management unit (PMU). The CPU and the PMU are respectively arranged at two faces of the PCB. The PMU and projection of the CPU on the PCB are partially or completely overlapped. The electronic terminal using the PCB chip layout structure comprises the PCB chip layout structure consisting of the PCB, the CPU and the PMU. The CPU and the PMU are respectively arranged at two faces of the PCB. The PMU and projection of the CPU on the PCB are partially or completely overlapped.

Owner:共青城赛龙通信技术有限责任公司

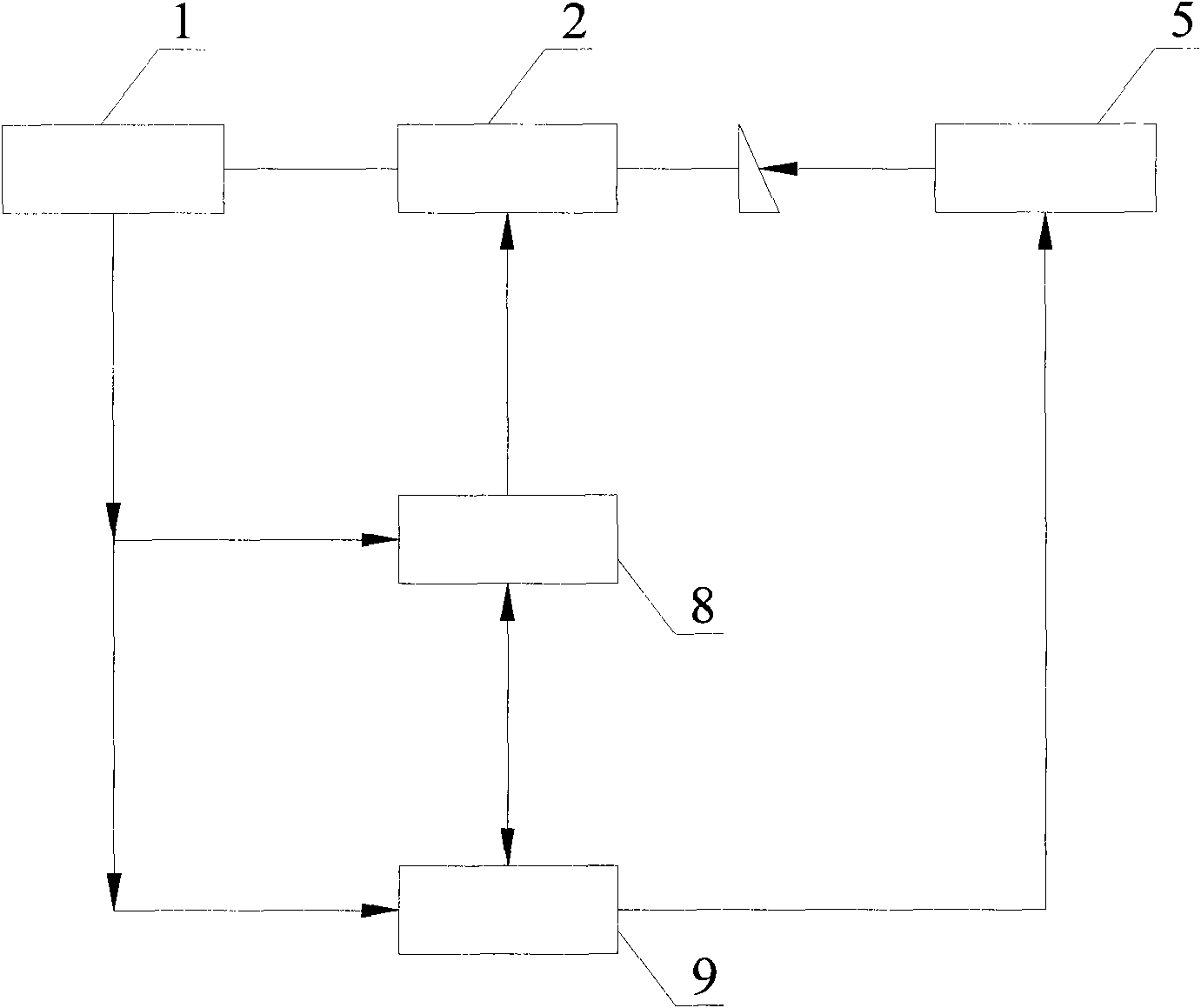

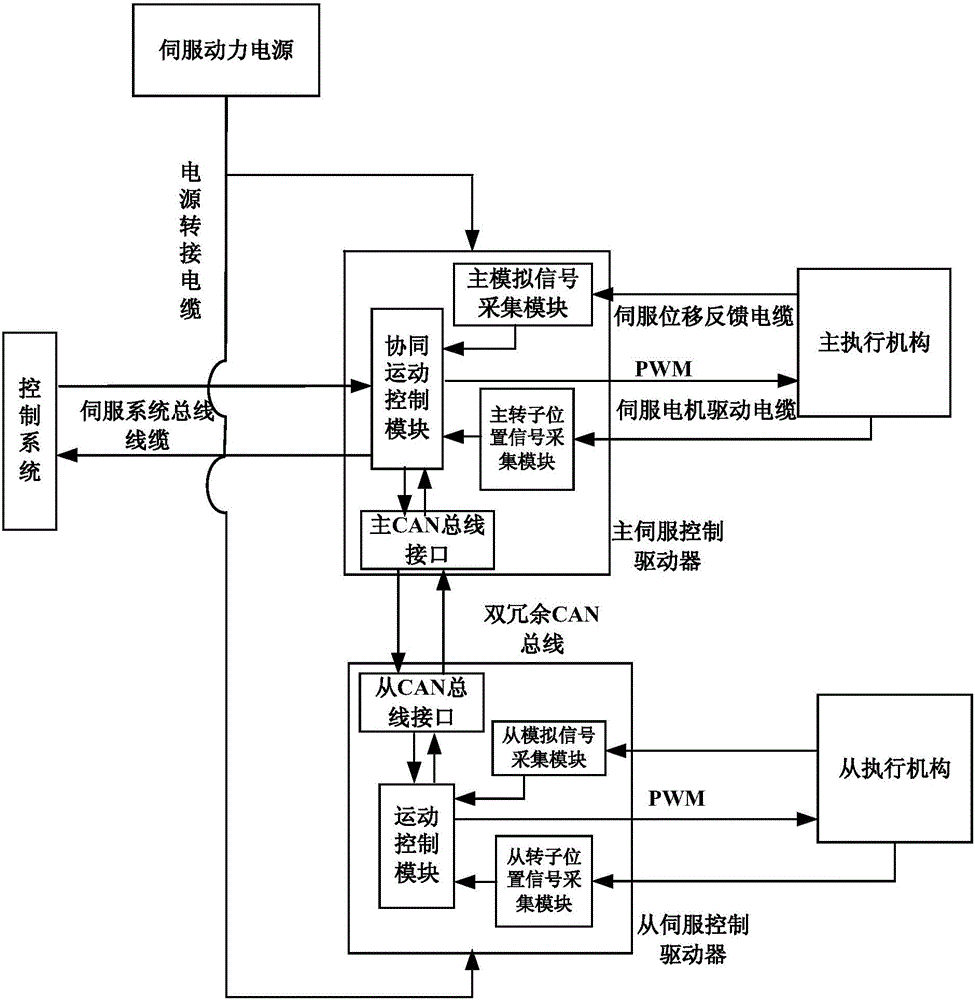

Master-slave type electromechanical servo cooperative motion control system

ActiveCN106411206AAchieve independenceConducive to independenceElectronic commutation motor controlAC motor controlComplete inversionEngineering

The invention relates to a master-slave type electromechanical servo cooperative motion control system, and relates to the field of aerospace thrust vector control electromechanical servo. The system aggregates signals, such as a bus instruction of a control system, linear displacement feedback of a master actuator and linear displacement feedback of a slave actuator; according to the swing angle of a spray tube, the corresponding telescopic lengths of the master and slave actuators and the accelerated factor and the acceleration factor of master and slave motion tracks are calculated in real time; a real-time motion track plan of the master and slave actuators is realized; an instruction signal of the master actuator is output in real time; a master-slave servo control driver completes inversion control of a direct-current power supply on a guided missile through a motor space vector control algorithm; a servo motor drives an electromechanical transmission mechanism to act a load, so that the purpose of controlling a thrust vector is achieved; the characteristic that synchronous control is strictly realized by master-slave cooperation is realized; furthermore, a basic technology is relatively matured and easy to realize; high integration and cooperative motion control of the system are realized; and thus, the technical problem that the spray tube is structurally damaged due to super-swing of the spray tube through a two-channel independent control method can be solved.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

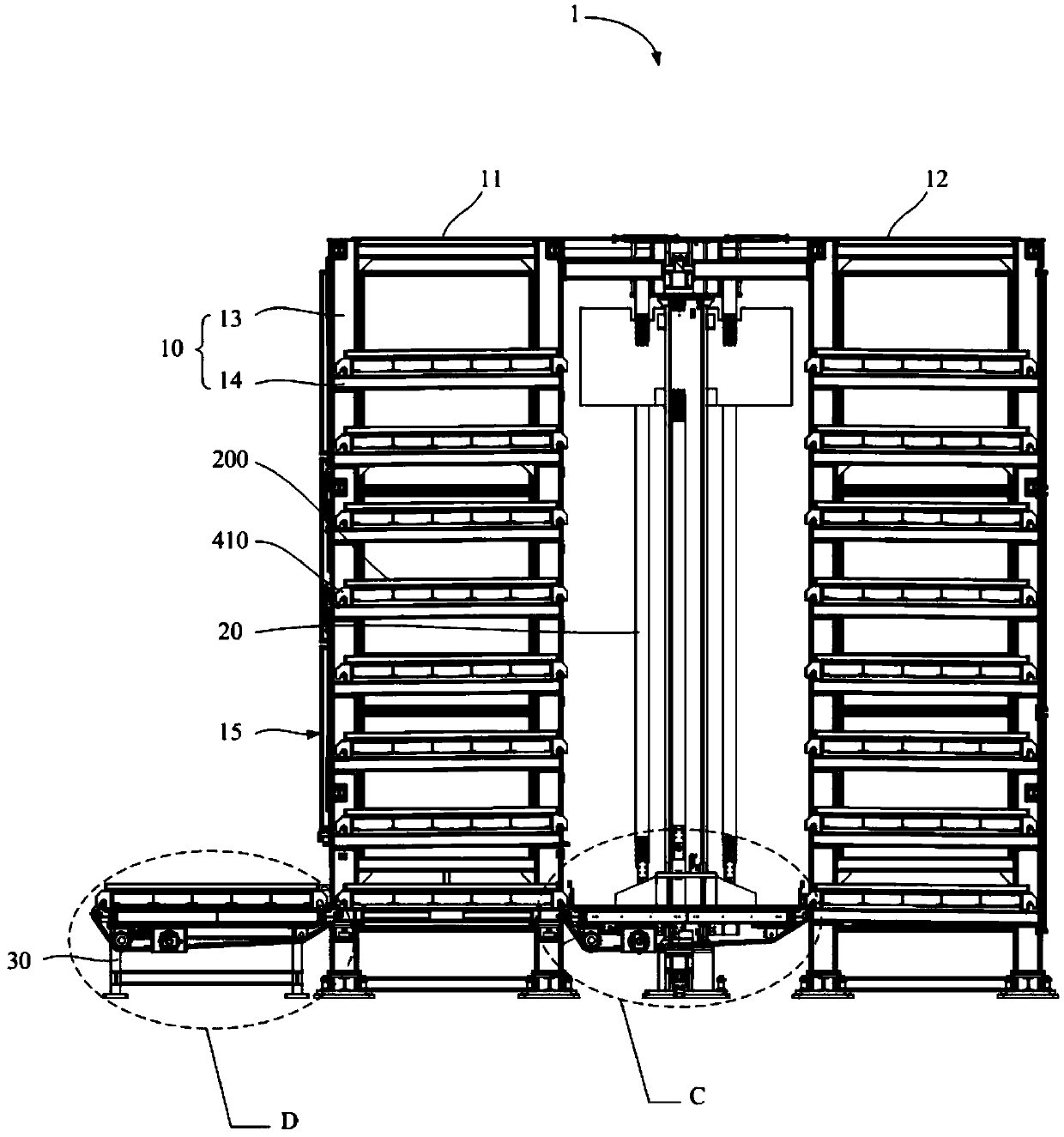

Automatic warehouse and method thereof for storing and tacking goods

InactiveCN111115072AEasy to pass throughImprove space utilizationStorage devicesEngineeringIndustrial engineering

The invention discloses an automatic warehouse and a method thereof for storing and tacking goods. The automatic warehouse comprises a main load shelf, a pallet, a main traction part, a main hook taking part, a warehouse body and a lifting device, wherein, a multi-layer storing shelf is arranged on the warehouse body, the pallet is located the storing shelf, the lifting device is located on one side of the warehouse body, the main load shelf is located on the lifting device, the main traction part is in an annular shape and arranged on the main load shelf in a sleeving mode, the main hook taking part comprises a clamping hook and a main connecting column, the main connecting column is fixedly connected with the main traction part, the clamping hook is fixedly arranged on the side wall of the pallet, or the clamping hook is fixedly connected with the main traction part, and the main connecting column is fixedly arranged on the side wall of the pallet. The automatic warehouse is high inspace utilization rate, and an extra space is no need to be reserved as the safety margin for moving the pallet.

Owner:KUSN HUAHENG ENG TECH CENT

Manufacturing process of bearing seat

InactiveCN102756089AImprove pass rateQuality improvementFoundry mouldsFoundry coresManganeseEngineering

The invention discloses a manufacturing process of a bearing seat. The manufacturing process of the bearing seat includes following steps: casting; smelting; preparing ramming mix, the ramming mix comprises fire clay, quartz sand and water; filling a cupola furnace with the ramming mix to make a lined furnace, and arranging a wind eye on the lined furnace; adjusting temperature of the cupola furnace to 500-700 DEG C to dry the lined furnace; making a fire in the cupola furnace, and allowing temperature to rise to 900 DEG C; filling the pond lined furnace with materials, and the materials comprise coal coke, novel iron, old iron, waste steel, silicon, manganese and iron; adjusting the temperature of the cupola furnace to 900-1200 DEG C, and smelting the materials in the cupola furnace; opening the cupola furnace to discharge melted iron, adding copper, chromium, molybdenum in the melted iron which is at 1400-1450 DEG C when the melted iron is discharged; casting the melted iron into a cavity of a mould by the aid of a crane ladle for casting; and unpacking and delivering. The manufacturing process of the bearing seat has the advantages of simple manufacturing process and short manufacturing cycle.

Owner:陆宝庆

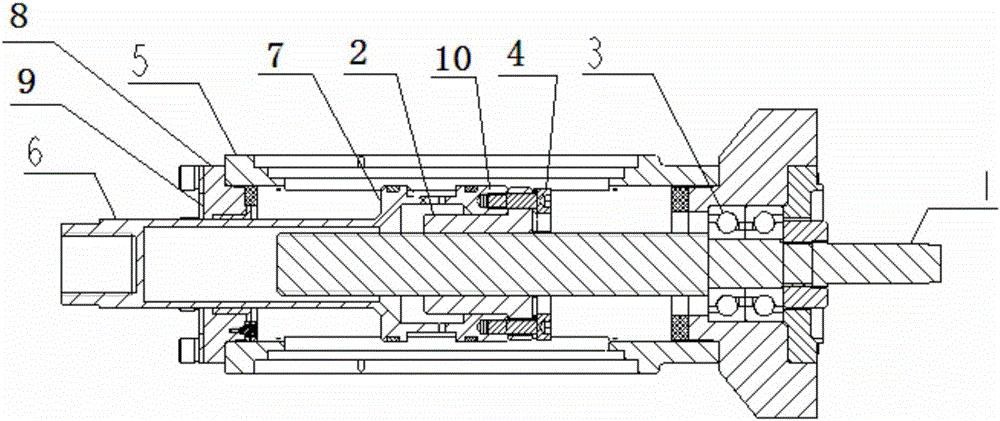

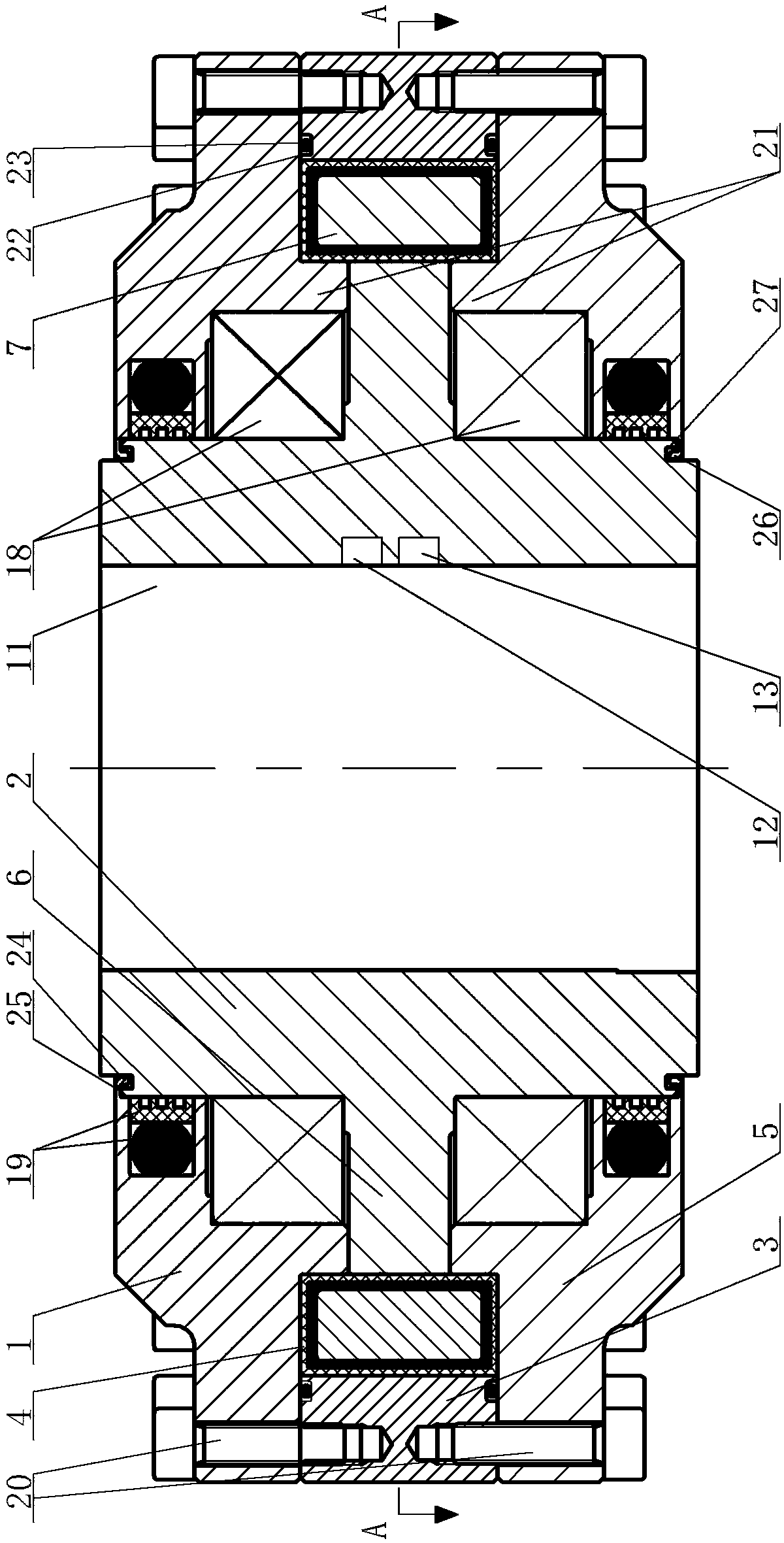

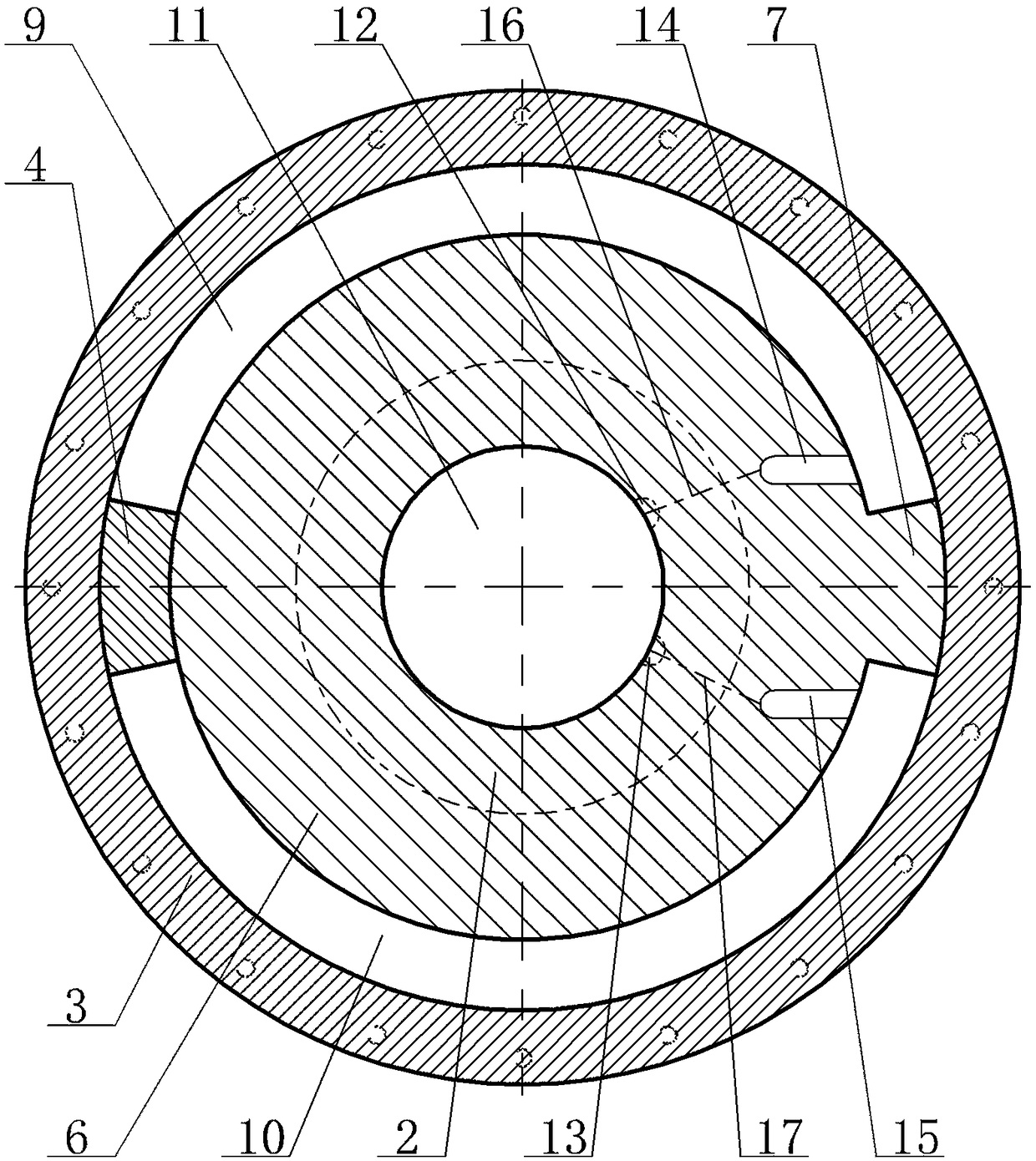

Special blade swinging type hydraulic cylinder for robot motion joint

PendingCN108775302AIncreased torque densitySimple structureEngine sealsJointsHydraulic cylinderTorque density

The invention provides a special blade swinging type hydraulic cylinder for a robot motion joint, and the special blade swinging type hydraulic cylinder can bear large axial force and capsizing moment. A mechanical seal structure is adopted, a dustproof ring is removed, and therefore the special blade swinging type hydraulic cylinder is simple in structure, compact in space layout, reasonable in design, little in inner leakage, large in torque density and convenient to integrate. The special blade swinging type hydraulic cylinder comprises an upper end cover, a rotation shaft, a cylinder body,a fixed sheet and a lower end cover. A side protruding ring is arranged on the outer ring face of the axial middle area of the rotation shaft, and a side protruding blade is arranged on the side protruding ring in the radial direction. An integral structure is integrally formed by the side protruding blade, the side protruding ring and the rotation shaft. The upper end cover sleeves the rotationshaft and is located at the upper portion of the side protruding ring. The lower end cover sleeves the rotation shaft and is located at the lower portion of the side protruding ring. The side protruding blade is in the zero-position state, and the other end opposite to the side protruding blade in the radial direction is provided with the fixed sheet. The inner wall of the fixed sheet and the outer wall of the side protruding ring are arranged in a clearance manner, and a sealing device is arranged in the axial direction of the fixed sheet and the side protruding blade.

Owner:JIANGSU DREAMWELL DYNAMICS TECH CO LTD

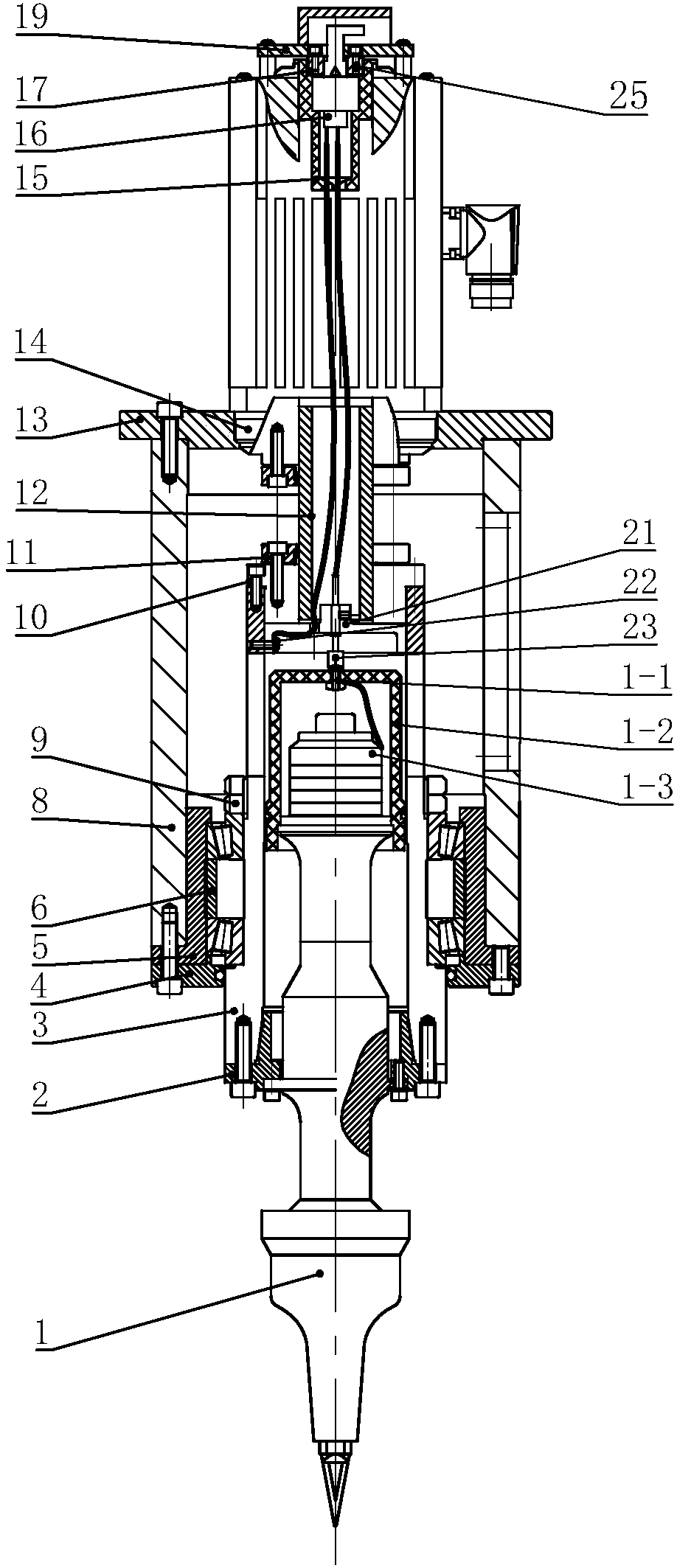

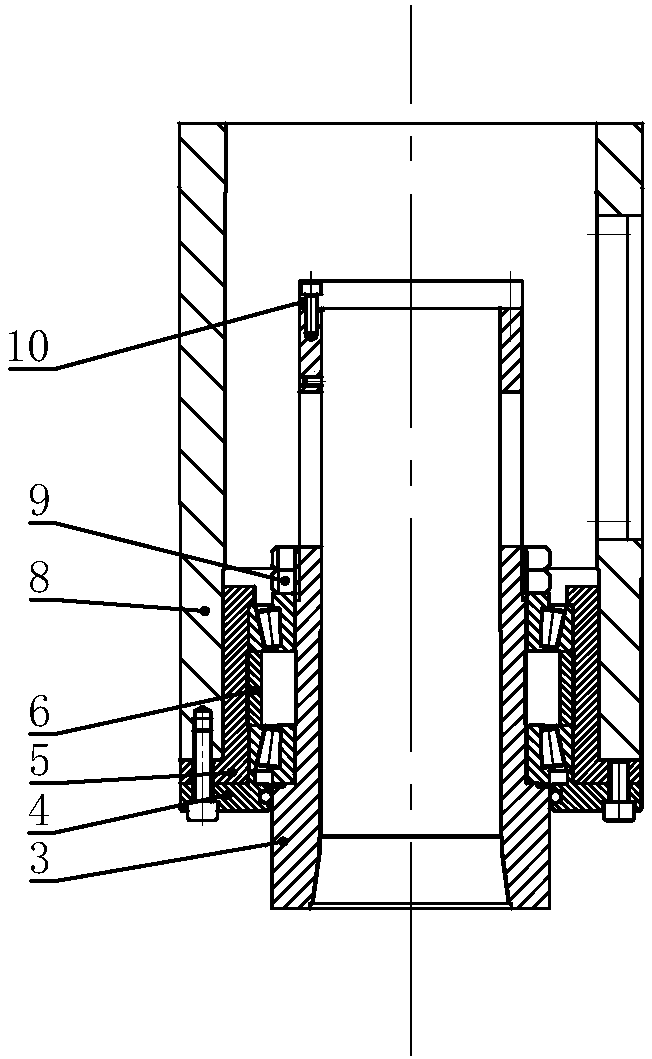

Ultrasonic cutting electric spindle driven by hollow servo motor

ActiveCN108381671AImprove rotational precisionImprove machining accuracyMechanical energy handlingMetal working apparatusElectricityElectric machine

The invention provides an ultrasonic cutting electric spindle driven by a hollow servo motor. The ultrasonic cutting electric spindle comprises an electric spindle body and an acoustic assembly, wherein the electric spindle body comprises a hollow main shaft, a shaft sleeve, a shell, a motor mounting plate and a hollow servo motor; the hollow main shaft is installed in the shaft sleeve through bearings, the shaft sleeve is coaxially installed at the lower end of the shell, the motor mounting plate is arranged at the upper end of the shell, and the hollow servo motor is installed on the motor mounting plate; and the acoustic assembly is coaxially installed in the hollow main shaft through a conical flange. According to the ultrasonic cutting electric spindle, the hollow shaft servo motor isused for driving, the hollow shaft is driven to rotate through an expansion sleeve and a hollow shaft so as to drive the acoustic assembly to realize ultrasonic cutting, a transmission chain is short, so that the rotating motion precision of the main shaft is improved, and therefore machining precision is improved; and meanwhile, a mercury conductive slip ring is used for conducting electricity,compared with a traditional ultrasonic cutting electric spindle utilizing the carbon brush to transmit electric signals, the space layout is more compact, and electric transmission is more reliable.

Owner:HANGZHOU DIANZI UNIV

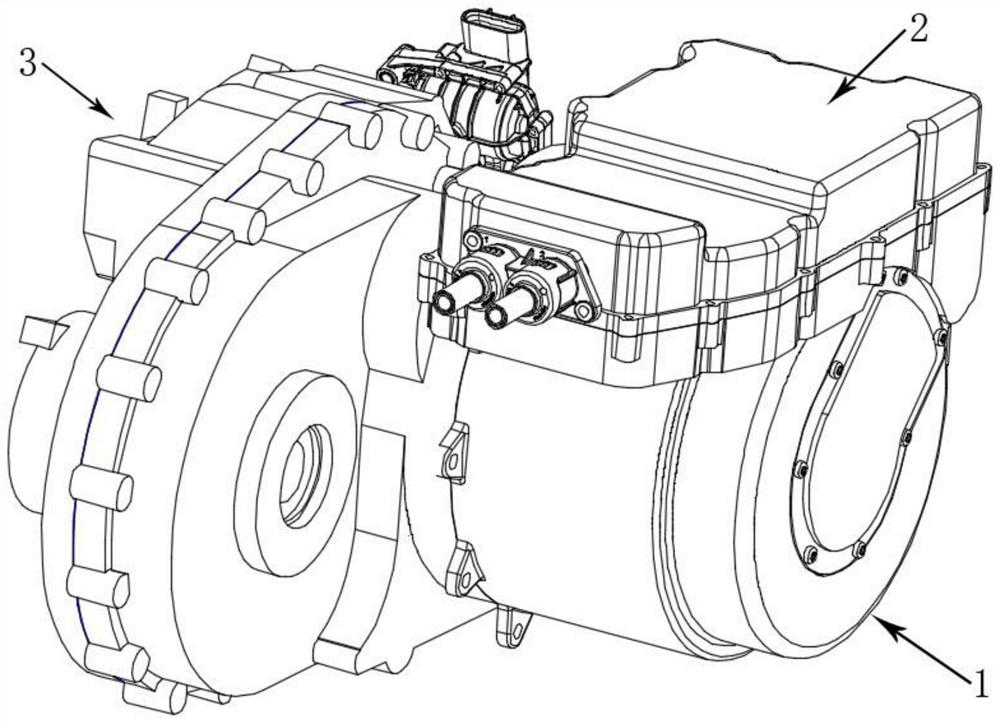

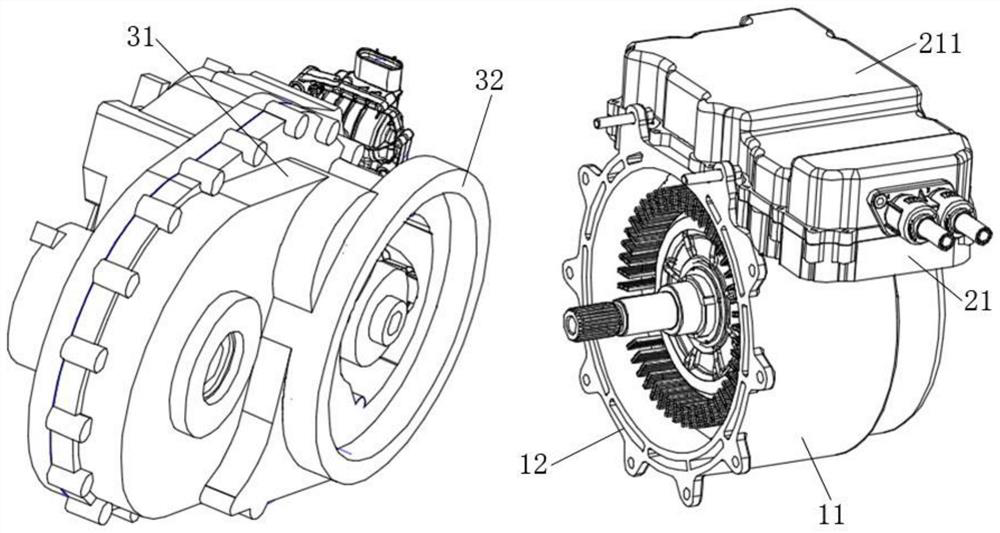

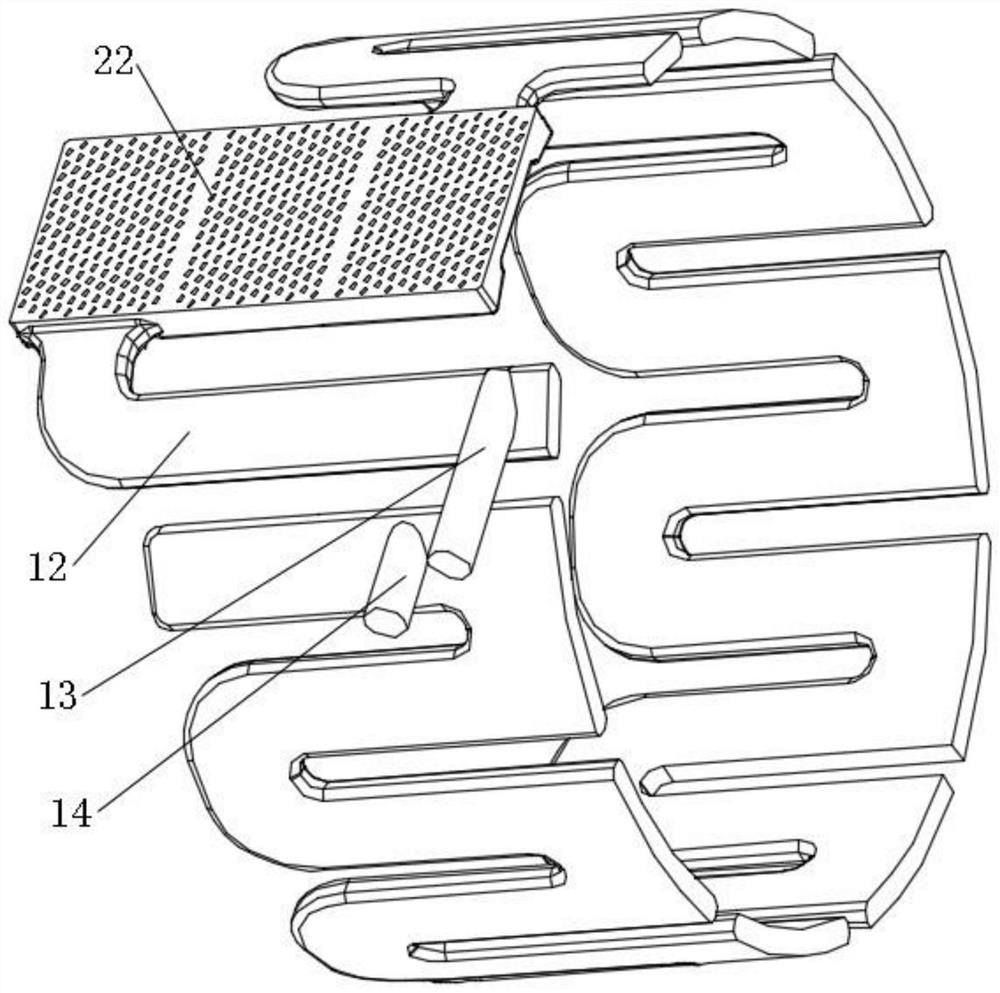

Electric drive system and automobile

PendingCN114337063AShorten the axial lengthReduce resistanceAssociation with control/drive circuitsMechanical energy handlingNew energyReduction drive

The invention relates to the technical field of new energy automobiles, and particularly discloses an electric drive system and an automobile. According to the inverter cooling water channel of the electric drive system, the inverter assembly and one part of the motor assembly are cooled in parallel, and then the other part of the motor assembly is cooled in series, so that the cooling water channel of the electric drive system is wholly shortened, and the flowing resistance of cooling liquid is reduced. The motor assembly and the inverter assembly are integrated in the radial direction, the motor assembly and the inverter assembly share a cooling water channel, the overall height of the electric drive system in the radial direction is reduced, the motor assembly and the speed reducer assembly are integrated in the axial direction, and the axial length of the electric drive system is reduced; the motor assembly and the inverter assembly share the cooling water channel, so that the cooling water channel of the electric drive system is shortened, the use of fastening parts, sealing parts and the like for connecting the cooling water channel of the inverter and the cooling water channel of the motor is reduced, and the risk of leakage of cooling liquid is reduced; in addition, the cooling water channel of the electric drive system can cool the speed reducer assembly at the same time.

Owner:CHINA FIRST AUTOMOBILE

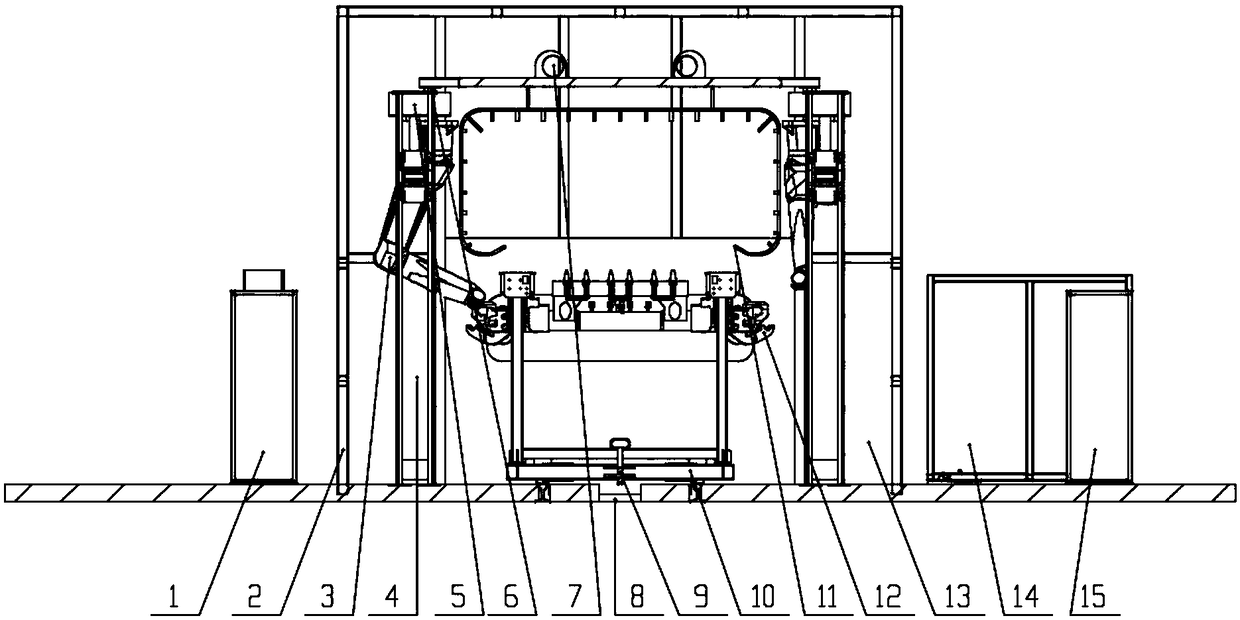

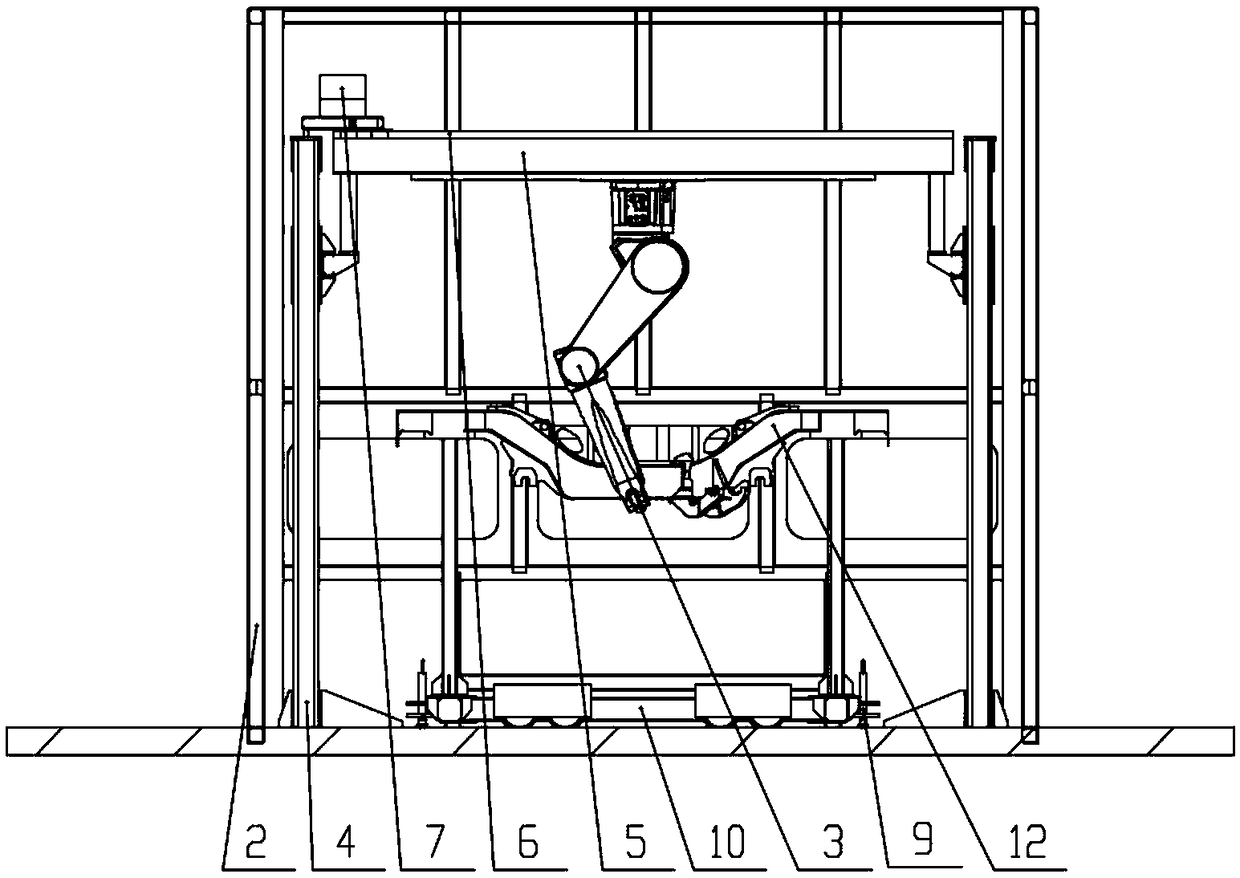

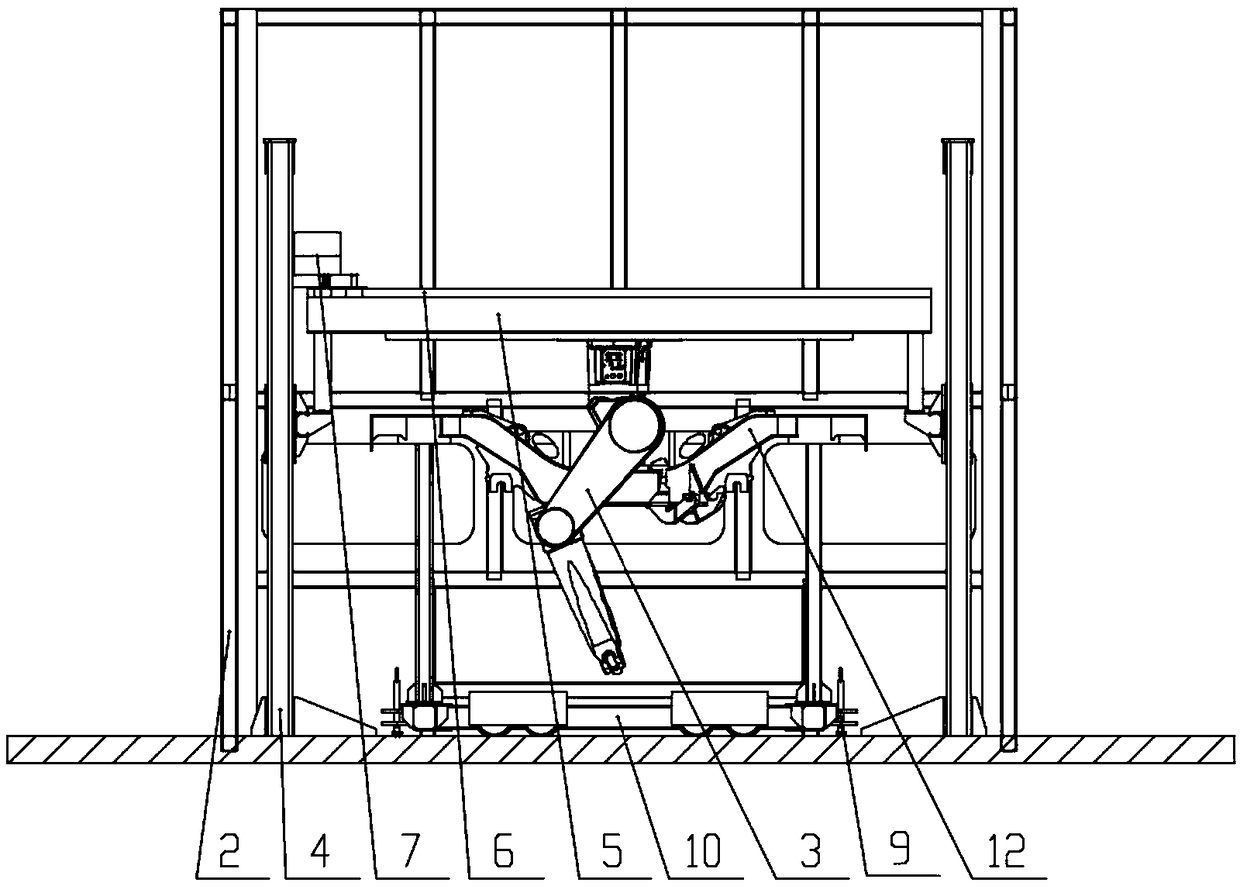

Cleaning and depainting system and inspection device for rail vehicle bogies

The invention provides a cleaning and depainting system and an inspection device for rail vehicle bogies. The cleaning and depainting system comprises a depainting machine, a cleaning machine, a robotarm, an elevator and a seventh shaft of the robot arm, wherein the depainting machine includes a depainting pistol head and the cleaning machine includes a cleaning pistol head. The robot arm is usedto bear the depainting pistol head and the cleaning pistol head. The elevator is used to move the robot arm to a first predetermined position in the longitudinal direction. The seventh shaft of the robot arm is connected with the elevator and is used to move the robot arm to a second predetermined position in the lateral direction. According to the technical scheme, the device achieves the technical purpose of improving the cleaning and depainting efficiency. In the process of cleaning and depainting, the system has the advantages of the compact space layout, the flexible action for washing and depainting, high flexibility, environmental friendliness and non adverse effect for a framework.

Owner:天津远程华瑞工业技术有限公司 +1

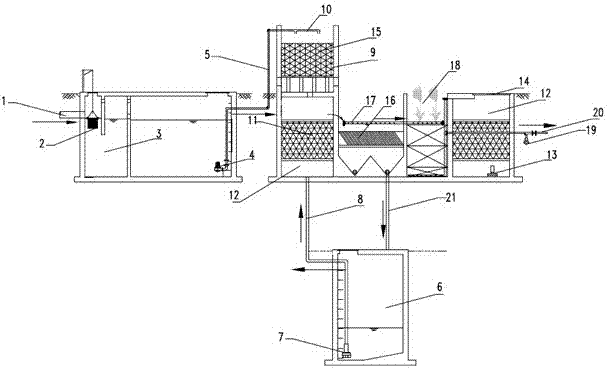

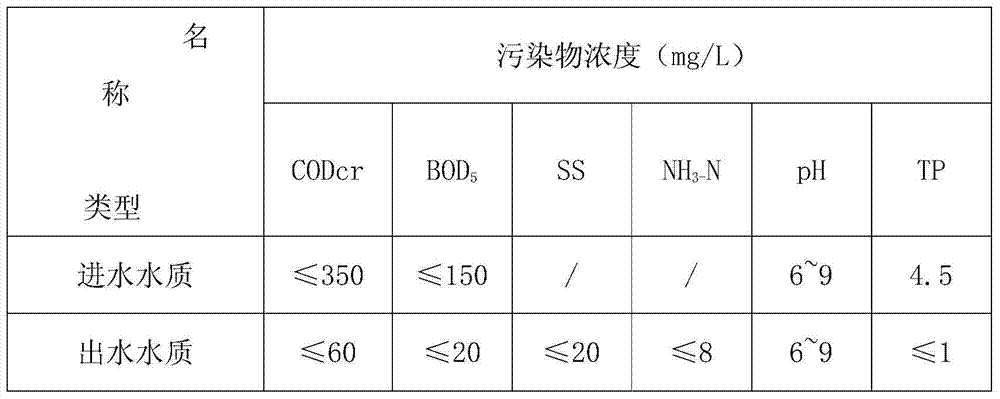

Micro-aeration circulation integrated sewage biological ecological treatment system and method

ActiveCN105084650BImprove adsorption capacityGood denitrification and dephosphorization treatment effectMultistage water/sewage treatmentSmall footprintGravity flow

A micro-aeration circulation integrated sewage biological ecological treatment system and method. The domestic sewage is firstly homogenized and equalized by the regulating tank, and then sent to the surface water distribution biological filter, where it is acidified and hydrolyzed to reduce some organic matter, and then flows into the circulating biological Strengthen the contact tank for aerobic biochemical treatment to remove most of the organic matter, nitrification and denitrification denitrification, sludge aerobic phosphorus absorption and other biochemical effects, the effluent flows to the inclined plate sedimentation tank for solid-liquid separation, and the supernatant flows to the vertical The phosphorus pollutants in the wastewater are further adsorbed and removed by the iron-rich materials in the filter, and the effluent flows to the clear water tank for discharge or reuse. This system integrates the surface water-distributed biological filter, circulating bio-enhanced contact pool, and artificial wetland. The space layout of each reaction unit is compact and the floor area is small; the process uses less equipment, and the waste water mainly depends on gravity flow and propulsion. Flow, strong automation, easy operation and management; small sludge return flow, good nitrogen and phosphorus removal treatment effect, especially high phosphorus removal rate.

Owner:CHONGQING UNIV

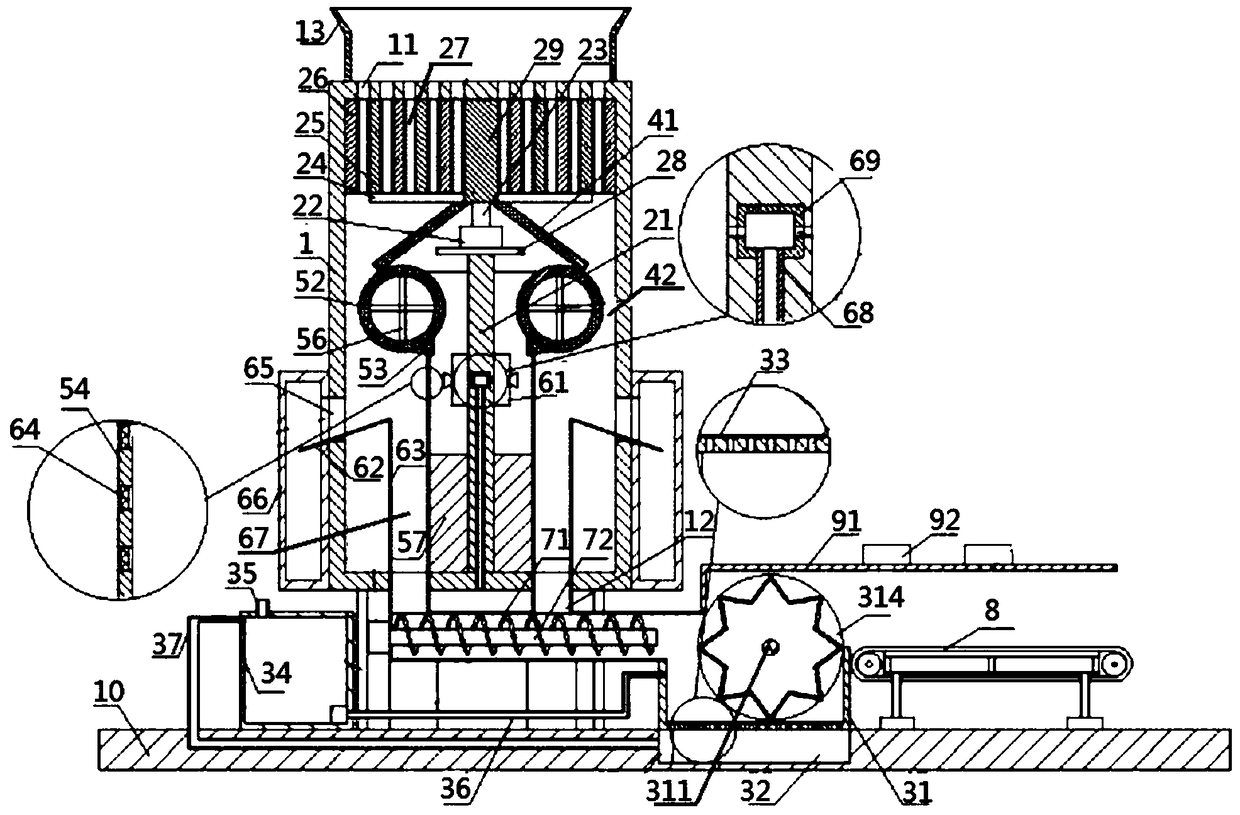

Automatic sesame shelling and sieving machine

ActiveCN103966013AWork lessPrevent fallingFatty-oils/fats productionMechanical engineeringSesame seed

The invention relates to an automatic sesame shelling and sieving machine comprising a rack, wherein the front and rear sides of the rack are symmetrically provided with mounting plates; the lower part of the rack is in sliding connection with a storage cabinet located in the rack; a first sieve plate is obliquely fixed at the middle part of the rack; a second sieve plate is obliquely arranged at the medium-upper part of the rack; a motor is arranged between the first sieve plate and the second sieve plate and is fixed on the rack; a shelling device is arranged above the second sieve plate; a transmission device is arranged at the front sides of the mounting plates; the shelling device is connected with the motor through the transmission device; the transmission device is driven by the motor, and then the power is transferred to the shelling device, therefore, shelling treatment on sesame is realized. The automatic sesame shelling and sieving machine has the advantages of reasonable structural design, low manufacturing cost, convenience in use and the like; the aim of efficiently sieving the sesame is achieved; a two-stage sieving way is adopted, so that sesame shelling, fine sesame sieving and sesame collecting processes are achieved, the manpower and material investments are reduced, and the sesame sieving quality is ensured.

Owner:黄翰天

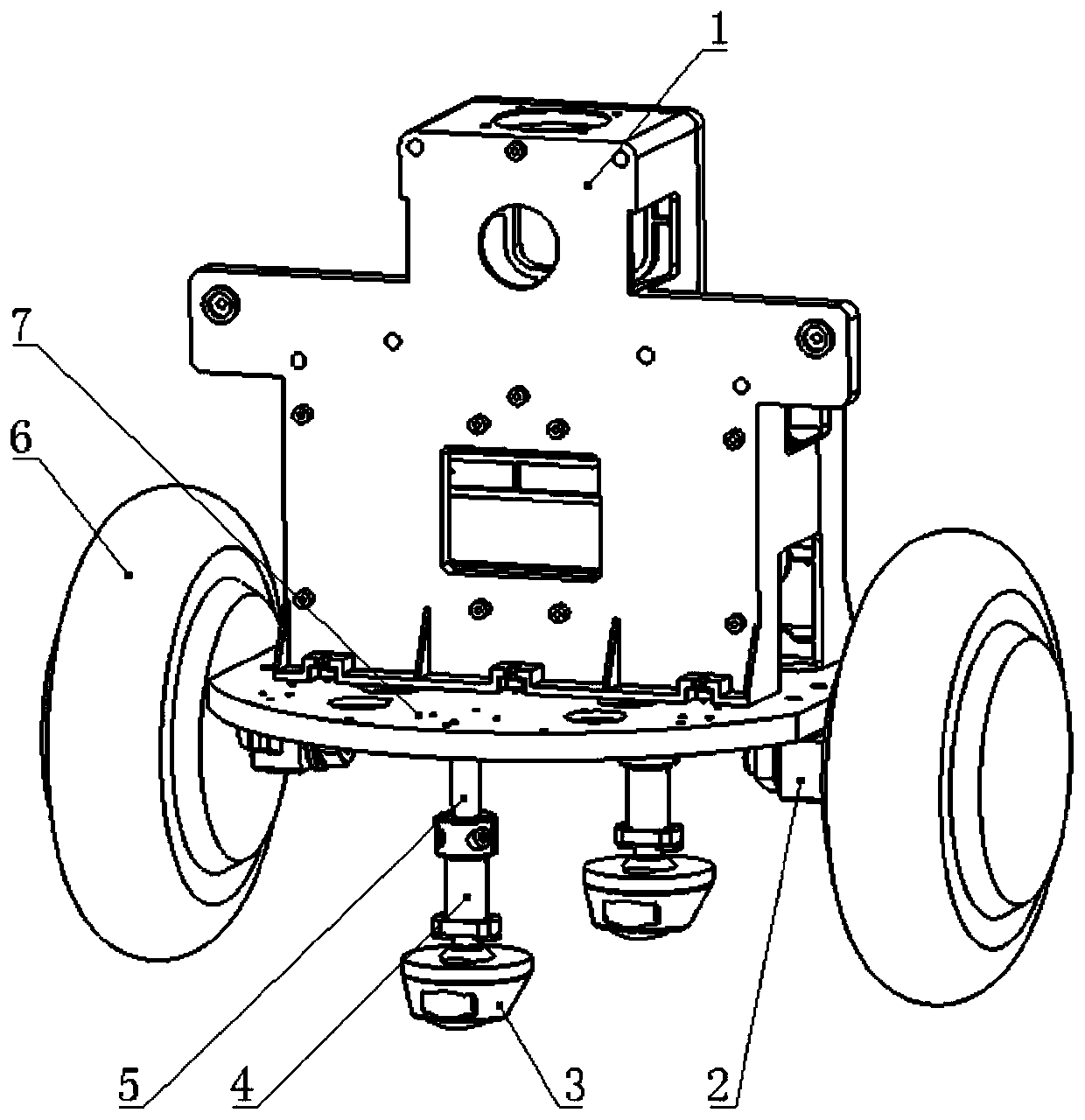

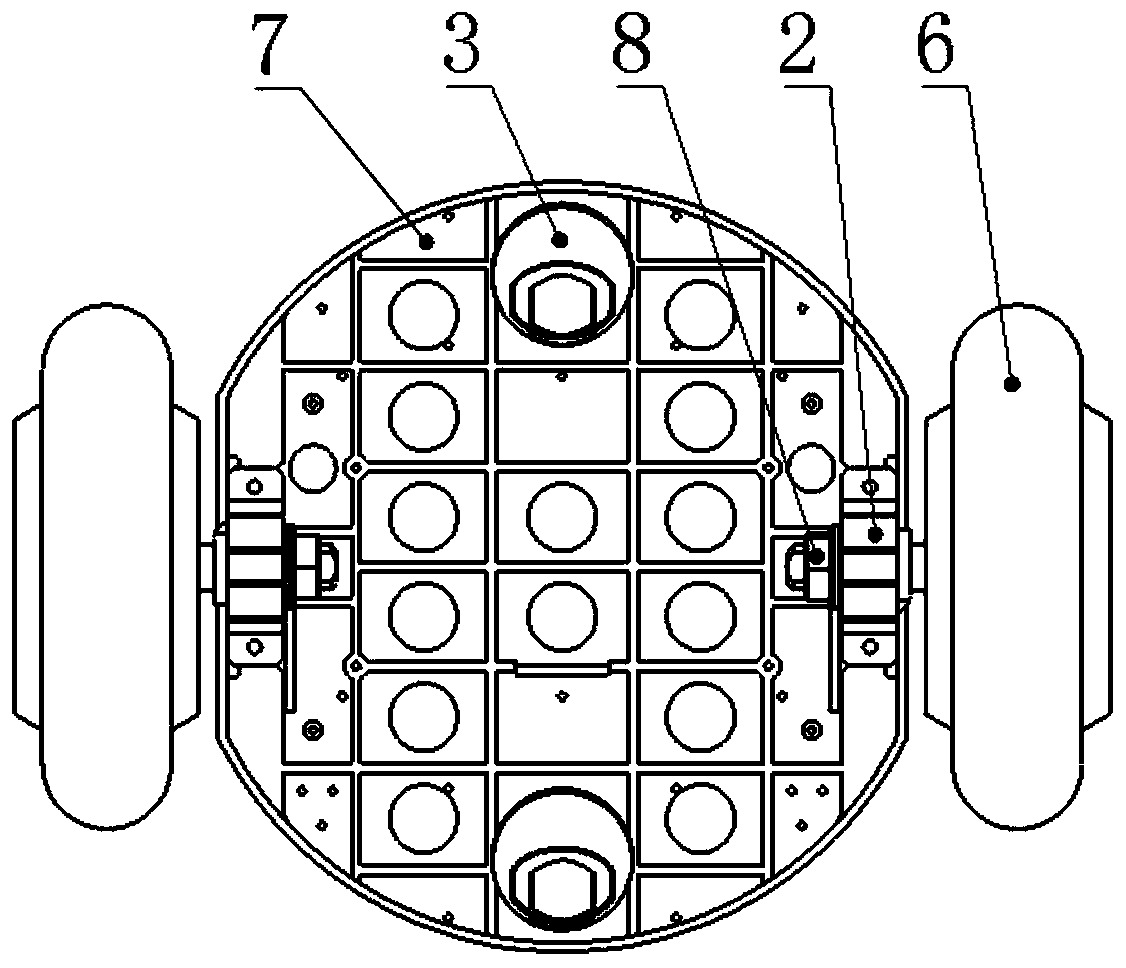

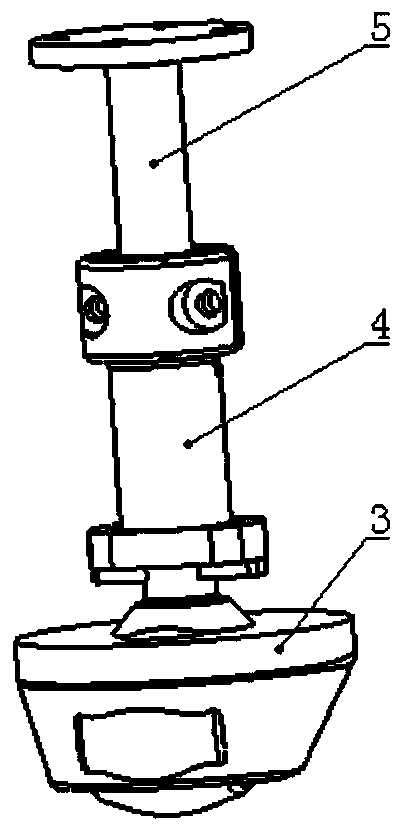

Robot chassis and robot

InactiveCN111347386ASimple structureLow costProgramme-controlled manipulatorVehiclesDrive wheelGravity center

The invention discloses a robot chassis which comprises a chassis mounting plate, a pair of driving wheel mounting seats, a pair of driving wheels, a chassis switching device and universal wheels. Thepair of driving wheel mounting seats are symmetrically arranged on two sides of the bottom of the chassis mounting plate; central shafts of the pair of driving wheels are fixedly mounted on the driving wheel mounting seats respectively; the chassis switching device is mounted on the chassis mounting plate, the longitudinal center line of the chassis switching device penetrates through the centerof the chassis mounting plate, and the center connecting lines of the chassis switching device and the two driving wheels are perpendicular to each other; and the universal wheels are arranged below the chassis switching device, and the chassis switching device can telescopically adjust the height of the universal wheels. The free switching of the motion mode between the four wheels and the self-balancing chassis is mainly achieved by manually adjusting the height of a free telescopic rod, the structure is simple and practical, the cost is low, the space layout is compact, driving wheel systems and universal wheel systems are both symmetrically arranged, the gravity center of a robot can be guaranteed to be in the center of motion, and the self-balancing motion is more facilitated.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

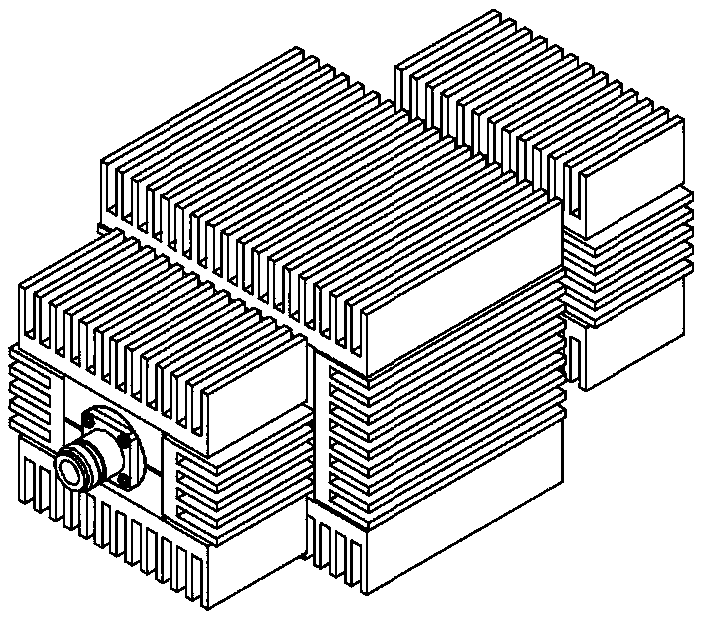

Flip-type broadband power combiner based on composite function curve ridge

ActiveCN109585996AHigh synthesis efficiencyWorking frequency bandwidthCoupling devicesPower combinerOperating frequency

The invention discloses a flip-type broadband power combiner based on a composite function curve ridge. The flip-type broadband power combiner comprises a plurality of electromagnetic signal input ports uniformly distributed in the same circular plane and having the same distance to the center of circle, wherein each input port is connected to a coupling probe disposed in an elliptic function gradual cavity; all elliptic function gradual cavities are connected to an output port; and the output port is disposed at the center of circle. The flip-type broadband power combiner can solve the difficulty in high power combination in an ultra-wide frequency band and the heat dissipation of a high-power high-density heat source. The power combiner of the invention is wide in operating frequency band, low in insertion loss, large in the number of combining channels, high in combining efficiency. The power distribution, the power amplification and the power combination are separately designed. The flip-type broadband power combiner many advantages such as high heat dissipation efficiency, simple and compact structure, and easy processing and assembly.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

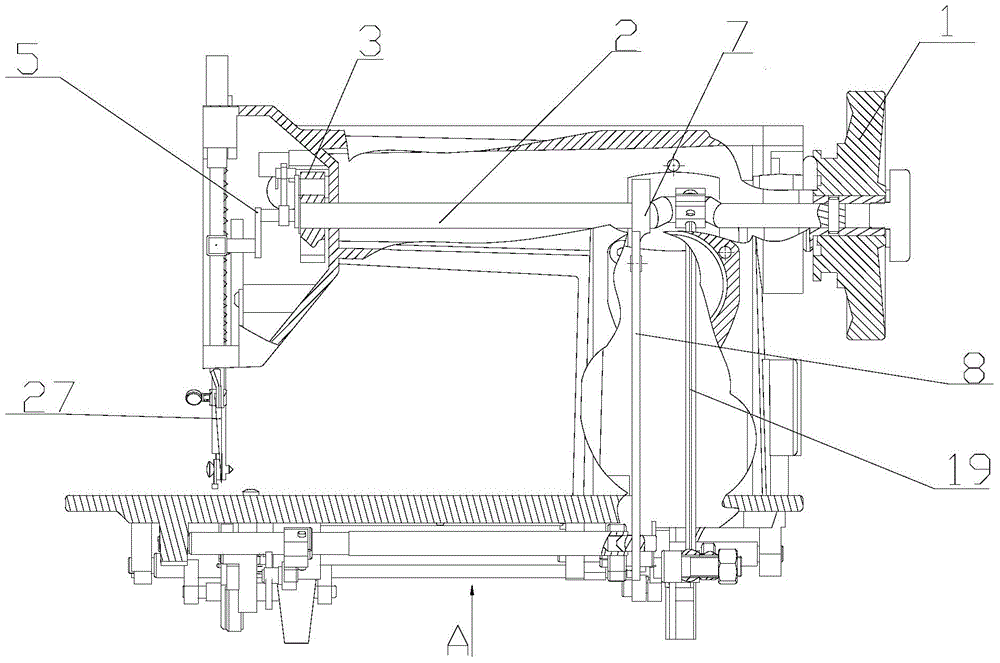

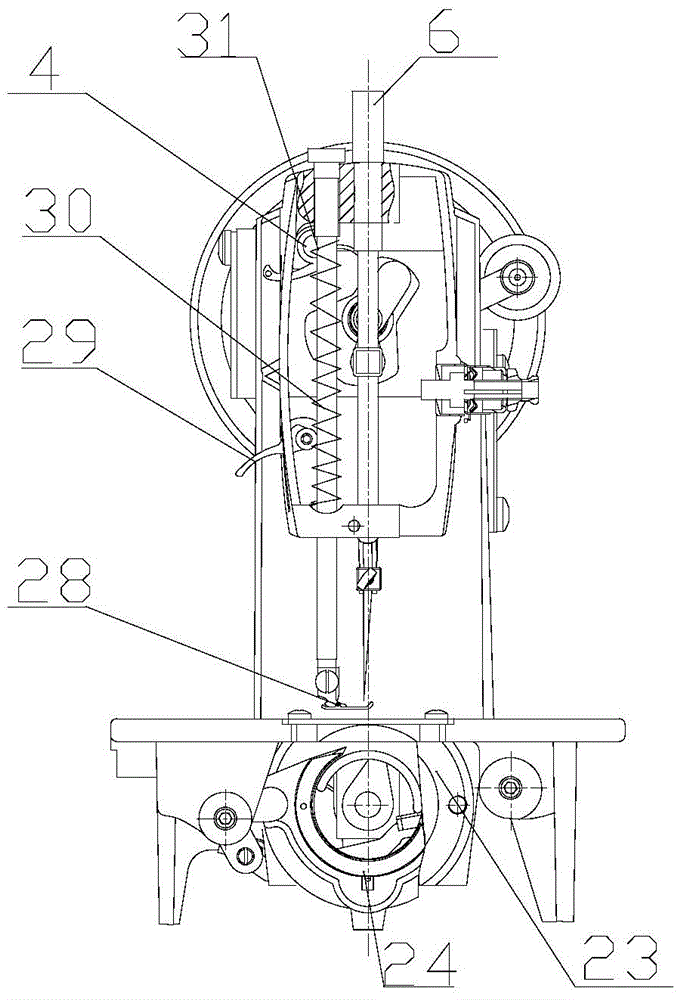

Sewing machine

InactiveCN104695138AEffective controlImprove dynamic performanceSewing-machine control devicesPressersMicrocontrollerMotor drive

The embodiment of the invention discloses a sewing machine. A mechanical structure part comprises a thread leading mechanism, a thread picking mechanism, a thread hooking mechanism and a cloth feeding mechanism. The thread leading mechanism, the thread picking mechanism, the thread hooking mechanism and the cloth feeding mechanism share an upper shaft connected with an upper wheel, and the upper wheel is connected with a motor through a transmission mechanism. An electrical control part comprises a microcontroller, an intelligent power module and a motor, wherein the microcontroller, the intelligent power module and the motor are sequentially connected, the microcontroller is connected with a plurality of sensing / inputting devices to receive corresponding signals / input parameters or commands, and PWM signals are generated and output to be converted to motor driving signals through the intelligent power module, so that the motor is driven. The mechanical structure and the electrical control part are improved, and product performance can be comprehensively improved.

Owner:周磊

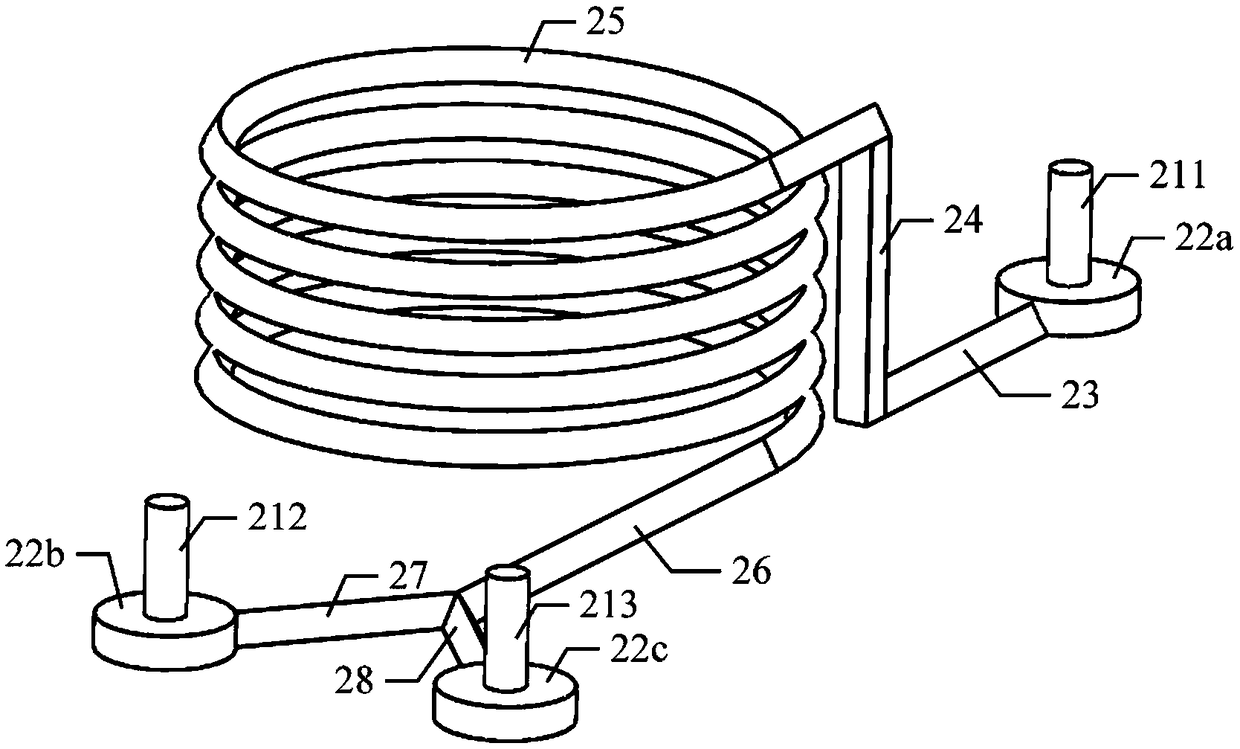

Air floating type full-angle multi-layer zero-gravity unloading system

PendingCN114408231AMeet the interferenceArea radius coverage adjustableCosmonautic condition simulationsZero gravityLinear displacement

The invention provides an air floating type full-angle multi-layer zero-gravity unloading system which comprises a leveling mechanism arranged on a supporting frame, the leveling mechanism can drive an air floating main shaft system to conduct linear displacement, and the lower end of the air floating main shaft system is fixedly connected to a wing frame of a flexible solar wing through a suspension unit. The air floating main shaft system is a solar wing floating suspension support, a center alignment unit is arranged on one side of the leveling mechanism and used for detecting the unfolding state of a solar wing, and the air floating main shaft system comprises an air floating shaft and a plurality of air floating sliding rails rotationally connected to the periphery of the air floating shaft in a sleeving mode. And one end of each air floatation sliding rail is fixedly connected to a wing frame of the solar wing through a suspension unit. According to the air floating type full-angle multi-layer zero-gravity unloading system, in the unloading process of the system, full passivity is achieved, in the rotating process, all sets of air floating bearings keep extremely low disturbance torque and free of air pipe interference, all suspension points can reach any position in a designated annular area, the area radius coverage range is adjustable, and the space layout is compact.

Owner:TIANJIN AEROSPACE ELECTROMECHANICAL EQUIP RES INST

Waste and regeneration device

PendingCN109014031AImprove recycling qualityImprove processing efficiencyMould handling/dressing devicesFoundryEngineering

The invention relates to the technical field of recovery of waste foundry sand, in particular to a waste sand regeneration device. The waste sand regeneration device comprises a main box, a grinding device and a cleaning device, wherein the main box is a square box, a plurality of discontinuous annular sand inlets are coaxially formed in the top surface of the main box from inside to outside, andsand outlets are formed in the two sides of the bottom surface of the main box; the grinding device is arranged at the top of the main box and comprises a supporting rod, a first driving device, a first rotary shaft, a plurality of fixed connecting rods, a plurality of first annular blocks with different diameters and a plurality of second annular blocks with different diameters, wherein the firstannular blocks are spaced from the second annular blocks; grinding gaps corresponding to the annular sand inlets are formed between the first annular blocks and the adjacent second annular blocks; and the cleaning device is arranged below the main box. According to the waste sand regeneration device, waste sand is sufficiently ground in the grinding gaps, so that impurities, rust and the like onthe surface of the waste sand are removed more sufficiently, and the waste sand recovery quality is higher.

Owner:柳晶机械设备(溧阳)有限公司

Art cold transfer printing system and method thereof

InactiveCN107150493AOvercome the defect that the overall design cannot be carried out for irregular objectsEnsure Structural IntegrityTransfer printingDecorative surface effectsEngineeringDesign pattern

The invention relates to an art cold transfer printing system and a method thereof. The system comprises an upper supporting device, a film-making device installed on the lower side of the upper supporting device, a shower coating device arranged on one side of the film-making device, and a coating device arranged on the shower The transfer device on one side of the coating device. The coating device is installed in the middle of the film making device and the transfer device. Using the system of the present invention helps to protect the overall structural integrity of the pattern to be transferred. After the printed object is cooled, the transfer pattern is attached to the surface of the object as a whole, and the transfer of irregular patterns or self-designed patterns can be completed according to different transfer patterns, which overcomes the inability of traditional spray printing to carry out overall design for irregular objects The disadvantages are compact space layout, reasonable and ingenious structure, suitable for large-scale production and promotion, and the method is simple and easy to operate.

Owner:PINGDINGSHAN UNIVERSITY

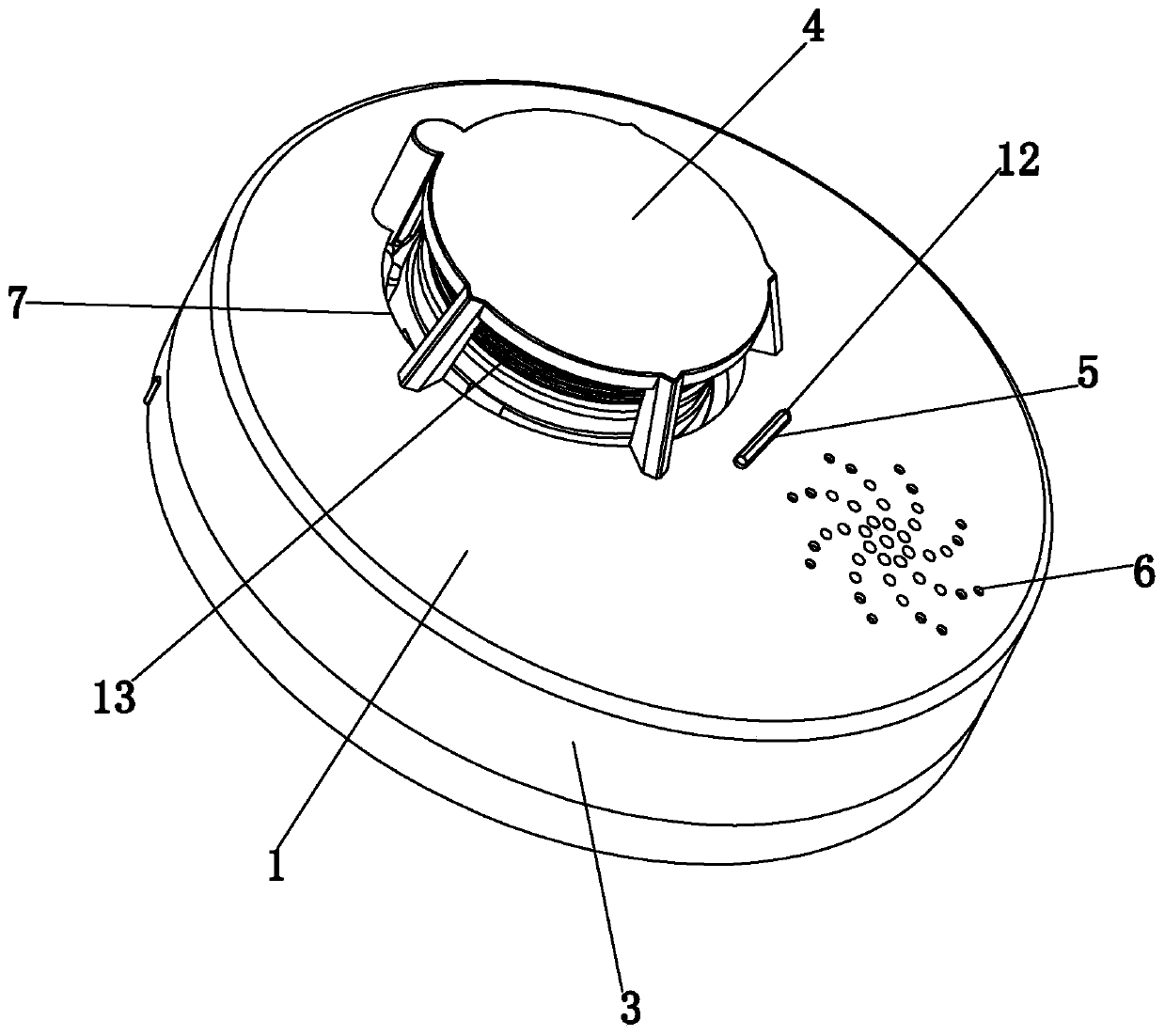

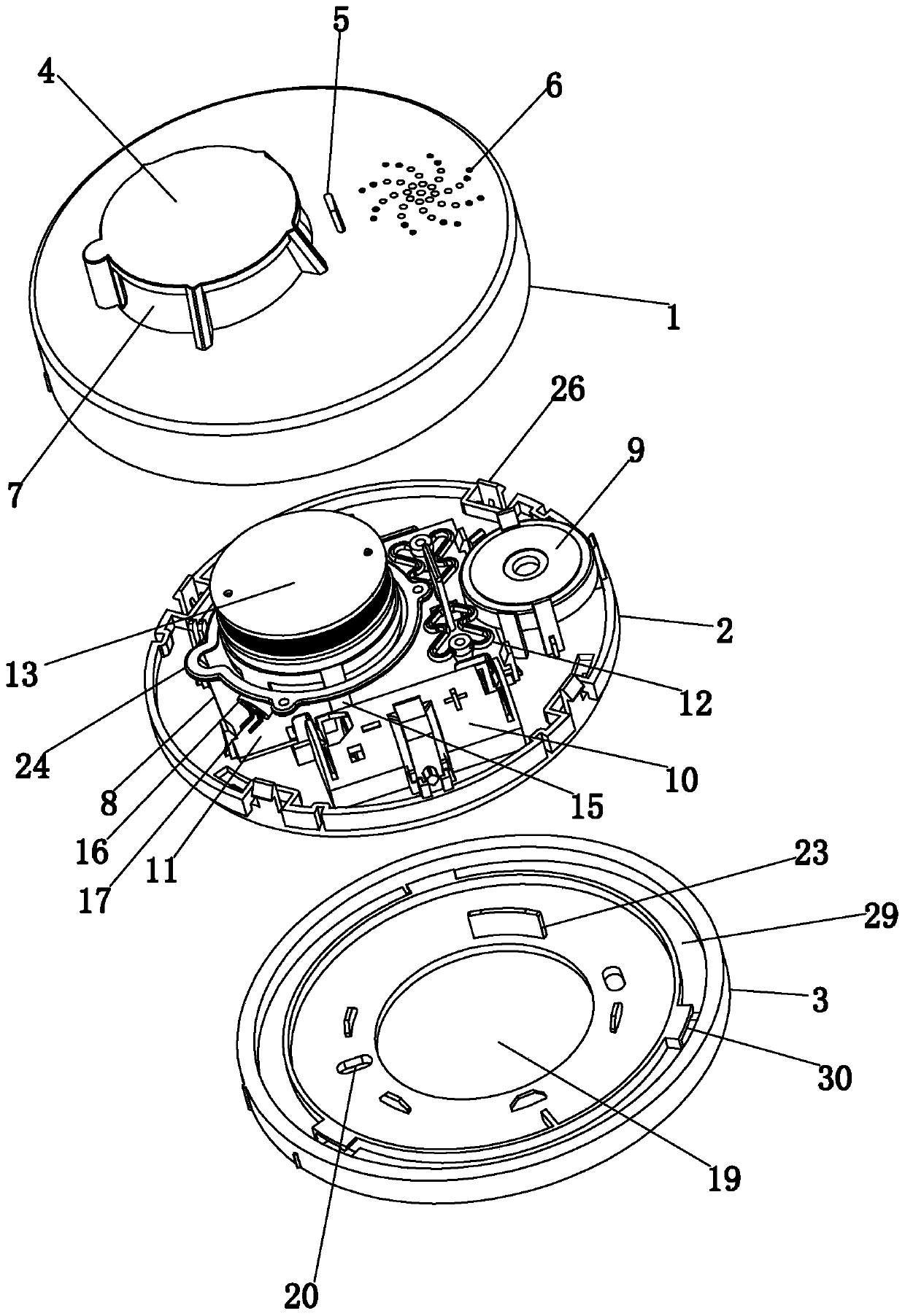

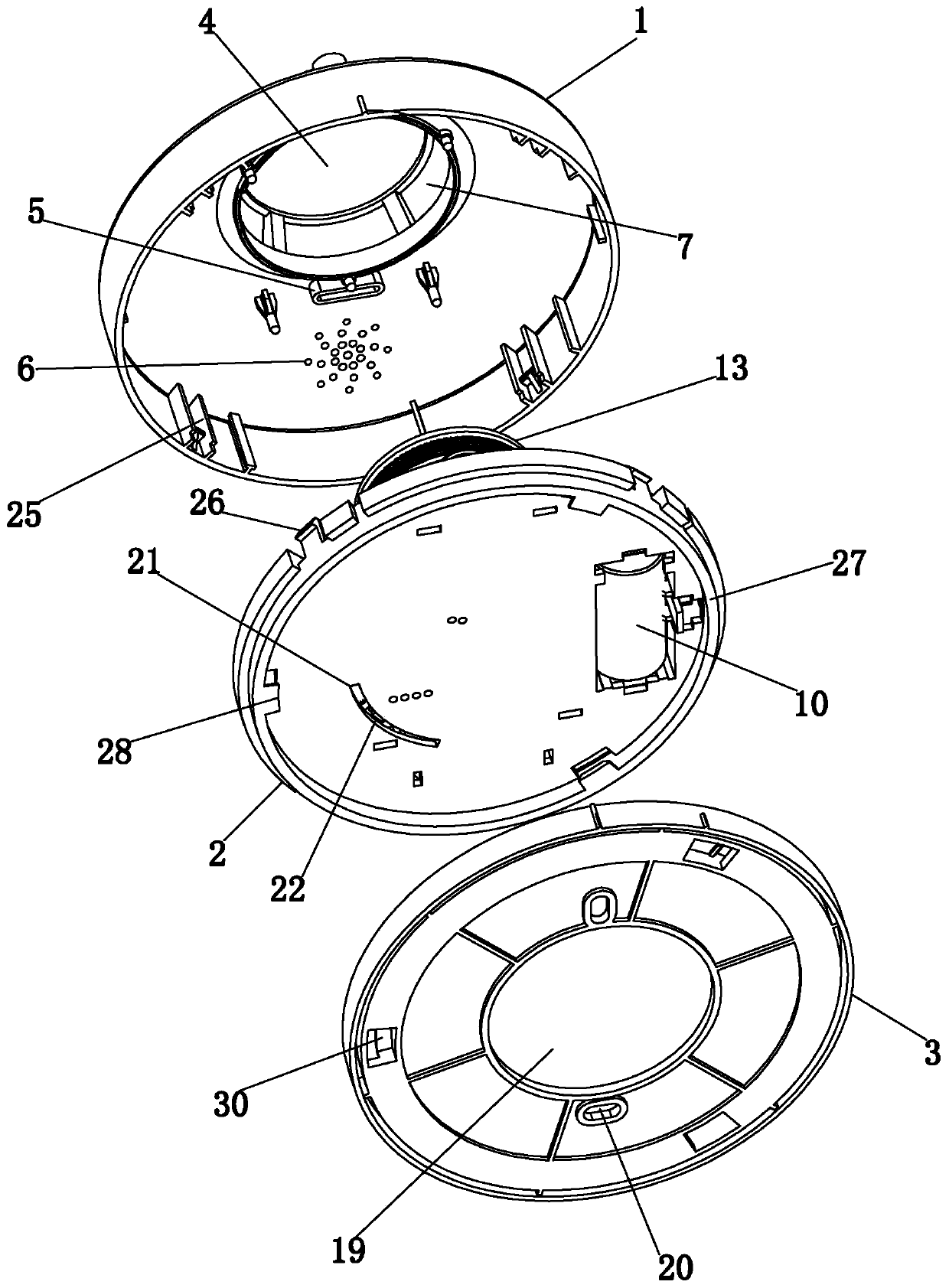

Independent-type smoke sensing detector

PendingCN110097731ARealize modular productionCutting stabilityFire alarmsFire protectionSurface mounting

The invention discloses an independent-type smoke sensing detector. According to the independent-type smoke sensing detector, novel and fine structural design is adopted, so that a shell, a middle buckle and a base can be detachably combined and fixed, and a PCB, a loudspeaker and the middle buckle are detachably combined and fixed; and therefore, the spatial arrangement of the independent-type smoke sensing detector is compact, the internal structure of the independent-type smoke sensing detector is firm, the limiting of components is stable, and assembly production and installation and maintenance are facilitated. A smoke sensing assembly, adopted as an internal core, is of an integrated structure; the PCB, a maze, a receiving tube shielding cover, an infrared emission tube and an infrared receiving tube are connected through surface-mounting processing so as to form an integrated body, and the integrated body is arranged in the middle buckle, so that the detector body of the detector can be assembled; yield is high; production efficiency is high; surface-mounting process difficulty and detector body assembly difficulty are greatly reduced; the internal structure of the independent smoke sensing product is more integrated; the modular production of the independent smoke sensing product is realized; the production efficiency of the independent smoke sensing product is improved; and the structure optimization design and function extension, research and development of the independent smoke sensing product are promoted. The independent-type smoke sensing detector is suitablefor intelligent fire protection.

Owner:浙江台谊消防股份有限公司

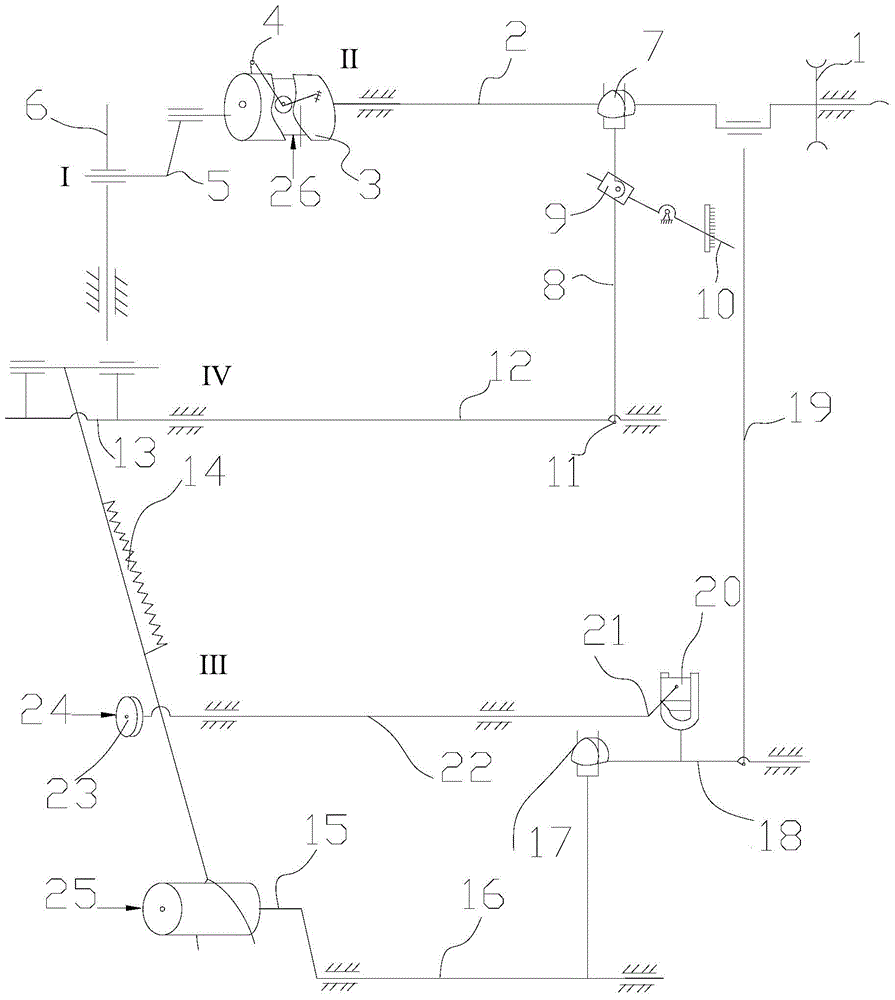

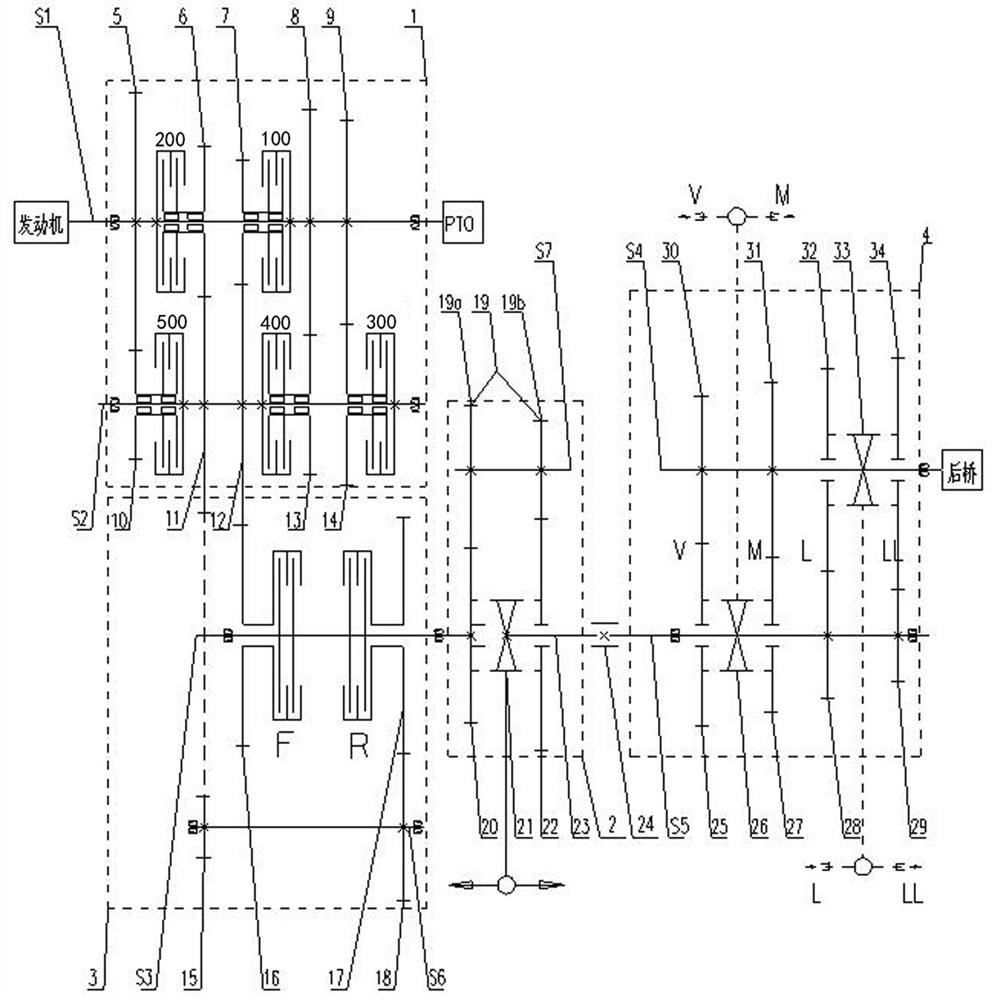

40F and 40R power gear shifting tractor gearbox

A 40F and 40R power gear shifting tractor gearbox comprises a power gear shifting transmission device, a creeper gear transmission device, a power reversing transmission device and a section gear shifting transmission device, wherein a first shaft and a second shaft are arranged in the power gear shifting transmission device; one end of the first shaft is connected with a tractor engine; the other end of the first shaft is connected with a tractor PTO; clutches and matched gears are mounted on the first shaft and the second shaft; the clutches are used for the achievement of different gears; a third shaft and a sixth shaft are arranged in the power reversing transmission device; a forward clutch and a backward clutch are arranged on the third shaft; a two-stage external meshing mechanism is arranged in the creeper gear transmission device; the input end of the creeper gear transmission device is connected with the third shaft; the output end of the creeper gear transmission device is connected with the input end of the section gear shifting transmission device; the output end of the section gear shifting transmission device is connected with a rear axle; the first shaft and a fourth shaft are distributed in the longitudinal center plane of a tractor; the second shaft and the third shaft are correspondingly positioned on two sides of the longitudinal center plane of the tractor; and a fifth shaft and the third shaft are arranged on one and the same straight line. The 40F and 40R power gear shifting tractor gearbox has the characteristics of being simple in structure, complete in function and high in transmission efficiency.

Owner:FIRST TRACTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com