Patents

Literature

1014 results about "Continuous/uninterrupted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus and process for making prosthetic suction sleeve

Owner:KAUPTHING BANK

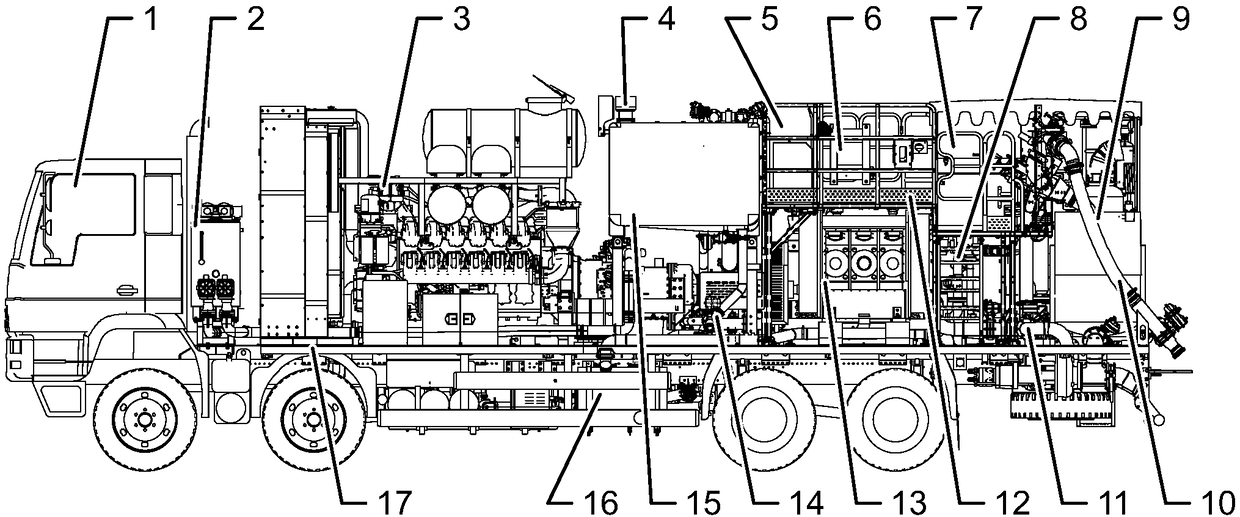

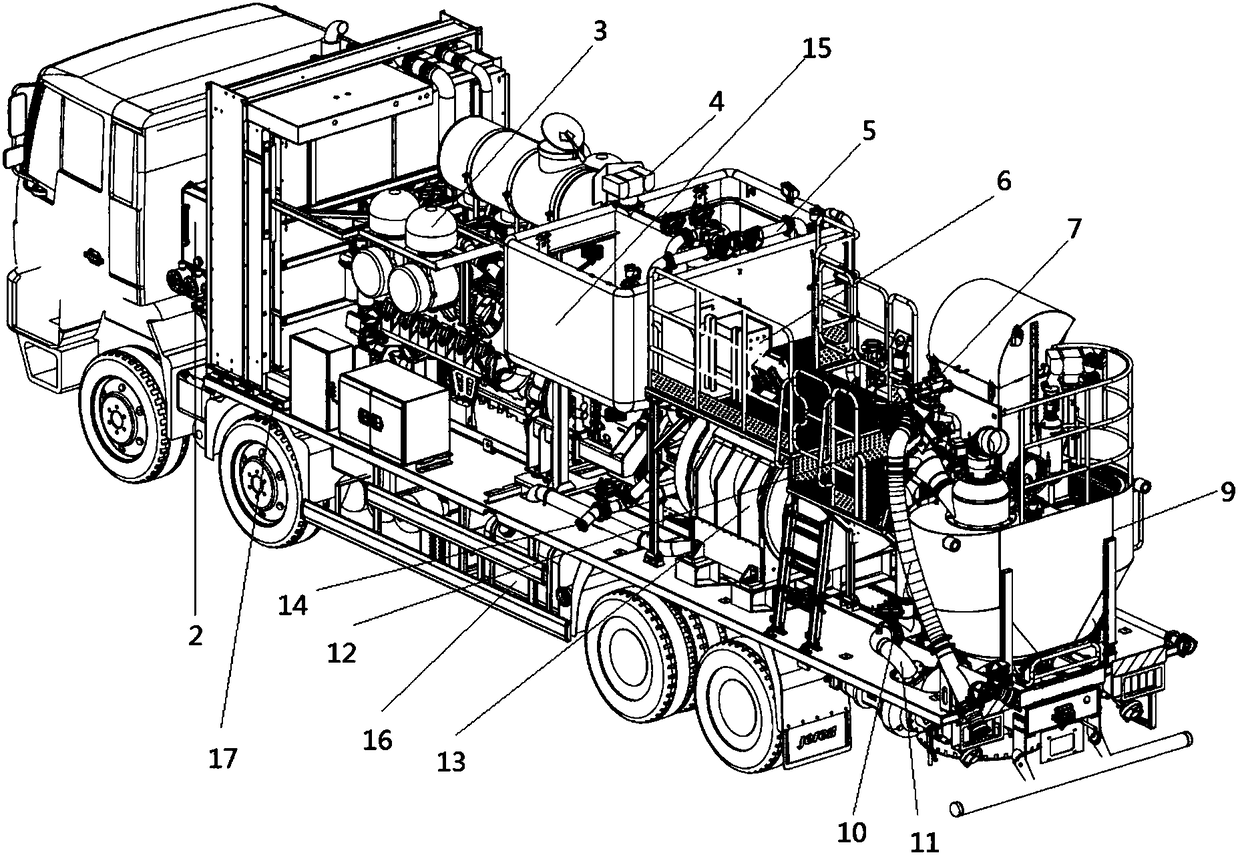

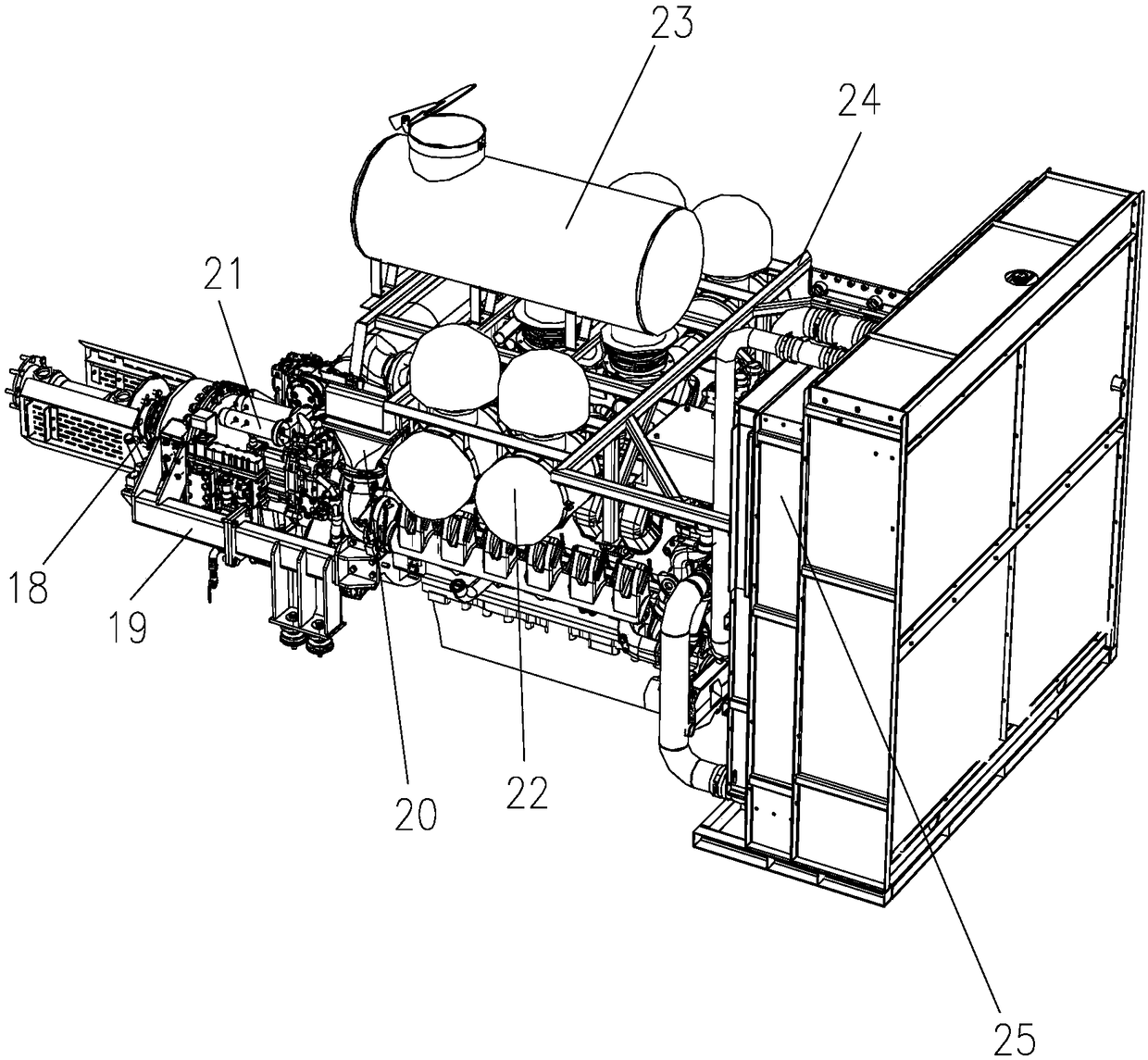

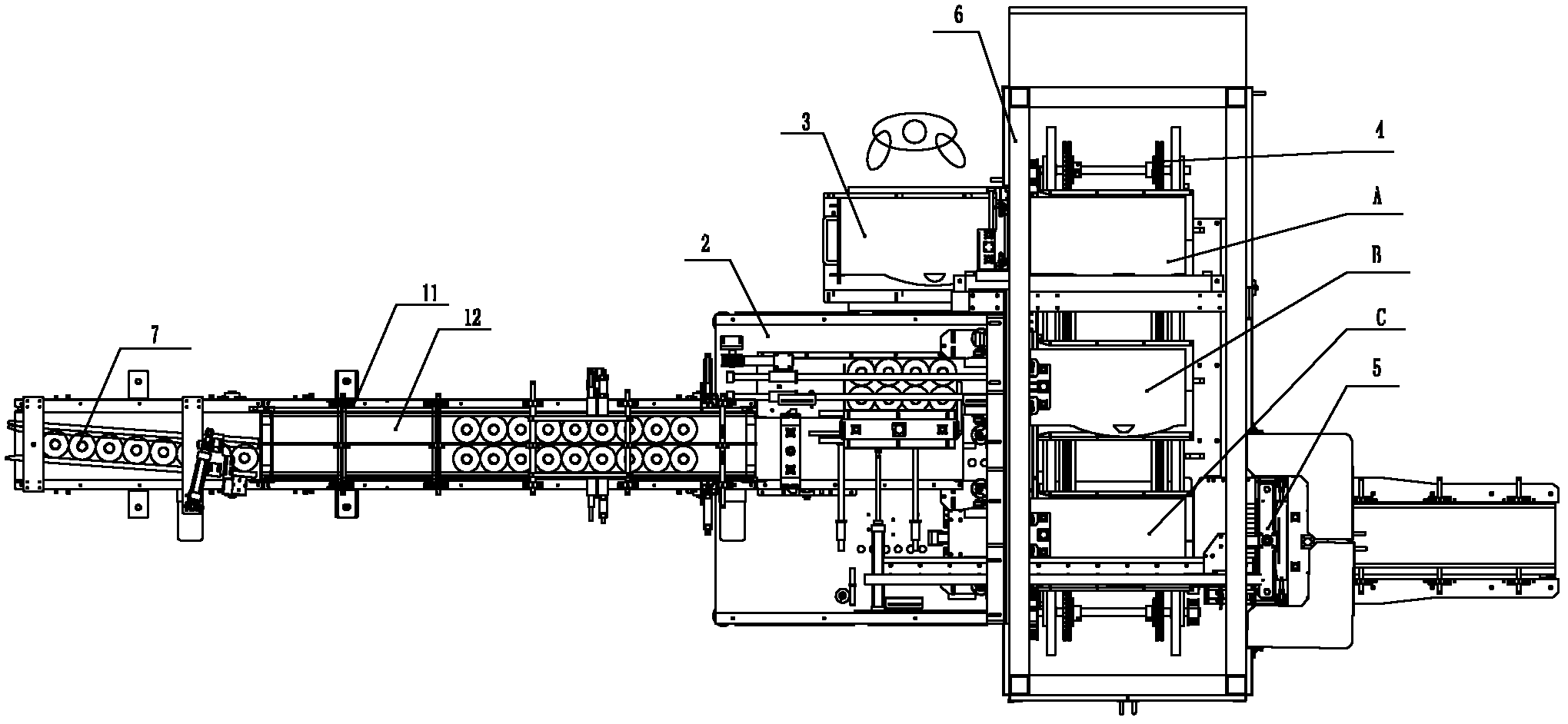

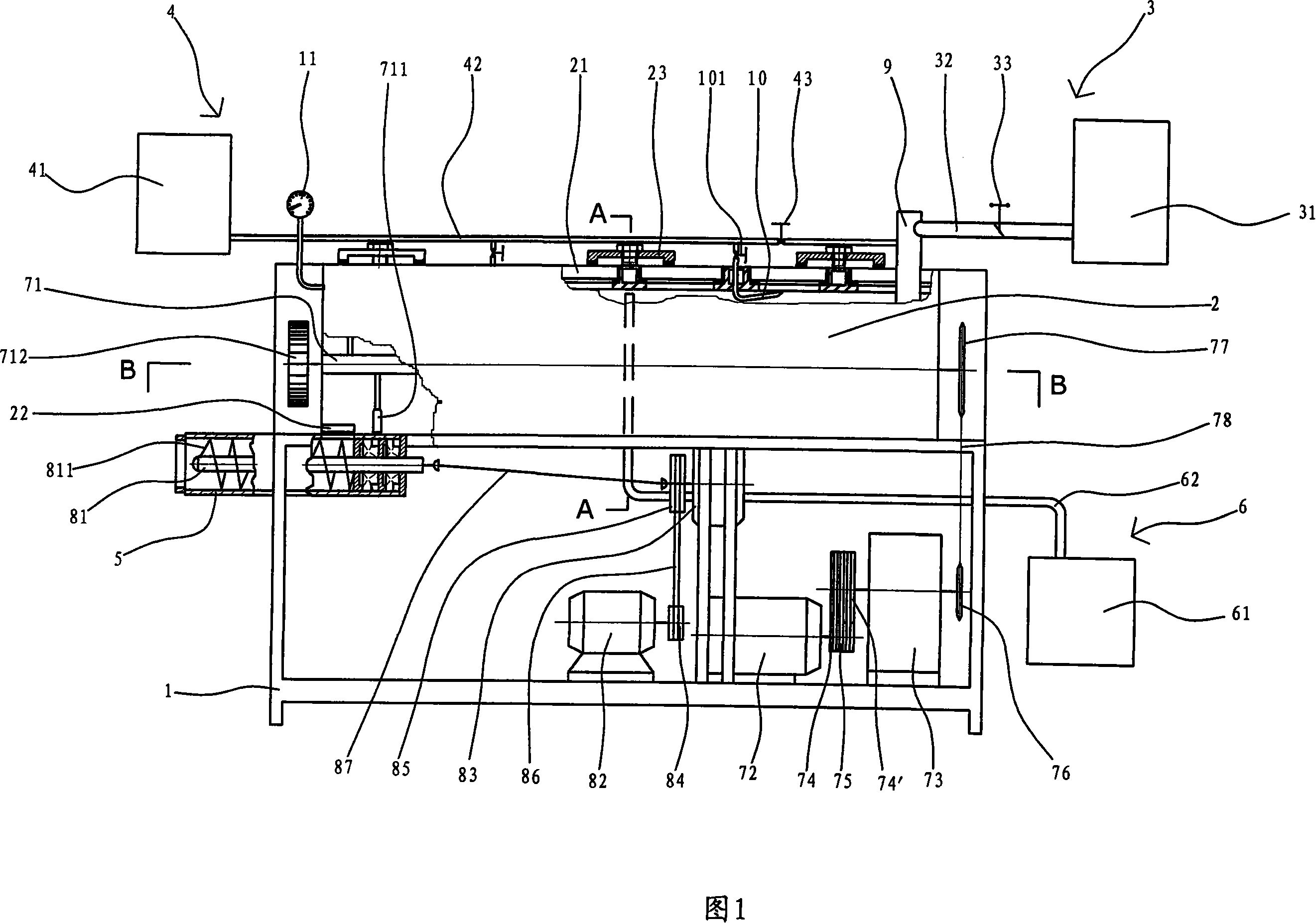

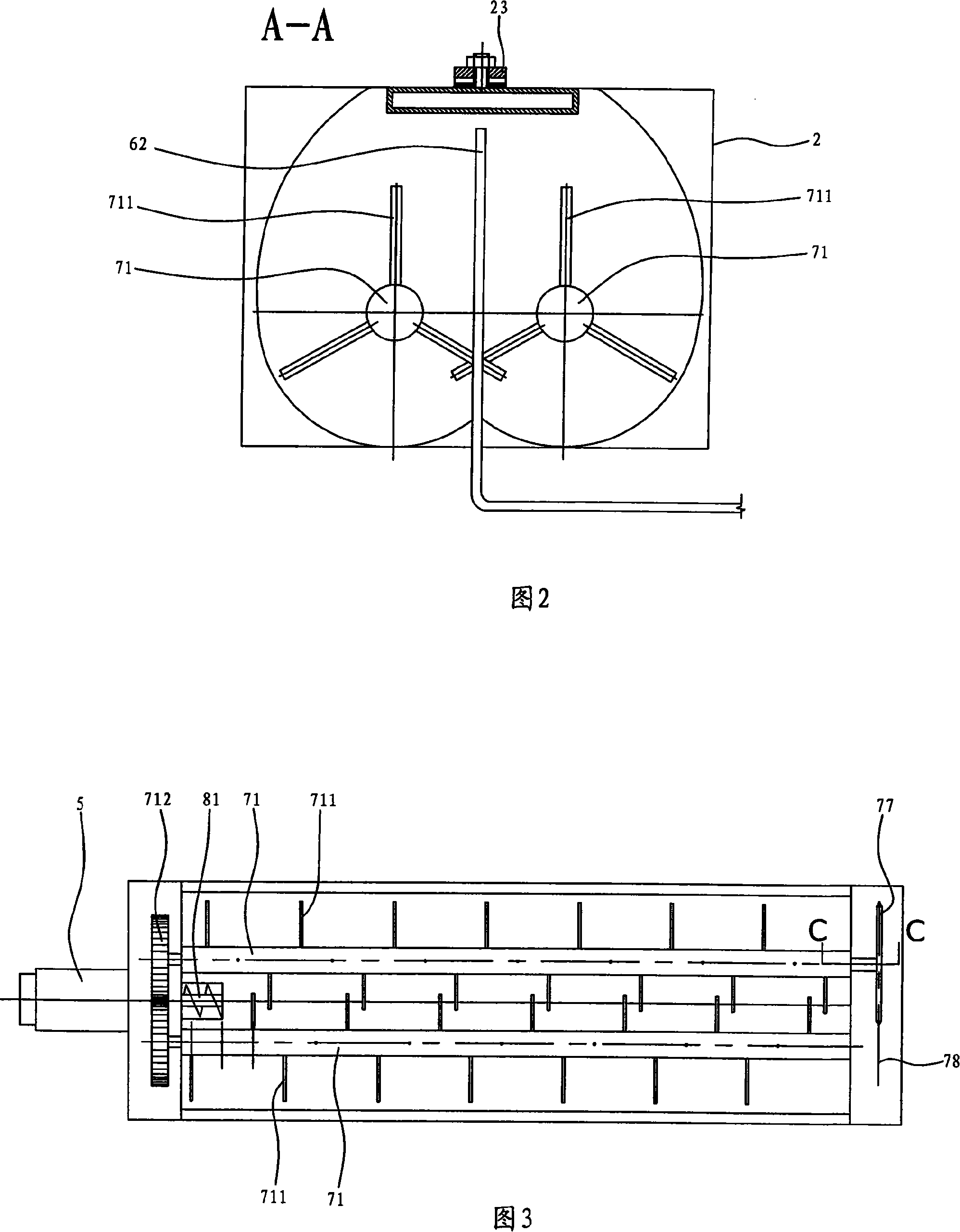

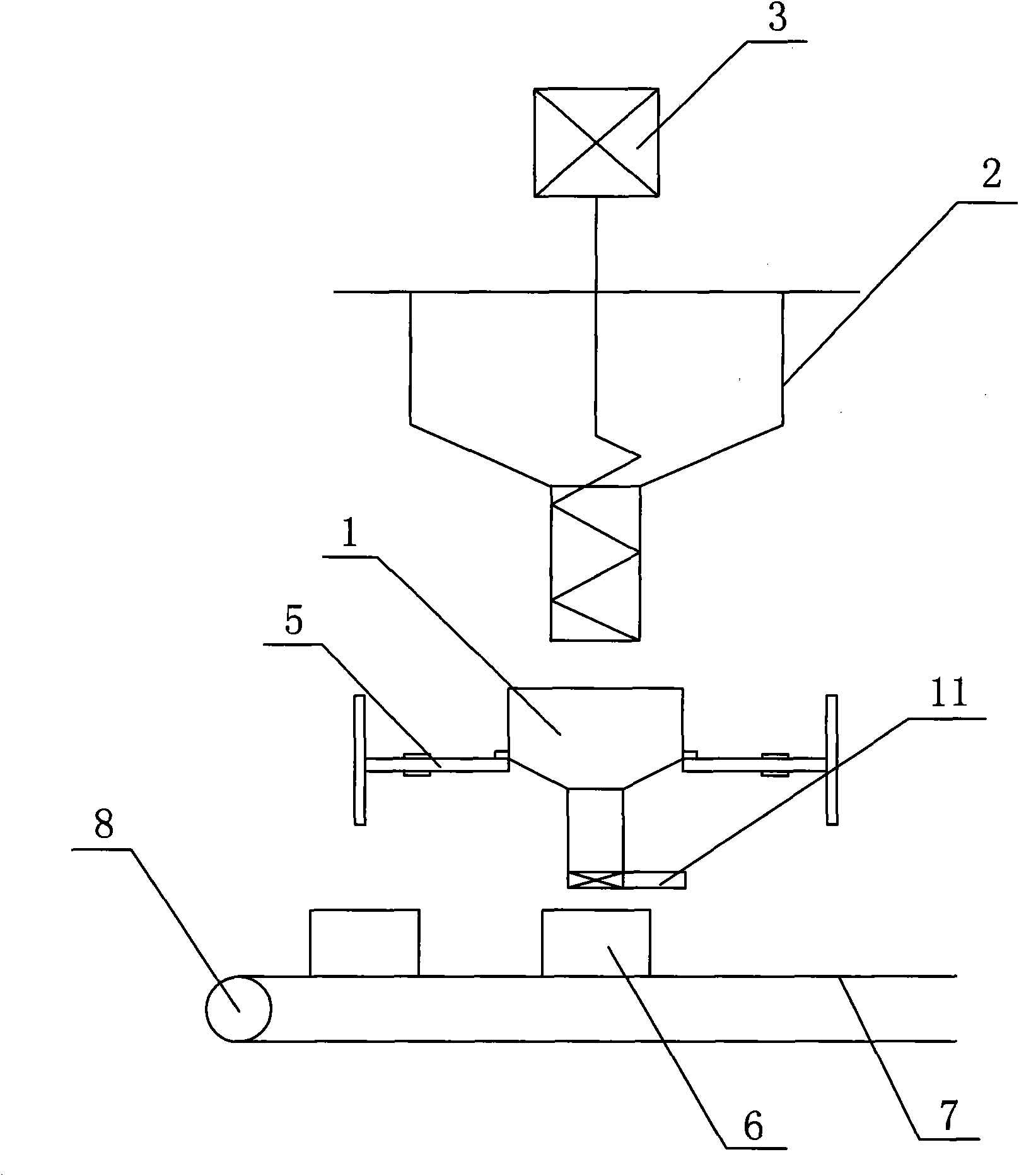

Novel ultra-high-power cementing equipment integrated with remote control

PendingCN108561098AQuick arrangementSave work spacePositive displacement pump componentsPumpsUltra high pressureDrivetrain

The present invention relates to the technical field of petroleum equipment, in particular to novel ultra-high-power cementing equipment integrated with remote control. The novel ultra-high-power cementing equipment integrated with remote control comprises a loading system and a secondary beam, wherein the secondary beam is connected with a hydraulic system, a power transmission system, a meteringtank, an electrical system, a gas circuit system, a control system and a mixing system from front to rear in sequence, the lower portion of the gas circuit system is provided with a plunger pump, theplunger pump is connected with a high-pressure discharge system; a control platform is arranged at the lower part of the electrical system; the control system is positioned above the control platform; and the control system is connected with the remote control system. The novel ultra-high-power cementing equipment integrated with remote control meets the requirements of high pressure, large displacement, long time and continuous uninterrupted operation during the ultra-deep cementing operation and the ultra-high pressure gas well operation; and the occupied area is small, the pipeline connection is simple, and the maintenance frequency is low.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

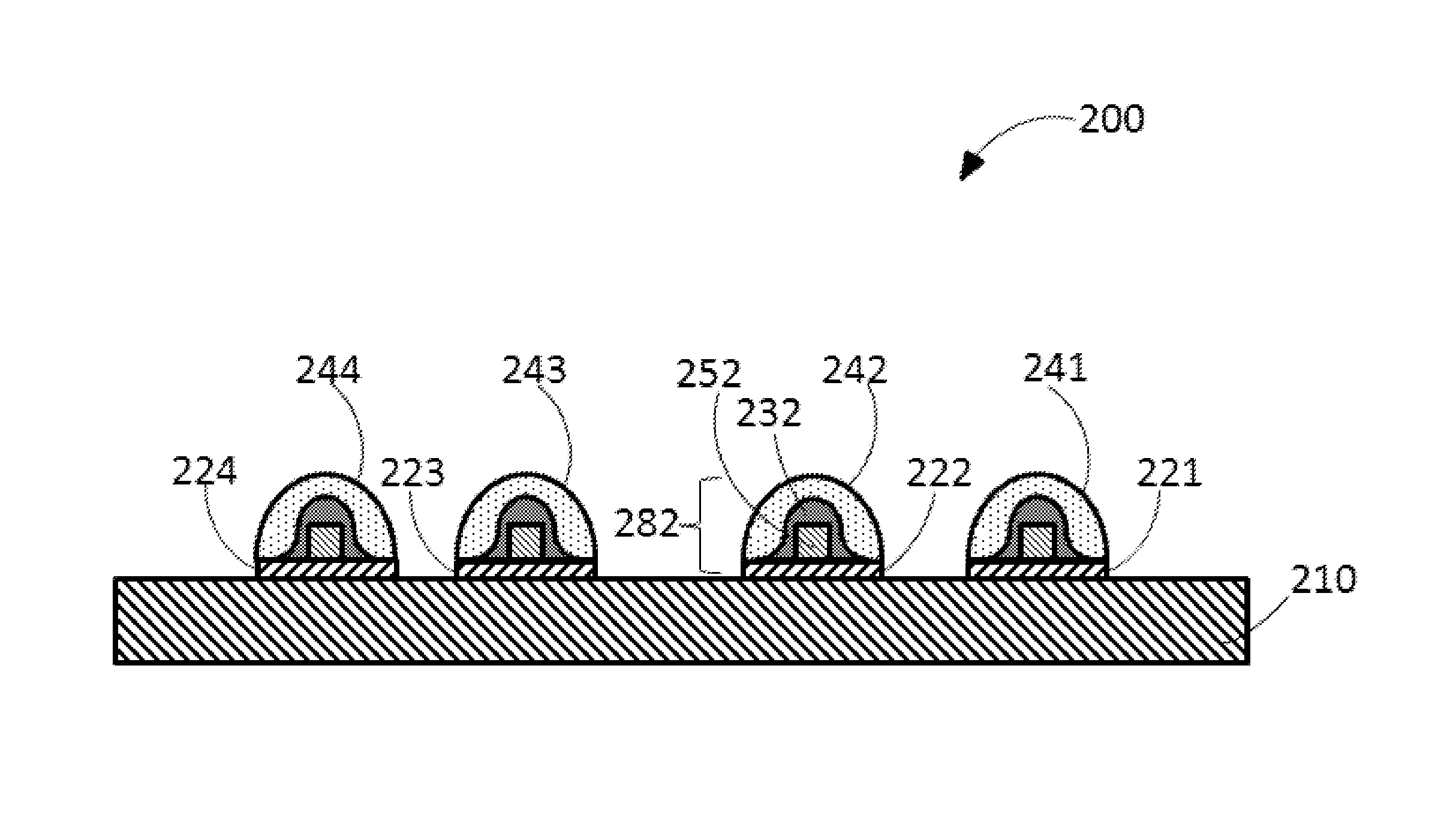

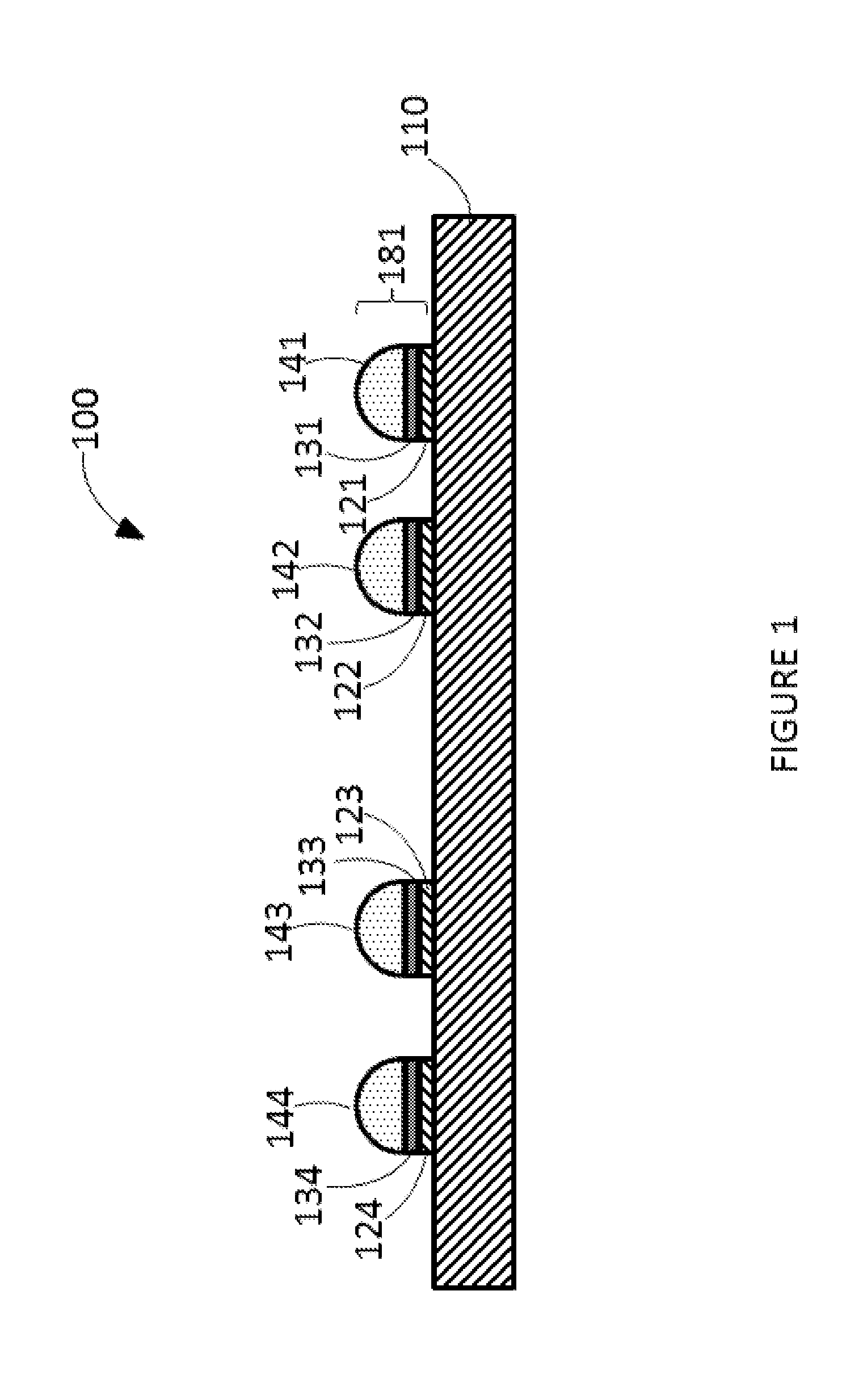

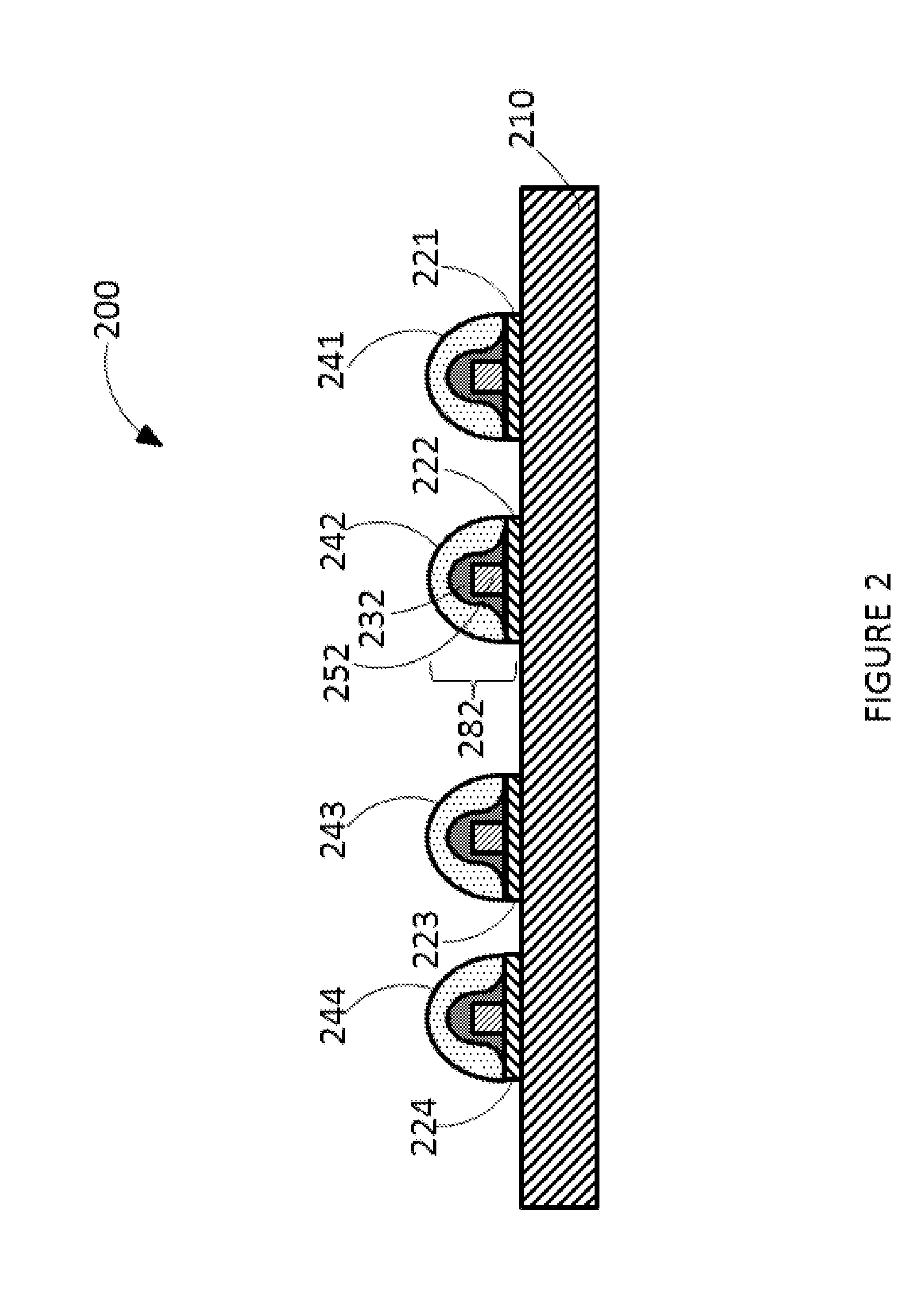

Systems and methods for testing and packaging a superconducting chip

ActiveUS20140246763A1Semiconductor/solid-state device testing/measurementSolid-state devicesContinuous/uninterruptedInterconnection

Superconductive interconnection structures providing continuous, uninterrupted superconducting signal paths between a superconducting chip and a superconducting chip carrier are described. The superconductive interconnection structures employ superconducting solder bumps and pillars of Under Bump Metal (“UBM”). The superconductive interconnection structures are employed in a two-stage solder bumping process in which the superconducting chip is first bonded to a testing module for screening and then bonded to a chip packaging module for operation. Either the testing module or the chip packaging module, or both, may include a multi-chip module for carrying multiple superconducting chips simultaneously.

Owner:D WAVE SYSTEMS INC

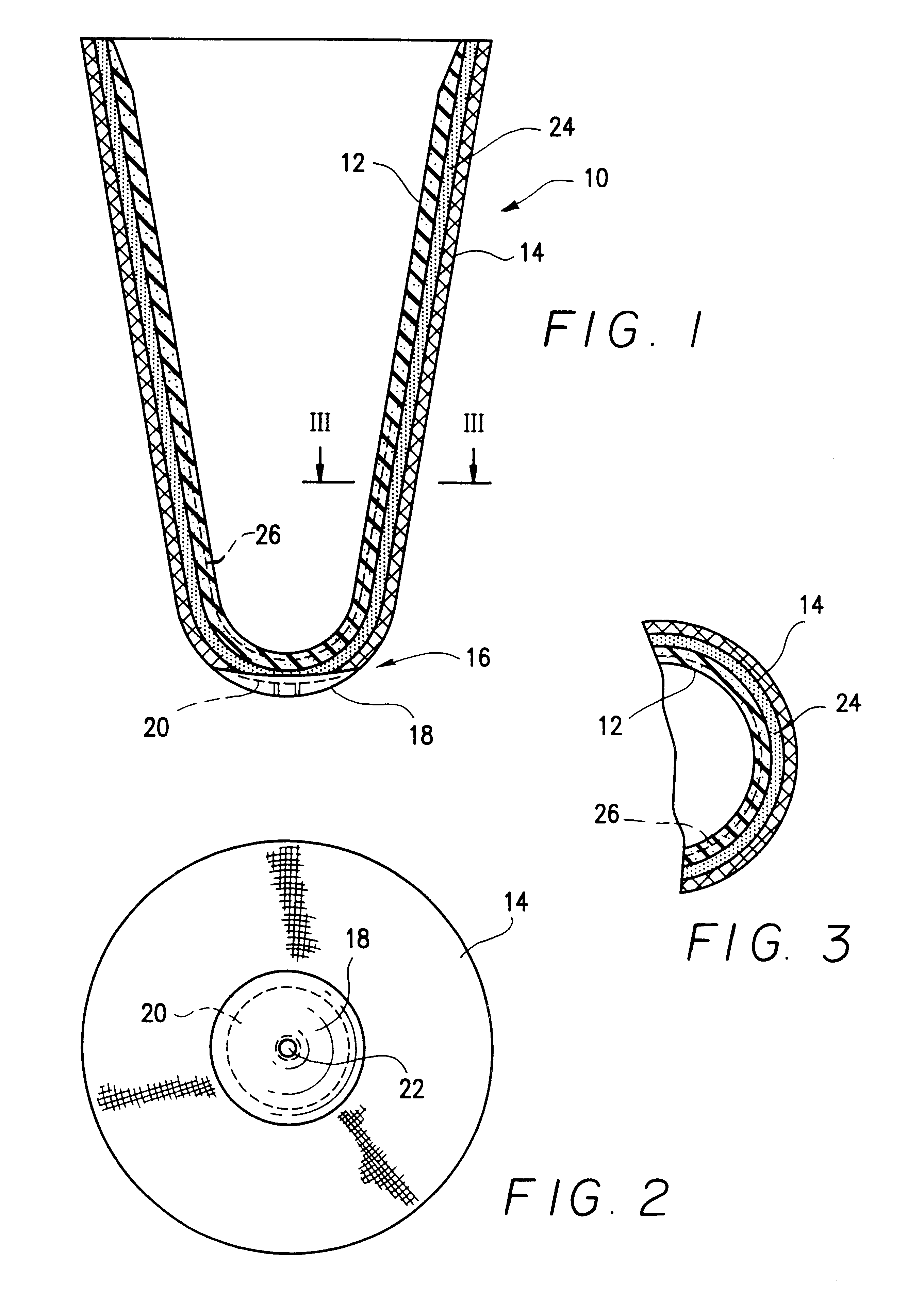

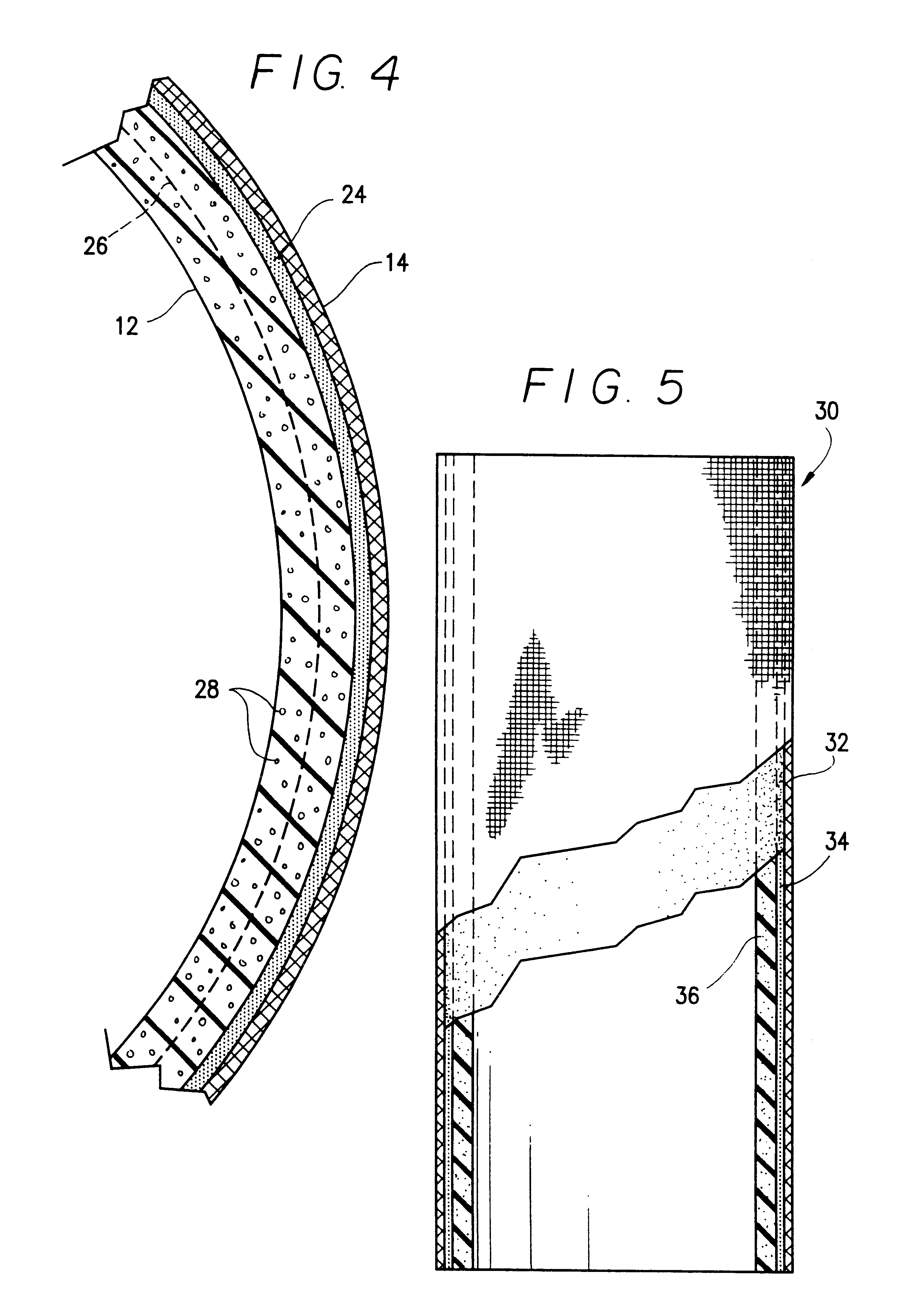

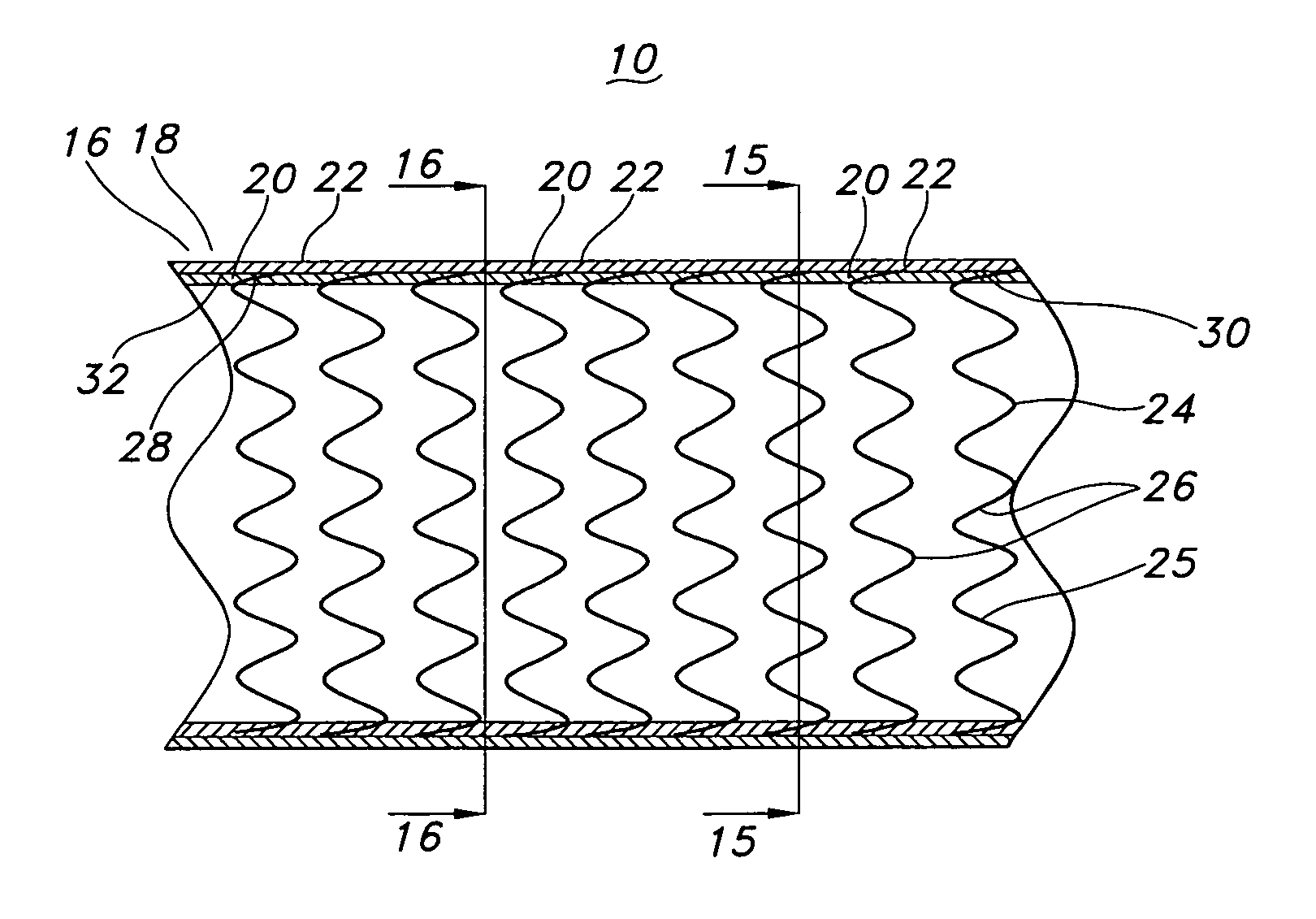

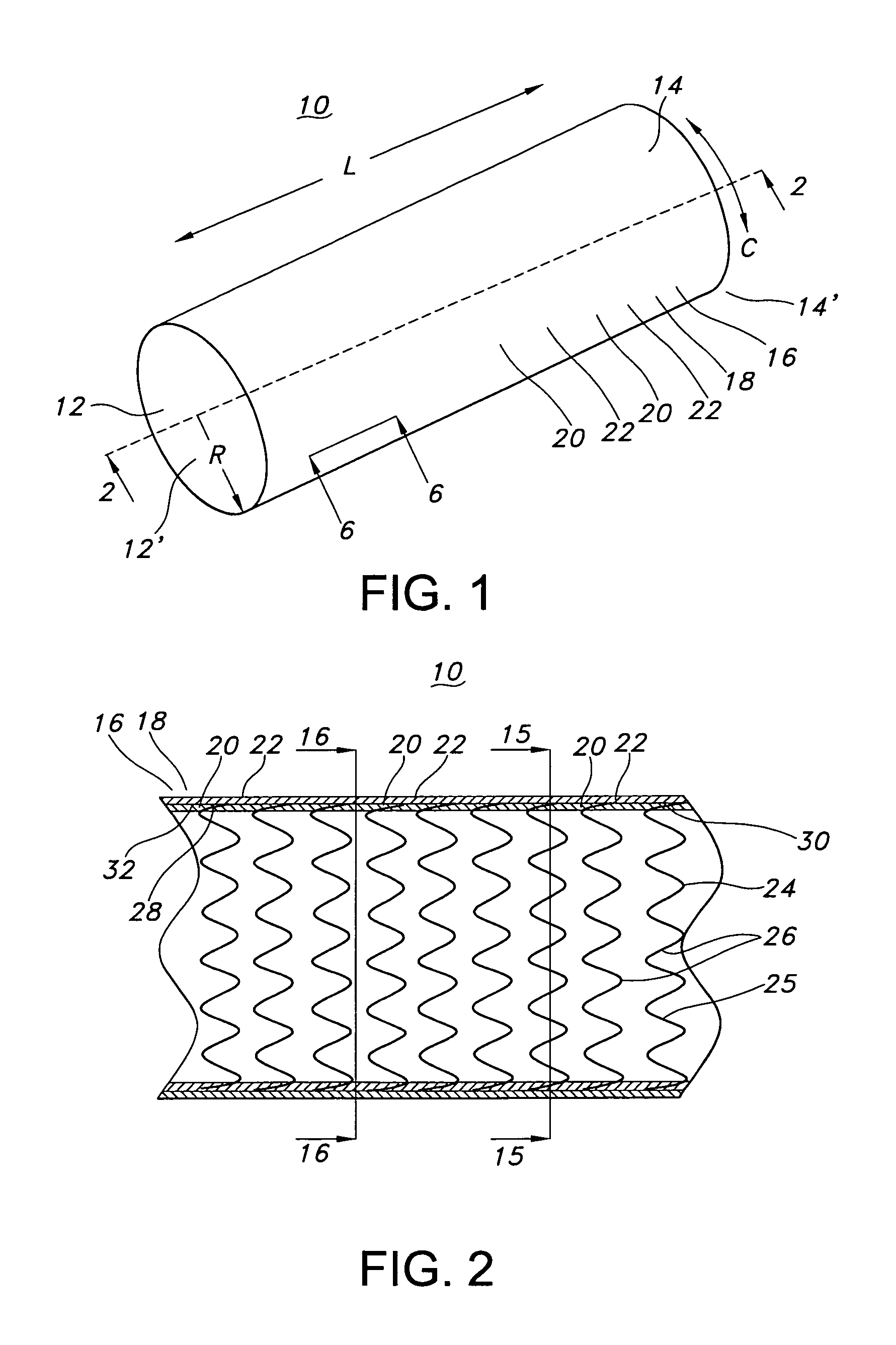

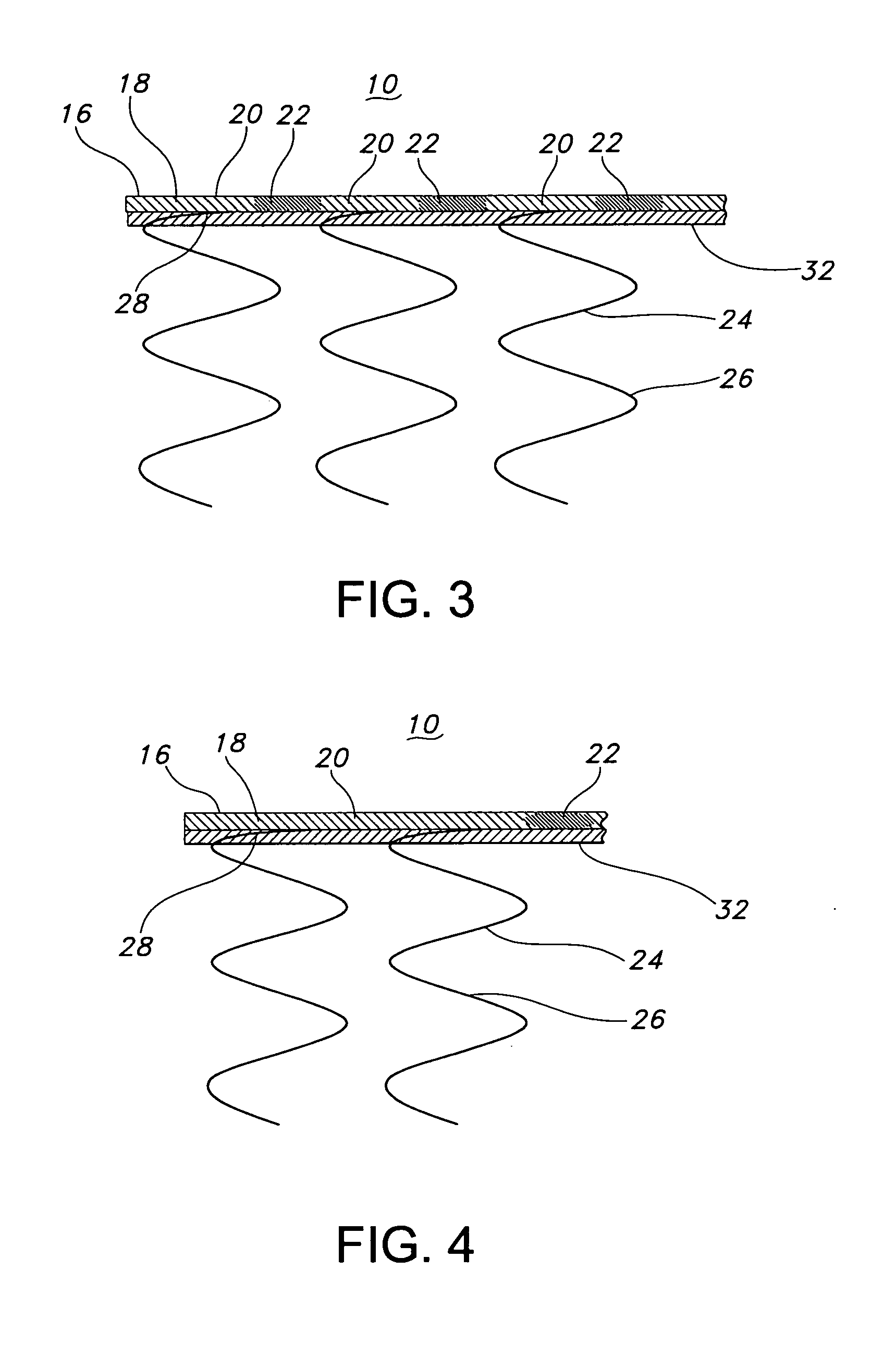

Stent-graft having flexible geometries and methods of producing the same

InactiveUS20070208421A1Increased bending flexibilityDifferent bending flexibilityStentsBlood vesselsContinuous/uninterruptedStent grafting

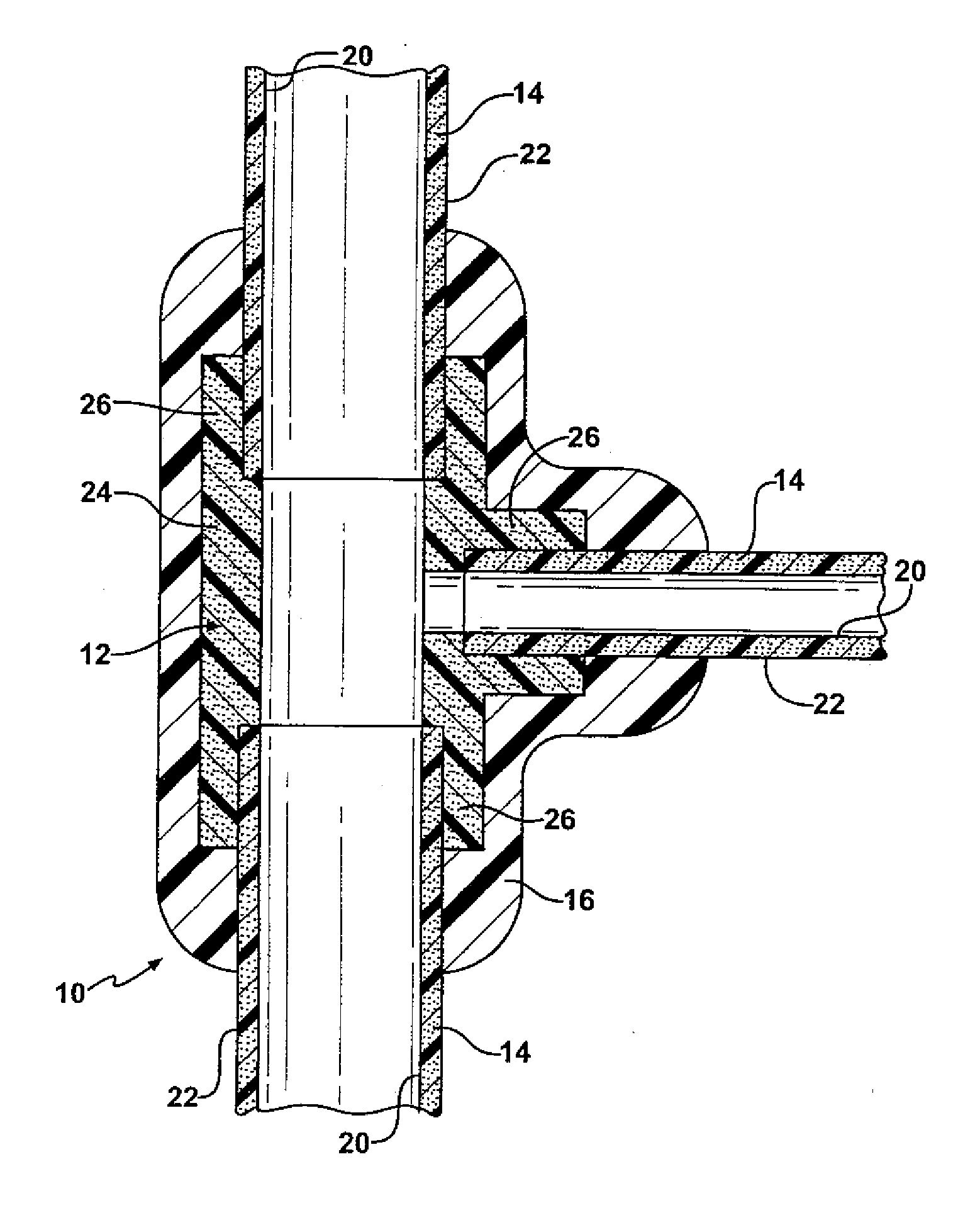

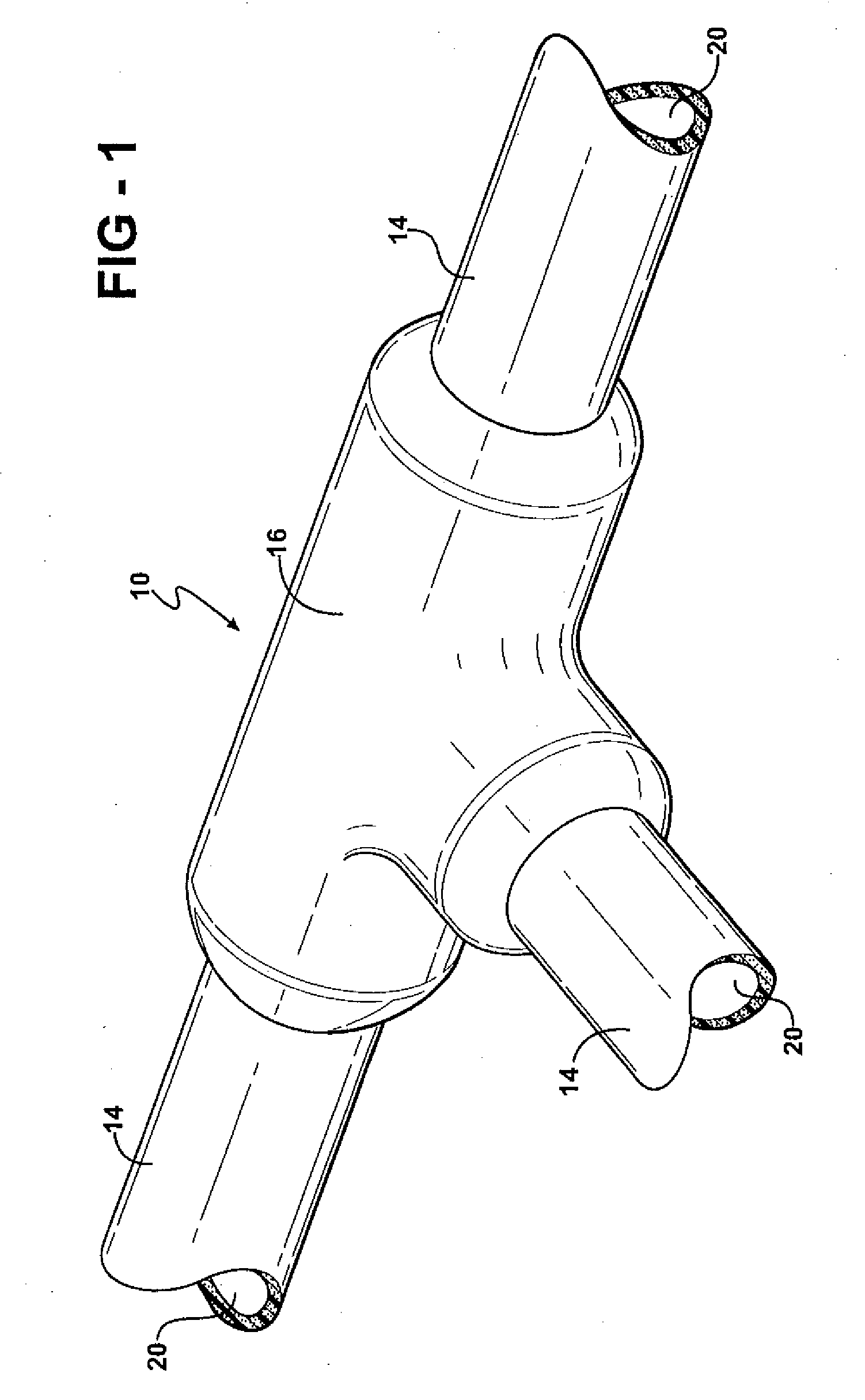

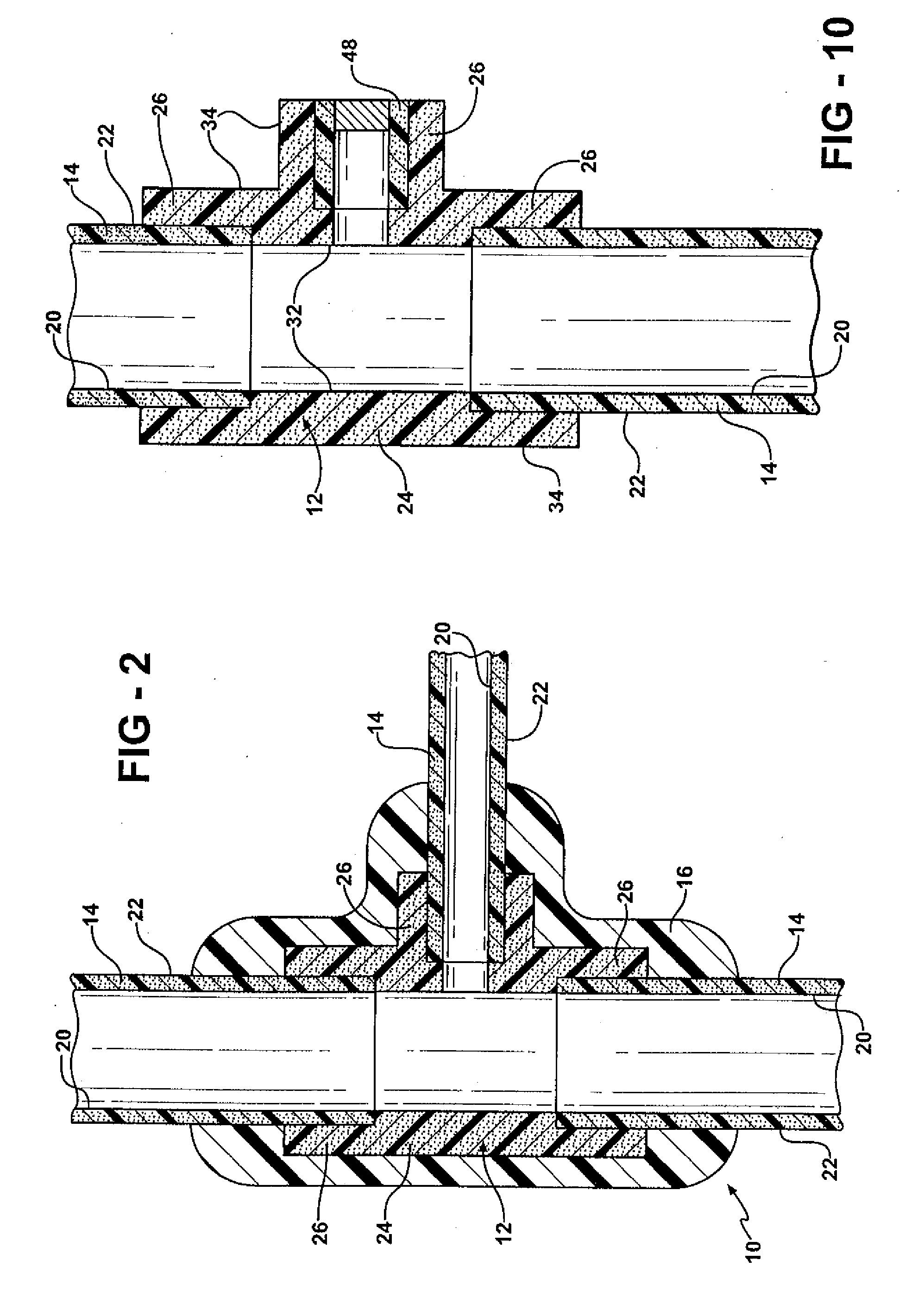

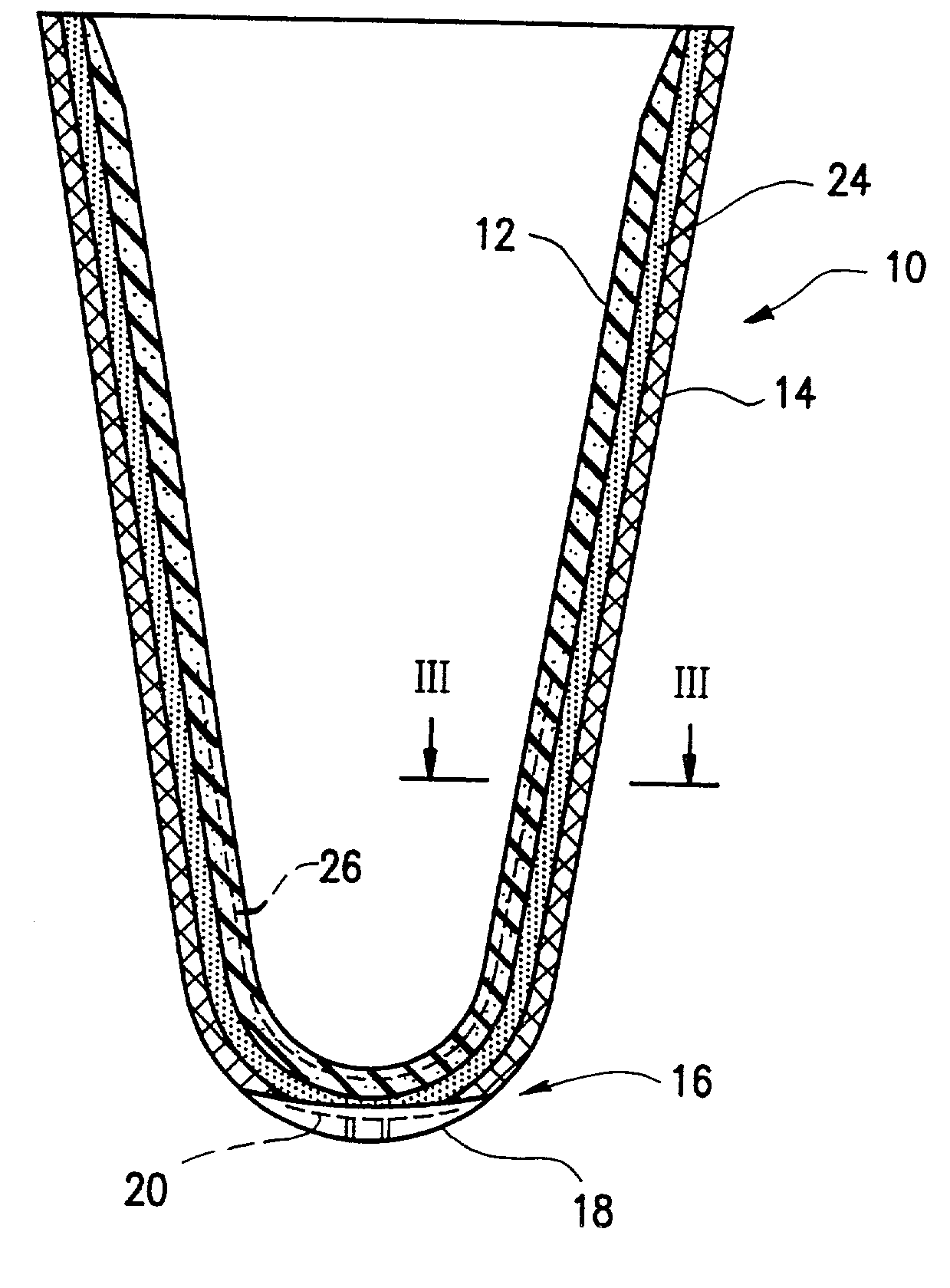

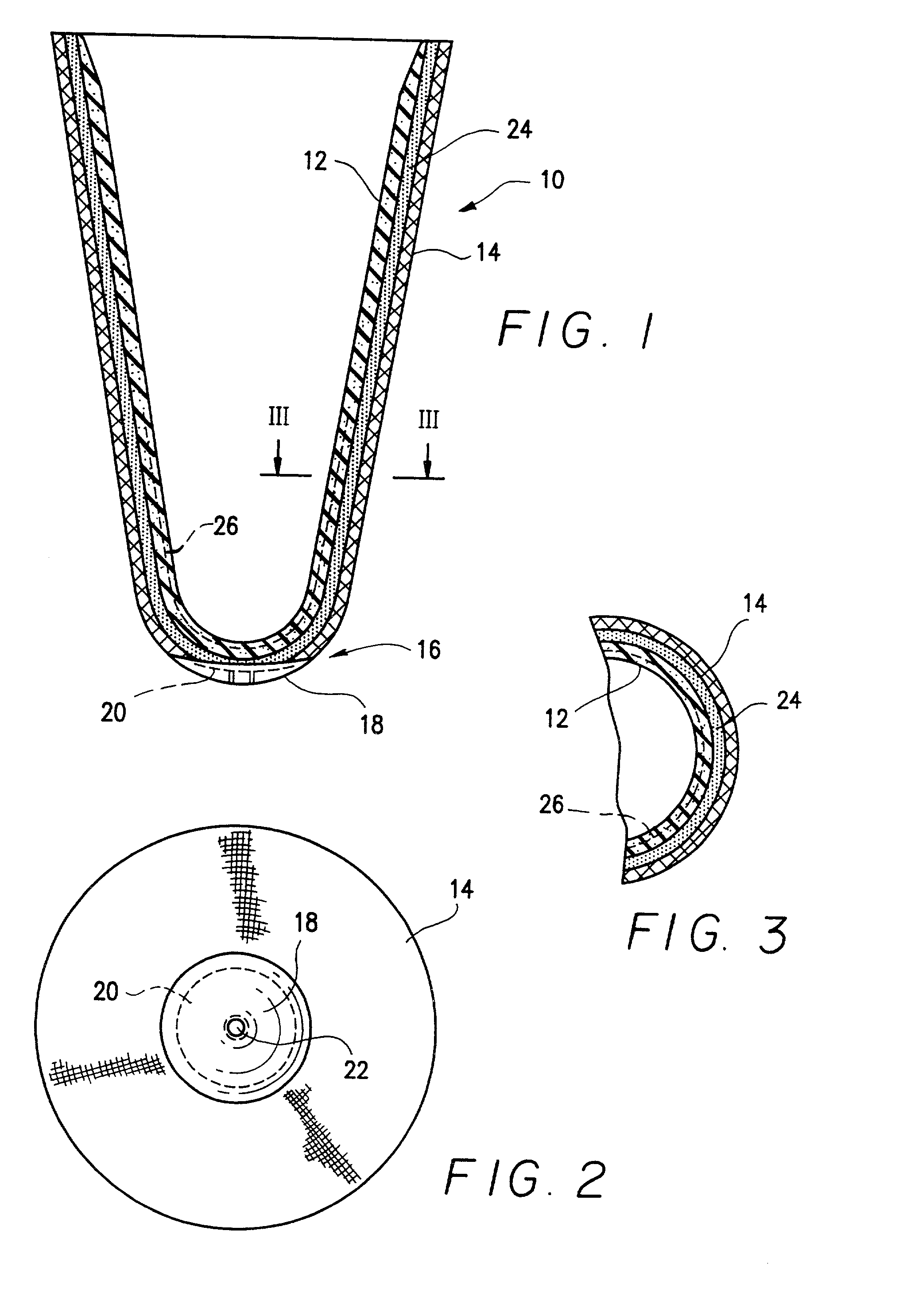

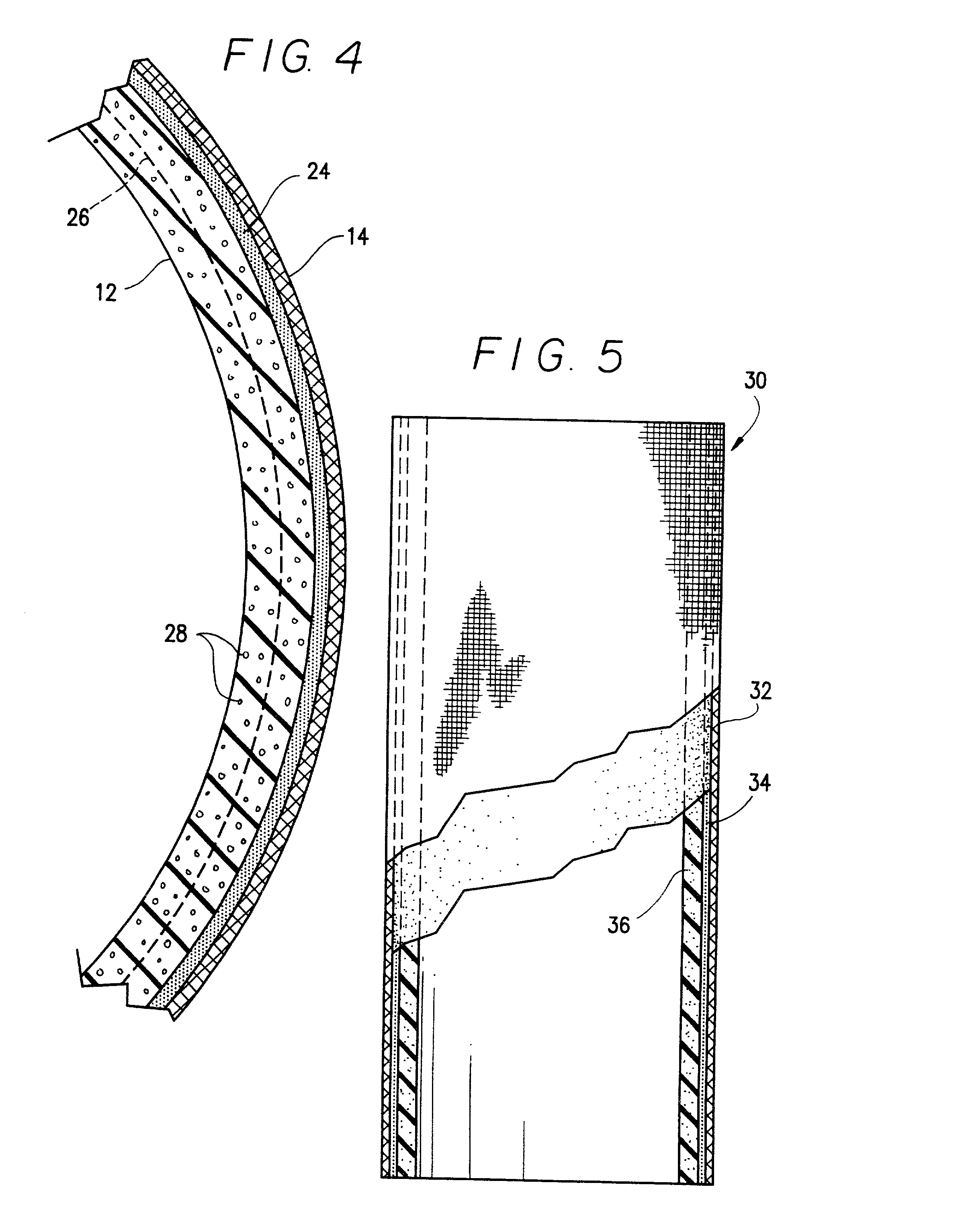

A stent-graft or prosthesis (10) with enhanced flexibility, in particular enhanced bending flexibility, includes a radially distensible stent (24) and at least one continuously uninterrupted ePTFE tubular graft or covering (18) having a node and fibril structure. The tubular stent (24) includes opposed open ends (12′, 14′) and a stent wall structure (26) having opposed exterior (28) and luminal surfaces (30). The ePTFE covering (18) is securably disposed to at least one of the stent surfaces (28, 30). The ePTFE graft or covering (18) includes a tubular wall (16) that is continuously uninterrupted and desirably substantially free of slits, apertures and folds. The ePTFE graft (18) further includes a first region (20) and a second region (22), where the first region (20) has a different bending flexibility from the second region (22).

Owner:LIFESHIELD SCI

Composite flexible and conductive catheter electrode

InactiveUS20070249923A1Meet functional requirementsAllow flexibilityEnvelopes/bags making machineryEar treatmentContinuous/uninterruptedElectricity

A flexible cardiac catheter for sensing electrical activity within and administering therapy to a patients' heart has a series of flexible, conductive electrode bands positioned in grooves in the catheter's tubular body. The bands consist of alternating flexible and conductive elements, providing flexibility and overall versatility to the catheter. The electrode bands have controllable flexibility due to the elastic properties of the flexible elements and continuous uninterrupted electrical current conductance from the one-piece design of the conductive element. The synergy of the components of the composite flexible and conductive bands will help solve problems current electrode bands have and will allow for a freedom in the design of catheter electrode band configurations in the future.

Owner:KEENAN ERICK

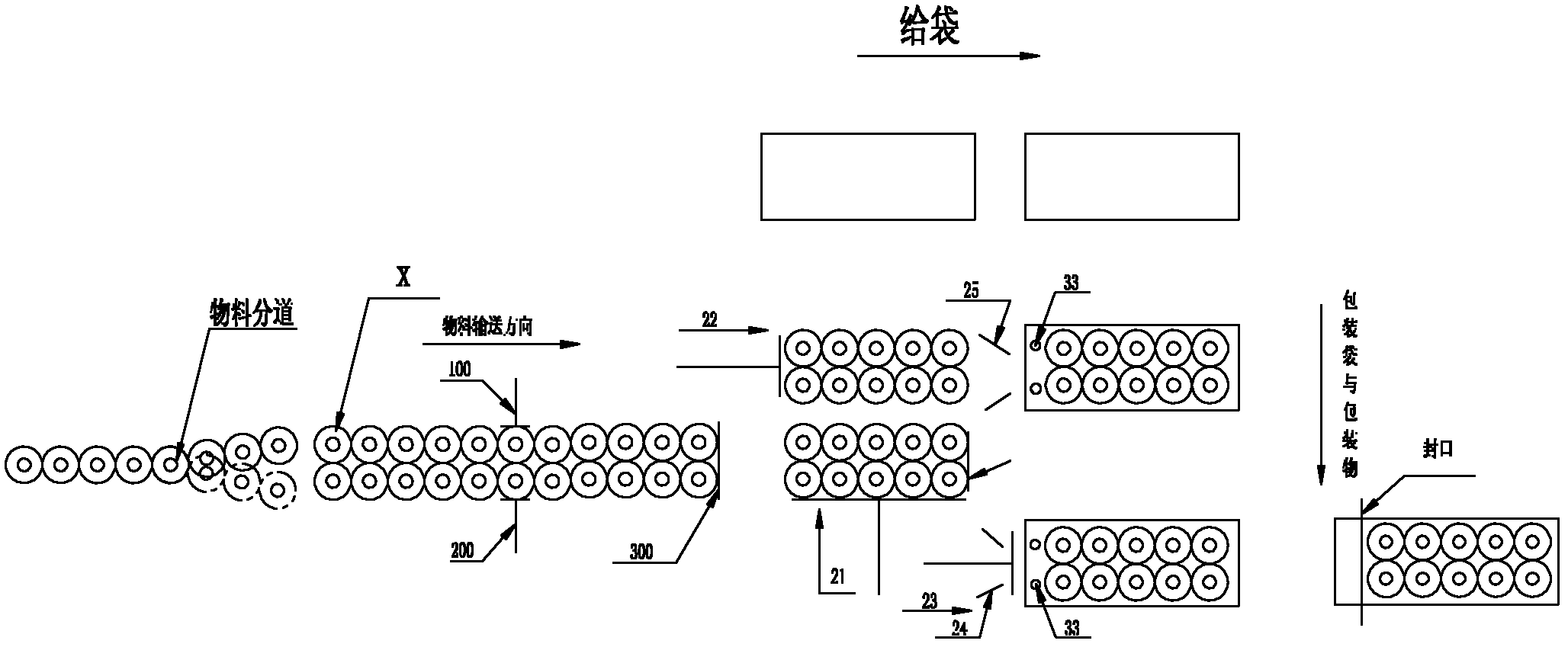

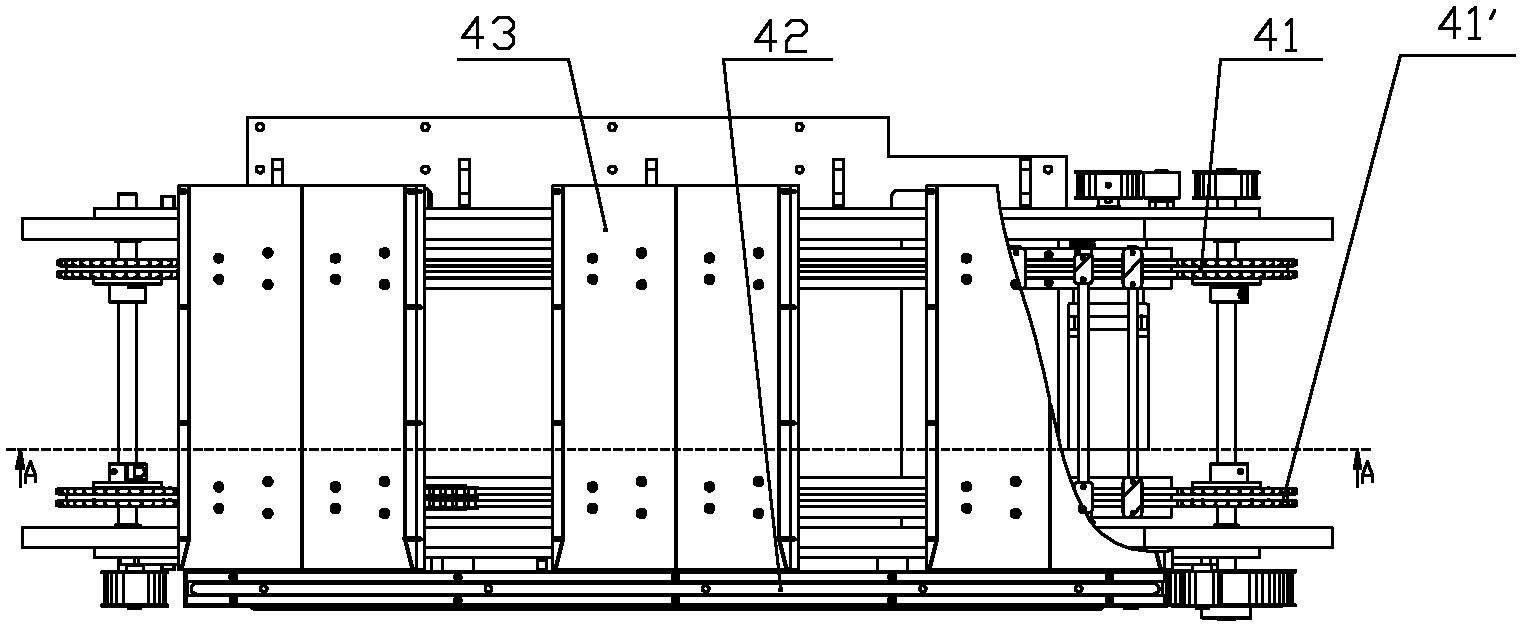

Roll paper packing machine

InactiveCN102556397AGuaranteed uniformityReduce labor costsPaper article packagingContinuous/uninterruptedRolling paper

The invention relates to a packing machine, in particular relates to a packing machine for packing roll paper. The roll paper packing machine is characterized by comprising a split conveying part, a feeding and managing conveying part, a bagging part, a packaging bag warehouse, a drag conveying part, a sealing output part and a frame part. The roll paper packing machine has the obvious advantages that: 1, the roll paper continuously enters the machine and forms the packaged finished products on sale finally, true whole assembly line operation is realized and true automatic operation is achieved; 2, labor cost is saved; and 3, a condition that the manual operation is influenced by different proficiency is avoided, and the automatic operation can fully ensure the unity of the final product quality.

Owner:SHANGHAI SOONTRUE MACHINERY EQUIP +2

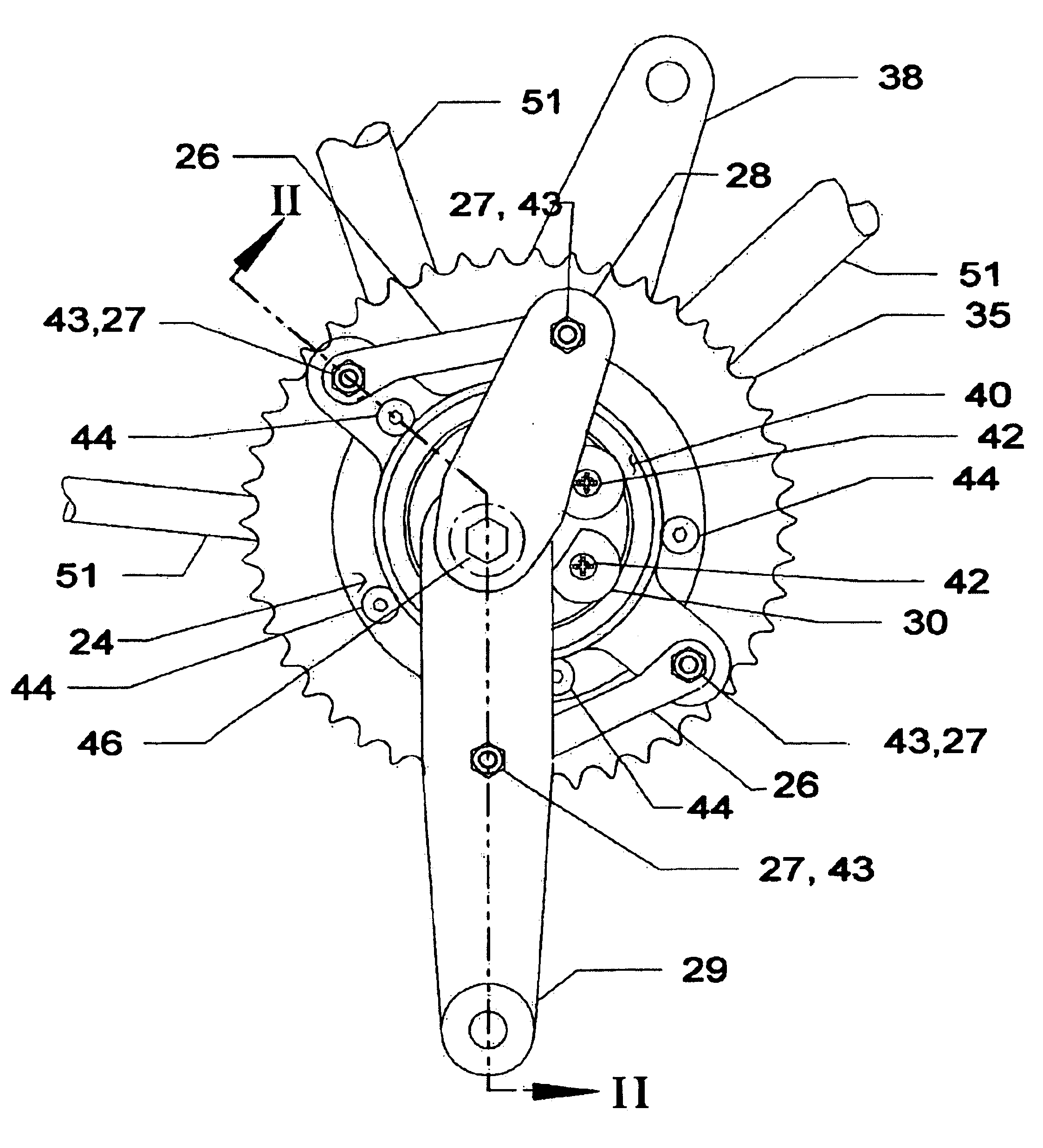

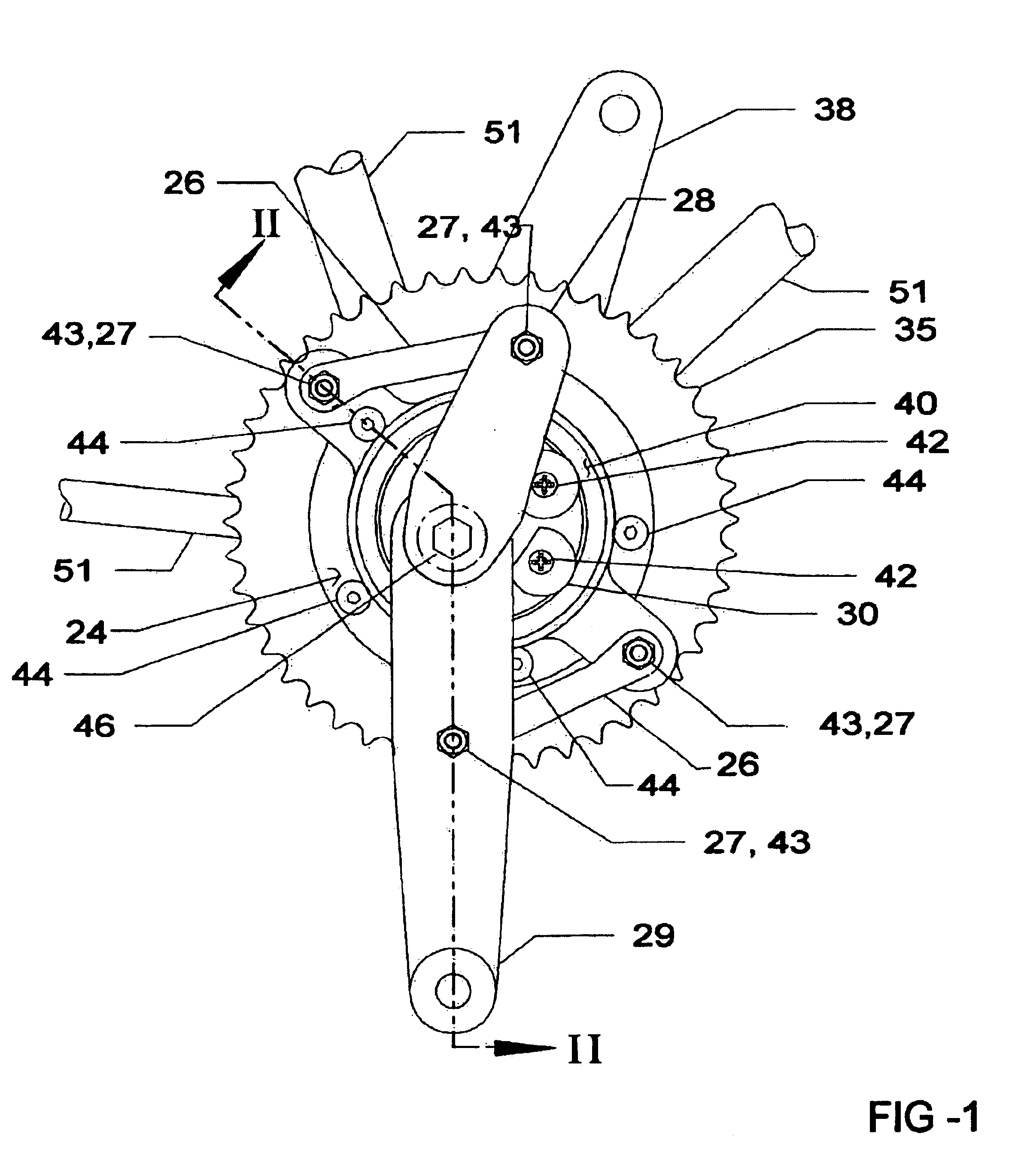

Pedal drive mechanism

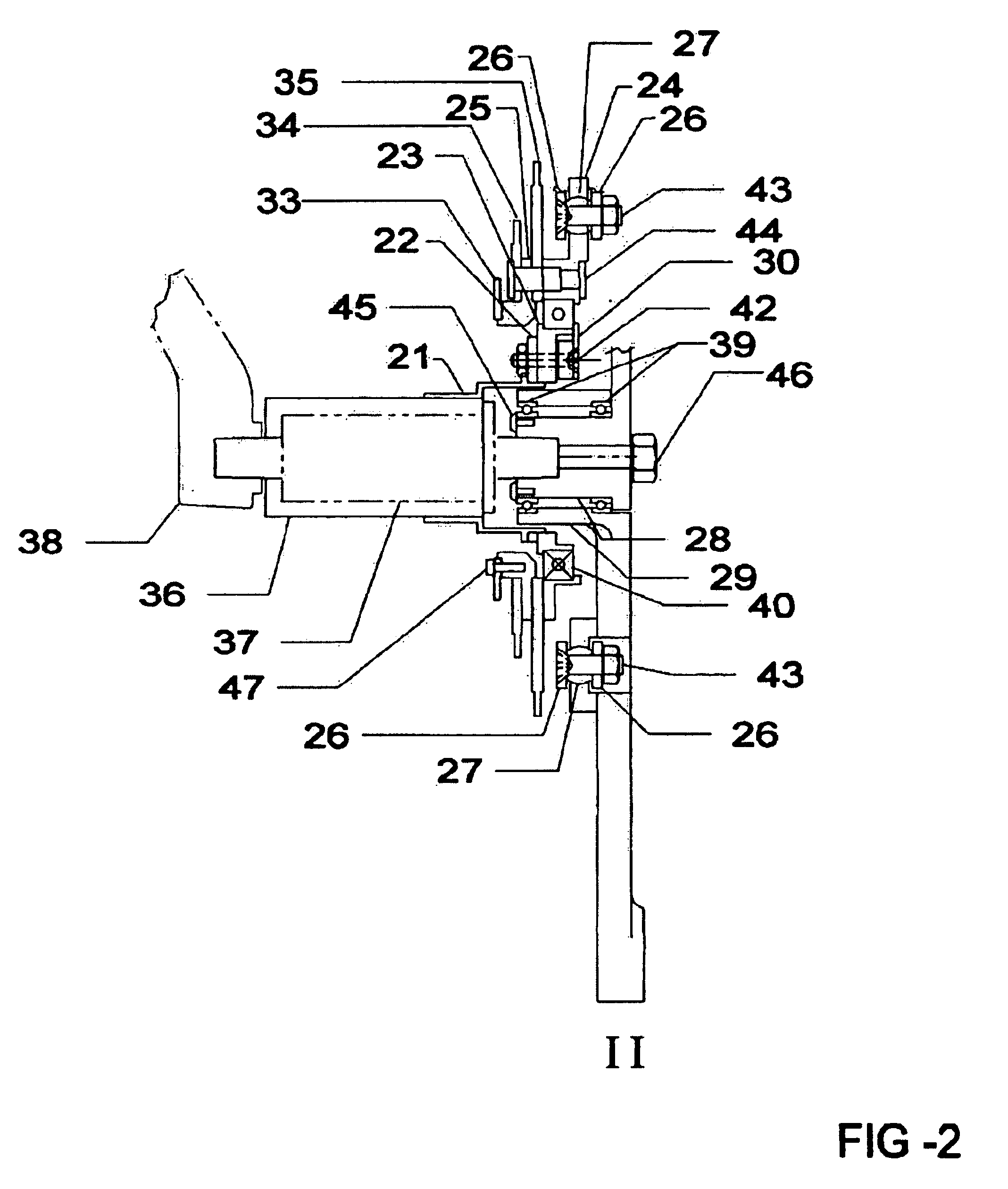

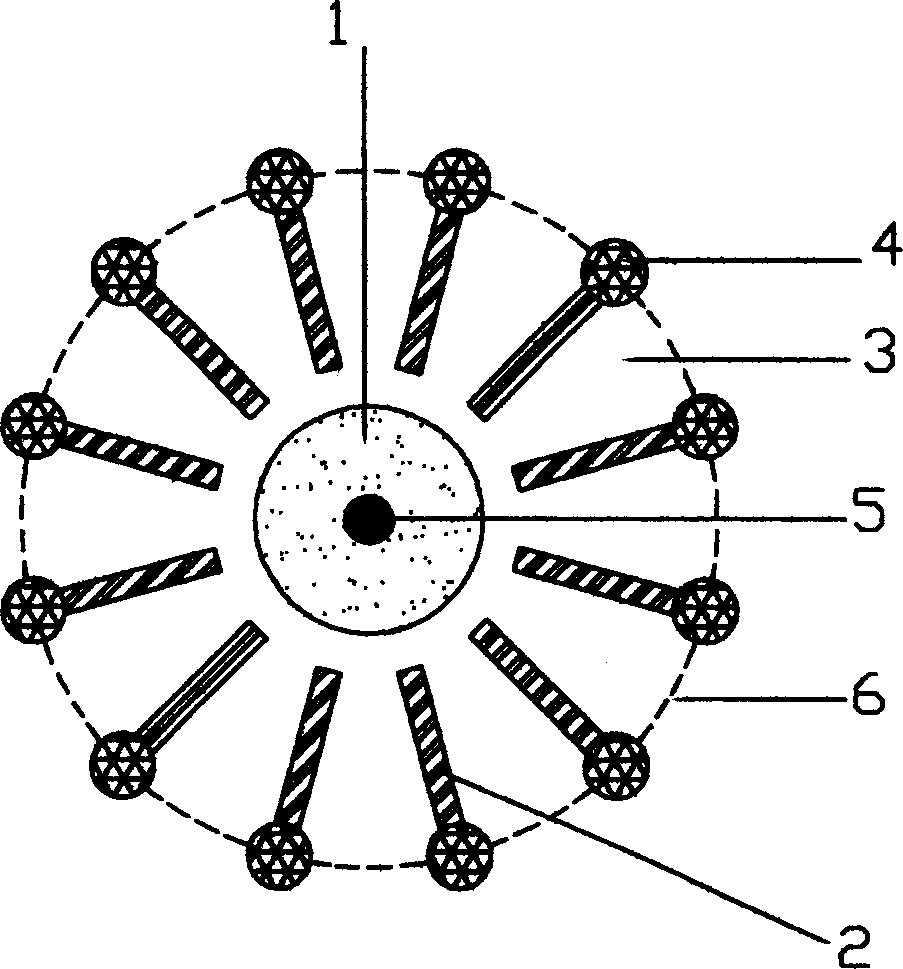

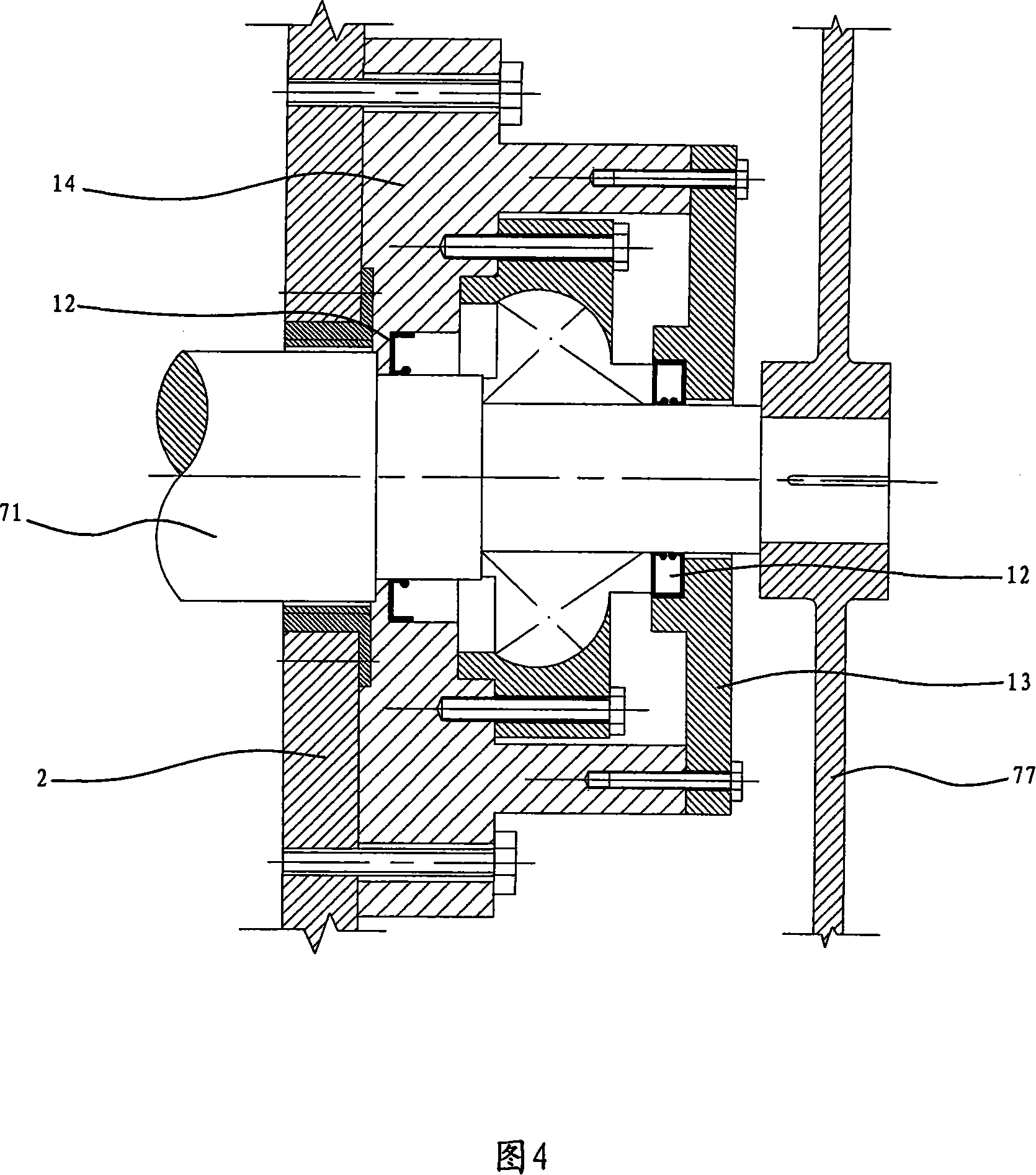

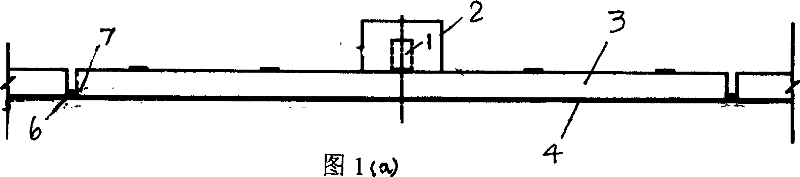

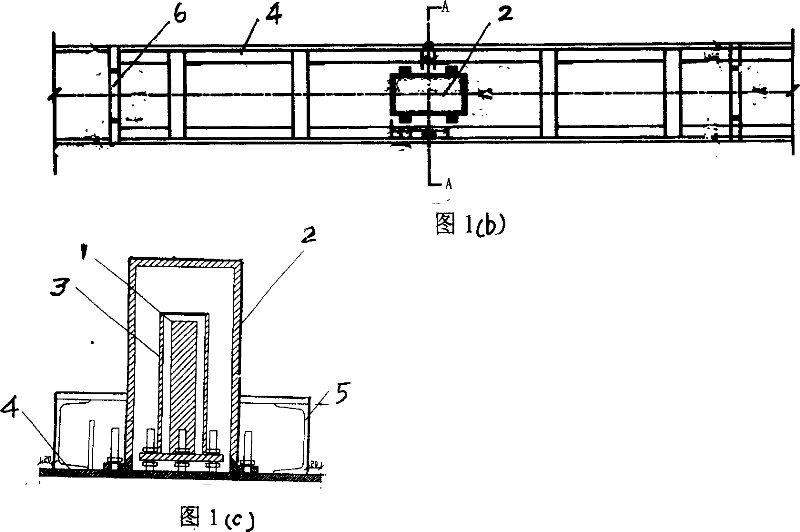

A pedal drive mechanism that provides continuous, uninterrupted torque to the drive chain or belt. The continuous torque effect is a result of establishing two separate but connectively joined axes of rotation that transmit pedal crank force to the drive chain (55). The assembly of a right pedal crank (29) rotative mounted about left pedal output crank (28) are connectively fastened (46) to the left pedal crank (38) through the bottombracket bearing (37) defines the first axis of rotation. The assembly of the chain sprockets (35, 34 and 33), sprocket interface (25) and sprocket support (24) are rotatively mounted by a sealed bearing (40) about a bearing inner race support (23) and eccentric flange (22) establish a second axis of rotation. The fixtures of these two axes of rotation are connectively joined by articulating links (26) with self-aligning sealed bearings (27).

Owner:JONES EARLE H

Redundant electrical power source, distribution and consumption system

InactiveUS6150736AWithout disrupting functionalityAvoid interferenceBatteries circuit arrangementsSingle network parallel feeding arrangementsElectricityContinuous/uninterrupted

Owner:UPTIME INST

Intelligent monitoring and operation maintenance system for photovoltaic power station

ActiveCN105187010AGo digitalRealize processPhotovoltaic monitoringCircuit arrangementsFailure rateData acquisition

The present invention discloses an intelligent monitoring and operation maintenance system for a photovoltaic power station. The intelligent monitoring and operation maintenance system comprises a photovoltaic power station user terminal application module, a photovoltaic power station panorama data monitoring and value-added service cloud platform, a photovoltaic power station base monitoring service cloud platform I, a photovoltaic power station base monitoring service cloud platform II, a photovoltaic power station base operation maintenance service cloud platform, a photovoltaic power station data acquisition and supervisory control cloud platform and a photovoltaic power station sensor global data exchange cloud platform. According to the present invention, the intelligent monitoring and operation maintenance system performs digital monitoring on the solar photovoltaic power station, continuous monitoring on numerous devices and detection points, as well as analysis and evaluation on the operation efficiency, the failure rate and other main indicators of critical equipment, realizes the simultaneous remote and local monitoring, and records the alarm of emergency failure events, the analysis of historical operation data, various date parameter graphs and reports, the calculation for economic indicators of operation of the entire power station, the analysis of operation benefits and the power prediction for a power generation system.

Owner:ZHEJIANG UNISUN HEZHONG NEW ENERGY CO LTD

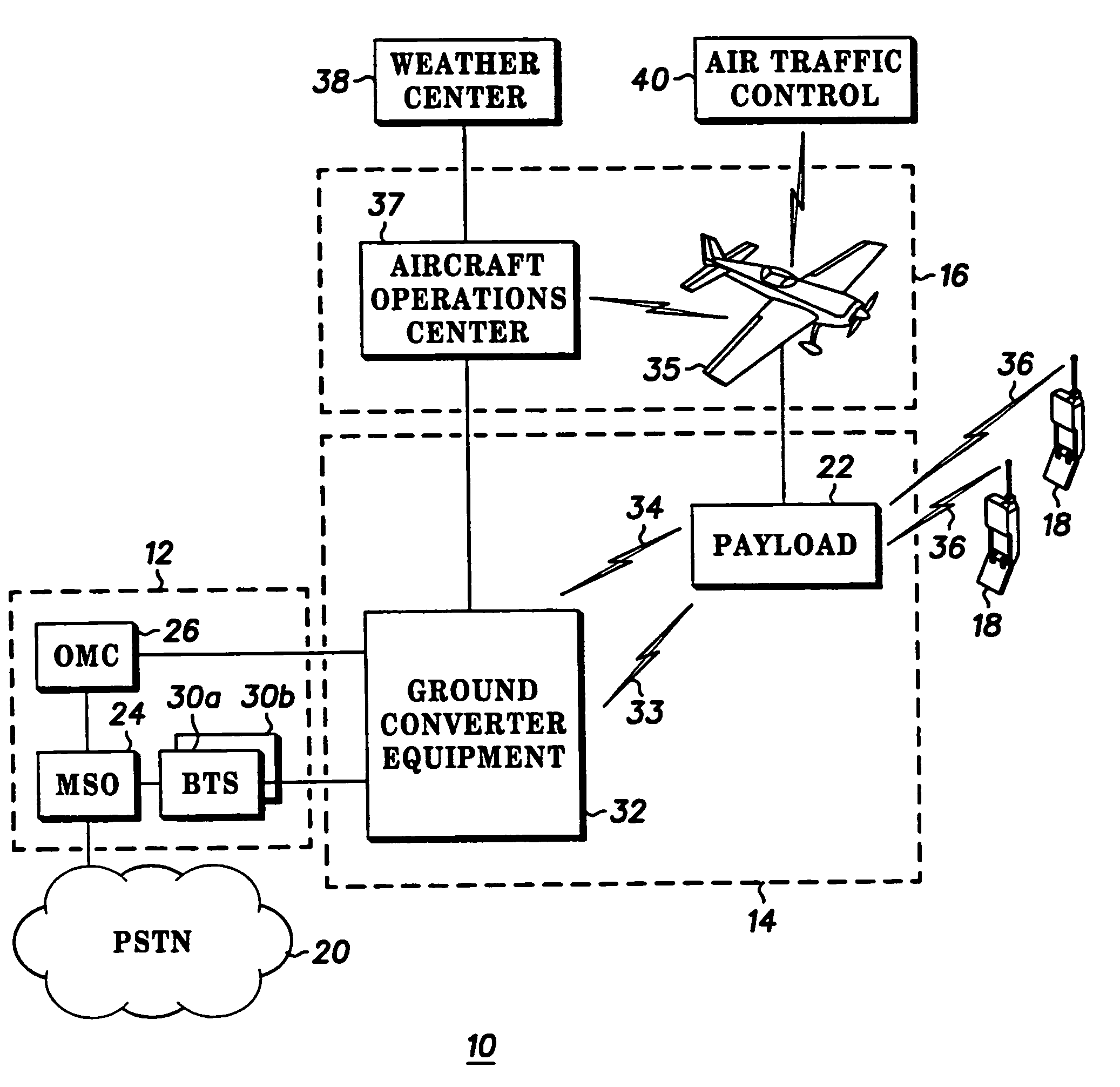

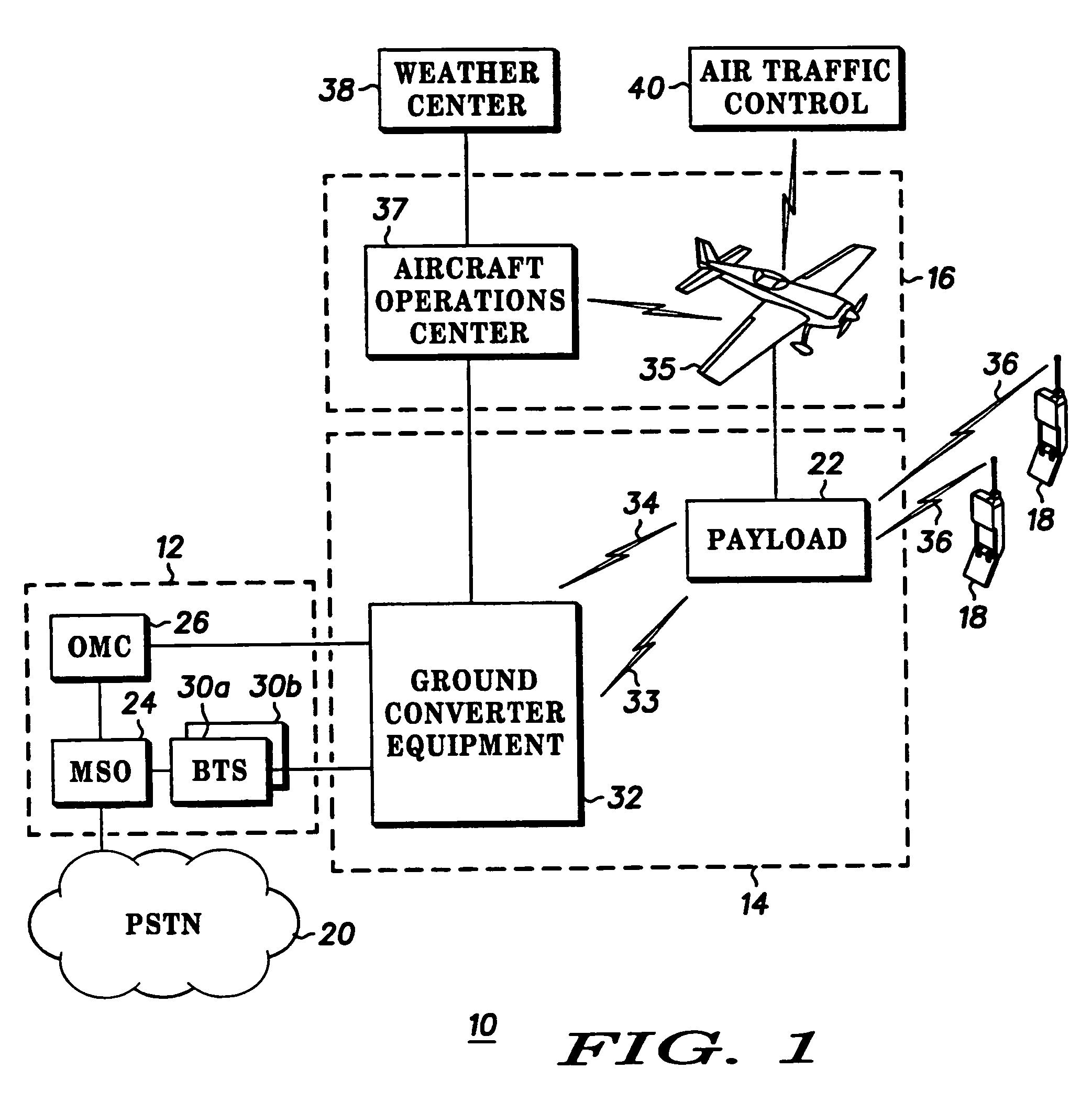

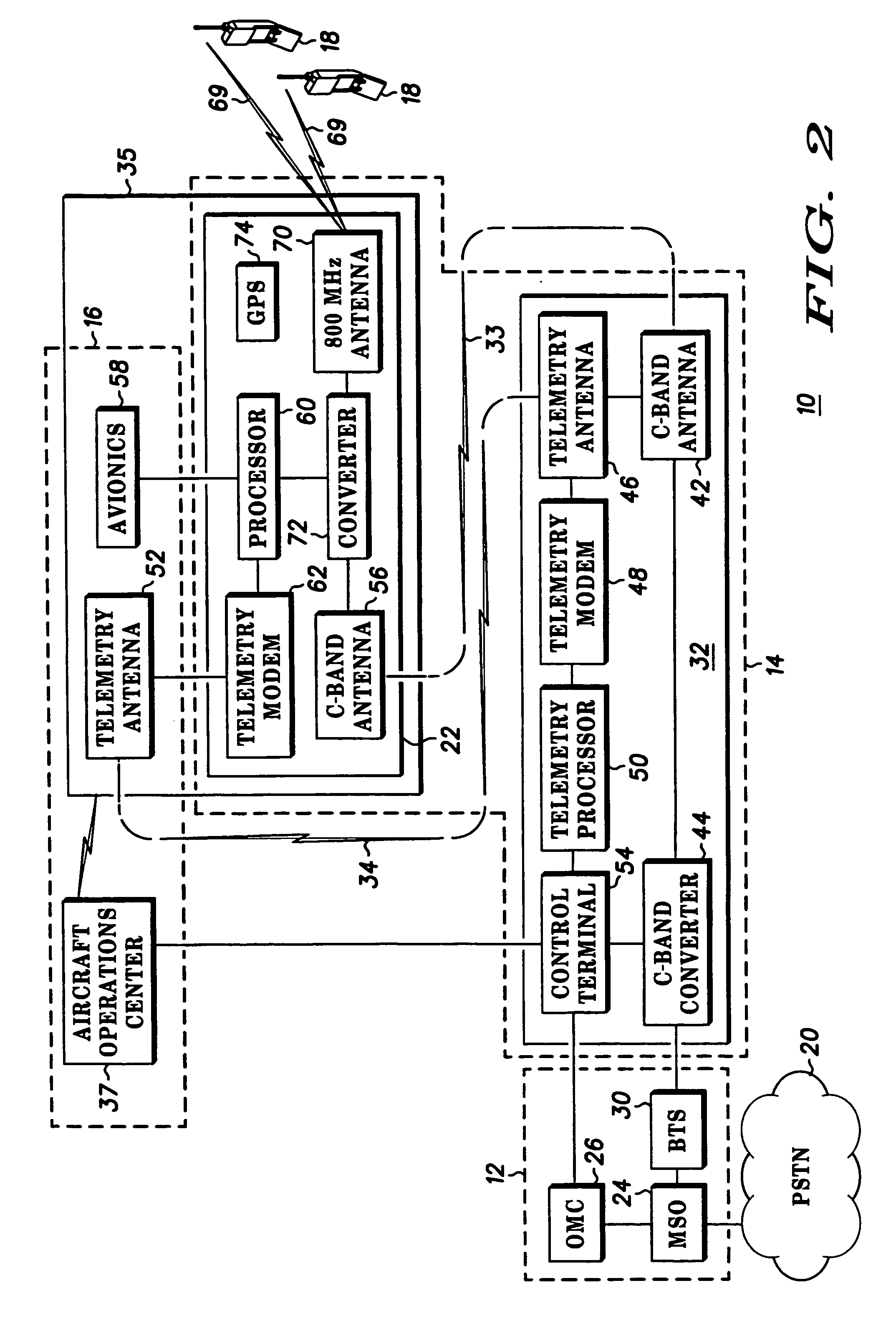

Multi-airplane cellular communications system

InactiveUS6968187B1Radio/inductive link selection arrangementsRadio transmissionJet aeroplaneGeographic feature

A communications link for a cellular communications system (10) includes a first airplane (35) for flying in a first pattern (86) and including a first antenna for transmitting RF beams (92) to form a first footprint (96) on a first target geographic area (98) to provide cellular phone users (18) within the footprint with a first communications link. A second airplane (35′) flies in a second pattern (86) and includes a second antenna for transmitting RF beams (92) to form a second footprint (96) on a second target geographic area (98) to provide cellular phone users (18) within the second footprint with a second communications link. The first and second airplanes each fly at an altitude that is below a high altitude level and that is varied to enable continuous uninterrupted coverage to be provided to a service area below in a weather pattern-independent and geographic feature-independent manner.

Owner:CDC PROPRIETE INTELLECTUELLE

Fluid Transfer Assembly

ActiveUS20080277926A1Easy to assembleEasy to processPipeline expansion-compensationCoatingsContinuous/uninterruptedSilicone

A fluid transfer assembly for transporting medicinal substances. The fluid transfer assembly includes flexible tubes and a manifold each comprising silicone. The manifold has an inner protrusion and connector portions having inner walls. Free ends of the tubes are inserted into complementary configured inner walls of the connector portions until each of the free ends abut the inner protrusion, which creates a continuous uninterrupted passageway between the inner bores of the tubes through the manifold.

Owner:DOW SILICONES CORP

Magnesium sea water battery

This invention relates to a Mg sea-water cell based on the fuel cell technology theory which converts the dissolved oxygen in the sea to a cathode active substance by inert cathode, takes the sea water as the cell electrolyte and applies high potential Mg alloy as the anode to make it an independent chemical cell after immerging it in the sea. The cell only consumes Mg alloy anode when working and changes a new one after the Mg alloy anode is finished. The cell can work for a long time at a reliable and stable situation since the cell has a large capacity not necessary to have any pressure container, one Mg alloy anode can work continuously for 1-2 years, especially suitable for the work in the deep sea or the bottom.

Owner:李华伦 +3

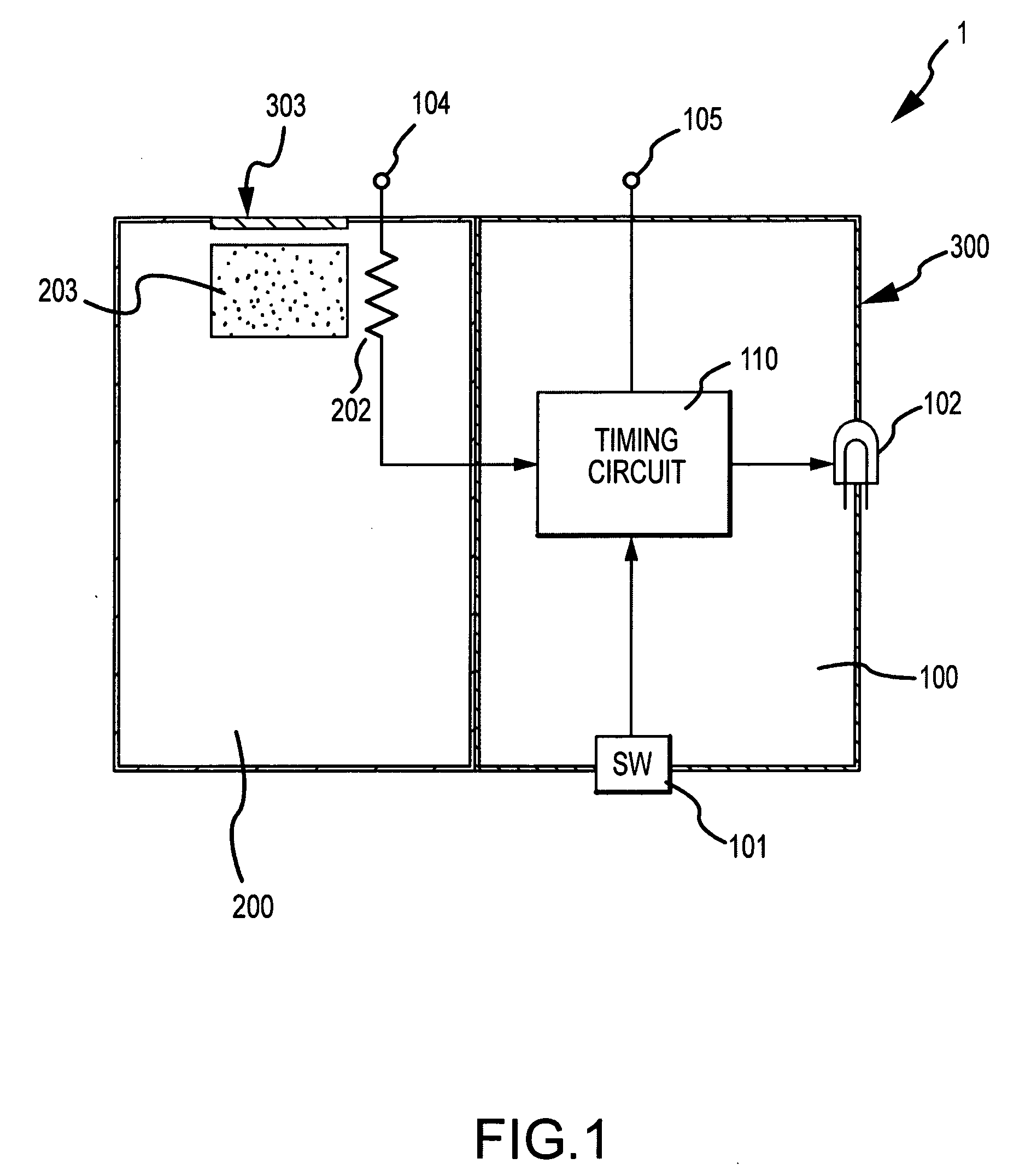

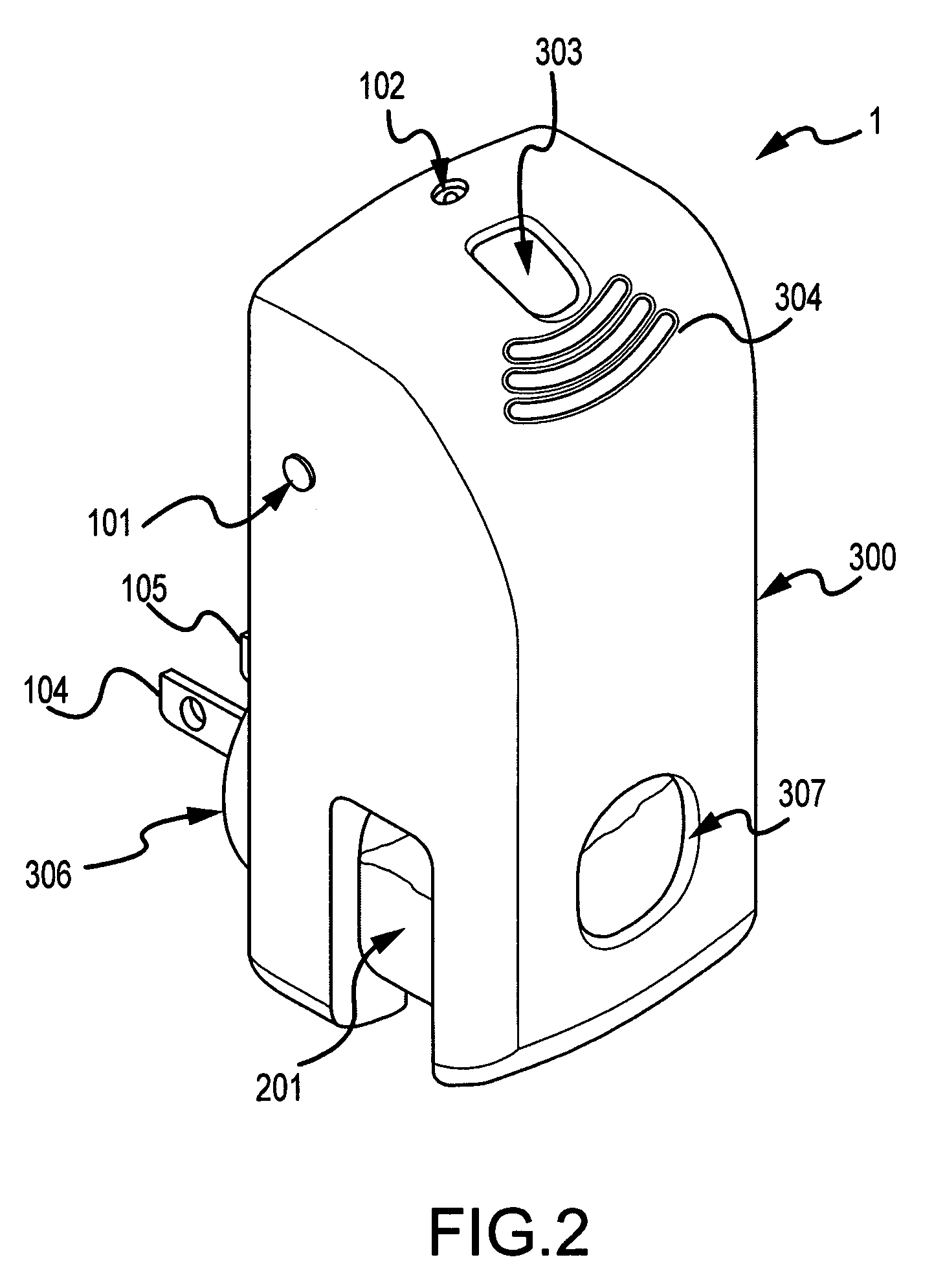

Energy conserving vapor-dispersing device with optional repeating off cycles

InactiveUS20100059601A1Lower device costLow costTobacco devicesGaseous substancesEngineeringElectrical and Electronics engineering

An electrical vapor-dispersing device is described that vaporizes volatizable material continuously and uninterrupted when first plugged into an AC electrical source, but upon operation of an initiator switch begins cycling fixed “OFF / ON” periods preset at from about 6 to about 18-hours to conserve both energy and volatizable material. In the preferred embodiment, an LED signals when the total elapsed “on-time” reaches a set value and refill of the volatizable material is required. The device is returned to constant operation only by unplugging from the electrical source and plugging back in to the electrical mains, or by electrical power failure / interruption.

Owner:DIAL CORPORATION

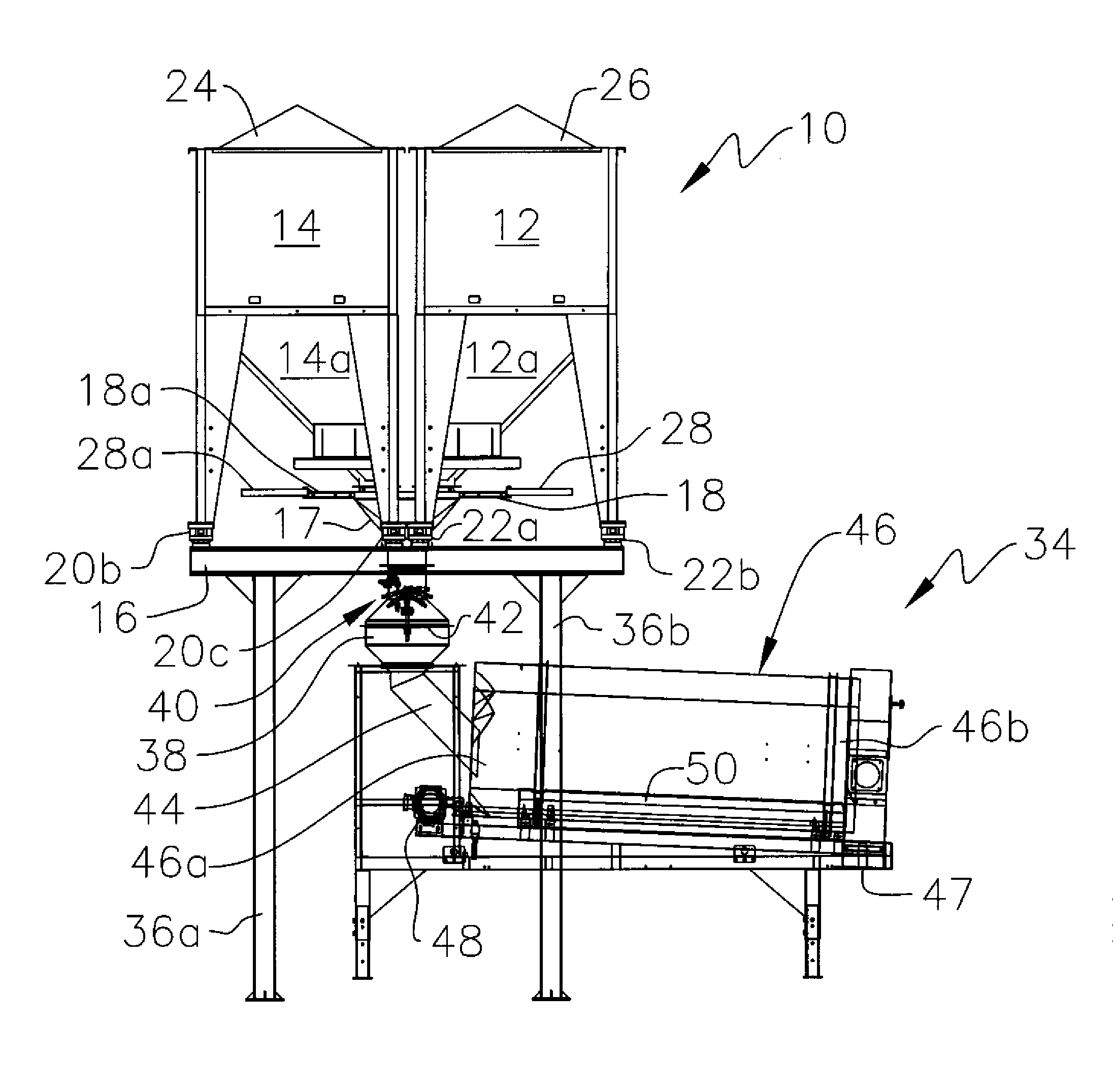

Multi-flow bulk weighing system

InactiveUS20120181093A1Precision therapyEasy to controlWeighing apparatus for continuous material flowWeighing apparatus with automatic feed/dischargeDischarge rateProcess engineering

An arrangement for weighing bulk materials includes plural hoppers each having its own weighing system for accurately determining material discharge rate (lbs / minute) and for directing the contents of the hoppers to a product processing stage either sequentially from one hopper at a time while the other hoppers are being re-filled to provide continuous, non-stop operation, or in the alternative, from two or more hoppers simultaneously for blending the materials under the precise control of a programmed controller. Material discharge rate from each hopper is determined by continuous weighing of each hopper and its contents and is controlled in real time by precise computer controlled positioning of each hopper's slide gate. In the blending mode of operation, accurate monitoring of the material discharge rate is coordinated with processing of the material in a subsequent processing stage to allow for variation of the discharge rate to precisely match the subsequent processing parameters.

Owner:KSI CONVEYORS

Continuous vacuum dough mixing machine and noodle producing equipment with the same

ActiveCN101147500AReduce labor intensityIncrease productivityRotary stirring mixersTransportation and packagingContinuous/uninterruptedControl circuit

The present invention relates to a continuous vacuum kneading machine and a noodles production equipment with said kneading machine. Said continuous vacuum kneading machine includes the following several portions: machine frame, kneading container, flour-conveying device, water-supplying device and control circuit. Said kneading container is equipped with a dough-discharging device. Besides, it also includes an evacuating device and a stirring-feeding device. Said invention also provides the working principle of said kneading machine and its concrete operation method.

Owner:山东江泷机械有限公司

Method for preparing solid catalyst in olefin polymerization catalyst

ActiveCN101054424AProduct quality is easy to controlHigh particle sphericityContinuous/uninterruptedPolymer science

The invention provides a preparation method of solid catalyst used in olefinic polymerization catalyst, the method synthetizes the solid catalyst of olefinic polymerization continuously by magnesium powder, simplifies the technology of preparing magnesium compounds solid firstly then preparing the solid catalyst of olefinic polymerization, reduces quantity of equipment needed in industrialization, has advantages of simple technics, easy operation, low industrializing installation cost, low production cost, easy controlled product quality. The ball solid catalyst of olefinic polymerization which D(50) is in range of 10-80 mum is produced through the method of the invention, the catalyst has particle sphericity height L / W<1.4 (L expresses the longest axle of the particle, W is the minimum axle of the particle), has advantages of high polymerization activity, hydrogen regulating sensibility, high isotacticity of the polymer, centralized particle-size distribution.

Owner:CHINA PETROLEUM & CHEM CORP +1

Packaged technology for underwater in situ automatically monitoring

ActiveCN101037864ASmooth and convenient in-situ monitoringShorten the timeArtificial islandsFoundation testingPore water pressureEarth surface

An in-situ automatic monitoring complete technology method for an underwater groundwork comprises a section surface subsidence monitoring method by multiple fixed inclinometers; a multipoint hydraulic difference surface subsidence monitoring method; a layered soil mass subsidence monitoring method; a pore water pressure monitoring method; and a horizontal and vertical displacement monitoring method; an automatic monitoring technology with a monitoring and control system disposed in the deep water sea bottom for long period. The invention can successfully and conveniently perform the in-situ monitoring of the underwater groundwork without disposing waterborne bases, arranging maritime platforms and passing through buildings; can perform full-course monitoring on the engineering, perform underwater automatic monitoring and real-time monitoring data transmission, in particular monitor continuously in the typhoon period; the automatic monitoring can save monitoring workers and cruise time; the automatic monitoring instruments are all disposed underwater, thereby having little influence on construction and decreasing instrument damage rate; the automatic monitoring can perform on-time on-point test to eliminate man-made reading error, and make the reading accurate, quick and precise.

Owner:TIANJIN PORT ENG INST LTD OF CCCC FIRST HARBOR ENG +1

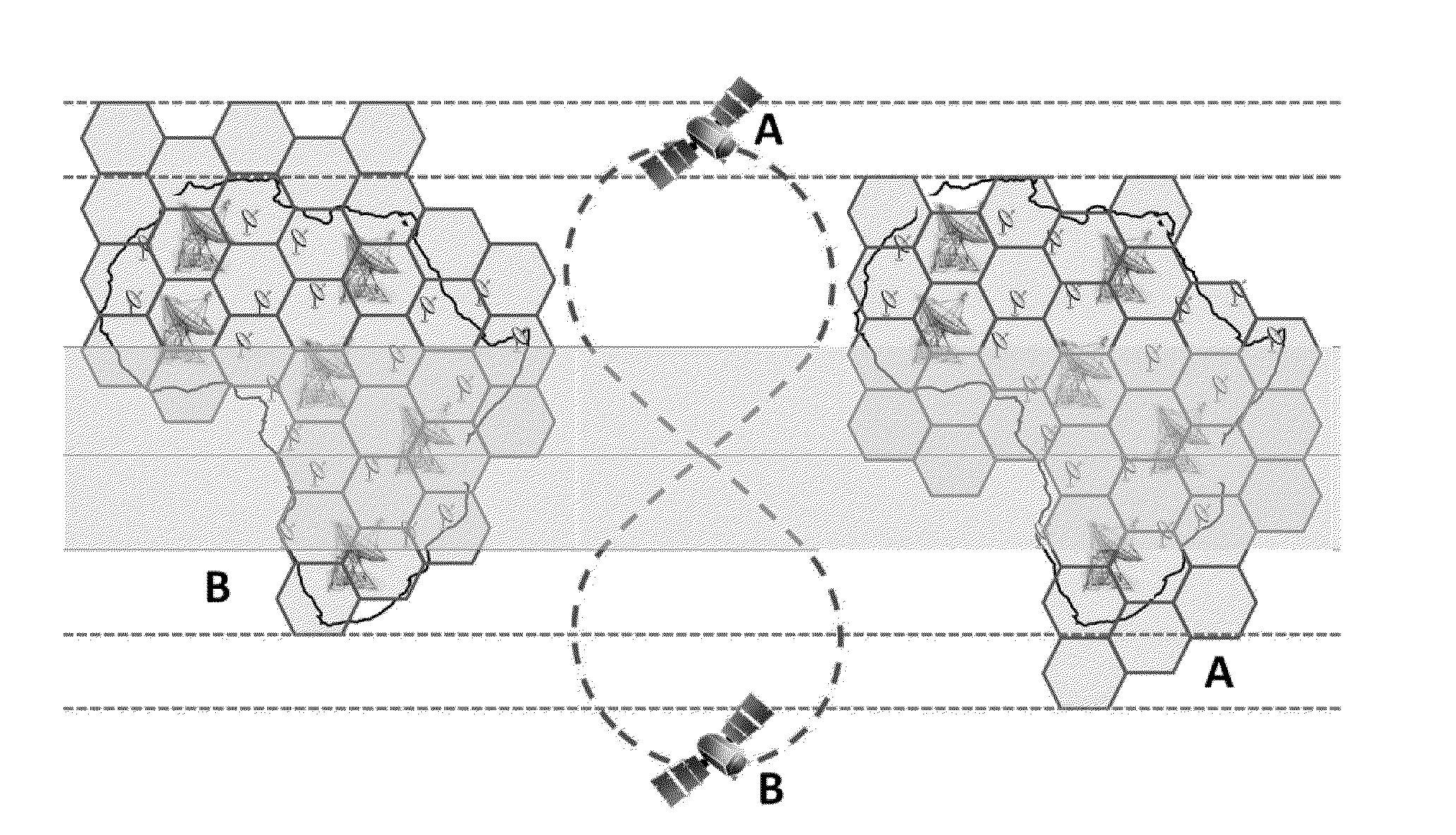

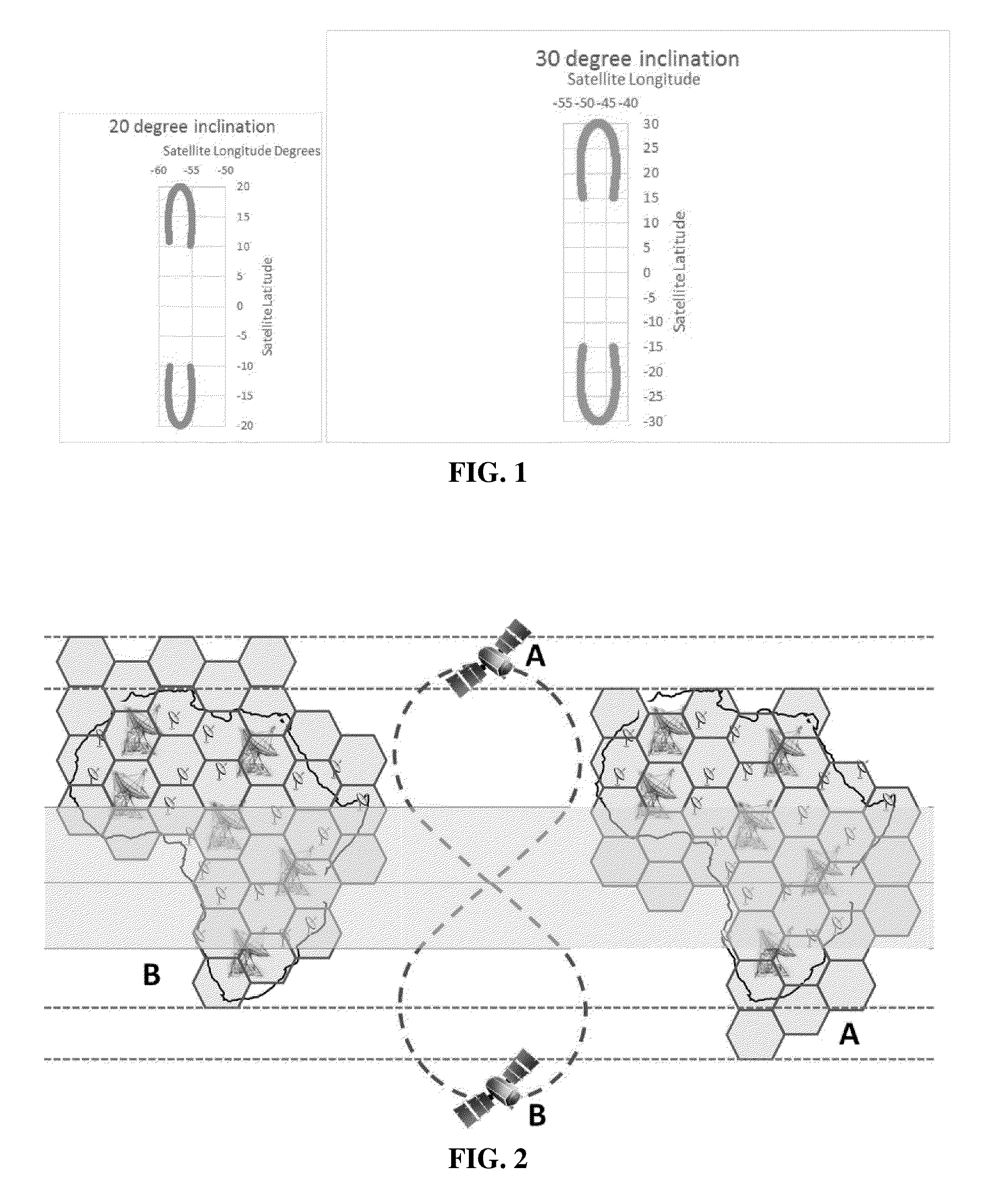

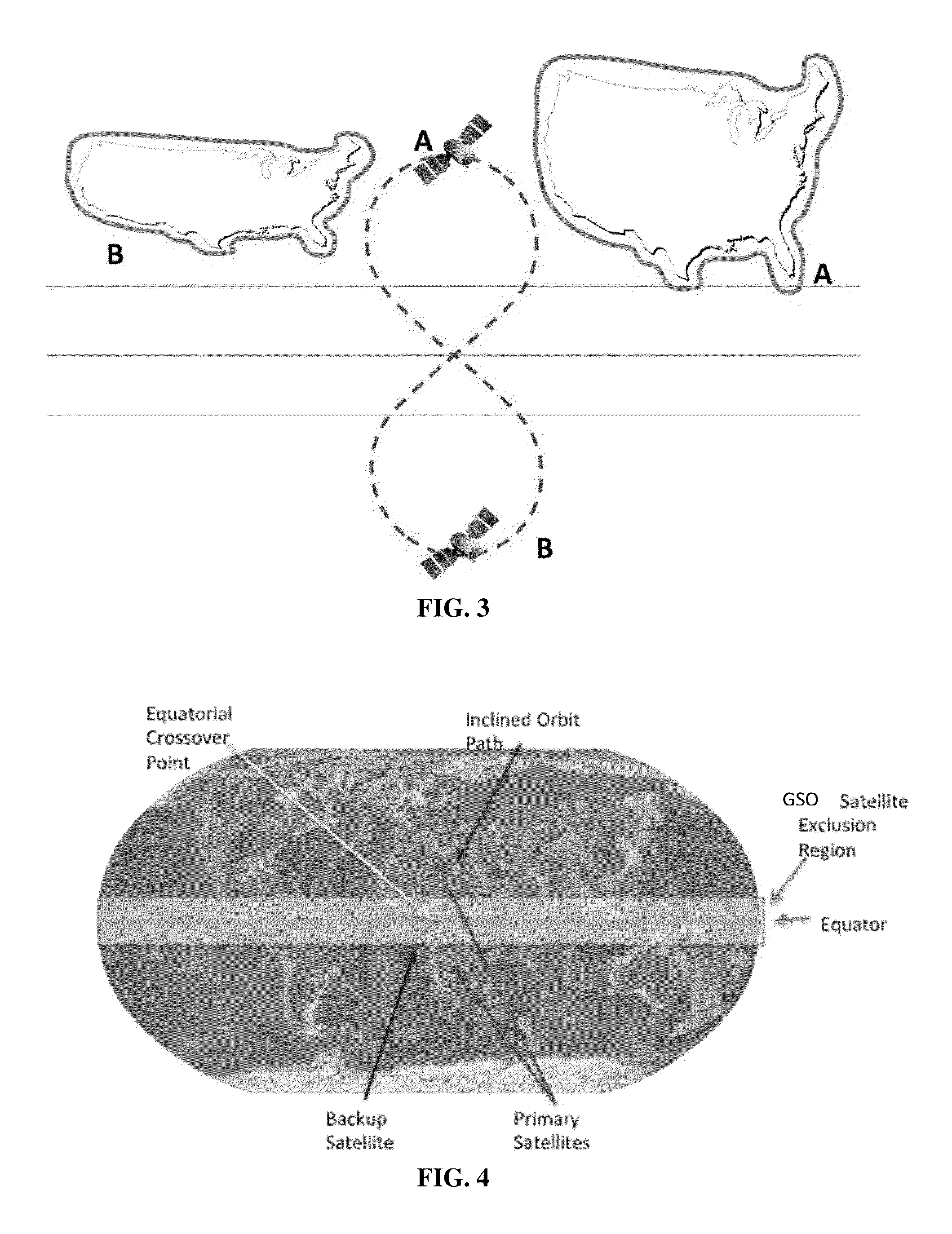

Inclined orbit satellite systems

InactiveUS20150158602A1Efficiently providedCosmonautic partsActive radio relay systemsContinuous/uninterruptedNatural satellite

The present disclosure is directed to an inclined geosynchronous orbit satellite system that can efficiently provide continuous communication to multiple geographic regions across the world using satellites in inclined geosynchronous orbital paths having an equatorial crossing and enabling the reuse of frequencies assigned within GSO orbital locations. The inclined orbit satellite system can include multiple inclined orbit satellites that are capable of co-existing with geostationary satellites to provide continuous uninterrupted service.

Owner:TAWSAT

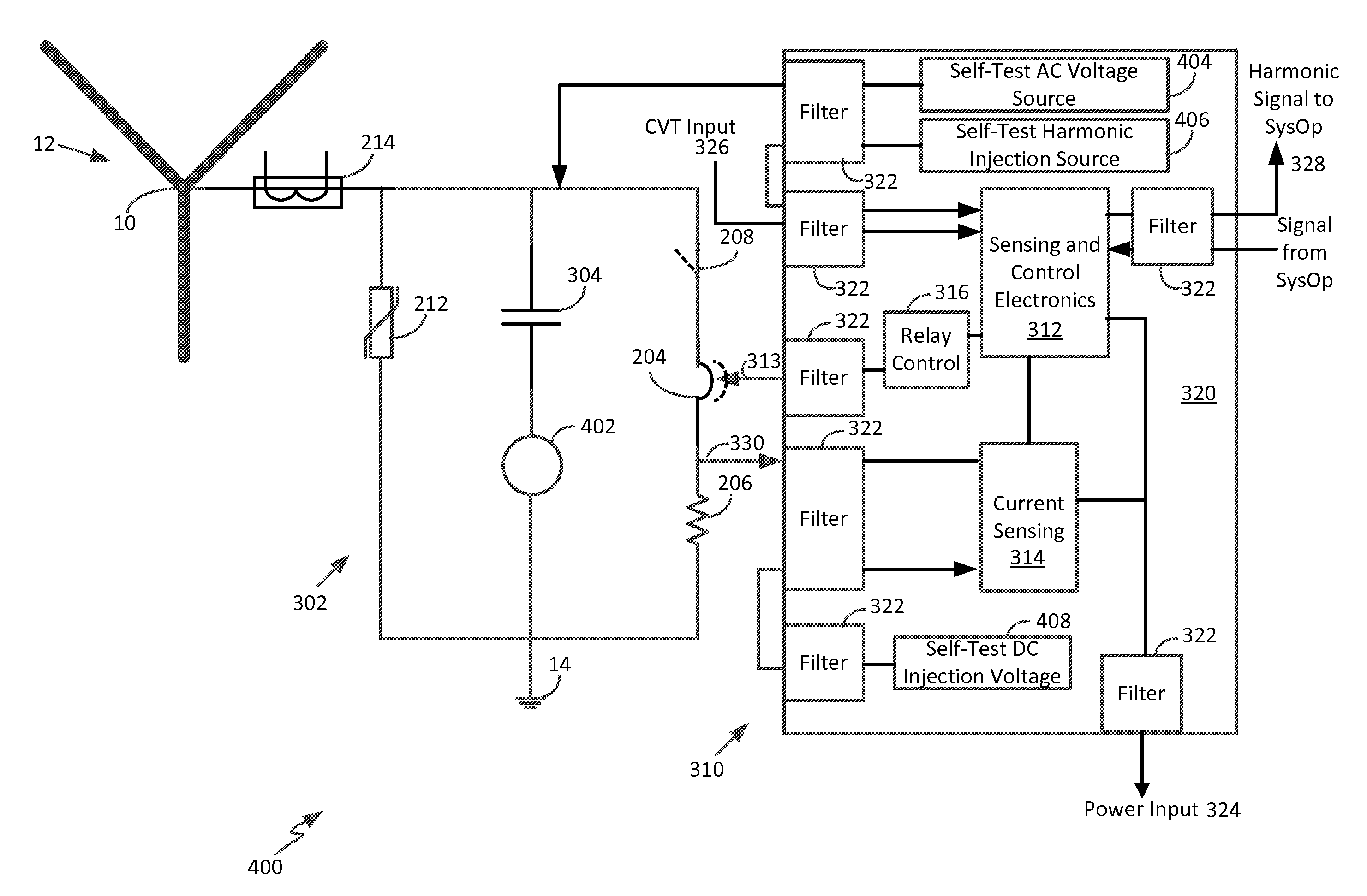

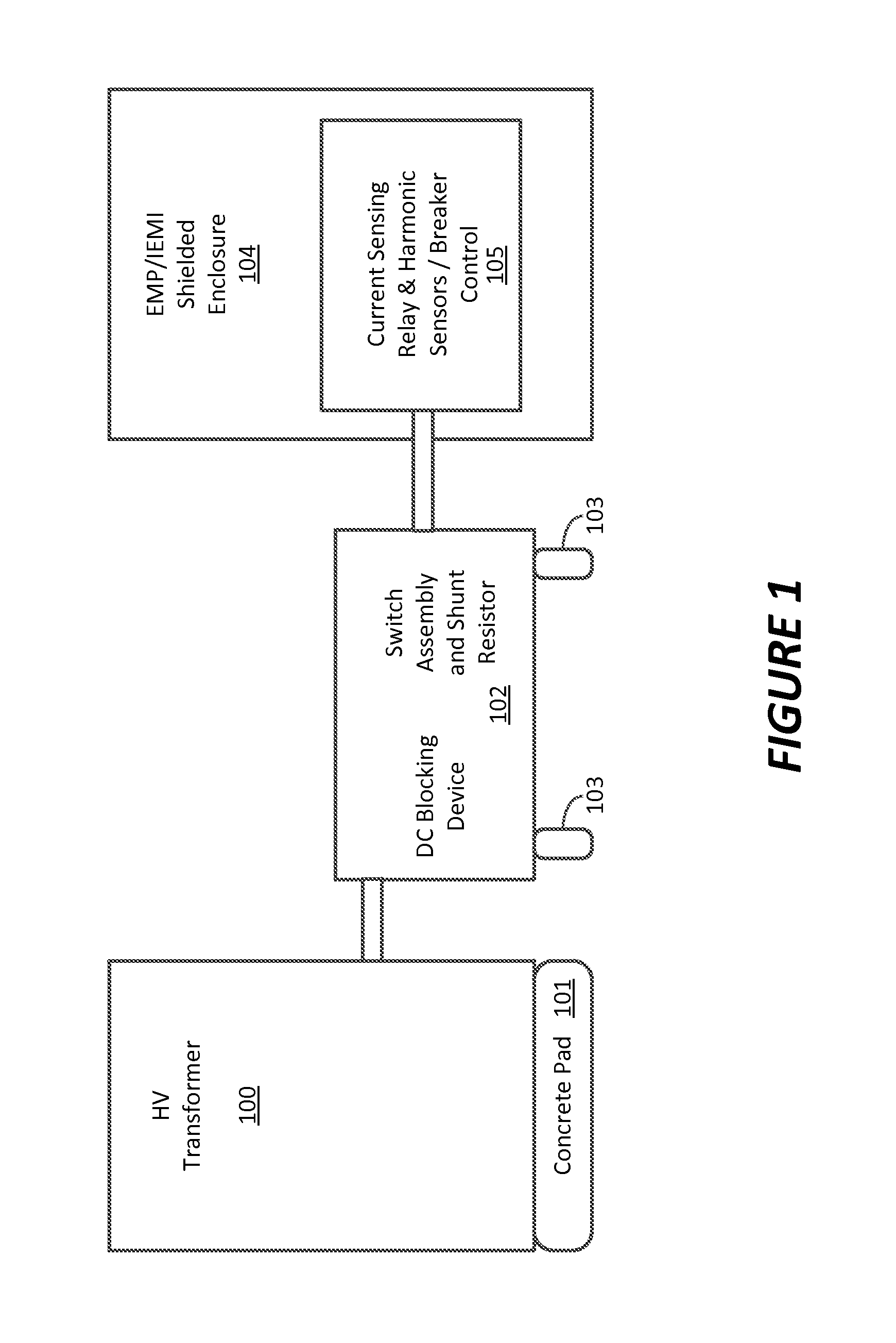

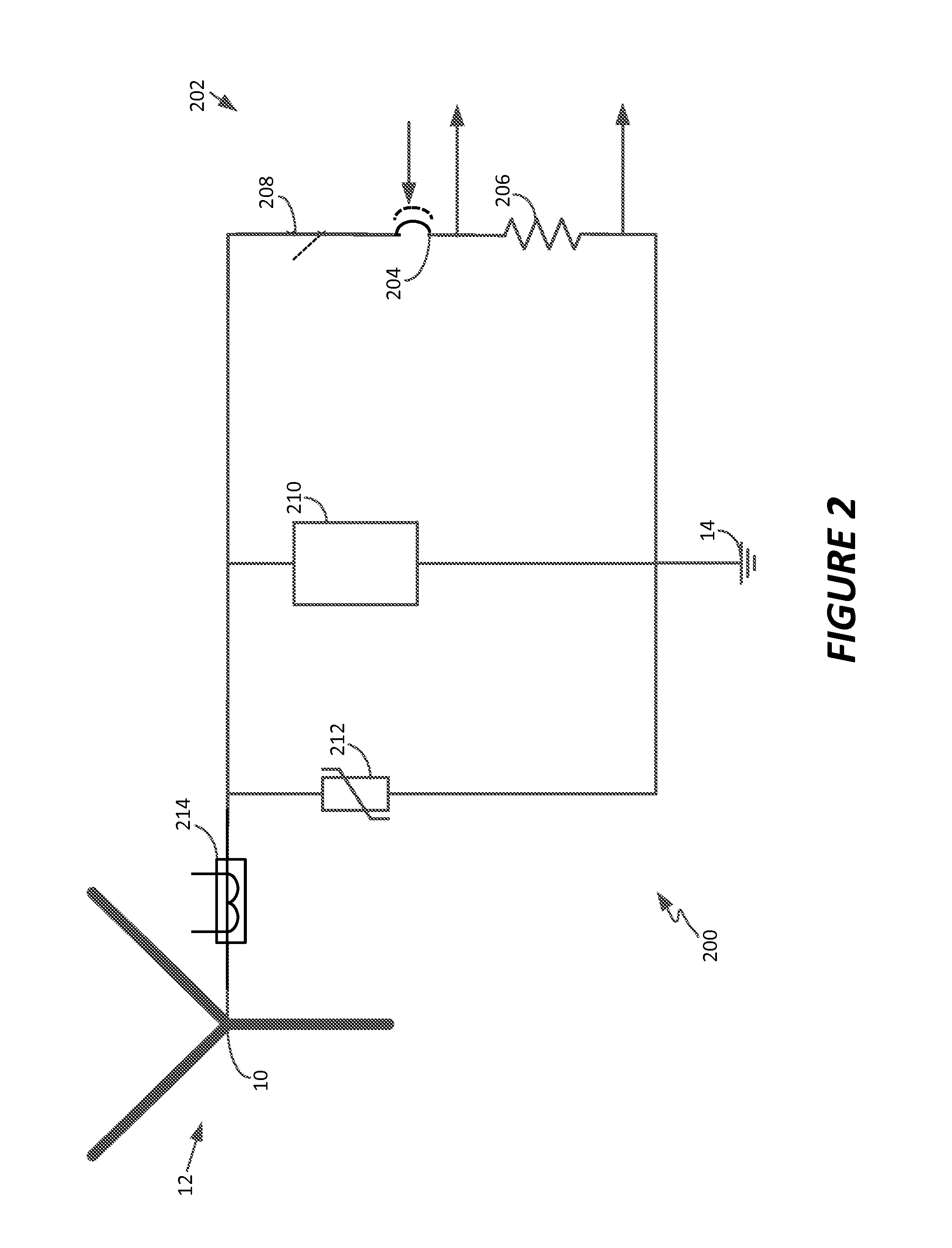

Continuous uninterruptable AC grounding system for power system protection

ActiveUS8878396B2Electric signal transmission systemsBatteries circuit arrangementsTransformerDc current

A continuous grounding system for use in an alternating current system including a transformer is disclosed. The system includes a switch assembly connected between a transformer neutral of a transformer and a ground, the switch assembly having an open position and a closed position, the open position disrupting the path through the switch assembly between the electrical connection and the transformer neutral, and the closed position establishing a path connecting the electrical connection to the transformer neutral through the switch assembly, wherein in normal operation of the alternating current electrical device the switch assembly remains in a closed position. The system also includes a DC blocking component positioned in parallel with the switch assembly and connected between the transformer neutral and the ground. The system further includes a control circuit configured to control the switch assembly, the control circuit including a sensor configured to actuate the switch assembly to an open position upon detection of a predetermined harmonic signal threshold at one of the transformer phases or a predetermined threshold of DC current between the transformer neutral and ground.

Owner:TECHHOLD LLC

Food product and method of preparation

Composite food products comprising a first soft plastic nonfrangible major portion having a water activity of 0.5 or less and about 1% to 15% % of a second food portion of small direct expanded puffed particulates fabricated from a cooked cereal dough. The puffed pieces are formed by direct puffing or expansion into individual pieces rather than by grinding or size reducing larger cereal pieces. The puffed cereal particulates thus have a continuous unbroken skin or surface surrounding the particulates as a result of the direct expansion formation. The particulates have a size ranging from about 0.5 to 2 mm, a moisture content of less than 6%, and, a bulk density ranging from about 0.15 to 0.25 g / cc. The cooked cereal dough from which the particulates are fabricated comprises at least 45% rice flour. The products exhibit a crispy texture notwithstanding the softer texture of the major phase.

Owner:GENERAL MILLS INC

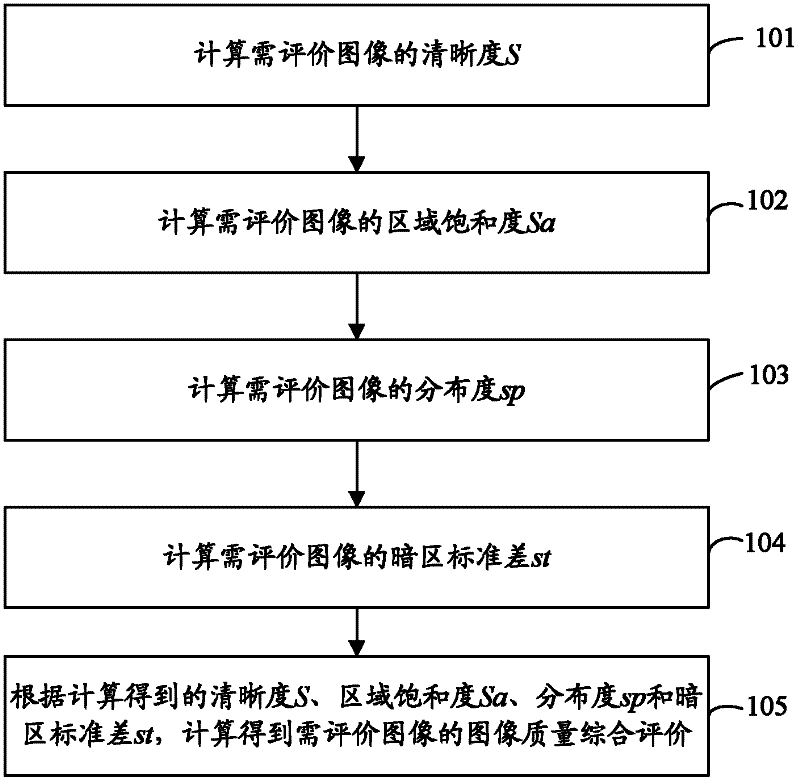

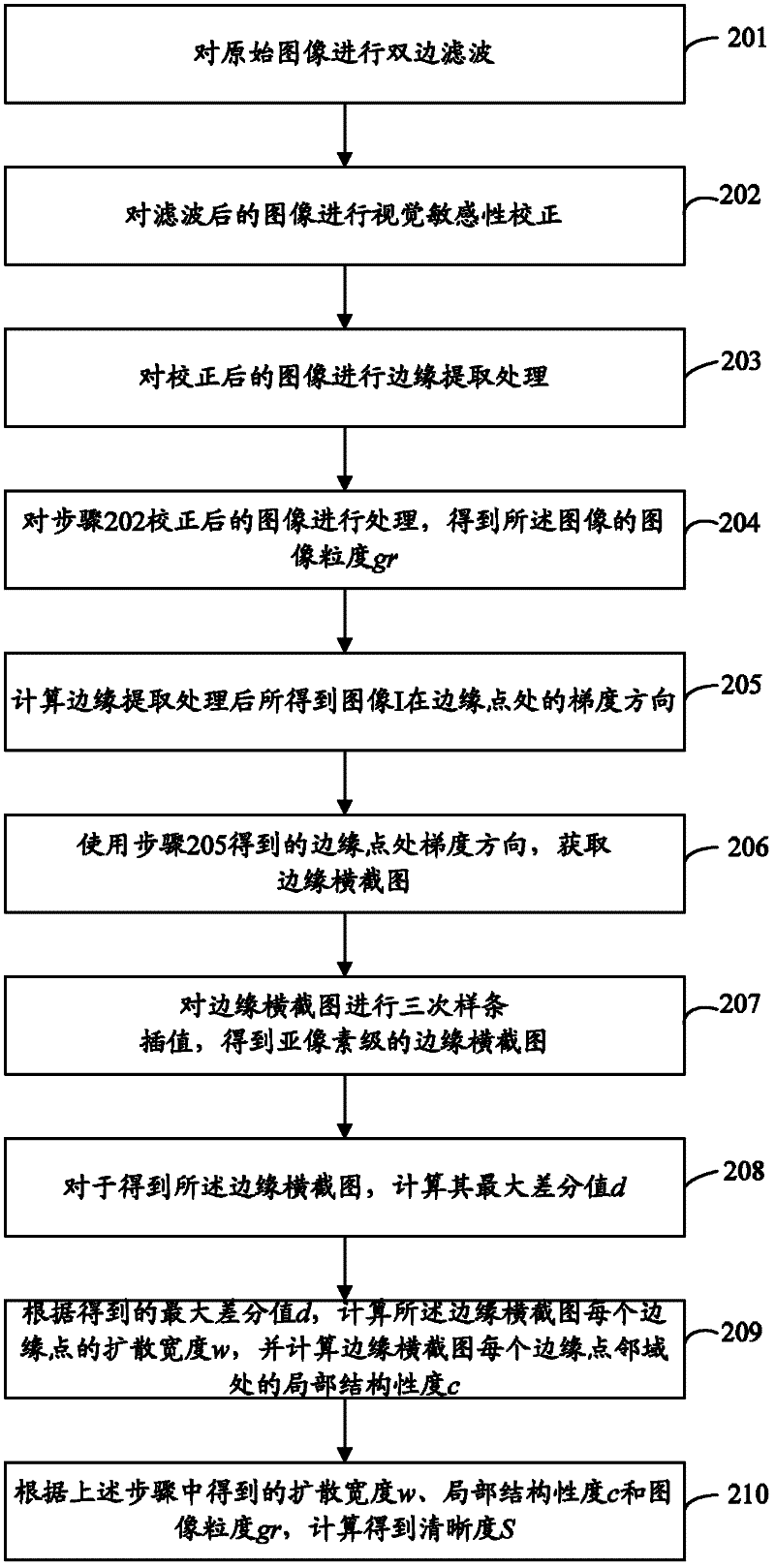

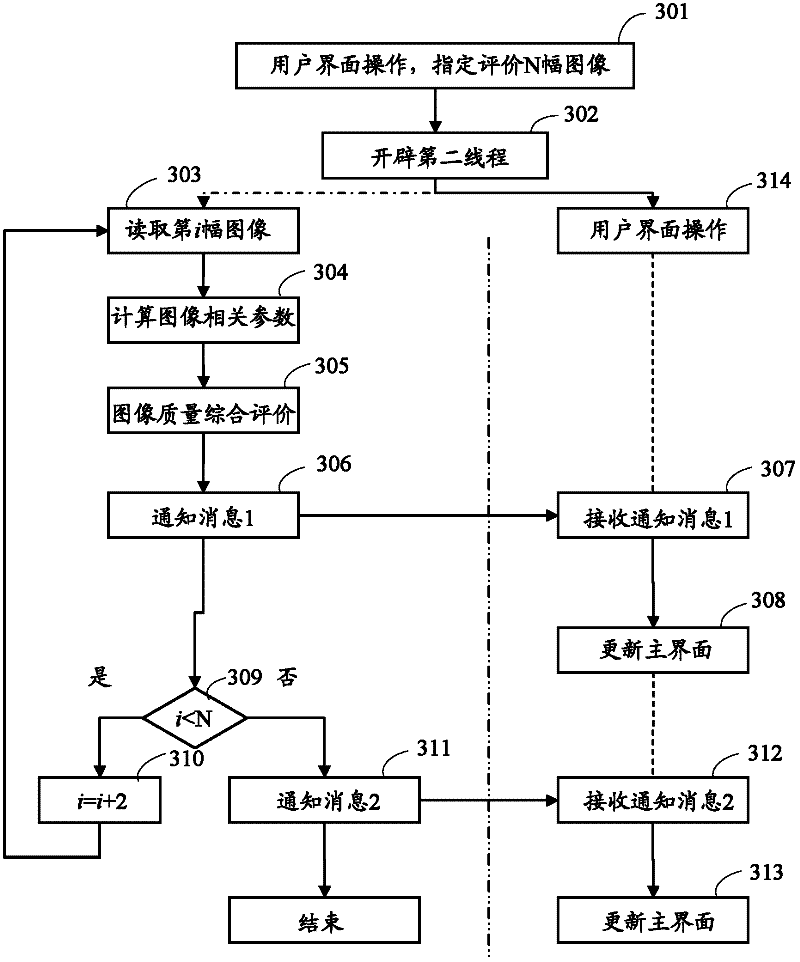

TFDS (Train Coach Machine Vision Detection System) image quality evaluation method and system

InactiveCN102609939AAuto-completion of quality evaluationSolve the problem of inconsistent evaluation resultsImage enhancementImage analysisDispersityContinuous/uninterrupted

The invention discloses a TFDS (Train Coach Machine Vision Detection System) image quality evaluation method. The method comprises the following steps: calculating the definition S of a required-to-be-evaluated image; calculating the regional saturation Sa of the required-to-be-evaluated image; calculating the dispersity sp of the required-to-be-evaluated image; calculating the dark region standard deviation st of the required-to-be-evaluated image; and according to the calculated definition S, regional saturation Sa, dispersity sp and dark region standard deviation st of the required-to-be-evaluated image, calculating the comprehensive image-quality evaluation f of the required-to-be-evaluated image. Accordingly, the invention also discloses a TFDS image quality evaluation system, which can automatically complete the quality evaluation on TFDS images, can carry out continuous uninterrupted evaluation on any number of images, and also can carry out comprehensive evaluation on a single image, then automatically give image quality evaluation results at real time, thereby solving the problem that evaluation results are non-uniform because of the differences of human factors.

Owner:BEIHANG UNIV

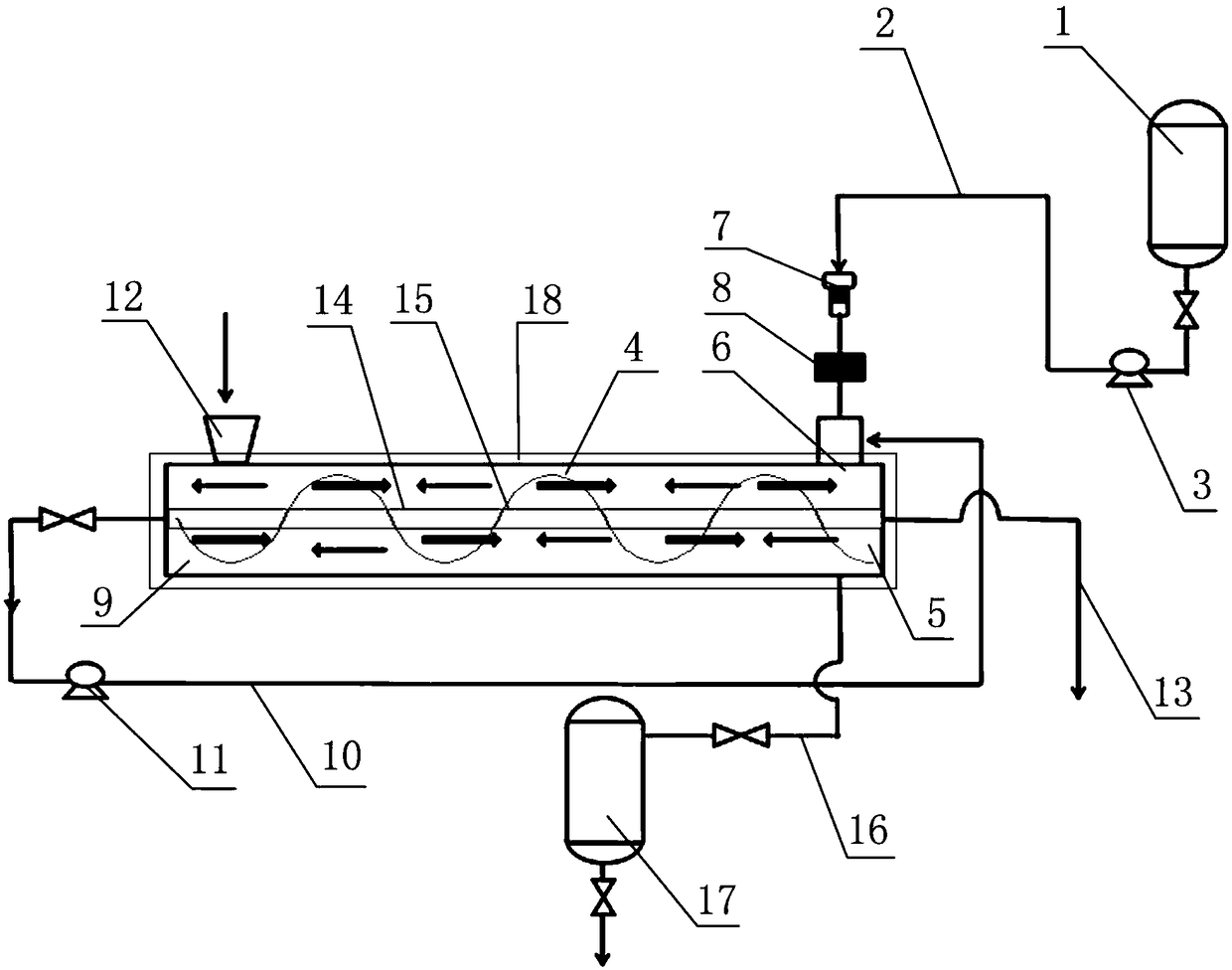

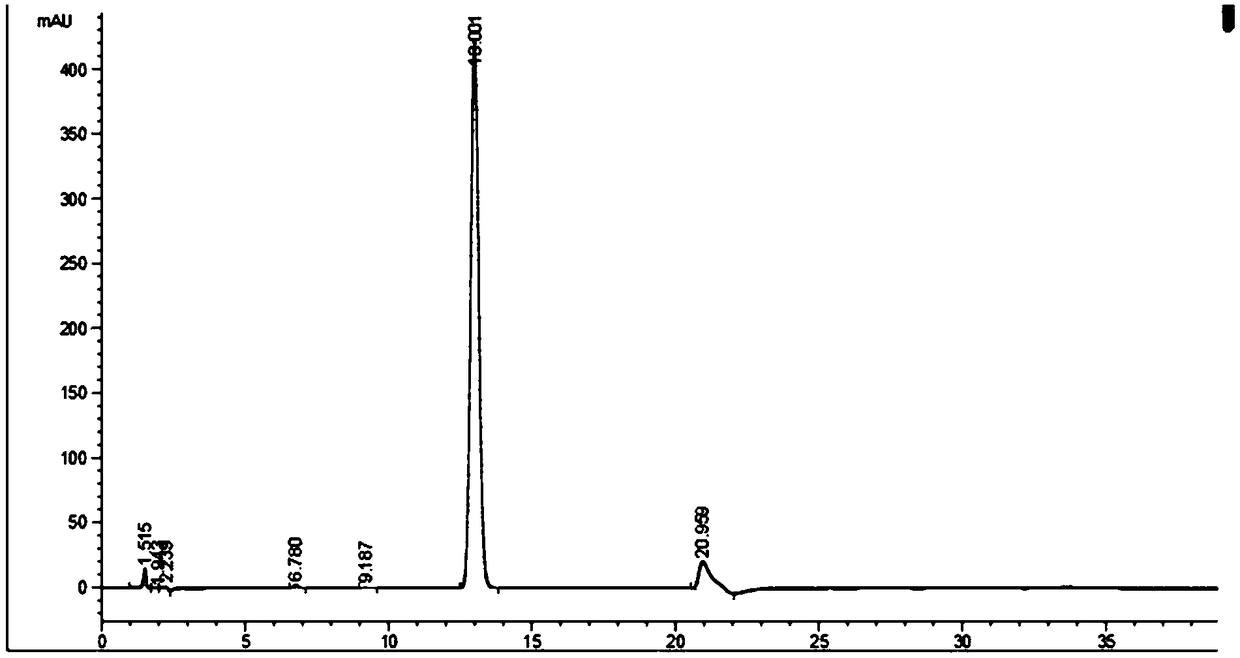

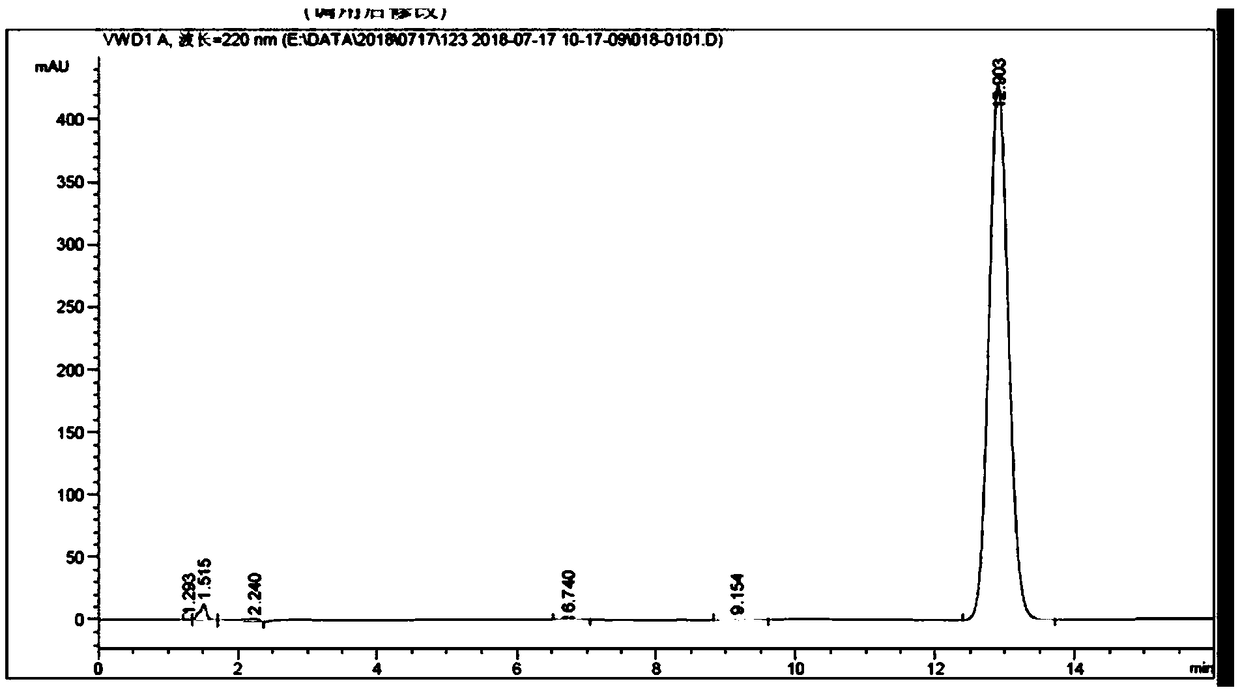

Method for extracting cannabidiol

InactiveCN109053388AHigh yieldReduce in quantityOrganic chemistryOrganic compound preparationContinuous/uninterruptedSolvent

The present invention provides a method for extracting cannabidiol, and belongs to the technical field of industrial extraction. The method comprises the following operation steps of drying the flowers and leaves of a mariguana plant, grinding and crushing, performing reverse extracting on the crushed coarse powder and a solvent in a reverse extracting device along the opposite directions, and enabling the solvent to extract the effective components of the coarse powder out of an extracting solution; performing pressure-relief heating on the extracting solution, and volatilizing the excessiveethanol in the extracting solution, so as to obtain a concentrated solution of cannabidiol; adding purified water into the concentrated solution of cannabidiol, diluting, eluting by a chromatography column in a gradient way, and collecting a target eluting solution; combining the target eluting solution, and performing pressure-relief concentrating at the temperature of 50 to 70 DEG C, so as to obtain a secondary concentrated solution of cannabidiol; adding 90%w / w ethanol over-saturated solution into the secondary concentrated solution of cannabidiol, obtaining a crystallized product, washingby the purified water, and drying, so as to obtain a cannabidiol product. The method has the advantages that the method can be applied to large-scale continuous production; the working is continuous without interruption; the output is high; the energy source is saved; the safety and reliability are realized.

Owner:上海昶健生物科技有限公司

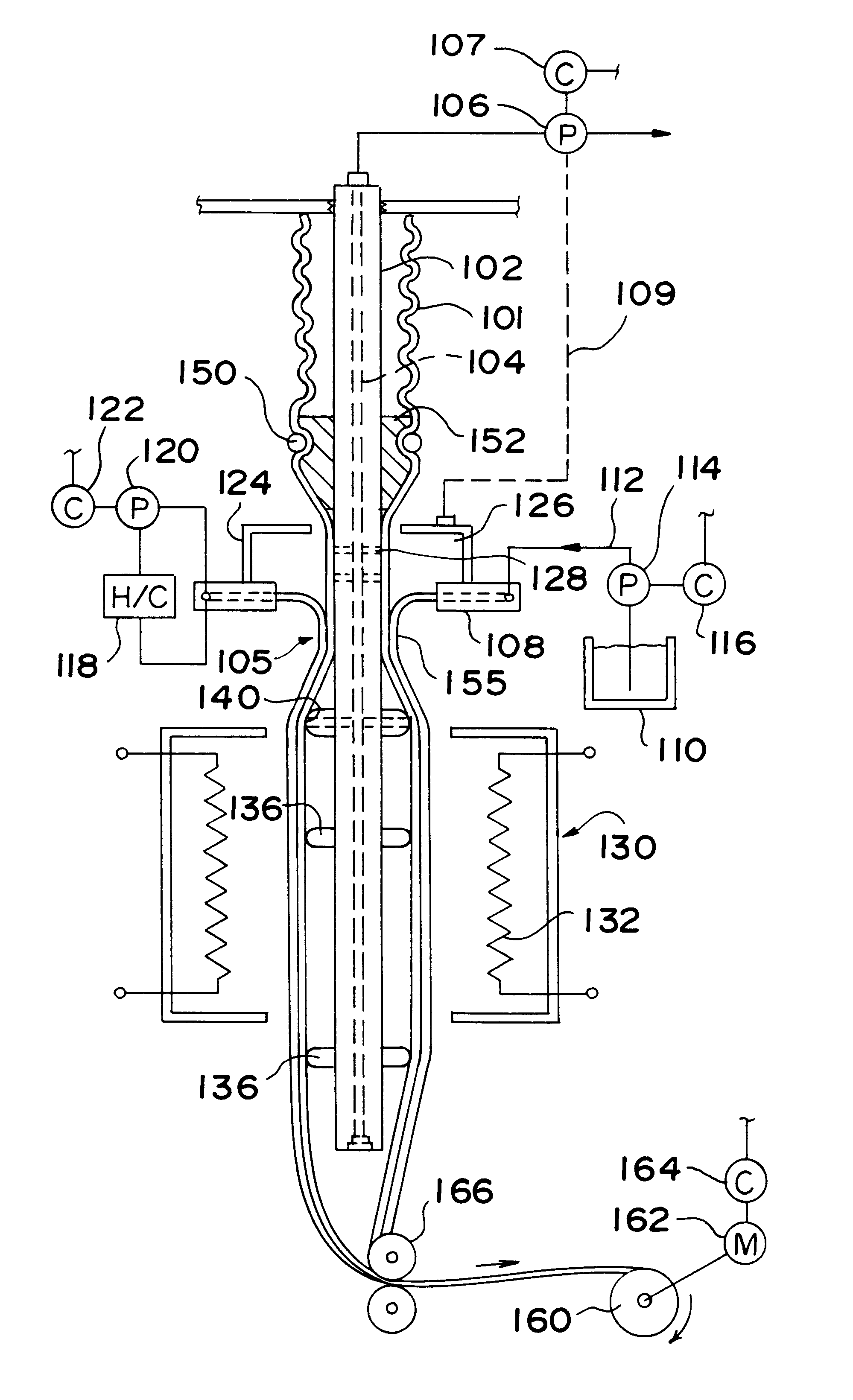

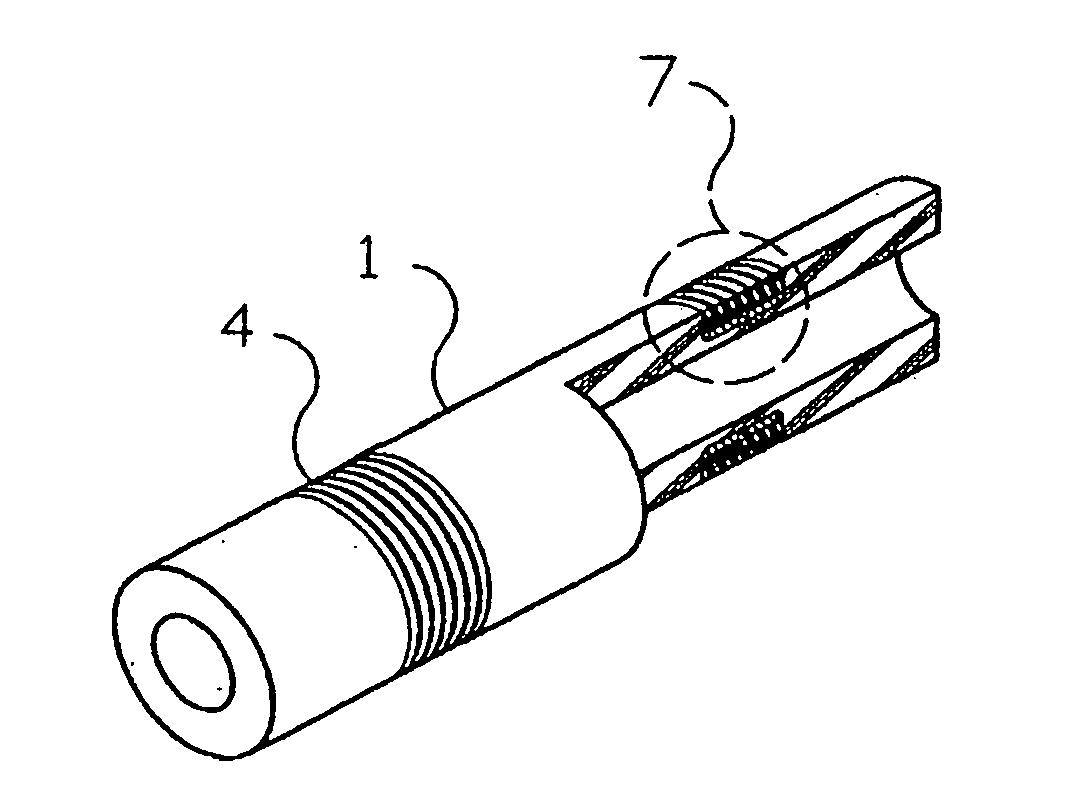

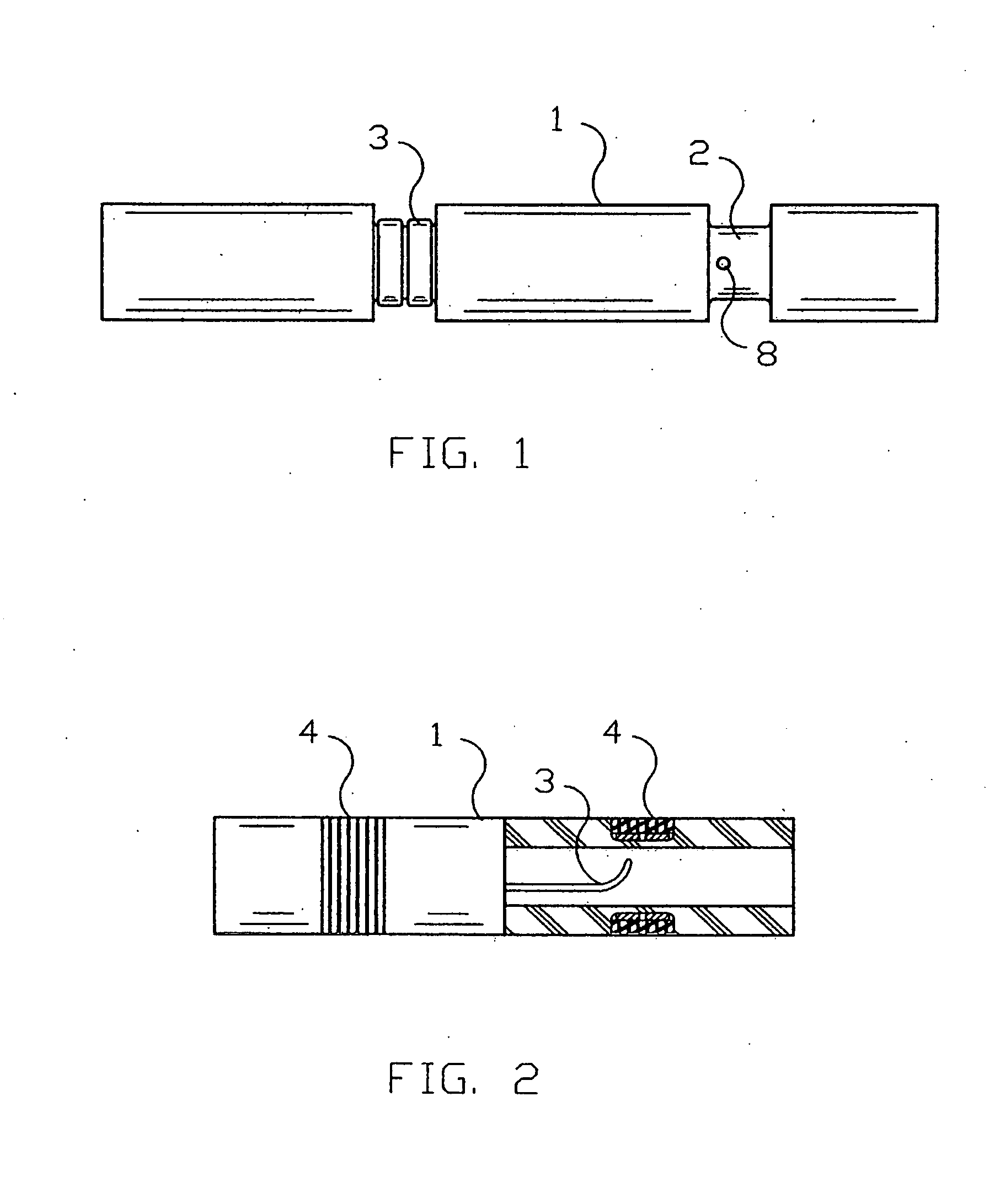

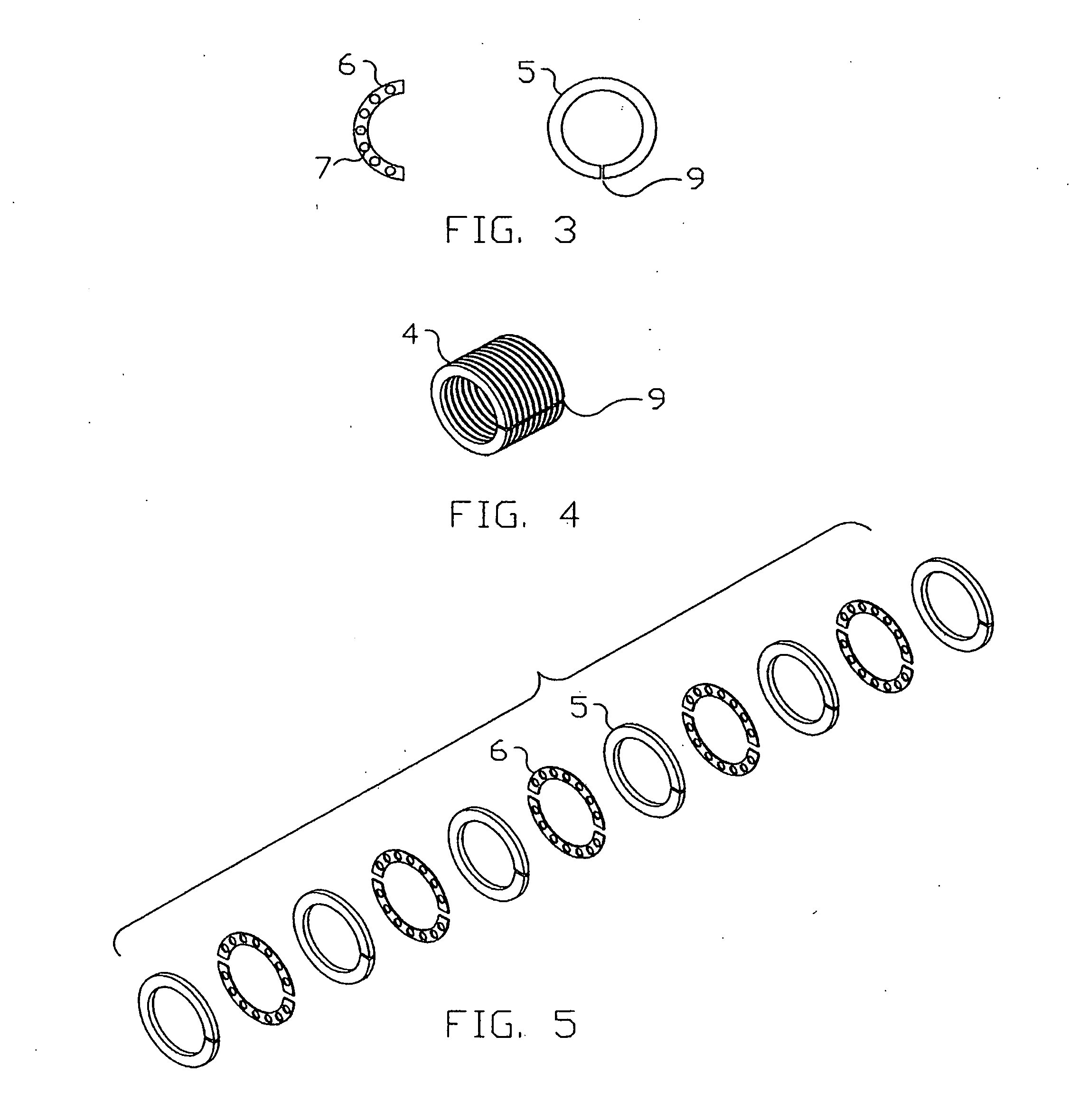

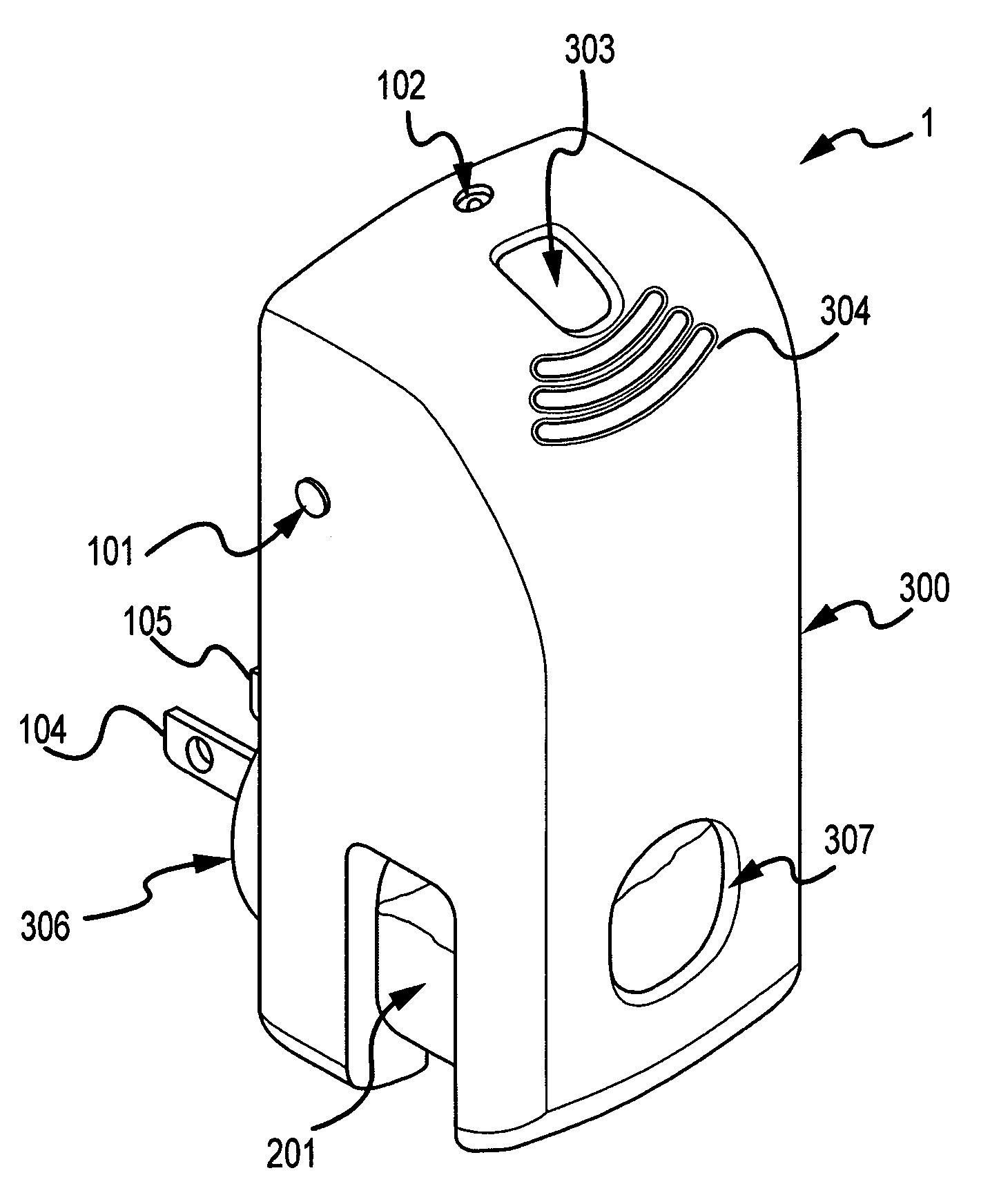

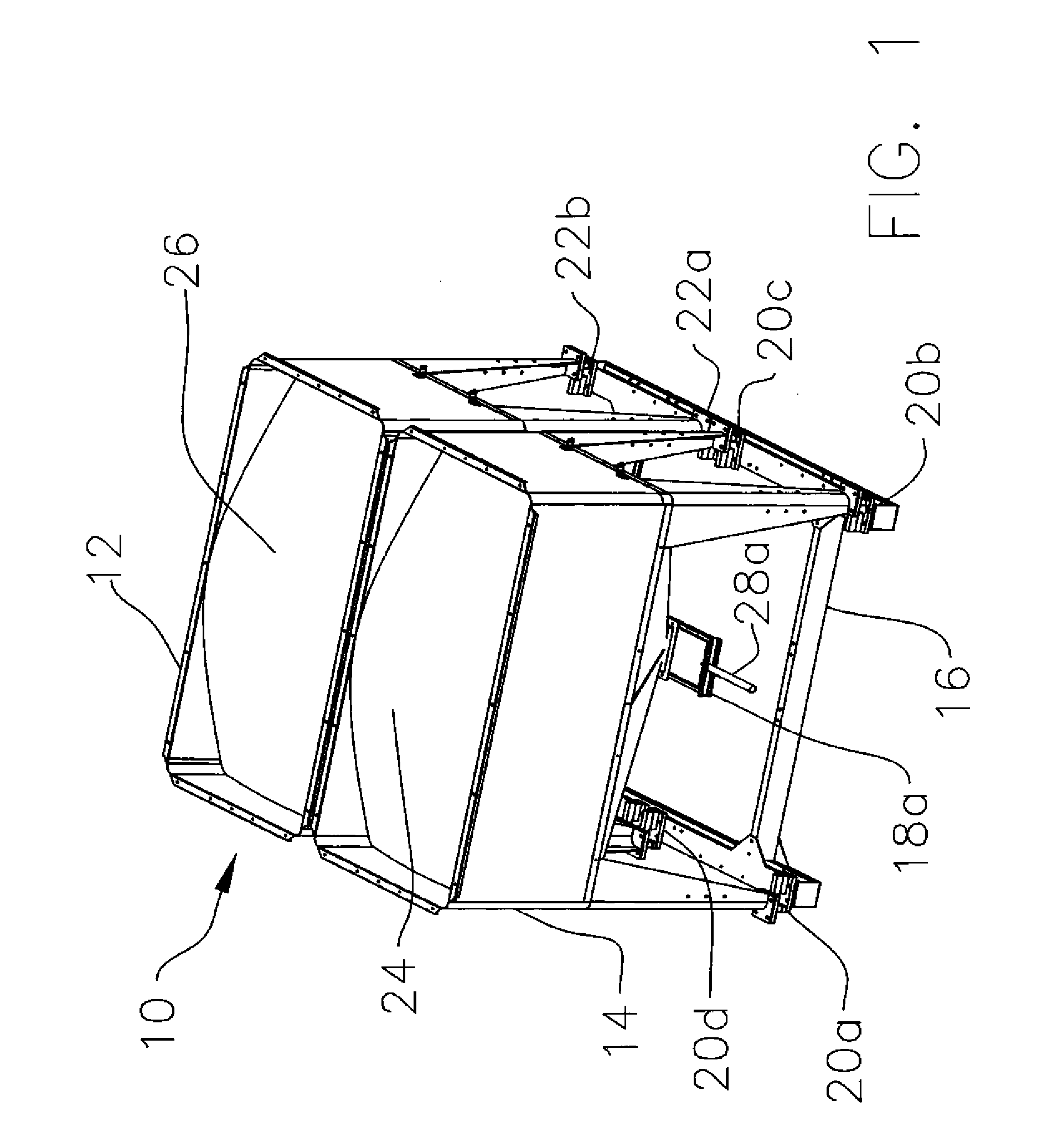

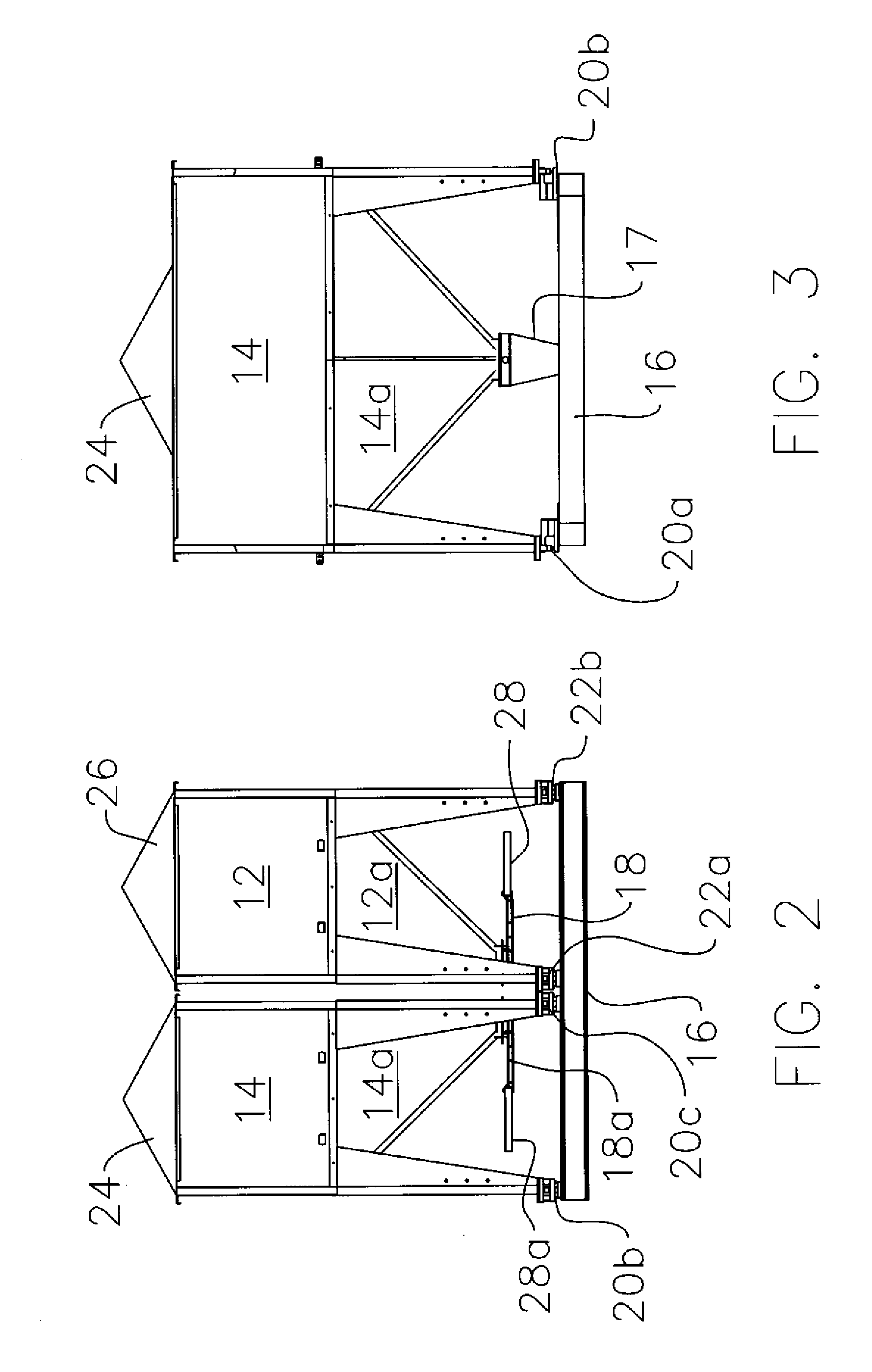

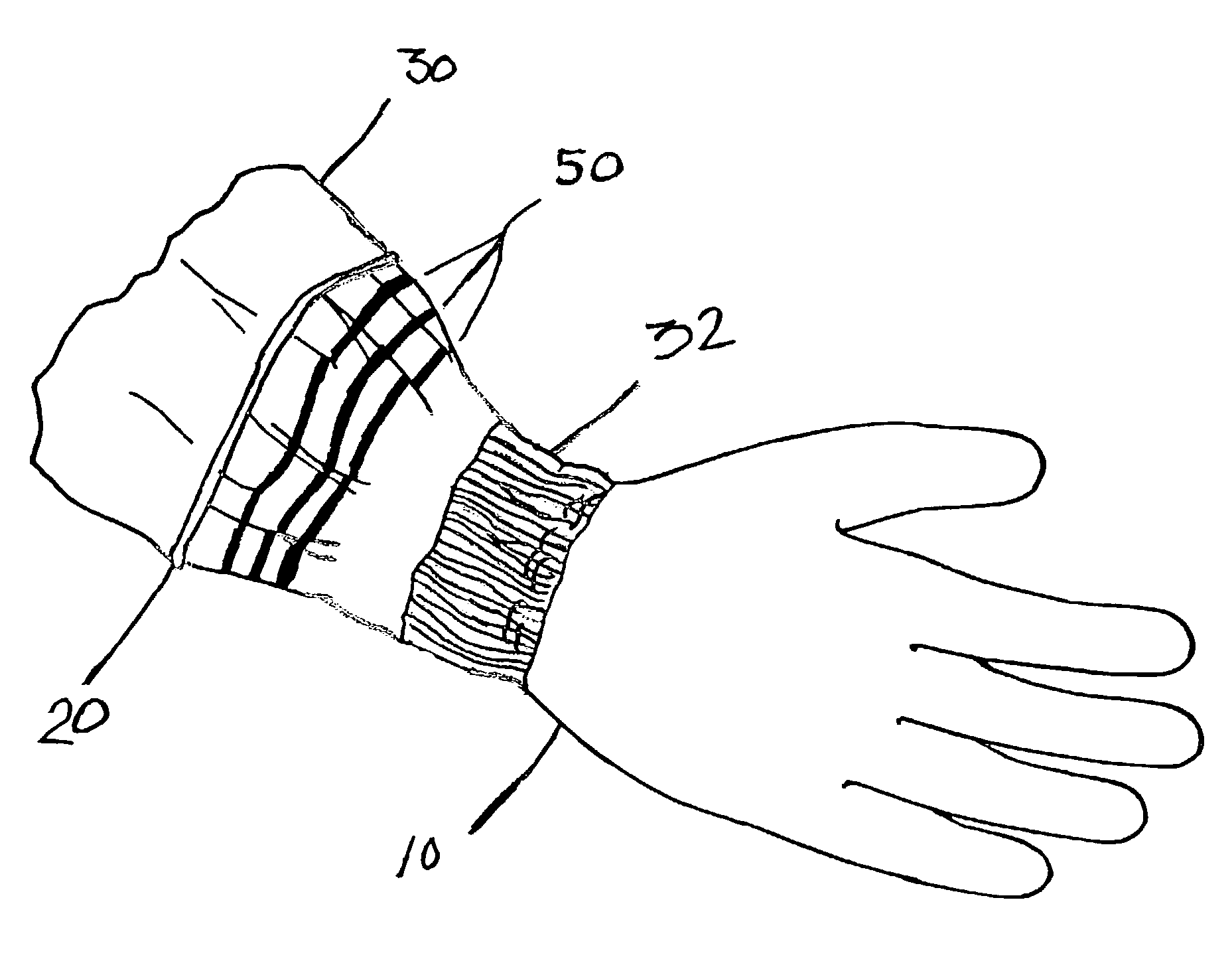

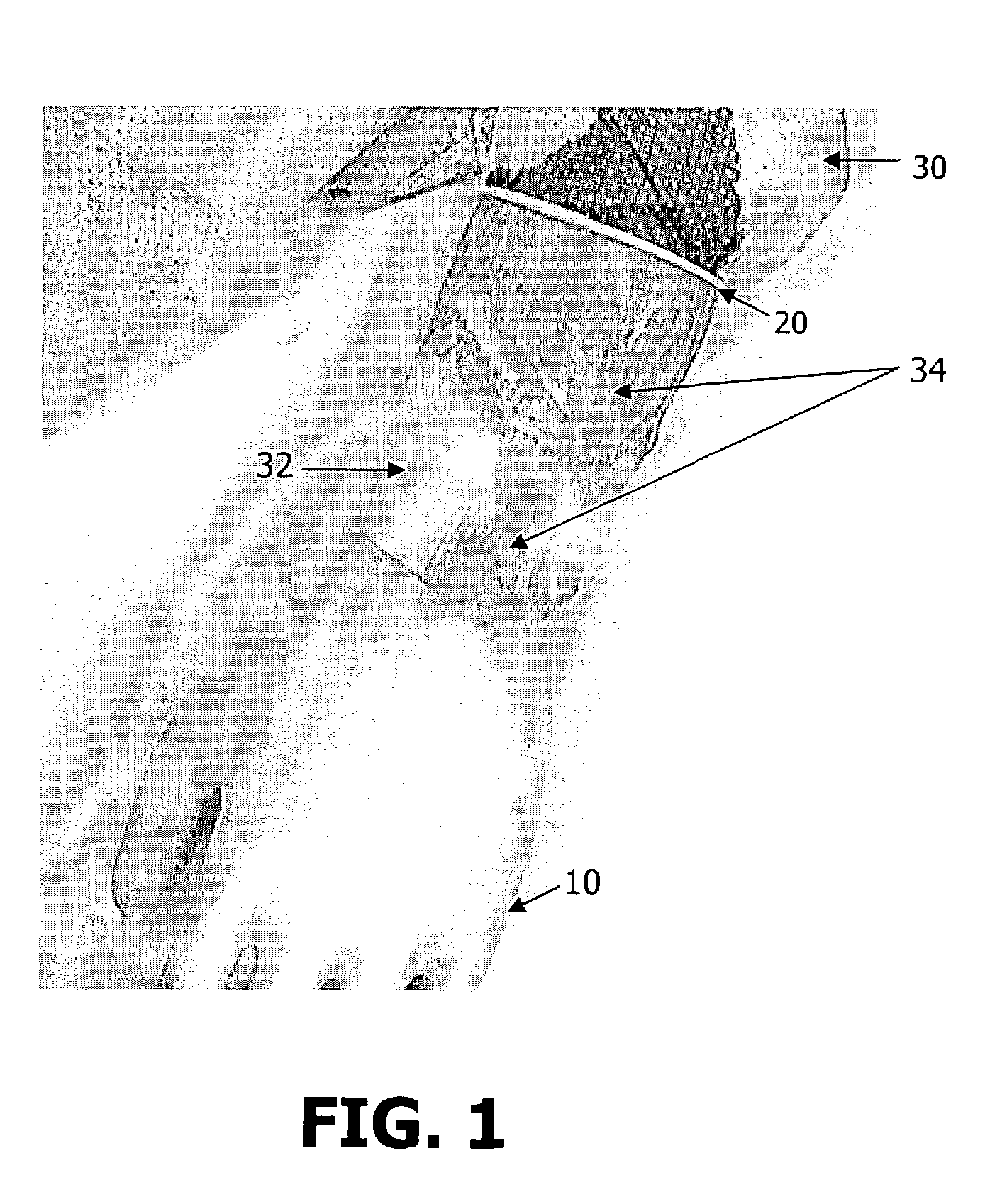

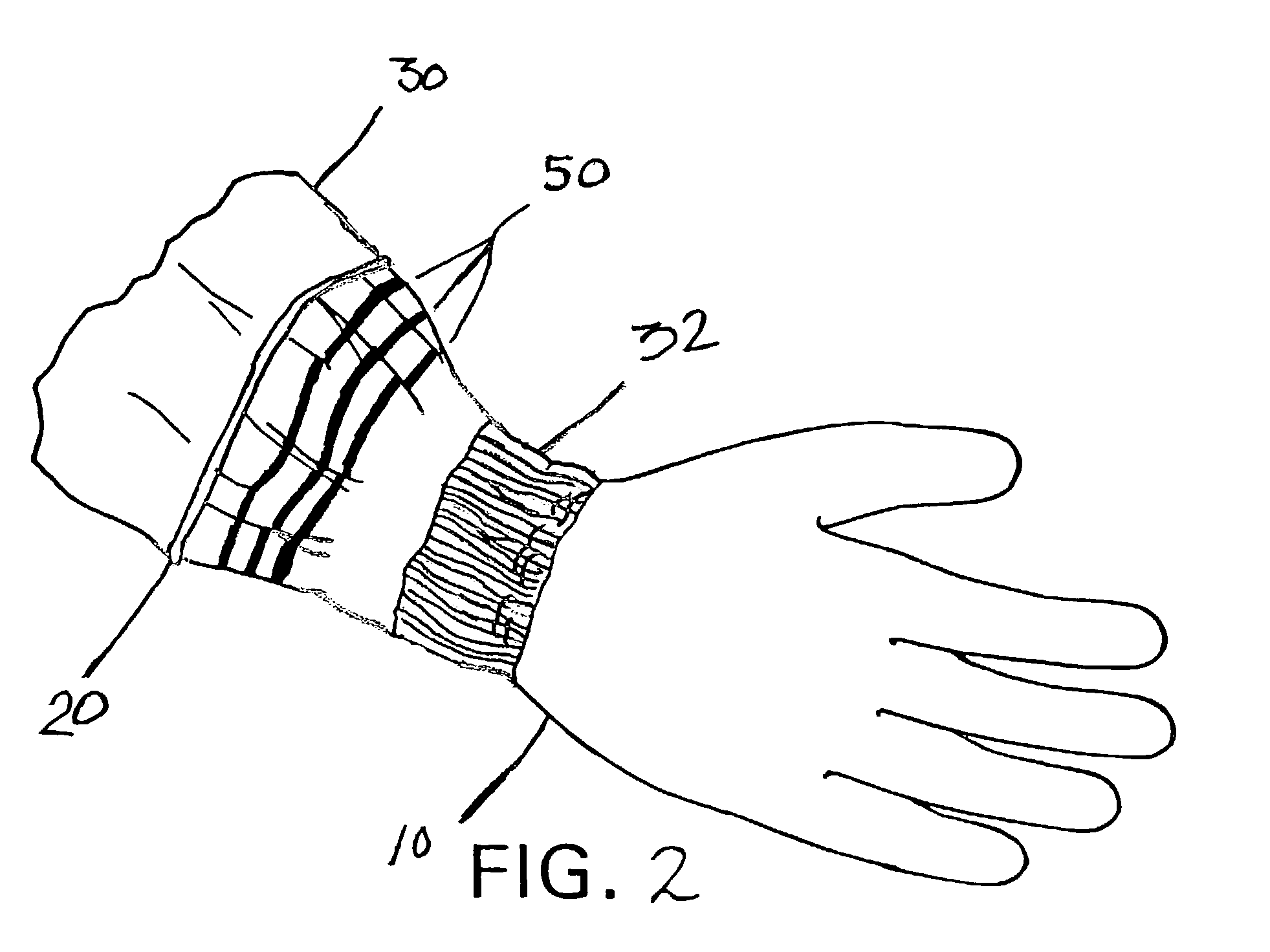

Apparatus and process for making prosthetic suction sleeve

The method of making a tubular member having a continuous and uninterrupted cured elastomeric resin coating on an outer surface of the member includes forming a continuous uninterrupted tubular layer of uncured elastomeric resin and drawing the resin layer against the surface of the tubular member to be coated by applying suction between the resin layer and the surface of the tubular member so that the resin adheres to the surface of the tubular member. The elastomeric resin may then be cured to produce the final product. Apparatus for carrying out the process is disclosed and includes, in sequence, a coating zone including a sub-atmospheric chamber, a heating zone and a feed mechanism for advancing the tubular member relative to the coating and heating zones. A method is also disclosed for molding a distal end cap on an open end of a length of a preformed tubular sleeve member that may be used for prosthetic applications. A process is also disclosed for molding a sleeve member having prosthetic applications using male and female die elements used to distribute uncured elastomer resin as a layer on a tubular elasticized fabric sleeve element.

Owner:KAUPTHING BANK

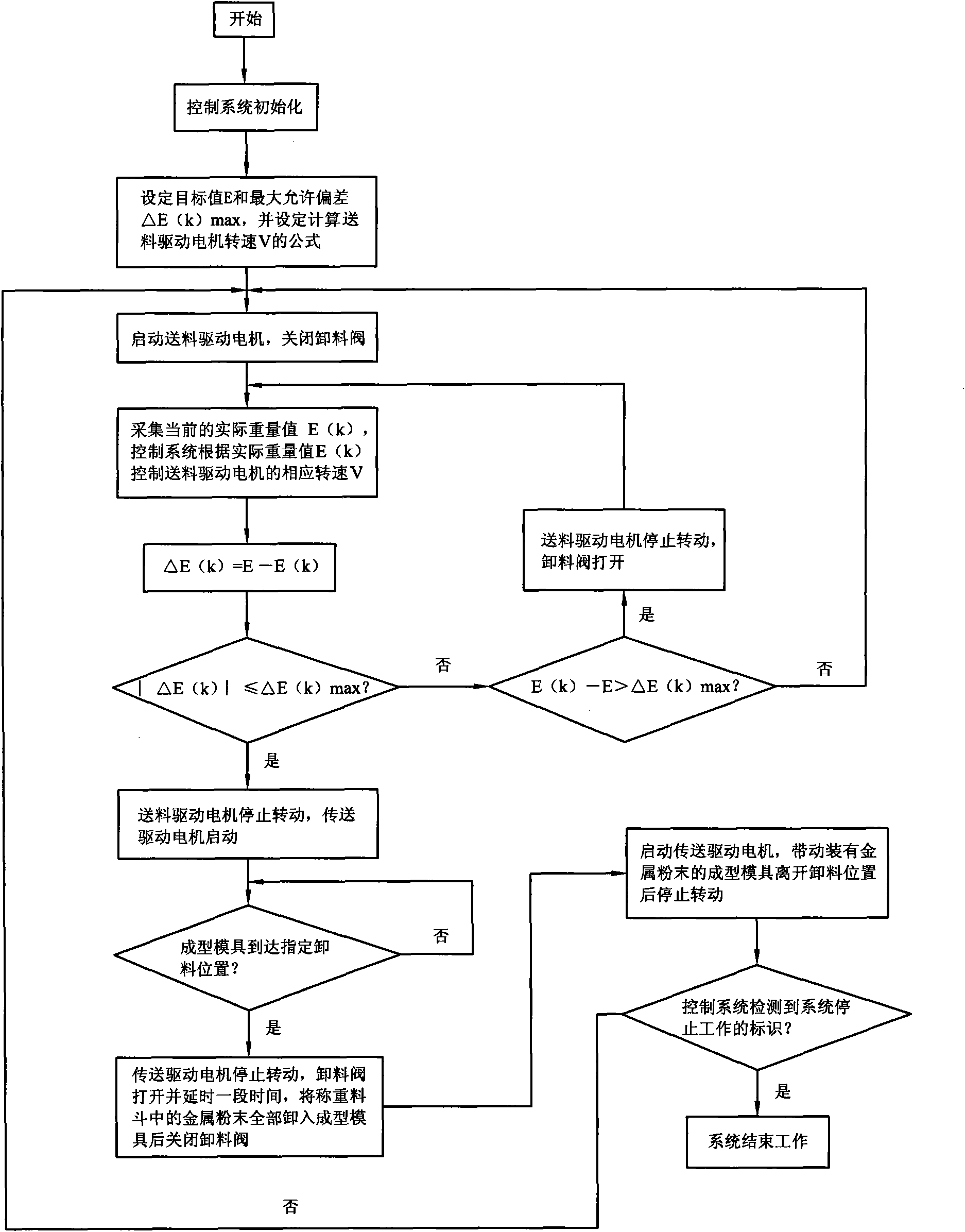

Control method for automatic weighting of metal powder

InactiveCN101620001AImprove uniformityImprove stabilityWeighing apparatus with automatic feed/dischargeContinuous/uninterruptedControl system

The invention discloses a control method for automatic weighting of metal powder, which has the advantages that the rotation speed of a feeding and driving motor is controlled by an improved proportion pulse width speed adjusting and control method, thus when the actual weight value of the metal powder in a weighting hopper is small, the rotation speed of the feeding and driving motor is high, and the feeding speed of the feeding and driving motor to the weighting hopper is high; when the actual weight value approaches to a target value; the rotation speed of the feeding and driving motor is low, and the feeding speed of the feeding and driving motor to the weighting hopper is low; the speed change of the feeding and driving motor is continuous, and the efficiency and the precision for feeding are both considered; a single microcomputer control system is adopted for the control system, so that the control method is relatively simple, and the cost is simultaneously reduced; in addition, as the feeding direction and the gravity direction of a screw feed mechanism arranged in a material storage hopper are consistent, the self gravity action of the metal powder is utilized while feeding, the uniformity and the stability for feeding are improved, and the system for achieving the whole control method is relatively simple.

Owner:NINGBO UNIV

Anti-wicking protective workwear and methods of making and using same

The present invention relates to protective outerwear for covering a body portion. The protective outerwear has an inside surface and an outside surface, with at least the outside surface including thereupon an ink jet printed low surface tension liquid blocking material in a continuous unbroken band, region, or combination of such, for blocking the wicking of liquid that is contained on the outside surface of the outerwear.

Owner:O&M HALYARD INC

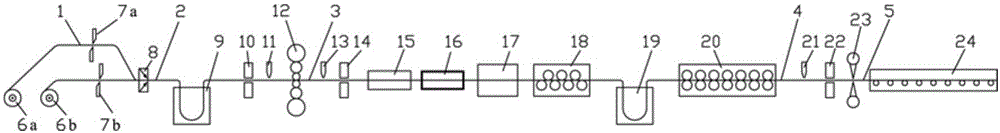

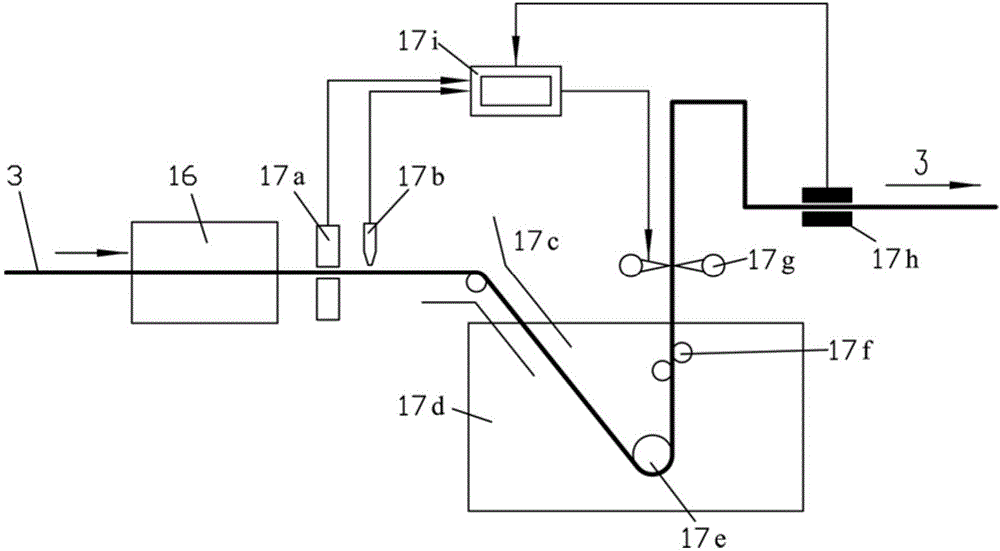

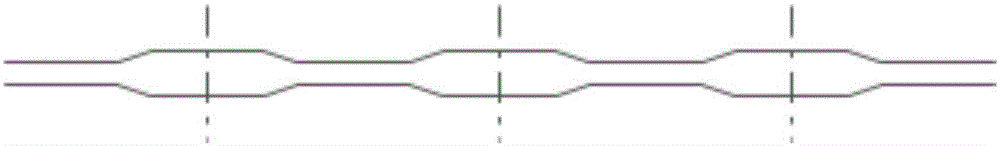

Continuous production method and line for variable-thickness profile

ActiveCN106623421ARealize continuous productionThickening rollingForging/pressing devicesMeasuring devicesVariable thicknessMaterials science

The invention discloses a continuous production method and line for a variable-thickness profile. Hot-rolled and pickled or cold-rolled equal-thickness strip steel is used as a raw material, all processes from rolling to surface coating to forming and cutting and the like of the strip steel are completed on line, production processes such as uncoiling, welding, variable-thickness rolling, degreasing, on-line heat treatment, online coating, flattening, roll-in forming, cutting and stacking are integrated, and the continuous production method is used for the fully-continuous automatic production of the variable-thickness profile. By using the continuous production method disclosed by the invention, the continuous production and coating of the variable-thickness profile can be realized, the defects of high production cost, high labor intensity, continuous production incapability and surface coating incapability of the existing variable-thickness profile are overcome, the production efficiency of the variable-thickness profile is greatly increased, and the favorable economic benefit is obtained. By using the continuous production method, a single or partially continuous production process in the prior art can be replaced, the production process of the variable-thickness profile can be simplified, and the continuous production of the variable-thickness profile can be realized.

Owner:上海宝钢型钢有限公司 +1

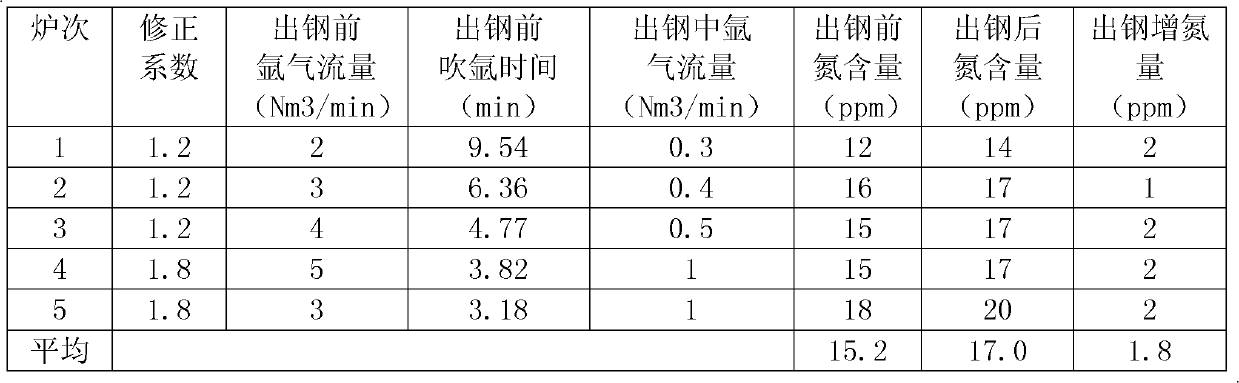

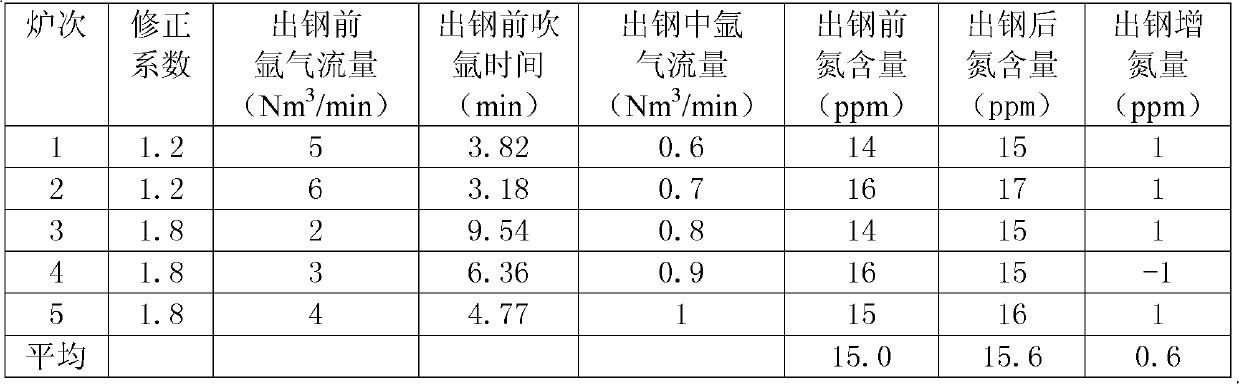

Method for prevention of nitrogen increase in molten steel during steel tapping from a converter

InactiveCN102559983AAvoid Nitrogen ProblemsReduce total nitrogenManufacturing convertersContinuous/uninterruptedNitrogen

The invention provides a method for prevention of nitrogen increase in molten steel during steel tapping from a converter, which comprises the steps of controlling the argon blowing time and argon flow before and during steel tapping from the converter, and blowing argon to the steel ladle in two segments or uninterruptedly till the finish of steel tapping. Thereafter, air in the steel ladle can be evacuated by the argon blown in to prevent the molten steel in the ladle contacting with air while tapping and to keep the molten steel in the ladle under the protection of argon all the time, which not only prevents molten steel contacting with air to cause nitrogen increase, but also removes the nitrogen [N] that can easily adsorb on the surface of the bubbles from the molten steel with the float and discharge of nitrogen bubbles. The method of the invention is simple and easy to implement and operate, and can remarkably reduce the possibility of nitrogen increase in the molten steel during tapping, so that the nitrogen increase in the molten steel can be controlled below 3ppm after tapping.

Owner:ANGANG STEEL CO LTD

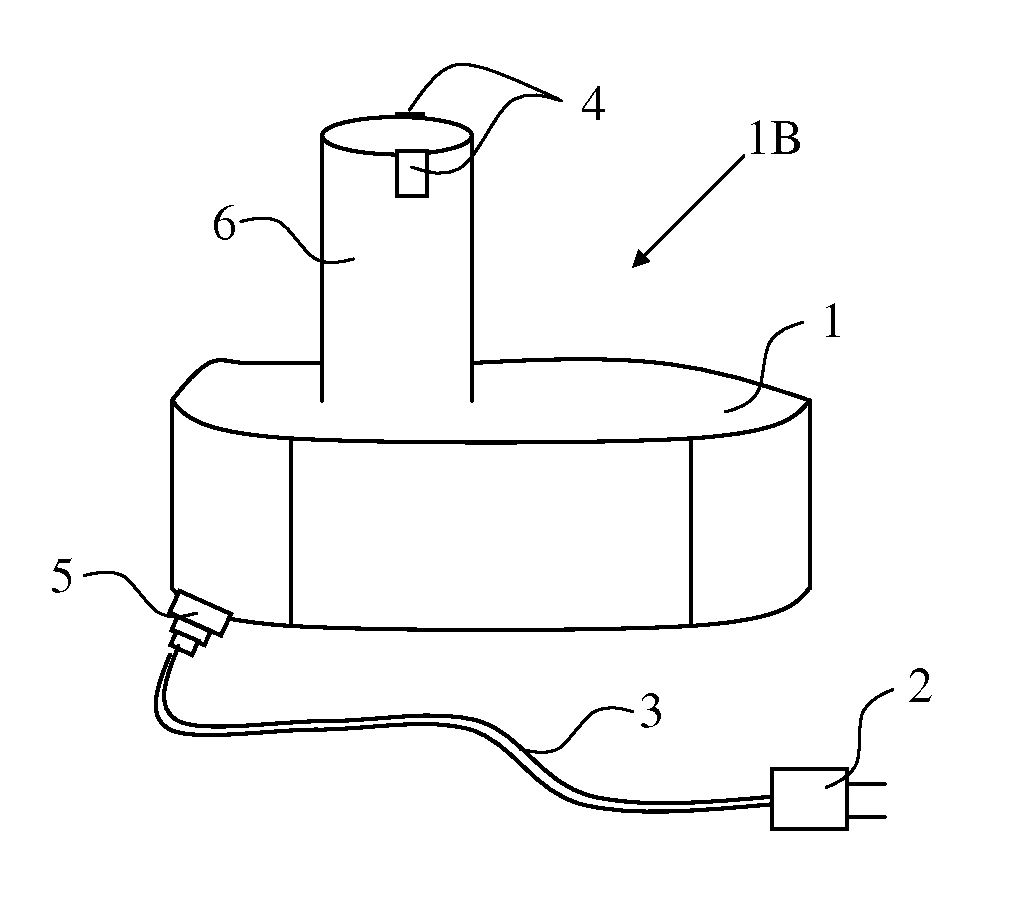

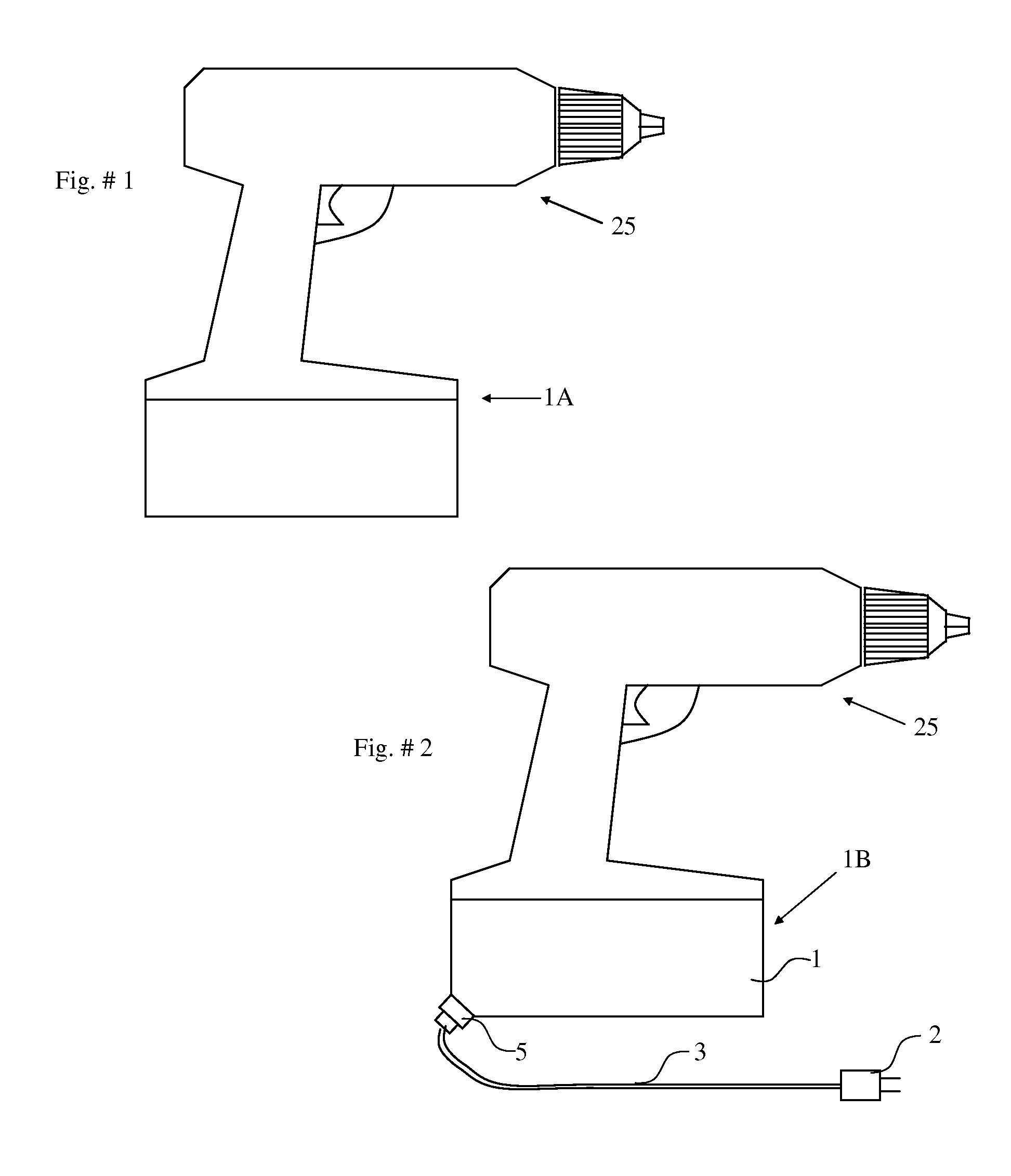

Battery Substitute Device For Power Tools

InactiveUS20120287691A1Slow changeExtend rechargeable life of batteryDummy cellsSecondary cellsContinuous/uninterruptedElectrical battery

A battery substitute device for providing an alternative power source for battery operated ‘cordless’ tools and similarly powered appliances. The battery substitute device is generally shaped like the battery pack it replaces and includes an AC-DC power converter powered by AC plug-in power through a flexible line and AC mains plug. The battery substitute device interchangeably mates with said tools and appliances providing the option of continuous uninterrupted, full power use of the tool and gives the user the option of optimized power source for material, torque and power properties, and user convenience. The battery substitute device reduces the need for multiple battery packs, extends the life of the battery packs and reduces waste caused by fully depleted battery packs. It also reduces the need to anticipate a project and charge battery packs. The battery substitute device will make a useful, effective tool much more useful and much more effective.

Owner:BREUNER EDWARD LOUIS

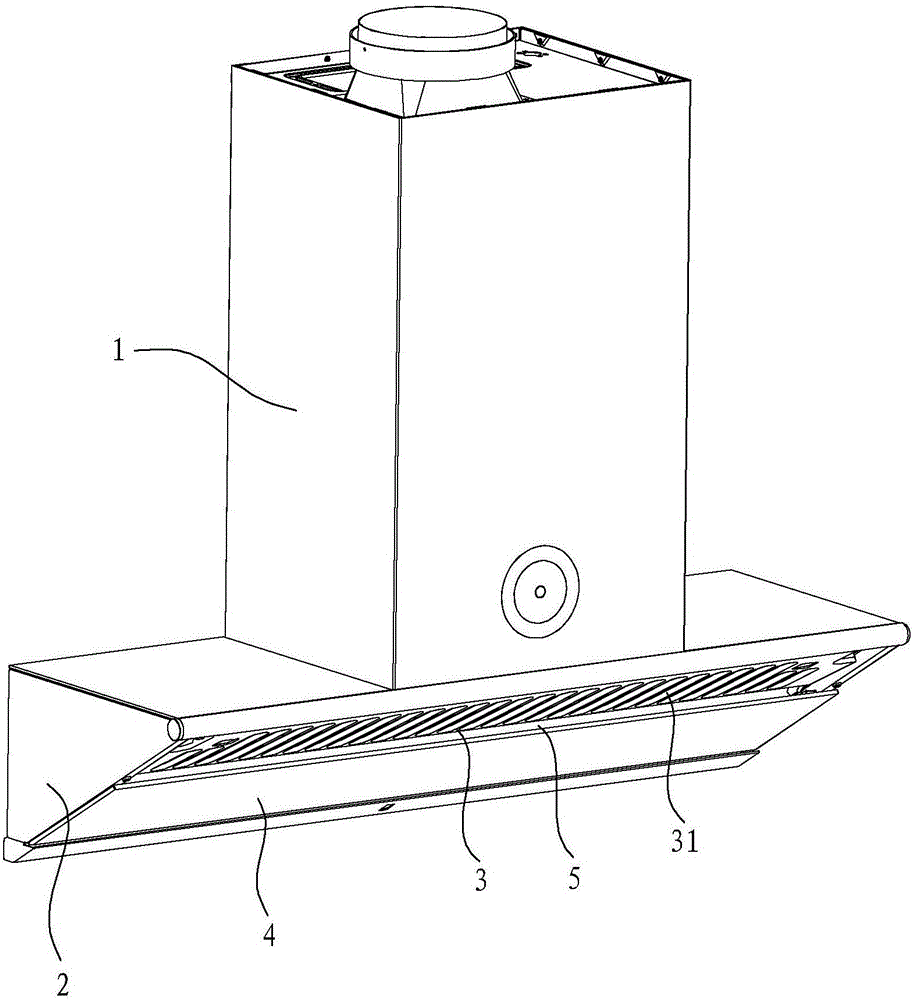

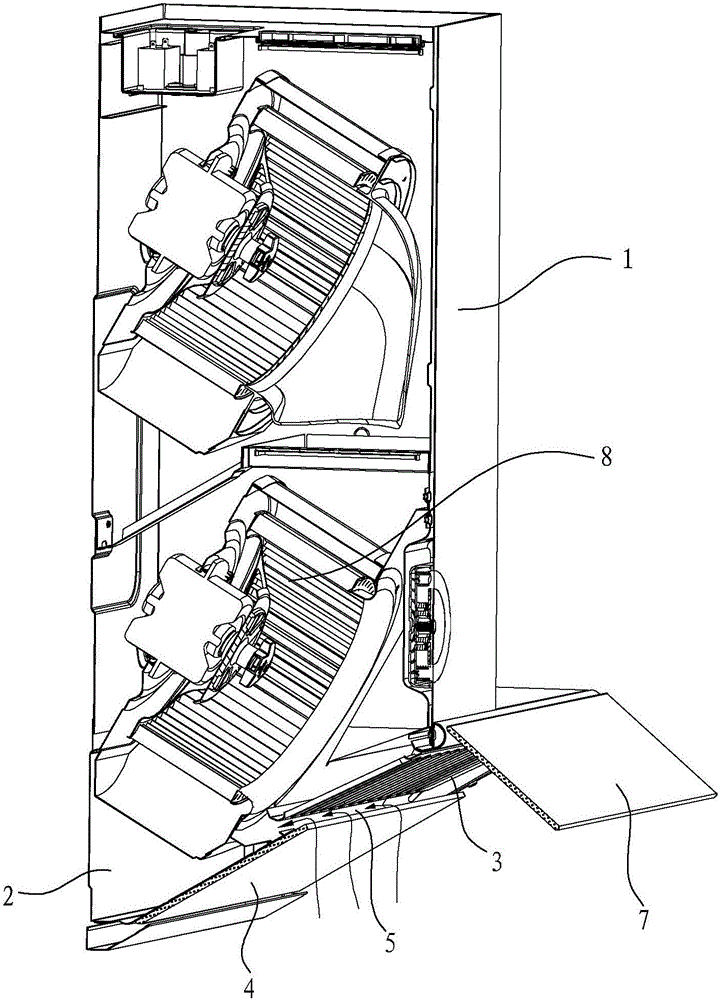

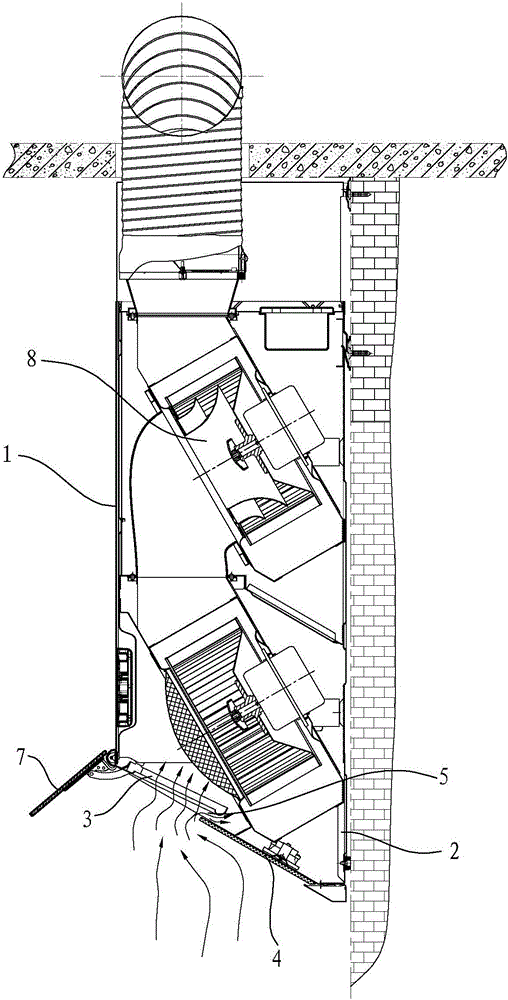

Range hood with auxiliary air inlet channel

ActiveCN106016404AImprove the smoke effectChange pathDomestic stoves or rangesLighting and heating apparatusTO-18Continuous/uninterrupted

The invention provides a range hood with an auxiliary air inlet channel. An oil filtering plate is installed on the front face of a cooking fume collecting cover. Main air inlets are formed in the oil filtering plate, and the oil filtering plate of the range hood is obliquely arranged towards the rear lower side from top to bottom. Auxiliary air inlets are formed in at least one of an area adjacent to the upper side edge of the oil filtering plate and an area adjacent to the lower side edge of the oil filtering plate. The auxiliary air inlets are in a long bar shape and are transversely through. Due to the fact that the auxiliary air inlets of the range hood are continuous and uninterrupted air inlet channels, the defect that gate-hole-shaped main air inlets are interrupted and not continuous can be overcome, and the air inlet area can be enlarged and a cooking fume path can be changed through the auxiliary air inlets. In addition, the included angle alpha between the oil filtering plate and the horizontal plane is designed to be larger than or equal to 18 degrees and smaller than or equal to 30 degrees, and under the condition that negative-pressure covering angles are the same, the negative-pressure covering area of a cooking bench is larger; and furthermore, after the auxiliary air inlets are arranged, the phenomenon that negative pressure is weakened and cooking fume escapes due to the fact that the inclination angle of a cooking fume guide plate relative to the horizontal plane becomes smaller can be effectively avoided, and therefore the cooking fume absorbing effect is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

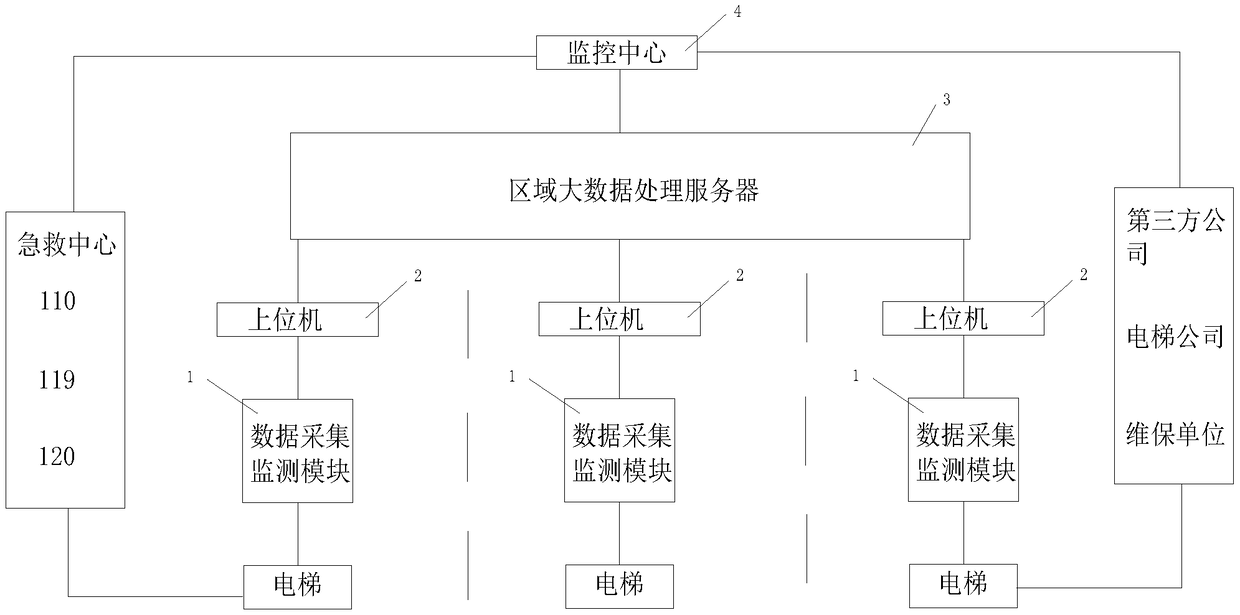

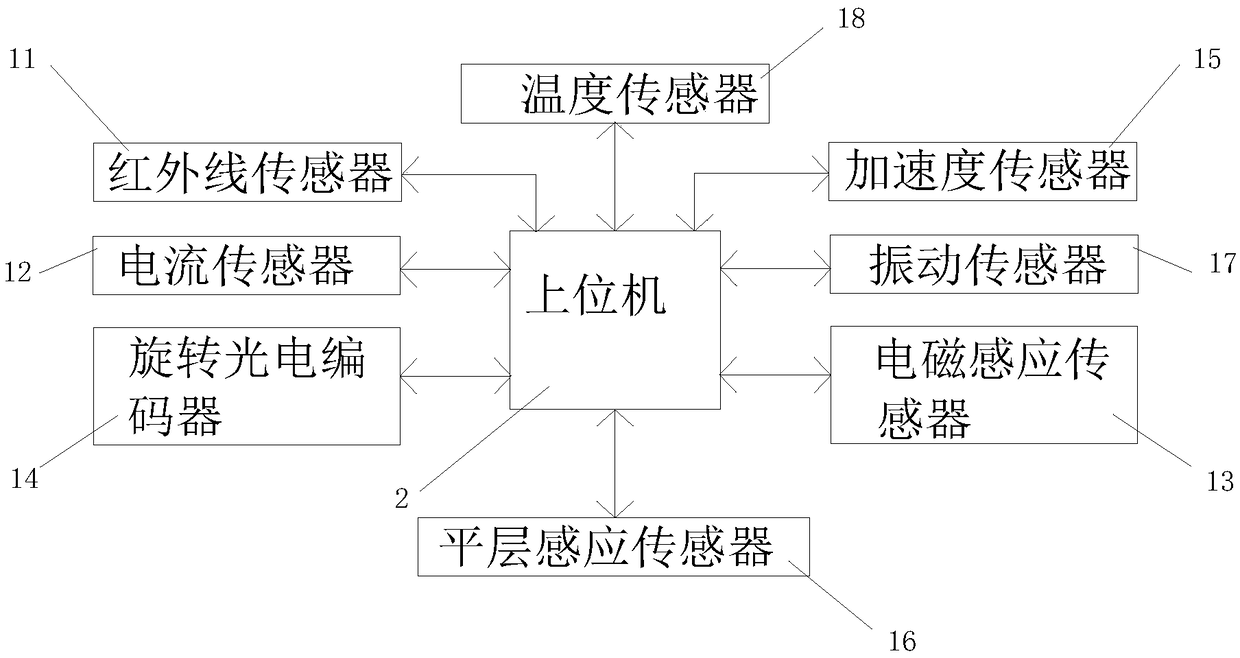

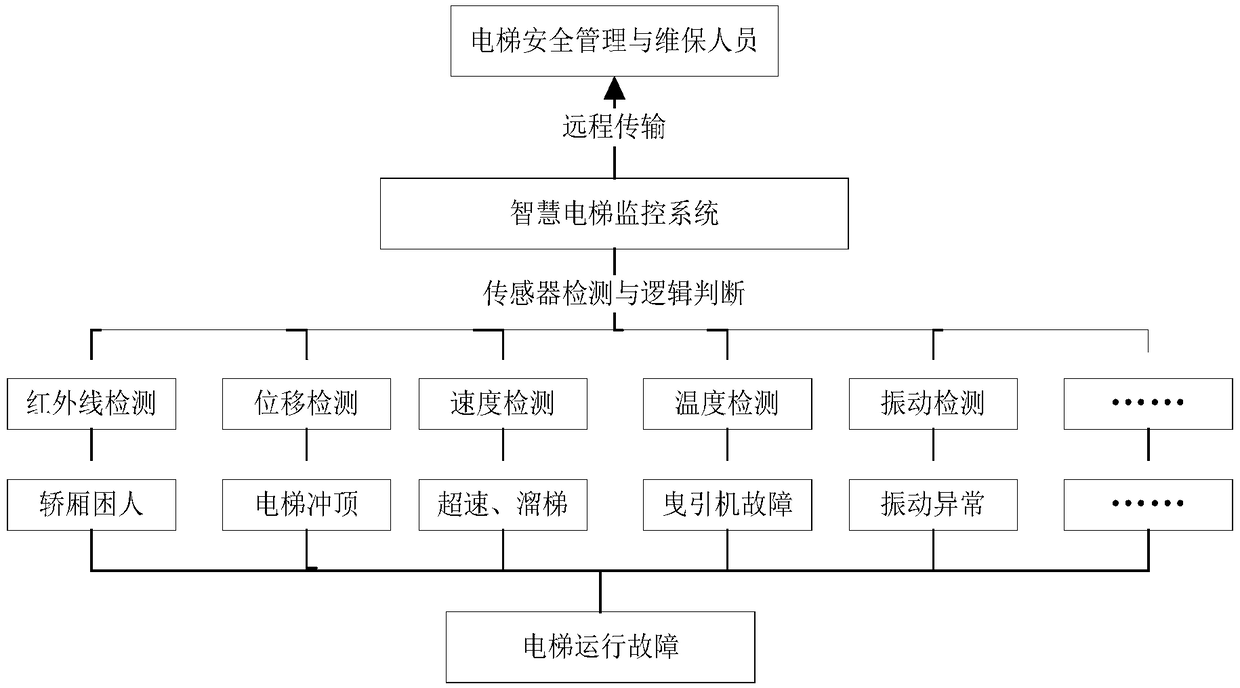

Wisdom elevator monitoring system based on internet of things big data

PendingCN108792871AGuaranteed uptimeImprove securityElevatorsContinuous/uninterruptedEmergency rescue

The invention provides a wisdom elevator monitoring system based on internet of things big data. The system comprises data acquiring and monitoring modules and upper computers arranged on all elevators, an area big data processing server and a monitoring center; the data acquiring and monitoring modules acquire elevator state data, and communicate with the upper computers through a wireless network or a wire network; the upper computers of all the elevators analyze the elevator state data and send the elevator state data to the area big data processing server for storage; the area big data processing server communicates with the monitoring center through an internet of things, and sends the elevator state data to the monitoring center; and the monitoring center analyzes and processes the elevator state data to realize continuous tracking and monitoring of the elevators in unattended state to automatically count the failure parts of the elevators and to analyze the failure factors. Thesystem can realize real-time monitoring and automatic alarm of remote elevator failures, person trapping pacification of the internet and emergency rescue.

Owner:MINJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com