Patents

Literature

31results about How to "Reduce self-corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrolyte corrosion inhibitor for aluminum-air cell, electrolyte and preparation method

InactiveCN103633396AReduce hydrogen evolution self-corrosion rateProne to anodic polarizationFuel and primary cellsAluminum anodePhysical chemistry

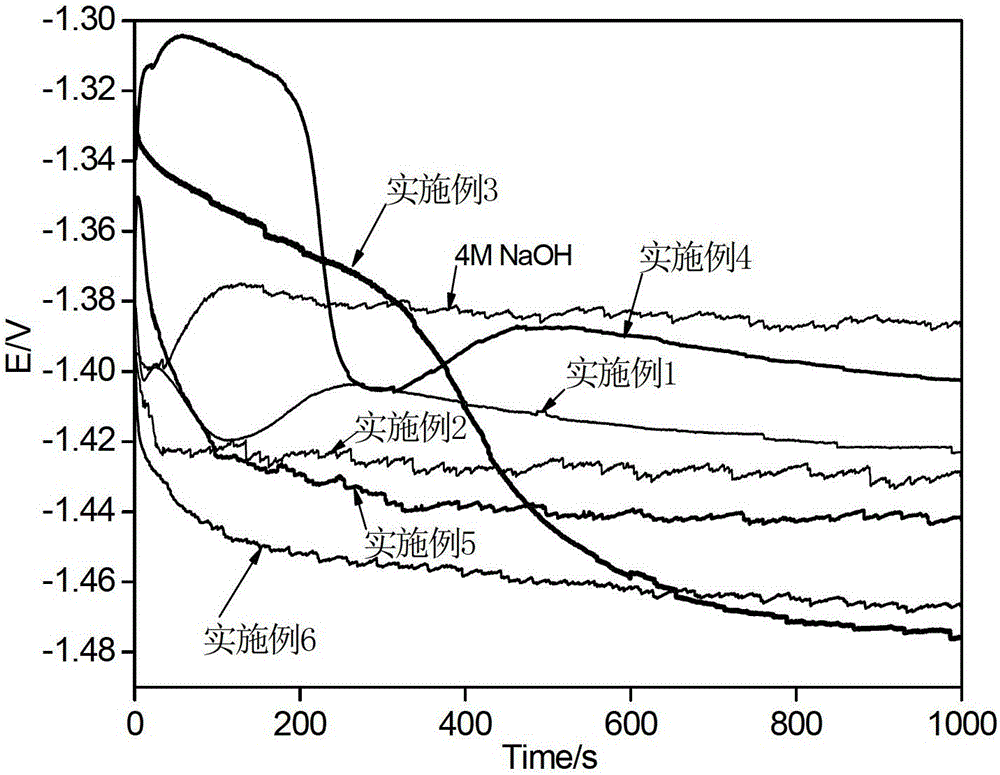

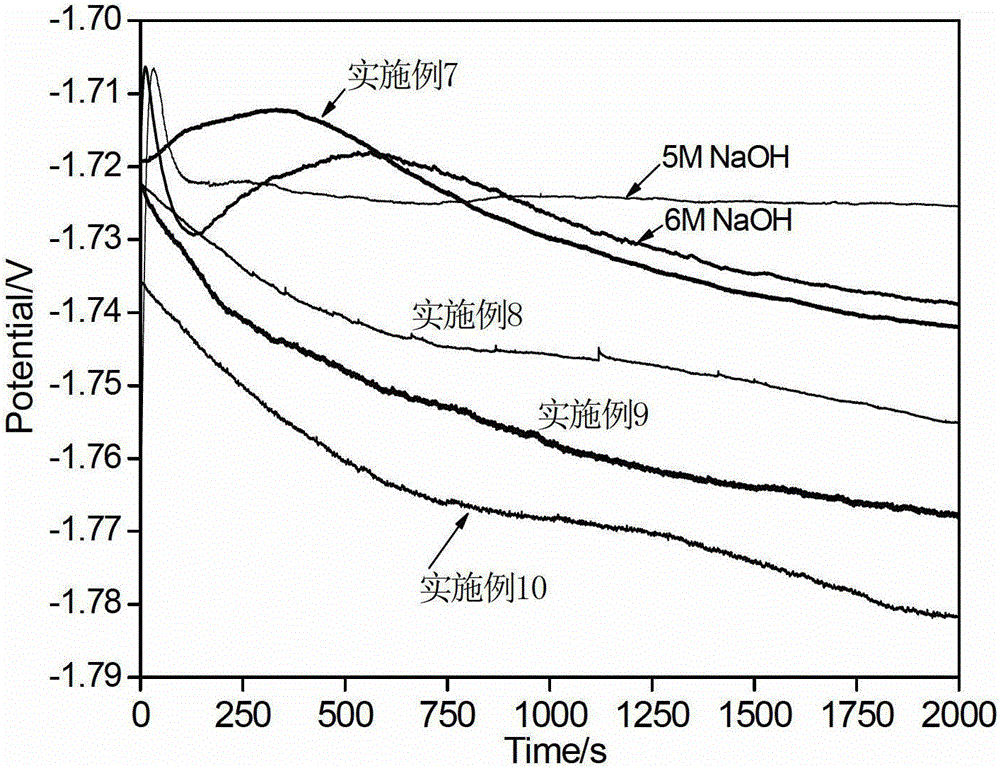

The invention discloses an electrolyte corrosion inhibitor for an aluminum-air cell, an electrolyte and a preparation method, belonging to the technical field of chemical batteries. The electrolyte corrosion inhibitor mainly comprises sodium hyposulfite which has a concentration of 0.005 to 0.2 mol / L in the electrolyte and may further comprise the auxiliary additive sodium stannate which has a concentration of 0.01 to 0.03 mol / L in the electrolyte. The aluminum-air cell provided by the invention has the advantages of simple composition, low cost, safety and accordance with environmental protection requirements, can substantially reduce the hydrogen evolution self-corrosion rate of an aluminum anode, enables the open circuit potential of the aluminum anode and working potential under the condition of impressed current to undergo substantial negative transfer, allows an aluminum anode alloy to have good corrosion resistance and high electrochemical activity and meets the requirement of an alkaline aluminum-air cell for large current density discharging.

Owner:HENAN UNIV OF SCI & TECH

Rare earth-containing amorphous/nanocrystal aluminum anode composite material, preparation method and aluminum air battery

InactiveCN104372206AImprove electrochemical performanceAbundant resourcesFuel and primary cellsCell electrodesRare-earth elementDissolution

The present invention discloses a rare earth-containing amorphous / nanocrystal aluminum anode composite material, a preparation method and an aluminum air battery, and belongs to the techncial field of air batteries. The aluminum anode composite material comprises, by weight, 0.5-5% of Mg, 0.02-2% of Sn, 0.02-2% of Ga, 0.1-5% of La or Ce, and the balance of Al. According to the present invention, aluminum with the purity of more than or equal to 99.8% is adopted as the base, the trae amounts of Mg, Sn, Ga and the rare earth element La or Ce are added so as to reduce the self-corrosion rate and improve the electrochemical property and the surface dissolution uniformity of the alloy, especially the trae amount of the rare earth element is added to the aluminum alloy, and the addition of the rare earth element to the aluminum has effects of oxygen removing, hydrogen removing, desulfuration, melting rate accelerating, metal burning loss reducing, change of species distribution and refinement modification of iron and other harmful impurities, and the like so as to slow down the self-corrosion of the aluminum alloy, such that the anode utilization rate is improved.

Owner:HENAN UNIV OF SCI & TECH

Magnesium dry cell

InactiveCN1466237AThickness is easy to controlReduce self-corrosionCell electrodesDry cellsAlkaline earth metalRare earth

This invention relates to a Mg dry battery with Mg alloy as the anode material in which, Mg is the main component is Mg alloy and the key point is that the said alloy also includes metal A which is either alkal; metal, alkali earth metal or or rare earth metal or any combination for thee materials. The thickness of the passive film can be controlled, voltage delay time can be controlled, the Mg electrode is seldom corroded and the said Mg alloy does not includes Hg and Cd.

Owner:FUJIAN HUAMEI NEW TECH DEV

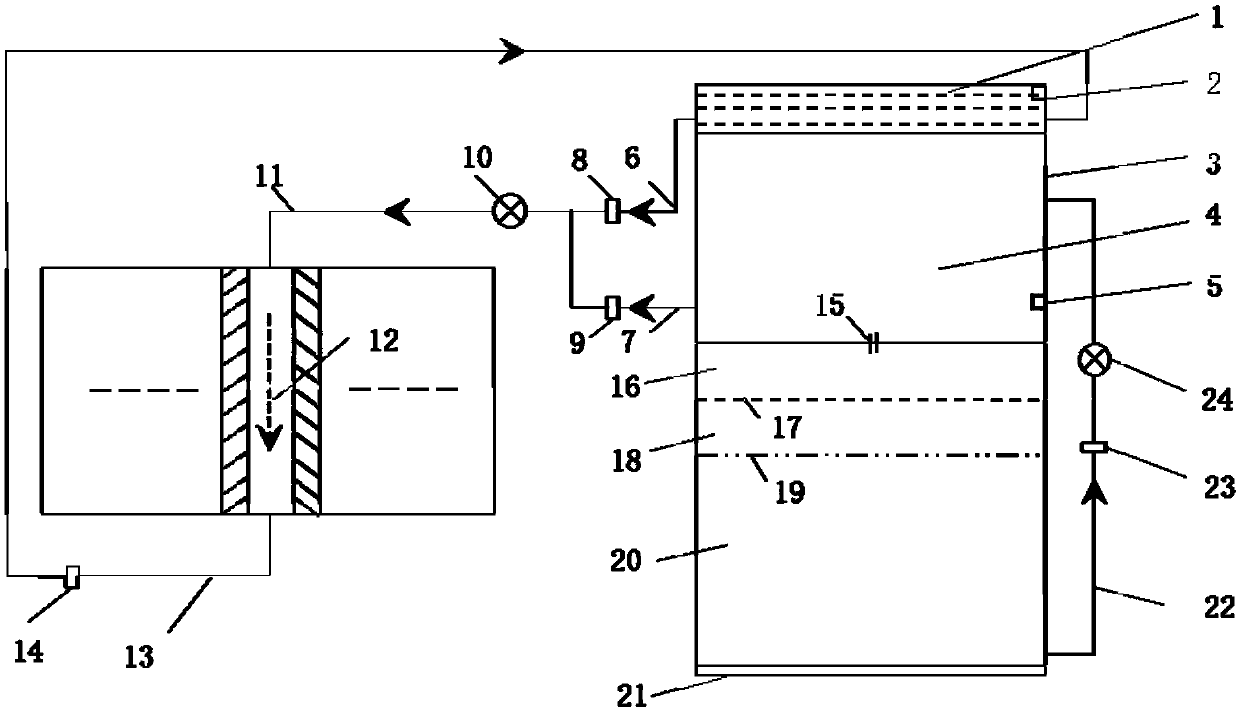

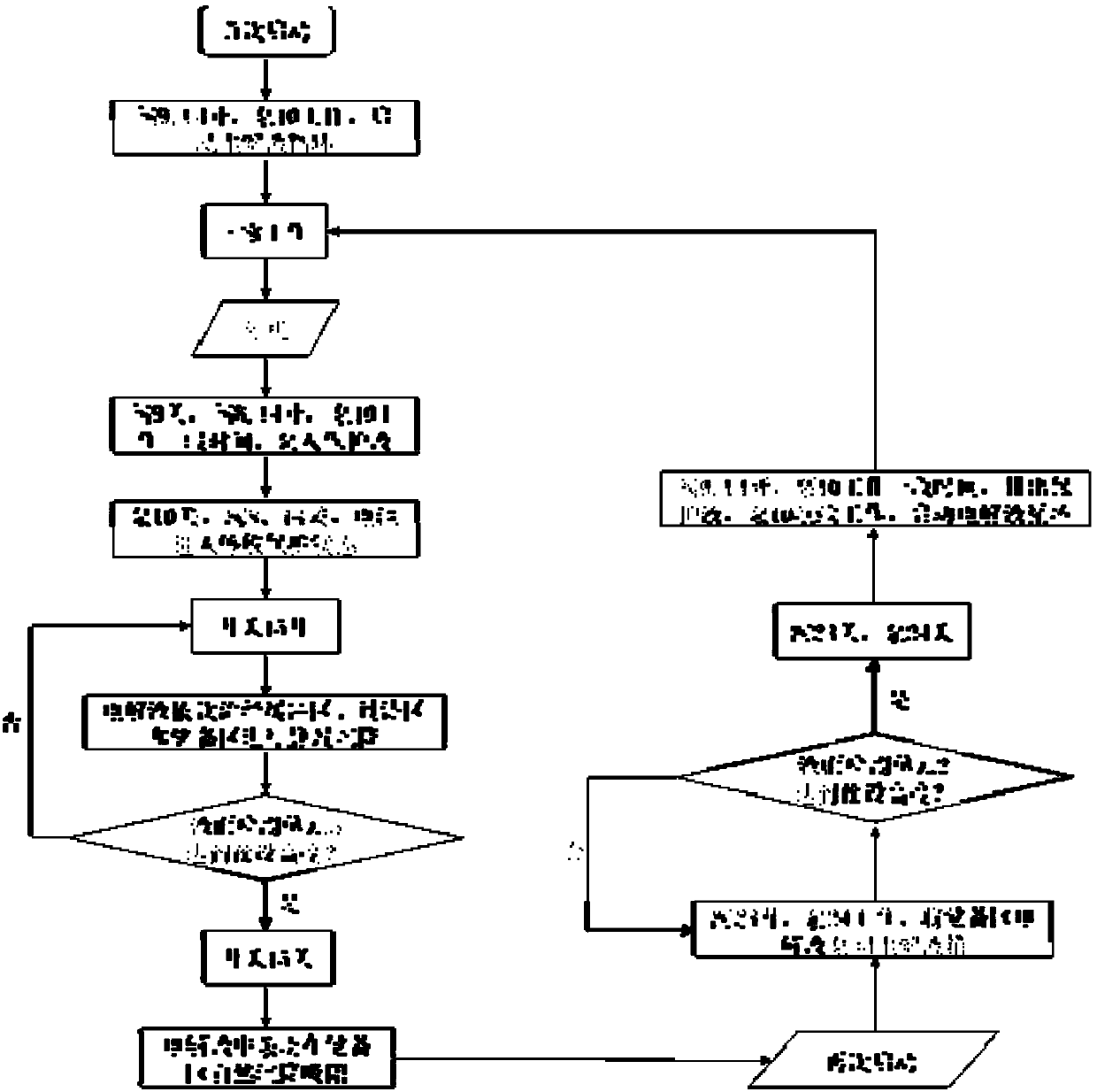

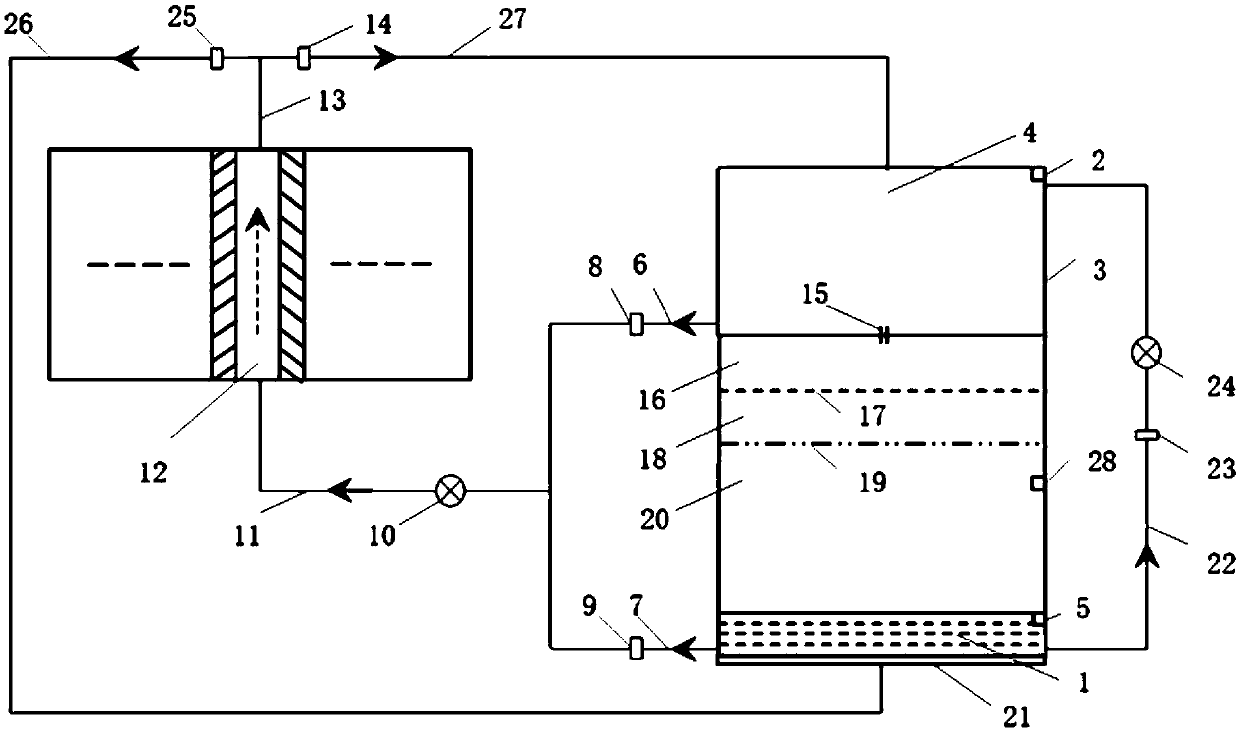

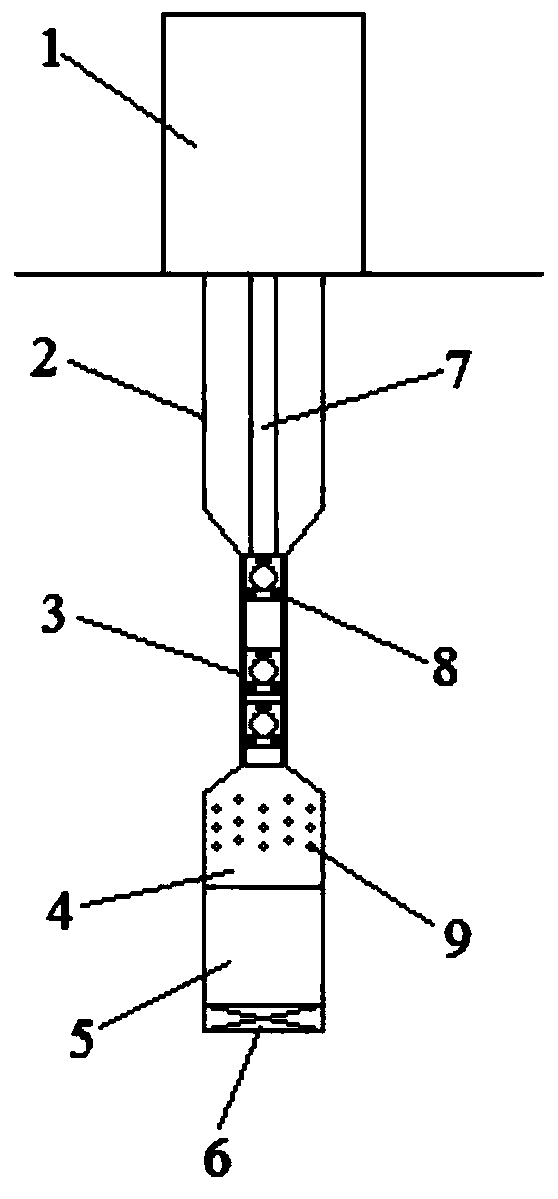

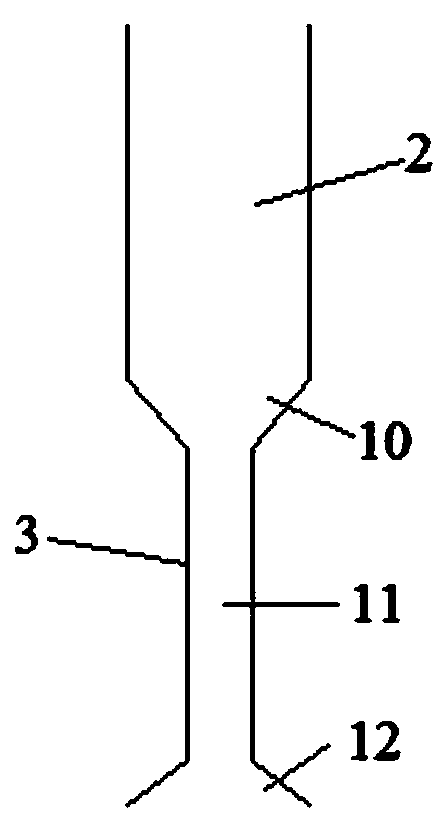

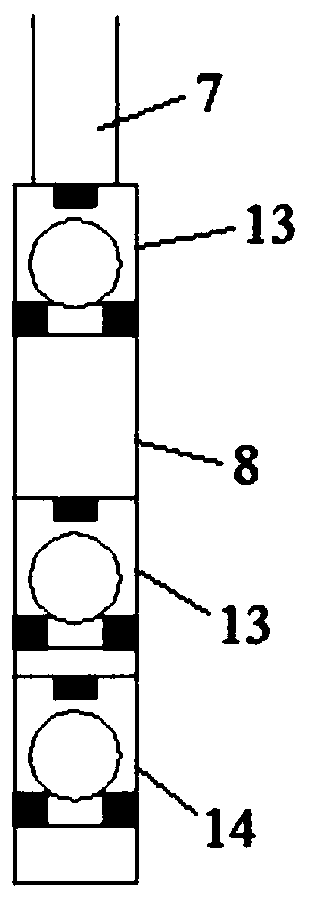

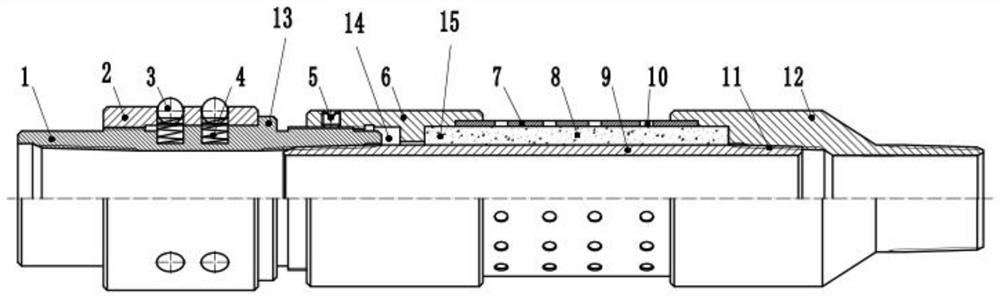

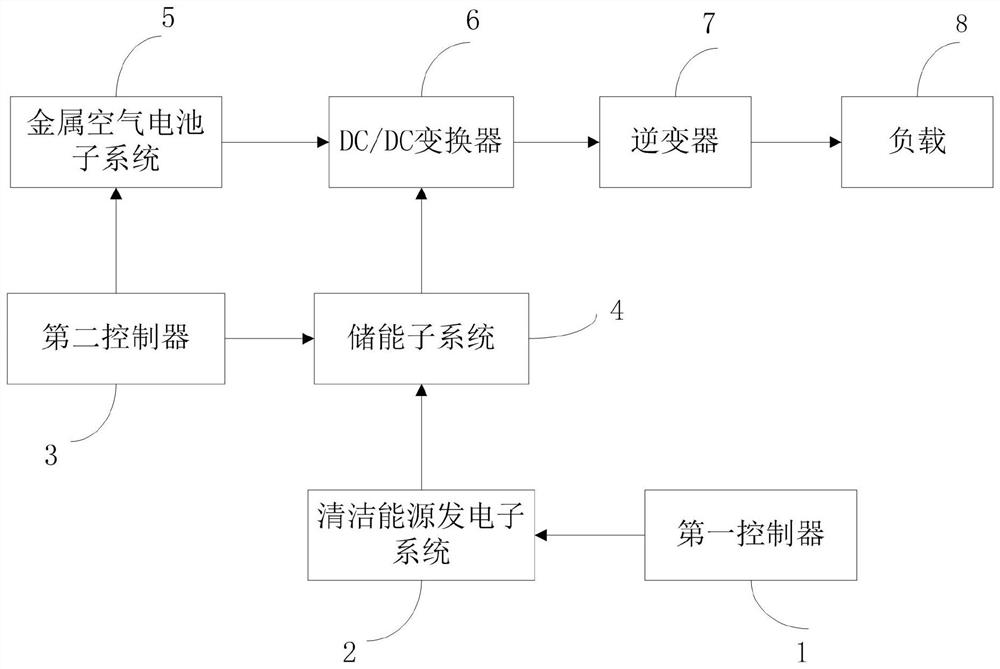

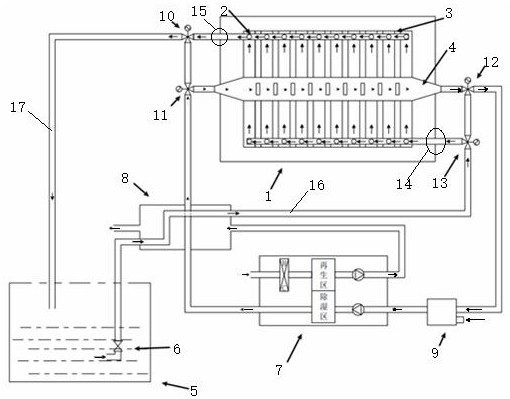

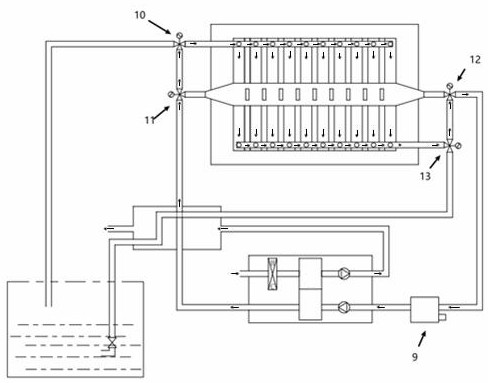

Comprehensive management system and method for metal-air fuel cell electrolyte

ActiveCN109638317AImprove work performanceExtended service lifeElectrolyte stream managementFuel cellsWork performance

The invention discloses a comprehensive management system and method for metal-air fuel cell electrolyte, and the system comprises an electrolyte-protection liquid circulating system which is used forsupplying or recycling the electrolyte or the protection liquid from a cell; a product filtering and separating system which is used for filtering and separating reaction products in the electrolyte;a control unit which is used for controlling the working states of a pump, a valve and a switch in the electrolyte-protection liquid circulating system through a liquid level detection unit and charging a circulation path of the electrolyte and the protection liquid through the working combination of the valve, the pump and the switch in the pipeline. The system can effectively improve the working performance of a metal-air fuel cell, significantly reduce the self-corrosion in the parking process, and prolong the service life of the cell.

Owner:TSINGHUA UNIV

Porous zinc-tin alloy negative electrode material for zinc-air battery and preparation method of porous zinc-tin alloy negative electrode material

InactiveCN105489970AImprove corrosion resistanceStable thermodynamic propertiesFuel and primary cellsCell electrodesTechnology developmentNew energy

The invention discloses a porous zinc-tin alloy negative electrode material for a zinc-air battery and a preparation method of the porous zinc-tin alloy negative electrode material, belonging to the field of new energy technology development. The porous zinc-tin alloy negative material comprises a foamed nickel substrate and a zinc-tin alloy plating layer, wherein the zinc-tin alloy plating layer is uniformly coated on the foamed nickel substrate, tin and zinc in the zinc-tin alloy plating layer are uniformly distributed, and the mole ratio of tin to zinc is (0.01-0.20):1. In the porous zinc-tin alloy negative electrode material, foamed nickel is taken as a negative electrode, electroplating is carried out in an electroplating liquid containing a complexing agent to obtain the porous zinc-tin alloy negative electrode material, and the electroplating liquid containing the complexing agent is selected from one of a pyrophosphate system electroplating liquid, a gluconate system electroplating liquid, a citrate system electroplating liquid and a tartaric acid system electroplating liquid. The porous zinc-tin alloy negative electrode material has the advantages that the material structure is reasonable in design, the preparation process is simple, and industrial application and production at a large scale are promoted.

Owner:CENT SOUTH UNIV

Aluminum air battery aluminum anode slurry for 3D printing and preparation method and application thereof

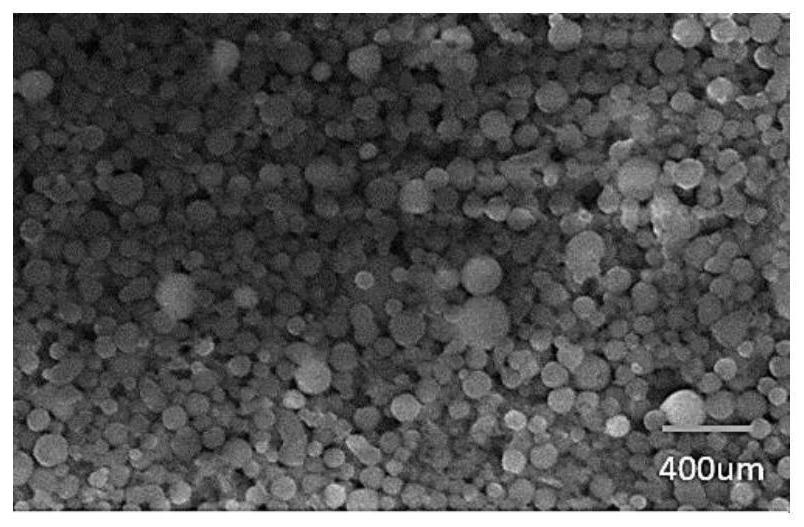

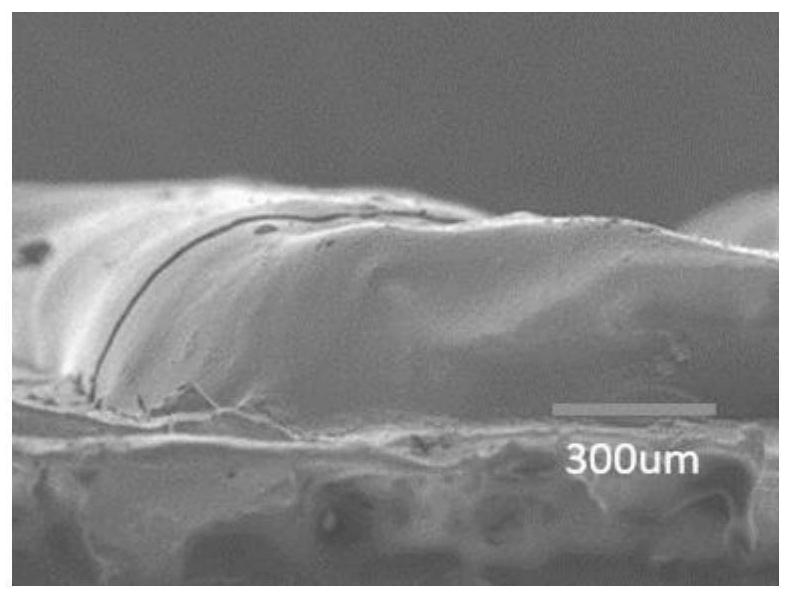

InactiveCN112820875AHigh porosityIncrease the hydrogen evolution overpotentialFuel and primary cellsAdditive manufacturing apparatusAluminum anodeAlcohol

The invention discloses aluminum air battery aluminum anode slurry for 3D printing and a preparation method and application thereof. The slurry comprises metal mixed powder and slurry, the ratio of the metal mixed powder to the slurry is 1g:(0.3-1.2) mL, the slurry comprises an antioxidant, a dispersing agent, an organic solvent and an organic adhesive, the metal mixed powder comprises Sn, In, Mg and the balance Al with the purity larger than or equal to 99.99%, and the metal mixed powder comprises Al with the purity larger than or equal to 99.99%. The viscosity of the slurry is 1-100 Pa.s; and the preparation method of the slurry comprises the following steps: (1) taking metal powder, and mixing and ball-milling the metal powder and absolute ethyl alcohol; (2) drying the ball-milled mixed solution until the alcohol is completely volatilized to obtain dried metal mixed powder; and (3) adding an antioxidant, a dispersing agent, an organic solvent and an organic adhesive into the dried metal mixed powder for ball milling, and obtaining slurry. The slurry can be applied to an aluminum anode of a 3D printing aluminum air battery. The slurry can increase the porosity of the anode, reduces the self-corrosion of the aluminum anode, is stable in performance, and improves the utilization rate of the anode.

Owner:南京信息工程大学滨江学院

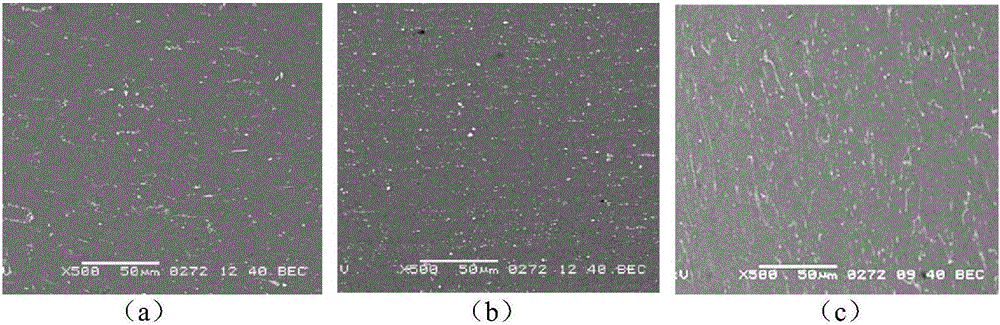

Aluminum alloy anode material for seawater battery and preparation method

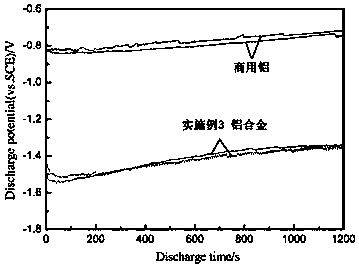

PendingCN111187947ANegative working potentialHigh activityCell electrodesWater batteryElectrical battery

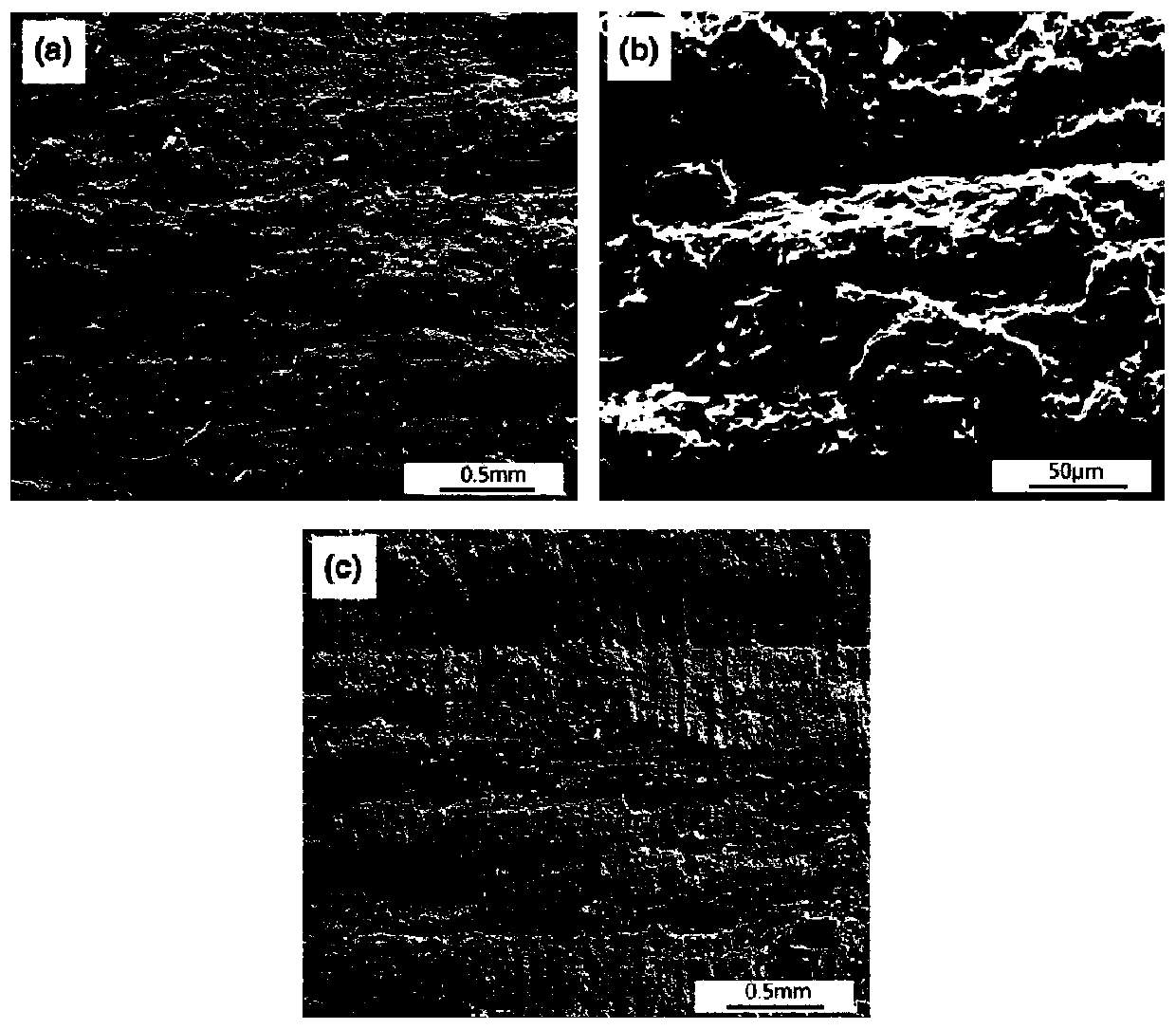

The invention provides an aluminum alloy anode material for a seawater battery and a preparation method. The electrochemical performance of an aluminum alloy in a seawater medium is improved through amicroalloying method. According to the preparation method, firstly, activating elements Ga, Bi, Cd and Pb are added to promote an oxidation film layer on the surface of the aluminum alloy to be dissolved and strip off, the potential of an anode is remarkably and negatively moved, and the activation performance of the anode is improved; secondly, elements Sn, Zn and Mn with the high hydrogen evolution potential are added, the hydrogen evolution overpotential of the aluminum alloy is increased to some extent, the probability of hydrogen evolution corrosion of the anode is reduced, and accordingly, the current efficiency of the anode is improved; and finally, by controlling the contents of impurity elements Fe and Cu in an aluminum ingot, self-corrosion of the aluminum alloy anode is reduced, and the dissolution morphology of the aluminum alloy anode is improved. In the preparation process of the anode, by controlling the feeding sequence and technological parameters of all the components, the anode material has the negative working potential, high activity and low self-corrosion rate in the seawater medium, and the driving potential and current efficiency of the aluminum-seawater battery can be effectively improved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

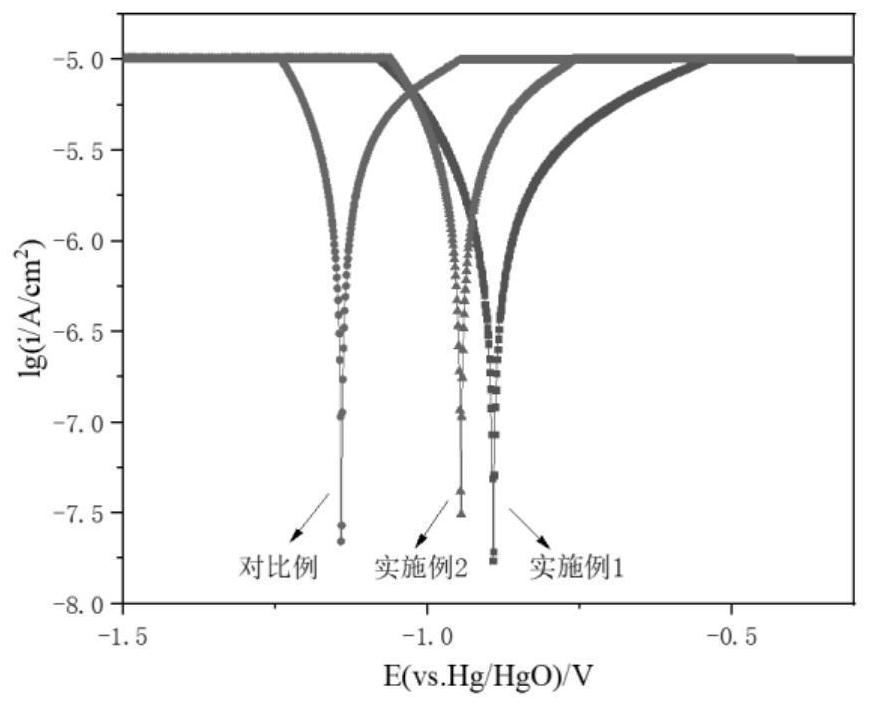

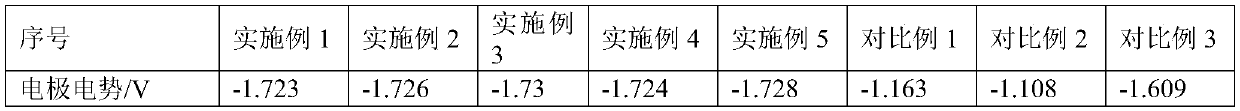

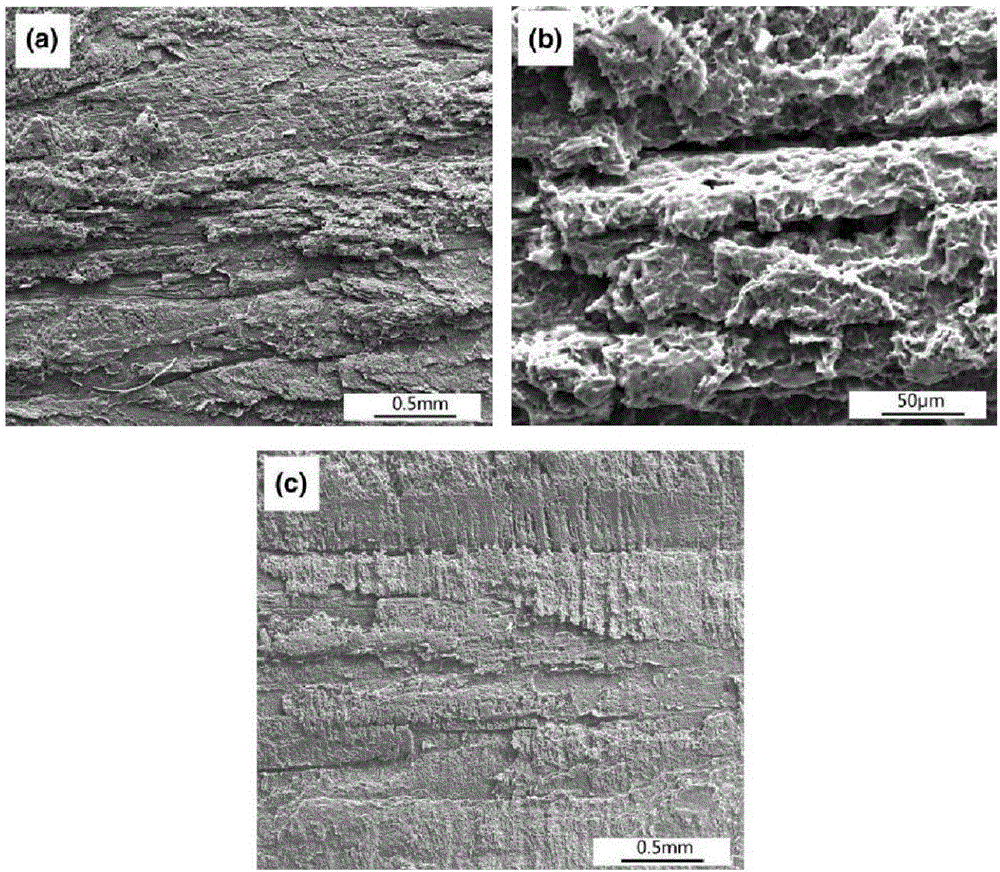

Aluminum-air battery anode and preparation method thereof

ActiveCN111180720AImprove electrochemical performanceReduce overpotentialFuel and primary cellsCell electrodesMetallurgyElectrical battery

The invention relates to the technical field of aluminum-air batteries. For the problems that an aluminum-air battery anode in the prior art is complex in preparation process and poor in corrosion resistance, the present invention discloses an aluminum-air battery anode and a preparation method thereof. The aluminum-air battery anode is prepared from the following components in percentage by mass:0.01-0.05 of Ga, 0.2-0.6% of Mn, 1-5% of Mg, 0.1-0.6% of Pb and the balance of Al. The method comprises the following steps: (1) melting aluminum; (2) adding Mn; (3) adding Ga and Pb; (4) adding Mg;(5) removing slag; and (6) performing casting. The battery anode alloy prepared by adopting the method is good in electrochemical performance, due to the addition of the alloy elements, the anisotropism of anode material grains is reduced, the corrosion uniformity of the alloy is improved, the overpotential is low, the self-discharge rate is low, the hydrogen evolution overpotential is high, the harmful influence of the Fe element on the electrode can be eliminated, the preparation process is simple, the synthesis period is short, and the synthesis efficiency is high.

Owner:CHAOWEI POWER CO LTD

Corrosion-resistant and high-temperature-resistant sacrificial anode material and preparation method thereof

The invention relates to a corrosion-resistant and high-temperature-resistant sacrificial anode material and a preparation method thereof. The material comprises the following components of, in percentage by mass, 4%-6% of Zn, 0.035%-0.05% of In, 0.04%-0.1% of Sn, 0.3%-1.0% of Mg, 0.01%-0.02% of La, 0.01%-0.02% of Y, 0.01%-0.02% of Nd, less than or equal to 0.26% of impurities and the balance Al.During preparation, electrolytic primary aluminum is molten into an aluminum alloy solution, then blowing, refining, degassing, slag pulling out are conducted, Zn, In, Sn and Mg are added, smelting isconducted at 760-800 DEG C, and then cooling is conducted; heating is conducted to achieve 800-820 DEG C, an Al-La intermediate alloy, an Al-Y intermediate alloy and an Al-Nd intermediate alloy are added, and refining, degassing and slag pulling out are conducted at 840-860 DEG C; and finally, heat preservation is conducted at 700-720 DEG C for 60-80 minutes, and then cooling is conducted to achieve the room temperature.

Owner:PETROCHINA CO LTD

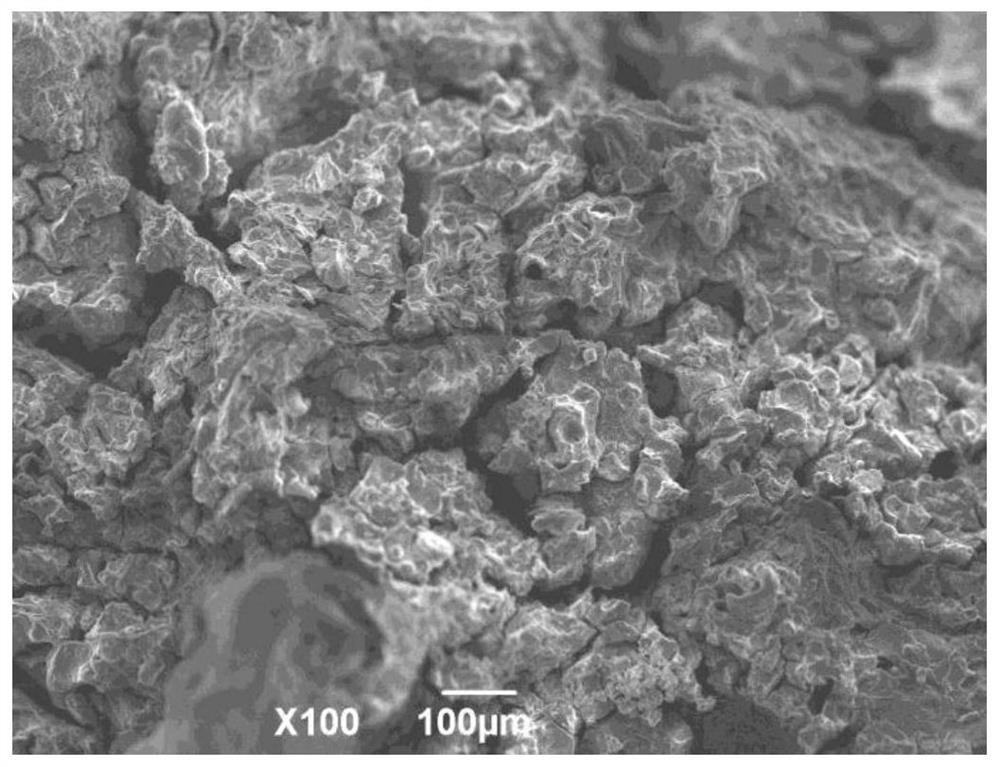

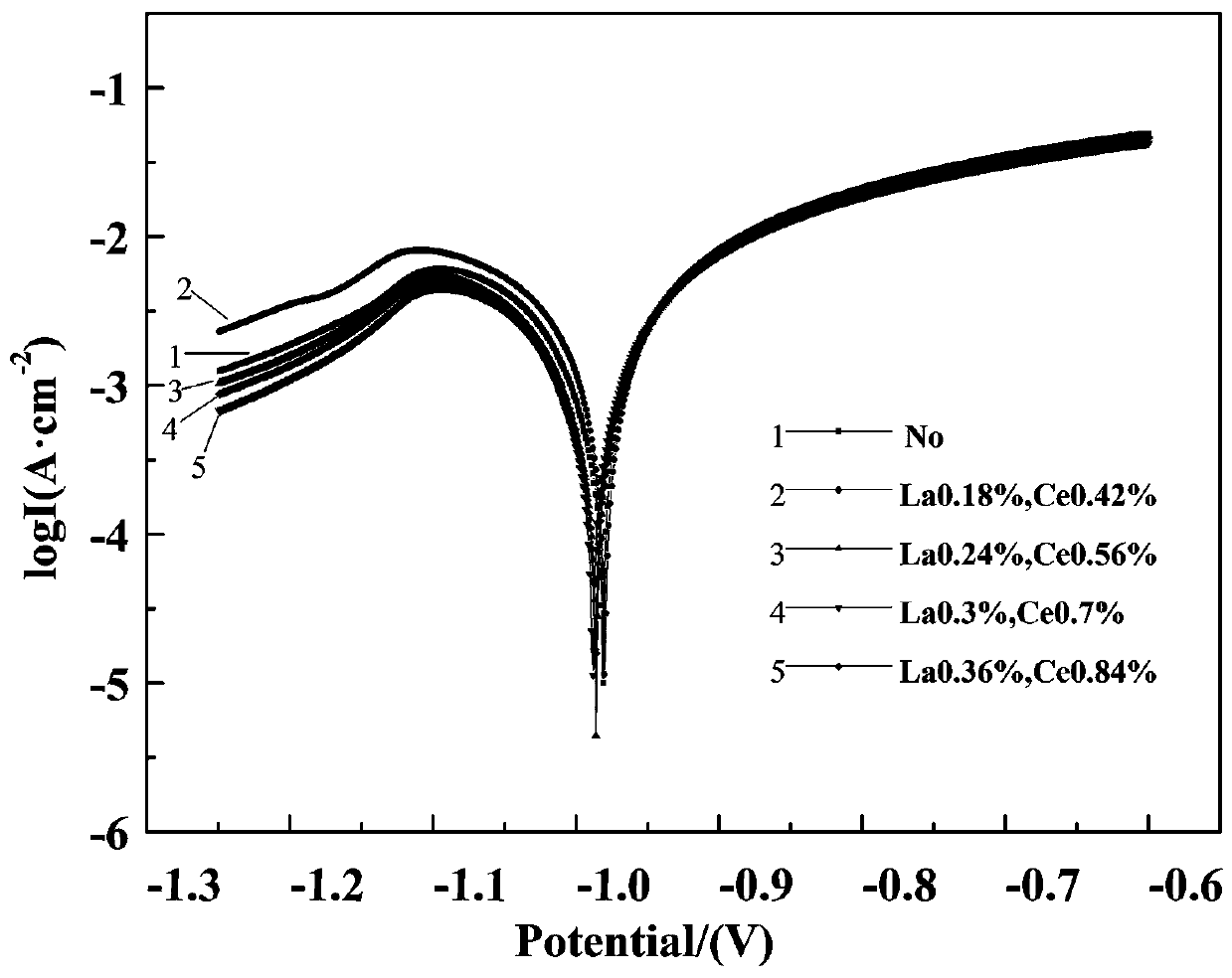

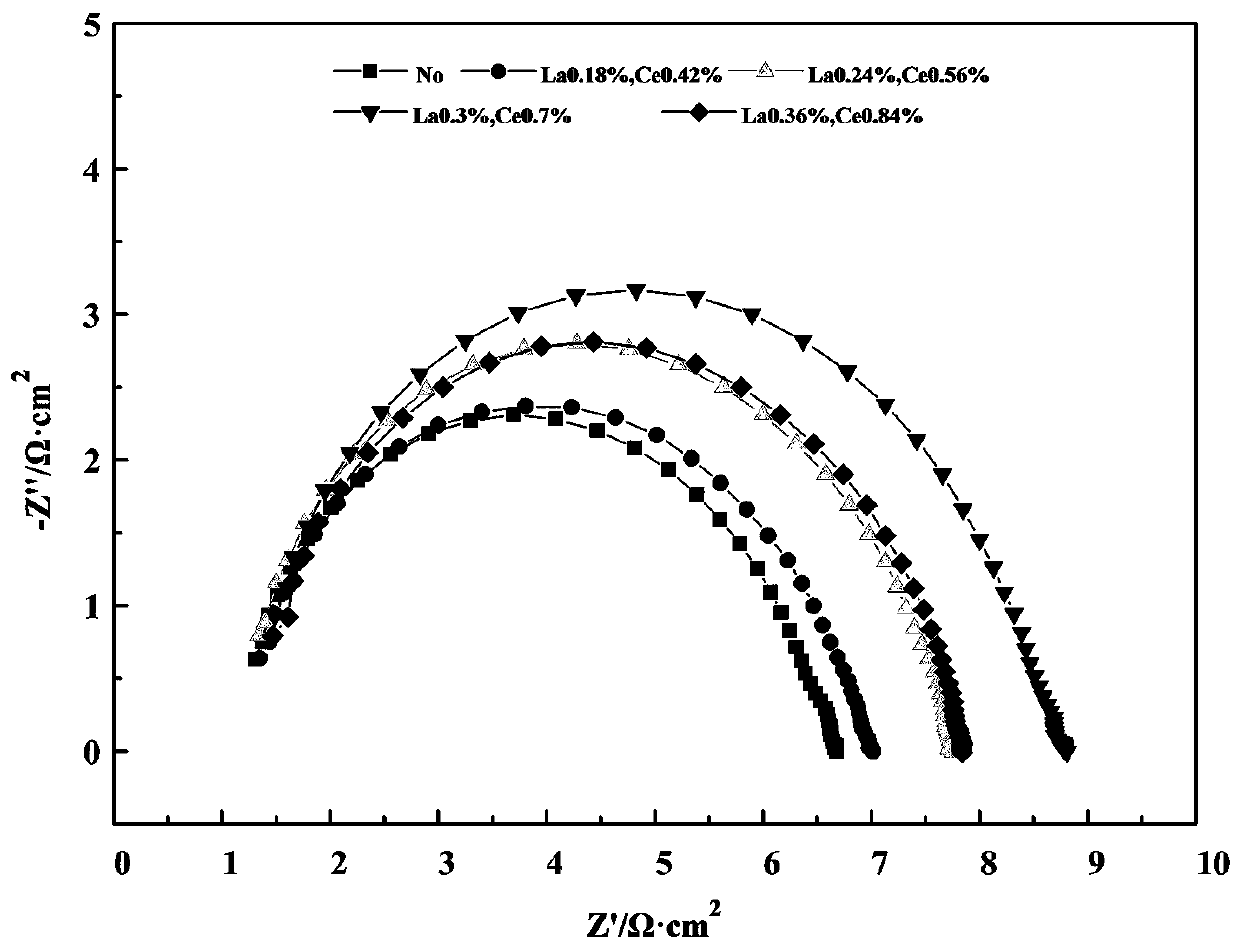

Zinc alloy sacrificial anode material for reinforced concrete structure in chlorine salt erosion environment

The invention belongs to a sacrificial anode protection material of a reinforced concrete structure, in particular, a zinc alloy sacrificial anode material for a reinforced concrete structure in a chlorine salt erosion environment. In order to solve problems in a sacrificial anode material in the prior art, the following technical schemes of the invention are adopted, the sacrificial anode material of the invention comprises the following components in percentage by mass: 0.5% of Al; 0.1% of Cd; 0.18%-0.36% of La; 0.42%-0.84% of Ce; 0 to 0.1% of impurities; and the balance of Zn. The zinc alloy sacrificial anode material provided by the invention has the advantages of good activation performance, uniform corrosion, good corrosion resistance and long service life, and meets the use requirements of reinforced concrete. The zinc alloy sacrificial anode material is excellent in electrochemical performance, and the current efficiency reaches about 95%. The surface corrosion product of the zinc alloy sacrificial anode material is likely to shed.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +2

Rotational flow efficiency-improving, anticorrosion and abrasion-resisting integrated lifting technology and mechanical extraction system

ActiveCN110107261AAvoid wastingTimely controlConstructionsGeothermal energy generationIndicator diagramRotational flow

The invention discloses a rotational flow efficiency-improving, anticorrosion and abrasion-resisting integrated lifting technology and a mechanical extraction system. The rotational flow efficiency-improving, anticorrosion and abrasion-resisting integrated lifting technology comprises the following steps that S1, before entering a well, a drift diameter gauge is used for inspecting the drift diameter of oil pipes one by one, it is inspected that a pump cylinder is in a perfect condition, and a structure of the downhole part is installed; S2, a machine is shut down, a brake is tensioned, a locking device is rocked down, power off is carried out, a warning board is suspended, and other structures are installed; S3, according to measurement data of an indicator diagram instrument, parametersare adjusted, and stratum feed flow is enabled to be matched with the oil well pump displacement; S4, the erosion prevention distance is adjusted, and oil pumping is started; and S5, pump inspection operation is carried out. According to the rotational flow efficiency-improving, anticorrosion and abrasion-resisting integrated lifting technology and the mechanical extraction system, well repair without the operation of lifting oil pipes and oil pumping rods is realized, the operating cost and time are saved, ground oil liquid pollution and pipe consumption are reduced, the pump inspection efficiency is improved, the service life of a whole well is prolonged, and the overall efficiency is improved.

Owner:KARAMAY SHENGLI PLATEAU MACHINERY CO LTD

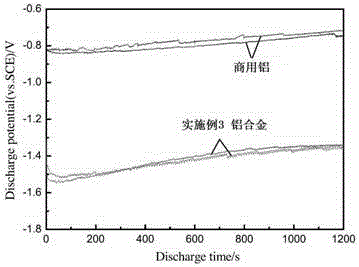

A kind of aluminum alloy negative electrode material for battery and preparation method thereof

ActiveCN106784772BImprove discharge performanceRefinement of discharge capacityCell electrodesIndiumLanthanum

The invention discloses an aluminum alloy anode material for batteries. The aluminum alloy anode material is prepared from the following components in percentage by mass: 0.001-1% of lanthanum, 0.001-1% of gallium, 0.001-1% of magnesium, 0.001-1% of indium and the balance of aluminum. The invention further provides a preparation method of the aluminum alloy anode material for batteries. According to the preparation method, three types of different thermal treatment processes such as high temperature and long time, medium temperature and short time and low temperature and long time are matched with a deformation process, and optimal regulation and control on material components, texture structures and alloy phase of the aluminum alloy anode material are achieved. The addition of alloy elements is appropriately adjusted, and with the combination of appropriate plastic formation processes and thermal treatment processes of the aluminum alloy anode material, optimal matching of multiple elements can be achieved, and requirements of power source discharge can be met under a large current density of 500mA / cm<2> / 1000mA / cm<2>. The aluminum alloy anode material disclosed by the invention is short in production process procedure, easy in process parameter control, good in aluminum alloy anode product quality, low in production cost and beneficial to on-scale production.

Owner:CHANGSHA XUNYANG NEW MATERIAL TECH CO LTD

A magnesium alloy and its sacrificial anode device and its oil casing potential anticorrosion device

The invention discloses a magnesium alloy, a sacrificial anode device and a potential anti-corrosion device for an oil casing, comprising 68 to 69.5 wt % of magnesium, 17 to 19 wt % of manganese, 9 to 10.5 wt % of calcium, 2.5 to 3.7 wt % % by weight of boron, 1.5 to 2.8% by weight of tin, and the rest are magnesium and impurities generated in the preparation process; the magnesium alloy electrode in the present invention has lower potential, more stable voltage, larger capacitance, more sufficient current, and energy It has the characteristics of higher density, stronger discharge activity, higher current efficiency, stronger electrochemical action, higher specific strength and specific stiffness, and better corrosion resistance; it achieves the purpose of high efficiency, durability and environmental protection, and achieves the price Low cost, reliable performance and cost-effective requirements.

Owner:MUDANJIANG XINXIANG PETROLEUM MASCH CO LTD

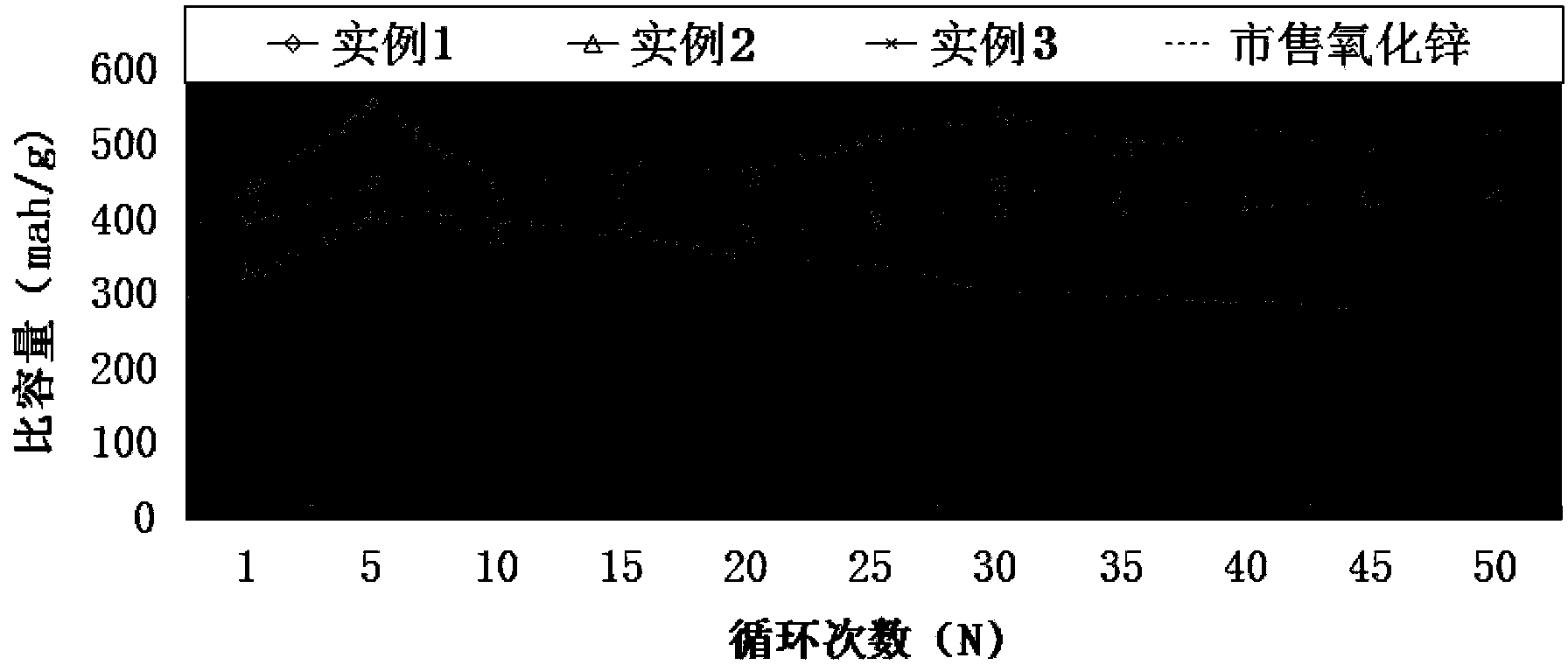

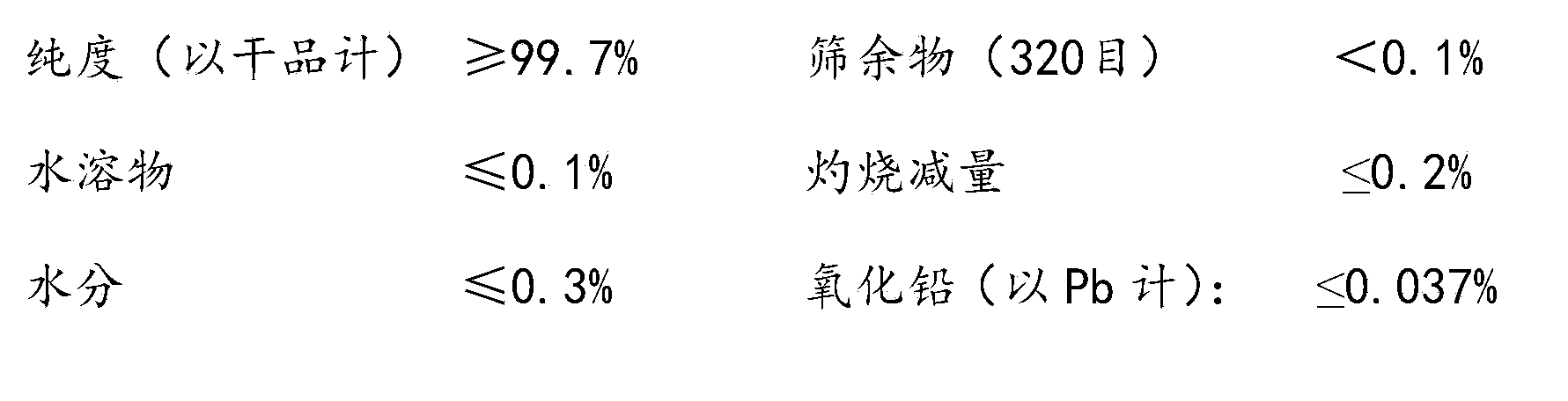

Method for preparing modified zinc oxide

ActiveCN103030171BSimple preparation processShorten the production cycleZinc oxides/hydroxidesCell electrodesPotassium hydroxideZinc

Owner:HUNAN FENGRI ELECTRIC GROUP

Porous zinc-nickel alloy negative electrode material for zinc-air battery and preparation method thereof

InactiveCN105609750BImprove corrosion resistanceStable thermodynamic propertiesFuel and secondary cellsCell electrodesNickel substrateNew energy

The invention discloses a porous zinc-nickel alloy negative electrode material for a zinc-air battery and a preparation method thereof, belonging to the field of new energy technology development. The porous zinc-nickel alloy negative electrode material of the present invention is composed of a foamed nickel substrate and a zinc-nickel alloy coating evenly coated on the foamed nickel substrate; the molar ratio of nickel to zinc in the zinc-nickel alloy coating is 0.01-0.20:1. In the present invention, nickel foam is used as the cathode, and zinc and nickel are deposited on the surface of the nickel foam substrate by electroplating in an electroplating solution containing functional additives to obtain a nickel-zinc molar ratio of 0.01-0.20:1, a pore diameter of 20-500 μm, and a coating thickness of 10 μm- 2000μm porous zinc-nickel alloy anode material for zinc-air batteries. The structure design of the material in the invention is reasonable, the preparation process is simple, and it is convenient for large-scale industrial application and production.

Owner:CENT SOUTH UNIV

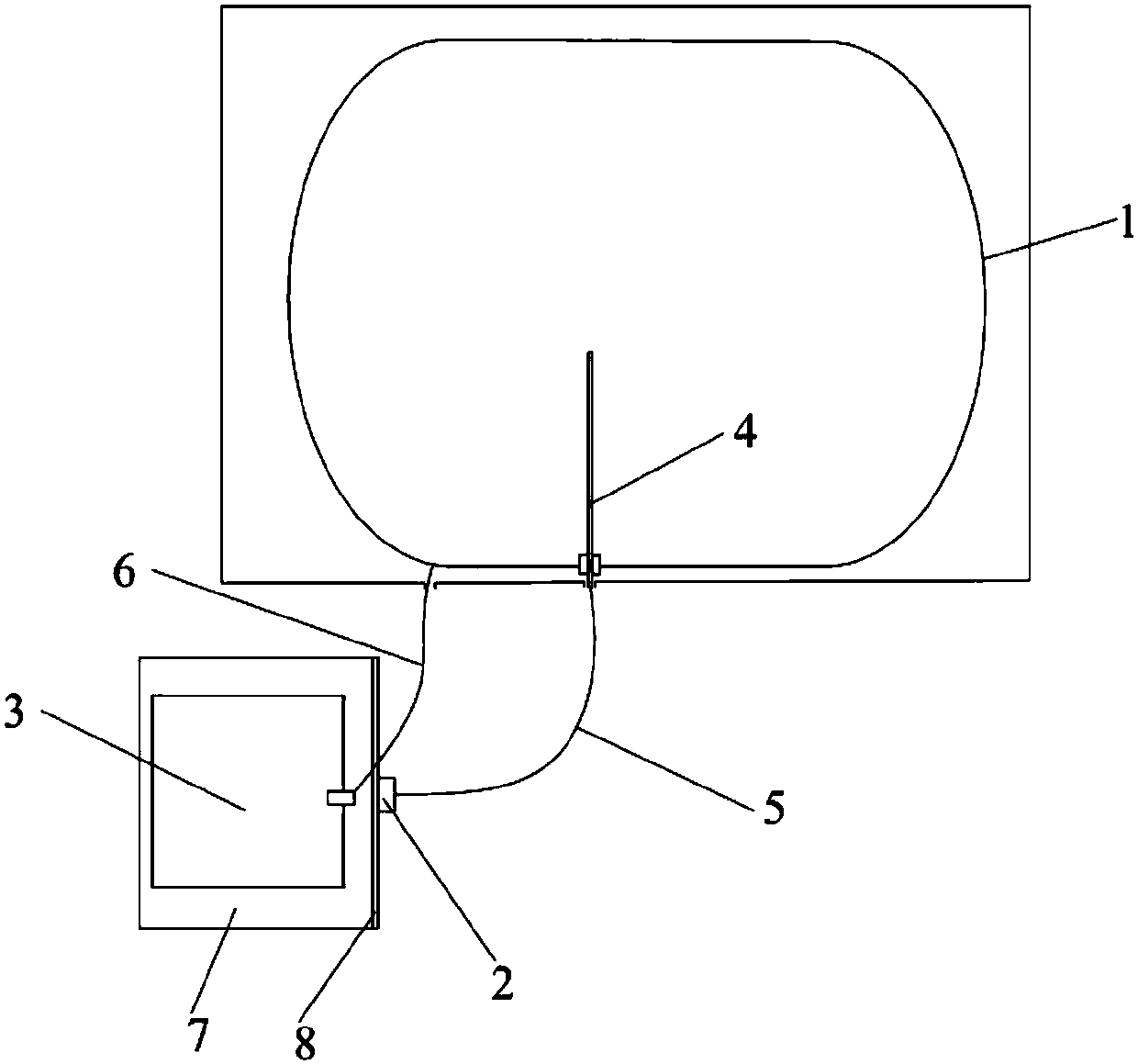

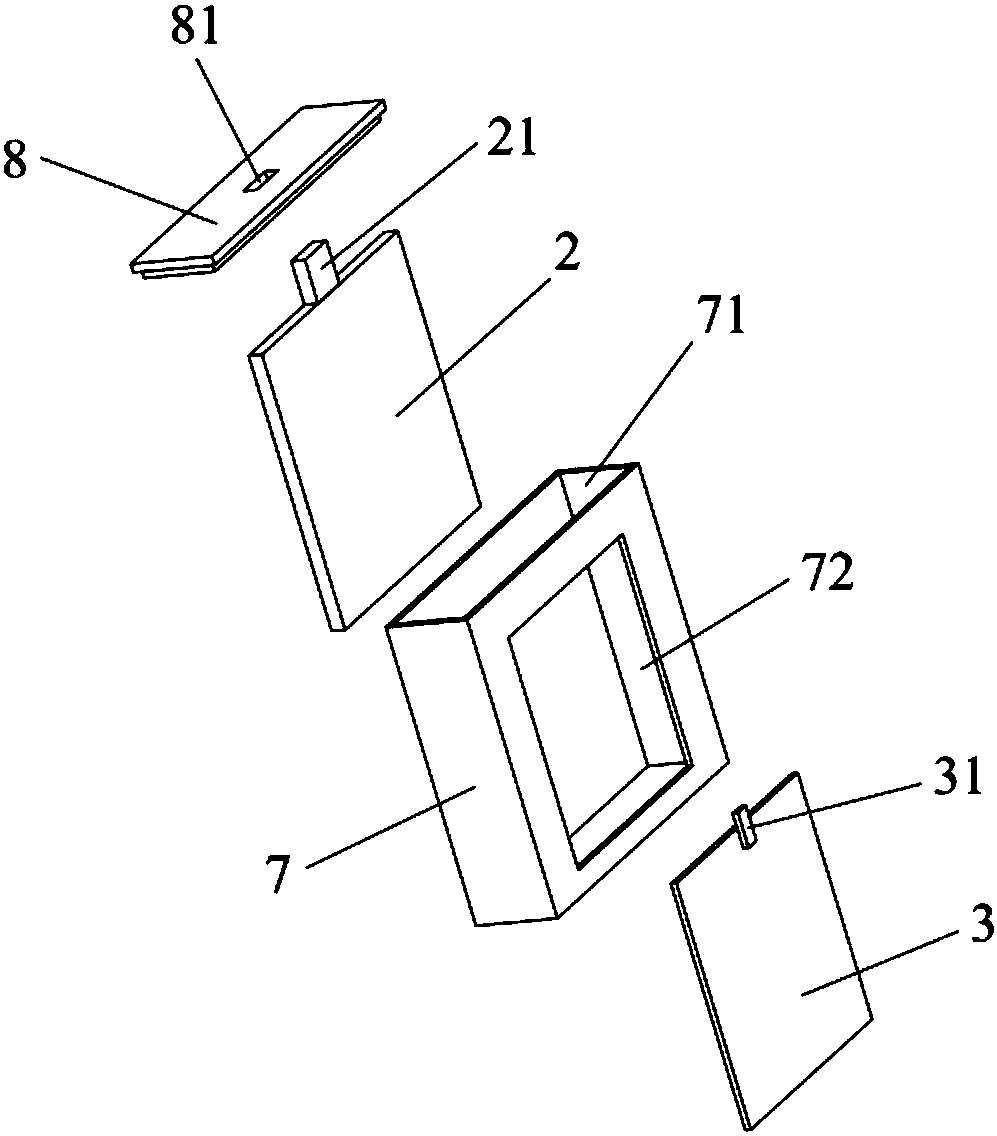

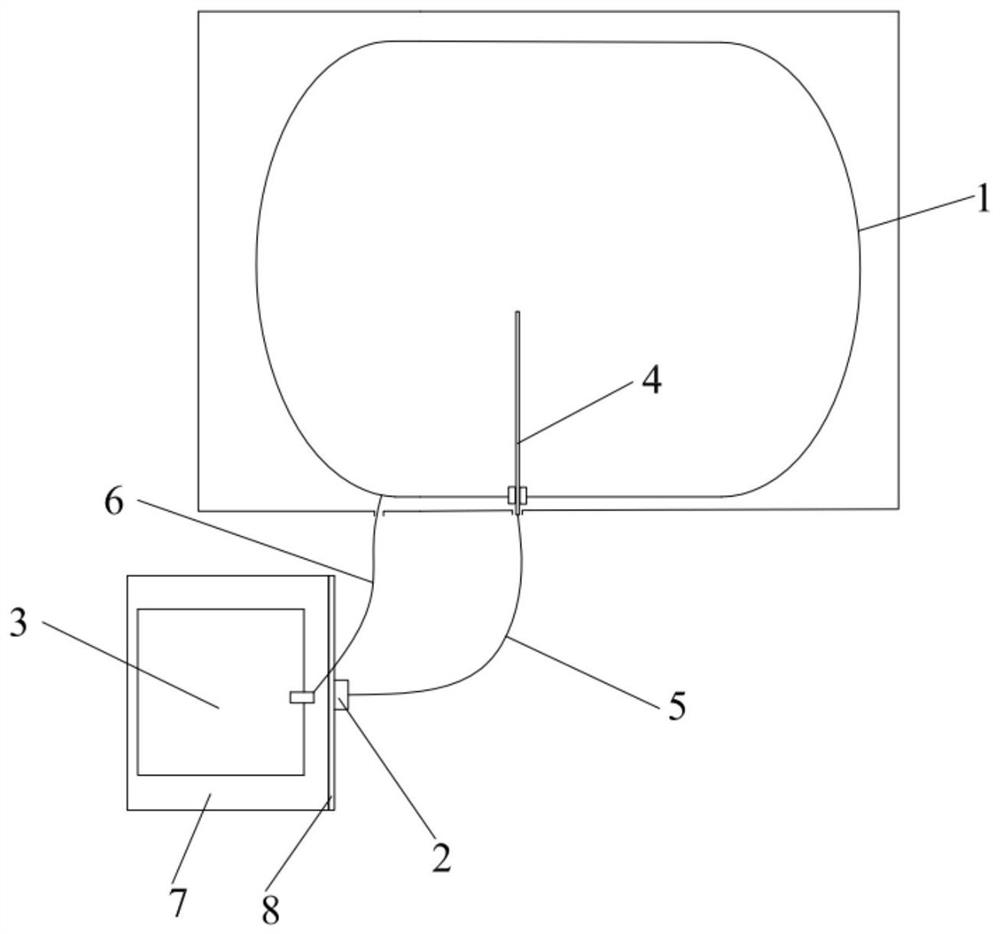

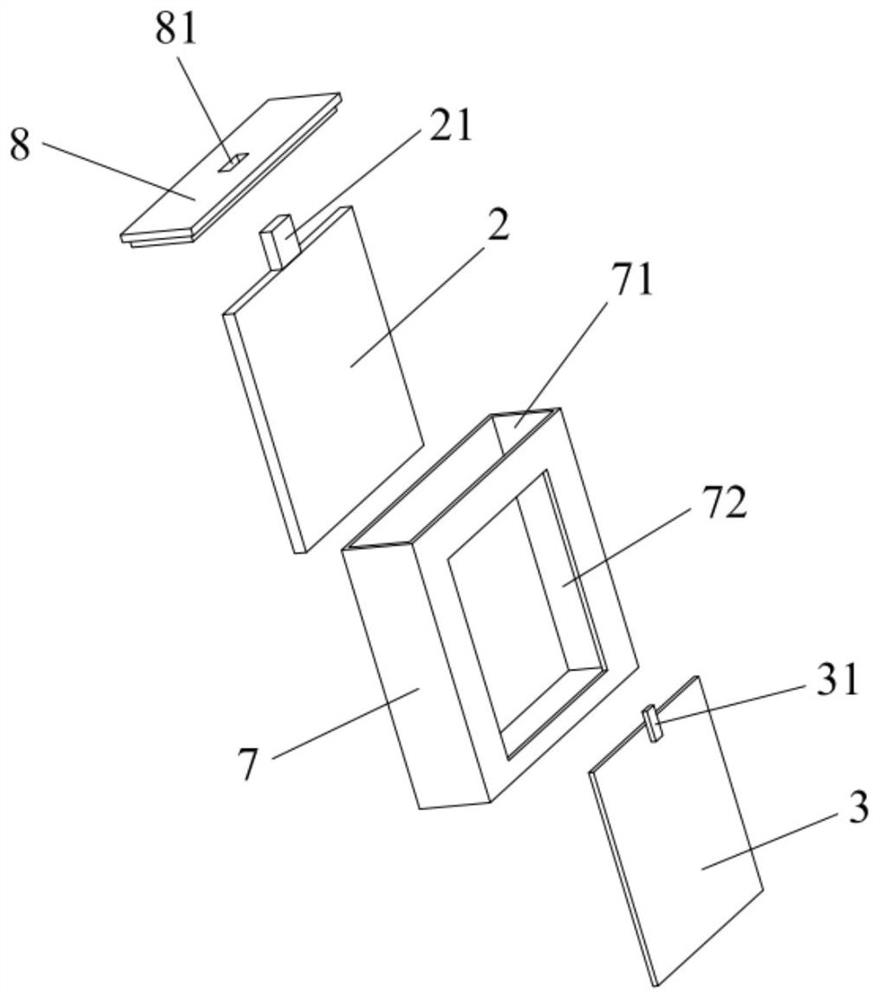

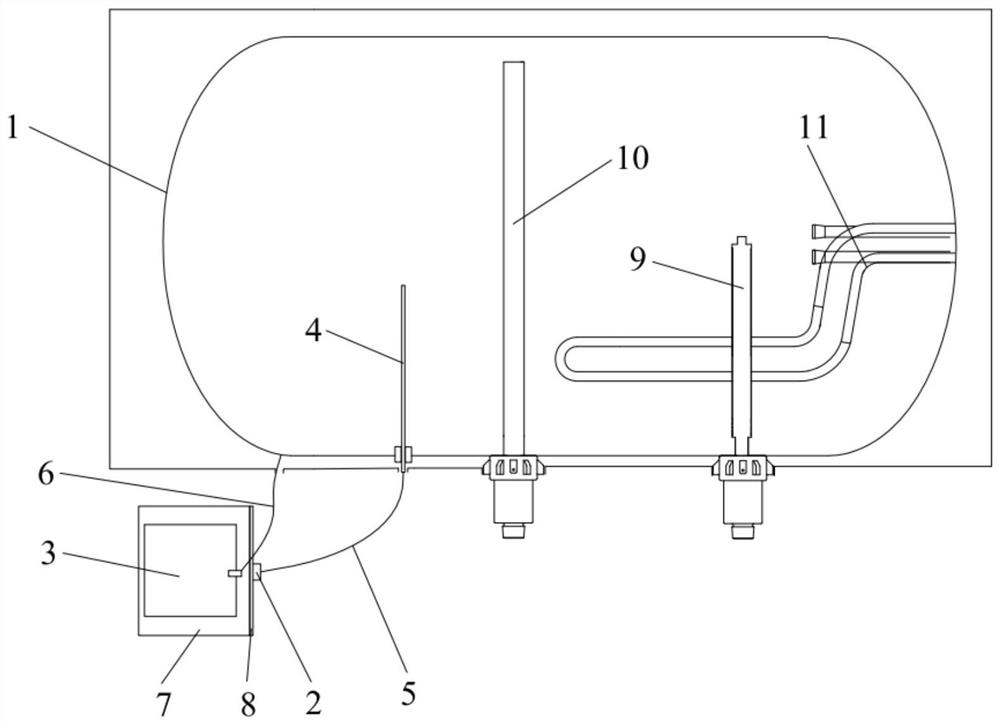

Corrosion preventing device and water heater

The invention discloses a corrosion preventing device and a water heater and belongs to the technical field of water heaters. Protecting metal and a cathode in the corrosion preventing device are located outside a water storing box and are in contact with an ionic solution; the protecting metal is connected with an auxiliary anode in the water storing box, and the cathode is connected with the water storing box; the auxiliary anode is in insulating connection with the water storing box; due to the fact that the protecting metal and the cathode are different in activity; under the effects of air, the cathode, the ionic solution and the protecting metal, the protecting metal is corroded, electrons are in lost and are provided for the water storing box through the cathode, and therefore migration of the electrons is formed, and the water storing box is protected; and besides, the protecting metal is arranged outside the water storing box, corrosion of the protecting metal cannot pollute water in the water storing box, the protecting metal is not in contact with high temperature water in the water storing box, self corrosion of the protecting metal is reduced, and the service life of the protecting metal is prolonged. The corrosion preventing device is adopted for the water heater, an external power source is not needed, more energy is saved, influences by power failure are avoided, and long-acting protecting can be formed for an inner container.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER

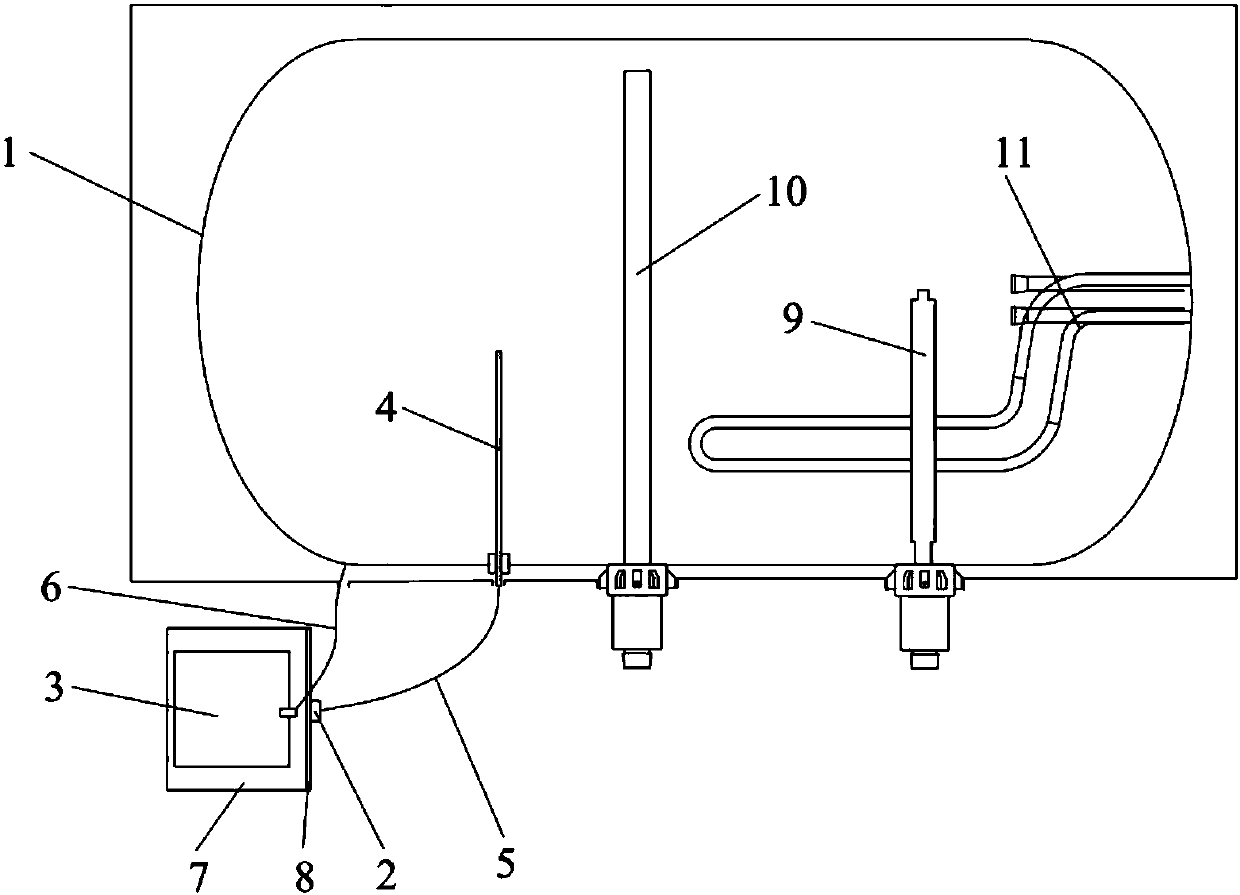

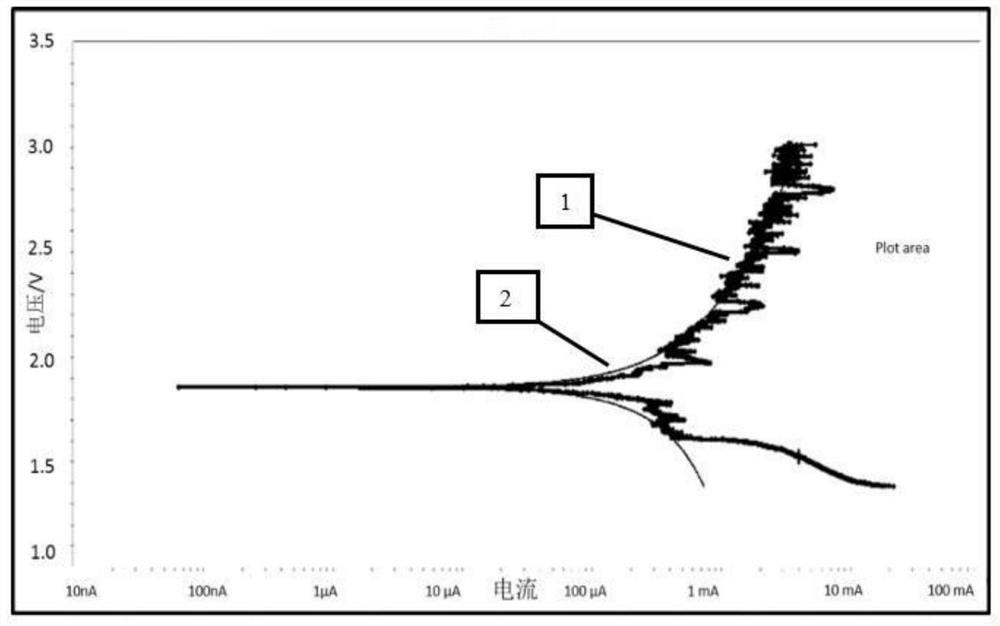

Anti-self-corrosion metal-air battery as well as preparation method and application thereof

ActiveCN112542596AAchieve separationReduce self-corrosionFuel and primary cellsReactant parameters controlElectrical batteryPhysical chemistry

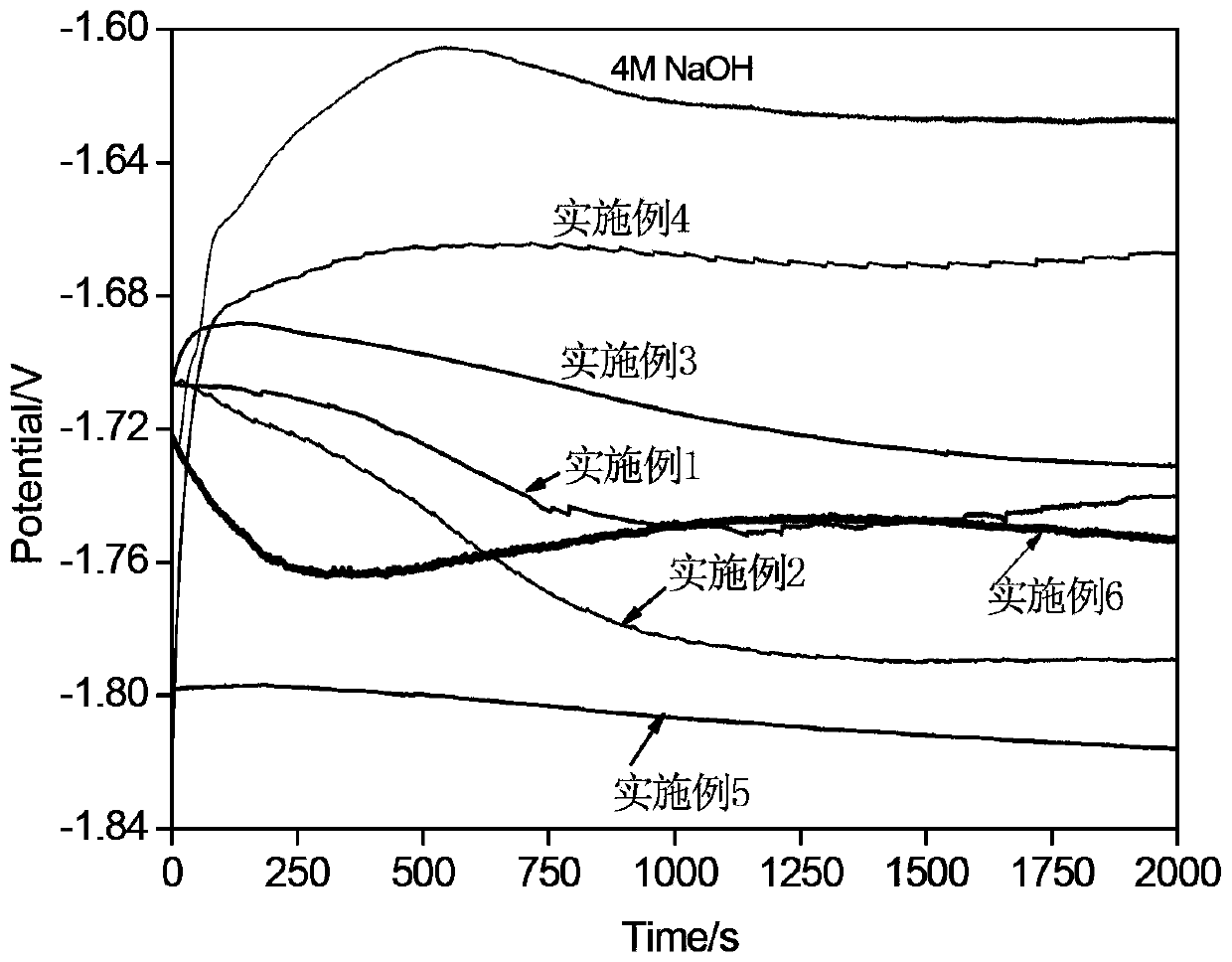

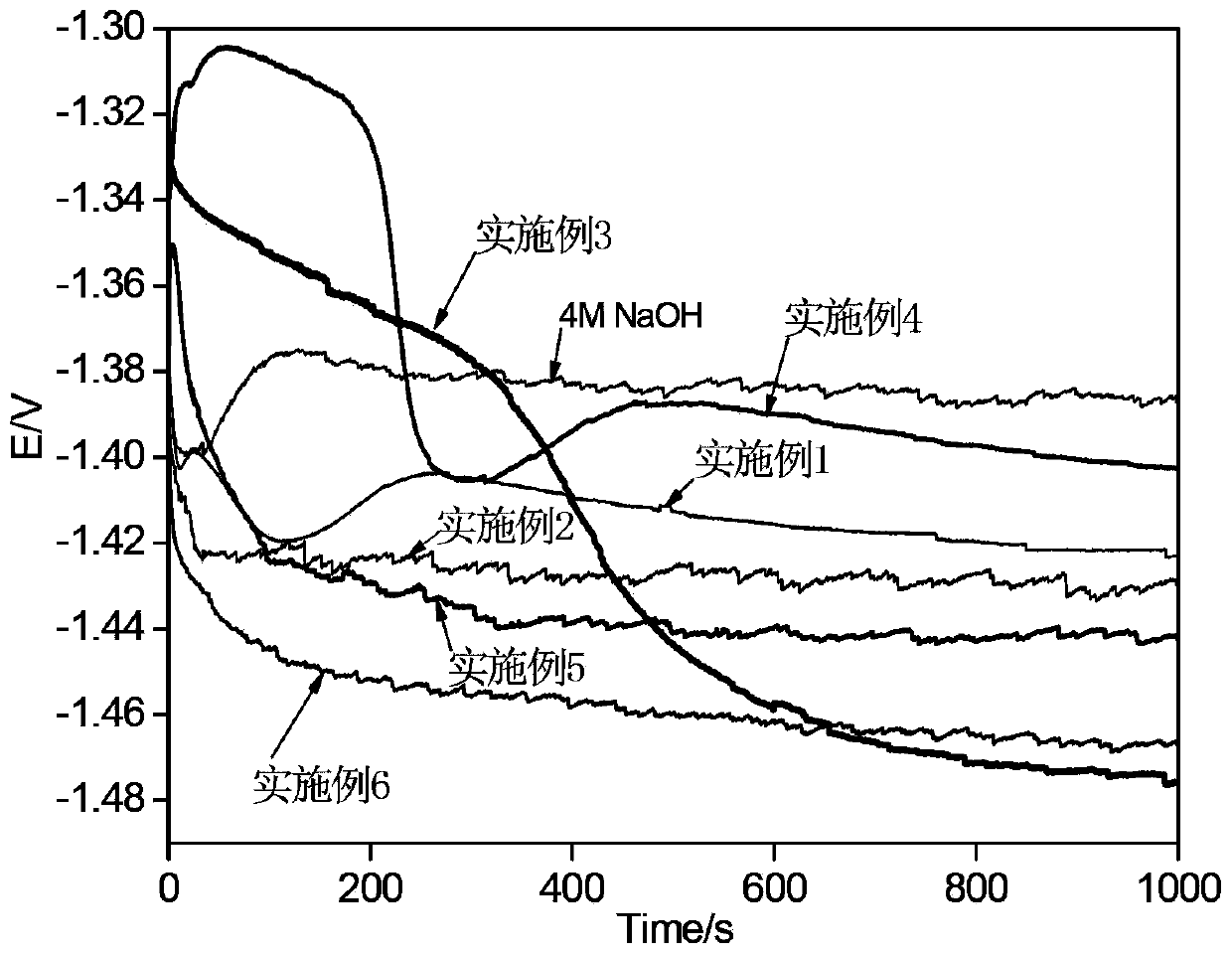

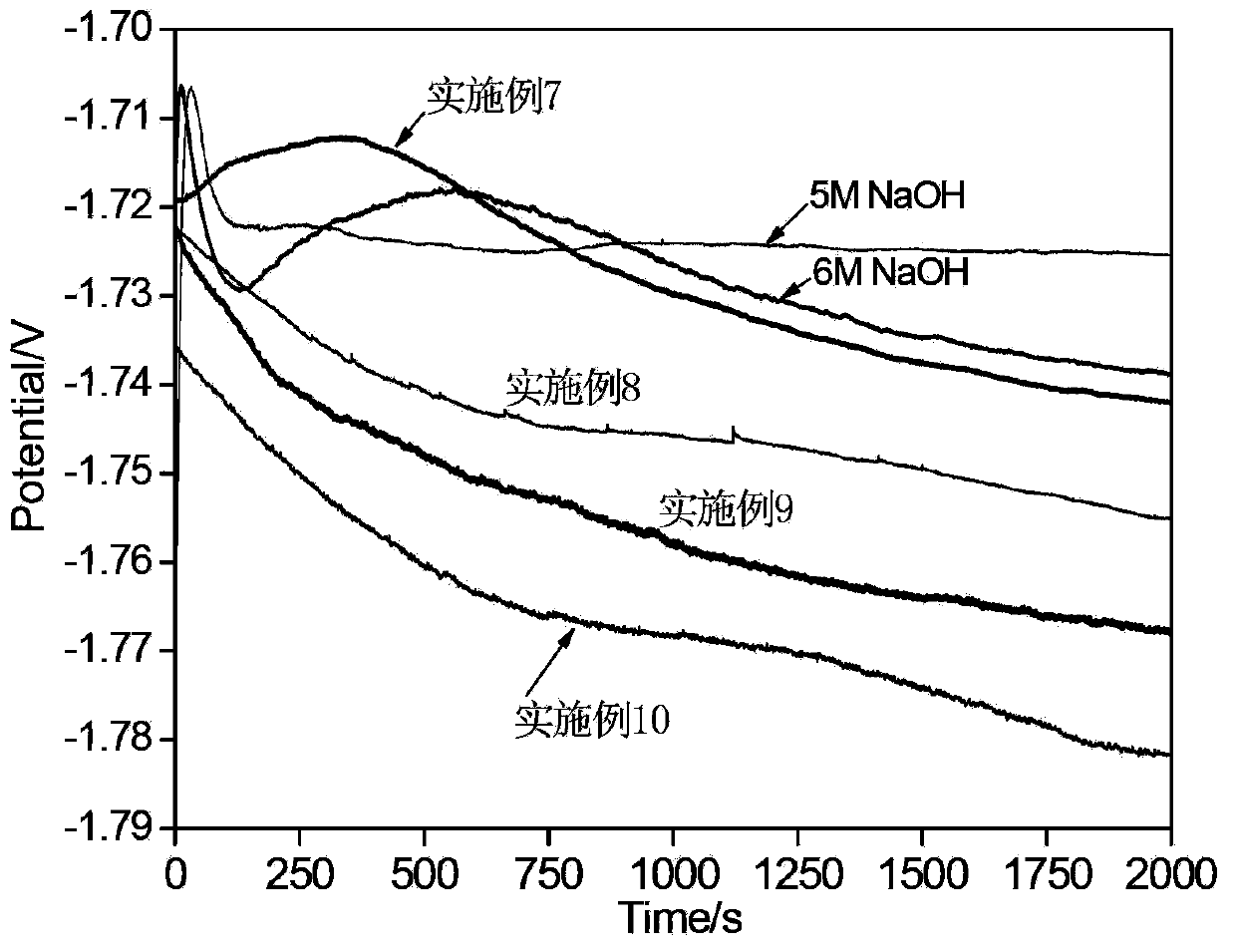

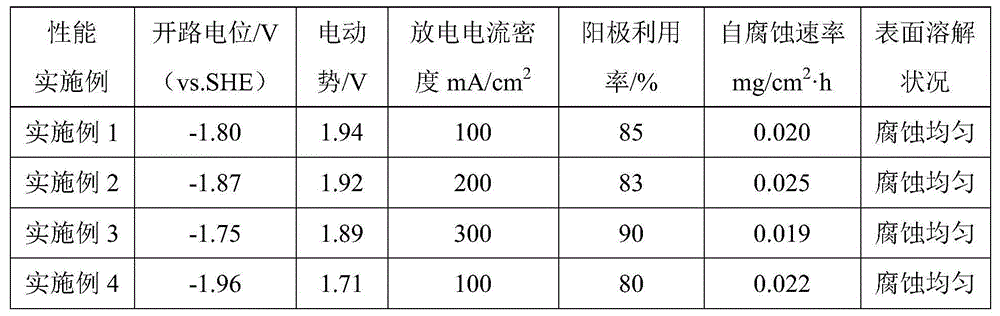

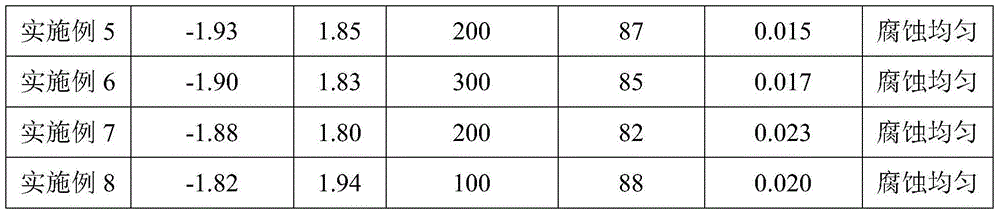

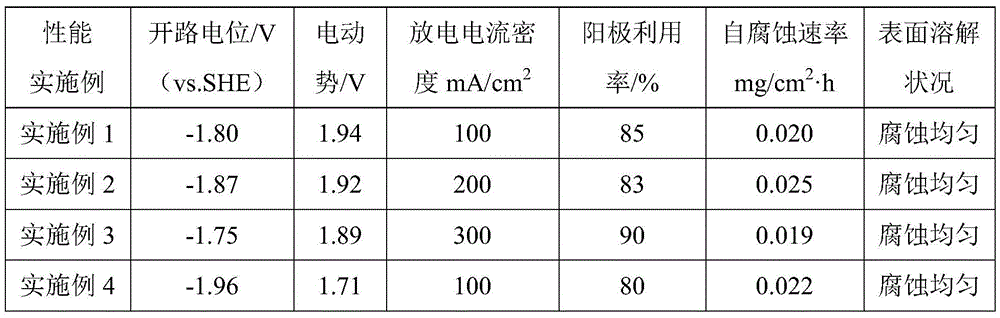

The invention provides an anti-self-corrosion metal-air battery as well as a preparation method and application thereof, and belongs to the field of air batteries. According to the self-corrosion-resistant metal-air battery provided by the invention, a metal-air battery structure is reconstructed; and the metal-air battery which can be filled with oil when the metal-air battery is in a standby state and filled with electrolyte when the metal-air battery works so as to realize oil-water separation is designed. During the standby period of the metal-air battery, the metal-air battery system is filled with the oil to replace an electrolyte solution, so that the self-corrosion of a metal anode during the standby period is greatly reduced. Data of the embodiment show that the open-circuit voltage of the anti-self-corrosion metal-air battery provided by the invention is 1.8-2.0 V, and the working voltage of the anti-self-corrosion metal-air battery is 1.3-1.7 V. Compared with the performanceof conventional anti-self-corrosion metal-air battery, the specific capacity and the specific energy of the anti-self-corrosion metal-air battery are improved by 2-3 times, and the monthly self-discharge rate of the anode of the anti-self-corrosion metal-air battery is 0.02-0.04% / month.

Owner:易航时代(北京)科技有限公司

A kind of rare earth-containing amorphous/nanocrystalline aluminum anode composite material, preparation method and aluminum-air battery

InactiveCN104372206BImprove electrochemical performanceAbundant resourcesFuel and primary cellsCell electrodesRare-earth elementDissolution

Owner:HENAN UNIV OF SCI & TECH

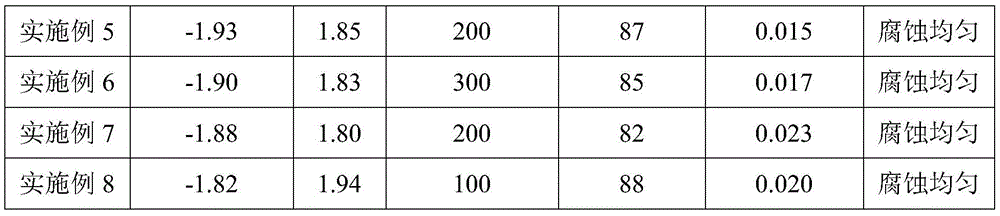

An integrated energy generation system

ActiveCN109818374BExtended service lifeReduce self-corrosionSingle network parallel feeding arrangementsAc network load balancingControl engineeringProcess engineering

Owner:易航时代(北京)科技有限公司

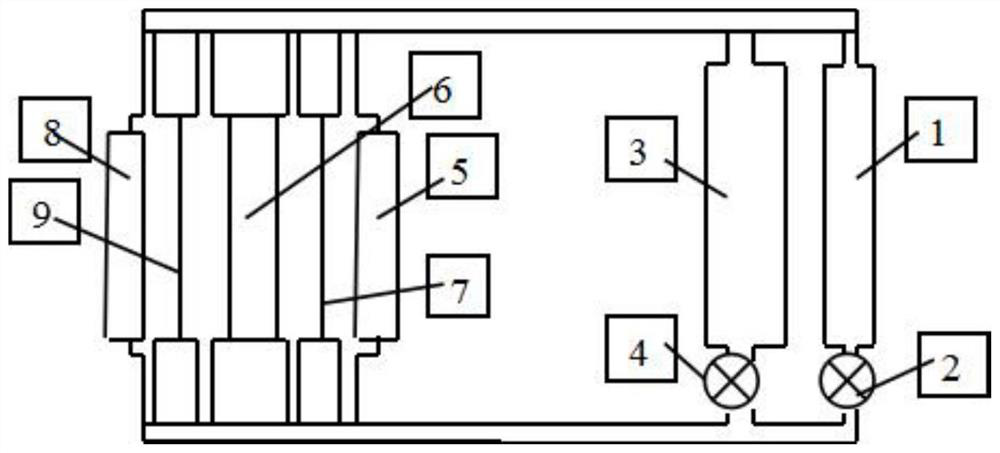

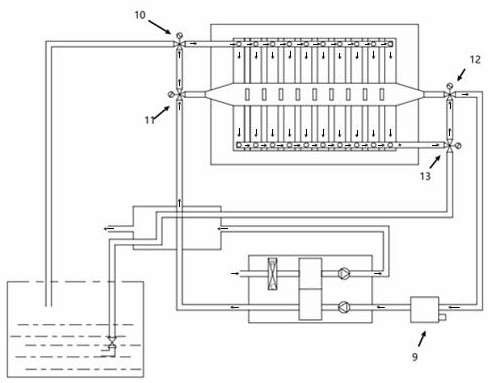

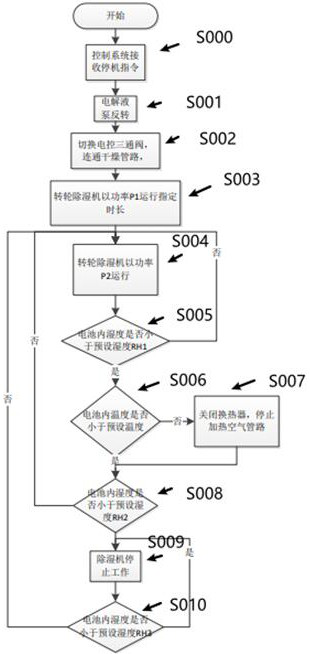

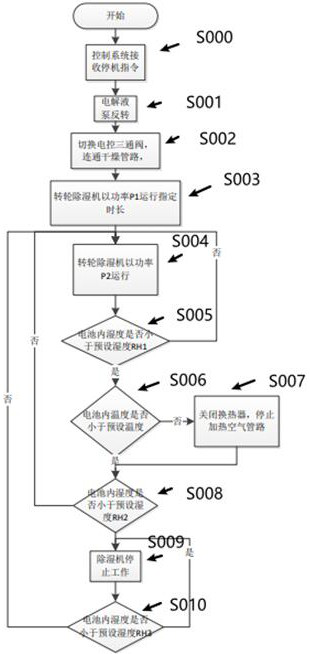

A large-scale aluminum-air battery pressurization and drying system and its pressurization and drying control method

ActiveCN112864496BGuaranteed Energy ConversionConstant humidity controlFuel and primary cellsElectrolyte stream managementElectrolytic agentAluminum anode

The invention relates to the technical field of aluminum-air batteries, and discloses a large-scale aluminum-air battery pressurization and drying system; The liquid inlet of the battery pack is connected with the electrolyte tank through the liquid replenishment pipe of the electrolyte pipe, and the liquid replenishment pipe is connected with the air pipe through the electric control three-way valve A, and the electrolyte pump is installed on the liquid replenishment pipe; the battery pack The liquid outlet is connected to the electrolyte tank through the liquid return pipe of the electrolyte pipeline, and the liquid return pipe is connected to the air pipe through the electric control three-way valve B; the inlet and outlet of the bipolar plate are covered by an air cover, and the air cover The ends are respectively connected to the air pipeline through the electronically controlled three-way valve C and the electronically controlled three-way valve D; the air pipeline is connected to the fresh air device and the dehumidifier in turn. The invention not only solves the self-corrosion problem of the aluminum anode, but also solves the problem of pressurization of the air pole and the temperature control problem of the electrolyte.

Owner:绿业中试低碳科技(镇江)有限公司

Porous zinc-tin alloy negative electrode material for zinc-air battery and preparation method thereof

InactiveCN105489970BImprove corrosion resistanceStable thermodynamic propertiesFuel and primary cellsCell electrodesTechnology developmentNew energy

Owner:CENT SOUTH UNIV

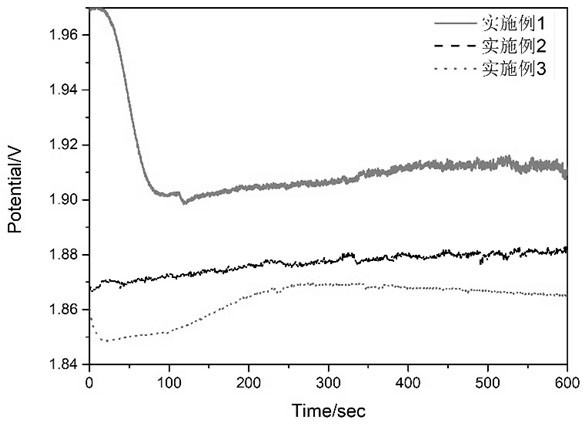

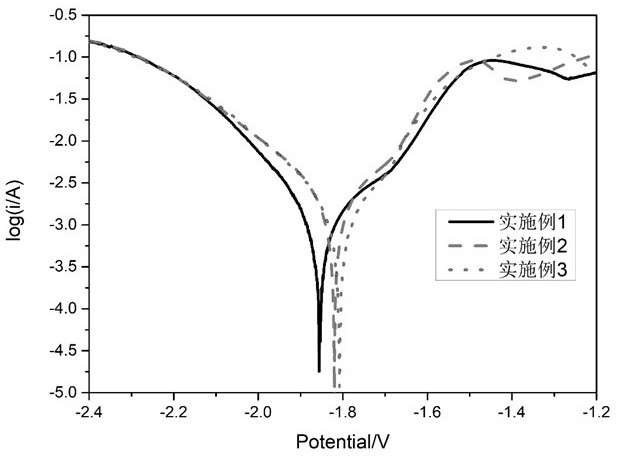

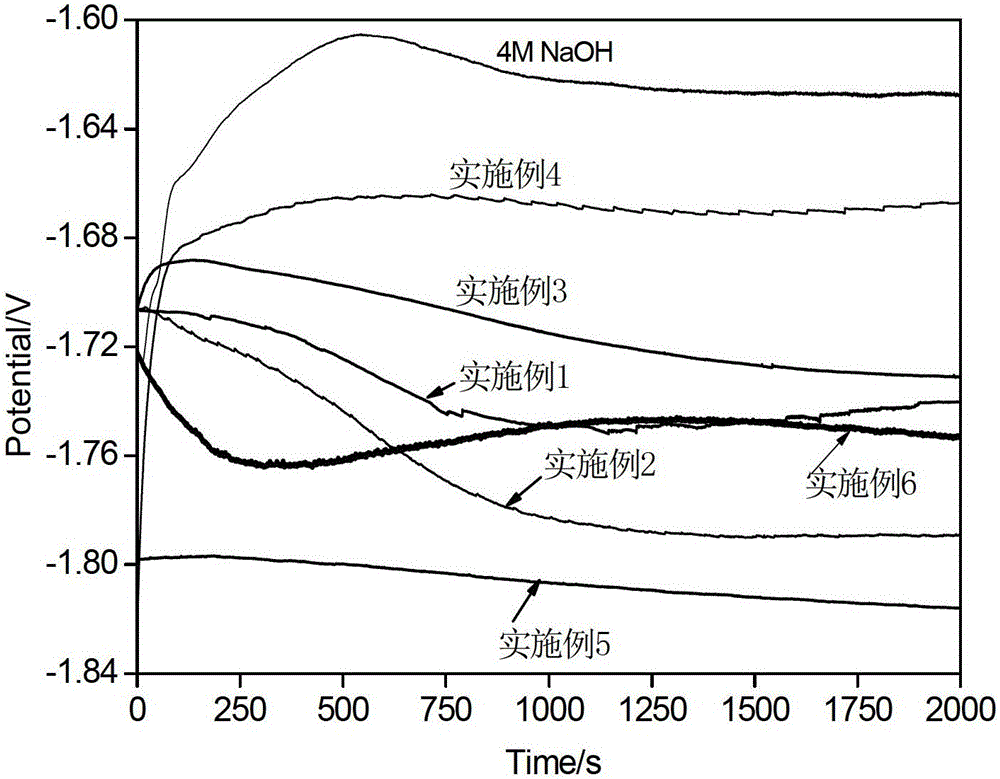

Anode material for alkaline aluminum-air battery and preparation method of anode material

ActiveCN113097471ASolid solutionMaintain active stateFuel and primary cellsPrimary cell electrodesAluminum anodeMetallurgy

The invention relates to an anode material for an alkaline aluminum-air battery. The anode material consists of the following components in percentage by weight: 0.5 to 1.2 percent of Zn, 0.05 to 0.1 percent of In, 0.05 to 0.1 percent of Sn, less than or equal to 0.01 percent of impurities and the balance of Al. The invention further provides a preparation method of the anode material, the anode material is assembled into an aluminum-air battery, the open circuit potential reaches 1.915 V, the corrosion current is 1.245 * 10 <-3 > A, the activity of an aluminum alloy anode is improved, and meanwhile hydrogen evolution corrosion of the aluminum anode is effectively relieved; meanwhile, under the large current of 10 A, the aluminum-air battery with the alloy components can stably discharge for 450 minutes or more at the voltage of 1.1 V.

Owner:ZHENGZHOU UNIV +1

Anti-corrosion device and water heater

ActiveCN109869910BReduce self-corrosionExtended service lifeMechanical apparatusWater storage tankEnvironmental engineering

The invention discloses an anticorrosion device and a water heater, which belong to the technical field of water heaters. In the anticorrosion device, a protective metal and a cathode are located outside a water storage tank and are in contact with an ion solution. The protective metal is connected to an auxiliary anode in the water storage tank, and the cathode is connected to the water storage tank. The auxiliary anode is insulated and connected to the water storage tank. Due to the different activity of the protective metal and the cathode, under the action of air, cathode, ion solution and the protective metal, the protective metal is corroded and loses electrons to provide electrons to the water storage tank through the cathode, thereby forming an electronic Migration, the water storage tank is protected; in addition, the protective metal is set outside the water storage tank, the corrosion of the protective metal will not pollute the water in the water storage tank, and the protective metal is not in contact with the high temperature water in the water storage tank, reducing the protection metal Self-corrosion, prolonging the service life of the protective metal. The water heater adopts the above-mentioned anti-corrosion device, does not need an external power supply, is more energy-saving, will not be affected by power failure, and can form long-term protection for the inner tank.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER

Aluminum alloy anode material for batteries and preparation method of aluminum alloy anode material

The invention discloses an aluminum alloy anode material for batteries. The aluminum alloy anode material is prepared from the following components in percentage by mass: 0.001-1% of lanthanum, 0.001-1% of gallium, 0.001-1% of magnesium, 0.001-1% of indium and the balance of aluminum. The invention further provides a preparation method of the aluminum alloy anode material for batteries. According to the preparation method, three types of different thermal treatment processes such as high temperature and long time, medium temperature and short time and low temperature and long time are matched with a deformation process, and optimal regulation and control on material components, texture structures and alloy phase of the aluminum alloy anode material are achieved. The addition of alloy elements is appropriately adjusted, and with the combination of appropriate plastic formation processes and thermal treatment processes of the aluminum alloy anode material, optimal matching of multiple elements can be achieved, and requirements of power source discharge can be met under a large current density of 500mA / cm<2> / 1000mA / cm<2>. The aluminum alloy anode material disclosed by the invention is short in production process procedure, easy in process parameter control, good in aluminum alloy anode product quality, low in production cost and beneficial to on-scale production.

Owner:CHANGSHA XUNYANG NEW MATERIAL TECH CO LTD

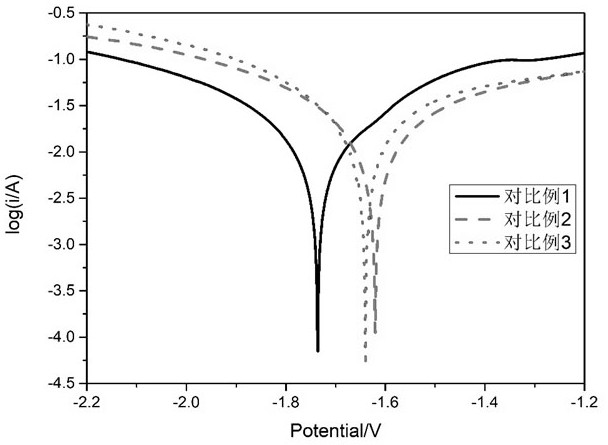

Electrolyte corrosion inhibitor for aluminum-air battery, electrolyte and preparation method

InactiveCN103633396BReduce hydrogen evolution self-corrosion rateProne to anodic polarizationFuel and primary cellsAluminum anodePhysical chemistry

The invention discloses an electrolyte corrosion inhibitor for an aluminum-air cell, an electrolyte and a preparation method, belonging to the technical field of chemical batteries. The electrolyte corrosion inhibitor mainly comprises sodium hyposulfite which has a concentration of 0.005 to 0.2 mol / L in the electrolyte and may further comprise the auxiliary additive sodium stannate which has a concentration of 0.01 to 0.03 mol / L in the electrolyte. The aluminum-air cell provided by the invention has the advantages of simple composition, low cost, safety and accordance with environmental protection requirements, can substantially reduce the hydrogen evolution self-corrosion rate of an aluminum anode, enables the open circuit potential of the aluminum anode and working potential under the condition of impressed current to undergo substantial negative transfer, allows an aluminum anode alloy to have good corrosion resistance and high electrochemical activity and meets the requirement of an alkaline aluminum-air cell for large current density discharging.

Owner:HENAN UNIV OF SCI & TECH

Magnesium dry cell

InactiveCN1317781CThickness is easy to controlReduce self-corrosionCell electrodesDry cellsAlkaline earth metalRare earth

Owner:FUJIAN HUAMEI NEW TECH DEV

Large aluminum air battery pressurizing and drying system and pressurizing and drying control method thereof

ActiveCN112864496AGuaranteed Energy ConversionConstant humidity controlFuel and primary cellsElectrolyte stream managementEngineeringFresh air

The invention relates to the technical field of aluminum air batteries, and discloses a large aluminum air battery pressurizing and drying system. The system is arranged based on a battery pack and comprises a plurality of single batteries, a bipolar plate, a dehumidifier, a fresh air device, an electrolyte tank, an electrolyte pipeline and an air pipeline, a liquid inlet of the battery pack is communicated with an electrolyte tank through the electrolyte pipeline and a liquid supplementing pipe, the liquid supplementing pipe is connected with the air pipeline through an electric control three-way valve A, and an electrolyte pump is mounted on the liquid supplementing pipe; a liquid outlet of the battery pack is connected with the electrolyte tank through an electrolyte pipeline liquid return pipe, and the liquid return pipe is connected with the air pipeline through an electric control three-way valve B; an air inlet and an air outlet of the bipolar plate are covered by an air hood; the two ends of the air hood are respectively connected with the air pipeline through an electric control three-way valve C and an electric control three-way valve D; and the air pipeline is sequentially connected with the fresh air device and the dehumidifier. The self-corrosion problem of the aluminum anode is solved, and meanwhile the air electrode pressurization problem and the electrolyte temperature control problem are solved.

Owner:绿业中试低碳科技(镇江)有限公司

A kind of organic composite corrosion inhibitor for pulp layer paper and its slurry

InactiveCN103789773BImprove conductivityImprove adhesionNon-fibrous pulp additionCoatingsElectrical batteryActive agent

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Primary alkaline battery negative electrode material and preparation method thereof

ActiveCN107039645BParticle size range controllableImprove uniformityMaterial nanotechnologyCell electrodesSol-gelCathode material

The invention discloses a primary alkaline battery cathode material which comprises the following components in parts by weight: 90-98 parts of zinc, 1-7 parts of gel agent, and rare earth oxide less than 0.1% of zinc, wherein 0.9-0.98 parts of zinc and the rare earth oxide form a core-shell nanomaterial; and the rest of zinc is a nanoscale material. The invention further discloses a preparation method of the primary alkaline battery cathode material. The preparation method comprises the steps of preparing a rare earth oxide @ zinc core-shell nanomaterial by a sol-gel method, mixing and dryly stirring the rare earth oxide @ zinc core-shell nanomaterial, zinc powder and the gel agent, adding an electrolyte, performing mixing and wet stirring, and finally performing defoaming treatment to prepare the primary alkaline battery cathode material. The primary alkaline battery cathode material has the benefits that the rare earth oxide @ zinc core-shell nanomaterial is used, so that a hydrogen evolution potential of zinc gel of a cathode is increased; a self-corrosion effect of the cathode is reduced; the leakage resistance is improved; and the service life of a battery is prolonged.

Owner:NINGBO FUBANG BATTERY

A kind of aluminum-air battery anode and preparation method thereof

ActiveCN111180720BImprove electrochemical performanceReduce overpotentialFuel and primary cellsCell electrodesMetallurgyElectrical battery

The invention relates to the technical field of aluminum-air batteries. Aiming at the problems of complex preparation process and poor corrosion resistance of aluminum-air battery anodes in the prior art, an aluminum-air battery anode and a preparation method thereof are disclosed. According to 100 mass points, Composition: 0.01‑0.05%Ga, 0.2‑0.6%Mn, 1‑5%Mg, 0.1‑0.6%Pb, and the rest are Al. Including: (1), melting aluminum; (2), adding Mn; (3), adding Ga and Pb; (4), adding Mg; (5), removing slag; (6), casting. The battery anode alloy prepared by the invention has good electrochemical properties, the addition of various alloy elements reduces the anisotropy of the anode material grains, improves the corrosion uniformity of the alloy, has low overpotential, low self-discharge rate, and relatively low hydrogen evolution overpotential High, and can eliminate the harmful effect of Fe element on the electrode, the preparation process is simple, the synthesis cycle is short, and the synthesis efficiency is high.

Owner:CHAOWEI POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com