A kind of aluminum-air battery anode and preparation method thereof

An aluminum-air battery and anode technology, applied in battery electrodes, fuel cell half-cells, primary battery half-cells, circuits, etc., can solve poor corrosion resistance, high hydrogen evolution overpotential, and low self-discharge rate and other problems, to achieve the effect of eliminating harmful effects, high hydrogen evolution overpotential, and low self-discharge rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

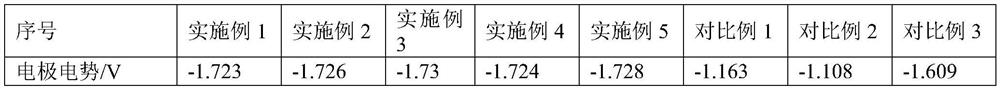

Examples

Embodiment 1

[0037] An anode for an aluminum-air battery, based on 100 mass points, contains components: 0.03% Ga, 0.45% Mn, 2.5% Mg, 0.3% Pb, and the rest of the components are Al.

[0038] A method for preparing an anode of an aluminum-air battery, wherein the aluminum alloy is smelted in a crucible, and the smelting and heating processes are all performed in a crucible smelting furnace, including the following preparation steps:

[0039] (1) Heat the crucible to 205°C, spray the mold release agent on the crucible, add pure aluminum and heat it to 780°C to melt, and keep the temperature for 1.3h;

[0040] (2), adding Mn: adding alloying element Mn to the high-temperature aluminum liquid at 735 °C, heating up to 765 °C and holding the temperature for 13 minutes to obtain molten metal A;

[0041] (3), adding Ga and Pb: adding alloying elements Ga and Pb to molten metal A at 735°C, and stirring for 13 min to obtain molten metal B;

[0042] (4), add Mg: add alloying element Mg in 735 ℃ of m...

Embodiment 2

[0046] The difference from Example 1 is that an aluminum-air battery anode, based on 100 mass points, contains components: 0.02% Ga, 0.3% Mn, 2% Mg, 0.2% Pb, and the rest are Al.

[0047] A method for preparing an anode of an aluminum-air battery, wherein the aluminum alloy is smelted in a crucible, and the smelting and heating processes are all performed in a crucible smelting furnace, including the following preparation steps:

[0048] (1) Heat the crucible to 202°C, spray the mold release agent on the crucible, add pure aluminum and heat it to 775°C to melt, and keep the temperature for 1.2h;

[0049] (2), adding Mn: adding alloying element Mn to the high-temperature aluminum liquid at 733 °C, heating up to 755 °C, and then maintaining the temperature for 11 min to obtain molten metal A;

[0050] (3), adding Ga and Pb: adding alloying elements Ga and Pb to the molten metal A at 732°C, and stirring for 11 min to obtain molten metal B;

[0051] (4), add Mg: add alloying elem...

Embodiment 3

[0055] The difference from Example 1 is that an aluminum-air battery anode, based on 100 mass points, contains components: 0.04% Ga, 0.5% Mn, 4% Mg, 0.5% Pb, and the rest are Al.

[0056] A method for preparing an anode of an aluminum-air battery, wherein the aluminum alloy is smelted in a crucible, and the smelting and heating processes are all performed in a crucible smelting furnace, including the following preparation steps:

[0057] (1) Heat the crucible to 208°C, spray the mold release agent on the crucible, add pure aluminum and heat to 785°C to melt, and keep the temperature for 1.4h;

[0058] (2), adding Mn: adding alloying element Mn to the high-temperature aluminum liquid at 738 °C, heating up to 775 °C and then keeping the temperature for 14 minutes to obtain molten metal A;

[0059] (3), adding Ga and Pb: adding alloying elements Ga and Pb to molten metal A at 738°C, and stirring for 14 min to obtain molten metal B;

[0060] (4), add Mg: in 738 ℃ of molten metal B,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com