Patents

Literature

215results about How to "Change the microstructure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

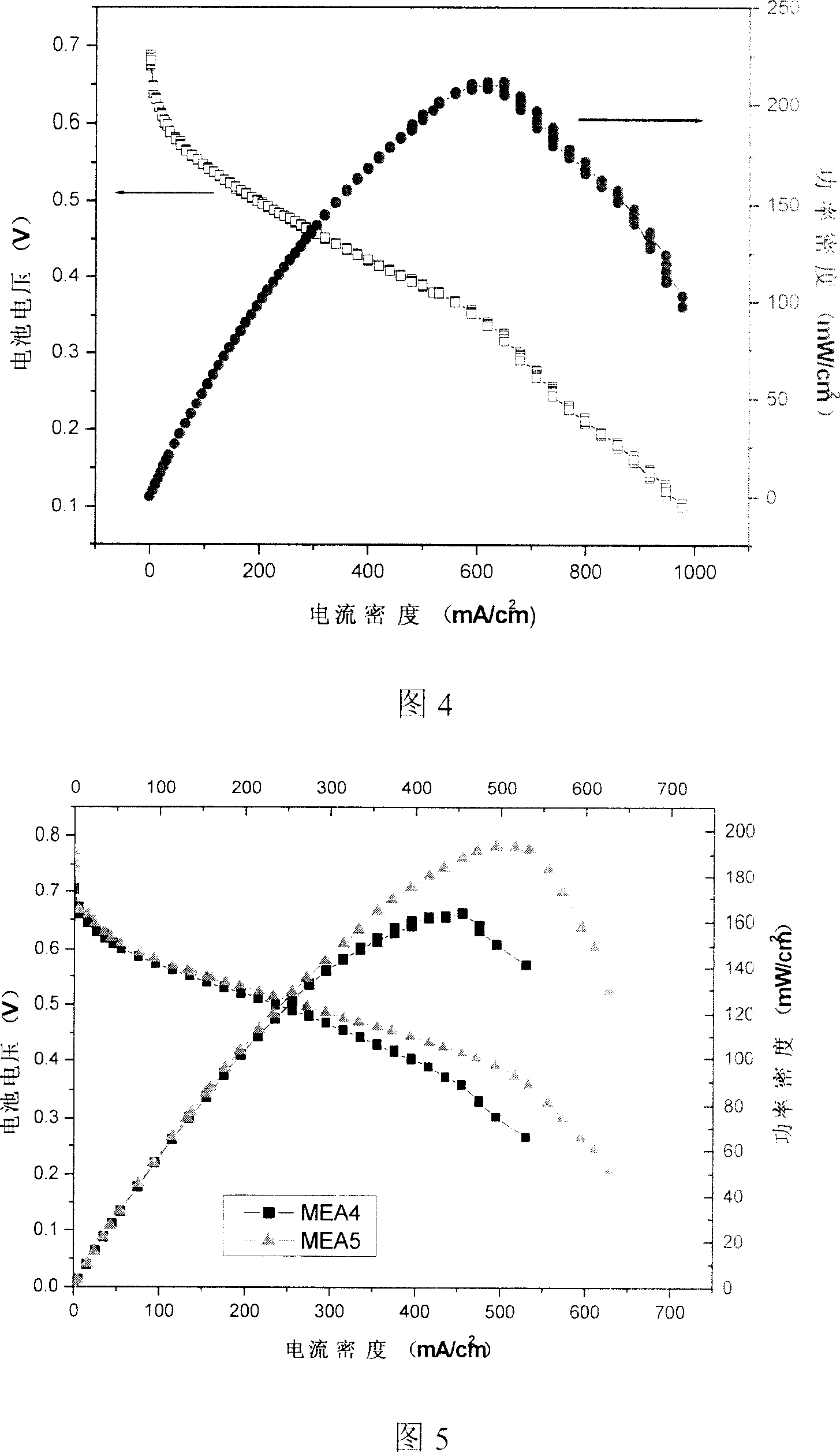

Nano carbon doped electrocatalyst for fuel cell, and application of nano carbon doped electrocatalyst

InactiveCN103050714AChange the microstructureChange Edge Face DefectsPhysical/chemical process catalystsCell electrodesMicrowave radiometryHigh heat

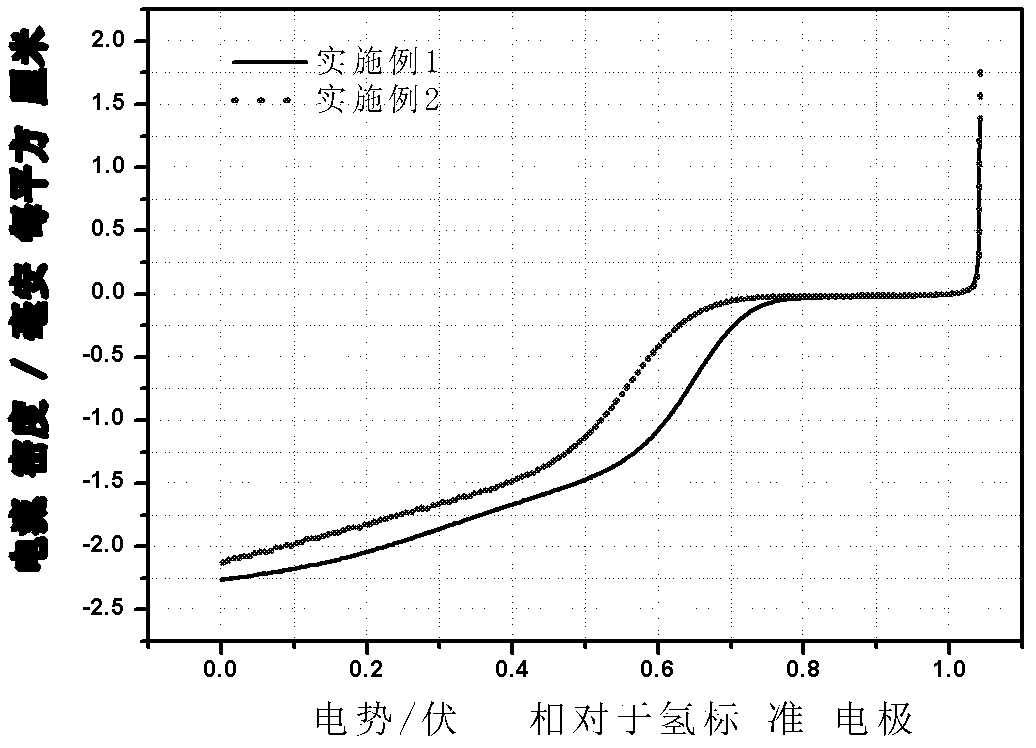

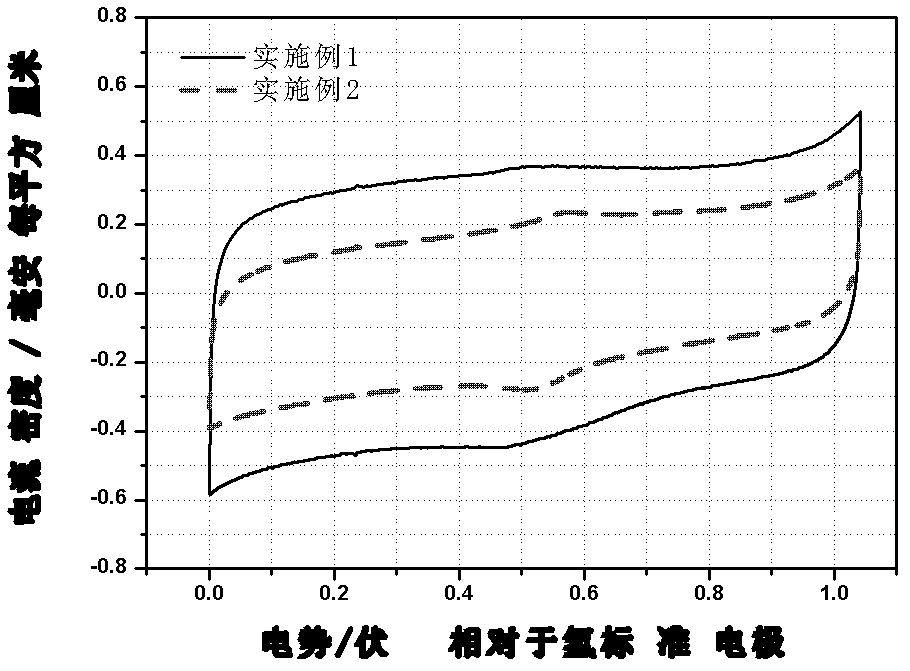

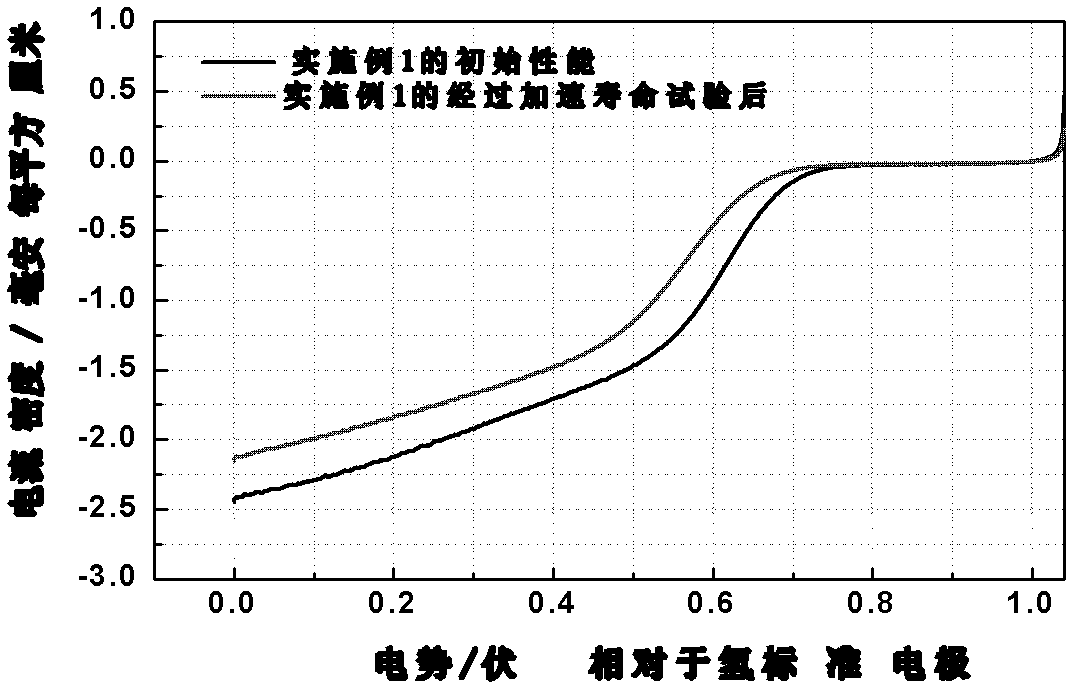

The invention relates to a nano carbon doped electrocatalyst for a fuel cell, and application of the nano carbon doped electrocatalyst. The electrocatalyst is prepared by adopting the steps of: complexing a nitrogen-containing and / or boron-containing organic precursor and a transition metal salt to form a composite; adding nano carbon as a carrier, and heating and reacting a mixture by adopting a microwave radiation method; and after the reaction is complete, filtering and drying, placing a product obtained after the reaction in an inert atmosphere and / or reducing atmosphere, and treating at a high temperature of 500-1500 DEG C to obtain the nano carbon doped electrocatalyst. The nano carbon doped electrocatalyst is very low in cost, high in activity and stability and excellent in anti-poisoning capacity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Hydrophilic modification method of PVDF ultrafilter membrane by utilization of nano-TiO2 sol

InactiveCN102688705ASimple film making processThe film making process is matureSemi-permeable membranesPorosityOrganic solvent

The invention discloses a hydrophilic modification method of a PVDF ultrafilter membrane by the utilization of nano-TiO2 sol and belongs to the field of membrane separation technologies. According to the method, PVDF is used as the main high-molecular membrane preparation material. The hydrophilic TiO2 sol prepared in advance is added into a casting solution containing PVDF, an organic solvent and an additive, and the hydrophilic PVDF ultrafilter membrane is prepared by the utilization of a phase inversion method. By the adoption of the method, water contact angle of the prepared PVDF ultrafilter membrane can be reduced from about 85 degrees to about 60 degrees, and hydrophilicity of the PVDF membrane is obviously raised. Various substances concerned in the invention comprise, by weight, 10-25% of polyvinylidene fluoride (PVDF), 60-80% of a solvent for dissolving polyvinylidene fluoride, 1-10% of the TiO2 sol, and 0-10% of the additive, wherein the additive contains a mixture of anhydrous LiCl and PVP. Porosity of the prepared membrane is 50-80% and its membrane pore size is 0.01-0.2 micron. The method provided by the invention has a simple membrane forming technology, is convenient to operate, and is easy to realize industrial production. In addition, the prepared ultrafiler membrane has good hydrophilicity and high water flux, and has a wide application prospect.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Rare earth thick film circuit electrical heating element based on aluminum nitride minicrystal ceramic substrates and its preparation technique

ActiveCN101321415AHigh thermal conductivityImprove electrical performanceHeating element materialsRare earthHigh power density

The invention provides a controllable electrical heating element of rare-earth thick-film circuit based on aluminum nitride microcrystal ceramic base plate and manufacturing method thereof, comprising base pieces and serial electronic sizing agents which are manufactured on the base pieces. The serial electronic sizing agents comprise package sizing agent and electronic sizing agent, and are all composed of three parts including a functional phase, an inorganic bonding phase and an organic carrier. The serial electronic sizing agents further comprise rare-earth resistance sizing agent. The base piece is ALN aluminum nitride microcrystal ceramic base piece. The serial electronic sizing agents are manufactured on the base piece by means of thick film circuit. The invention synchronously further provides formulations of ALN aluminum nitride microcrystal ceramic base piece, rare-earth envelopment sizing agent, rare-earth resistance sizing agent and rare-earth electrode sizing agent. The invention is environment-friendly, safe and reliable by providing with equal and controllable heating temperature field, large power, high power density, high efficiency of heat conduction, high speed of response, high efficiency for saving energy, strong capability of thermal-shock resistance, small volume and wide application range.

Owner:GUANGDONGSHENG YUCHEN ELECTRONICS & TECH CO LTD

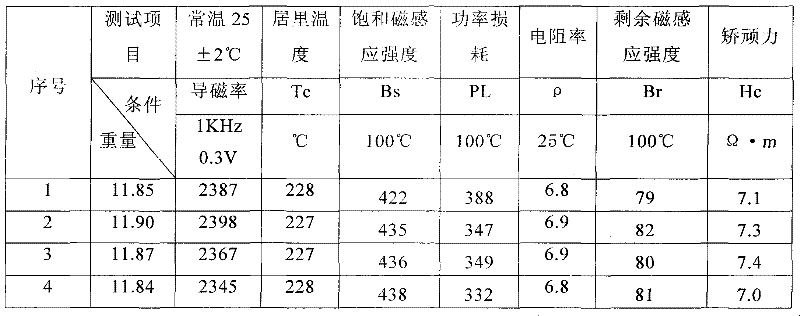

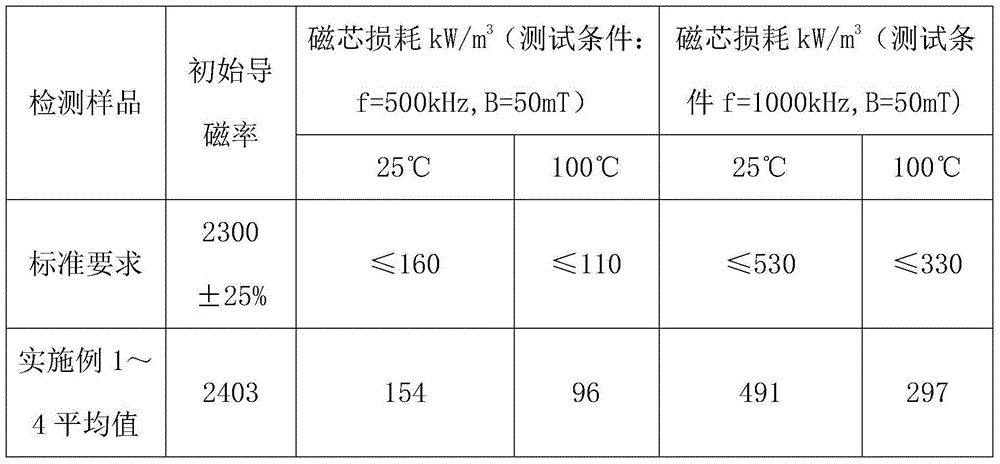

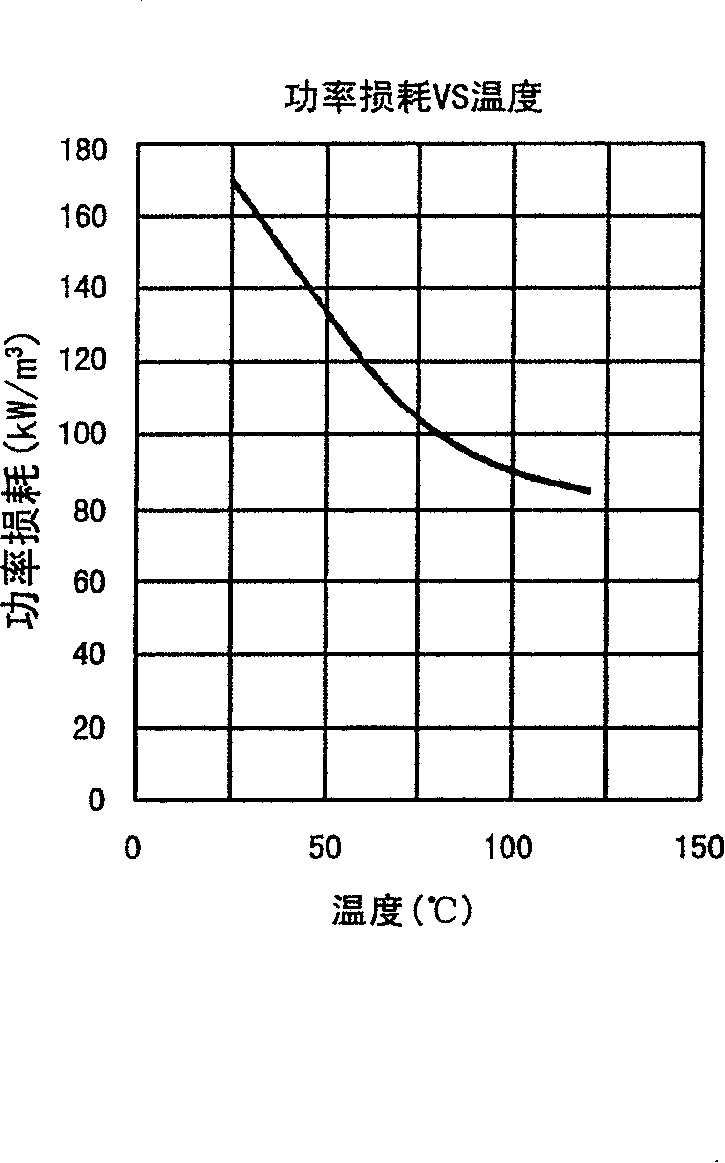

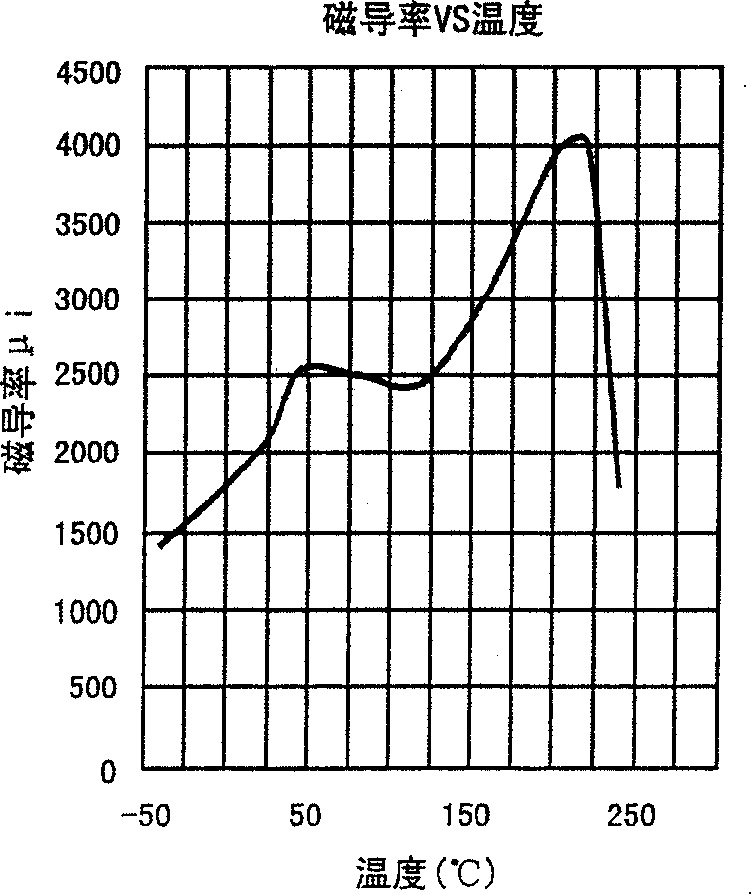

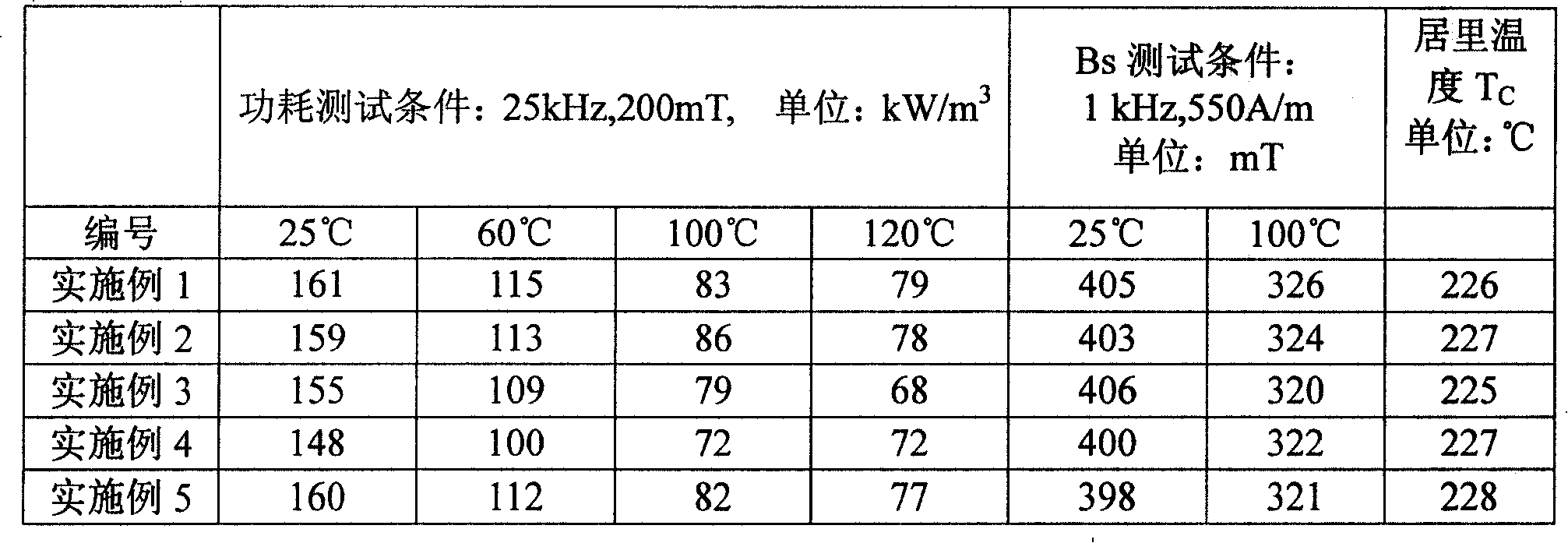

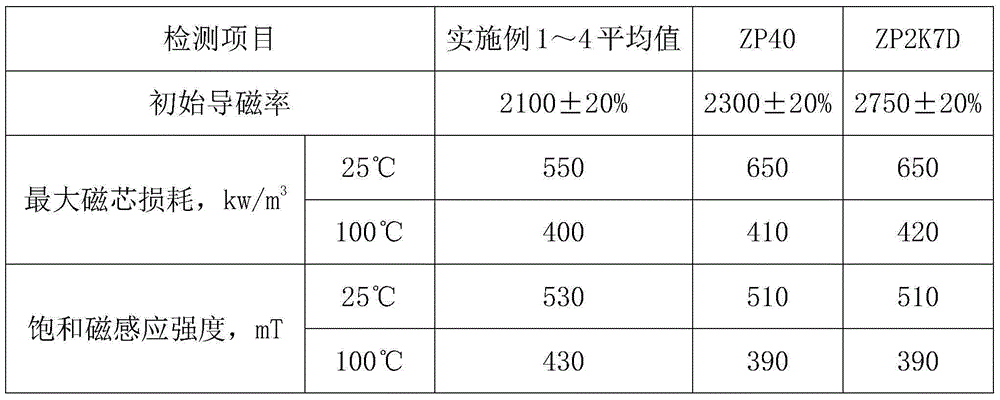

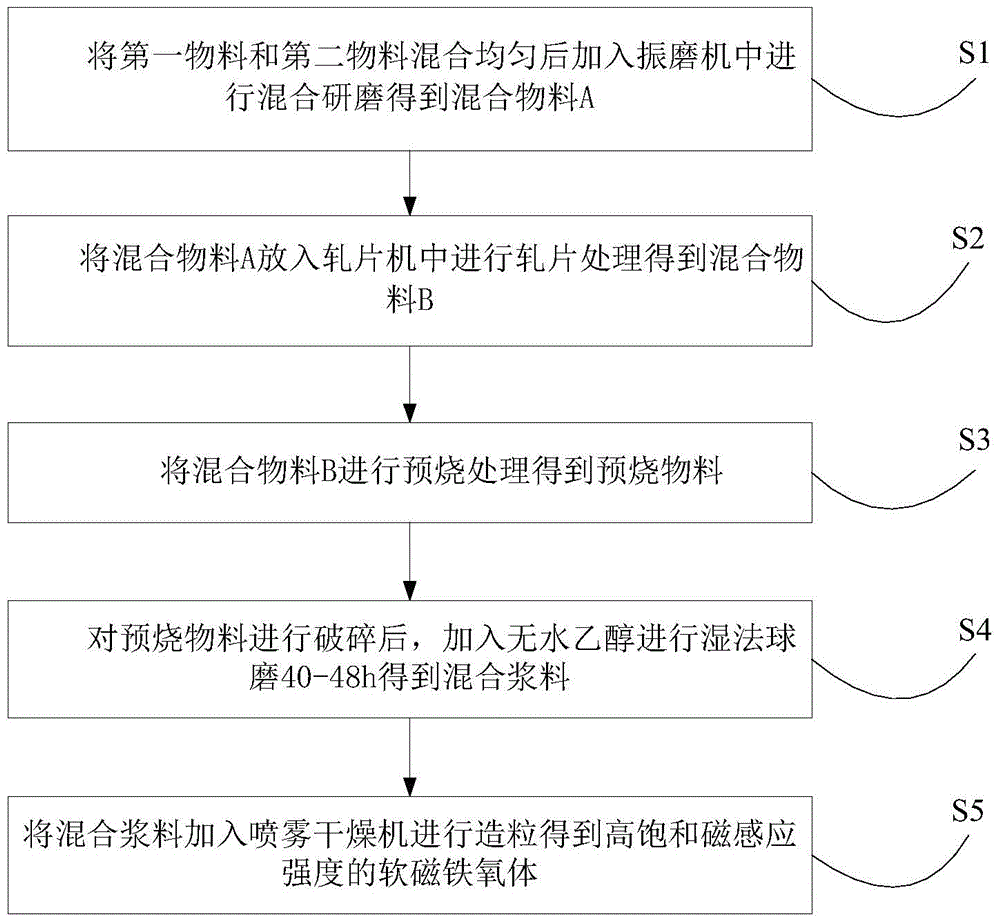

Soft magnetic ferrite material and preparation process thereof

ActiveCN102194561AHigh saturation flux densityReduce magnetic lossInorganic material magnetismMetallurgyMaterials science

The invention discloses a soft magnetic ferrite material and a preparation process thereof. The soft magnetic ferrite material comprises the following components: 52 to 55 mol of Fe2O3, 39 to 42 mol of Mn3O4, 5-8 mol of ZnO, 0.1 to 0.6 mol of additive 1, 0.1 to 0.2 mol of additive 2 and 0.006 to 0.06 mol of ZrO2, wherein the additive 1 is one or more of SnO2, CaCO3 and V2O5; and the additive 2 isone or more of Nb2O5, K2CO3, CaCO3, Ta2O5, SnO2 and V2O5. The soft magnetic ferrite material prepared by the process overcomes defects of the prior art and has the advantages of high frequency, high saturation magnetic flux density and low magnetic loss.

Owner:WUXI SPINEL MAGNETICS

Soft magnetic ferrite material and preparation process thereof

The invention discloses a soft magnetic ferrite material. Raw materials for preparing the soft magnetic ferrite material comprise composite materials and auxiliary materials. The composite materials comprise iron oxide, manganese oxide and zinc oxide. The auxiliary materials comprise 0-6000 ppm of nickel oxide, 100-800 ppm of calcium carbonate, 0-500 ppm of lithium carbonate, 20-120 ppm of silicon dioxide, 0-230 ppm of magnesium oxide, 0-180 ppm of niobium oxide, 700-2000 ppm of cobalt oxide, 0-350 ppm of bismuth oxide, 100-600 ppm of vanadium oxide, 0-2500 ppm of titanium dioxide, 0-500 ppm of copper oxide, and 100-500 ppm of zirconium oxide. The invention also discloses a preparation process of the soft magnetic ferrite material. The soft magnetic ferrite material has high initial magnetic permeability and low magnetic core loss.

Owner:ZHONGDE ELECTRONICS

Rare earth electrode slurry of rare earth thick film circuit based on metal plate and its preparation technology

ActiveCN1909748AIntermolecular bonding strength and improved manufacturabilitySolid combinationOhmic-resistance electrodesNon-conductive material with dispersed conductive materialSolid phasesYttrium

The invention relates to a rare-earth electrode slurry of rare-earth circuit, based on the metal base board and a relative production, wherein it is characterized in that: said slurry is formed by solid material and organic solvent carrier, while their mass ratio is 70-90:30-10; the solid component comprises: silver, palladium, and yttrium composite power and micro-crystal glass powder, while their mass percentage is 99.4-94:0.6-6; said composite power is formed by silver, palladium, and yttrium powders at the ratio as 0.6-10:99-82:0.4-8; said micro-crystal glass is the one in SiO2-Al2O3-CaO-B2O3-Bi2O3-La2O3 group. And the production comprises: (1), preparing rare-earth micro-crystal glass powder; (2), preparing silver, palladium, and yttrium composite powder; (3), preparing organic solvent carrier; (4), mixing material in three-dimension and rolling with three rollers; (5), preparing the rare-earth slurry; (6), bottling. The invention is environment friendly and better humidity compatibility.

Owner:GUANGDONGSHENG YUCHEN ELECTRONICS & TECH CO LTD

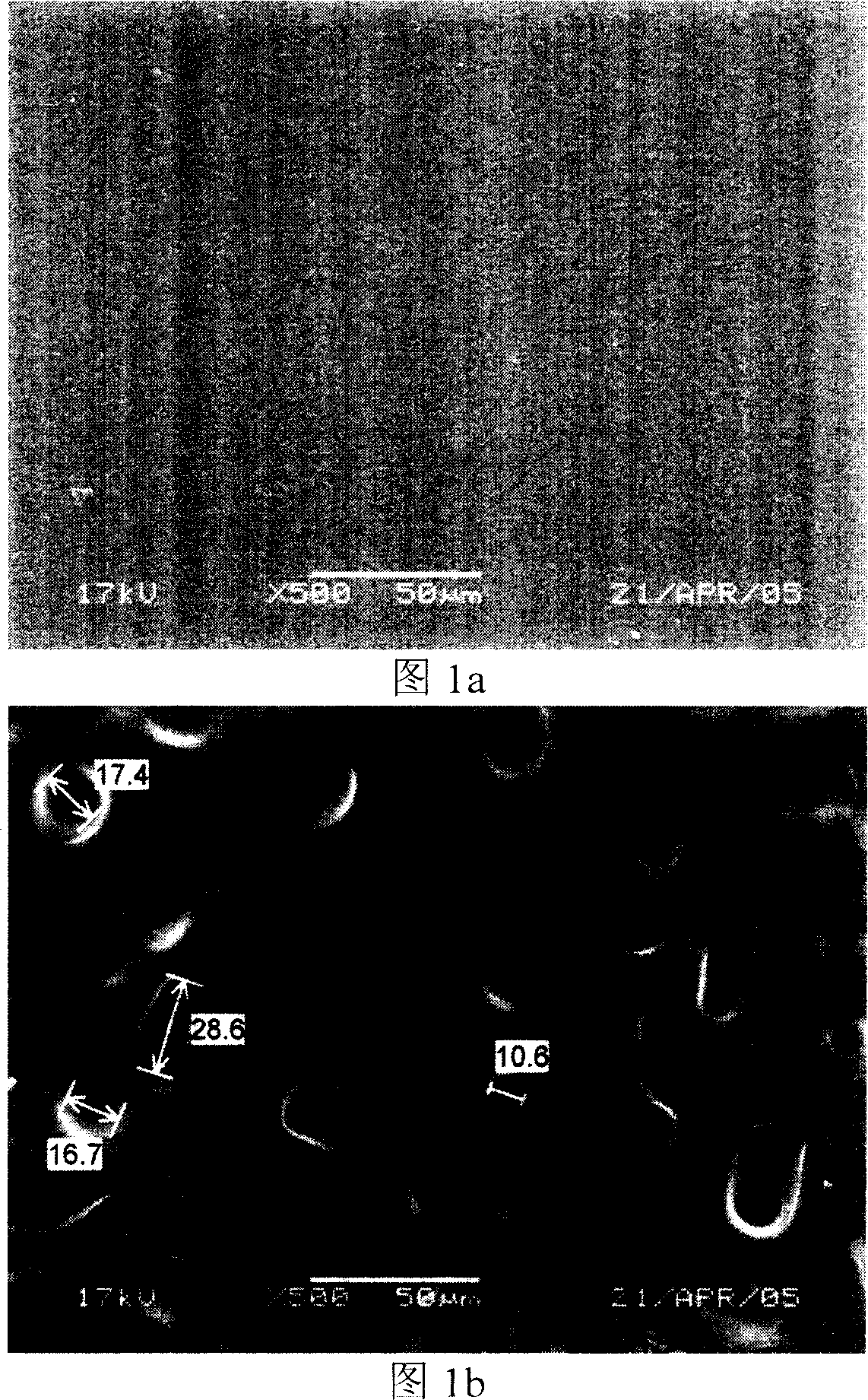

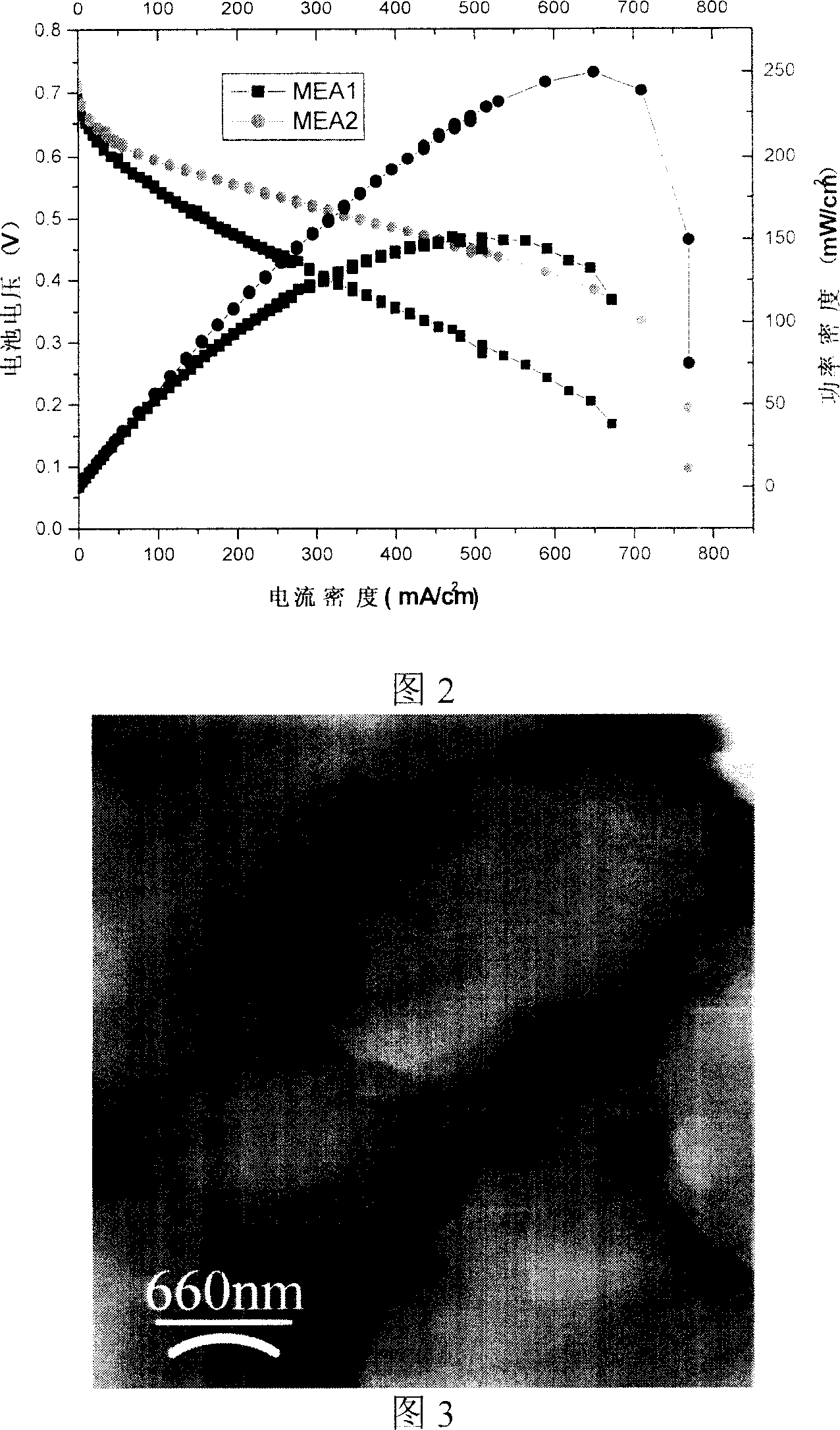

Ordered membrane electrode of proton-exchange membrane fuel battery

InactiveCN1983684AImprove conductivityImprove performanceCellsCell electrodesElectrical conductorEngineering

The invention is concerned with a method to increase extraction efficiency of semiconductor LBD by texturing film transfer. Develop conventional semiconductor LBD, weld the core of flip semiconductor LBD, product template with micro / nanometer-figures by the designed light-etched domain, select and confect a kind of prepolymer in appropriate proportion and print the ultrastructure figure on the prepolymer colloid with micro / nanometer print technology and solidify the prepolymer colloid film, peel off the prepolymer film with ultrastructure figure and get the texturing film medium film. The step of texturing film transferring is spreading transparent PMMA glue on underlay of LBD, setting the side of texturing film with figure upside and pasting on the core of diode, setting the side of texturing film with figure peeled off upside and pasting on the core of diode, adding proper temperature to solidify the transparent agglutinating glue.

Owner:中科军联(张家港)新能源科技有限公司

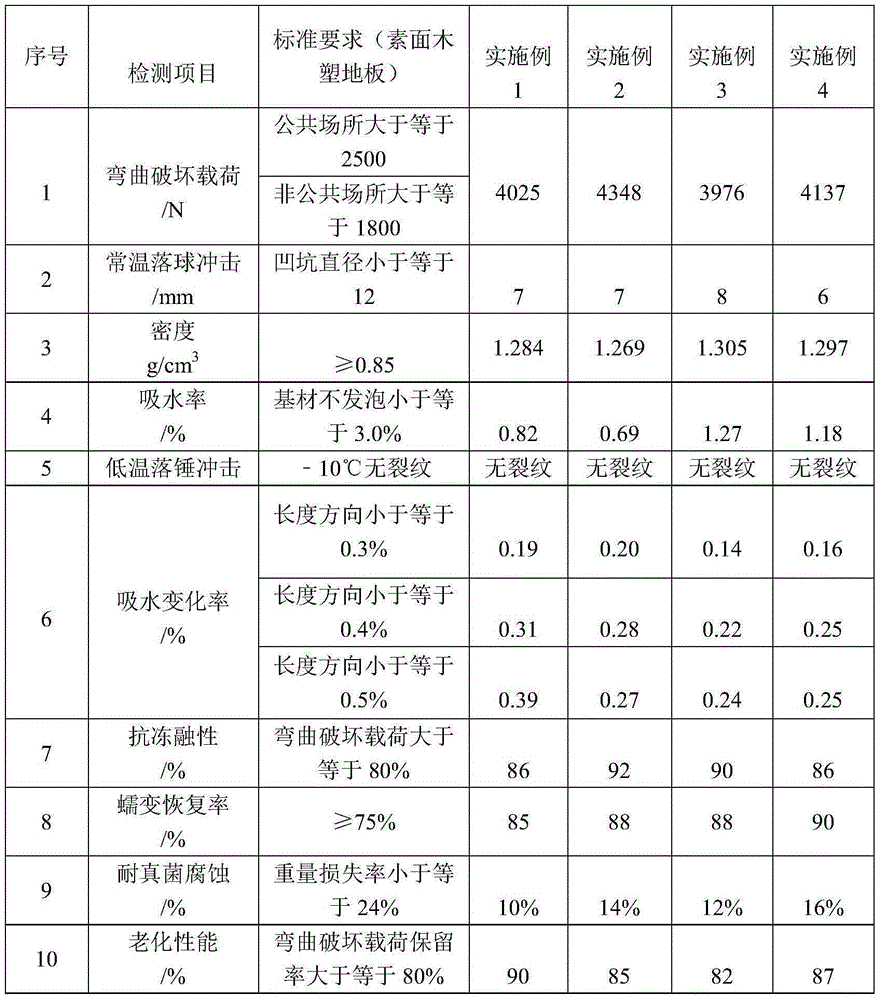

Chinese medicine residue reinforced reprocessed plastic composite material, and preparation method thereof

InactiveCN105400052AImprove physical performanceImprove mechanical propertiesWeather resistanceNational standard

The invention relates to a Chinese medicine residue reinforced reprocessed plastic composite material, and a preparation method thereof, and belongs to the field of composite material. The Chinese medicine residue reinforced reprocessed plastic composite material comprises, by mass, 50 to 70% of Chinese medicine residue, 20 to 40% of modified reprocessed plastic, 2 to 10% of a mineral filling material, 2 to 5% of a compatilizer, 1 to 5% of a lubricant, 1 to 3% of a colouring agent, 1 to 3% of an anti-oxidant, and 1 to 3% of a light stabilizer. The preparation method comprises following steps: Chinese medicine residue pretreatment; reprocessed plastic modification; material mixing; pelletizing; extrusion moulding, and surface post-processing. The physical properties, mechanical properties, and weathering resistance of the Chinese medicine residue reinforced reprocessed plastic composite material are equal to or better than that disclosed in national standard GB / T 24508-2009 <wood-plastic flooring>; and the Chinese medicine residue reinforced reprocessed plastic composite material is capable of satisfying market requirements, and possesses insect expelling effect and mould resistance.

Owner:南京聚锋新材料有限公司 +1

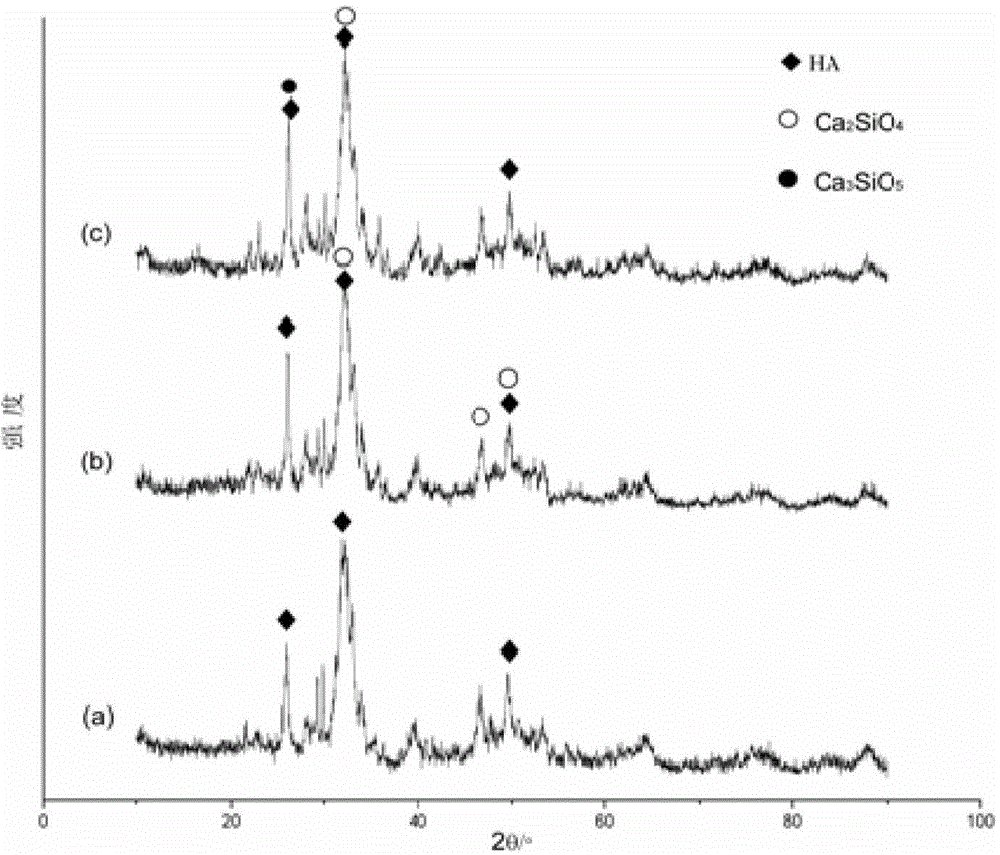

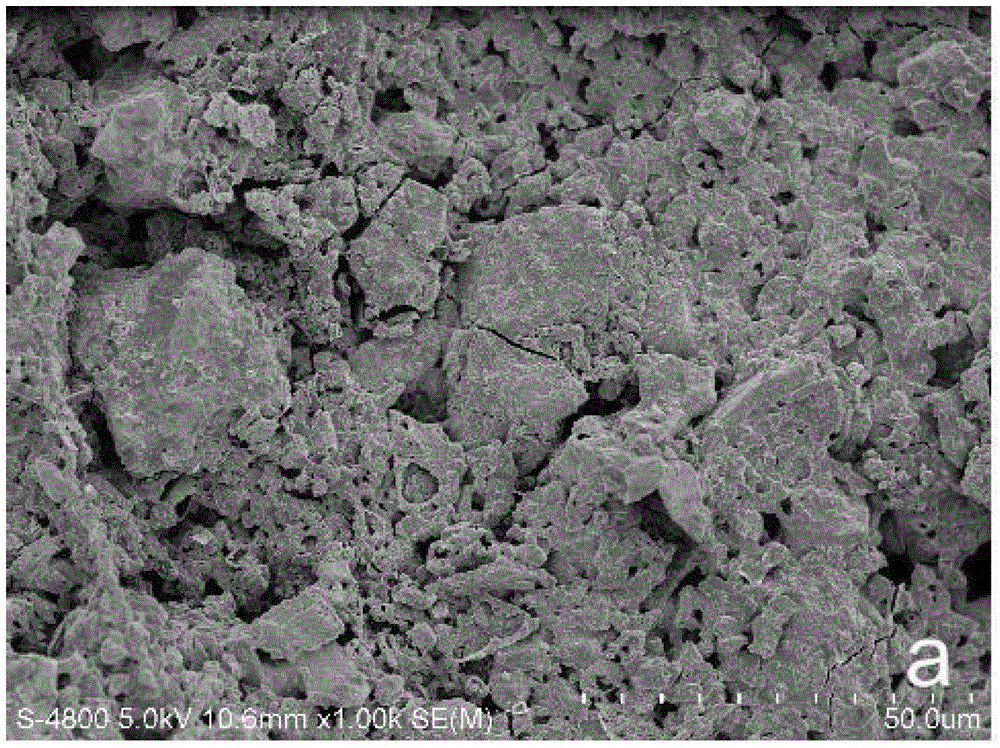

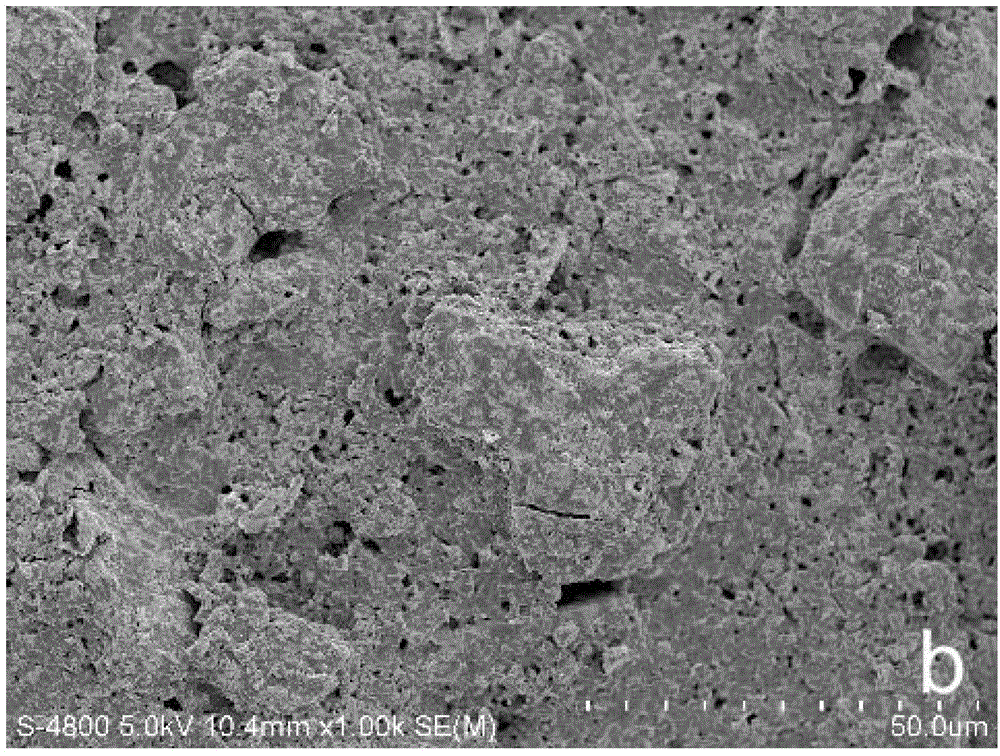

Composite biological material capable of injecting bioglass-calcium phosphate bone cement and preparation

InactiveCN103143063AImprove mechanical propertiesGood application prospectSurgeryProsthesisSolid phasesBiological materials

The invention discloses a composite biological material capable of injecting bioglass-calcium phosphate bone cement and a preparation method thereof. The prepared composite biological material capable of injecting bioglass-calcium phosphate bone cement is composed of solid phase powder and liquid phase, wherein, the liquid phase is monopotassium phosphate and dipotassium phosphate water solution which the concentration is 1M, and the ratio between the solid phase powder and the liquid phase is 2.0 g / ml-3.0 g / ml; the solid phase powder is composed of calcium phosphate bone cement and 45S4 bioglass in a mixed mode based on a weight ratio, wherein the addition of the 45S5 bioglass accounts for 5%-40% of the gross of the solid phase powder; and the calcium phosphate bone cement is composed of tetra calcium phosphate and anhydrous calcium phosphate dibasic in a mixed mode with a 1:1 molar ratio. The composite biological material capable of injecting bioglass-calcium phosphate bone cement and the preparation have the advantages of being capable of having good liquidity, higher mechanics performance, degradation rate and biological activity, offsetting the defects of single calcium phosphate cement (CPC) or the bioglass, and being used for bone defect recovery of an oral cavity, a skull facial portion and orthopedics.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

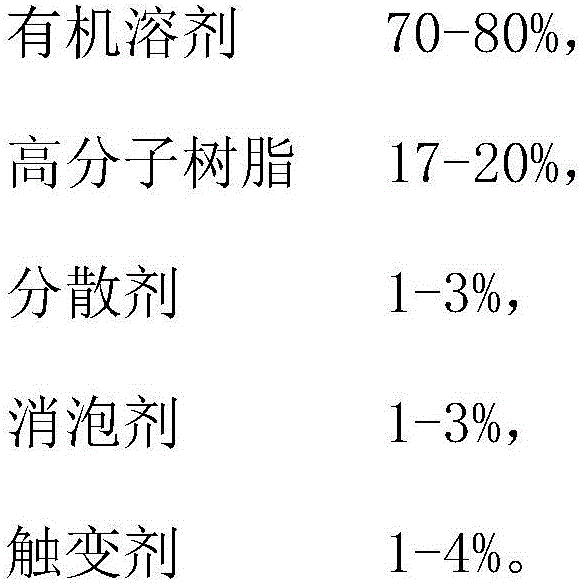

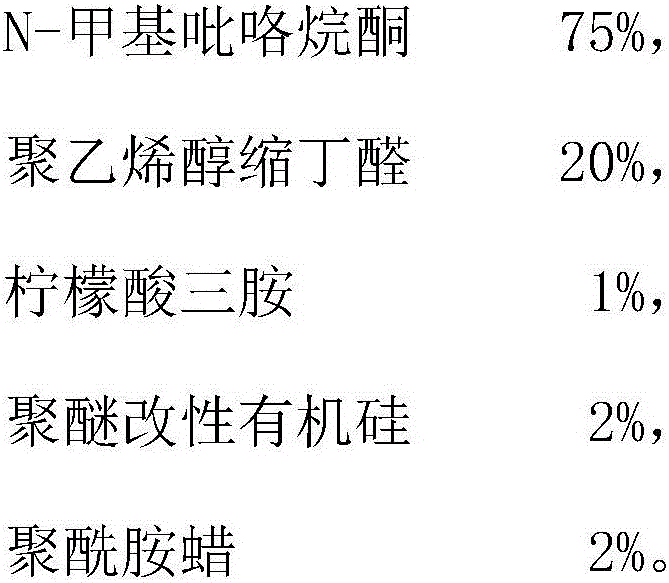

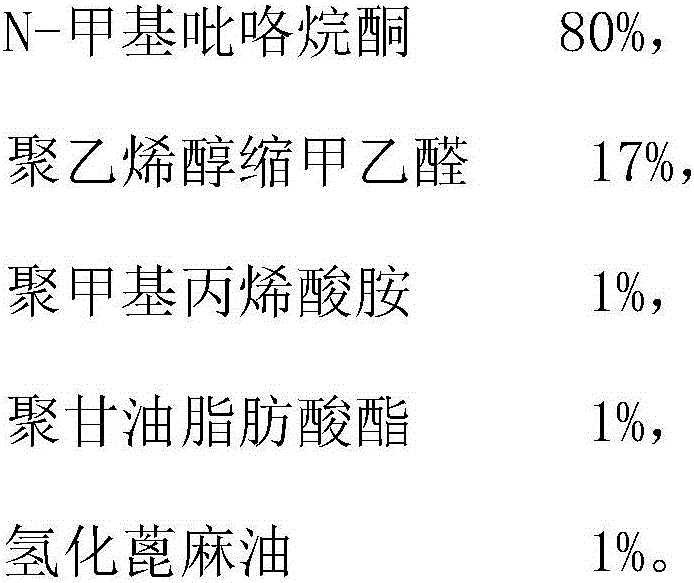

High-temperature high-power rare earth resistance paste and preparation method thereof

InactiveCN106131982ACompatibility improvements improvedGood compatibilityNon-conductive material with dispersed conductive materialHeating element materialsMicrometerRare earth

The invention discloses a high-temperature high-power rare earth resistance paste and a preparation method thereof. The high-temperature high-power rare earth resistance paste comprises a functional phase, an inorganic adhesive phase, a burning promoter and an organic carrier, wherein the functional phase is composite powder consisting of micrometer silver powder and bismuth ruthenate powder; the inorganic adhesive phase is lead-free pyroceram powder consisting of SiO2, MgO, B2O3, ZnO, Bi2O3, rare earth oxides and a nucleation agent; and the organic carrier is a mixture consisting of a solvent, resin, a dispersing agent, a deforming agent and a thixotropic agent. The resistance paste has the advantages that firstly, the damages of lead on the environment and human bodies can be avoided; secondly, the resistance paste is high in compatibility, wettability, thermal performance, electrical performance, manufacturability and adaptability; thirdly, the resistance paste is high in binding performance with ceramic and stainless steel substrates; and fourthly, the resistance paste is high in printing performance, burning performance and compatibility. The preparation method comprises preparation of the inorganic adhesive phase, preparation of the functional phase, preparation of the organic carrier and preparation of the resistance paste in sequence, and the resistance paste can be produced and prepared effectively.

Owner:DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

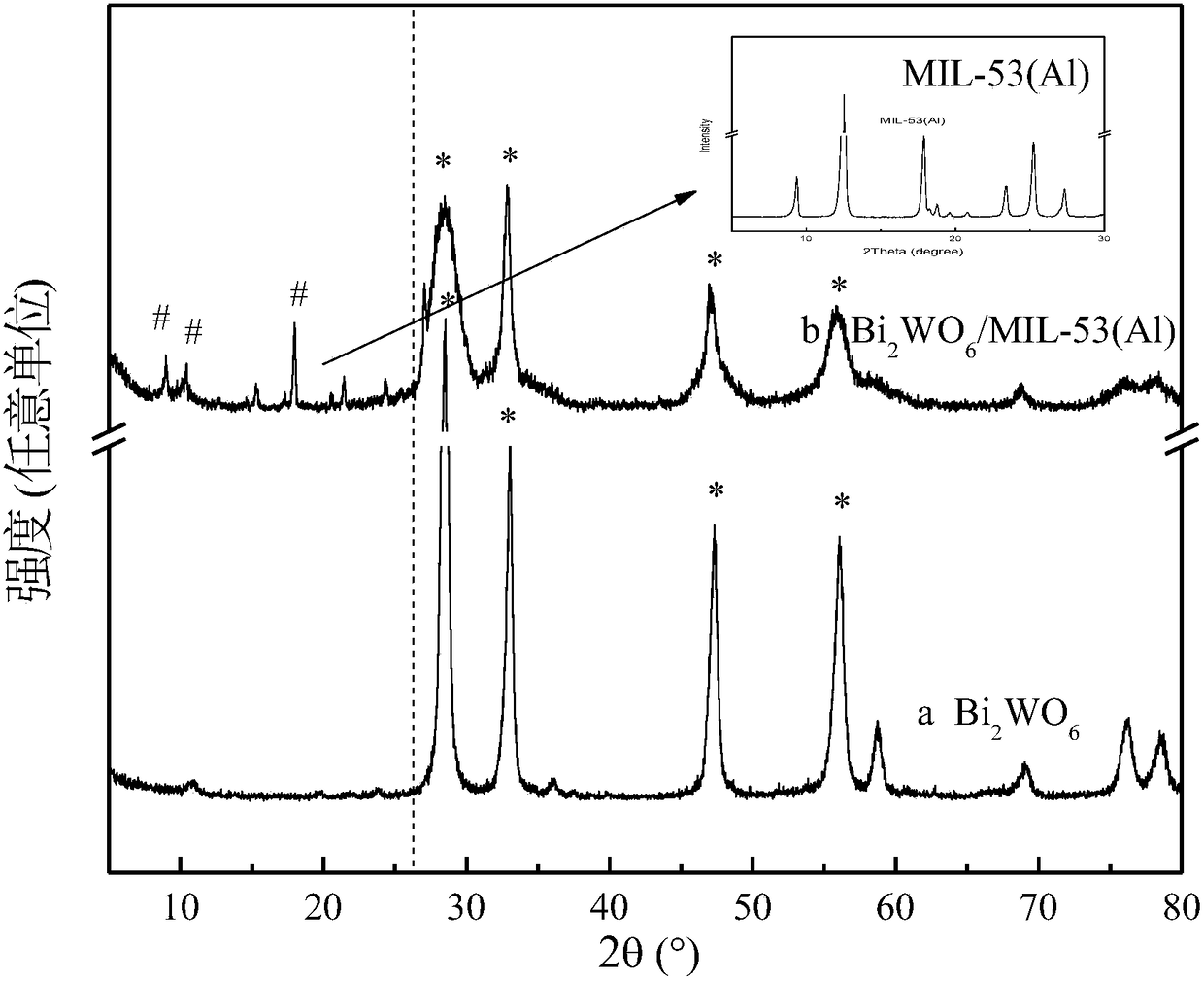

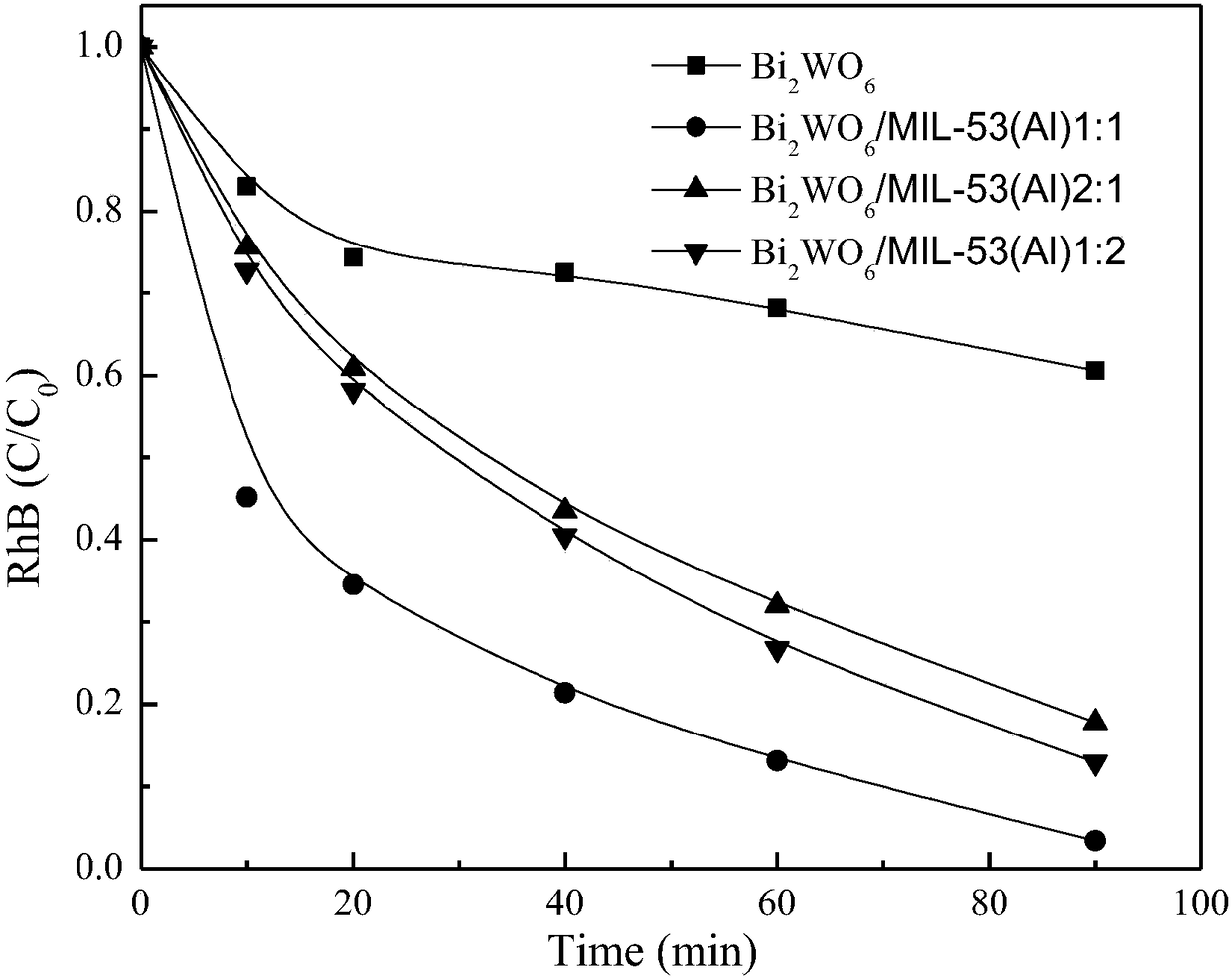

Bismuth tungstate-MIL-53 (Al) composite material and preparation method and application thereof

ActiveCN108126756AImprove stabilityEasy to useWater/sewage treatment by irradiationWater treatment compoundsTungstateMetal-organic framework

The invention discloses a bismuth tungstate-MIL-53 (Al) composite material and a preparation method and application thereof. The preparation method comprises adding a metal-organic framework materialMIL-53 (Al) into a metal salt solution for Bi2WO6 synthesis, carrying out full stirring, adjusting pH through a NaOH solution and preparing a loaded visible photocatalyst Bi2WO6 / MIL-53(Al) composite material through a solvothermal method. Through control of reaction conditions of the solvothermal method, the microstructure and morphology of the composite material are adjusted. The loaded Bi2WO6 / MIL-53(Al) composite material has bulk morphology. Bi2WO6 is uniformly distributed on the carrier MIL-53(Al). The loaded composite material photocatalyst has high catalytic activity, has a rhodamine B degradation rate of 97% and has a certain stability and reusability. The preparation method has simple processes and low energy consumption and is easy to industrialize.

Owner:SHANGHAI UNIV

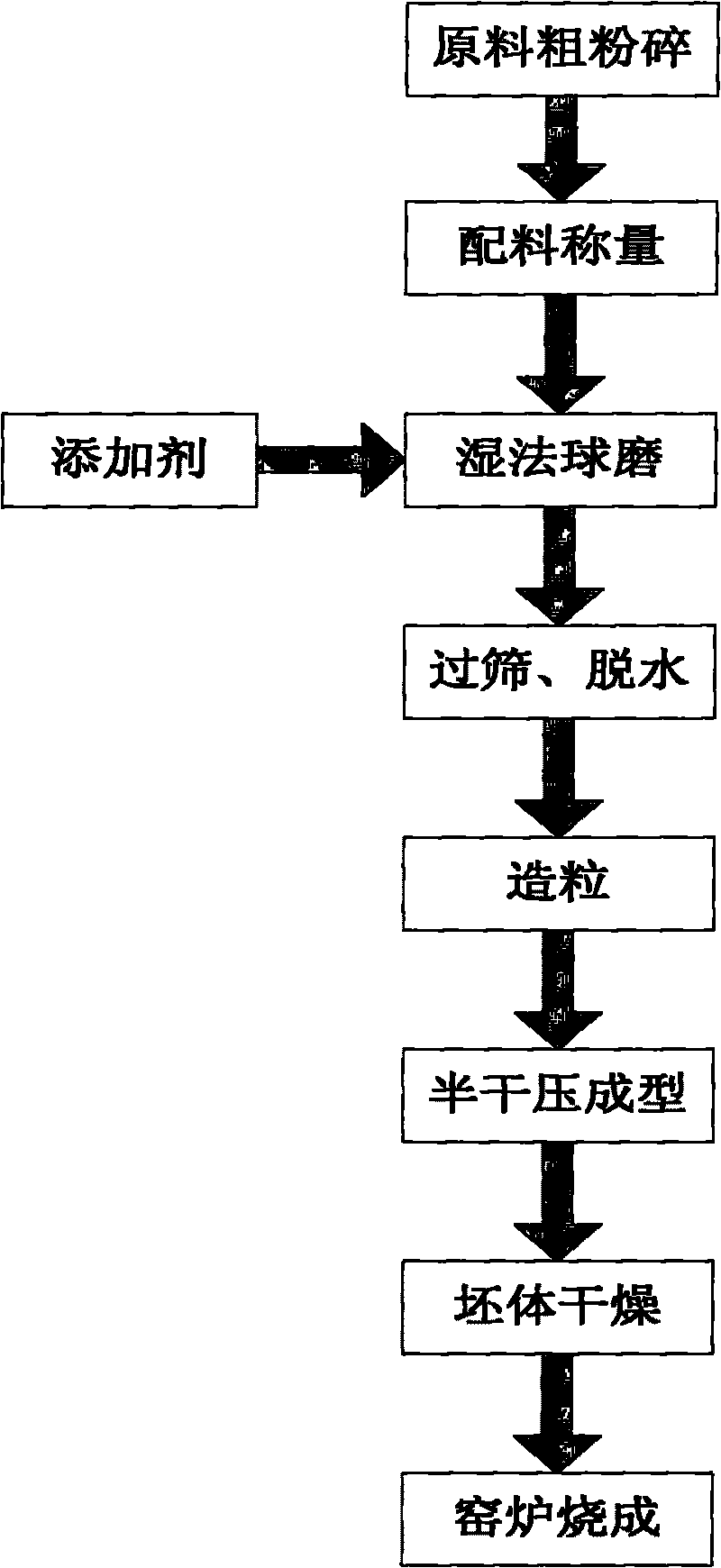

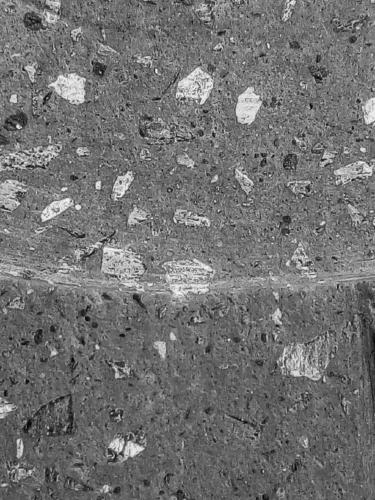

Method for firing porous filtering ceramic tiles with ceramic polishing scrap

InactiveCN101709001AIncrease contentIncrease the number ofSolid waste disposalCeramicwareCordieriteMaterials processing

The invention discloses a method for firing porous filtering ceramic tiles with ceramics polishing scrap. The method is implemented through raw materials processing, powder preparation, pressing molding, sintering and other processes performed on 50 to 70 percent of building ceramics polishing scrap mixed with 18 to 22 percent of calcined alumina, 0 to 10 percent of fired talc and 28 to 35 percent of light magnesium oxide. The porous filtering ceramic tiles prepared by the method not only have the function of protecting and purifying environment, but also have high modulus of rupture and good filtration performance. The method can effectively solve the problem of dealing with the building ceramics polishing scrap, can save natural ceramic raw materials, is simple in technological process of utilizing the ceramics polishing scrap to fire cordierite porous filtering ceramic tiles and low in cost, and has good application prospects in the fields of liquid pollution treatment, precise filtration and the like.

Owner:SOUTH CHINA UNIV OF TECH

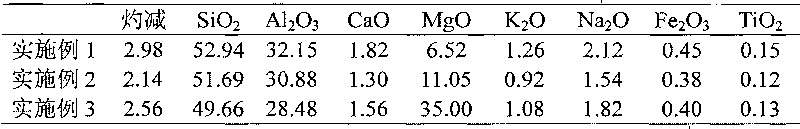

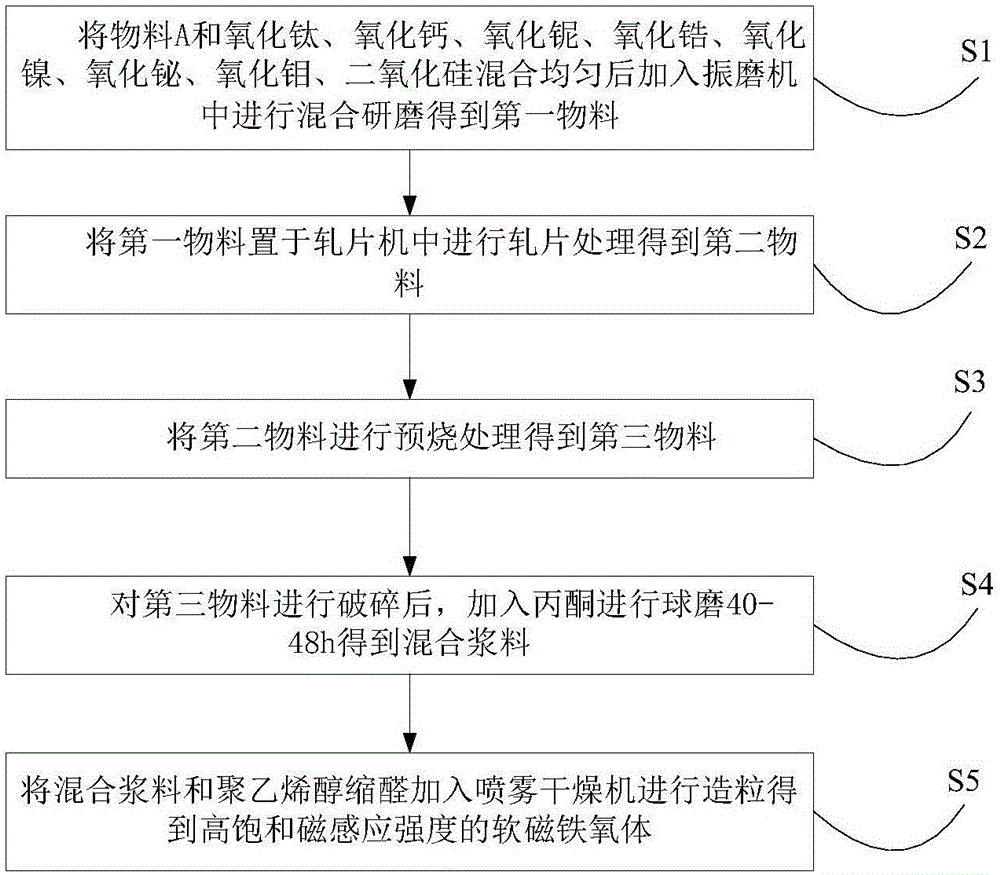

Soft-magnetic ferrite with low loss and high saturation flux density and preparation method therefor

The invention discloses a soft-magnetic ferrite with low loss and a high saturation flux density. The raw materials comprise materials A and materials B. The materials A comprise, by mole, 56-60 parts of iron oxide, 40-45 parts of manganese oxide, 7-10 parts of zinc oxide and 2-4 parts of copper oxide. With the total weight of the materials A as a base, the materials B comprise 2500-3000ppm, 300-700ppm of calcium oxide, 100-300ppm of niobium oxide, 400-800ppm of zirconium oxide, 1500-2000ppm of nickel oxide, 300-800ppm of bismuth oxide, 300-500ppm of molybdenum oxide, 200-500ppm of silicon oxide and 2000-2500ppm of bonding agents. The invention also discloses a preparation method for the soft-magnetic ferrite with low loss and a high saturation flux density.

Owner:ZHONGDE ELECTRONICS

High bending force resistant permanent magnet materials and preparation method thereof

ActiveCN103106992AReduce stray magnetic fieldEasy to useMagnetic materialsRheniumManufactured material

The invention discloses high bending force resistant permanent magnet materials and a preparation method thereof. The magnet materials comprise, by weight, 22-30% neodymium, 4.4-6% praseodymium, 0.044-0.06% lanthanum, 2-5% boron, 0.044-0.06% molybdenum, 0.044-0.06% nickel, 0.044-0.06% rhenium, 0.044-0.06% scandium and the balance ferrum. The high bending force resistant permanent magnet materials are uniform in organization, strong in structure and capable of improving bending force resistant performance of the materials and magnetic performance. The preparation method of the magnet material takes full use of praseodymium-neodymium waste to directly produce raw materials used by alloy, composition proportion is flexible, quality is well controlled, cost is lowered, the process is simple and powder waste with high oxygen content is fully used.

Owner:XUZHOU NANFANG YONGCI MATERIAL

Modified calcium-based desulfurizing agent for dry desulfurization of sintering gas and preparation method of modified calcium-based desulfurizing agent

InactiveCN103537177AChange the microstructureAvoid stickingDispersed particle separationSludgeAnthracite

The invention discloses a modified calcium-based desulfurizing agent for dry desulfurization of sintering gas and a preparation method of the modified calcium-based desulfurizing agent. The desulfurizing agent comprises the following raw material components in weight percent: 85-95% of limestone, 2.5-10% of urban domestic sludge and 2.5-6% of anthracite duff. A preparation method comprises the following steps: 1) uniformly mixing the limestone, the urban domestic sludge and the anthracite duff according to the proportions for further use; and 2) roasting the mixed raw materials for 20-30 minutes at 1000-1100 DEG C, naturally cooling to normal temperature, and crushing the materials until the grain size is 0.1-0.2mm, thus obtaining the modified calcium-based desulfurizing agent for dry desulfurization of sintering gas. The modified calcium-based desulfurizing agent for dry desulfurization of sintering gas, prepared by using the preparation method disclosed by the invention, has the advantages that the desulfurization efficiency for the sintering gas is over 93 percent, the preparation process is simple, and the raw materials are wide in source and low in cost.

Owner:武汉钢铁有限公司 +1

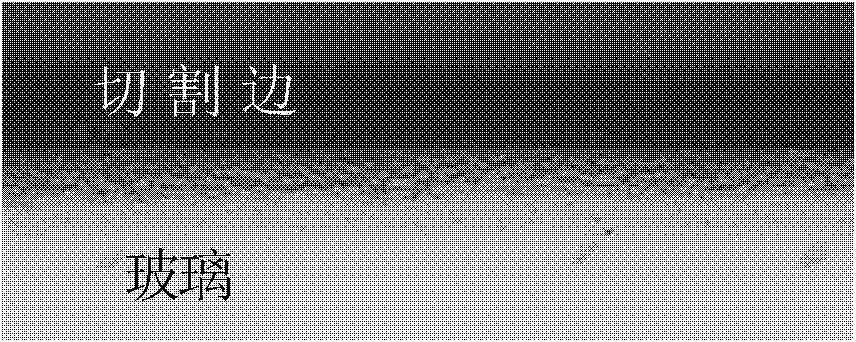

Method for increasing compressive strength of cut toughened glass

InactiveCN102424530ARealize blockbuster processChange the microstructureHydrofluoric acidCompressive strength

The invention discloses a method for increasing the compressive strength of cut toughened glass, characterized by corroding the edge of the cut toughened glass through using a chemical corrosive agent, wherein, the chemical corrosive agent is a hydrofluoric acid solution. According to the invention, by processing the cut edge of the cut toughened (tempered) glass through chemical corrosion, the glass edge defect point (point breakage, edge breakage) is narrowed down from 0.05 mm to less than 0.01 mm, the edge sawtooth turns into smooth, the edge appearance turns into uniform regular crystals from irregular serration, thus the microstructure of the toughened glass edge is changed, the crushing stress thin spots are eliminated, the consistency of the compressive strength is achieved, and the glass strength reaches more than 350 MPa. By adopting the method of chemically corroding the edge of the cut toughened glass to increase the compressive strength, the advantages of realization of sheet process, high efficiency, greatly reduced operation staff, and high yield rate are achieved, thus the invention has huge advantages of production cost, and realizes the sheet process of the toughened (tempered) glass.

Owner:TRULY OPTO ELECTRONICS

Thick film nanometer gold electrode slurry and preparation method thereof

InactiveCN101436441ASmall particle sizeChange the microstructureConductive materialNon-conductive material with dispersed conductive materialCelluloseSlurry

The invention relates to a lead-free thick film nanometer gold electrode slurry which selects nanometer gold powder as a main functional phase, in particular to a thick film nanometer gold electrode slurry and a method for preparing the same. The thick film nanometer gold electrode slurry is characterized by comprising the following components by weight portion: 60 to 90 portions of inorganic part and 40 to 10 portions of organic solvent, wherein the inorganic part comprises the following components by weight portion: 90 to 98 portions of noble metal nanometer gold powder, 2 to 10 portions of lead-free glass powder and 0 to 6 portions of inorganic additive; and the organic solvent comprises the following components by weight portion: 40 to 90 portions of terpineol, 4 to 10 portions of ethyl cellulose, 3 to 30 portions of ethyl caproate, 1 to 6 portions of nitro cellulose, 1 to 25 portions of triethanolamine, and 1 to 6 portions of sodium dodecylsulphonate. The invention changes the microstructure of the gold electrode slurry so as to change the conductivity, the printing performance and the connecting firmness of the slurry, thus the application of the gold electrode slurry to electronic parts and components, in particular high precision electronic parts and components is greatly expanded.

Owner:IRICO

Resin binder modified by Nano silicon dioxide, and preparation method

InactiveCN1727423AHigh strengthHigh tensile strengthNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesHigh resistancePolymer science

A nano-SiO2 modified resin adhesive for abrasive cloth is proportionally prepared from nano-SiO2, phenol, and form-aldehyde and aluminium oxide through dispersing, synthesizing and dewatering. Its advantages are high adhesion and high resistance to high temp, wearing and water.

Owner:张刚

Thick film circuit rare-earth electrode slurry based on stainless steel base material and preparation method thereof

InactiveCN106205773AAvoid harmSolve urgent problemsNon-conductive material with dispersed conductive materialCable/conductor manufactureOrganic solventRare earth

The invention discloses a thick film circuit rare-earth electrode slurry based on a stainless steel base material. The thick film circuit rare-earth electrode slurry comprises a compound function phase, an inorganic binding phase and an organic carrier, wherein the compound function phase consists of nano silver powder, palladium powder and a rare earth oxide; the inorganic binding phase consists of SiO2, CaO, B2O3, Al2O3, Bi2O3 and a nucleation agent; and the organic carrier consists of an organic solvent, macromolecule resin, a dispersing agent, a defoaming agent and a thixotropic agent. A preparation method of the thick film circuit rare-earth electrode slurry comprises the following steps: preparing the compound function phase; preparing the inorganic binding phase; preparing the organic carrier; and preparing the electrode slurry. The thick film circuit rare-earth electrode slurry prepared by the invention is good in electrical conductivity, high in adhesive force, high in weldability, high in welding dissolution resistance, good in printing and sintering characteristics and high in environmental protection capability, is matched with the stainless steel base material, and is good in wettability and compatibility with dielectric slurries and resistance slurries.

Owner:DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

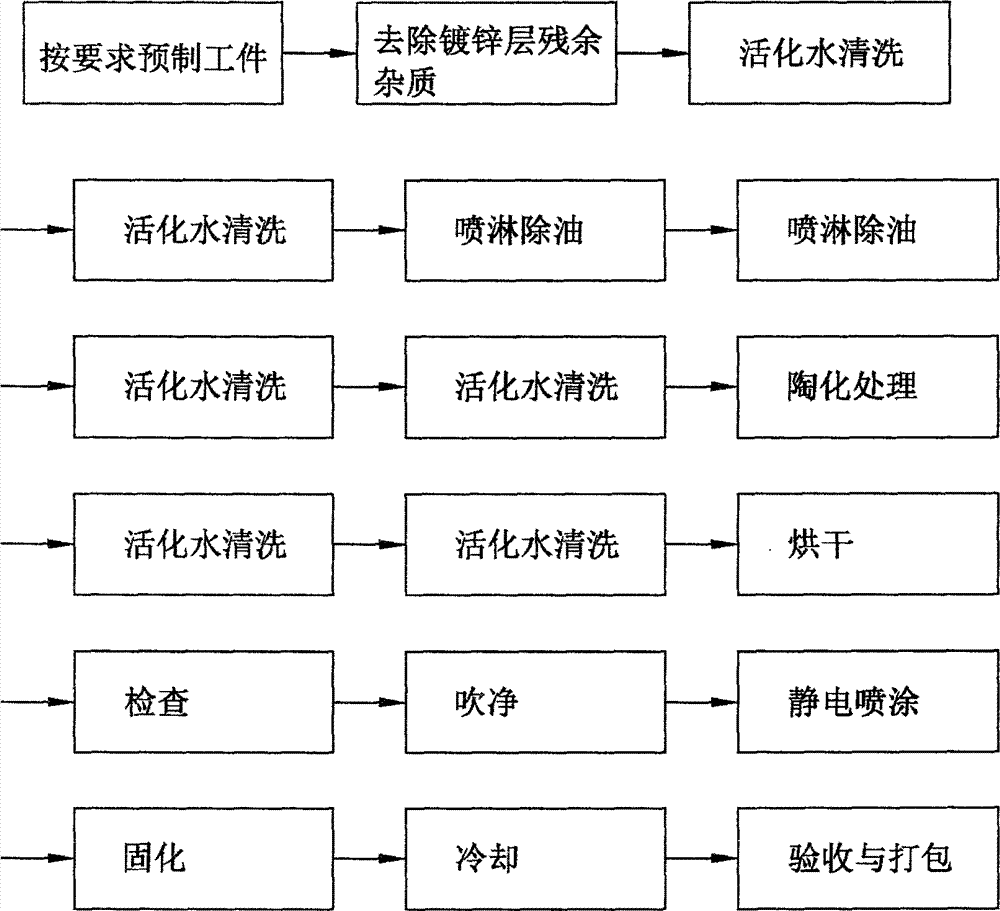

Surface rust preventing treatment process for iron art products

ActiveCN103205751AImprove coating qualityImprove water saving performanceLiquid surface applicatorsSuperimposed coating processProduction lineWater based

The invention relates to a surface rust preventing treatment process for iron art products and provides a novel spraying line production technique. The surface rust preventing treatment process is characterized in that traditional phosphating is replaced by ceramic treatment on a spraying flow production line, common urban tap water is replaced by small cluster water with activity in each washing link during spraying, and common water base degreasing fluid is replaced by small cluster water base degreasing fluid. Compared with traditional phosphating, the method uses non-phosphorus ceramic treatment for pretreatment in prior to nano spaying, and accordingly adhesive force between coating and metal can be increased evidently, and corrosion-resistant time of metal can be prolonged.

Owner:广东鸿图新材料科技有限公司

MnZn ferrite material and magnetic core for energy-saving lamp and electronic ballast

InactiveCN101183584AReduce manufacturing costEase of mass productionInorganic material magnetismInductances/transformers/magnets manufactureEngineeringBallast

The invention relates to a MnZn soft ferrite material and magnetic core used for an integrated energy-saving lamp and an electronic ballast; wherein the soft ferrite material comprises the Fe2O3 of 49mol% to 53 mol% and the MnO of 34mol% to 40mol%, and the rest ZnO. A first accessory component of CaCO3, one or both of the second accessory components of SiO2 and WO3, one but not only limited to one of the third accessory components of SnO2, TiO2, Nb2O5, V2O5, CoO are added to the principal component. The invention has the advantages that the MnZn soft ferrite magnetic core can be used for, but not only limited to the integrated energy-saving lamp and the electronic ballast field.

Owner:广东肇庆微硕电子有限公司 +1

Baking-free brick and production method thereof

The invention provides a baking-free brick and a production method thereof. The soil and regenerated aggregate can be added into the manufacturing raw material as raw materials for brick making, cement is used as a gelling agent, the actions of admixtures and a fusion agent are used to package and blend the soil and the fusion agent, the waste residue and waste material is fully utilized, and thusthe prepared baking-free brick has the characteristics that the strength is high, the waterproof effect is good, the curing period is short, the application of raw materials is wide, the resource comprehensive utilization benefit is high, the cost is low, the production process is environment-friendly, the raw materials can be recycled and reused, and the like.

Owner:欧施林

Method for preparing rare-earth-doped manganese-zinc ferrite material

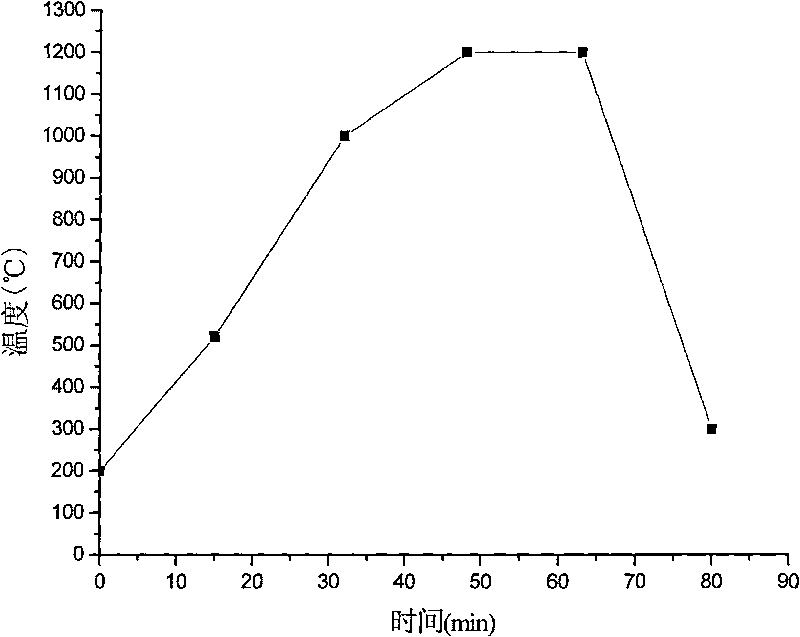

InactiveCN109553408AChanging grain boundary compositionChange ionic valencePolyvinyl alcoholRare earth

The invention relates to the technical field of magnetic materials, and discloses a method for preparing a rare-earth-doped manganese-zinc ferrite material, comprising the steps of adding manganese oxide, zinc oxide and iron oxide as main components to a ball mill and conducting ball milling to obtain a mixture A; pre-firing the mixture A, and then conducting cooling to room temperature to obtaina pre-fired material; adding the pre-sintered material, vanadium oxide, niobium oxide, bismuth trioxide, molybdenum oxide, phosphorus pentoxide, copper oxide and a composite rare earth additive into aball mill, and conducting secondary ball milling and drying to obtain a mixture B, wherein the composite rare earth additive is composed of cerium oxide, yttrium oxide and lanthanum oxide; adding a polyvinyl alcohol solution to the mixture B, conducting mixing and granulation, and then conducting sieving by a sieve of 40-80 mesh, so as to obtain pellets; adding the pellets into a molding machinefor pressing, so as to obtain a blank; and sintering the blank and conducting cooling. The rare-earth-doped manganese-zinc ferrite material prepared by the method of the invention has high initial magnetic conductivity and saturation magnetic flux density.

Owner:ZHONGDE ELECTRONICS

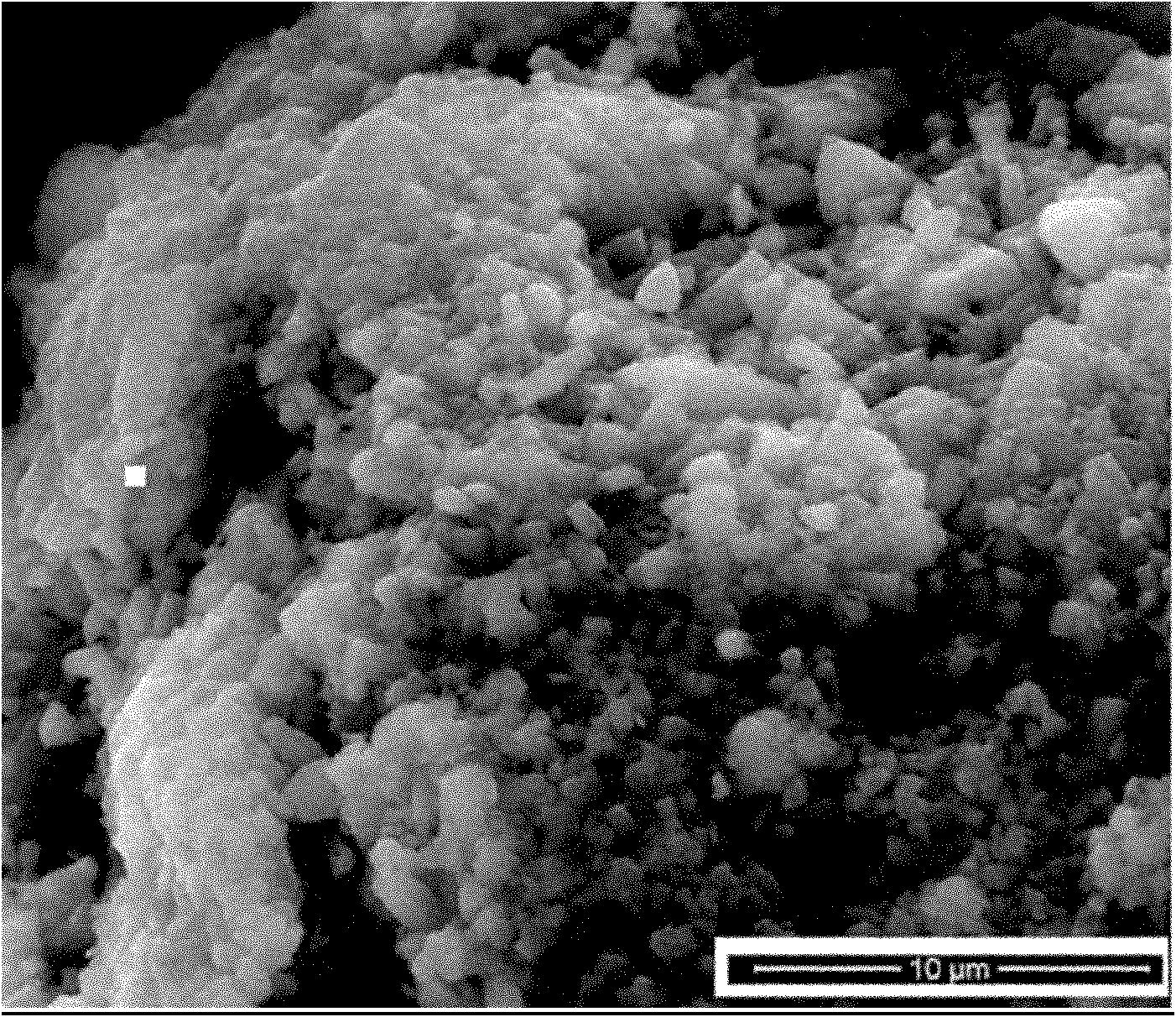

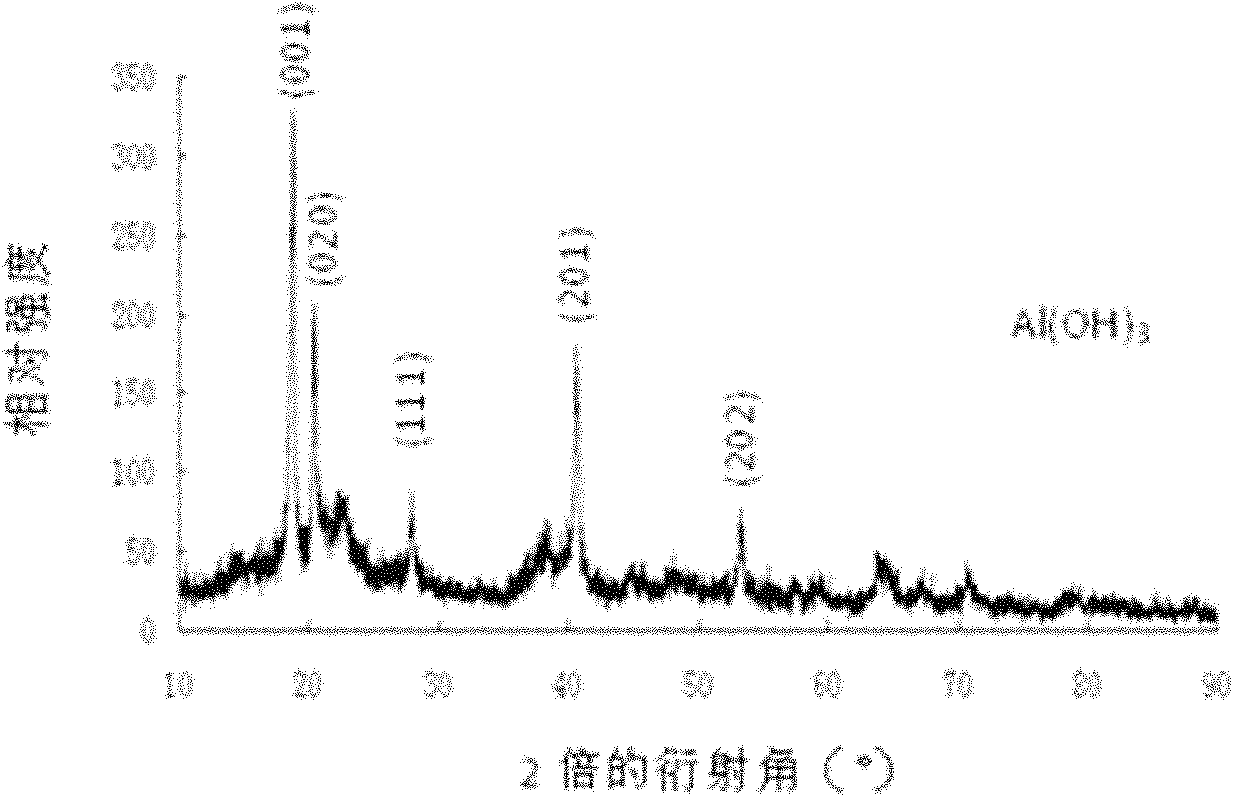

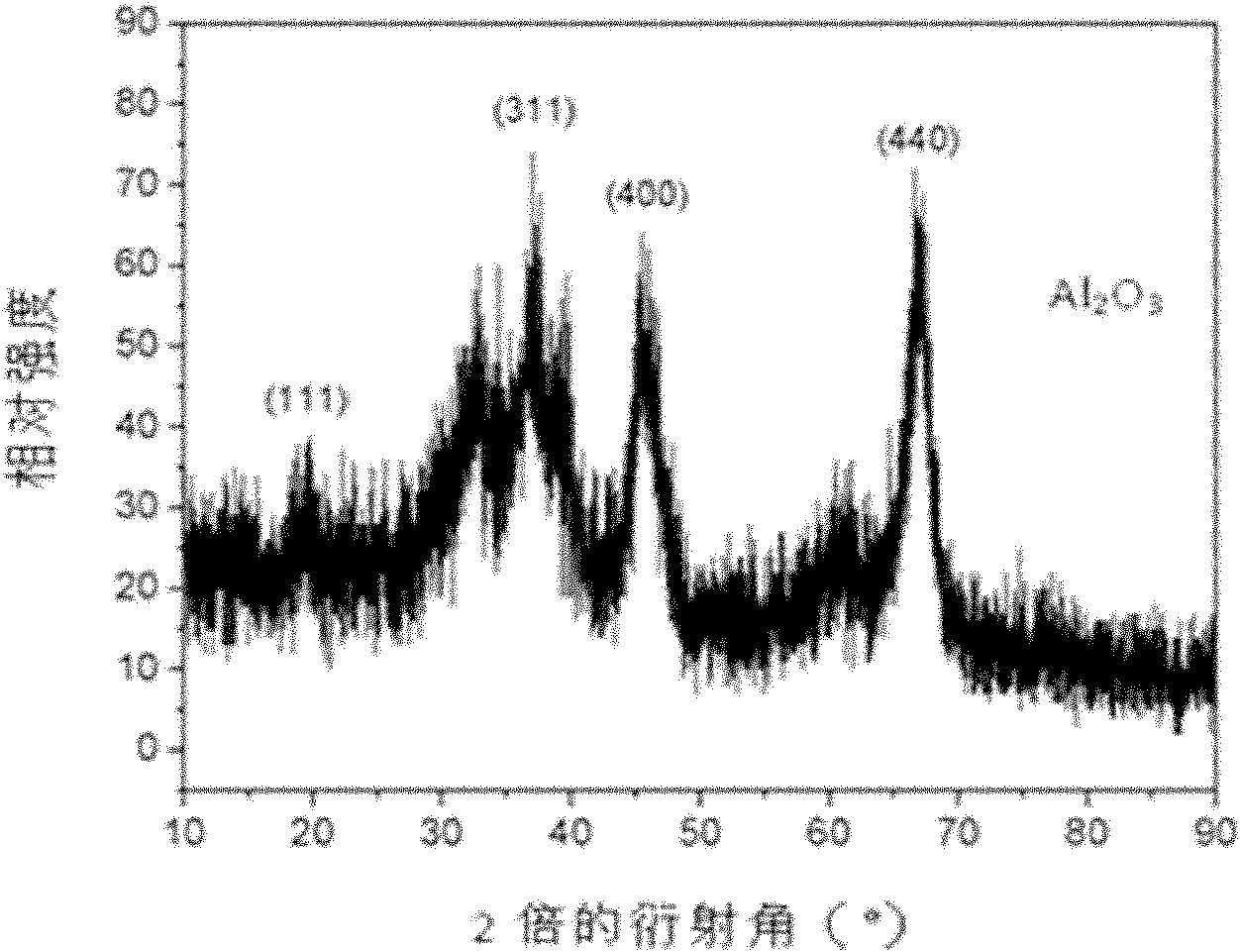

Preparation method of lamellar gamma-phase nano aluminum oxide

InactiveCN102107899ALow costReduce energy consumptionAluminium oxide/hydroxide preparationNanotechnologyElectrical resistance and conductanceNano al2o3

The invention relates to a preparation method of lamellar gamma-phase nano aluminum oxide, which comprises the following steps: (1) putting an aluminum powder material, of which the purity is greater than 99.5% and the particle size is 95-100 mu m, into a rolling vibrating mill of which the volume is 2.5 liters and the power is 0.12KW, and milling for 2-3 hours; (2) mixing the aluminum powder prepared in the step (1) and tap water in a weight ratio of 1:10, putting the mixture into an ultrasonic vibrator, and carrying out ultrasonic dispersion for 2-4 hours to prepare a white lacteal Al(OH)3 colloid; (3) putting the white lacteal Al(OH)3 colloid into a constant temperature drying box, and drying at 80 DEG C for 6 hours to obtain Al(OH)3 powder; and (4) finally, putting the Al(OH)3 powder into a box-type resistance furnace, drying at the constant temperature of 160-210 DEG C for 4 hours, and taking out to obtain the lamellar gamma-phase nano Al2O3. The preparation method provided by the invention is implemented at low temperature, is simple, and does not need any additive; and the prepared lamellar gamma-phase nano aluminum oxide has the advantages of low cost, low energy consumption, easy control, no environmental pollution and high repeatability, and is convenient for realizing industrialization.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

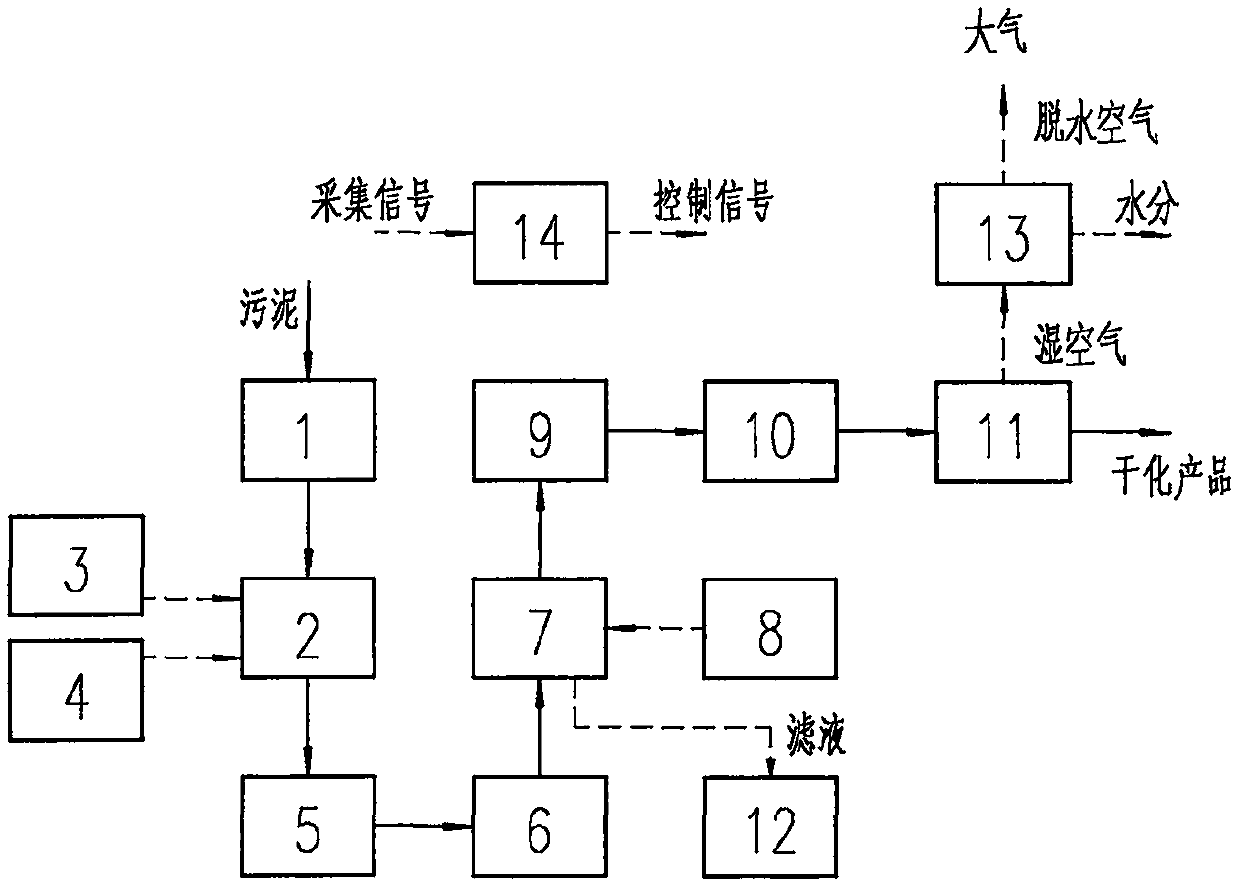

Heat-free sludge drying method and device system thereof

InactiveCN111153579AImprove dehydration effectLow viscositySludge treatment by de-watering/drying/thickeningSludge cakeProcess engineering

The invention discloses a heat-free sludge drying method and a device system thereof. The heat-free sludge drying method comprises the following technological steps: 1, sludge to be treated is conveyed into a stirring machine, a chemical conditioner and a physical conditioner are added, and mixing is performed until uniformity; (2) the uniformly mixed sludge is conveyed into a reaction tank, and stays for a certain time to ensure sufficient reaction; (3) after the reaction is completed, the sludge enters a squeezing device and is rapidly dehydrated; (4) the dehydrated mud cake enters a crusherand is crushed; (5) the crushed mud cake enters a drying bin and undergoes forced ventilation drying; and (6) the generated sewage enters a water treatment device and is treated. The dehydration process is short in time, and heating is not needed in the drying process; and the method has the advantages of high treatment efficiency, low energy consumption, low treatment cost, no secondary pollution and the like. The moisture content of the dried sludge cake is 20-40% and is adjustable, and the import requirements of various sludge final treatment processes can be met.

Owner:秦皇岛尼科环境科技有限公司

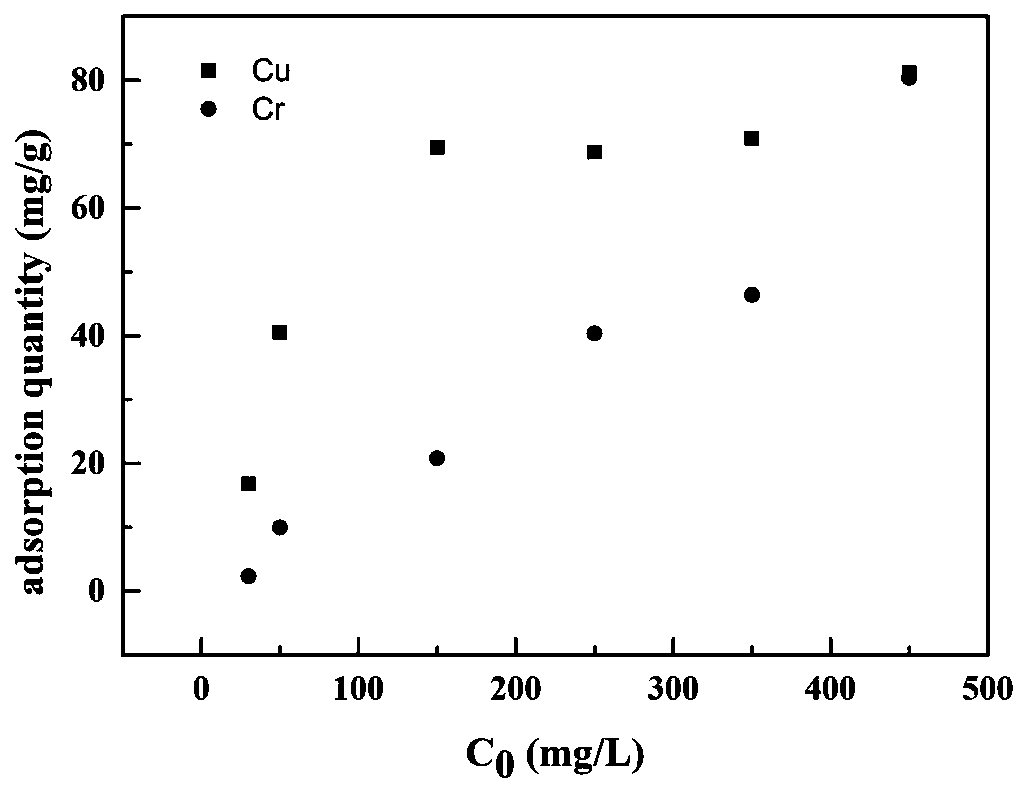

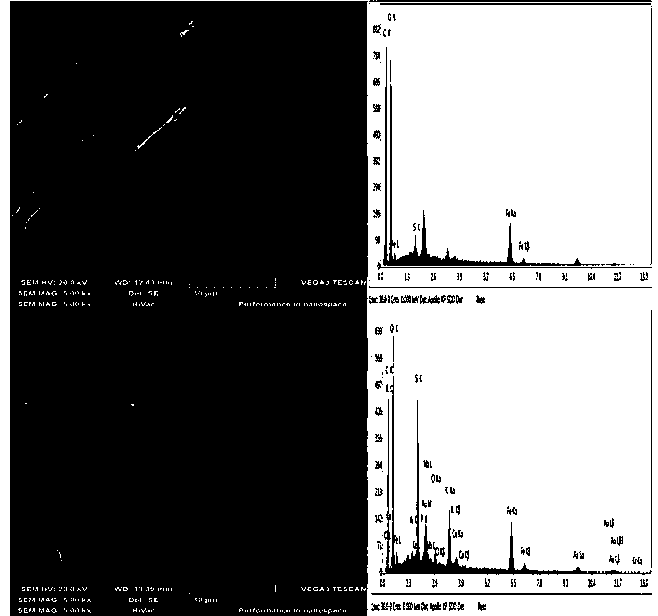

Preparation and applications of biocarbon supported thermally activated iron containing ore composite material

InactiveCN110841594ALow priceSimple manufacturing methodOther chemical processesWater contaminantsOxidation-Reduction ActivityMining engineering

The invention relates to preparation and applications of a biocarbon supported thermally activated iron containing ore composite material. Thermally activated iron containing ores are loaded on the surface of biocarbon. The preparation method comprises following steps: grinding iron containing ores and a biomass material, then evenly mixing ores and the biomass material according to a certain massratio, evenly pressing and moulding the mixture, burning the mixture in a reductive atmosphere, naturally cooling, and milling the mixture in an anaerobic atmosphere to obtain fine powder, namely thebiocarbon supported thermally activated iron containing ore composite material. The prepared biocarbon supported thermally activated iron containing ore composite material has the characteristics oflarge specific surface area, high stability, and strong oxidizing-reducing activity. Compared with biomass or thermally activated iron containing ores, the composite material has a prominently improved performance on removing or stabilizing heavy metal ions in water and soil, and thus can be used to process heavy metal pollution of water and soil.

Owner:CENT SOUTH UNIV

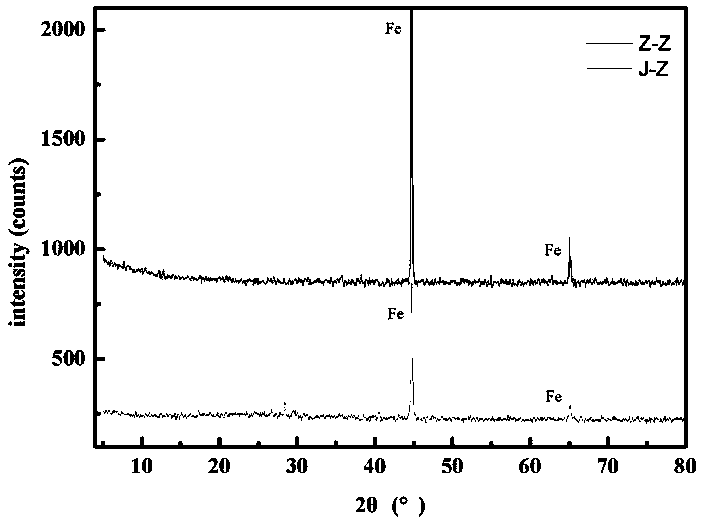

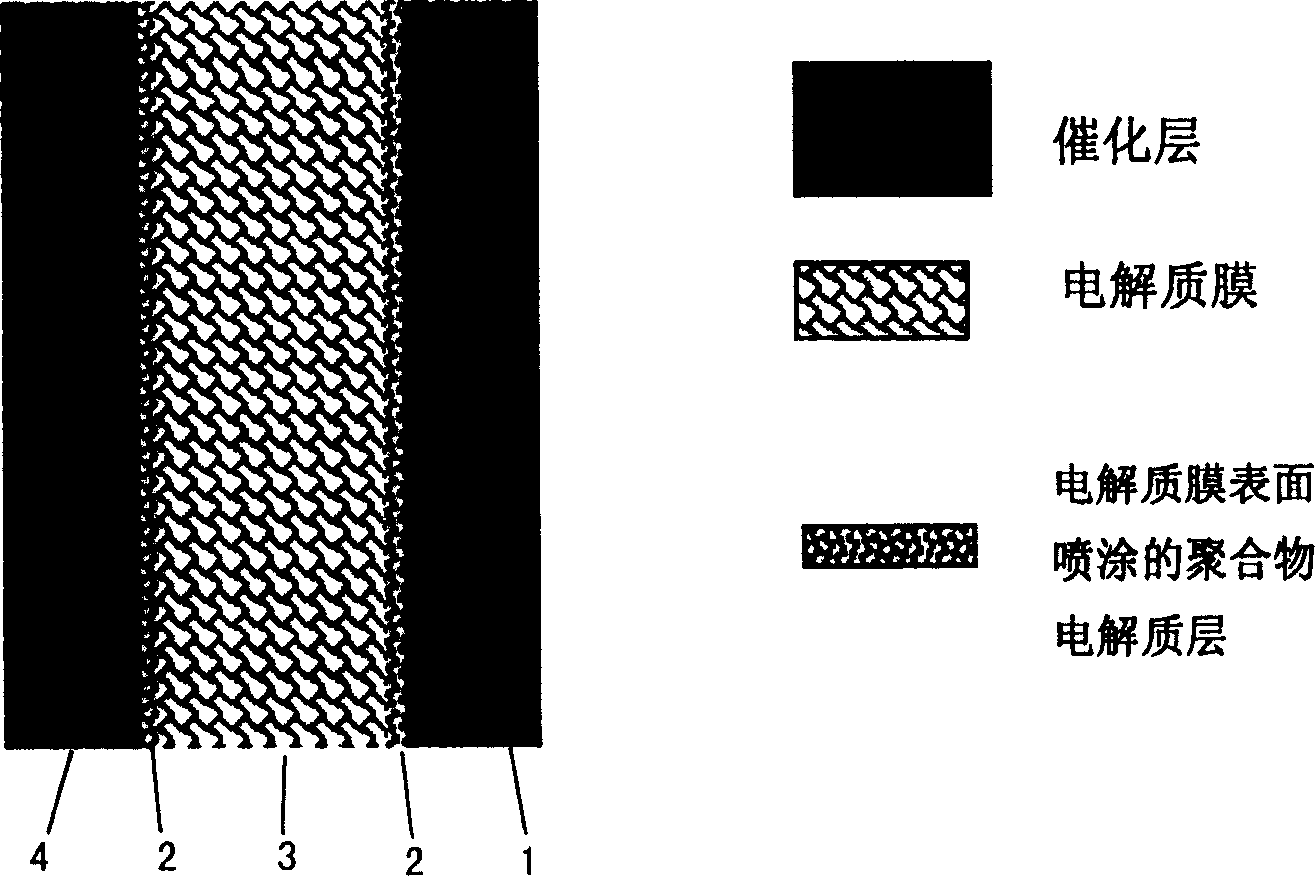

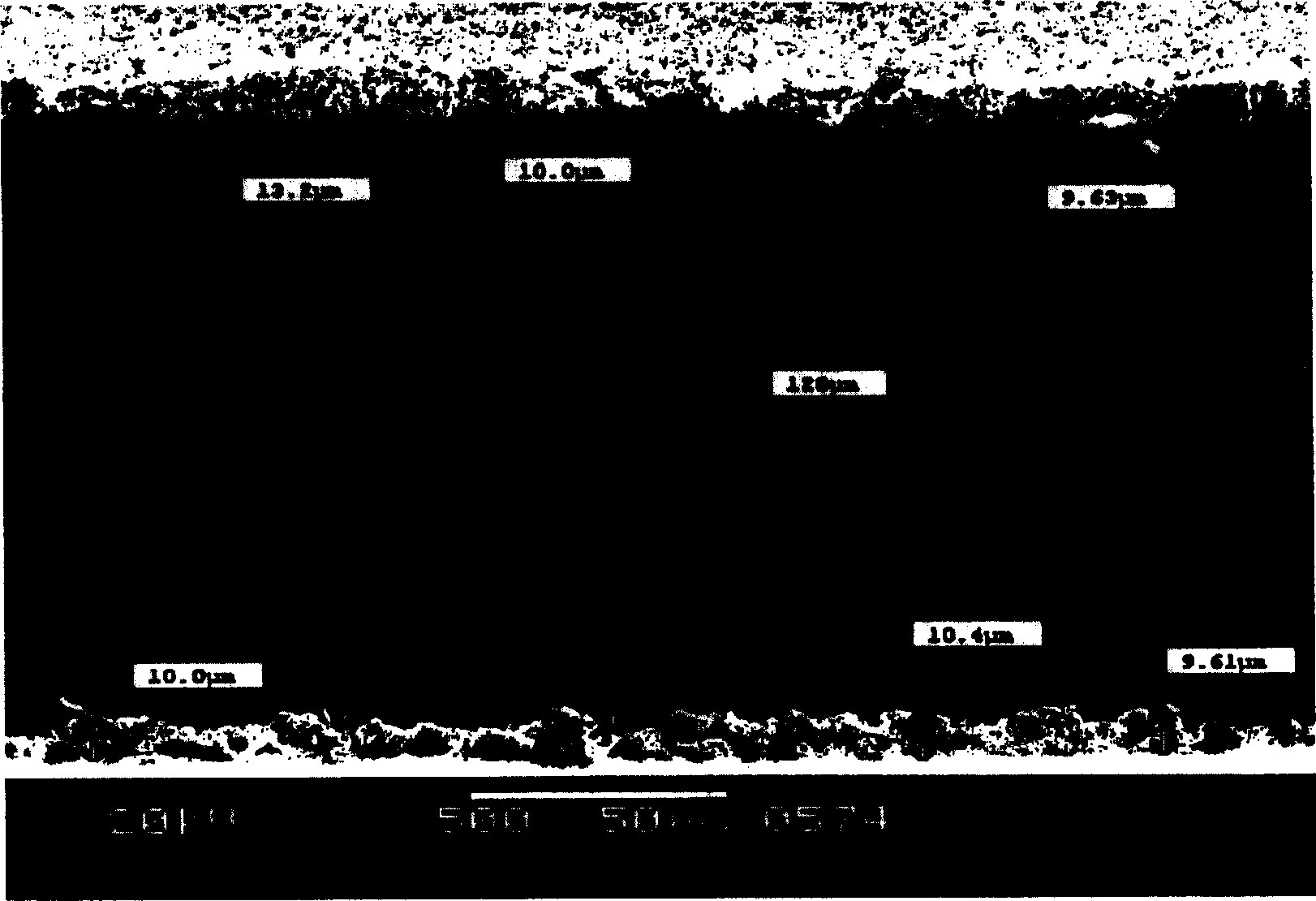

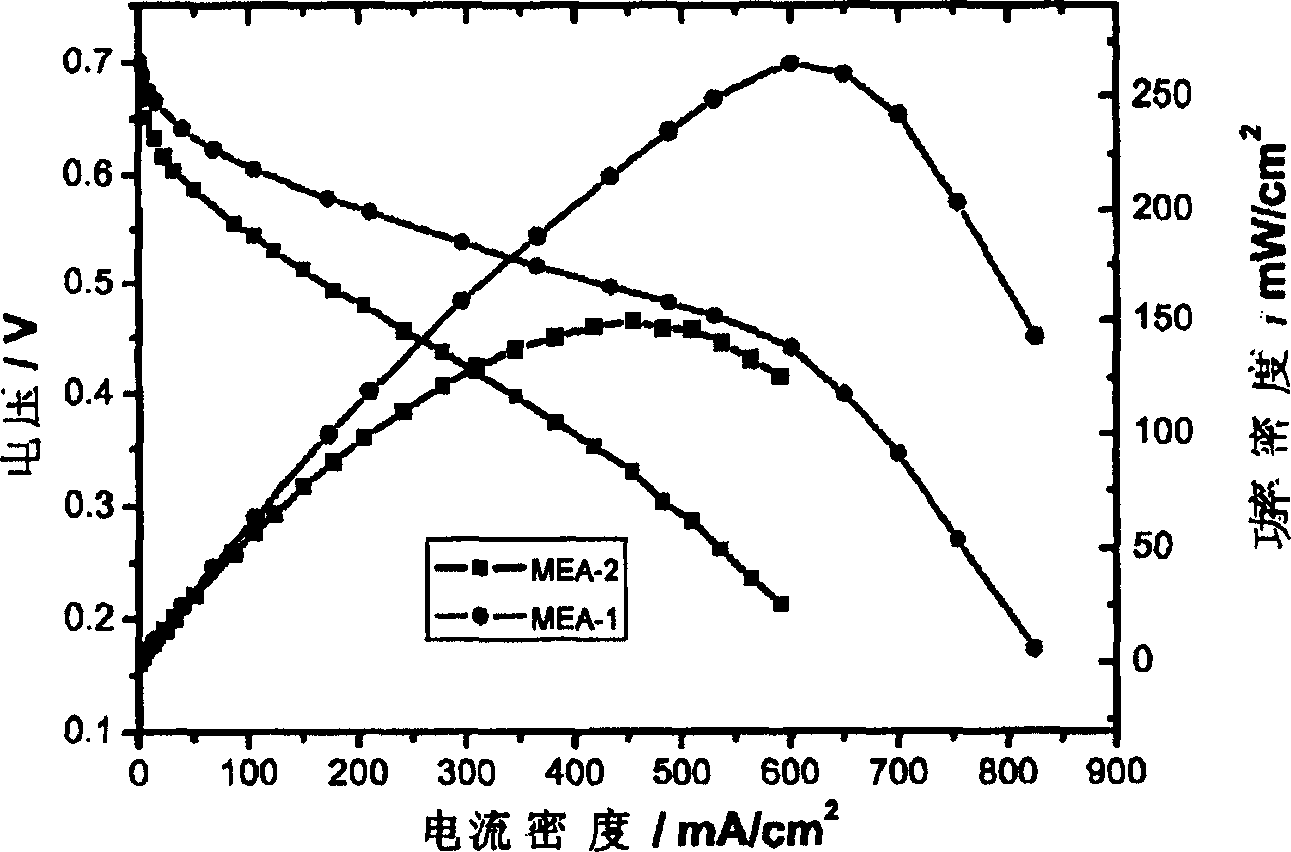

Proton exchange membrane fuel cell multi-layer membrane electrode structure and its preparing method

The membrane electrode in multiple layers is composed of anodic catalysis layer, membrane of electrolyte and cathodal catalysis layer. There is a layer of polymer dielectric between the membrane of electrolyte and the anodic catalysis layer, the cathodal catalysis layer. The layer of polymer dielectric can change microstructure of interface between the membrane of electrolyte and the anodic catalysis layer, the cathodal catalysis layer. The method includes steps: (1) preparing the layer of polymer dielectric; (2) preparing catalyst slurry; (3) preparing the anodic catalysis layer, the cathodal catalysis layer so as to obtain membrane electrode; (4) heat treating the membrane electrode obtained from step (3) so as to produce finished product. The invention improves binding force between catalysis layer and membrane of electrolyte, lowers contact resistance between membrane and electrode as well as enhances conduction of protons and electrons.

Owner:中科军联(张家港)新能源科技有限公司

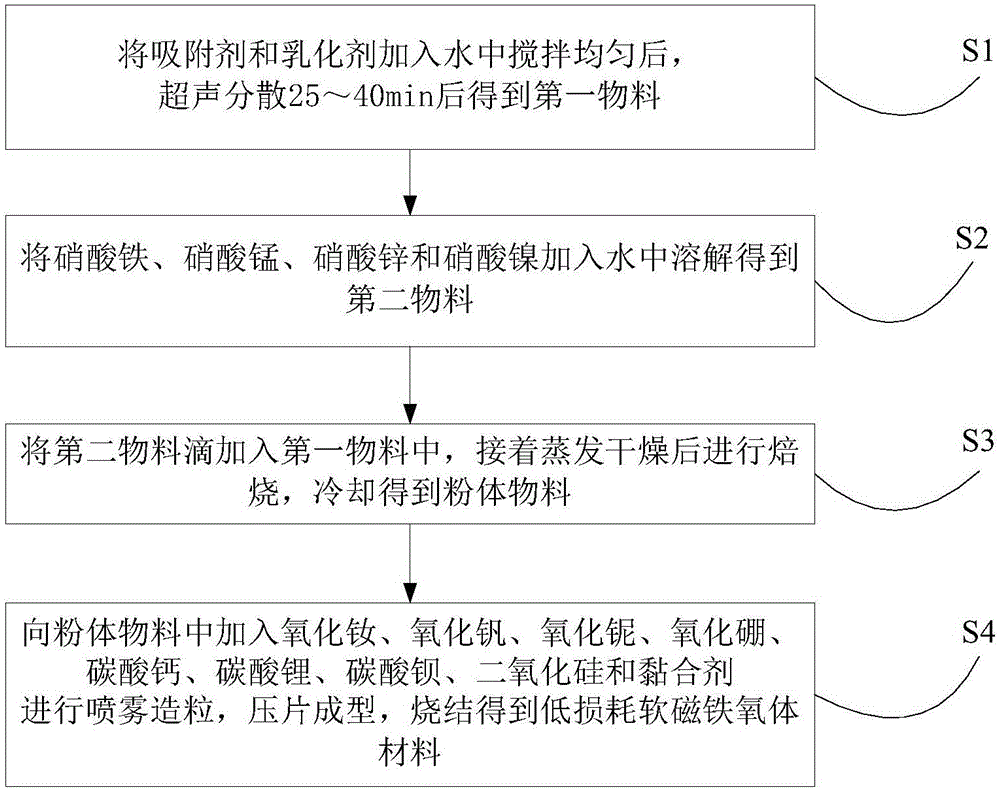

Low-loss soft magnetic ferrite material and preparation method thereof

The invention discloses a low-loss soft magnetic ferrite material which comprises main materials and auxiliary materials, wherein the main materials comprise the following components in parts by mole: 57 to 60 parts of ferric nitrate, 40 to 42 parts of manganese nitrate, 9-12 parts of zinc nitrate and 8 to 10 parts of nickel nitrate; by using the total weight of the main materials as a reference, the auxiliary materials comprise the following components: 300 to 400 ppm of neodymium oxide, 300 to 400 ppm of vanadium oxide, 400 to 600 ppm of niobium oxide, 300 to 700 ppm of boron oxide, 50 to 200 ppm of calcium carbonate, 20 to 100 ppm of lithium carbonate, 20 to 80 ppm of barium carbonate, 250 to 800 ppm of silica, 2000 to 2500 ppm of an adhesive, 3*10<6> to 5*10<6> ppm of an adsorbent, 300 to 500 ppm of an emulsifier. The invention also discloses a method for preparing the low-loss soft magnetic ferrite material; the magnetic core is low in loss and the saturation induction density is high.

Owner:ZHONGDE ELECTRONICS

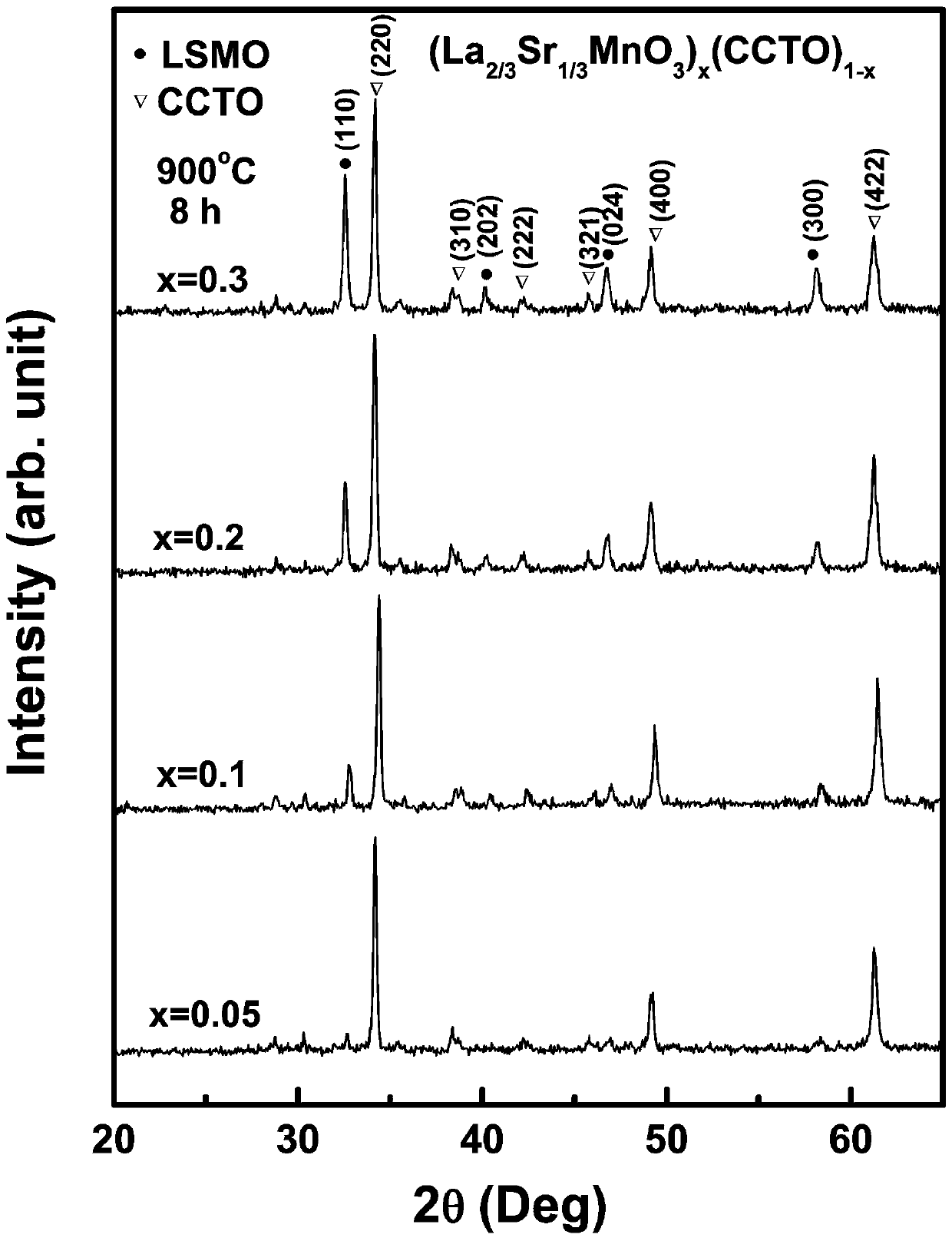

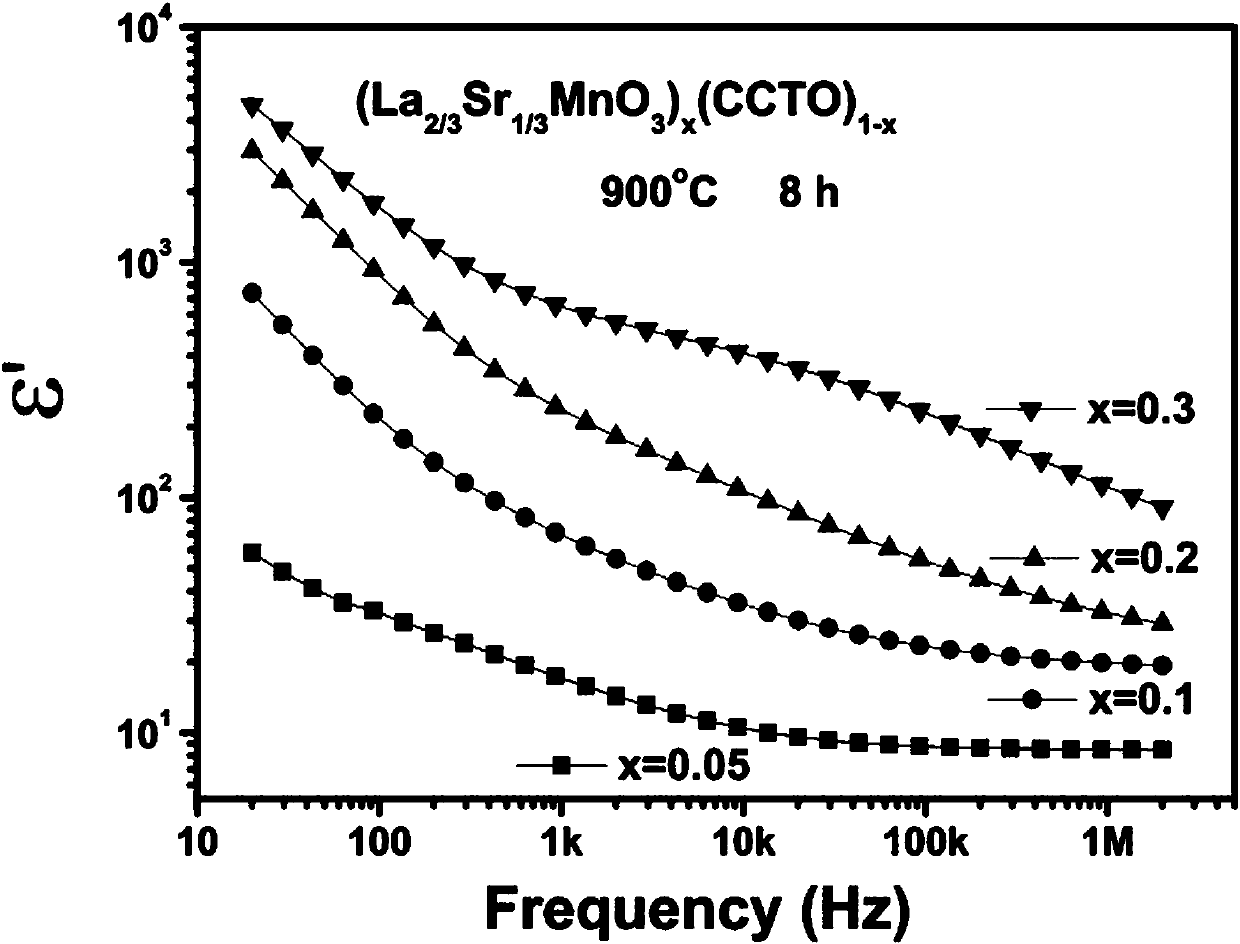

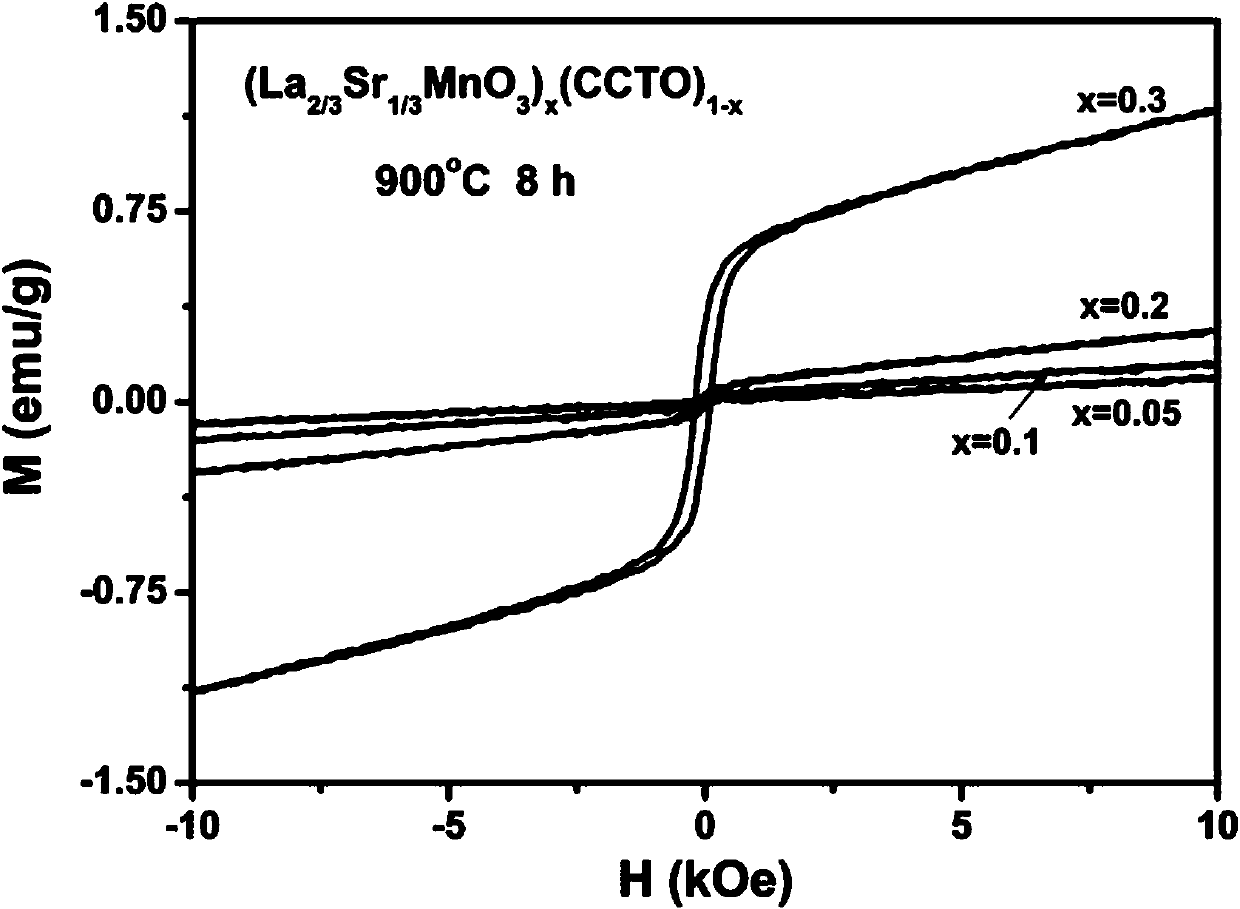

Method for preparing lanthanum strontium manganite/copper calcium titanate composite magnetoelectric ceramic material by virtue of sol-gel method

InactiveCN107759216AImprove uniformityImprove featuresInductances/transformers/magnets manufactureLanthanum strontium manganiteAdhesive

The invention belongs to the technical field of ceramic synthesis and provides a method for preparing a strontium lanthanum manganate / copper calcium titanate composite magnetoelectric ceramic materialby virtue of a sol-gel method. The method comprises the steps of respectively preparing lanthanum strontium manganite (LSMO) precursor powder, copper calcium titanate and CCTO precursor powder by virtue of the sol-gel method, mixing the LSMO precursor powder with the CCTO precursor powder, adding an adhesive, uniformly mixing, pressing to form a ceramic blank, and sintering a ceramic blank, so asto obtain a strontium lanthanum manganate / copper calcium titanate (LSMO-CCTO) composite magnetoelectric ceramic sample. The method has the beneficial effects that the raw materials are low in cost; components in the reaction process are controllable, and an impure phase is avoided; the gelling time is short; a preparation process is simple, and the dielectric property and magnetism of the ceramicsample have very strong regularity; a ceramic wafer is high in density and grain uniformity; and the process is simple and easy for industrial production, the prepared ceramic sample is high in density and grain uniformity and excellent in magnetoelectric performance.

Owner:TAIYUAN UNIV OF TECH

Soft-magnetic ferrite with high saturation magnetic induction and preparation method thereof

The invention discloses soft-magnetic ferrite with high saturation magnetic induction. Raw materials of the soft-magnetic ferrite comprise first group of materials and second group of materials; the first group of materials comprise, in percent by substance amount, 52.0-53.5 mol% of ferric oxide, 38.0-42.0 mol% of manganese oxide, and 6.0-8.0 mol% of zinc oxide; by taking the total mass of the first group of materials as a reference, the second group of materials comprise 25-100 ppm of silicon oxide, 300-800 ppm of calcium oxide, 300-700 ppm of niobium oxide, 300-500 ppm of zirconium oxide, and 2500-3000 ppm of nickel oxide. The invention also discloses a preparation method of the above soft-magnetic ferrite with high saturation magnetic induction. The obtained soft-magnetic ferrite possesses high saturation magnetic induction, relatively high initial magnetic permeability and low magnetic core loss.

Owner:ZHONGDE ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com