Soft-magnetic ferrite with low loss and high saturation flux density and preparation method therefor

A technology of magnetic induction and soft ferrite, which is applied in the field of soft ferrite, can solve problems such as the inability to guarantee mass production, and achieve the effects of promoting mass transfer and sintering, increasing resistivity, and reducing core loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

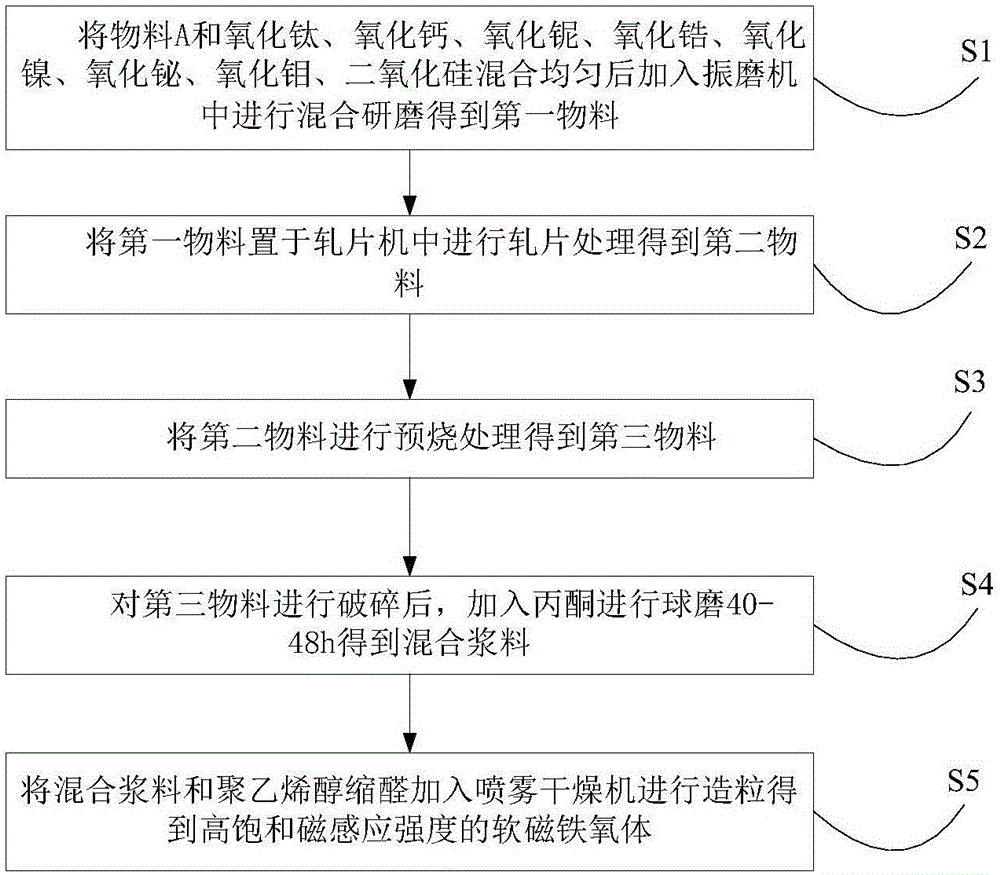

[0023] refer to figure 1 , the preparation method of a soft ferrite with low loss and high saturation magnetic induction proposed by the present invention comprises the following steps:

[0024] S1. Mix material A with titanium oxide, calcium oxide, niobium oxide, zirconium oxide, nickel oxide, bismuth oxide, molybdenum oxide, and silicon dioxide evenly, then add it to a vibration mill for mixing and grinding to obtain the first material;

[0025] S2, placing the first material in a flaking machine for flaking to obtain a second material;

[0026] S3. Pre-burning the second material to obtain the third material;

[0027] S4. After crushing the third material, add acetone and perform ball milling for 40-48 hours to obtain a mixed slurry;

[0028] S5. Add the mixed slurry and binder into a spray dryer for granulation to obtain soft ferrite with high saturation magnetic induction.

Embodiment 1

[0031] A kind of soft magnetic ferrite with low loss and high saturation magnetic induction proposed by the present invention, its raw material includes material A and material B; wherein material A comprises 56 parts by mole of iron oxide, 45 parts of manganese oxide, 7 parts of zinc oxide, 4 parts of copper oxide; based on the total mass of material A, material B includes: 2500ppm titanium oxide, 700ppm calcium oxide, 100ppm niobium oxide, 800ppm zirconium oxide, 1500ppm nickel oxide, 800ppm bismuth oxide, 300ppm molybdenum oxide, and 500ppm silicon dioxide , Adhesive 2000ppm.

[0032] The preparation method of the above-mentioned soft ferrite with low loss and high saturation magnetic induction that the present invention also proposes comprises the following steps:

[0033] S1. Mix material A with titanium oxide, calcium oxide, niobium oxide, zirconium oxide, nickel oxide, bismuth oxide, molybdenum oxide, and silicon dioxide evenly, then add it to a vibration mill for mixin...

Embodiment 2

[0039] A kind of soft magnetic ferrite with low loss and high saturation magnetic induction proposed by the present invention, its raw material includes material A and material B; wherein material A comprises 60 parts by mole of iron oxide, 40 parts of manganese oxide, 10 parts of zinc oxide, 2 parts of copper oxide; based on the total mass of material A, material B includes: 3000ppm titanium oxide, 300ppm calcium oxide, 300ppm niobium oxide, 400ppm zirconium oxide, 2000ppm nickel oxide, 300ppm bismuth oxide, 500ppm molybdenum oxide, and 200ppm silicon dioxide , Adhesive 2500ppm.

[0040] The preparation method of the above-mentioned soft ferrite with low loss and high saturation magnetic induction that the present invention also proposes comprises the following steps:

[0041] S1. Mix material A with titanium oxide, calcium oxide, niobium oxide, zirconium oxide, nickel oxide, bismuth oxide, molybdenum oxide, and silicon dioxide evenly, then add it to a vibration mill for mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com