Patents

Literature

56331results about How to "Promote growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

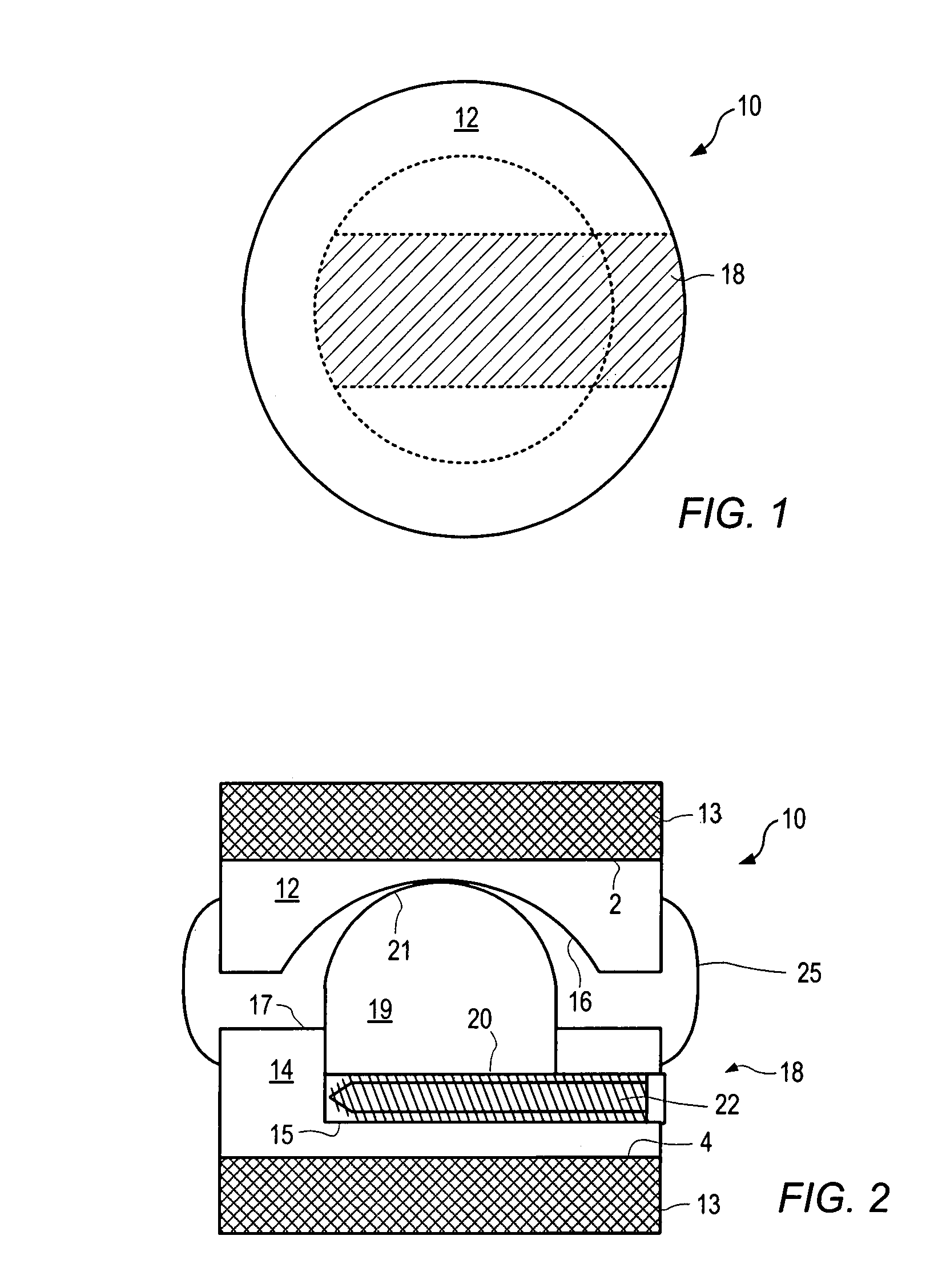

Porous tissue scaffoldings for the repair of regeneration of tissue

InactiveUS6333029B1Promote growthPromote regenerationPeptide/protein ingredientsAntipyreticRepair tissueOpen cell

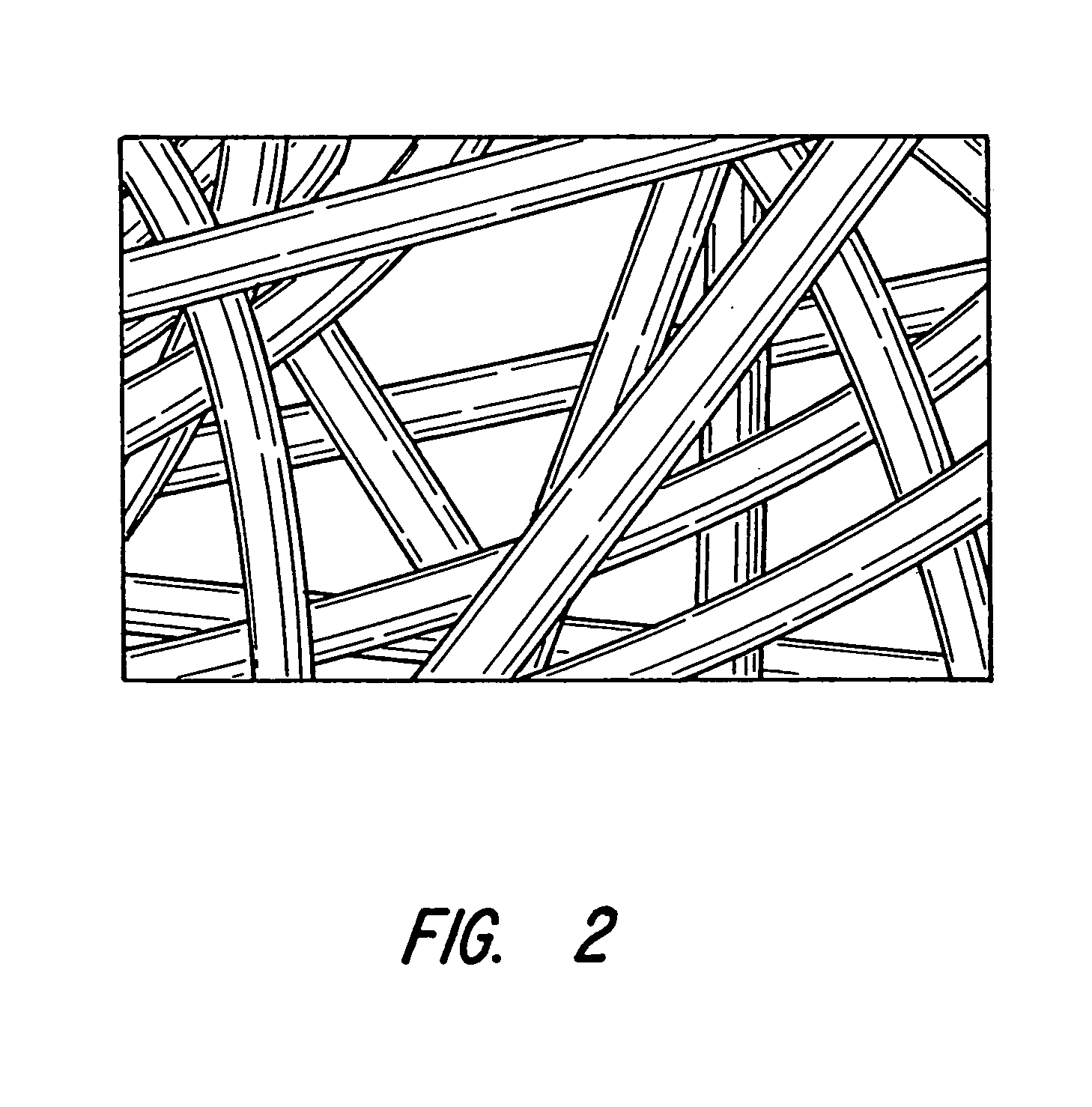

The present patent describes a three-dimensional inter-connected open cell porous foams that have a gradient in composition and / or microstructure through one or more directions. These foams can be made from a blend of absorbable and biocompatible polymers that are formed into foams having a compositional gradient transitioning from predominately one polymeric material to predominately a second polymeric material. These gradient foams are particularly well suited to tissue engineering applications and can be designed to mimic tissue transition or interface zones.

Owner:ETHICON ENDO SURGERY INC

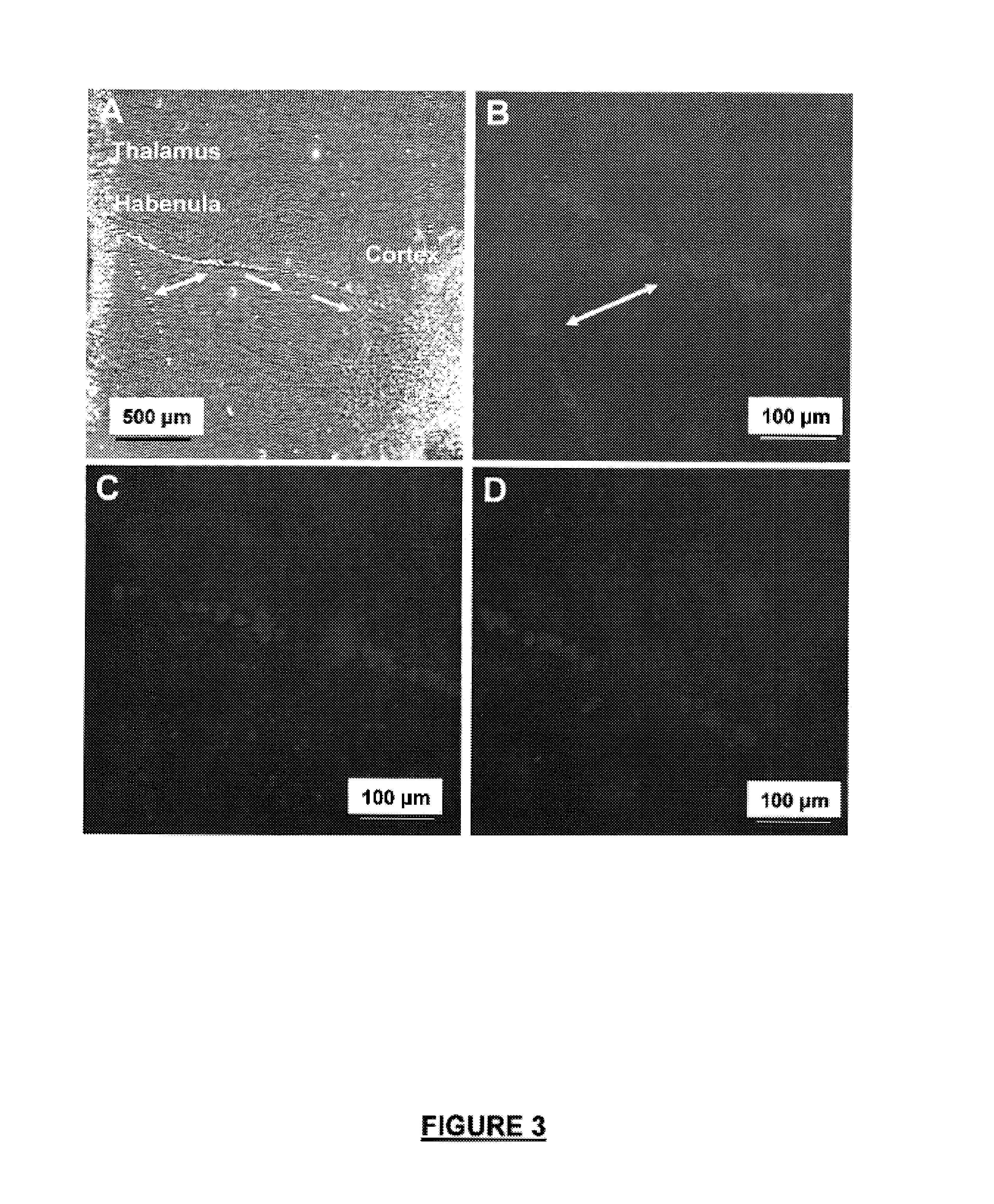

Neural regeneration peptides and methods for their use in treatment of brain damage

InactiveUS7563862B2High expressionEasy SurvivalPeptide/protein ingredientsGenetic material ingredientsNervous systemInjury brain

The invention discloses a family of peptides termed NRP compounds or NRPs that can promote neuronal migration, neurite outgrowth, neuronal proliferation, neural differentiation and / or neuronal survival, and provides compositions and methods for the use of NRPs in the treatment of brain injury and neurodegenerative disease. NRP compounds can induce neurons and neuroblasts to proliferate and migrate into areas of damage caused by acute brain injury or chronic neurodegenerative disease, such as exposure to toxins, stroke, trauma, nervous system infections, demyelinating diseases, dementias, and metabolic disorders. NRP compounds may be administered directly to a subject or to a subject's cells by a variety of means including orally, intraperitoneally, intravascularly, and directly into the nervous system of a patient. NRP compounds can be formulated into pharmaceutically acceptable dose forms for therapeutic use. Methods for detecting neural regeneration, neural proliferation, neural differentiation, neurite outgrowth and neural survival can be used to develop other neurally active agents.

Owner:CURONZ HLDG

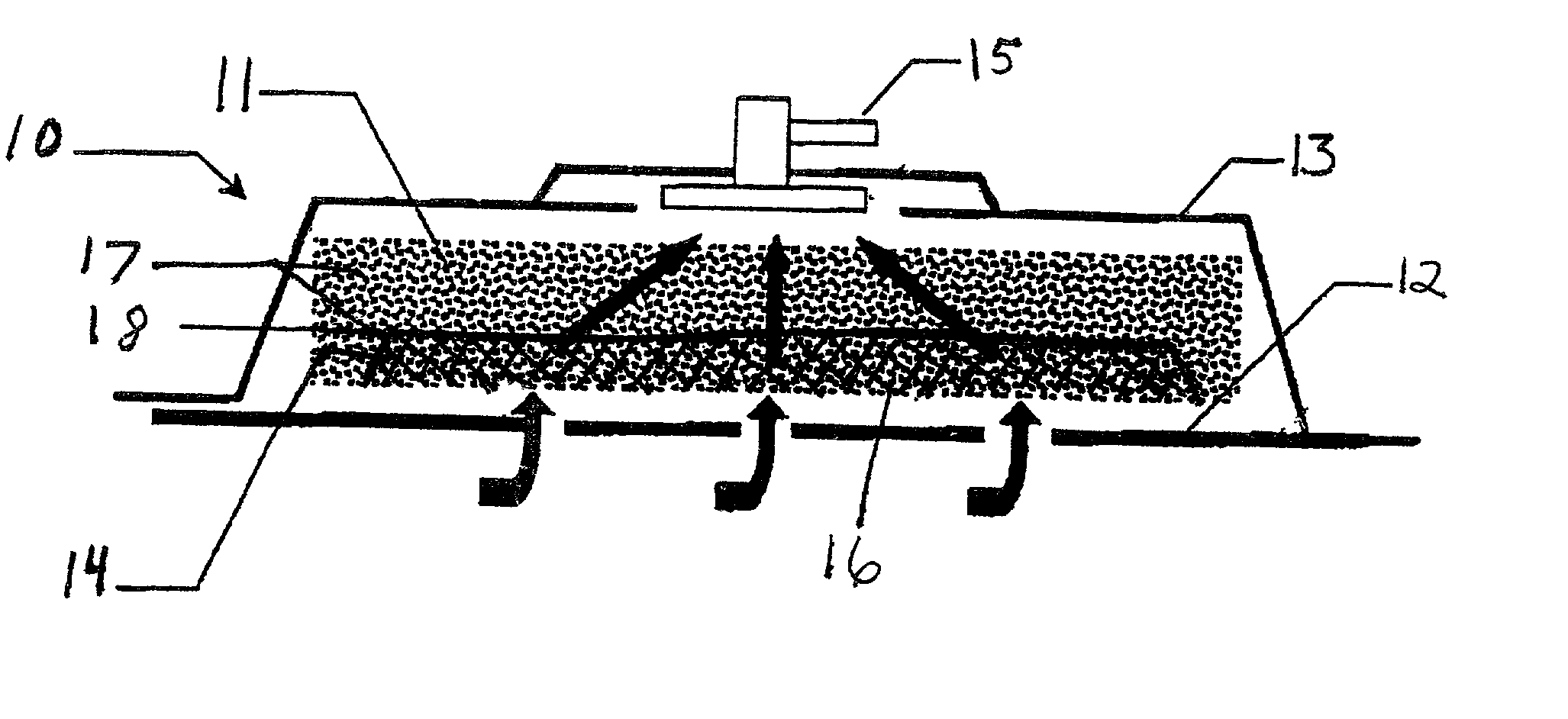

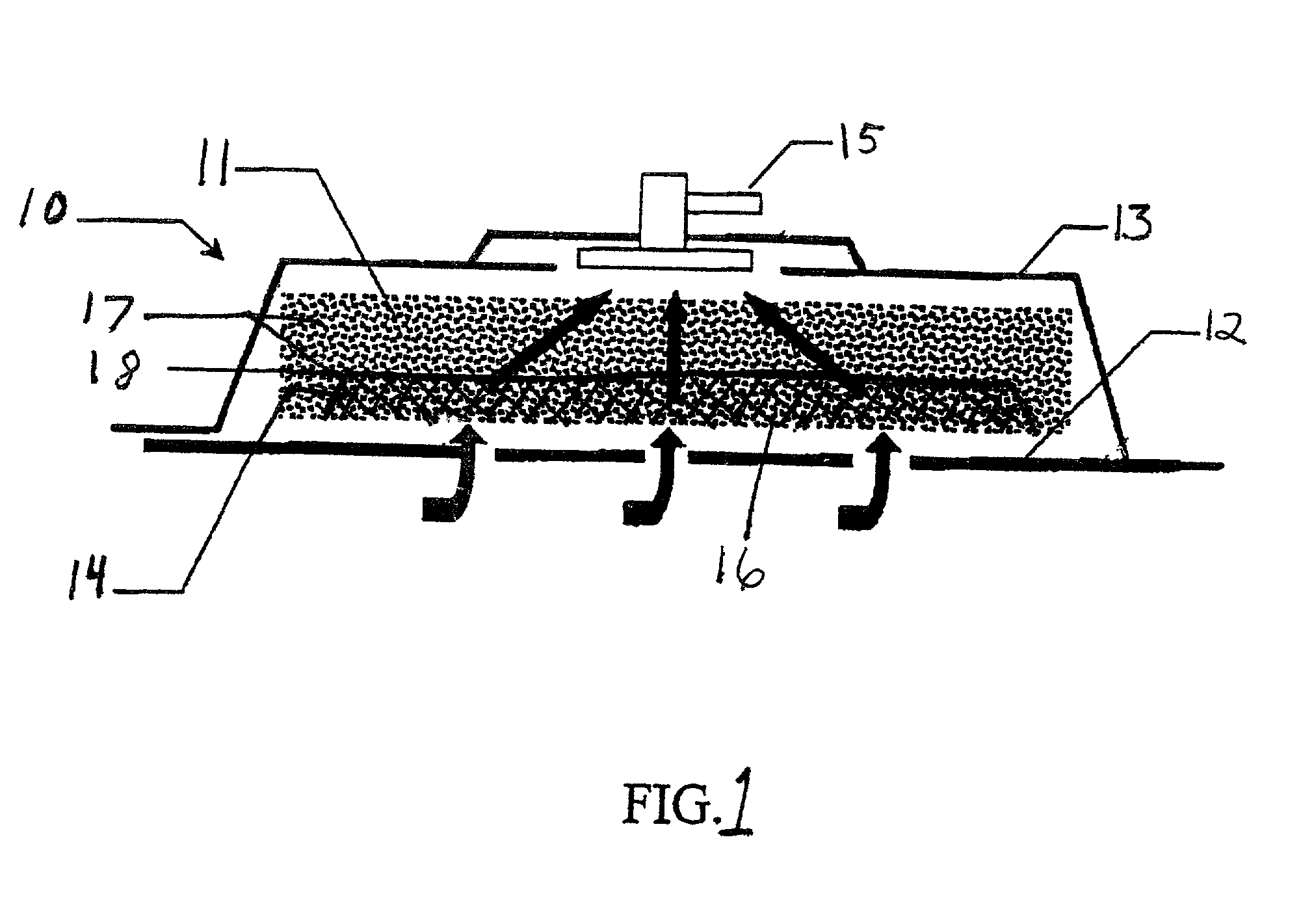

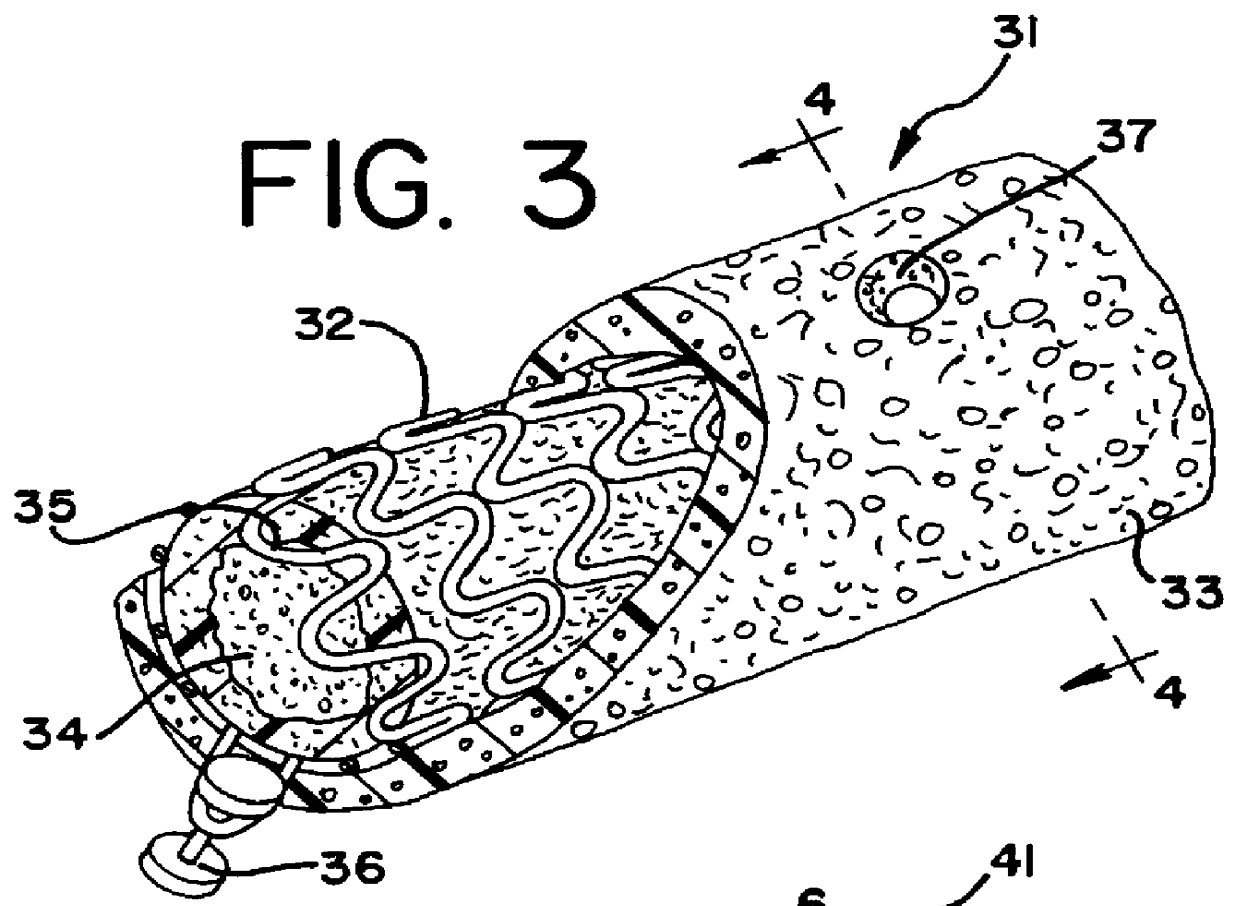

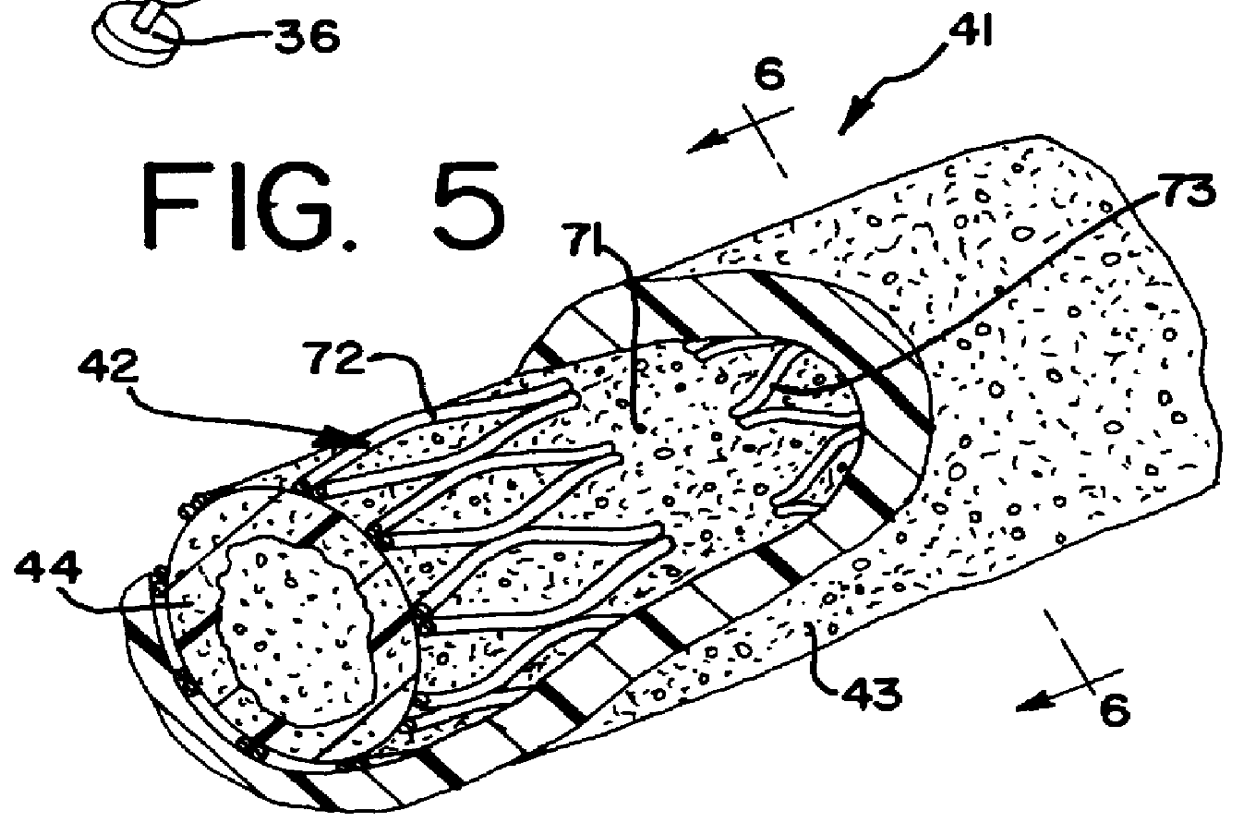

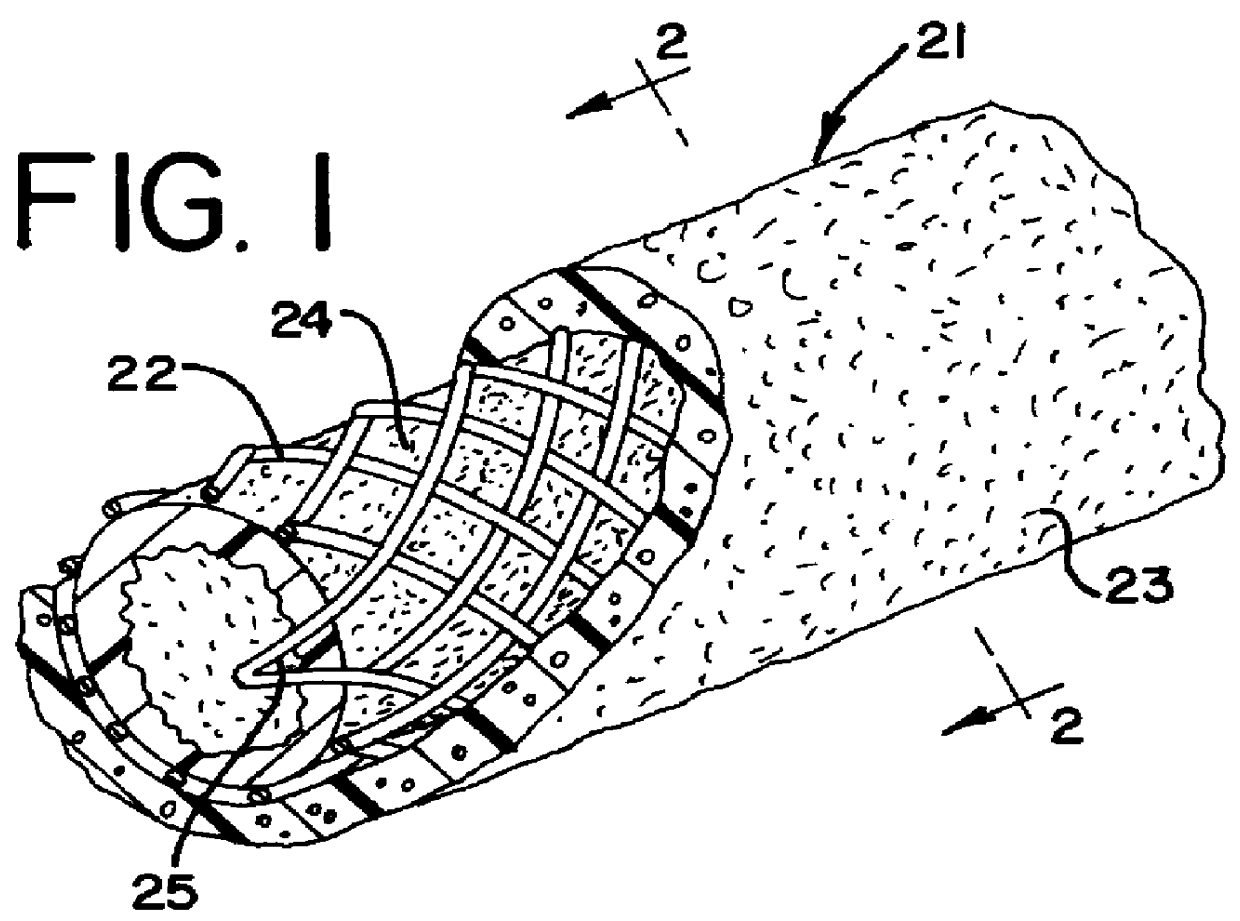

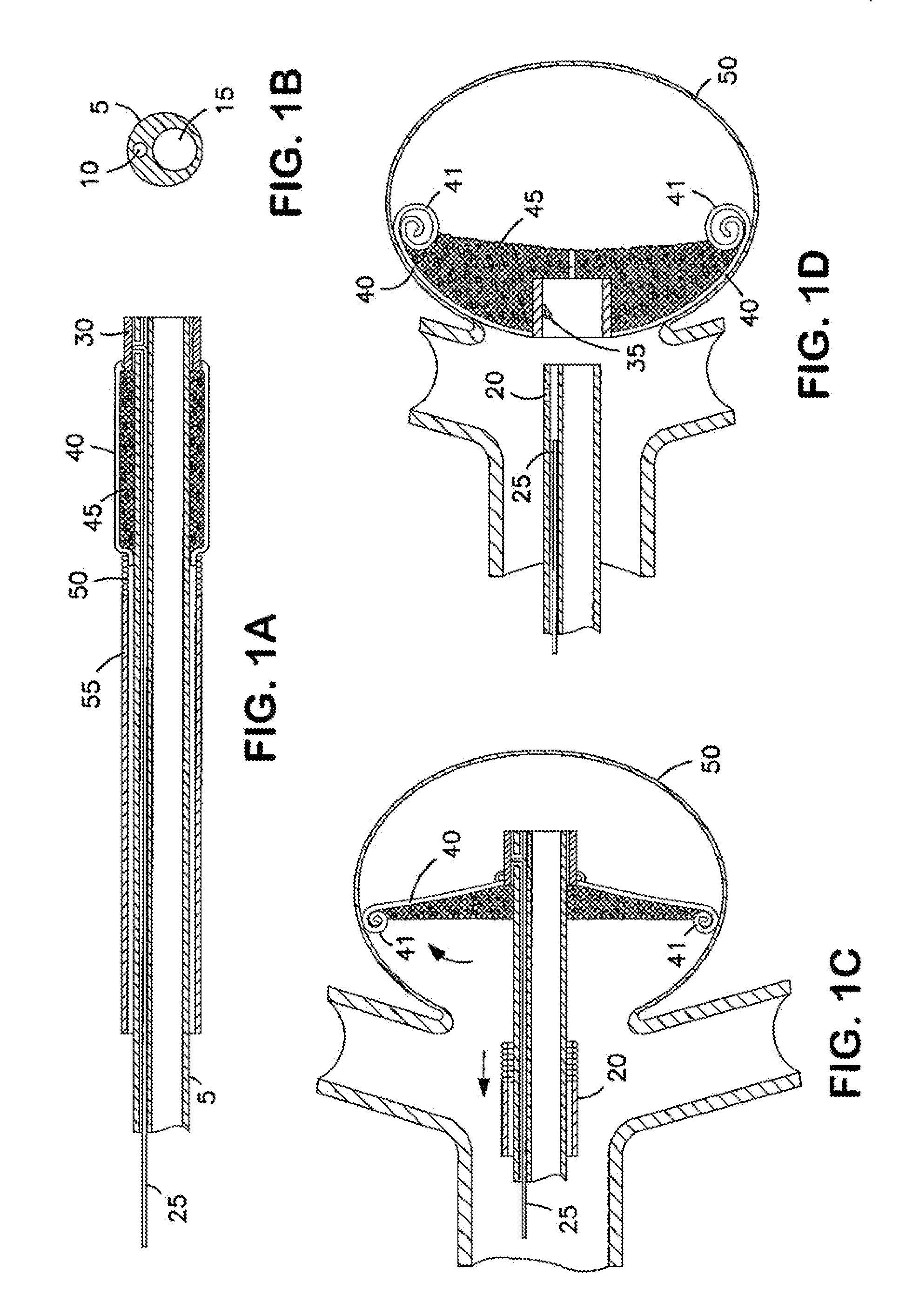

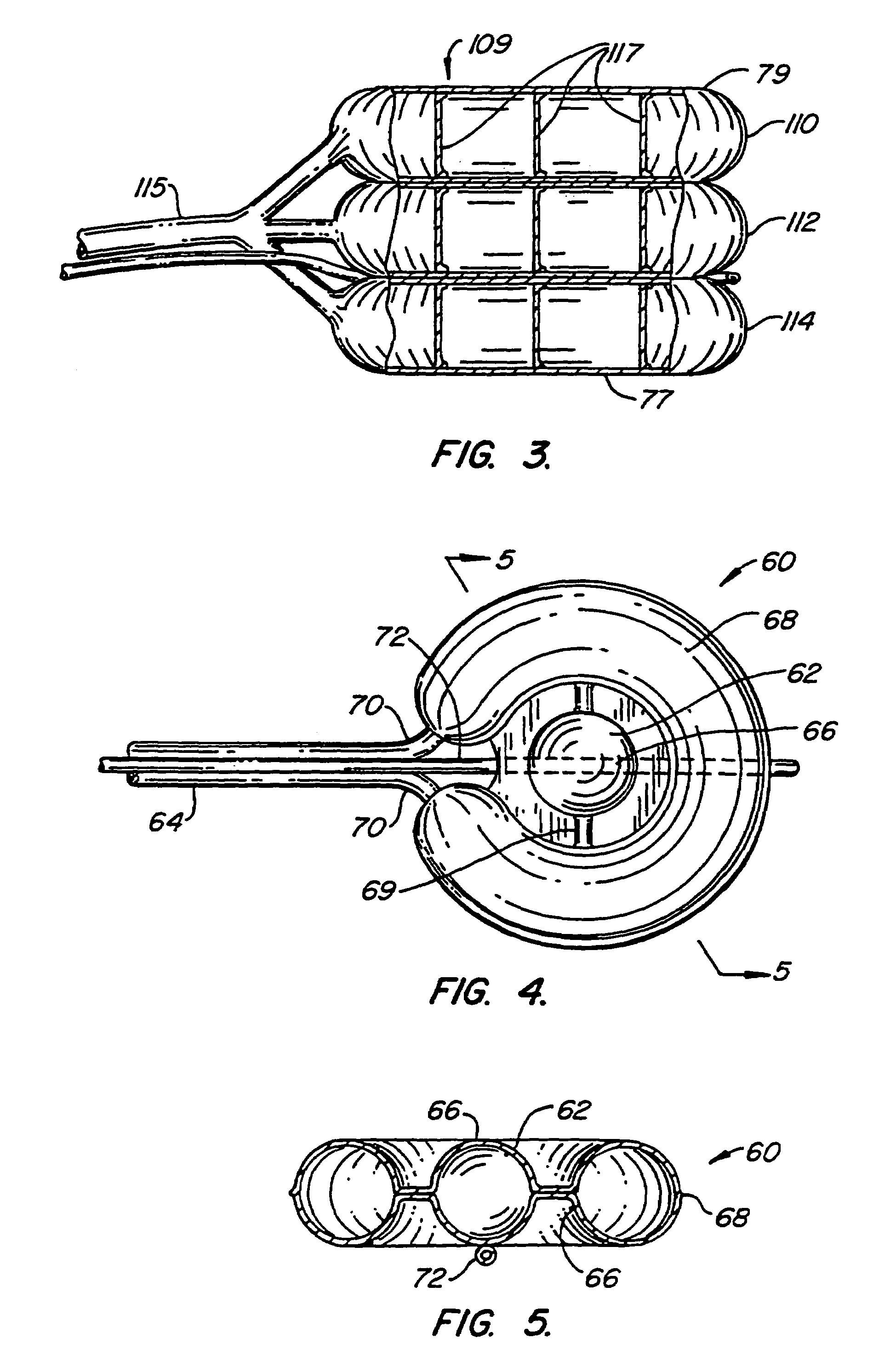

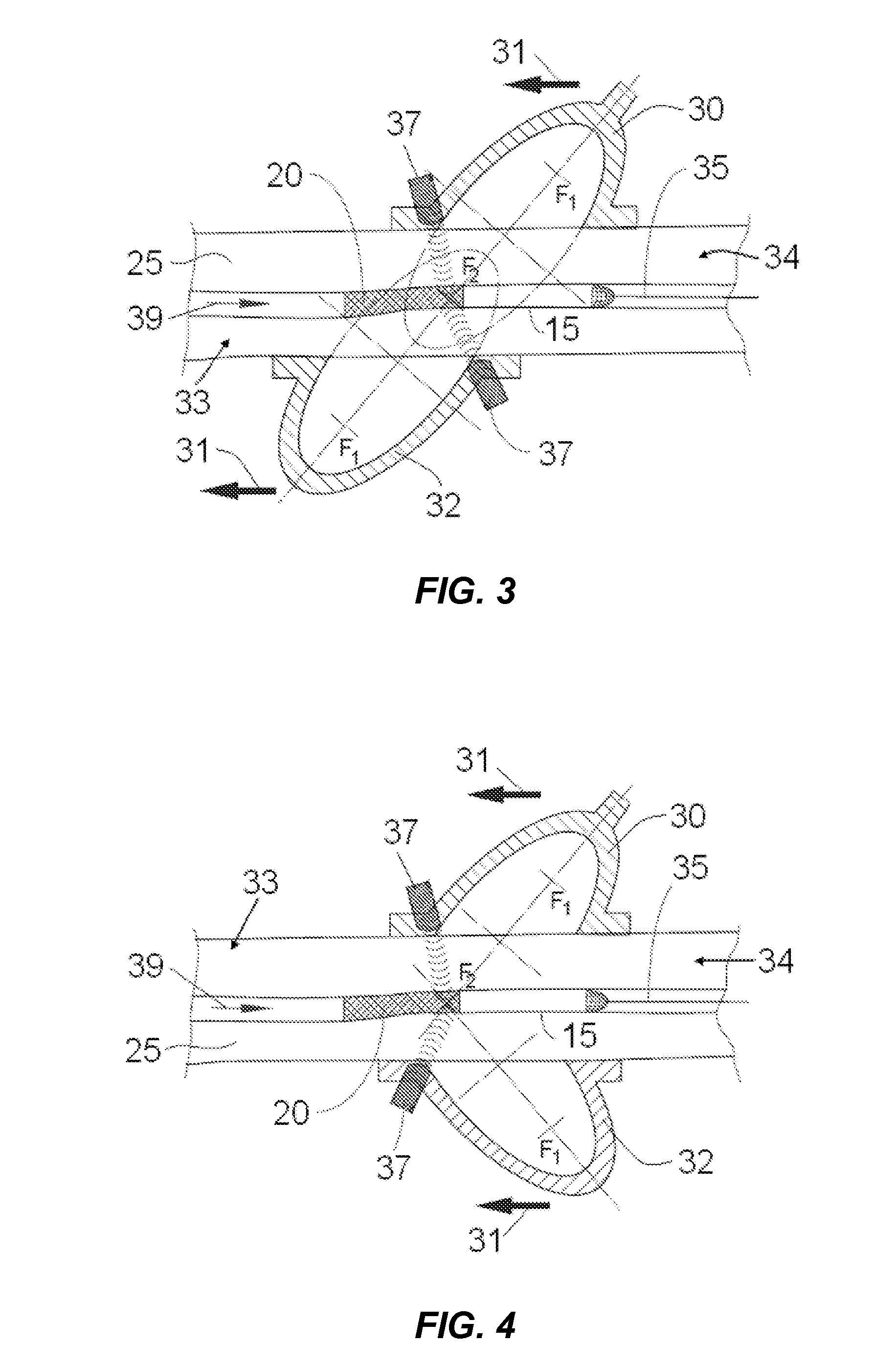

Biocompatible wound dressing

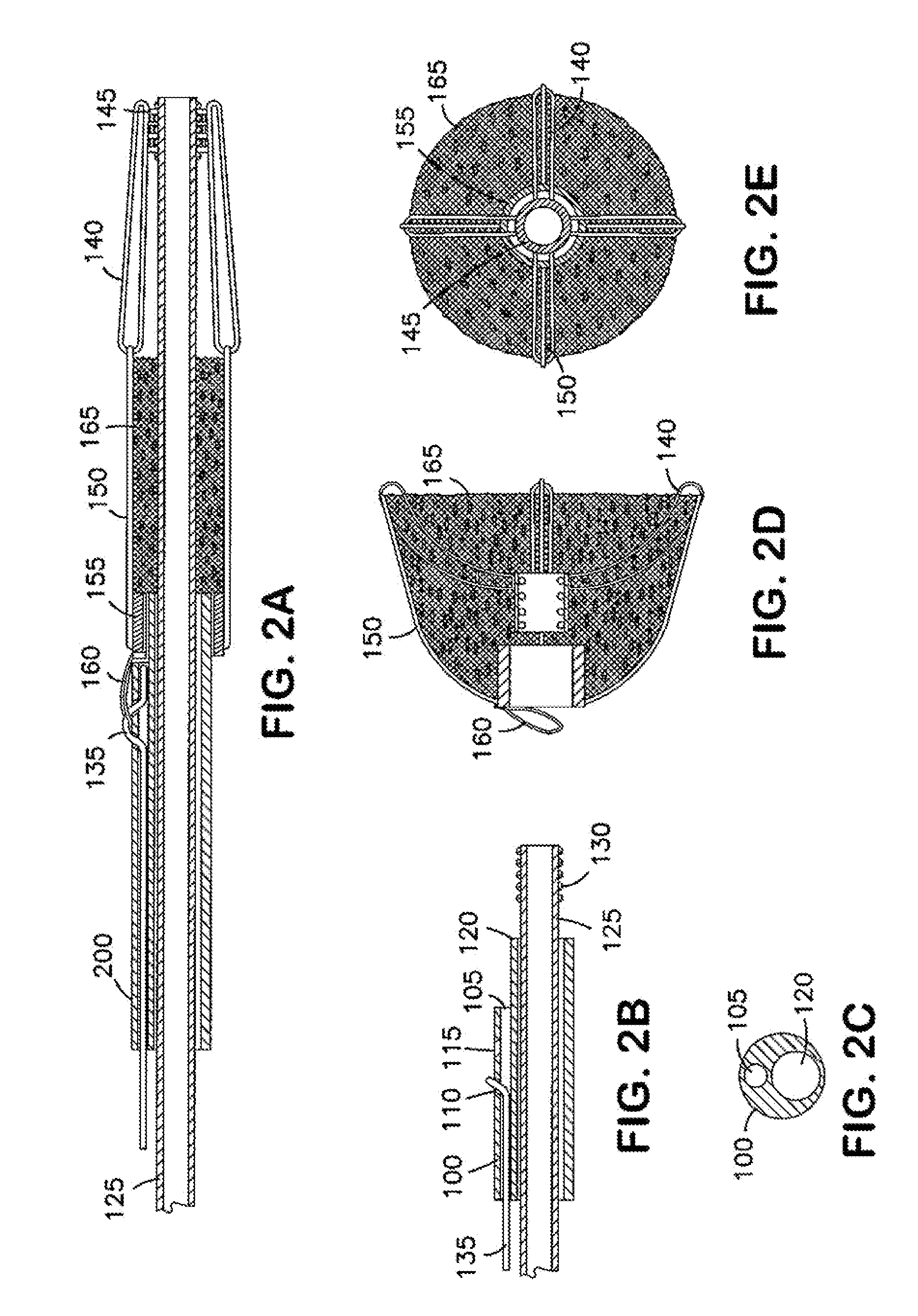

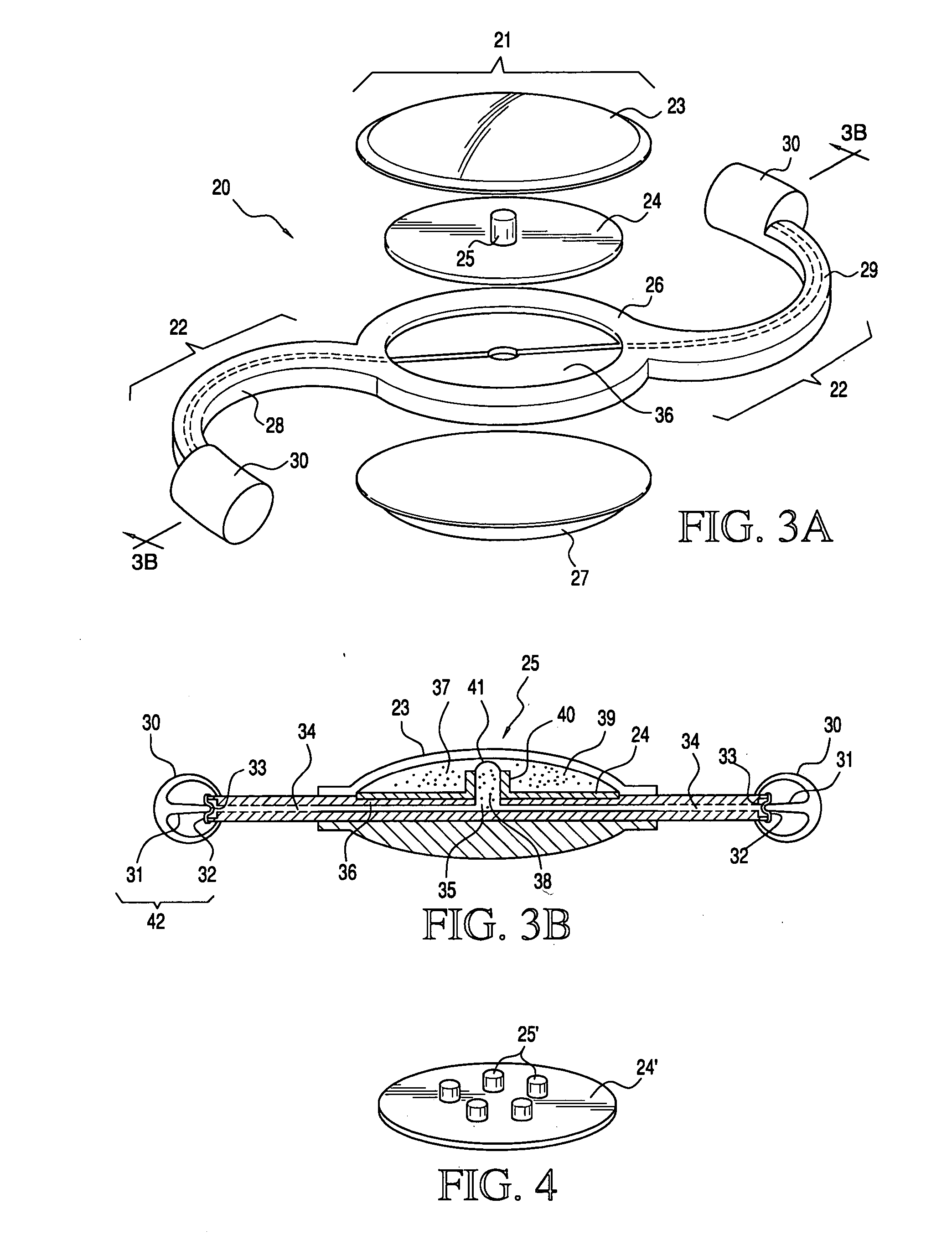

InactiveUS7070584B2Promote cell growthPrevent vacuum leakageWound drainsMedical applicatorsWound dressingWound site

A biocompatible wound dressing comprised of a pad for insertion substantially into a wound site and a wound drape for sealing enclosure of the foam pad at the wound site. The pad, comprised of a foam or other like material having relatively few open cells in contact with the areas upon which cell growth is to be encouraged so as to avoid unwanted adhesions, but having sufficiently numerous open cells so that drainage and negative pressure therapy may continue unimpaired, is placed in fluid communication with a vacuum source for promotion of fluid drainage, as known in the art. The pad is further comprised of an ultra-low density fused-fibrous ceramic, or a bioabsorbable branched polymer, or cell growth enhancing matrix or scaffolding.

Owner:KCI LICENSING INC

Expandable supportive endoluminal grafts

An endoluminal graft which is both expandable and supportive is provided either in a longitudinal form or in a bifurcated form. The graft expands between a first diameter and a second, larger diameter. The support component is an expandable stent endoprosthesis. A cover, liner, or a liner, or both a cover and a liner are applied to the endoprosthesis in the form of a stretchable wall material that is porous, elastomeric and biocompatible in order to allow normal cellular invasion upon implantation, without stenosis, when the expandable and supportive graft is at its second diameter. Preferably, the elastomeric wall material is a polycarbonate urethane.

Owner:LIFEPORT SCI

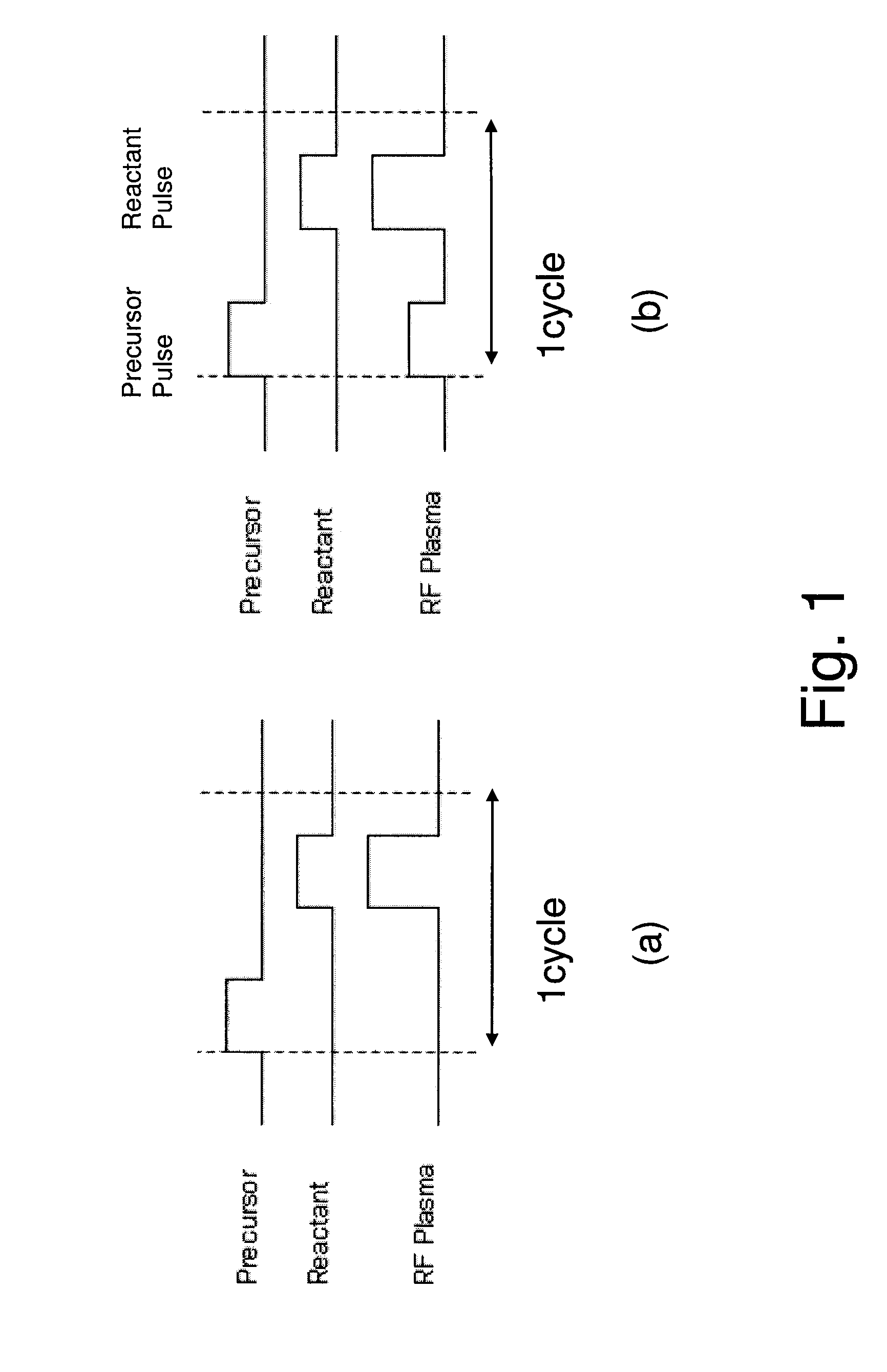

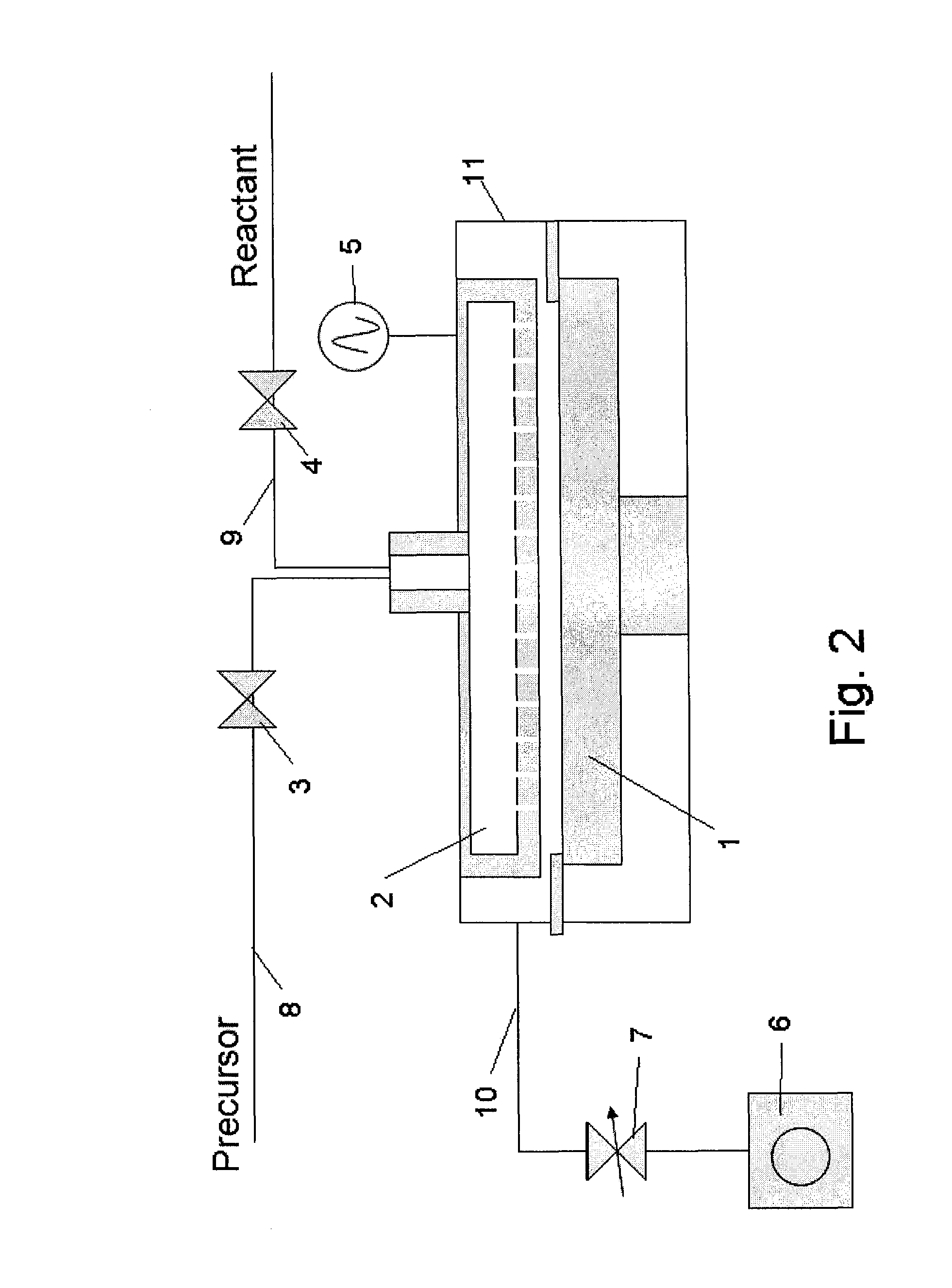

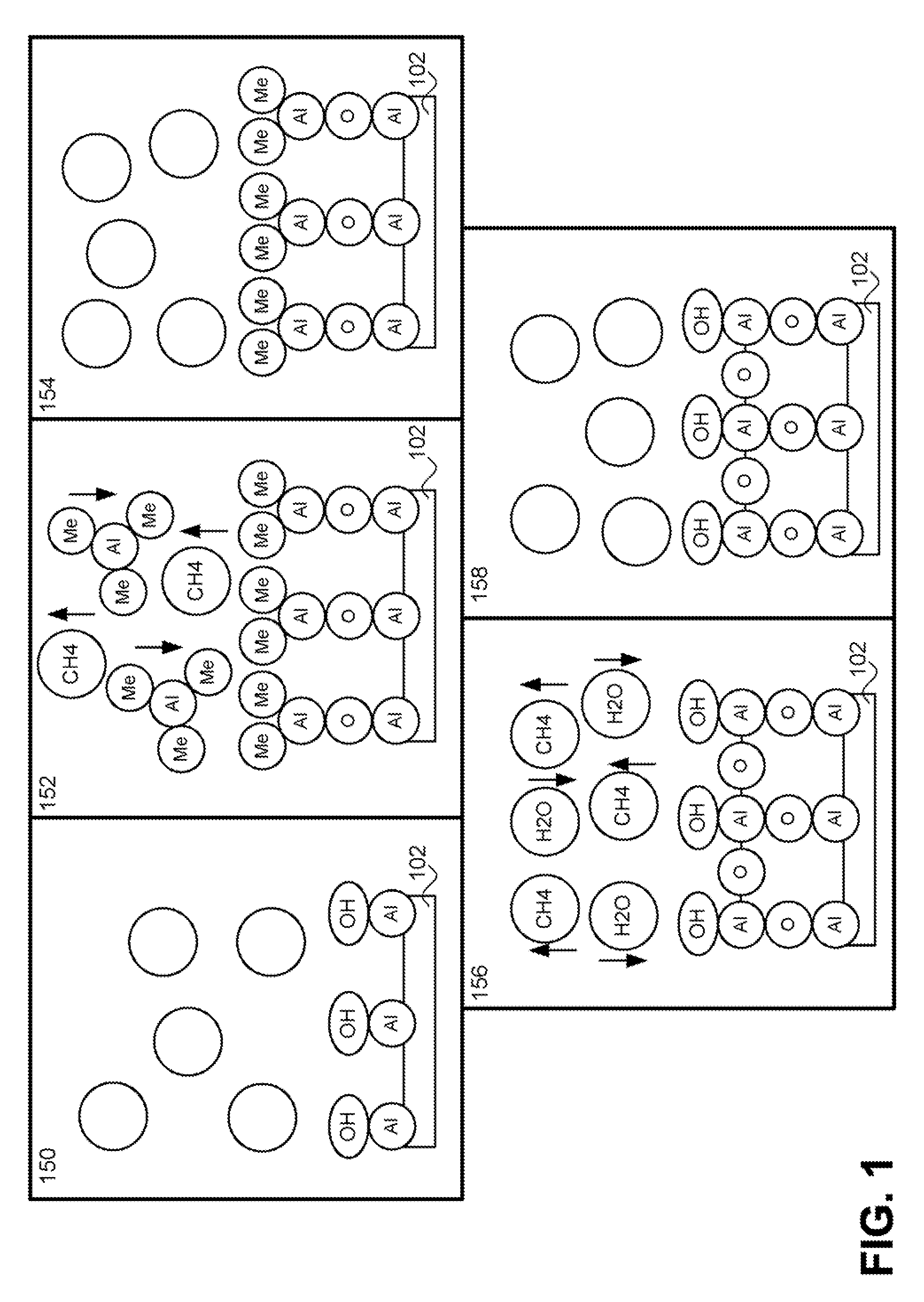

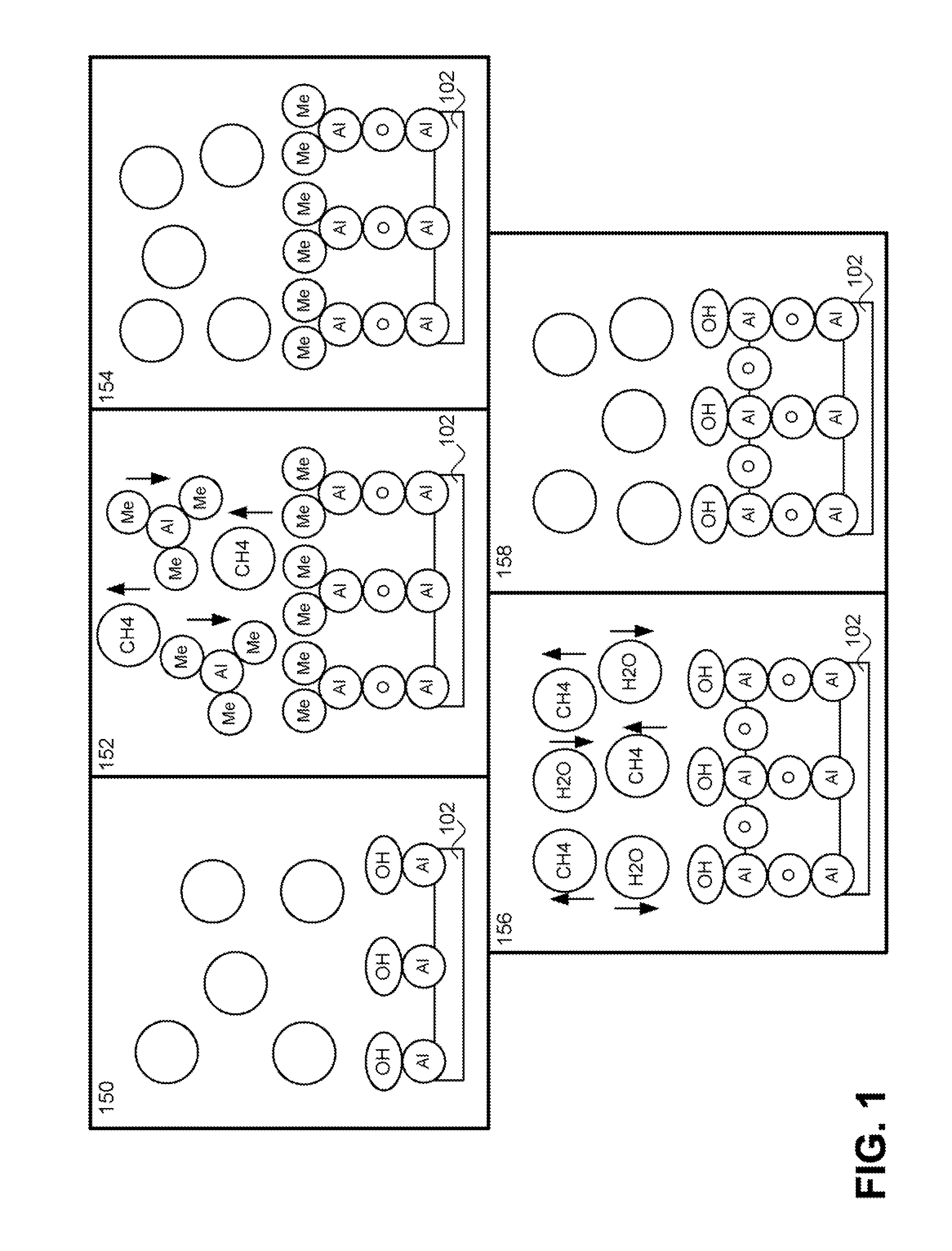

Method of Forming Insulation Film by Modified PEALD

ActiveUS20100124621A1Increase coverageImprove throughputSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringPhysical chemistry

Owner:ASM JAPAN

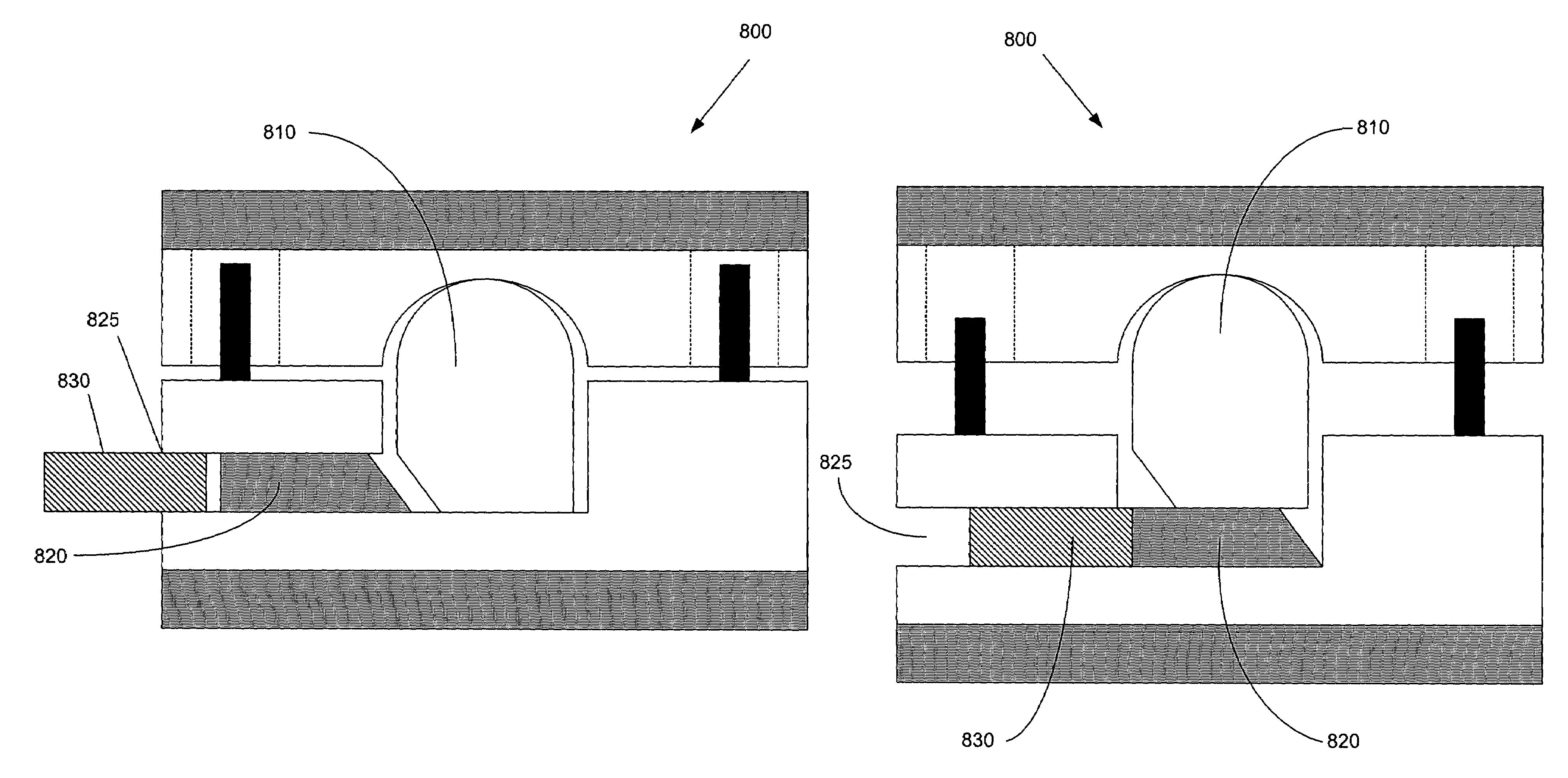

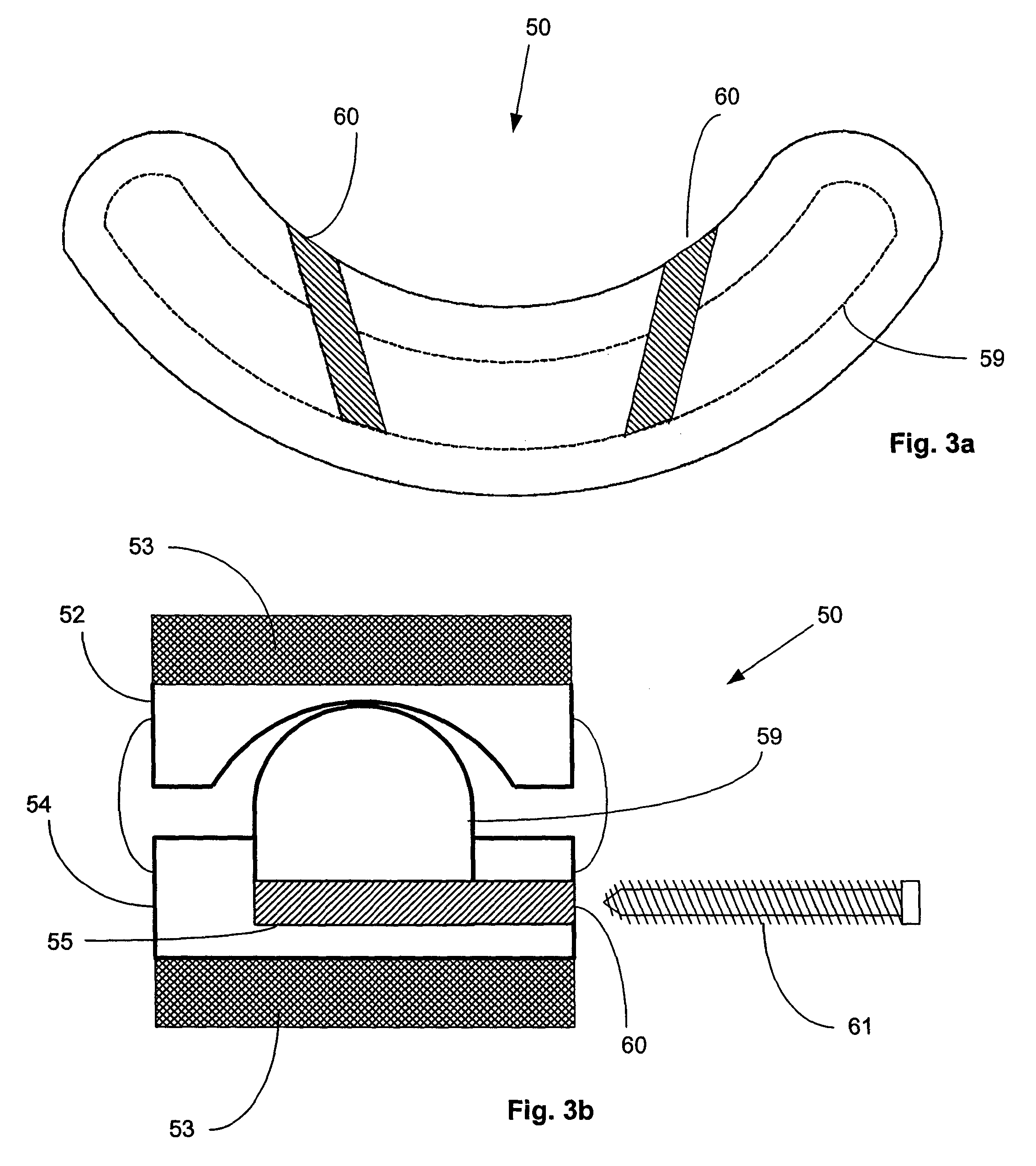

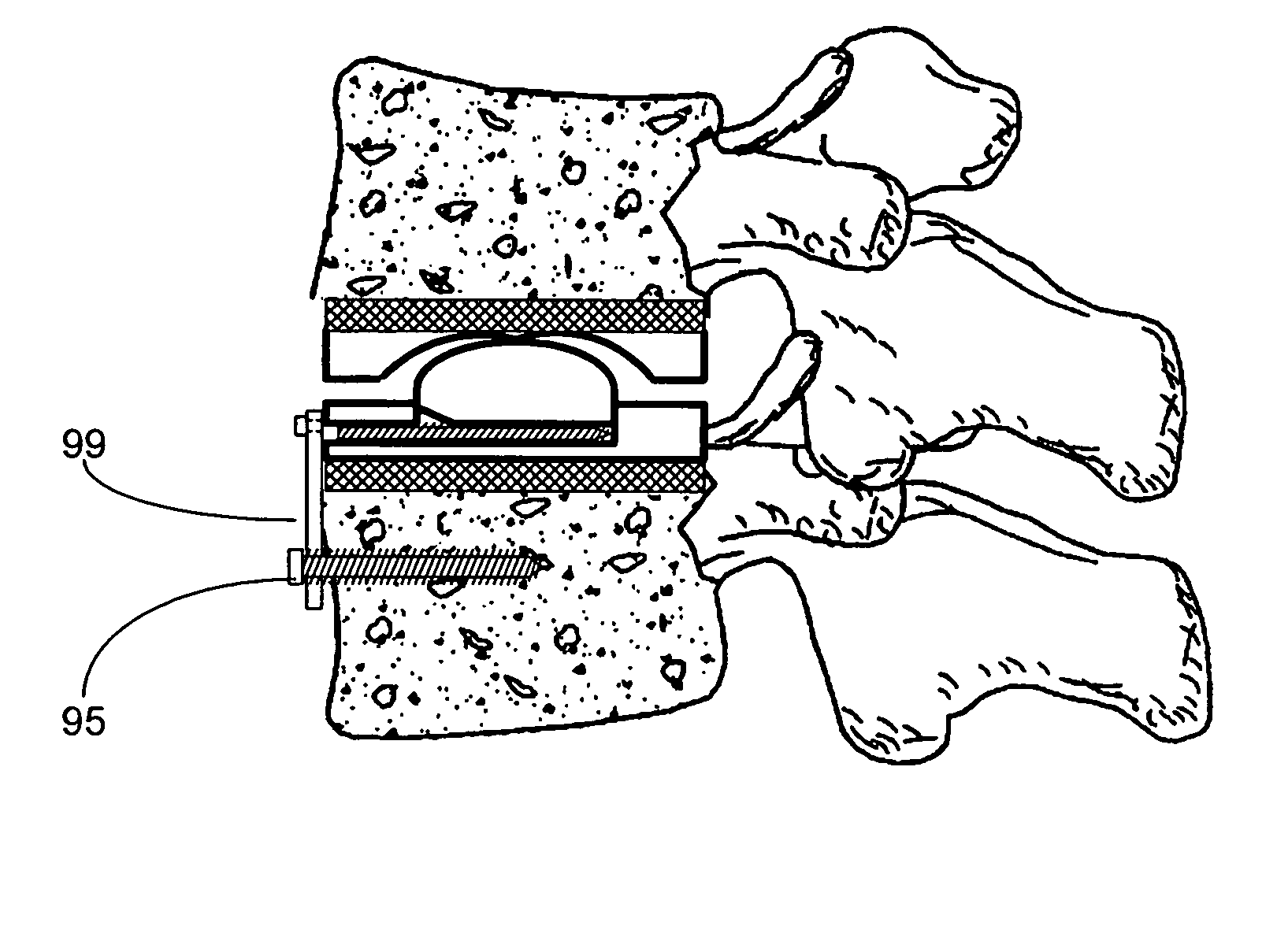

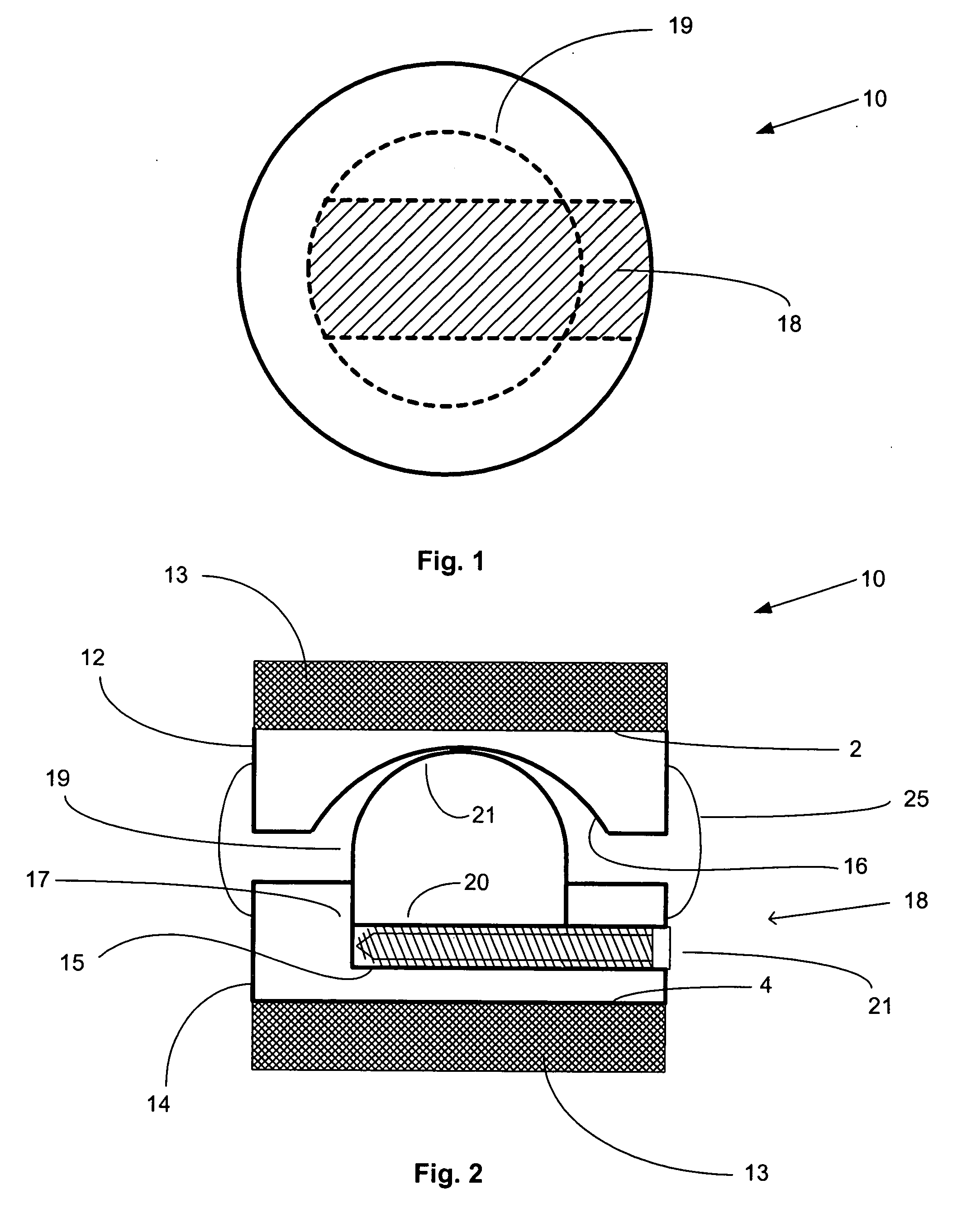

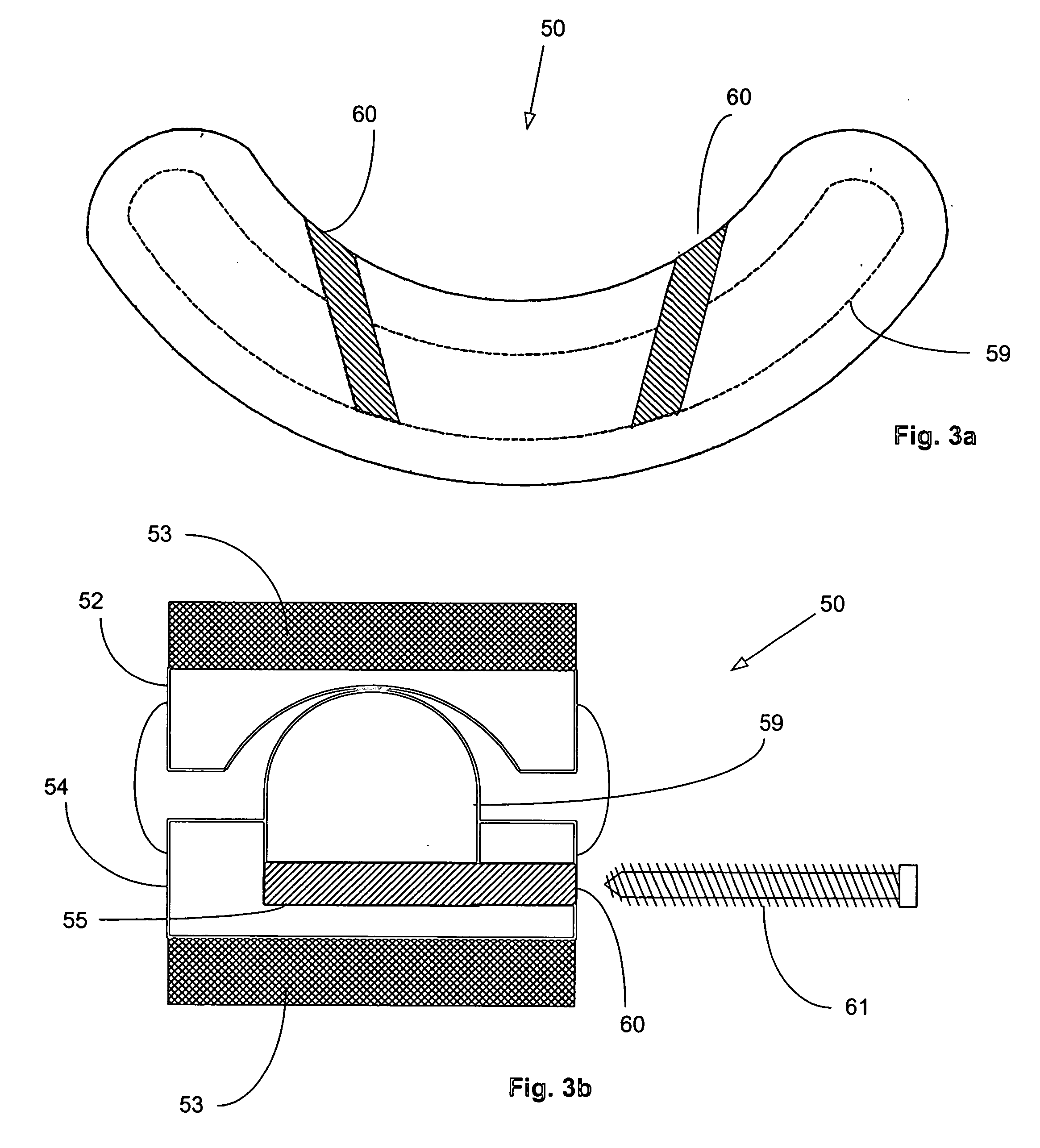

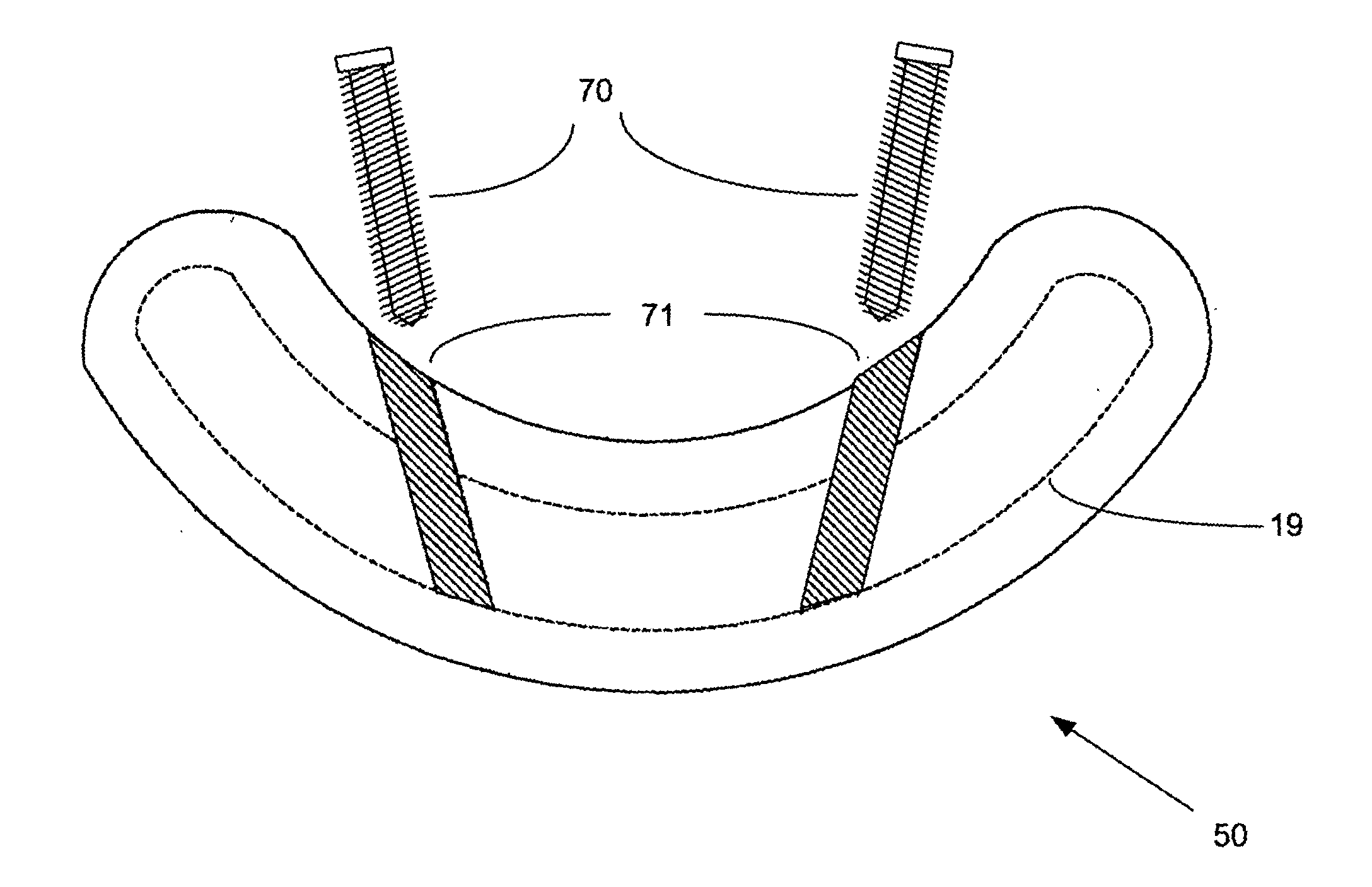

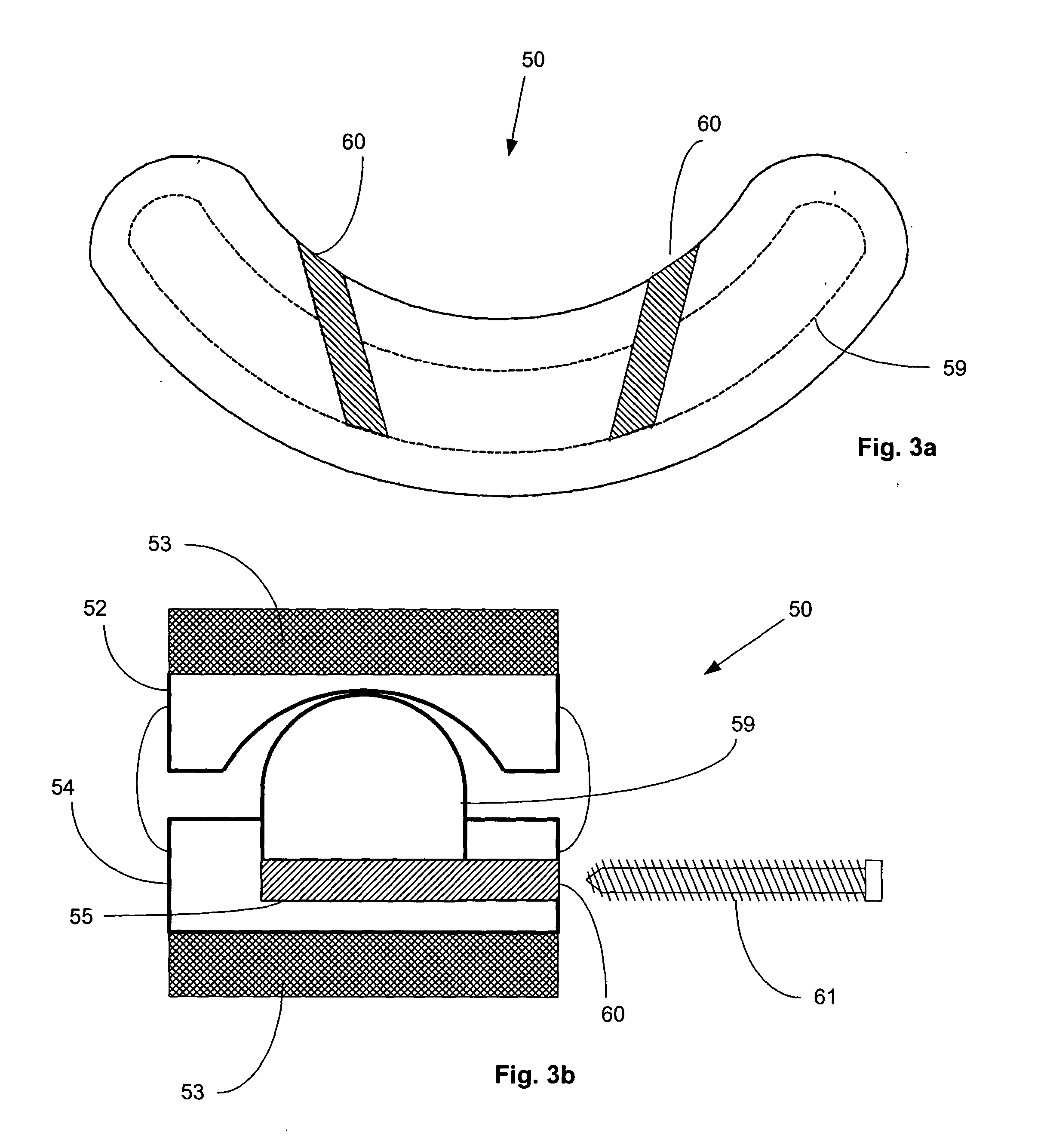

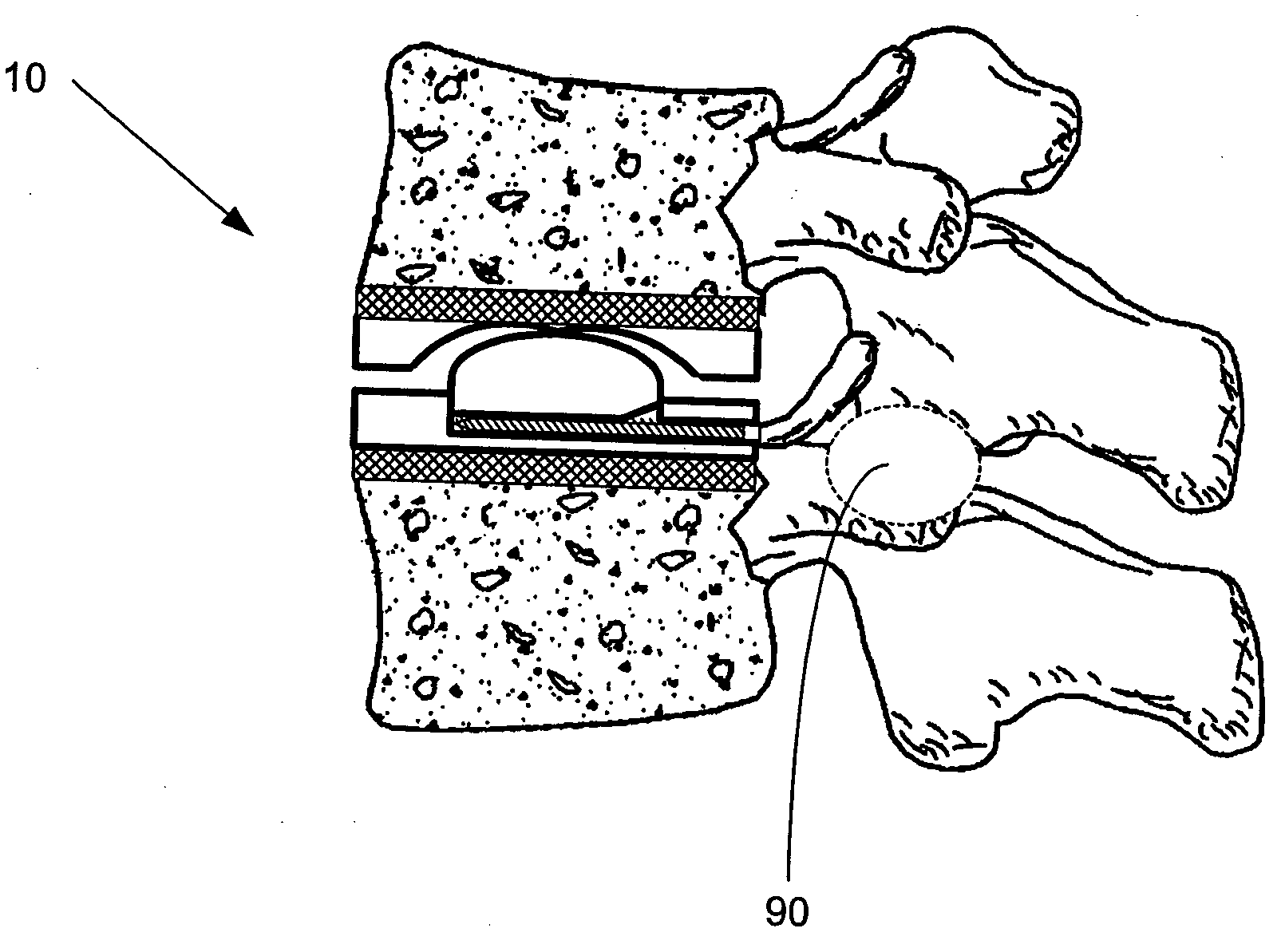

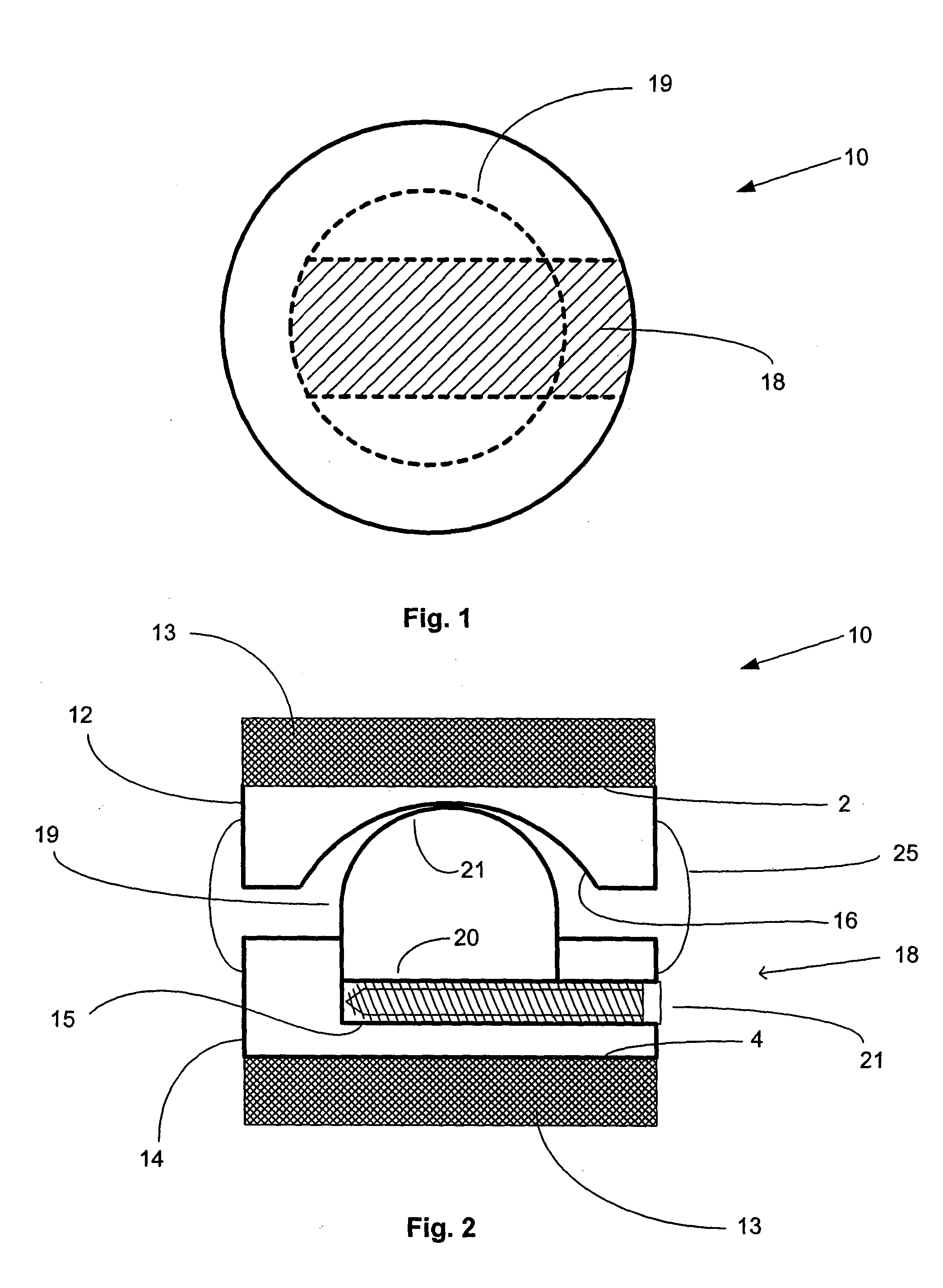

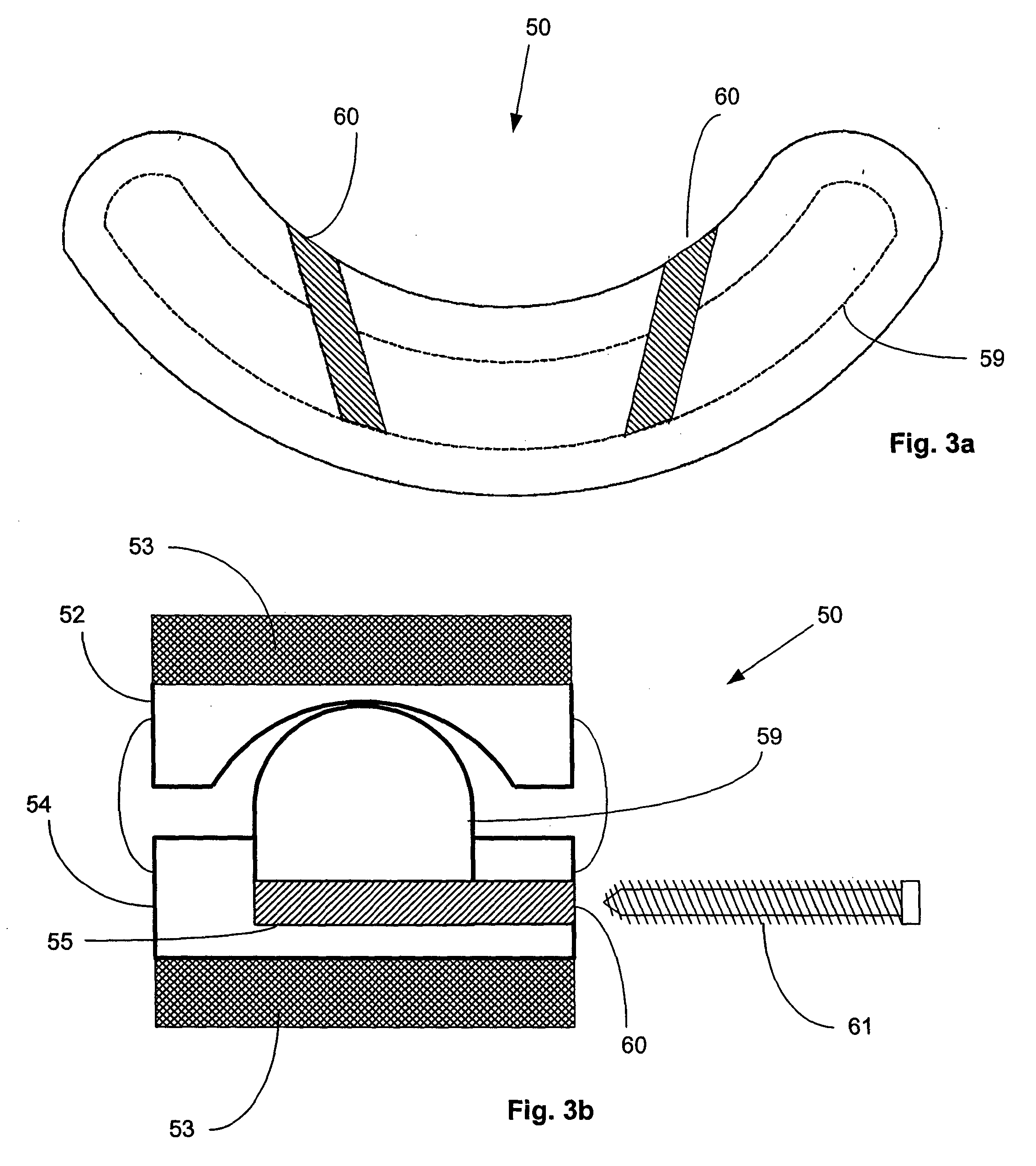

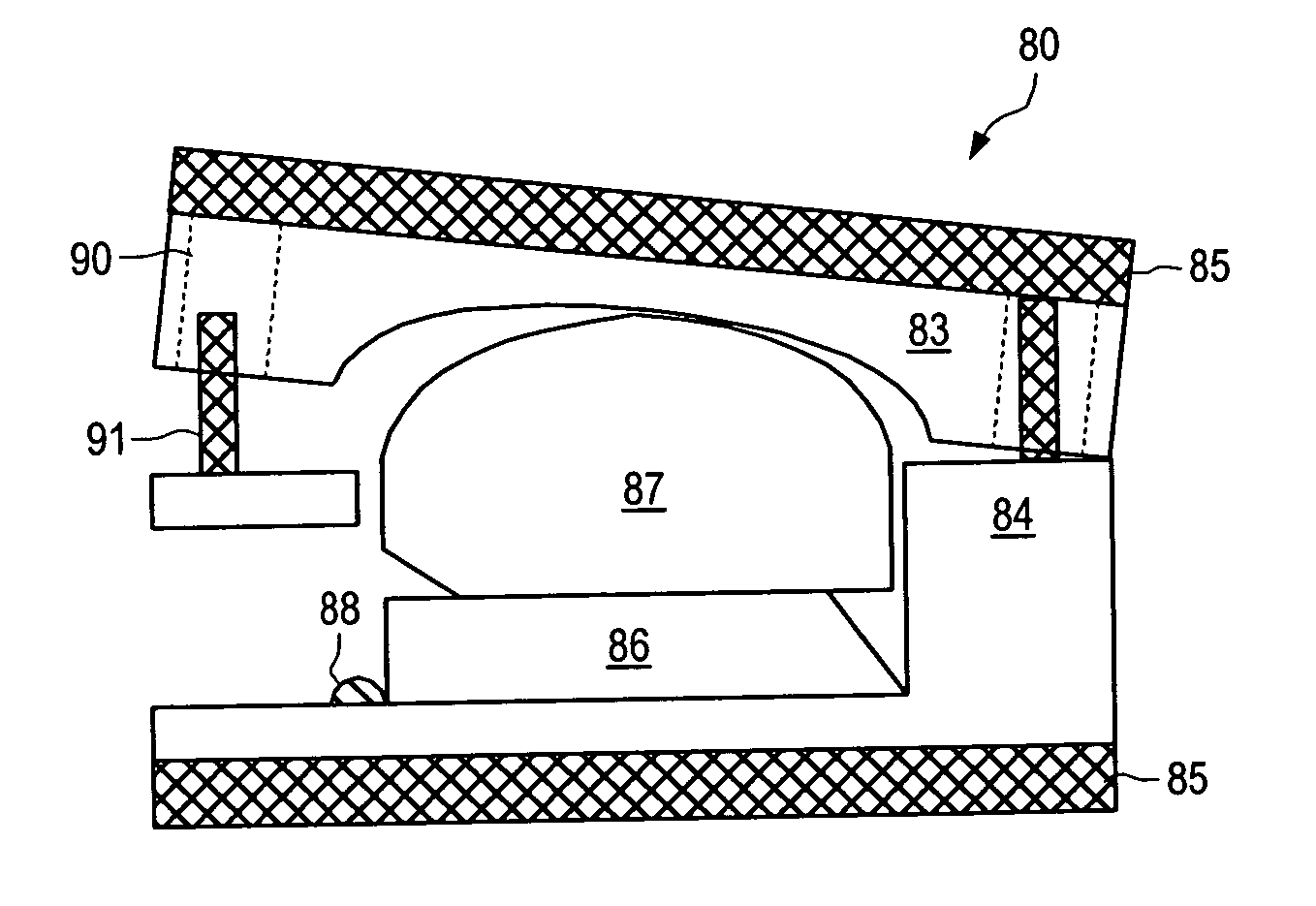

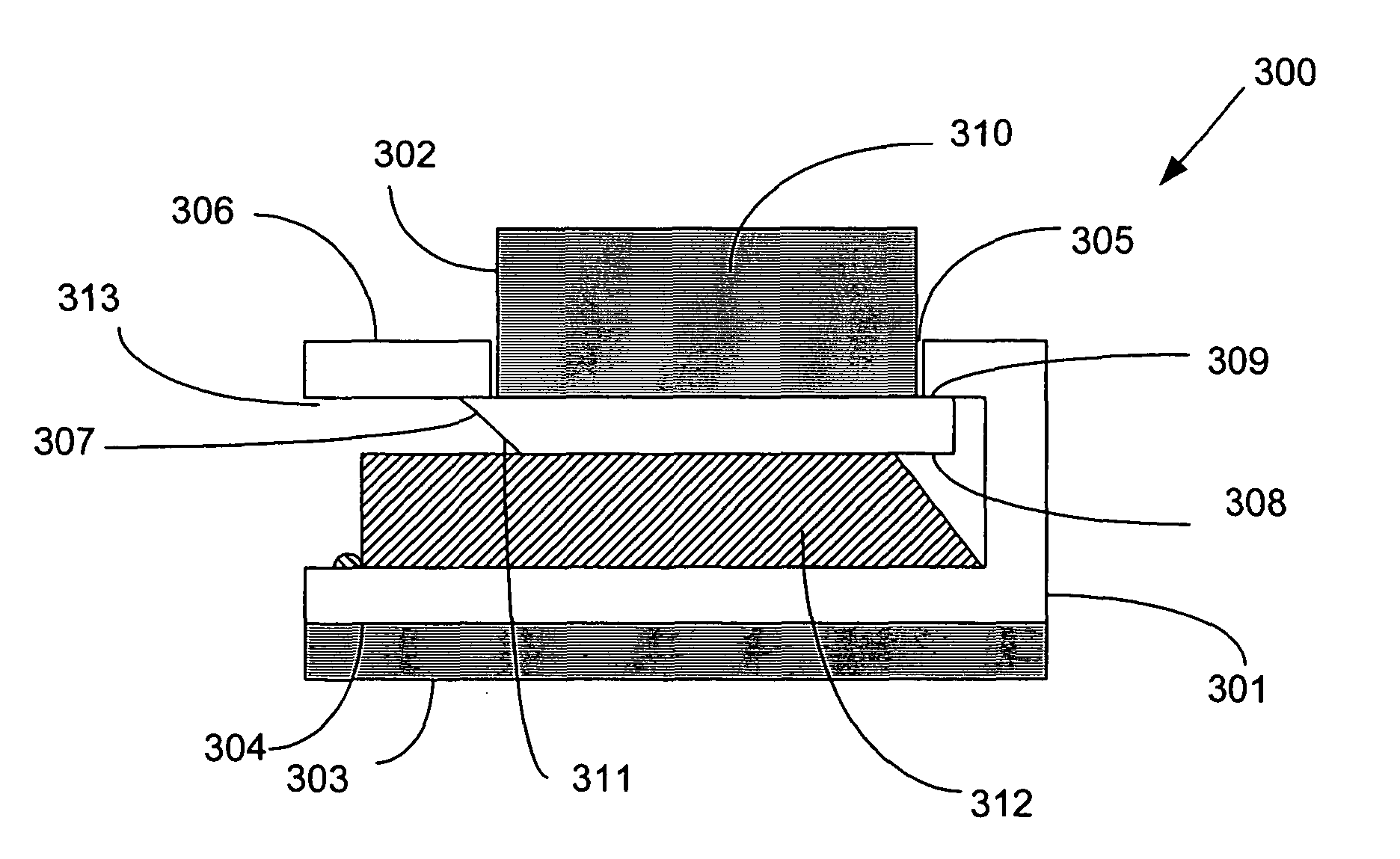

Artificial functional spinal unit assemblies

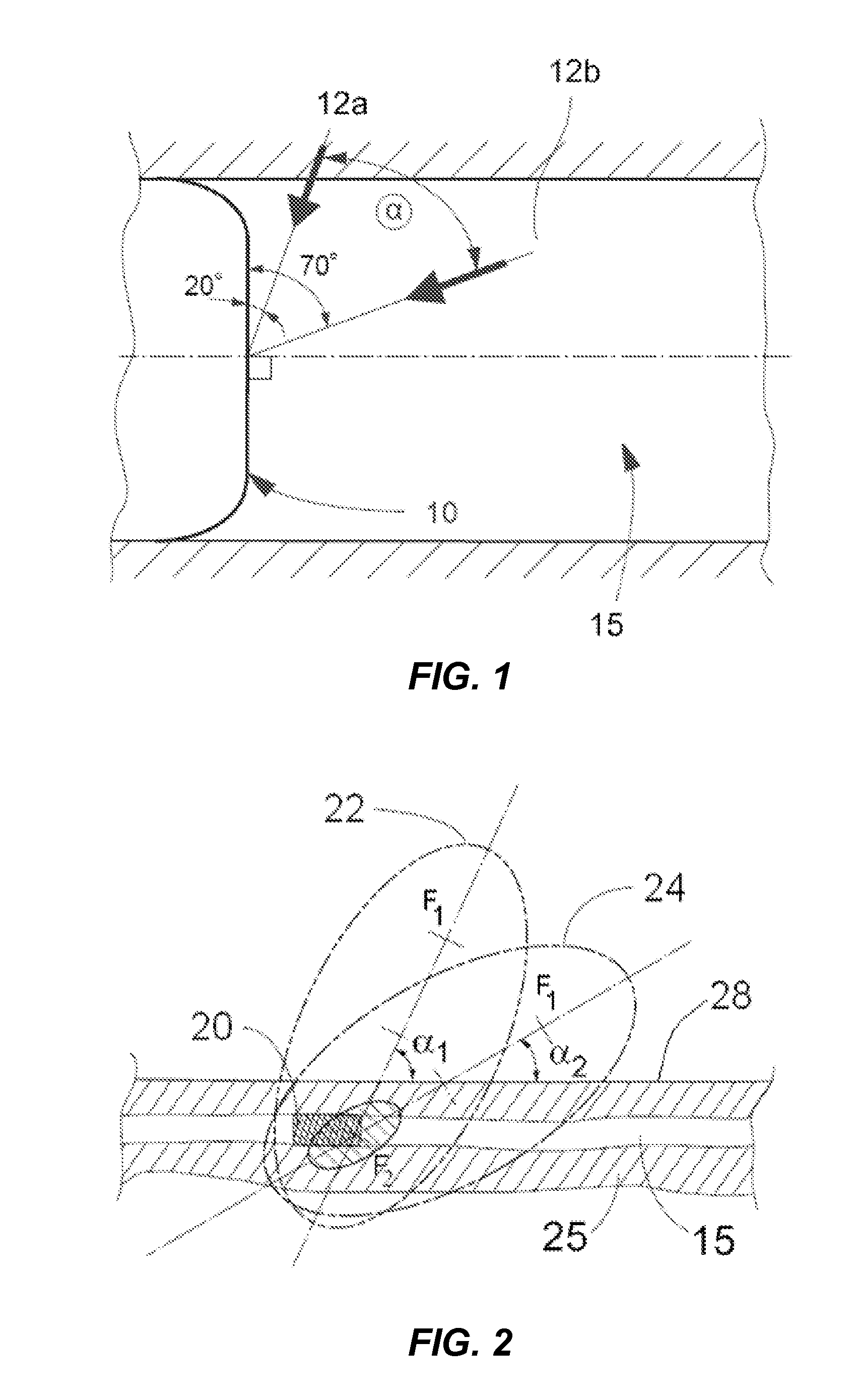

InactiveUS7316714B2Promote growthPromoting bony end growthInternal osteosythesisJoint implantsSurgical operationSurgical approach

An artificial functional spinal unit is provided comprising, generally, an expandable artificial intervertebral implant that can be placed via a posterior surgical approach and used in conjunction with one or more artificial facet joints to provide an anatomically correct range of motion. Expandable artificial intervertebral implants in both lordotic and non-lordotic designs are disclosed, as well as lordotic and non-lordotic expandable cages for both PLIF (posterior lumber interbody fusion) and TLIF (transforaminal lumbar interbody fusion) procedures. The expandable implants may have various shapes, such as round, square, rectangular, banana-shaped, kidney-shaped, or other similar shapes. By virtue of their posteriorly implanted approach, the disclosed artificial FSU's allow for posterior decompression of the neural elements, reconstruction of all or part of the natural functional spinal unit, restoration and maintenance of lordosis, maintenance of motion, and restoration and maintenance of disc space height.

Owner:FLEXUSPINE INC

Artificial spinal unit assemblies

ActiveUS20050033432A1Prohibit some movementPrevent movementInternal osteosythesisJoint implantsSpinal columnSurgical approach

An artificial functional spinal unit is provided comprising, generally, an expandable artificial intervertebral implant that can be placed via a posterior surgical approach and used in conjunction with one or more artificial facet joints to provide an anatomically correct range of motion. Expandable artificial intervertebral implants in both lordotic and non-lordotic designs are disclosed, as well as lordotic and non-lordotic expandable cages for both PLIF (posterior lumber interbody fusion) and TLIF (transforaminal lumbar interbody fusion) procedures. The expandable implants may have various shapes, such as round, square, rectangular, banana-shaped, kidney-shaped, or other similar shapes. By virtue of their posteriorly implanted approach, the disclosed artificial FSU's allow for posterior decompression of the neural elements, reconstruction of all or part of the natural functional spinal unit, restoration and maintenance of lordosis, maintenance of motion, and restoration and maintenance of disc space height.

Owner:FLEXUSPINE

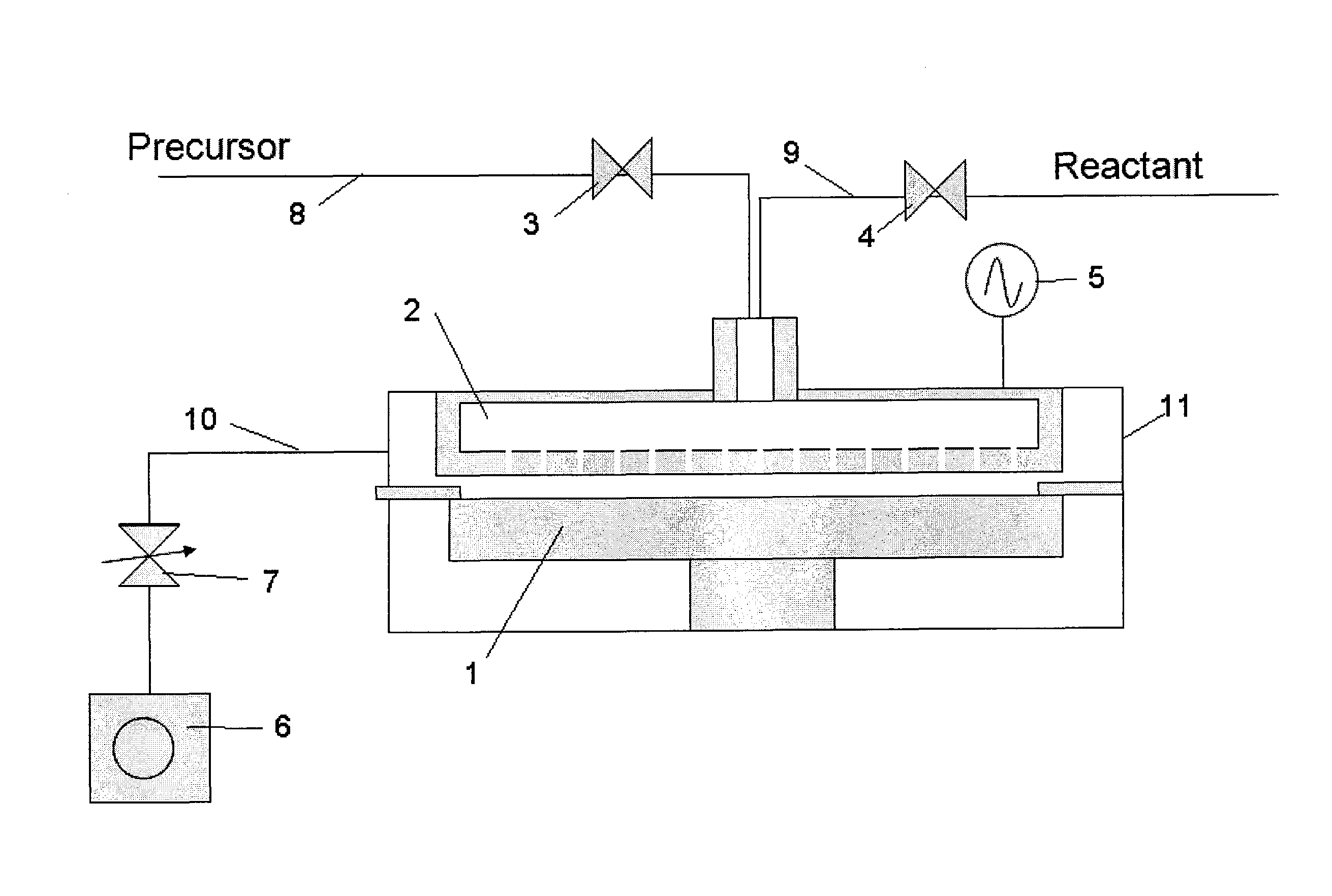

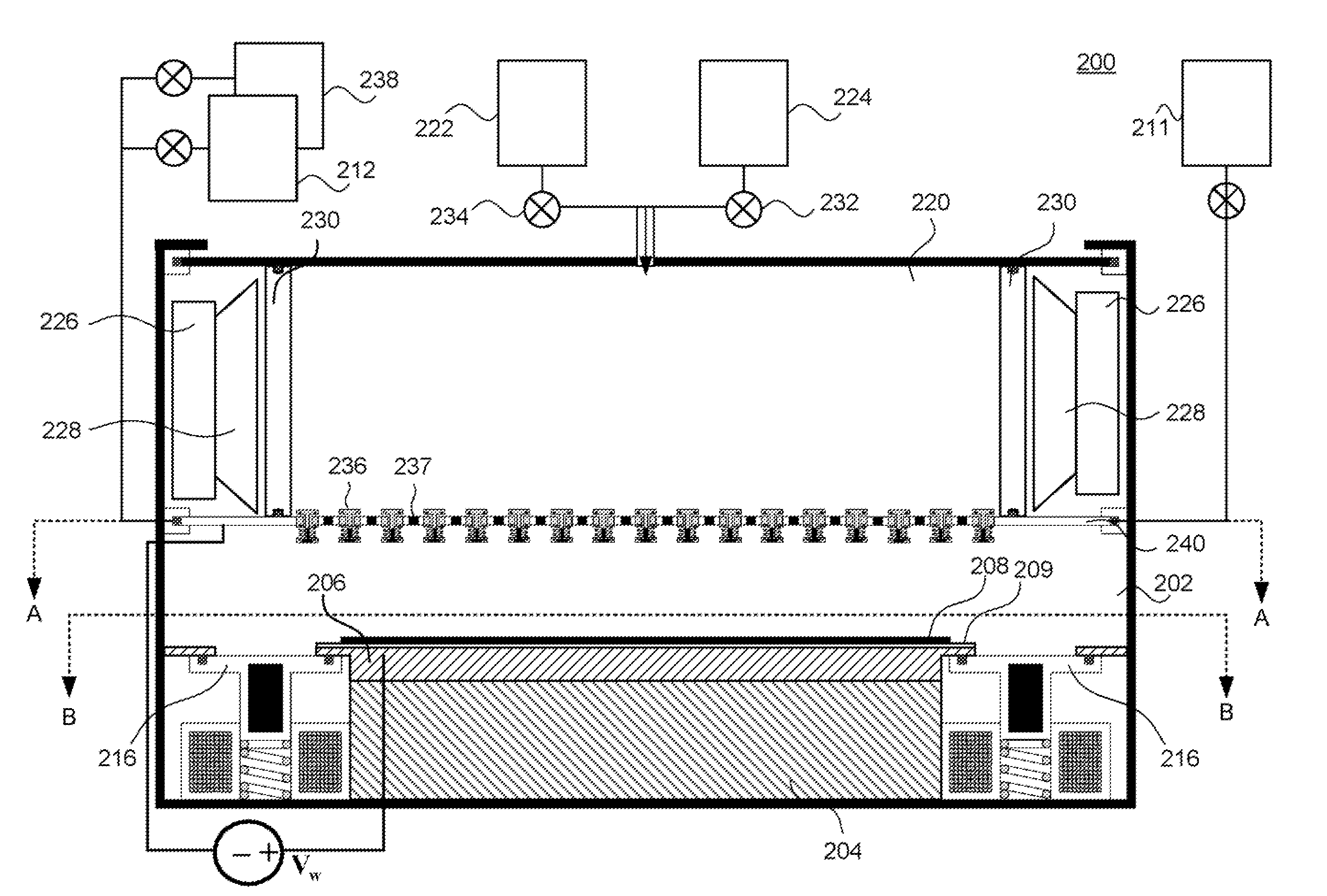

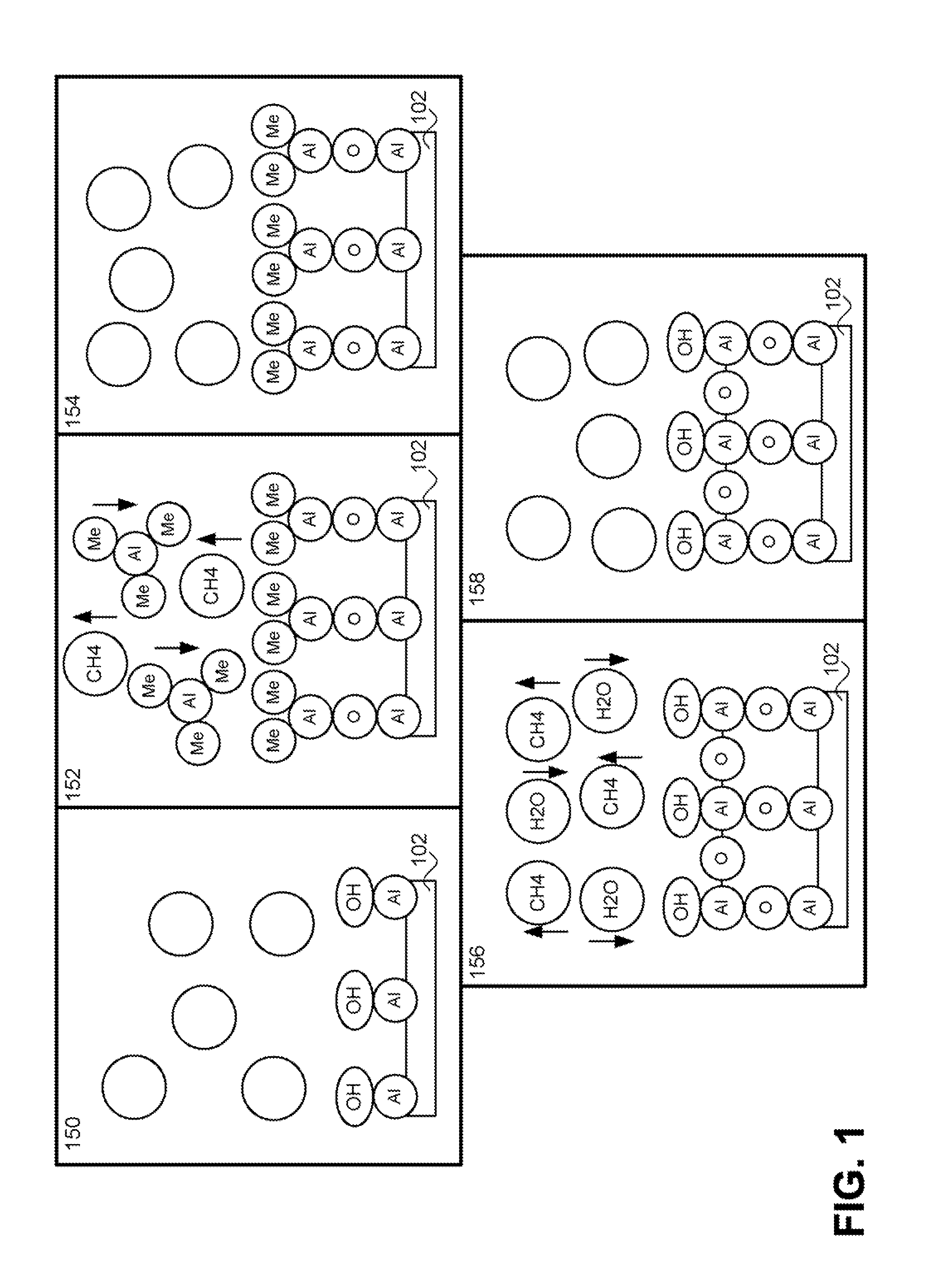

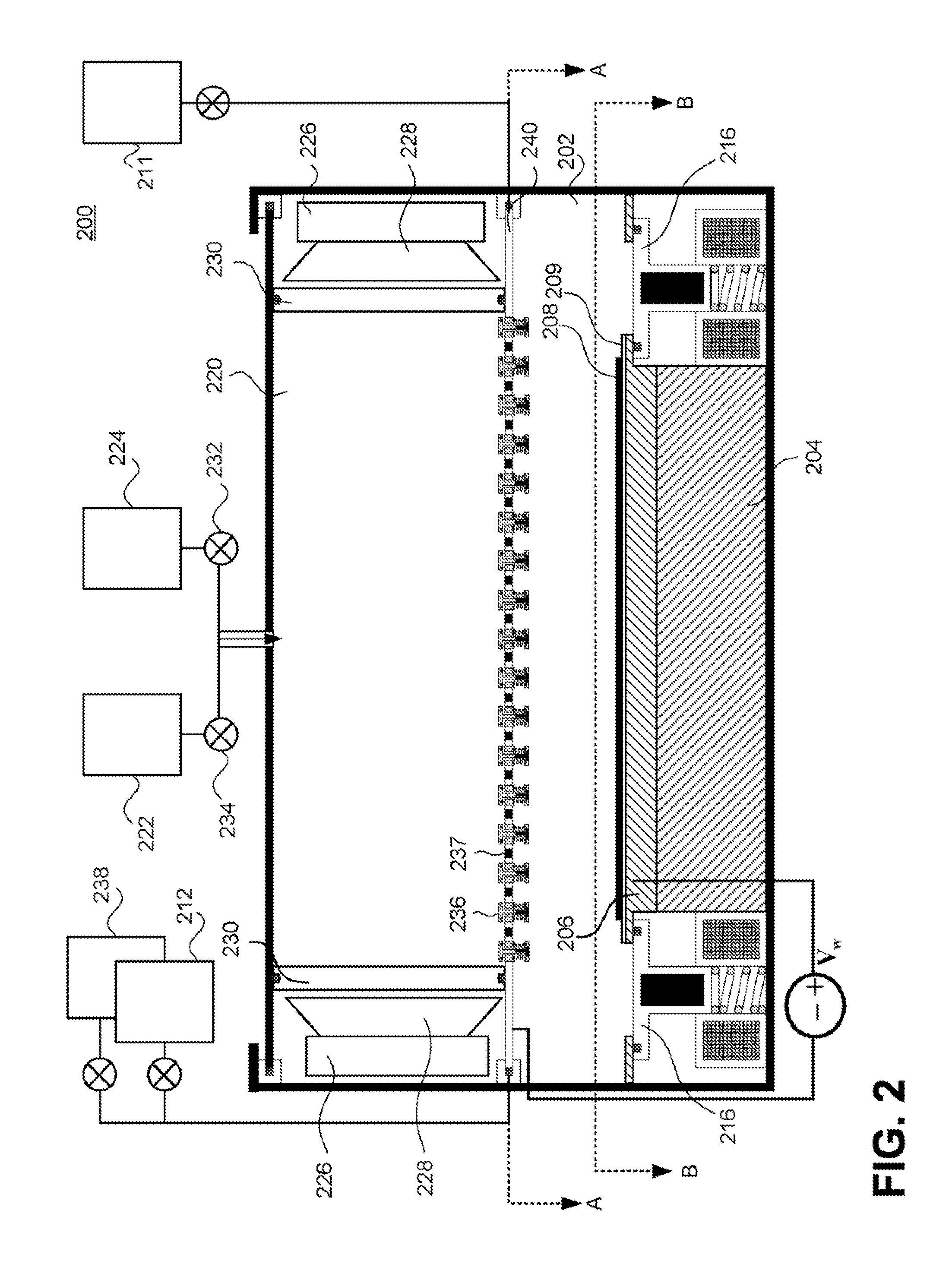

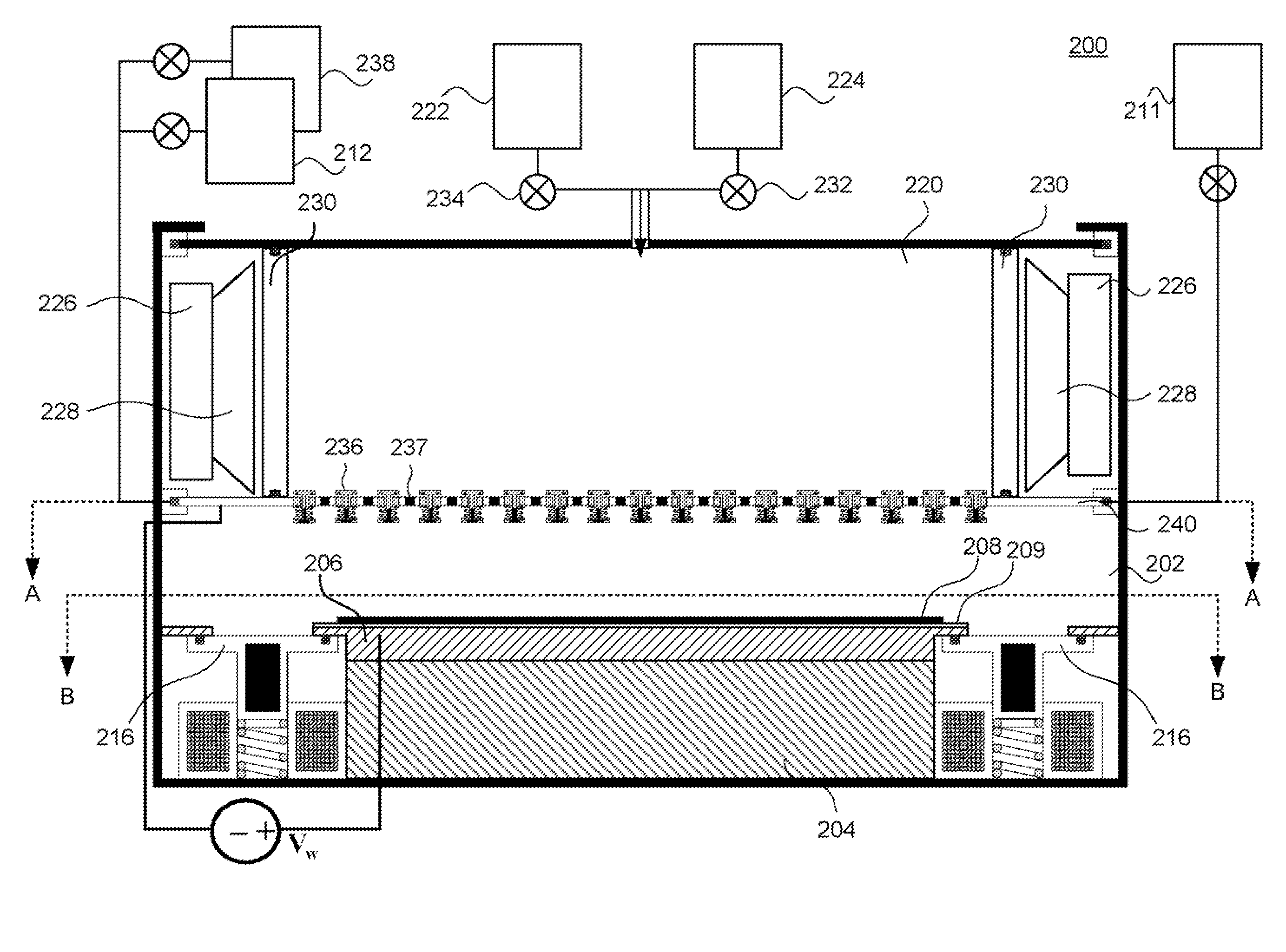

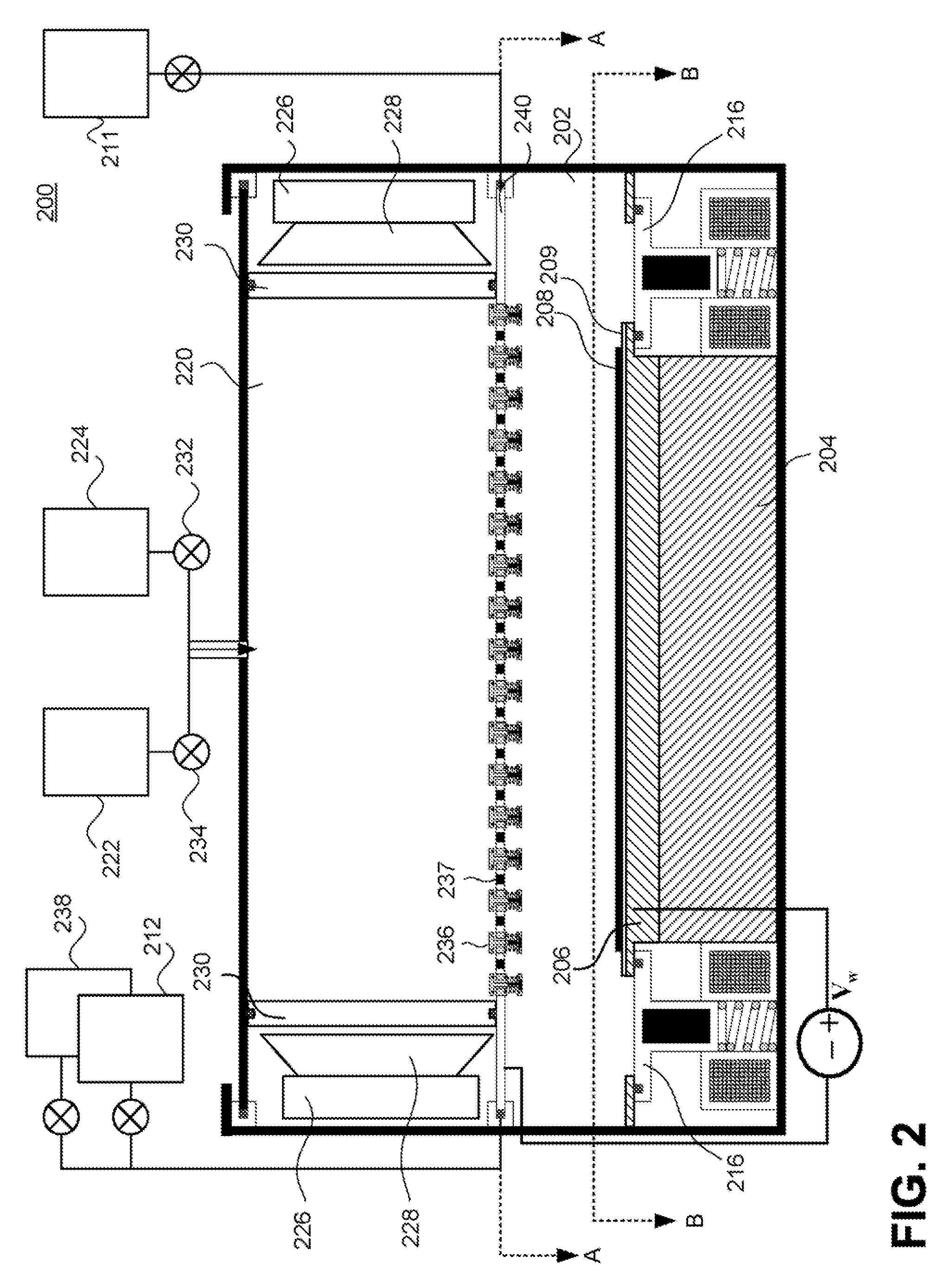

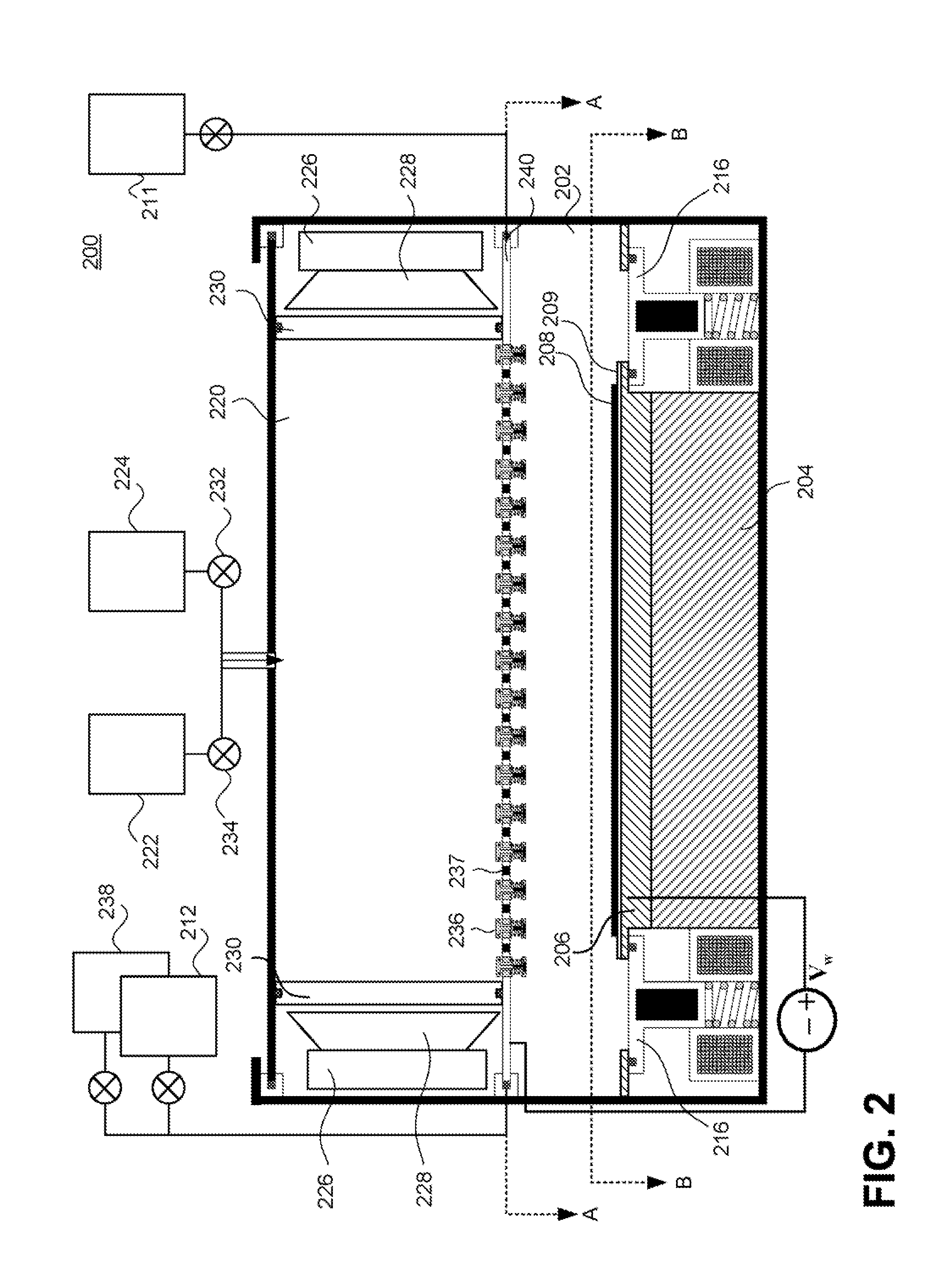

Systems for Atomic Layer Deposition of Oxides Using Krypton as an Ion Generating Feeding Gas

InactiveUS20070277735A1Great efficiencyGreat capabilitySolid-state devicesSemiconductor/solid-state device manufacturingIonOxide

An atomic layer deposition system and method utilizing radicals generated from a high-density mixed plasma for deposition is disclosed. A high-quality oxide or oxynitride can be deposited by exposing a substrate to a first precursor which is adsorbed onto the substrate during a first phase of one deposition cycle. After purging the deposition chamber, the substrate is exposed to a second precursor which includes oxygen radicals and krypton ions formed from the high-density mixed plasma. The ions and radicals are formed by introducing a radical generating feed gas (e.g., O2) and an ion generating feed gas into a plasma chamber and exciting the gases to form the high-density mixed plasma. The radicals and ions are then introduced to the substrate where they react with the first precursor to deposit a layer of the desired film. Krypton is preferably used as the ion generating feed gas because the metastable states of krypton lead to an efficient dissociation of oxygen into oxygen radicals when compared with other inert gases.

Owner:SANDISK TECH LLC

Atomic Layer Deposition of Oxides Using Krypton as an Ion Generating Feeding Gas

InactiveUS20070281105A1Improve abilitiesImprove efficiencyChemical vapor deposition coatingPlasma techniqueKryptonHigh density

An atomic layer deposition system and method utilizing radicals generated from a high-density mixed plasma for deposition is disclosed. A high-quality oxide or oxynitride can be deposited by exposing a substrate to a first precursor which is adsorbed onto the substrate during a first phase of one deposition cycle. After purging the deposition chamber, the substrate is exposed to a second precursor which includes oxygen radicals and krypton ions formed from the high-density mixed plasma. The ions and radicals are formed by introducing a radical generating feed gas (e.g., O2) and an ion generating feed gas into a plasma chamber and exciting the gases to form the high-density mixed plasma. The radicals and ions are then introduced to the substrate where they react with the first precursor to deposit a layer of the desired film. Krypton is preferably used as the ion generating feed gas because the metastable states of krypton lead to an efficient dissociation of oxygen into oxygen radicals when compared with other inert gases.

Owner:SANDISK TECH LLC

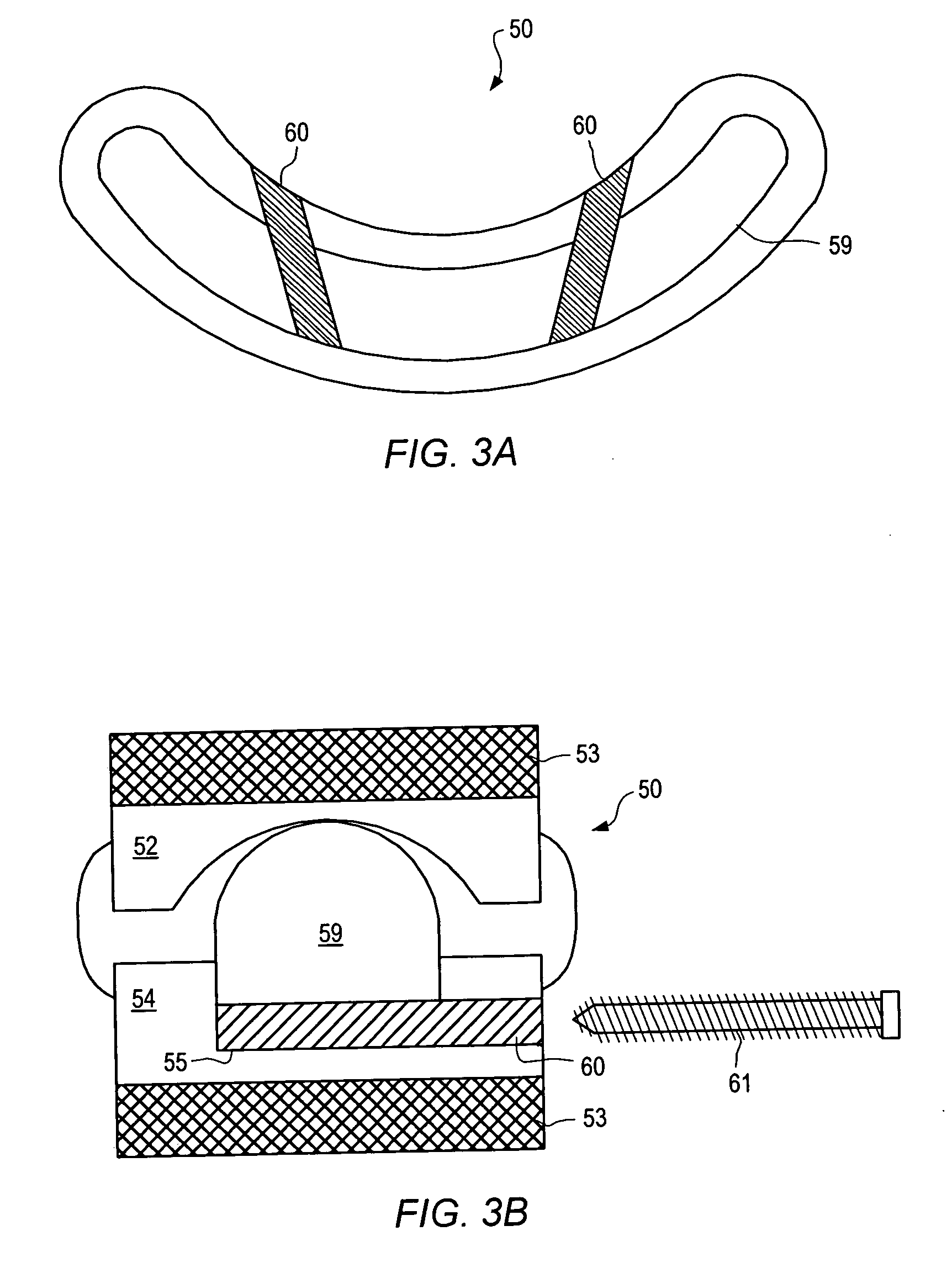

Aneurysm Occlusion Devices

InactiveUS20080281350A1Promote endothelial growthEliminate riskDilatorsCatheterMedicineImplanted device

An implantable occlusion device for bridging the neck of an aneurysm comprises a biocompatible matrix. The device is movable between a compressed position prior to implantation and a generally concave or cup-shaped position following implantation. The device may comprise a frame having a plurality of elements. The frame elements have a first pre-deployment position generally parallel to a major axis of the delivery lumen, and a second post-deployment position spread radially from the major axis of the delivery lumen. The biocompatible matrix and / or the frame elements may also form or be manipulated to form a generally concave or cupped shape. The matrix can be porous or semiporous, such as a foam or a reticulated matrix. The occlusion device can be folded, twisted and / or stretched to adopt a narrow profile for loading into a coaxial delivery device and expand in place as it adopts its original shape on release. The device may be released or manipulated to a desired shape to occlude an aneurysm. Methods of using the implantable device are also provided.

Owner:BIOMERIX CORP

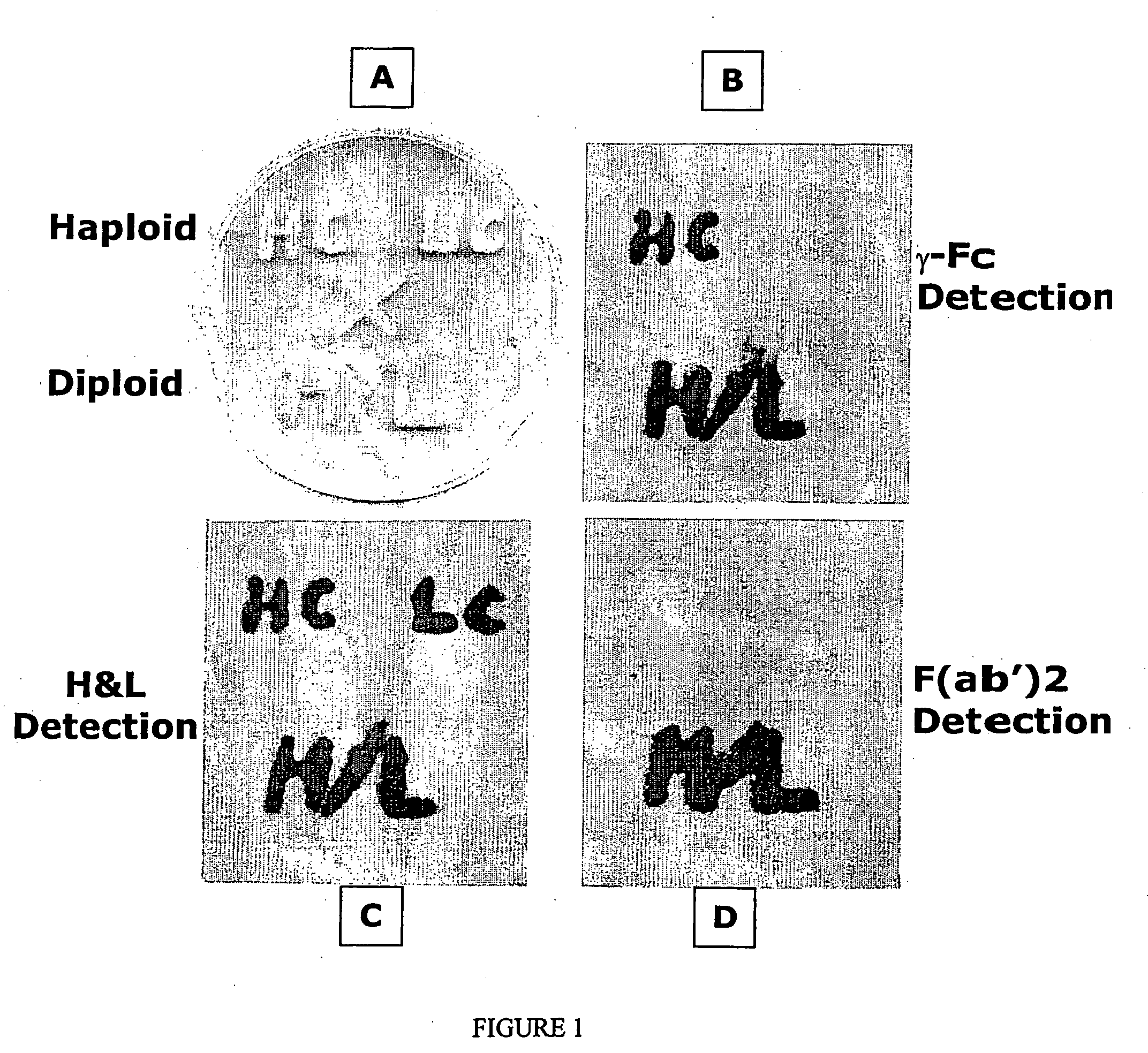

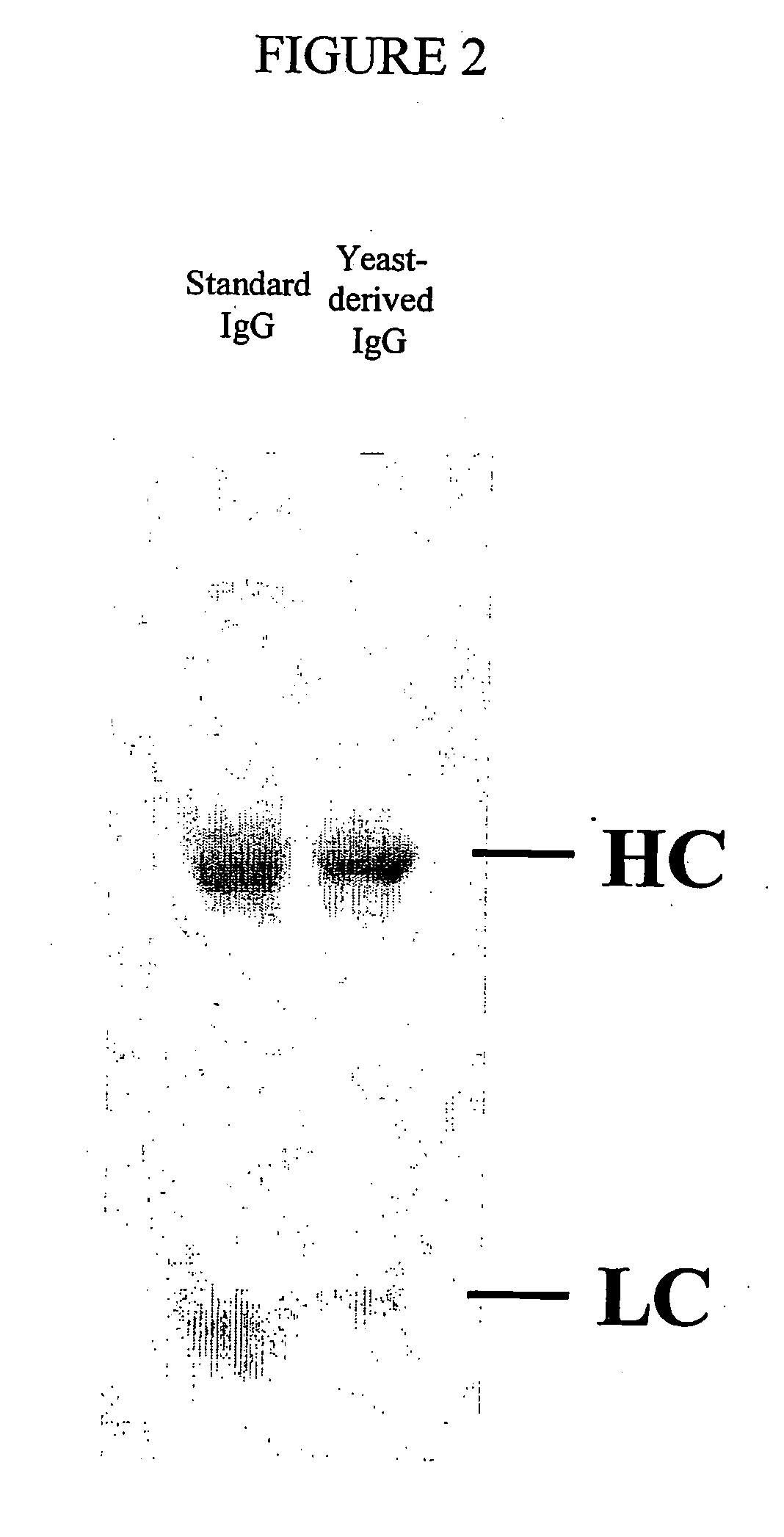

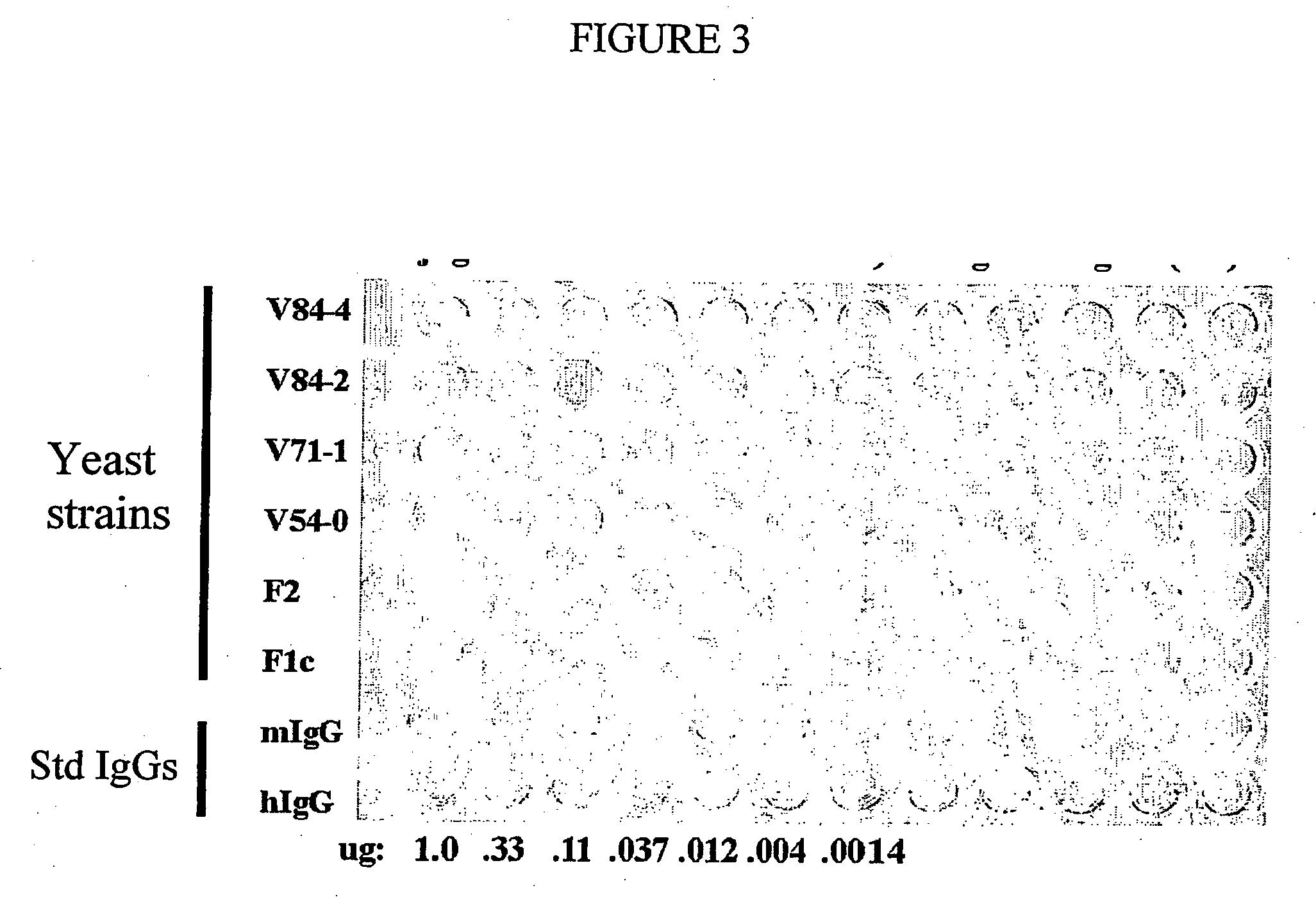

Methods of synthesizing heteromultimeric polypeptides in yeast using a haploid mating strategy

ActiveUS20060270045A1Enhance full-length product generationIncrease secretionFungiMicrobiological testing/measurementBiotechnologyMating

Methods are provided for the synthesis and secretion of recombinant proteins preferably large mammalian proteins or hetero-multimeric proteins at high levels and for prolonged time in polyploid, preferably diploid yeast. These methods use various mating competent yeast, including Pichia. In a preferred embodiment, a first expression vector is transformed into a first haploid cell; and a second expression vector is transformed into a second haploid cell. The transformed haploid cells, each individually synthesizing a non-identical polypeptide, are identified and then genetically crossed or fused. The resulting diploid strains are utilized to produce and secrete fully assembled and biologically functional hetero-multimeric protein.

Owner:KECK GRADUATE INST OF APPLIED LIFE SCI +1

Artificial functional spinal unit assemblies

ActiveUS20050033439A1Promote growthPromoting bony end growthInternal osteosythesisJoint implantsSurgical approachFunctional spinal unit

An artificial functional spinal unit is provided comprising, generally, an expandable artificial intervertebral implant that can be placed via a posterior surgical approach and used in conjunction with one or more artificial facet joints to provide an anatomically correct range of motion. Expandable artificial intervertebral implants in both lordotic and non-lordotic designs are disclosed, as well as lordotic and non-lordotic expandable cages for both PLIF (posterior lumber interbody fusion) and TLIF (transforaminal lumbar interbody fusion) procedures. The expandable implants may have various shapes, such as round, square, rectangular, banana-shaped, kidney-shaped, or other similar shapes. By virtue of their posteriorly implanted approach, the disclosed artificial FSU's allow for posterior decompression of the neural elements, reconstruction of all or part of the natural functional spinal unit, restoration and maintenance of lordosis, maintenance of motion, and restoration and maintenance of disc space height.

Owner:FLEXUSPINE INC

Flash Heating in Atomic Layer Deposition

InactiveUS20070281082A1Control performanceSave stepsSolid-state devicesPretreated surfacesMetallurgyAtomic layer deposition

System and methods for flash heating of materials deposited using atomic layer deposition techniques are disclosed. By flash heating the surface of the deposited material after each or every few deposition cycles, contaminants such as un-reacted precursors and byproducts can be released from the deposited material. A higher quality material is deposited by reducing the incorporation of impurities. A flash heating source is capable of quickly raising the temperature of the surface of a deposited material without substantially raising the temperature of the bulk of the substrate on which the material is being deposited. Because the temperature of the bulk of the substrate is not significantly raised, the bulk acts like a heat sink to aid in cooling the surface after flash heating. In this manner, processing times are not significantly increased in order to allow the surface temperature to reach a suitably low temperature for deposition.

Owner:SANDISK TECH LLC

Artificial functional spinal unit assemblies

InactiveUS20050033431A1Promote growthPromoting bony end growthInternal osteosythesisJoint implantsSurgical approachFunctional spinal unit

An artificial functional spinal unit is provided comprising, generally, an expandable artificial intervertebral implant that can be placed via a posterior surgical approach and used in conjunction with one or more artificial facet joints to provide an anatomically correct range of motion. Expandable artificial intervertebral implants in both lordotic and non-lordotic designs are disclosed, as well as lordotic and non-lordotic expandable cages for both PLIF (posterior lumber interbody fusion) and TLIF (transforaminal lumbar interbody fusion) procedures. The expandable implants may have various shapes, such as round, square, rectangular, banana-shaped, kidney-shaped, or other similar shapes. By virtue of their posteriorly implanted approach, the disclosed artificial FSU's allow for posterior decompression of the neural elements, reconstruction of all or part of the natural functional spinal unit, restoration and maintenance of lordosis, maintenance of motion, and restoration and maintenance of disc space height.

Owner:FLEXUSPINE INC

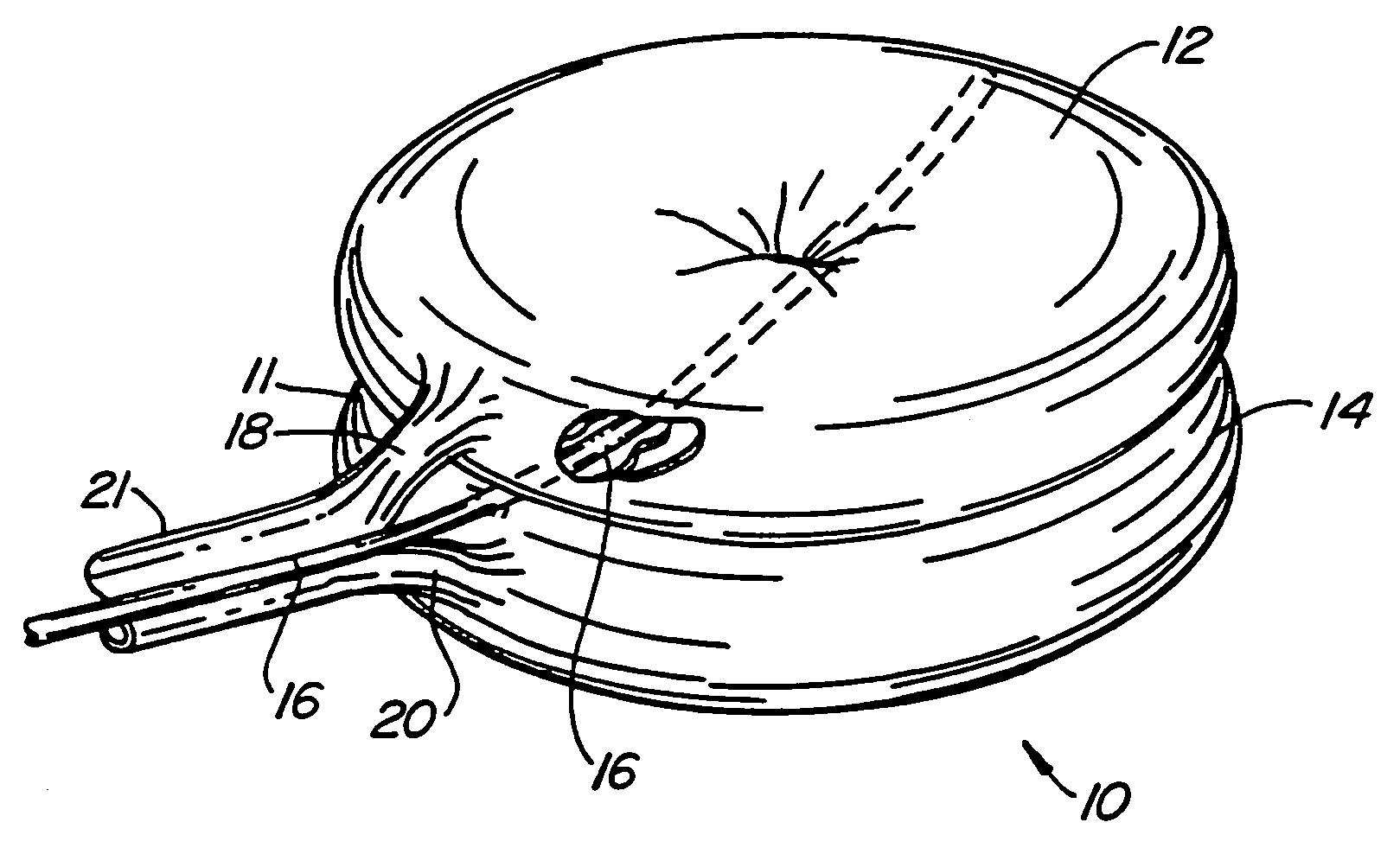

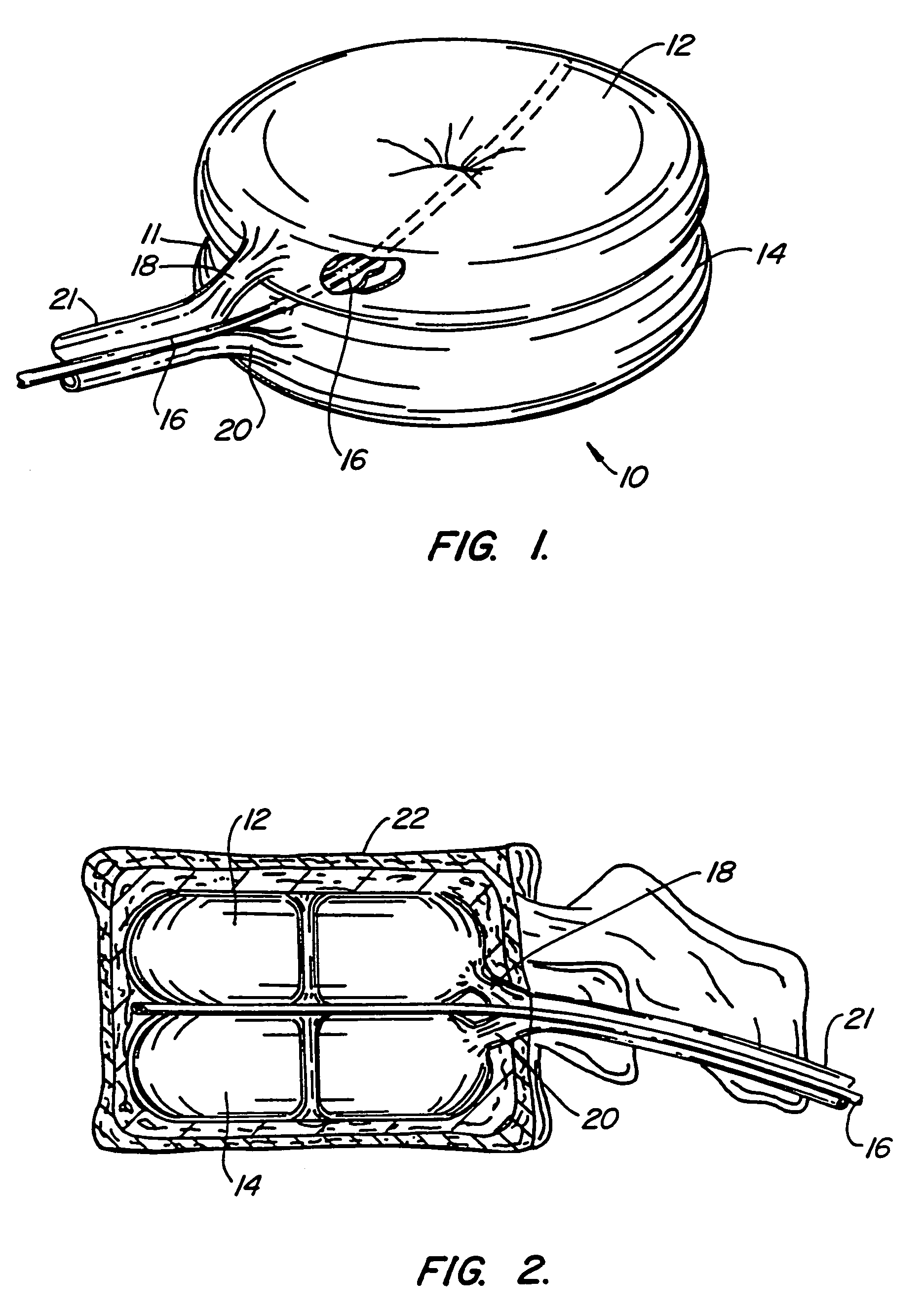

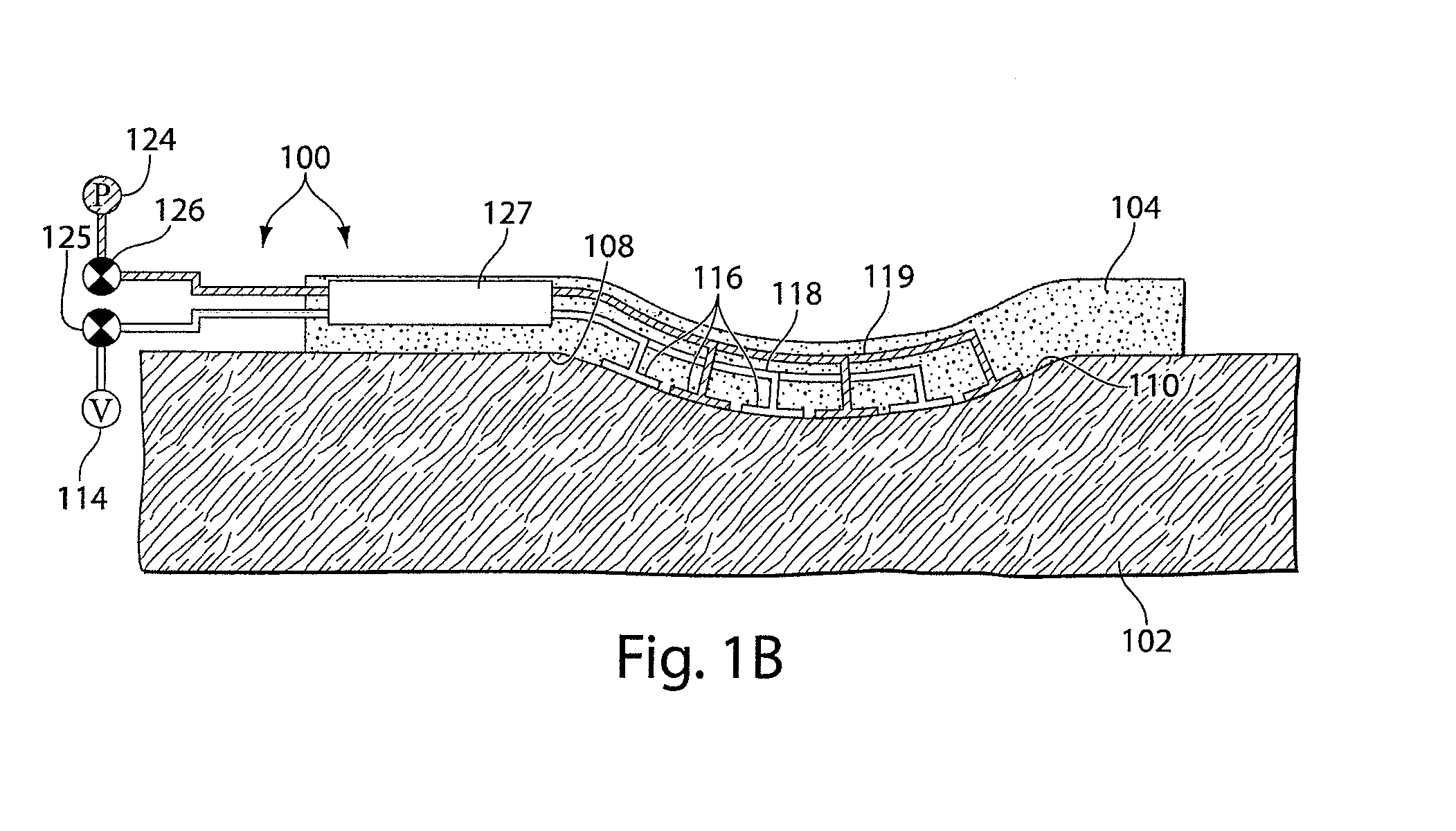

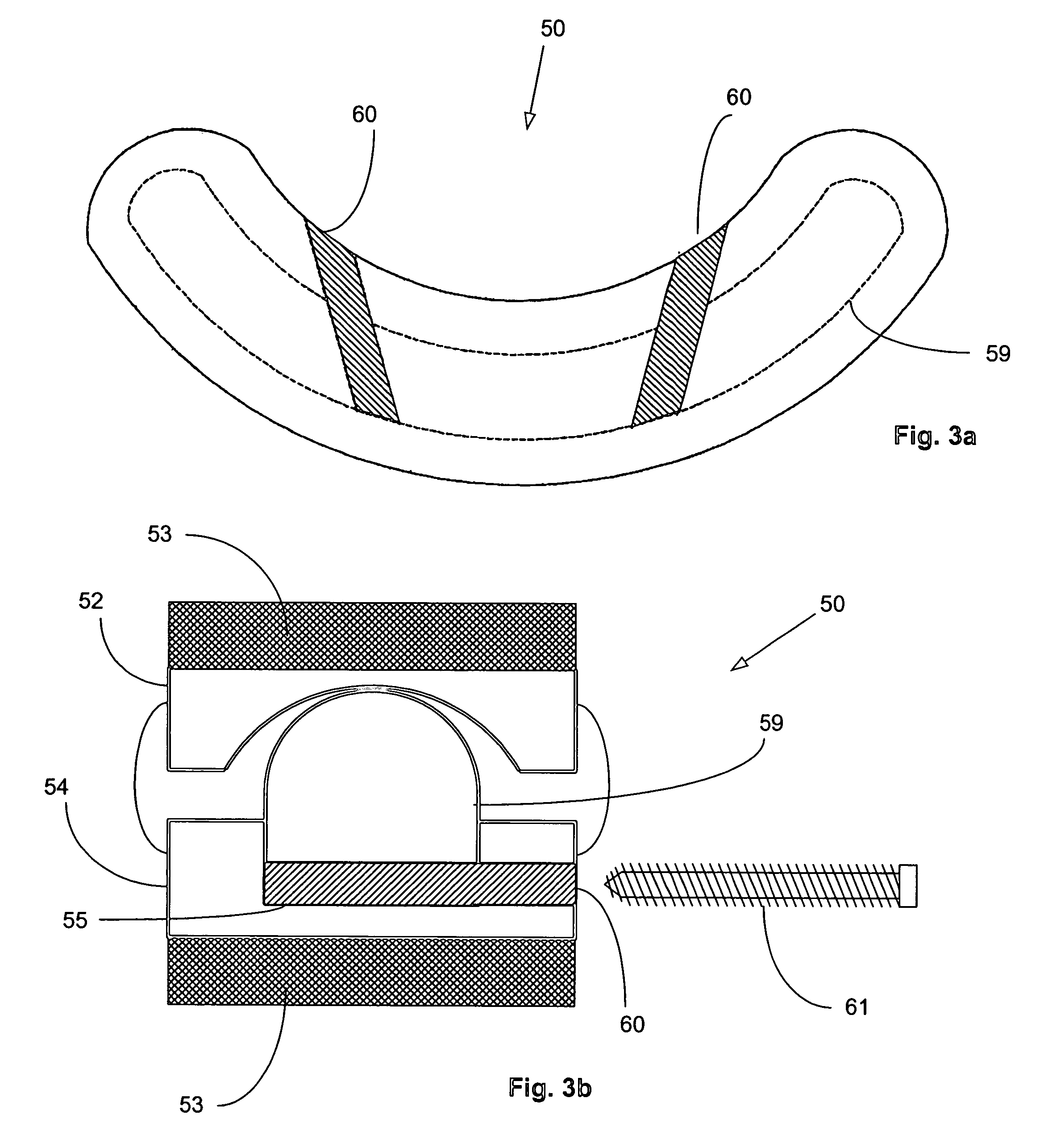

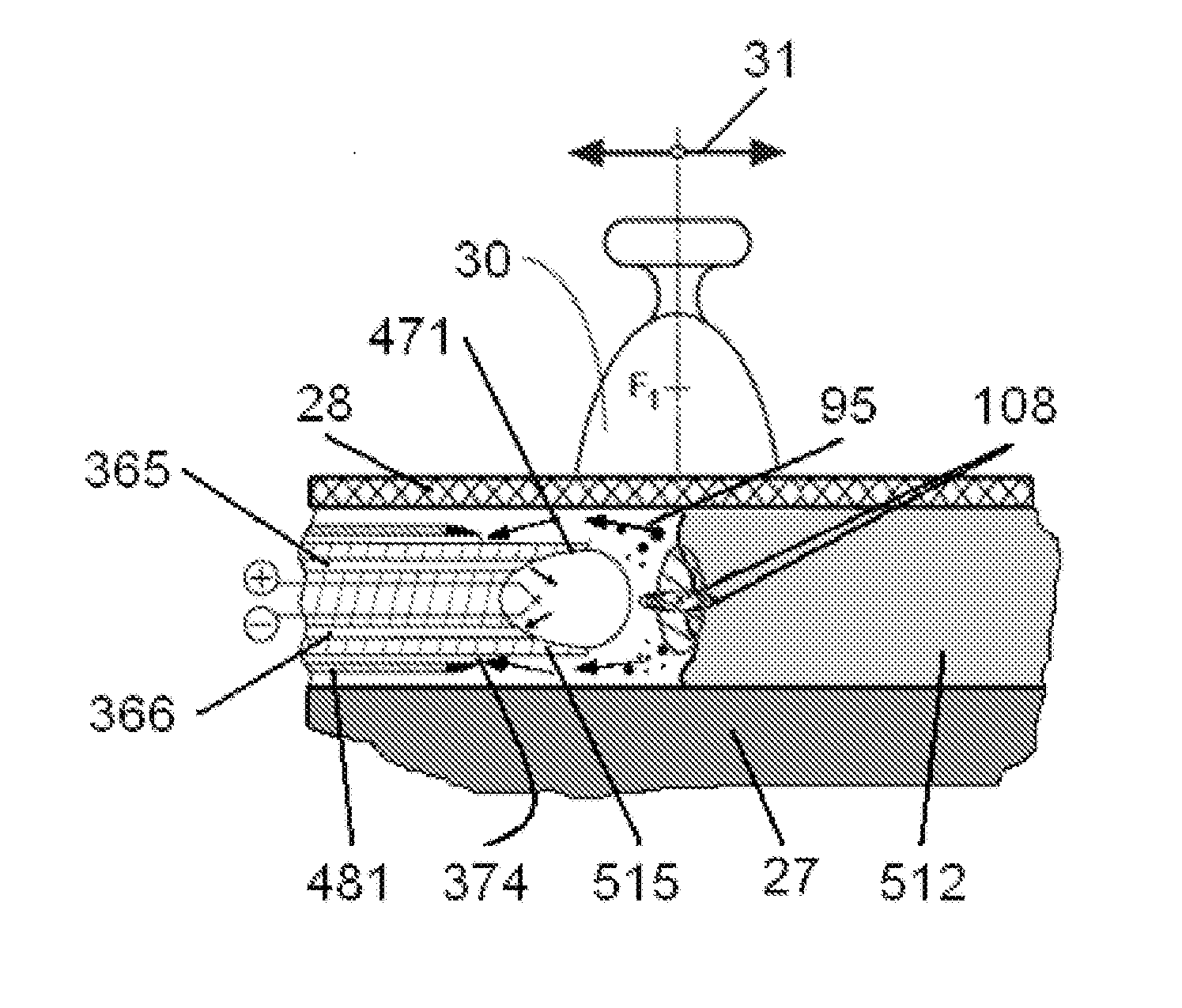

Inflatable device for use in surgical protocol relating to fixation of bone

InactiveUS7261720B2Easy to compressEasy to foldSurgical furnitureInternal osteosythesisBone CortexTrabecular bone

A balloon for use in compressing cancellous bone and marrow (also known as medullary bone or trabecular bone). The balloon comprises an inflatable balloon body for insertion into said bone. The body has a shape and size to compress at least a portion of the cancellous bone to form a cavity in the cancellous bone and / or to restore the original position of the outer cortical bone, if fractured or collapsed. The balloon desirably incorporates restraints which inhibit the balloon from applying excessive pressure to various regions of the cortical bone. The wall or walls of the balloon are such that proper inflation of the balloon body is achieved to provide for optimum compression of the bone marrow. The balloon can be inserted quickly into a bone. The balloon can be made to have a suction catheter. The balloon can be used to form and / or enlarge a cavity or passage in a bone, especially in, but not limited to, vertebral bodies. Various additional embodiments facilitate directionally biasing the inflation of the balloon.

Owner:ORTHOPHOENIX

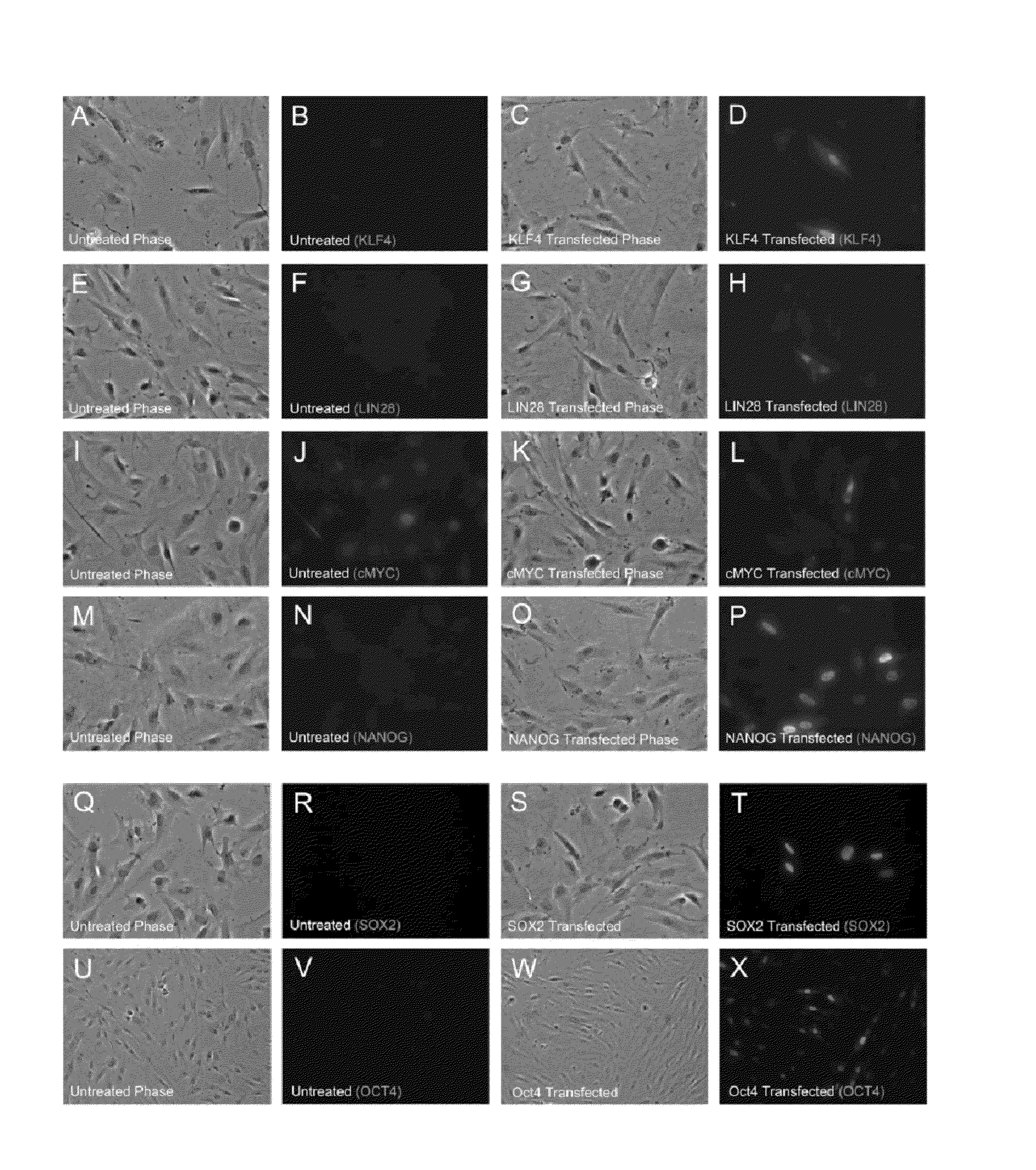

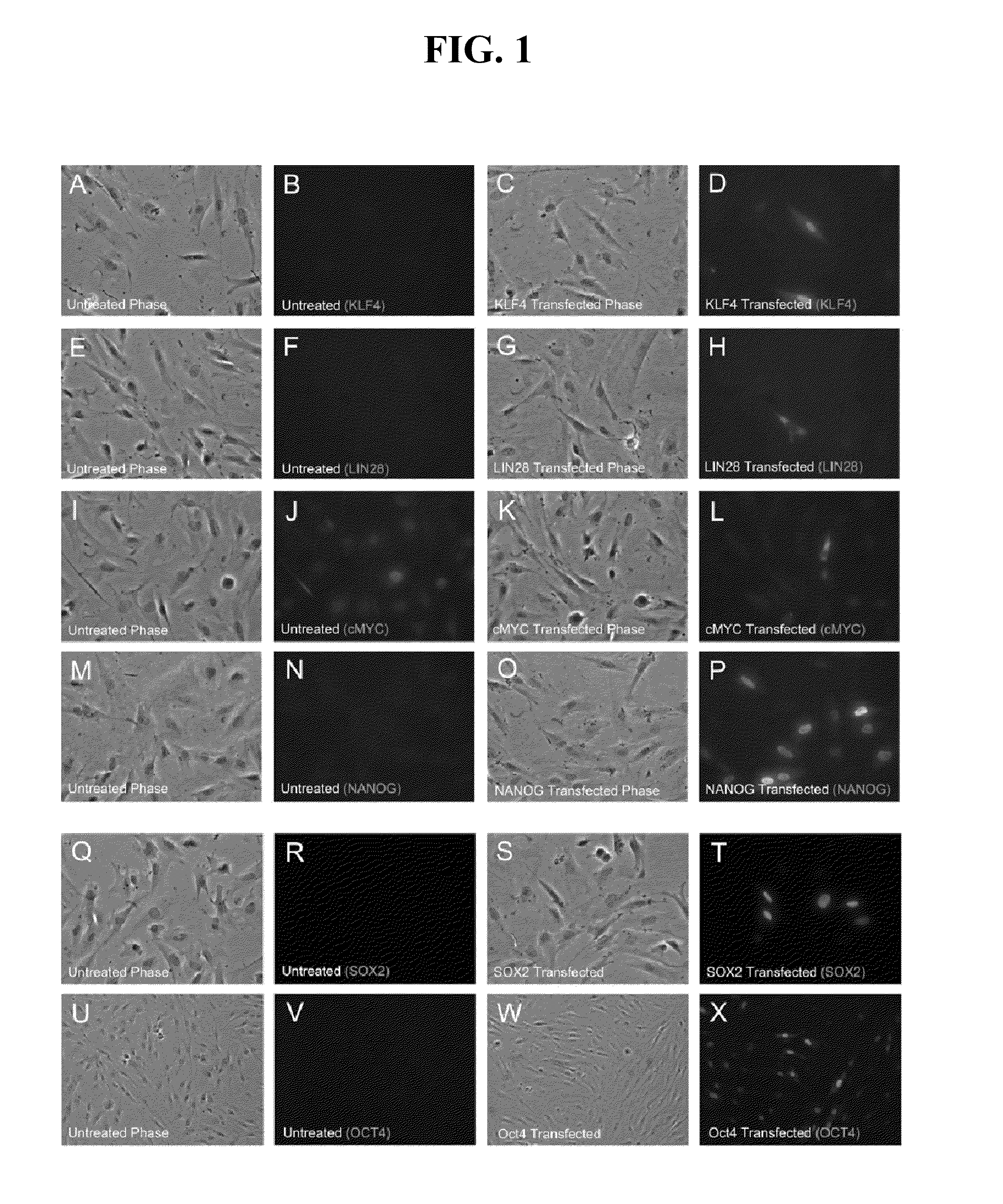

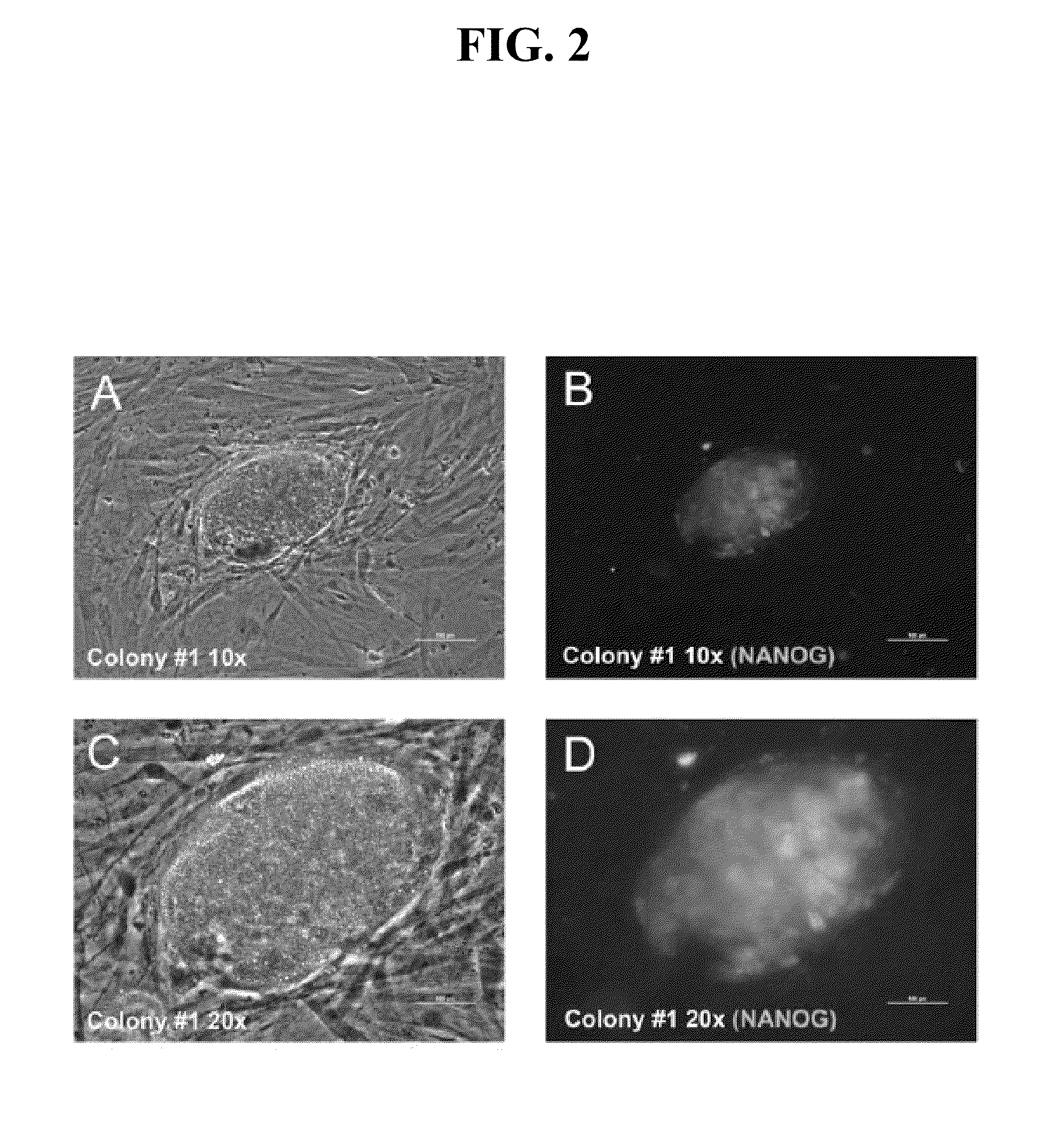

RNA preparations comprising purified modified RNA for reprogramming cells

ActiveUS20110143397A1Promote growthArtificial cell constructsCell culture active agentsSingle strandSomatic cell

The present invention provides compositions and methods for reprogramming somatic cells using purified RNA preparations comprising single-strand mRNA encoding an iPS cell induction factor. The purified RNA preparations are preferably substantially free of RNA contaminant molecules that: i) would activate an immune response in the somatic cells, ii) would decrease expression of the single-stranded mRNA in the somatic cells, and / or iii) active RNA sensors in the somatic cells. In certain embodiments, the purified RNA preparations are substantially free of partial mRNAs, double-stranded RNAs, un-capped RNA molecules, and / or single-stranded run-on mRNAs.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

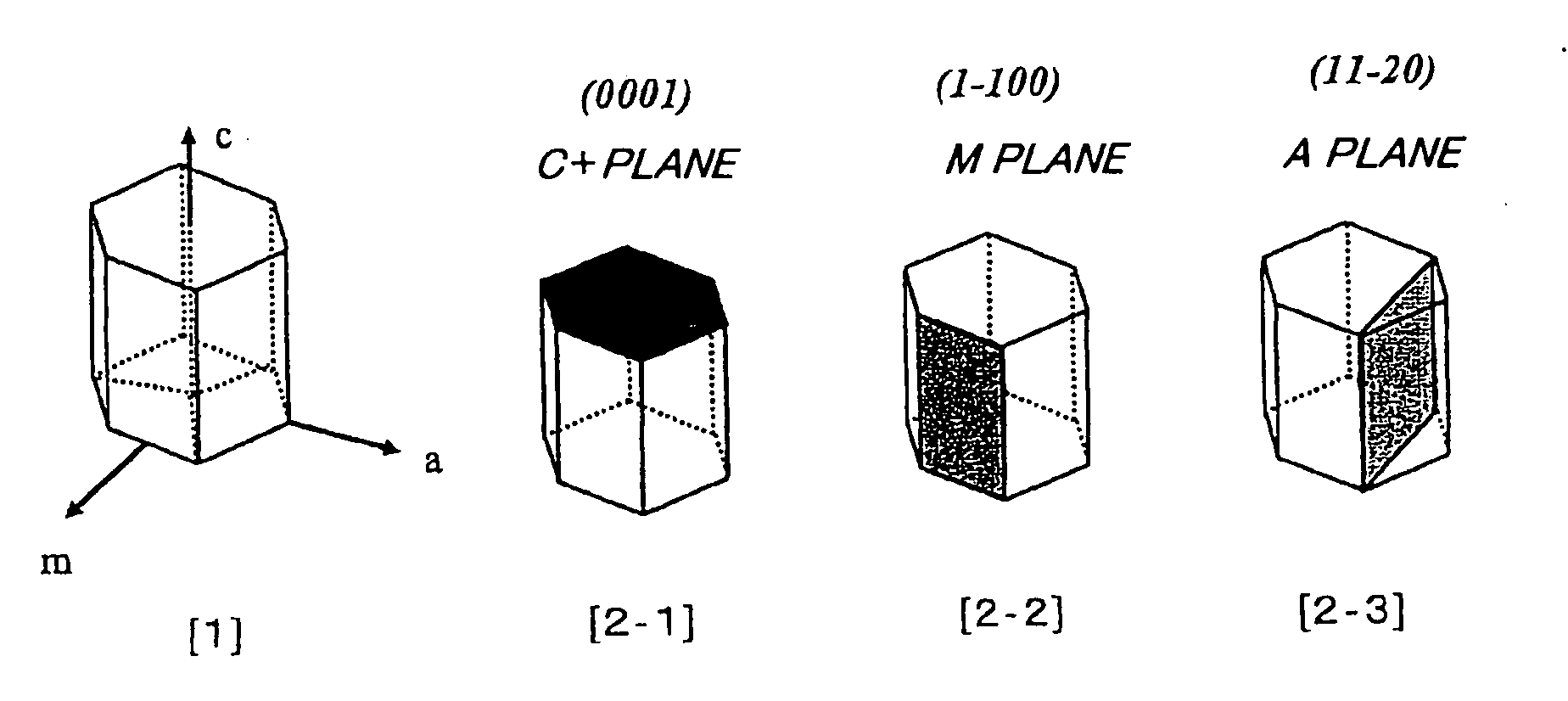

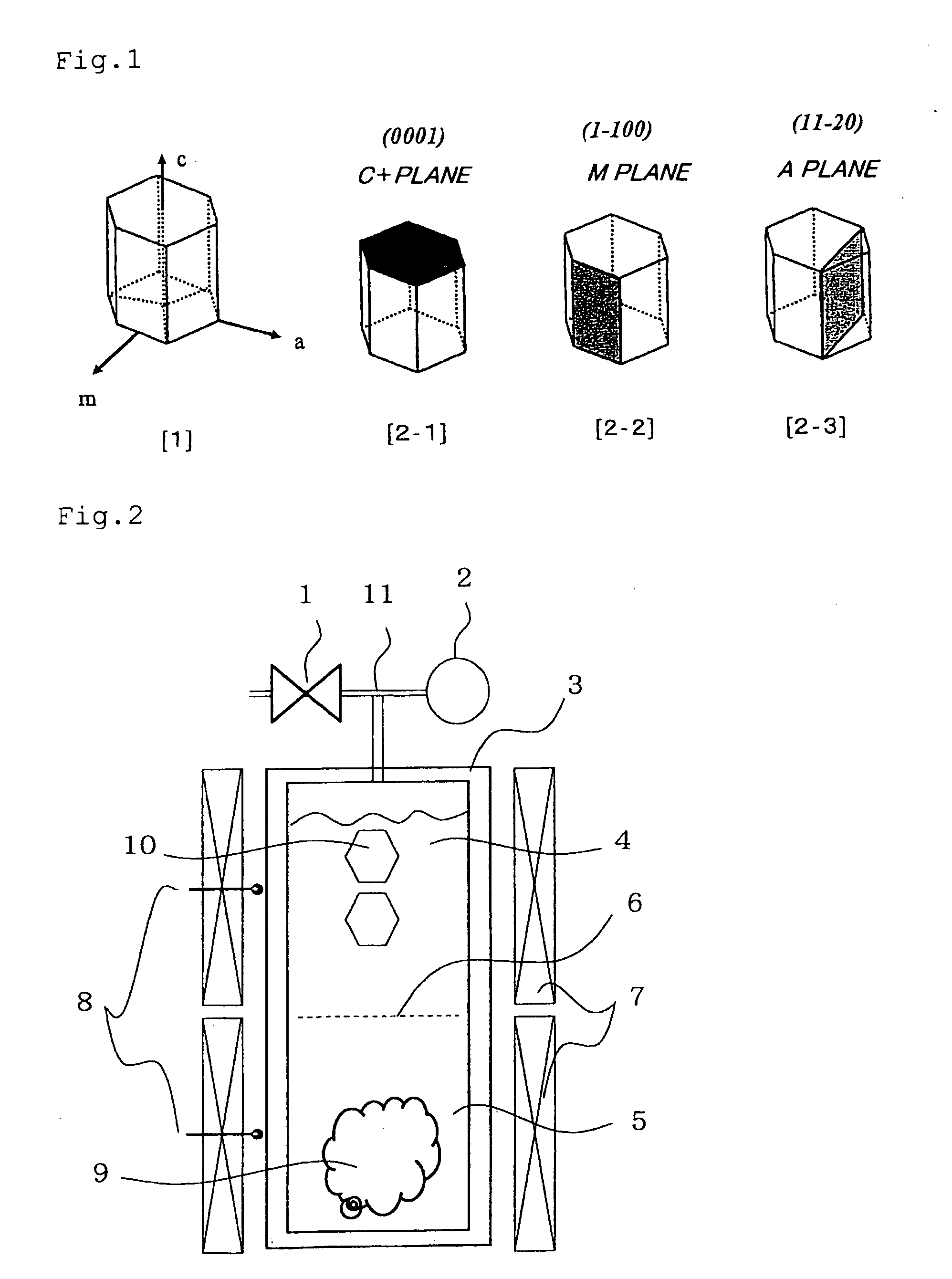

Method for producing nitride semiconductor, crystal growth rate increasing agent, single crystal nitride, wafer and device

InactiveUS20100104495A1Improve performanceIncrease probabilityPolycrystalline material growthFrom normal temperature solutionsNitrogenCrystal structure

A method for producing a nitride semiconductor, comprising controlling temperature and pressure in a autoclave containing a seed having a hexagonal crystal structure, a nitrogen element-containing solvent, a raw material substance containing a metal element of Group 13 of the Periodic Table, and a mineralizer so as to put said solvent into a supercritical state and / or a subcritical state and thereby ammonothermally grow a nitride semiconductor crystal on the surface of said seed, wherein the crystal growth rate in the m-axis direction on said seed is 1.5 times or more the crystal growth rate in the c-axis direction on said seed. By the method, a nitride semiconductor having a large-diameter C plane or a nitride semiconductor thick in the m-axis direction can be efficiently and simply produced.

Owner:MITSUBISHI CHEM CORP +1

Artificial functional spinal unit assemblies

InactiveUS20060195192A1Promote growthPromoting bony end growthInternal osteosythesisJoint implantsSurgical approachFunctional spinal unit

An artificial functional spinal unit is provided comprising, generally, an expandable artificial intervertebral implant that can be placed via a posterior surgical approach and used in conjunction with one or more artificial facet joints to provide an anatomically correct range of motion. Expandable artificial intervertebral implants in both lordotic and non-lordotic designs are disclosed, as well as lordotic and non-lordotic expandable cages for both PLIF (posterior lumber interbody fusion) and TLIF (transforaminal lumbar interbody fusion) procedures. The expandable implants may have various shapes, such as round, square, rectangular, banana-shaped, kidney-shaped, or other similar shapes. By virtue of their posteriorly implanted approach, the disclosed artificial FSU's allow for posterior decompression of the neural elements, reconstruction of all or part of the natural functional spinal unit, restoration and maintenance of lordosis, maintenance of motion, and restoration and maintenance of disc space height.

Owner:FLEXUSPINE INC

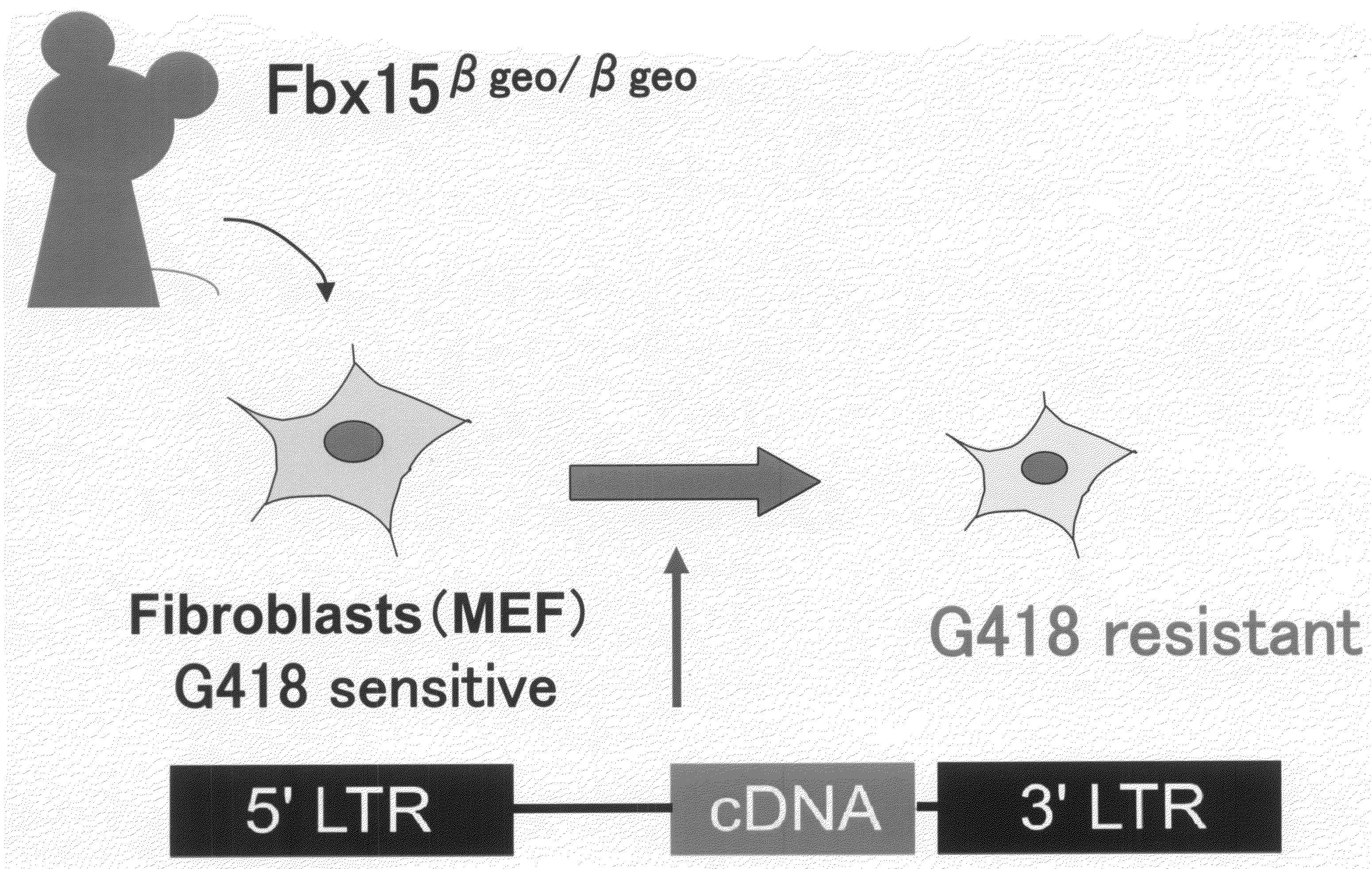

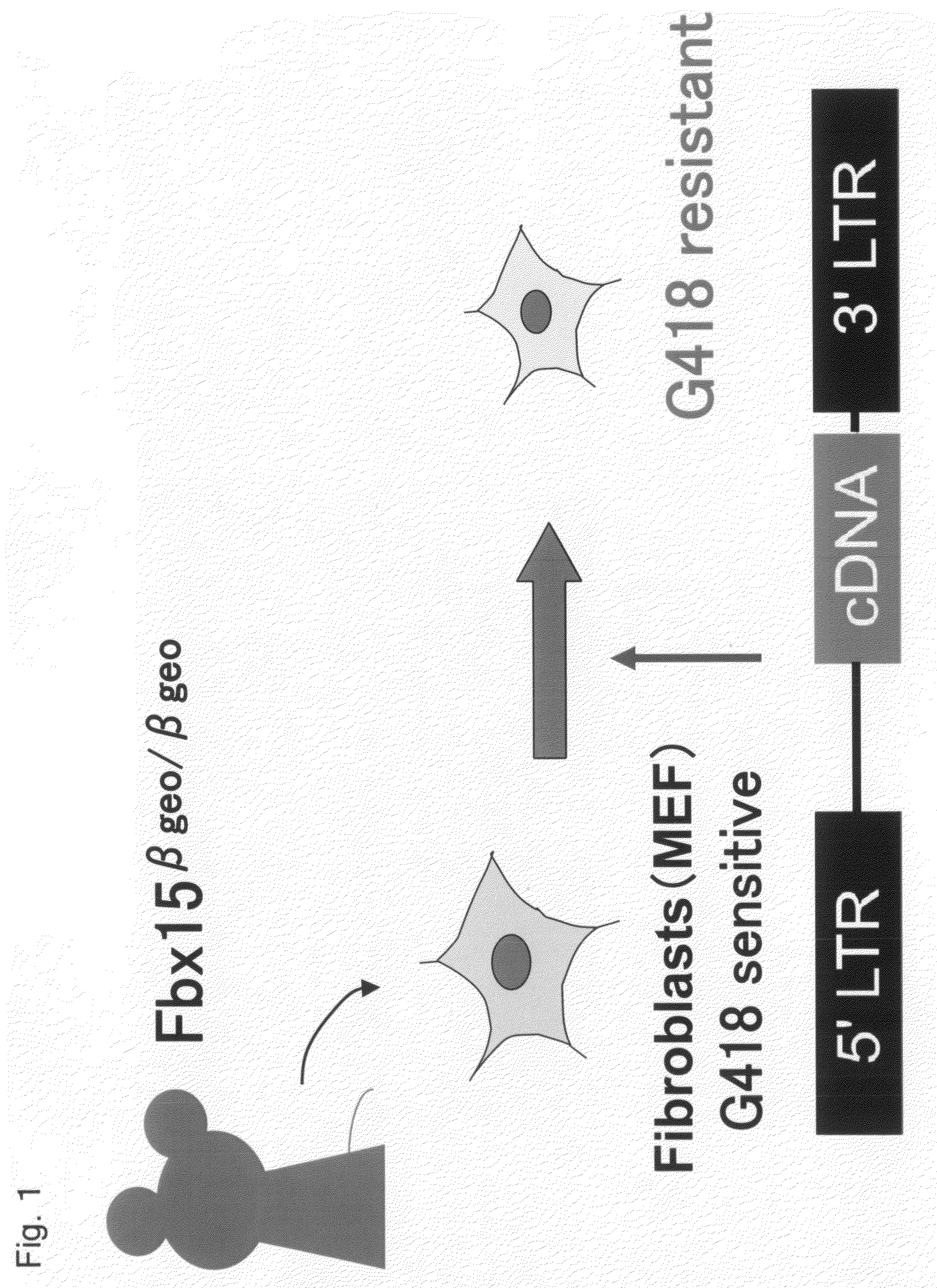

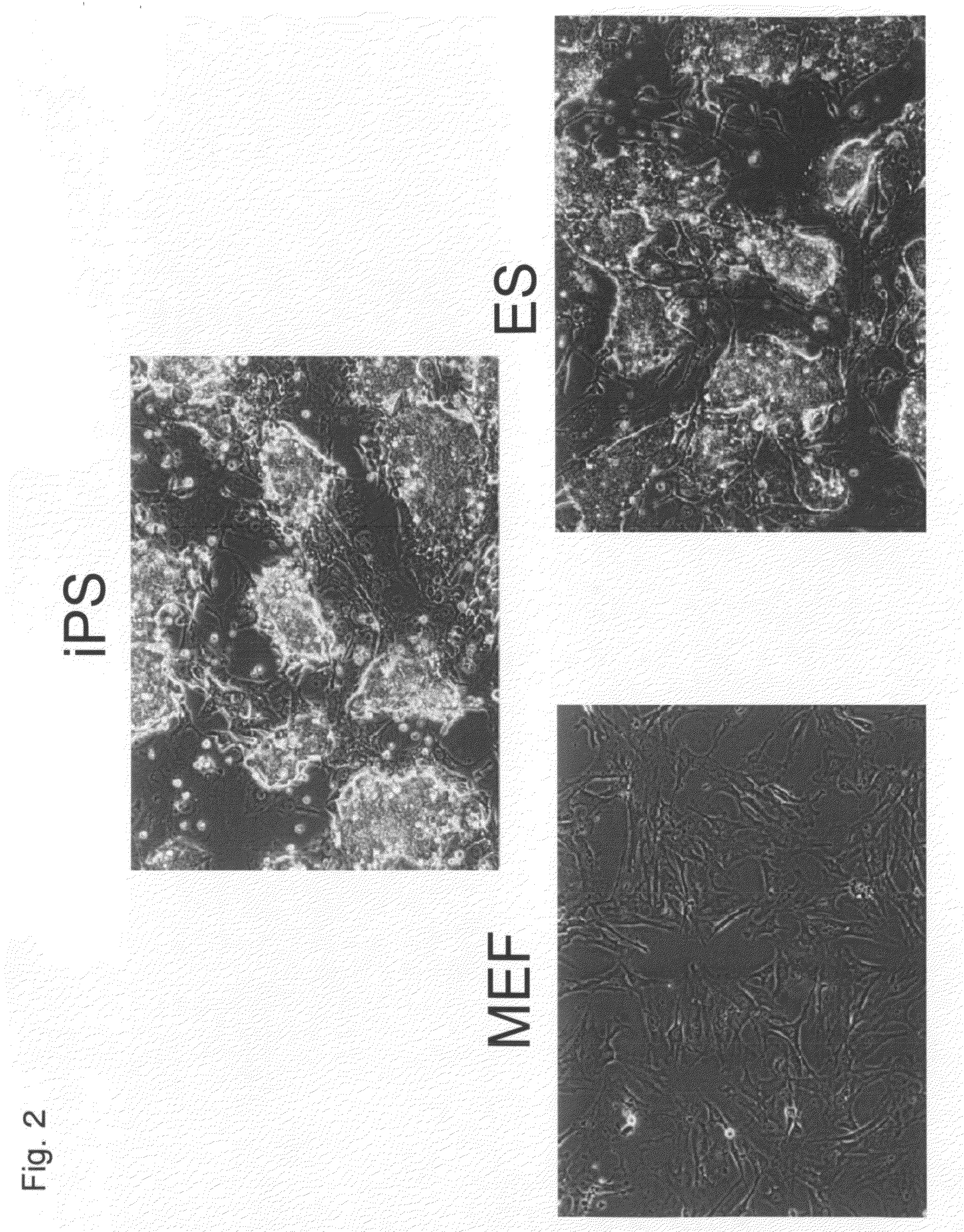

Nuclear Reprogramming Factor

There is provided a nuclear reprogramming factor for a somatic cell, which comprises a gene product of each of the following three kinds of genes: an Oct family gene, a Klf family gene, and a Myc family gene, as a means for inducing reprogramming of a differentiated cell to conveniently and highly reproducibly establish an induced pluripotent stem cell having pluripotency and growth ability similar to those of ES cells without using embryo or ES cell.

Owner:KYOTO UNIV

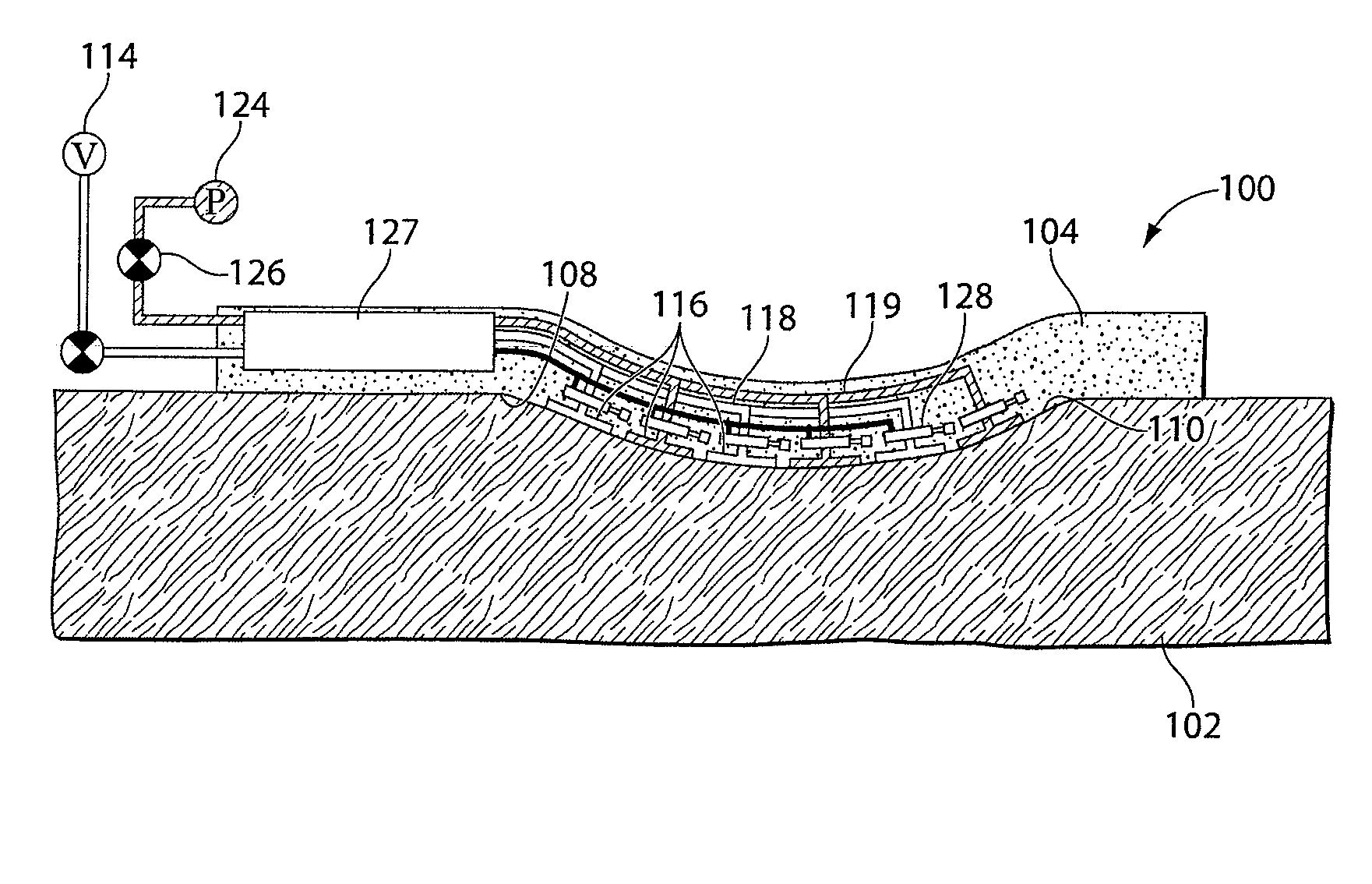

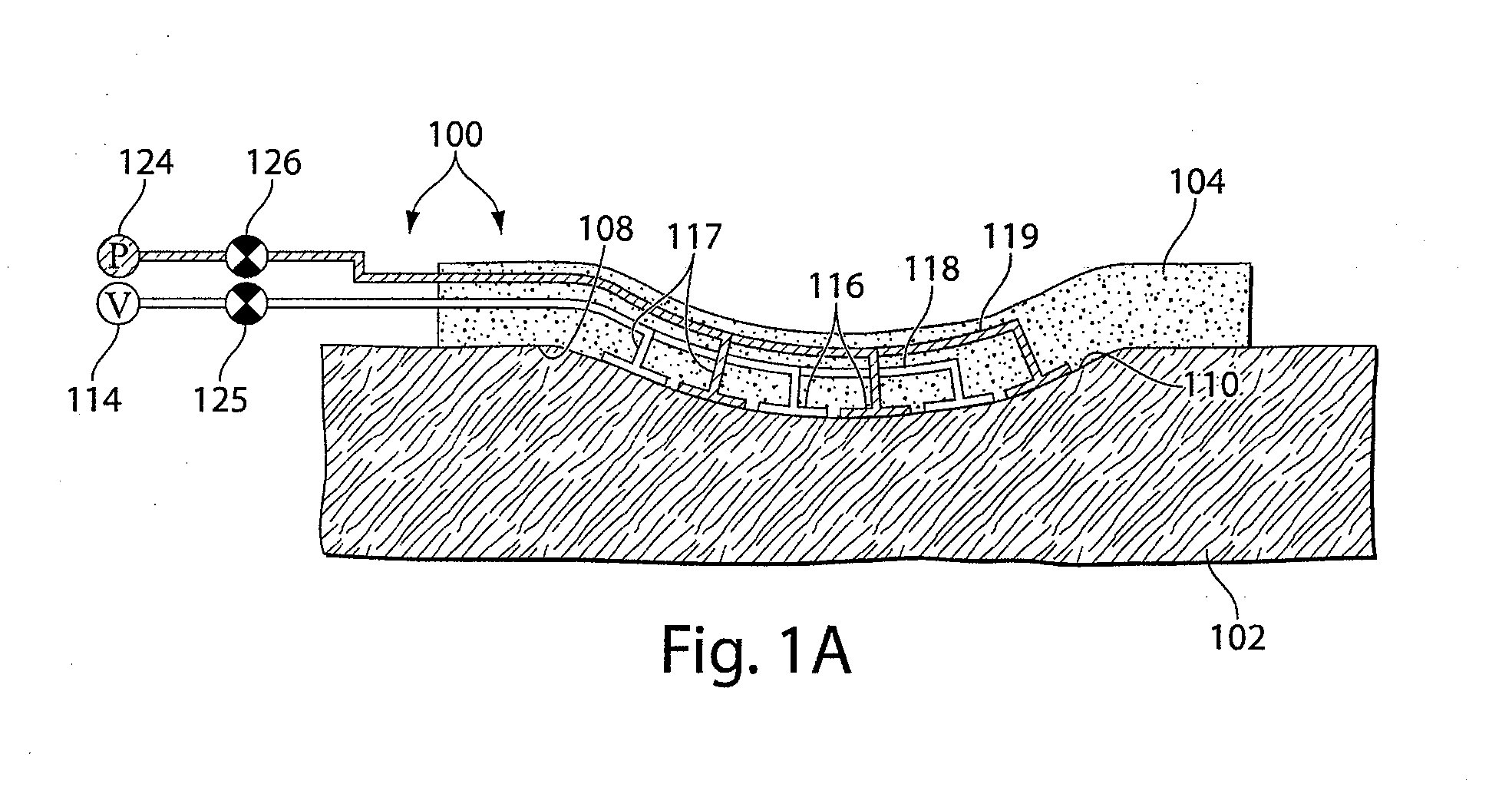

Wound healing device

ActiveUS20080275409A1Promote growthPromote woundWound drainsVaccination/ovulation diagnosticsMicron scaleVacuum pressure

Methods and devices transmit micromechanical forces locally on the millimeter to micron scale for promoting wound healing. Micromechanical forces can selectively be applied directly to tissue, in some embodiments, by using microchambers fluidically connected to microchannels. Each chamber, or in some cases, group of chambers, may be associated with a valve to control vacuum pressure, positive pressure, liquid delivery, and / or liquid removal from each chamber or group of chambers. Application of embodiments of the invention may shorten wound-healing time, reduce costs of therapy, enable restoration of functional tissue, and reduce the need for more invasive therapies, including surgery.

Owner:THE BRIGHAM & WOMEN S HOSPITAL INC

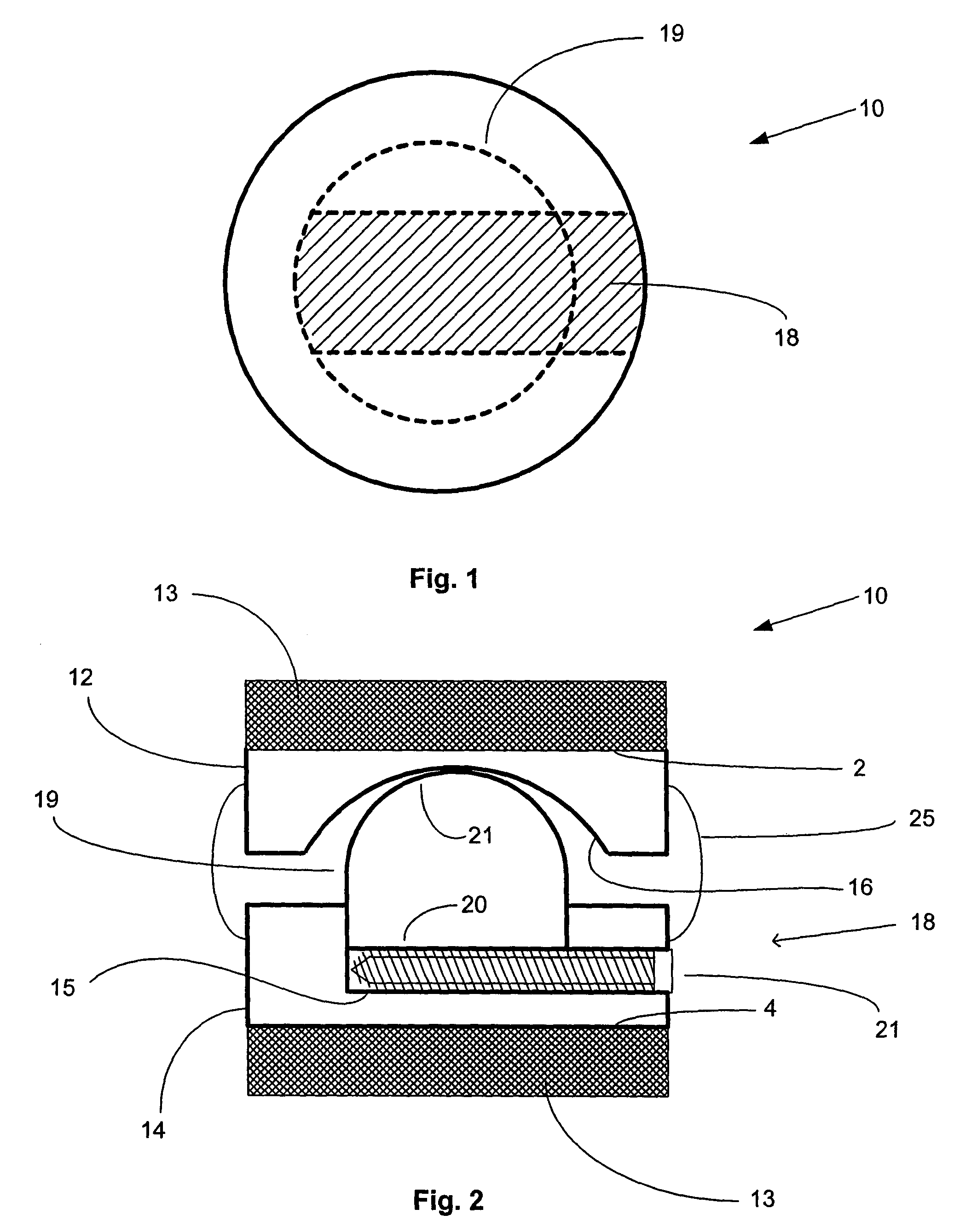

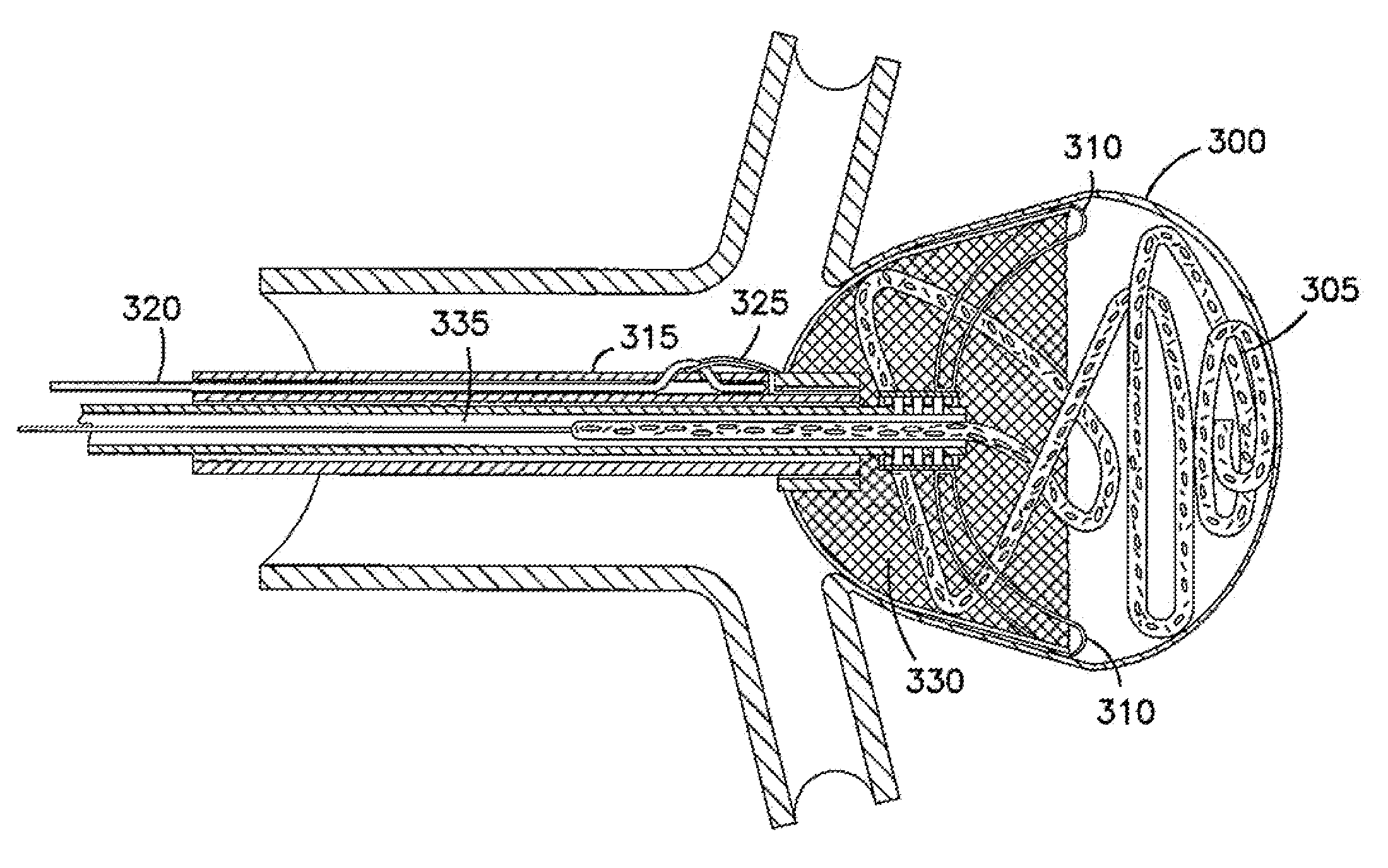

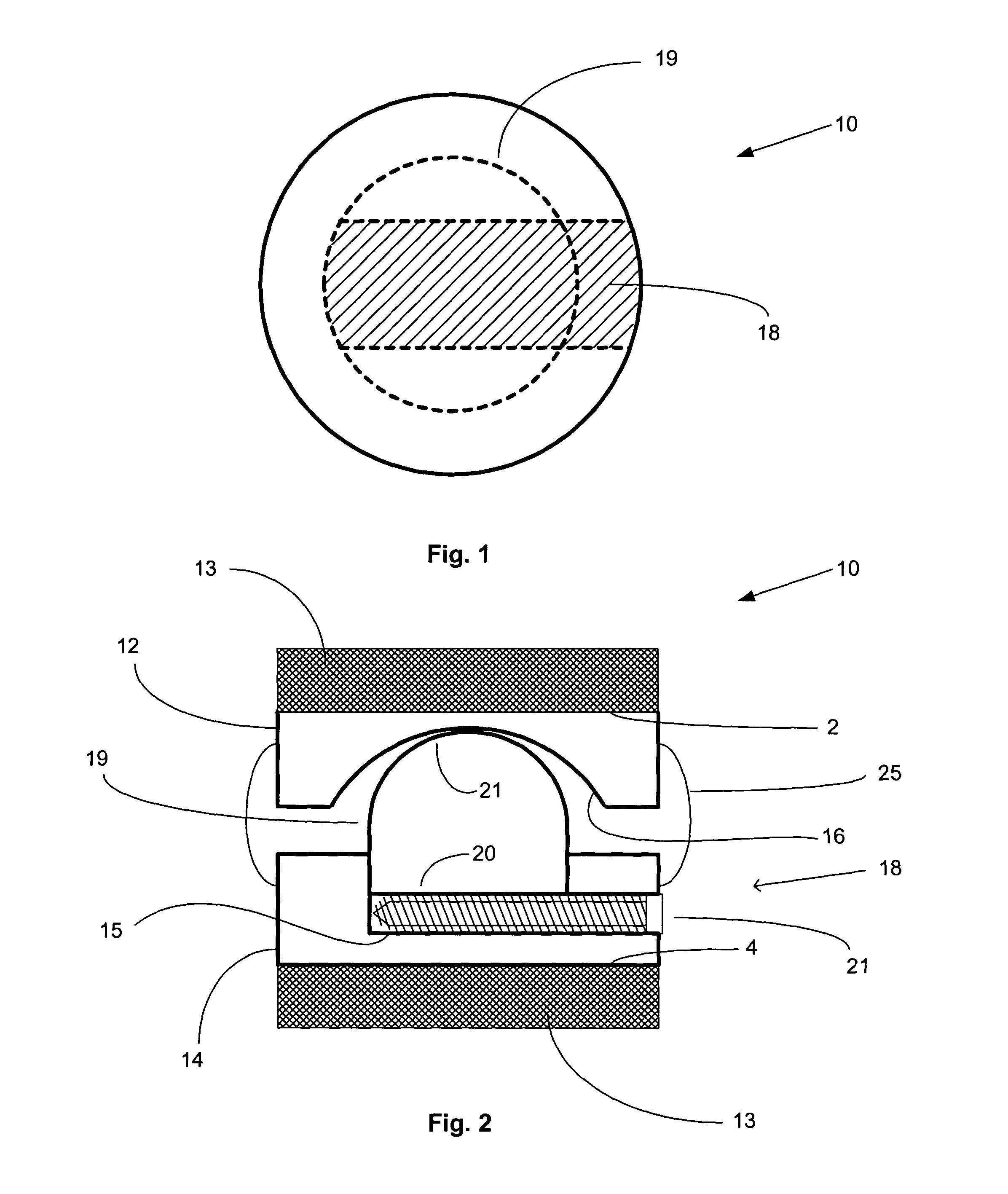

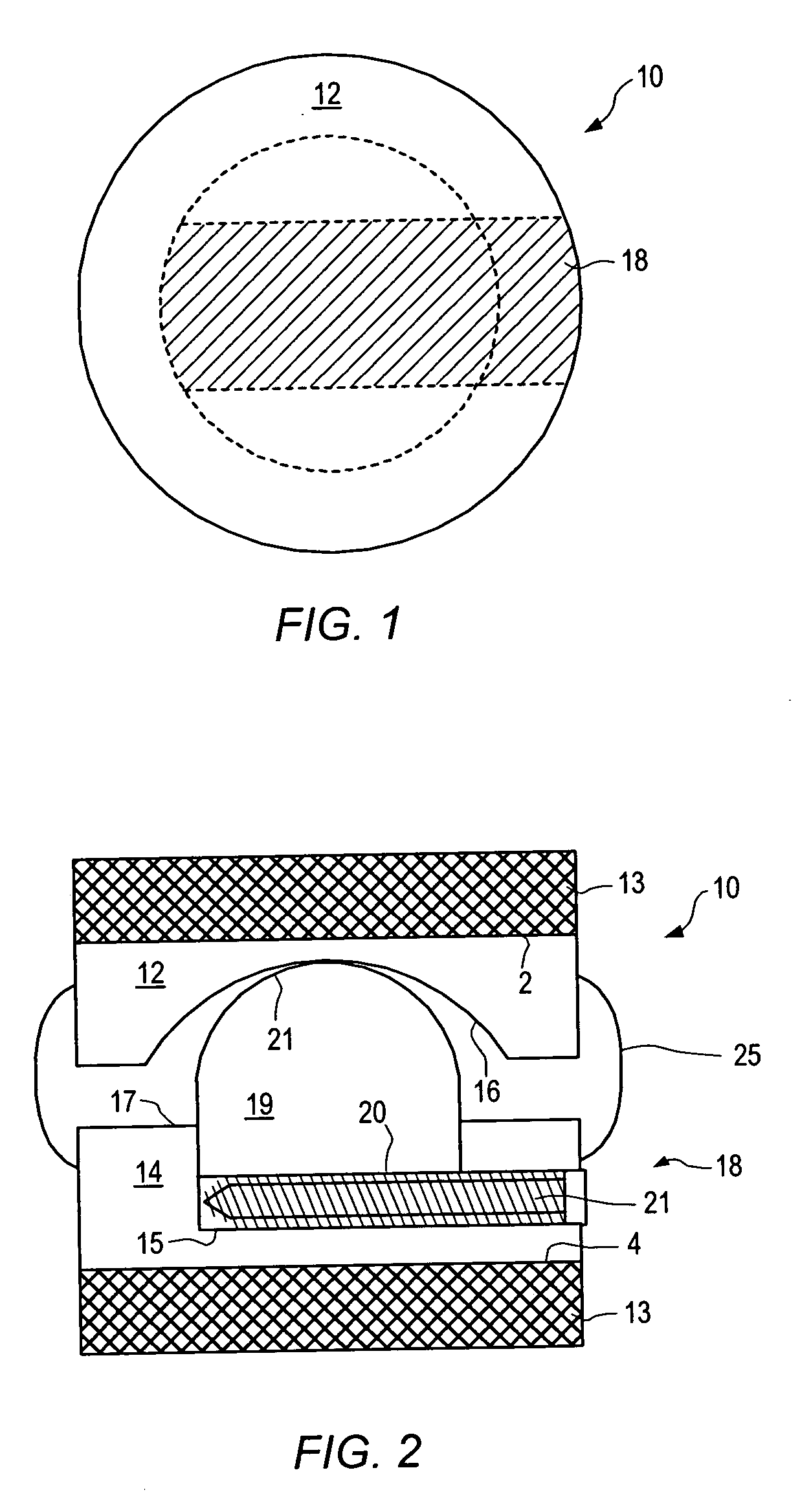

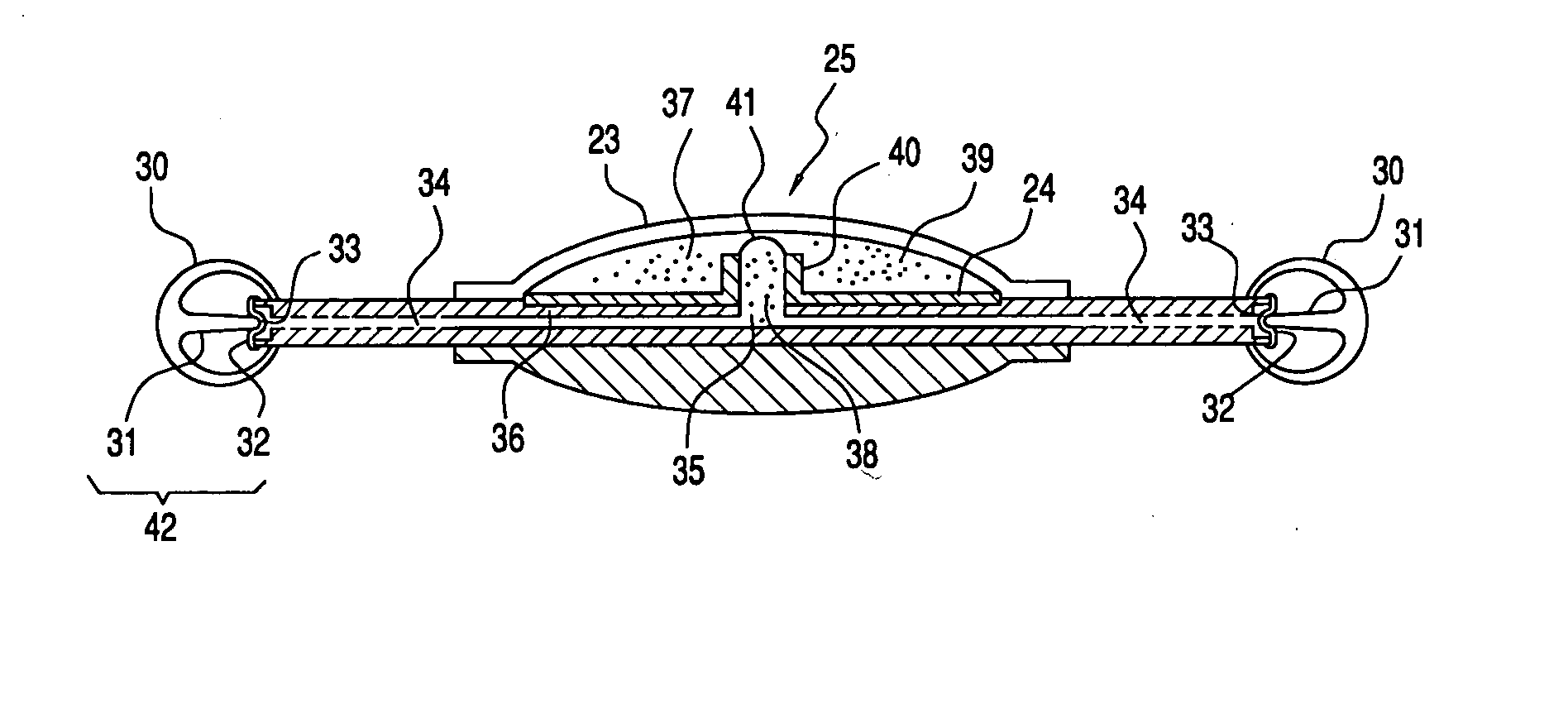

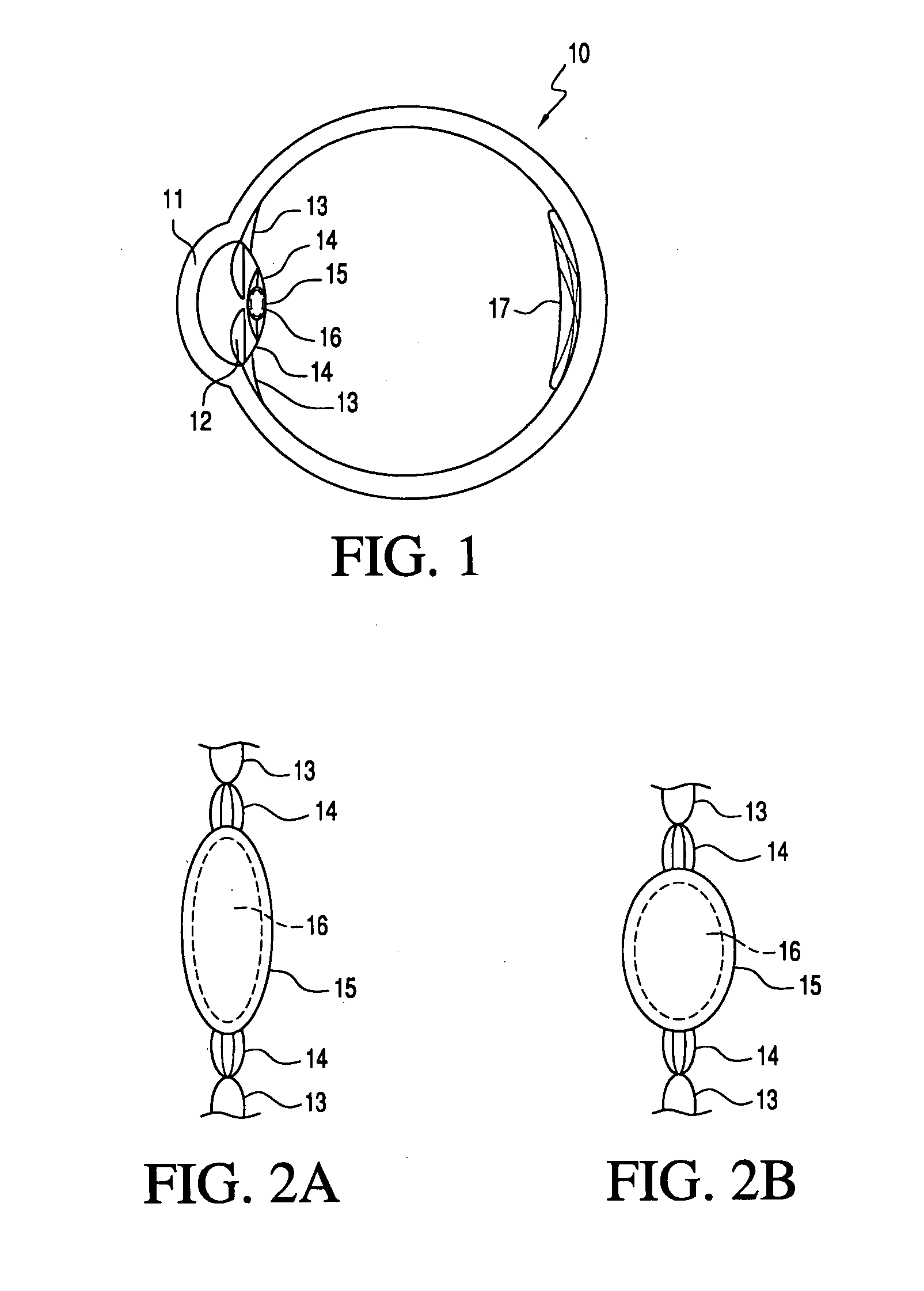

Accommodating intraocular lens system utilizing direct force transfer from zonules and method of use

InactiveUS20070088433A1Efficiently manipulatedEnhancing resistance to migrationIntraocular lensIntraocular lensOptical power

An accommodating intraocular lens is provided having optical parameters that are altered in-situ, wherein an optic portion of the lens includes a lens piston that alters the shape of a lens element of the lens to alter the optical power of the lens, responsive to forces applied to a haptic portion to the lens by contraction of the ciliary muscles. Forces applied to the haptic portion are transferred hydraulically to cause the lens to become more or less accommodated. The haptic portion is retained in a fixed unaccommodated state during an initial healing period following implantation to facilitate affixation of the haptic portion to the capsule.

Owner:POWERVISION

Artificial spinal unit assemblies

ActiveUS7909869B2Promote growthPromoting bony end growthInternal osteosythesisJoint implantsSpinal columnSurgical operation

An artificial functional spinal unit is provided comprising, generally, an expandable artificial intervertebral implant that can be placed via a posterior surgical approach and used in conjunction with one or more artificial facet joints to provide an anatomically correct range of motion. Expandable artificial intervertebral implants in both lordotic and non-lordotic designs are disclosed, as well as lordotic and non-lordotic expandable cages for both PLIF (posterior lumber interbody fusion) and TLIF (transforaminal lumbar interbody fusion) procedures. The expandable implants may have various shapes, such as round, square, rectangular, banana-shaped, kidney-shaped, or other similar shapes. By virtue of their posteriorly implanted approach, the disclosed artificial FSU's allow for posterior decompression of the neural elements, reconstruction of all or part of the natural functional spinal unit, restoration and maintenance of lordosis, maintenance of motion, and restoration and maintenance of disc space height.

Owner:FLEXUSPINE INC

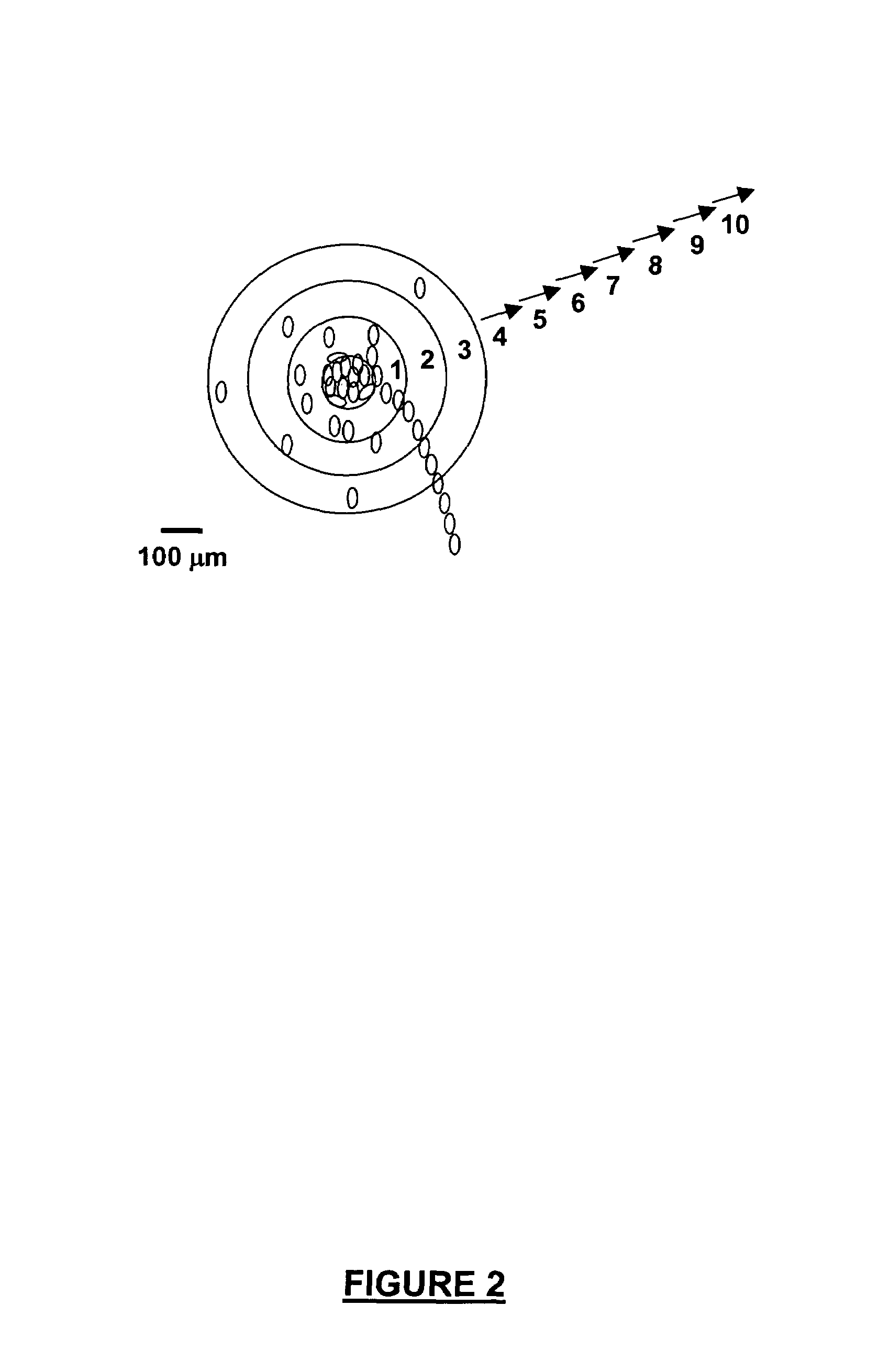

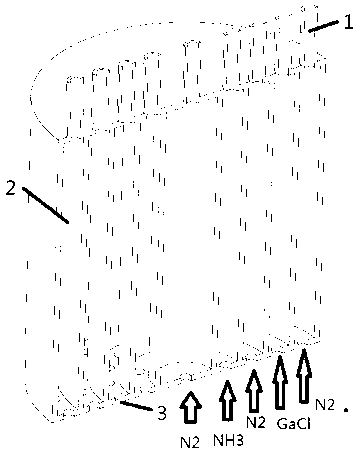

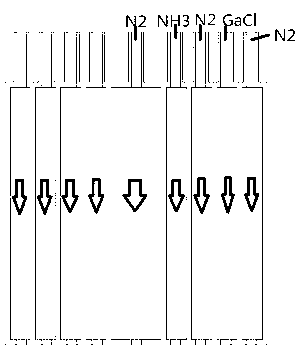

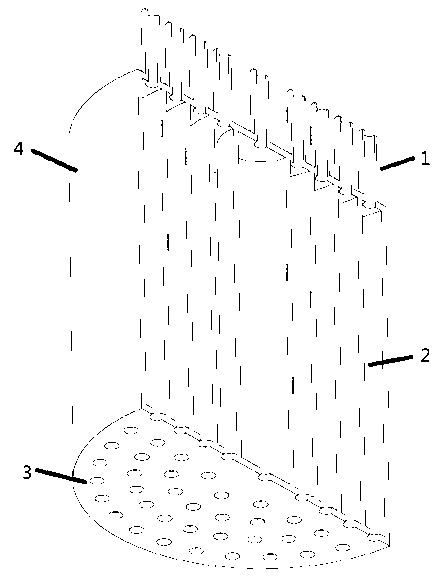

Concentric-ring sprayer structure for material vapor phase epitaxy

InactiveCN103014846ANo effect on growthGrowth impactFrom chemically reactive gasesVapour phase epitaxySprayer

The invention discloses a concentric-ring sprayer structure for material vapor phase epitaxy, which solves the problem that the large-area deposition region provides a uniform flow field of a precursor gas mixture in a large-substrate or multi-substrate crystal growth process. The sprayer structure comprises more than one independent air inlet pipeline, wherein each air inlet pipeline is provided with a controller for monitoring and regulating inlet gas flow speed and flow rate; the bottom of the sprayer is provided with an air outlet baffle; more than one concentric ring is arranged in the sprayer; independent cavities are formed among the concentric rings and are mutually separated; the top end of each concentric ring is connected with one independent air inlet pipeline; and the air outlet baffle at the bottom end of each concentric ring is provided with one or more air outlets. The air sources are mutually separated and independently controlled; and the multi-sprayer integrated use mode obviously improves the quality of the large-area deposited grown crystal, and greatly enhances the production efficiency.

Owner:SINO NITRIDE SEMICON +1

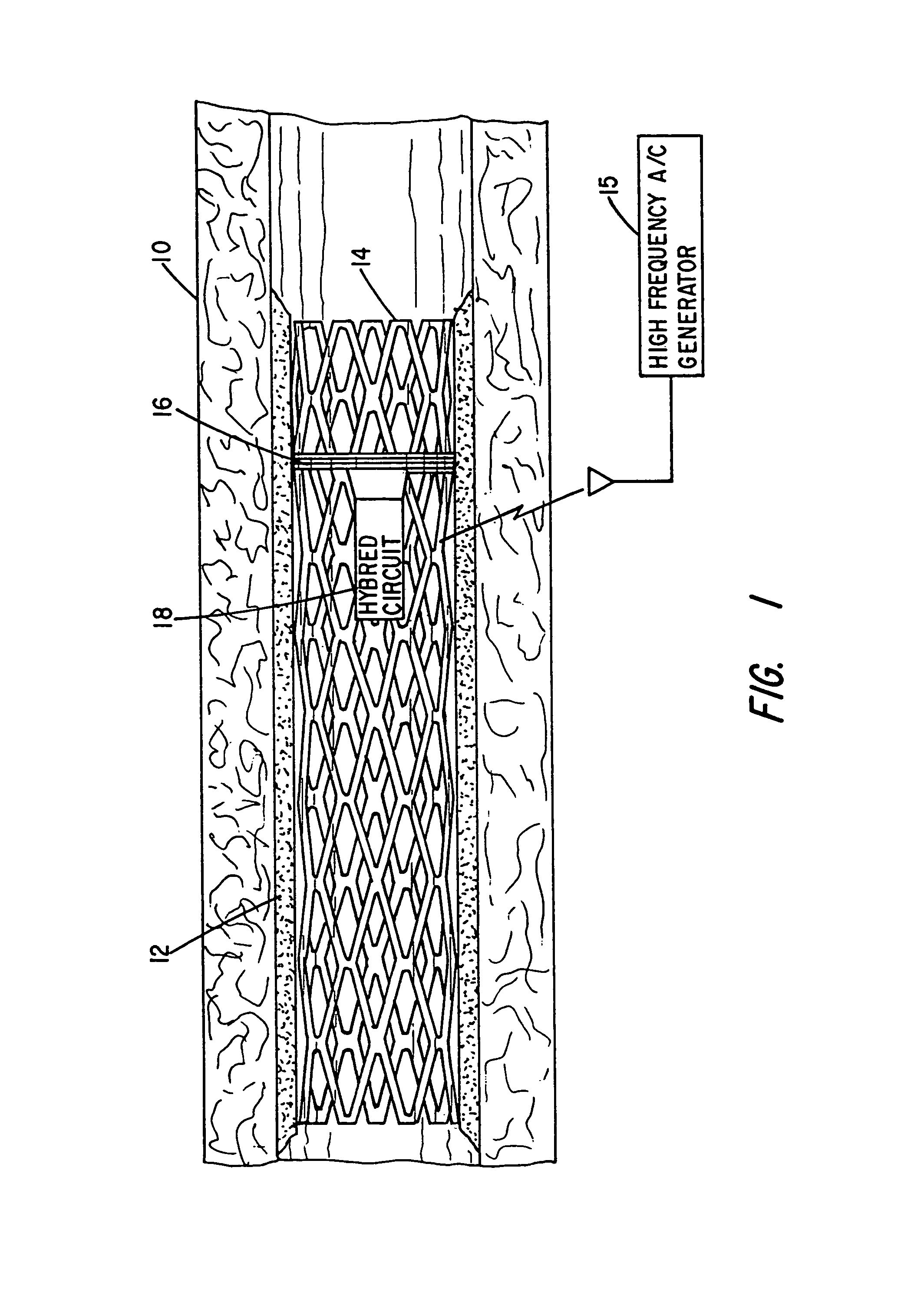

Usage of Extracorporeal and Intracorporeal Pressure Shock Waves in Medicine

ActiveUS20110034832A1Reduce inflammationPromote nerve regenerationUltrasound therapyPneumatic massageMedicineFocal volume

A shock wave applicator includes a shock wave generator and an asymmetrical reflector portion in a housing. Asymmetry of the reflector portion is combined with one or more wave generators to produce a variety of focal volumes and wave fronts for medical treatment.

Owner:SANUWAVE INC

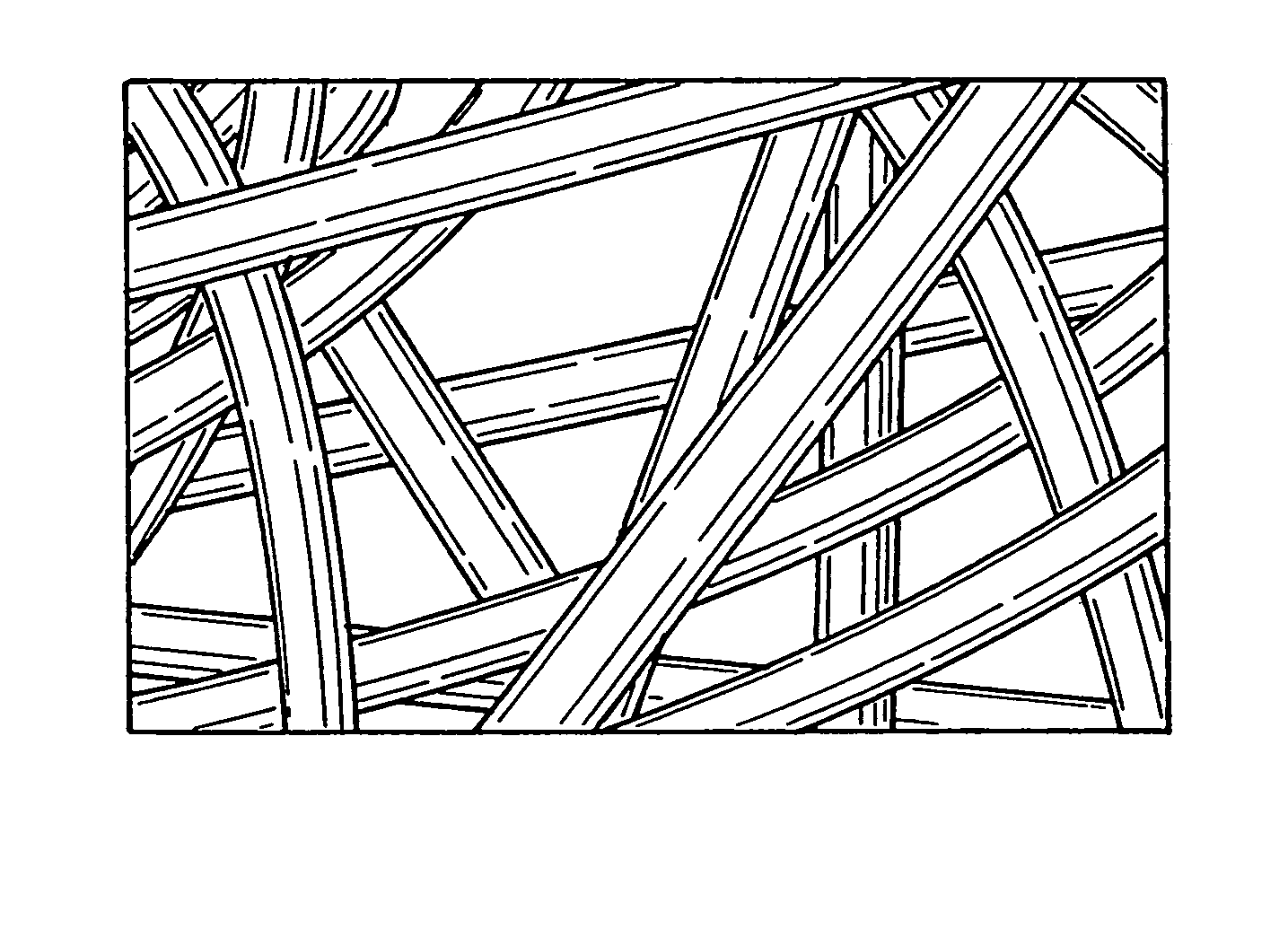

Implantable device for promoting repair of a body lumen

An implantable stent having surface features adapted to promote an organized growth pattern of infiltrating cells when implanted in a tubular organ is provided. The surface features comprise depressions, pores, projections, pleats, channels or grooves in the stent body and are designed to increase turbulence or stagnation in the flow of a liquid, such as blood through the stent, and / or to promote the growth of infiltrating cells in an organized pattern. Alternatively, the invention stent can be populated with living cells prior to implant and can be heatable from an external source of energy, thereby inducing production of therapeutic bioactive agents from ingrowing cells. The invention also provides an implantable heatable stent for transcutaneously monitoring the flow of fluid through a lumen into which the stent is implanted by measuring the rate at which the heated stent cools in response to blood flow when the source of heat is removed.

Owner:TRICARDIA

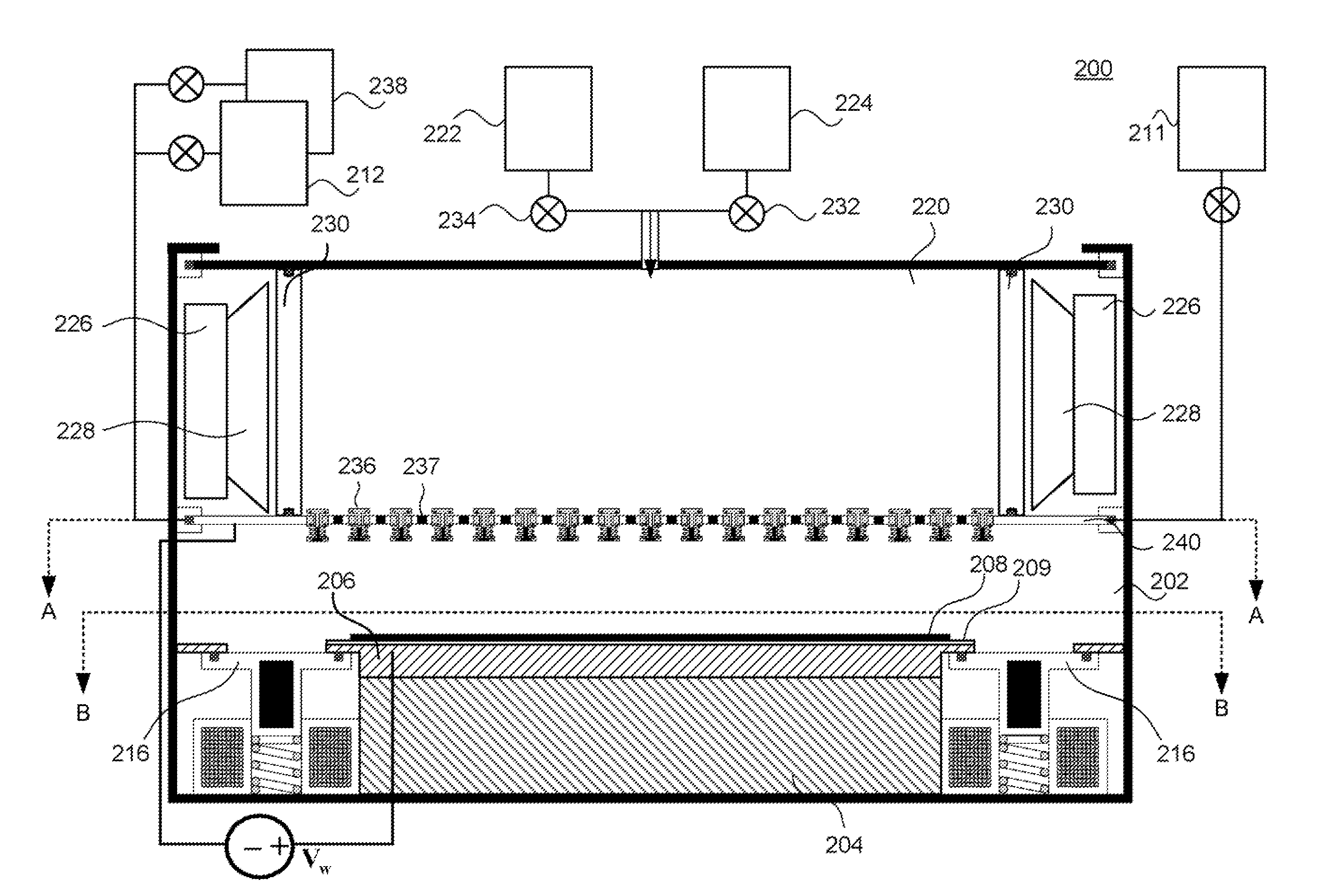

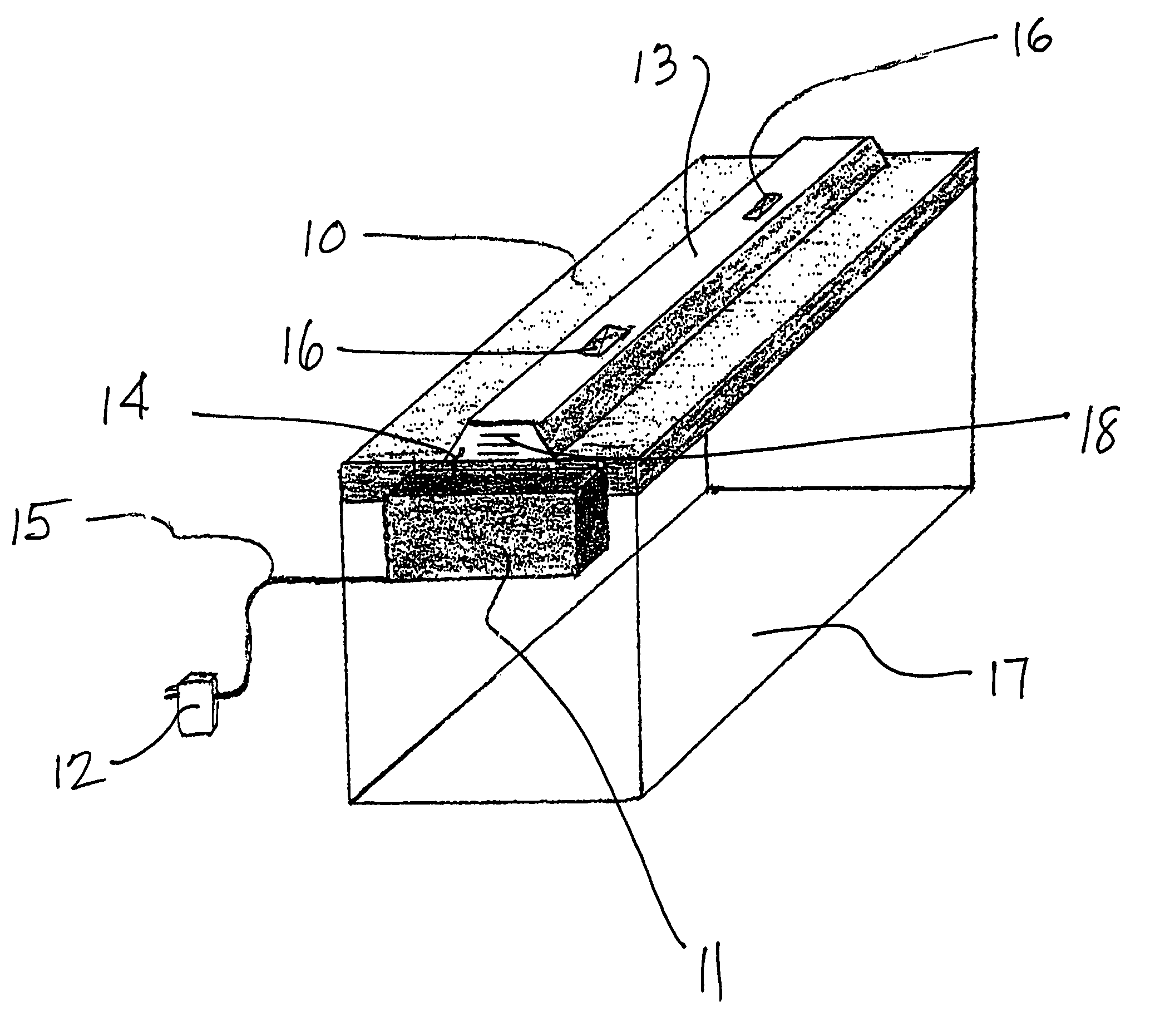

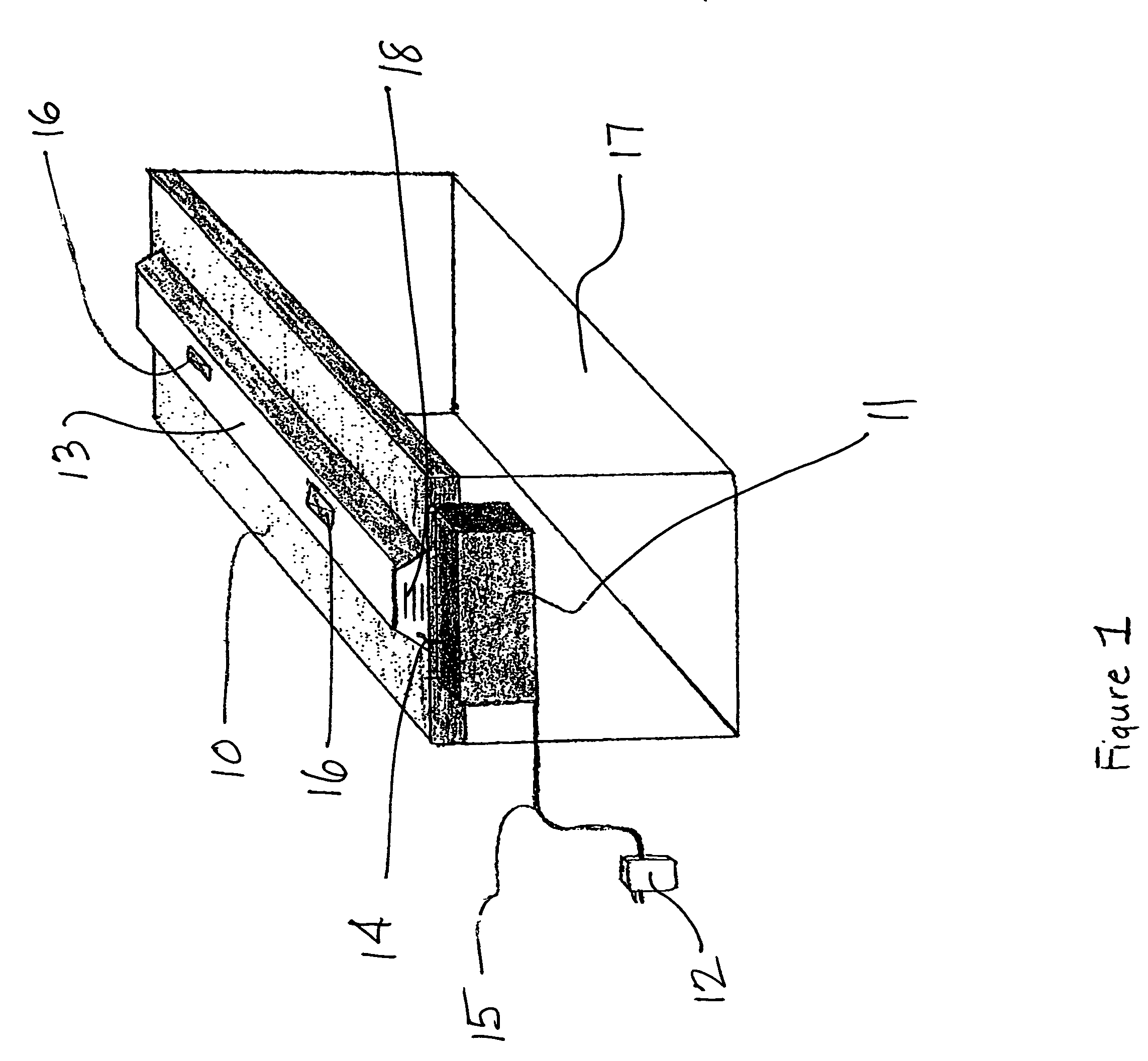

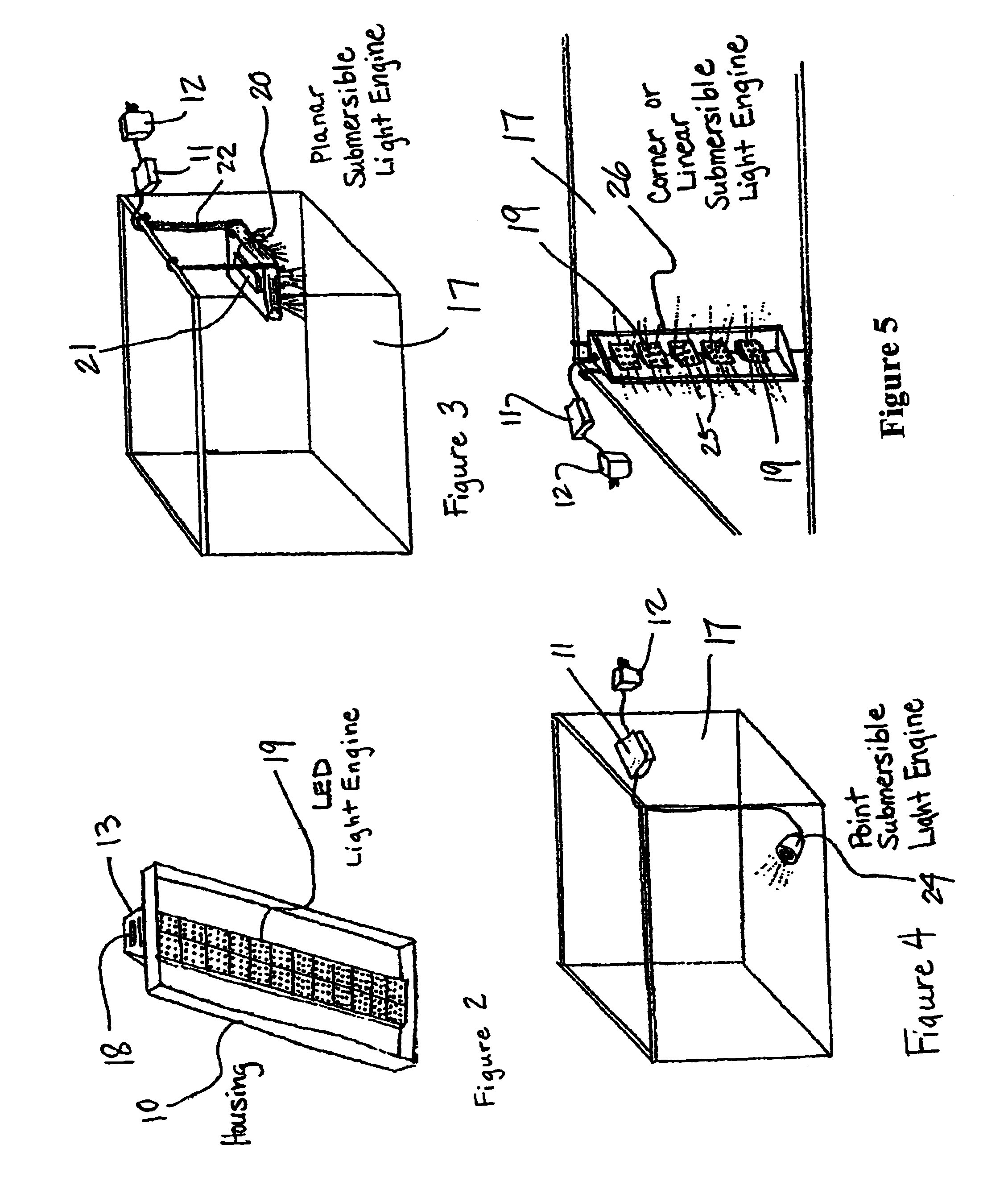

Marine LED lighting system and method

InactiveUS7220018B2High outputIncrease light intensityElectrical apparatusElectric circuit arrangementsMarine habitatsEngineering

A method and apparatus of lighting a marine habitat for growth utilizing an LED light system. The light system includes an LED light source, a power supply for such light source and a controller for controlling the activation status and the intensity of the LED light source.

Owner:ORBITAL TECH

Conformable tissue repair implant capable of injection delivery

A conformable tissue implant is provided for use in repairing or augmenting a tissue defect or injury site. The tissue implant contains a tissue carrier matrix comprising a plurality of biocompatible, bioresorbable granules and at least one tissue fragment in association with the granules. The tissue fragment contains one or more viable cells that can migrate from the tissue and populate the tissue carrier matrix. Also provided is a method for injectably delivering the tissue implant.

Owner:DEPUY SYNTHES PROD INC

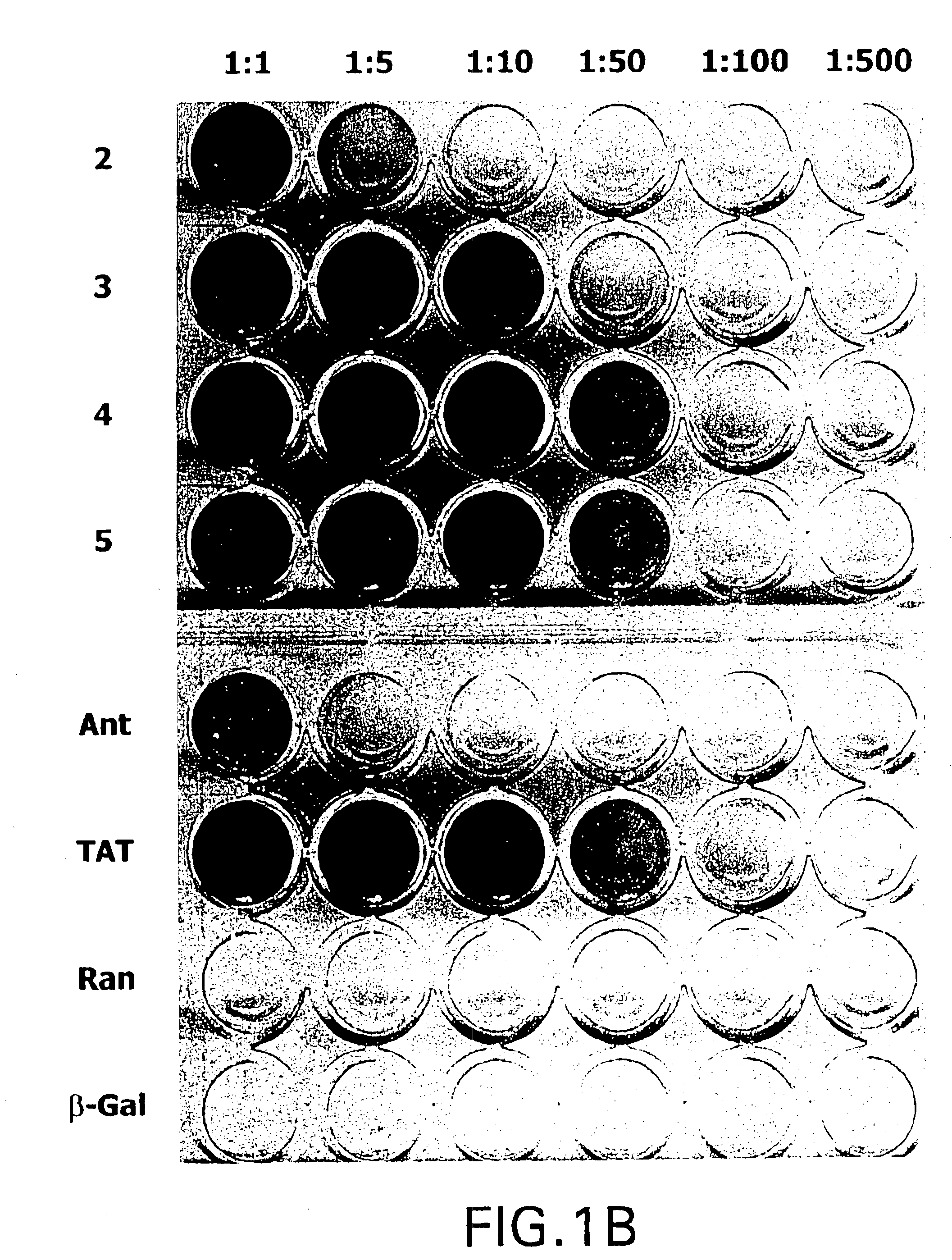

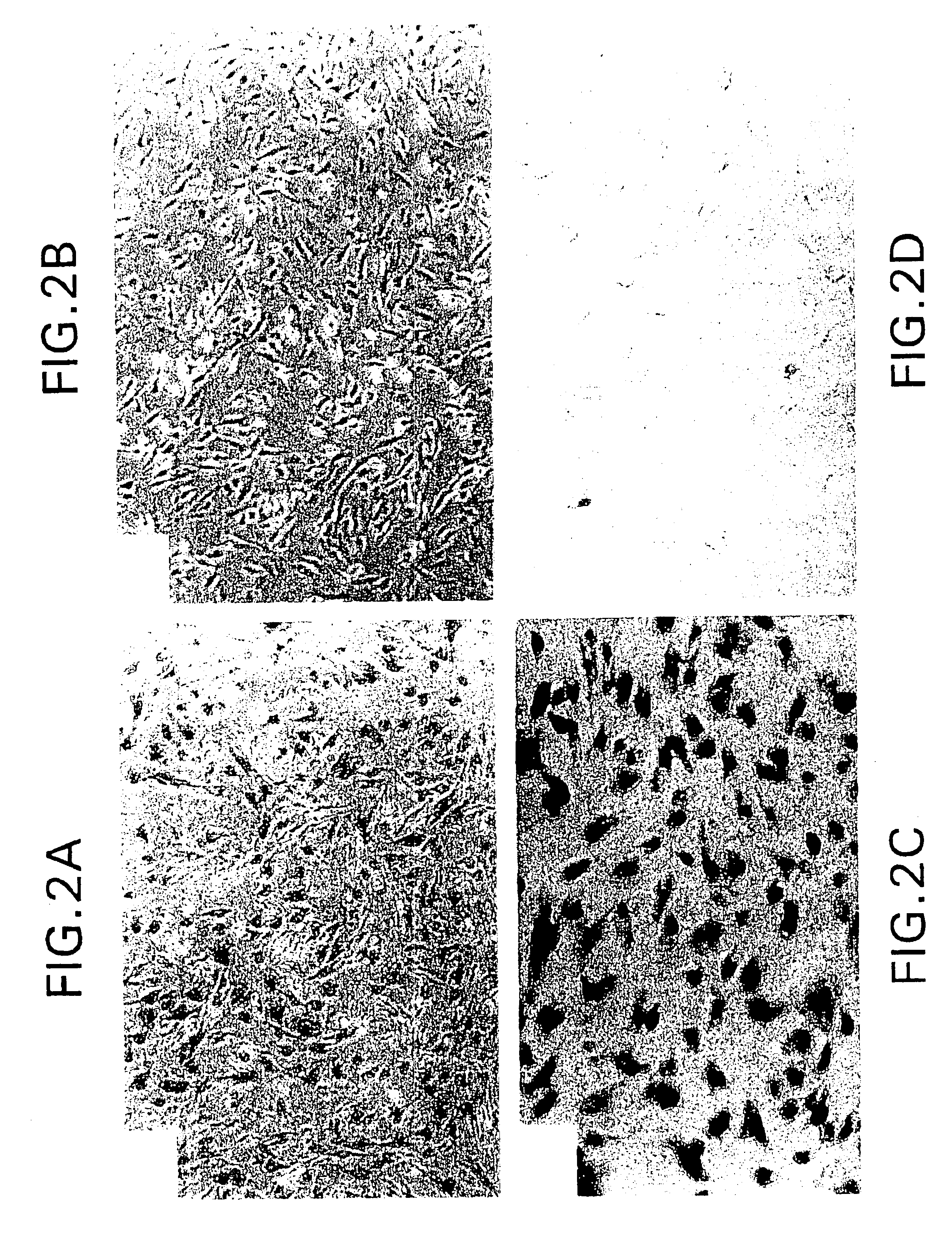

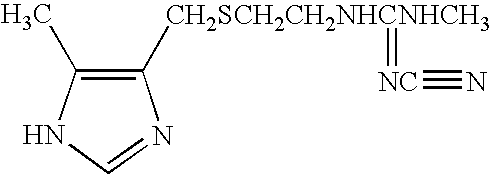

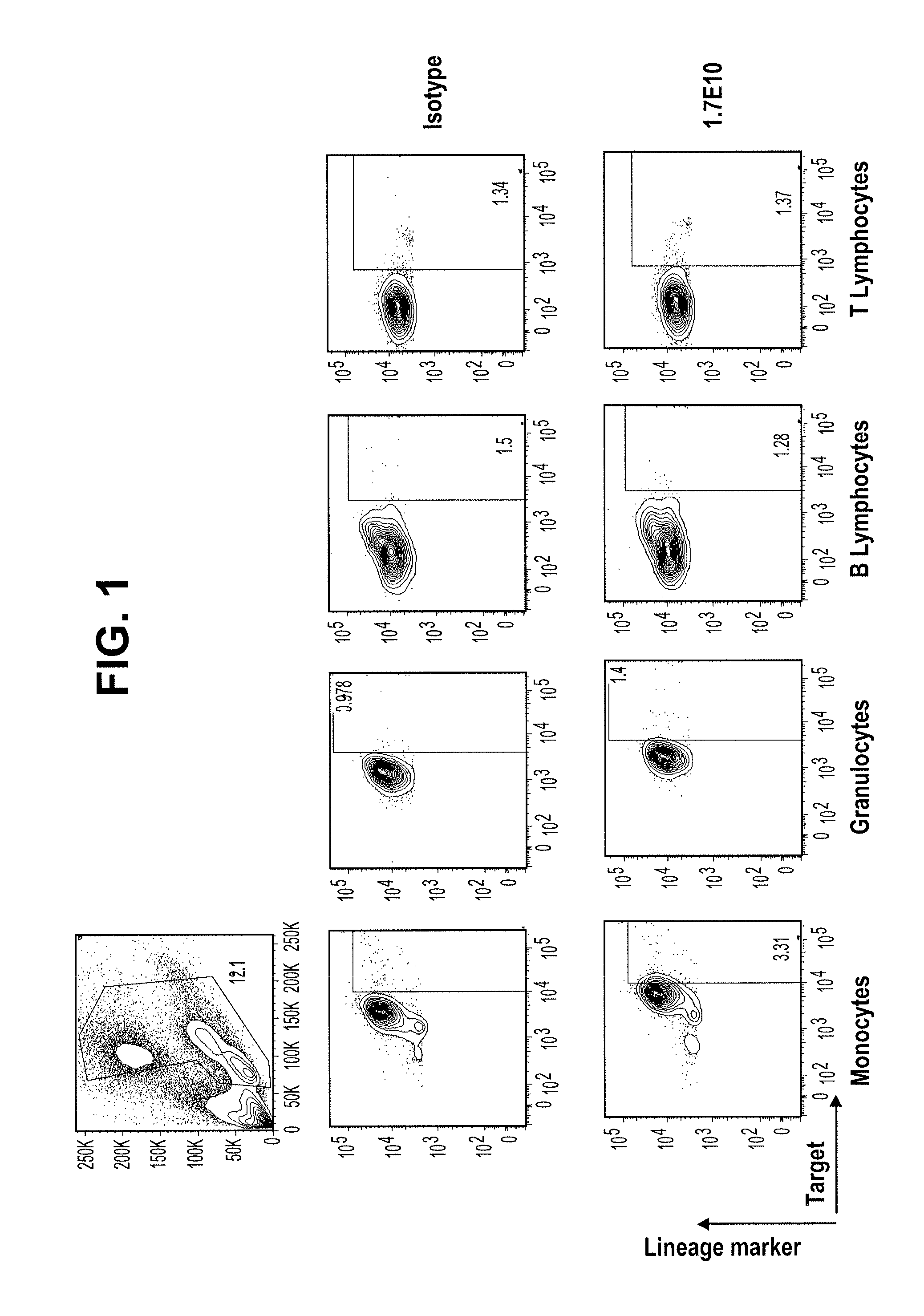

Identication of peptides that facilitate uptake and cytoplasmic and/or nuclear transport of proteins, DNA and virues

InactiveUS6881825B1Reduce deliveryFacilitating uptakeCompound screeningApoptosis detectionIn vivoCell type

The present invention relates to internalizing peptides which facilitate the uptake and transport of cargo into the cytoplasm and nuclei of cells as well as methods for the identification of the peptides, and methods of use for the peptides. The internalizing peptides of the present invention are selected for their ability to efficiently internalize cargo into a wide variety of cell types both in vivo and in vitro.

Owner:UNIVERSITY OF PITTSBURGH

Oral care compositions containing combinations of anti-bacterial and host-response modulating agents

InactiveUS20070053849A1Potent anti-inflammatory activityPromote progressAntibacterial agentsCosmetic preparationsWhole bodyOral bacterial infection

The present invention encompasses topical oral care compositions comprising the combination of an anti-bacterial agent with an anti-inflammatory agent in an orally acceptable carrier for effective treatment and prevention of bacteria-mediated diseases and conditions in the oral cavity and for modulating host reaction to bacterial pathogens present in the oral cavity and to the toxins, endotoxins, inflammatory cytokines and mediators released by or prompted by these pathogens. The present invention also encompasses methods of use of these compositions comprising topical application to the oral cavity. The benefits of the present compositions and methods extend beyond treating and preventing oral bacterial infections in the oral cavity to promoting whole body or systemic health.

Owner:THE PROCTER & GAMBLE COMPANY

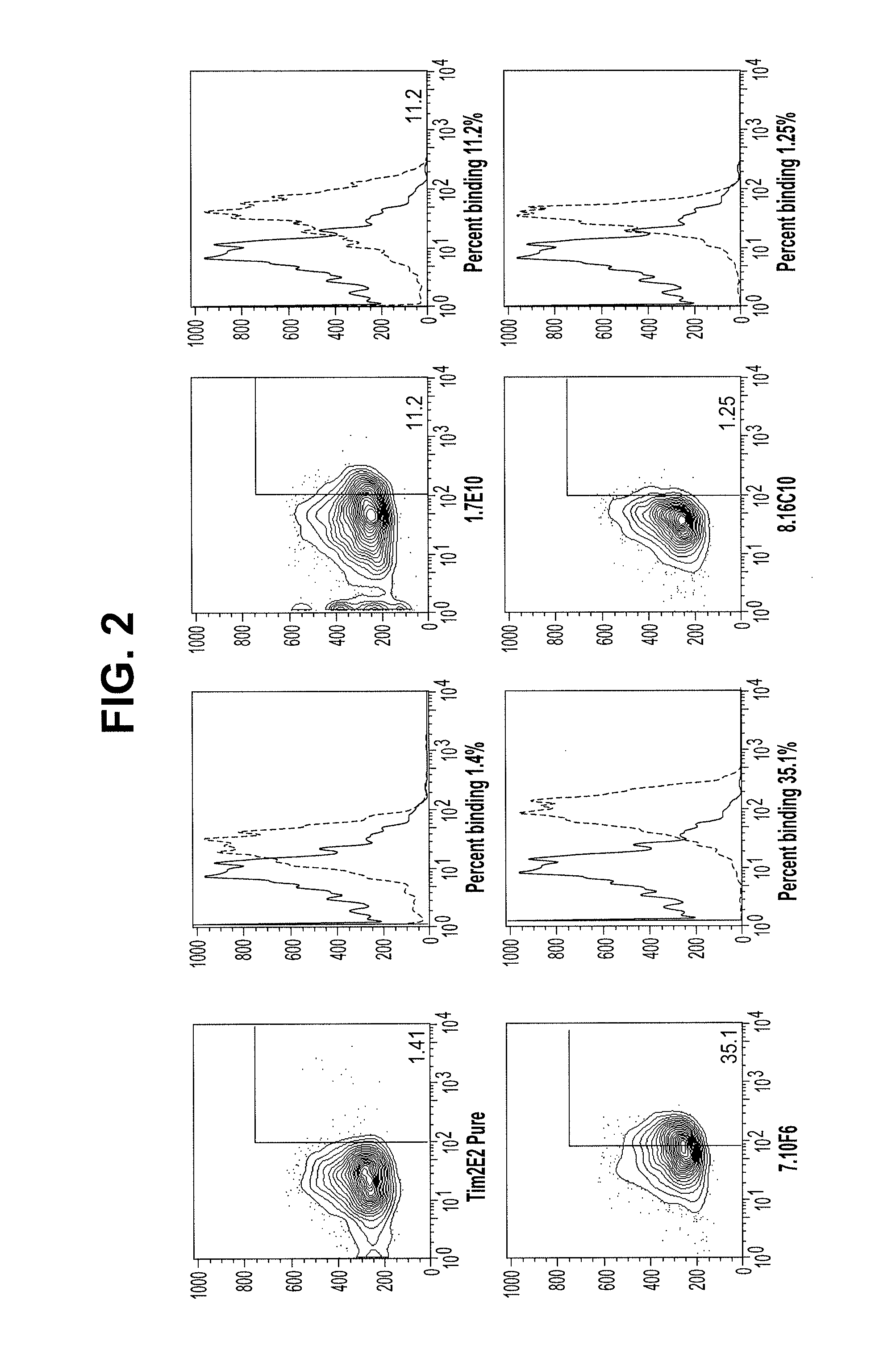

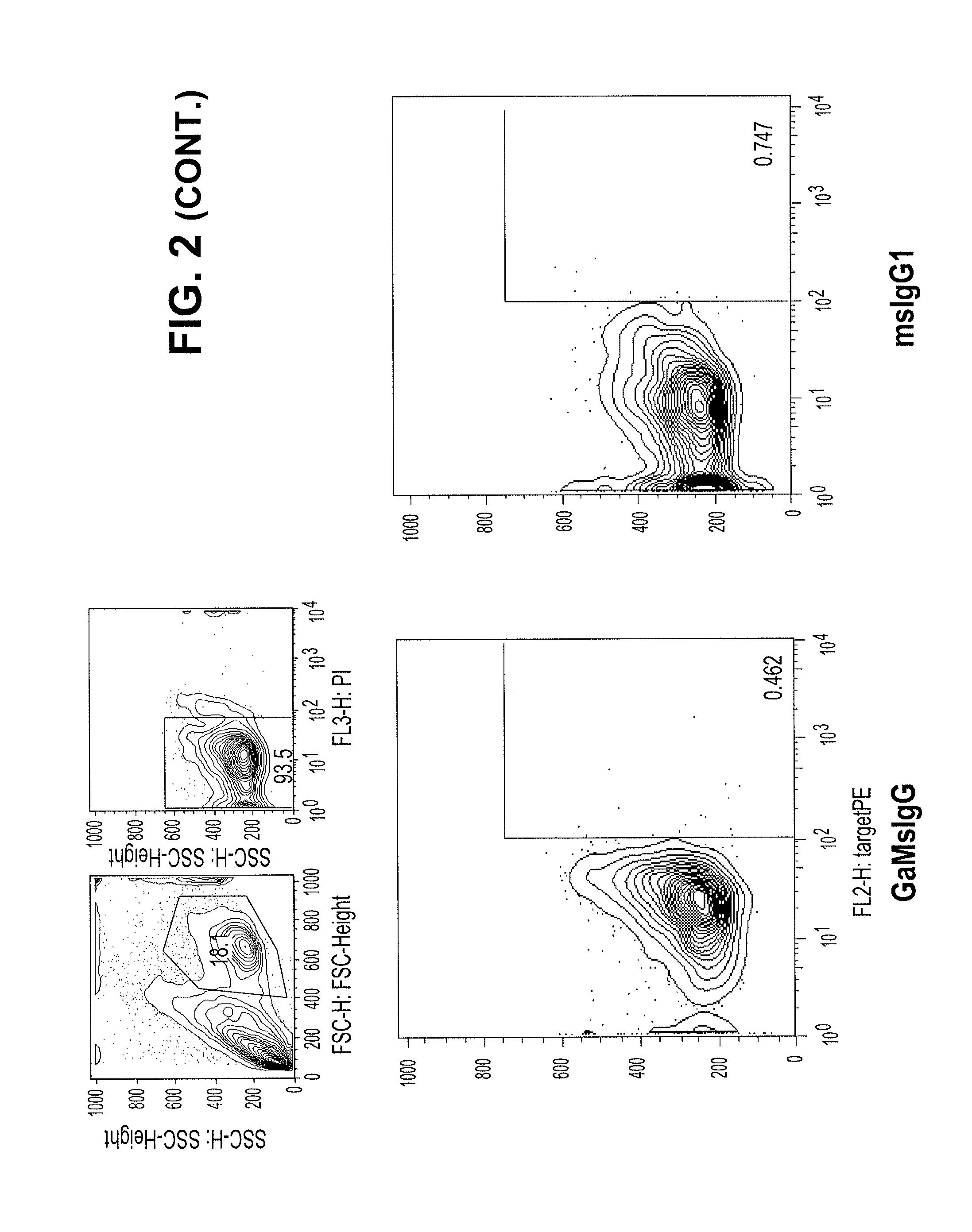

Antibodies that specifically bind to TIM3

ActiveUS8841418B2Promote growthReduce inflammationHeavy metal active ingredientsPeptide/protein ingredientsCancer cellAntibody

Provided herein are antibodies specific for TIM3 that can be used to detect cancer cells, in particular, cancer stem cells. The antibodies can also be used in therapeutic compositions for treating cancer and reducing inflammation.

Owner:ONK THERAPEUTICS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com