Patents

Literature

14909results about "Plasma technique" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

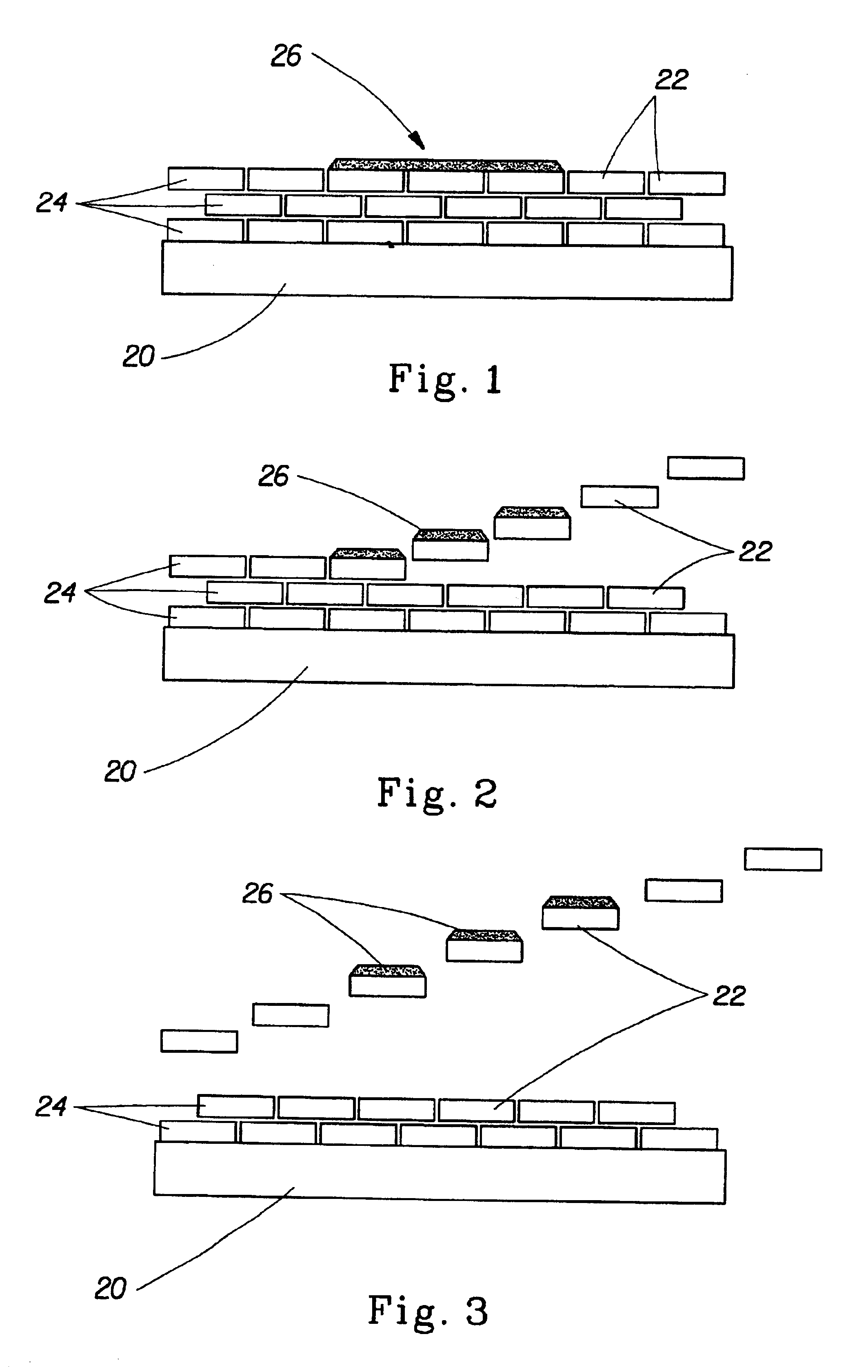

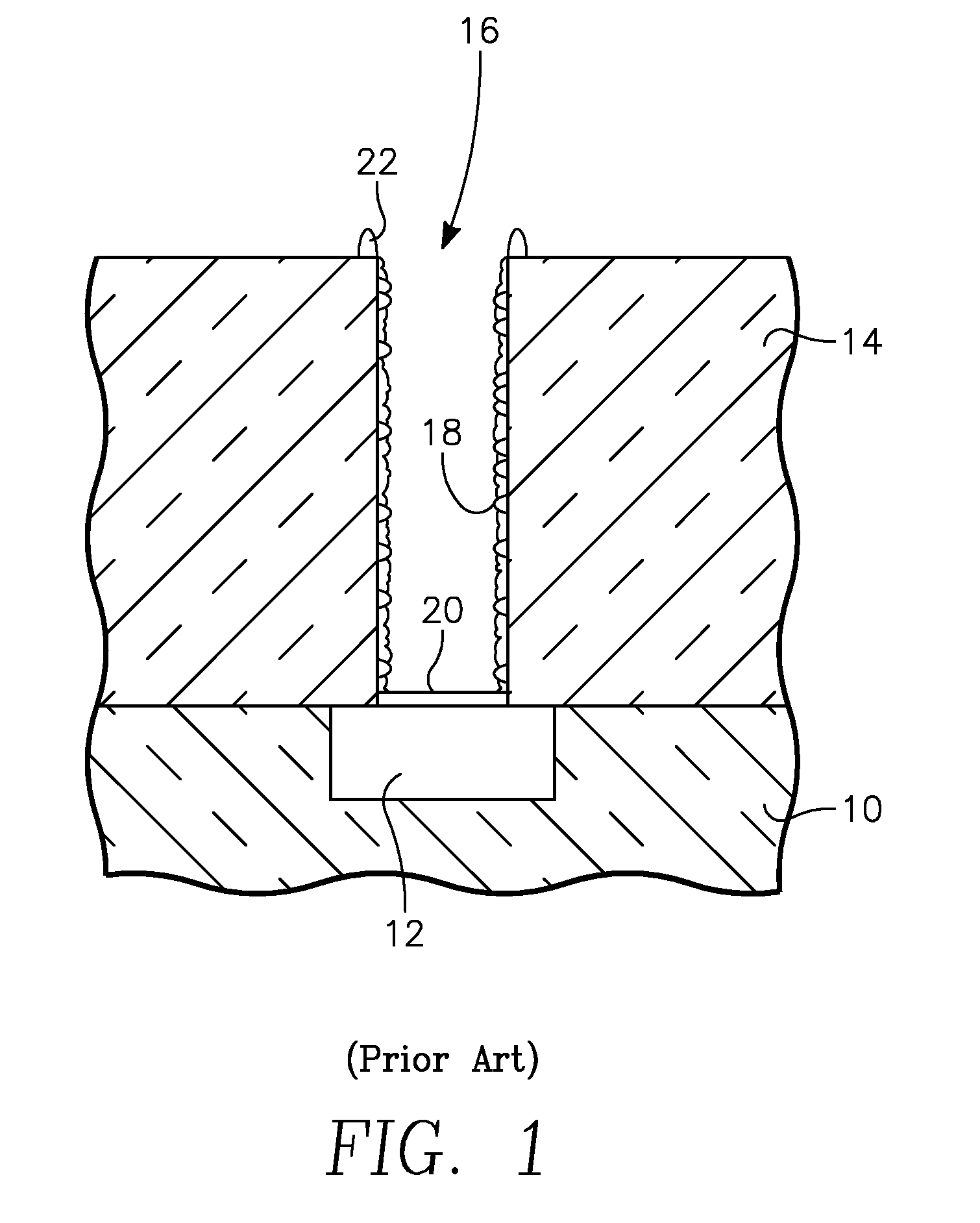

Tissue resurfacing

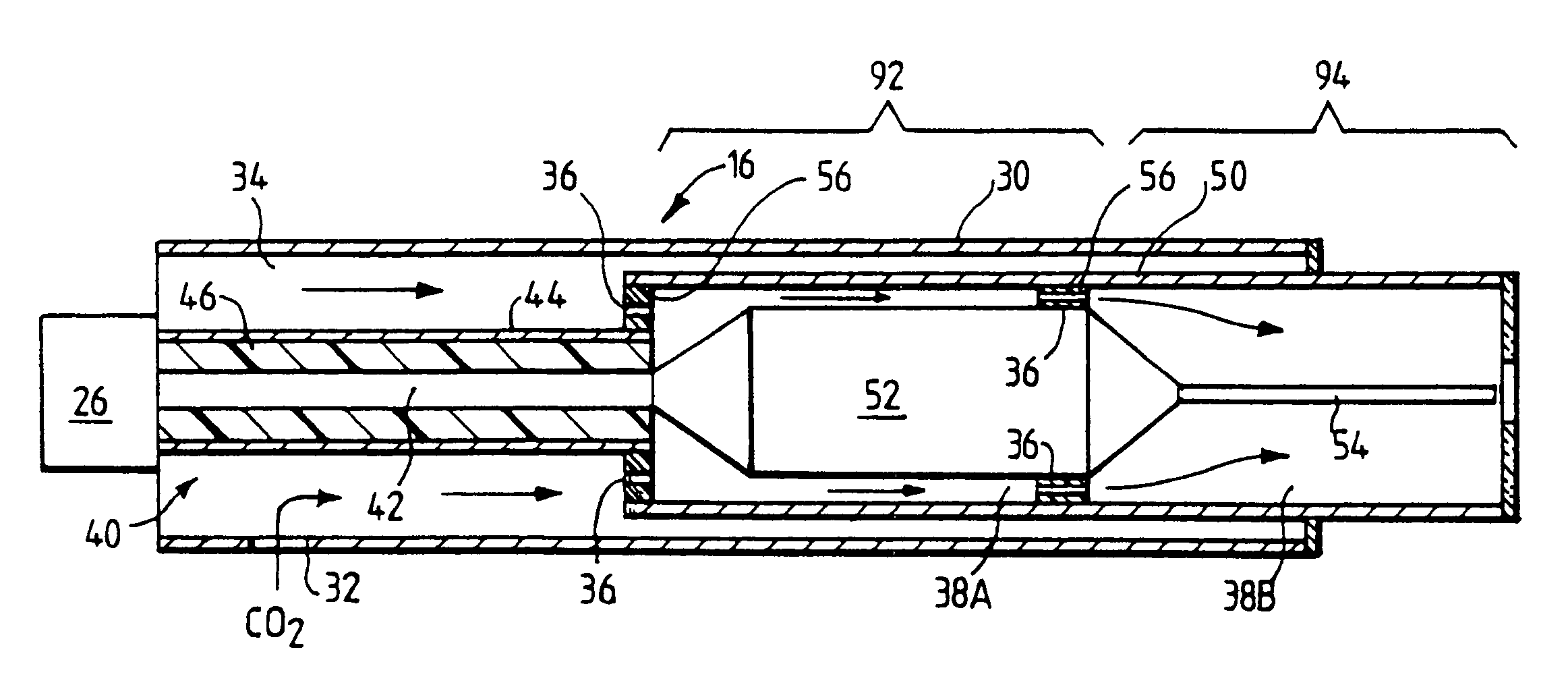

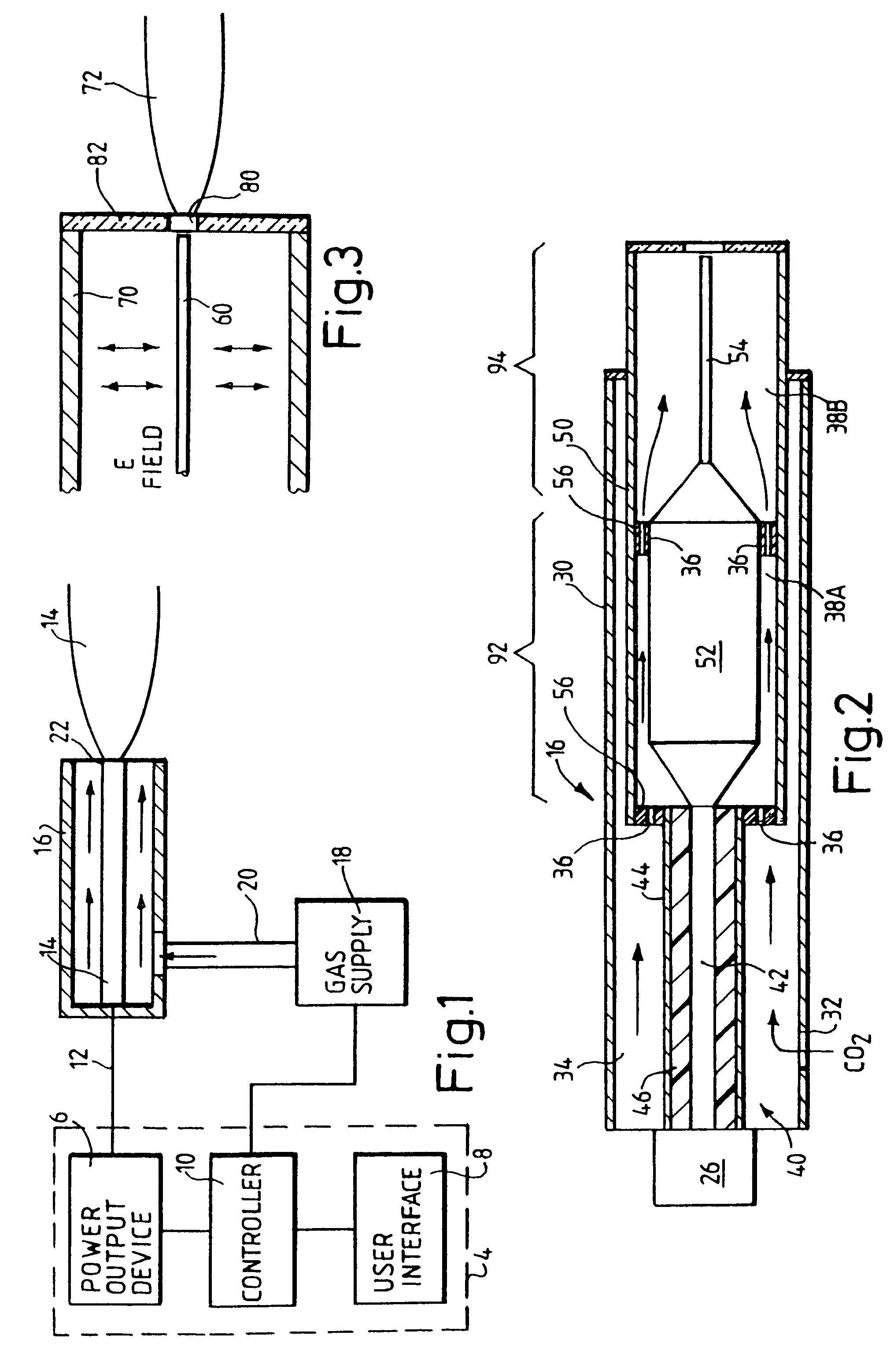

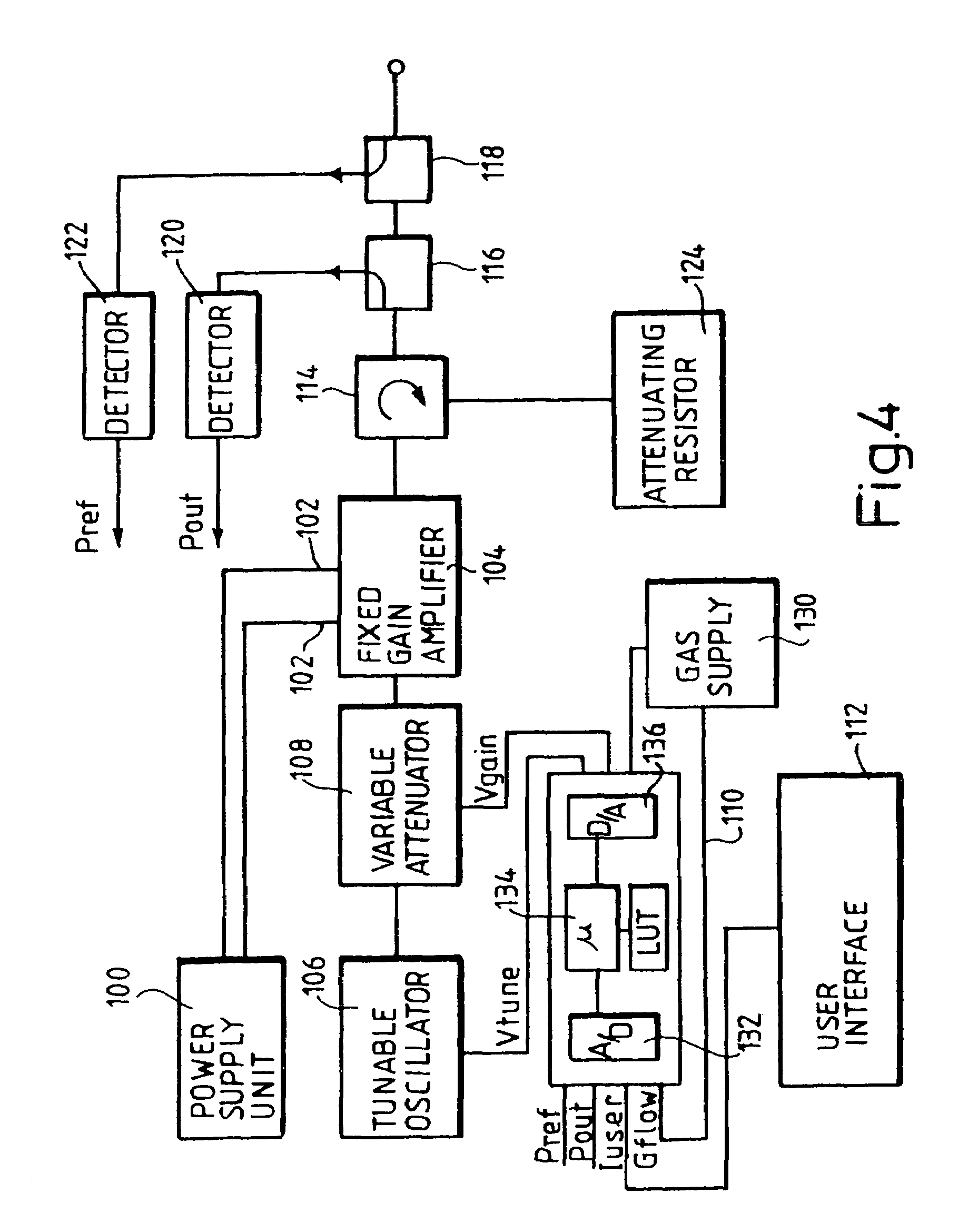

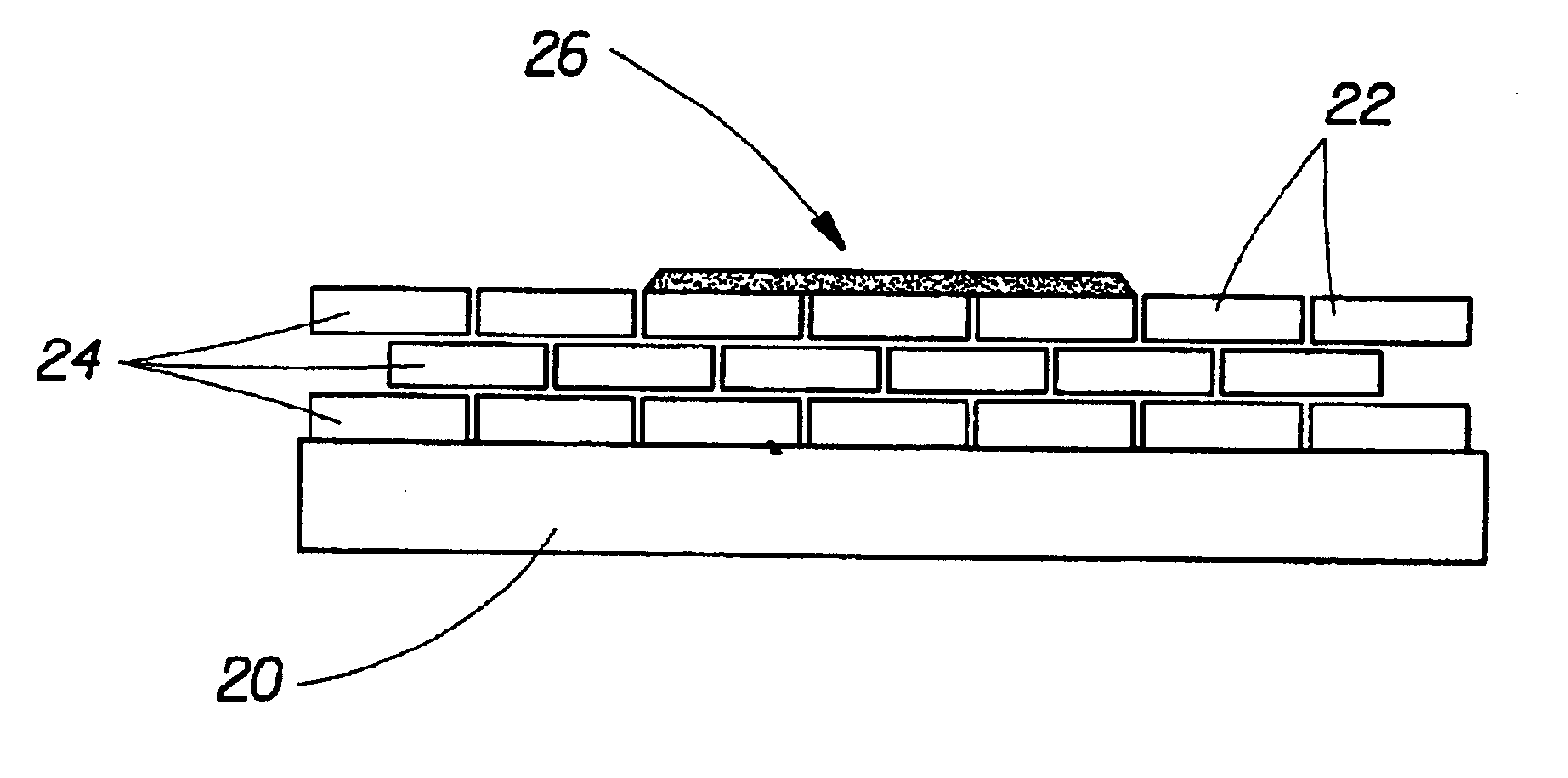

InactiveUS7335199B2Easy to getRapid treatment at the tissue surfaceInstrument handpiecesSurgical instruments for heatingSkin treatmentsSkin surface

Owner:ENERGIST

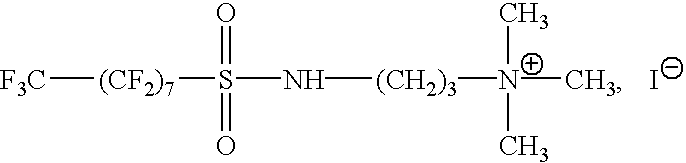

Method of hydrophilizing materials

InactiveUS6863933B2Easy to controlGood removal effectInorganic/elemental detergent compounding agentsRadiation applicationsPolymer scienceNanoparticle

Coating compositions, methods and articles of manufacture comprising a nanoparticle system employing same to impart surface modifying benefits for all types of soft surfaces, and in some cases, hard surfaces, are disclosed. In some embodiments, dispersement of nanoparticles in a suitable carrier medium allows for the creation of coating compositions, methods and articles of manufacture that create multi-use benefits to the modified surfaces. These surface modifications can produce long lasting or semi-permanent multi-use benefits that, in some embodiments, may include at least one of the following improved surface properties: cleaning, wettability, liquid strike-through, comfort, stain resistance, soil removal, malodor control, modification of surface friction, reduced damage to abrasion and color enhancement, relative to the surfaces unmodified with such nanoparticle systems.

Owner:THE PROCTER & GAMBLE COMPANY

Method for hydrophilizing materials using hydrophilic polymeric materials with discrete charges

A method of rendering materials having hard and soft surfaces hydrophilic or more hydrophilic is disclosed. The method involves hydrophilizing such materials by applying a high energy treatment and charged particles and / or one or more hydrophilic polymeric materials with discrete charges to such materials.

Owner:THE PROCTER & GAMBLE COMPANY

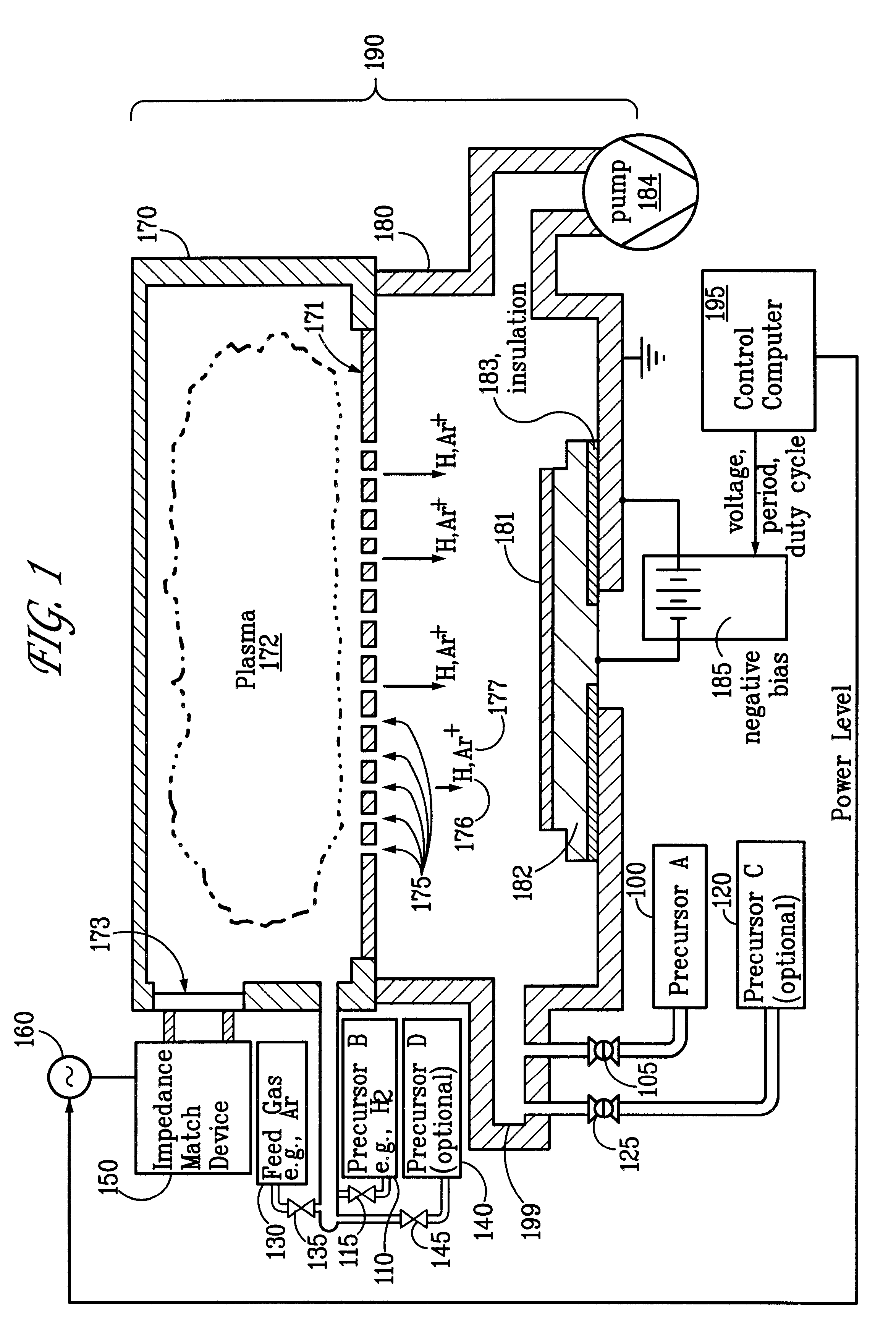

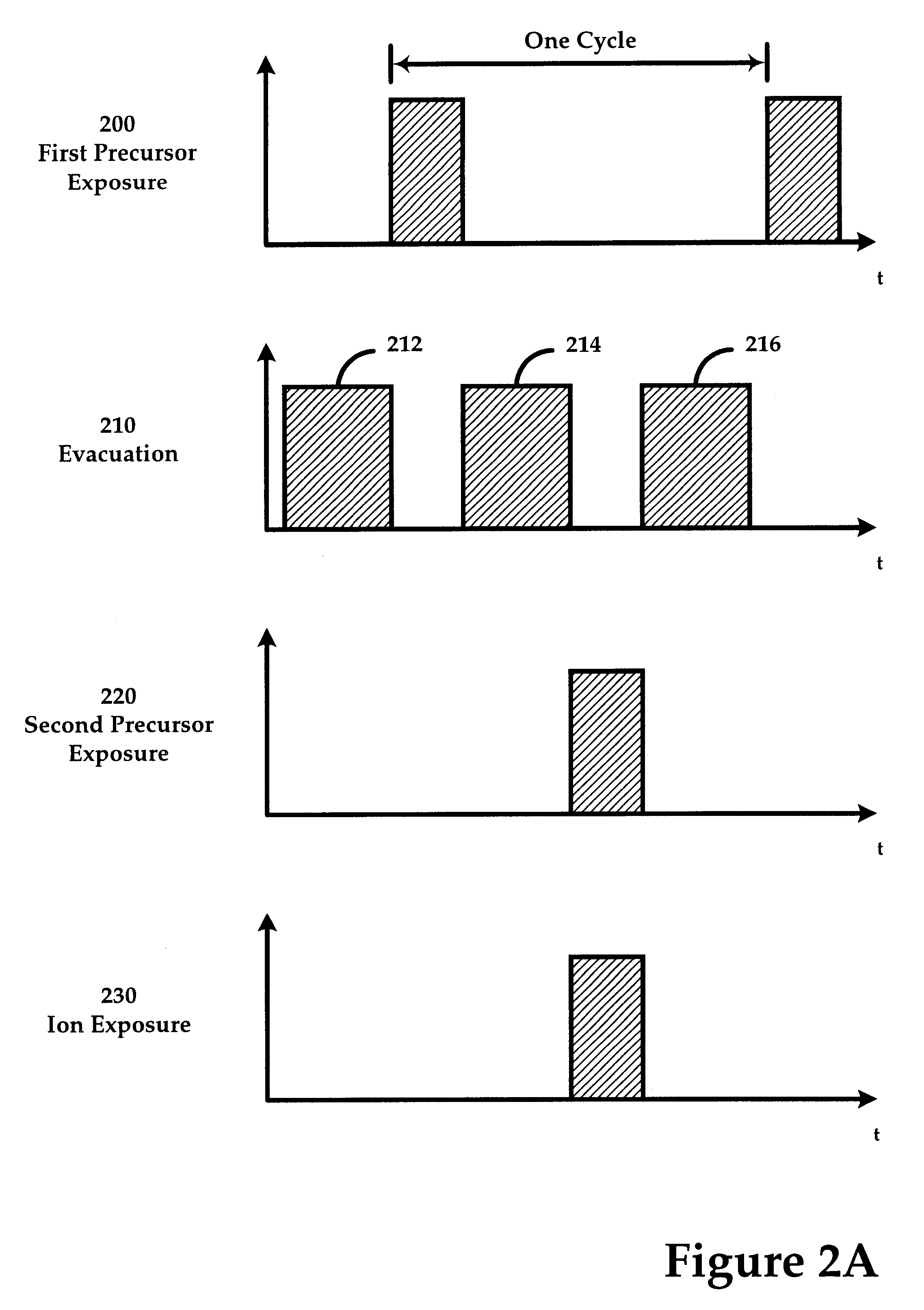

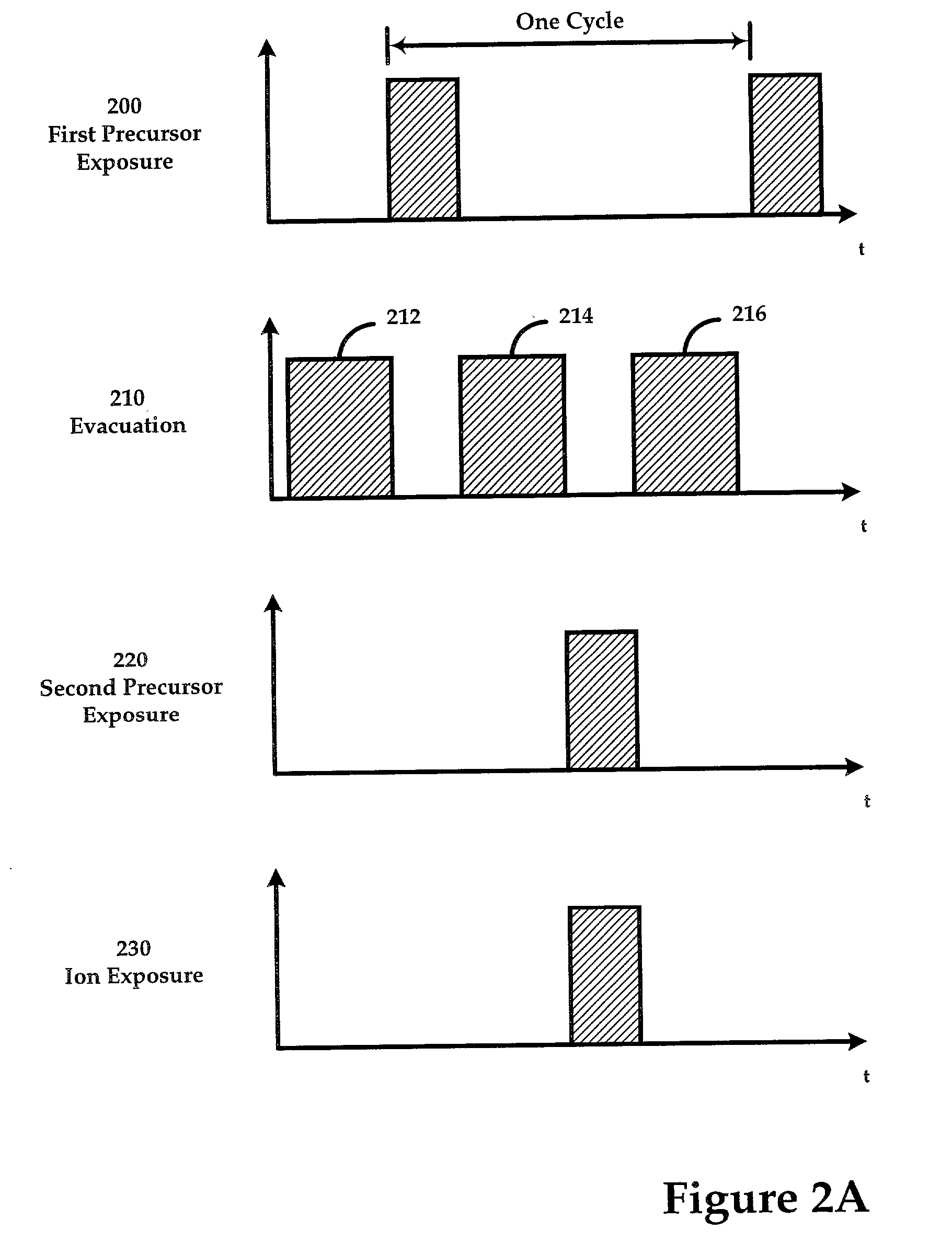

Sequential method for depositing a film by modulated ion-induced atomic layer deposition (MII-ALD)

InactiveUS6428859B1Faster efficient meanSimple methodVacuum evaporation coatingSputtering coatingSequential methodHigh density

The present invention relates to an enhanced sequential atomic layer deposition (ALD) technique suitable for deposition of barrier layers, adhesion layers, seed layers, low dielectric constant (low-k) films, high dielectric constant (high-k) films, and other conductive, semi-conductive, and non-conductive films. This is accomplished by 1) providing a non-thermal or non-pyrolytic means of triggering the deposition reaction; 2) providing a means of depositing a purer film of higher density at lower temperatures; and, 3) providing a faster and more efficient means of modulating the deposition sequence and hence the overall process rate resulting in an improved deposition method. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:NOVELLUS SYSTEMS

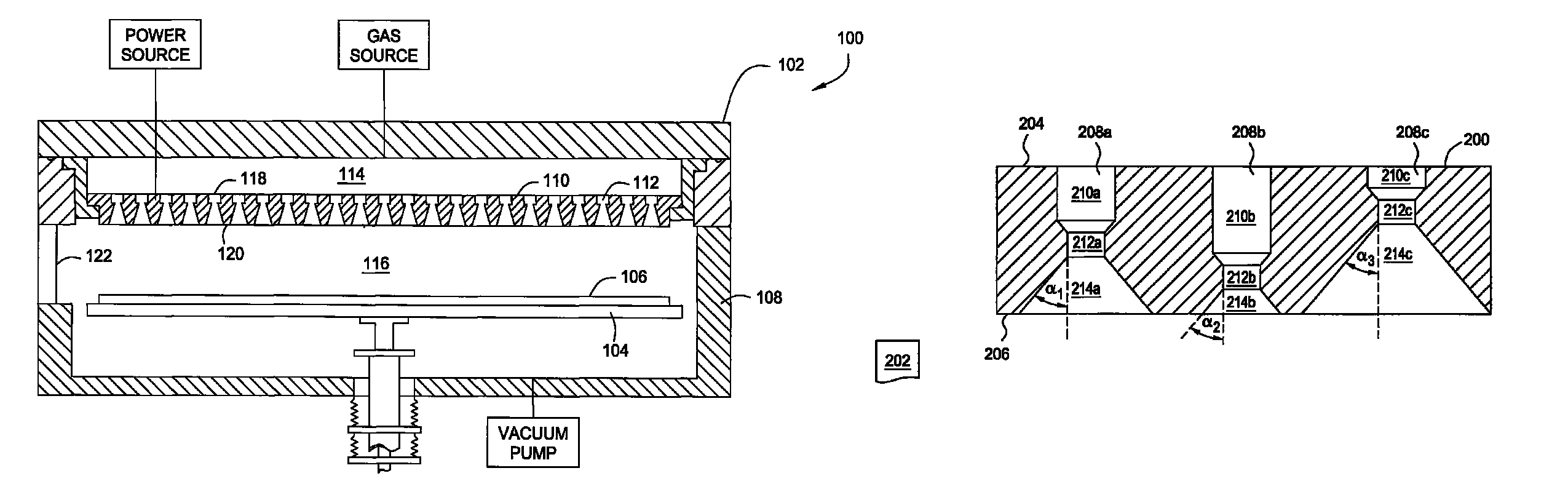

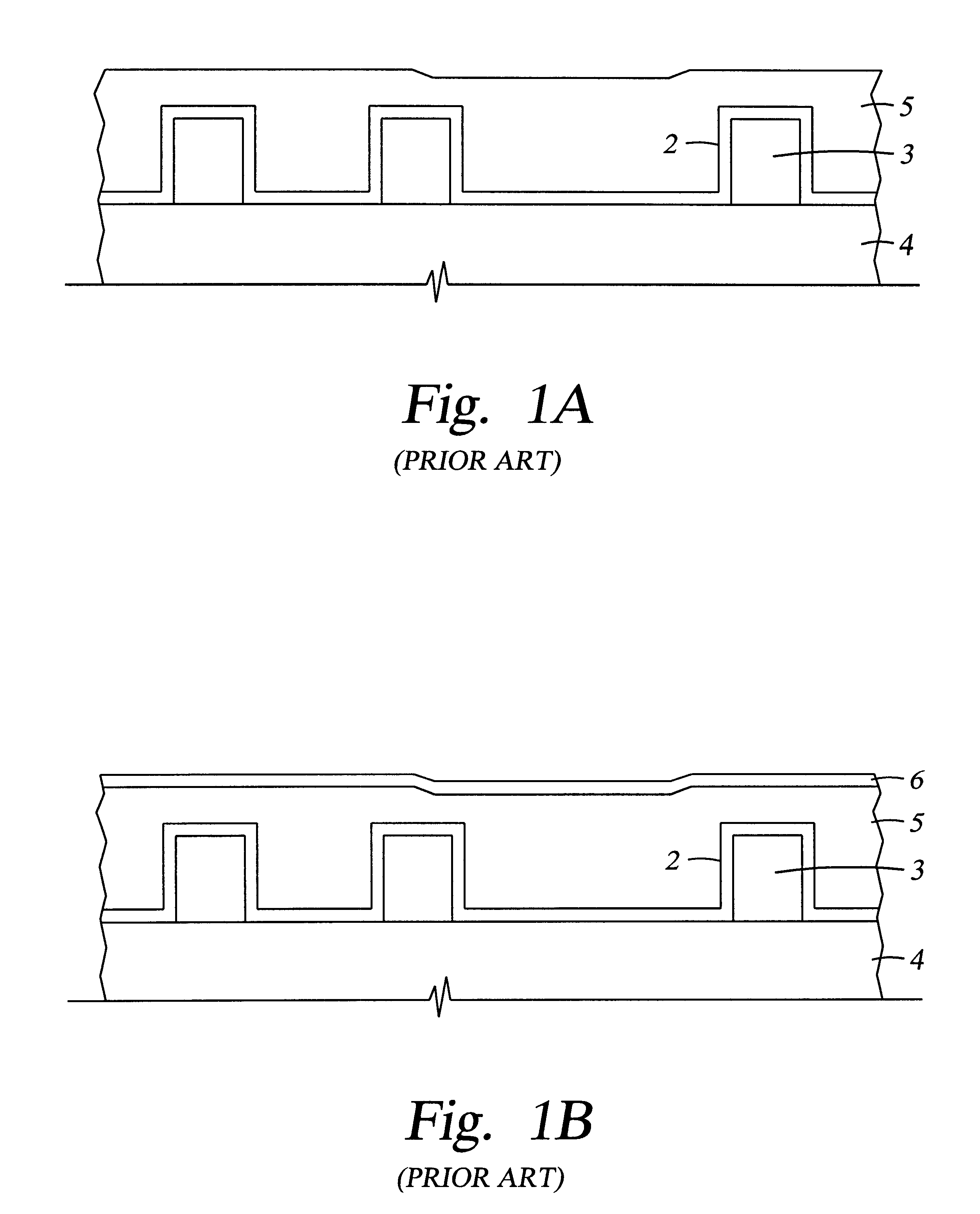

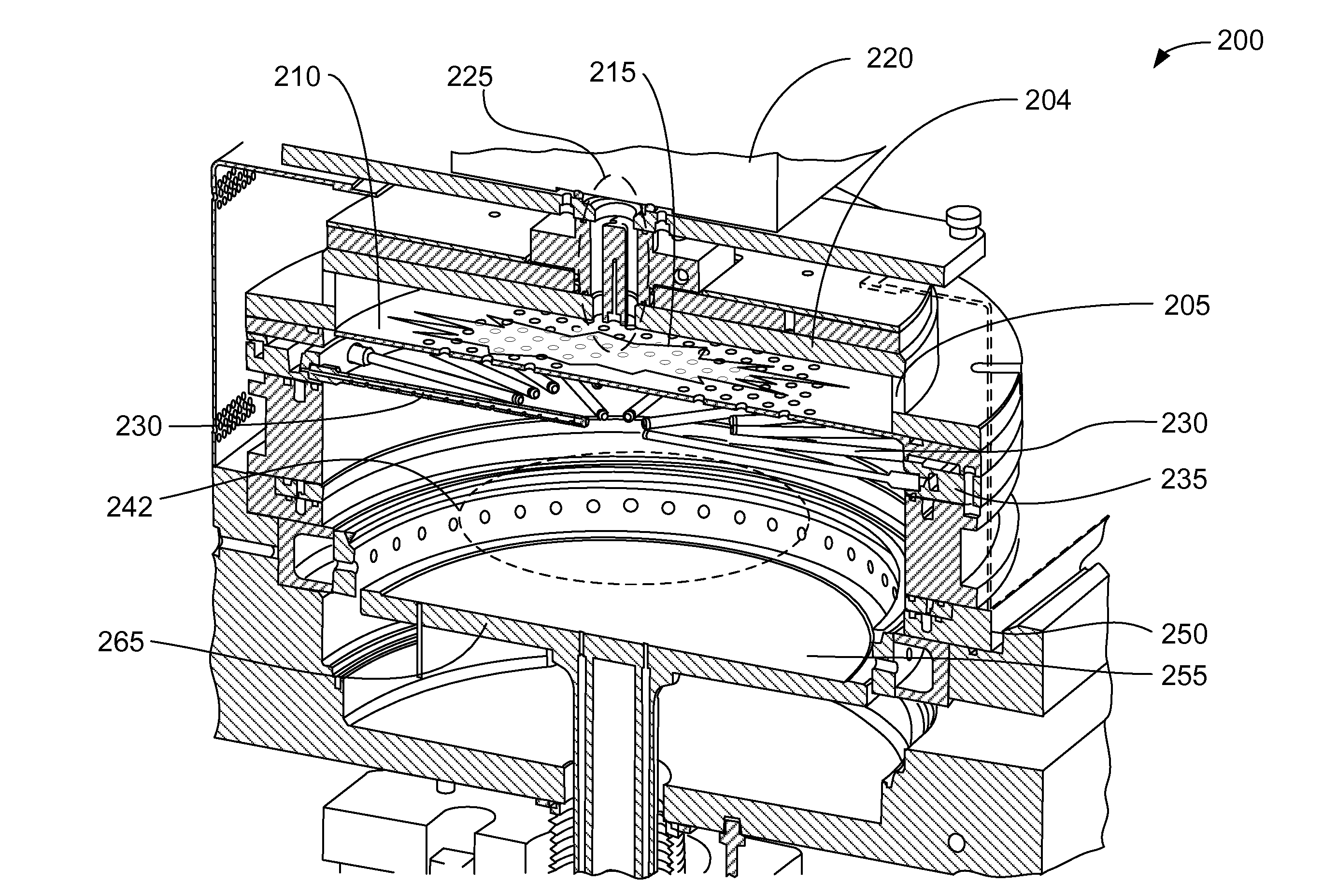

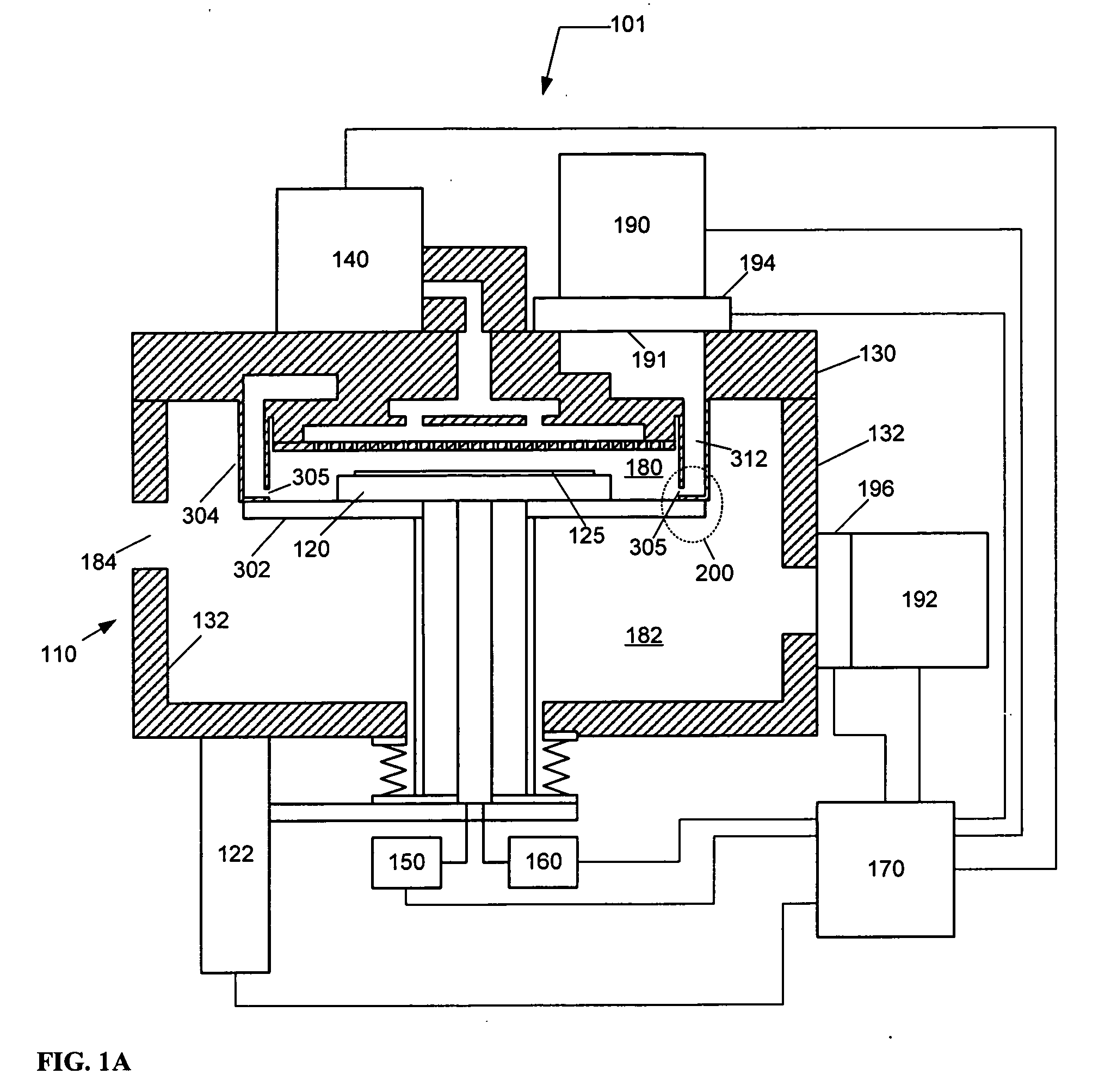

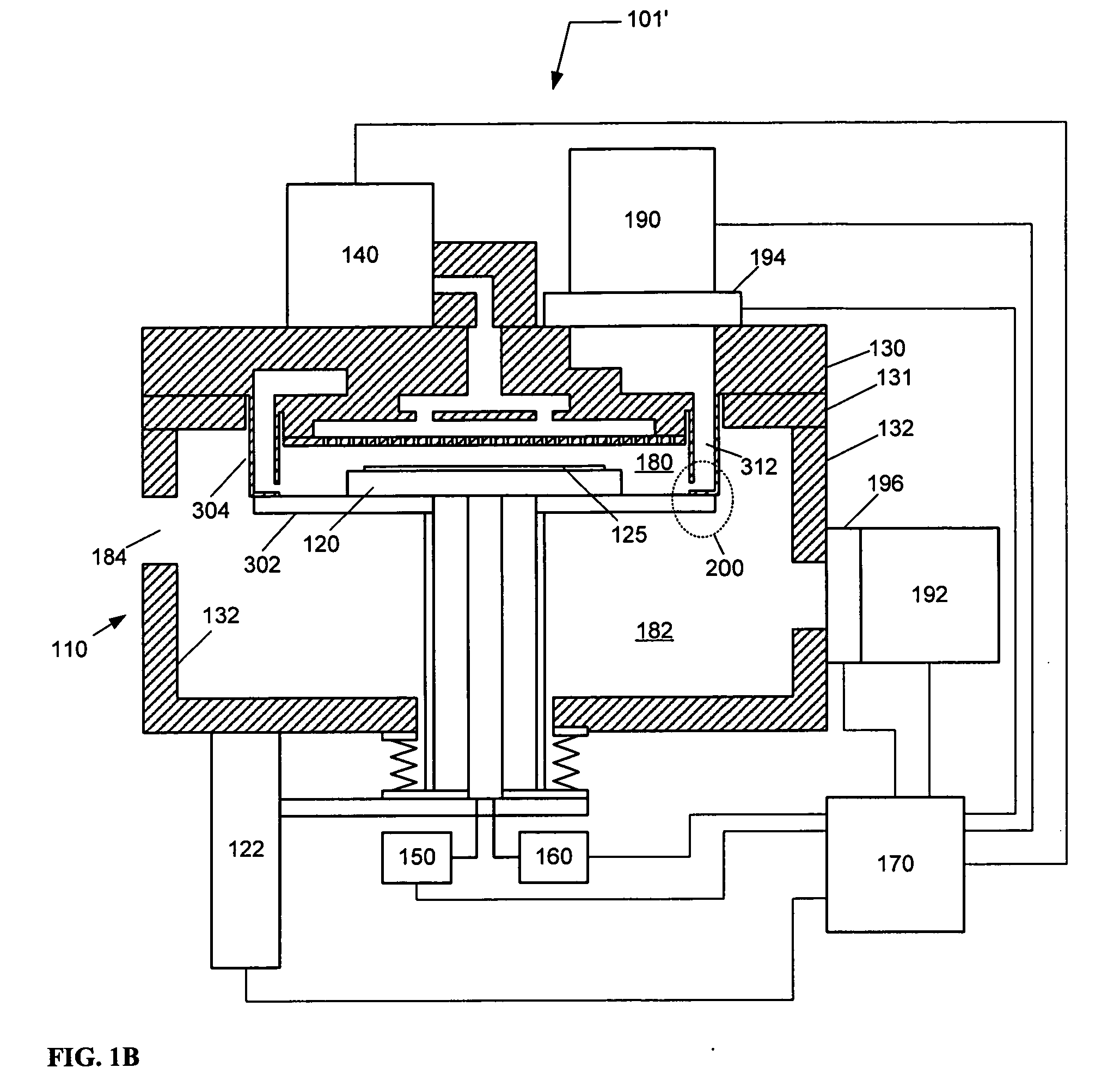

Diffuser plate with slit valve compensation

InactiveUS8328939B2Uniform plasma distributionUniform film thicknessLiquid surface applicatorsMolten spray coatingEngineeringMechanical engineering

The present invention generally comprises a diffuser plate for a PECVD chamber. The diffuser plate comprises a plurality of hollow cathode cavities. The edge of the diffuser plate that will reside closest to a slit valve within a processing chamber may have the shape and / or size of the hollow cathode cavities adjusted to compensate for the proximity to the slit valve. By adjusting the shape and / or size of the hollow cathode cavities closest to the slit valve, the diffuser plate may permit a uniform plasma distribution across the processing chamber and thus, a uniform film thickness upon a substrate during a PECVD process.

Owner:APPLIED MATERIALS INC

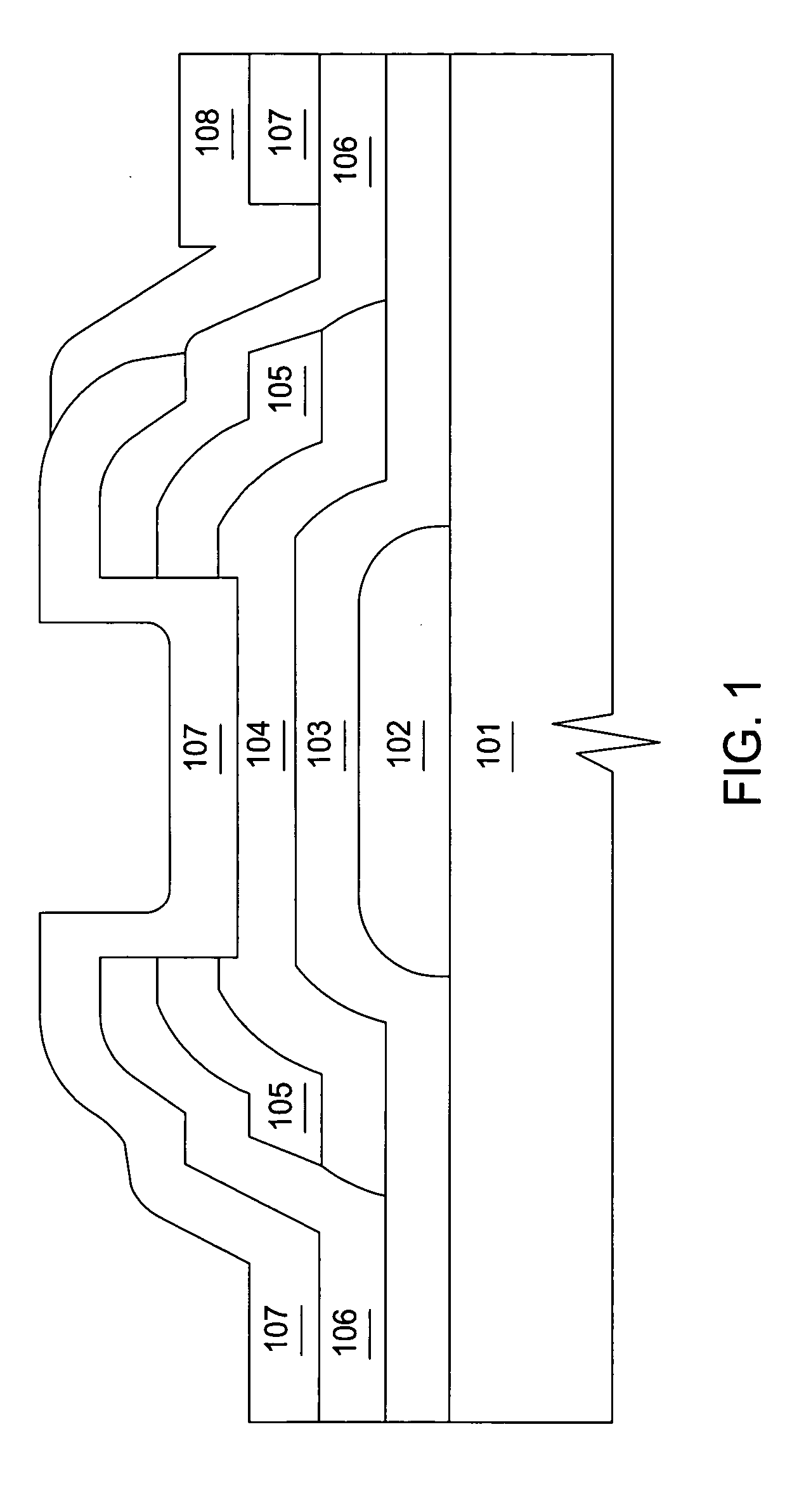

Formation of a liquid-like silica layer by reaction of an organosilicon compound and a hydroxyl forming compound

InactiveUS6413583B1Semiconductor/solid-state device detailsSolid-state devicesSilicon oxideSilicon dioxide

A method for depositing silicon oxide layers having a low dielectric constant by reaction of an organosilicon compound and a hydroxyl forming compound at a substrate temperature less than about 400° C. The low dielectric constant films contain residual carbon and are useful for gap fill layers, pre-metal dielectric layers, inter-metal dielectric layers, and shallow trench isolation dielectric layers in sub-micron devices. The hydroxyl compound can be prepared prior to deposition from water or an organic compound. The silicon oxide layers are preferably deposited at a substrate temperature less than about 40° C. onto a liner layer produced from the organosilicon compound to provide gap fill layers having a dielectric constant less than about 3.0.

Owner:APPLIED MATERIALS INC

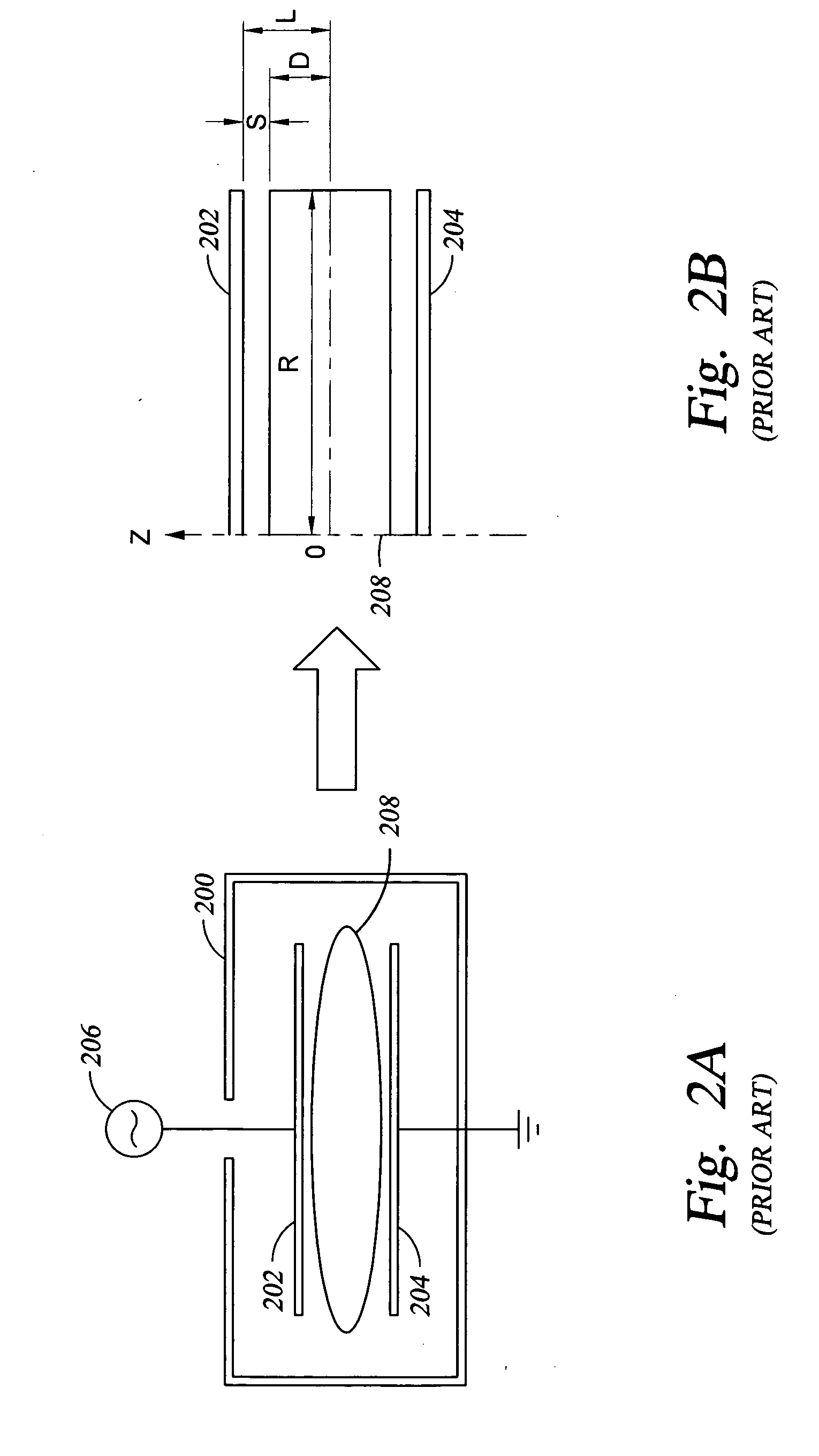

Apparatus for treating the surface with neutral particle beams

InactiveUS6935269B2Wide effective cross sectionImprove throughputRadiation/particle handlingElectric discharge tubesTarget surfaceMetal

The present invention relates to an apparatus for treating the surface with neutral particle beams comprising an antenna container, a plasma generating part, a neutral particle beam generating part and a treating part, wherein the antenna container comprises antennas connected to high frequency electric power supply through which high frequency electric power supplies, the plasma generating part transfers gases from a gas injector into plasmas with the supplied power, the neutral particle beam generating part reverts the obtained plasmas to neutral particle beams via the collision thereof with metal plates, and the treating part treats the surface of a target with the neutral particle beams.

Owner:SEM TECH CO LTD +1

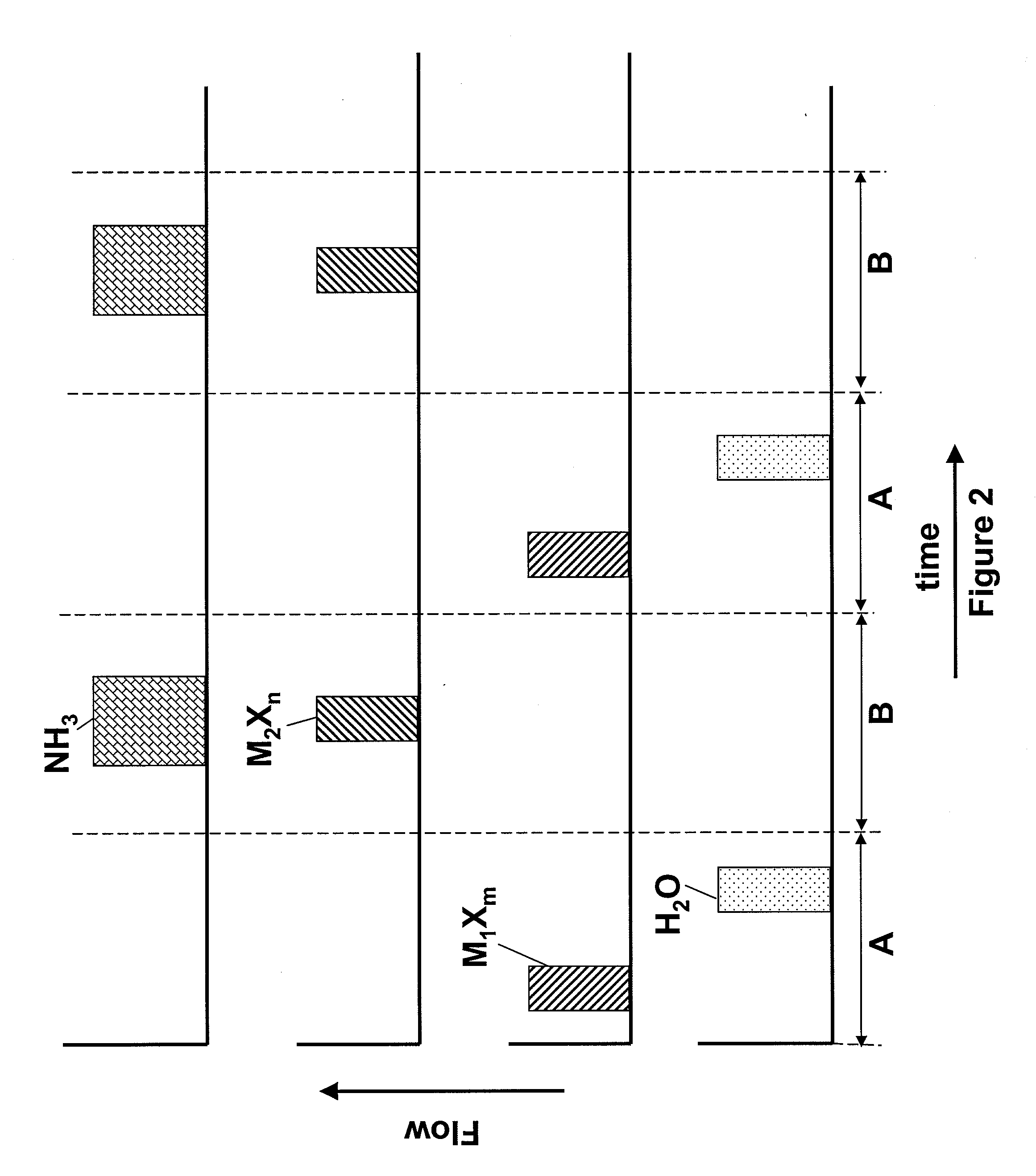

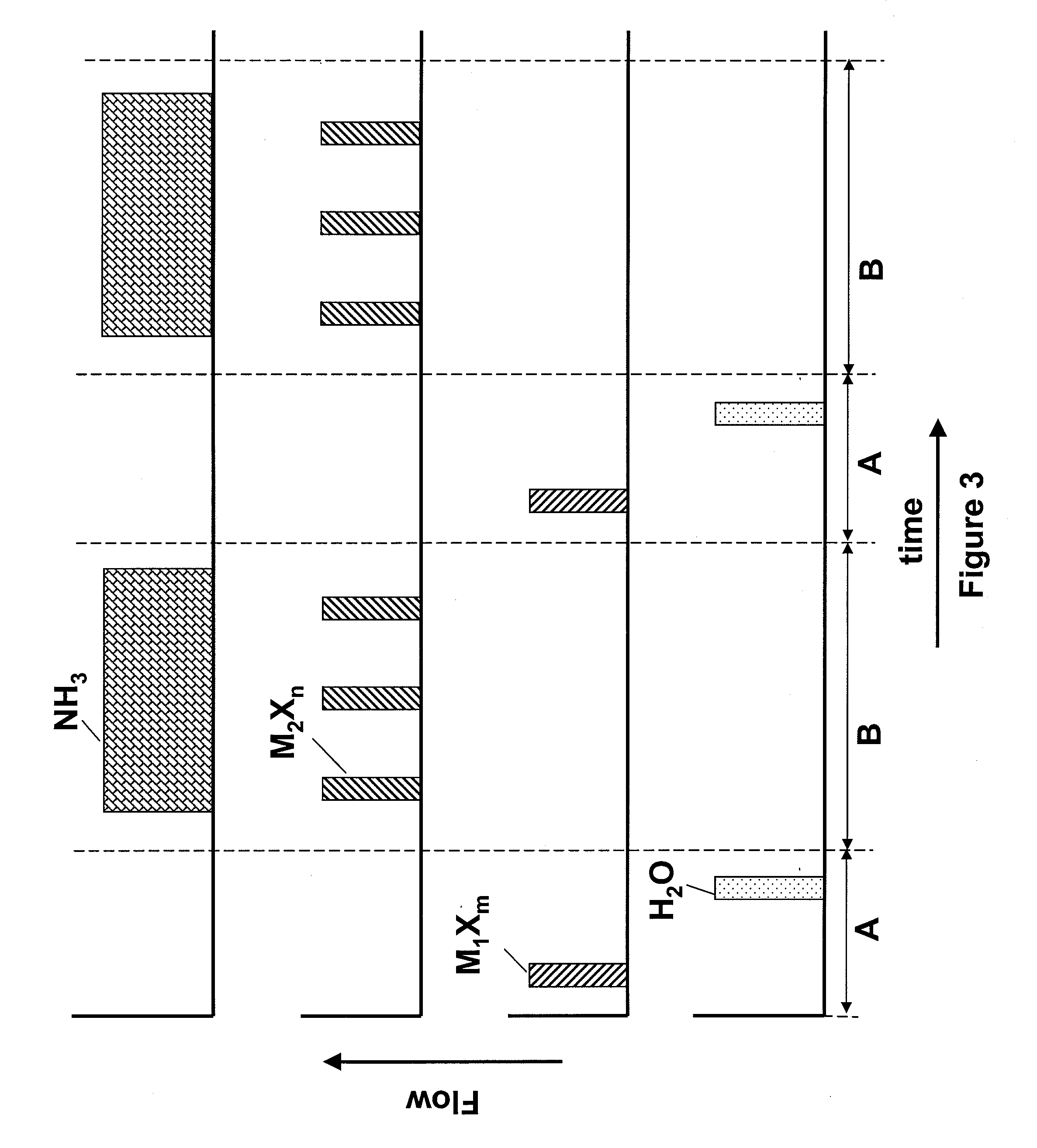

Vapor deposition method for ternary compounds

InactiveUS20100102417A1High resistivitySolid-state devicesSemiconductor/solid-state device manufacturingNitrogen plasmaGas phase

Embodiments provide a method for depositing or forming titanium aluminum nitride materials during a vapor deposition process, such as atomic layer deposition (ALD) or plasma-enhanced ALD (PE-ALD). In some embodiments, a titanium aluminum nitride material is formed by sequentially exposing a substrate to a titanium precursor and a nitrogen plasma to form a titanium nitride layer, exposing the titanium nitride layer to a plasma treatment process, and exposing the titanium nitride layer to an aluminum precursor while depositing an aluminum layer thereon. The process may be repeated multiple times to deposit a plurality of titanium nitride and aluminum layers. Subsequently, the substrate may be annealed to form the titanium aluminum nitride material from the plurality of layers. In other embodiments, the titanium aluminum nitride material may be formed by sequentially exposing the substrate to the nitrogen plasma and a deposition gas which contains the titanium and aluminum precursors.

Owner:APPLIED MATERIALS INC

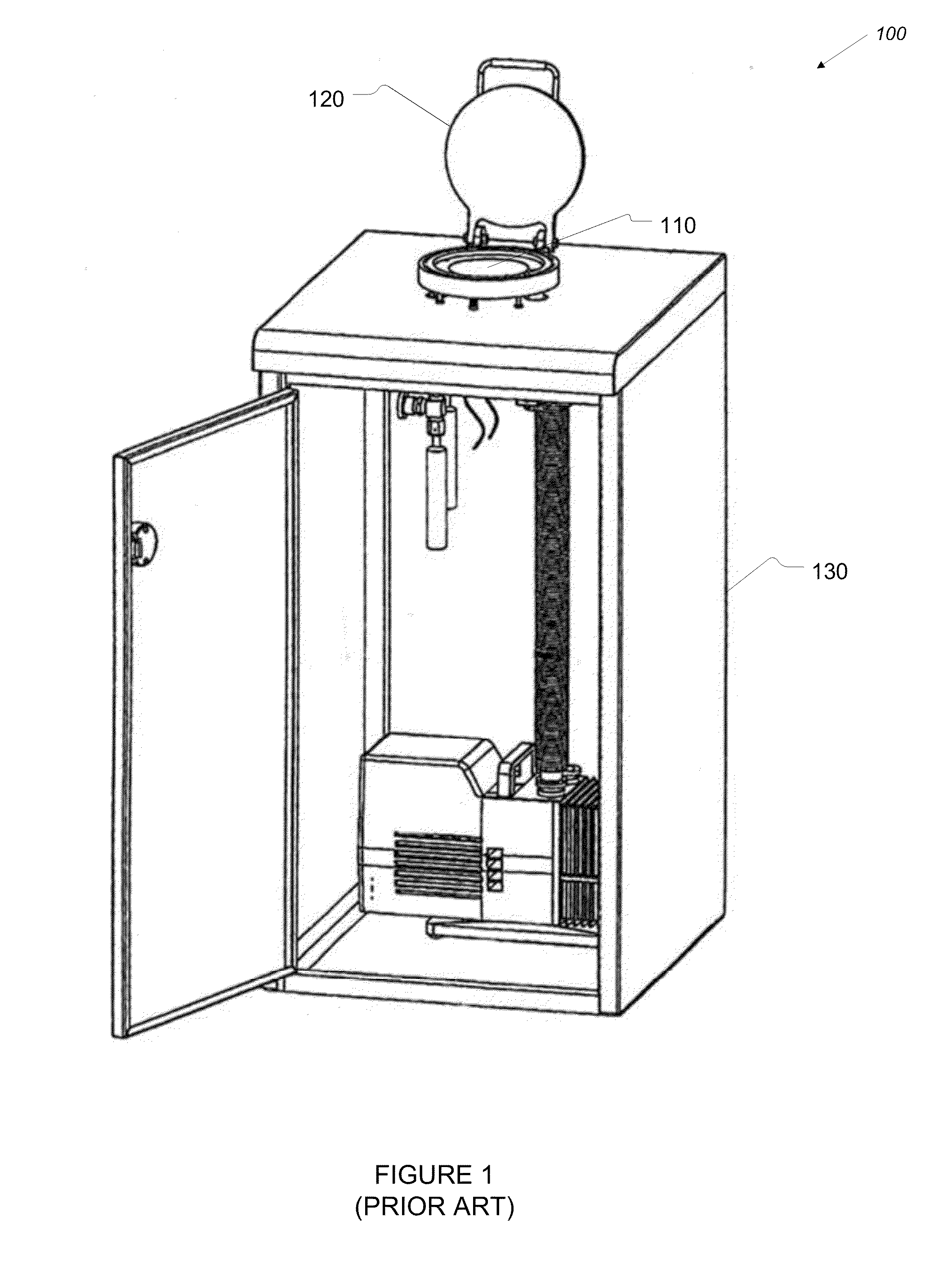

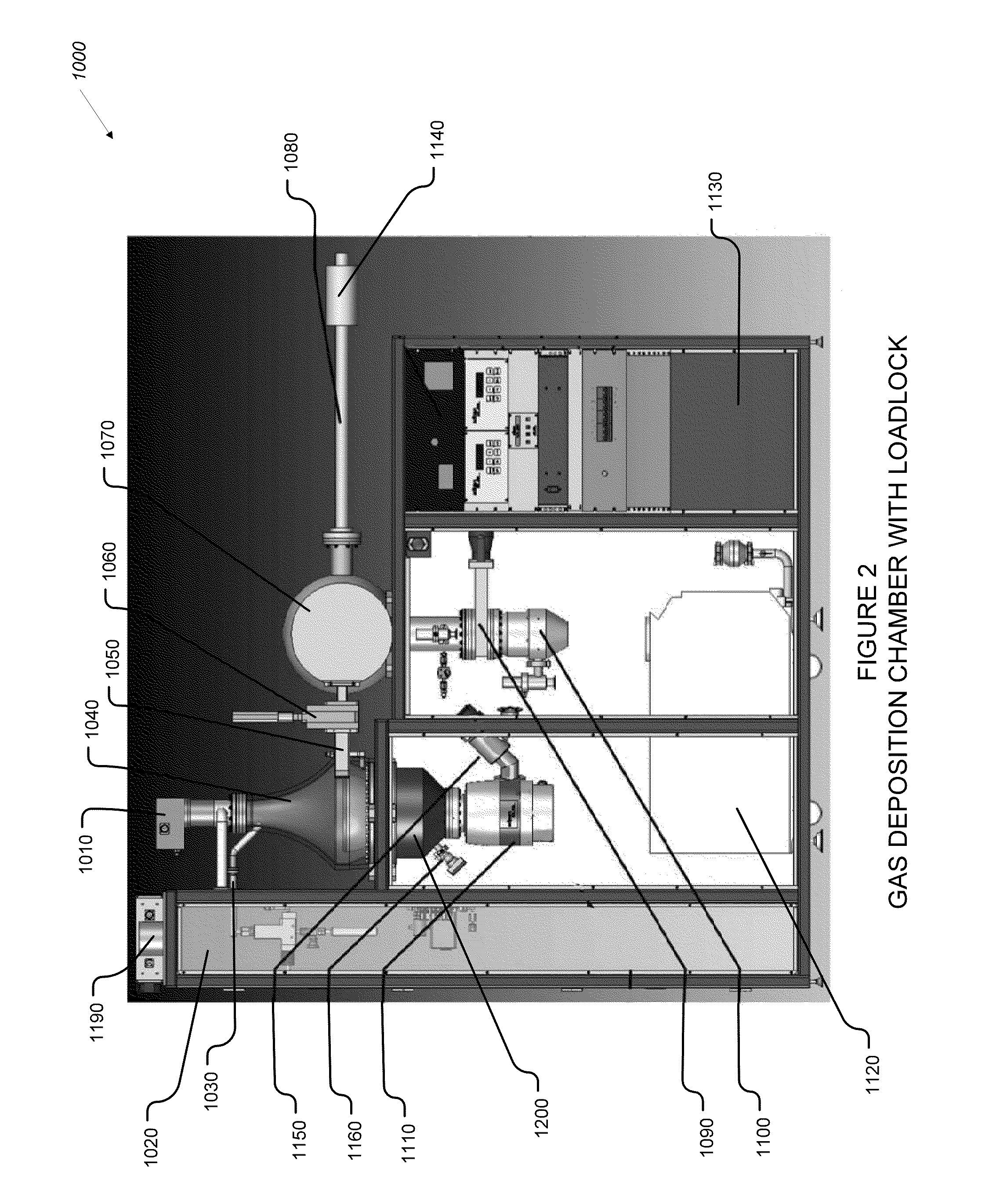

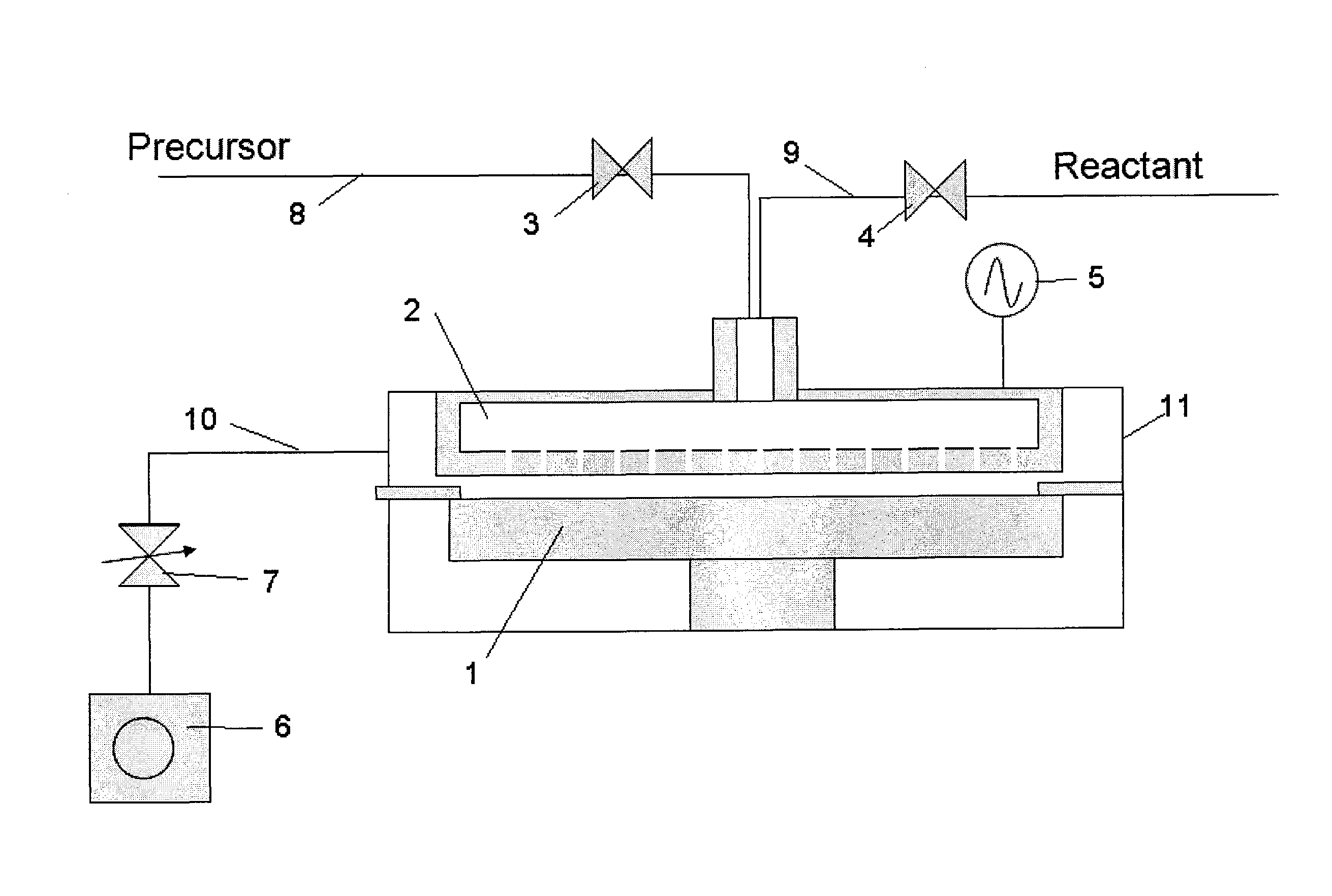

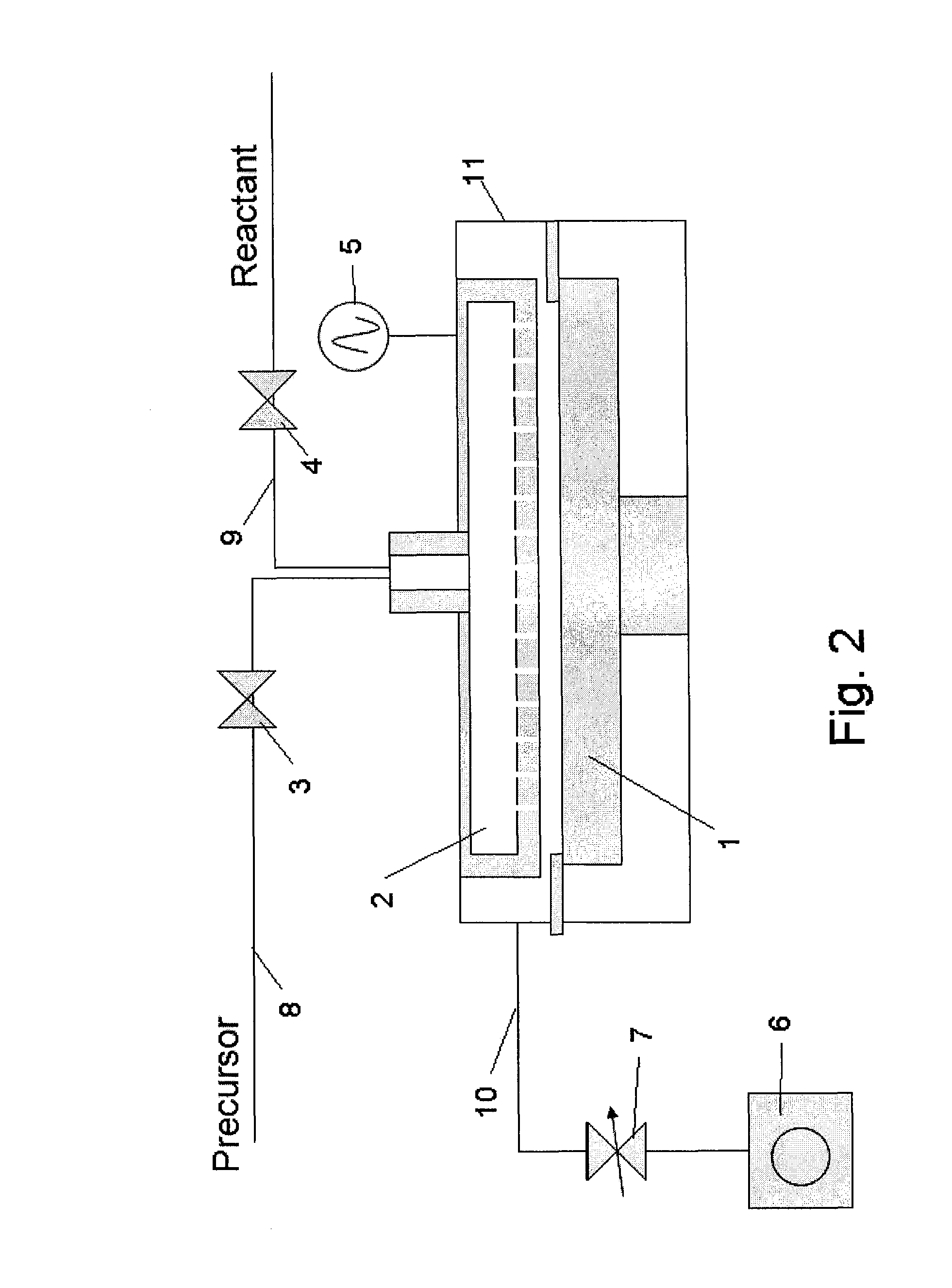

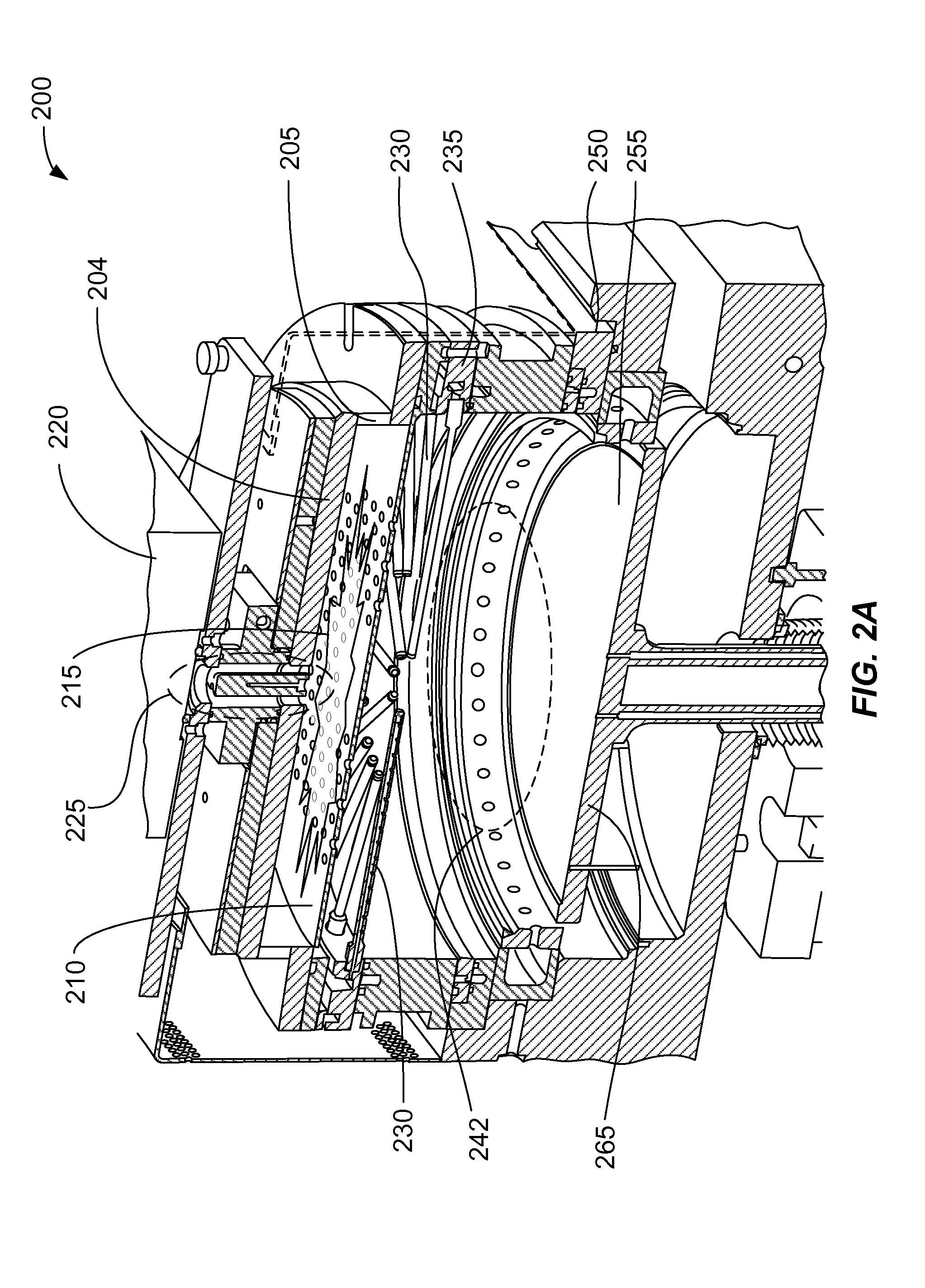

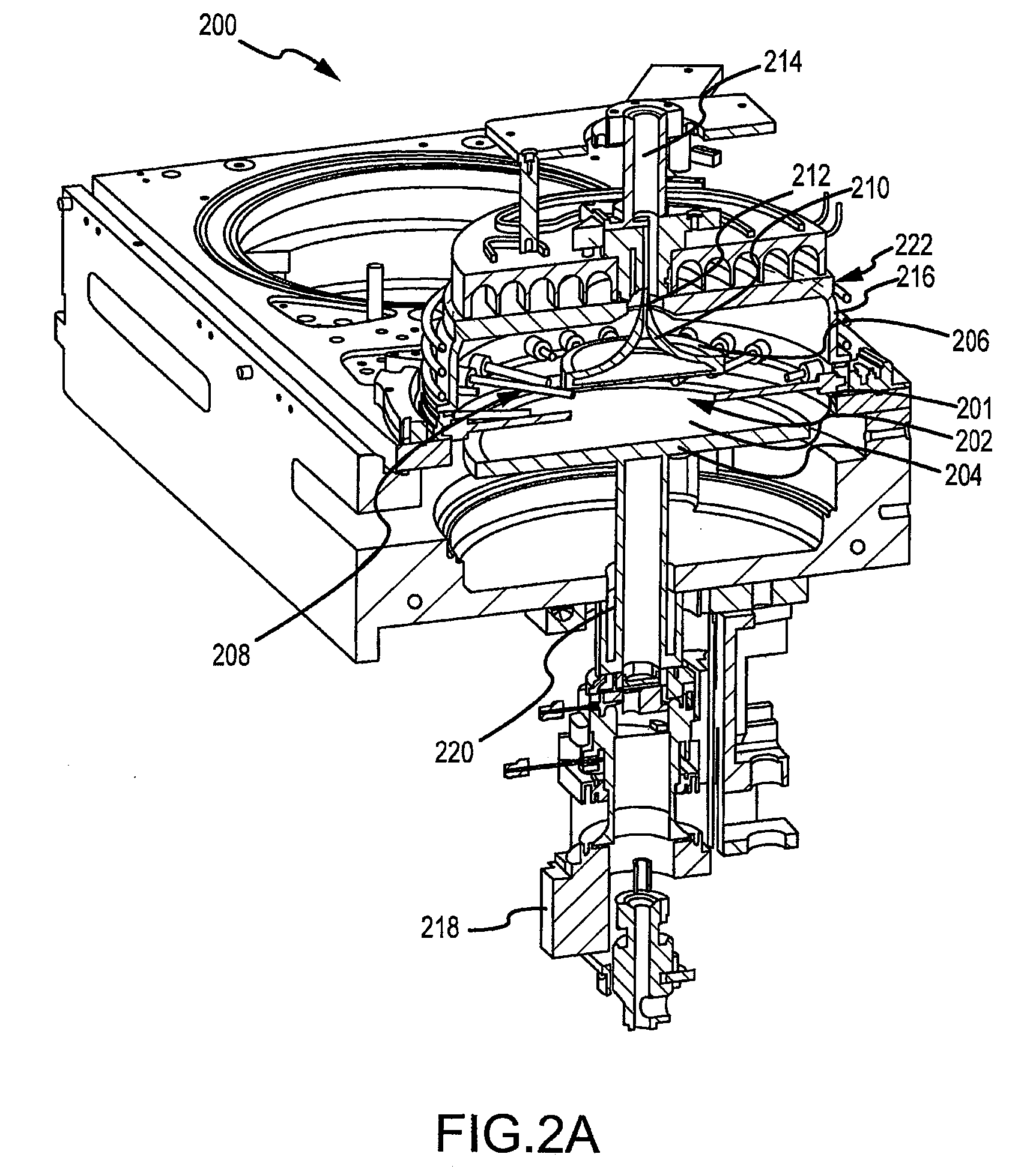

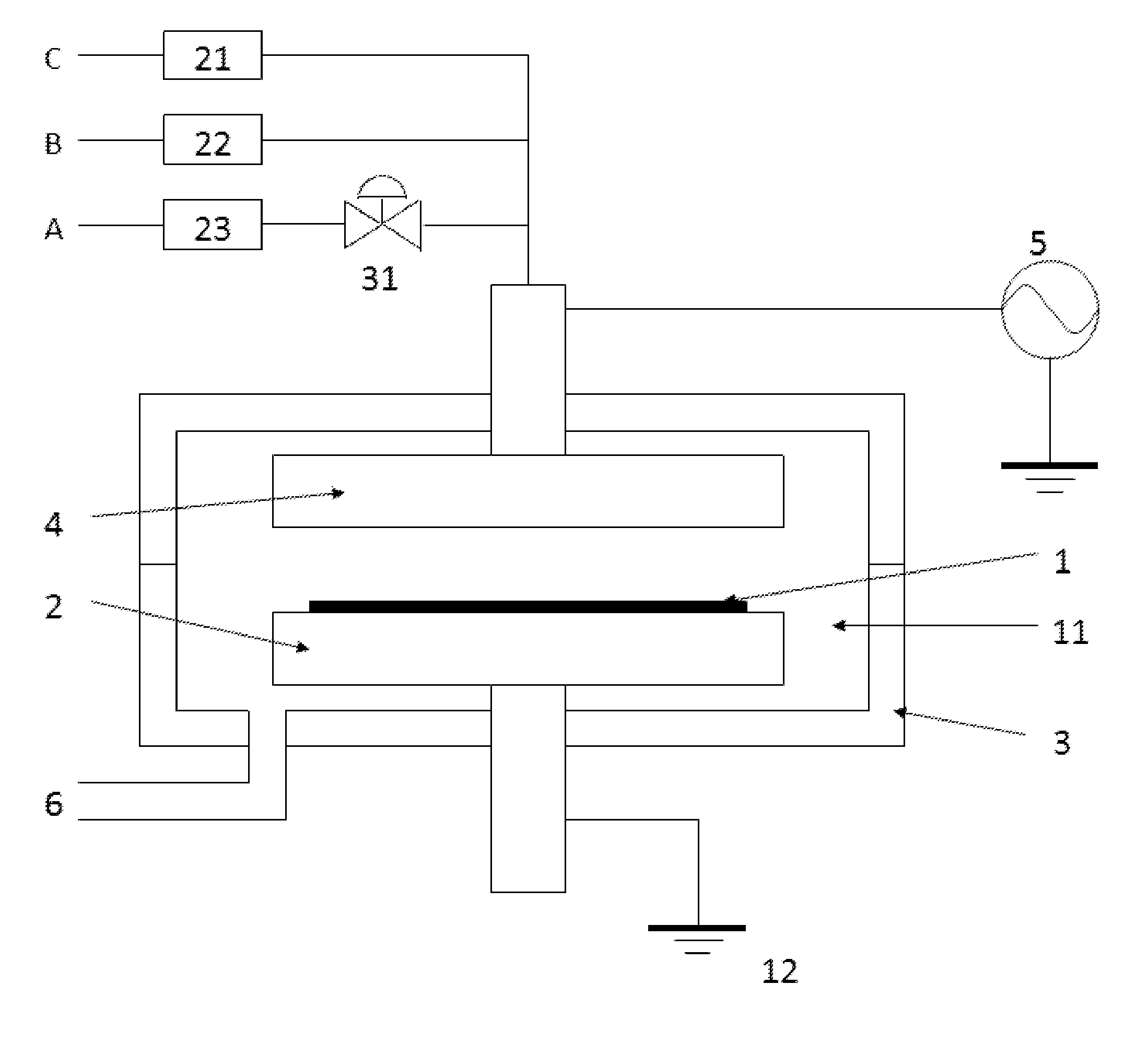

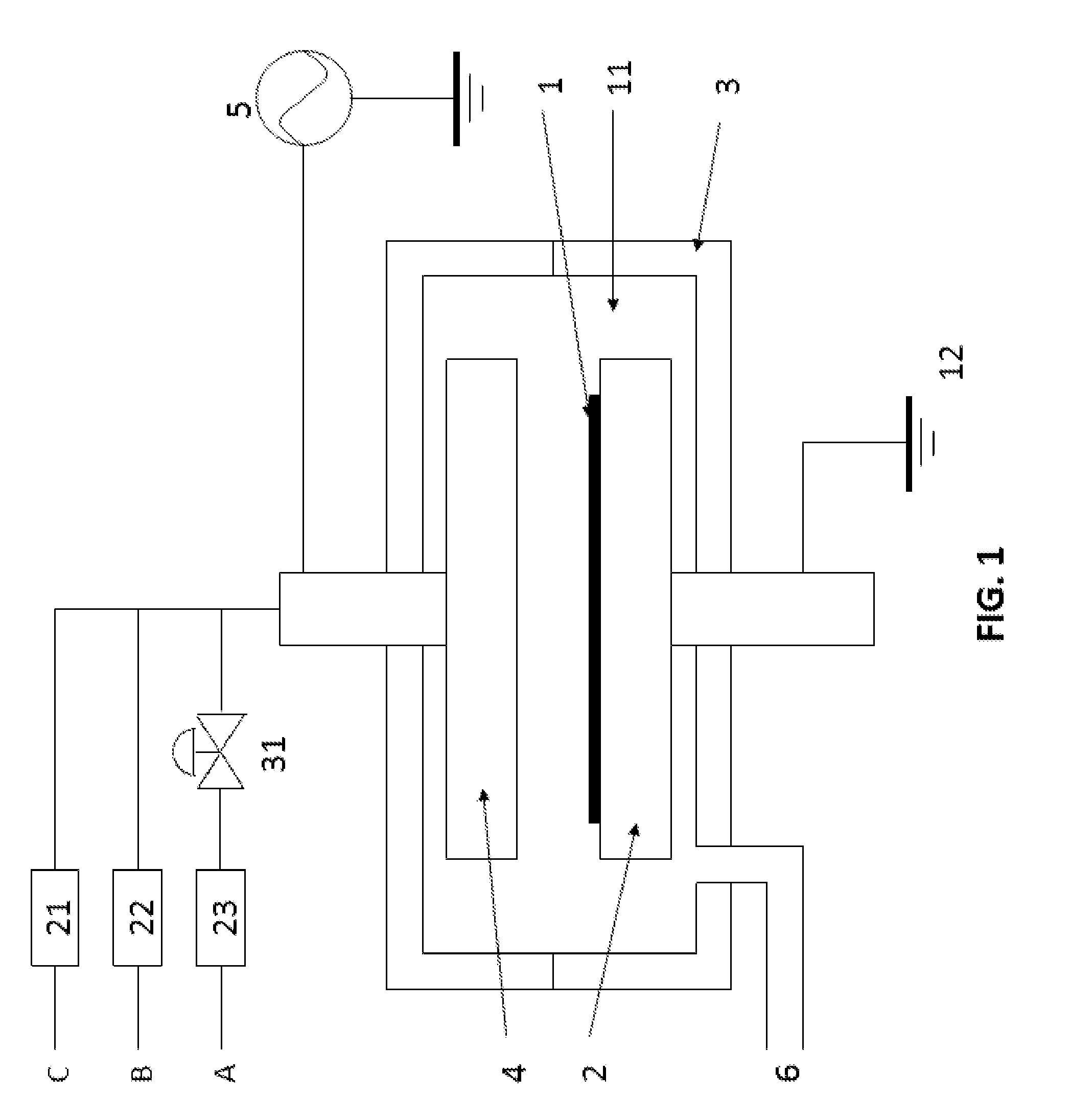

Plasma atomic layer deposition system and method

InactiveUS20100183825A1Lower the volumeShorten cycle timeChemical vapor deposition coatingPlasma techniqueEngineeringAtomic layer deposition

An improved gas deposition chamber includes a hollow gas deposition volume formed with a volume expanding top portion and a substantially constant volume cylindrical middle portion. The hollow gas deposition volume may include a volume reducing lower portion. An aerodynamically shaped substrate support chuck is disposed inside gas deposition chamber with a substrate support surface positioned in the constant volume cylindrical middle portion. The volume expanding top portion reduces gas flow velocity between gas input ports and the substrate support surface. The aerodynamic shape of the substrate support chuck reduces drag and helps to promote laminar flow over the substrate support surface. The volume reducing lower portion helps to increase gas flow velocity after the gas has past the substrate support surface. The improved gas deposition chamber is configurable to 200 mm diameter semiconductor wafers using ALD and or PALD coating cycles. An improved coating method includes expanding process gases inside the deposition chamber prior to the process gas reaching surfaces of a substrate being coated. The method further includes compressing the process gases inside the deposition chamber after the process gas has flowed past surfaces of the substrate being coated.

Owner:ULTRATECH INT INC

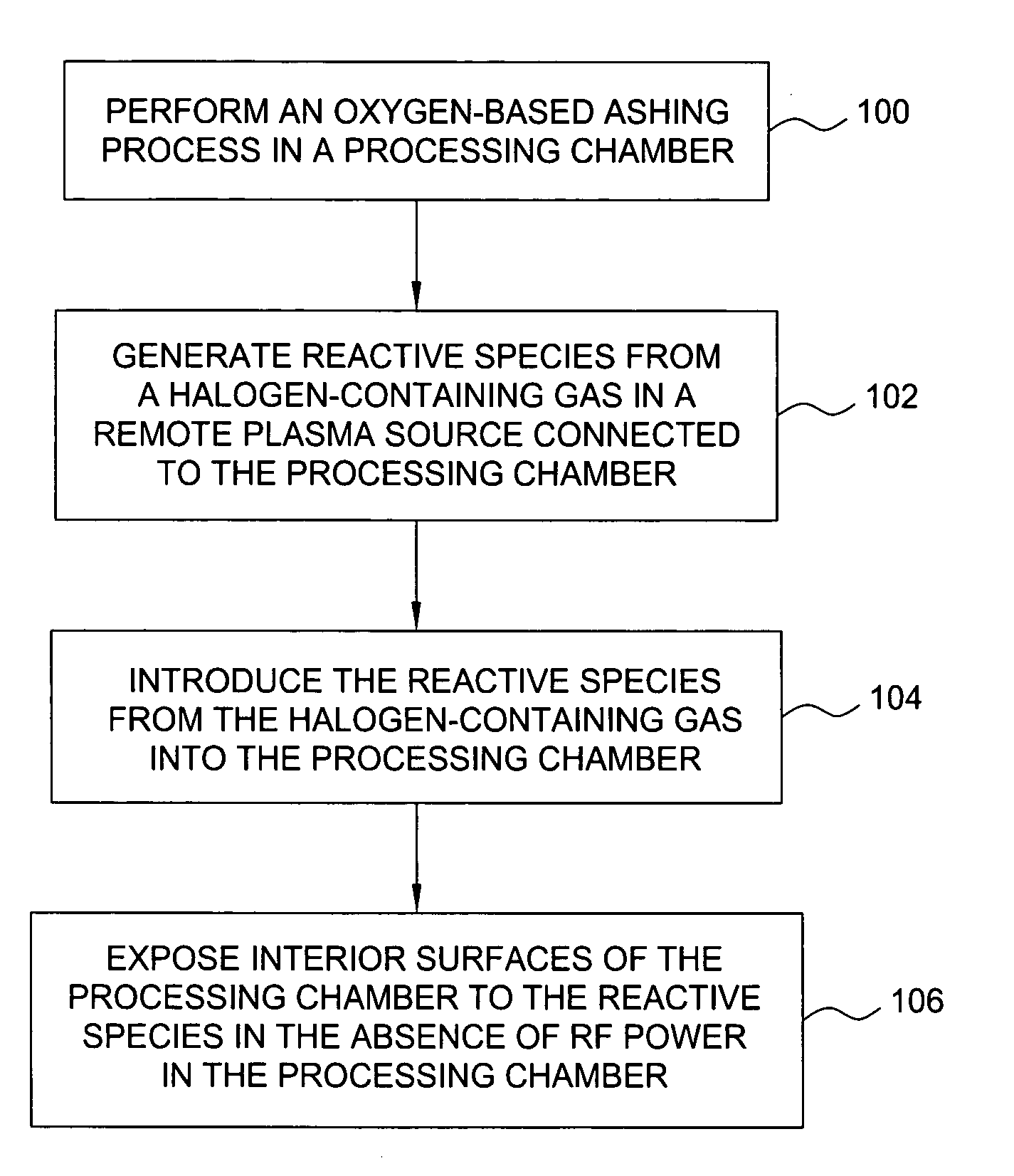

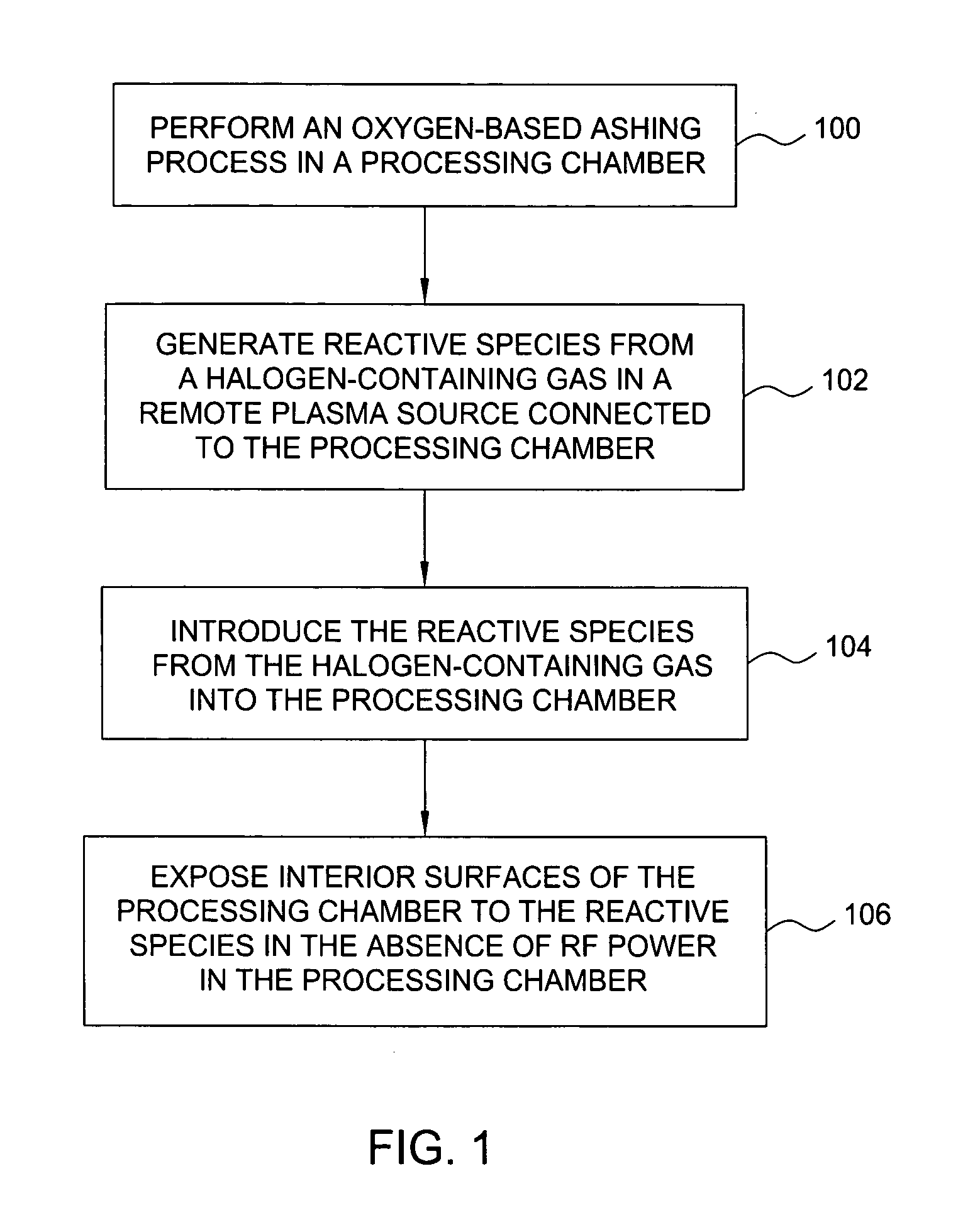

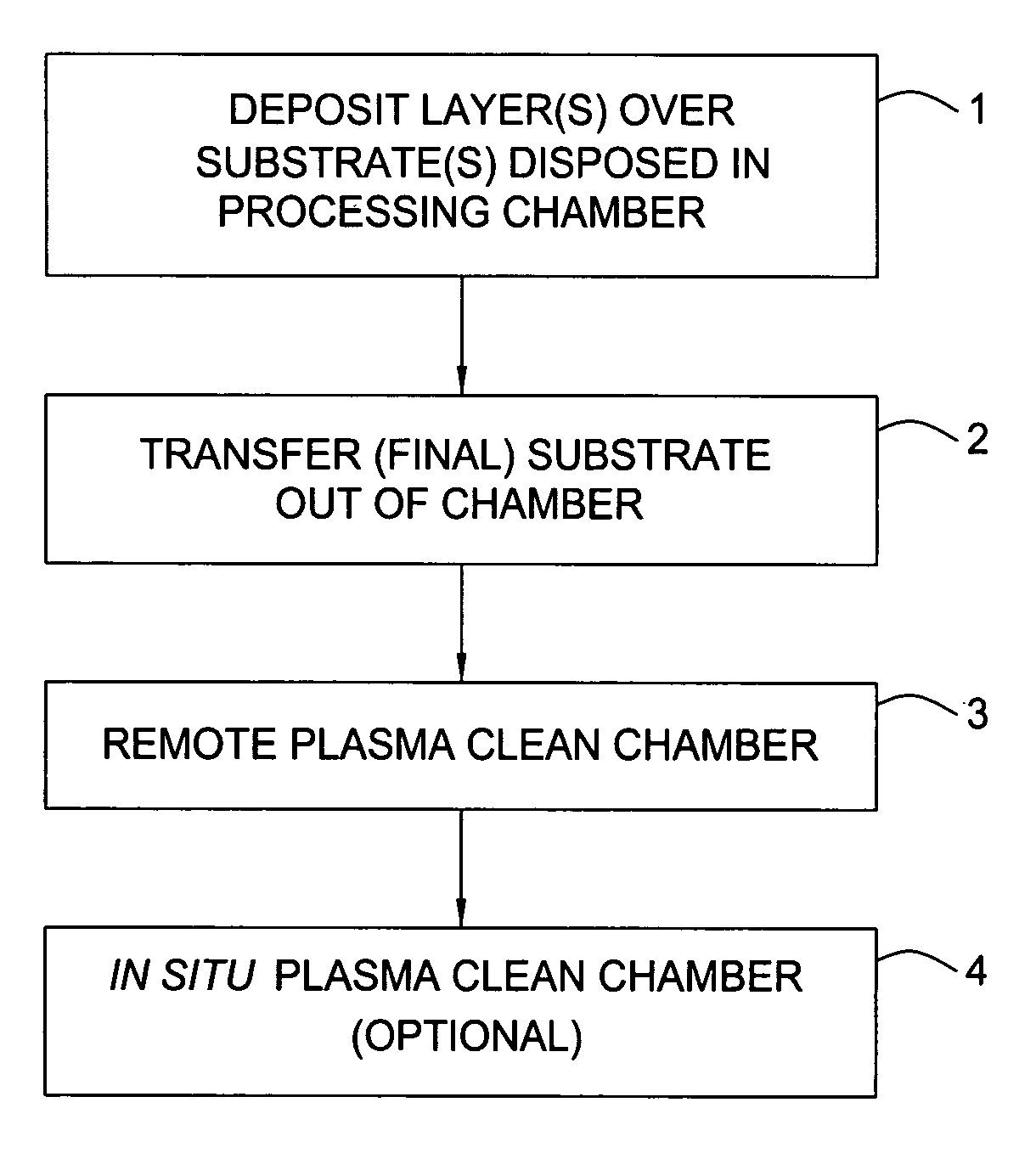

Enhancement of remote plasma source clean for dielectric films

Methods for cleaning semiconductor processing chambers used to process carbon-containing films, such as amorphous carbon films, barrier films comprising silicon and carbon, and low dielectric constant films including silicon, oxygen, and carbon are provided. The methods include using a remote plasma source to generate reactive species that clean interior surfaces of a processing chamber in the absence of RF power in the chamber. The reactive species are generated from an oxygen-containing gas, such as O2, and / or a halogen-containing gas, such as NF3. An oxygen-based ashing process may also be used to remove carbon deposits from the interior surfaces of the chamber before the chamber is exposed to the reactive species from the remote plasma source.

Owner:APPLIED MATERIALS INC

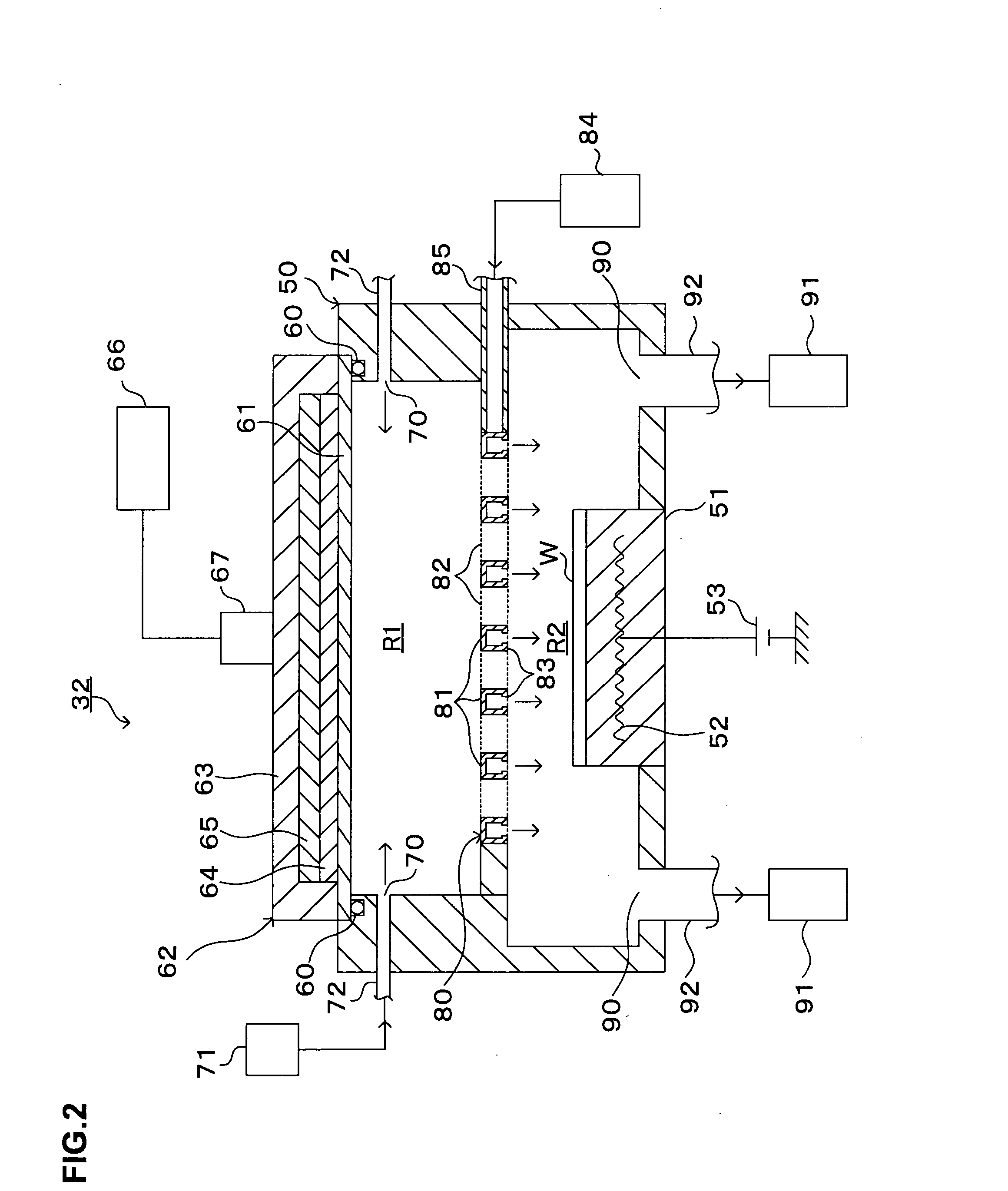

Substrate processing method, computer readable recording medium and substrate processing apparatus

InactiveUS20070062453A1Low dielectric constantImprove heat resistanceElectric discharge tubesSemiconductor/solid-state device detailsMicrowaveEngineering

In the present invention, Ar gas for plasma generation is supplied to a plasma generation region and butyne gas having a multiple bond is supplied to a film formation region at a substrate side as source gas, inside of a process vessel in an insulating film forming apparatus. A microwave is supplied inside of the process vessel from a radial line slot antenna under a state in which a bias voltage is not applied to a substrate W. A plasma is thereby generated in the plasma generation region, the butyne gas in the film formation region is activated by the plasma, and an insulating film of amorphous carbon is formed on the substrate.

Owner:TOKYO ELECTRON LTD

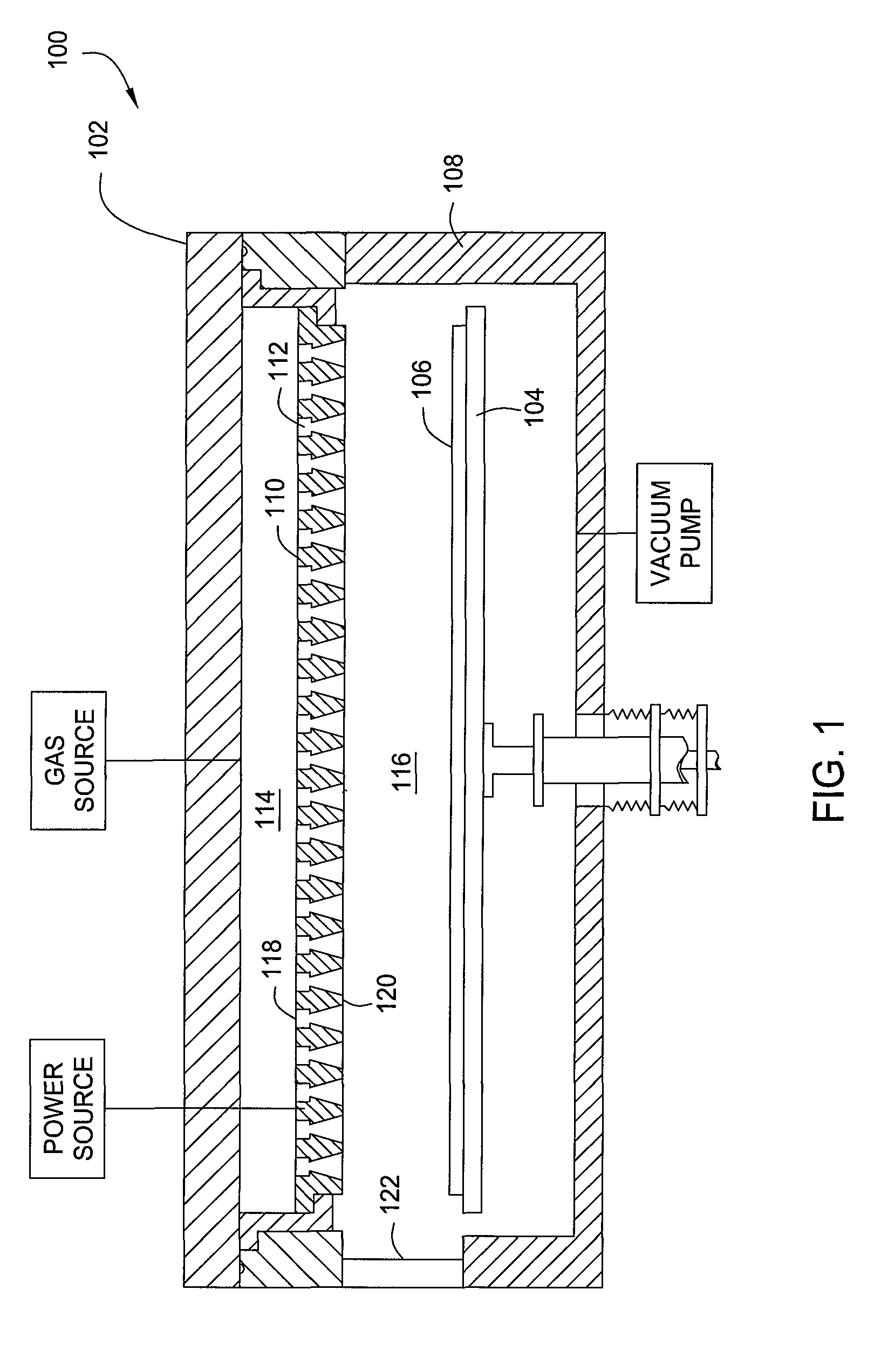

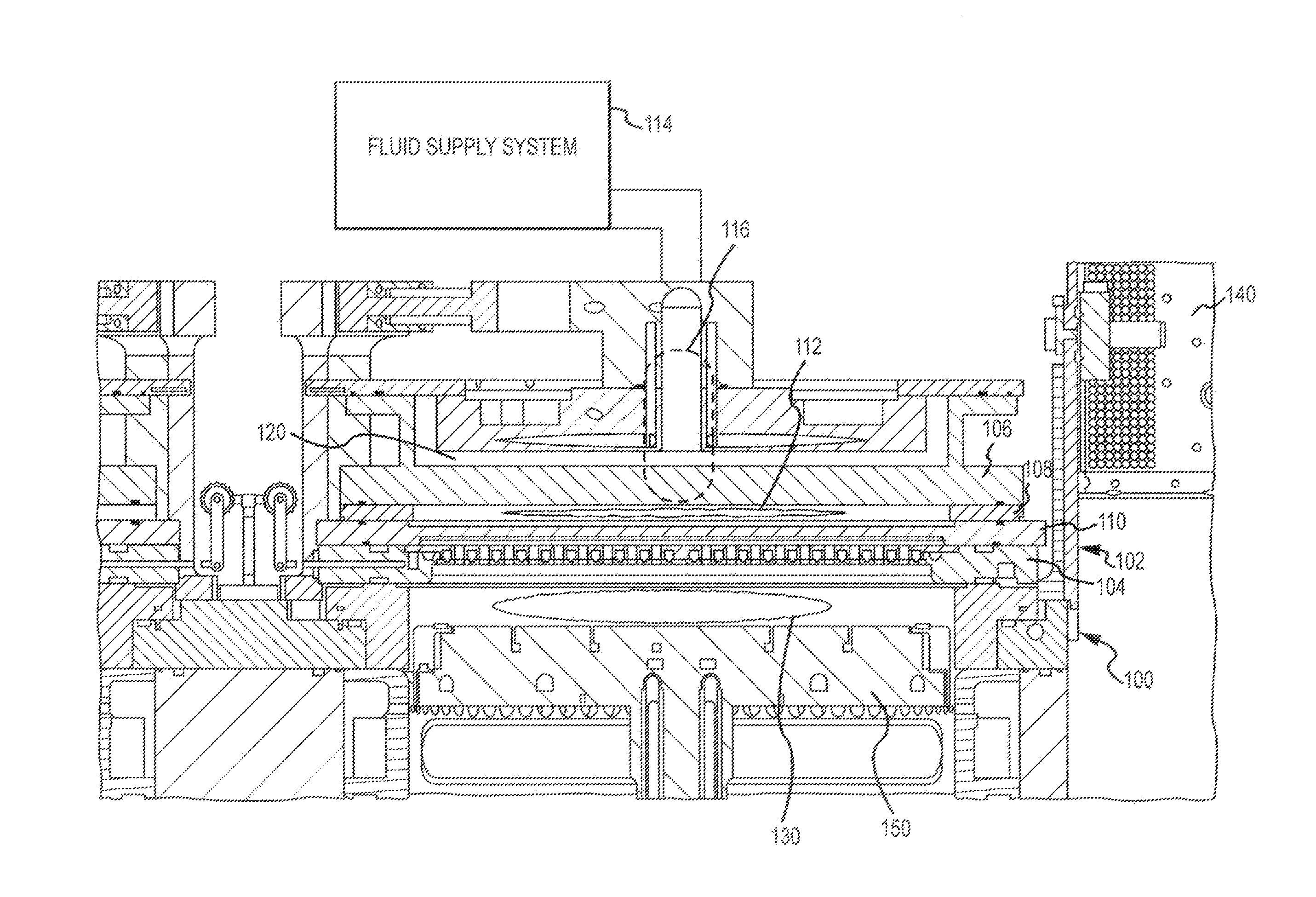

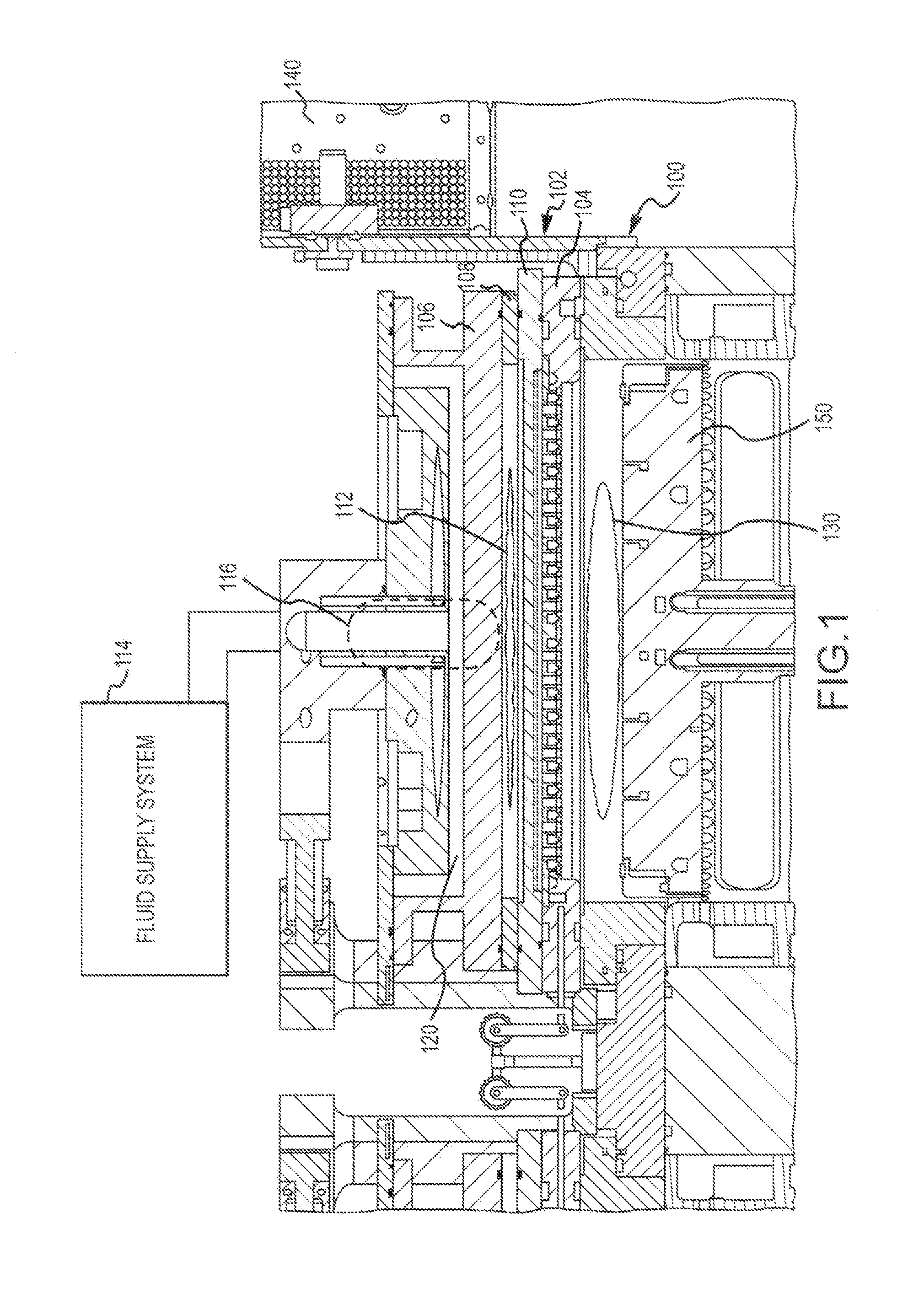

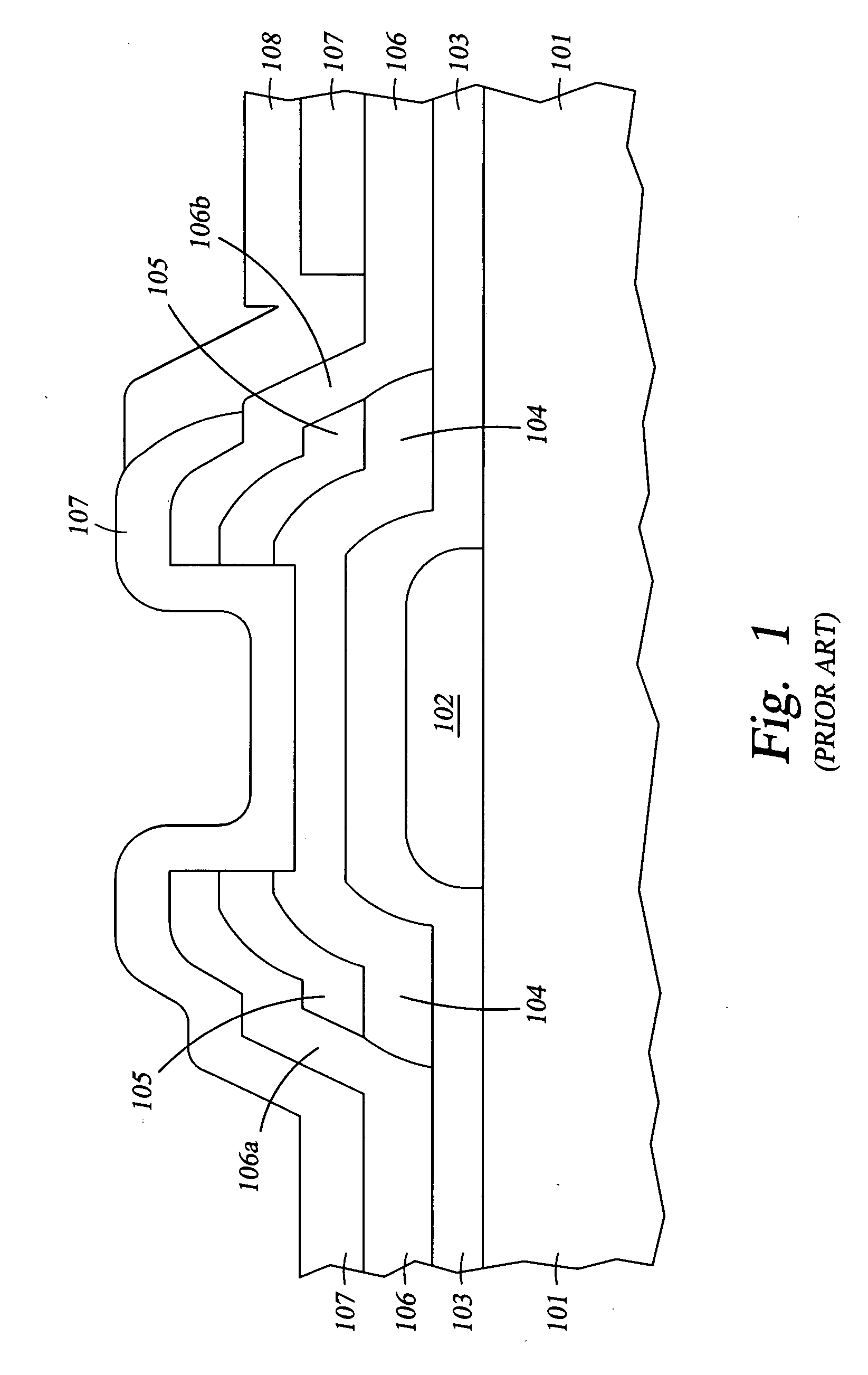

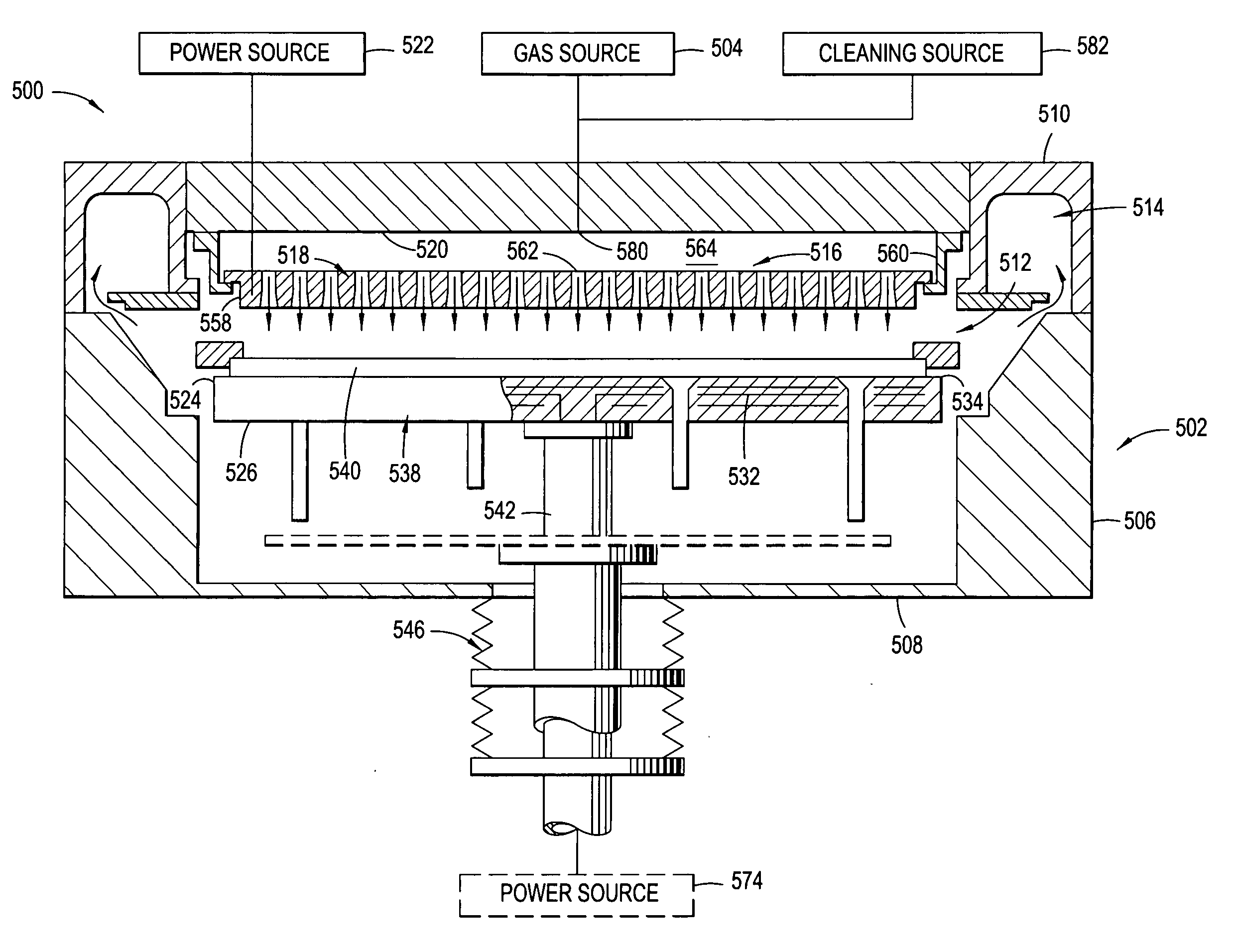

Semiconductor processing system and methods using capacitively coupled plasma

InactiveUS20120180954A1Conducive to environmental controlEliminate and reduce numberElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceSemiconductor

Substrate processing systems are described that have a capacitively coupled plasma (CCP) unit positioned inside a process chamber. The CCP unit may include a plasma excitation region formed between a first electrode and a second electrode. The first electrode may include a first plurality of openings to permit a first gas to enter the plasma excitation region, and the second electrode may include a second plurality of openings to permit an activated gas to exit the plasma excitation region. The system may further include a gas inlet for supplying the first gas to the first electrode of the CCP unit, and a pedestal that is operable to support a substrate. The pedestal is positioned below a gas reaction region into which the activated gas travels from the CCP unit.

Owner:APPLIED MATERIALS INC

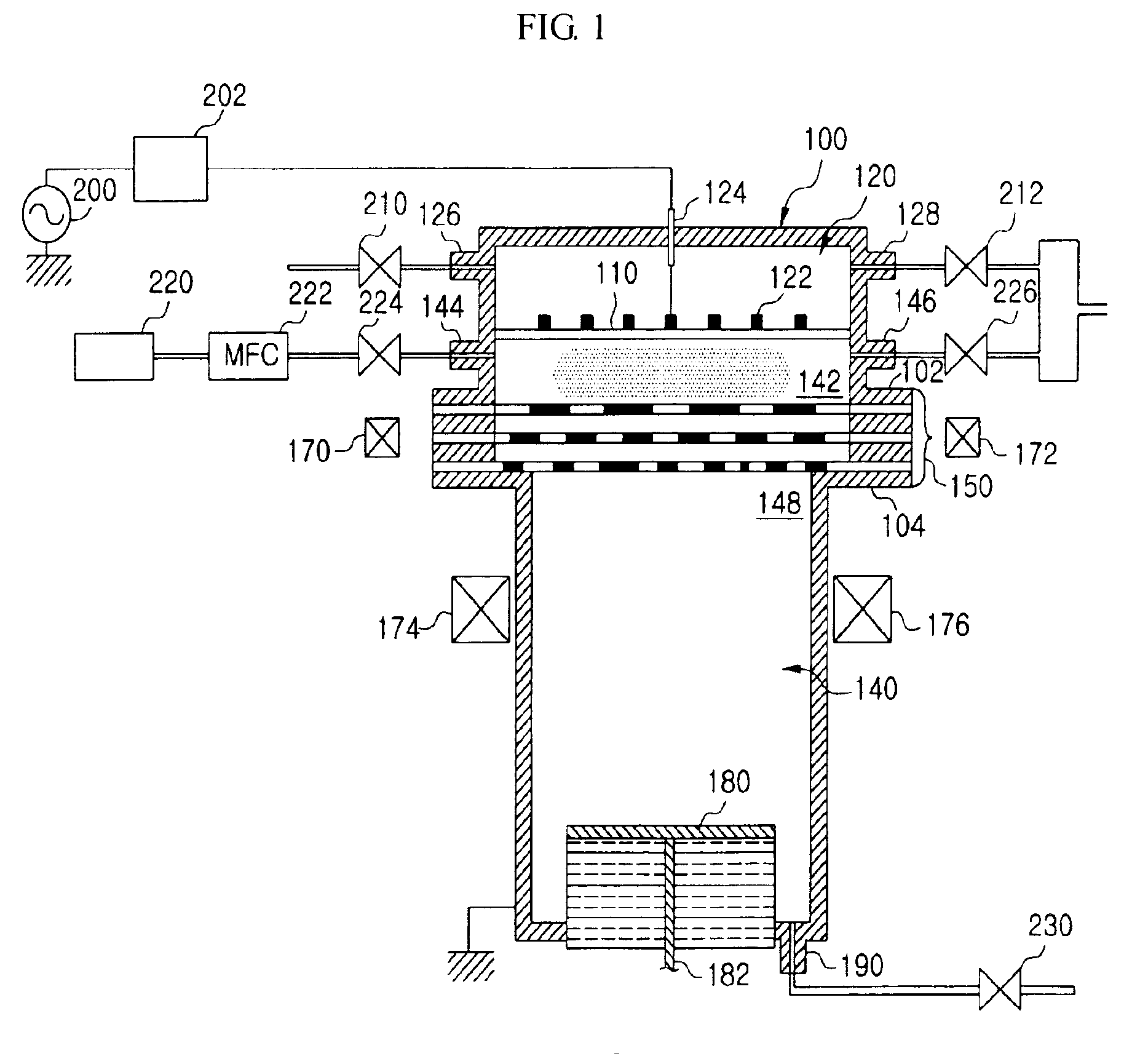

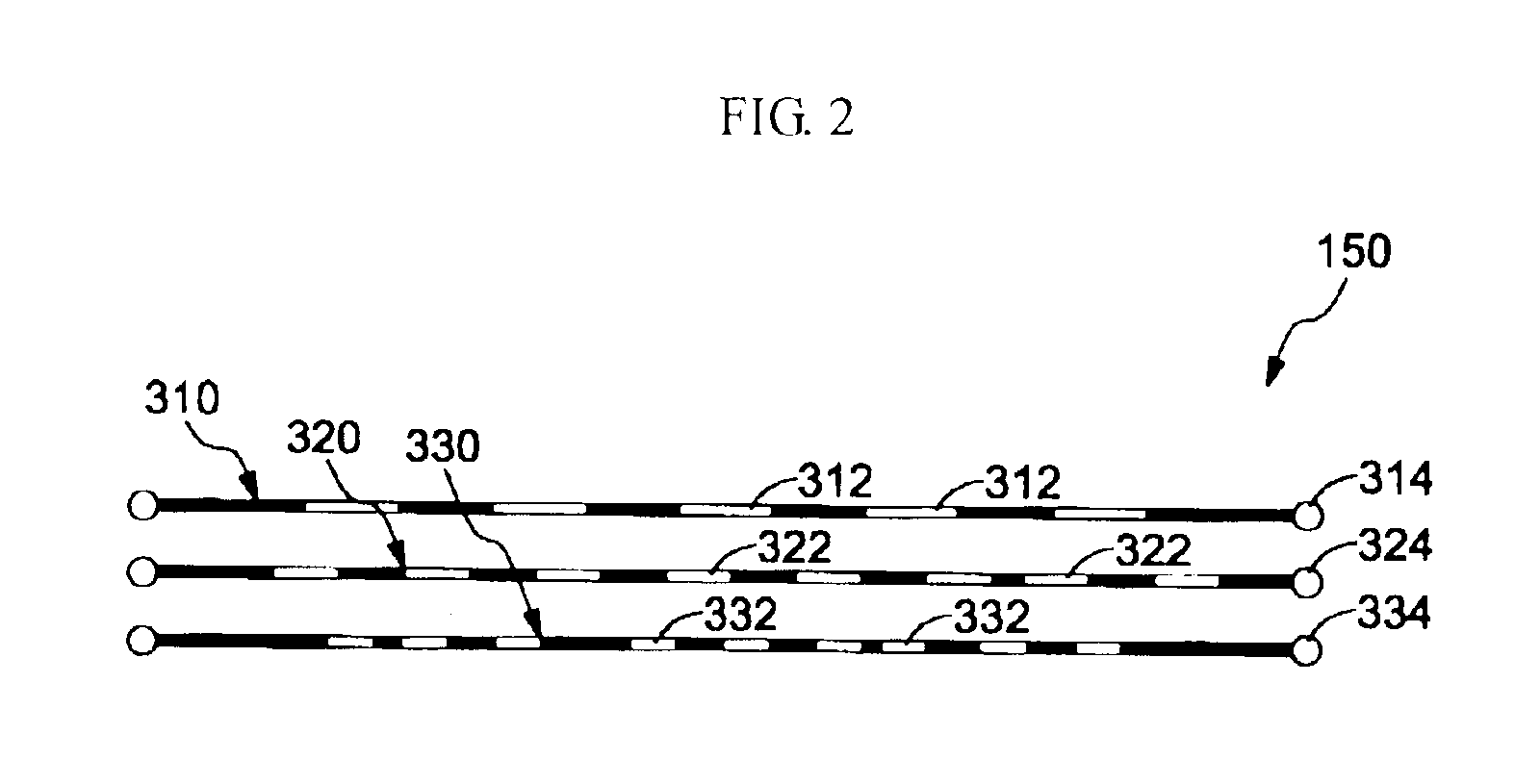

Method of controlling the film properties of PECVD-deposited thin films

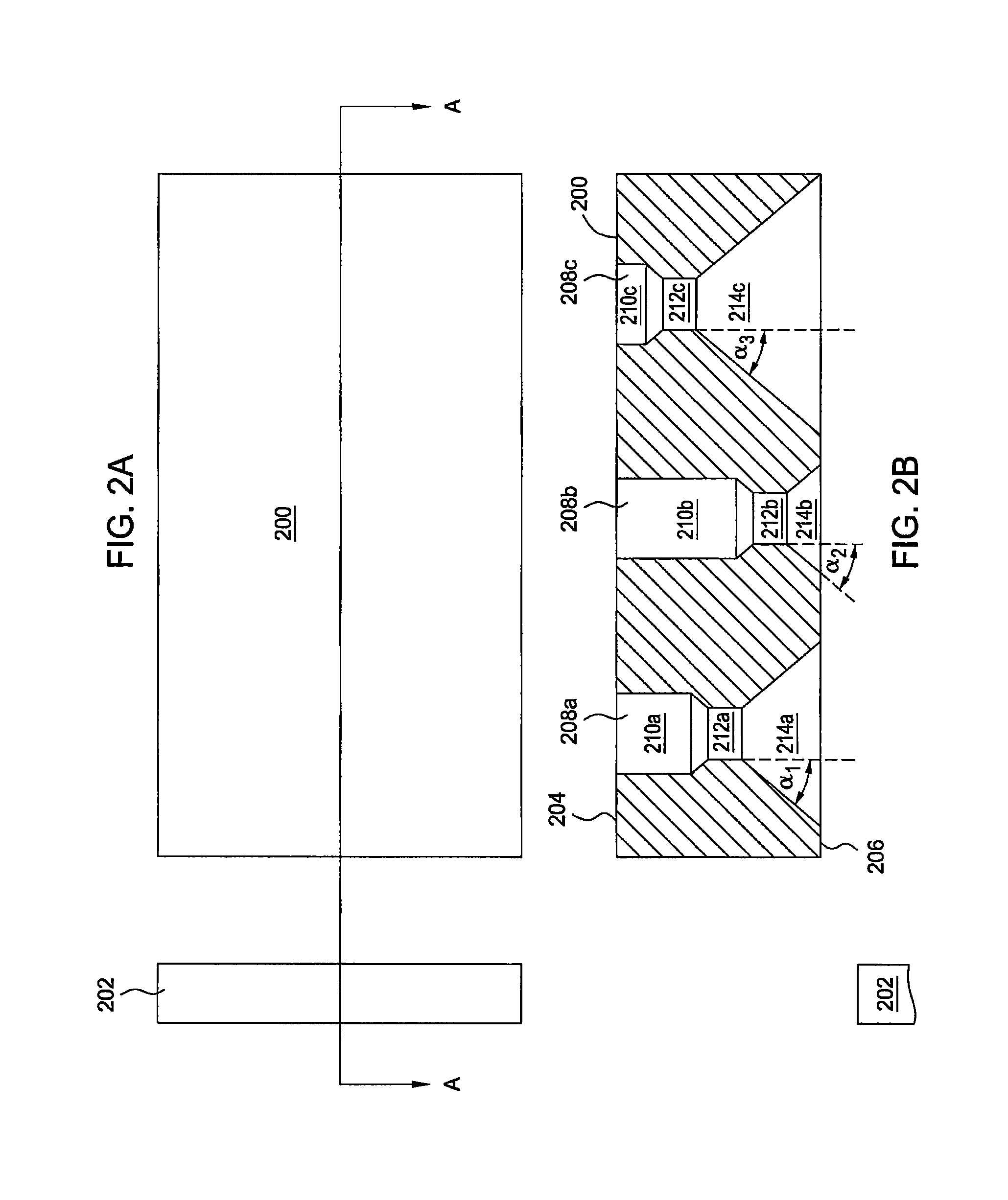

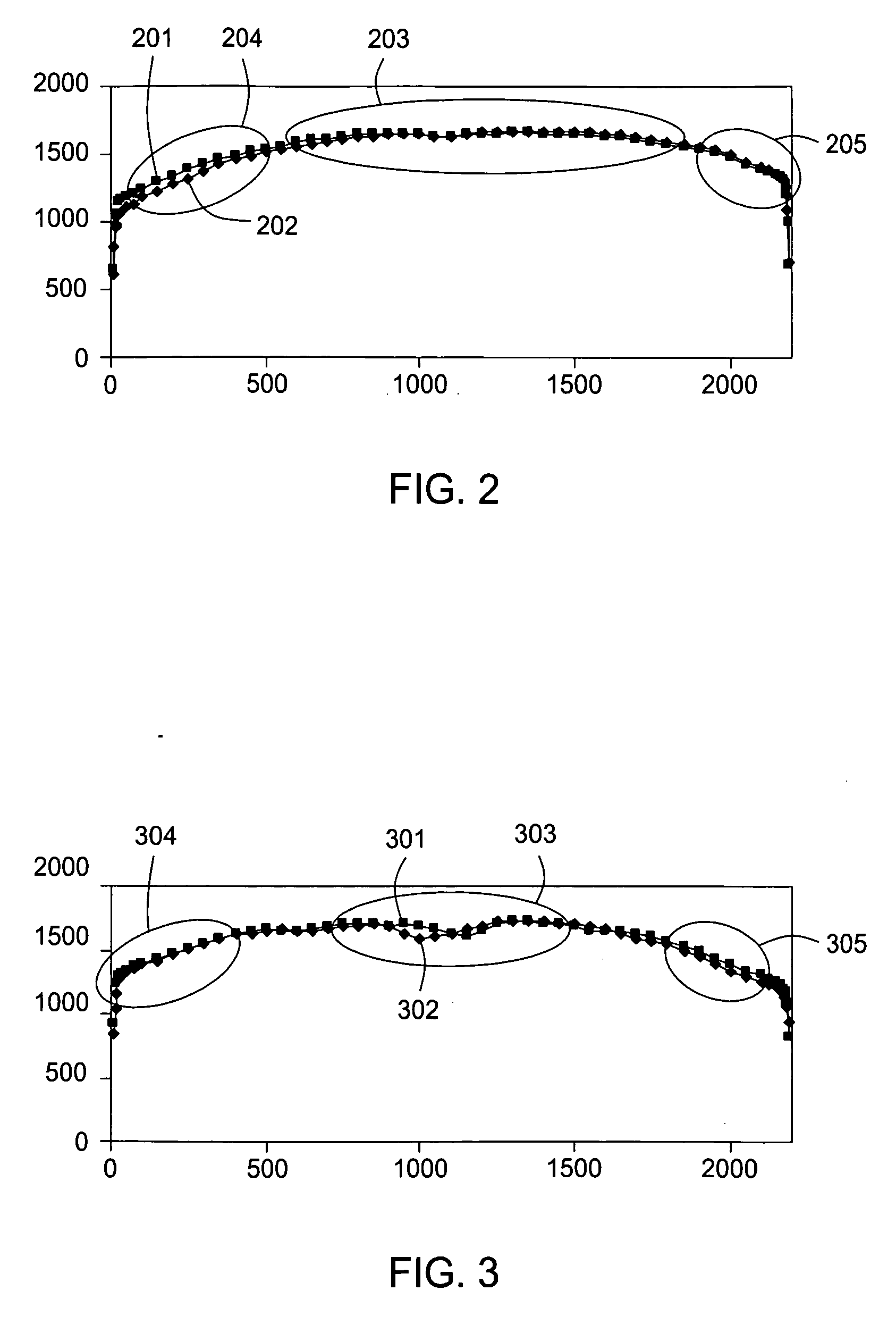

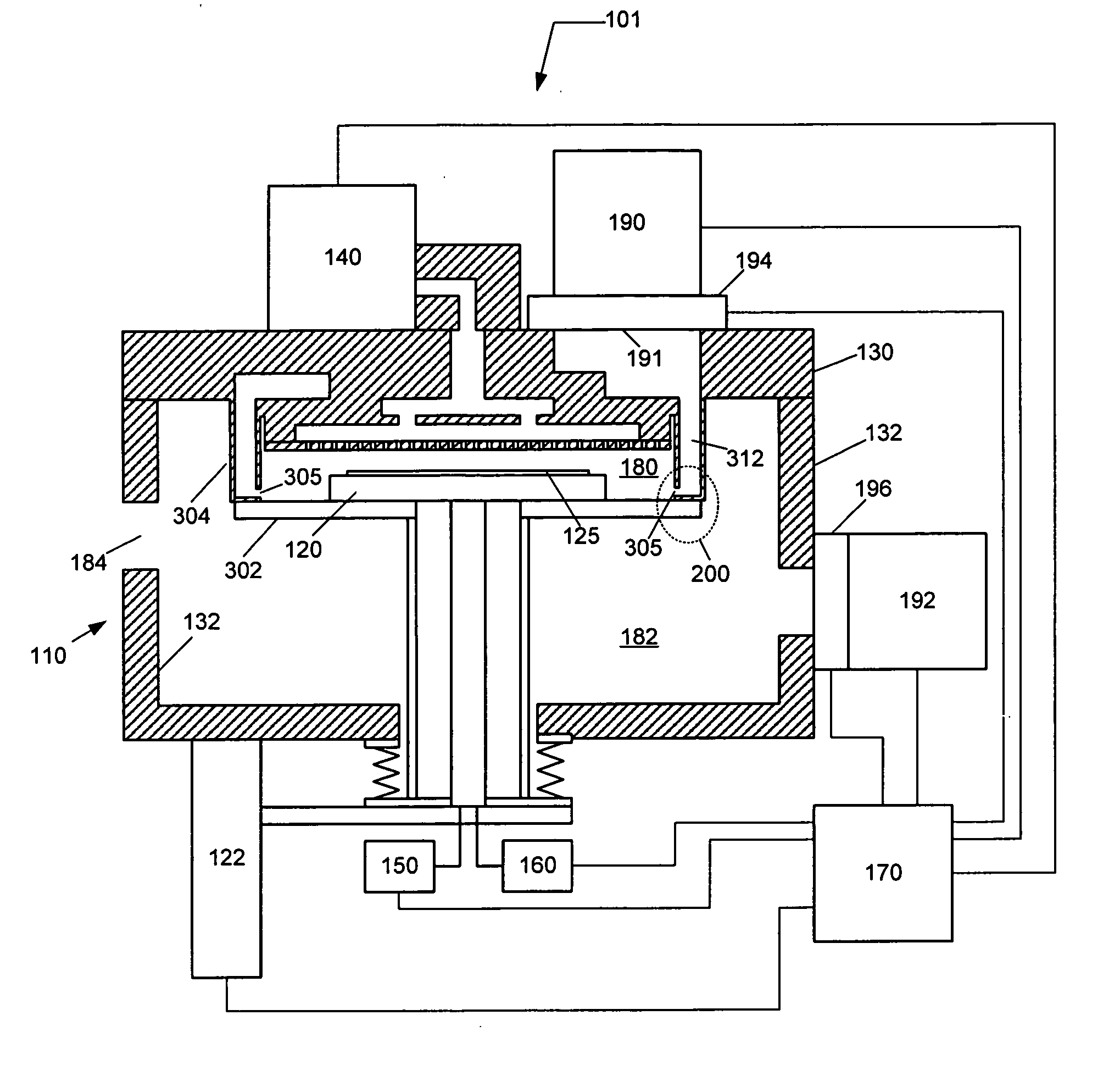

ActiveUS20050255257A1Increase in hollow cathode effectIncrease surface areaElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma densityEngineering

We have discovered methods of controlling a combination of PECVD deposition process parameters during deposition of thin films which provides improved control over surface standing wave effects which affect deposited film thickness uniformity and physical property uniformity. By minimizing surface standing wave effects, the uniformity of film properties across a substrate surface onto which the films have been deposited is improved. In addition, we have developed a gas diffusion plate design which assists in the control of plasma density to be symmetrical or asymmetrical over a substrate surface during film deposition, which also provides improved control over uniformity of deposited film thickness.

Owner:APPLIED MATERIALS INC

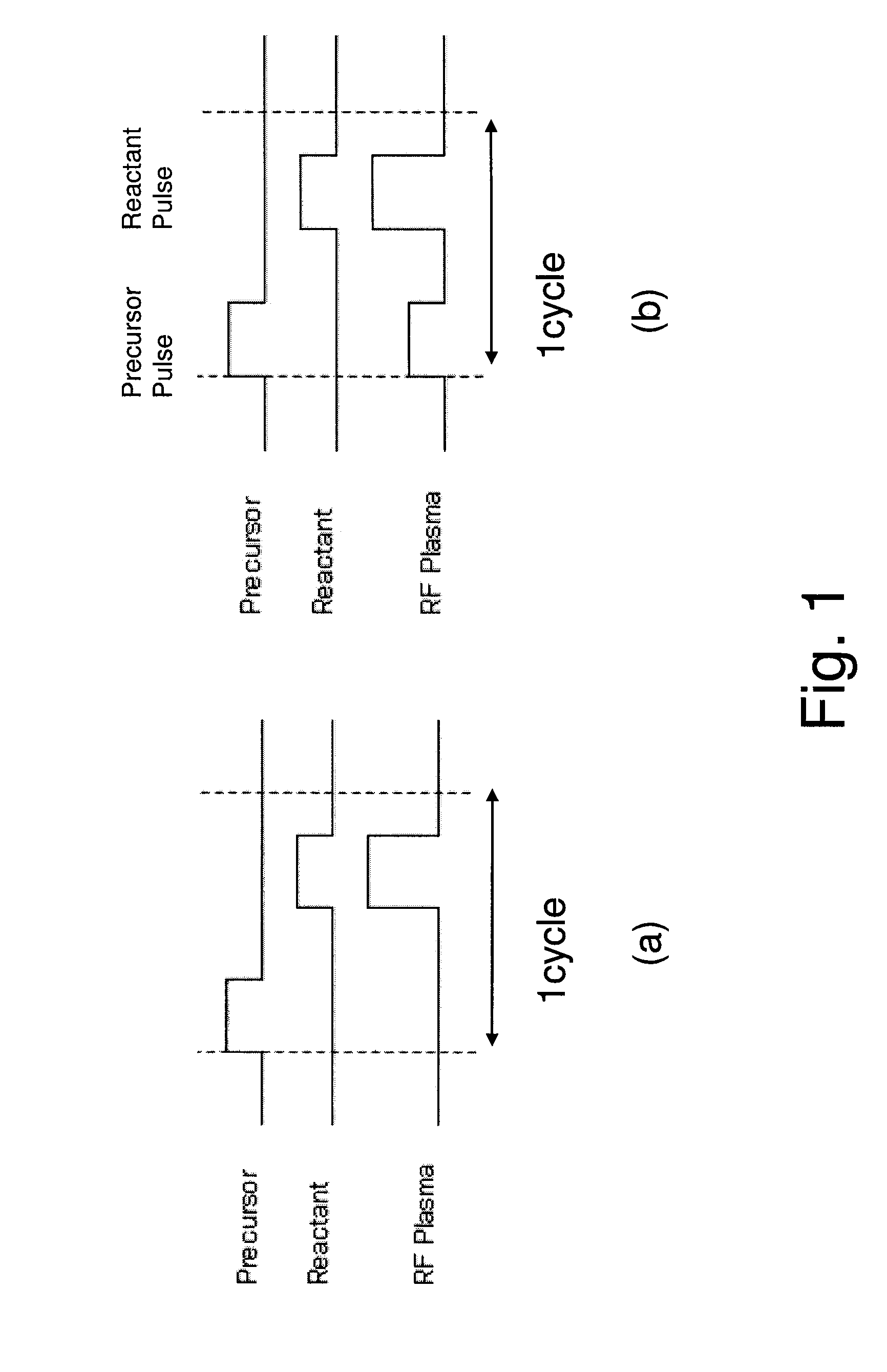

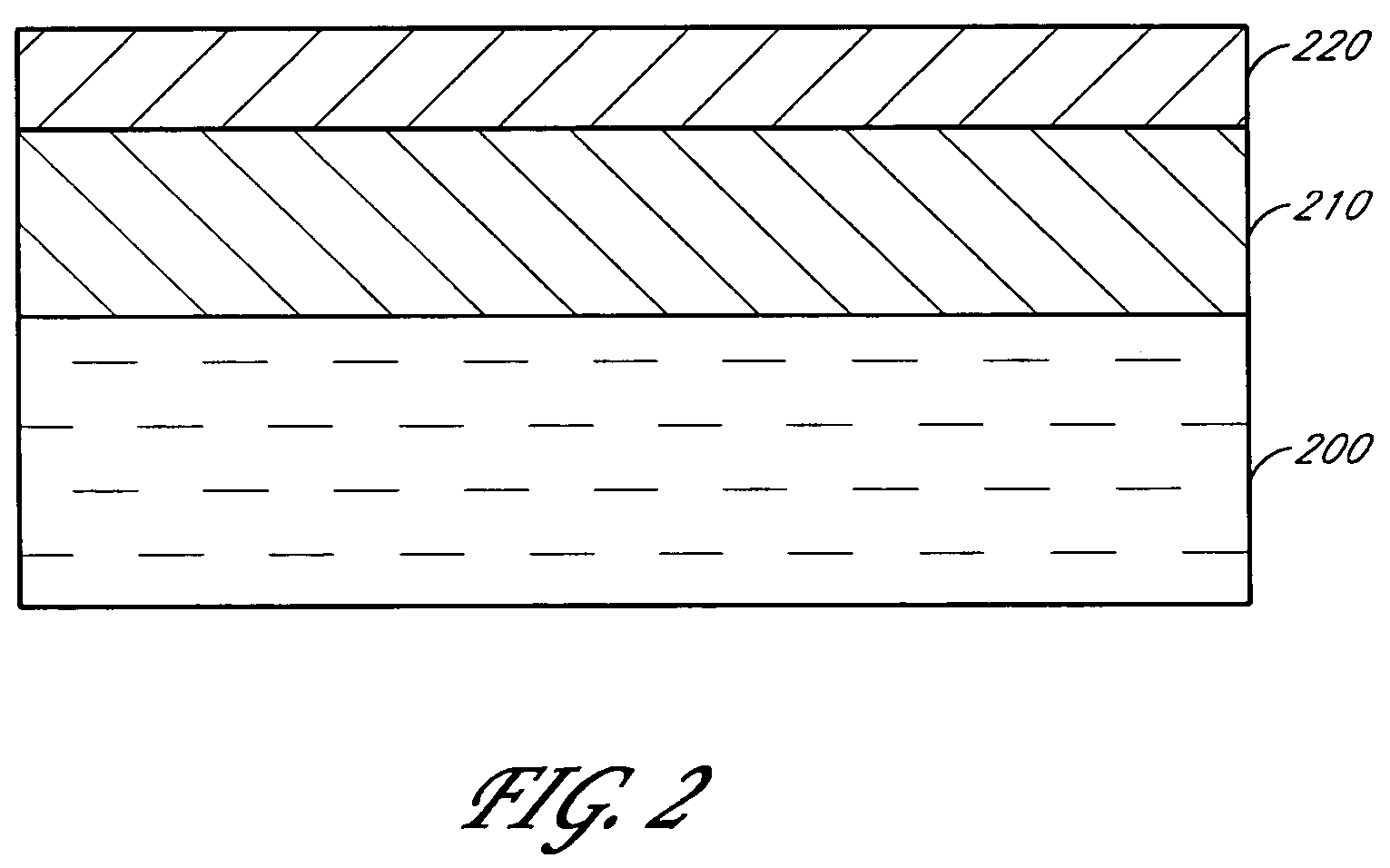

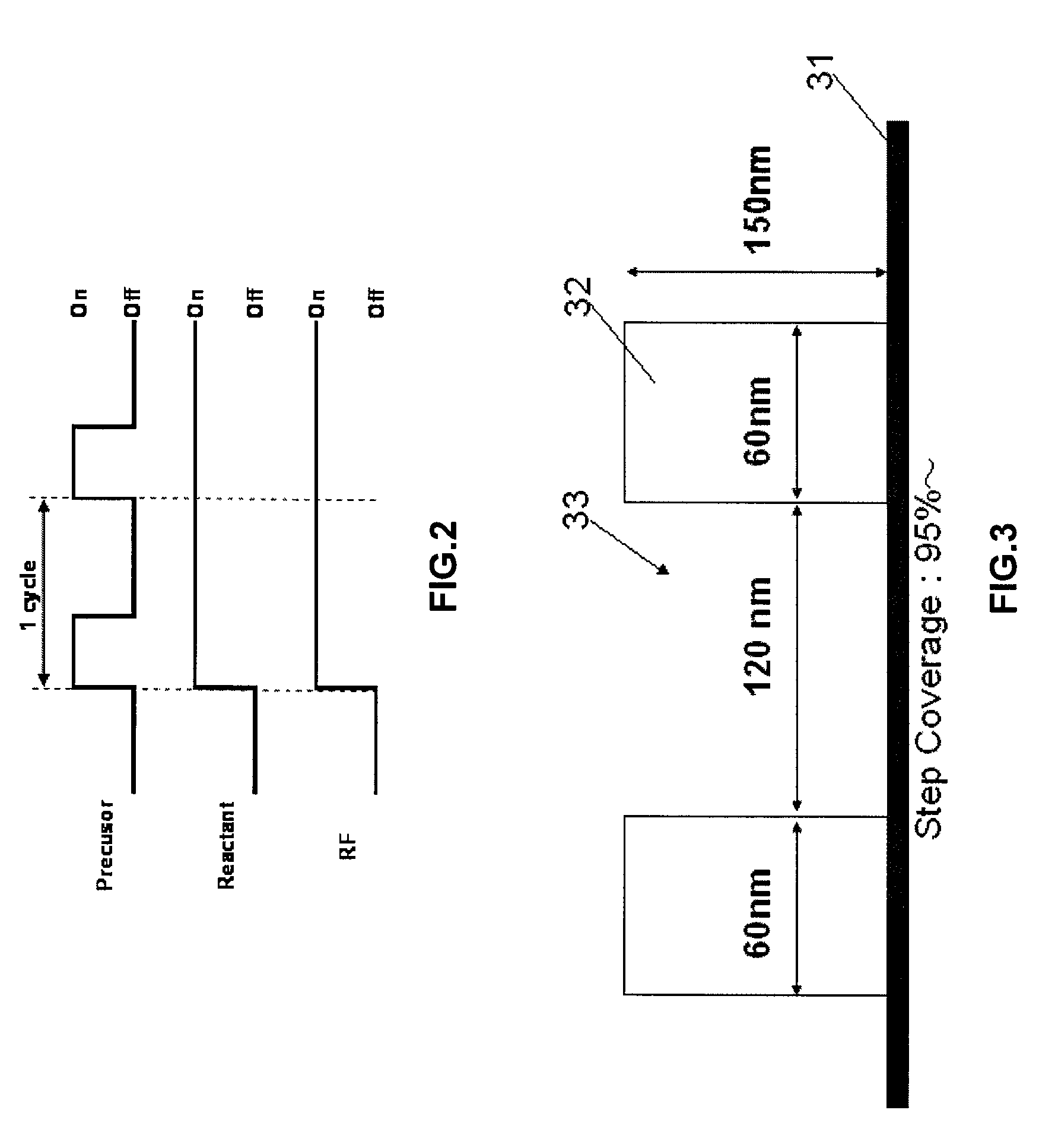

Method of Forming Insulation Film by Modified PEALD

ActiveUS20100124621A1Increase coverageImprove throughputSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringPhysical chemistry

Owner:ASM JAPAN

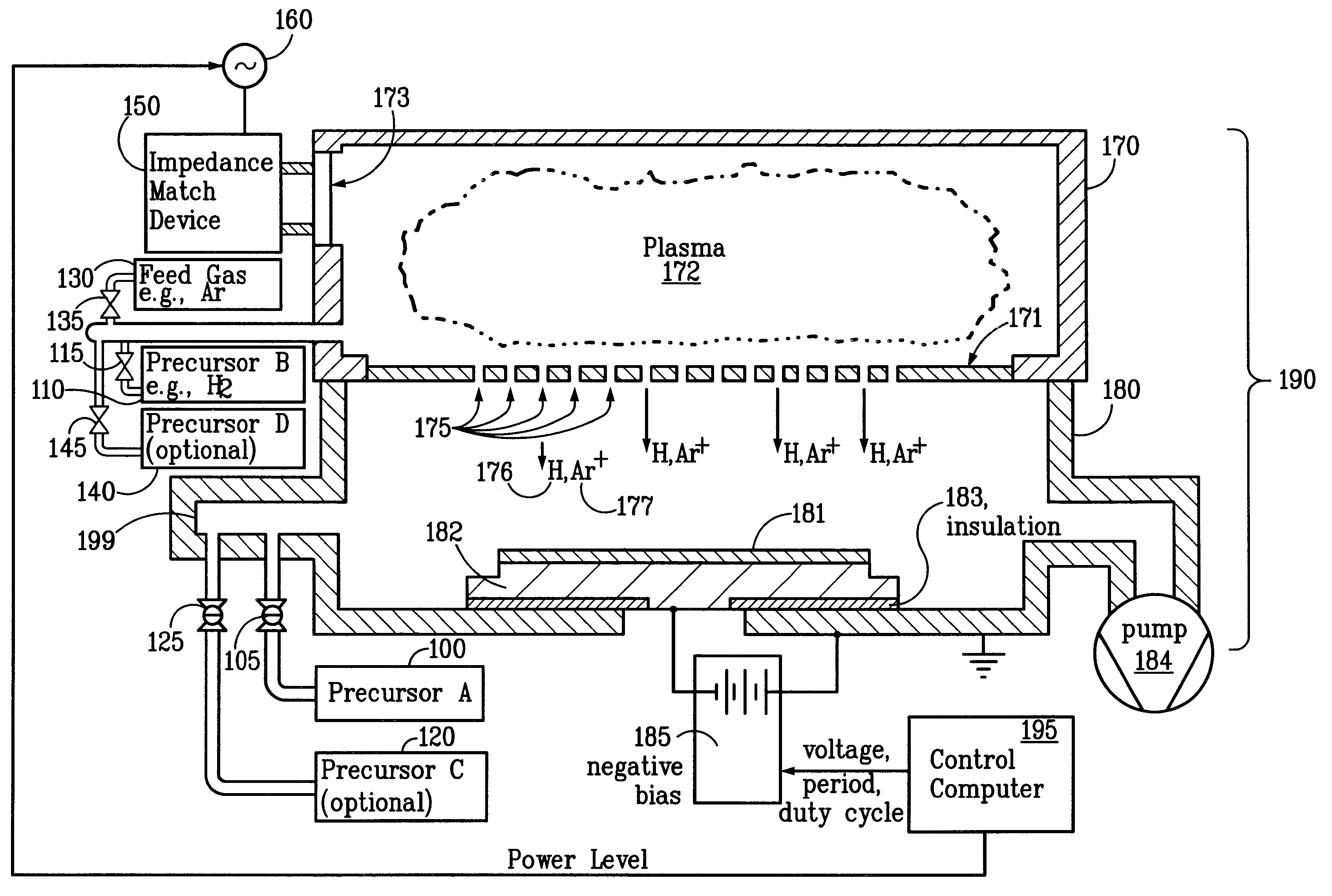

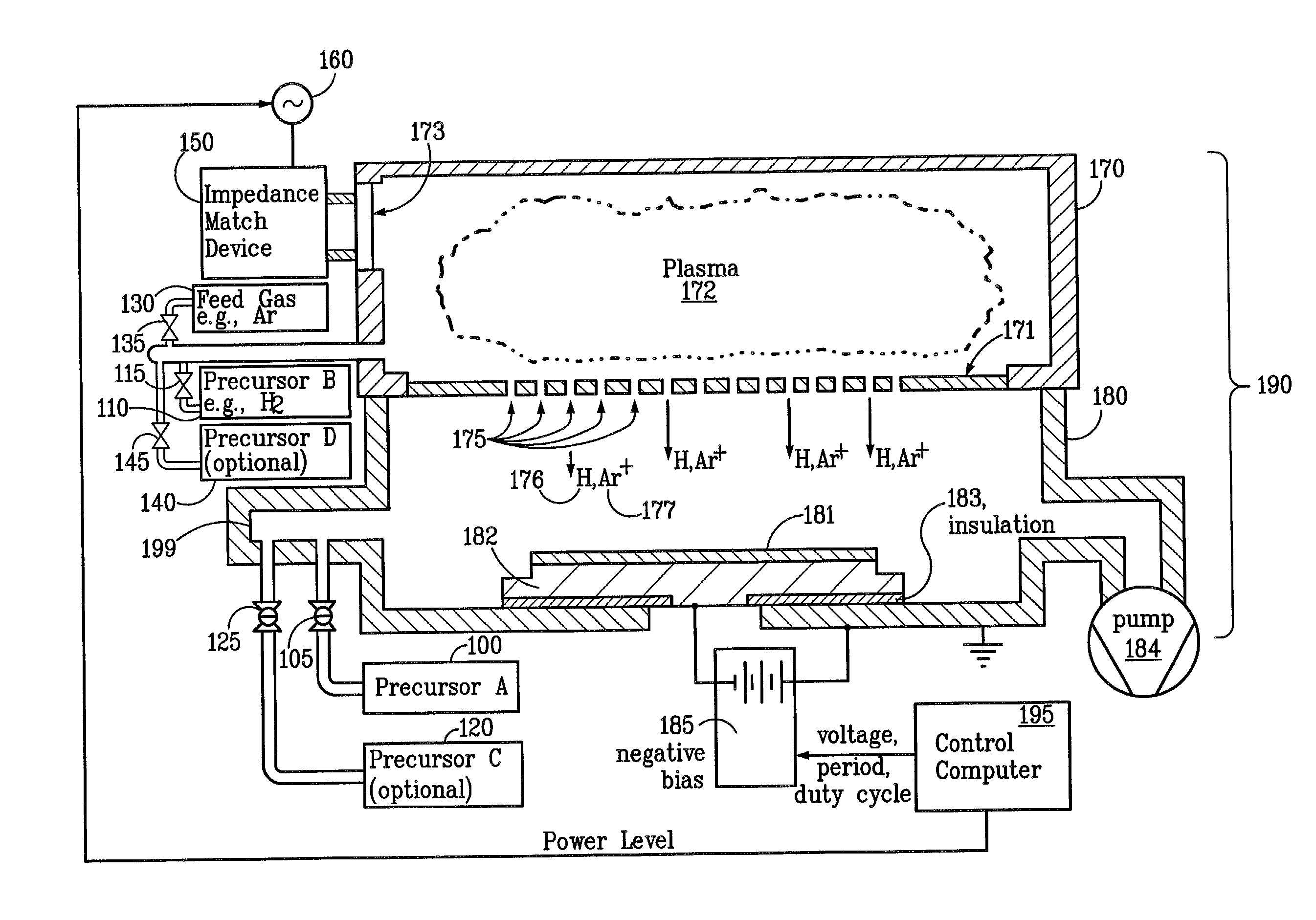

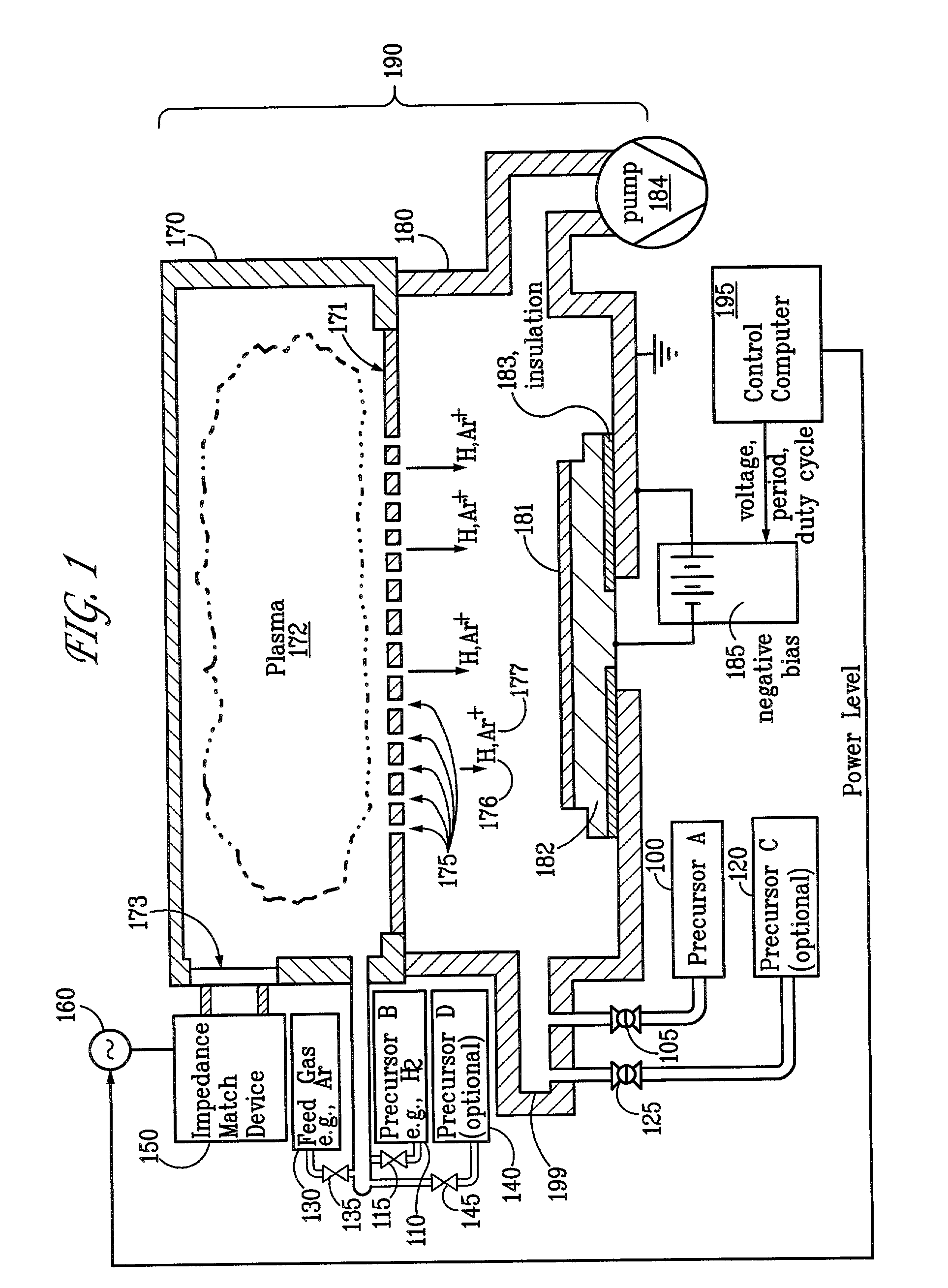

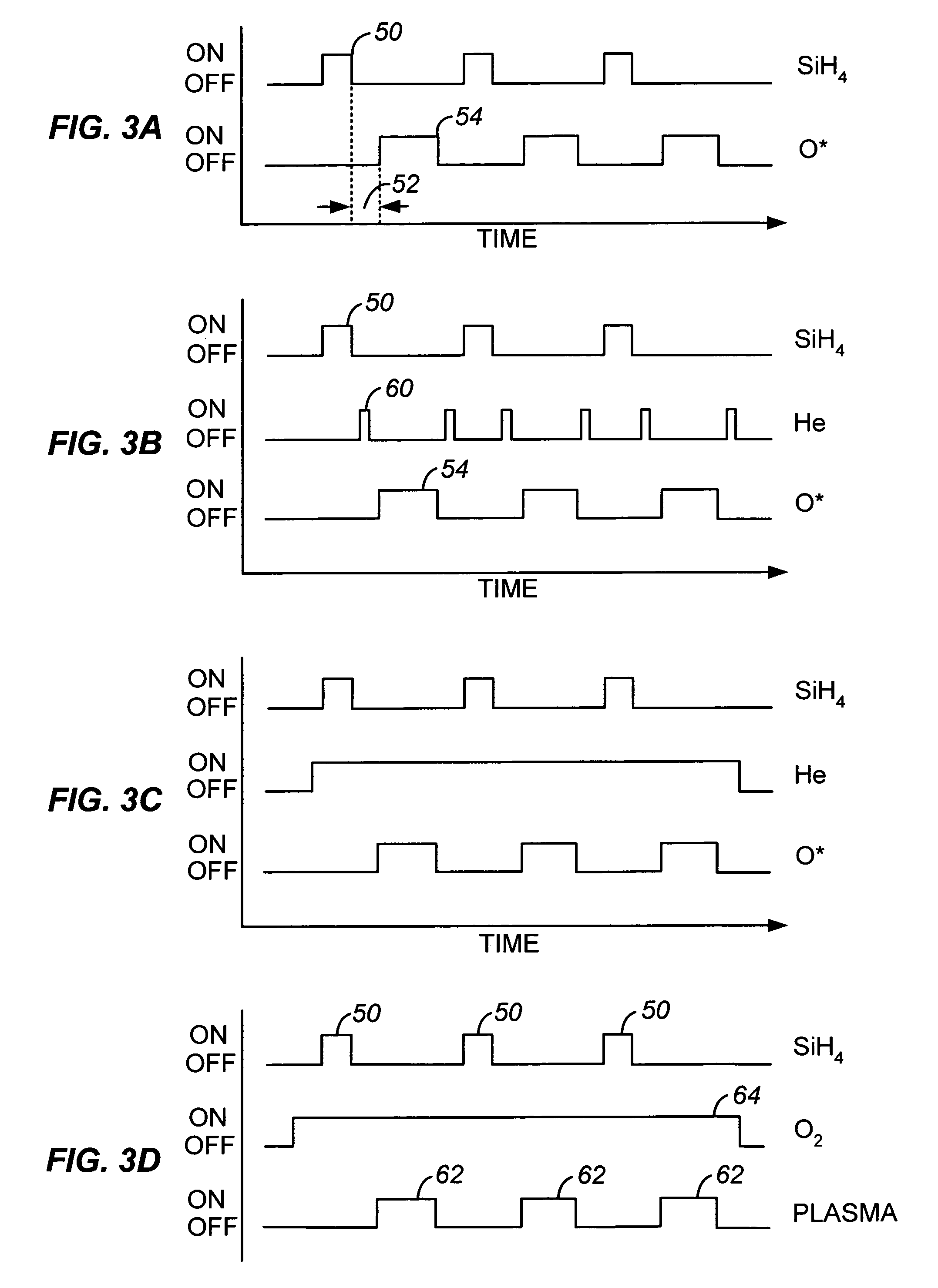

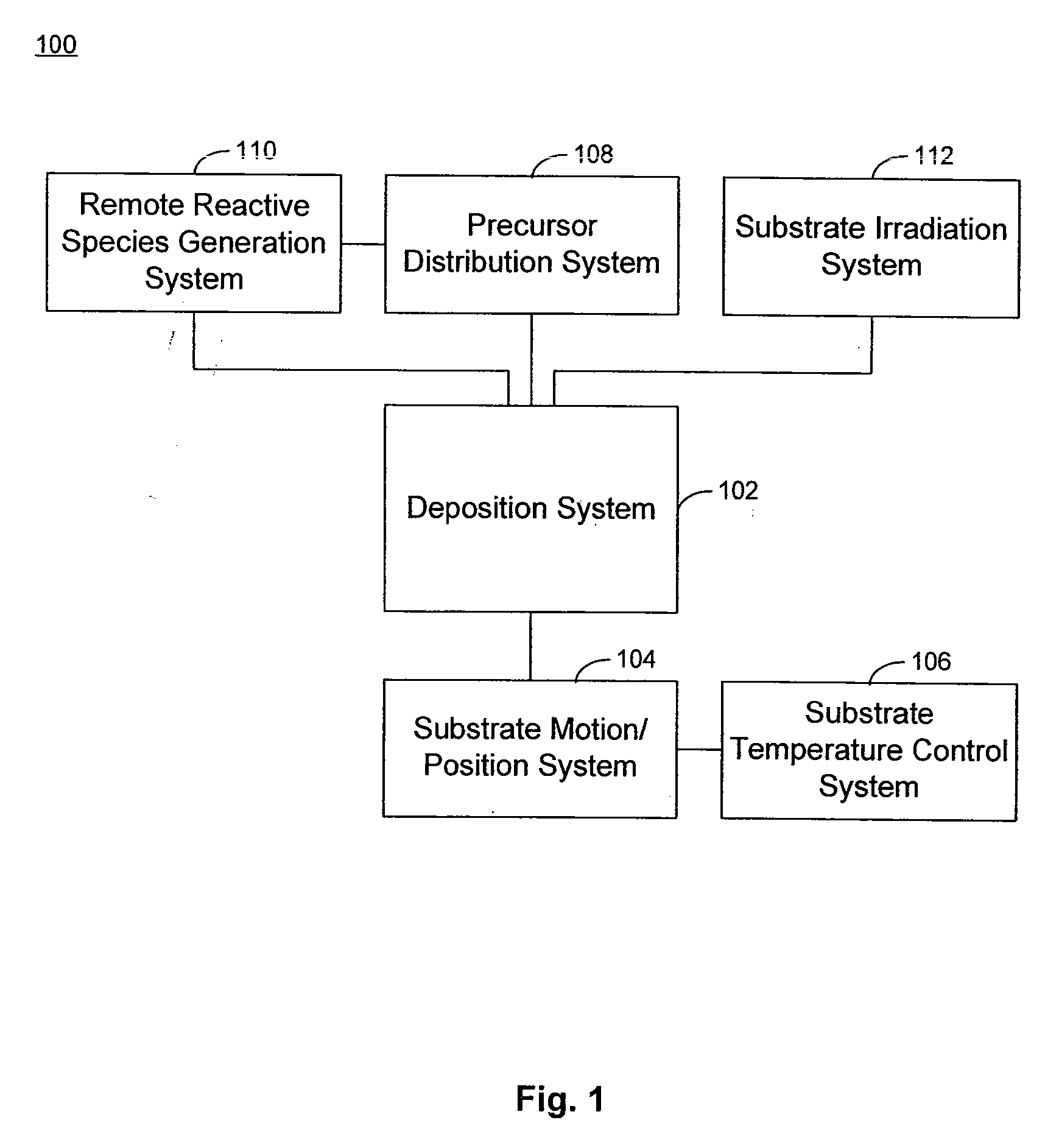

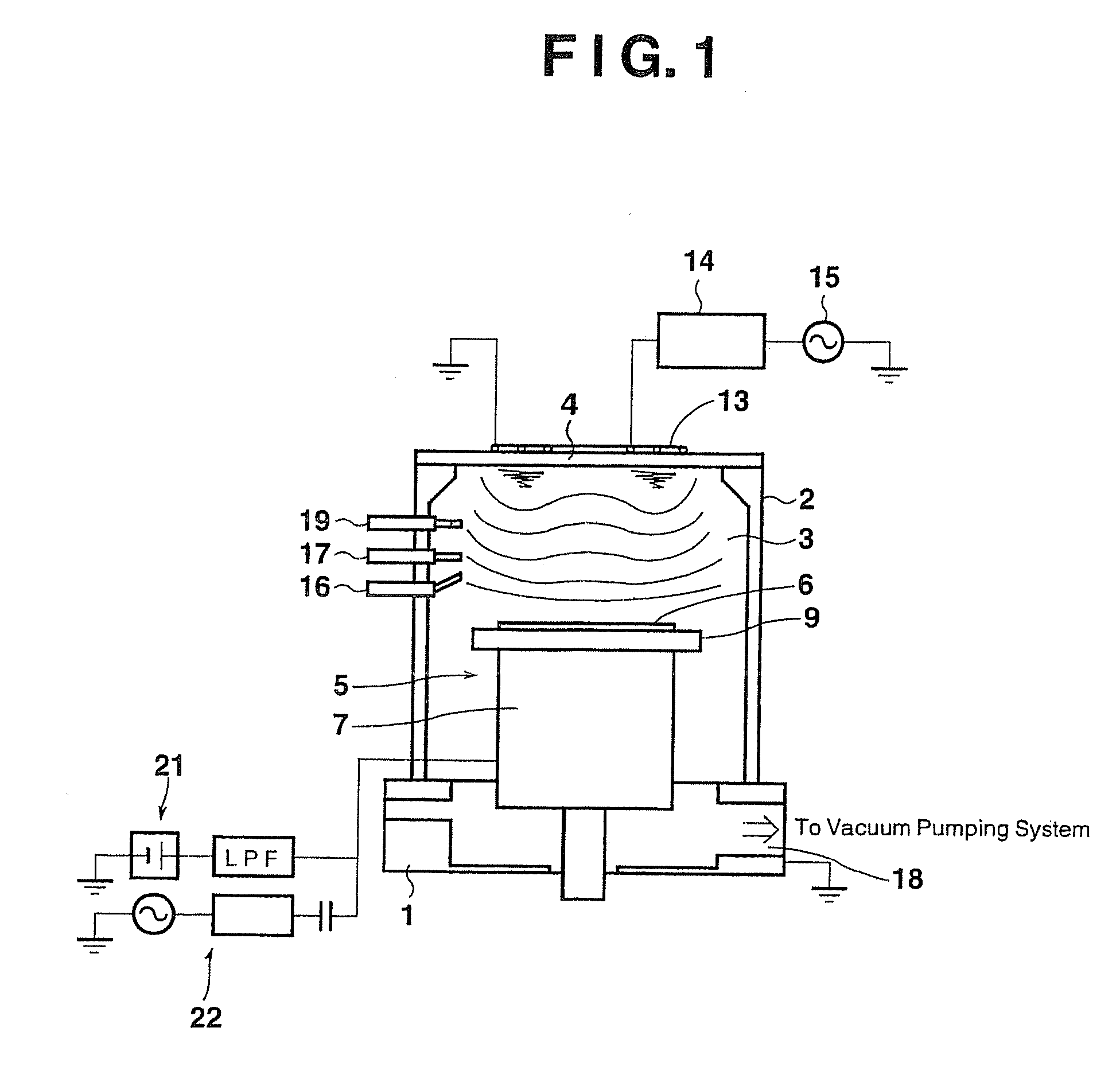

System and method for modulated ion-induced atomic layer deposition (MII-ALD)

InactiveUS20020104481A1Faster efficient meanSimple methodSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHigh densitySubject matter

The present invention relates to an enhanced sequential or non-sequential atomic layer deposition (ALD) apparatus and technique suitable for deposition of barrier layers, adhesion layers, seed layers, low dielectric constant (low-k) films, high dielectric constant (high-k) films, and other conductive, semi-conductive, and non-conductive films. This is accomplished by 1) providing a non-thermal or non-pyrolytic means of triggering the deposition reaction; 2) providing a means of depositing a purer film of higher density at lower temperatures; 3) providing a faster and more efficient means of modulating the deposition sequence and hence the overall process rate resulting in an improved deposition method; and, 4) providing a means of improved radical generation and delivery. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims. [37 C.F.R. § 1.72(b)].

Owner:ANGSTRON SYST

Atomic layer deposition method of depositing an oxide on a substrate

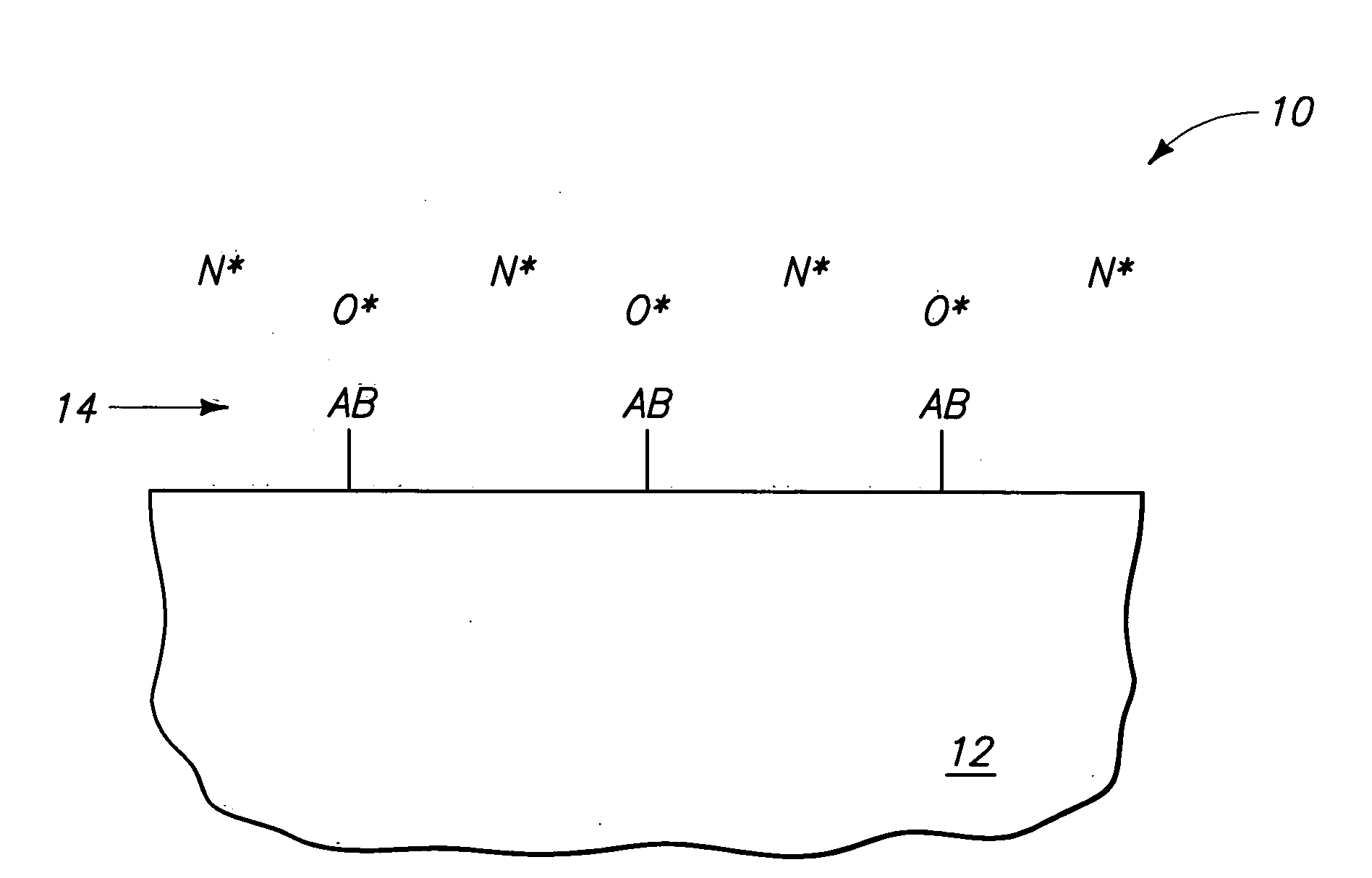

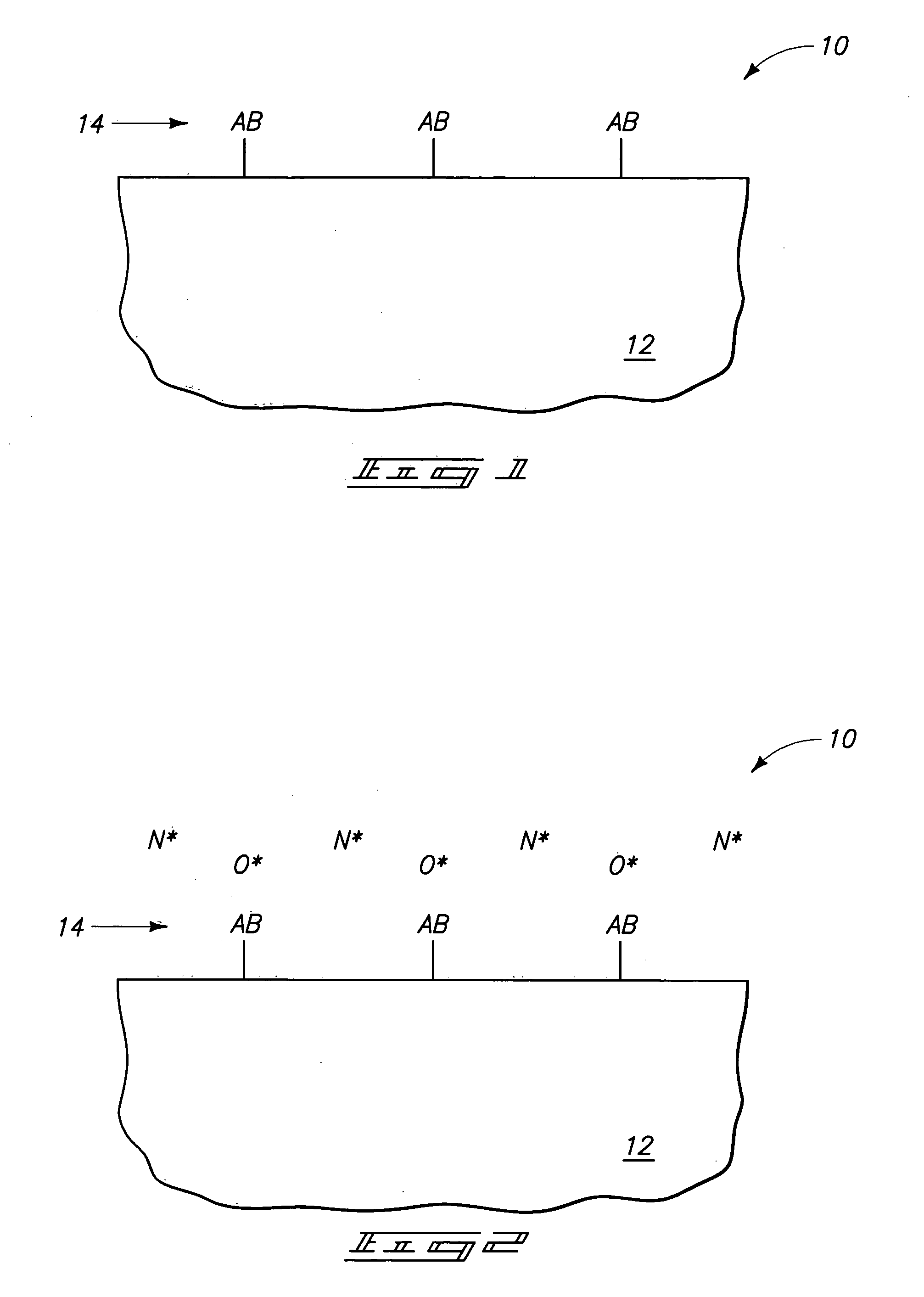

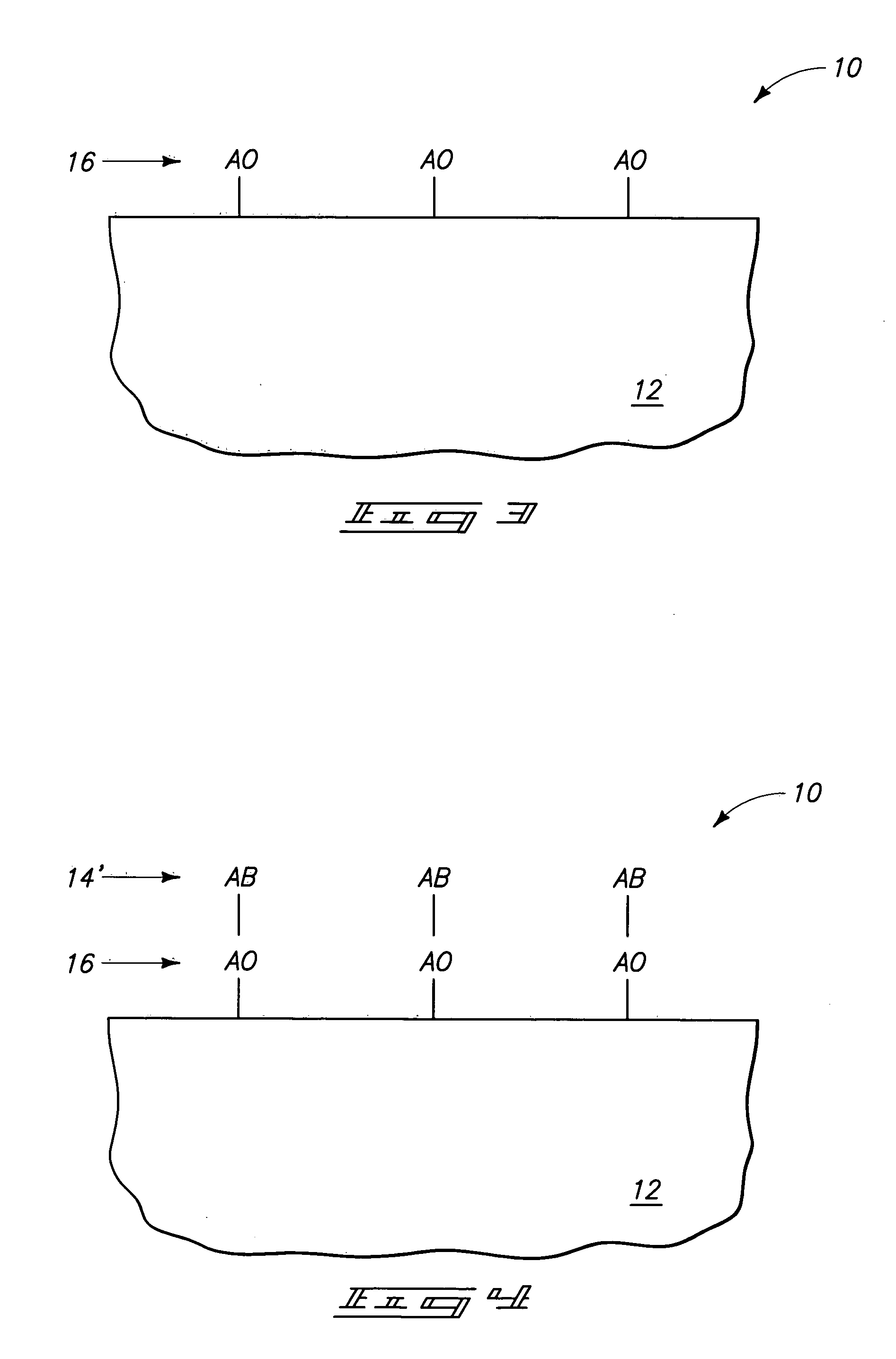

The invention includes atomic layer deposition methods of depositing an oxide on a substrate. In one implementation, a substrate is positioned within a deposition chamber. A first species is chemisorbed onto the substrate to form a first species monolayer within the deposition chamber from a gaseous precursor. The chemisorbed first species is contacted with remote plasma oxygen derived at least in part from at least one of O2 and O3 and with remote plasma nitrogen effective to react with the first species to form a monolayer comprising an oxide of a component of the first species monolayer. The chemisorbing and the contacting with remote plasma oxygen and with remote plasma nitrogen are successively repeated effective to form porous oxide on the substrate. Other aspects and implementations are contemplated.

Owner:MICRON TECH INC

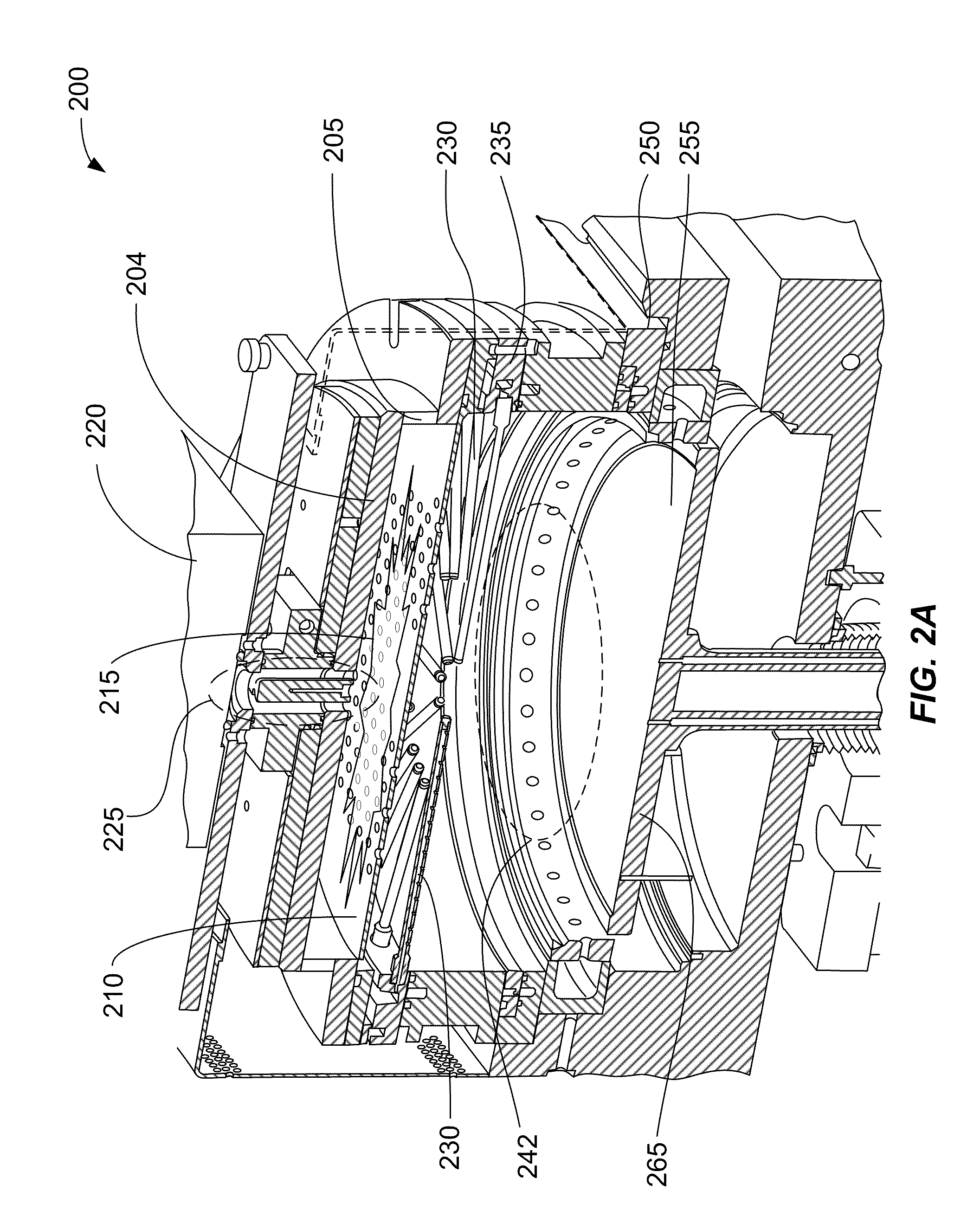

High-power dielectric seasoning for stable wafer-to-wafer thickness uniformity of dielectric CVD films

InactiveUS20060093756A1Liquid surface applicatorsSemiconductor/solid-state device manufacturingDielectricCleaning methods

A method for seasoning a deposition chamber wherein the chamber components and walls are densely coated with a material that does not contain carbon prior to deposition of an organo-silicon material on a substrate. An optional carbon-containing layer may be deposited therebetween. A chamber cleaning method using low energy plasma and low pressure to remove residue from internal chamber surfaces is provided and may be combined with the seasoning process.

Owner:APPLIED MATERIALS INC

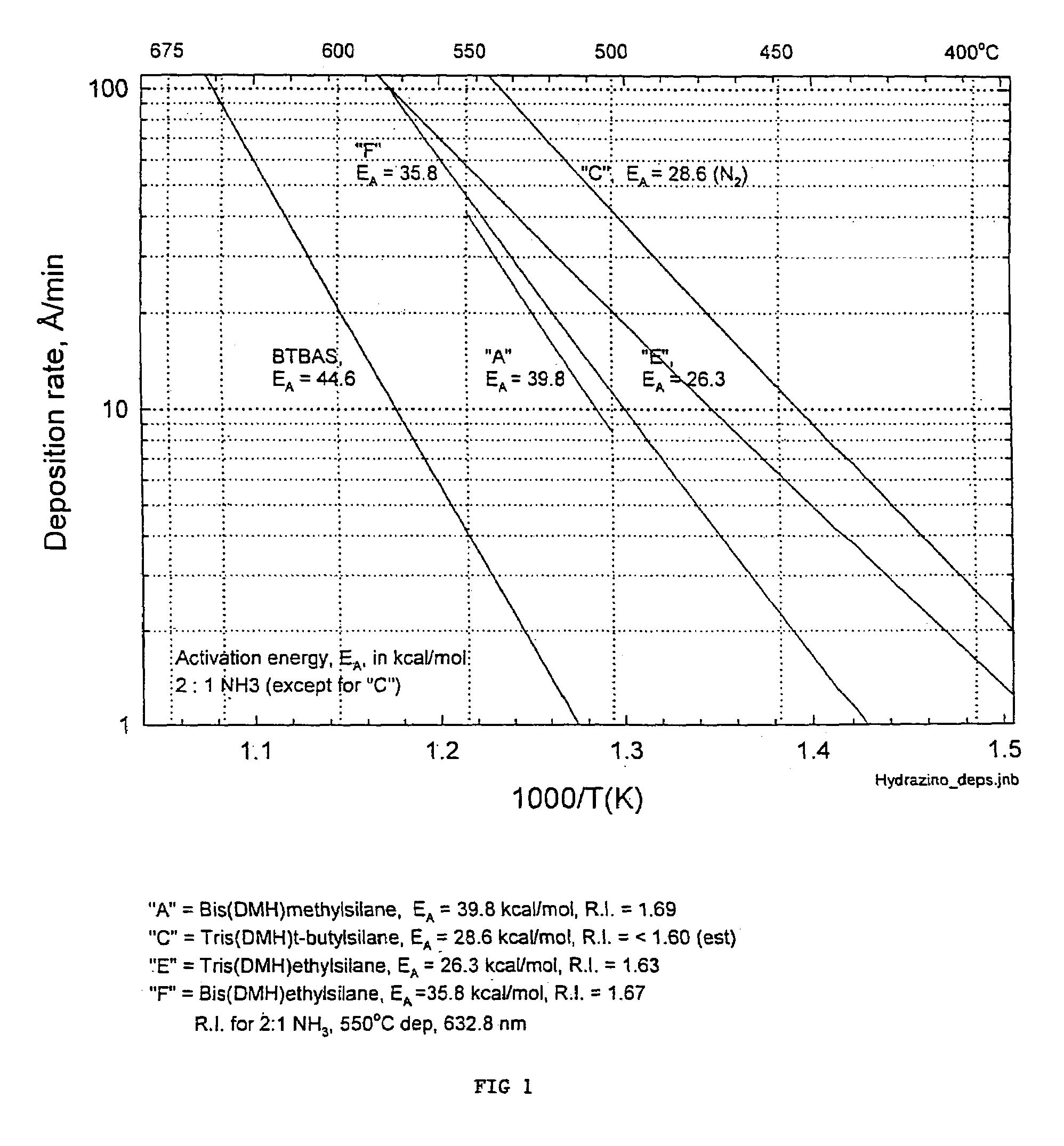

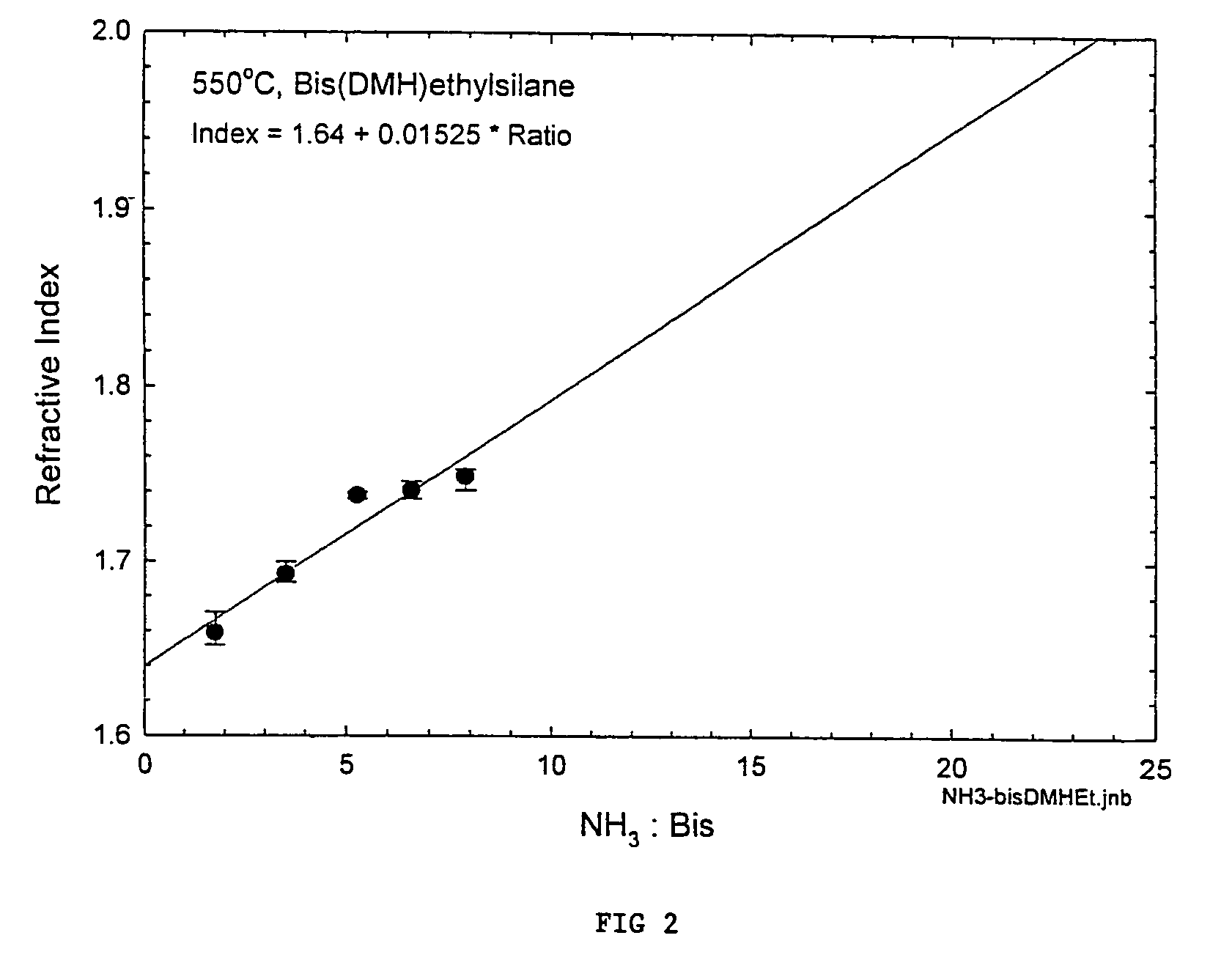

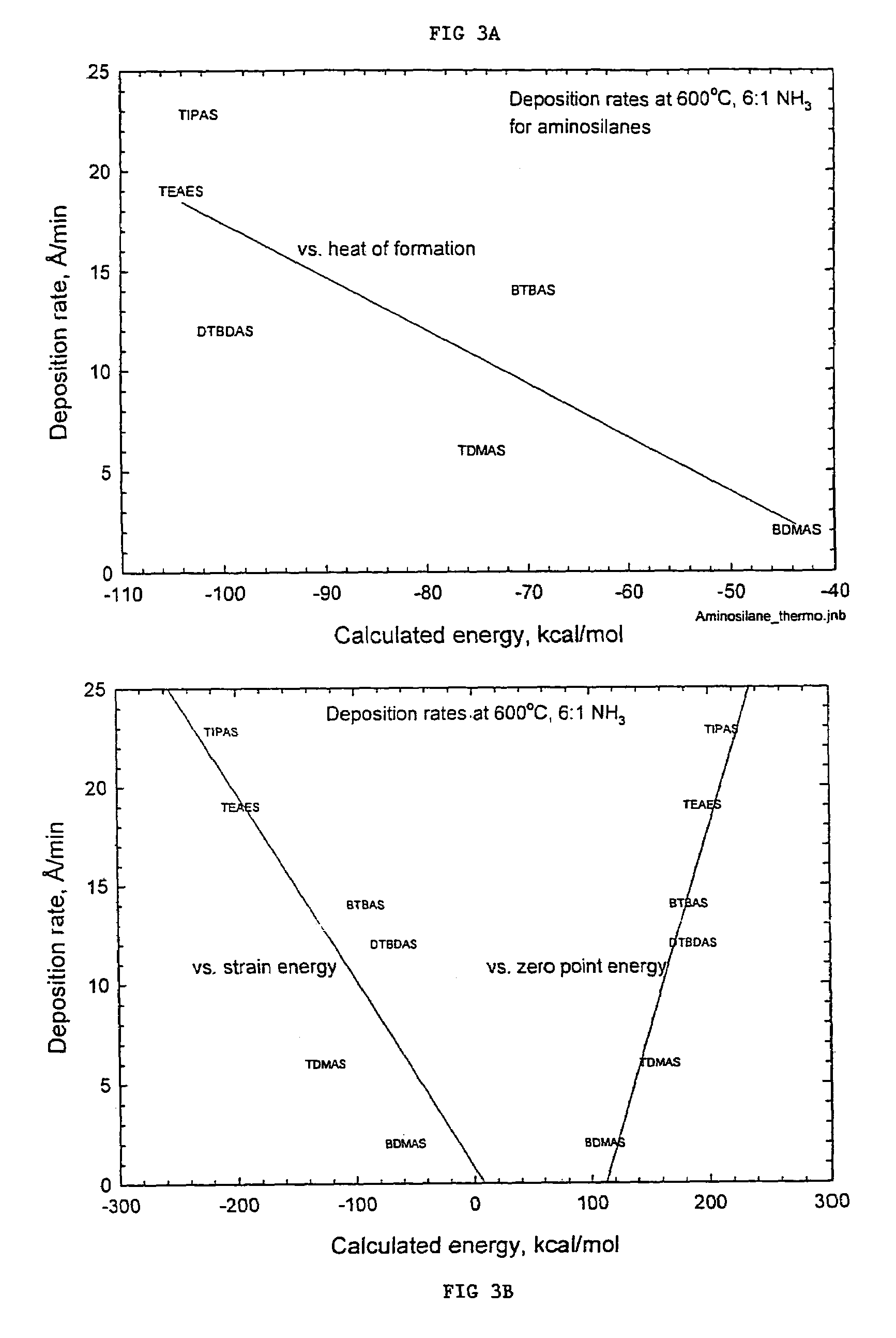

Precursors for depositing silicon containing films and processes thereof

Processes for precursors for silicon dielectric depositions of silicon nitride, silicon oxide and silicon oxynitride on a substrate using a hydrazinosilane of the formula:[R12N—NH]nSi(R2)4−nwhere each R1 is independently selected from alkyl groups of C1 to C6; each R2 is independently selected from the group consisting of hydrogen, alkyl, vinyl, allyl, and phenyl; and n=1–4. Some of the hydrazinosilanes are novel precursors.

Owner:VERSUM MATERIALS US LLC

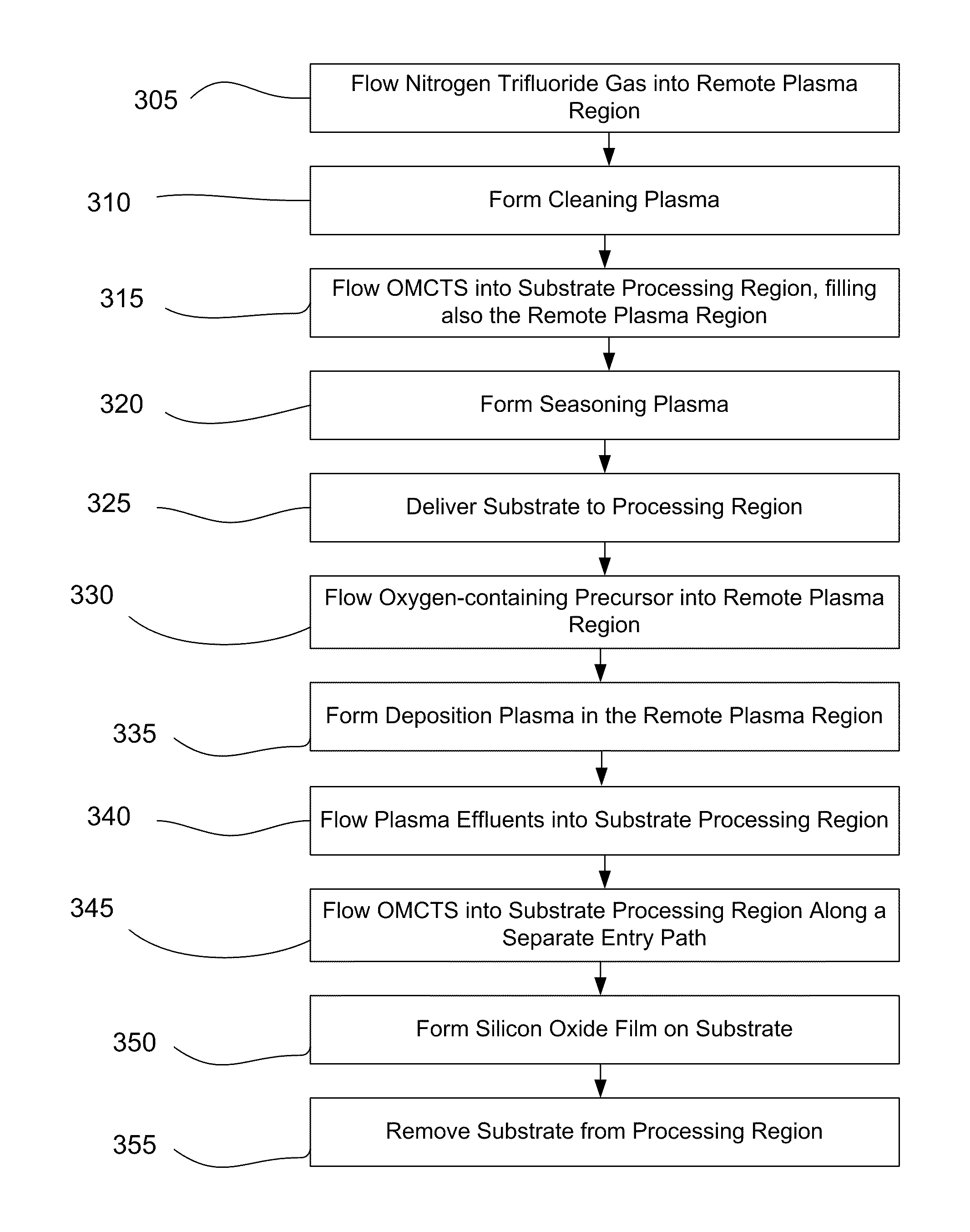

Remote plasma source seasoning

ActiveUS7989365B2Increase deposition rateImprove uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaDeposition process

Methods of seasoning a remote plasma system are described. The methods include the steps of flowing a silicon-containing precursor into a remote plasma region to deposit a silicon containing film on an interior surface of the remote plasma system. The methods reduce reactions with the seasoned walls during deposition processes, resulting in improved deposition rate, improved deposition uniformity and reduced defectivity during subsequent deposition.

Owner:APPLIED MATERIALS INC

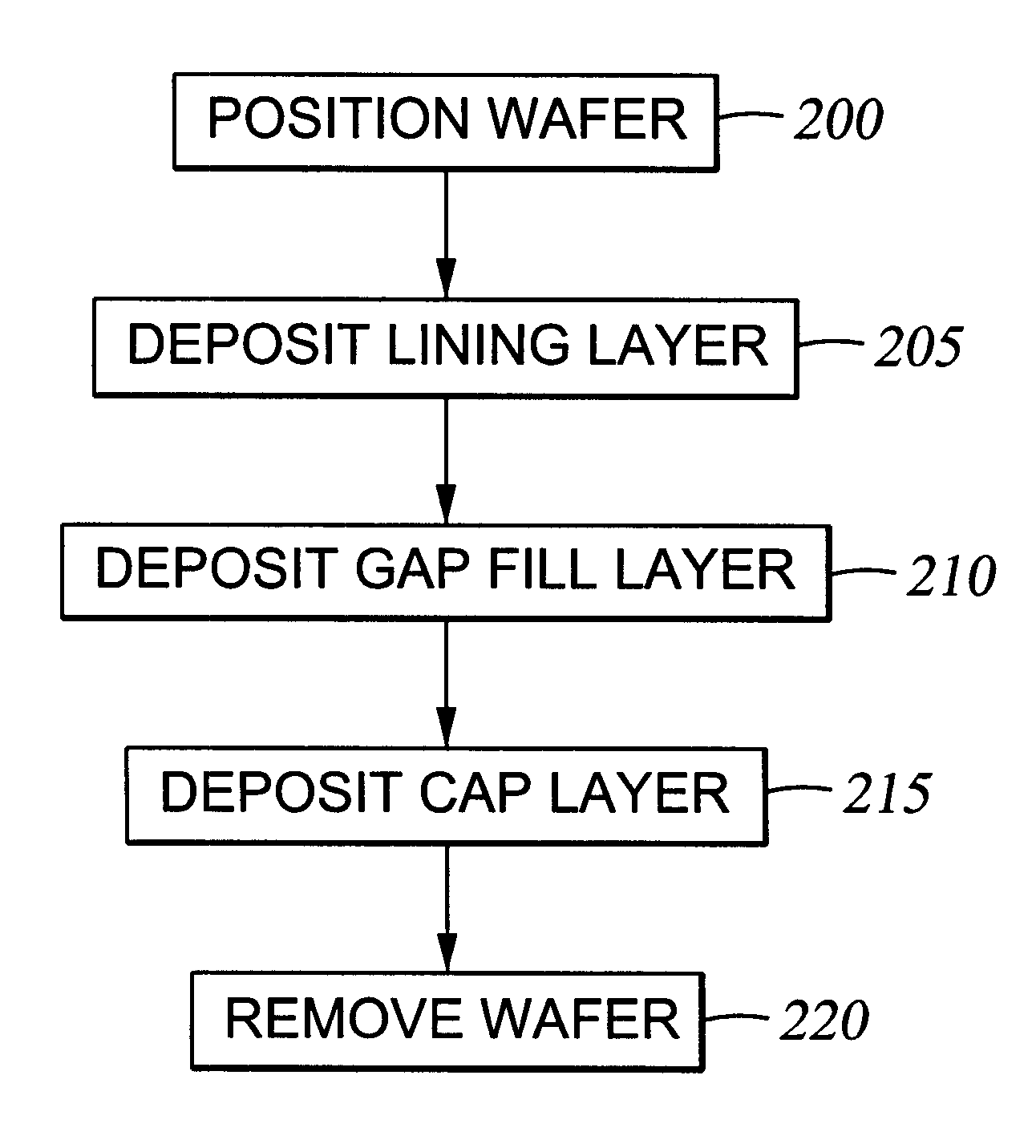

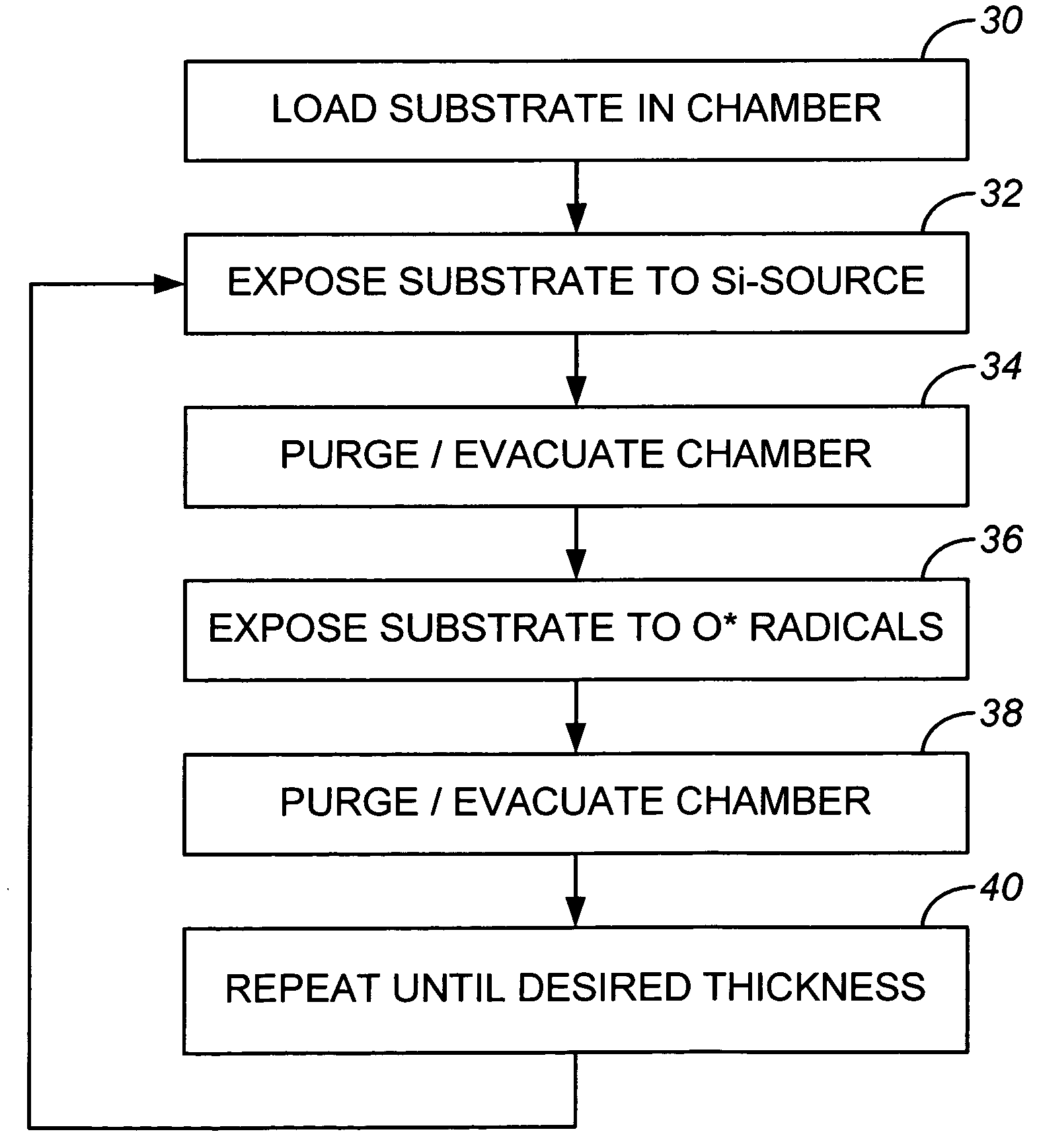

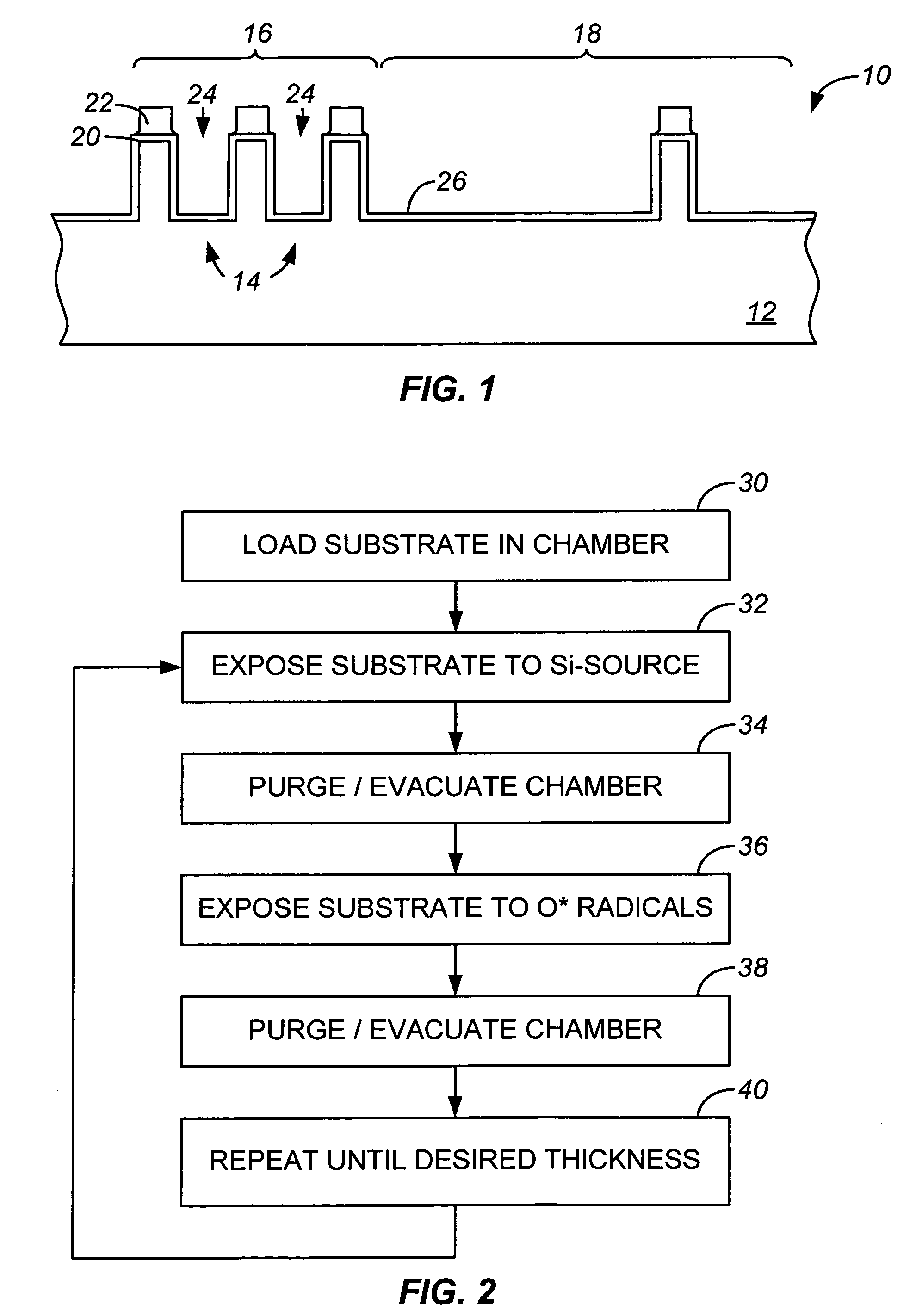

Sequential gas flow oxide deposition technique

A method of depositing a silica glass insulating film over a substrate. In one embodiment the method comprises exposing the substrate to a silicon-containing reactant introduced into a chamber in which the substrate is disposed such that one or more layers of the silicon-containing reactant are adsorbed onto the substrate; purging or evacuating the chamber of the silicon-containing reactant; converting the silicon-containing reactant into a silica glass insulating compound by exposing the substrate to oxygen radicals formed from a second reactant while biasing the substrate to promote a sputtering effect, wherein an average atomic mass of all atomic constituents in the second reactant is less than or equal to an average atomic mass of oxygen; and repeating the exposing, purging / evacuating and exposing sequence a plurality of times until a desired film thickness is reached.

Owner:APPLIED MATERIALS INC

Remote plasma source seasoning

ActiveUS20110045676A1Increase deposition rateReduce defectsElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaDeposition process

Methods of seasoning a remote plasma system are described. The methods include the steps of flowing a silicon-containing precursor into a remote plasma region to deposit a silicon containing film on an interior surface of the remote plasma system. The methods reduce reactions with the seasoned walls during deposition processes, resulting in improved deposition rate, improved deposition uniformity and reduced defectivity during subsequent deposition.

Owner:APPLIED MATERIALS INC

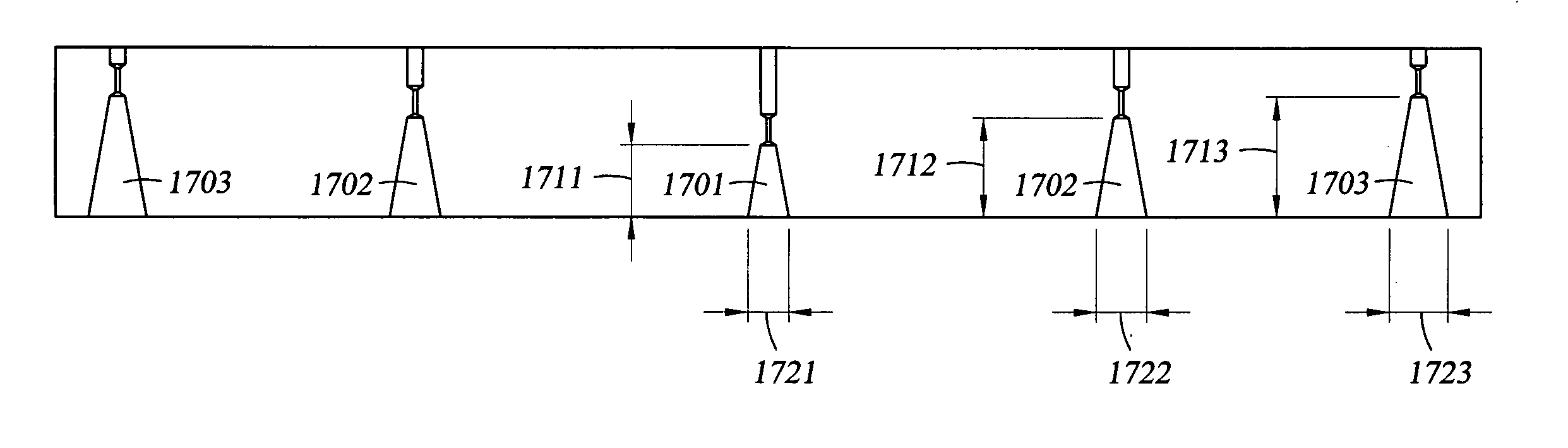

Plasma uniformity control by gas diffuser curvature

ActiveUS20060228496A1Improve thickness uniformityImprove filmElectric discharge tubesSemiconductor/solid-state device manufacturingGaseous diffusionAmorphous silicon

Embodiments of a gas distribution plate for distributing gas in a processing chamber are provided. In one embodiment, a gas distribution assembly for a plasma processing chamber comprises a diffuser plate with gas passages passing between its upstream and downstream sides and hollow cathode cavities at the downstream side of the gas passages. The downstream side of the diffuser plate has a curvature to improve the thickness uniformity and film property uniformity of thin films deposited by PECVD, particularly SiN and amorphous silicon films. The curvature is preferably described by an arc of a circle or ellipse, the apex thereof located at the center point of the diffuser plate. In one aspect, the hollow cathode cavity volume density, surface area density, or the cavity density of the diffuser increases from the center of the diffuser to the outer edge. Methods for manufacturing such a diffuser plate are also provided.

Owner:APPLIED MATERIALS INC

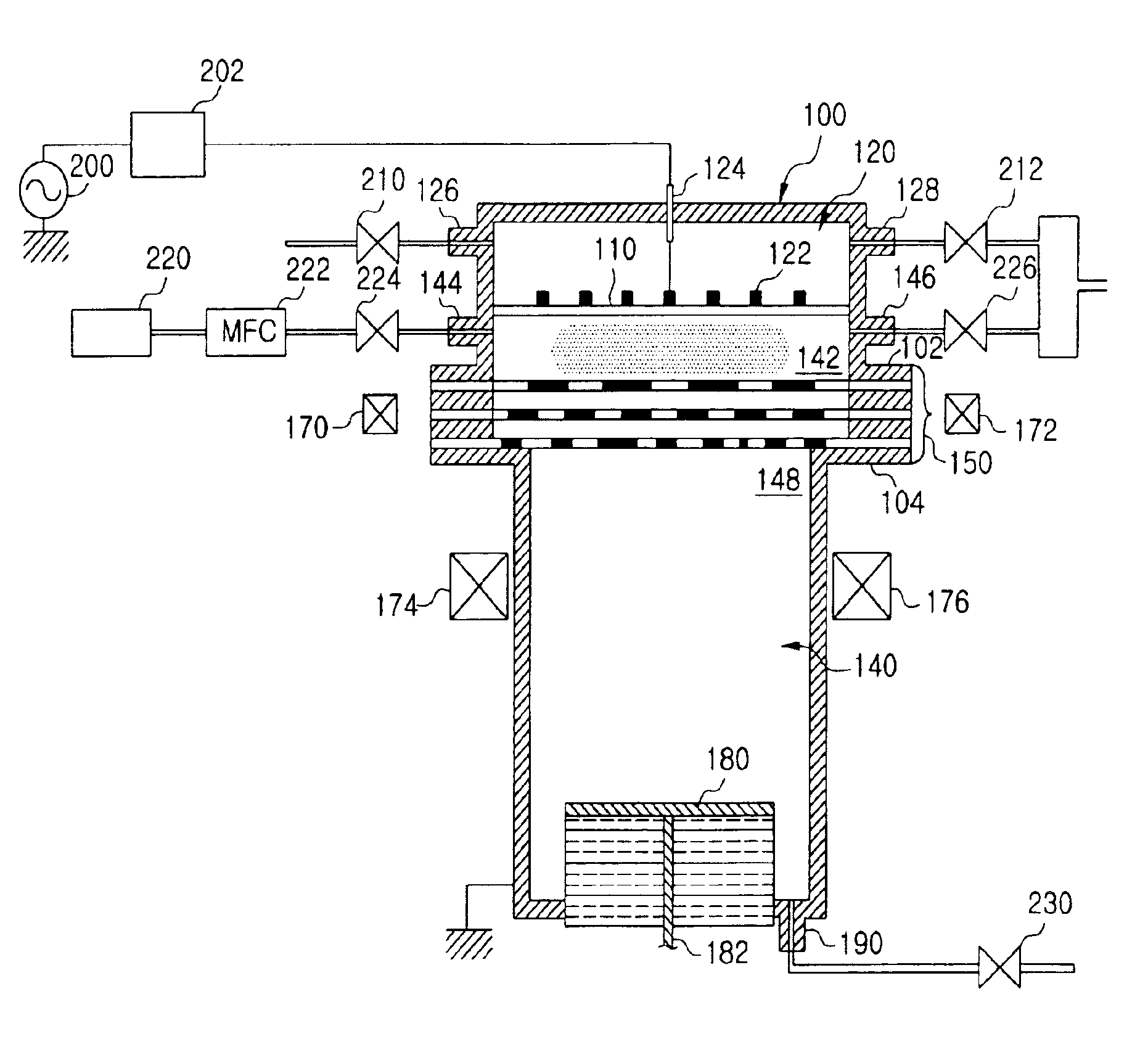

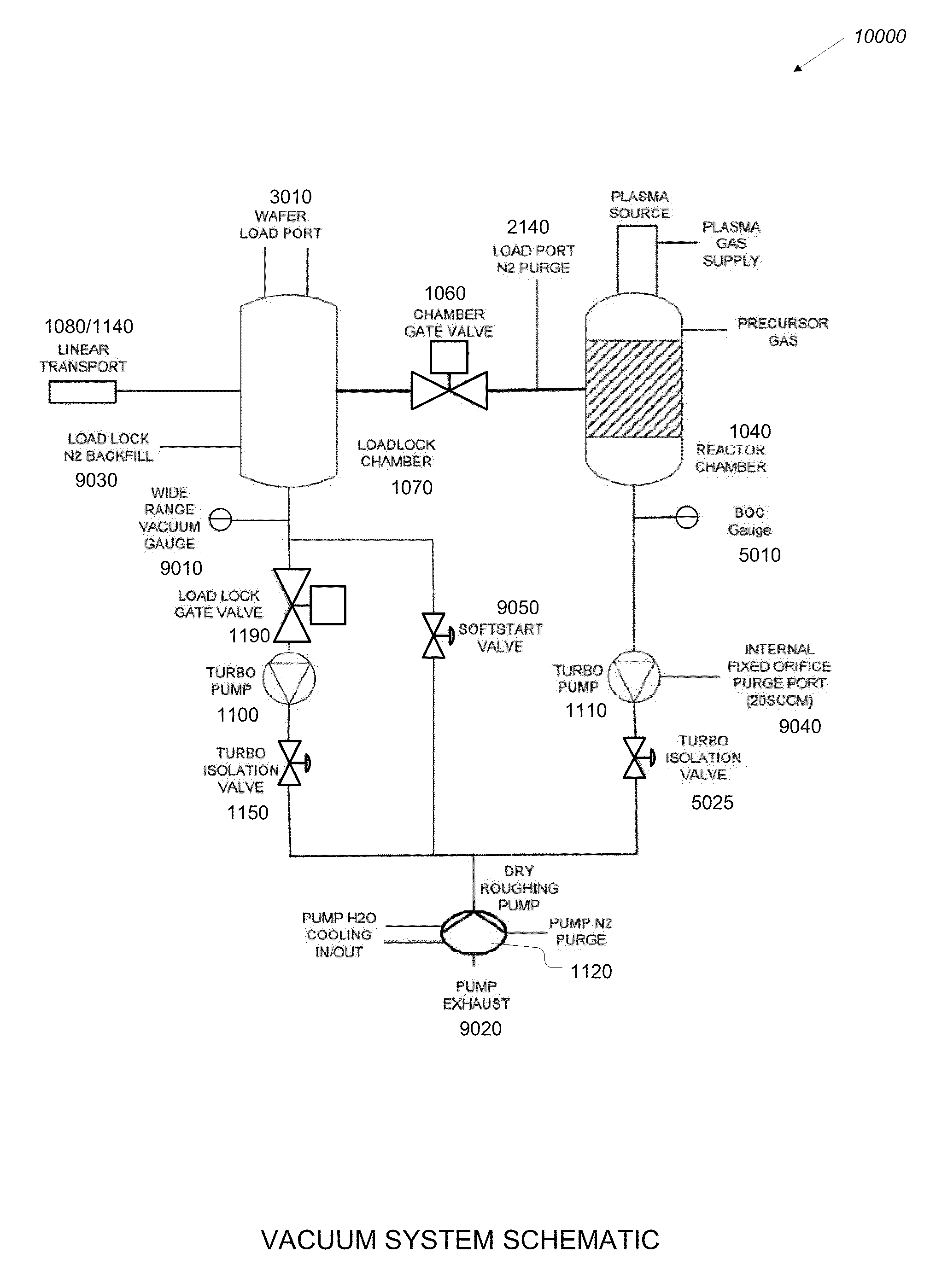

Apparatus for thermal and plasma enhanced vapor deposition and method of operating

InactiveUS20070116873A1Reduce pollutionElectric discharge tubesSemiconductor/solid-state device manufacturingGas phaseProcess engineering

A method, computer readable medium, and system for vapor deposition on a substrate that maintain a first assembly of the vapor deposition system at a first temperature, maintain a second assembly of the vapor deposition system at a reduced temperature lower than the first temperature, dispose the substrate in a process space of the first assembly that is vacuum isolated from a transfer space in the second assembly, and deposit a material on the substrate. As such, the system includes a first assembly having a process space configured to facilitate material deposition, a second assembly coupled to the first assembly and having a transfer space to facilitate transfer of the substrate into and out of the deposition system, a substrate stage connected to the second assembly and configured to support the substrate, and a sealing assembly configured to separate the process space from the transfer space. The first assembly is configured to be maintained at a first temperature and the second assembly is configured to be maintained at a reduced temperature lower than the first temperature.

Owner:TOKYO ELECTRON LTD

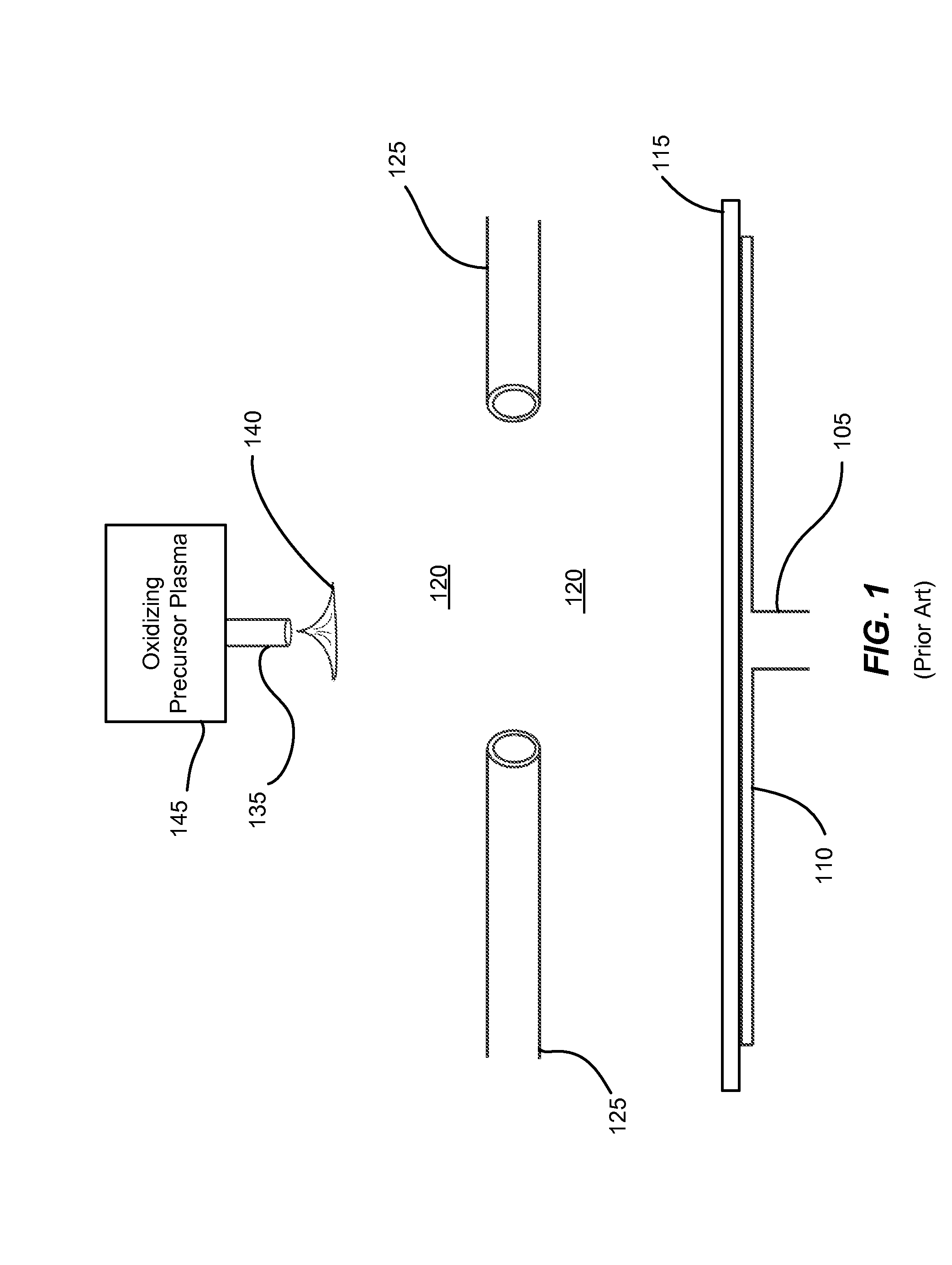

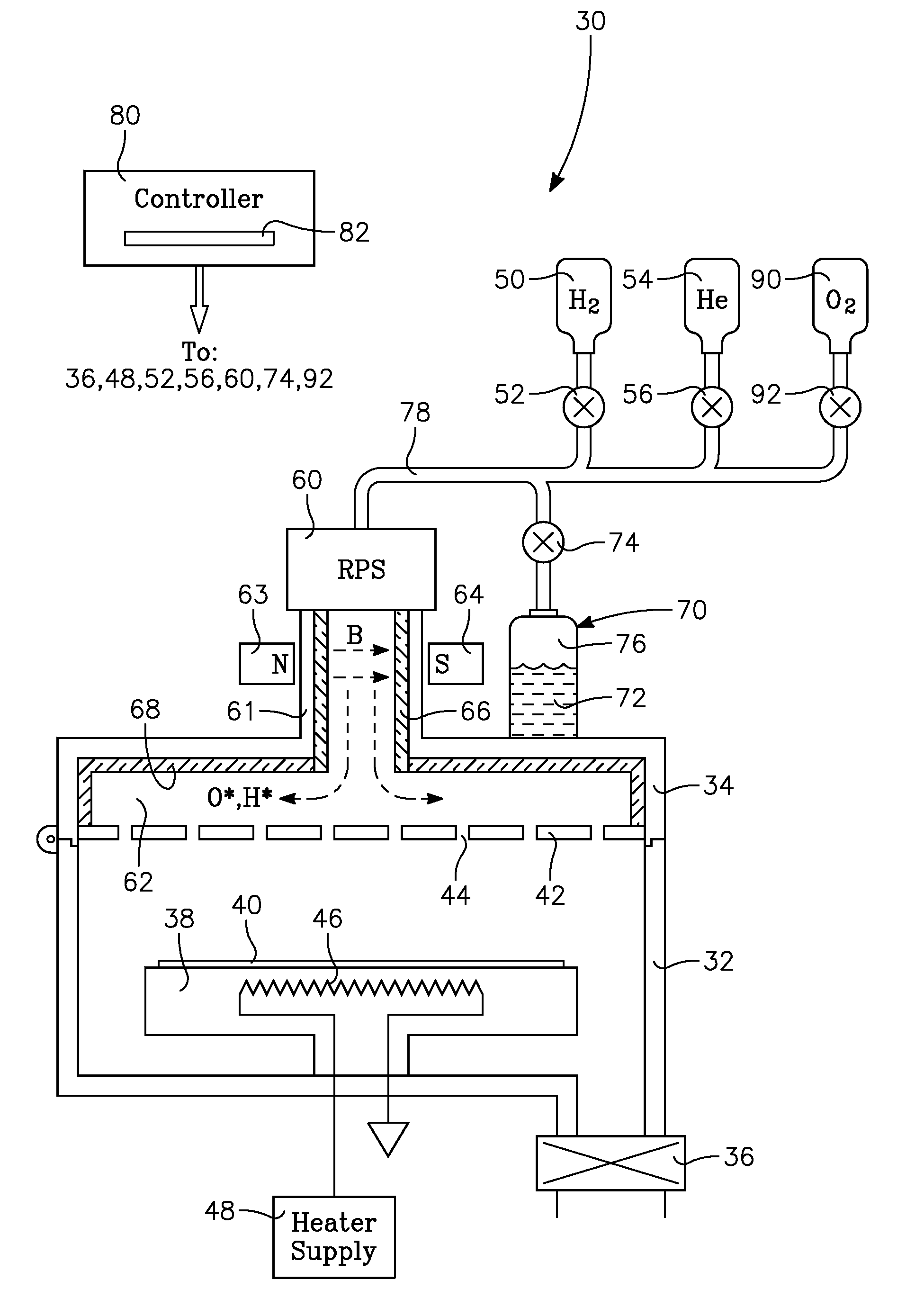

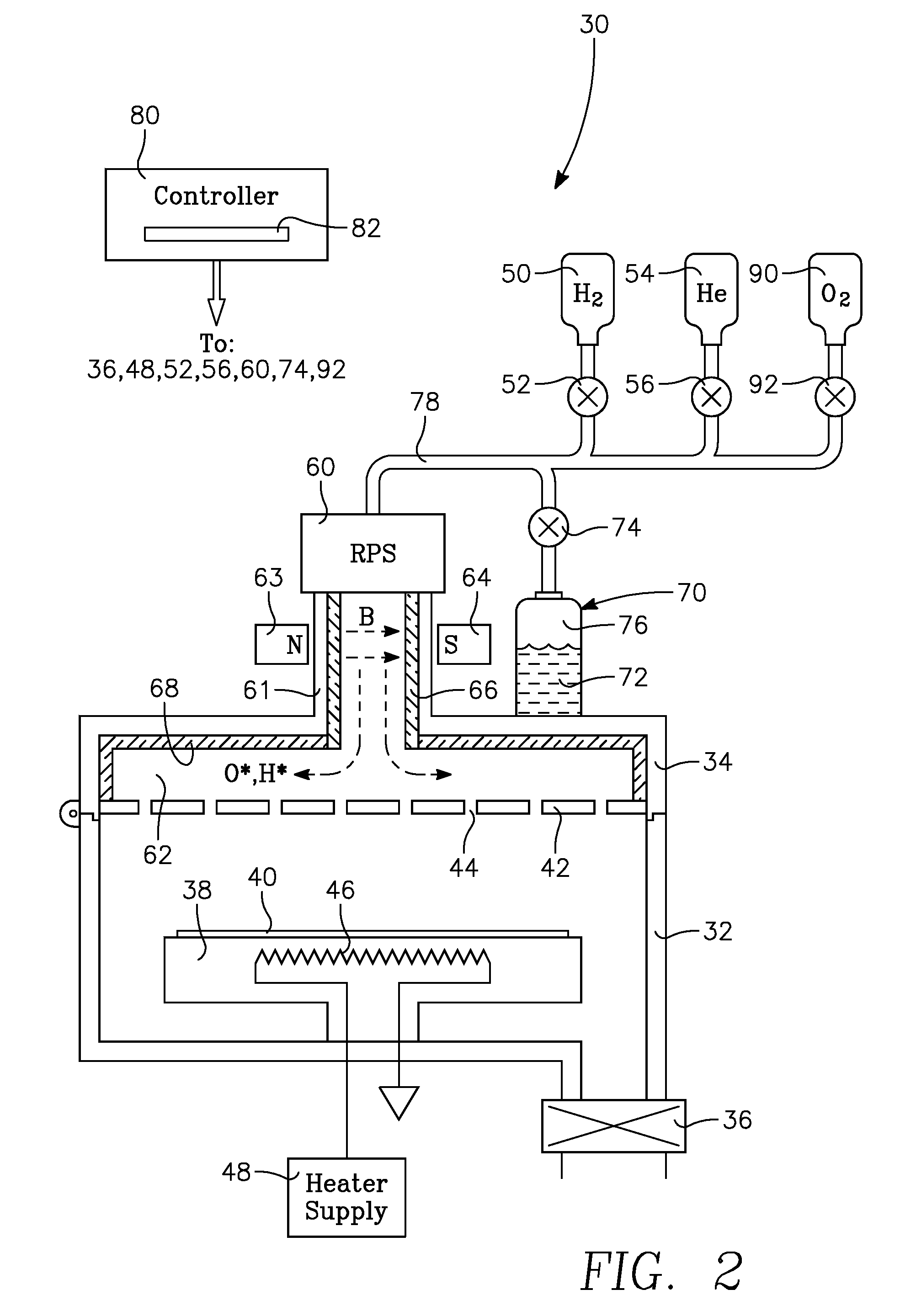

Remote Plasma Source for Pre-Treatment of Substrates Prior to Deposition

ActiveUS20090017227A1Electric discharge tubesSemiconductor/solid-state device manufacturingOxygenRefractory metals

A plasma processing chamber particularly useful for pre-treating low-k dielectric films and refractory metal films subject to oxidation prior to deposition of other layers. A remote plasma source (RPS) excites a processing gas into a plasma and delivers it through a supply tube to a manifold in back of a showerhead faceplate. The chamber is configured for oxidizing and reducing plasmas in the same or different processes when oxygen and hydrogen are selectively supplied to the RPS. The supply tube and showerhead may be formed of dielectric oxides which may be passivated by a water vapor plasma from the remote plasma source. In one novel process, a protective hydroxide coating is formed on refractory metals by alternating neutral plasmas of hydrogen and oxygen.

Owner:APPLIED MATERIALS INC

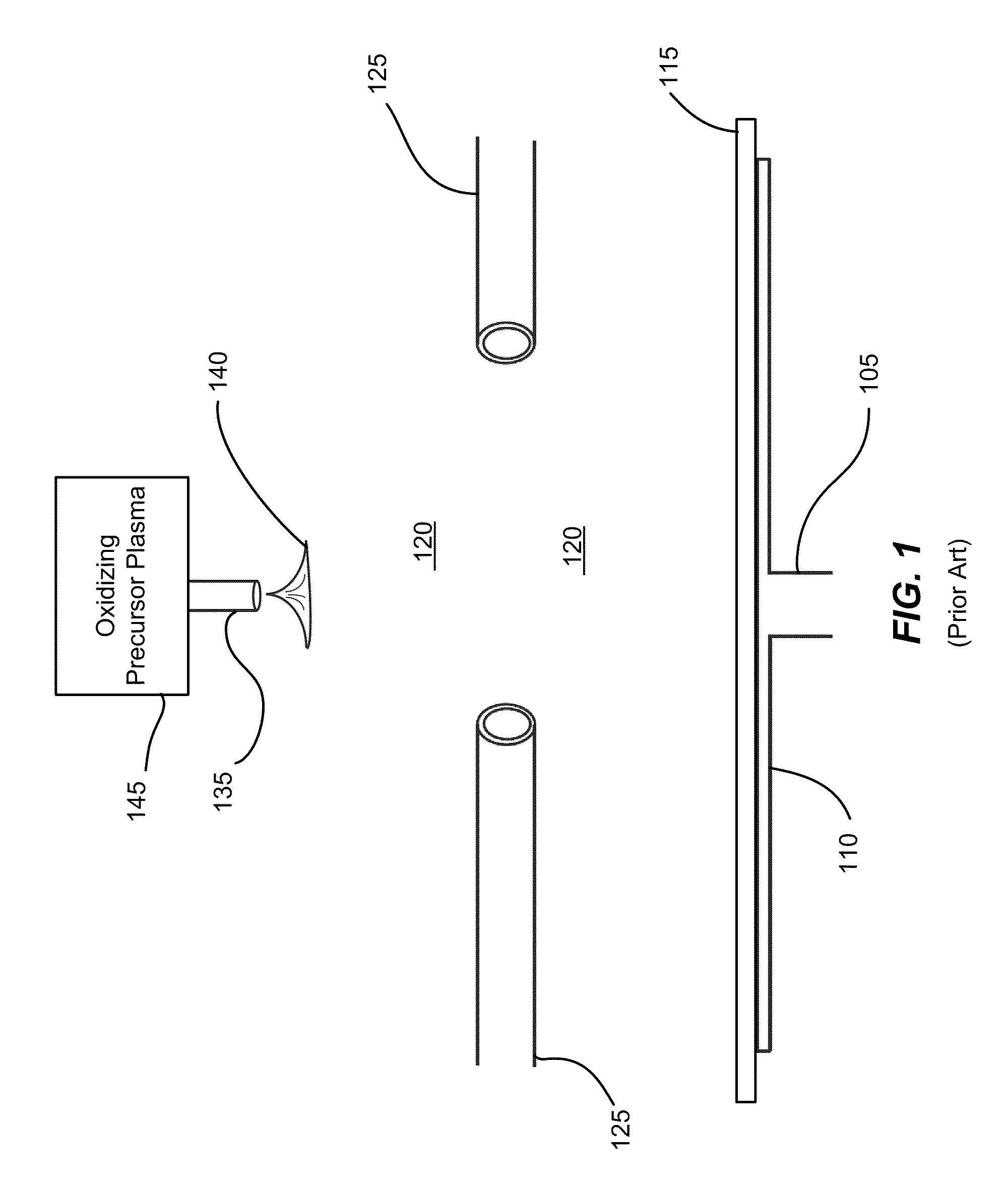

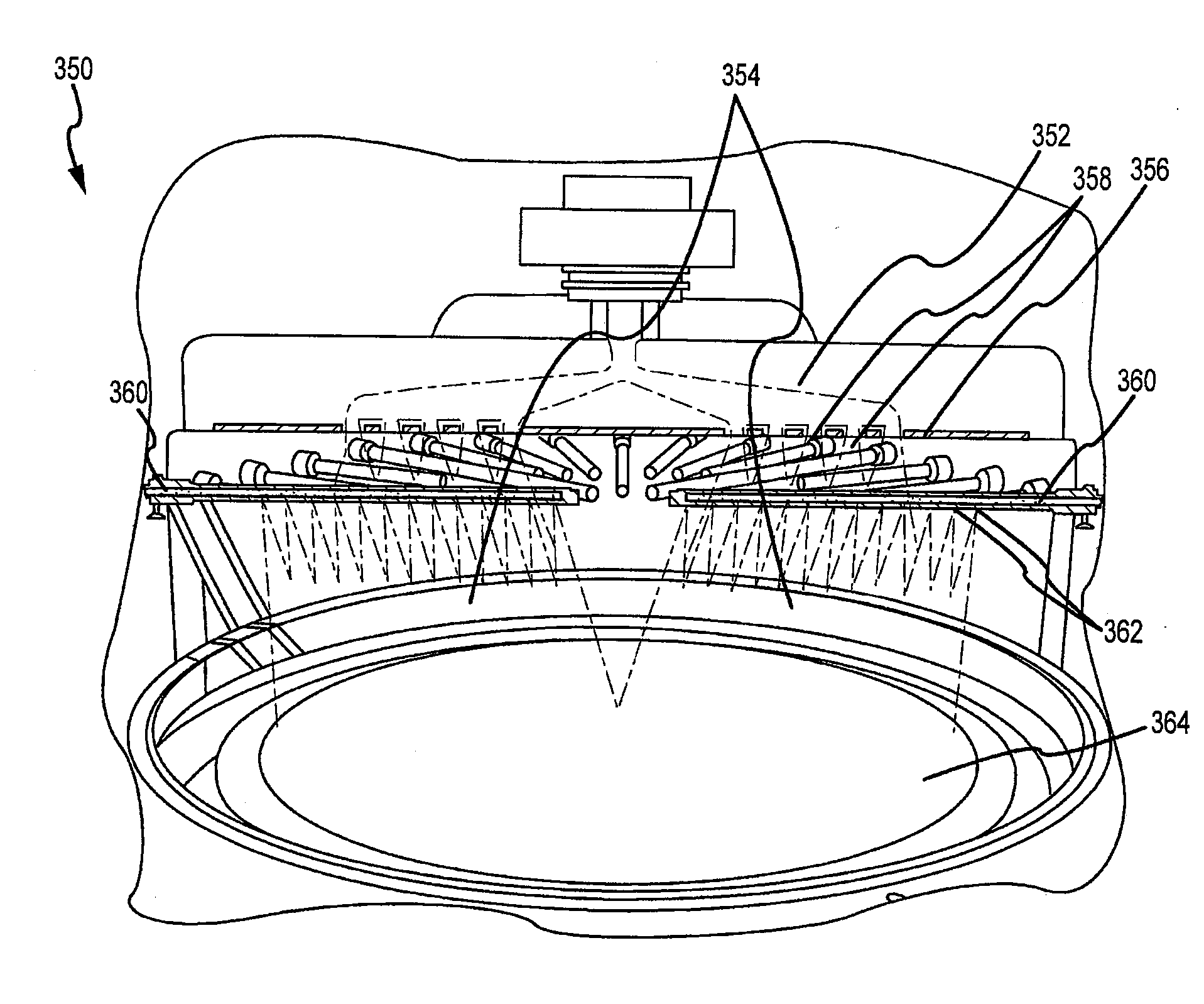

Process chamber for dielectric gapfill

InactiveUS20070281106A1Electric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaDistribution system

A system to form a dielectric layer on a substrate from a plasma of dielectric precursors is described. The system may include a deposition chamber, a substrate stage in the deposition chamber to hold the substrate, and a remote plasma generating system coupled to the deposition chamber, where the plasma generating system is used to generate a dielectric precursor having one or more reactive radicals. The system may also include a precursor distribution system that includes at least one top inlet and a plurality of side inlets. The top inlet may be positioned above the substrate stage and the side inlets may be radially distributed around the substrate stage. The reactive radical precursor may be supplied to the deposition chamber through the top inlet. An in-situ plasma generating system may also be included to generate the plasma in the deposition chamber from the dielectric precursors supplied to the deposition chamber.

Owner:APPLIED MATERIALS INC

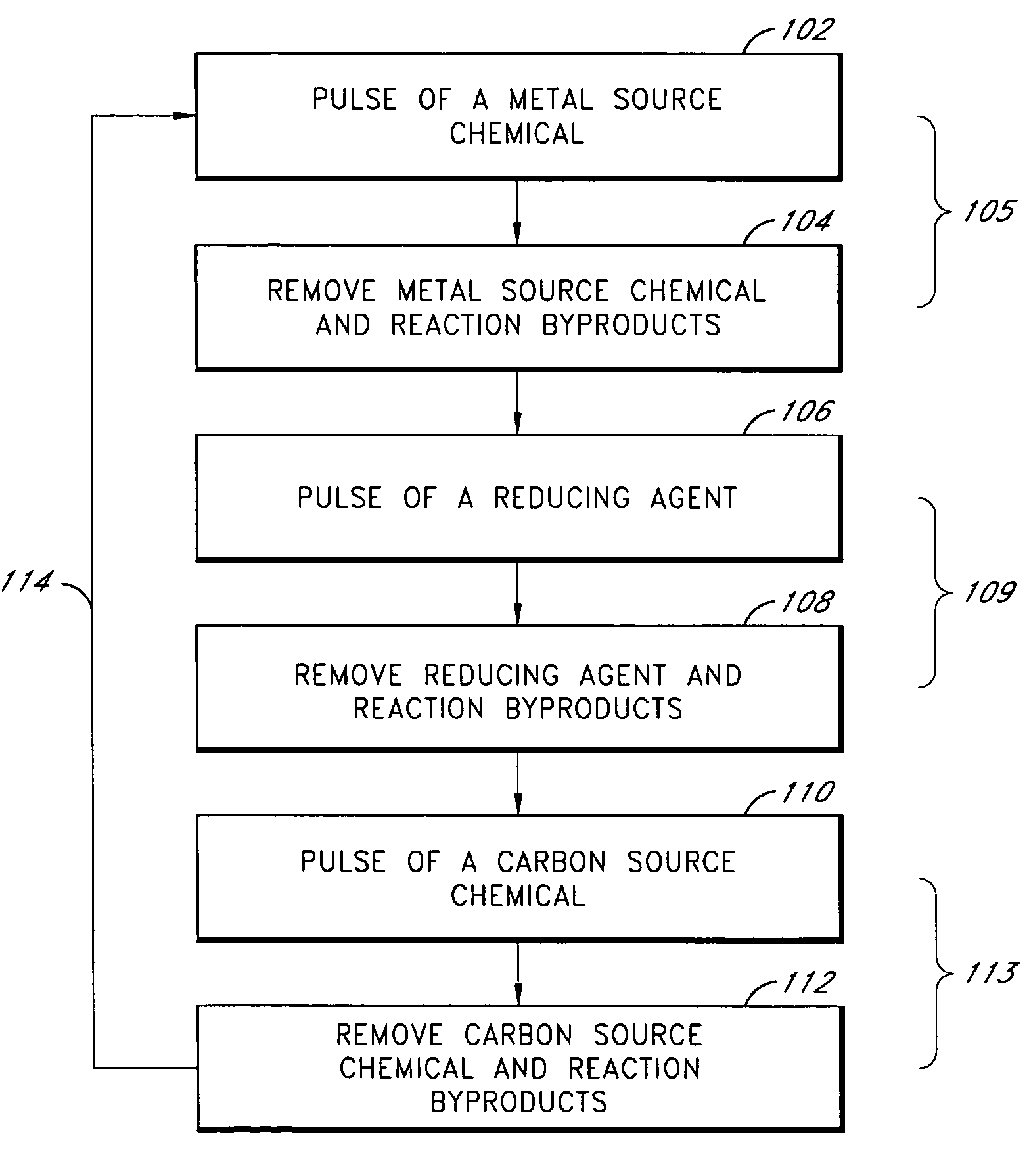

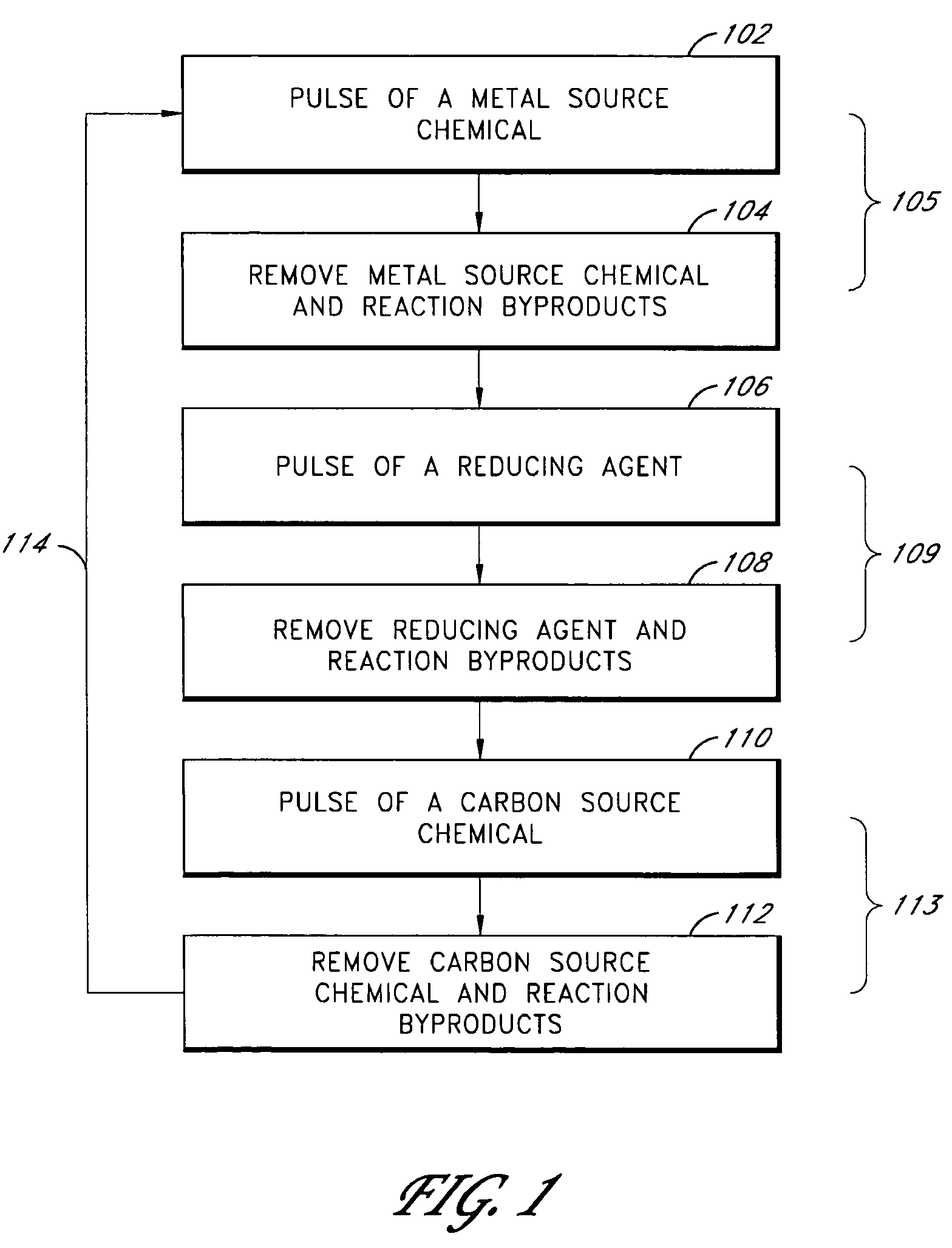

Vapor deposition of metal carbide films

Methods of forming metal carbide thin films are provided. According to preferred embodiments, metal carbide thin films are formed in an atomic layer deposition (ALD) process by alternately and sequentially contacting a substrate in a reaction space with spatially and temporally separated vapor phase pulses of a metal source chemical, a reducing agent and a carbon source chemical. The reducing agent is preferably selected from the group consisting of excited species of hydrogen and silicon-containing compounds.

Owner:ASM IP HLDG BV

Method of forming conformal film having si-N bonds on high-aspect ratio pattern

ActiveUS8394466B2Increasing mobilityIncreasing diffusivitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSiliconConformal map

Owner:ASM JAPAN

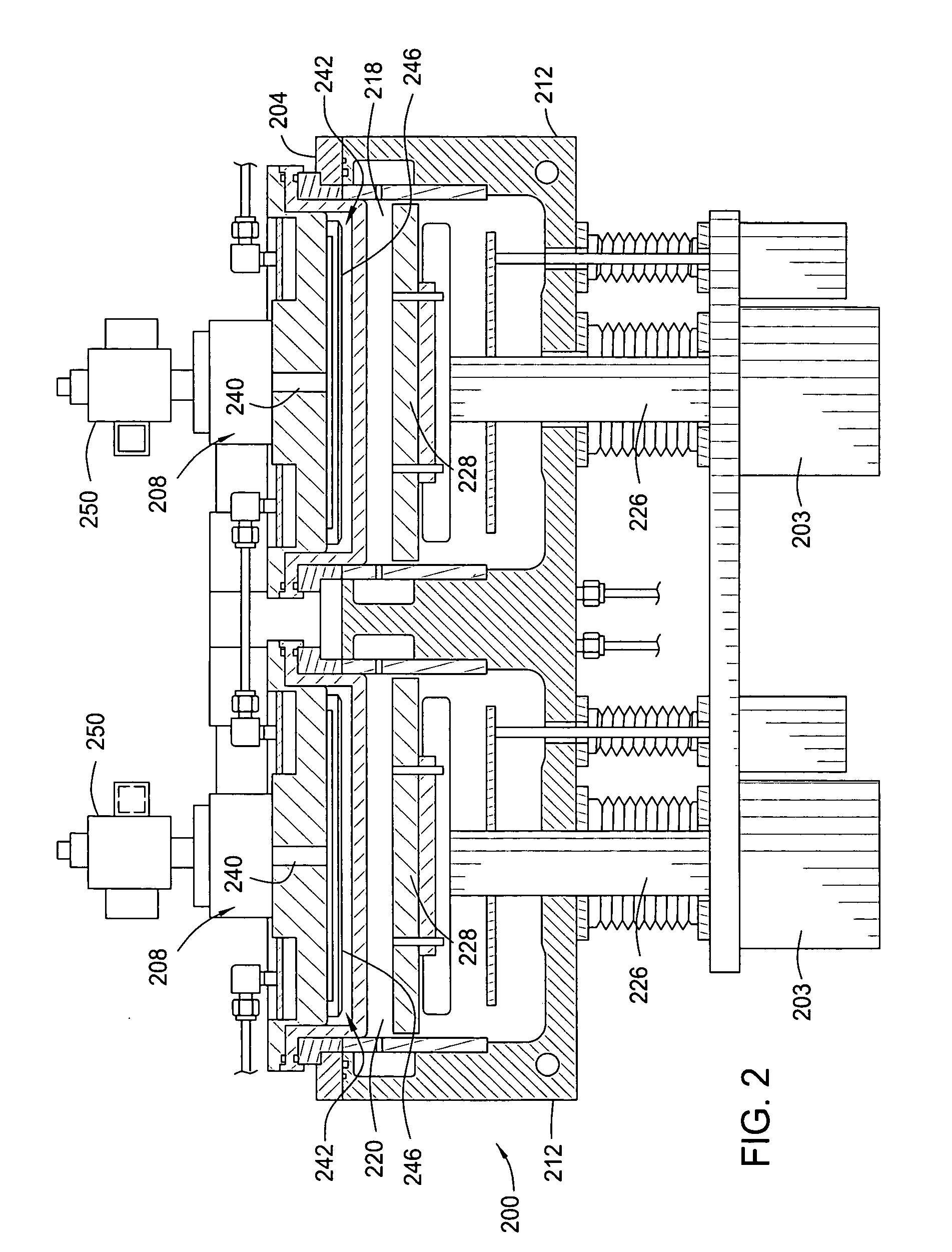

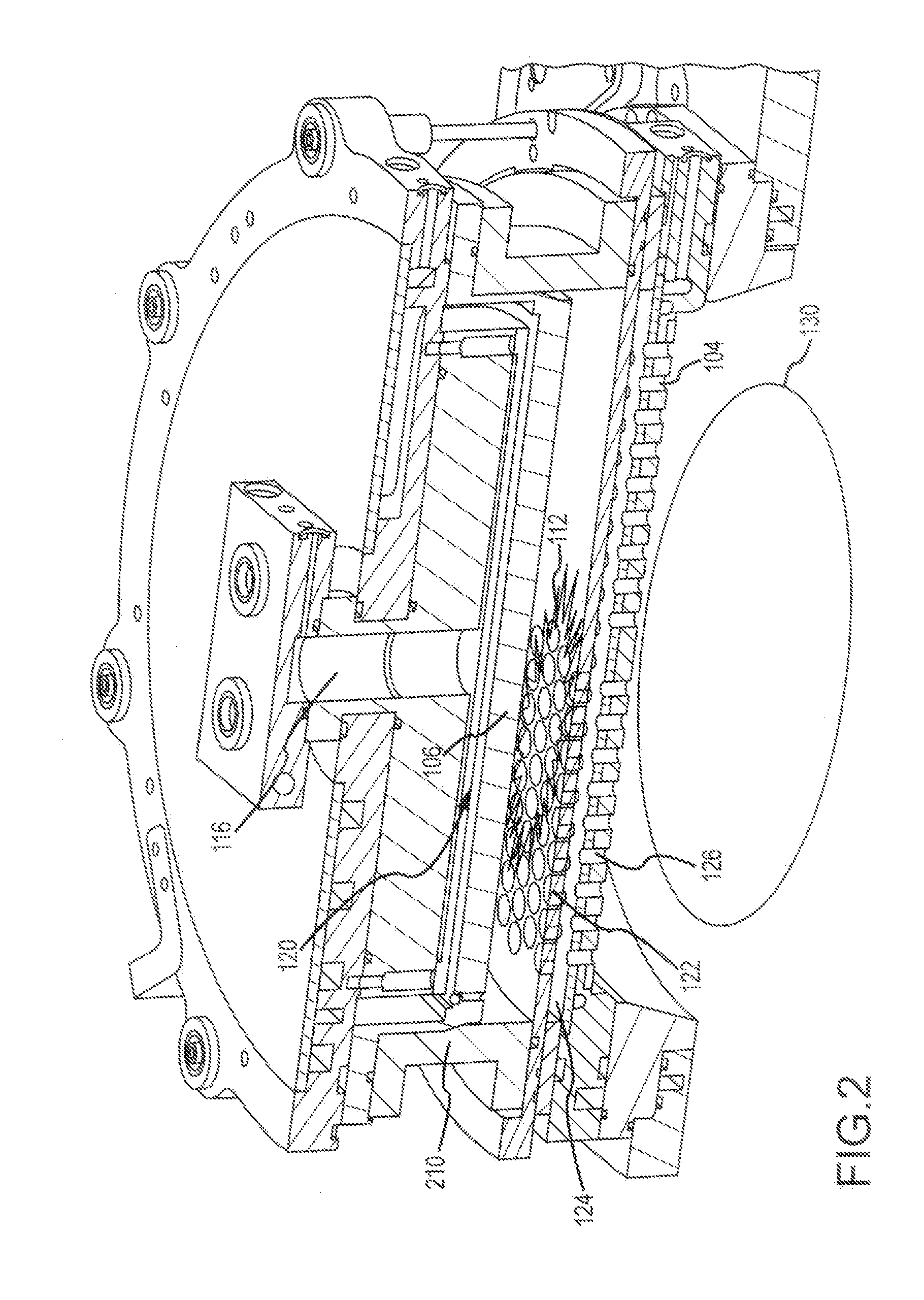

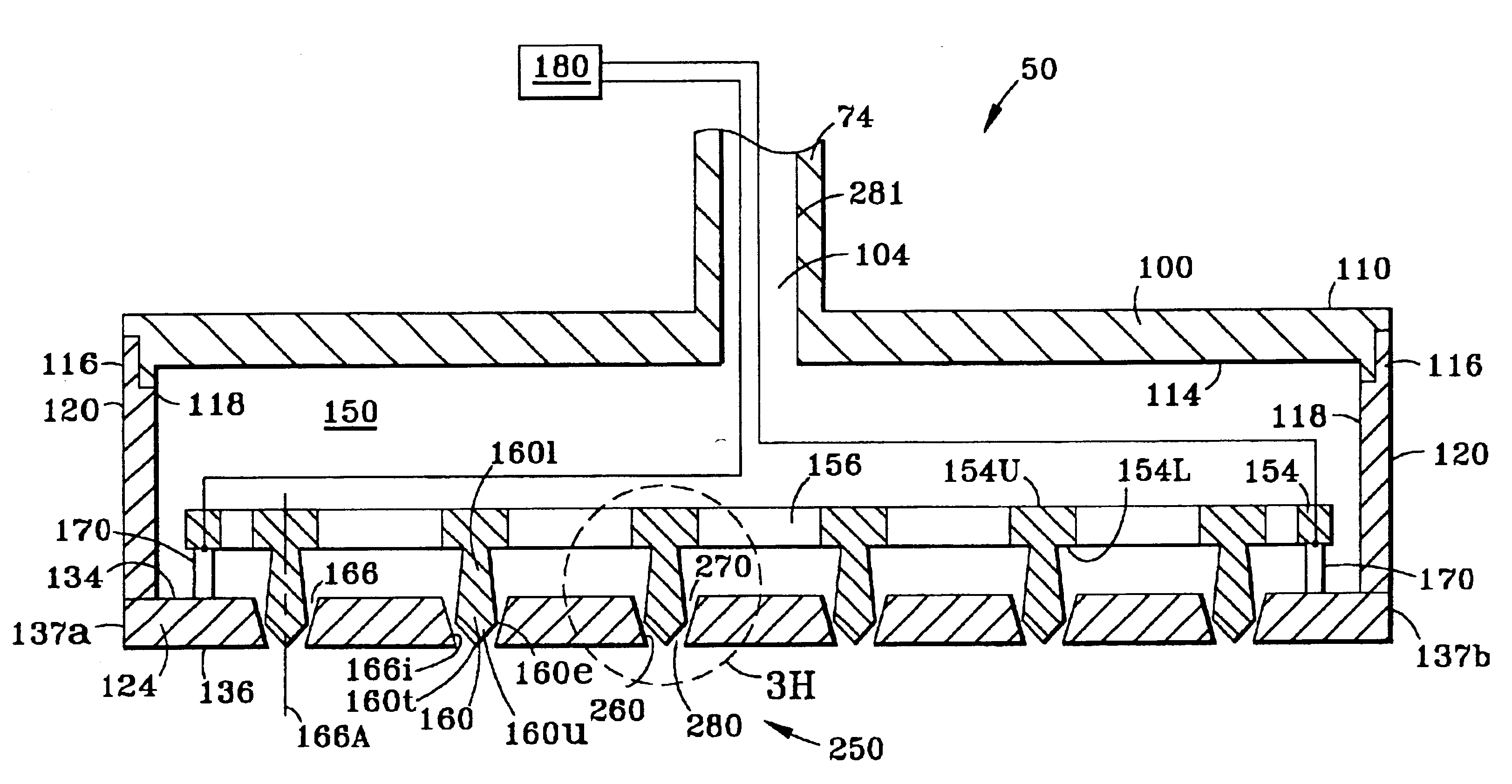

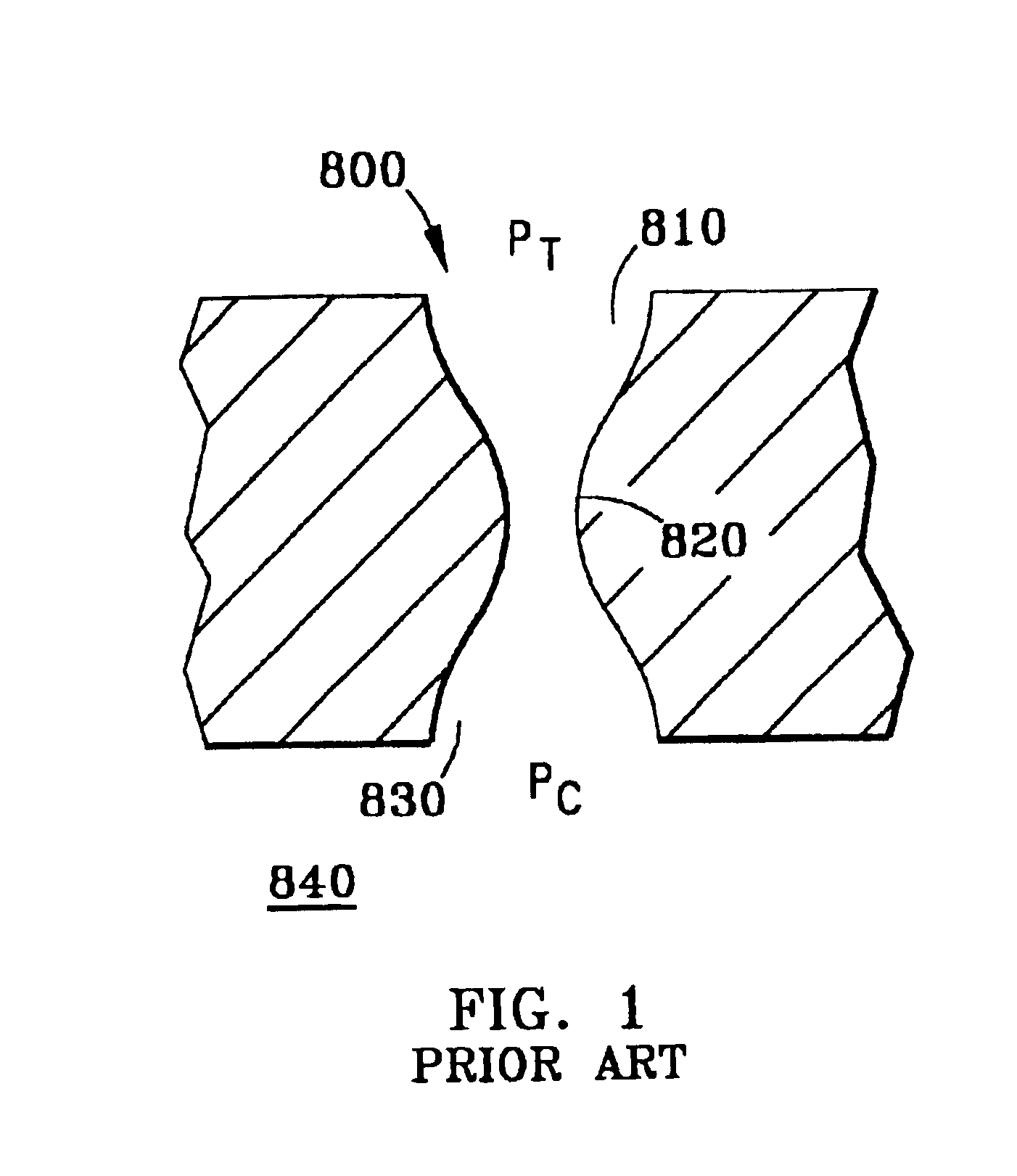

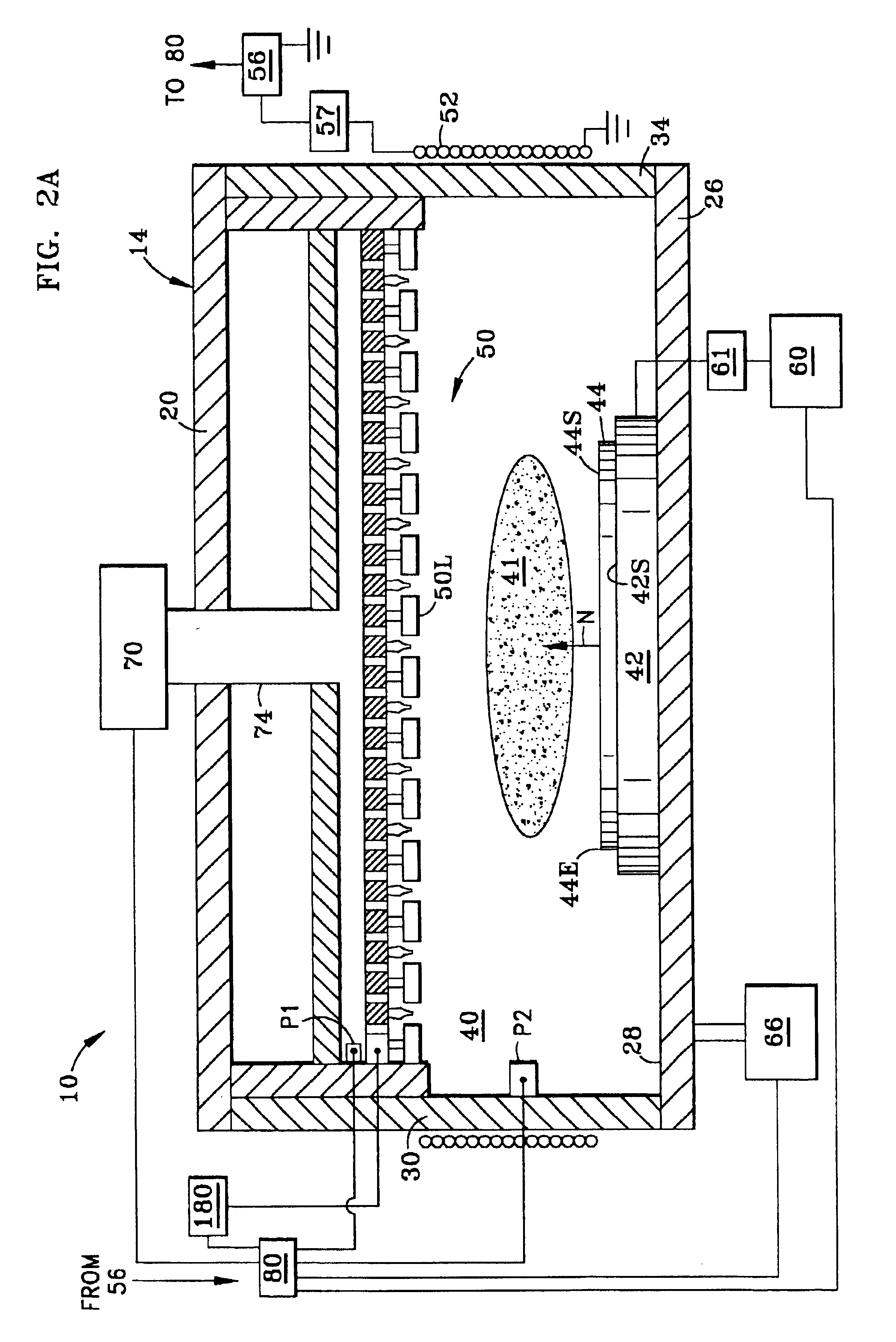

Method of and apparatus for tunable gas injection in a plasma processing system

InactiveUS6872259B2Control expansionElectric discharge tubesSemiconductor/solid-state device manufacturingElectronic communicationProduct gas

A method of and apparatus for providing tunable gas injection in a plasma processing system (10, 10′). The apparatus includes a gas injection manifold (50) having a pressurizable plenum (150) and an array of adjustable nozzle units (250), or an array of non-adjustable nozzles (502, 602), through which gas from the plenum can flow into the interior region (40) of a plasma reactor chamber (14) capable of containing a plasma (41). The adjustable nozzle units include a nozzle plug (160) arranged within a nozzle bore (166). A variety of different nozzle units are disclosed. The nozzle plugs are axially translatable to adjust the flow of gas therethrough. In one embodiment, the nozzle plugs are attached to a plug plate (154), which is displacable relative to an injection plate (124) via displacement actuators (170) connecting the two plates. The displacement actuators are controlled by a displacement actuator control unit (180), which is in electronic communication with a plasma processing system control unit (80). The gas flow into the chamber interior region is preferably controlled by monitoring the pressure in the plenum and in the chamber and adjusting the nozzle units accordingly. Where the nozzle units are not adjustable, a portion of the nozzles are sized to a first flow condition, and another portion of the nozzles are sized to a second flow condition.

Owner:TOKYO ELECTRON LTD

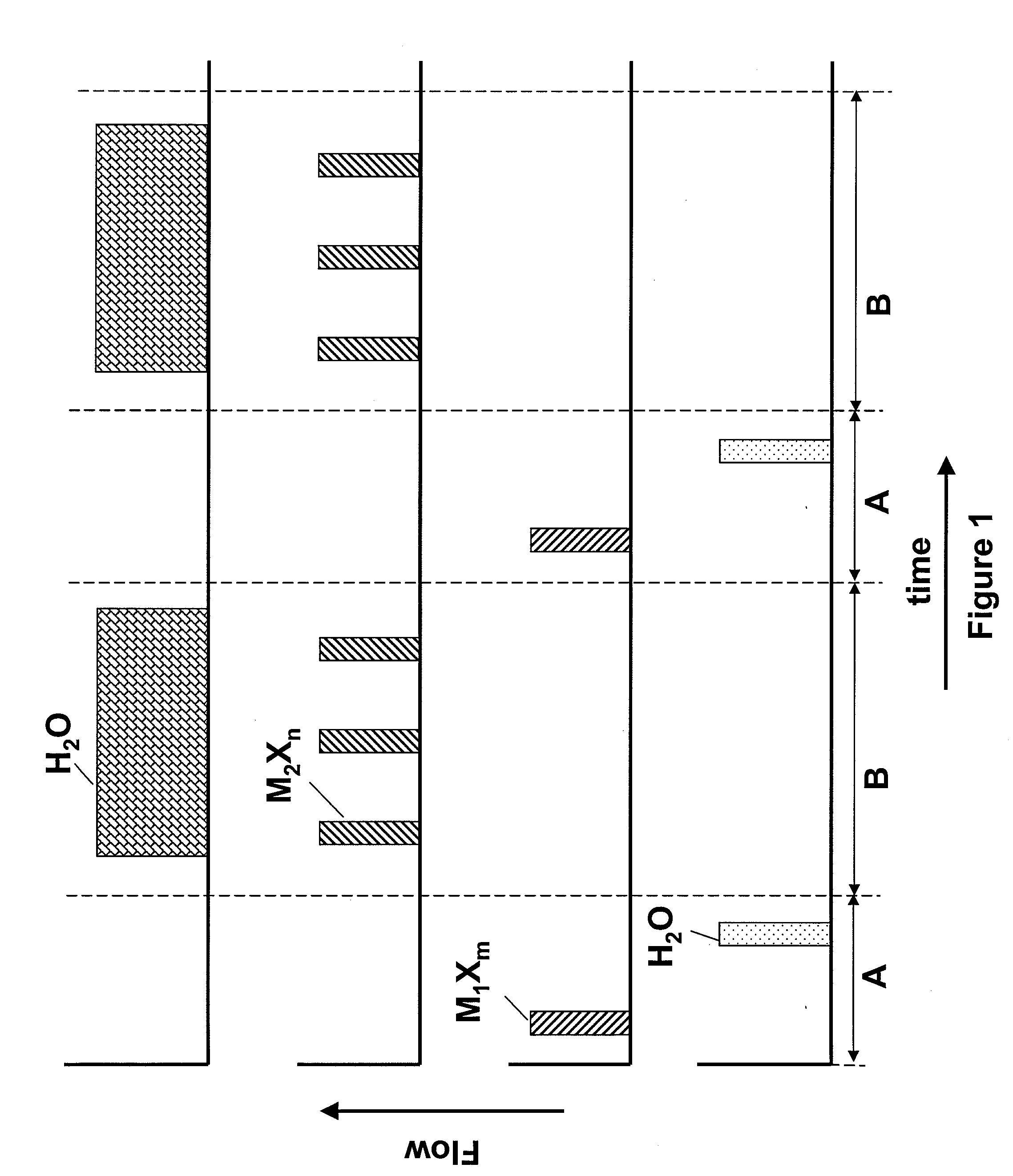

Method for depositing thin films by mixed pulsed CVD and ald

ActiveUS20080317972A1Easy to customizeImprove responseSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChemical vapor depositionAtomic layer deposition

Films are deposited on a substrate by a process in which atomic layer deposition (ALD) is used to deposit one layer of the film and pulsed chemical vapor deposition (CVD) is used to deposit another layer of the film. During the ALD part of the process, a layer is formed by flowing sequential and alternating pulses of mutually reactive reactants that deposit self-limitingly on a substrate. During the pulsed CVD part of the process, another layer is deposited by flowing two CVD reactants into a reaction chamber, with at least a first of the CVD reactants flowed into the reaction chamber in pulses, with those pulses overlapping at least partially with the flow of a second of the CVD reactants. The ALD and CVD parts of the process ca be used to deposit layers with different compositions, thereby forming, e.g., nanolaminate films. Preferably, high quality layers are formed by flowing the second CVD reactant into the reaction chamber for a longer total duration than the first CVD reactant. In some embodiments, the pulses of the third reactant at separated by a duration at least about 1.75 times the length of the pulse. Preferably, less than about 8 monolayers of material are deposited per pulse of the first CVD reactant.

Owner:ASM INTERNATIONAL

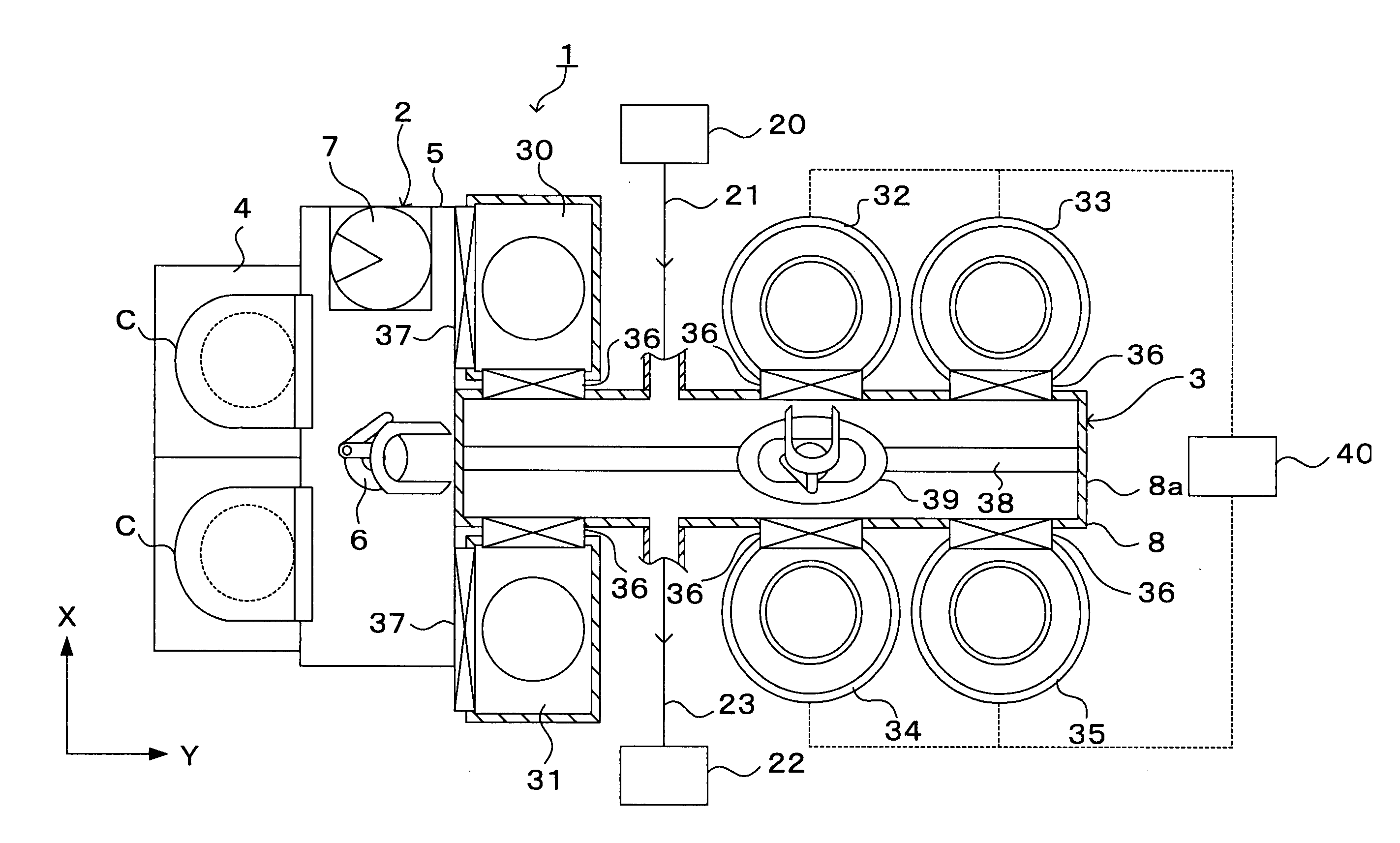

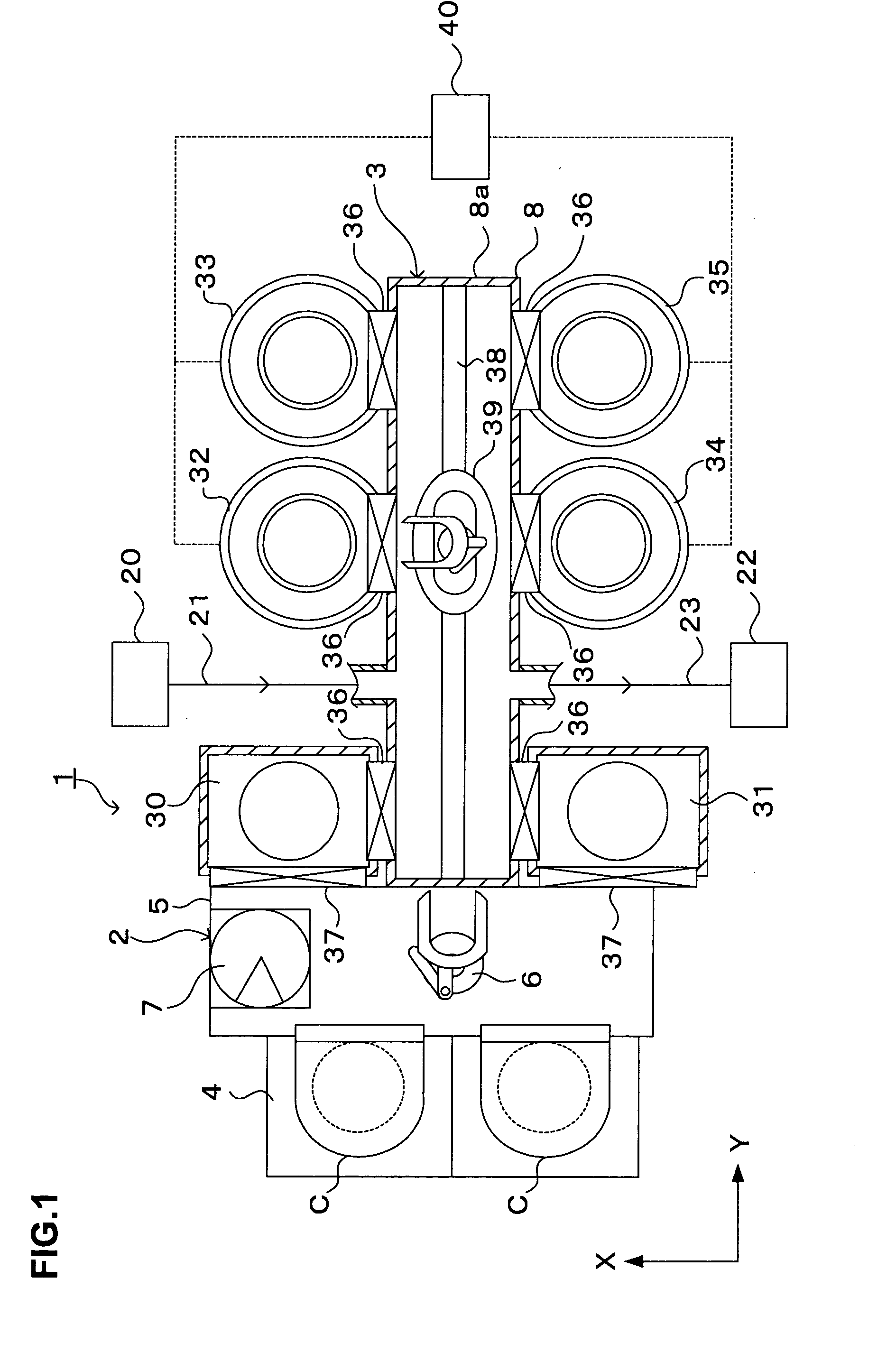

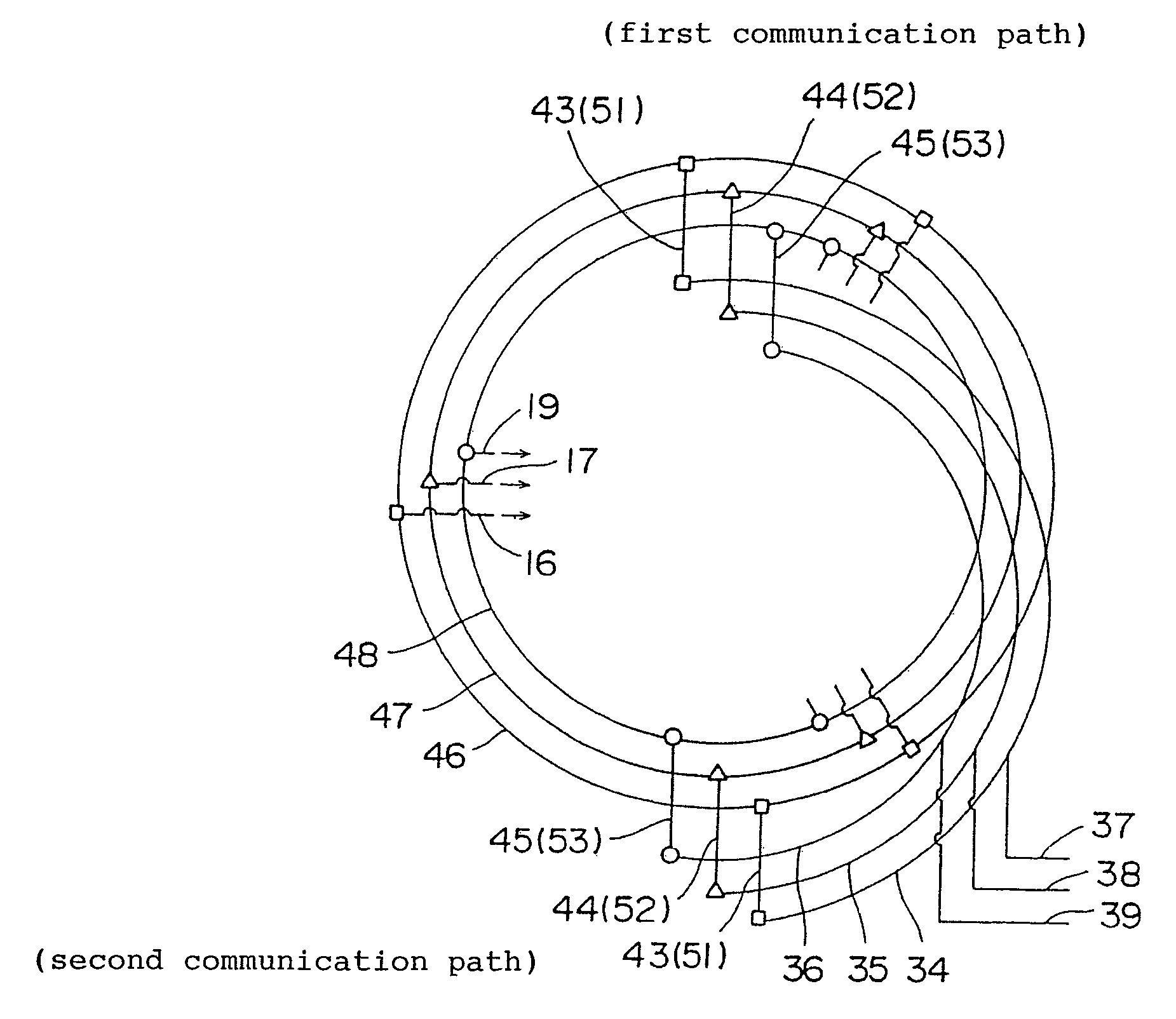

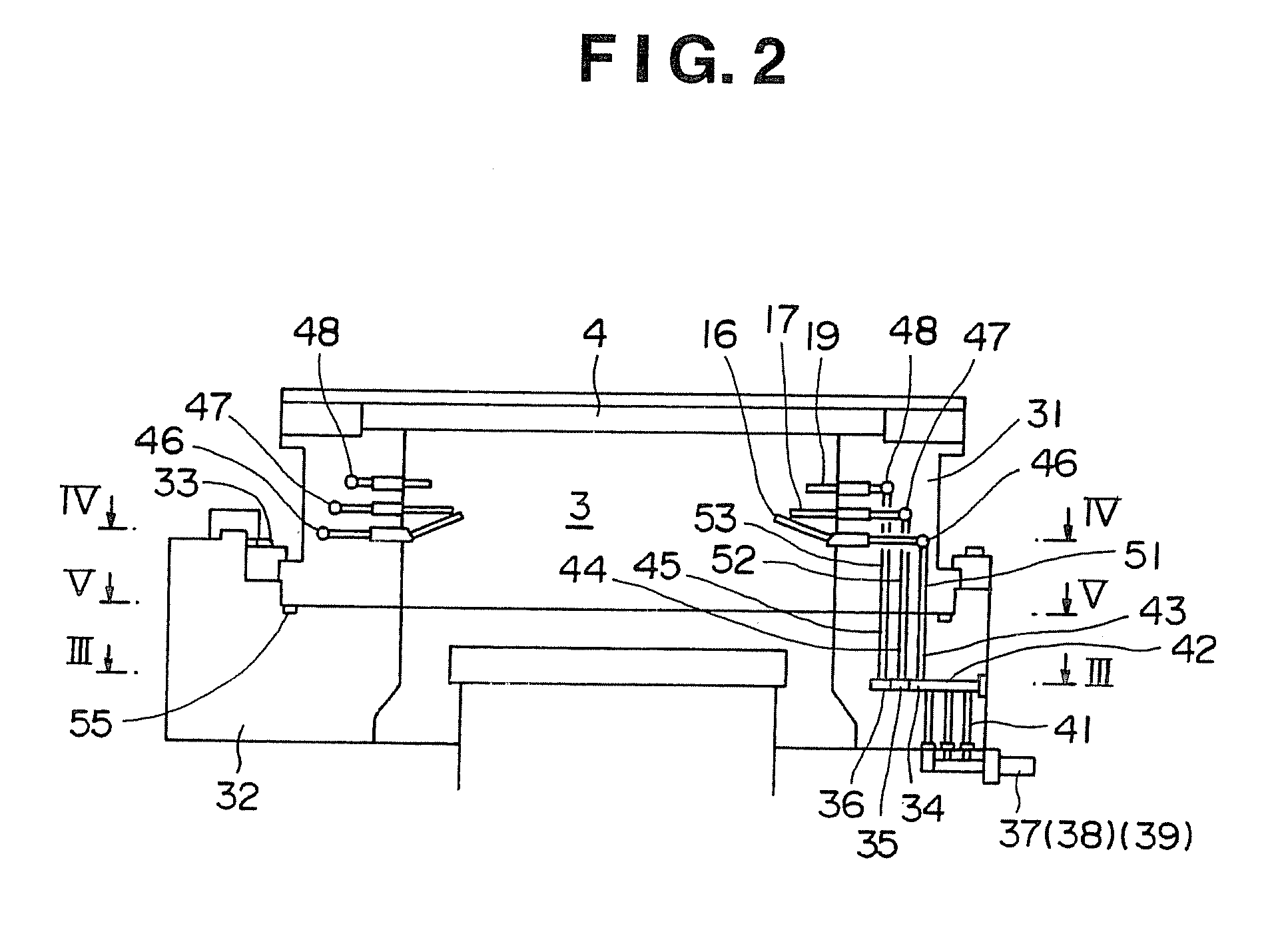

Plasma treatment apparatus

InactiveUS7806078B2Simply the configuration of the containerContainer can be simplifiedElectric discharge tubesSemiconductor/solid-state device manufacturingProduct gasEngineering

A plasma CVD apparatus has a container, and channels composed of introduction grooves and circumferential grooves for different types of gases are formed within the container. The gases introduced through source gas piping, auxiliary gas piping, and cleaning gas piping are equally supplied to a plurality of supply nozzles, a plurality of auxiliary gas supply nozzles, and a plurality of cleaning gas nozzles. The configuration of the container can be simplified without complicating pipings for the gases.

Owner:MITSUBISHI HEAVY IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com