Patents

Literature

227 results about "Capacitively coupled plasma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A capacitively coupled plasma (CCP) is one of the most common types of industrial plasma sources. It essentially consists of two metal electrodes separated by a small distance, placed in a reactor. The gas pressure in the reactor can be lower than atmosphere or it can be atmospheric.

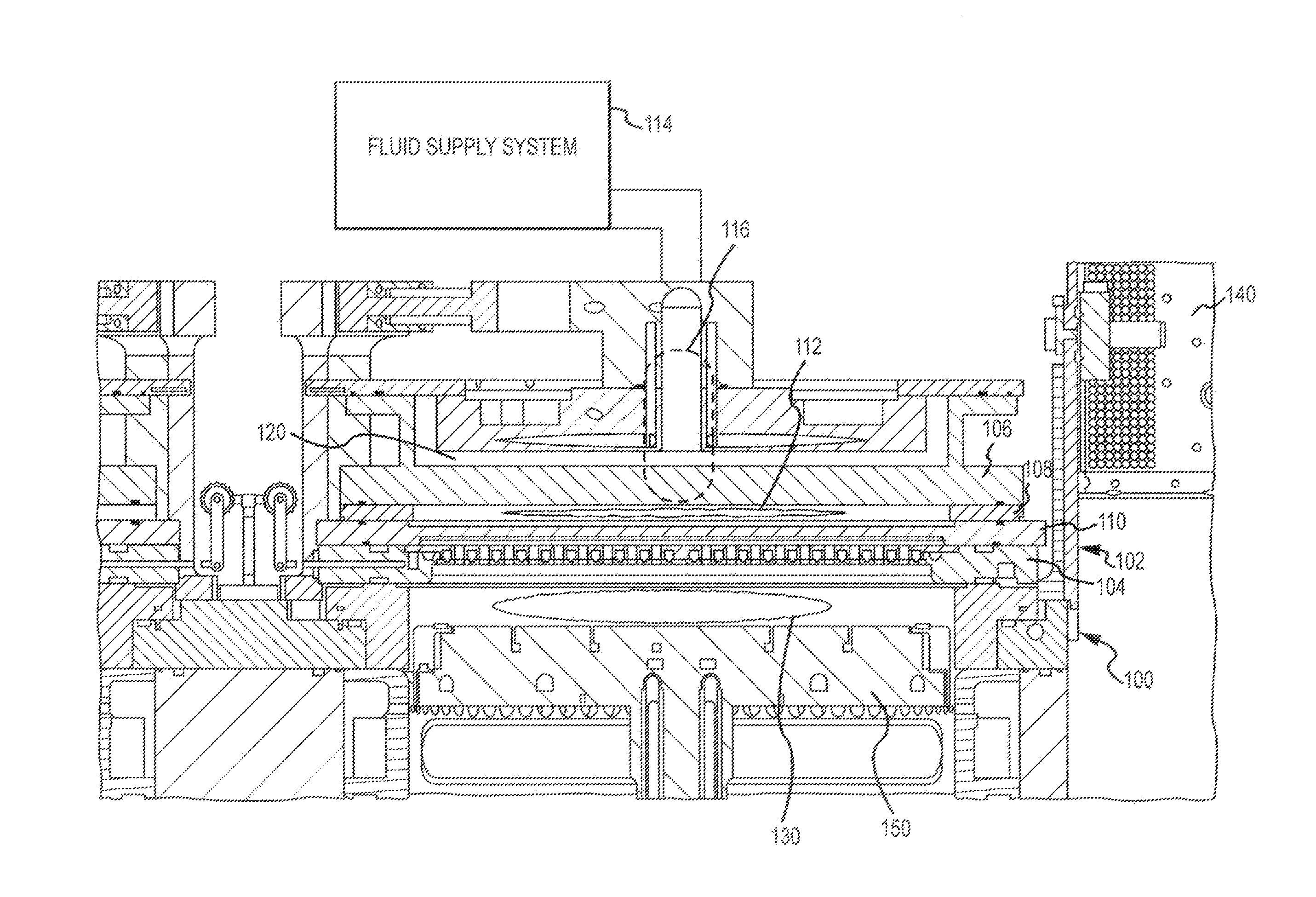

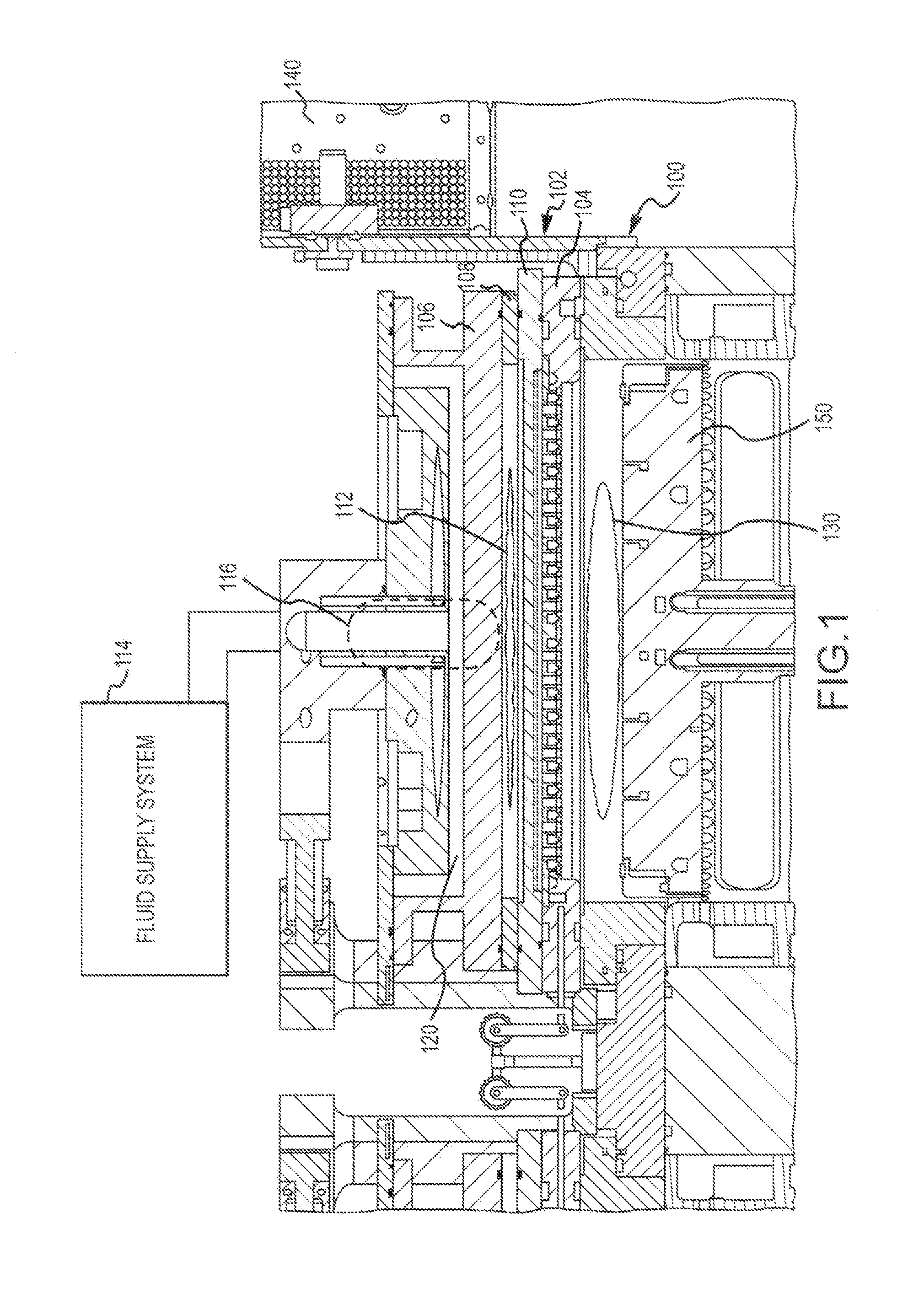

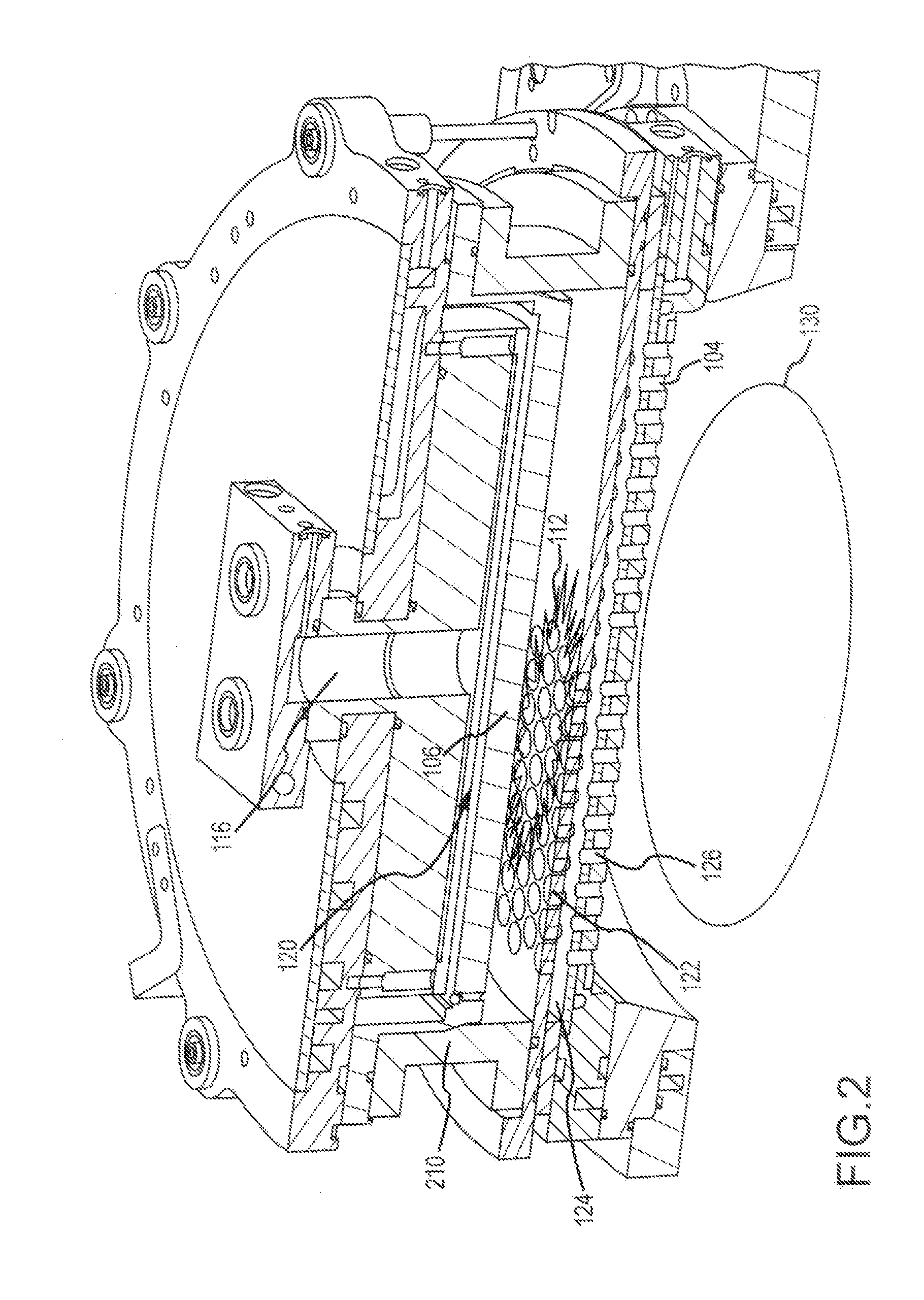

Semiconductor processing system and methods using capacitively coupled plasma

InactiveUS20120180954A1Conducive to environmental controlEliminate and reduce numberElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceSemiconductor

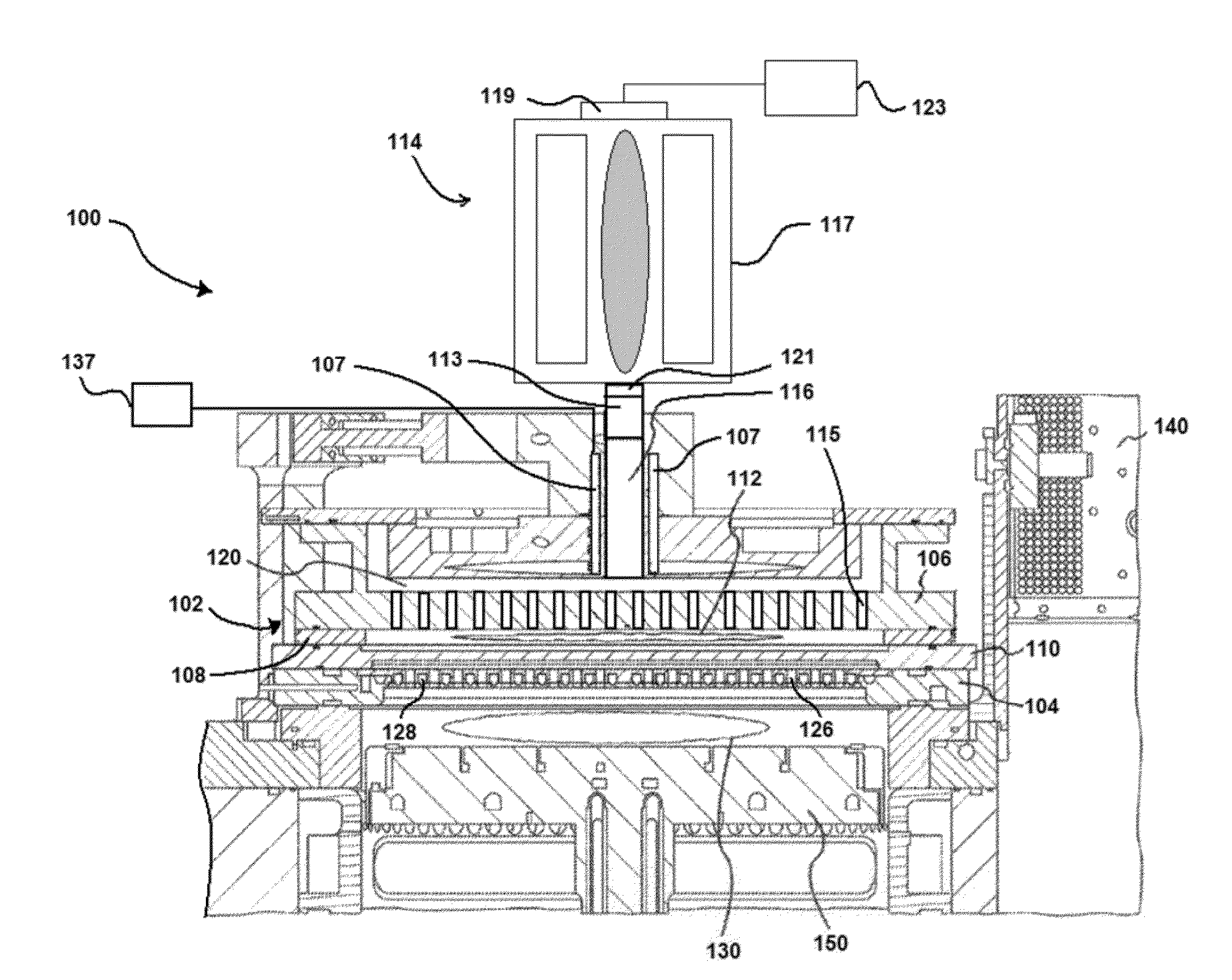

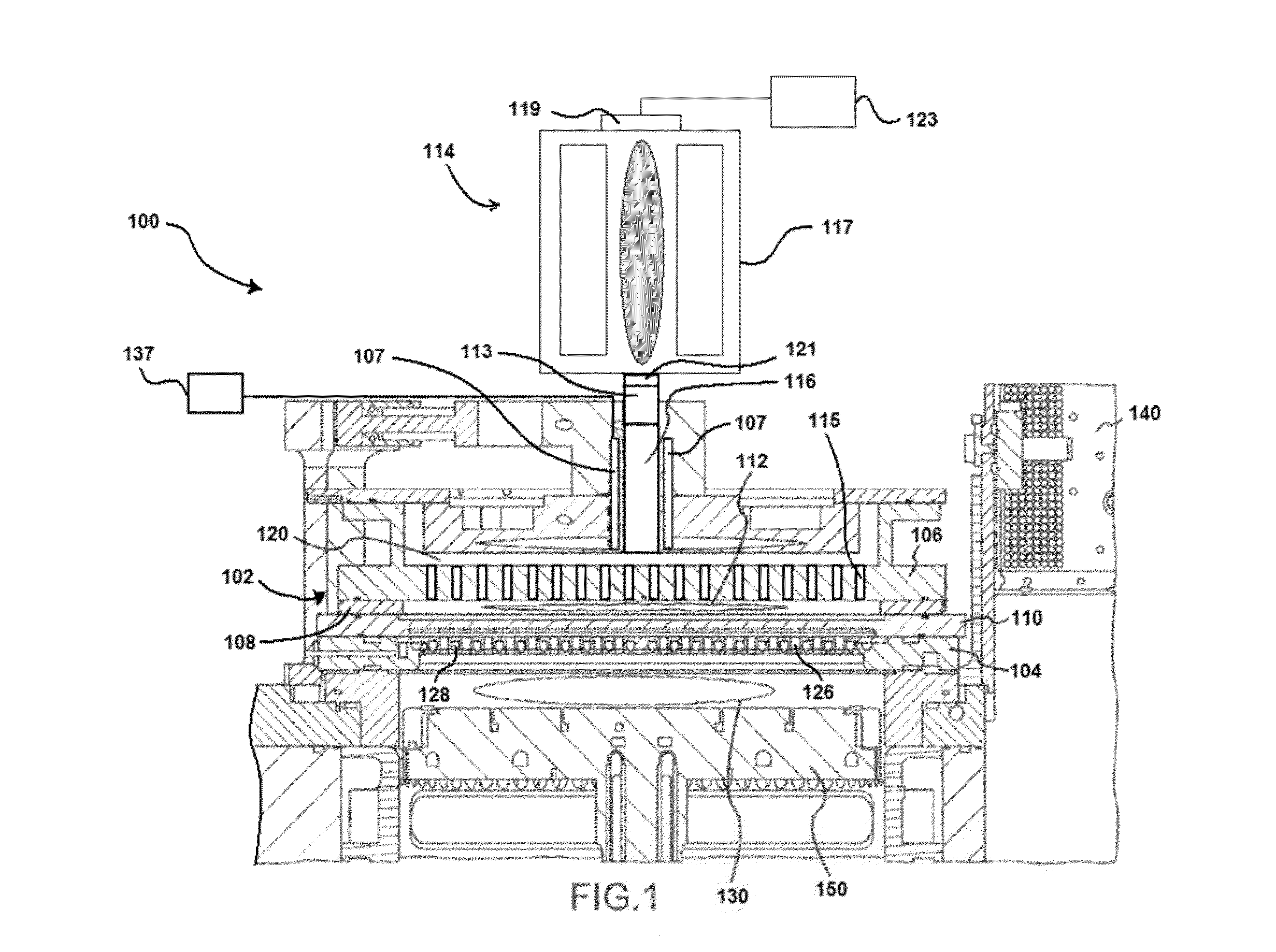

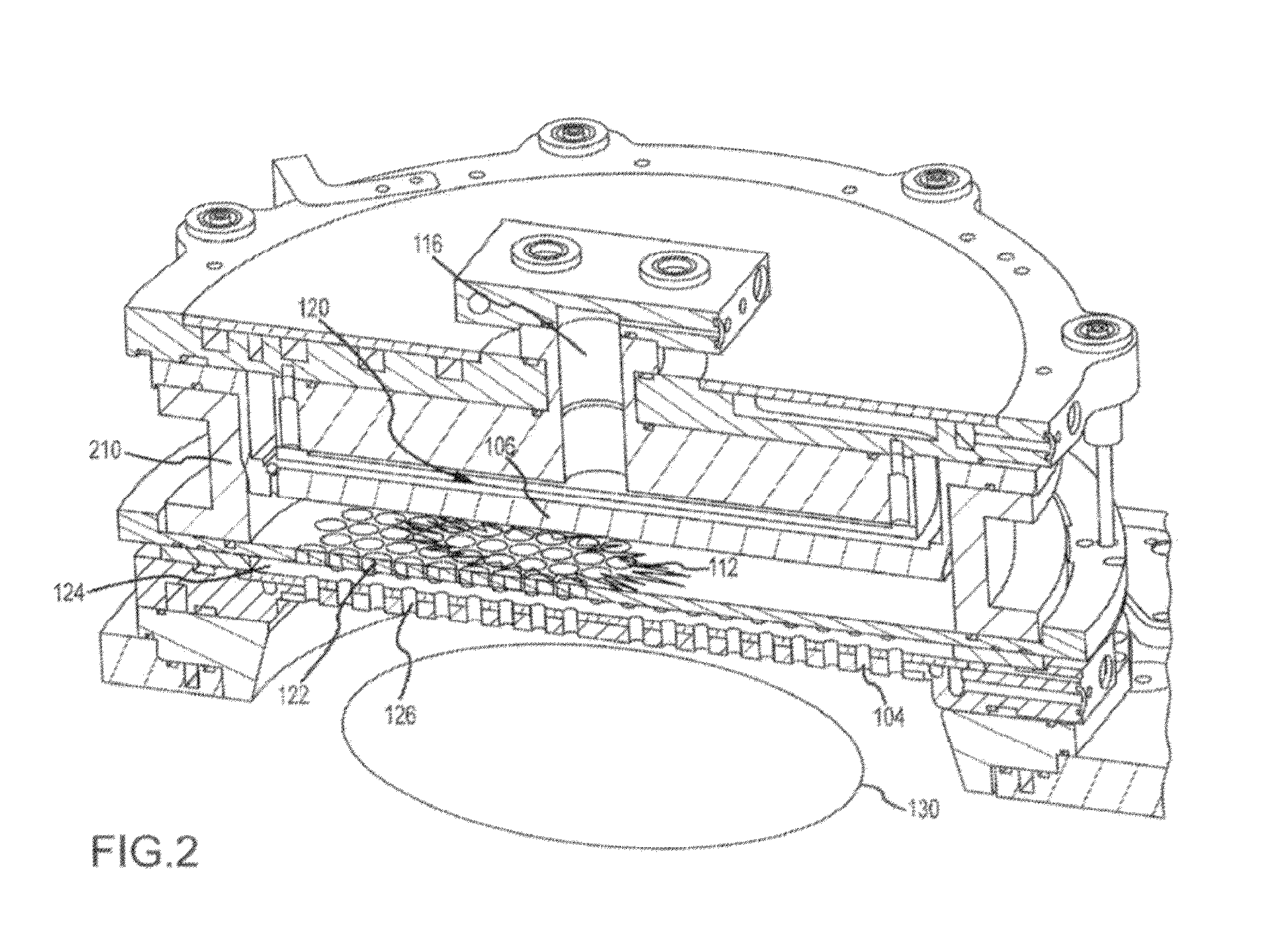

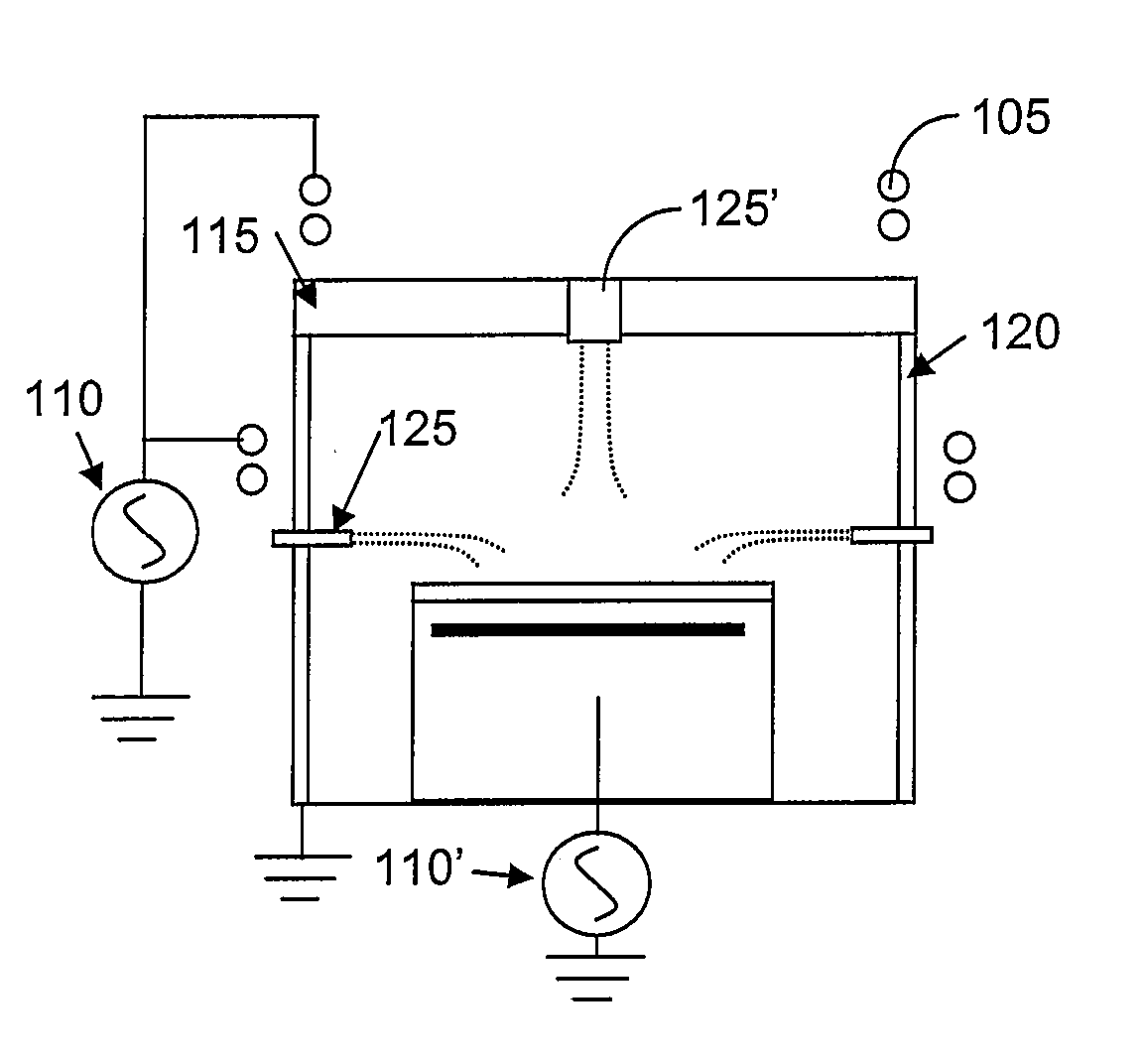

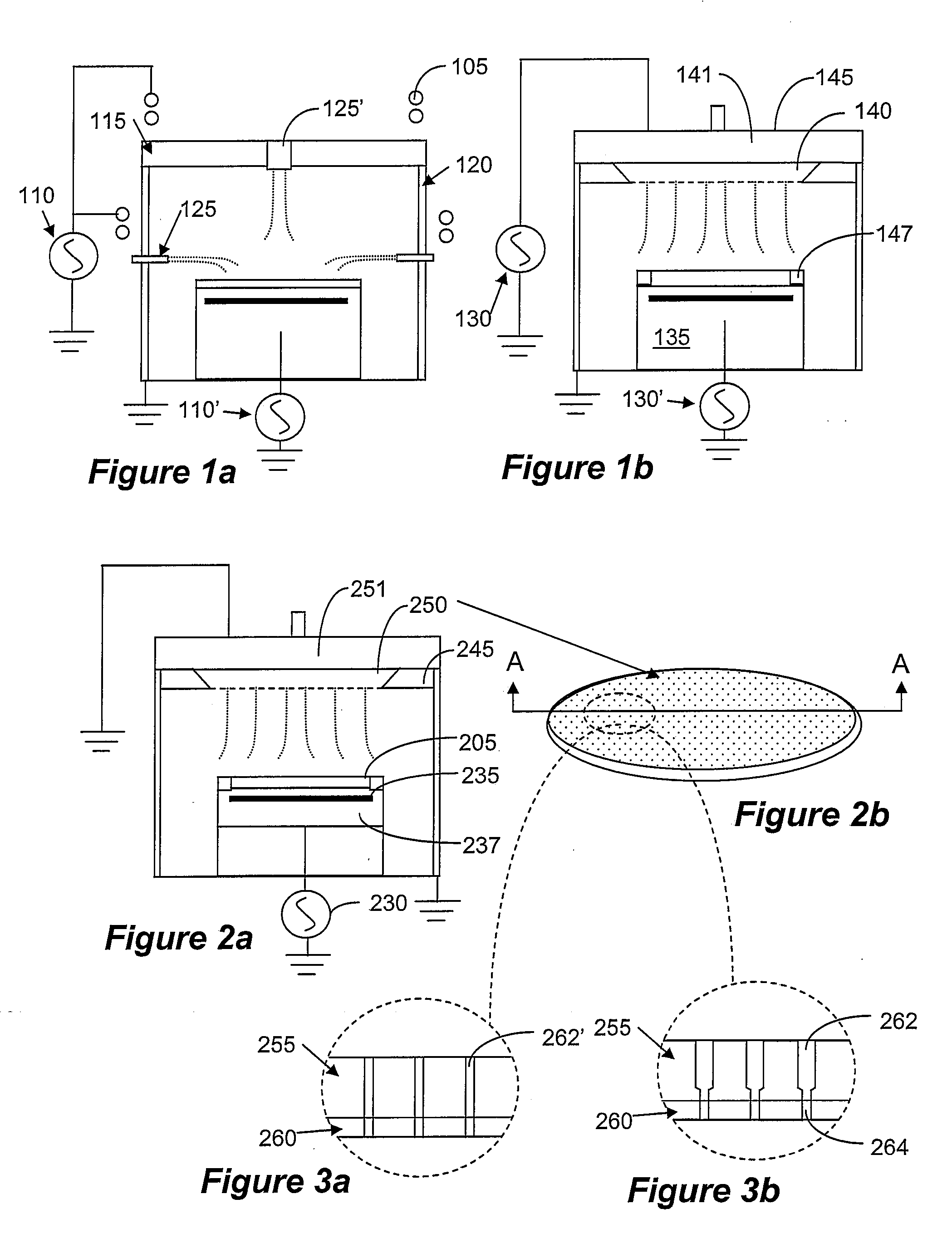

Substrate processing systems are described that have a capacitively coupled plasma (CCP) unit positioned inside a process chamber. The CCP unit may include a plasma excitation region formed between a first electrode and a second electrode. The first electrode may include a first plurality of openings to permit a first gas to enter the plasma excitation region, and the second electrode may include a second plurality of openings to permit an activated gas to exit the plasma excitation region. The system may further include a gas inlet for supplying the first gas to the first electrode of the CCP unit, and a pedestal that is operable to support a substrate. The pedestal is positioned below a gas reaction region into which the activated gas travels from the CCP unit.

Owner:APPLIED MATERIALS INC

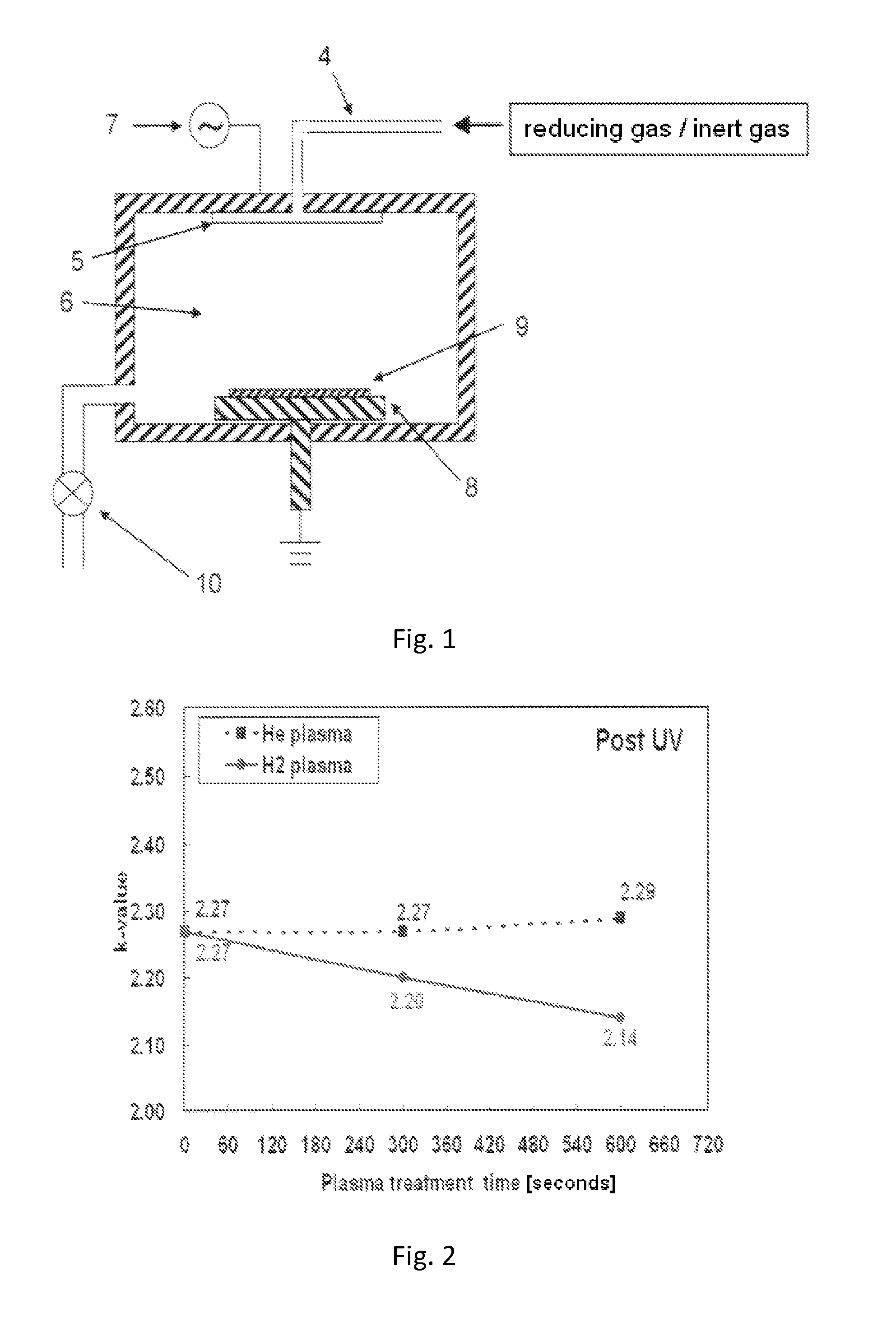

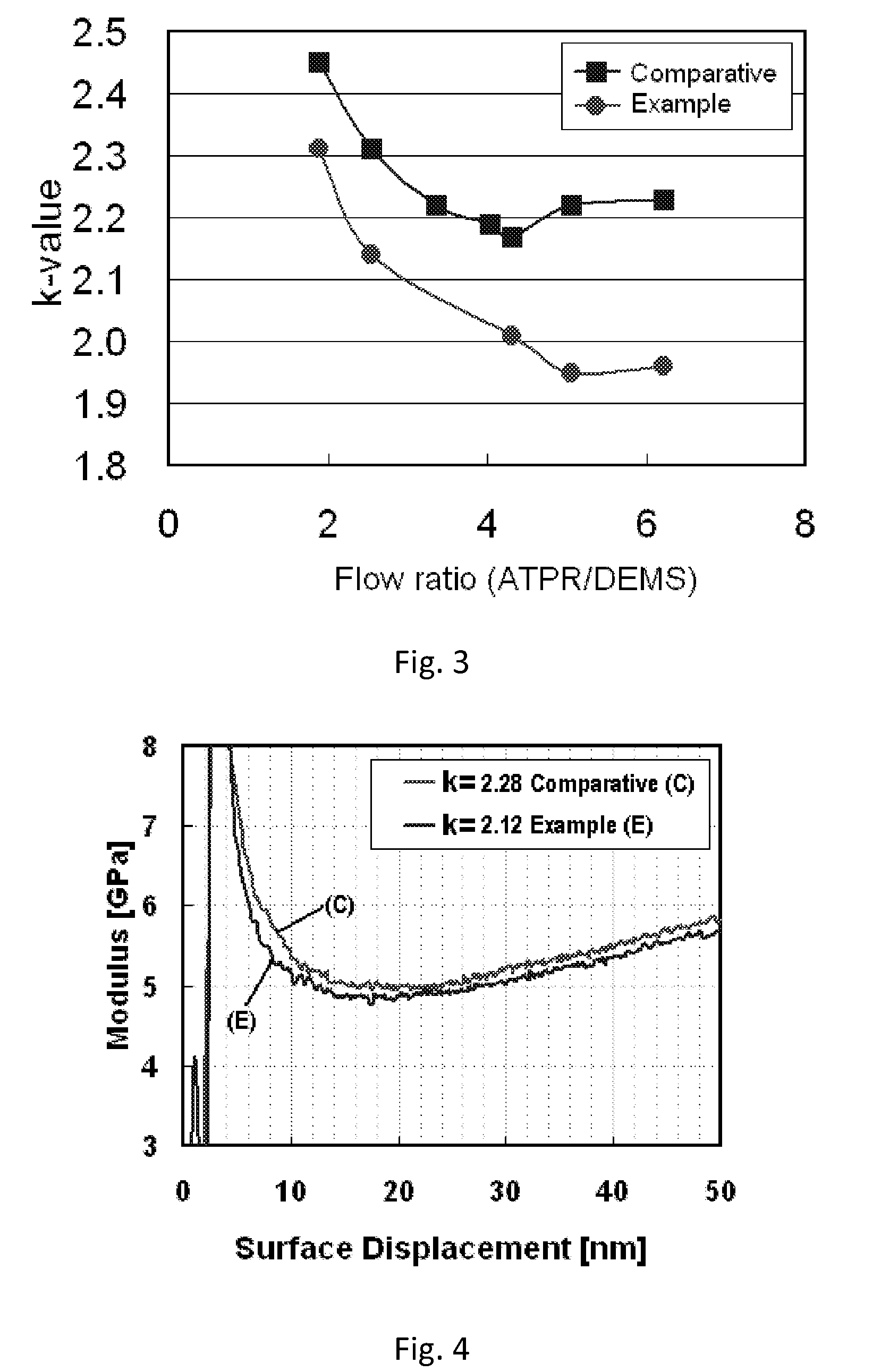

Method for reducing dielectric constant of film using direct plasma of hydrogen

ActiveUS8551892B2Low dielectric constantMaintain mechanical strengthElectric shock equipmentsSemiconductor/solid-state device detailsDielectricCapacitance

A method for reducing a dielectric constant of a film includes (i) forming a dielectric film on a substrate; (ii) treating a surface of the film without film formation, and (III) curing the film. Step (i) includes providing a dielectric film containing a porous matrix and a porogen on a substrate, step (ii) includes, prior to or subsequent to step (iii), treating the dielectric film with charged species of hydrogen generated by capacitively-coupled plasma without film deposition to reduce a dielectric constant of the dielectric film, and step (iii) includes UV-curing the dielectric film to remove at least partially the porogen from the film.

Owner:ASM JAPAN

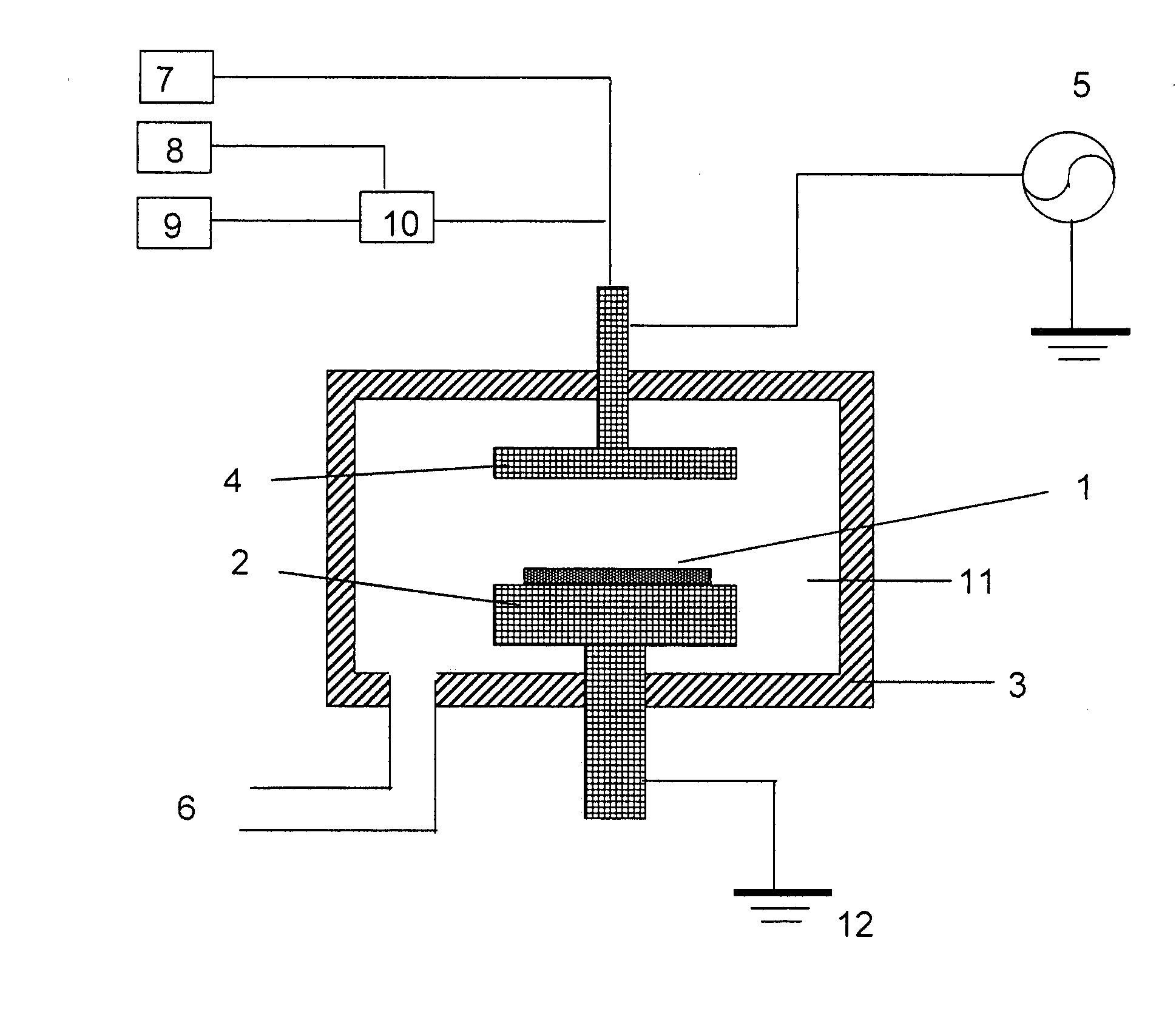

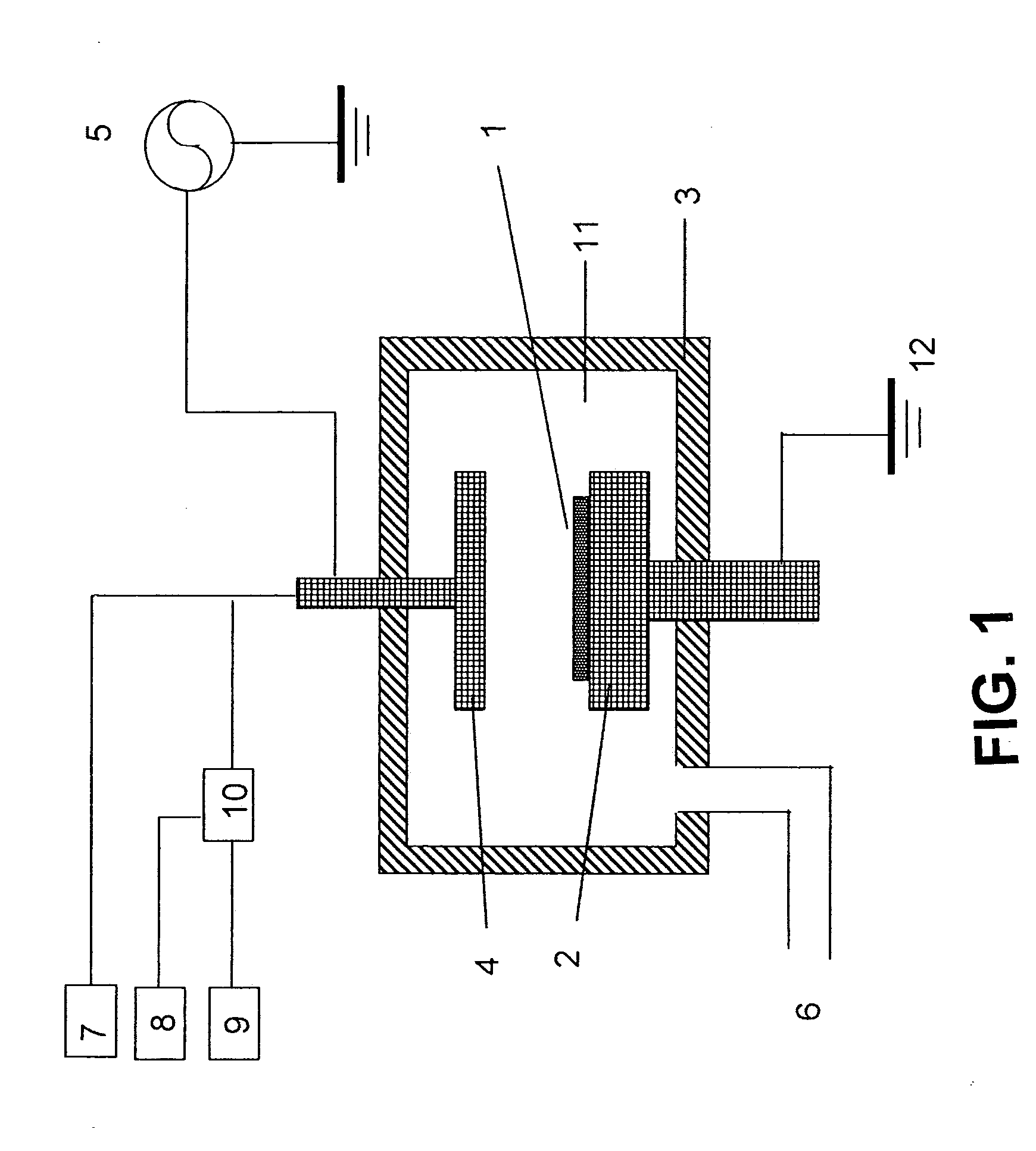

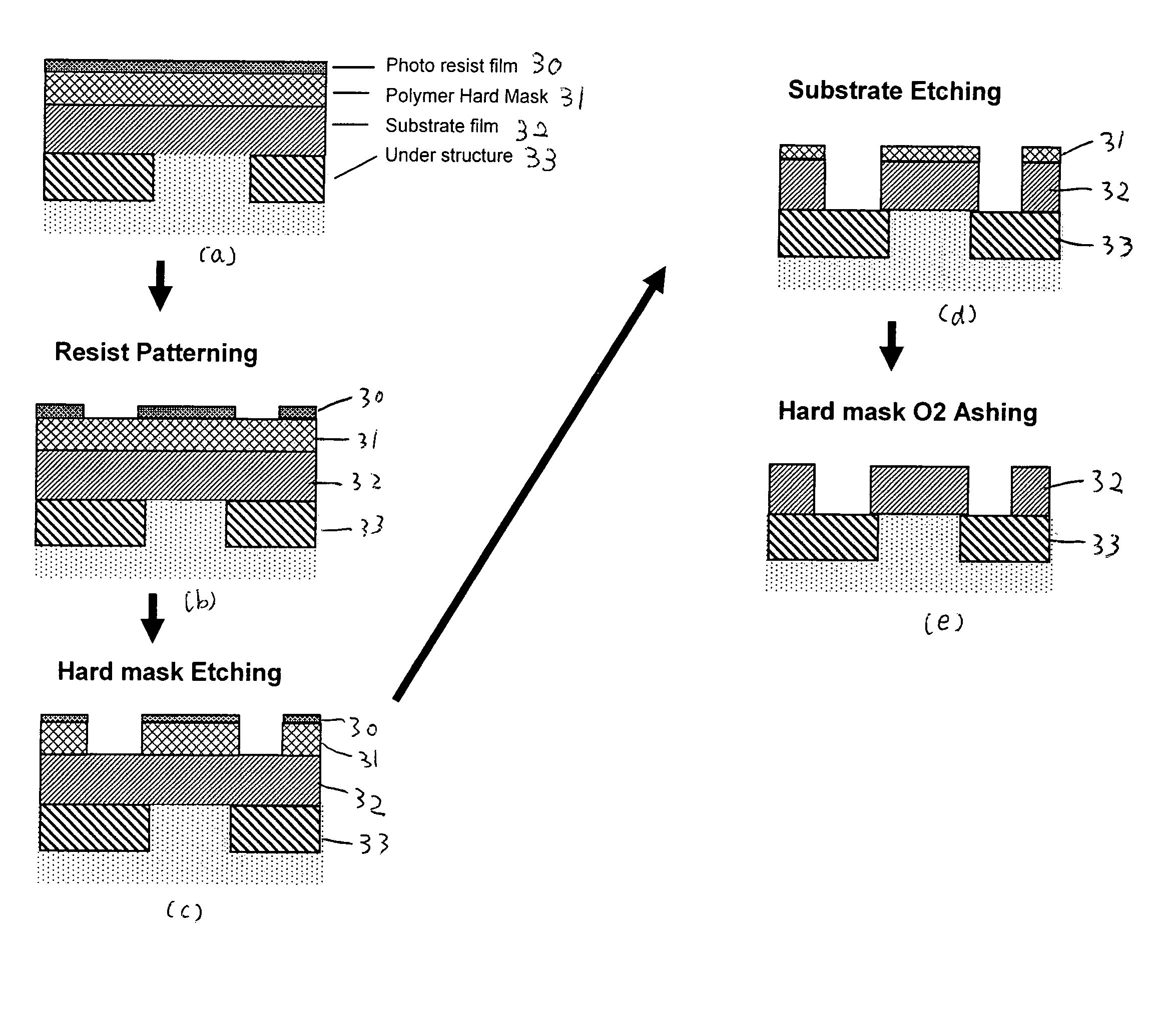

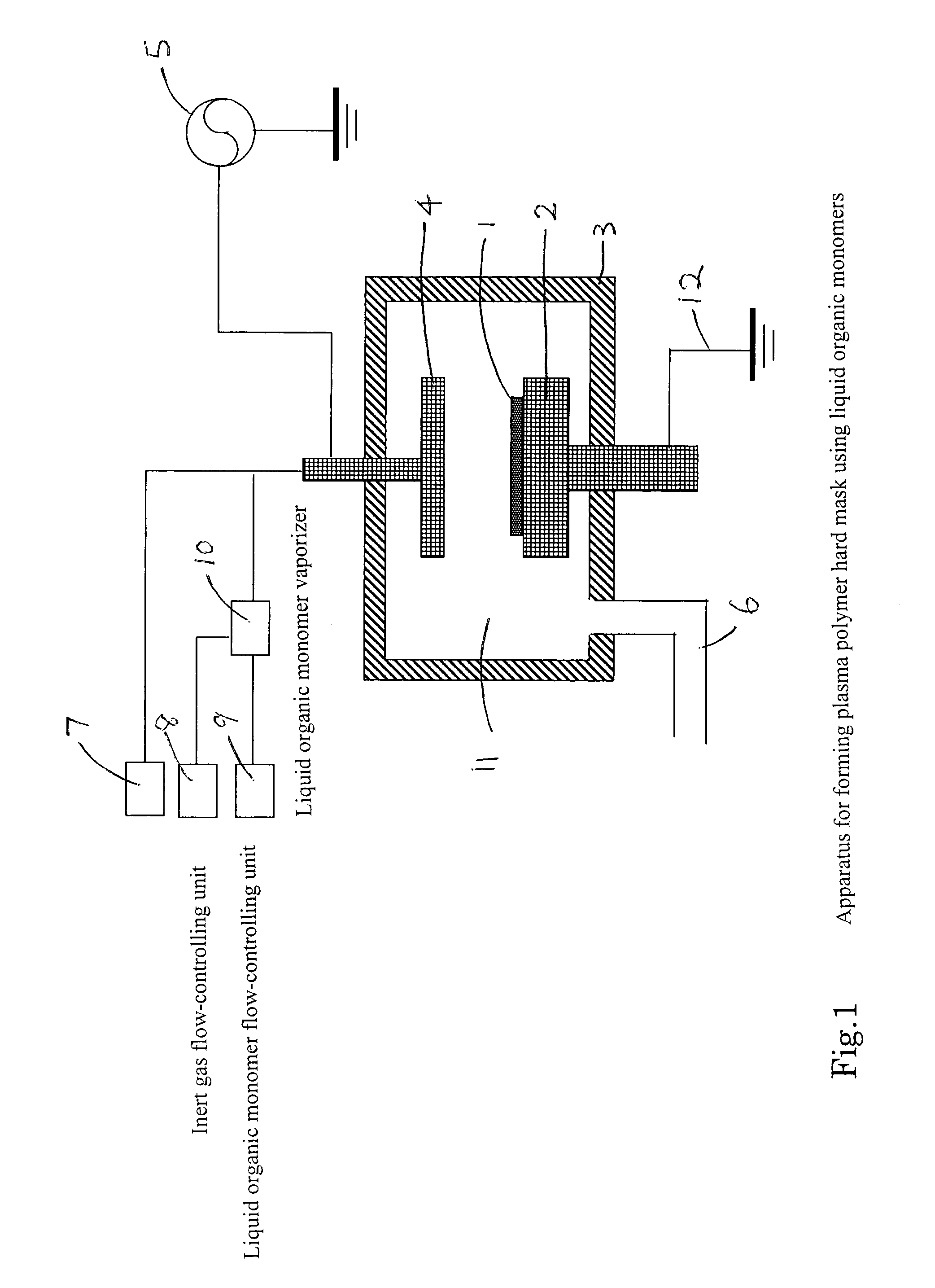

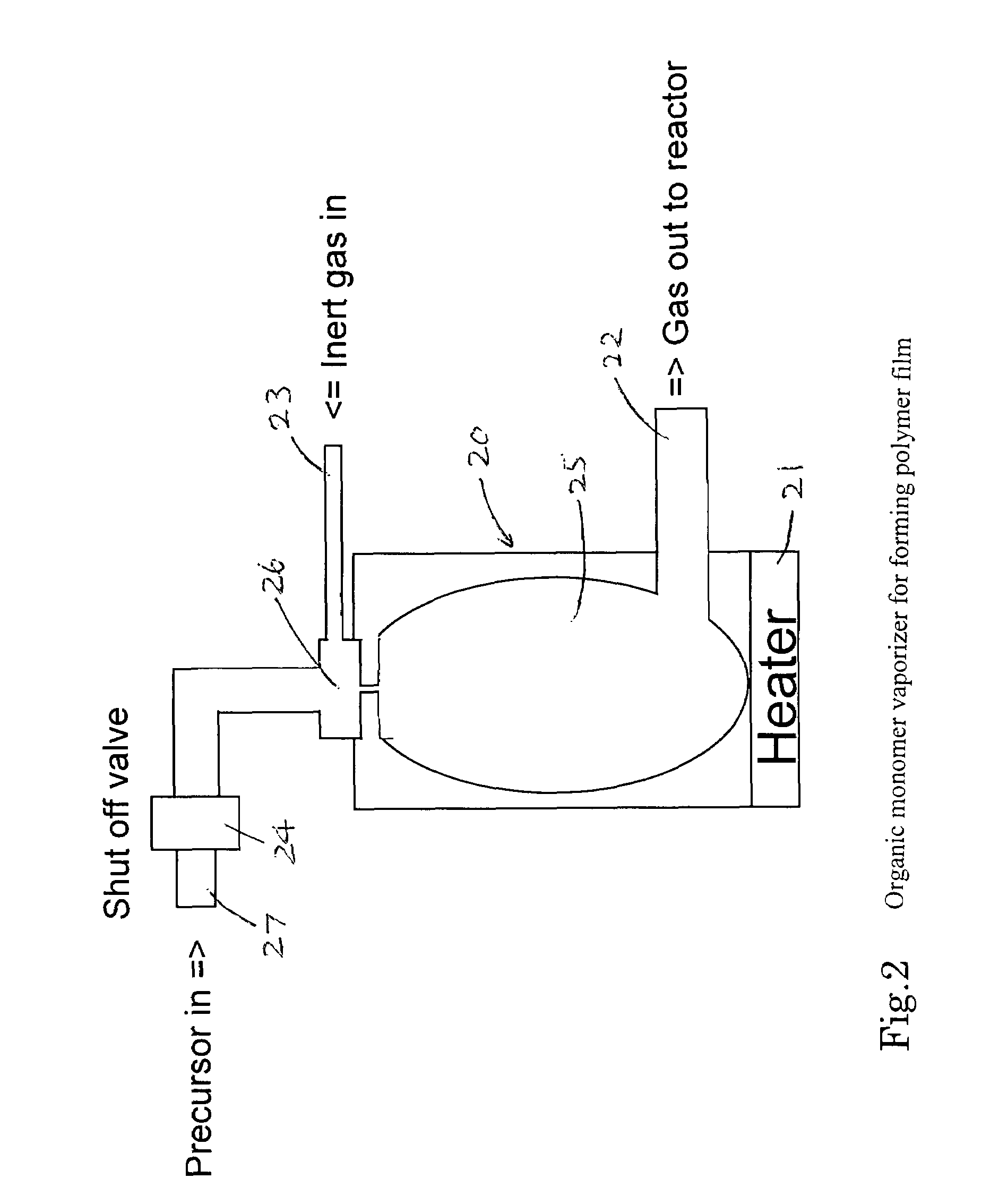

Method of forming a carbon polymer film using plasma CVD

ActiveUS20070218705A1Improve featuresFunction increaseLiquid surface applicatorsPhotomechanical apparatusCapacitanceBoiling point

A method forms a hydrocarbon-containing polymer film on a semiconductor substrate by a capacitively-coupled plasma CVD apparatus. The method includes the steps of: vaporizing a hydrocarbon-containing liquid monomer (CαHβXγ, wherein α and β are natural numbers of 5 or more; γ is an integer including zero; X is O, N or F) having a boiling point of about 20° C. to about 350° C.; introducing the vaporized gas into a CVD reaction chamber inside which a substrate is placed; and forming a hydrocarbon-containing polymer film on the substrate by plasma polymerization of the gas.

Owner:ASM JAPAN

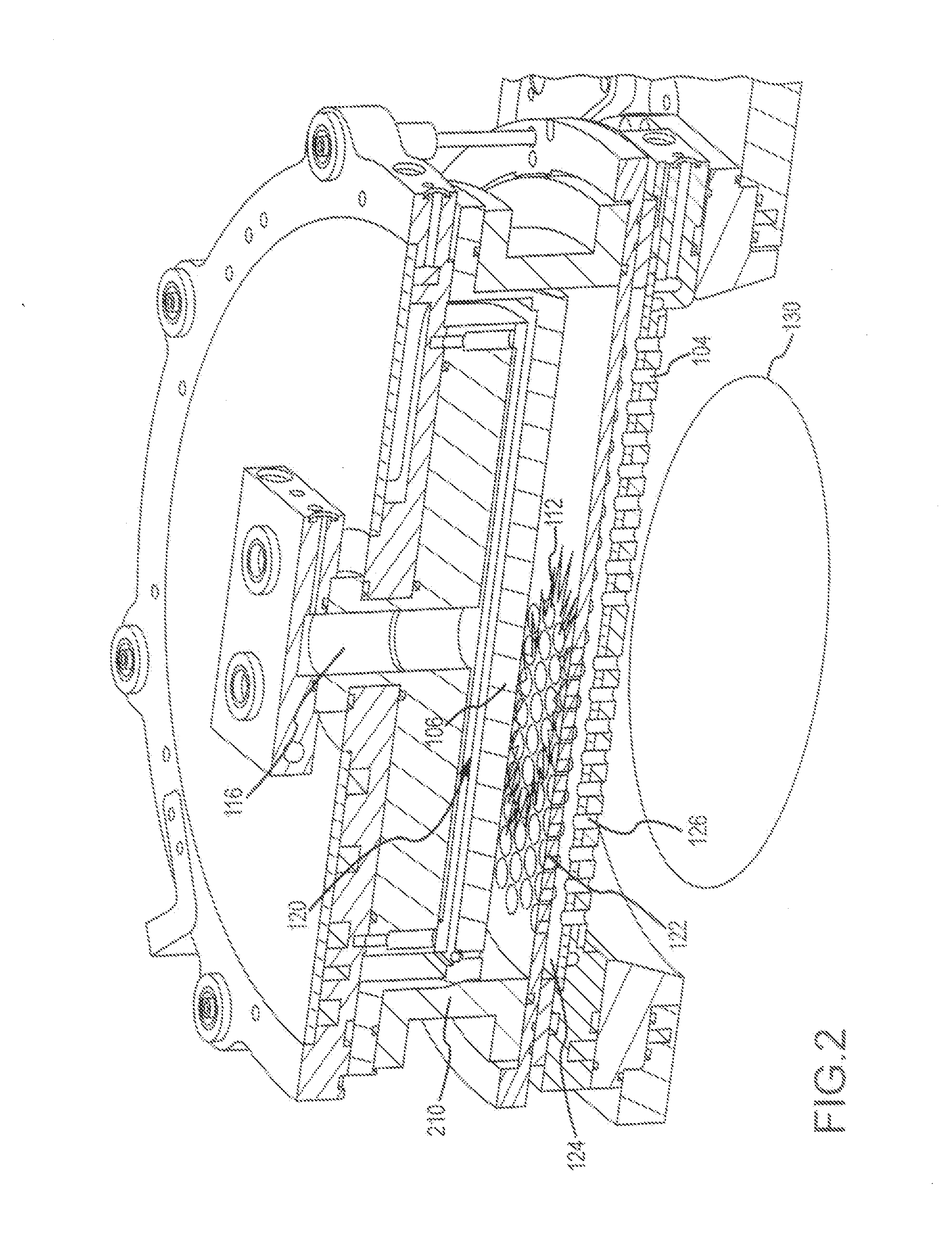

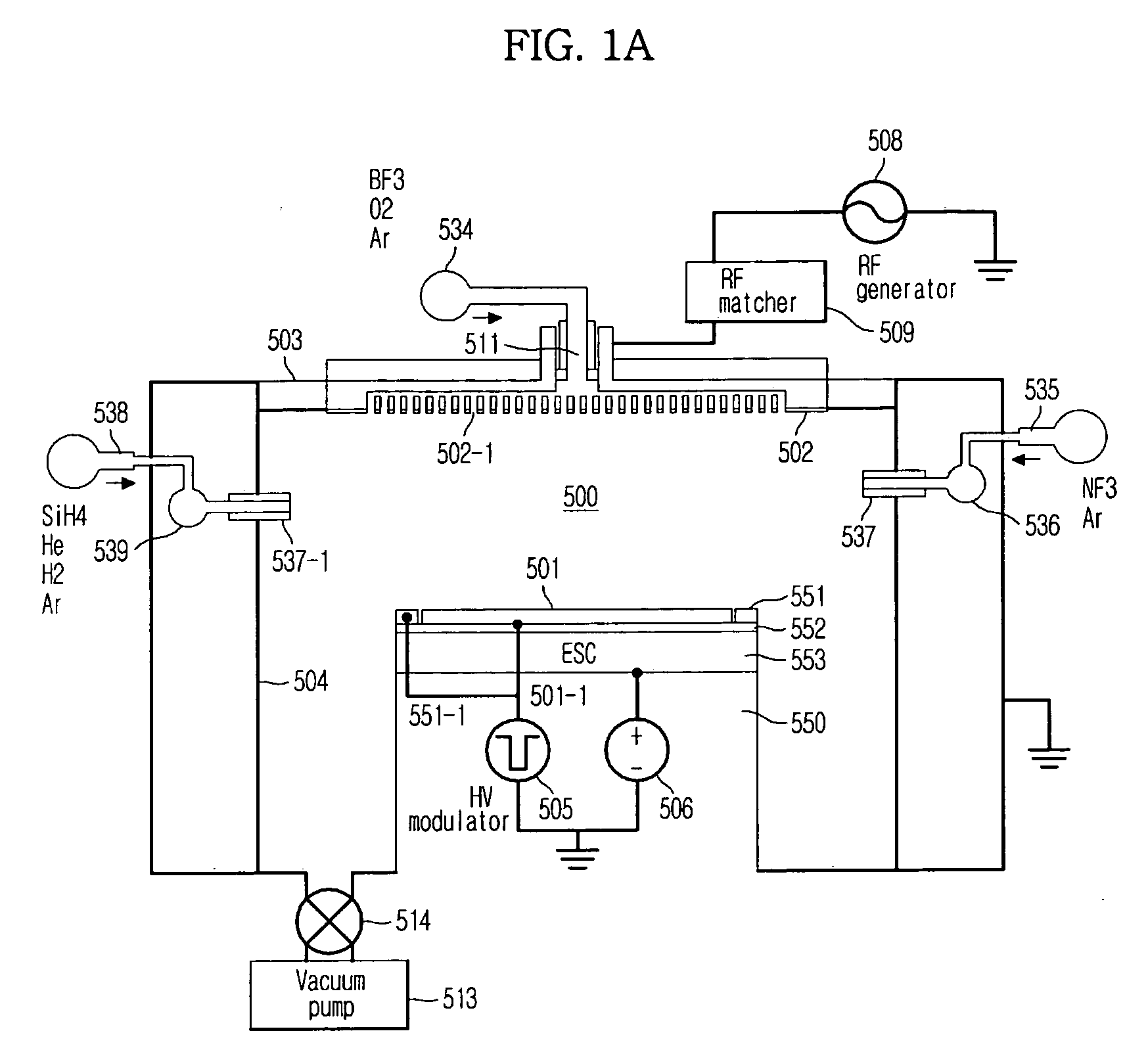

Rps assisted RF plasma source for semiconductor processing

ActiveUS20150221479A1CellsSemiconductor/solid-state device testing/measurementCapacitanceRemote plasma

Owner:APPLIED MATERIALS INC

Method of forming a carbon polymer film using plasma CVD

ActiveUS7504344B2Improve featuresFunction increaseLiquid surface applicatorsPhotomechanical apparatusCapacitanceBoiling point

A method of forming a hydrocarbon-containing polymer film on a semiconductor substrate by a capacitively-coupled plasma CVD apparatus. The method includes the steps of: vaporizing a hydrocarbon-containing liquid monomer (CαHβXγ, wherein α and β are natural numbers of 5 or more; γ is an integer including zero; X is O, N or F) having a boiling point of about 20° C. to about 350° C. which is not substituted by a vinyl group or an acetylene group; introducing the vaporized gas into a CVD reaction chamber inside which a substrate is placed; and forming a hydrocarbon-containing polymer film on the substrate by plasma polymerization of the gas.

Owner:ASM JAPAN

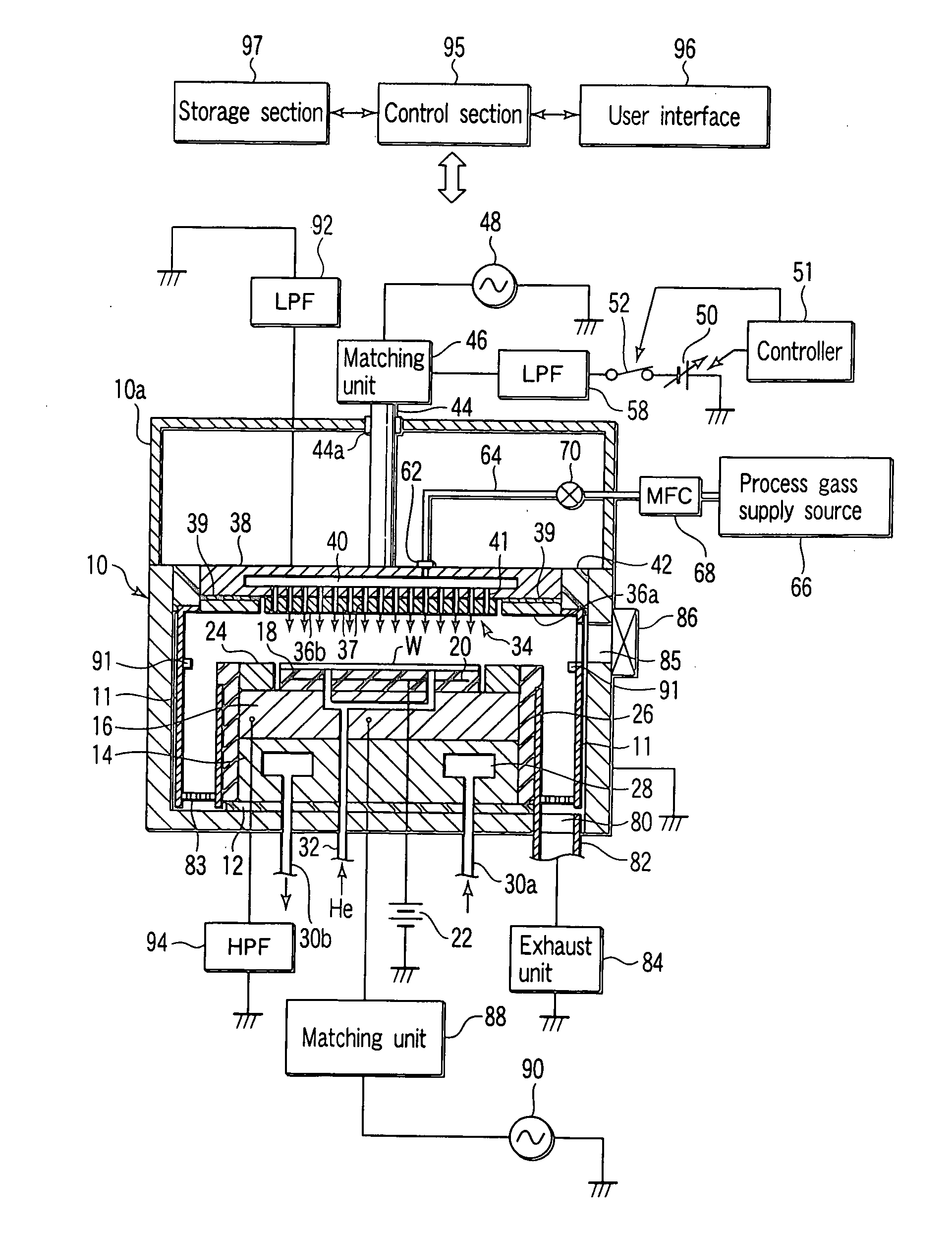

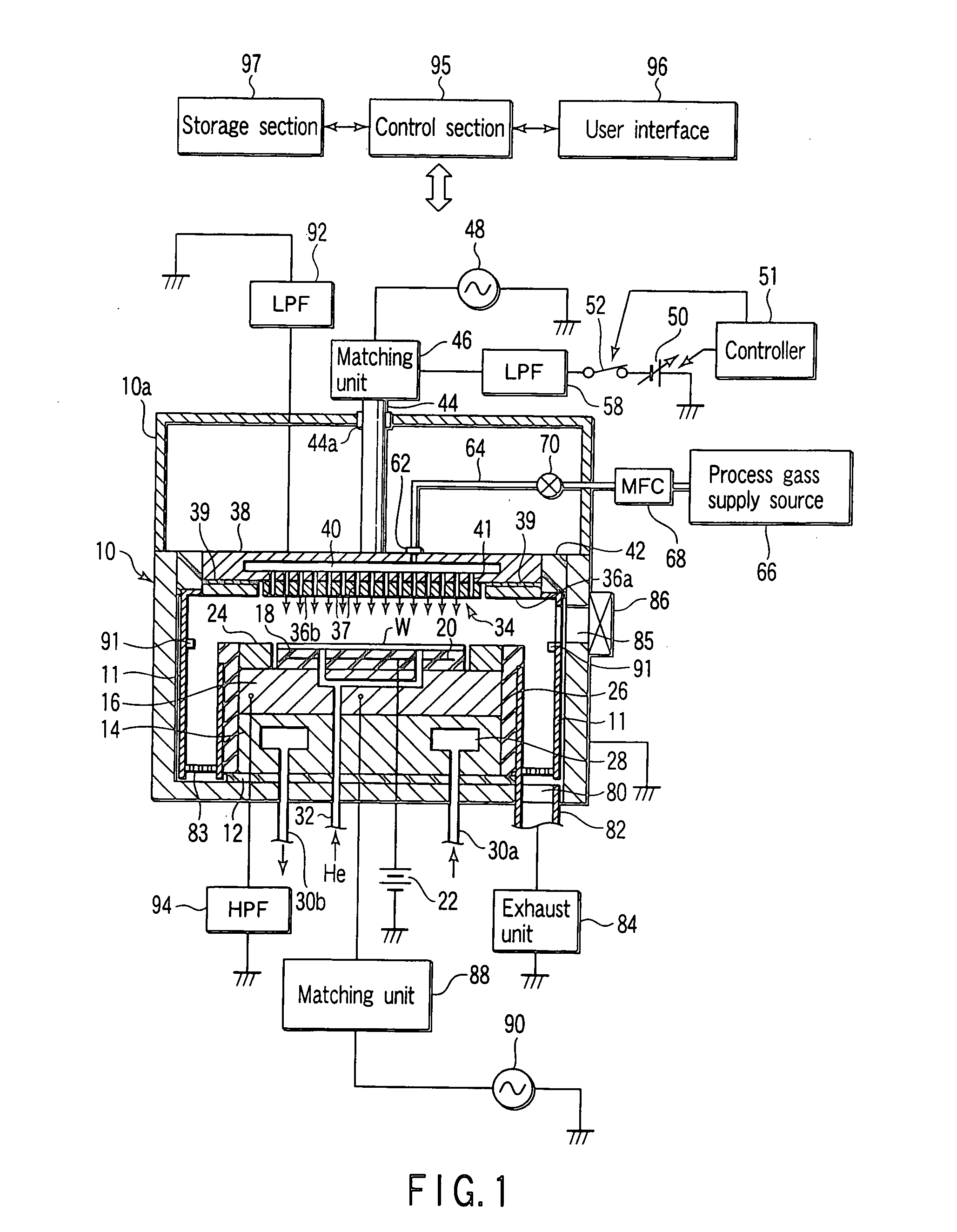

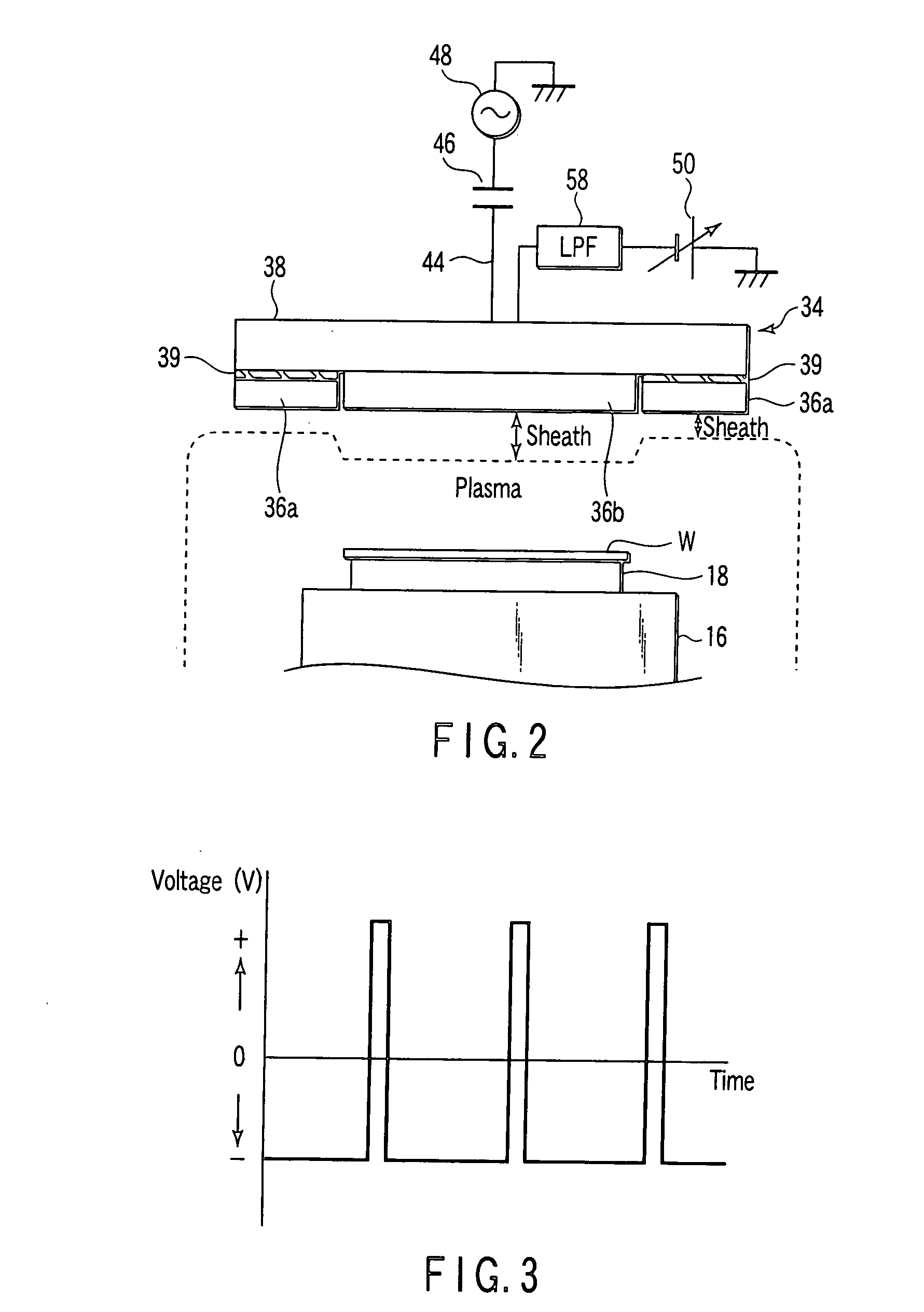

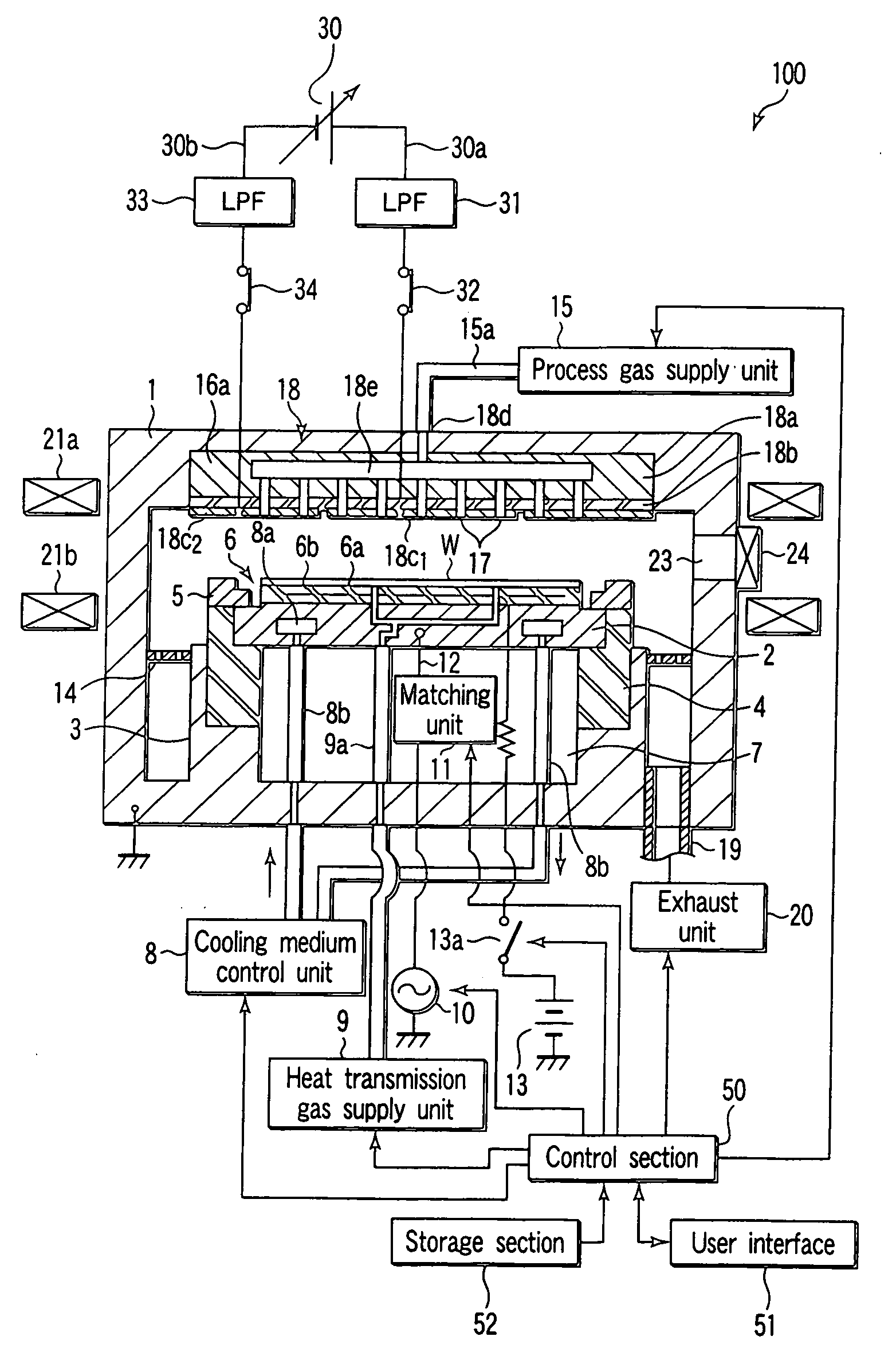

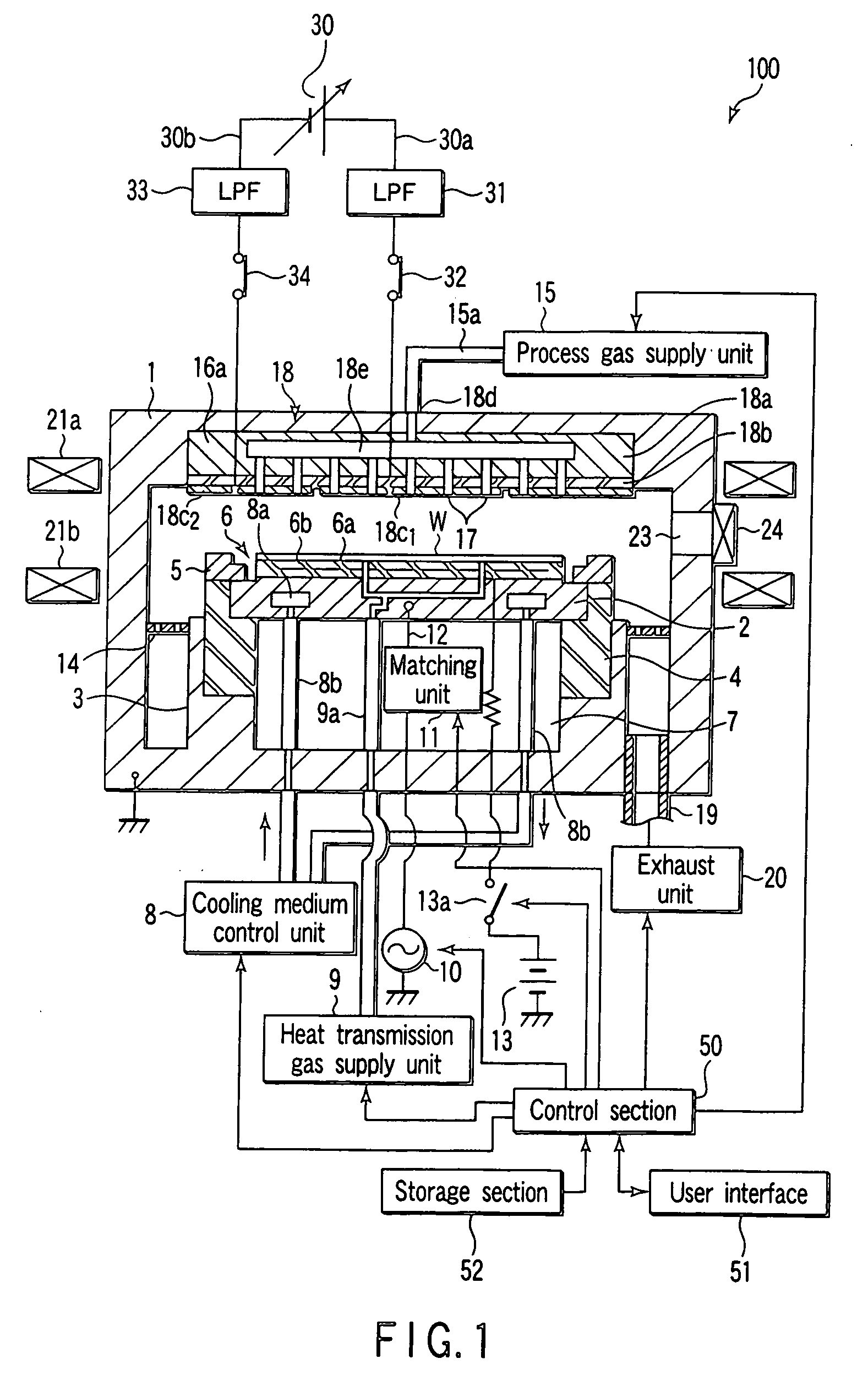

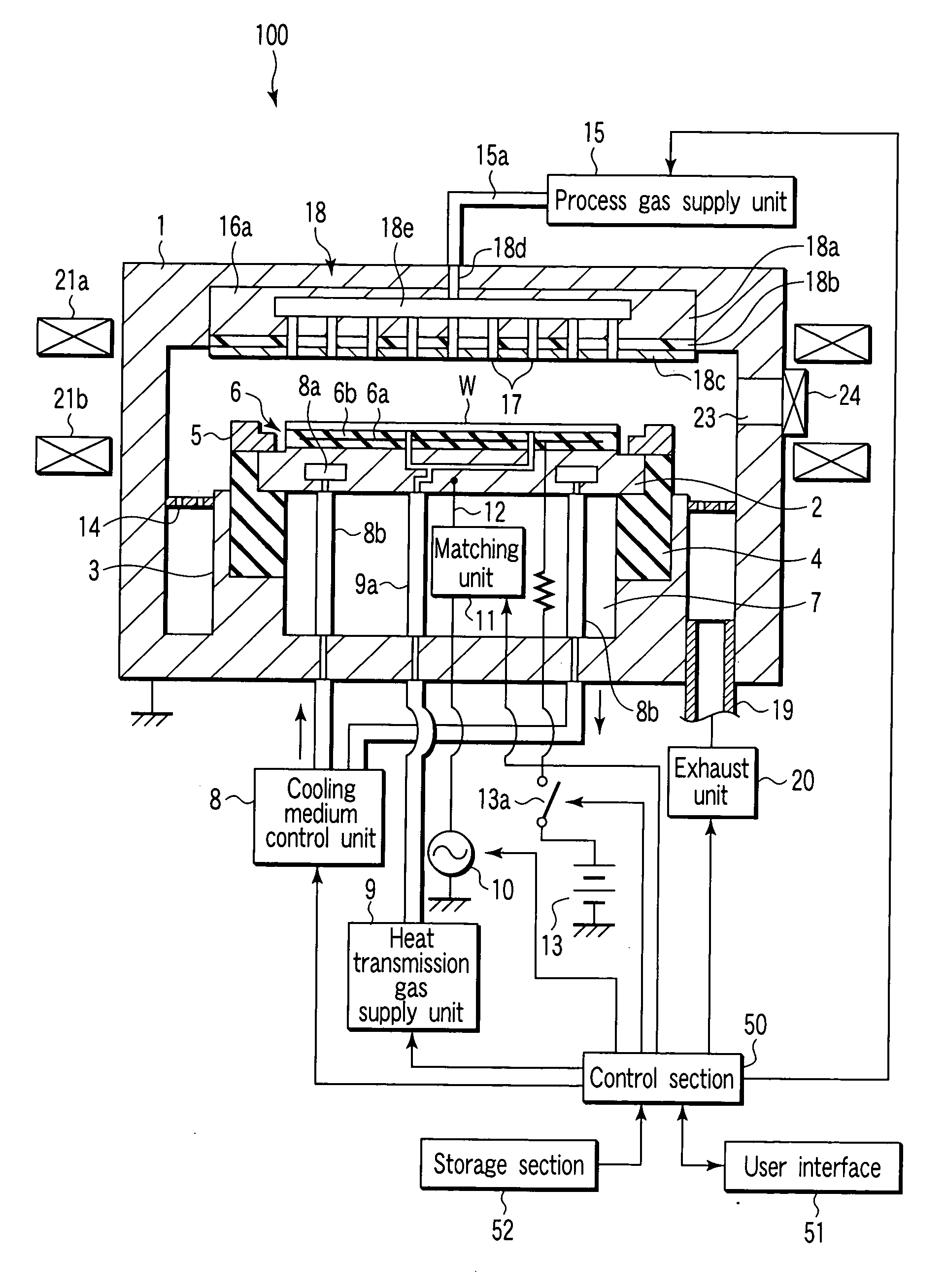

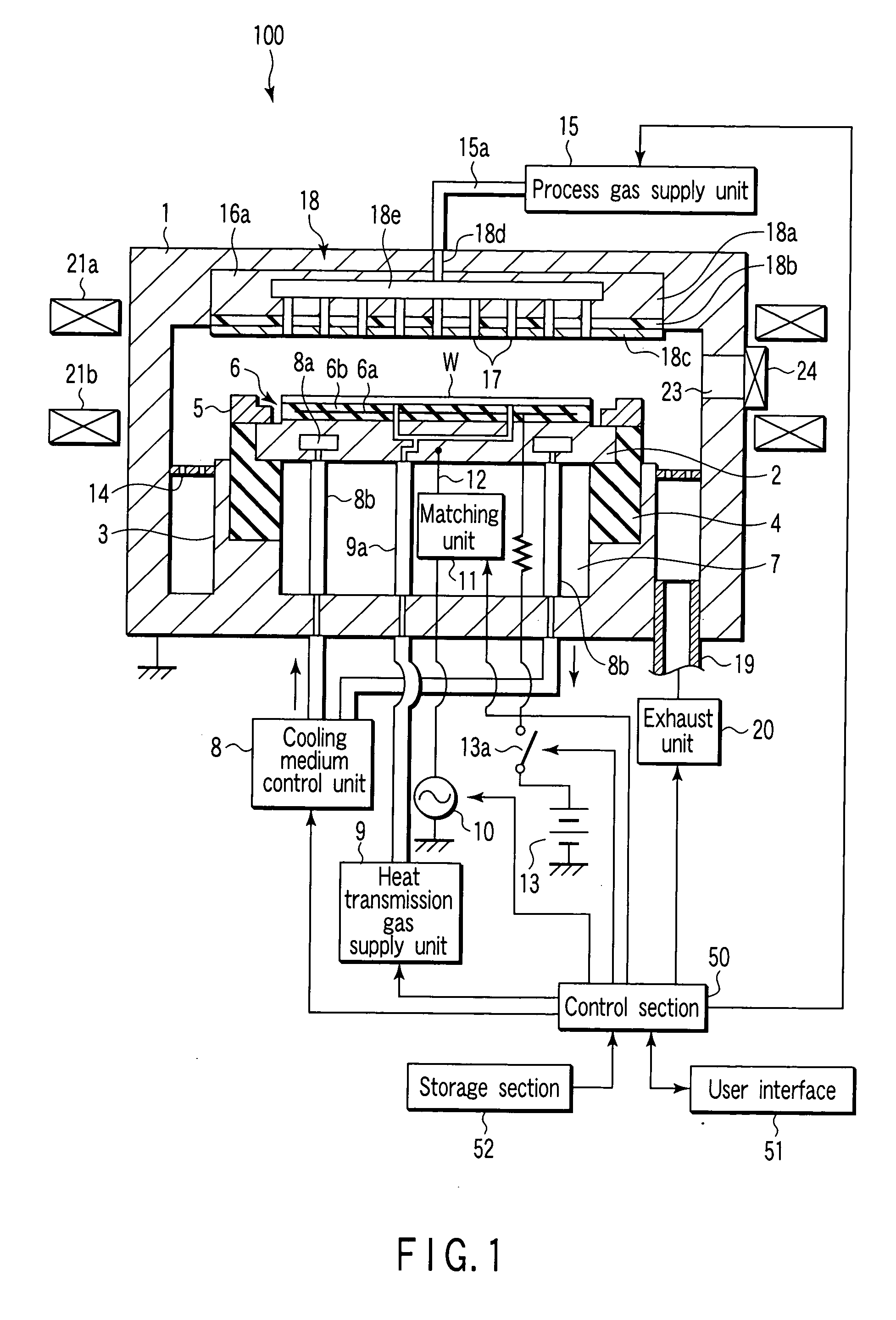

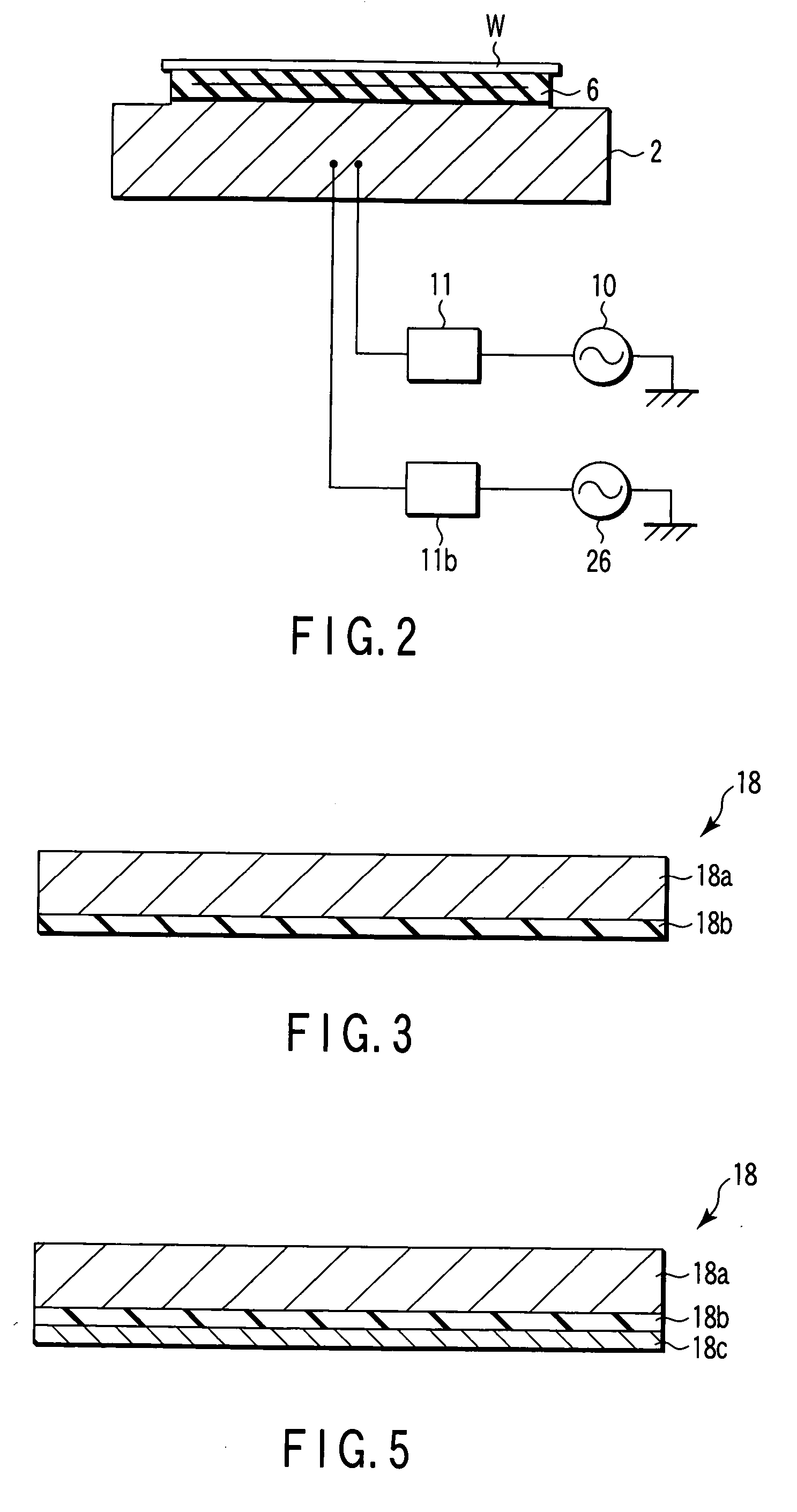

Capacitive coupling plasma processing apparatus and method for using the same

ActiveUS20060219363A1High plasma uniformityImprove uniformityElectric discharge tubesElectric arc lampsCapacitanceCapacitive coupling

A plasma processing apparatus includes a process container configured to accommodate a target substrate and to be vacuum-exhausted. A first electrode and a second electrode are disposed opposite each other within the process container. The first electrode includes an outer portion and an inner portion both facing the second electrode such that the outer portion surrounds the inner portion. An RF power supply is configured to apply an RF power to the outer portion of the first electrode. A DC power supply is configured to apply a DC voltage to the inner portion of the first electrode. A process gas supply unit is configured to supply a process gas into the process container, wherein plasma of the process gas is generated between the first electrode and the second electrode.

Owner:TOKYO ELECTRON LTD

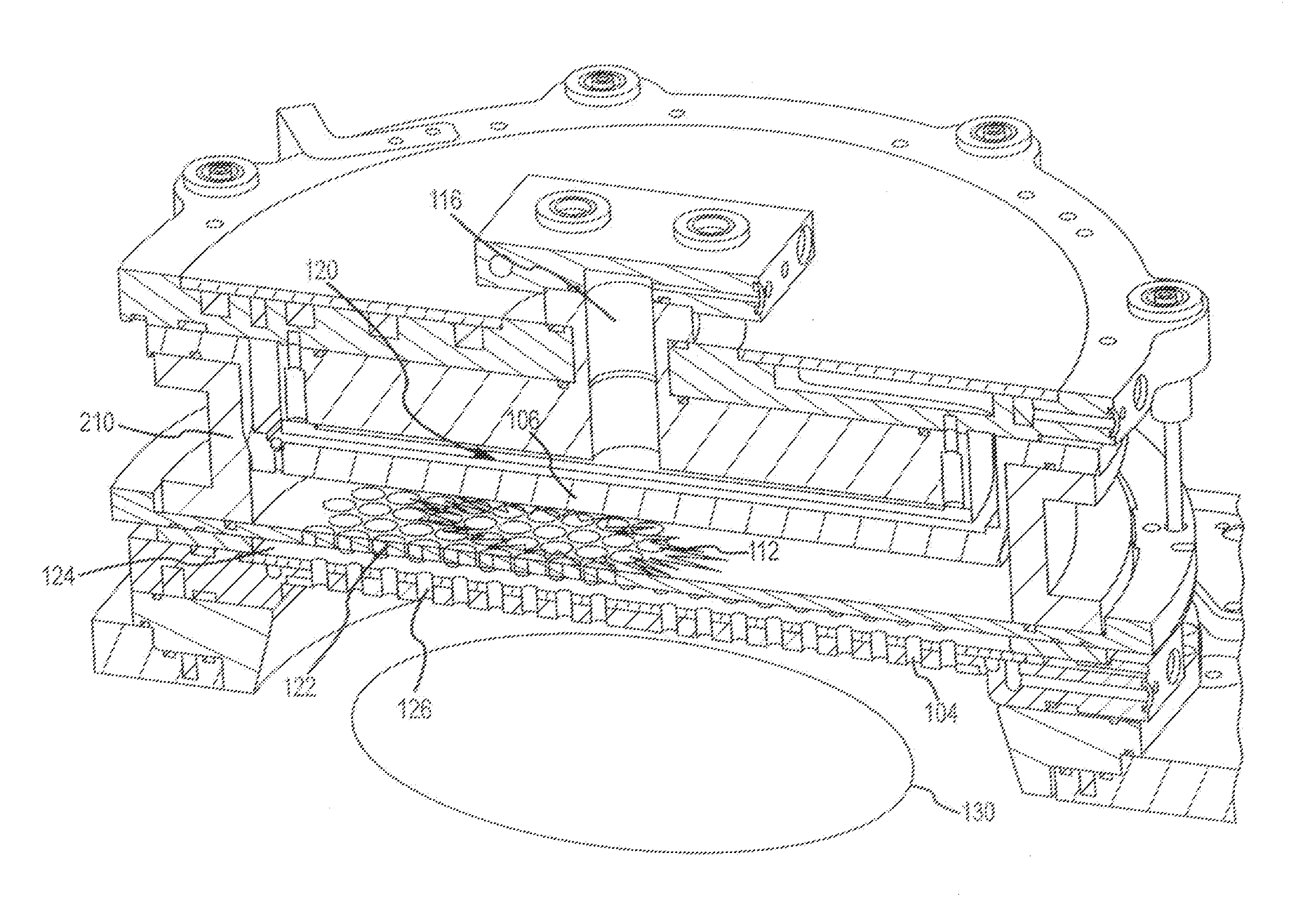

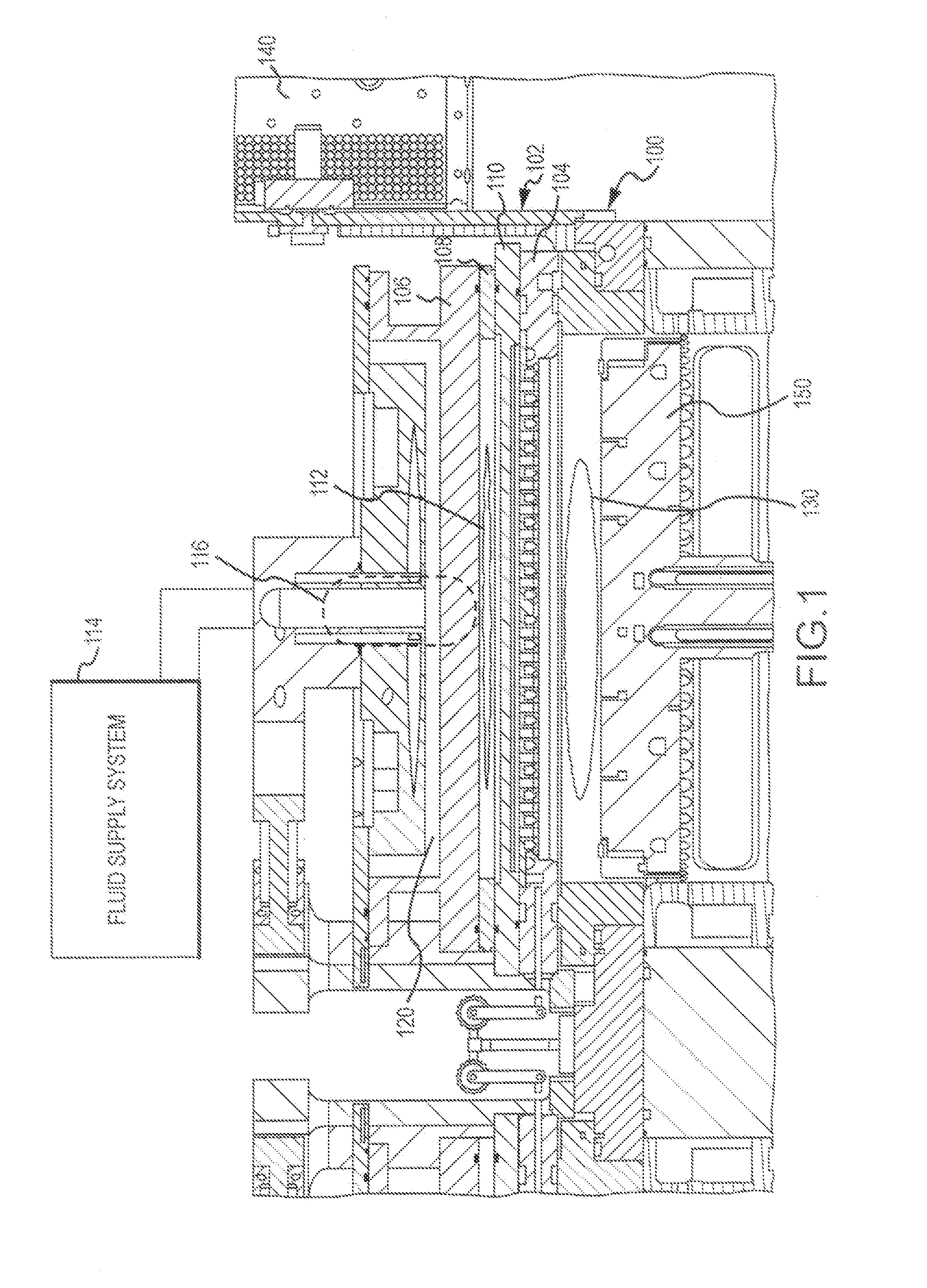

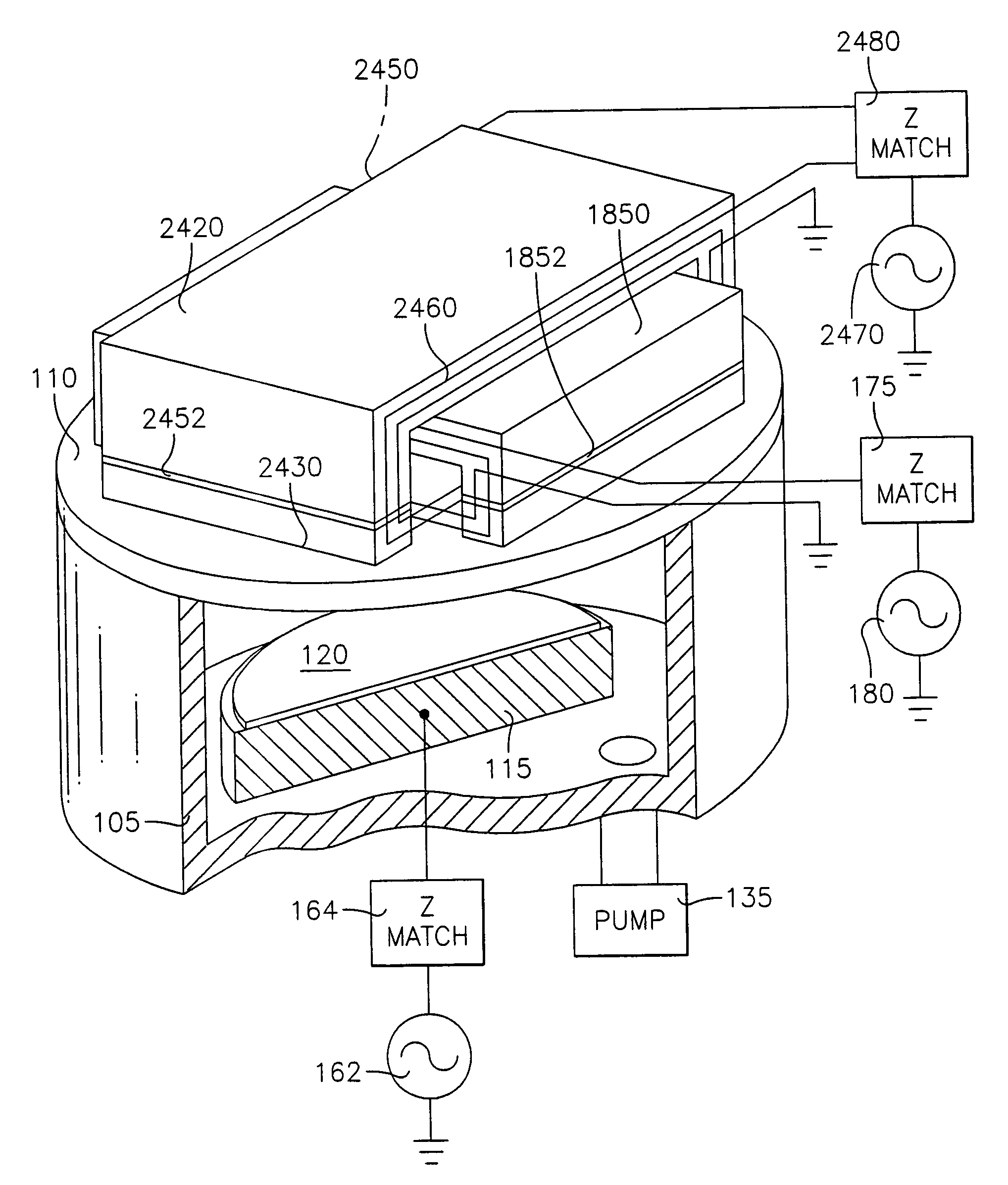

Semiconductor processing system and methods using capacitively coupled plasma

ActiveUS20130082197A1Conducive to environmental controlPrecise control of etchRadiation/particle handlingElectrode and associated part arrangementsCapacitanceSemiconductor

Substrate processing systems are described that have a capacitively coupled plasma (CCP) unit positioned inside a process chamber. The CCP unit may include a plasma excitation region formed between a first electrode and a second electrode. The first electrode may include a first plurality of openings to permit a first gas to enter the plasma excitation region, and the second electrode may include a second plurality of openings to permit an activated gas to exit the plasma excitation region. The system may further include a gas inlet for supplying the first gas to the first electrode of the CCP unit, and a pedestal that is operable to support a substrate. The pedestal is positioned below a gas reaction region into which the activated gas travels from the CCP unit.

Owner:APPLIED MATERIALS INC

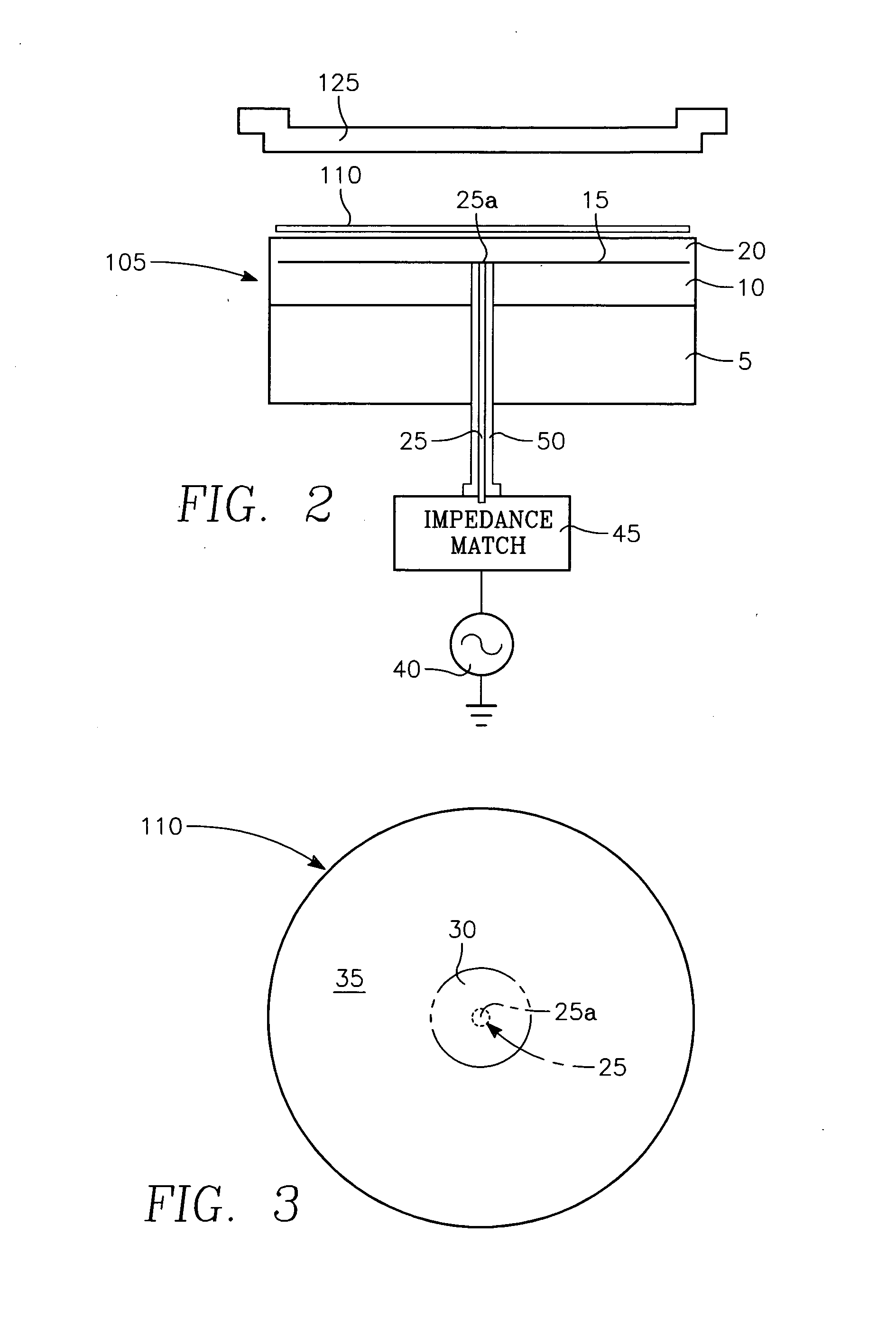

Capacitively coupled plasma reactor with uniform radial distribution of plasma

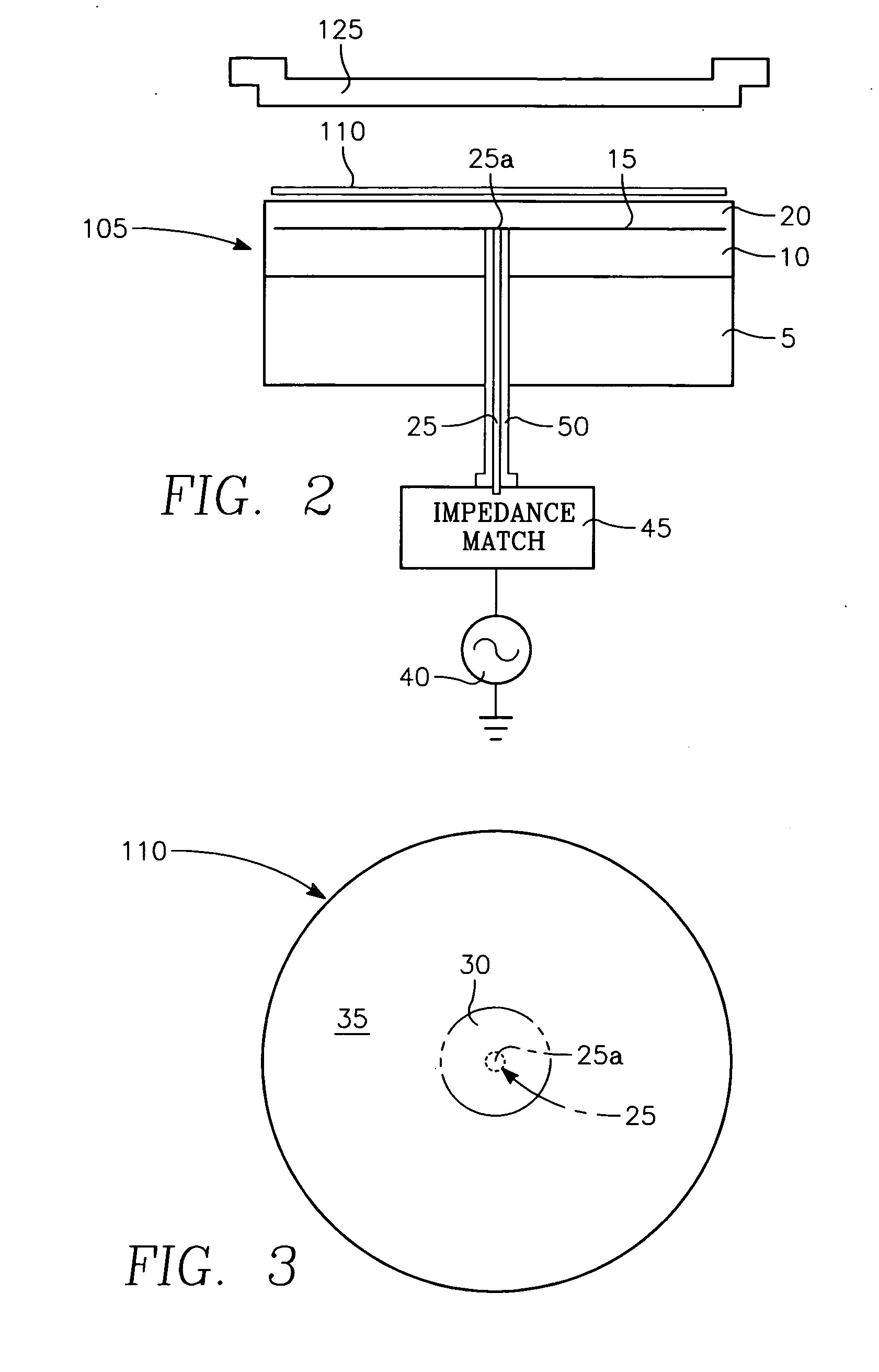

InactiveUS6900596B2Enhances plasma ion density uniformityImprove density uniformityElectric discharge tubesElectric arc lampsCapacitanceElectrical conductor

A plasma reactor for processing a semiconductor wafer includes a side wall and an overhead ceiling defining a chamber, a workpiece support cathode within the chamber having a working surface facing the ceiling for supporting a semiconductor workpiece, process gas inlets for introducing a process gas into the chamber and an RF bias power generator having a bias power frequency. There is a bias power feed point at the working surface and an RF conductor is connected between the RF bias power generator and the bias power feed point at the working surface. A dielectric sleeve surrounds a portion of the RF conductor, the sleeve having an axial length along the RF conductor, a dielectric constant and an axial location along the RF conductor, the length, dielectric constant and location of the sleeve being such that the sleeve provides a reactance that enhances plasma ion density uniformity over the working surface. In accordance with a further aspect, the reactor can include an annular RF coupling ring having an inner diameter corresponding generally to a periphery of the workpiece, the RF coupling ring extending a sufficient portion of a distance between the working surface and the overhead electrode to enhance plasma ion density near a periphery of the workpiece.

Owner:APPLIED MATERIALS INC

Capacitively coupled remote plasma source with large operating pressure range

InactiveUS20100101727A1System costExtension of timeElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceRadio frequency

A radio frequency (RF) coaxial resonator feeding a saltshaker-like gas distributing electrode assembly forms a capacitively coupled plasma source. This apparatus can generate plasma of high density over a wide pressure range and large process window. The system may be used as a remote radical-rich plasma source for materials surface processing.

Owner:JI HELIN

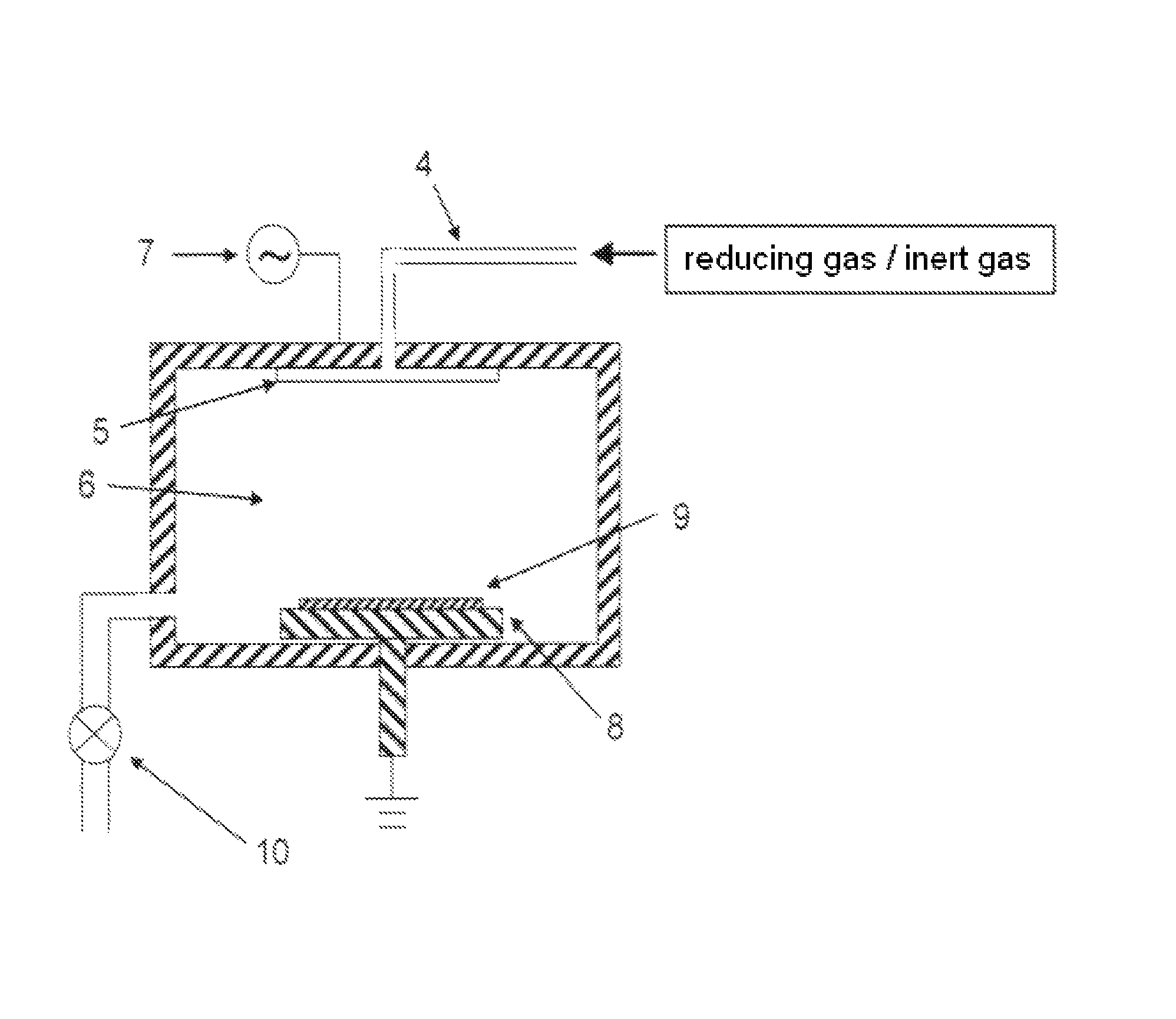

Method and apparatus for generating plasma

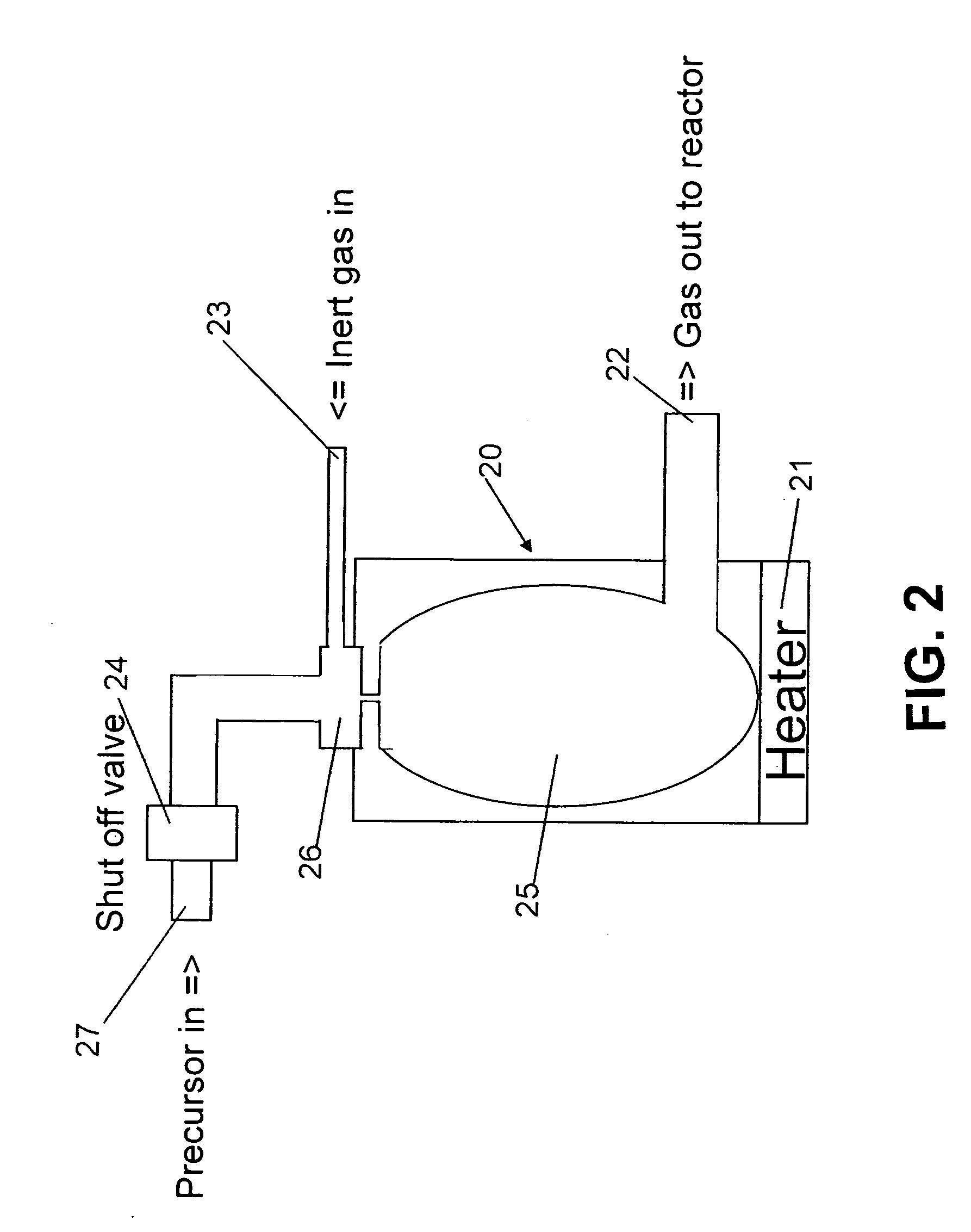

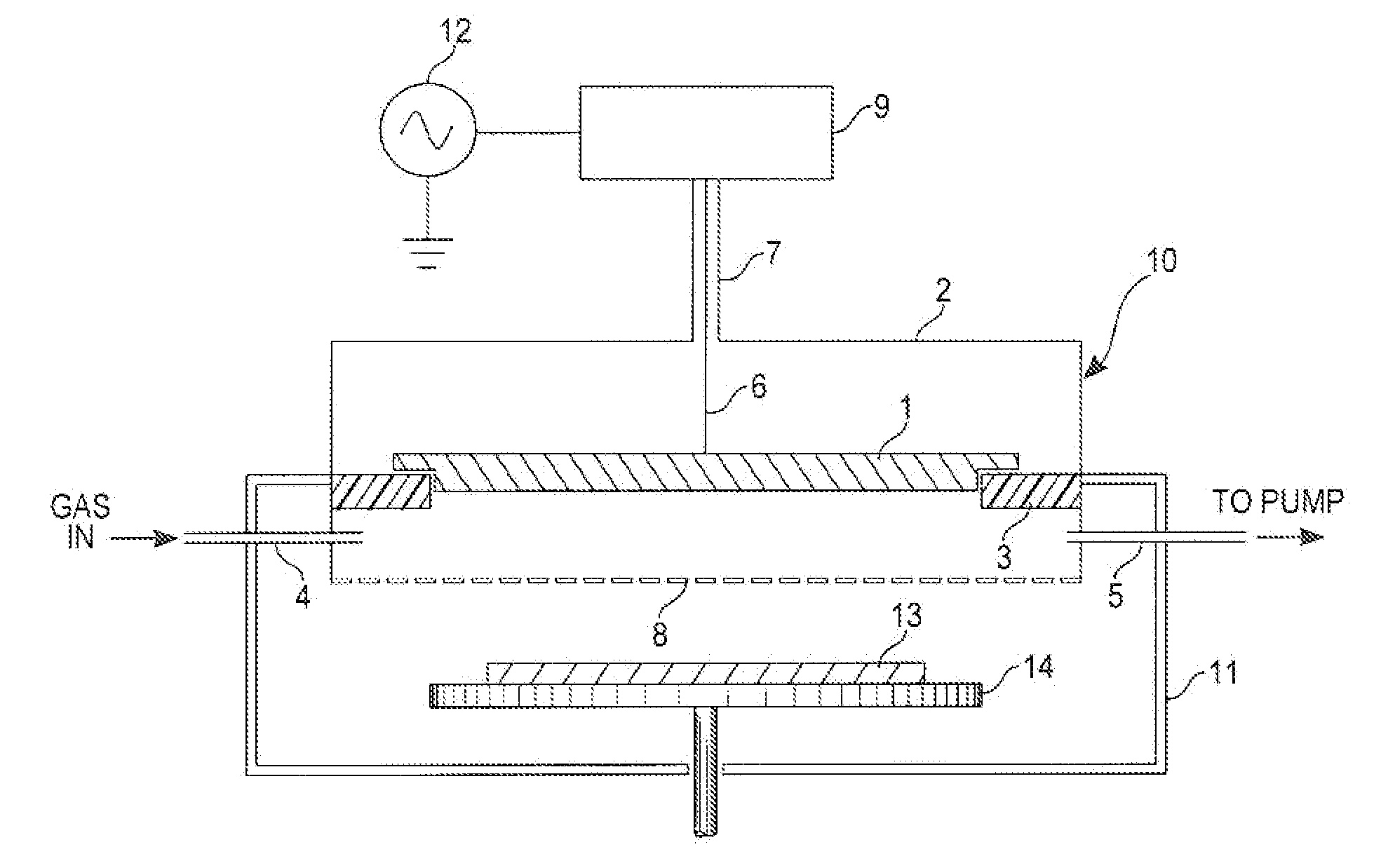

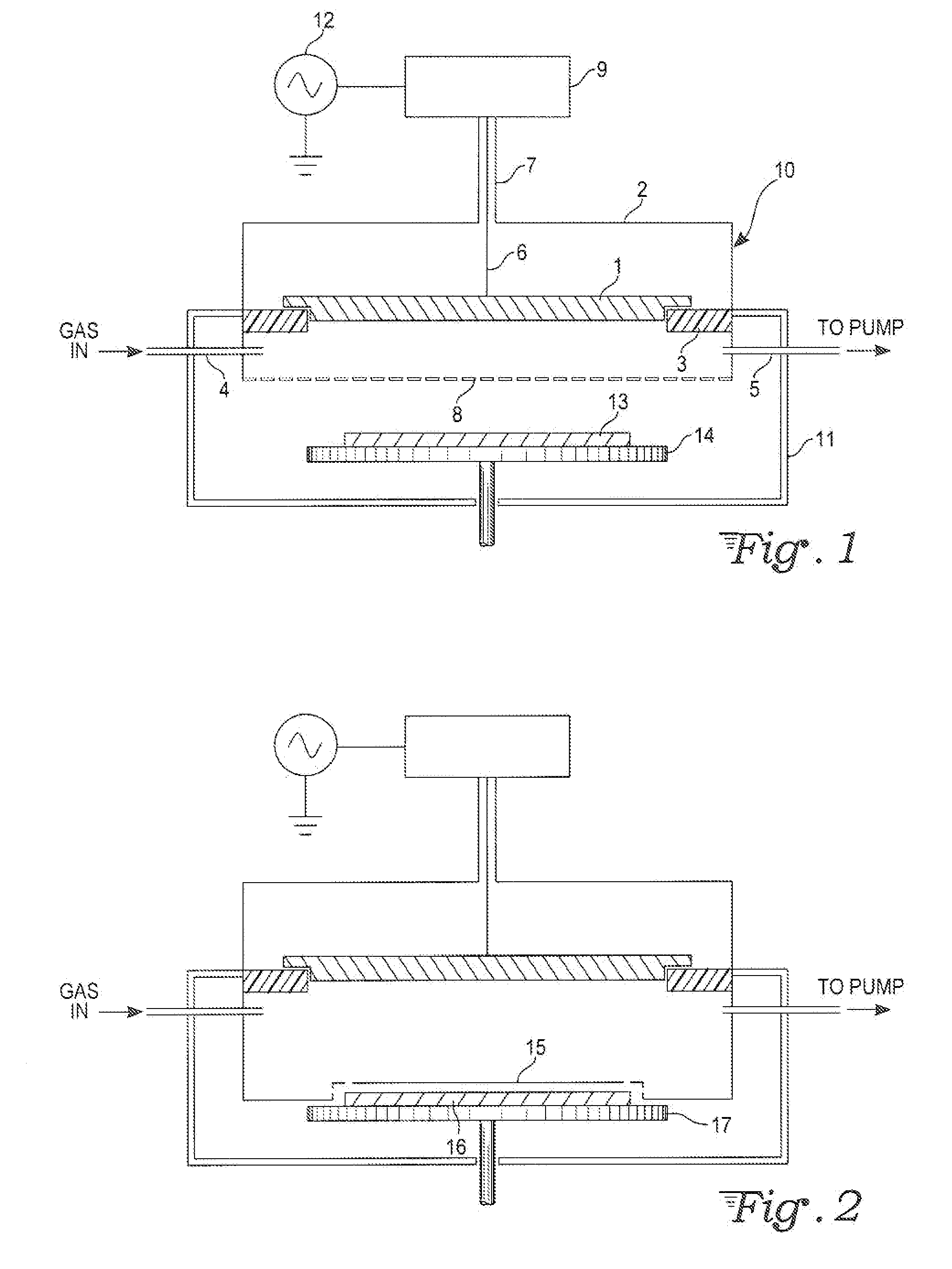

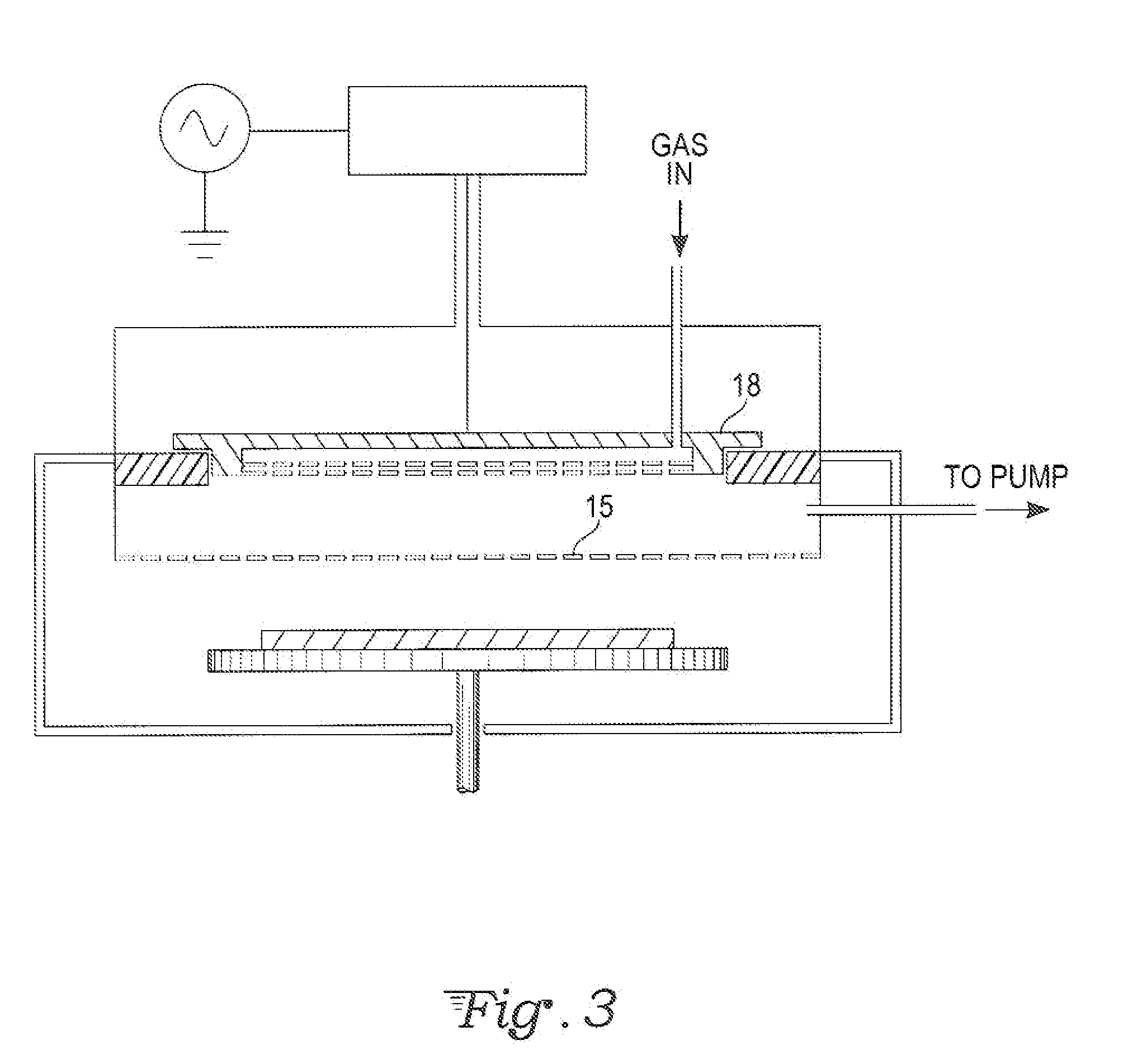

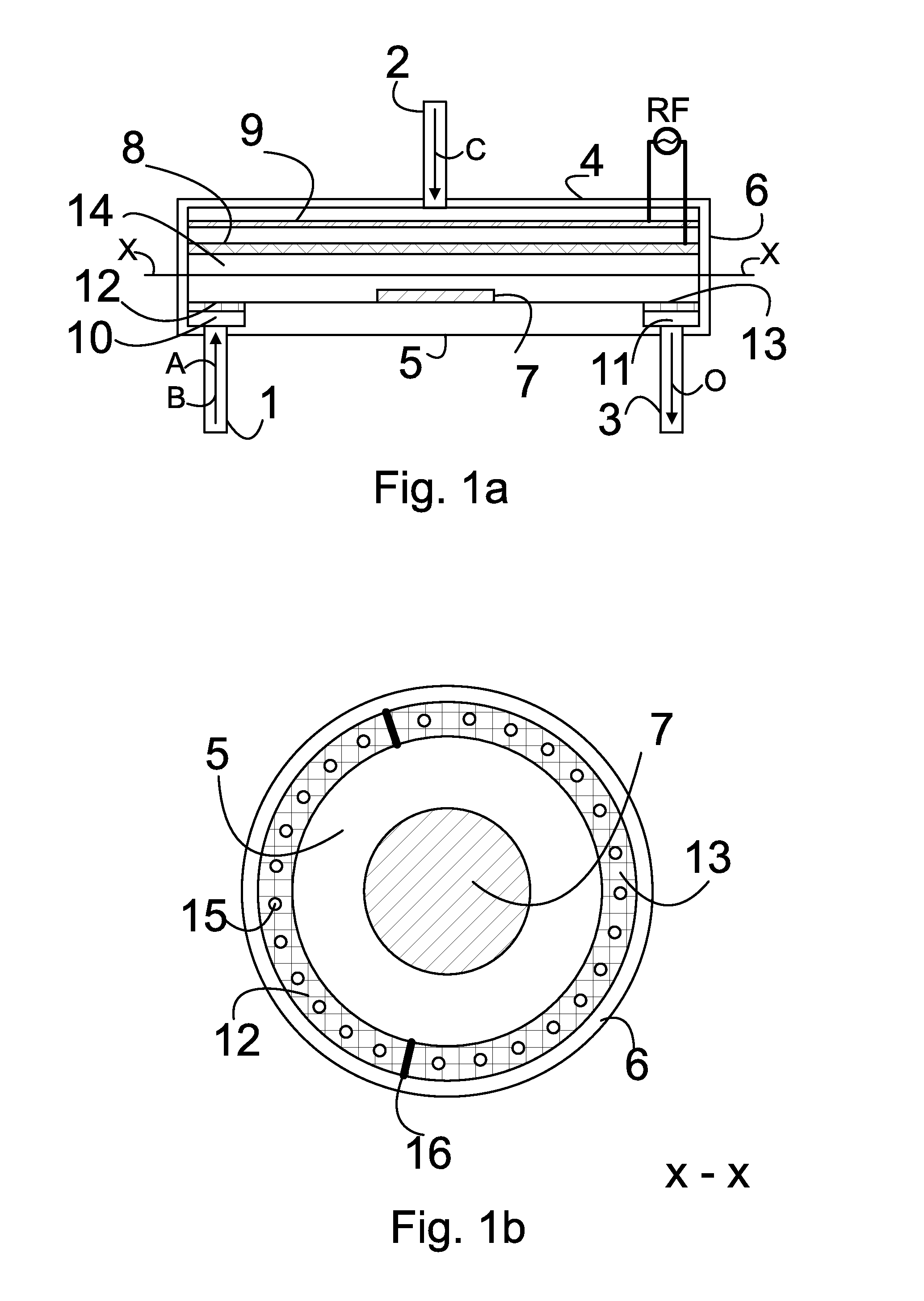

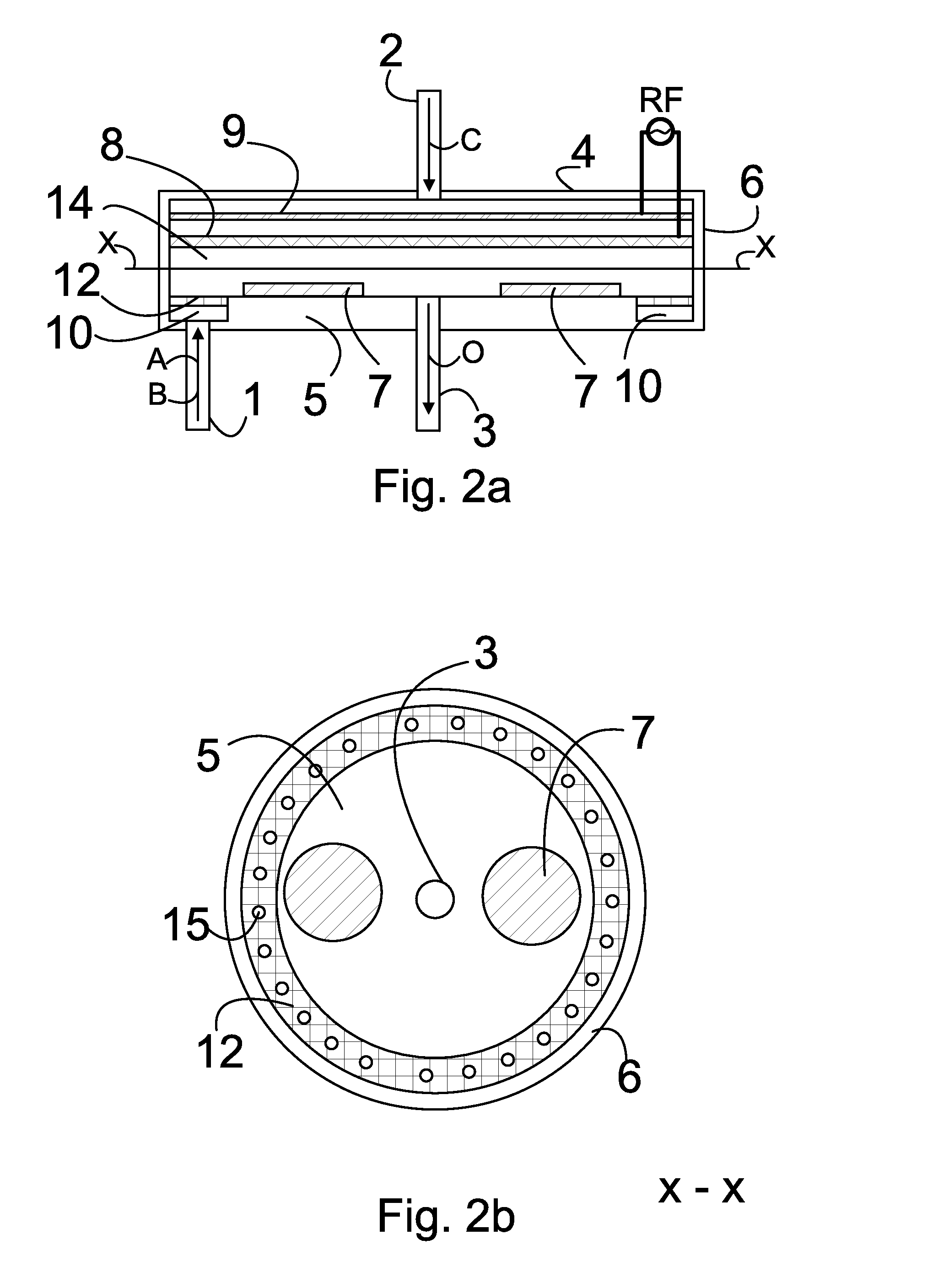

InactiveUS20110003087A1Easy to controlImprove uniformityElectric discharge tubesChemical vapor deposition coatingSurface reactionGas phase

A reaction chamber of a reactor for coating or treating a substrate by an atomic layer deposition process (ALD) by exposing the substrate to alternately repeated surface reactions of two or more gas-phase reactants. The reaction chamber is configured to generate capacitively coupled plasma and comprises a reaction space within said reaction chamber, a first inlet to guide gases into the reaction chamber and an outlet to lead gases out of the reaction chamber. The reaction chamber is configured to lead the two or more reactants into the reaction chamber such that the two or more reactants may flow through the reaction space across the substrate in a direction essentially parallel to the inner surface of the lower wall.

Owner:BENEQ OY

Capacitive-coupled plasma processing apparatus and method for processing substrate

ActiveUS20130032574A1Adjust electric field strengthIncrease the electric field strengthElectric discharge tubesDecorative surface effectsCapacitanceHigh pressure

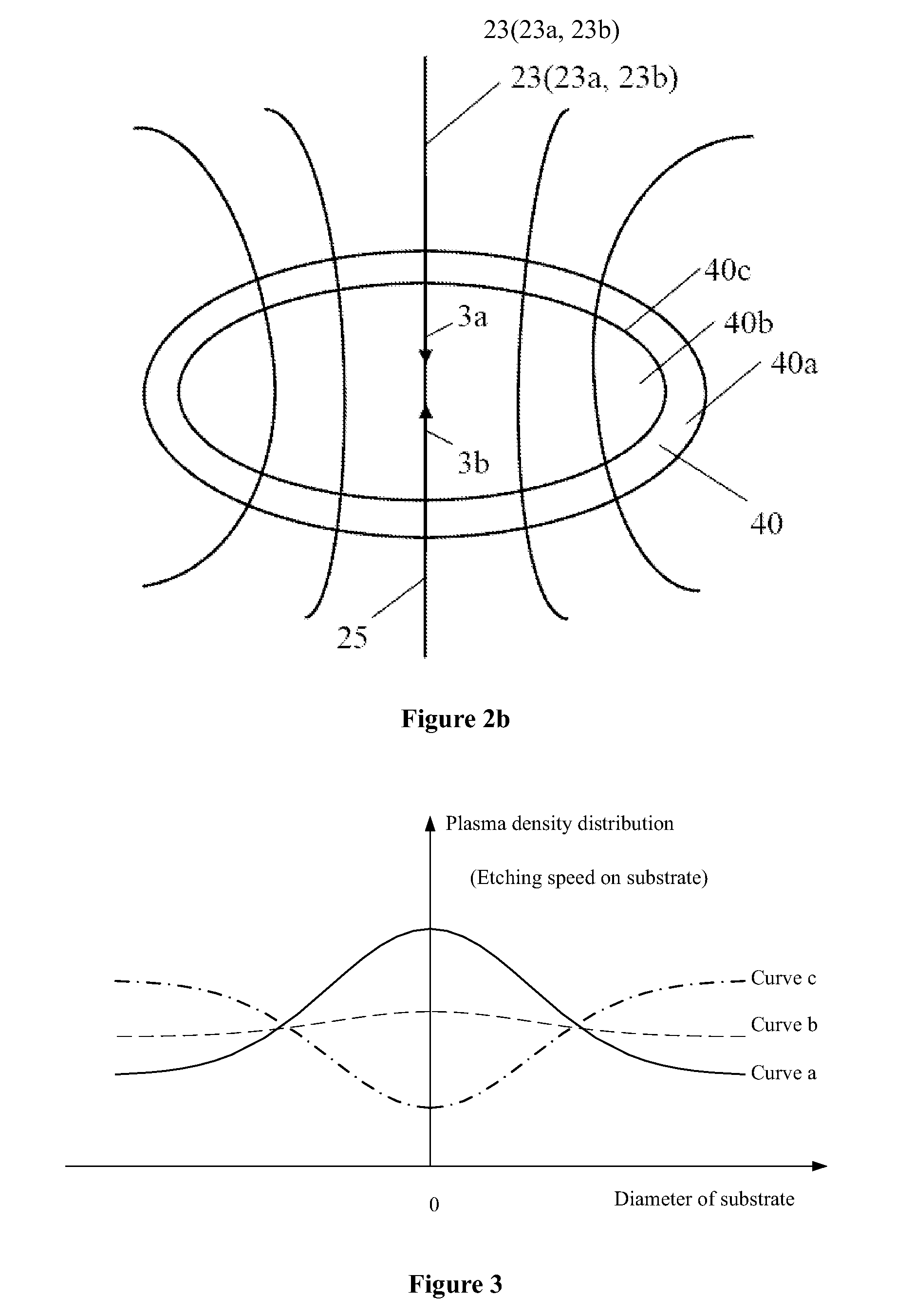

The present invention relates to a capacitive-coupled plasma processing apparatus, wherein an electric field regulating element, i.e., an “electric field lens”, is arranged in the reaction chamber to generate a regenerated electric field in a direction opposite to that of the original radio frequency electric field in the reaction chamber, so that the non-uniformity of etching rate on the surface of the substrate of the plasma incurred by the original radio frequency electric field is decreased; and the electric field regulating element, i.e., the “electric field lens”, further decreases the equivalent quality factor Q value of the reaction chamber, expands the radio frequency band, and prevents high-voltage electric arcing. The present invention further provides a method for processing the substrate using the processing apparatus.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

Silicon Carbide Gas Distribution Plate and RF Electrode for Plasma Etch Chamber

ActiveUS20080202688A1Low resistivitySuitable for useElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceGraphite

A showerhead for use in a capacitively-coupled plasma chamber and made of low resistivity bulk layer coated with CVD SiC. The bulk low resitivity material may be, for example, graphite, Silicon Carbide (SiC), converted graphite, SiC+C, etc. Sintered SiC may be used as the bulk material coated with CVD SiC to provide a showerhead that is suitable for use in a capacitively-coupled plasma chamber.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

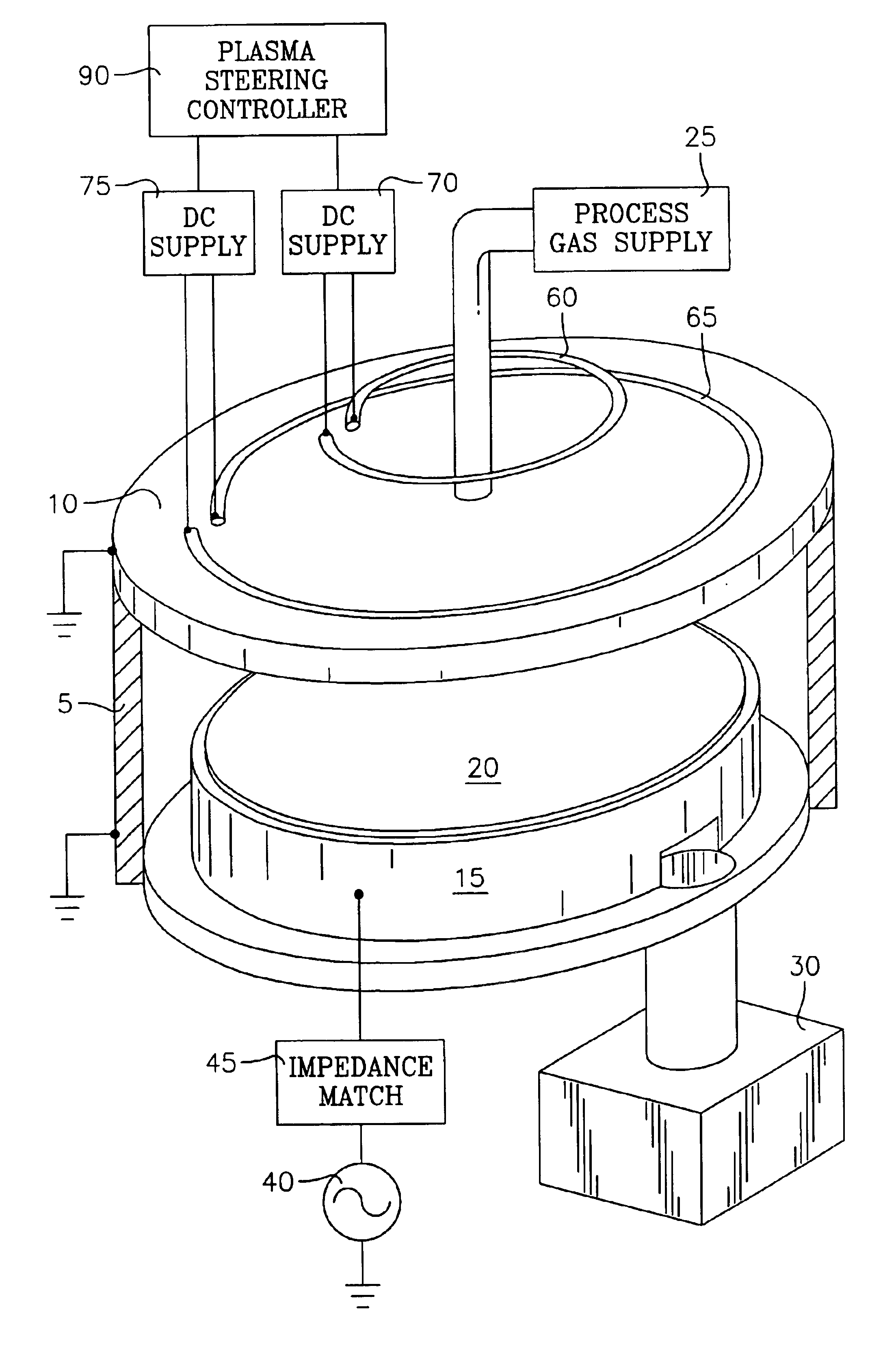

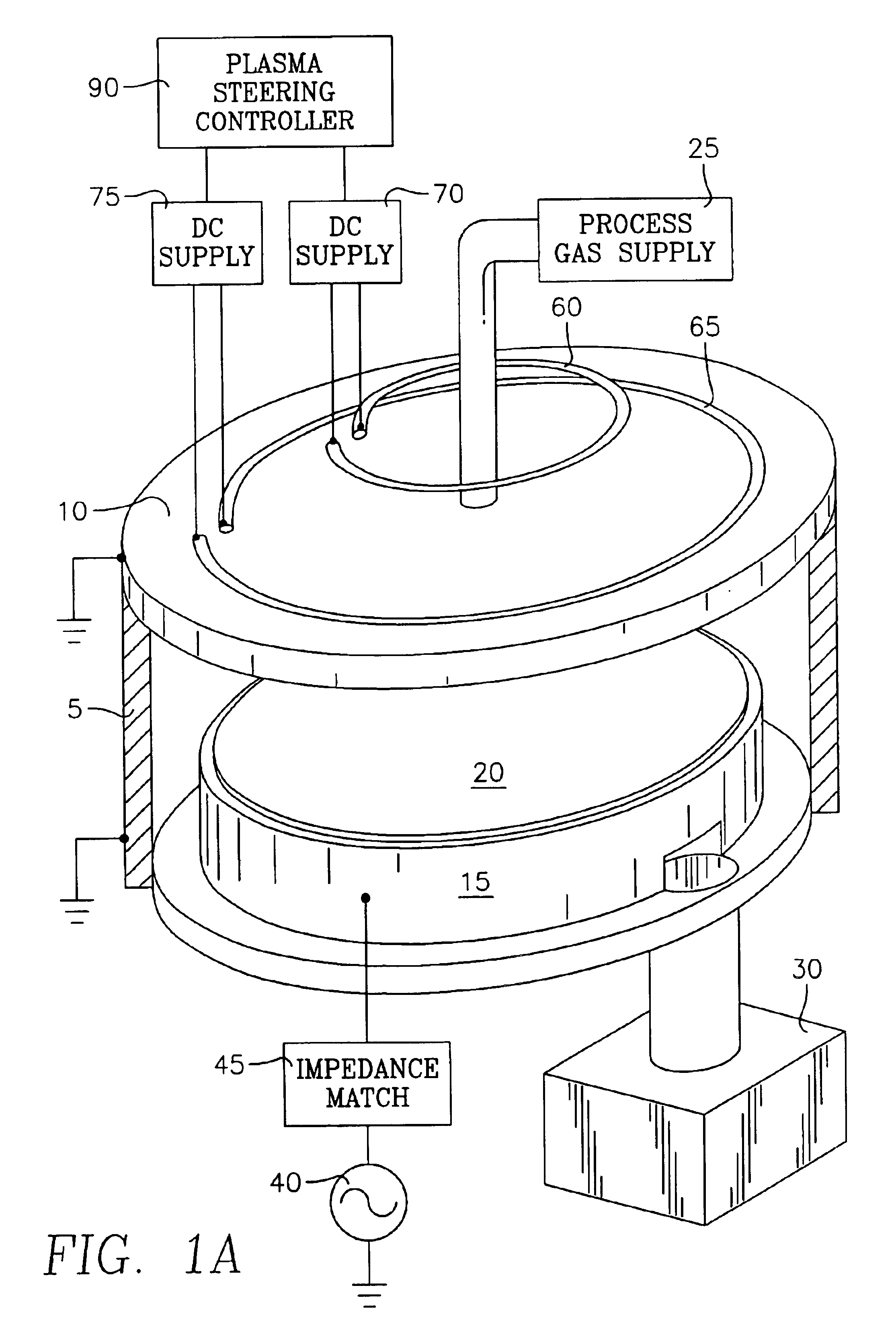

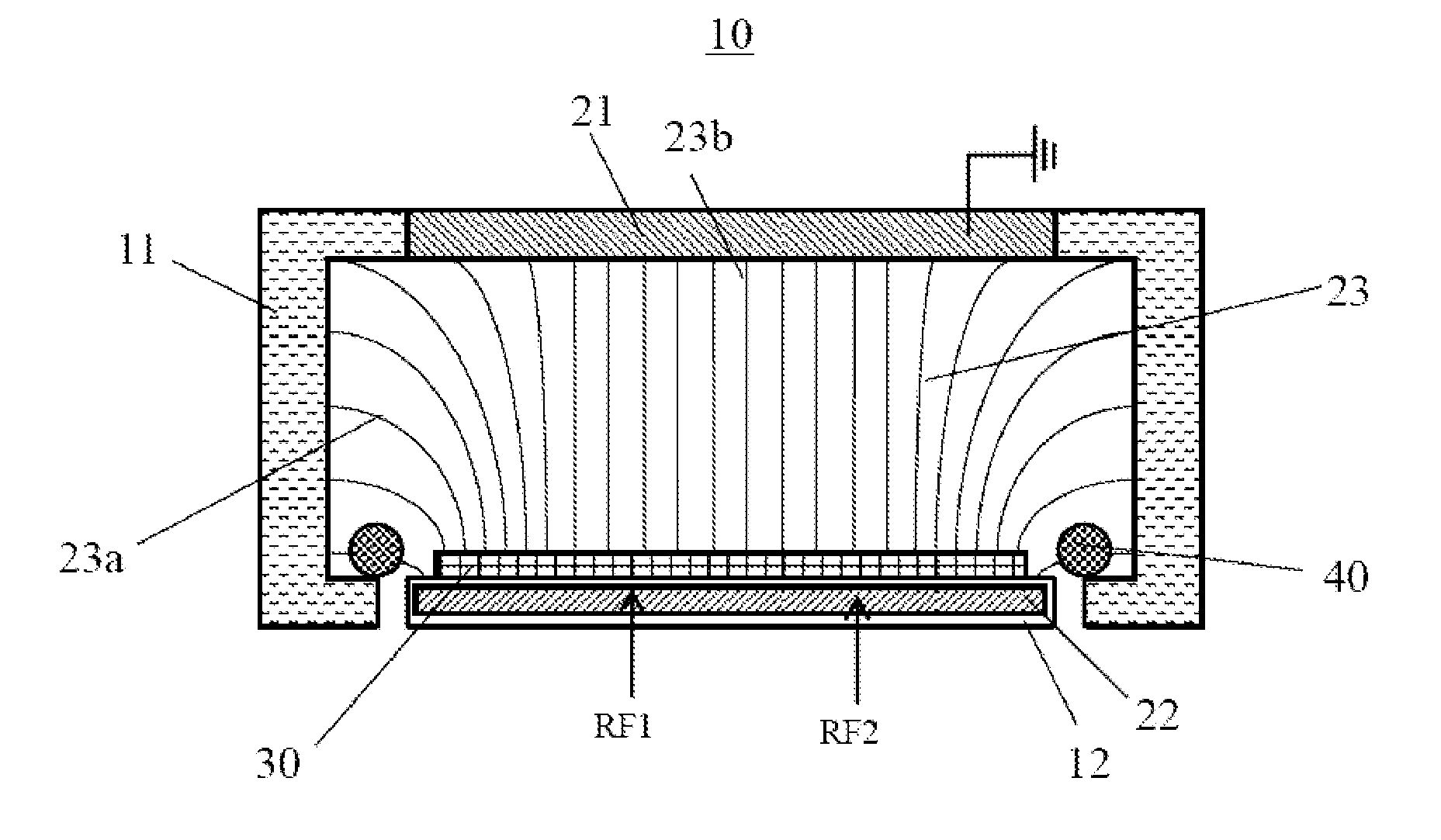

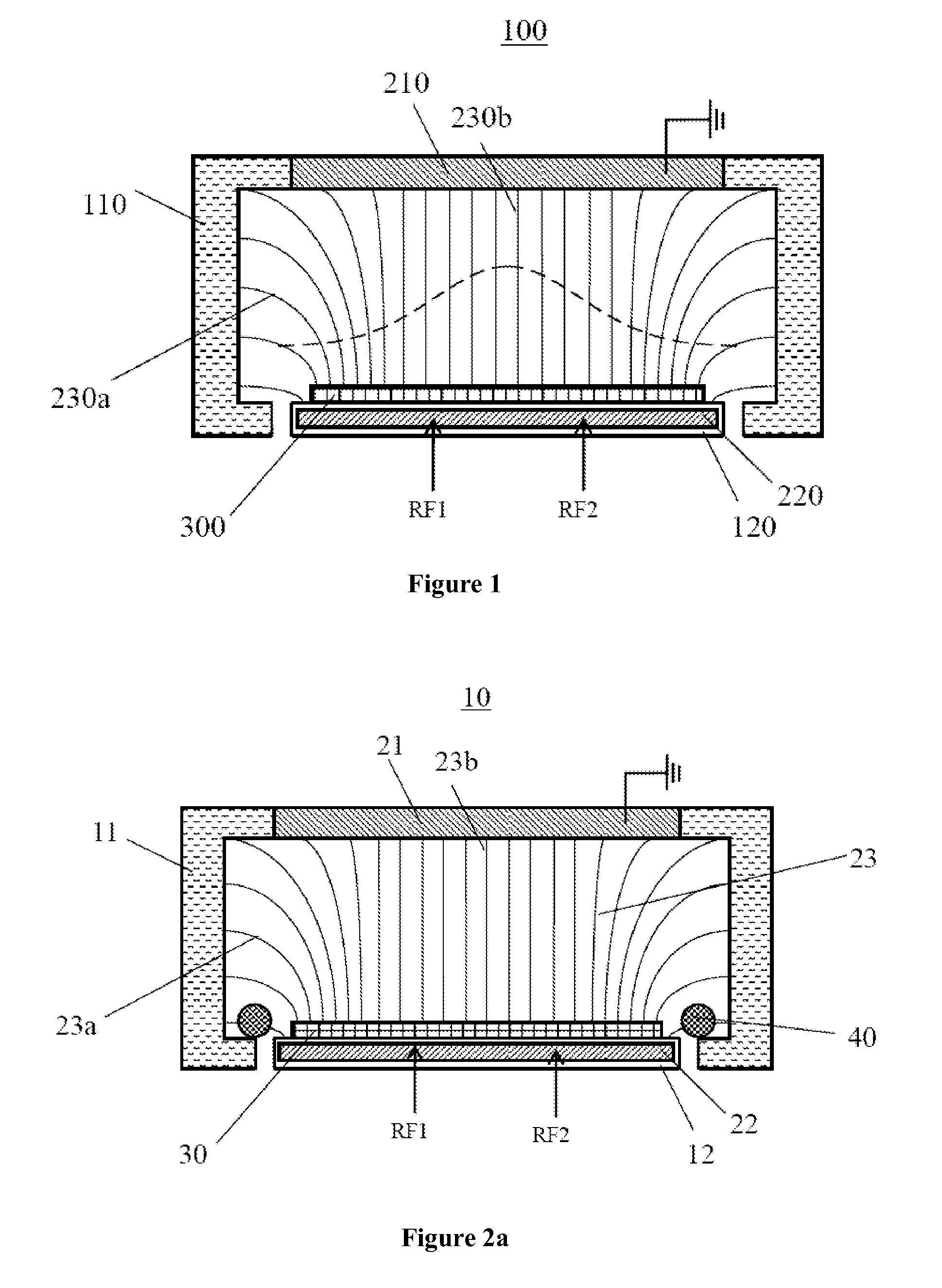

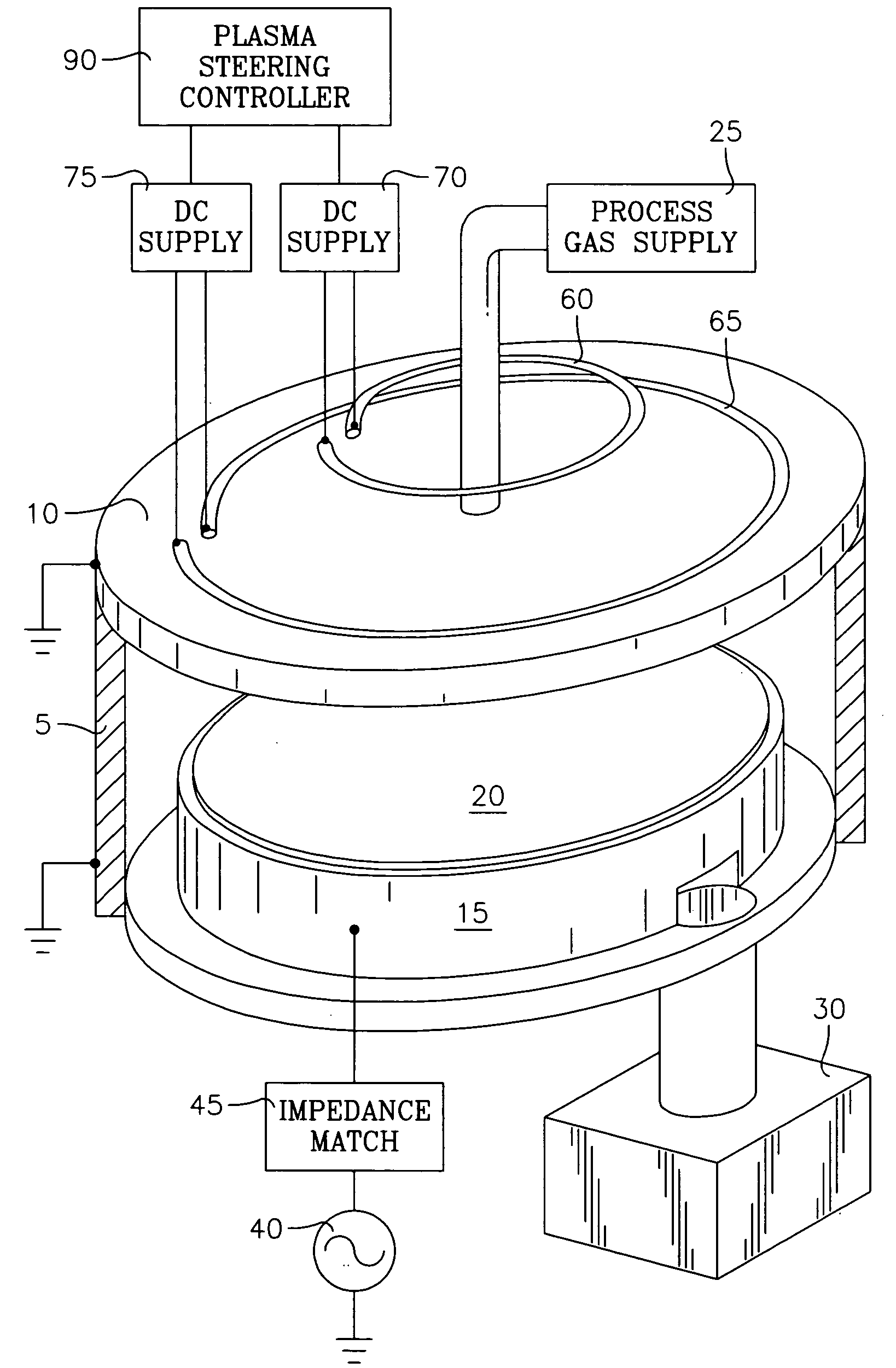

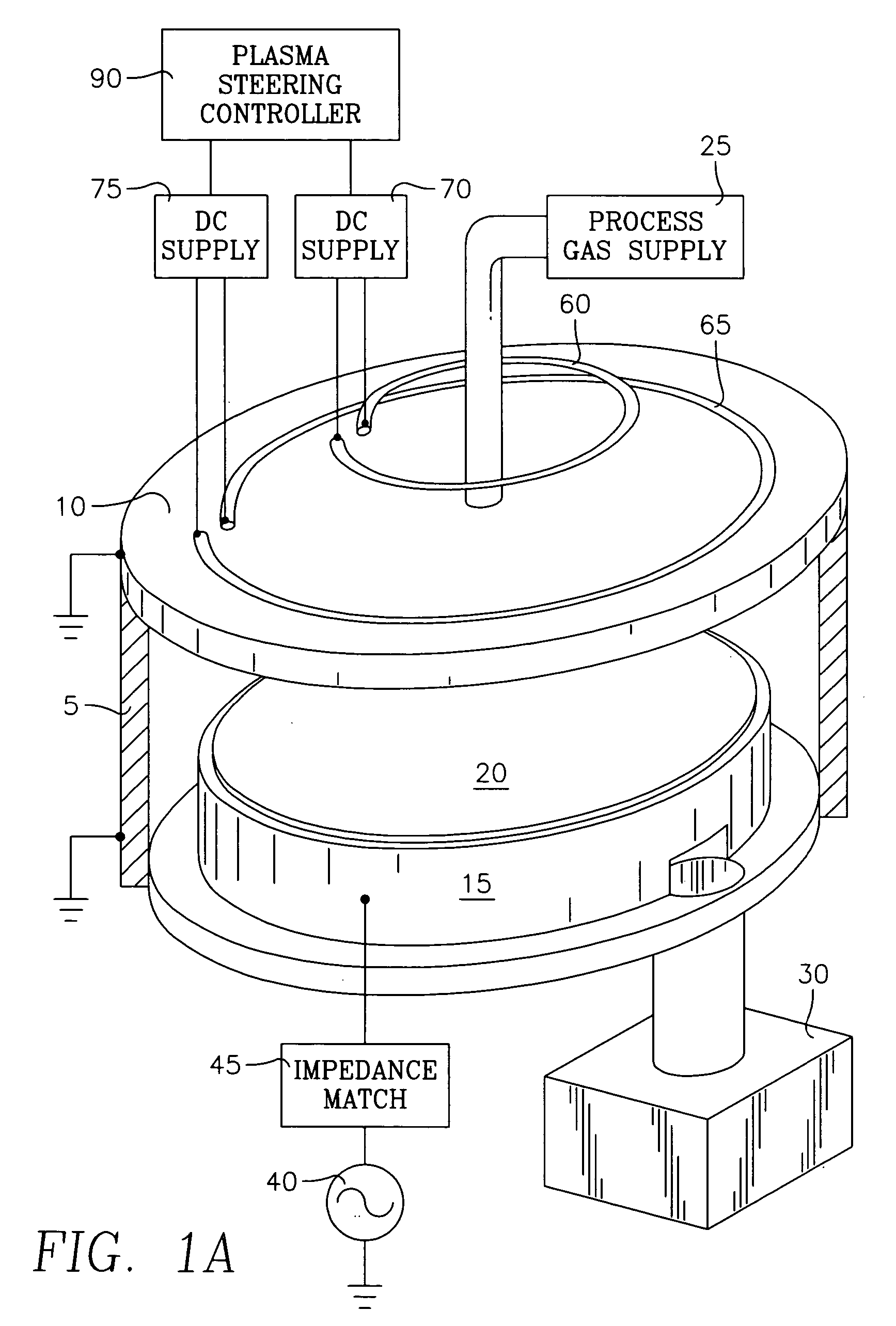

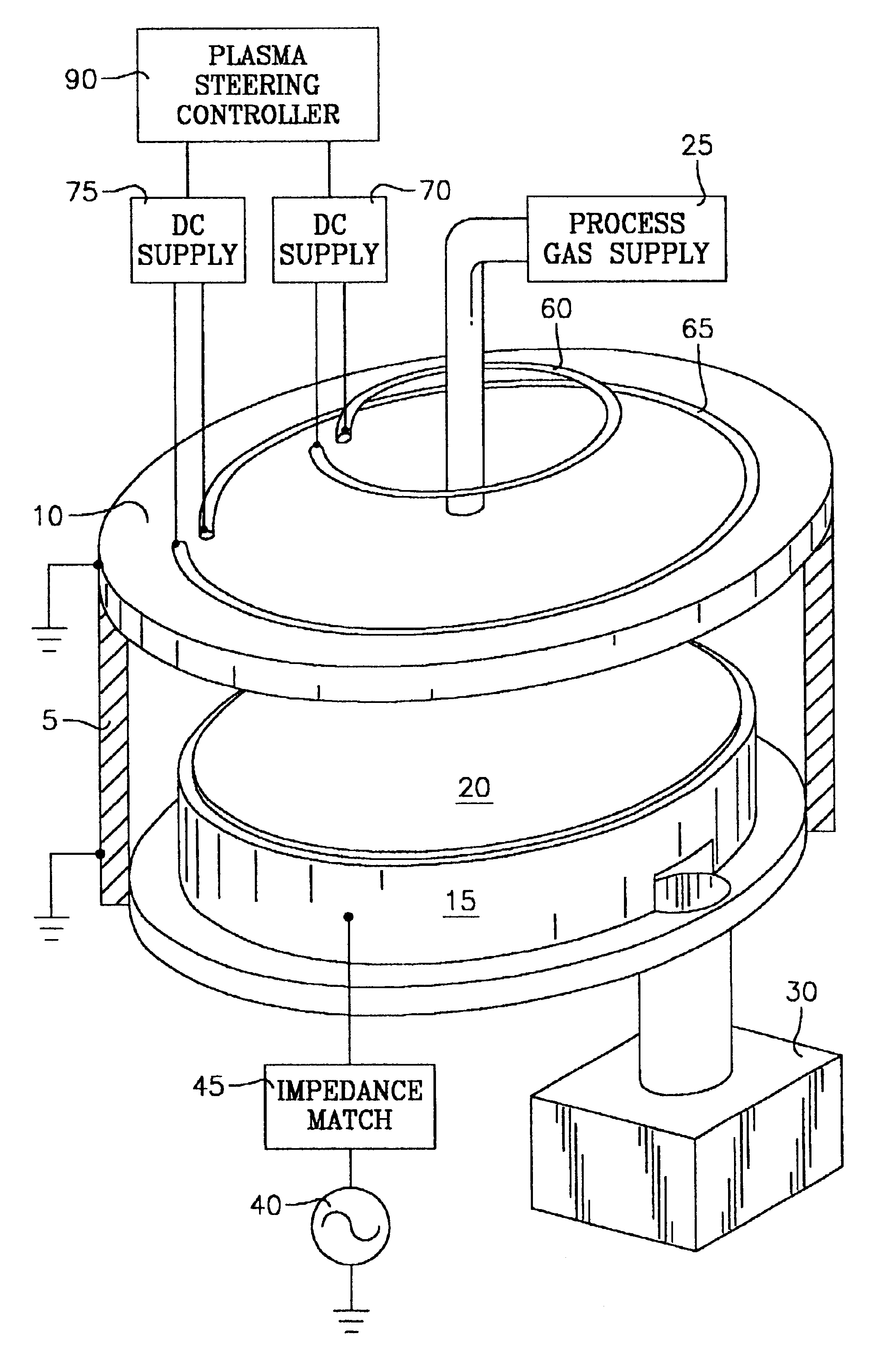

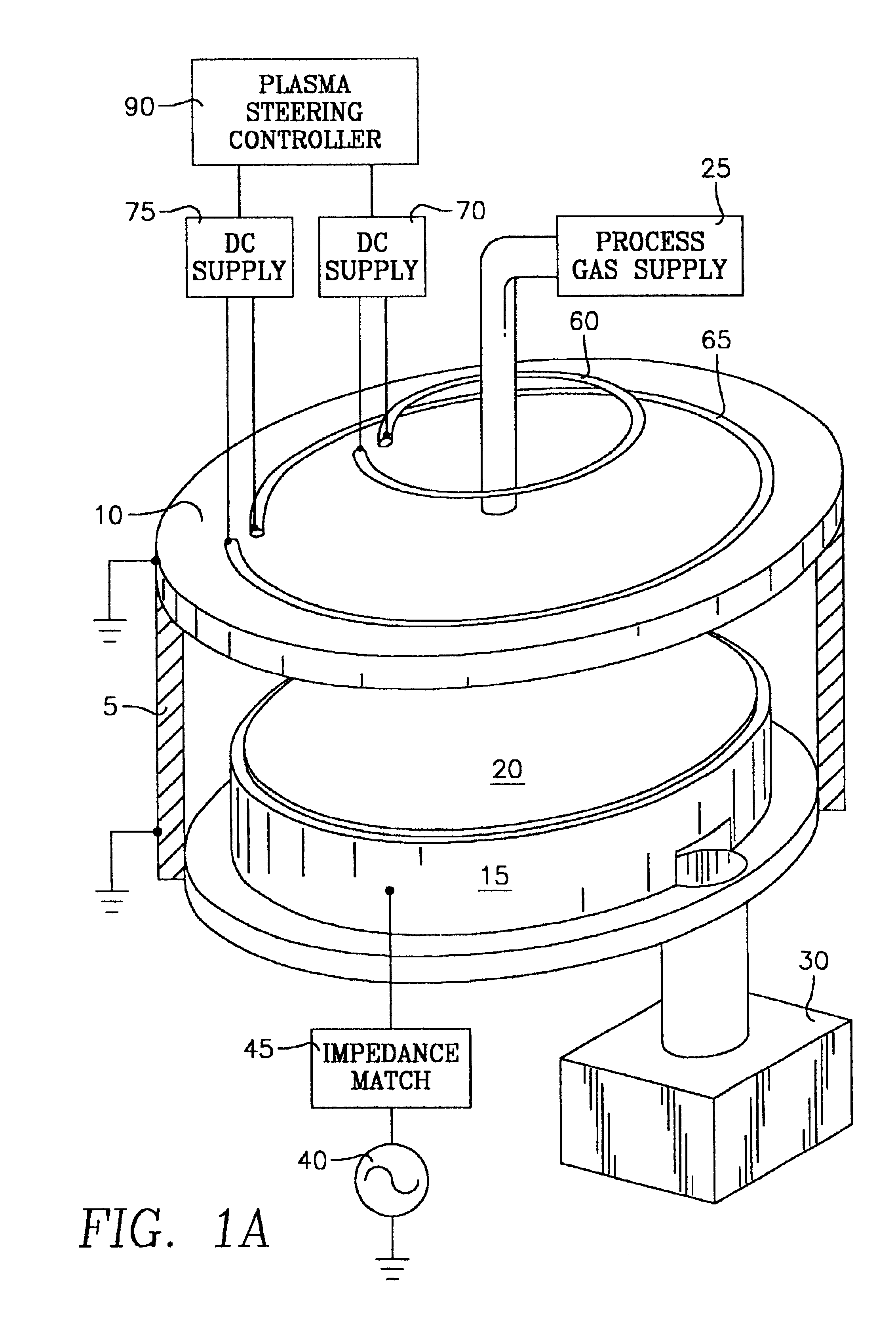

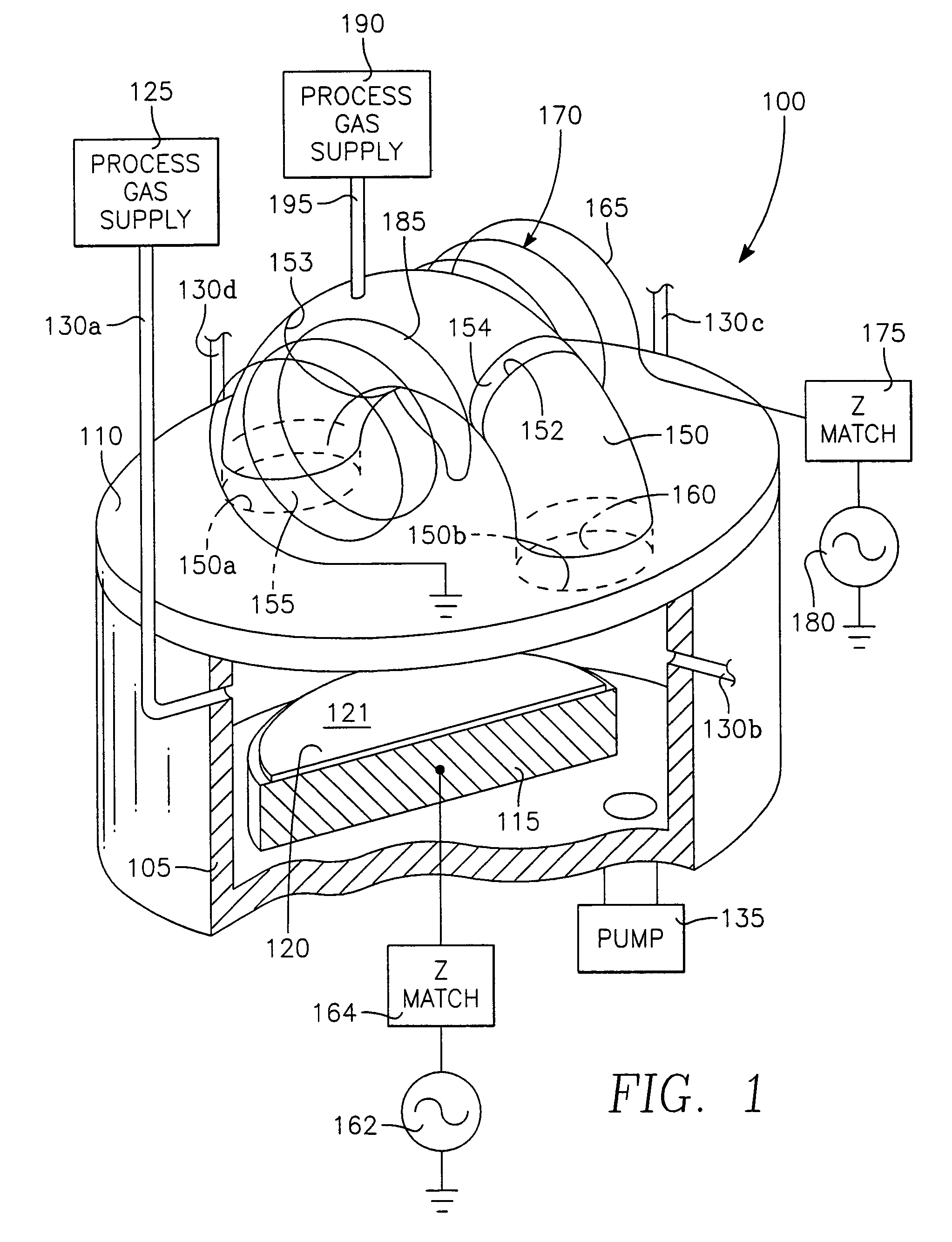

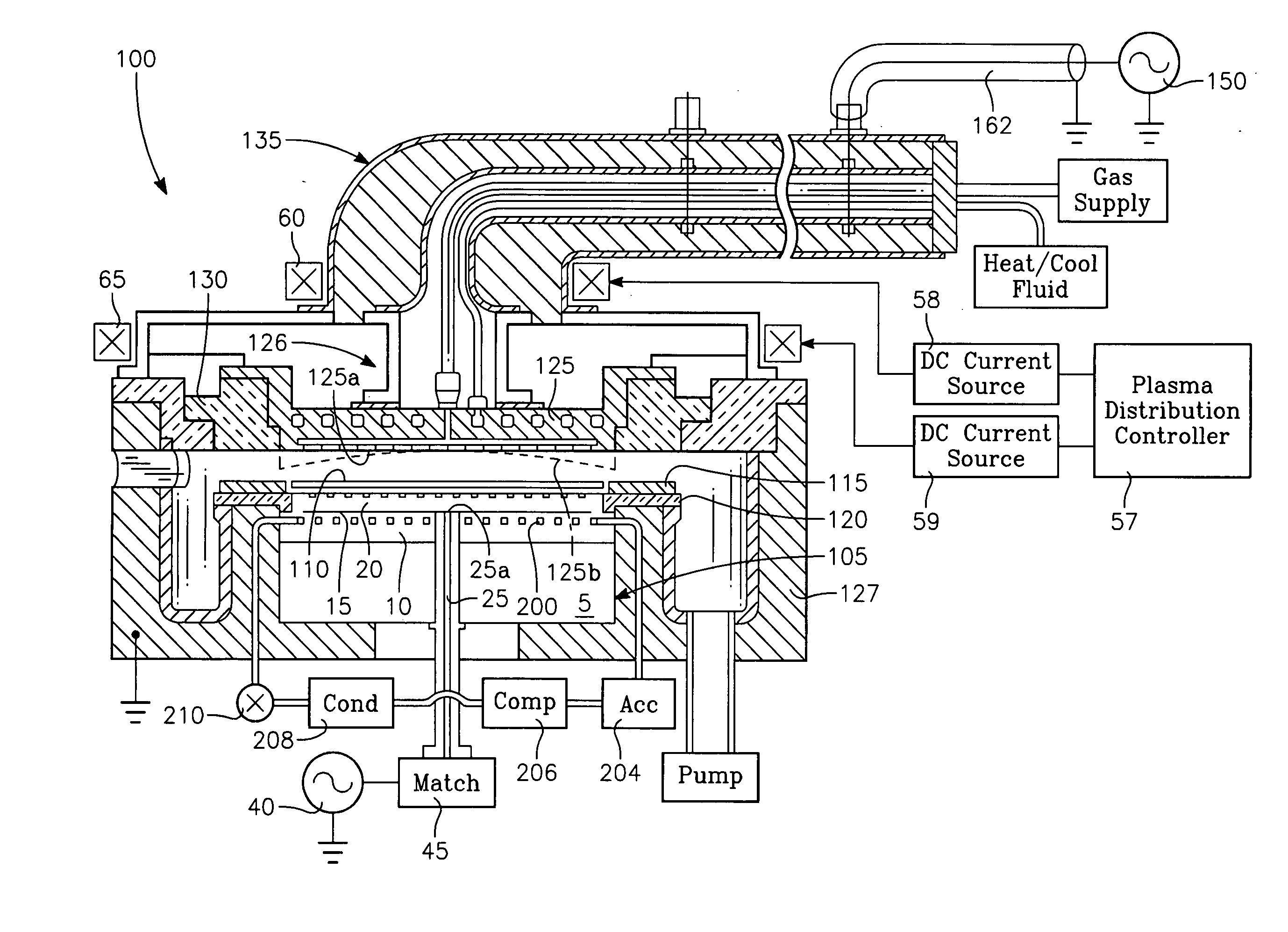

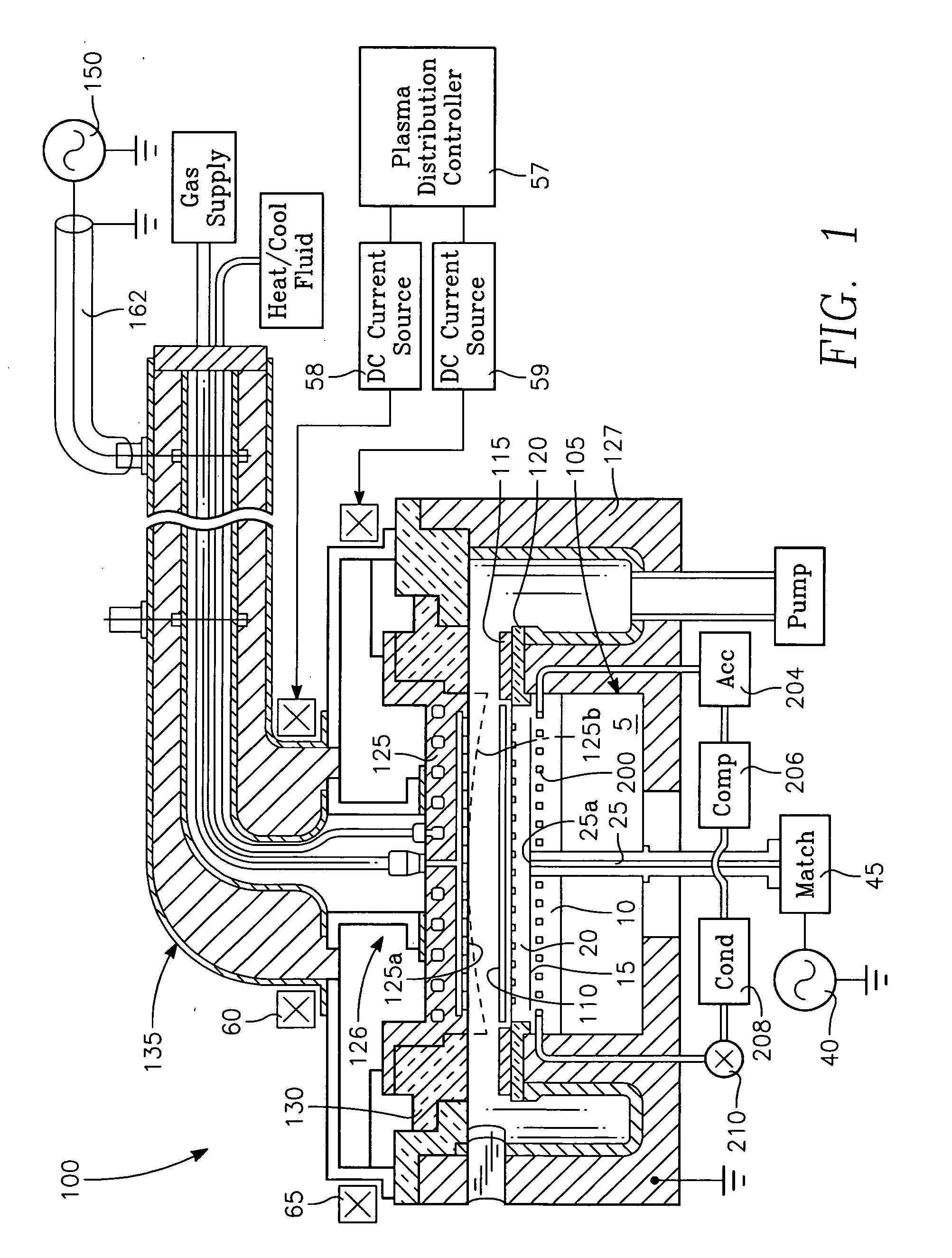

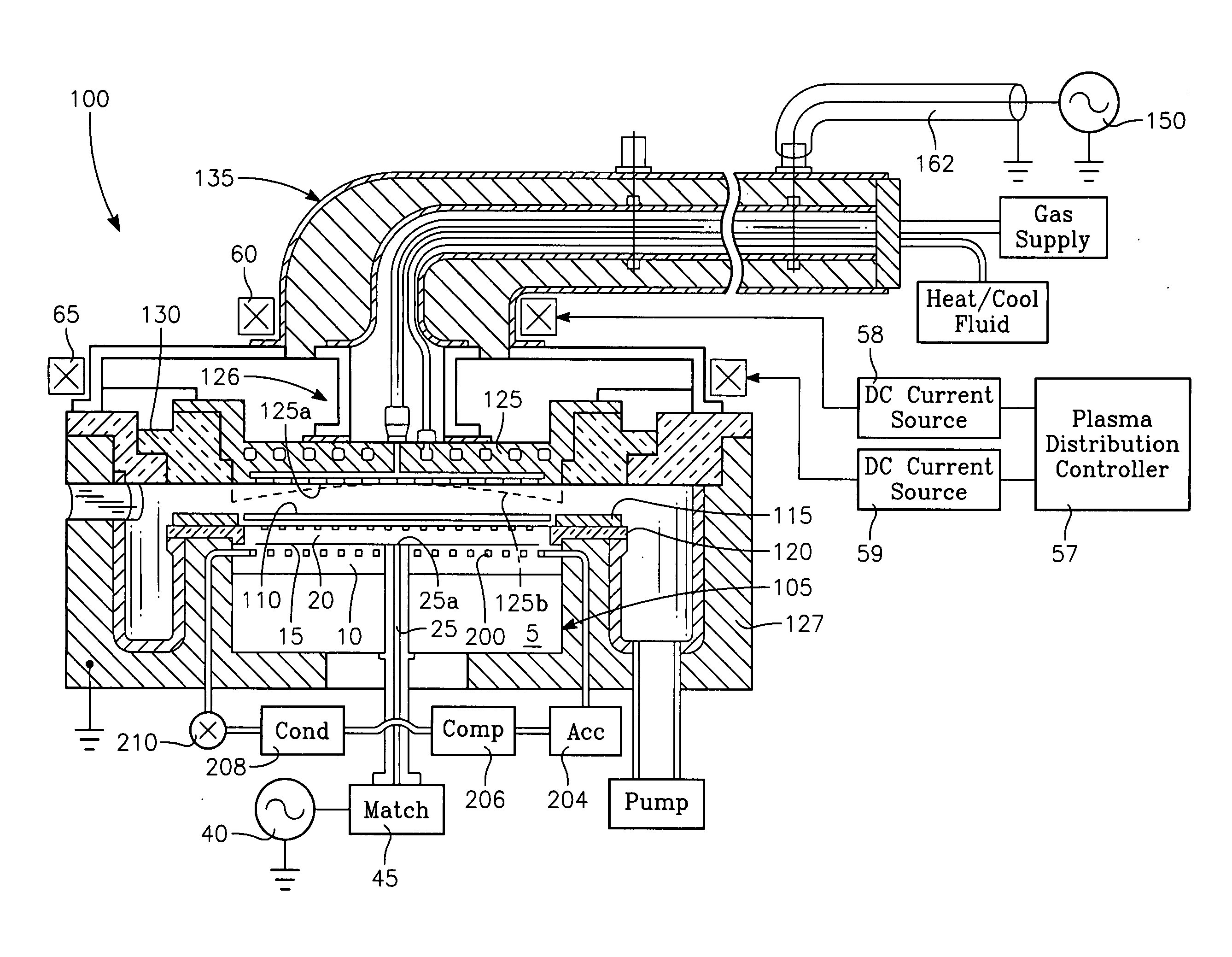

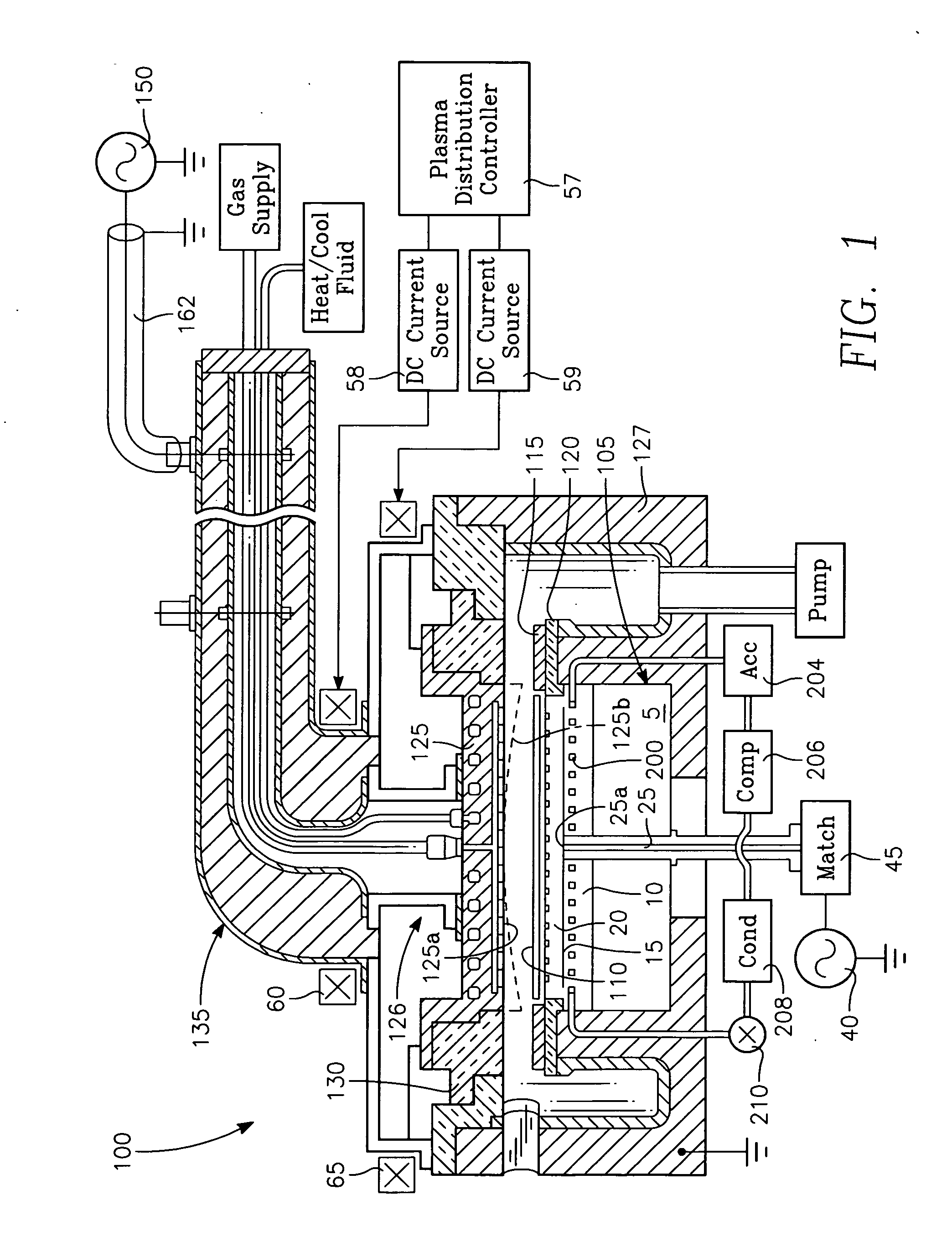

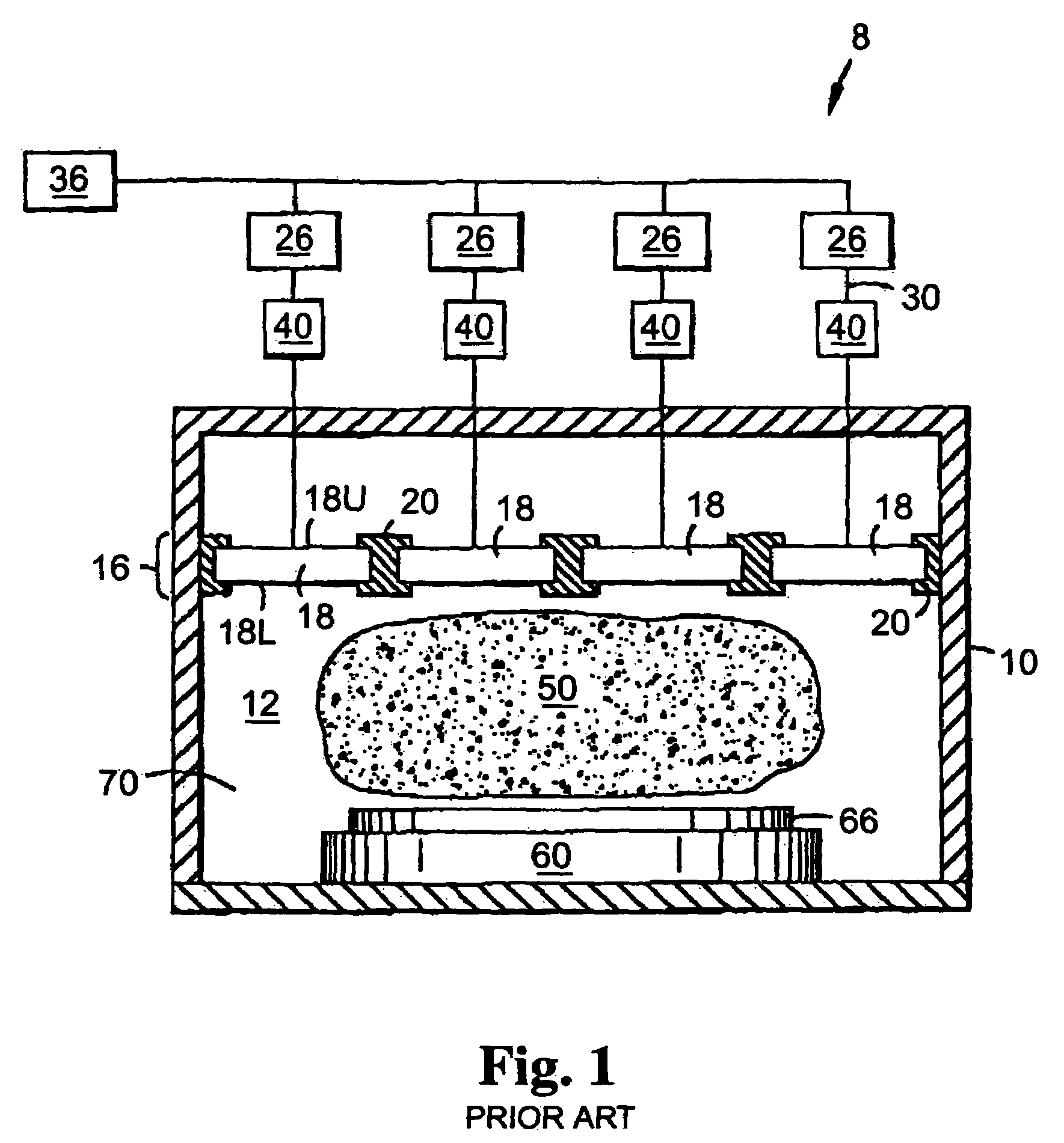

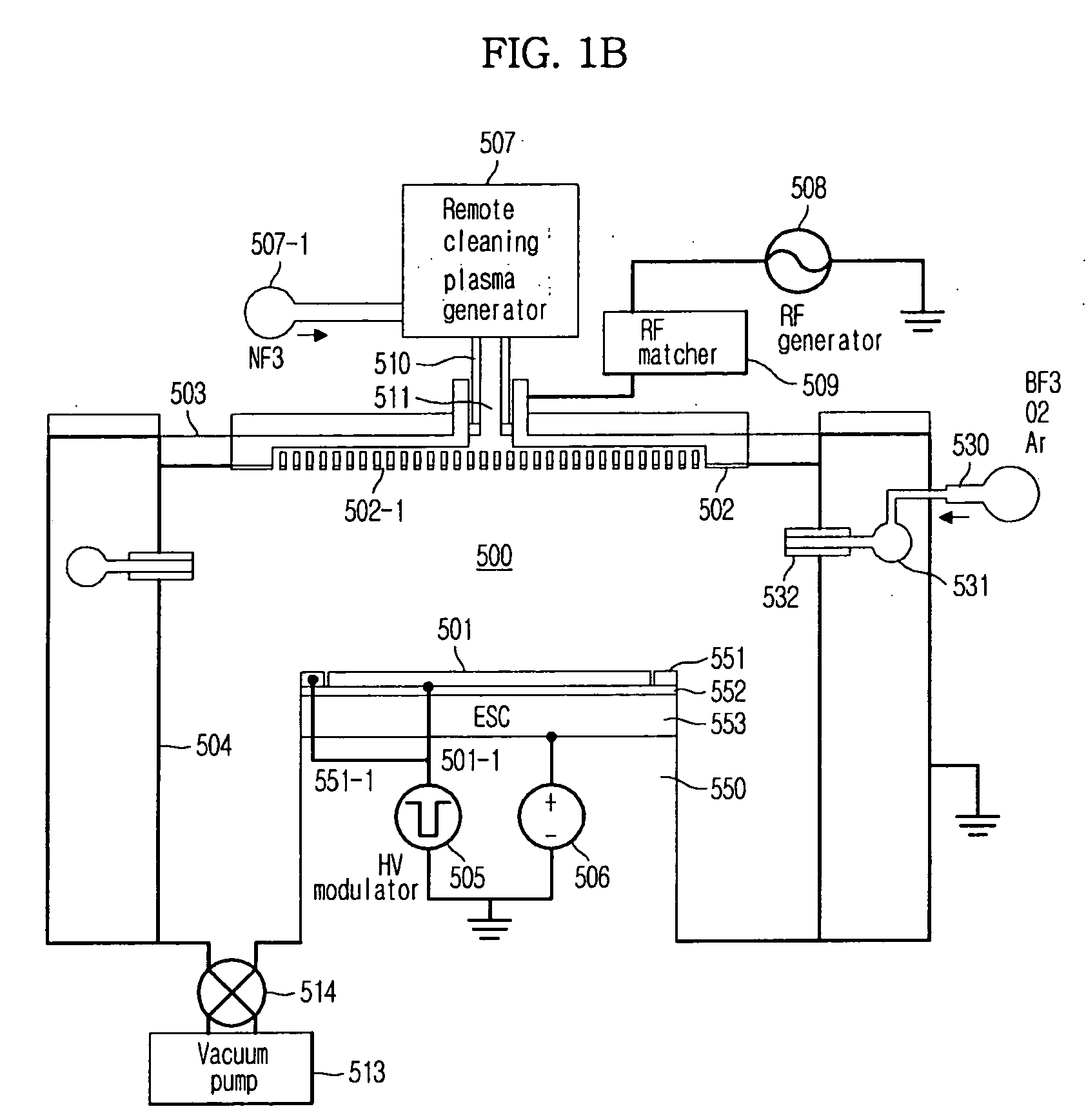

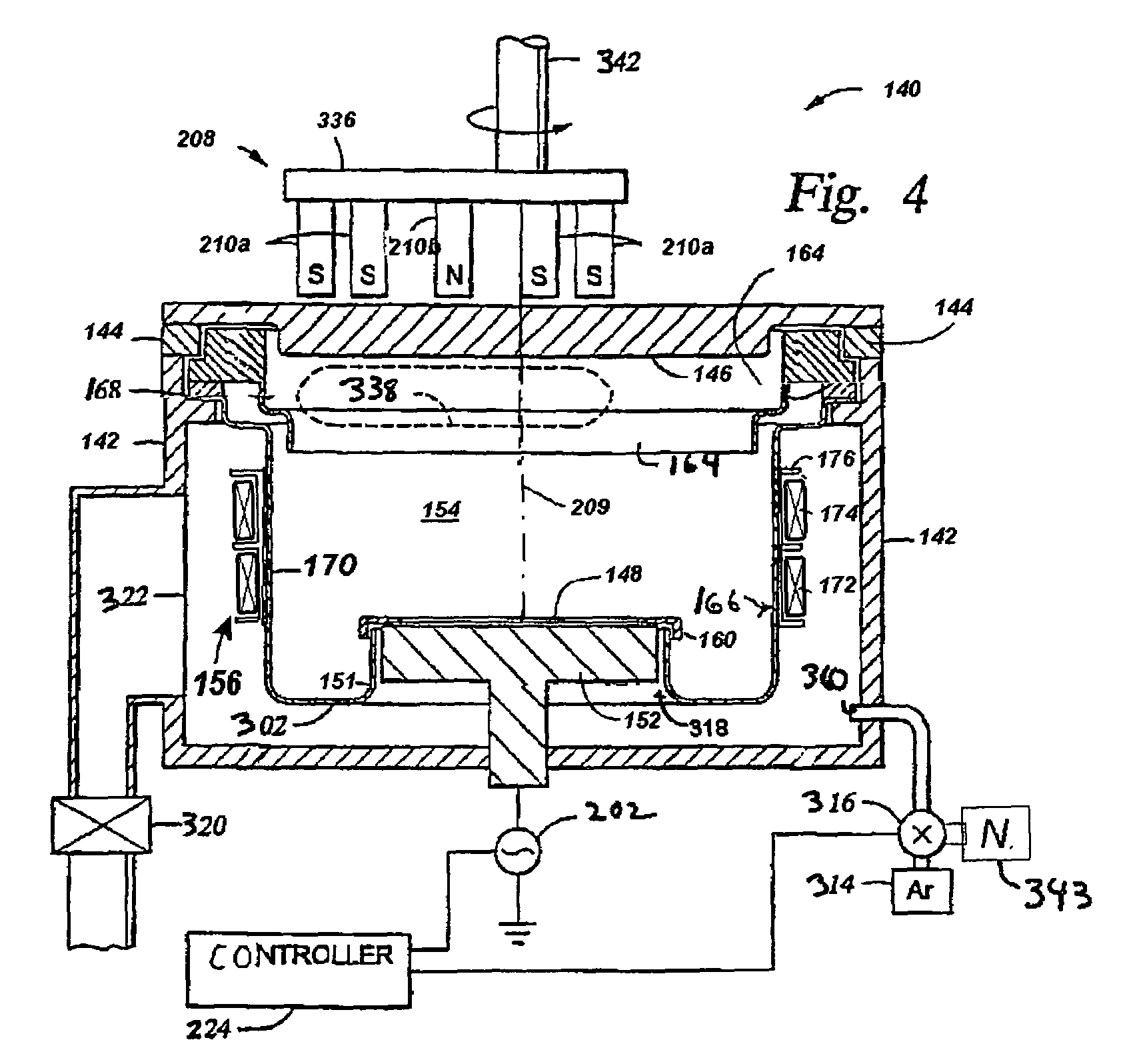

Capacitively coupled plasma reactor with magnetic plasma control

InactiveUS20050001556A1Plasma uniformity can be improvedImprove uniformityElectric discharge tubesElectric arc lampsCapacitanceAxis of symmetry

A plasma reactor includes a vacuum enclosure including a side wall and a ceiling defining a vacuum chamber, and a workpiece support within the chamber and facing the ceiling for supporting a planar workpiece, the workpiece support and the ceiling together defining a processing region between the workpiece support and the ceiling. Process gas inlets furnish a process gas into the chamber. A plasma source power electrode is connected to an RF power generator for capacitively coupling plasma source power into the chamber for maintaining a plasma within the chamber. The reactor further includes at least a first overhead solenoidal electromagnet adjacent the ceiling, the overhead solenoidal electromagnet, the ceiling, the side wall and the workpiece support being located along a common axis of symmetry. A current source is connected to the first solenoidal electromagnet and furnishes a first electric current in the first solenoidal electromagnet whereby to generate within the chamber a magnetic field which is a function of the first electric current, the first electric current having a value such that the magnetic field increases uniformity of plasma ion density radial distribution about the axis of symmetry near a surface of the workpiece support.

Owner:APPLIED MATERIALS INC

Capacitively coupled plasma reactor with magnetic plasma control

InactiveUS6853141B2Plasma uniformity can be improvedImprove uniformityElectric arc lampsSemiconductor/solid-state device manufacturingCapacitanceAxis of symmetry

A plasma reactor includes a vacuum enclosure including a side wall and a ceiling defining a vacuum chamber, and a workpiece support within the chamber and facing the ceiling for supporting a planar workpiece, the workpiece support and the ceiling together defining a processing region between the workpiece support and the ceiling. Process gas inlets furnish a process gas into the chamber. A plasma source power electrode is connected to an RF power generator for capacitively coupling plasma source power into the chamber for maintaining a plasma within the chamber. The reactor further includes at least a first overhead solenoidal electromagnet adjacent the ceiling, the overhead solenoidal electromagnet, the ceiling, the sidewall and the workpiece support being located along a common axis of symmetry. A current source is connected to the first solenoidal electromagnet and furnishes a first electric current in the first solenoidal electromagnet whereby to generate within the chamber a magnetic field which is a function of the first electric current, the first electric current having a value such that the magnetic field increases uniformity of plasma ion density radial distribution about the axis of symmetry near a surface of the workpiece support.

Owner:APPLIED MATERIALS INC

Alternating asymmetrical plasma generation in a process chamber

InactiveUS20050241762A1Improving uniformity of plasma processImprove uniformityElectric discharge tubesDecorative surface effectsCapacitanceNon symmetric

Embodiments of the invention generally provide etch or CVD plasma processing methods and apparatus used to generate a uniform plasma across the surface of a substrate by modulation pulsing the power delivered to a plurality of plasma controlling devices found in a plasma processing chamber. The plasma generated and / or sustained in the plasma processing chamber is created by the one or more plasma controlling devices that are used to control, generate, enhance, and / or shape the plasma during the plasma processing steps by use of energy delivered from a RF power source. Plasma controlling devices may include, for example, one or more coils (inductively coupled plasma), one or more electrodes (capacitively coupled plasma), and / or any other energy inputting device such as a microwave source.

Owner:APPLIED MATERIALS INC

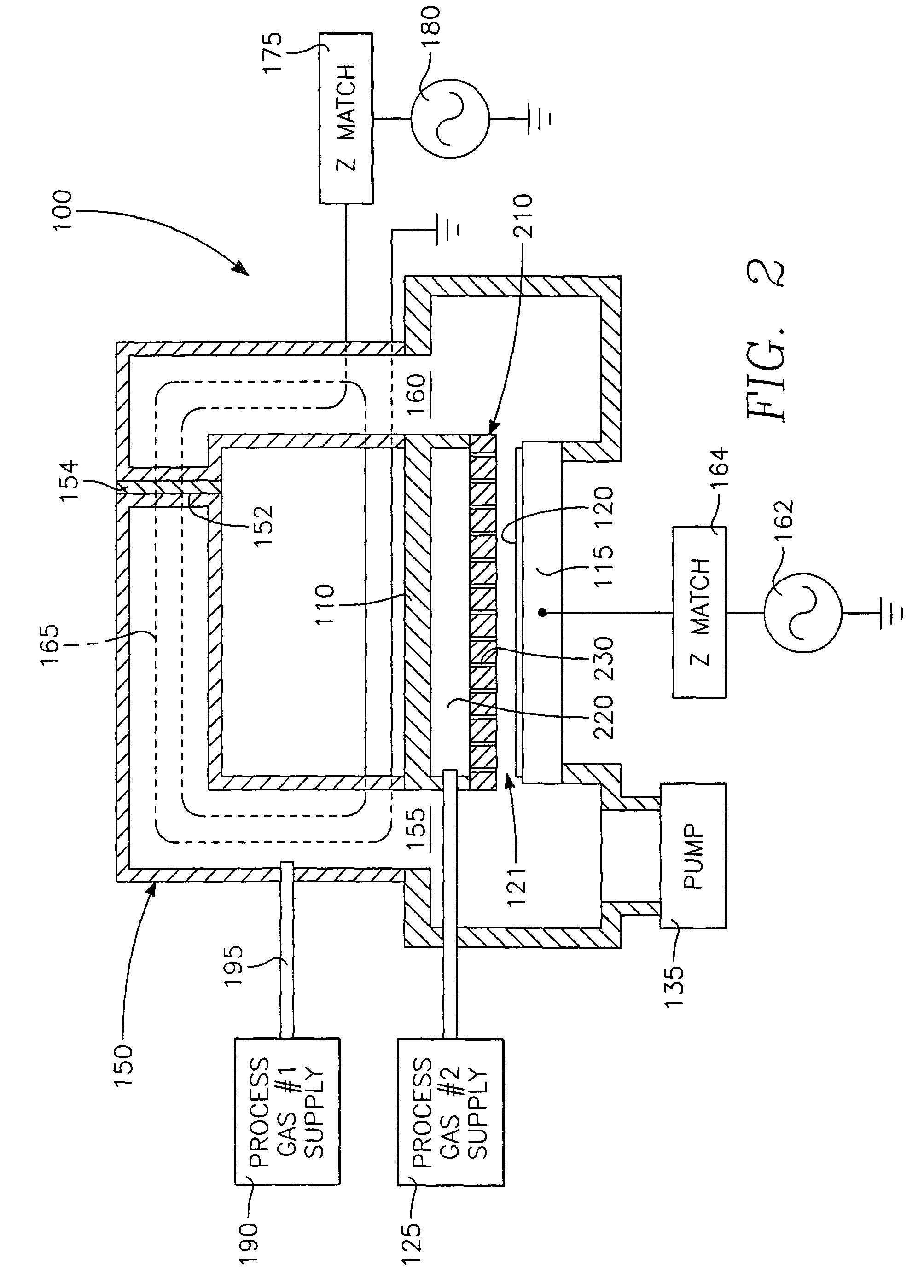

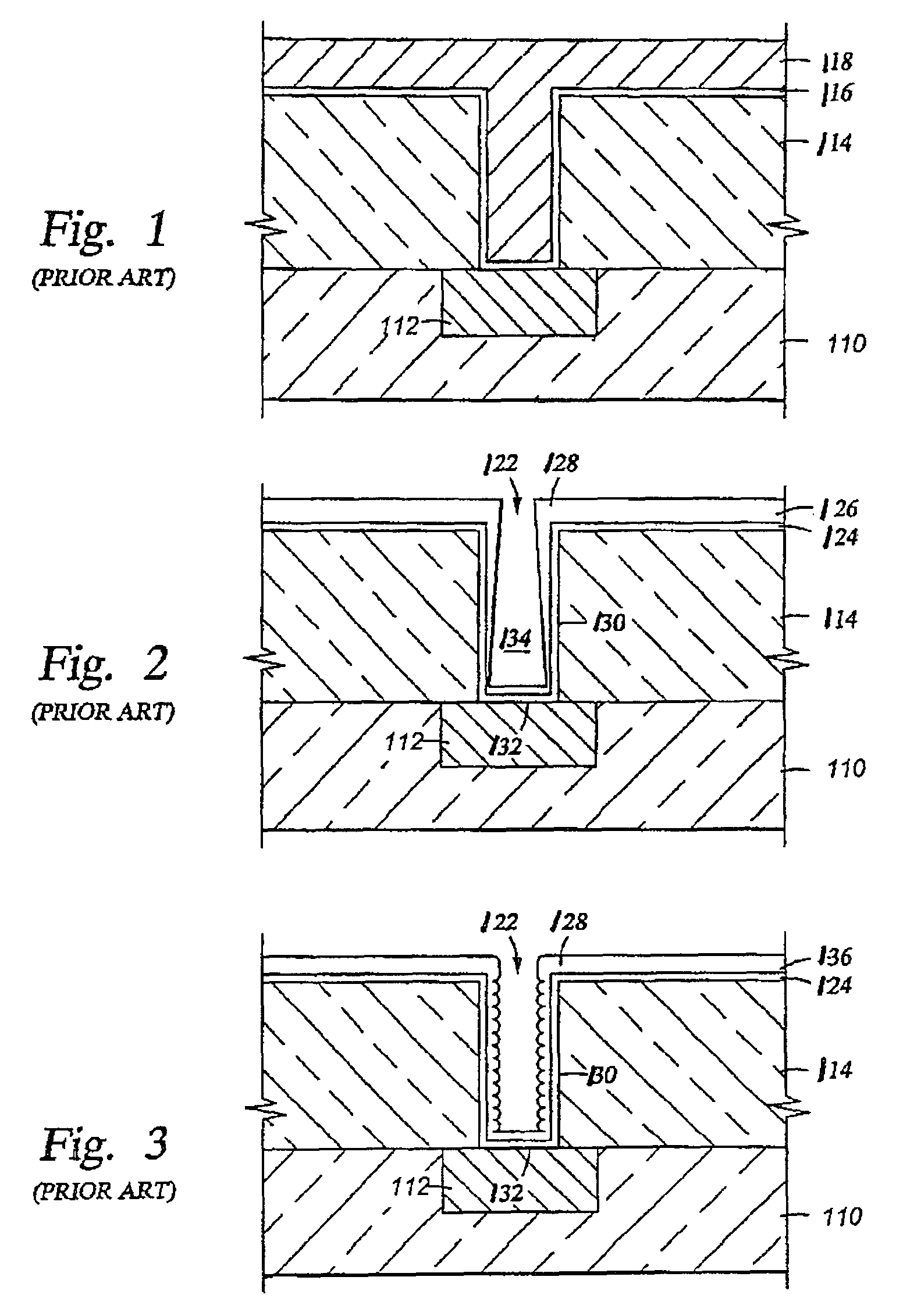

Plasma immersion ion implantation process using a capacitively coupled plasma source having low dissociation and low minimum plasma voltage

InactiveUS7037813B2Electric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceSurface layer

A method for implanting ions in a surface layer of a workpiece includes placing the workpiece on a workpiece support in a chamber with the surface layer being in facing relationship with a ceiling of the chamber, thereby defining a processing zone between the workpiece and the ceiling, and introducing into the chamber a process gas including the species to be implanted in the surface layer of the workpiece. The method includes generating from the process gas a plasma by capacitively coupling RF source power across the workpiece support and the ceiling or the sidewall from an RF source power generator. The method further includes applying an RF bias from an RF bias generator to the workpiece support.

Owner:APPLIED MATERIALS INC

Plasma immersion ion implantation process using a capacitively couple plasma source having low dissociation and low minimum plasma voltage

InactiveUS7291545B2Electric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceSemiconductor materials

A method of ion implanting a species in a workpiece to a selected ion implantation profile depth includes placing a workpiece having a semiconductor material on an electrostatic chuck in or near a processing region of a plasma reactor chamber and applying a chucking voltage to the electrostatic chuck. The method further includes introducing into the chamber a precursor gas including a species to be ion implanted in the workpiece and applying an RF bias to the electrostatic chuck, the RF bias having a bias level corresponding to the ion implantation profile depth.

Owner:APPLIED MATERIALS INC

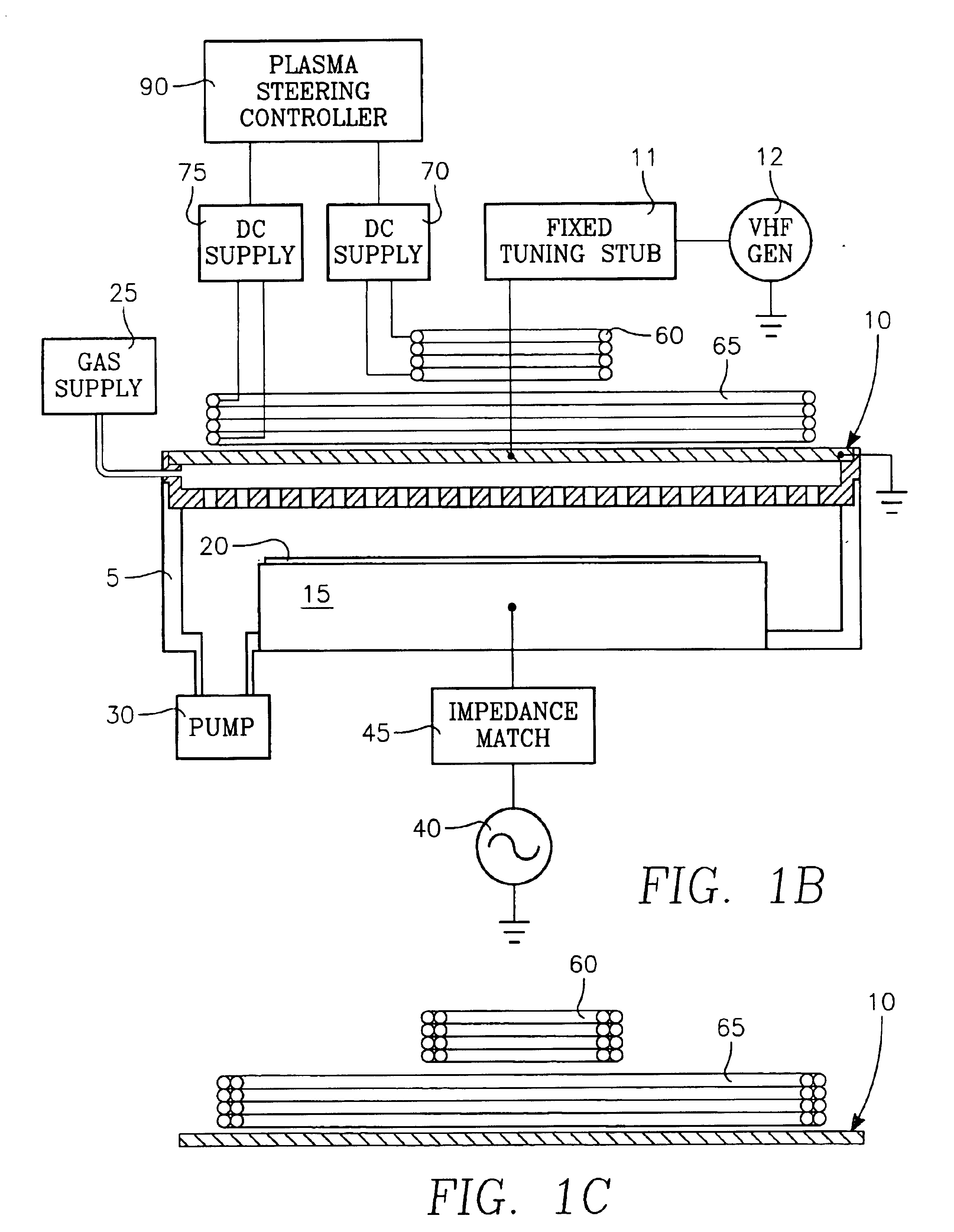

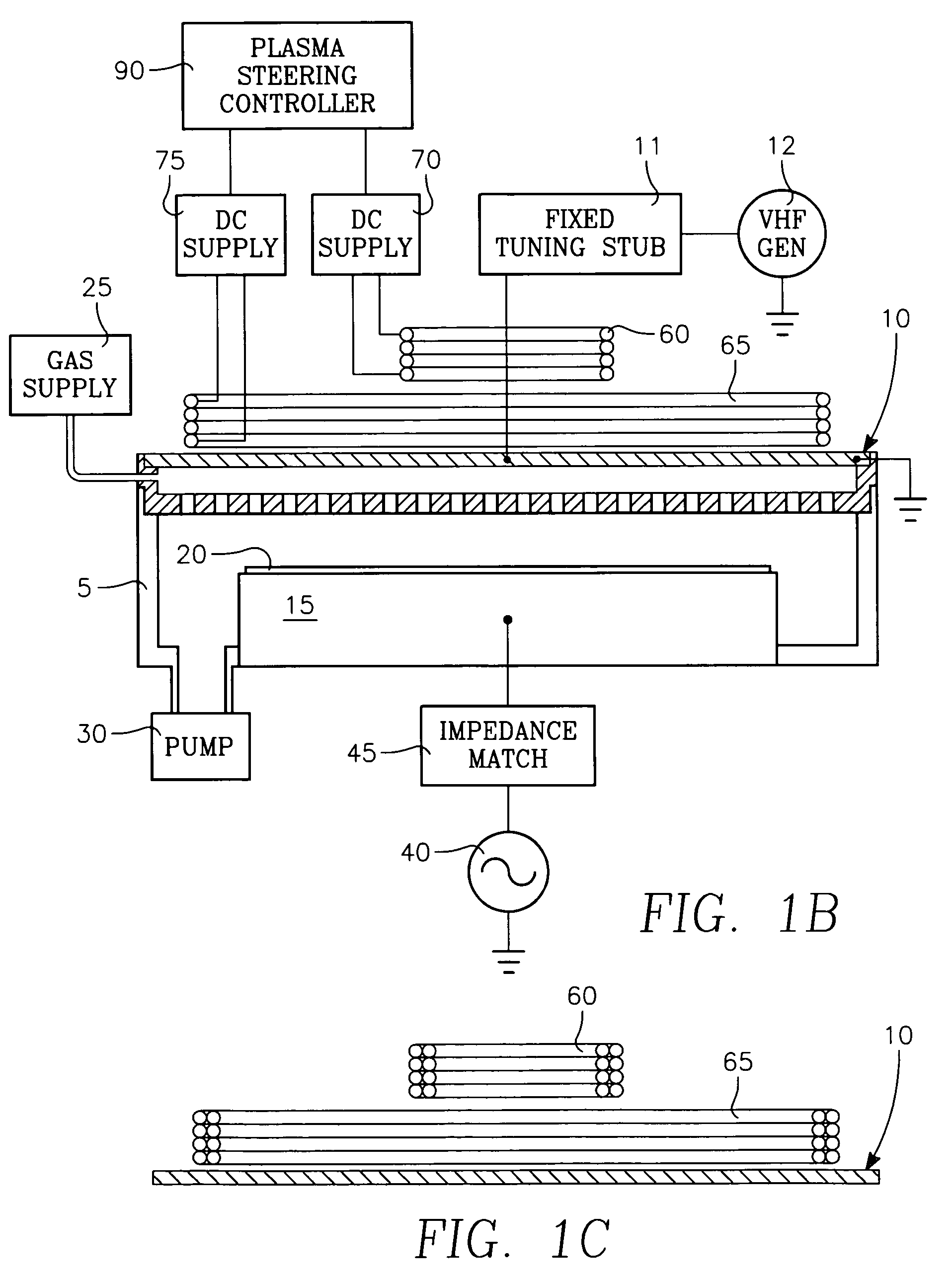

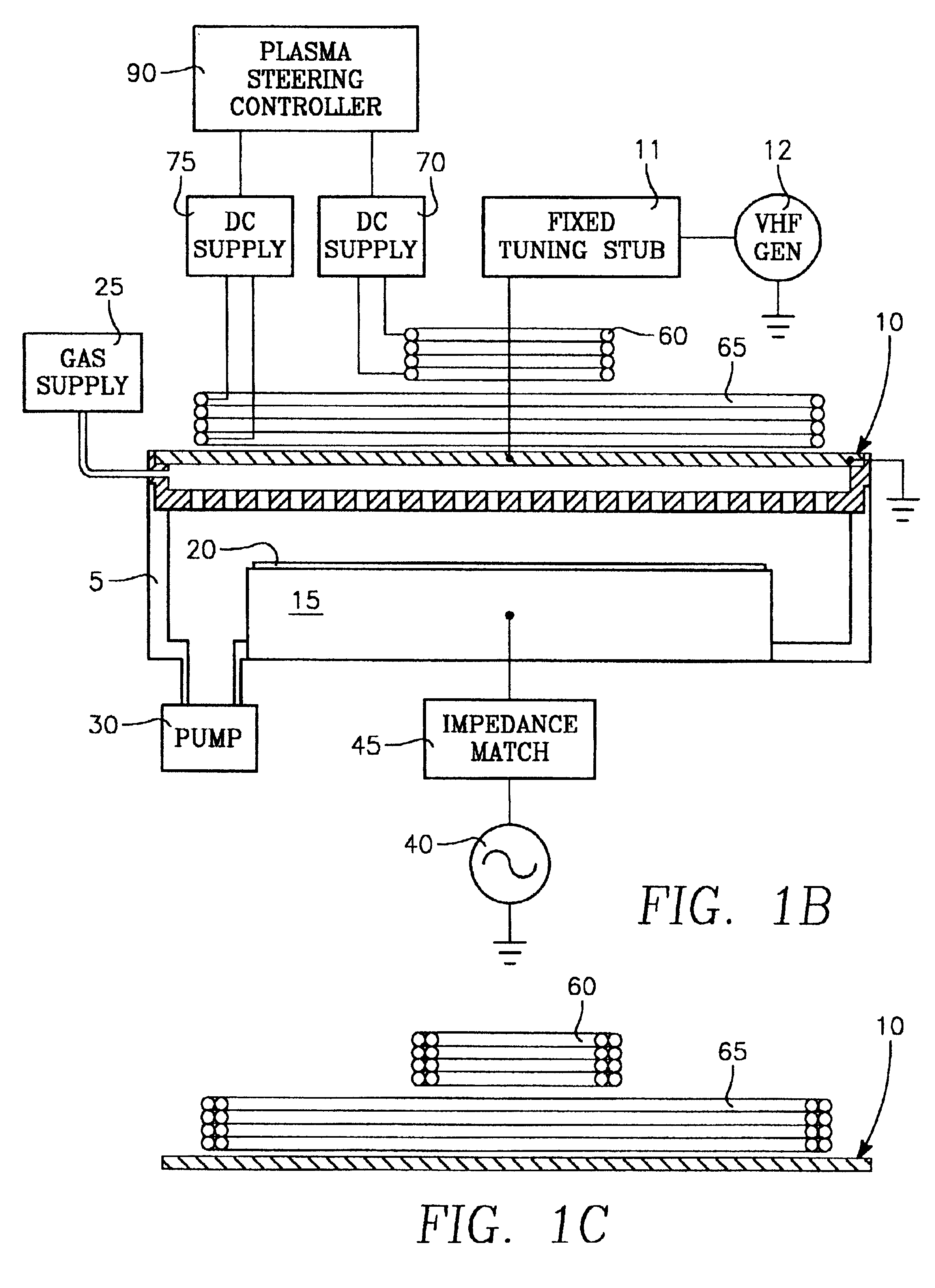

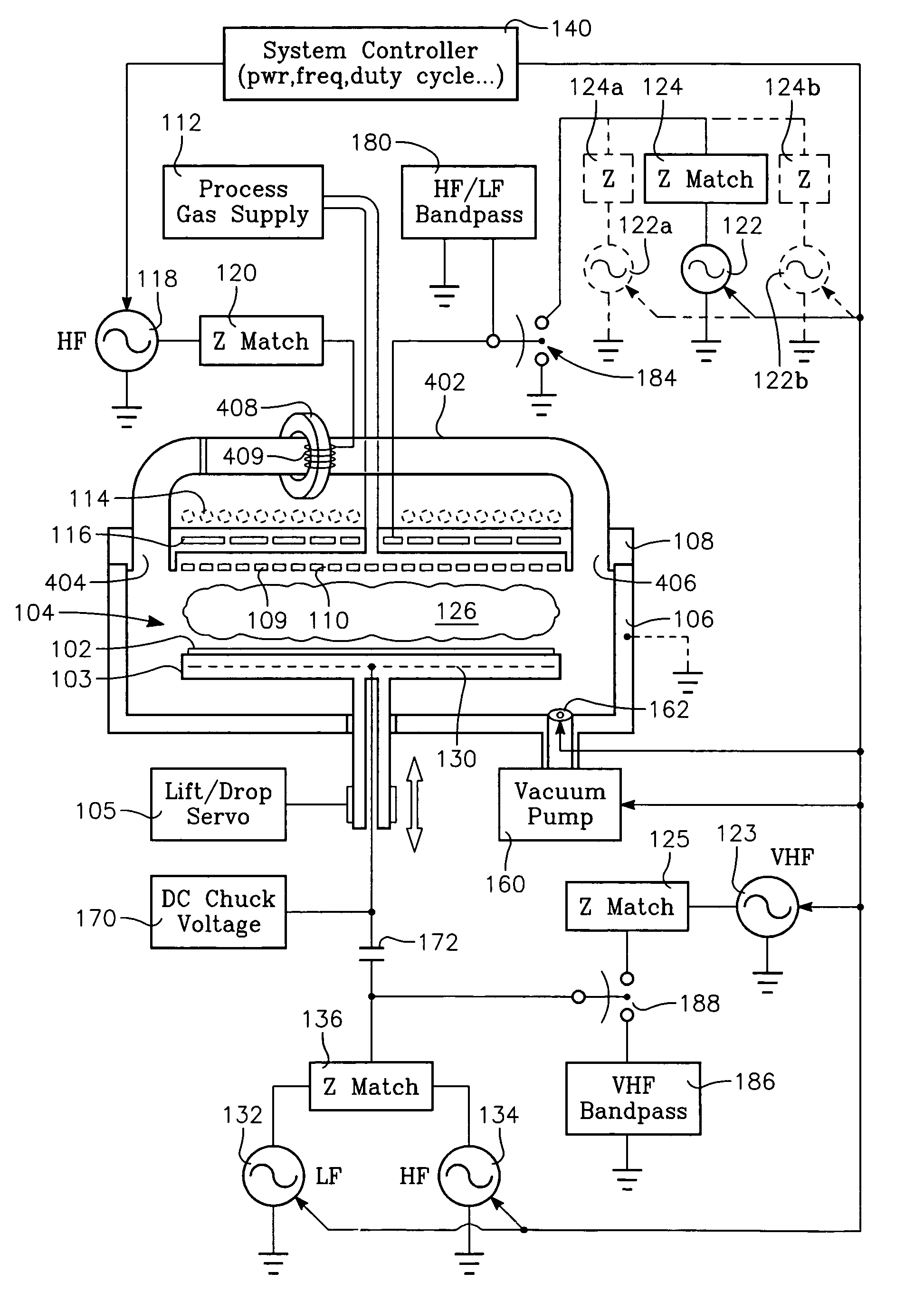

Plasma reactor apparatus with a VHF capacitively coupled plasma source of variable frequency

A plasma reactor for processing a workpiece includes a reactor chamber and a workpiece support within the chamber, the chamber having a ceiling facing the workpiece support, a capacitively coupled plasma source power applicator comprising a source power electrode at one of: (a) the ceiling (b) the workpiece support, and plural VHF power generators of different fixed frequencies coupled to the capacitively coupled source power applicator, and a controller for independently controlling the power output levels of the plural VHF generators so as to control an effective VHF frequency applied to the source power electrode. In a preferred embodiment, the reactor further includes a plasma bias power applicator that includes a bias power electrode in the workpiece support and one or more RF bias power generators of different frequencies coupled to the plasma bias power applicator.

Owner:APPLIED MATERIALS INC

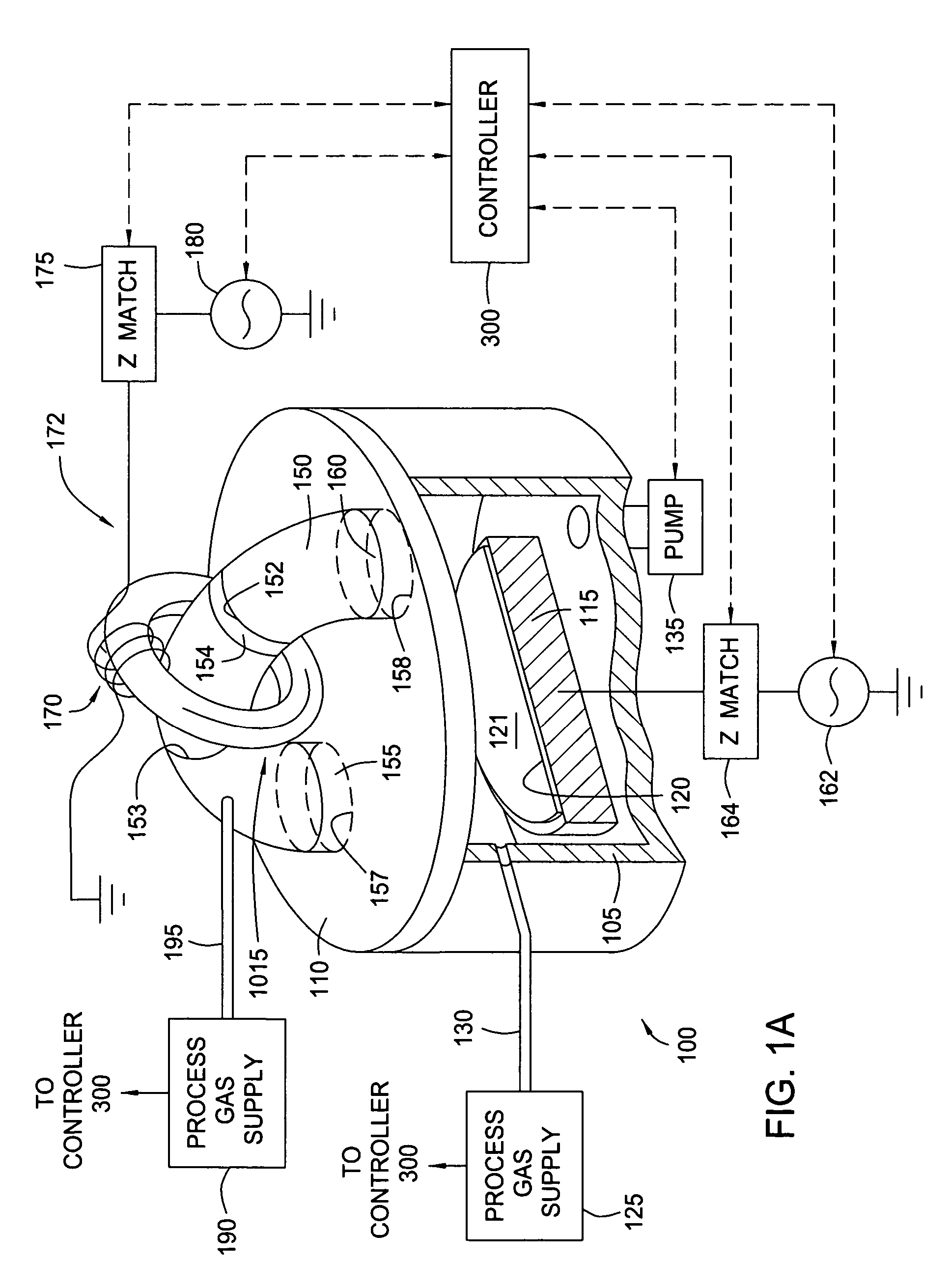

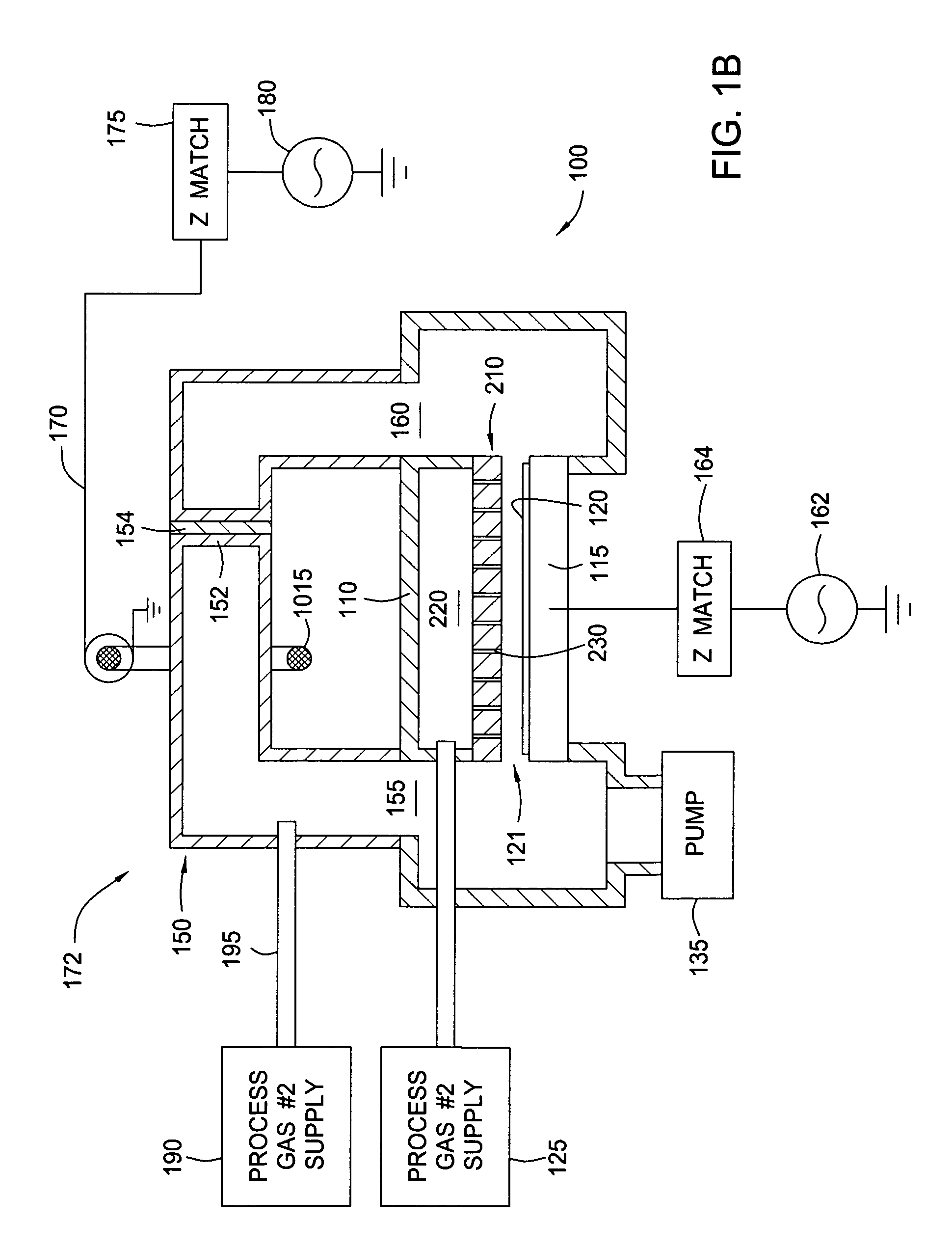

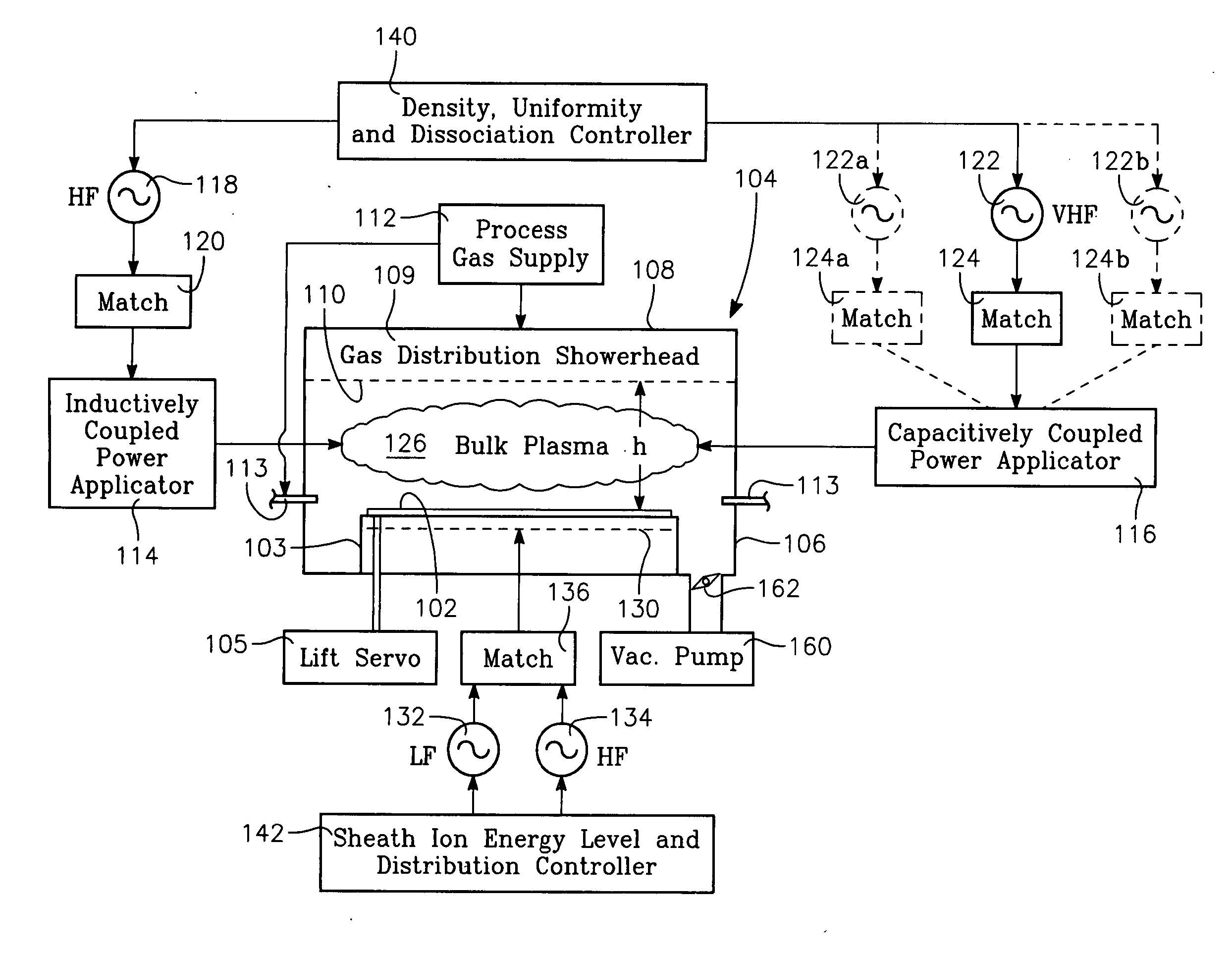

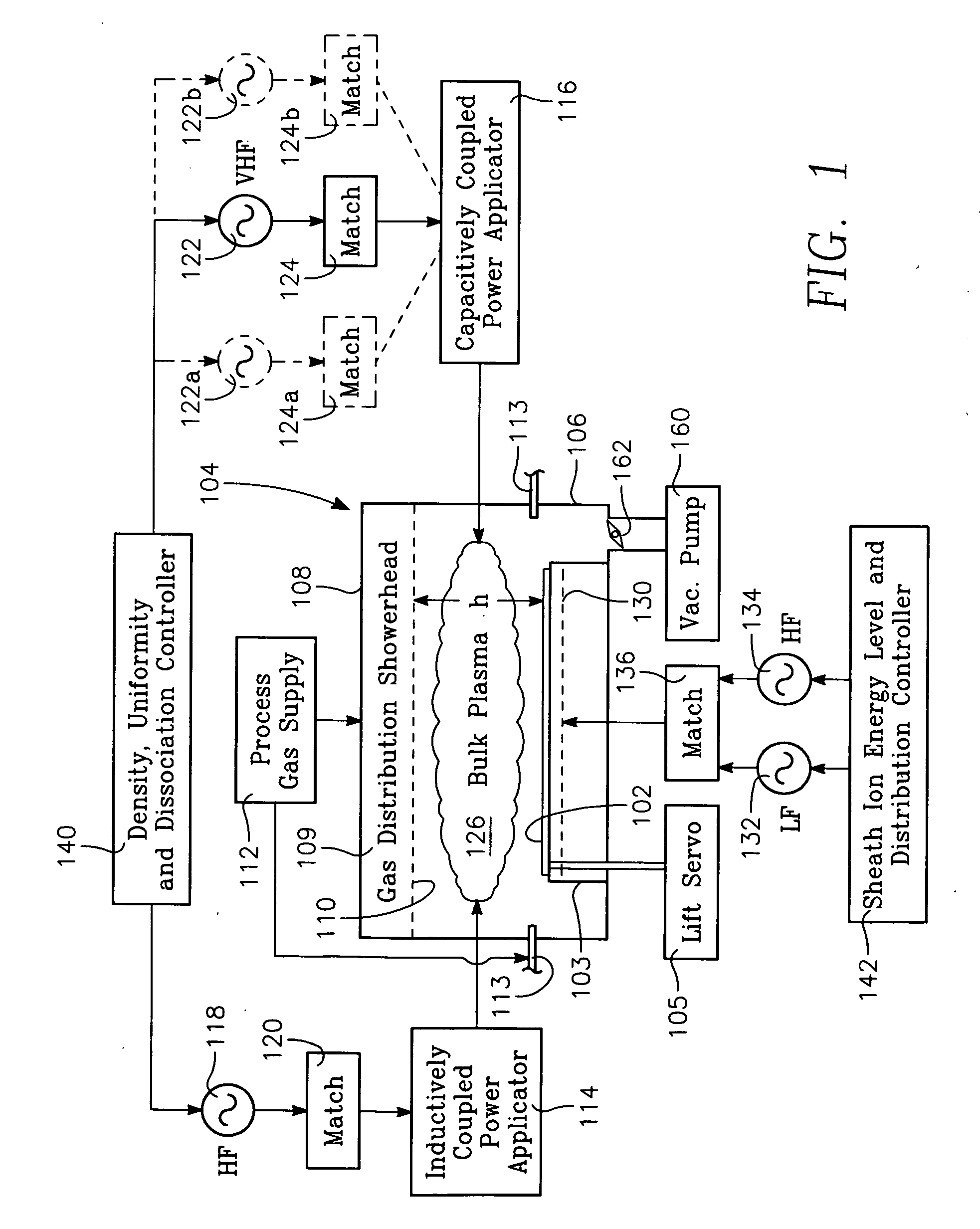

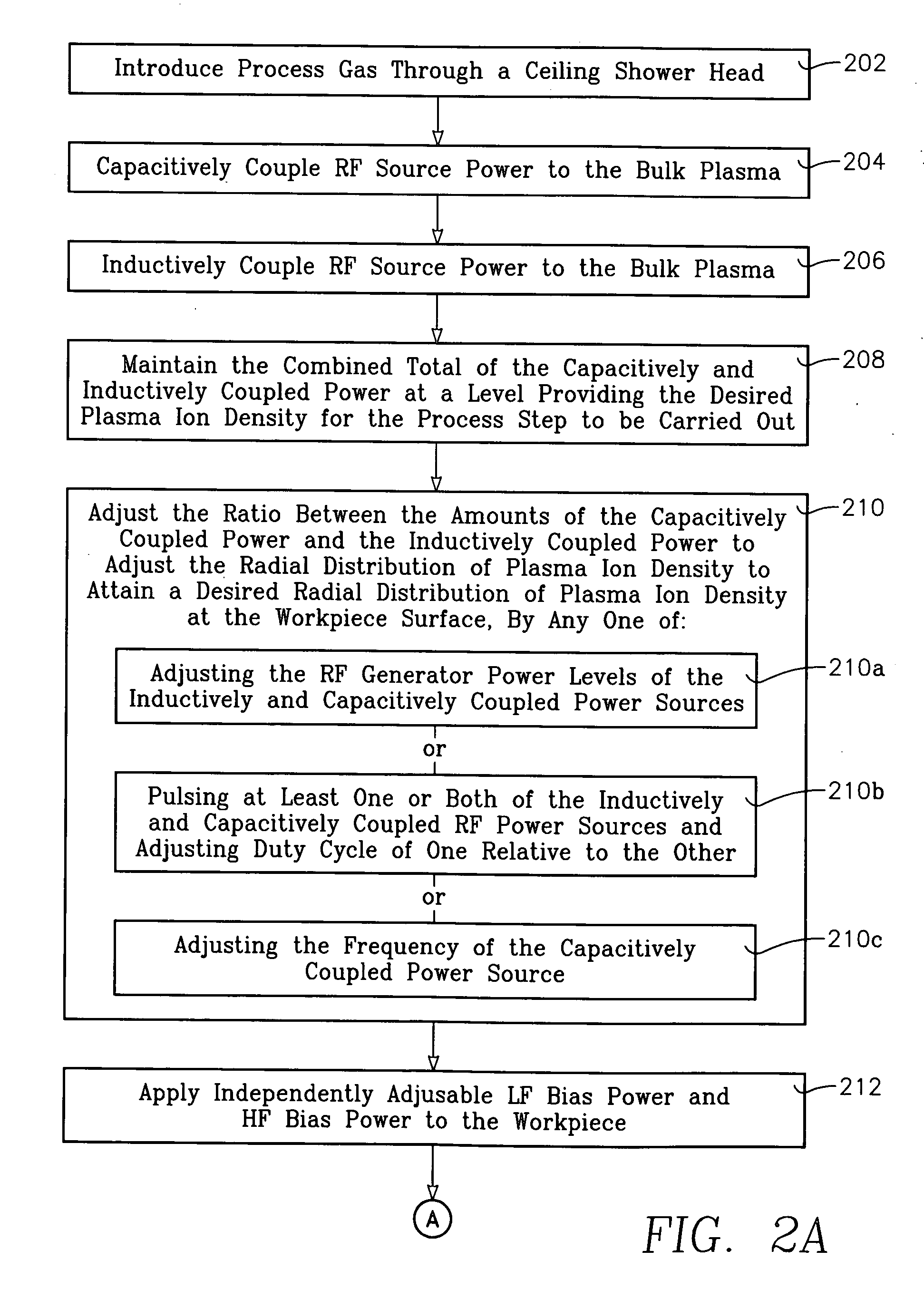

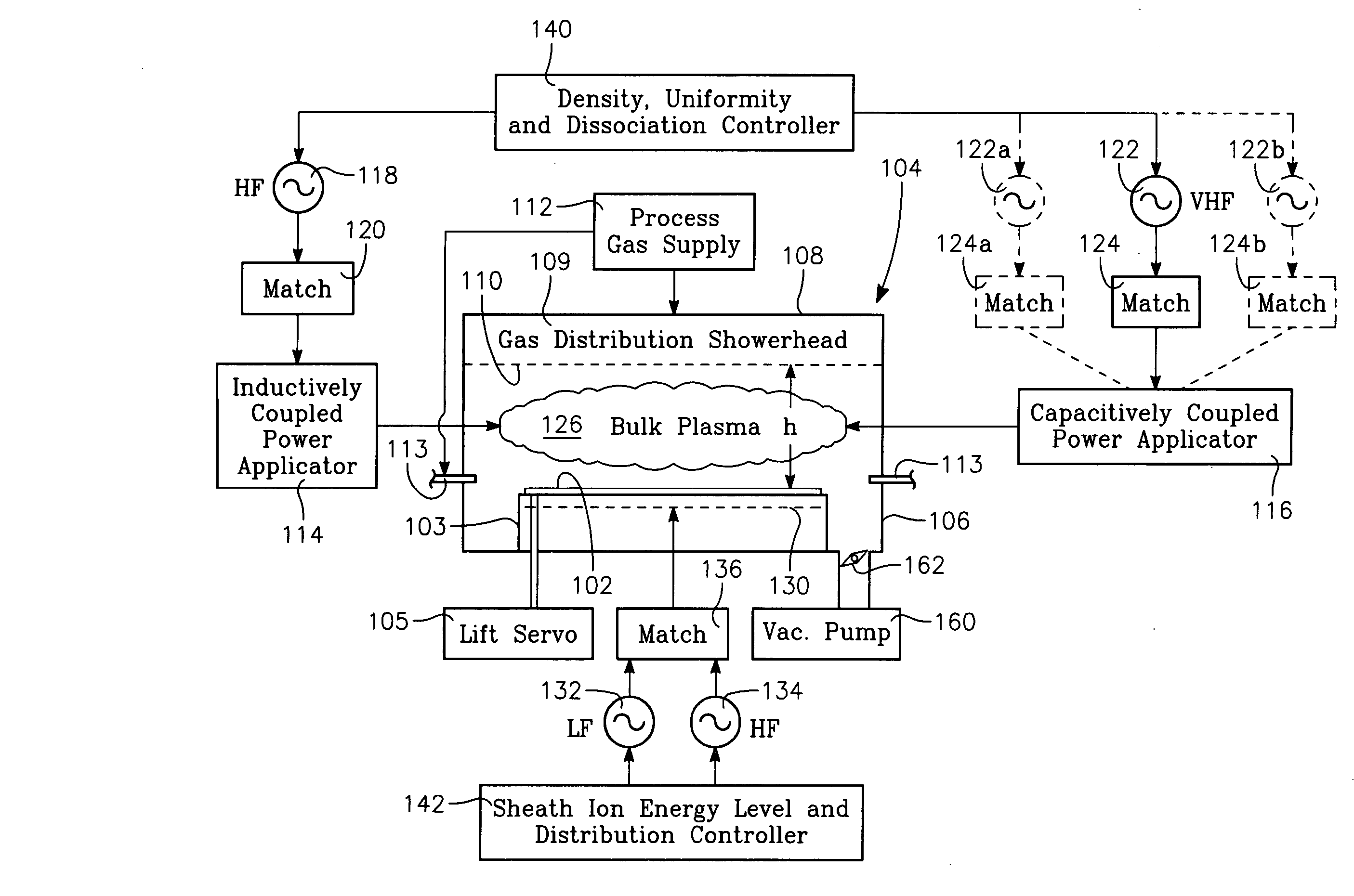

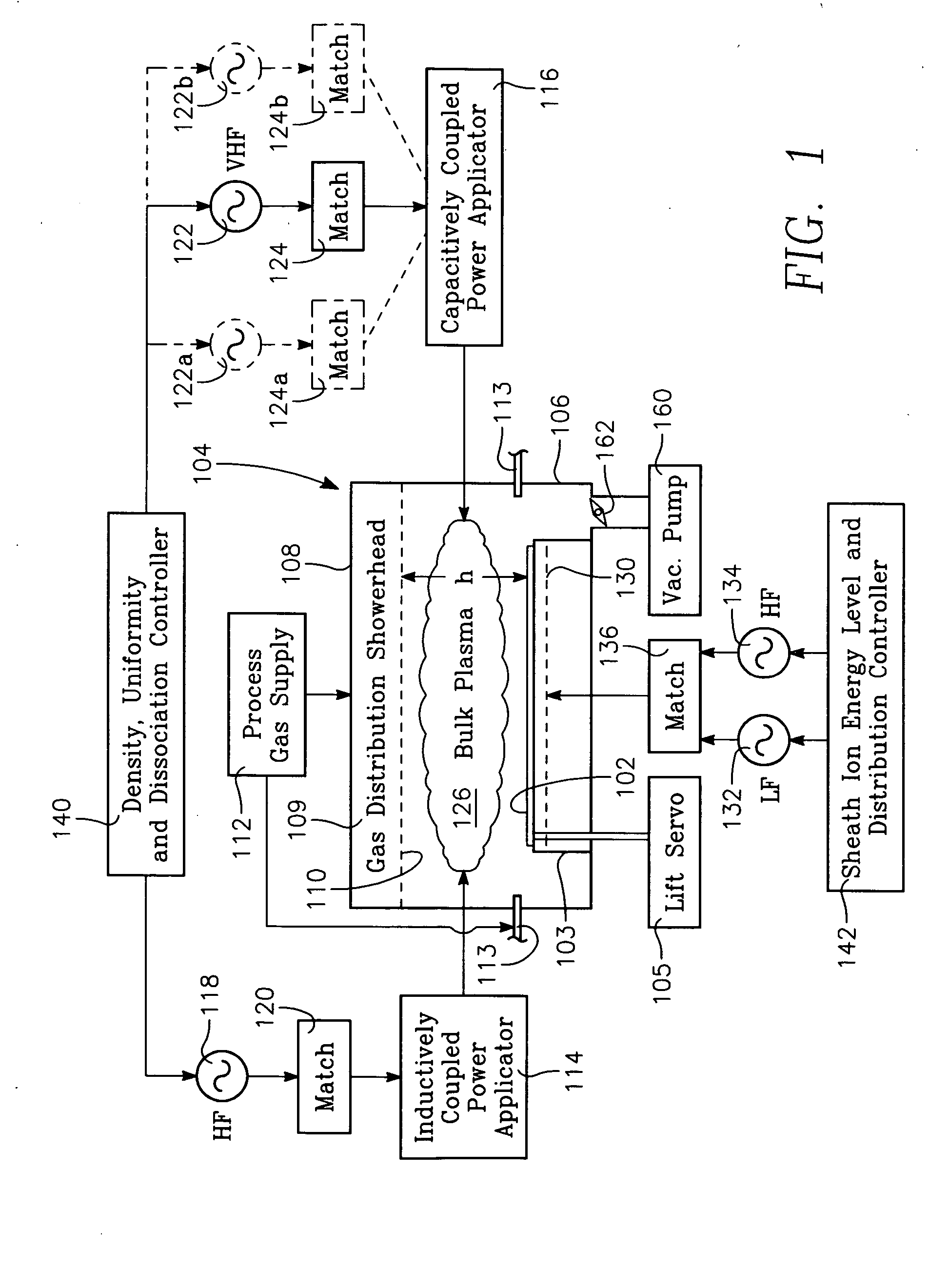

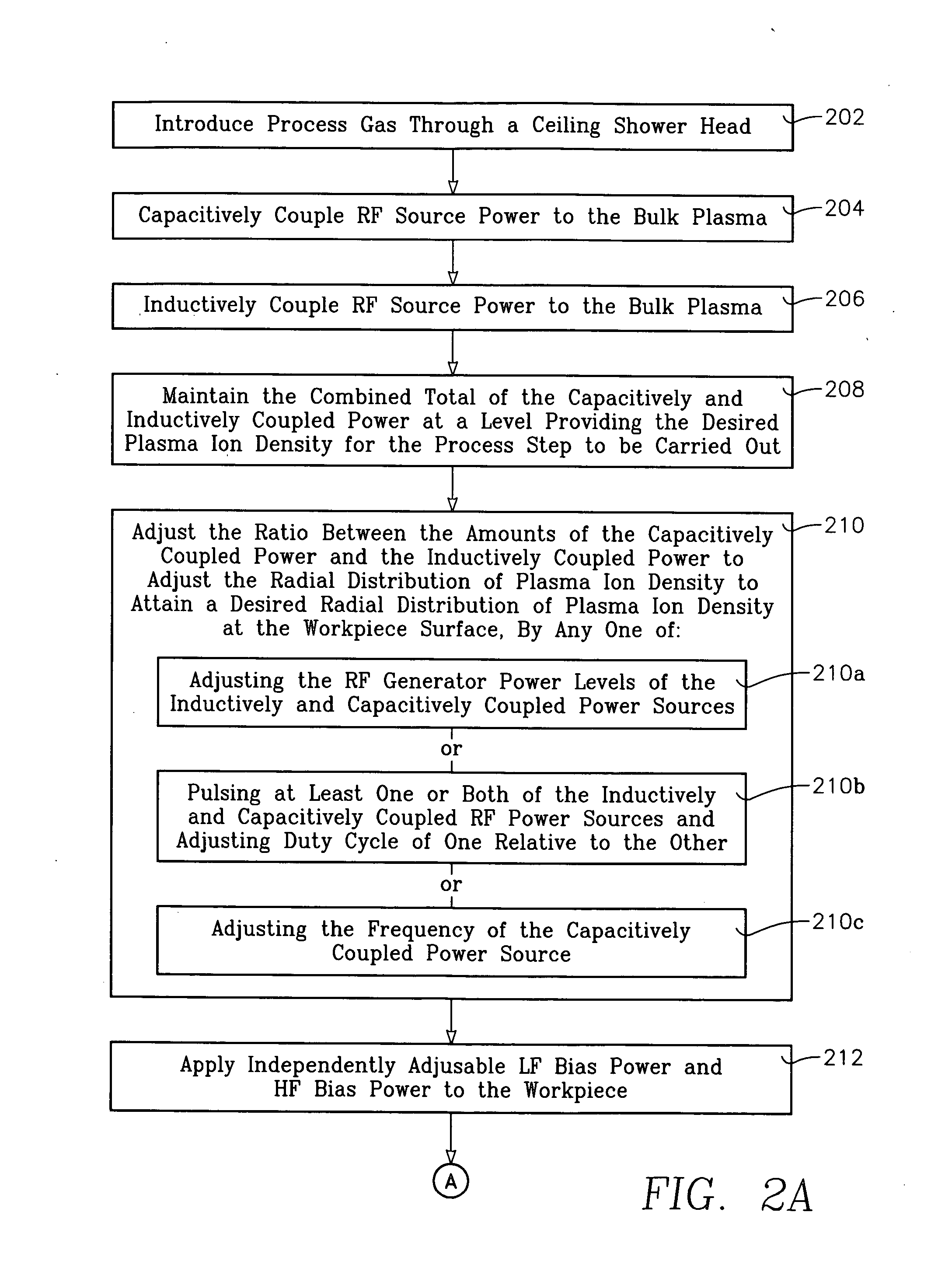

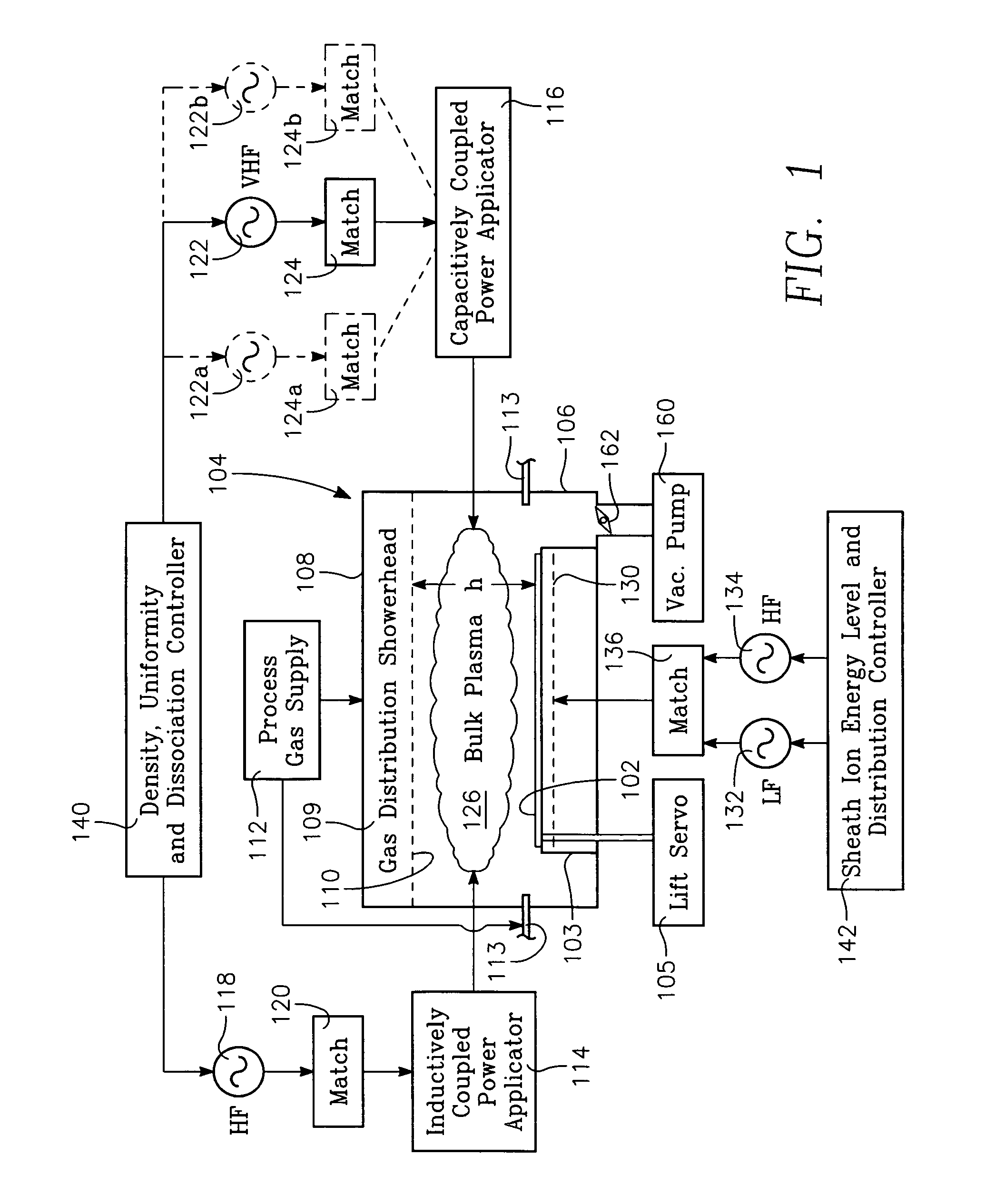

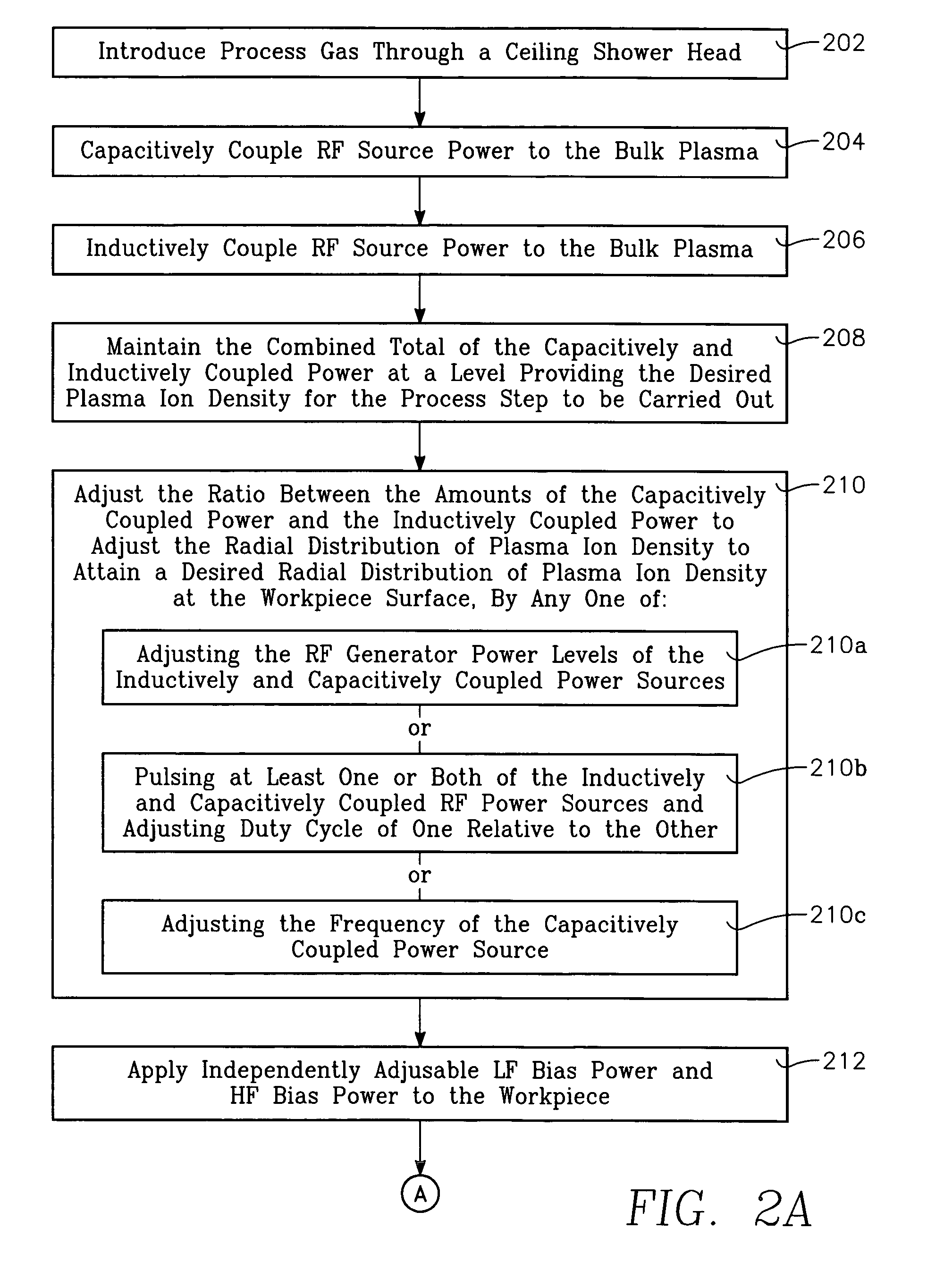

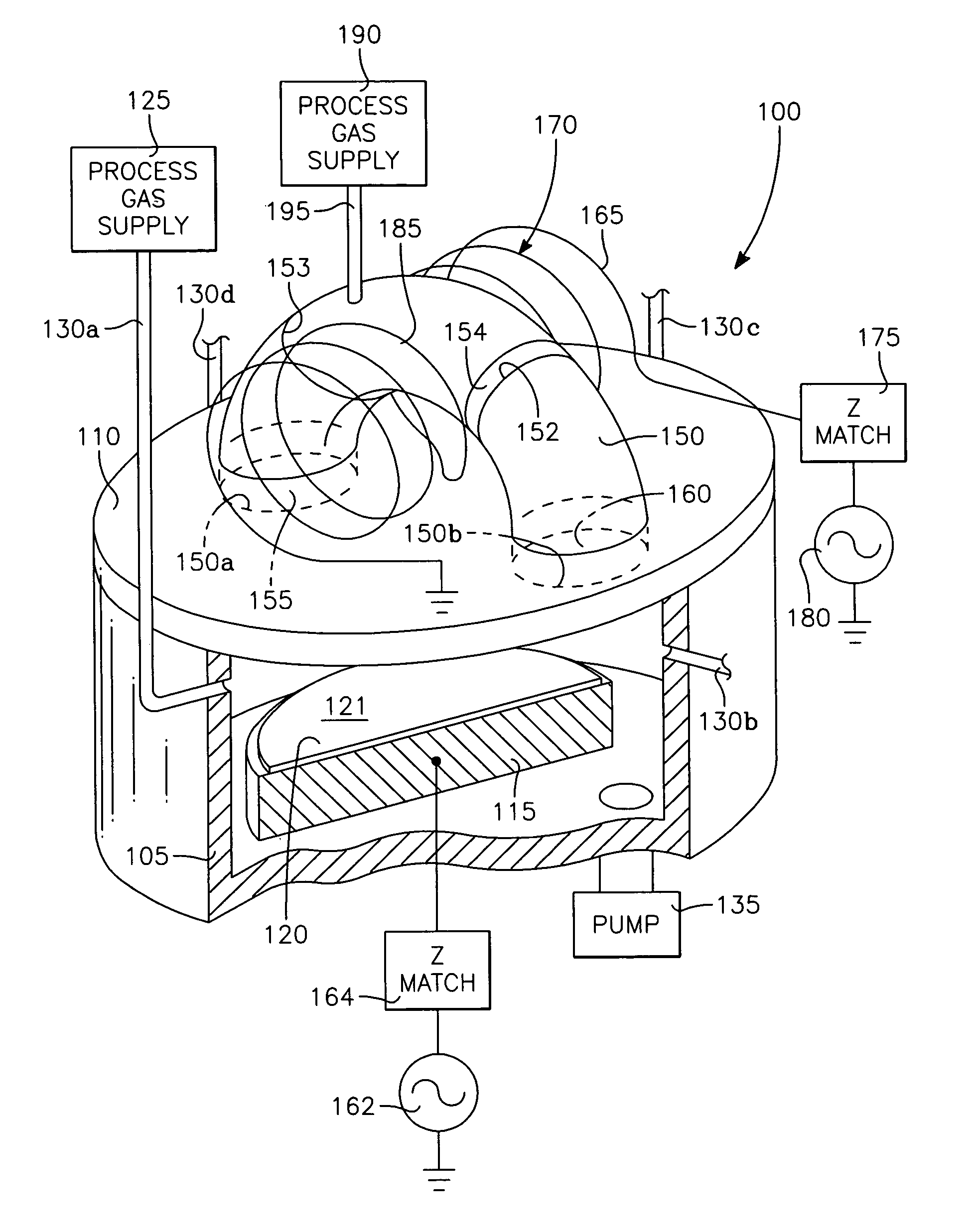

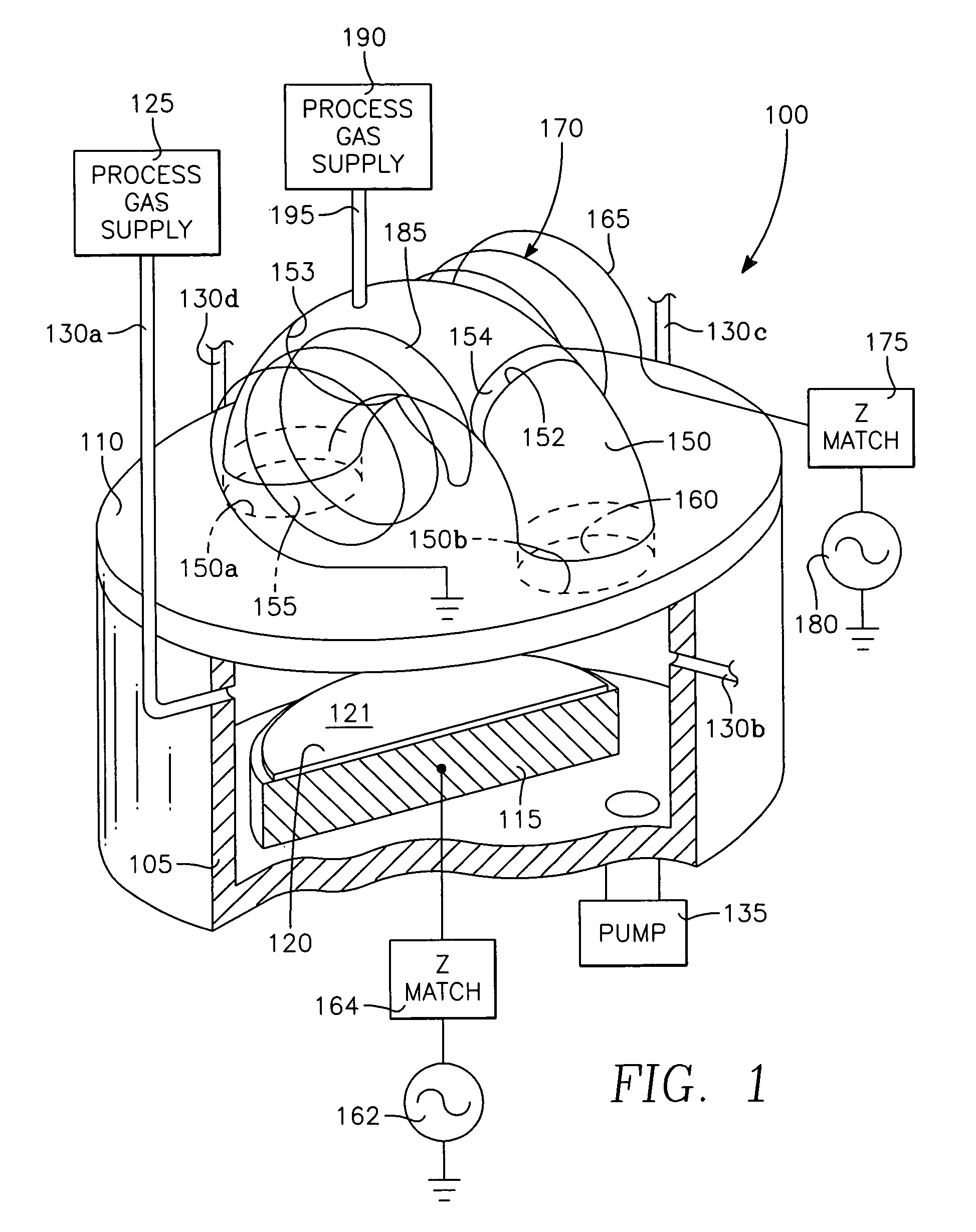

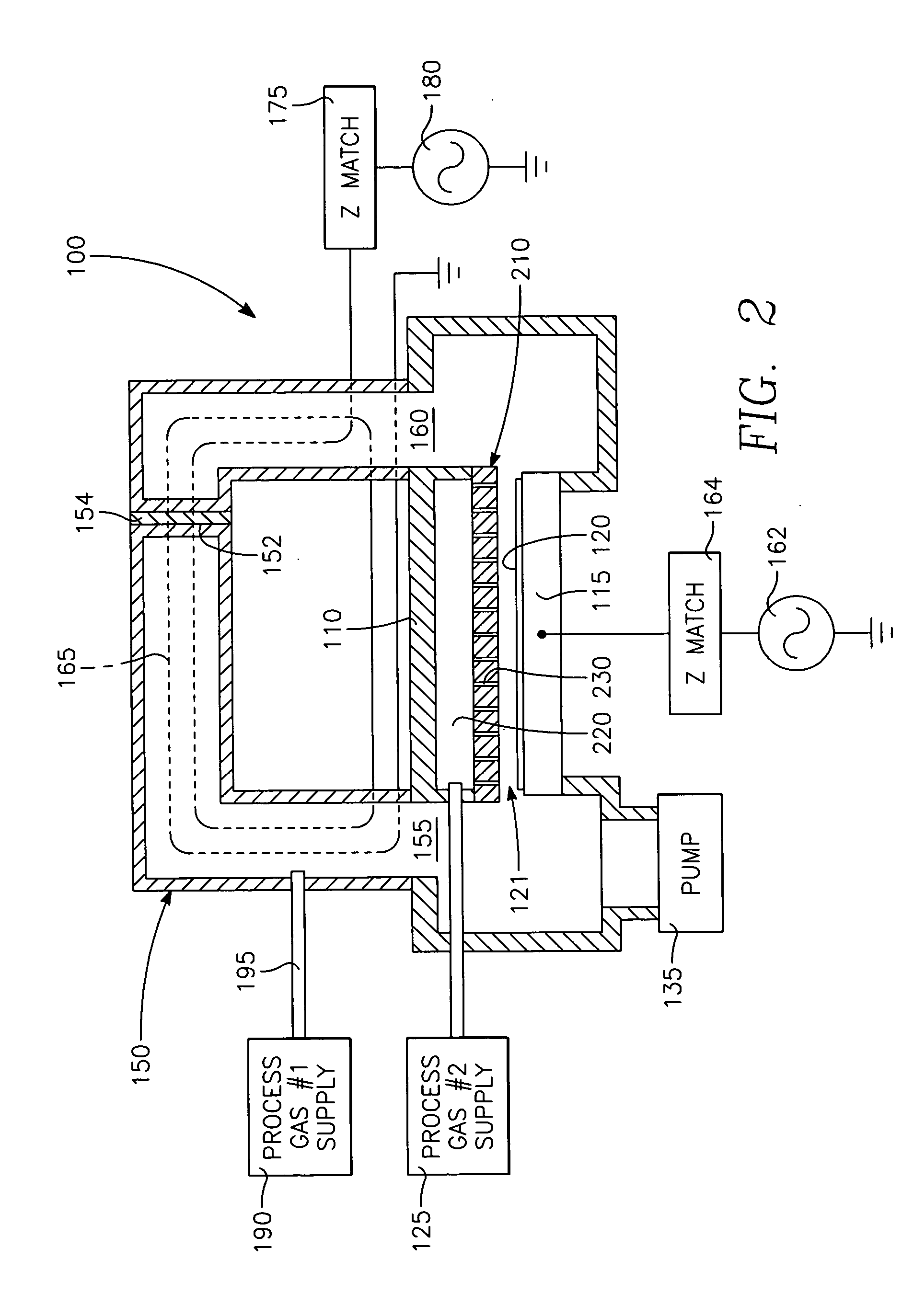

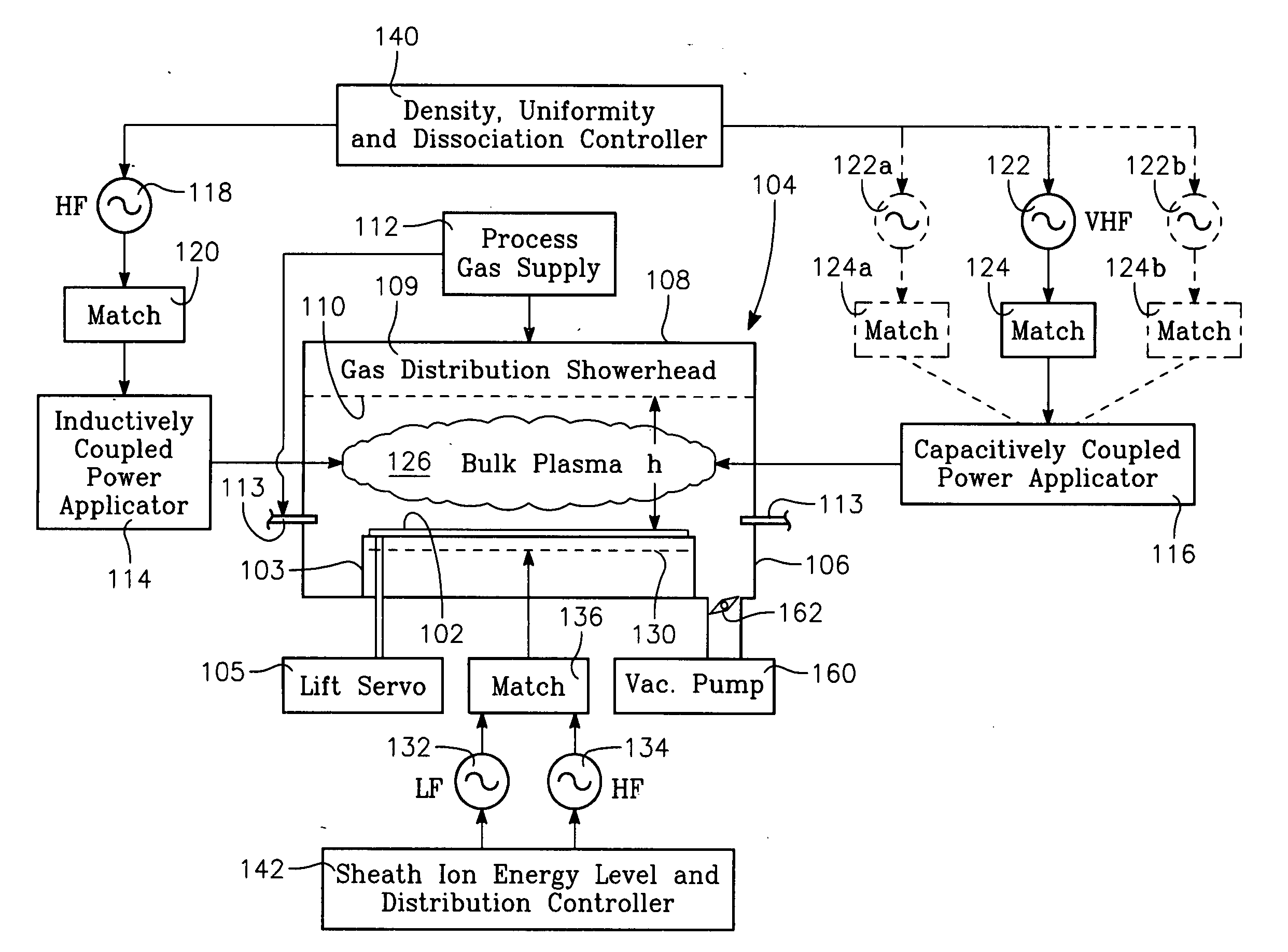

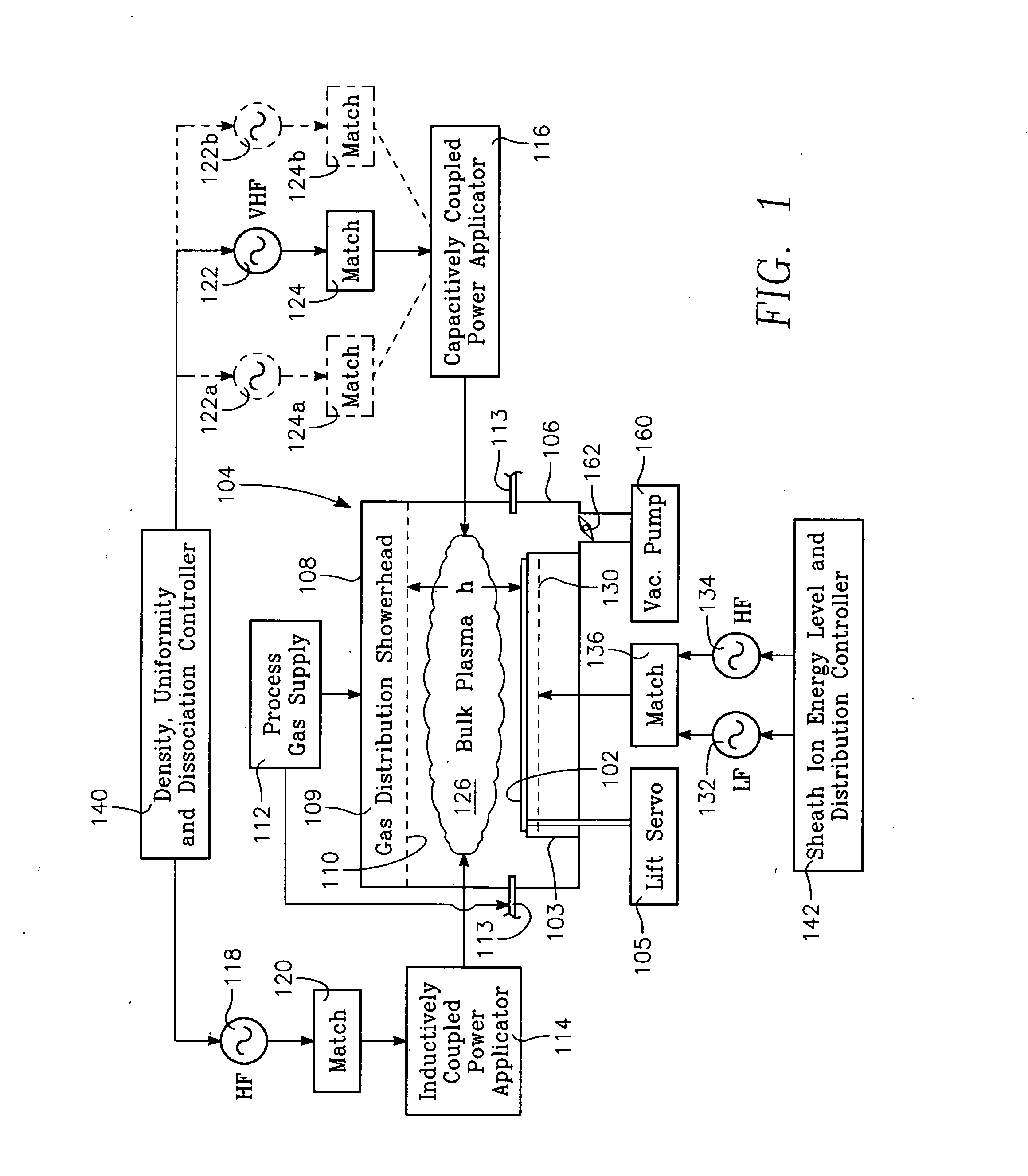

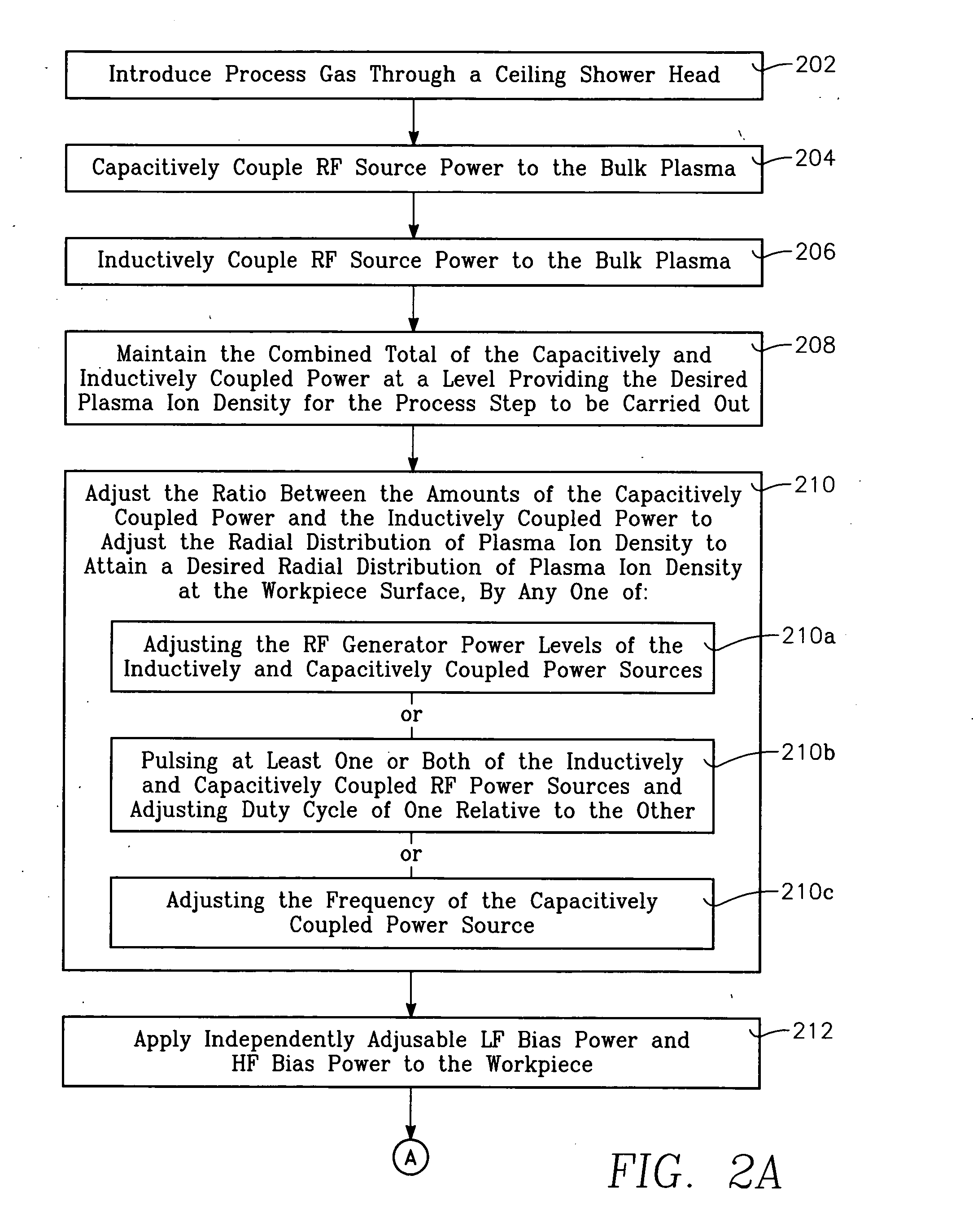

Plasma reactor apparatus with independent capacitive and inductive plasma sources

InactiveUS20070246163A1Electric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceNuclear engineering

A plasma reactor for processing a workpiece includes a reactor chamber and a workpiece support within the chamber, the chamber having a ceiling facing the workpiece support, an inductively coupled plasma source power applicator overlying the ceiling, and an RF power generator coupled to the inductively coupled source power applicator, and a capacitively coupled plasma source power applicator comprising a source power electrode at one of: (a) the ceiling (b) the workpiece support, and a VHF power generator coupled to the capacitively coupled source power applicator. The reactor further includes a plasma bias power applicator comprising a bias power electrode in the workpiece support and at least a first RF bias power generator coupled to the plasma bias power applicator, process gas distribution apparatus comprising a gas distribution showerhead in the ceiling, a vacuum pump for evacuating the chamber, and a first controller capable of adjusting the relative amounts of power simultaneously coupled to plasma in the chamber by the inductively coupled plasma source power applicator and the capacitively coupled plasma source power applicator.

Owner:APPLIED MATERIALS INC

Capacitively coupled plasma reactor having a cooled/heated wafer support with uniform temperature distribution

ActiveUS20070081295A1Improve uniformityWide pressure rangeSemiconductor/solid-state device manufacturingCapacitanceGas phase

A plasma reactor for processing a workpiece includes a reactor chamber, an electrostatic chuck within the chamber for supporting a workpiece, an RF plasma bias power generator coupled to apply RF power to the electrostatic chuck and a refrigeration loop having an evaporator inside the electrostatic chuck with a refrigerant inlet and a refrigerant outlet. Preferably, the evaporator includes a meandering passageway distributed in a plane beneath a top surface of the electrostatic chuck. Preferably, refrigerant within the evaporator is apportioned between a vapor phase and a liquid phase. As a result, heat transfer between the electrostatic chuck and the refrigerant within the evaporator is a constant-temperature process. This feature improves uniformity of temperature distribution across a diameter of the electrostatic chuck.

Owner:BE AEROSPACE INCORPORATED

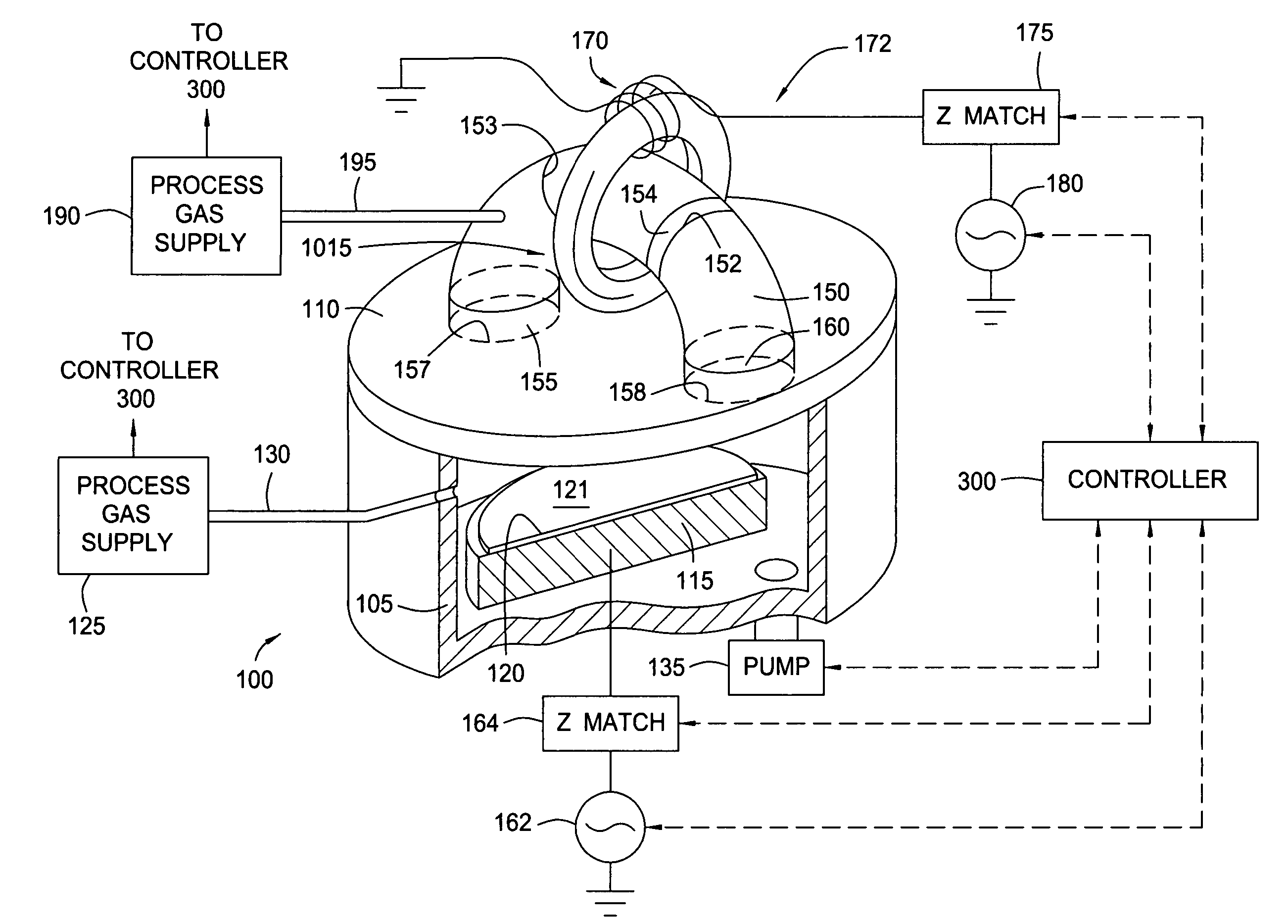

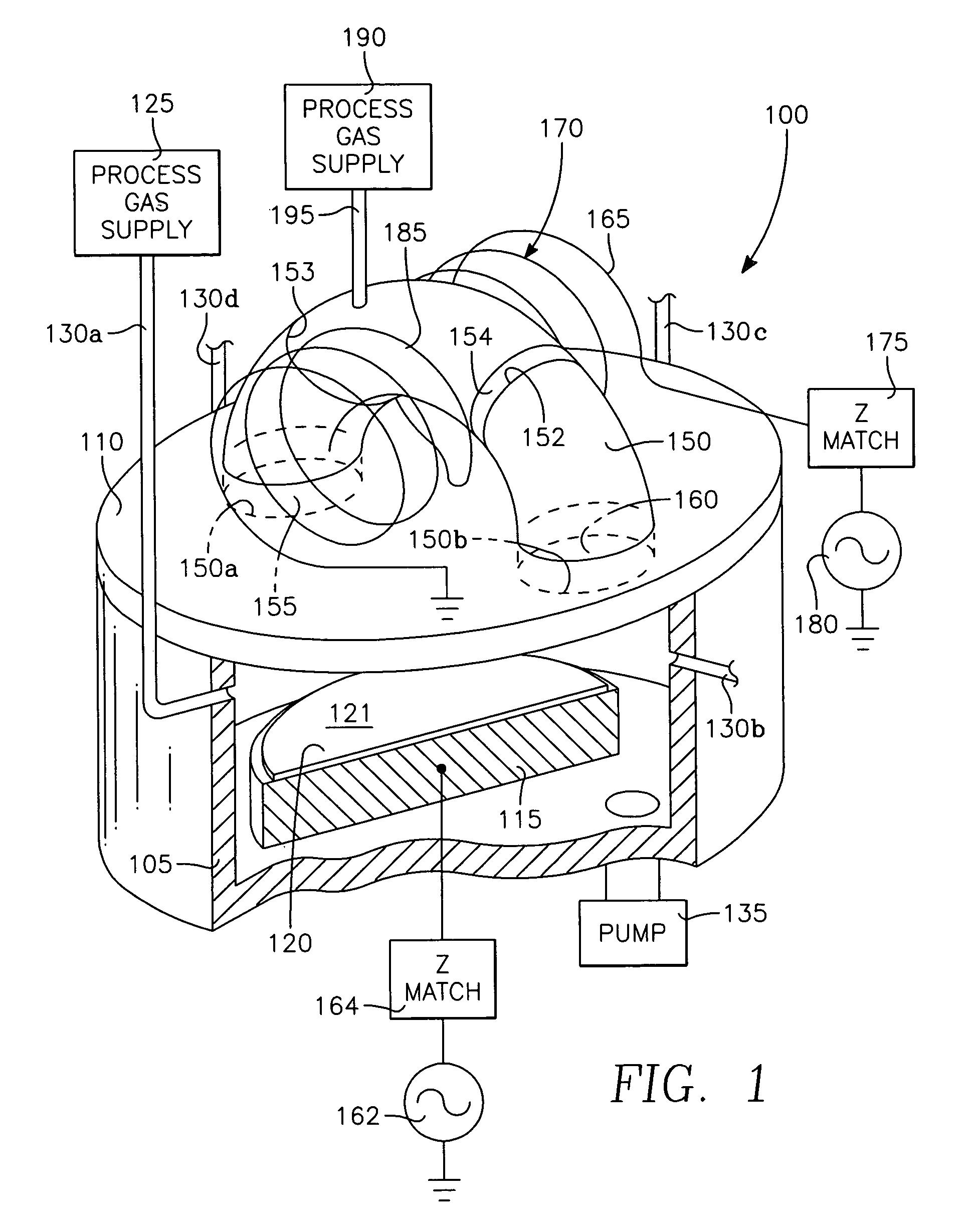

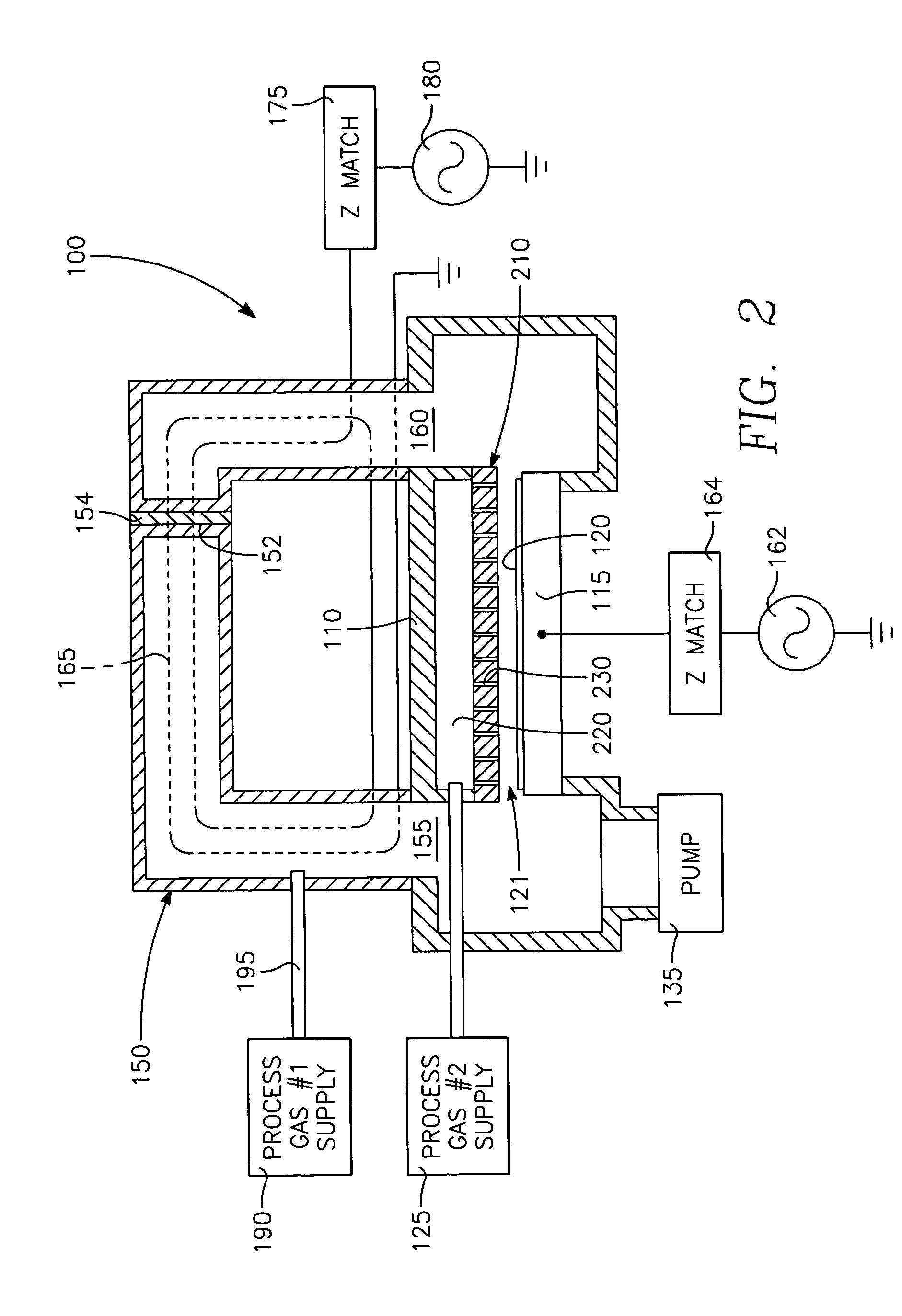

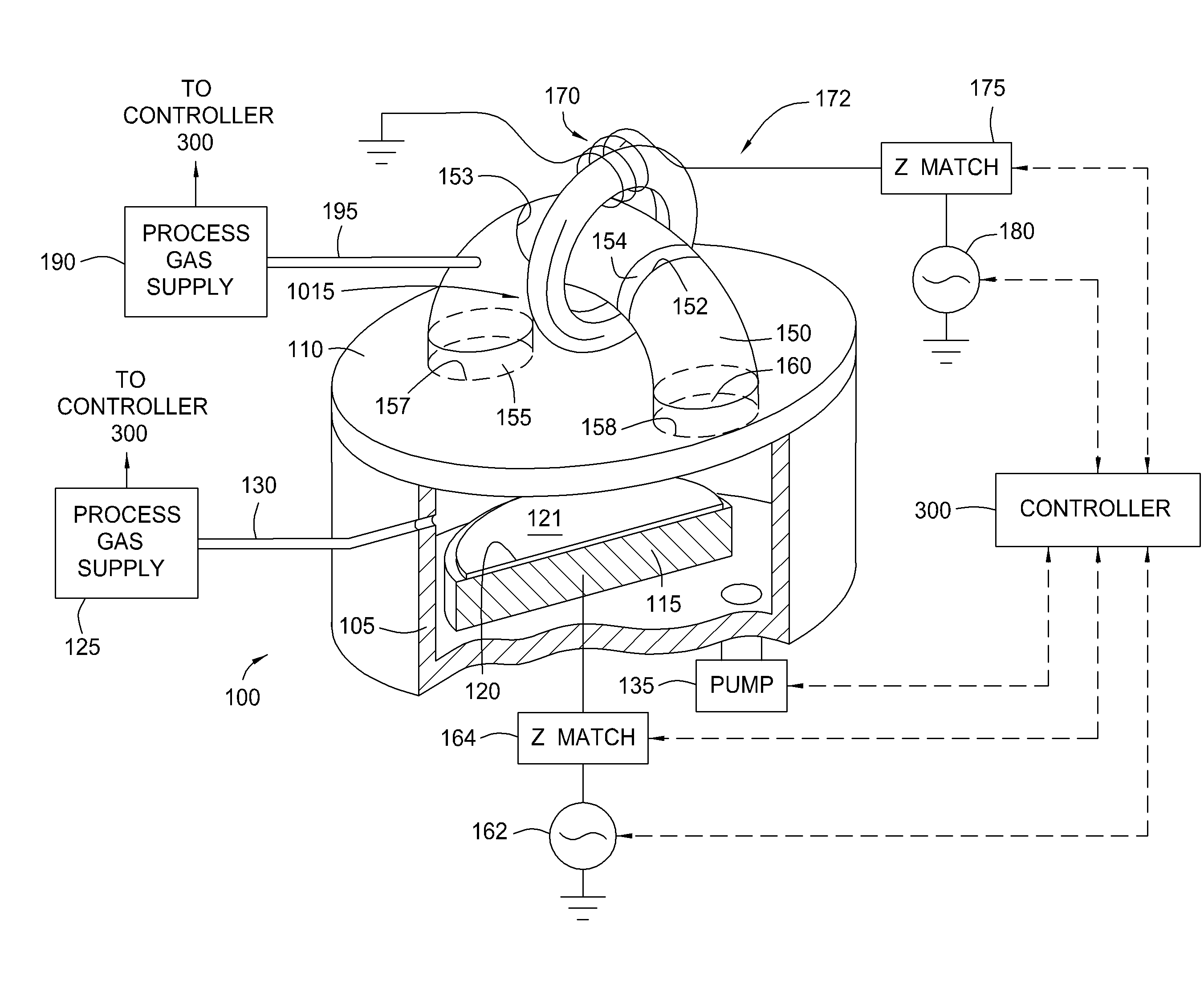

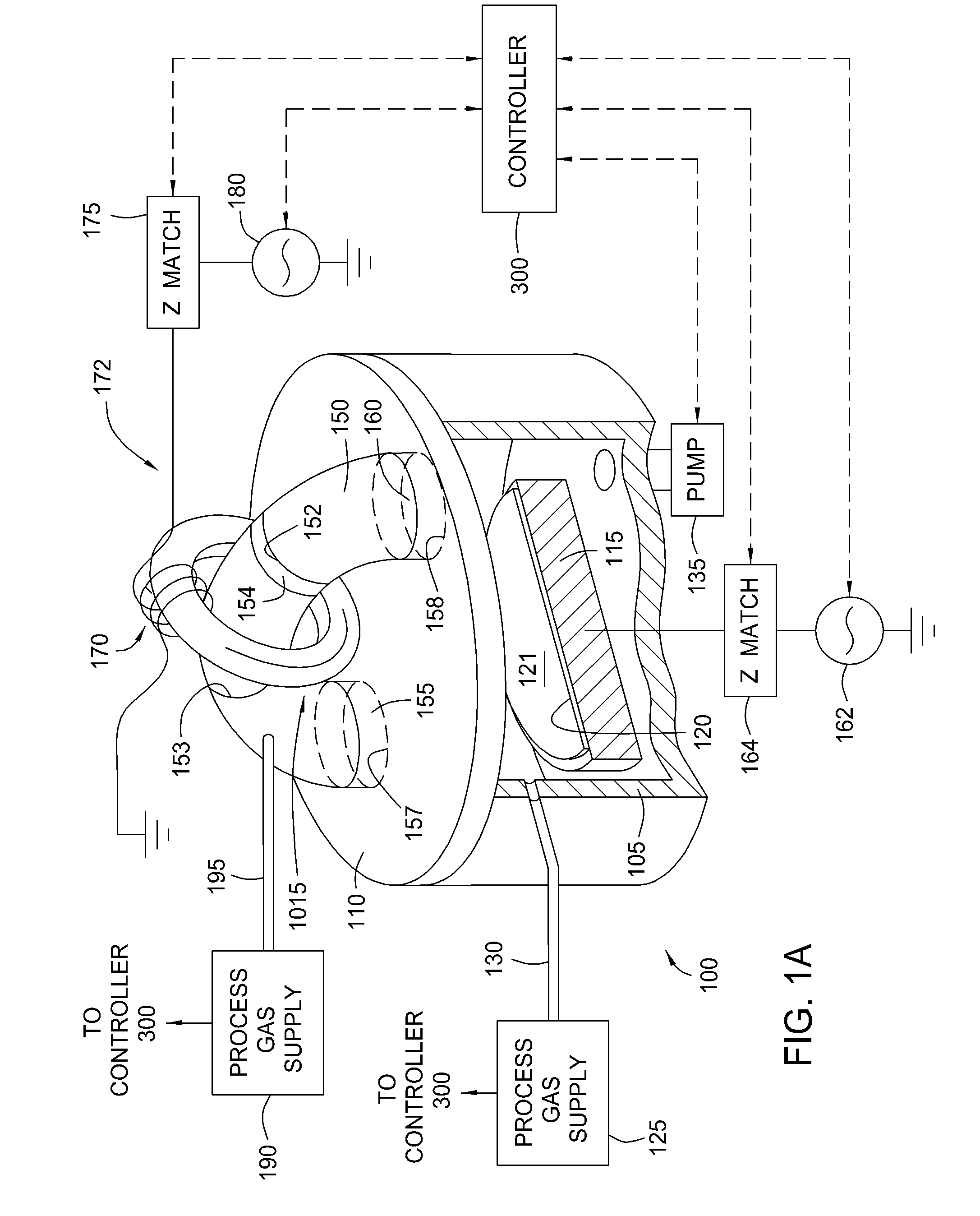

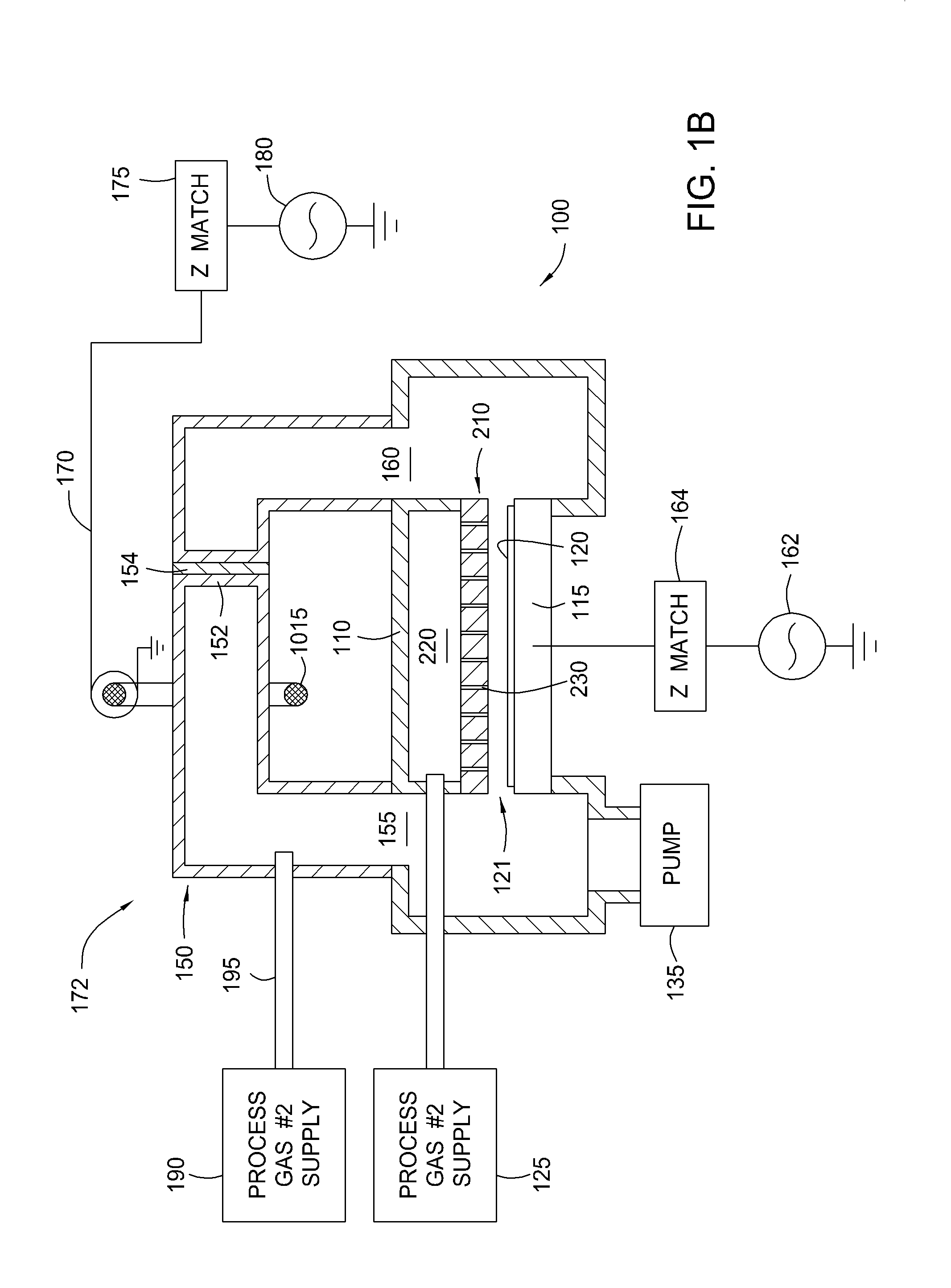

Plasma reactor apparatus with independent capacitive and toroidal plasma sources

InactiveUS7264688B1Increase ratingsIncrease ion densityElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceEngineering

A plasma reactor includes a toroidal plasma source having an RF power applicator, and RF generator being coupled to the RF power applicator. The reactor further includes a capacitively coupled plasma source power applicator or electrode at the ceiling or the workpiece support, a VHF power generator being coupled to the capacitively coupled source power applicator, a plasma bias power applicator or electrode in the workpiece support and an RF bias power generator coupled to the plasma bias power applicator. A controller adjusts the relative amounts of power simultaneously coupled to plasma in the chamber and conduit by the toroidal plasma source and by the capacitively coupled plasma source power applicator.

Owner:APPLIED MATERIALS INC

Method of operating a capacitively coupled plasma reactor with dual temperature control loops

ActiveUS20070081296A1Decorative surface effectsSemiconductor/solid-state device manufacturingCapacitanceTemperature control

In a plasma reactor having an electrostatic chuck with an electrostatic chuck top surface for supporting a workpiece, thermal transfer medium flow channels in the interior of the electrostatic chuck, a method for controlling temperature of the workpiece during plasma processing includes circulating thermal transfer medium through the thermal transfer medium flow passages and supplying a thermally conductive gas between the workpiece and the electrostatic chuck top surface, and changing thermal transfer medium thermal conditions of thermal transfer medium flowing in the thermal transfer medium flow channels so as to change the temperature of the electrostatic chuck at a first rate limited by the thermal mass of the electrostatic chuck. The method further includes changing the backside gas pressure of the thermally conductive gas so as to change the temperature of the workpiece at a second rate faster than the first rate.

Owner:BE AEROSPACE INCORPORATED

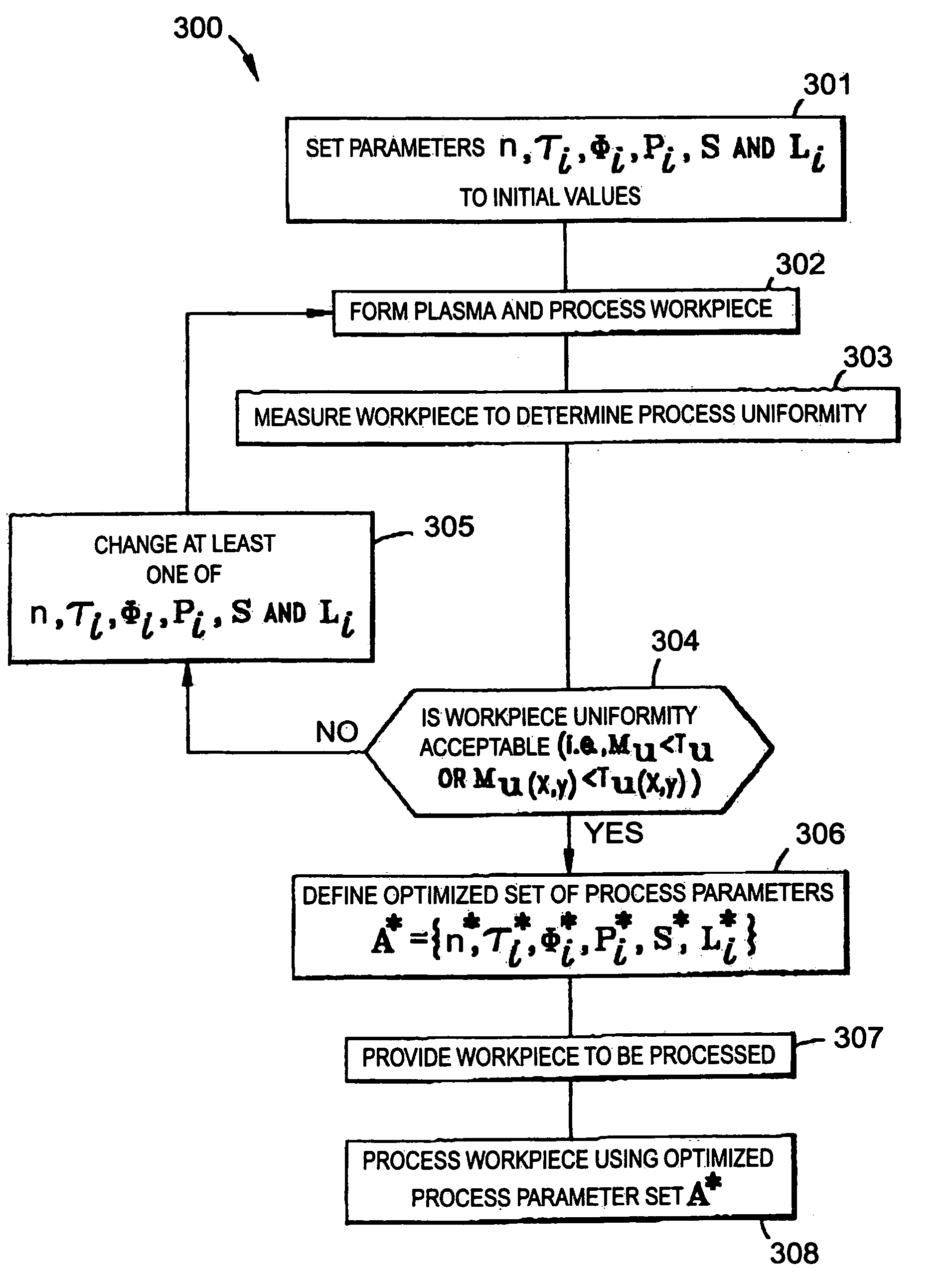

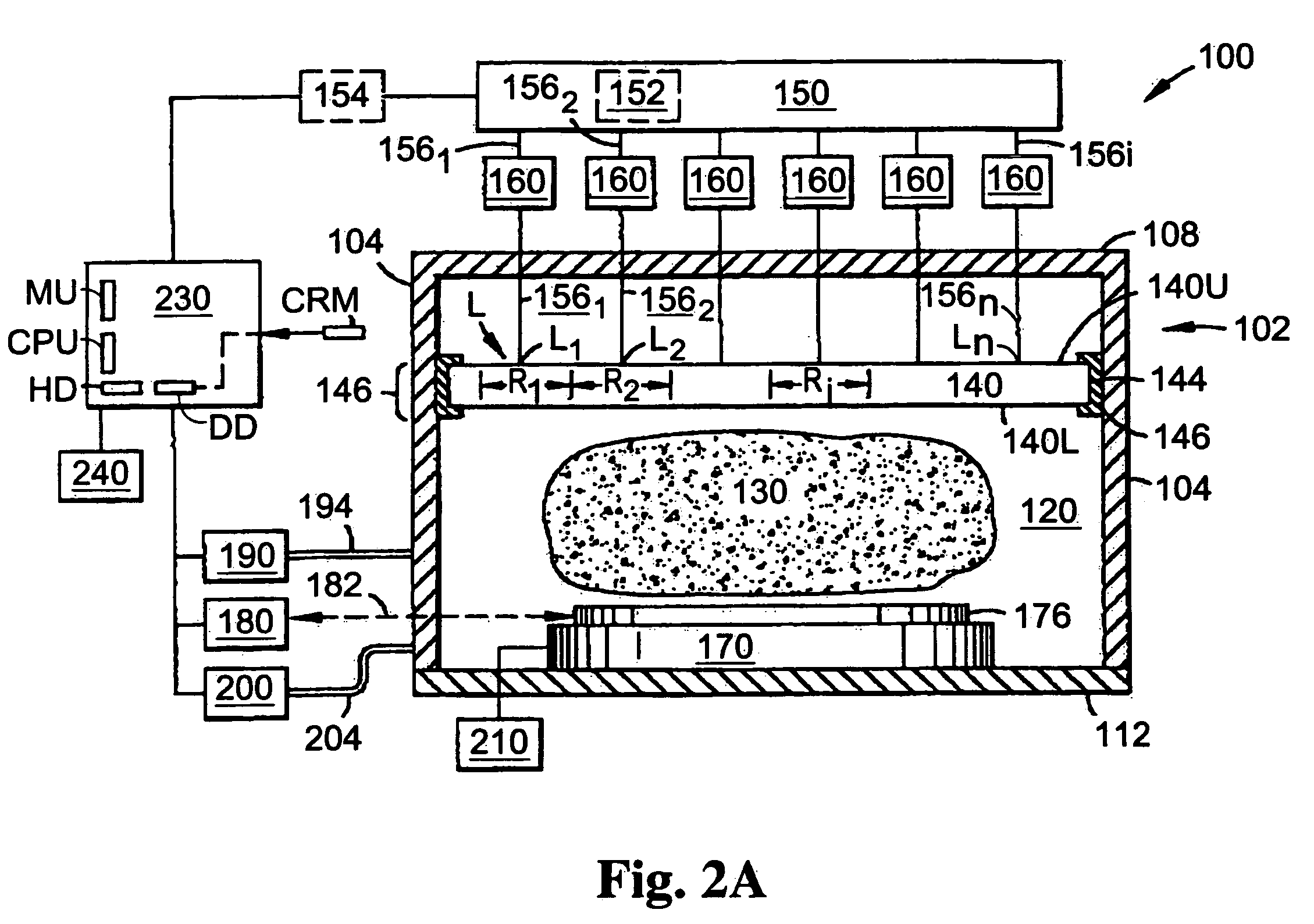

Method and apparatus for improved plasma processing uniformity

InactiveUS7164236B2High degree of process uniformityHigh degree of processingElectric discharge tubesElectric arc lampsPlasma processingCapacitively coupled plasma

A method and apparatus for generating and controlling a plasma (130) formed in a capacitively coupled plasma system (100) having a plasma electrode (140) and a bias electrode in the form of a workpiece support member (170), wherein the plasma electrode is unitary and has multiple regions (Ri) defined by a plurality of RF power feed lines (156) and the RF power delivered thereto. The electrode regions may also be defined as electrode segments (420) separated by insulators (426). A set of process parameters A={n, τi, Φi, Pi, S; Li} is defined; wherein n is the number of RF feed lines connected to the electrode upper surface at locations Li, τi is the on-time of the RF power for the ith RF feed line, Φi is the phase of the ith RF feed line relative to a select one of the other RF feed lines, Pi is the RF power delivered to the electrode through the ith RF feed line at location Li, and S is the sequencing of RF power to the electrode through the RF feed lines. One or more of these parameters are adjusted so that operation of the plasma system results in a workpiece (176) being processed with a desired amount or degree of process uniformity.

Owner:TOKYO ELECTRON LTD

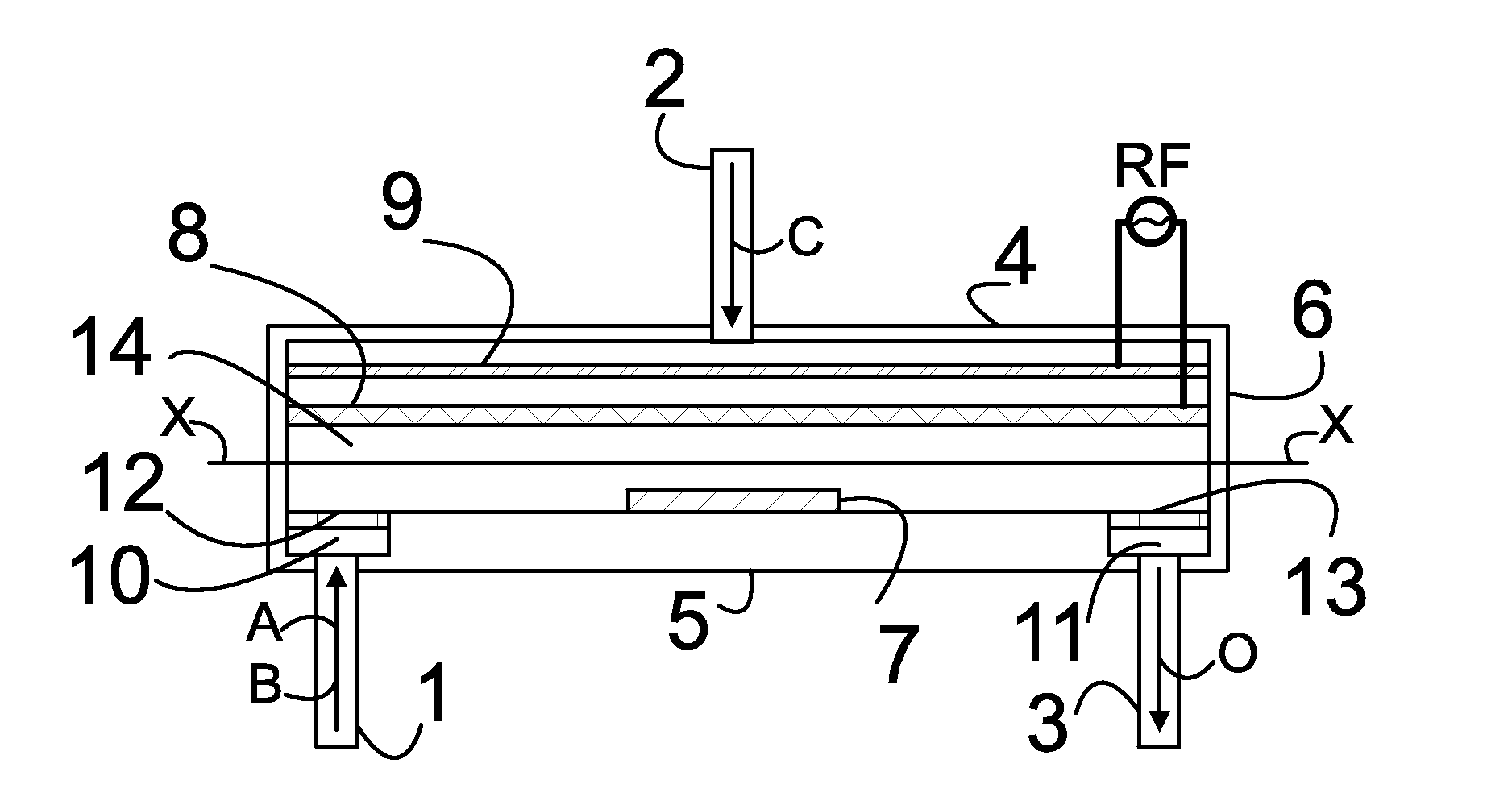

Capacitive coupling plasma processing apparatus

ActiveUS20060221540A1High planar uniformityPrevent charging damageElectric discharge tubesVacuum evaporation coatingCapacitanceCapacitive coupling

A capacitive coupling plasma processing apparatus includes a process chamber configured to have a vacuum atmosphere, and a process gas supply section configured to supply a process gas into the chamber. In the chamber, a first electrode and a second electrode are disposed opposite each other. The second electrode includes a plurality of conductive segments separated from each other and facing the first electrode. An RF power supply is configured to apply an RF power to the first electrode to form an RF electric field within a plasma generation region between the first and second electrodes, so as to turn the process gas into plasma by the RF electric field. A DC power supply is configured to apply a DC voltage to at least one of the segments of the second electrode.

Owner:TOKYO ELECTRON LTD

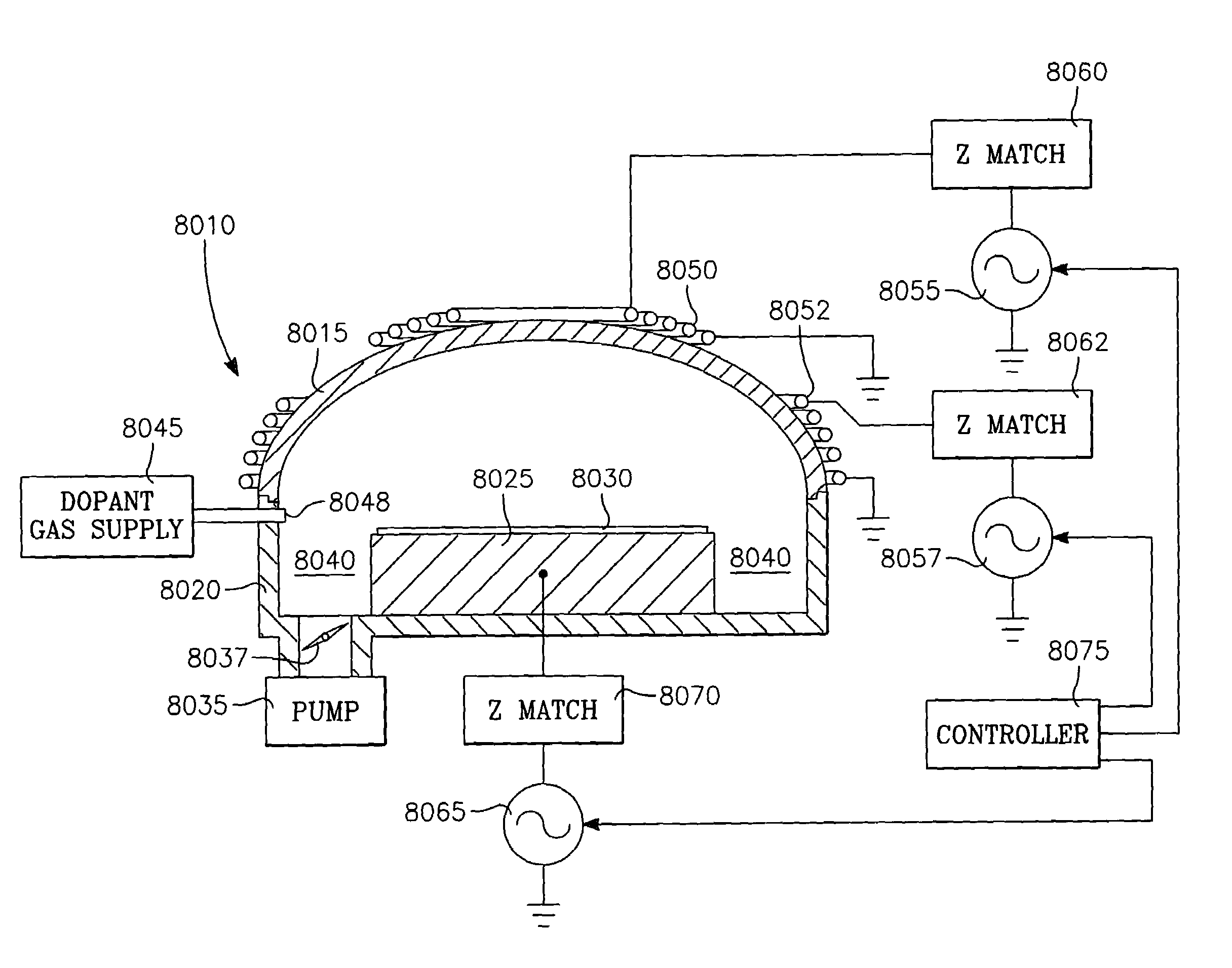

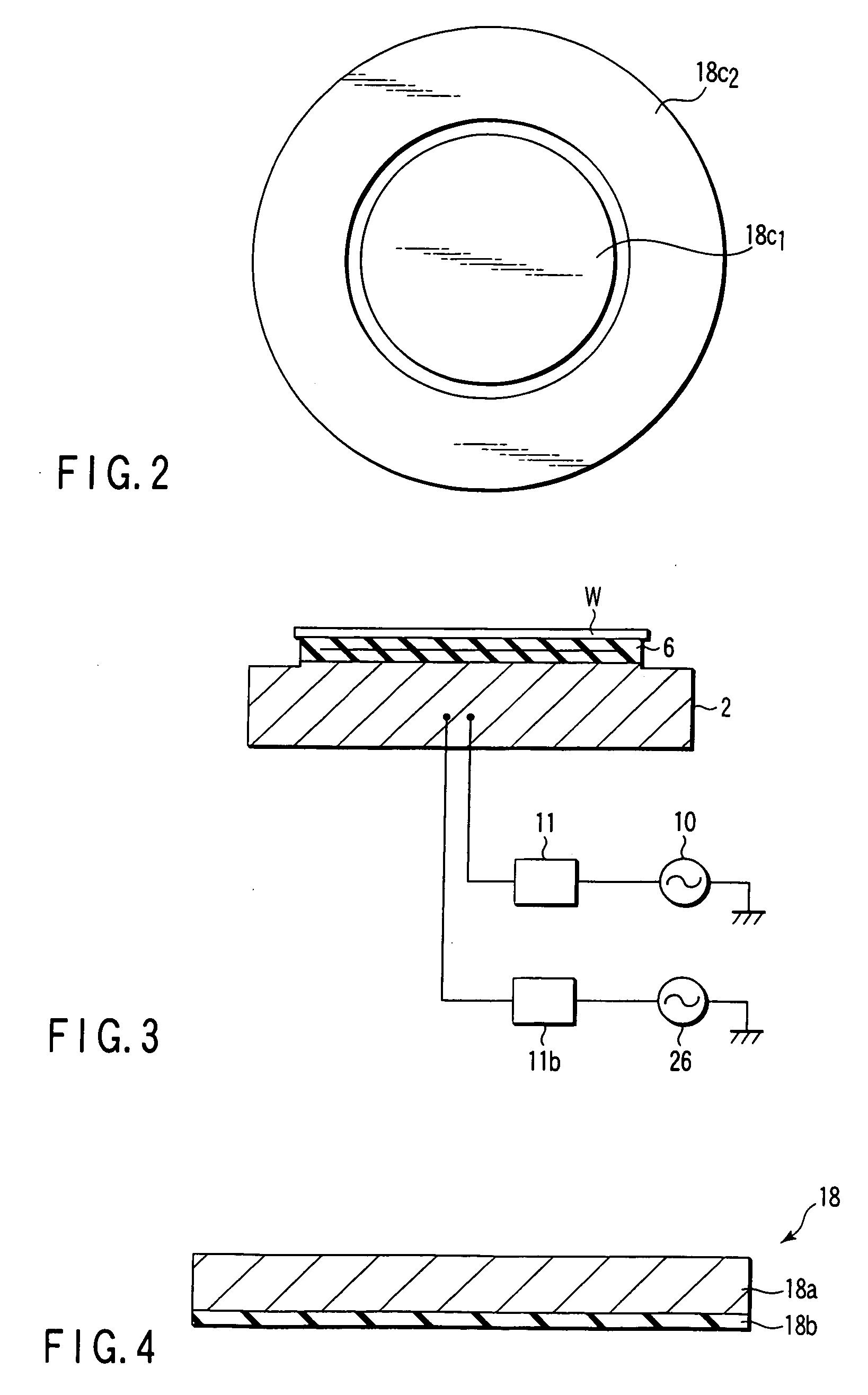

Plasma based ion implantation system

InactiveUS20080289576A1Improve processing efficiencyUniformity of plasmaElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceVacuum chamber

A plasma based ion implantation system capable of generating a capacitively coupled plasma having beneficial characteristics for an ion implantation, including the generation of necessary ions and radicals only for an ion implantation process instead of generating an inductively coupled plasma, which generates unnecessary ions and excessively dissociates radicals. The plasma based ion implantation system easily controls plasma ions implanted by cleaning a vacuum chamber, minimizes problems of unnecessary deposition and occurrence of contaminants and increases the number of components used only for the plasma ion implantion by reducing the deposition of polymer layer on a workpiece. The plasma based ion implantation system easily control uniformity of the plasma by using a flat type electrode, thereby easily ensuring uniformity of plasma ions implanted into the workpiece.

Owner:SAMSUNG ELECTRONICS CO LTD

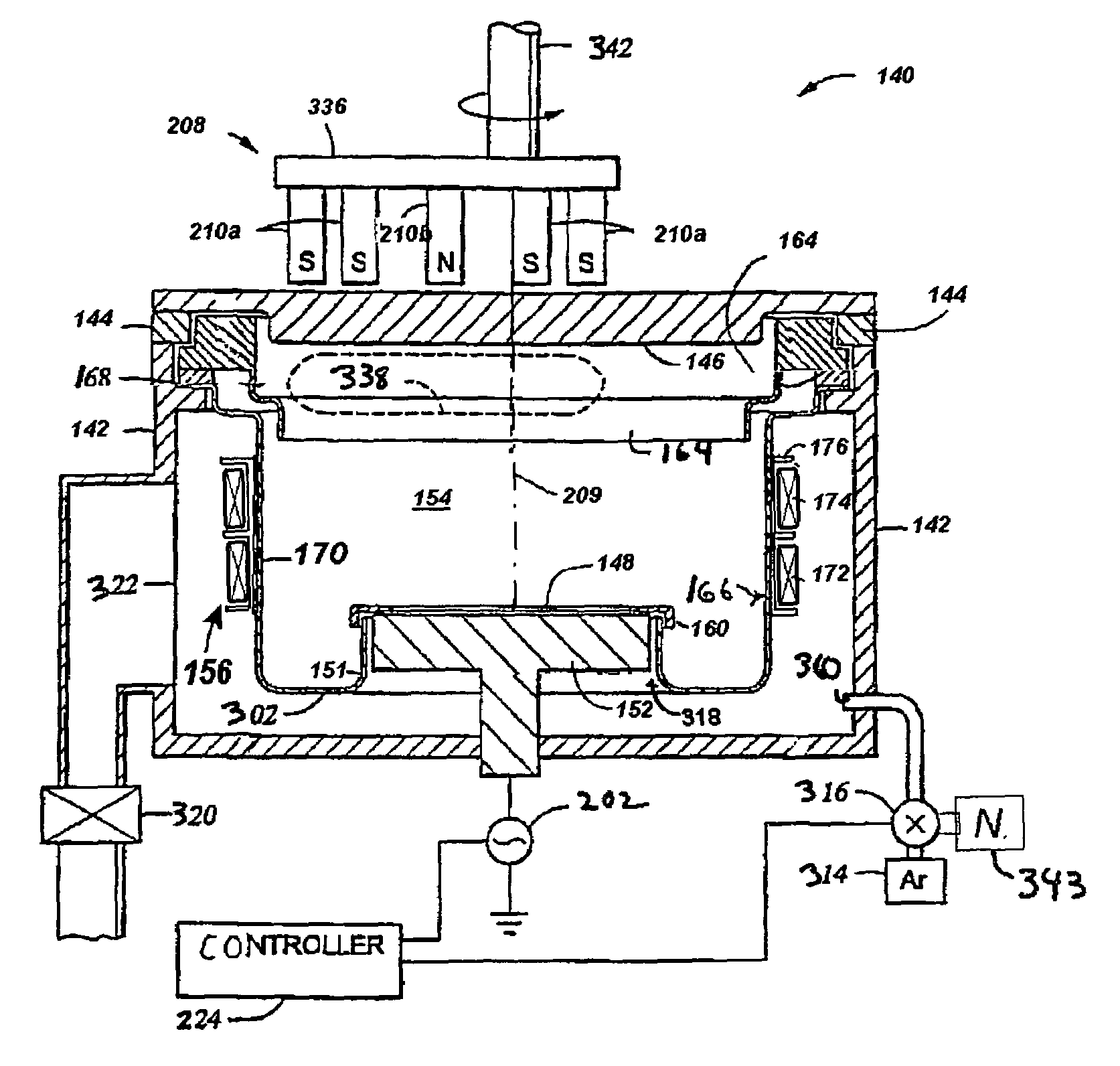

Self-ionized and capacitively-coupled plasma for sputtering and resputtering

InactiveUS7504006B2Raise the ratioIncrease plasma densityCellsElectric discharge tubesCapacitanceTantalum nitride

A DC magnetron sputter reactor for sputtering deposition materials such as tantalum and tantalum nitride, for example, and its method of use, in which self-ionized plasma (SIP) sputtering and capacitively coupled plasma (CCP) sputtering are promoted, either together or alternately, in the same chamber. Also, bottom coverage may be thinned or eliminated by inductively-coupled plasma (ICP) resputtering. SIP is promoted by a small magnetron having poles of unequal magnetic strength and a high power applied to the target during sputtering. CCP is provided by a pedestal electrode which capacitively couples RF energy into a plasma. The CCP plasma is preferably enhanced by a magnetic field generated by electromagnetic coils surrounding the pedestal which act to confine the CCP plasma and increase its density.

Owner:APPLIED MATERIALS INC

Plasma immersion ion implantation process using a capacitively coupled plasma source having low dissociation and low minimum plasma voltage

InactiveUS20060073683A1High ion fluxElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceSemiconductor materials

A method of ion implanting a species in a workpiece to a selected ion implantation profile depth includes placing a workpiece having a semiconductor material on an electrostatic chuck in or near a processing region of a plasma reactor chamber and applying a chucking voltage to the electrostatic chuck. The method further includes introducing into the chamber a precursor gas including a species to be ion implanted in the workpiece and applying an RF bias to the electrostatic chuck, the RF bias having a bias level corresponding to the ion implantation profile depth.

Owner:APPLIED MATERIALS INC

Alternating asymmetrical plasma generation in a process chamber

InactiveUS20080023443A1Improve uniformityElectric discharge tubesDecorative surface effectsCapacitanceNon symmetric

Embodiments of the invention generally provide etch or CVD plasma processing methods and apparatus used to generate a uniform plasma across the surface of a substrate by modulation pulsing the power delivered to a plurality of plasma controlling devices found in a plasma processing chamber. The plasma generated and / or sustained in the plasma processing chamber is created by the one or more plasma controlling devices that are used to control, generate, enhance, and / or shape the plasma during the plasma processing steps by use of energy delivered from a RF power source. Plasma controlling devices may include, for example, one or more coils (inductively coupled plasma), one or more electrodes (capacitively coupled plasma), and / or any other energy inputting device such as a microwave source.

Owner:PATERSON ALEXANDER +6

Plasma reactor apparatus with an inductive plasma source and a VHF capacitively coupled plasma source with variable frequency

InactiveUS20070246162A1Increase ratingsIncrease ion densityElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceNuclear engineering

A plasma reactor for processing a workpiece includes a reactor chamber and a workpiece support within the chamber, the chamber having a ceiling facing the workpiece support, an inductively coupled plasma source power applicator overlying the ceiling, and an RF power generator coupled to the inductively coupled source power applicator, a capacitively coupled plasma source power applicator comprising a source power electrode at one of: (a) the ceiling (b) the workpiece support, and plural VHF power generators of different fixed frequencies coupled to the capacitively coupled source power applicator, and a controller for independently controlling the power output levels of the plural VHF generators so as to control an effective VHF frequency applied to the source power electrode. In a preferred embodiment, the reactor further includes a plasma bias power applicator including a bias power electrode in the workpiece support and one or more RF bias power generators of different frequencies coupled to the plasma bias power applicator.

Owner:APPLIED MATERIALS INC

Capacitive coupling plasma processing apparatus

InactiveUS20060081337A1High planar uniformityPrevent charging damageCellsElectric discharge tubesCapacitanceTarget surface

A capacitive coupling plasma processing apparatus includes a process chamber configured to have a vacuum atmosphere, and a process gas supply section configured to supply a process gas into the chamber. In the chamber, a first electrode serving as a cathode electrode, and a second electrode grounded to serve as an anode electrode are disposed opposite each other. An RF power supply is disposed to supply an RF power to the first electrode to form an RF electric field within a plasma generation region between the first and second electrodes, so as to turn the process gas into plasma. The target substrate is supported by a support member between the first and second electrodes such that a process target surface thereof faces the second electrode. The second electrode includes a conductive counter surface facing the first electrode and exposed to the plasma generation region.

Owner:TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com