Patents

Literature

784results about How to "Increase the electric field strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

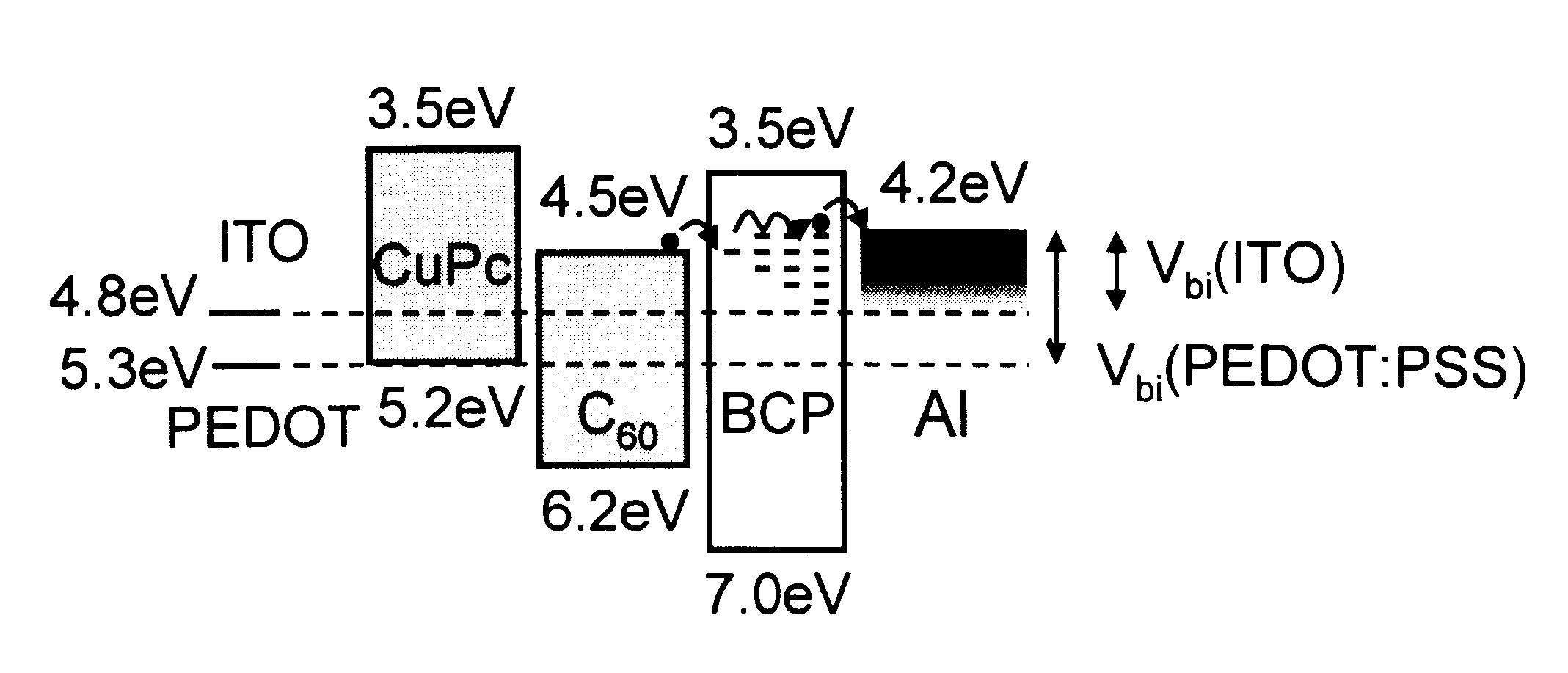

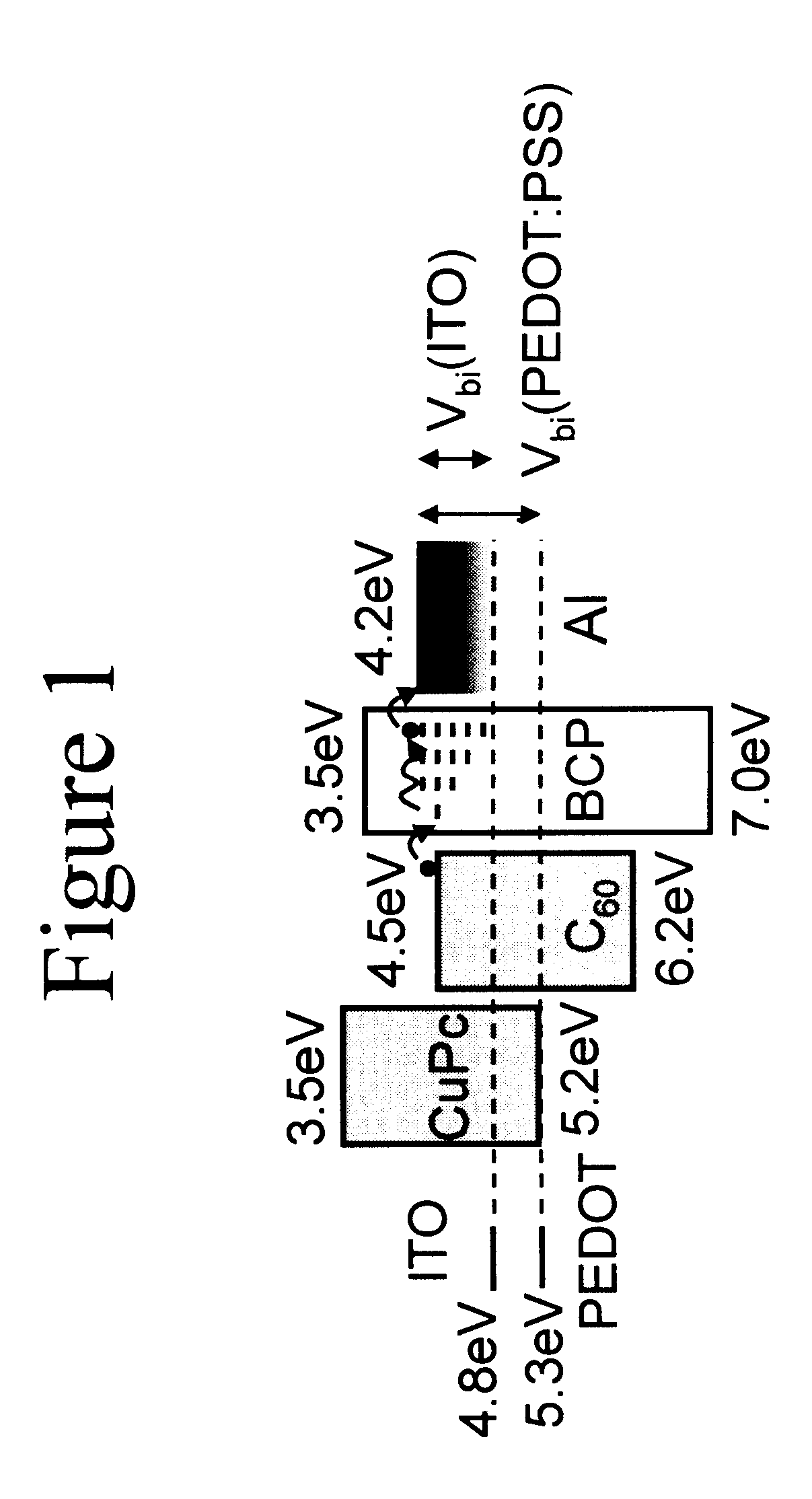

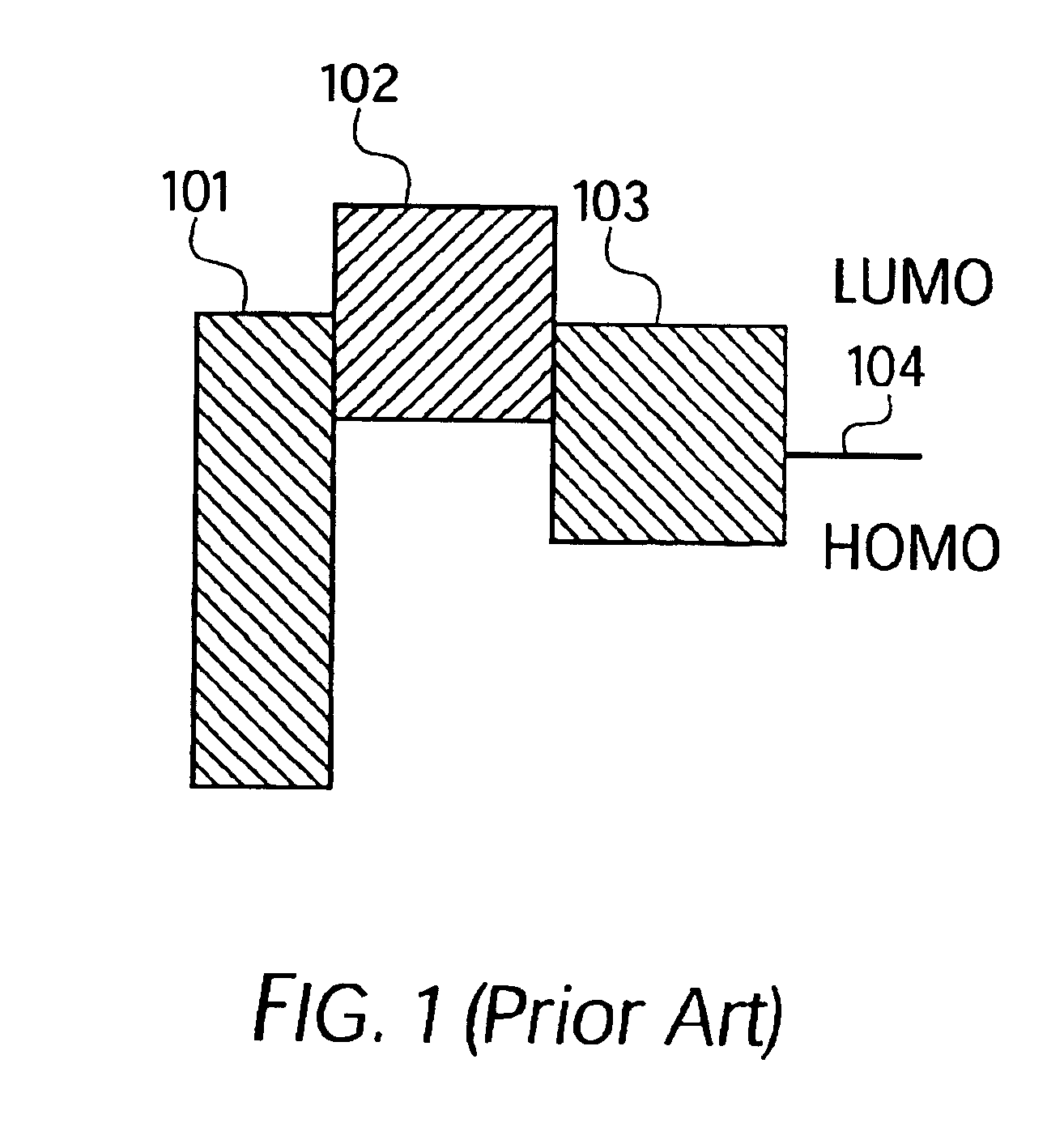

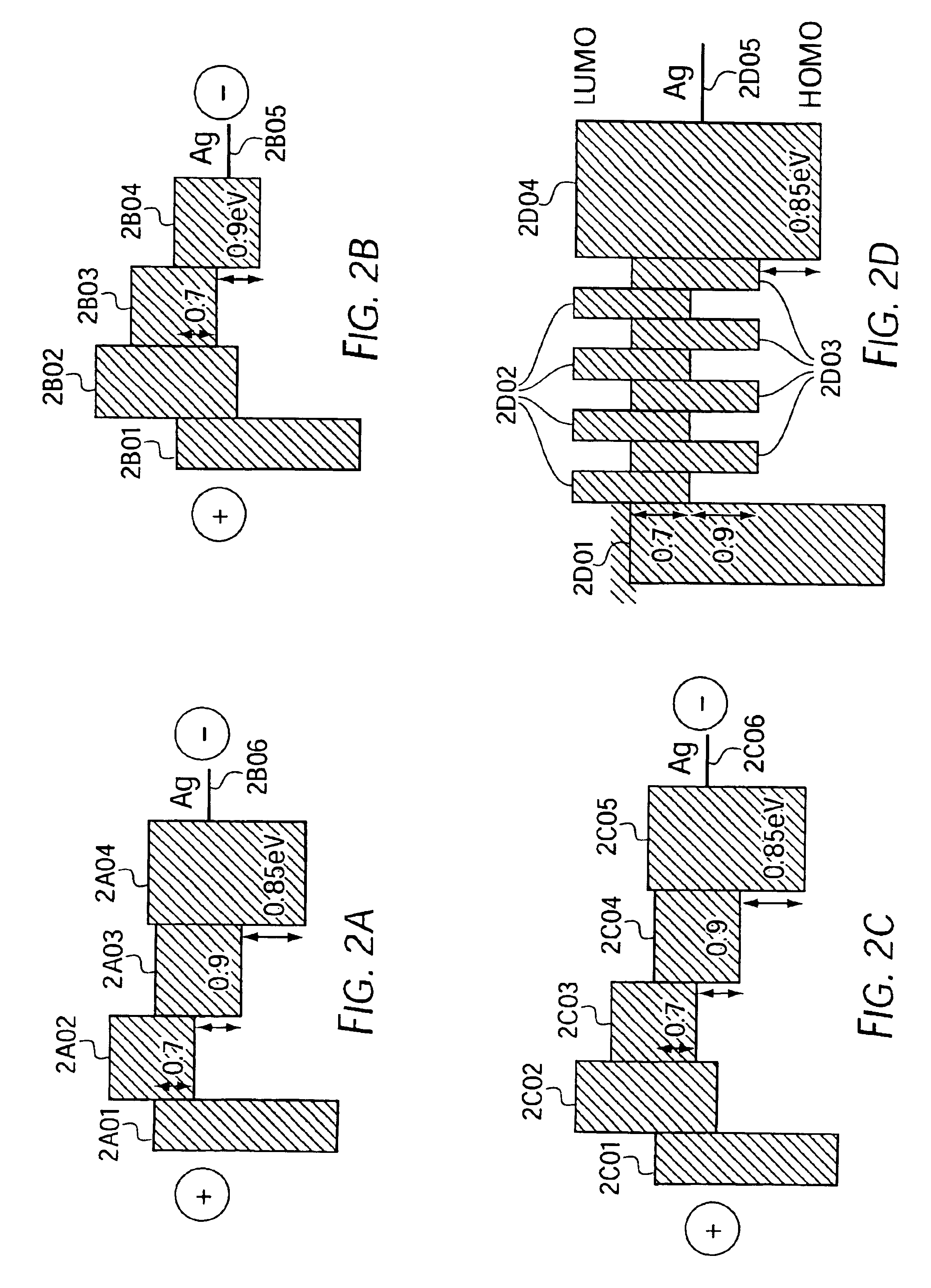

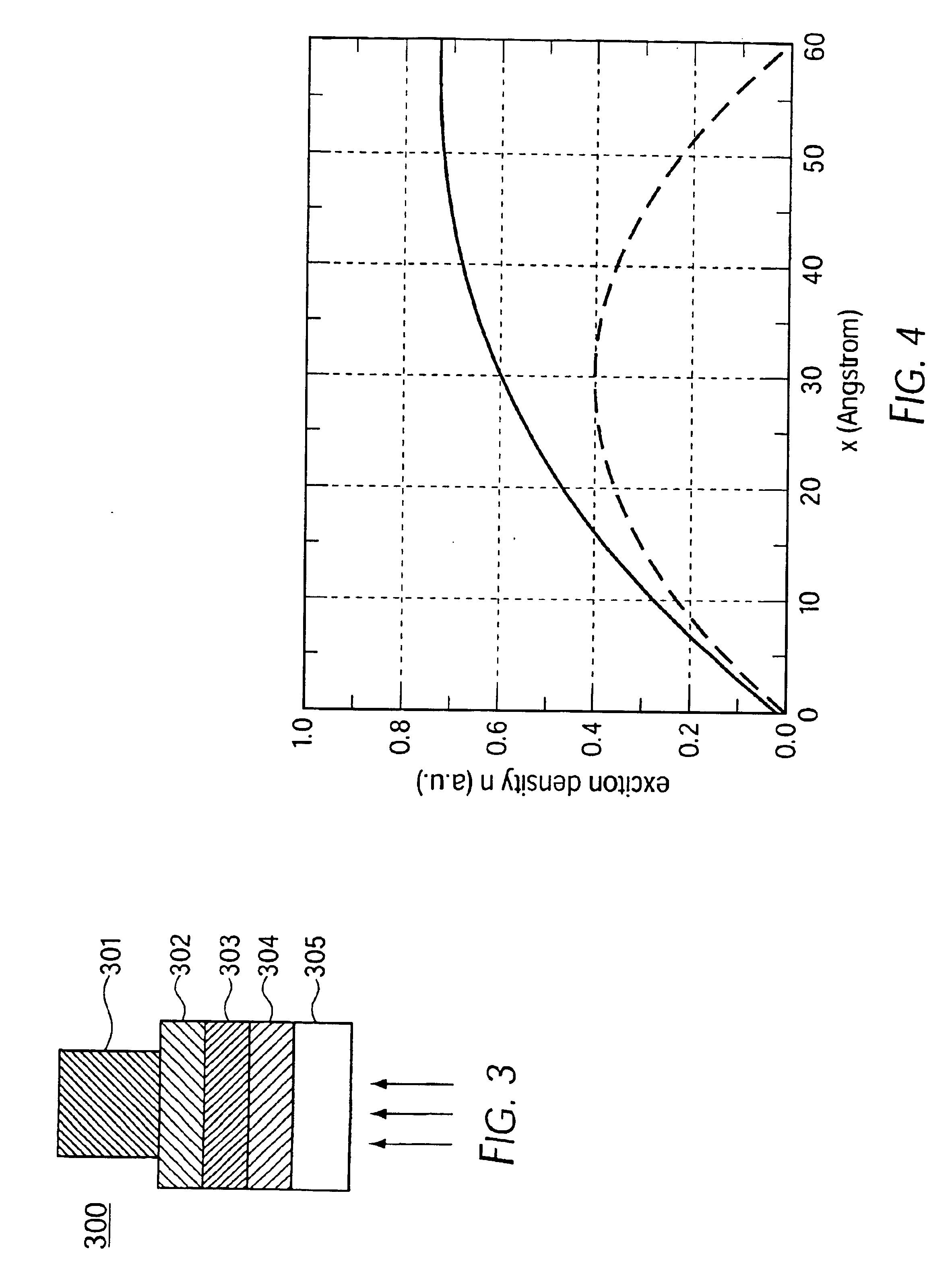

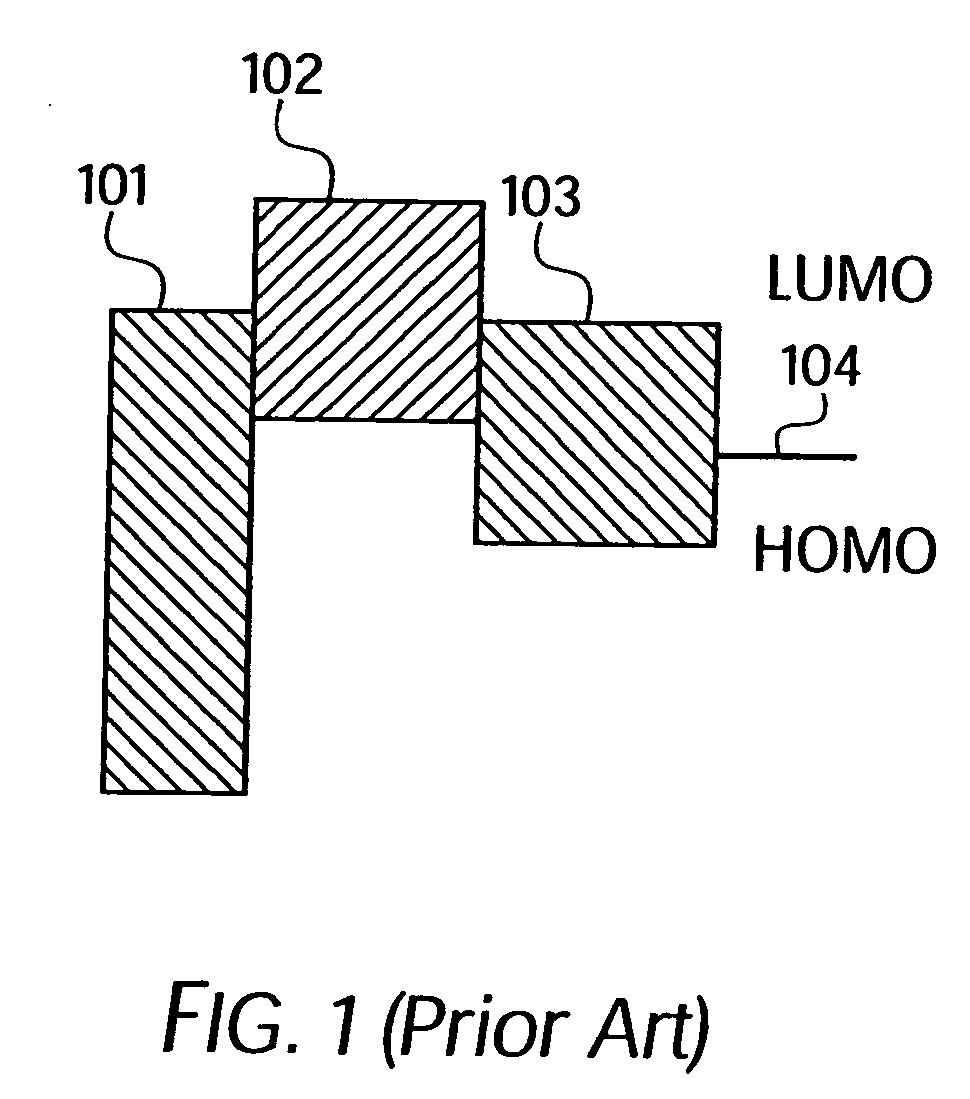

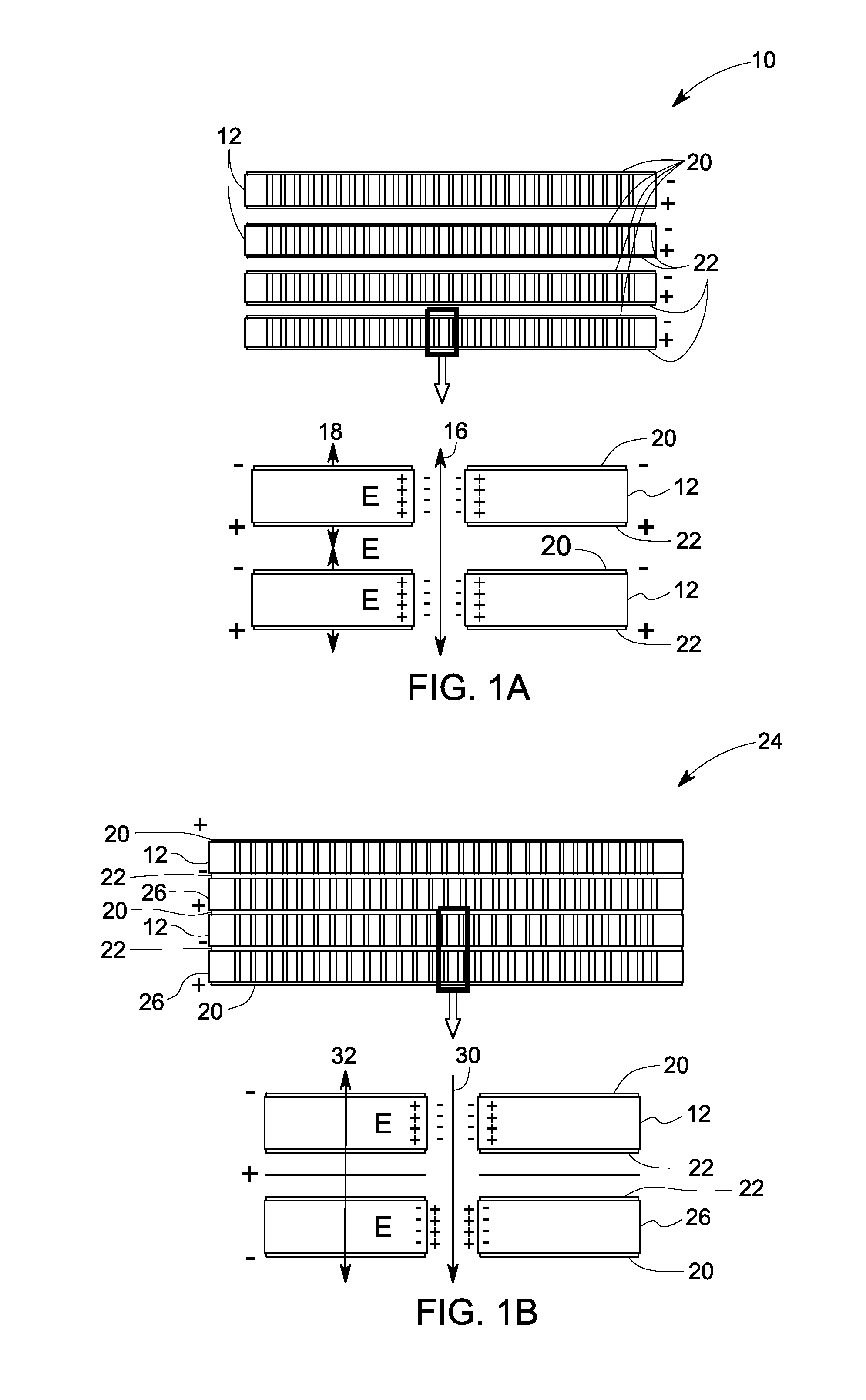

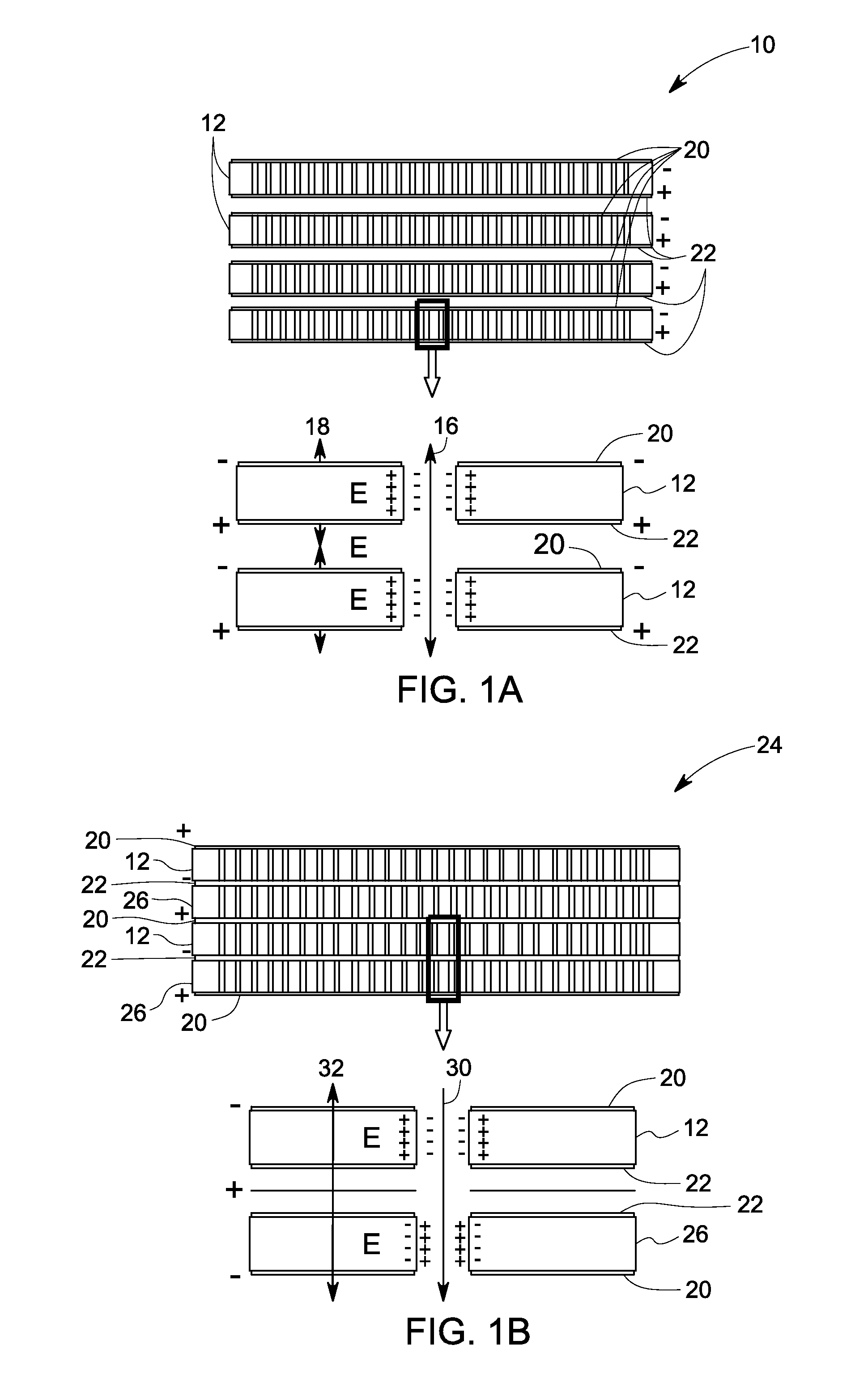

Solar cells using fullerenes

InactiveUS6580027B2Improve efficiencyIncrease the electric field strengthPV power plantsNanoinformaticsSolar cellFullerene

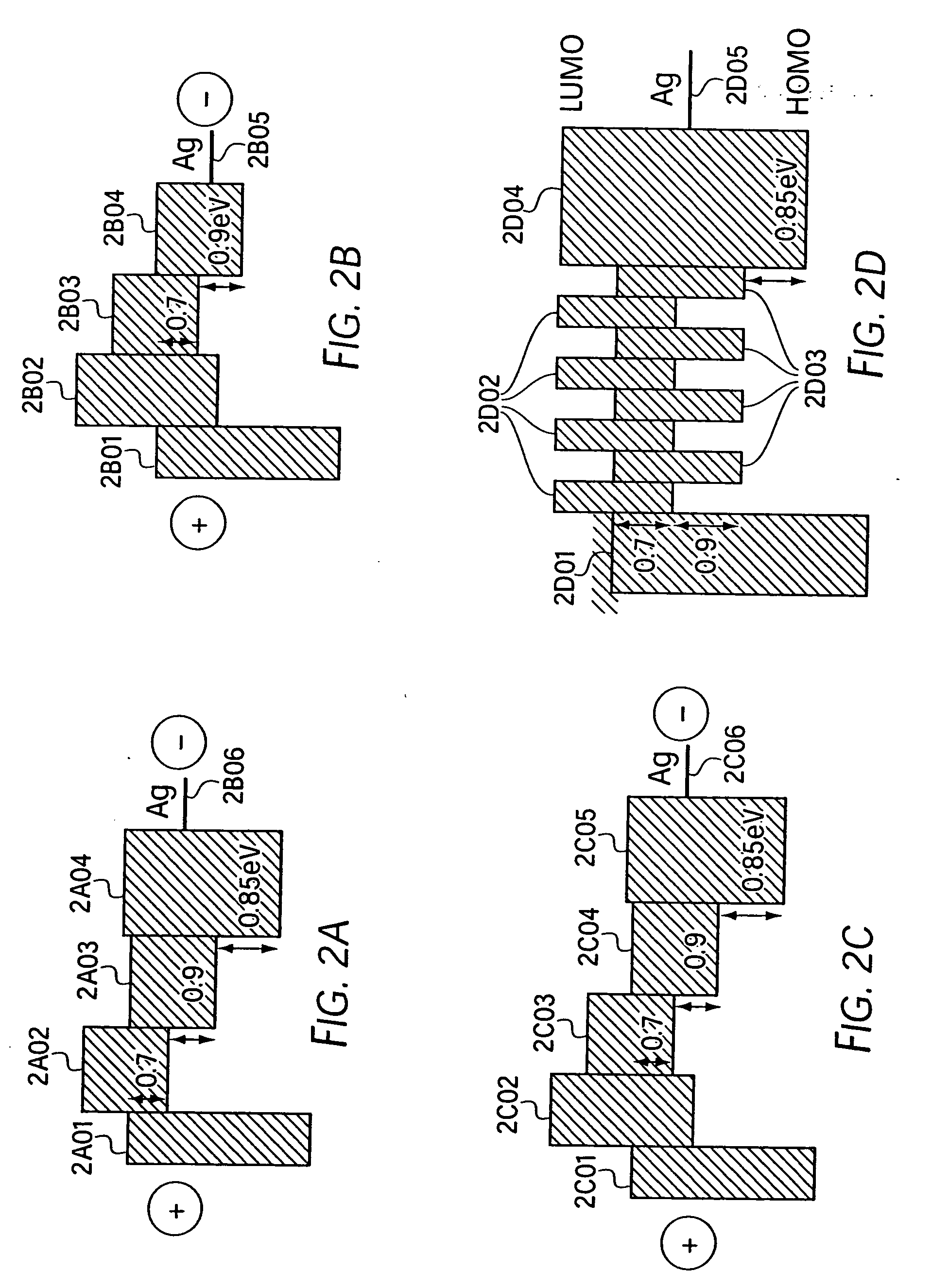

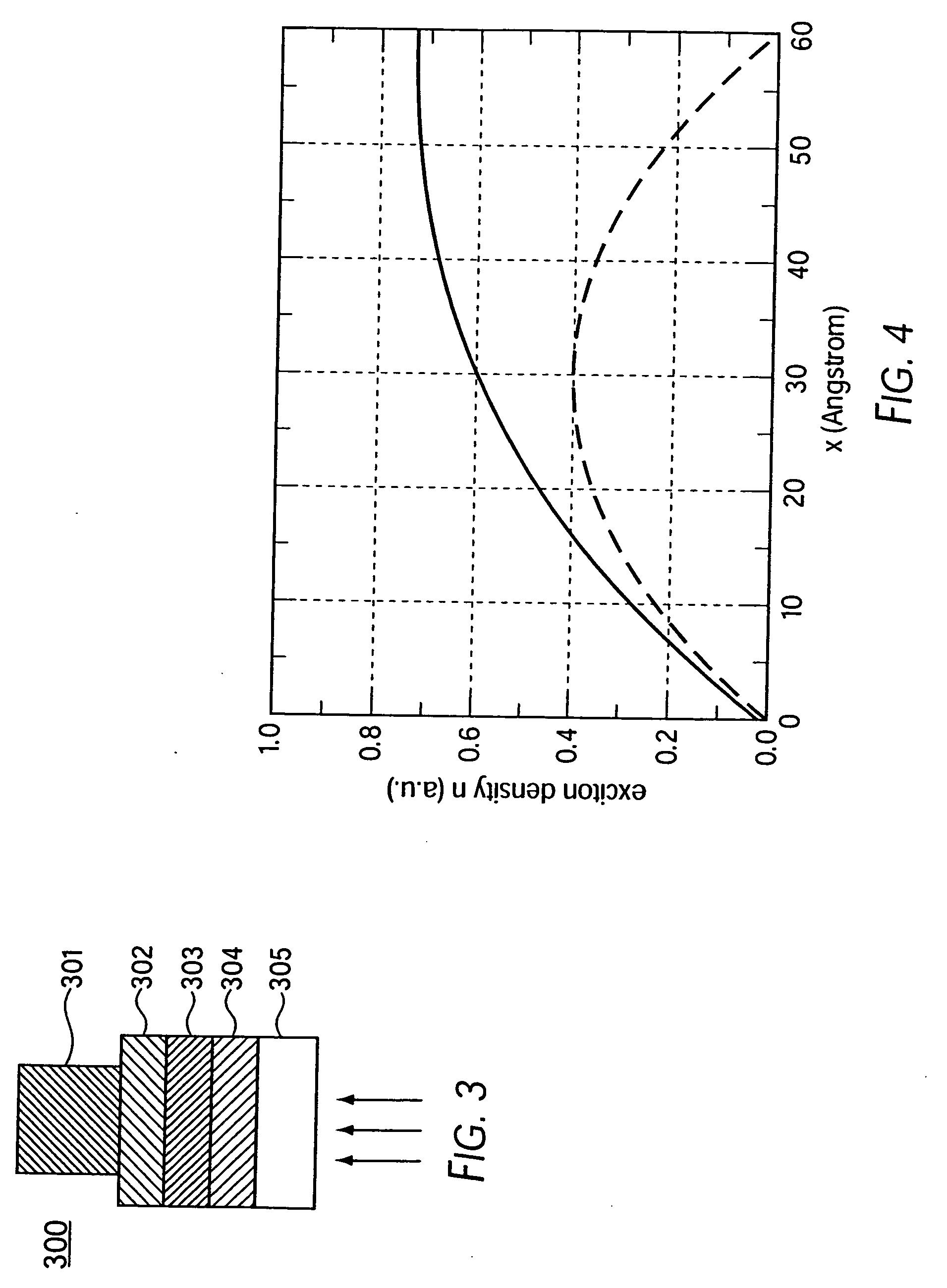

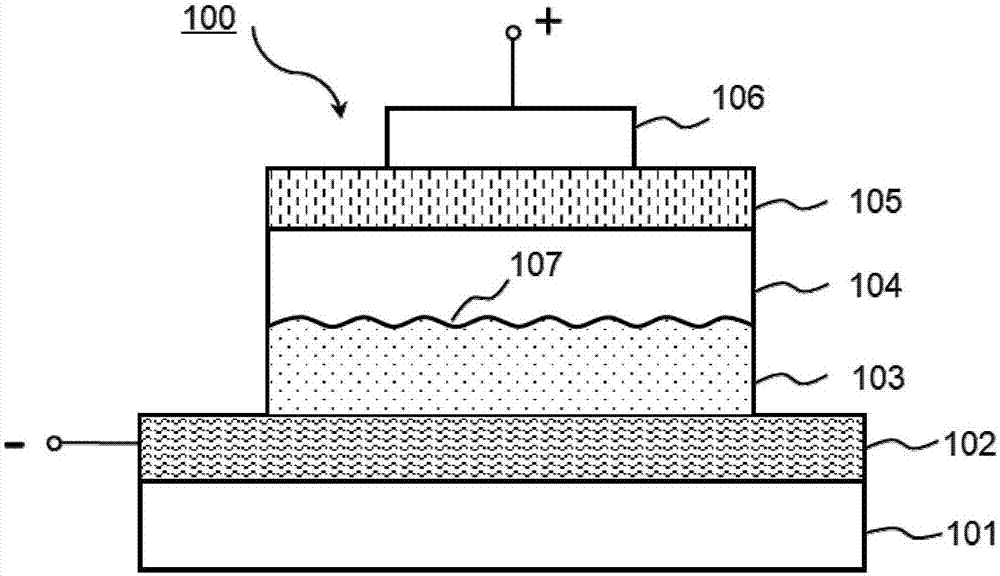

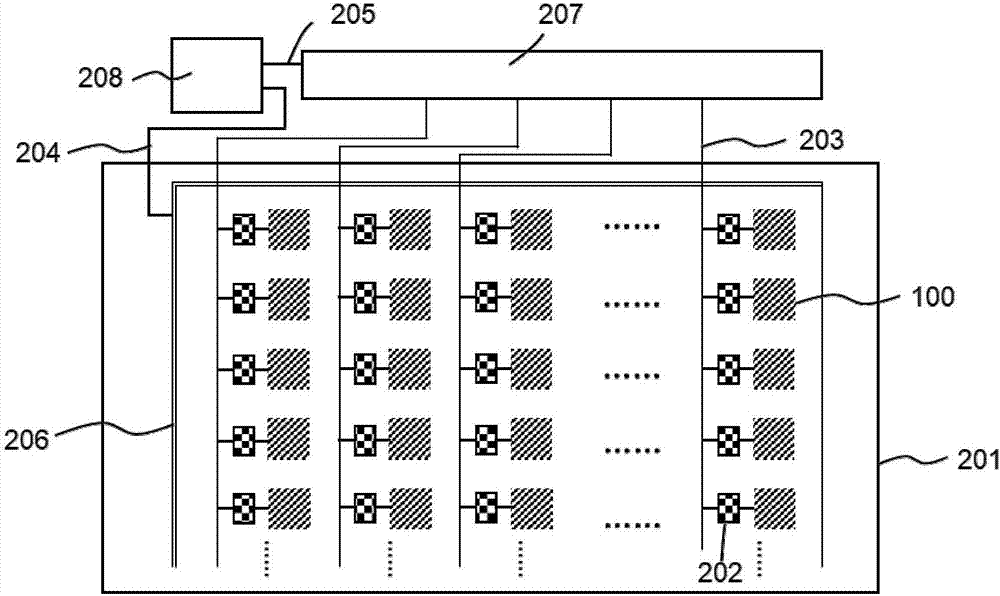

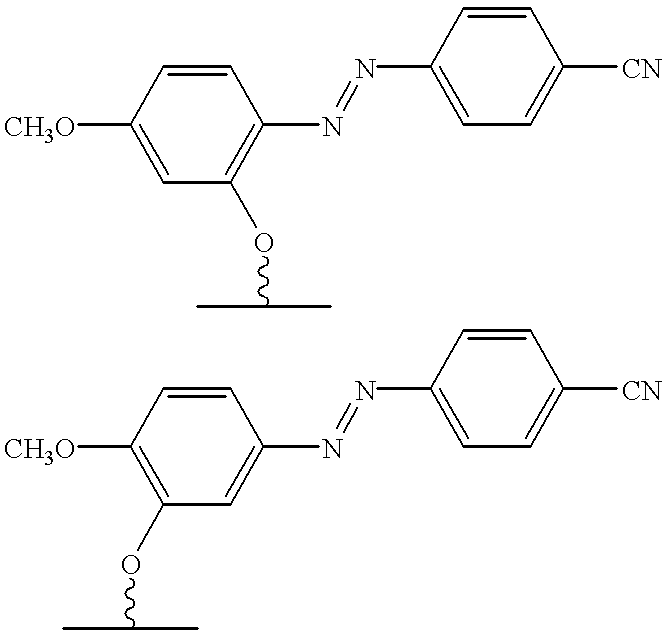

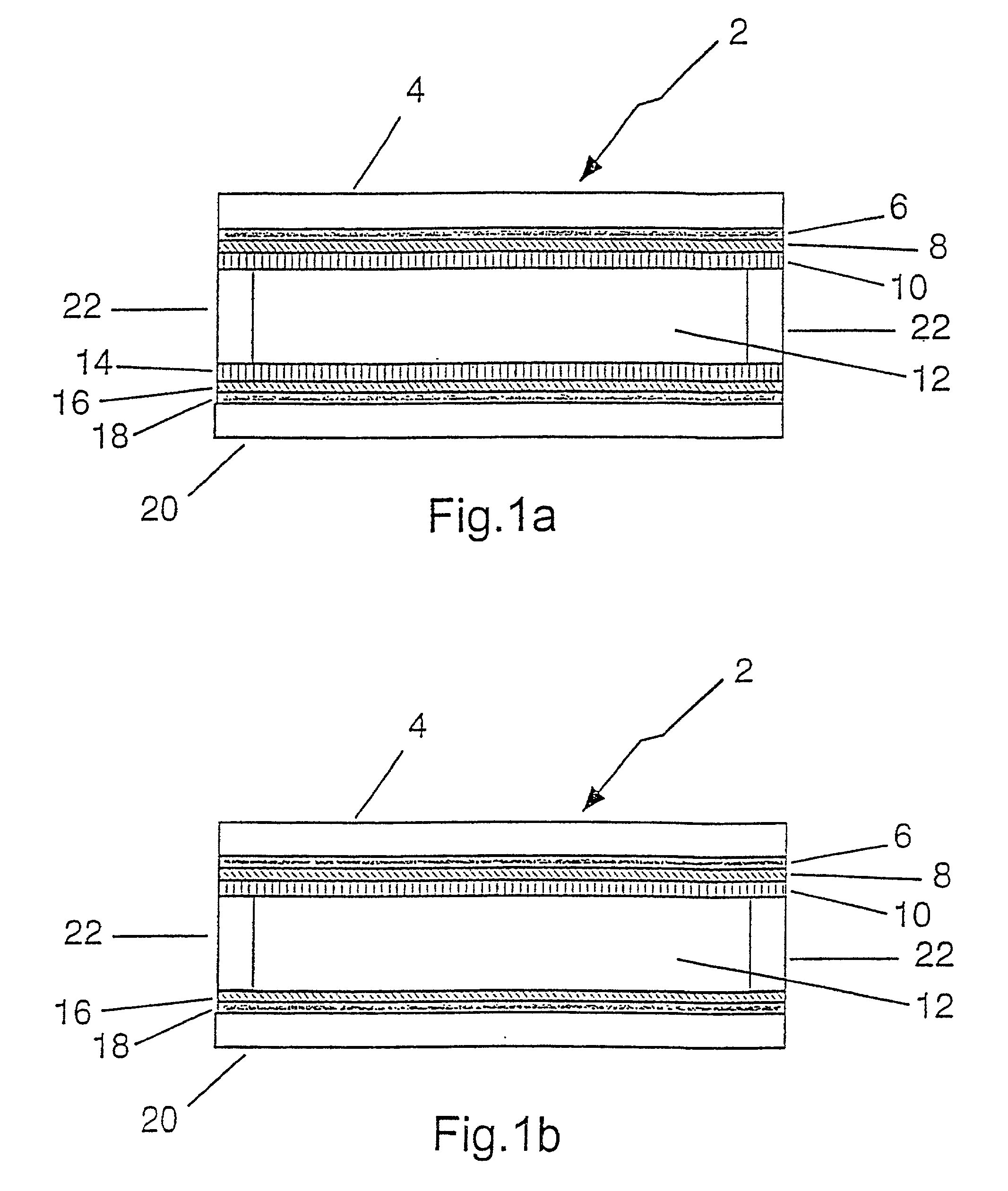

Organic photosensitive optoelectronic devices are disclosed. The devises comprise photoconductive organic thin films in a heterostructure, which include an exciton blocking layer to enhance device efficiency. The use of fullerenes in the electron conducting layer has lead to devices with high efficiency. Single heterostructure, stacked and wave-guide type embodiments are disclosed. Devices having multilayer structures and an exciton blocking layer are also disclosed. Guidelines for selection of exciton blocking layers are provided.

Owner:THE TRUSTEES FOR PRINCETON UNIV

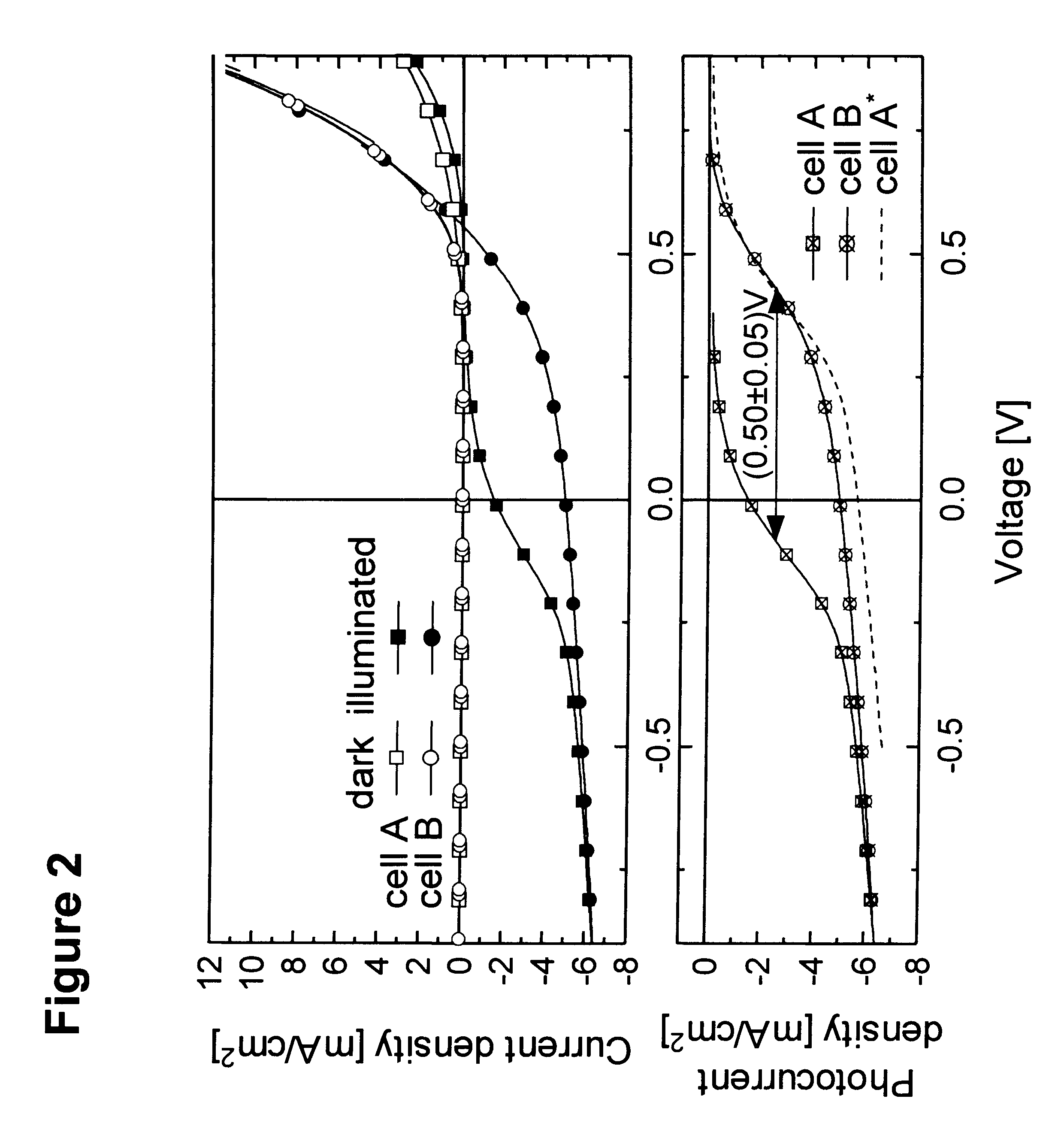

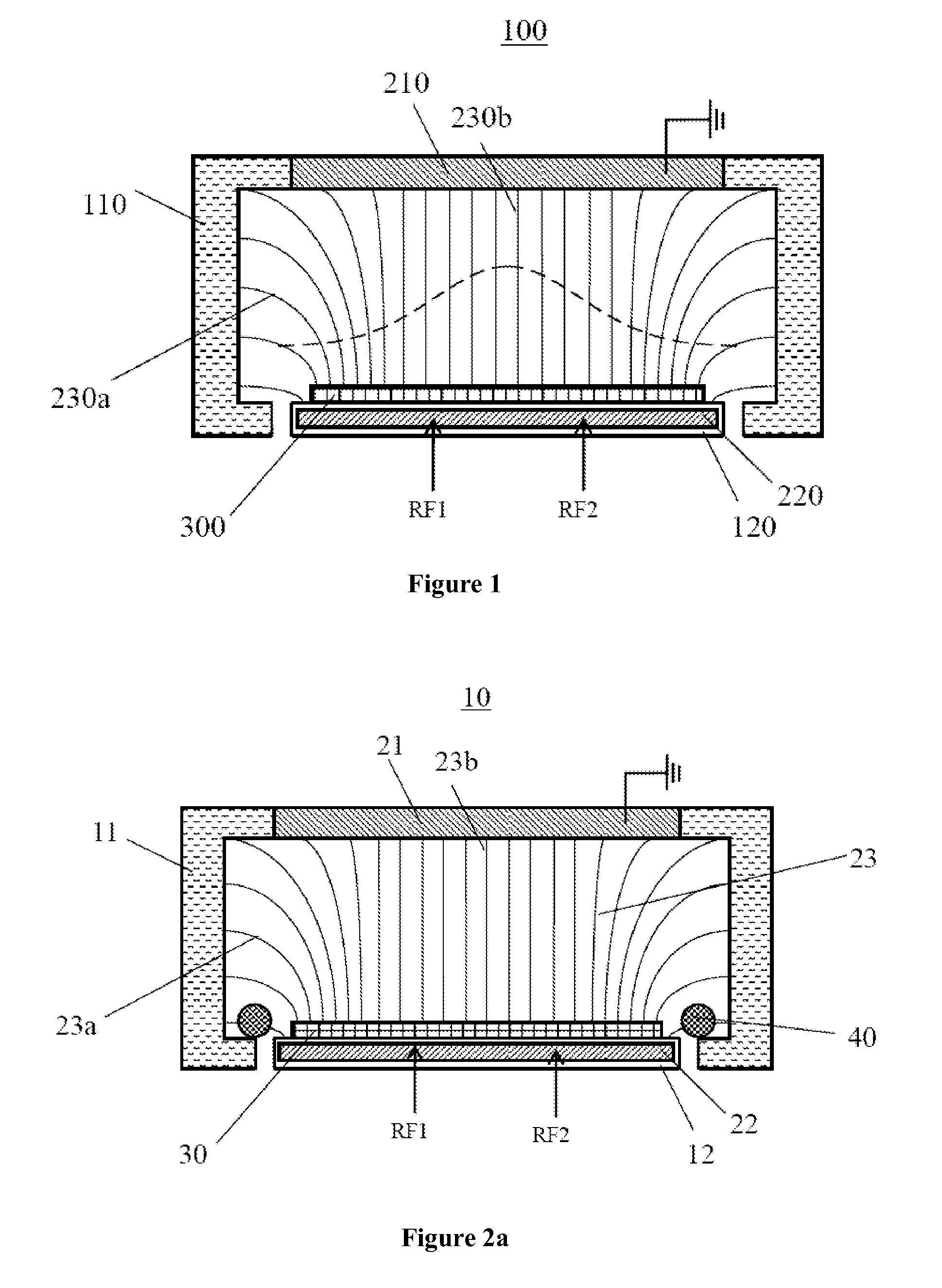

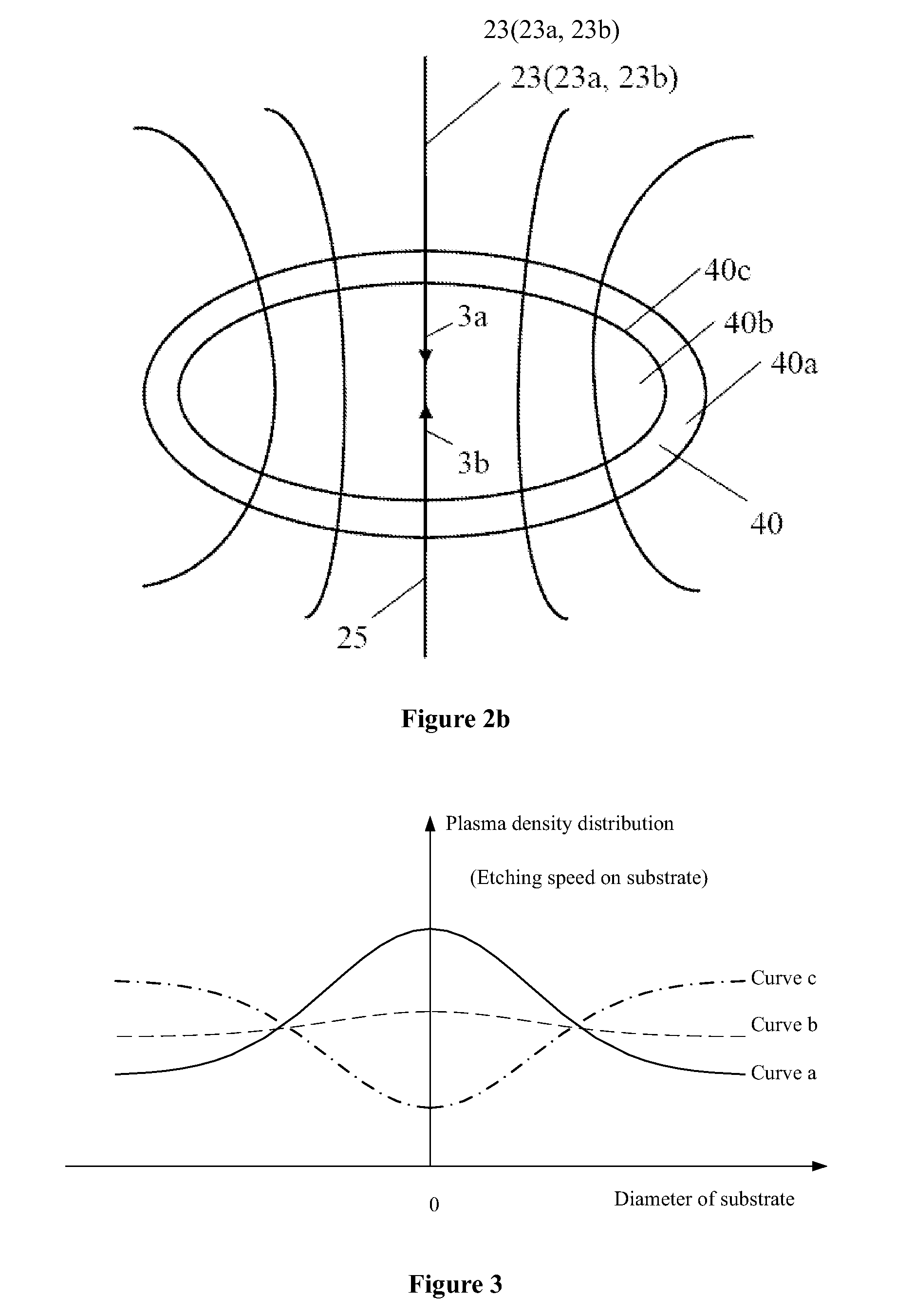

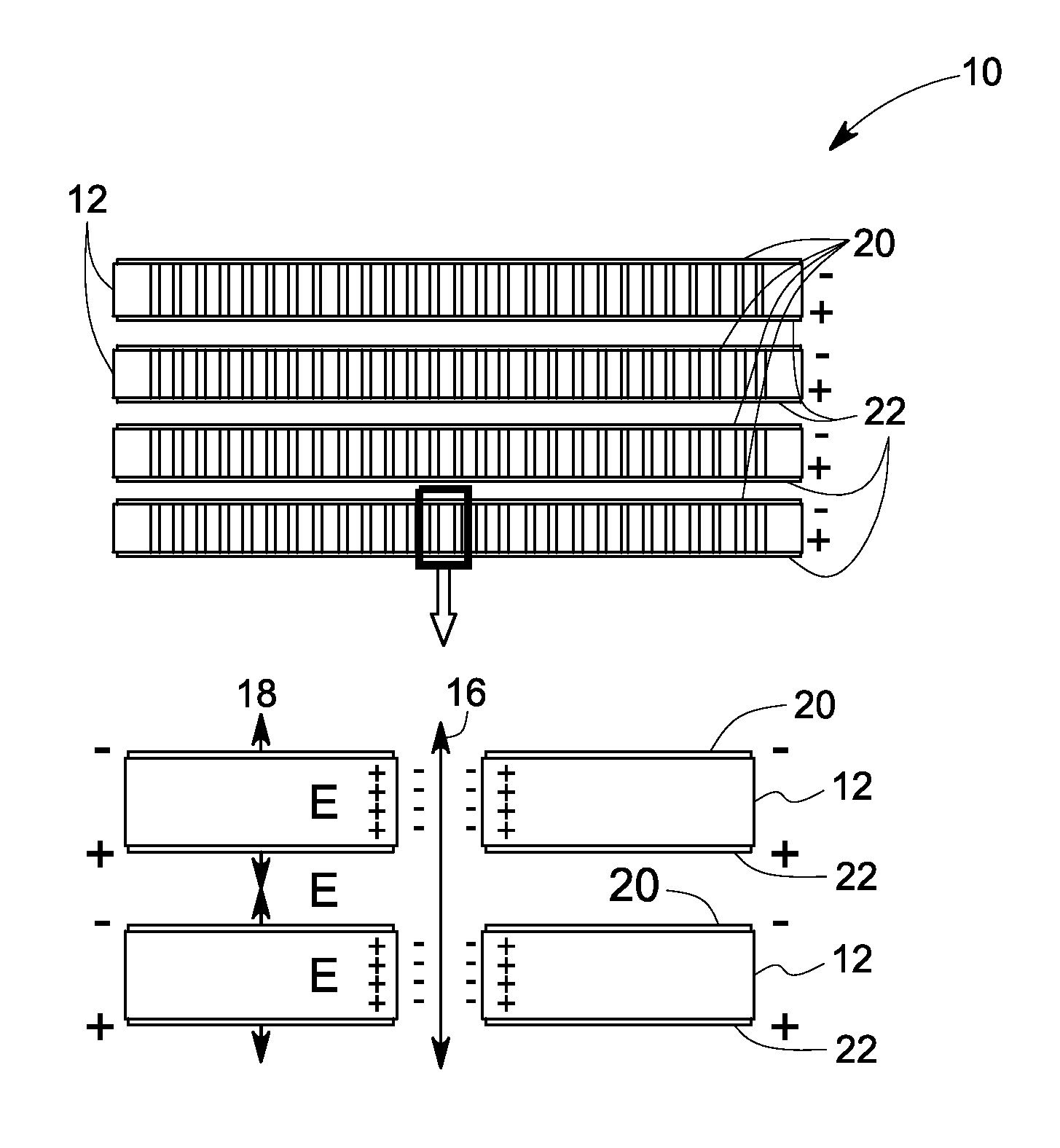

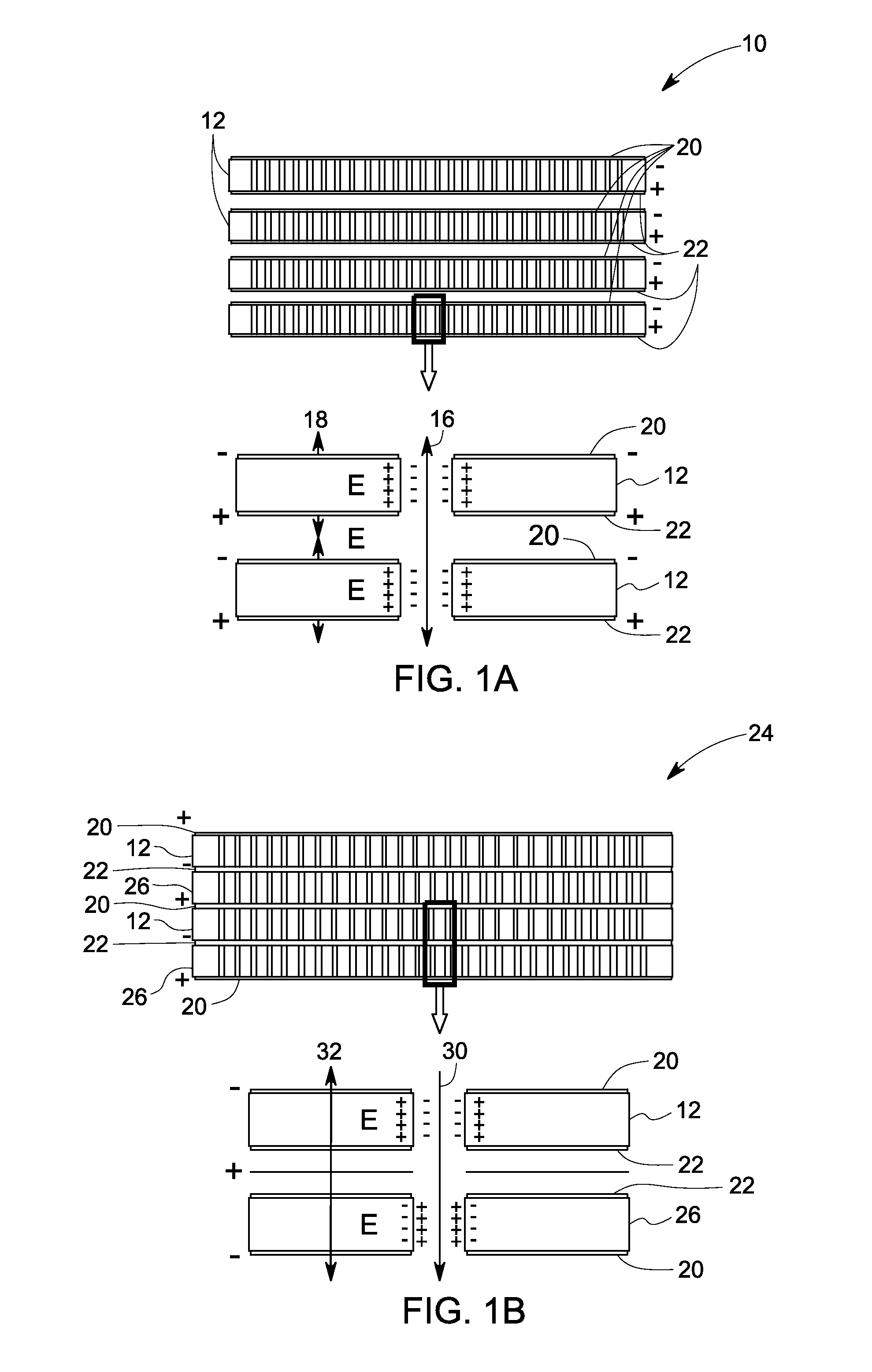

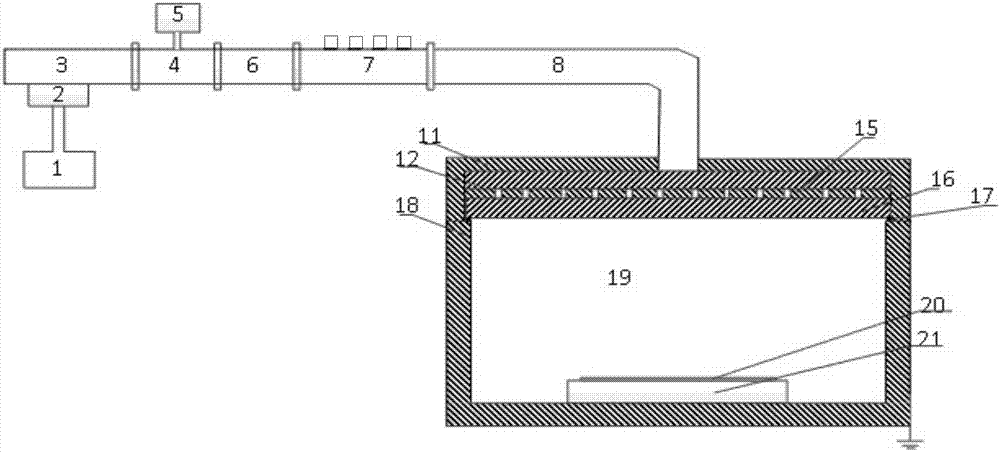

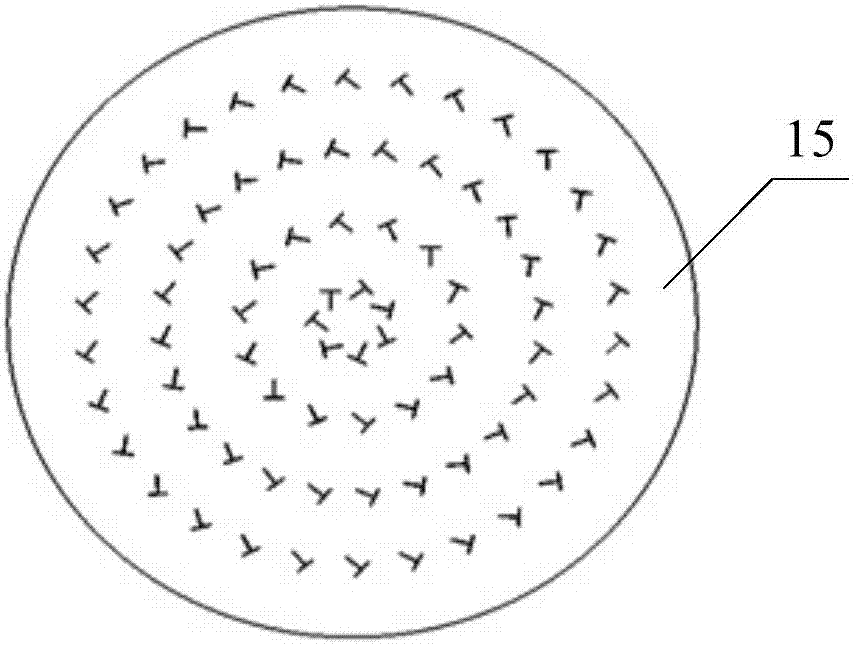

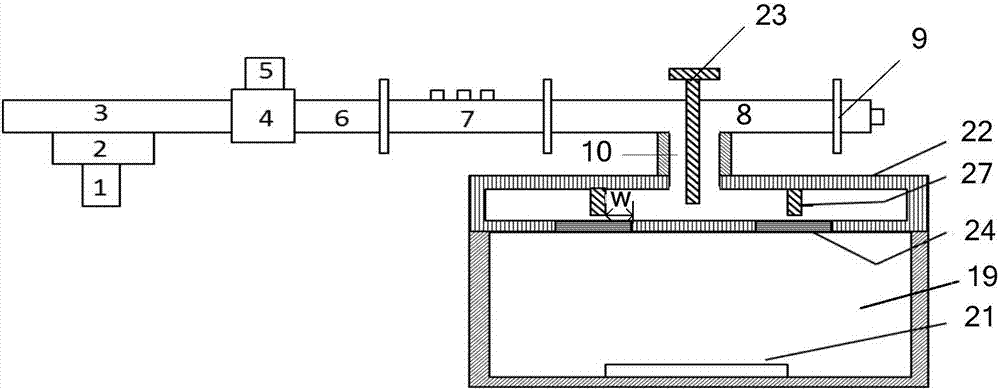

Capacitive-coupled plasma processing apparatus and method for processing substrate

ActiveUS20130032574A1Adjust electric field strengthIncrease the electric field strengthElectric discharge tubesDecorative surface effectsCapacitanceHigh pressure

The present invention relates to a capacitive-coupled plasma processing apparatus, wherein an electric field regulating element, i.e., an “electric field lens”, is arranged in the reaction chamber to generate a regenerated electric field in a direction opposite to that of the original radio frequency electric field in the reaction chamber, so that the non-uniformity of etching rate on the surface of the substrate of the plasma incurred by the original radio frequency electric field is decreased; and the electric field regulating element, i.e., the “electric field lens”, further decreases the equivalent quality factor Q value of the reaction chamber, expands the radio frequency band, and prevents high-voltage electric arcing. The present invention further provides a method for processing the substrate using the processing apparatus.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

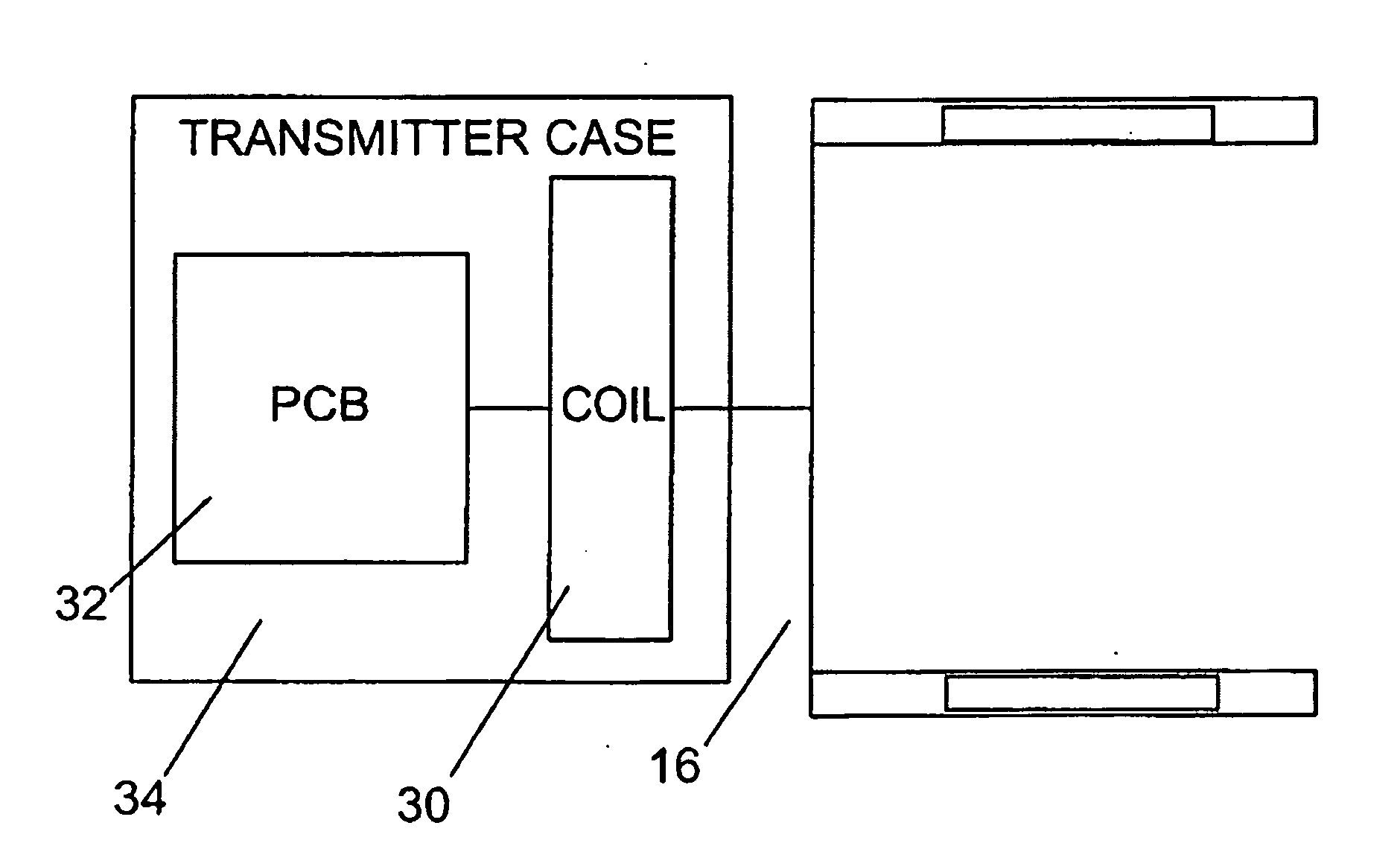

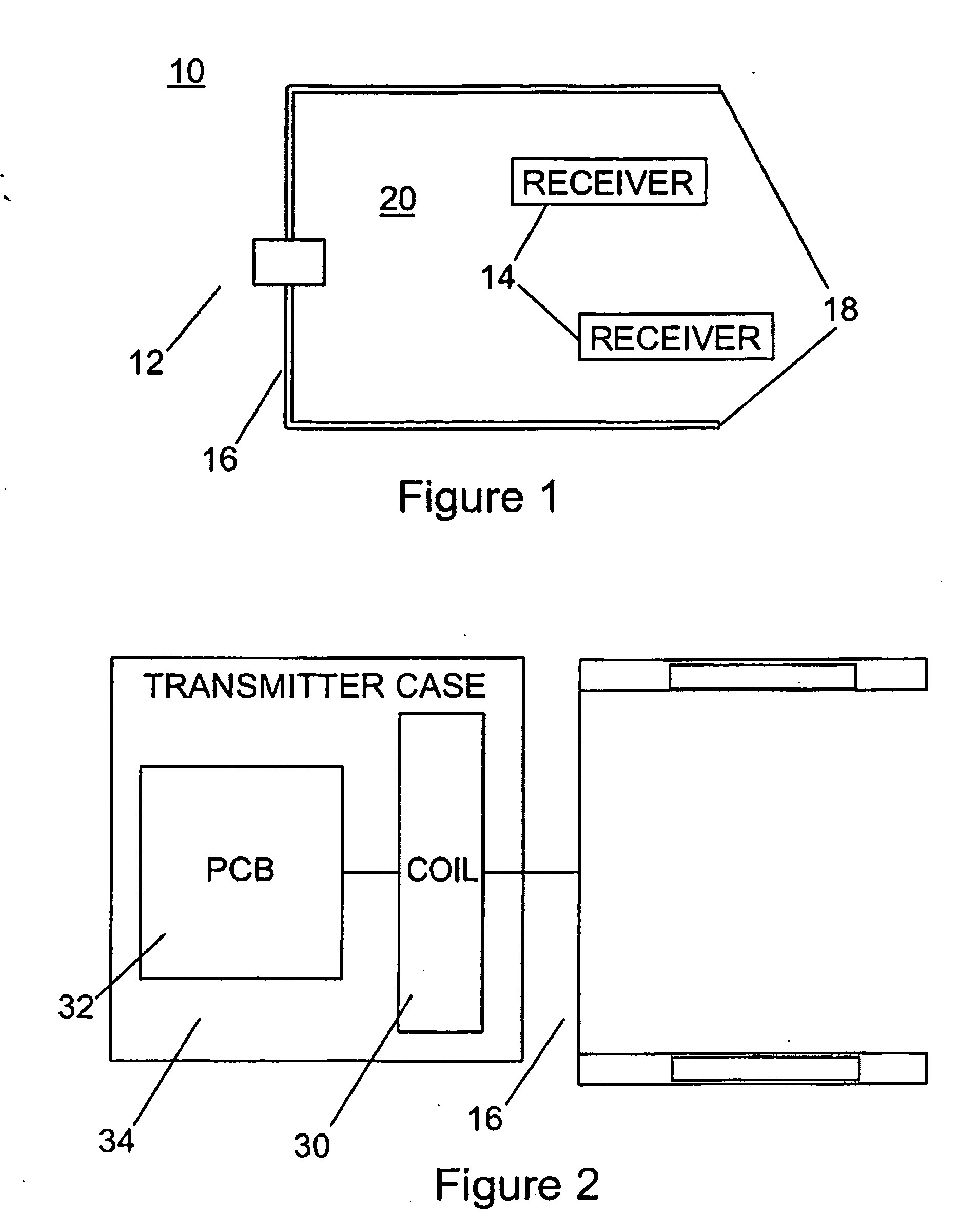

Wireless electric field power transmission system and method

ActiveUS20130147427A1Prevent electromagnetic field (EMF) leakageIncrease the electric field strengthNear-field transmissionElectromagnetic wave systemElectrical conductorTransfer system

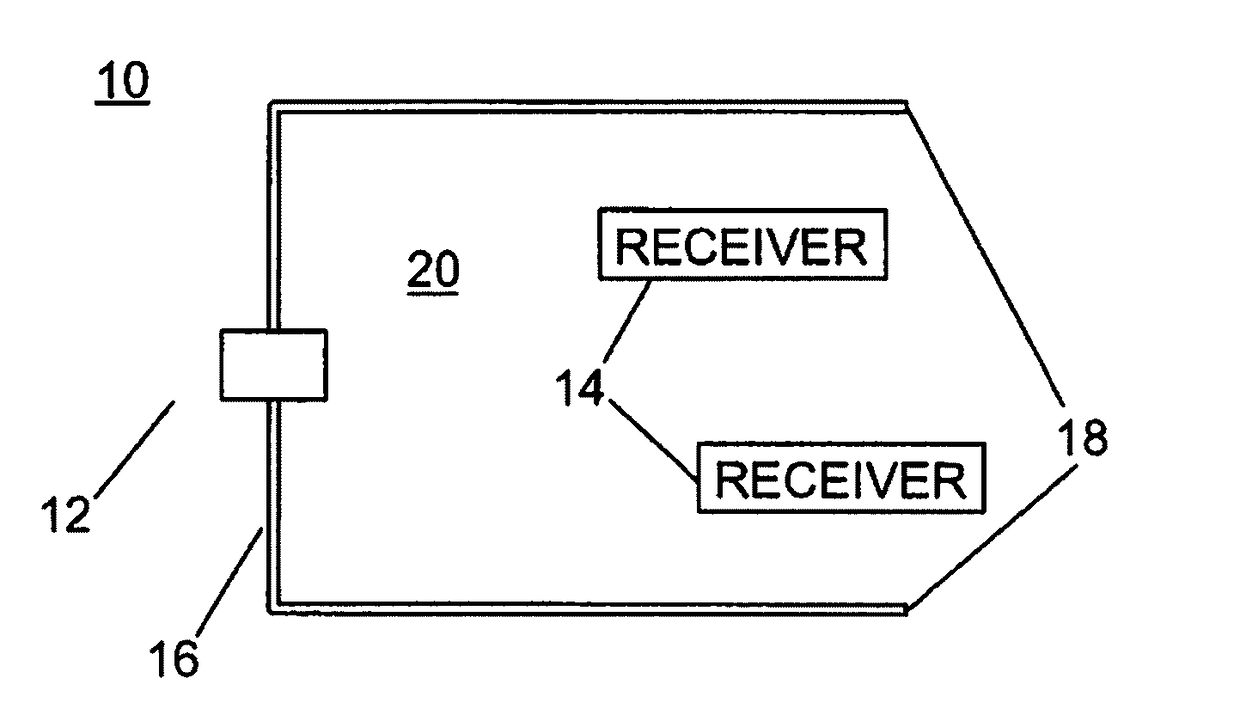

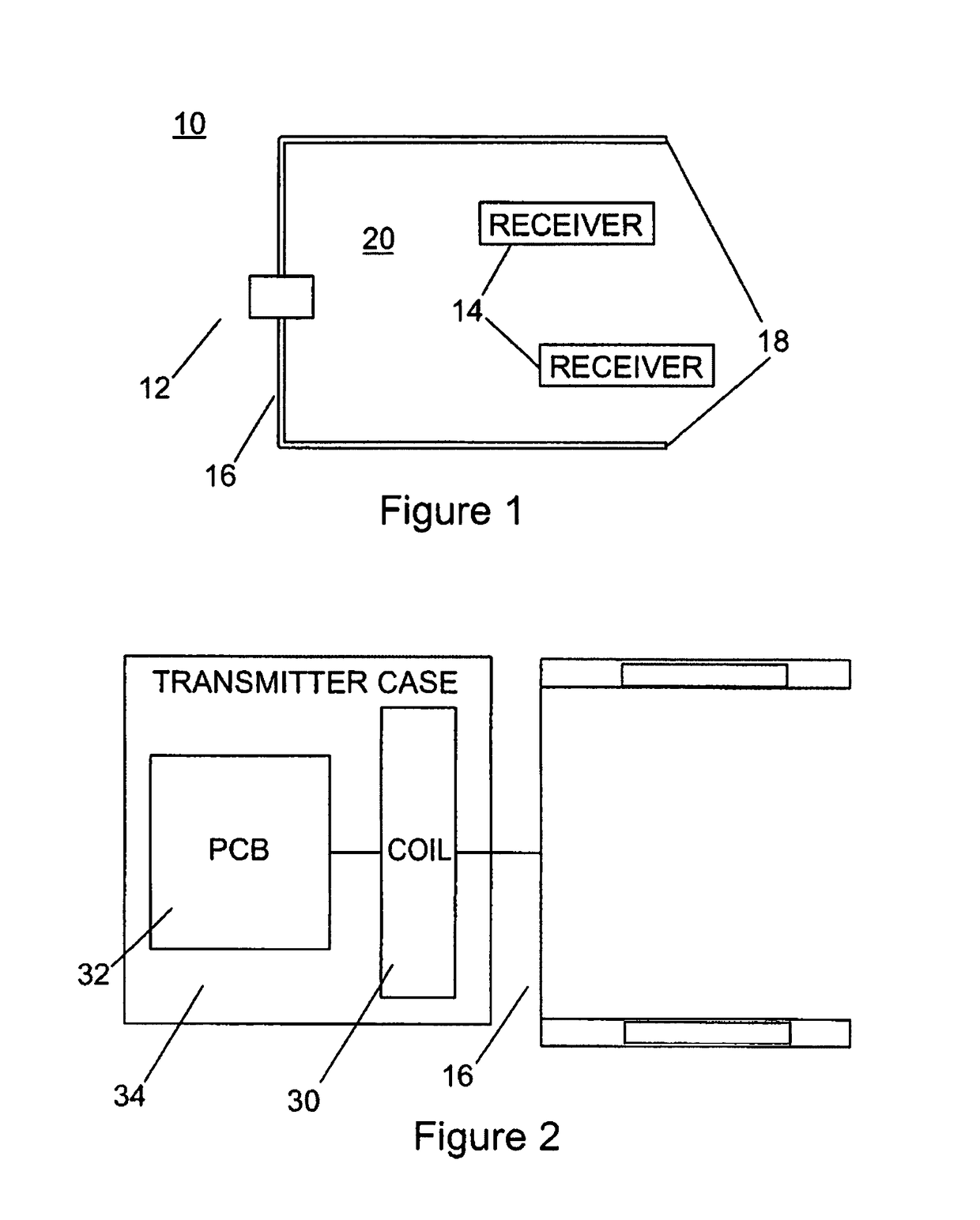

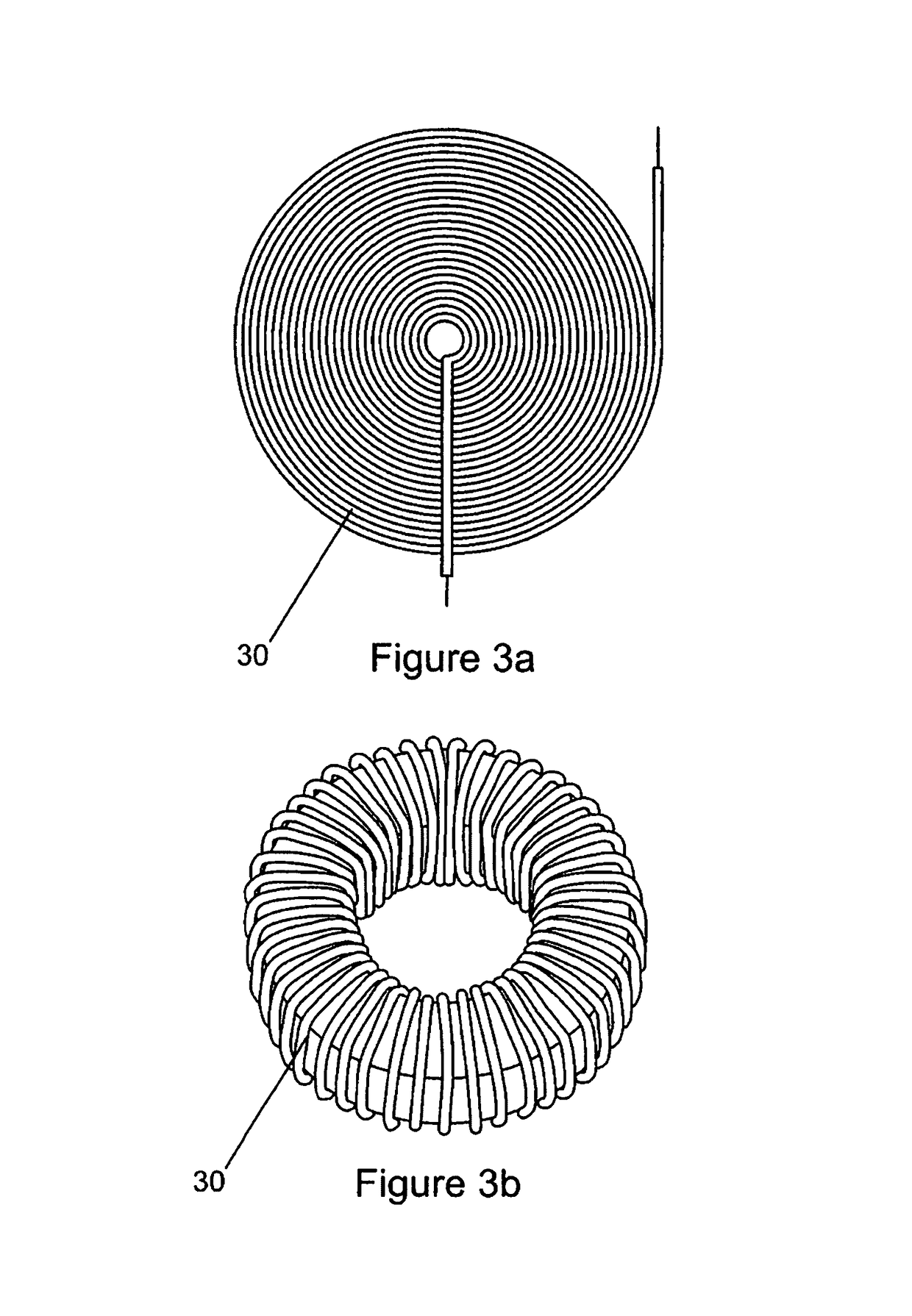

A wireless electric field power transmission system comprises: a transmitter comprising a transmitter antenna, the transmitter antenna comprising at least two conductors defining a volume therebetween; and at least one receiver, wherein the transmitter antenna transfers power wirelessly via electric field coupling when the at least one receiver is within the volume.

Owner:SOLACE POWER INC

Method of fabricating an organic photosensitive optoelectronic device with an exciton blocking layer

InactiveUS6844025B2Increase the electric field strengthEasy to separateLayered productsNanoinformaticsPhotodetectorBlocking layer

Organic photosensitive optoelectronic devices (“OPODs”) are disclosed which include an exciton blocking layer to enhance device efficiency. Single heterostructure, stacked and wave-guide type embodiments are disclosed. Photodetector OPODs having multilayer structures and an exciton blocking layer are also disclosed. Guidelines for selection of exciton blocking layers are provided.

Owner:PRINCETON UNIV

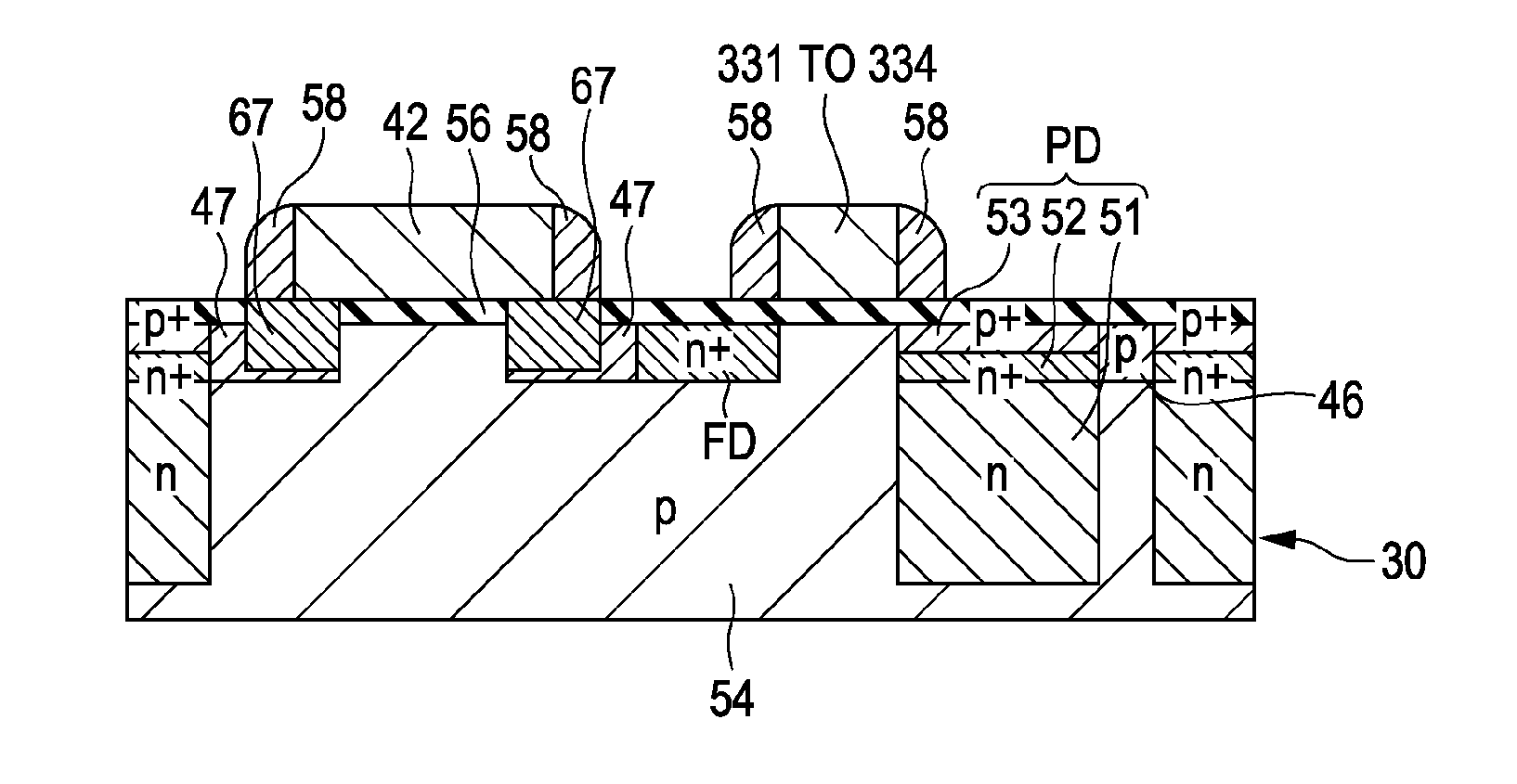

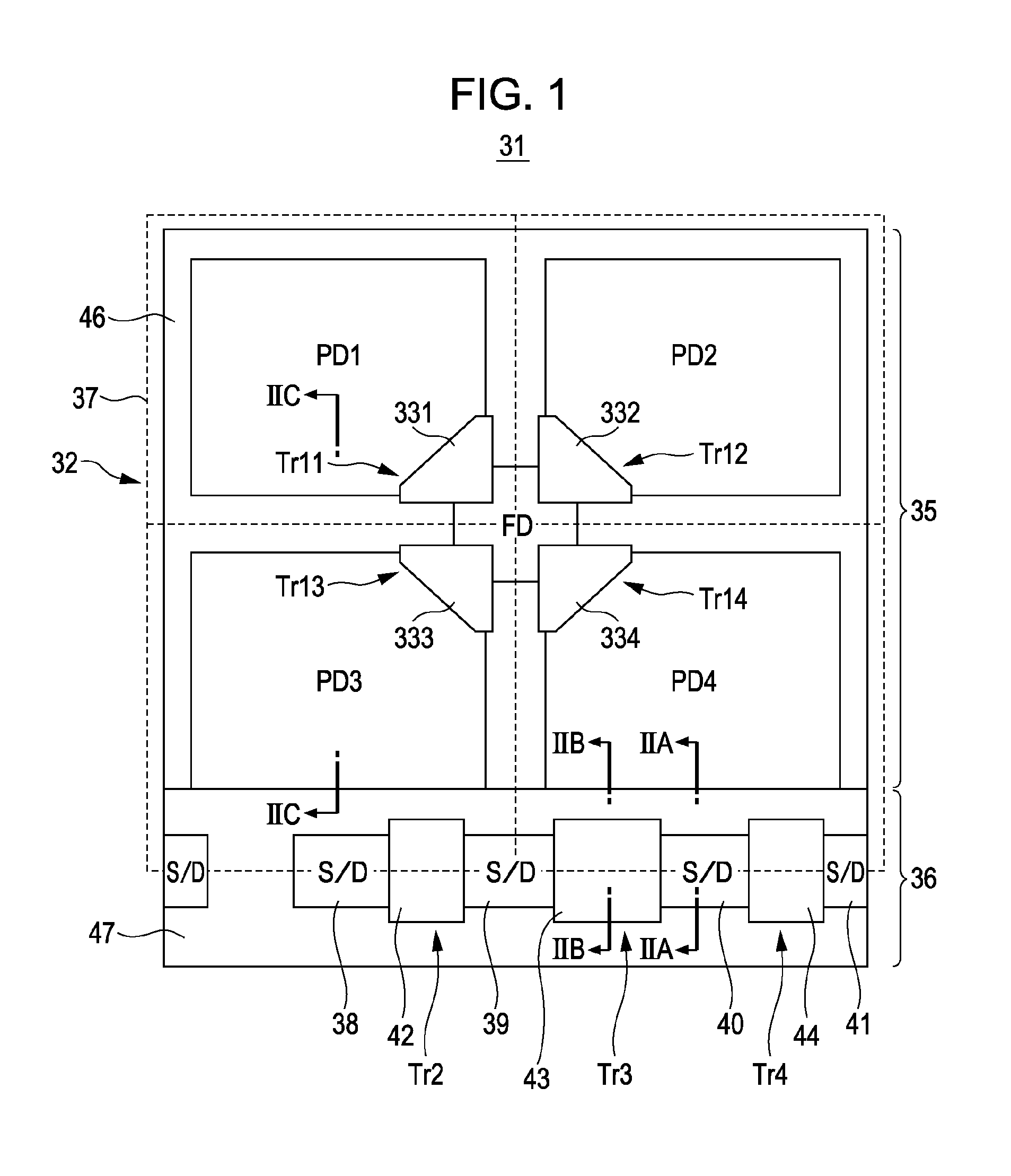

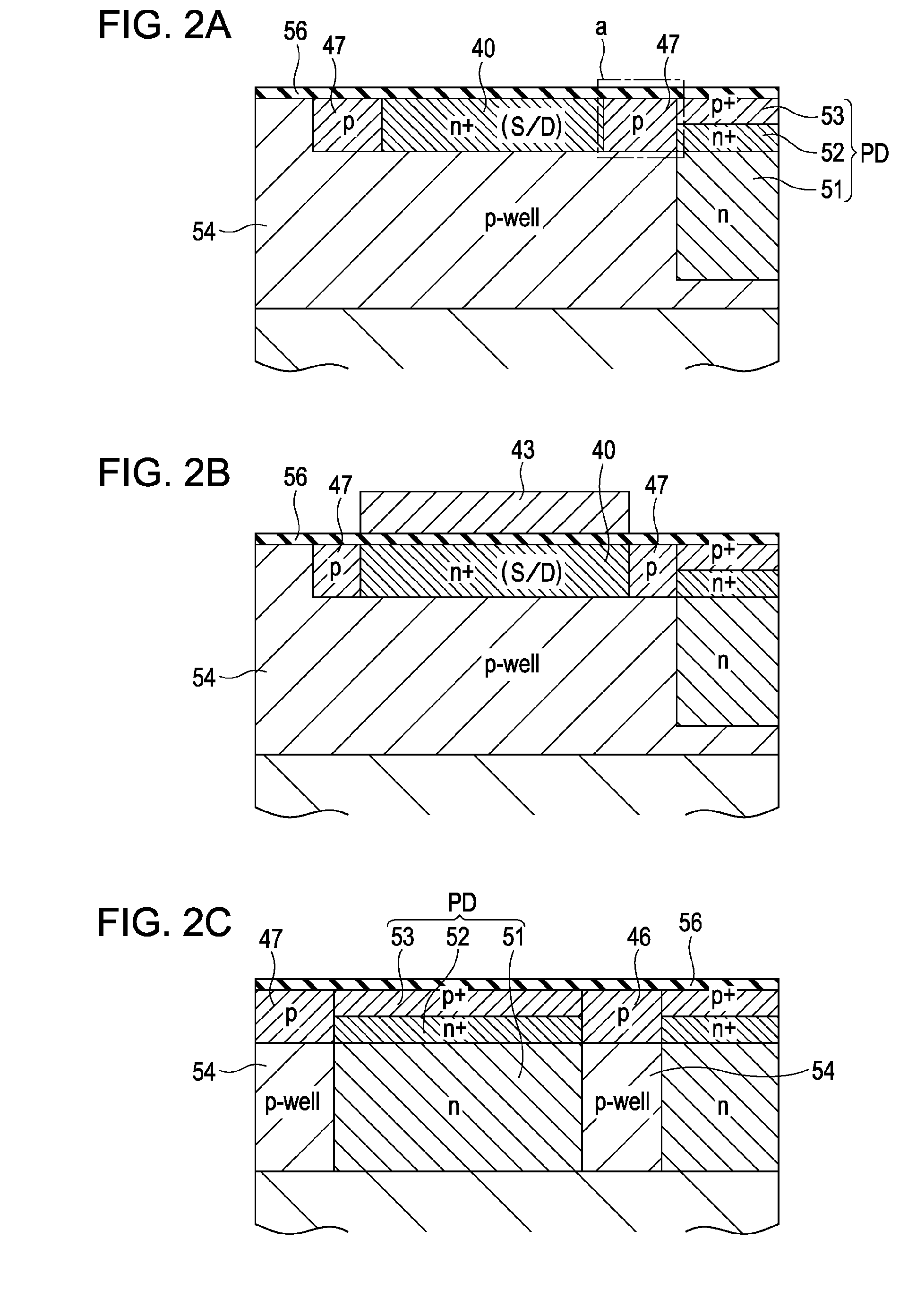

Solid-state imaging device, method of manufacturing the same, and electronic apparatus

ActiveUS20110127408A1Promote escapeReduce the effective areaTransistorSolid-state devicesEngineeringPhotodiode

A solid-state imaging device includes: a pixel having a photodiode and a pixel transistor; a first isolation region using a semiconductor region containing impurities formed between neighboring photodiodes; and a second isolation region using an semiconductor region containing impurities formed between the photodiode and the pixel transistor, wherein an impurity concentration of the first isolation region is different from an impurity concentration of the second isolation region.

Owner:SONY CORP

Organic photosensitive optoelectronic device with an exciton blocking layer

InactiveUS20050136232A1Increase the electric field strengthEasy to separateLayered productsNanoinformaticsPhotovoltaic detectorsPhotodetector

Owner:THE TRUSTEES FOR PRINCETON UNIV

Quantum dot light emitting diode and manufacturing method thereof

InactiveCN107293647AReduce reflectionEasy injectionSolid-state devicesSemiconductor/solid-state device manufacturingElectron holeQuantum dot

The invention discloses a quantum dot light emitting diode and a manufacturing method thereof. The quantum dot light emitting diode comprises a substrate, a cathode, an electron transport layer, a quantum dot light emitting layer, a hole transport layer, and an anode stacked in sequence. The quantum dot light emitting diode is characterized in that the upper surface of the electron transport layer is provided with a nano convex-concave structure which is in quasi-periodic or aperiodic shape, and refractive index of the nano convex-concave structure shows gradient changes along an emergent light direction. Efficiency of an inverted structure quantum dot light emitting diode is obviously improved, and the efficiency is far ahead efficiency of other inverted quantum dot devices.

Owner:SUZHOU UNIV

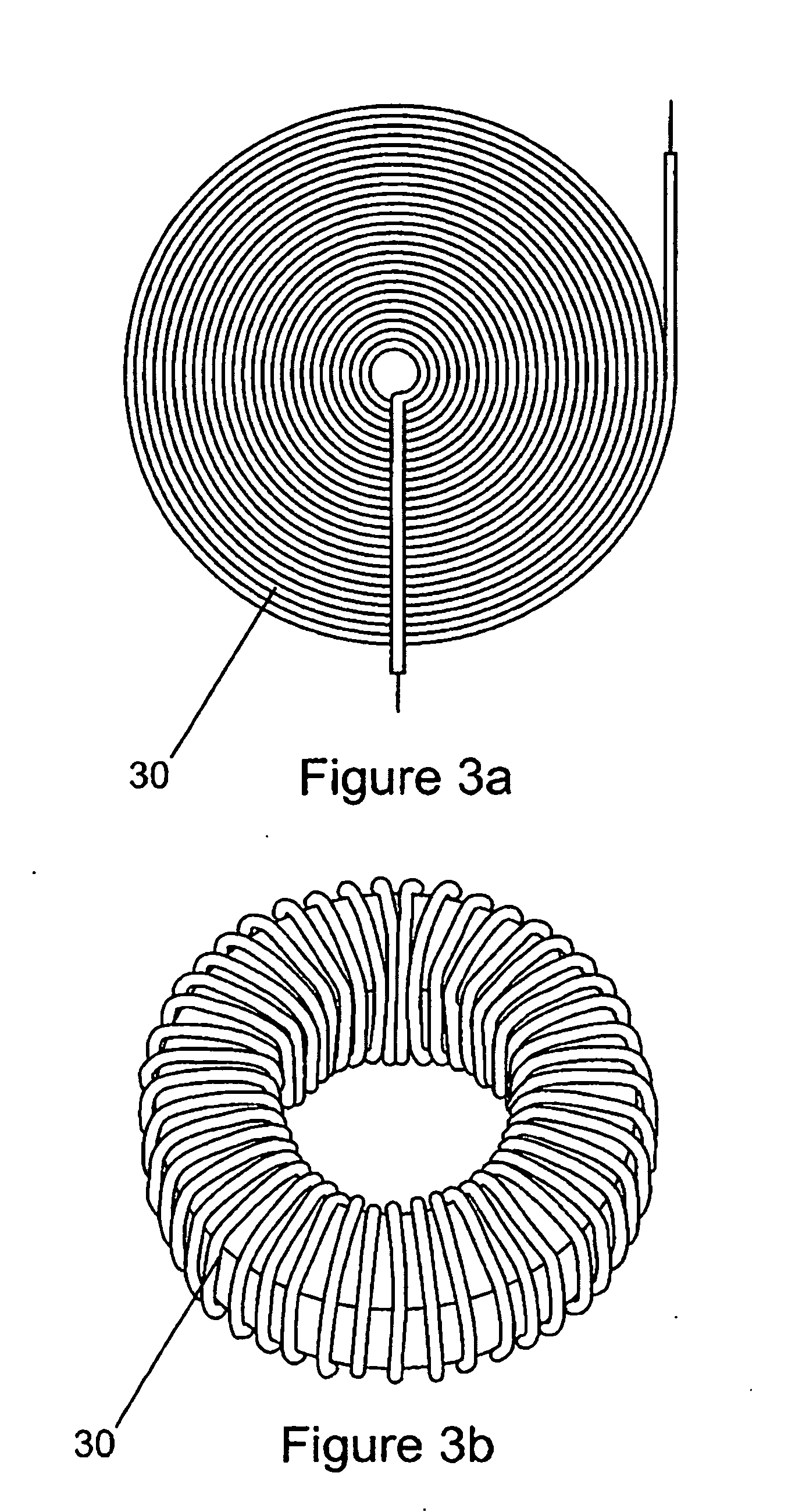

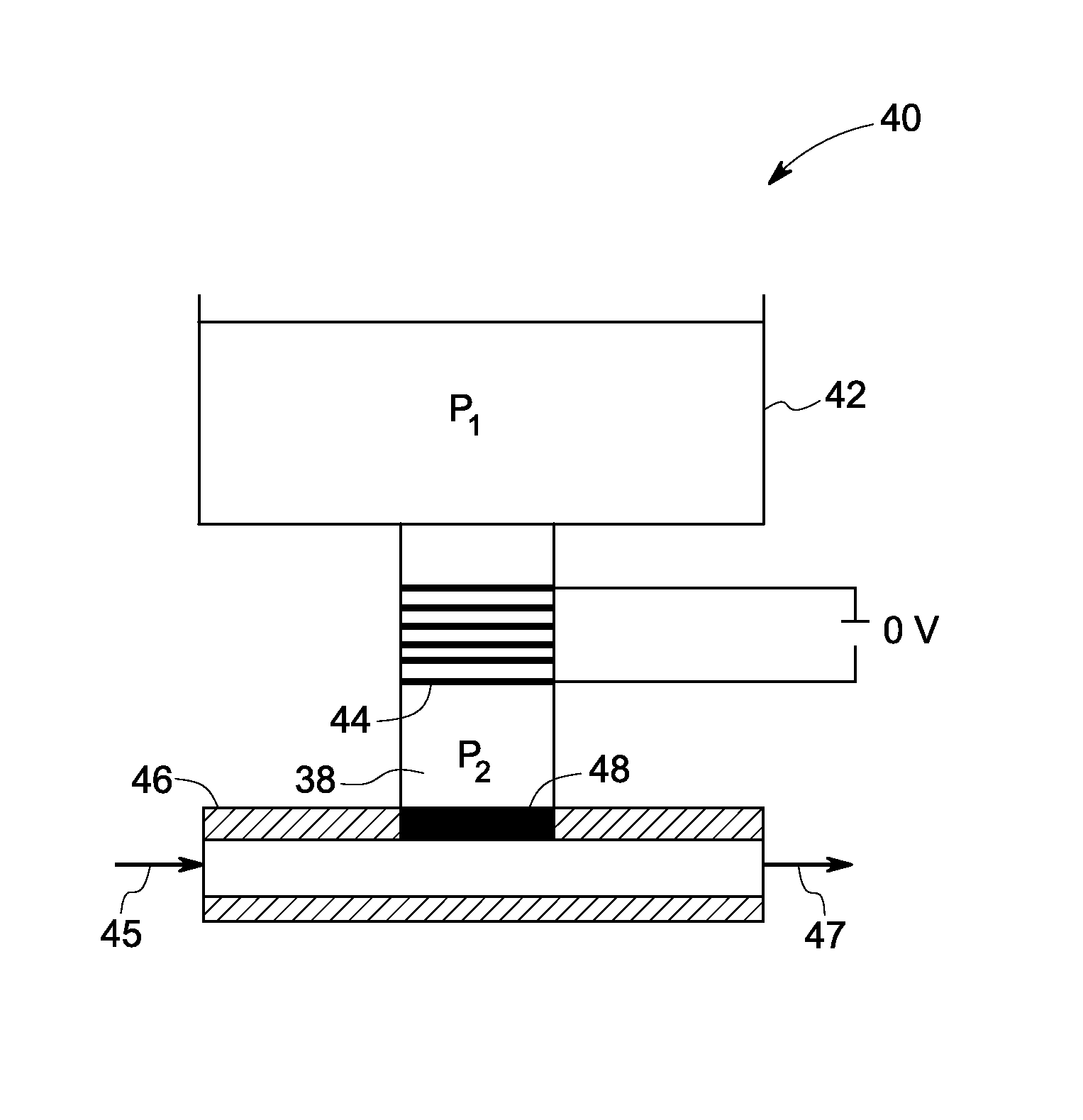

Wireless resonant electric field power transfer system and method using high Q-factor coils

ActiveUS9653948B2Prevent leakageIncrease the electric field strengthNear-field transmissionResonant circuit tuningElectrical conductorTransfer system

A wireless electric field power transmission system comprises: a transmitter comprising a transmitter antenna, the transmitter antenna comprising at least two conductors defining a volume therebetween; and at least one receiver, wherein the transmitter antenna transfers power wirelessly via electric field coupling when the at least one receiver is within the volume.

Owner:SOLACE POWER INC

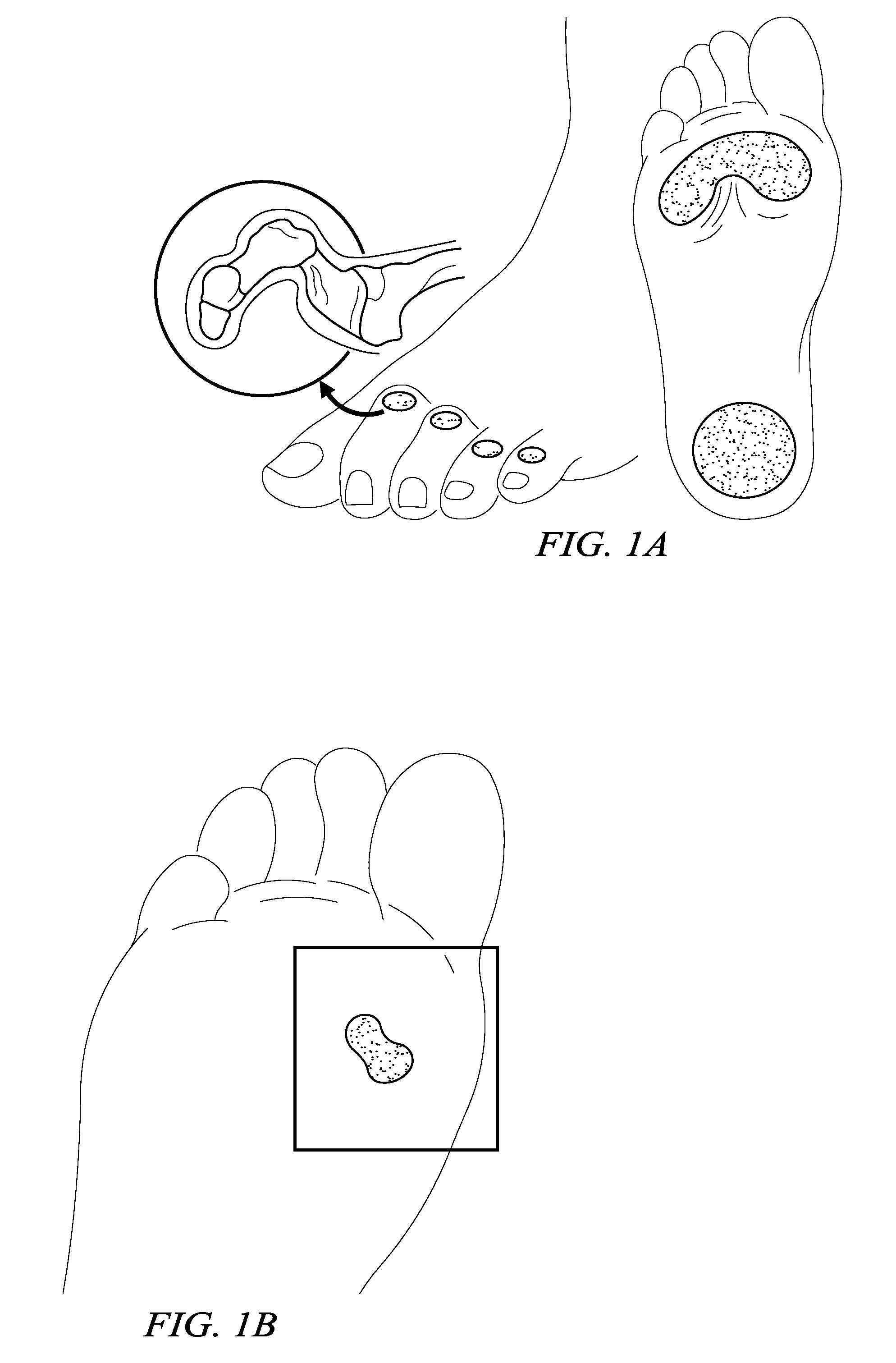

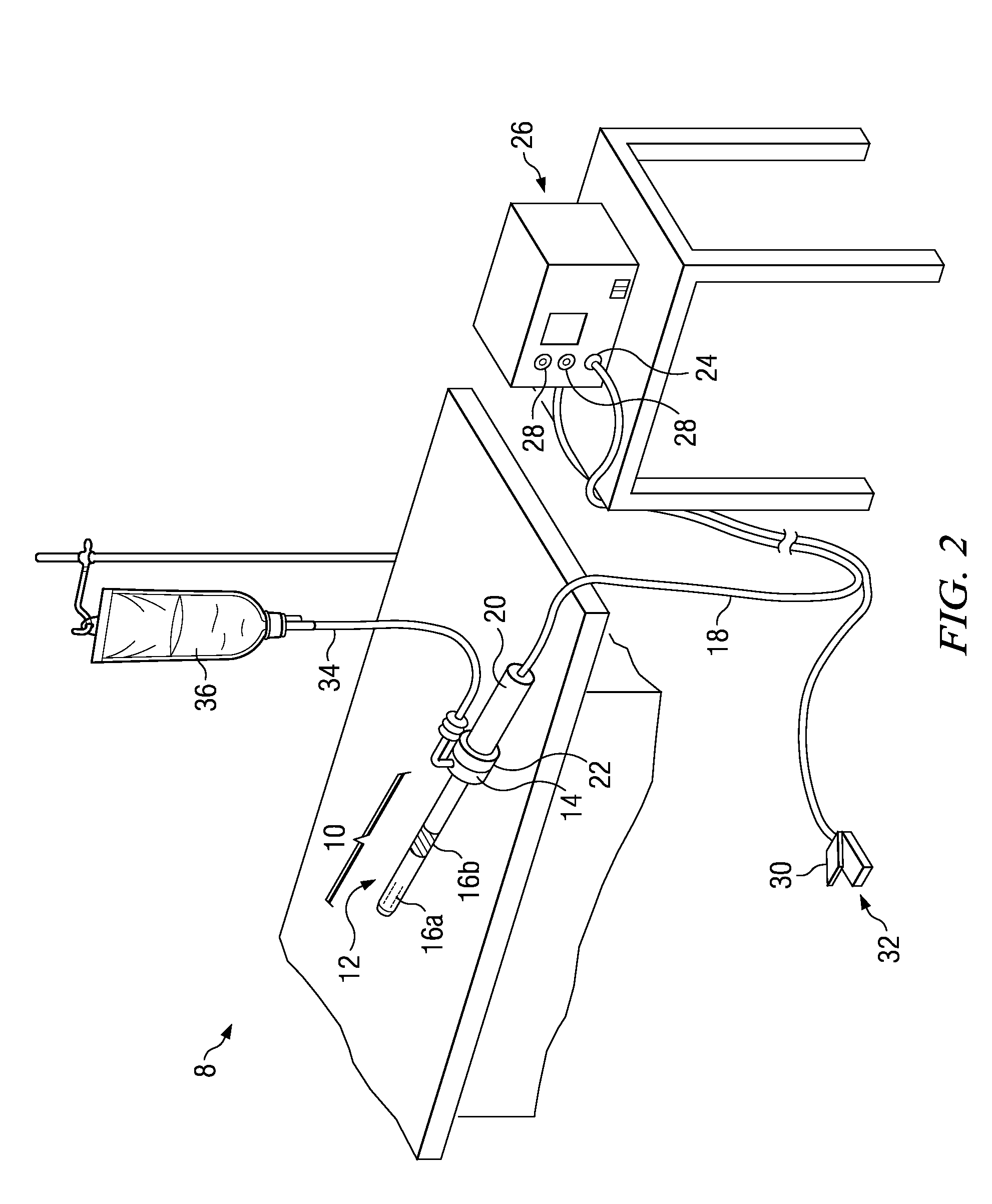

Electrosurgical system and method for sterilizing chronic wound tissue

ActiveUS20100087812A1Increase the electric field strengthRemove necrotic or unhealthy tissueSurgical instruments for heatingSurgical instruments for aspiration of substancesProximateChronic wound

An electrosurgical method for sterilizing chronic wound tissue, comprising: positioning an active electrode in proximity to the chronic wound tissue; delivering an electrically conductive fluid proximate the active electrode; and applying a high frequency voltage between the active electrode and a return electrode in the presence of the electrically conductive liquid sufficient to generate an ionized vapor layer at the active electrode, wherein the ionized vapor layer sterilizes at least a portion of the chronic wound tissue.

Owner:ARTHROCARE

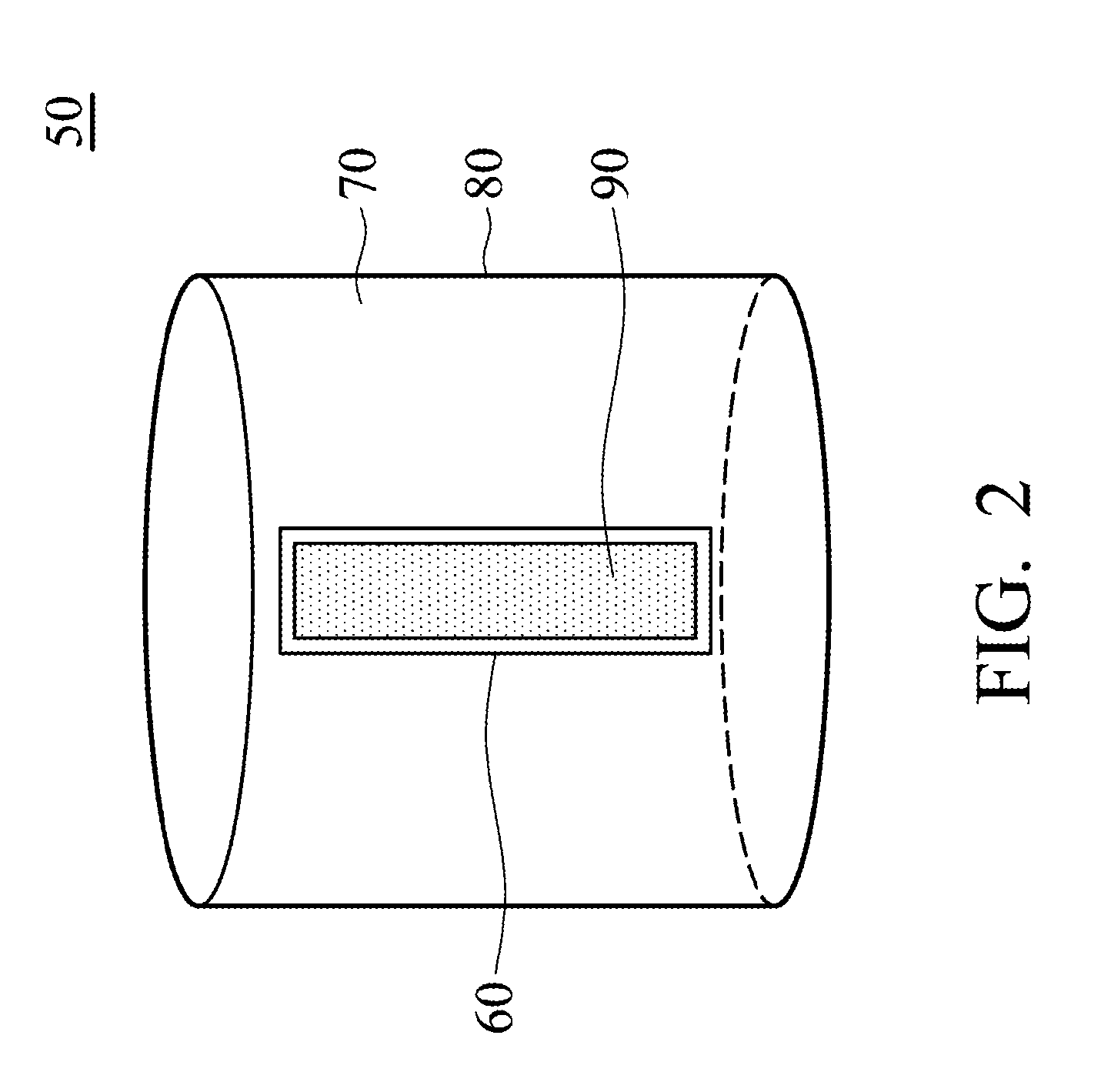

Non-woven cloth production device for curtain solid pin electrode nano fiber

InactiveCN102704194AAvoid cloggingMeet batch preparationFilament/thread formingNon-woven fabricsFiberBiochemical engineering

The invention discloses a production device for a curtain solid pin electrode nano fiber, which mainly includes a liquid storage tank, a curtain solid pin electrode thread ejector, a receiving device and a high-voltage electrostatic generator, wherein the curtain solid pin electrode thread ejector is characterized by consisting of a metal curtain, a solid pin electrode and a rotating roller; the breadth of the curtain pin electrode thread ejector ranges from 20 to 200cm, and the pin density of the solid pin electrode is 1 to 16 / cm2; the solid pin electrode is characterized in that the pin structure is either forked, cylindrical, conical or pyramidal; the solid pin electrode (22) is characterized in that the pin length ranges from 1 to 4cm, the pin tip dipping length ranges from 0.2 to 1mm. The industrial production device is sufficient for the production of the spinning solution electrospun nano fiber with the density amounting to more than 25%, the critical voltage thereof is generally no higher than 25kV, the production efficiency is higher than 50g / min, the diameter of the prepared nano fiber ranges from 50 to 500nm, and the uniform diameter is smaller than 400nm.

Owner:TIANJIN POLYTECHNIC UNIV

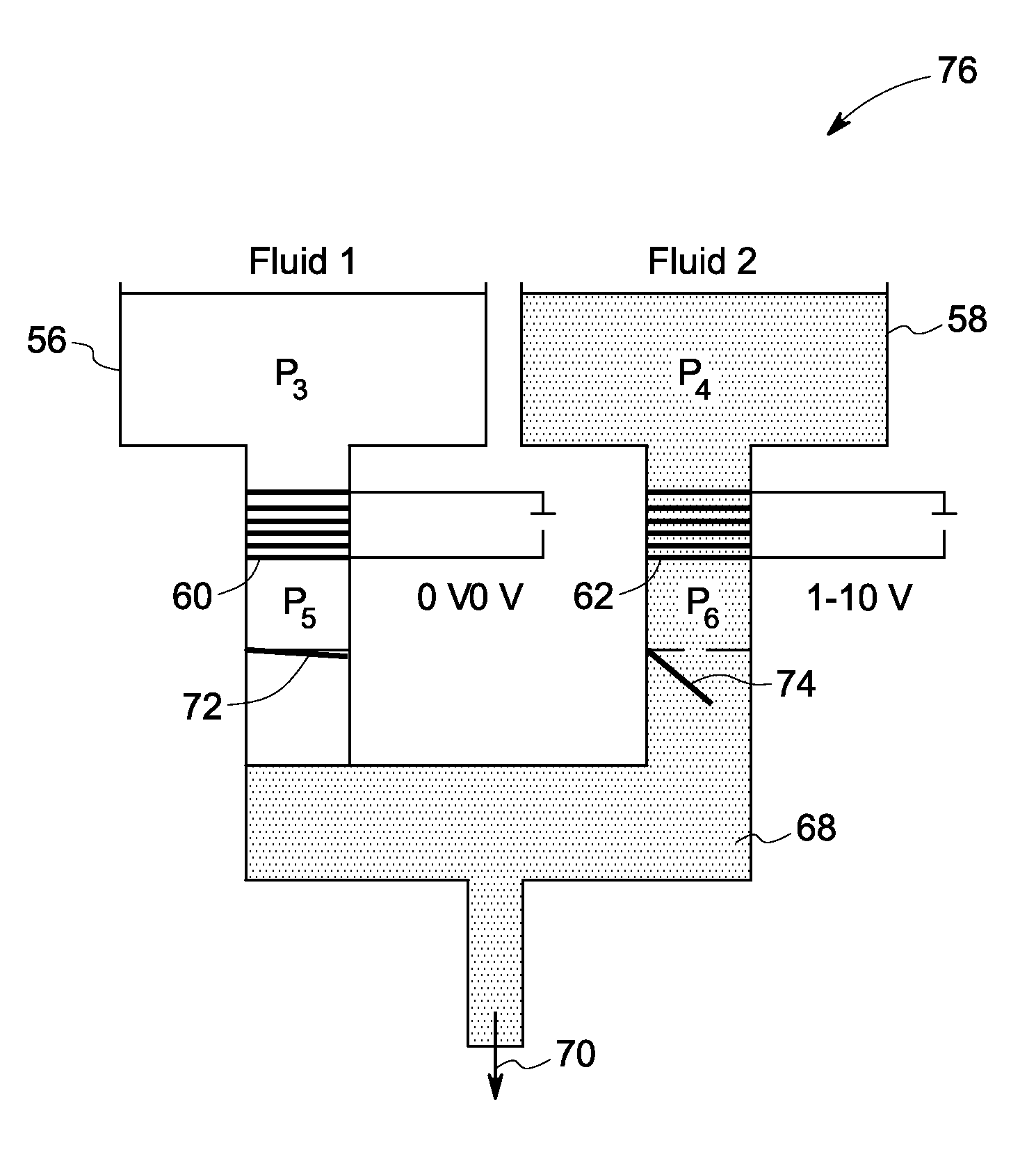

Actuation of valves using electroosmotic pump

InactiveUS20130153797A1Increase the electric field strengthIncrease pressureOperating means/releasing devices for valvesMicrobiological testing/measurementEngineeringAnode

A method of actuating a valve, comprises operatively coupling the valve with an electroosmotic pump; flowing a fluid through the electroosmotic pump; and generating a fluidic pressure of at least 0.75 PSI to actuate the valve, wherein the electroosmotic pump comprises one or more thin, porous, positive electroosmotic membranes and one or more thin porous, negative electroosmotic membranes; a plurality of electrodes comprising cathodes and anodes, and a power source; wherein each of the positive and negative electroosmotic membranes are disposed alternatively and wherein at least one of the cathodes is disposed on one side of one of the membranes and at least one of the anodes is disposed on the other side of the membrane and wherein at least one of the cathodes or anodes is disposed between a positive and a negative electroosmotic membrane.

Owner:GENERAL ELECTRIC CO

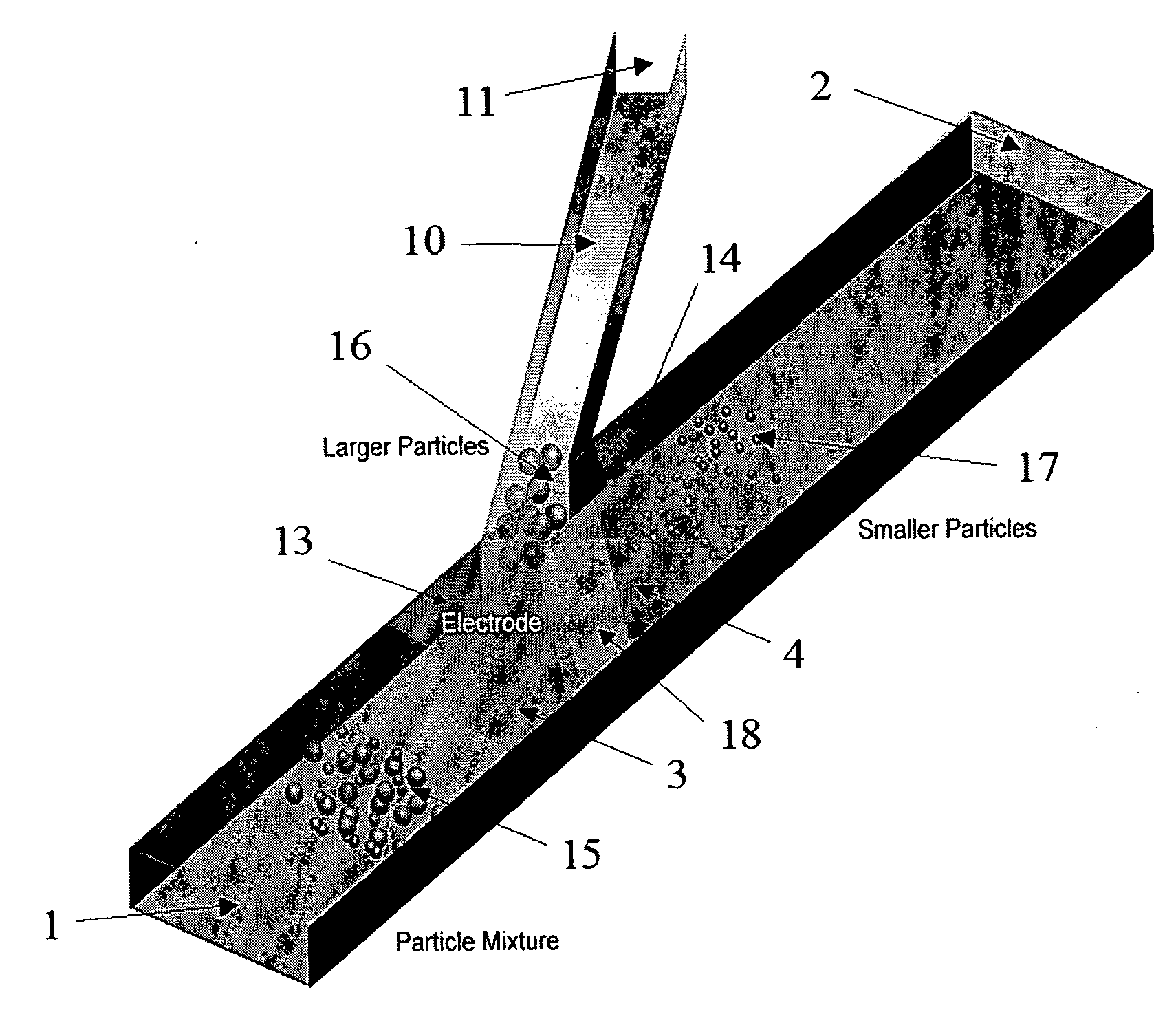

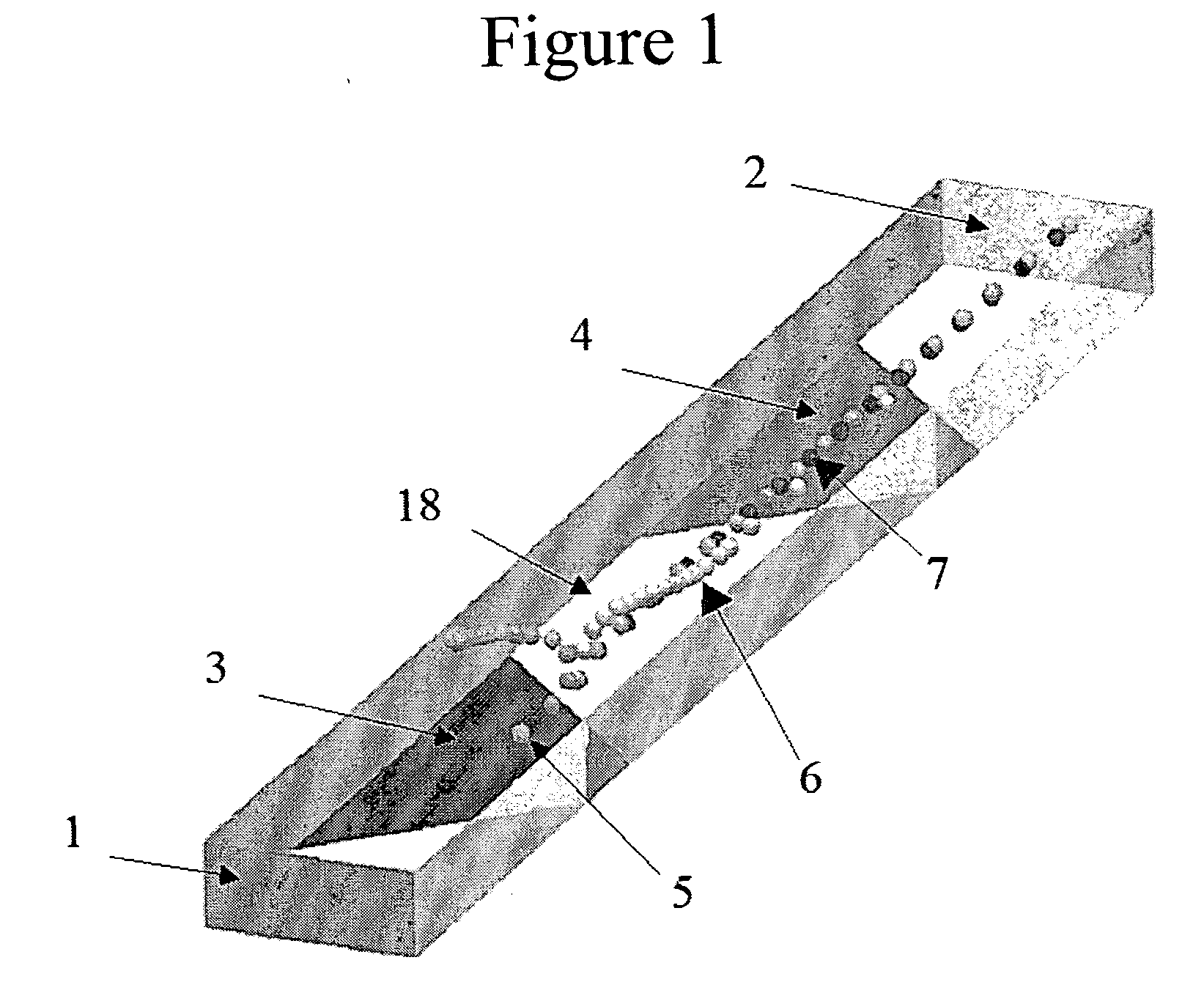

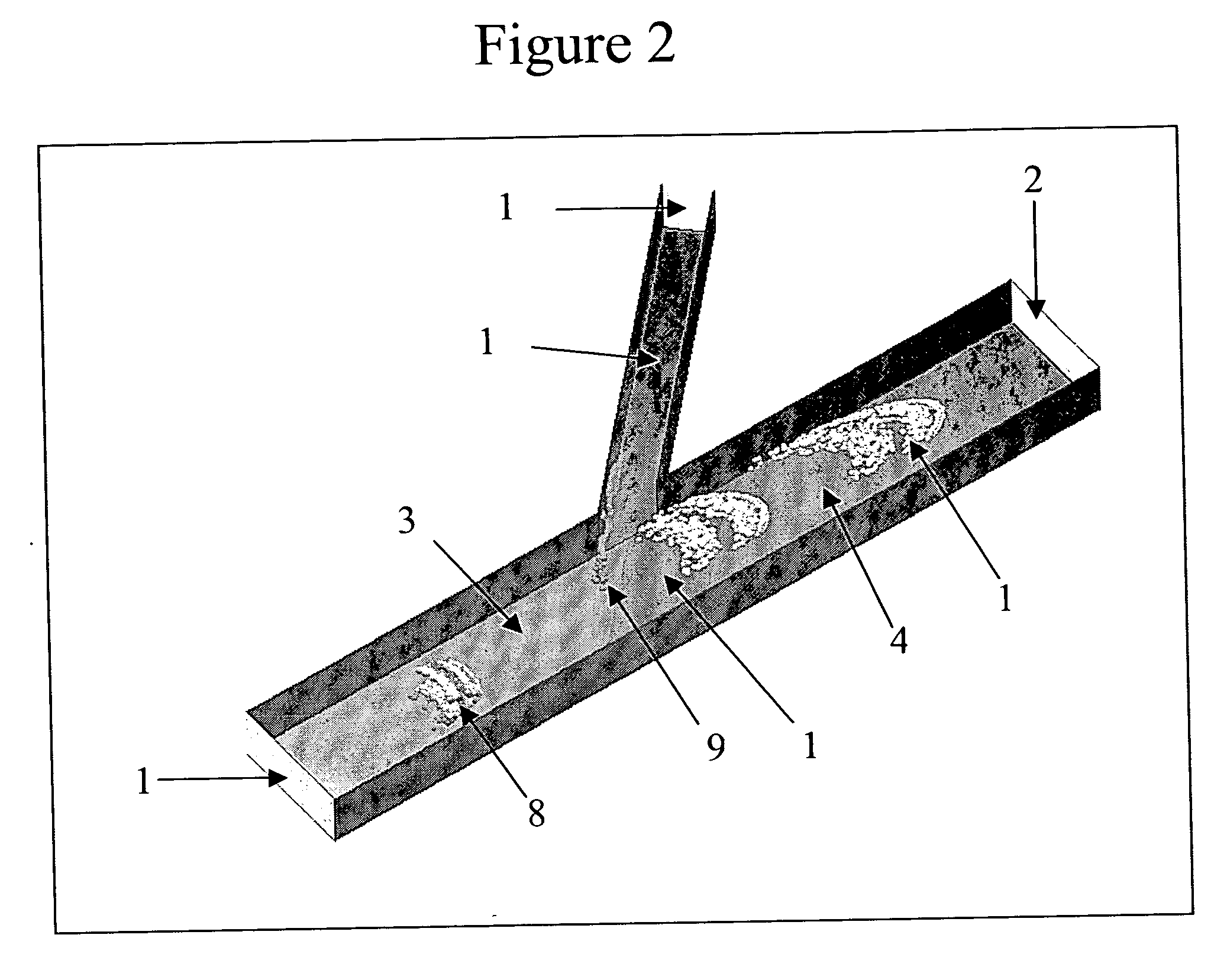

Method and apparatus for separating particles by dielectrophoresis

ActiveUS20060290745A1Easy to adjustHigh strengthDielectrophoresisElectrostatic separatorsElectricityPlanar electrode

Methods and apparatus for the micro-scale, dielectrophoretic separation of particles are provided. Fluid suspensions of particles are sorted and separated by dielectrophoretic separation chambers that have at least two consecutive, electrically coupled planar electrodes separated by a gap in a fluid flow channel. The gap distance as well as applied potential can be used to control the dielectrophoretic forces generated. Using consecutive, electrically coupled electrodes rather than electrically coupled opposing electrodes facilitates higher flow volumes and rates. The methods and apparatus can be used, for example, to sort living, damaged, diseased, and / or dead cells and functionalized or ligand-bound polymer beads for subsequent identification and / or analysis.

Owner:CFD RES CORP

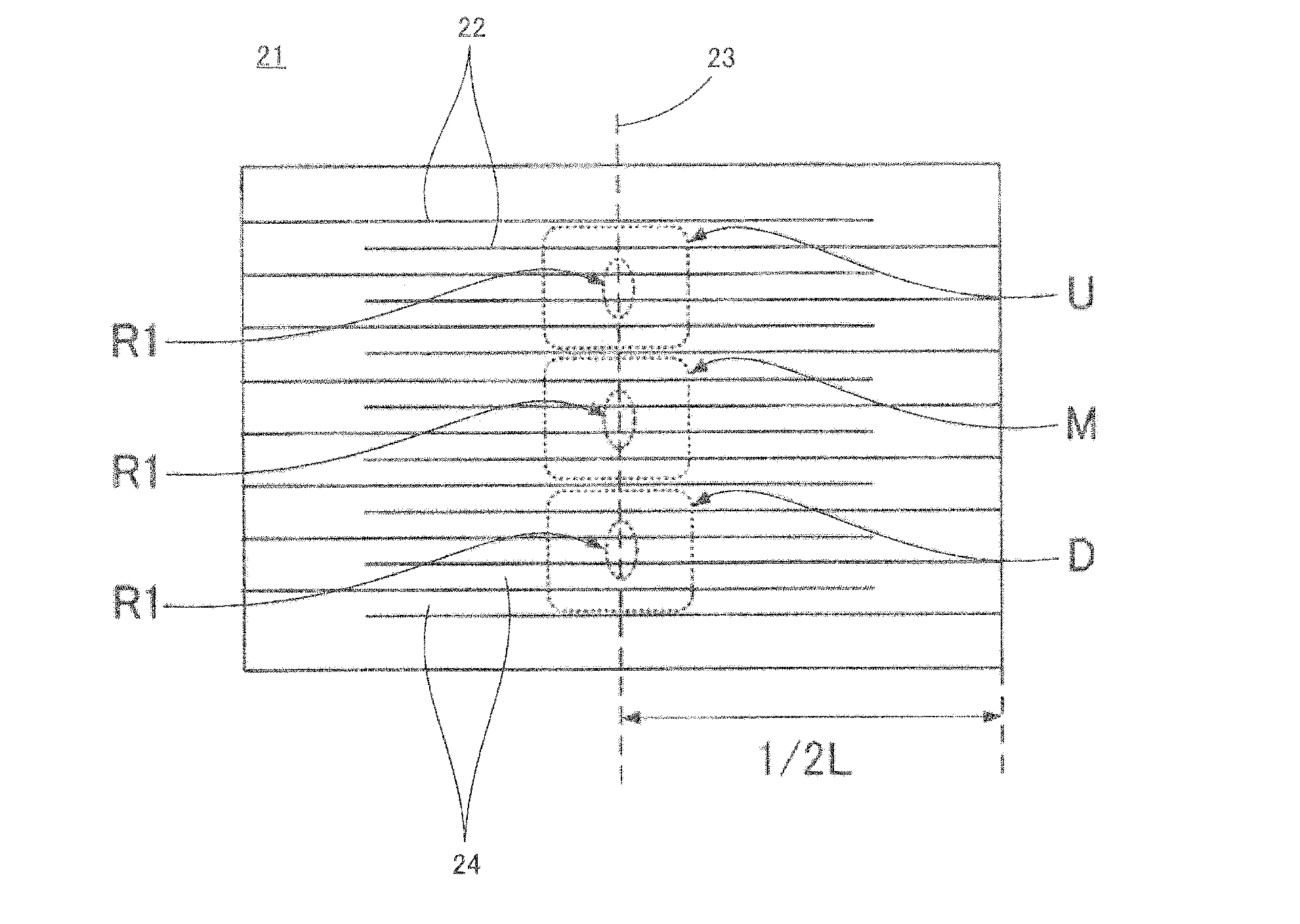

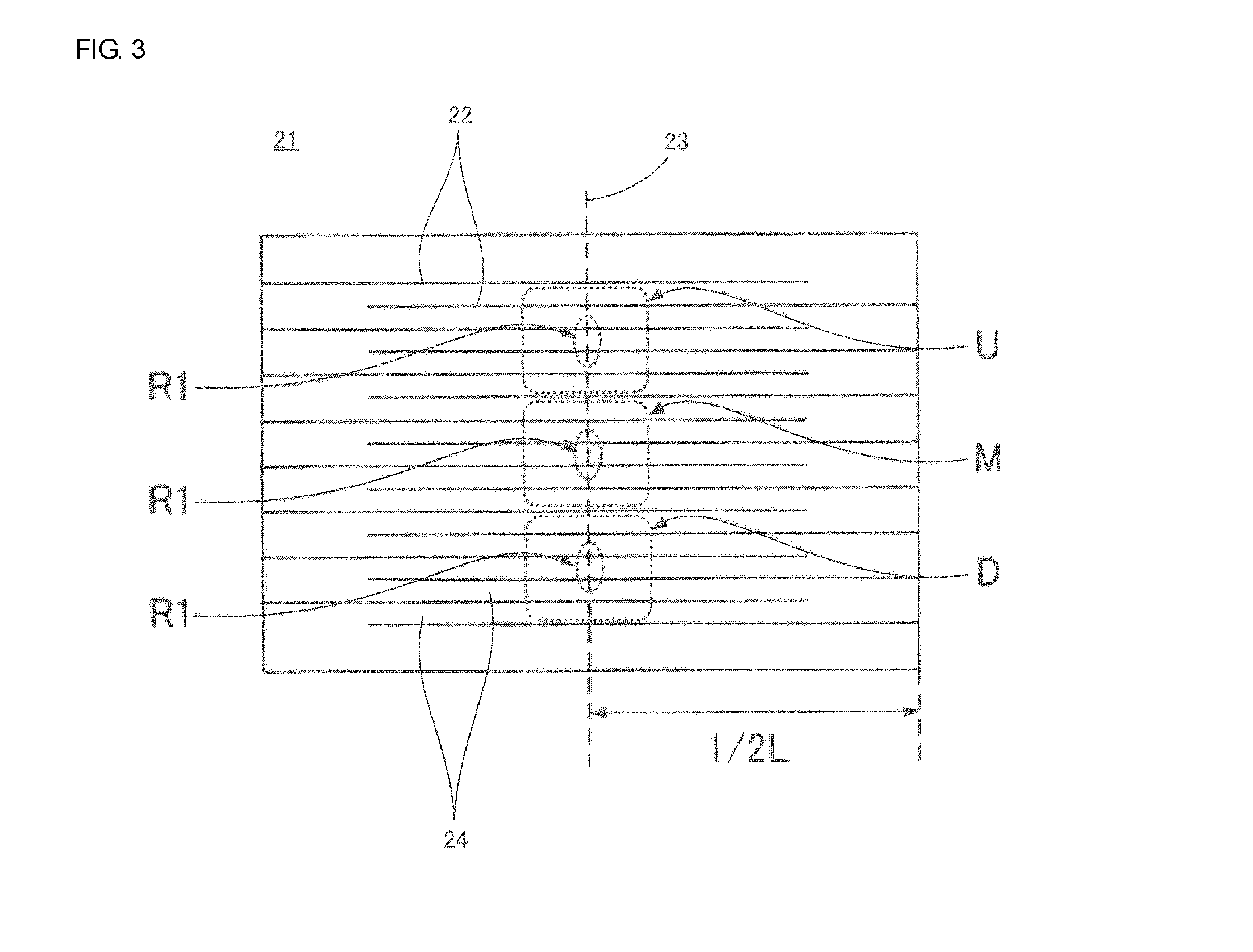

Multilayer ceramic capacitor and method for producing the same

ActiveUS20160118188A1High dielectric constantIncrease the electric field strengthAlkaline earth titanatesFixed capacitor electrodesRare-earth elementCeramic capacitor

A dielectric ceramic that forms dielectric ceramic layers of a multilayer ceramic capacitor contains a Ba and Ti containing perovskite compound, Ca, R (R denotes a rare earth element, such as La), M (M denotes Mn or the like), and Si. The Ca content ranges from 0.5 to 2.5 molar parts, the R content ranges from 0.5 to 4 molar parts, the M content ranges from 0.5 to 2 molar parts, and the Si content ranges from 1 to 4 molar parts, based on 100 molar parts of Ti. In perovskite crystal grains, the Ca diffusion depth is 10% or less of the average grain size of the crystal grains, and the Ca concentration in a Ca diffusion region is 0.2 to 5 molar parts higher than the Ca concentration near the center of each of the crystal grains.

Owner:MURATA MFG CO LTD

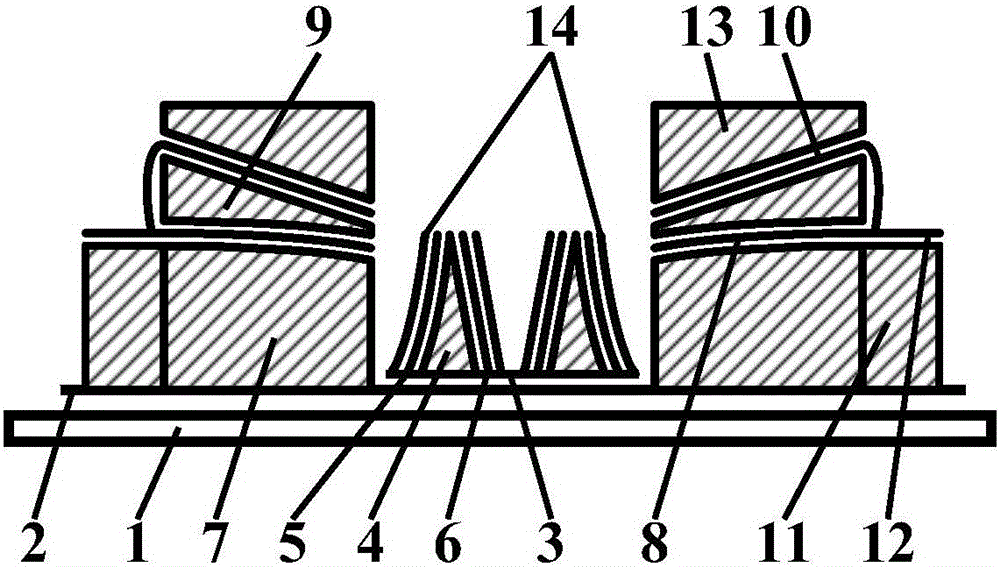

Luminescent display with bilateral ring flat concave angle spine and cathode combination slope surface gate controlled structure

ActiveCN106024556AIncrease distanceReduce manufacturing costImage/pattern display tubesElectric discharge lampsFlat glassPhosphor

The invention discloses a luminescent display with bilateral ring flat concave angle spine and cathode combination slope surface gate controlled structure. The display comprises a vacuum chamber formed by an upper flat glass sealing plate, a lower flat glass sealing plate and a transparent glass frame, an anode film connection layer on the upper flat glass sealing plate, a phosphor layer formed on the anode film connection layer and an anode silver outer conductive layer connected with the anode film connection layer, a bilateral ring flat concave angle spine and cathode combination slope surface gate controlled structure on the lower flat glass sealing plate as well as a getter in the vacuum chamber and isolation insulation wall attached components. The luminescent display of the invention has the advantages of being manufactured at low production cost and through simple production process while achieving high brightness.

Owner:山东菏益科技有限公司

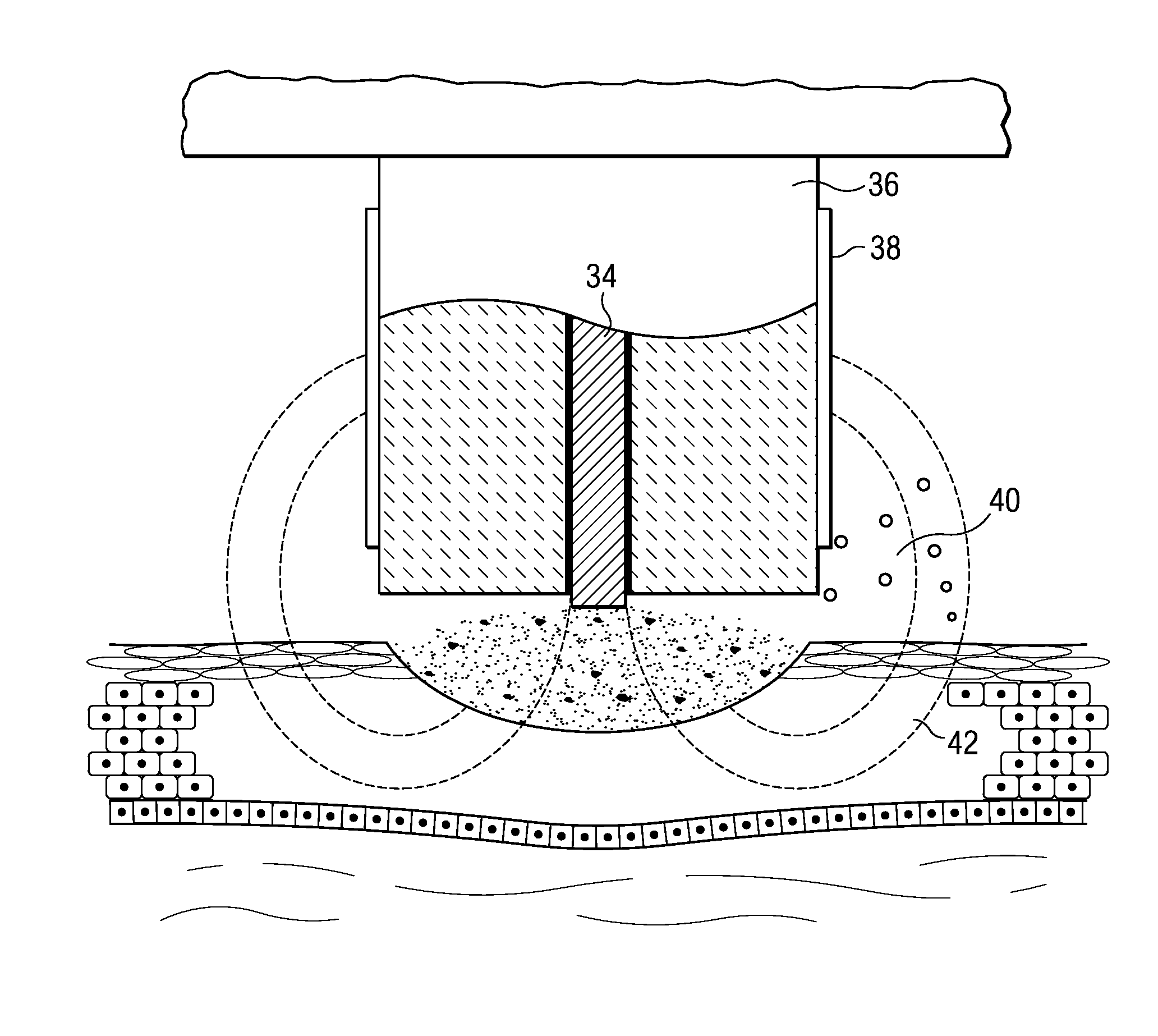

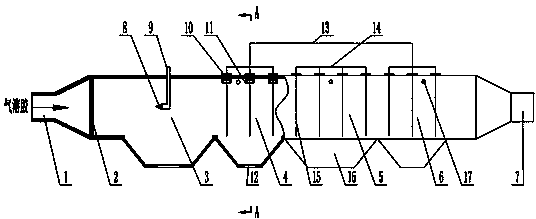

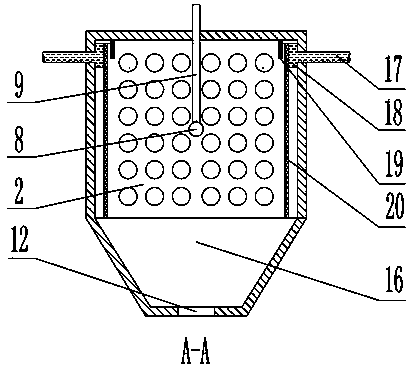

Efficient multi-field-coordination fine particulate matter removal device and method

ActiveCN103768886AAvoid back coronaAvoid secondary dustSemi-permeable membranesAuxillary pretreatmentMulti fieldWater vapor

The invention discloses an efficient multi-field-coordination fine particulate matter removal device and an efficient multi-field-coordination fine particulate matter removal method. The device comprises an outer field coagulation area, a direct current dust pre-collecting area, a pulse charge coagulation area and a direct current dust collecting area which are connected in sequence, wherein water steam and a chemical agglomeration agent are introduced from a nozzle of the outer field coagulation area respectively; the direct current dust pre-collecting area and the direct current dust collecting area are arranged in a line-plate type symmetric structure, a line electrode applies negative direct current high voltage, and a plate electrode is grounded and adopts layout of a water film electrode; the pulse charge coagulation area is arranged in the line-plate type symmetric structure, the line electrode applies positive pulse high voltage, and the plate electrode is grounded and adopts layout of the water film electrode. The device and the method aim at mineral particulate matters discharged by a fixed source; aerosol particulate matters, particularly fine particulate matters, can be subjected to efficient coagulation removal in a structural form of double coagulation areas and double dust collecting areas by using a multi-field-coordination method combined by a phase-change coagulation growth technology, a chemical agglomeration and flocculation mechanism and an electric coagulation technology, so that the phenomena of back corona, re-entrainment of dust, ash deposition and corrosion of the plate electrode are effectively avoided.

Owner:ZHEJIANG UNIV

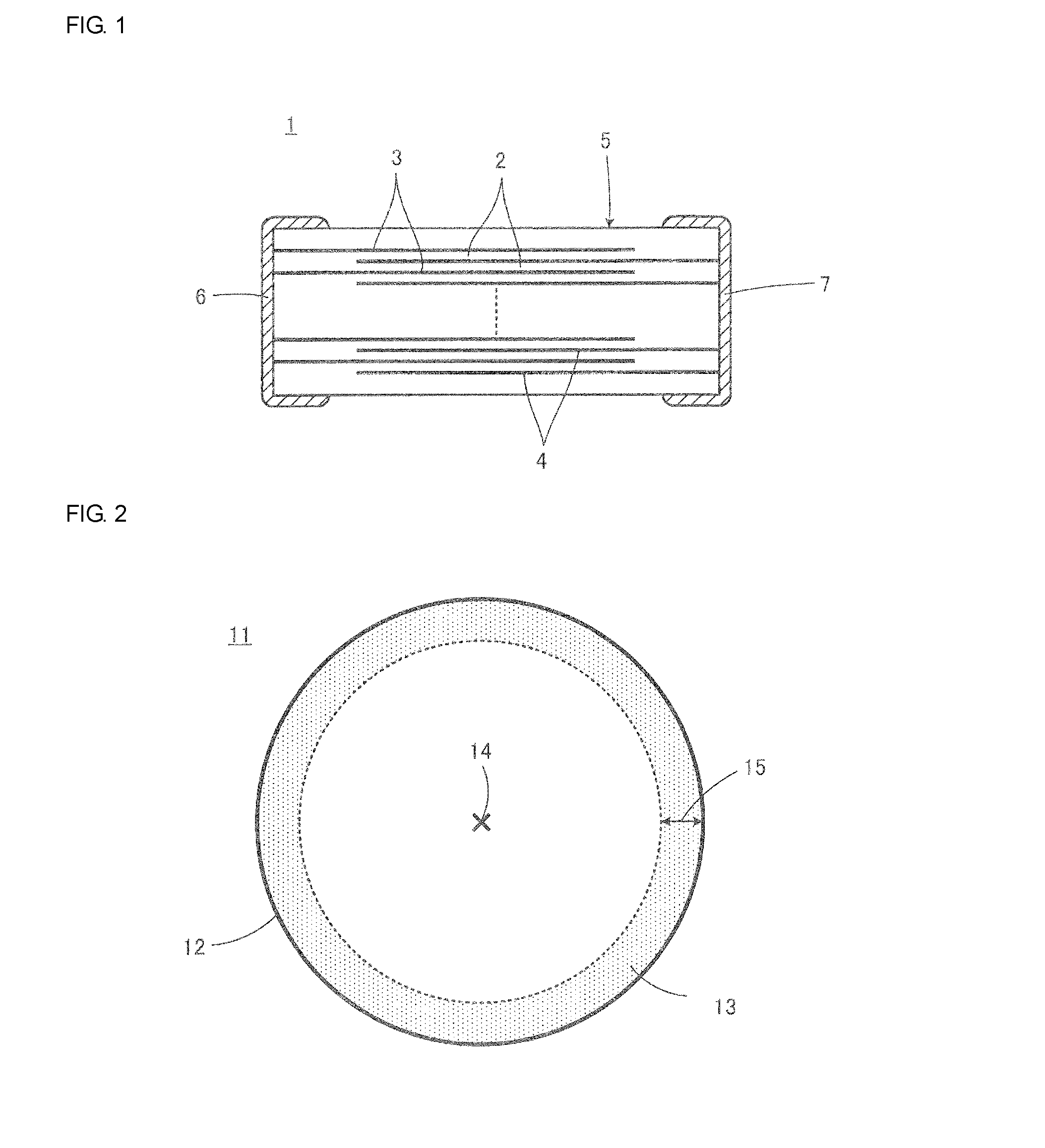

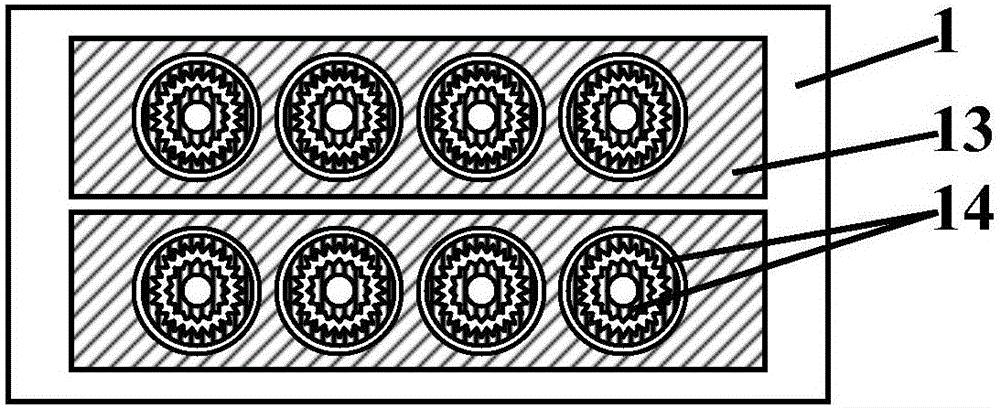

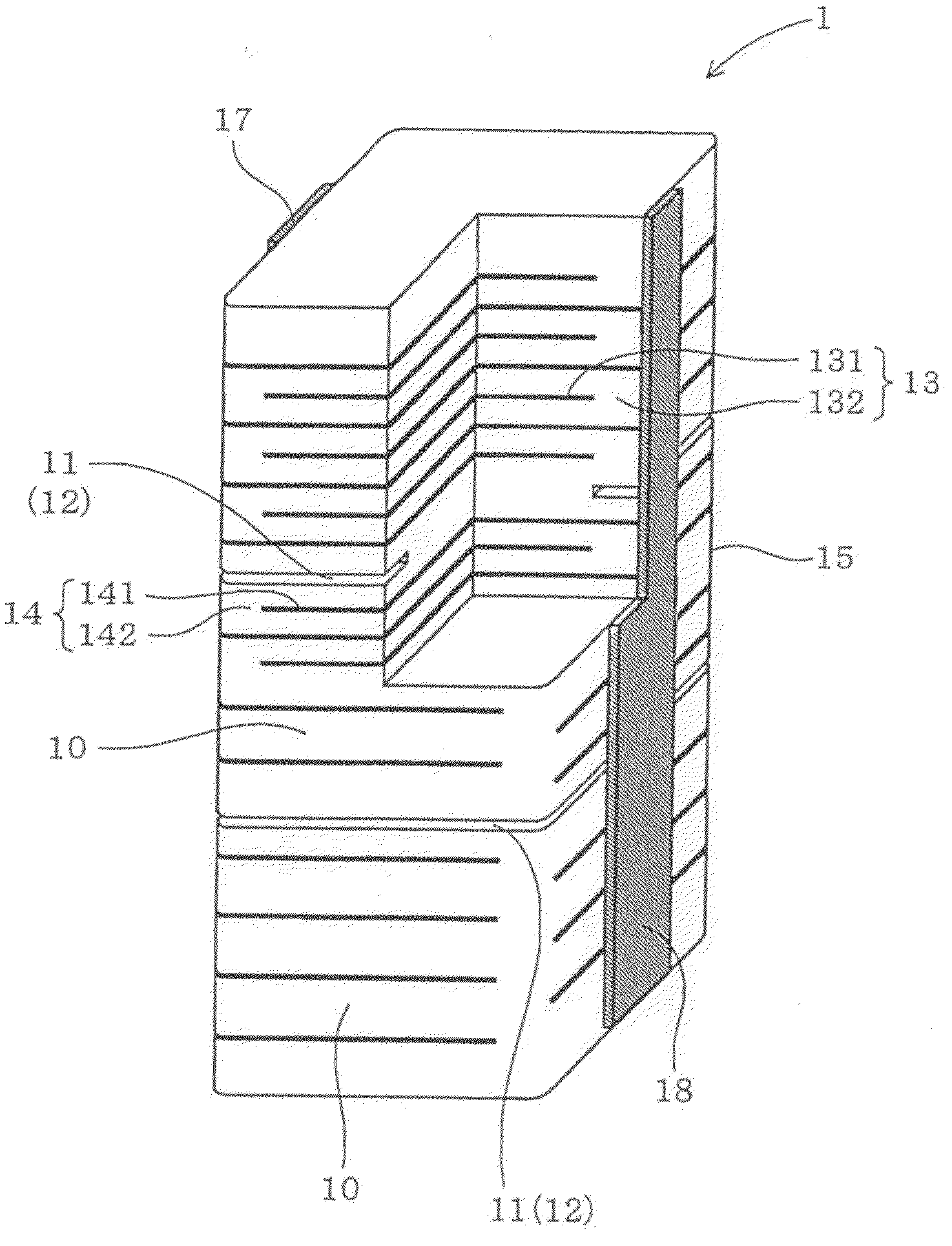

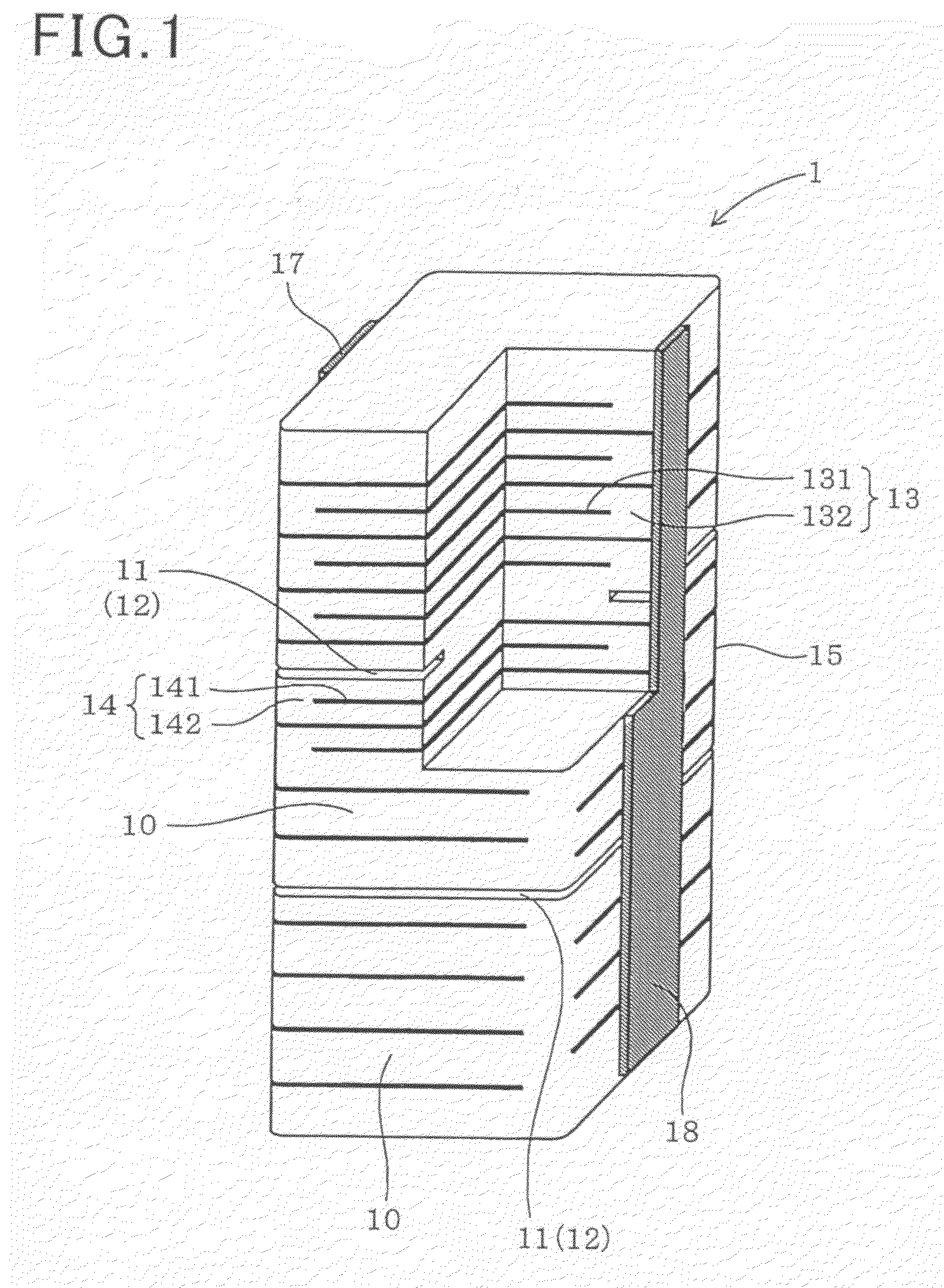

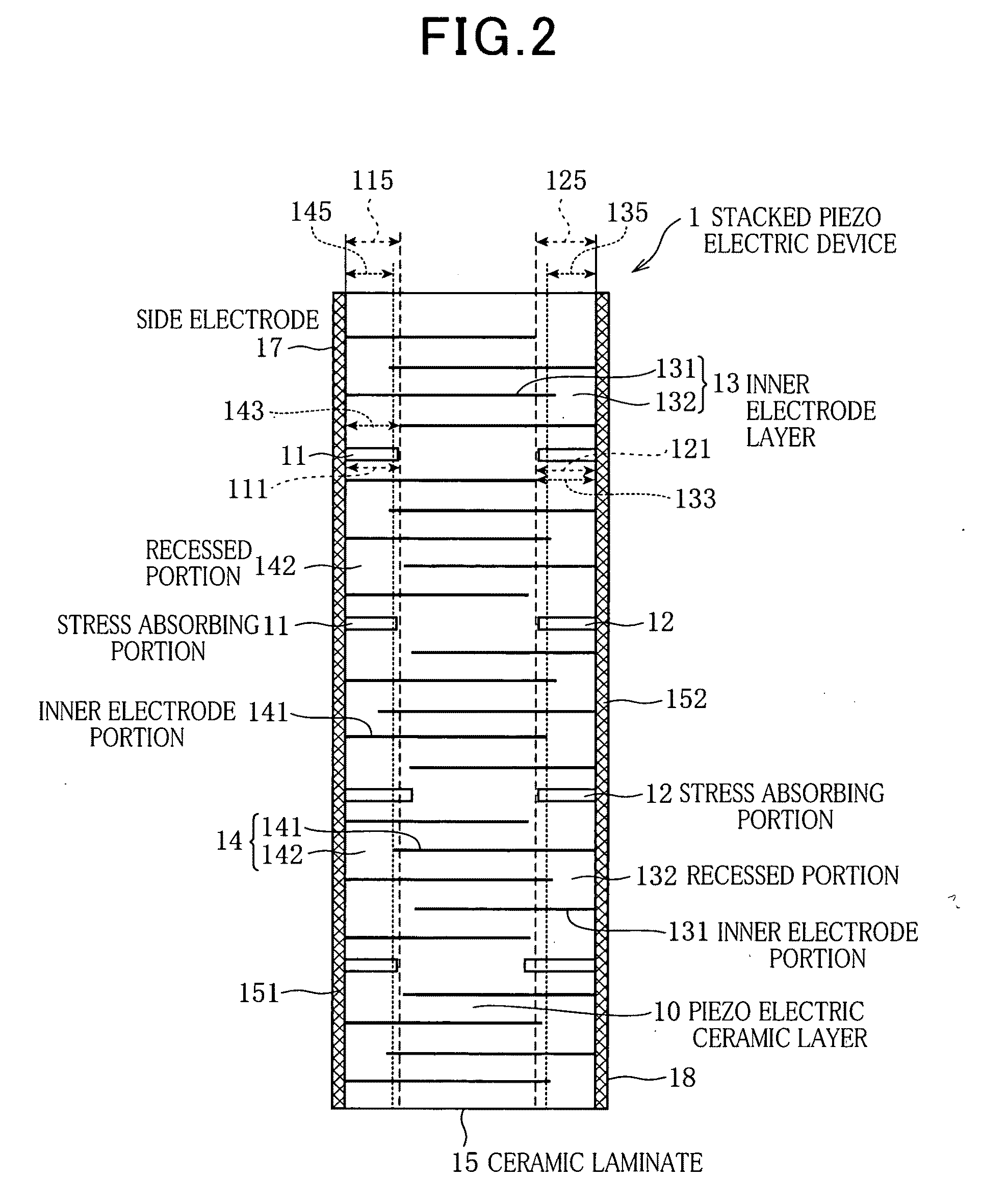

Stacked piezoelectric device

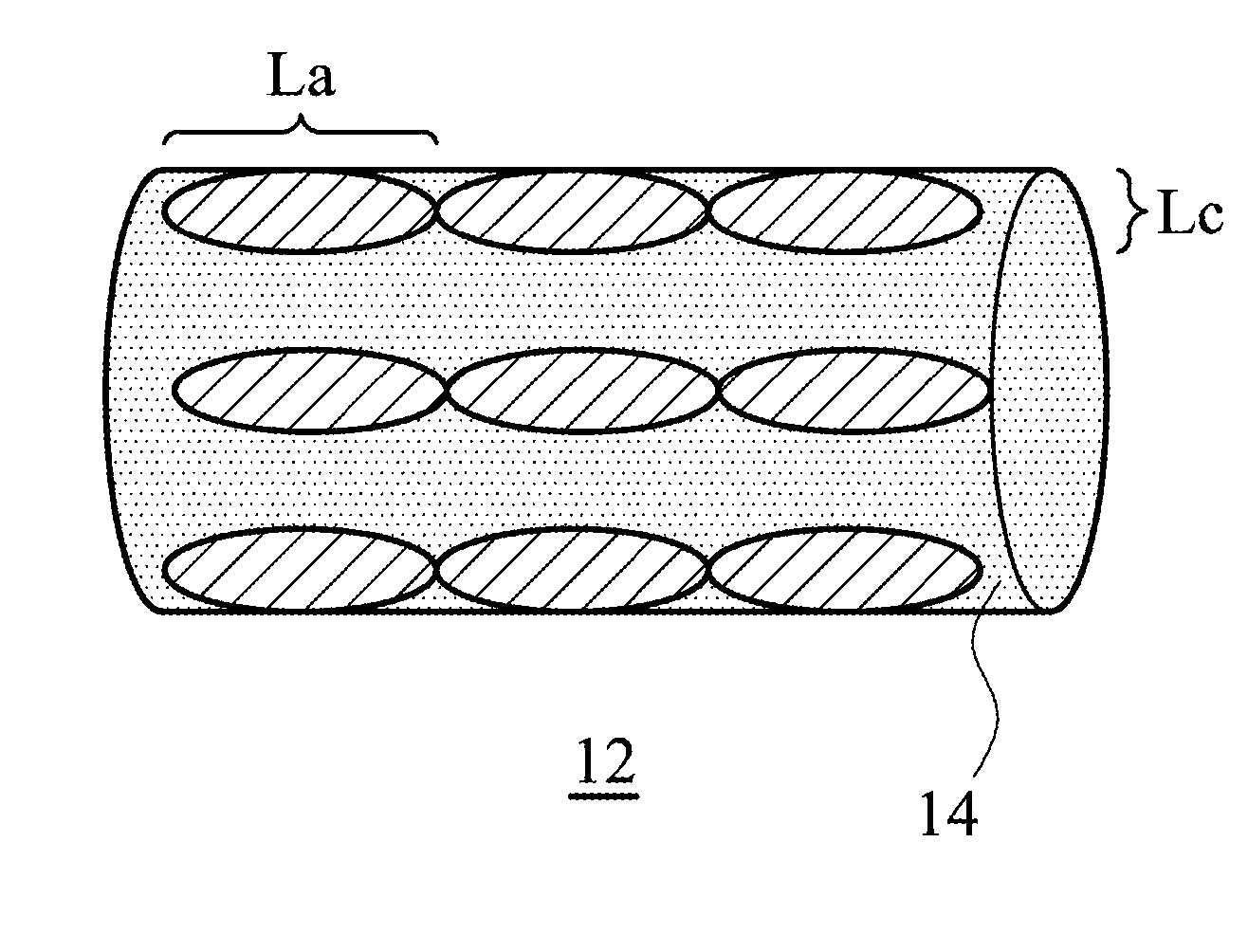

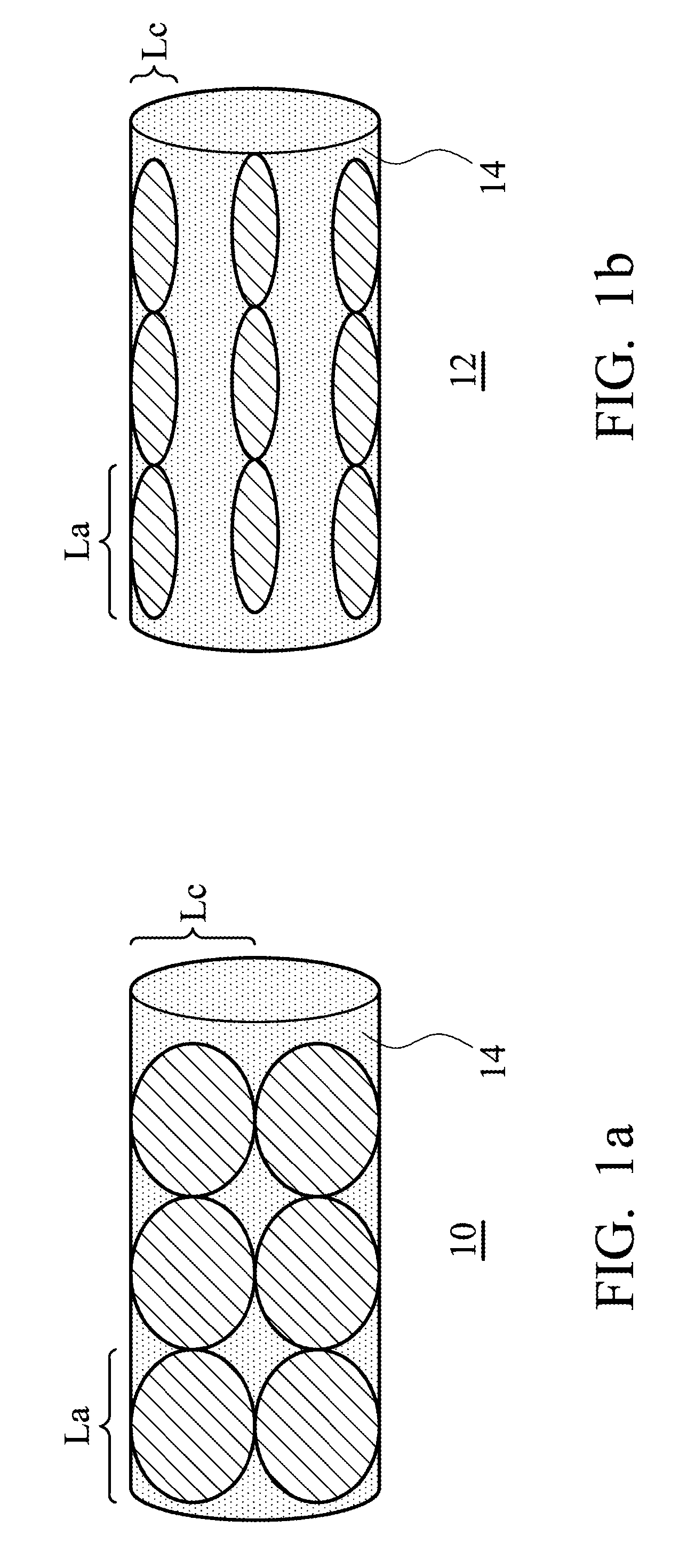

ActiveUS20100140379A1Avoid drop in insulation resistanceSacrificing amountPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesMaterials science

A stacked piezoelectric device 1 including a ceramic laminate formed by laminating piezoelectric ceramic layers and inner electrode layers alternately and a pair of side electrodes. The inner electrode layers 13 and 14 have inner electrode portions 131 and 141 and the recessed portions 132 and 142. The ceramic laminate 15 has the stress absorbing portions 11 and 12. A recessed distance of one of two of the recessed portions 132 and 142 which interleave the stress absorbing portions 11 and 12 therebetween which is located on the same side surface as the stress absorbing portion 11 or 12 is greater than the depth of the stress absorbing portion 11 and 12.

Owner:DENSO CORP

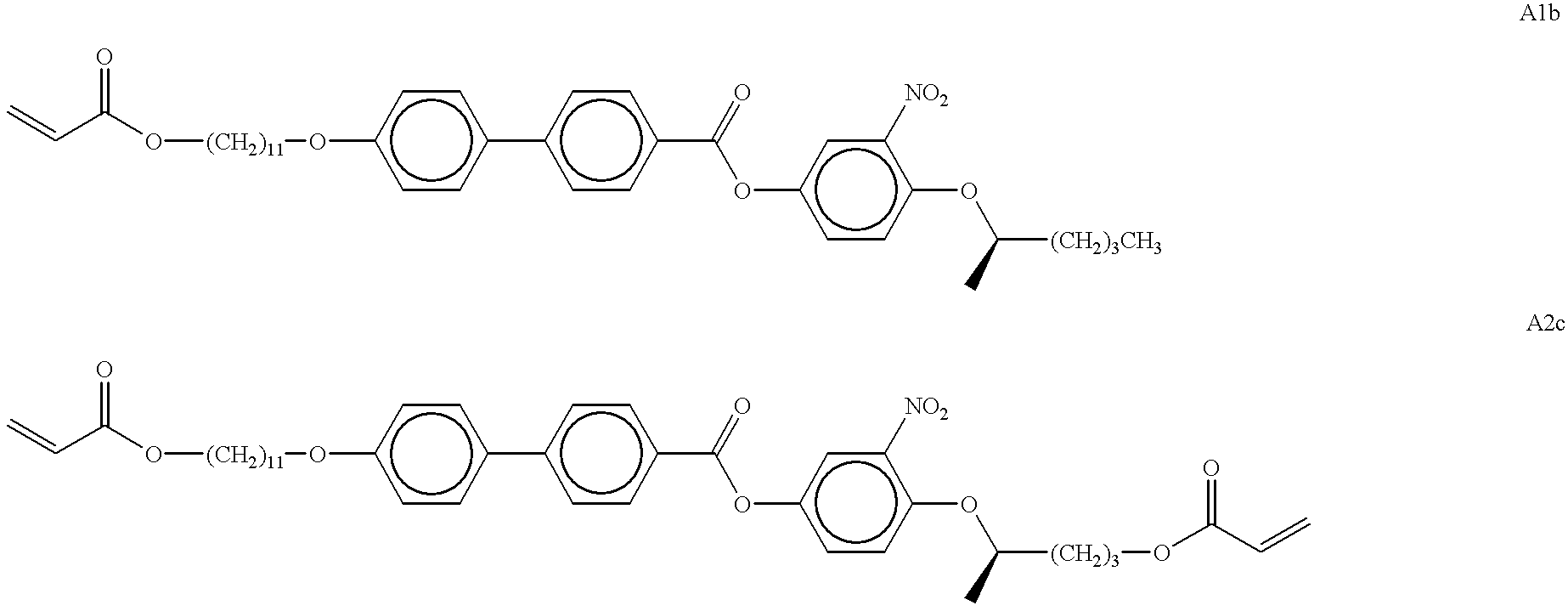

Liquid crystal device and a method for producing it

InactiveUS20010005249A1Rapid responseEnhanced advantageLiquid crystal compositionsLayered productsFlat glassOligomer

An electrooptic device (2), and the methods for manufacturing, including a liquid crystal material (12) disposed between electroded flat glass or polymer substrates (4, 20) which have been precoated with a e.g. a chiral smectic surface layer (10, 14) in such way that the surface layer is able to mediate switching of the liquid crystal (12) between different optical states. The chiral smectic surface layer can be a polymer, oligomer or monomer liquid crystal with paraelectric, ferroelectric, ferrielectric or antiferroelectric response, which is insoluble in the liquid crystal used for the bulk (12) between the electroded substrates (4, 20). the switchable surface director enforces a certain orientation of the optic axis in the bulk liquid crystal (12), which can be a conventional non-chiral or chiral nematic or smectic in a twisted or non-twisted configuration.

Owner:ECSIBEO PPF1

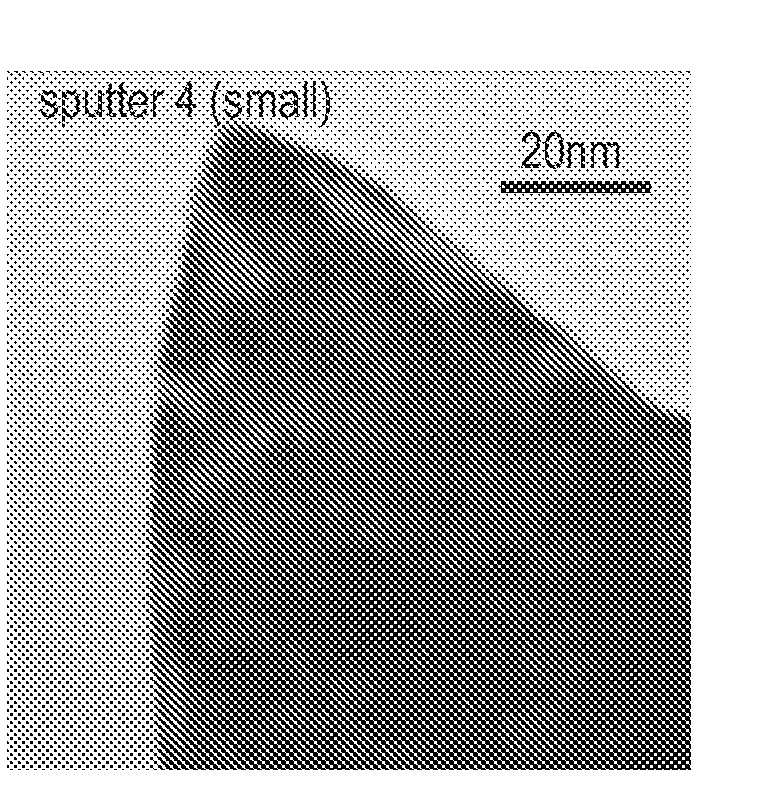

High module carbon fiber and method for fabricating the same

The invention provides a high module carbon fiber and a fabrication method thereof. The high module carbon fiber includes the product fabricated by the following steps: subjecting a pre-oxidized carbon fiber to a microwave assisted graphitization process, wherein the pre-oxidized carbon fiber is heated to a graphitization temperature of 1000-3000° C. for 1-30 min. Further, the high module carbon fiber has a tensile strength of between 2.0-6.5 GPa and a module of between 200-650 GPa.

Owner:IND TECH RES INST

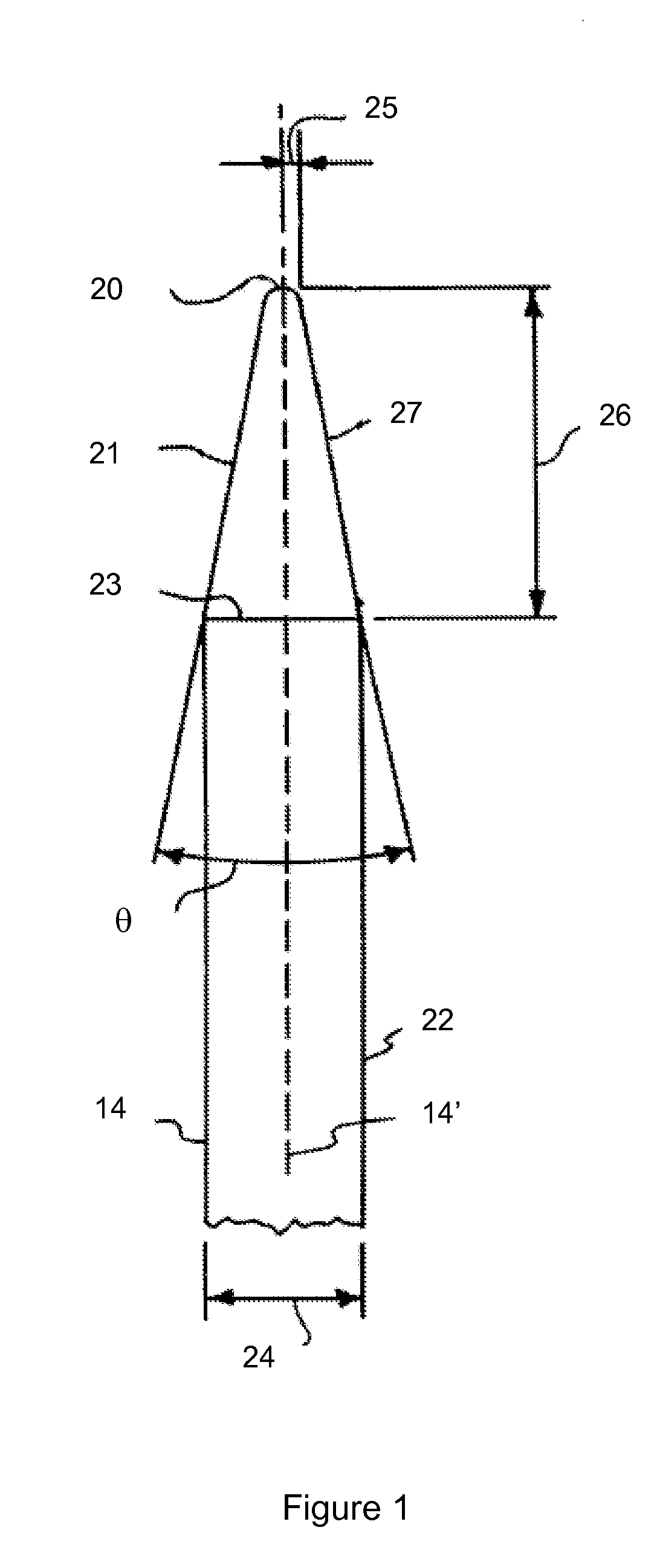

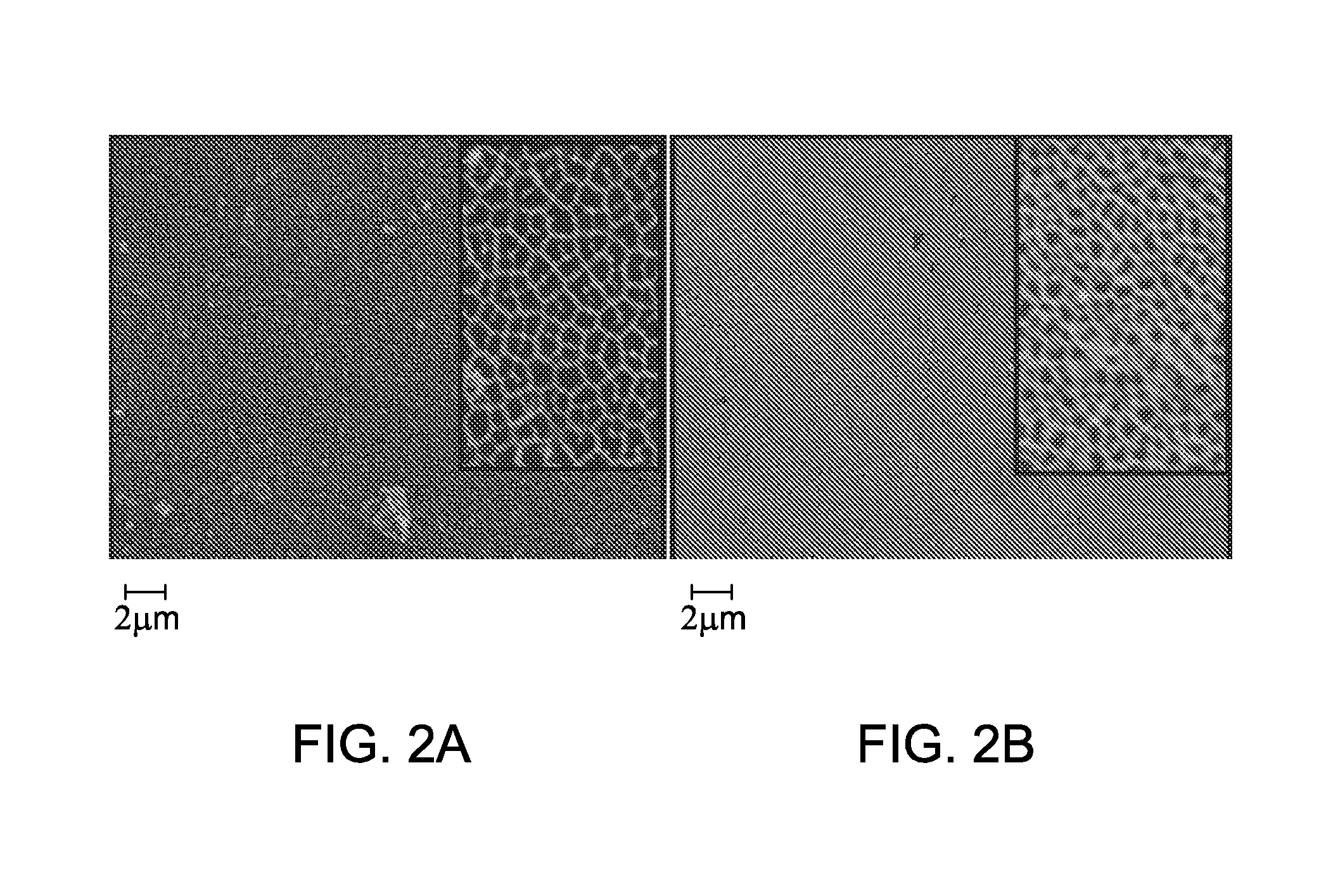

Nanometer-scale sharpening of conductor tips

InactiveUS20080105539A1Increase productionLarge spotCellsVacuum evaporation coatingNanowireConductive coating

The invention provides methods for sharpening the tip of an electrical conductor. The methods of the invention are capable of producing tips with an apex radius of curvature less than 2 nm. The methods of the invention are based on simultaneous direction of ionized atoms towards the apex of a previously sharpened conducting tip and application of an electric potential difference to the tip. The sign of the charge on the ions is the same as the sign of the electric potential. The methods of the invention can be used to sharpen metal wires, metal wires tipped with conductive coatings, multi-walled carbon nanotubes, semiconducting nanowires, and semiconductors in other forms.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Electroosmotic pump and method of use thereof

InactiveUS20130153425A1Increase the electric field strengthIncrease pressureCellsSludge treatmentMembrane configurationChemistry

Owner:GENERAL ELECTRIC CO

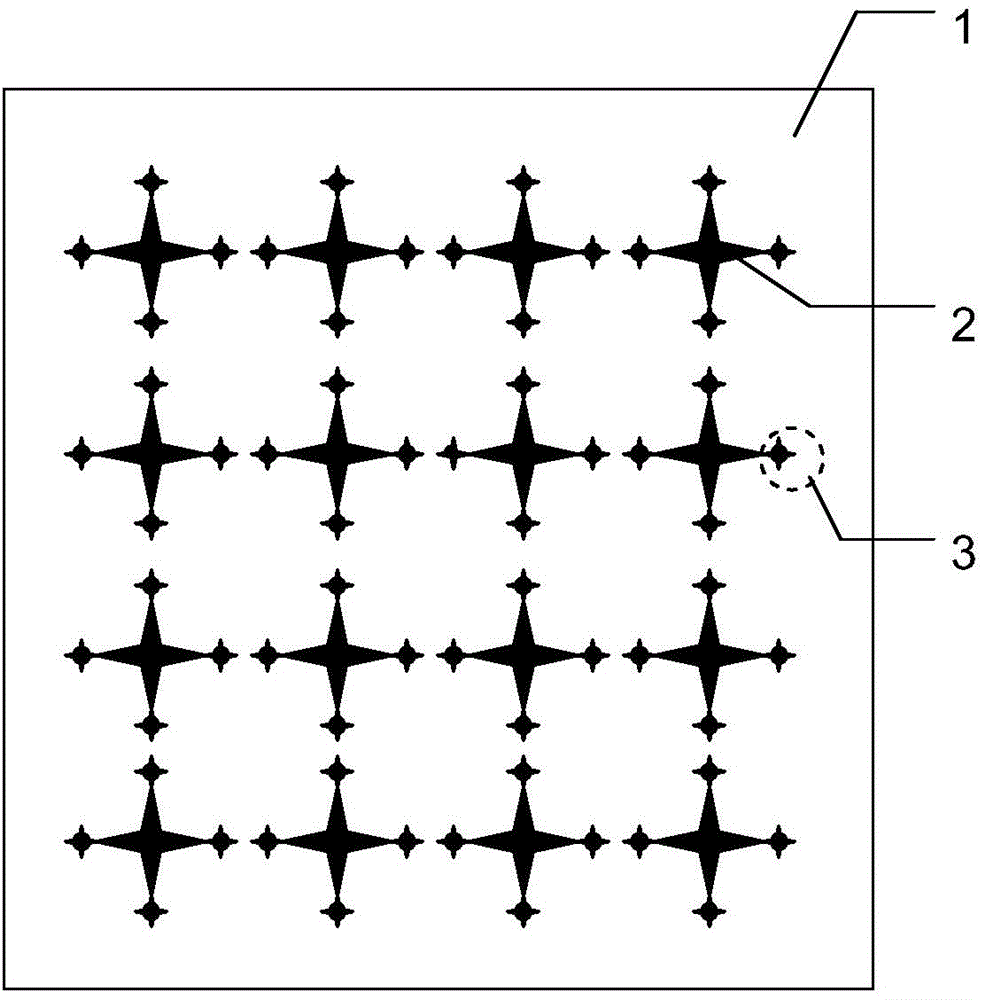

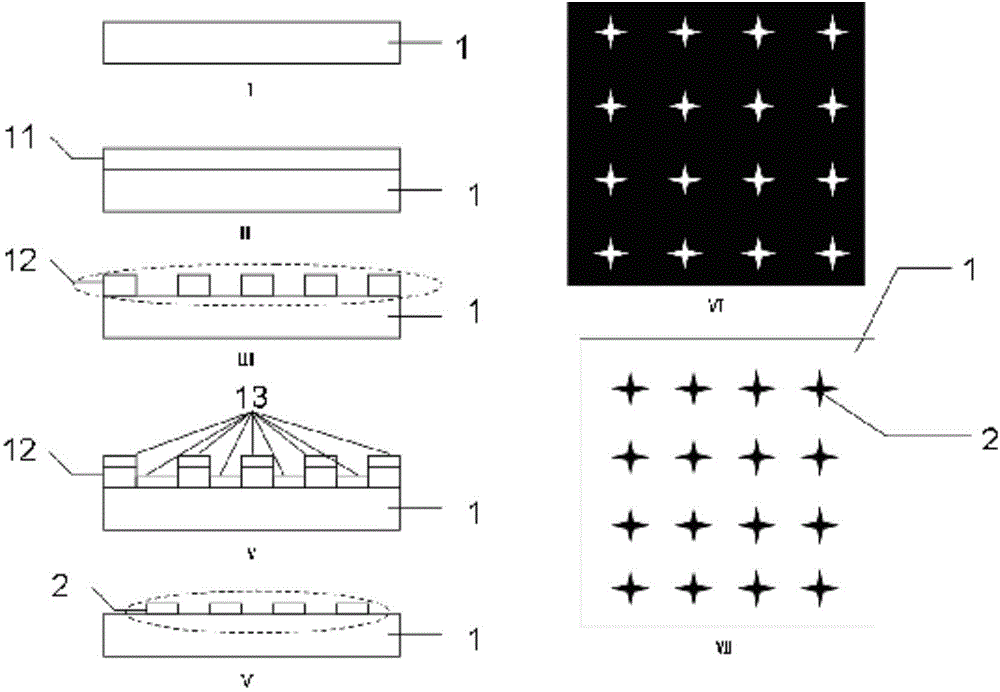

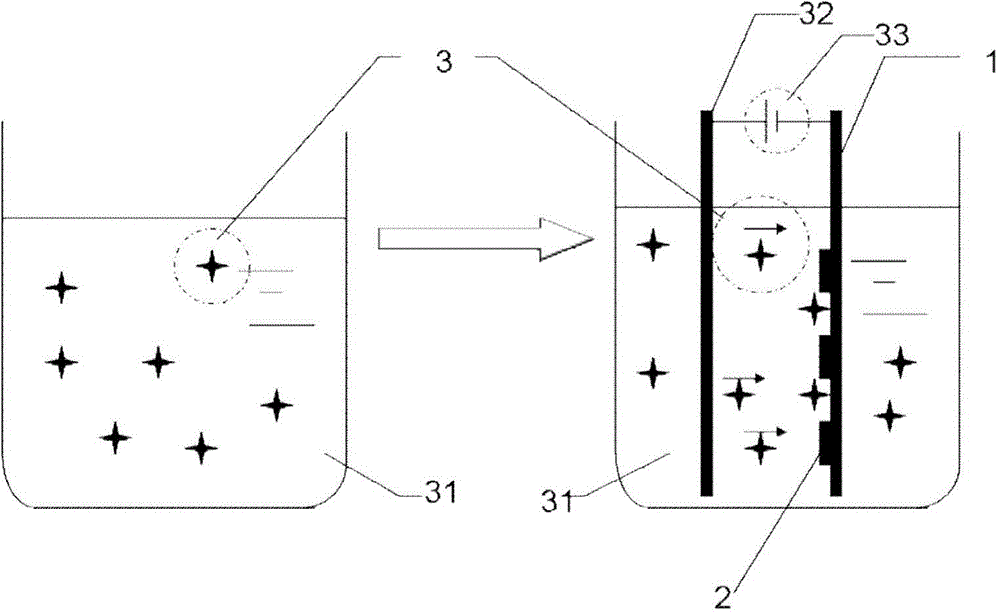

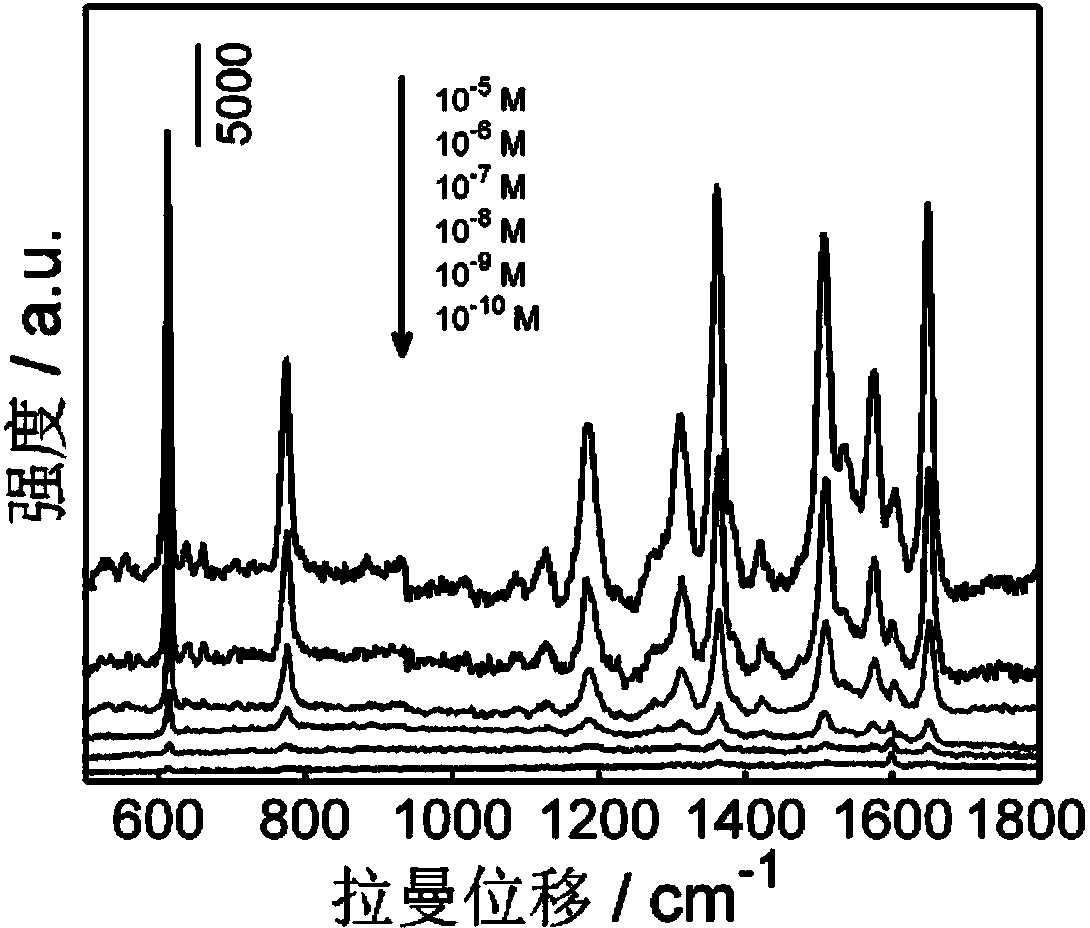

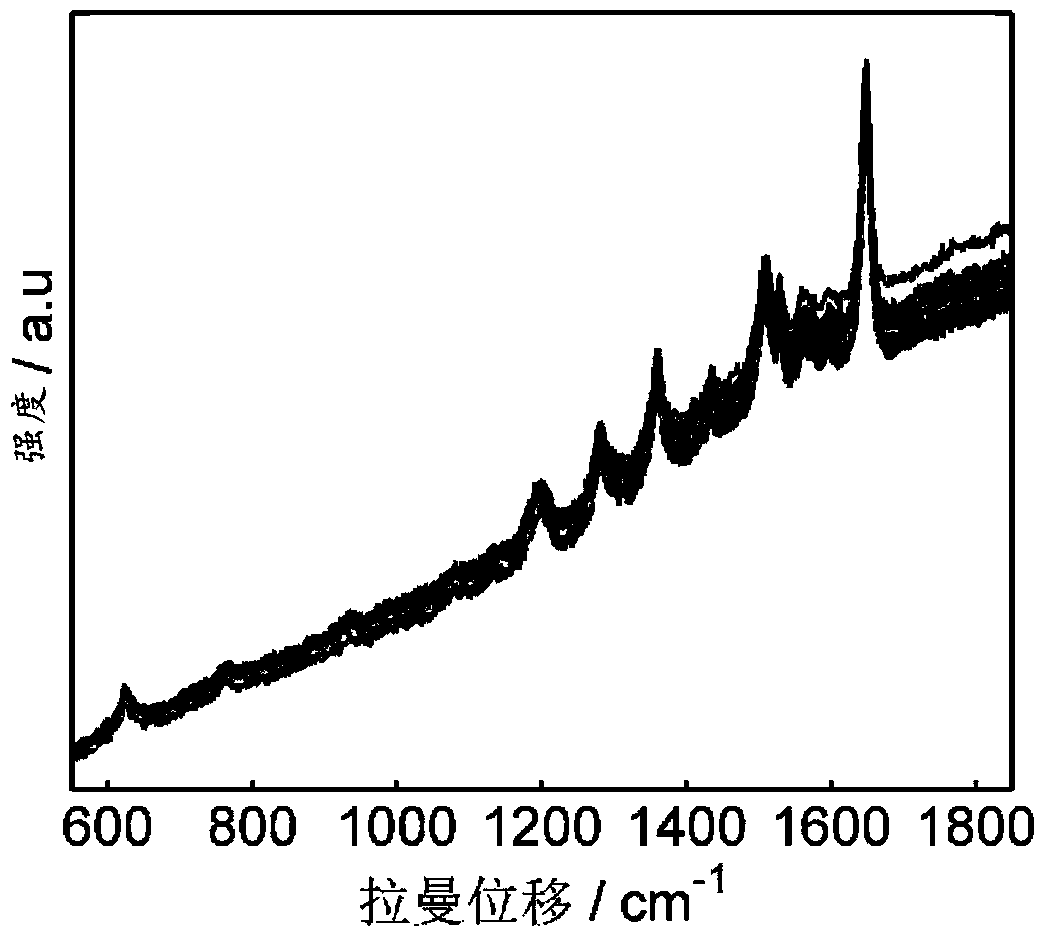

Surface-enhanced Raman spectroscopy substrate and preparation method thereof

ActiveCN104792766AIncrease the electric field strengthEasy to useElectrolytic coatingsRaman scatteringSurface-enhanced Raman spectroscopyElectrophoresis

The invention discloses a surface-enhanced Raman spectroscopy substrate and a preparation method thereof. The surface-enhanced Raman spectroscopy substrate comprises a conducting substrate, a two-dimensional noble metal micro-nano structure array and gold nanostars, wherein each array unit is a starlike noble metal film unit; the size of each starlike noble metal film unit is 150-1000 nm; the distance between every two adjacent starlike noble metal film units is 10-500 nm; the gold nanostars are deposited at tips of all the starlike noble metal film units in the two-dimensional noble metal micro-nano structure array through electrophoresis; the deposition position of each gold nanostar is 1-5 nm away from the tips of the corresponding starlike noble metal film unit. On one hand, the own electric fields of gold nanostar particles are enhanced; on the other hand, the tips of all the starlike noble metal film units in the two-dimensional noble metal micro-nano structure array are further coupled with those of the gold nanostar particles. Therefore, the electric field strength in a nearby area is greatly improved, and the high-sensitivity surface-enhanced Raman spectroscopy substrate is obtained.

Owner:JIANGSU UNIV OF TECH

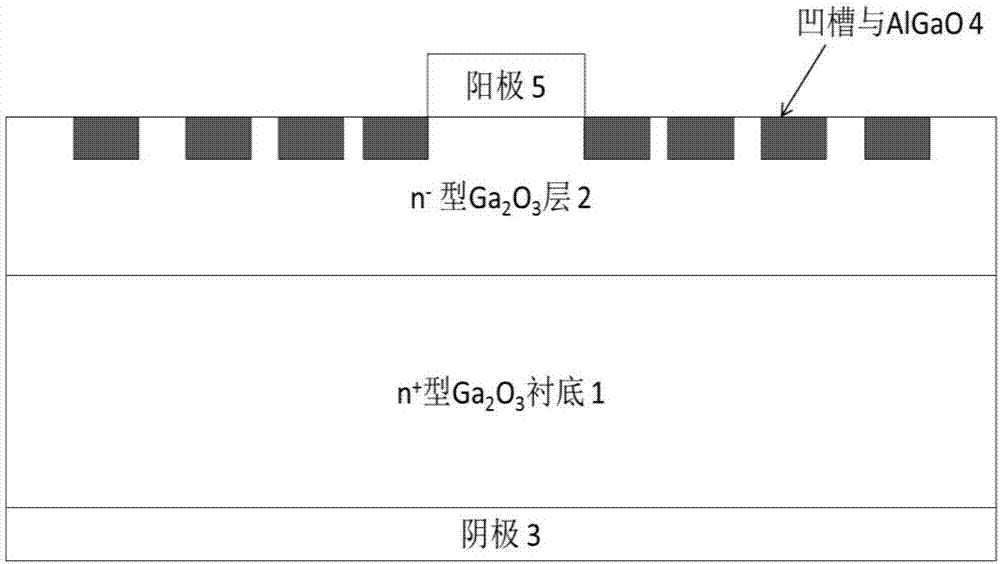

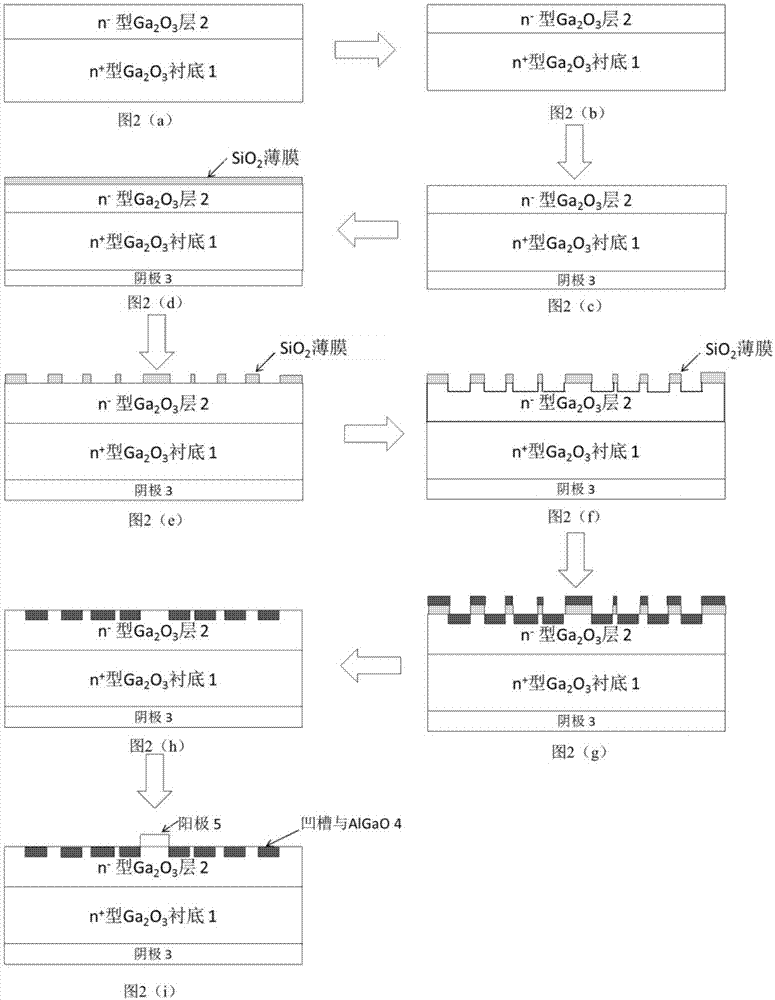

Ga2O3 Schottky diode device structure and manufacturing method thereof

ActiveCN106887470AMaintain positive characteristicsImprove breakdown voltageSemiconductor/solid-state device manufacturingSemiconductor devicesOhmic contactParasitic capacitance

The invention discloses a Ga2O3 Schottky diode device structure and a manufacturing method thereof, and mainly aims at solving the problems that a present Schottky diode device is low in reverse breakdown voltage and the parasitic capacitance in a field plate structure is high. The Ga2O3 Schottky diode device structure comprises a cathode electrode, a heavily-doped n type Ga2O3 substrate, a low-doped n type Ga2O3 epitaxial layer and an anode electrode from bottom to top; Schottky contact is formed in the part where the anode makes contact with the epitaxial layer, the cathode and the substrate make ohmic contact, grooves are distributed separately in the low-doped n type Ga2O3 epitaxial layer, intervals of grooves are increased progressively within the range of 0.3 to 0.5 micron, the first groove is positioned below the edge of the anode, the distance between the last groove and the first groove ranges from 10 to 15 micron, and AlGaO layers in which the Al component is greater than 20% are grown in an epitaxial manner in the grooves respectively. Thus, the reverse breakdown voltage is improved, the parasitic capacitance is reduced, positive characteristic is kept unchanged, and the structure and manufacturing method thereof can be used for high-speed integration circuits and microwave technologies.

Owner:XIDIAN UNIV

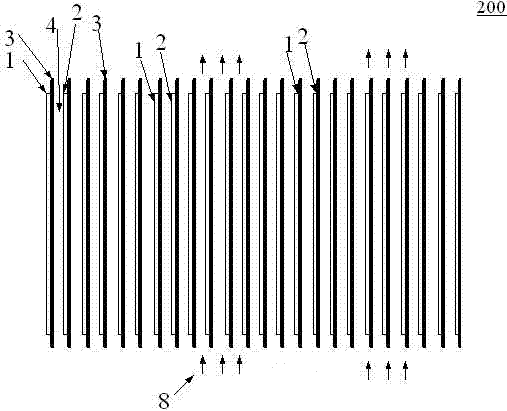

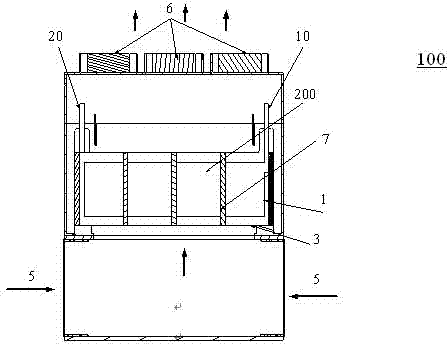

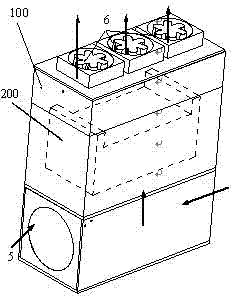

Dust collecting module and electrostatic air cleaning apparatus

InactiveCN103752411AImprove primary purification rateReduce weightElectrode constructionsParticulatesAir cleaning

The invention provides a dust collecting module. The dust collecting module (200) is used to collect electric particles in gas, and at least comprises conductive thin films and insulated panels (3) which are arranged alternately, so that channels (4) allowing air to pass are formed by the insulated panels (3) and adjacent conductive thin films. The invention also provides an electrostatic air cleaning apparatus, and the apparatus comprises the dust collecting module (200). The provided dust collecting module and the electrostatic air cleaning apparatus help to substantially improve the air cleaning efficiency; especially the dust collecting module generates little ozone or none, is capable of fully eliminating flip-flop noise caused by breakdown of air, and almost does not have overflowing of positive ions; and the manufacturing is convenient and the cost is relatively low.

Owner:HANVON CORP

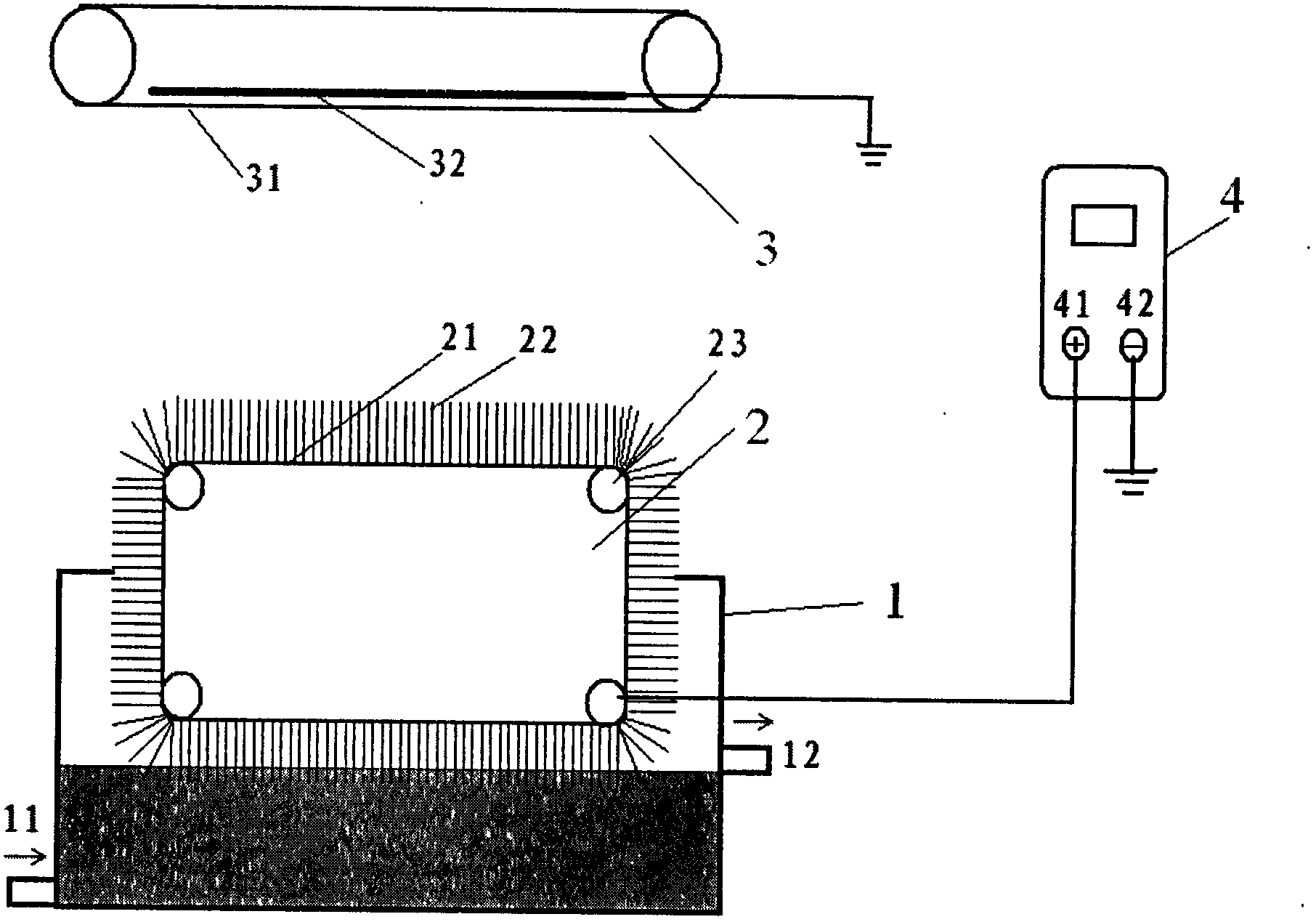

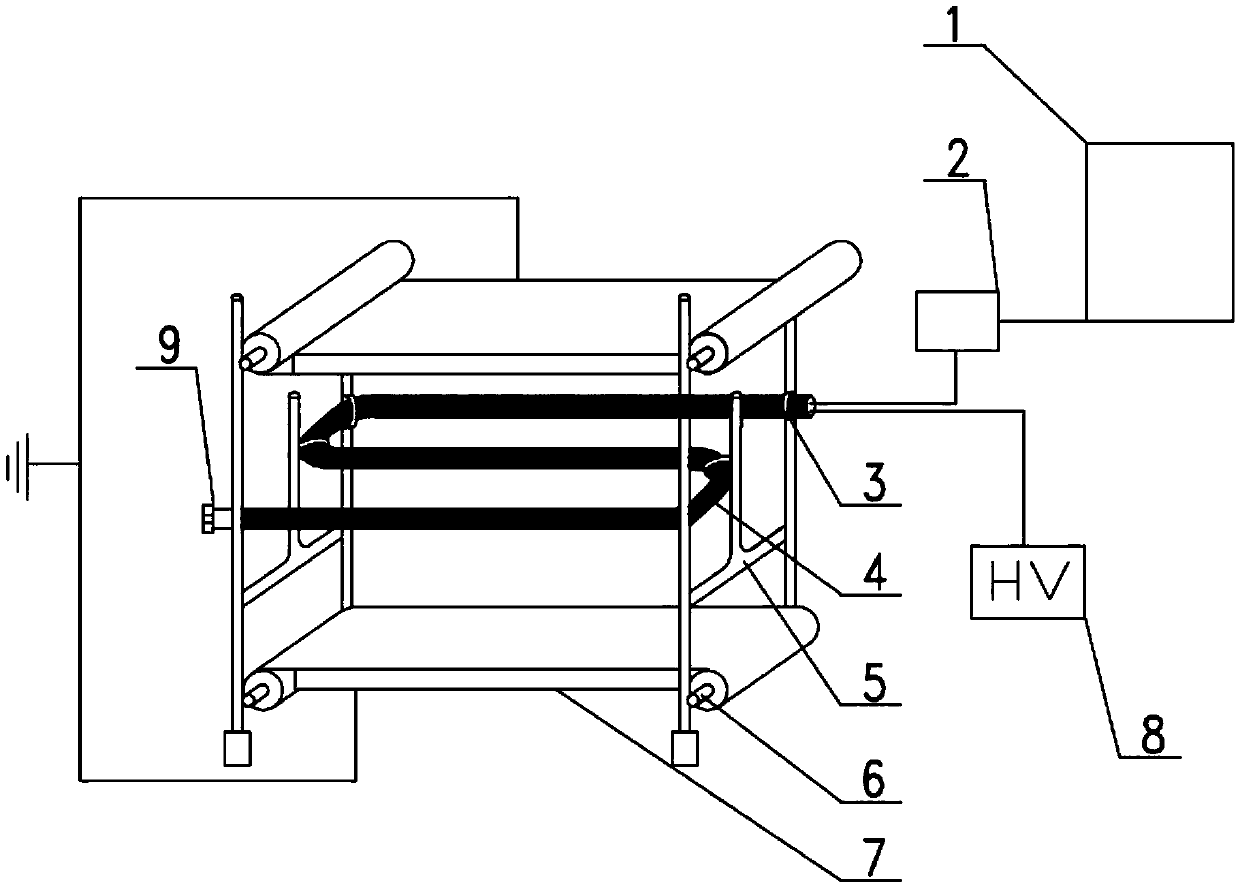

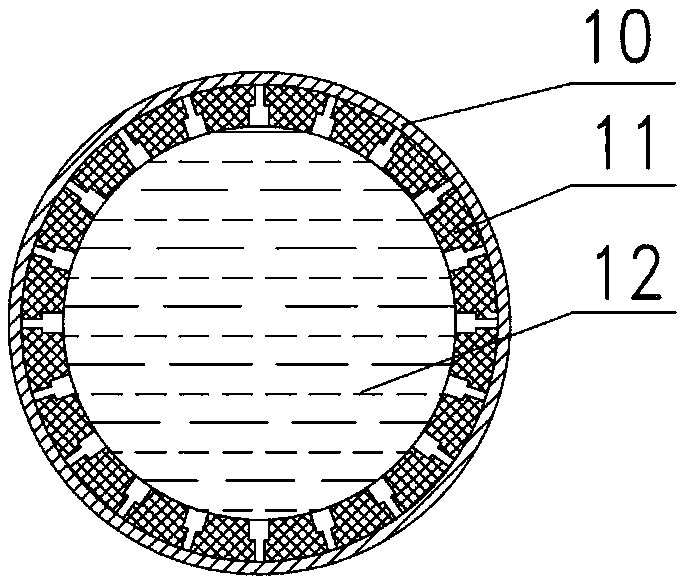

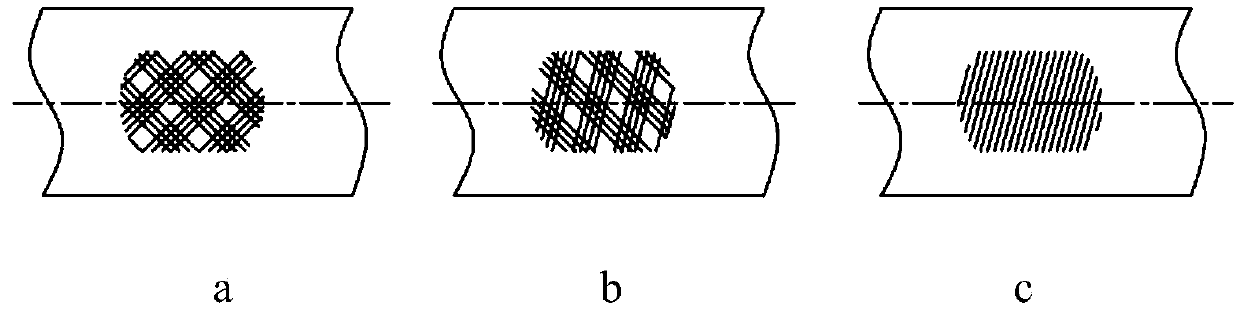

Needleless electrostatic spinning device with porous flexible pipe

ActiveCN105369366AWell formedIncrease the electric field strengthFilament/thread formingFiberNanofiber

The invention discloses a needleless electrostatic spinning device with a porous flexible pipe. The device comprises a spinning solution storage chamber, a hydraulic pump, a porous flexible pipe, a supporting framework, clamping hoops, a high-voltage static generator, receiving net curtains and guide rollers, wherein the hydraulic pump is connected to the spinning solution storage chamber; a feeding hole is located in one end of the porous flexible pipe; the porous flexible pipe is fixed on the supporting framework by the clamping hoops made of an insulating material; the clamping hoops and the supporting framework are connected by threads; the other end of the porous flexible pipe is sealed by a pipe joint; the high-voltage static generator is connected to the outer surface of the porous flexible pipe; receiving devices are located right above and right below the porous flexible pipe; the guide rollers are fixed on the supporting framework; the receiving net curtains are fixed on the guide rollers; the receiving net curtains can output packaged nano-fiber mats with rolling of the guide rollers, and the receiving net curtains are grounded by conducting wires. The device disclosed by the invention has the advantages that the bore diameter of an inner pipe can be changed through adjustment of the back pressure of a spinning solution inside the pipe based on adjustment of the hydraulic pump, and metal wire edges distributed in various forms can be formed on the surface of a metal flexible pipe, so that more jet flows can be generated easily.

Owner:BEIJING UNIV OF CHEM TECH

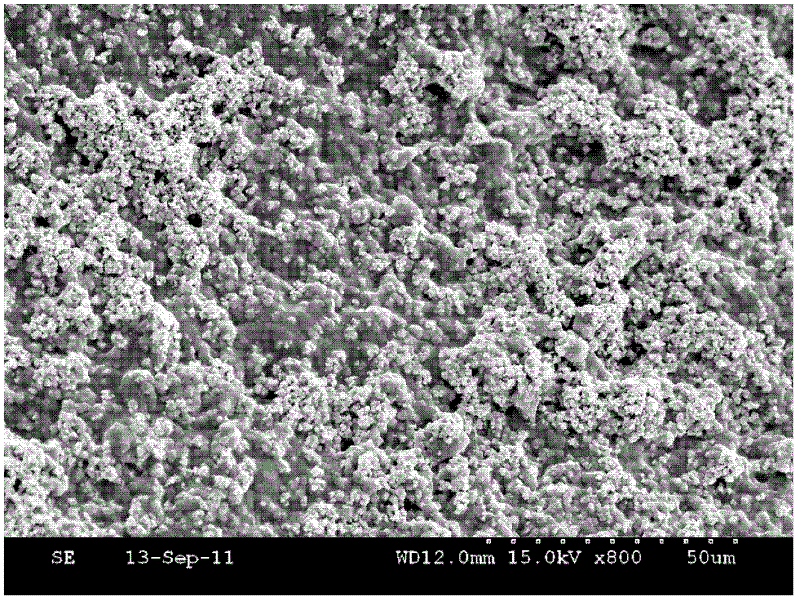

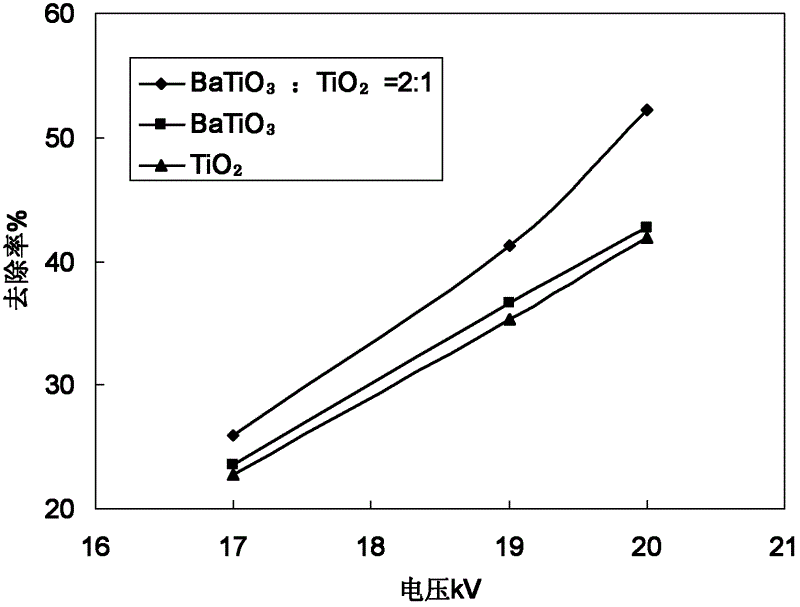

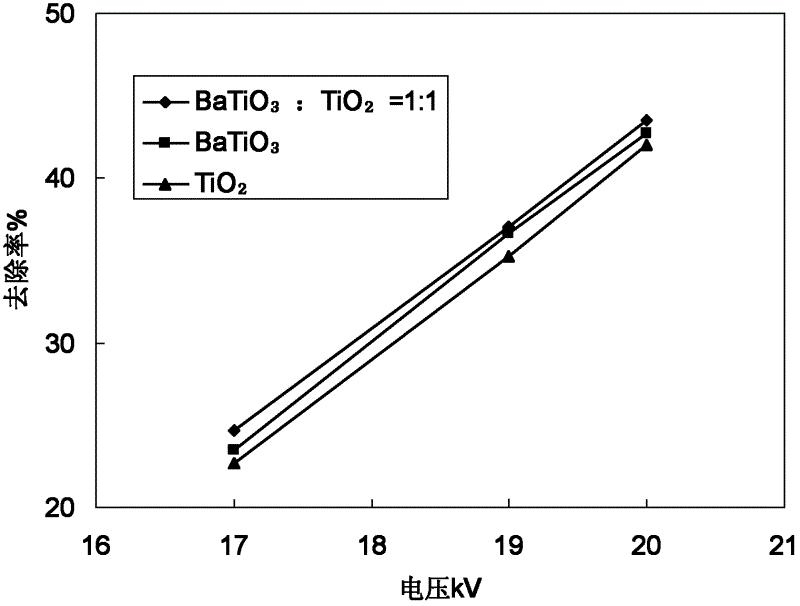

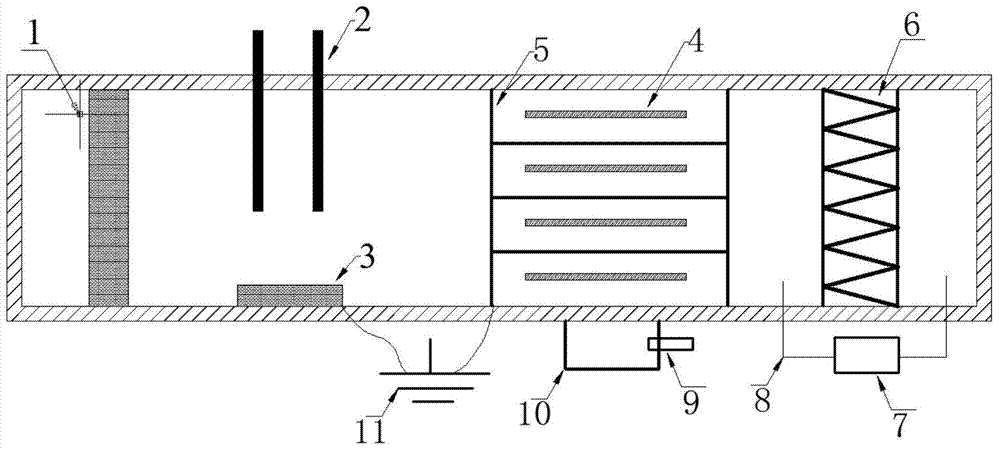

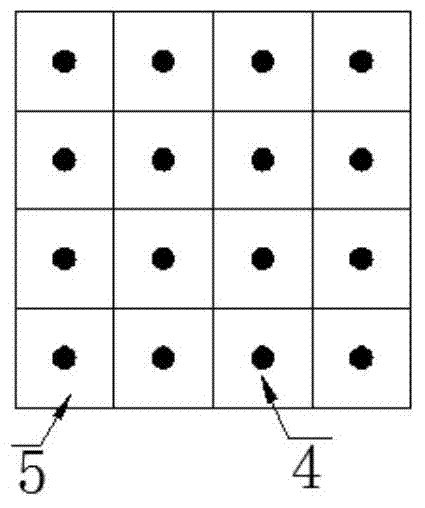

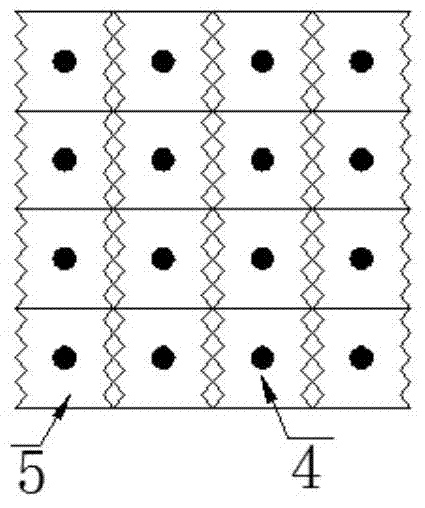

Low-temperature plasma catalyst, and preparation method and application thereof

ActiveCN102614860AIncrease the electric field strengthHigh removal rateDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPowder mixtureAlcohol

Low-temperature plasma catalyst, and a preparation method and application thereof belong to the field of catalytic chemistry. The low-temperature plasma catalyst is formed by loading nano-scale mixture of barium titanate and titanium dioxide on the surfaces of Al2O3 particles. Mass ratio of the barium titanate and the titanium dioxide is 2:1-1:2. The preparation method includes: sequentially using nitric acid solution, NaOH solution and water to pretreat Al2O3 particulate carrier and drying; mixing nano-scale BaTiO3 and TiO2 powder according to the mass ratio of 2:1-1:2 and grinding, and dispersing the mixture to mixture of epoxy resin, firming agent and absolute ethyl alcohol to form emulsion; dispersing the treated Al2O3 particles into the emulsion, and allowing both resin and the powder mixture to adhere to the surfaces of the particles form adhesive layers; and pulling out the loaded Al2O3 particles, and naturally drying the particles in air. The low-temperature plasma catalyst enables removal rate of organic pollutant to be increased and power consumption to be lowered.

Owner:BEIJING UNIV OF TECH

High-dust holding capacity and high-efficiency composite electrostatic air purification device

InactiveCN103691240AReduced dust holding capacityExtended service lifeCombination devicesBacterial virusAir filter

The invention discloses a high-dust holding capacity and high-efficiency composite electrostatic air purification device, which sequentially comprises a primary filtering screen, a carbon brush charge region, an electrostatic dust removal region, an air filter and a dust hopper, wherein a differential pressure transducer is arranged at the two ends of the air filter; a material level sensor is arranged in the dust hopper. According to the composite electrostatic air purification device, charged particles are collected by the electrostatic dust removal region, so that the air filter is protected, and the service life of the air filter is prolonged; the dust holding capacity of the air filter is reduced, pressure drop is reduced, and labor is saved; the exposure time of air, dust and particles on the air filter is reduced, and secondary pollution to the air caused by gas pollutants and bacterial viruses in a particle filtering process is reduced; the filtering efficiency of the electrostatic dust removal region is insensitive to blast volume changes, and the influence of proper increase of the blast volume to the overall dust removal efficiency of the device is limited, so that the purification device is suitable for blast volume variable buildings.

Owner:TIANJIN UNIV

Raman base

InactiveCN103969241AHigh sensitivityImprove uniformityRaman scatteringElectrical field strengthGraphene

The invention provides a Raman base which comprises a Raman base substrate, a metal layer arranged on the Raman base substrate, and a graphene film arranged on the metal layer. According to the Raman base, the graphene film is compounded with the metal layer, and the graphene film has an atomic-scale thickness, and is capable of effectively enhancing the strength of an electric field and amplifying a Raman signal, so that when the Raman base provided by the invention is used for Raman detection, the sensitivity, the uniformity and the reliability of the Raman detection are preferable. Experiment results indicate that the Raman base provided by the invention is used for Raman detection, an object to be detected with a mol concentration of 10<-4> mol / L-10<-9> mol / L is detected, the detected spatial discrimination Raman diagram color of the object to be detected is uniform, and the detected Raman spectrum is displayed to be consistent with a Raman signal.

Owner:UNIV OF SCI & TECH OF CHINA

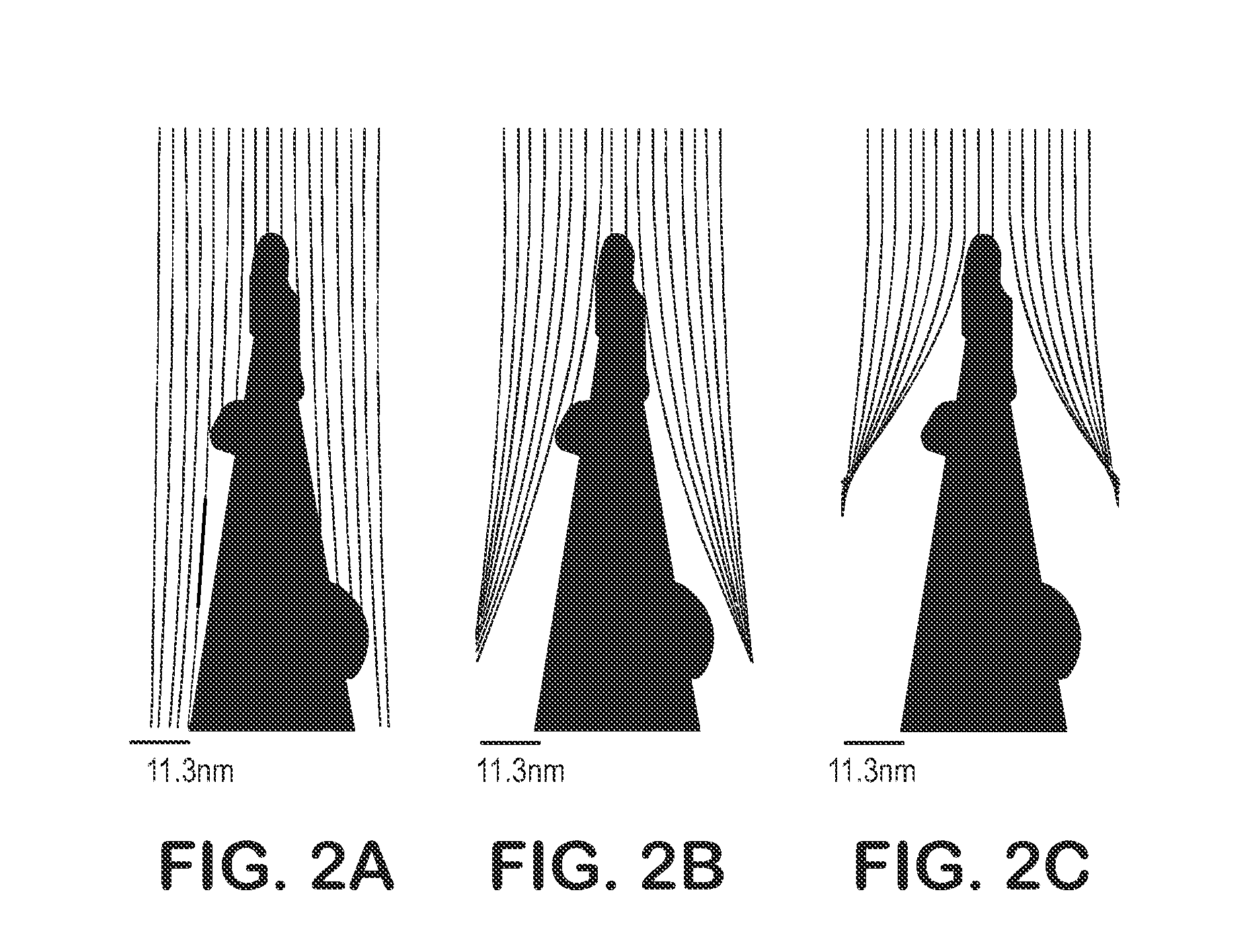

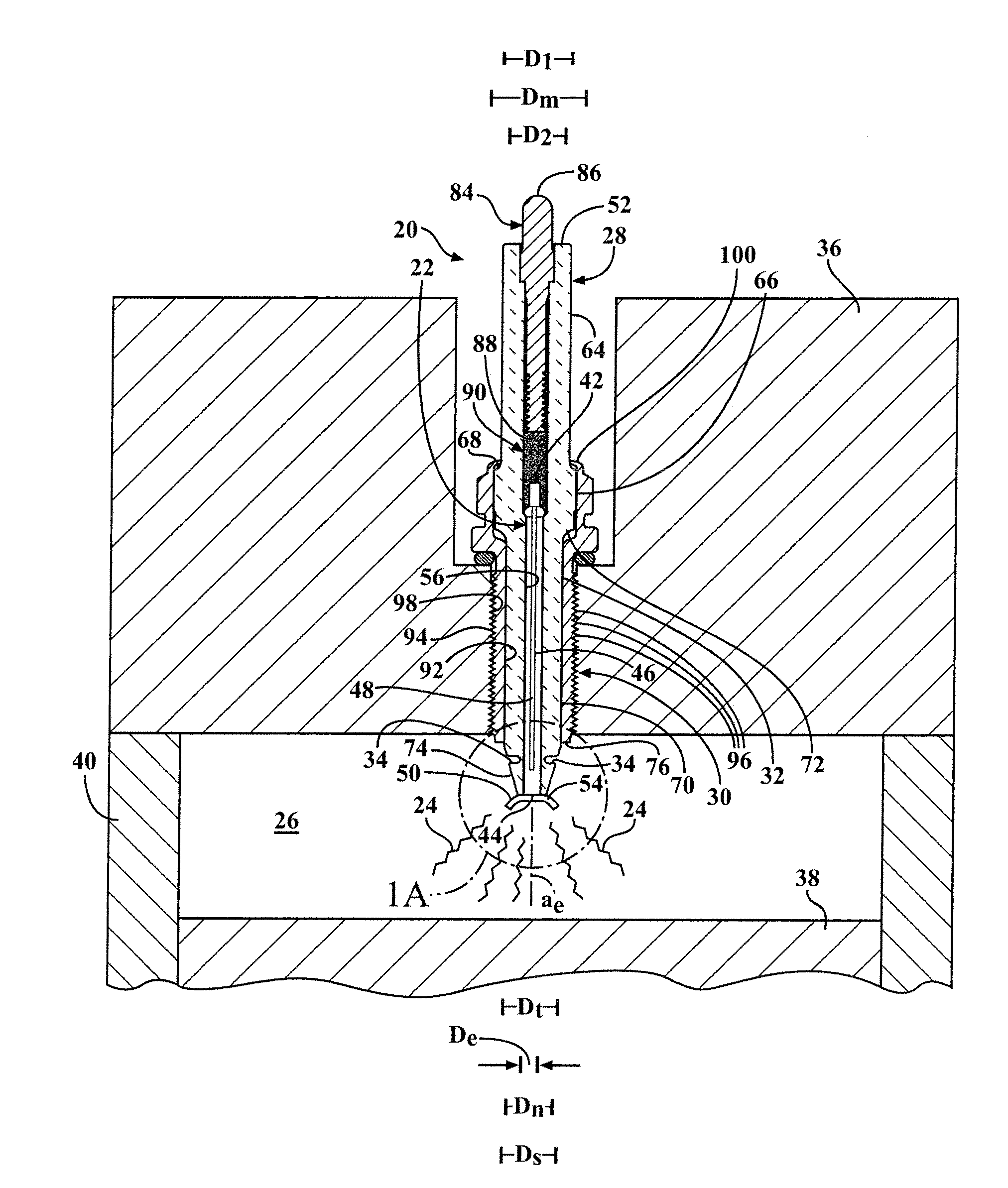

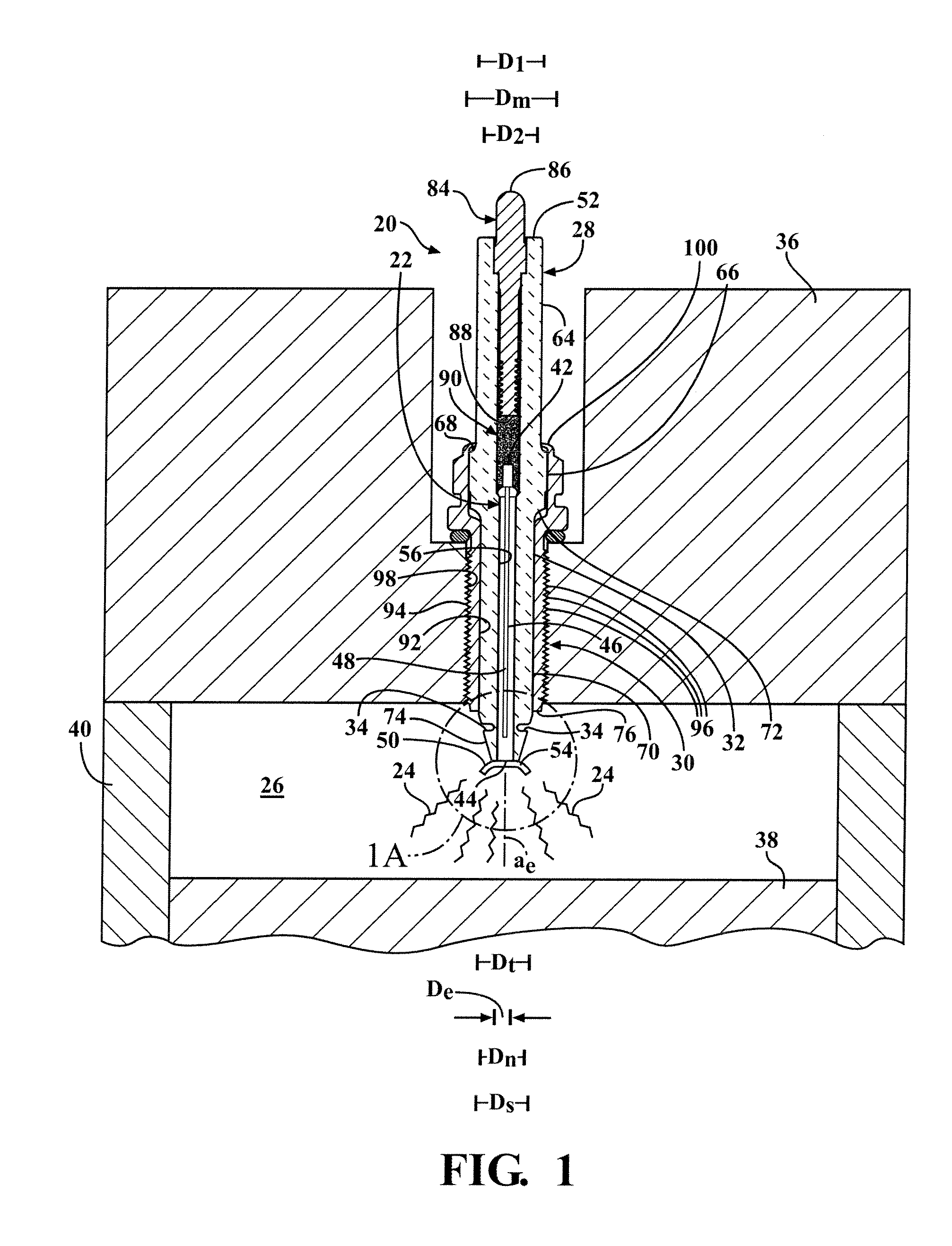

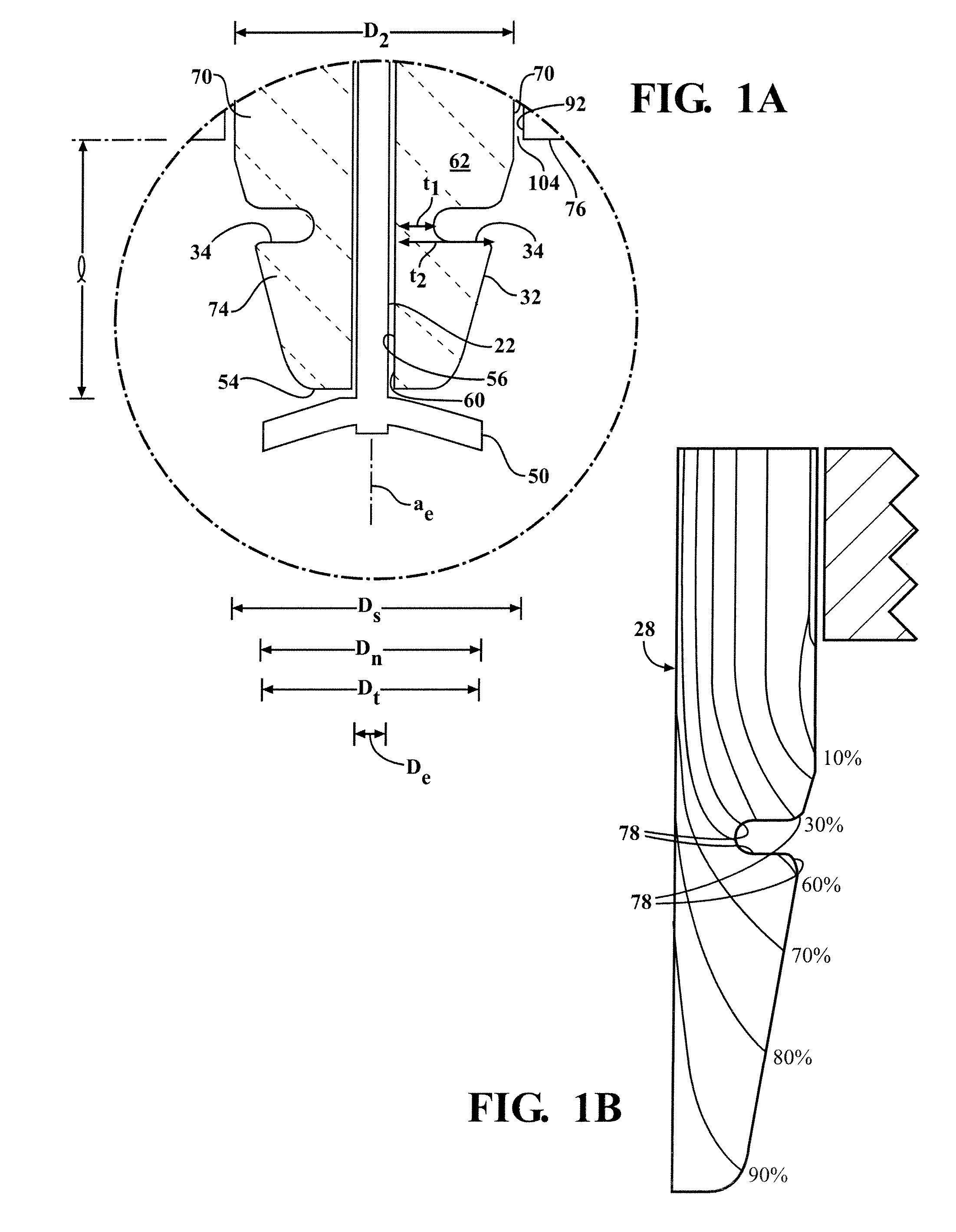

Corona igniter having shaped insulator

ActiveUS20120181916A1Increase the electric field strengthAvoid arcingSpark gapsSparking plugs manufactureCorona dischargeEngineering

A corona igniter (20) for emitting a radio frequency electric field and providing a corona discharge (24) includes a central electrode (22) at a positive voltage, a grounded metal shell (30), and an insulator (28) with an abruption (34) extending radially outward relative to the central electrode (22). The abruption (34) is typically an increase of at least 15% of a local thickness (t) of the insulator (28) over less than 25% of a nose length (1) of an insulator nose region (74). The abruption (34) is typically one flank (82) of a protrusion or a notch, and the flank (82) faces the shell (30). The abruption (34) reverses the electric field and voltage potential gradient along the insulator outer surface (32), repels charged ions away from the insulator (28), and thus prevents the formation of a conductive path between the central electrode (22) and the shell (22).

Owner:FEDERAL MOGUL IGNITION

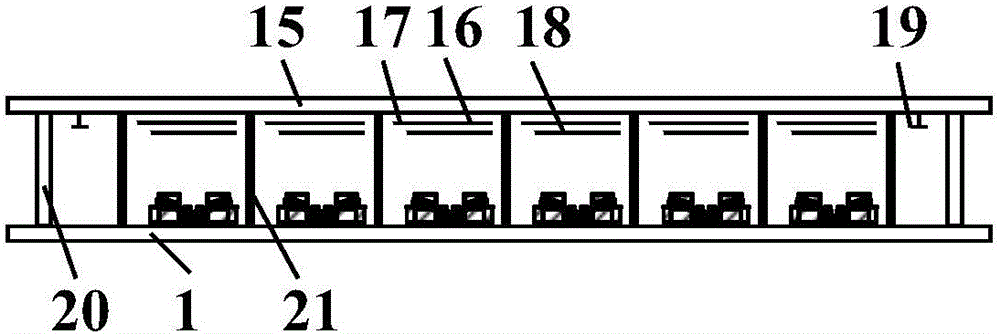

Surface wave plasma device

PendingCN107155256AMeet processing needsAdjust the maximum transmission powerElectric discharge tubesPlasma techniqueResonant cavityMicrowave

The invention provides a surface wave plasma device. A connection cavity is used to connect a resonant cavity and a rectangular waveguide. A screw probe extends into the resonant cavity via the rectangular waveguide and the connection cavity, so that microwave energy is fed in the connection cavity and the resonant cavity. By arranging a plurality of quartz windows in the bottom wall of the resonant cavity, the electric field of a standing wave formed in the resonant cavity by a microwave, and plasma is activated in the vacuum cavity. The plurality of quartz windows are equal to a plurality of plasma sources, which achieves uniformization of the plasma in the vacuum cavity in a large area compared with the conventional single plasma source, so as to meet the processing requirement for large-scale wafers.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Actuation of valves using electroosmotic pump

InactiveUS8603834B2Easy to controlIncrease the electric field strengthOperating means/releasing devices for valvesMicrobiological testing/measurementEngineeringMembrane configuration

A method of actuating a valve, comprises operatively coupling the valve with an electroosmotic pump; flowing a fluid through the electroosmotic pump; and generating a fluidic pressure of at least 0.75 PSI to actuate the valve, wherein the electroosmotic pump comprises one or more thin, porous, positive electroosmotic membranes and one or more thin porous, negative electroosmotic membranes; a plurality of electrodes comprising cathodes and anodes, and a power source; wherein each of the positive and negative electroosmotic membranes are disposed alternatively and wherein at least one of the cathodes is disposed on one side of one of the membranes and at least one of the anodes is disposed on the other side of the membrane and wherein at least one of the cathodes or anodes is disposed between a positive and a negative electroosmotic membrane.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com