Patents

Literature

5023results about "Fibre chemical features" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

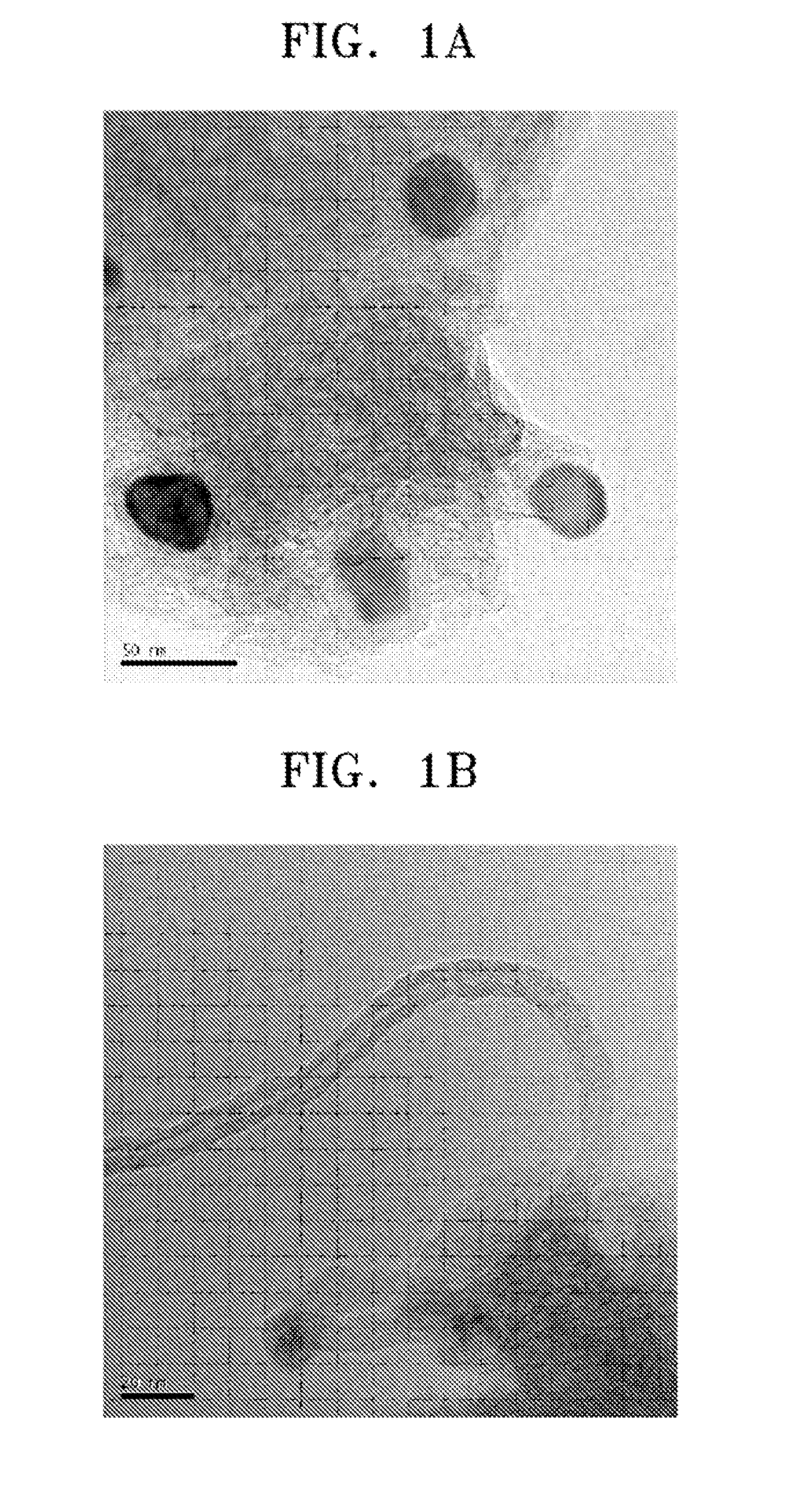

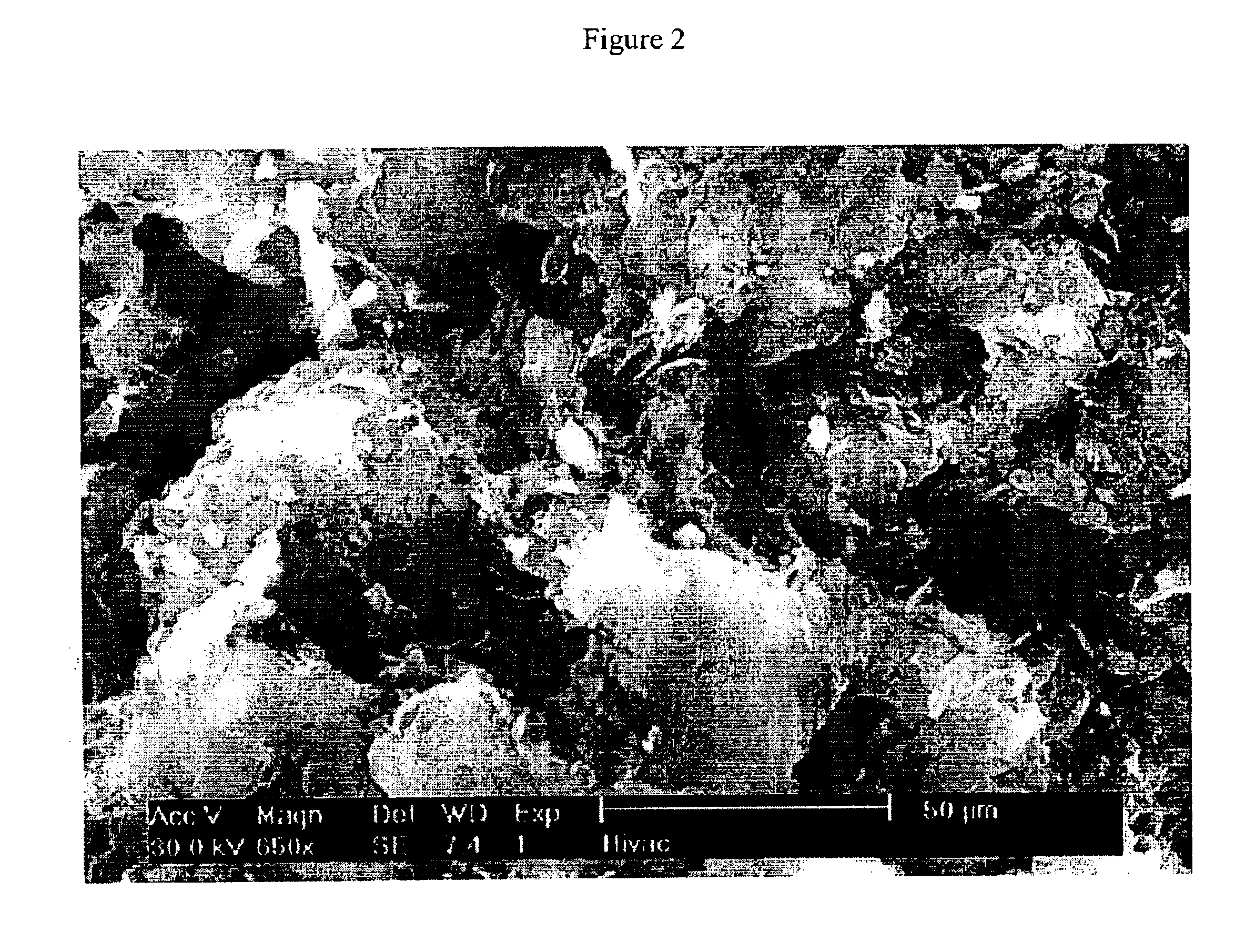

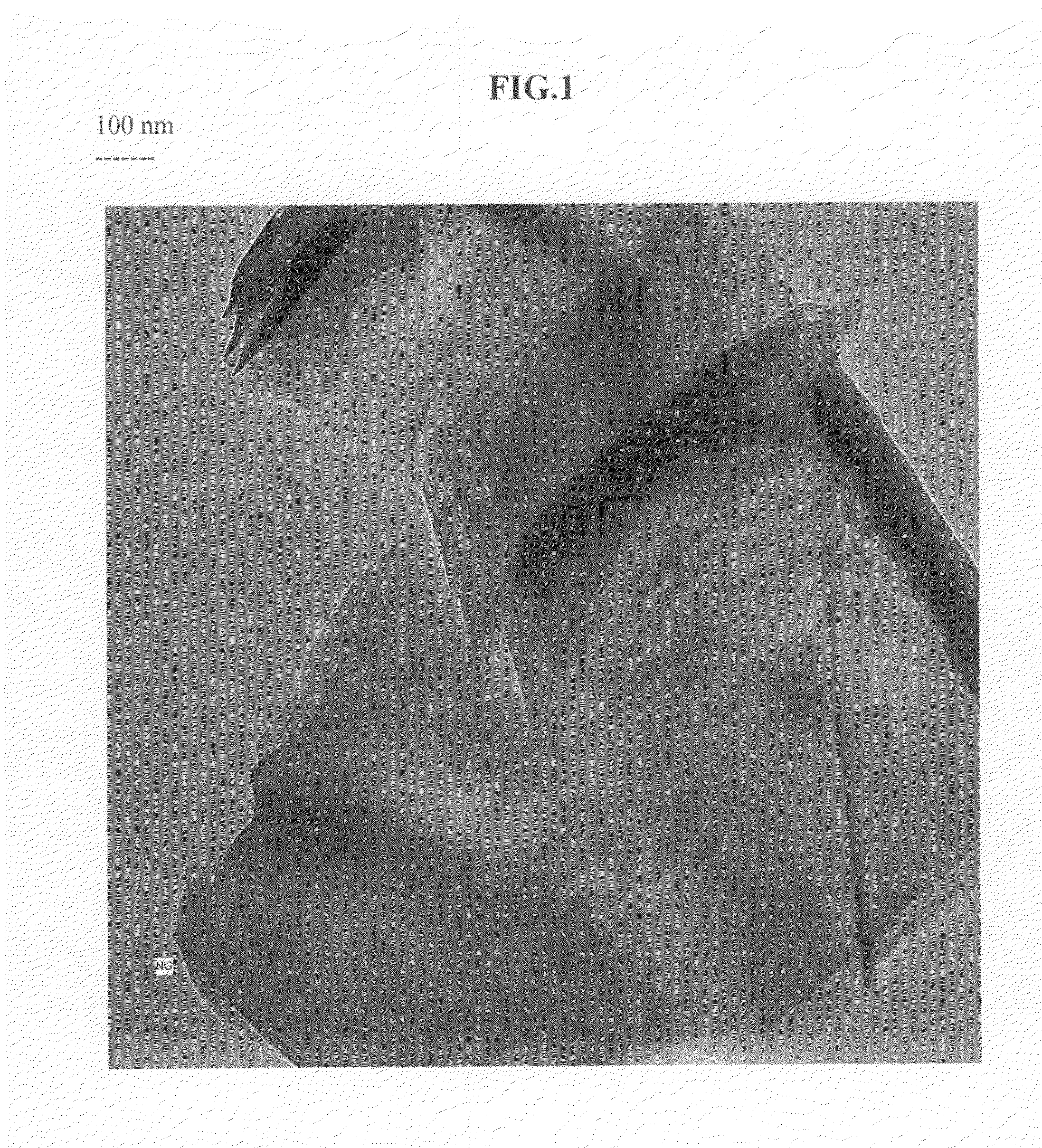

Nano-scaled graphene plates

A nano-scaled graphene plate material and a process for producing this material. The material comprises a sheet of graphite plane or a multiplicity of sheets of graphite plane. The graphite plane is composed of a two-dimensional hexagonal lattice of carbon atoms and the plate has a length and a width parallel to the graphite plane and a thickness orthogonal to the graphite plane with at least one of the length, width, and thickness values being 100 nanometers or smaller. The process for producing nano-scaled graphene plate material comprises the steps of: a). partially or fully carbonizing a precursor polymer or heat-treating petroleum or coal tar pitch to produce a polymeric carbon containing micron- and / or nanometer-scaled graphite crystallites with each crystallite comprising one sheet or a multiplicity of sheets of graphite plane; b). exfoliating the graphite crystallites in the polymeric carbon; and c). subjecting the polymeric carbon containing exfoliated graphite crystallites to a mechanical attrition treatment to produce the nano-scaled graphene plate material.

Owner:GLOBAL GRAPHENE GRP INC

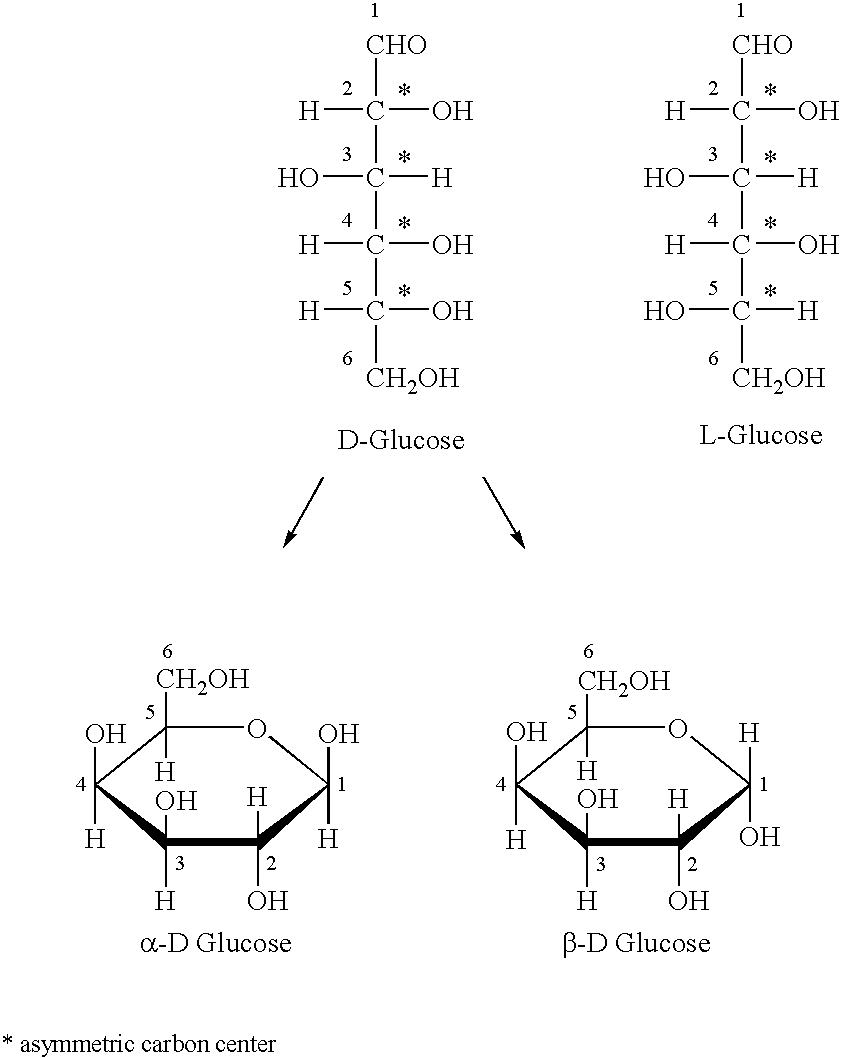

Polysaccharide fibers

This invention pertains to novel fibers made of α(1→;3) polysaccharides, and a process for their production. The fibers of the invention have “cotton-like” properties but can be produced as continuous filaments on a year-round basis. The fibers are useful in textile applications.

Owner:DUPONT IND BIOSCIENCES USA LLC

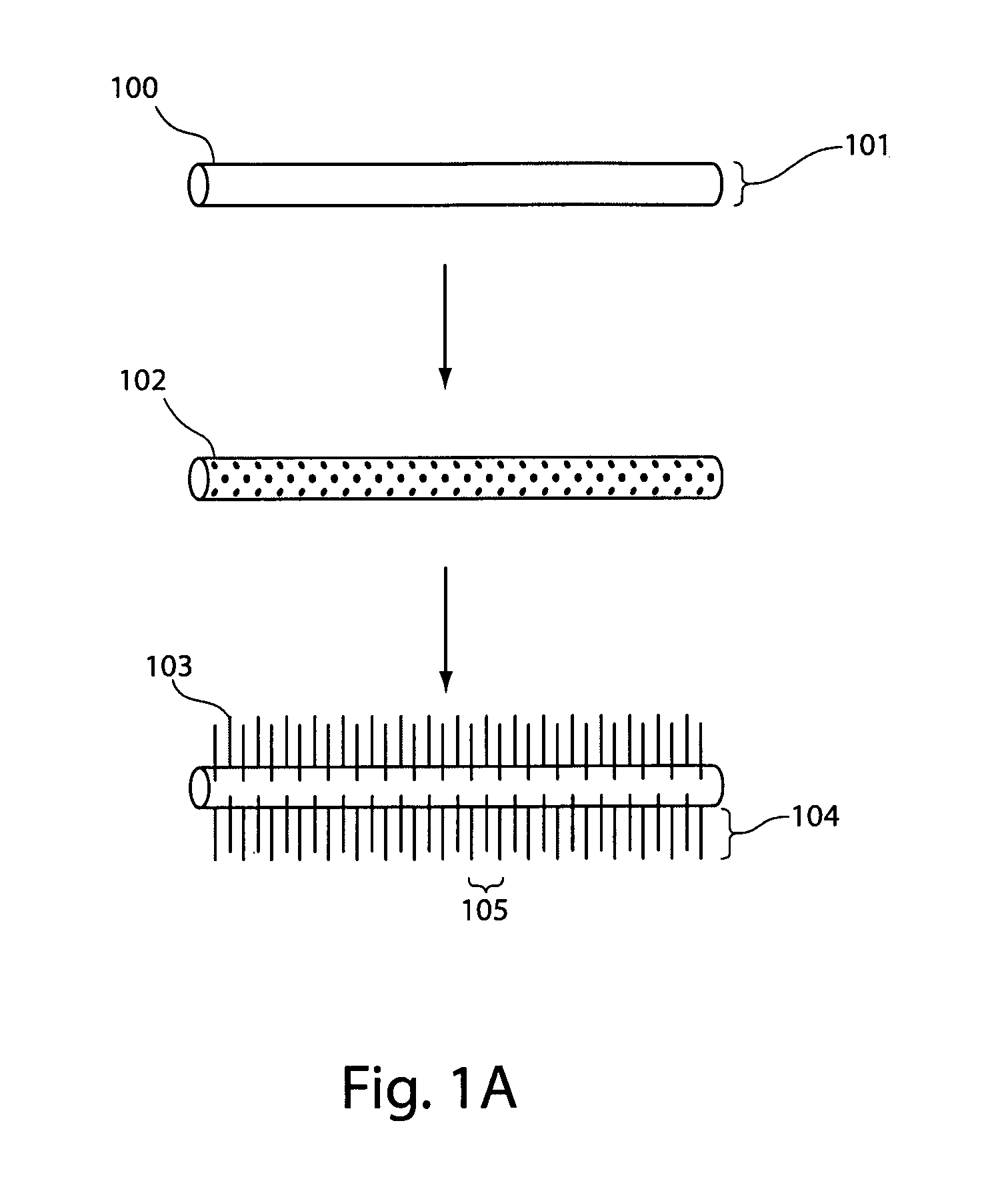

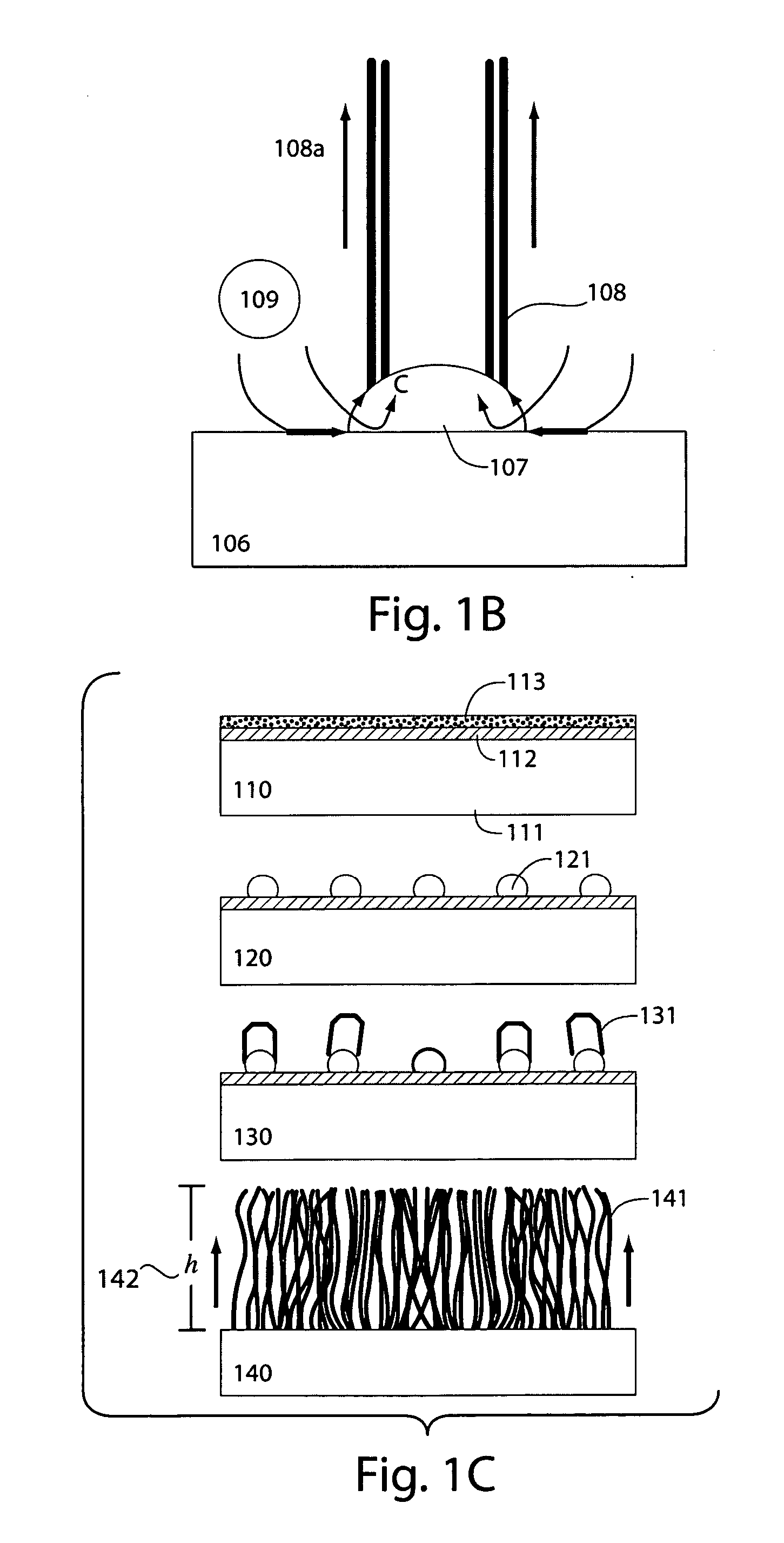

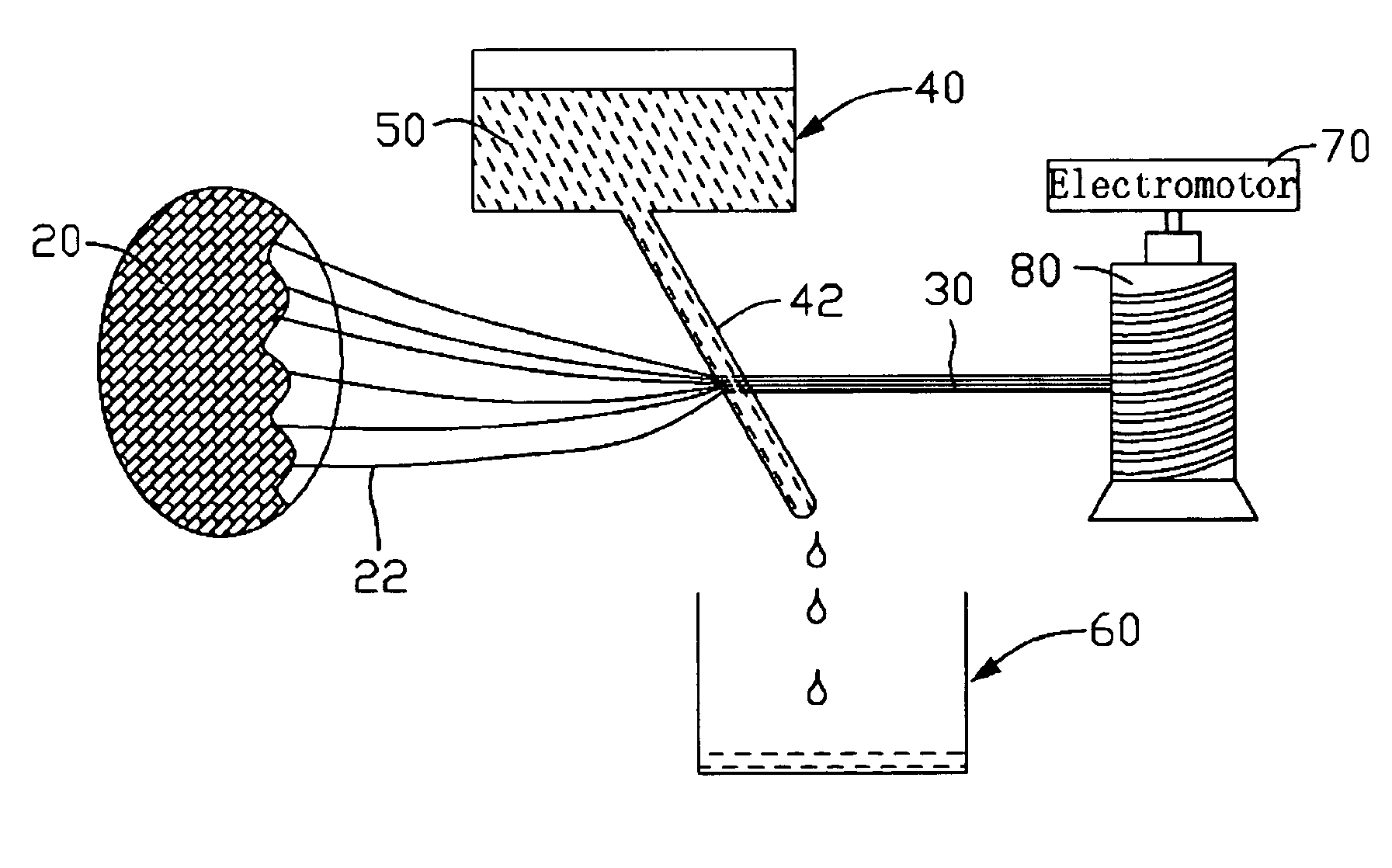

Method for fabricating carbon nanotube yarn

ActiveUS20040053780A1Material nanotechnologyCatalyst activation/preparationFurnace temperatureCarbon nanotube yarn

A method of fabricating a long carbon nanotube yarn includes the following steps: (1) providing a flat and smooth substrate; (2) depositing a catalyst on the substrate; (3) positioning the substrate with the catalyst in a furnace; (4) heating the furnace to a predetermined temperature; (5) supplying a mixture of carbon containing gas and protecting gas into the furnace; (6) controlling a difference between the local temperature of the catalyst and the furnace temperature to be at least 50° C.; (7) controlling the partial pressure of the carbon containing gas to be less than 0.2; (8) growing a number of carbon nanotubes on the substrate such that a carbon nanotube array is formed on the substrate; and (9) drawing out a bundle of carbon nanotubes from the carbon nanotube array such that a carbon nanotube yarn is formed.

Owner:HON HAI PRECISION IND CO LTD +1

Method for fabricating carbon nanotube yarn

ActiveUS7045108B2Material nanotechnologyCatalyst activation/preparationFurnace temperatureCarbon nanotube yarn

A method of fabricating a long carbon nanotube yarn includes the following steps: (1) providing a flat and smooth substrate; (2) depositing a catalyst on the substrate; (3) positioning the substrate with the catalyst in a furnace; (4) heating the furnace to a predetermined temperature; (5) supplying a mixture of carbon containing gas and protecting gas into the furnace; (6) controlling a difference between the local temperature of the catalyst and the furnace temperature to be at least 50° C.; (7) controlling the partial pressure of the carbon containing gas to be less than 0.2; (8) growing a number of carbon nanotubes on the substrate such that a carbon nanotube array is formed on the substrate; and (9) drawing out a bundle of carbon nanotubes from the carbon nanotube array such that a carbon nanotube yarn is formed.

Owner:HON HAI PRECISION IND CO LTD +1

Carbon nanotube hybrid system using carbide-derived carbon, a method of making the same, an electron emitter comprising the same, and an electron emission device comprising the electron emitter

InactiveUS20080248310A1Improve uniformityLong life-timeMaterial nanotechnologyNanostructure manufactureHybrid systemHalogen

A carbon nanotube hybrid system includes: a carbide-derived carbon prepared by reacting a carbide compound and a halogen group containing gas to extract elements of the carbide compound except carbons; metals supported on the carbide-derived carbon or remaining in the carbide-derived carbon; and carbon sources from which carbon nanotubes are grown from the carbide-derived carbon. A method of preparing the carbon nanotube hybrid system includes preparing the carbide-derived carbon, extracting elements therefrom, and growing carbon nanotubes from the carbide-derived carbon. The carbon nanotube hybrid system has excellent uniformity and a long lifetime. An electron emitter having improved electron emitting properties can be inexpensively prepared using the carbon nanotube hybrid system compared to conventional carbon nanotubes. An electron emission device having excellent electron emitting properties can be prepared using the electron emitter.

Owner:SAMSUNG SDI CO LTD

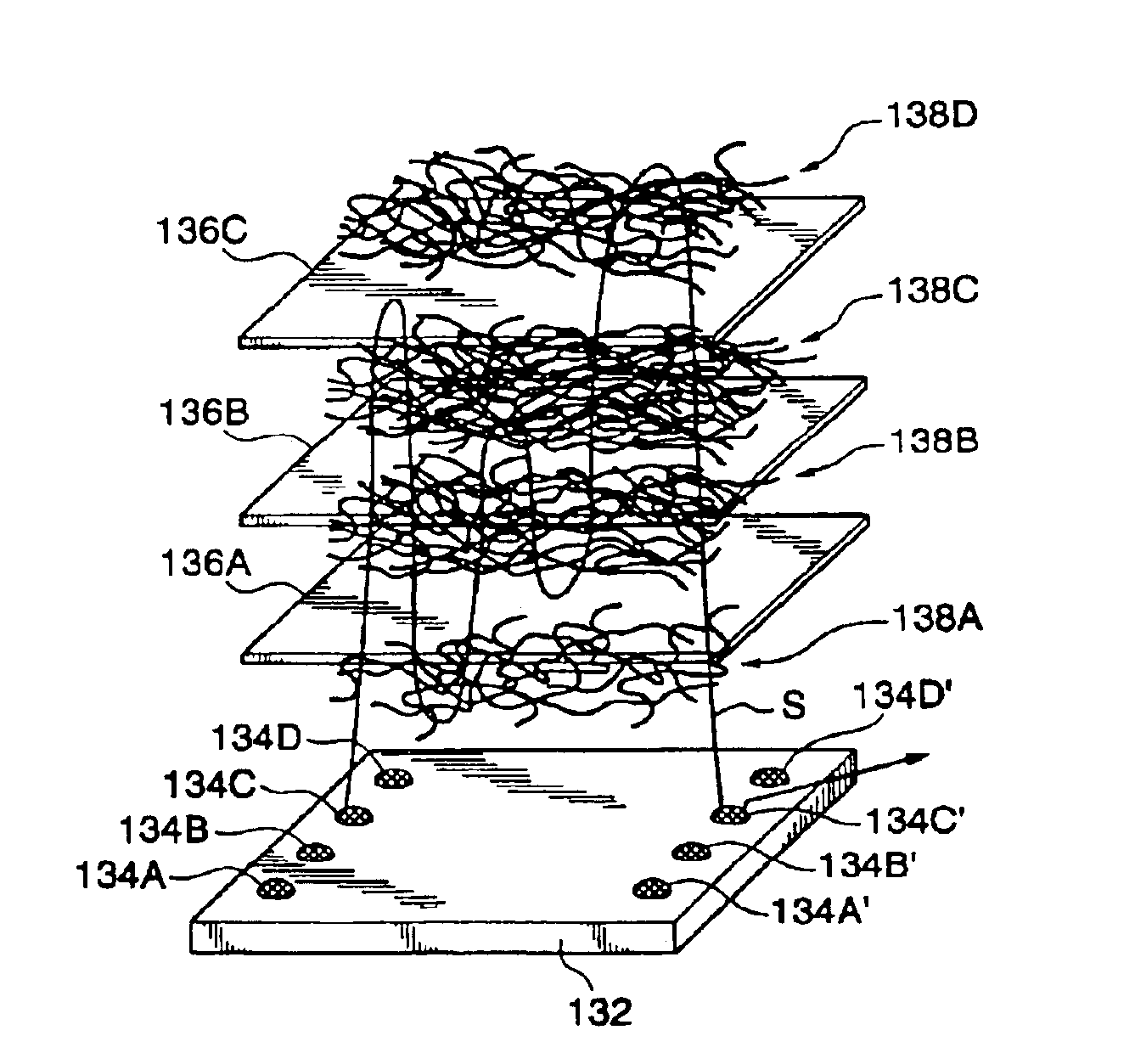

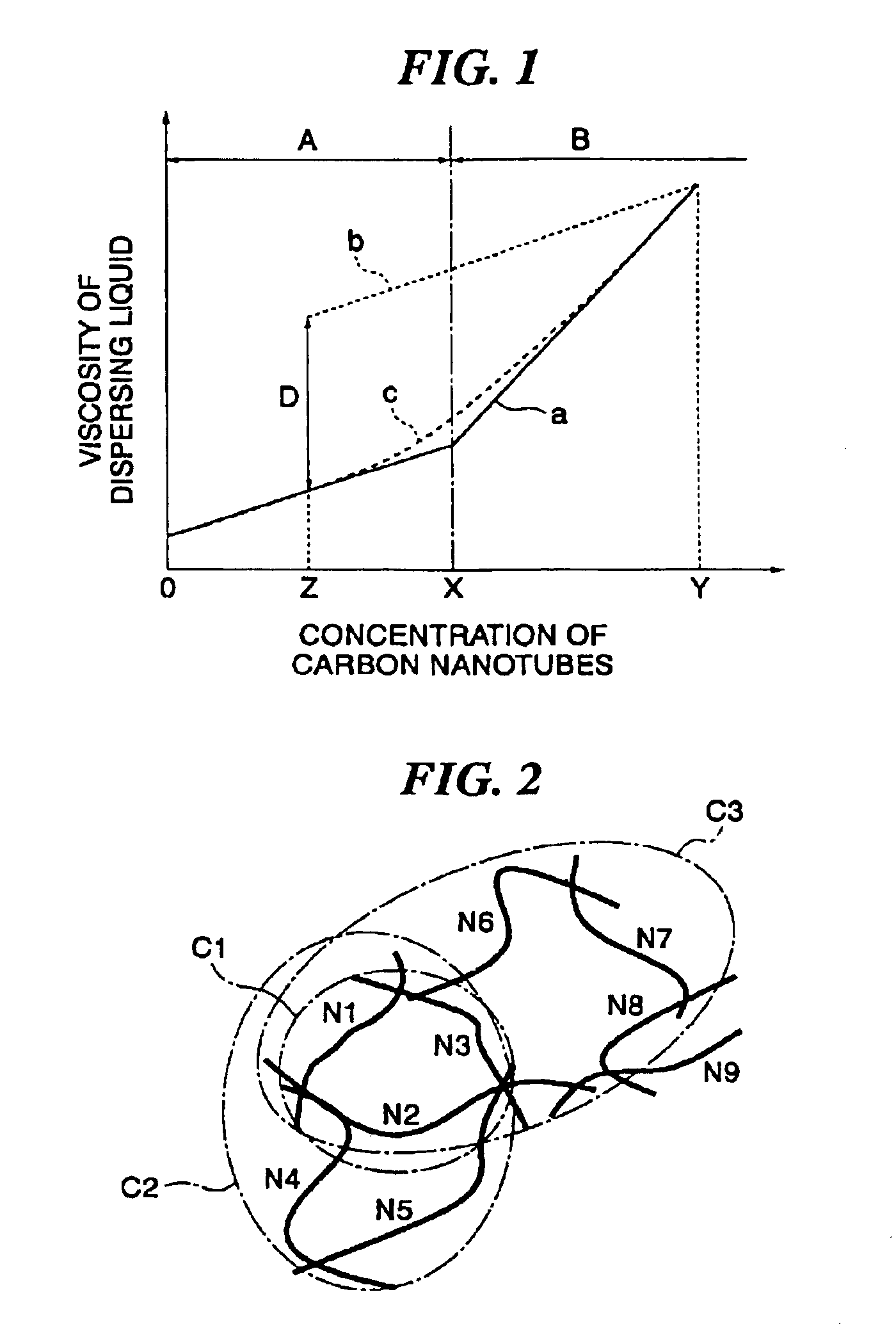

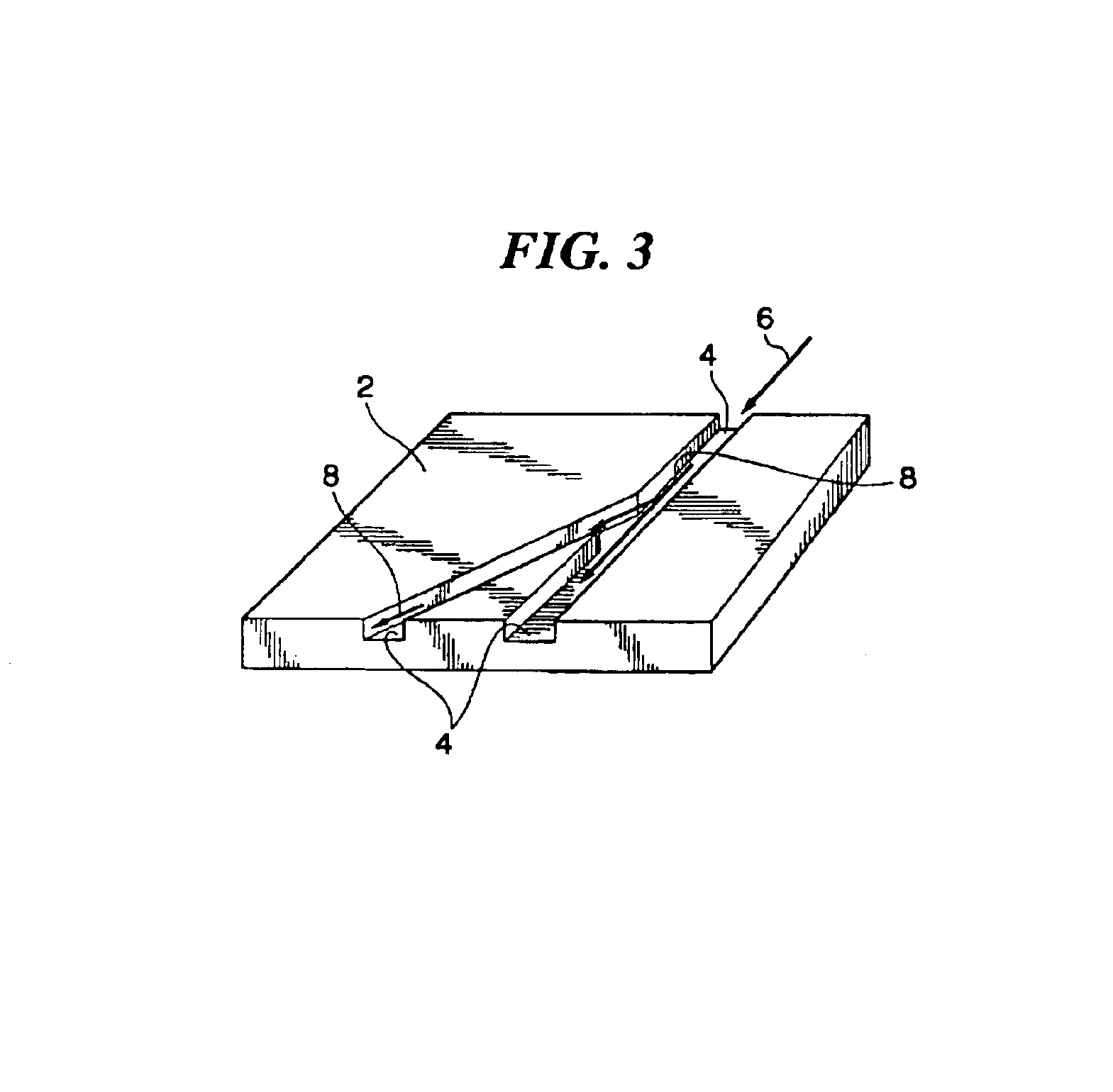

Carbon nanotube structures, carbon nanotube devices using the same and method for manufacturing carbon nanotube structures

InactiveUS6921575B2Easy to manufactureMaterial nanotechnologyCarbon compoundsElectricityCarbon nanotube

Carbon nanotube structures are provided, in which the networks with a desired area and volume, where the carbon nanotubes are electrically or magnetically connected, are formed and the method for easily manufacturing the carbon nanotube structures with less carbon nanotube structures. Carbon nanotube devices are also provided, to which the useful carbon nanotube structures mentioned above are applied. A method for manufacturing carbon nanotube structures includes the steps of applying carbon nanotubes to a low-viscosity dispersion medium to obtain a high-viscosity dispersing liquid which includes carbon nanotubes, and forming a network of the carbon nanotubes having electrical and / or magnetic connections therebetween by removing the low-viscosity dispersion medium from the high-viscosity dispersed liquid.

Owner:FUJIFILM BUSINESS INNOVATION CORP

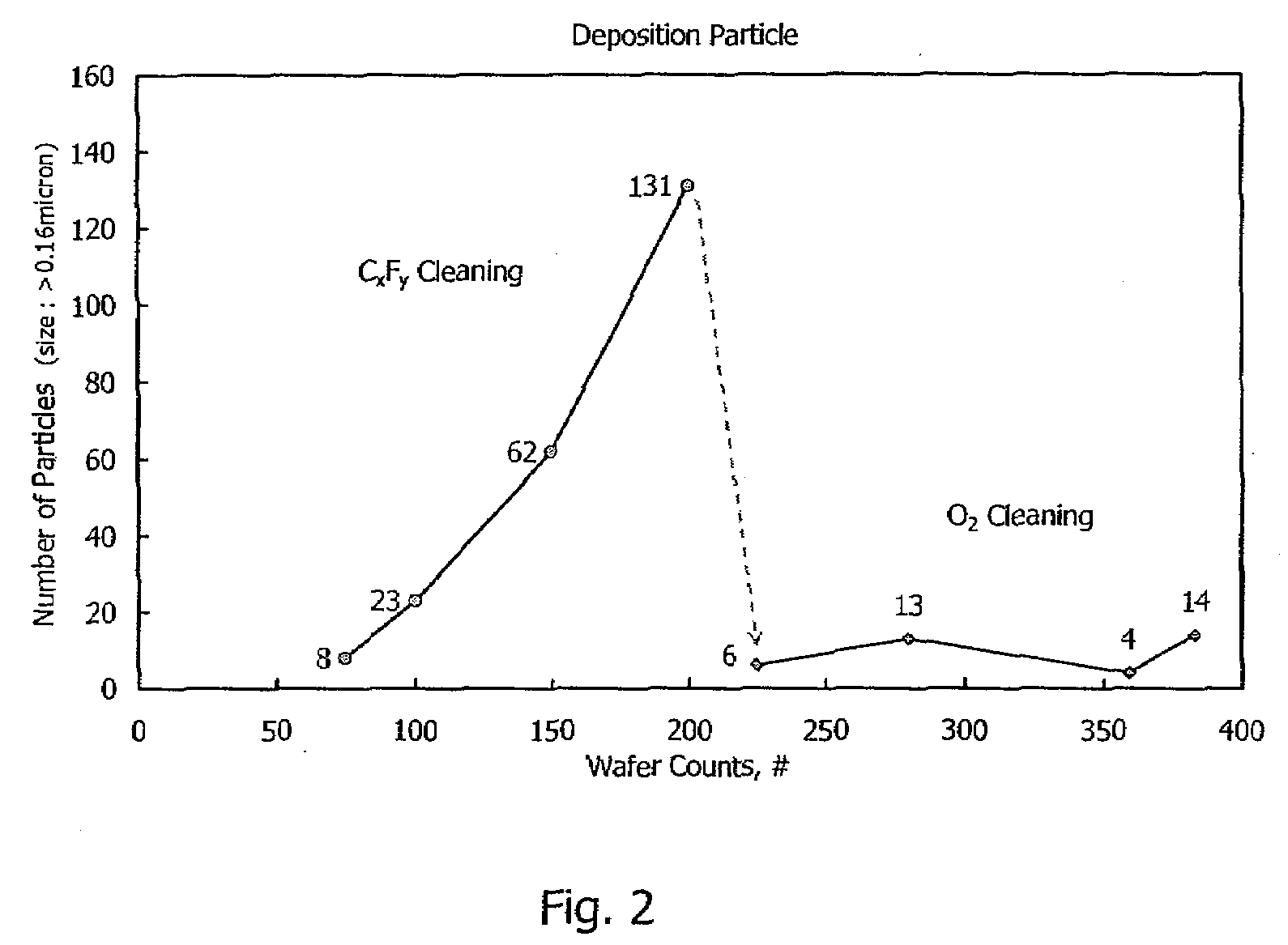

Method of self-cleaning of carbon-based film

InactiveUS20070248767A1Hollow article cleaningVacuum evaporation coatingNitrogen oxidePlasma reactor

A method of self-cleaning a plasma reactor upon depositing a carbon-based film on a substrate a pre-selected number of times, includes: (i) exciting oxygen gas and / or nitrogen oxide gas to generate a plasma; and (ii) exposing to the plasma a carbon-based film accumulated on an upper electrode provided in the reactor and a carbon-based film accumulated on an inner wall of the reactor.

Owner:ASM JAPAN

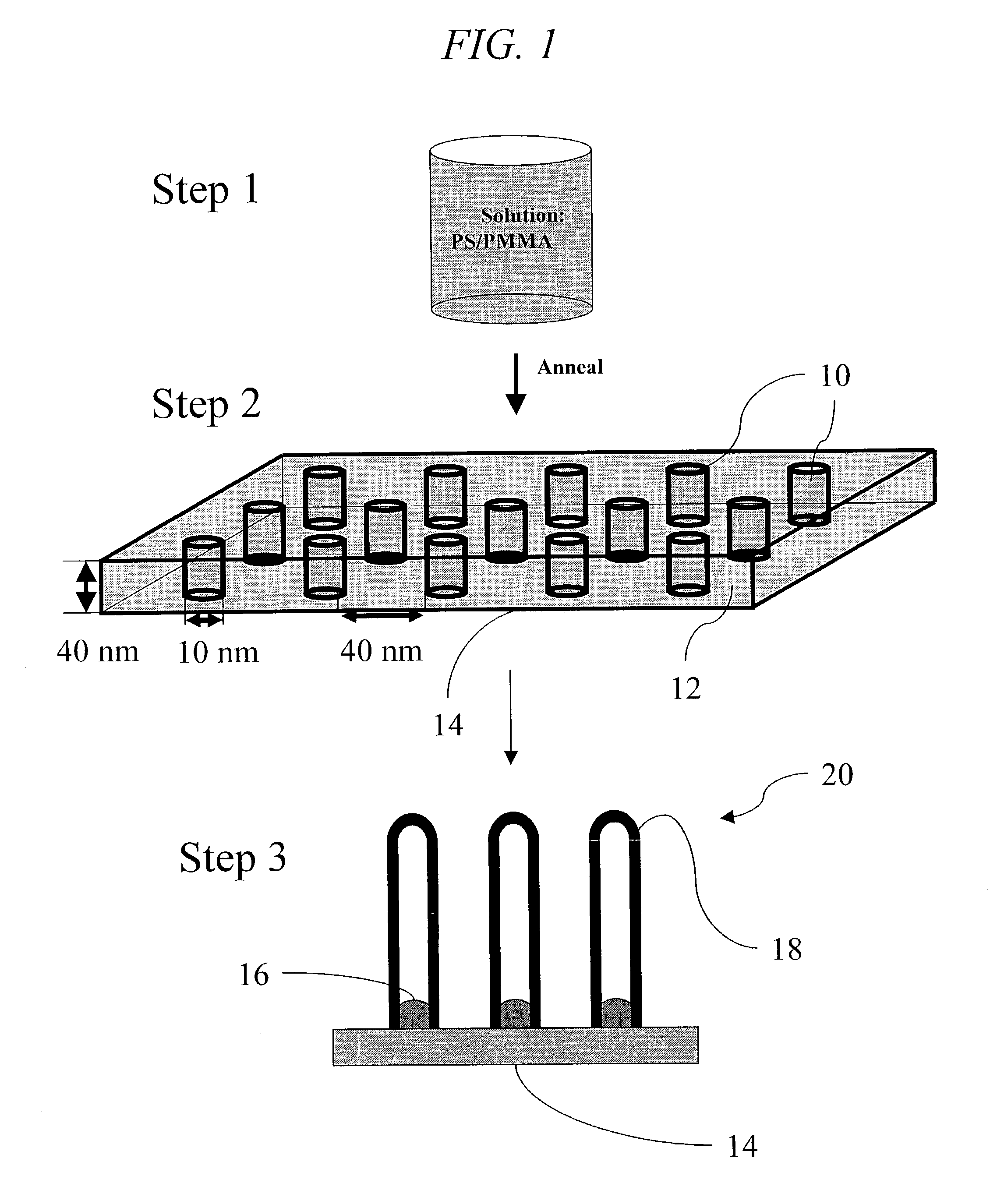

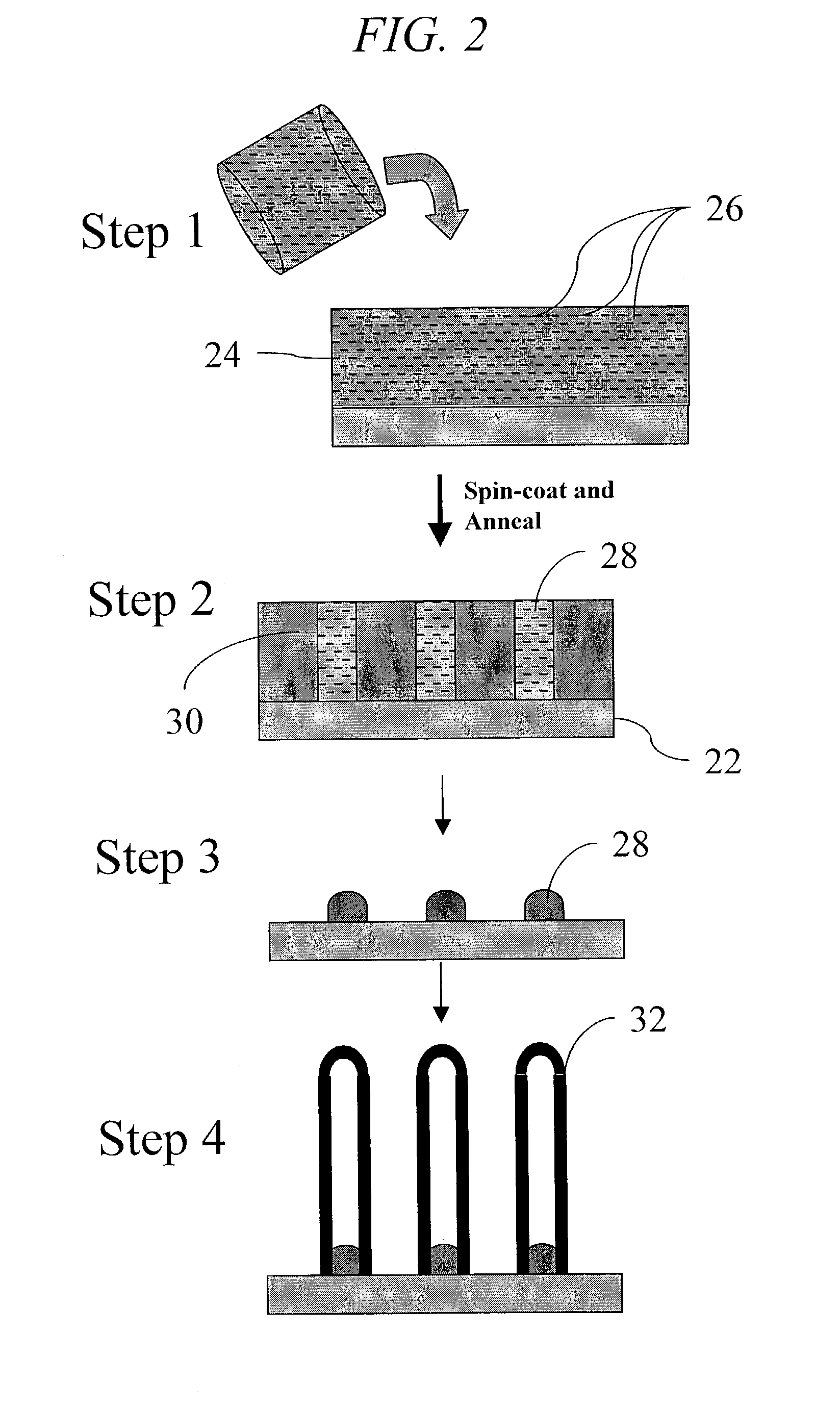

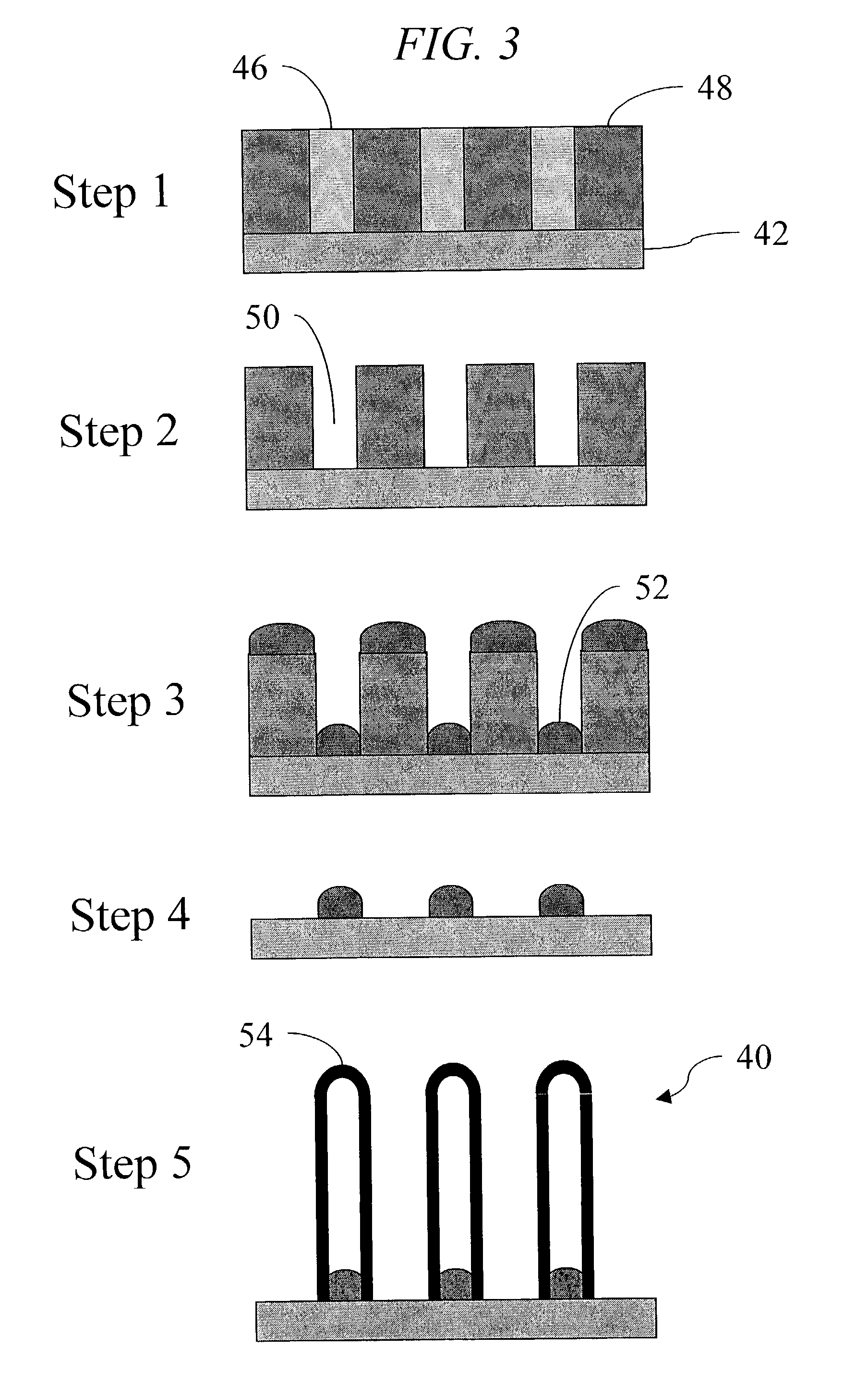

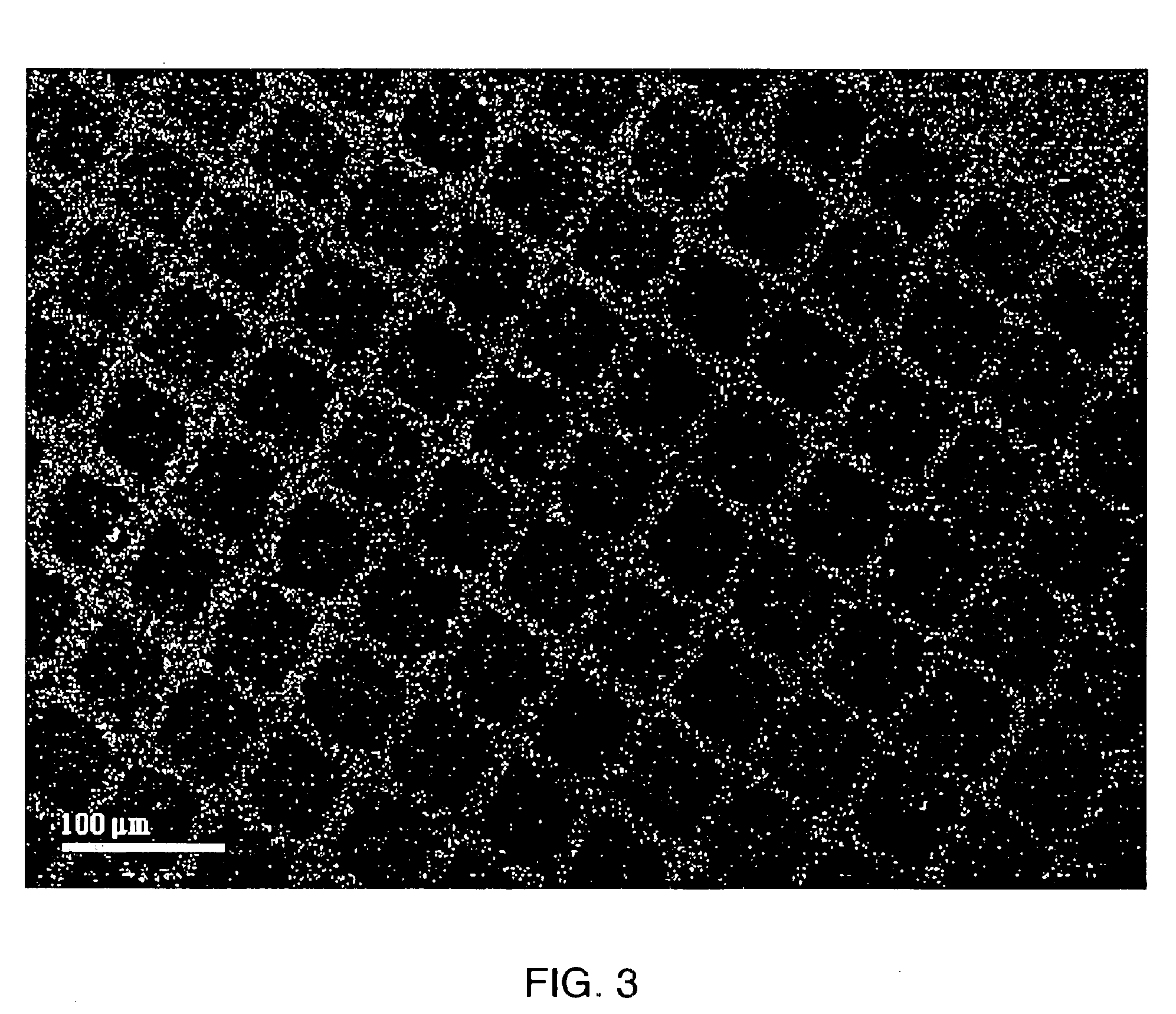

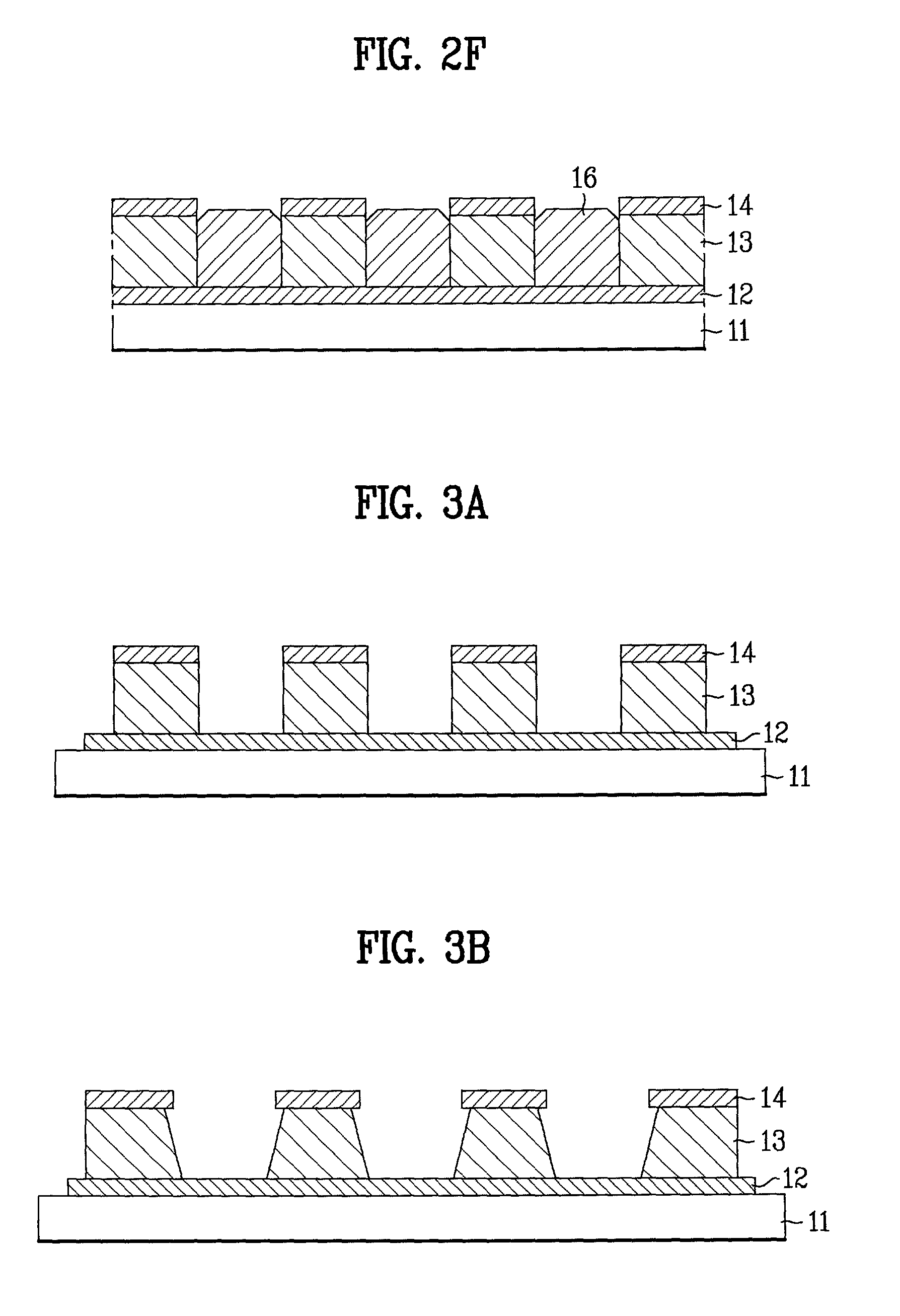

Method of producing regular arrays of nano-scale objects using nano-structured block-copolymeric materials

A method of forming a periodic array of nano-scale objects using a block copolymer, and nano-scale object arrays formed from the method are provided. The method for forming the arrays generally includes the steps of depositing a block copolymer of at least two blocks on a substrate to form an ordered meso-scale structured array of the polymer materials, forming catalytic metal dots based on the meso-scale structure, and growing nano-scale objects on the catalytic dots to form an ordered array of nano-scale objects.

Owner:CALIFORNIA INST OF TECH

Method of preparing catalyst for manufacturing carbon nanotubes

InactiveUS20070020167A1Improve uniformityMinimize agglomerationMaterial nanotechnologyNanostructure manufactureFreeze-dryingCarbon nanotube

A novel method of forming catalyst particles, on which carbon nanotubes grow based, on a substrate with increased uniformity, and a method of synthesizing carbon nanotubes having improved uniformity are provided. A catalytic metal precursor solution is applied to a substrate. The applied catalytic metal precursor solution is freeze-dried, and then reduced to catalytic metal. The method of forming catalyst particles can minimize agglomeration and / or recrystallization of catalyst particles when forming the catalyst particles by freeze-drying the catalyst metal precursor solution. The catalyst particles formed by the method has a very uniform particle size and are very uniformly distributed on the substrate.

Owner:SAMSUNG SDI CO LTD

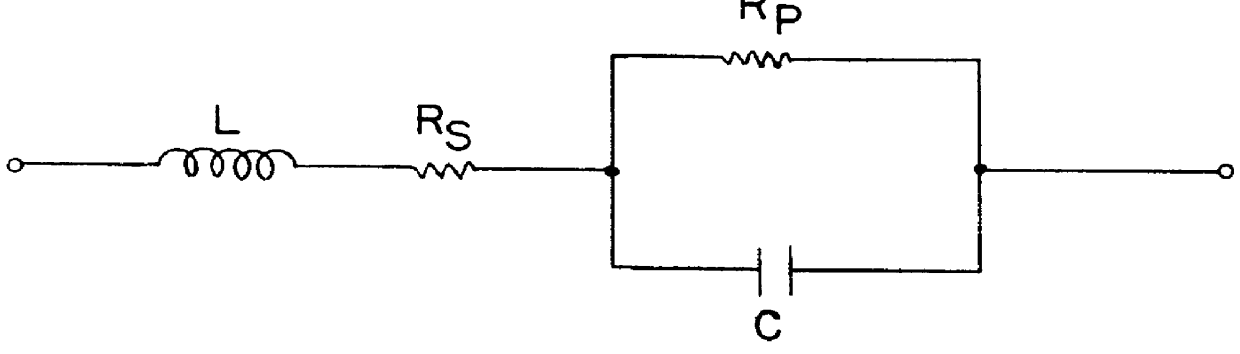

Graphitic nanofibers in electrochemical capacitors

Graphitic nanofibers, which include tubular fullerenes (commonly called "buckytubes"), nanotubes and fibrils, which are functionalized by chemical substitution, are used as electrodes in electrochemical capacitors. The graphitic nanofiber based electrode increases the performance of the electrochemical capacitors. Preferred nanofibers have a surface area greater than about 200 m2 / gm and are substantially free of micropores.

Owner:HYPERION CATALYSIS INT

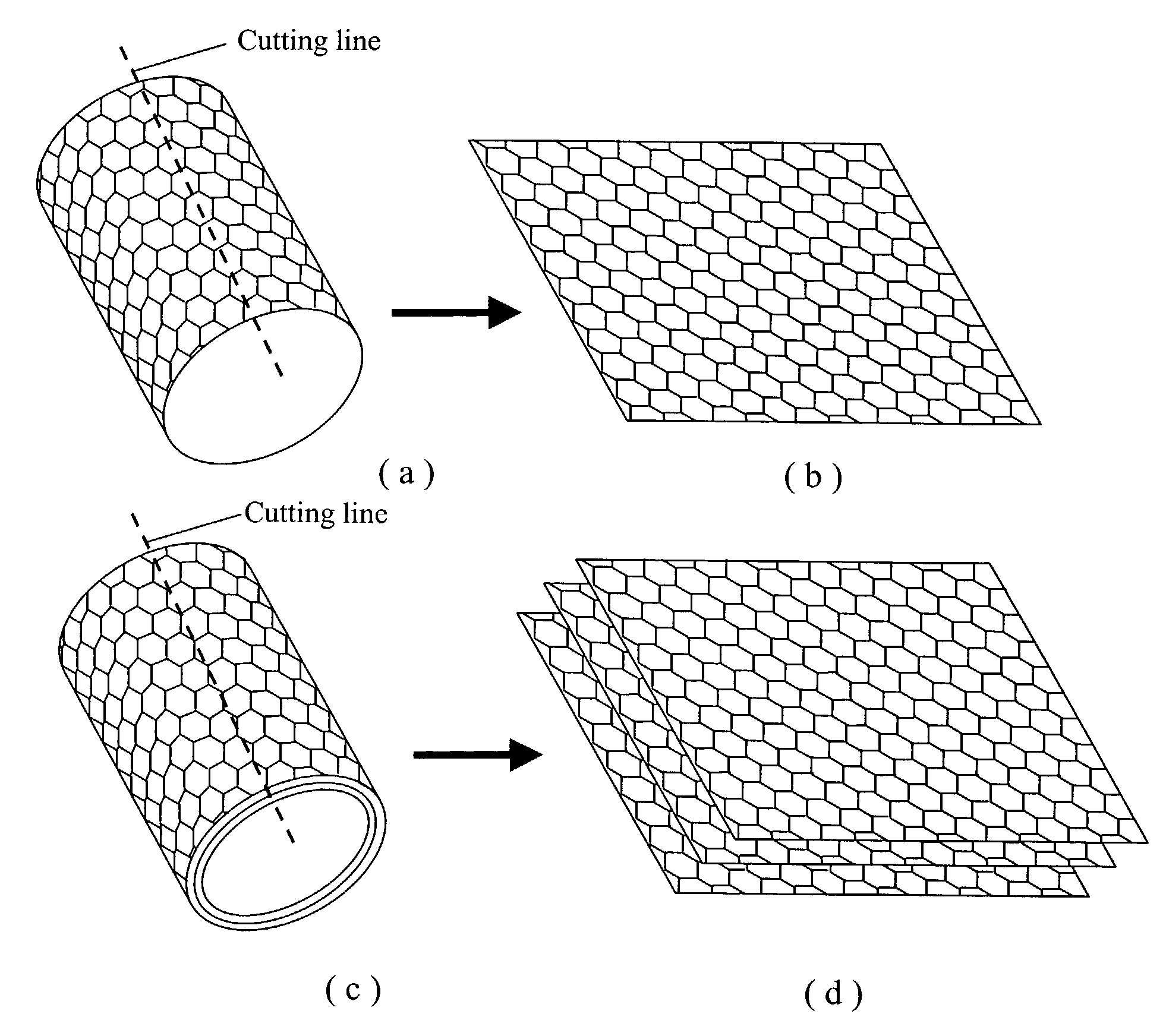

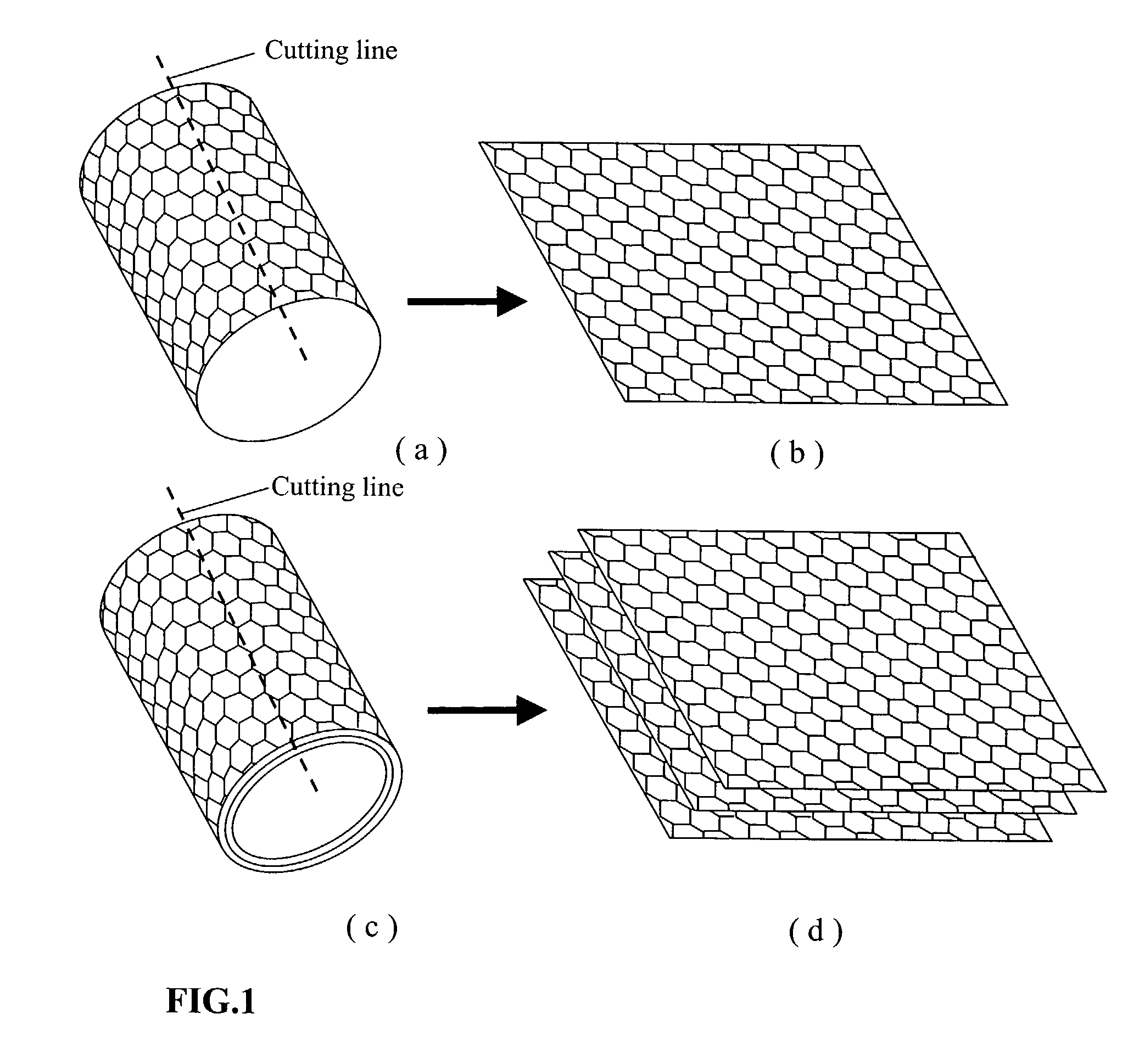

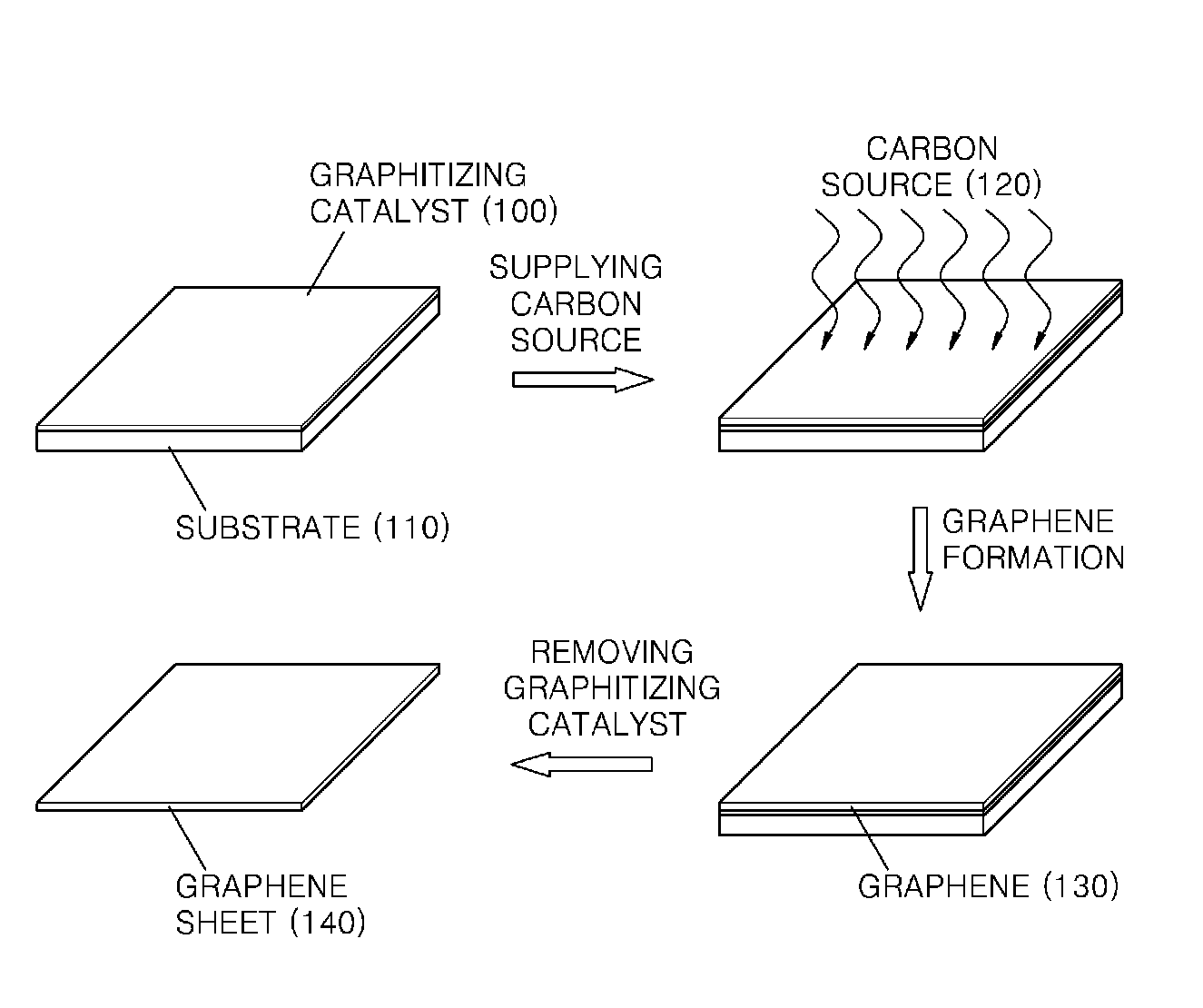

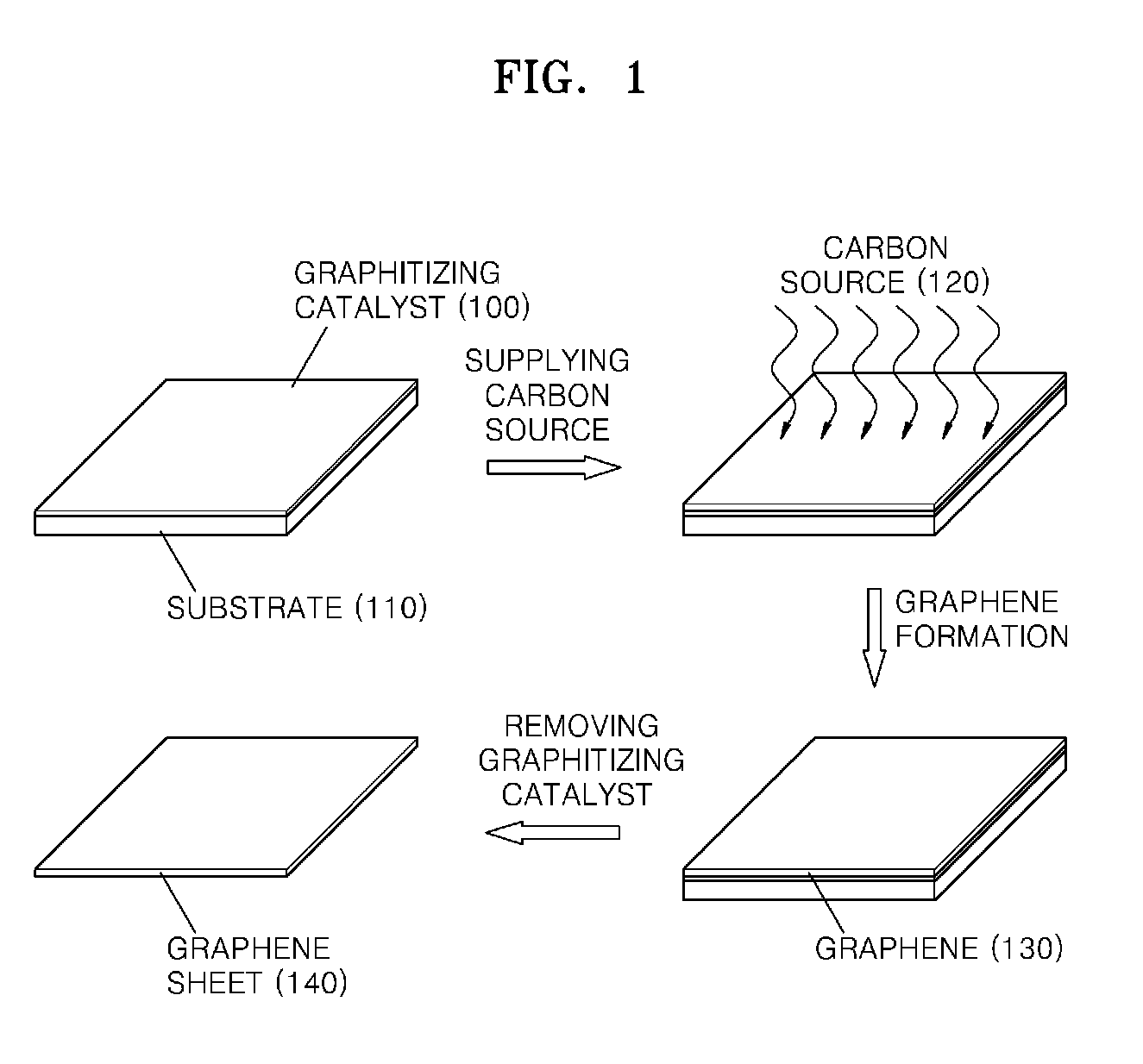

Graphene sheet and method of preparing the same

An economical method of preparing a large-sized graphene sheet having a desired thickness includes forming a film, the film comprising a graphitizing catalyst; heat-treating a gaseous carbon source in the presence of the graphitizing catalyst to form graphene; and cooling the graphene to form a graphene sheet. A graphene sheet prepared according to the disclosed method is also described.

Owner:SAMSUNG ELECTRONICS CO LTD

Coatings comprising carbon nanotubes and methods for forming same

InactiveUS7060241B2Reduce manufacturing costImprove efficiencyMaterial nanotechnologyConductive layers on insulating-supportsSingle-Walled NanotubeCoating

Owner:NANO C INC

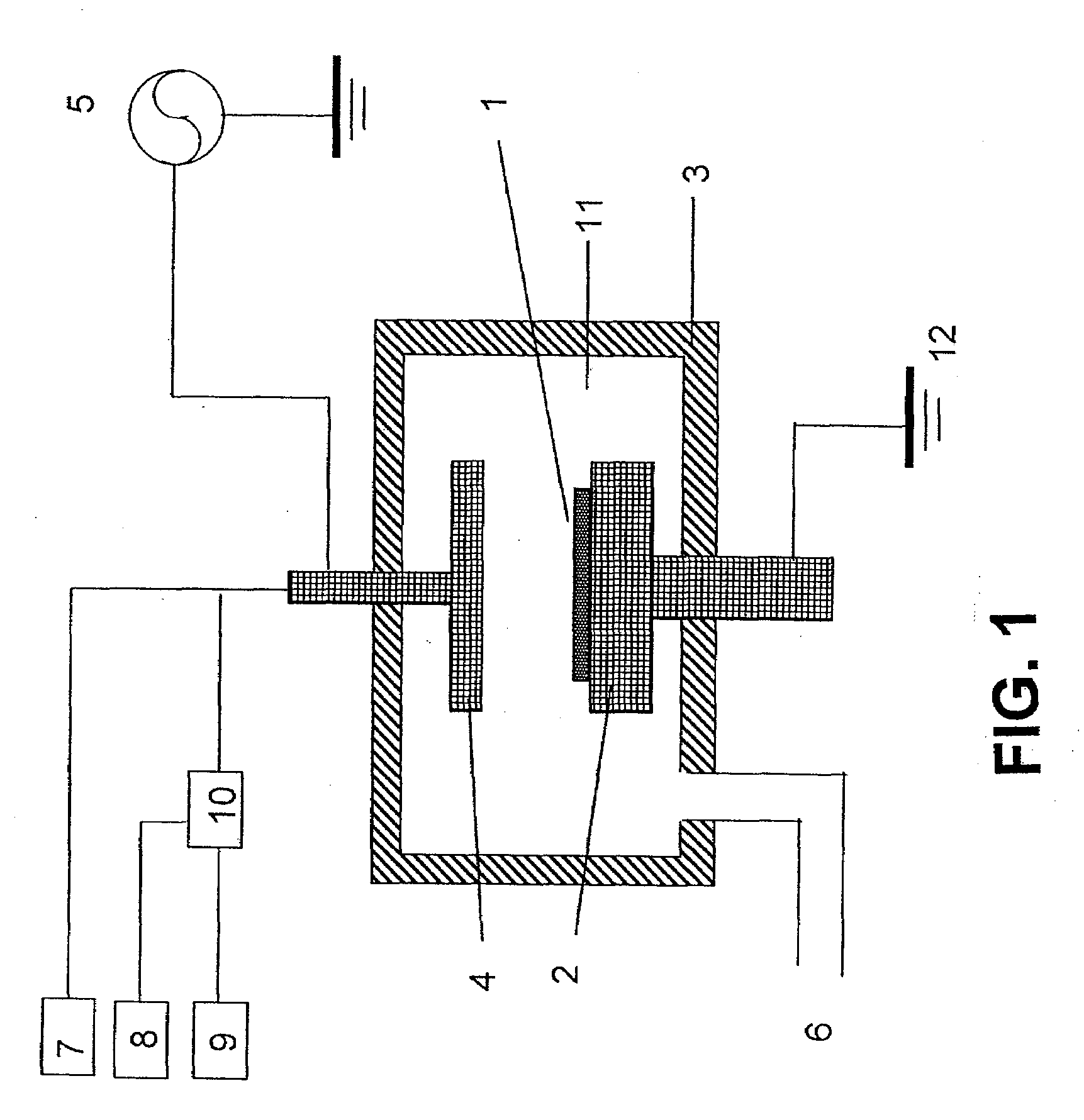

Process for producing single wall nanotubes using unsupported metal catalysts

InactiveUS6221330B1Continuous and efficient productionMaterial nanotechnologyFibre chemical featuresHydrogenGas phase

A process for producing hollow, single-walled carbon nanotubes by catalytic decomposition of one or more gaseous carbon compounds by first forming a gas phase mixture carbon feed stock gas comprising one or more gaseous carbon compounds, each having one to six carbon atoms and only H, O, N, S or Cl as hetero atoms, optionally admixed with hydrogen, and a gas phase metal containing compound which is unstable under reaction conditions for said decomposition, and which forms a metal containing catalyst which acts as a decomposition catalyst under reaction conditions; and then conducting said decomposition reaction under decomposition reaction conditions, thereby producing said nanotubes.

Owner:HYPERION CATALYSIS INT

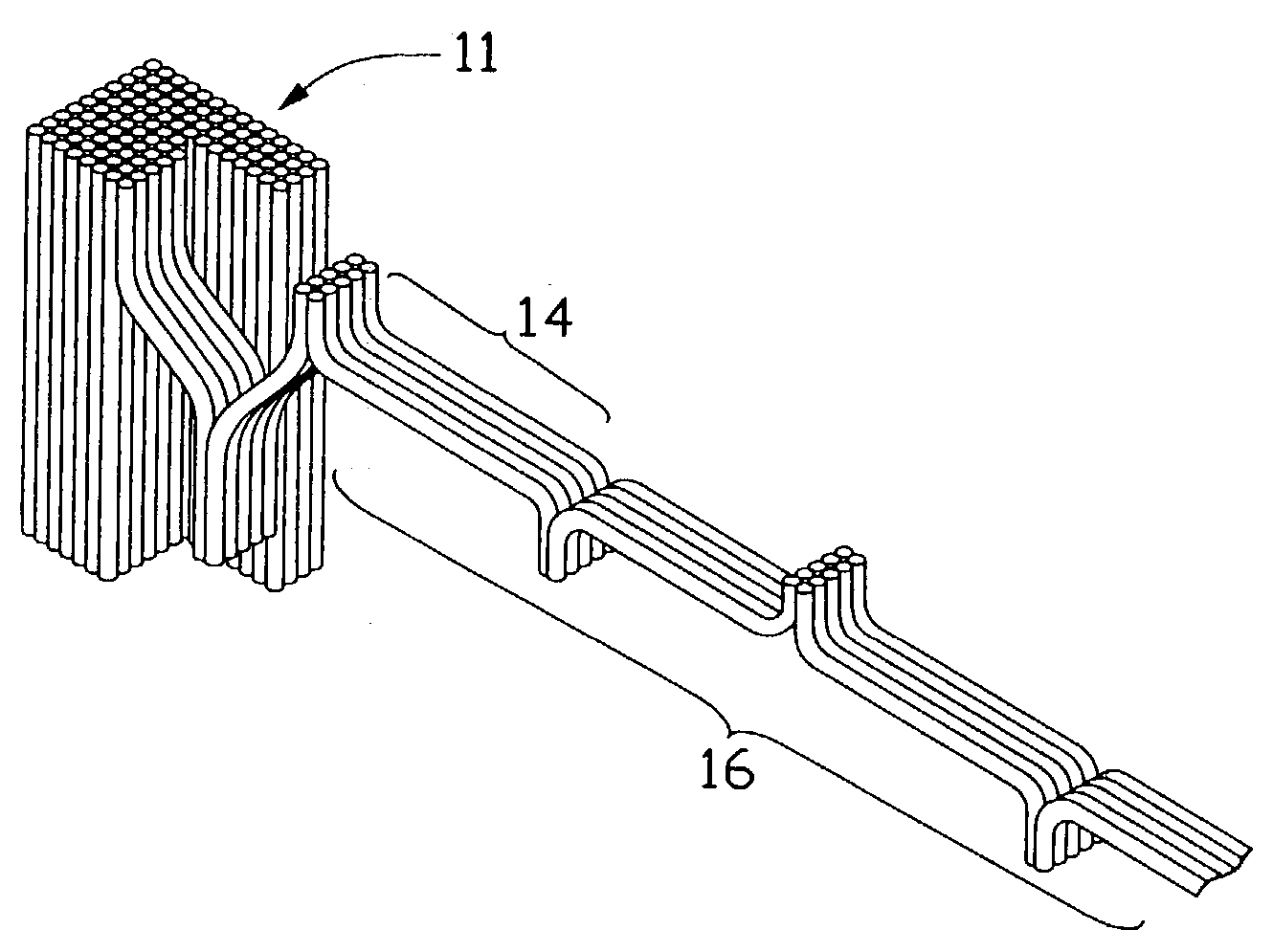

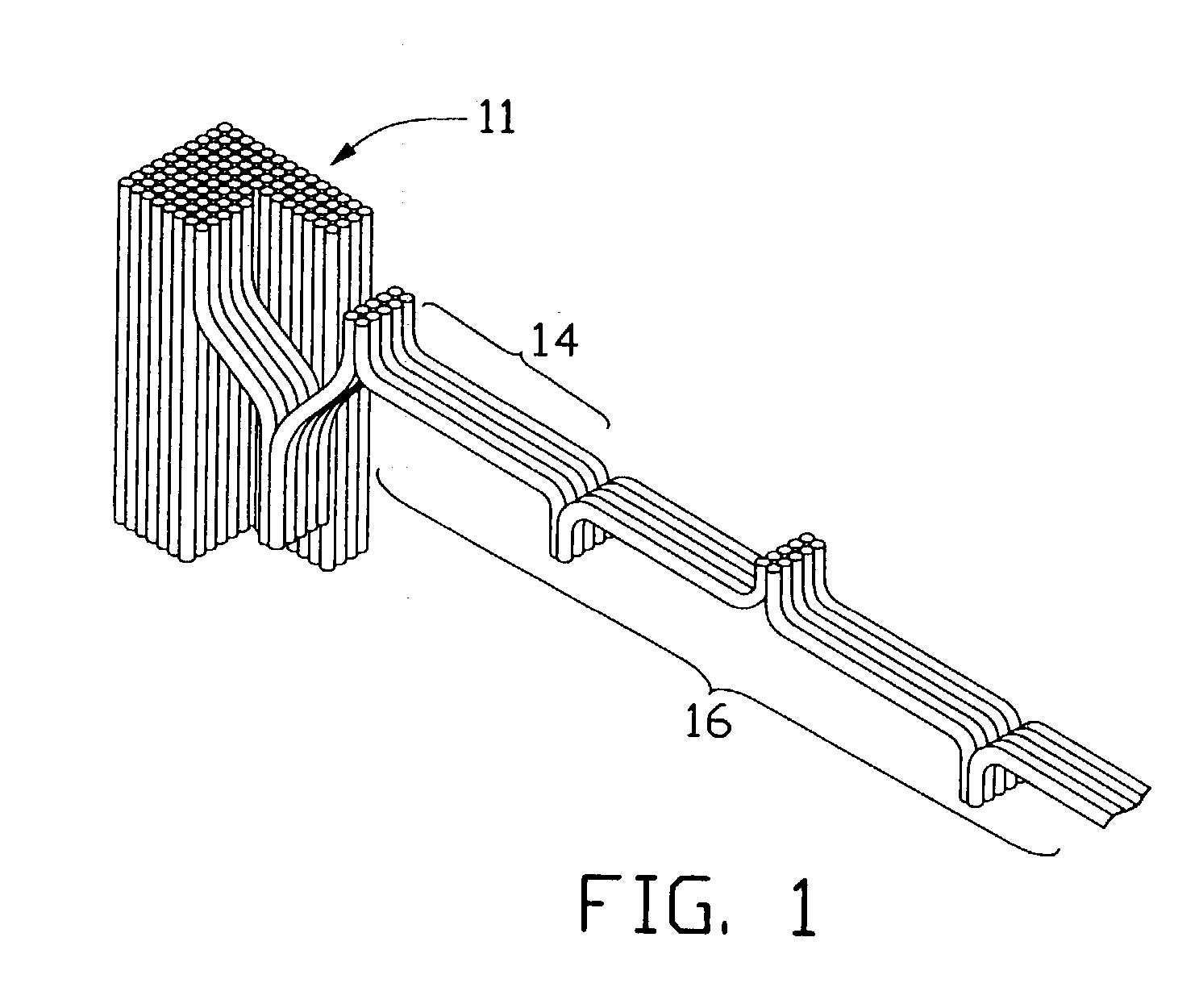

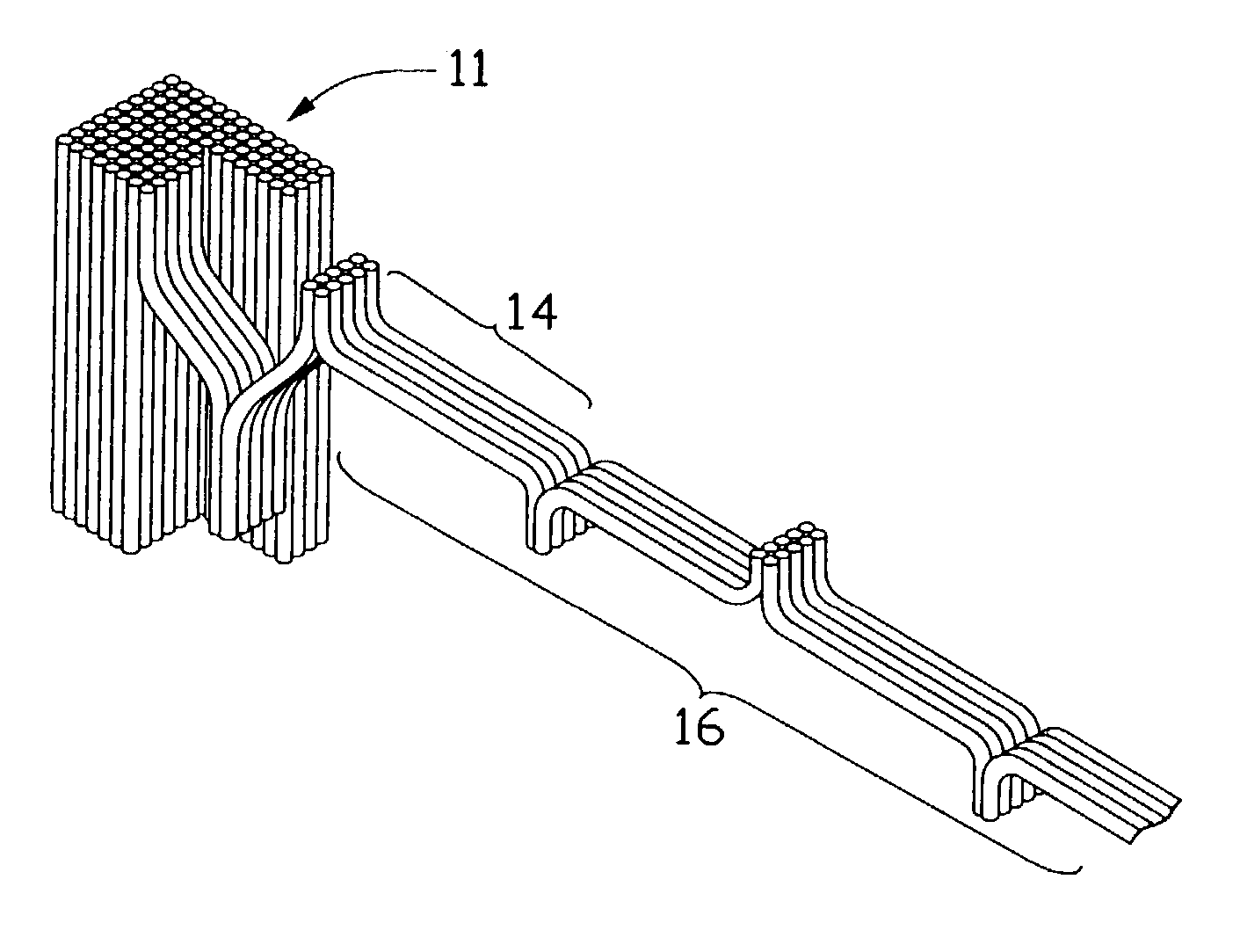

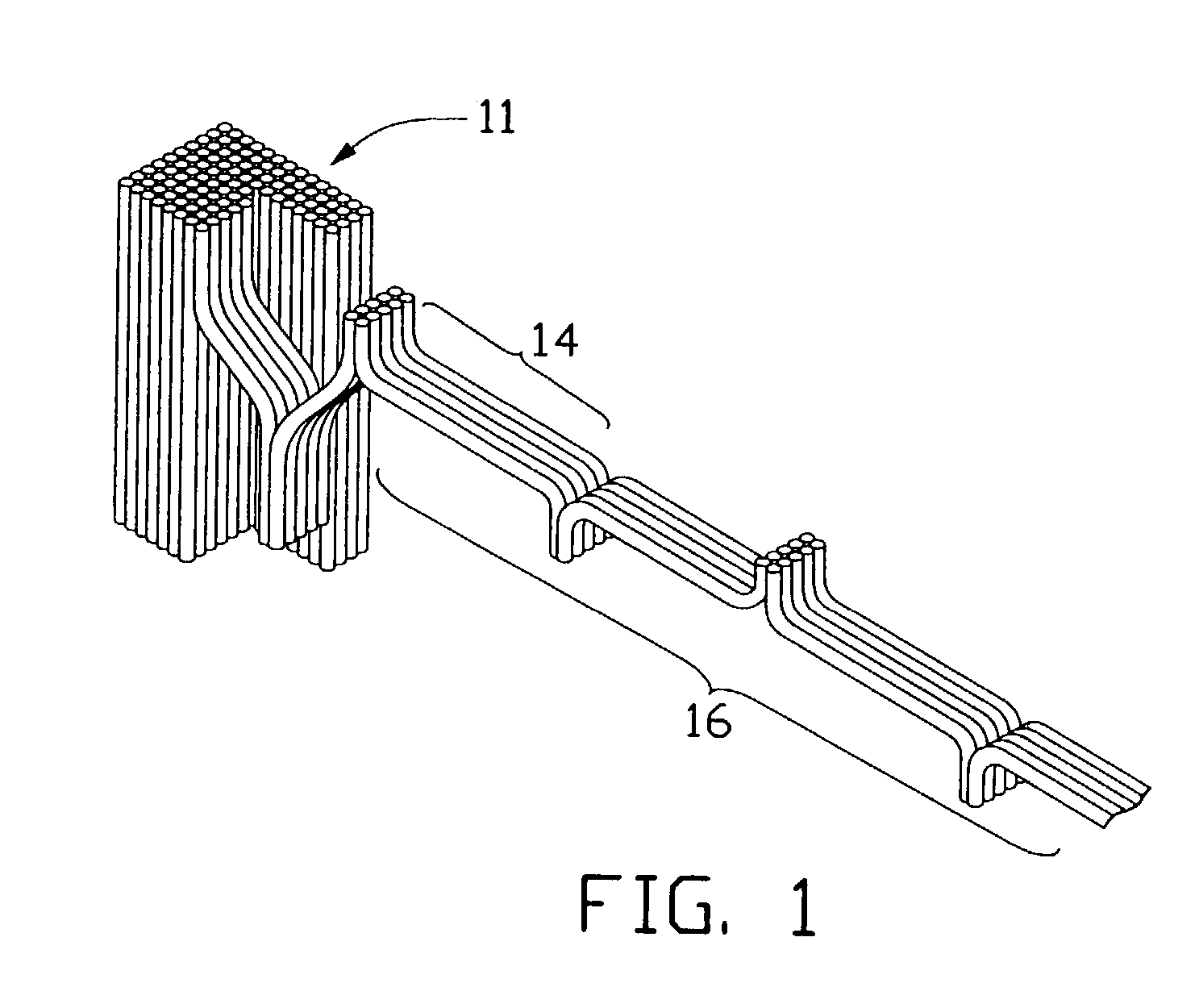

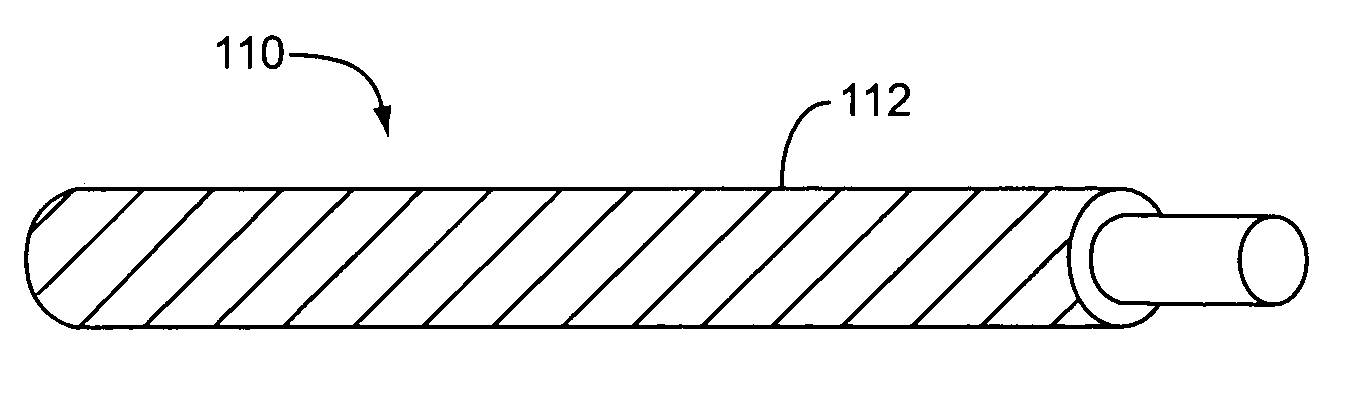

Carbon nanotube yarn and method for making the same

A carbon nanotube yarn includes a number of carbon nanotube yarn strings bound together, and each of the carbon nanotube yarn strings includes a number of carbon nanotube bundles that are joined end to end by van der Waals attractive force, and each of the carbon nanotube bundles includes a number of carbon nanotubes substantially parallel to each other. A method for making the carbon nanotube yarn includes soaking the at least one carbon nanotube yarn string drawn out from a carbon nanotube array in an organic solvent to shrink it and then collecting it.

Owner:TSINGHUA UNIV

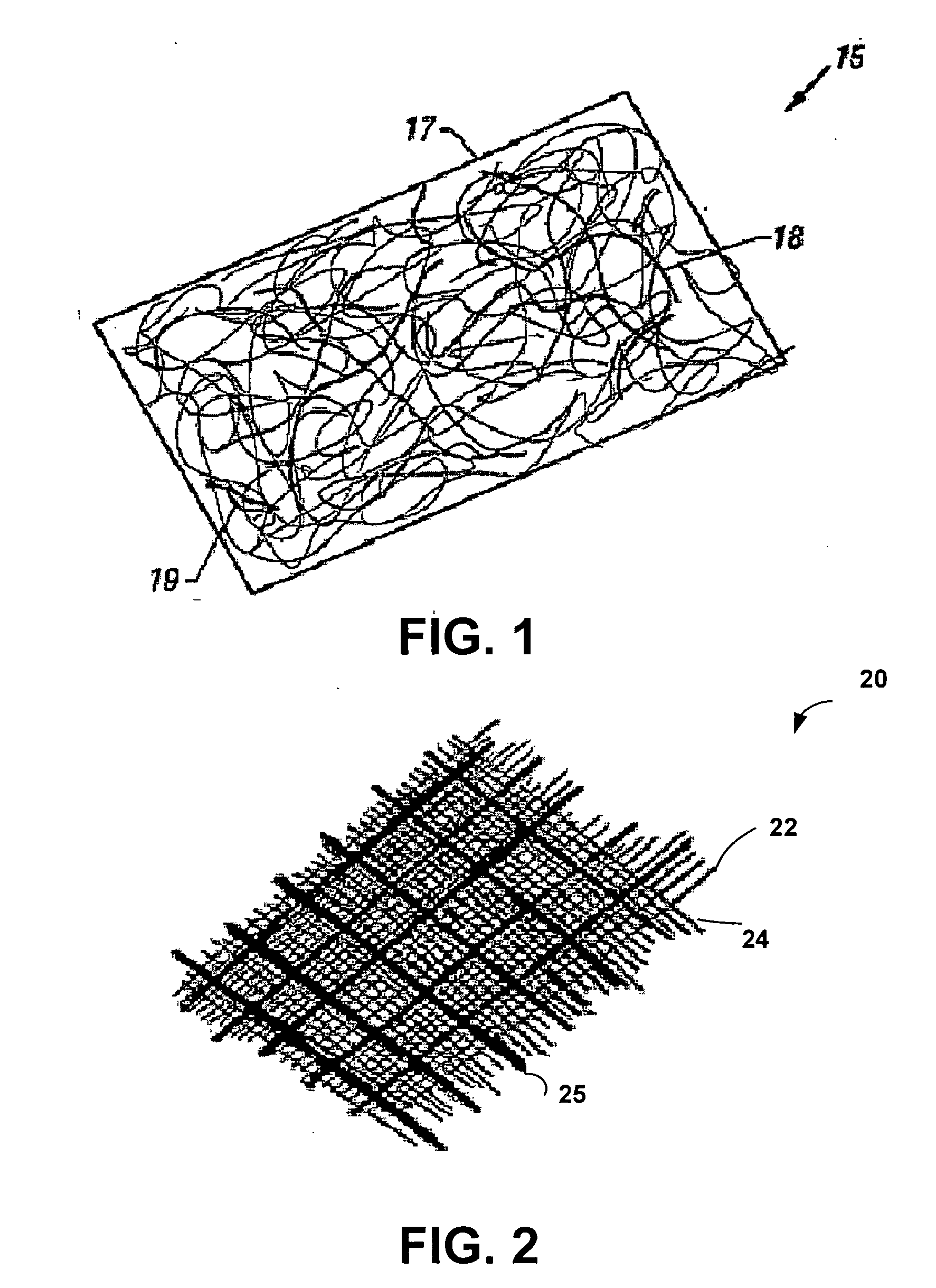

Entangled single-wall carbon nanotube solid material and methods for making same

InactiveUS6899945B2Material nanotechnologySynthetic resin layered productsCross-linkSolvent evaporation

Buckyrock is a three-dimensional, solid block material comprising an entangled network of single-wall carbon nanotubes (SWNT), wherein the block comprises greater than 75 wt % SWNT. SWNT buckyrock is mechanically strong, tough and impact resistant. The single-wall carbon nanotubes in buckyrock form are present in a random network of individual single-wall carbon nanotubes, SWNT “ropes” and combinations thereof. The random network of the SWNT or SWNT ropes can be held in place by non-covalent “cross-links” between the nanotubes at nanotube contact points. In one embodiment, SWNT buckyrock is made by forming a SWNT-water slurry, slowly removing water from the slurry which results in a SWNT-water paste, and allowing the paste to dry very slowly, such that the SWNT network of the SWNT-water paste is preserved during solvent evaporation. Buckyrock can be used in applications, such as ballistic protection systems, involving light-weight material with mechanical strength, toughness and impact resistance.

Owner:RICE UNIV

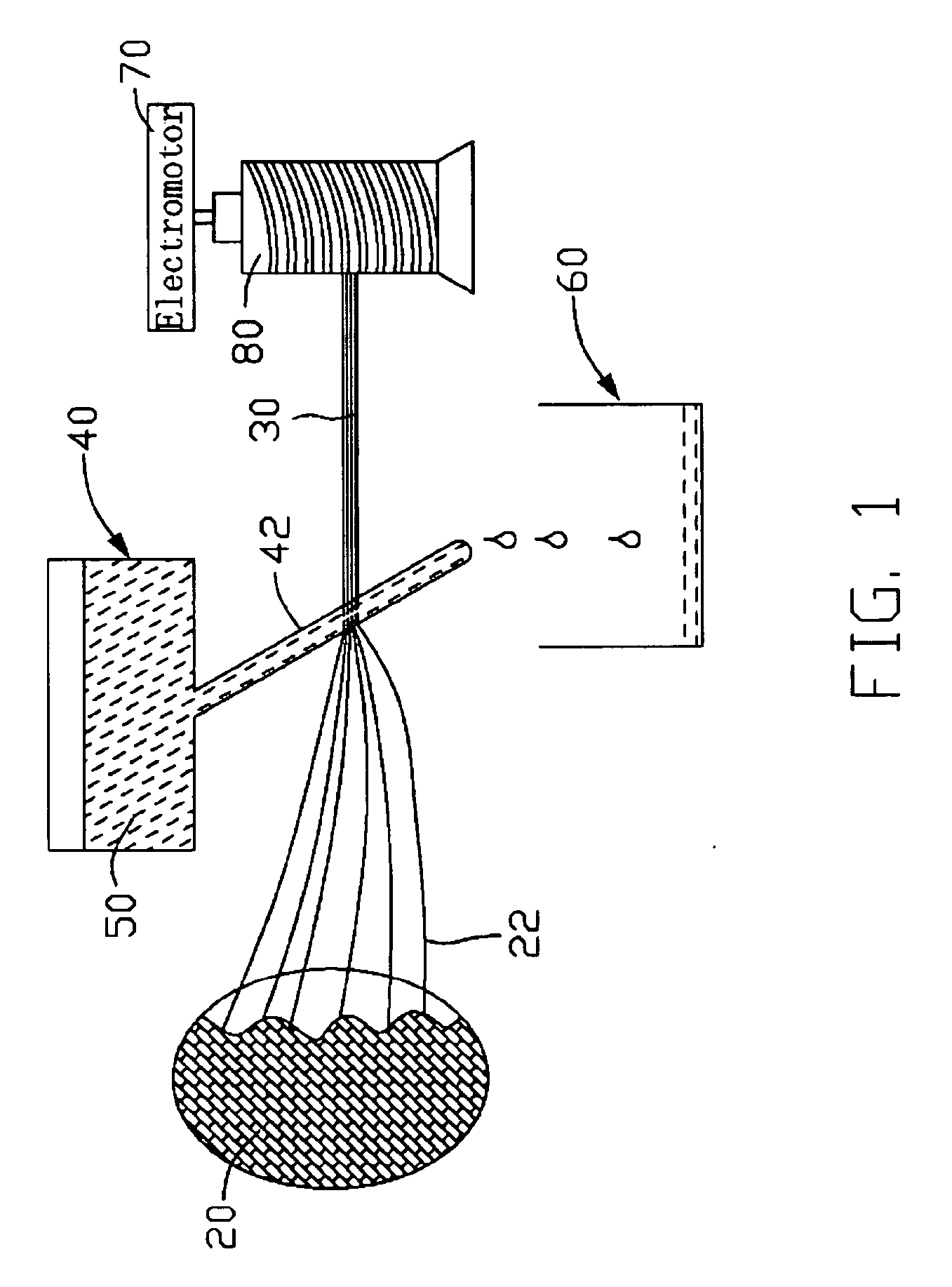

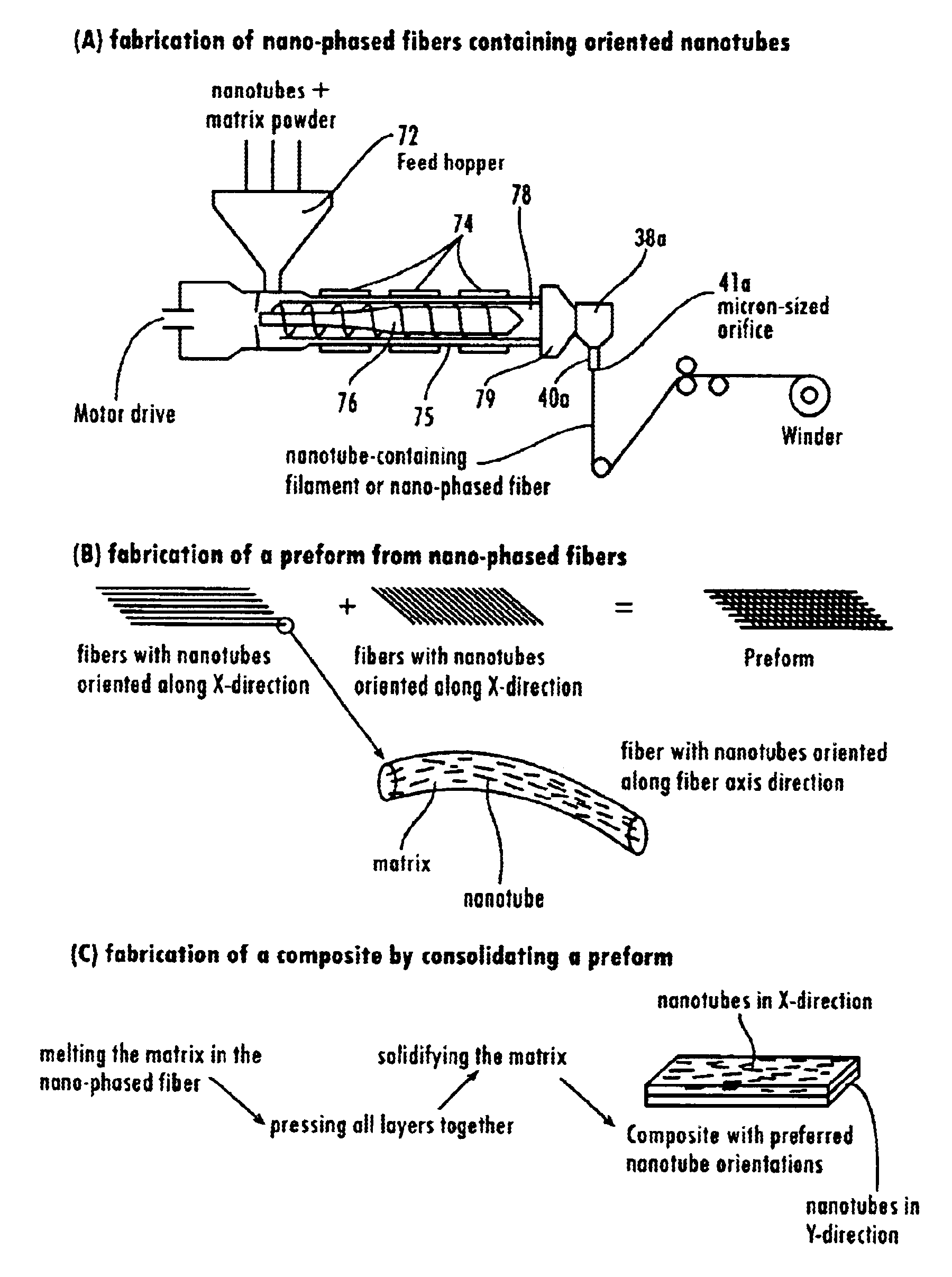

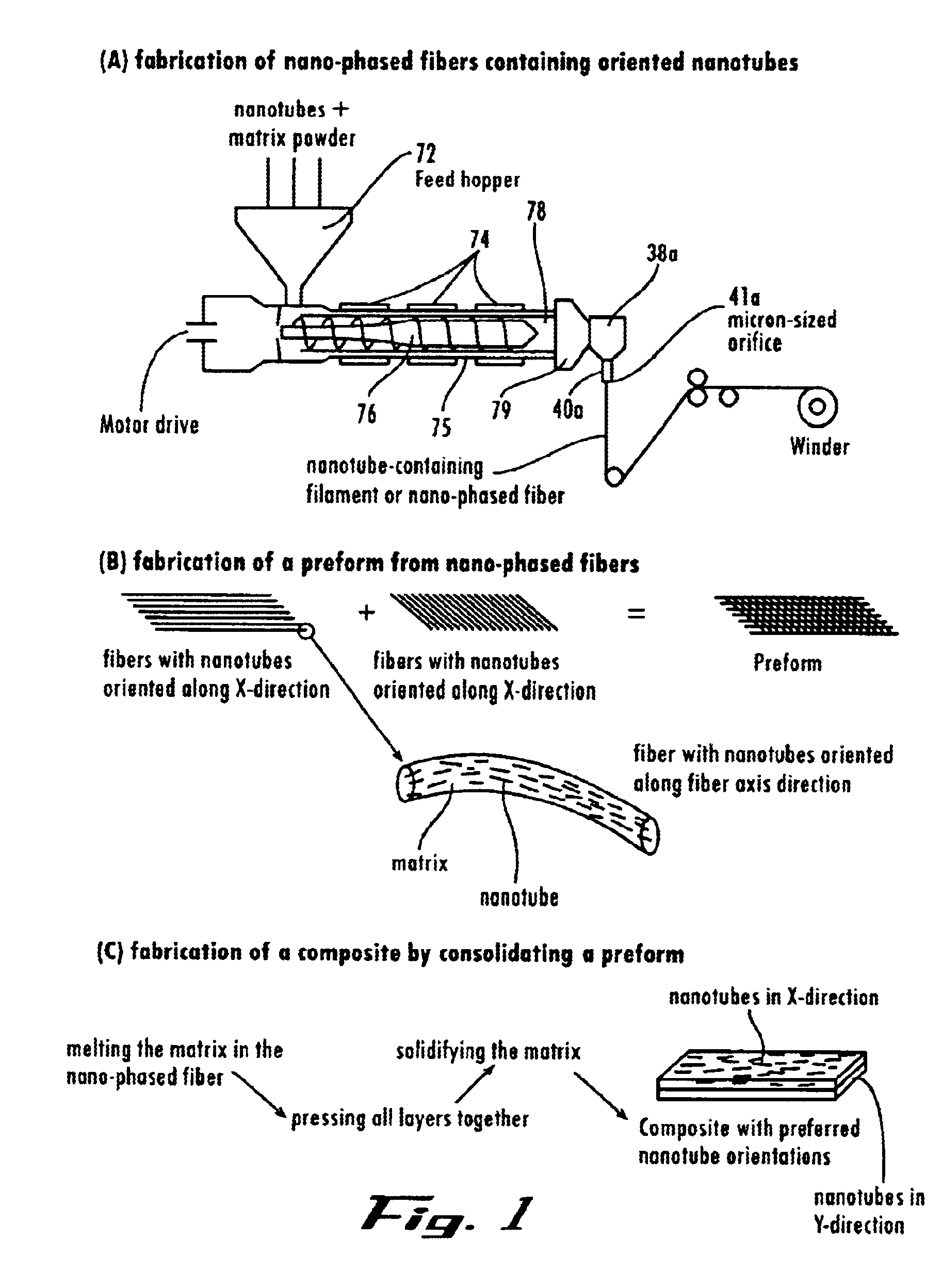

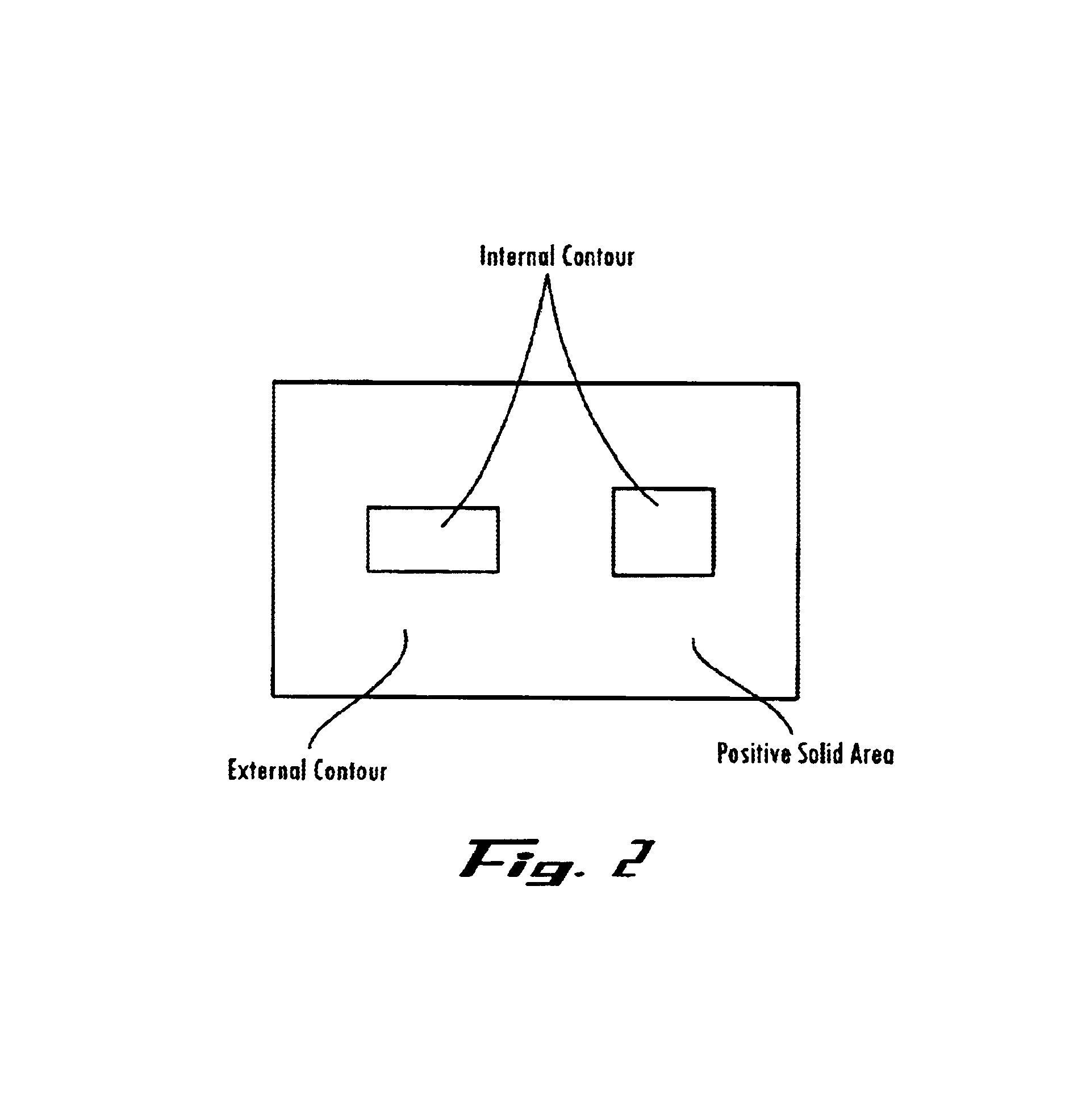

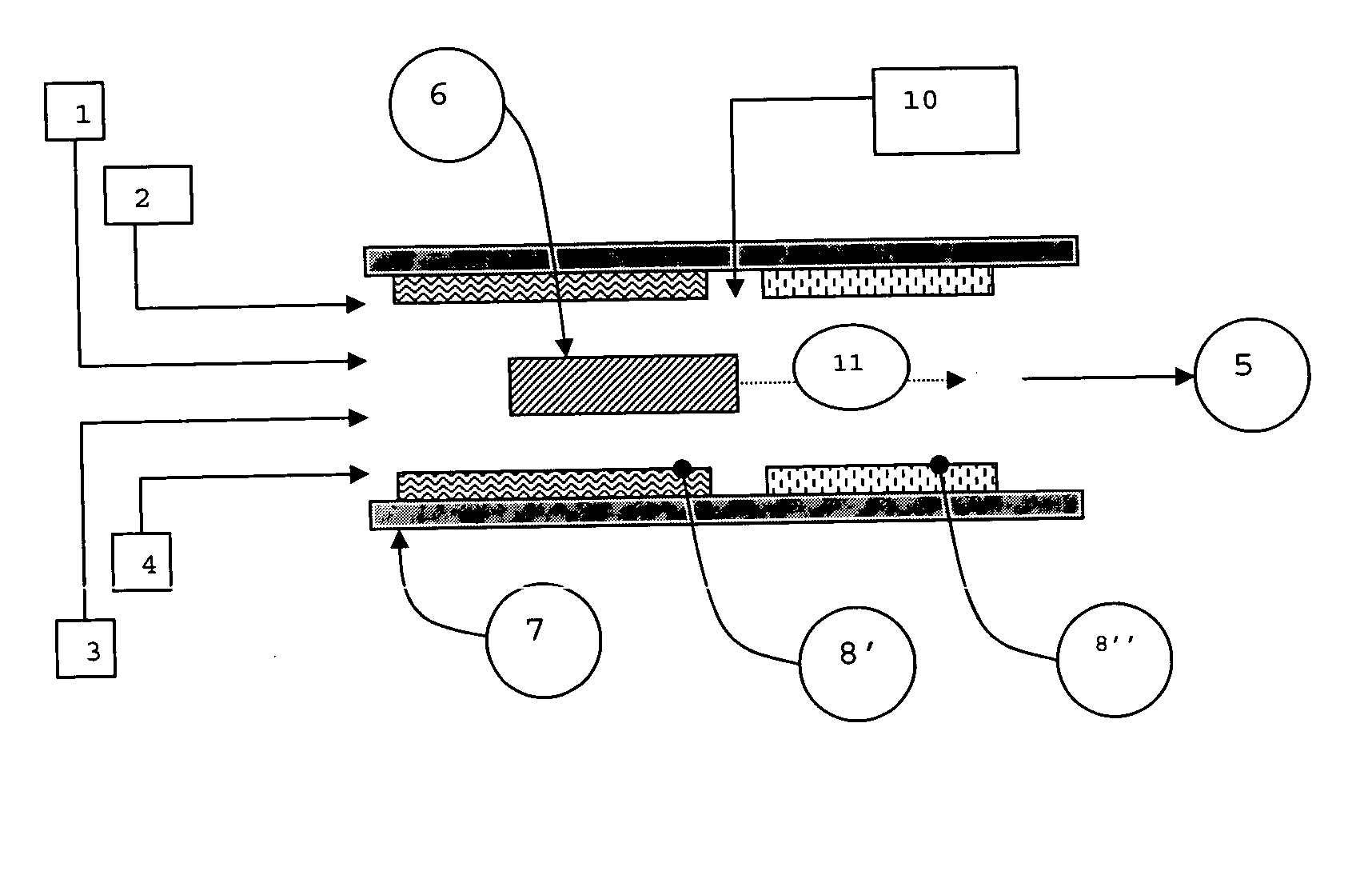

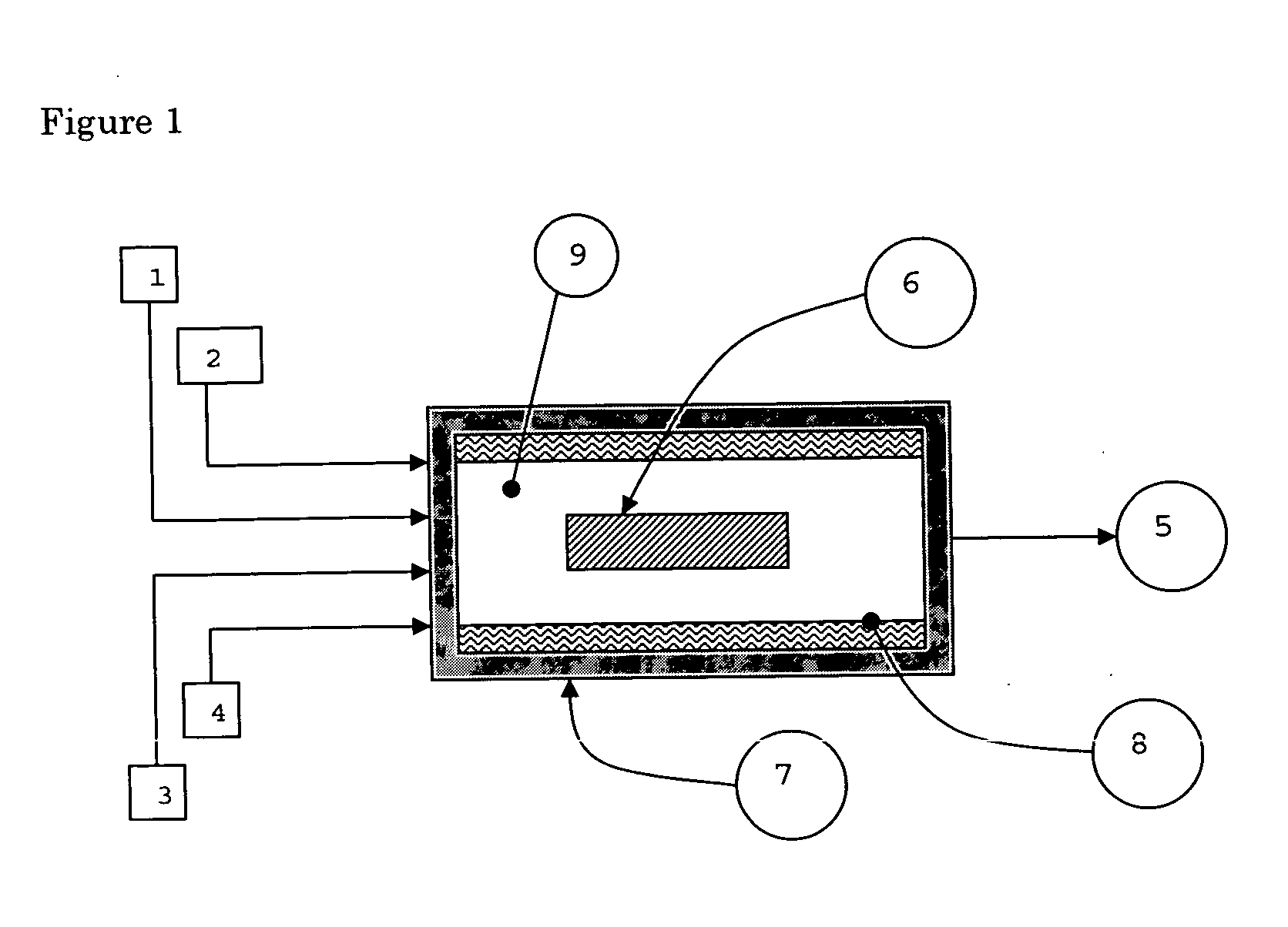

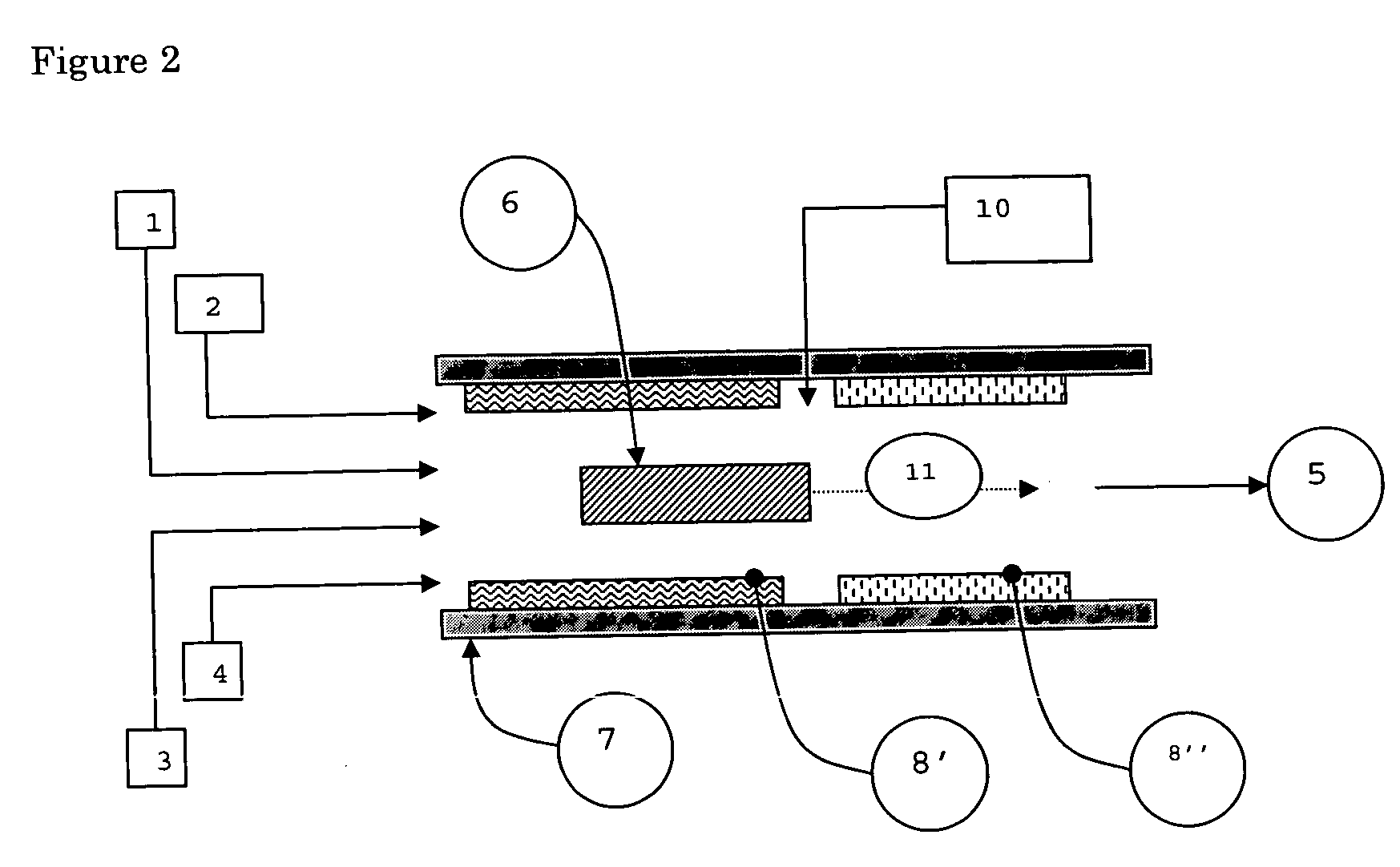

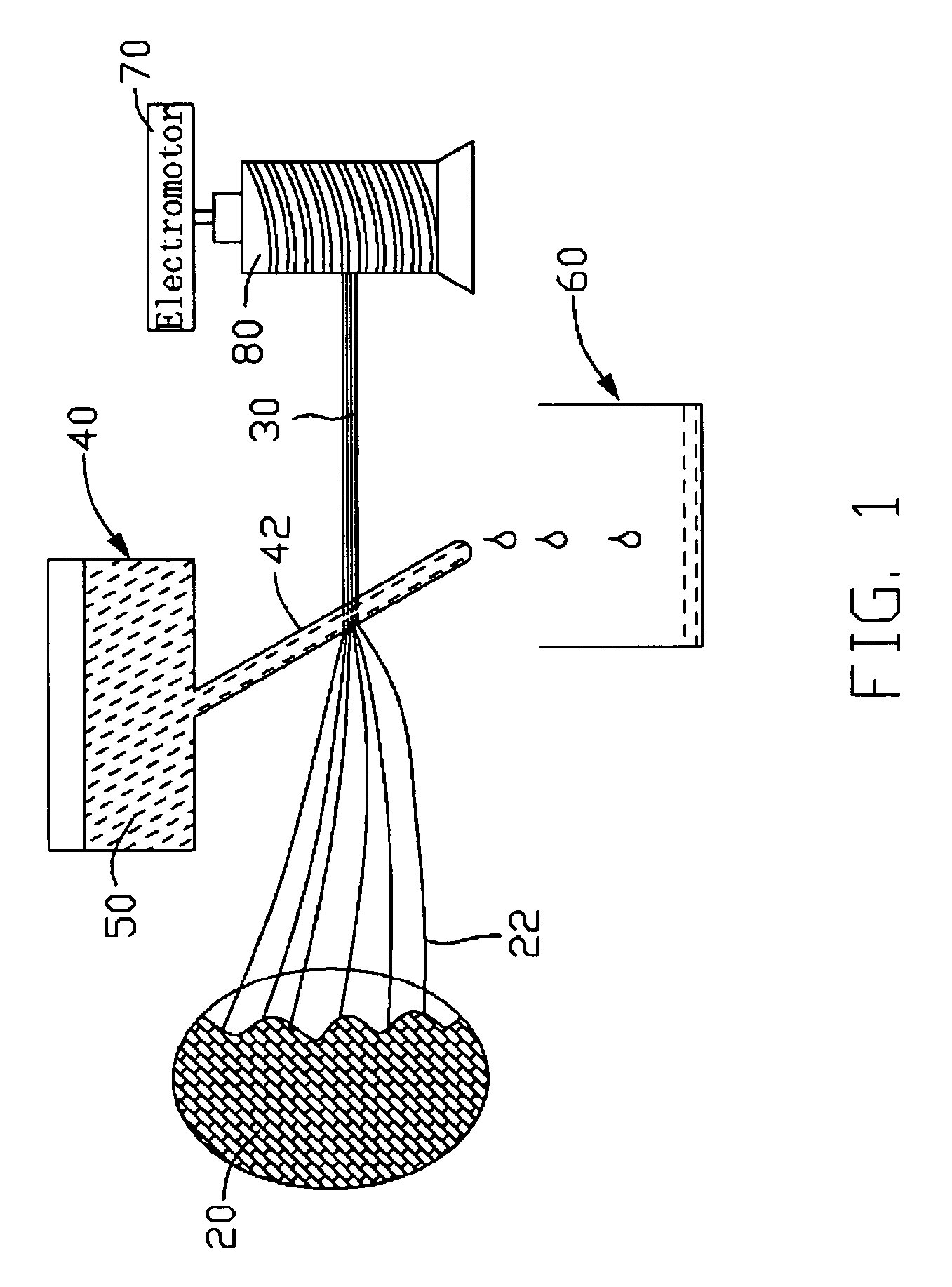

Nanotube fiber reinforced composite materials and method of producing fiber reinforced composites

InactiveUS6934600B2Requires minimizationGenerate efficientlyMaterial nanotechnologyAdditive manufacturing apparatusFiber-reinforced compositeMotion controller

Owner:AUBURN UNIV

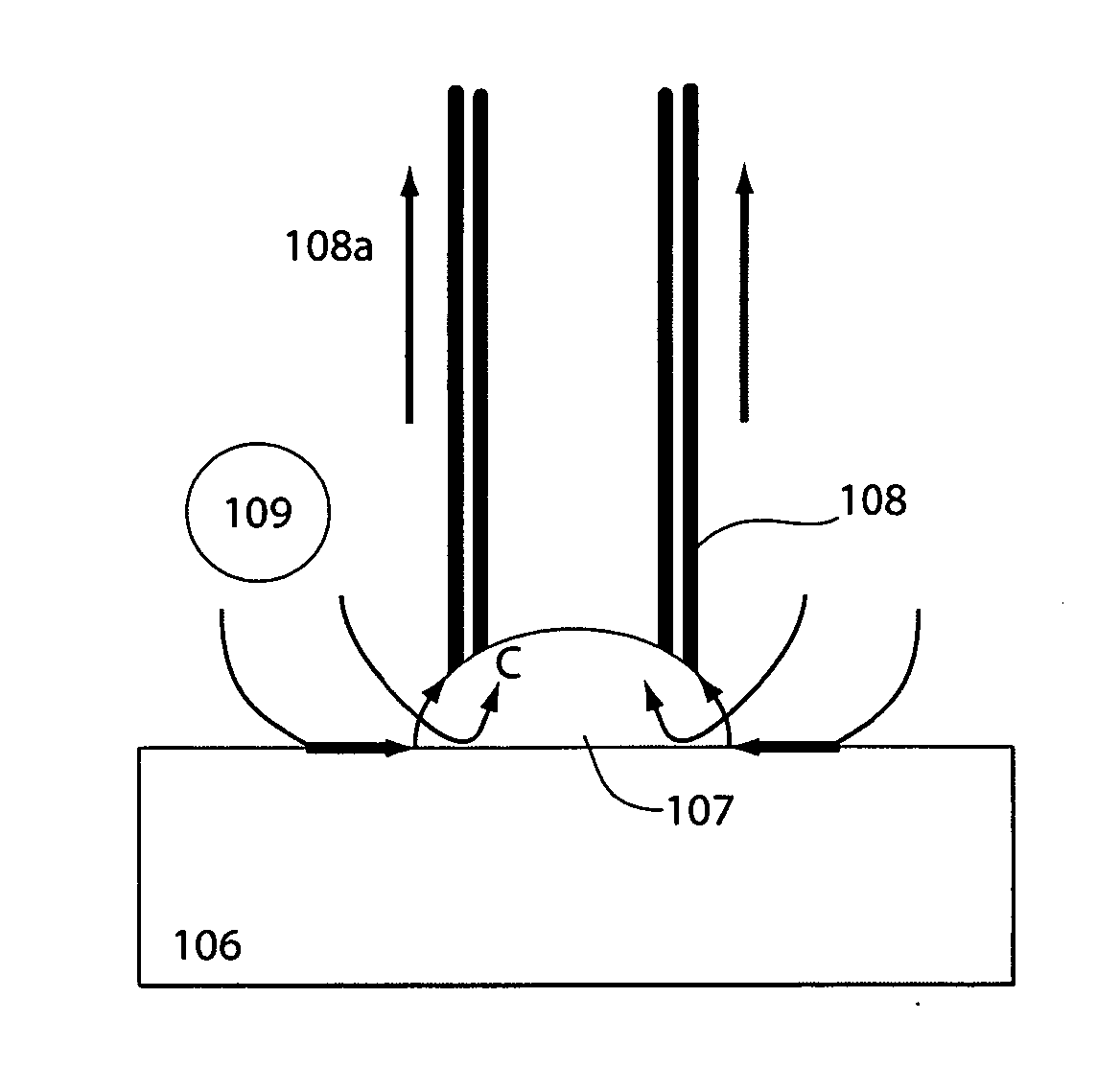

Nanotube/metal substrate composites and methods for producing such composites

InactiveUS20050238810A1Simplified and advantageous mannerReduce productionMaterial nanotechnologyIndirect heat exchangersHydrogen fuel cellChemical vapor deposition

Carbon nanotubes are grown directly on metal substrates using chemical vapor deposition. Metal substrates are comprised of catalysts which facilitate or promote the growth of carbon nanotubes. The nanotube coated metal substrates have applications including, but not limited to, heat transfer and thermal control, hydrogen storage, fuel cell catalytic reformers, electronics and semiconductors, implantable medical devices or prostheses, and tribological wear and protective coatings.

Owner:MAINSTREAM ENG

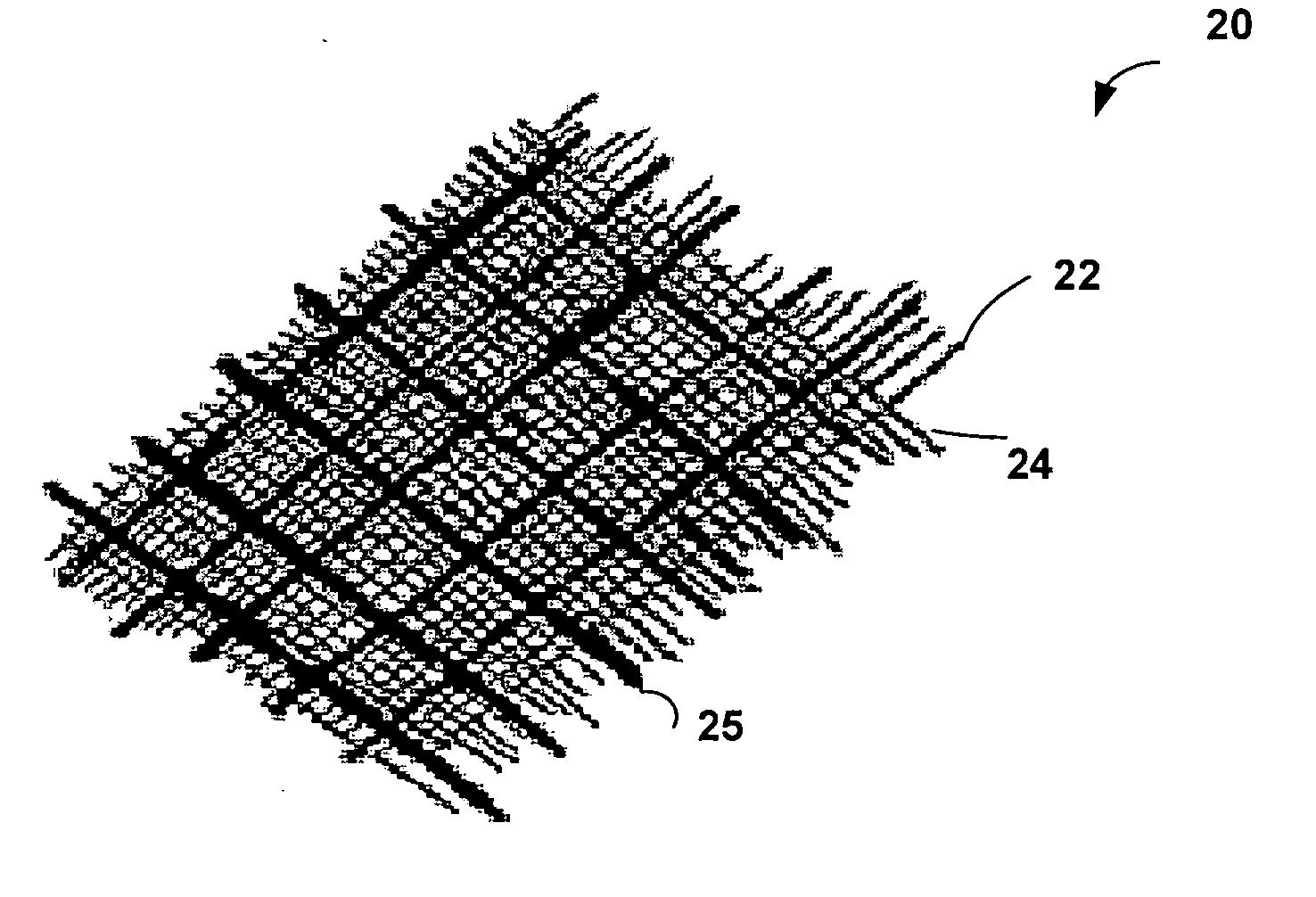

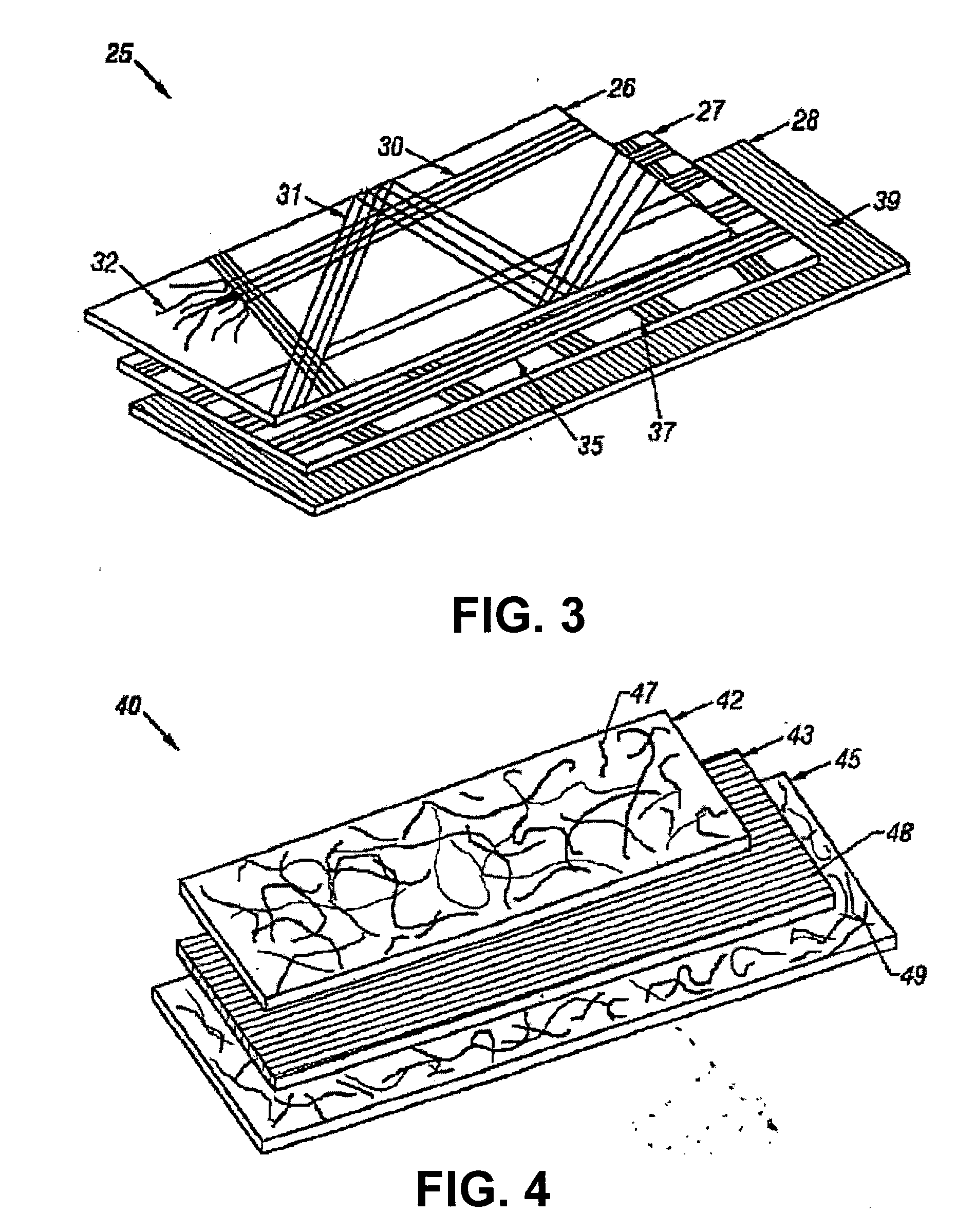

Carbon nanotube fabrics

The present invention provides fabrics that have unique chemical, electrical, and thermal properties. The fabrics comprise layers of yarns woven together wherein the yarns further comprise carbon nanotube fibers. These carbon nanotube fibers may be either single-walled or multi-walled carbon nanotubes. The use of carbon nanotube fibers allows the fabrics to insulate, semi-conduct or super-conduct electrical charges. Additionally, the thermal properties of carbon nanotubes allow thermal energy to flow efficiently between the fabric and a heat sink or source. Additional yarns of materials other than carbon nanotubes can be integrated or woven into the fabric to provide other unique properties for the fabric. These fabrics can be layered to form unique garments or structures.

Owner:LOCKHEED MARTIN CORP

Nanostructure-reinforced composite articles and methods

ActiveUS20080075954A1Material nanotechnologyIndividual molecule manipulationElectronic propertiesNanostructure

The present invention provides methods for uniform growth of nanostructures such as nanotubes (e.g., carbon nanotubes) on the surface of a substrate, wherein the long axes of the nanostructures may be substantially aligned. The nanostructures may be further processed for use in various applications, such as composite materials. For example, a set of aligned nanostructures may be formed and transferred, either in bulk or to another surface, to another material to enhance the properties of the material. In some cases, the nanostructures may enhance the mechanical properties of a material, for example, providing mechanical reinforcement at an interface between two materials or plies. In some cases, the nanostructures may enhance thermal and / or electronic properties of a material. The present invention also provides systems and methods for growth of nanostructures, including batch processes and continuous processes.

Owner:MASSACHUSETTS INST OF TECH

Catalytic growth of single-wall carbon nanotubes from metal particles

InactiveUS6692717B1Material nanotechnologyFibre chemical featuresMetal catalystCatalytic decomposition

Owner:RICE UNIV

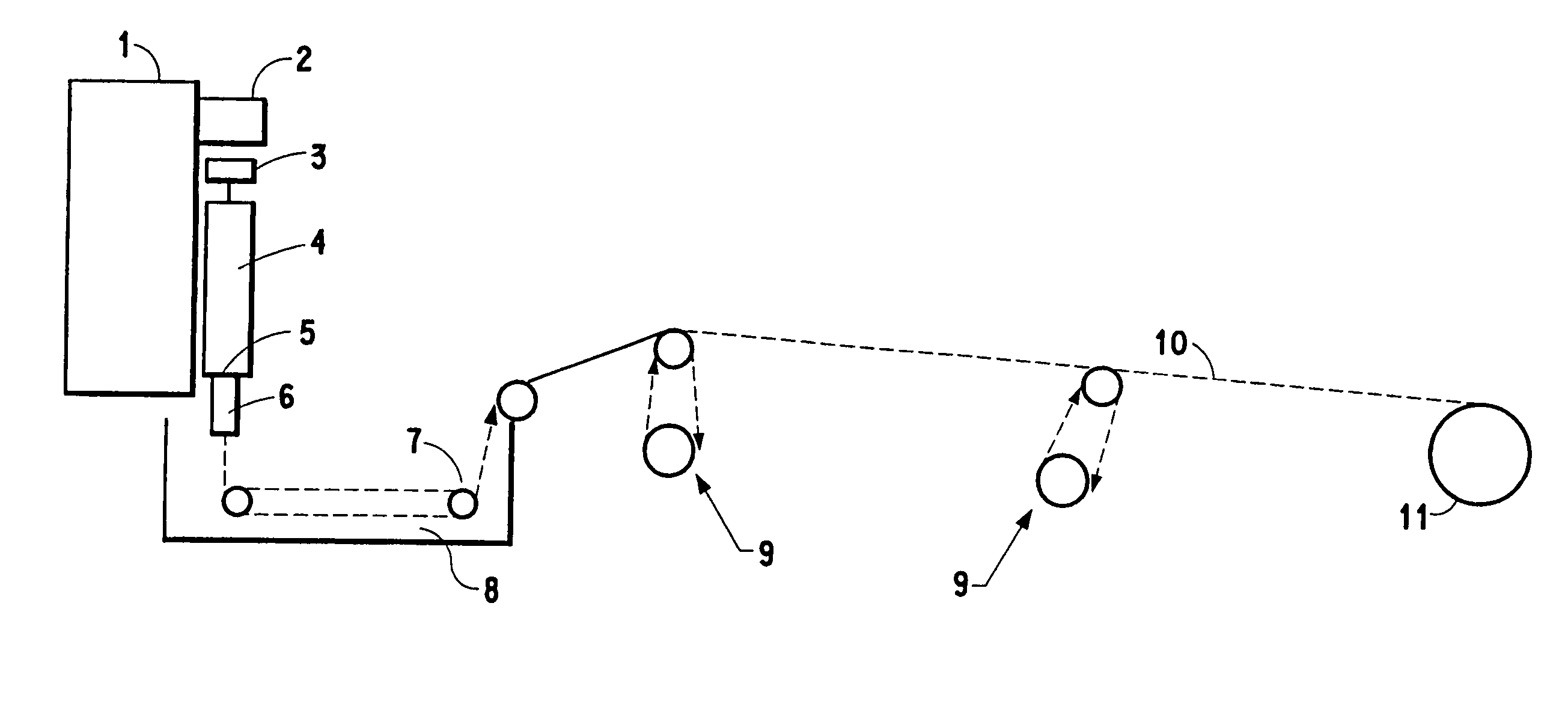

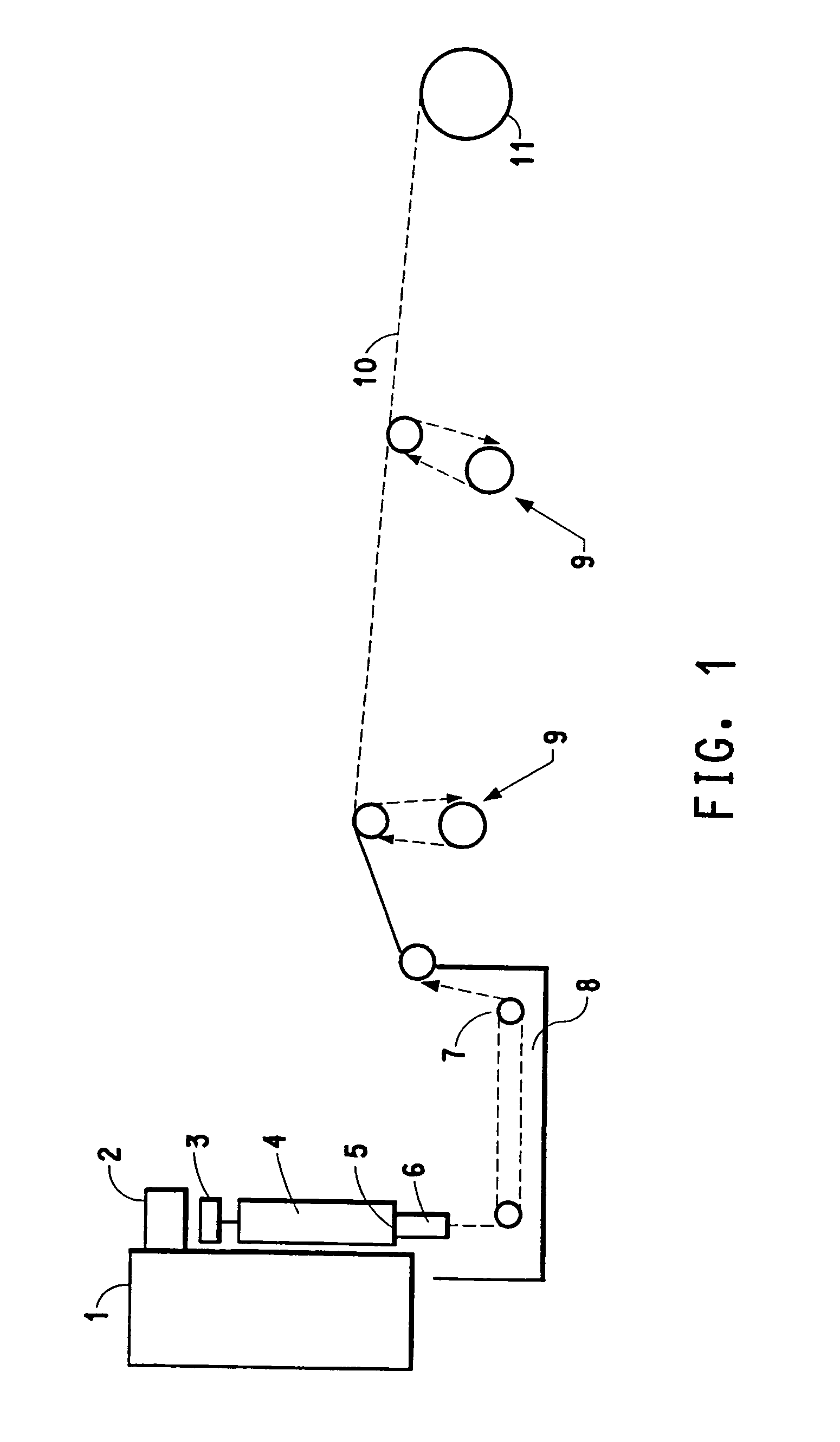

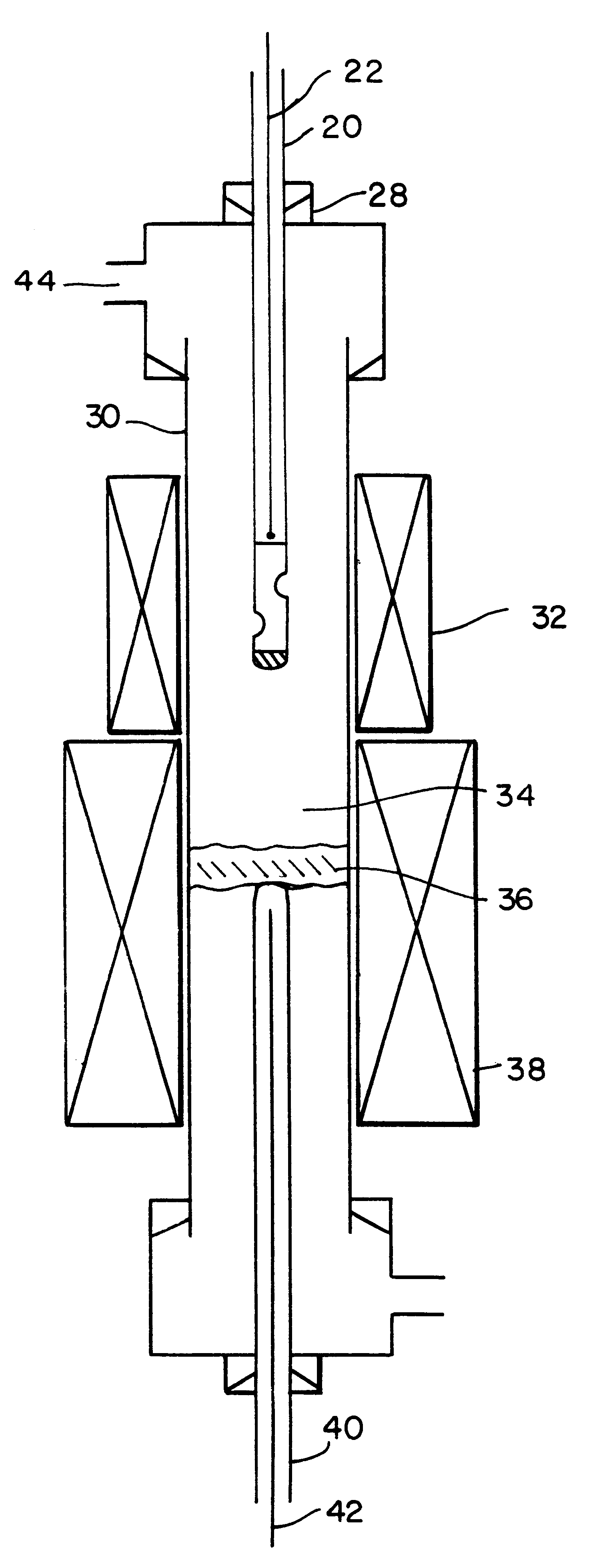

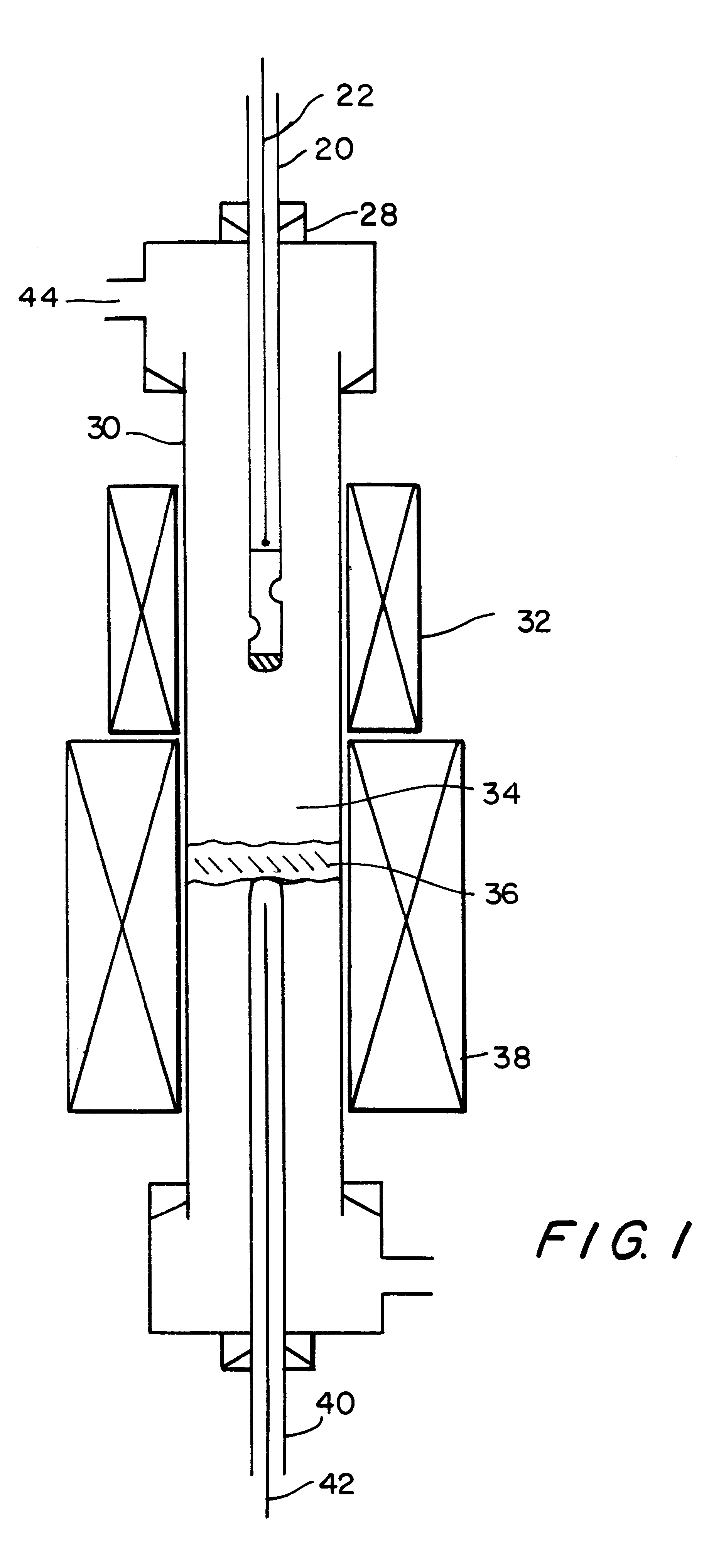

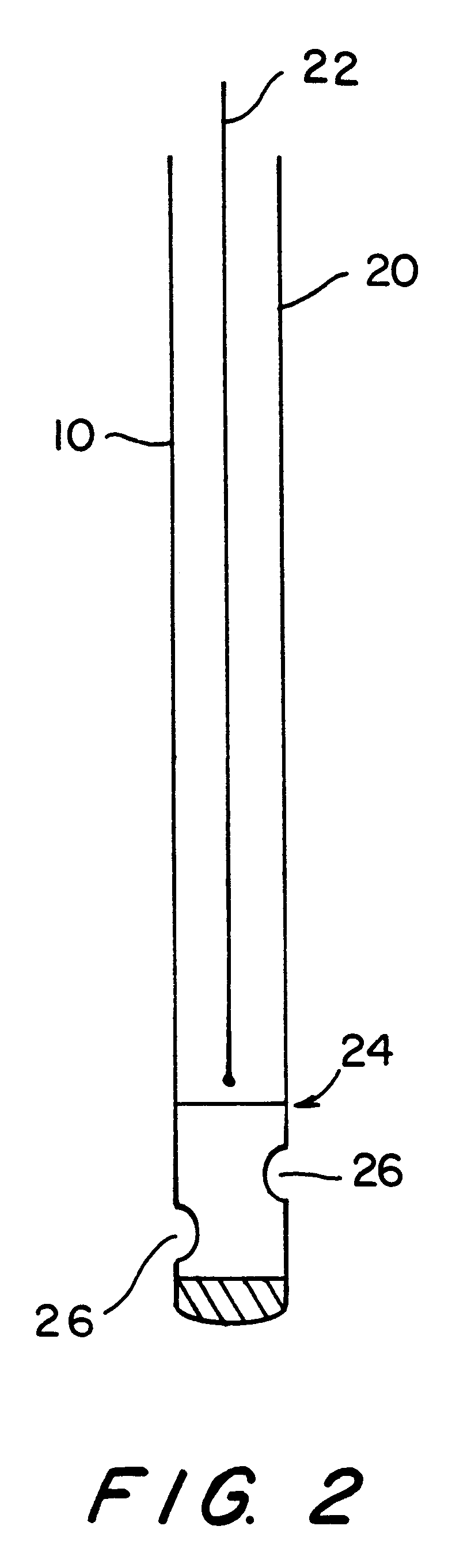

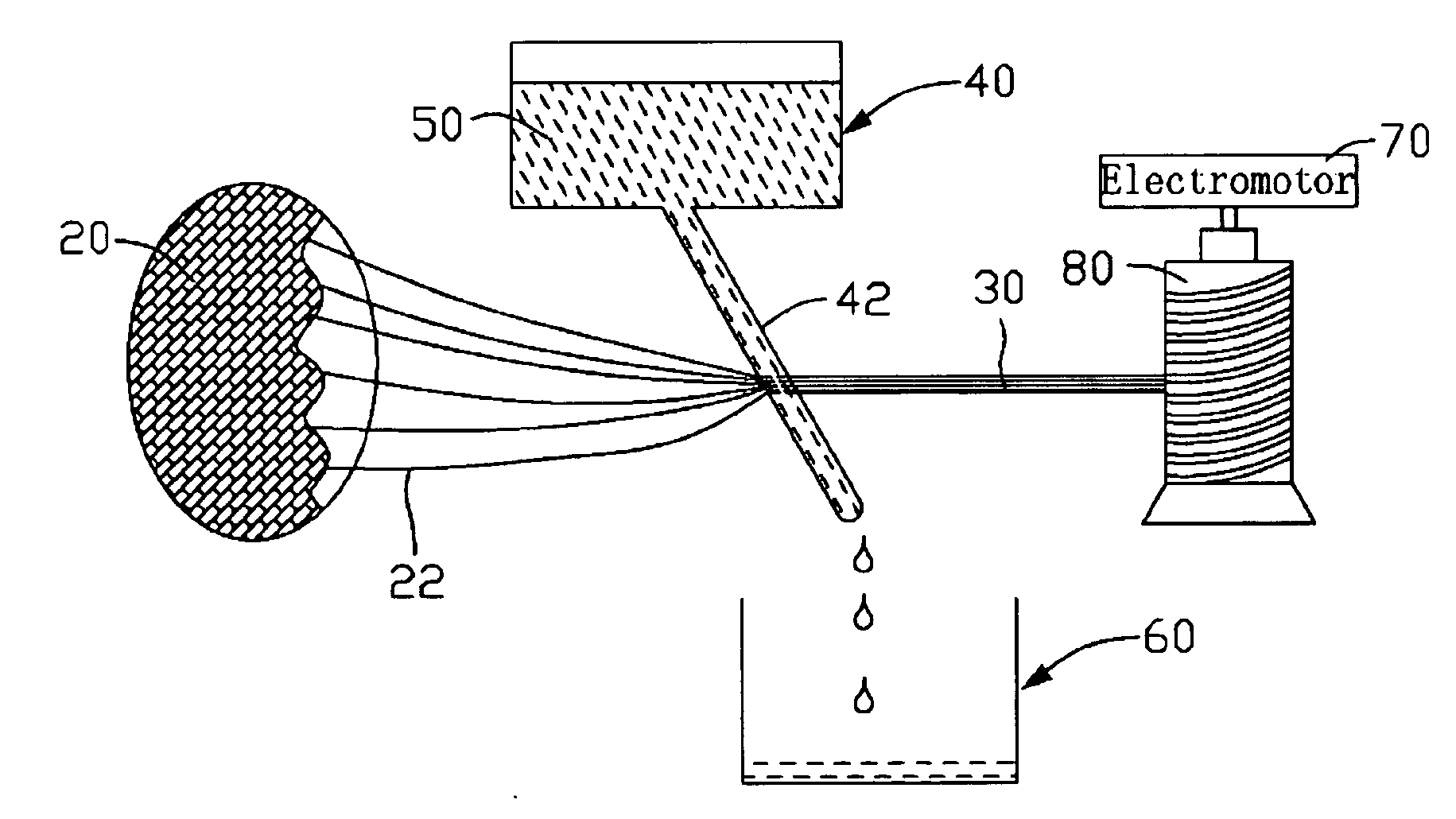

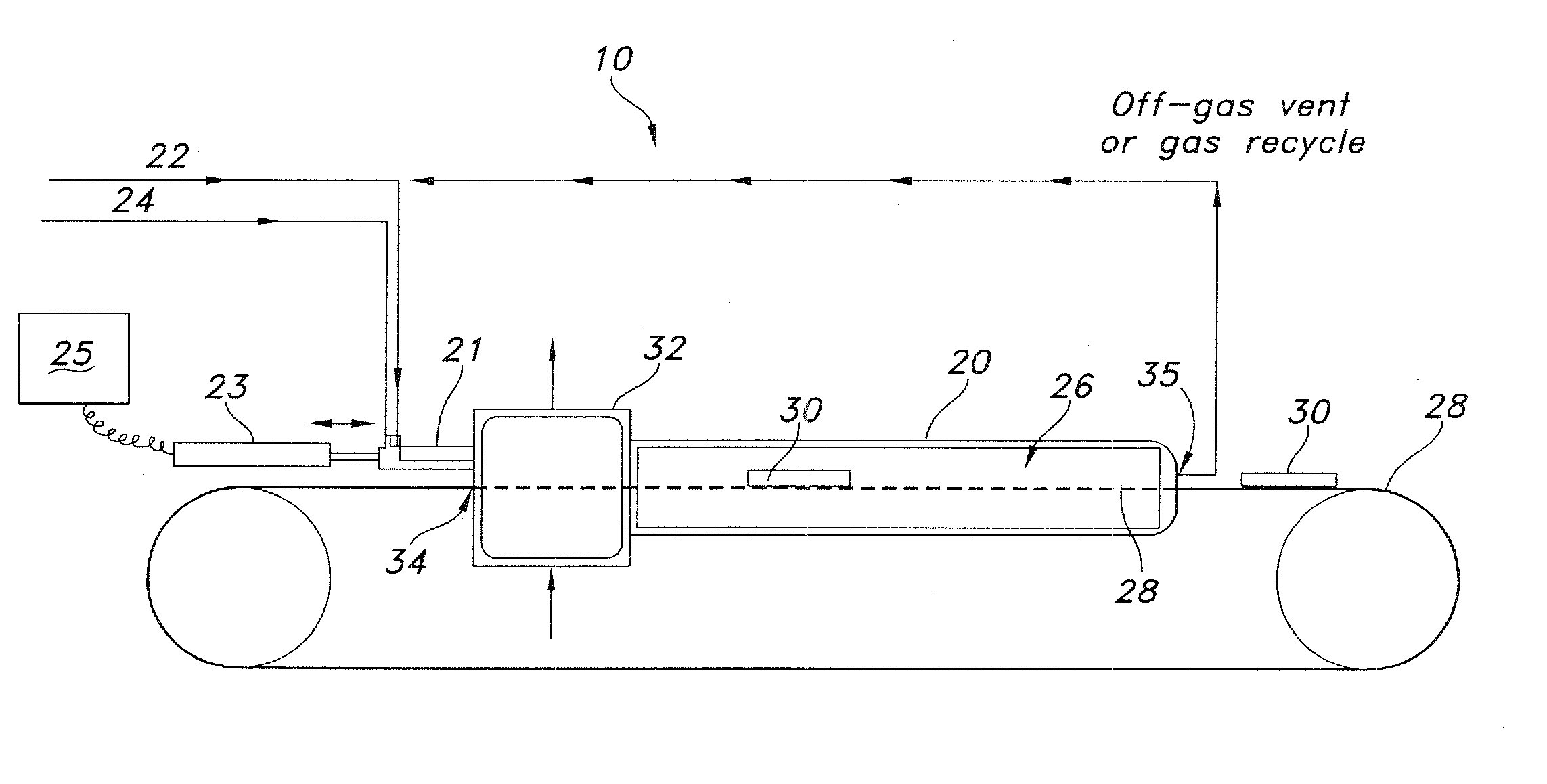

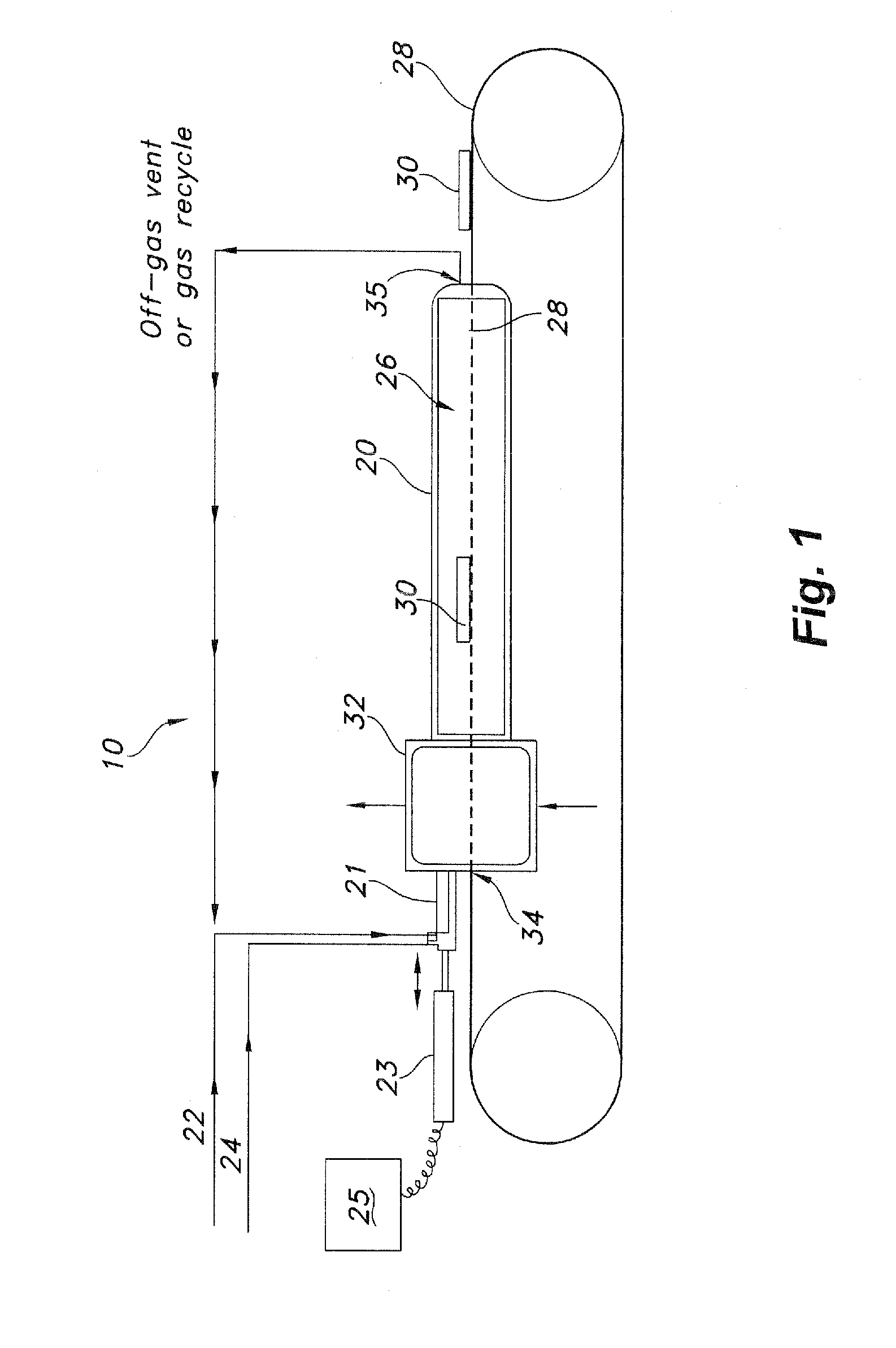

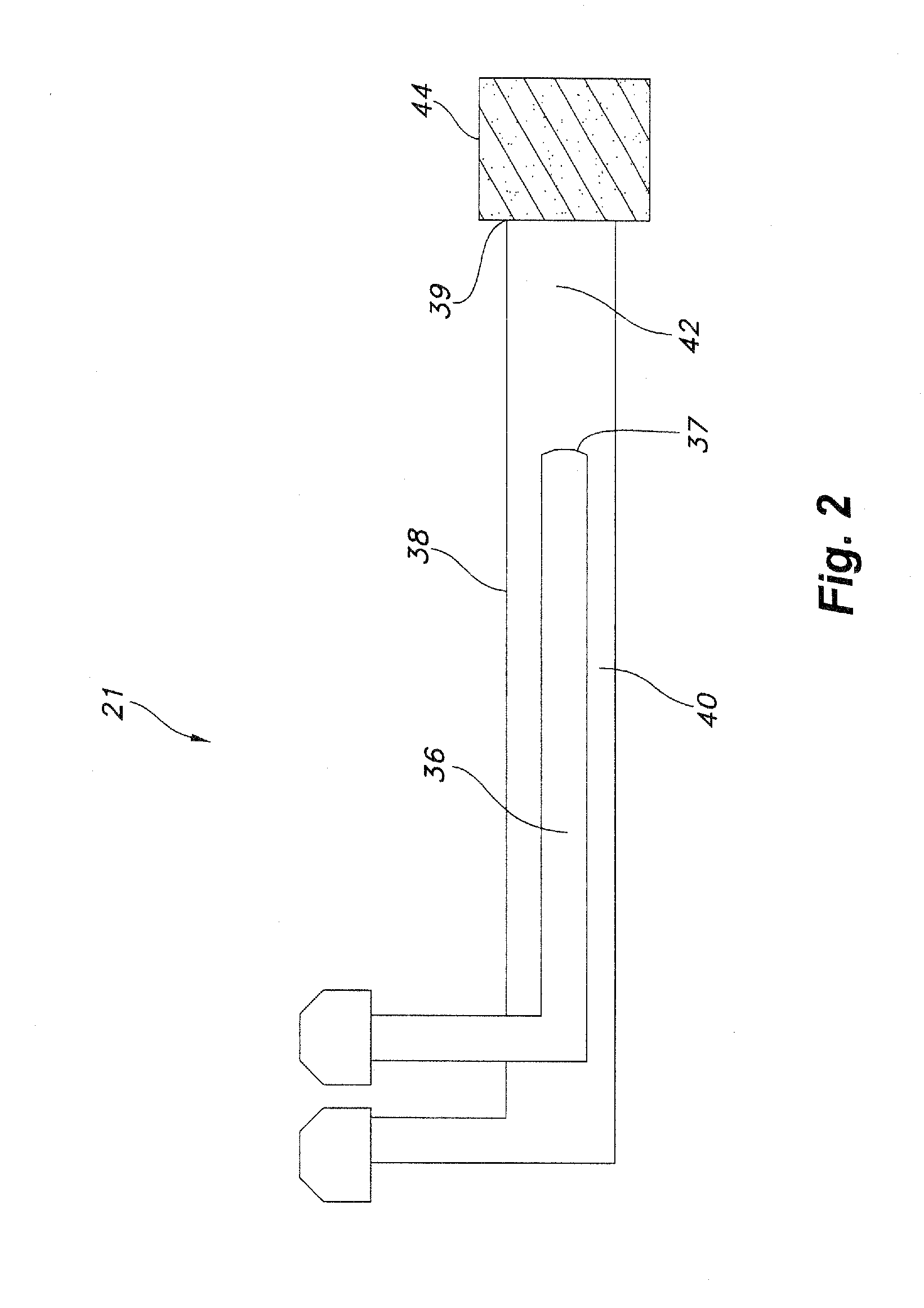

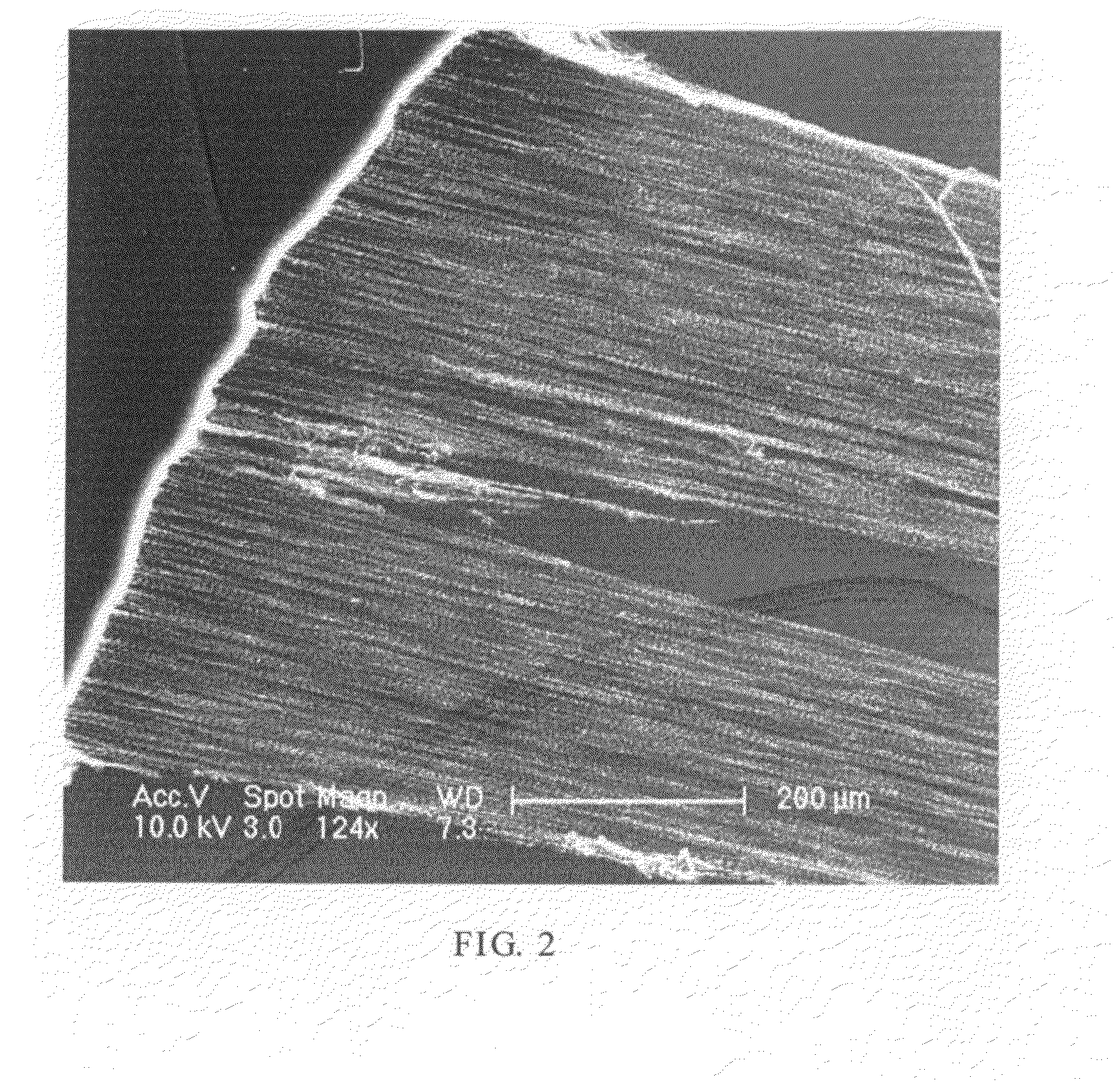

Process for the continuous production of aligned carbon nanotubes

ActiveUS7160531B1Improve flow characteristicsMaterial nanotechnologyCarbon compoundsMetal catalystPorous medium

Novel methods and apparati for continuous production of aligned carbon nanotubes are disclosed. In one aspect, the method comprises dispersion of a metal catalyst in a liquid hydrocarbon to form a feed solution, and volatilizing the feed solution in a reactor through which a substrate is continuously passed to allow growth of nanotubes thereon. In another aspect, the apparatus comprises a reactor, a tube-within-a-tube injector, and a conveyor belt for passing a substrate through the reactor. The present invention further discloses a method for restricting the external diameter of carbon nanotubes produced thereby comprising passing the feed solution through injector tubing of a specified diameter, followed by passing the feed solution through an inert, porous medium. The method and apparati of this invention provide a means for producing aligned carbon nanotubes of a particular external diameter which is suitable for large scale production in an industrial setting.

Owner:UNIV OF KENTUCKY RES FOUND

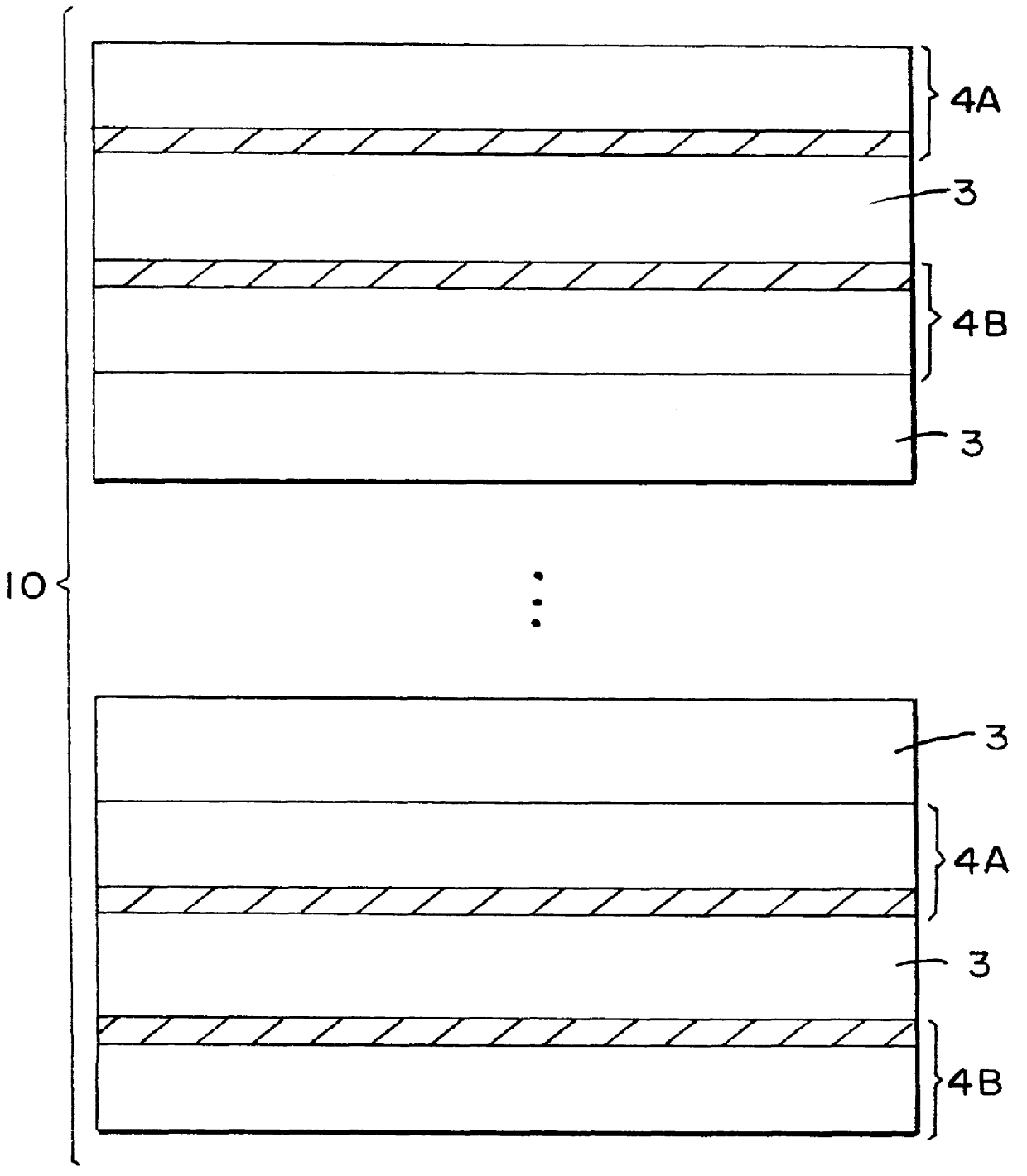

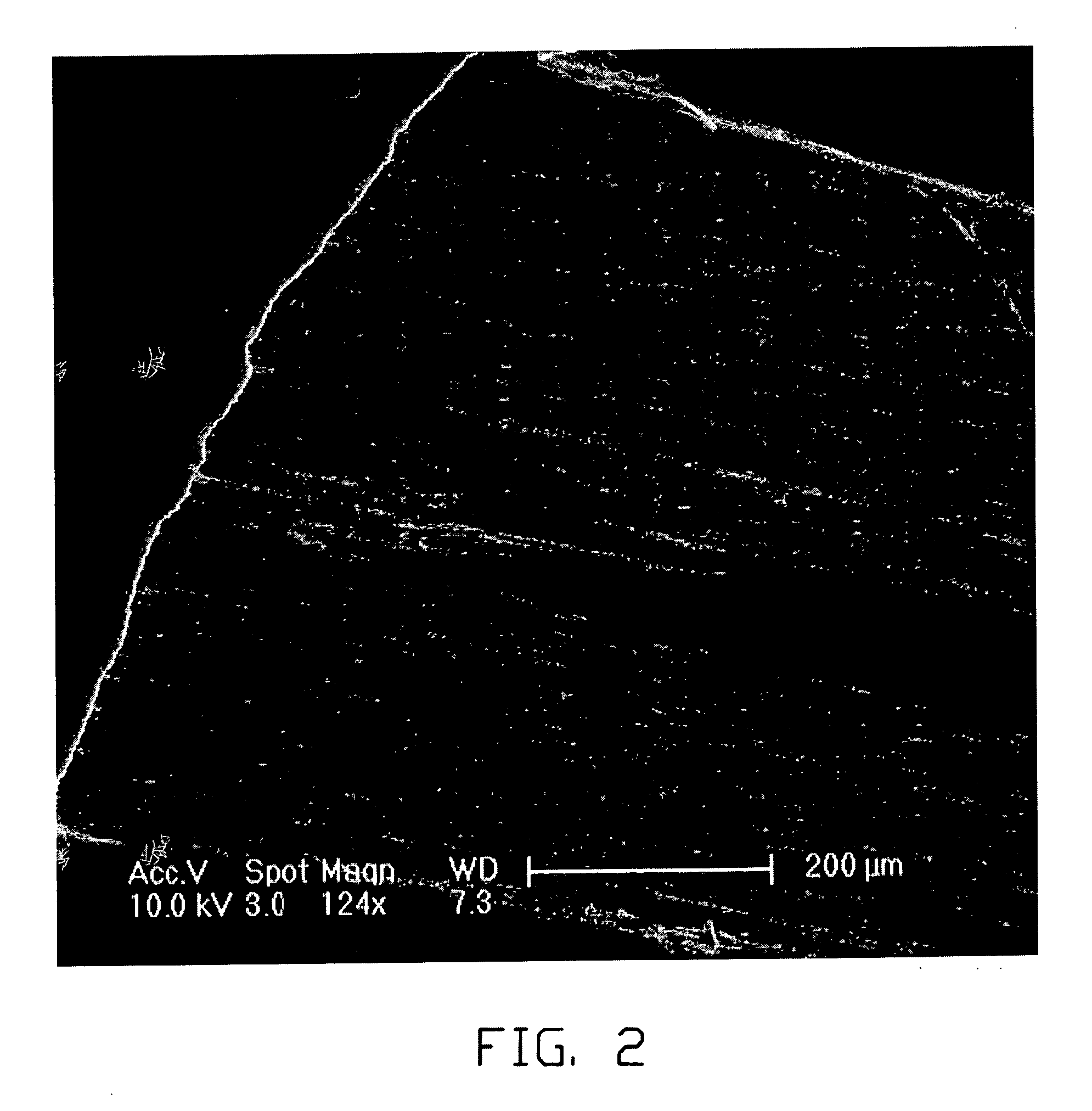

Method of producing exfoliated graphite, flexible graphite, and nano-scaled graphene platelets

ActiveUS20080279756A1Good dispersionImprove conductivityCarbon compoundsFibre chemical featuresFiberLiquid medium

The present invention provides a method of exfoliating a layered material (e.g., graphite and graphite oxide) to produce nano-scaled platelets having a thickness smaller than 100 nm, typically smaller than 10 nm. The method comprises (a) dispersing particles of graphite, graphite oxide, or a non-graphite laminar compound in a liquid medium containing therein a surfactant or dispersing agent to obtain a stable suspension or slurry; and (b) exposing the suspension or slurry to ultrasonic waves at an energy level for a sufficient length of time to produce separated nano-scaled platelets. The nano-scaled platelets are candidate reinforcement fillers for polymer nanocomposites. Nano-scaled graphene platelets are much lower-cost alternatives to carbon nano-tubes or carbon nano-fibers.

Owner:GLOBAL GRAPHENE GRP INC

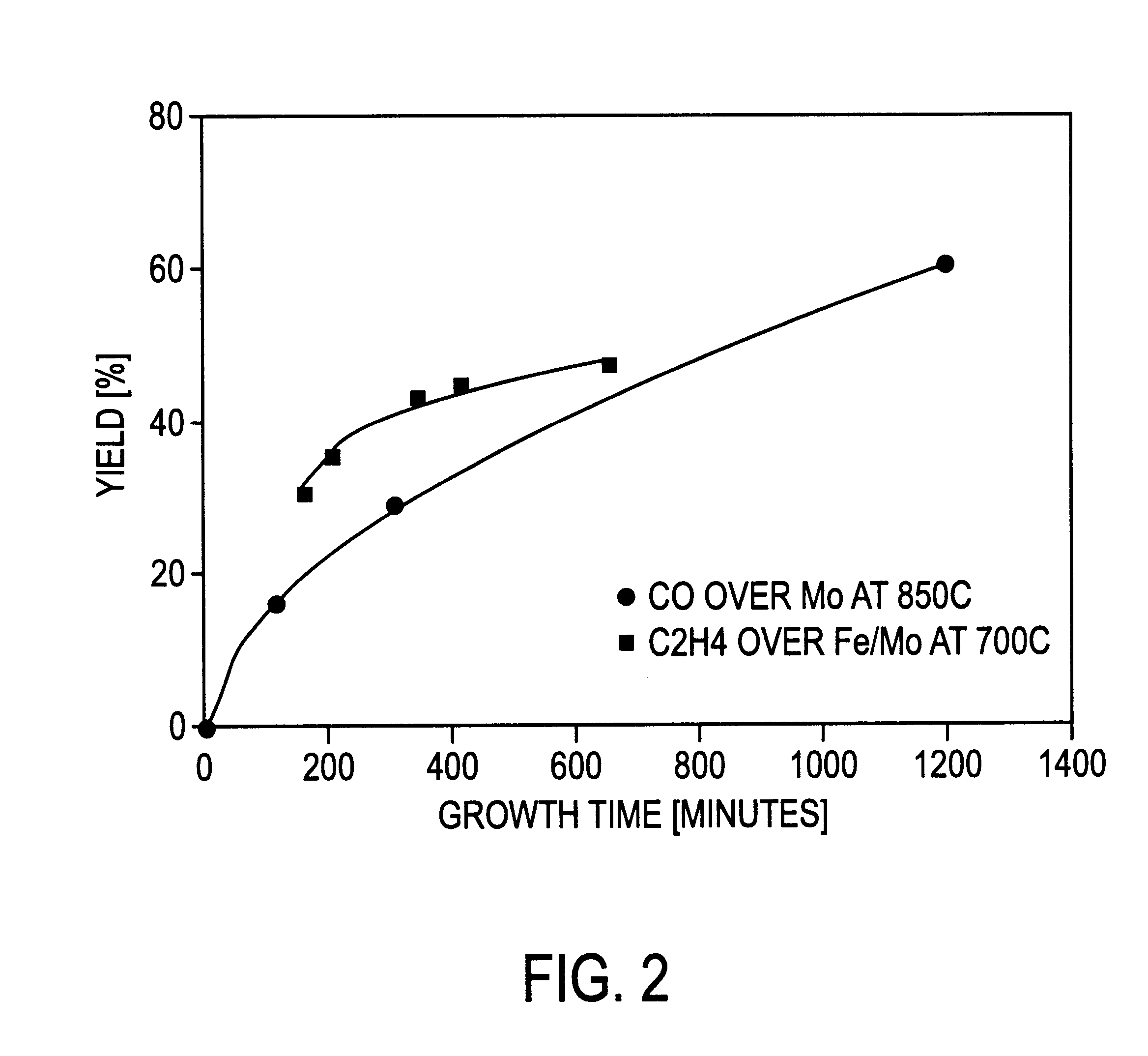

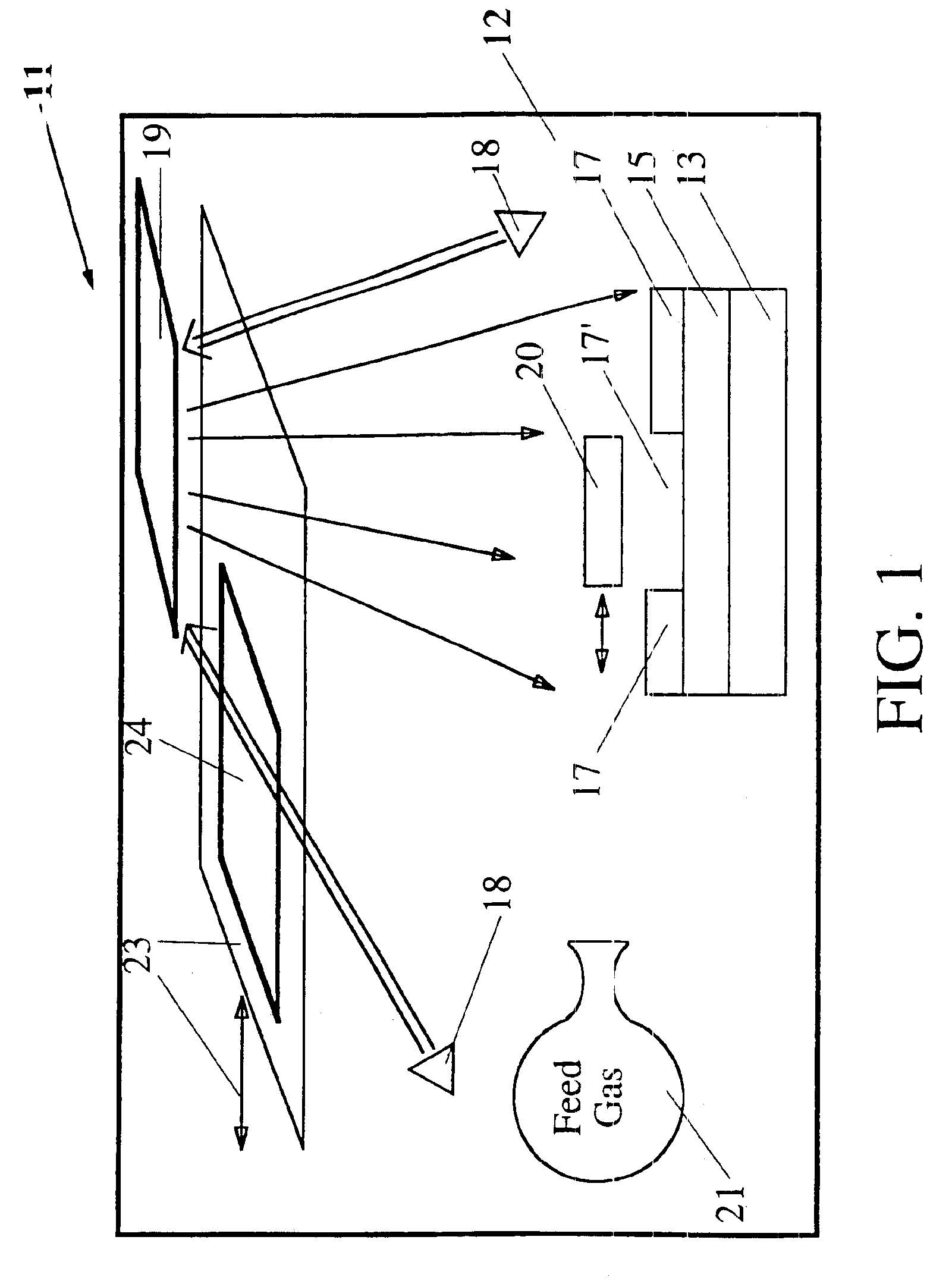

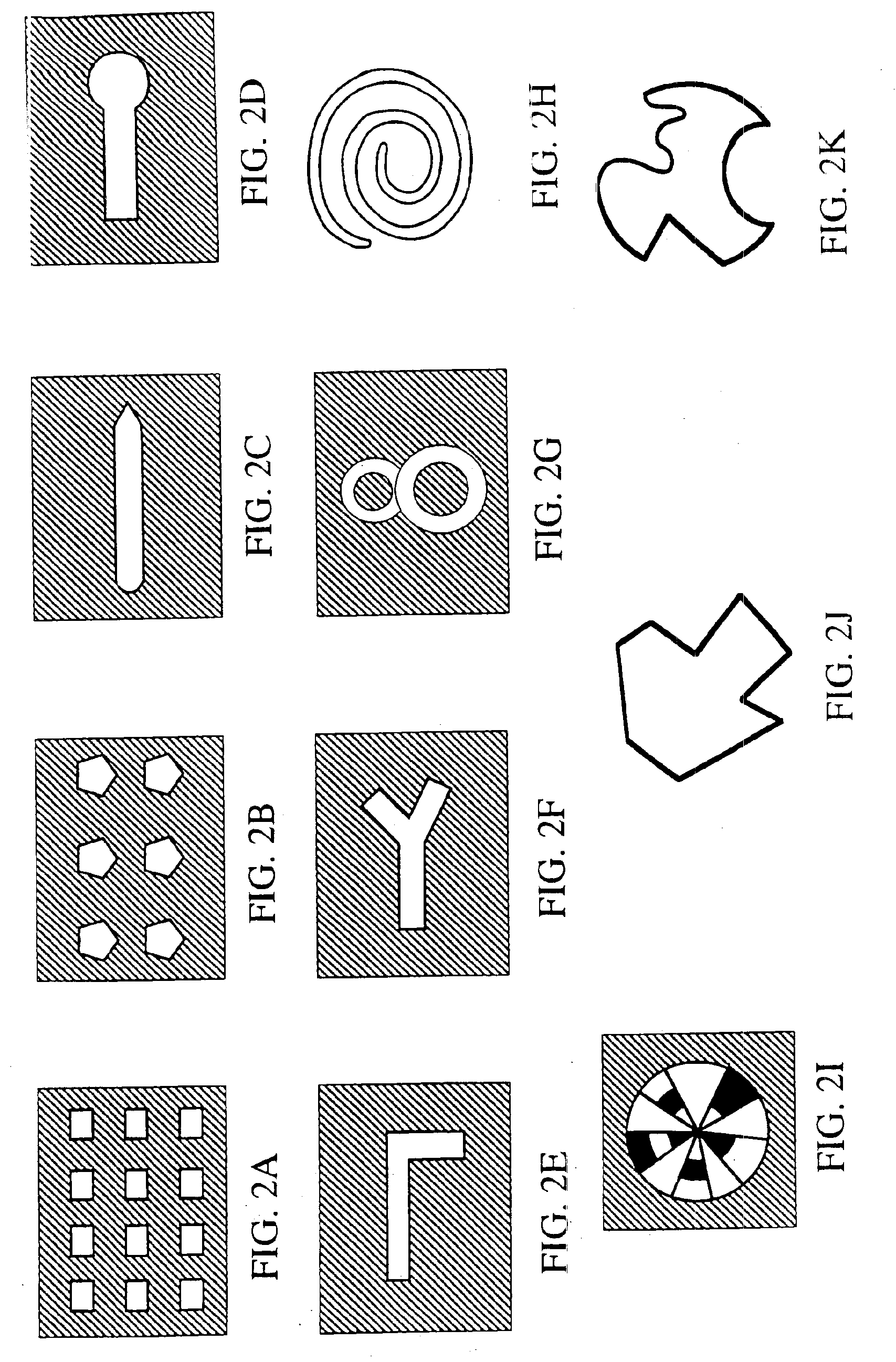

Controlled patterning and growth of single wall and multi-wall carbon nanotubes

Method and system for producing a selected pattern or array of at least one of a single wall nanotube and / or a multi-wall nanotube containing primarily carbon. A substrate is coated with a first layer (optional) of a first selected metal (e.g., Al and / or Ir) and with a second layer of a catalyst (e.g., Fe, Co, Ni and / or Mo), having selected first and second layer thicknesses provided by ion sputtering, arc discharge, laser ablation, evaporation or CVD. The first layer and / or the second layer may be formed in a desired non-uniform pattern, using a mask with suitable aperture(s), to promote growth of carbon nanotubes in a corresponding pattern. A selected heated feed gas (primarily CH4 or C2Hn with n=2 and / or 4) is passed over the coated substrate and forms primarily single wall nanotubes or multiple wall nanotubes, depending upon the selected feed gas and its temperature. Nanofibers, as well as single wall and multi-wall nanotubes, are produced using plasma-aided growth from the second (catalyst) layer. An overcoating of a selected metal or alloy can be deposited, over the second layer, to provide a coating for the carbon nanotubes grown in this manner.

Owner:NASA +1

Method for making carbon nanotube yarn

A carbon nanotube yarn includes a number of carbon nanotube yarn strings bound together, and each of the carbon nanotube yarn strings includes a number of carbon nanotube bundles that are joined end to end by van der Waals attractive force, and each of the carbon nanotube bundles includes a number of carbon nanotubes substantially parallel to each other. A method for making the carbon nanotube yarn includes soaking the at least one carbon nanotube yarn string drawn out from a carbon nanotube array in an organic solvent to shrink it and then collecting it.

Owner:TSINGHUA UNIV

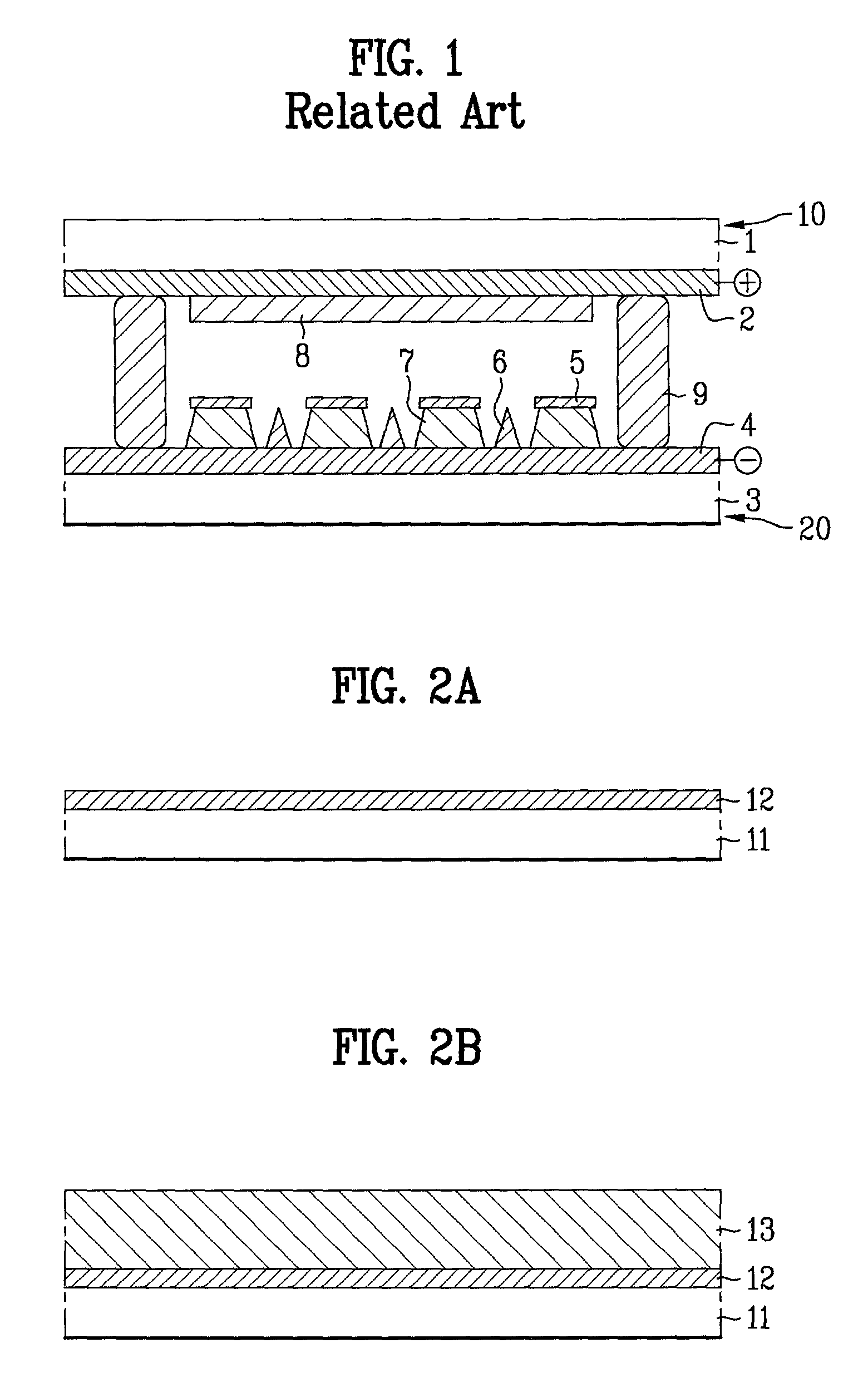

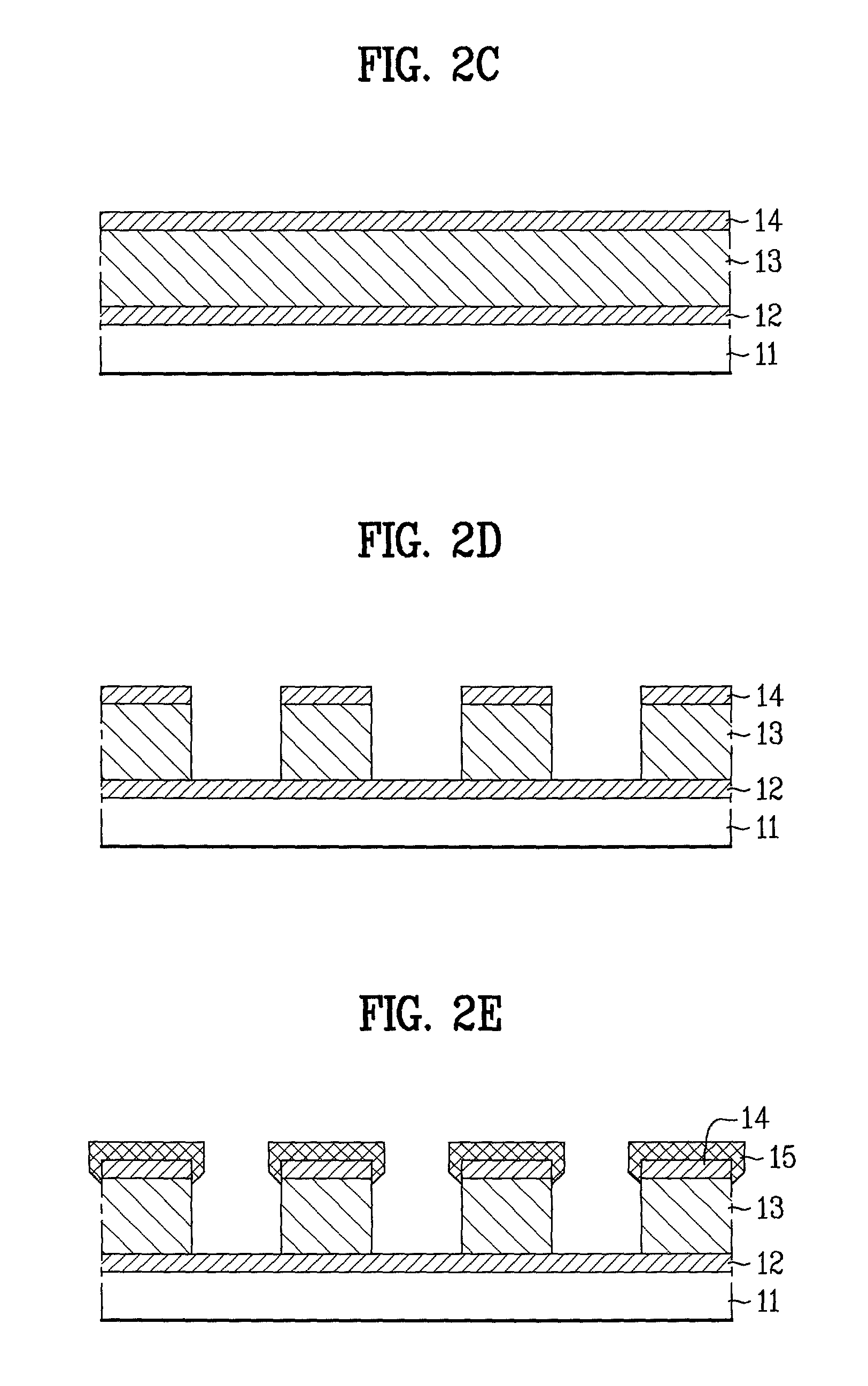

Field emission display and method for fabricating the same

InactiveUS20010004979A1Stable driving voltageUniform characteristicsMaterial nanotechnologyDecorative surface effectsLow voltageCarbon nanotube

Field emission display and method for fabricating the same, the field emission display including a cathode array having a cathode electrode formed on a substrate, insulating layers and carbon nanotube films for use as emitter electrodes formed alternately on the cathode electrode, and a gate electrode formed on the insulating layer, thereby permitting fabrication of a large sized cathode plate at a low cost because the film is formed by screen printing and exposure, which can reduce the cumbersome steps in fabrication of the related art Spindt emitter tip, and both a low voltage and a high voltage FEDs because the carbon nanotube film used as the emitter has a low work function, with an easy and stable electron emission capability.

Owner:LG ELECTRONICS INC

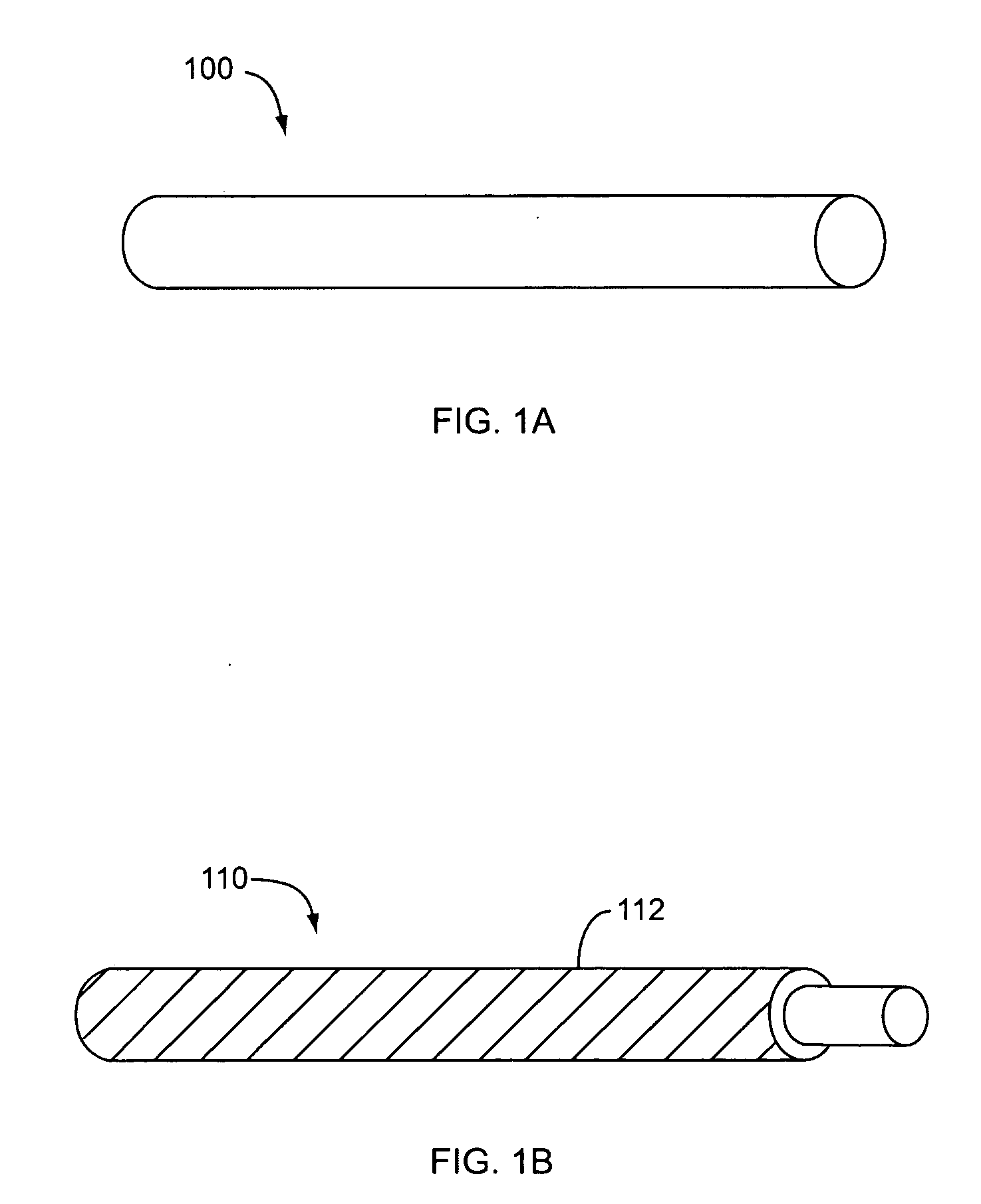

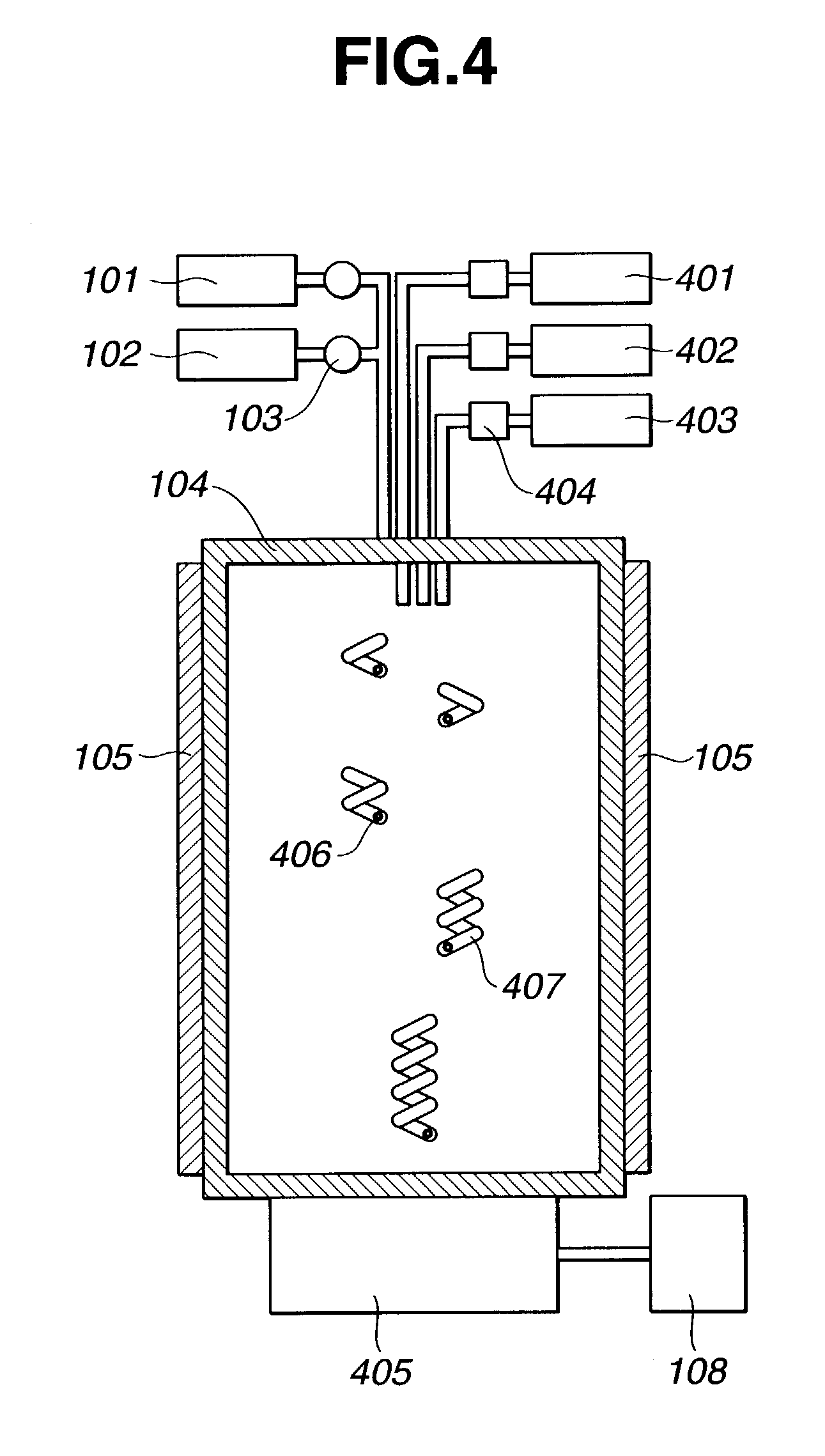

Systems and methods for harvesting and integrating nanowires

ActiveUS20060008942A1Ease of mass productionImprove device performanceLayered productsNanoinformaticsNanowireInk printer

The present invention is directed to methods to harvest, integrate and exploit nanomaterials, and particularly elongated nanowire materials. The invention provides methods for harvesting nanowires that include selectively etching a sacrificial layer placed on a nanowire growth substrate to remove nanowires. The invention also provides methods for integrating nanowires into electronic devices that include placing an outer surface of a cylinder in contact with a fluid suspension of nanowires and rolling the nanowire coated cylinder to deposit nanowires onto a surface. Methods are also provided to deposit nanowires using an ink-jet printer or an aperture to align nanowires. Additional aspects of the invention provide methods for preventing gate shorts in nanowire based transistors. Additional methods for harvesting and integrating nanowires are provided.

Owner:ONED MATERIAL INC

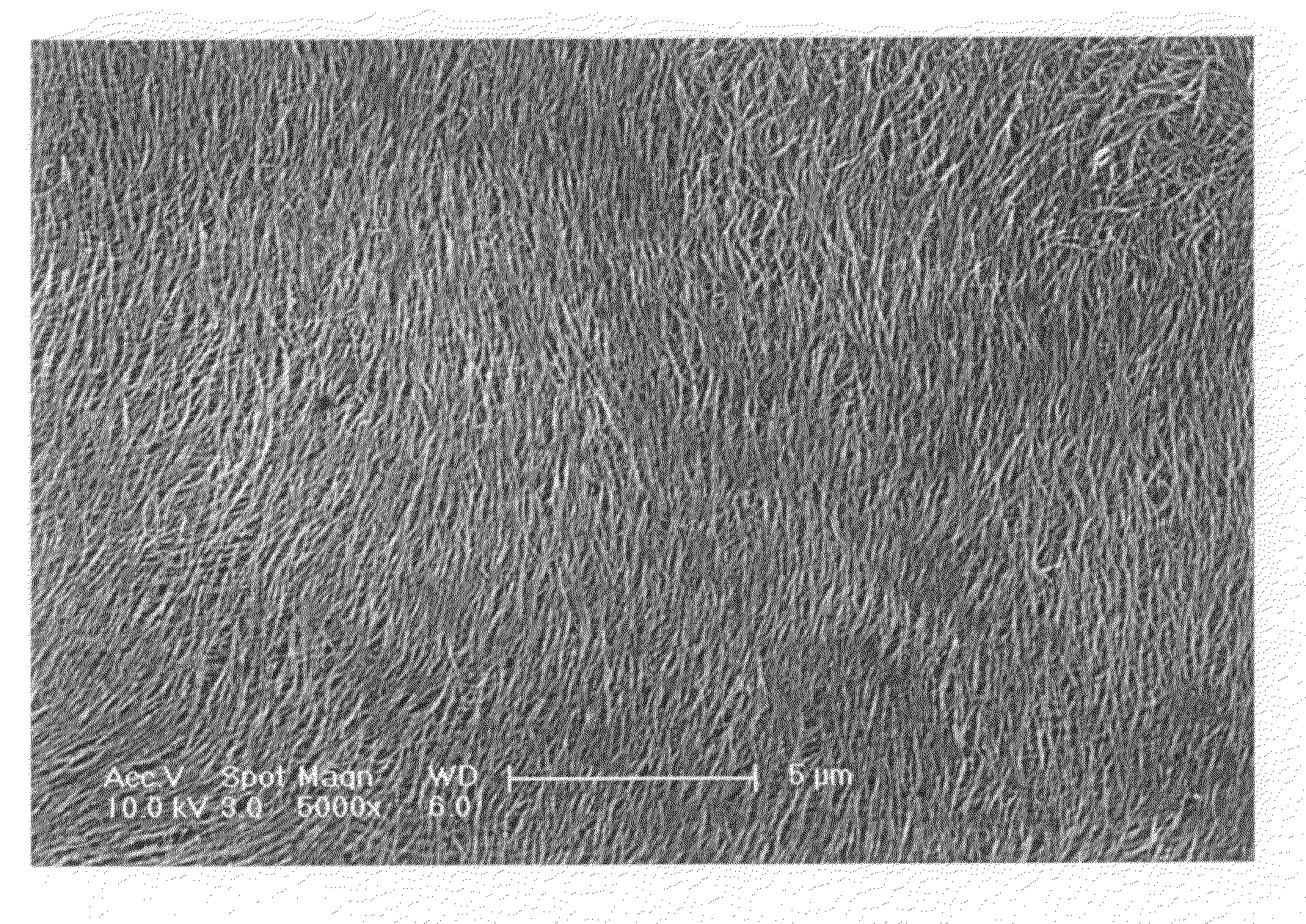

Method for making a carbon nanotube film

ActiveUS20080299031A1High strengthSimple methodMaterial nanotechnologyLayered productsCarbon nanotubeNanotube array

The present invention relates to a method for making a carbon nanotube film. The method includes the steps of: (a) forming an array of carbon nanotubes on a substrate; and (b) press the array of carbon nanotubes using a compressing apparatus, thereby forming a carbon nanotube film.

Owner:BEIJING FUNATE INNOVATION TECH +1

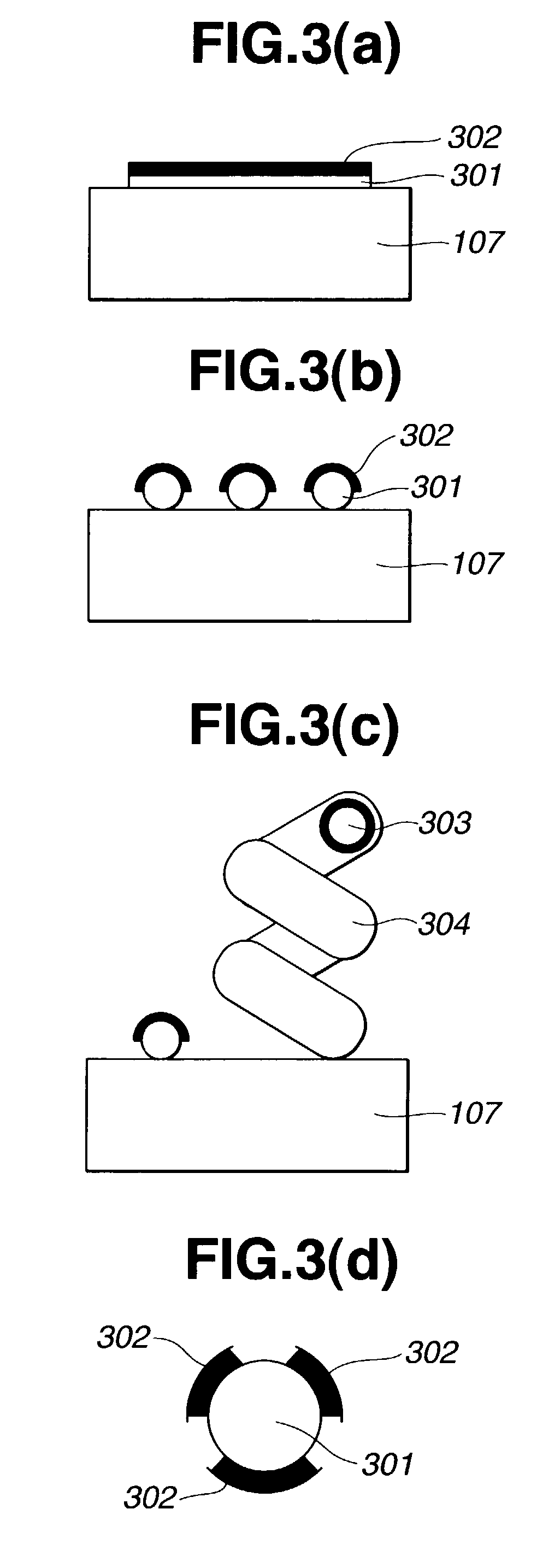

Carbon-Based Fine Structure Array, Aggregate of Carbon-Based Fine Structures, Use Thereof and Method for Preparation Thereof

ActiveUS20080095694A1Long and strong aggregateEasy alignmentMaterial nanotechnologyLayered productsFine structureStrong interaction

An aggregate of carbon-based fine structures in which a plurality of carbon-based fine structures are collected, wherein respective carbon-based fine structures are oriented in the same direction. The above aggregate of carbon-based fine structures is an aggregate of a plurality of carbon-based fine structures in a state they are pulled by one another with strong interaction, and has such a length that allows the improvement of the handleability and workability thereof.

Owner:NIPPON SANSO CORP

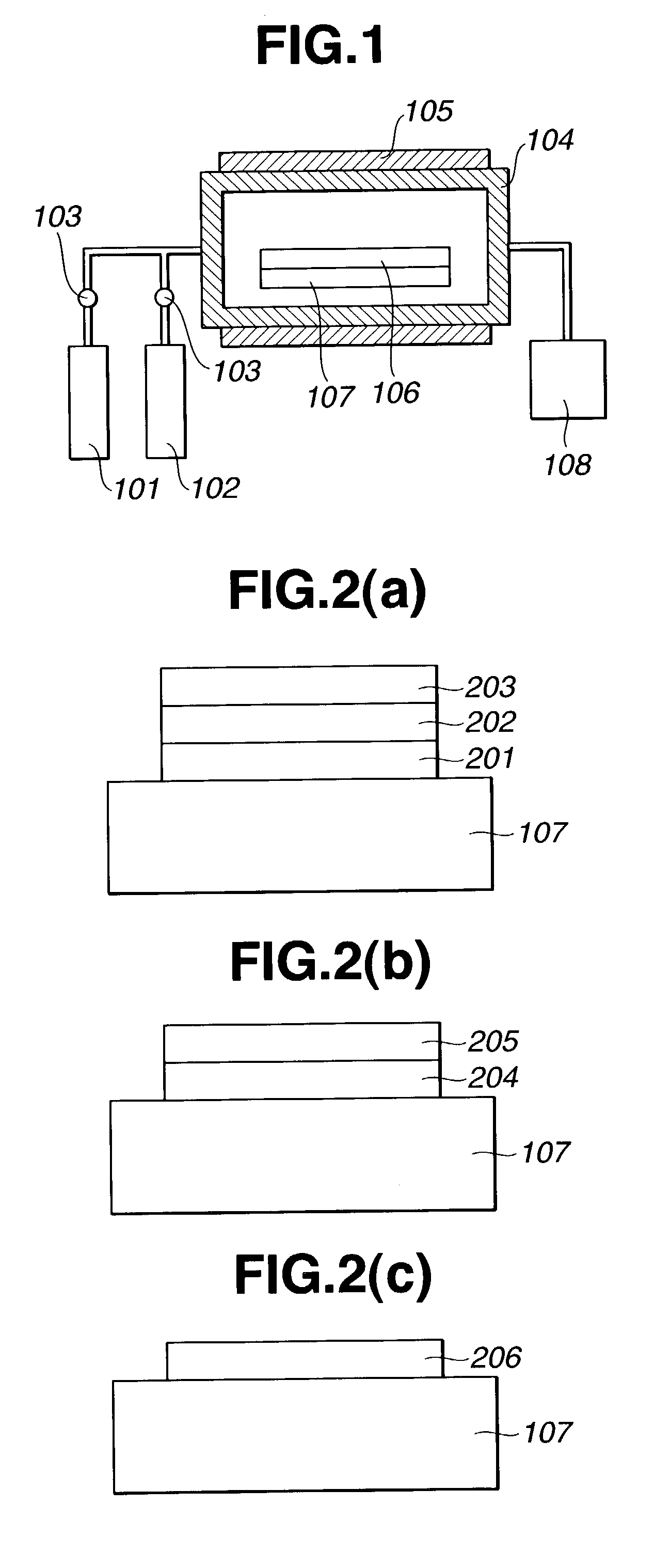

Method for preparing nano-carbon fiber and nano-carbon fiber

A carbon nano-fiber, particularly twisted carbon nano-fiber such as a carbon nano-coil, carbon nano-twist, carbon nano-rope is produced by means of a catalyst CVD method using carbon-containing gas as a raw material and a catalyst comprising one or plural components selected from the group consisting of Cr, Mn, Fe, Co, Ni and oxide thereof and one or plural components selected from the group consisting of Cu, Al, Si, Ti, V, Nb, Mo, Hf, Ta, W and oxide thereof is used.

Owner:FUTABA CORPORATION

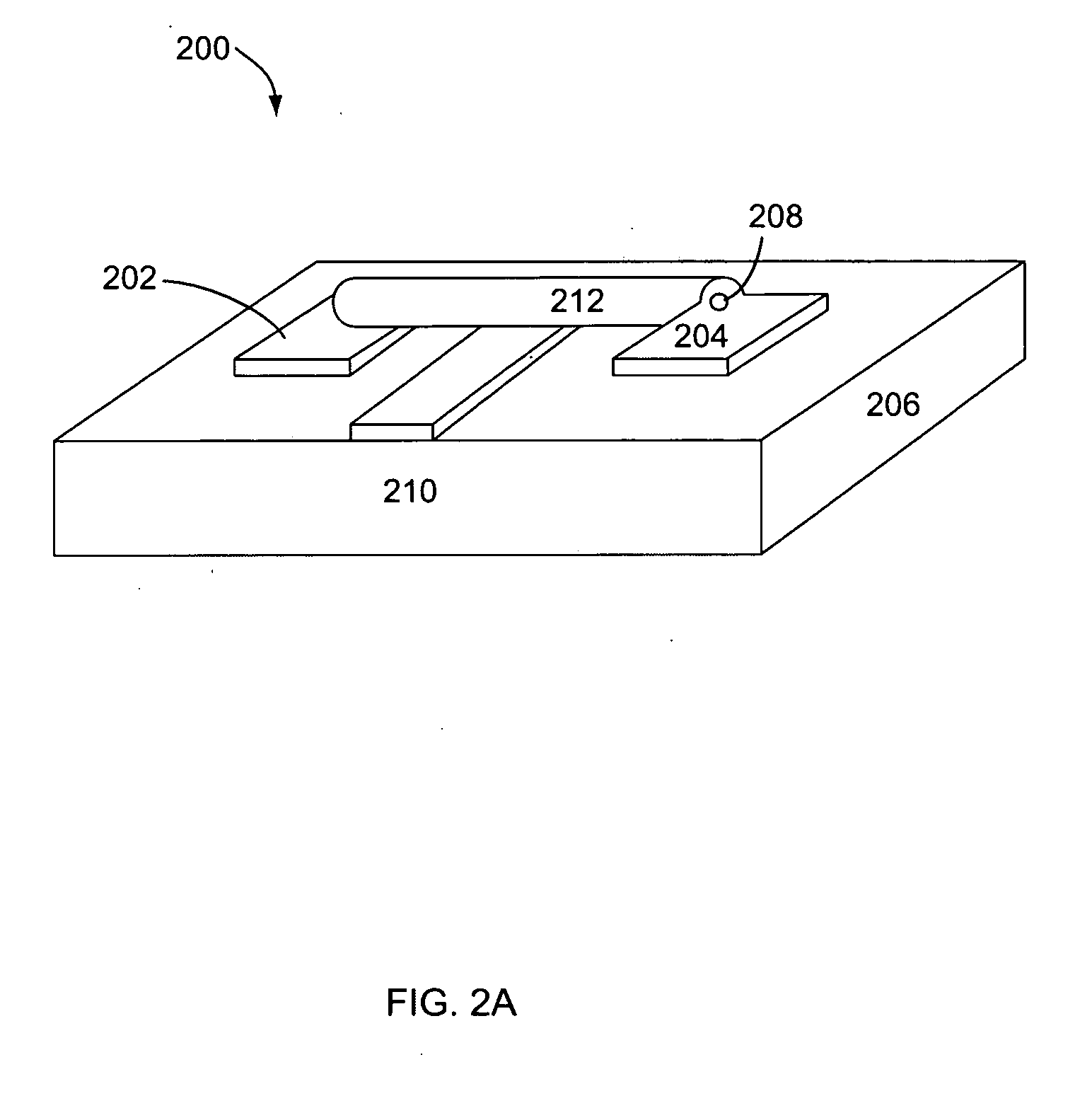

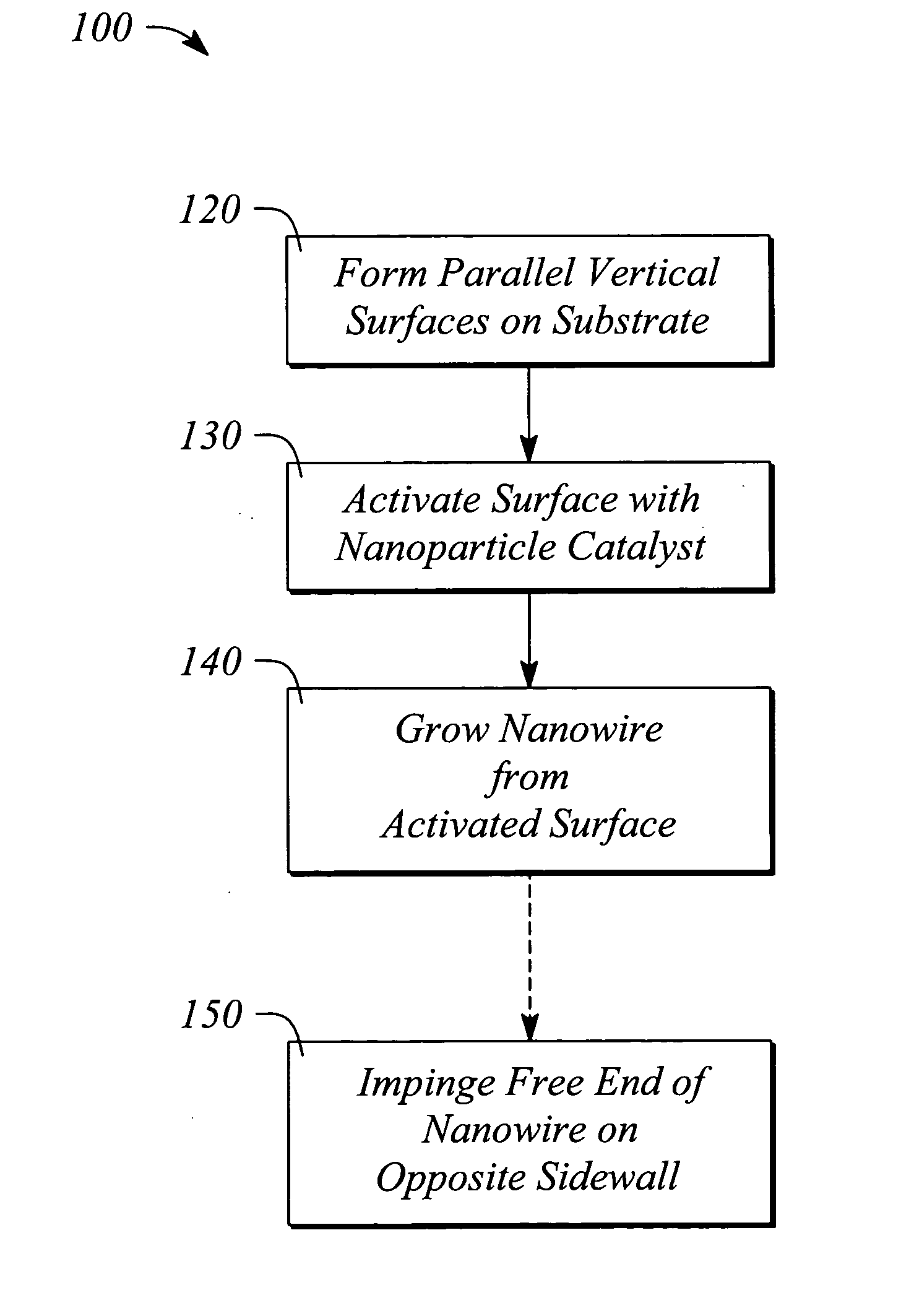

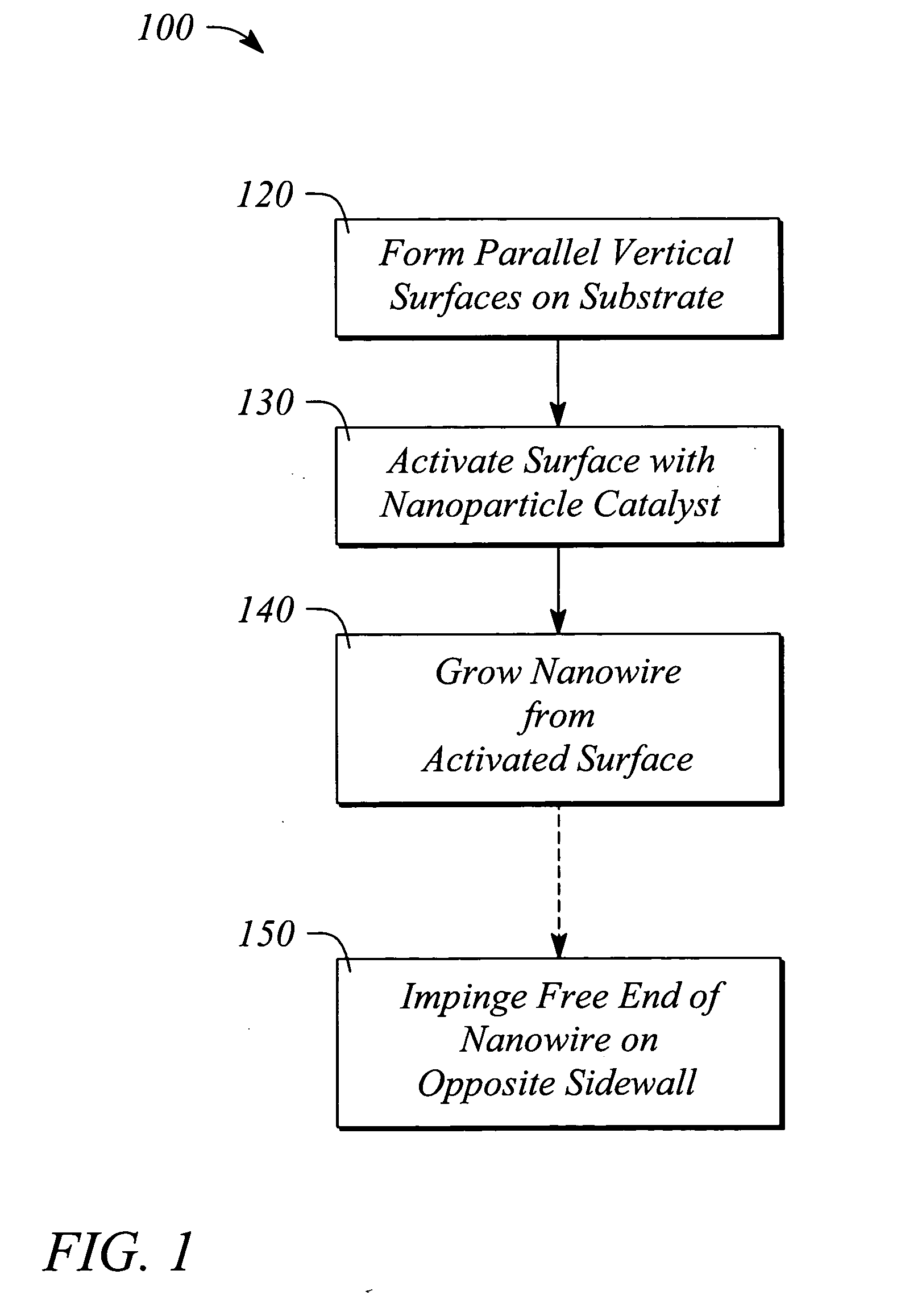

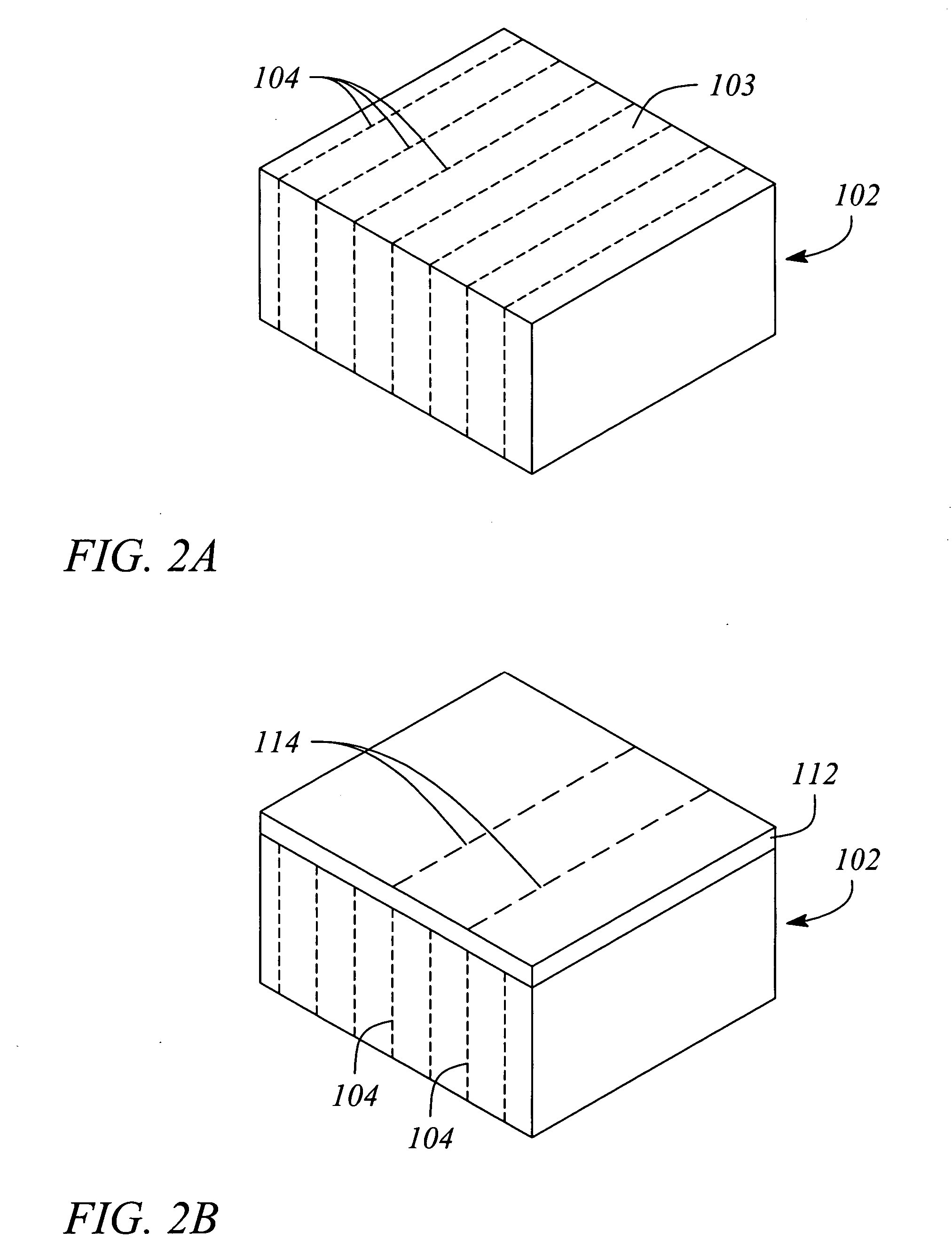

Methods of bridging lateral nanowires and device using same

InactiveUS20050133476A1Material nanotechnologyPolycrystalline material growthNanowireDevice material

A semiconductor nanowire is grown laterally. A method of growing the nanowire forms a vertical surface on a substrate, and activates the vertical surface with a nanoparticle catalyst. A method of laterally bridging the nanowire grows the nanowire from the activated vertical surface to connect to an opposite vertical surface on the substrate. A method of connecting electrodes of a semiconductor device grows the nanowire from an activated device electrode to an opposing device electrode. A method of bridging semiconductor nanowires grows nanowires between an electrode pair in opposing lateral directions. A method of self-assembling the nanowire bridges the nanowire between an activated electrode pair. A method of controlling nanowire growth forms a surface irregularity in the vertical surface. An electronic device includes a laterally grown nano-scale interconnection.

Owner:HEWLETT PACKARD DEV CO LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com