Patents

Literature

114results about How to "Continuous and efficient production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

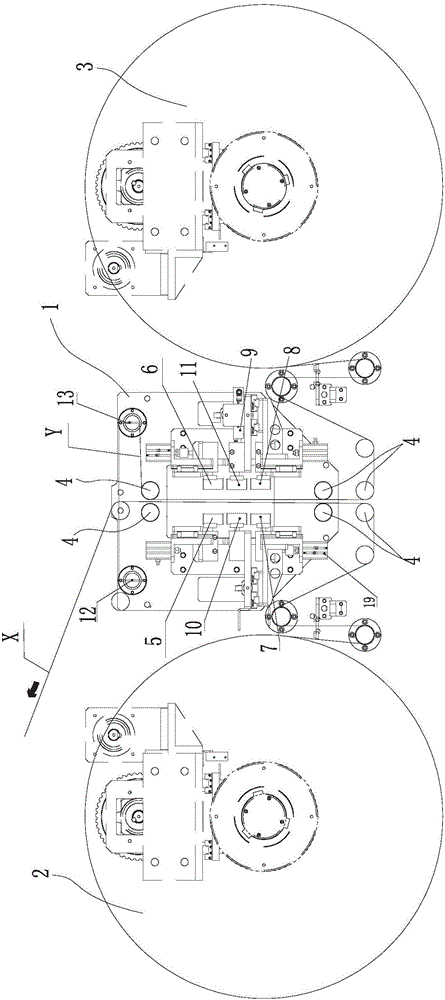

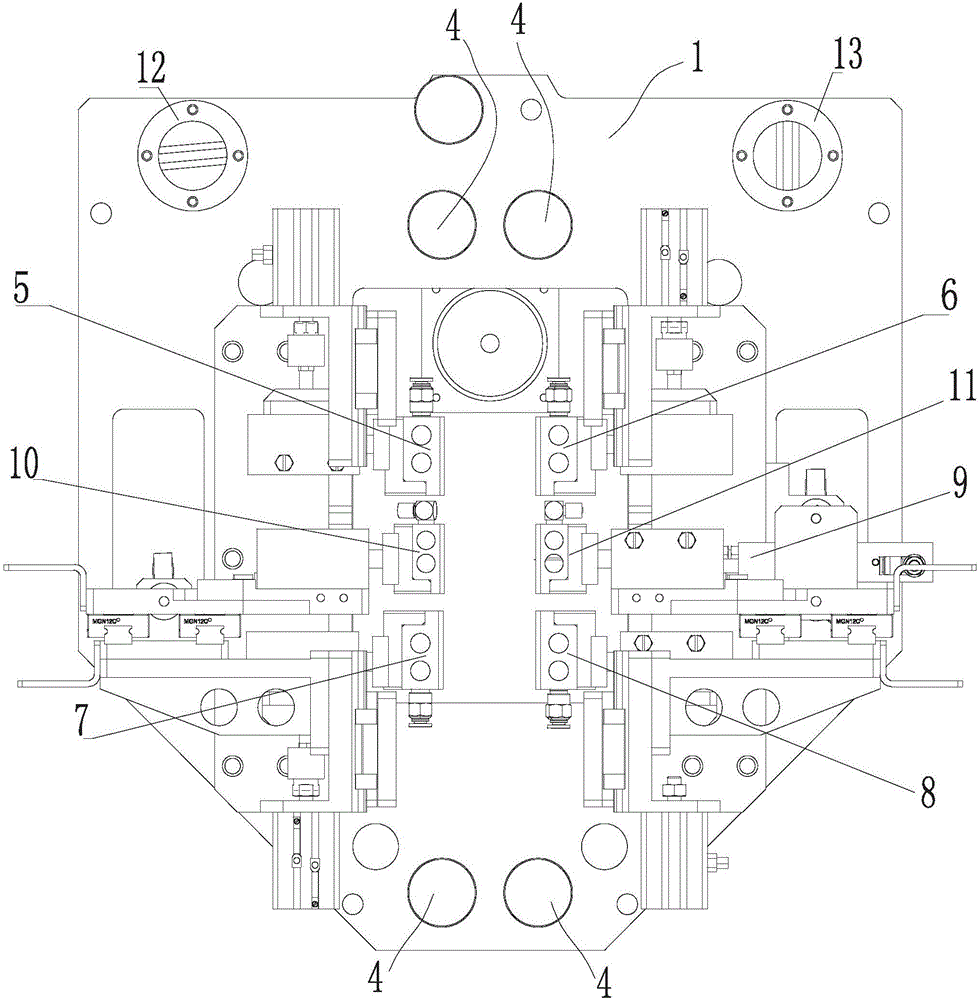

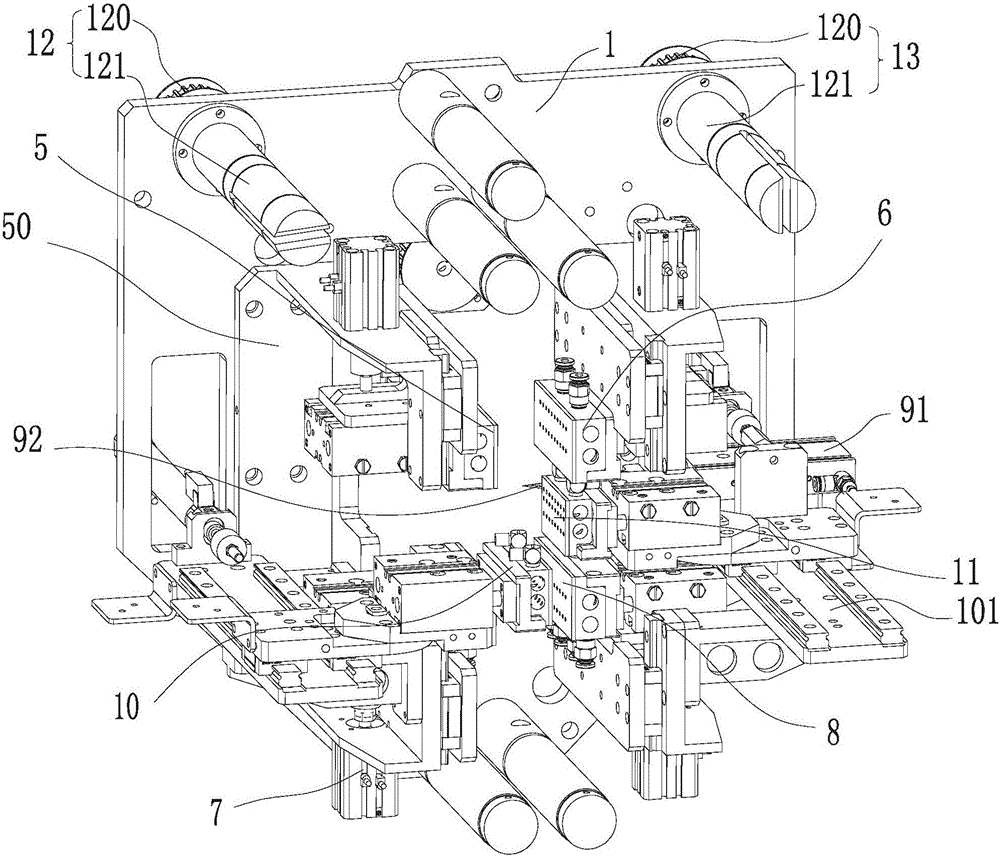

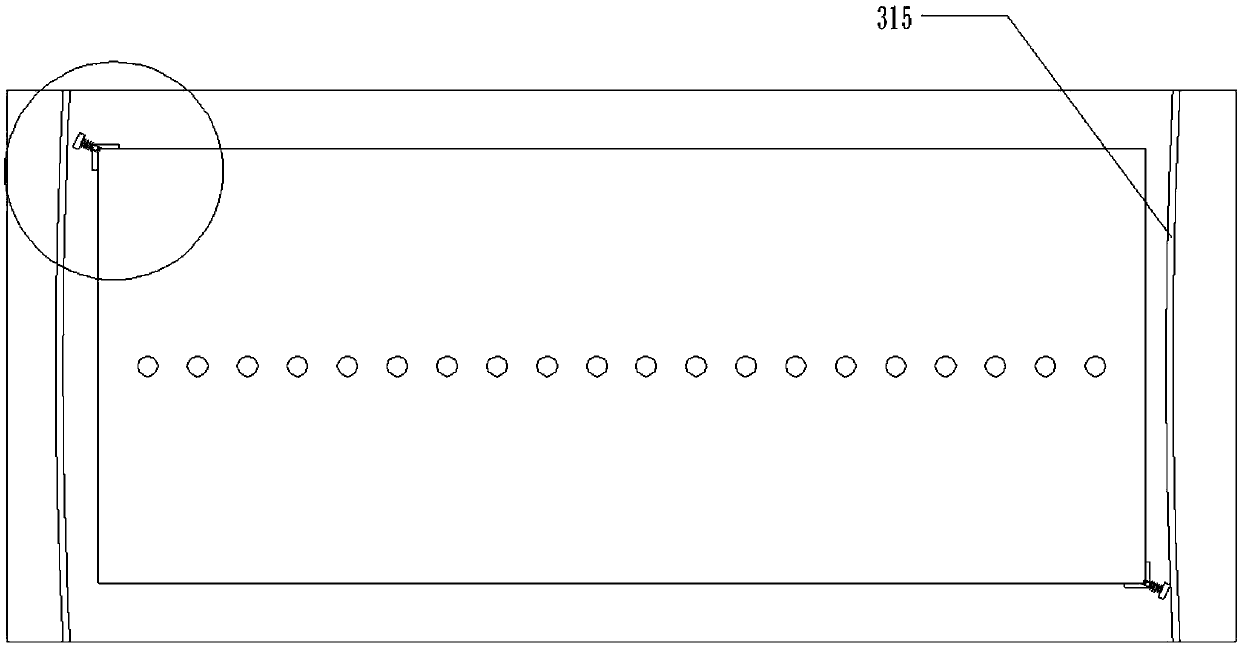

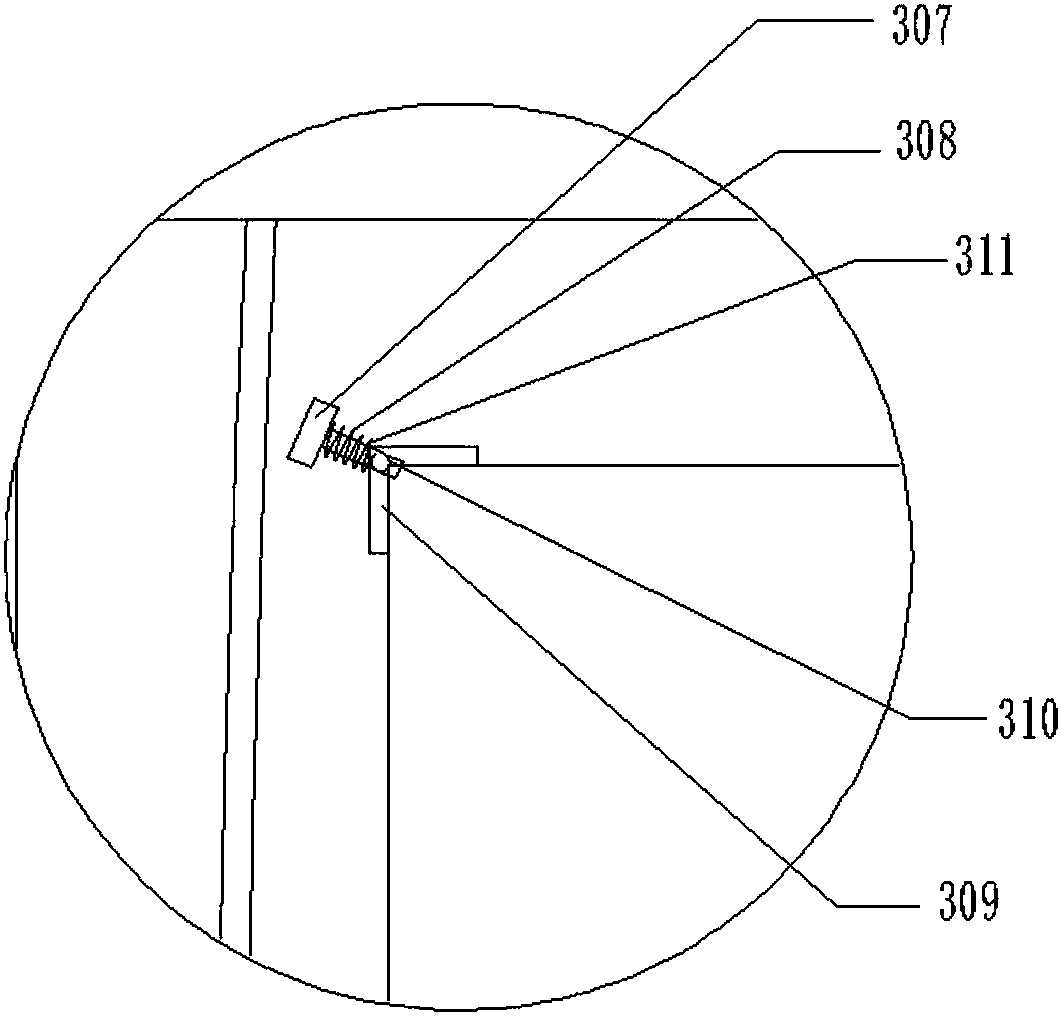

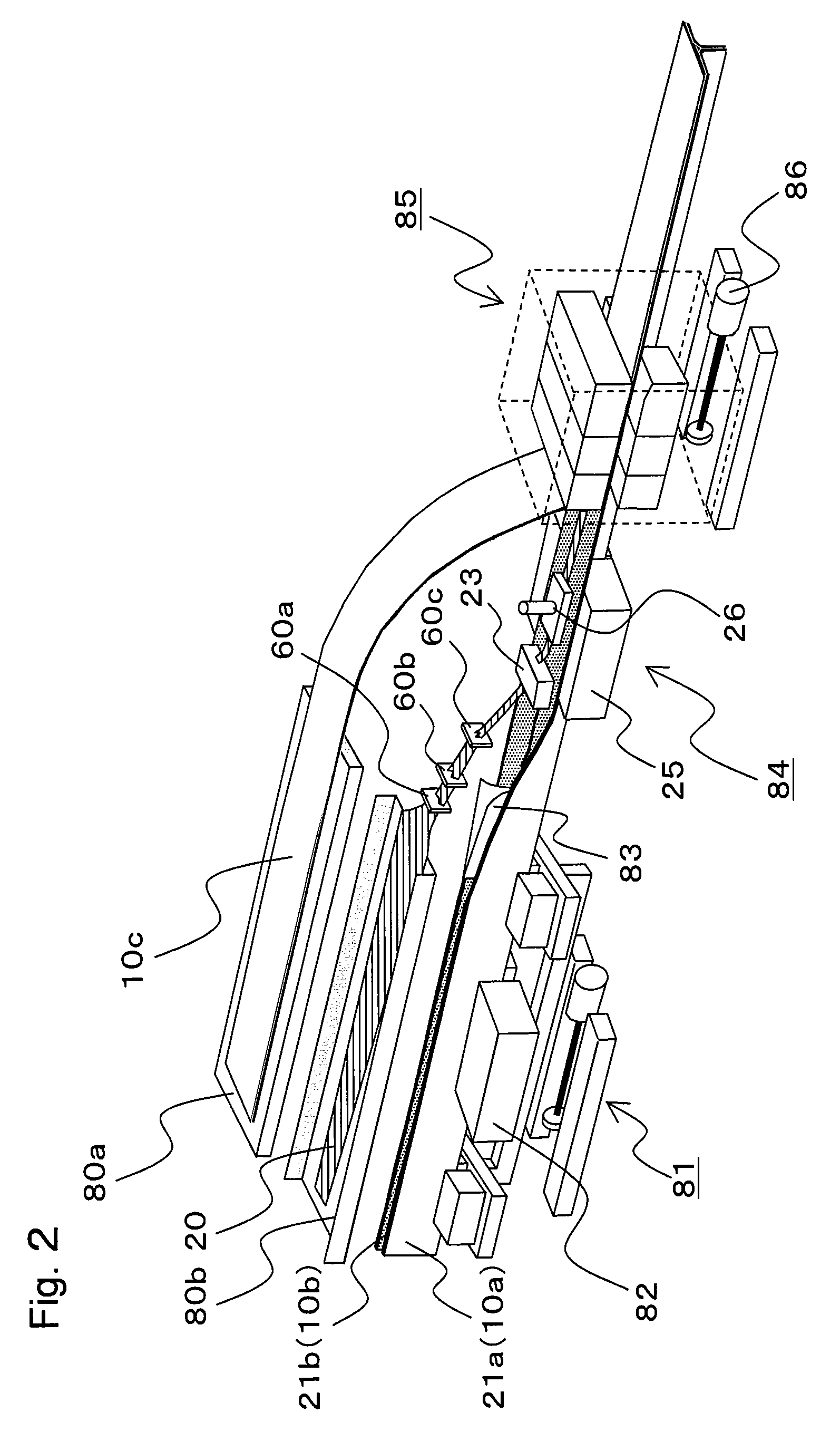

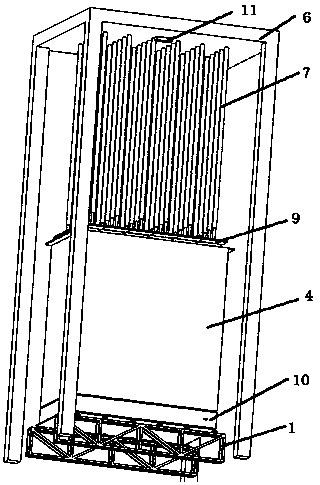

Automatic reel changing device for pole pieces

ActiveCN106006128AHigh degree of automationImprove work efficiencyWebs handlingPole pieceEngineering

The invention relates to an automatic reel changing device for pole pieces. The automatic reel changing device for the pole pieces comprises a substrate, wherein a main material reel mechanism and a standby material reel mechanism which back up for each other are respectively mounted on two sides of the substrate; a plurality of rollers which are arrayed in two rows and facilitate free suspending of the pole pieces are respectively mounted in the middle of the substrate; a left upper side adsorption positioning mechanism and a right upper side adsorption positioning mechanism which adsorb side surfaces of upper parts of the guided-out pole pieces are mounted on the upper part of the substrate; a left lower side adsorption positioning mechanism and a right lower side adsorption positioning mechanism which adsorb side surfaces of lower parts of the guided-out pole pieces are mounted on the lower part of the substrate; a pole piece shearing mechanism which cuts off the pole pieces from the middles simultaneously is mounted on the substrate and positioned between the right upper side adsorption positioning mechanism and the right lower side adsorption positioning mechanism; a left side pole piece changeover mechanism and a right side pole piece changeover mechanism which are used for adhering two sides of a head part of each new pole piece to two sides of the tail part of a corresponding running pole piece are respectively mounted on two corresponding sides of the substrate; and a main waste material reeling mechanism and a standby waste material reeling mechanism which are used for reeling and withdrawing the waste materials of the head parts of the new pole pieces are mounted on sides of the top of the substrate.

Owner:ZHUHAI HIGRAND ELECTRONICS TECH

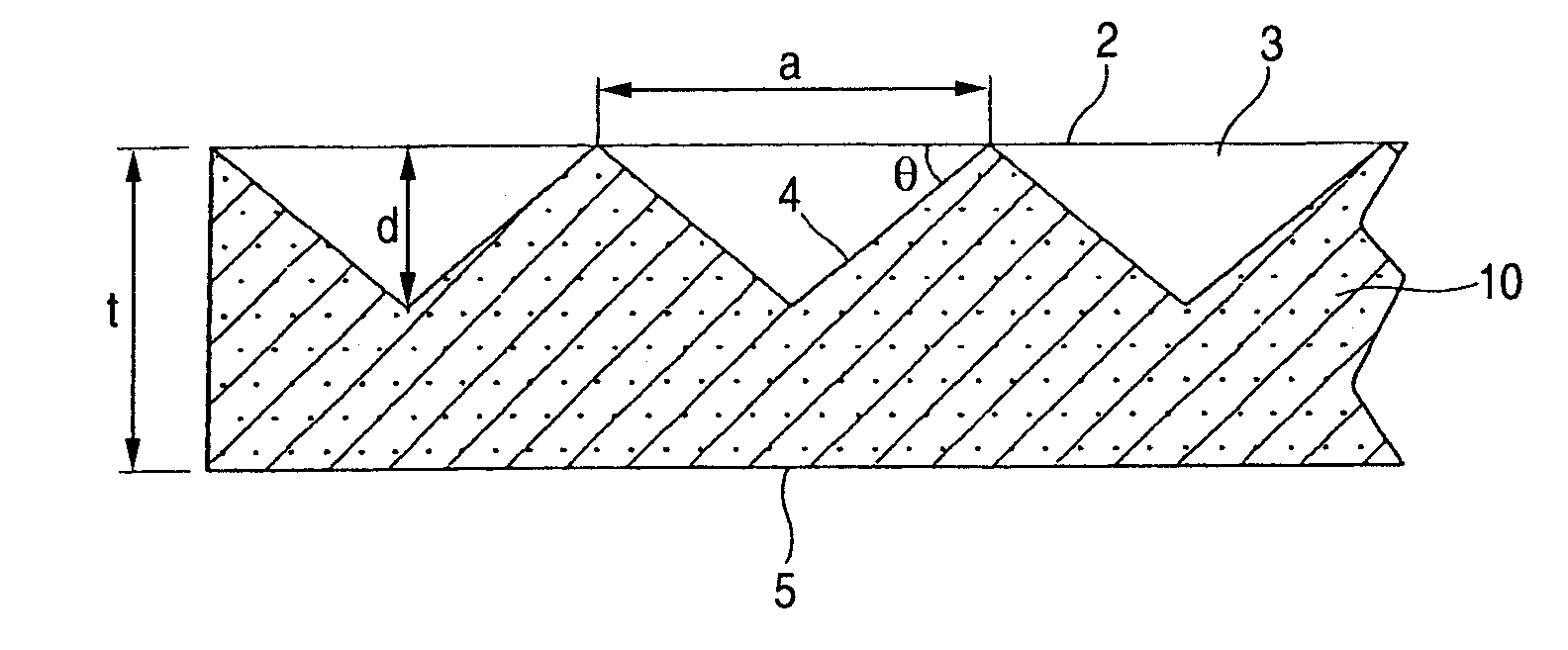

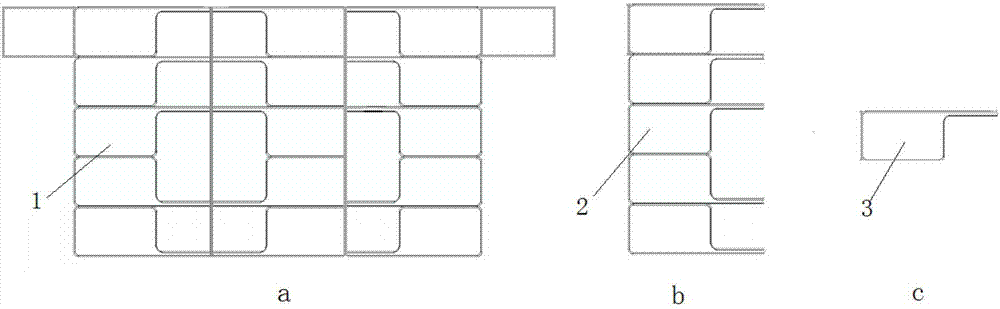

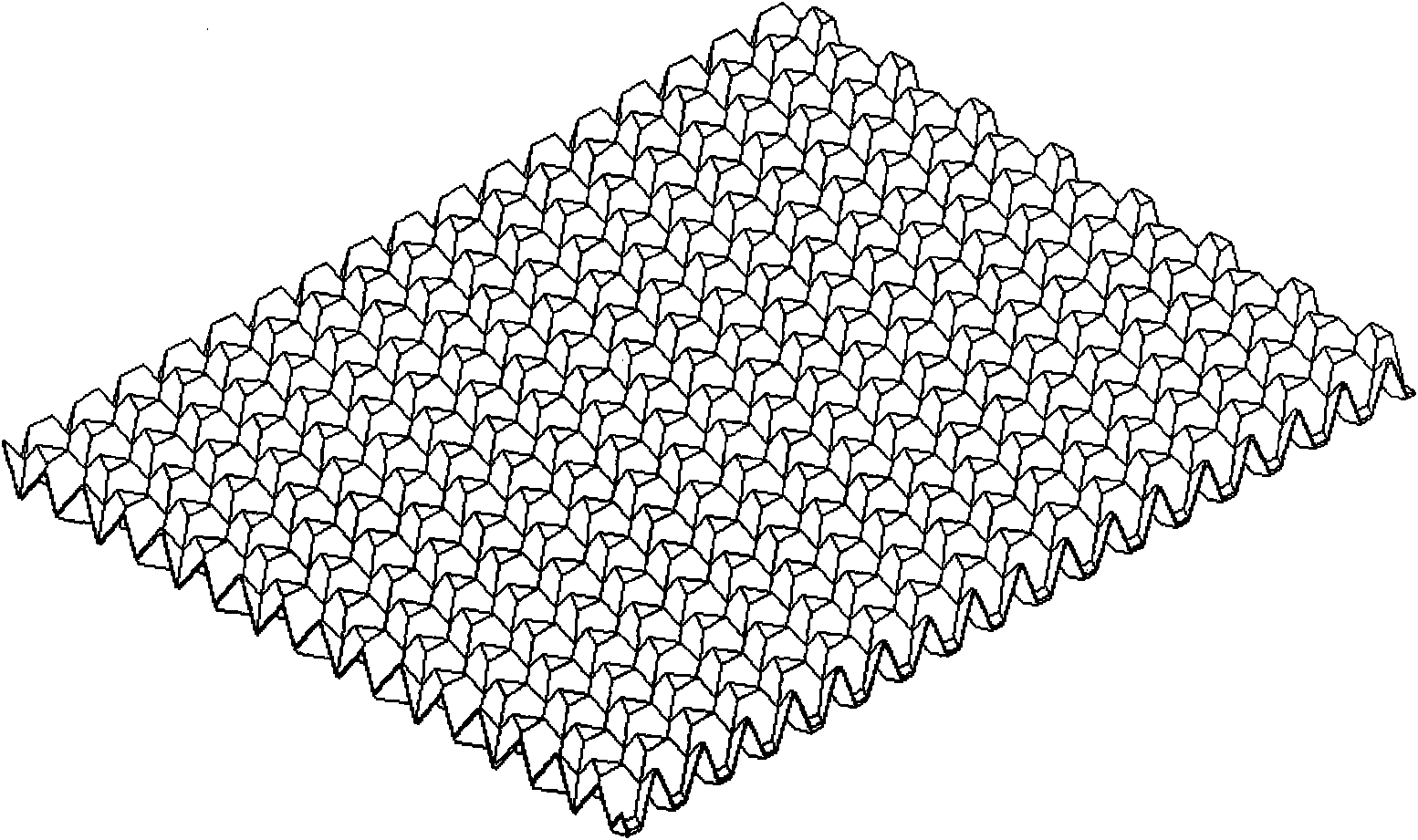

Novel fiber reinforced cellular board and preparation method thereof

InactiveCN101797822AImprove mechanical propertiesWon't hurtLaminationLamination apparatusEpoxyWhole body

The invention provides a novel fiber reinforced cellular board and a preparation method thereof. The novel fiber reinforced cellular board consists of panels on the two sides and a cellular core of a pyramid-shaped structure. The cellular core of the pyramid-shaped structure is prepared by the following steps: injecting high-strength dispersed short-cut fiber cotton / felt into an epoxy resin substrate; or presoaking the epoxy resin substrate by the high-strength dispersed short-cut fiber of 10 mm to 30 mm to form a pre-mixed molding material; and heating, pressurizing and molding the pre-mixed molding material. The prepared cellular core consists of a series of concave-convex staggered pyramid-shaped platform bodies which form a stable whole body together under the action of the two panels on the two sides, so the novel fiber reinforced cellular board has various high mechanical properties. The novel fiber reinforced cellular board has very simple molding process and low production cost, and can realize continuous high-efficiency production.

Owner:王韬

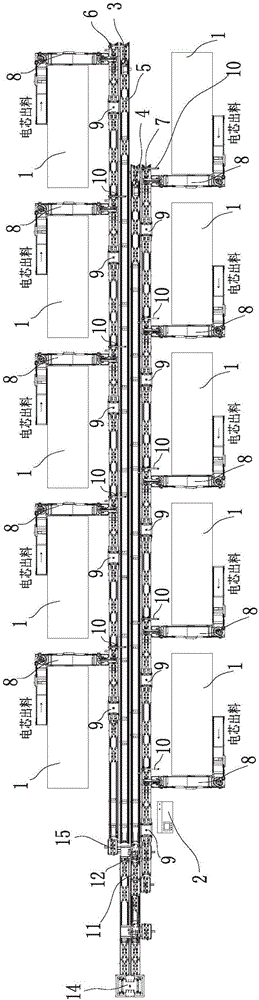

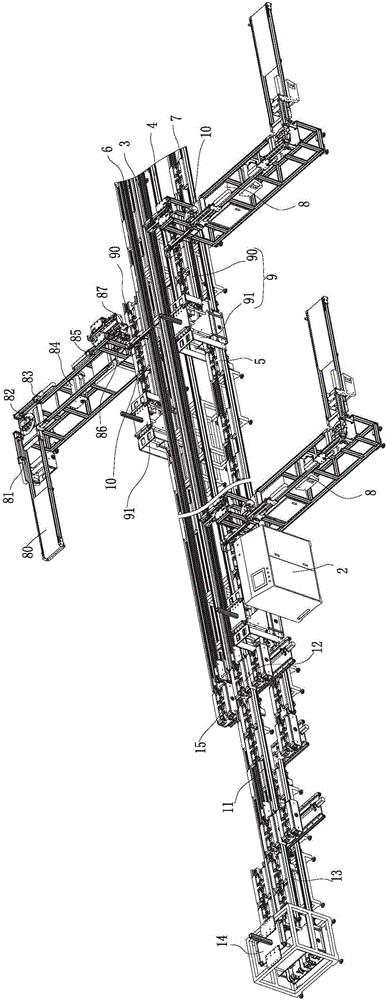

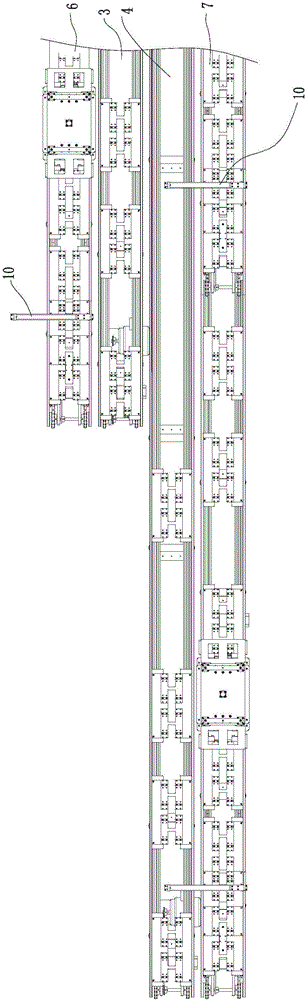

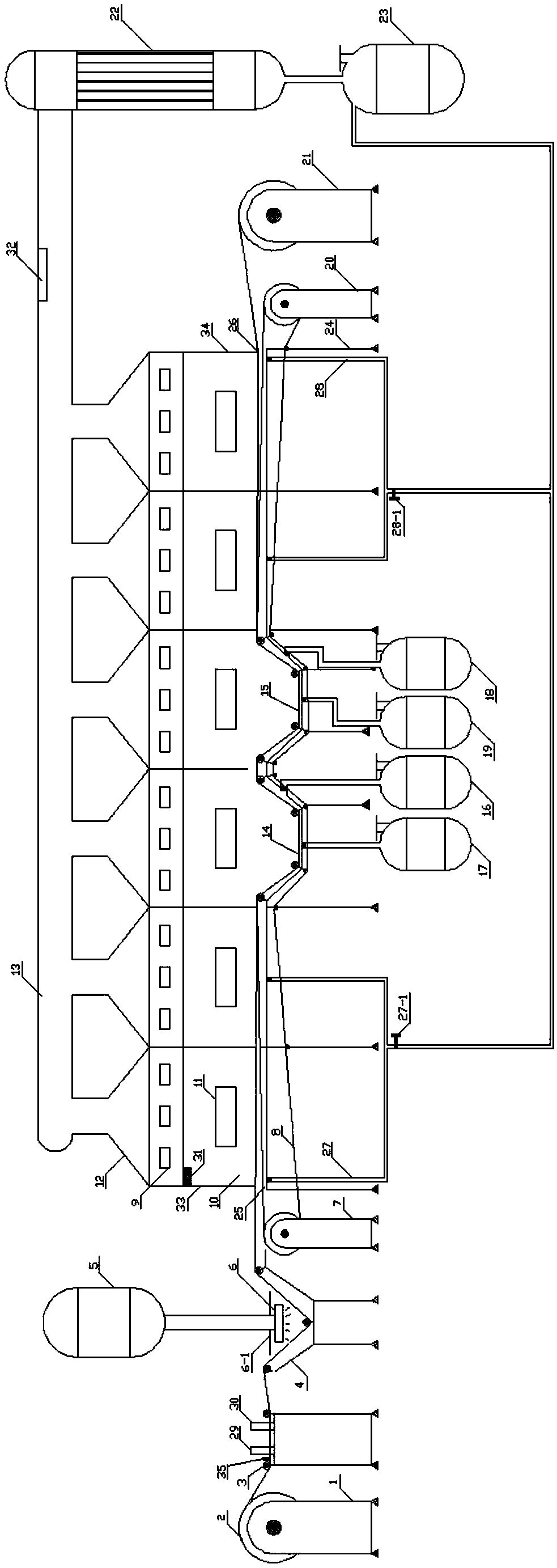

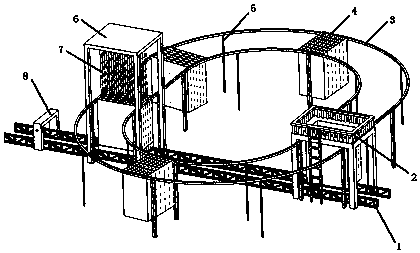

Automatic cell conveying line

ActiveCN106081597AReduce backlogImprove work efficiencyConveyorsConveyor partsWinding machineEngineering

The invention relates to an automatic cell conveying line. The automatic cell conveying line comprises a plurality of cell winding machines and a main control box and further comprises a first main conveying belt and a second main conveying belt which are located in the center. Carrying boxes carrying naked cells are arranged on the first main conveying belt and the second main conveying belt. A first empty carrying box conveying belt is further arranged on the lower layer of the outer side of the first main conveying belt, and a second empty carrying box conveying belt is further arranged on the lower layer of the outer side of the second main conveying belt. A cell feeding and conveying device is further arranged beside each cell winding machine. Each empty carrying box conveying belt is further provided with an empty carrying box lifting device lifting and transferring empty carrying boxes to the corresponding main conveying belt. A shared conveying belt for transferring the carrying boxes to one conveying belt for facilitating discharging is further arranged at the tail ends of the first main conveying belt and the second main conveying belt. In the full-automatic production process, the naked cells can be effectively diverted, accumulation of the naked cells is relieved, the work efficiency of the cell winding machines is higher, the overall production speed is increased, the quality of the naked cells is guaranteed, and the automatic cell conveying line is more environment-friendly and more reliable.

Owner:ZHUHAI HIGRAND ELECTRONICS TECH

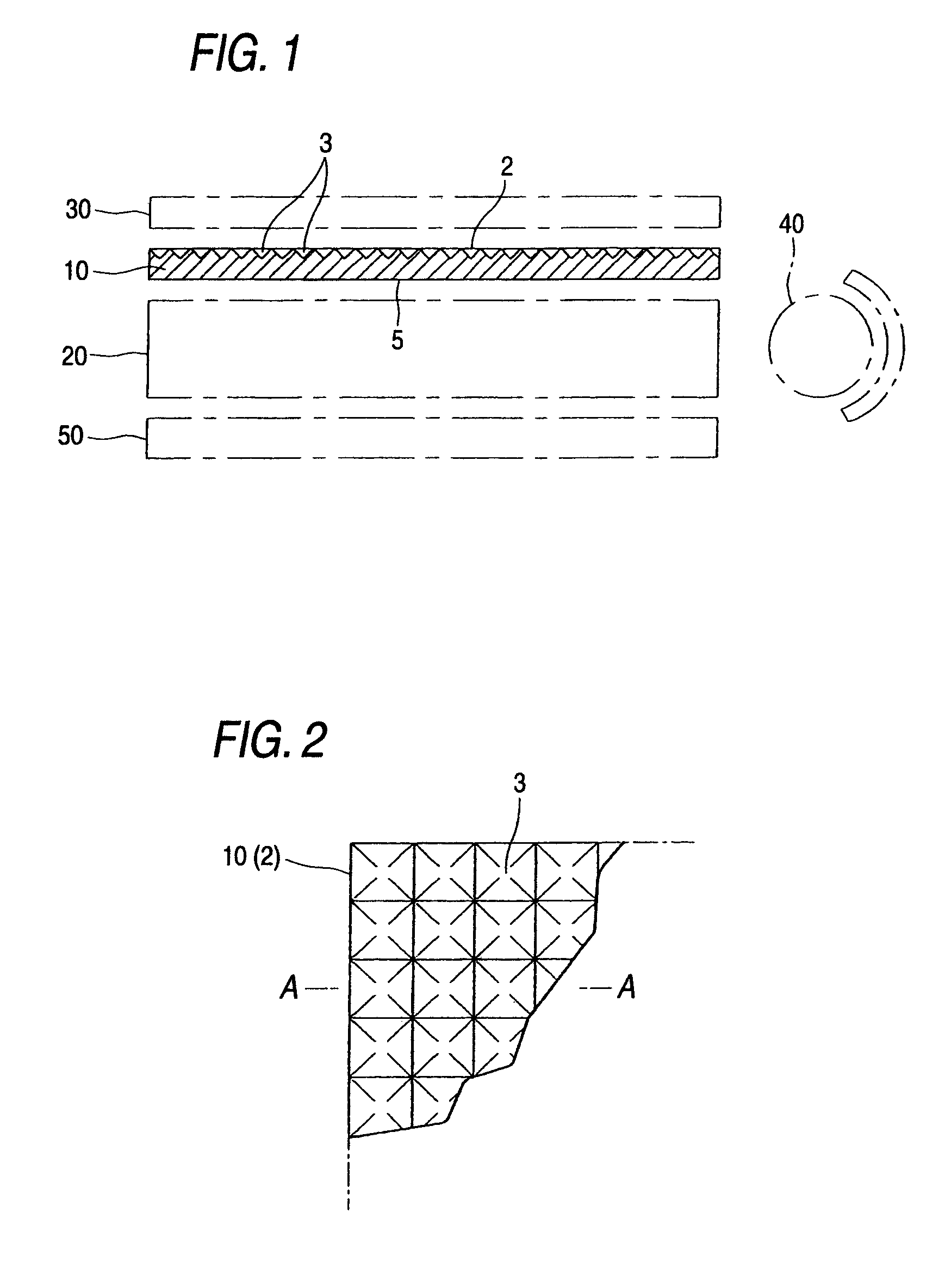

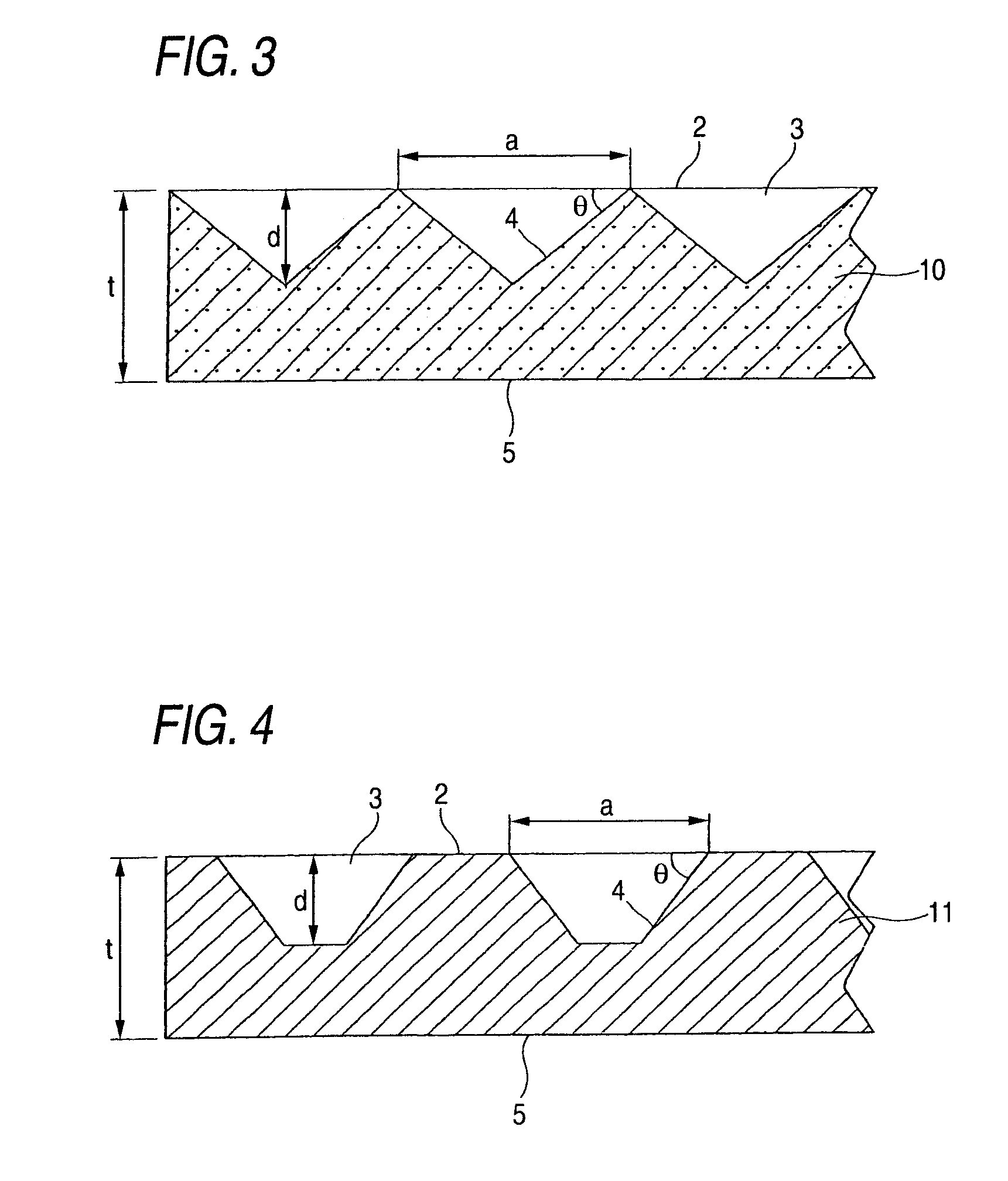

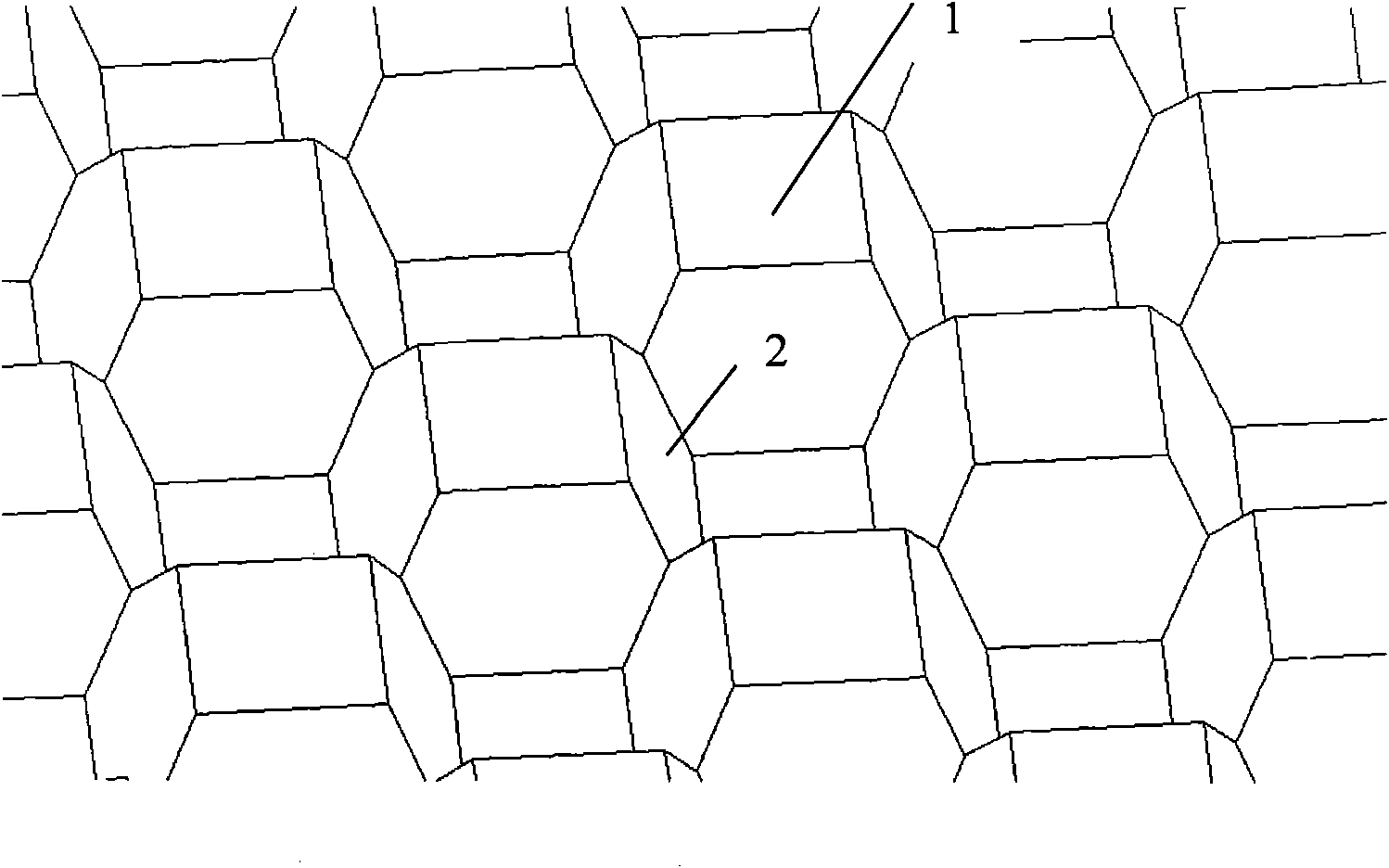

Light diffusing sheet and backlight unit using the light diffusing sheet

InactiveUS7645058B2Well formedContinuous and efficient productionMechanical apparatusDiffusing elementsProduction rateLight emission

To provide a light diffusing sheet which enables the light from a lightguide plate or light source of a backlight unit to be conducted to lens film after having been converted to diffused light having a small brightness peak angle, and which generates neither a moiré or interference fringe nor luminance unevenness, and is advantageous also in terms of productivity and cost, and to provide a backlight unit having this light diffusing sheet incorporated therein, and the surface of the sheet with fine recesses formed therein serves as a light emission side. The light diffusing sheet comprises a light-transmitting resin, characterized by having fine recesses formed in at least one of the surfaces thereof, the fine recesses having a shape which is any of the shapes of an inverted polyangular pyramid, an inverted truncated polyangular pyramid, an inverted cone, and an inverted truncated cone.

Owner:TAKIRON CO LTD

Method for continuous production of a perfluoroalkyl iodide telomer

InactiveUS6919490B2Less impuritiesContinuous and efficient productionOrganic chemistry methodsMetal/metal-oxides/metal-hydroxide catalystsTetrafluoroethyleneHydrogen

The present invention relates to a process for continuously producing a perfluoroalkyl iodide represented by the general formula Rf(CF2CF2)nI, wherein Rf is a C1-6 perfluoroalkyl and n is an integer from 1 to 4, the method comprising continuously supplying a perfluoroalkyl iodide as a telogen represented by the general formula RfI, wherein Rf is as defined above, and tetrafluoroethylene as a taxogen to a tubular reactor packed with a metal catalyst comprising a powdery spherical metal or a sintered metal; and conducting telomerization at a temperature of 60 to 160° C. under a pressure of 0.1 to 5 MPa (gauge pressure).According to the present invention, medium-chain perfluoroalkyl iodides can be continuously and efficiently produced with little generation of impurities, such as hydrogen-containing organic compounds and the like.

Owner:DAIKIN IND LTD

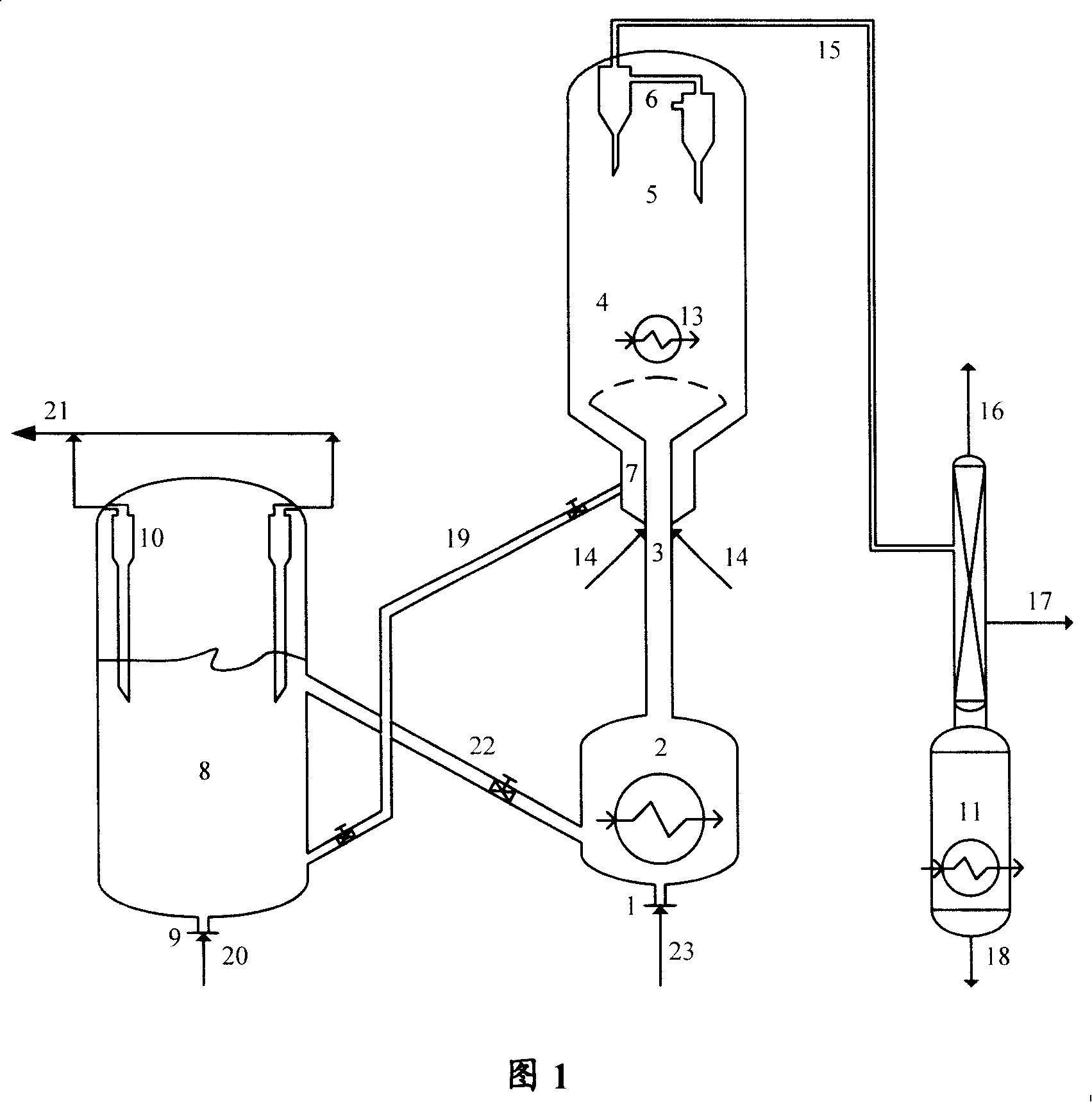

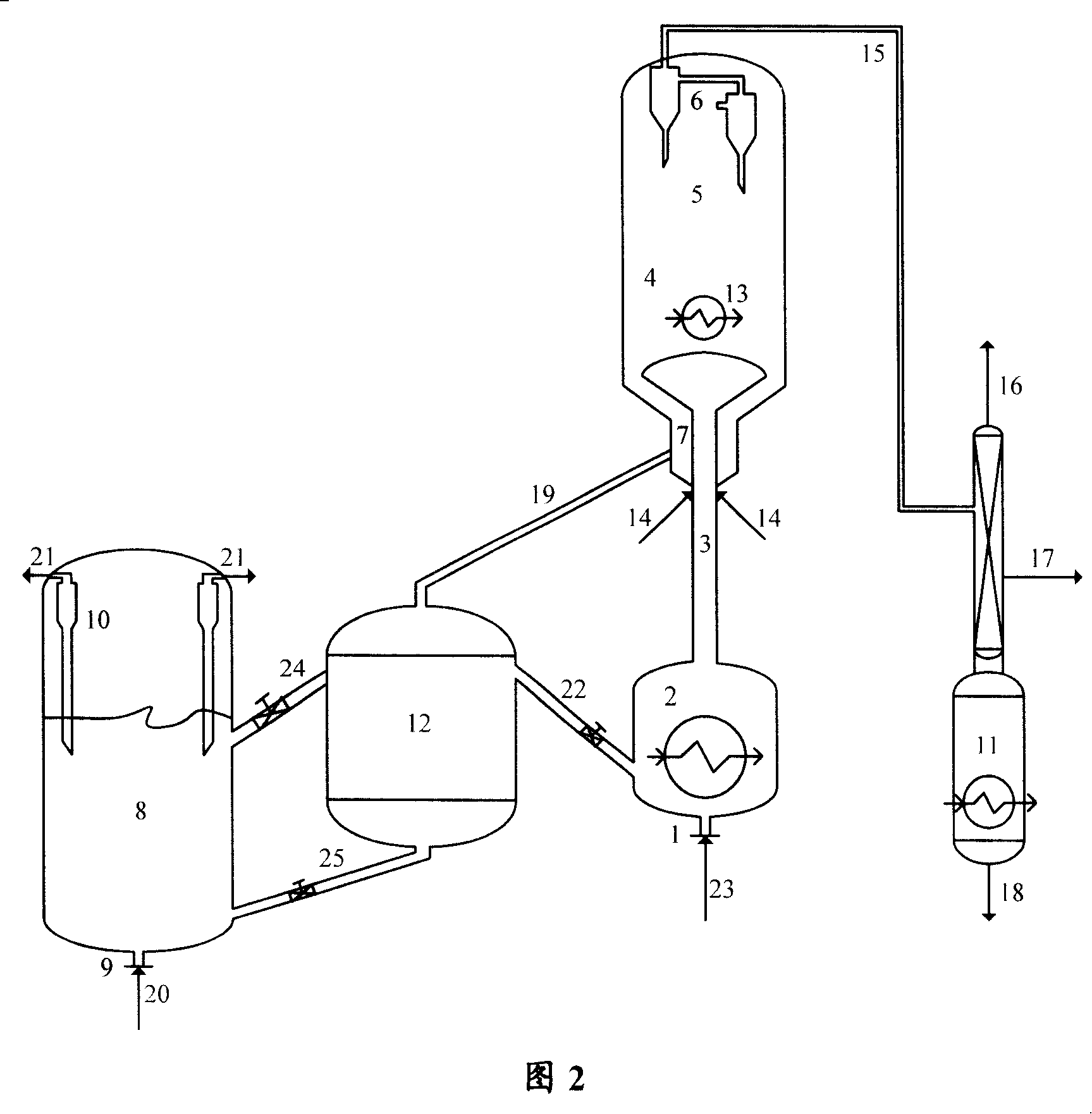

Liquefaction catalytic conversion method for producing dimethyl ether with methanol

ActiveCN101152997AImprove mass transfer efficiencyImprove heat transfer efficiencyEther/acetal/ketal group formation/introductionChemical recyclingFixed bedDimethyl ether

The present invention provides a fluidization and conversion method using methanol to prepare dimethyl ether. The methanol material, cooled regenerated catalyst and pre-lifting medium orderly enter a circulating fluidized bed. At a temperature between 150 and 500 DEG C, under pressure between 0.1MPa and 1.0MPa and at a liquid space-time speed of 0.5 to 4 hours, the -1, catalyst and methanol material react with a weight ratio of 1 to 20. In the reaction process, heat is removed from the circulating fluidized bed; the reaction material flow and catalyst to be generated are separated. Wherein, the target product dimethyl ether can be got by separation of the reaction material flow. The catalyst to be generated is recycled orderly after gas extraction, regeneration and cooling. Compared with a fixed-bed, the circulating fluidized bed of the method provides better gas-solid contact, and has gas-solid phase medium and high heat transfer efficiency. Therefore, the method improves the conversion rate of methanol and the selectivity of dimethyl ether product.

Owner:CHINA PETROLEUM & CHEM CORP +1

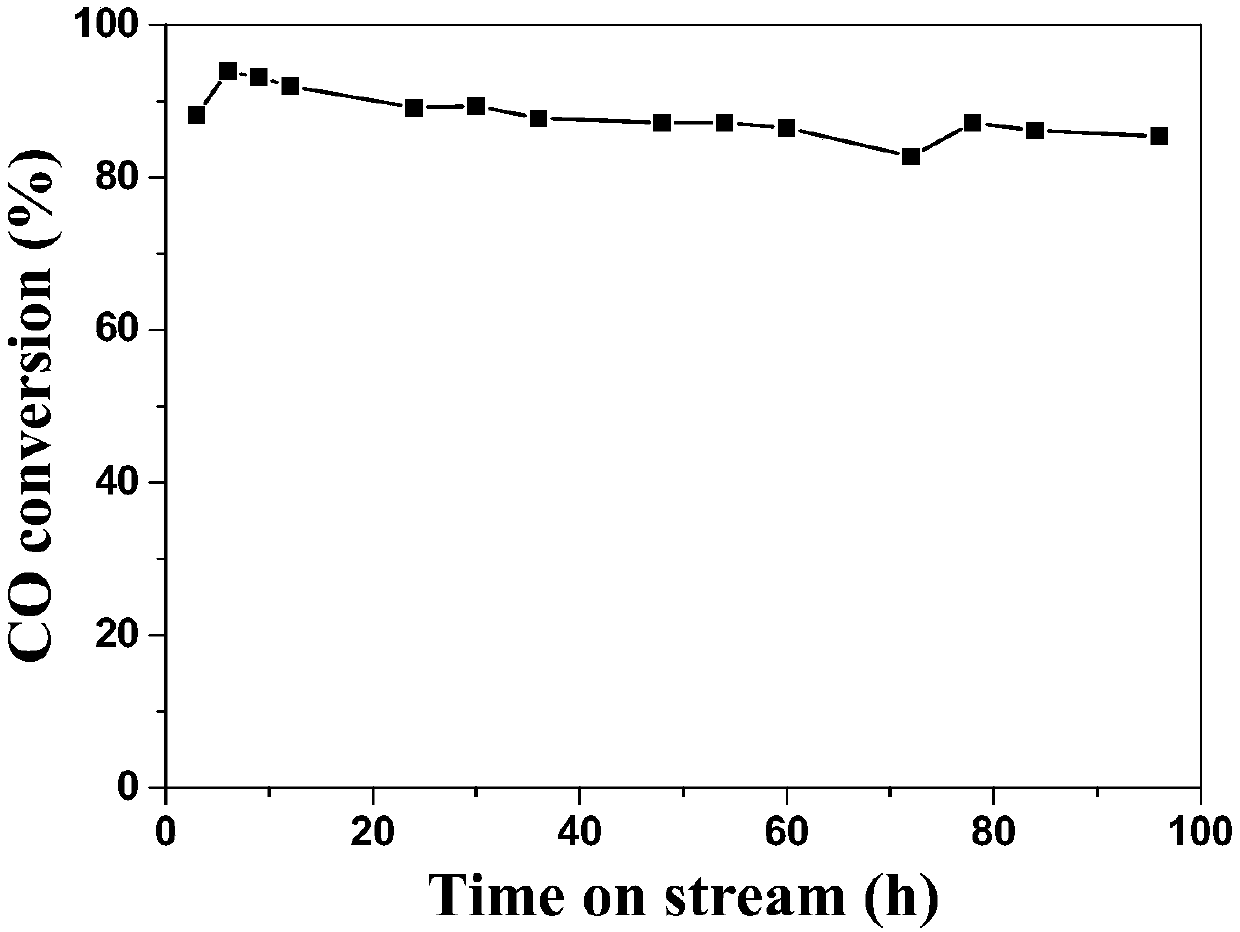

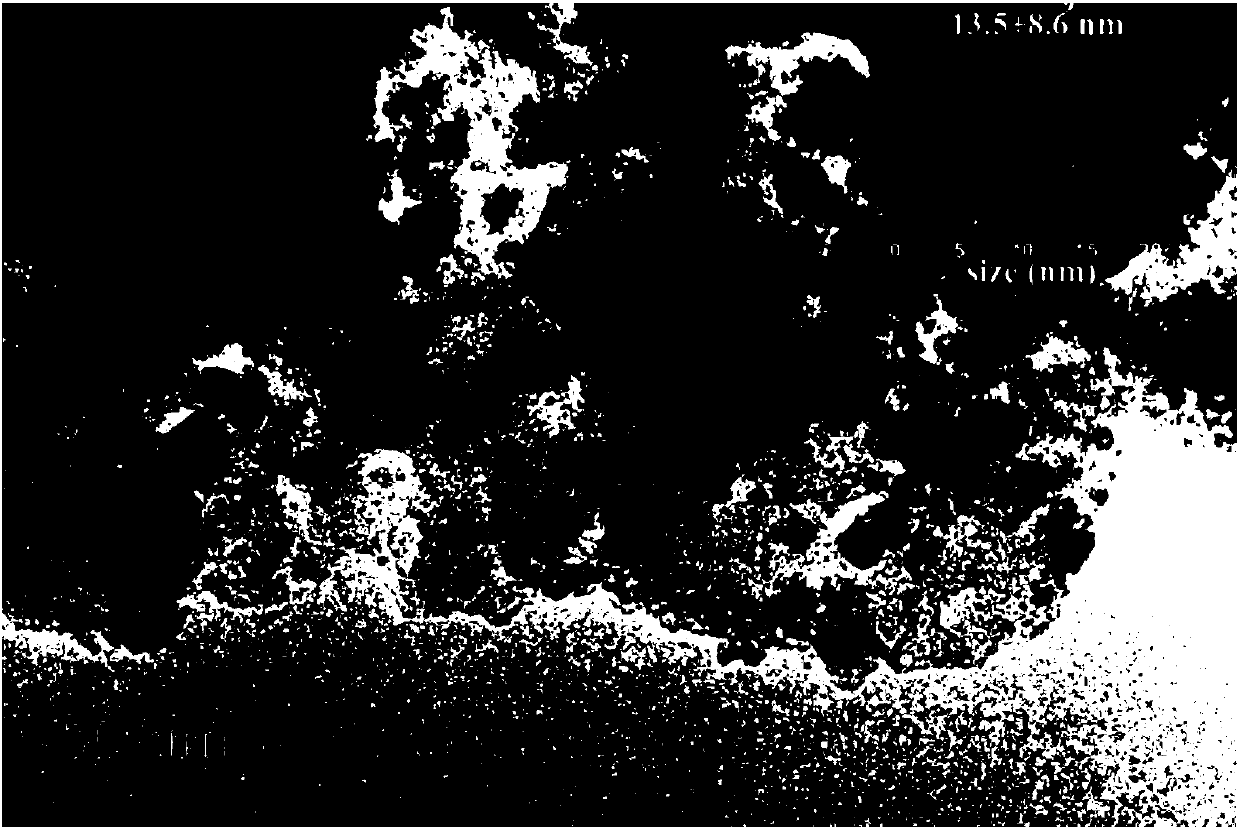

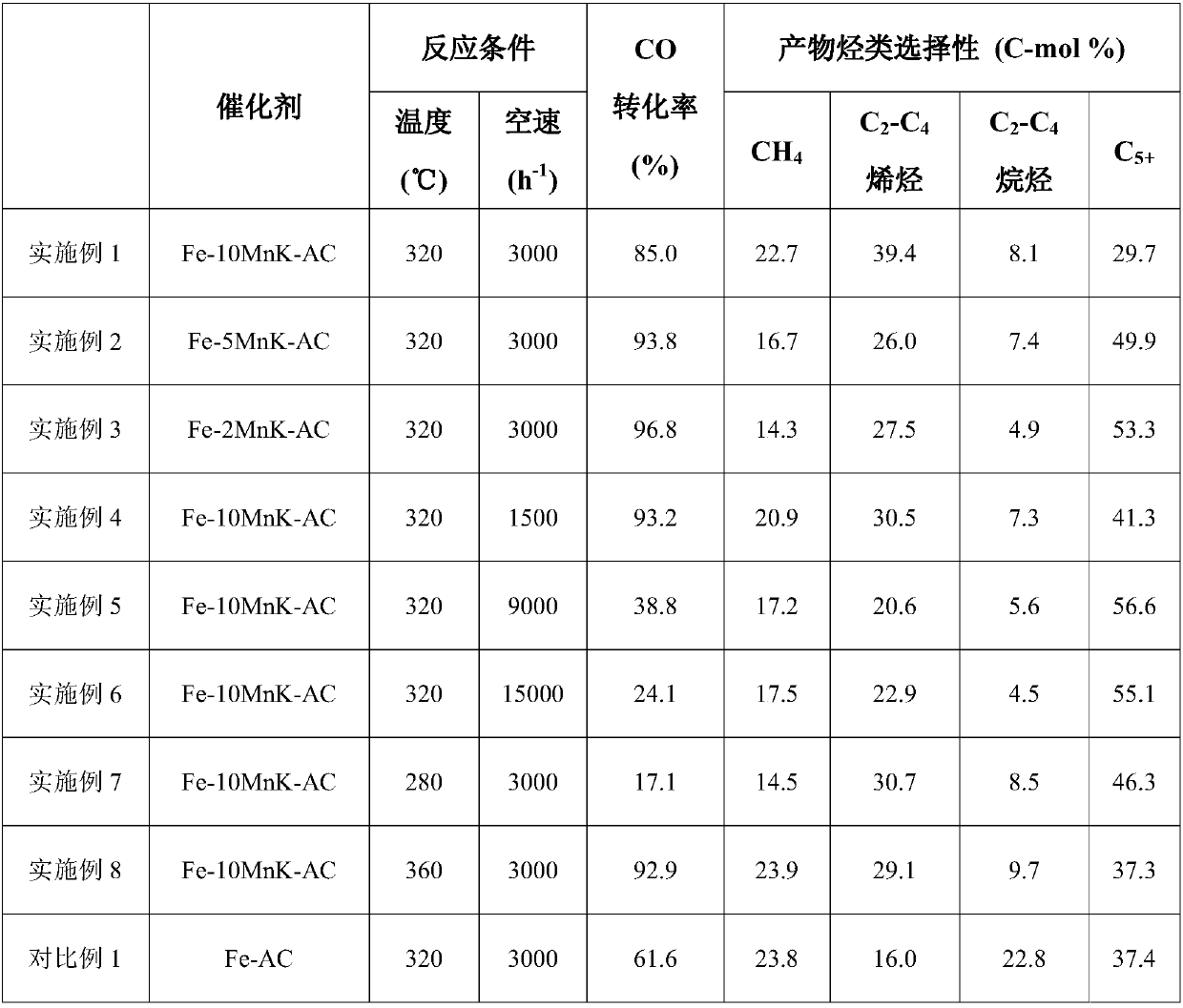

Catalyst used for preparing low-carbon olefin from synthetic gas and application of catalyst

InactiveCN107930643ASmall particle sizeHigh activityHydrocarbon from carbon oxidesCatalyst activation/preparationPotassiumManganese

The invention discloses a catalyst used for preparing low-carbon olefin from synthetic gas. The catalyst takes active carbon as a carrier, and adopts iron as an active metal component and potassium and manganese as auxiliary agents, wherein the load capacity of iron is 5-20 wt%, the load capacity of potassium is 2-5 wt%, and the load capacity of manganese is 10-30 wt%. The prepared catalyst is relatively high in dispersiveness and relatively small in particle size, has high activity and low-carbon olefin selectivity, and is good in stability. The catalyst can still maintain relatively high reaction activity after the reaction has been finished for 100 h. The problem that metal active particles are easy to undergo transfer polymerization in a high-temperature high-pressure reaction condition, which results in small quantity of efficient active sites, more by-products and relatively low selectivity to low-carbon olefin, in a traditional carbon-loaded iron-based catalyst, is solved. The catalyst has bright industrial application prospects.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

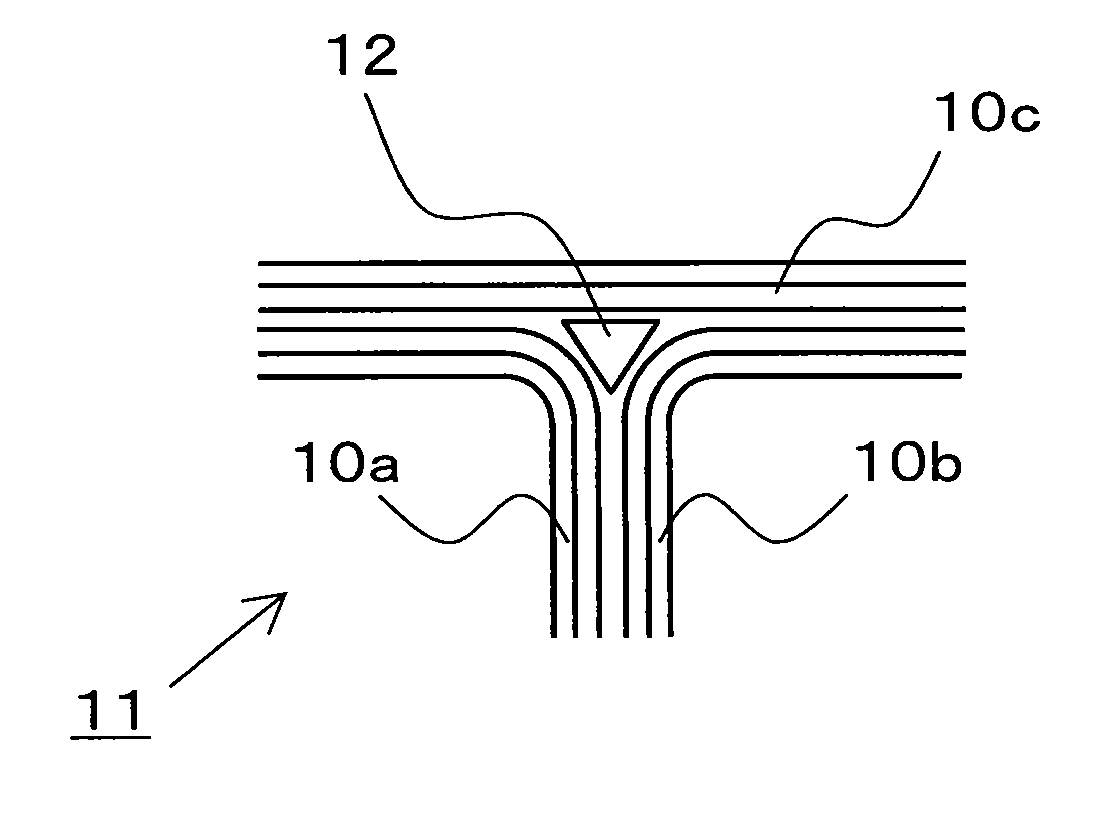

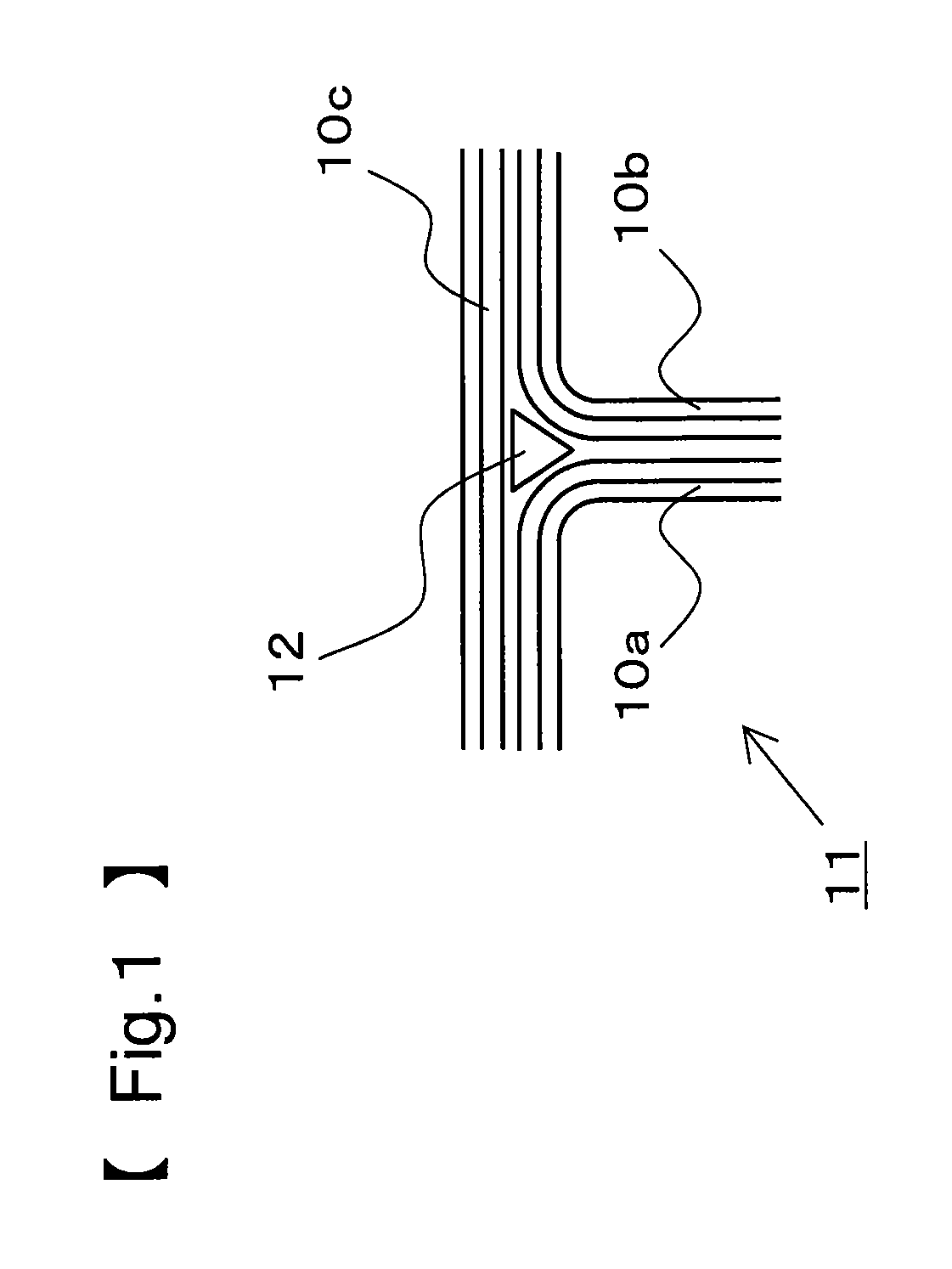

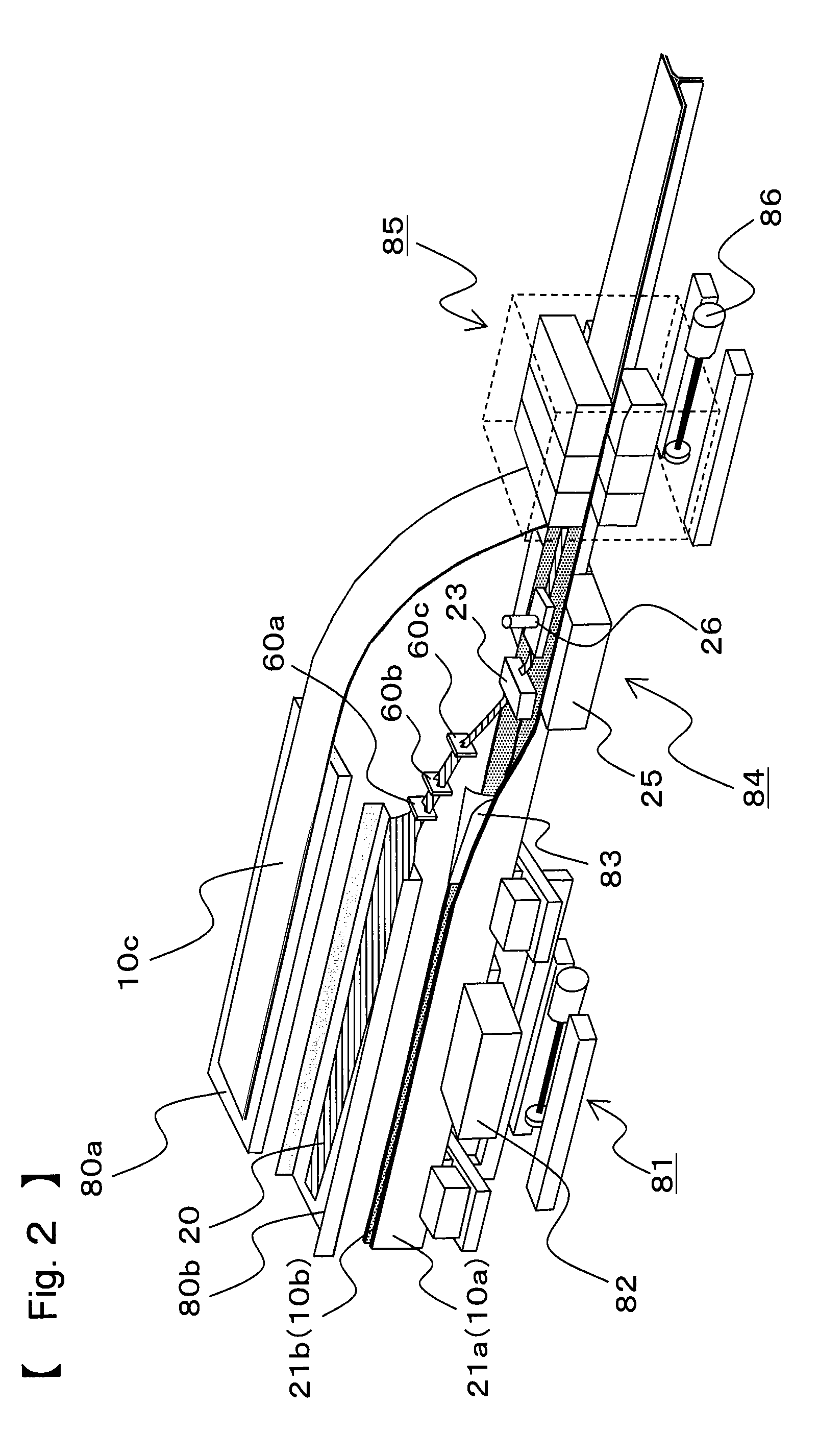

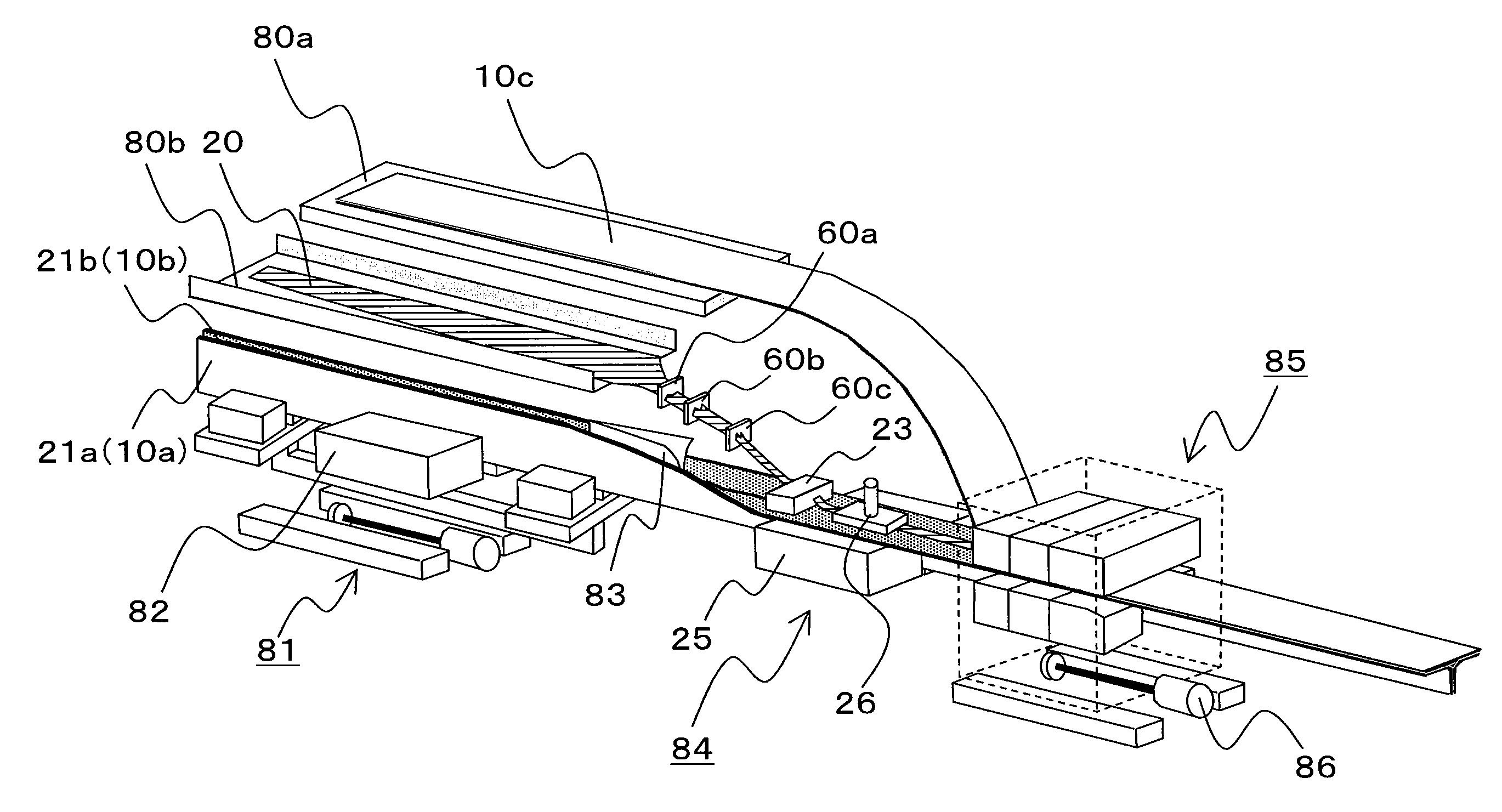

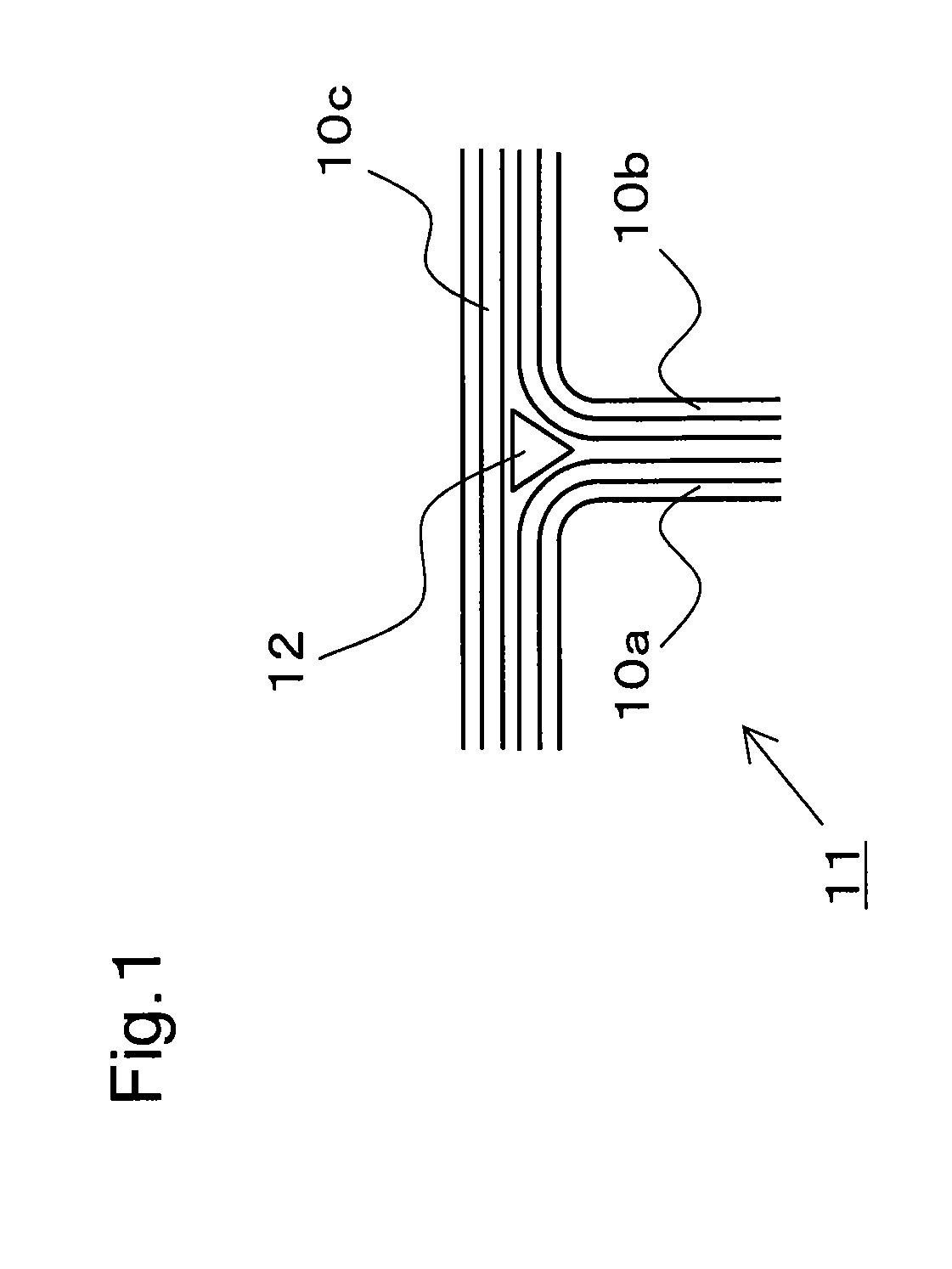

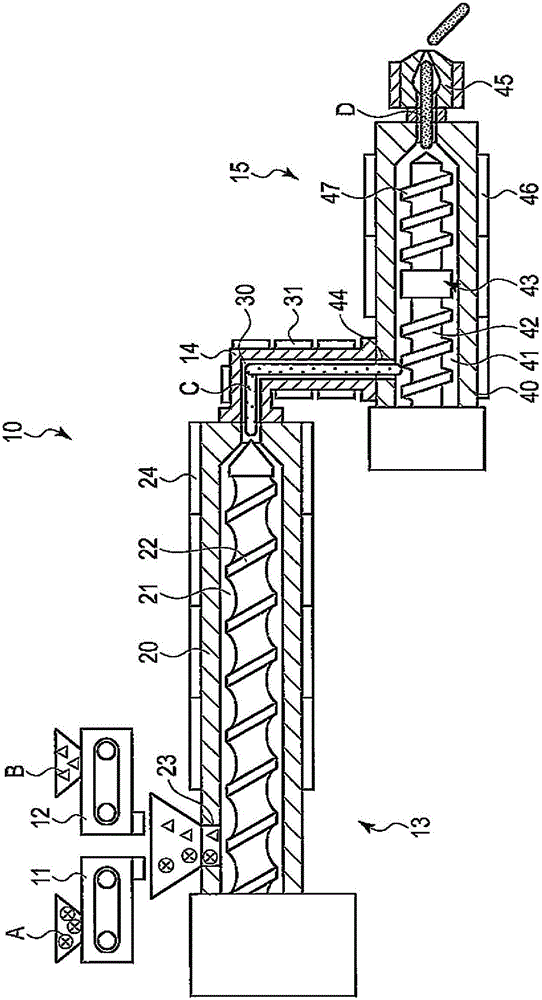

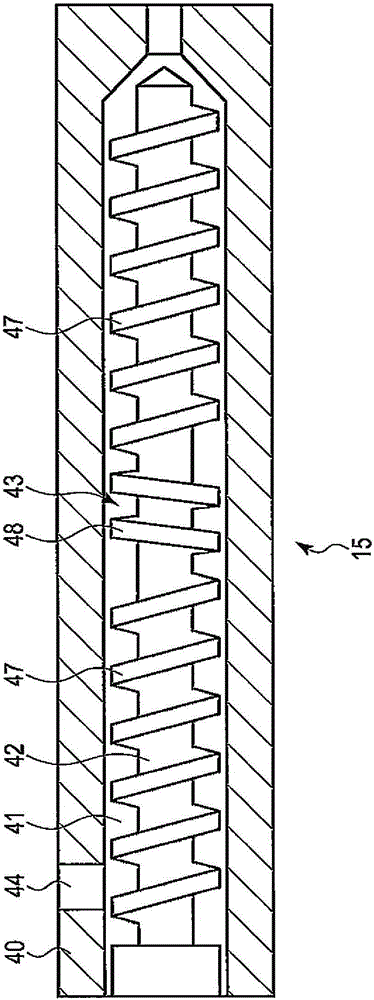

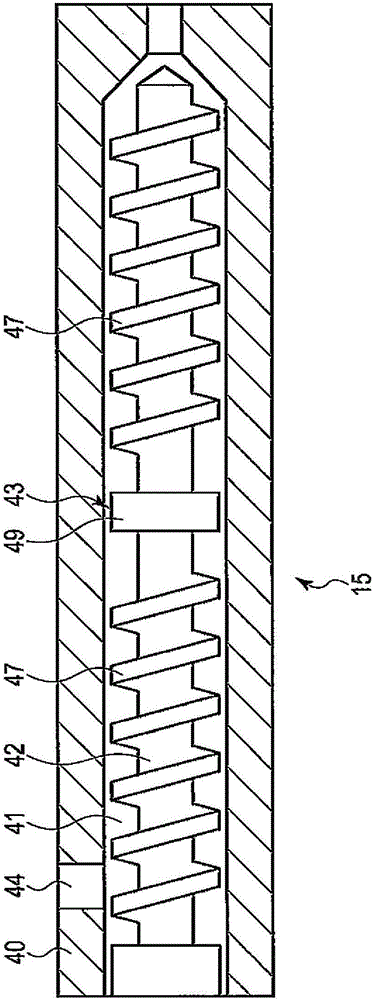

Process and apparatus for producing beam member

ActiveUS20120196083A1Gap is continuously and efficientlyContinuous and efficient productionLamination ancillary operationsLaminationFiberEngineering

A process for producing a beam member formed by a reinforcing fiber base material which has a web portion and at least a pair of flange portions extending to both sides via at least a branching point from the web portion, at a cross-sectional surface orthogonal to a longitudinal direction of the beam member, and by a shaped filler which fills a gap having a wedge shape formed at the branching point, is provided. The shaped filler is produced by: (A) a filler supply process for supplying a filler member configured by reinforcing fibers; (B) a preshaping process for providing a preshaped filler having at least a wedge projection portion, by pressurizing the filler member by a preshaping mold; and (C) a filler deforming process for providing a shaped filler by deforming the preshaped filler.

Owner:TORAY IND INC

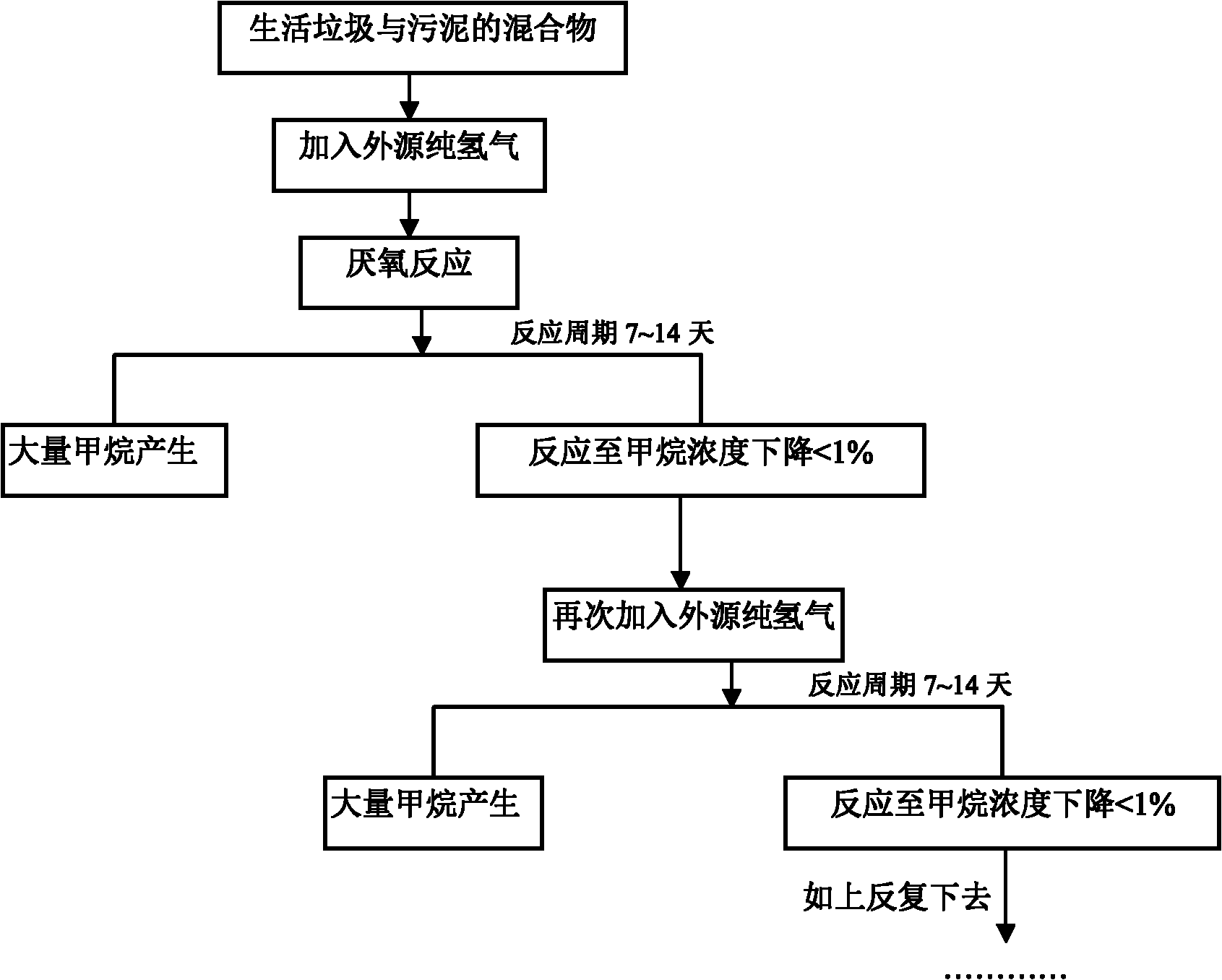

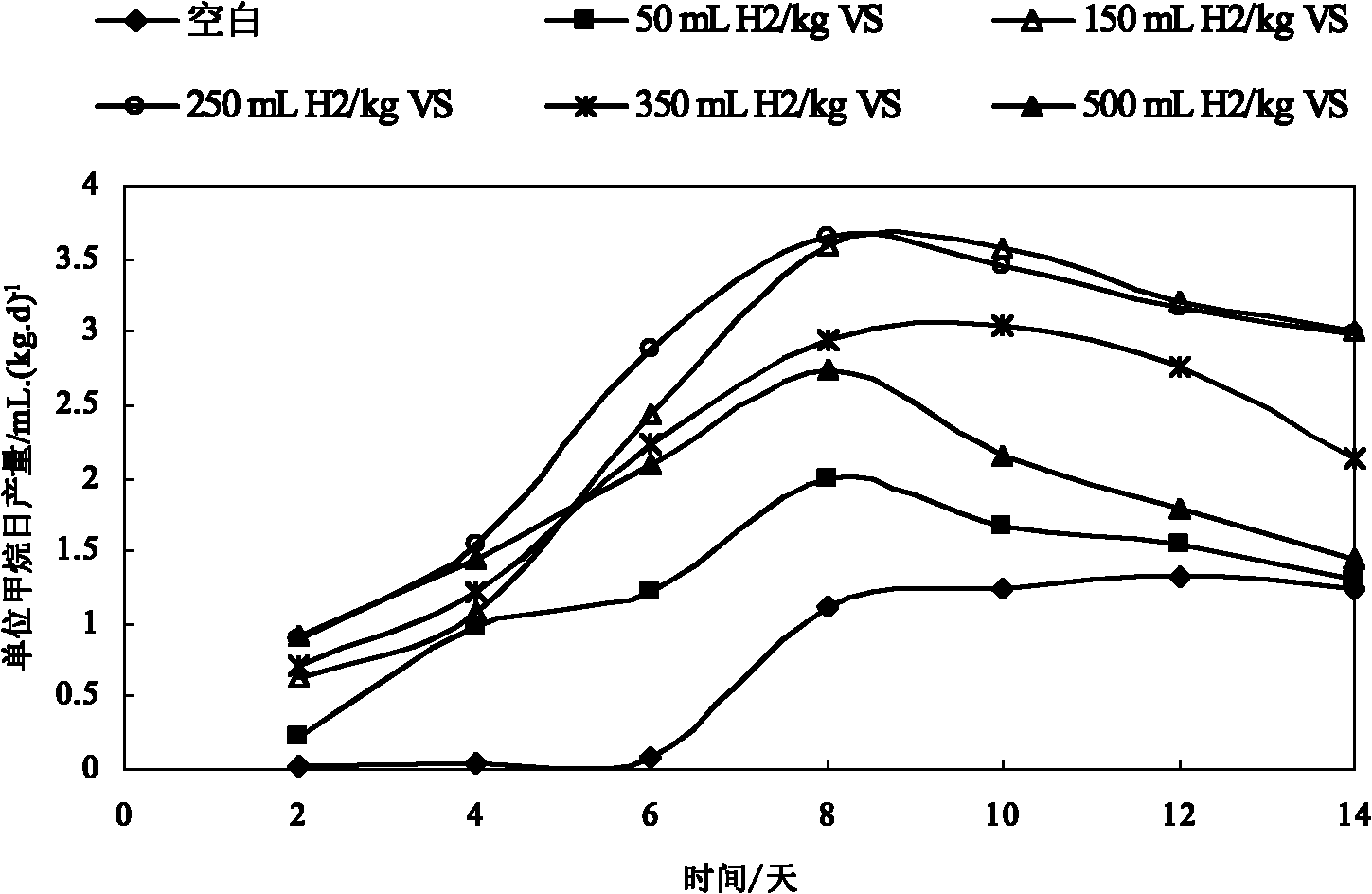

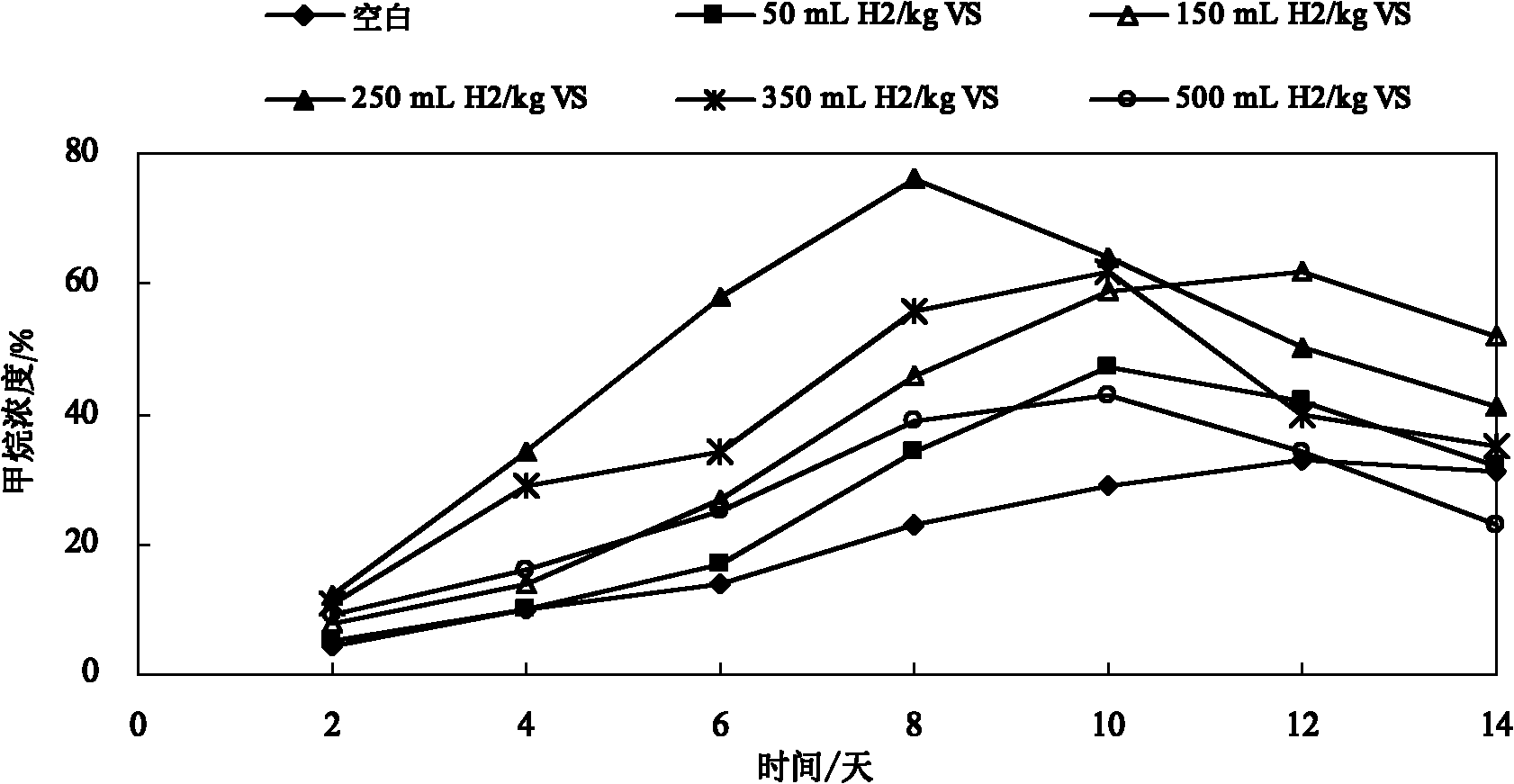

Method for promoting rapid preparation of methane from organic waste by utilizing exogenous hydrogen

InactiveCN102181486AReduce CO2 concentrationRaise the pHWaste based fuelFermentationWater contentGreenhouse gas

The invention relates to a method for promoting the rapid preparation of methane from organic waste by utilizing exogenous hydrogen. The method comprises the following steps of: mixing sludge and domestic garbage in a weight ratio of 1:(2-4), wherein the content of volatile substances (VS) in the mixture is 20 to 65 percent, and the water content is 18 to 68 percent; and performing anaerobic fermentation reaction on the mixture for a period of 7 to 14 days at the temperature of between 35 and 37 DEG C and at the pH value of between 6.5 and 7.5, and introducing exogenous pure hydrogen under the pressure of between 1.1 and 5.5MPa from the bottom of the mixture in the second day of each period, wherein the maximum daily output of the methane can reach 3.65L / kg.d when the introducing amount is 50 to 150mL H2 / kg VS, and is 2.81 times the yield of the methane when the hydrogen is not added. The concentration of the methane can be improved from 33.2 percent to 75.5 percent. The cost is low, the method is easy to operate, the problem of environmental pollution of municipal refuse and greenhouse gas is solved, and the clean energy is also provided, so that the method has good social benefit and economic benefit. The method can be widely applied to the rapid preparation of the methane from the organic waste in middle and small-sized landfill sites.

Owner:TONGJI UNIV

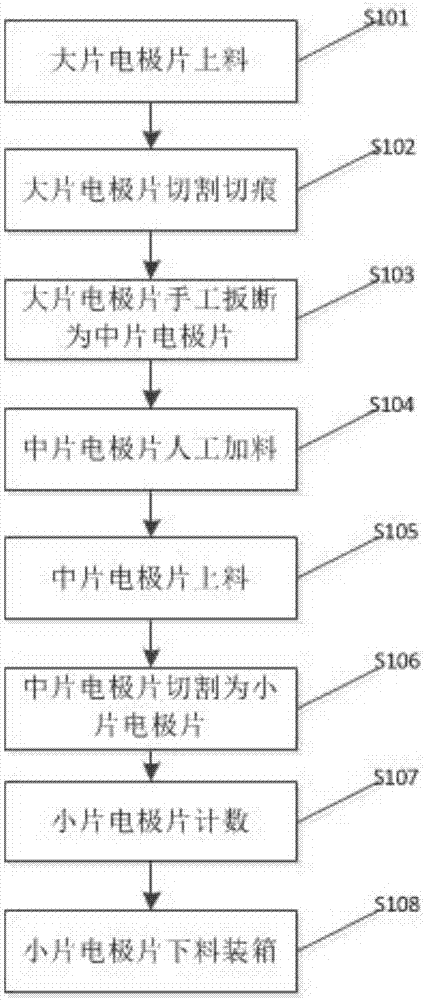

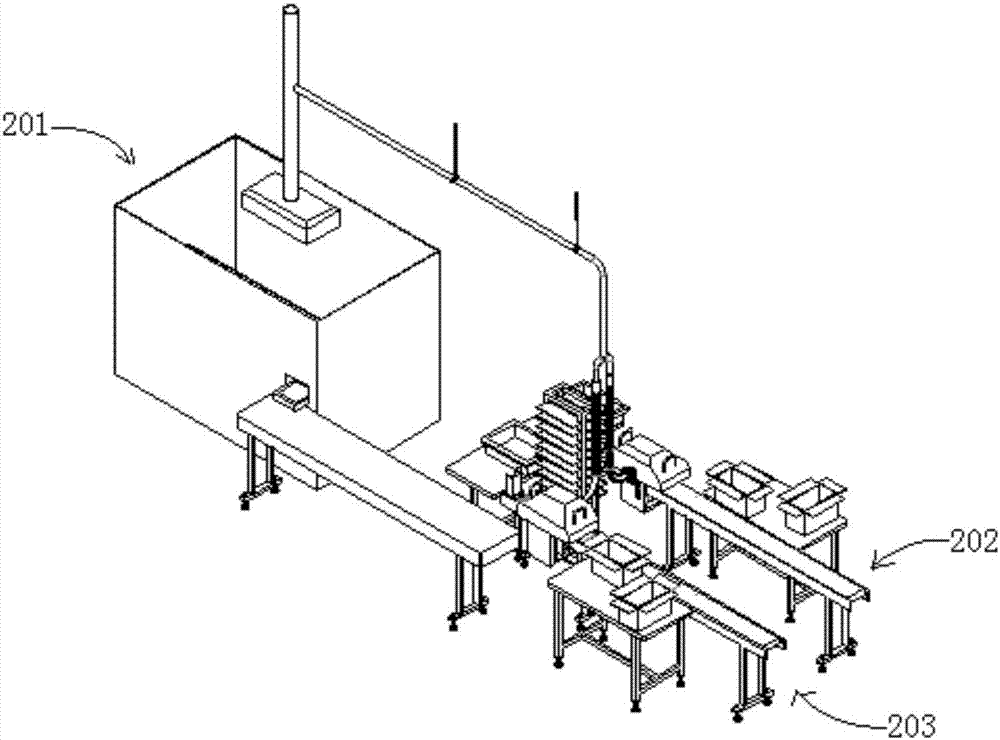

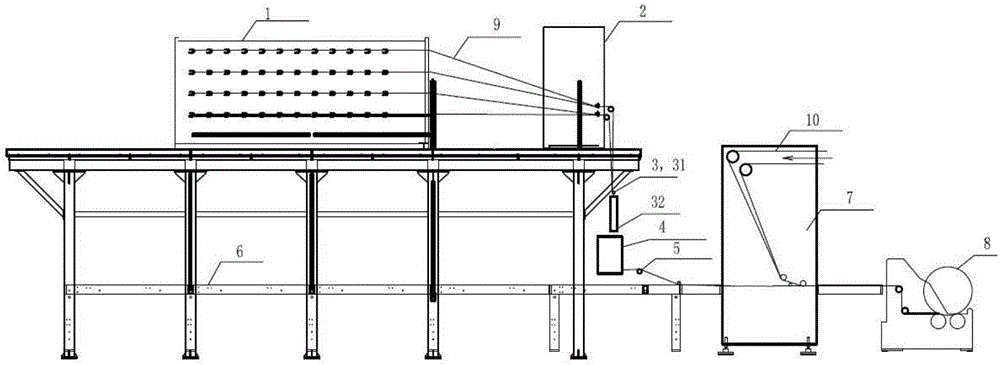

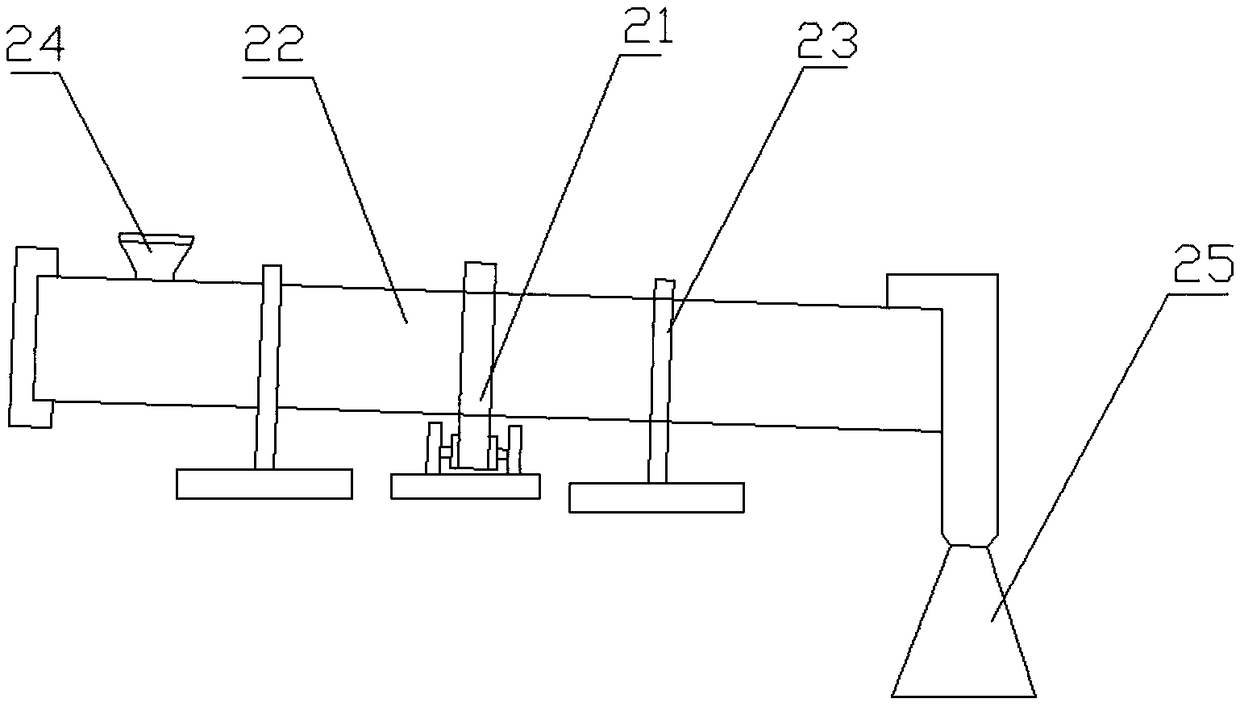

Semi-automatic slicing method and system for battery electrode slices

ActiveCN107403901ASimple ideaEasy to implementElectrode manufacturing processesLarge distanceEngineering

The invention discloses a semi-automatic slicing method and system for battery electrode slices. In the process of cutting medium electrode slices into small electrode slices, the medium electrode slices are stacked in a separating cylinder and automatically hooked out of the separating cylinder by chains with pulling sheets slice by slice; the medium electrode slices are conveyed to a slicer and are sliced into a group of small electrode slices arranged orderly; the small electrode slices are driven to be away from the slicer by pressure belts dependent on friction; a sensor is arranged at the front section of a conveying belt for discharging, and moves one small step forward automatically for each group of small slices and counts the number automatically for each group of small slices entering; when the counted number reaches the set value of the electrode slices in one box, an arranging conveying belt moves a large distance rapidly, so that a box of the electrode slices which can be distinguished remarkably is formed on the conveying belt; the semi-automatic slicing system comprises a production line for cutting large slices into medium slices and a production line for cutting medium slices into small slices. According to the semi-automatic slicing method and system for the battery electrode slices, an existing production line is transformed, the slicer and corresponding conveying lines are added, the purpose of cutting large electrode slices into small electrode slices is achieved, and body burdens of workers are reduced while production efficiency is improved.

Owner:GUANGDONG INST OF INTELLIGENT MFG +1

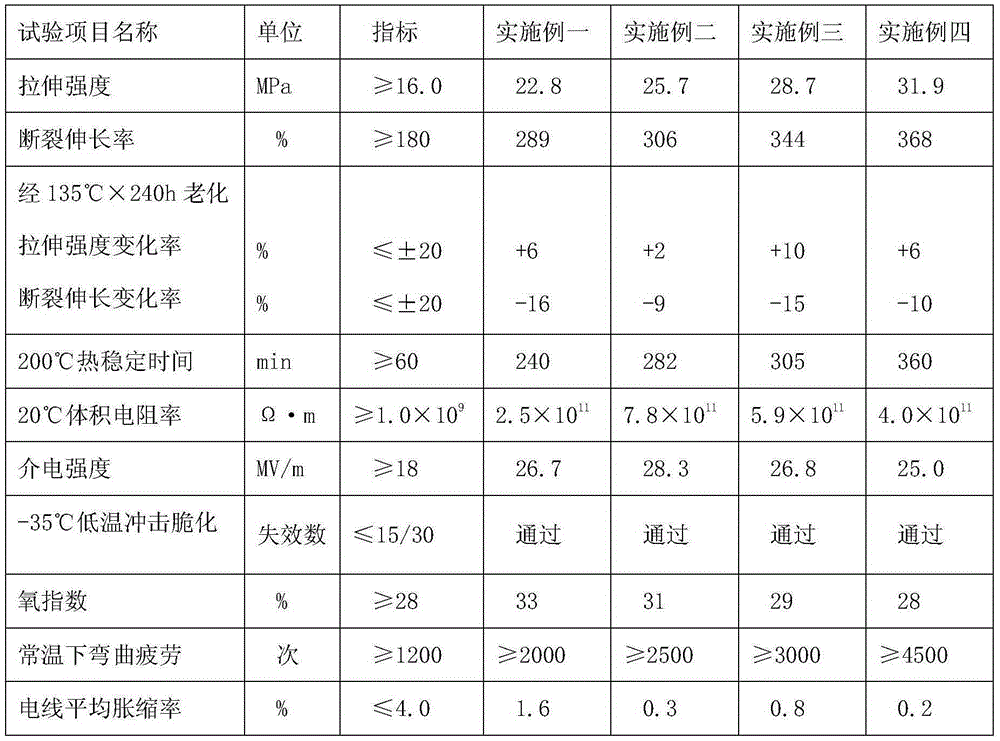

Polyvinyl chloride/polyurethane alloy cable material and preparation method thereof

The invention discloses a polyvinyl chloride / polyurethane alloy cable material and a preparation method thereof. The polyvinyl chloride / polyurethane alloy cable material comprises, by weight, 40-80 parts of polyurethane, 20-60 parts of polyvinyl chloride resin, 5-50 parts of a plasticizer, 1-10 parts of a stabilizer, 1-5 parts of a fire retardant, 0-80 parts of a filler, 0.5-2.0 parts of an antioxidant, and 1.0-6.0 parts of a processing assistant, wherein the processing assistant is one or a mixture of more of oxidized polyethlene wax, erucamide and acrylate polymers. The restriction of modification of polyvinyl chloride by polyurethane in the prior art is broken, a new polyurethane and polyvinyl chloride compatibility idea is provided, different compatibilities of polyurethane and polyvinyl chloride are carried out in a range wider than that in the prior art according to different product requirements, and the alloy cable material with extremely good anti-fatigue service life and extremely low swelling-shrinkage is obtained through reasonable compatibility.

Owner:WUXI JAKE PLASTIC

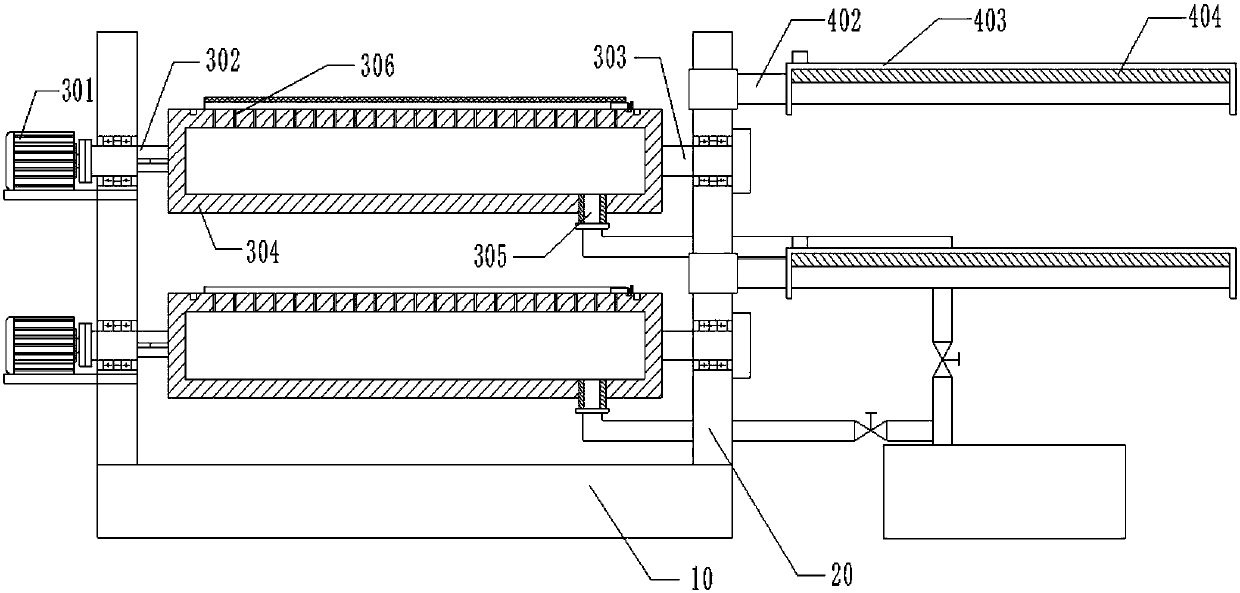

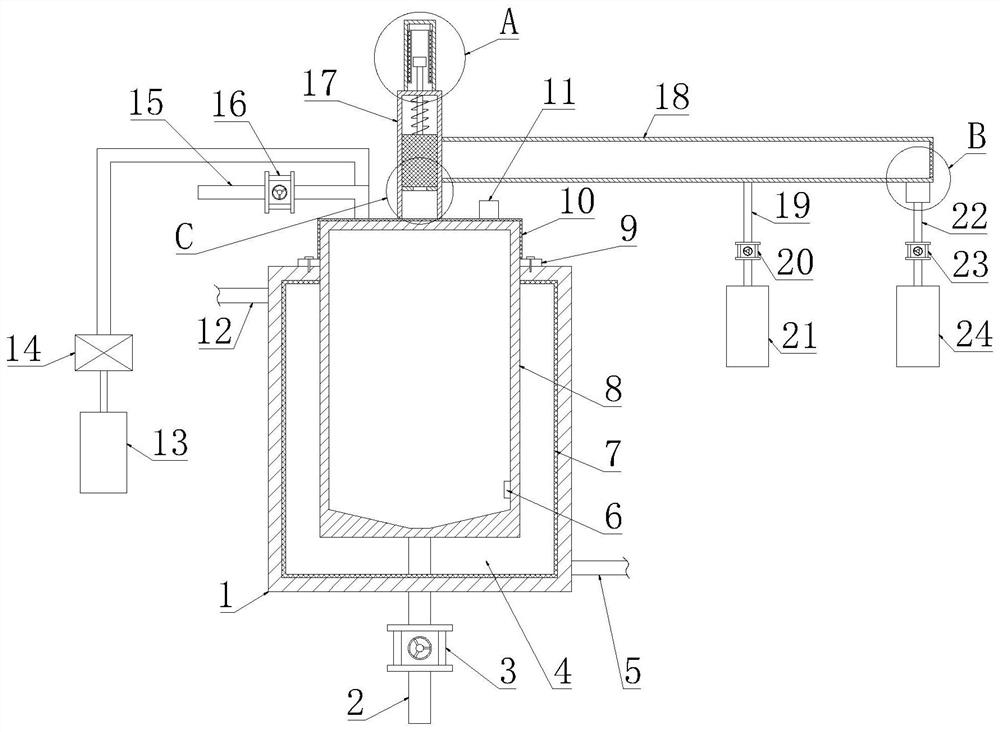

Microwave integrated machine for production of aerogel material and method for continuous production of aerogel material

ActiveCN109529735AAvoid sparkingAvoid accidentsAerogel preparationEnergy based chemical/physical/physico-chemical processesMicrowaveThermal insulation

A microwave integrated machine for production of an aerogel material and a method for continuous production of the aerogel material are disclosed. The invention belongs to the technical field of aerogel material production and especially relates to a microwave integrated machine and an efficient production method for continuous production of the aerogel material by using the microwave technique. The invention aims to solve the technical problem that existing aerogel preparation methods have long production period and the internal skeleton structure is collapsed and the thermal insulation performance is reduced. The method of the invention comprises the following steps: preparing a wet aerogel material, letting the wet aerogel material enter a solvent replacement device and then enter a hydrophobic modification device, and drying to obtain the aerogel material; letting the evaporated solvent gas enter a shell and tube condenser, condensing for gas-liquid separation, recycling the solvent, returning an inert gas to the equipment for recycling so as to complete a production period. According to the method, each solvent replacement only takes more than ten minutes, and each hydrophobicmodification only takes more than ten minutes. Thereby, production efficiency is greatly improved.

Owner:江西宏柏新材料股份有限公司

Carbon-glass one-step hybrid weaving technology and device

The invention discloses a carbon-glass one-step hybrid weaving technology and device. The technology comprises the steps that carbon fiber is unwound through a constant tension creel, subjected to yarn collection through a yarn collection rack and subjected to thread-used fiber spread by a fiber spread device, the carbon fiber, glass fiber spun yarn which is conveyed by a weft laying device in the same direction and glass fiber which is conveyed in the other direction synchronously enter a multi-axial warp knitting machine to be woven into carbon-glass hybrid fabric, and then rolling is conducted. According to the carbon-glass one-step hybrid weaving technology and device, a novel technology route is provided, controlled thread-used fiber spread which is synchronous with weaving is adopted, one-step hybrid weaving is achieved, the production cost and labor cost are lowered, the labor intensity of workers is lowered, the waste is reduced, and the energy is greatly saved.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

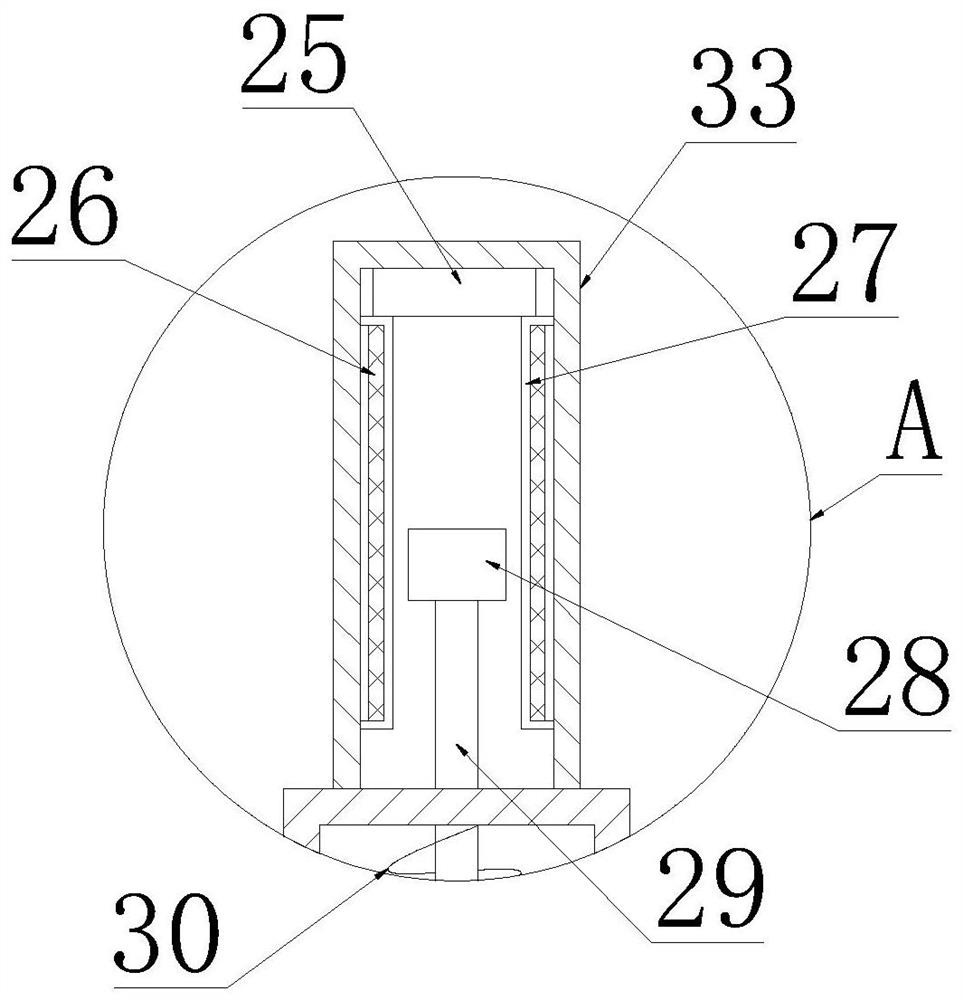

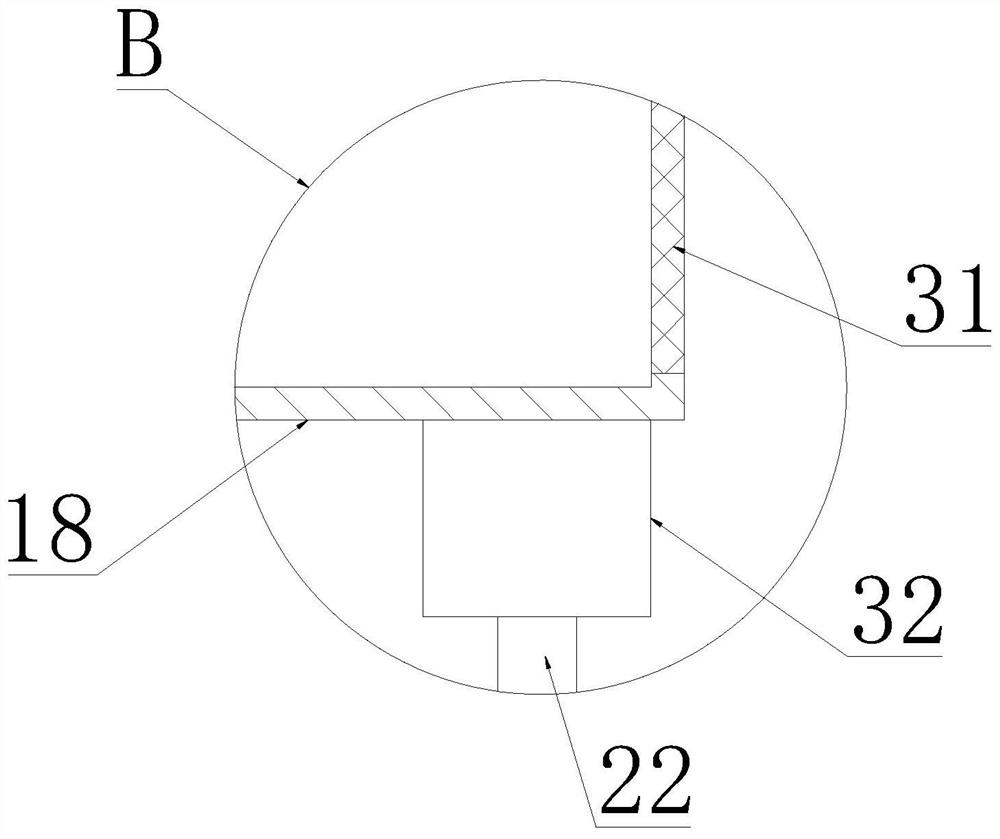

Turnover device for diode package

ActiveCN109560007AFixedImplement encapsulationSemiconductor/solid-state device manufacturingEngineeringProcess engineering

The invention provides a turnover device for diode package. The turnover device comprises a base, columns, a packaging process 1, a baking mechanism 1, a packaging process 2 and a baking mechanism 2.The two columns are vertically and oppositely arranged on the base, the baking mechanism 1, the packaging process 1, the baking mechanism 2 and the packaging mechanism 2 are horizontally arranged between the two columns from top to bottom, the two ends of the packaging process 1 and the packaging process 2 penetrate the two columns, the packaging process 1 and the packaging process 2 can be rotated for 180 degrees, one ends of the baking mechanism 1 and the baking mechanism 2 sleeve the column at the right side, and the baking mechanism 1 and the baking mechanism 2 can be rotated for 180 degrees around the column at the right side. The turnover device for diode package can achieve integrated packaging and forming of the bottom material piece, the chip and the cover material piece in the diode package process so as to effectively avoid the problem that the three are prone to external factor influences to generate paste deviation when artificial and semi-artificial package is performed,ensure the package processing quality and improve the product efficiency.

Owner:TIANJIN TIANXING ELECTRONICS

Process for producing tofu

InactiveCN1449255AEasy to shapeGreat tasteOther dairy technologyCheese manufactureLine tubingChemistry

Owner:FUJI OIL CO LTD

Electromagnetic shielding paper and preparation method thereof

ActiveCN107630386AShould not fall offImprove stabilityNon-fibrous pulp additionMagnetic/electric field screeningFiberElectrical resistance and conductance

The invention provides electromagnetic shielding paper and a preparation method thereof, and is characterized in that whisker-shaped carbon nanotubes are synthesized by a chemical vapor deposition method, thermosetting resin is used as a surface graft material for the carbon nanotubes, the carbon nanotubes are subjected to acidification surface treatment and then are grafted with the thermosettingresin, a composite material with high performance is formed, the composite material is composited with paper fibers, and then the electromagnetic shielding composite paper is prepared by a vacuum suction filtration method. The composite paper has both flexibility and electrical conductivity, and has remarkable functions of preventing electromagnetic information leakage, preventing electromagneticinterference, preventing infrared imaging and the like; the shape and resistance are controllable; and the paper fiber and the carbon nanotubes in the composite paper can be perfectly combined and are not easy to fall off, and the properties are stable.

Owner:TAIZHOU LION KING SIGNAL

Process and apparatus for producing beam member

ActiveUS8940119B2Continuous and efficient productionCross-sectional secondary moment becomes largeLamination ancillary operationsLaminationFiberEngineering

A process for producing a beam member formed by a reinforcing fiber base material which has a web portion and at least a pair of flange portions extending to both sides via at least a branching point from the web portion, at a cross-sectional surface orthogonal to a longitudinal direction of the beam member, and by a shaped filler which fills a gap having a wedge shape formed at the branching point, is provided. The shaped filler is produced by: (A) a filler supply process for supplying a filler member configured by reinforcing fibers; (B) a preshaping process for providing a preshaped filler having at least a wedge projection portion, by pressurizing the filler member by a preshaping mold; and (C) a filler deforming process for providing a shaped filler by deforming the preshaped filler.

Owner:TORAY IND INC

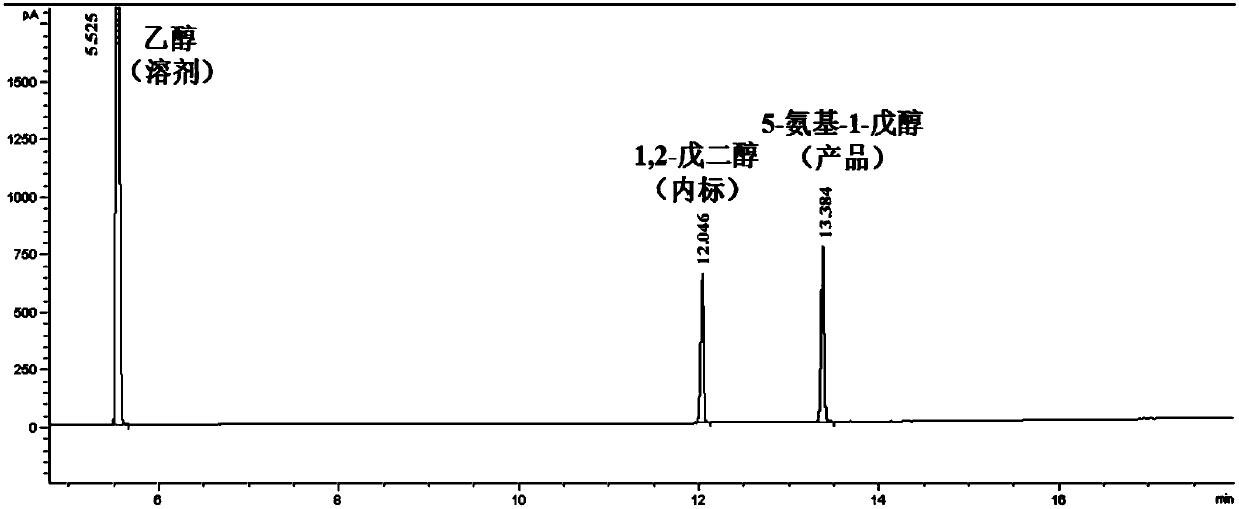

Method for continuously producing 5-amino-1-amyl alcohol

ActiveCN109678732AContinuous and efficient productionRaw materials are cheap and easy to getOrganic compound preparationAmino-hyroxy compound preparationFiltrationHydrogen pressure

The invention discloses a method for continuously producing 5-amino-1-amyl alcohol. The method comprises the following step: carrying out a continuous reductive amination reaction on a mixed reactionsystem with a dihydropyran aquo-complex, ammonium hydroxide and a loaded type nickel catalyst in a fixed bed reactor, thereby obtaining the 5-amino-1-amyl alcohol. According to the method, the dihydropyran aquo-complex and the ammonium hydroxide which are low in price and easy to obtain are adopted as raw materials, a loaded type non-noble heavy nickel is adopted as the catalyst in the fixed bed reactor, continuous production of the 5-amino-1-amyl alcohol at a low reaction temperature and low hydrogen pressure is achieved, a reaction product is directly separated from the catalyst in the reaction process, independent filtration or centrifugation treatment is not needed, the catalyst is good in service life stability, the method is simple in operation and process, the production efficiencycan be remarkably improved, the production cost can be lowered, and on-scale industrial production can be facilitated.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

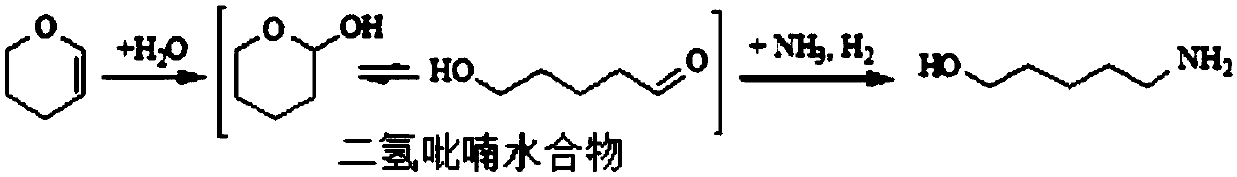

Production line and process for recycling waste granite powder

InactiveCN108772173A100% utilizationAvoid secondary pollutionSievingScreeningProduction linePulp and paper industry

Owner:杭州一诺再生资源利用有限公司

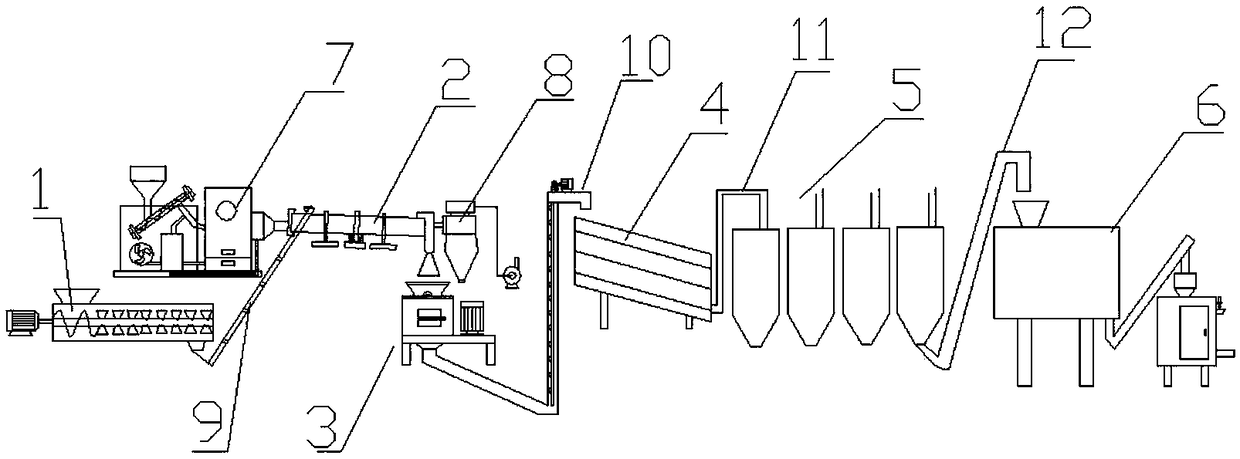

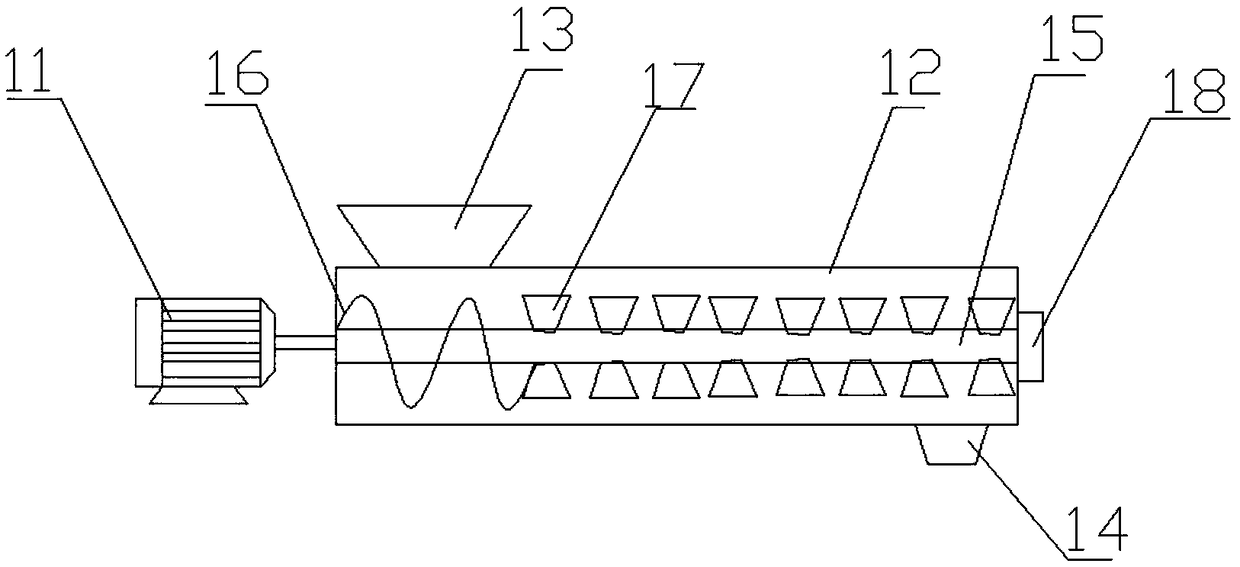

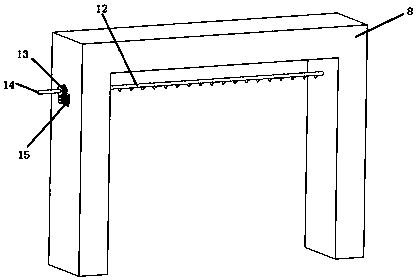

Novel rapid building block core filling device

PendingCN107891520AImprove the quality of the working environmentContinuous and efficient productionCeramic shaping plantsAuxillary shaping apparatusConstruction engineeringWorking environment

The invention discloses a novel rapid building block core filling device and belongs to the technical field of building block processing. The filling can be applied to other fields after being subjected to simple modification, for solving the problems that the conventional manual building block core filling efficiency is low, the operating environment is poor, the time and labor are consumed, theproduction cost is increased, and continuous and high-efficiency production is not facilitated. The novel rapid building block core filling device disclosed by the invention comprises a rack, a powerdevice, a transfer device, a rapid filling device, a cleaning device and a detection device, and is characterized in that a transport device on the rack drives a mold to move forwards by virtue of chain drive, and the rapid filling device, the high-pressure cleaning device and the detection device are arranged on the rack. The novel rapid building block core filling device disclosed by the invention is simple in structure, ingenious in design, low in cost and high in reliability, full-automatic, high-efficiency and high-quality filling is realized, and the core filling efficiency in the production process is increased. Meanwhile, the labor intensity of the staff is reduced, and the operating environment quality of the staff is improved.

Owner:UNIV OF JINAN

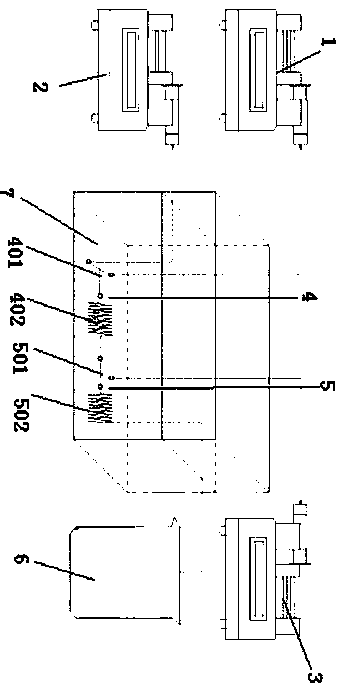

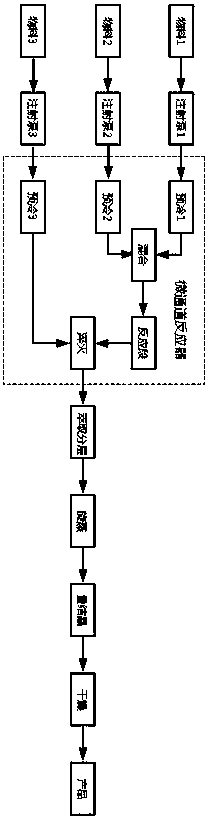

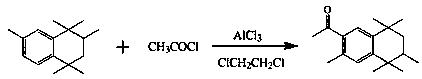

Micro-continuous flow technology for producing tonalide

InactiveCN110950746ASimple and efficient operationImprove securityChemical/physical/physico-chemical microreactorsCarbonyl compound preparation by condensationProcess engineeringDichloroethane

The invention discloses a micro-continuous flow technology for producing tonalide. The technology taking 1,1,3,4,4,6-hexamethyltetrahydronaphthalene (HMT) and acetyl chloride as raw materials, anhydrous aluminum chloride as a catalyst and dichloroethane and other organic matters as a solvent comprises the following steps: mixing the anhydrous aluminum chloride, the solvent and acetyl chloride under a low-temperature condition to obtain a catalyst phase; mixing and dissolving the raw material HMT with the solvent to obtain a raw material phase; respectively pre-cooling the raw material phase and the catalyst phase, and introducing the pre-cooled raw material phase and catalyst phase into a micro-channel reactor, and performing a reaction; and finally, introducing the obtained reaction product into a microstructure mixing module, quenching and layering the obtained reaction product, and then carrying out extraction, rotary evaporation, recrystallization and drying to obtain the tonalide.The micro-continuous flow technology has the advantages of short retention time, continuousness in operation, increase of the production efficiency of the product, improvement of the production safety and the product yield by timely removing heat in the reaction process, and reduction of the risk of the quenching process by timely removing heat in the quenching process.

Owner:FUZHOU UNIVERSITY

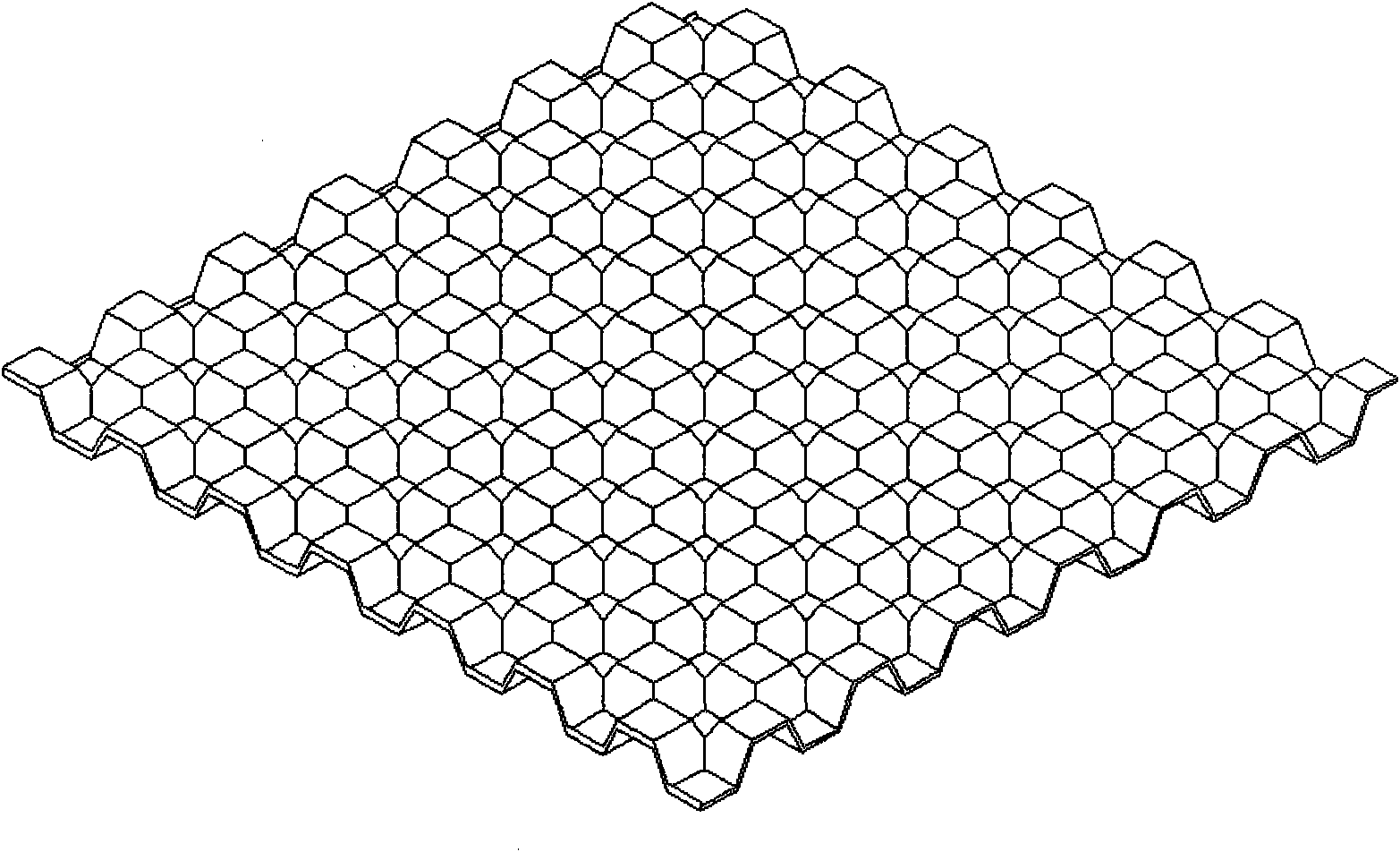

Novel water storage and drainage plate

InactiveCN102071674APrevent passageAvoid blockingProtective foundationRoof drainageWater storageEngineering

The invention discloses a novel water storage and drainage plate, which has strong bearing capacity and good mechanical property and is convenient for forming and multifunctional. The novel water storage and drainage plate is a double-sided concave-convex pyramid plate made of plastic. In the pyramid plate, a series of double-sided concave-convex staggered truncated pyramid supporting bodies are processed on a whole plate / sheet by using a method of die pressing, plastic absorption, rolling and the like; the adjacent truncated pyramid units are mutually communicated through a V-shaped groove; and during construction, a geotextile filter layer is spread on the water storage and drainage plate. The novel water storage and drainage plate has excellent mechanical property, can bear load, resist trample, store and discharge water, regulate water quantity and steam, preserve moisture and hold water and soil, is easy for construction and simple and convenient to assemble, can be widely applied in the fields of building engineering, urban greening and the like, is simple in manufacture, is suitable for large-scale batch production, and is low in cost.

Owner:王韬

Method for producing transparent resin composition

According to this method for producing a transparent resin composition, a molten mixed resin is produced by continuously supplying a polycarbonate resin and an acrylic resin to a twin screw extruder, and the molten mixed resin is supplied to a single screw extruder that has a screw provided with a shearing unit. A transparent resin composition is continuously produced by kneading the molten mixed resin by means of the shearing unit that rotates at a speed of from 500 rpm to 4,000 rpm (inclusive).

Owner:TOSHIBA MASCH CO LTD +1

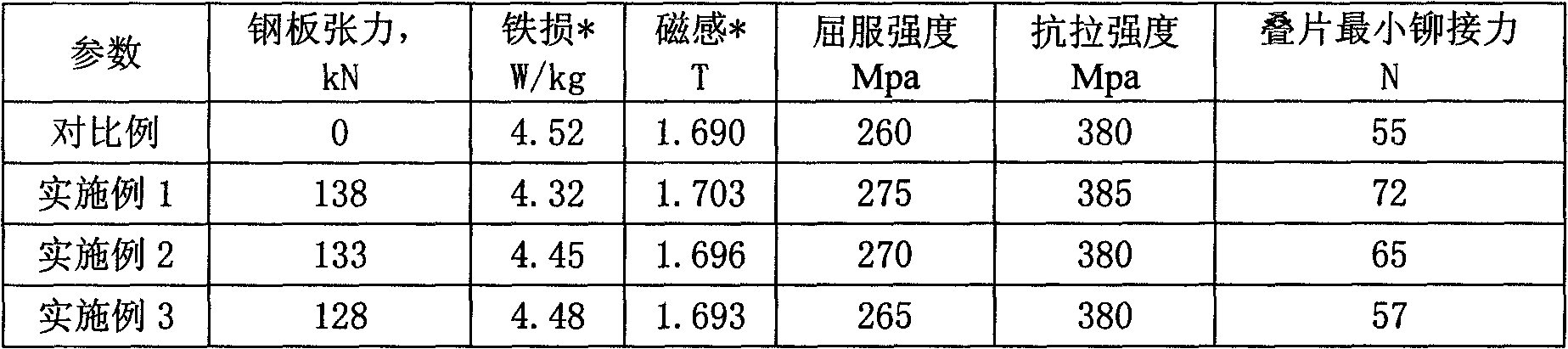

Production method of non-oriented electrical steel coating semi-processed product

ActiveCN103031421AContinuous and efficient productionReduce energy consumptionSteel platesElectrical steel

The invention provides a production method of a non-oriented electrical steel coating semi-processed product. The production method of the non-oriented electrical steel coating semi-processed product mainly comprises the procedures of smelting, hot rolling, cold rolling, annealing, coating, rewinding and packing. The production method of the non-oriented electrical steel coating semi-processed product is characterized in that on a rewinding operating line, a stretching procedure is added between an unwinding technology section and a winding technology section and realized by a group of straightening and withdrawal devices; a pull force F is applied onto a coated steel plate; and moreover, F which is more than or equal to S*Rp0.2 but less than or equal to 1.2*S*Rp0.2 is satisfied, wherein S represents the cross sectional area of a finished steel plate and Rp0.2 represents the yield strength of the finished steel plate. With the adoption of the production method of the non-oriented electrical steel coating semi-processed product, not only can the continuous high-efficiency production be realized, but also the energy consumption can be saved and the smoothing procedure can be omitted; not only can the processing performance and the mechanical performance required by a user be kept, but also the electromagnetic performance abnormality improvement after the reannealing can be realized; not only can the excellent characteristics of the traditional semi-processed product be kept, but also the great improvement in the installation performance through the coating can be realized; and in addition, the standard grade of steel can be selected while marks are reduced and the production stability of the whole system can be maintained.

Owner:ANGANG STEEL CO LTD

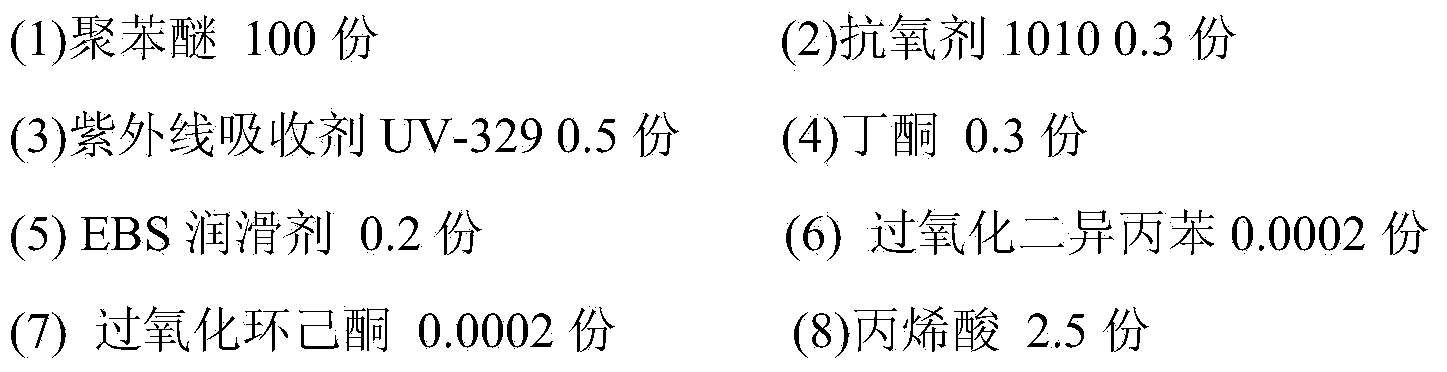

Preparation method of high-purity grafted functionalized copolymer

InactiveCN104292392AImprove diffusion abilityEffective penetrationBulk chemical productionGraft reactionUv absorber

The invention relates to a preparation method of a high-purity grafted functionalized copolymer. The preparation method comprises the following steps: mixing and adding matrix resin, an antioxidant, an ultraviolet absorbent, other auxiliaries, an initiator and a grafted monomer into a double-screw extruder, grafting and copolymerizing at the melting temperature of the matrix resin, to obtain a crude grafted copolymer; adding the crude grafted copolymer into an autoclave, heating, keeping constant temperature, injecting carbon dioxide until the carbon dioxide is at supercritical state, maintaining for 5-120min, performing pressure relief to obtain the high-purity grafted functionalized copolymer. The high-purity grafted copolymer is prepared by firstly performing melt-grafting reaction through the double-screw extruder and purifying supercritical carbon dioxide, so that the preparation method is unique and novel and simple in preparation technology.

Owner:NINGBO NENGZHIGUANG NEW MATERIALS TECH

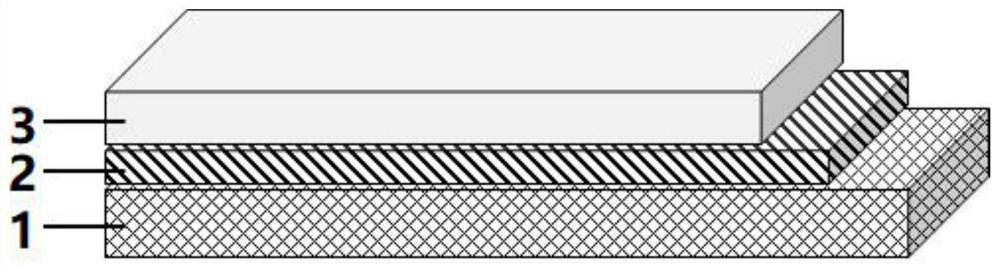

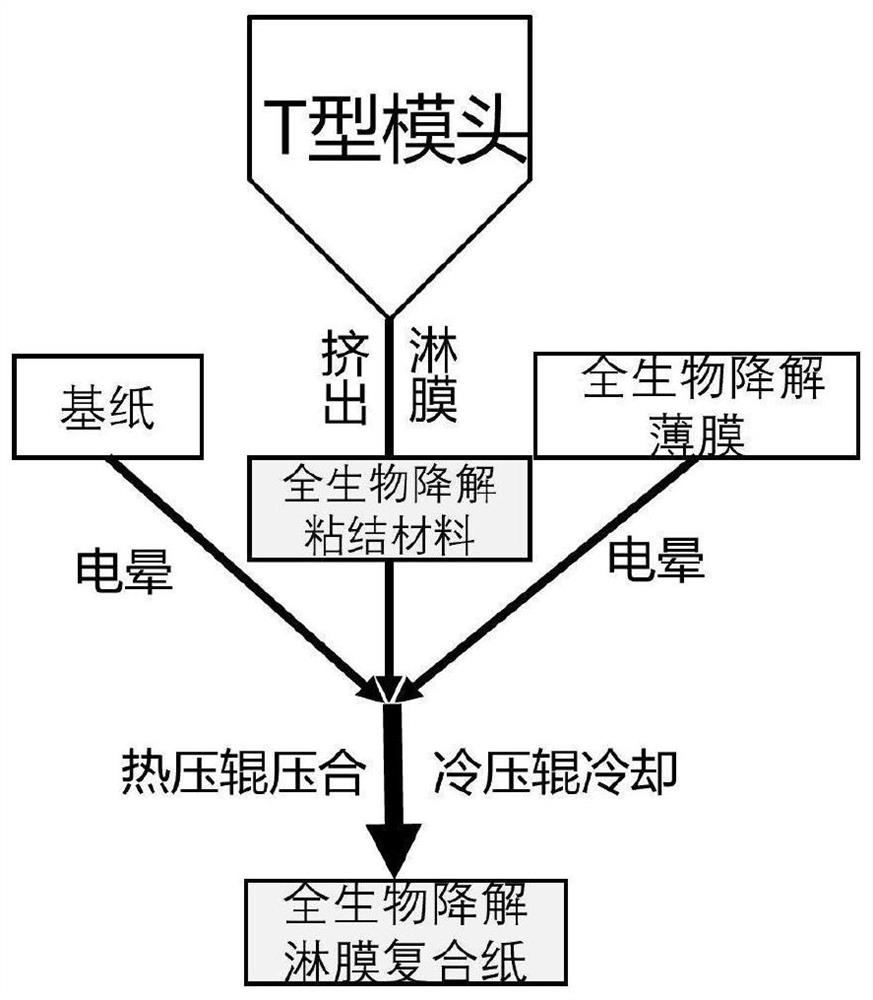

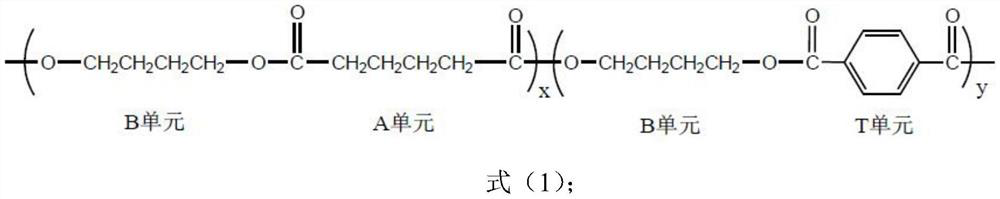

Full-biodegradable lamination composite paper material and preparation method thereof

ActiveCN113355950AImprove performanceBrown sports strongCoatings with pigmentsSpecial paperPolymer scienceAdhesive

The invention discloses a full-biodegradable lamination composite paper material and a preparation method thereof. According to the full-biodegradable composite paper material disclosed by the invention, the biodegradable binding material is used for replacing a traditional chemical adhesive to be applied to compounding of laminated composite paper so as to reduce residues of toxic and harmful substances; and through a mode of compounding the paper and the film, the defects of easiness in roll sticking, low production efficiency and poor material barrier property caused by laminating PBAT resin on a single paper surface are overcome. According to the invention, all the parts are made of full-biodegradable materials, so that the whole body has good biodegradability. After being discarded, the material can be fully biodegraded in the natural environment and does not pollute the environment. The relative biological decomposition rate is greater than or equal to 90%.

Owner:RACHEM CHINA CO LTD +1

Monoglyceride distillation and purification kettle

ActiveCN112807729AHigh purityEasy to operateChemical industryVapor condensationThermodynamicsMonoglyceride

A monoglyceride distillation and purification kettle comprises a shell, a liquid discharge pipe, a liquid storage barrel, two groups of condensers, two groups of vacuum generators, a liquid adding pipe, a mounting barrel, an air outlet pipe, an exhaust pipe and a collecting barrel; a liquid storage cylinder is arranged in the shell; a heating bin is defined by the peripheral face of the liquid storage cylinder and the inner wall of the shell; the heating bin is provided with a liquid inlet pipe and a liquid outlet pipe on the shell; one group of vacuum generators communicate with the liquid storage cylinder and one group of condensers through air pipes; the liquid discharge pipe hermetically penetrates through the shell and communicates with the interior of the liquid storage cylinder; the mounting barrel is connected with the upper end face of the liquid storage cylinder, a piston is slidably arranged in the mounting barrel, and a driving assembly for driving the piston to move is arranged on the mounting barrel; the air outlet pipe is arranged on the mounting barrel; the other end of the air outlet pipe is provided with a condensing plate and communicates with the other group of vacuum generators; the lower end surface of the air outlet pipe is provided with a collecting box and the exhaust pipe; the exhaust pipe communicates with the other group of condensers; and the collecting box communicates with the interior of the collecting barrel through a collecting pipe. The monoglyceride distillation and purification kettle is easy to operate and convenient to use, and the high-purity monoglyceride can be efficiently prepared.

Owner:佳力士添加剂(海安)有限公司

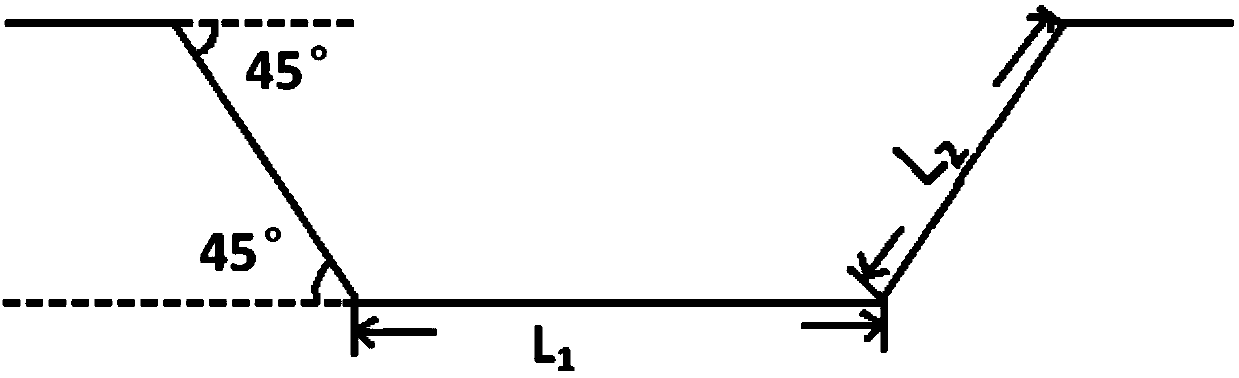

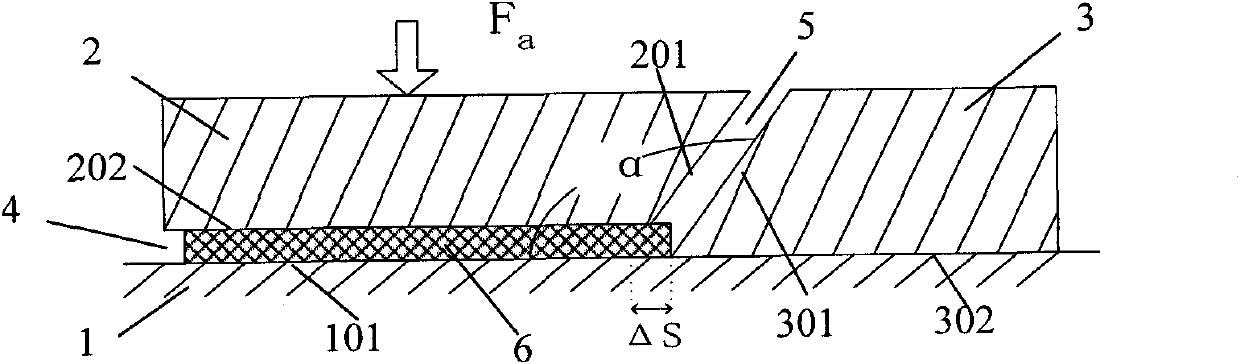

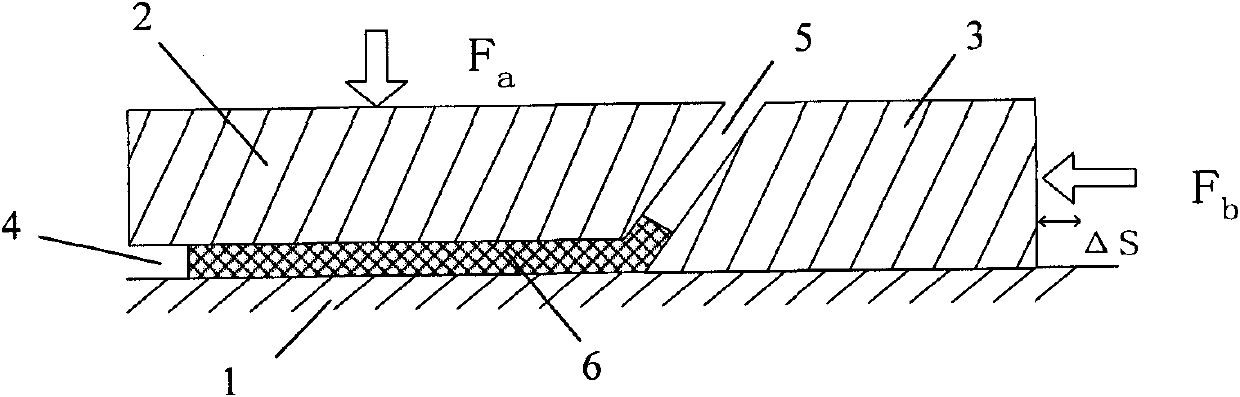

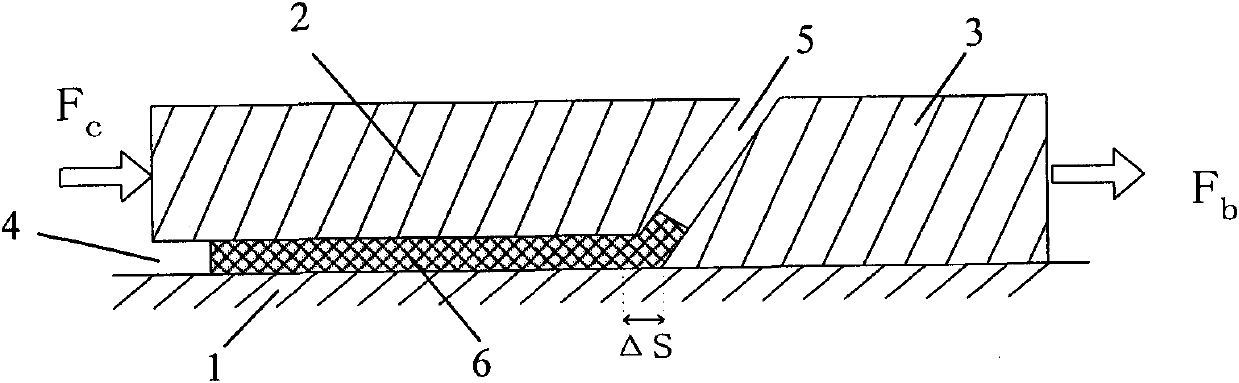

Severe plastic deformation method for grain refinement

ActiveCN102199741AExtended range of materialsContinuous and efficient productionCrystalliteEngineering

A severe plastic deformation method for grain refinement comprises the following steps: 1) a severe plastic deformation channel is formed by employing three modules, wherein a first module is on the bottom and a second module is arranged above the first module to form a first channel, and a third module arranged on the first module and the second module form a second channel; 2) a workpiece to be processed is disposed in the first channel, and a vertical pressure is applied on the second module to compact the workpiece to be processed; 3) a push force parallel to the first channel is applied on the third module to drive the second module to move a step along a direction against the first channel, so that the workpiece is extruded into the second channel by a step; 4) the positive pressure applied on the second module and the third module push force are released to drive the second module and the third module to retreat to initial positions; 5) step 2-4 are repeated to complete extruding. According to the invention, demands of die material and precision by the severe plastic deformation can be lowered, preparative material scope is widened, integrally uniform refinement crystal grains can be obtained, and a workpiece dimension maintains the same after processing.

Owner:BAOSHAN IRON & STEEL CO LTD

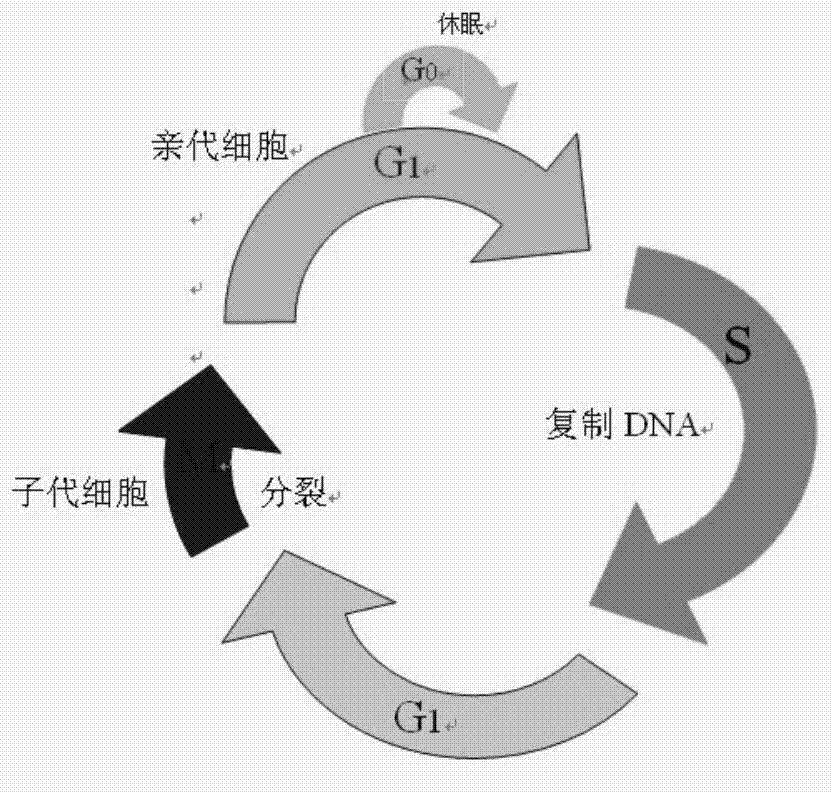

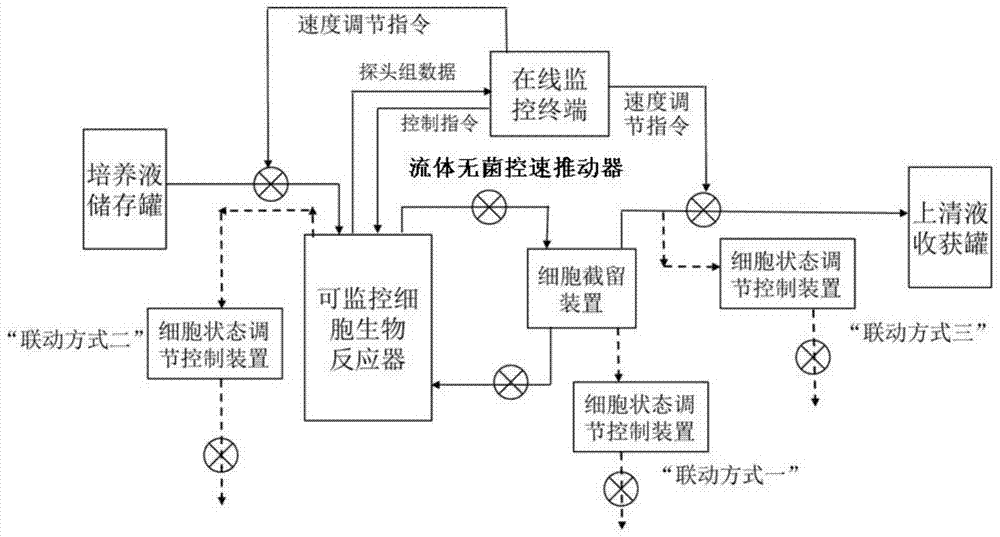

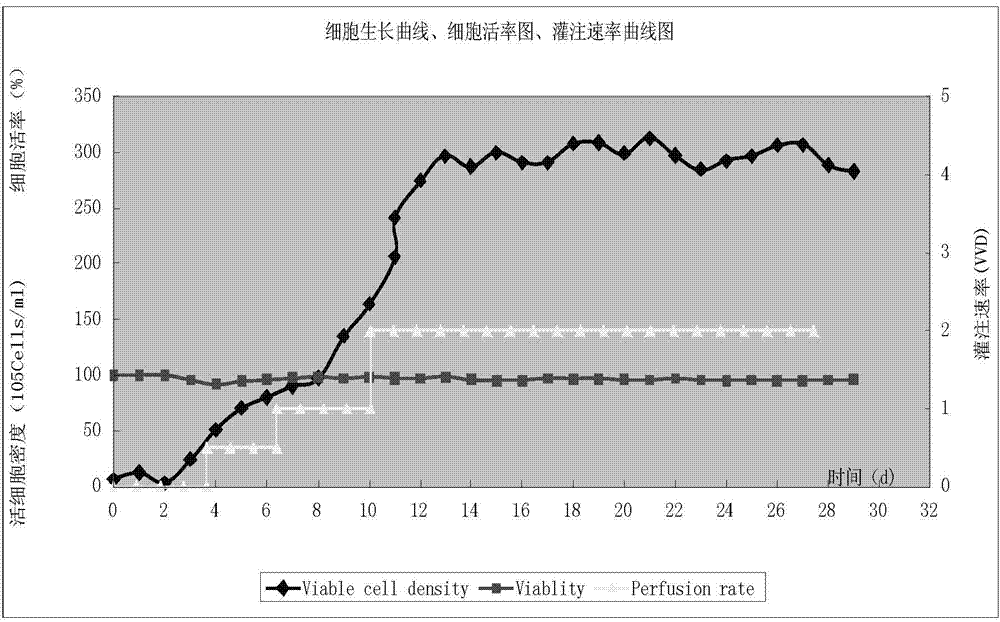

Apparatus and method for producing anti-CD52 monoclonal antibodies through online industrially robust regulation of cell states

InactiveCN104845881AStable growth environmentConstant vigorBioreactor/fermenter combinationsBiological substance pretreatmentsControl cellCvd risk

The present invention discloses a bioreactor cell culture apparatus capable of onlinely and continuously monitoring physiological and biochemical indexes in a variety of cell culture environments and directly regulating and controlling cell states (including cell cycle and the like), and a method for producing anti-CD52 monoclonal antibodies through the apparatus. With the apparatus and the method of the present invention, the bacterial pollution risk during the cell culture process can be reduced, the stable cell growth environment can be maintained, the constant cell growth viability can be maintained, and the high-quality, high-efficiency and continuous anti-CD52 monoclonal antibody production can be achieved.

Owner:上海泰因生物技术有限公司

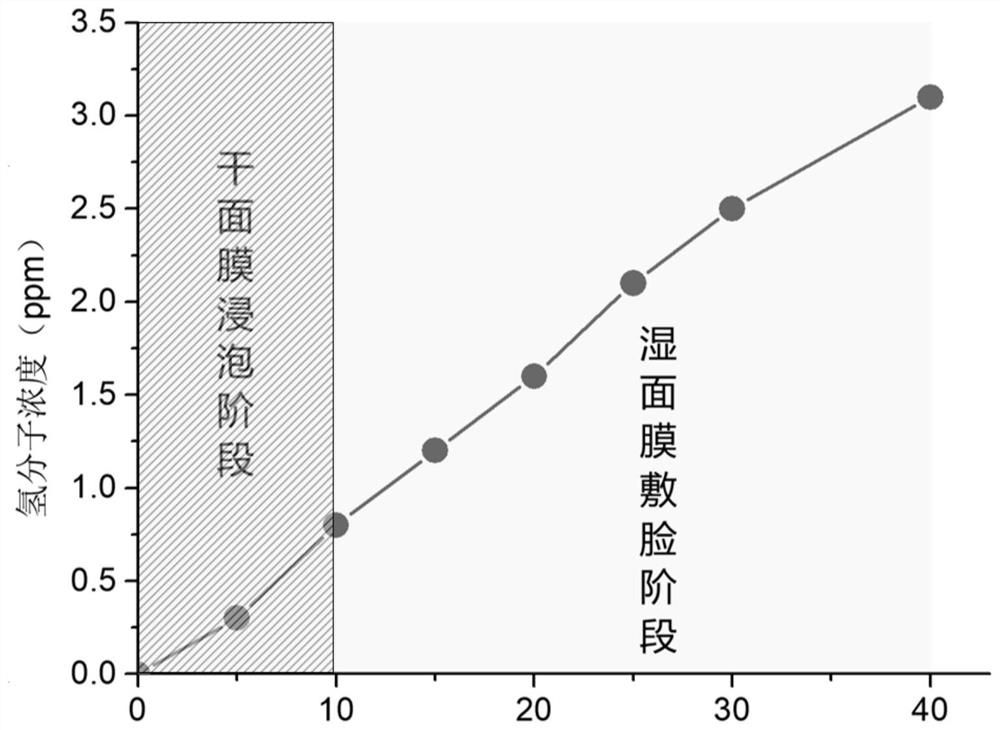

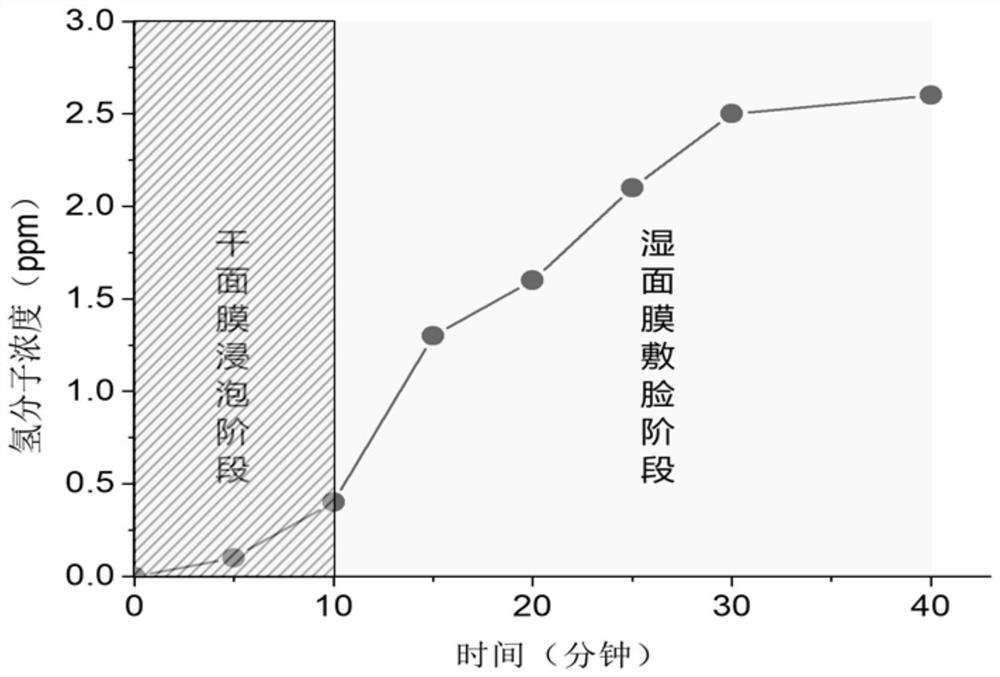

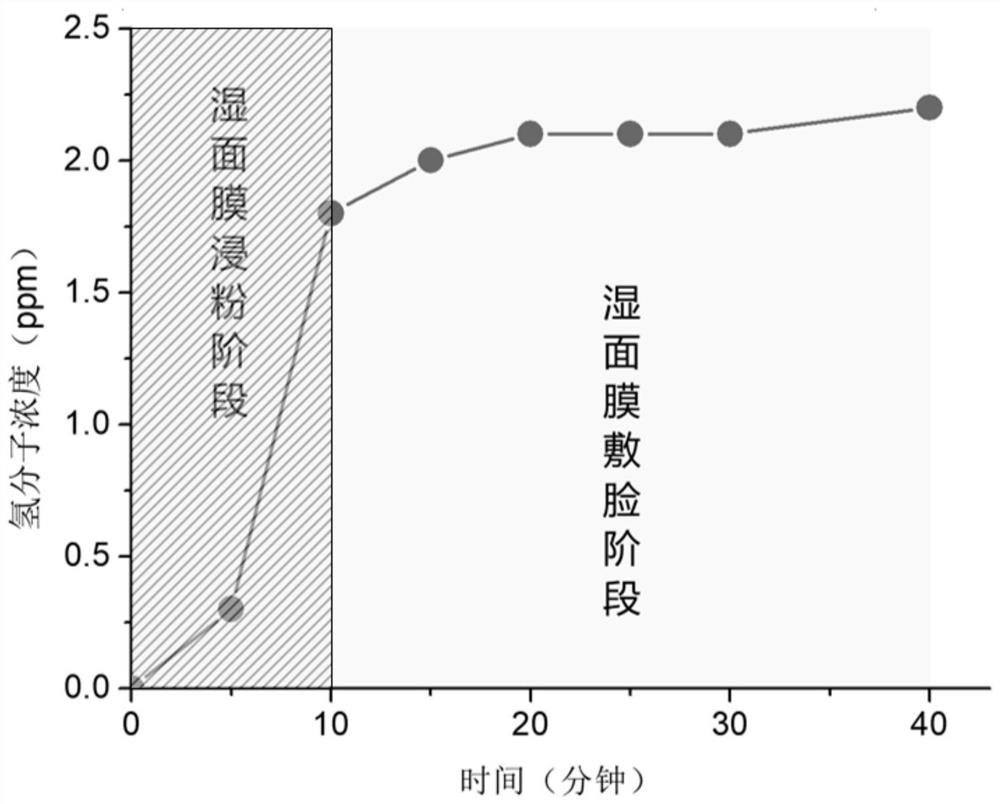

Hydrogen-enriched mask and preparation method thereof

PendingCN111870546AImprove inflammationImprove permeabilityCosmetic preparationsToilet preparationsBiotechnologyHigh concentration

The invention relates to a hydrogen-enriched mask and a preparation method thereof. The hydrogen-enriched mask comprises a mask matrix and nutrient substances, wherein the nutrient substances comprisethe following components in percentage by mass of 0.01%-2% of a hydrogen production basic component, 0.05%-5% of a hydrogen controlled release component, 0%-0.5% of a hydrogen molecule activation component, 0.01%-2% of a water replenishing and moisturizing component and the balance water. The hydrogen-enriched mask provided by the invention can be prepared into various different product forms, including a dry mask, a dry film- et liquid combined mask and a wet film-dry powder combined mask. The hydrogen-enriched mask provided by the invention has the characteristic of continuously and efficiently generating high-concentration active hydrogen, a reaction decomposition product is safe and non-toxic to a human body, the generated high-concentration active hydrogen can efficiently resist inflammation and oxidation, and the hydrogen-enriched mask has the effects of improving skin inflammation, removing acnes, enhancing permeation and absorption of moisture and active ingredients, whiteningskin, removing freckles, resisting wrinkles, removing scars and the like.

Owner:深圳氢欣科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com