Automatic reel changing device for pole pieces

A pole piece, automatic technology, applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of increasing equipment idle time, reducing production efficiency, increasing pollution, etc., to improve the degree of production automation and production efficiency , Realize the effect of production automation and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

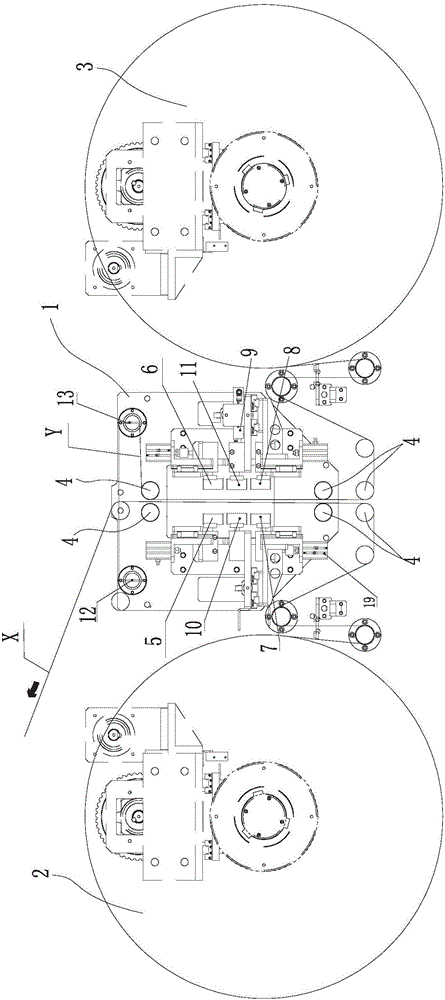

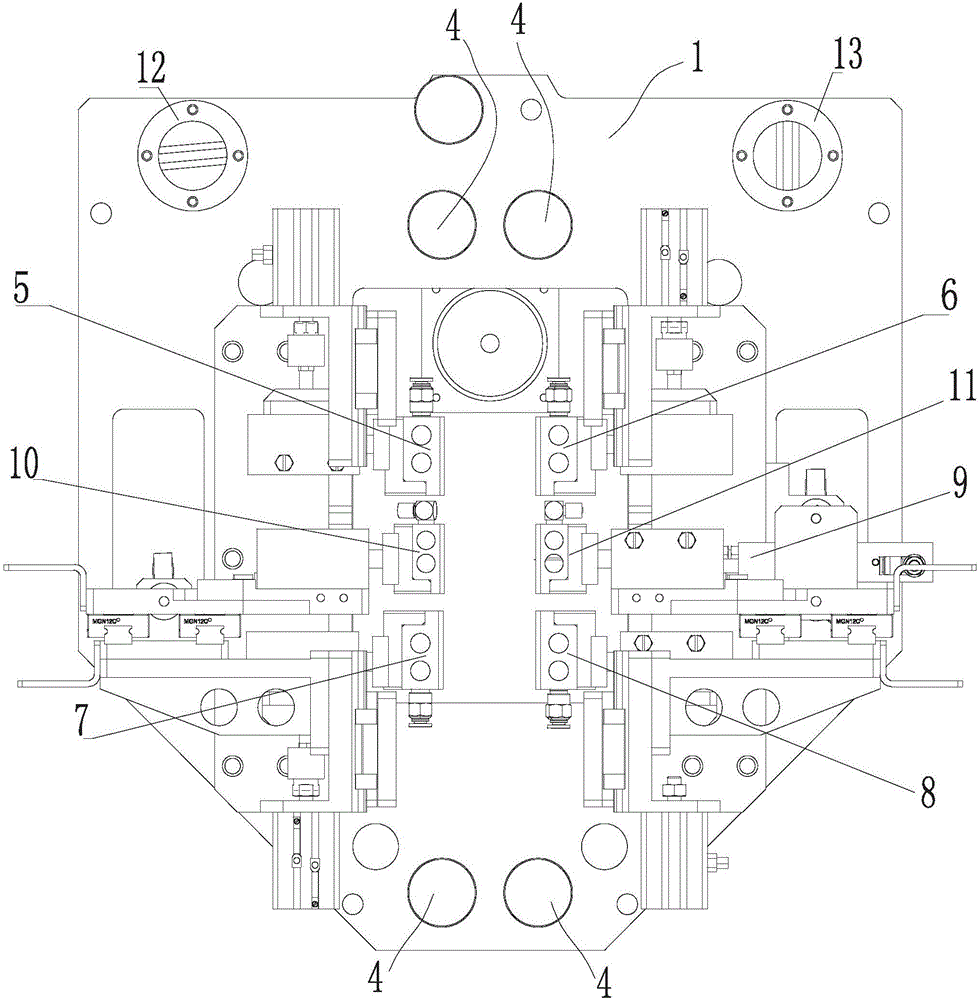

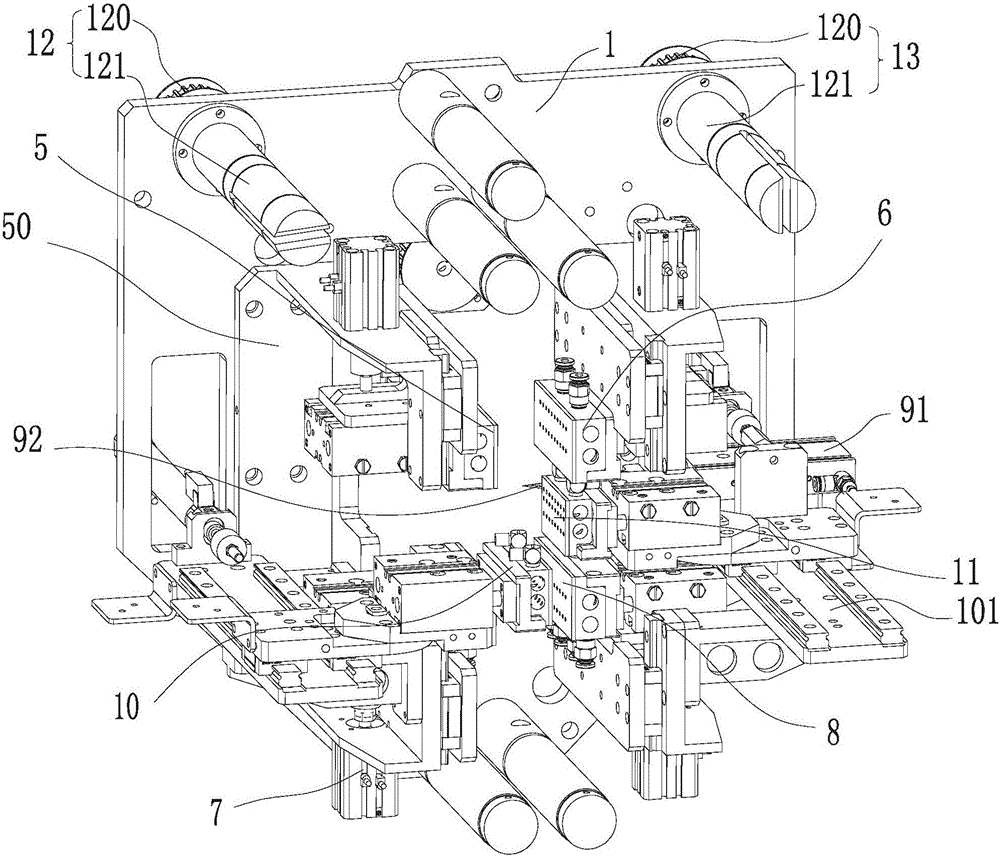

[0030] Pole sheet automatic changing device, such as Figure 1 to Figure 7 As shown, it is used for the winding process of the battery automatic winding machine, including a vertically established substrate 1, and the transmission direction of the running pole piece X is perpendicular to the substrate 1; The spare main roll mechanism 2 and the spare roll mechanism 3, the mutually spare pole piece rolls installed on the main roll mechanism 2 and the spare roll mechanism 3 provide the released pole pieces in turn for the winding process; In the middle of the substrate 1, two rows of rollers 4 that are convenient for the running pole piece X of the main roll mechanism 2 and the spare pole piece Y on the spare roll mechanism 3 to be threaded respectively are respectively drawn and suspended in the air.

[0031] Such as Figure 1 to Figure 5 As shown, on both sides of the upper part of the substrate 1, there are installed in parallel on both sides of the upper side of the upper le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com