Patents

Literature

2951results about "Packaging by pressurising/gasifying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

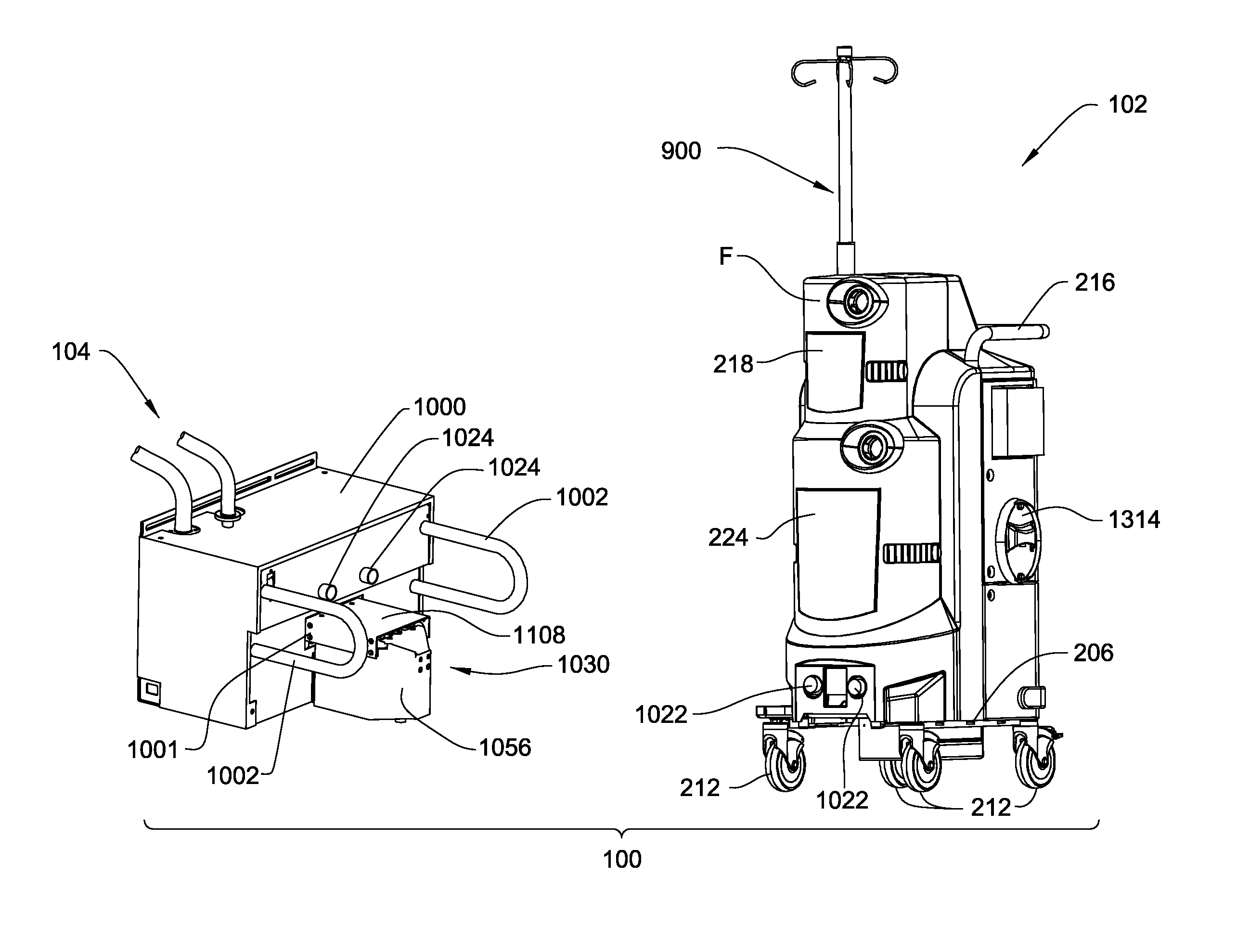

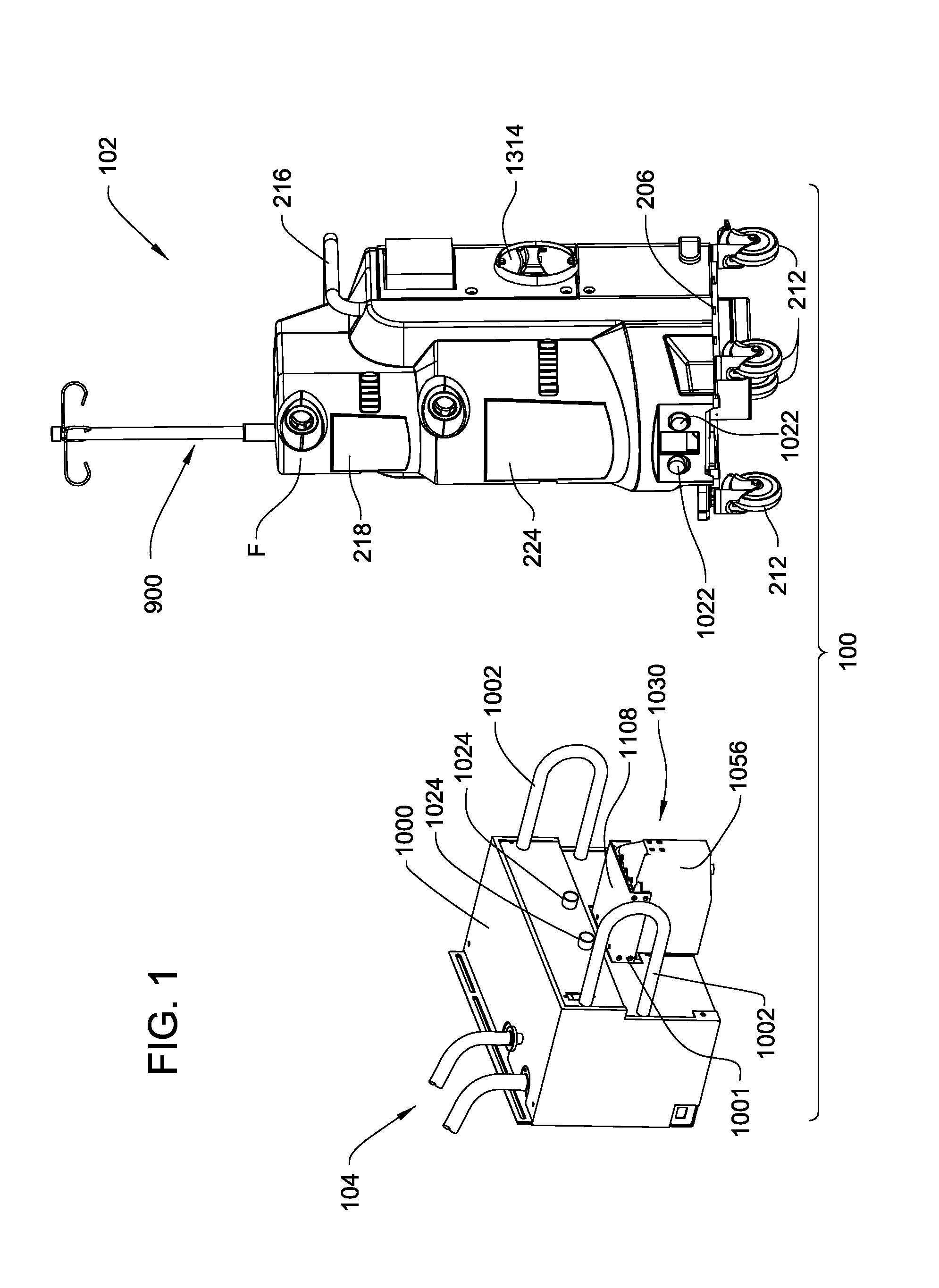

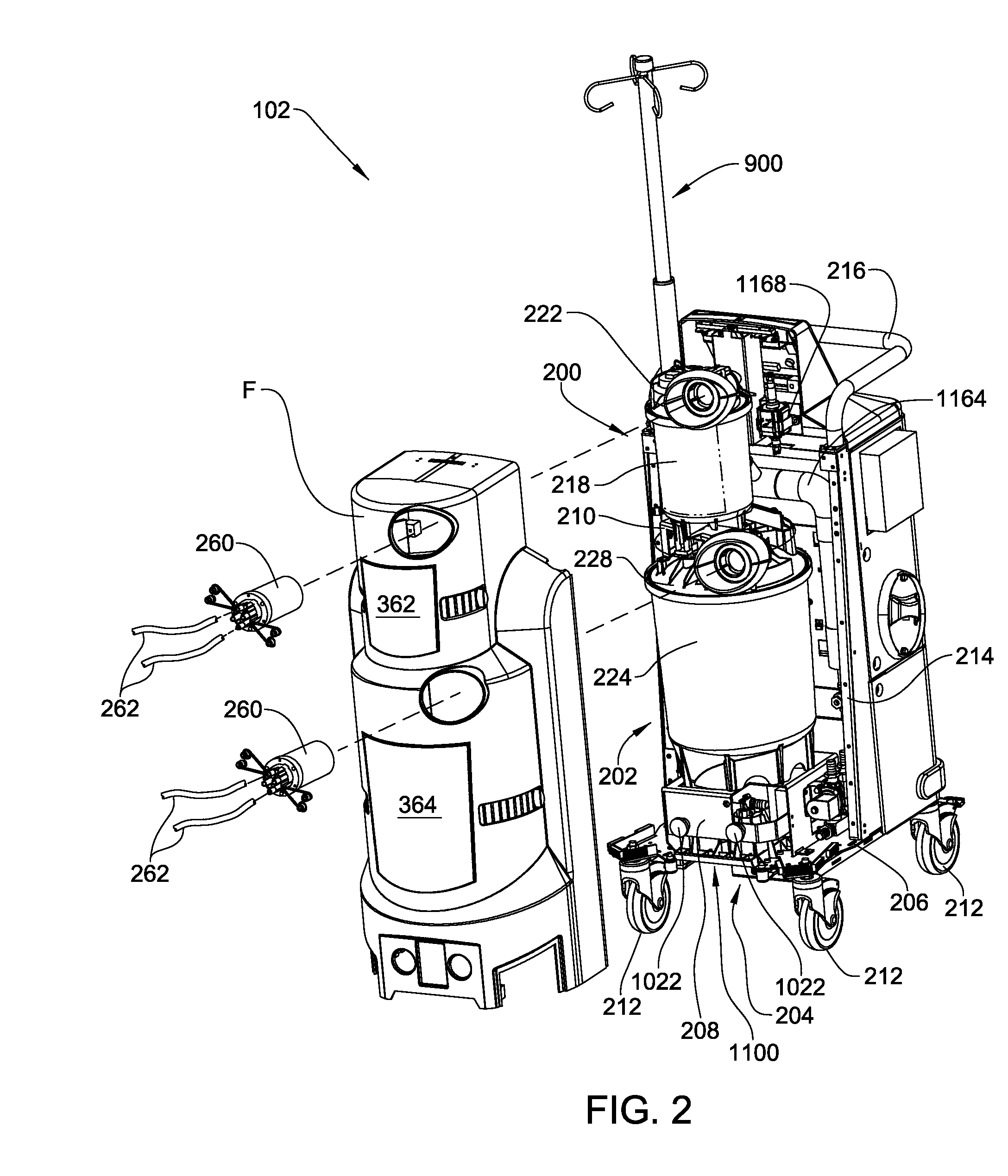

Medical/surgical waste collection unit including waste containers of different storage volumes with inter-container transfer valve and independently controlled vacuum levels

ActiveUS7621898B2Reduce in quantityLarge storage capacityMechanical apparatusDispersed particle filtrationDocking stationVacuum level

Owner:STRYKER CORP

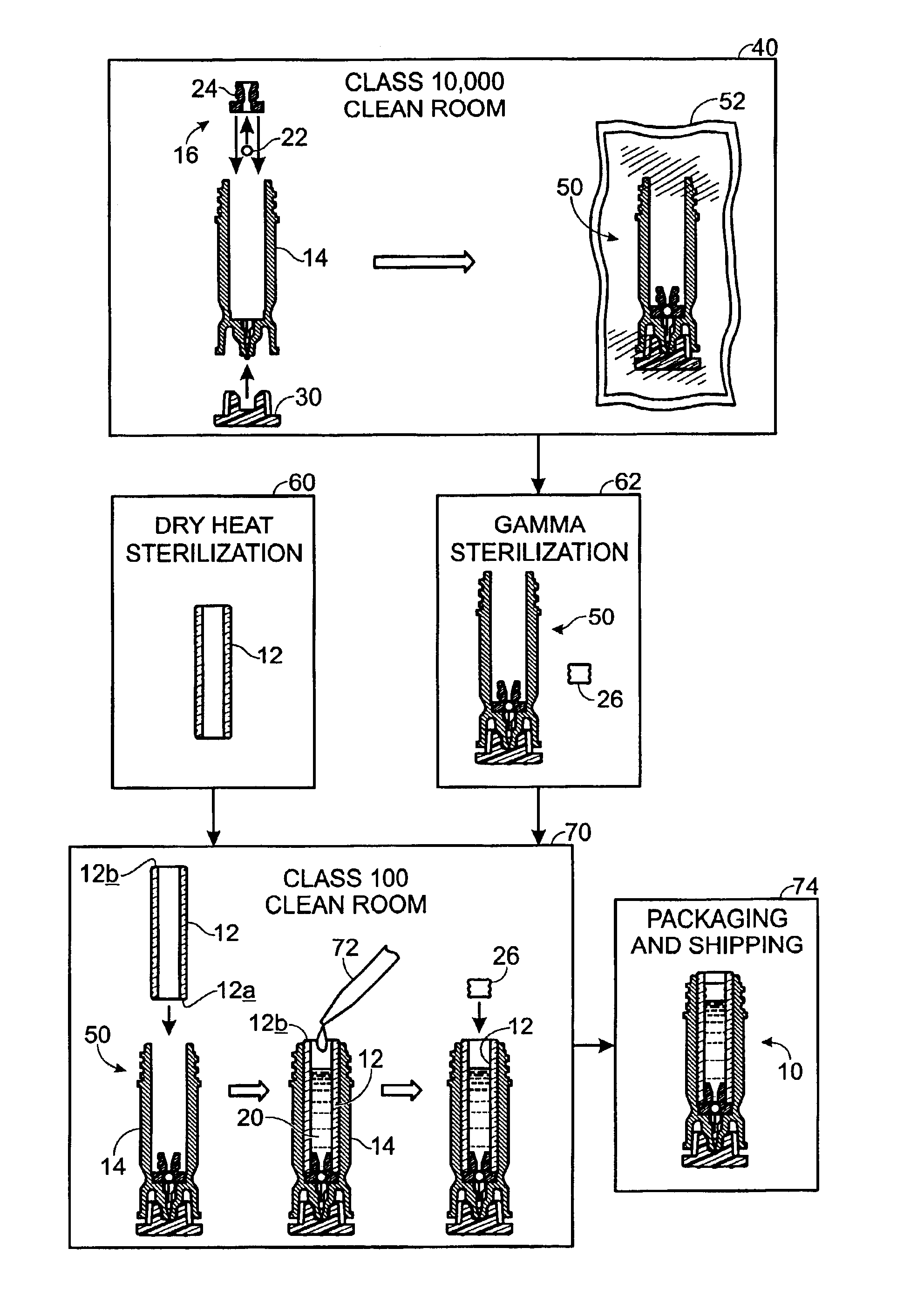

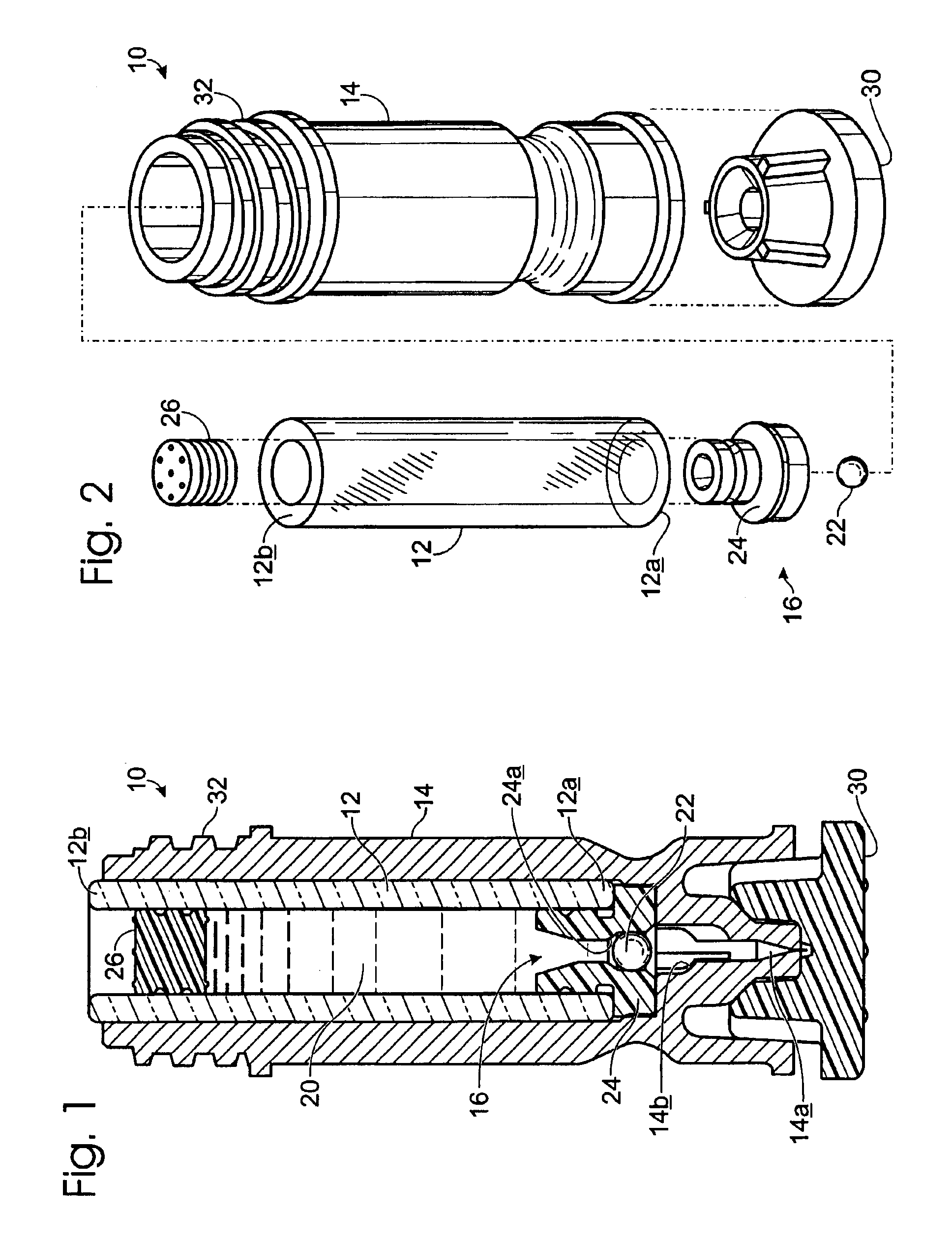

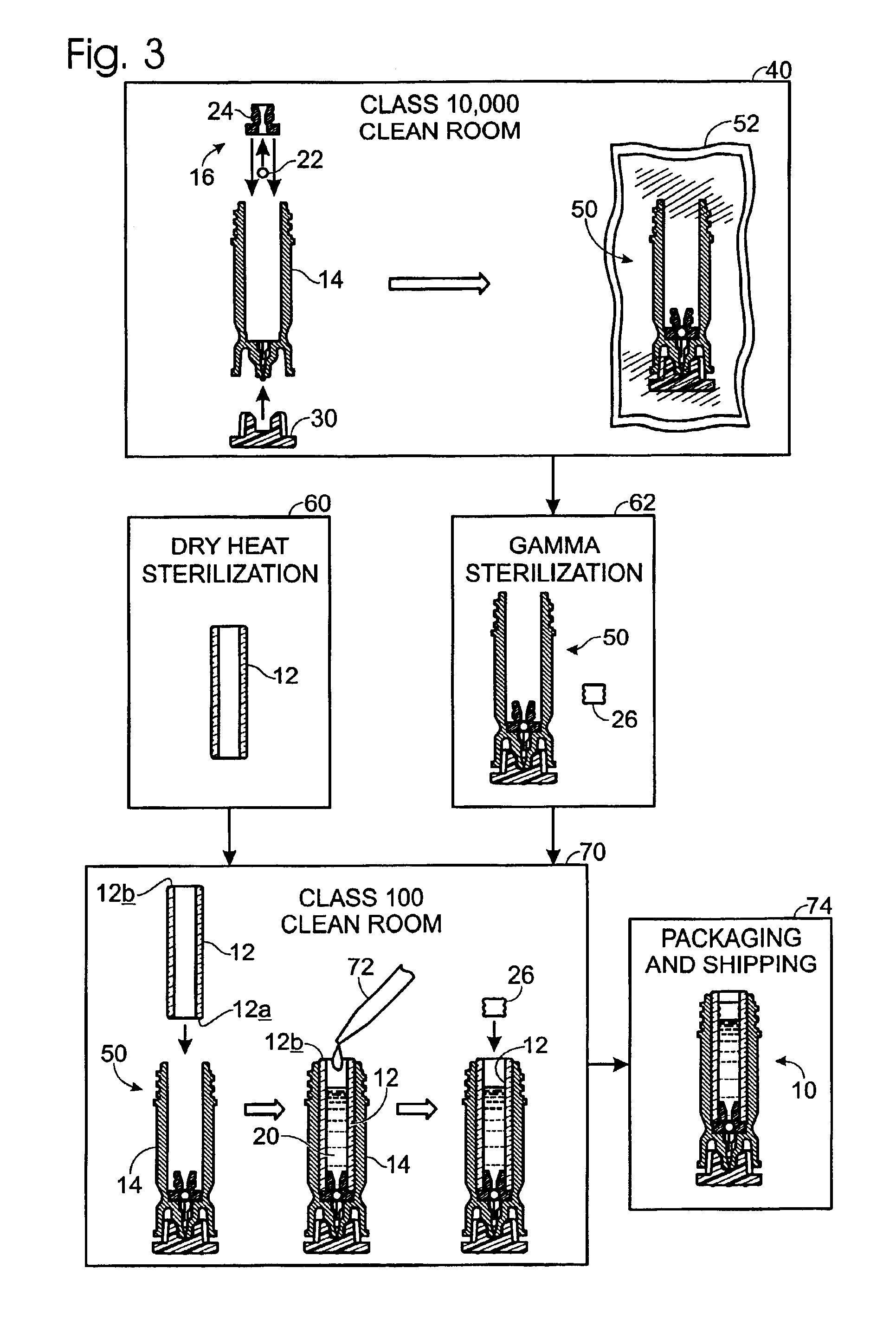

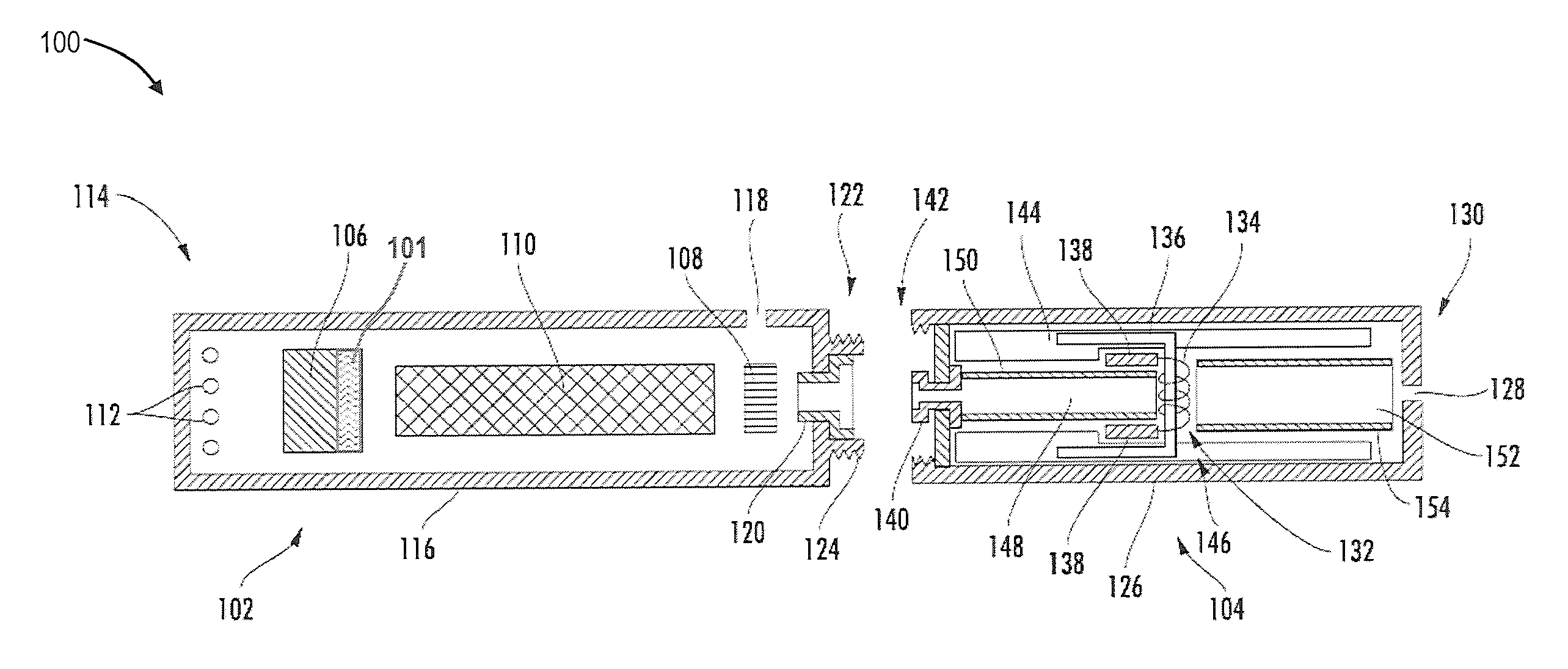

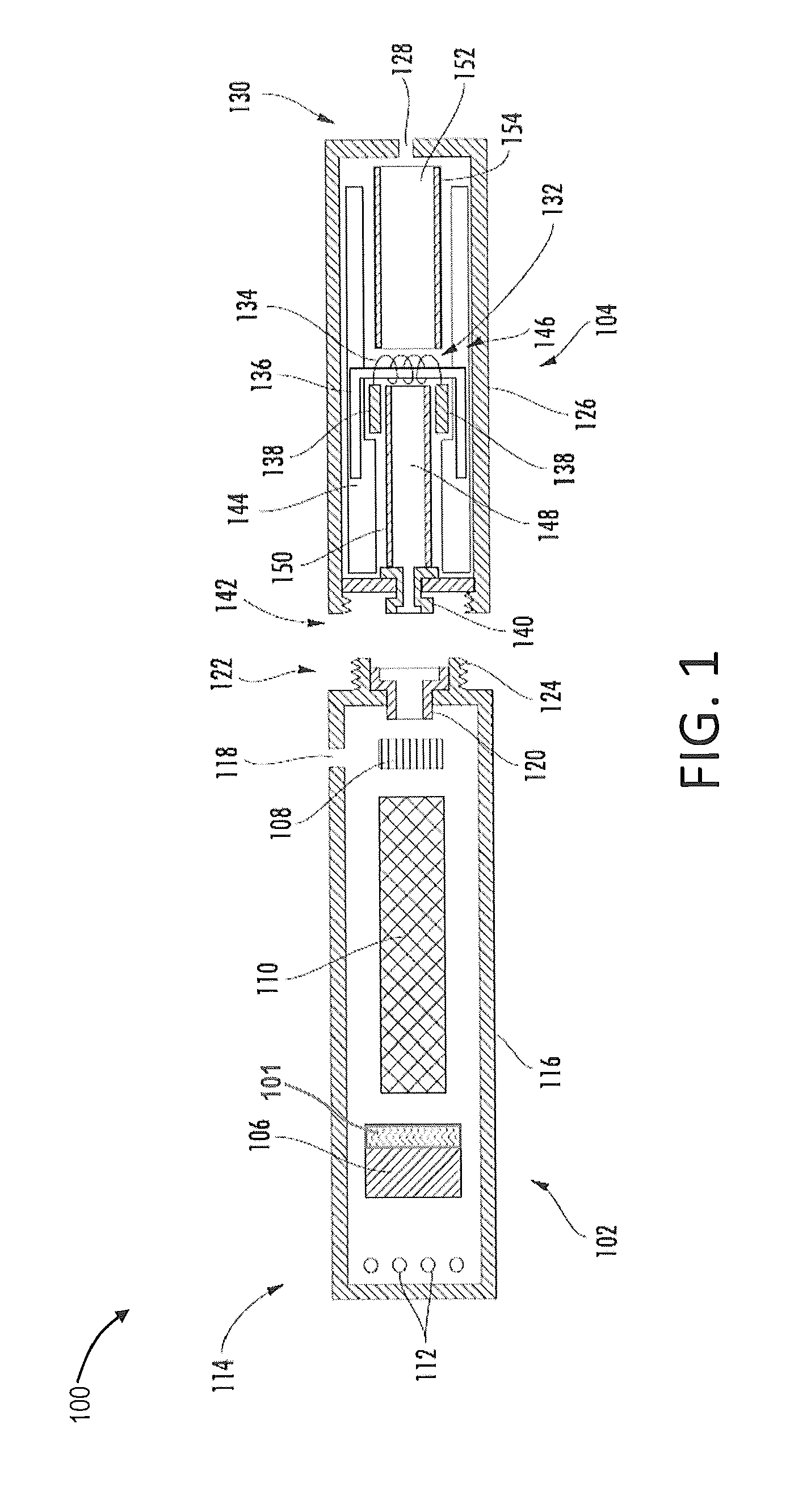

Drug cartridge assembly and method of manufacture

A method of manufacture for a drug cartridge assembly. The method includes providing a drug cartridge, providing a nozzle sub-assembly, and sterilizing the drug cartridge and nozzle sub-assembly. The method further includes assembling the drug cartridge and nozzle sub-assembly together in a configuration that enables ejection of liquid out of the drug cartridge through the nozzle sub-assembly. The method further includes filling the drug cartridge with a liquid, such as an injectable drug. The method may include separate sterilization of the drug cartridge and nozzle sub-assembly, using different sterilization processes. Portions of the method may be performed prior to sterilization within a first cleanroom, with subsequent steps being performed in a second cleanroom having a substantially lower particulate-per-volume rating than the first cleanroom.

Owner:BIOJECT

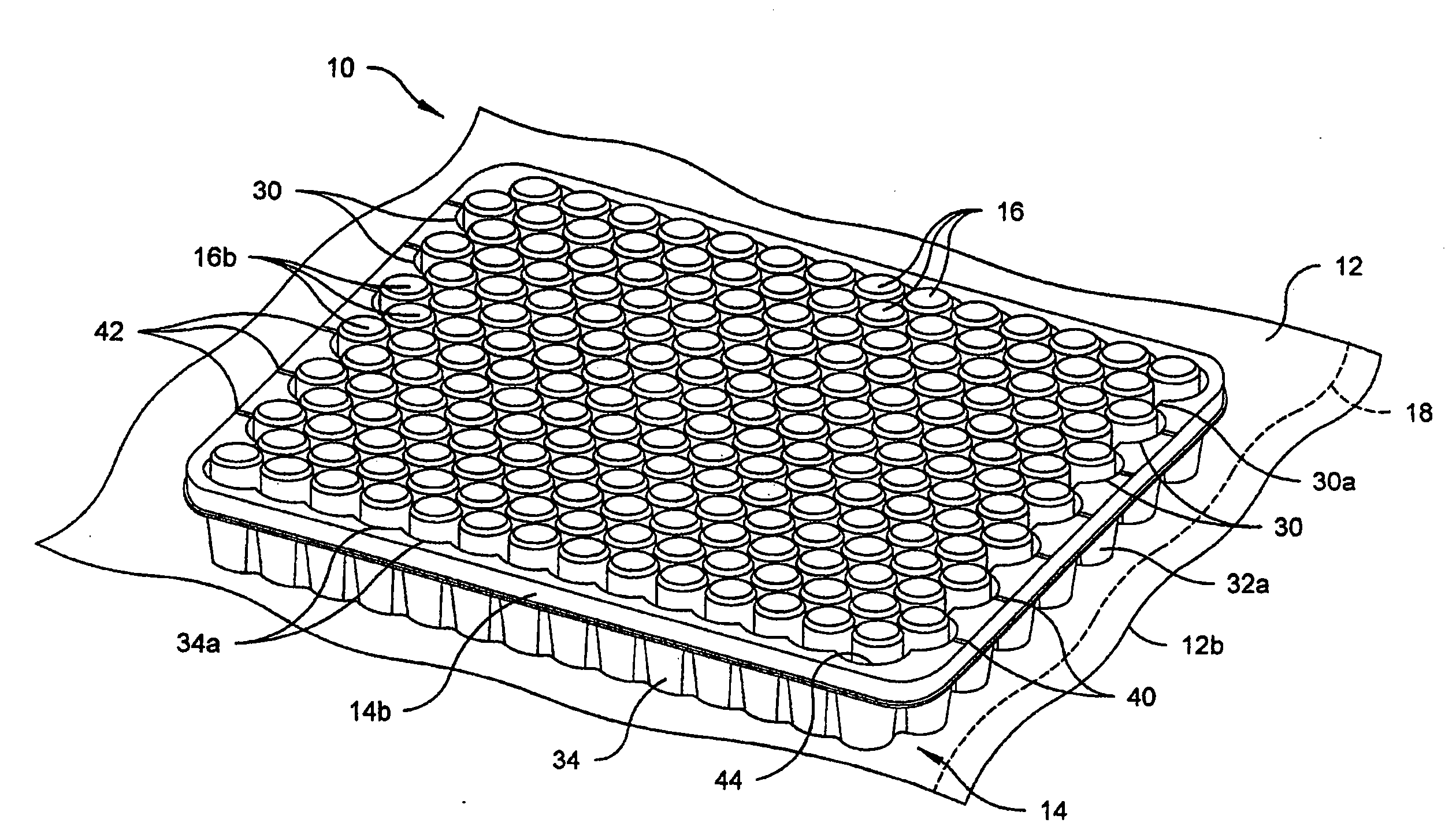

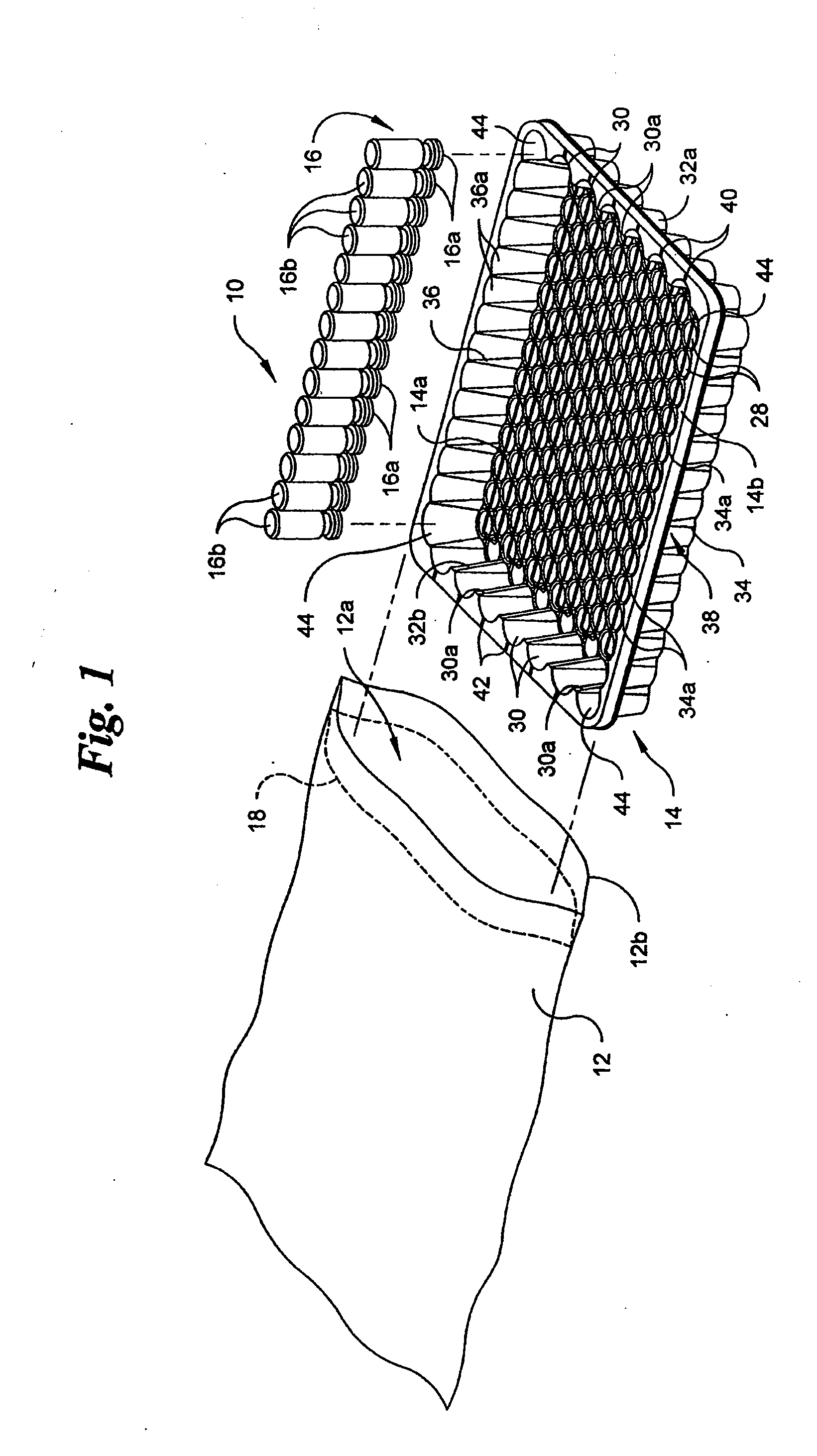

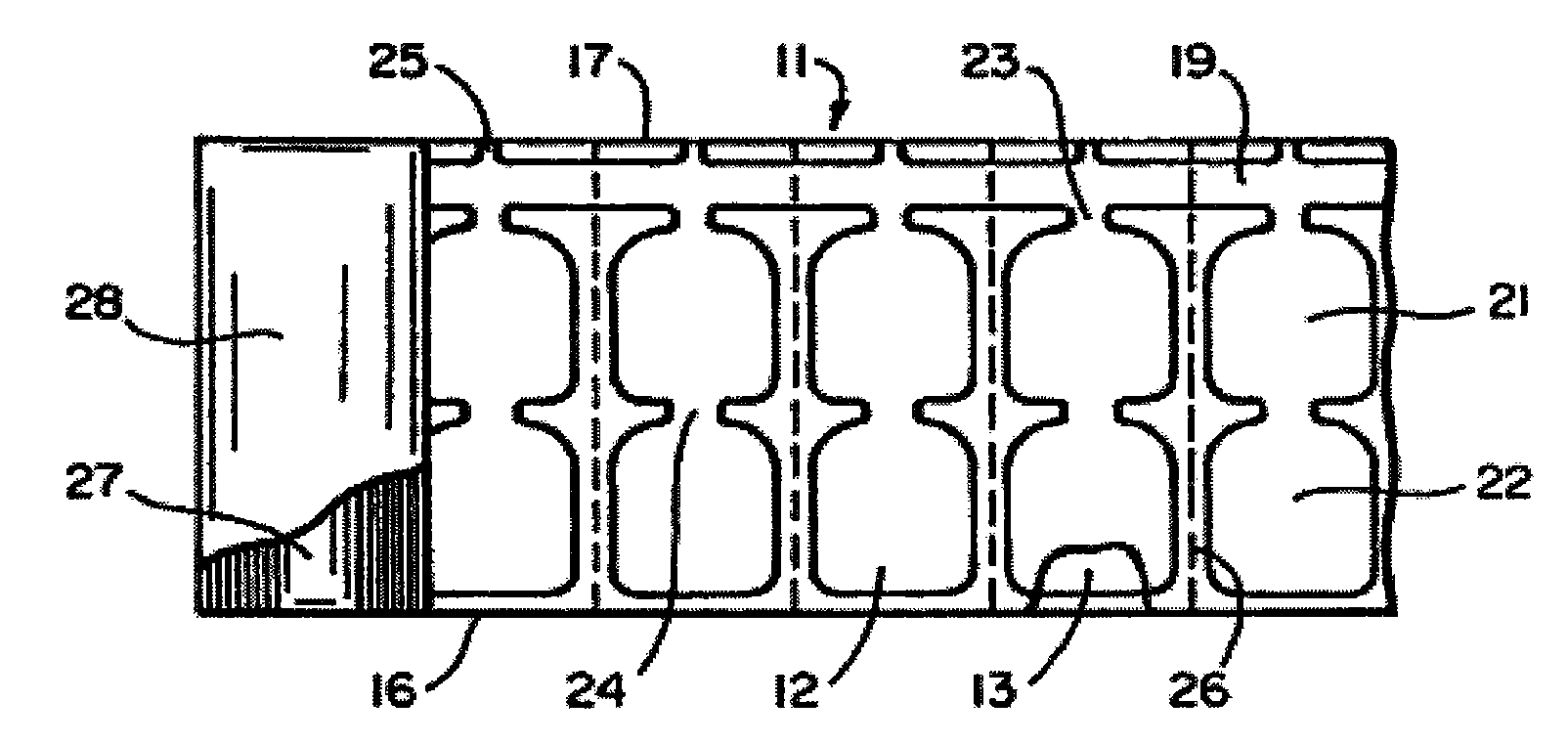

Vacuum package system

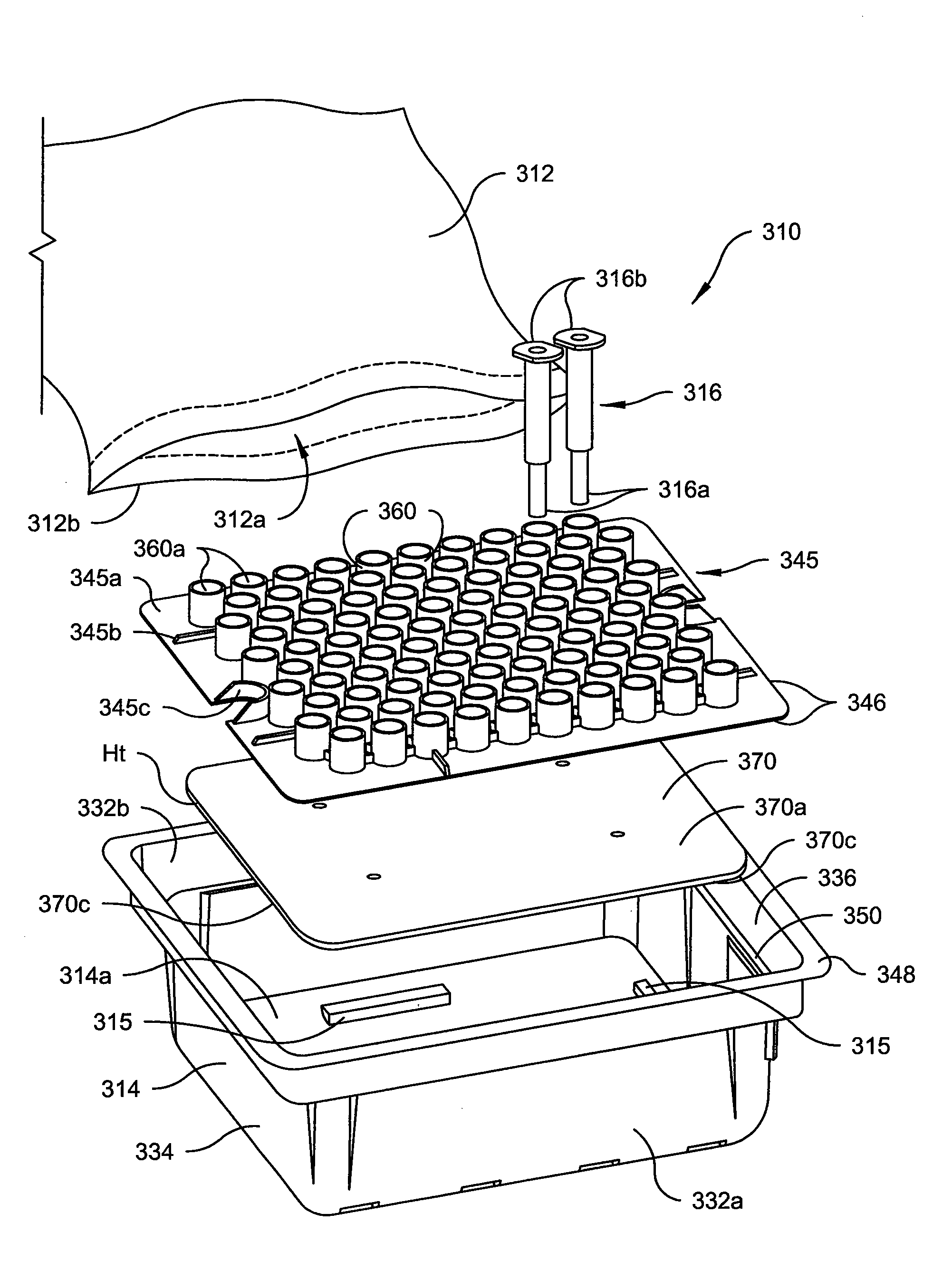

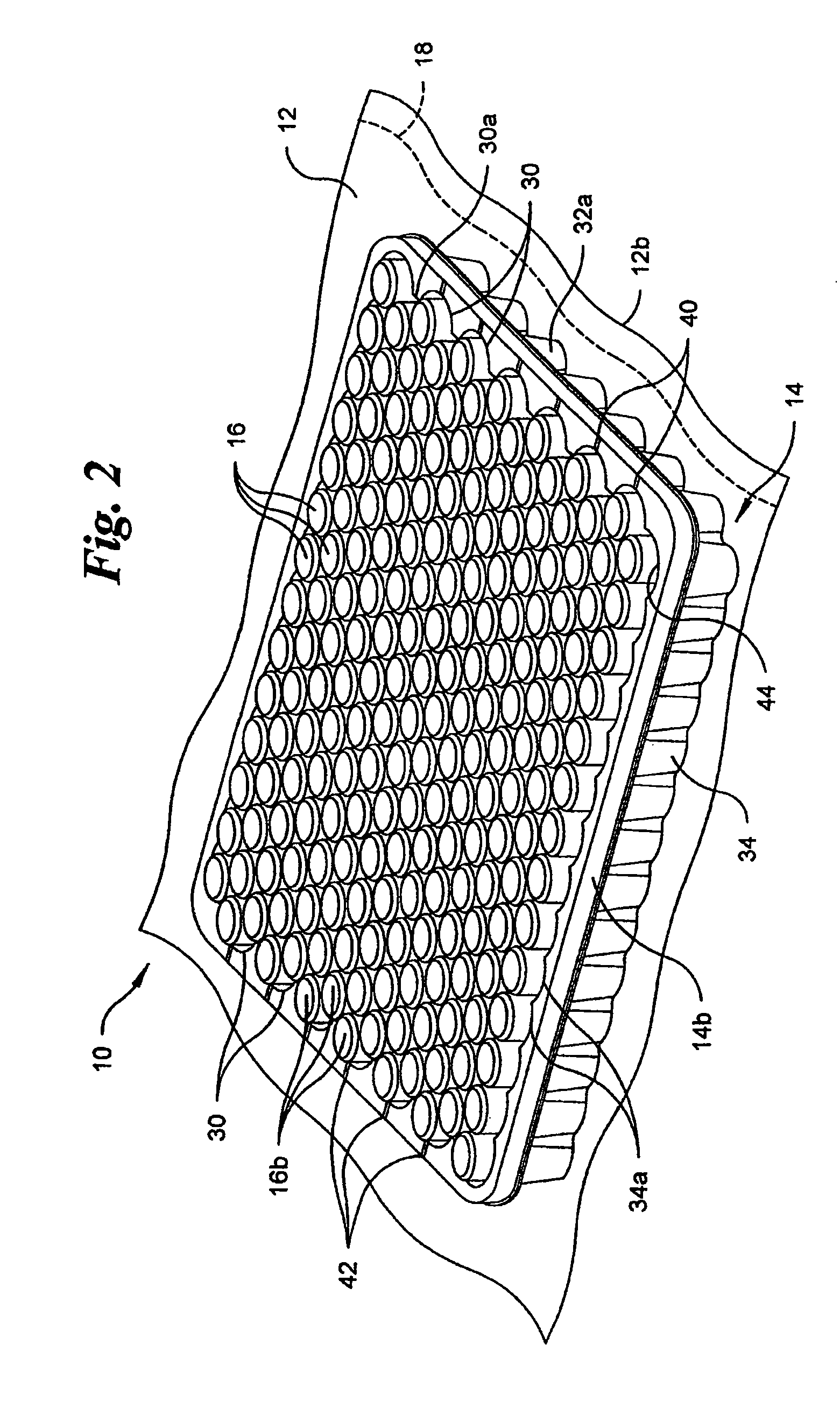

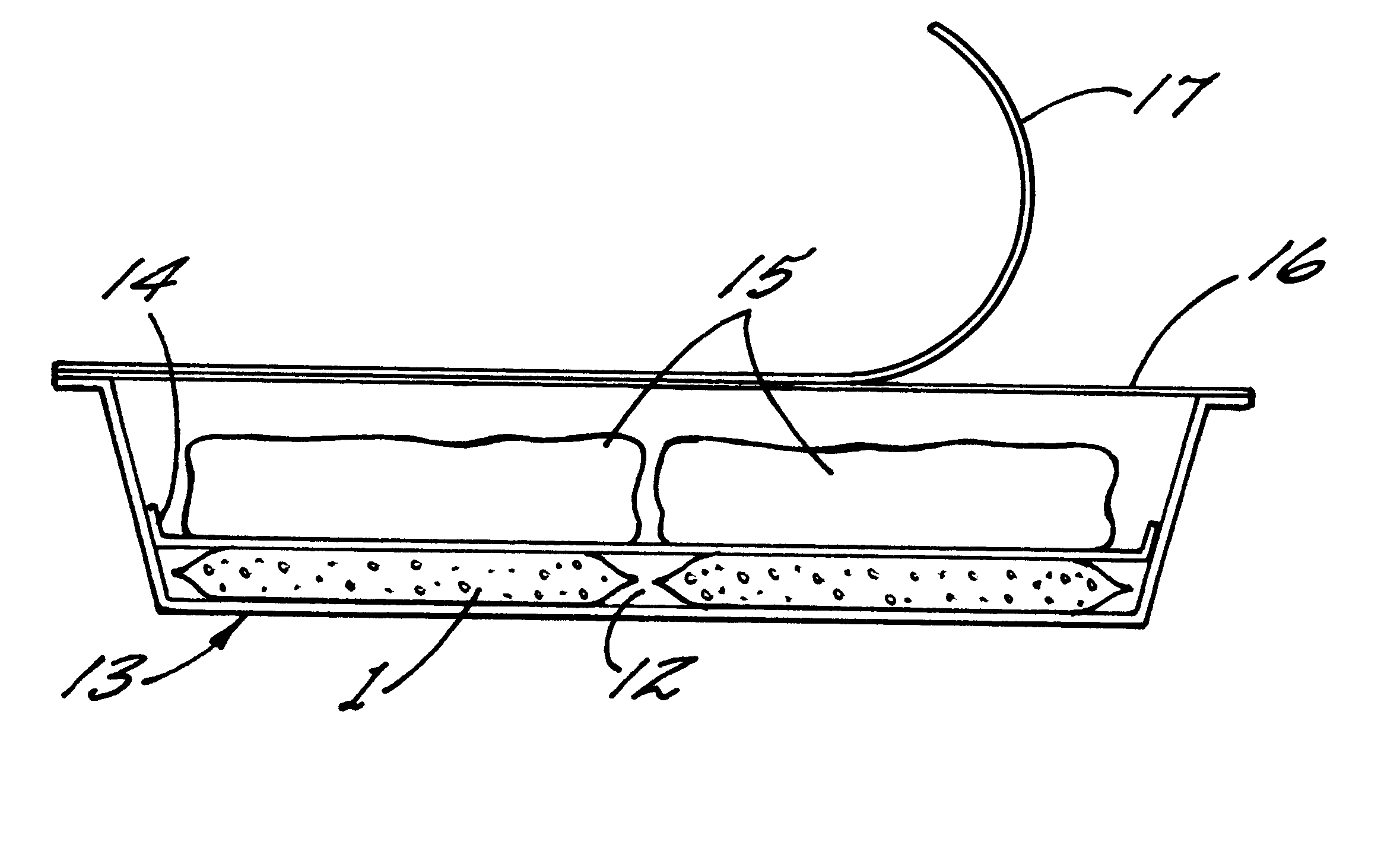

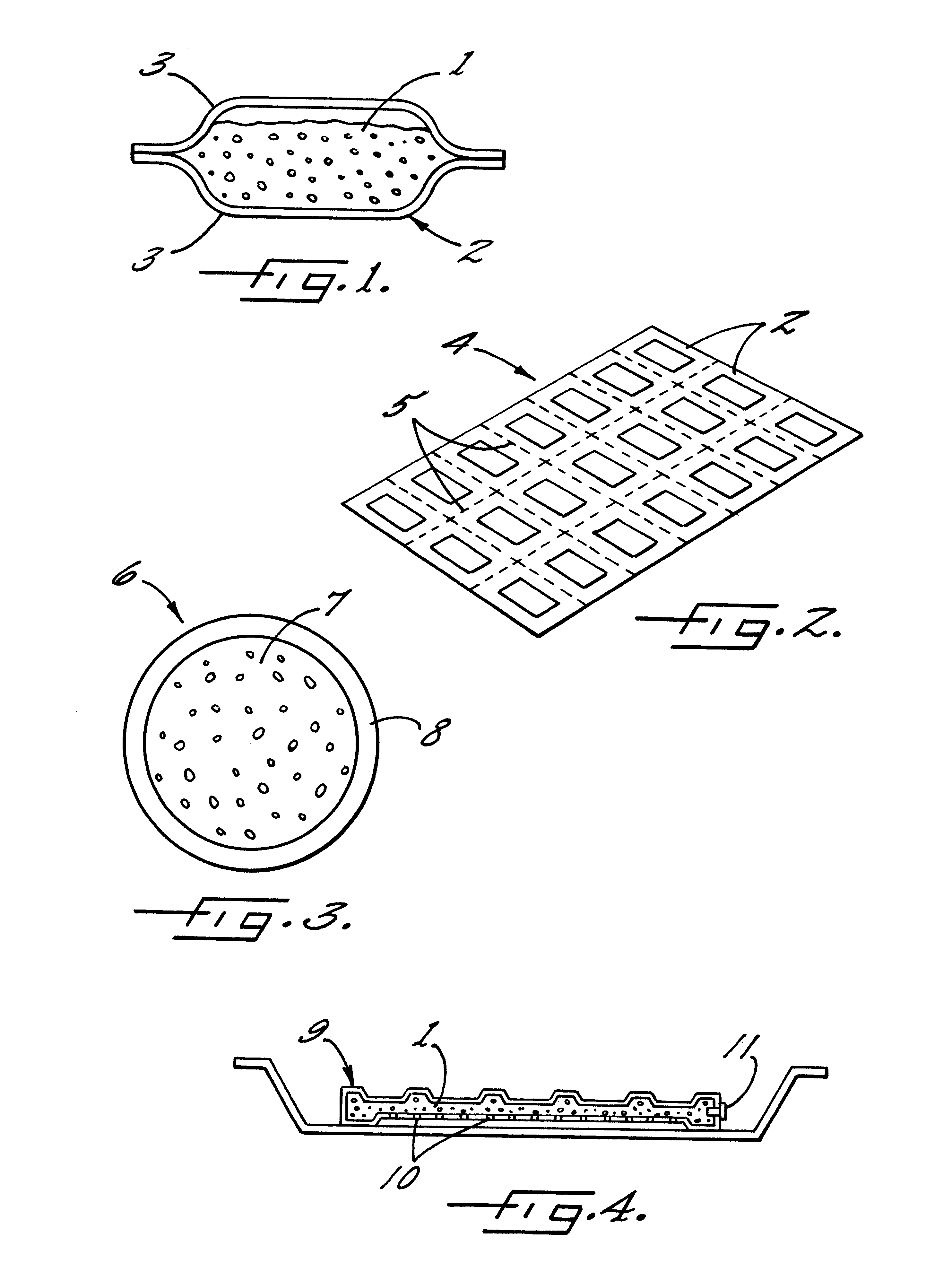

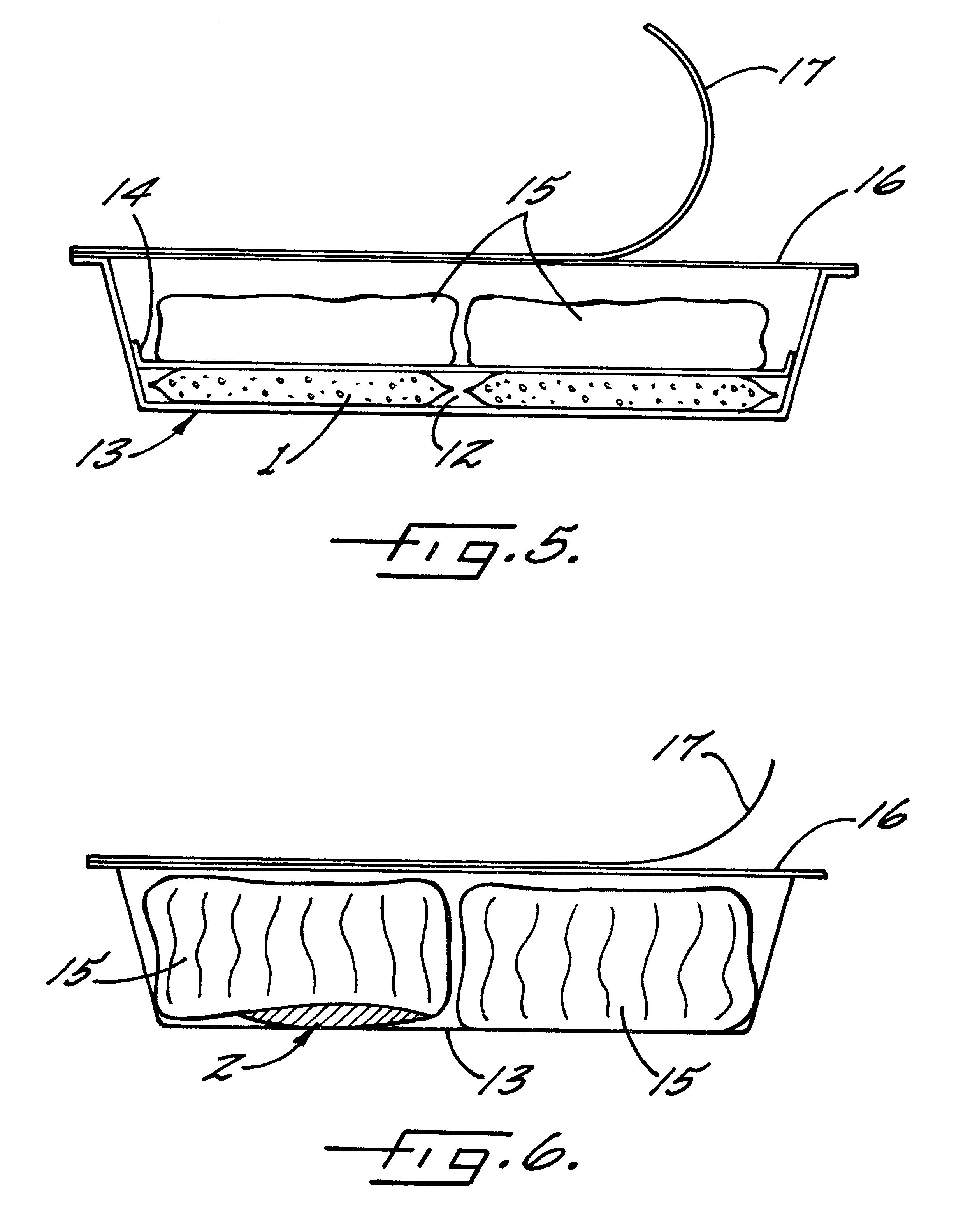

A vacuum packaging system for transporting a plurality of medical containers includes a plurality of medical containers each having a head side and a base side and a tray that receives and supports the medical containers. The tray includes opposing first and second sidewalls, opposing front and rear walls and a bottom floor. The walls extend generally vertically from the floor of the tray. At least one platform generally extends parallel to the floor of the tray. An air impervious flexible film defines an internal cavity. The air impervious flexible film completely surrounds the tray and the medical containers and the internal cavity is evacuated to and maintained at a predetermined vacuum level below atmospheric pressure. One of the head side and the base side of each medical container contacts a top surface of at least one platform when the medical containers are positioned in the tray.

Owner:WEST PHARM SERVICES INC +1

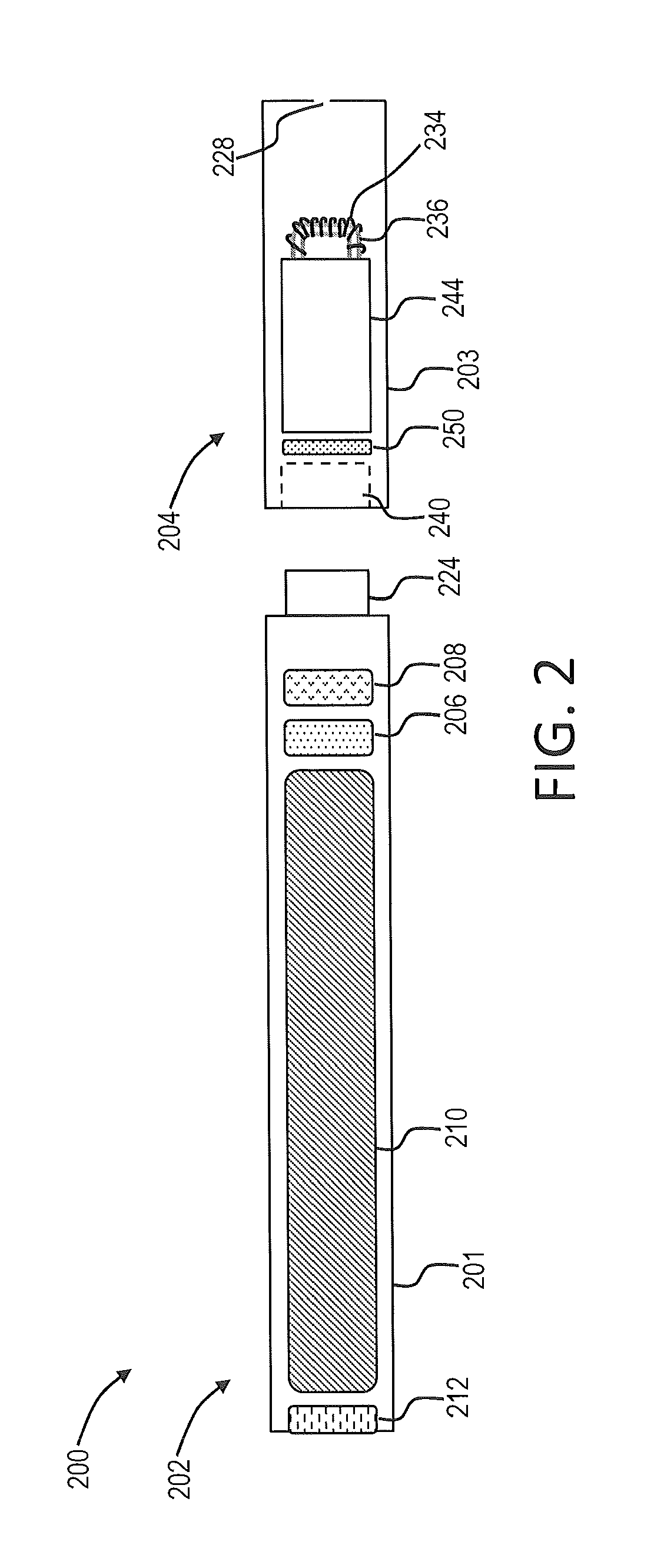

Electronic smoking article with improved storage of aerosol precursor compositions

The present disclosure relates to electronic smoking articles exhibiting improved moisture control of a reservoir contained therein. The reservoir can be formed of fibrous materials, such as cellulose acetate fiber, thermoplastic fiber, non-thermoplastic fiber, or a combination thereof. The disclosure further provides methods for forming electronic smoking articles and methods of packaging electronic smoking articles (including cartridges thereof) so as to improve moisture control of the reservoir.

Owner:RAI STRATEGIC HLDG INC

Method and device for pressurizing containers

Owner:INOFLATE

Inflation device for forming inflated containers

Owner:SEALED AIR U S

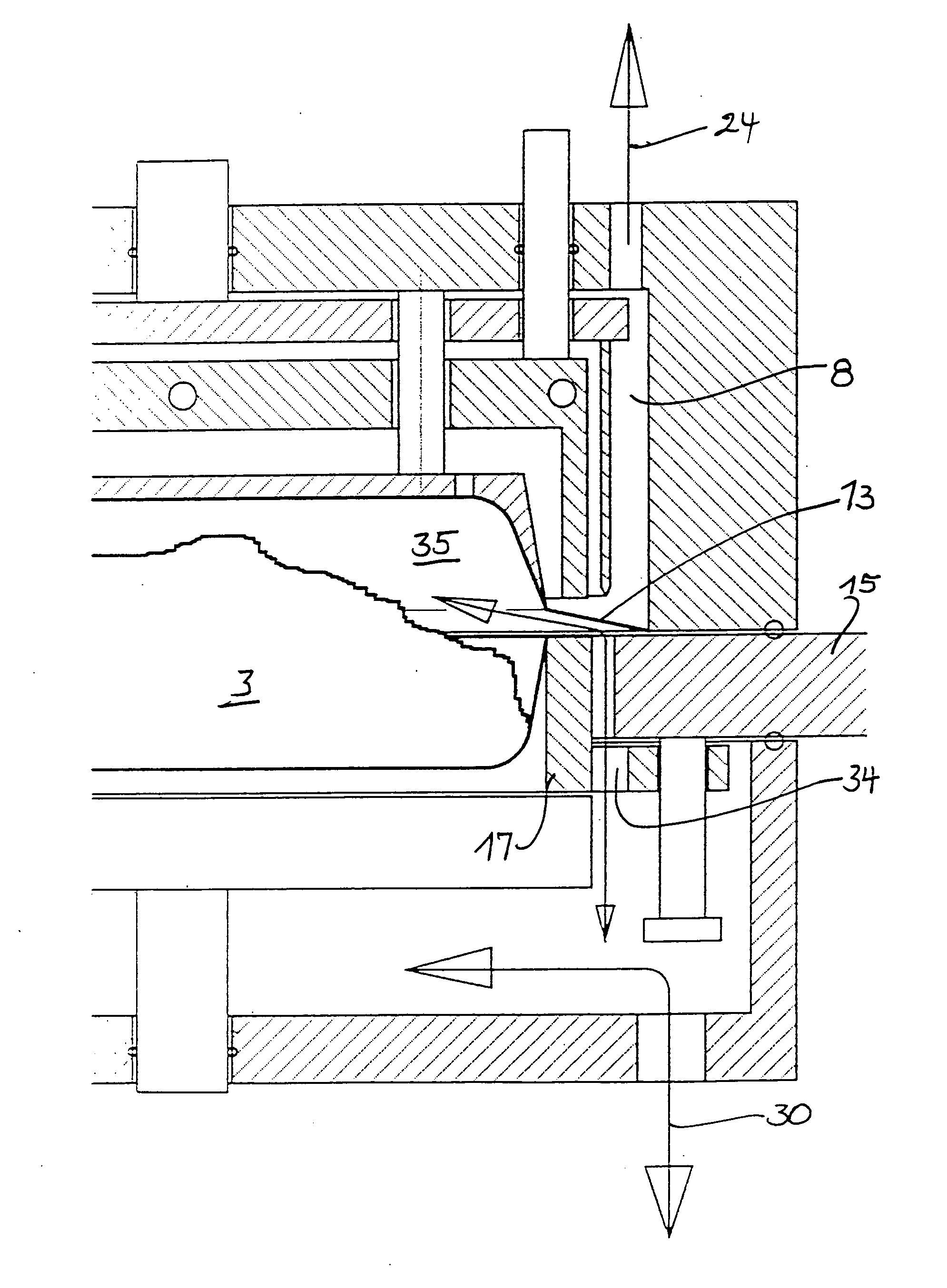

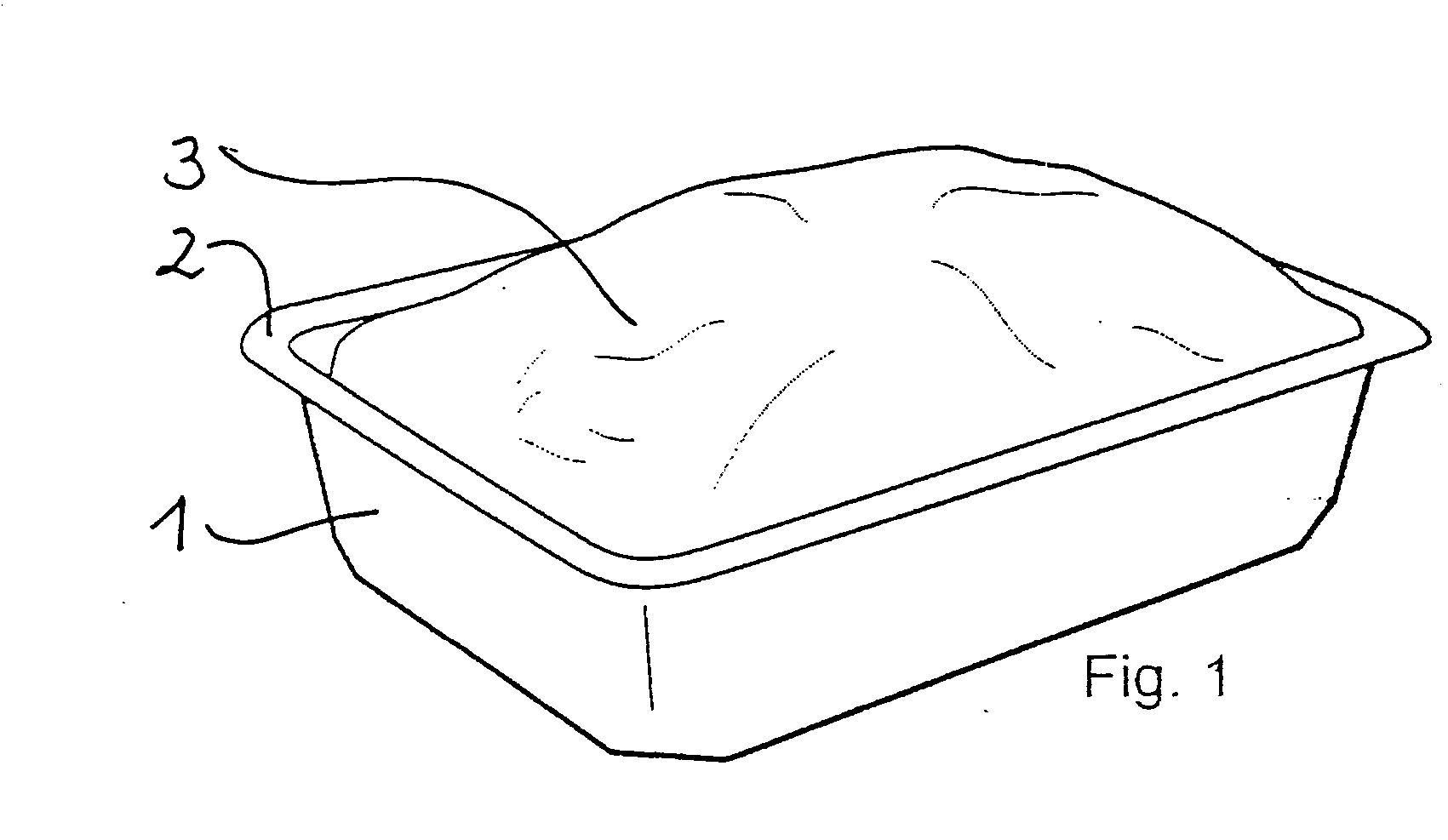

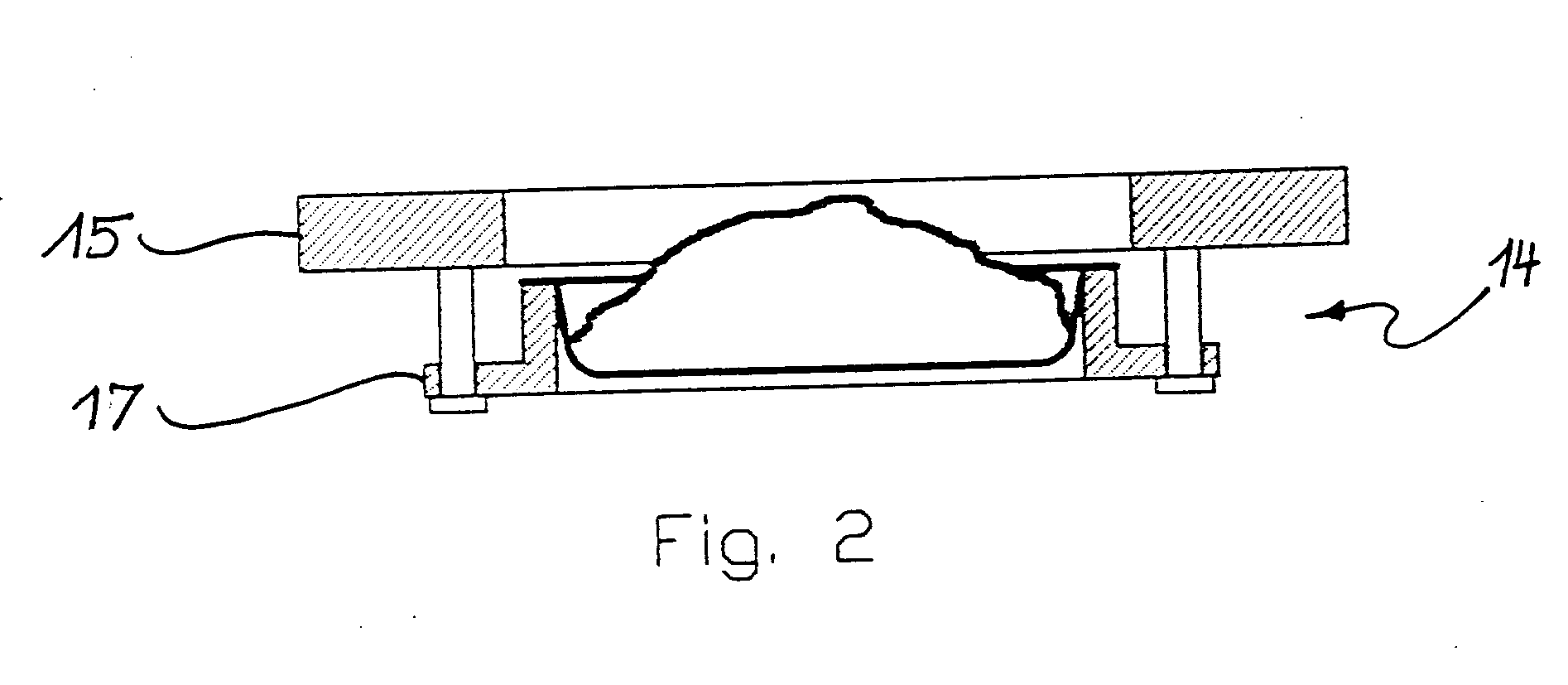

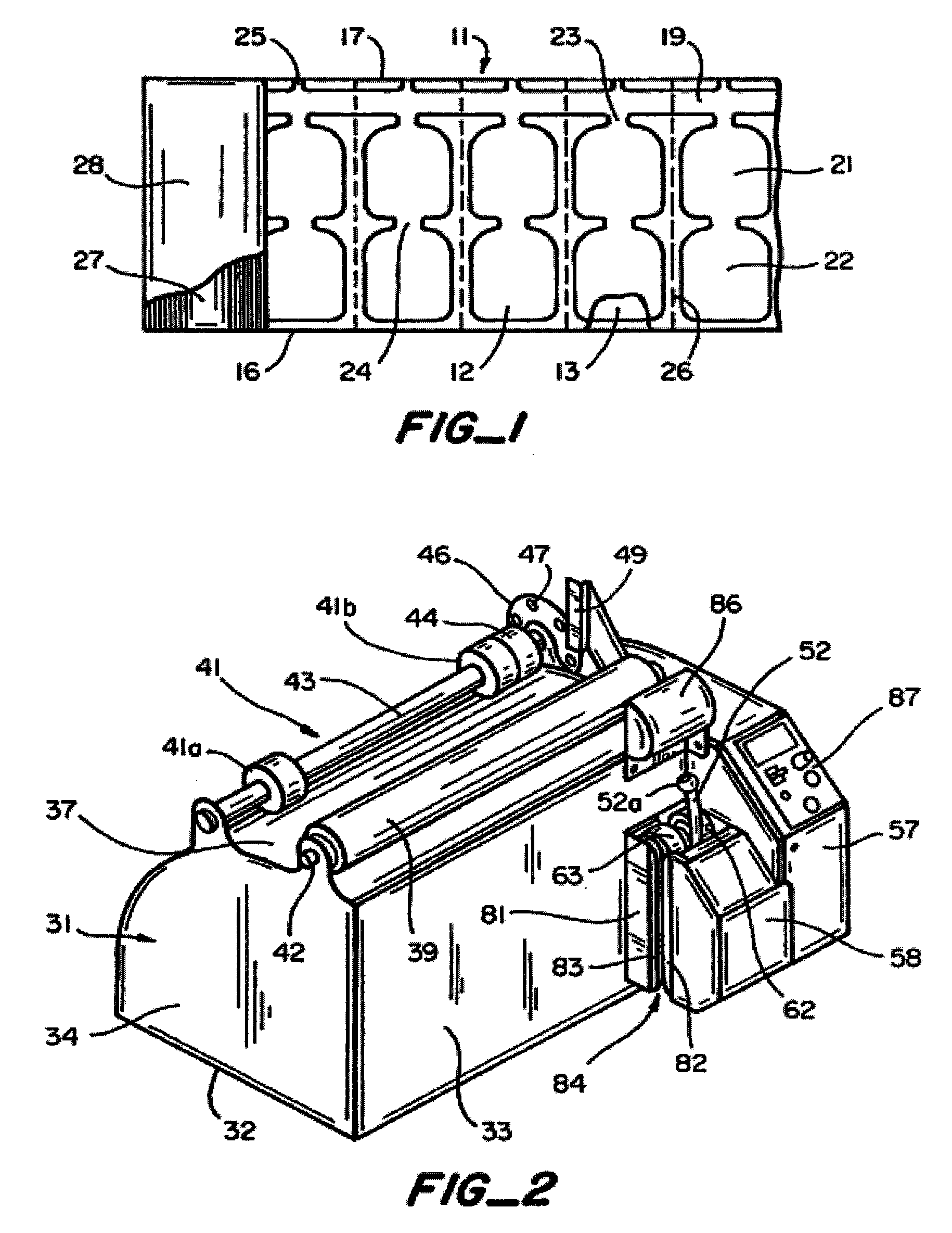

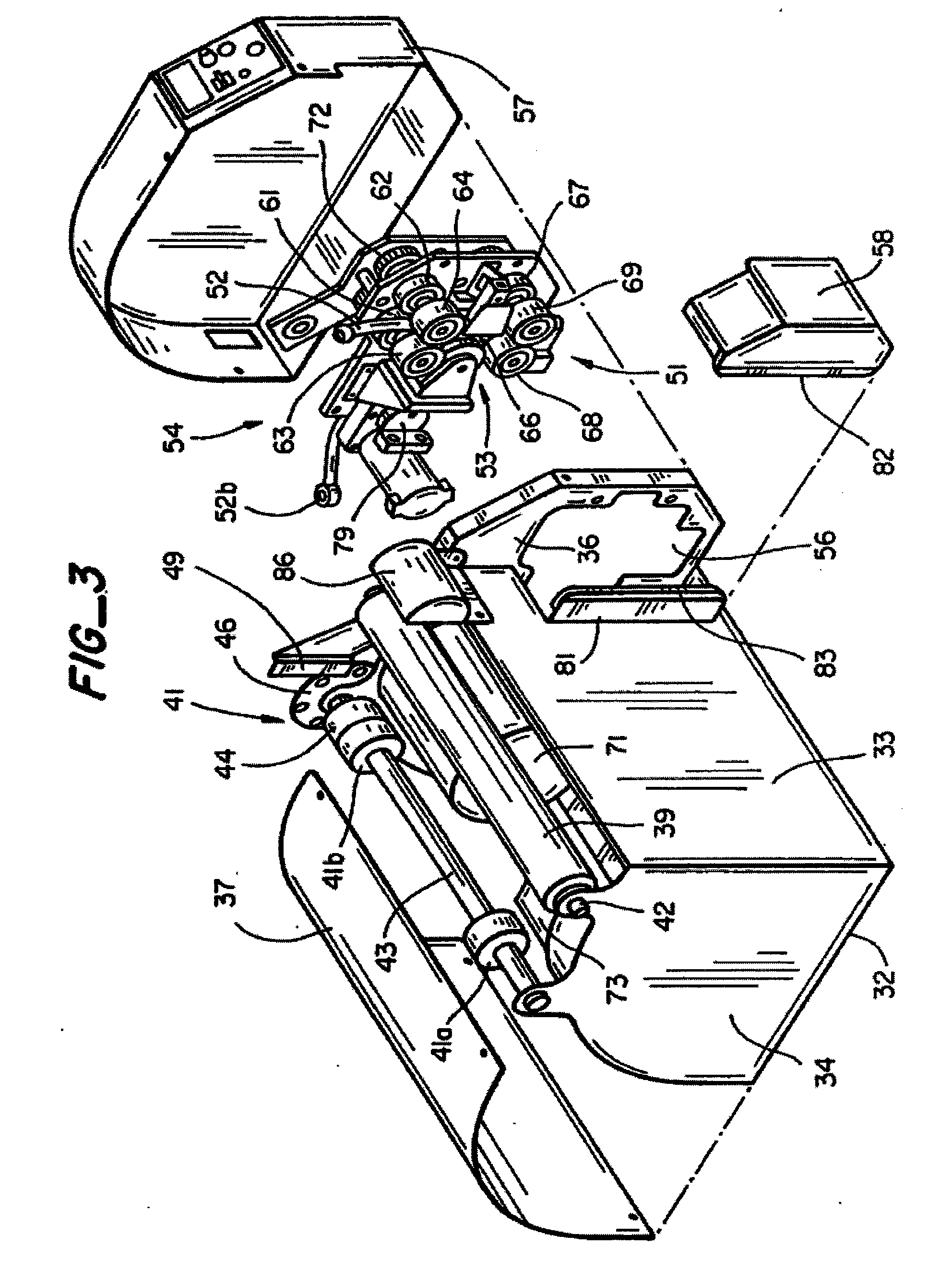

Method and packaging machine for packaging a product arranged in a tray

InactiveUS20050257501A1Reliable manufacturingImprove presentationPackaging by pressurising/gasifyingPackaging under vacuum/special atmosphereEngineeringPackaging machine

A method for packaging a product arranged in a tray is provided. An upper film located in a distance above the product is clamped along an edge surrounding the tray and is deformed in a direction extending away from the product. Subsequently, evacuating of the space surrounding the product is performed, then a raising of the tray towards the upper film and finally a sealing of the film and of the edge of the tray. In this way, the seam of the upper film and the edge of the tray is attained to be free from creases such that a long-living and good looking package is produced. Additionally, a packaging machine for performing the method is provided.

Owner:CREAVIS GES FUER TECH +1

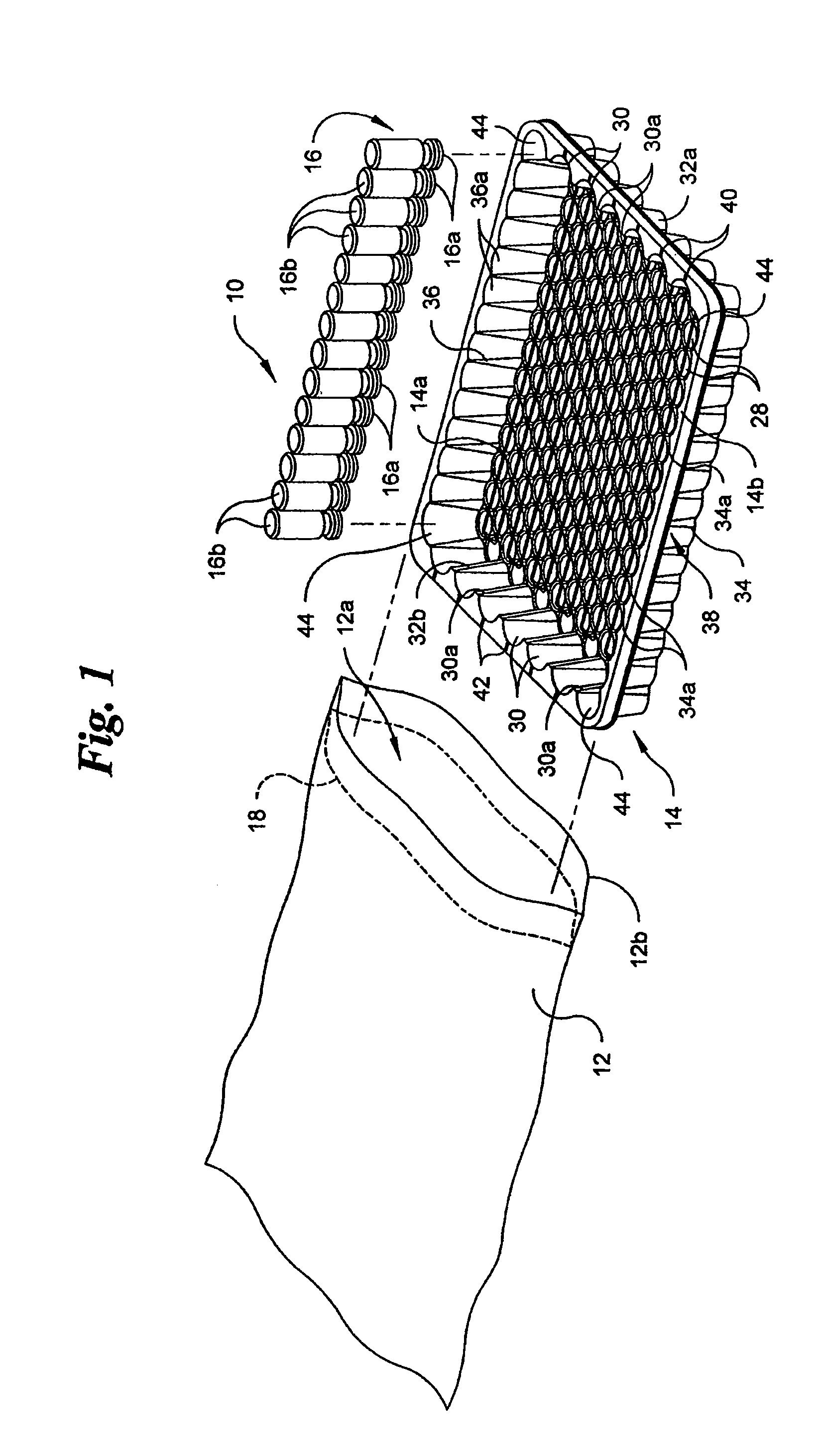

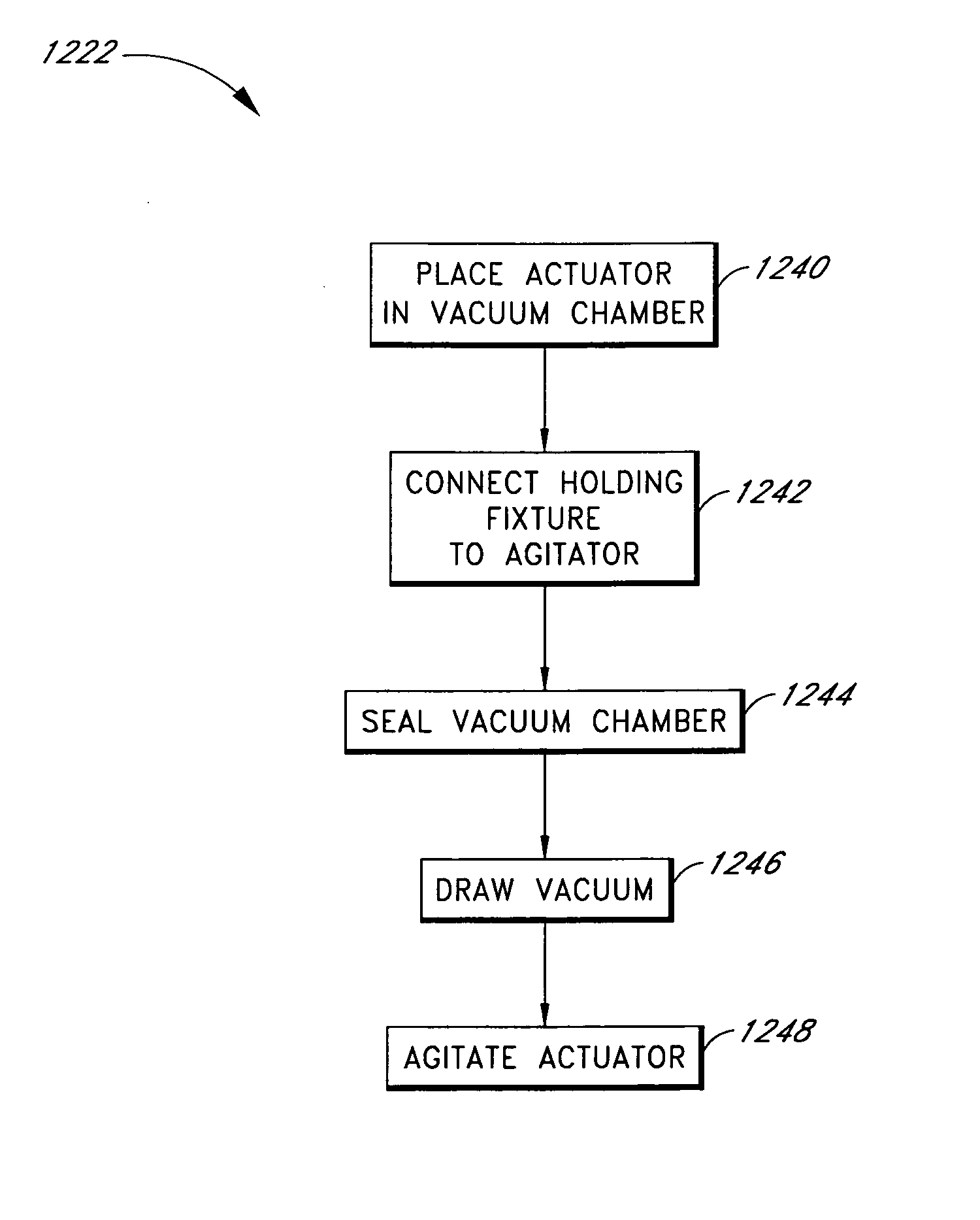

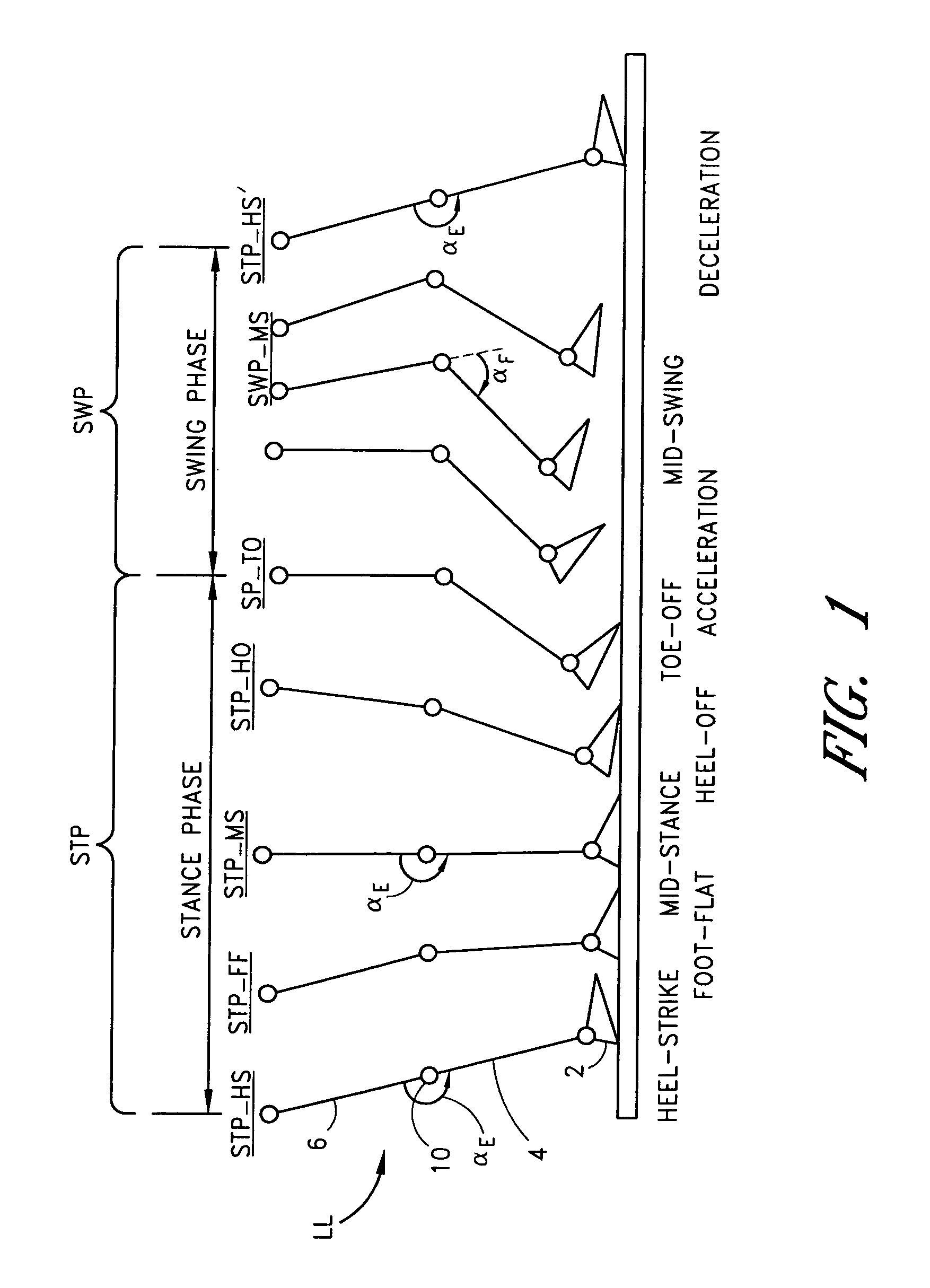

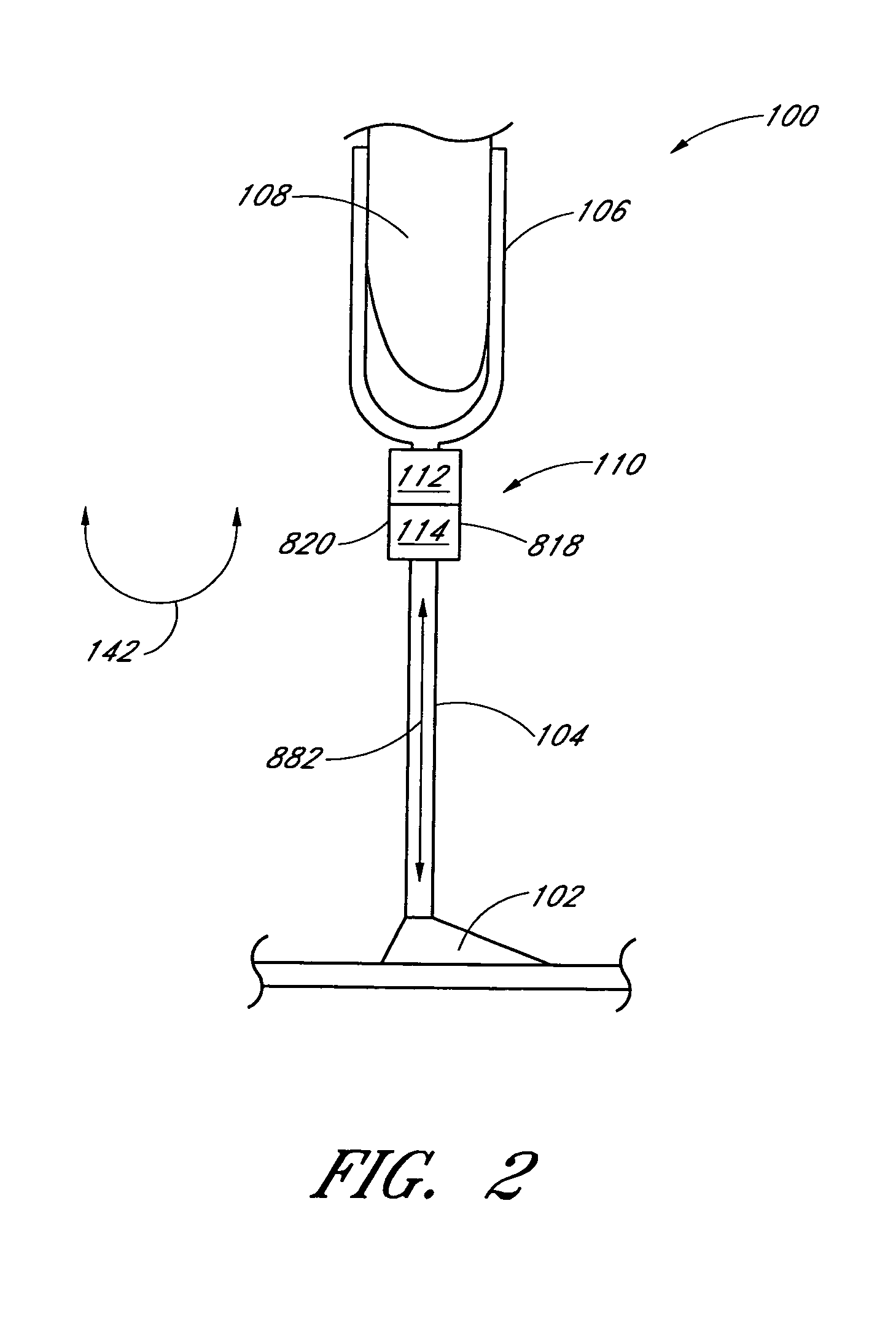

Systems and methods of loading fluid in a prosthetic knee

InactiveUS7198071B2Efficient loadingIncrease speedLiquid fillingOther chemical processesMagnetorheological fluidEngineering

The invention in some embodiments relates to systems and methods of loading fluid in a prosthetic knee. A vacuum fill technique is utilized in one embodiment to load magnetorheological fluid within small gaps in a chamber of a prosthetic knee. Advantageously, this allows for an efficient loading scheme thereby desirably allowing for faster manufacturing speed. Another advantage is that the magnetorheological fluid is substantially uniformly distributed within the small gaps thereby desirably providing consistent production.

Owner:OSSUR HF

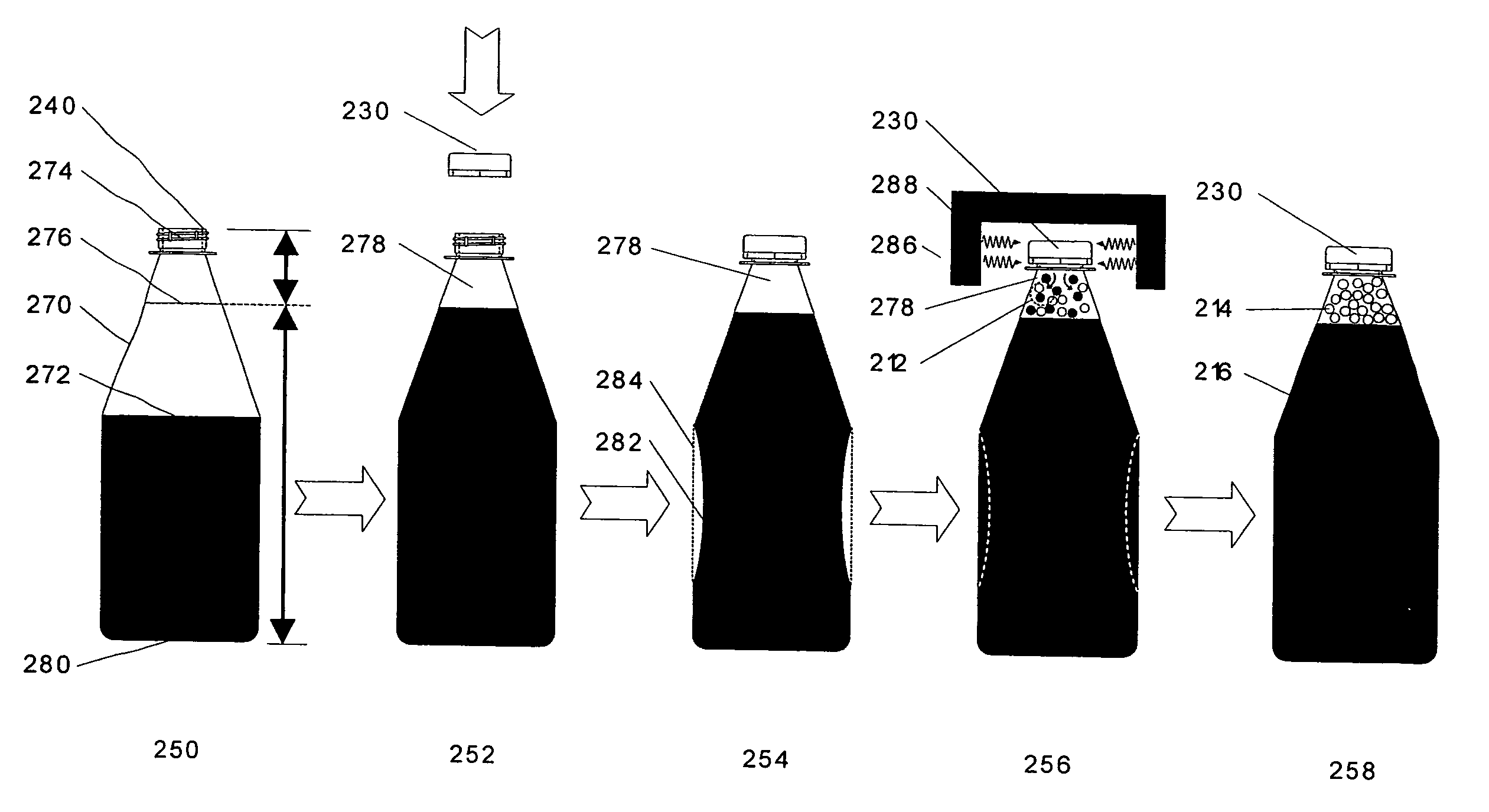

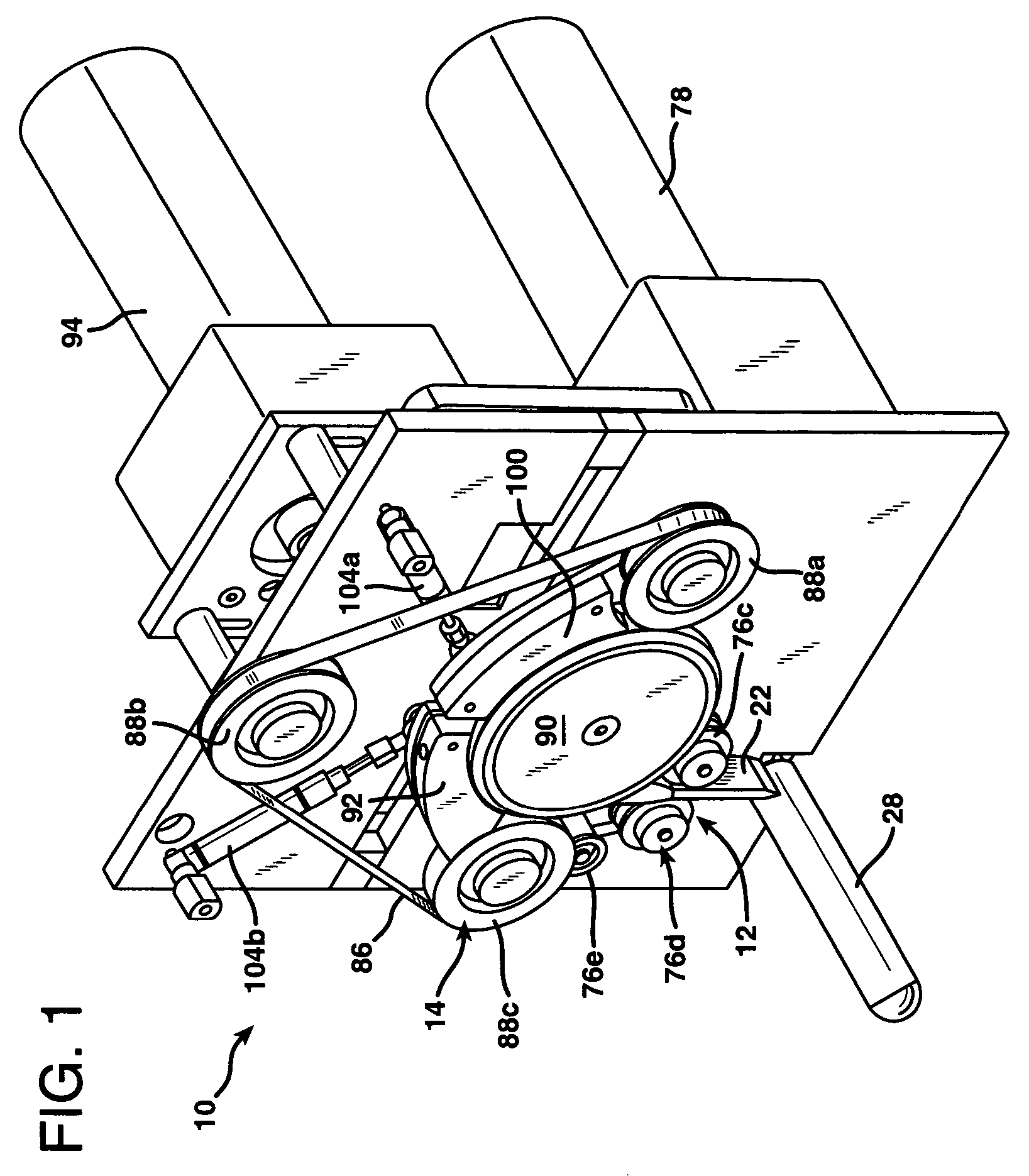

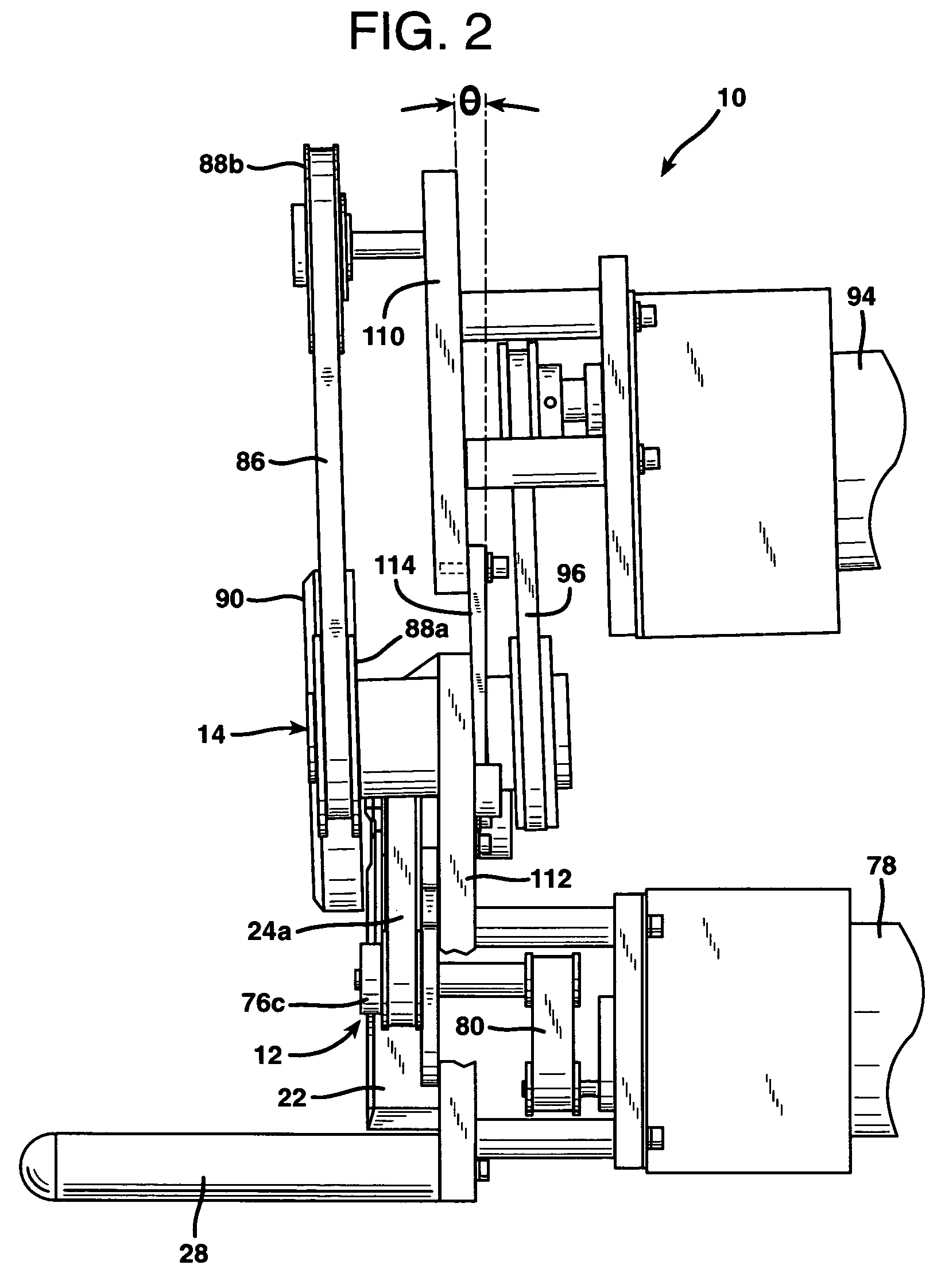

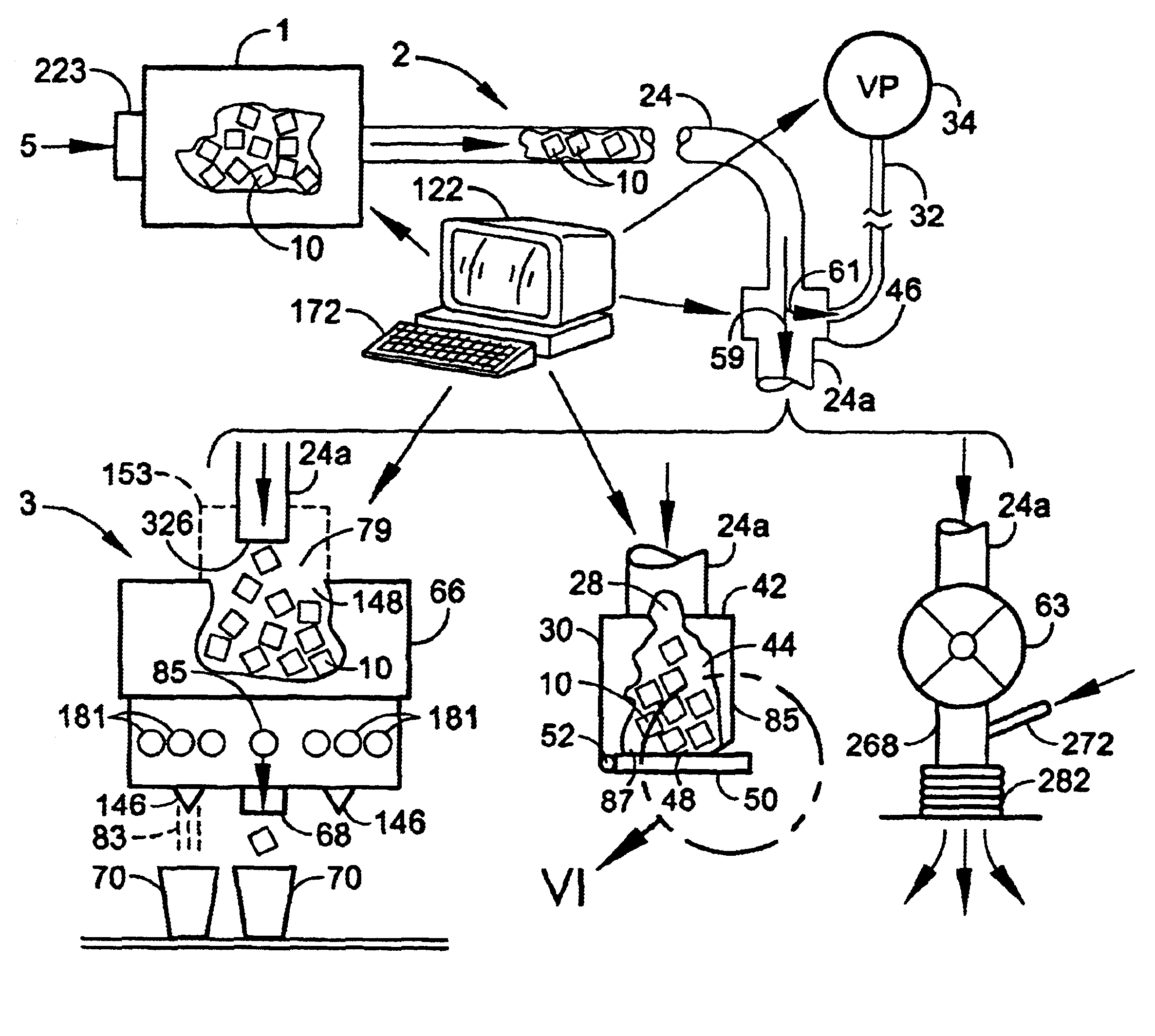

System, method and apparatus for filling containers

InactiveUS6357490B1Simple designEasy to usePackaging by pressurising/gasifyingSolid materialEngineeringMechanical engineering

Method and apparatus for providing a precisely controlled amount of dry material to a container. A powder slug is formed, preferably under vacuum, in a dosing hole formed in a dosing plate. The powder slug represents a precisely metered amount of material to be deposited into the container. The dosing plate is translated to a position such that the powder slug is above, and may be expelled into, a container located in a dosing wheel that has been moved into proper position for container filling to occur. In another embodiment, a system is provided for automated container filling.

Owner:CIVITAS THERAPEUTICS

Vacuum package system

A vacuum packaging system for transporting a plurality of medical containers includes a plurality of medical containers each having a head side and a base side and a tray that receives and supports the medical containers. The tray includes opposing first and second sidewalls, opposing front and rear walls and a bottom floor. The walls extend generally vertically from the floor of the tray. At least one platform generally extends parallel to the floor of the tray. An air impervious flexible film defines an internal cavity. The air impervious flexible film completely surrounds the tray and the medical containers and the internal cavity is evacuated to and maintained at a predetermined vacuum level below atmospheric pressure. One of the head side and the base side of each medical container contacts a top surface of at least one platform when the medical containers are positioned in the tray.

Owner:WEST PHARM SERVICES INC +1

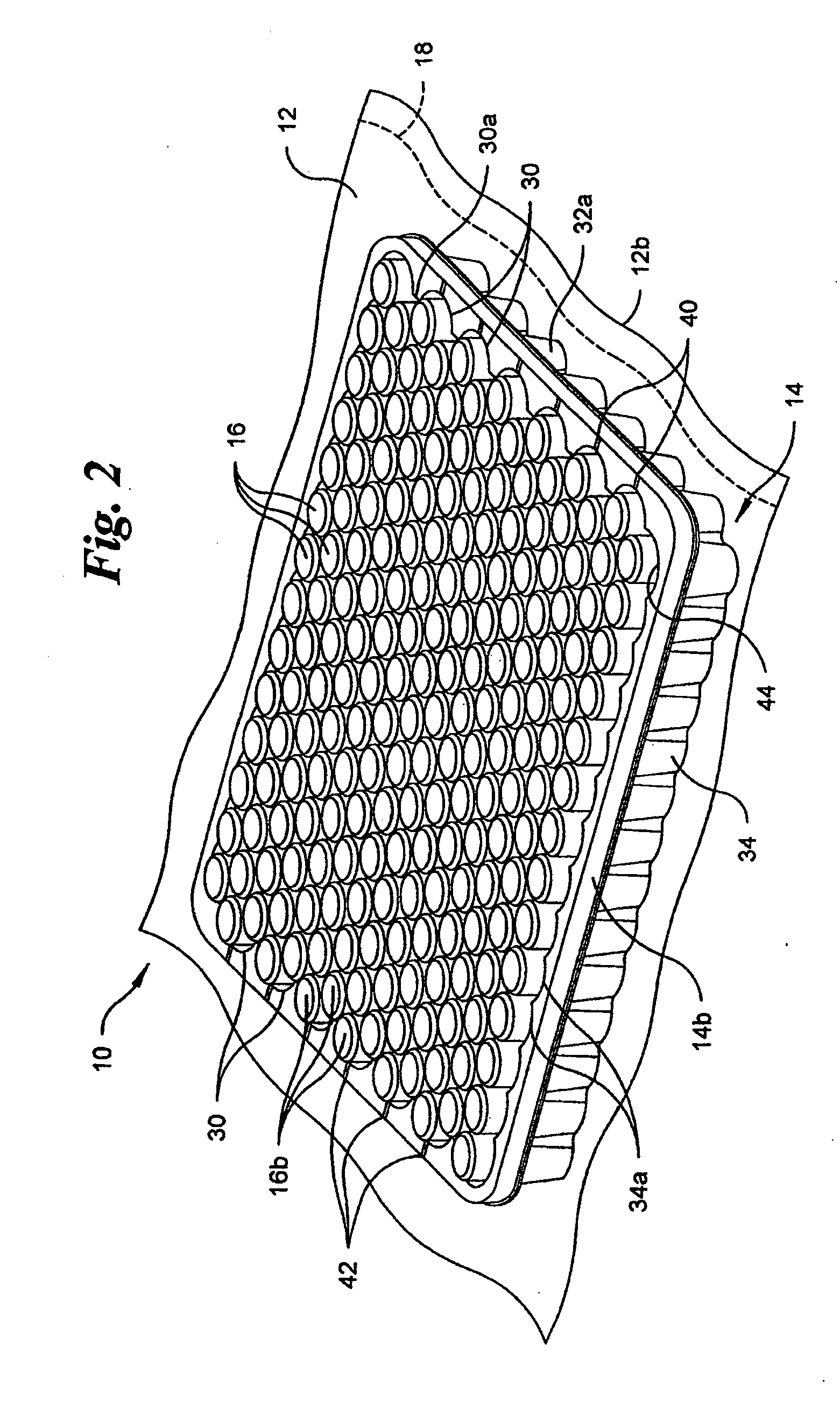

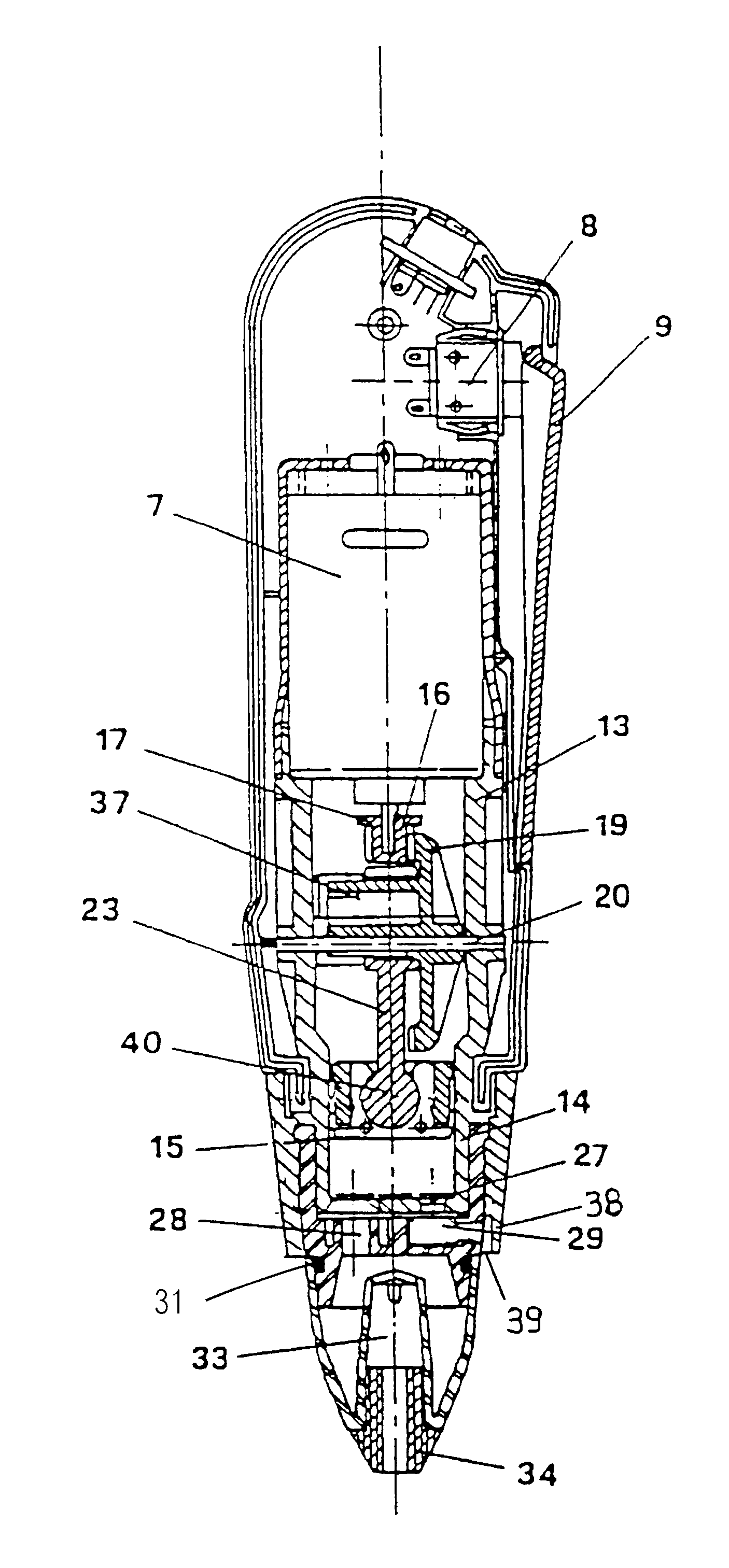

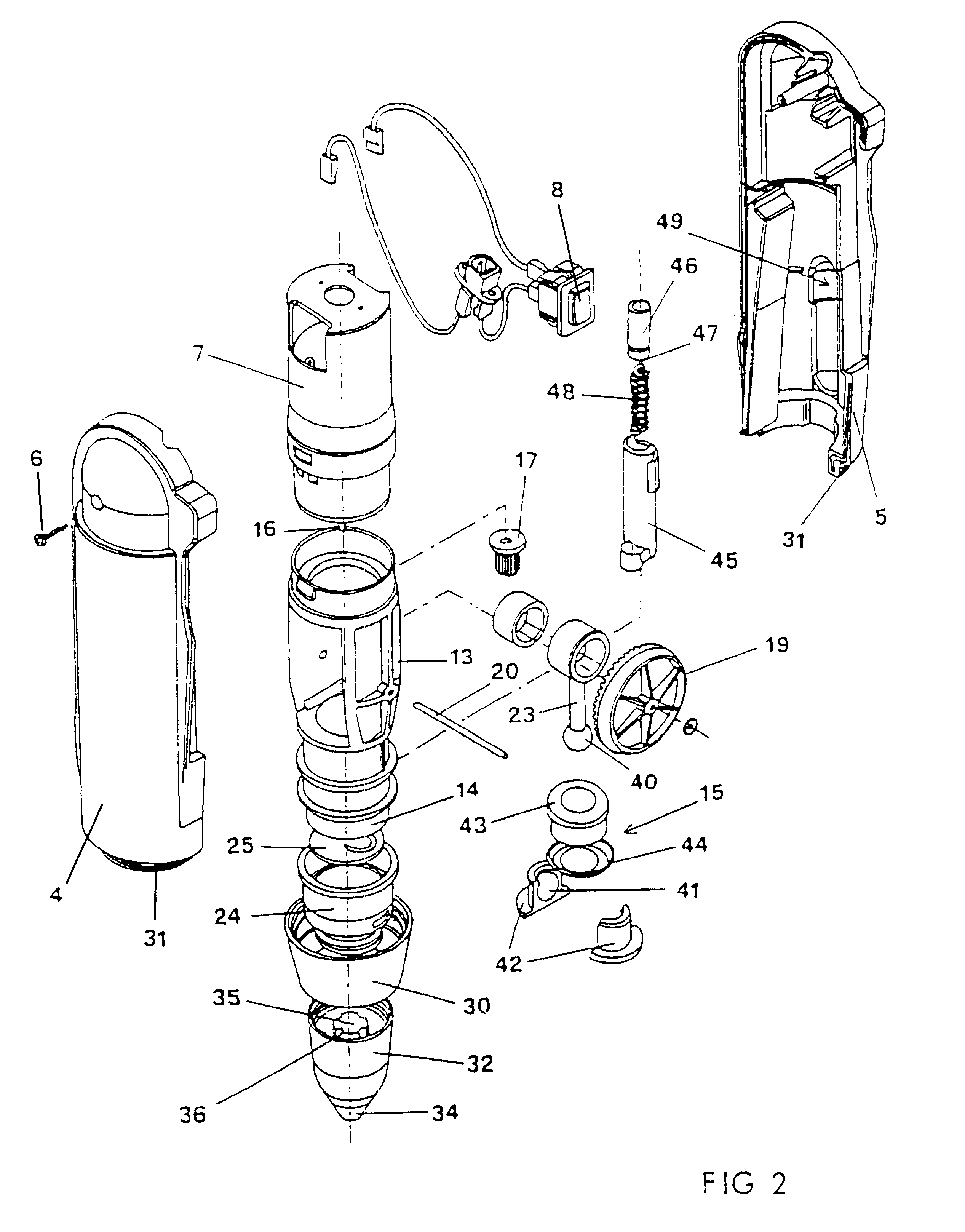

Hand-held suction pump

A hand-held suction pump for creating a vacuum in a container (2) provided with a suction valve (3), comprising an elongated outer casing in which an electric motor (7) and a piston pump (14, 15) driven by the motor (7) are accommodated, wherein the pump chamber (14) of the piston pump is connected by an inlet valve and a suction duct (28) to a hollow tip (34) at the free end of the casing for direct coupling with the suction valve of the container, the pump chamber being further connected by an outlet valve to an exhaust duct (29) having a duct opening on the outer surface of the wall of the outer casing for porting an exhaust flow to the exterior of the outer casing. In order to reduce noise caused by the exhaust flow, the duct opening of the exhaust duct (29) is overlapped by a baffle (38) which is separated by a gapped distance from the outer surface of the wall of the outer casing so as to deflect the exhaust flow exiting the duct opening by a substantial angle.

Owner:ARACARIA

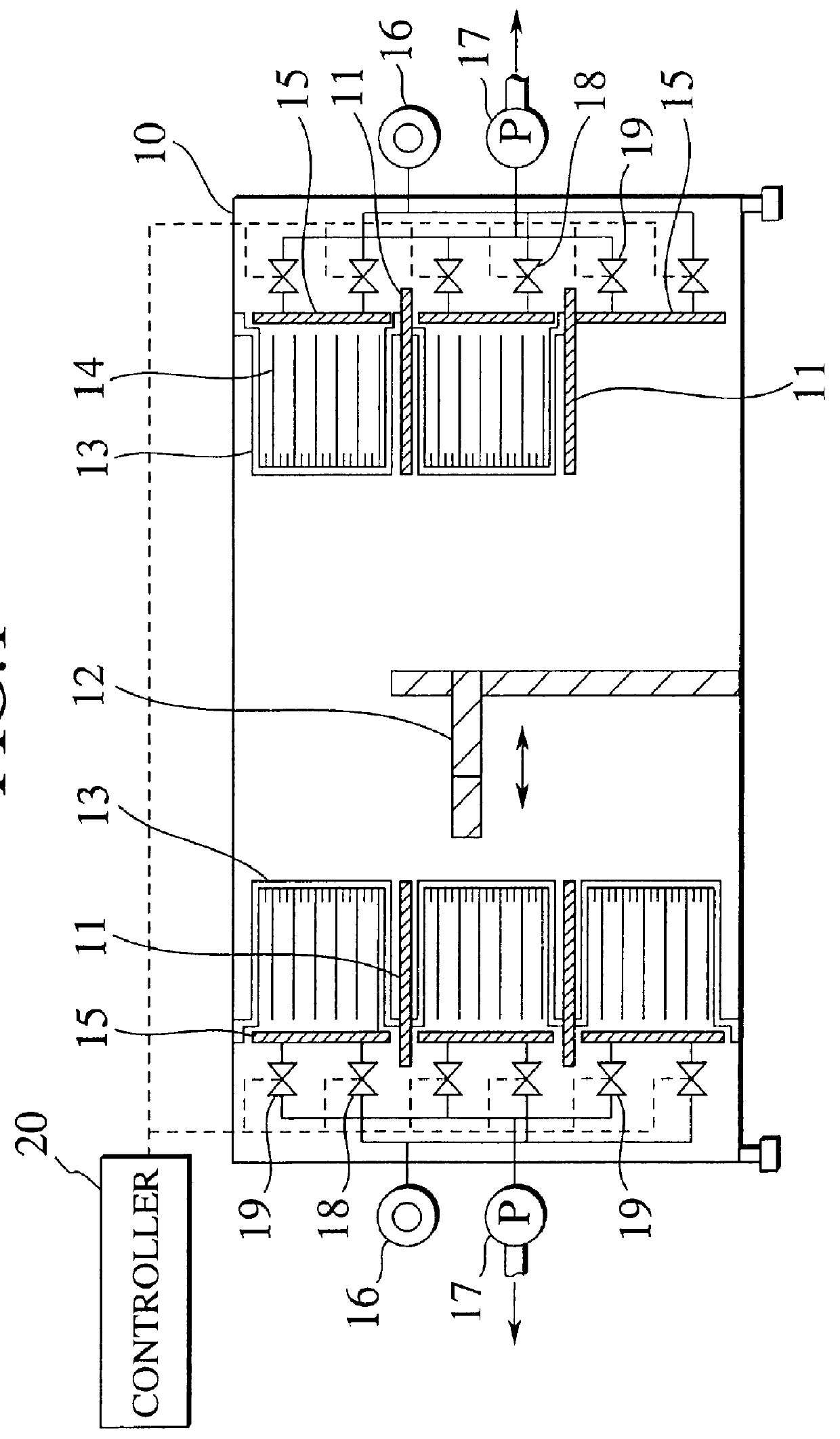

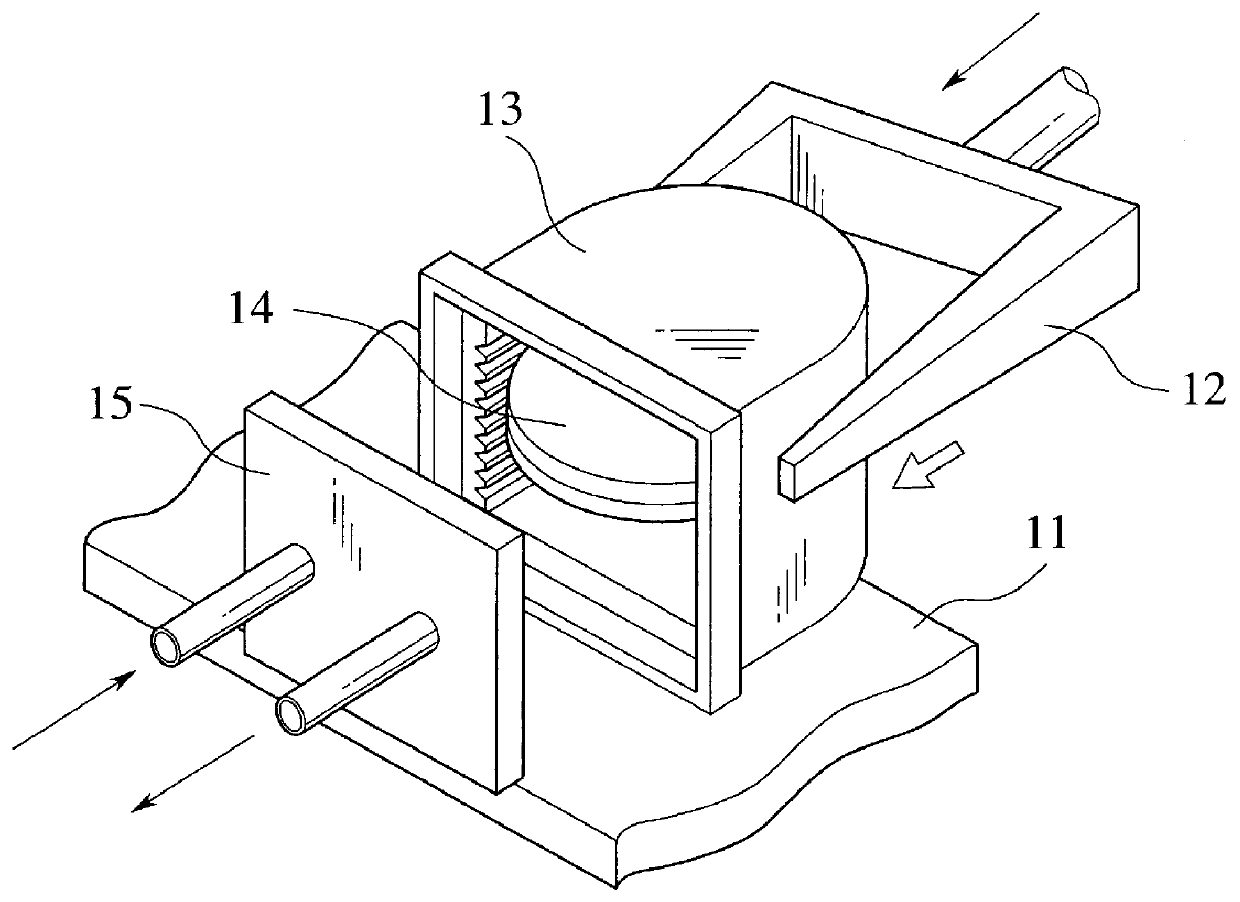

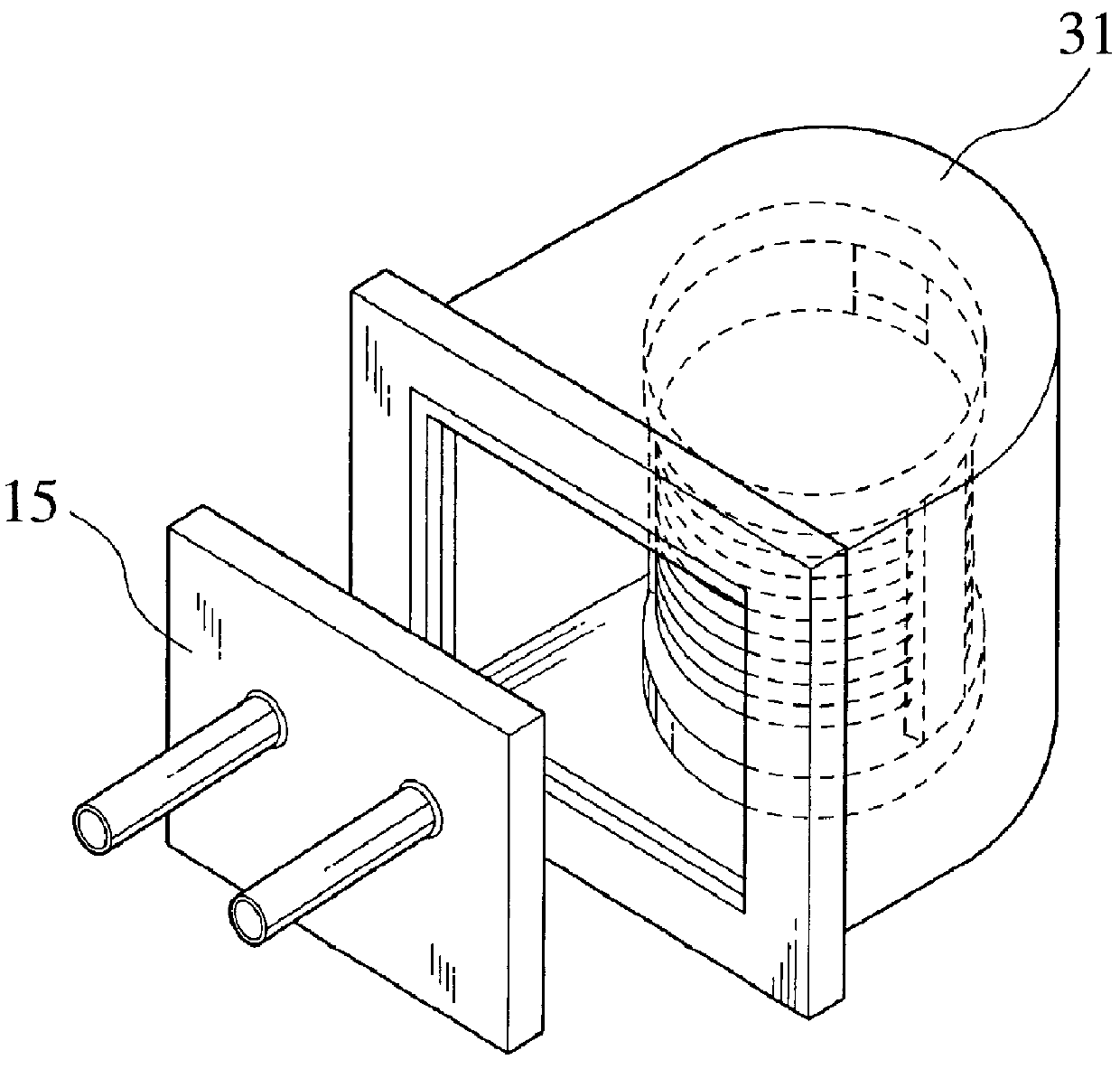

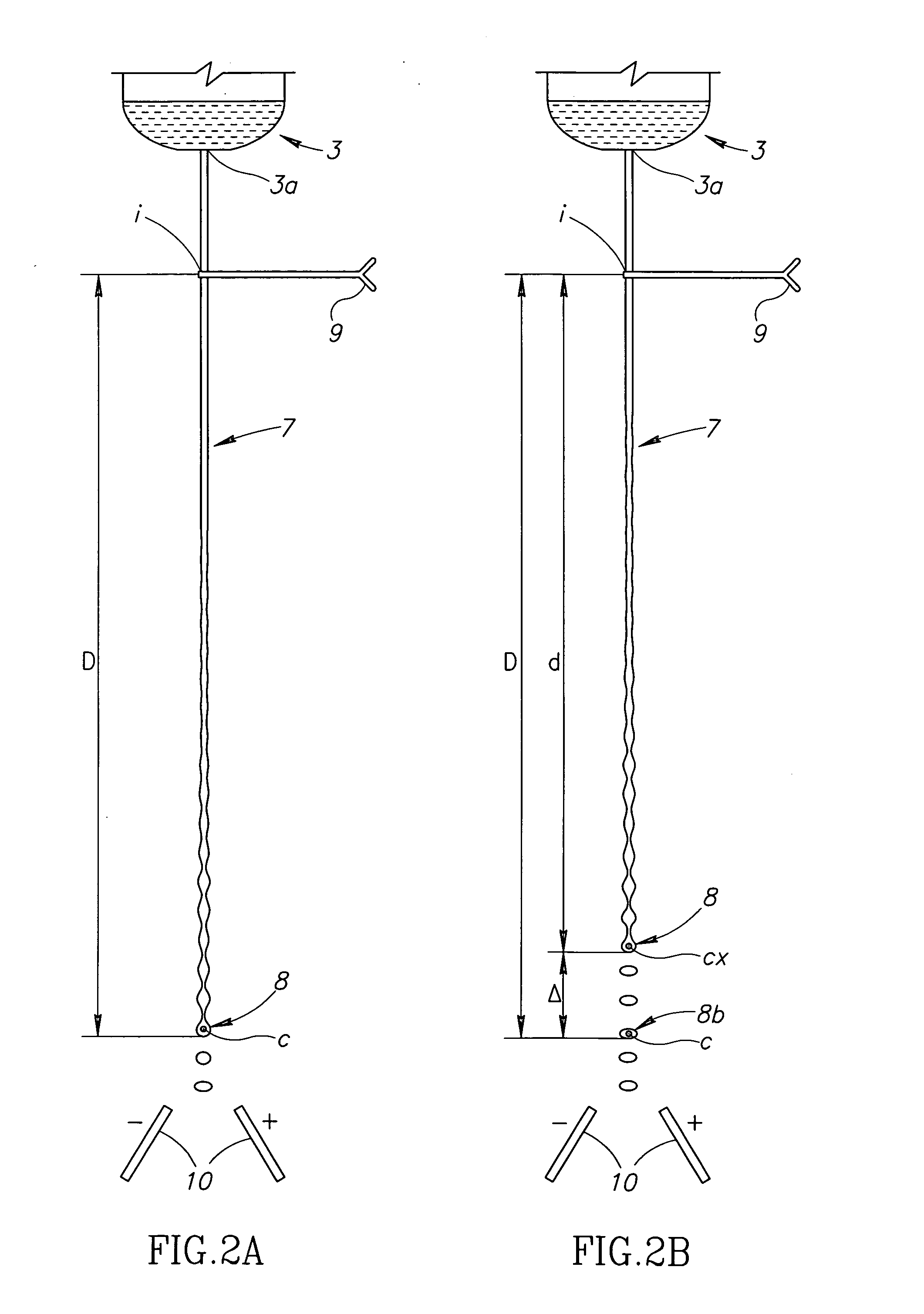

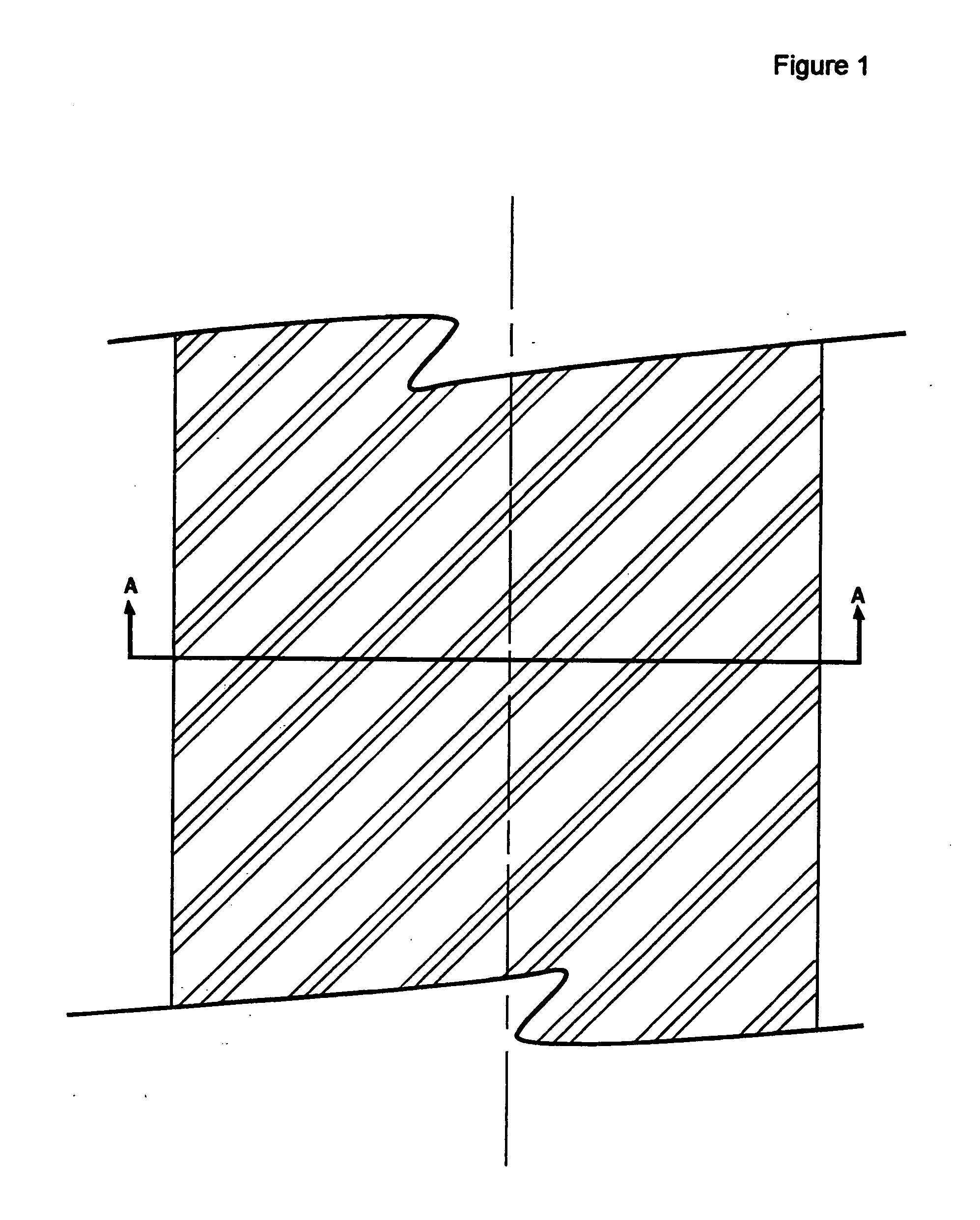

Method for filling insulated glass units with insulating gas

An apparatus and method for replacing air with an insulating gas during manufacture of an insulated glass article having two parallel panes and a peripheral spacer between the panes. The apparatus includes an upright first platen, a second platen confronting the first platen, a mechanism for moving at least one of the platens toward and away from the other platen, and a peripheral resilient seal positioned to define a sealed enclosure between the platens. The apparatus may further include a conveyer for conveying a partially assembled insulating glass article between the platens, an exhaust mechanism for drawing gas from the enclosure, and an intake mechanism for introducing insulating gas to the enclosure. One method of the invention involves filling such an insulated glass article and measuring the thickness of the article to detect bulging or cupping.

Owner:CARDINAL CG

Clean storage equipment for substrates and method of storing substrates

Storage equipment simply and effectively maintains the cleanness of substrates stored therein. The substrates in the storage equipment are set in a pod. The storage equipment has removable covers, a unit for fitting the covers to pods, respectively, a unit for holding the pods with the covers, a gas supply unit for individually supplying gas into the pods through the covers, and an exhaust unit for individually discharging an atmosphere from the pods through the covers. Each pod is closed with the cover in the storage equipment, and the gas supply unit and exhaust unit periodically replace an atmosphere in each pod with inert gas or evacuate each pod, to control the storage conditions of each pod in the storage equipment.

Owner:KK TOSHIBA

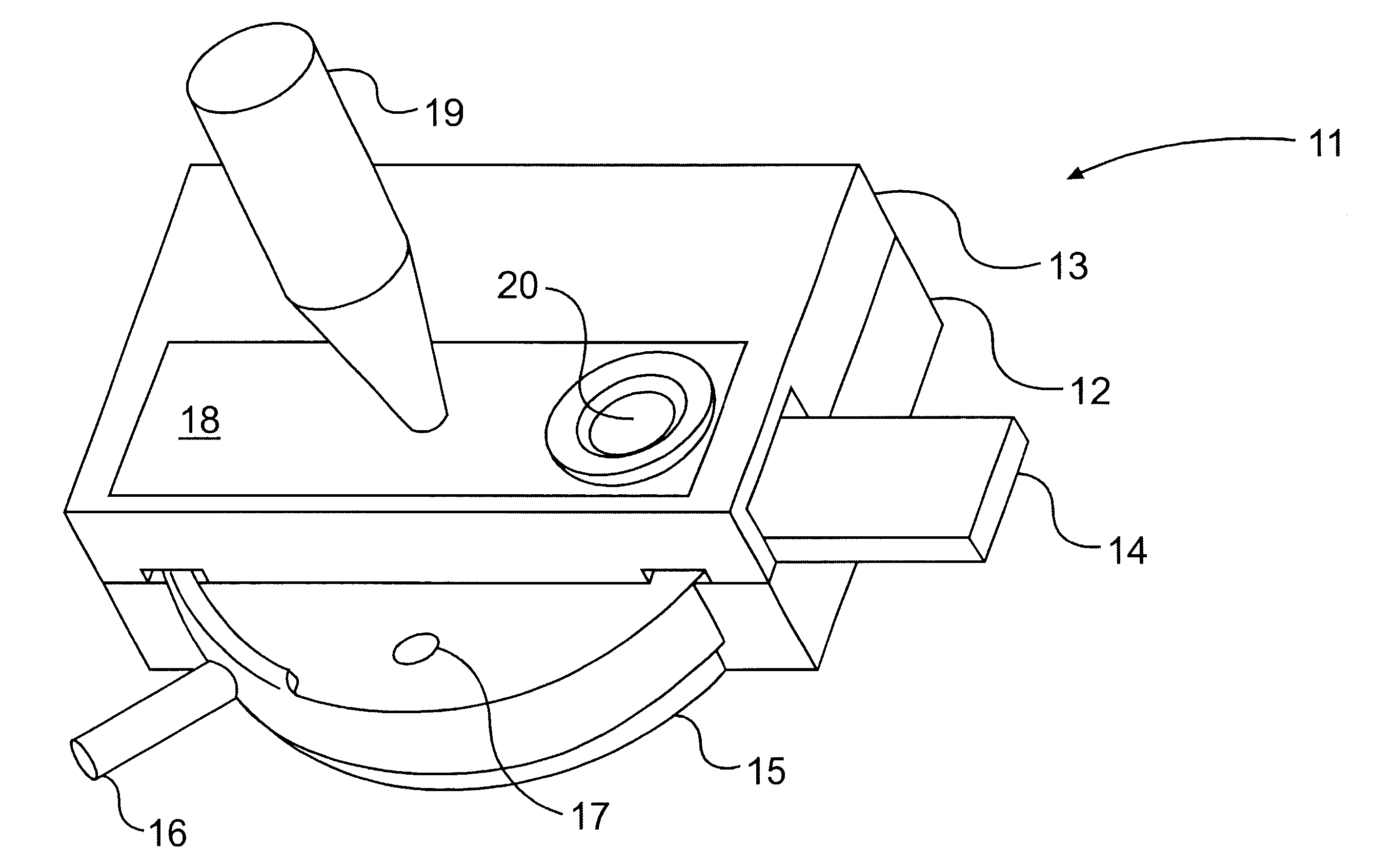

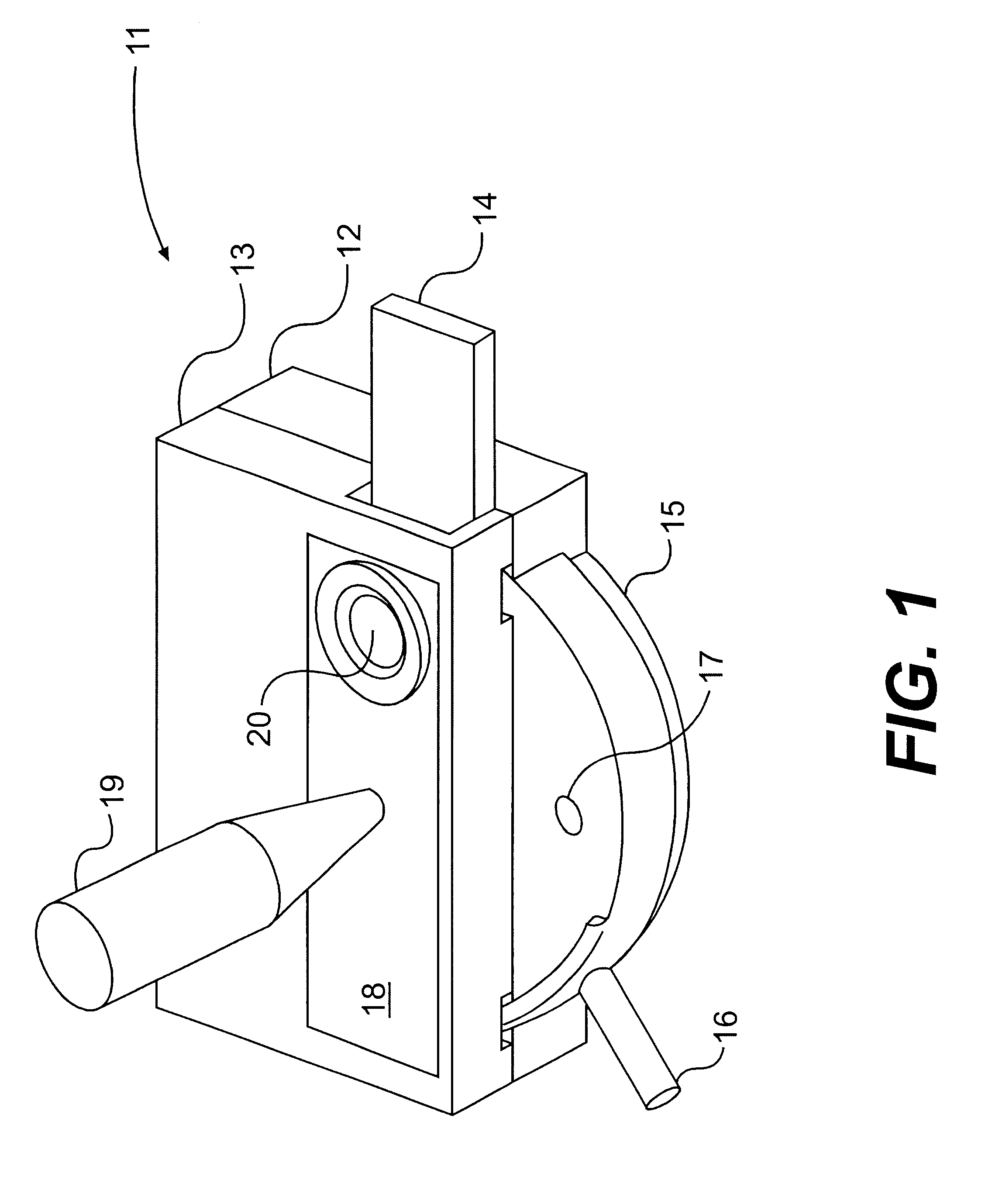

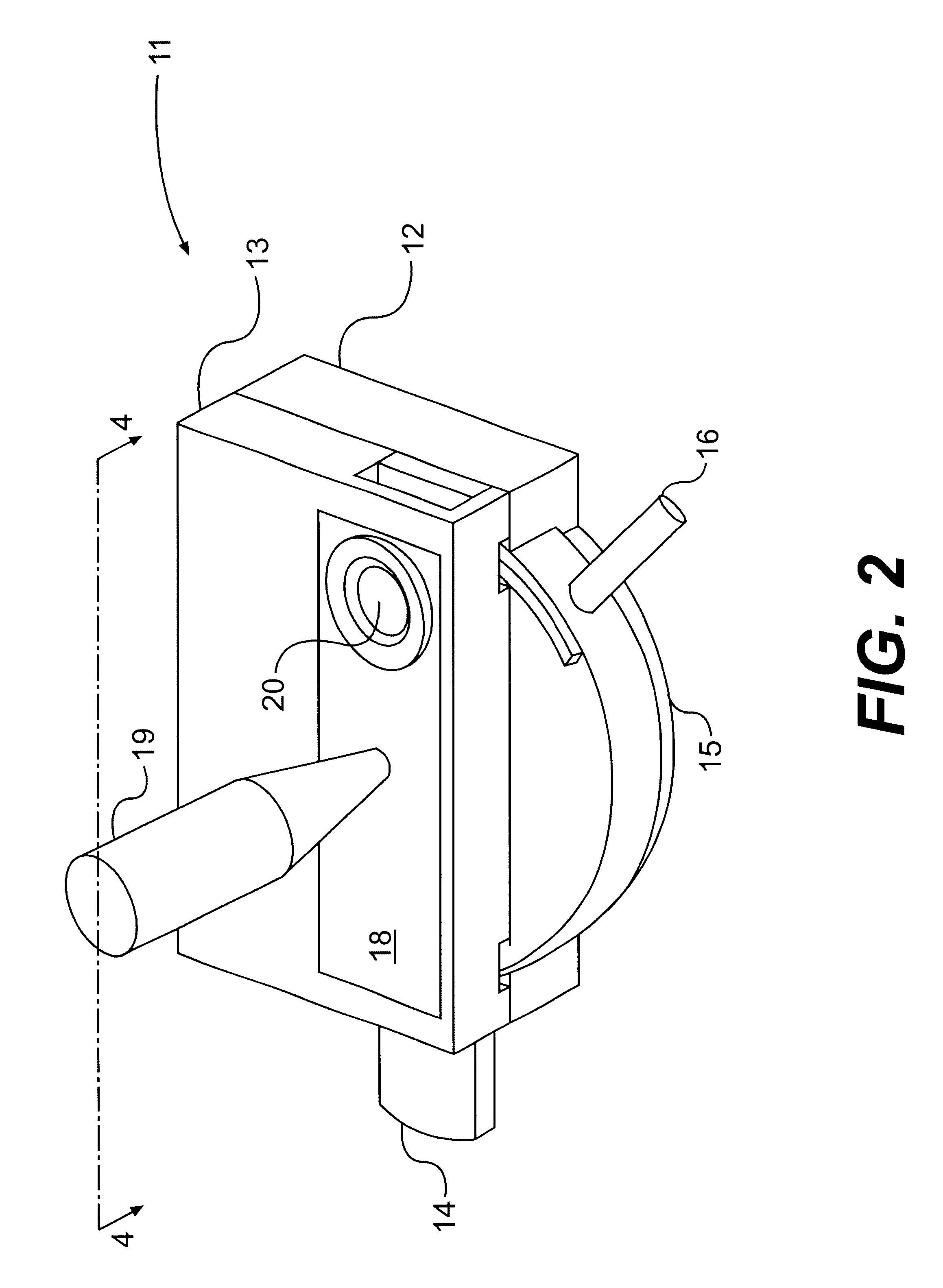

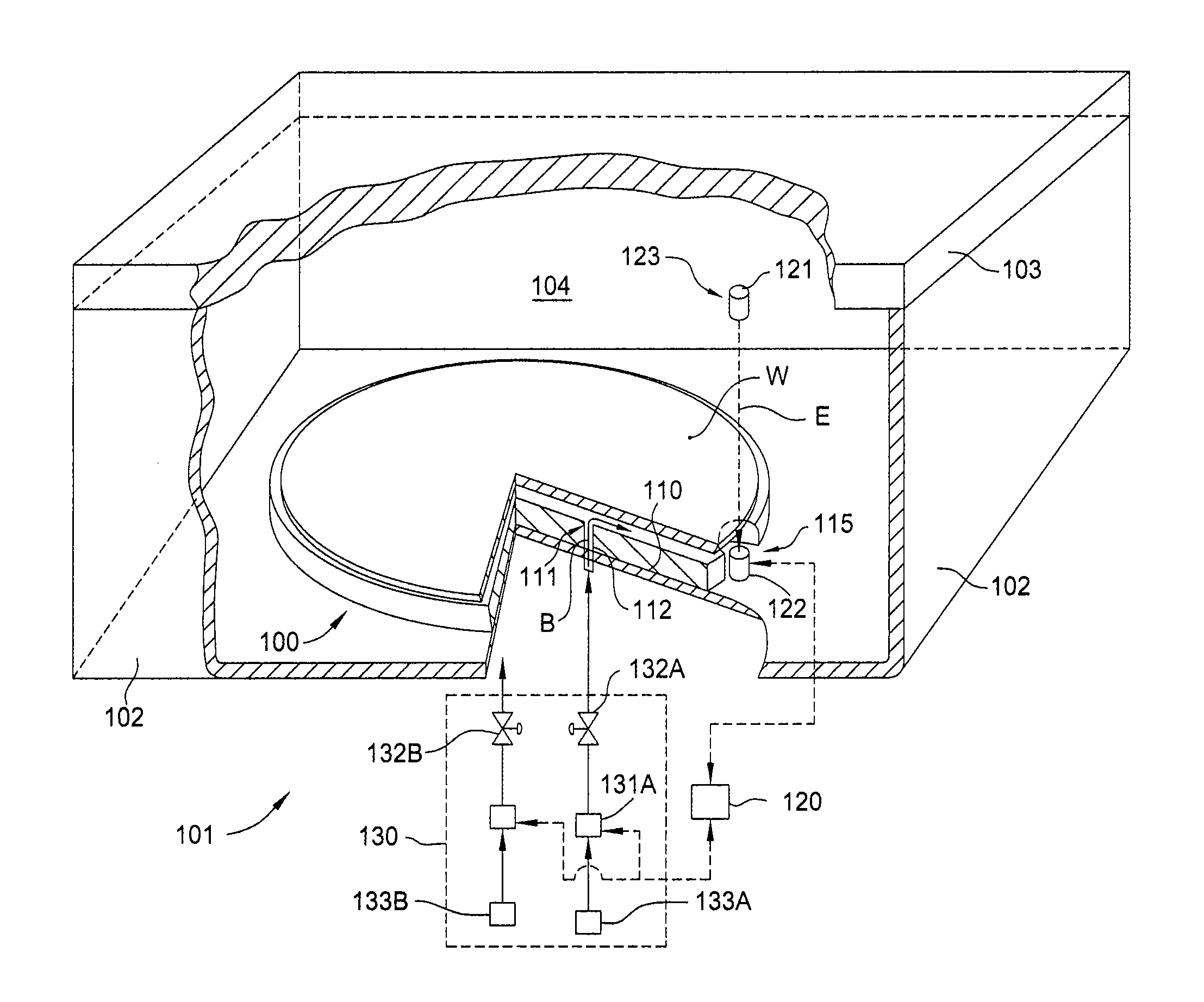

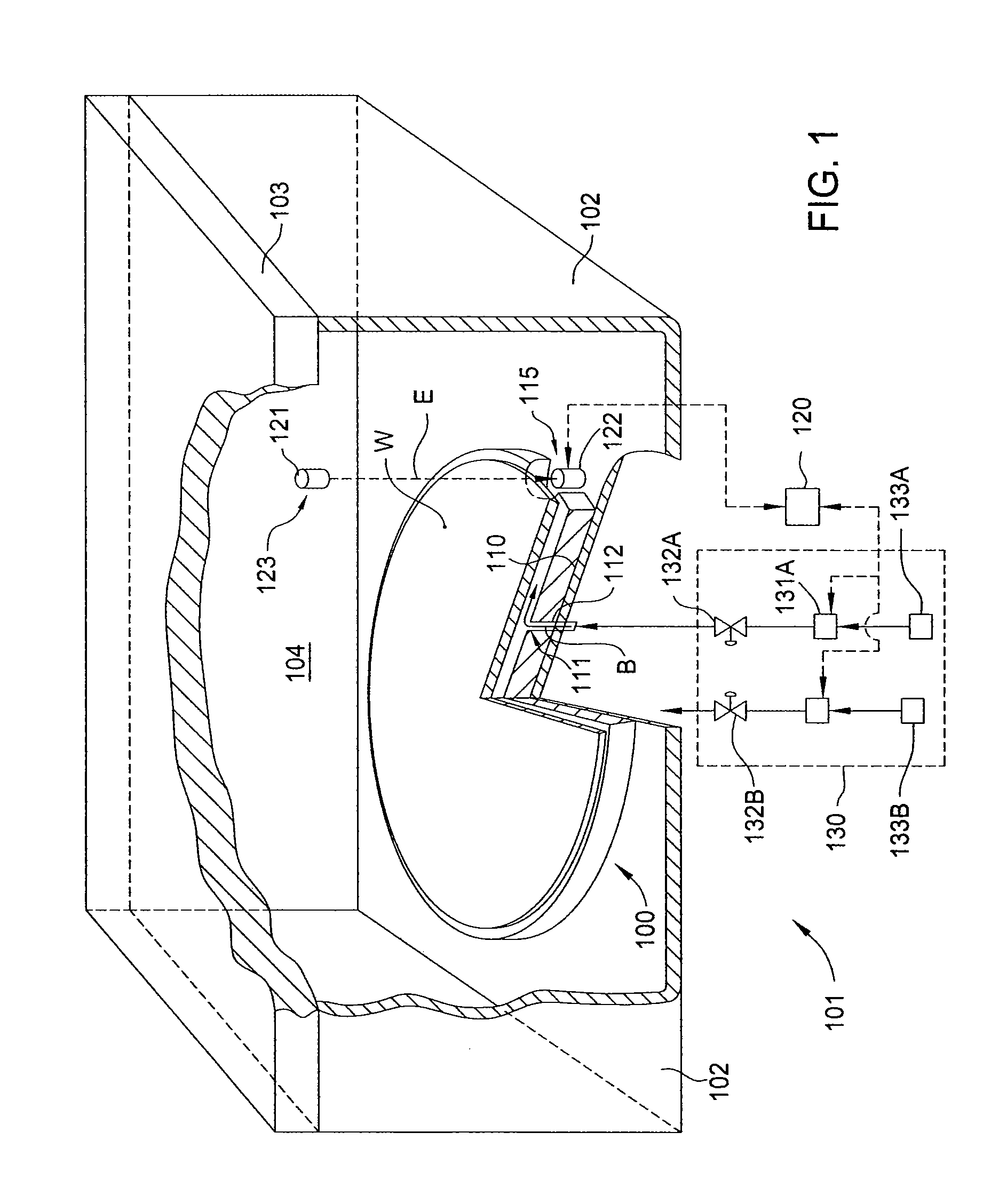

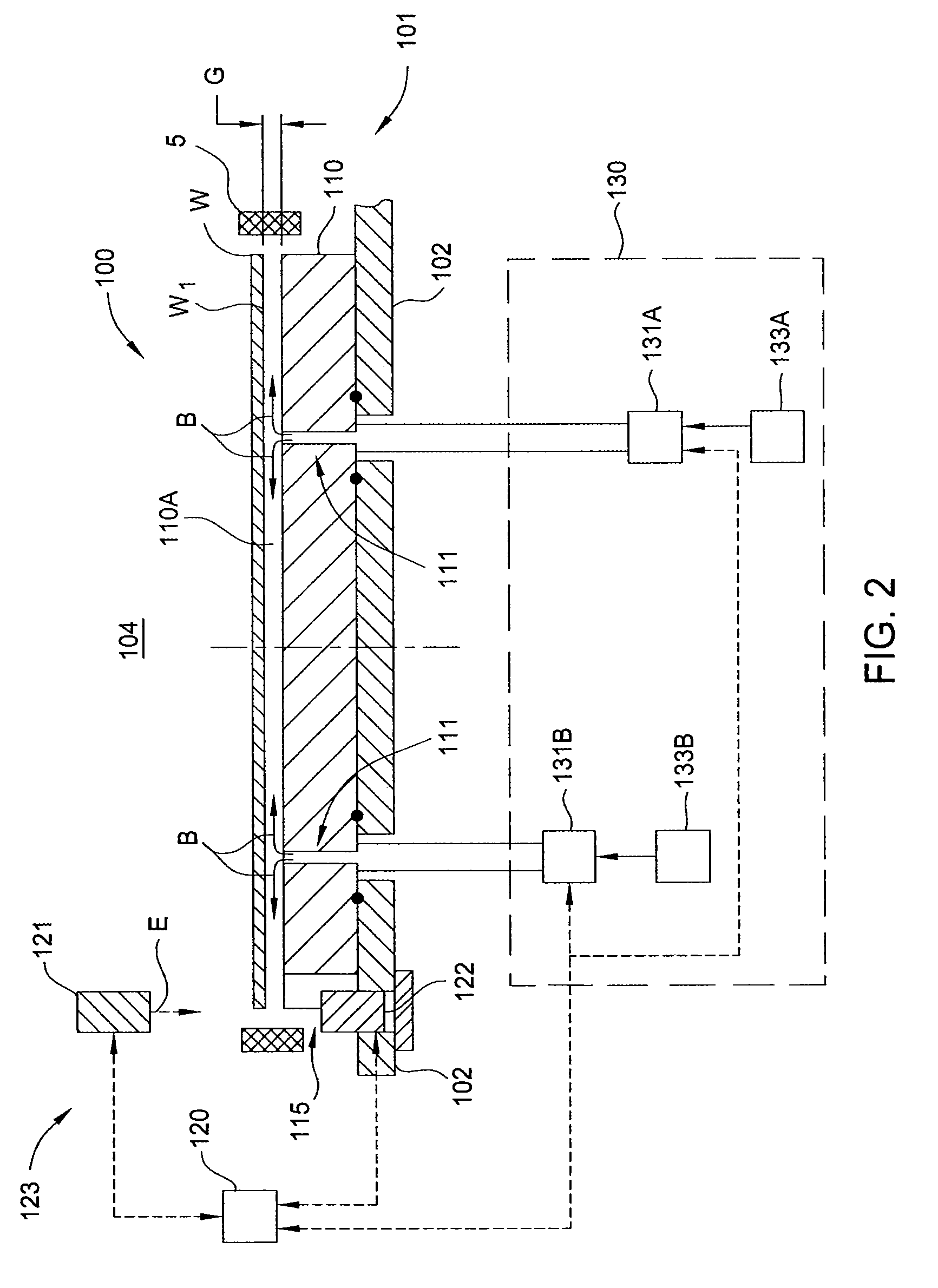

Apparatus and method for supporting, positioning and rotating a substrate in a processing chamber

ActiveUS20080280453A1Liquid surface applicatorsSemiconductor/solid-state device manufacturingGas phaseEngineering

Embodiments of the invention contemplate a method, apparatus and system that are used to support, position, and rotate a substrate during processing. Embodiments of the invention may also include a method of controlling the transfer of heat between a substrate and substrate support positioned in a processing chamber. The apparatus and methods described herein remove the need for complex, costly and often unreliable components that would be required to accurately position and rotate a substrate during one or more processing steps, such as an rapid thermal processing (RTP) process, a chemical vapor deposition (CVD) process, a physical vapor deposition (PVD) process, atomic layer deposition (ALD) process, dry etching process, wet clean, and / or laser annealing process.

Owner:APPLIED MATERIALS INC

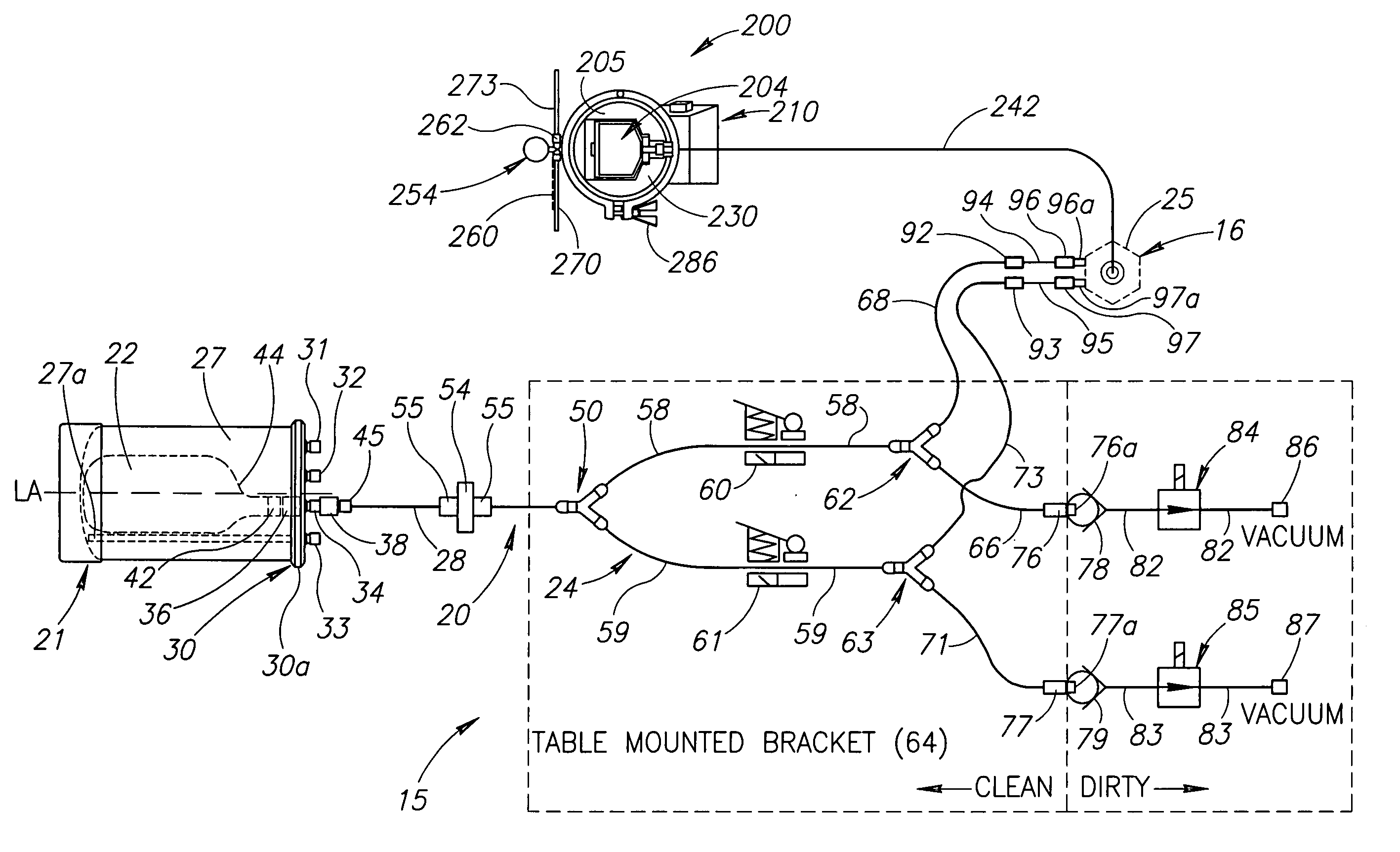

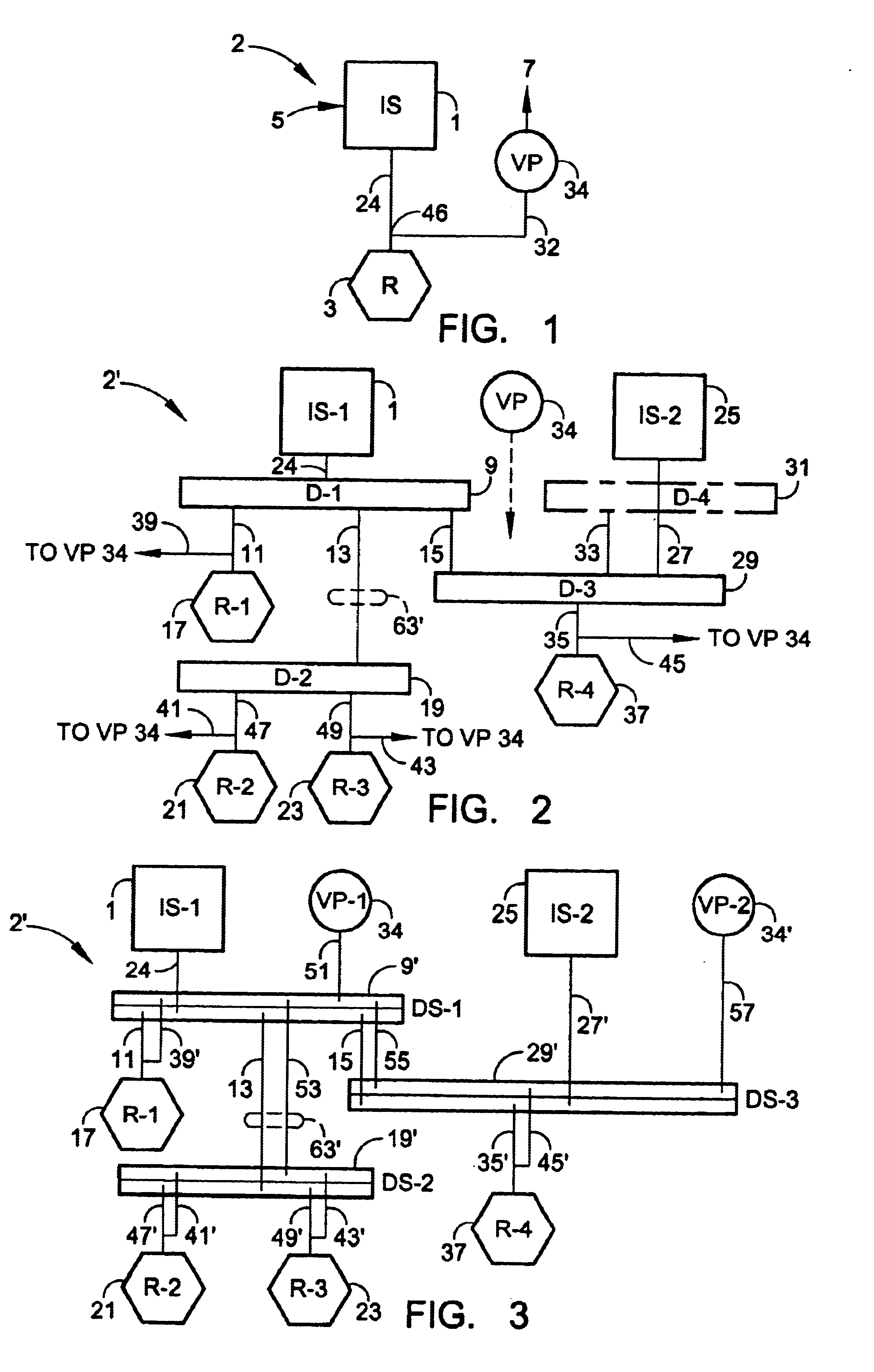

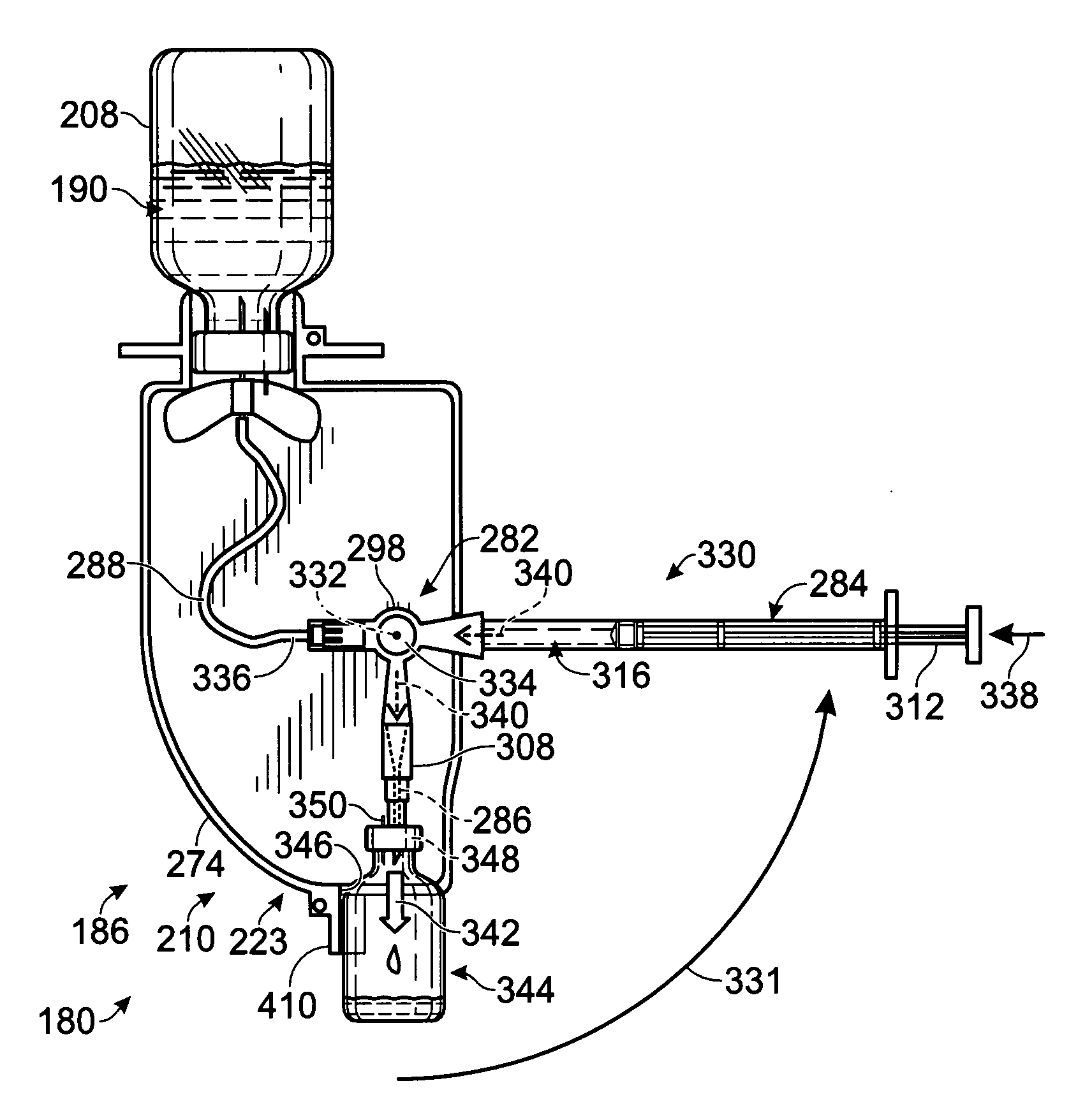

Fluid delivery system for a flow cytometer

InactiveUS20050011582A1Easy to transportAvoid formingPackaging by pressurising/gasifyingIndividual particle analysisFluid transportEngineering

Systems for sheath fluid and sample fluid transport from containers to an analytic device, such as a flow (cell) cytometer, are disclosed. These systems are sterile and remain so, as they are closed to the ambient environment. As a result, fluids of high purity reach the analytic device, and in the case of a flow cytometer, the desired cells are sorted in sort of high purity.

Owner:STOWERS INST FOR MEDICAL RES

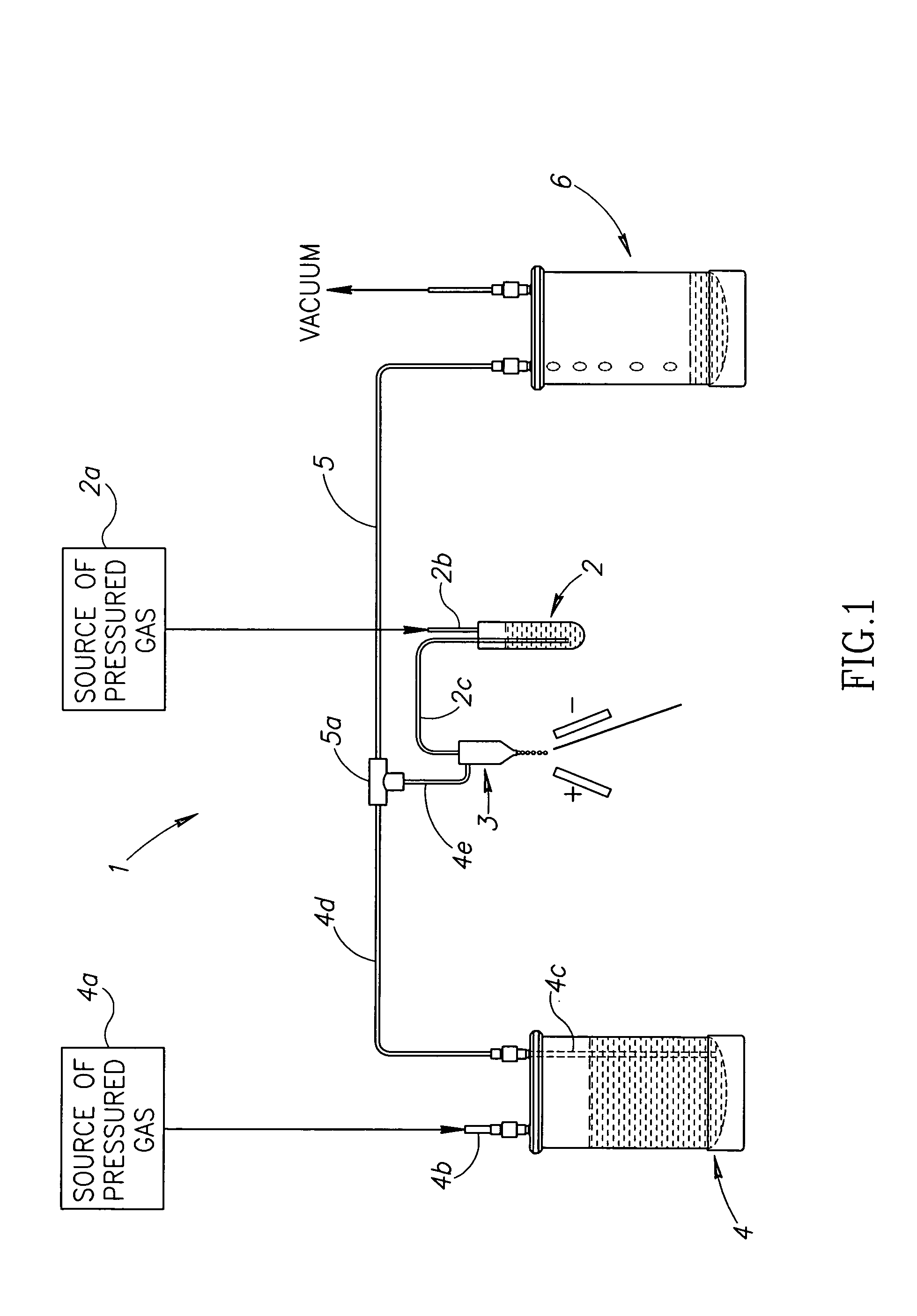

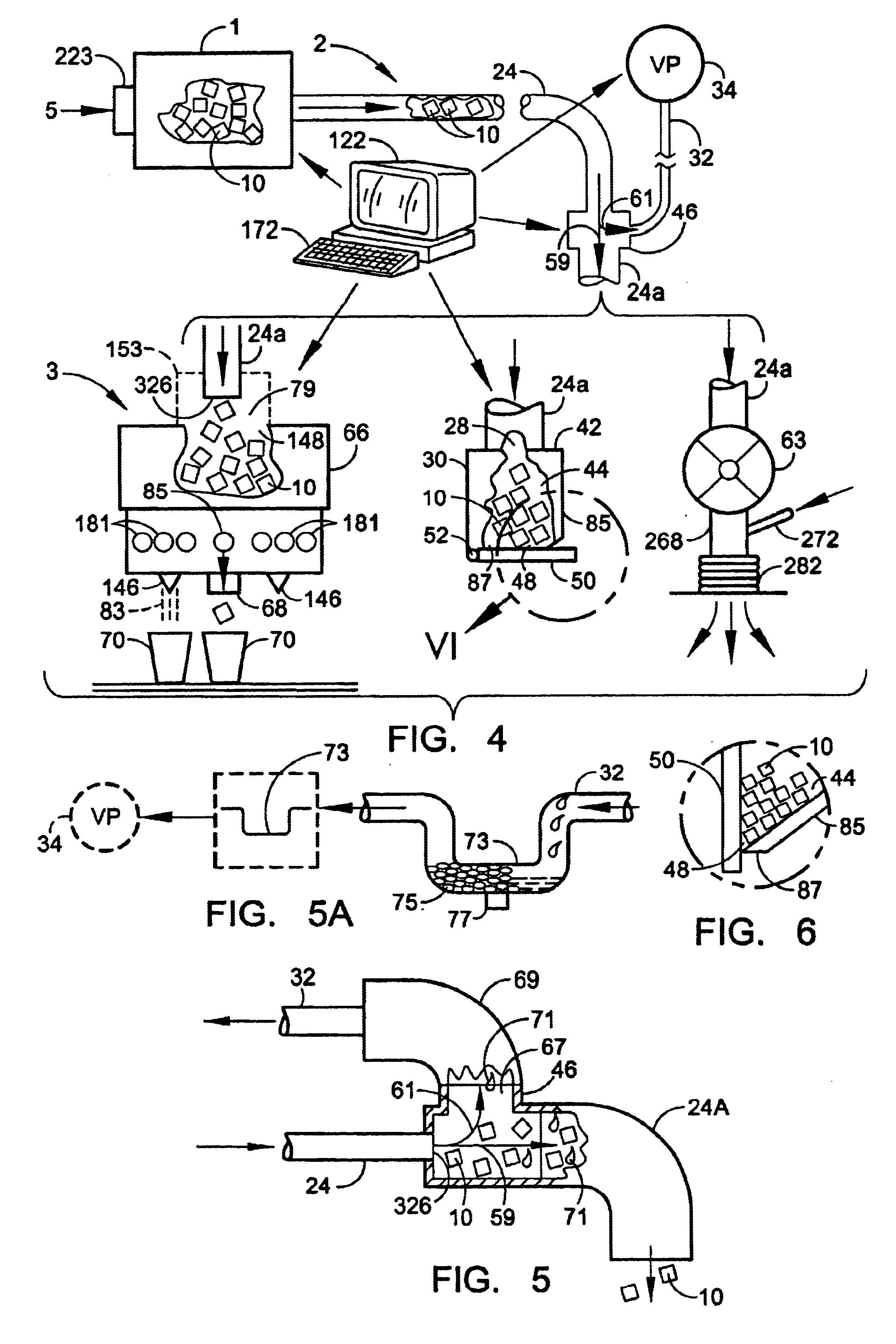

Vacuum pneumatic system for conveyance of ice

InactiveUS6827529B1Readily vacuum conveyedLess costlyLighting and heating apparatusIce productionSystem configurationEngineering

Vacuum pneumatic conveying apparatus and method are described to provide for a simple, economical, convenient (and preferably automatic) system for conveying ice on an as-required basis from a source such as an ice maker to one or more receptors at locations remote from that source. The system can be configured such that dispensing locations can be added or eliminated from the system or temporarily taken "off line" from the system without the need to change the basic system configuration or the central ice providing apparatus. The apparatus in various embodiments includes an ice source, a conveying conduit from the source to the receptor, a vacuum pump for moving the ice through the conduit by vacuum, and the receptor to collect the conveyed ice. The receptor may be an ice / beverage dispenser, an accumulator for retention and discharge to further devices, an intermediate storage dispenser, or an air lock device from where the ice can be projected over significant distances. Ice and vacuum may simultaneously be routed into different branched routes, utilizing a unique diverter / air shifter with the capability of providing routing to up to four different routes. Appropriate sensors and controllers, which may be microprocessor-based, may be used to automate the system. The entire system is easily cleanable. The system is advantageously used by restaurants, groceries, hotels and motels, hospitals, laboratories, and many other establishments where the providing of ice at various locations is desirable or required.

Owner:TEK SOLUTIONS

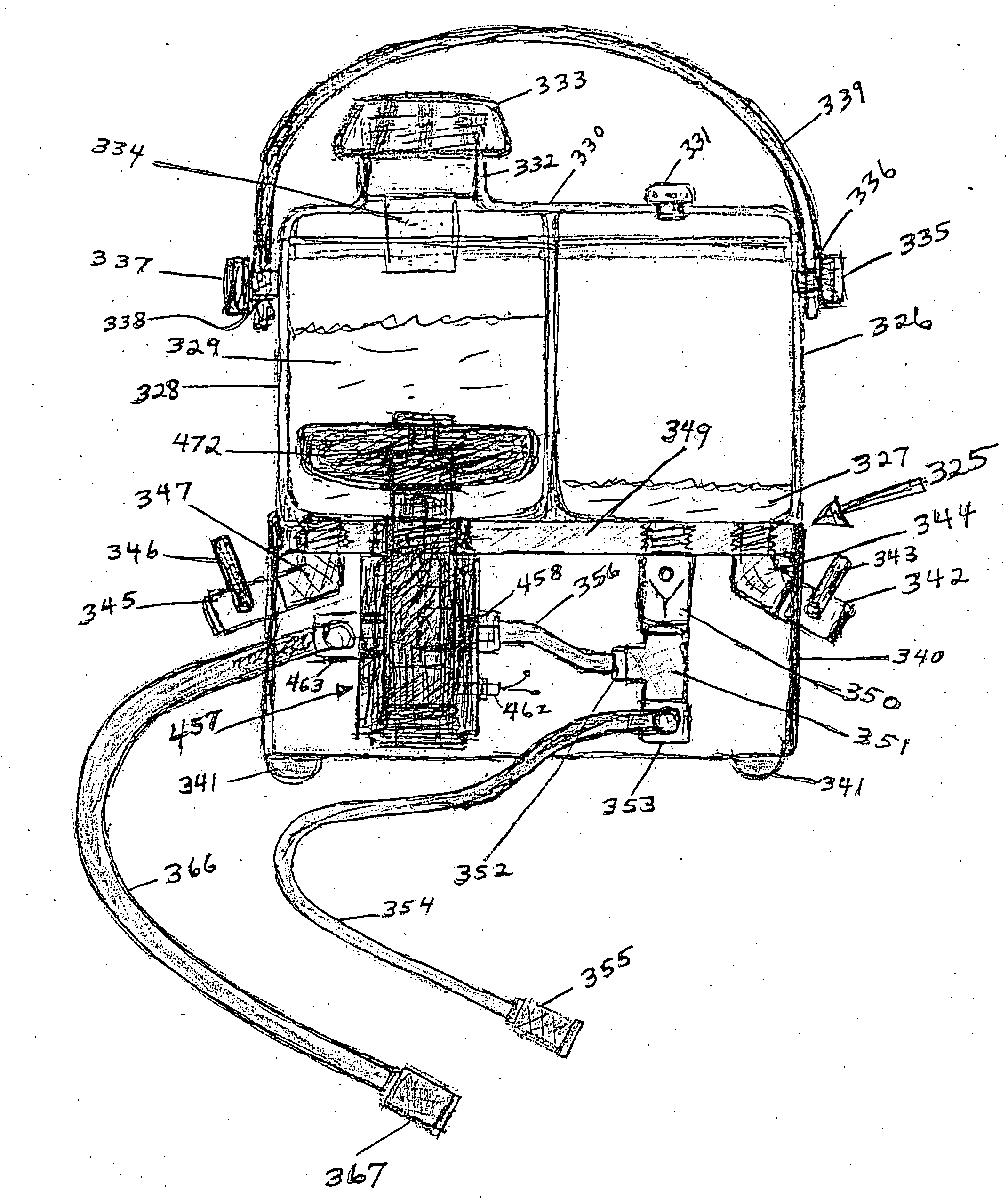

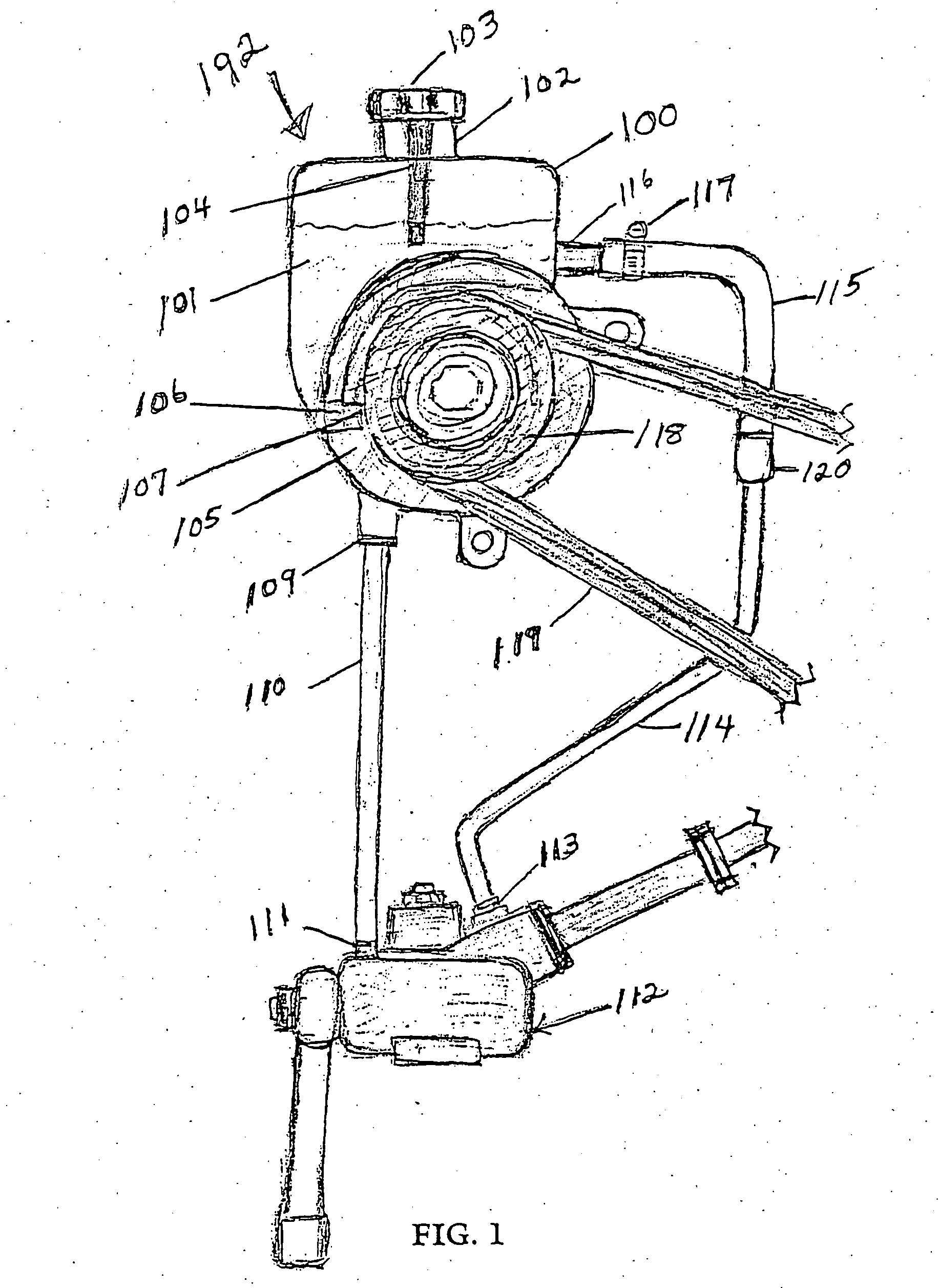

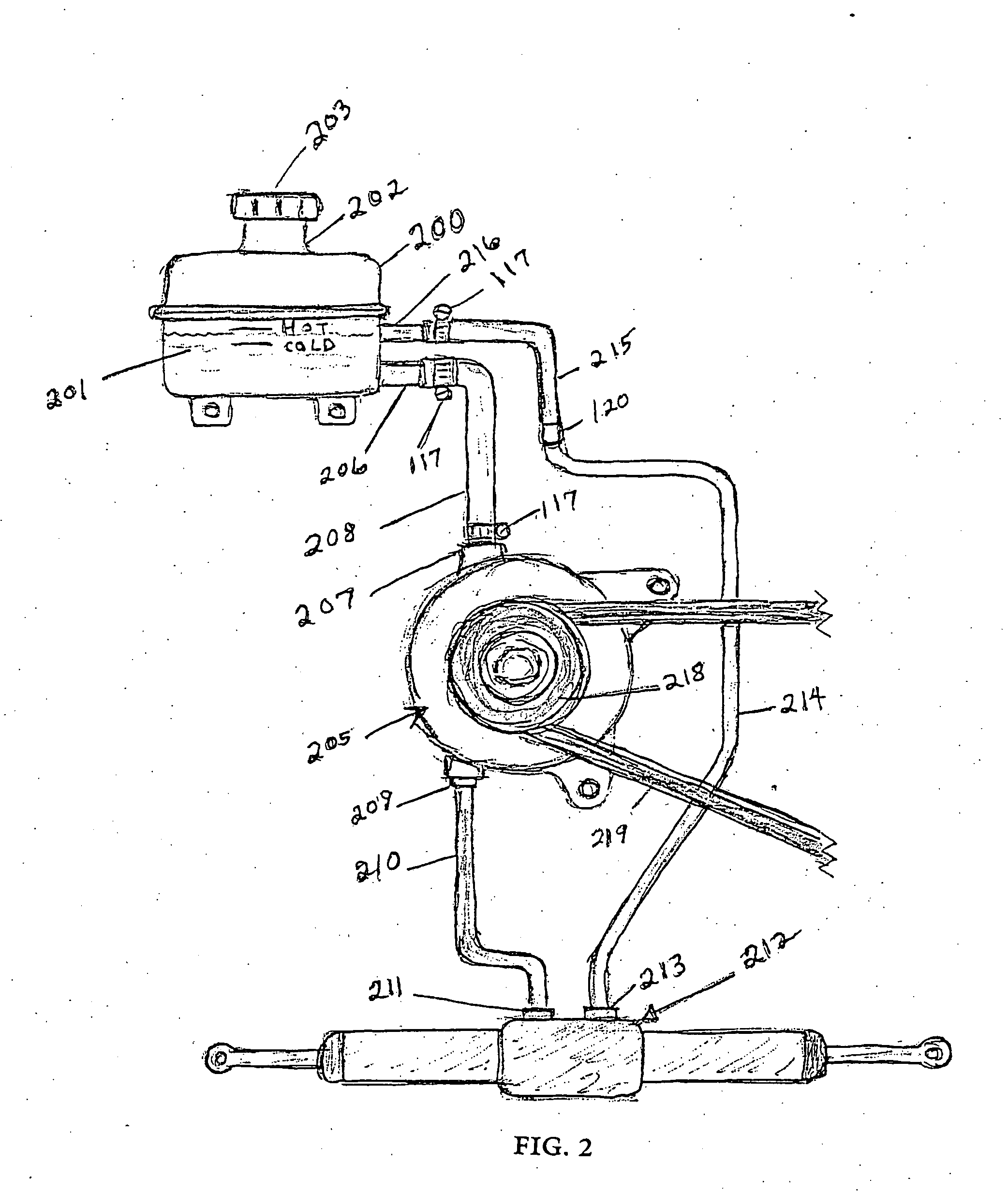

Automatic fluid exchanger

InactiveUS20050166993A1Preventing air infusionEffective blockingLiquid fillingPackaging by pressurising/gasifyingFluid controlPositive pressure

A fluid exchanger for servicing the fluid circuits of vehicular power steering systems and other fluid circulating or hydraulic circuits. The fluid exchanger uses a float operated fluid control valve to harness fluid pressure provided by a pump of an accessed hydraulic circuit. The fluid control valve uses both negative and positive pressure of the circuit's pump to control fluid flow patterns. The float and fluid control valve are matched to be either mechanical / hydraulic or electrical / hydraulic in design. If the exchanger is provided with a mechanically operated fluid control valve, a mechanical float is provided in the exchanger's fresh fluid reservoir and is directly connected to the valve slide of the fluid control valve. If the exchanger is provided with an electric solenoid operated fluid control valve, a float operated electrical switch is provided in the exchanger's fresh fluid reservoir and is wired to control the solenoid of the valve.

Owner:VIKEN JAMES P +1

Packaging for meat and foodstuff

InactiveUS6447826B1Preventing inflationMaintain internal pressureReady-for-oven doughsFlexible coversFood packagingLow oxygen

Methodology for packaging and packages for meat or other foodstuffs in a carbon dioxide rich low oxygen environment by including without the packages carbon dioxide generating material and oxygen removing material where the production of carbon dioxide is not dependent upon removal of oxygen.

Owner:SEALED AIR NZ +1

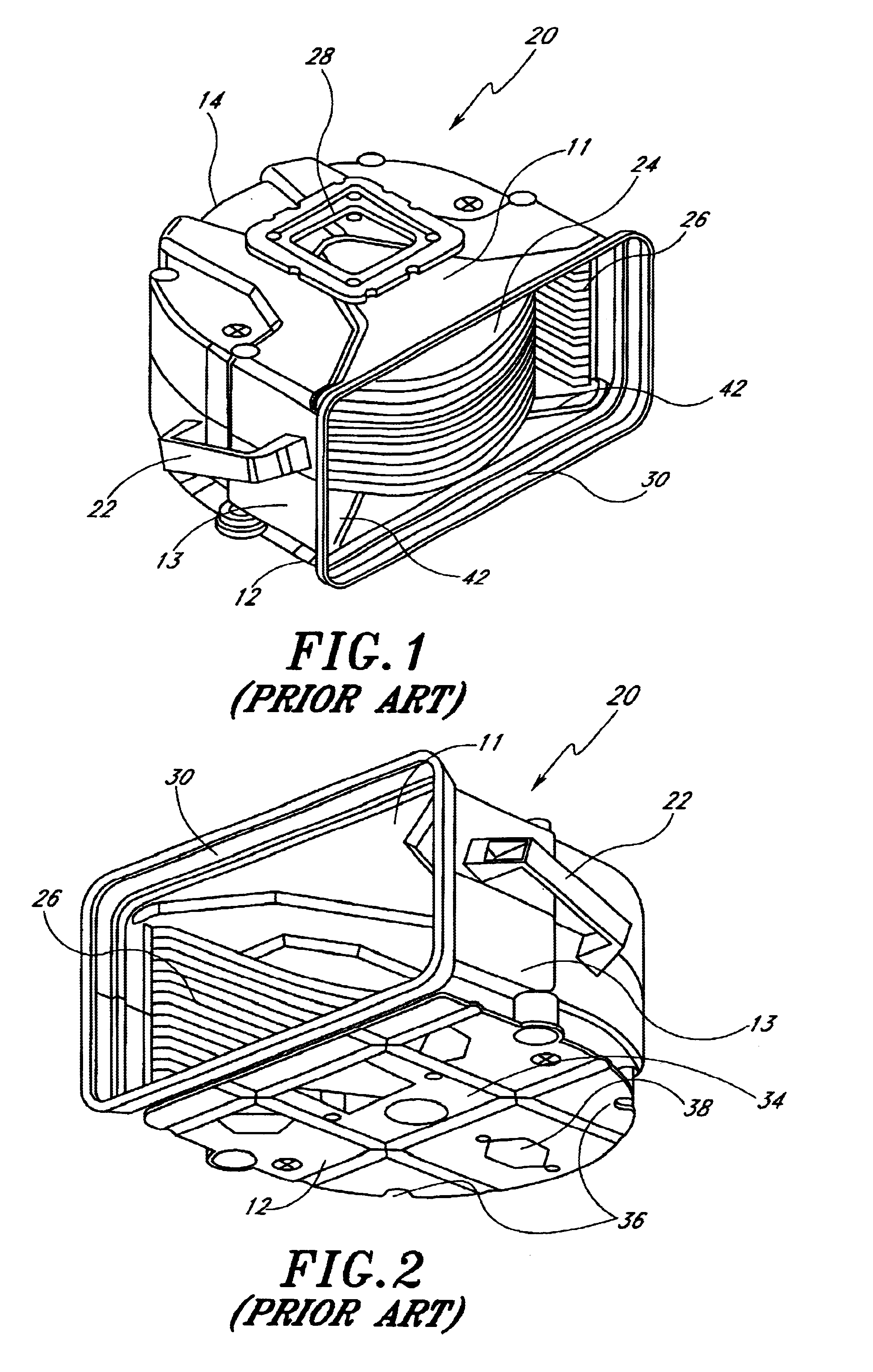

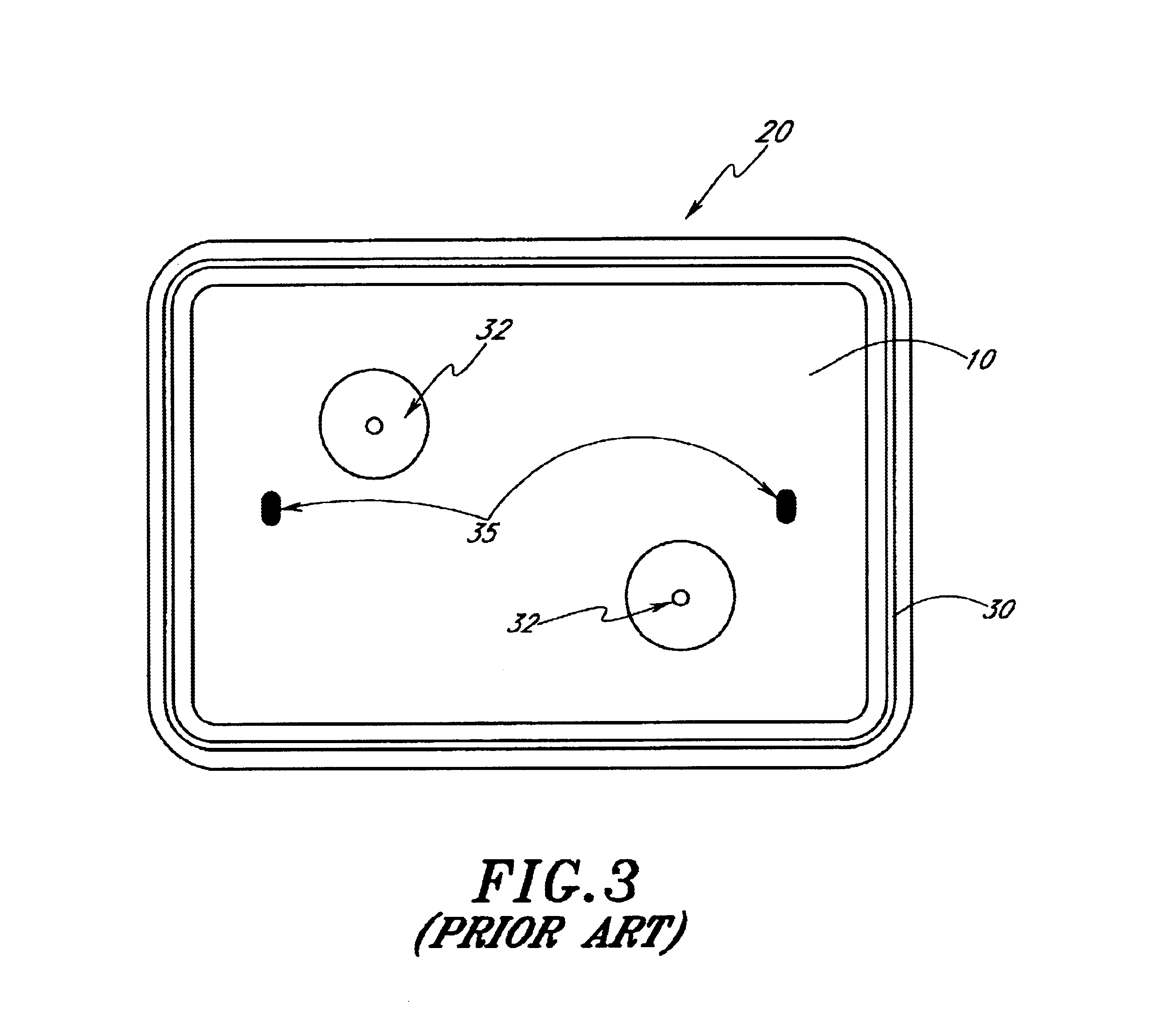

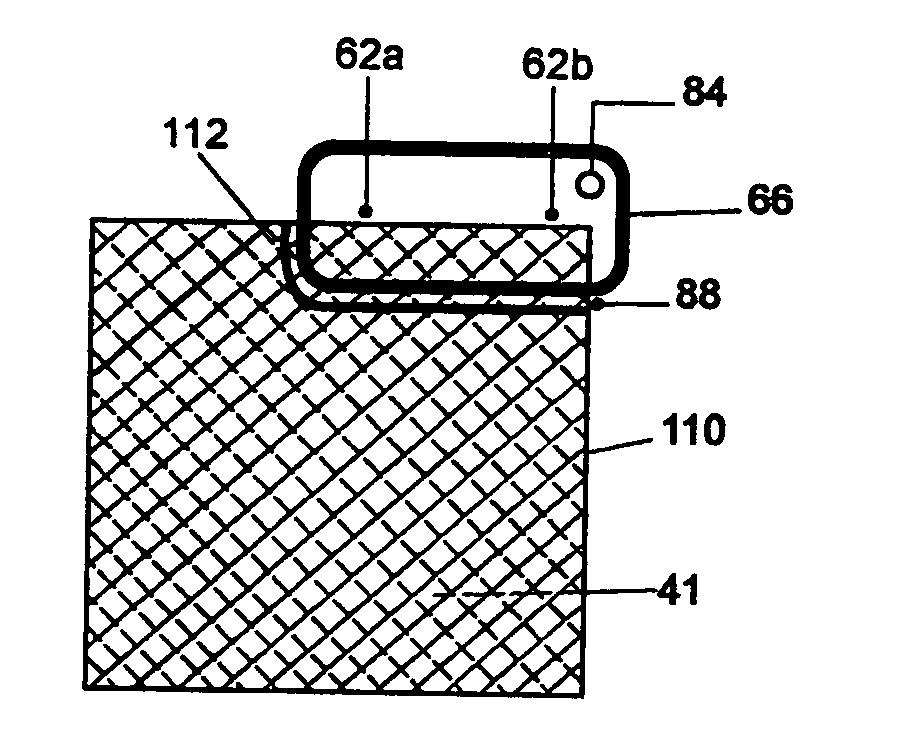

Front opening unified pod

InactiveUS6899145B2Reduce contentLiquid fillingSemiconductor/solid-state device manufacturingMechanical engineeringSemiconductor

A front opening unified pod (FOUP) used for temporarily and portably storing semiconductor wafers between processing steps includes a manifold for uniformly distributing a purge gas in the FOUP during a purging process between wafer processing steps. The manifold can be a variety of shapes, and can be located in a number of appropriate locations within the FOUP. The manifold generally extends the full height of the FOUP and includes a plurality of openings configured to direct a flow of purge gas above and below each wafer held by the FOUP.

Owner:ASM IP HLDG BV

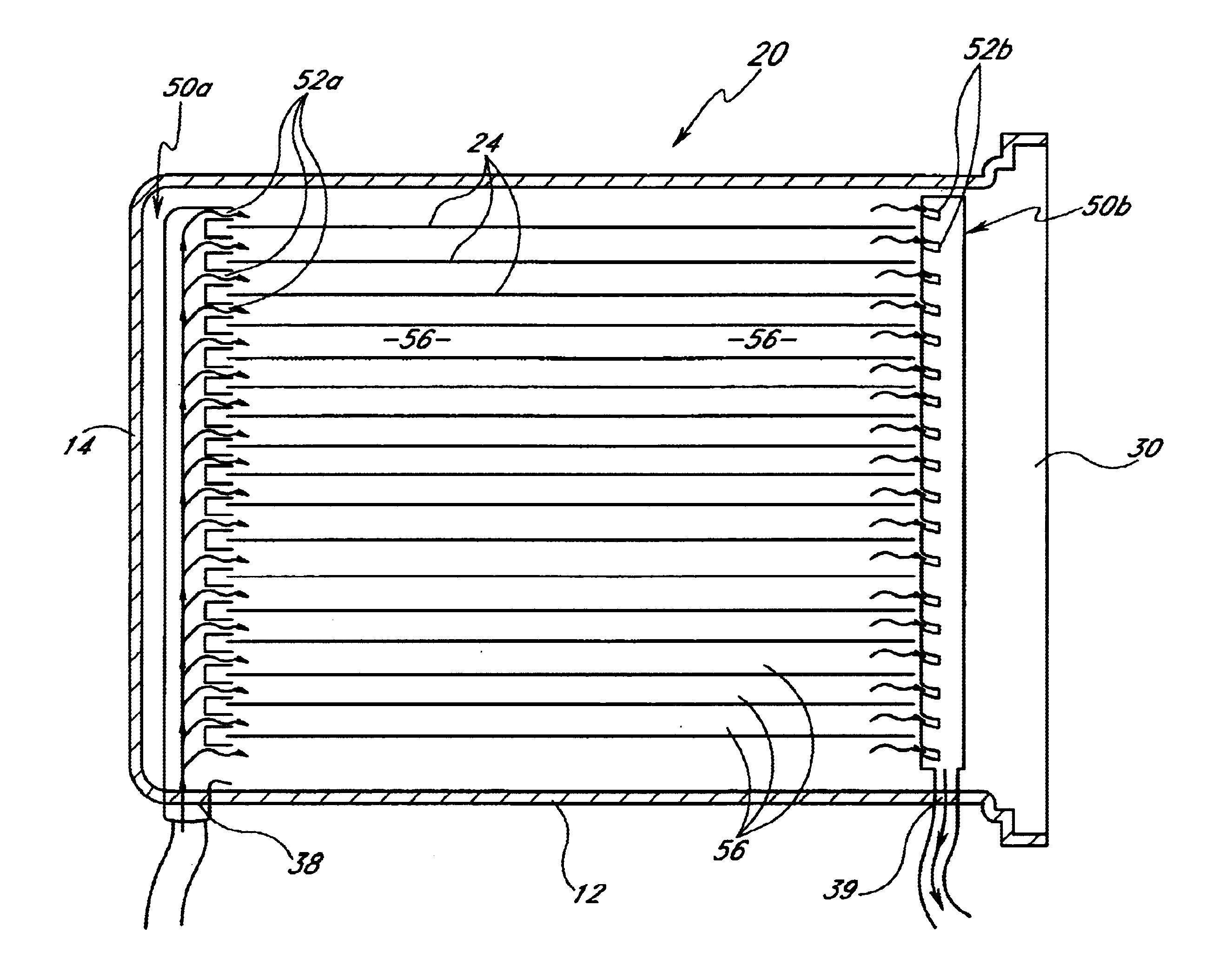

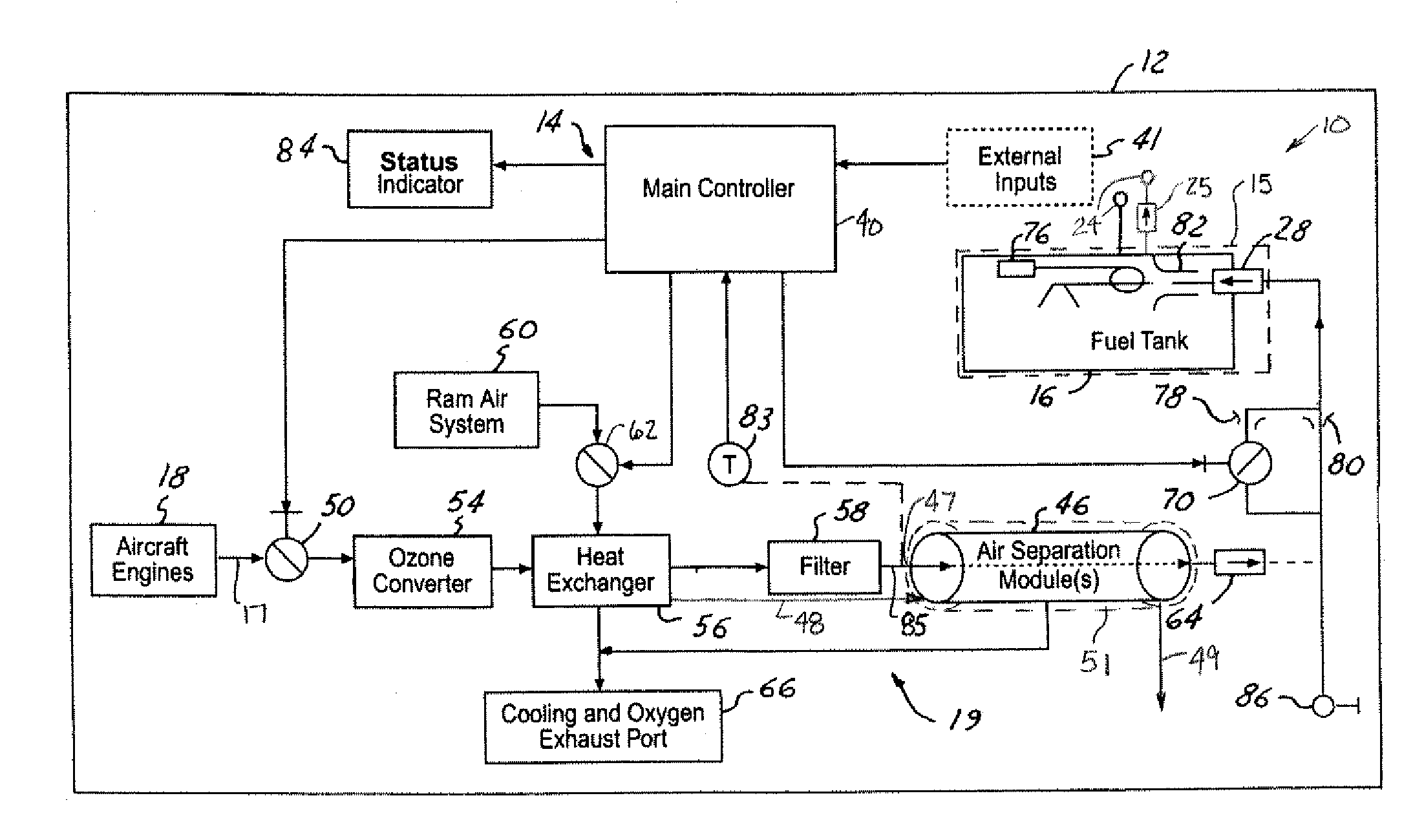

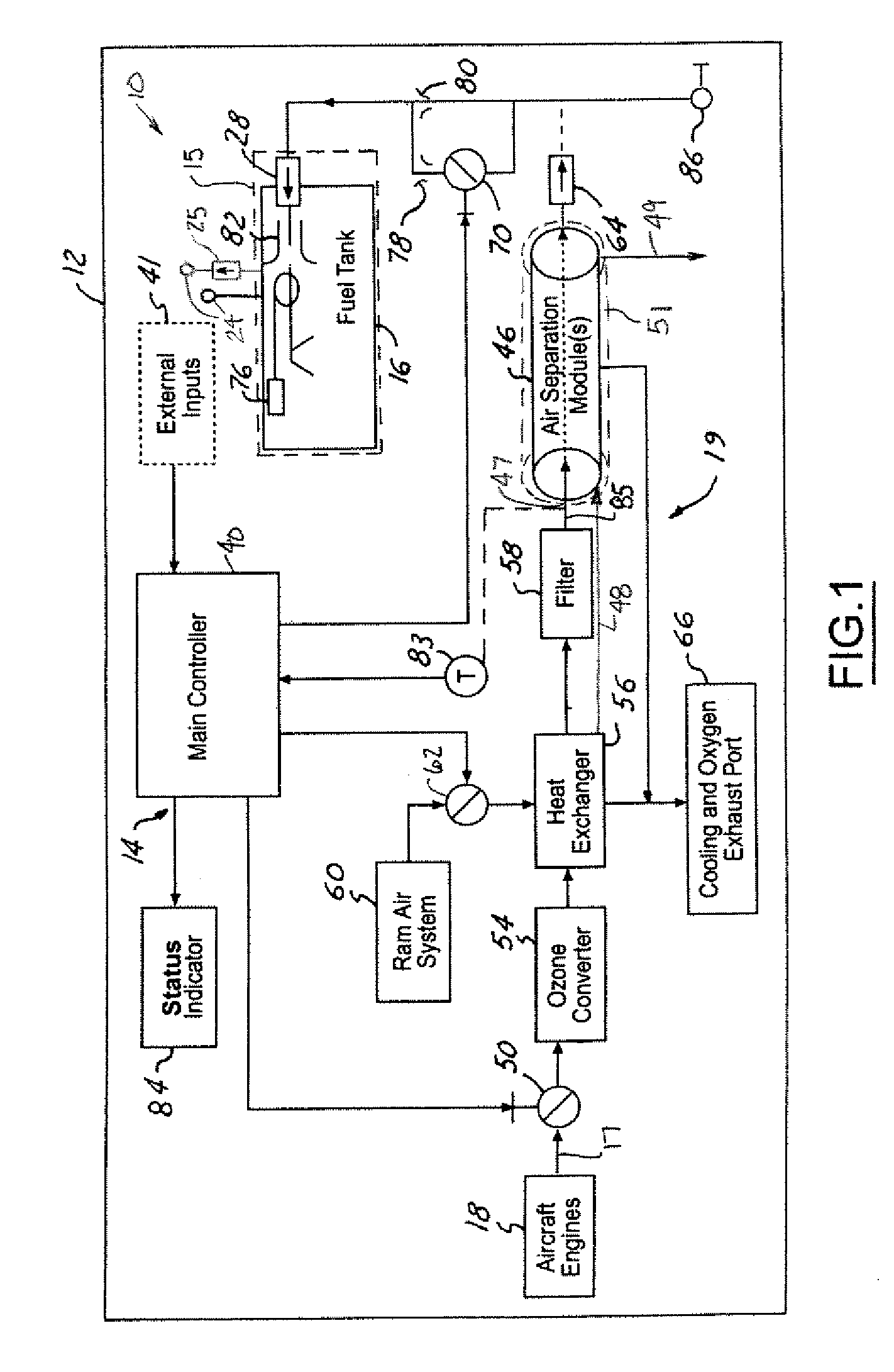

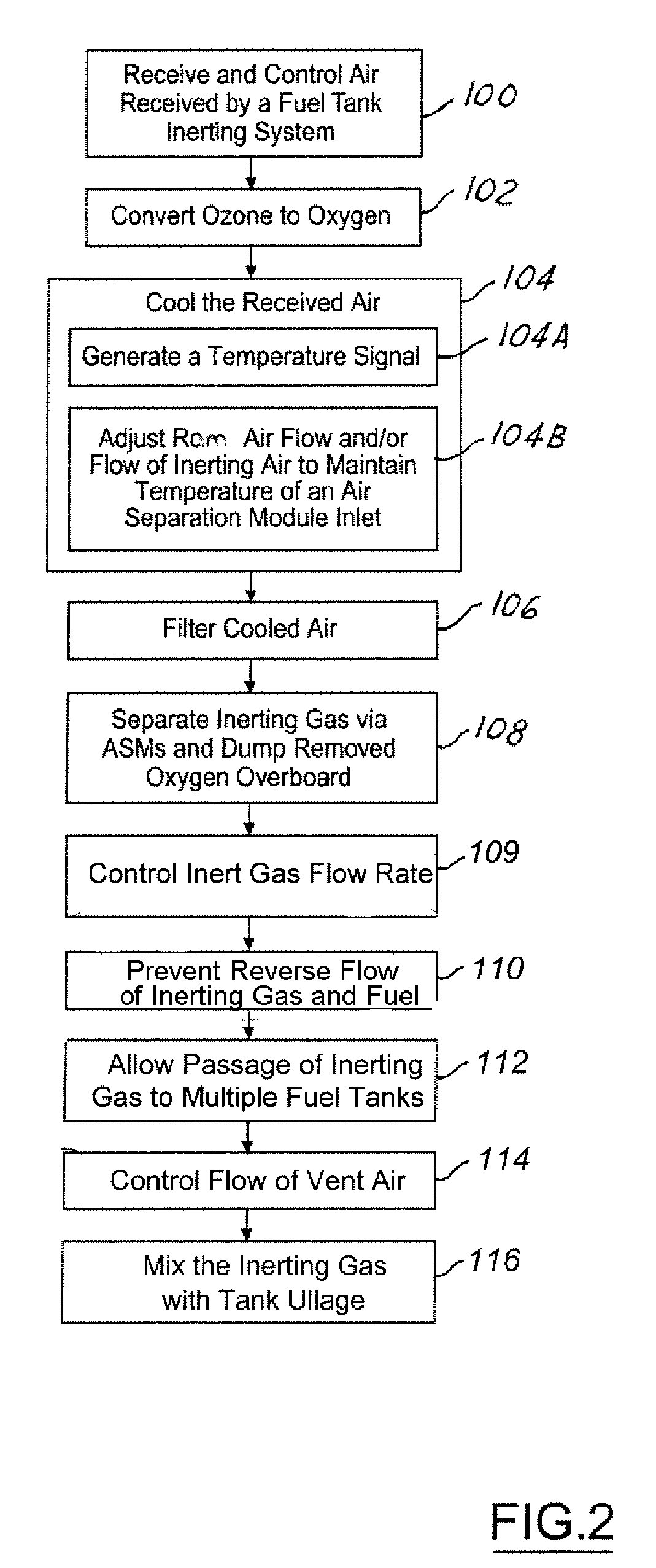

Commercial aircraft on-board inerting system

ActiveUS7152635B2Reduce flammabilityImprove flammabilityLiquid fillingPower plant fuel tanksInerting systemOn board

An inerting system (10) for an aircraft (12) includes one or more fuel tank circuits (15) associated with fuel tanks (16). An air source (17) supplies pressurized air. A heat exchanger (56) cools the pressurized air. An air separation module (46) is in fluid communication with the heat exchanger (56) and separates inerting gas from the pressurized air. A controller (40) controls flow of the inerting gas from the air separation module (46) to the fuel tanks (16).

Owner:THE BOEING CO

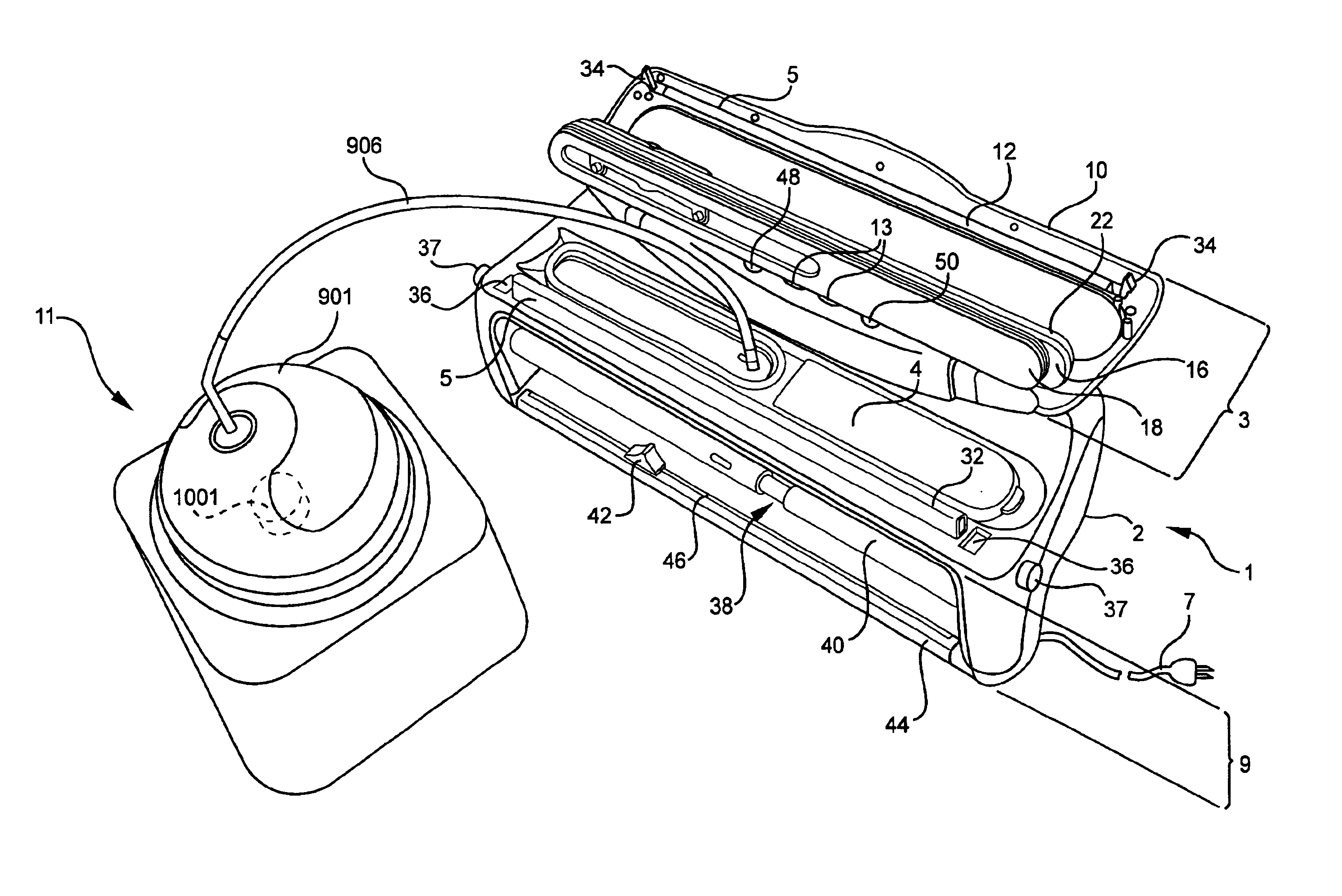

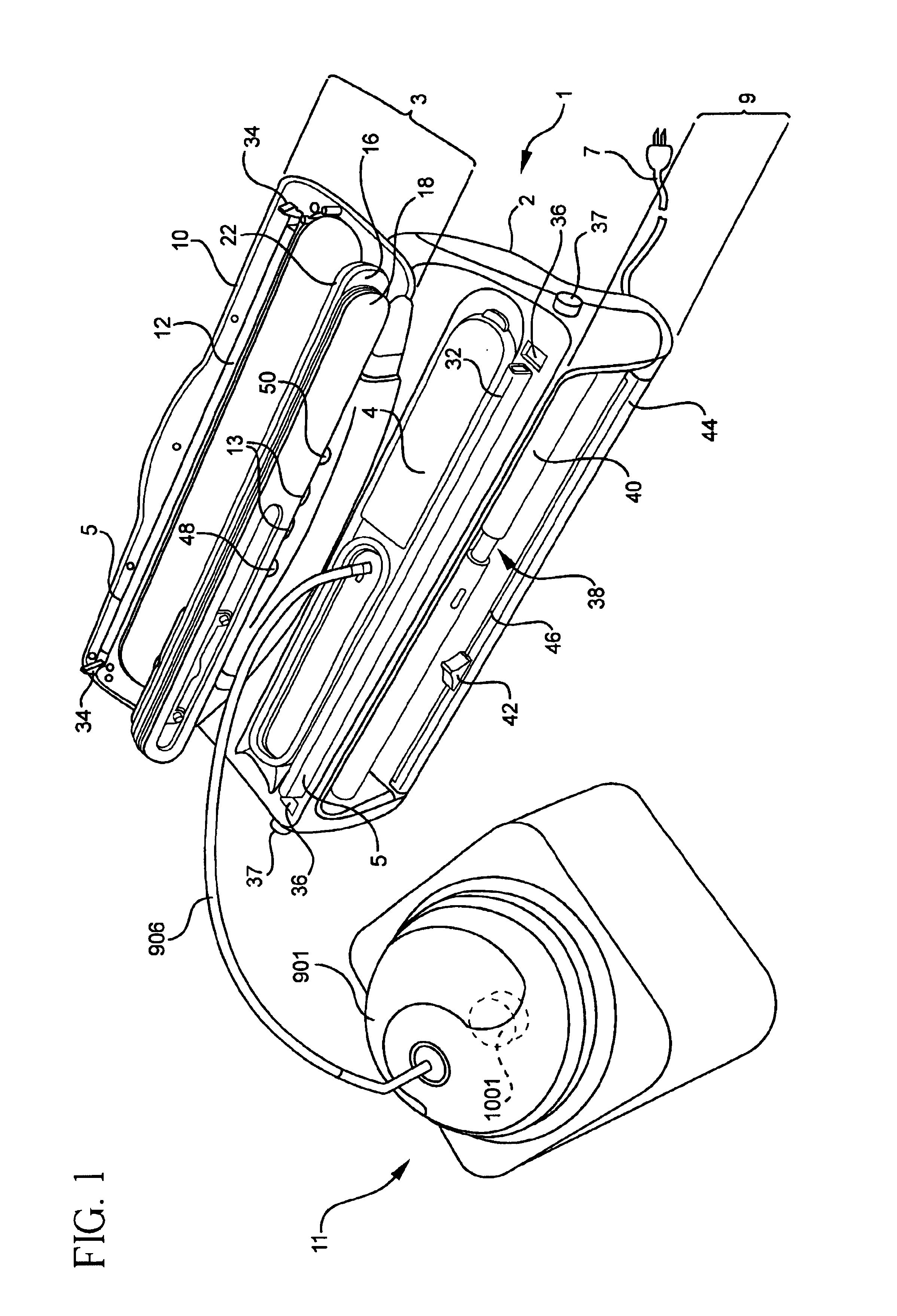

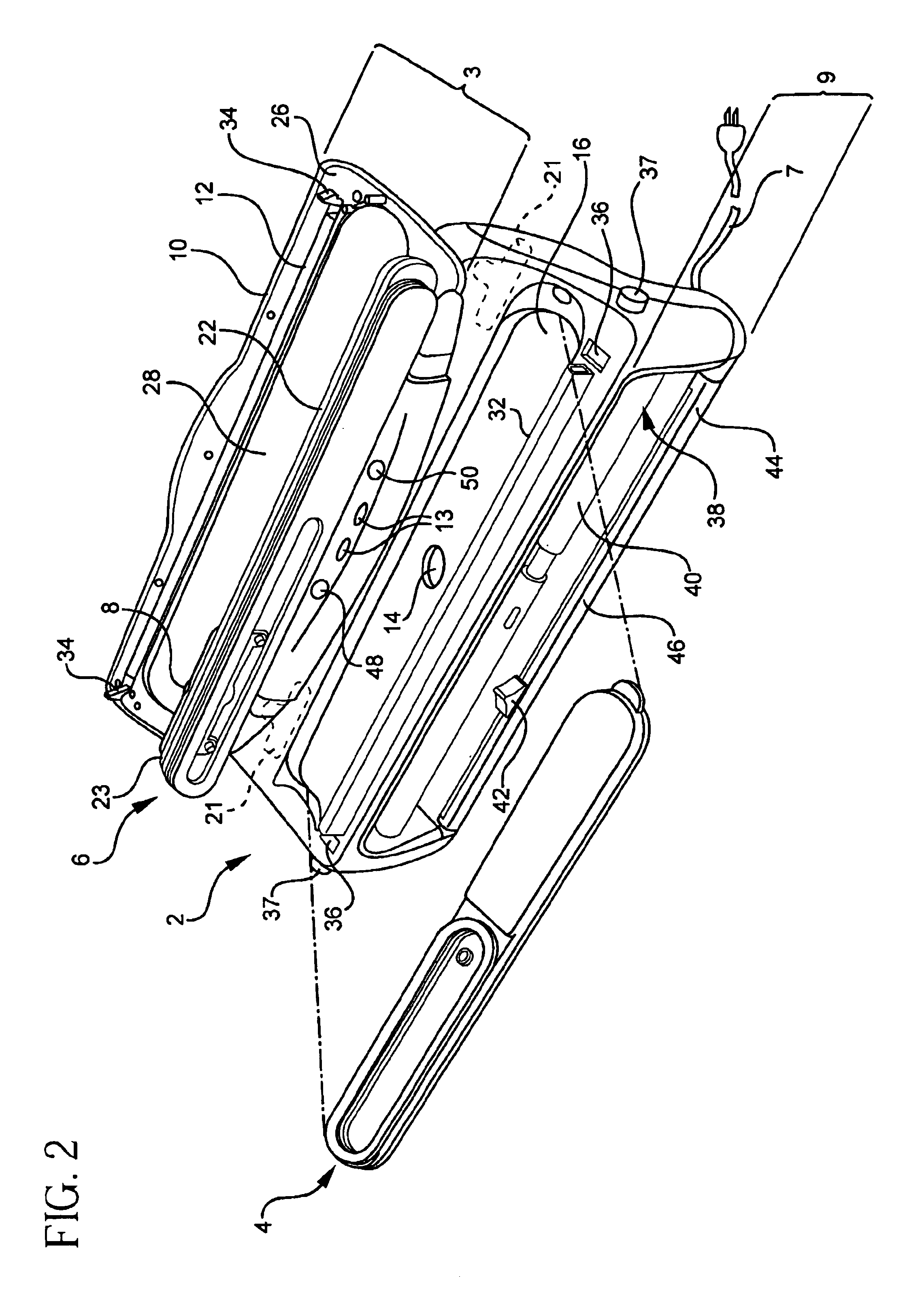

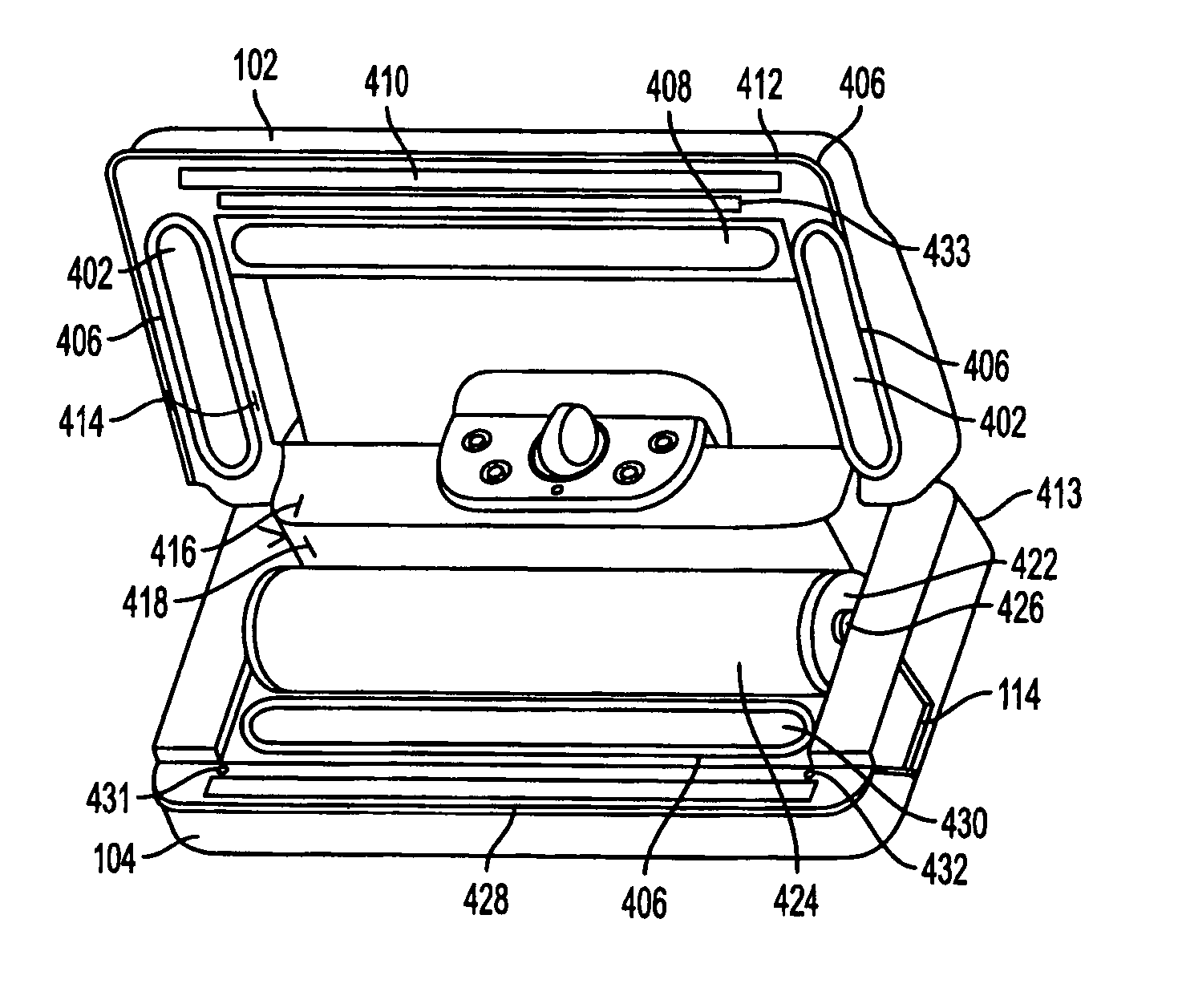

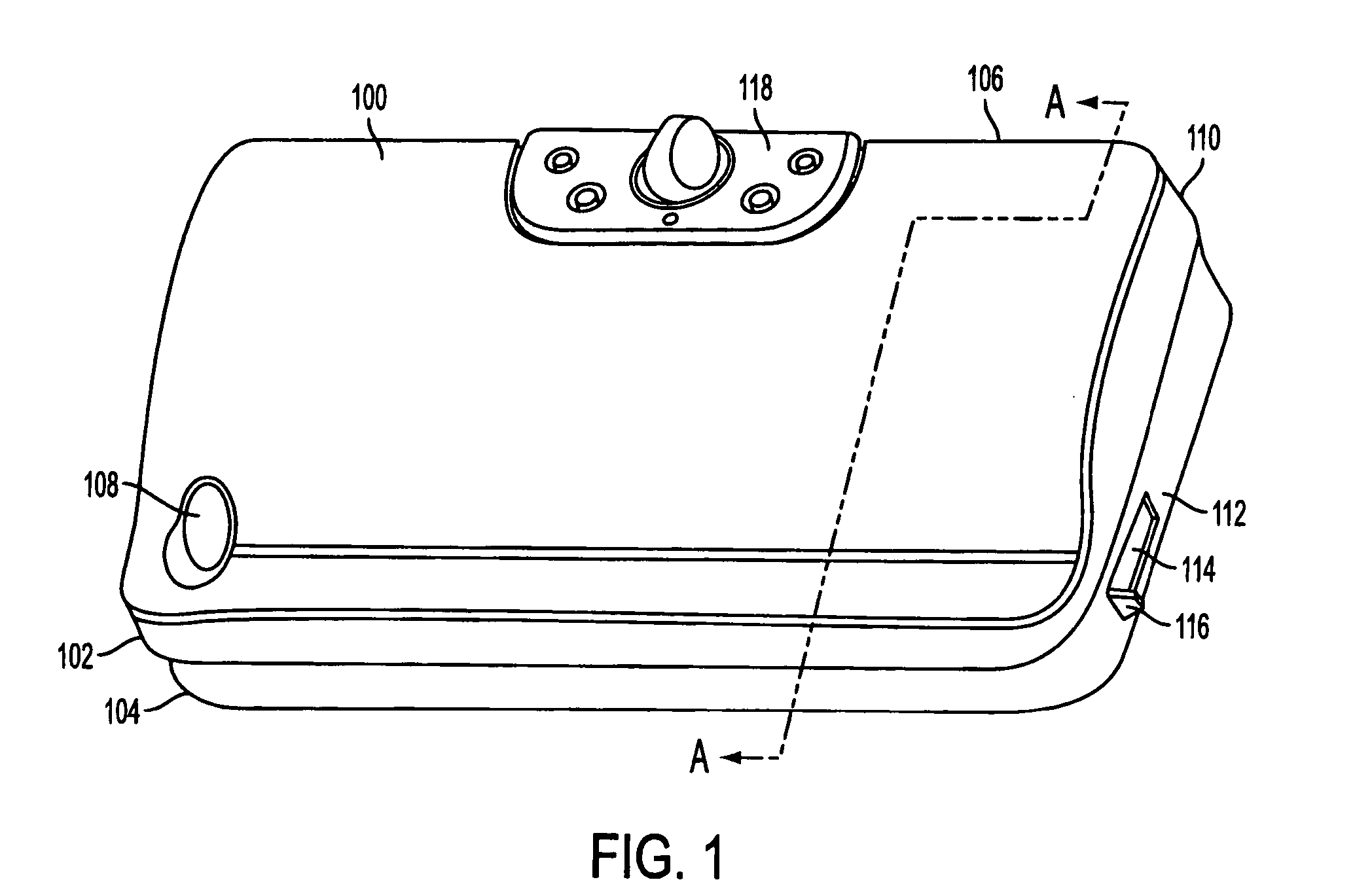

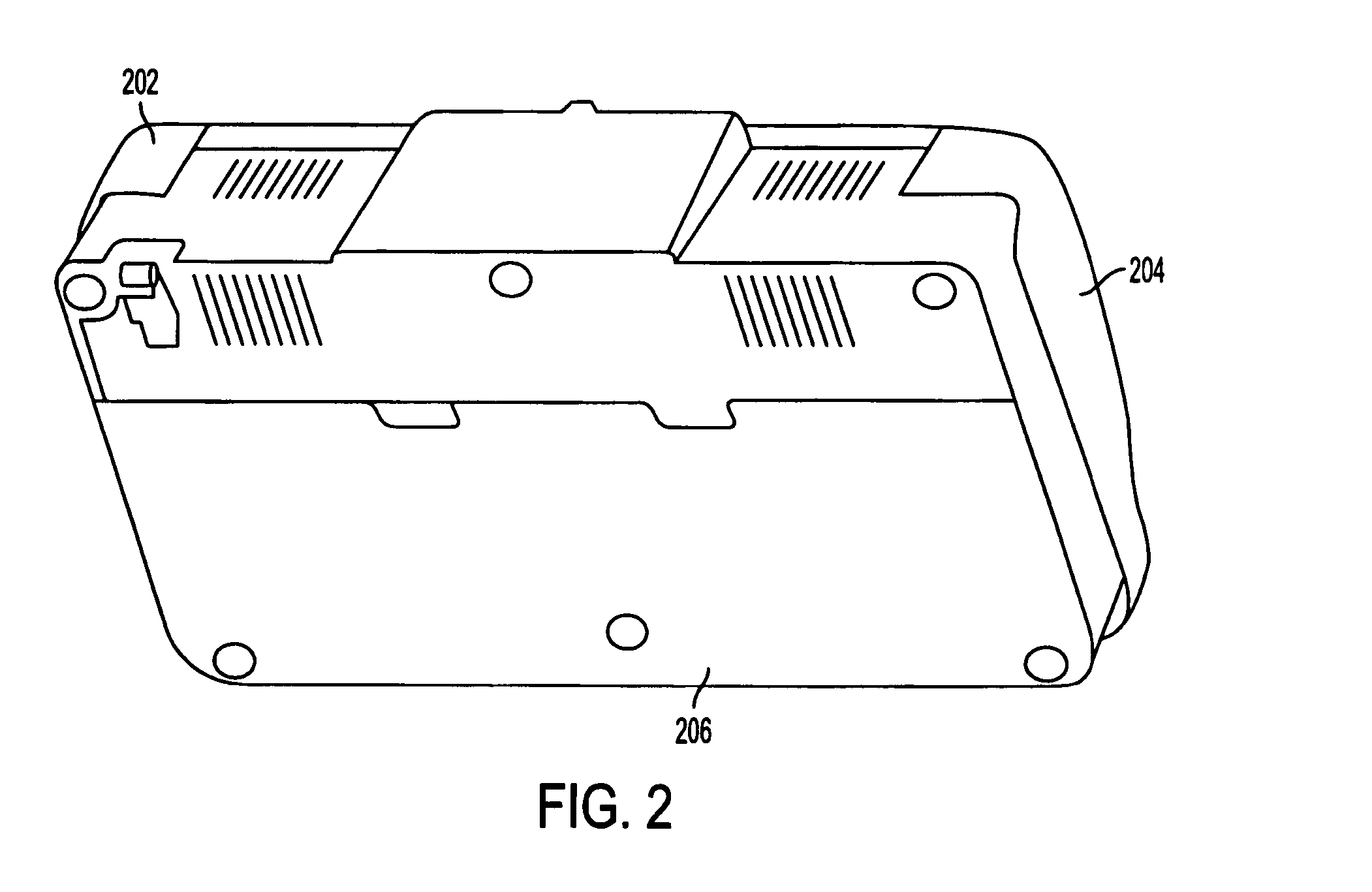

Appliance for vacuum sealing food containers

A system for evacuating containers. The system includes a base housing defining a recess having a vacuum inlet port in communication with a vacuum source. An inner door is hinged to the base housing and is sized to cover the recess when in a closed position, and an outer door having a sealing member is hinged to close over the inner door. A vacuum nozzle extends at least partially between the inner and outer doors and is in communication with the recess. The inner and outer doors cooperate to retain a flexible container therebetween and around the nozzle so that the nozzle is positioned for fluid communication with an inside of the container. A removable drip pan is positioned to retain fluids drawn by the nozzle.

Owner:HOLMES GRP THE

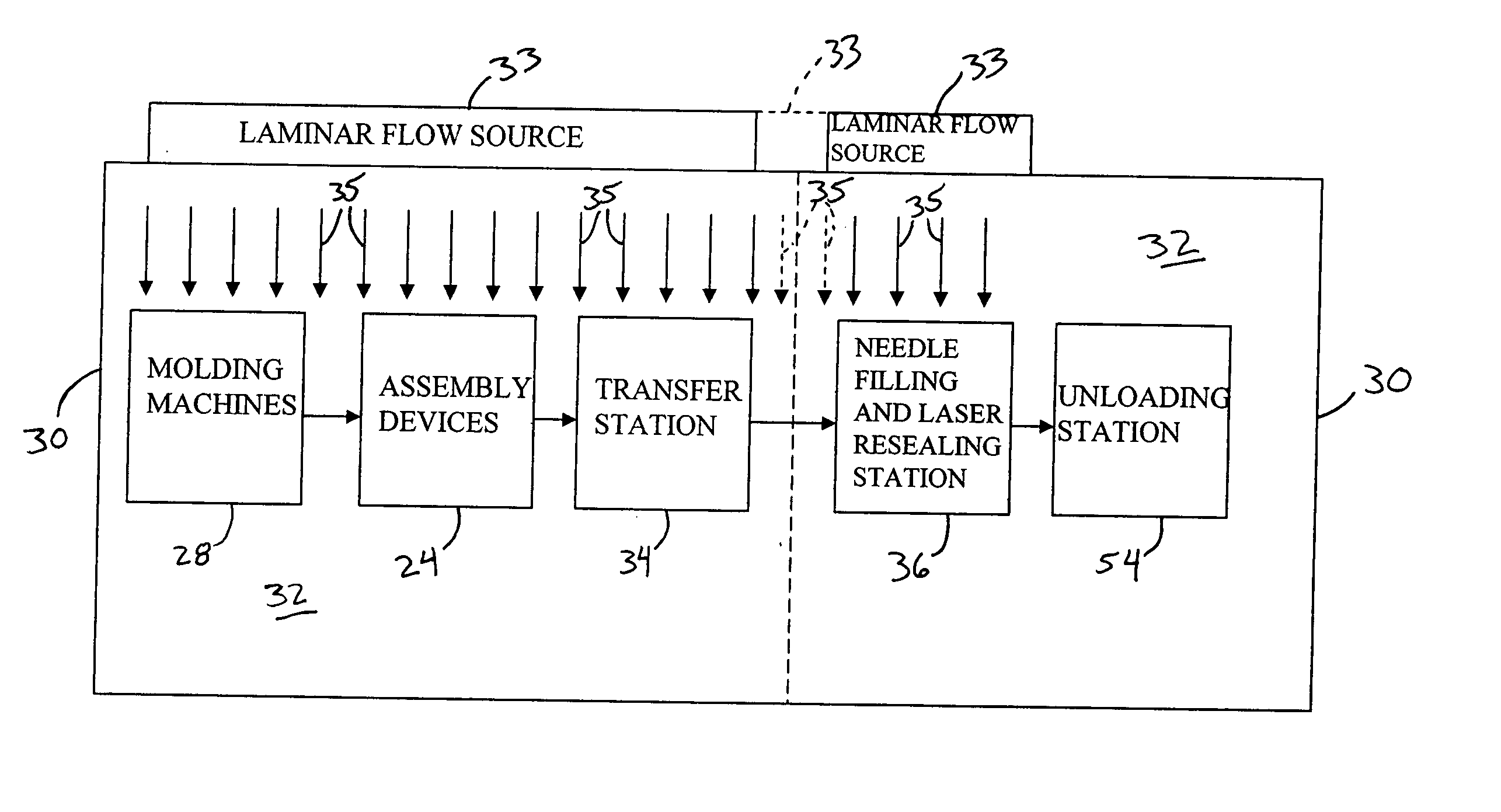

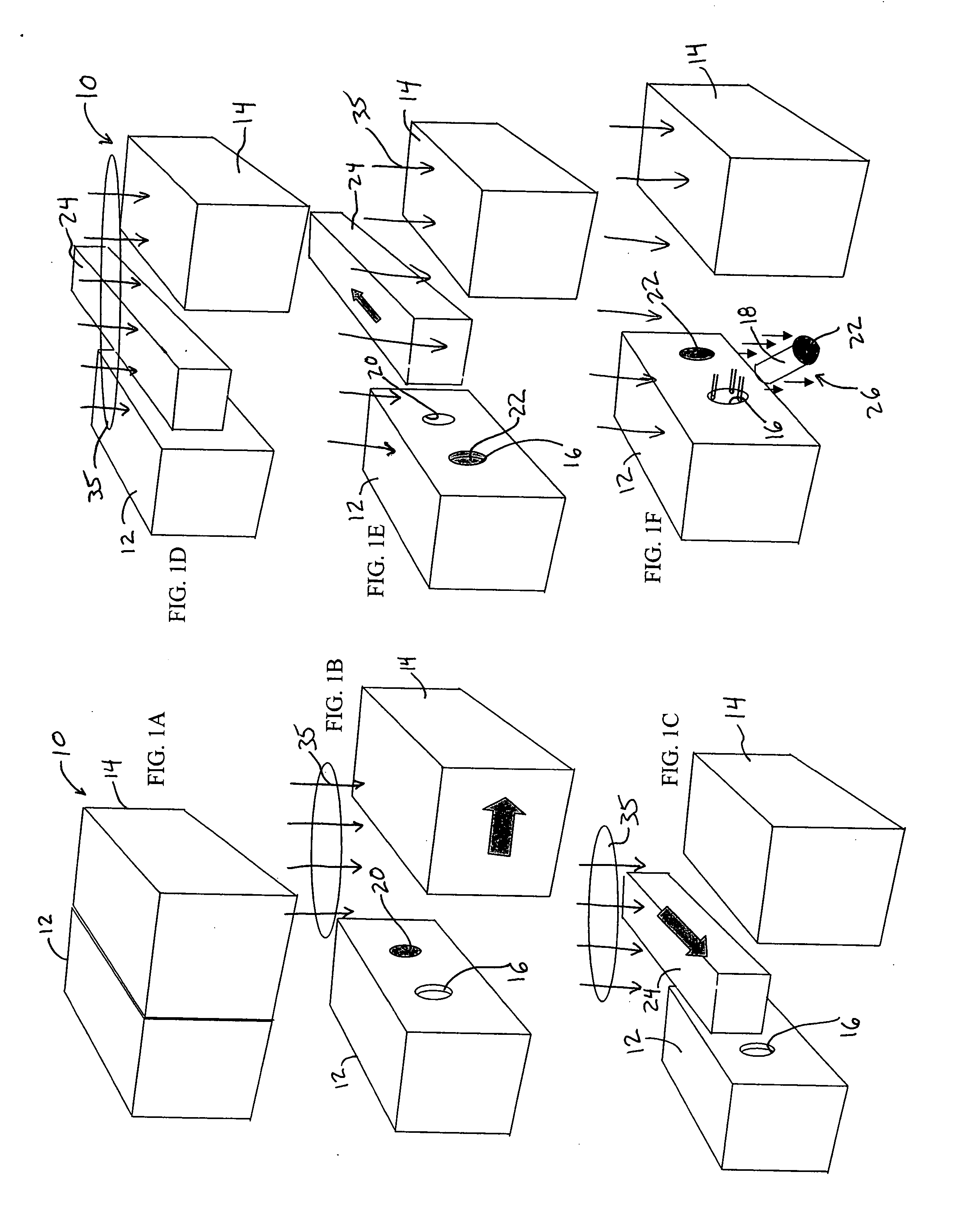

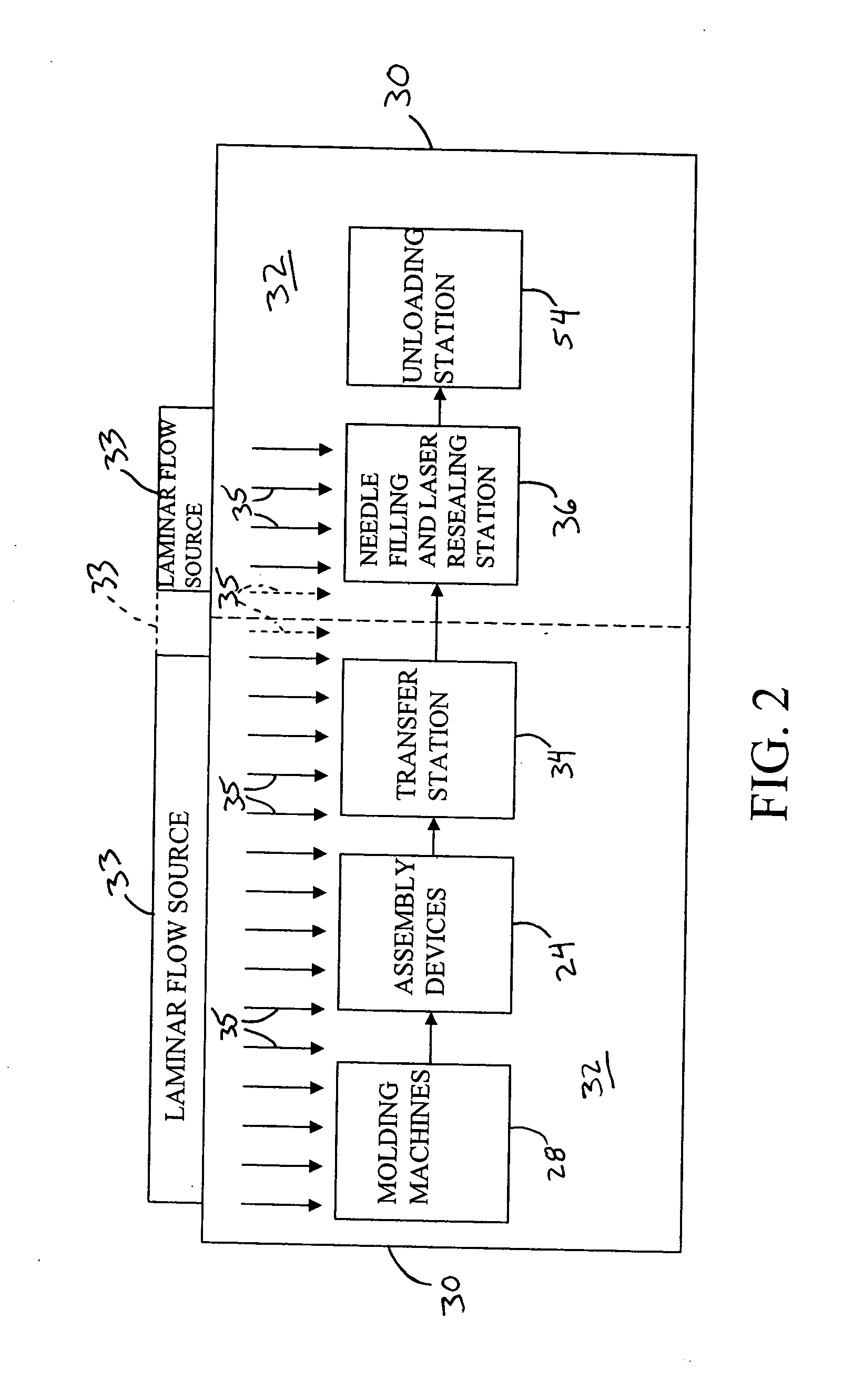

Method for molding and assembling containers with stoppers and filling same

A stopper and container body are molded in the same molding machine. An assembly device, such as a pick and place robot, transfers the stopper from one mold cavity into the opening in the container body located within another mold cavity, or vice versa, to assemble the stopper and container body. Then, the assembled container body and stopper are removed from the molding machine and transported to a needle filling and laser resealing station for filling and laser resealing. A laminar flow source directs a substantially laminar flow of air or sterile gas over the mold surfaces, stoppers and container bodies, and assembly device, to prevent contamination during assembly.

Owner:MEDINSTILL DEV

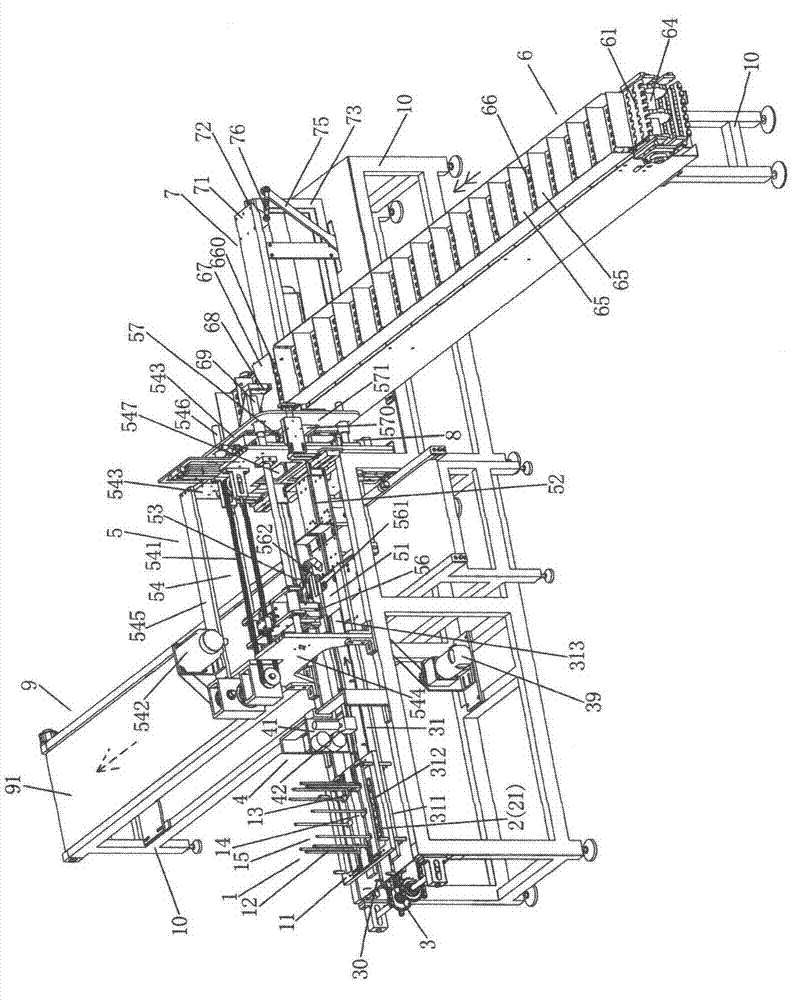

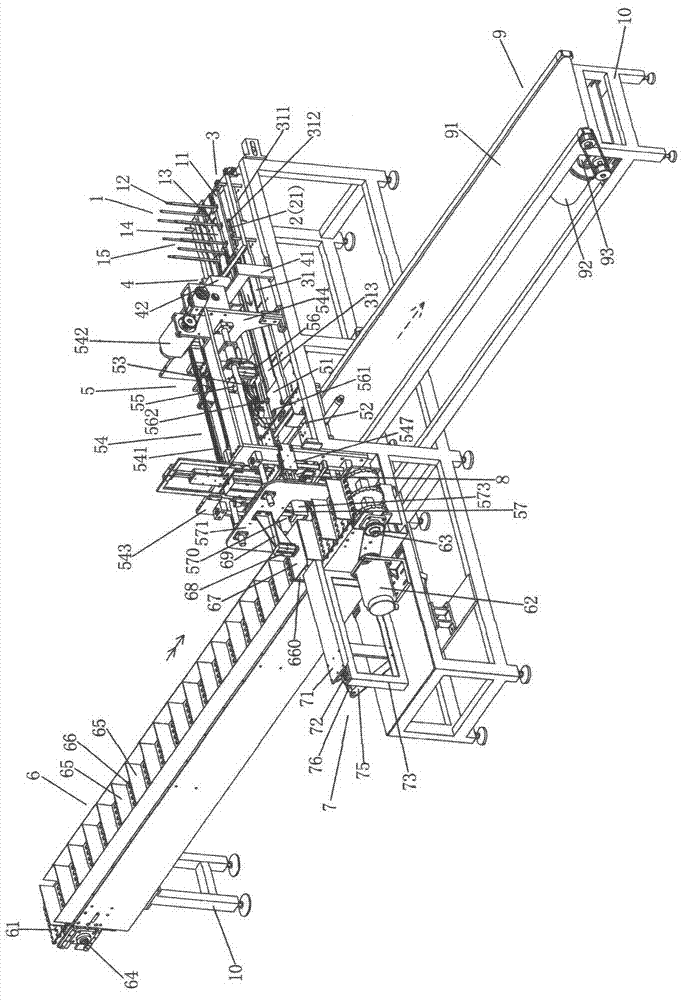

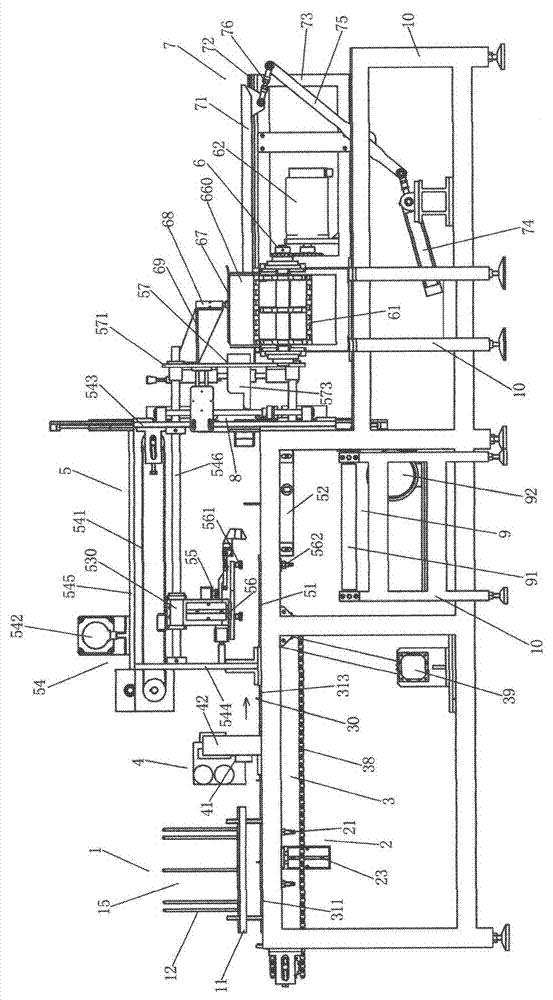

Bag-feeding pillow type packaging machine

ActiveCN103241409AHigh degree of automationIncrease productivityPackaging by pressurising/gasifyingWrapper twisting/gatheringEngineeringPackaging machine

Disclosed is a bag-feeding pillow type packaging machine. A horizontal bag conveyor is disposed between a bag feeder and a horizontal bag opener. A feeding part of the horizontal bag conveyor is located below the bag feeder. A discharge part of the horizontal bag conveyor is connected with the rear end of the horizontal bag opener. A bag picker is located below the horizontal bag conveyor. The bag picker extends into the bag feeder through the feeding part of the horizontal bag conveyor. The horizontal bag opener is disposed on the conveying direction of the horizontal bag conveyor, a conveying device is disposed in front of the horizontal bag opener, the conveying direction of the conveying device is perpendicular to that of the horizontal bag conveyor, a horizontal feeding device is disposed on one side of the conveying device and located on the conveying direction of the horizontal bag conveyor, a motion direction of the horizontal feeding device is perpendicular to the conveying direction of the conveying device, a sealing device is disposed on the horizontal bag opener, a finished product output device is disposed below the horizontal bag opener, and the conveying direction of the finished product output device is perpendicular to that of the horizontal bag conveyor.

Owner:广东宏川环宇智能装备有限公司

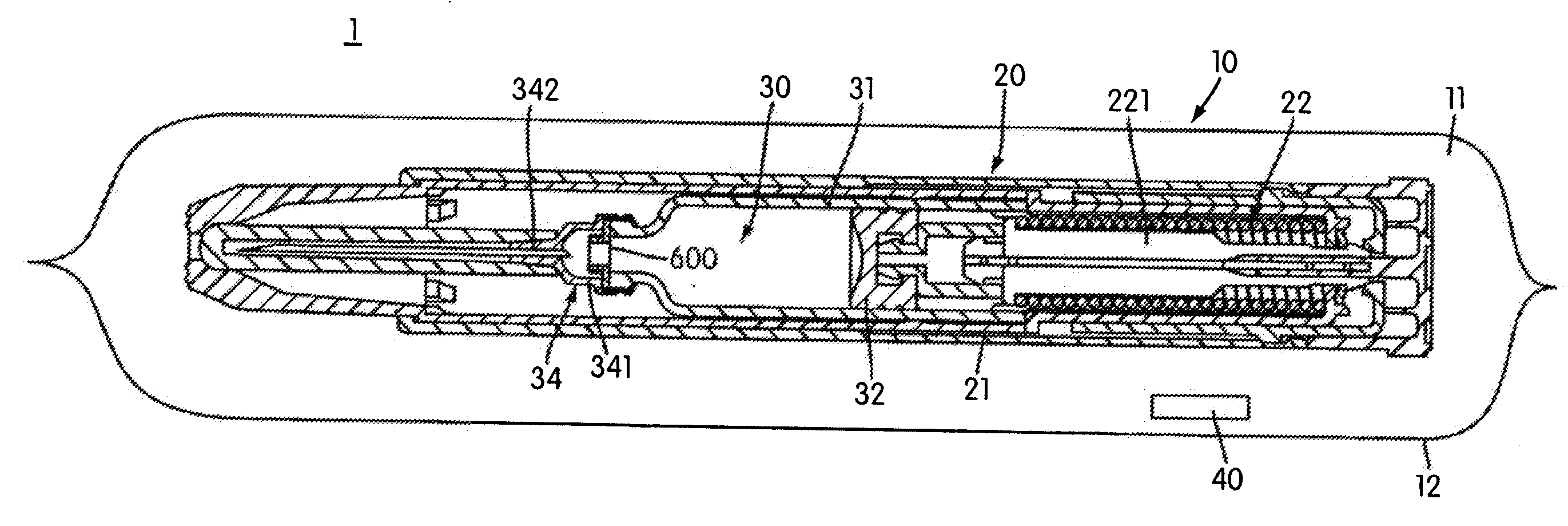

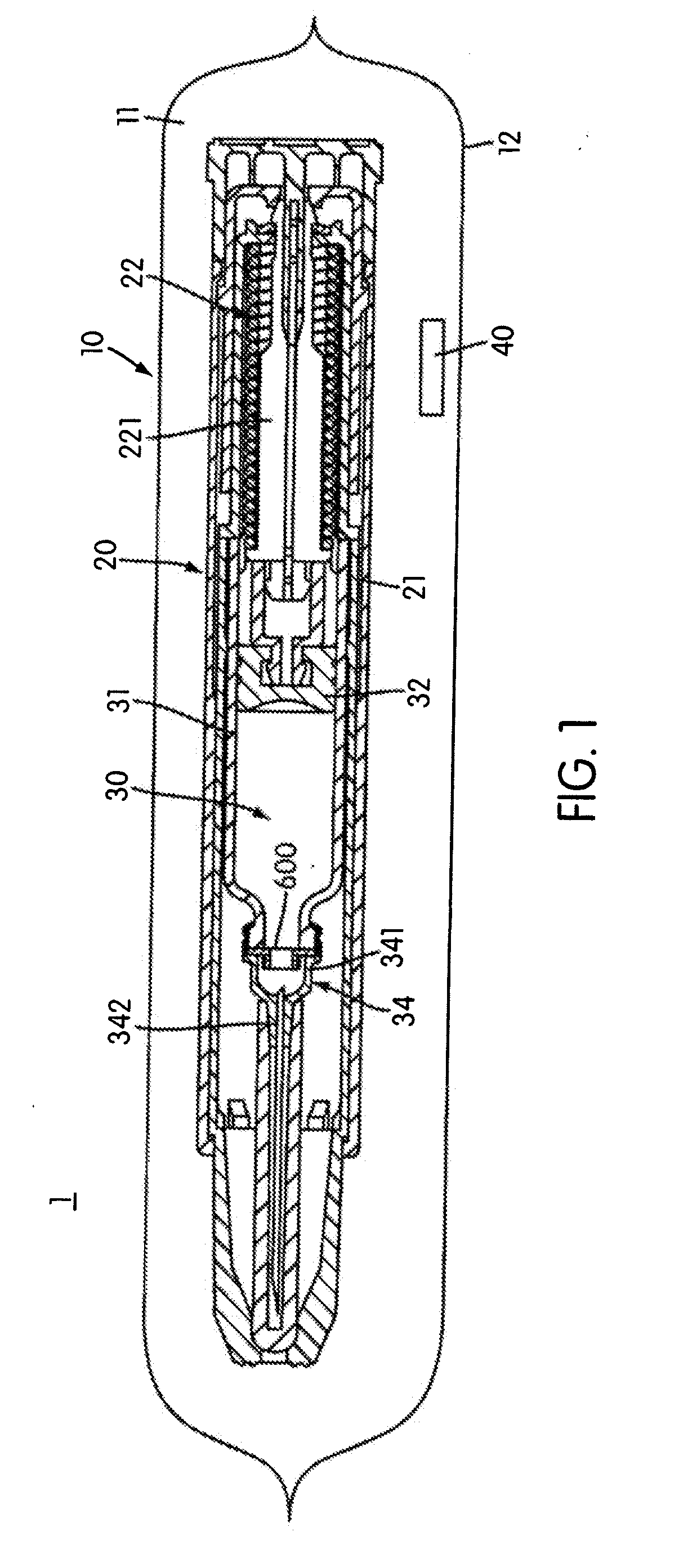

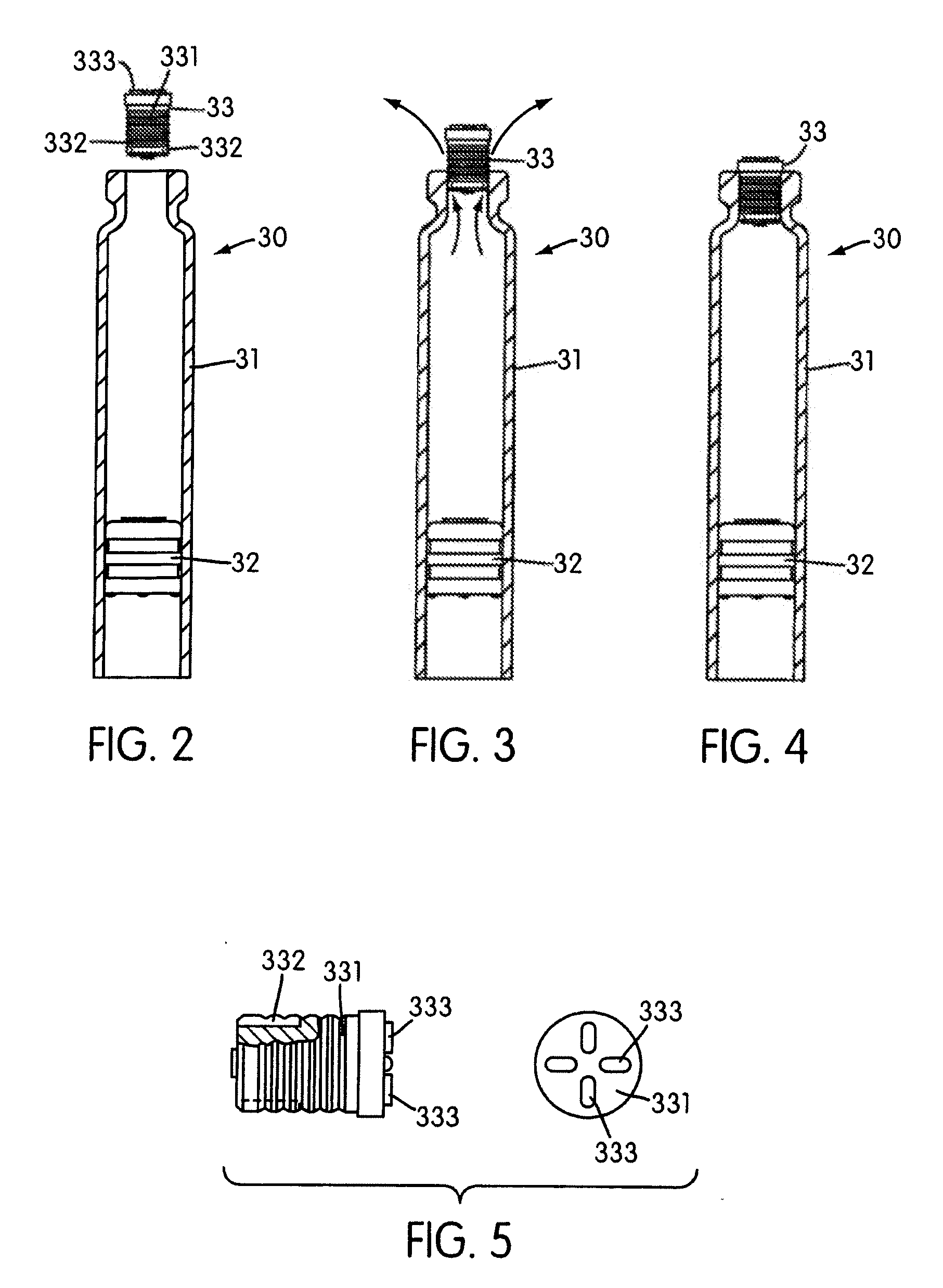

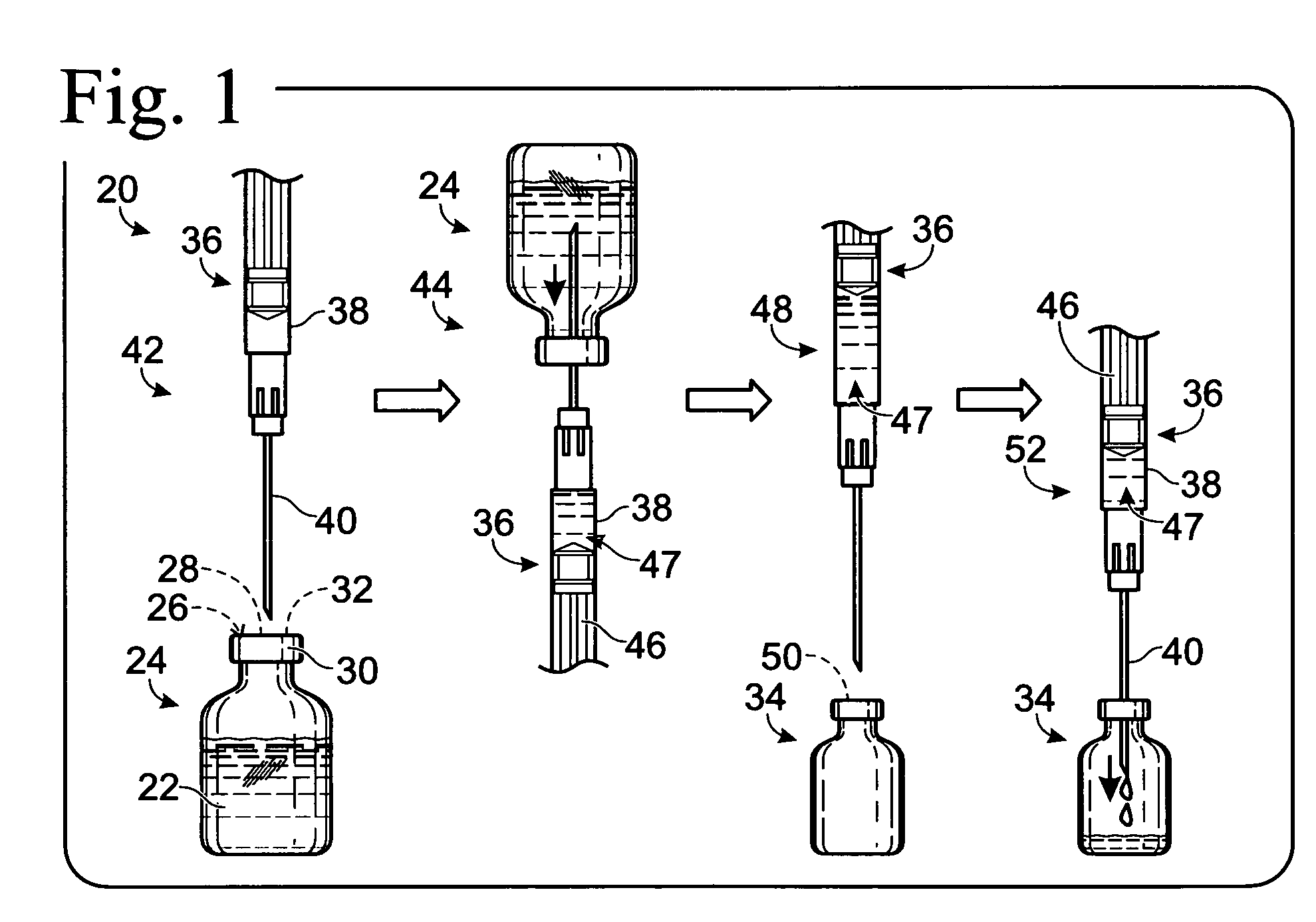

Methods of venting, sealing, and dispensing from a medicament container

InactiveUS20100174268A1Minimizes exposure to oxygenEasy to manageAmpoule syringesJet injection syringesBiomedical engineeringDrug

A sealing assembly movable within an opening of a medicament container allows (1) gases to be vented from the container, (2) medication to be stored in the container, and (3) medication to be dispensed from the container. Methods of limiting exposure of the medication to oxygen to prevent degradation of the medication while in the medicament container are also disclosed.

Owner:MERIDIAN MEDICAL TECH

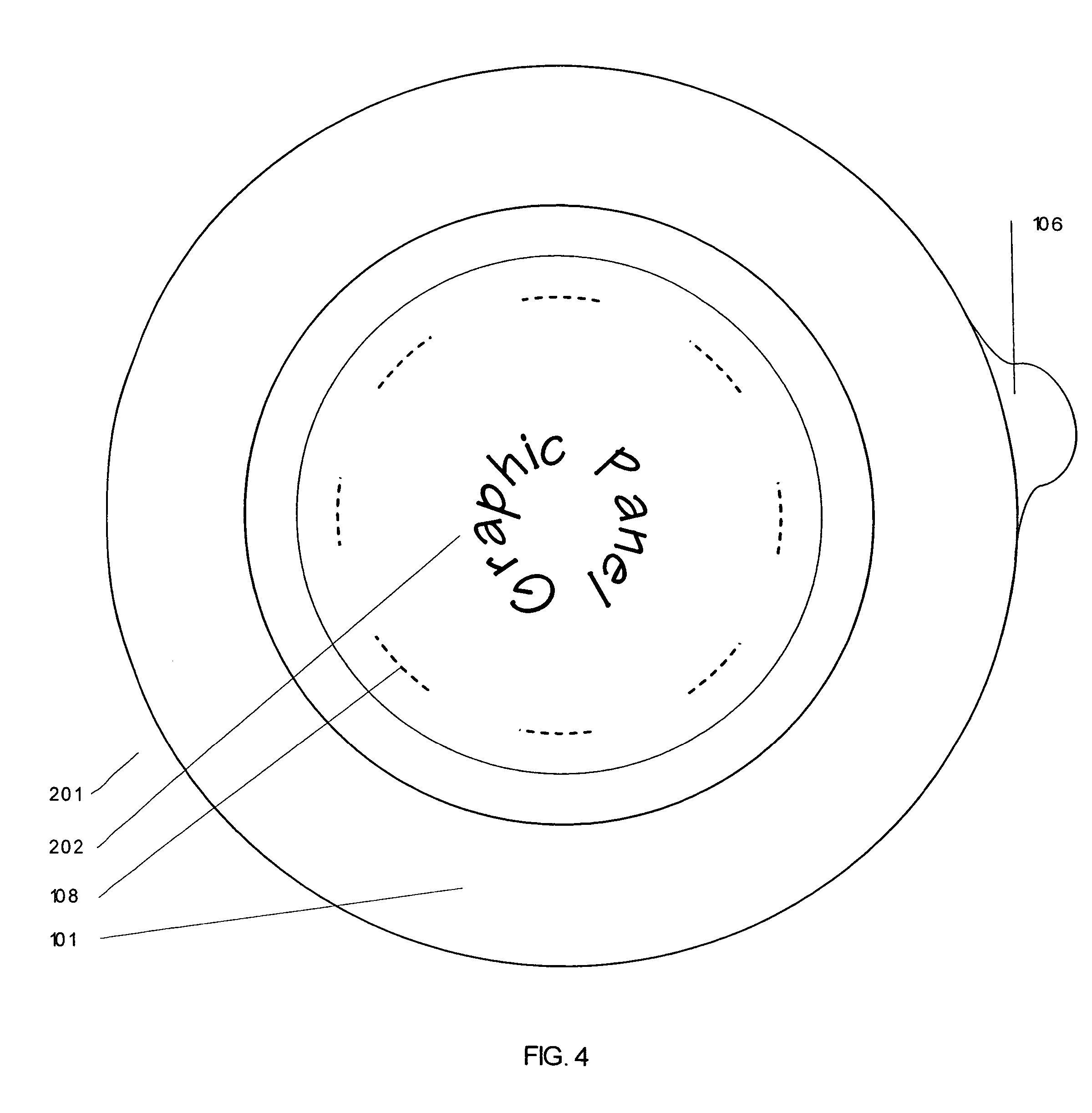

Method And Apparatus For Inflating And Sealing Packing Cushions Employing Film Recognition Controller

An apparatus for inflating and sealing packing cushions utilizes a controller adapted for acquiring information from preconfigured film material and automatically setting one or more operation parameters suitable for inflating and sealing the film. The controller can avoid or limit the need for user input, thus simplifying use of the apparatus.

Owner:PREGIS INNOVATIVE PACKAGING

Fluid sensing in a drip tray

InactiveUS20050039420A1Enhances heat sealing operationQuantity minimizationCapsCapping machinery safety/controlCapacitanceElectrical resistance and conductance

A vacuum packaging appliance that detects the amount of liquid present while evacuating and sealing a container is disclosed. The appliance comprises a lid adapted to define a vacuum chamber when it is moved to a closed position relative to a trough in the base of the device. The trough in the lower portion of the device contains a heat-sealing element used to seal the contents of the bag once the vacuum packaging is complete. Disclosed are several embodiments relating to a liquid sensor molded into the walls of the trough. The liquid sensor comprises two electrodes that may be located on opposite sides of the trough or on the same side of the trough. When liquid is present in the trough, the capacitance and resistance between the electrodes changes, thereby sending a signal to a controller indicative of the amount of liquid within the trough while the container is being evacuated. The exact amount of liquid present is compared to a predetermined level of liquid. A vacuum pump controller may suspend operations if the amount of detected liquid exceeds a predetermined amount. The heat-sealing element is also controlled in accordance with the amount of liquid sensed in the trough. The amount of liquid sensed is also indicated to the operator.

Owner:TILIA INT INC

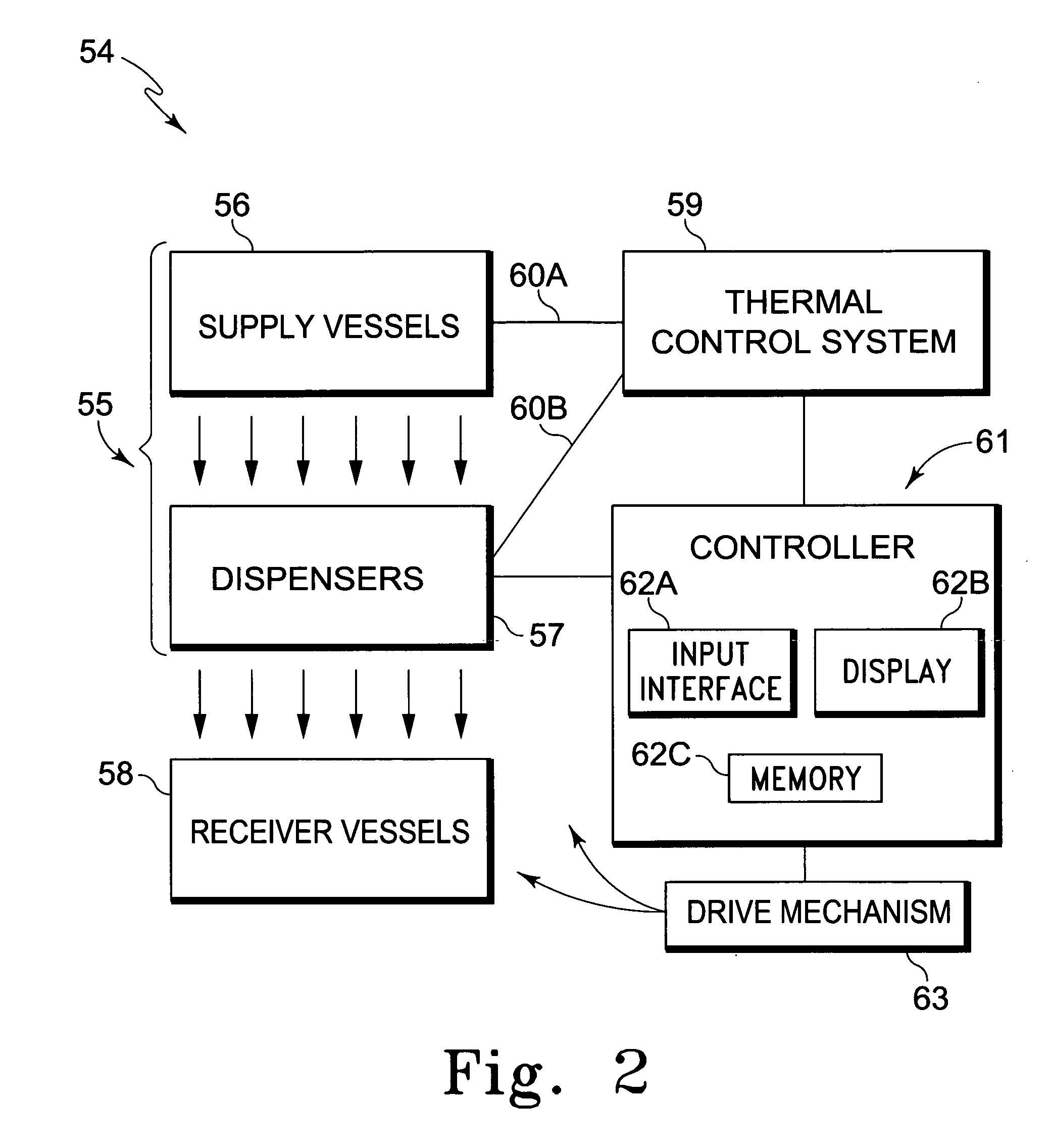

System for dispensing biological fluids

InactiveUS20090145509A1Reduce sensitivityEasy to controlPharmaceutical containersMedical packagingBiological fluidsBiomedical engineering

Owner:EXSCRIBE

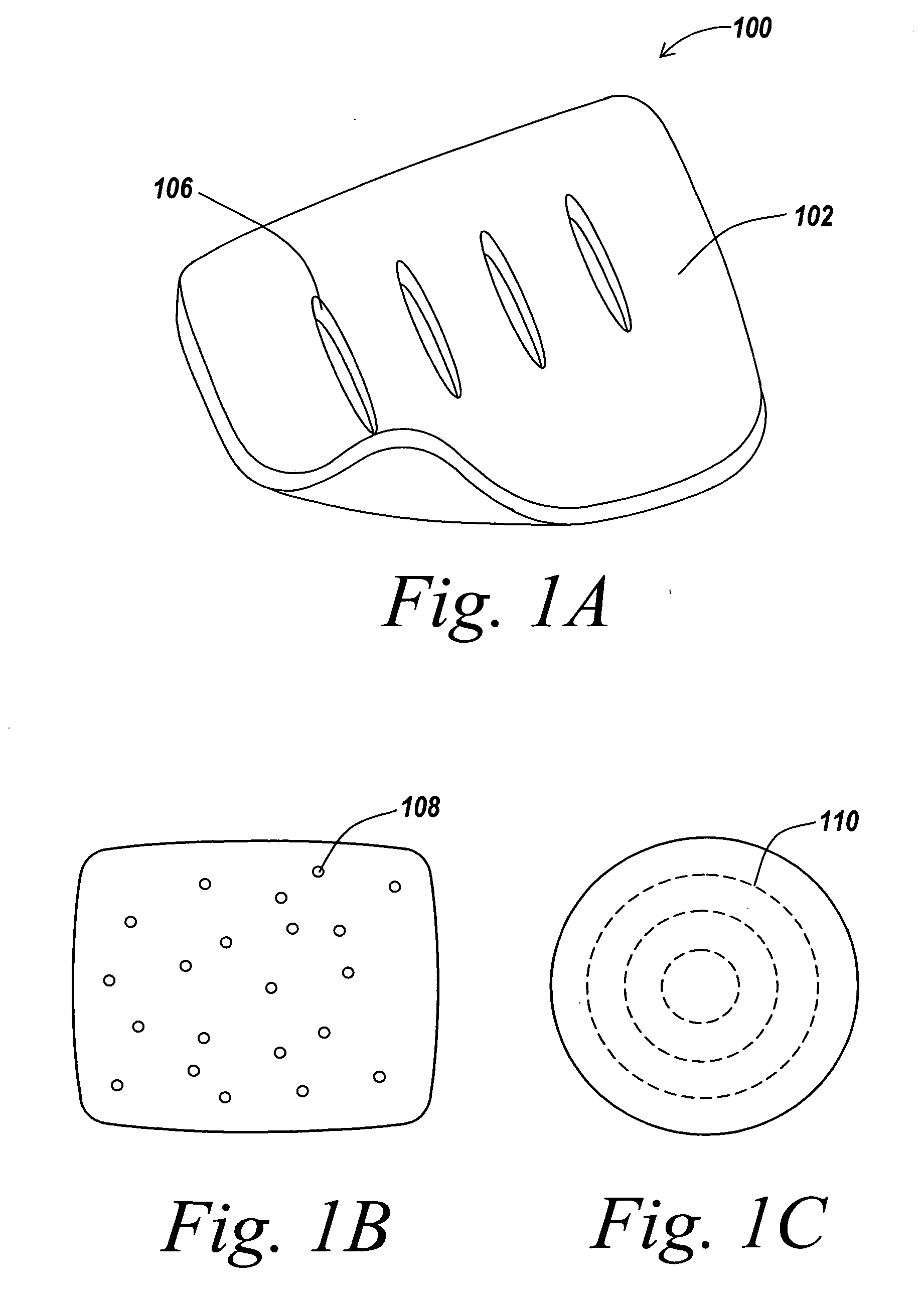

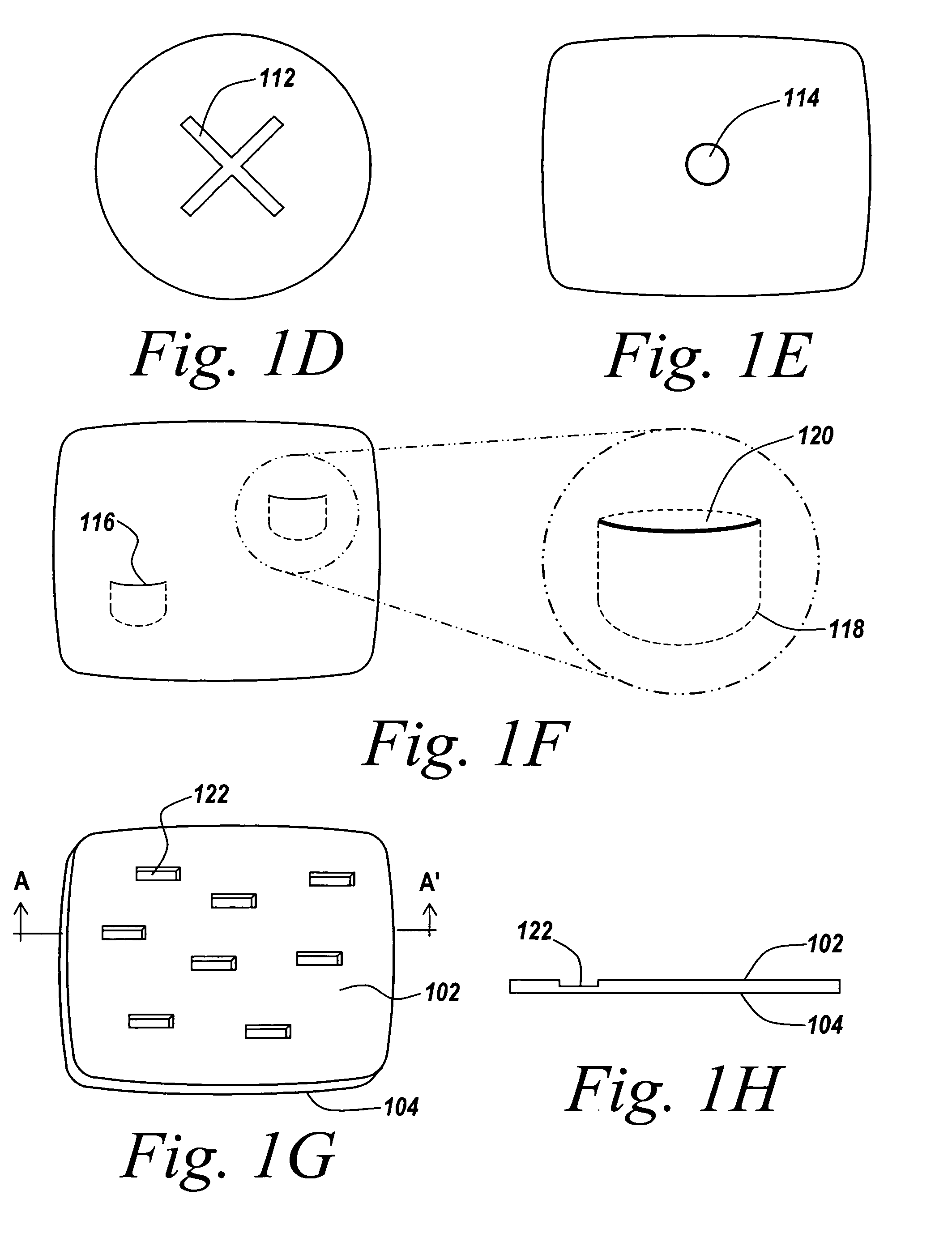

Perforated bioabsorbable oil film and methods for making the same

ActiveUS20070071798A1Improve bioabsorptionMaintain propertiesCosmetic implantsDiagnosticsWound healingMedicine

A bio-absorbable stand-alone film is derived at least in part from fatty acids. The bio-absorbable stand-alone film can have anti-adhesive, anti-inflammatory, non-inflammatory, and wound healing properties, and can additionally include one or more therapeutic agents incorporated therein. The stand-alone film has one or more perforations or depressions formed therein. Corresponding methods of making the bio-absorbable stand-alone film with one or more perforations or depressions include molding, cutting, carving, puncturing or otherwise suitable methods to create the perforations or depressions in the bio-absorbable stand-alone film. The resulting stand-alone film is bioabsorbable.

Owner:ATRIUM MEDICAL

Vacuum packaging system

InactiveUS20050205455A1Precise positioningAvoid drawingEnvelopes/bags making machineryBag making operationsHand heldFront loading

A system for vacuum packaging foods and other perishable items, including a front loading appliance and a hand held appliance. A multiple stage vacuum and sealing process enhances performance. Low cost vacuum bags are formed using a continuous process. A visible indicator assures consumers that a safe level of vacuum has been reached and maintained.

Owner:HARRISON HOWARD ROBERT

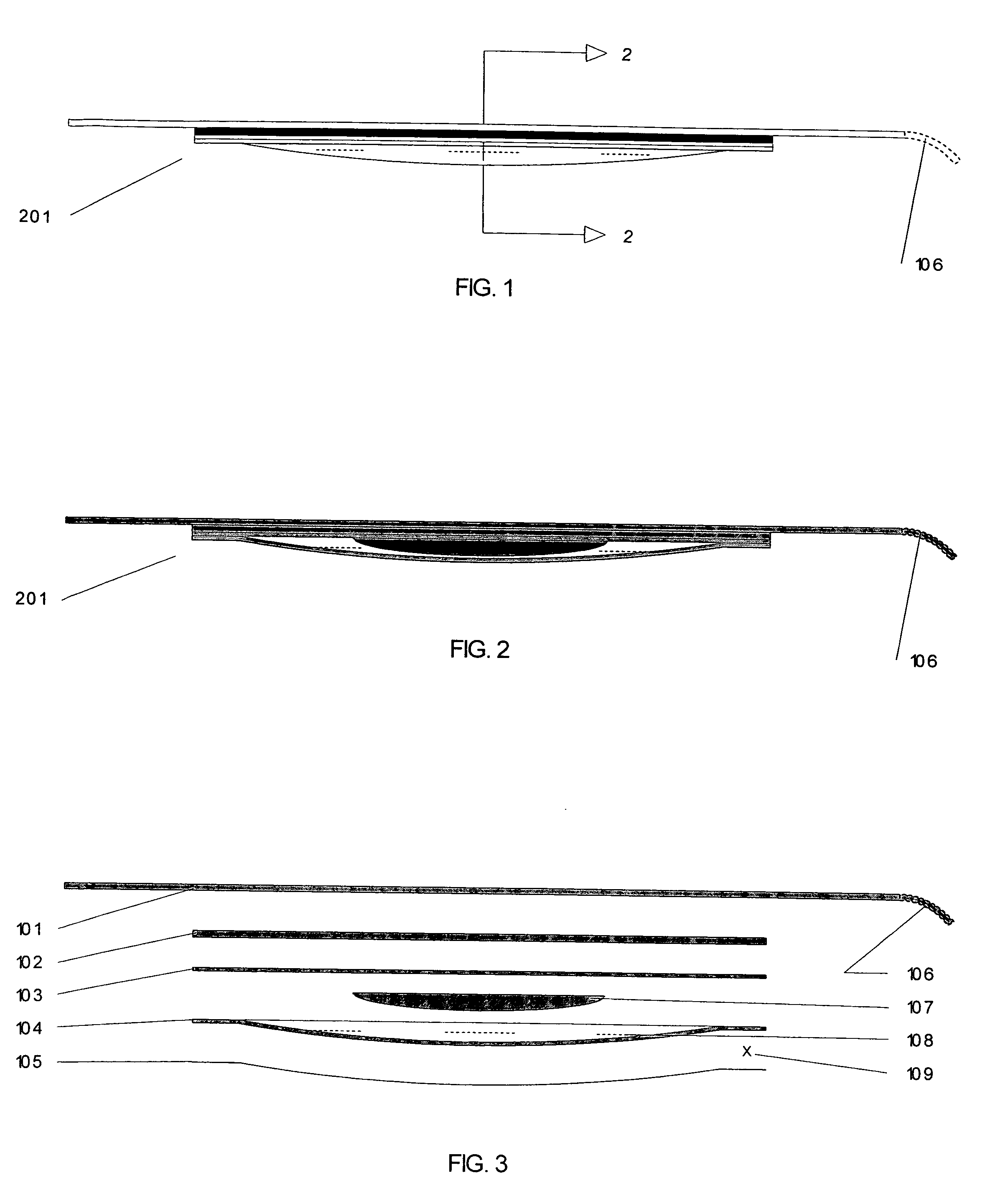

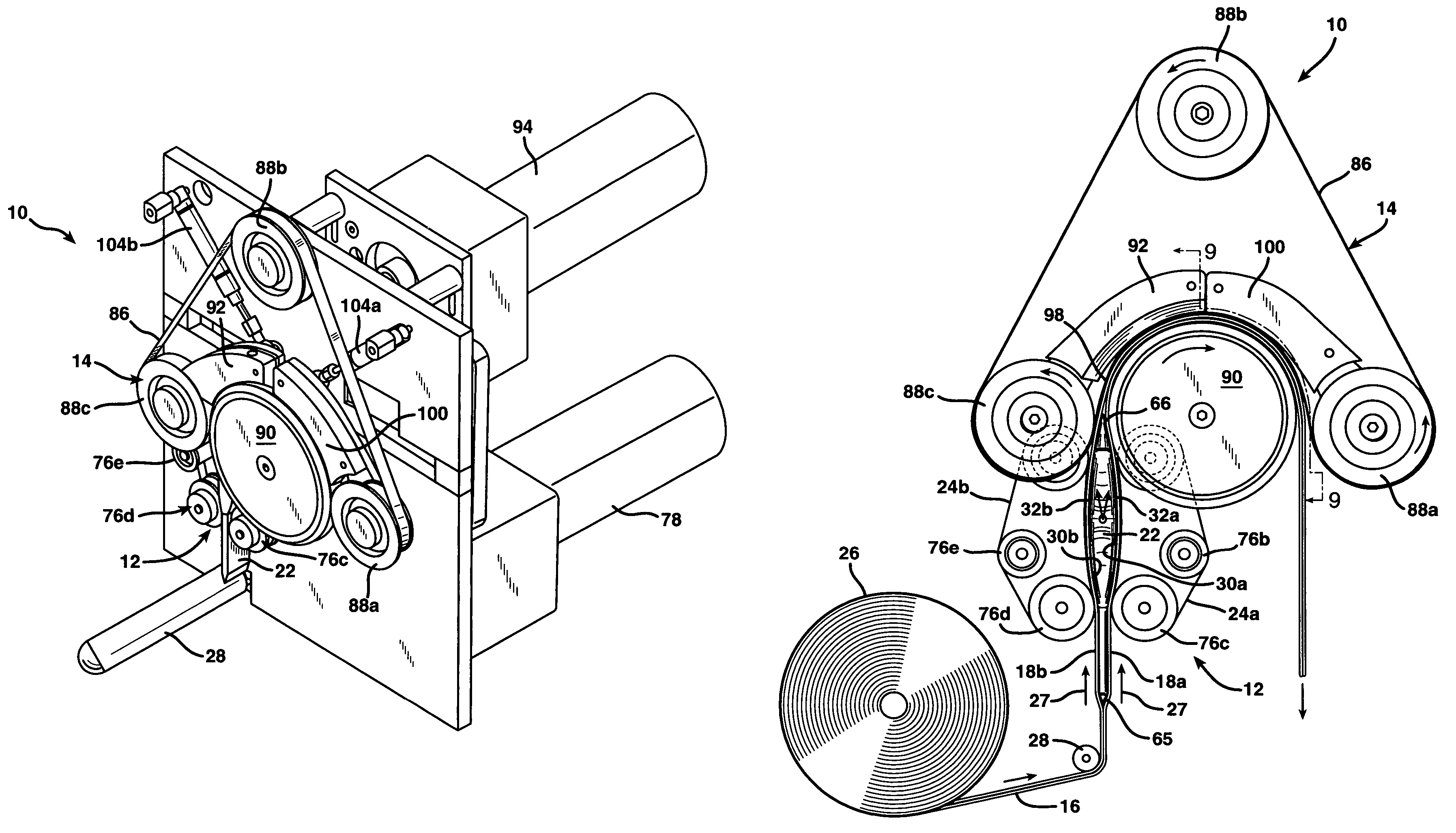

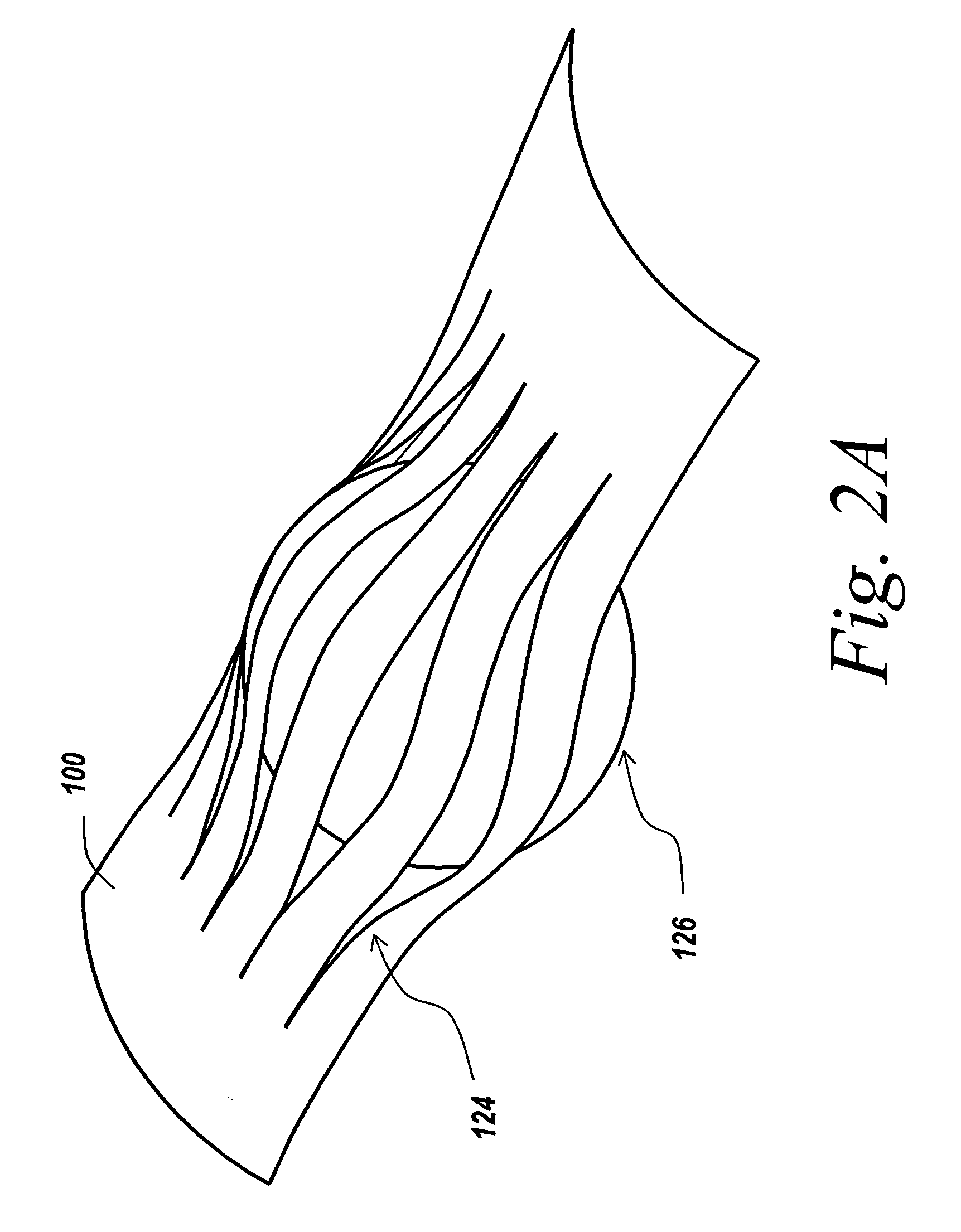

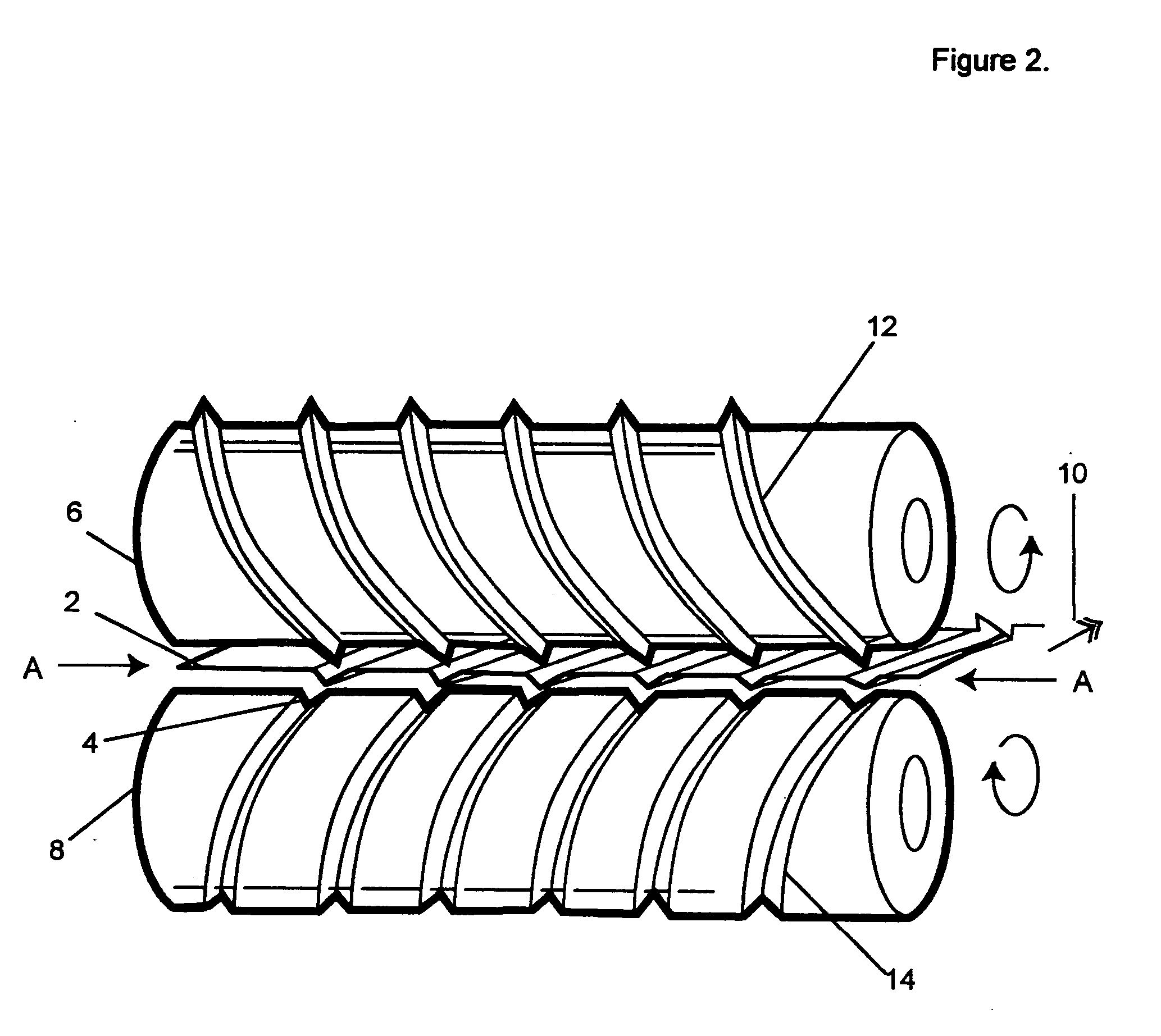

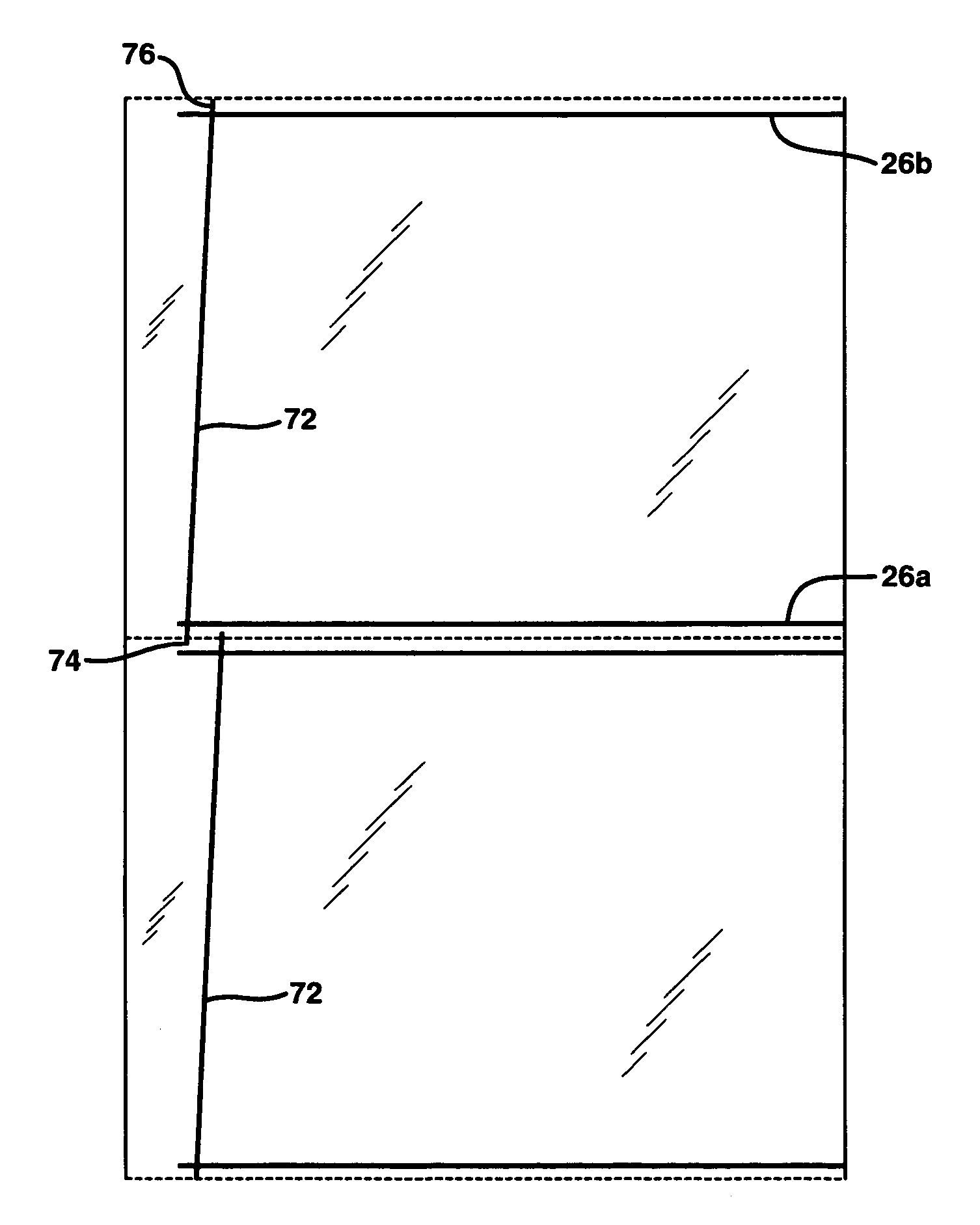

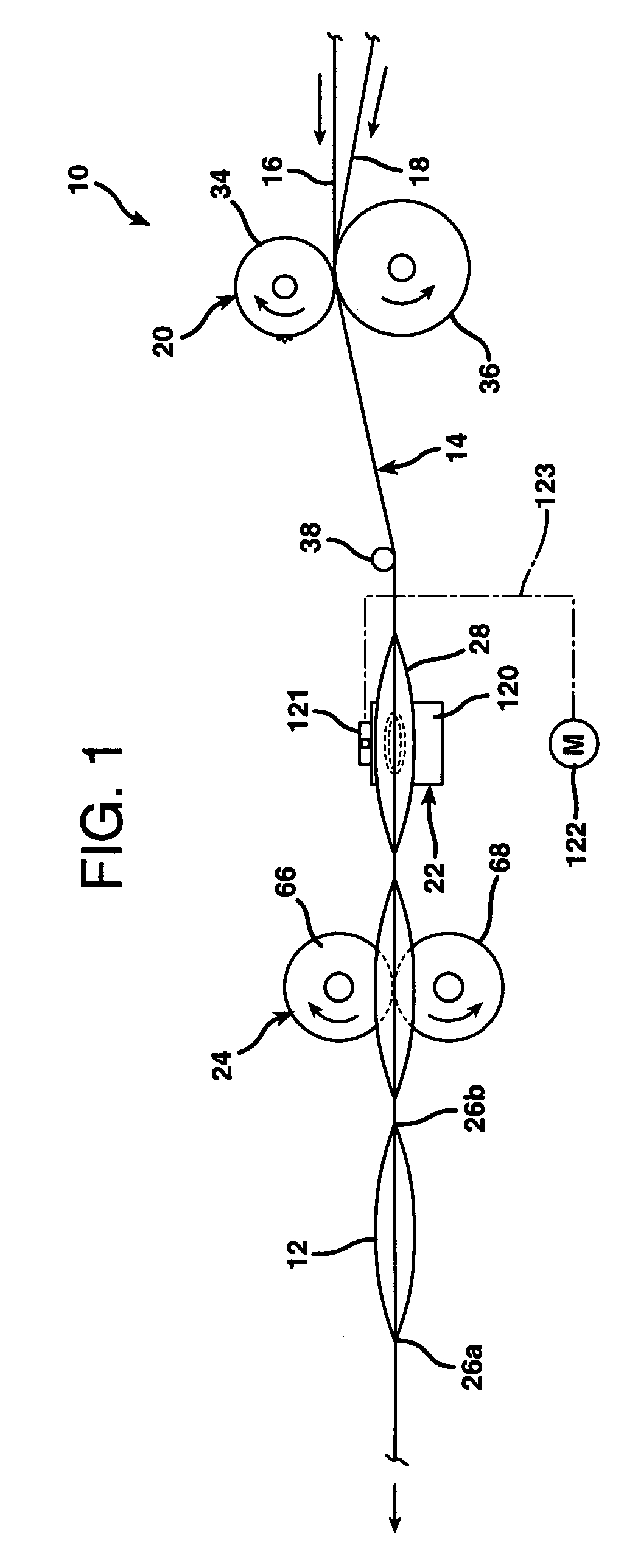

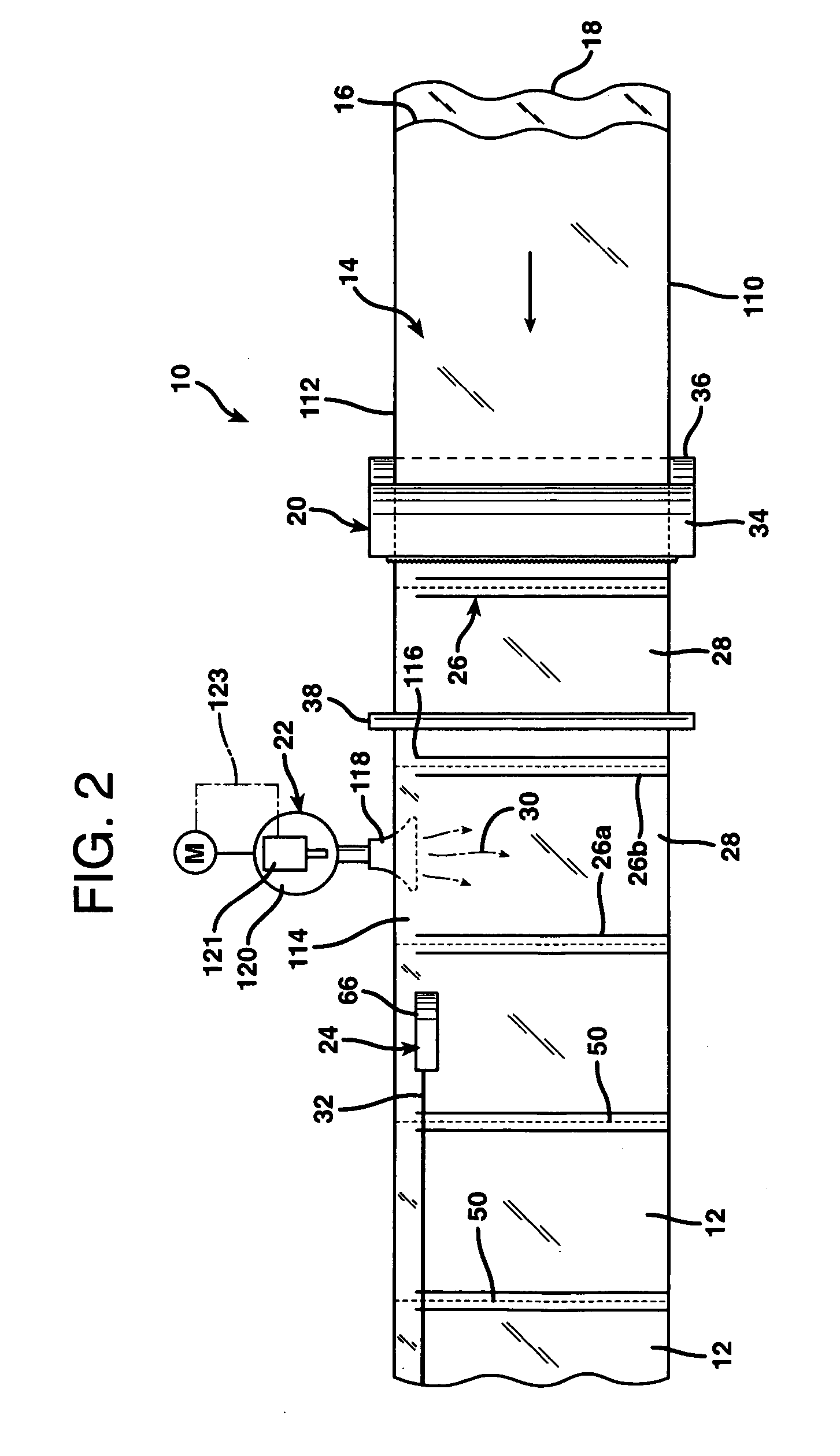

Apparatus and method for forming inflated articles

An apparatus for making inflated articles from a film web having two juxtaposed film plies. One version of the apparatus generally includes a first rotary sealing device for producing transverse seals that bond the film plies together, an inflation assembly for directing gas between the film plies, and a second rotary sealing device for producing a longitudinal seal between the film plies. The longitudinal seal intersects the transverse seals so that the gas is enclosed between the longitudinal seal, transverse seals, and film plies to thereby form an inflated article.

Owner:SEALED AIR U S

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com