Patents

Literature

138results about How to "Avoid drawing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

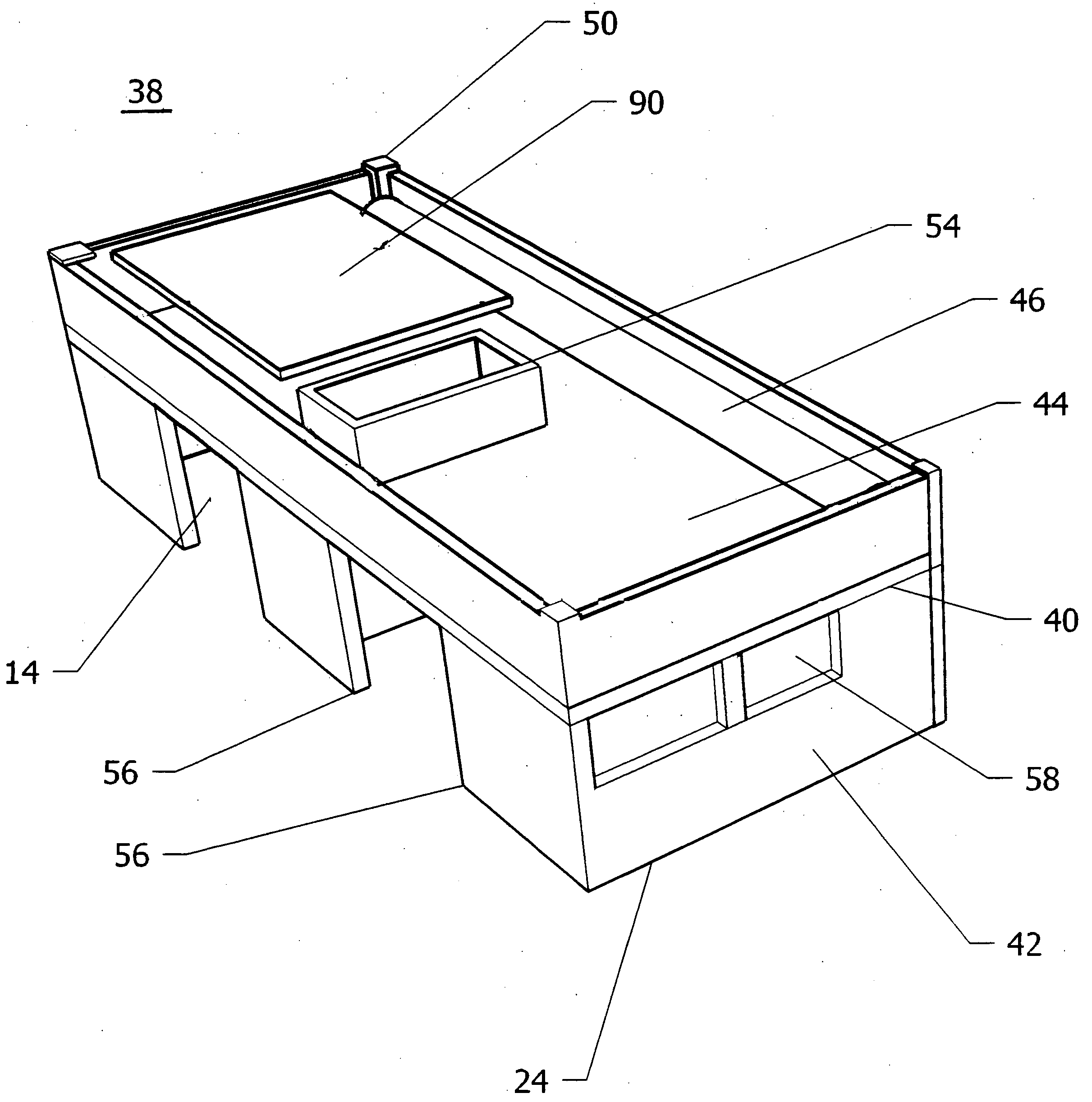

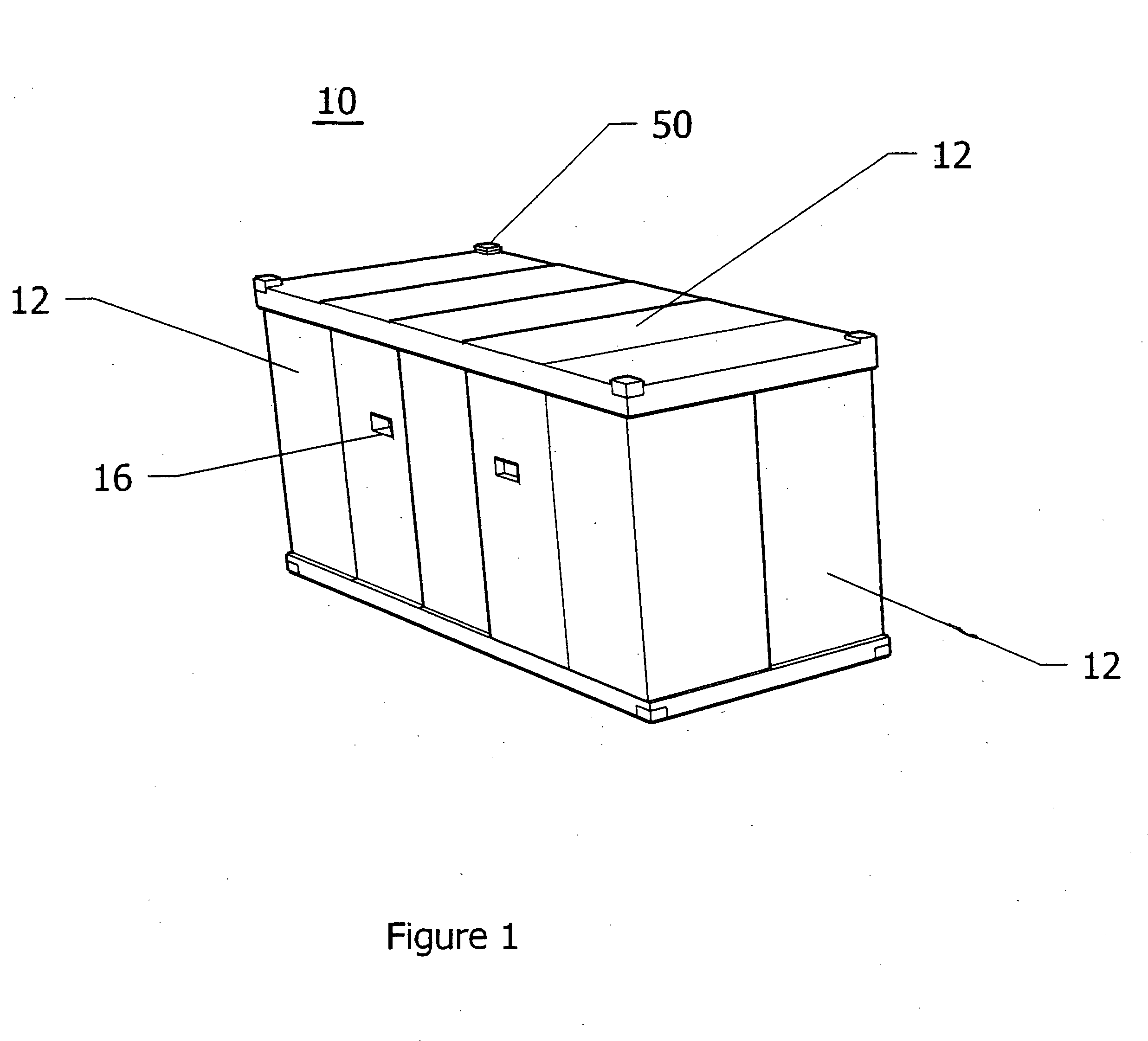

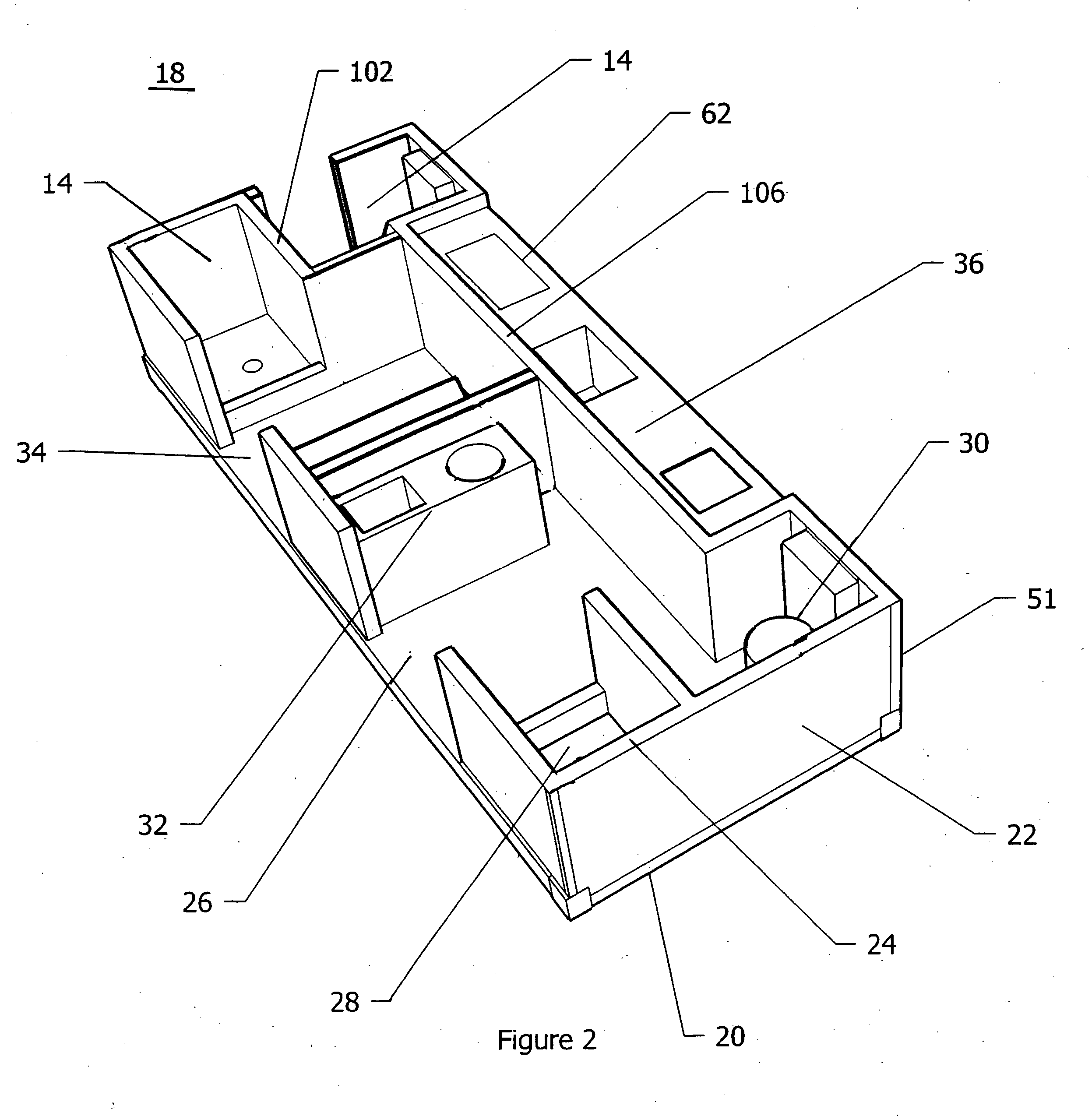

Prefabricated containerized housing

InactiveUS20090223143A1Easy and efficient assemblyEasy and efficient to manufacturePublic buildingsBuilding repairsContainerizationEngineering

A single, self-contained housing core configured for containerization is provided. The housing core includes a first section having a floor and a first portion of walls. A second section is connected with the first section to define at least one cavity. The second section includes a ceiling and a second portion of the walls. The second section also includes a reservoir. Deployment items are disposed with the first and second sections. Implants are disposed within the first and second sections. Loose items are disposed with the first and second sections. Methods and systems of constructing a dwelling unit including the housing core and transporting the housing core via intermodal transport are also disclosed.

Owner:ESPOSITO JOSEPH

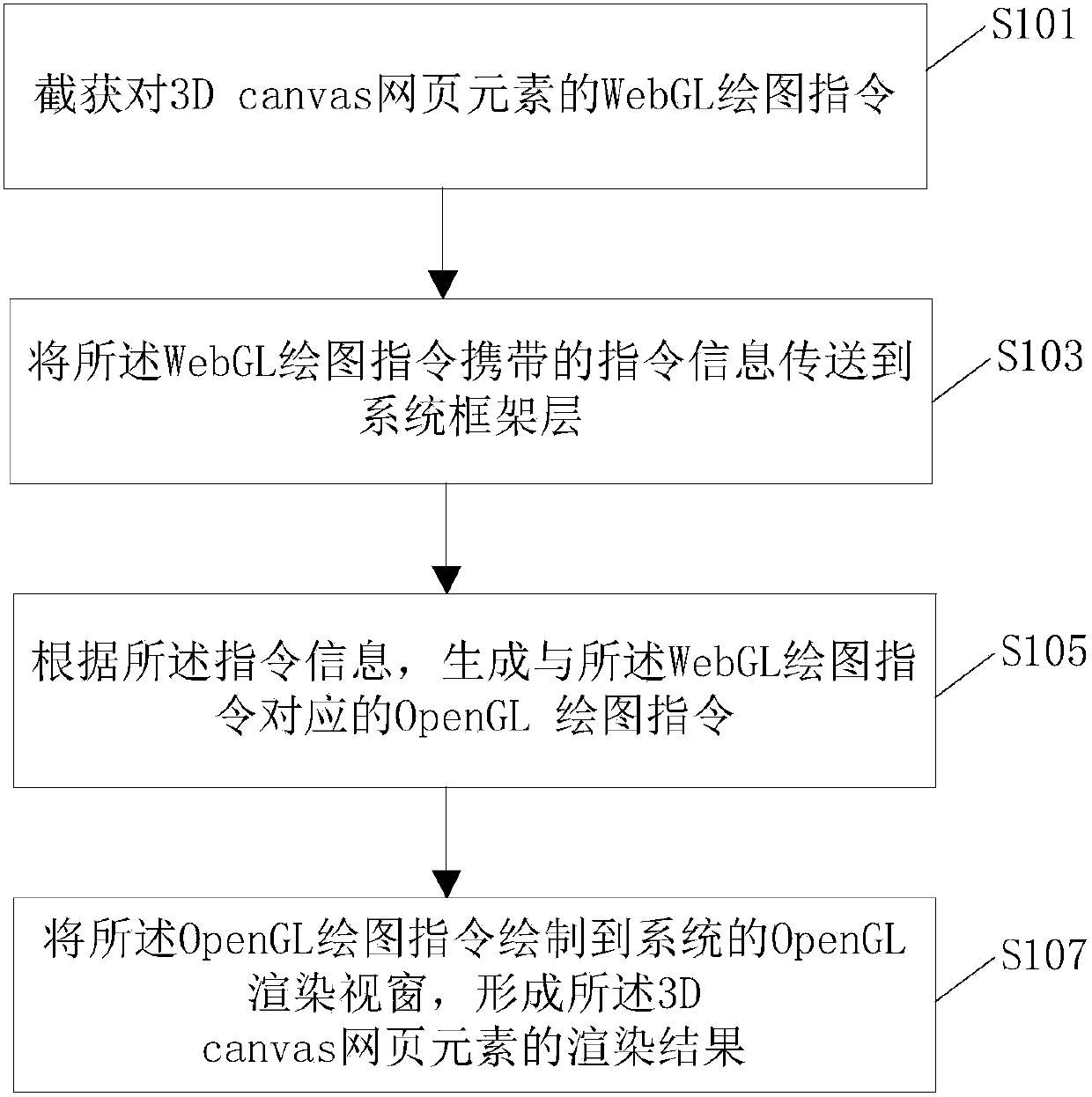

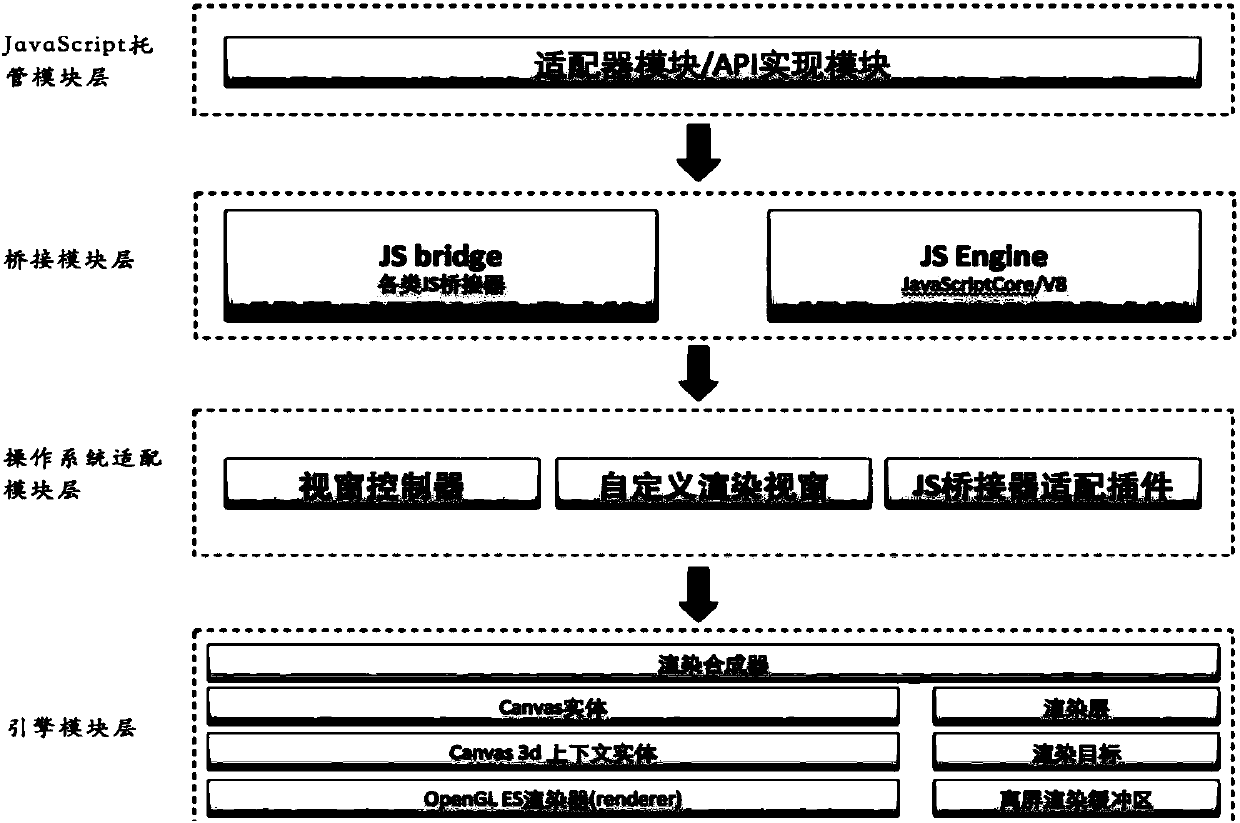

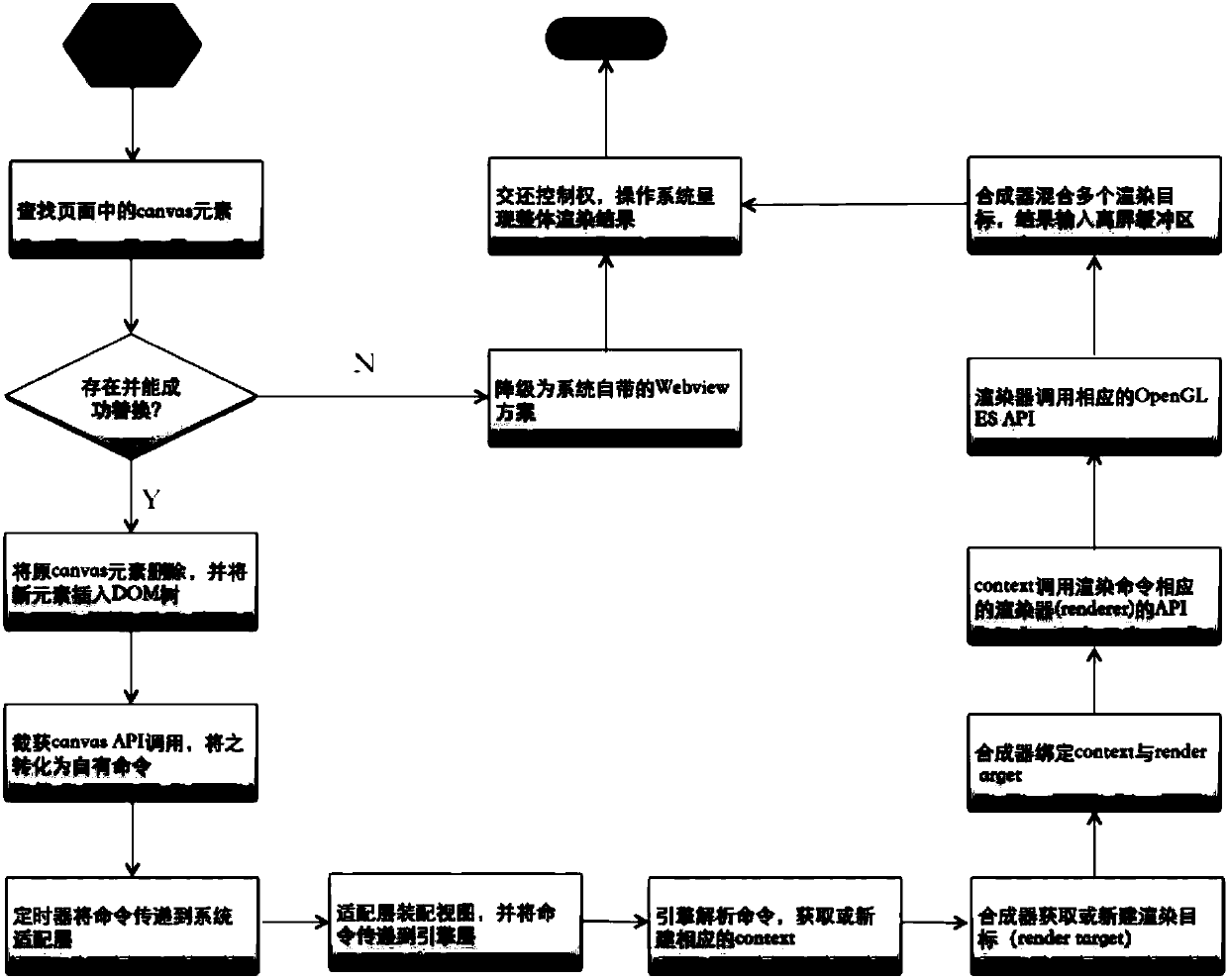

3D canvas webpage element rendering method and device and electronic equipment

ActiveCN107832108AAvoid drawingImprove compatibilityExecution for user interfacesComputer graphics (images)Web page

The invention discloses a 3D canvas webpage element rendering method and device, electronic equipment of 3D canvas webpage element rendering, a 2D canvas webpage element rendering method and device and electronic equipment of 2D canvas webpage element rendering. The 3D canvas webpage element rendering method includes the steps of intercepting a WebGL drawing instruction of 3D canvas webpage elements; sending instruction information carried by the WebGL drawing instruction to a system framework layer; according to the instruction information, generating an OpenGL drawing instruction corresponding to the WebGL drawing instruction; drawing the OpenGL drawing instruction onto an OpenGL rendering view window of a system, and generating a rendering result of the 3D canvas webpage elements. According to the method, the application of a Webview of the system for rendering and drawing of the 3D canvas webpage elements can be avoided, and therefore the effect of improving the supportable compatibility and coverage fraction of the 3D canvas is achieved.

Owner:ALIBABA GRP HLDG LTD

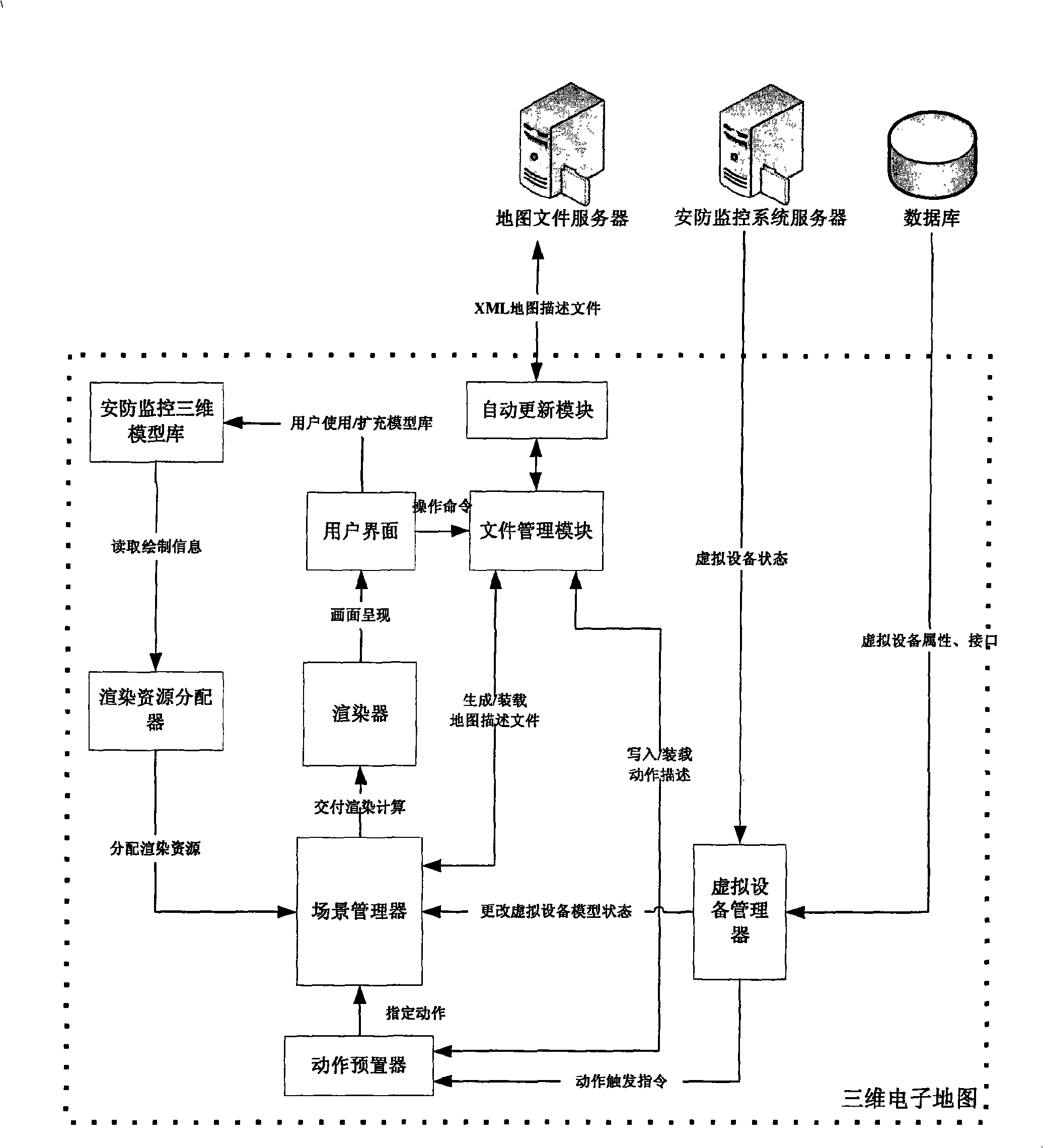

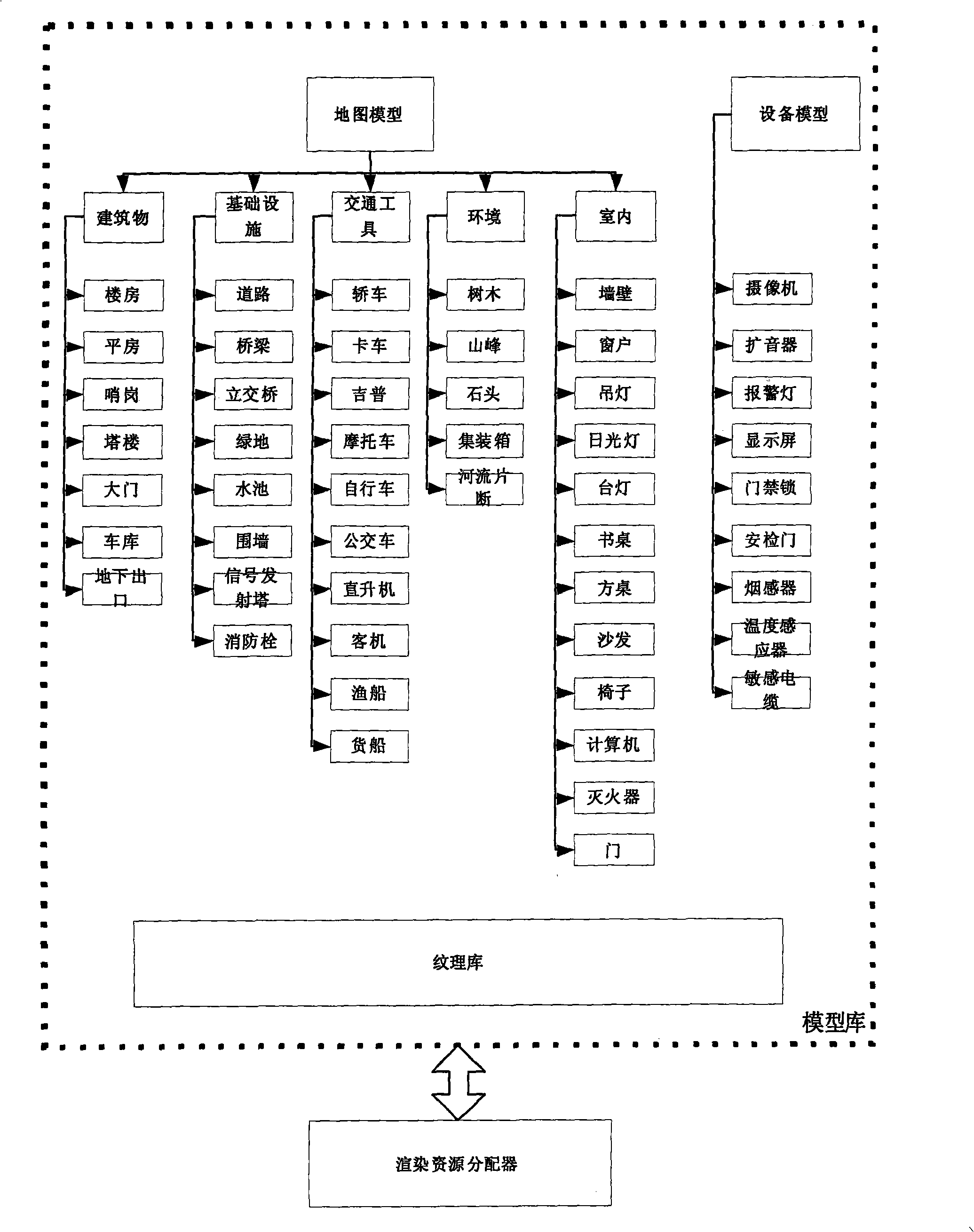

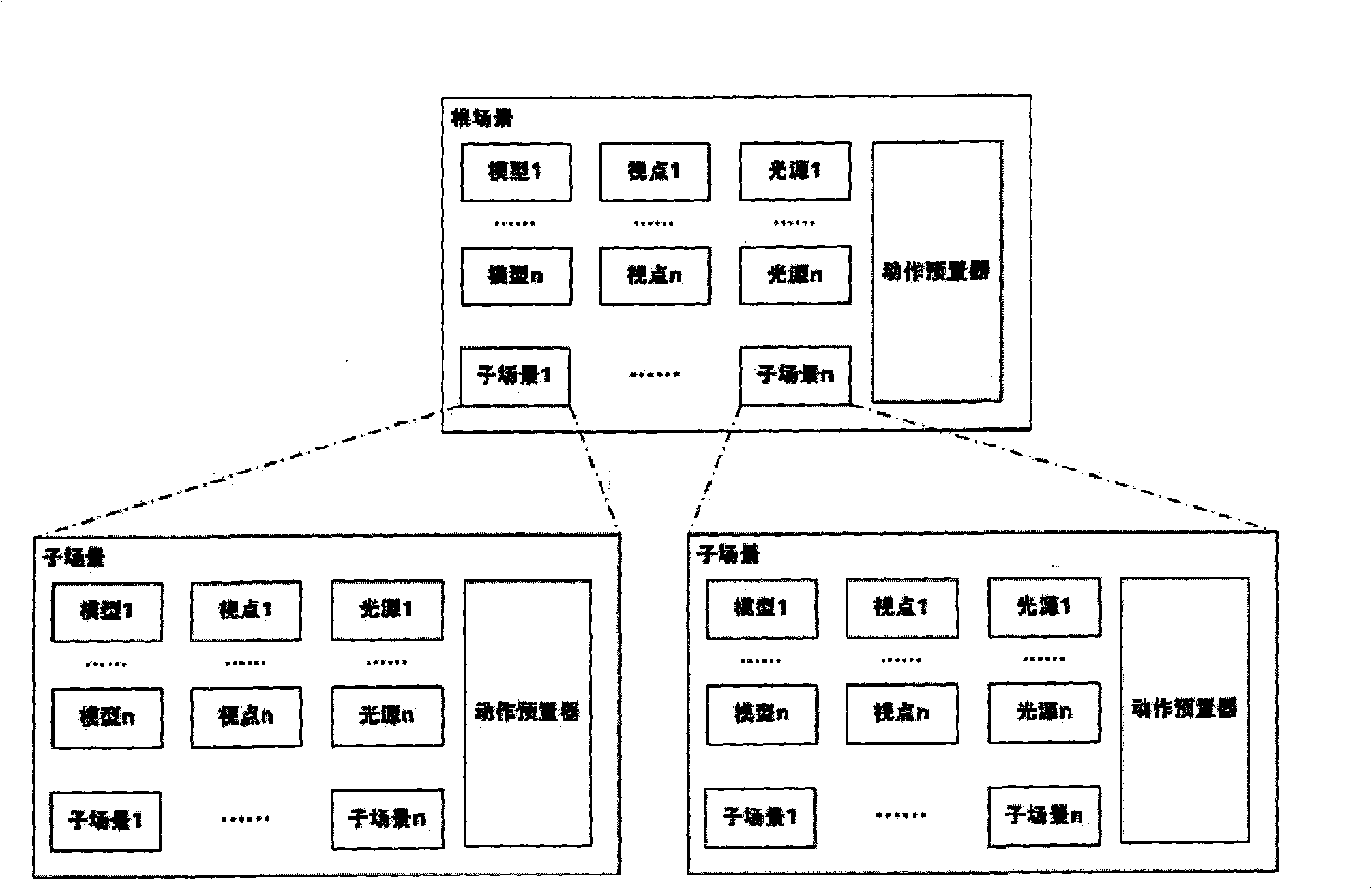

Quickly configurable and real time rendering safety protection three-dimensional electronic map

InactiveCN101286240ARich means of operationIntuitive and vivid monitoring sceneMaps/plans/charts3D-image renderingVirtual deviceSecurity monitoring

The invention relates to a security three-dimensional electronic map for rapid deployment and real-time rendering, comprising a virtual device manager, an action pre-setter, a field manager, a renderer, a rendering resource distributor, a security monitoring three-dimensional model library and a user interface. The map applies a three-dimensional field map in the security monitoring system to replace the traditional two-dimensional electronic map and the expandable model library is designed according to the characteristics of the security monitoring system, thus realizing the rapid deployment of the electronic map. The models in the model library carry out the control on the complexity of the structure and the texture against the specific needs of the security monitoring, sharing of the rendering resources, rendering, reducing and other means are simultaneously adopted to realize the aim of real-time rendering. The map is in line with the application requirements on district division rendering, detail control and all-direction roaming of the security monitoring field. The concept of the virtual device is introduced, the expansion and compatibility of the device can be realized by the deployment of a database; the map can rapidly set up various fields, provide the real-time rendering performance, thus improving the visualization and the modernization level of the security monitoring system.

Owner:BEIHANG UNIV

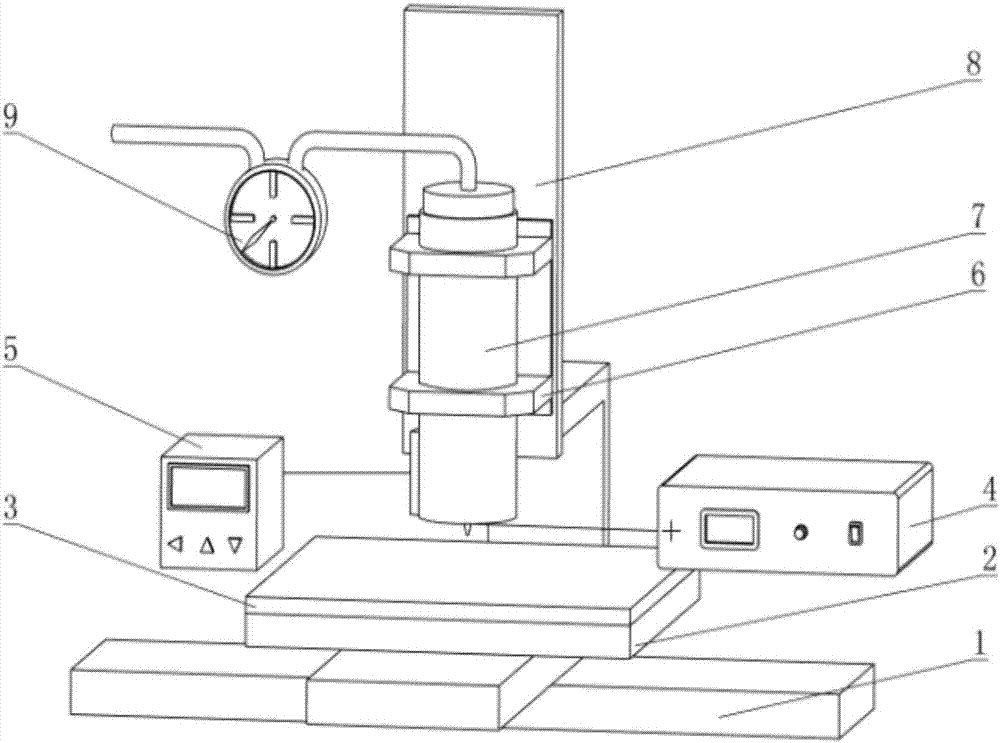

Molten jetting deposition 3D printing device driven by electric field, and working method thereof

InactiveCN107160685AAvoid cloggingEvenly heatedManufacturing heating elements3D object support structuresScale structureHigh pressure

The invention discloses a molten jetting deposition 3D printing device driven by an electric field, and a working method thereof. The problems that the molten droplet jetting 3D printing accuracy is low, the printing materials are limited and the micro-scale structure printing is hard to achieve are solved, and the high-accuracy and high-efficiency macro / micro-scale manufacturing of complex 3D structures using thermal phase transition and thermoplastic polymer materials and composite materials is achieved. According to the technical scheme, the 3D printing device comprises a two-dimensional stage which is provided with a printing bed, and an insulating thermal-conductive substrate is attached to the printing bed; a jetting unit is arranged above the insulating thermal-conductive substrate, and connected to a Z-axis workbench; the jetting unit comprises a print head comprising a nozzle and a material storage barrel which are connected to each other, and the print head is connected to the anode of a high-voltage pulse power supply; the nozzle is a musashi conductive nozzle; the material storage barrel is connected to a backpressure control unit; and a heater is sheathed outside the print head, and connected to a temperature control unit.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

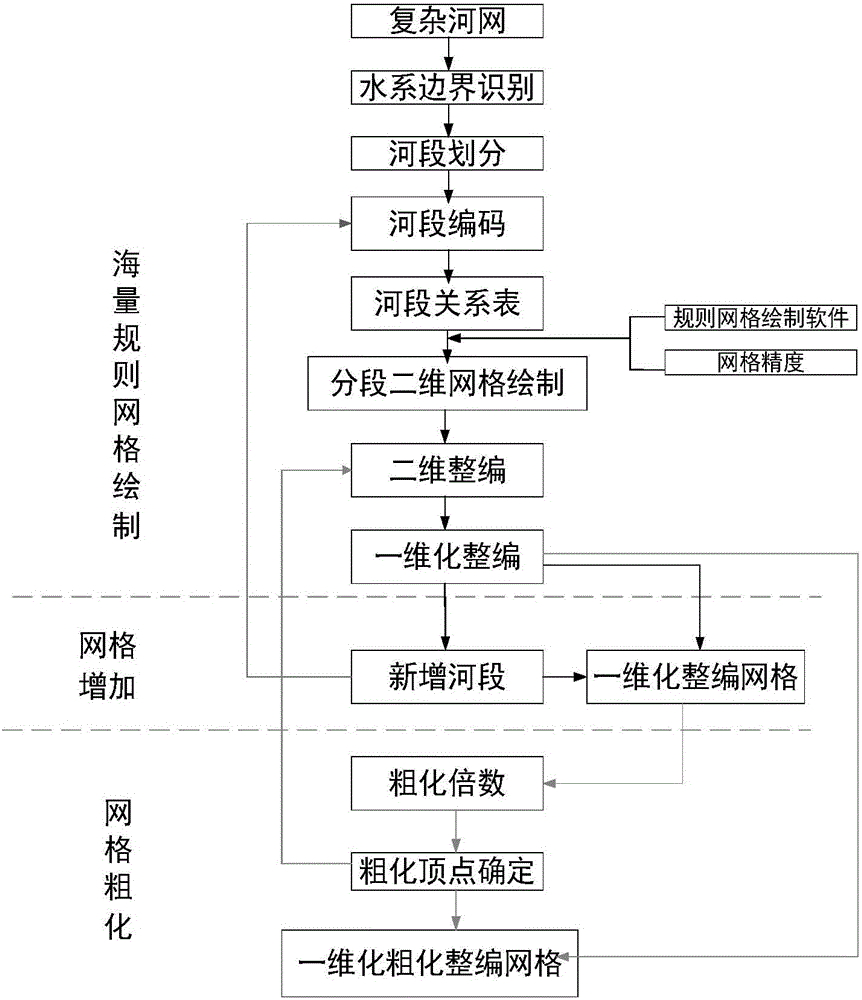

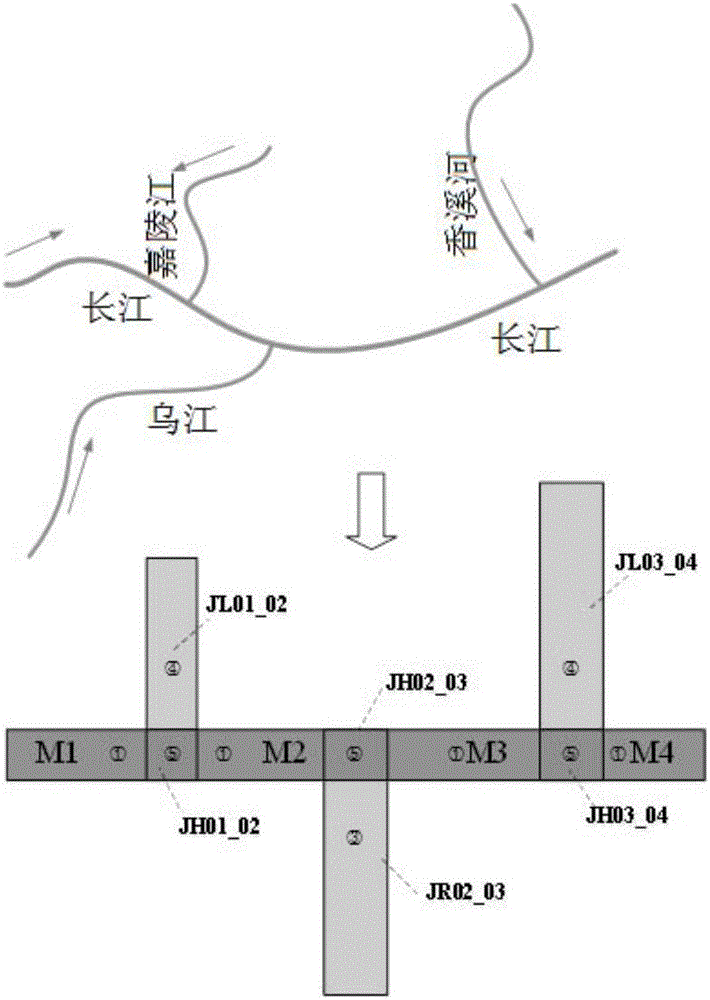

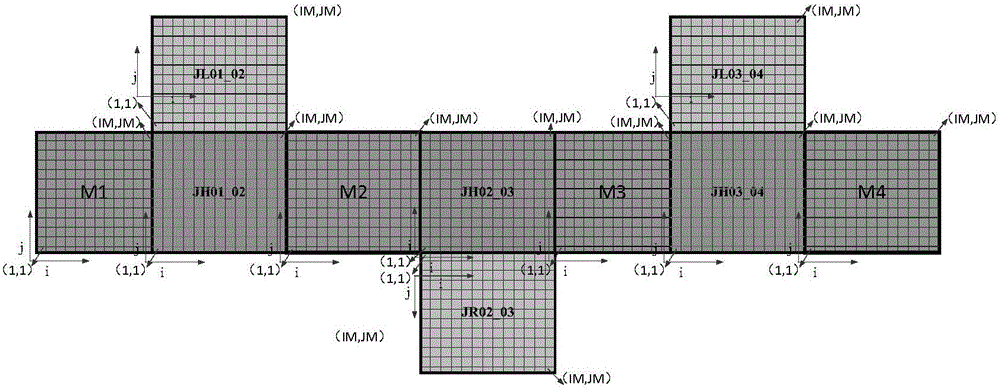

Drawing and coding method for large-scale complex river network massive fine regular grids of river basin

ActiveCN106202265AAvoid the problem of fine massive mesh drawingAvoid drawingGeographical information databasesSpecial data processing applicationsRegular gridRiver network

The invention discloses a drawing and coding method for large-scale complex river network massive fine regular grids of a river basin. The method comprises the steps of S1, identifying structure layers and boundary range layers of a river basin water system body; S2, obtaining river reaches of rivers of a river basin water system segment by segment; S3, drawing two-dimensional regular grids of the rivers and coding the grids in the rivers; S4, carrying out two-dimensional compilation on the two-dimensional regular grids, thereby obtaining an integrated grid; S5, carrying out one-dimensional compilation on the integrated regular grid; and S6, establishing one-dimensional grid relationships. According to the method, on the basis of an existing massive regular grid method and tool, the large-scale massive grids are increased, reduced and coarsened simply and effectively, the grids are drawn once and can be used for life, and the data support is provided for calculation of values based on the regular grids.

Owner:WUHAN UNIV

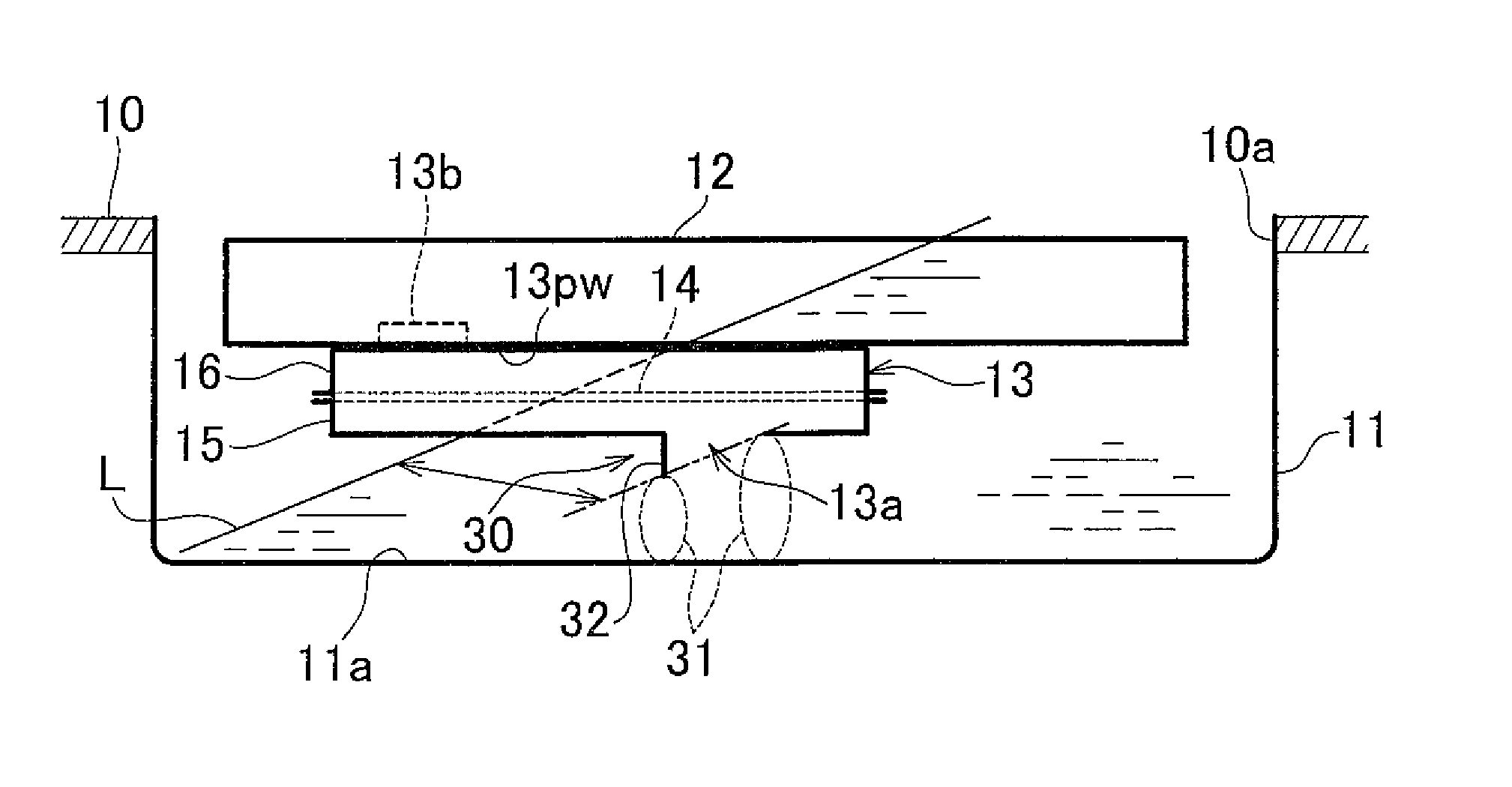

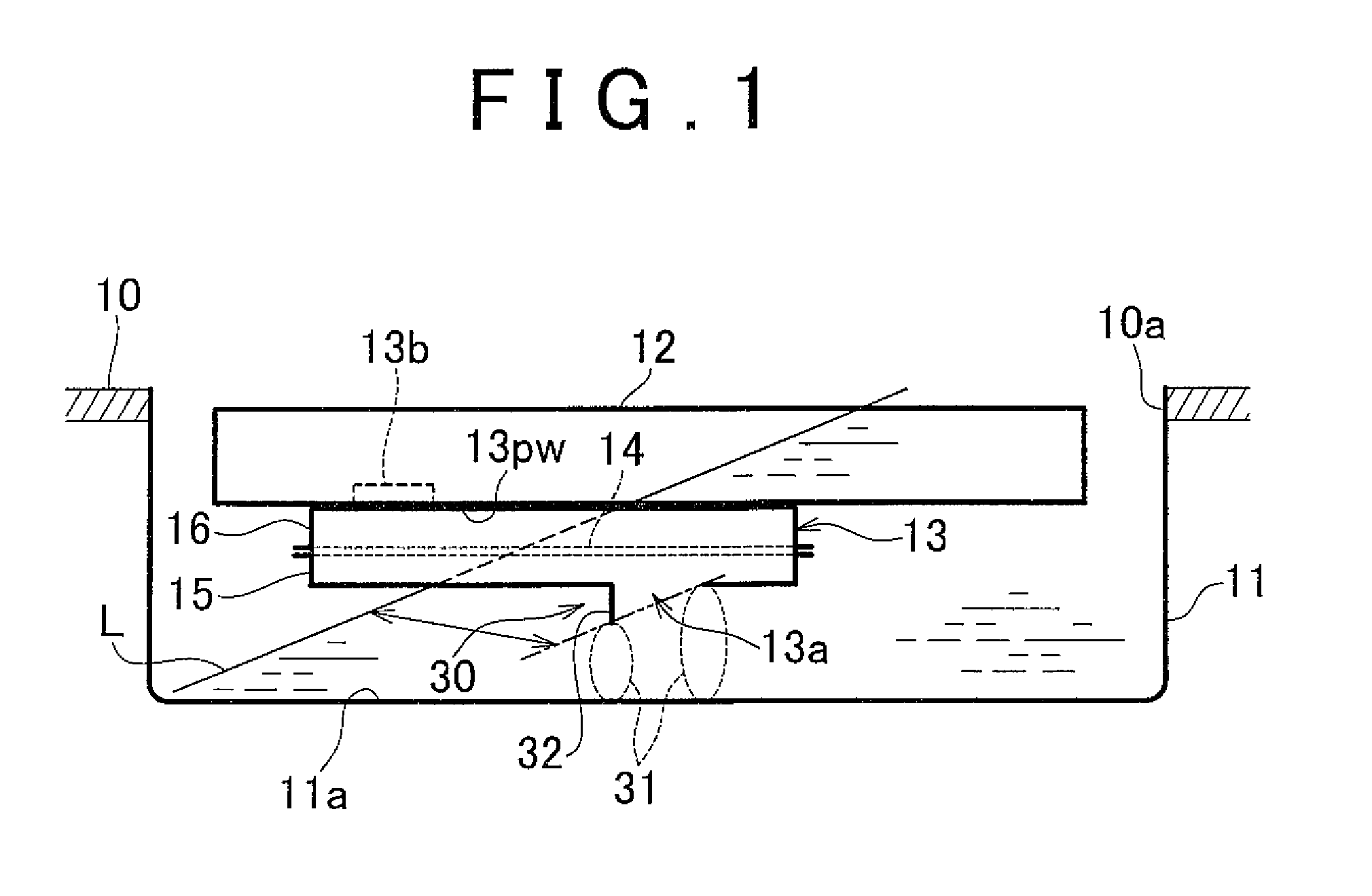

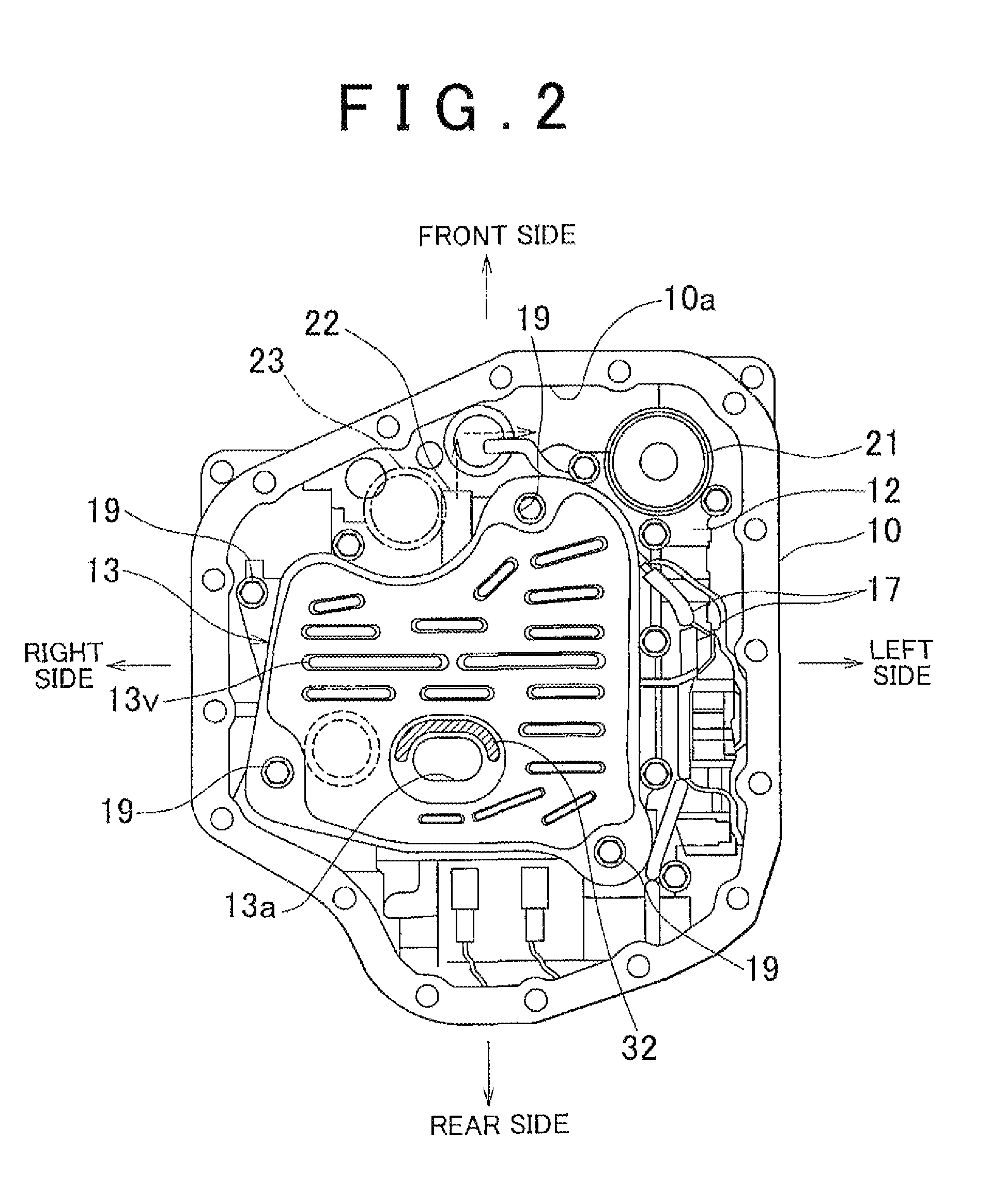

Oil suction system

ActiveUS8292036B2Easy constructionAvoid drawingGearboxesGear lubrication/coolingEngineeringLiquid surfaces

In an oil suction system for drawing up oil stored in an oil reservoir through a strainer, the oil reservoir is constructed such that, when the liquid surface of the oil is inclined due to movement of the stored oil, the level of the liquid surface close to the suction port varies in accordance with a plurality of directions of inclination of the liquid surface, and the level of the liquid surface close to the suction port is lower in a particular direction as one of the directions of inclination of the liquid surface than those in the other directions of inclination, and an inflow resistance portion is provided at a lowered liquid-level side of the suction port on which the liquid level is lowered when the oil surface is inclined in the particular direction, for increasing the resistance to flow of the oil from the lowered liquid-level side toward the suction port, to be larger than the resistance to flow of the oil from a raised liquid-level side of the suction port on which the liquid level is raised due to inclination in the particular direction, toward the suction port.

Owner:TOYOTA JIDOSHA KK

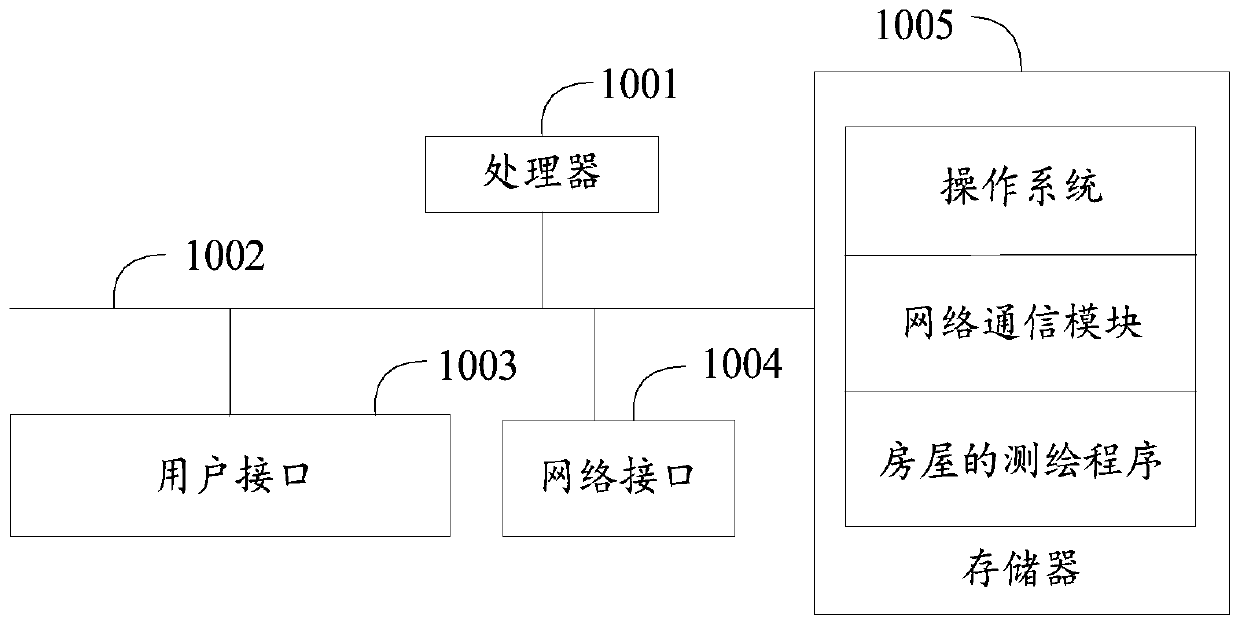

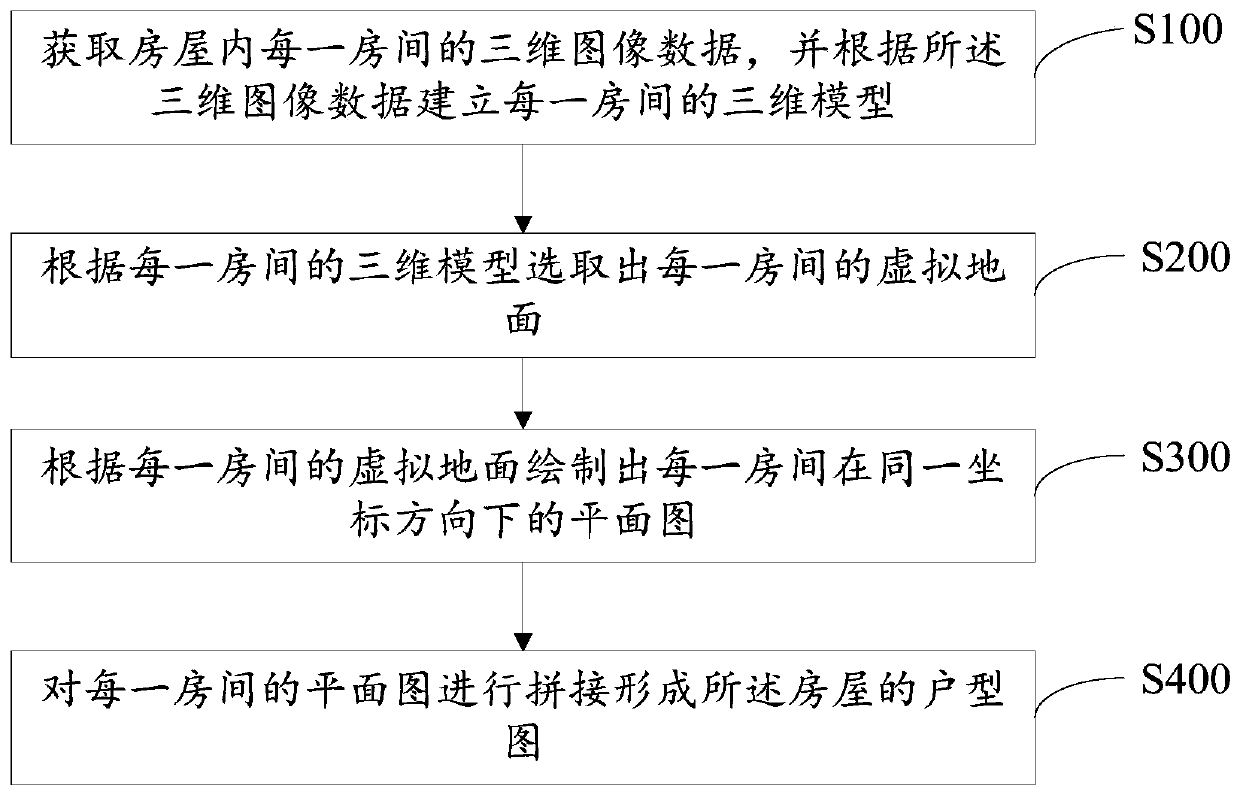

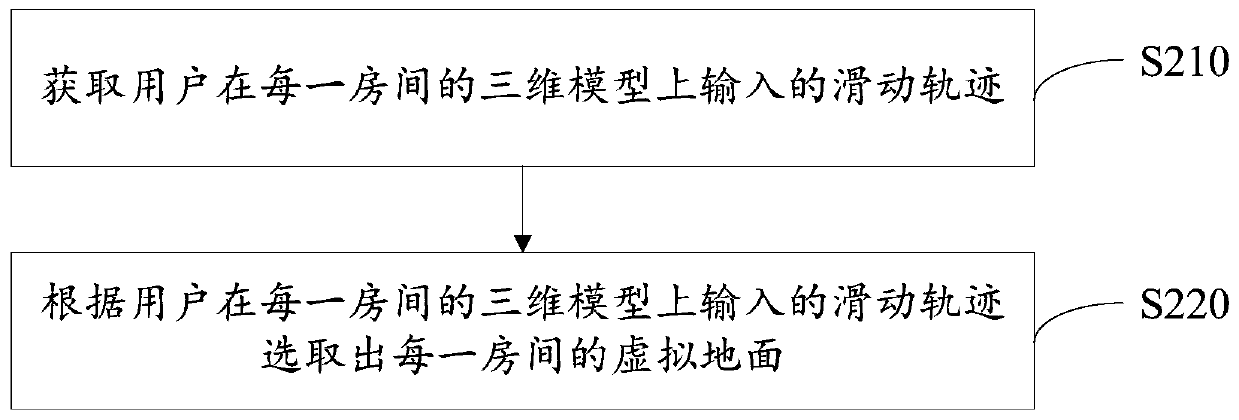

House surveying and mapping method and device, terminal and computer readable storage medium

PendingCN110059351AAvoid drawingEasy to drawGeometric CADSpecial data processing applicationsThree dimensional modelEnhancement Technologies

The invention discloses a house surveying and mapping method. The method comprises the steps of obtaining three-dimensional image data of each room in a house; establishing a three-dimensional model of each room according to the three-dimensional image data; selecting a virtual ground of each room according to the three-dimensional model; drawing a plane graph of each room in the same coordinate direction according to the virtual ground of each room; and splicing the plane graphs of the rooms to form a house type graph of the house. The invention further discloses a house surveying and mappingdevice, a terminal and a computer readable storage medium. According to the technical scheme provided by the invention, the house is processed based on image recognition; the plane graph of each roomin the same coordinate direction is drawn; due to the consistency of planar graph directions, the planar graphs of all the rooms are spliced to form the house type graph of the house, the house typegraph of the house can be generated according to the measurement result of the virtual enhancement technology, later manual drawing is avoided, and great convenience is brought to house measurement and house type graph drawing.

Owner:PINGAN CITY CONSTR TECH SHENZHEN CO LTD

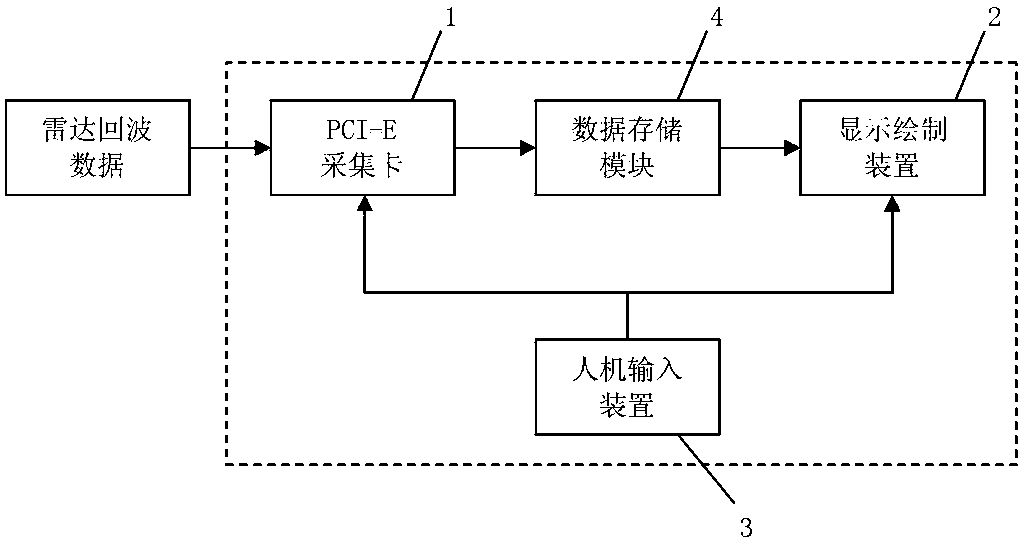

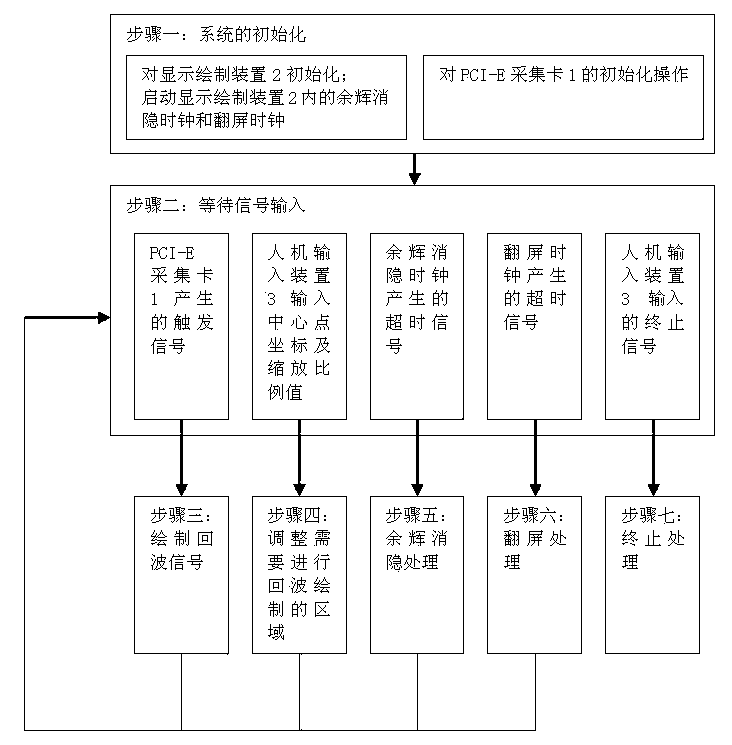

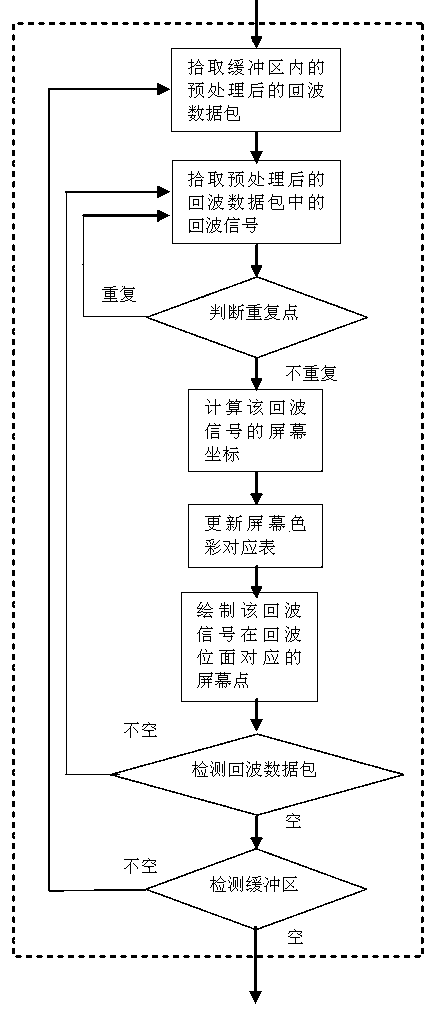

Rendering method used for real-time echo of scene surveillance radar

ActiveCN103399311AMeet the needs of high speedReal-timeWave based measurement systemsComputer graphics (images)Radar

Aiming to solve the difficult problem that real-time echo is hard to be rendered in real time by a conventional scene surveillance radar for a civil airport, the invention provides a rendering method for real-time echo of a scene surveillance radar. The method comprises the following steps: initialization is performed on a rendering display device and a PCI-E capture card; the rendering display device waits for signal input and subsequent processing is performed according to signal types; echo signals are rendered; regions requiring for echo rendering are adjusted; after-glow blanking processing is performed; screen flip processing is performed; and the processing is ended. The rendering method provided by the invention has the positive technical effects that the method can meet the requirements of high rotational speed of the radar for scene monitoring in an airport, achieves real-time rendering to the picture of radar echo and after-glow blanking effect, ensures smooth and flowing display pictures, and is independent of the support of a specific display card.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

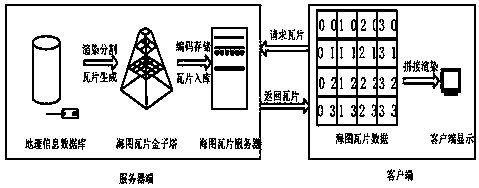

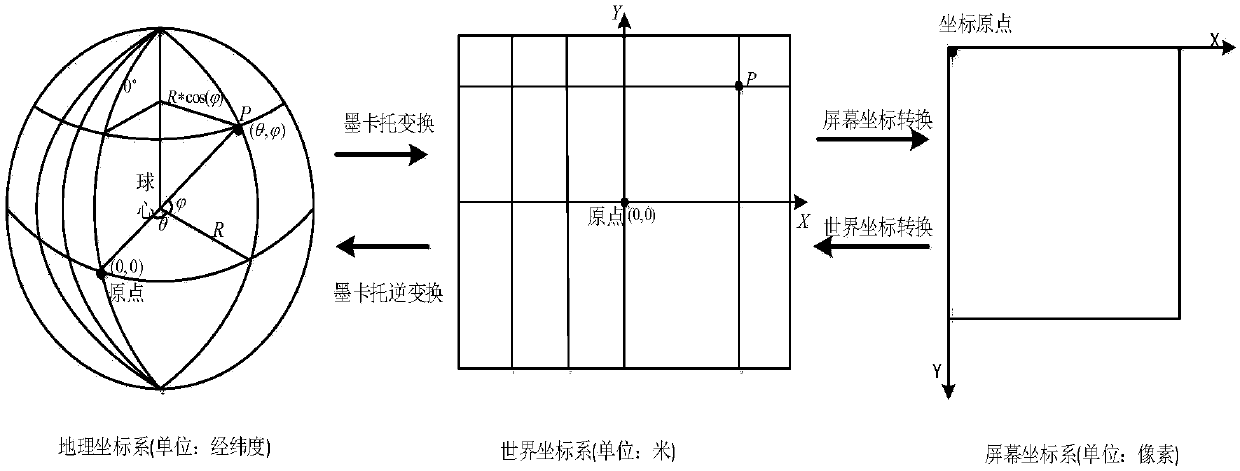

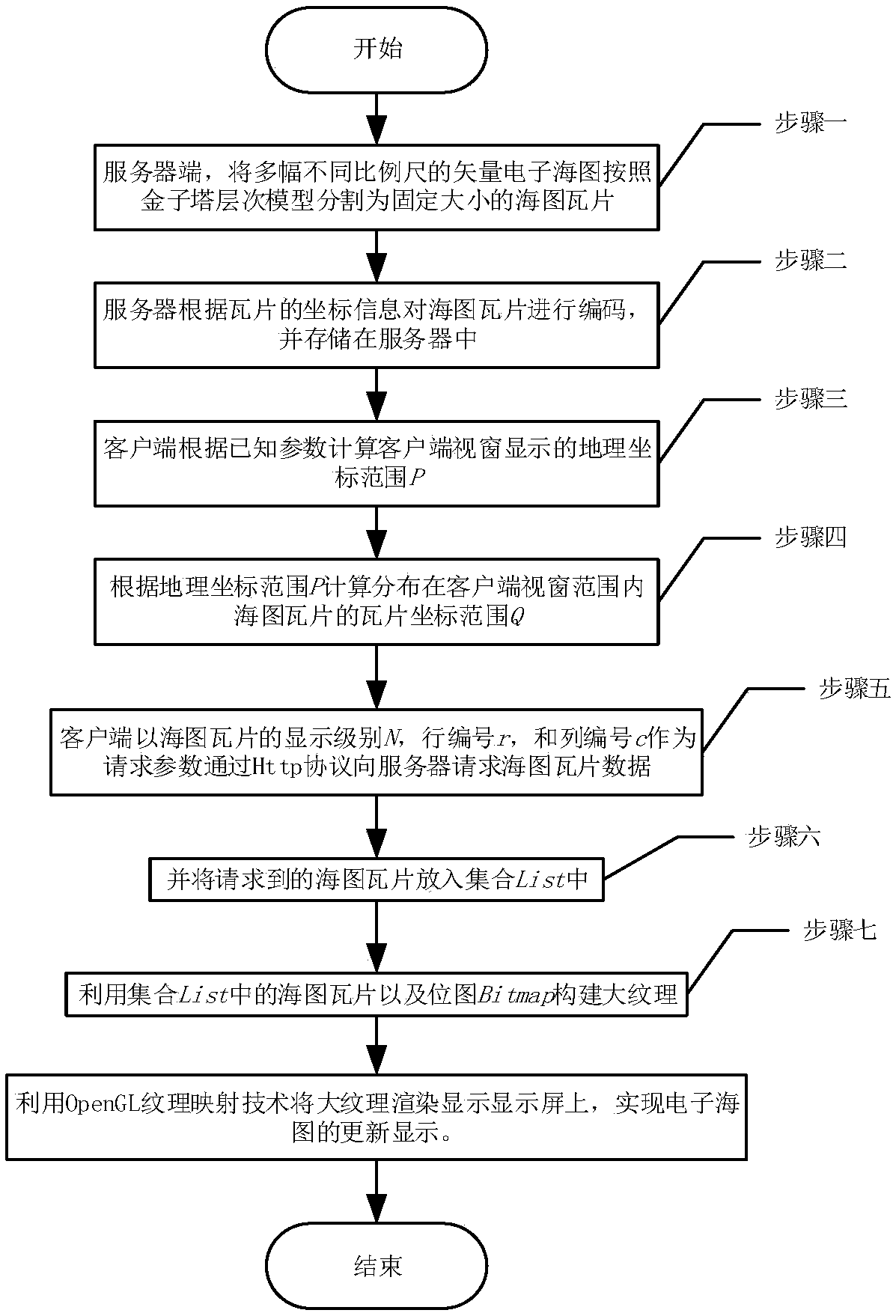

Electronic chart displaying method based on tile technology

InactiveCN108052642AQuick responseQuick drawingTexturing/coloringImage codingComputer graphics (images)Client-side

The invention discloses an electronic chart displaying method based on a tile technology. The method comprises the steps that firstly, a server segments multiple electronic charts which have differentmeasuring scales into square lattice pictures with the fixed size according to a pyramid hierarchical model, and these lattice pictures are chart tiles; then, the server codes the map tiles accordingto the hierarchy and the coordinate information of a pyramid where the tiles are located, and stores the tiles according to coding information of the chart tiles; then, a client side determines a geographical coordinate range displayed by a view window according to a coordinate conversion formula, converts the geographical coordinate range into a serial number range of the chart tiles, and requests the chart tiles from the server according to the serial numbers of the tiles; finally, the client side splices the obtained electronic chart tiles into large textures, and displays the large textures on a screen in a rendering mode through an OpenGL texture mapping technology. By means of the electronic chart displaying method based on the tile technology, the displaying efficiency of the electronic charts is improved, and the application scene of the electronic chart is expanded.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

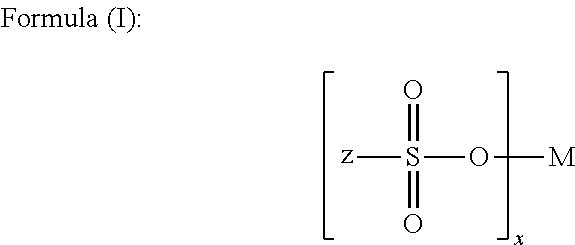

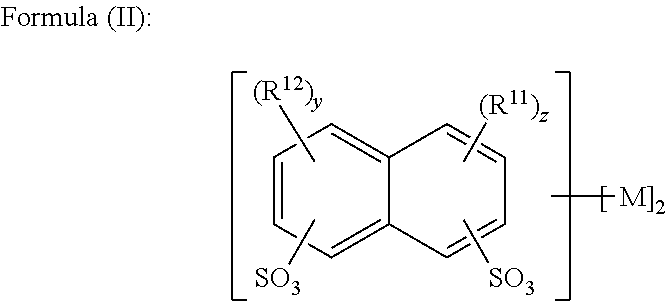

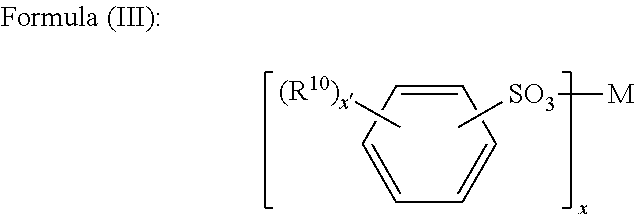

Lower temperature cure coating compositions

ActiveUS20150197665A1Excellent etch resistanceHigh hardnessElectric shock equipmentsPretreated surfacesEpoxyAcid catalyzed

Select metal salts of mono and di aromatic sulfonic acids and aliphatic sulfonic acids are effective latent acid catalysts in coating compositions capable of acid catalyzed crosslinking and provide coating compositions with lower cure temperature and quicker cure times than encountered with conventional sulfonic acid catalysts, have excellent storage stability and avoid drawbacks of epoxy and amine blocked sulfonic acid catalysts.

Owner:KING INDUSTRIES INC

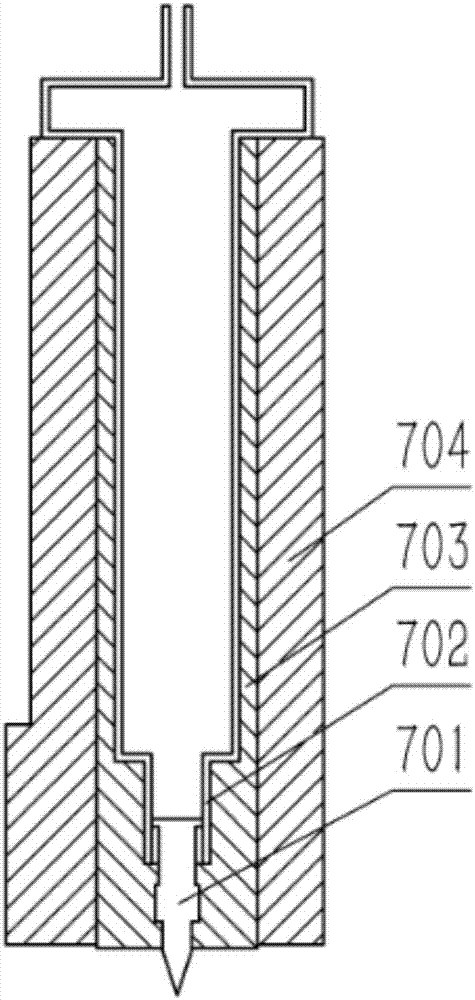

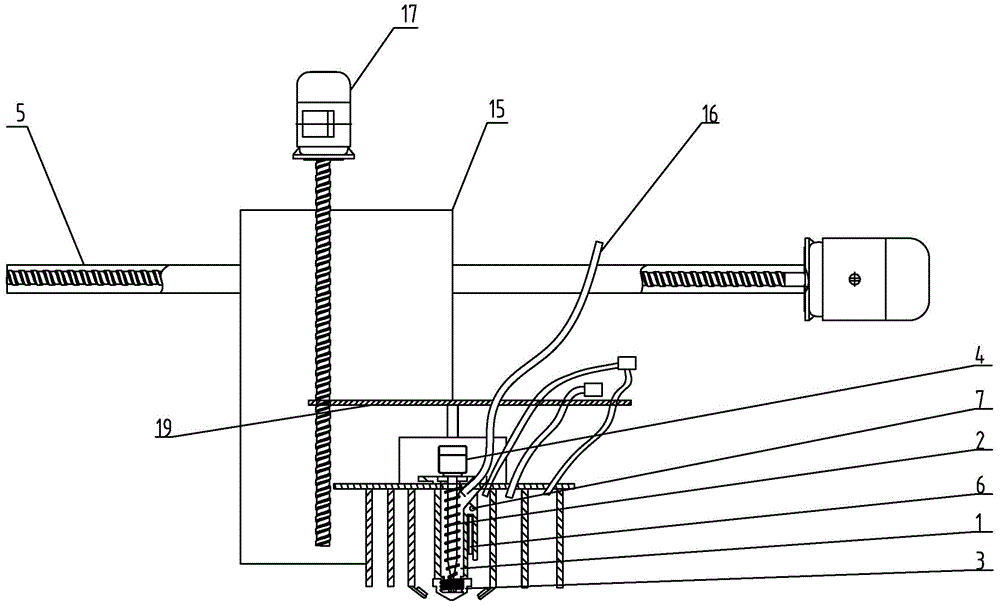

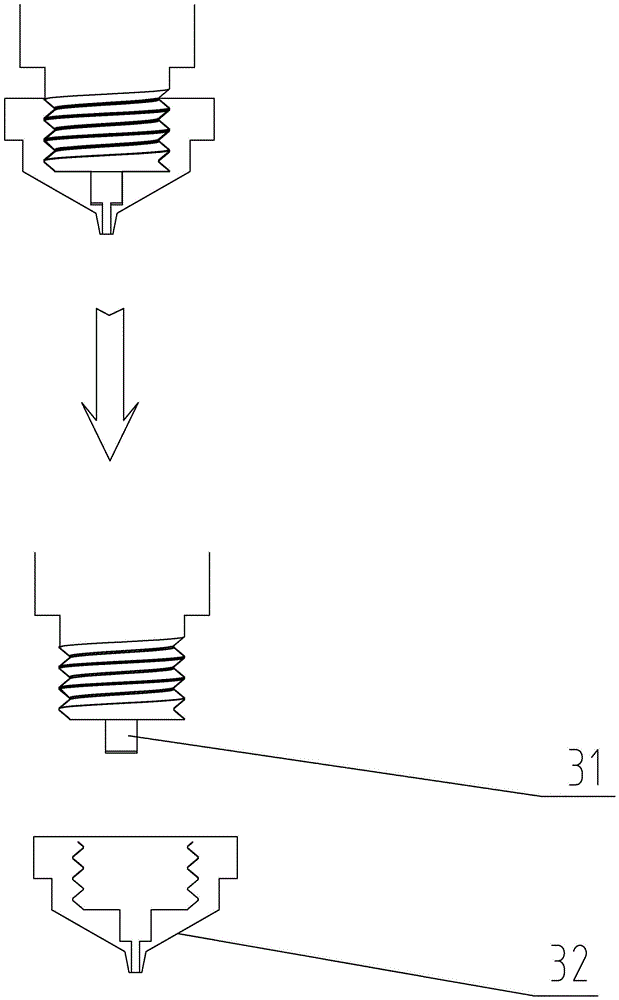

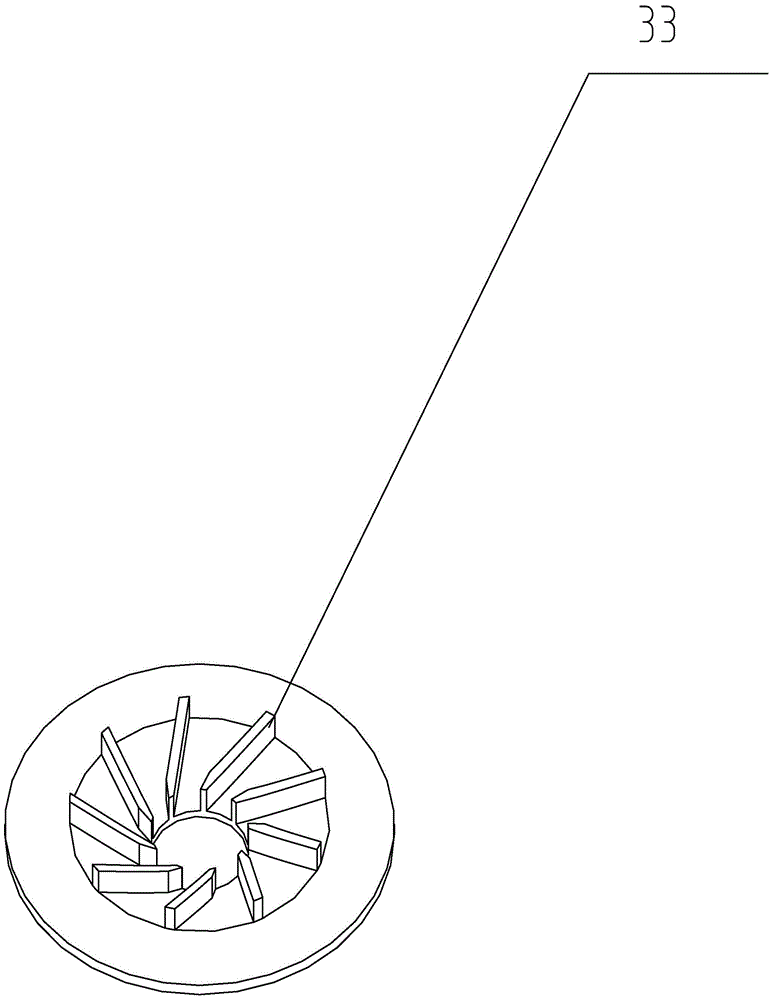

Multifunctional 3D printing head

The invention discloses a multifunctional 3D printing head, which is suitable for 3D printers in any hot melting additive stacking forms. The 3D printing head includes a hot melting chamber, an extrusion pump, a double sleeve spray nozzle, a hot air polishing and cold air shaping apparatus. During 3D printing by means of the multifunctional 3D printing head, a plurality of sub spray nozzles in different pore diameters can be selected conveniently. A raw material is hot-melted in the hot melting chamber, and then the hot-melted material is outputted by means of an extruding pump in an extruded manner. The double sleeve spray nozzle extrudes a paste-like melted wire which is then subjected to re-treatment through the hot air polishing and cold air shaping apparatus, wherein the extruded material is polished and extruded through spiral hot air, and meanwhile, the hot air is pumped back, and then the stacked material is cooled and shaped by means of cold air generated through semi-conductor refrigeration. Through the hot air for polishing and flatting and the cold air for cooling the material, printing precision is greatly increased, and the material after additive printing is flat and smooth and is free of deformation. A shaped product is more firm.

Owner:CHANGZHOU DONGKE ELECTRONICS TECH CO LTD

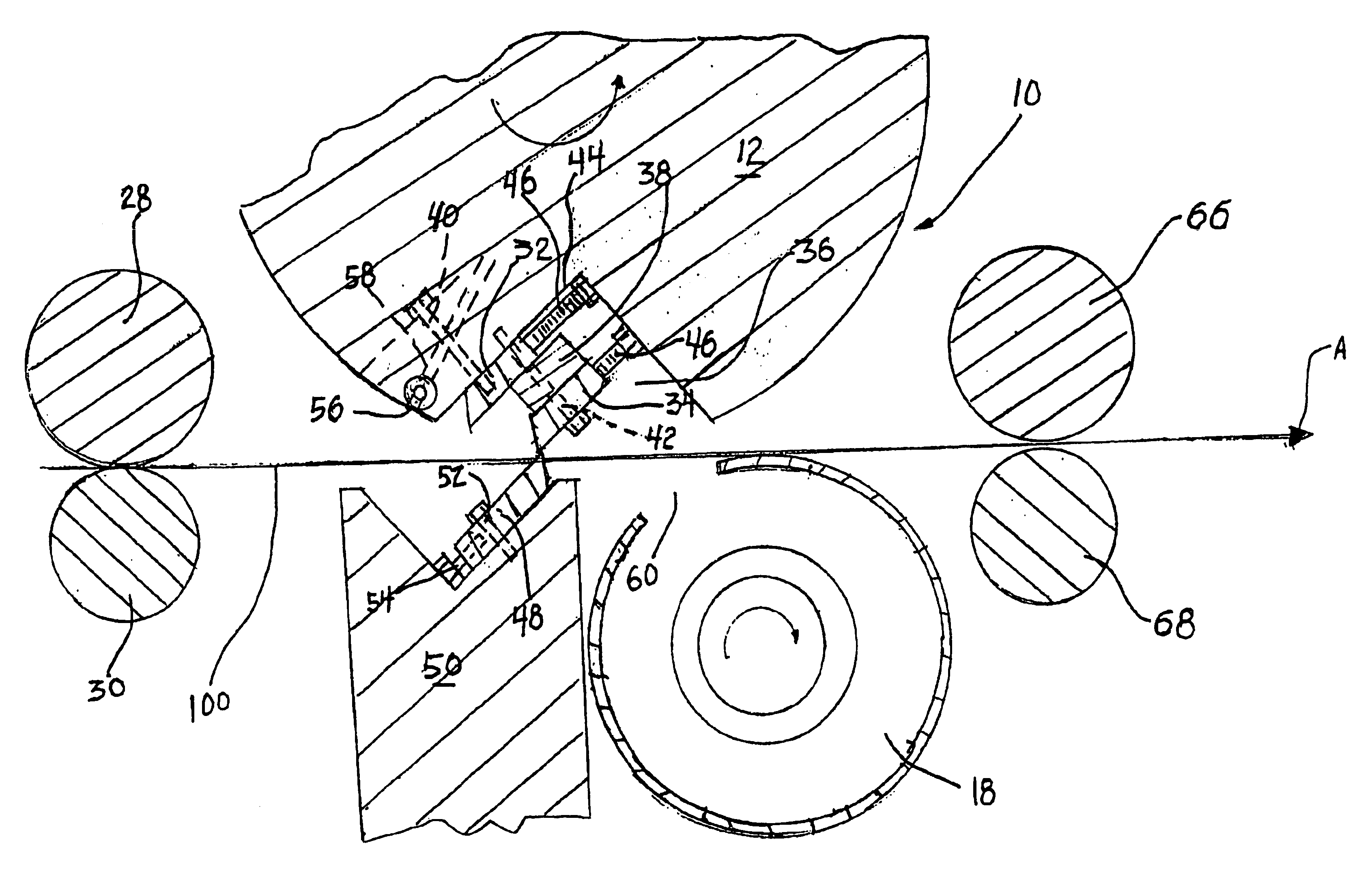

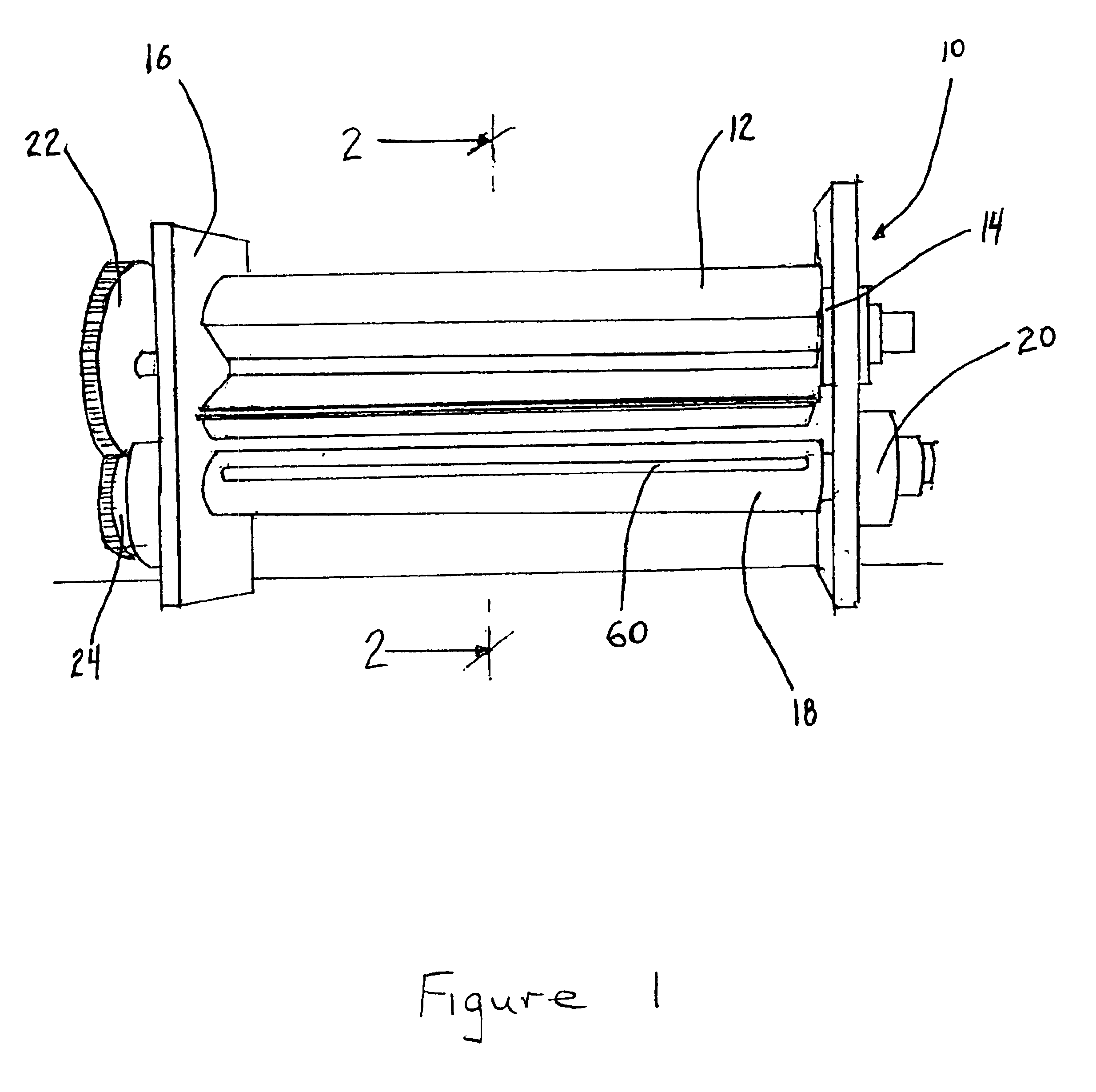

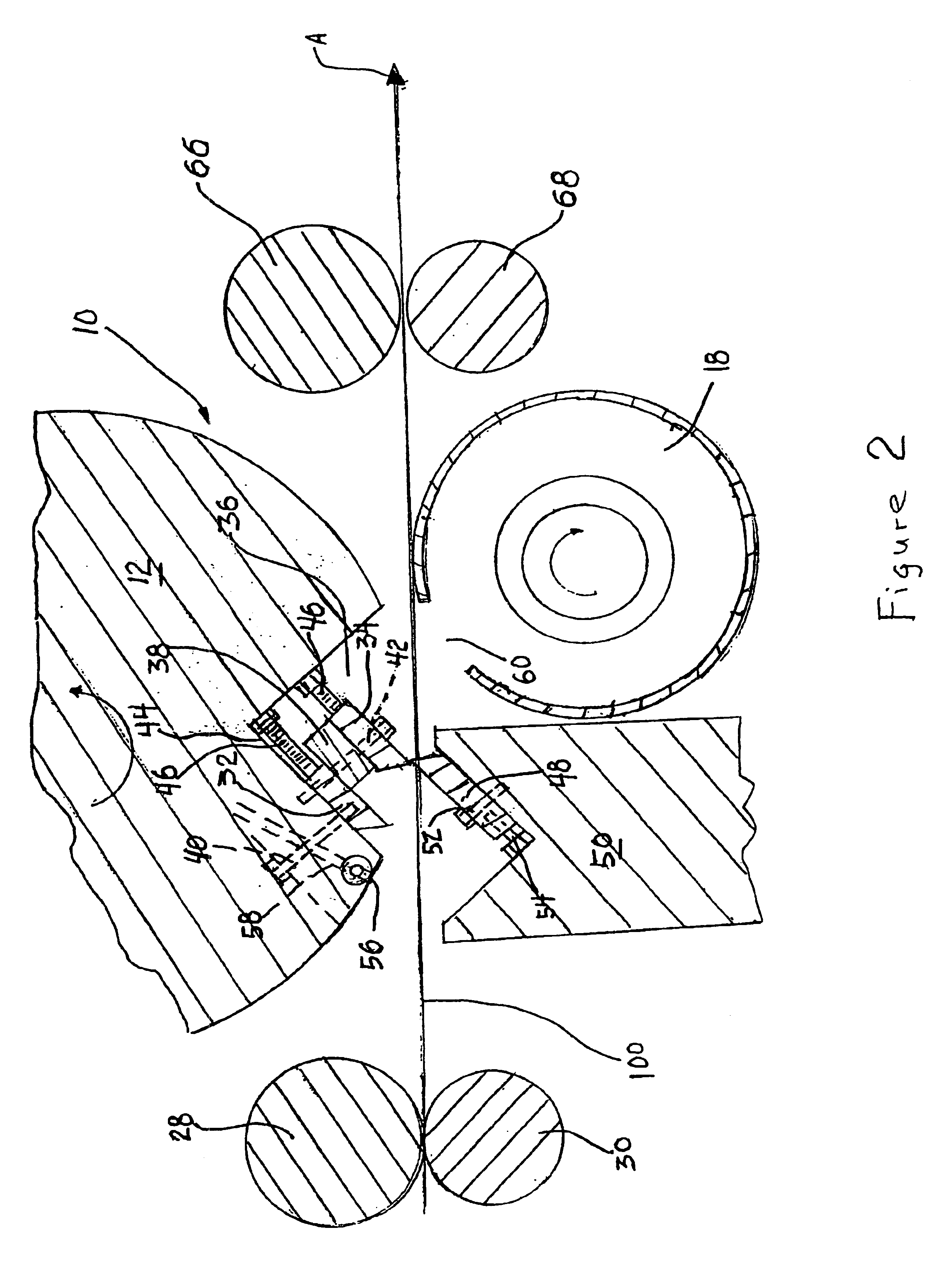

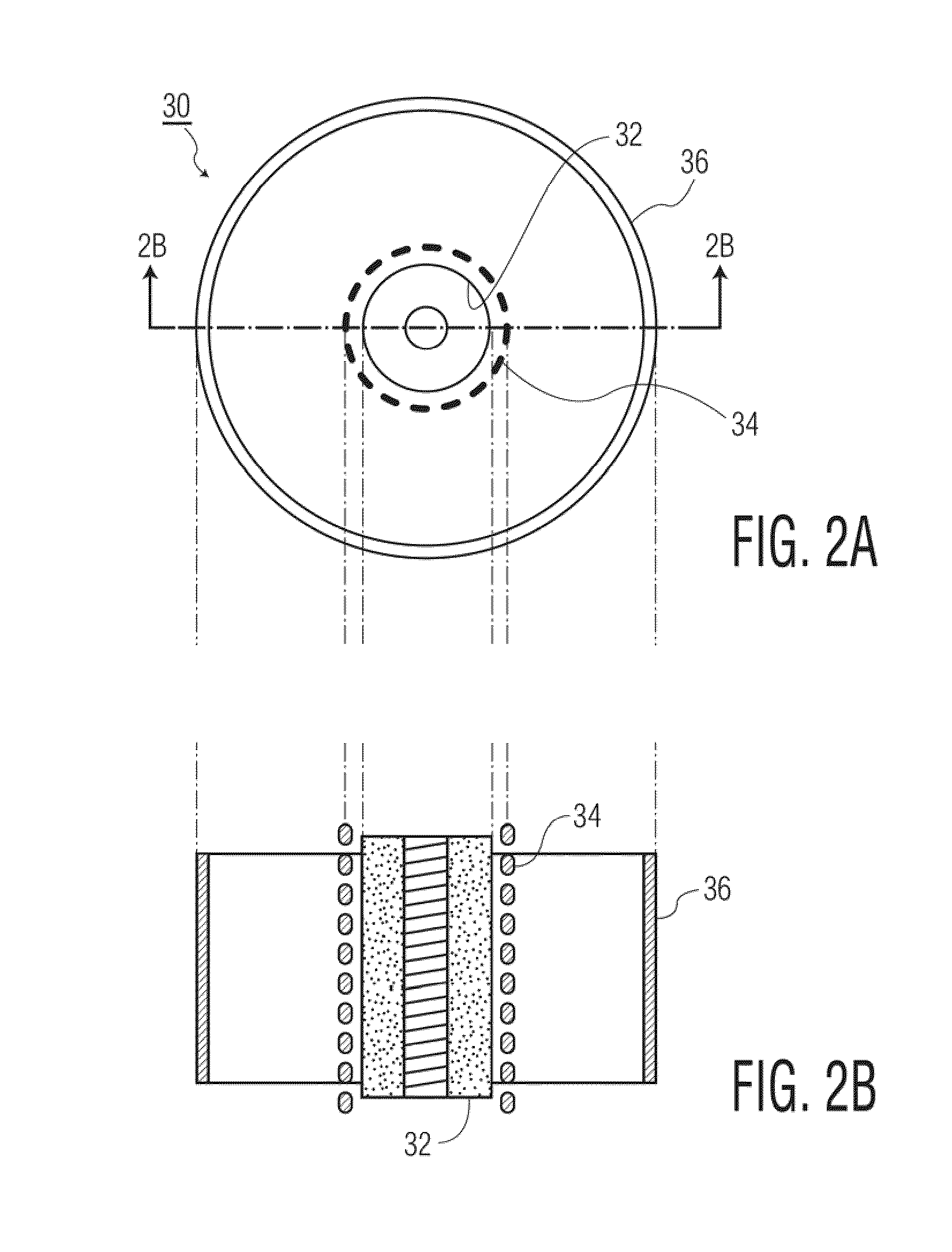

Rotary sheeter having an improved vacuum means for cross trim removal

InactiveUS6895845B2Economical and simple and effectiveAvoids blade fouling and cloggingStock shearing machinesMetal working apparatusEngineeringMechanical engineering

Apparatus for continuously cutting a web and removing trim strips therefrom, including a pair of circumferentially spaced knives supported on a cutting shaft, the shaft being rotationally mounted for cutting, in a cutting area, the web transverse to its direction of movement for forming trim strips, a cylinder mounted along the underside of the web for rotation about an axis which is generally perpendicular to the direction of the moving web, the cylinder having a hollow bore communicating with a low pressure source and an opening formed in the surface of the cylinder communicating with the bore for providing low pressure at the opening, the cylinder being rotated at a predetermined speed such that the opening is positioned in the cutting area immediately downstream of the knives each time a trim strip is cut from the web and the opening is rotated away from the cutting area immediately thereafter.

Owner:ADVANCE GRAPHICS EQUIP OF YORK

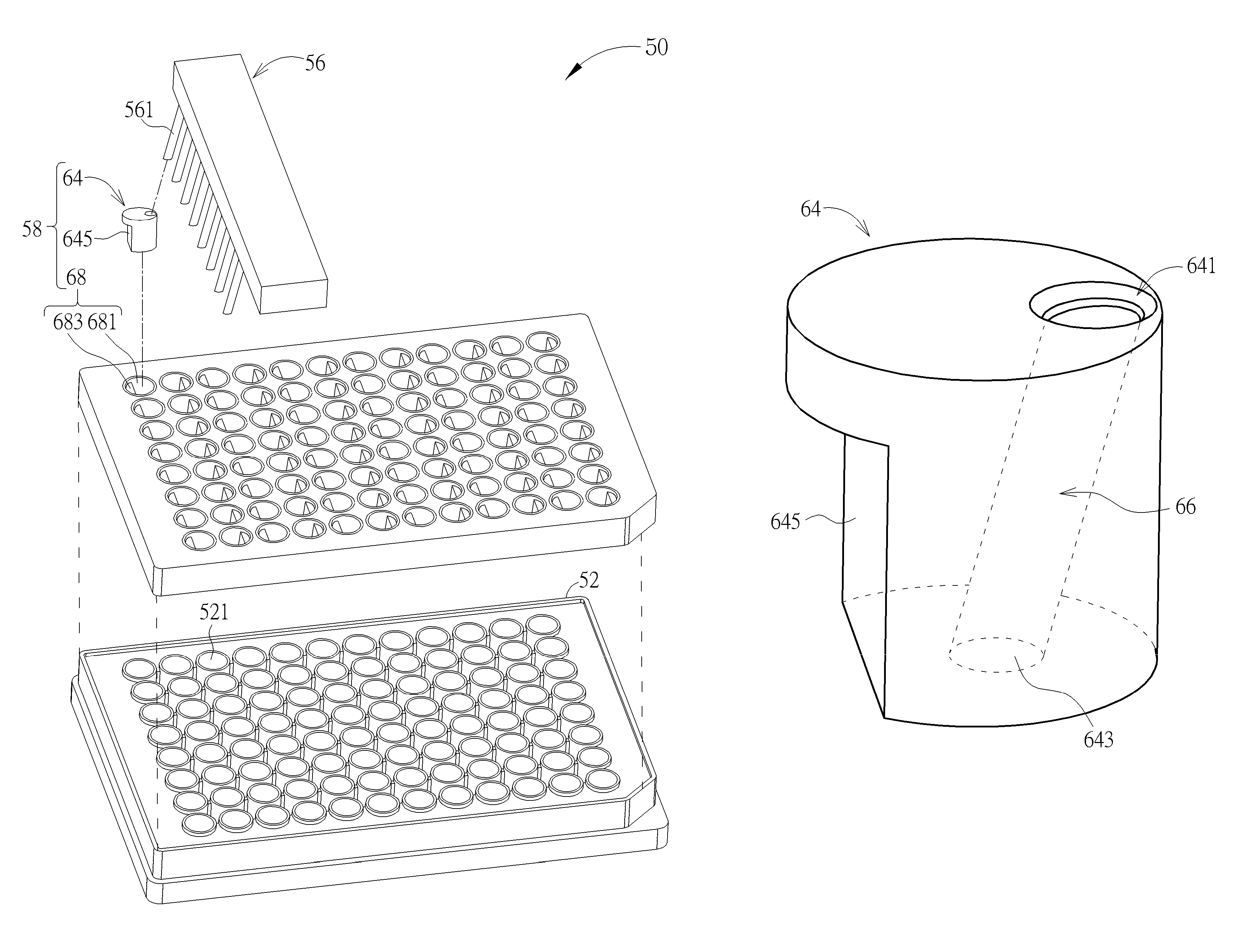

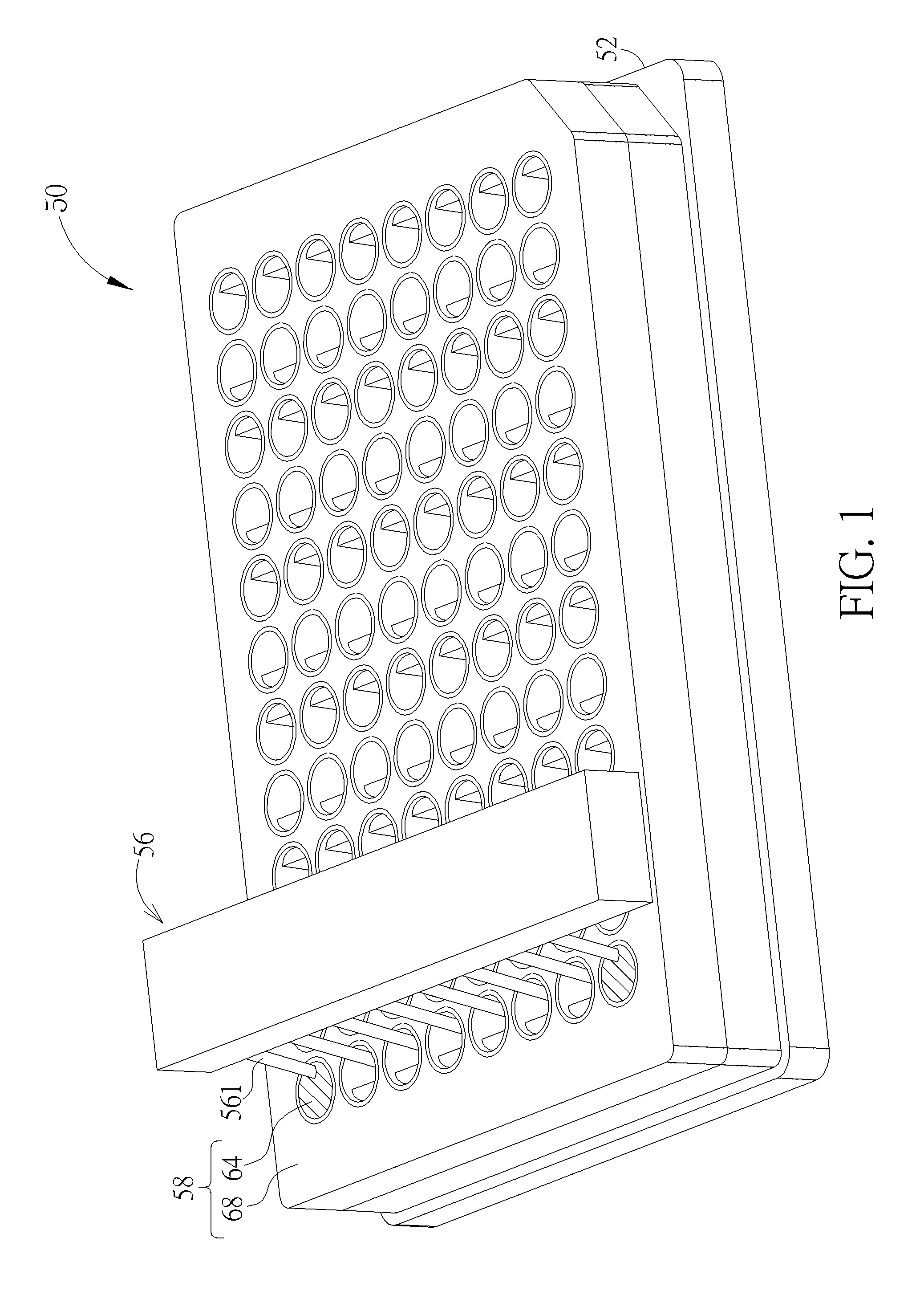

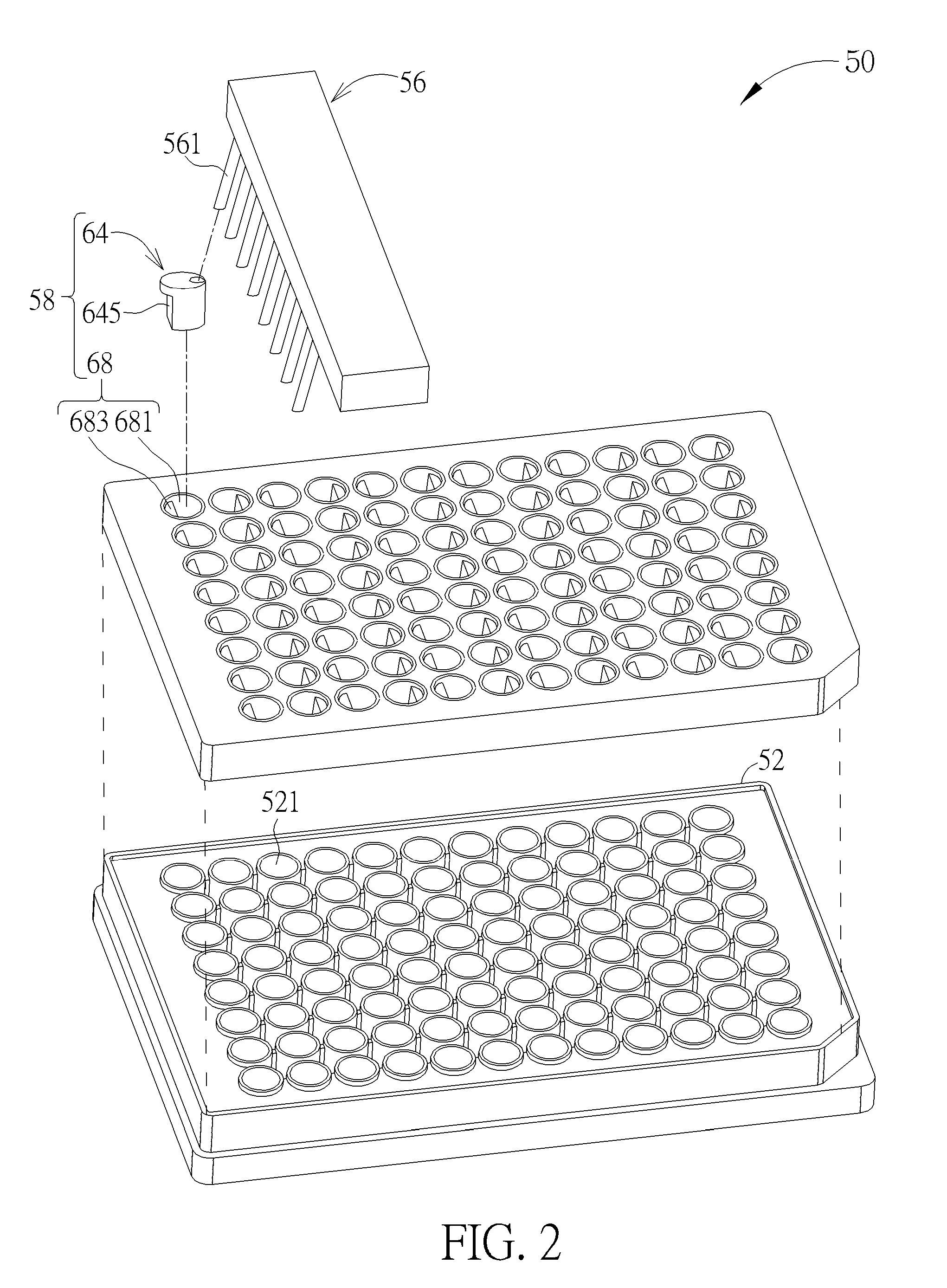

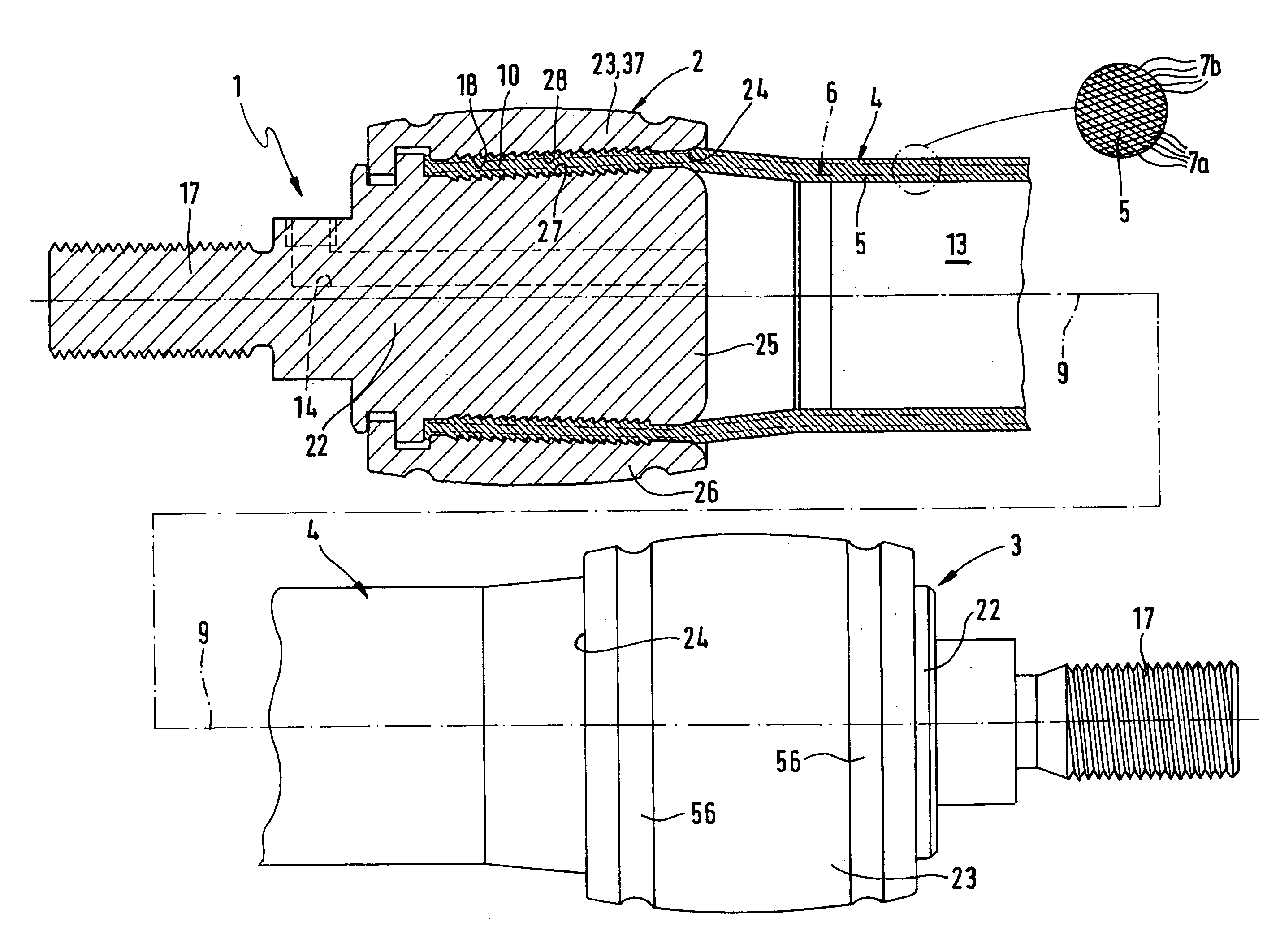

Guiding device for guiding a despenser to draw solution from at least one well on a microplate

ActiveUS9464739B2Avoid drawingImprove convenienceBurettes/pipettesPipe-jointsMicrowell PlateEngineering

The present invention discloses a guiding device for guiding a dispenser to draw solution from at least one well on a microplate. The guiding device includes a column body whereon a first opening and a second opening are formed on opposite sides, and a slotting structure passing through the column body and communicating with the first opening and the second opening. A pipe of the dispenser passes through the first opening, the slotting structure and the second opening to reach inside the at least one well on the microplate for drawing the solution contained in the at least one well.

Owner:WISTRON CORP

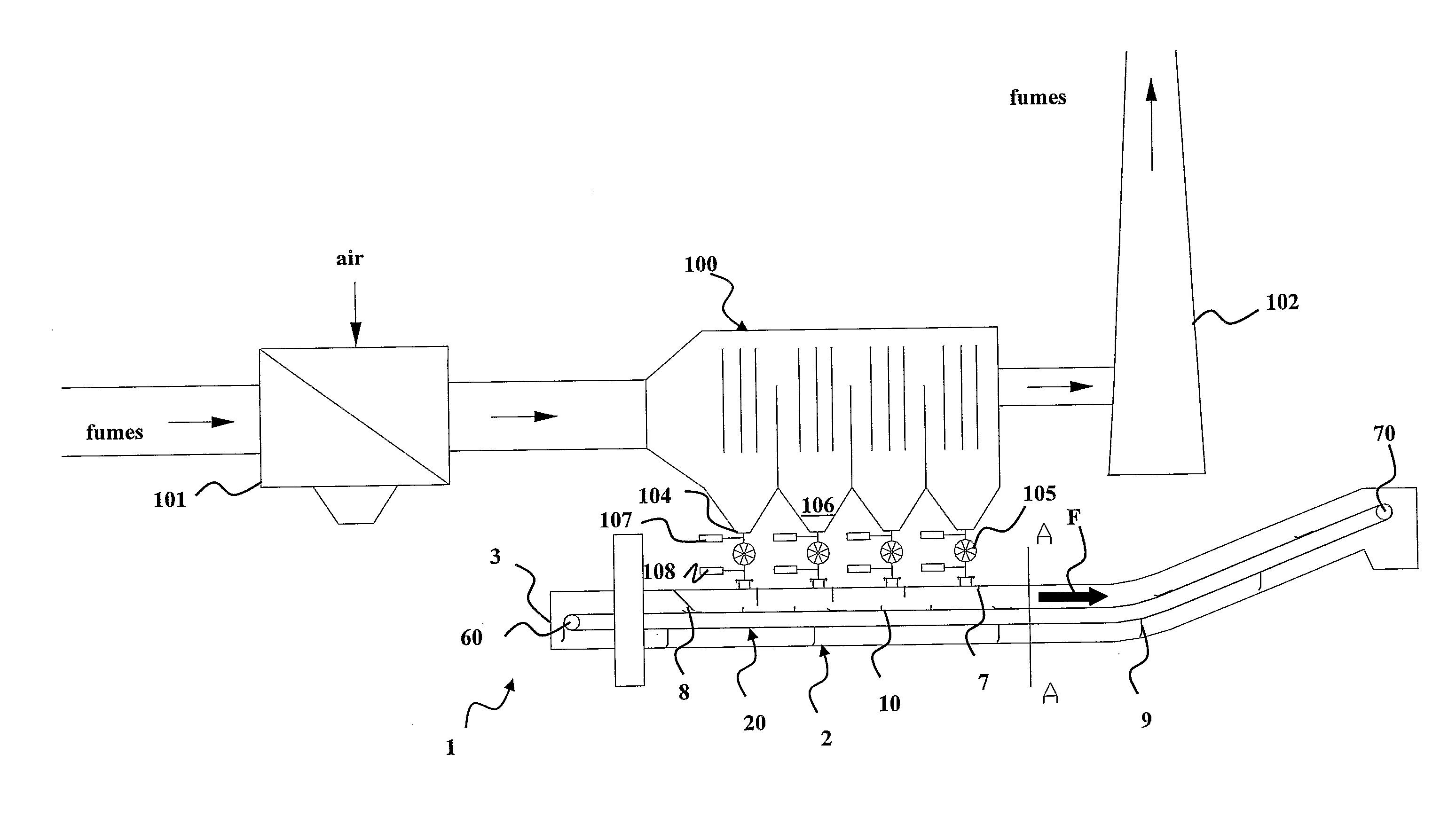

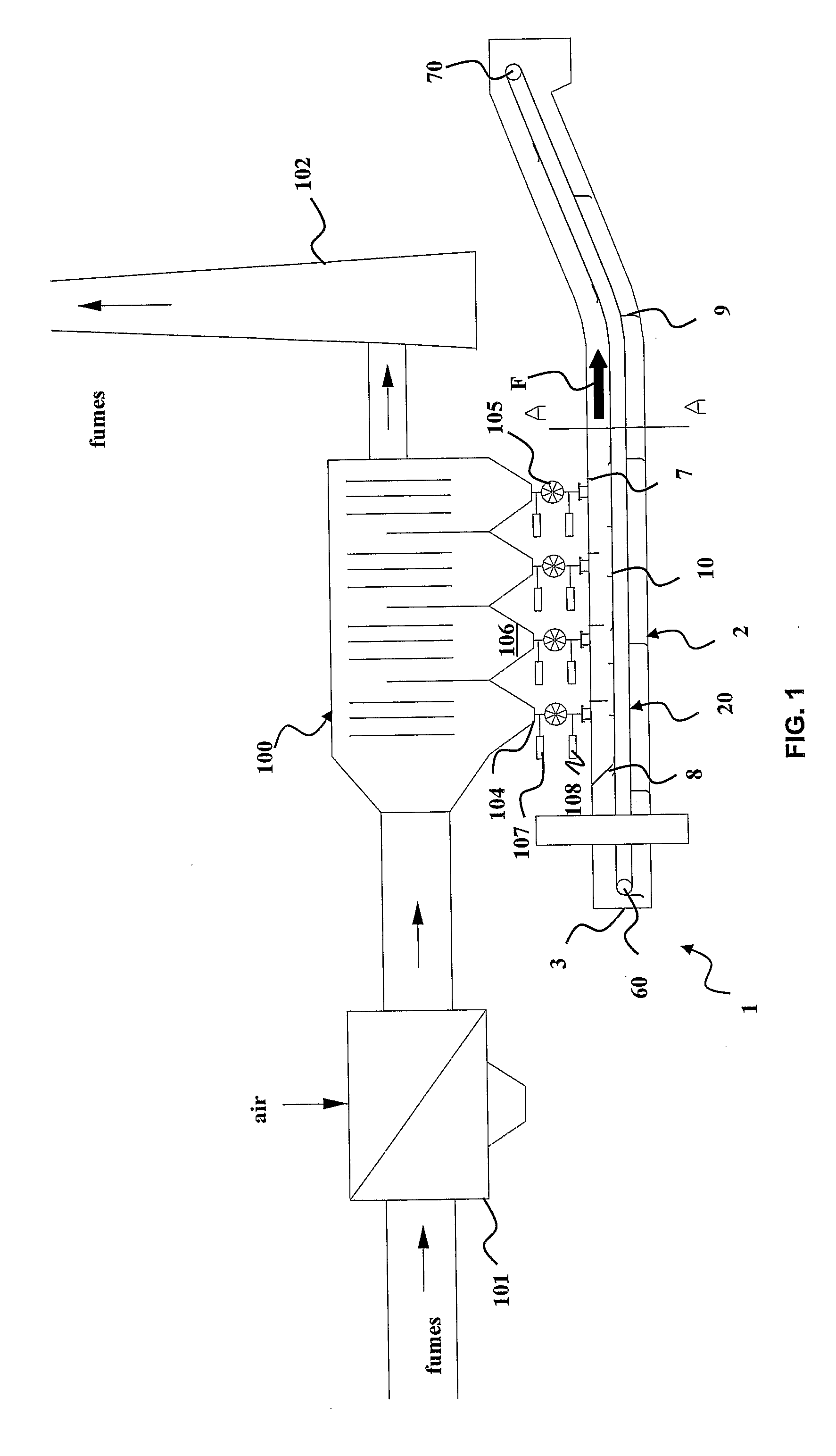

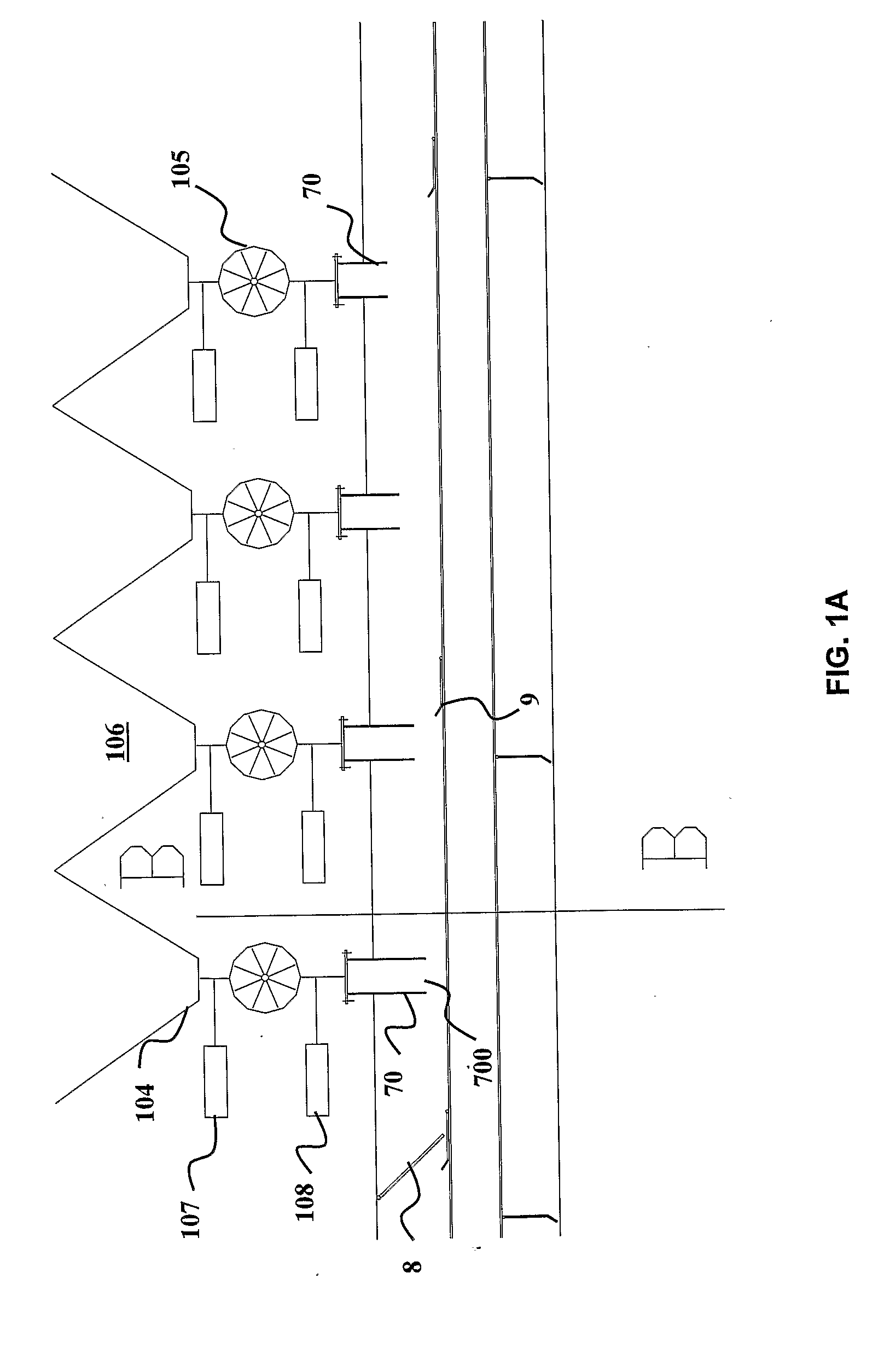

System for extraction and transport of light ashes by means of a steel belt conveyor

InactiveUS20120183376A1Wear problemExpenditure complexityConveyorsTravelling cranesRelative motionFly ash

A transport apparatus for dry extraction and transport of fly ashes produced inside solid fuel boilers, adapted to be associated with a fume dedusting system and including: a metal belt conveyor, having a plurality of slats partially overlapped, adapted to support a bed of fly ashes to transport the bed along a preset path, and a sealed metal casing inside which the slats move; and containment means for fly ashes, adapted to confine the ashes on the slats and along the transport path so as to limit relative motion between ashes and conveyor, which means comprises transverse boards, leveling members, side boards and a movable rear baffle.

Owner:MAGALDI IND SRL

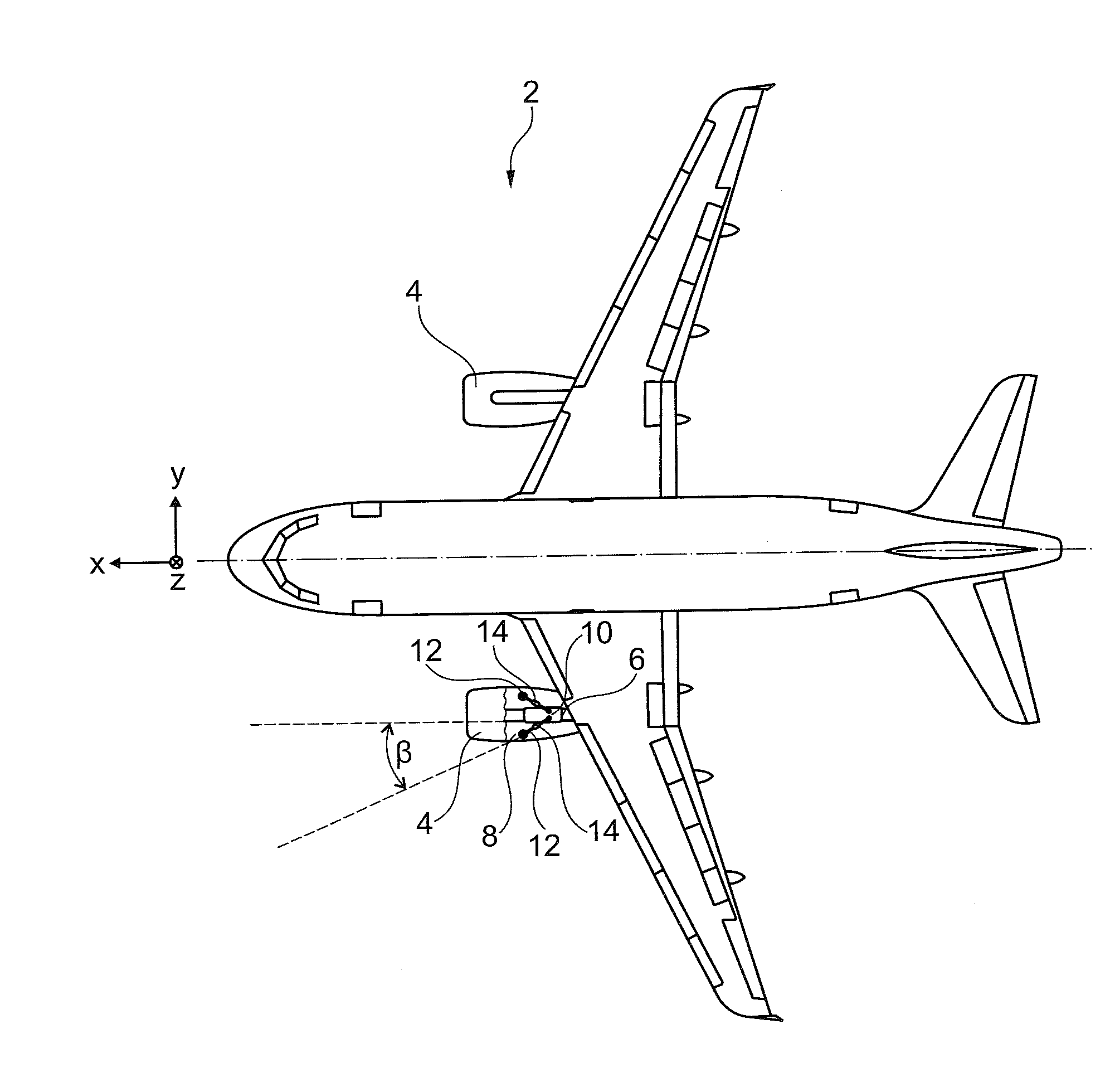

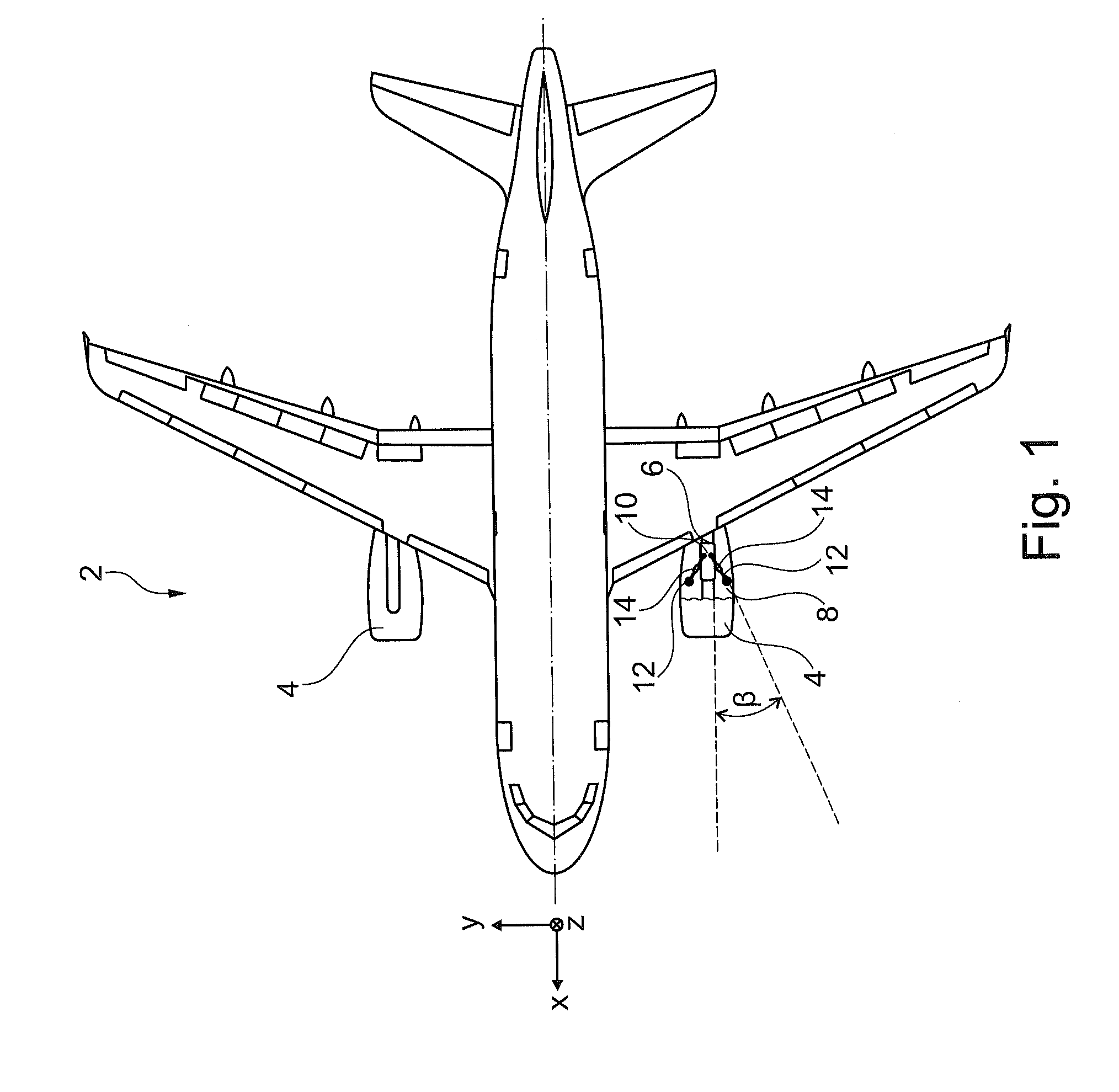

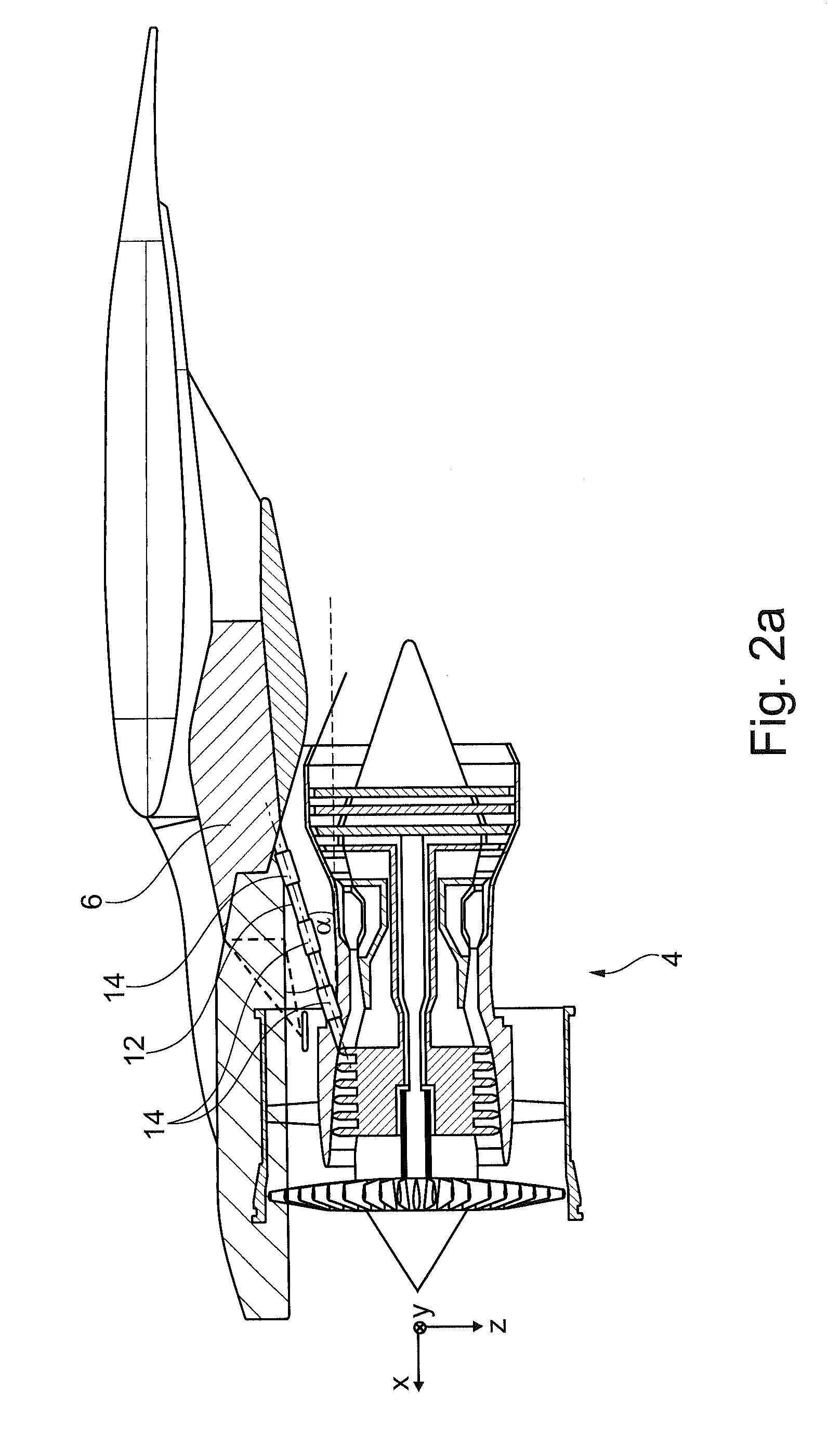

Method and apparatus for determining the thrust on a vehicle

ActiveUS20130311112A1Simple methodHigh precisionPower plant arrangements/mountingForce measurementEngineeringStructural element

A method for determining the thrust of at least one engine, which is held on a supporting structure of a vehicle, includes the steps of acquiring the elongation of at least one structural element onto which the thrust of the at least one engine acts, by means of at least one strain gage; calculating the force causing the elongation in the at least one structural element, taking into account the materials characteristics of the structural element; and determining the thrust of the at least one engine as an effective force component in the direction of thrust of the vehicle. It is thus not necessary to carry out an estimate of the thrust on the basis of other physical variables such as shaft speeds, pressure or exhaust gas temperature of engines.

Owner:AIRBUS OPERATIONS GMBH

Actuating means able to be activated by fluid action

InactiveUS20050265870A1Minimize dangerAvoid damageFlexible member pumpsFluid-pressure actuatorsEngineeringBiological activation

Owner:FESTO AG & CO KG

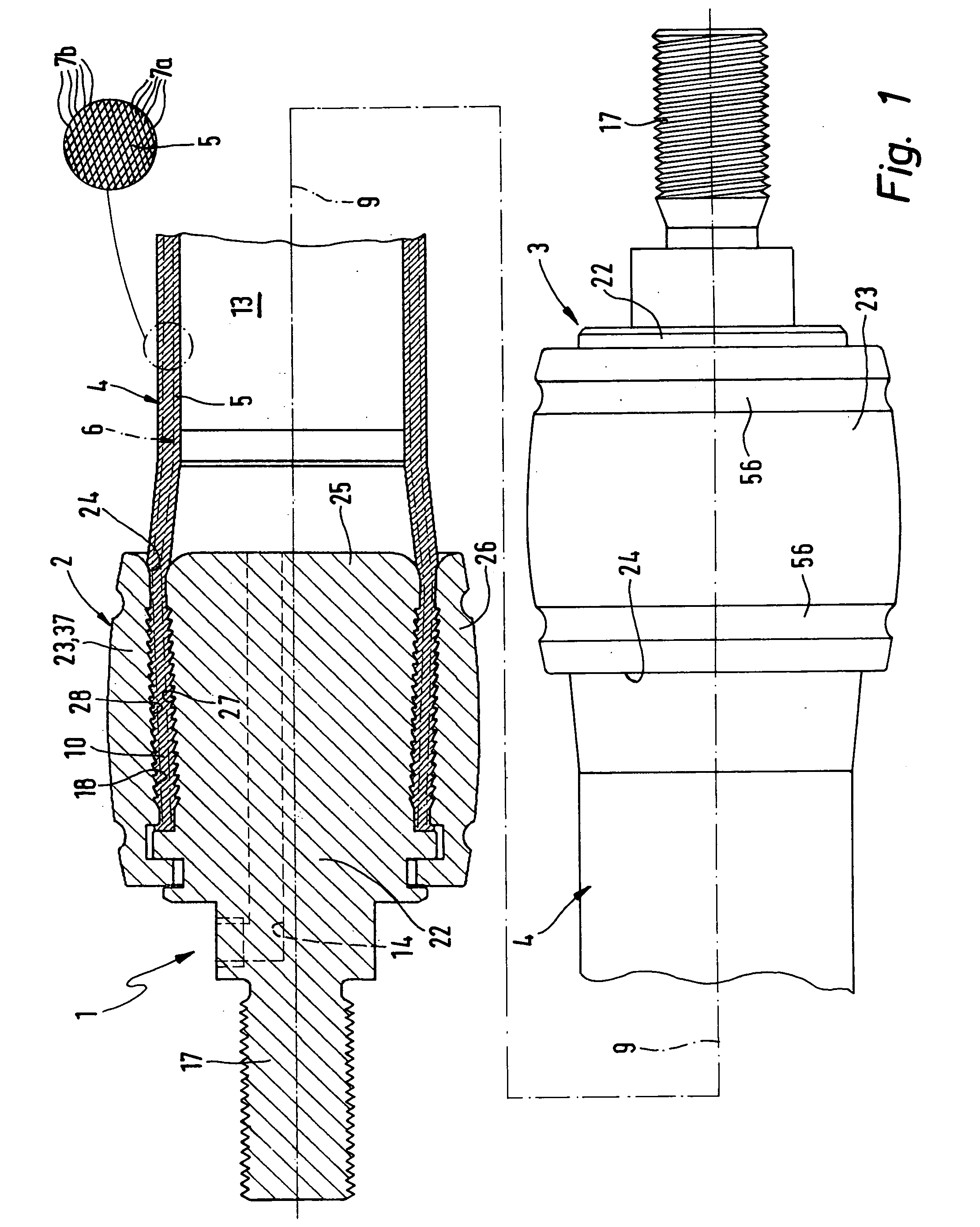

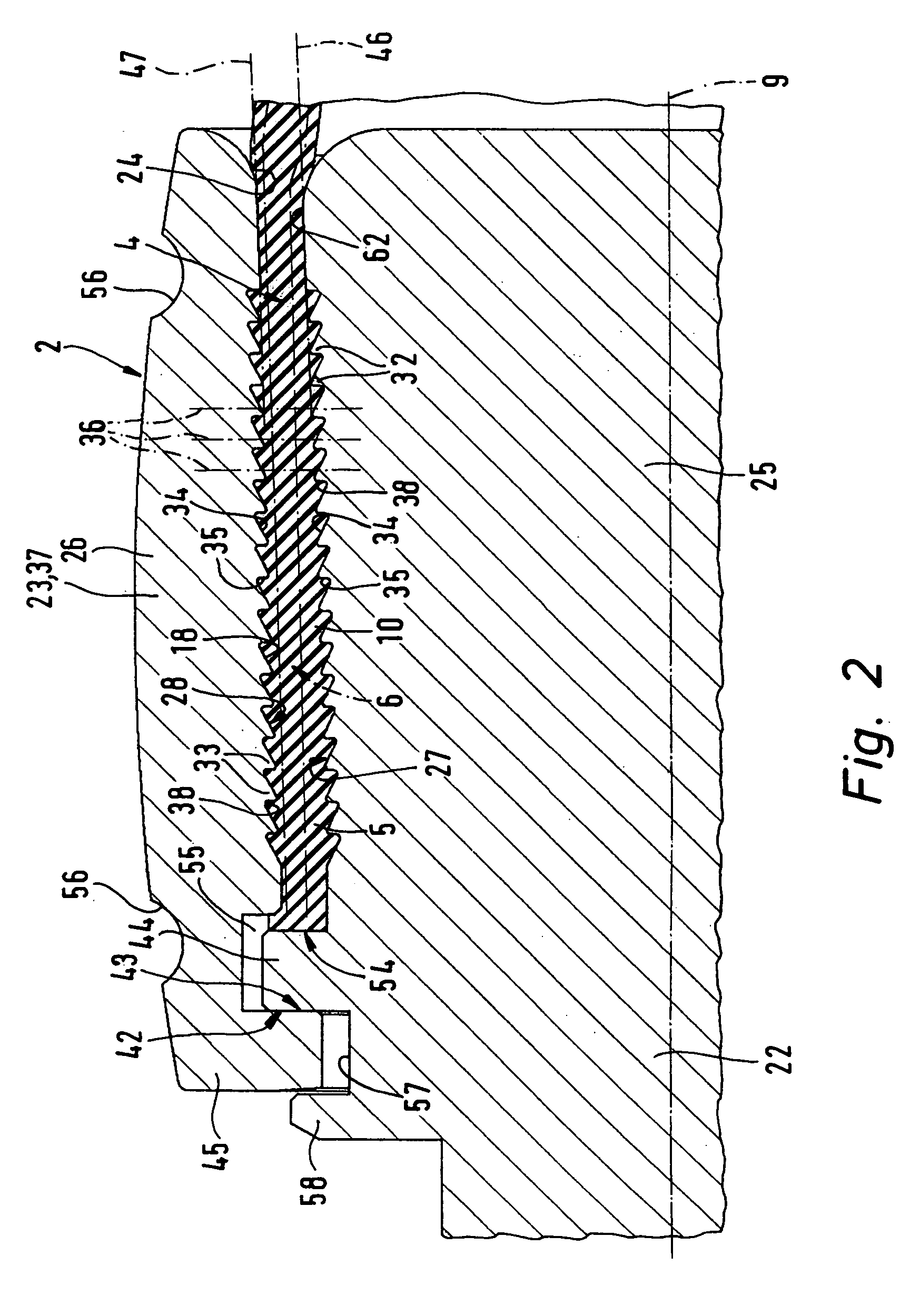

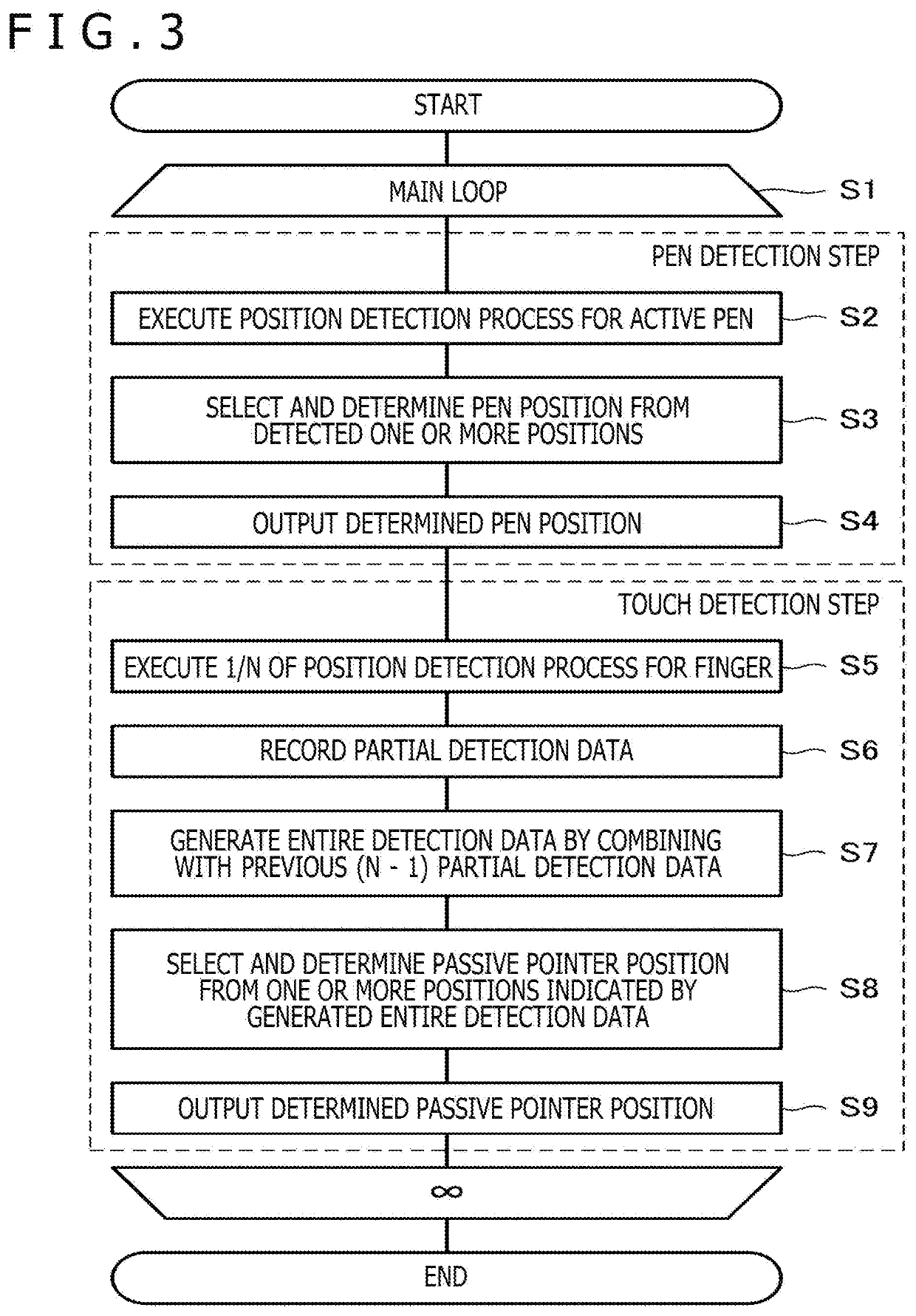

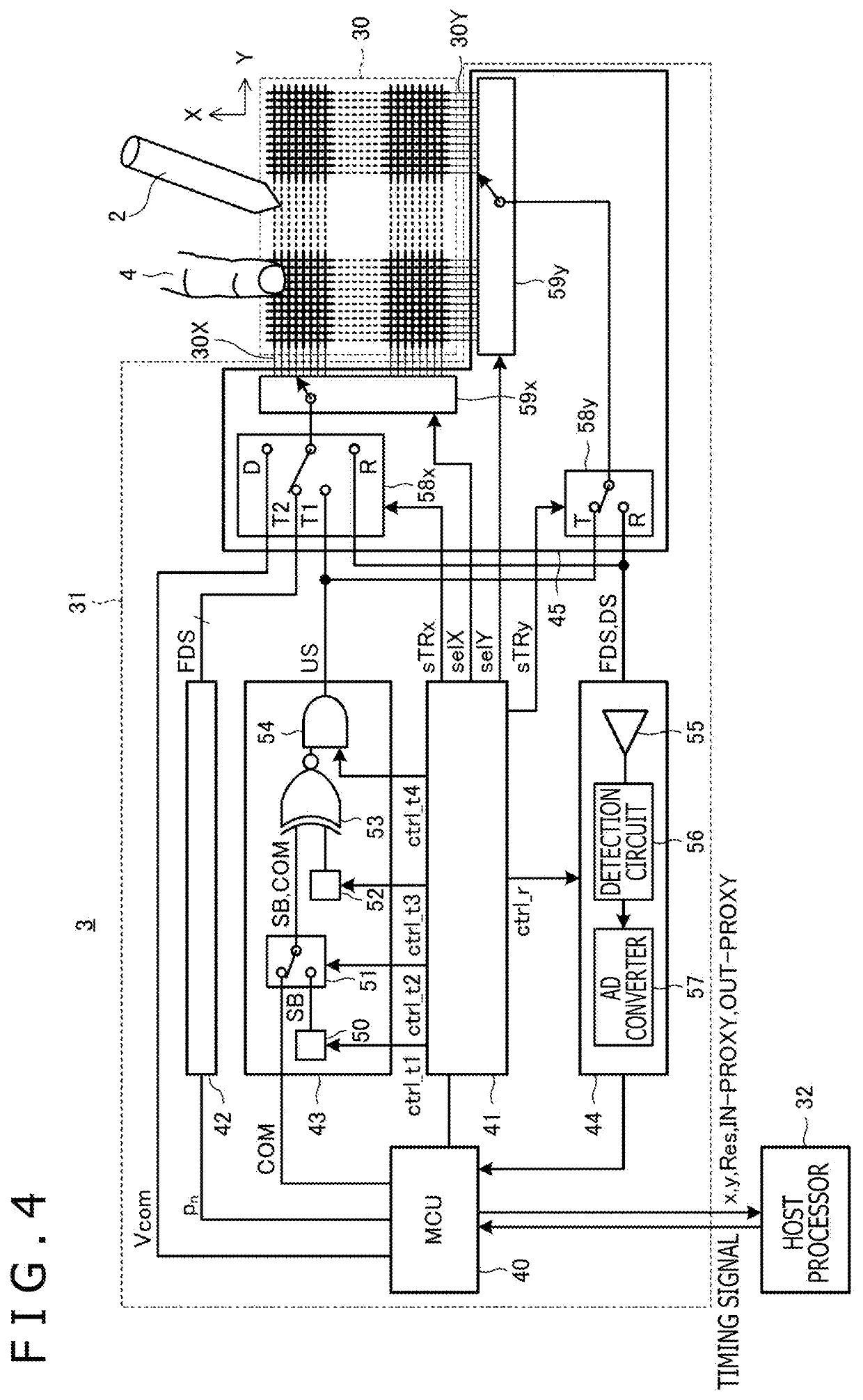

Pointer position detection method

A pointer position detection method performed by a sensor controller connected to a sensor pattern includes: detecting a pen signal transmitted via a pen electrode provided at a distal end of an active pen, detecting a position of the active pen based on a level of the pen signal detected; detecting one or more candidate touch positions of a passive pointer that does not transmit a signal by detecting one or more changes of one or more capacitances of the sensor pattern, and outputting, as the position of the passive pointer, the one or more candidate touch positions remaining after excluding the position of the active pen from the one or more candidate touch positions.

Owner:WACOM CO LTD

Adjustable-flow 3D printing jet head

InactiveCN109263044AFlow adjustableRealize continuous self-primingManufacturing heating elementsApplying layer meansEddy current effectPiston

The invention discloses an adjustable-flow 3D printing jet head, which comprises a jet head main body, a piston, a rotating disc and a heating cavity, wherein the top end inside the jet head main bodyis provided with a piston cavity; a heating cavity is arranged inside the jet head main body arranged under the piston cavity; a reserving cavity is arranged inside the jet head main body arranged under the heating cavity; a funnel-shaped discharging opening is formed in the bottom of the jet head main body arranged under the reserving cavity. Through the vertical movement of the piston, the continuous self-suction of raw materials is realized without machine halt for replacing a jet head device; the printing efficiency is improved; when one end of a screw rod penetrates through different inserting holes to be fixed with a rotating disc, the flow of the jet head can be changed; meanwhile, when the piston downwards moves, a fixing rod rotates; the raw materials can downwards move along external screws and are discharged out, so that raw materials inside the piston cavity generate an eddy current effect; similar stirring is performed; the raw materials are prevented from being solidified in the piston cavity; the heating efficiency of an electric heating pipe on the raw materials is also improved; the raw materials are prevented from generating wiredrawing at the funnel-shaped discharging opening after the jetting is completed.

Owner:ANHUI POLYTECHNIC UNIV

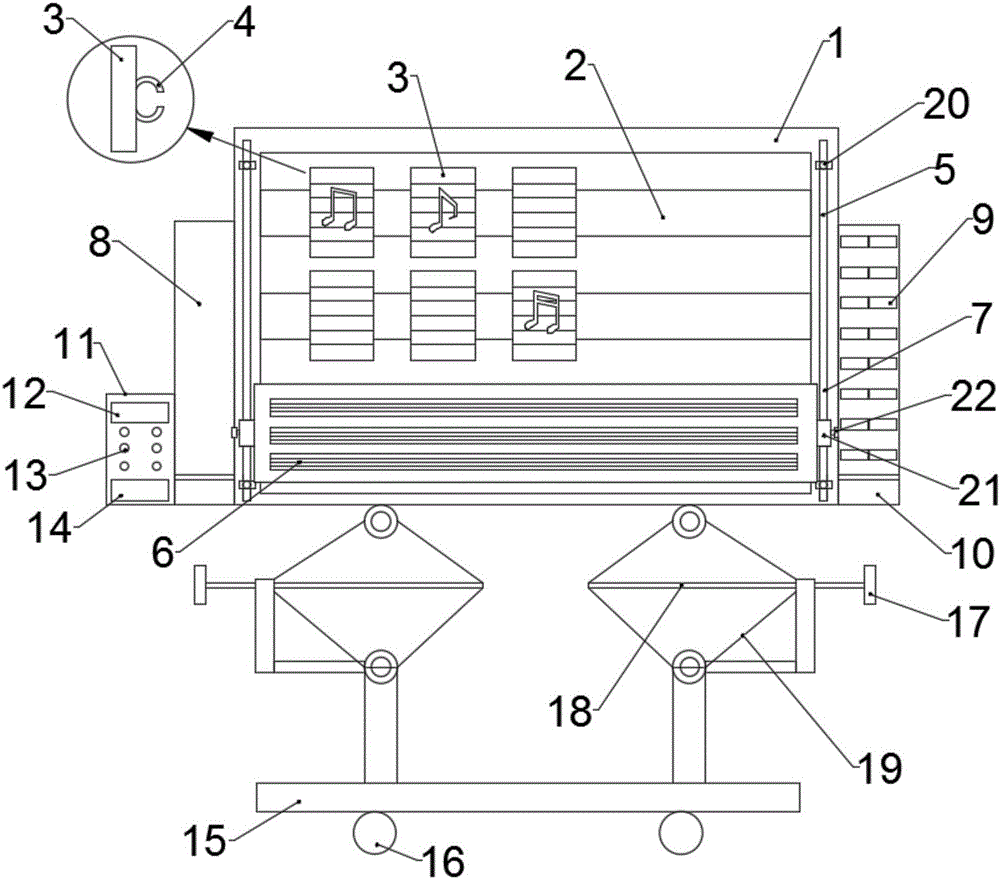

Musical notation writing demonstration device for college music education

The invention discloses a musical notation writing demonstration device for college music education, and the device comprises a demonstration plate body. The interior of the demonstration plate body is provided with a plurality of longitudinally distributed cylindrical rollers, and a note plate is clamped on the cylindrical rollers through buckles fixed on a back surface. A musical notation writing plate is disposed between two sliding column fine rods, and the central parts of two sides of the musical notation writing plate are provided with moving sliding sleeves. The left side edge of the demonstration plate body is provided with a lyric display region, and the left side edge of the demonstration plate body is provided with a music list region. The lower end of the left side of the demonstration plate body is provided with a recording player, and the bottom of the demonstration plate body is provided with a height adjustment apparatus. According to the invention, the note plate is clamped on the cylindrical rollers through the buckles fixed on the back surface, and a teacher can change different note plates conveniently according to the needs, and also can carry out the comparative demonstration, thereby bringing convenience to students for enhancing the memorizing in a discriminating process.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

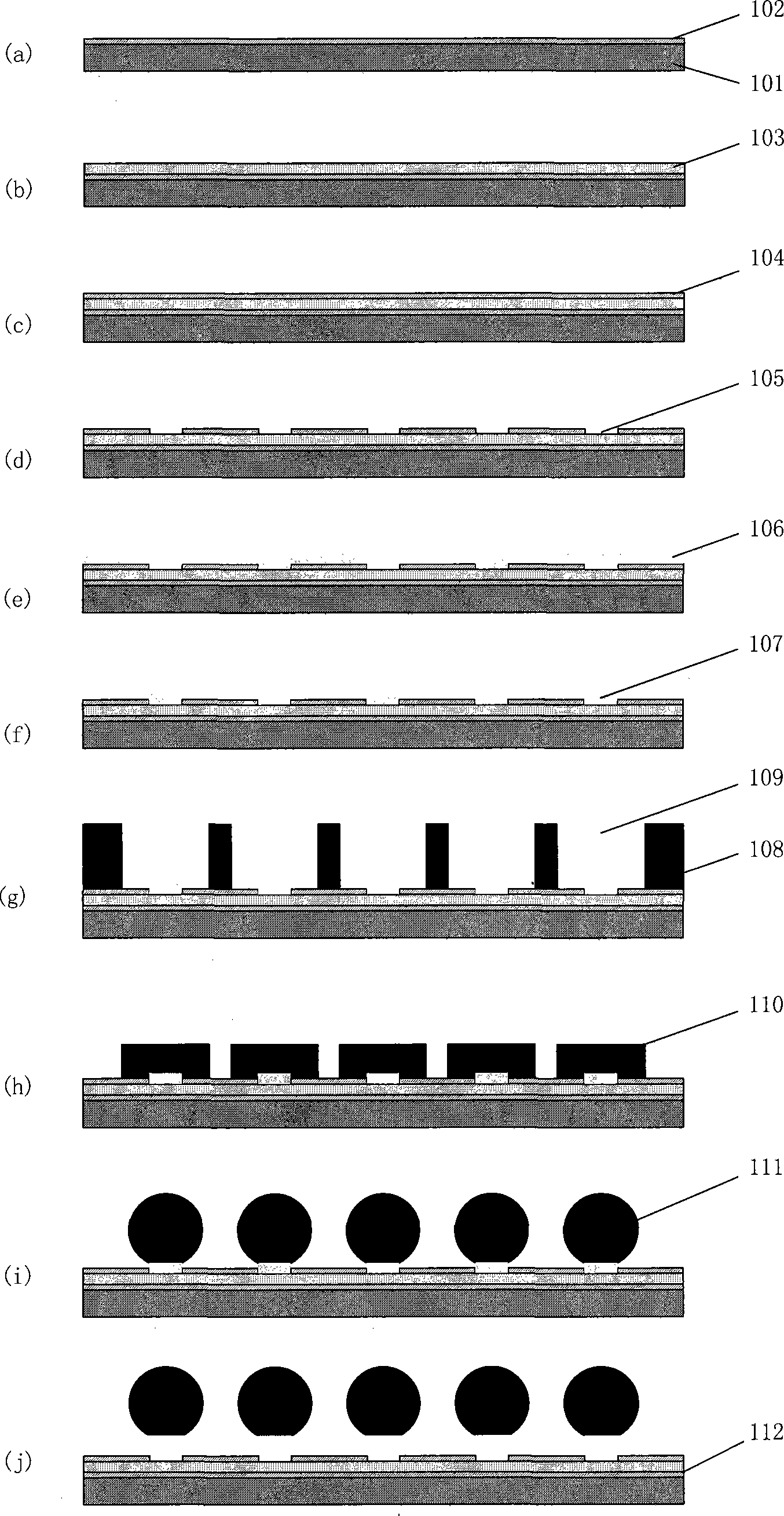

Method for producing tiny soldered balls with repeatedly-usable substrates

InactiveCN101246828ANarrow particle size distributionPrevent surface oxidationSolid-state devicesSemiconductor/solid-state device manufacturingResistSputtering

The invention relates to a method for manufacturing a small solder ball, in which a substrate is reusable. The invention is characterized in: firstly, the reusable substrate is prepared by means of IC manufacture process: a silicon wafer is used as a base, a metal conducting layer is sputtered from the front after heat oxidation treatment; secondly, the small solder ball is manufactured on the reusable substrate: a metal sacrificial layer is sputtered on the substrate to cover the opening of the conducting layer, thick photosensitive resist is coated and an electroplating window is photoetched, then solder is electroplated, the thick photosensitive resist is removed after electroplating, the solder is reflowed to form a solder ball, thereafter the metal sacrificial layer is corroded to be removed, so that the solder ball can drop off completely from the reusable substrate, and finally the solder ball is collected. According to the invention, the manufacturing procedure is simple and consumes small energy, the process has good controllability, the bottleneck of low productivity is overcome; the manufactured solder ball has smooth surface, good sphericity and uniform size, with the smallest grain diameter being 0.15mm.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

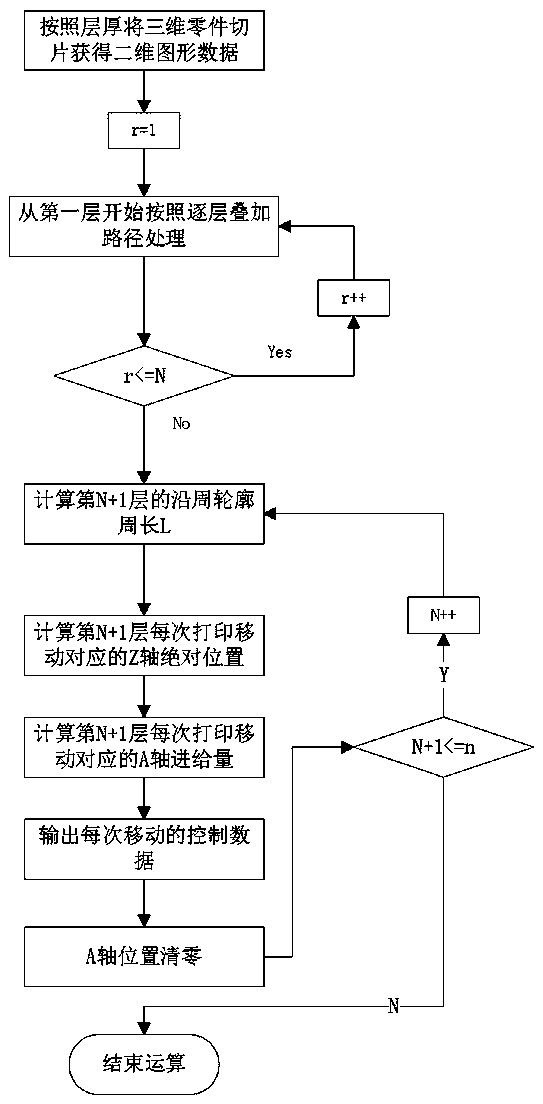

Product molding method based on FDM technology

ActiveCN109109311AReduce downtimeReduce the number of jumpsAdditive manufacturing apparatus3D object support structuresElectrical and Electronics engineering3D printing

The invention belongs to the technical field of 3D printing, and discloses a product molding method based on a FDM technology. The product molding method comprises: (1) printing the circumferential contour of the first layer pattern of a bottom surface according to the input two-dimensional pattern data of the bottom surface; (2) printing an internal structure in a reciprocating movement manner byusing the previous printing ending point as a starting point for printing the bottom surface internal structure; (3) after printing the first layer pattern, moving a printing head to the circumferential contour of the next layer pattern according to the coordinates set by the two-dimensional pattern data, and returning to the step (1) until the patterns on all layers of the bottom surface are completed; (4) moving the printing head to the circumferential contour of the pattern on the bottom surface; (5) printing a side wall by the printing head according to a designed spiral lifting path until the side wall is printed; and (6) if the product has a top surface, returning to the step (1), and printing the top surface by using the same method as the bottom surface printing, otherwise, endingthe printing. According to the present invention, the printing efficiency of the method is high.

Owner:NINGXIA KOCEL MOLD

SMT chip-mounting technology

InactiveCN104029506AGuaranteed stabilityAvoid drawingOther printing apparatusSilver pasteSilver colloid

The invention discloses an SMT chip-mounting technology which comprises the following steps that a. a steel plate web plate is erected on a silk-screen machine table, then a steel ruler is used for printing, and the fact that the thicknesses of conducting silver paste printed from sheet materials are the same is guaranteed; b. silver colloid printing ink is poured onto the steel plate web plate, a steel ruler scraper is arranged on the machine table, a printing stroke is debugged, the sheet materials are placed on the machine table, a STAR key is pressed, after the steel ruler scraper and the steel plate web plate coincide, the scraper walks from left to right, silver colloids on the steel plate web plate are permeated onto the sheet materials through pressure, and silver colloid points are formed; and c. after silver colloid printing, the materials are put into an SMT automatic ship mounter, an SMT chip-mounting feeder is arranged, then a mounting program is debugged on computer software, after machine debugging, a lamp can be arranged, after lamp mounting, roasting is carried out in an drying oven, the materials are taken out, manual dispensing is carried out, and after dispensing, a next procedure is carried out for assembling. The technology has the advantages that the stability of scraper pressure during printing is guaranteed, and the speed and the quality pass percent are greatly improved compared with the prior art.

Owner:HAIMEN ZHONGDE ELECTRONICS DEV CO LTD

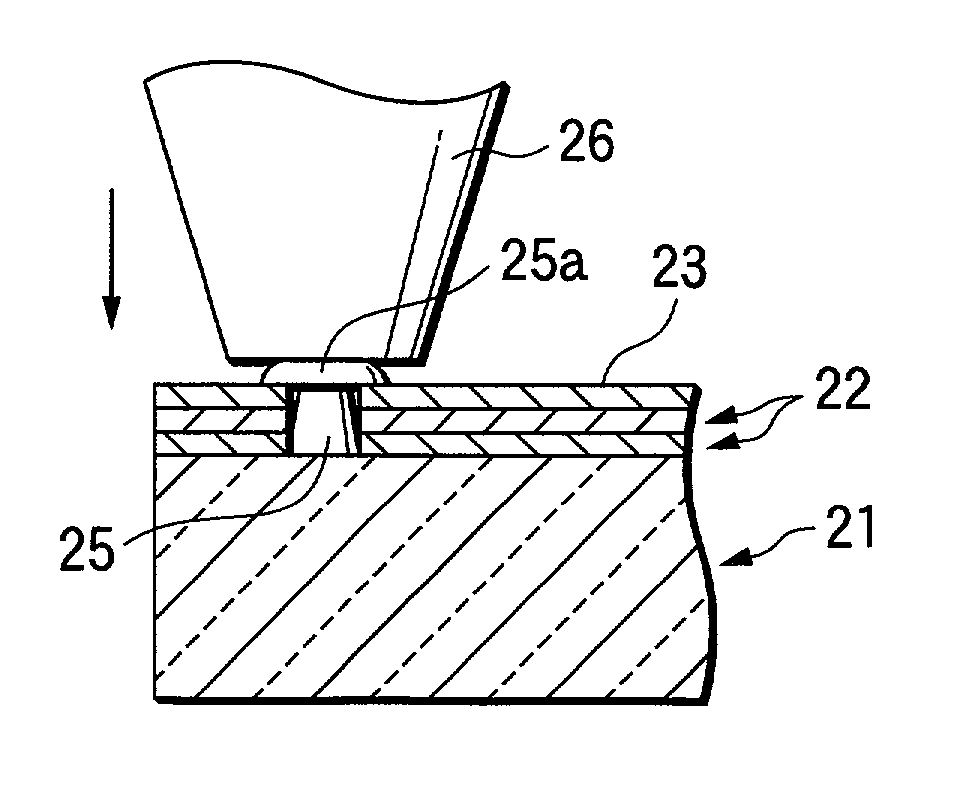

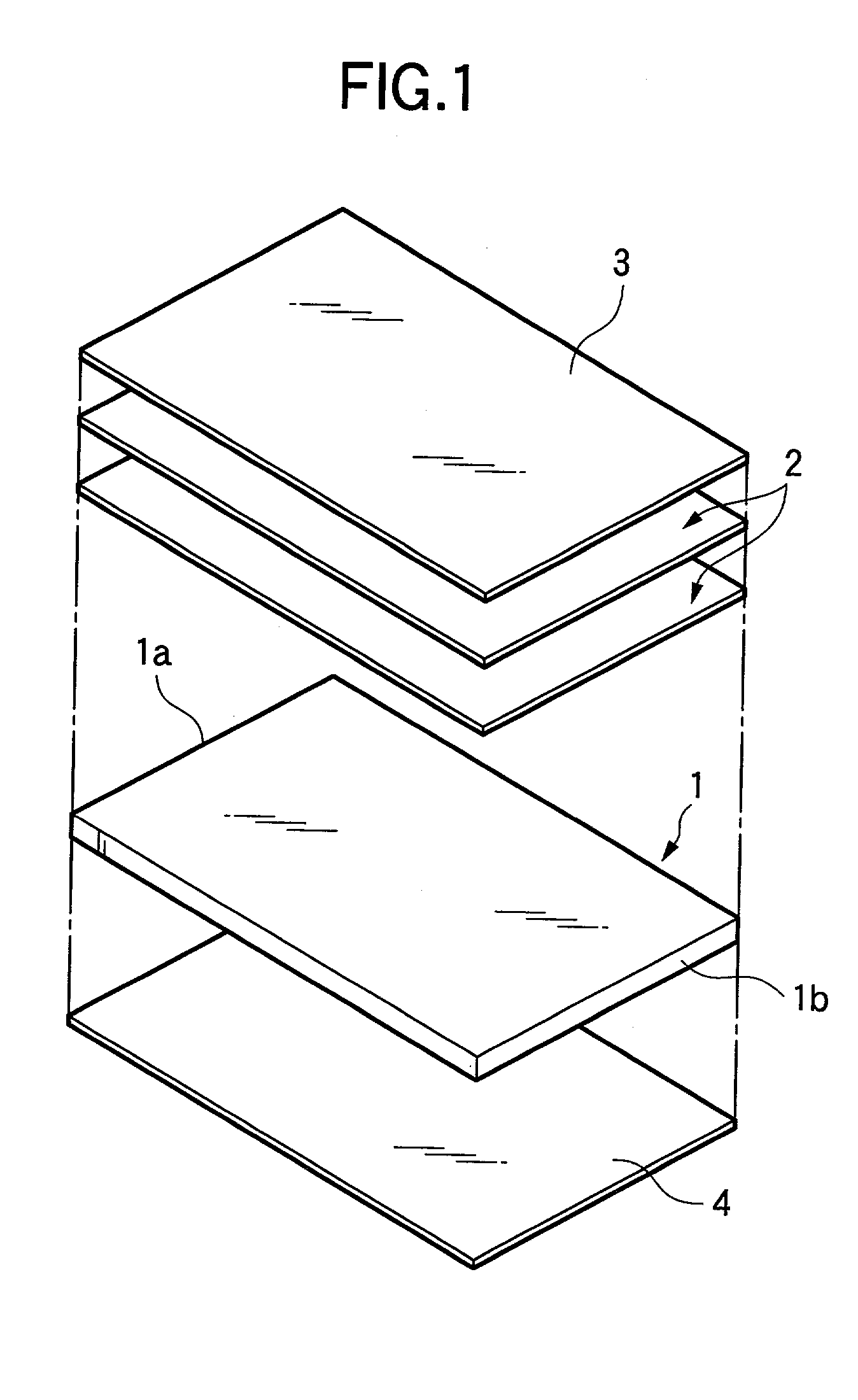

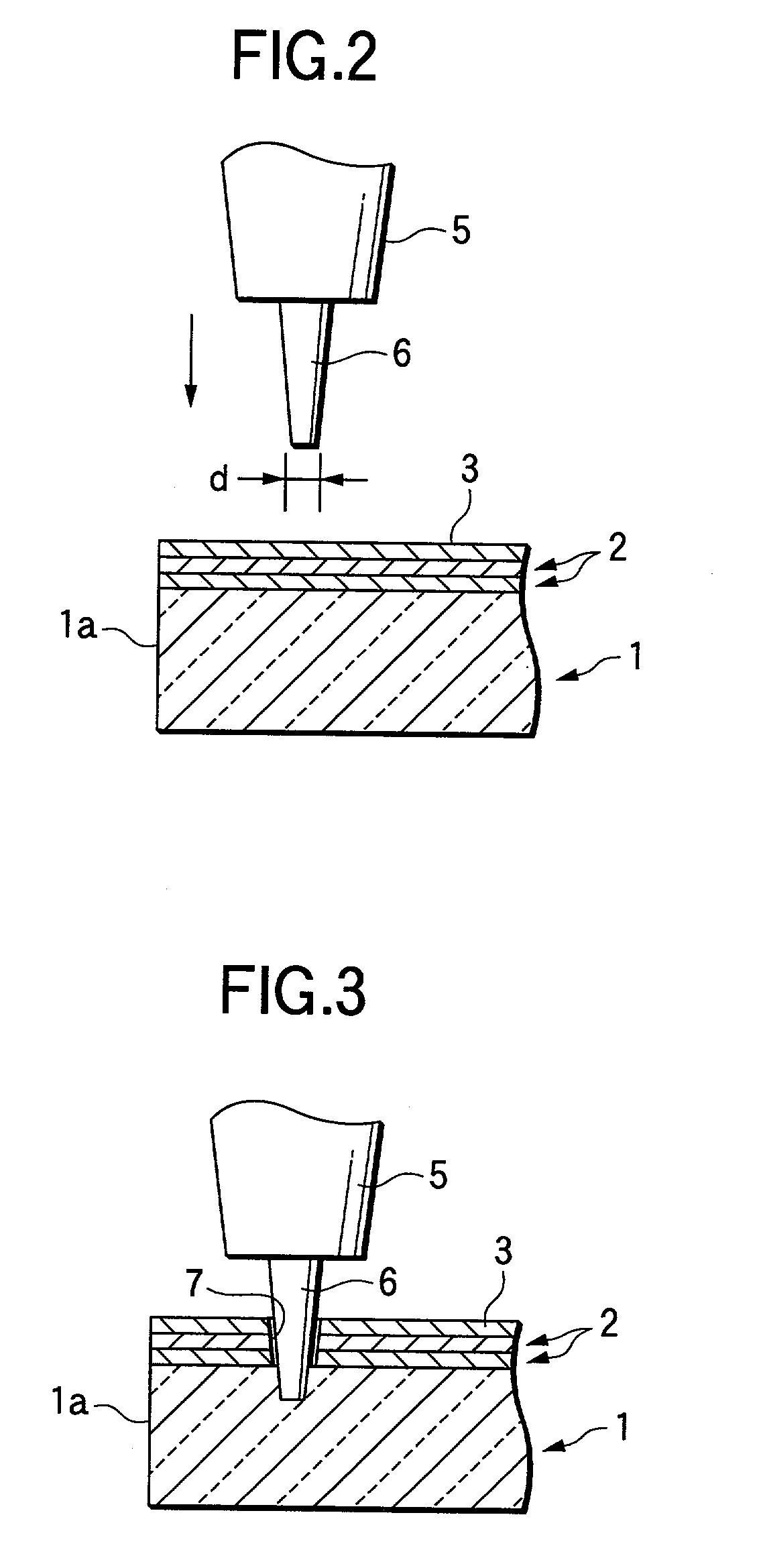

Back light unit for liquid crystal display device and method for manufacturing the unit

InactiveUS7173677B2Small sizeHeavy weightMechanical apparatusLight guides for lighting systemsLiquid-crystal displayLight guide

A pin 6 provided at a horn 5 for ultrasonic welding is press-fitted to the depth reaching the light guide plate 1 breaking through the various kind of sheets 2 and 3 from surface side thereof.Another embodiment of the invention is that pins 25 constructed so as to break through various kind of sheets 22 and 23 on the surface of the plate are provided on the light guide plate 21, and the various kind of sheets 22 and 23 are fixed on the light guide plate 1 by distorting by caulking using ultrasonic vibration of the tip end of the pin.

Owner:ROHM CO LTD

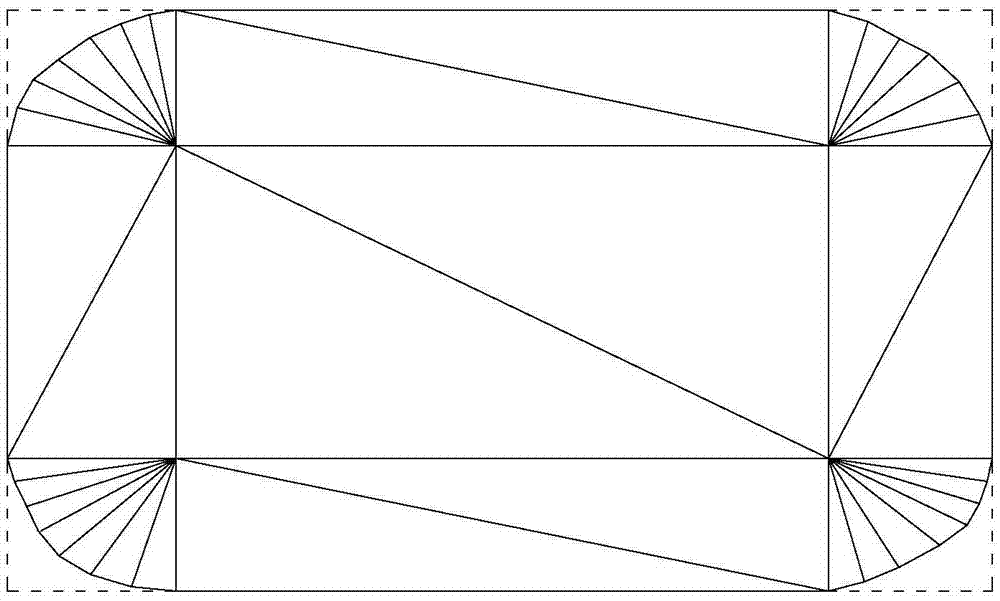

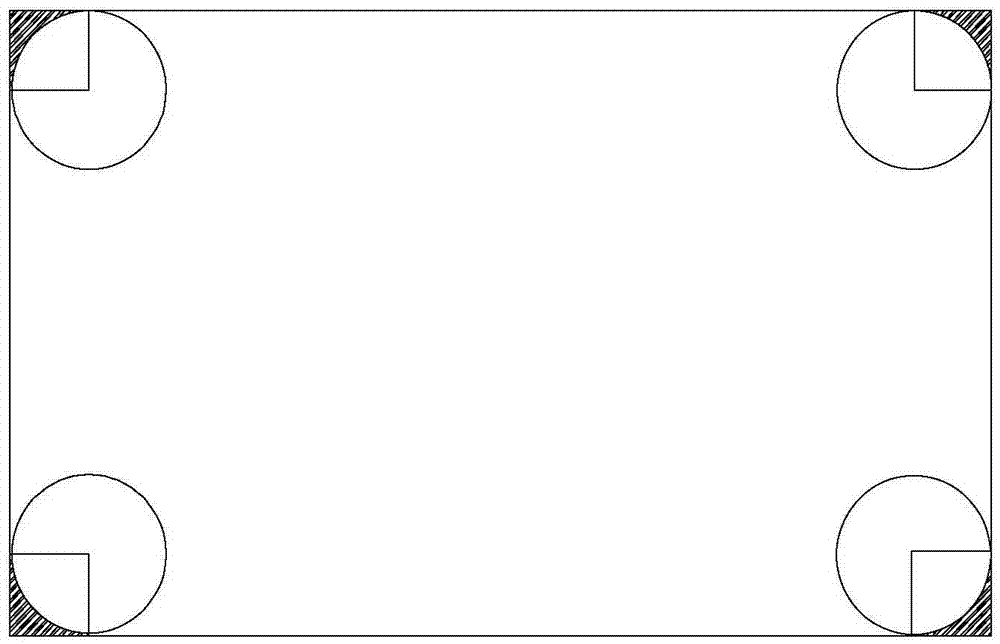

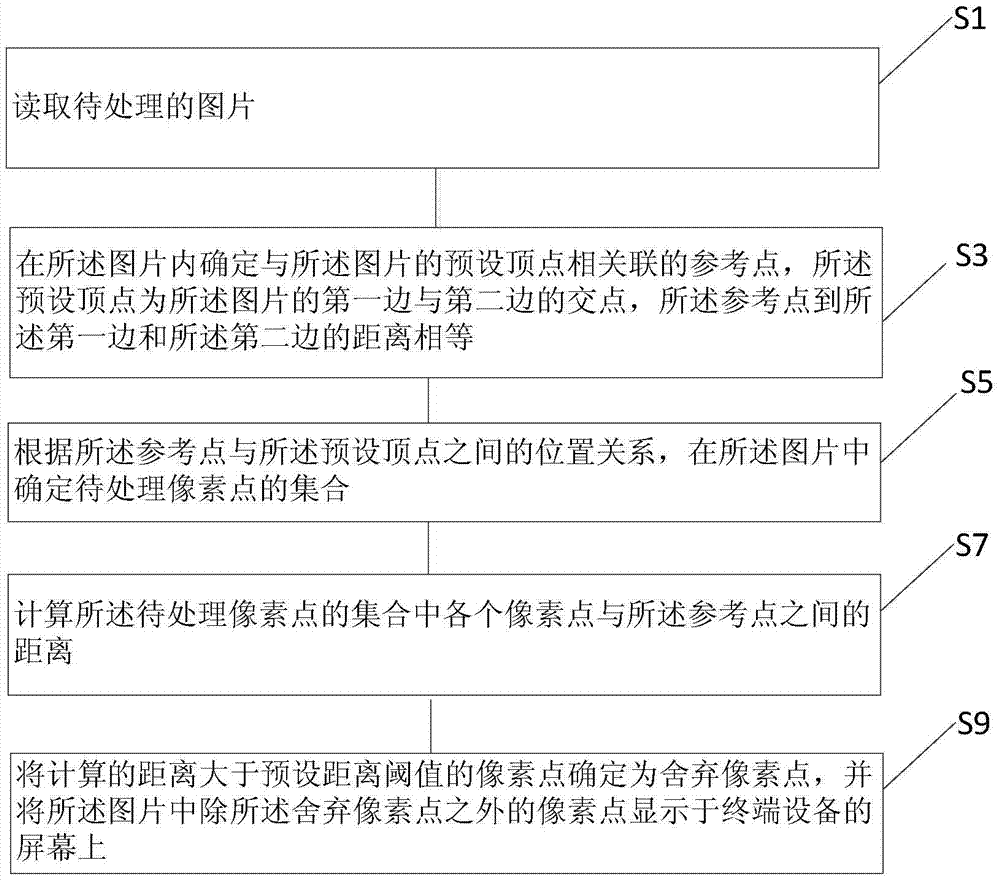

Methods and device of displaying picture

ActiveCN107229439AAvoid drawingDigital output to display deviceComputer graphics (images)Terminal equipment

The application provides a method and a device of displaying a picture. The method comprises: determining a reference point associated with a preset vertex in the picture, wherein the preset vertex is an intersection point of a first edge and a second edge of the picture, and a distance from the reference point to the first edge and a distance from the reference point to the second edge are equal; determining a set of to-be-processed pixel points in the picture according to a position relationship between the reference point and the preset vertex; calculating distances between all the pixels points in the set of the to-be-processed pixel points and the reference point; and determining the pixel points, of which the calculated distances are greater than a preset distance threshold value, as discarded pixel points, and displaying the pixel points other than the discarded pixel points in the picture on a screen of a terminal device. According to the method and the device of displaying the picture provided by the embodiment of the application, a picture with smooth rounded-corner areas can be drawn in a case where utilizing basic elements to segment the picture is avoided.

Owner:ALIBABA GRP HLDG LTD

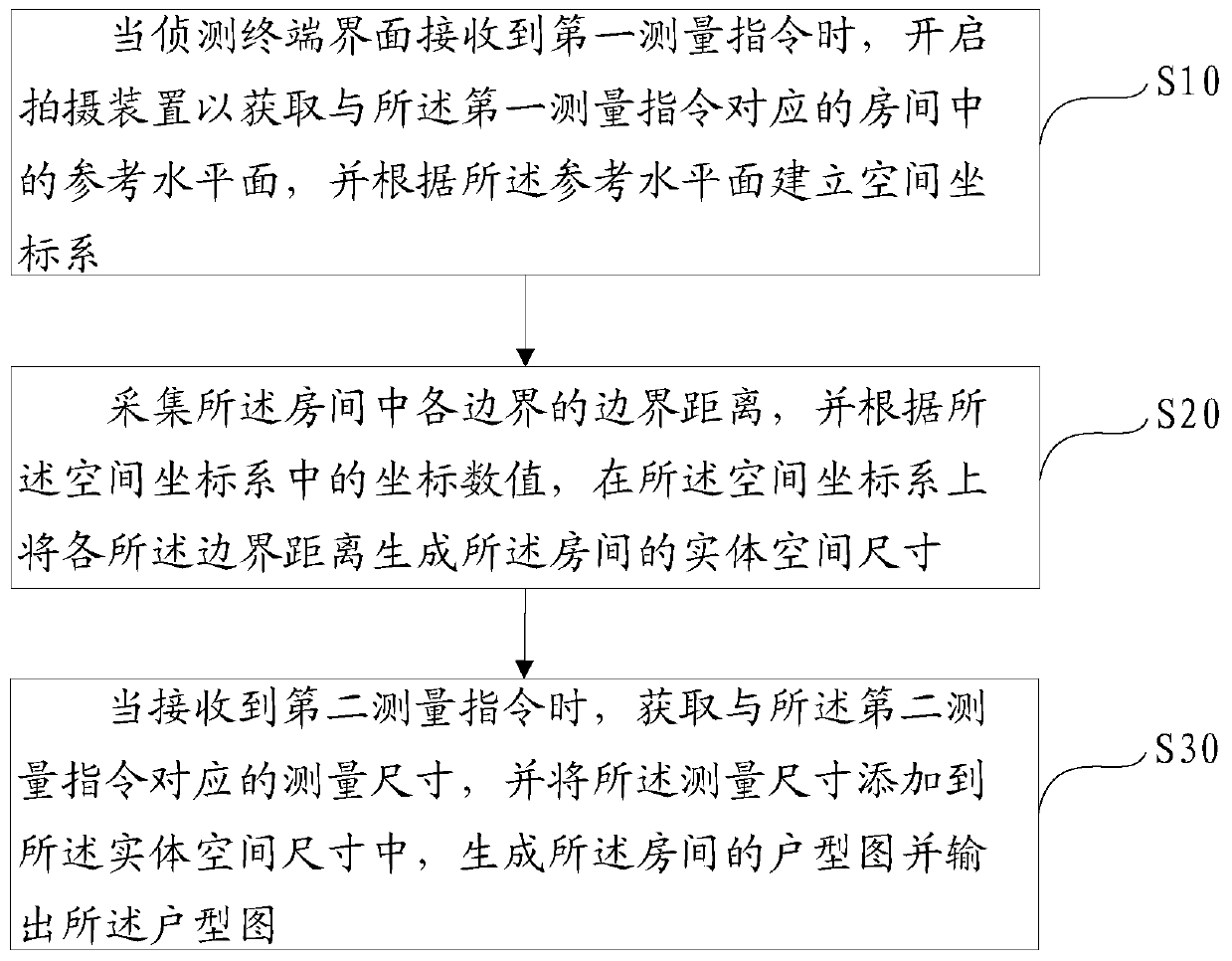

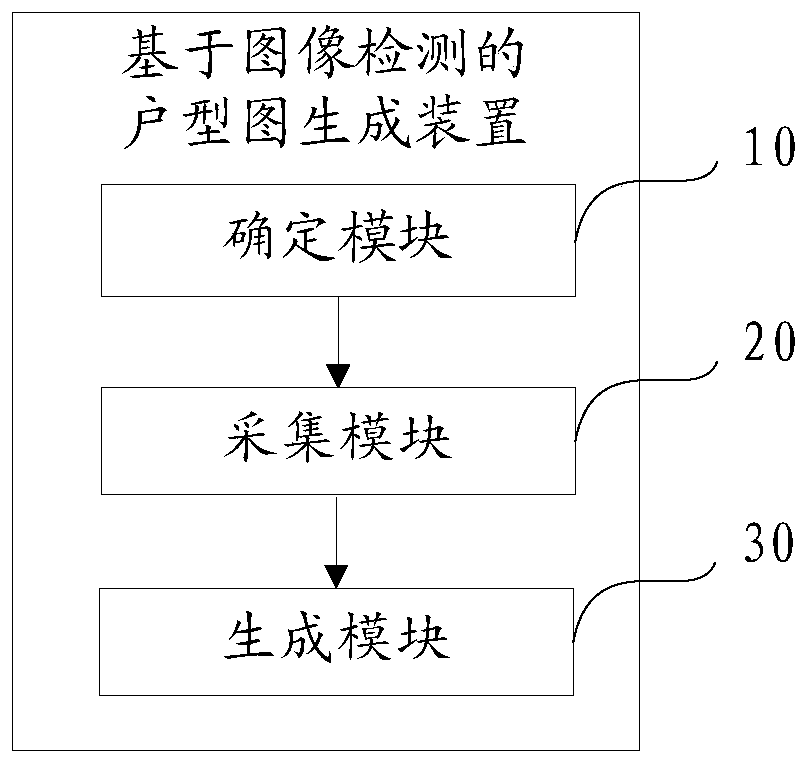

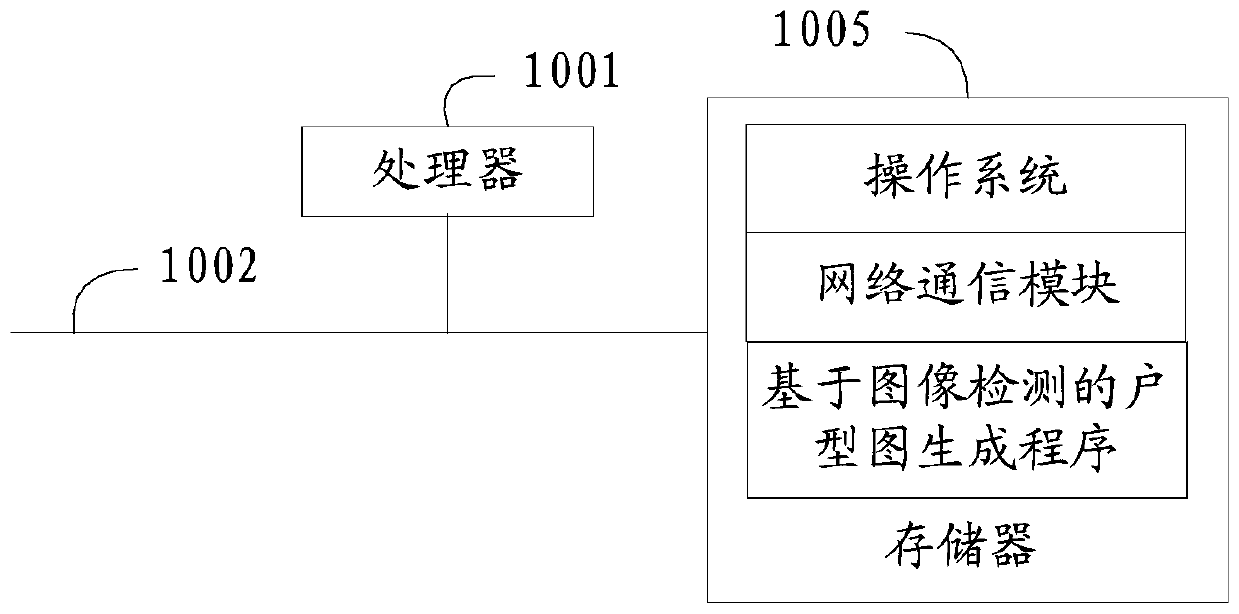

House type chart generation method, device and equipment based on image detection and storage medium

InactiveCN110686648AImprove production efficiencyAvoid Manual MeasurementsPicture taking arrangementsUsing optical meansImage detectionMechanical engineering

The invention discloses a house type chart generation method, device and equipment based on image detection and a storage medium. The method comprises the steps: when detecting that a terminal interface receives a first measurement instruction, starting a shooting device to obtain a reference horizontal plane in a room corresponding to the first measurement instruction, and establishing a space coordinate system according to the reference horizontal plane; collecting boundary distance of all boundaries in the room, and according to coordinate values in the space coordinate system, generating an entity space size of the room based on the boundary distance in the space coordinate system; and when a second measurement instruction is received, obtaining a measurement size corresponding to thesecond measurement instruction, adding the measurement size to the entity space size, generating a house type chart of the room, and outputting the house type chart. According to the scheme, the housetype chart of the room is established based on the image detection technology, so that the operation process of room measurement is simplified, and the house type chart generation efficiency based onimage detection is improved.

Owner:PINGAN CITY CONSTR TECH SHENZHEN CO LTD

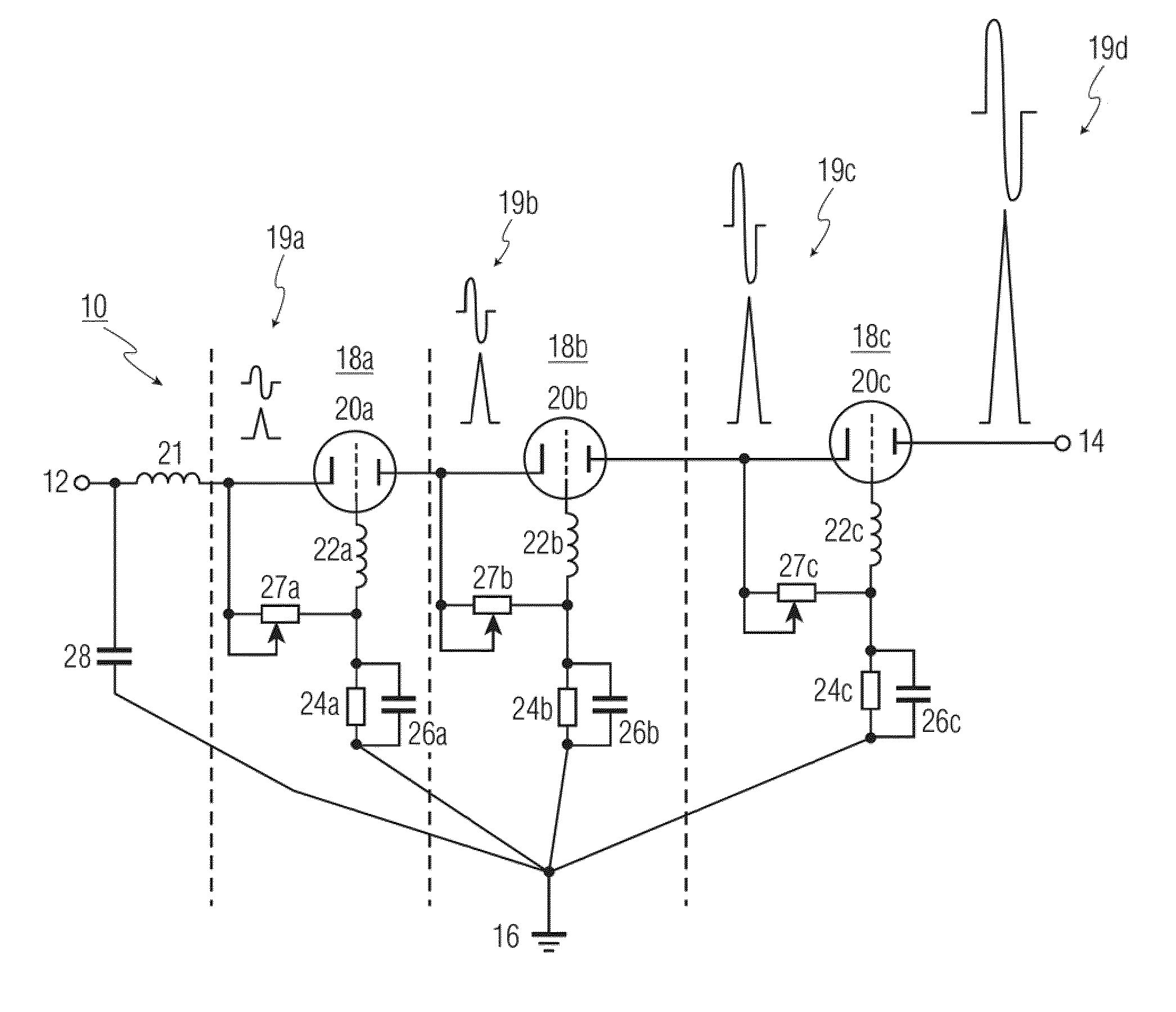

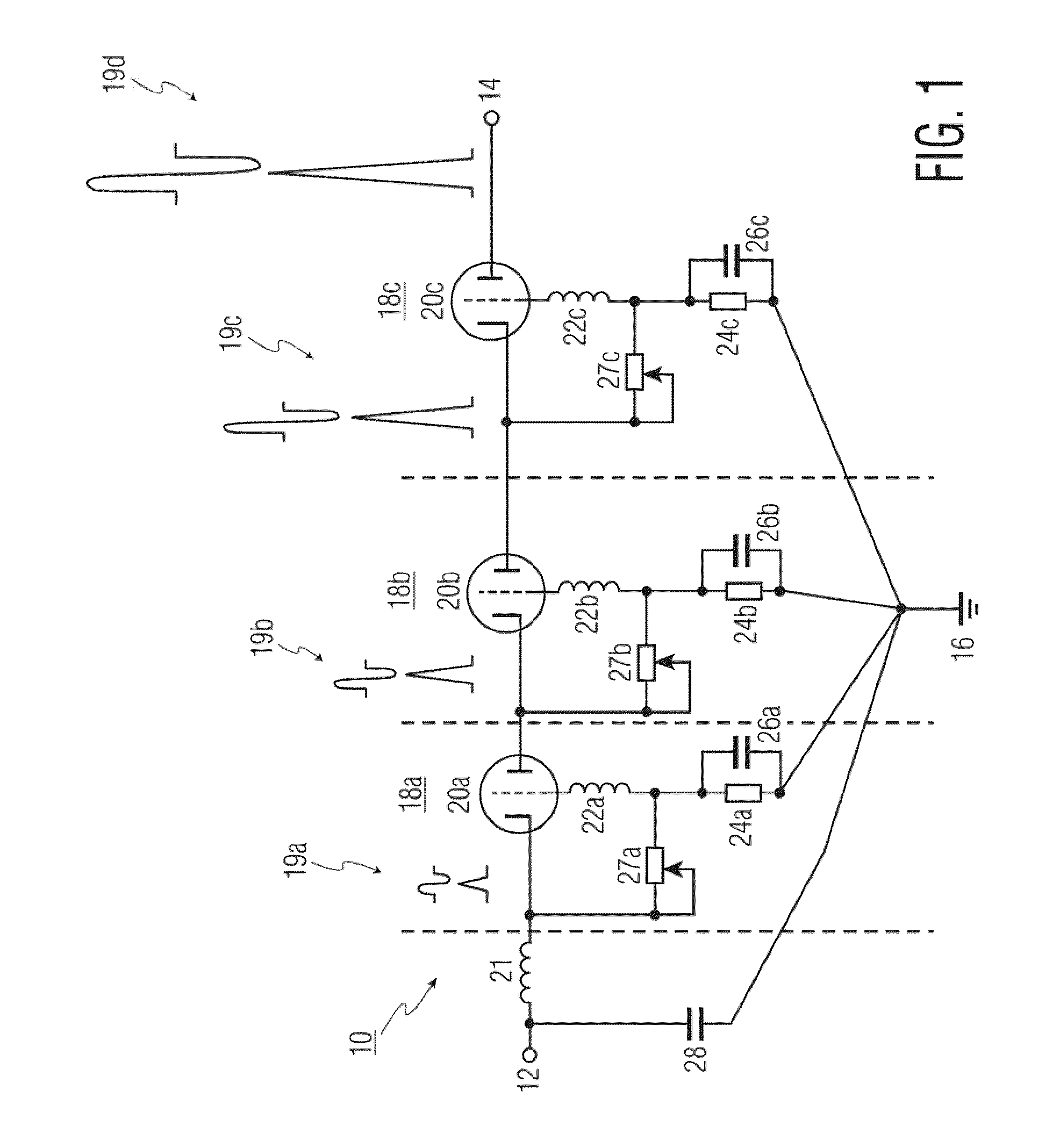

Cascade Voltage Amplifier and Method of Activating Cascaded Electron Tubes

ActiveUS20100289577A1Avoids reliability and jitter problemSusceptibility to saturationContaminated soil reclamationDischarge tube/lamp detailsAudio power amplifierIntermediate stage

Disclosed is a cascade voltage amplifier for producing an amplified output in pulse or continuous wave form comprises at least one non-final stage with an electron tube configured as a switching and Class A or C amplifying structure. A final stage comprises an electron tube configured as a Class A or C amplifying structure. The at least one non-final stage and the final stage are connected in series, and the amplified output has a voltage of at least 1000 volts. Further disclosed is a method of activating a plurality of cascaded electron tube stages within a common vacuum enclosure. Beneficially, a sufficient amount of energy supplied to the first stage serially propagates through any intervening stage to the final stage so as to facilitate activation of all tube stages.

Owner:ADVANCED FUSION SYST LLC

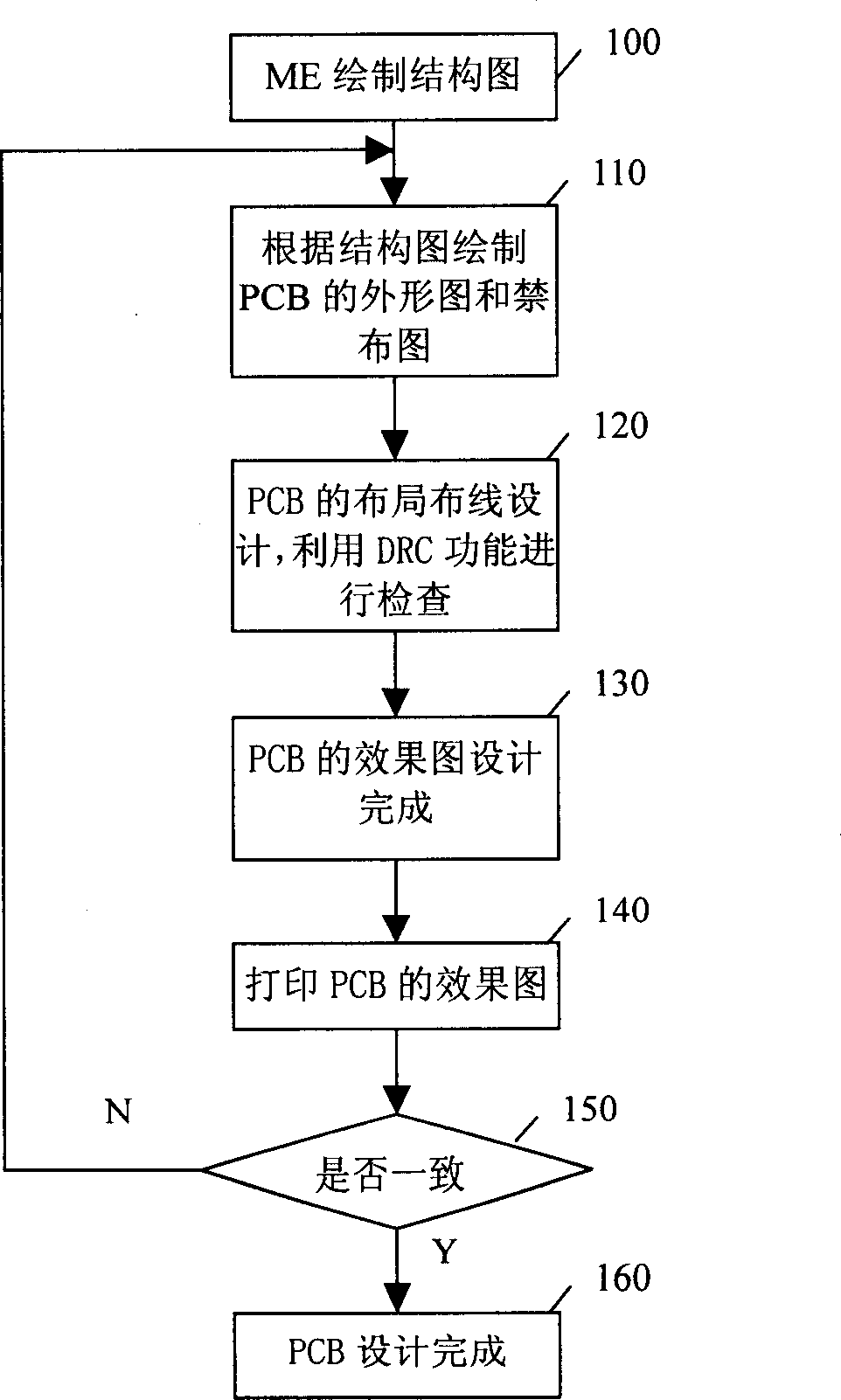

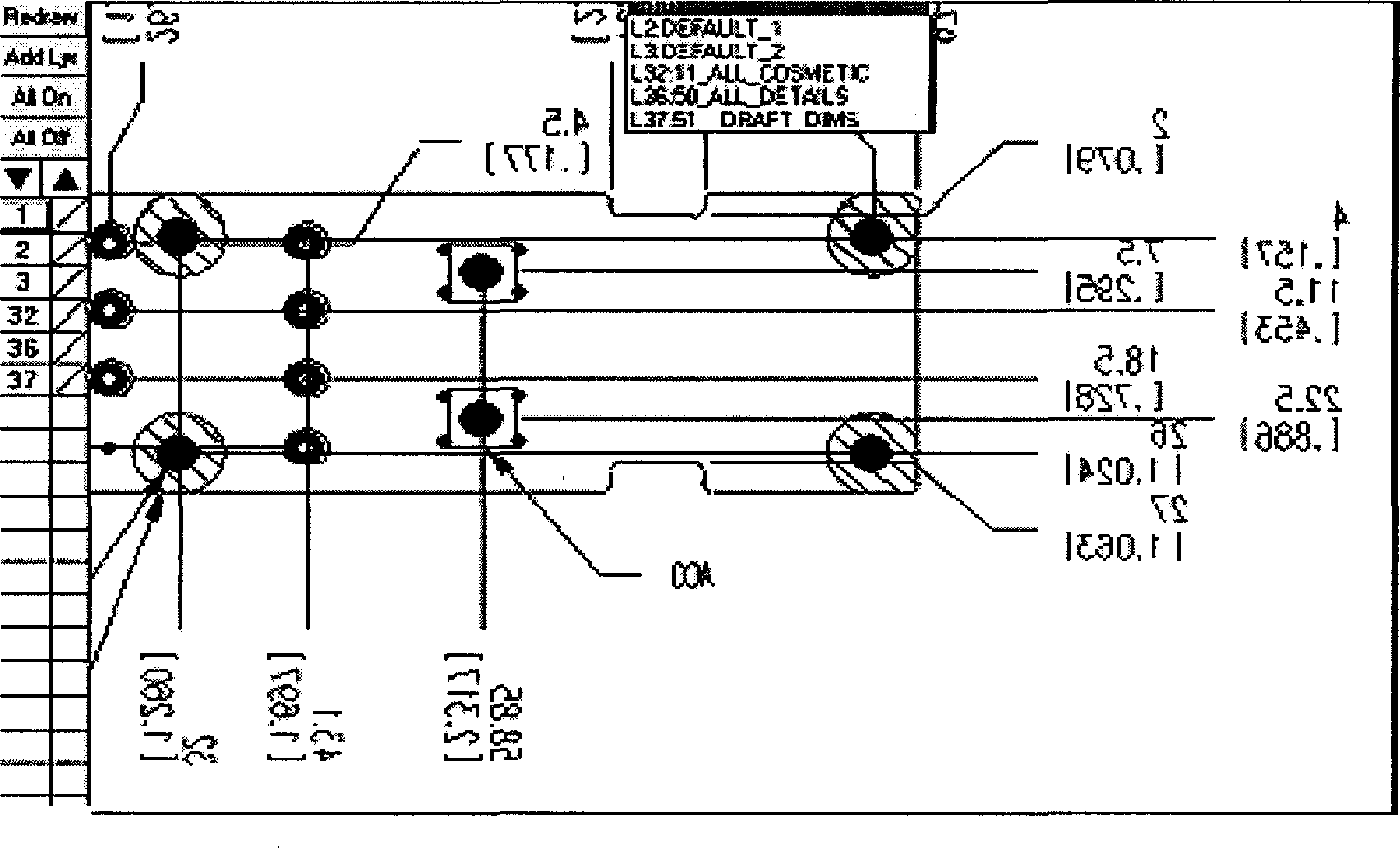

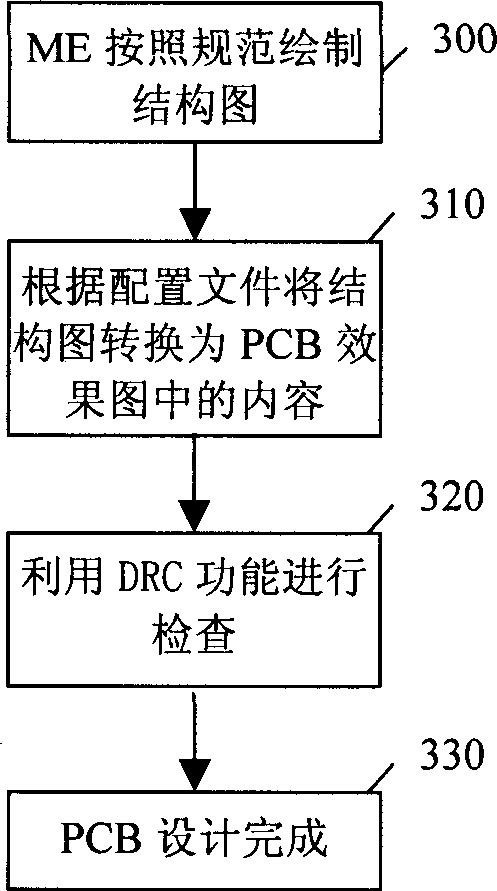

Method and apparatus for implementing PCB design

InactiveCN1804845ASimple design methodShorten design timeSpecial data processing applicationsEngineering

The invention provides a method and apparatus for achieving PCB design. The method comprises: ascertaining the layer norm of the structure picture, ascertaining the corresponding relation between each norm layer and each layer of the PCB design picture, when it needs to dose PCB design, drawing the corresponding structure picture by the layer norm of the structure picture and transferring the structure picture into the PCB design picture.

Owner:HUAWEI TECH CO LTD

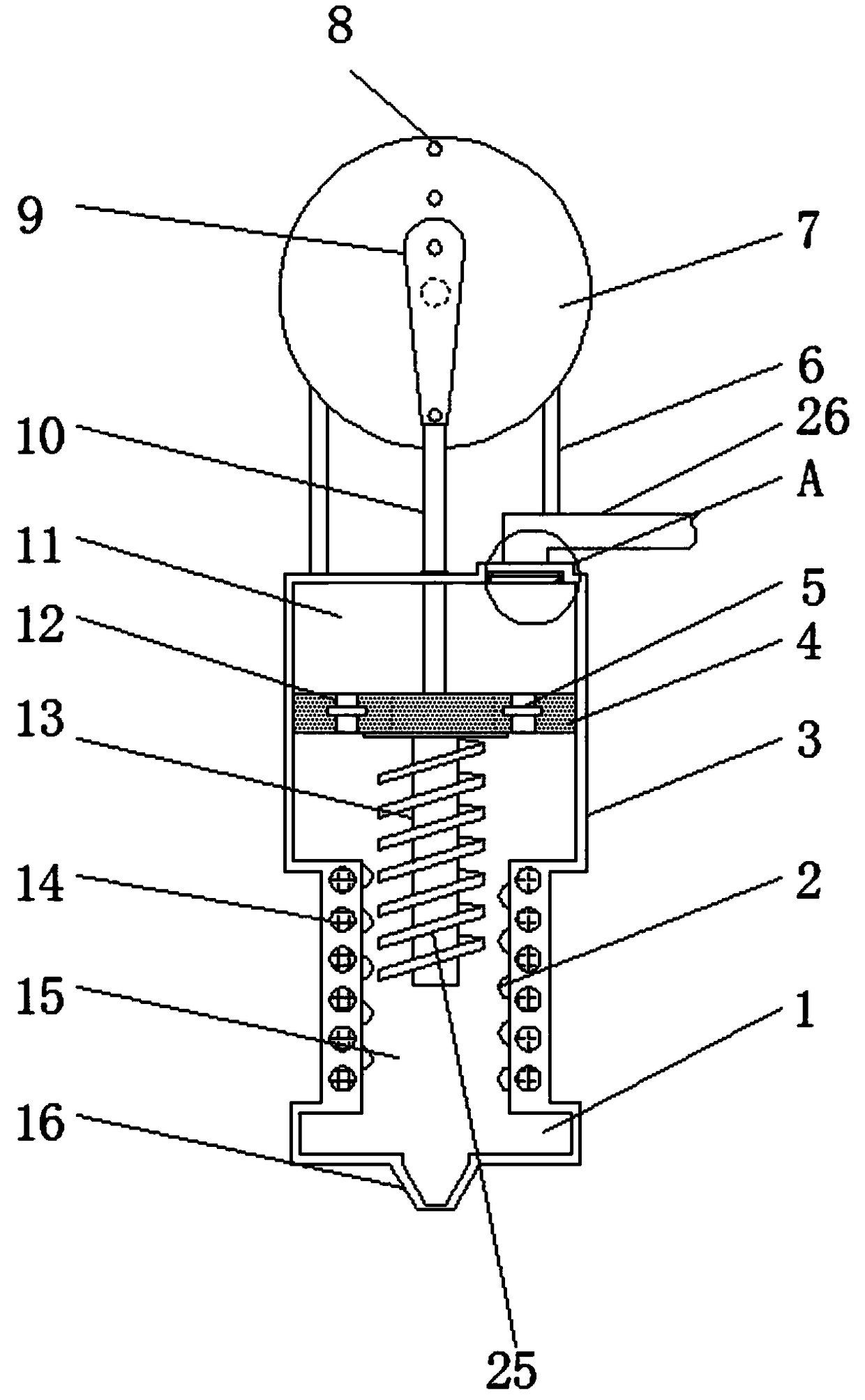

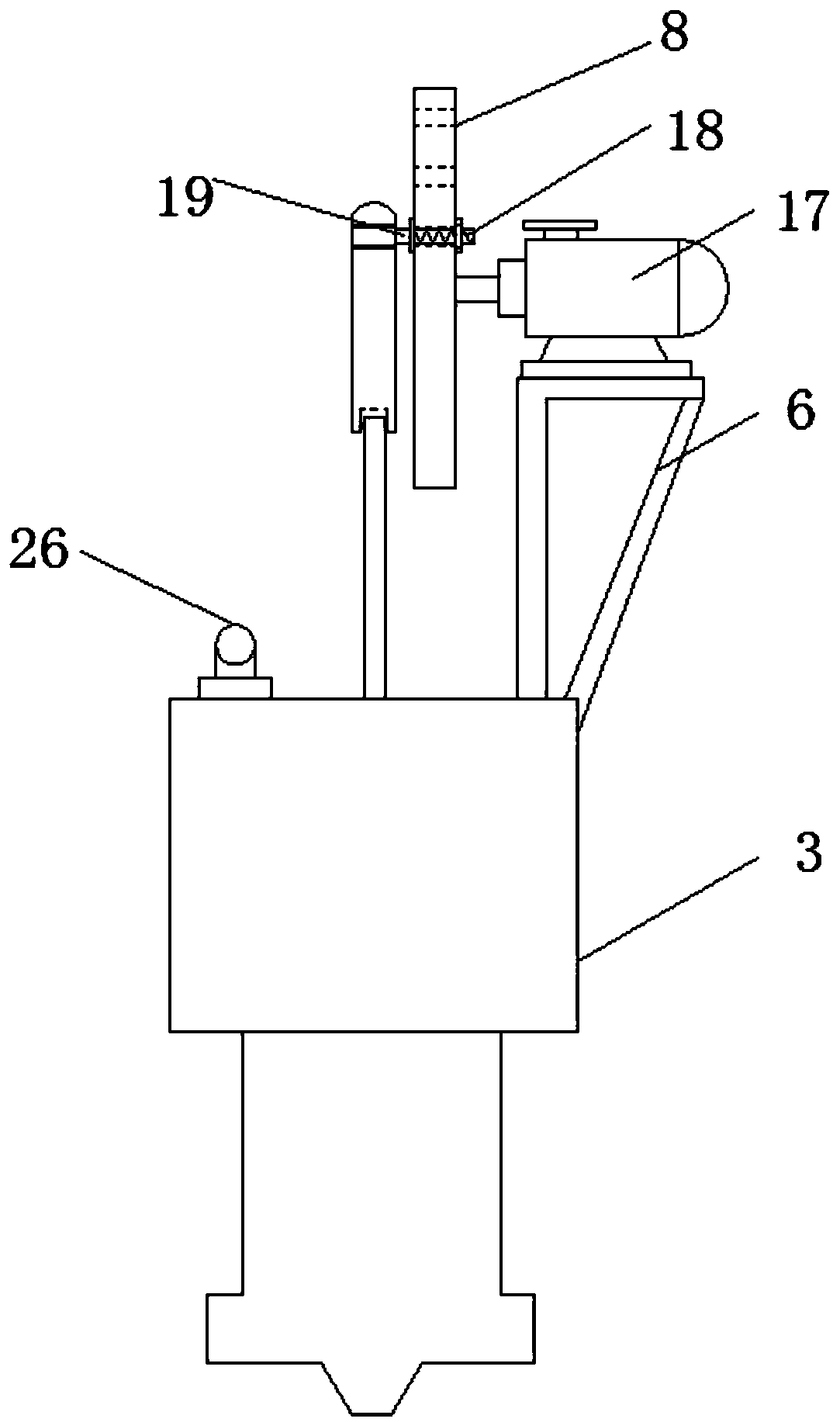

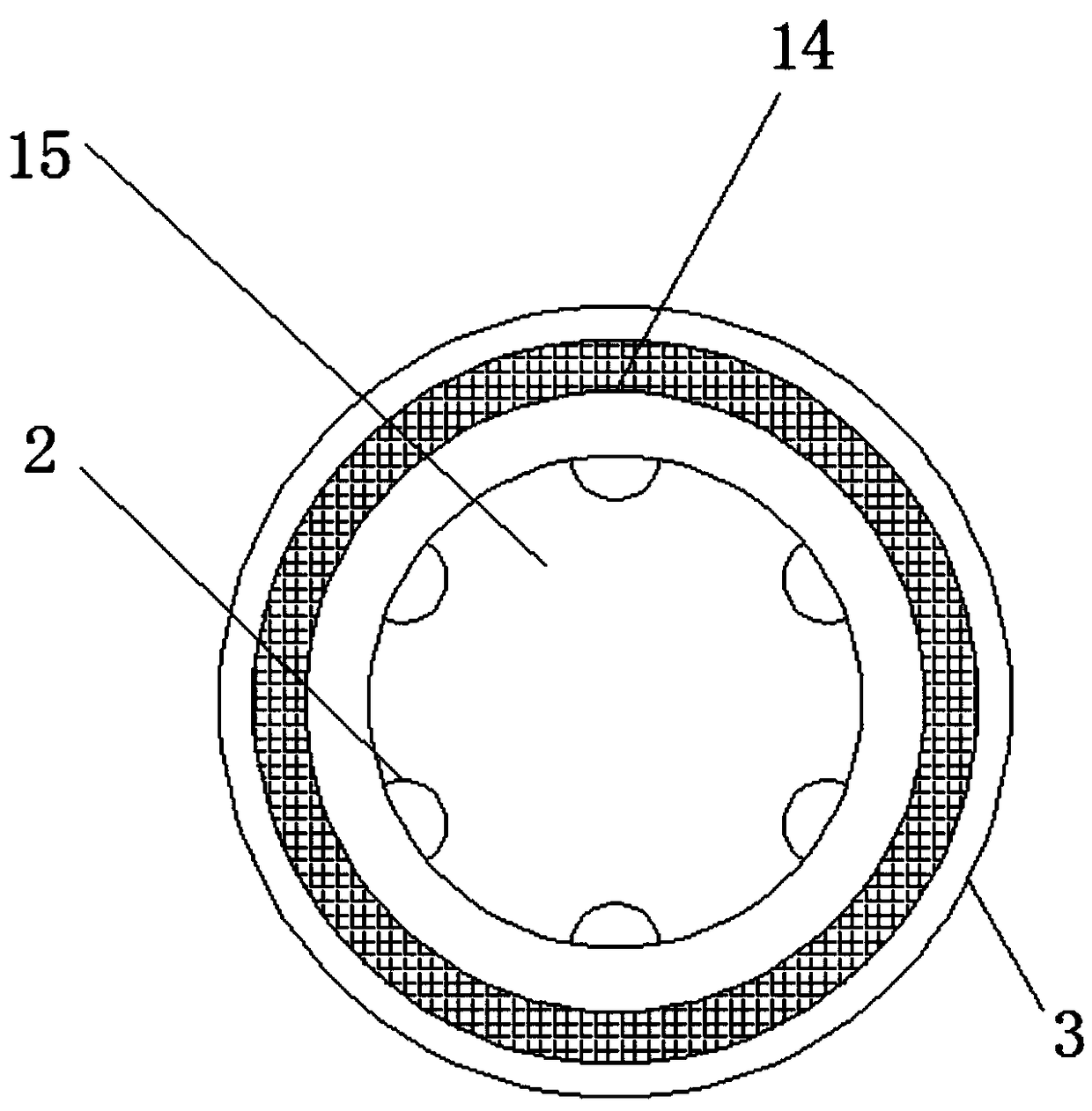

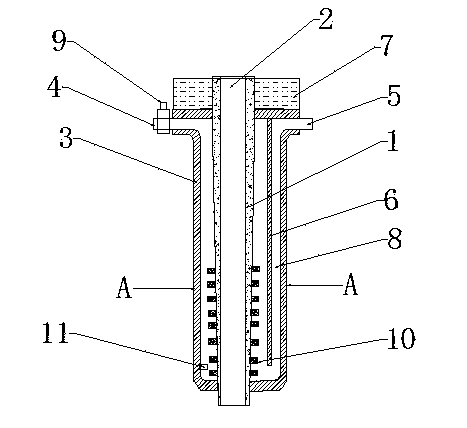

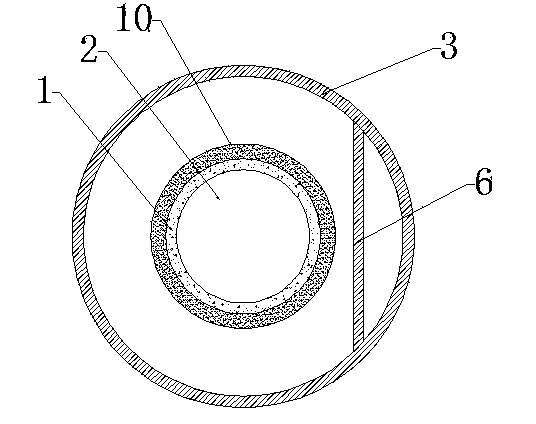

High-efficiency radiating double-pipe water-cooling pouring gate sleeve with temperature detection function

The invention discloses a high-efficiency radiating double-pipe water-cooling pouring gate sleeve with a temperature detection function. An outer pipe (3) is arranged outside a pouring gate sleeve (1); a cavity of which the two ends are sealed is formed between the pipe wall of the outer pipe (3) and the pipe wall of the pouring gate sleeve (1); a water outlet baffle (6) is arranged at a water outlet (5); the water outlet baffle (6) is arranged in the cavity between the outer pipe (3) and the pouring gate sleeve (1); a distance is reserved between the bottom surface of the water outlet baffle (6) and the bottom surface of the outer pipe (3); a valve (9) is arranged at a water inlet (4); flaky radiating fins (10) are arranged on the lower part of the pouring gate sleeve (1); a temperature sensor (11) is arranged at the lower end of the outer pipe (3). The radiating efficiency is improved by the radiating fins; the temperature sensor detects the temperature of cooling water at the lower end of the pouring gate sleeve (1) in real time; a valve at the water outlet is adjusted, the flow speed of the cooling water is adjusted to a best value; the radiating efficiency is improved; the circulation volume of the cooling water is saved.

Owner:昆山鼎庆精密模具有限公司

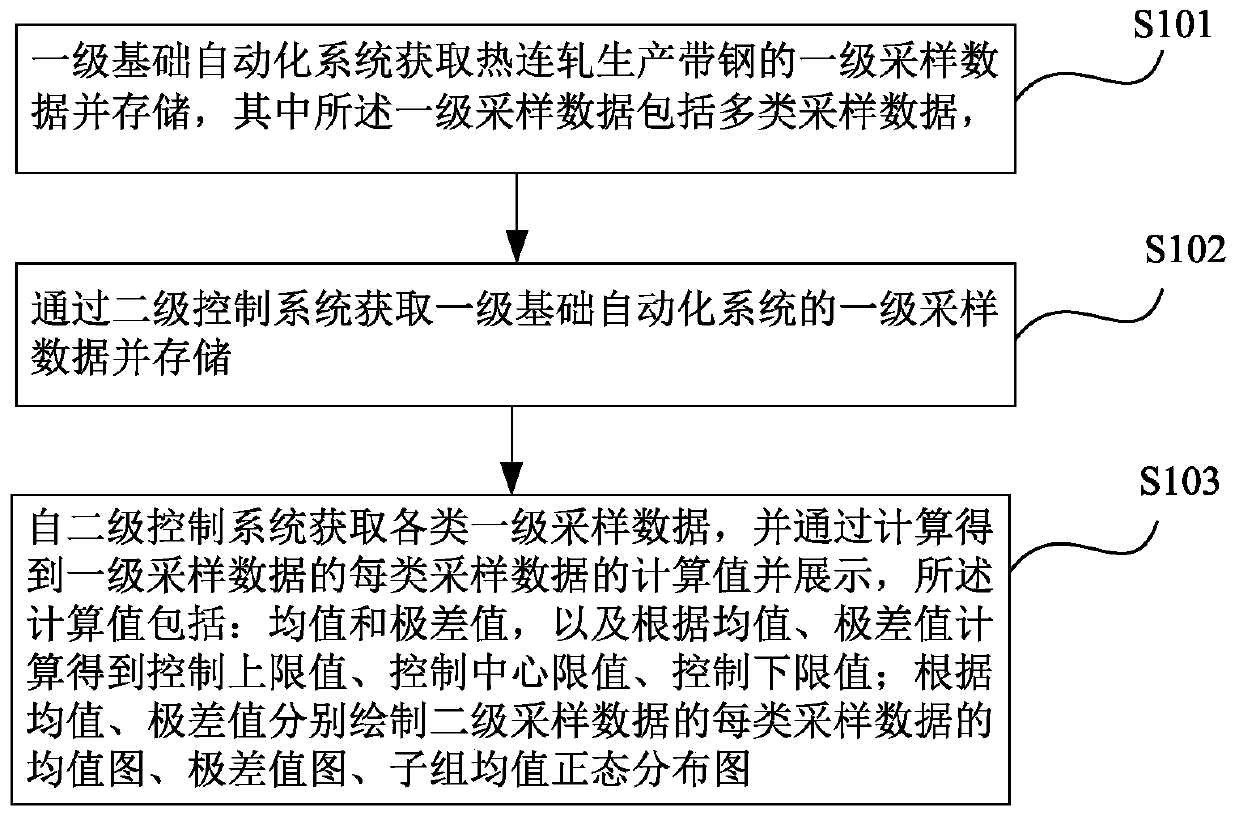

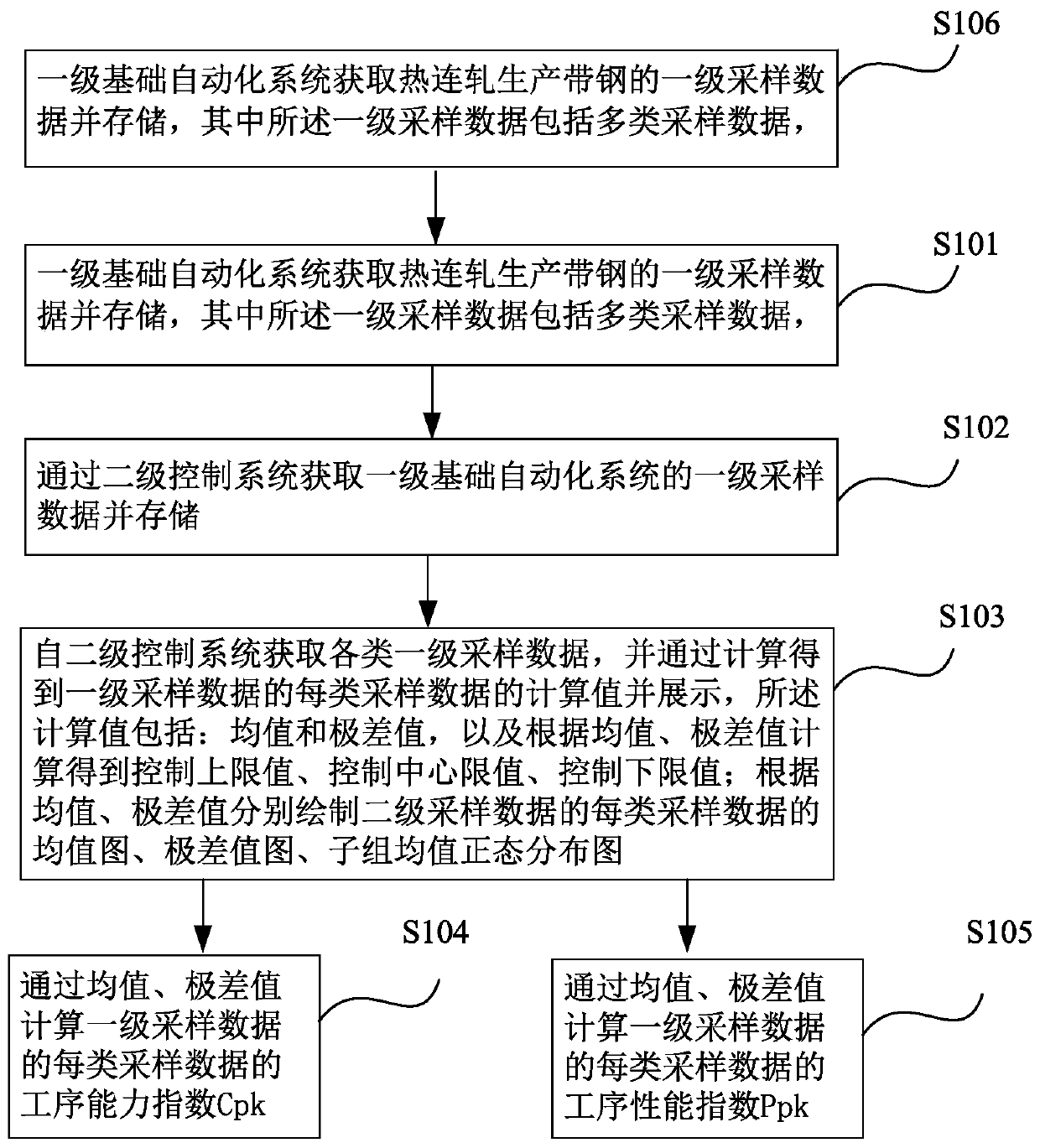

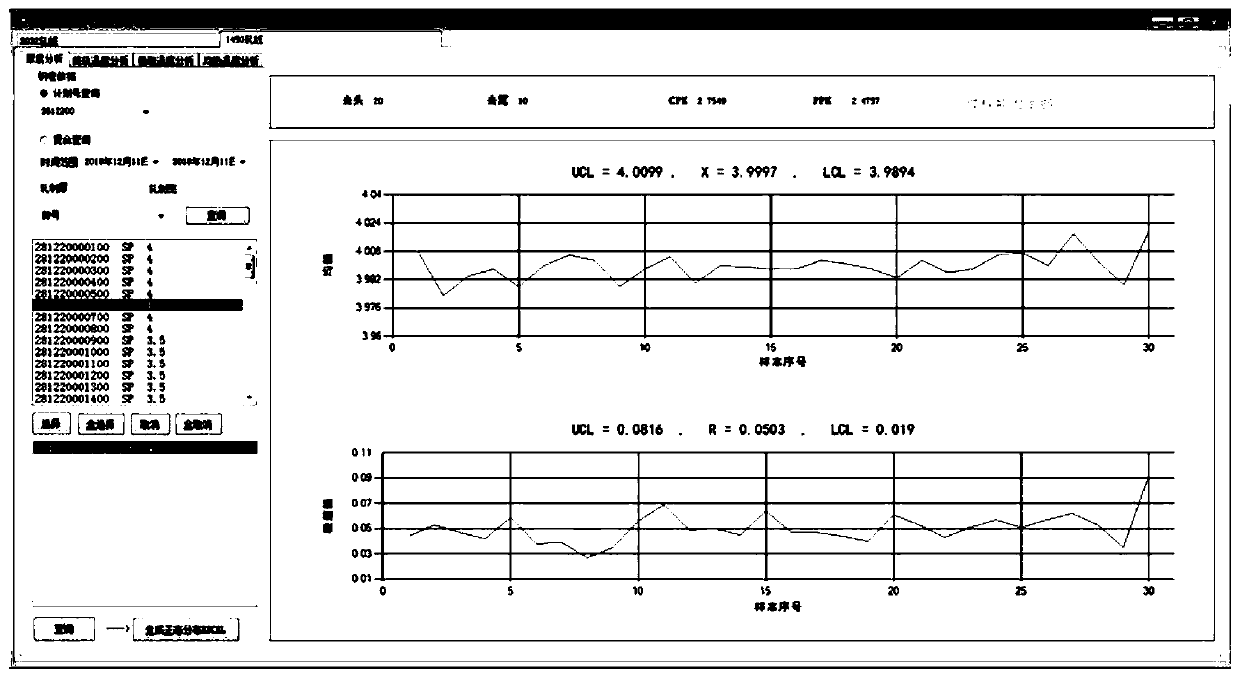

Automatic statistics and analysis method based on hot continuous rolling production

InactiveCN110442092ARealize automatic collectionReduce labor costsTotal factory controlProgramme total factory controlLower limitControl system

The embodiment of the invention provides an automatic statistics and analysis method based on hot continuous rolling production. The method comprises the following steps of step A, acquiring first-class sampling data of a hot continuous rolling production strip steel and storing the first-class sampling data by a first-class basic automation system, wherein the first-class sampling data comprise multiple types of sampling data, namely: the soaking temperature, the finishing rolling temperature, and the coiling temperature, thickness and width; step B, acquiring and storing the first-class sampling data of the first-class basic automation system through a second-class control system; and step C, acquiring various types of first-class sampling data from the second-class control system, and calculating and displaying calculated values of various type of sampling data of the first-class sampling data, wherein the calculated values comprise an average value and a range value, and a controlupper limit value, a control center limit value and a control lower limit value calculated according to the average value and the range value. According to the automatic statistics and analysis methodbased on the hot continuous rolling production provided by the invention, by automatically acquiring sampling point data and counting and calculating the work average value, a result can be automatically output and displayed; and besides, the efficiency is high, the calculation result is more accurate, and the accuracy is high.

Owner:LIUZHOU IRON & STEEL

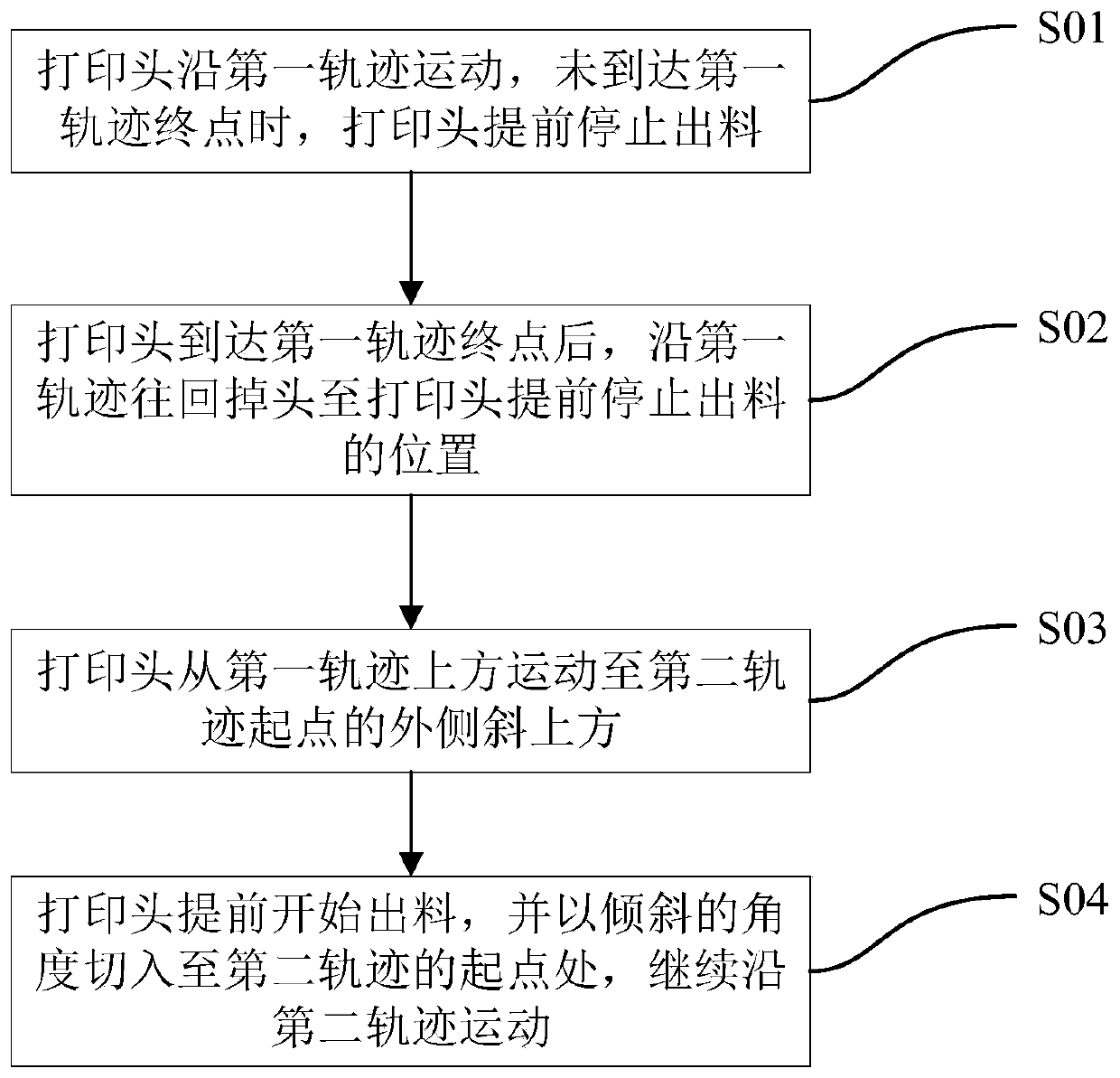

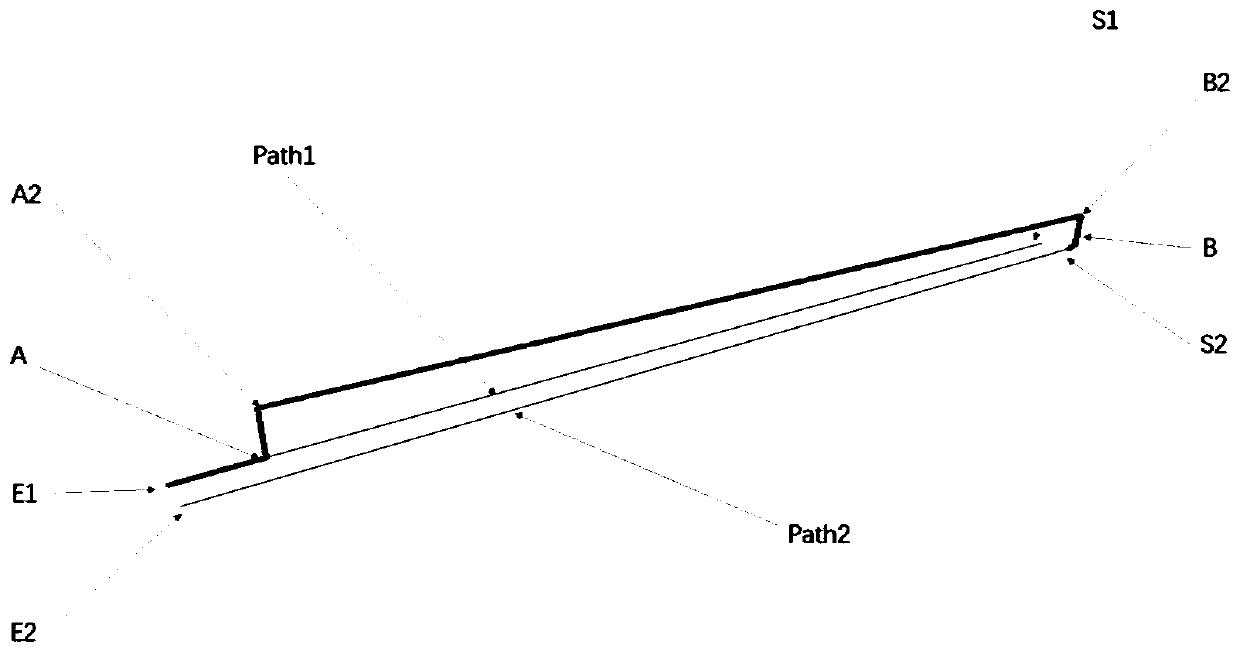

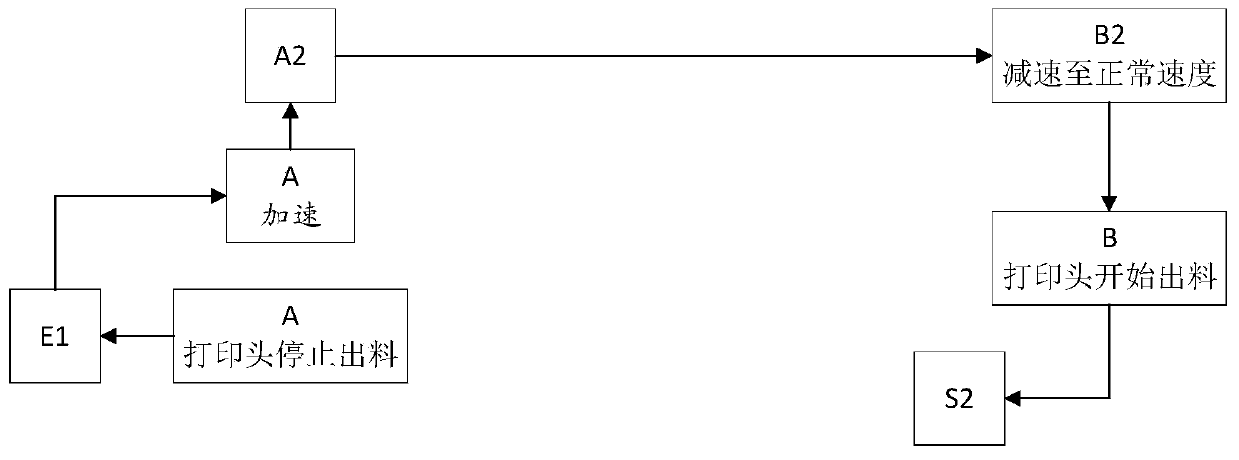

3D printing back drawing motion track planning method

PendingCN111113886ASolve the easy-to-produce drawingSolve the accumulationAdditive manufacturing apparatus3D object support structures3d printEngineering

The invention discloses a 3D printing back drawing motion track planning method. A back drawing motion track is planned between a first track and a second track of 3D printing. The method includes theprocesses that a printing head moves along the first track, and when the printing head does not reach the end point of the first track, the printing head stops conducting discharging in advance; after the printing head moves to the end point of the first track, the printing head turns around back along the first track to reach the position where discharging is stopped in advance; the printing head moves to the position above the outer side of the starting point of the second track from the position above the first track; and discharging begins when the printing head does not reach the starting point of the second track, the printing head is switched to the starting point of the second track with a downward switching inclined angle and moves continuously along the second track. By means ofthe 3D printing back drawing motion track planning method, the printing head stops discharging in advance and turns round back when back drawing begins, and the phenomena of wire drawing and materialaccumulating of back drawing are avoided; and when back drawing is over, the printing head conducts discharging in advance and is switched to the track of the next segment with the inclined angle, the phenomenon of shortage of the printing track due to delayed discharging of the spray head is avoided, large components can be printed, and the component printing quality is greatly improved.

Owner:上海酷鹰机器人科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com