Patents

Literature

21153 results about "3D printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

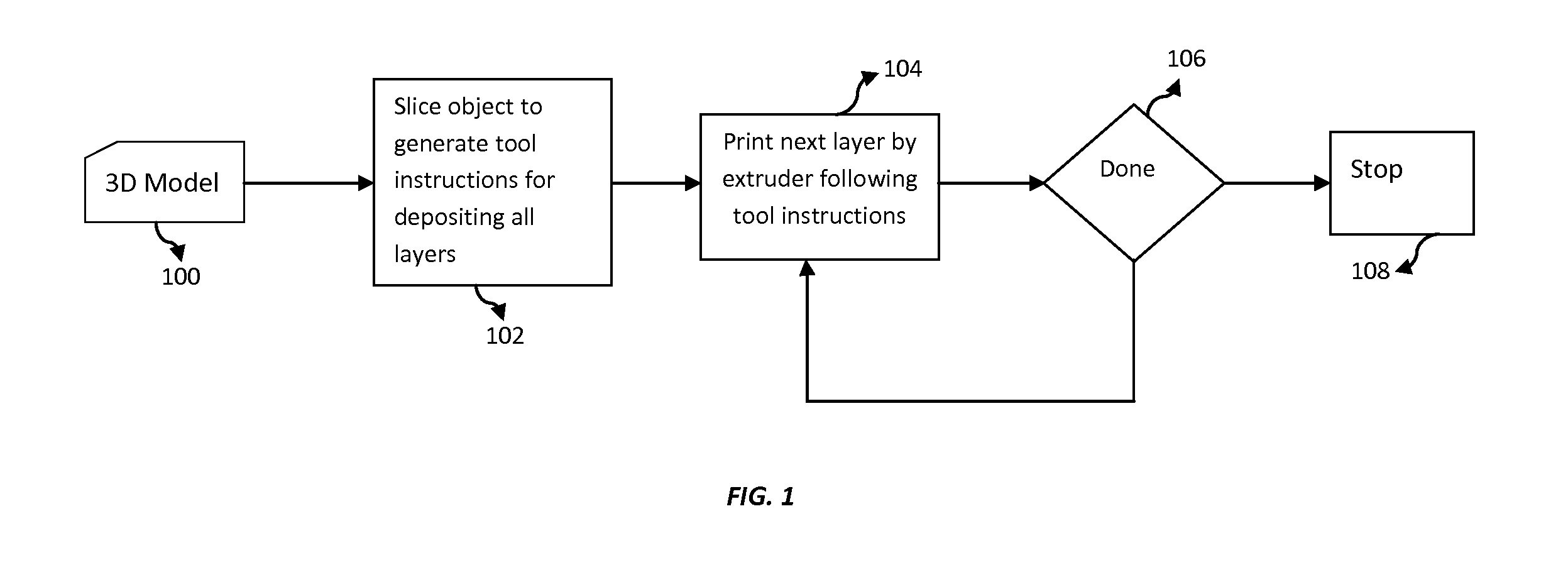

The 3D printing process builds a three-dimensional object from a computer-aided design (CAD) model, usually by successively adding material layer by layer, which is why it is also called additive manufacturing, unlike conventional machining, casting and forging processes, where material is removed from a stock item (subtractive manufacturing) or poured into a mold and shaped by means of dies, presses and hammers.

3D printing using spiral buildup

ActiveUS20140265034A1High and accurate level of detailShort timeManufacturing platforms/substratesManufacturing driving meansSingle CenterPhotopolymer

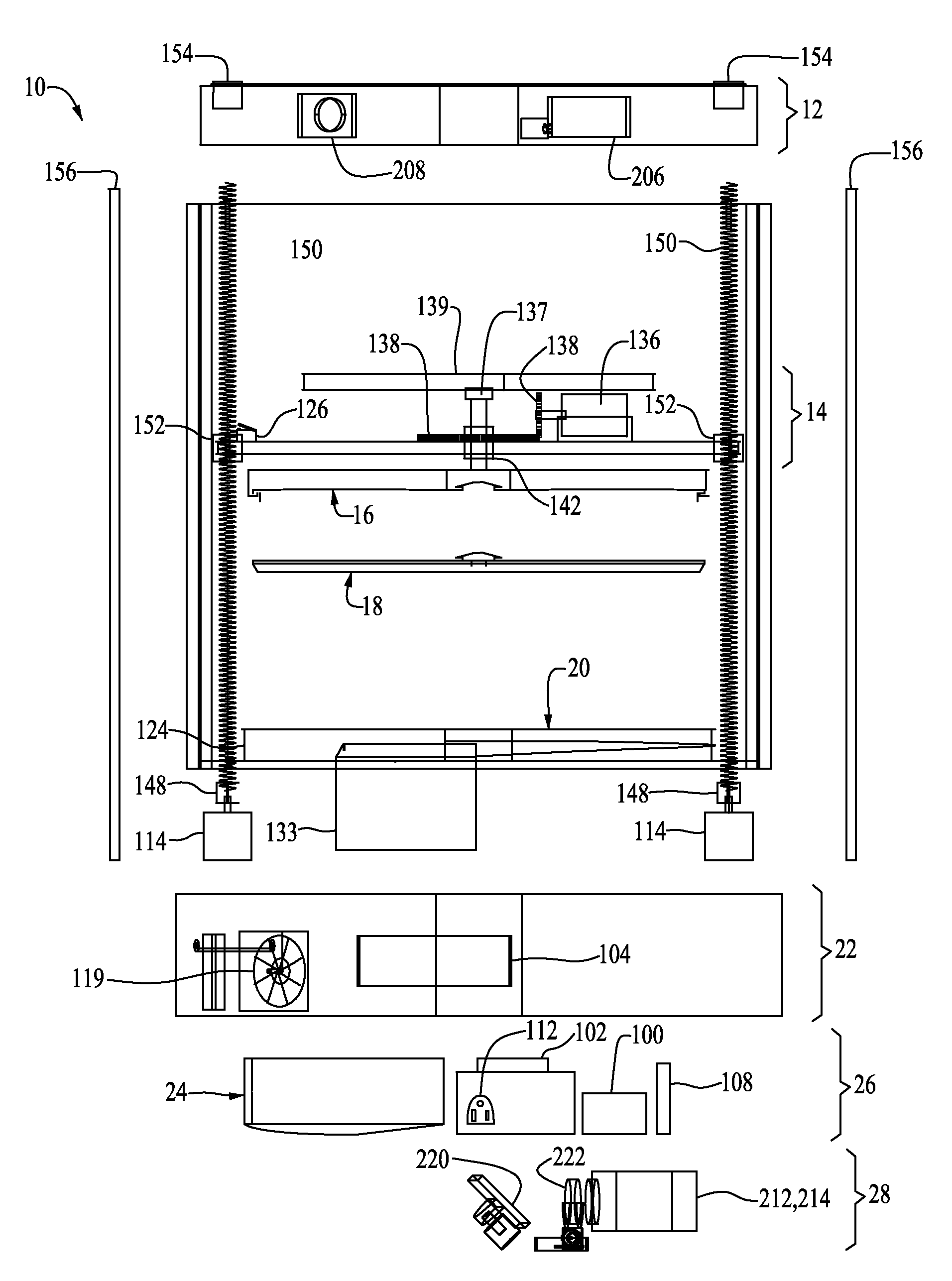

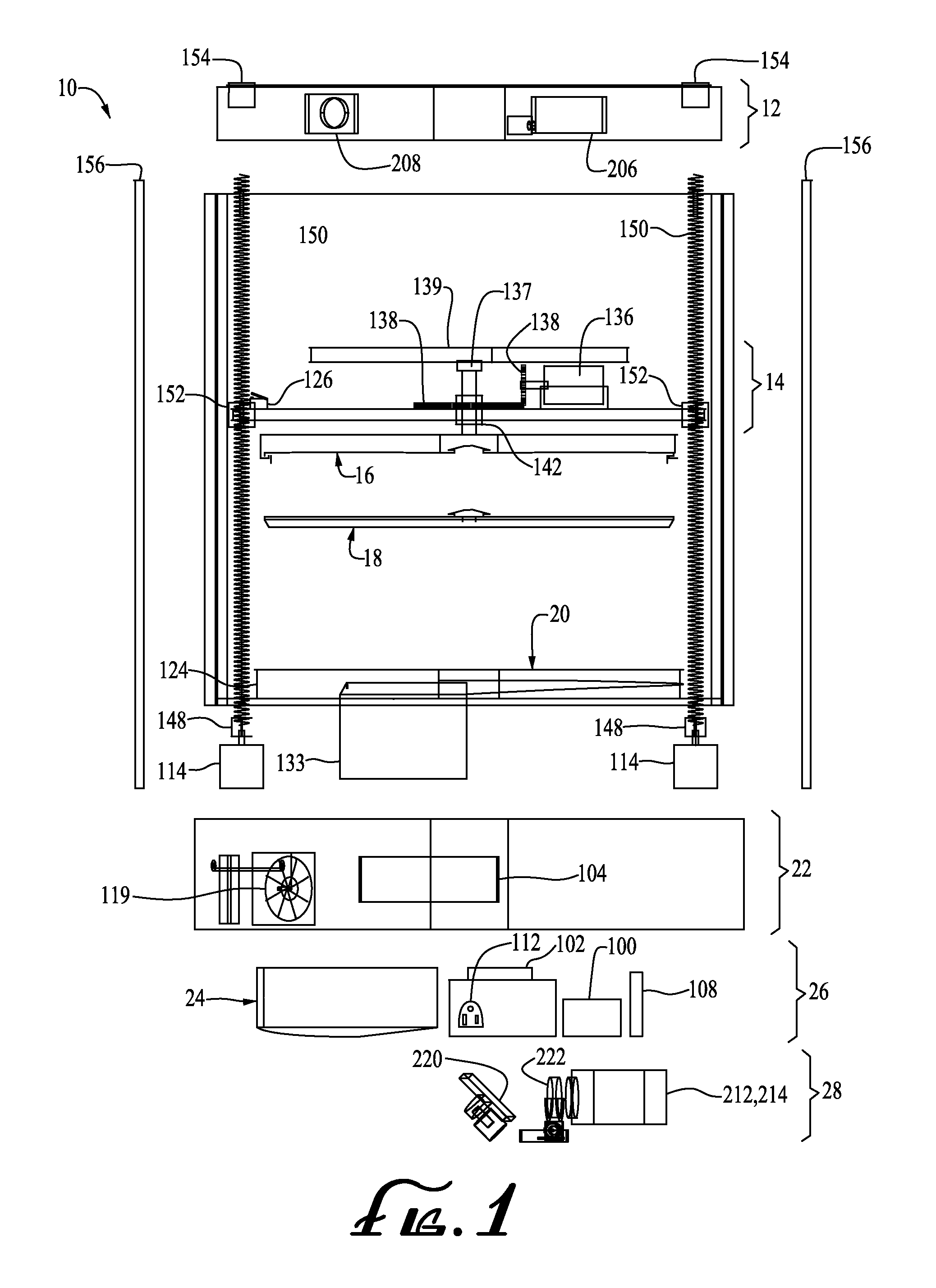

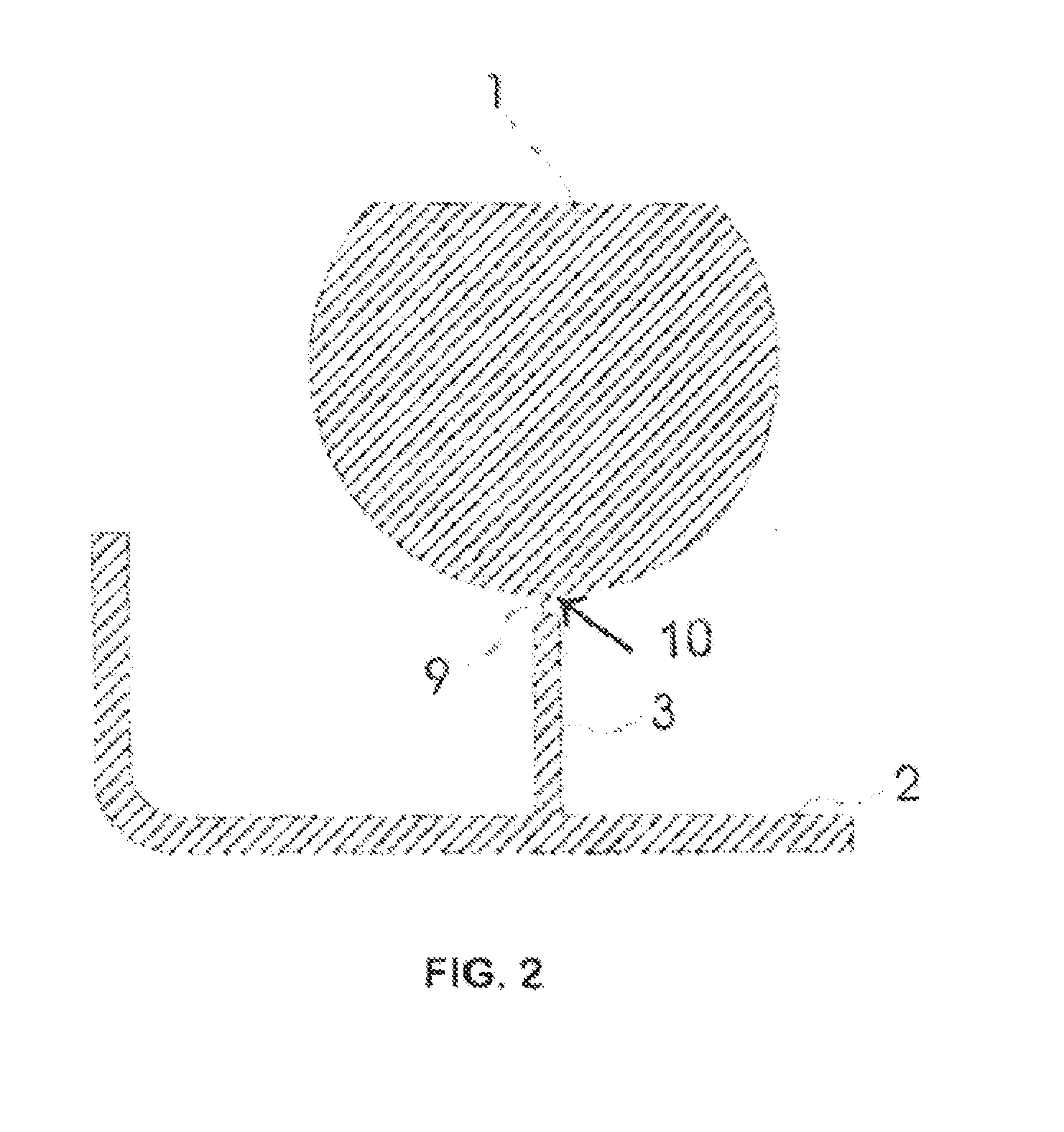

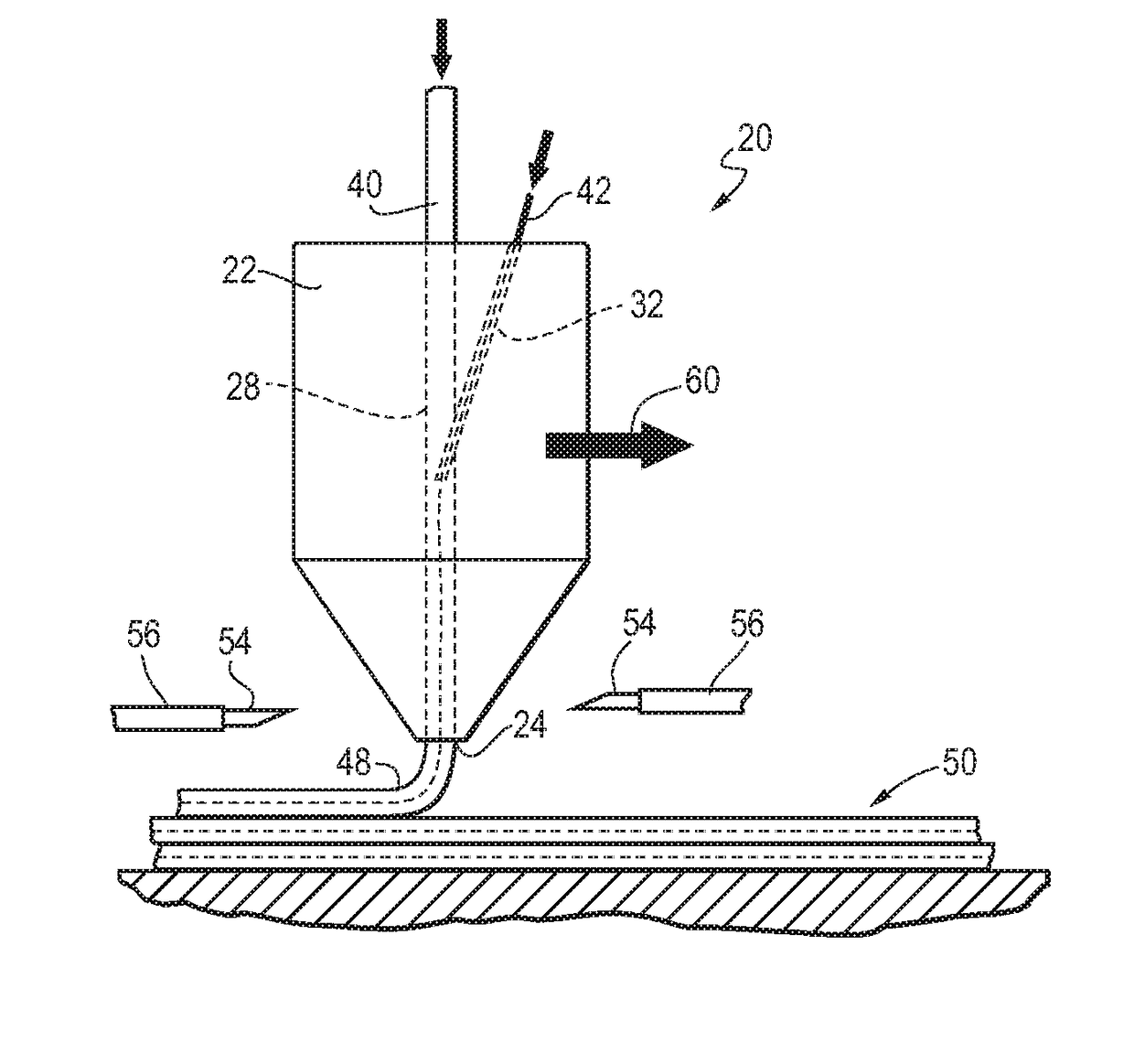

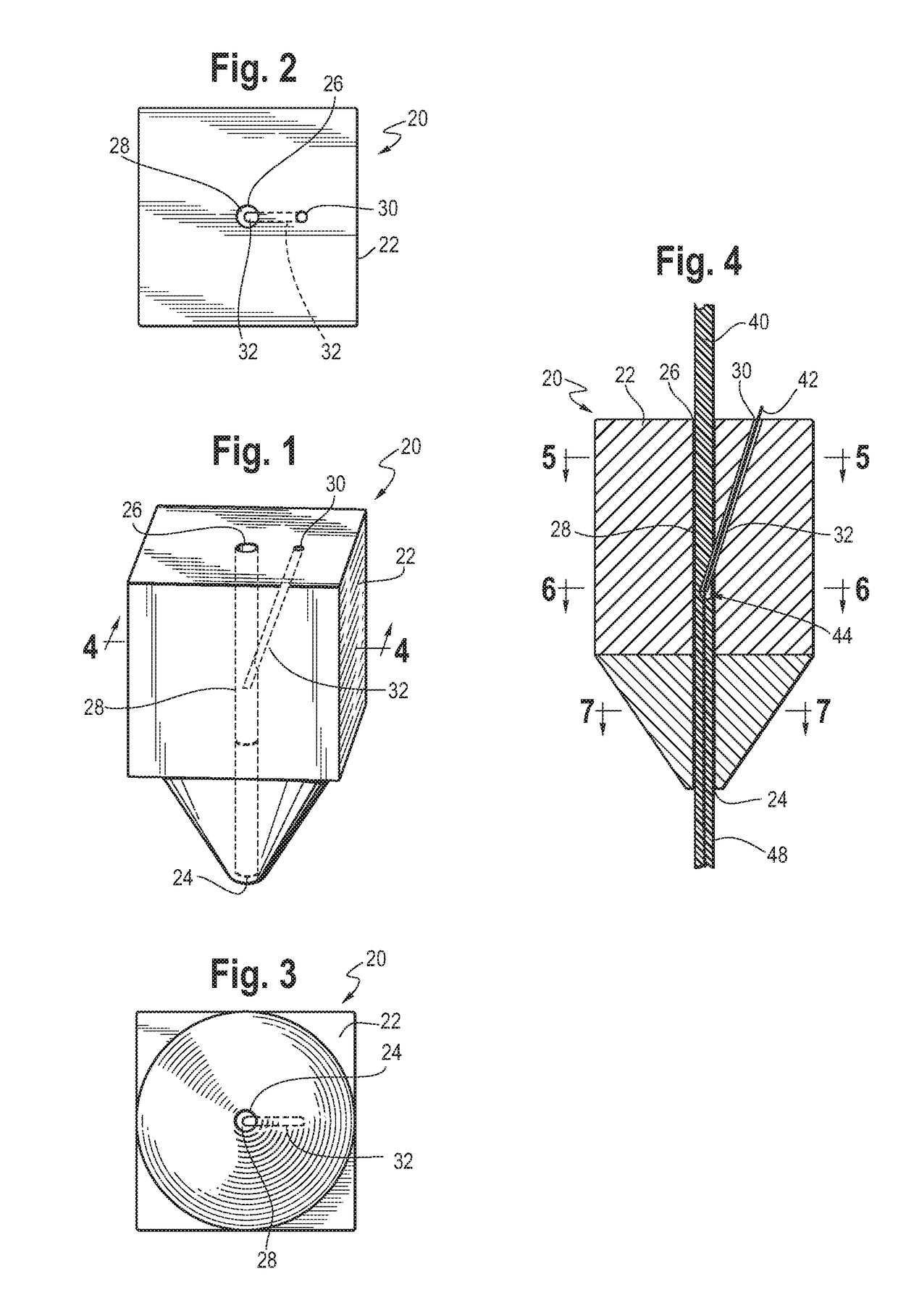

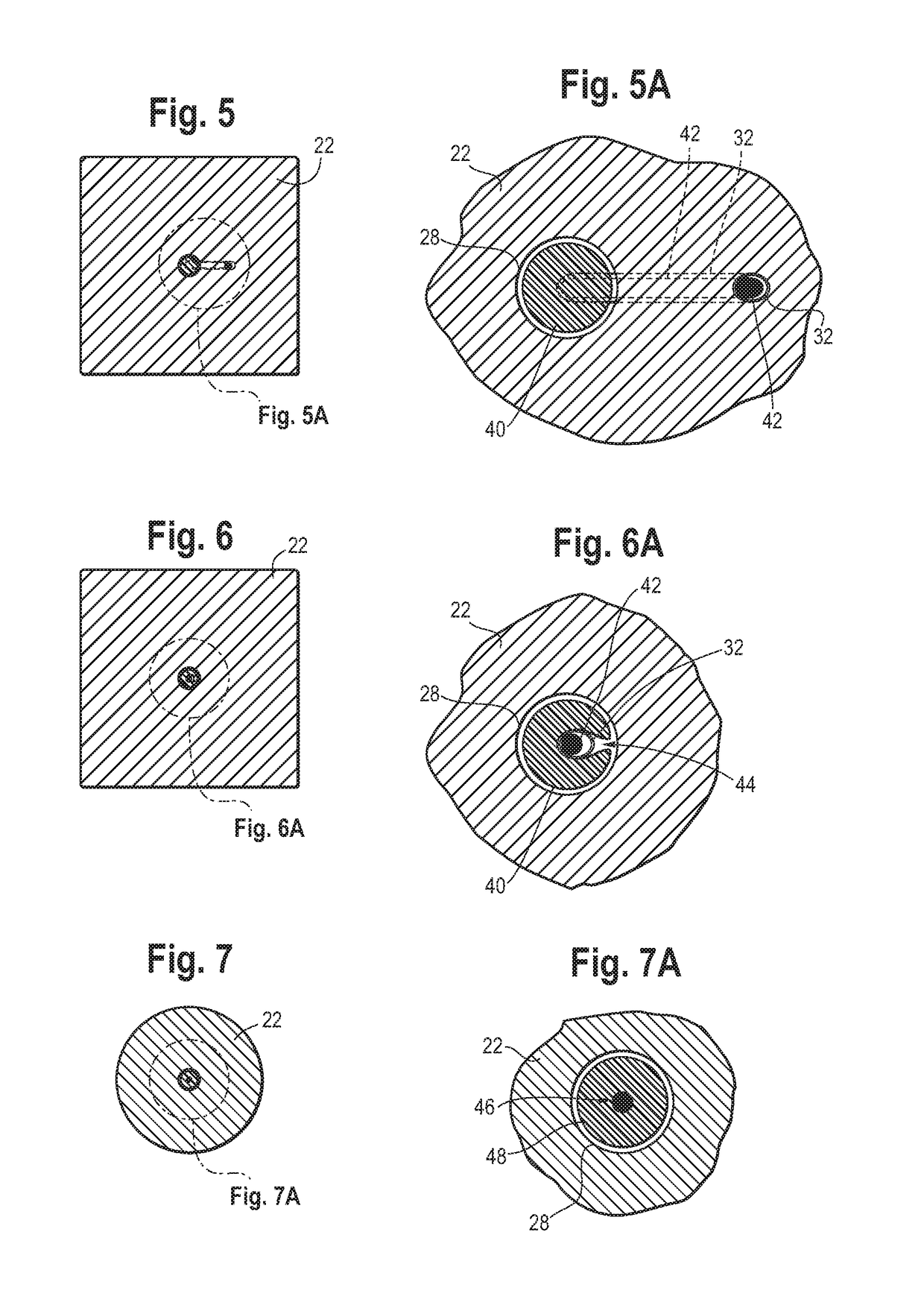

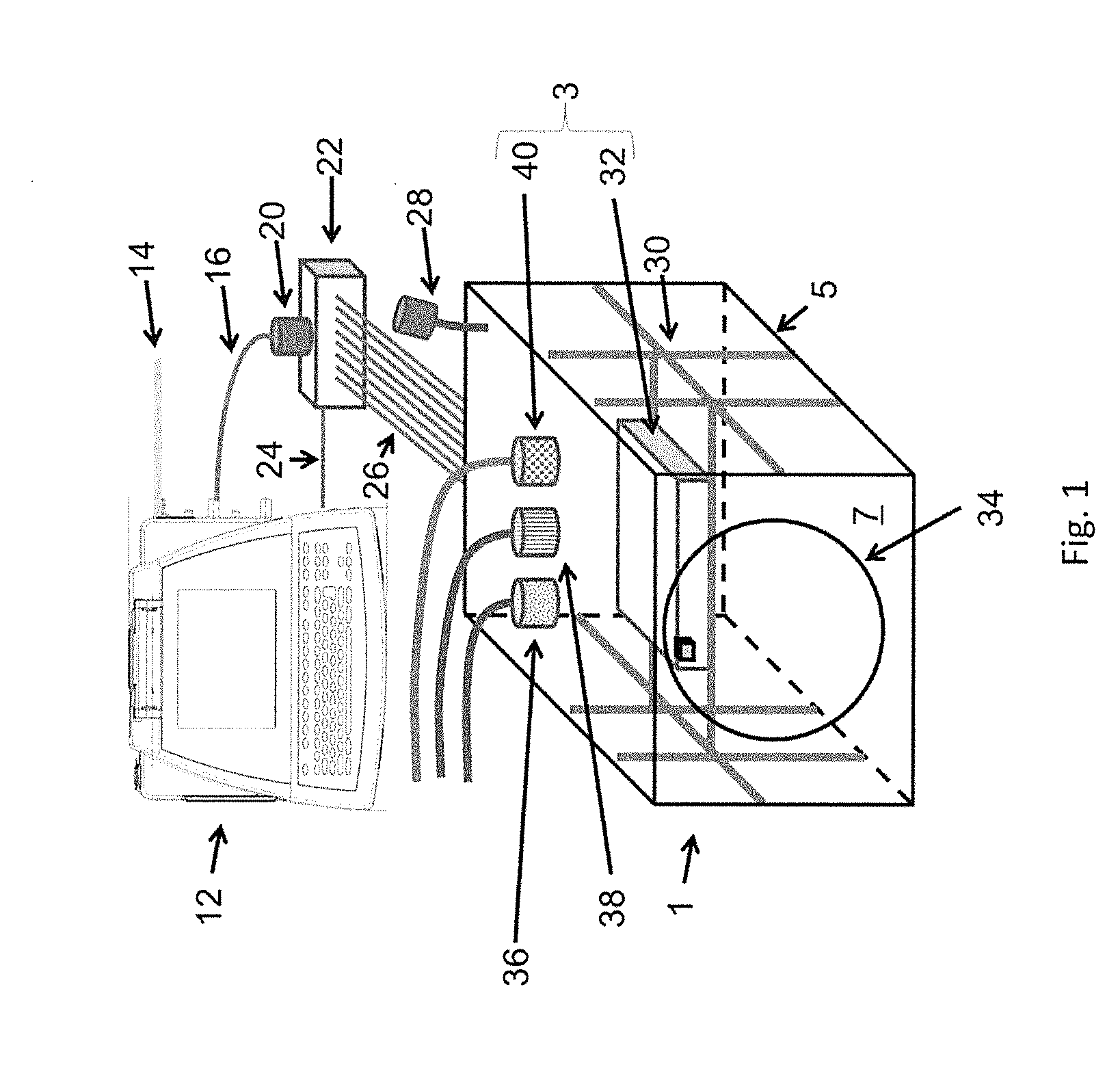

Methods, devices and systems for efficient 3D printing that address conventional inefficiencies while utilizing a single compact device are set forth. Some embodiments utilize a circular-shaped build area revolving symmetrically around a single center point utilizing a continuous helical printing process. In one embodiment a liquid photopolymer for solidification is deposited on a build platform to form the physical object The Build platform is continuously rotated and simultaneously raised in a gradual programmed manner. Focused from below the platform produces a single continuous “layer” of material deposited and bonded in a helical fashion.

Owner:ORANGE MAKER

Ceramic slurry preparation and 3D (three dimensional) printing light curing molding method

ActiveCN106810215ALow viscosityHigh solid contentAdditive manufacturing apparatusCeramic shaping apparatusFlexural strengthVolumetric Mass Density

The invention provides a ceramic slurry preparation and 3D (three dimensional) printing light curing molding method. 25-85vol% of ceramic powder and 15-75vol% of an optical resin premix solution are mainly involved, and the method includes: A), preparation of the optical resin premix : namely stirring a low polymer, a reactive diluent, a photoinitiator, a dispersing agent, a photosensitizer and a sensitizer according to a certain proportion under intermediate speed for 0.5-3 hours to enable the components to be mixed evenly; B), placing the premix solution and the ceramic powder in a ball mill according to certain volume for ball-milling for 5-15 hours to prepare the ceramic slurry high in solid content and low in viscosity; subjecting the ceramic slurry to curing molding layer by layer gradually on a 3D light curing molding machine to obtain a ceramic green body prior to aftertreatment of drying, degreasing, sintering and the like to obtain ceramic part. The method is high in preparation molding precision and free of molds to prepare complex structure parts, the ceramic product can reach more than 92% in density, 320-1750MPa in flexural strength and 1800-4500MPa in compression strength.

Owner:重庆摩方科技有限公司

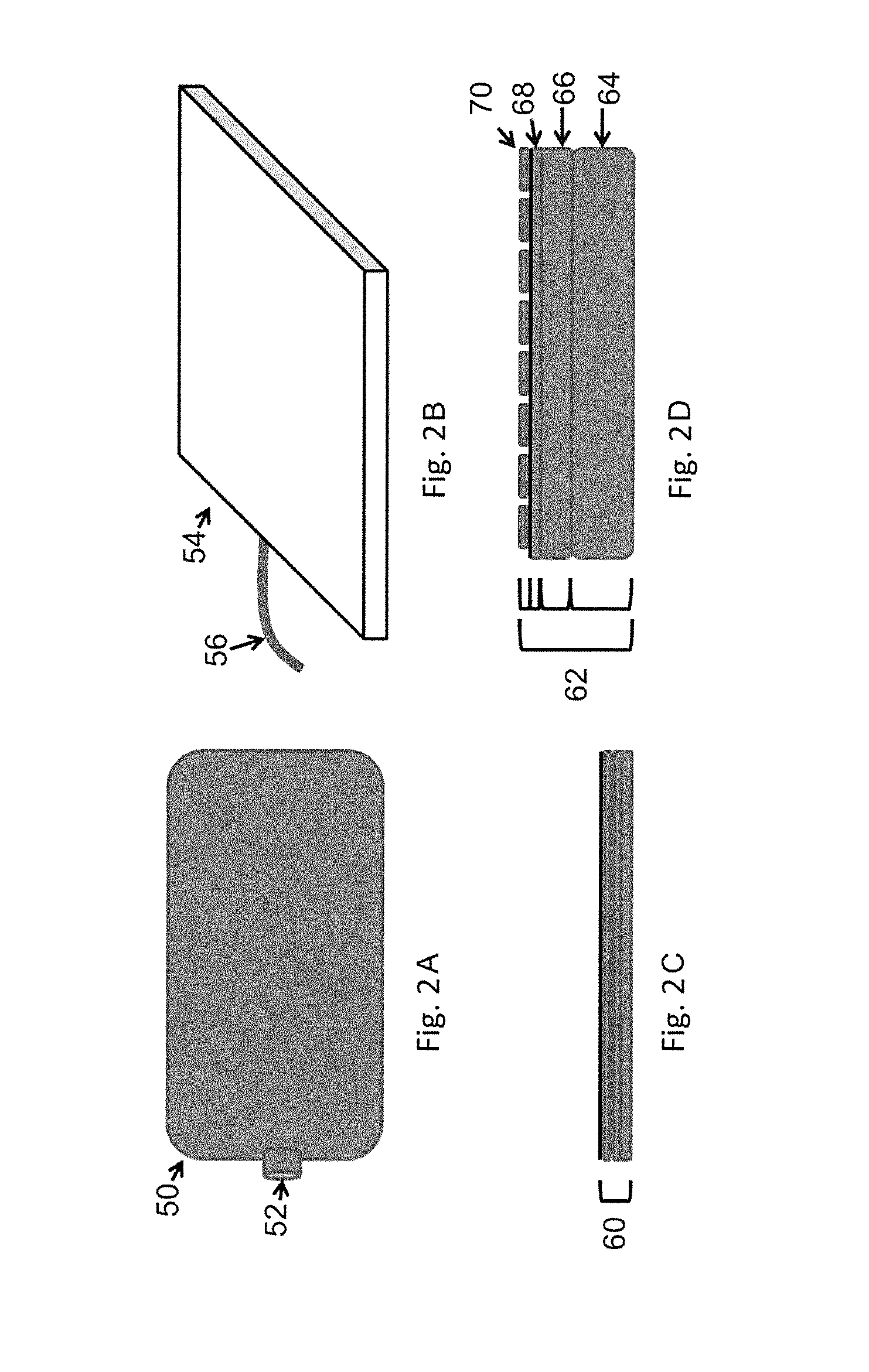

Coextruded, multilayer and multicomponent 3D printing inputs field

PendingUS20160297104A1Small sizeHigh viscosityAdditive manufacturing apparatusFilament/thread formingEngineering3d printer

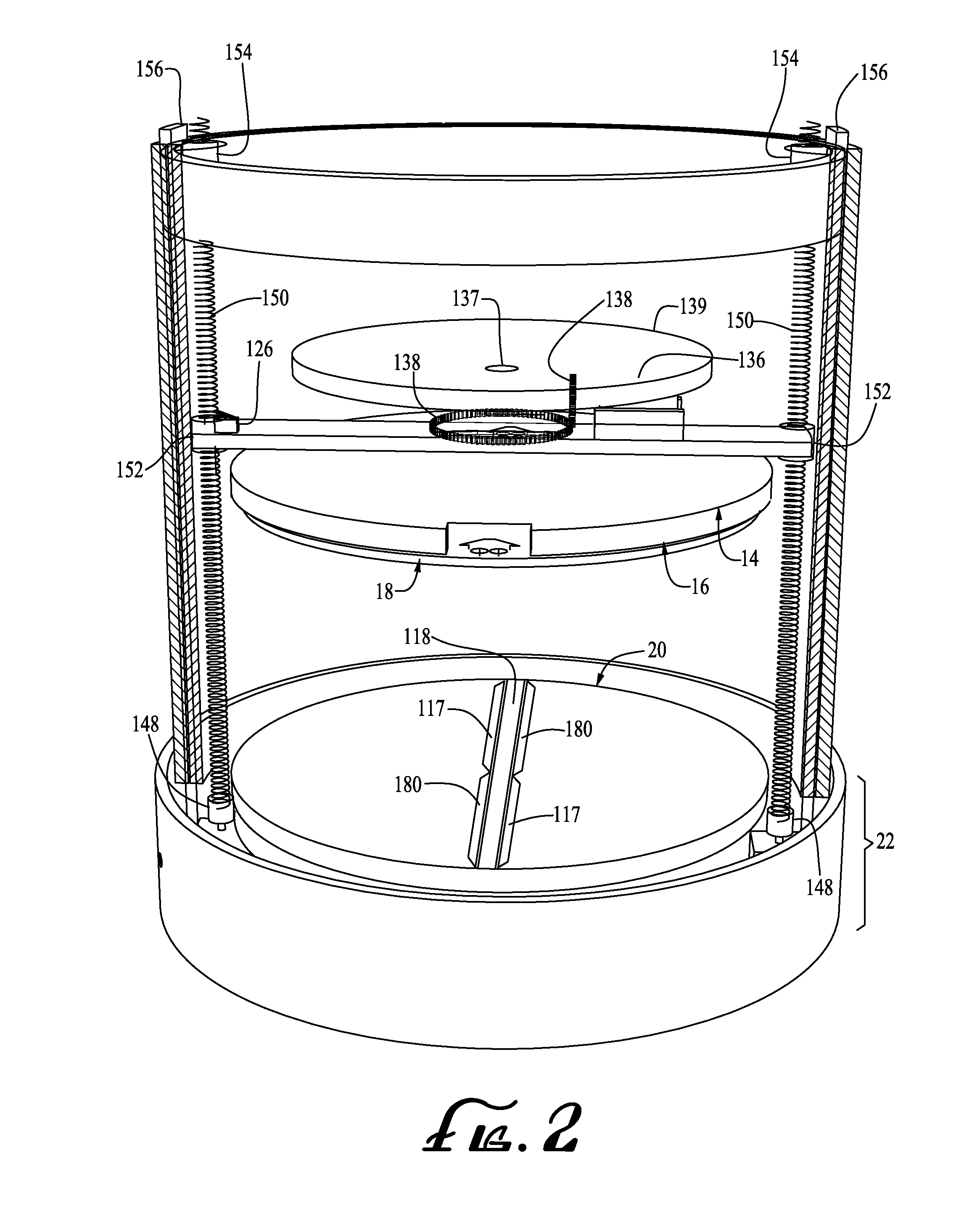

The present invention relates to 3D printer inputs including filaments comprising separated layers or sections. These inputs particularly including filaments may be prepared by coextrusion, microlayer coextrusion or multicomponent / fractal coextrusion. These inputs and specifically filaments enable layering or combining different materials simultaneously through one or more nozzles during the so-called 3D printing process. These techniques facilitate smaller layer sizes (milli, micro, and nano) different layer configurations as well as the potential to incorporate materials that would otherwise not be usable in standard 3D printer methods.

Owner:GUILL TOOL & ENG

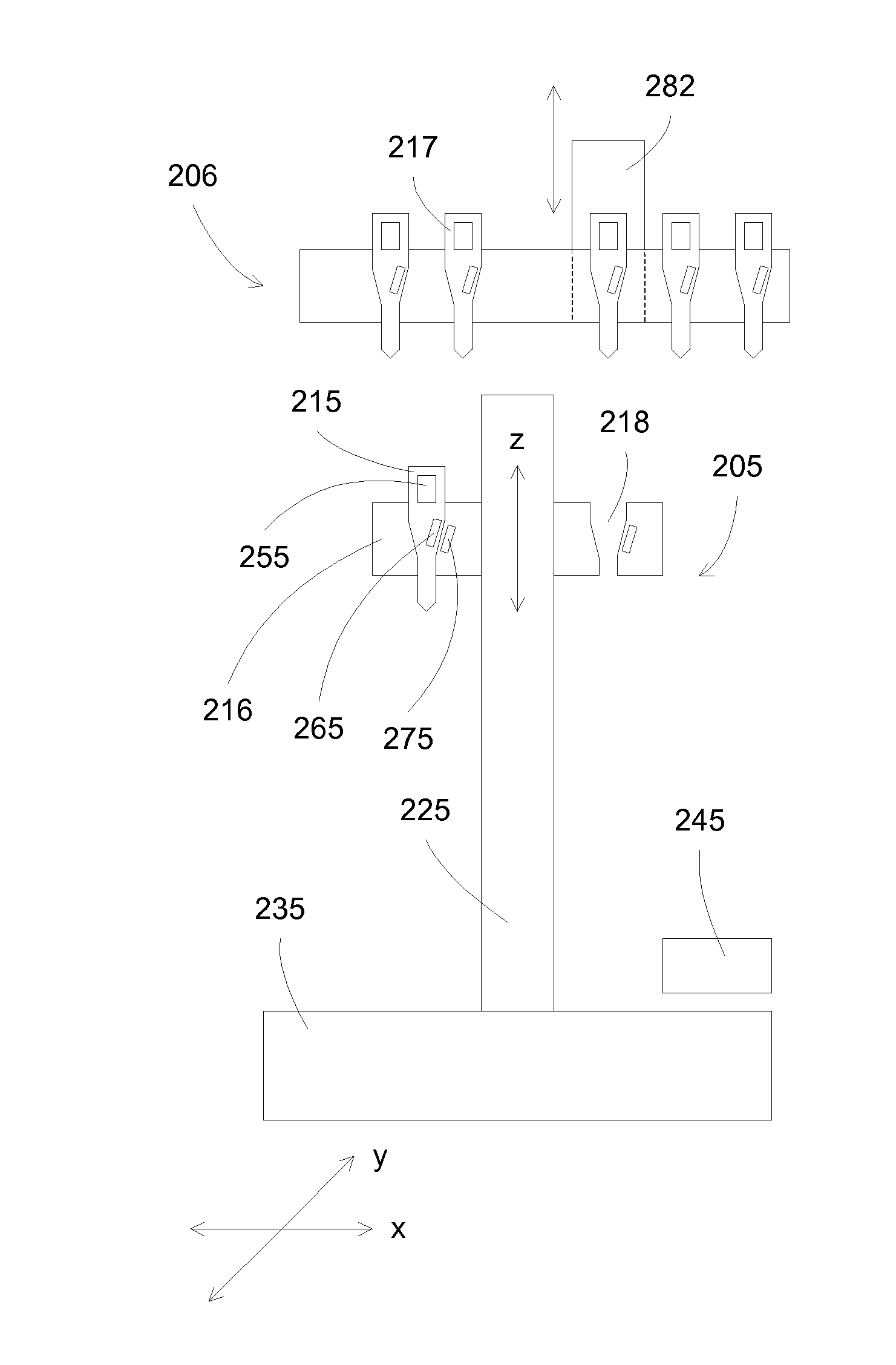

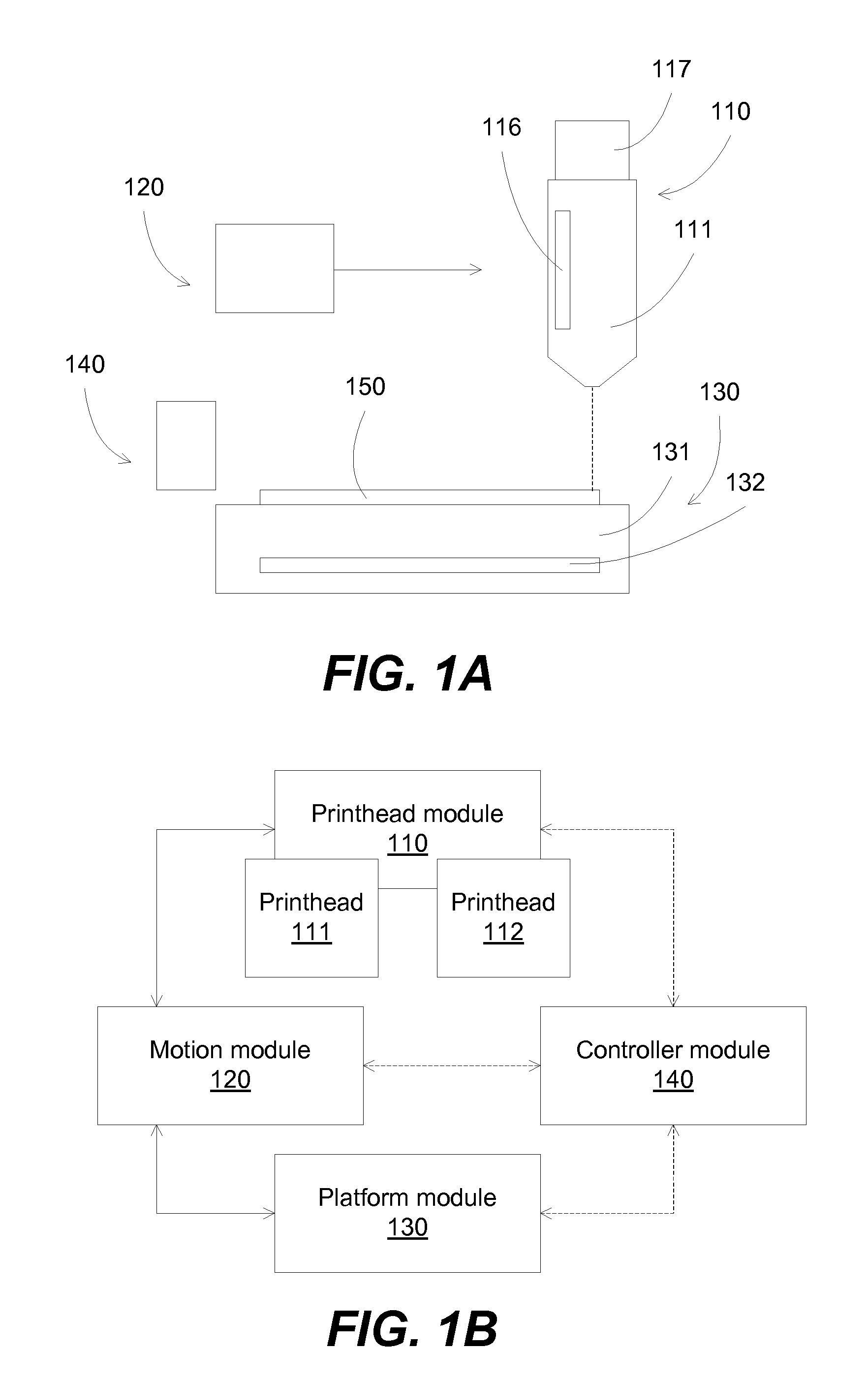

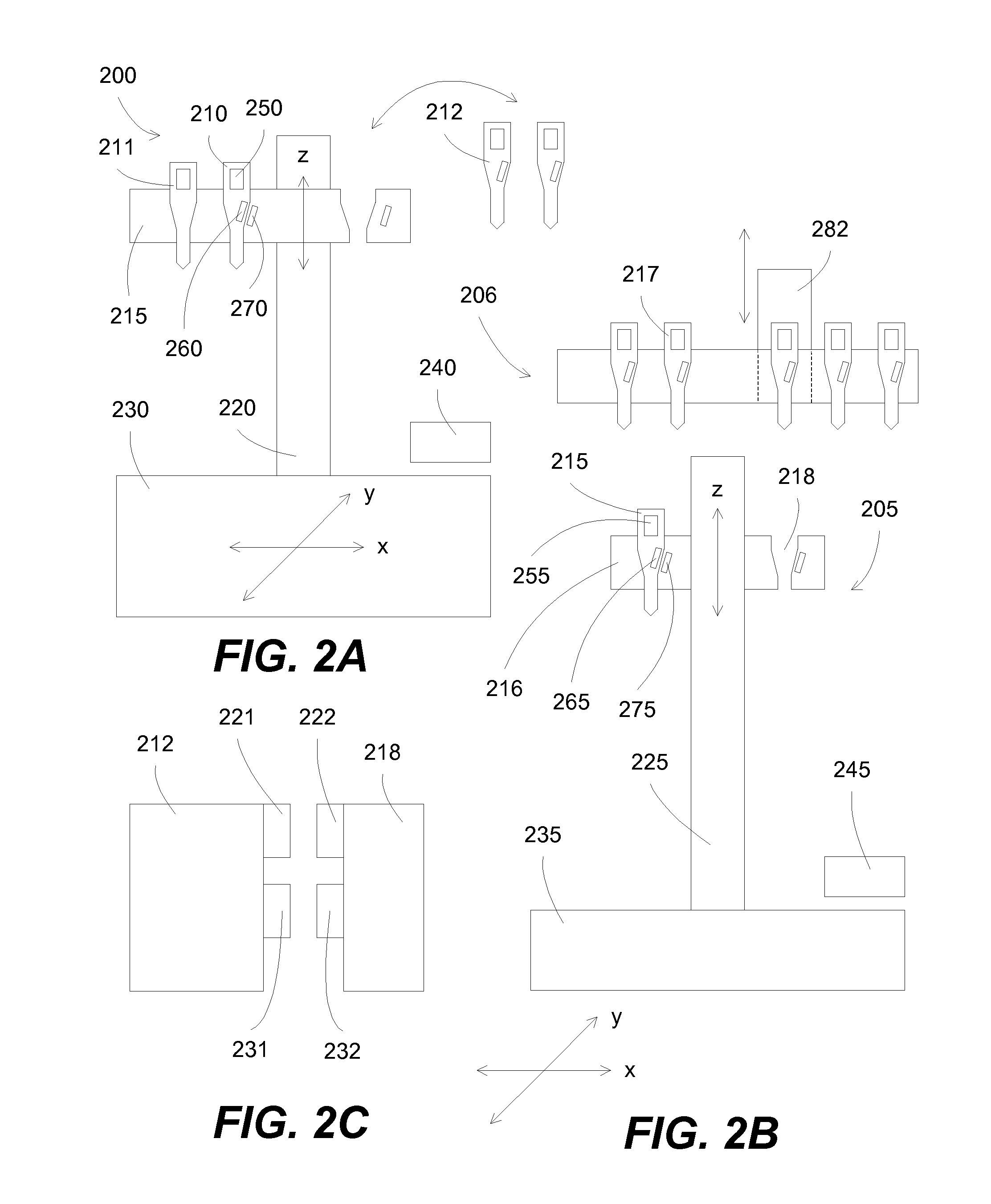

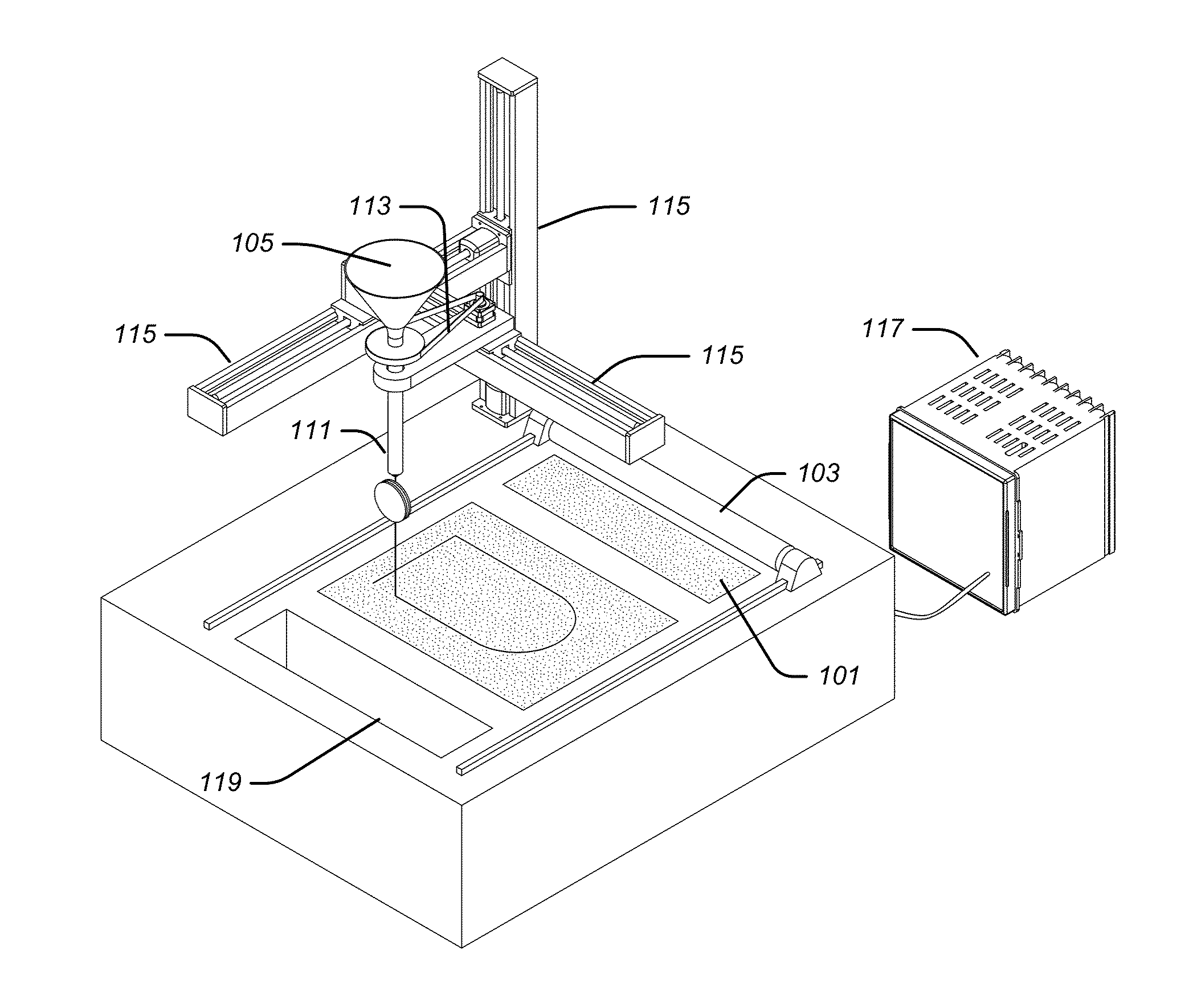

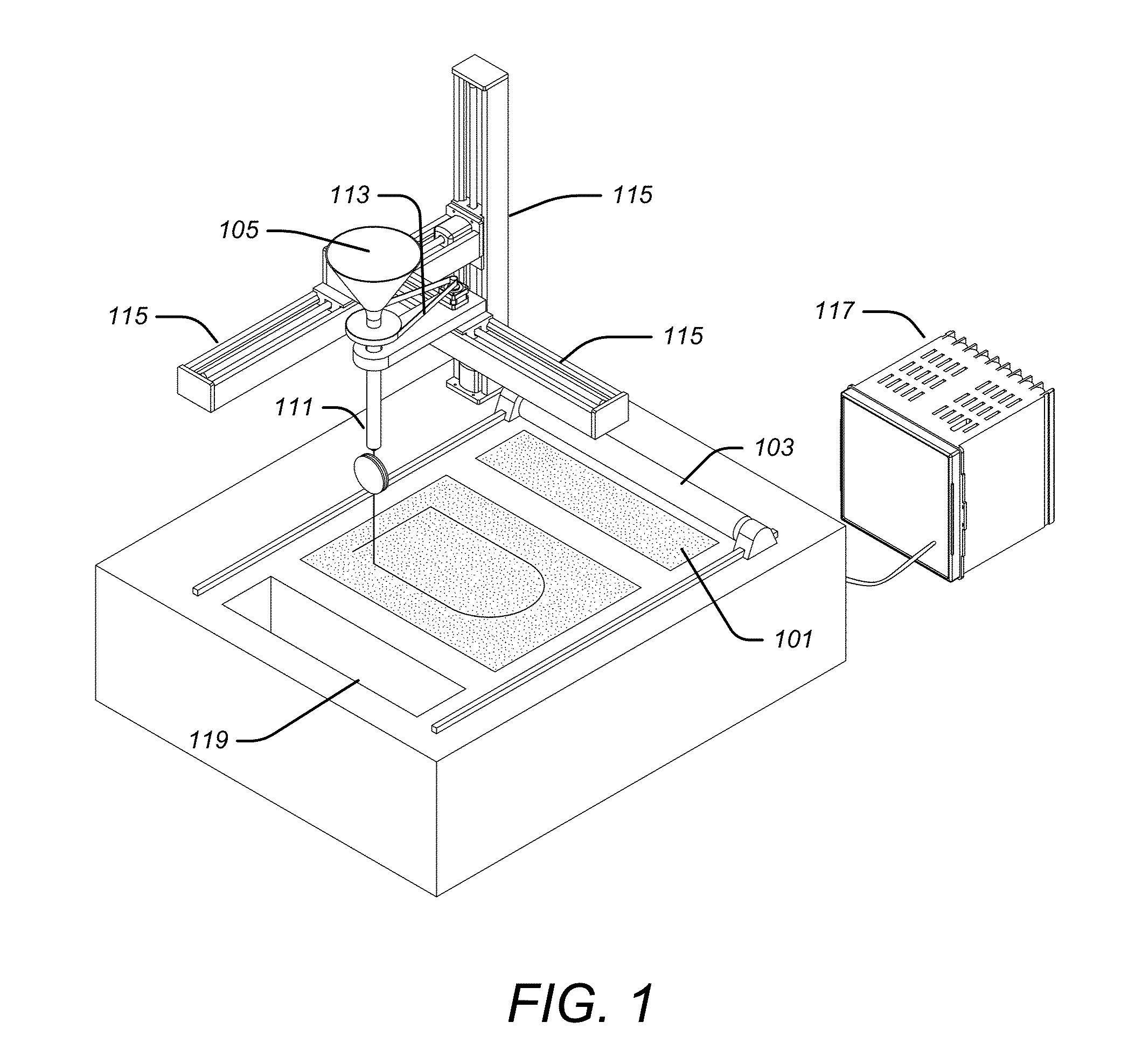

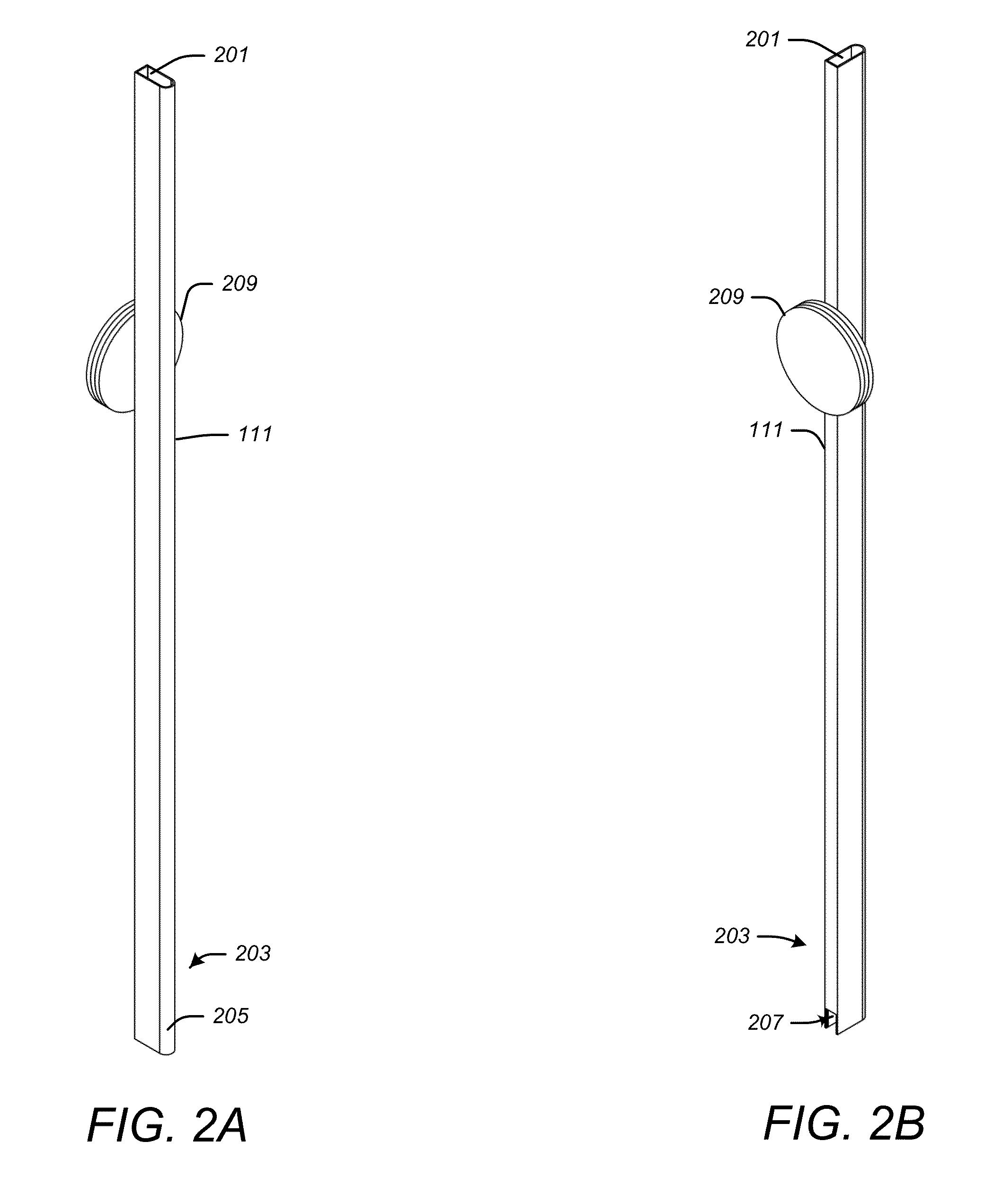

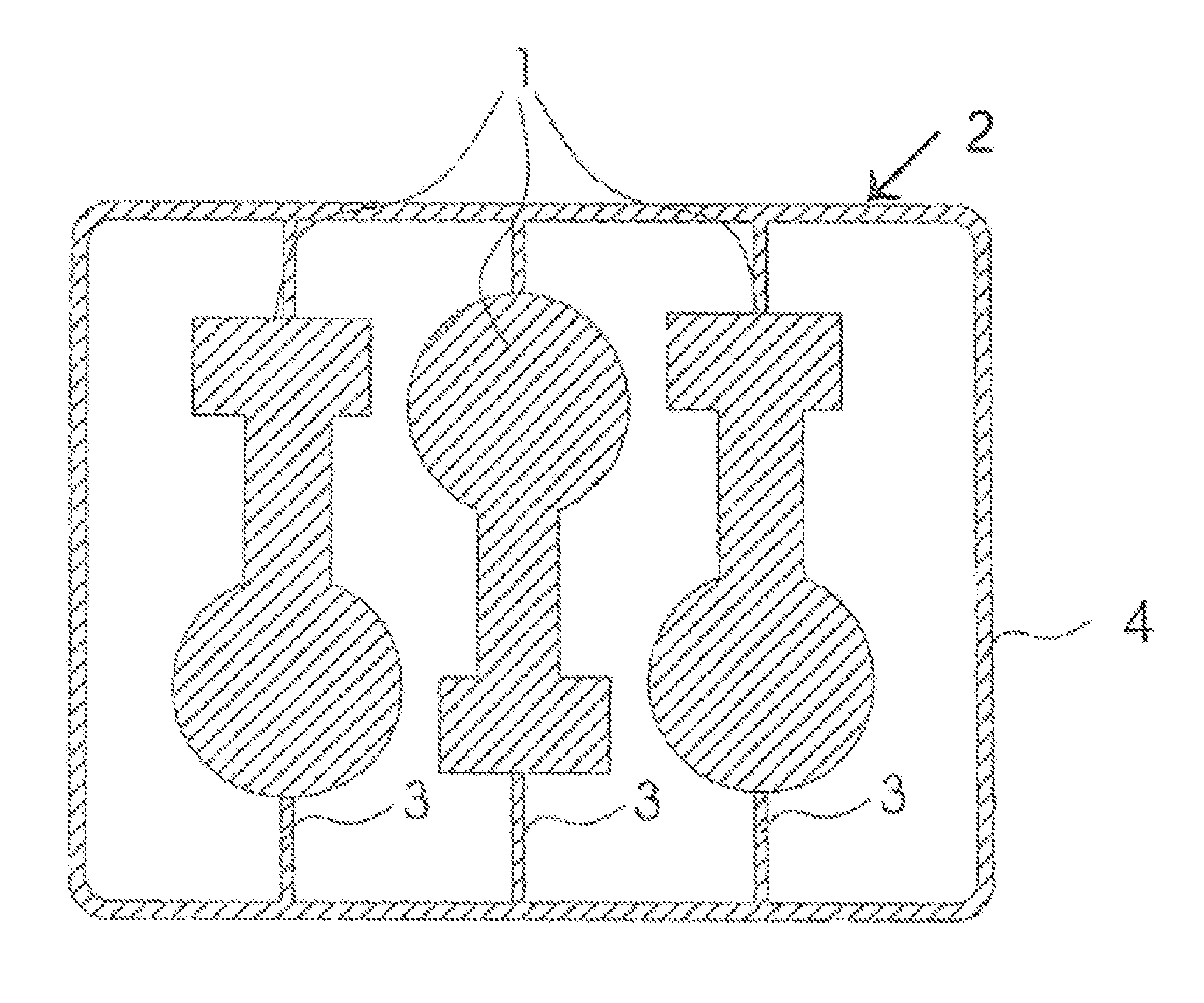

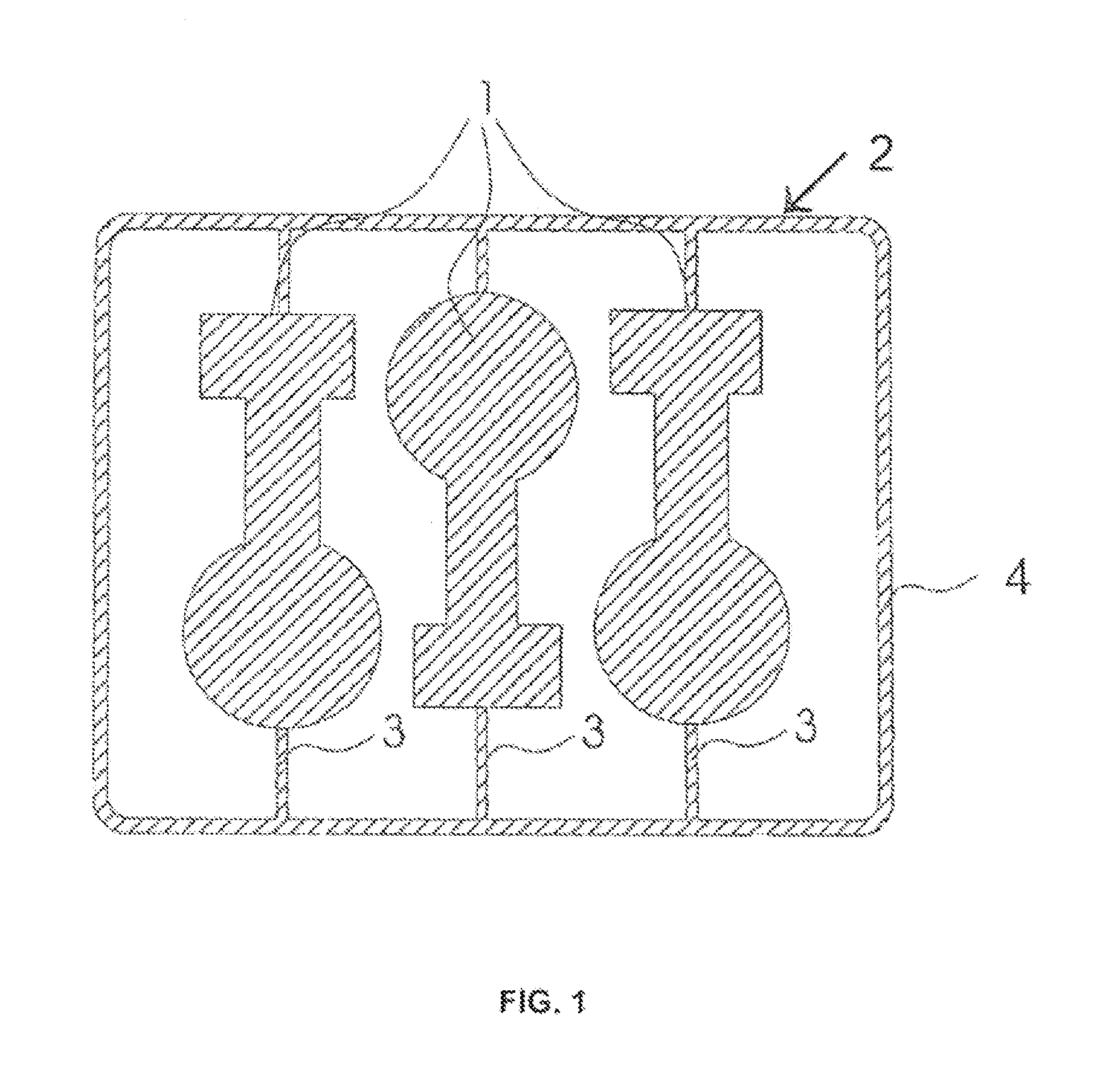

Systems and methods for 3D printing with multiple exchangeable printheads

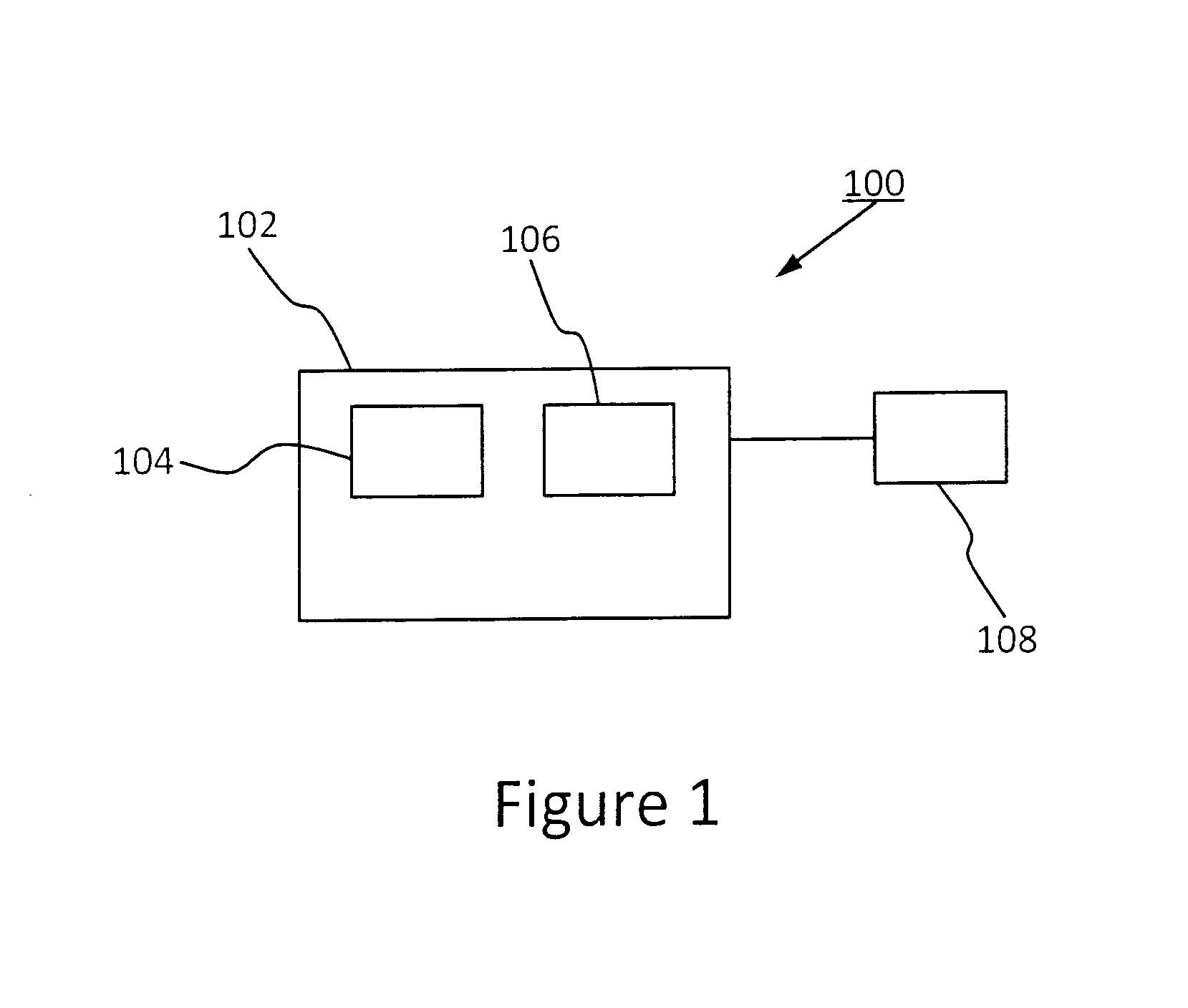

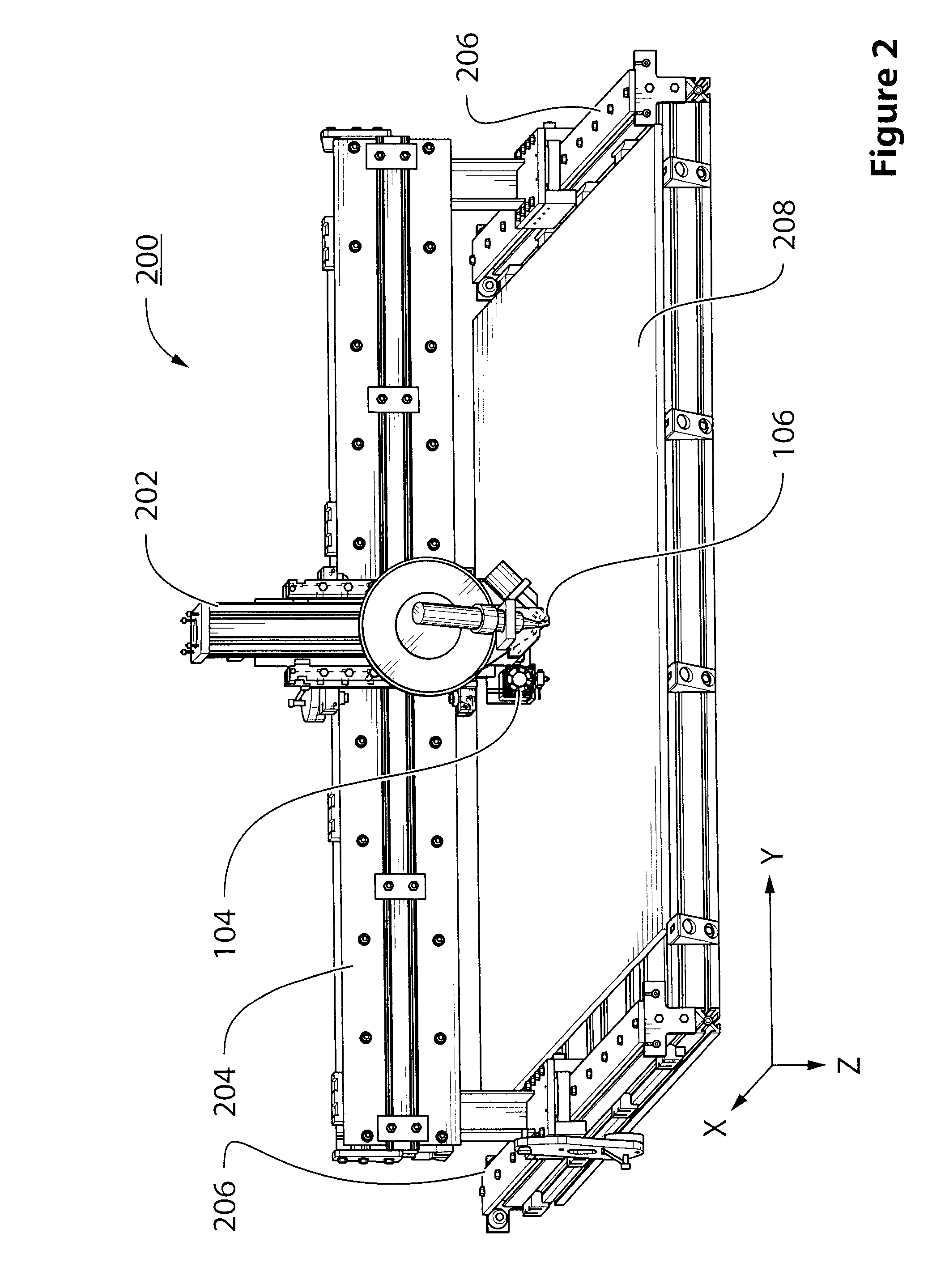

A modular 3D printer system can include a base subsystem and multiple exchangeable components. The base subsystem can have a 3D motion module, a printhead module and a platform module. The multiple exchangeable components can include printheads having different configurations and functionalities, which can be exchangeably installed in the printhead module. The multiple exchangeable components can include platform supports having different configurations and functionalities, which can be exchangeably installed in the platform module.

Owner:GIFFORD KARL JOSEPH +3

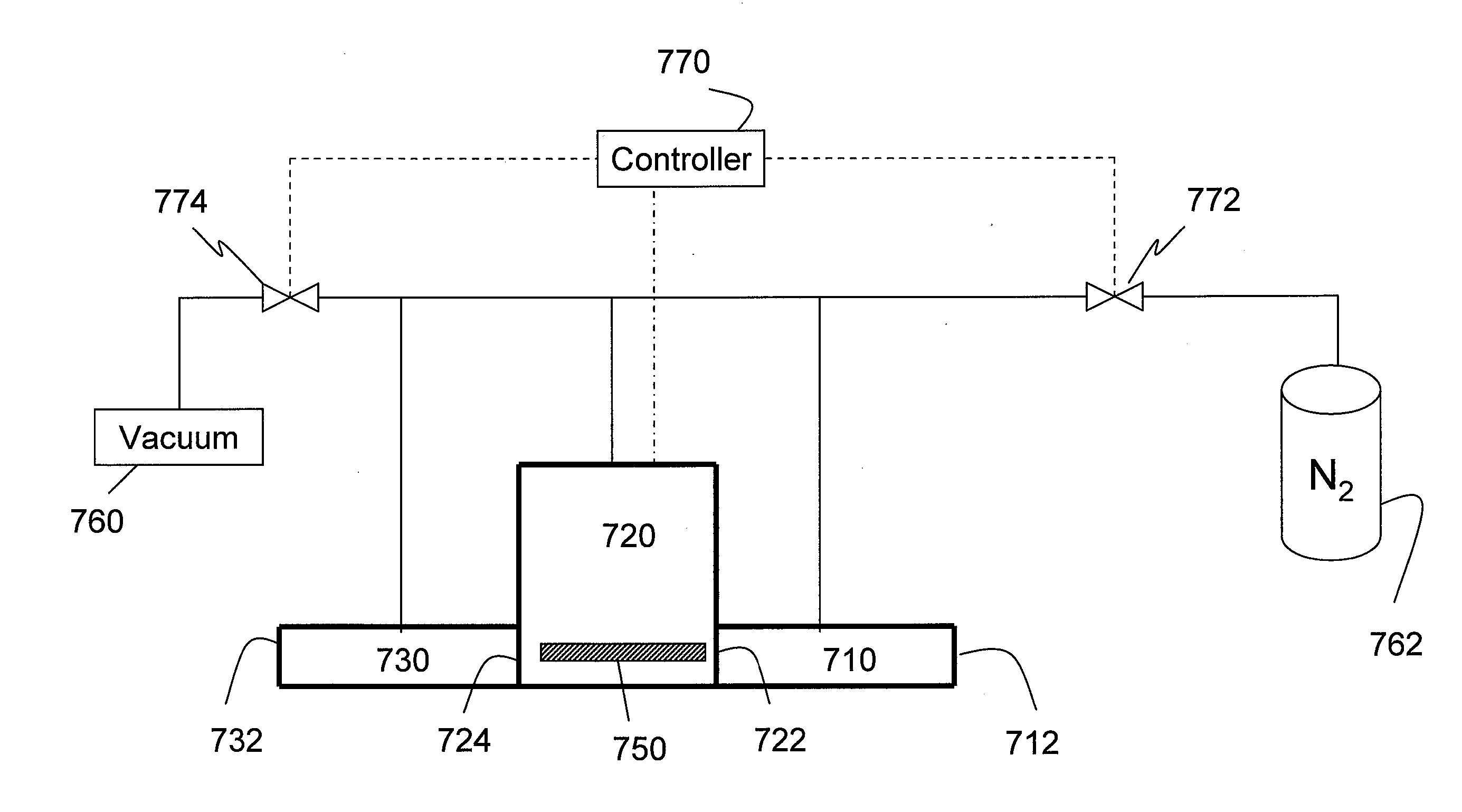

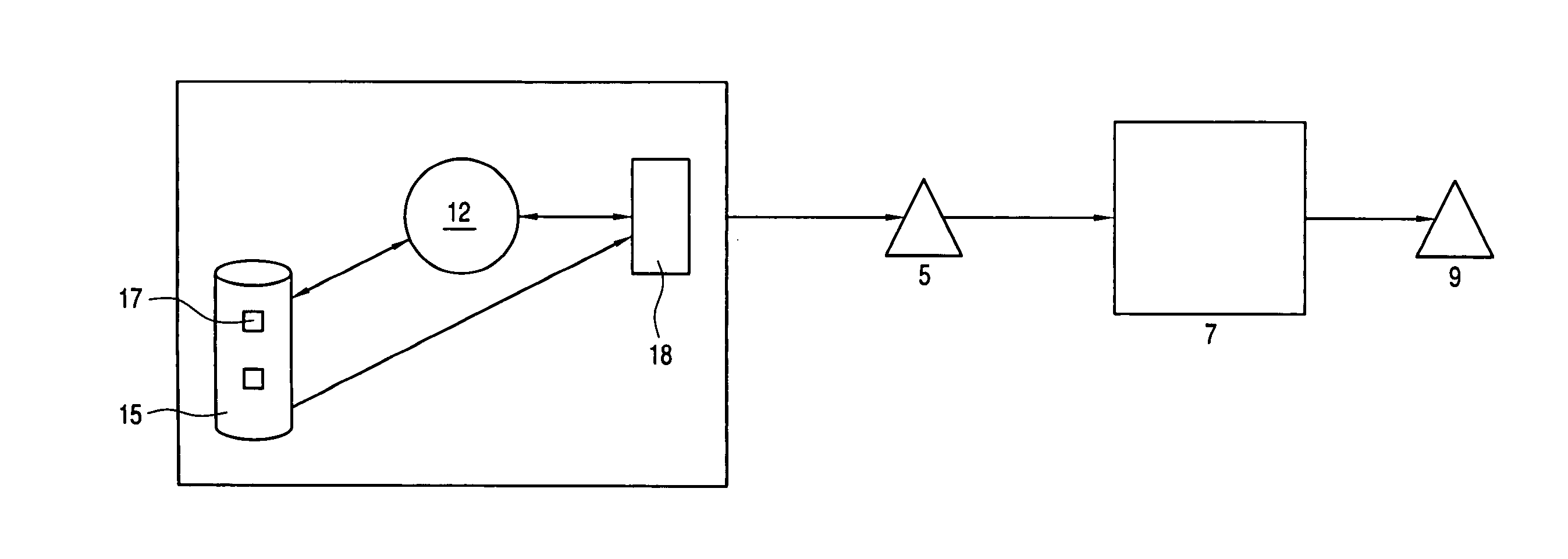

Method And Apparatus for Load-Locked Printing

ActiveUS20100201749A1Prevent oxidationAvoid contaminationInking apparatusMolten spray coatingElectrical and Electronics engineering3D printing

The disclosure relates to a method and apparatus for preventing oxidation or contamination during a circuit printing operation. The circuit printing operation can be directed to OLED-type printing. In an exemplary embodiment, the printing process is conducted at a load-locked printer housing having one or more of chambers. Each chamber is partitioned from the other chambers by physical gates or fluidic curtains. A controller coordinates transportation of a substrate through the system and purges the system by timely opening appropriate gates. The controller may also control the printing operation by energizing the print-head at a time when the substrate is positioned substantially thereunder.

Owner:KATEEVA

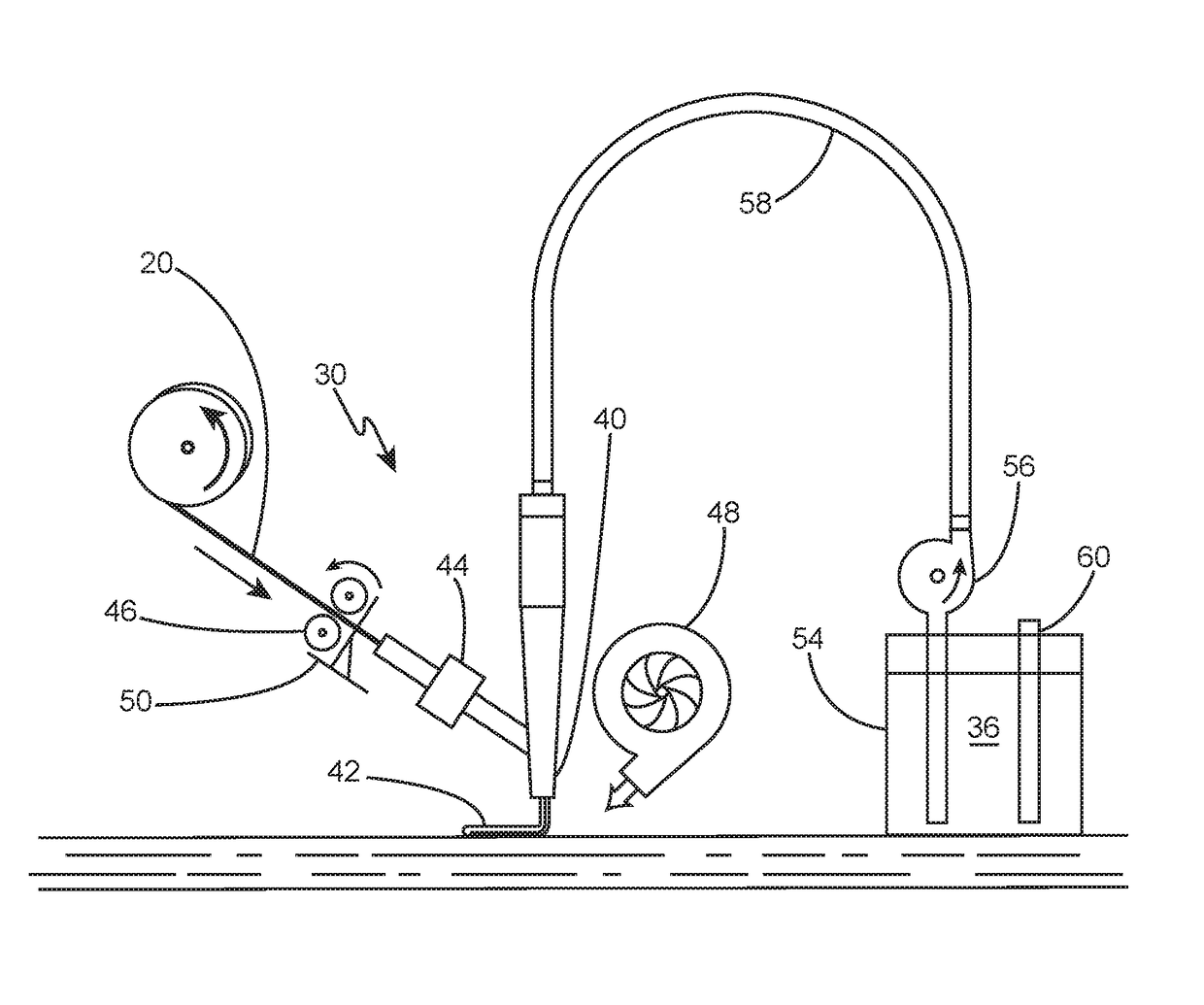

Method and Apparatus for Additive Mechanical Growth of Tubular Structures

InactiveUS20160031155A1High strengthEliminate needLiquid surface applicatorsManufacturing driving meansAdditive layer manufacturing3D printing

Owner:CONTINUOUS COMPOSITES INC

Aluminum/magnesium 3D-Printing rapid prototyping

InactiveUS20060045787A1Additive manufacturing apparatusTransportation and packagingCopperRapid prototyping

A 3D Printing Rapid Prototyping process using Al / Mg particles coated with a metal (i.e. copper, nickel, zinc, or tin) that (1) prevents oxidation of the Al / Mg particles, and (2) either alone, or when alloyed with the aluminum or magnesium core metal, melts below the liquidus temperature of the core.

Owner:GM GLOBAL TECH OPERATIONS LLC

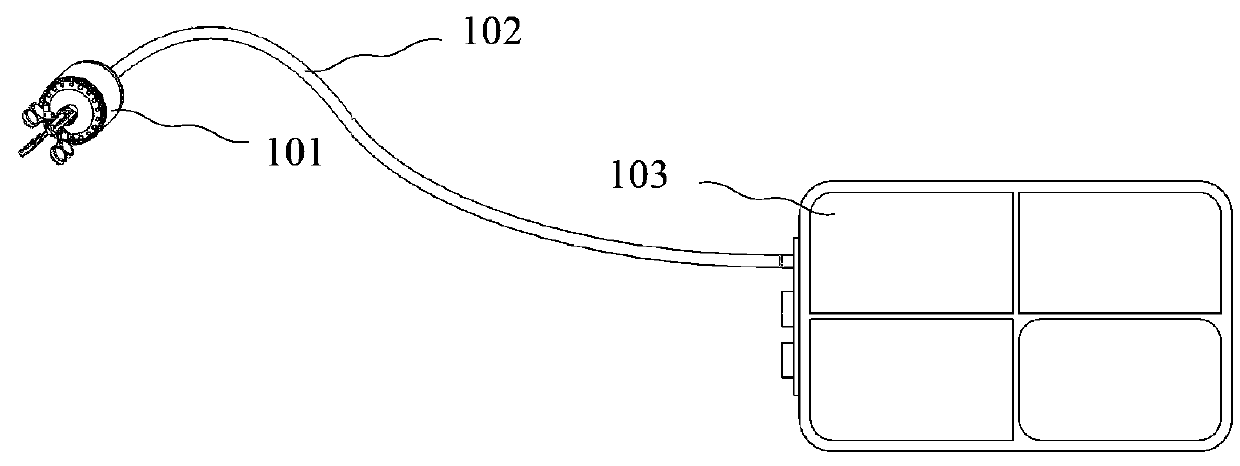

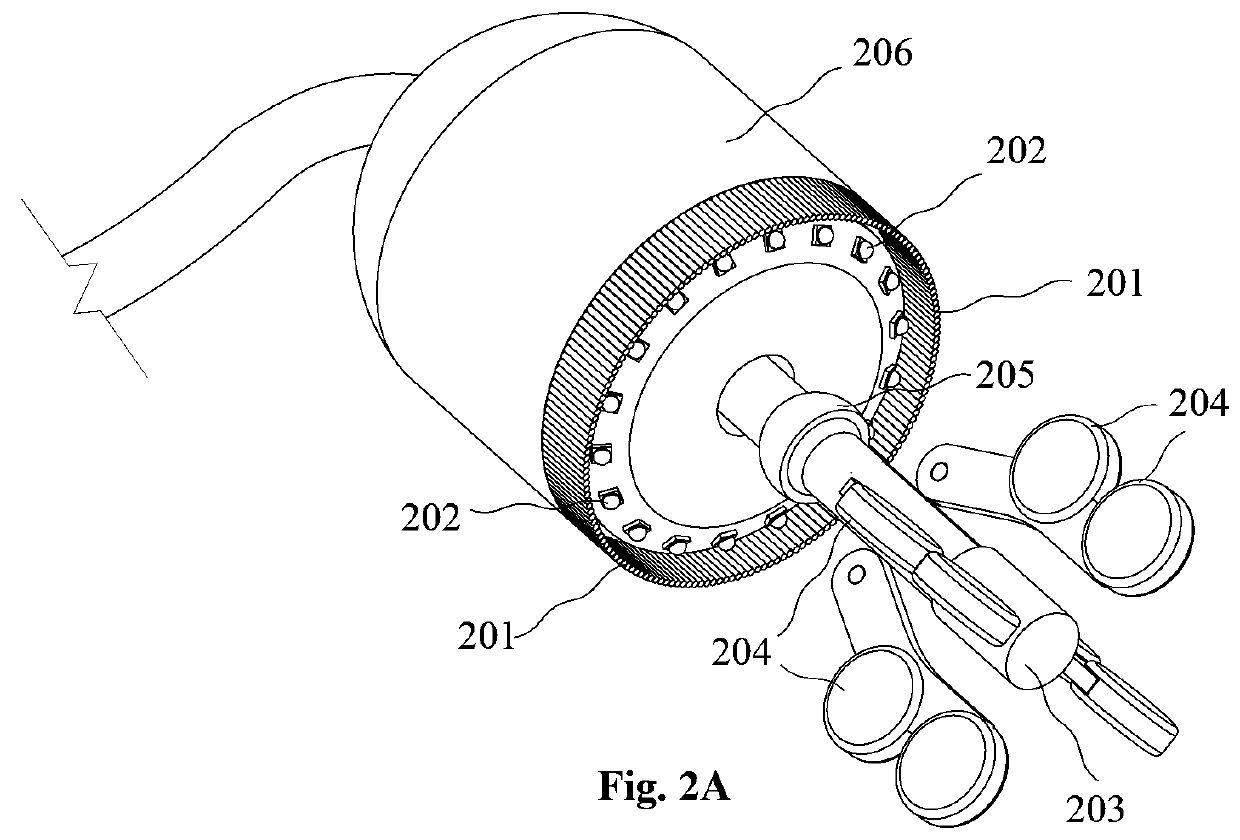

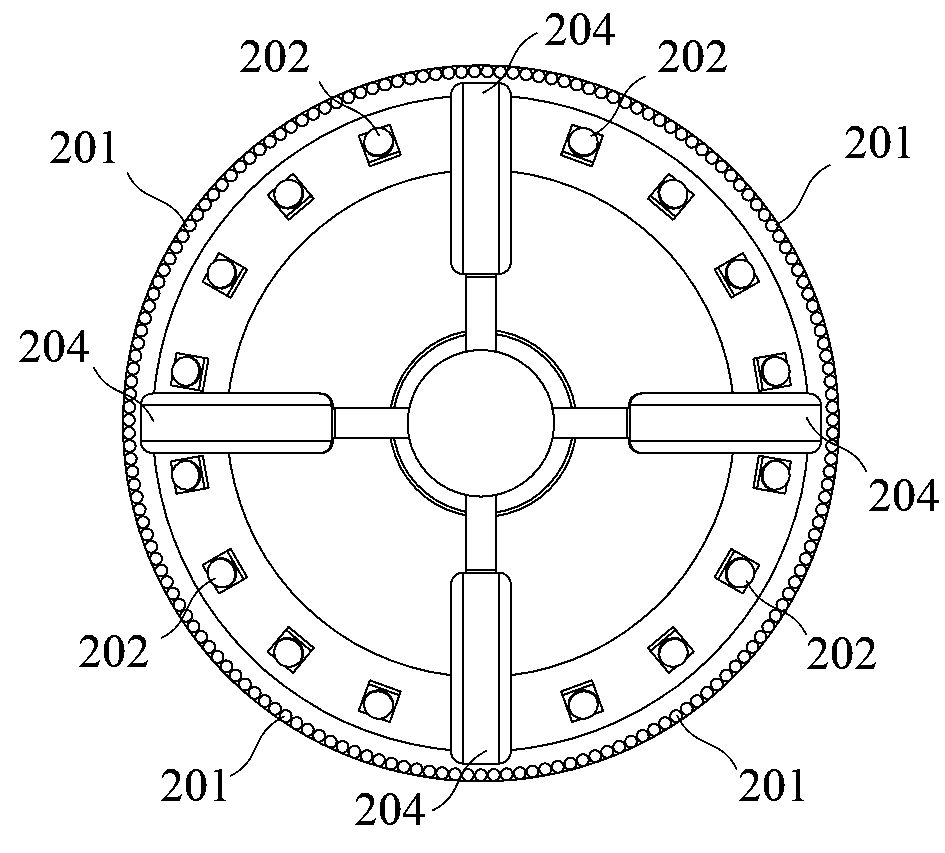

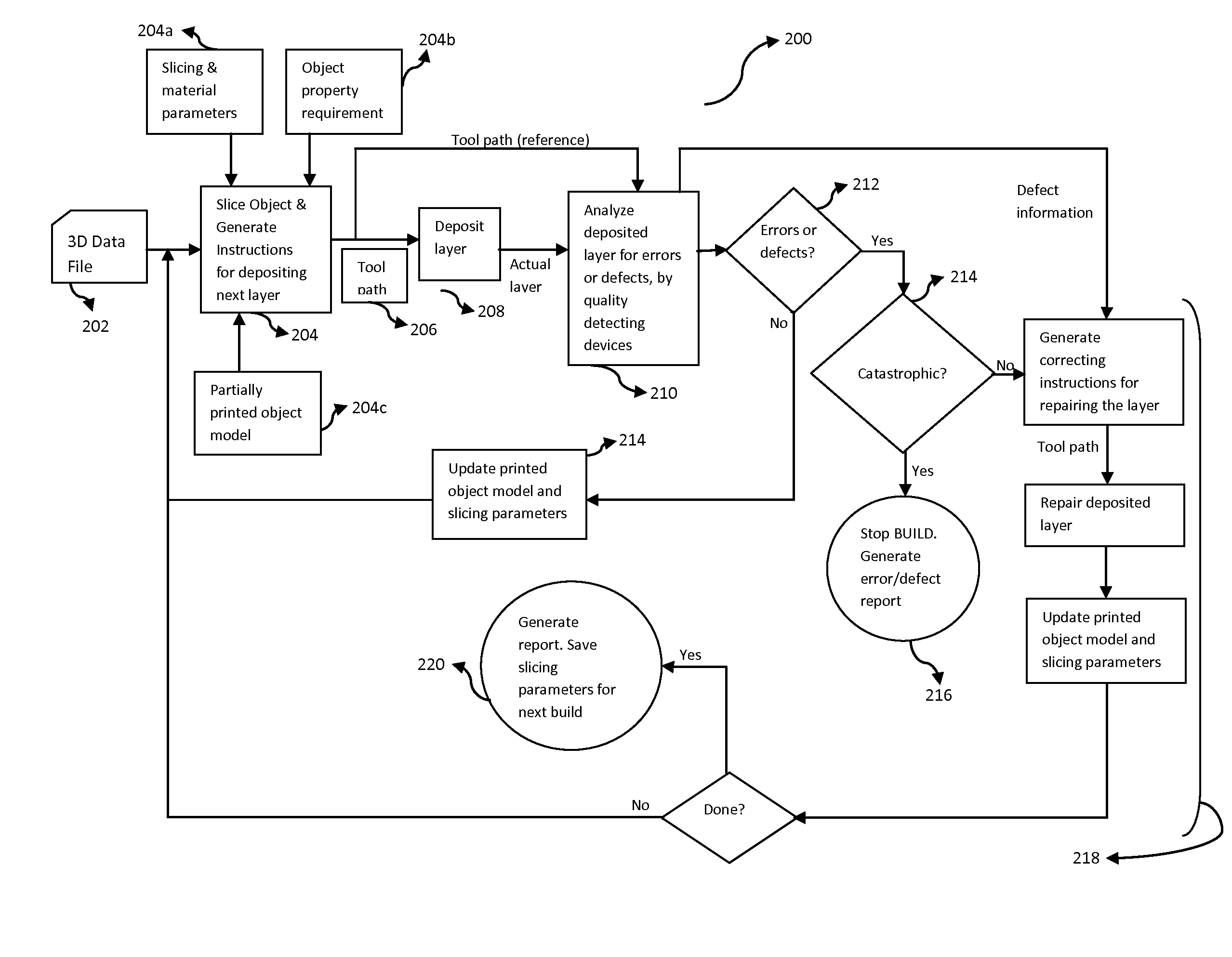

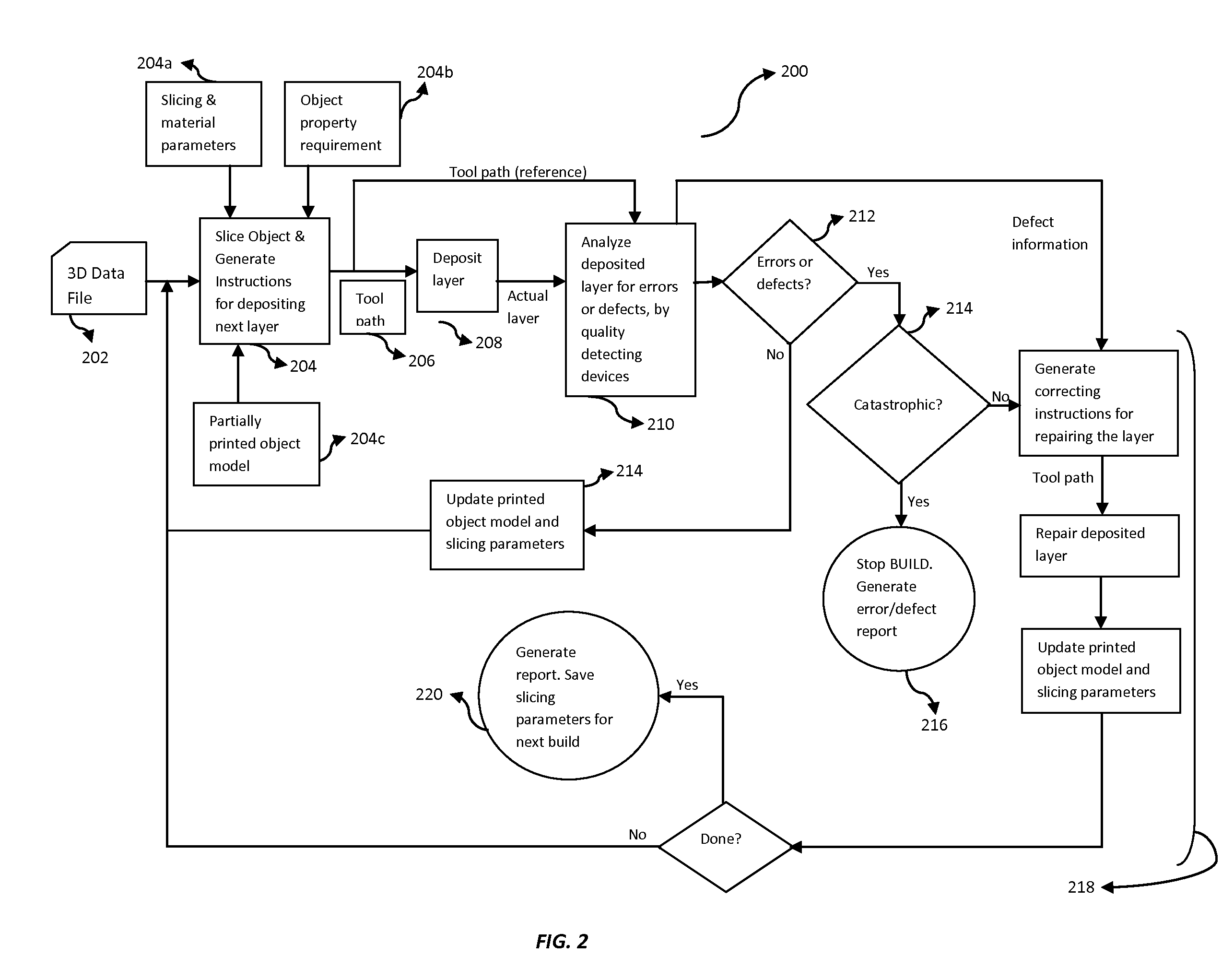

Method to monitor additive manufacturing process for detection and in-situ correction of defects

ActiveUS20160236414A1Minimize presenceProgramme controlAdditive manufacturing apparatusStructural geometryEngineering

The present invention provides a system and a method for real time monitoring and identifying defects occurring in a three dimensional object build via an additive manufacturing process. Further, the present invention provides in-situ correction of such defects by a plurality of functional tool heads possessing freedom of motion in arbitrary planes and approach, where the functional tool heads are automatically and independently controlled based on a feedback analysis from the printing process, implementing analyzing techniques. Furthermore, the present invention provides a mechanism for analyzing defected data collected from detection devices and correcting tool path instructions and object model in-situ during construction of a 3D object. A build report is also generated that displays, in 3D space, the structural geometry and inherent properties of a final build object along with the features of corrected and uncorrected defects. Advantageously, the build report helps in improving 3D printing process for subsequent objects.

Owner:AREVO INC

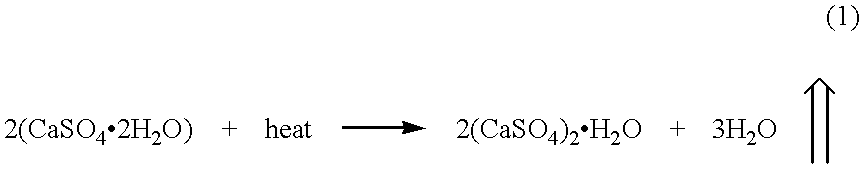

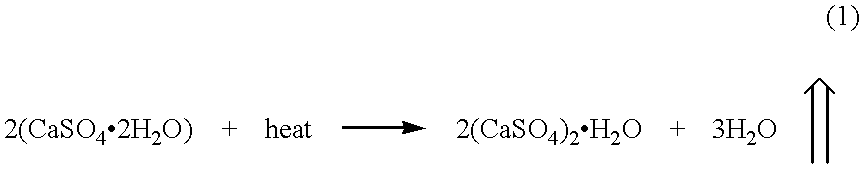

Three dimensional printing material system and method

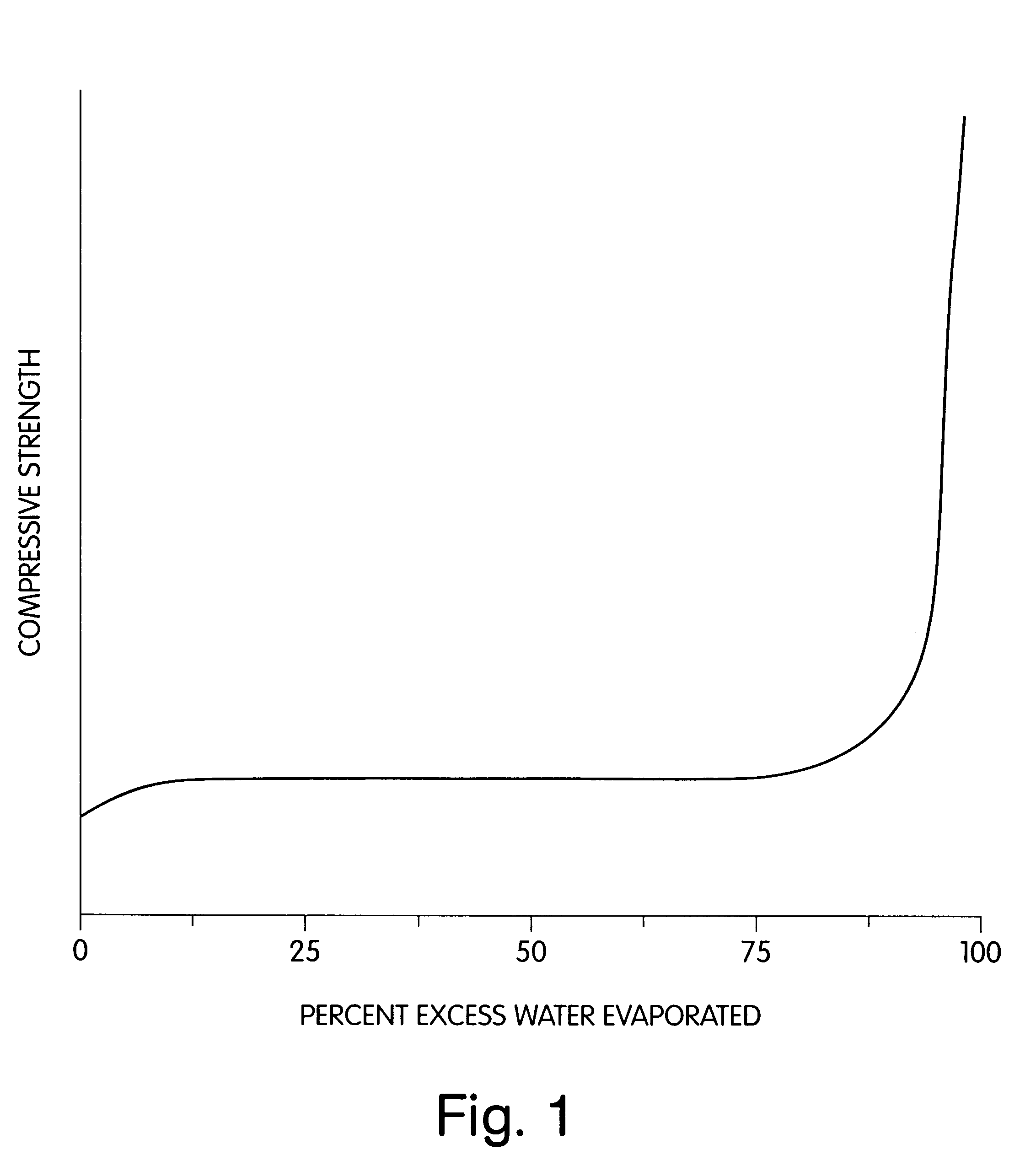

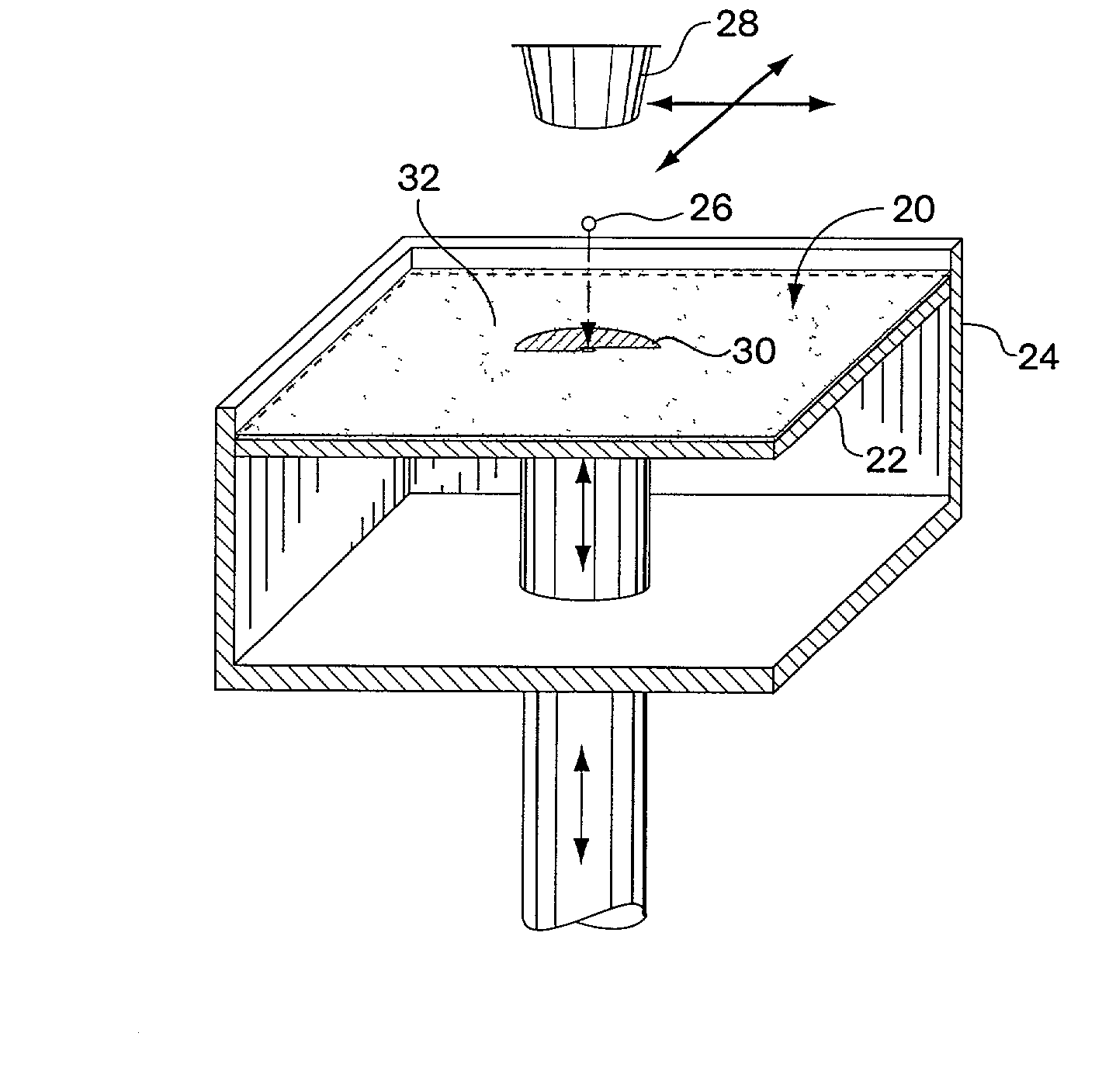

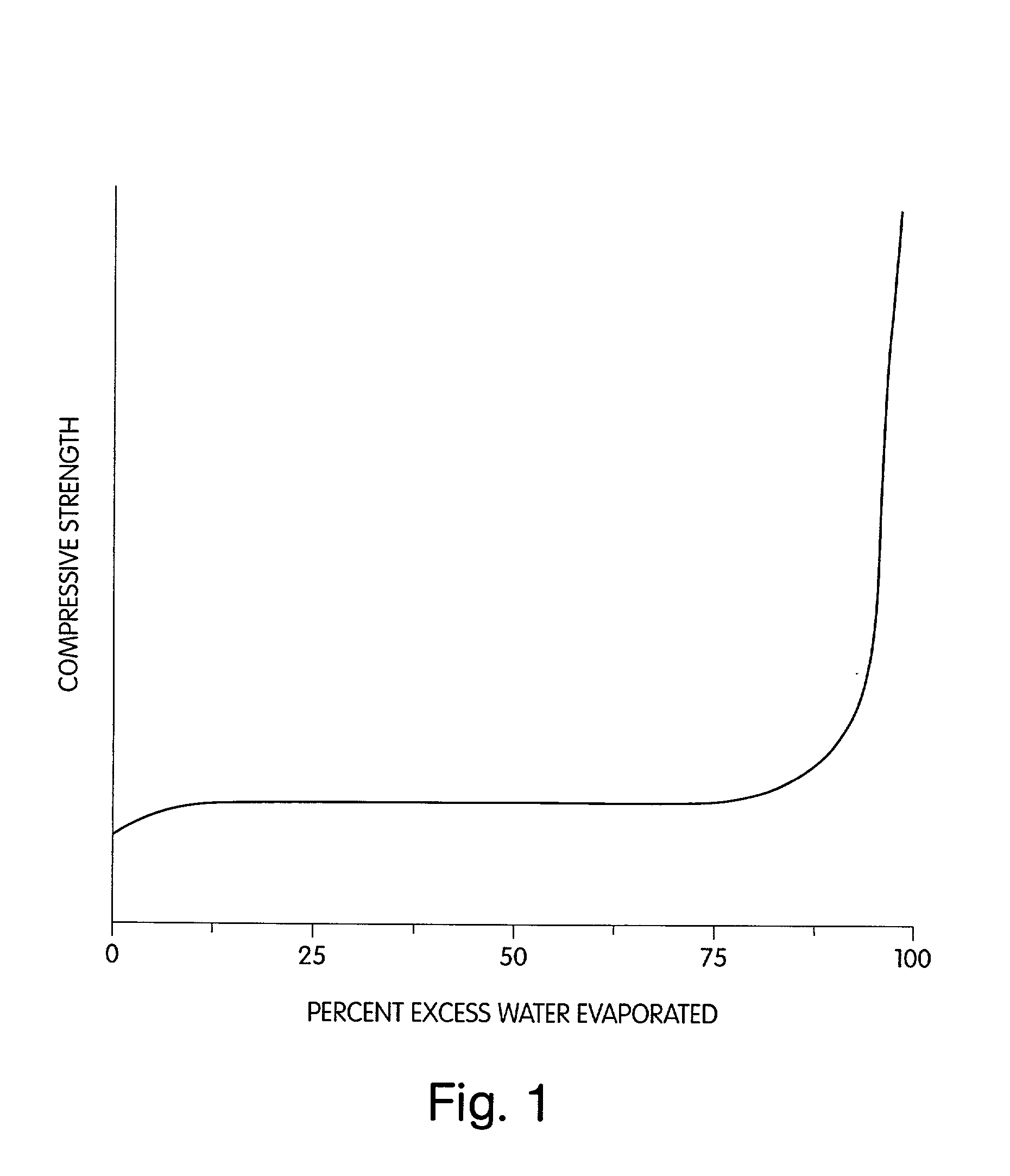

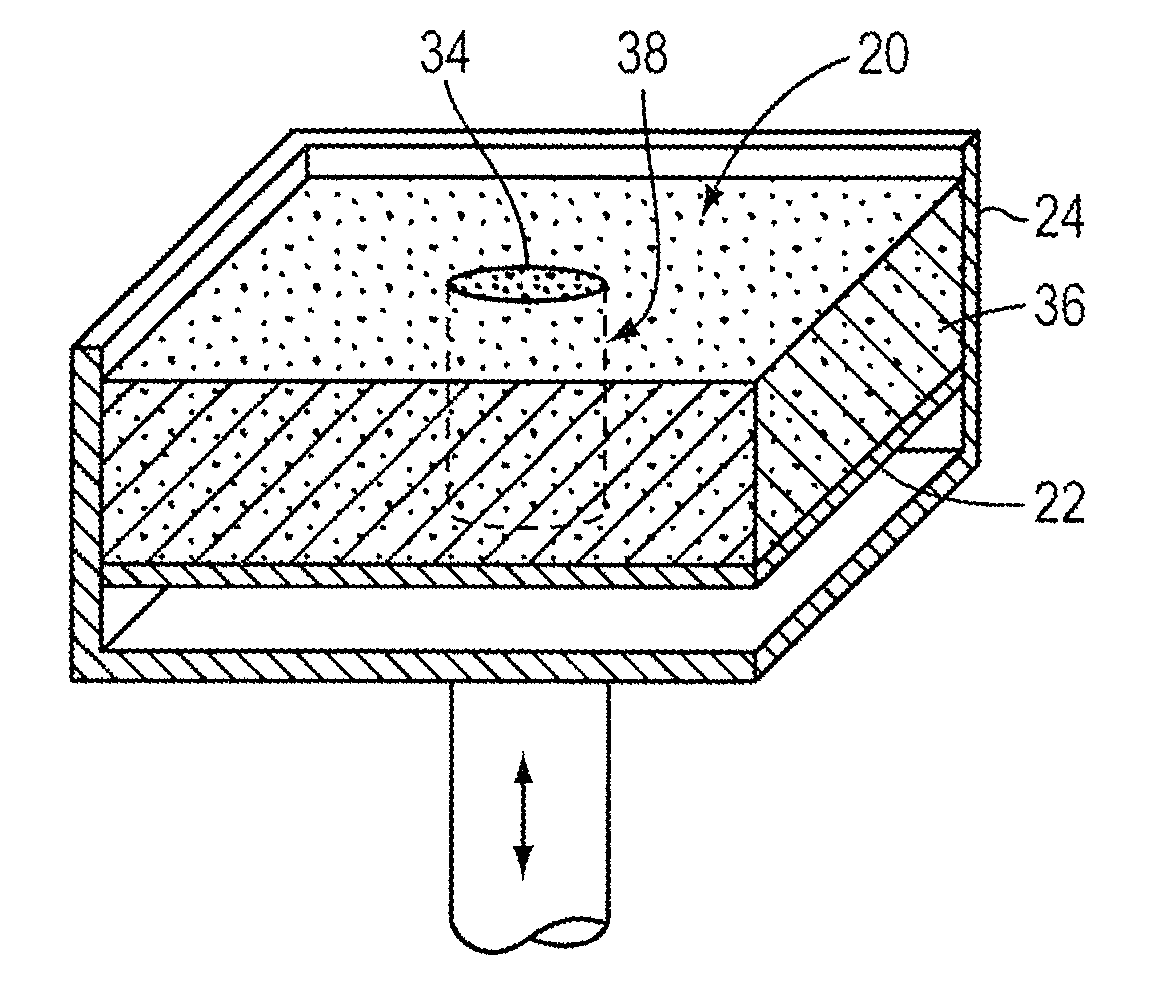

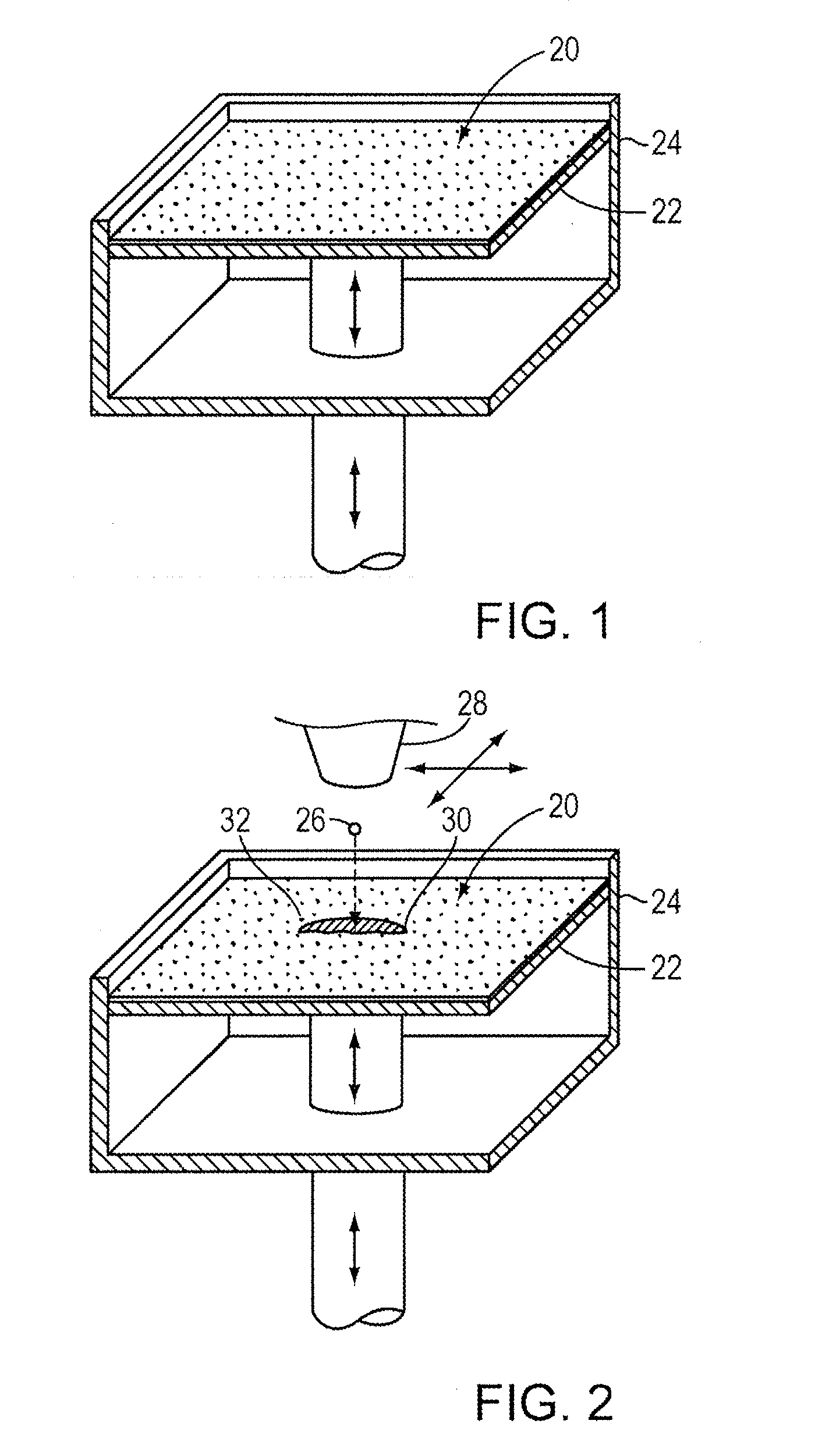

InactiveUS6610429B2High strengthReduce the amount of solutionAdditive manufacturing apparatusLamination ancillary operationsEngineeringLayer wise

The present invention is directed to a 3DP(TM) material system ad method, and an article made therefrom. The method of the present invention includes building cross-sectional portions of a three-dimensional article, and assembling the individual cross-sectional areas in a layer-wise fashion to form a final article. The individual cross-sectional areas are built by using an ink-jet printhead to deliver an aqueous fluid to a particulate material that includes plaster.

Owner:3D SYST INC

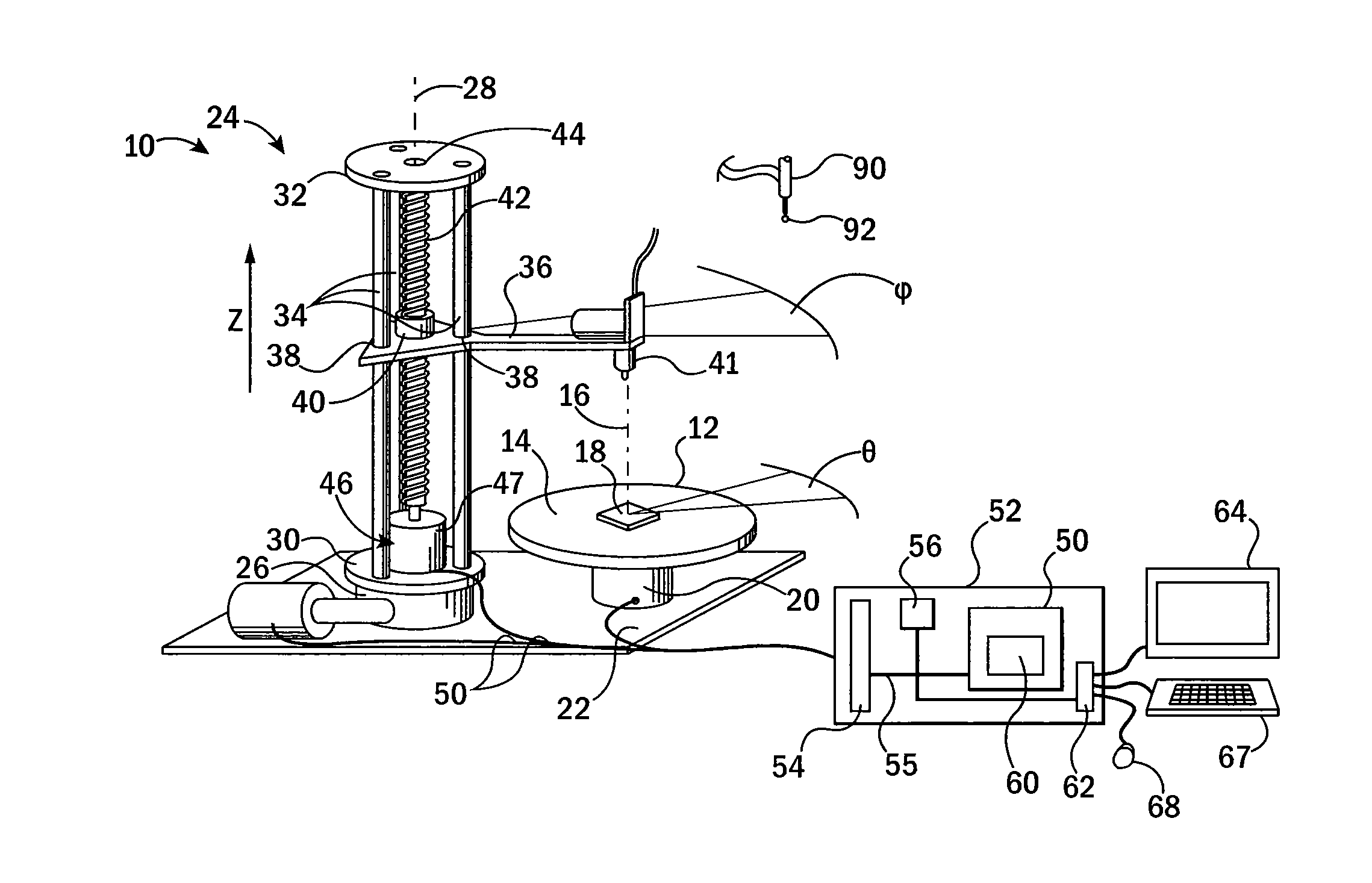

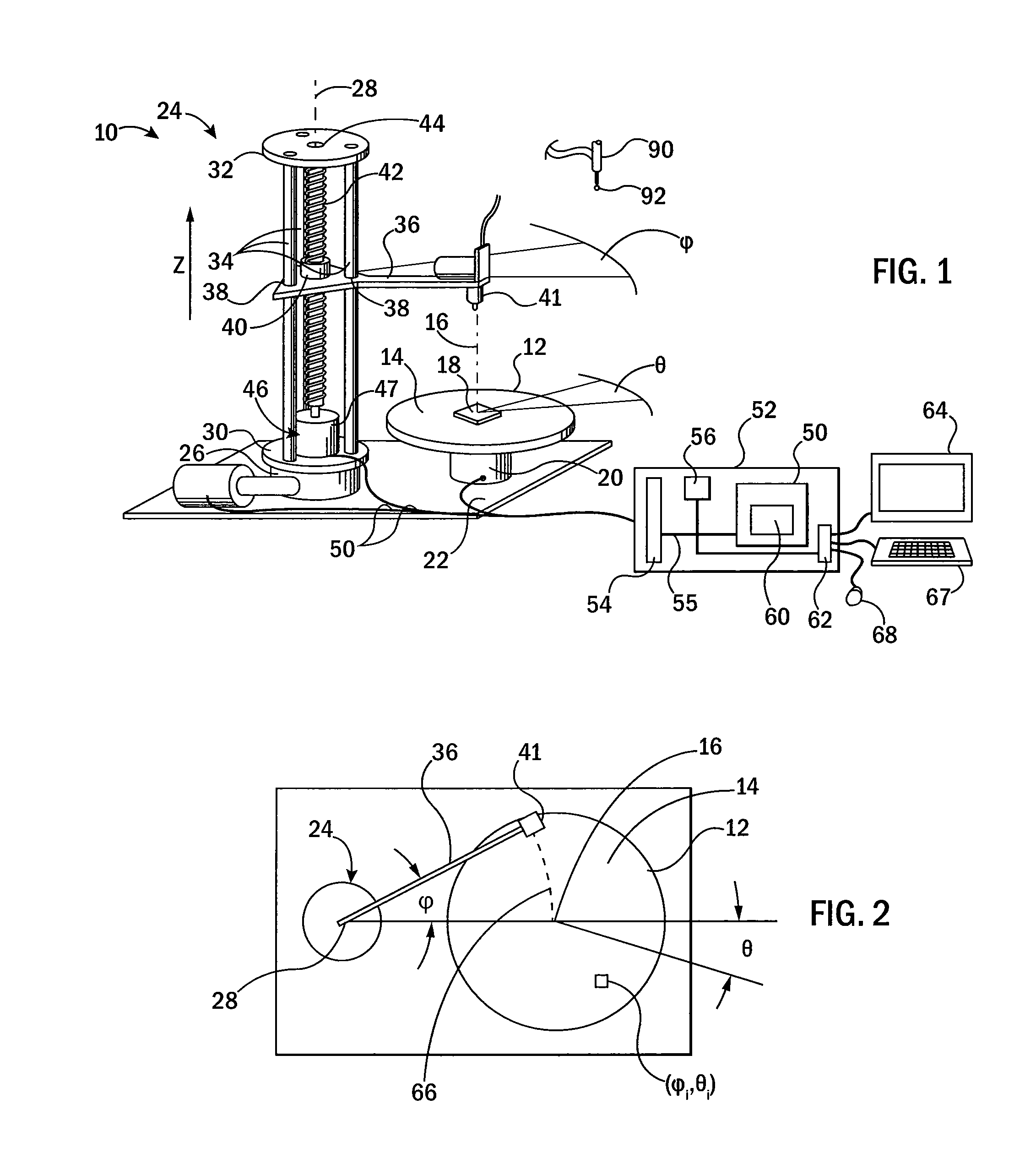

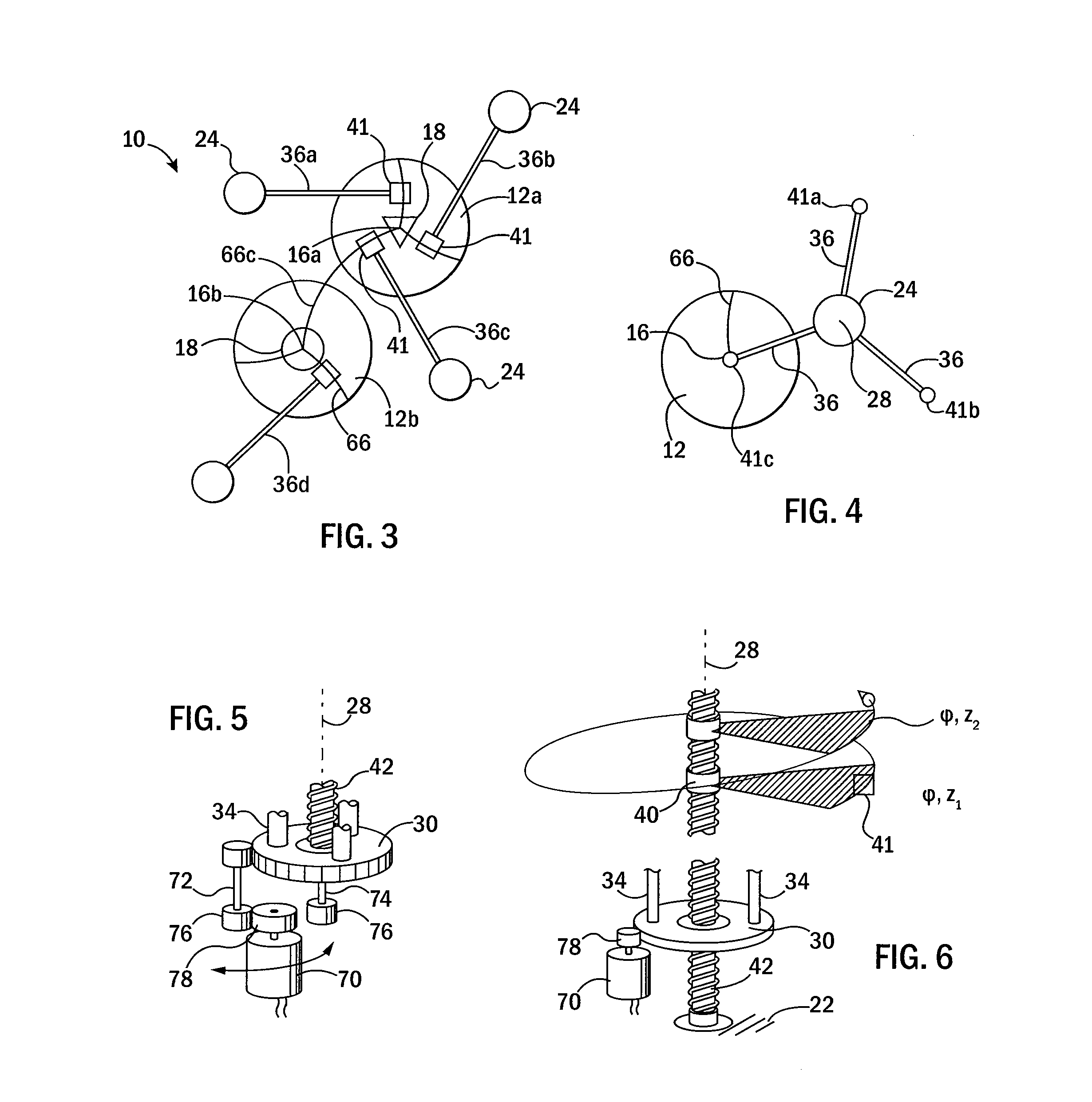

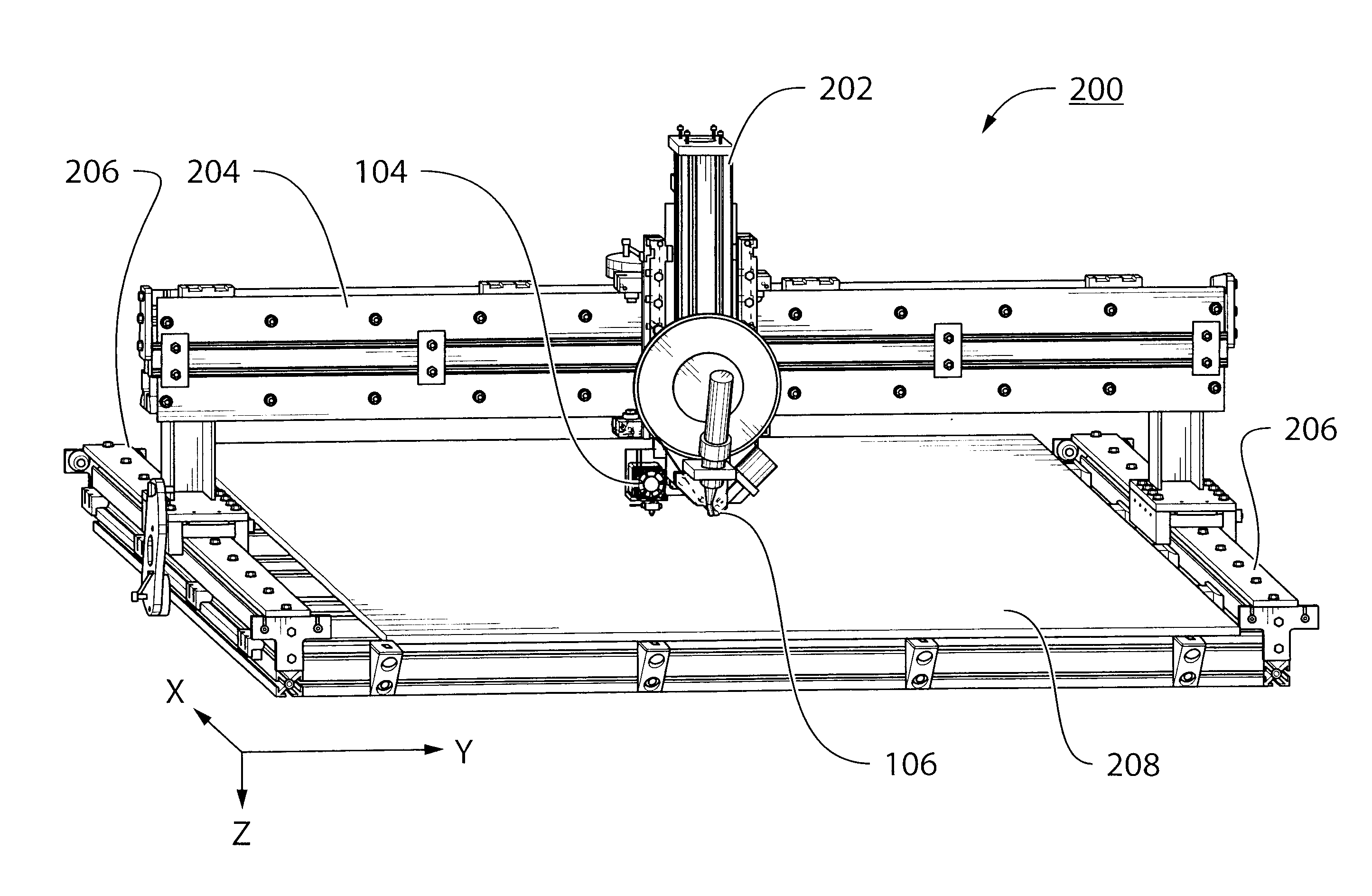

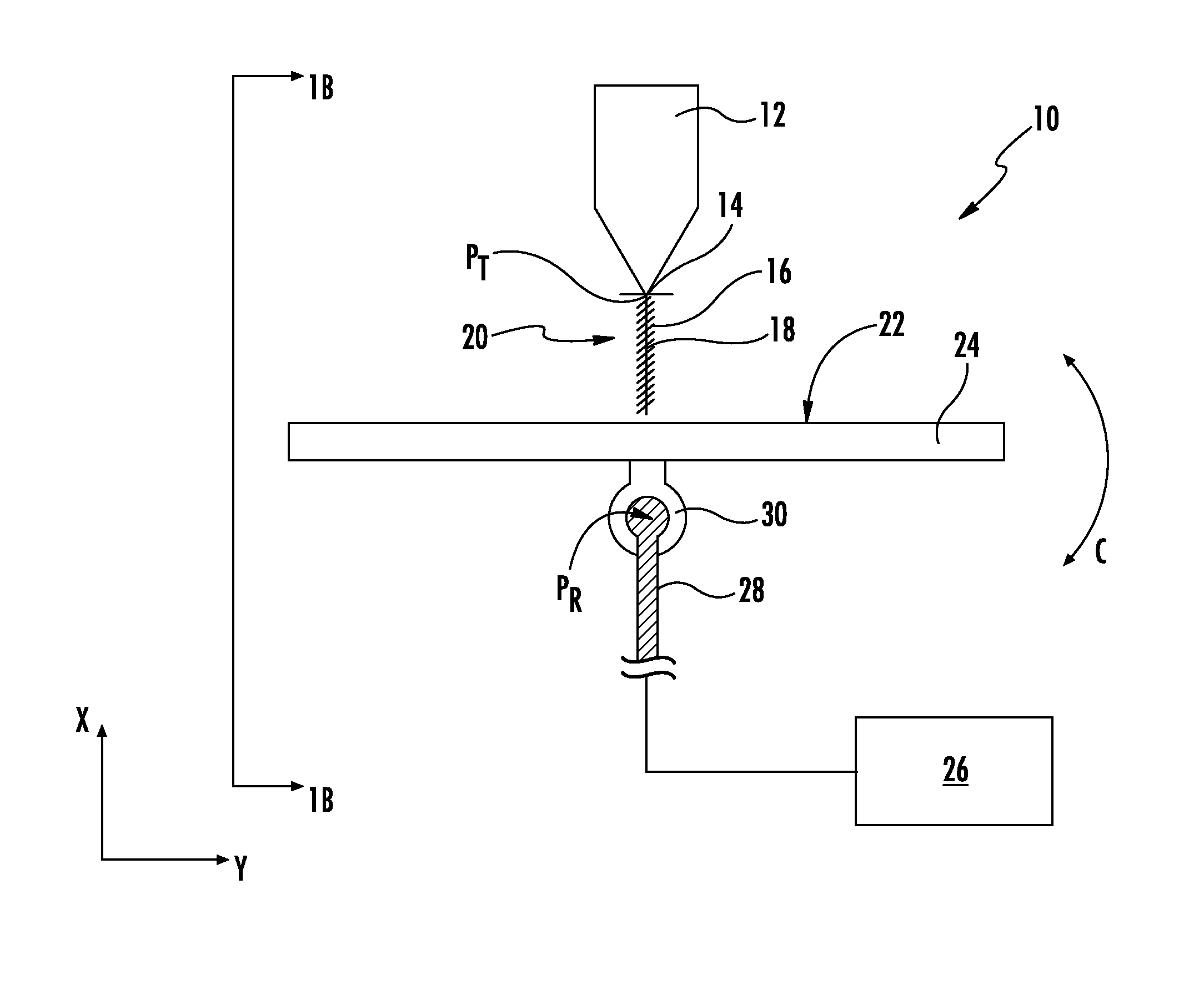

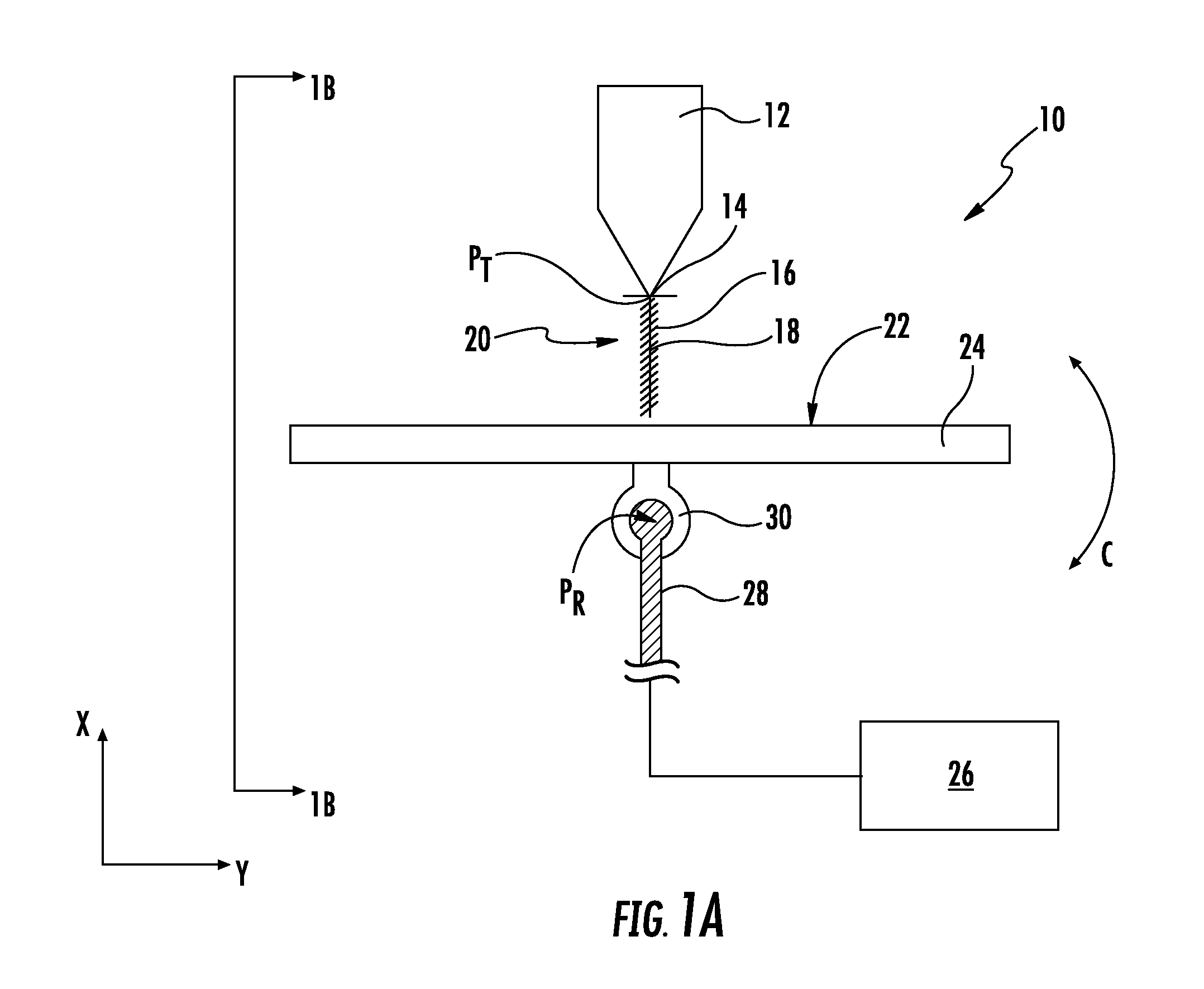

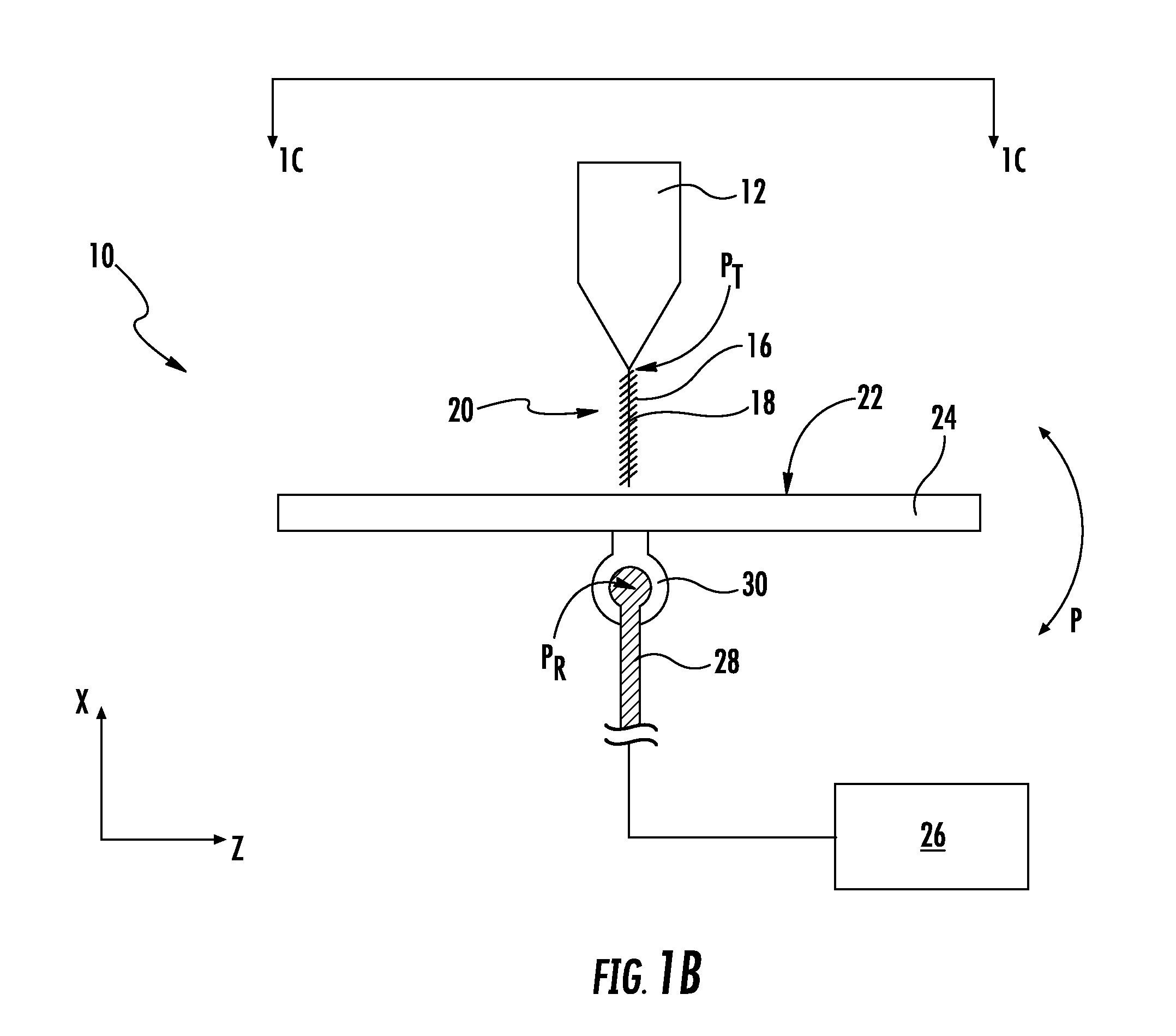

Three-Dimensional Printing System Using Dual Rotation Axes

ActiveUS20130189435A1Promote sportsImprove throughputAdditive manufacturing apparatusAdditive manufacturing with liquidsRotational axisLinear motion

A 3-D printer system moves a printed tool over a print surface with a mechanism controlling a rotational angle of an arm holding the print tool and a revolutionary angle of axis of rotation of the printable area to eliminate the disadvantages of conventionally used linear motion mechanisms

Owner:WISCONSIN ALUMNI RES FOUND

Machine and a Method for Additive Manufacturing with Continuous Fiber Reinforcements

InactiveUS20170151728A1Manufacturing heating elementsAdditive manufacturing with liquidsUltimate tensile strengthPolymer

Several examples of additive manufacturing machines and methods for depositing a bead of composite polymer material having continuous fiber reinforcement are disclosed. A length of fiber reinforcement is provided to a nozzle. The fiber reinforcement is embedded into a stream of a base polymer material at the nozzle and deposited as a bead of composite polymer material having fiber reinforcement. The fiber reinforcement may be dry or pre-impregnated with a reinforcing polymer. The additional strength of the composite polymer material having fiber reinforcement allows for true, three-dimensional printing of articles having unsupported regions.

Owner:UT BATTELLE LLC

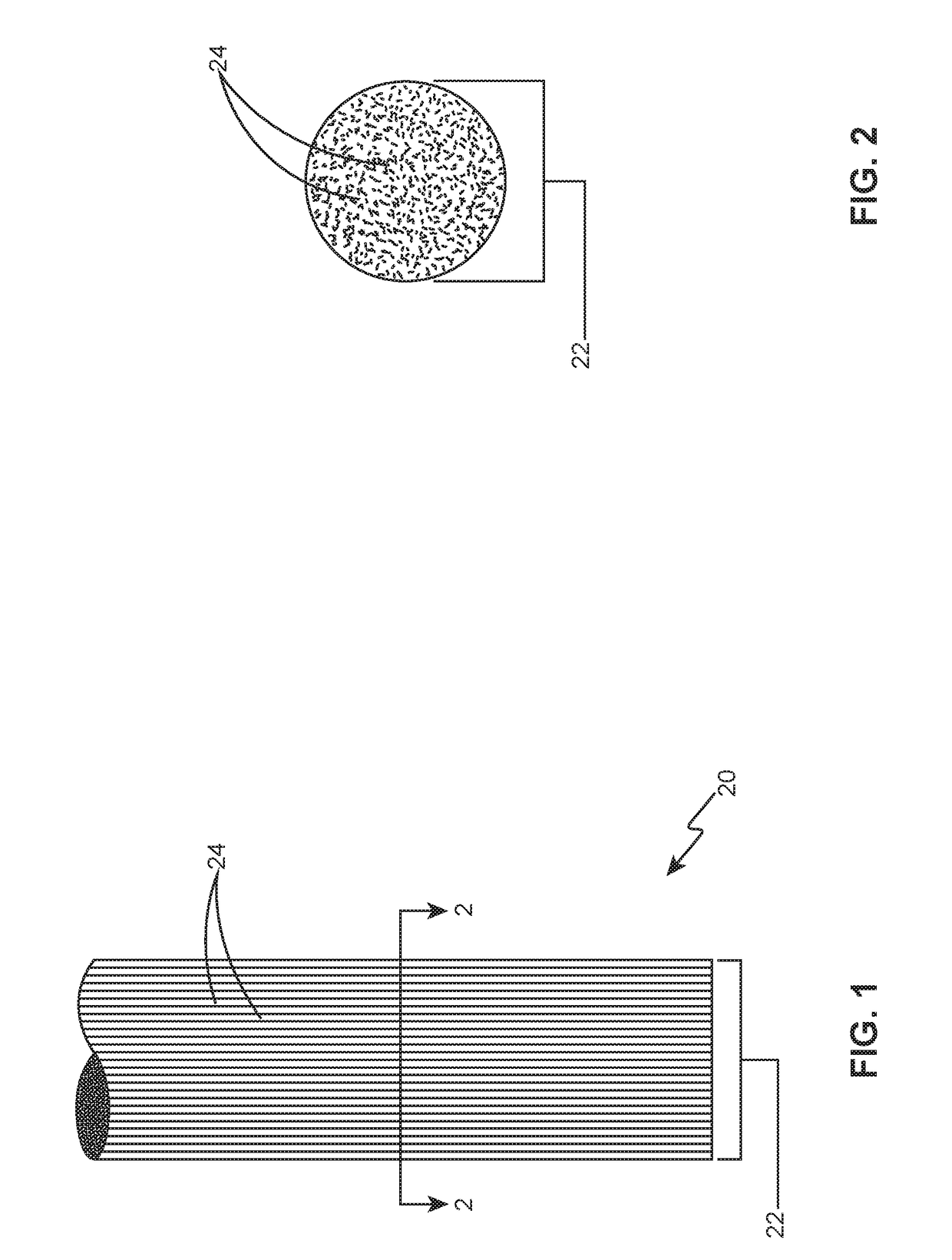

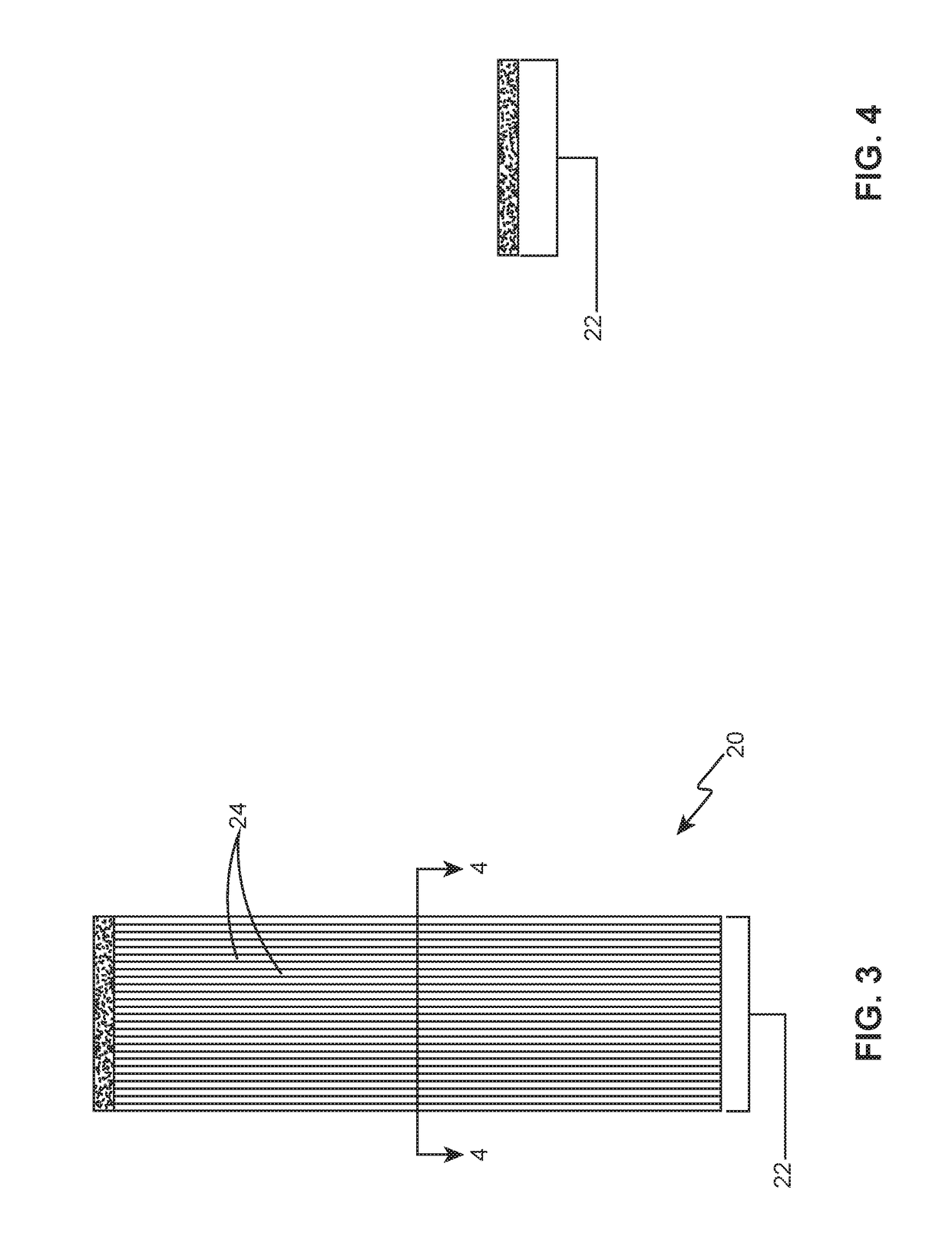

Surface modified particulate and sintered or injection molded products

ActiveUS20150080495A1Simple technologyWeaken energyConductive materialCeramic shaping apparatusParticulatesPolymer science

Disclosed are interfacially modified particulate and polymer composite material for use in injection molding processes, such as metal injection molding and additive process such as 3D printing. The composite material is uniquely adapted for powder metallurgy processes. Improved products are provided under process conditions through surface modified powders that are produced by extrusion, injection molding, additive processes such as 3D printing, Press and Sinter, or rapid prototyping.

Owner:TUNDRA COMPOSITES LLC

Three Dimensional Printing Material System and Method Using Peroxide Cure

ActiveUS20080138515A1High strengthEliminate needAdditive manufacturing apparatusLiquid surface applicatorsPeroxideParticulate material

A materials system and methods are provided to enable the formation of articles by Three Dimensional Printing. The materials system includes a transition metal catalyst that facilitates the reaction of an acrylate-containing binder with a particulate material.

Owner:3D SYST INC

Apparatus and process for forming three-dimensional objects

ActiveUS20170021565A1Additive manufacturing apparatusAdditive manufacturing with liquidsFiberBiomedical engineering

An apparatus for forming a three-dimensional (3D) object includes a 3D printing head, for fabricating a first portion of the 3D object by forming a plurality of successive layers of a first material. The apparatus also includes a delivery head for fabricating a second portion of the 3D object by dispensing onto the first portion of the 3D object a plurality of layers of a continuous-fiber reinforced second material. Further, the delivery head includes comprising a roller for pressing the continuous-fiber rein-forced second material into place during the dispensing thereof. A controller controls the 3D printing head and the delivery head to cooperatively form the 3D object, based on a dataset corresponding to a 3D object model.

Owner:MAGNA INTERNATIONAL INC

Three dimensional printing material system and method

InactiveUS20020026982A1High strengthReduce the amount of solutionSolid waste managementCeramic shaping apparatusEngineeringLayer wise

The present invention is directed to a 3DP(TM) material system ad method, and an article made therefrom. The method of the present invention includes building cross-sectional portions of a three-dimensional article, and assembling the individual cross-sectional areas in a layer-wise fashion to form a final article. The individual cross-sectional areas are built by using an ink-jet printhead to deliver an aqueous fluid to a particulate material that includes plaster.

Owner:3D SYST INC

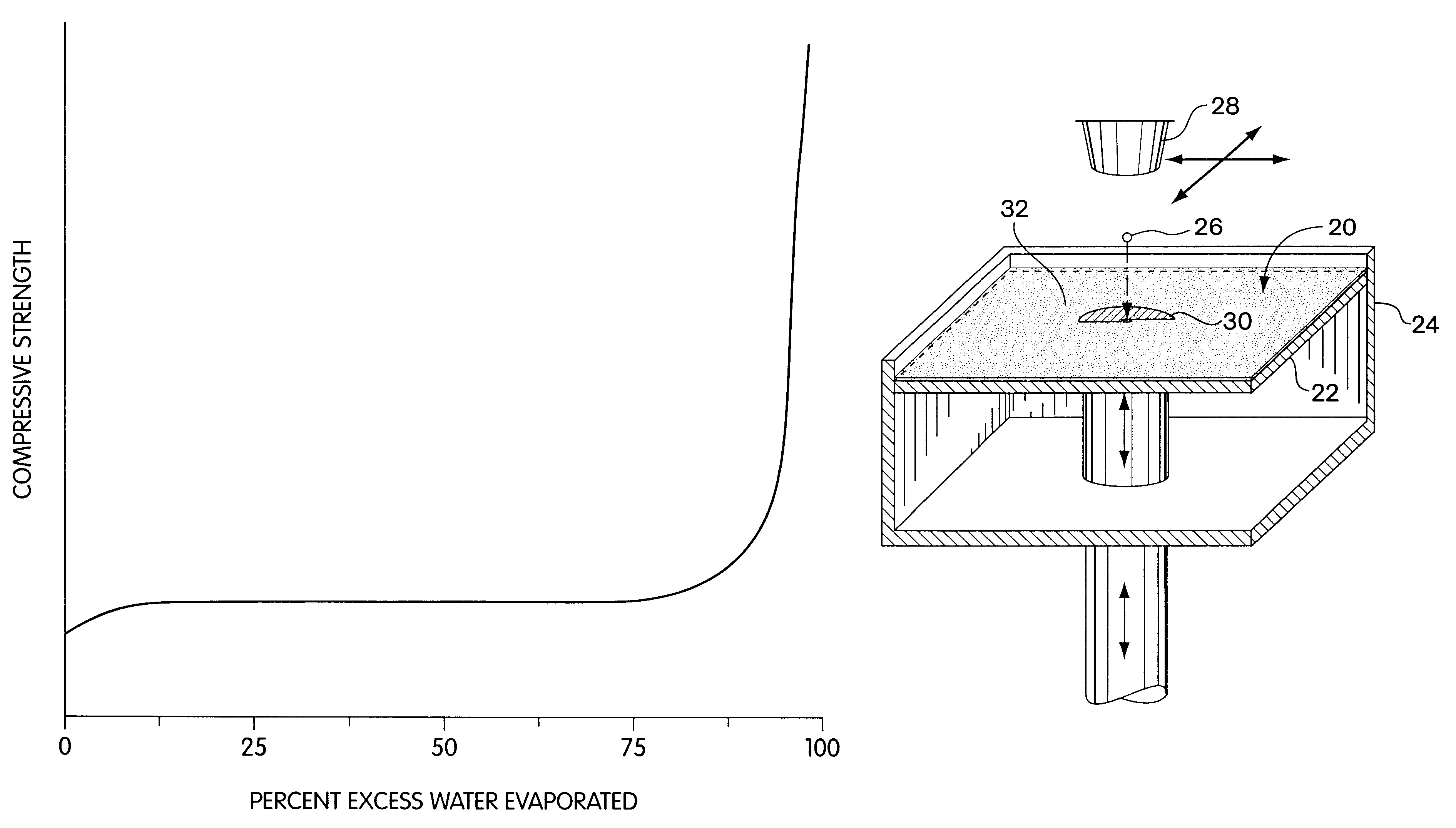

Three-Dimensional Printing Material System With Improved Color, Article Performance, and Ease of Use

ActiveUS20080187711A1Strong and durable prototypeHigh green part strengthAdditive manufacturing apparatusOther chemical processesParticulatesWhitening Agents

A materials system and methods are provided to enable the formation of articles by three dimensional printing. The materials system includes particulate mixtures having a whitening agent and a solid particulate additive comprising an acid, the latter adapted for modifying a cure rate of an infiltrant. The materials system also includes aqueous fluids including optical brightening agents.

Owner:3D SYST INC

Inserting inhibitor to create part boundary isolation during 3D printing

A 3D printing system may print a desired 3D object. A fusible powder may fuse when subjected to a fusing condition. A deposition system may deposit portions of the fusible powder on a substrate. A fusing system may apply the fusing condition to the deposited fusible powder. Inhibitor material may not fuse when subjected to the fusing condition. An insertion system may insert a portion of the inhibitor material between portions of the deposited fusible powder after having been deposited by the deposition system, but before being fused by the fusing system, so as to form a boundary that defines at least a portion of a surface of the desired 3D object.

Owner:UNIV OF SOUTHERN CALIFORNIA

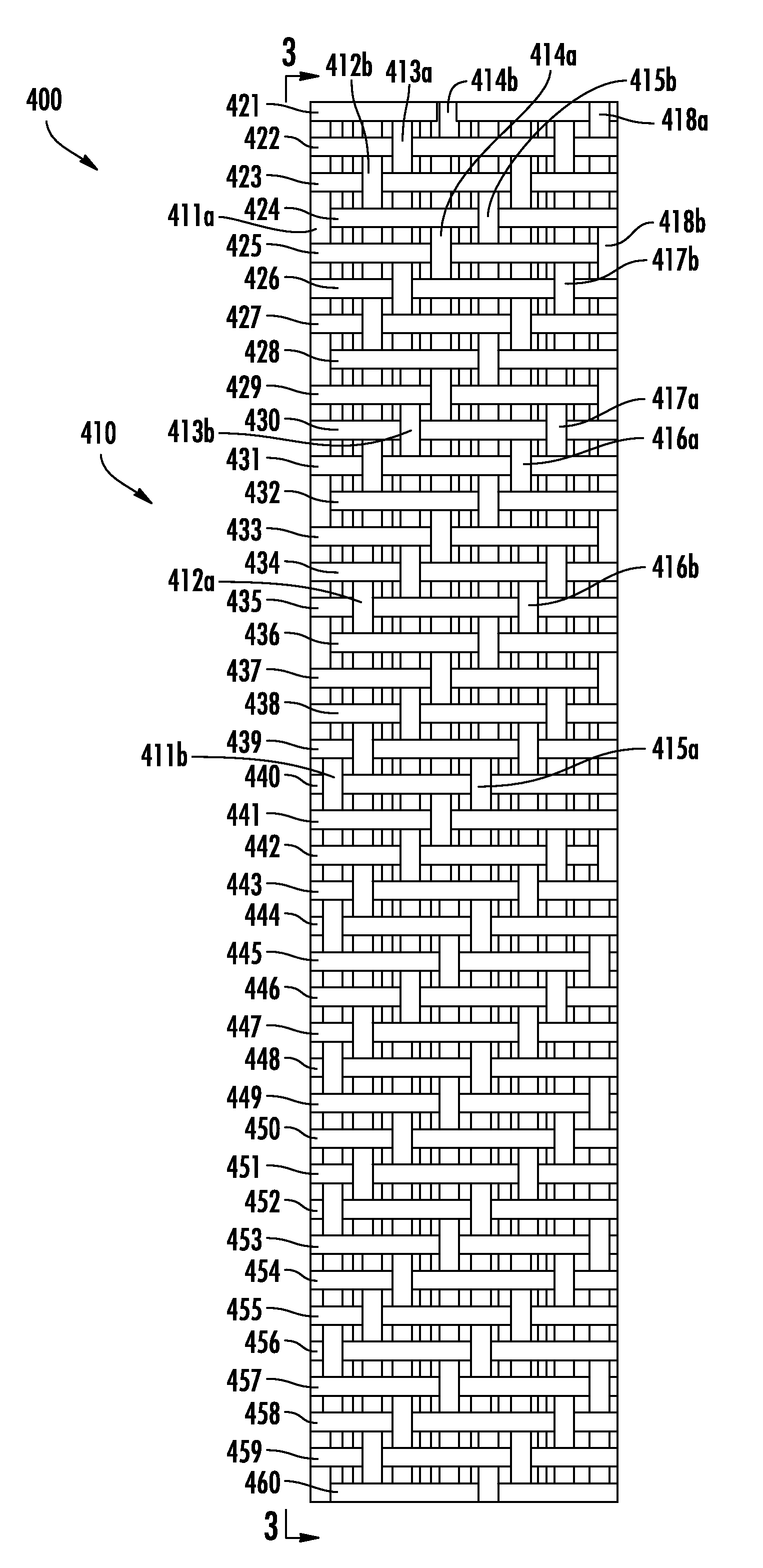

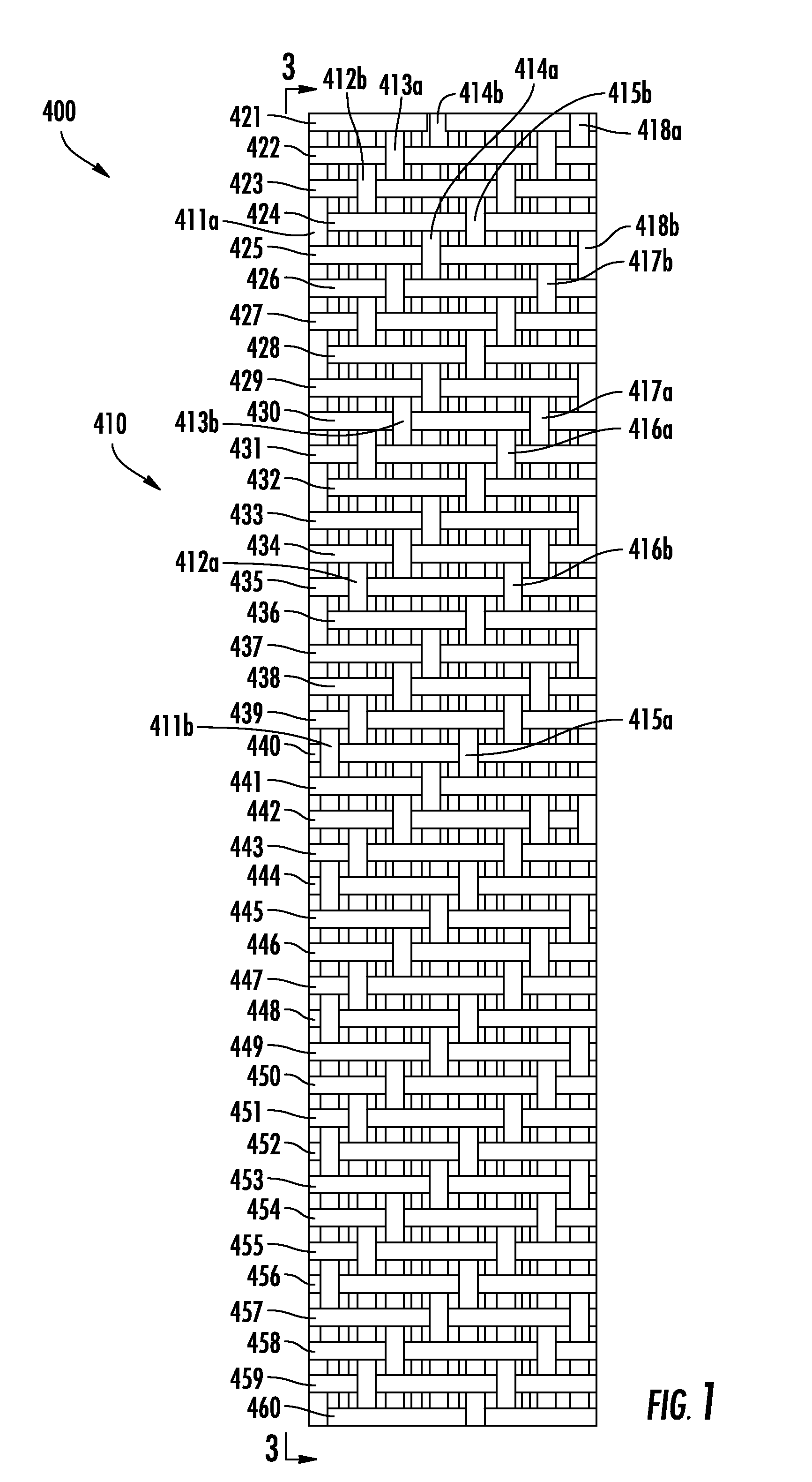

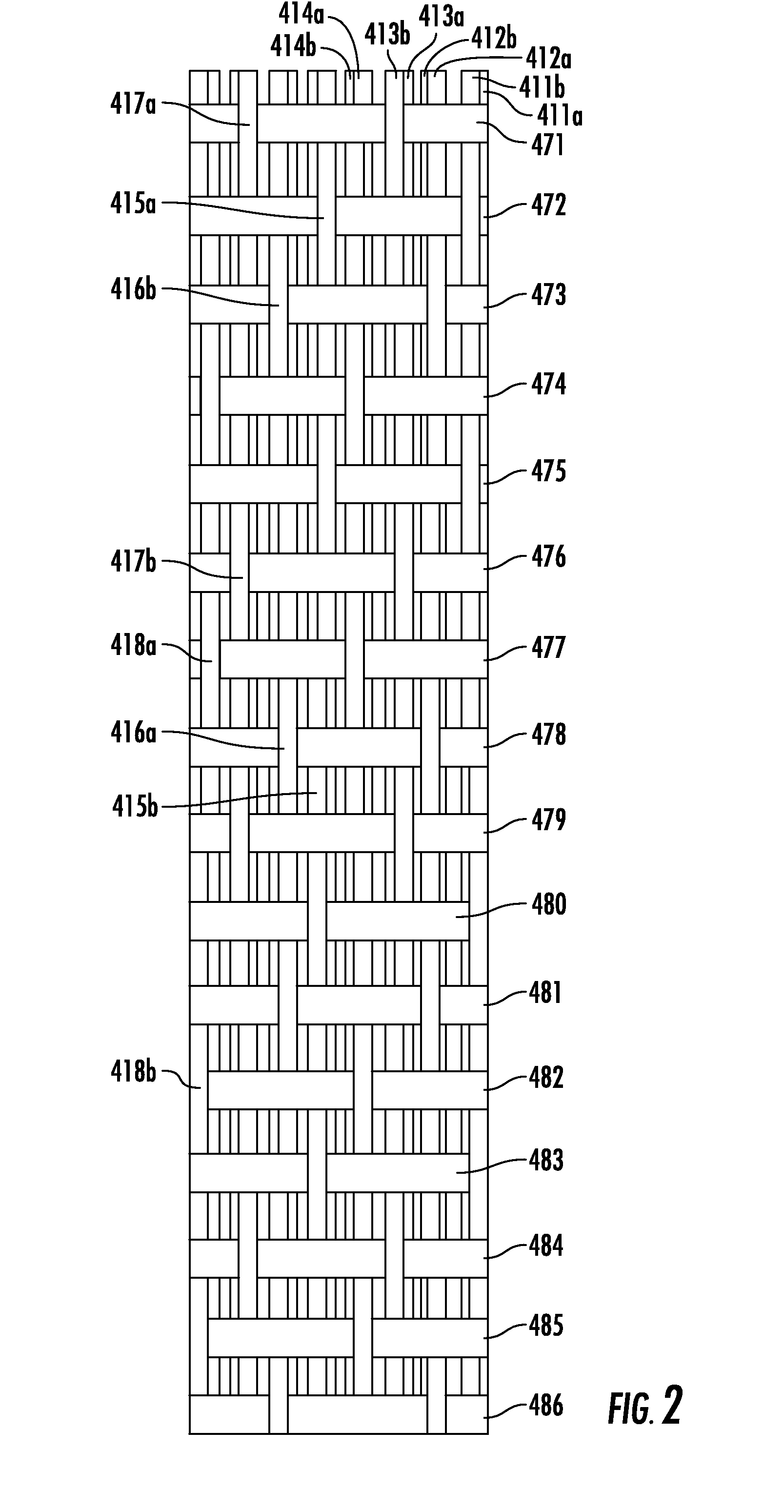

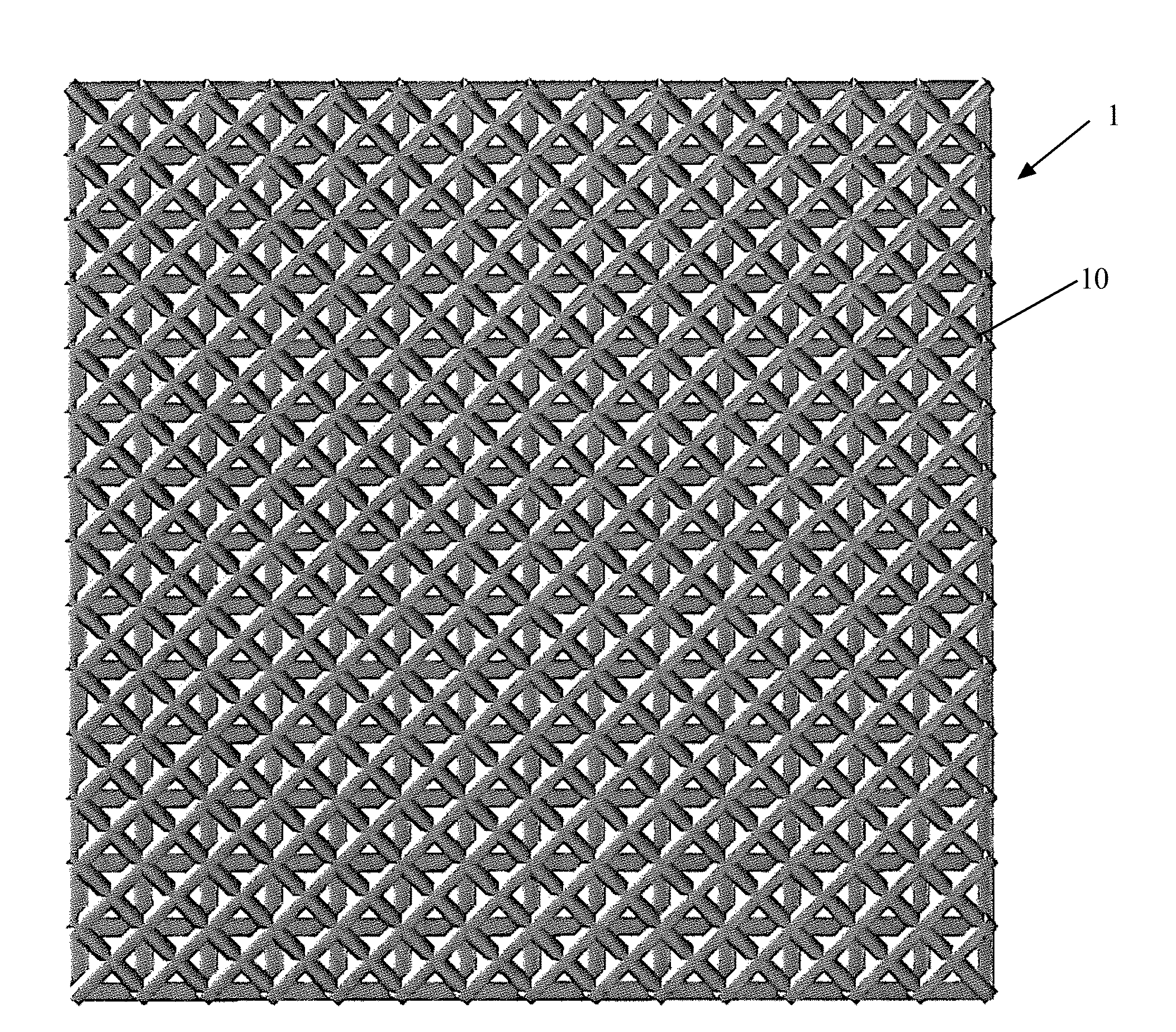

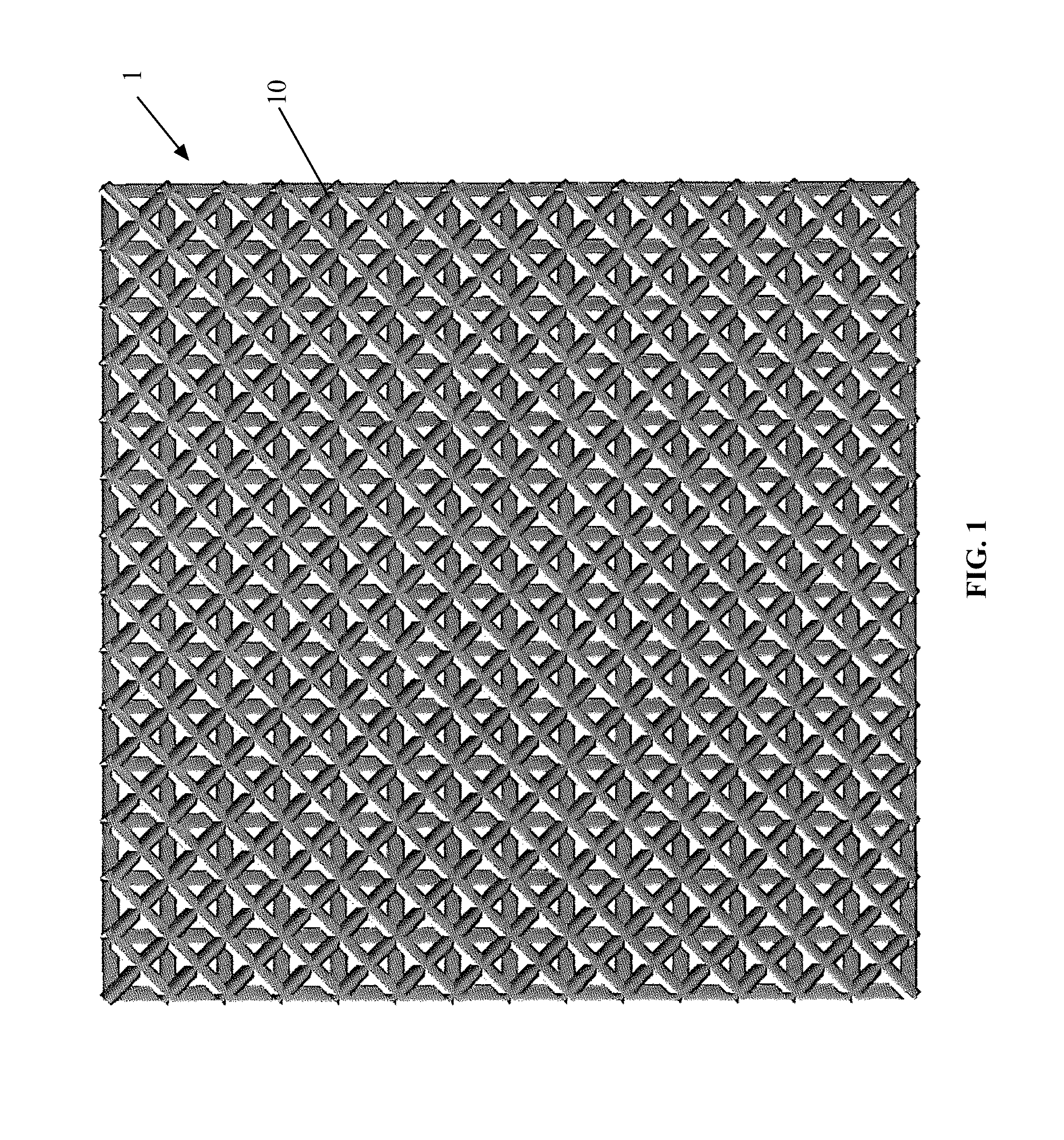

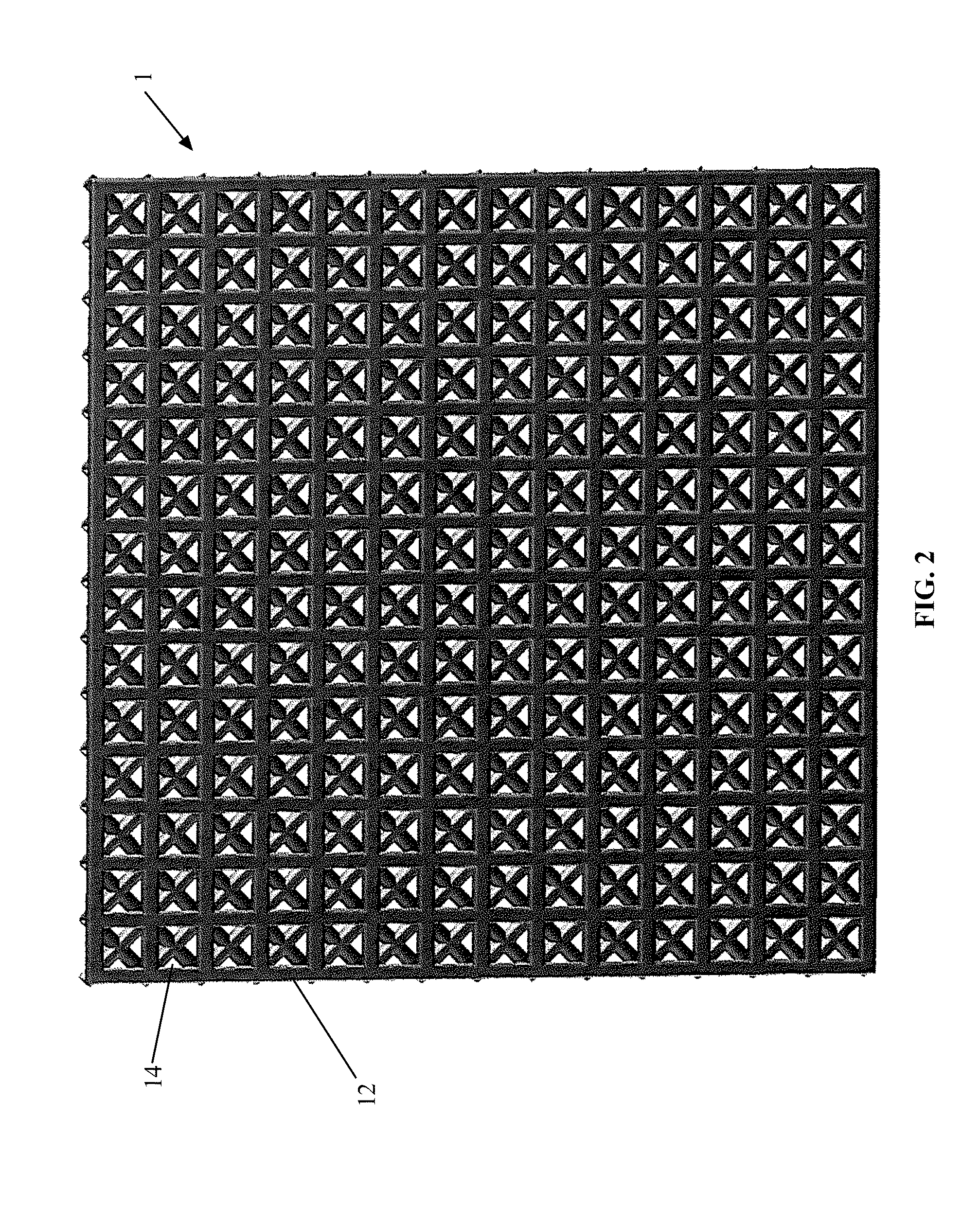

Fabric formed by three-dimensional printing process

InactiveUS20150102526A1Additive manufacturing apparatusCeramic shaping apparatusEngineering3D printing

Owner:WEAVEXX

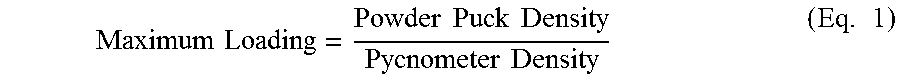

3-D Printing of near net shape products

InactiveUS20100279007A1Easy to handleHigh porosityAdditive manufacturingCeramic shaping apparatusPorosityCeramic metal

The disclosed method relates to manufacture of a near net-shaped products such as ceramic containing products such as ceramic-metal composites. The method entails forming a mixture of a build material and a binder and depositing that mixture onto a surface to produce a layer of the mixture. An activator fluid then is applied to at least one selected region of the layer to bond the binder to the build material to yield a shaped pattern. These steps may be repeated to produce a porous whitebody that is heat treated to yield a porous greenbody preform having a porosity of about 30% to about 70%. The greenbody then is impregnated with a molten material such as molten metal. Where the build material is SiC, the molten metal employed is Si to generate a SiC—Si composite.

Owner:STORM DEV LLC +1

Integrated robotic 3D printing system for printing of fiber reinforced parts

ActiveUS20170057167A1Manufacturing platforms/substratesAdditive manufacturing with liquidsPrint mediaRobotics

A system for printing a three-dimensional object is provided. The system can include at least one print head configured to receive a continuous fiber and at least partially encase the continuous fiber with a formation material to create a composite material. The at least one print bed can be configured to move in at least six different degrees of freedom. The system can also include at least one print bed comprising a printing surface onto which the composite material may be selectively applied to form a work piece. The at least one print head can be positioned relative to the at least one print bed and configured to advance print media thereon.

Owner:UNIVERSITY OF SOUTH CAROLINA +1

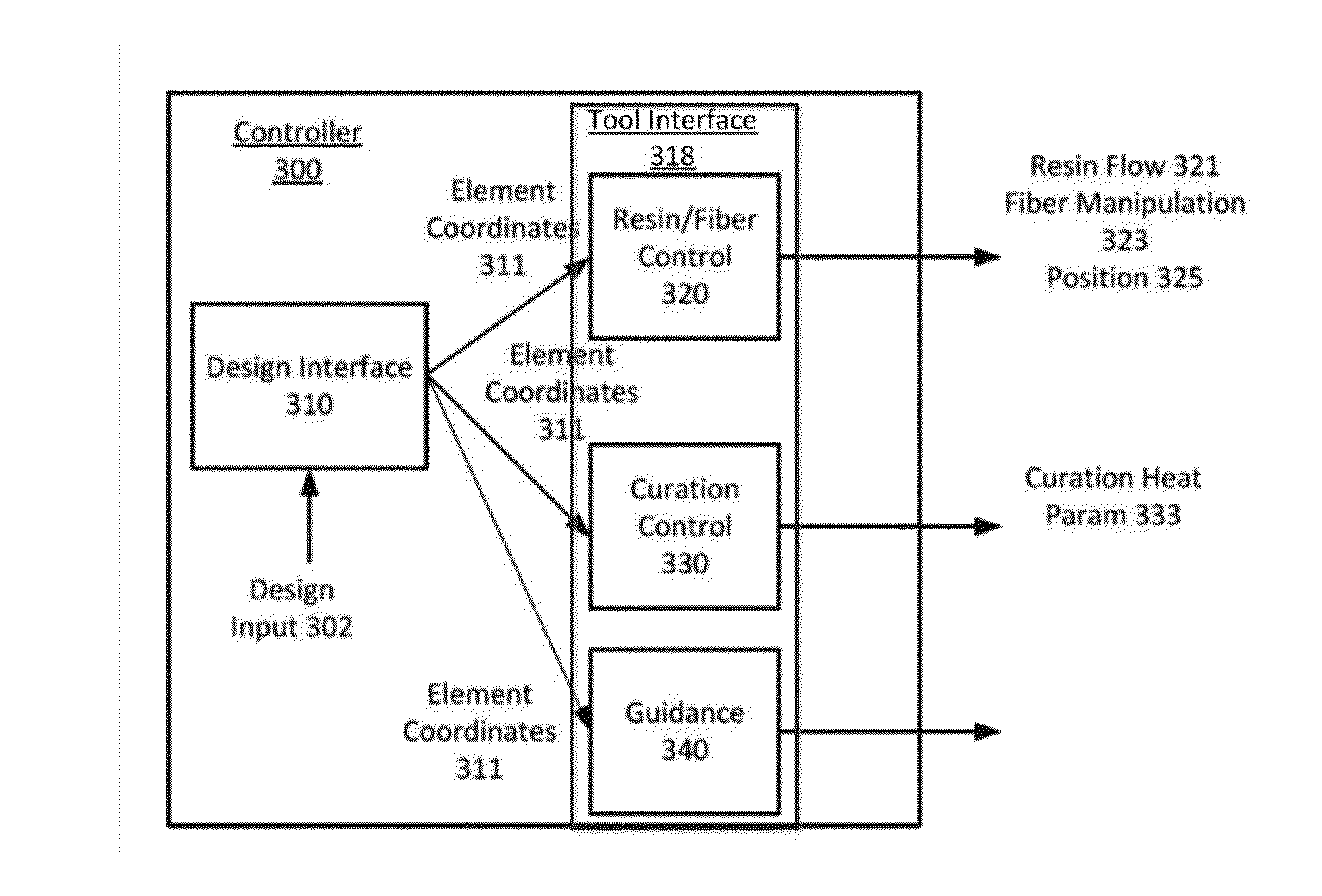

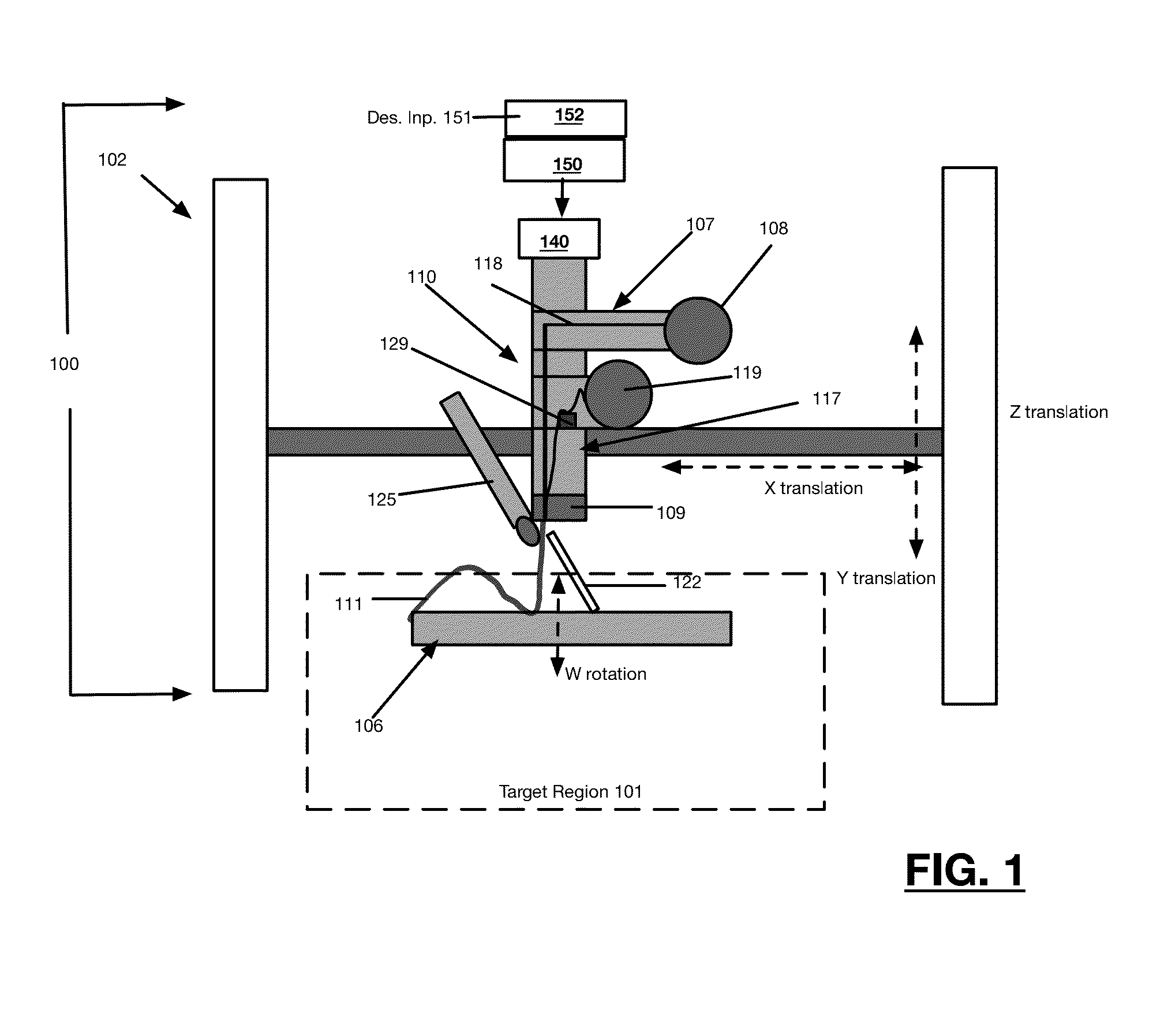

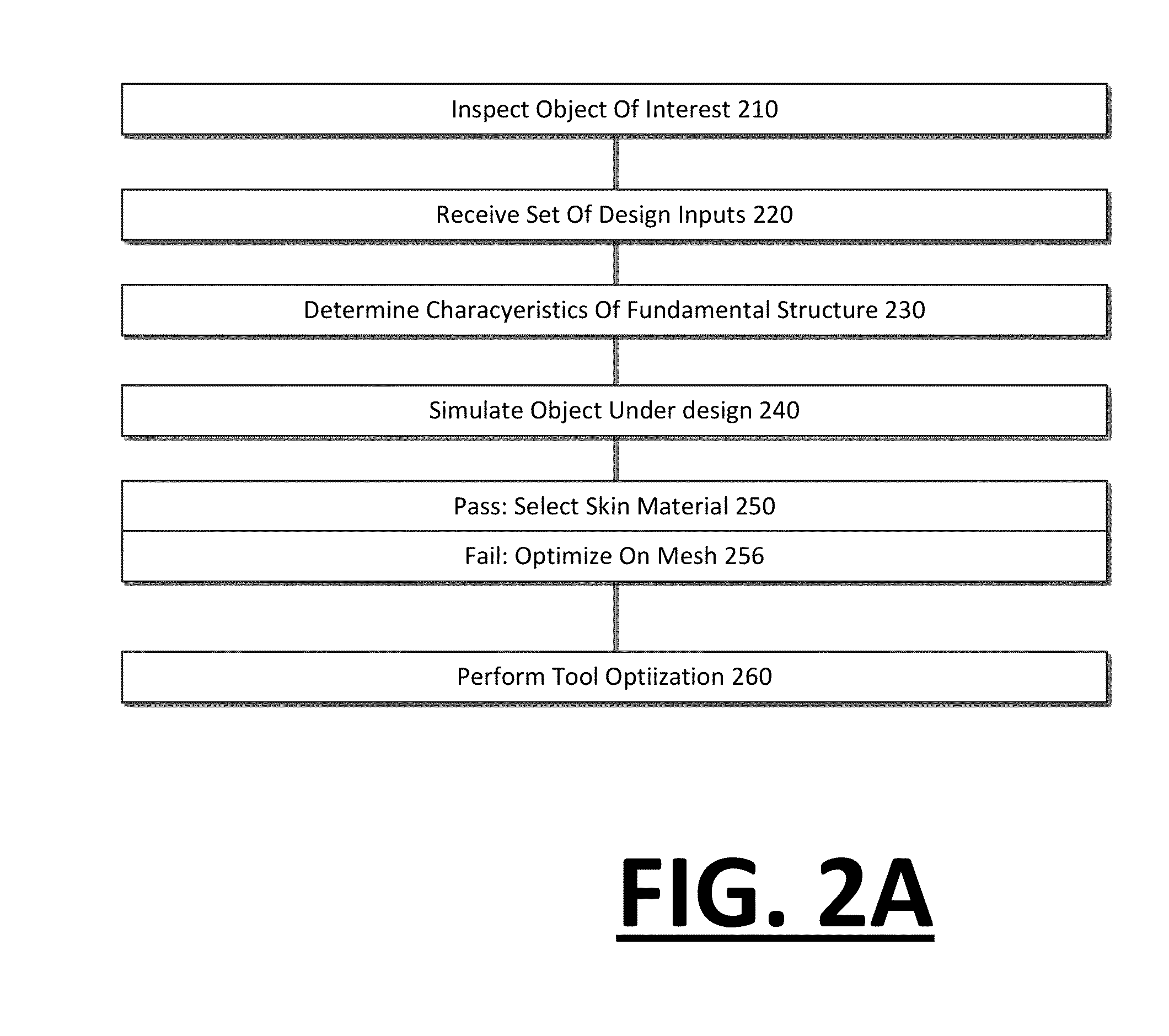

Automated design, simulation, and shape forming process for creating structural elements and designed objects

InactiveUS20160243762A1Additive manufacturing with liquidsPrinted circuit manufactureEngineeringStructuring element

A three-dimensional printer, system and method is provided for individually creating three-dimensional structural elements (individually termed fundamental structures) which are sequentially positioned into formation of a shaped object.

Owner:FLEMING ROBERT J

Manufacturing process for papermaking belts using 3D printing technology

ActiveUS20160159007A1Good choiceAdditive manufacturing apparatusMachine wet endFiberPulp and paper industry

A papermaking belt including zones of material laid down successively using a 3D printing process. The zones include at least a pocket zone configured to form three dimensional structures in a paper web by applying vacuum to pull the paper web against the pocket zone. In at least one exemplary embodiment, the zone also include at least one vacuum breaking zone configured to limit an amount of paper fibers pulled through the pocket zone by the applied vacuum.

Owner:STRUCTURED I

Method for producing three-dimensional components

ActiveUS20120113439A1Easy to disassembleDigitally marking record carriersAdditive manufacturing apparatusEngineeringBuilding construction

Owner:VOXELJET AG

Device and method for 3D printing with long-fiber reinforcement

ActiveUS20170157851A1Eliminate point3D object support structuresAdditive mnaufacturing with solid and fluidAdvanced composite materialsPolymer

A process and device for 3D printing parts incorporating long-fiber reinforcements in an advanced composite material is disclosed. A nozzle for a 3D printing device receives a polymer material and a reinforcing fiber through separate inlets. A passage from the reinforcing fiber inlet cleaves the passage containing the polymer material, creating an interstitial cavity into which the reinforcing fiber is introduced. The polymer material closes back on itself and encapsulates the reinforcing fiber, then drags the fiber along with the flow and exits nozzle to be deposited on a work surface or part being manufactured.

Owner:NORTHROP GRUMMAN SYST CORP

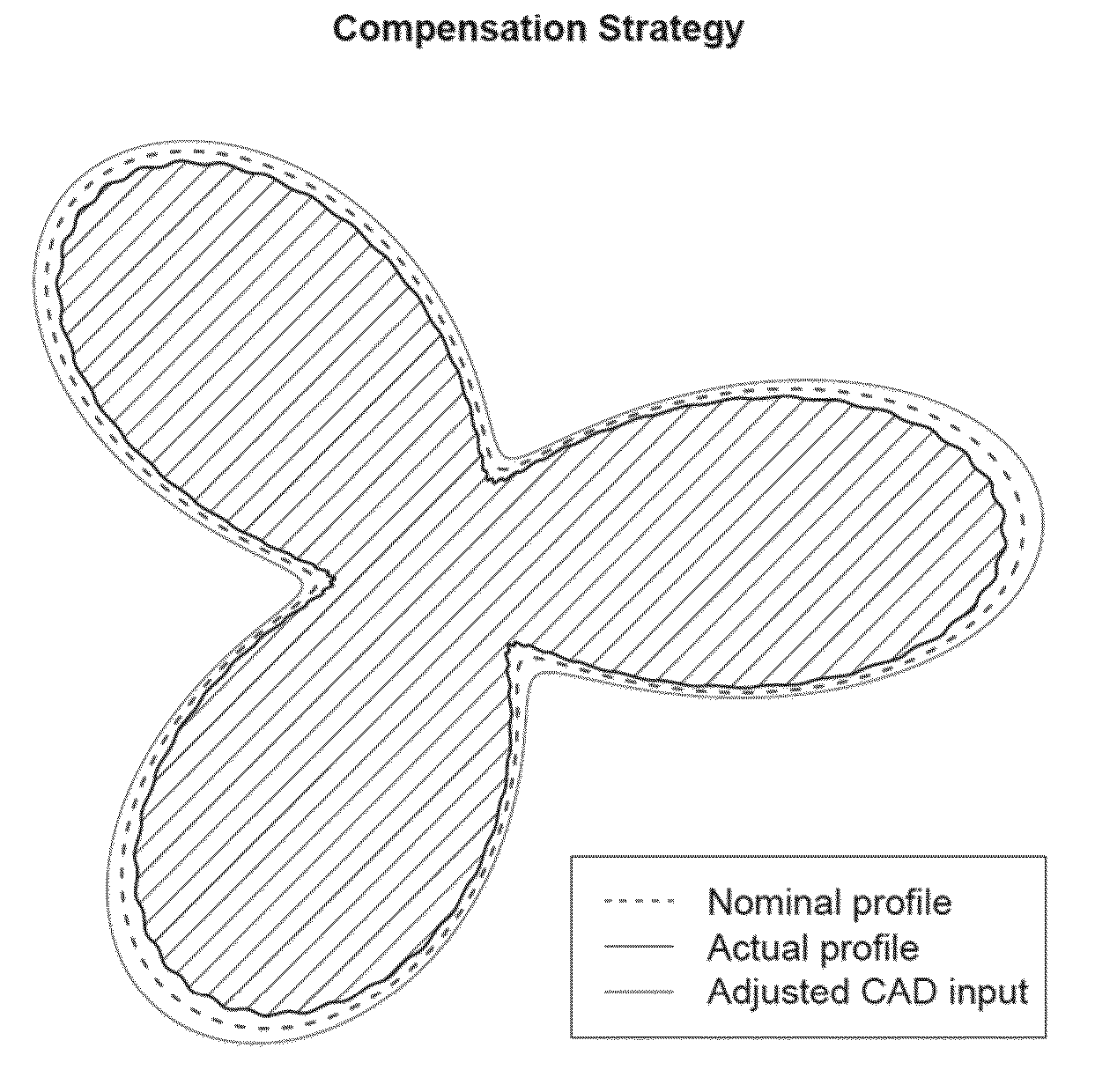

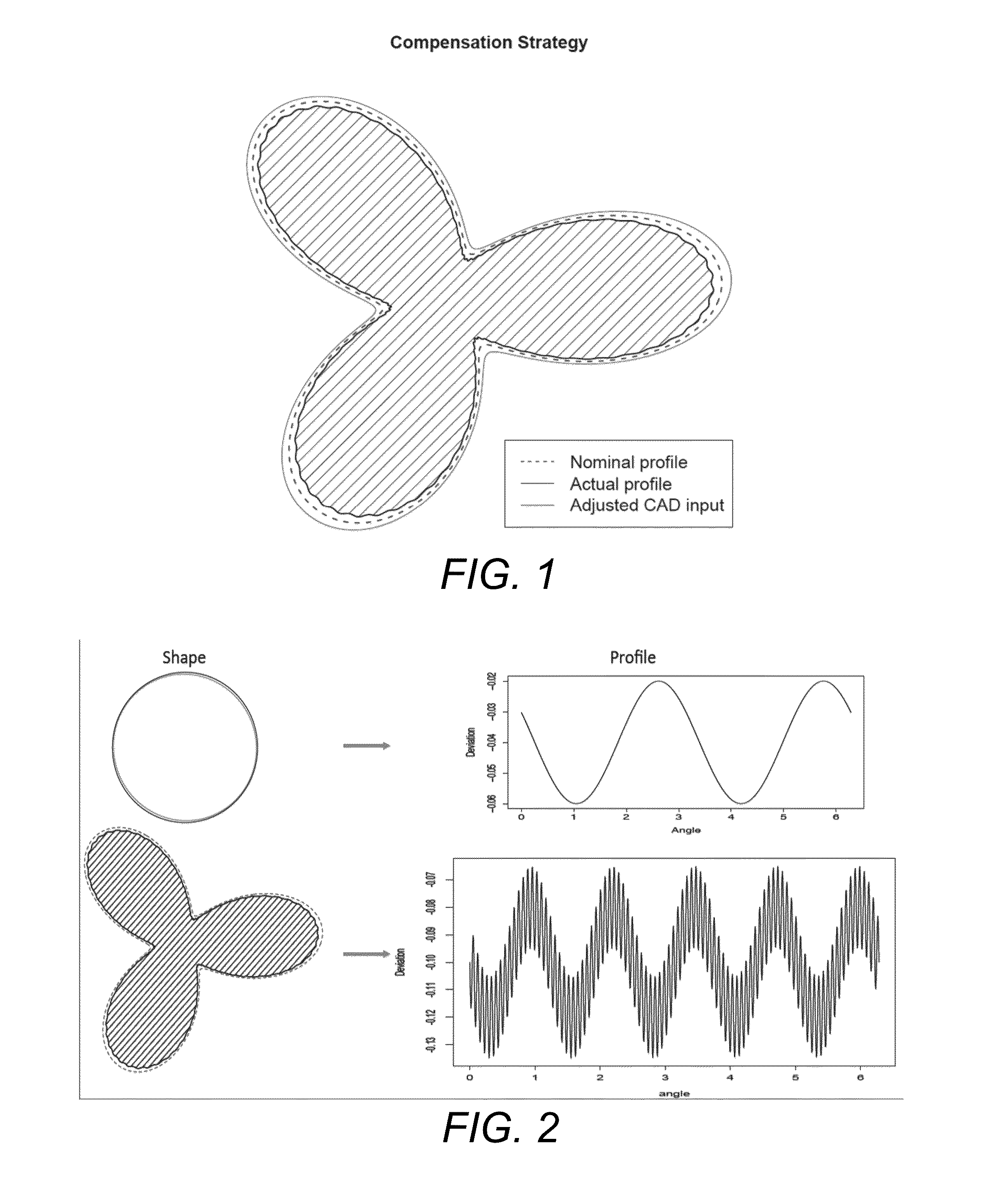

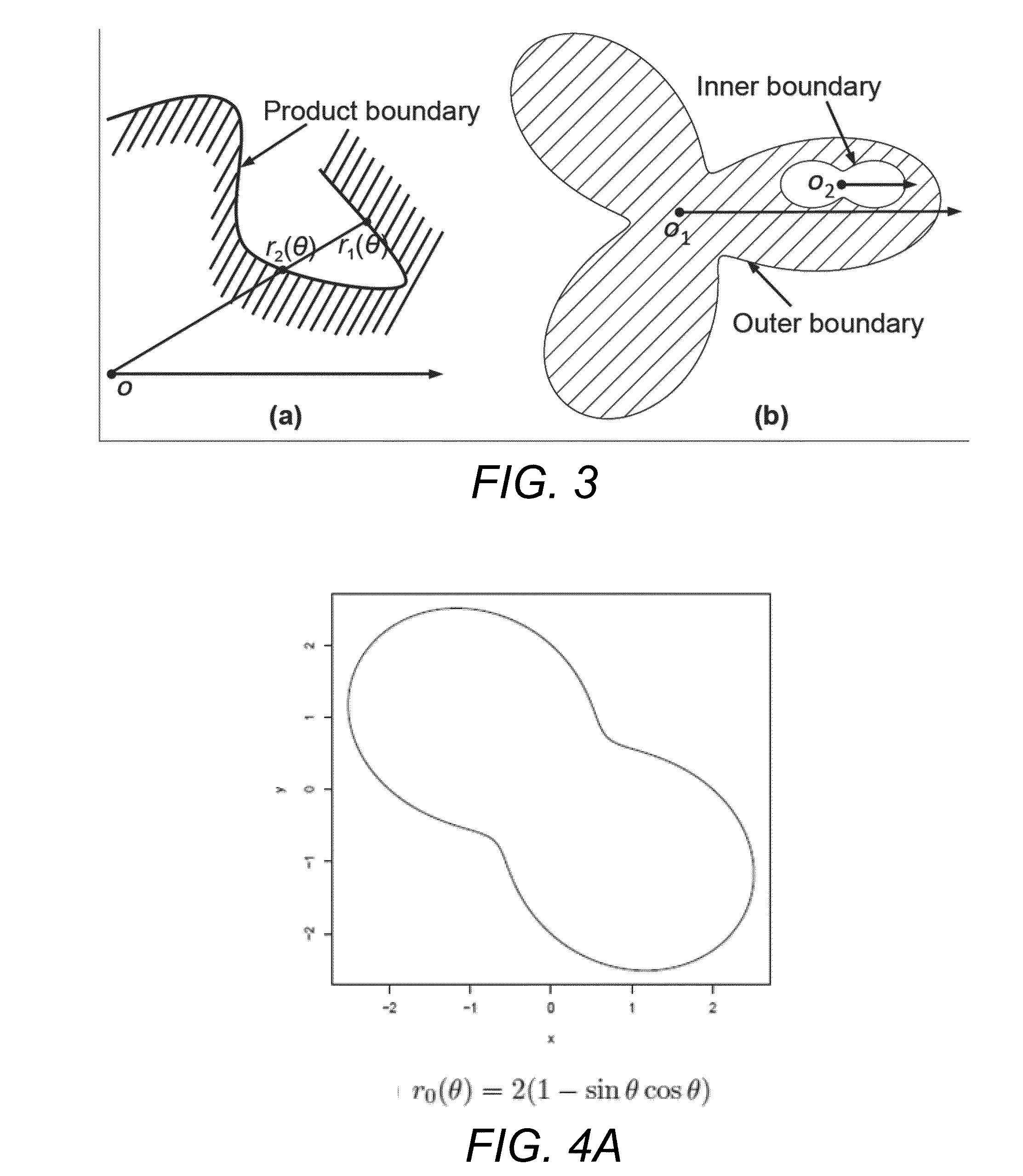

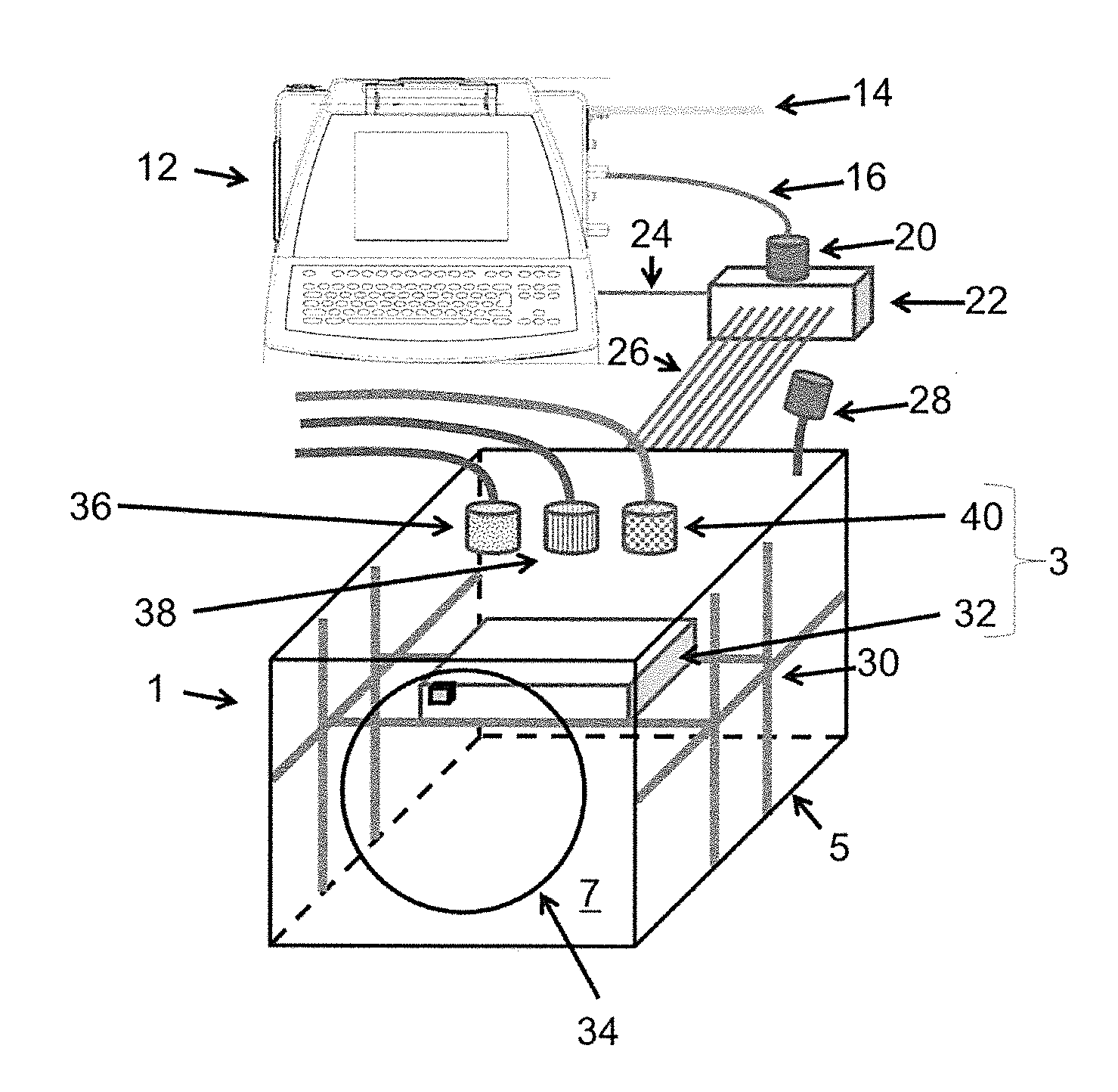

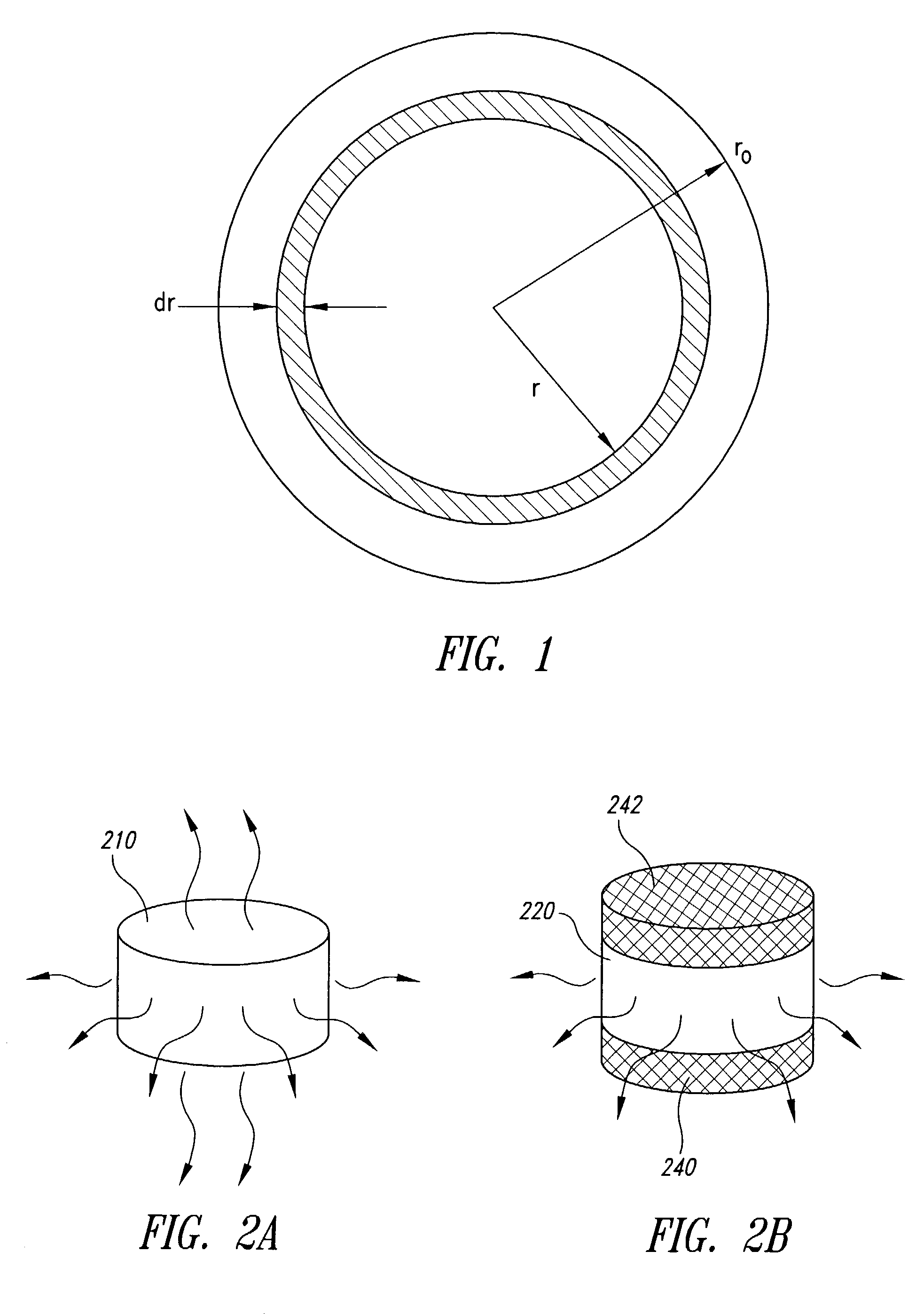

3D printing shrinkage compensation using radial and angular layer perimeter point information

ActiveUS20140107823A1Error minimizationIncreasing energy efficiency3D object support structuresMultiple pointComputer science

Errors caused by shrinkage during 3D printing may be minimized. A shape that most closely corresponds to the shape of a layer to be printed may be selected from a library of shapes. Each shape in the library may have shrinkage information associated with it that includes, for each of multiple points that define a perimeter of the library shape, a radial distance to the point from an origin of a coordinate system, an angle the radial distance makes with respect to an axis of the coordinate system, and information indicative of an anticipated amount by which the point will deviate from its specified location when the shape is printed due to shrinkage. Compensation for anticipated shrinkage may be calculated based on the shrinkage information that is associated with the selected shape from the library. The information indicative of the shape of the layer to be printed may be modified to minimize errors cause by shrinkage based on the calculated compensation.

Owner:UNIV OF SOUTHERN CALIFORNIA

Manufacturing within a single-use container

ActiveUS20160068793A1Function increaseProgramme-controlled manipulatorBioreactor/fermenter combinationsNumerical controlThree degrees of freedom

A manufacturing assembly has at least a sterilizable chamber containing at least one of a three-dimensional printing device (additive manufacturing), a Computer Numerical Controlled (CNC) finishing head (subtractive manufacturing), a vacuum-forming unit, an injection-molding unit, a laser-cutting unit, a ultrasonic-welding unit, a robotic arman analysis device, a sampling device or a combination thereof. A plurality of individual sterilizable chambers may be aseptically connected into a network of sterilizable chambers that provides additional functionality for the manufacturing assembly. A sterilizable printer assembly may include at least one printing head, a printing platform, and a driving mechanism adapted to perform a movement of the at least one printing head relative to the printing platform along three degrees of freedom; a printer housing enclosing the printer assembly in a sterile manner, at least one aseptic connector fluidly connected to a corresponding one of the at least one printing head.

Owner:SARTORIUS STEDIM BIOTECH GMBH

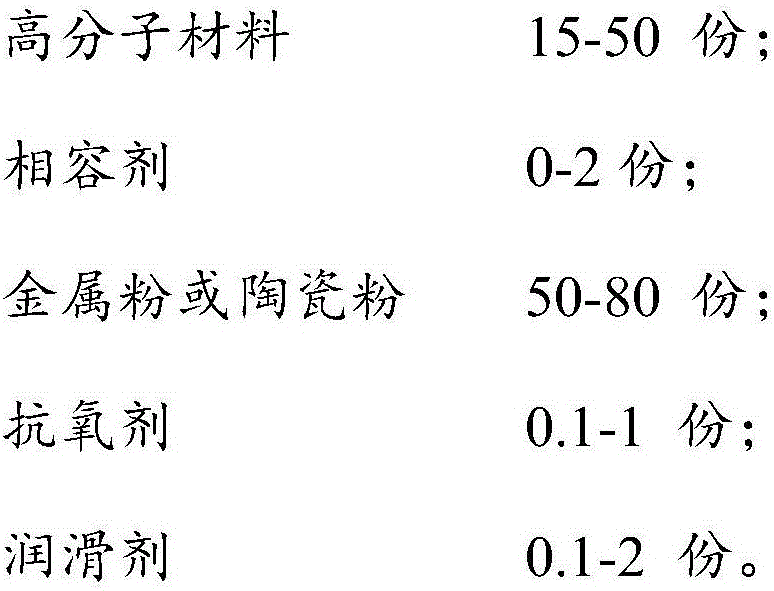

Metal or ceramic consumable item for FDM 3D printing, preparation method for metal or ceramic consumable item and finished product printing method

InactiveCN105665697AEasy to handleUnlimited structureAdditive manufacturing apparatusTransportation and packagingMiniaturizationVolumetric Mass Density

The invention discloses a metal or ceramic consumable item for FDM 3D printing, a preparation method for the metal or ceramic consumable item and a finished product printing method. The metal or ceramic consumable item comprises, by weight, 15-50 parts of a high polymer material, 0-2 parts of a compatilizer, 50-80 parts of metal powder or ceramic powder, 0.1-1 part of an antioxygen and 0.1-2 parts of a lubricating agent. The cost for equipment, the materials and machining is low; a printing structure is free of limitation, collapsing conditions do not exist in the printing process, supports can be removed before fusion sintering of the product, and treatment is easier compared with a manner that the supports are removed after SLS or EBAM fusion sintering; the requirements for the sphericity degree, the size distribution, the mobility and the like are relatively low; the types of metal and ceramic capable of being printed are wider; and the density of the finished products is higher, the strength is high, the degree of finish is higher, the miniaturization capacity is high, the thin-wall capacity is high, the complexity is high, the design tolerance level is high, and the material adaption scope is wide.

Owner:HUIZHOU RES INST OF SUN YAT SEN UNIV

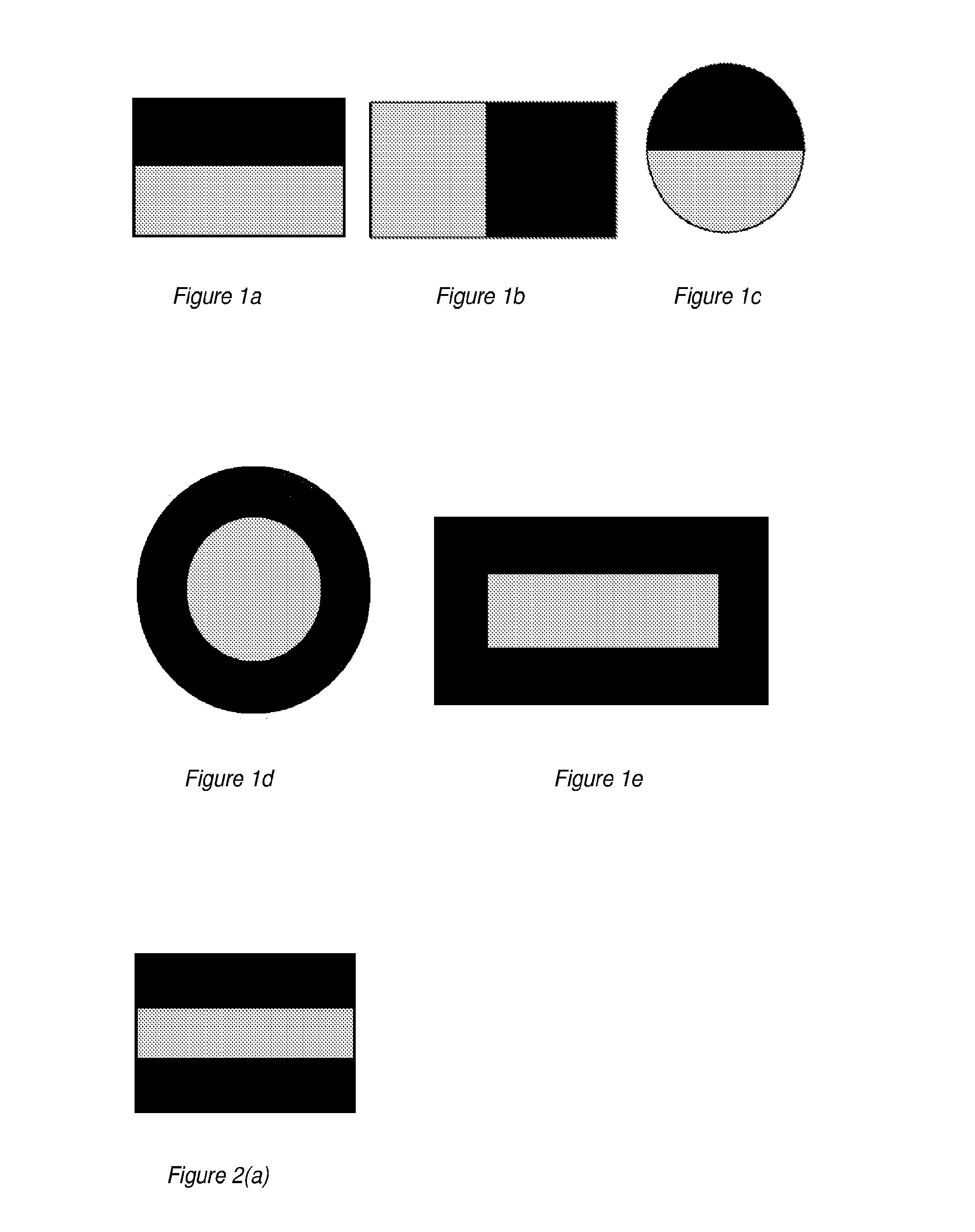

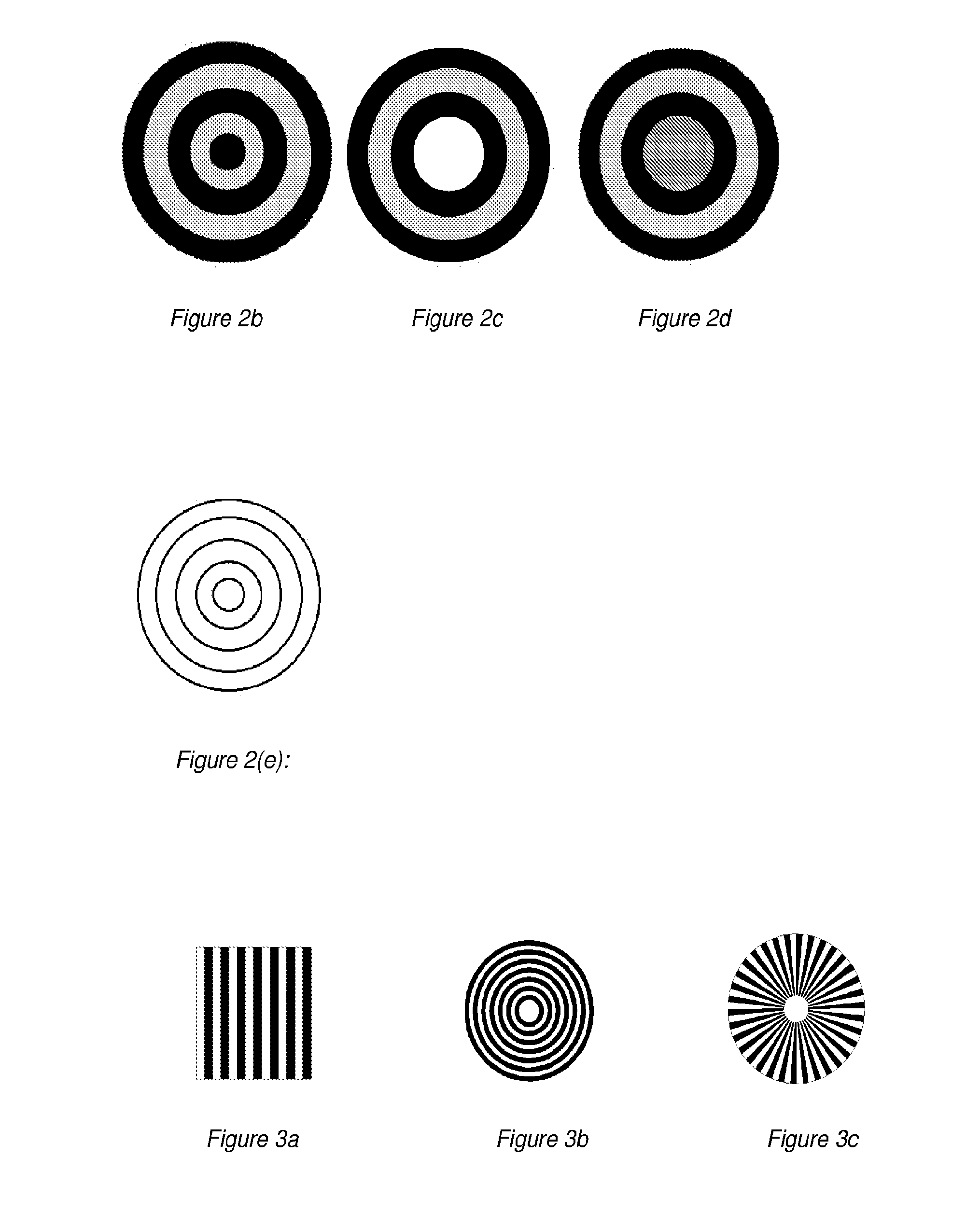

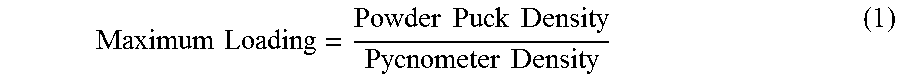

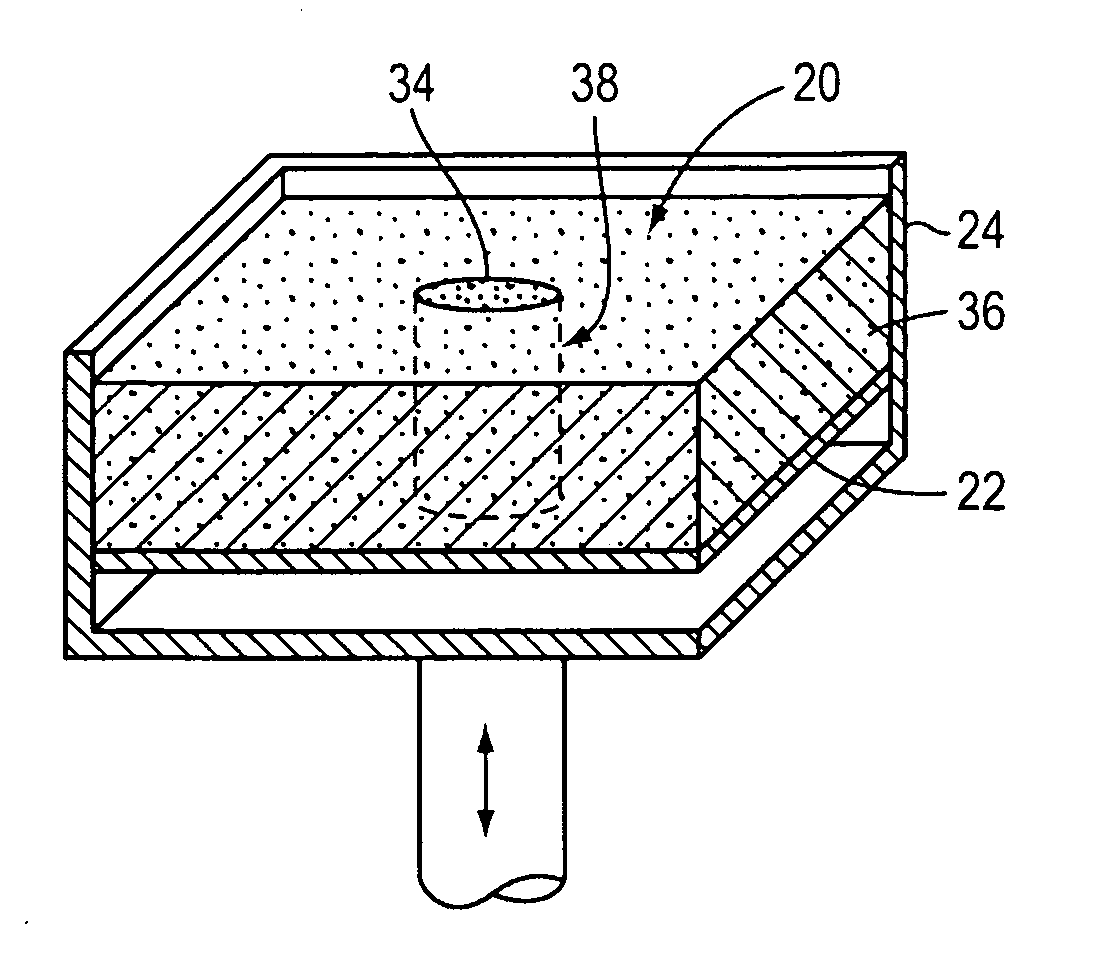

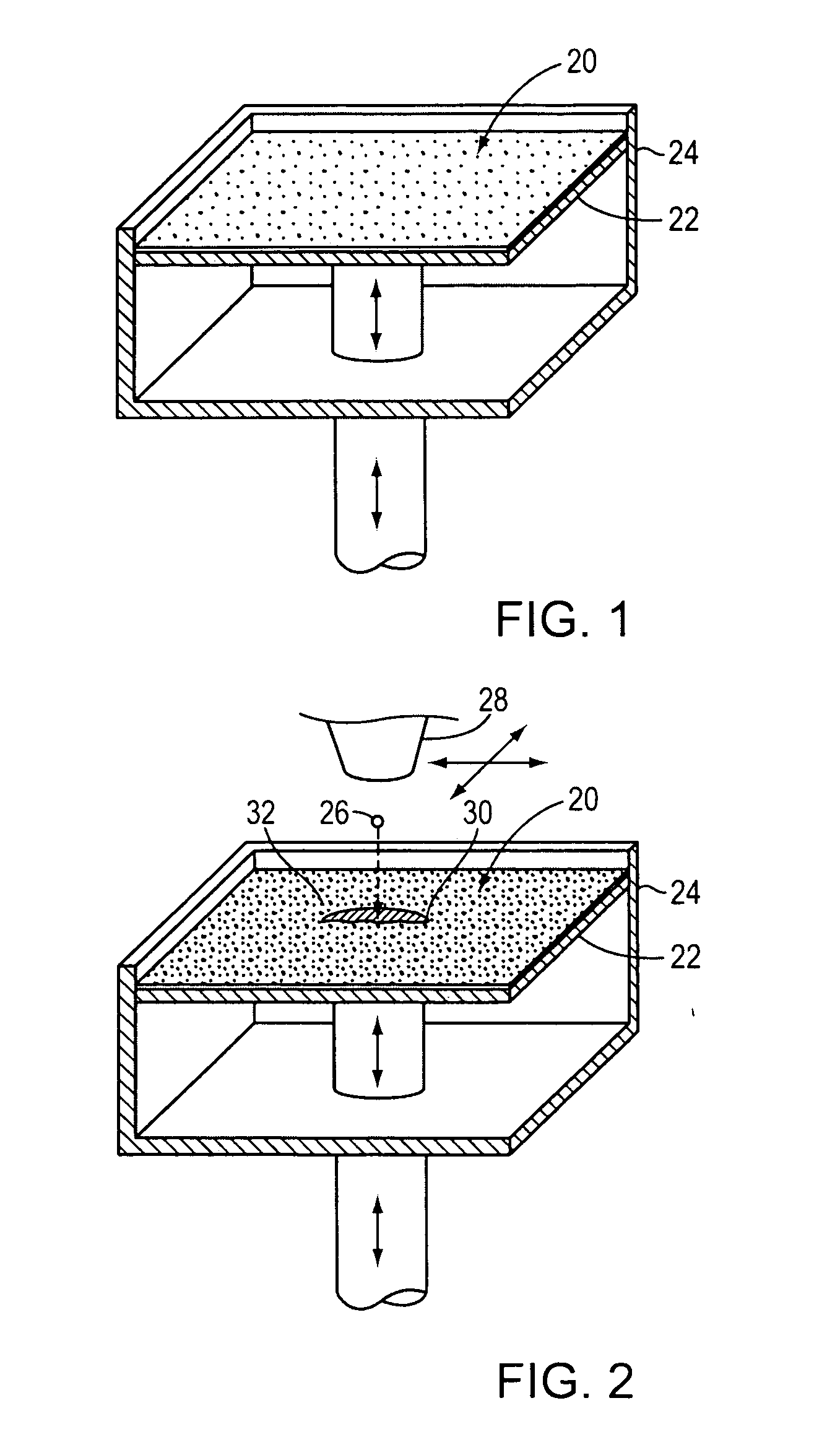

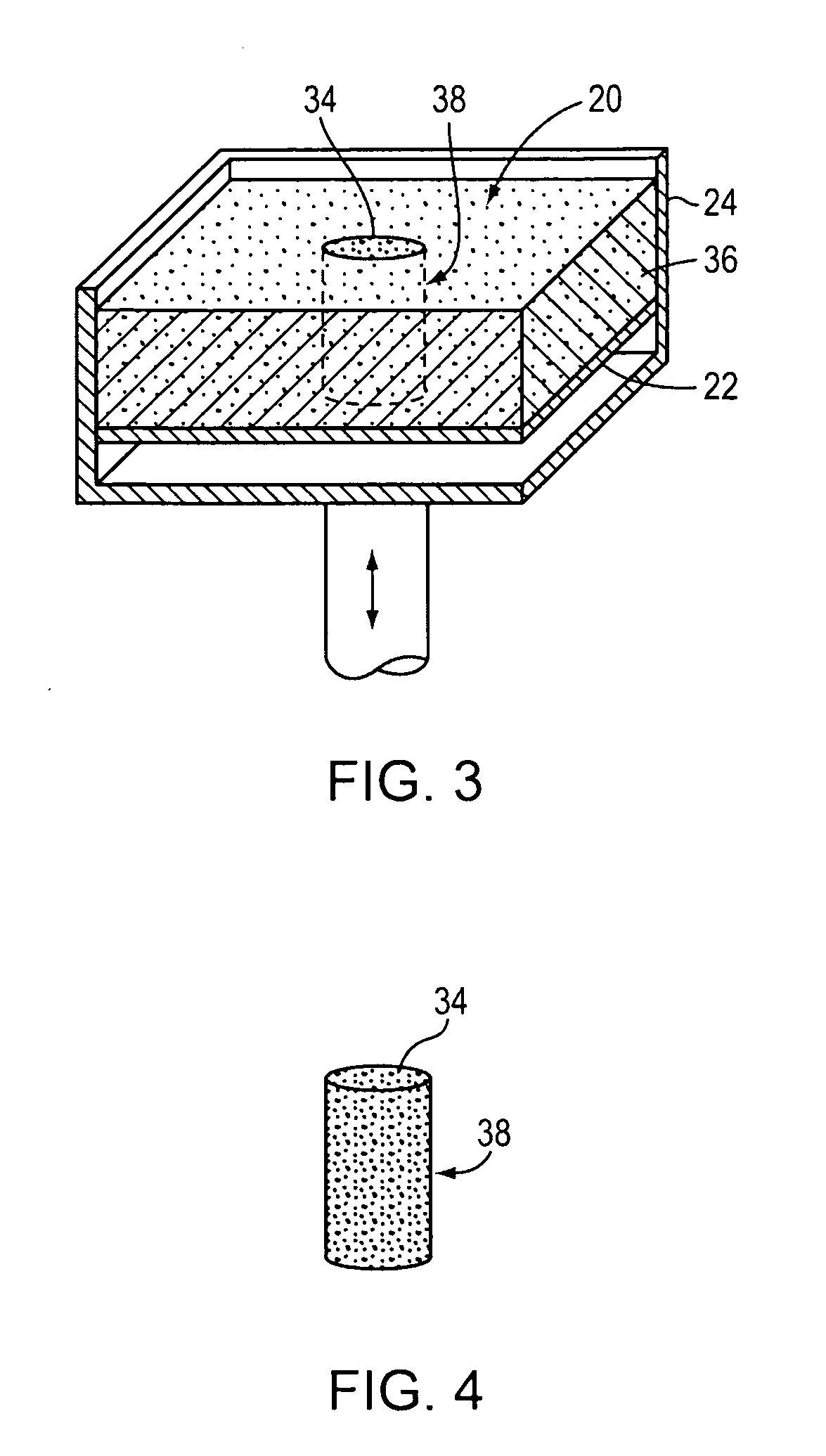

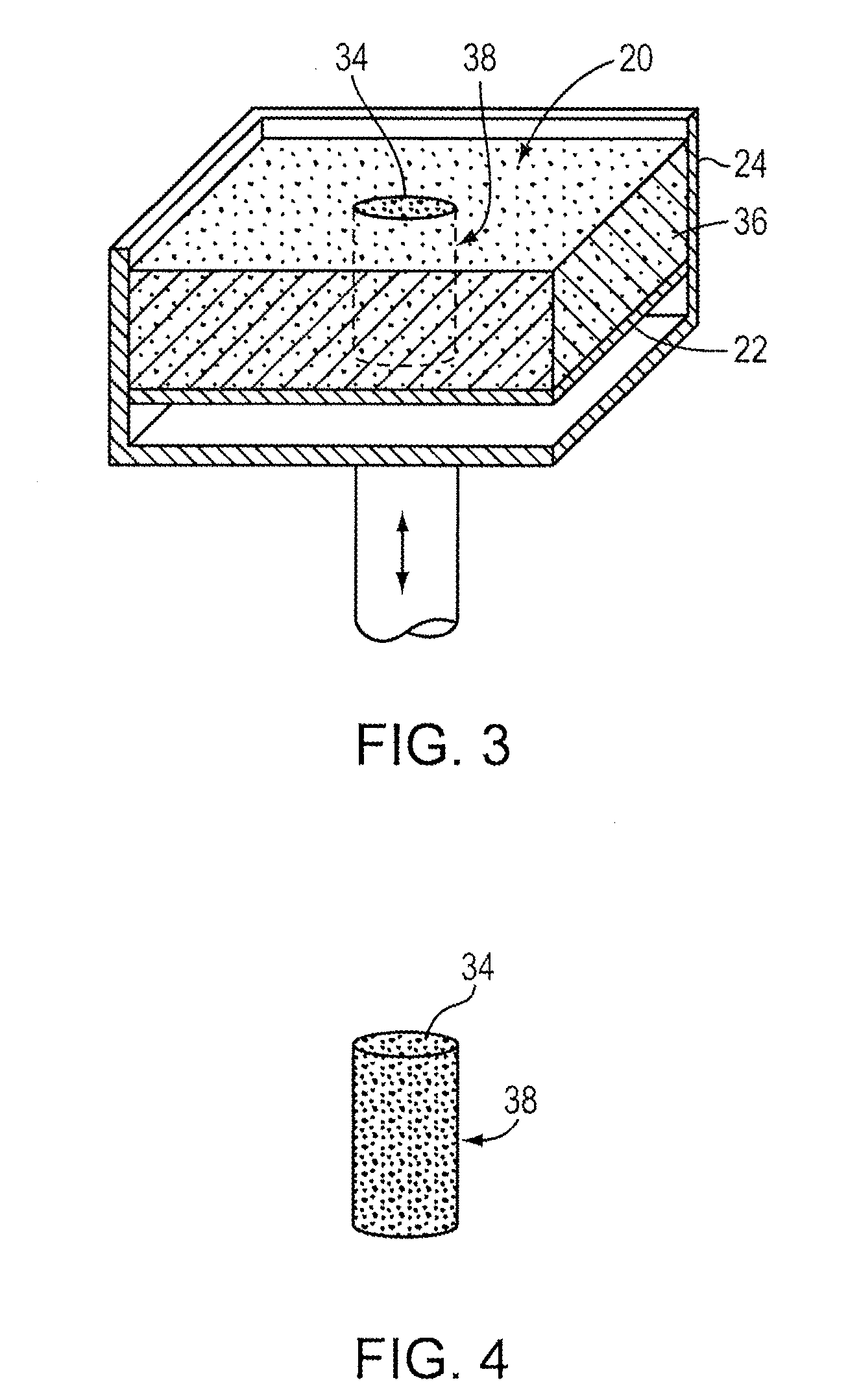

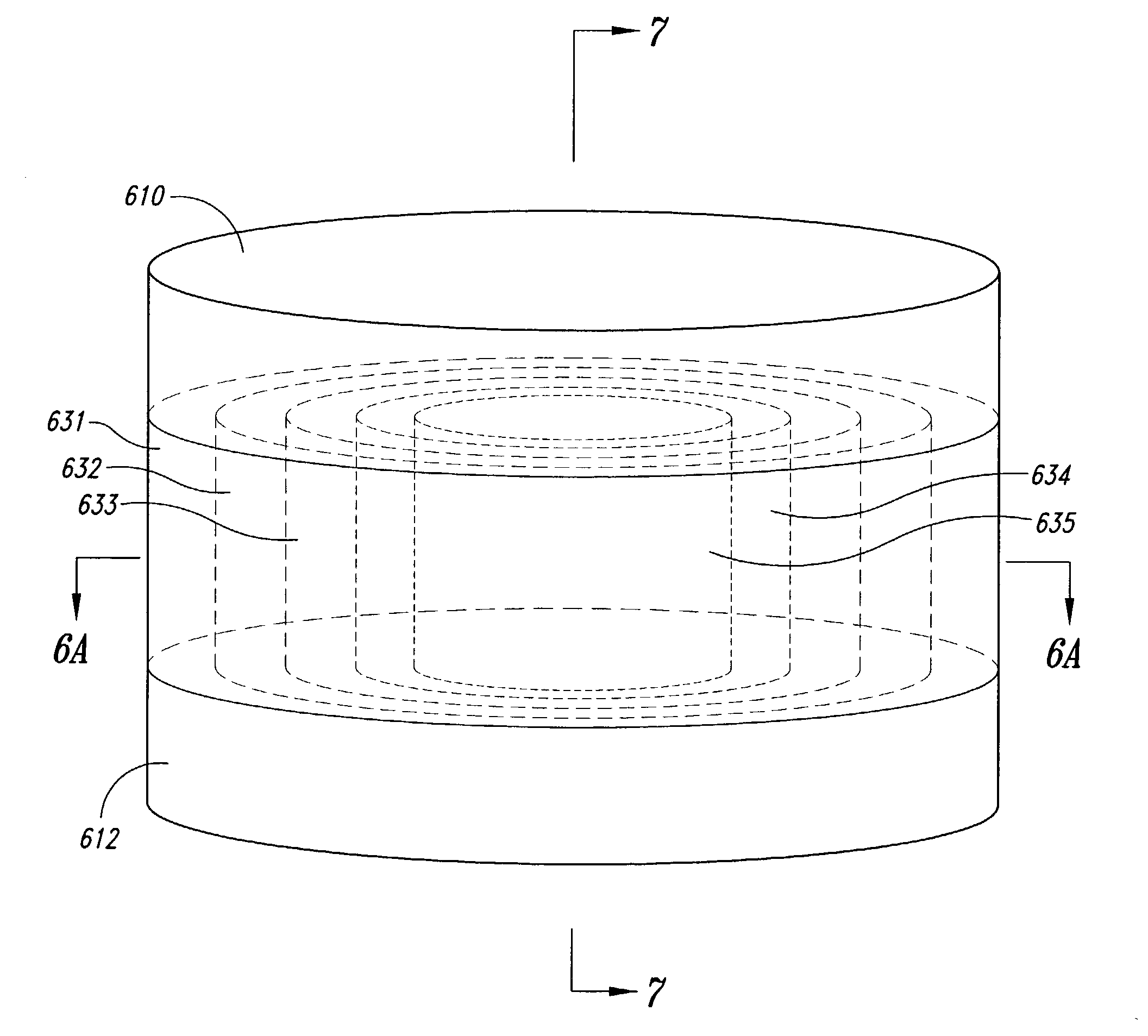

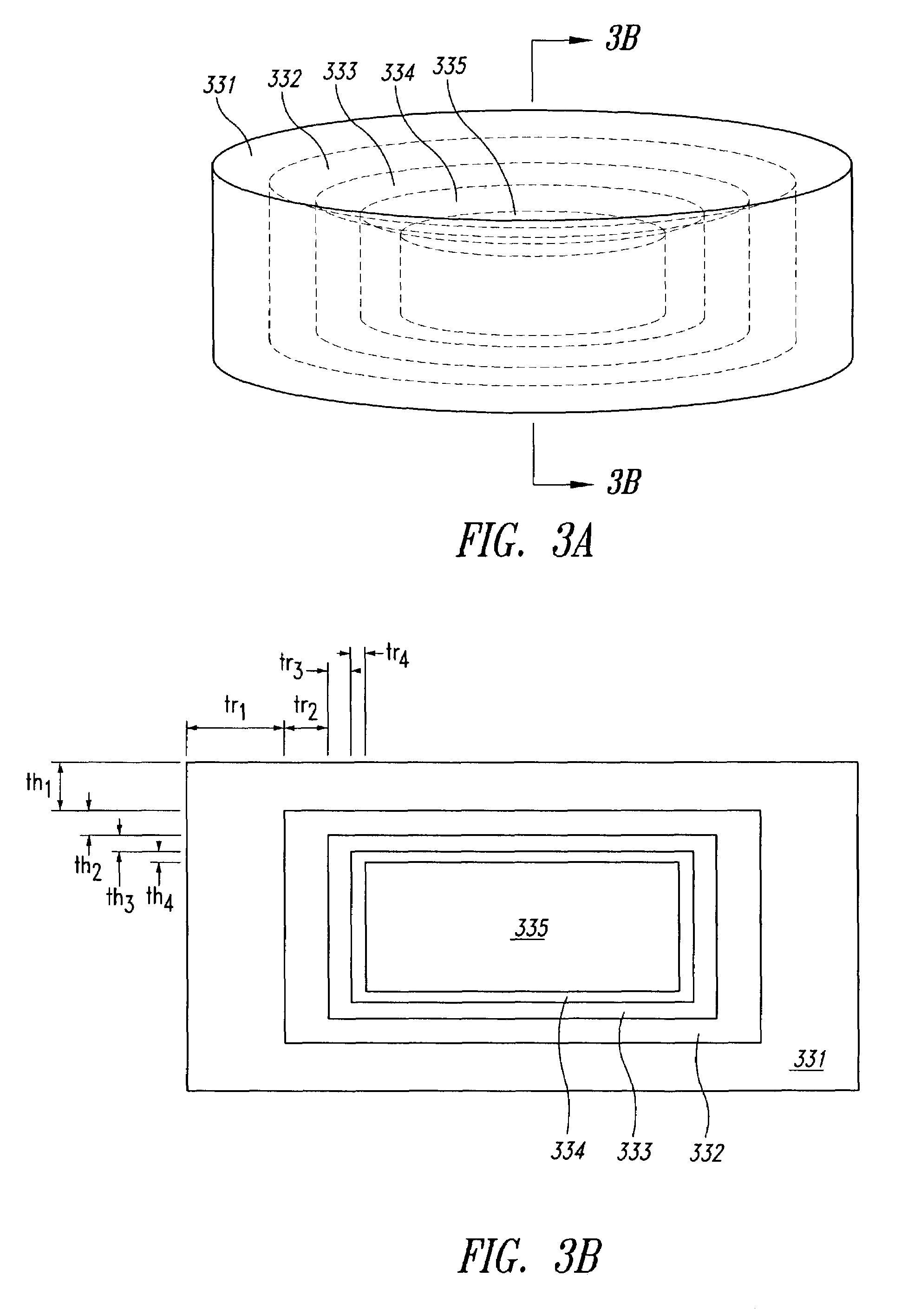

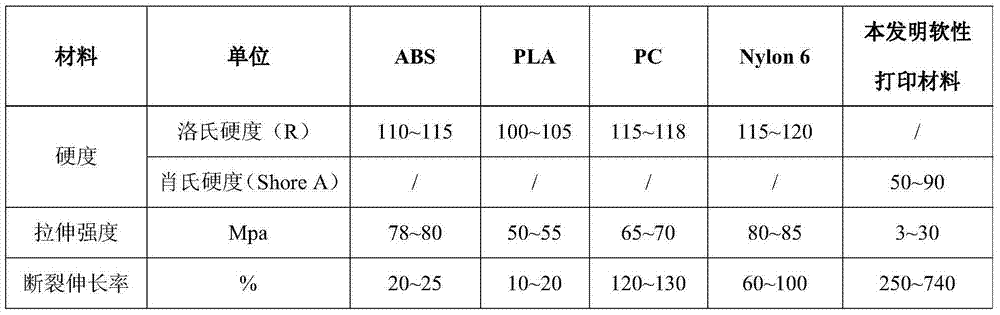

System for manufacturing controlled release dosage forms, such as a zero-order release profile dosage form manufactured by three-dimensional printing

ActiveUS7300668B2Additive manufacturing apparatusInorganic non-active ingredientsHomogeneous distributionTape Dosage Form

The present invention includes controlled release dosage forms and methods of designing and manufacturing dosage forms to obtain specific release profiles, for example, zero-order release profiles, escalating release profiles or decreasing release profiles. The dosage forms of the present invention can include spatial variation of API concentration in the dosage form and can include nested regions. Dosage forms according to the present invention may be manufactured by any appropriate method for obtaining the internal structure as disclosed herein for producing zero-order release profiles and increasing or decreasing release profiles. The invention further includes methods of manufacturing such dosage forms, such as by three-dimensional printing, possibly also including compression of the dosage form after three-dimensional printing. The invention further includes methods of designing such dosage forms. Release profiles from non-uniform distributions of API concentration may be predicted based on simple experiments with uniform-concentration dosage forms.

Owner:MASSACHUSETTS INST OF TECH +1

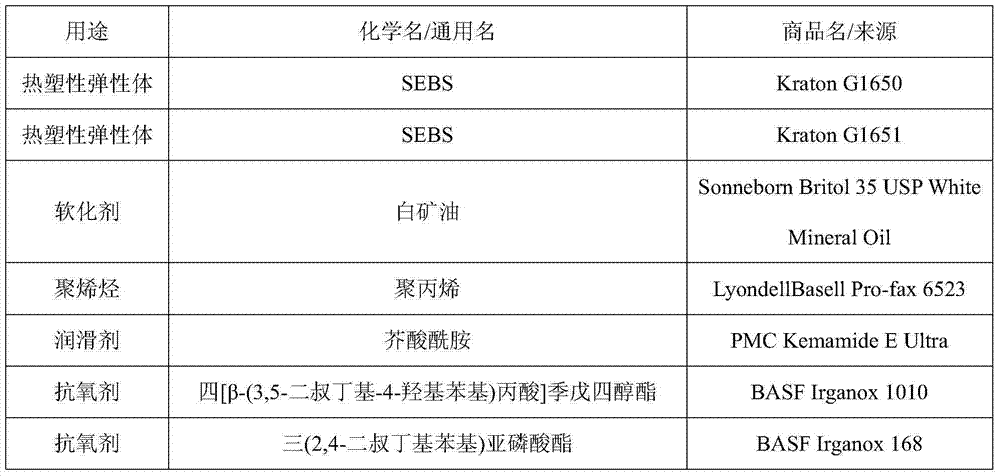

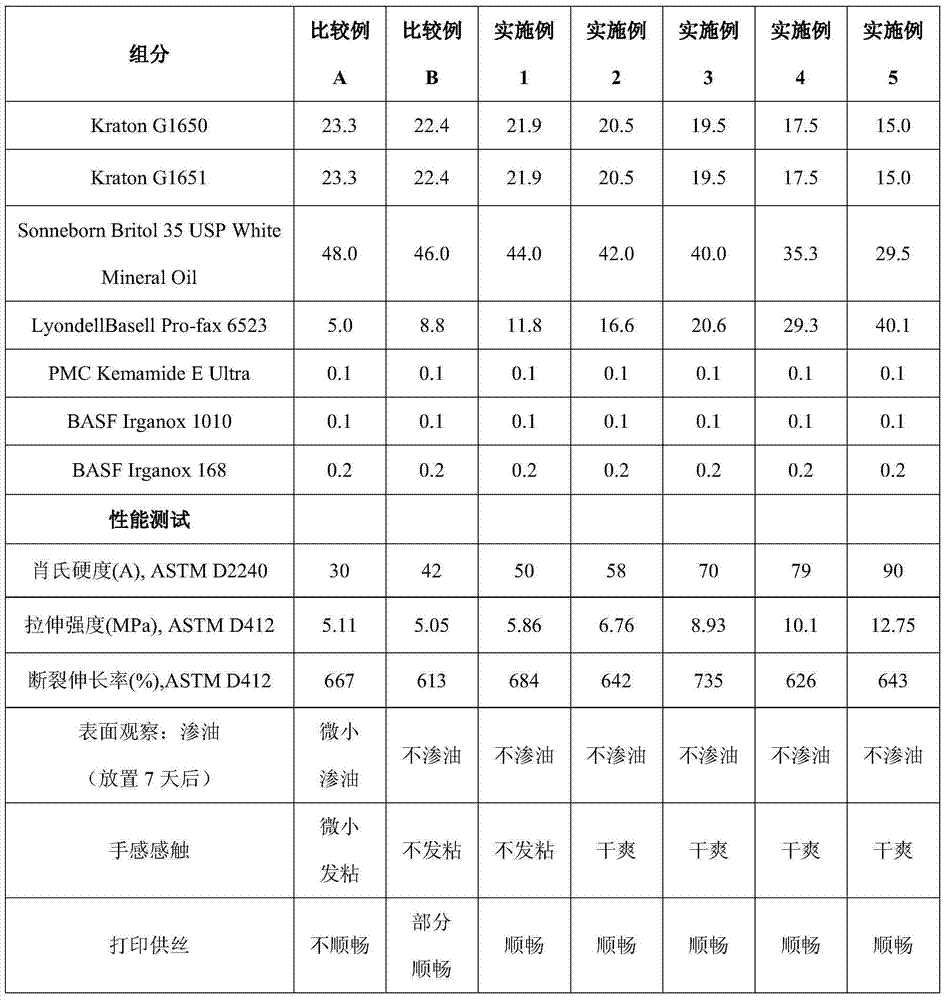

Thermoplastic elastomer composition for preparing flexible printing material for three-dimensional printing rapid prototyping

The invention discloses a thermoplastic elastomer composition for preparing a flexible printing material for three-dimensional printing rapid prototyping. The thermoplastic elastomer composition comprises the following components in percent by weight: 16.8-90.0% of thermoplastic elastomer, 1.0-49.8% of polyolefin, 0-44.0% of softening agent, 0.1-1.3% of lubricating agent and 0.2-0.3% of antioxidant. The hardness of the thermoplastic elastomer is Shore hardness of 50-90A, and the prepared flexible printing material is low in hardness, has outstanding flexibility and toughness and excellent handfeel and is particularly applied to the fields of special industrial design and consumer applications such as the manufacturing of toys, jewelries and fingerprints.

Owner:朱叶周

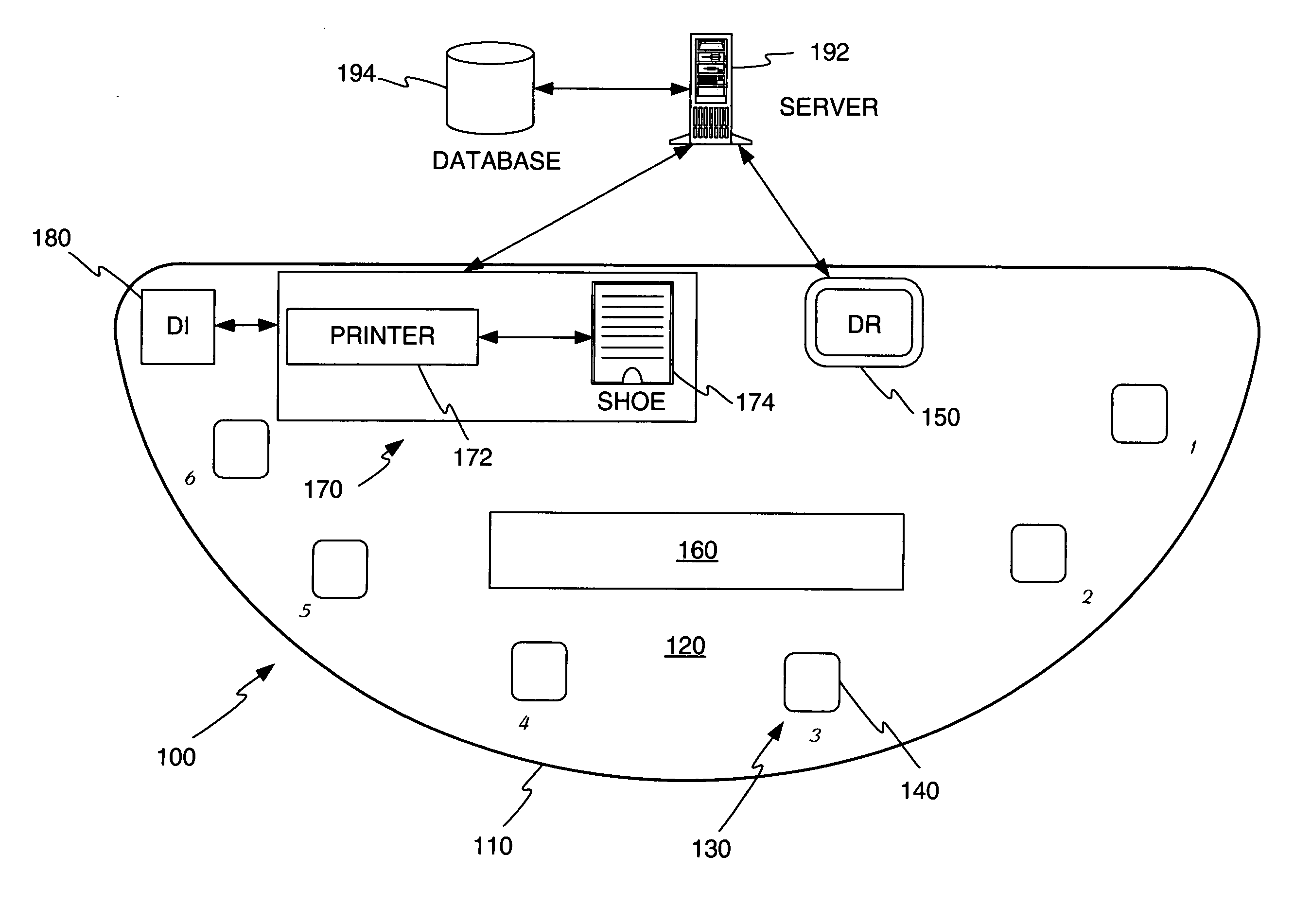

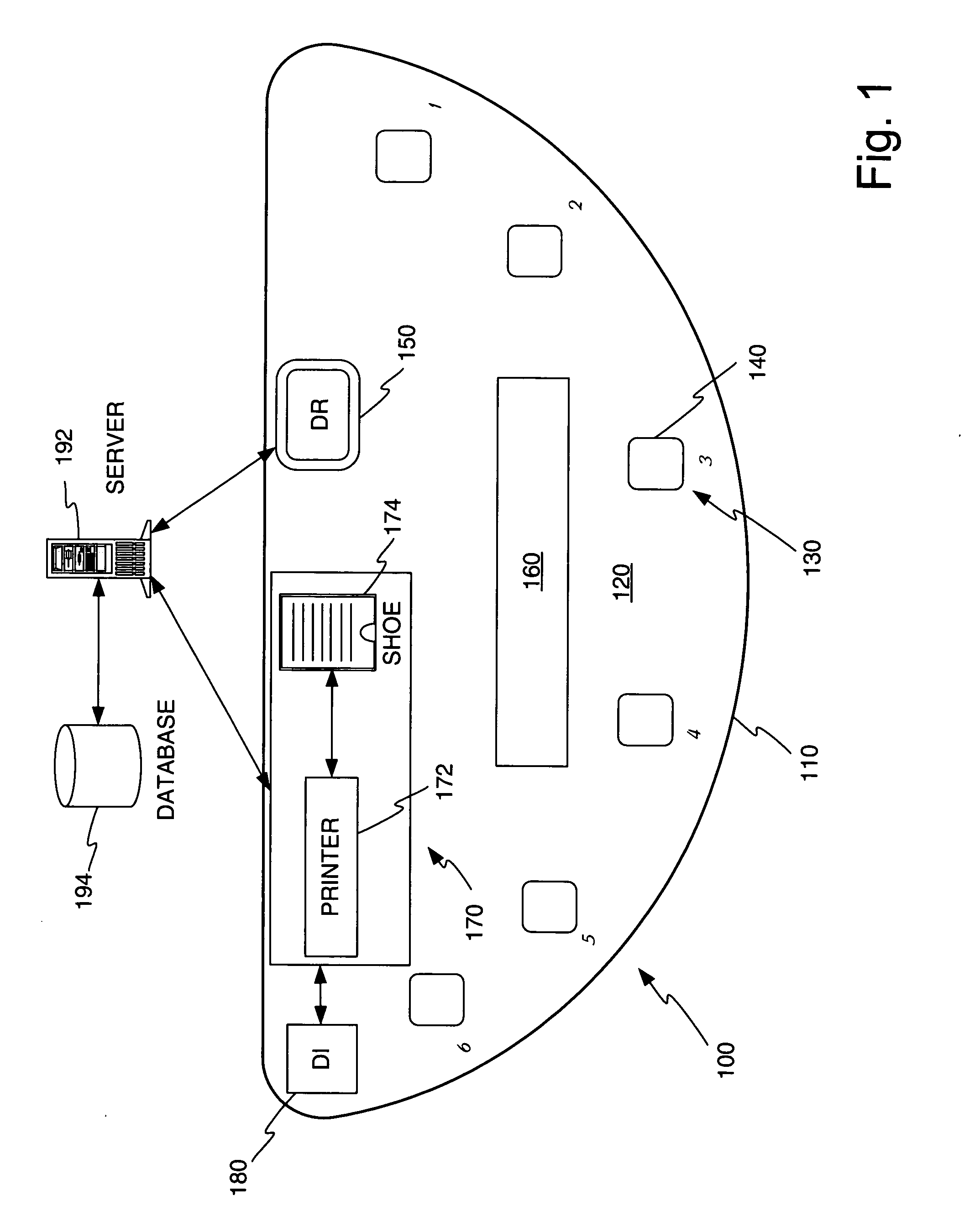

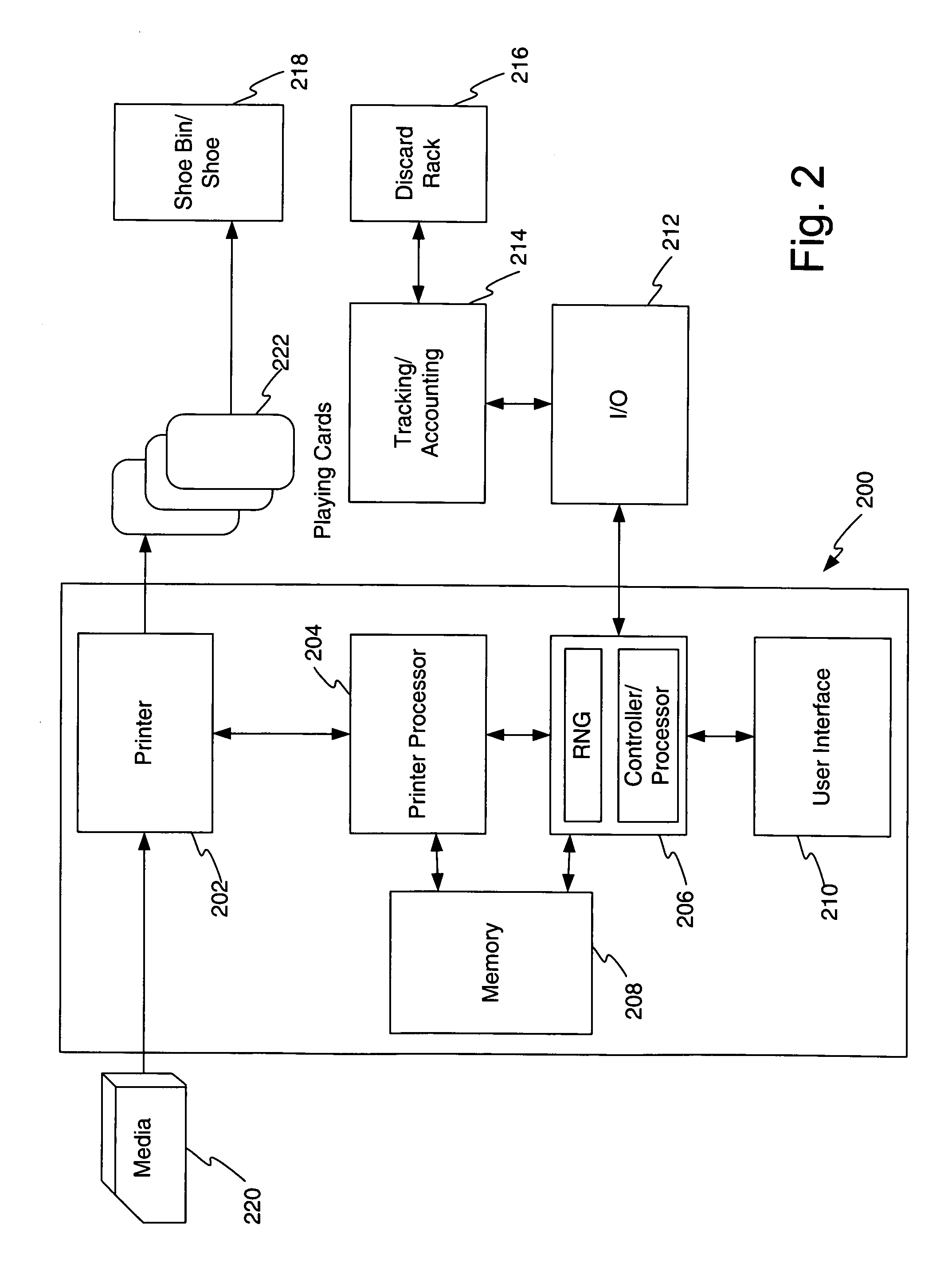

Method and apparatus for card printing

A printer system and method for printing media during a wagering game is disclosed. The system comprises a print device configured to receive blank media and print the blank media responsive to a request during the wagering game. A map corresponding to at least a suit and a value of at least one playing card of one or more decks of playing cards may be created and stored after receiving the request. Printed media configured as playing cards or coupons may be stored or distributed after printing with the print device during play of the wagering game. The playing cards may also be printed with authorization data. The system may further comprise a discard rack to receive and monitor playing cards discarded during play of the wagering game. Playing cards that are in the discard rack may be destroyed if they are authorized and retained if they are unauthorized.

Owner:IGT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com