Patents

Literature

5932results about How to "Reduce hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

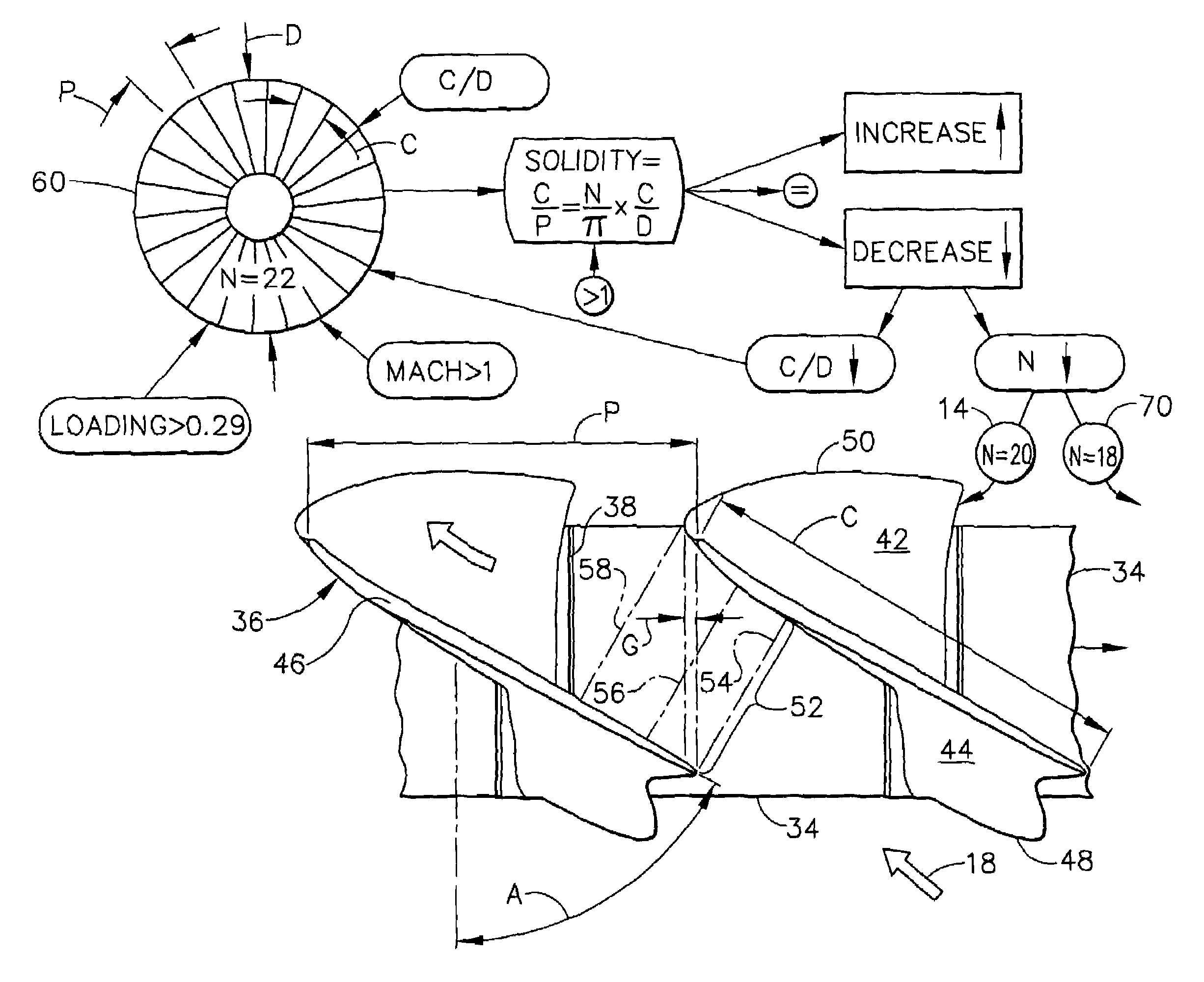

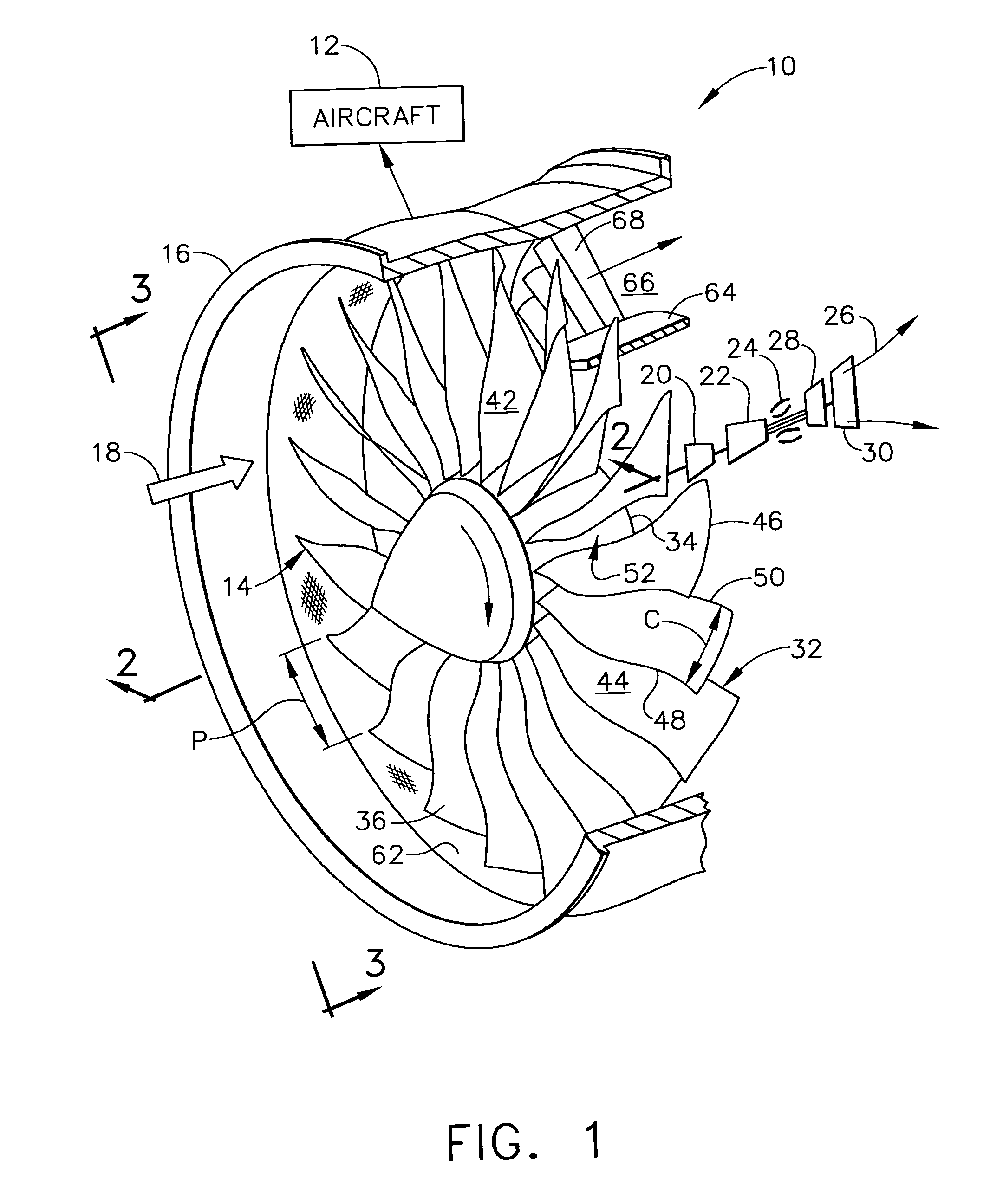

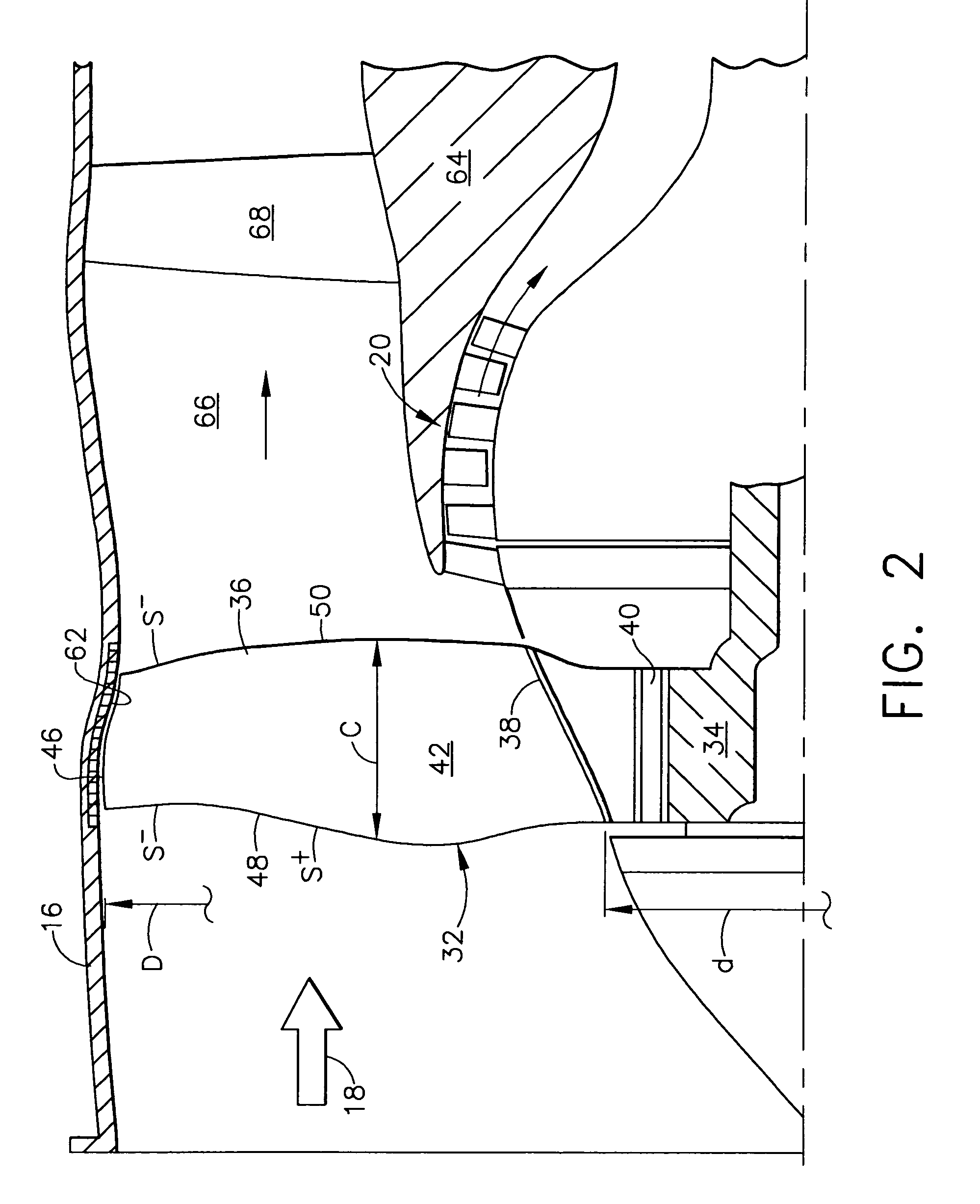

Low solidity turbofan

A turbofan includes a row of fan blades extending from a supporting disk inside an annular casing. Each blade includes an airfoil having opposite pressure and suction sides extending radially in span between a root and tip and axially in chord between leading and trailing edges. Adjacent airfoils define corresponding flow passages therebetween for pressurizing air. Each airfoil includes stagger increasing between the root and tip, and the flow passage has a mouth between the airfoil leading edge and the suction side of an adjacent airfoil and converges to a throat aft from the mouth. The row includes no more than twenty fan blades having low tip solidity for increasing the width of the passage throat.

Owner:GENERAL ELECTRIC CO

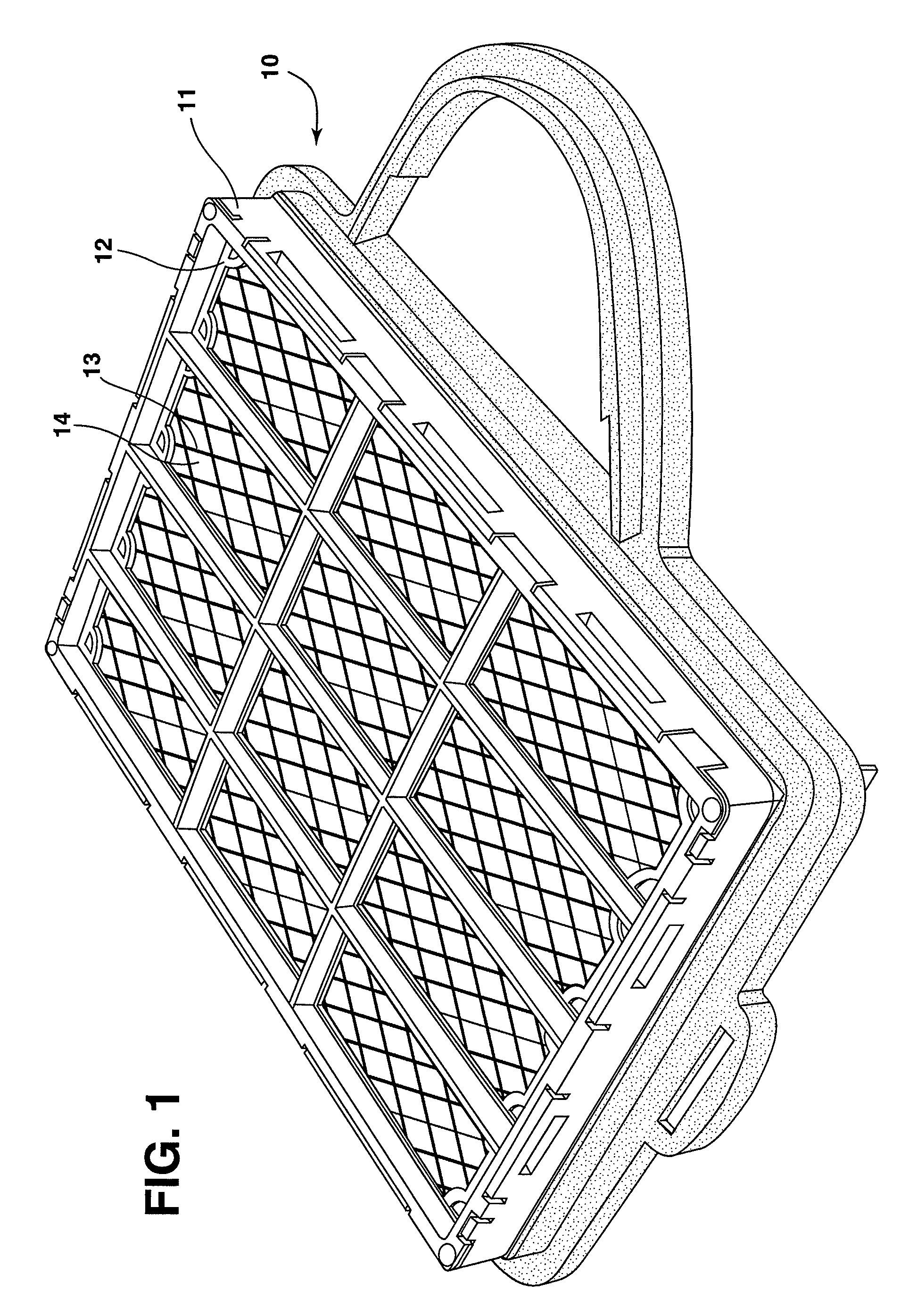

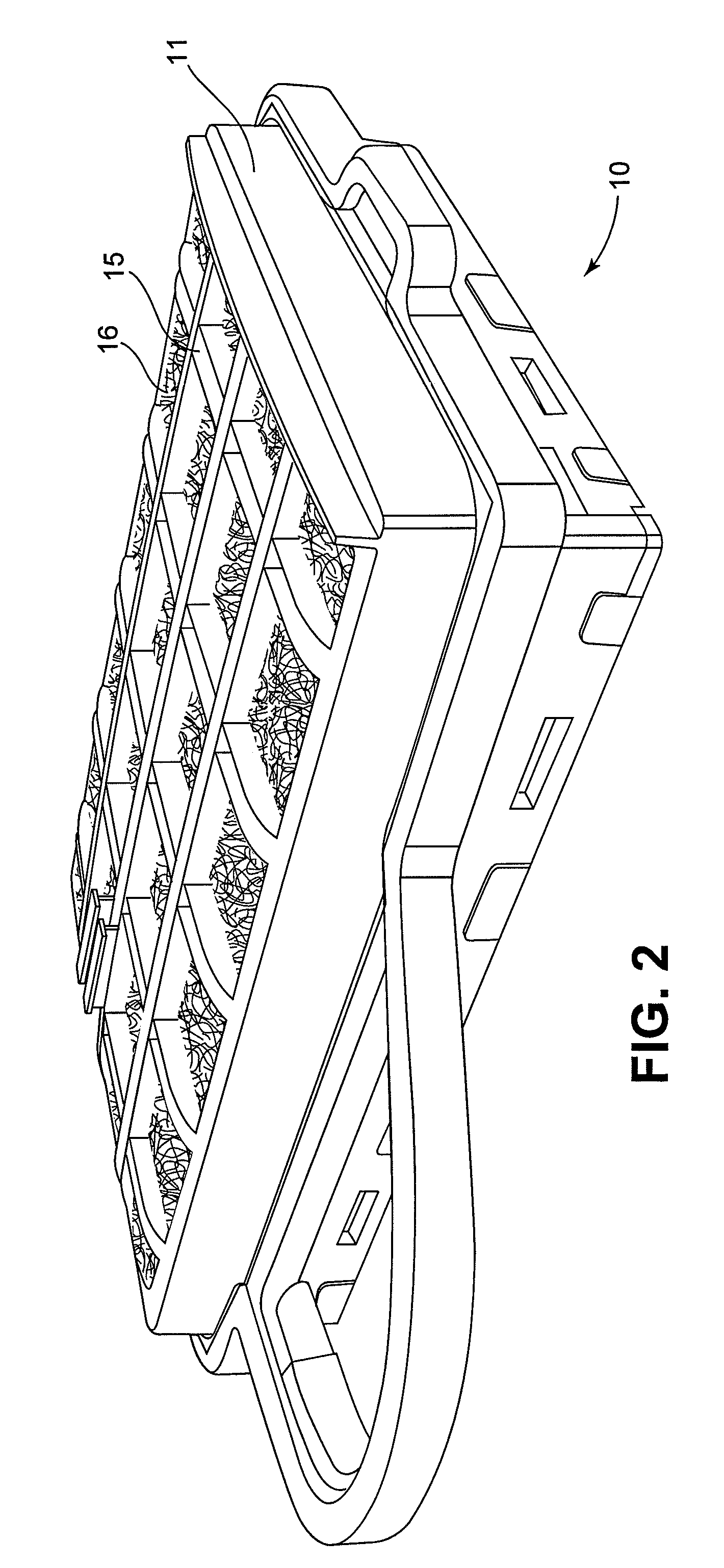

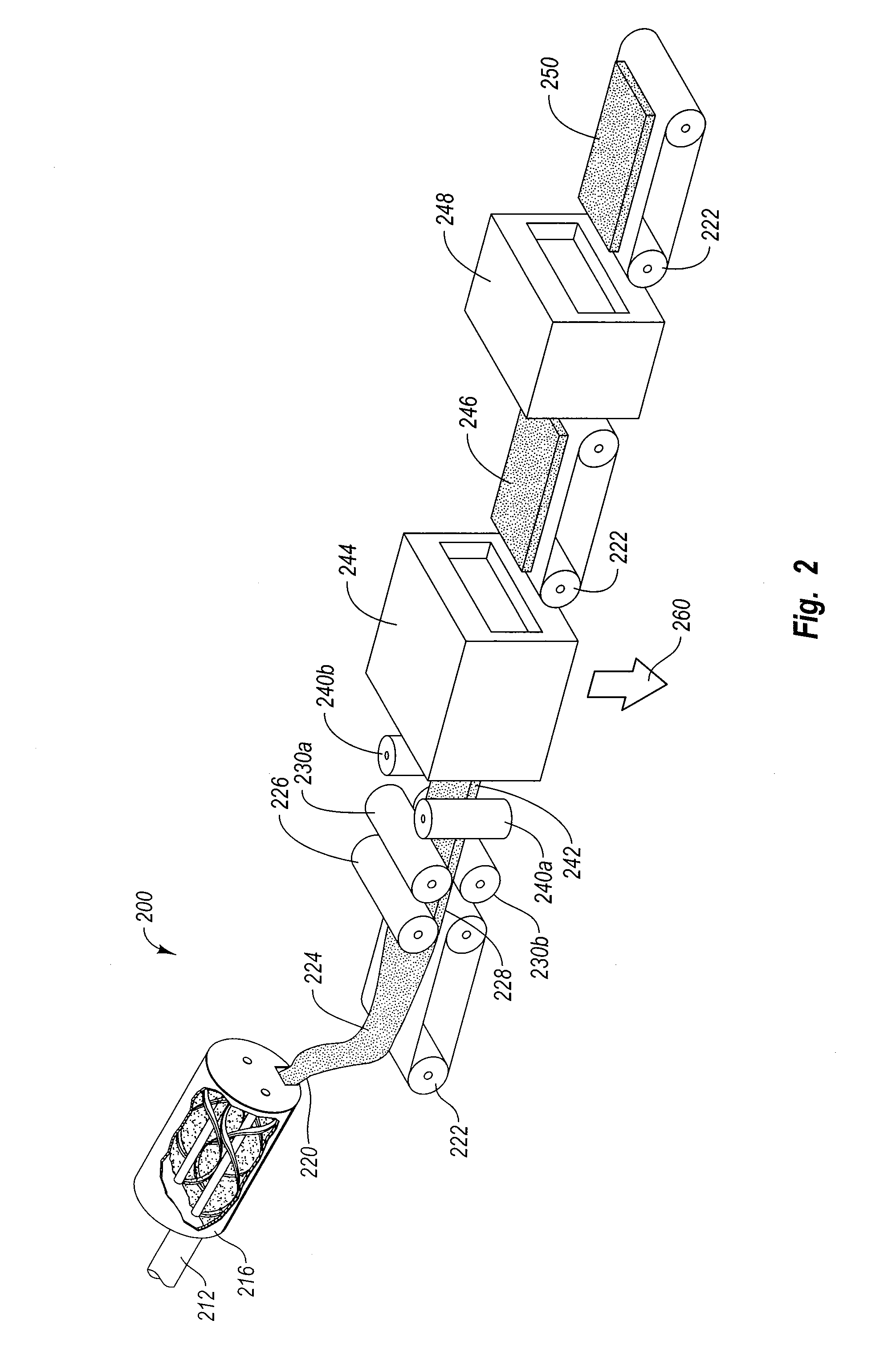

Filter element and method

InactiveUS20090044702A1Life of element can be lengthenedIncrease capacityCombination devicesNon-fibrous pulp additionMultiple formsParticulates

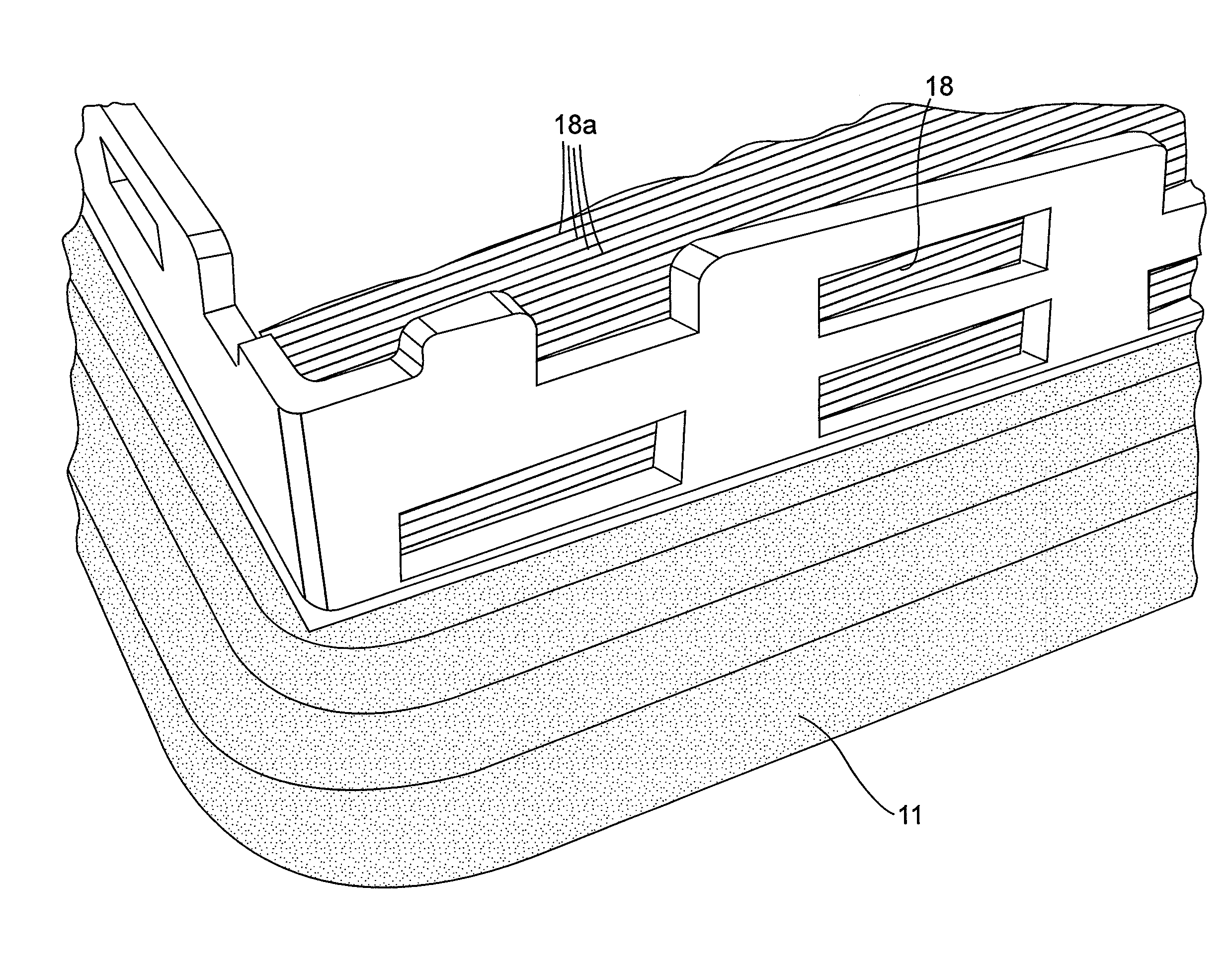

A filter element having multiple formed layers of filtration media is disclosed. The media are layered so as to form a pore size gradient. The filter element is capable of removing both solid and liquid particulates from a moving fluid stream. The filter element has high strength and compressibility. The layers can be supported on a porous or perforate support to provide mechanical stability during filtering operations. The filtration media layers can be formed into various filter element forms such as panels, cartridges, inserts, and the like.

Owner:DONALDSON CO INC

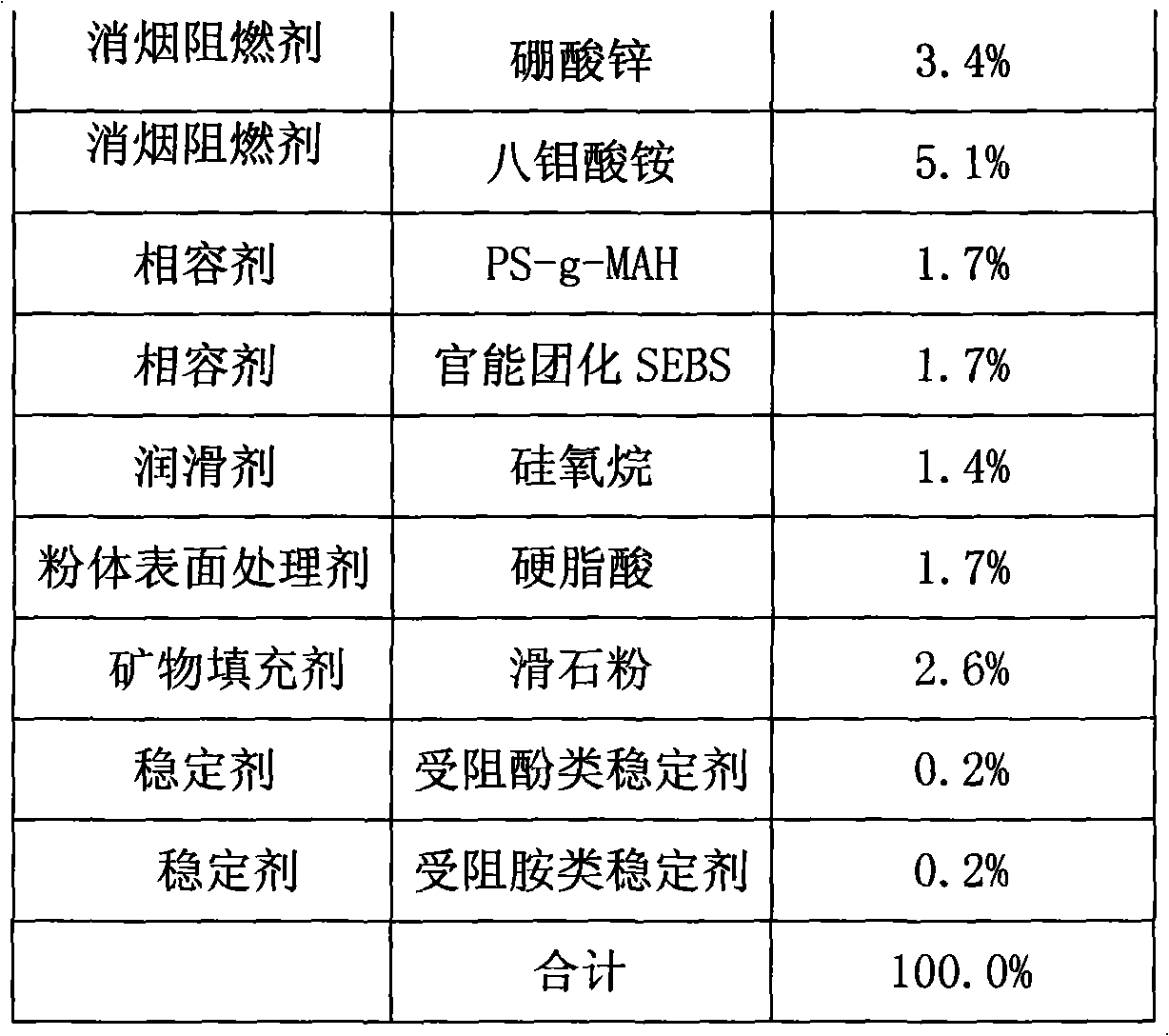

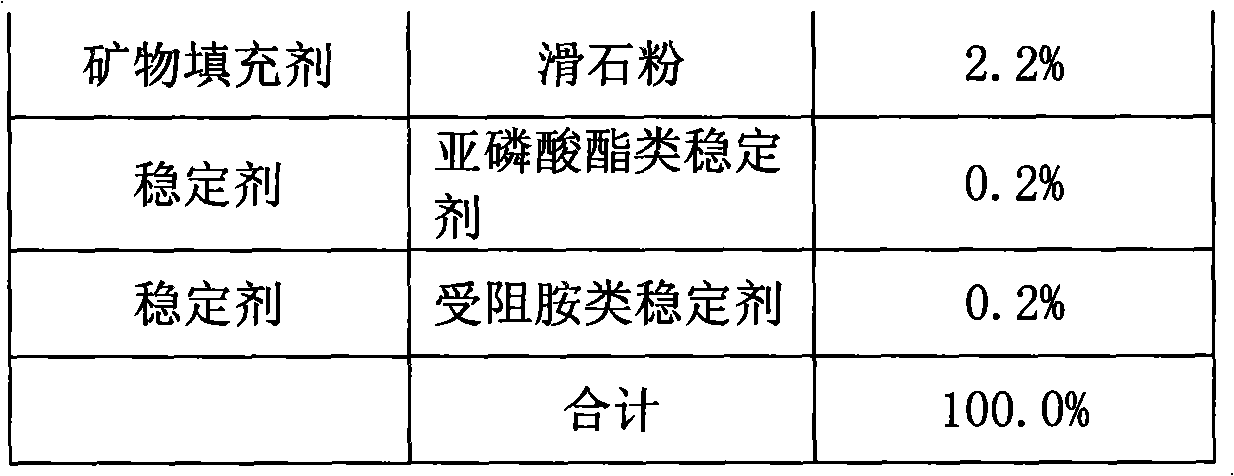

Halogen-free flame-retardant thermoplastic elastomer electrical cable material using polyphenylene ether as base material and preparation method thereof

InactiveCN101358028AGood compatibilityReduce stratificationInsulated cablesInsulated conductorsElastomerPolyphenylene oxide

The invention discloses a halogen-free flame-retardant thermoplastic elastomer cable material with polyphenylether as the base materials and a preparation method thereof. The raw material of the cable material contains the components with the following weight percentage: 10 to 35 percent of matrix resin A; 5 to 15 percent of matrix resin B; 10 to 25 percent of elastomer; 5 to 25 percent of softening plasticizer; 8 to 15 percent of flame-retardant plasticizer; 20 to 40 percent of smoke-suppression flame retardant; 3 to 10 percent of compatilizer; 1 to 5 percent of lubricant; 1 to 5 percent of powder surface conditioner; 0 to 10 percent of mineral filler; 0.1 to 1 percent of stabilizing agent. The invention adds matrix resin, polyphenylether of strong polarity and functional group of styrene-ethylene / butylene-styrene segmented copolymer, which effectively improves the compatibility of non-polar elastomer with polyphenylether; the invention also adds plasticizer, which reduces the hardness of the material and increases the flexibility; and through the optimization and interaction of the softening plasticizer and the flame-retardant plasticizer, the invention reduces the hardness and improves the tactility of the material, and the flame retardant performance is excellent.

Owner:NINGBO SHIP PLASTIC CO LTD

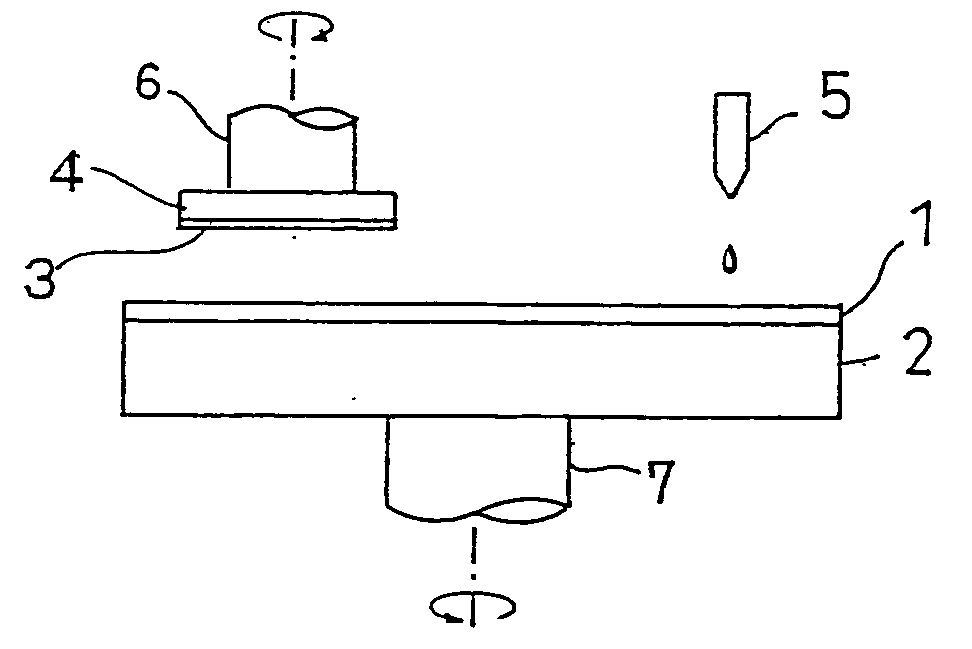

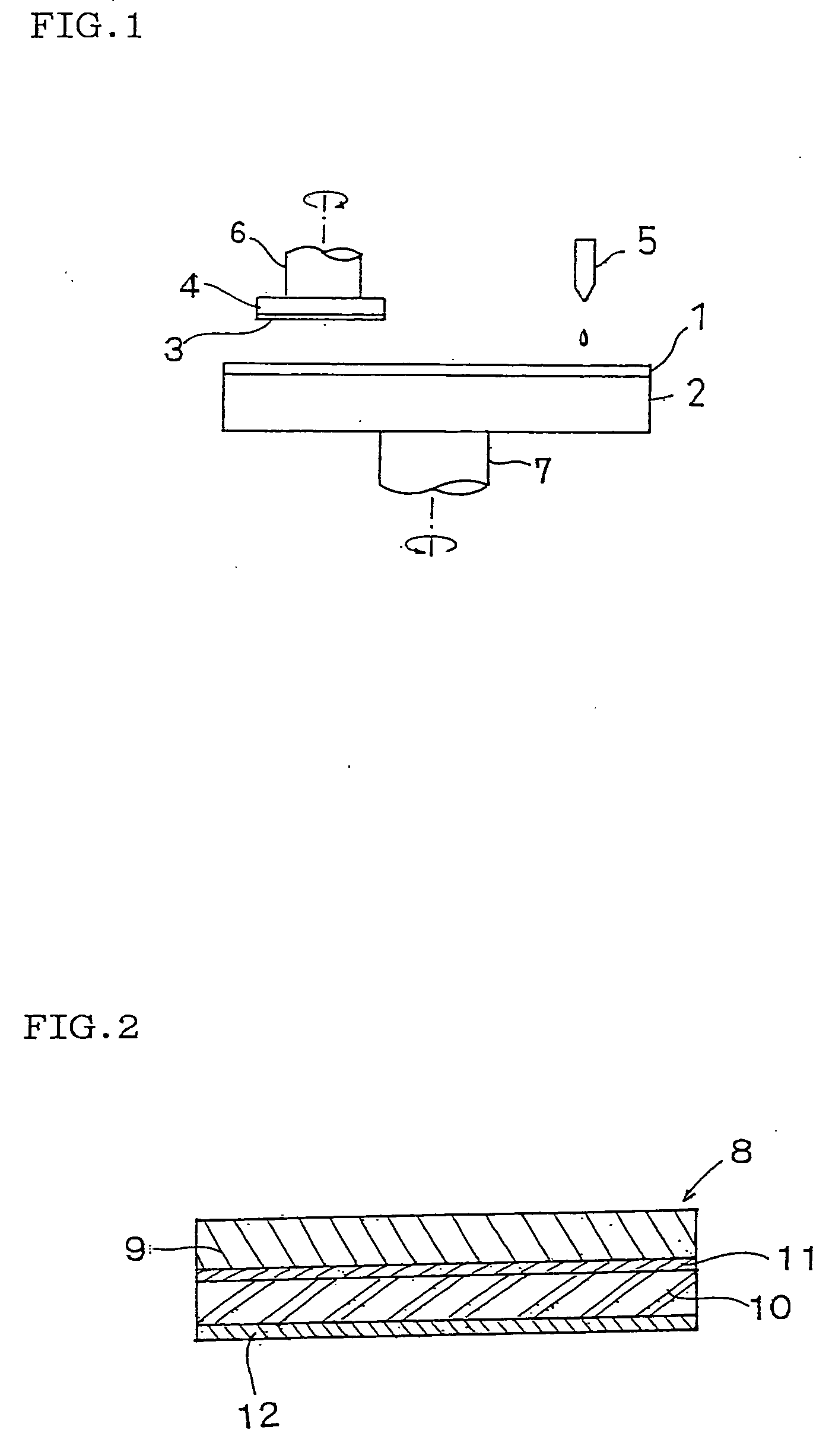

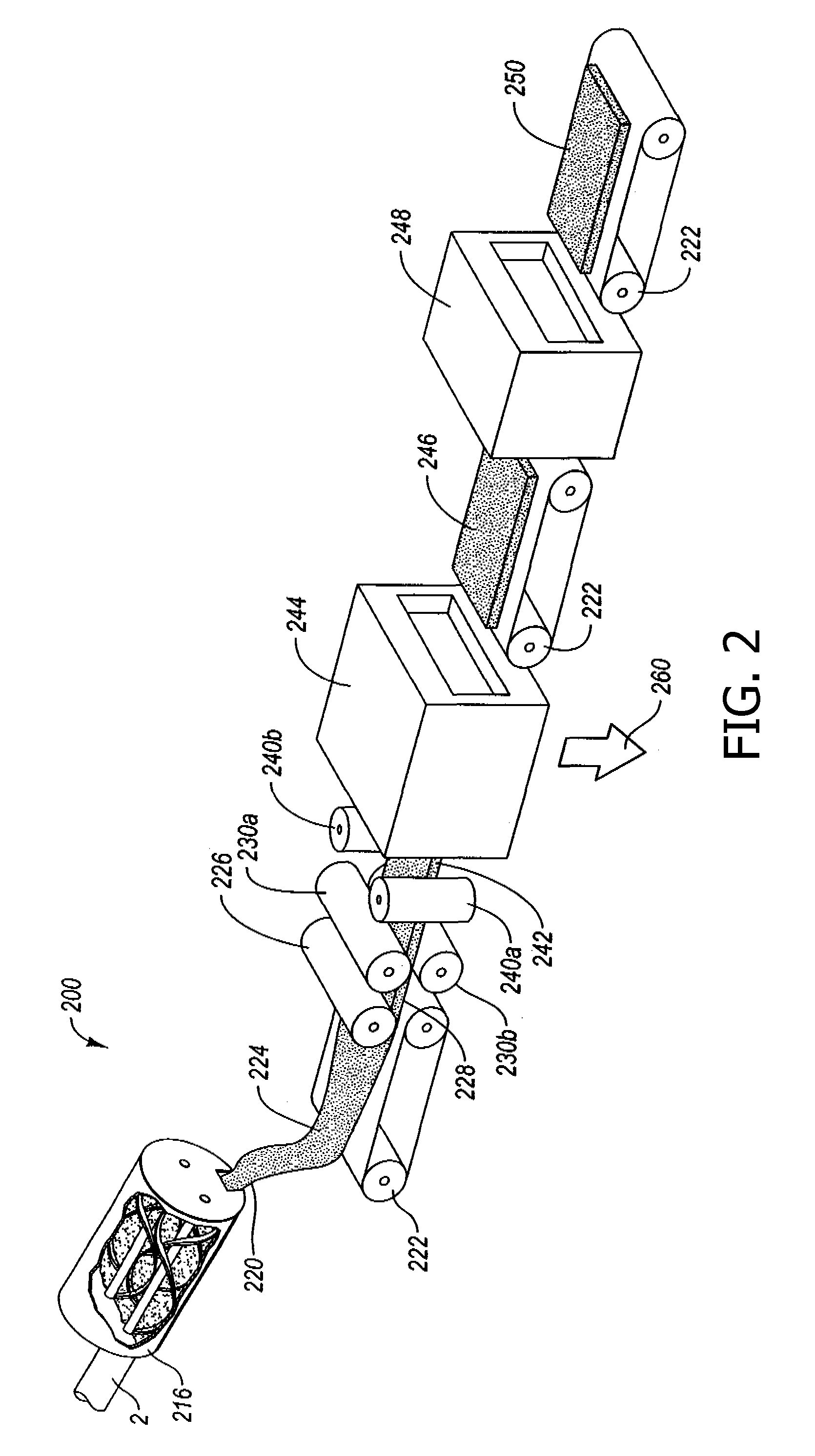

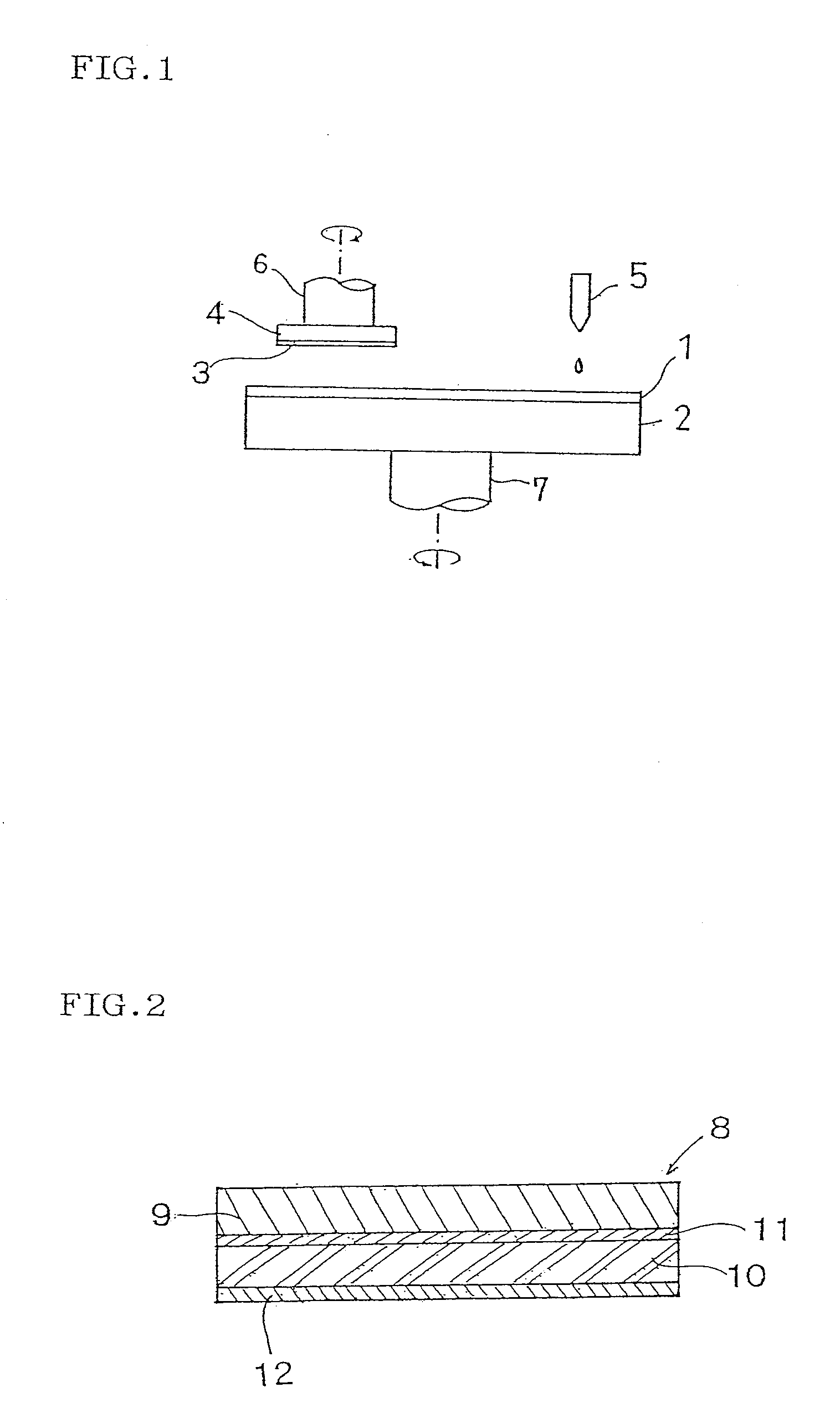

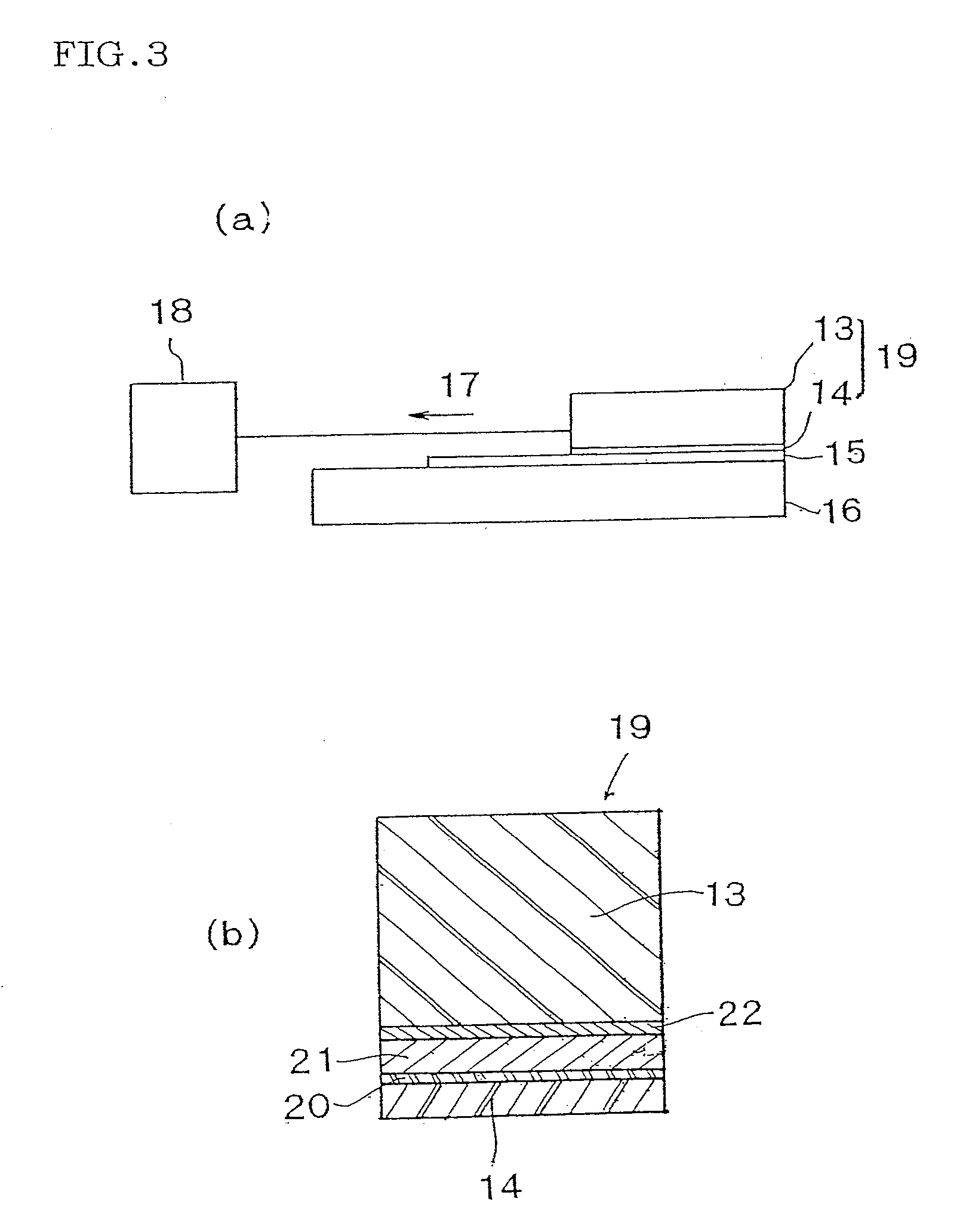

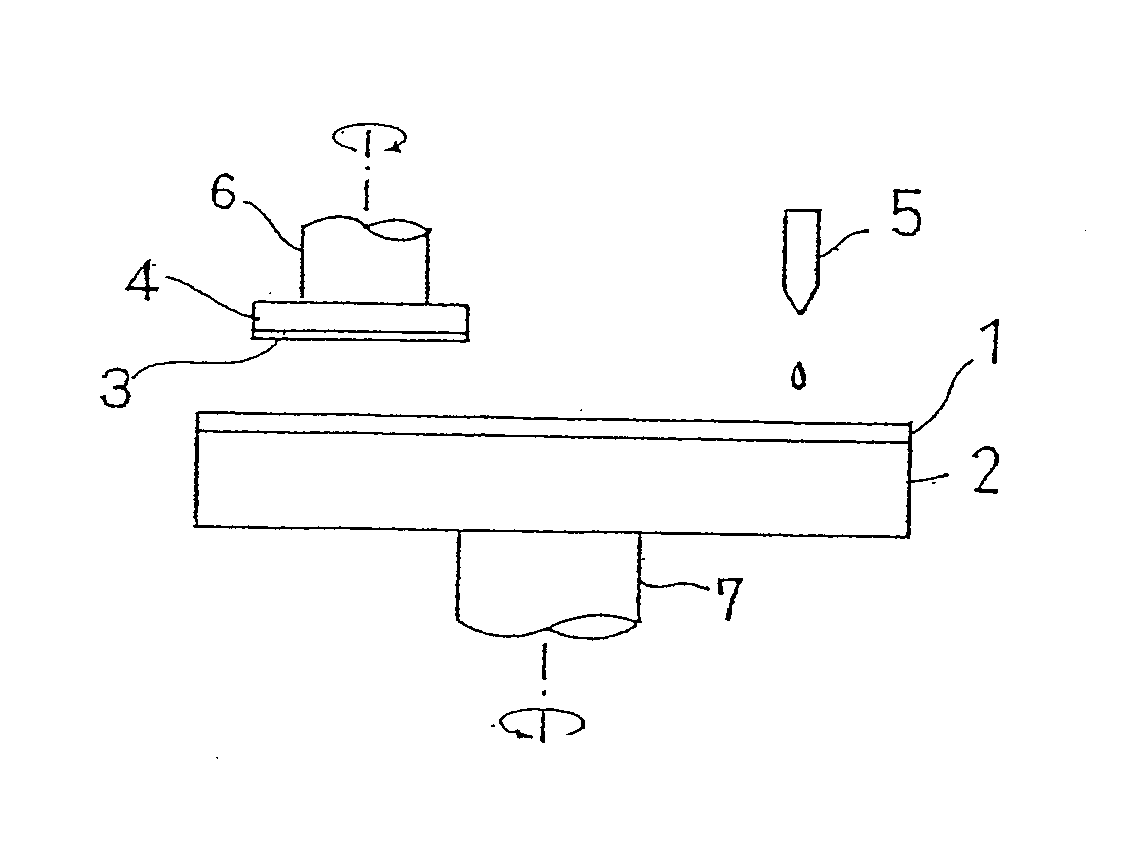

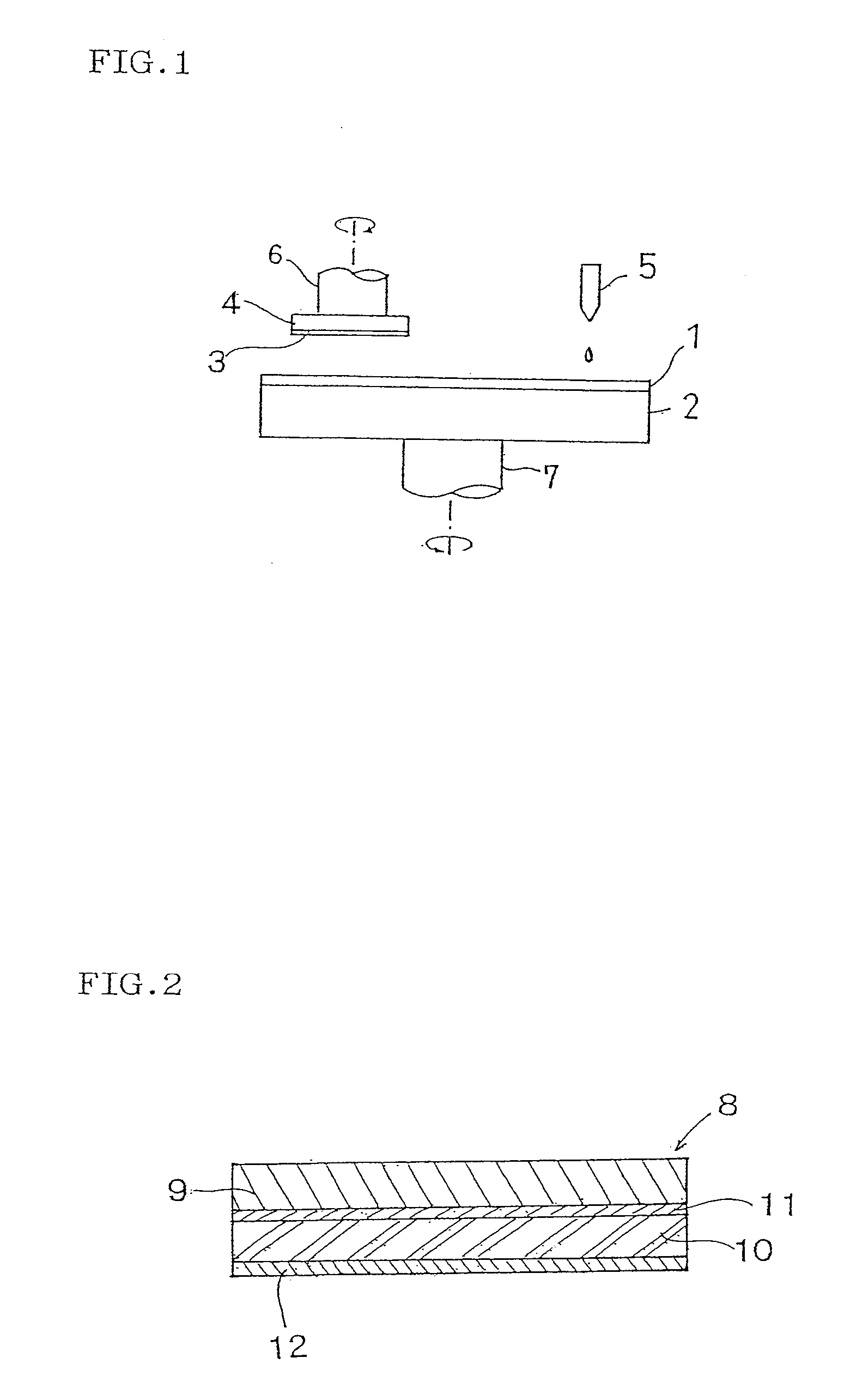

Grinding pad and method of producing the same

InactiveUS20050064709A1Reduce rateReduce hardnessLayered productsAbrasion apparatusAluminum substrateSemiconductor

The invention provides a polishing pad by which optical materials such as lenses, reflecting mirrors etc., or materials requiring a high degree of surface planarity, as in the polishing of silicone wafers, glass substrates or aluminum substrates for hard disks, or general metal polishing, can be flattened with stability and high polishing efficiency. The invention also provides a polishing pad for semiconductor wafers, which is superior in planarizing characteristic, is free from scratches and can be produced at low cost. There is provided a polishing pad which is free from dechucking error so that neither damage to wafers nor decrease in operating efficiency occurs. There is provided a polishing pad which is satisfactory in planarity, within wafer uniformity, and polishing rate and produces less change in polishing rate. There is provided a polishing pad which can make planarity improvement and scratch decrease compatible.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

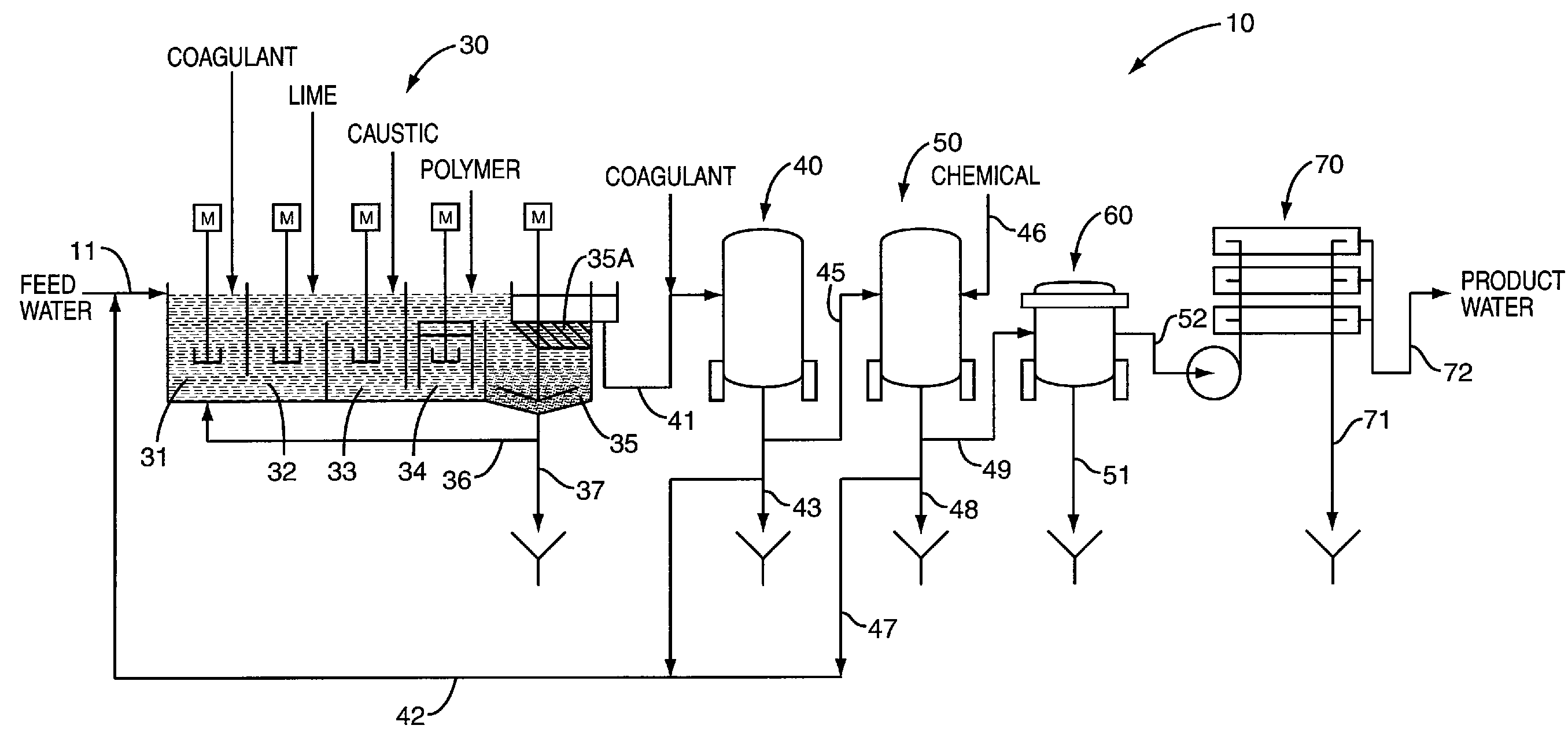

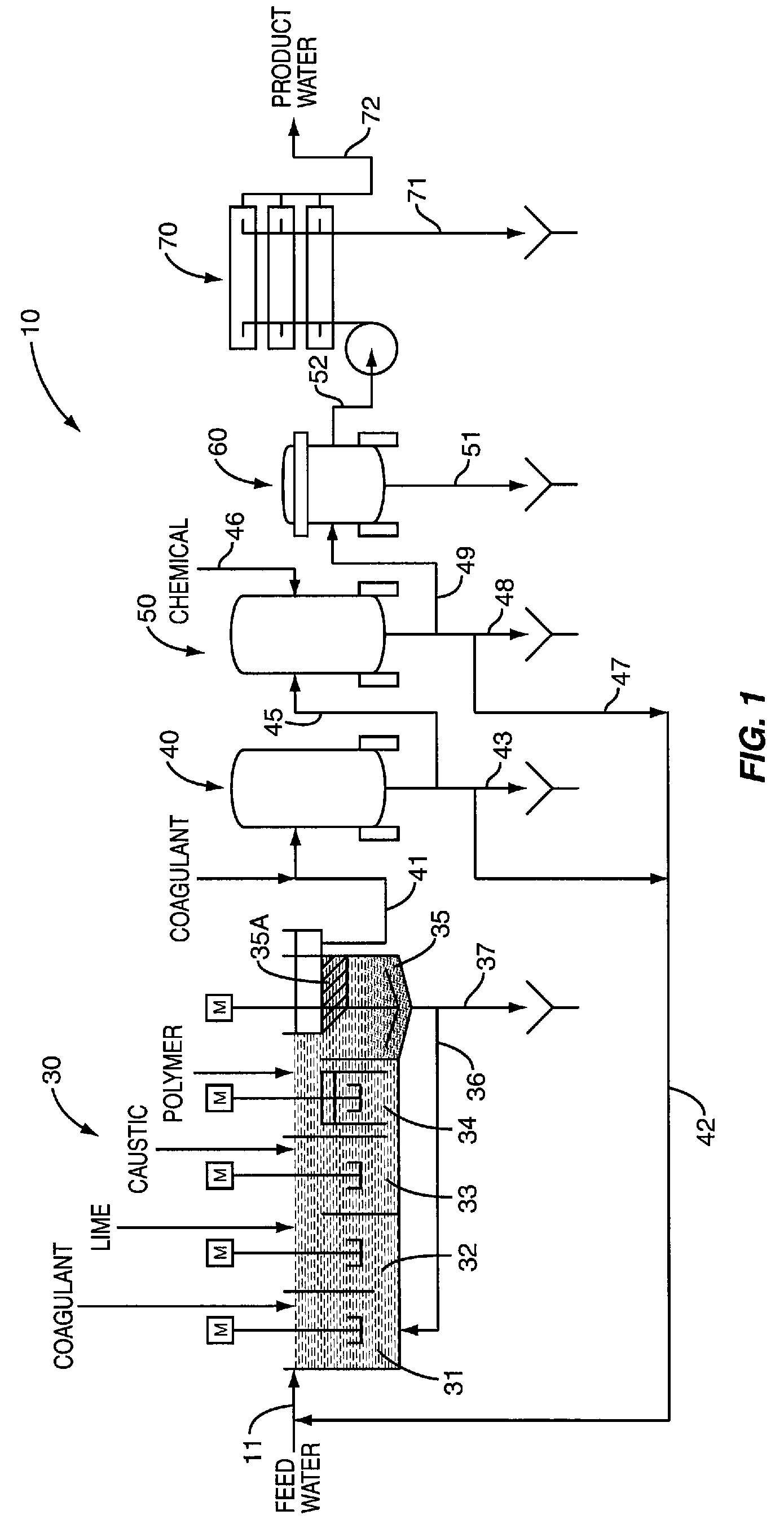

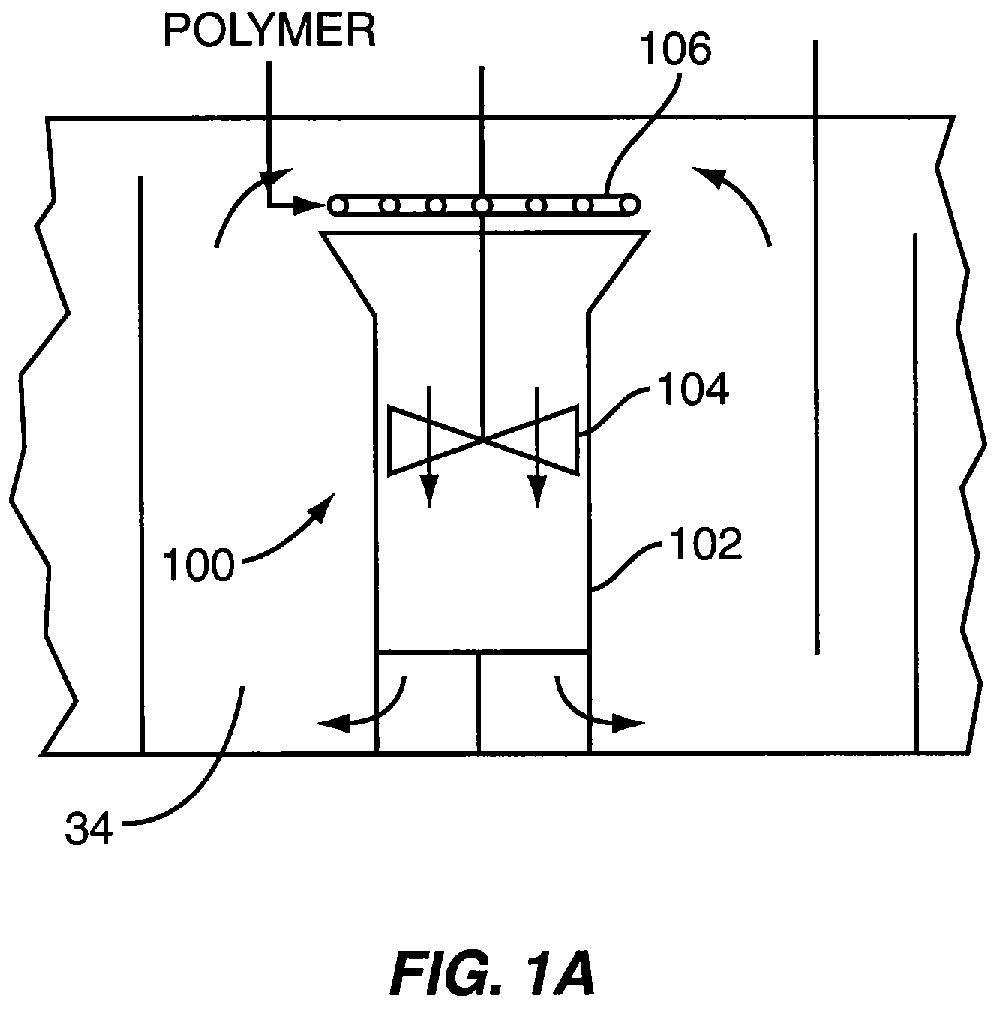

Method for treating wastewater or produced water

ActiveUS7815804B2Reduce hardnessReduce dissolved solidWaste water treatment from quariesGeneral water supply conservationWastewaterIon exchange

A method or process for treating wastewater containing high organics, silica, boron, hardness, and suspended and dissolved solids. The method includes degasifying the wastewater for the removal of dissolved gases and thereafter chemically softening the wastewater. After the chemical softening step, the wastewater is directed through a media filter or membrane which removes additional solids and precipitants. Thereafter the wastewater is directed through a sodium ion exchange that further softens the wastewater. The effluent from the ion exchange is directed through a cartridge filter and the effluent from the cartridge filter is directed through one or more reverse osmosis units. At a selected phase of the process, prior to the wastewater reaching the reverse osmosis unit or units, the pH of the wastewater is raised and maintained such that the pH of the wastewater reaching a reverse osmosis unit is at a pH greater than 10.5.

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

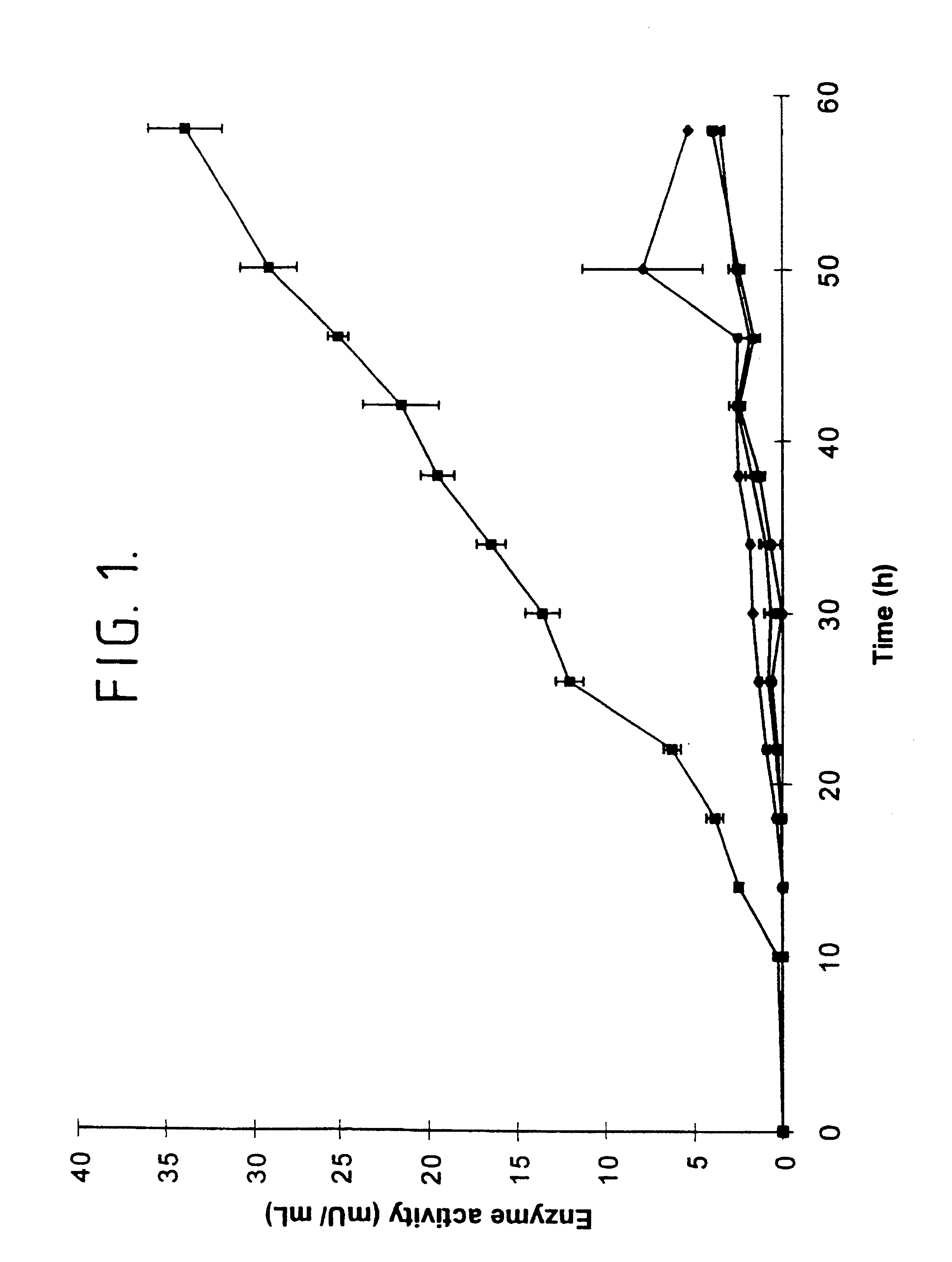

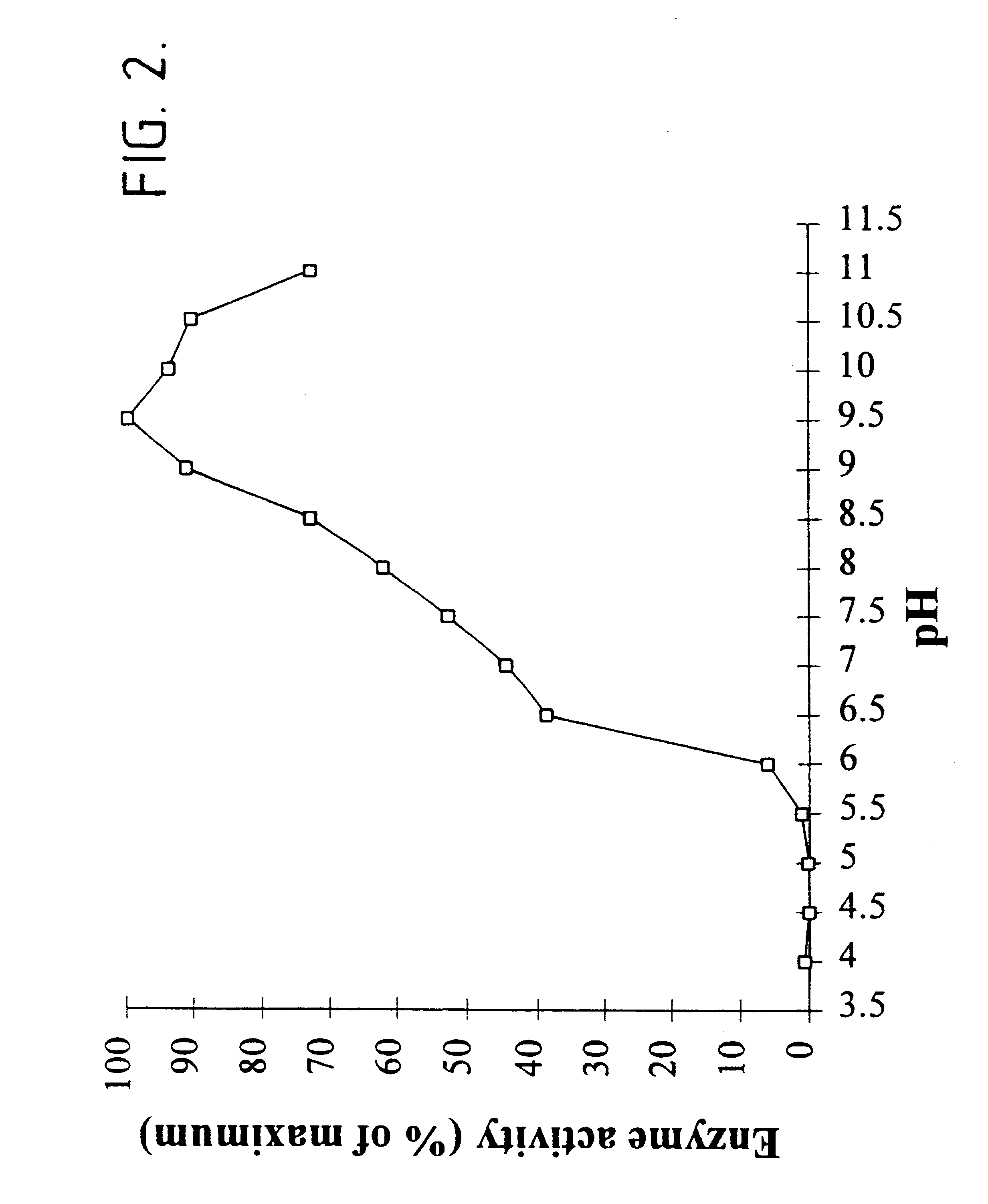

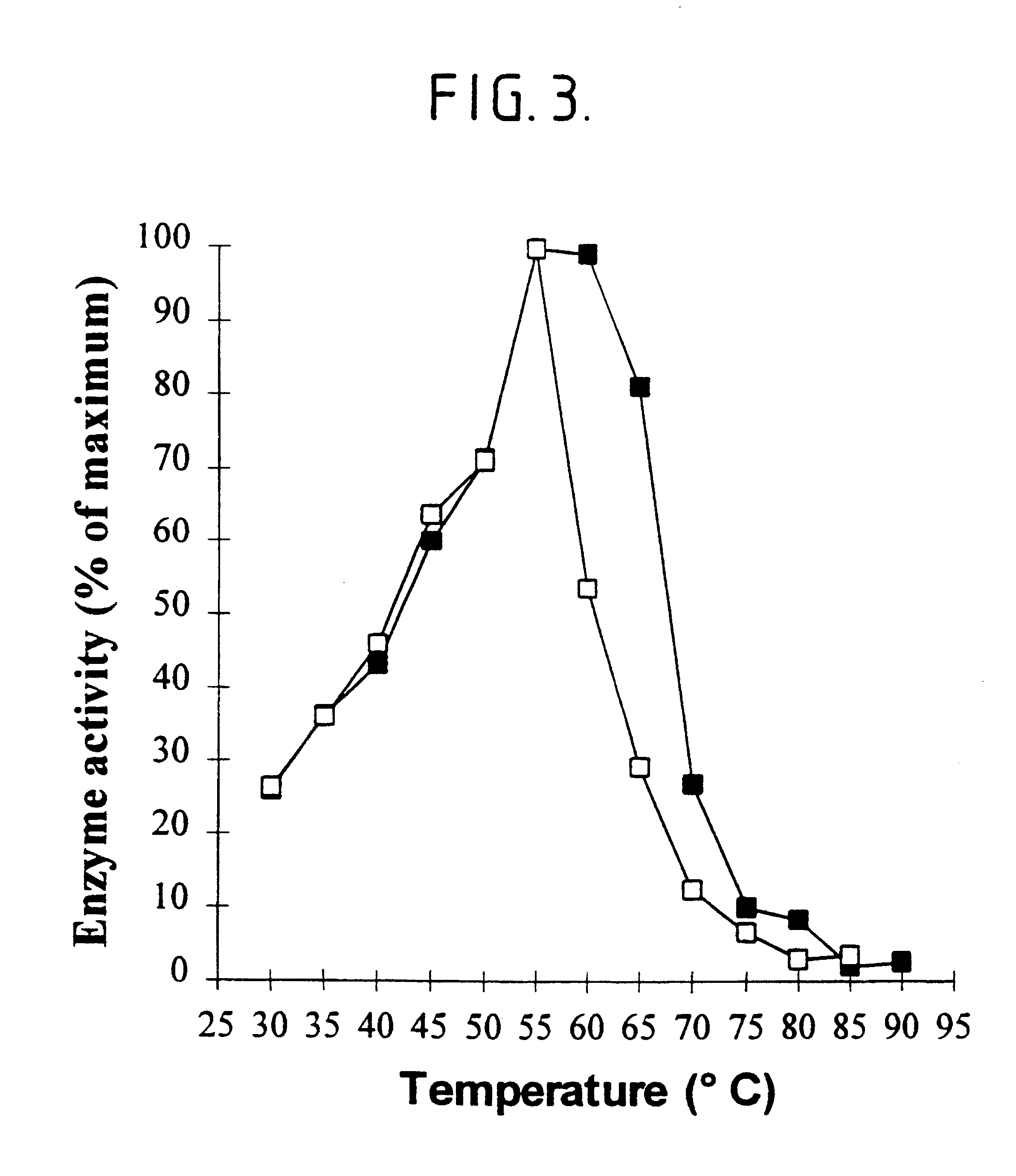

Non-maltogenic exoamylases and their use in retarding retrogradation of starch

InactiveUS6667065B1Highly effective in retarding or reducing detrimental retrogradationImprove propertiesDough treatmentHydrolasesAmylosucrase activitySide chain

The present invention relates to a process for making a bread product. The process includes the addition of a non-maltogenic exoamylase that hydrolyses starch to a starch medium, and the application of heat to the starch medium. The non-maltogenic exomylase cleaves one or more linear malto-oligosaccharides, predominantly consisting of from four to eight D-glucopyranosyl units, from non-reducing ends of amylopectin side chains. The non-maltogenic exoamylase has an endoamylase activity of less than 0.5 endoamylase units (EAU) per unit of exoamylase activity.

Owner:DUPONT NUTRITION BIOSCIENCES APS

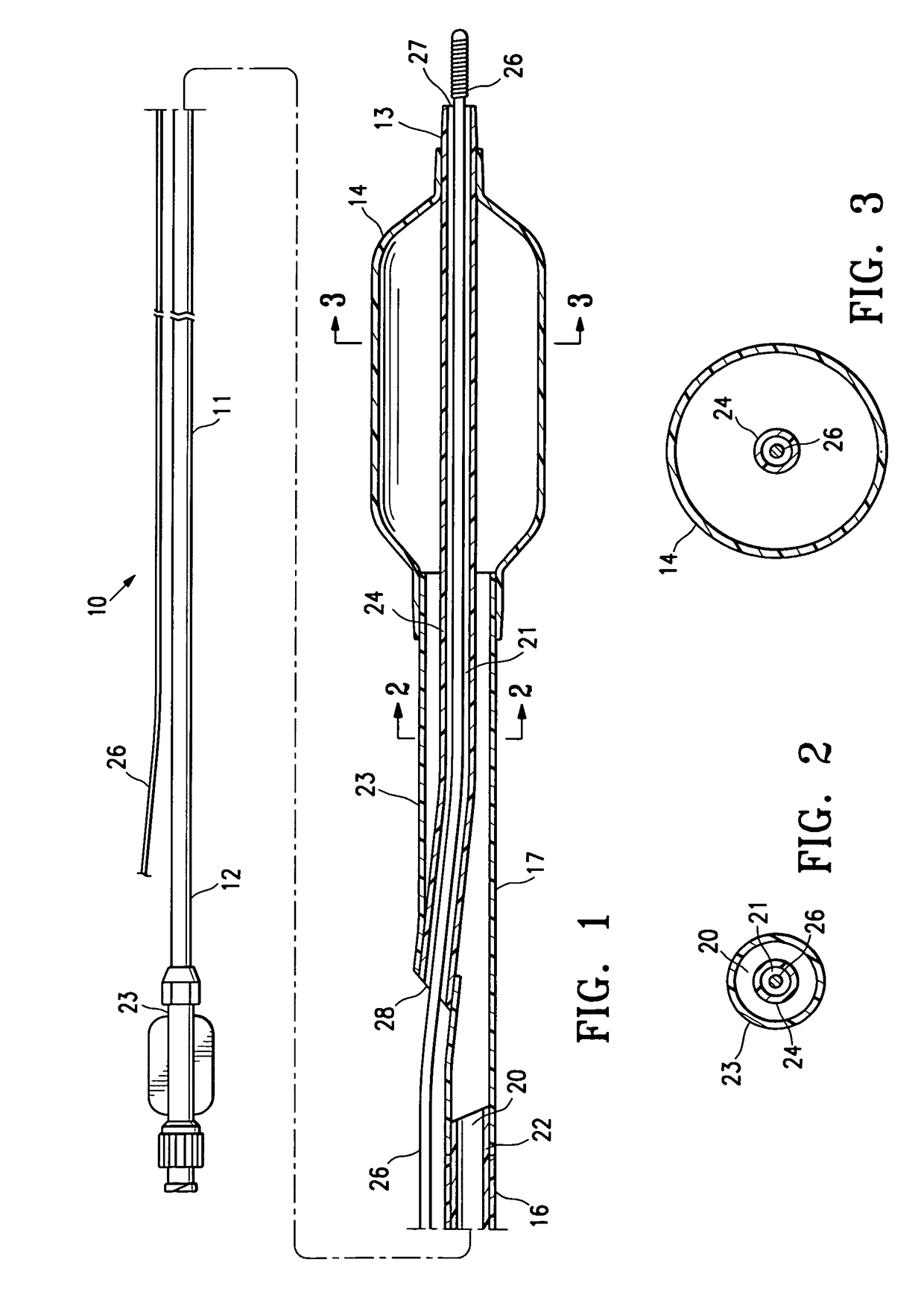

Method of making a balloon catheter shaft having high strength and flexibility

A catheter having an elongated shaft with a tubular member which forms at least a portion of the shaft and which is formed of a biaxially oriented thermoplastic polymeric material, and a method of forming the catheter shaft by radially and longitudinally expanding the tubular member to biaxially orient the polymeric material. A catheter of the invention has an improved combination of low bending stiffness, high rupture pressure, and high tensile strength, for improved catheter performance.

Owner:ABBOTT CARDIOVASCULAR

Cementitious composites having wood-like properties and methods of manufacture

InactiveUS20080099122A1Harder to saw, nail or screwLow densityPlastic recyclingLaminationPorosityBuilding product

A method of manufacturing a cementitious composite includes: (1) forming mixing an extrudable cementitious composition by first forming a fibrous mixture comprising fibers, water and a rheology modifying agent and then adding hydraulic cement; (2) extruding the extrudable cementitious composition into a green extrudate, wherein the green extrudate is characterized by being form-stable and retaining substantially a predefined cross-sectional shape; (3) removing a portion of the water by evaporation to reduce density and increase porosity; and (4) causing or allowing the hydraulic cement to hydrate to form the cementitious composite. Such a process yields a cementitious composite that is suitable for use as a wood substitute. The wood-like building products can be sawed, nailed and screwed like ordinary wood.

Owner:E KHASHOGGI INDS

Extruded fiber reinforced cementitious products having wood-like properties and ultrahigh strength and methods for making the same

InactiveUS20100136269A1High yield stressImmediate form stabilityLayered productsPlastic recyclingPorosityFlexural strength

A method of manufacturing a cementitious composite including: (1) mixing an extrudable cementitious composition by first forming a fibrous mixture comprising fibers, water and a rheology modifying agent and then adding hydraulic cement; (2) extruding the extrudable cementitious composition into a green extrudate, wherein the green extrudate is characterized by being form-stable and retaining substantially a predefined cross-sectional shape; (3) removing a portion of the water by evaporation to reduce density and increase porosity; and (4) heating the green extrudate at a temperature from greater than 65° C. to less than 99° C. is disclosed. Such a process yields a cementitious composite that is suitable for use as a wood substitute. Particularly, by using higher curing temperatures for preparing the cementitious building products, the building products have a lower bulk density and a higher flexural strength as compared to conventional products. The wood-like building products can be sawed, nailed and screwed like ordinary wood.

Owner:E KHASHOGGI INDS

Thermoplastic resin composition and elastomer composition

Provided are a thermoplastic resin composition which is excellent in oil resistance, heat resistance, weatherability, impact resistance, transparency, and moldability, and which can be produced economically, an elastomer composition with low hardness and high tensile strength which is excellent in oil resistance and compression set, and a molded object produced by molding the thermoplastic resin composition or elastomer composition. The composition is produced by compounding a thermoplastic resin or an elastomer with a block copolymer having at least one methacrylic ester polymer block and at least one acrylic ester polymer block. Also provided are a process for producing a methacrylic ester-acrylic ester-methacrylic ester block copolymer which requires hardly any purification, which is excellent in heat resistance and weatherability, and in which the molecular weight and the molecular-weight distribution are controlled, and a methacrylic ester-acrylic ester-methacrylic ester block copolymer produced by the process.

Owner:KANEKA CORP

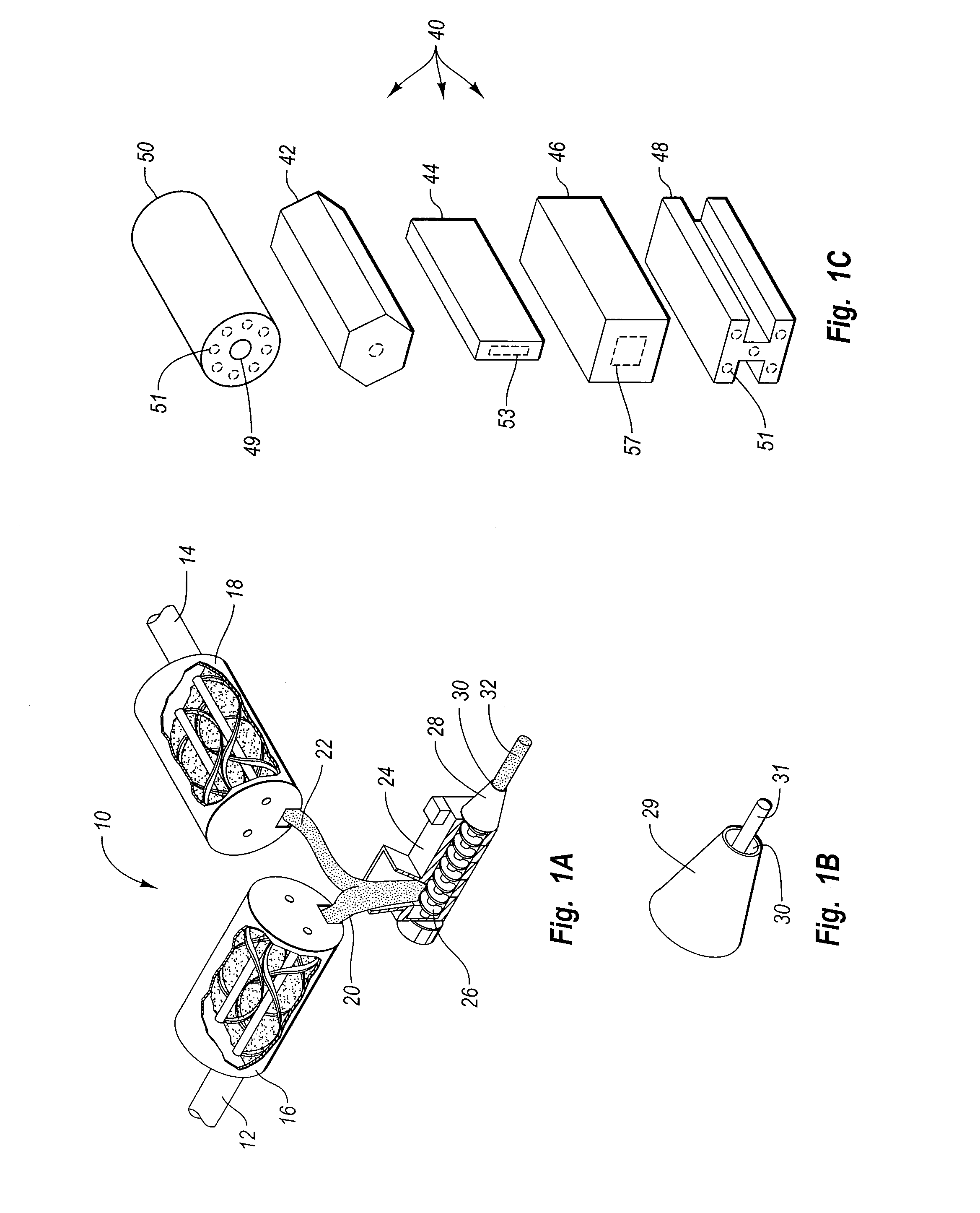

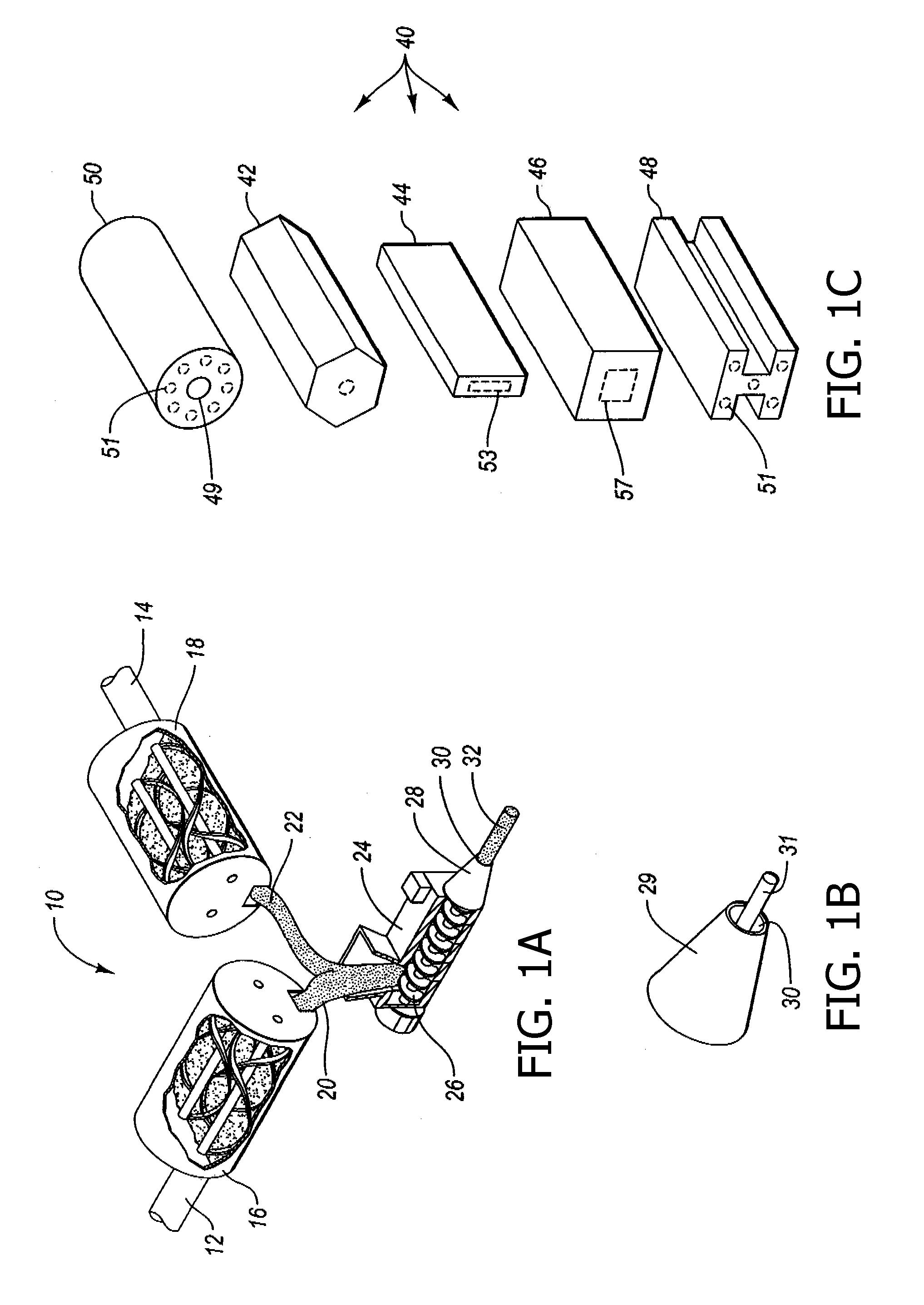

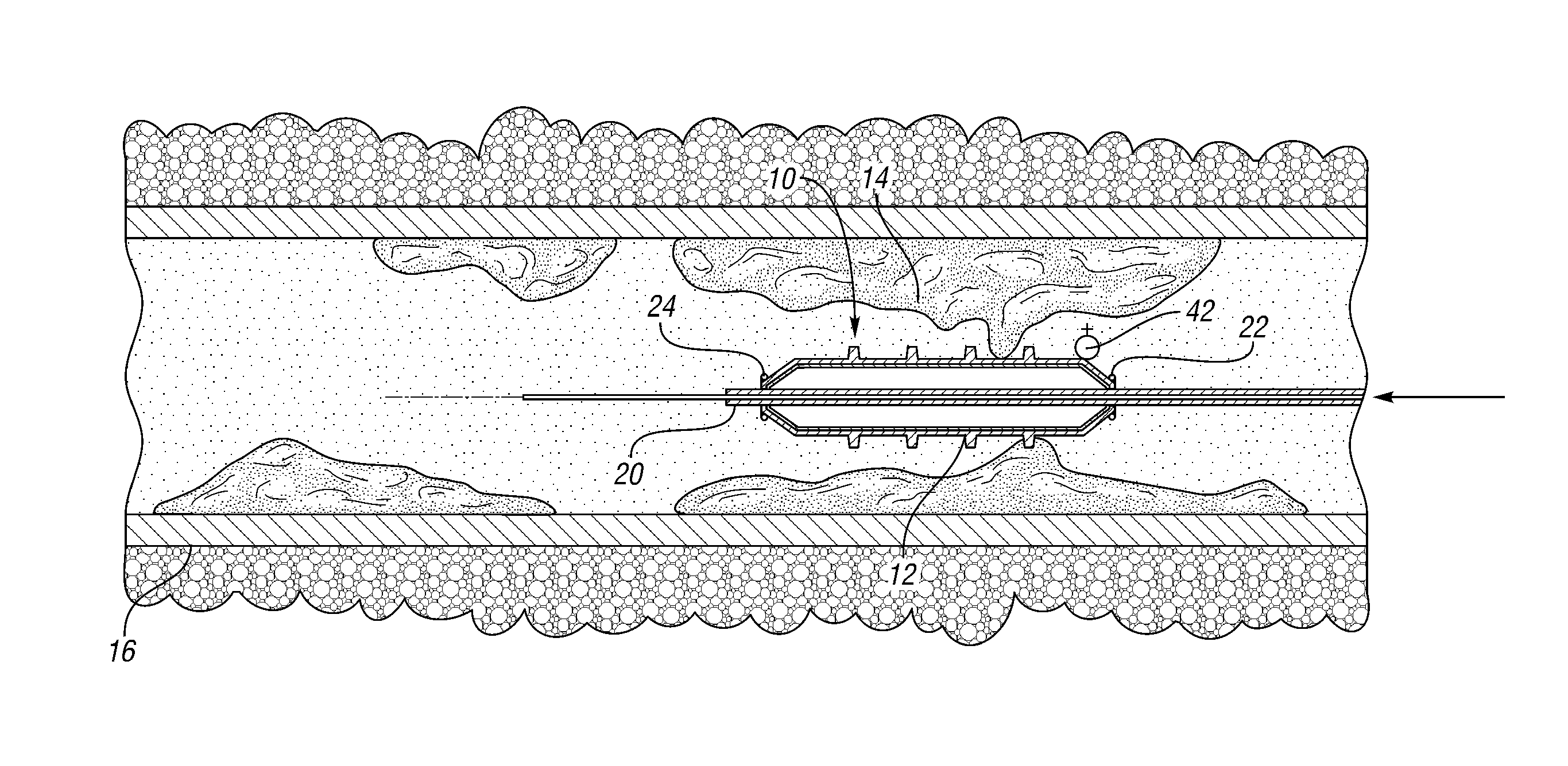

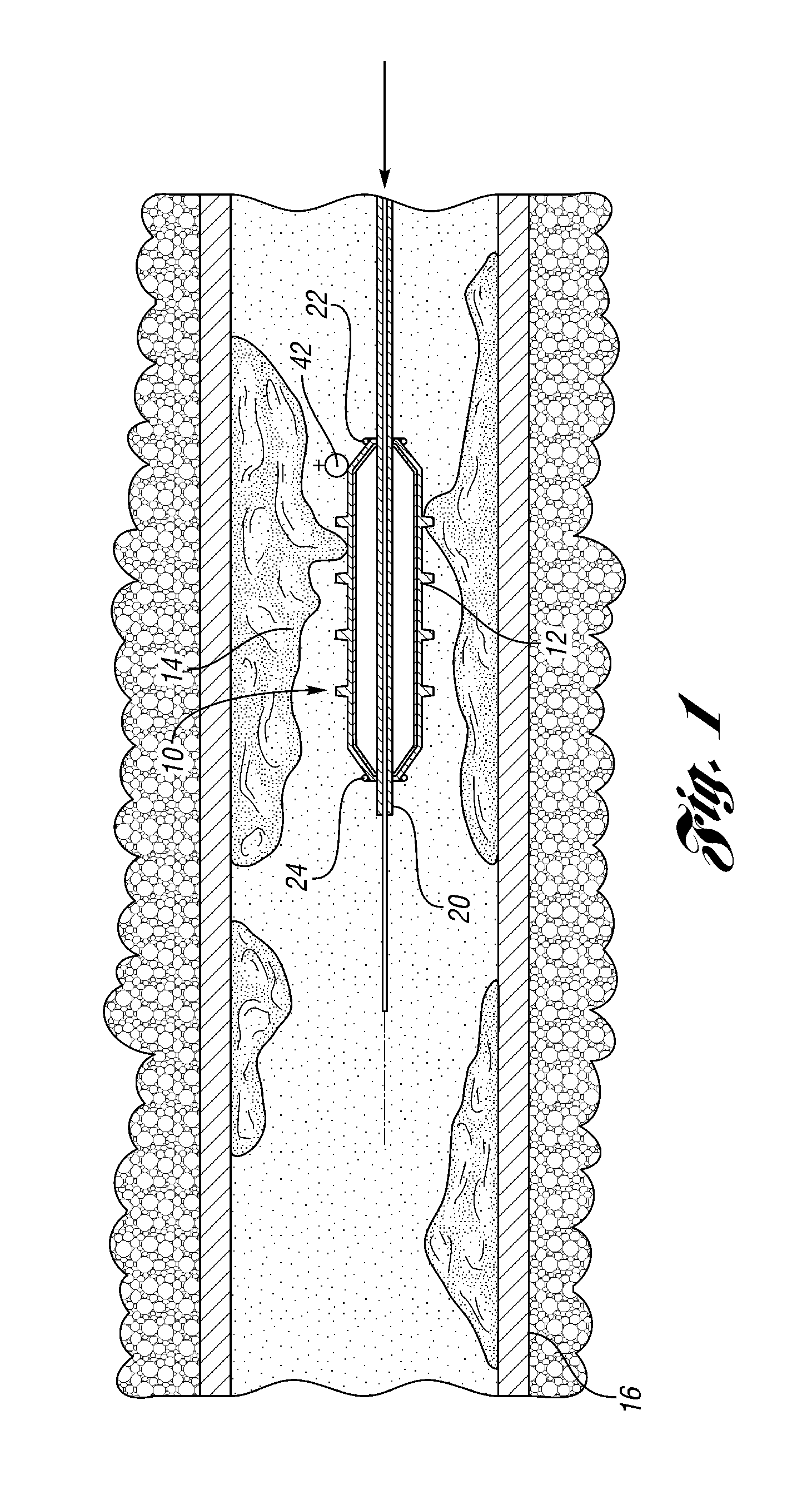

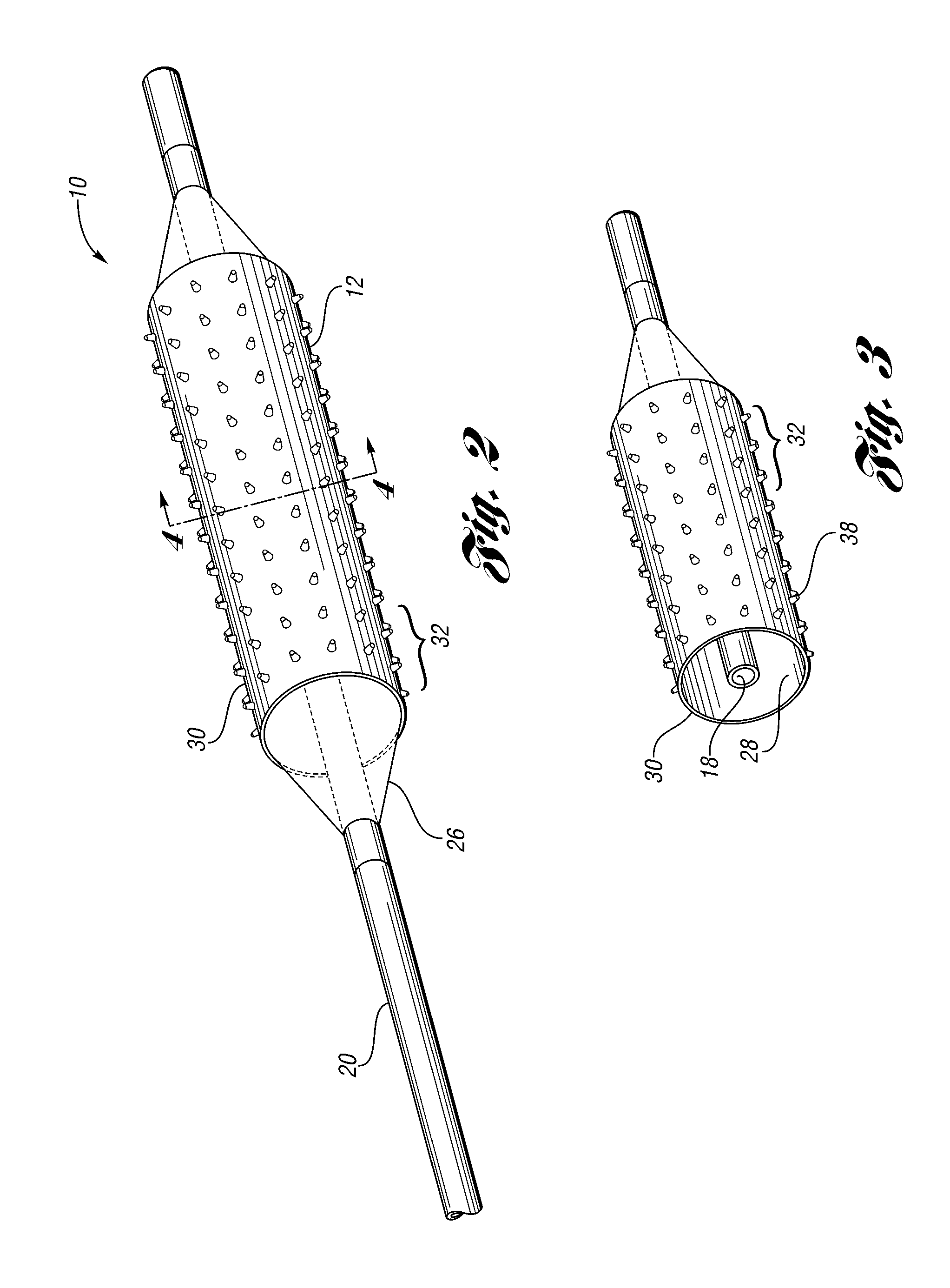

Catheter system with balloon-mounted plaque-modifying elements

A plaque-modifying balloon and method for use in an endovascular procedure includes an elongated balloon that defines a longitudinal axis and is inflatable from a first deflated configuration to a second radially expanded configuration. One or more plaque-modifying elements are mounted on the outside of the inflatable balloon. Optionally, a compressible sheath made of a relatively low durometer, flexible material is mounted on the balloon to cover the elements during transit of the plaque-modifying balloon to and from the treatment site.

Owner:KASSAB KUGHN ENDOVASCULAR DEVICES

Oral cavity disintegrating tablet and method of producing the same

ActiveUS20100278930A1Easy to produceDisintegrates quicklyBiocideOrganic active ingredientsSucroseOrally disintegrating tablet

The invention provides an orally disintegrating tablet containing (a) one or more saccharides or sugar alcohols selected from the group consisting of mannitol, lactose, xylitol, sucrose, erythritol and glucose and (b) low substituted hydroxypropylcellulose and substantially free of a starch disintegrant, which tablet is produced by steps of granulating a composition containing the above-mentioned components (a) and (b) by an agitation granulation method, and compression-molding the obtained granulation product. The invention also provides a method of producing an orally disintegrating tablet substantially free of a starch disintegrant, including steps of granulating a composition containing the above-mentioned components by an agitation granulation method, and compression-molding the obtained granulation product.

Owner:SAWAI PHARMA

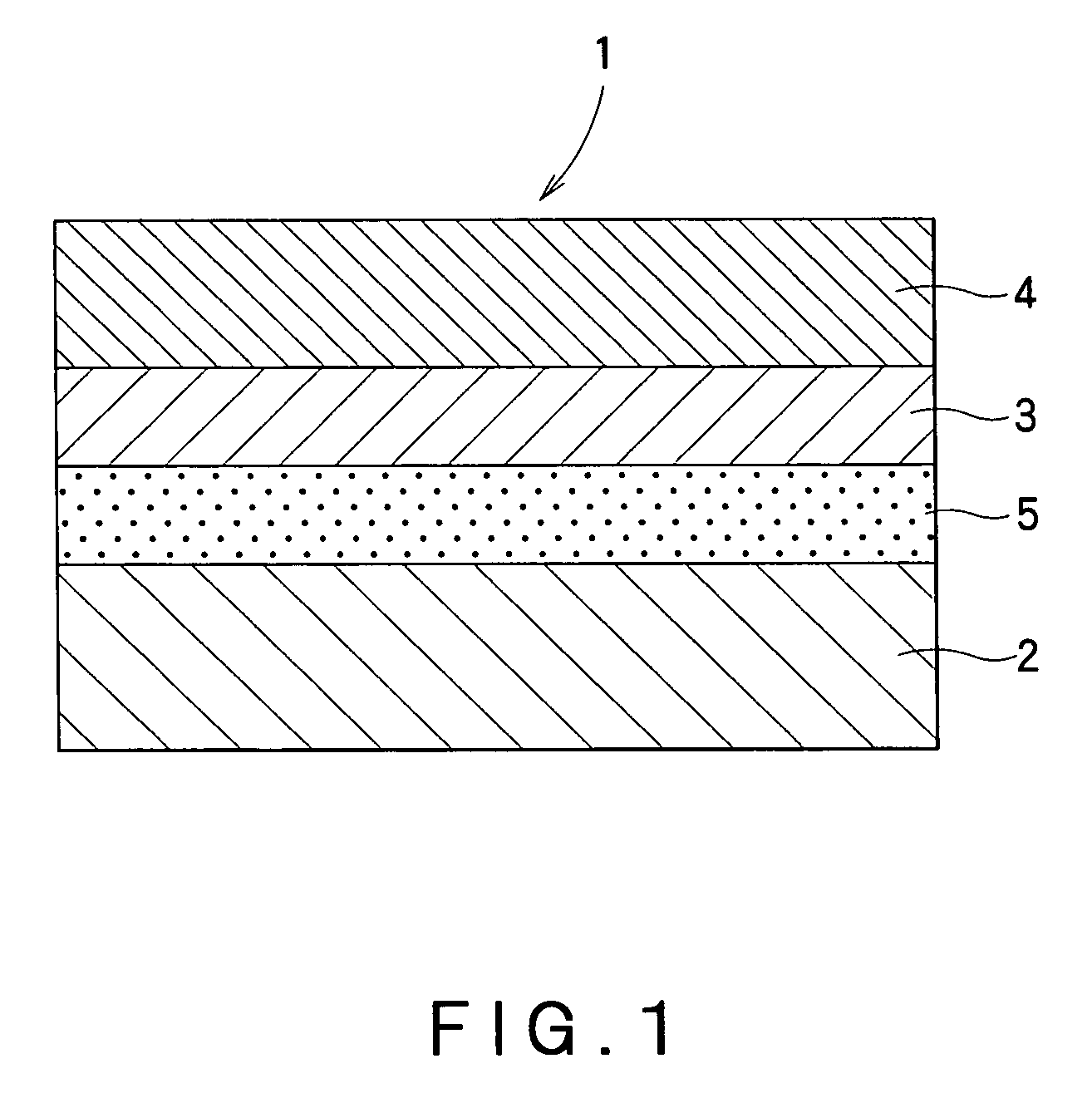

Antireflection laminate

InactiveUS20060269733A1Improve mechanical strengthLow refractive indexSynthetic resin layered productsPretreated surfacesPolymer chemistryRefractive index

There is provided an antireflective laminate having a low refractive index and excellent mechanical strength, which comprises a coating layer of an ionizing radiation curing-type resin composition comprising ionizing radiation curing group-containing hollow silica fine particles. The antireflective laminate comprises a light transparent base material and at least a low refractive index layer having a refractive index of not more than 1.45 provided on the light transparent base material, wherein the low refractive index layer comprises an ionizing radiation curing-type resin composition and silica fine particles having an outer shell layer with the interior of the silica fine particles being porous or void, and, for a part or all of the silica fine particles, at least a part of the surface of the silica fine particle has been treated with an ionizing radiation curing group-containing silane coupling agent.

Owner:JGC CATALYSTS & CHEM LTD +1

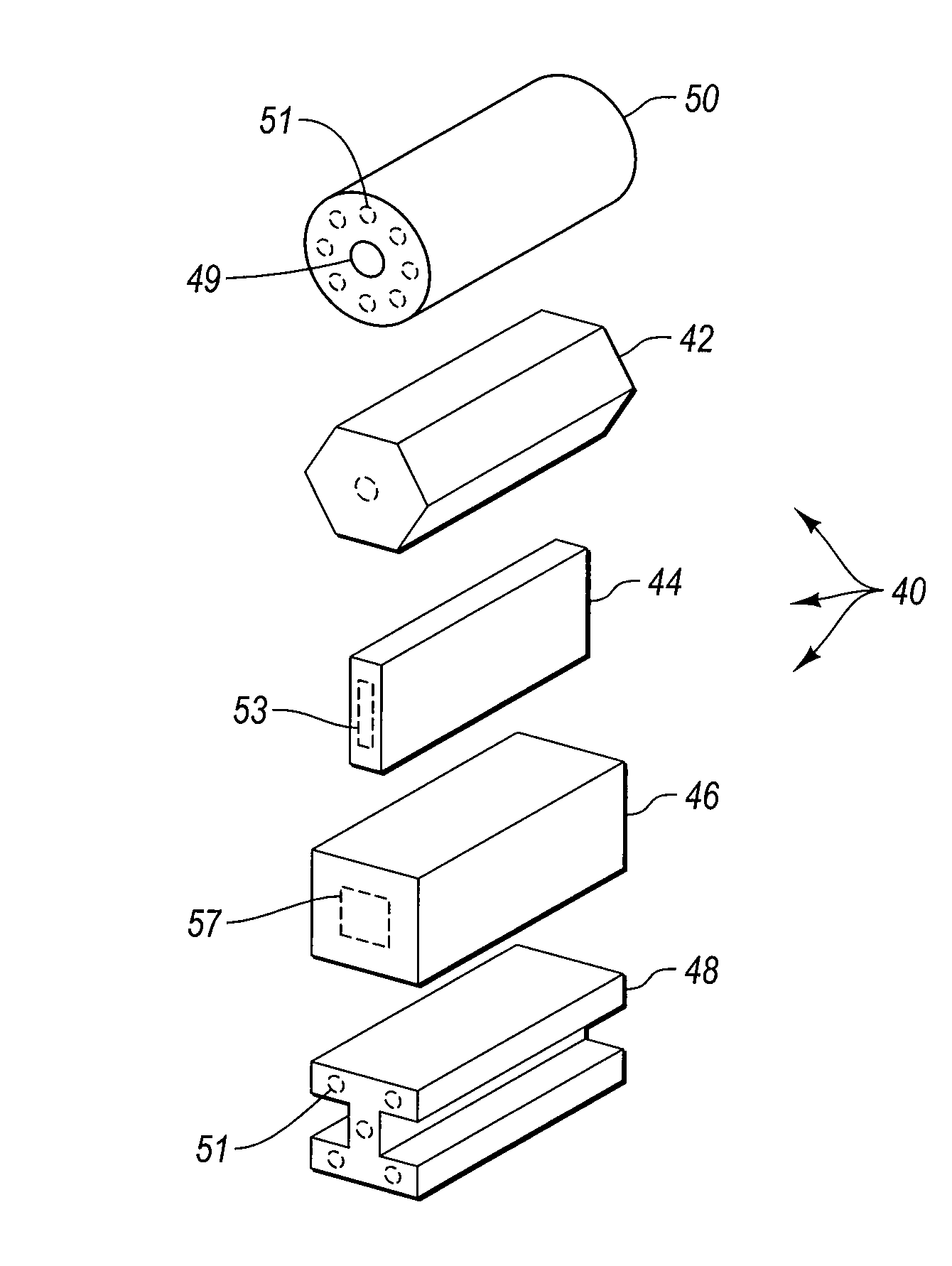

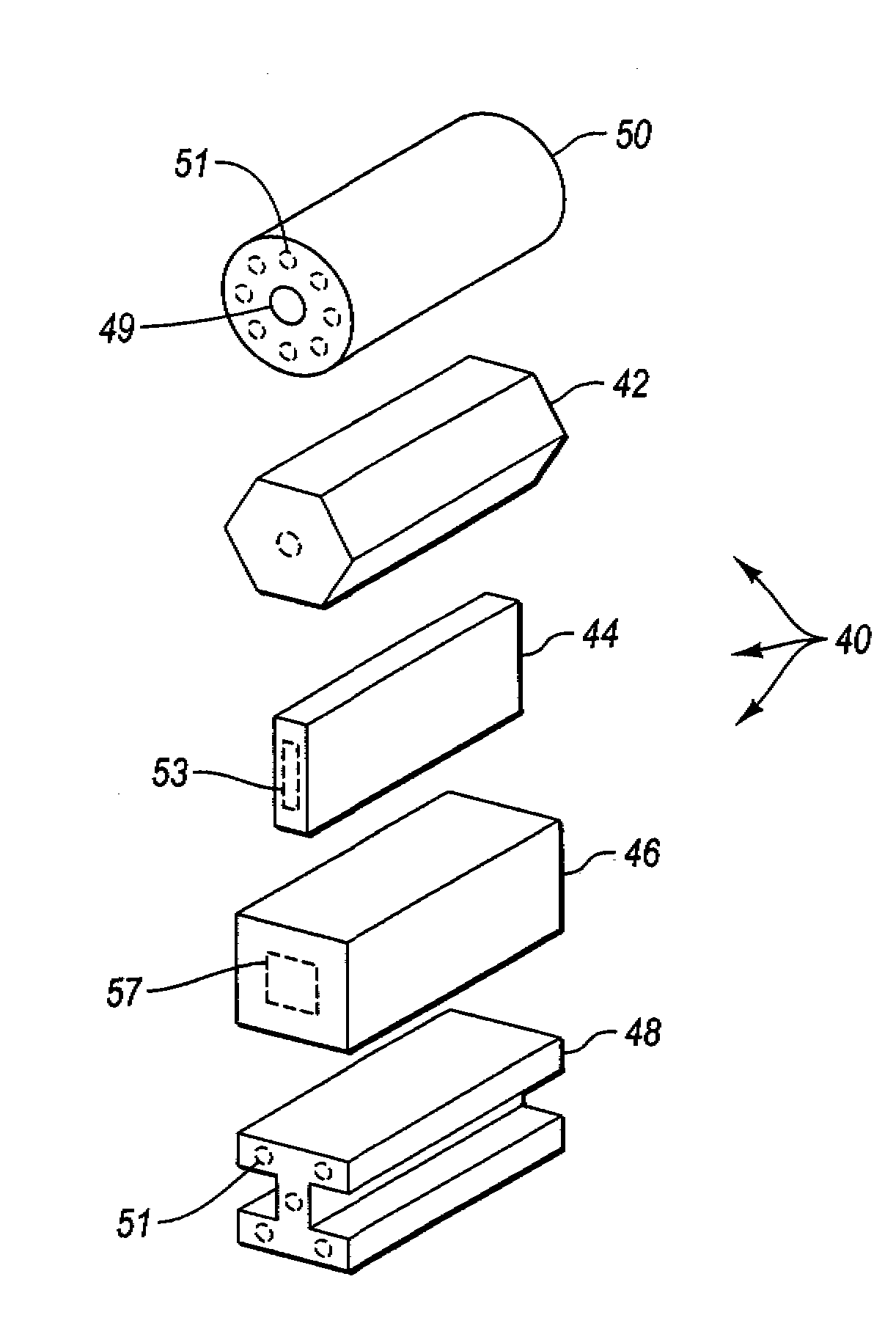

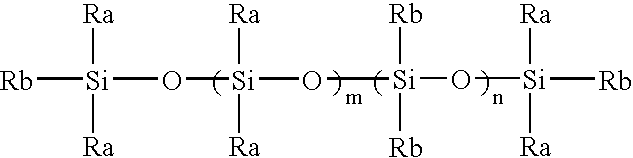

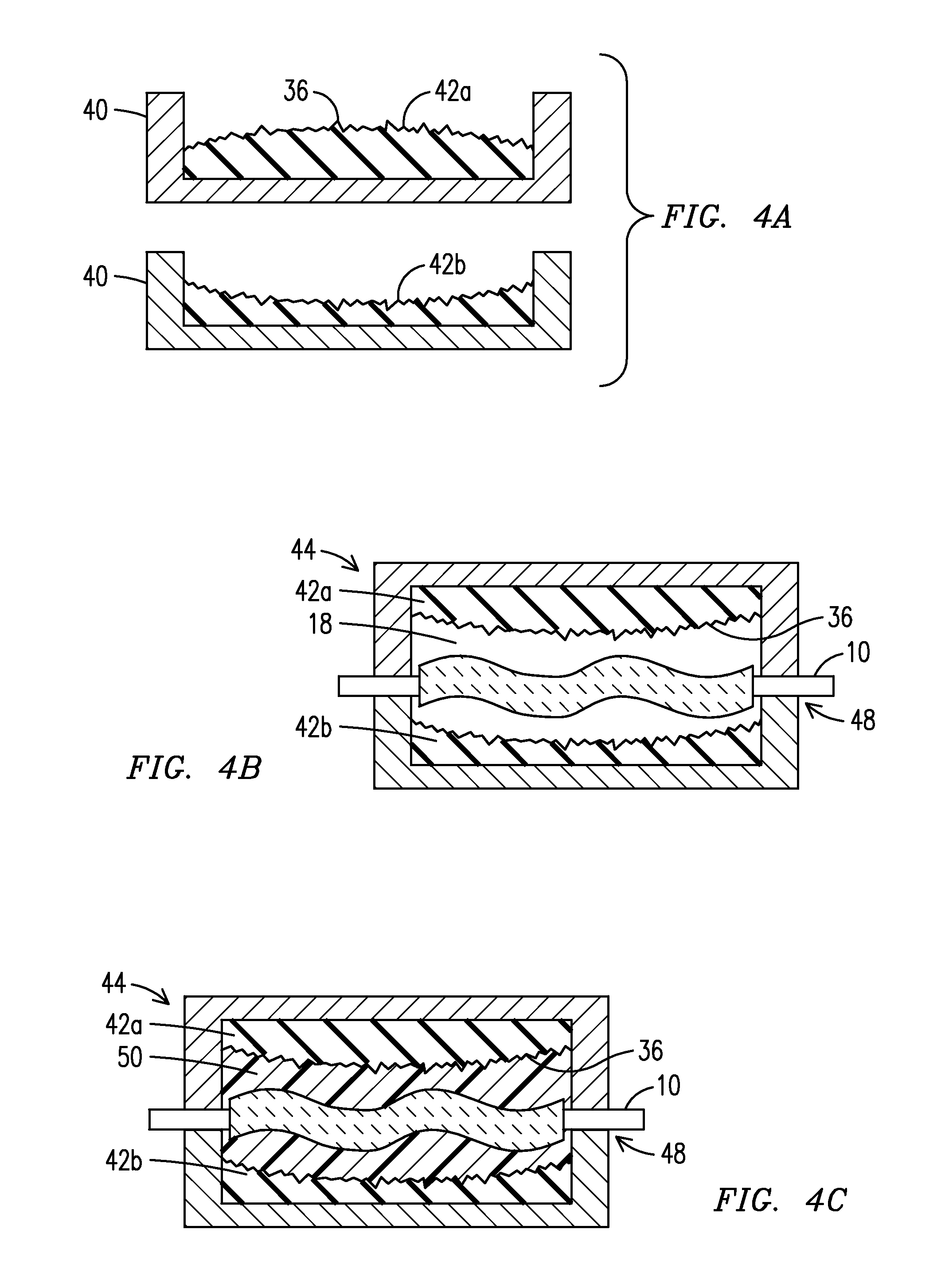

Investment casting utilizing flexible wax pattern tool for supporting a ceramic core along its length during wax injection

InactiveUS20130333855A1Reducing incidence of damage and movementIncrease pressureFoundry mouldsFoundry coresInjection pressureInvestment casting

An investment casting process wherein the wax pattern tool (42) is flexible to provide compliant support for an enclosed ceramic core (10) and to facilitate removal of the tool from the cast wax pattern (52) even when the cast shape would otherwise require multiple pull planes. Positioning pins (106) may extend from the flexible tool to make compliant contact against the core during the wax injection step. The pins may cooperate with a pedestal (128) formed on the core to support the core along multiple axes during wax injection, thereby allowing a higher wax injection pressure without damage to the core.

Owner:MIKRO SYSYTEMS INC +1

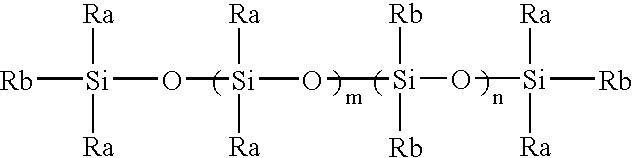

Thermoplastic elastomer composition

The present invention relates to a soft thermoplastic elastomer composition that is free of thermoplastic resin that can be utilized in manufacturing shoe sole inserts, seals, gaskets, wheels, and that can be overmolded on a hard substrate, such as a metal or a thermoplastic resin, for grips or handles on various household items. The present invention more specifically discloses a thermoplastic elastomer composition that is made by a process comprising: (1) mixing (A) a block copolymer comprising a first polymeric block that is comprised of repeat units that are derived from a vinyl aromatic monomer and a second block that is comprised of repeat units that are derived from a conjugated diolefin monomer, wherein the repeat units in the second block are hydrogenated, and wherein the repeat units in the second block are elastomeric in nature, (B) a crosslinkable elastomer, and (C) an oil, to produce an un-crosslinked three component blend; and (2) dynamically crosslinking the crosslinkable elastomer in the un-crosslinked three component blend during a thermo-mechanical mixing step; wherein the thermoplastic elastomer composition is void of thermoplastic resins.

Owner:THE GOODYEAR TIRE & RUBBER CO +1

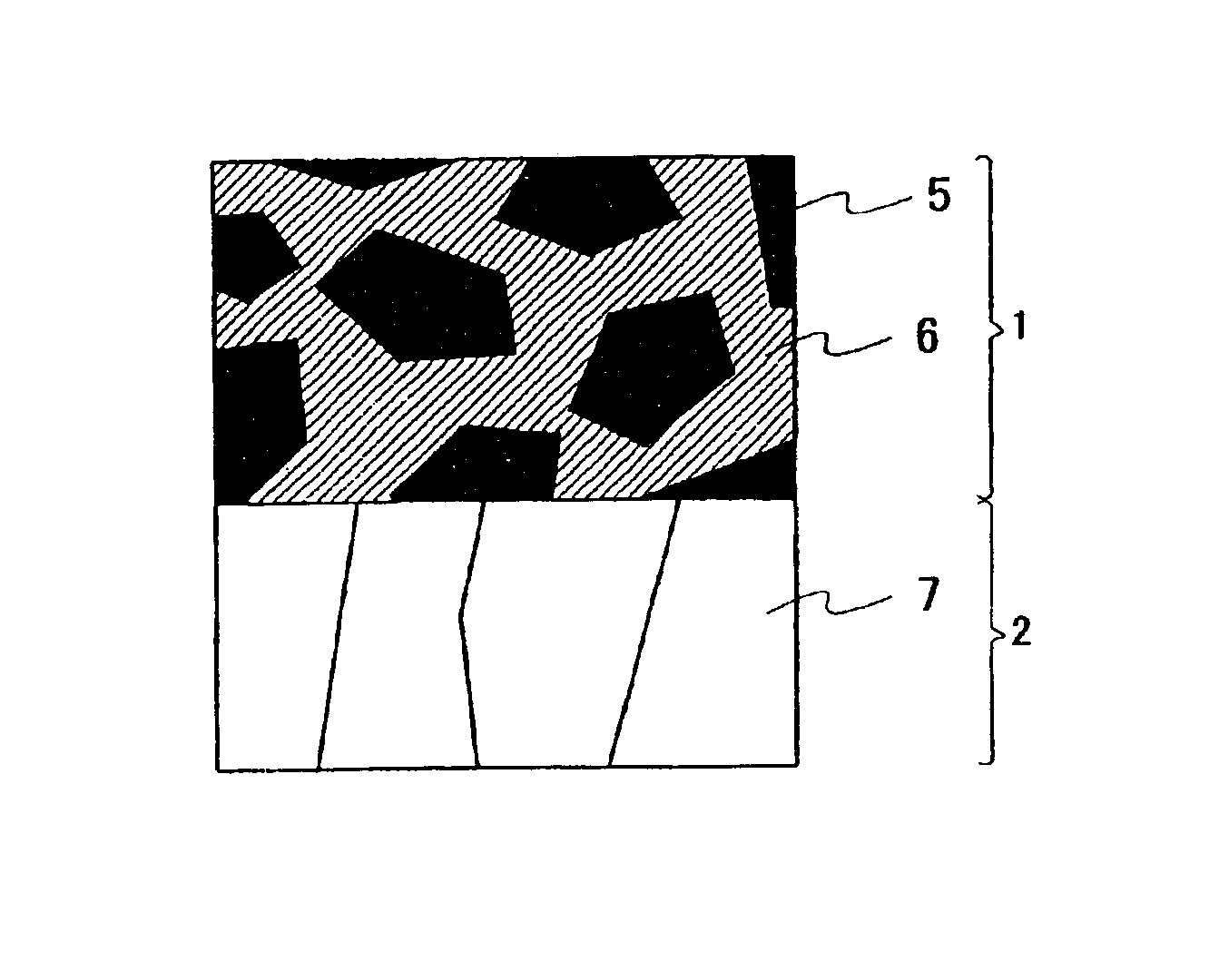

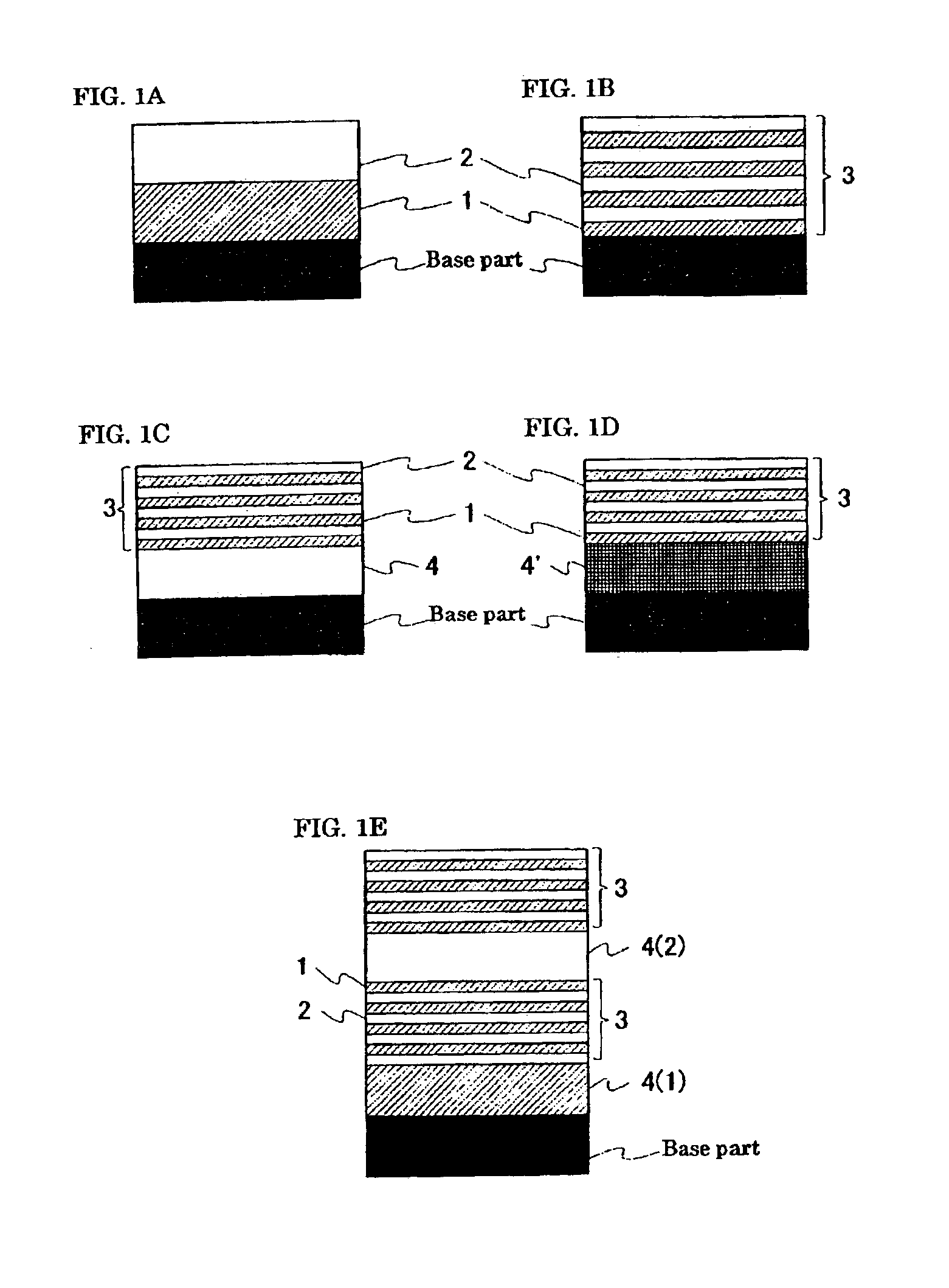

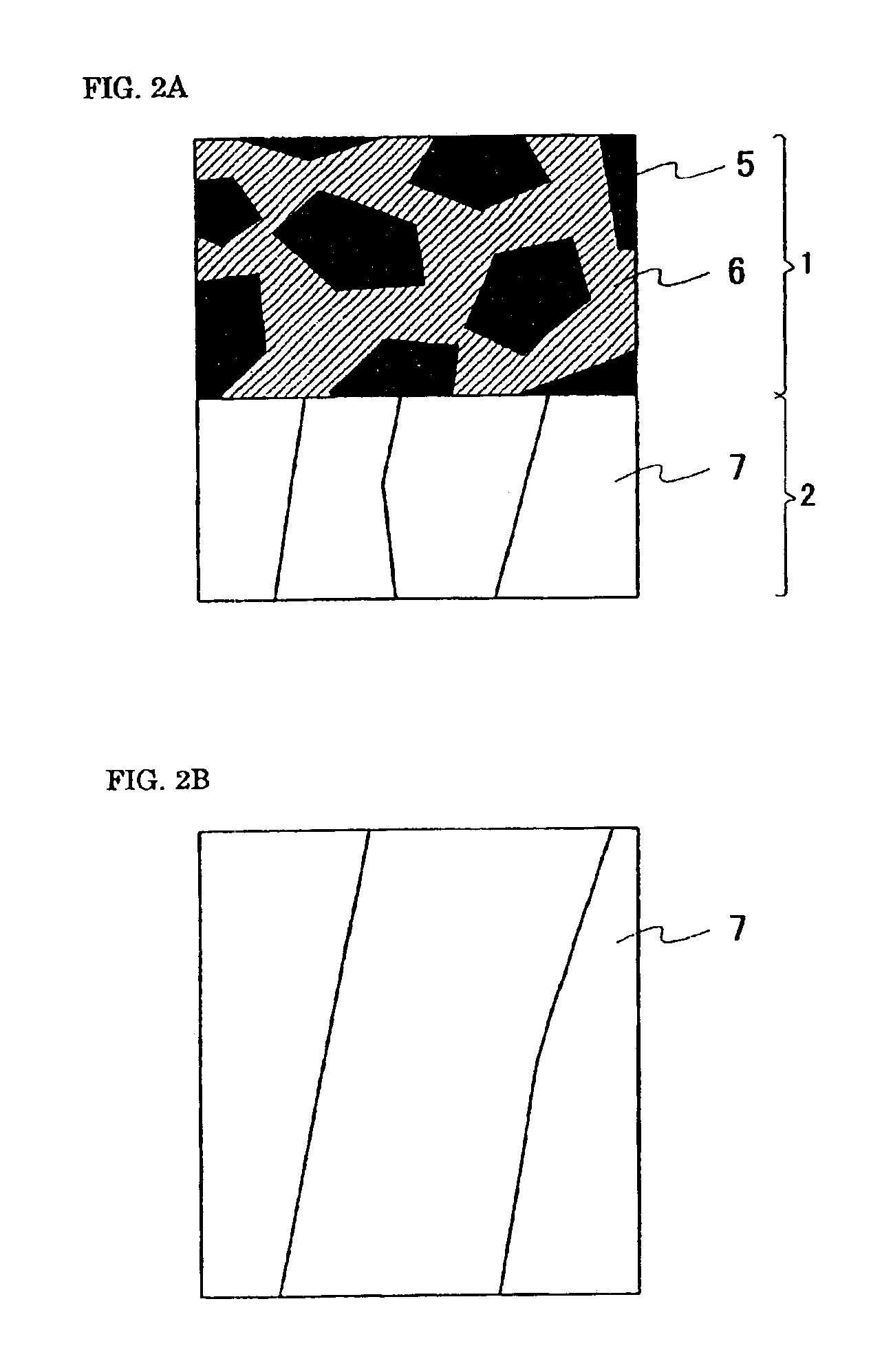

Coated tool

ActiveUS7060345B2High hardnessImprove wear resistancePigmenting treatmentMilling cuttersCarbideNitrogen oxide

Coating-film furnished coated tools that are lubricative while maintaining resistance to wear are realized by coated tools in which a plurality of coating films is furnished on a base part. Furnished as the coating are one or more layers of, respectively: a first film composed of one compound selected from nitrides, carbides, carbonitrides, oxynitrides and carboxynitrides of TiSi; and a second film composed of one compound selected from nitrides, carbides, carbonitrides, oxynitrides and carboxynitrides of one metal M selected from Ti, Cr, and TiCr. The first film and the second film are laminated in alternation.

Owner:SUMITOMO ELECTRIC IND LTD

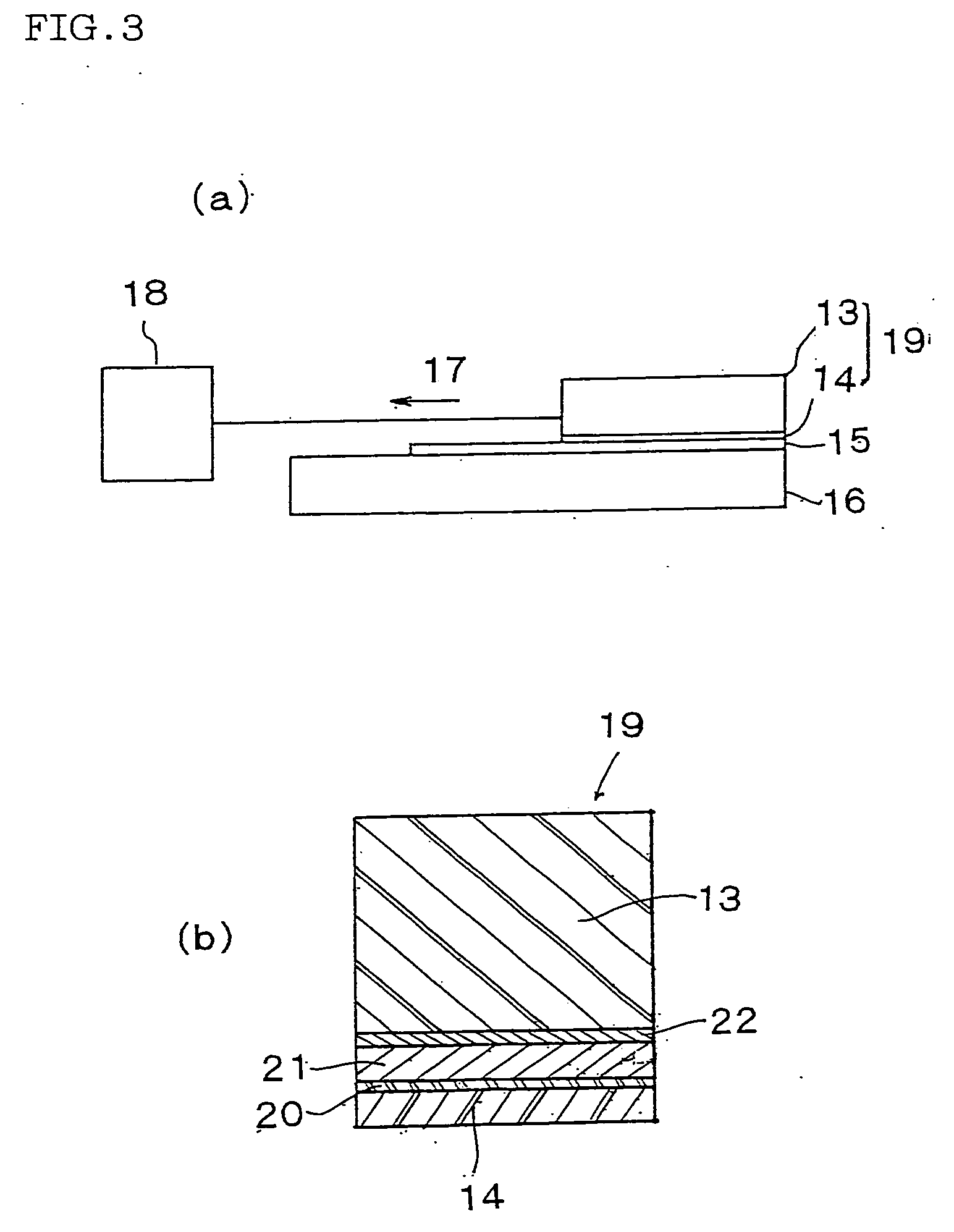

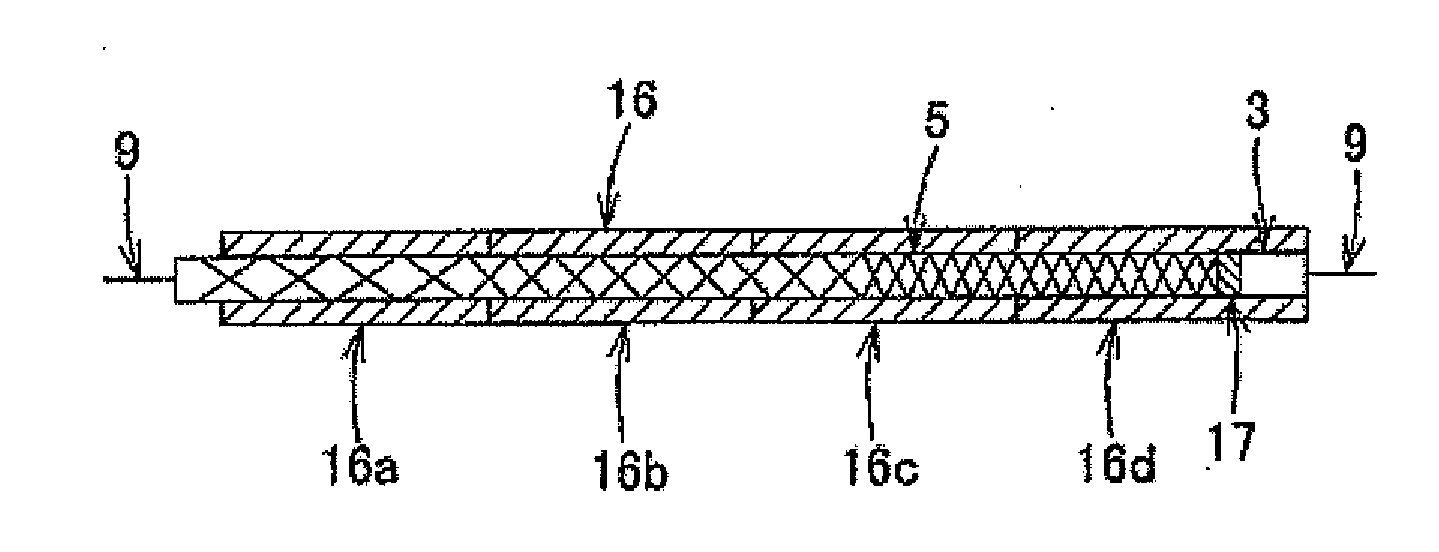

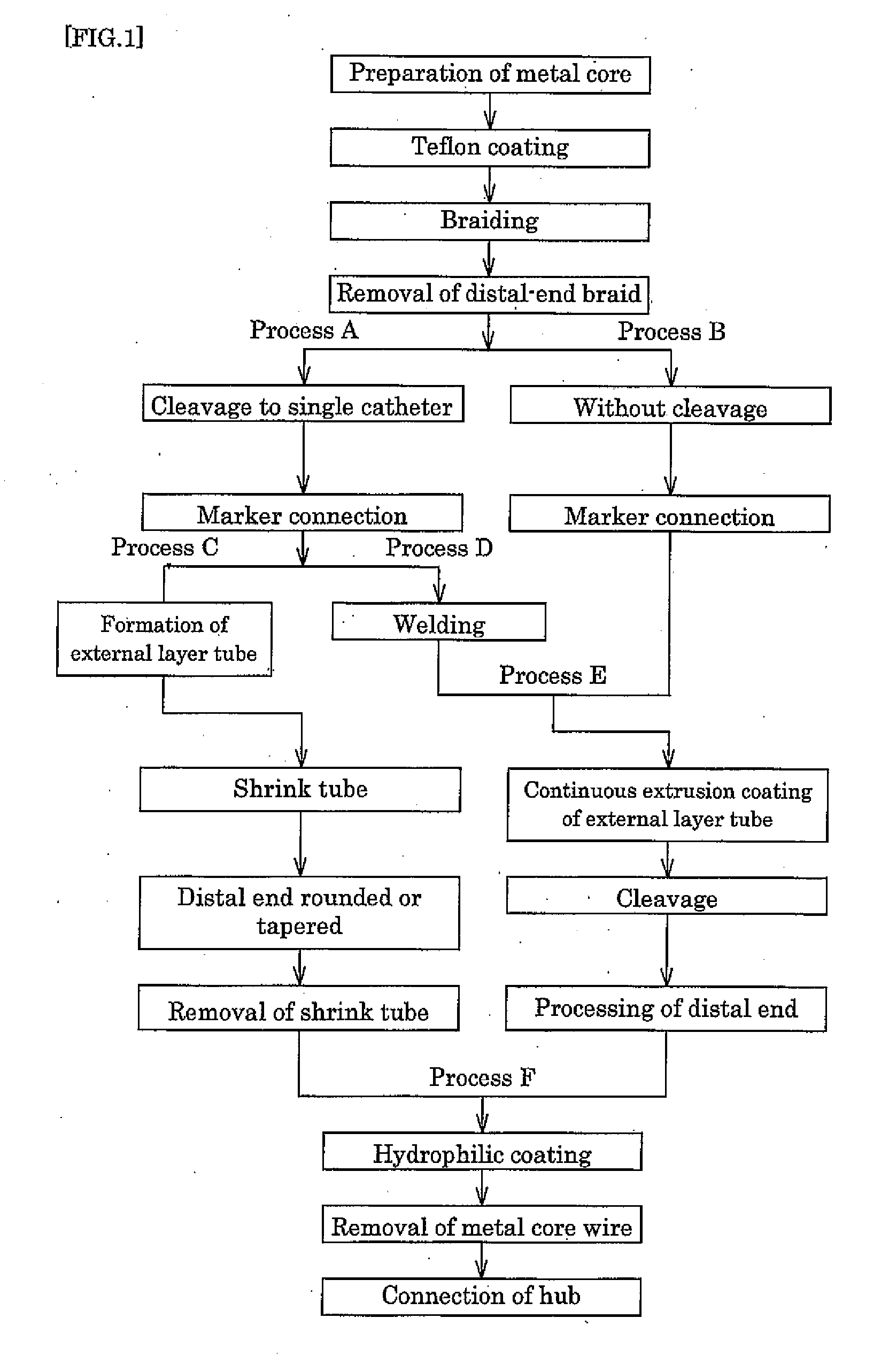

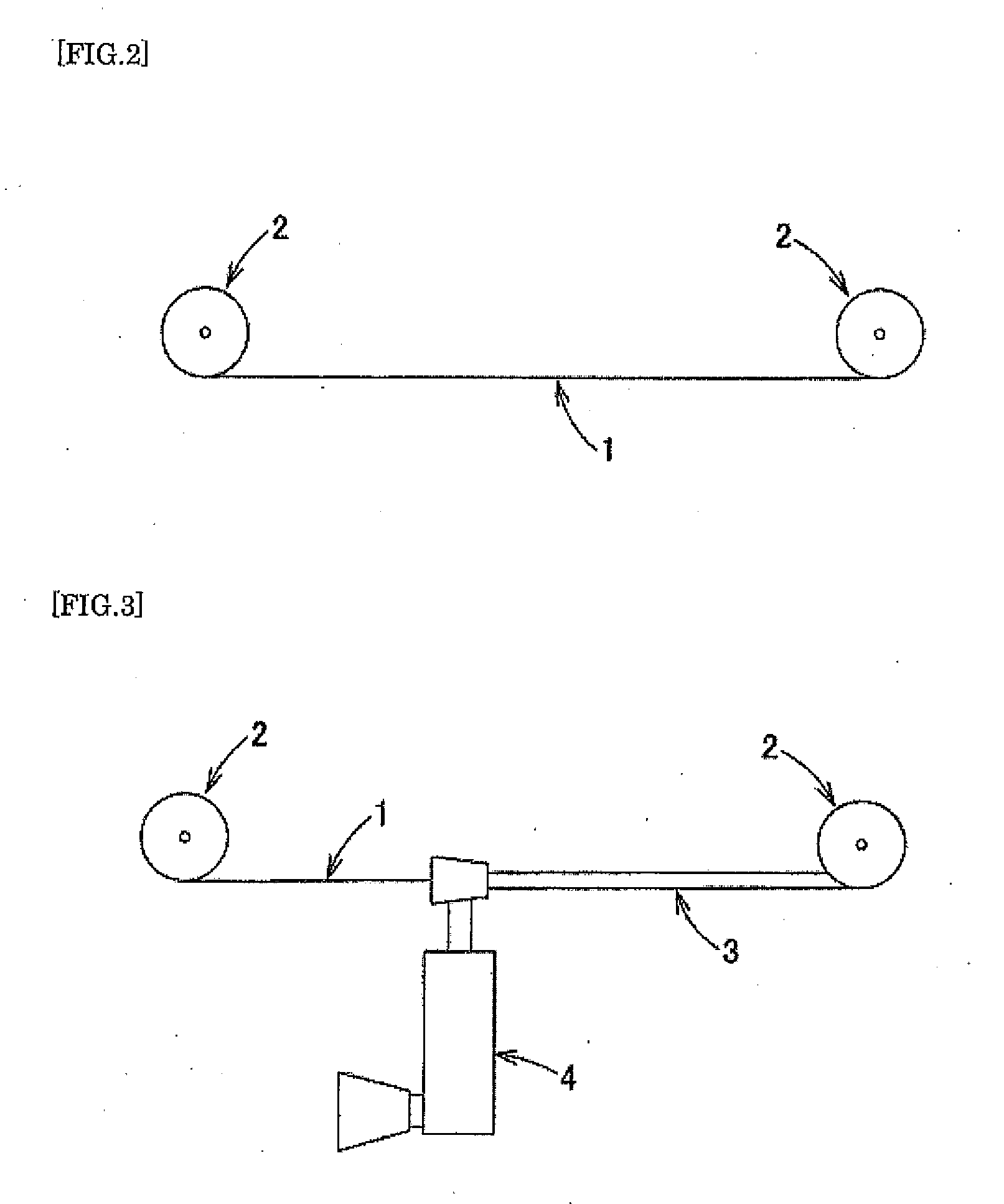

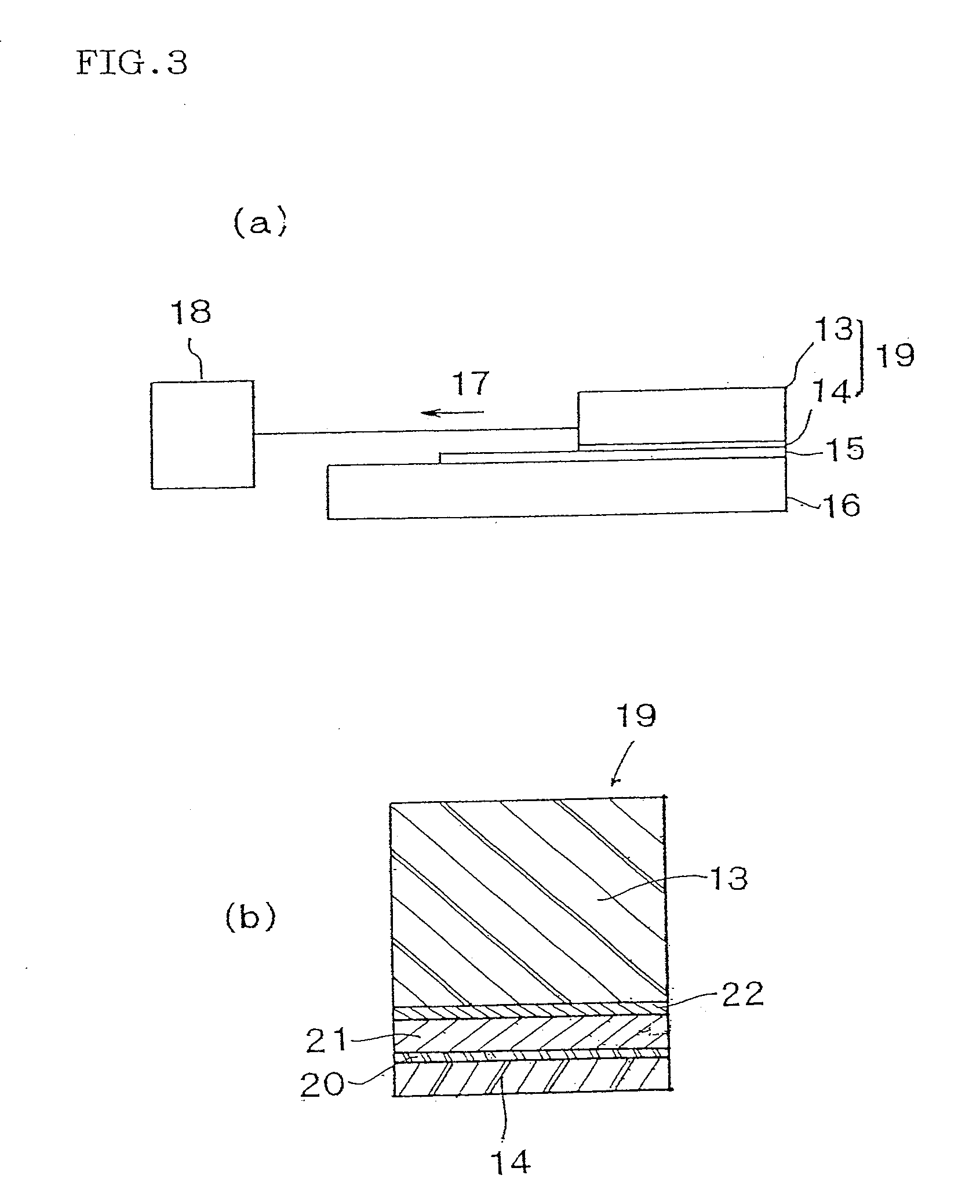

Medical catheter tube and process for producing the same

InactiveUS20090240235A1Precise positioningIncrease freedomGlovesPretreated surfacesCatheterBiomedical engineering

There is provided a medical catheter tube capable of exhibiting excellent flexibility, and provided a process for producing the same. In particular, there is provided a medical catheter tube having, arranged from a base edge side, a base part, a forefront part and a cutting edge part The medical catheter tube comprises an inner layer tube of resin pipe; a reinforcing material layer produced by knitting of a wire around the inner layer tube; a marker disposed by winding and covering of the inner layer tube at the forefront part with a roentgenopaque metal member; and an outer layer tube of resin pipe covering the reinforcing material layer and the marker. The inner layer tube, reinforcing material layer, marker and outer layer tube of the medical catheter tube are united together.

Owner:KANEKA CORP

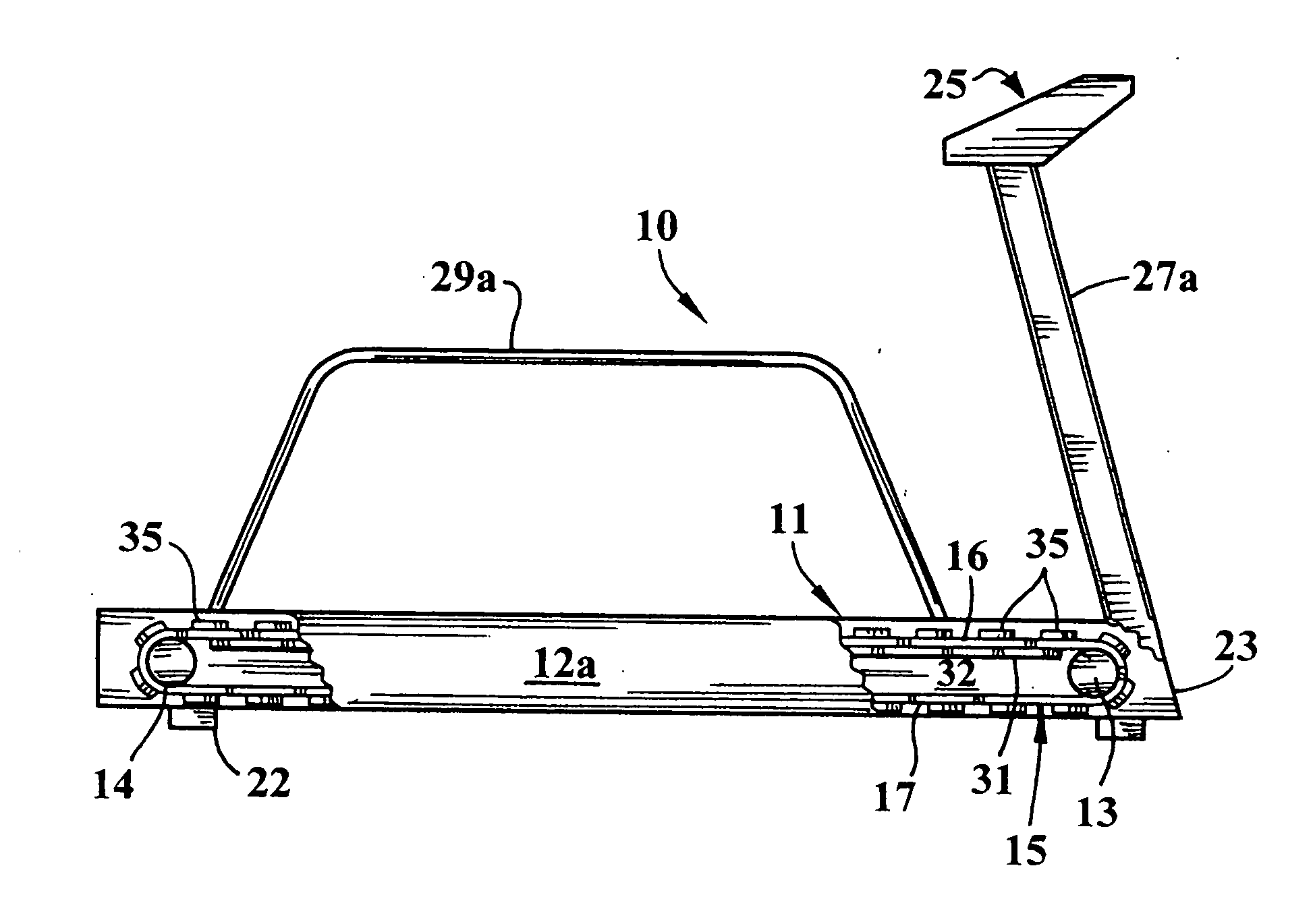

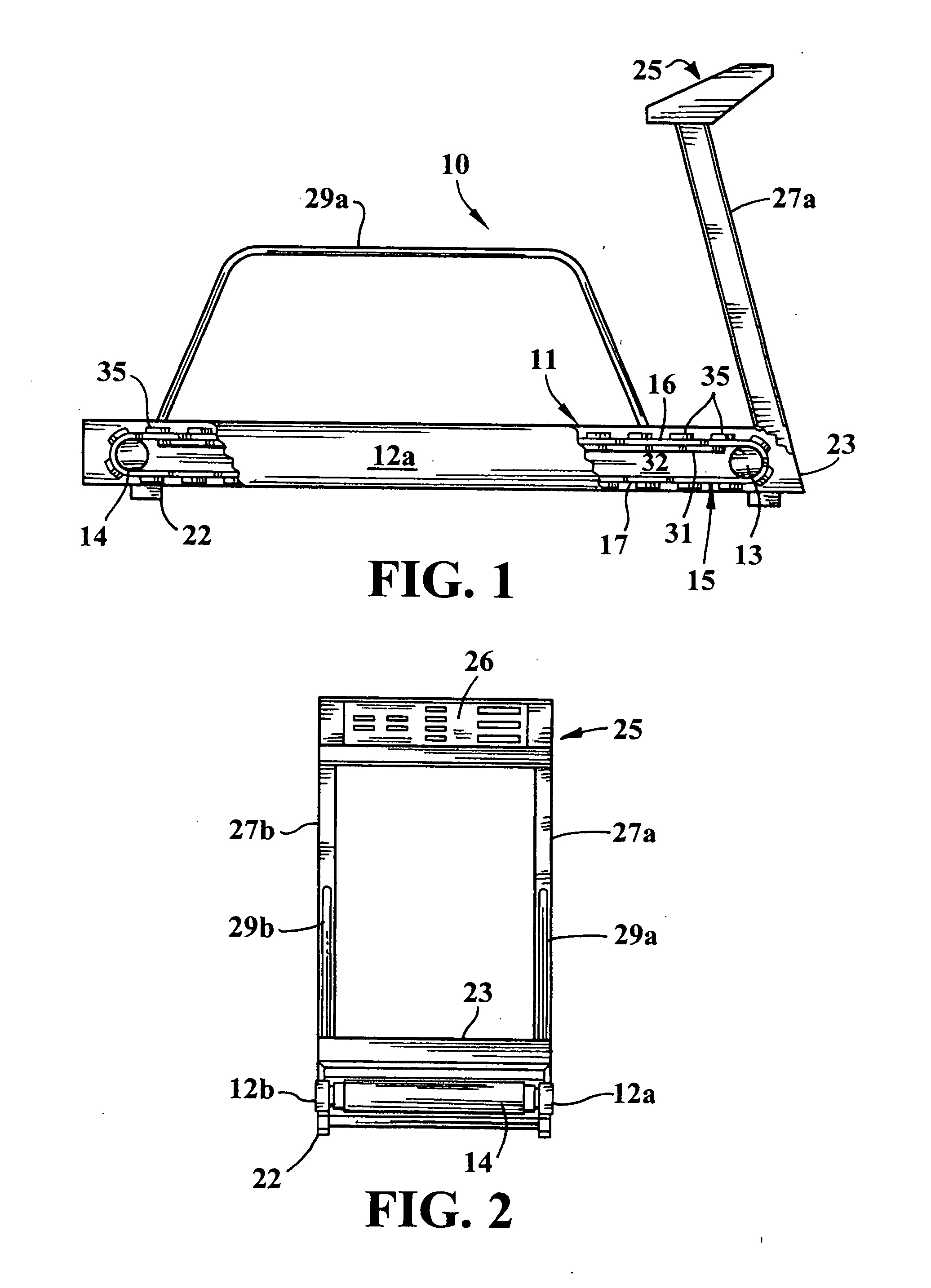

Surface-modified exercise belt for a treadmill

InactiveUS20070298937A1Safely strengthenAvoid hard impactTherapy exerciseMovement coordination devicesTerrainHardness

An exercise belt for a treadmill is provided having a modified surface that simulates natural ground terrain for the purpose of strengthening the muscles of the exerciser's ankles. The modified surface is produced by regions of variable effective thickness which may be protrusions or attached pads of varied shape, thickness, hardness and spacing. In another aspect, a kit is provided having a large number of pads of varied shape, thickness and hardness adhesively attachable to the belt.

Owner:SHAH ASHOK H +1

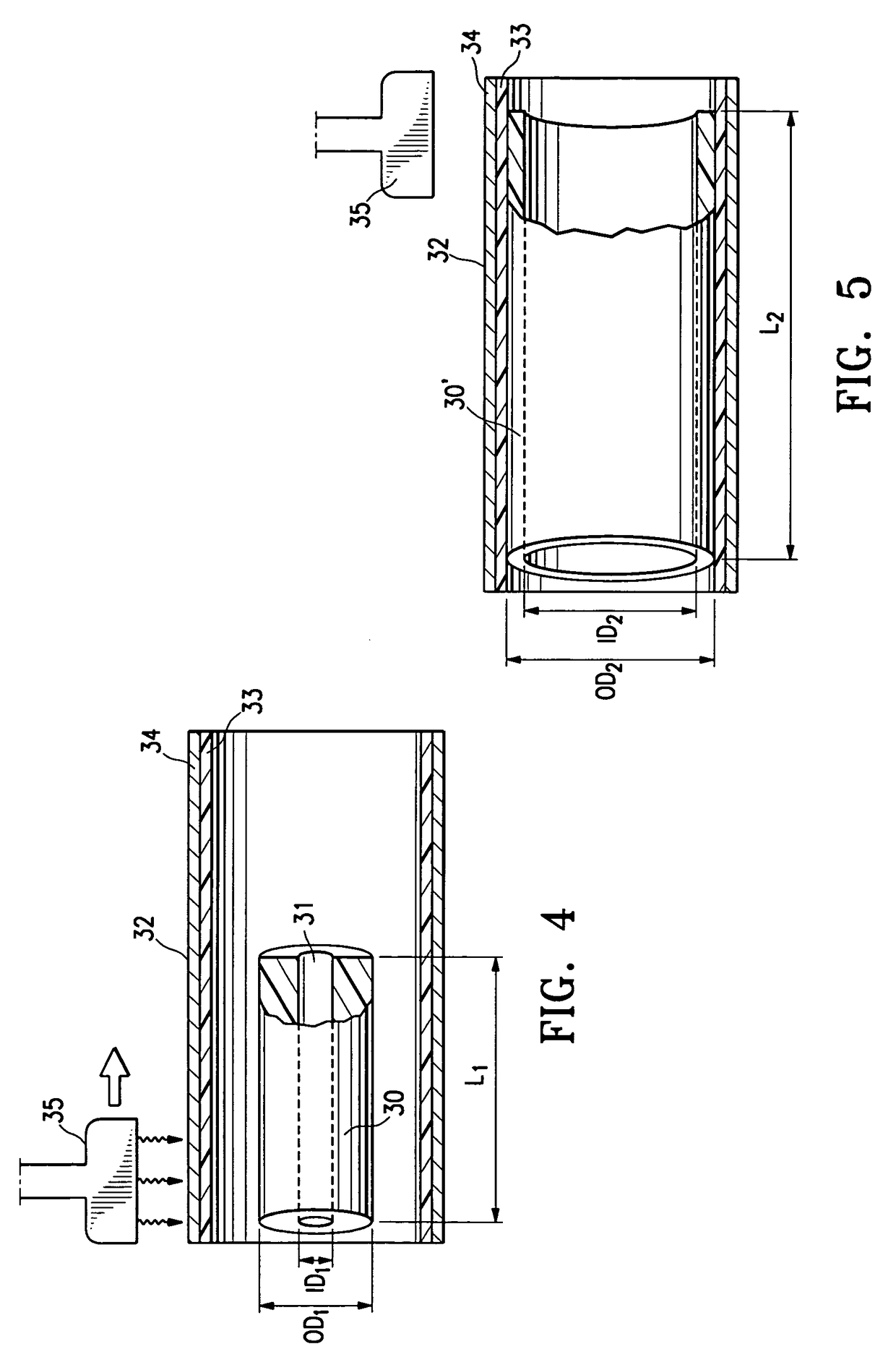

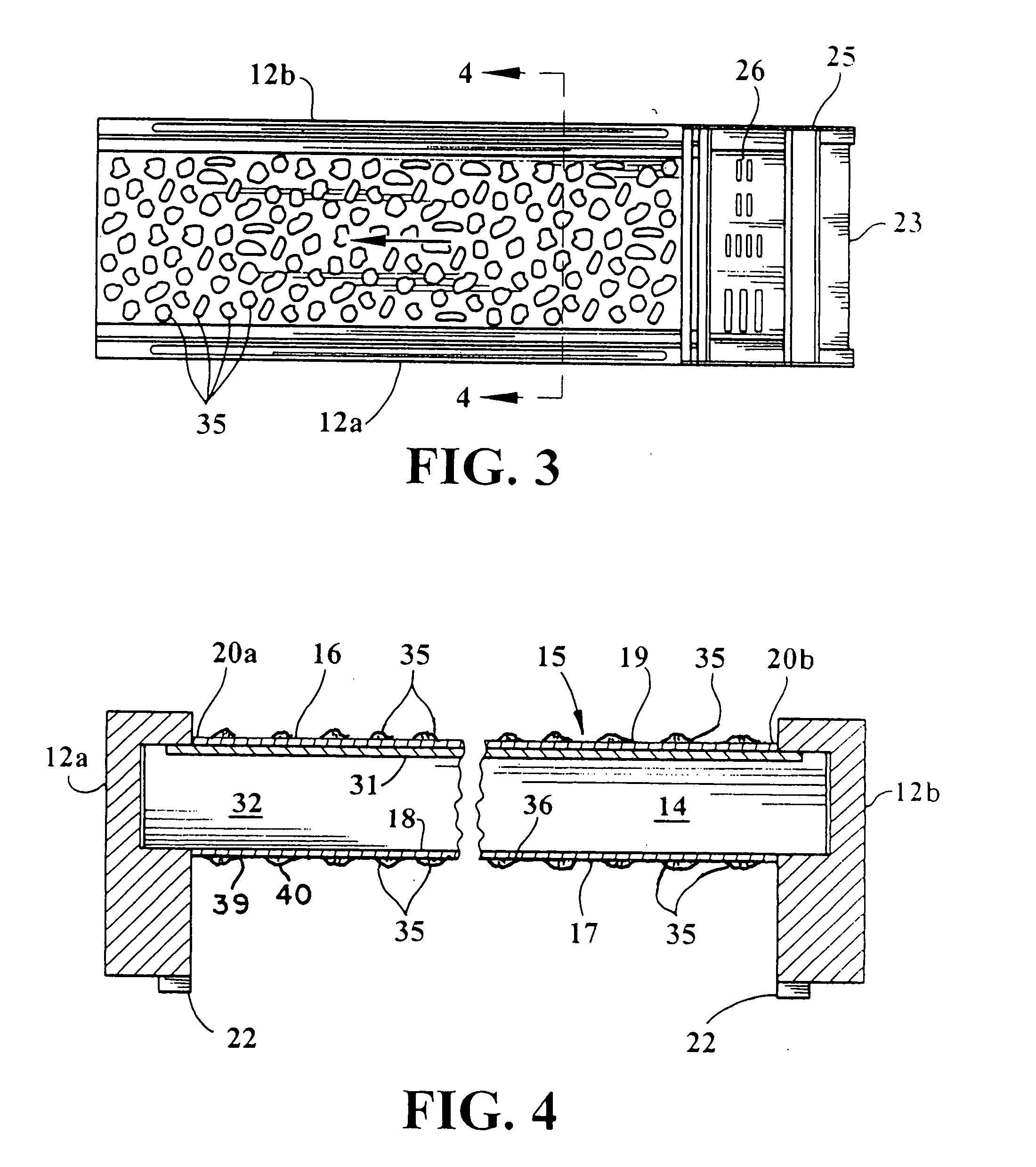

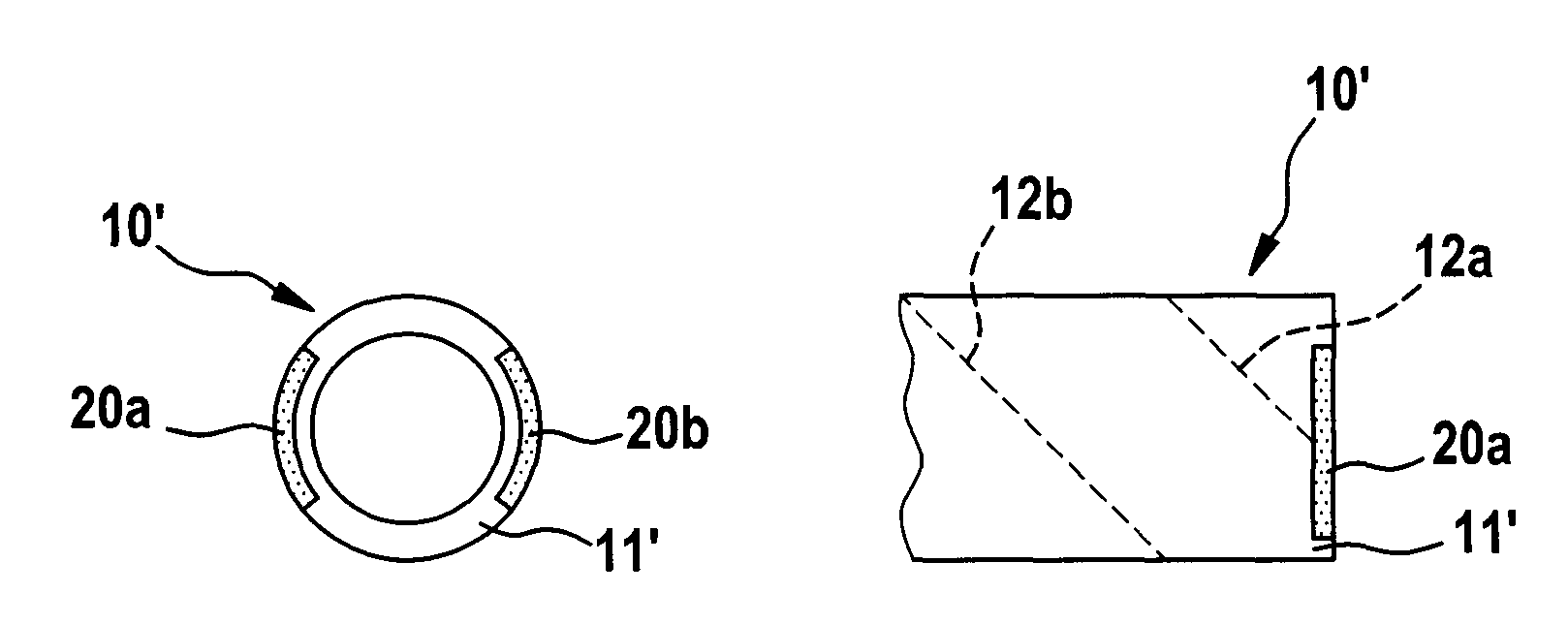

Device for insertion of electrode lines or other medical instruments into a body

InactiveUS7787963B2Avoid traumaReduce hardnessTransvascular endocardial electrodesCatheterElectrical conductorPlastic materials

An insertion device (10), by which a medical instrument or an electrode line or a guide wire or a medical therapeutic agent may be inserted into a body cavity, comprises a lumen section (11) manufactured from a flexible plastic material, having a longitudinal axis, a proximal end and a distal end, and a distal end area enclosing the distal end, at least one electrically conductive means (20) in the distal end area to sense physiological signals or stimulate the surrounding body tissue suitably, as well as at least one conductor, which extends from the proximal end to the distal end and is capable of conducting physiological signals to the proximal end and / or stimulation pulses to the distal end. The at least one electrically conductive means is produced from a flexible, not exclusively metallic, electrically conductive substrate.

Owner:BIOTRONIK SE & CO KG

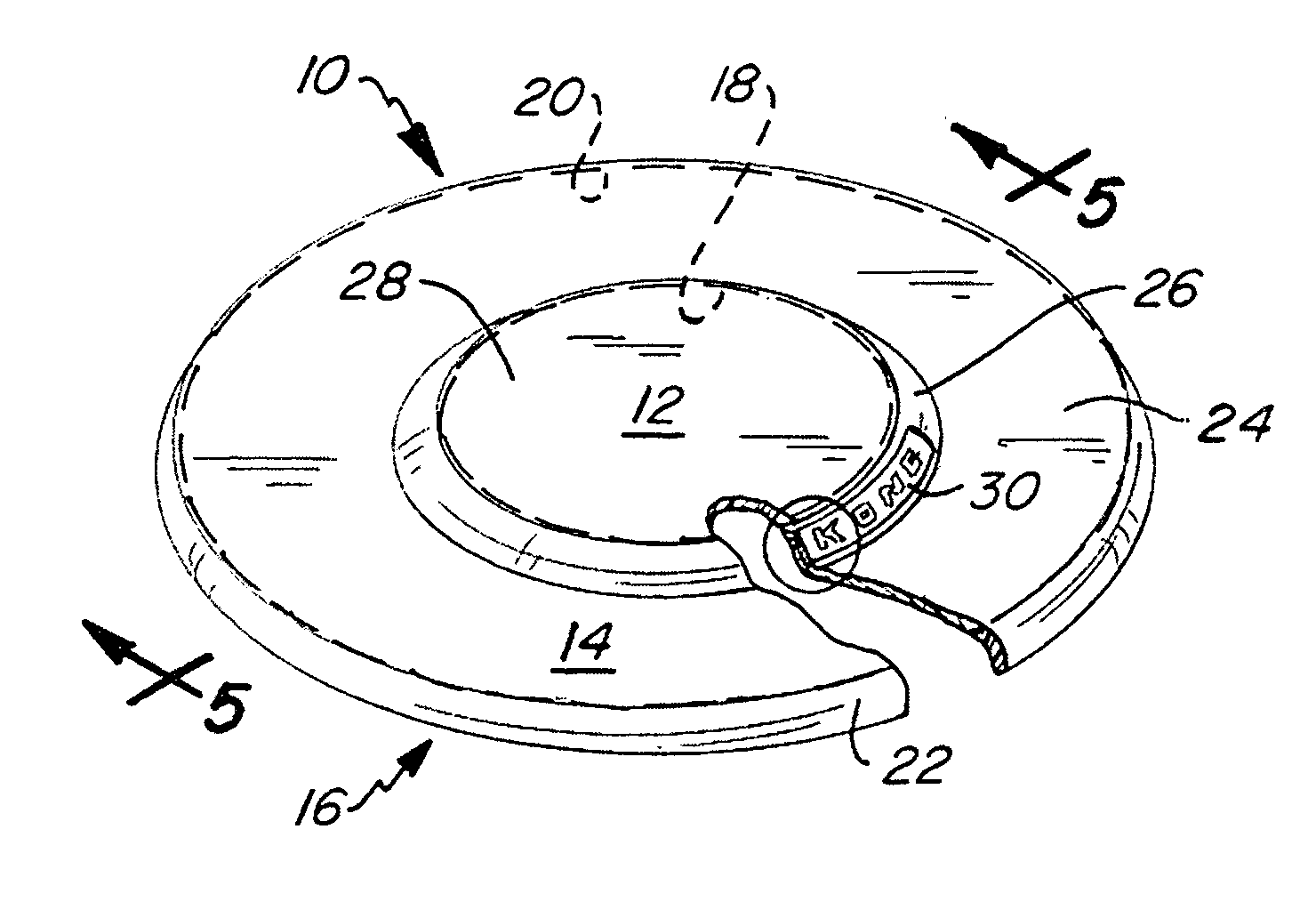

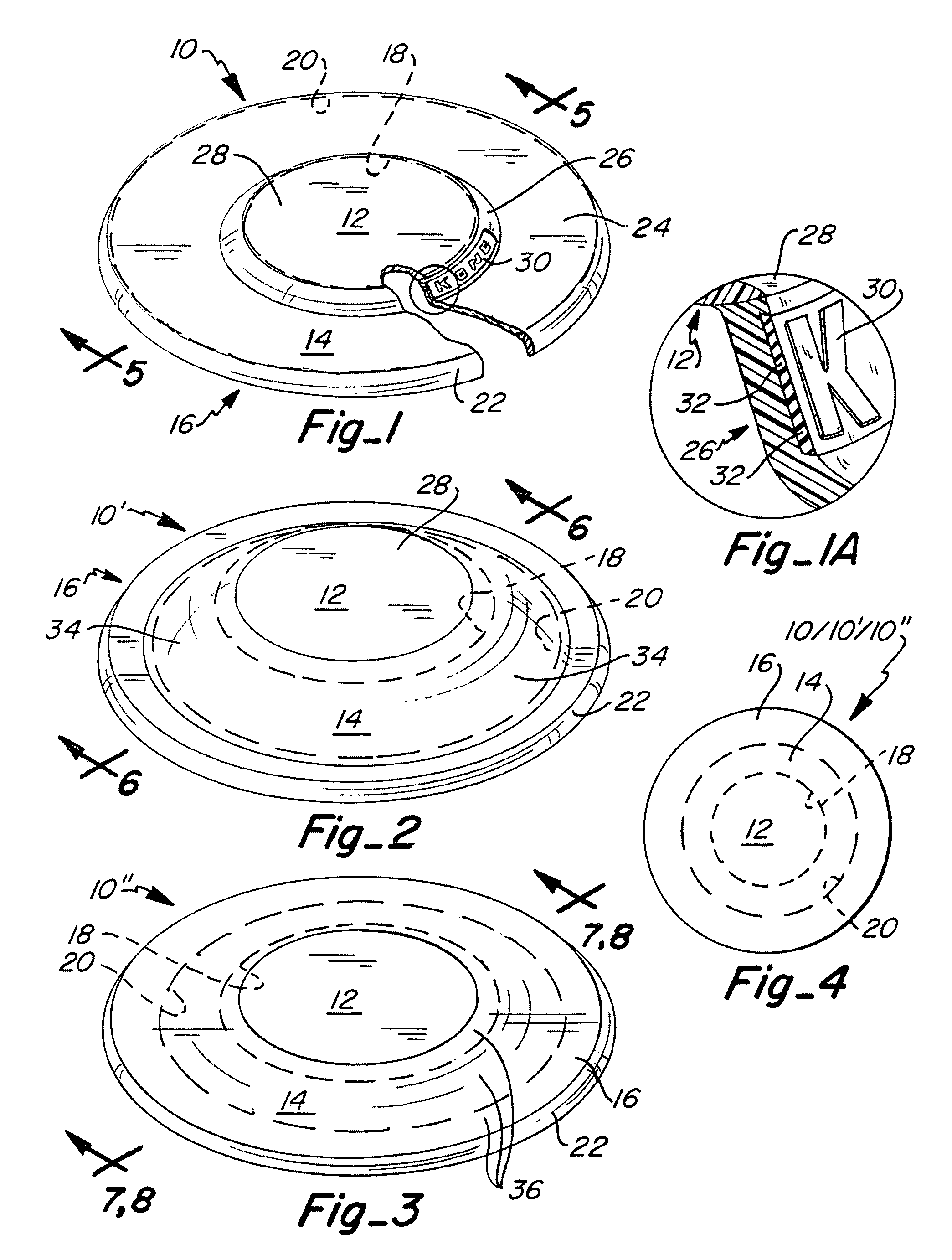

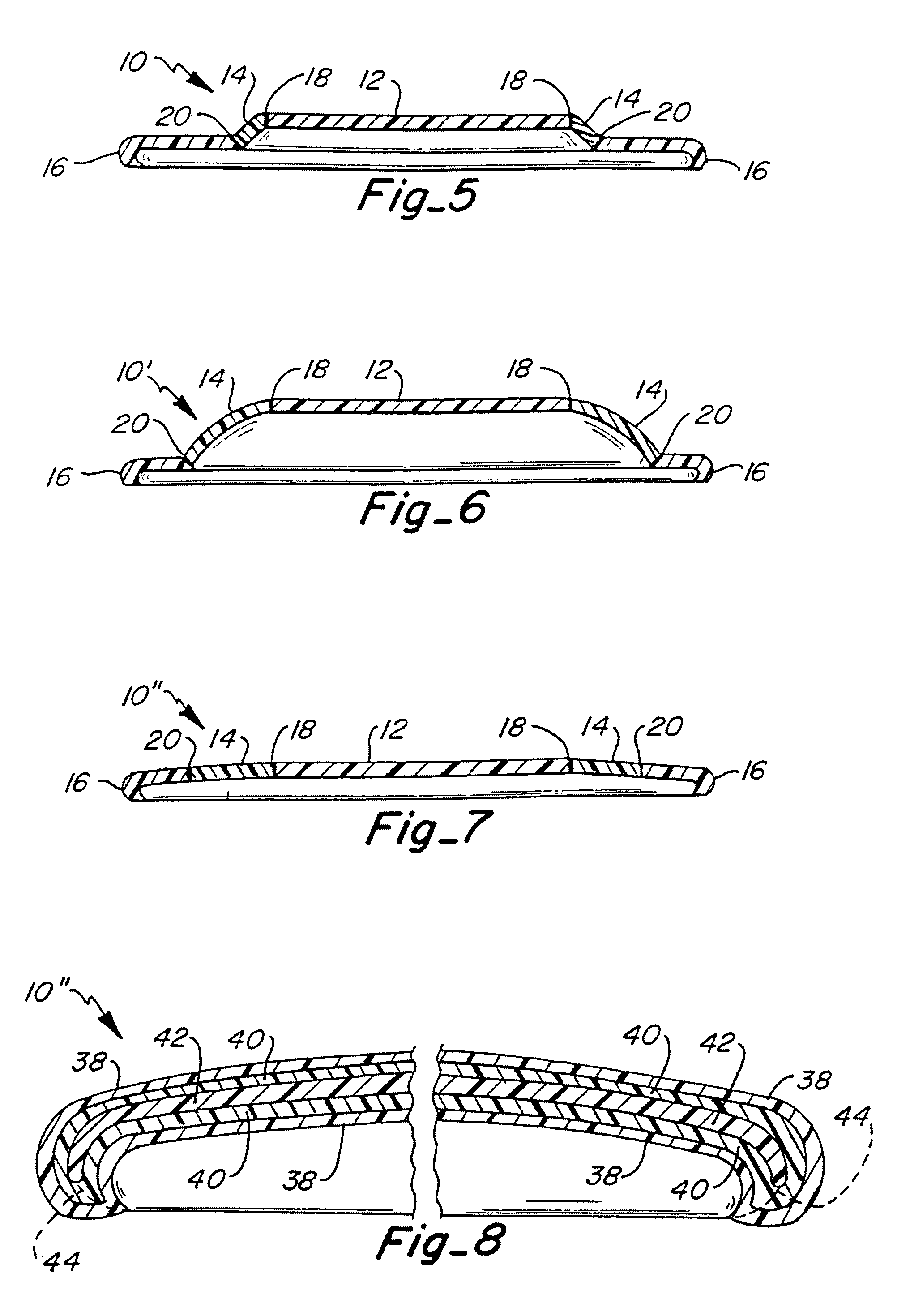

Pet toys incorporating multiple hardness sections

A molded pet toy includes sections or layers of various hardnesses. The pet toy may be constructed through known injection molding, transfer, or compression molding processes. The layers and sections typically have varying hardnesses which facilitates use of the pet toy for a specific purpose. For use as a pet toy, an optimal arrangement provides that the outermost section or layer is of a lower hardness, while the inner sections or layers have a higher hardness. Durability of the pet toy is increased through the molding process which prevents separation between the layers. The pet toy is preferably shaped aerodynamically so it may be easily thrown by a user.

Owner:MARKHAM JOSEPH P

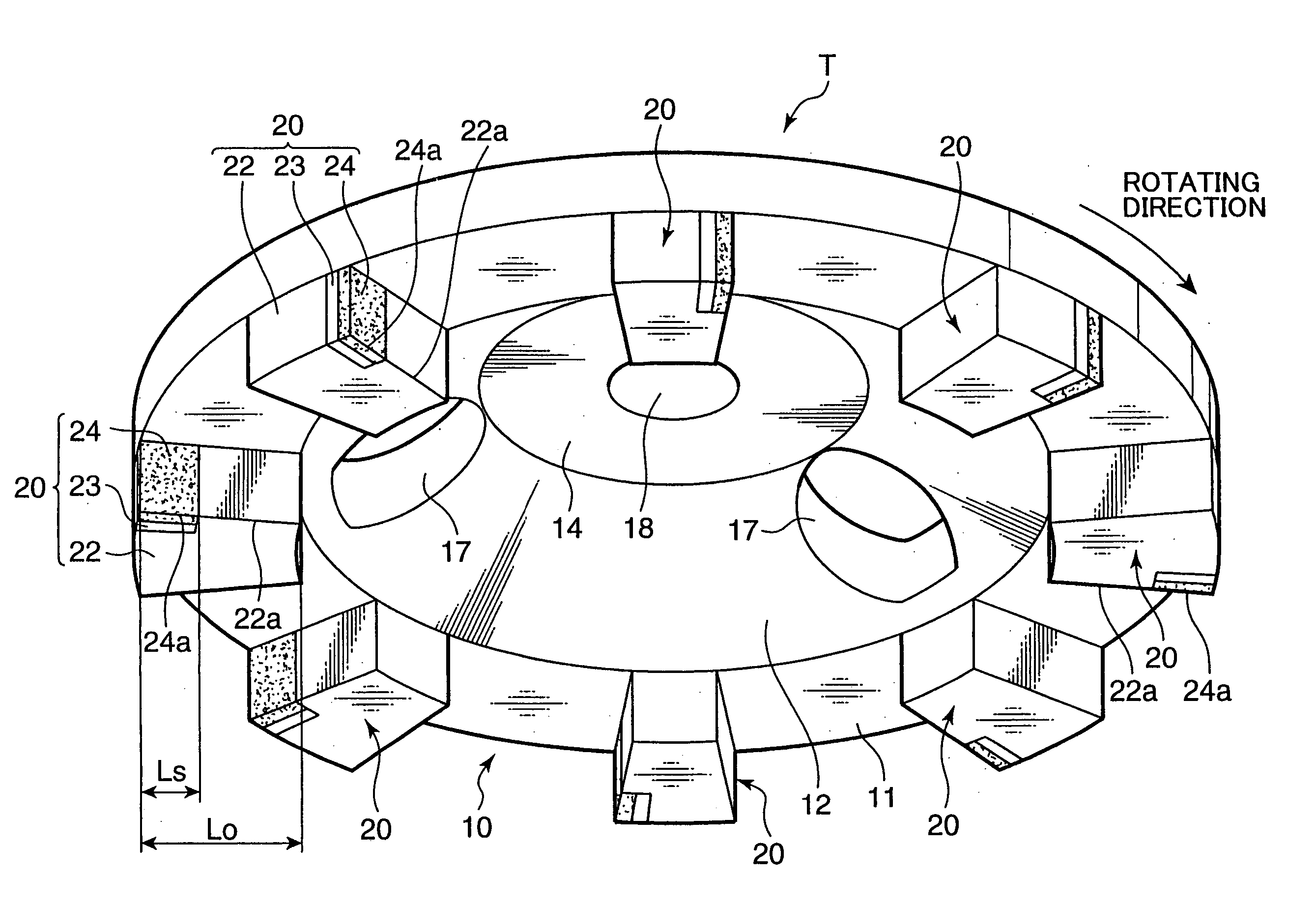

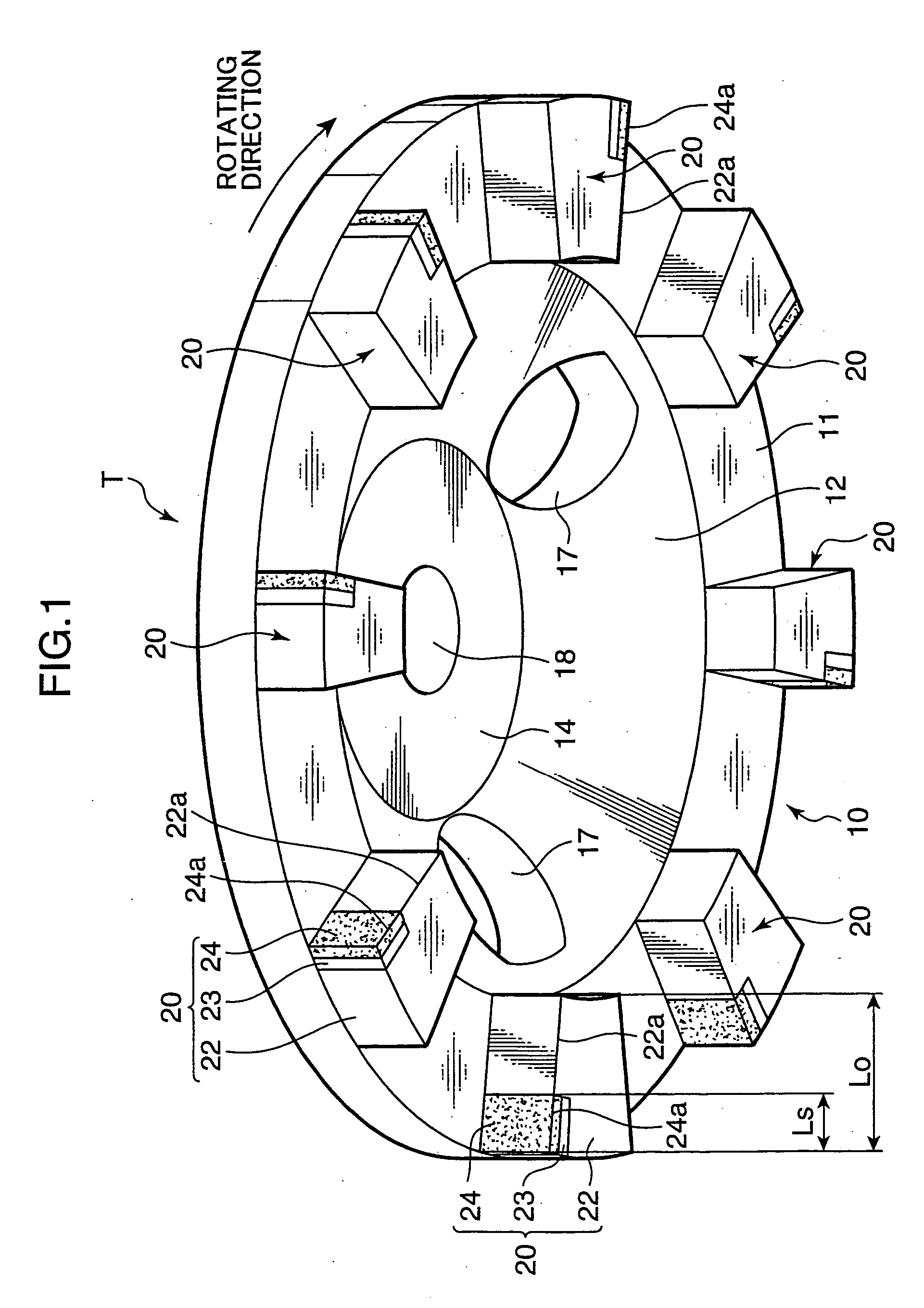

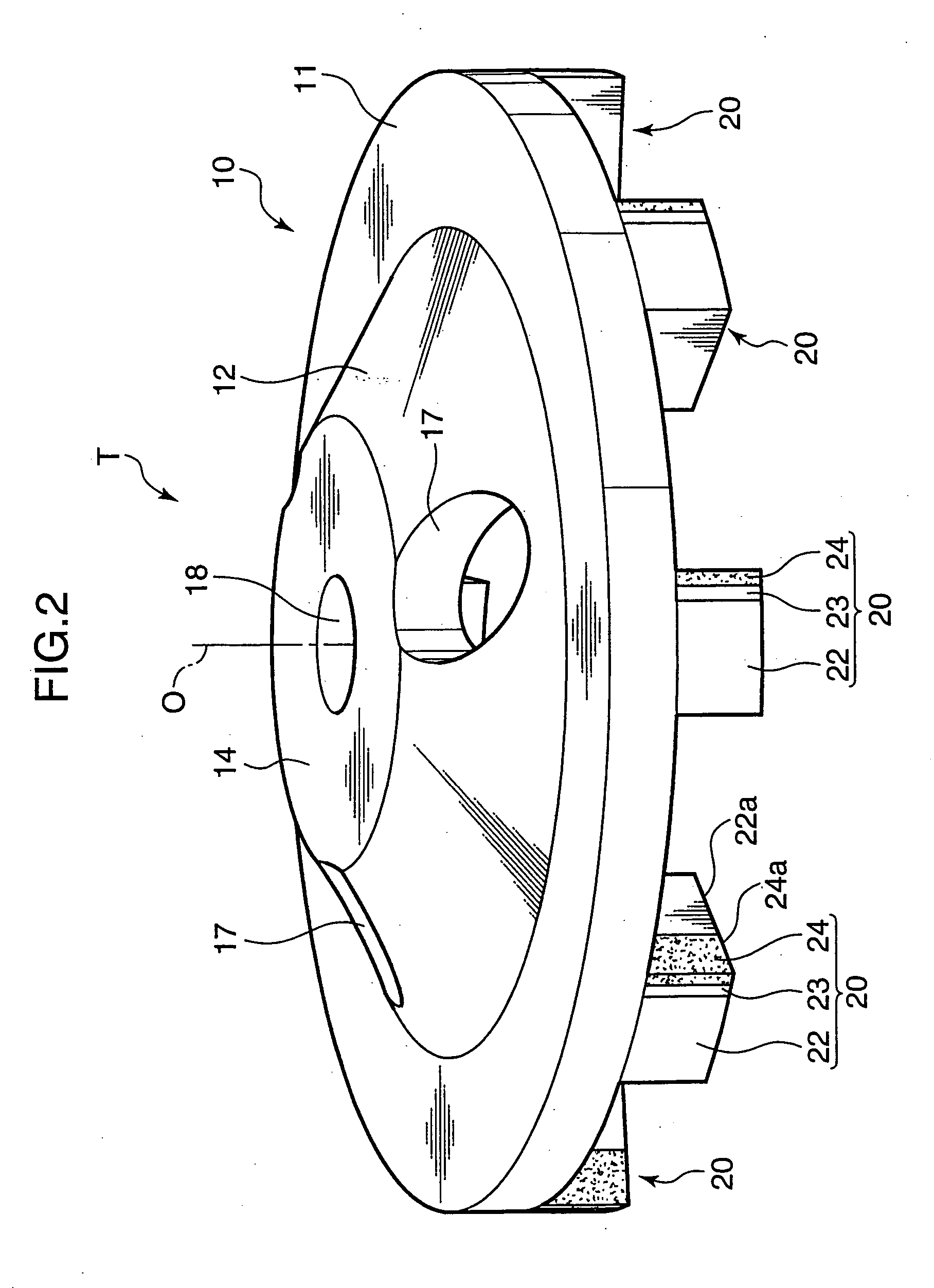

Rotary tool and its cutting part

InactiveUS20050164620A1Few or no effectsSharp cutting qualityRevolution surface grinding machinesMilling cuttersMetallurgy

A rotary tool (T) has a rotary segment (10) with an opposed surface opposed to a work surface and a plurality of cutting parts (20) arranged on the opposed surface. Some cutting parts (20) include tips (22a) made of a grinding tool segment obtained by binding abrasive grains by a metal binder and the other cutting parts (20) include tips (24a) made of a sintered material harder than the grinding tool segment, and the respective cutting parts (20) are arranged such that the tips (24a) are located at positions more outward than the tips (22a) with respect to radial directions of the rotary segment.

Owner:SANWA KENMA

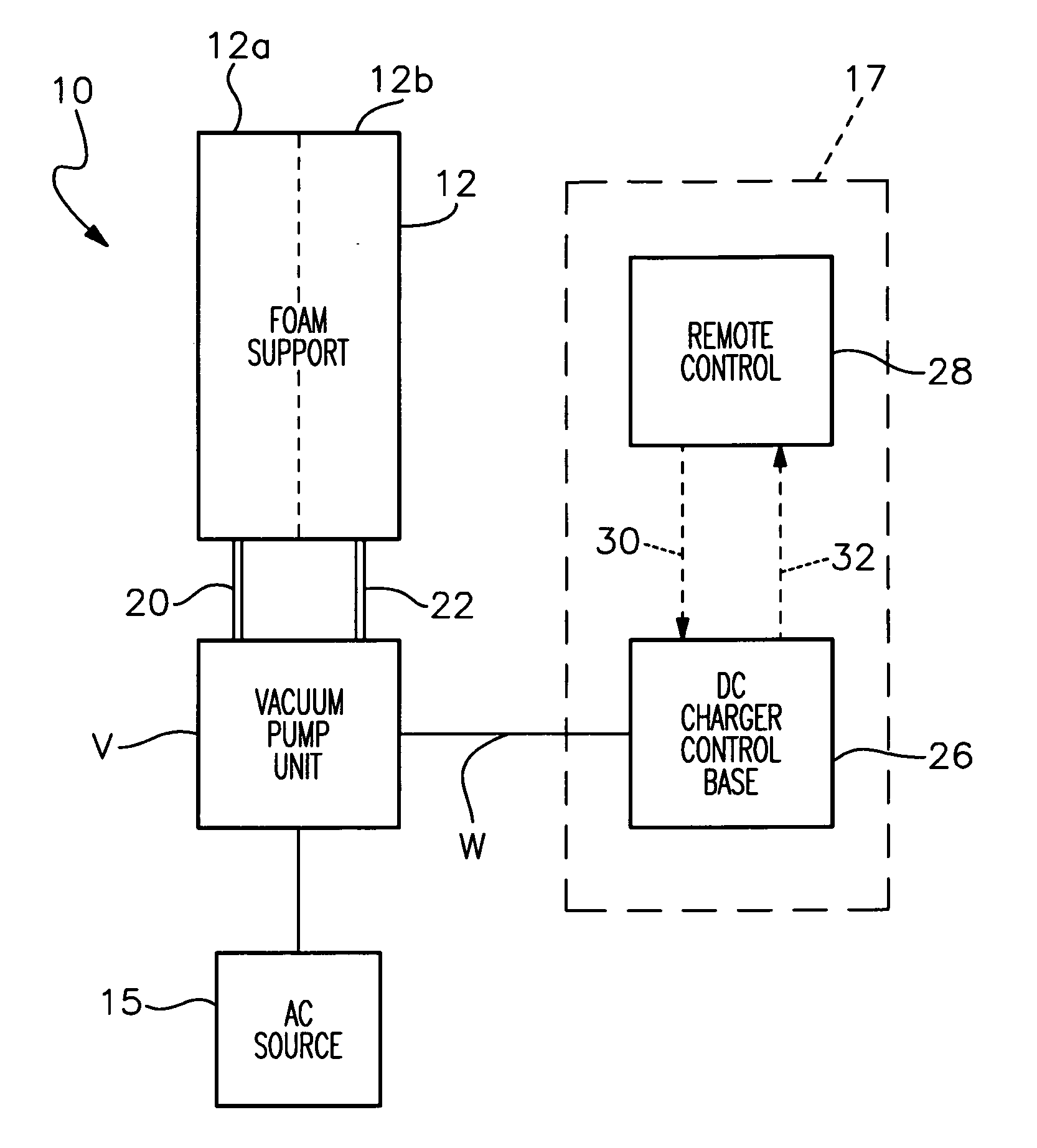

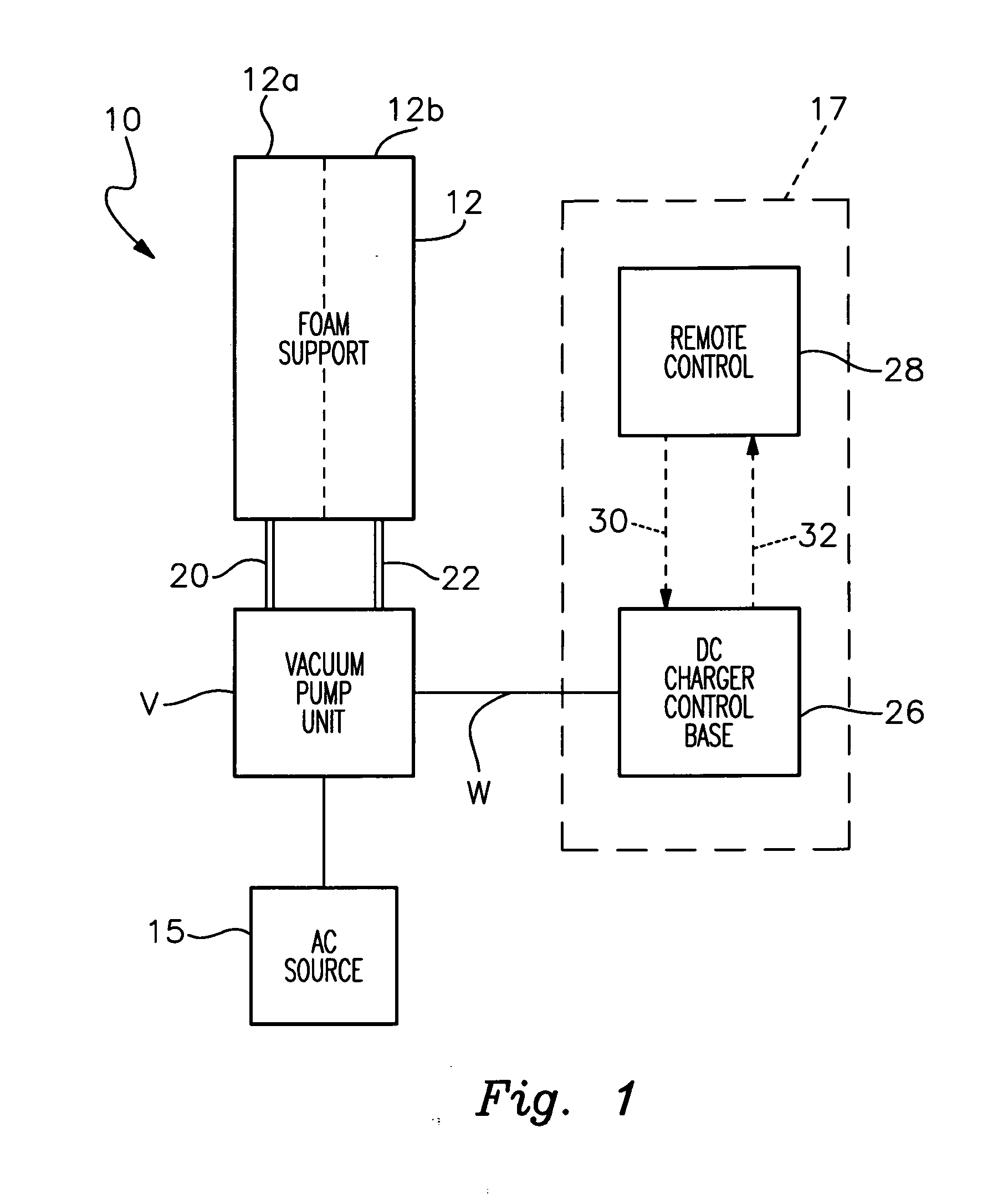

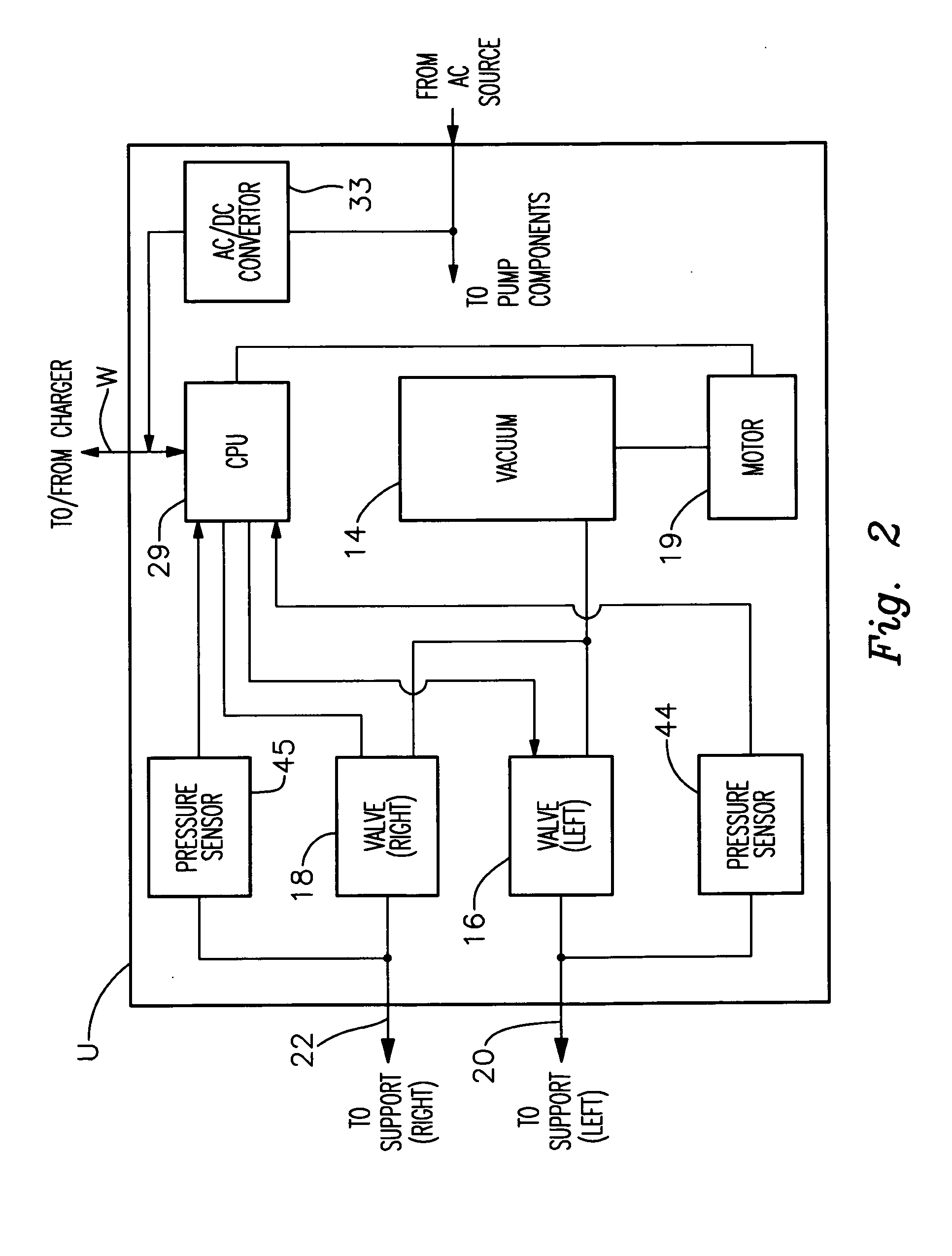

Pressure control and feedback system for an adjustable foam support apparatus

ActiveUS20120090698A1Effectively accurately achievingQuickly and conveniently adjustedStuffed mattressesCheck valvesControl signalHermetic seal

A pressure control and feedback system for an adjustable foam support includes a vacuum pump for drawing air from a hermetically sealed foam core to reduce the firmness of the core. A valve opens to permit and closes to block the passage of air into and out of the core. A remotely operated controller generates control signals to selectively start and stop operation of the pump, and selectively open and close the valve, which provides a selected level of pneumatic pressure and corresponding firmness in the core. A pressure sensor detects the pressure and firmness of the core and generates representative feedback signals. An indicator device responsive to the feedback signals indicates the sensed firmness of the core. Software calibrates the system and provides the system with intelligent operation.

Owner:GIORI GUALTIERO G +1

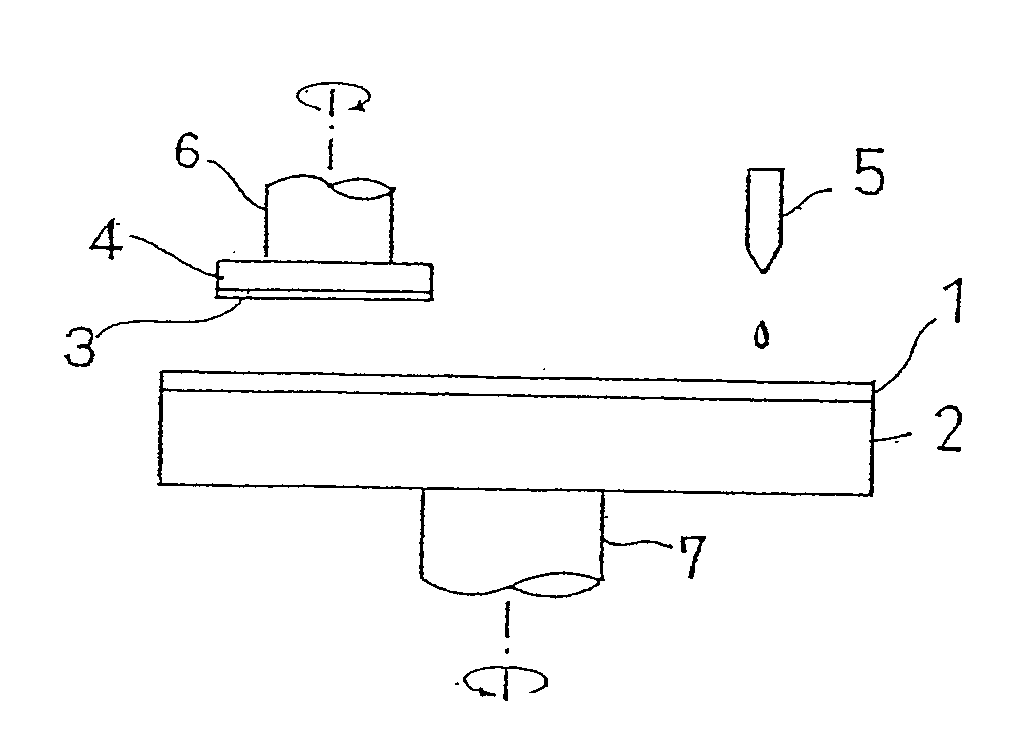

Polishing pad and method of producing the same

InactiveUS20060280930A1Reduce rateReduce hardnessEdge grinding machinesLayered productsAluminum substrateSemiconductor

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

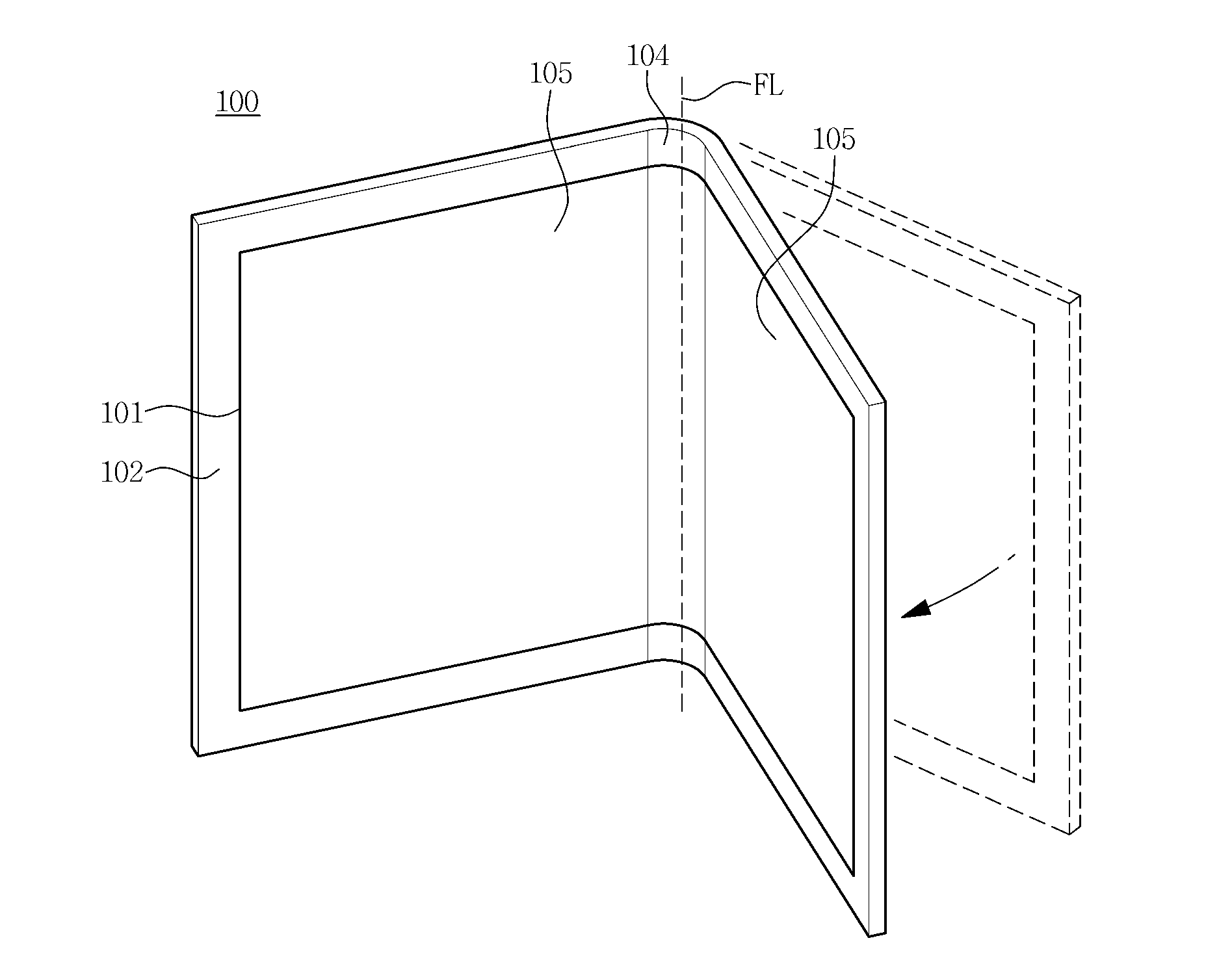

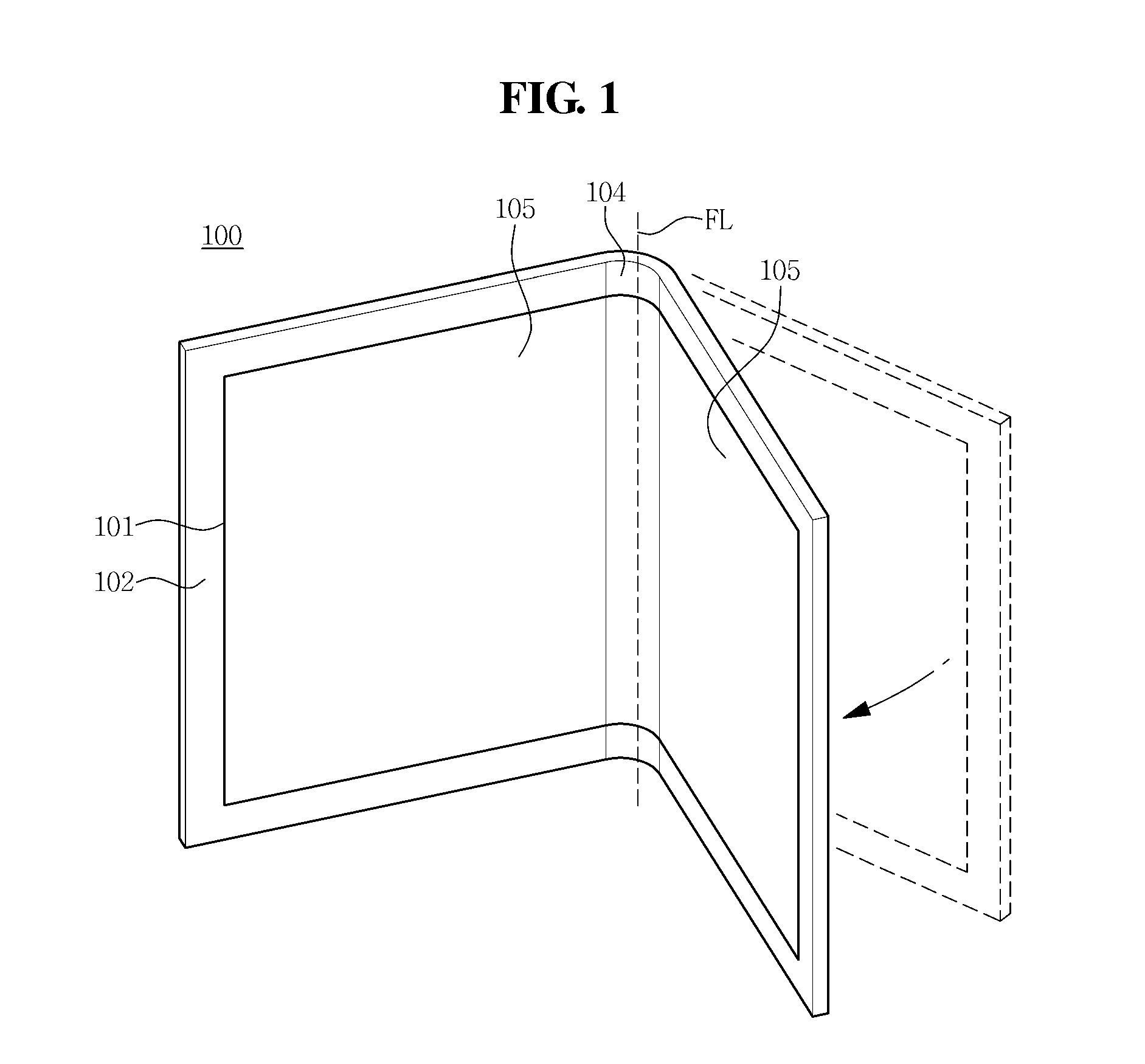

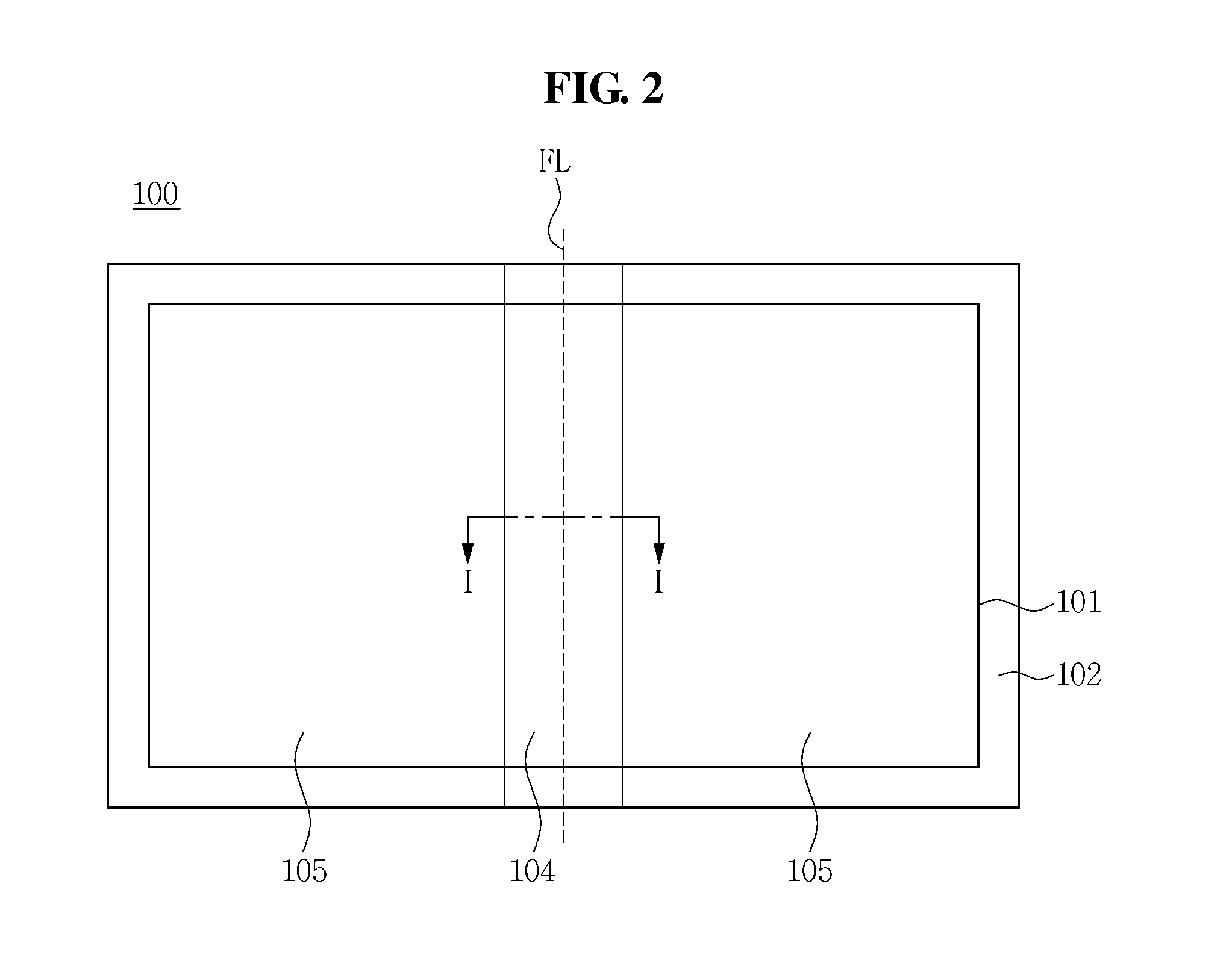

Foldable display device

ActiveUS20160014881A1Good flexibilityReduce hardnessPrinted circuit detailsCasings with display/control unitsDisplay deviceCoating

A foldable display device includes: a display panel having a folded portion bendable along a fold line; and a cover window disposed on the display panel, wherein the cover window includes: at least a soft pattern disposed on the folded portion of the display panel; and a hard coating layer disposed on the display panel having the soft pattern formed thereon, and the soft pattern has a triangular cross section.

Owner:SAMSUNG DISPLAY CO LTD

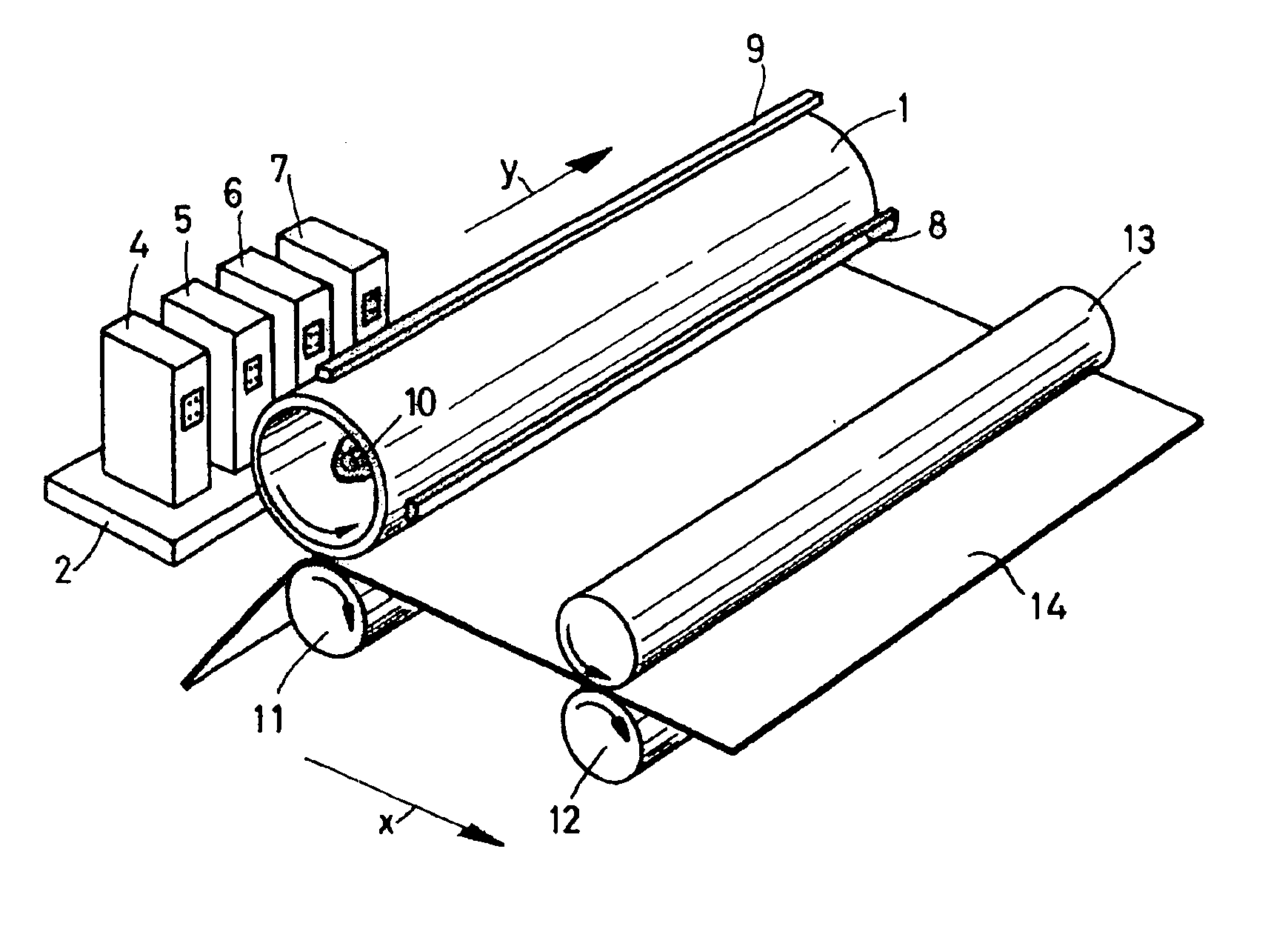

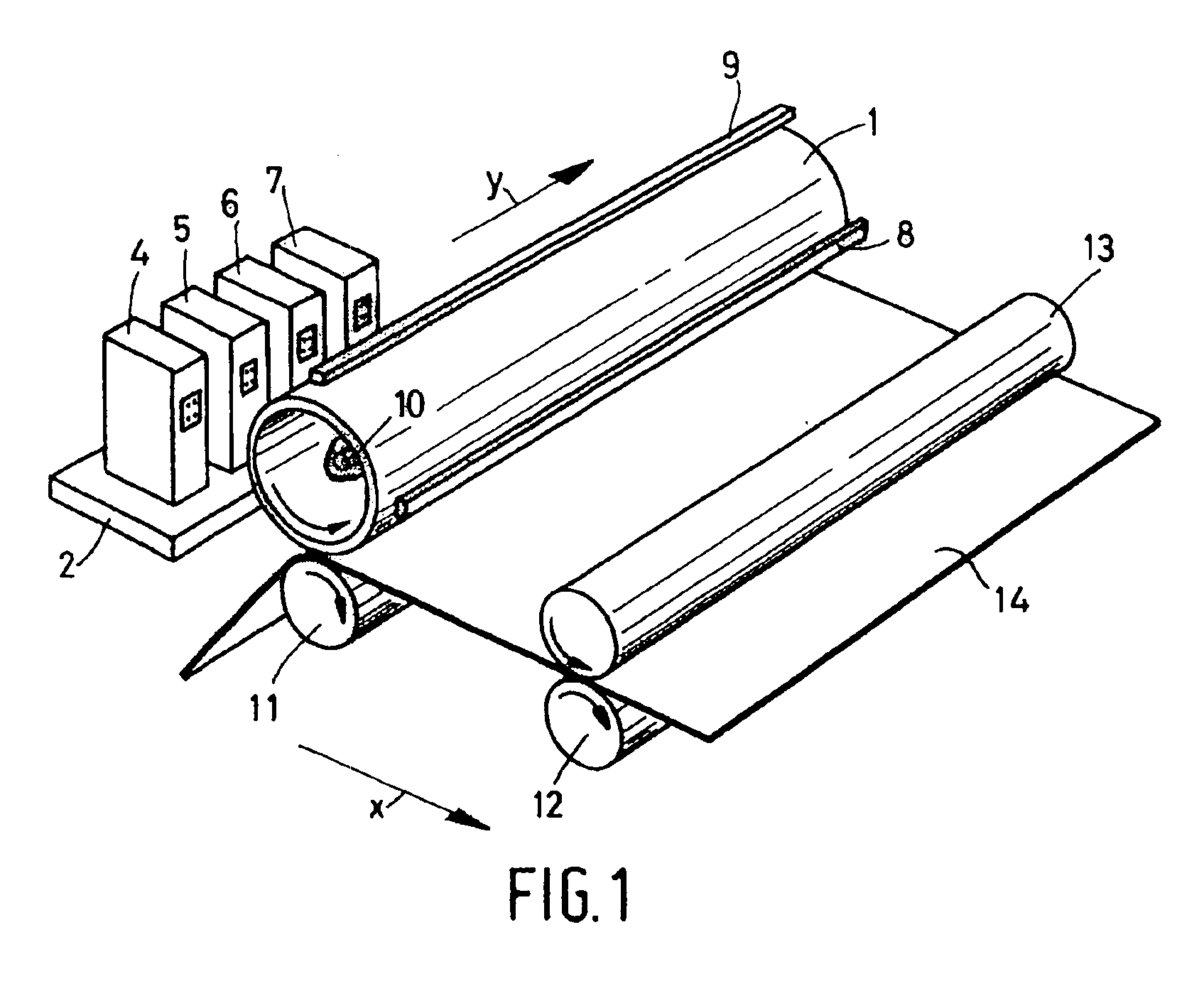

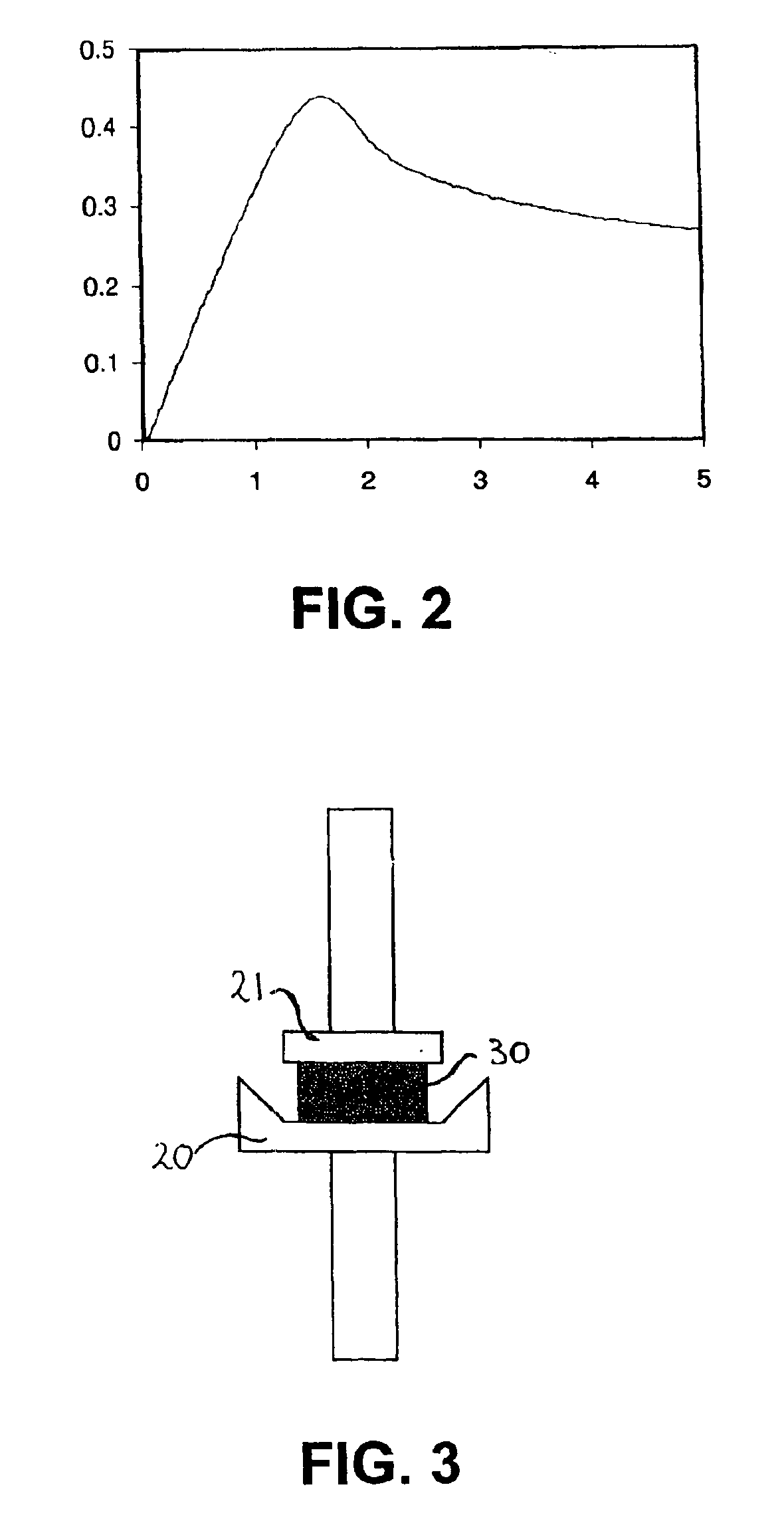

Method of printing a receiving material with hot melt ink and an inkjet printer suitable for applying such a method

InactiveUS6905203B2Reduce hardnessImprove transfer rateMeasurement apparatus componentsPrintingElastomerInk printer

A method of printing a receiving material with hot melt ink using an intermediate element having a surface containing an elastomer with a surface tension in which the polar part thereof is less than or equal to 20 mN / m, wherein the receiving material is brought into contact with the intermediate element in such manner that the ink transfers from the intermediate element to the receiving material, and wherein the elastomer has a hardness of less than 80 Shore A, a thermal conductivity coefficient greater than 0.15 W / mK, and in absorption of less than 10%, and a tanδ of less than 0.3.

Owner:OCE TECH

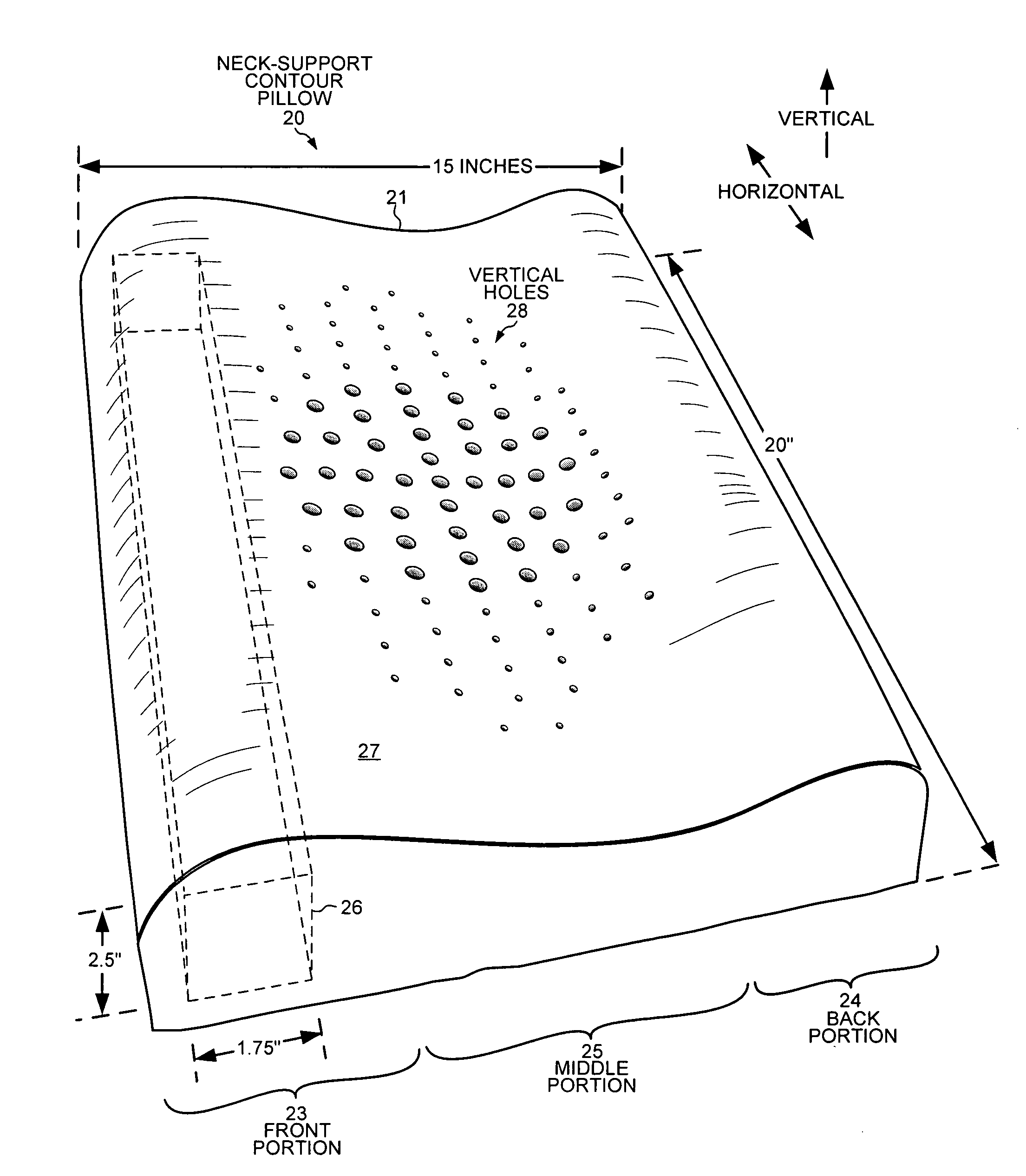

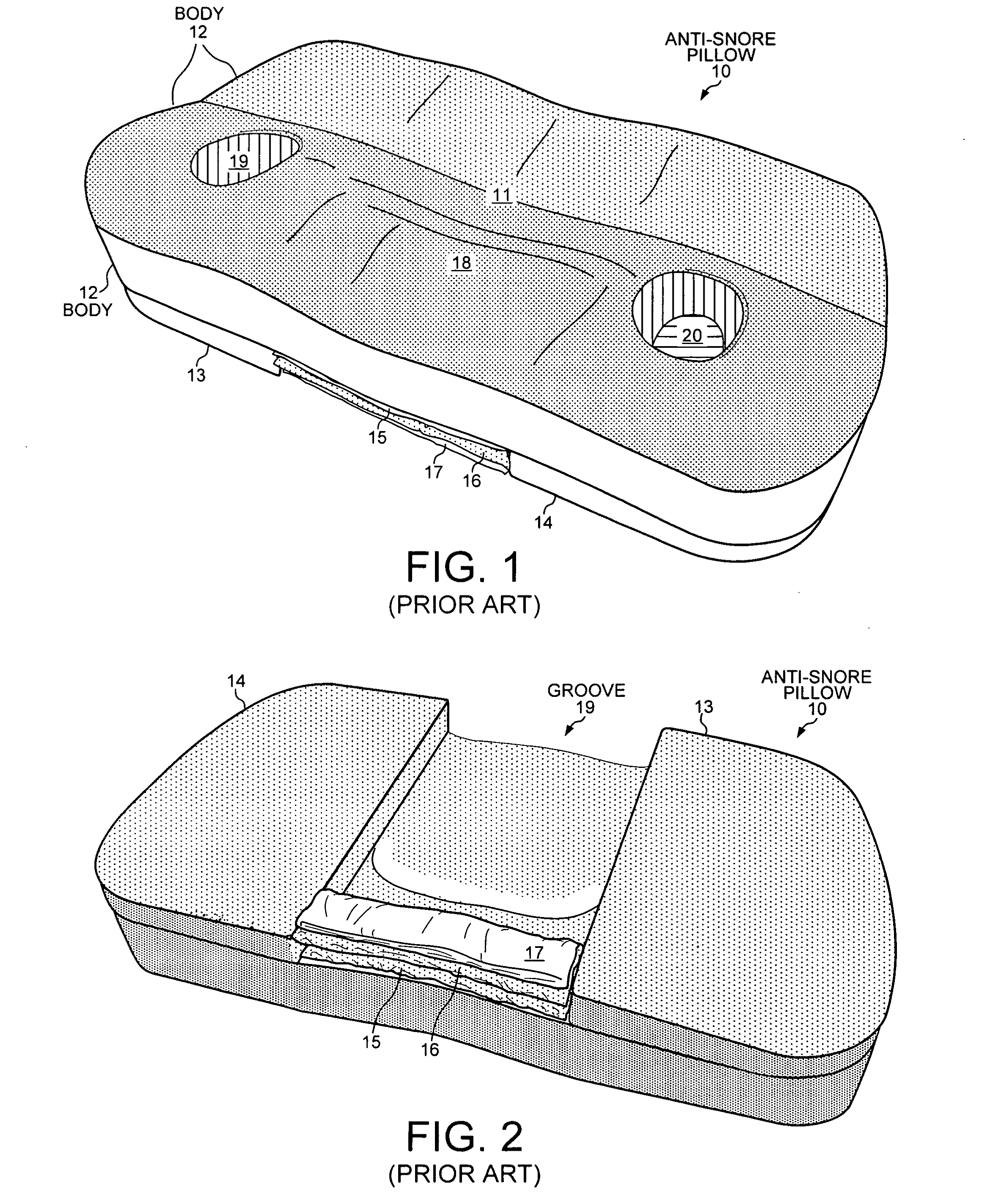

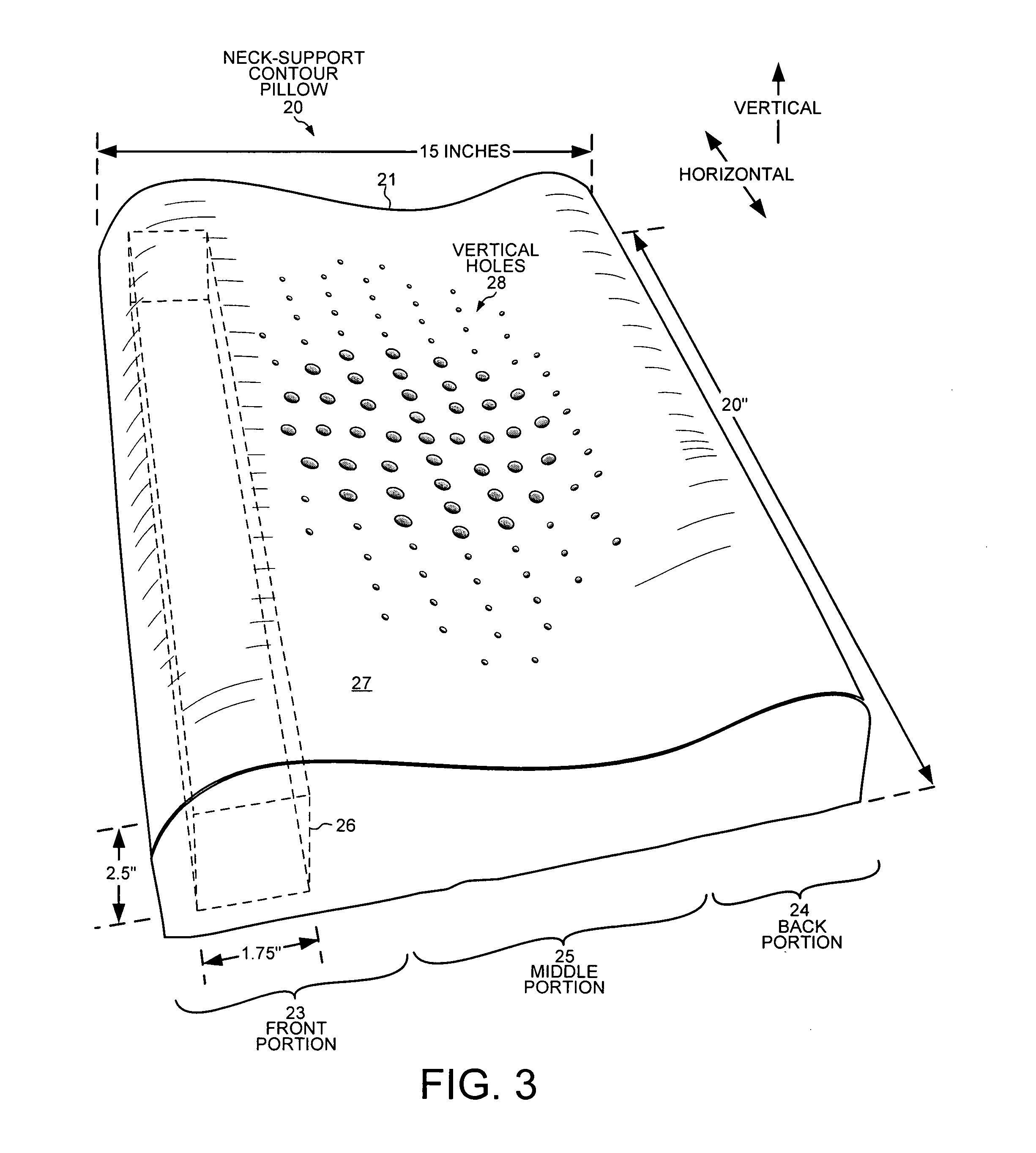

Anti-snore neck-support contour pillow

Owner:ZINUS

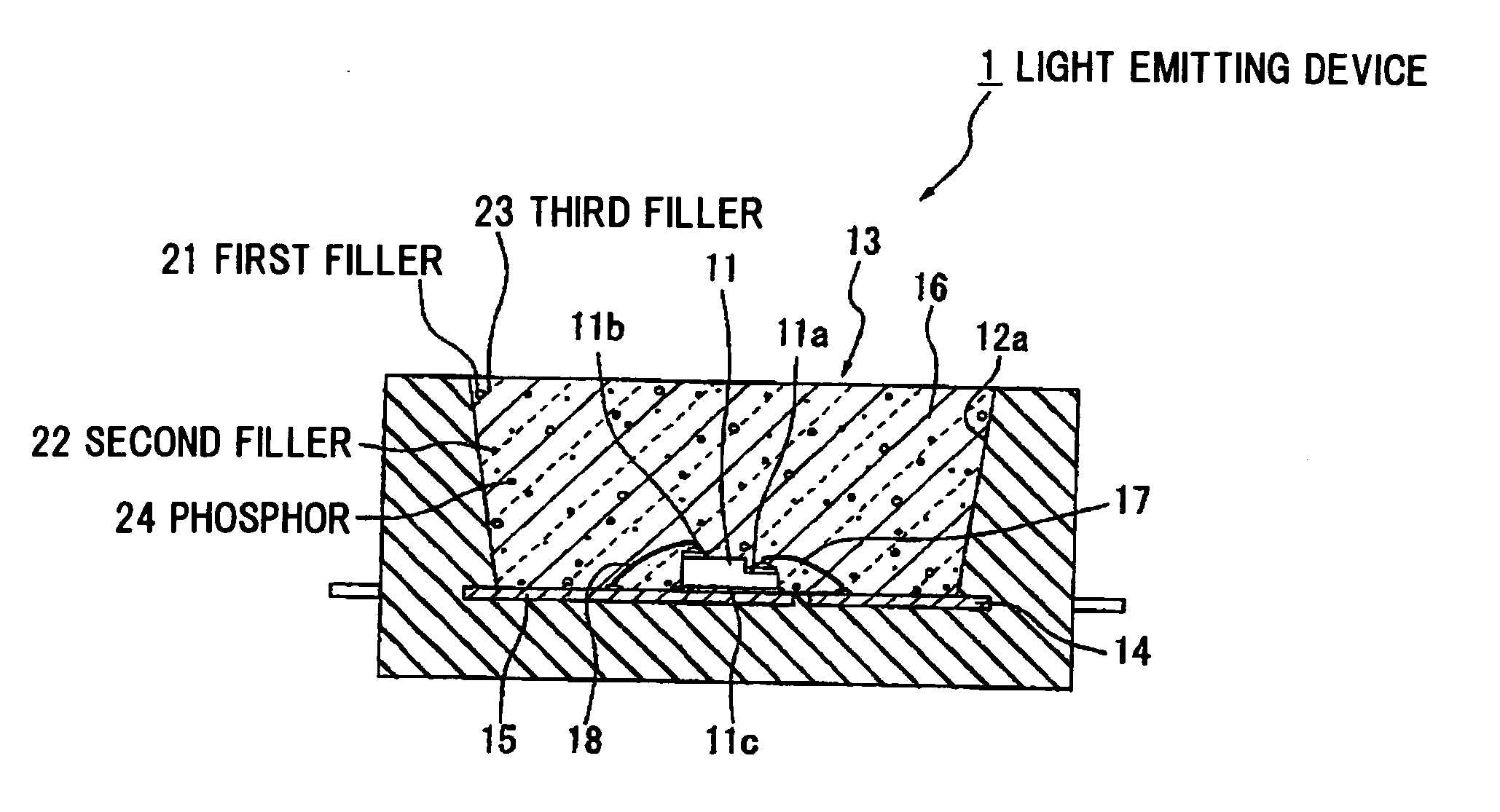

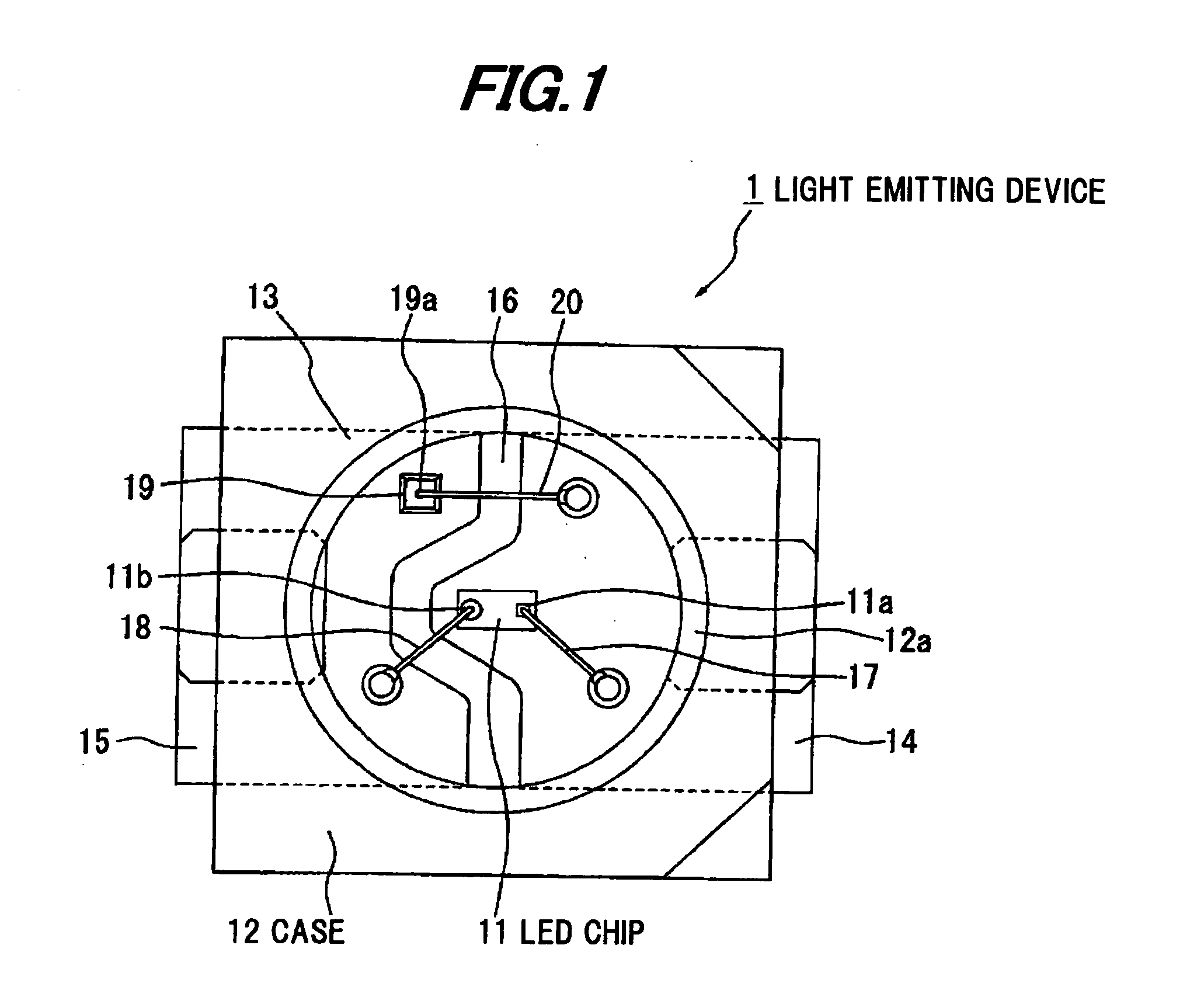

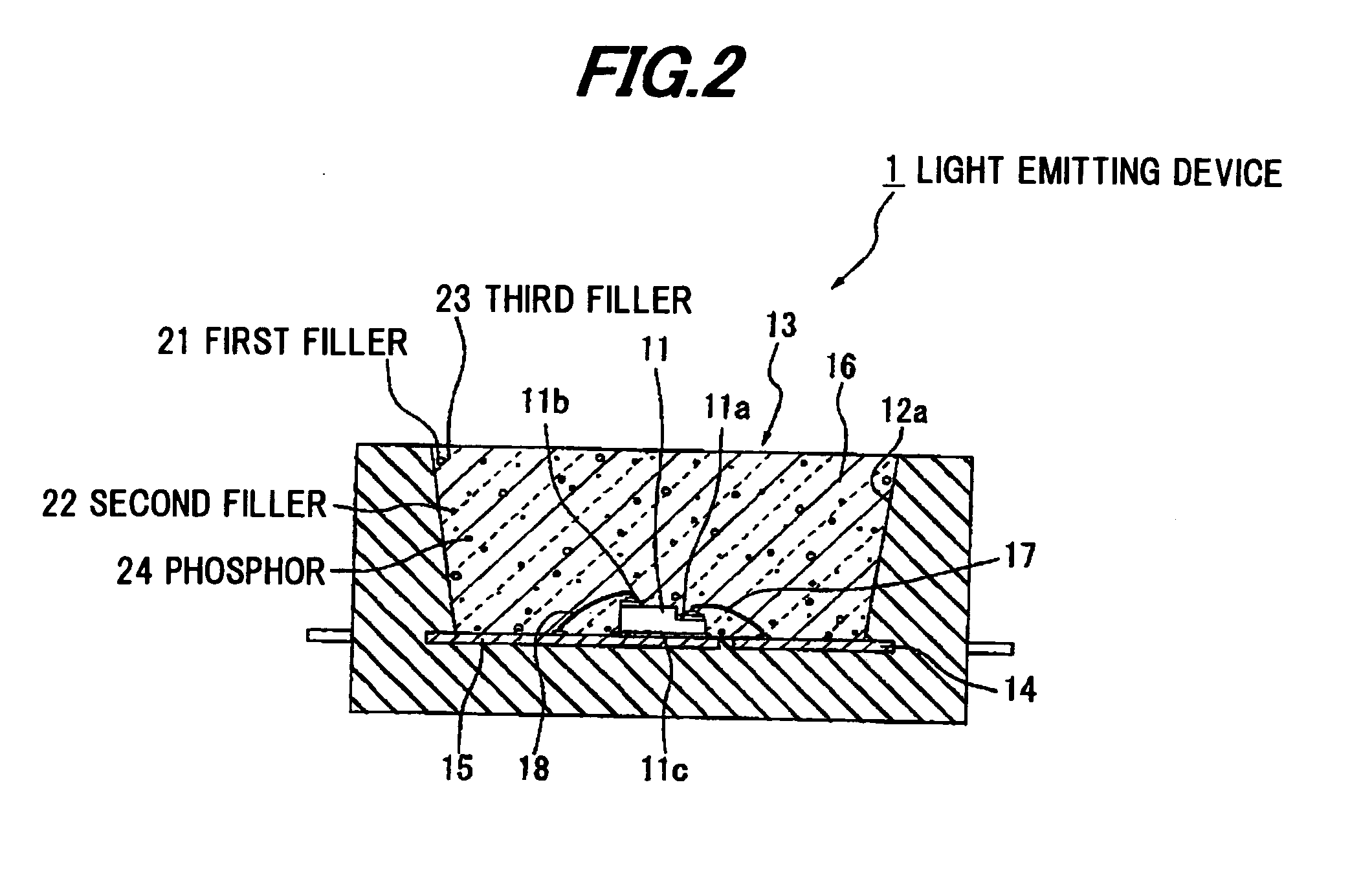

Light emitting device

ActiveUS20100025709A1Low Shore A hardnessAvoid disconnectionSolid-state devicesSemiconductor devicesLight emitting devicePhysics

A light emitting device includes a light emitting element, a sealing material for sealing the light emitting element, a first filler included in the sealing material, and a second filler included in the sealing material. The second filler includes a particle diameter smaller than that of the first filler.

Owner:TOYODA GOSEI CO LTD

Polishing pad and method of producing the same

InactiveUS20060280929A1Reduce rateReduce hardnessEdge grinding machinesLayered productsAluminum substrateSemiconductor

The invention provides a polishing pad by which optical materials such as lenses, reflecting mirrors etc., or materials requiring a high degree of surface planarity, as in the polishing of silicone wafers, glass substrates or aluminum substrates for hard disks, or general metal polishing, can be flattened with stability and high polishing efficiency. The invention also provides a polishing pad for semiconductor wafers, which is superior in planarizing characteristic, is free from scratches and can be produced at low cost. There is provided a polishing pad which is free from dechucking error so that neither damage to wafers nor decrease in operating efficiency occurs. There is provided a polishing pad which is satisfactory in planarity, within wafer uniformity, and polishing rate and produces less change in polishing rate. There is provided a polishing pad which can make planarity improvement and scratch decrease compatible.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

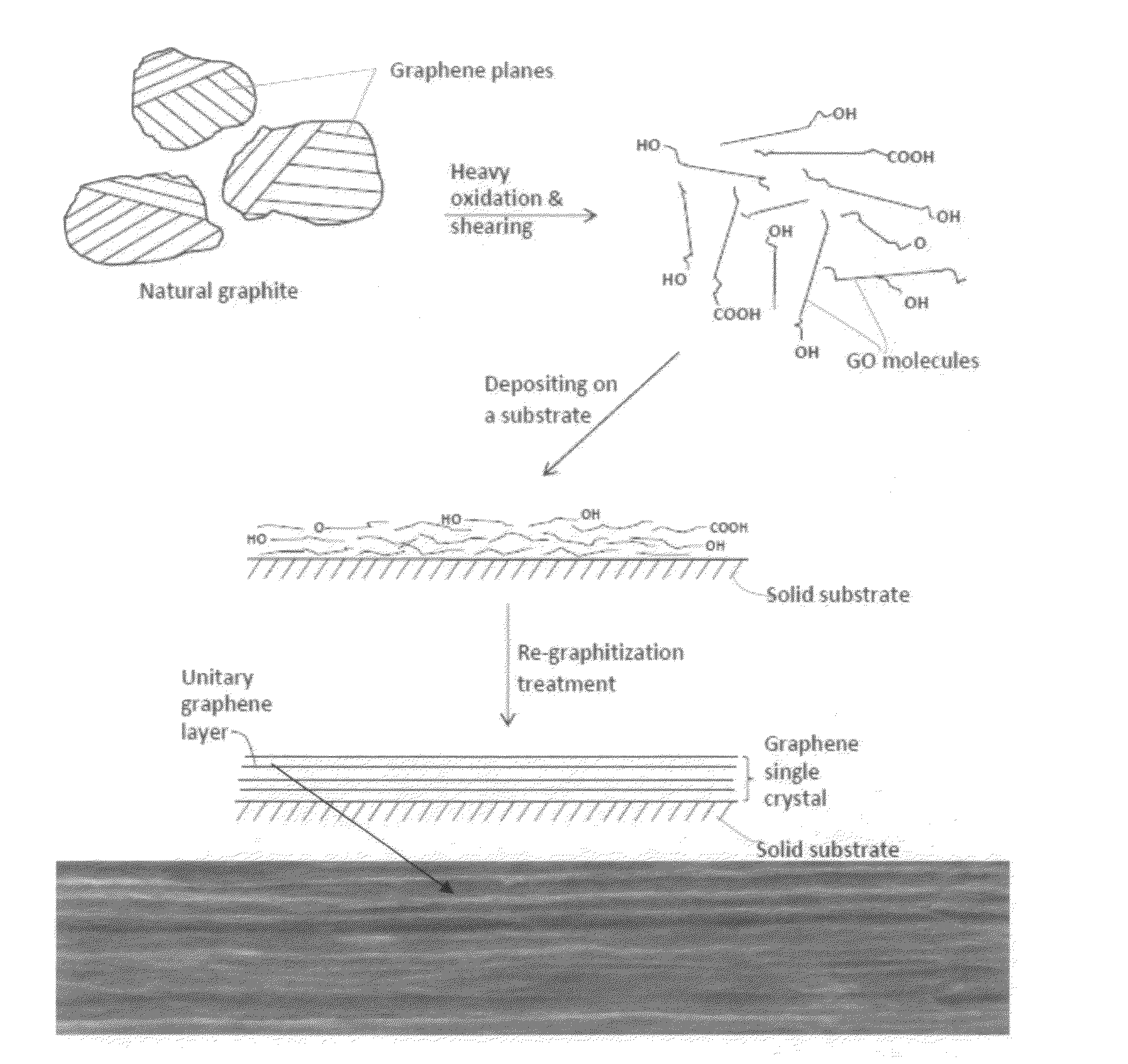

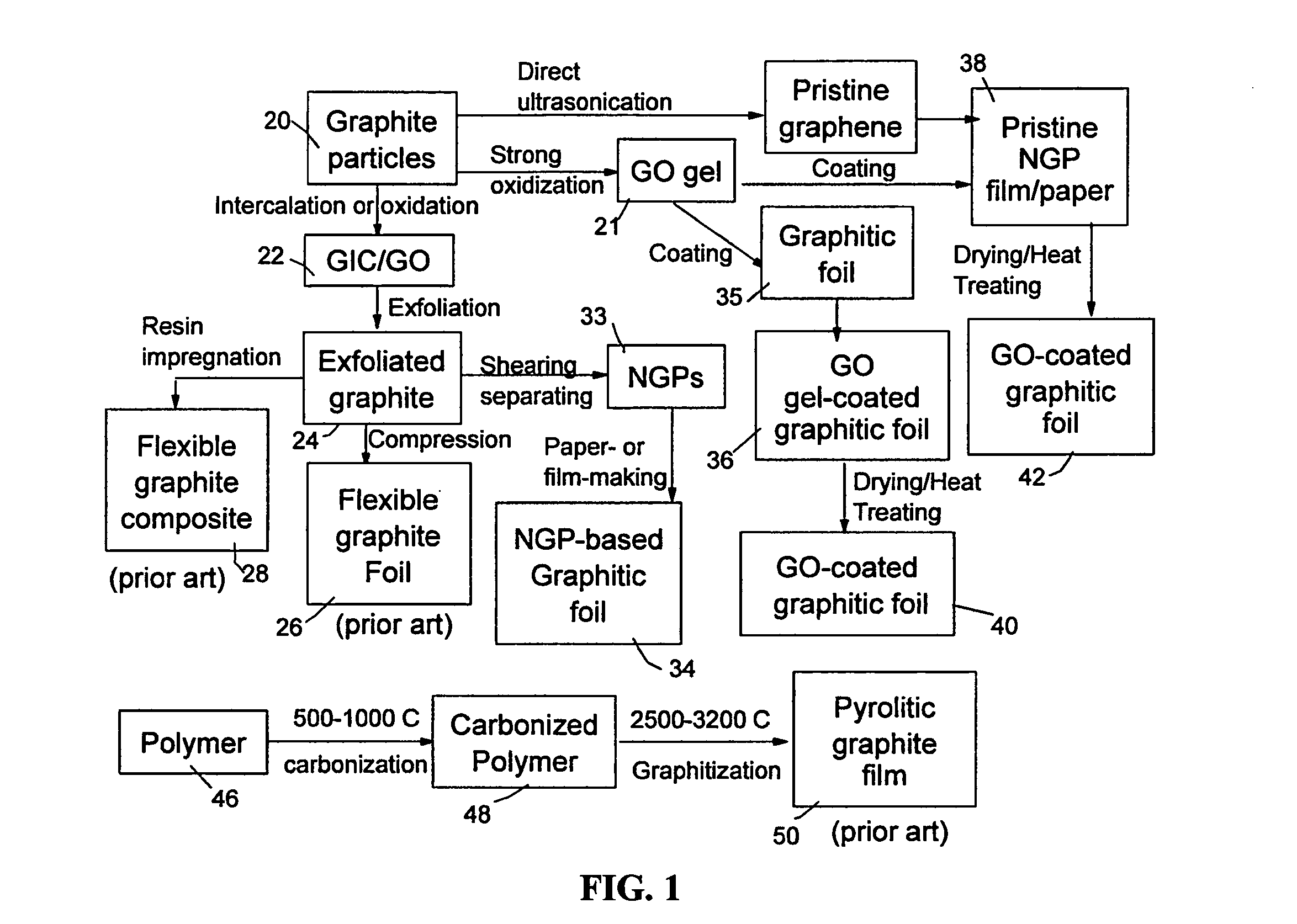

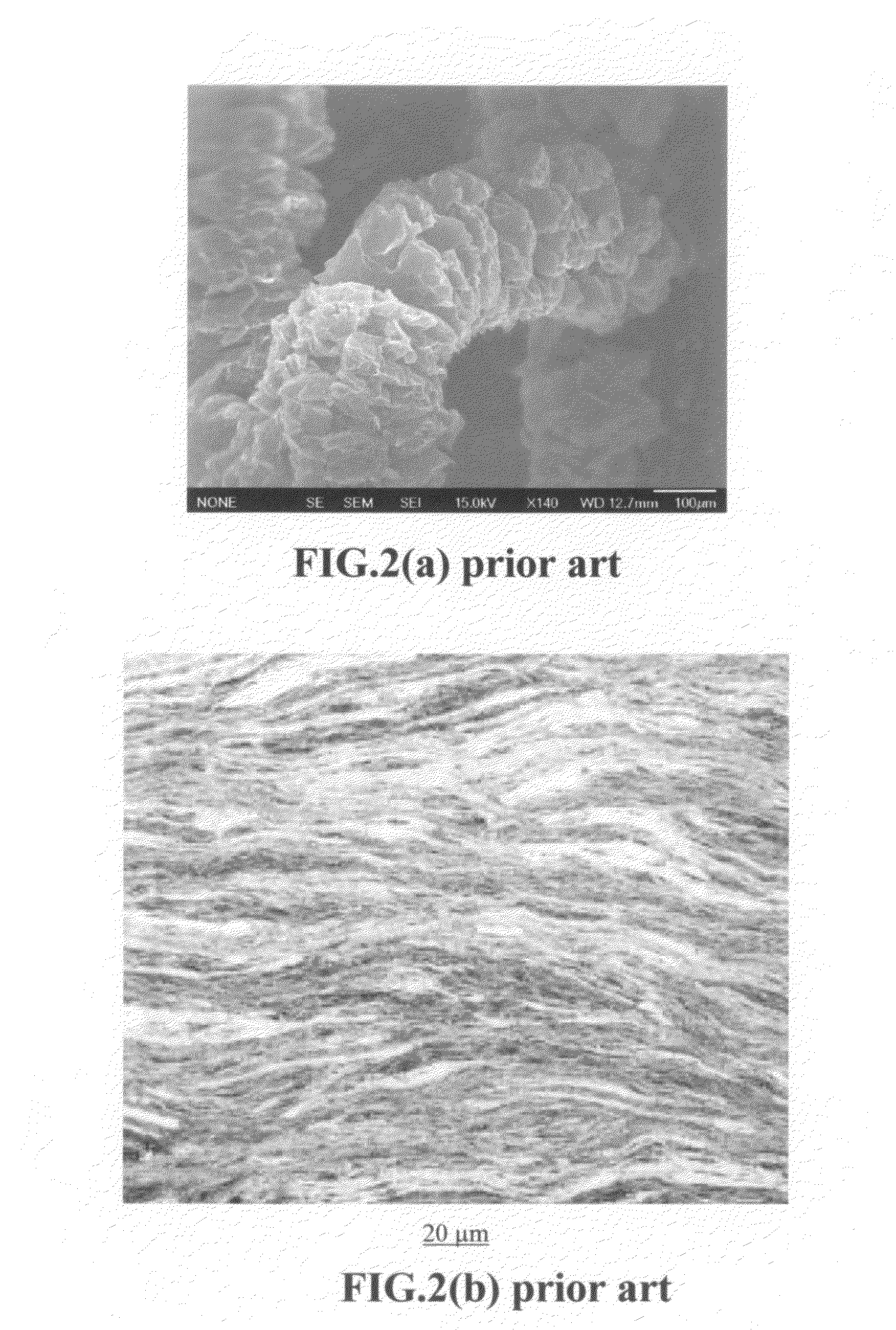

Graphene oxide-coated graphitic foil and processes for producing same

ActiveUS20140127488A1Reduce eliminateImprove surface smoothnessMaterial nanotechnologyGraphiteCarbon compositesFiber

A graphene oxide-coated graphitic foil, composed of a graphitic substrate or core layer having two opposed primary surfaces and at least a graphene oxide coating layer deposited on at least one of the two primary surfaces, wherein the graphitic substrate layer has a thickness preferably from 0.34 nm to 1 mm, and the graphene oxide coating layer has a thickness preferably from 0.5 nm to 1 mm and an oxygen content of 0.01%-40% by weight based on the total graphene oxide weight. The graphitic substrate layer may be preferably selected from flexible graphite foil, graphene film, graphene paper, graphite particle paper, carbon-carbon composite film, carbon nano-fiber paper, or carbon nano-tube paper. This graphene oxide-coated laminate exhibits a combination of exceptional thermal conductivity, electrical conductivity, mechanical strength, surface smoothness, surface hardness, and scratch resistance unmatched by any thin-film material of comparable thickness range.

Owner:GLOBAL GRAPHENE GRP INC

Non-Phosphorus composite anti incrustation eorrosion snhibiter and its application in water treatment

ActiveCN1785853AImprove performanceExcellent resistance to CaCO

<sub>3</sub>

Dirt performanceScale removal and water softeningMolybdatePolyaspartic acid

The present invention relates to a phosphorus-free composite antiincrustation corrosion inhibitor. It includes polyaspartic acid and / or polyepoxysuccinic acid and at least one kind of scale inhibition and dispersion agent, in which the scale inbibition and dispersion agent is polymer containing carboxylic acid group, or it includes polyaspartic acid and / or polyepoxysuccinic acid, zinc salt, molybdate or tungstate and polymer containing carboxylic acid group. Said invention is applicable to treatment of circulating cooling water.

Owner:BEIJING YANHUA PETRO CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com