Halogen-free flame-retardant thermoplastic elastomer electrical cable material using polyphenylene ether as base material and preparation method thereof

A thermoplastic elastomer and polyphenylene ether technology, which is used in the field of halogen-free flame retardant thermoplastic elastomer cable material and its preparation, can solve the problems of hard and comfortable hand feeling, flame retardant performance, unsatisfactory softness, etc. Delamination phenomenon, effect of low hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

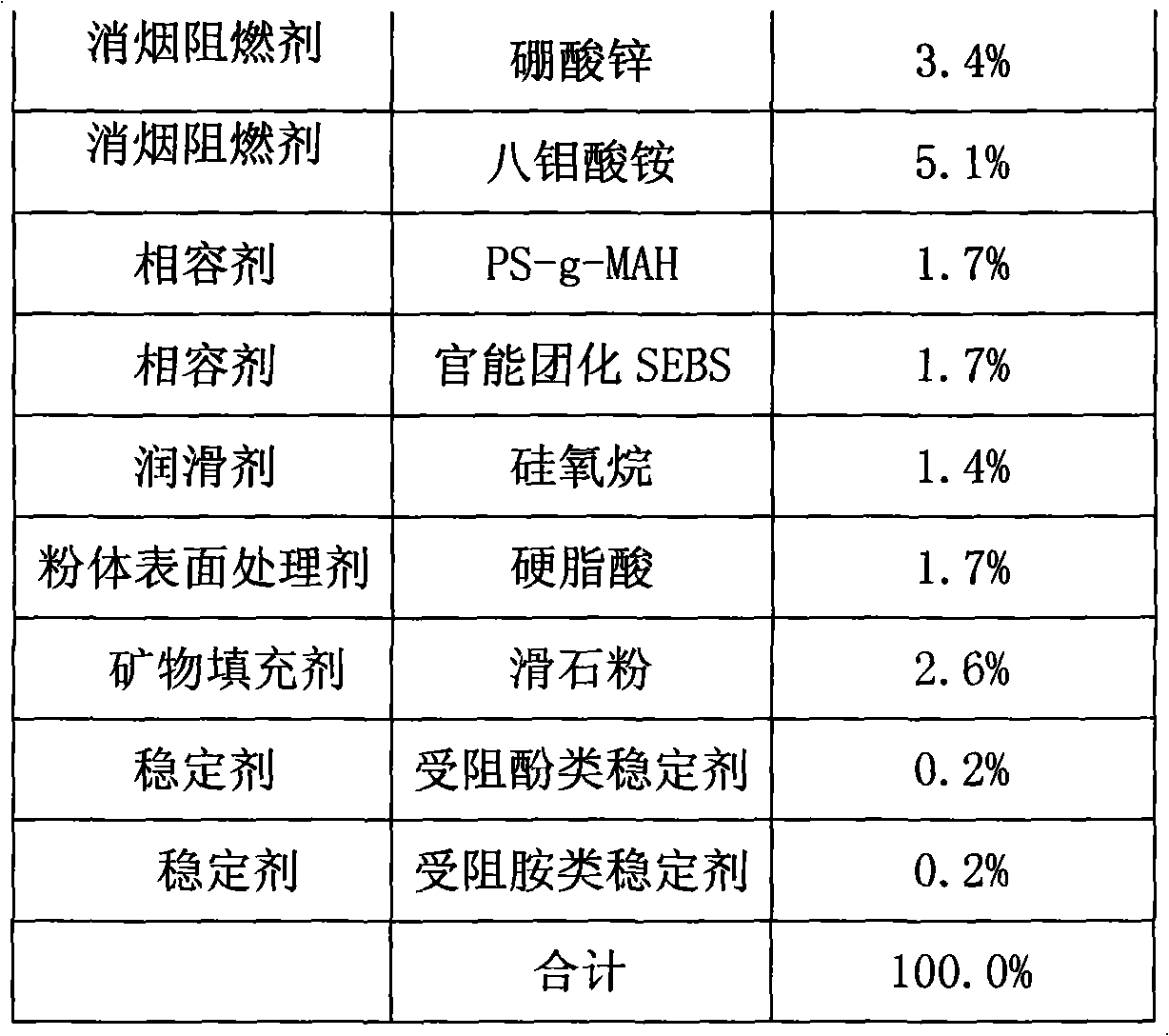

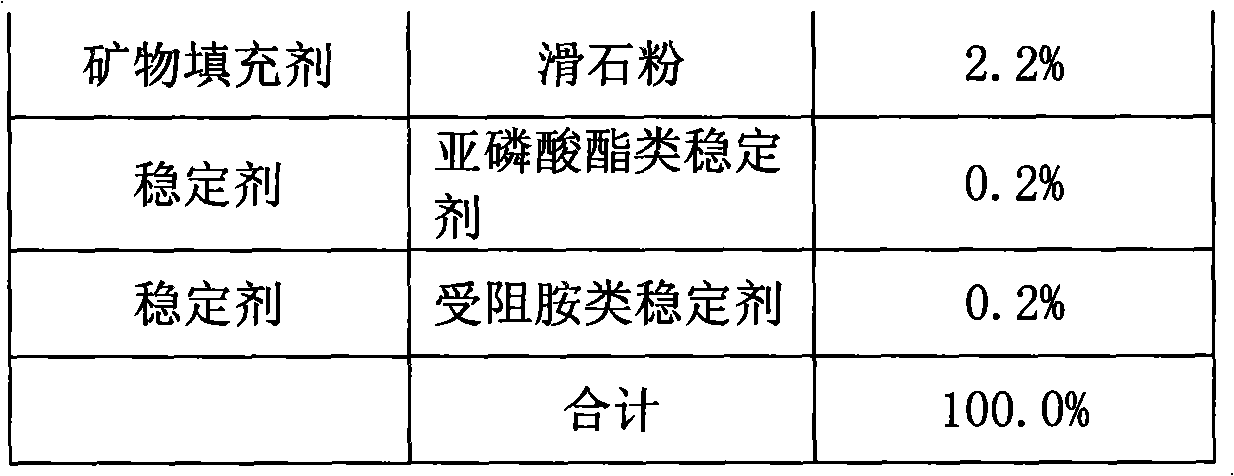

[0039] 1. Weighing by weight percentage: weigh base resin A polyphenylene ether homopolymer PPO 18.0%, base resin B high impact polystyrene GPPS 4.5%, elastomer styrene-butadiene-styrene block copolymer SBS 10.8%, softening plasticizer saturated linear paraffin oil 9.0%, flame retardant plasticizer: triphenyl phosphate TTP 9.0%, smoke suppressing flame retardant: melamine cyanurate MGA 5.4%, ammonium polyphosphate APP 9.0%, aluminum hydroxide ATH 23.4%, compatibilizer: polystyrene-maleic anhydride graft PS-g-MAH 1.8%, functionalized styrene-ethylene / butylene-styrene block copolymer SEBS 1.8%, lubricant: polyethylene candle 1.4%, powder surface treatment agent: stearic acid 1.8%, mineral filler: talcum powder 3.6%, stabilizer: hindered phenol stabilizer 0.4%, total 100%, spare.

[0040] 2. Powder treatment: first add the powder required for the weighed material, such as smoke suppressing flame retardant and mineral filler, into the mixer, stir with a high-speed mixer for 10 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com