Patents

Literature

682 results about "High impact polystyrene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

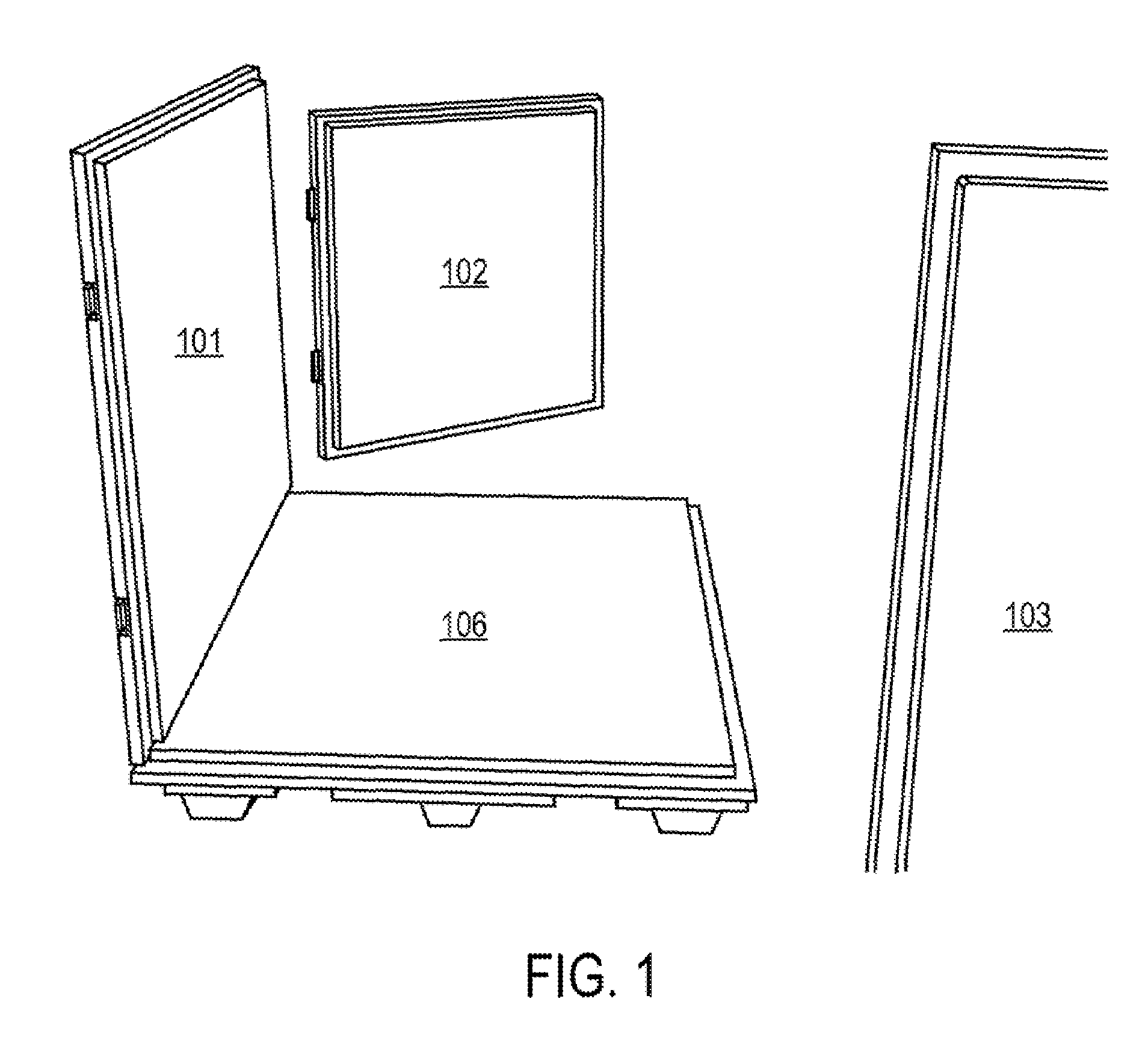

Dunnage platform

InactiveUS7128797B2Easy to moveAdhesive processesMechanical working/deformationDunnageChemical combination

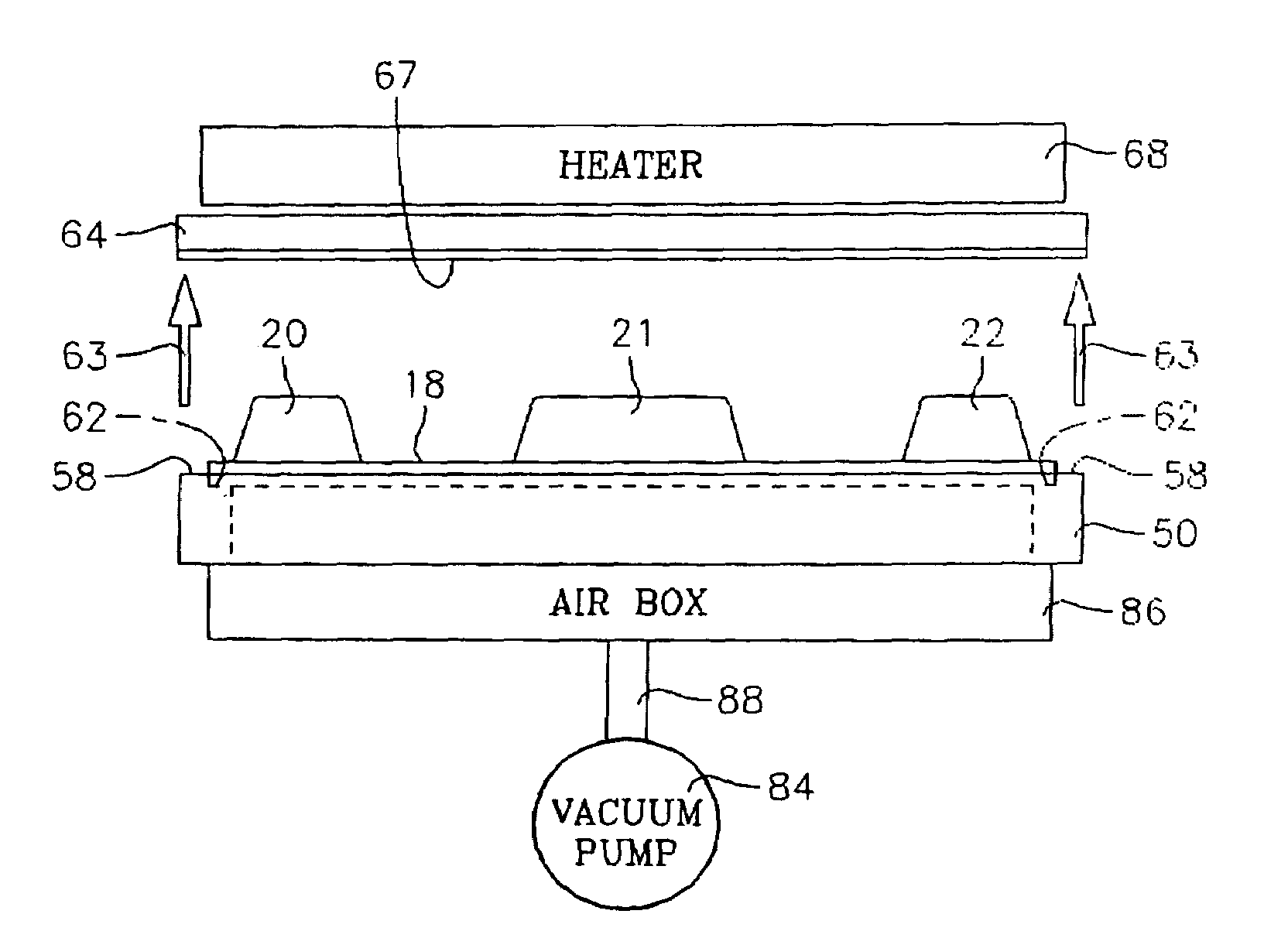

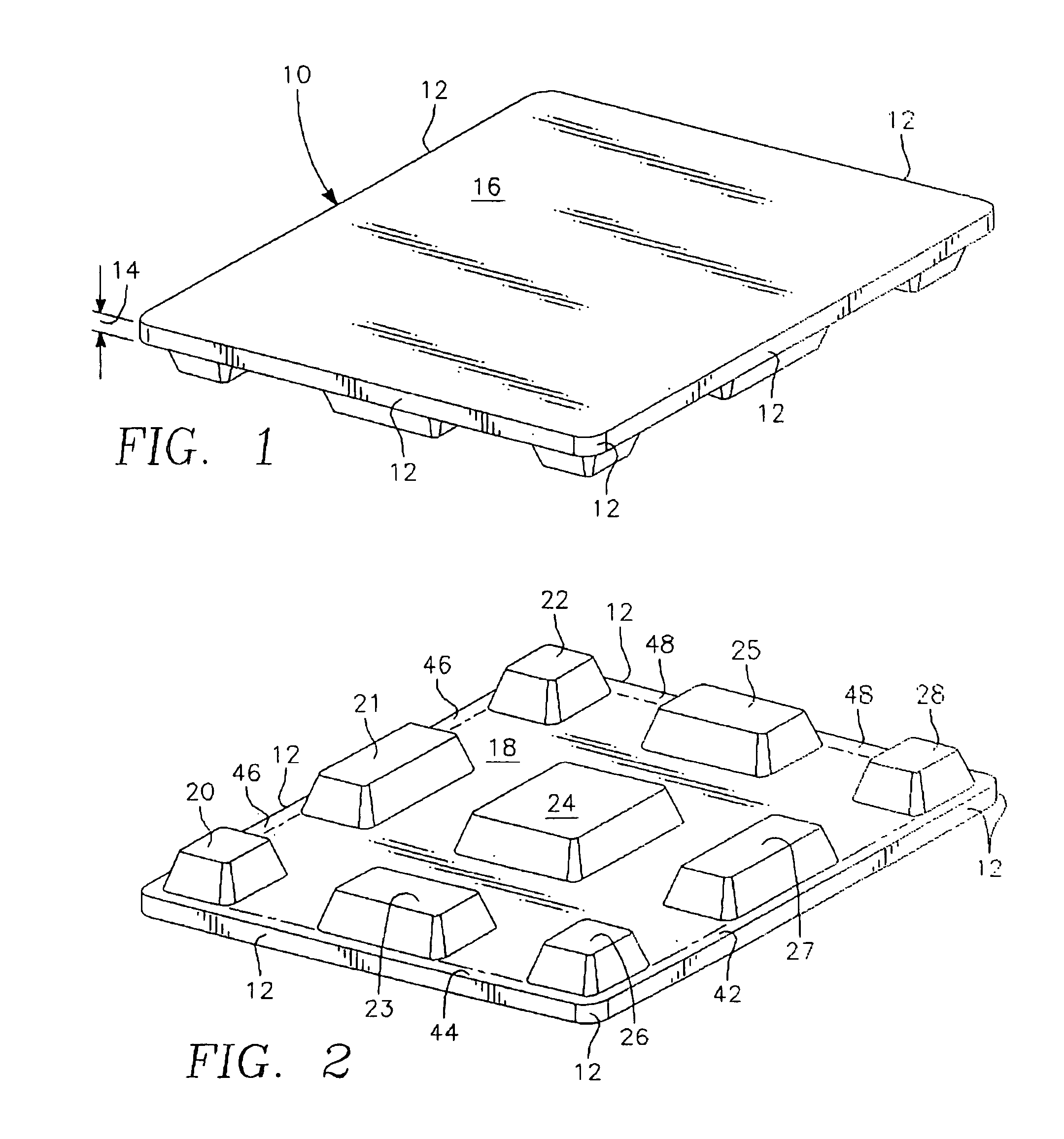

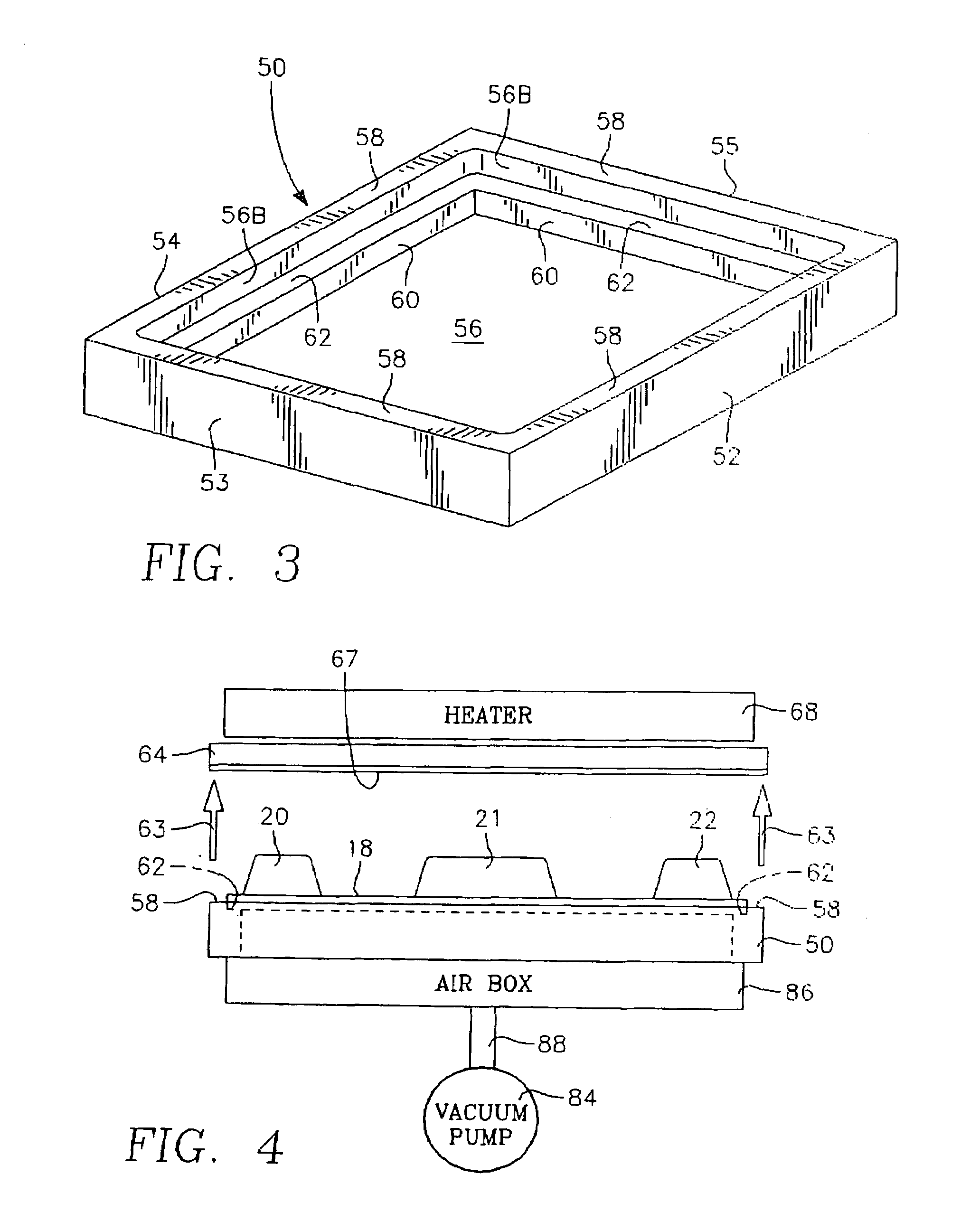

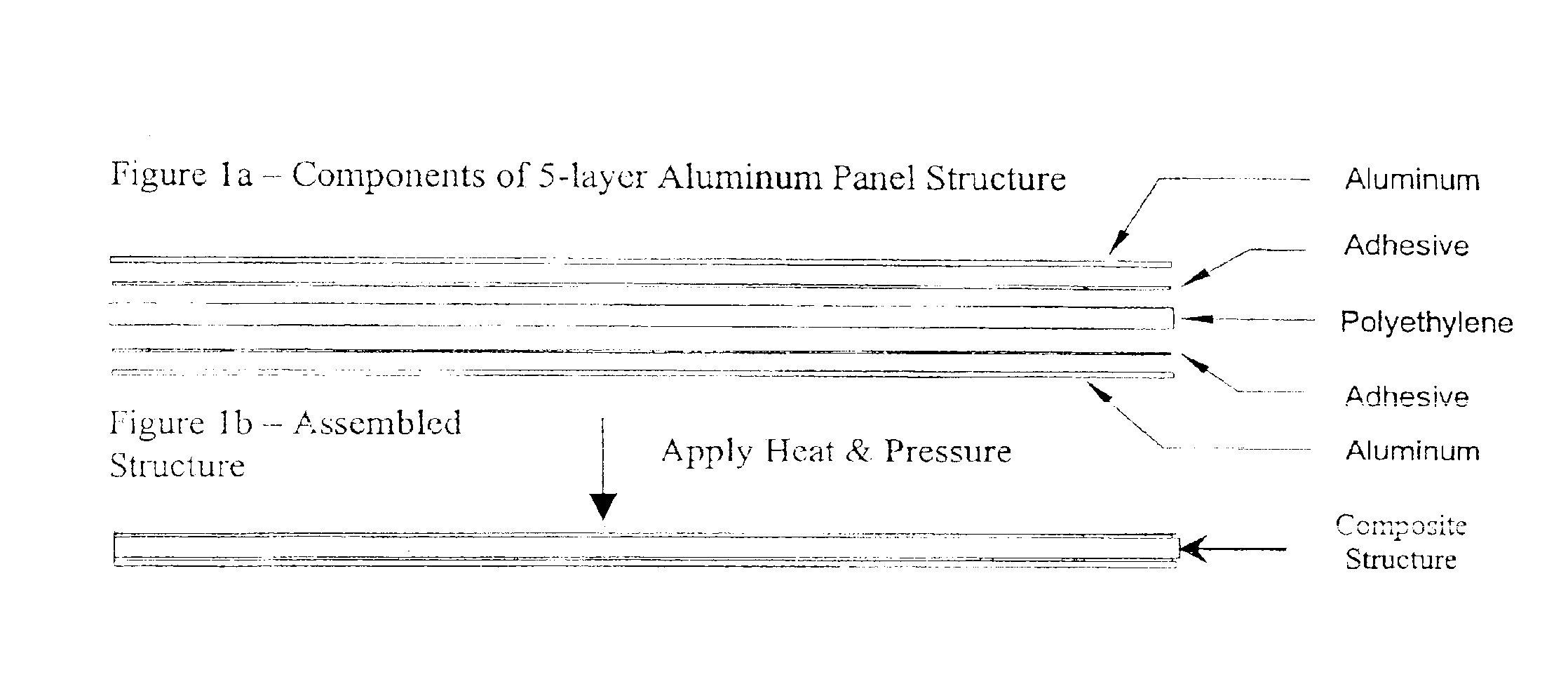

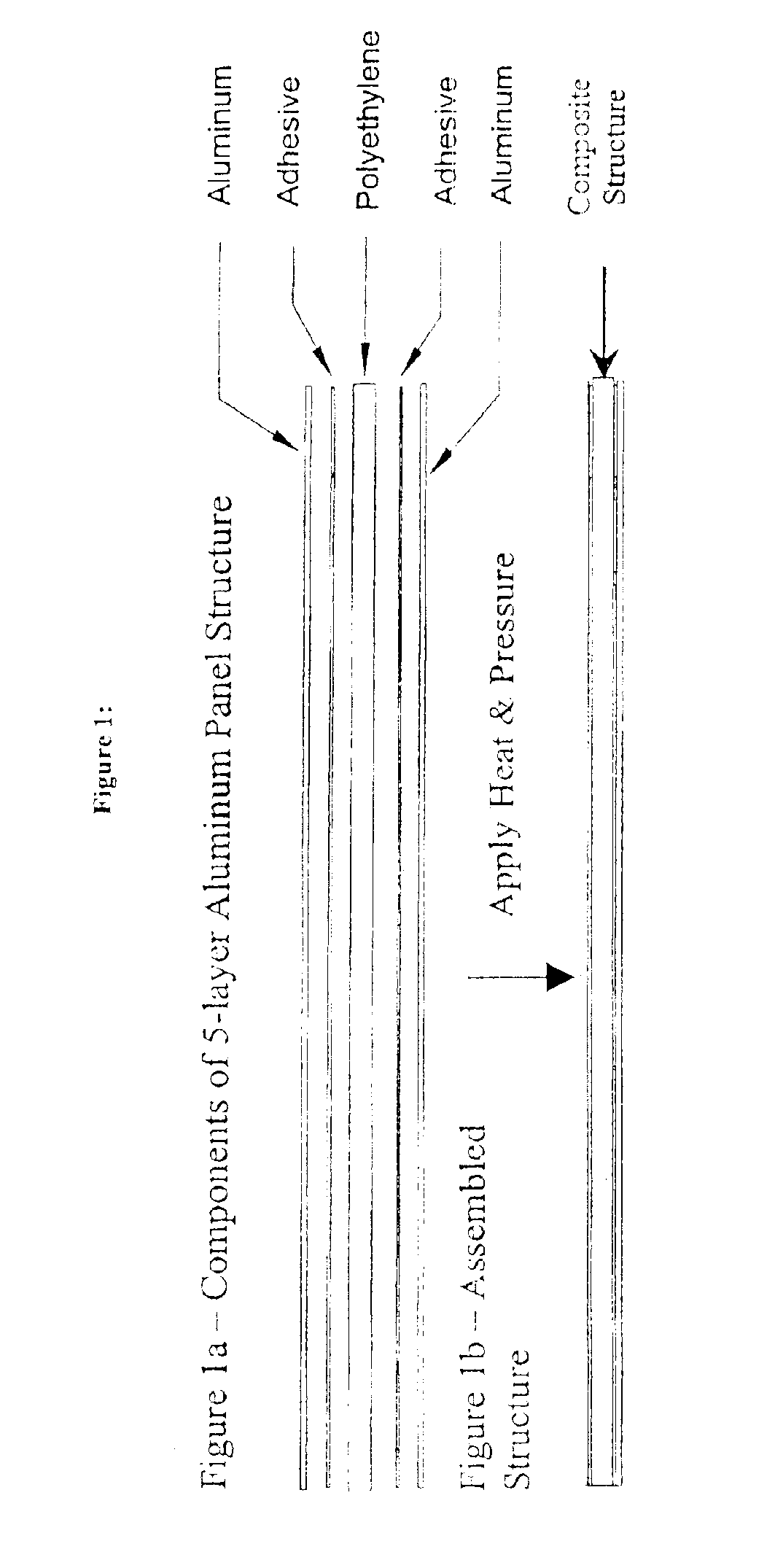

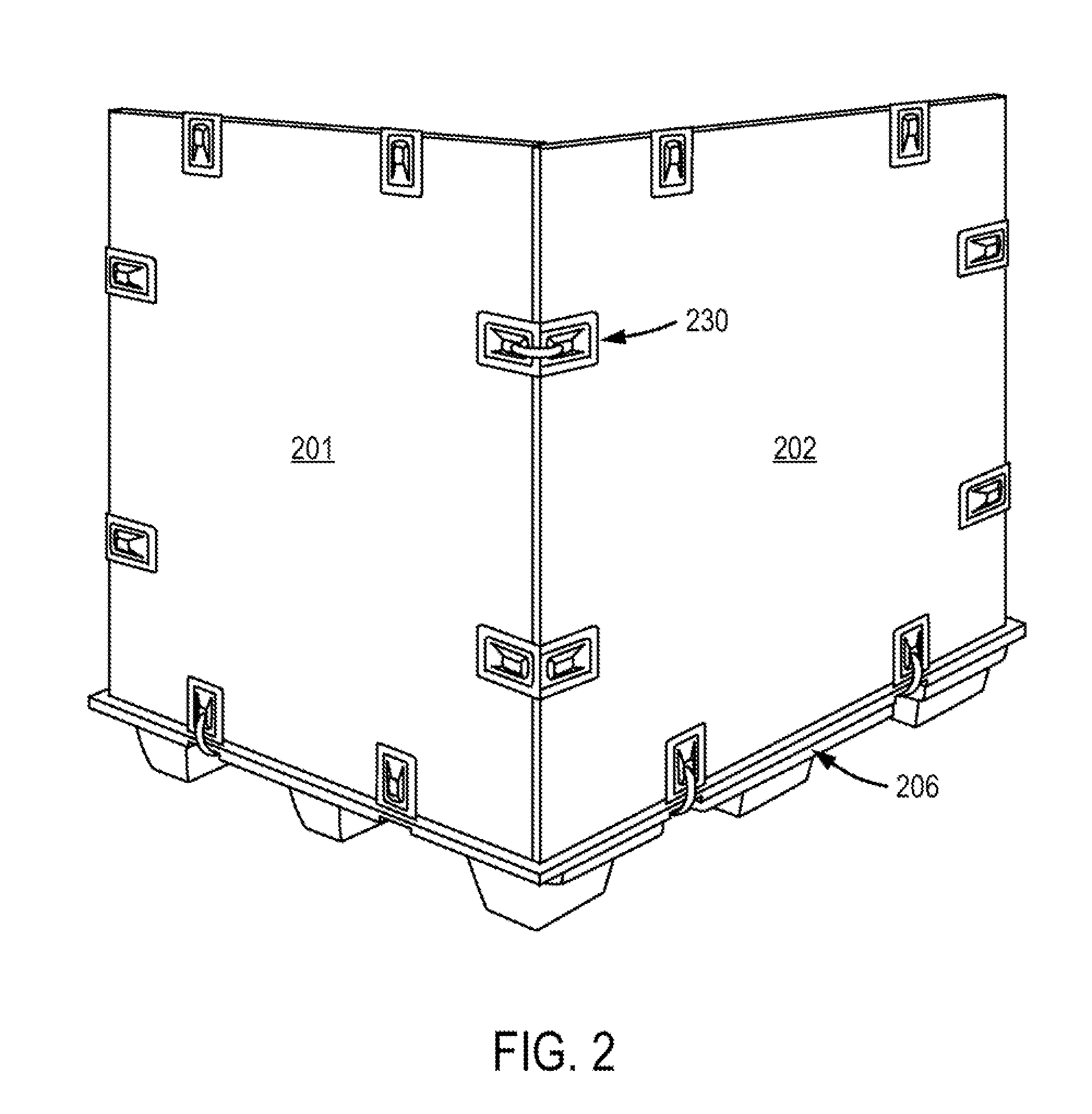

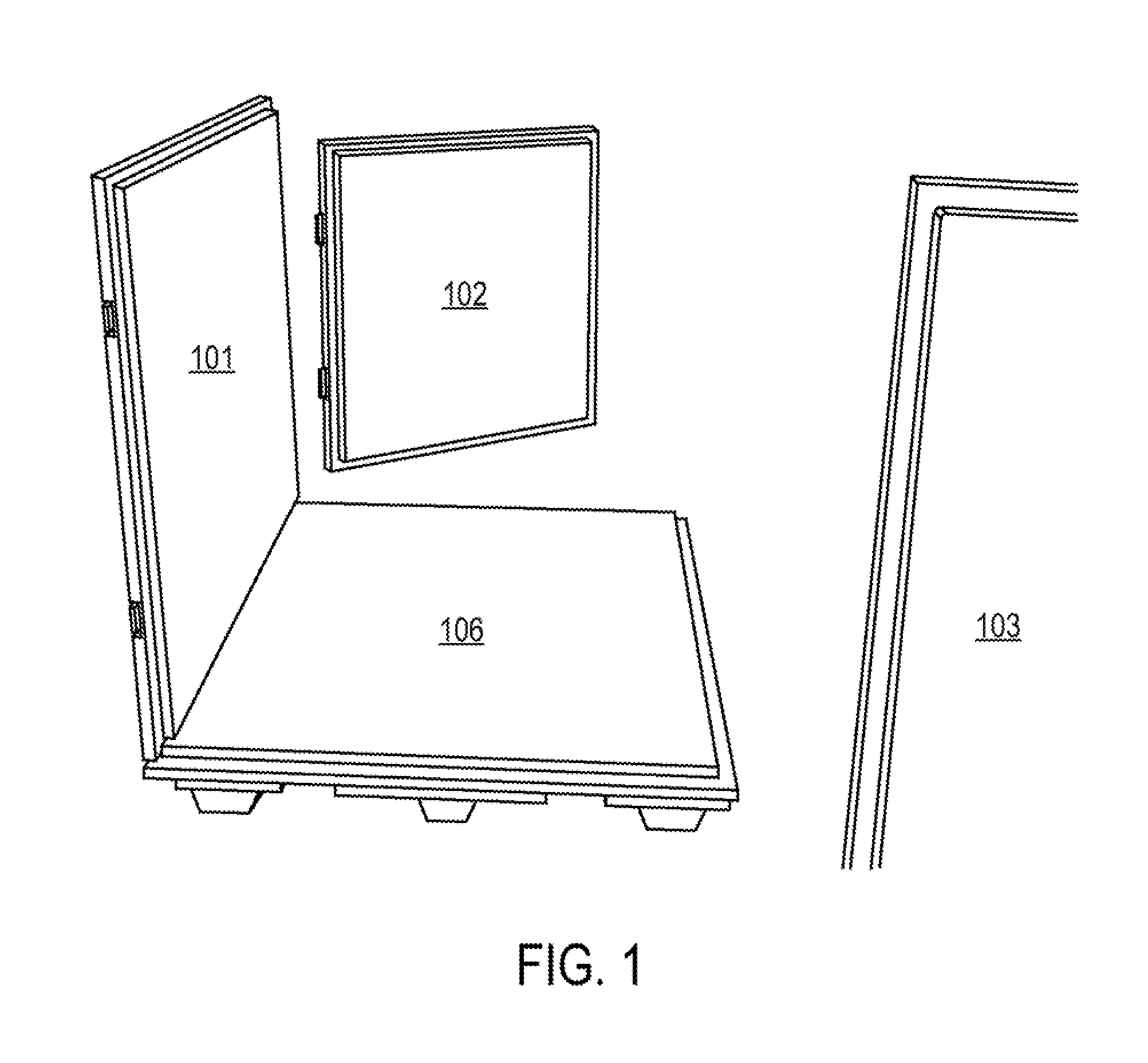

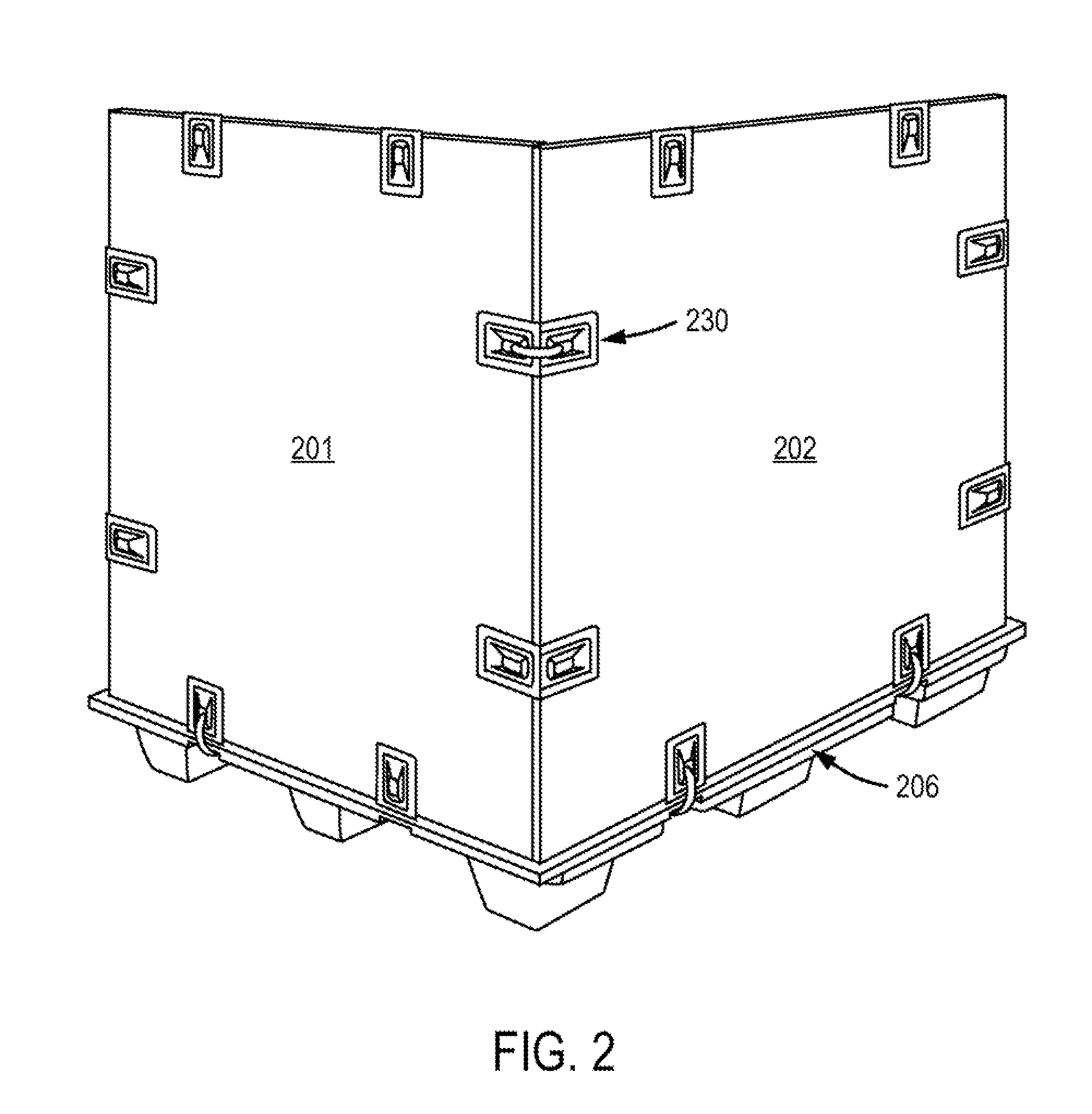

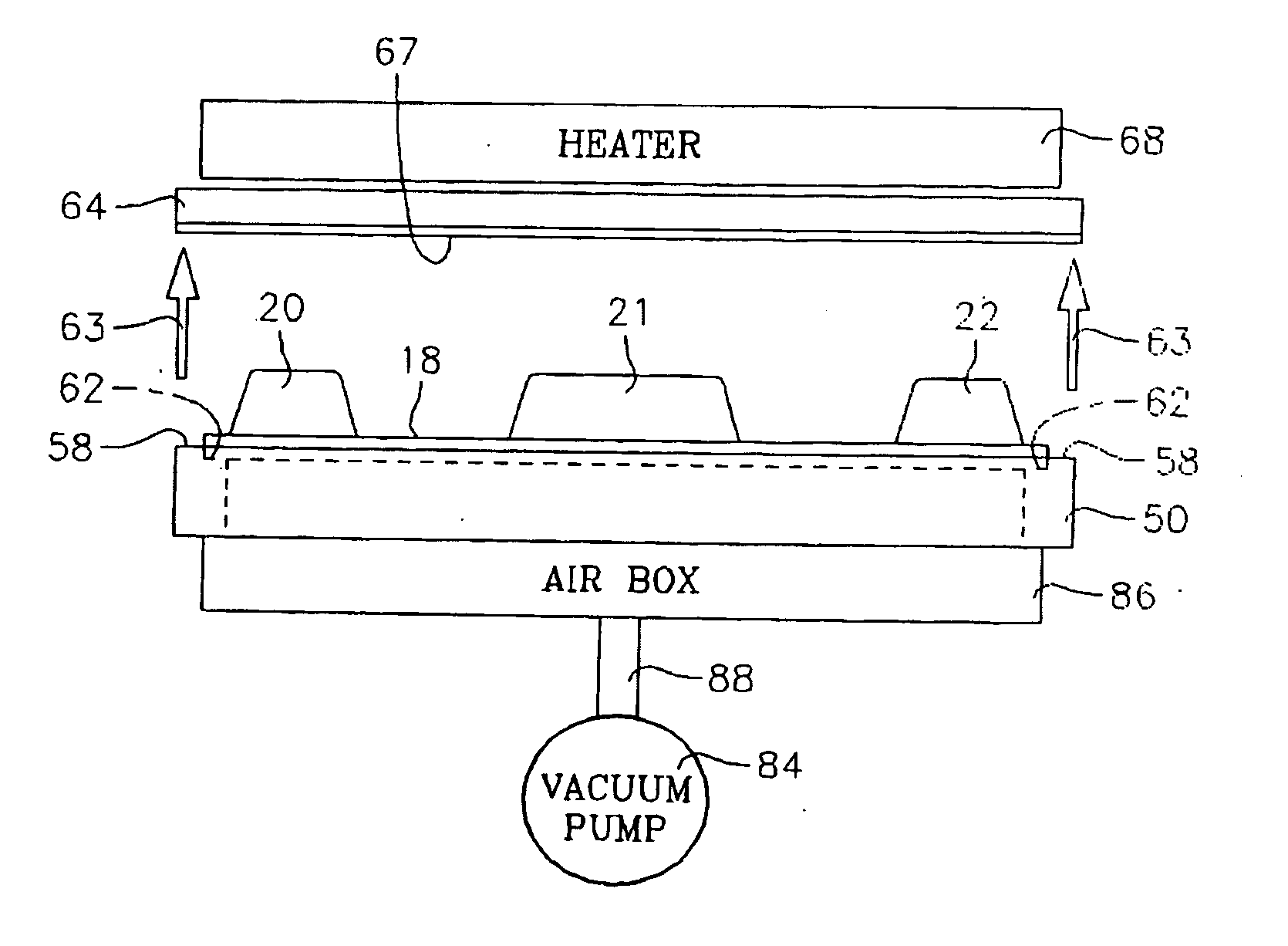

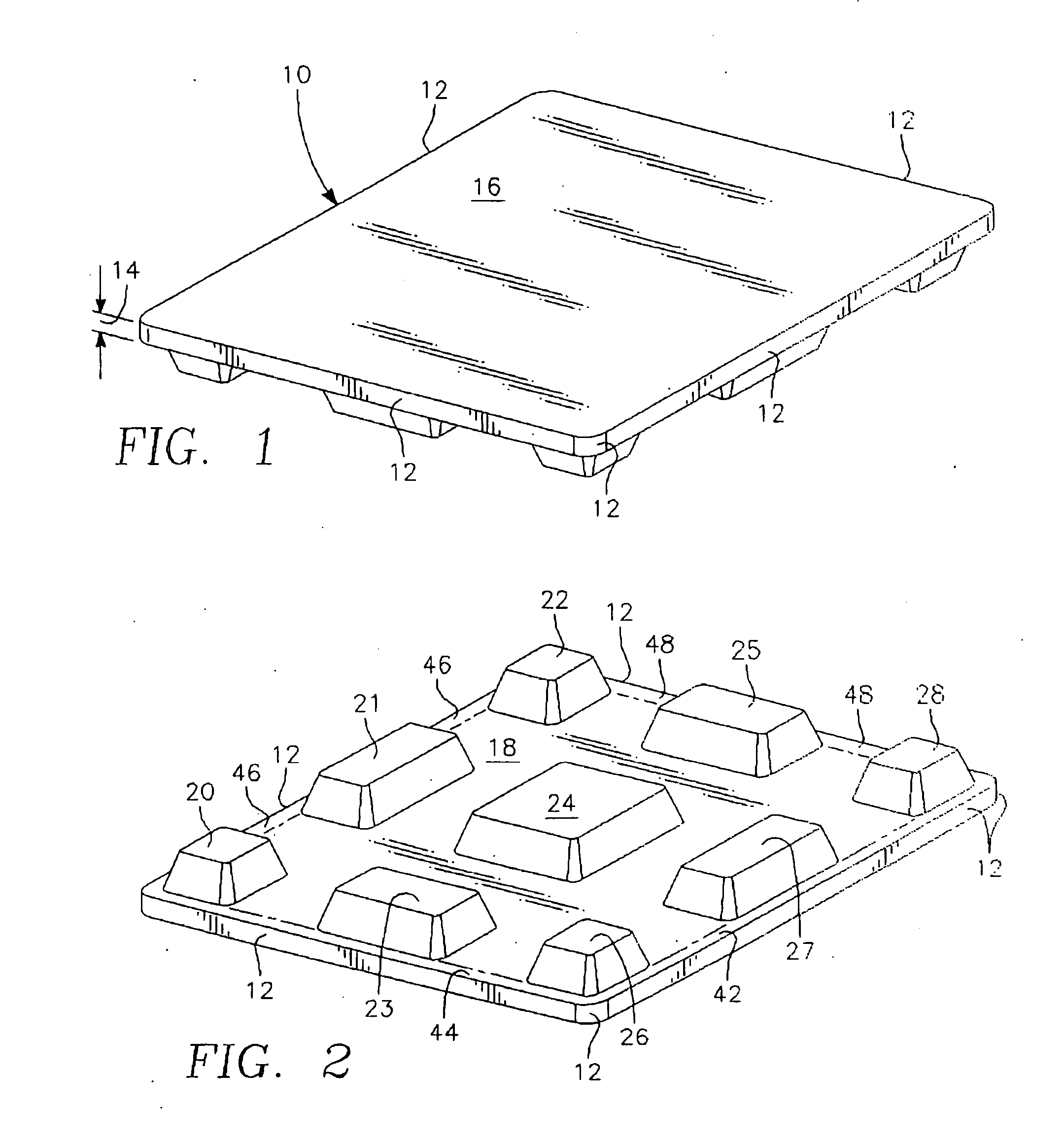

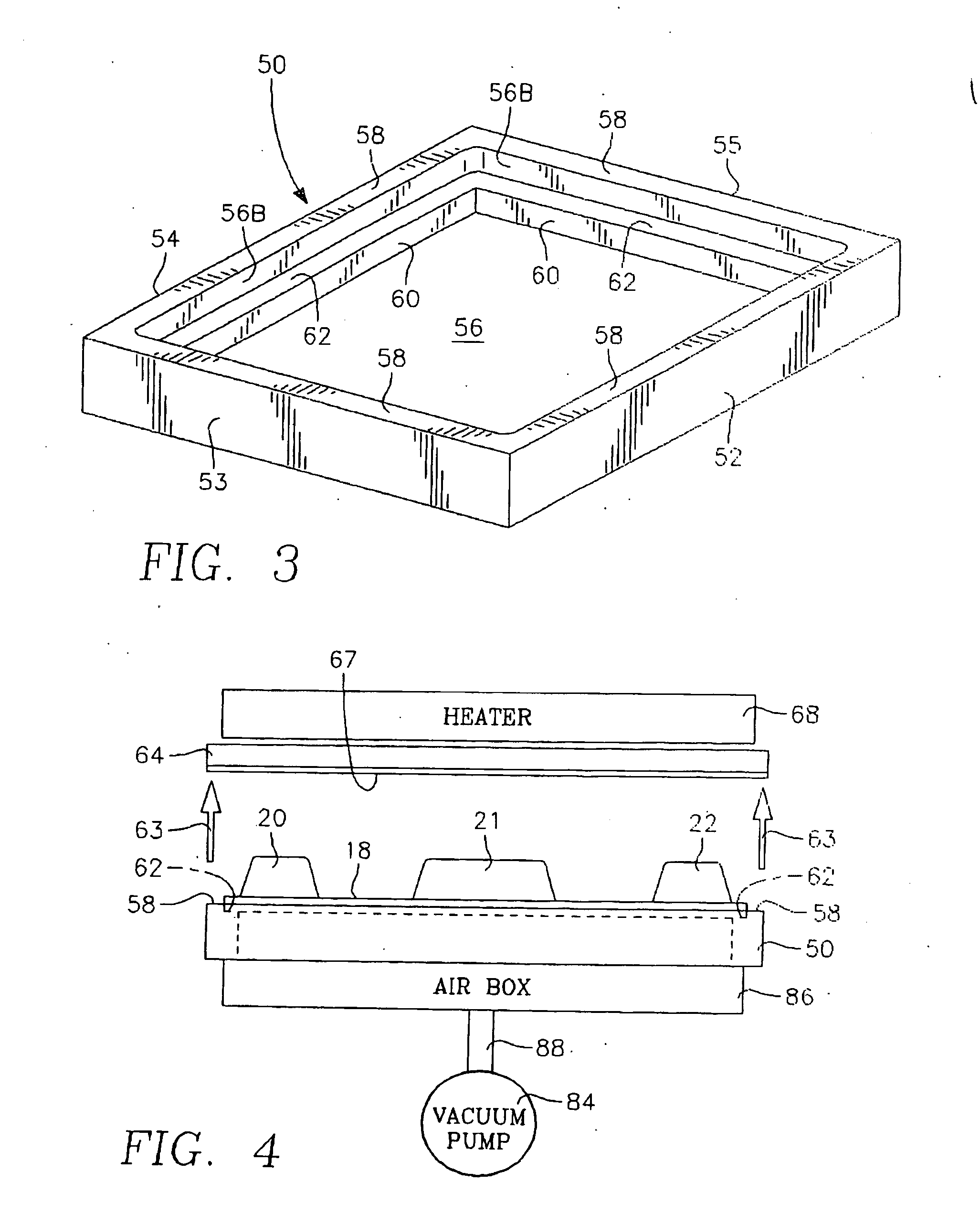

A dunnage platform is in the general shape of a rectangular slab with legs extending form one side. The dunnage platform is made from an expanded polystyrene core. A chemical combination process is used to chemically combine portion of the core proximal to its surface with high impact polystyrene. In a first of two parts of the combination process, the core is placed in a forming mold with one of its two sides and two thirds of its thickness extending therefrom. A heated sheet of high impact polystyrene is brought into contact with the portion of the core extending from the mold. In a similar manner, the other of the two sides of the core is made to extend from the forming mold for contact with a heated sheet of high impact polystyrene.

Owner:AIRDEX CORP

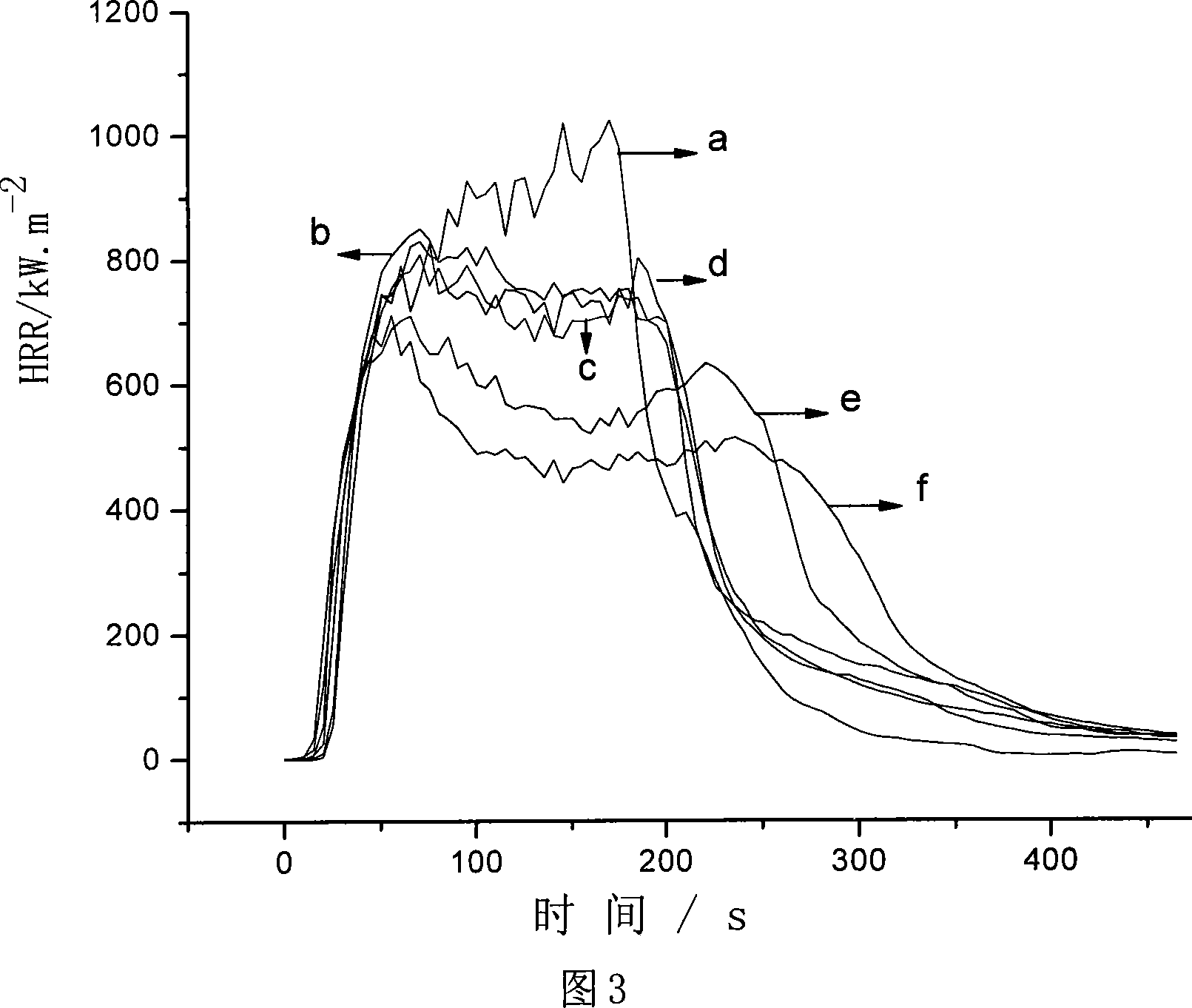

High-impact polystyrene blend and preparation thereof

InactiveCN101372548AFlame-retardant high-impact polystyrene blend, environmentally friendlyEnvironmentally friendlyAntioxidantMechanical property

The invention relates to a synthetic material, in particular to a halogen-free flame retardant high impact polystyrene blend and a preparation method thereof. The high impact polystyrene blend comprises high impact polystyrene resin with the mass percent of 35-75%, an inorganic flame retardant with the mass percent of 7-45%, an intumescent flame retardant with the mass percent of 5-20%, a flame retardant synergist with the mass percent of 1-5%, a toughening agent with the mass percent of 10-20%, a coupling agent with the mass percent of 0.5-2.0%, a lubricant with the mass percent of 0.5-3.0% and an antioxidant with the mass percent of 0.2-3.0%. The halogen-free flame retardant high impact polystyrene blend is produced by high-speed premixing and extrusion prilling, and has the advantages of environmental protection, flame retardation, low smoke, weather resistance, good thermal stability and mechanical property, easy machine shaping, etc.

Owner:珠海市远康企业有限公司

Low-smoke halogen-freeflame-proof polyphenylene oxide electric wire and cable material, and method for producing the same

InactiveCN101130616AImprove flame retardant performanceImprove toughnessInsulated cablesInsulated conductorsElastomerPliability

The invention discloses a low smoke non-bitter flame-proof polyphenyl ether electric wire and cable material and preparing method, which is characterized by the following: allocating 40-80 wt polyphenyl ether PPO, 20-60 wt high impact polystyrene HIPS, 10-70 wt elastic body, 1-20 wt functional polyphenyl ether, 10-60 wt fire retardant, 5-20 wt smoke suppressor, 1-3 wt anti-oxidant and 3-5 wt environmental protection color master particle; using higher rigidity, good electrical isolation property and water resistance of the polyphenyl ether material; decreasing hardness of blending system; increasing tenacity; adding into inclusive property; increasing cohesion between the PPO and the elastic body; improving combination mechanical property of the blending material. This product is environmental protection product, which possesses good water resistance property and electrical isolation property.

Owner:SHENZHEN KEJU NEW MATERIAL

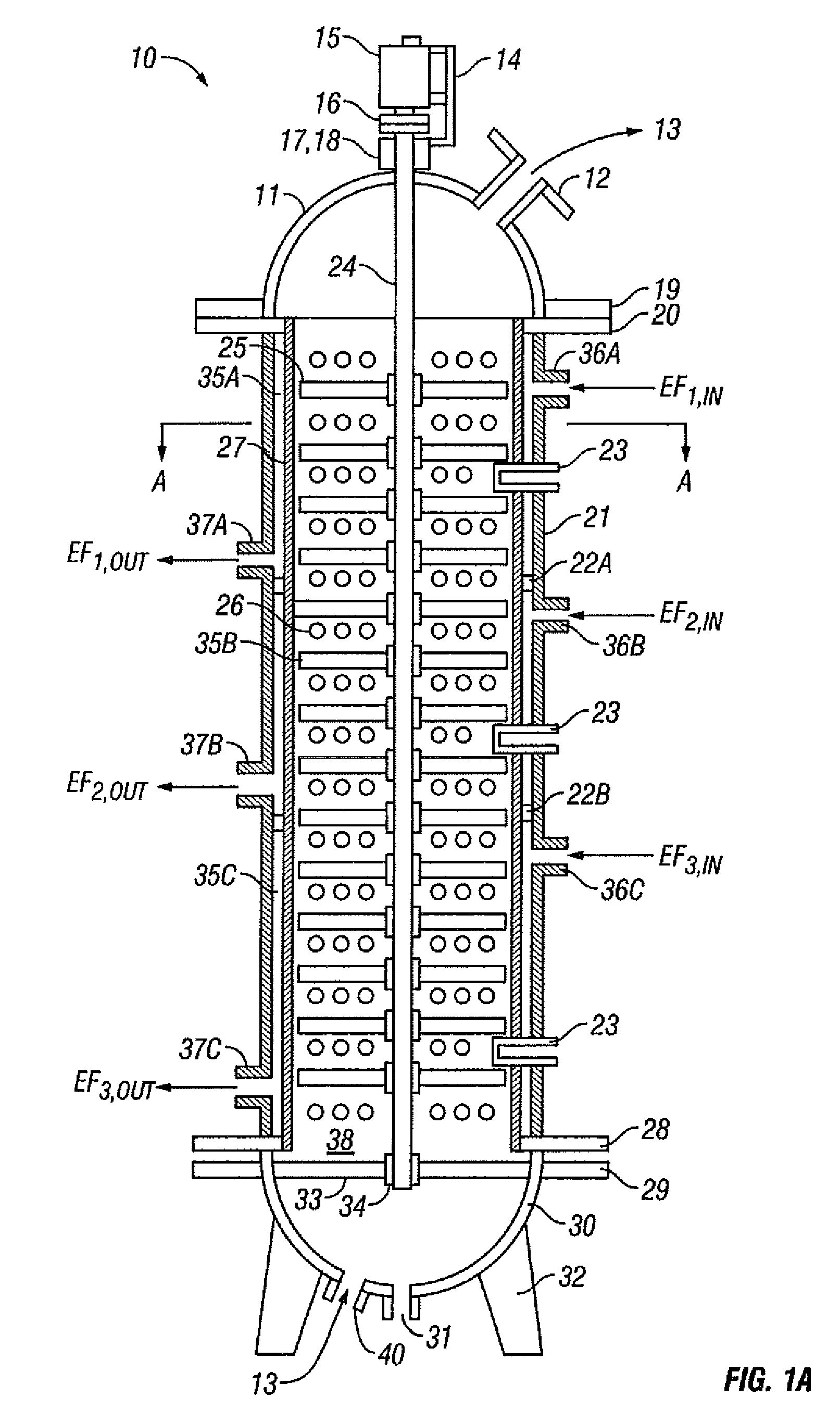

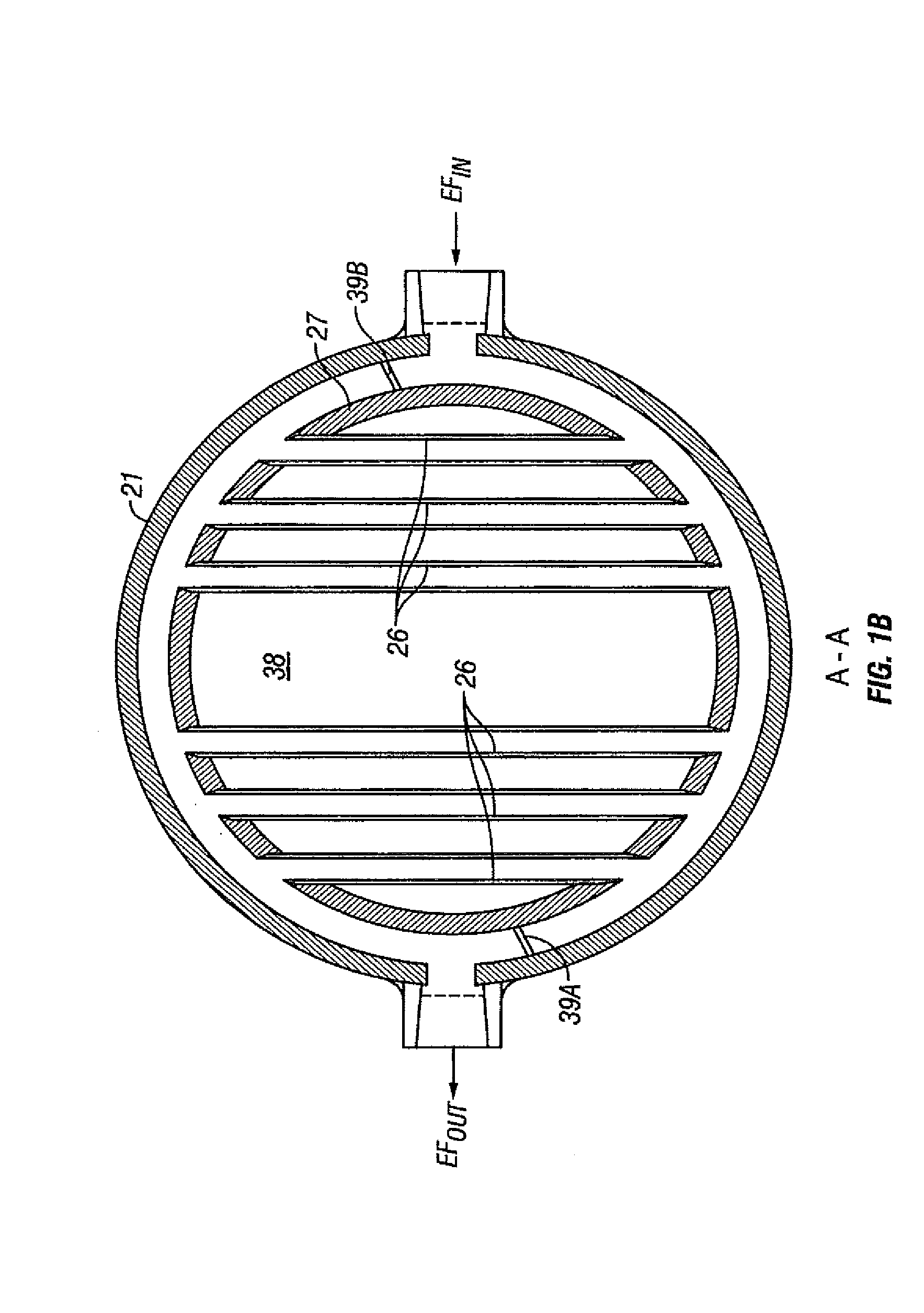

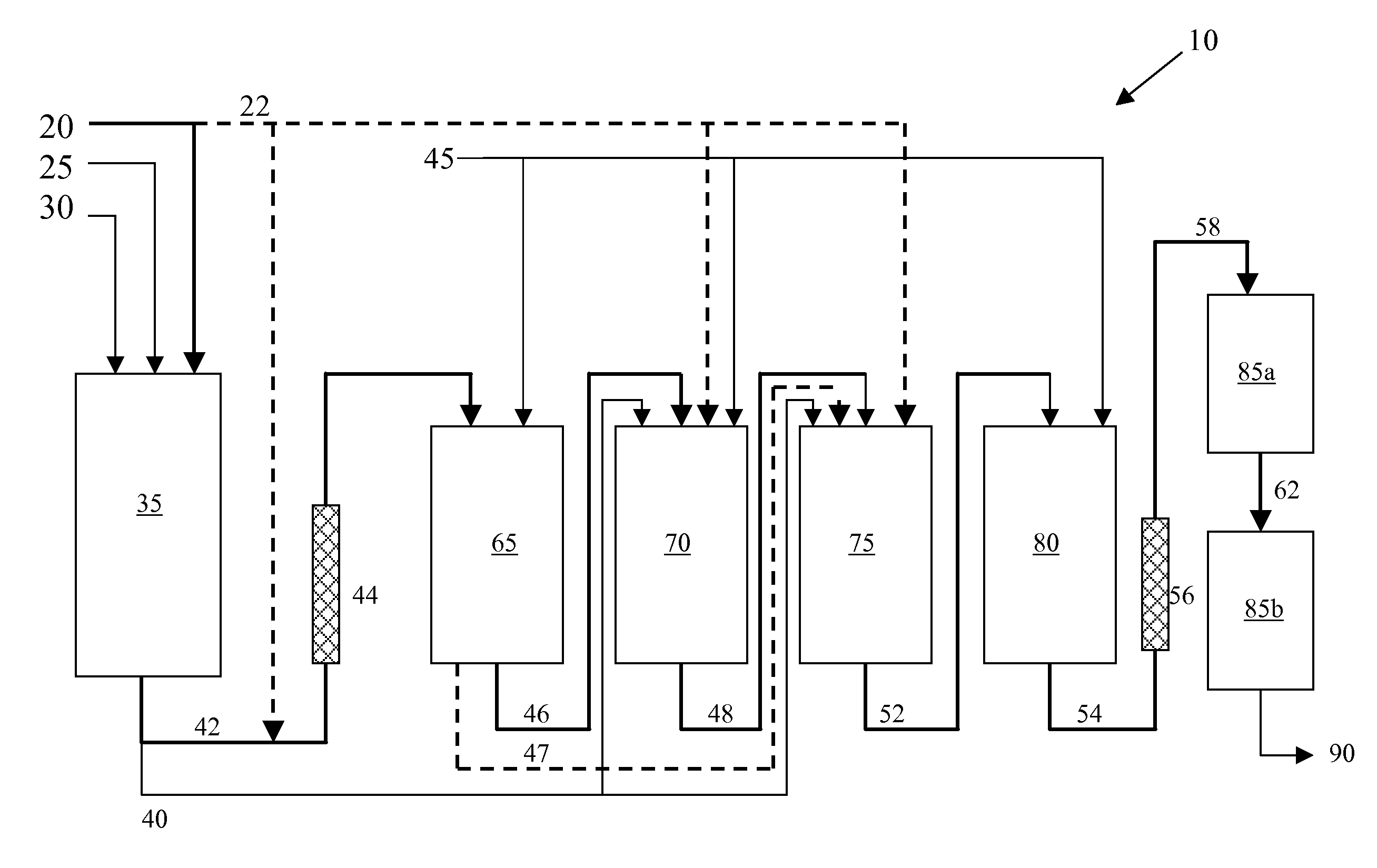

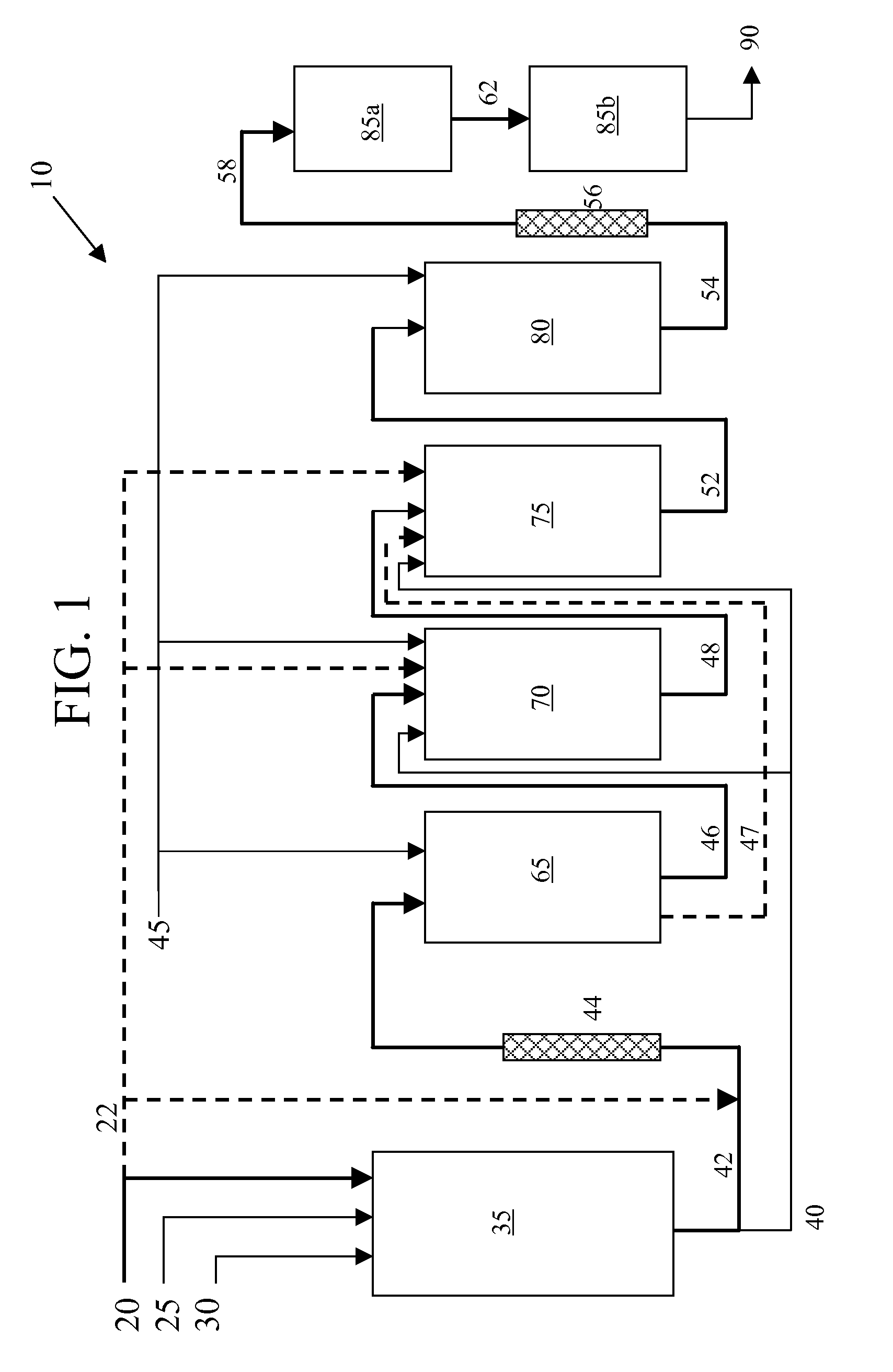

Plug flow reactor and polymers prepared therewith

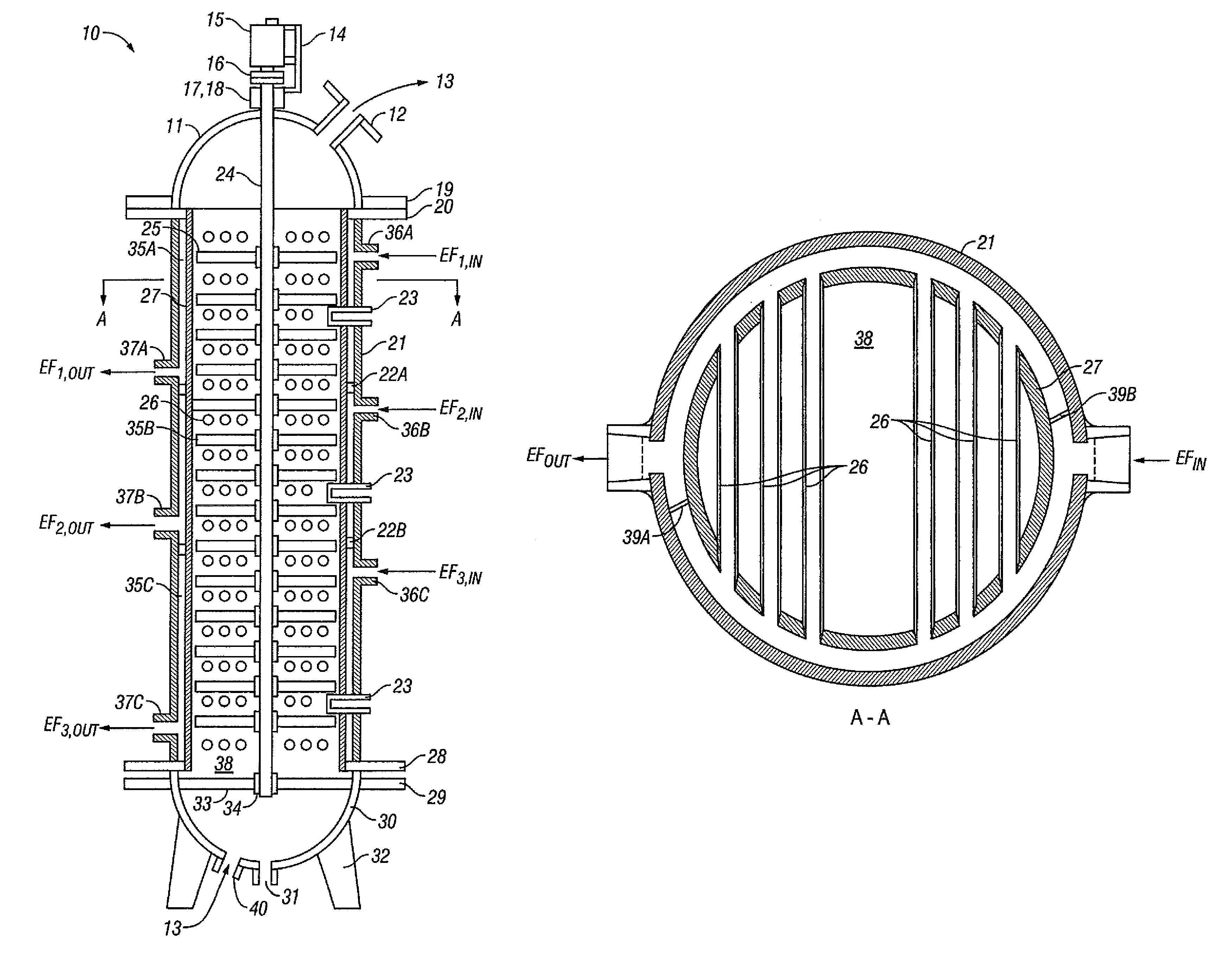

InactiveUS7511101B2Domestic stoves or rangesSpace heating and ventilationProcess engineeringHigh impact polystyrene

A plug flow reactor having an inner shell 27 surrounded by outer shell 21 and having at least one annular flow passage 35 therebetween can be used to prepare compositions, including polymers. The plug flow reactor also includes inlet port 36, an outlet port 37 and a plurality of exchanger tubes 26 wherein the exchanger tubes are in fluid communication to the at least one annular flow passage. Polystyrene and high impact polystyrene can be prepared using the reactor.

Owner:FINA TECH

Low activation temperature adhesive composition with high peel strength and cohesive failure

The present invention provides a resin composition made from admixing starting materials comprising: (a) 0 to 90 parts by weight of a polyolefin; (b) 5 to 95 parts by weight of a functional polyolefin; (c) 5 to 40 parts by weight of a polystyrenic; and (d) 0 to 30 parts by weight of an elastomer, where the total amount of components of (a), (b), (c) and (d) in the resin composition is 100 parts by weight. In a further embodiment, component (a) is a non-olefin copolymer and component (c) is high impact polystyrene. The resin compositions are useful as adhesives for metal and polyolefin substrates.

Owner:PERFORMANCE MATERIALS NA INC

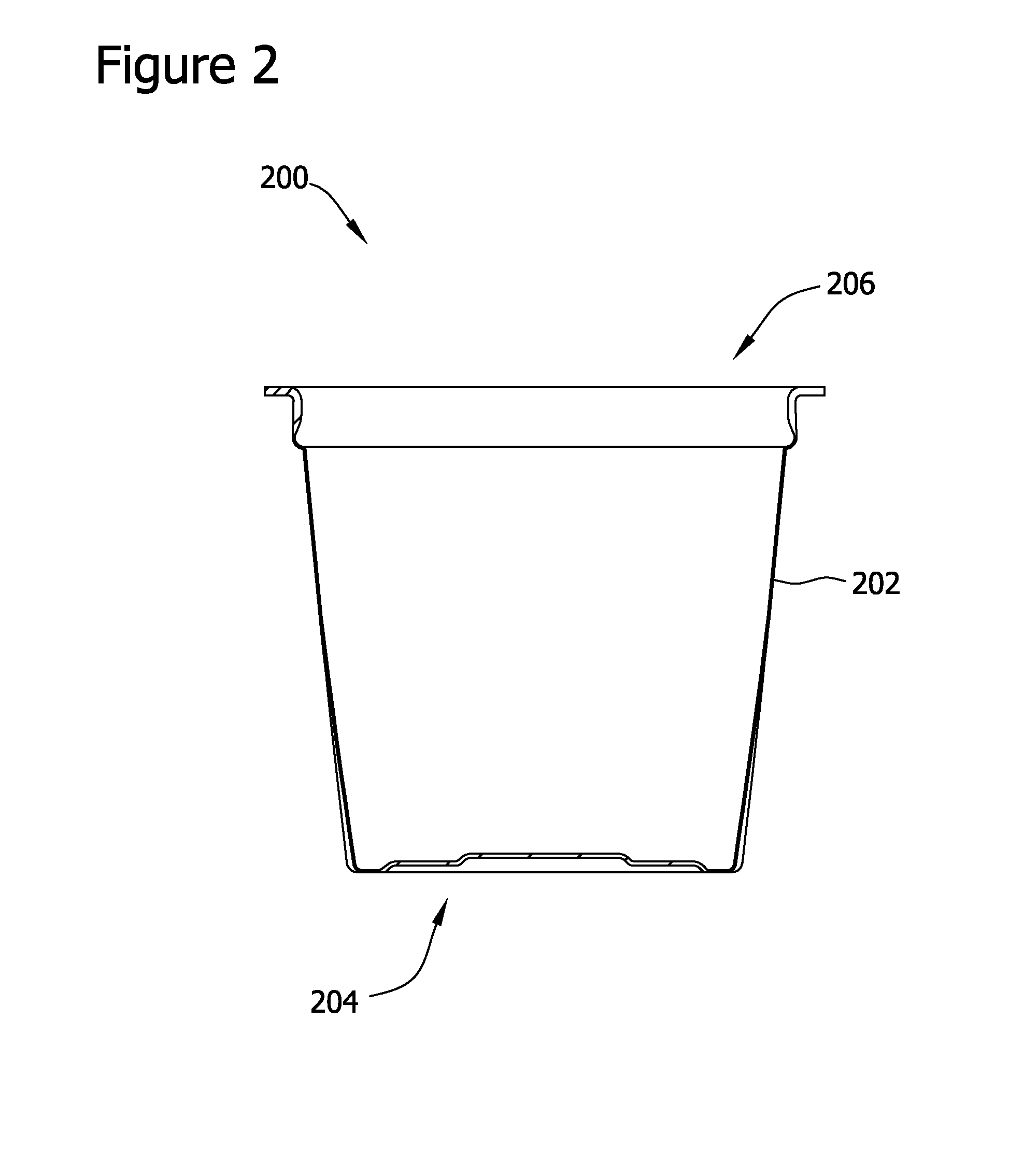

Disposable lid having polymer composite of polyolefin and mineral filler

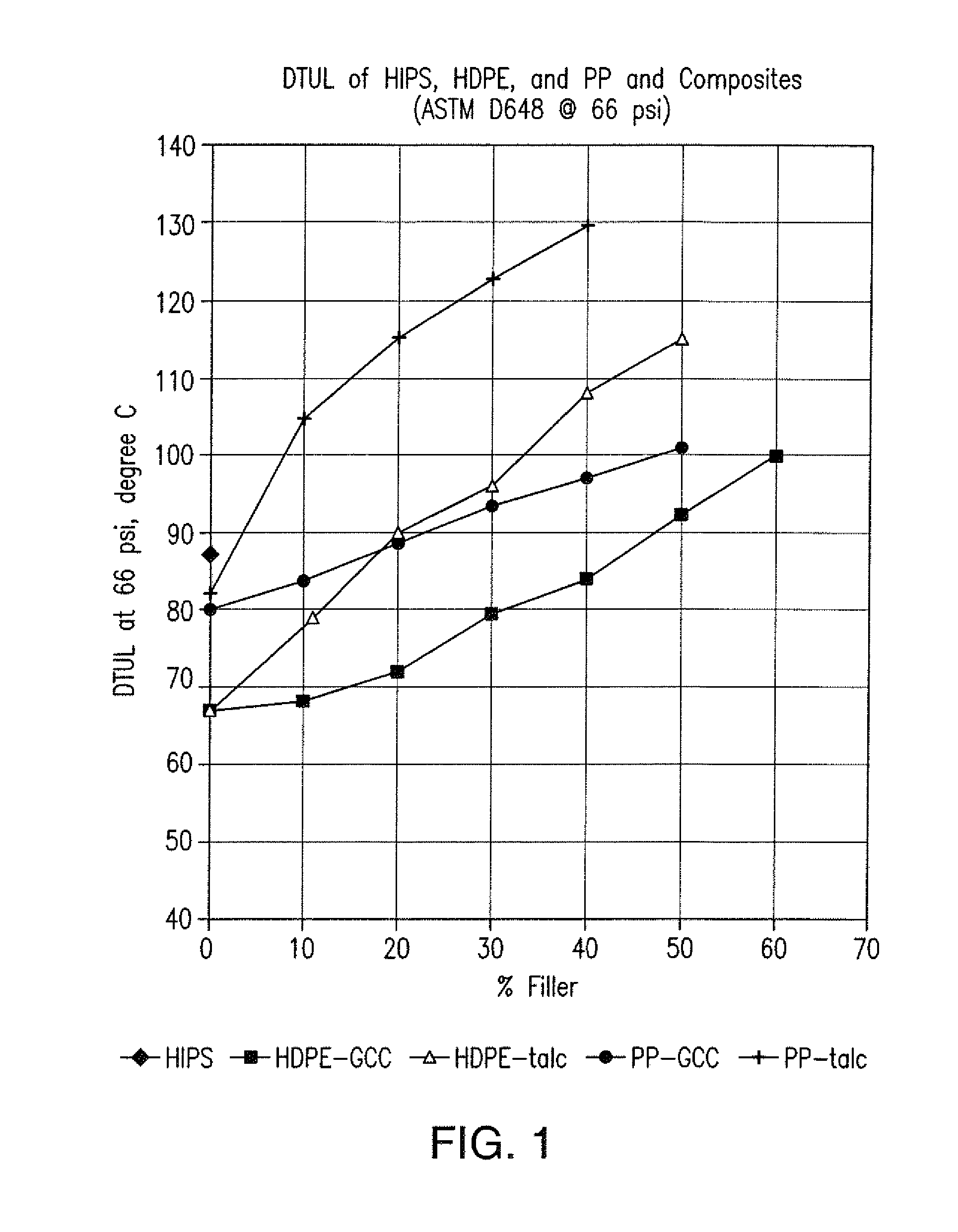

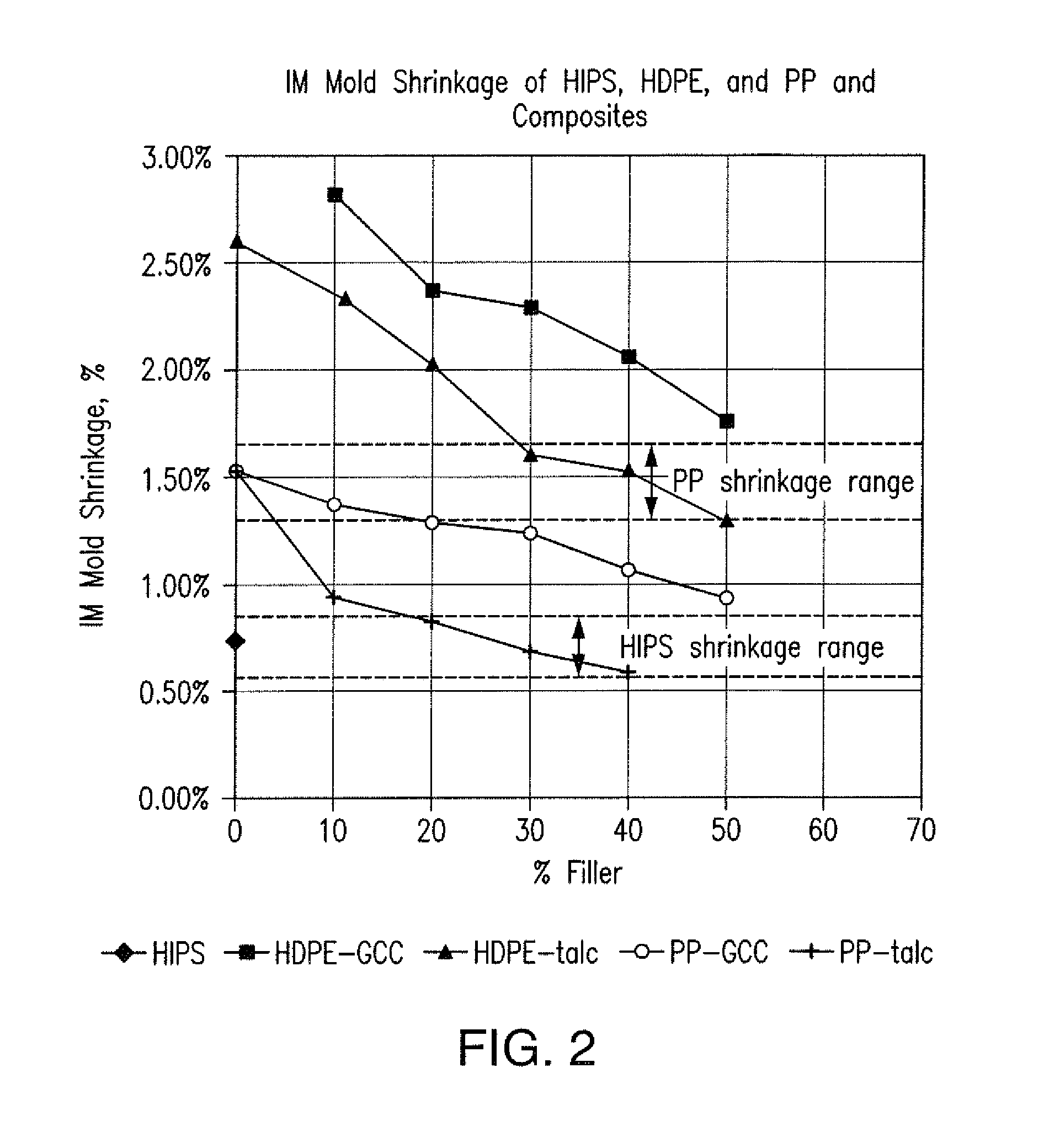

InactiveUS20120267368A1High densityCapsClosure using stoppersHeat deflection temperaturePolymer science

Disposable lid comprises a thermoformed sheet in the shape of a lid for a hot beverage container. The sheet comprises a polymer composite of a polyolefin and at least one mineral filler. The sheet has a thickness less than about 0.035 inches and a heat deflection temperature at least comparable to that of high impact polystyrene.

Owner:PACTIV CORP

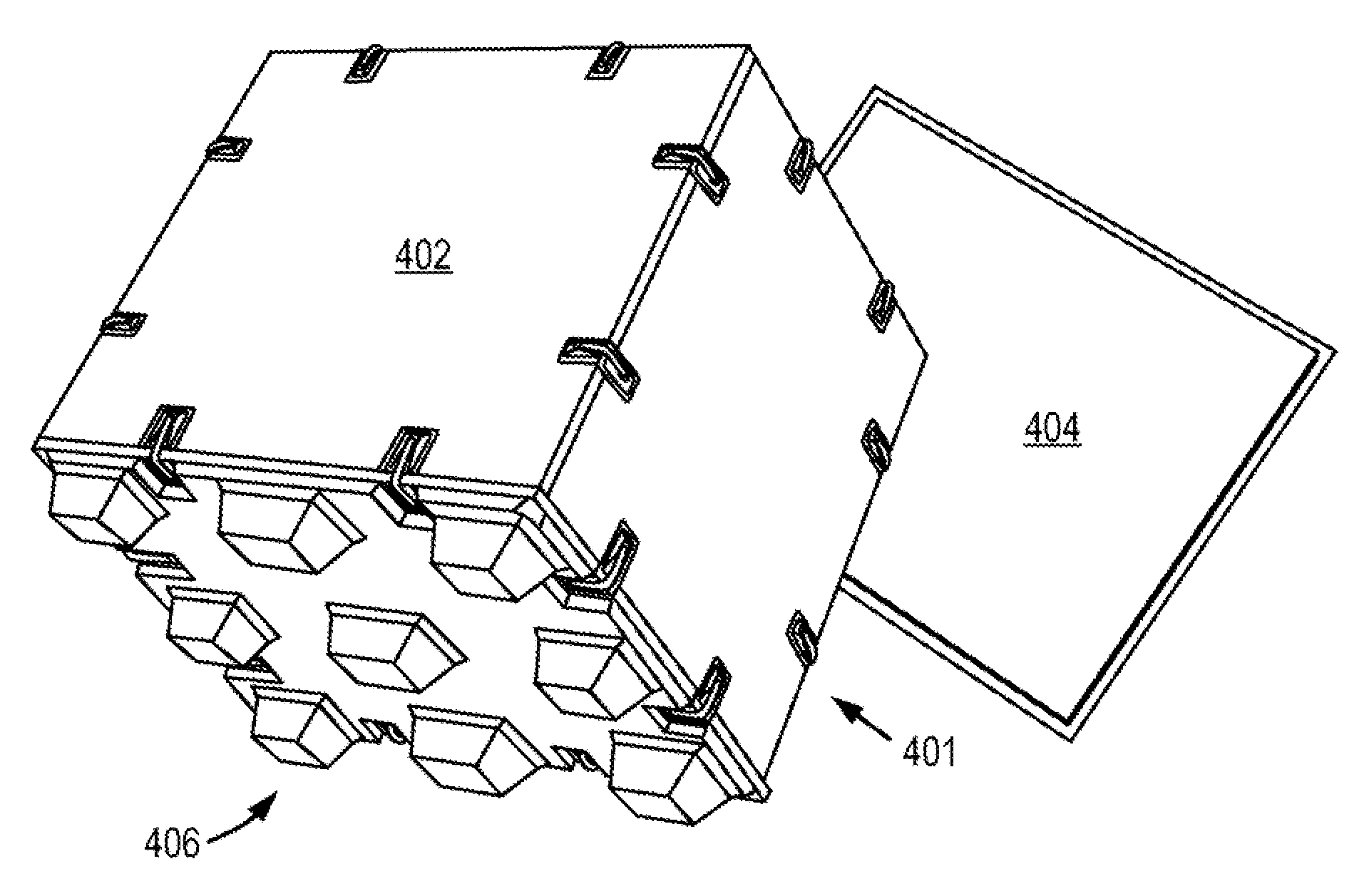

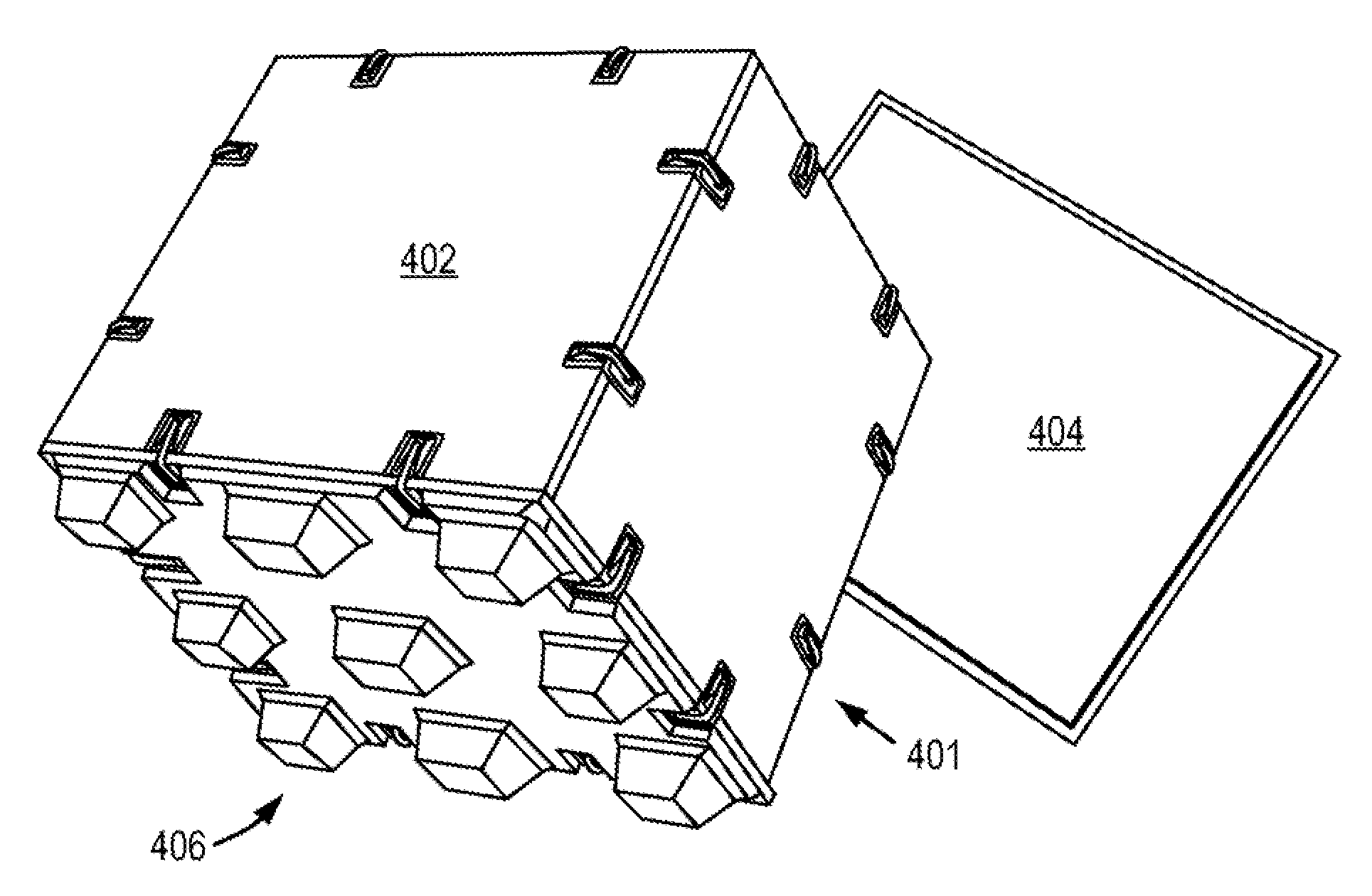

Modular, knock-down, light weight, thermally insulating, tamper proof shipping container and fire retardant shipping container bag

InactiveUS7963397B2Lower the volumeEasy to disassembleDomestic cooling apparatusLighting and heating apparatusTamper resistanceUltraviolet

Owner:AIRDEX CORP

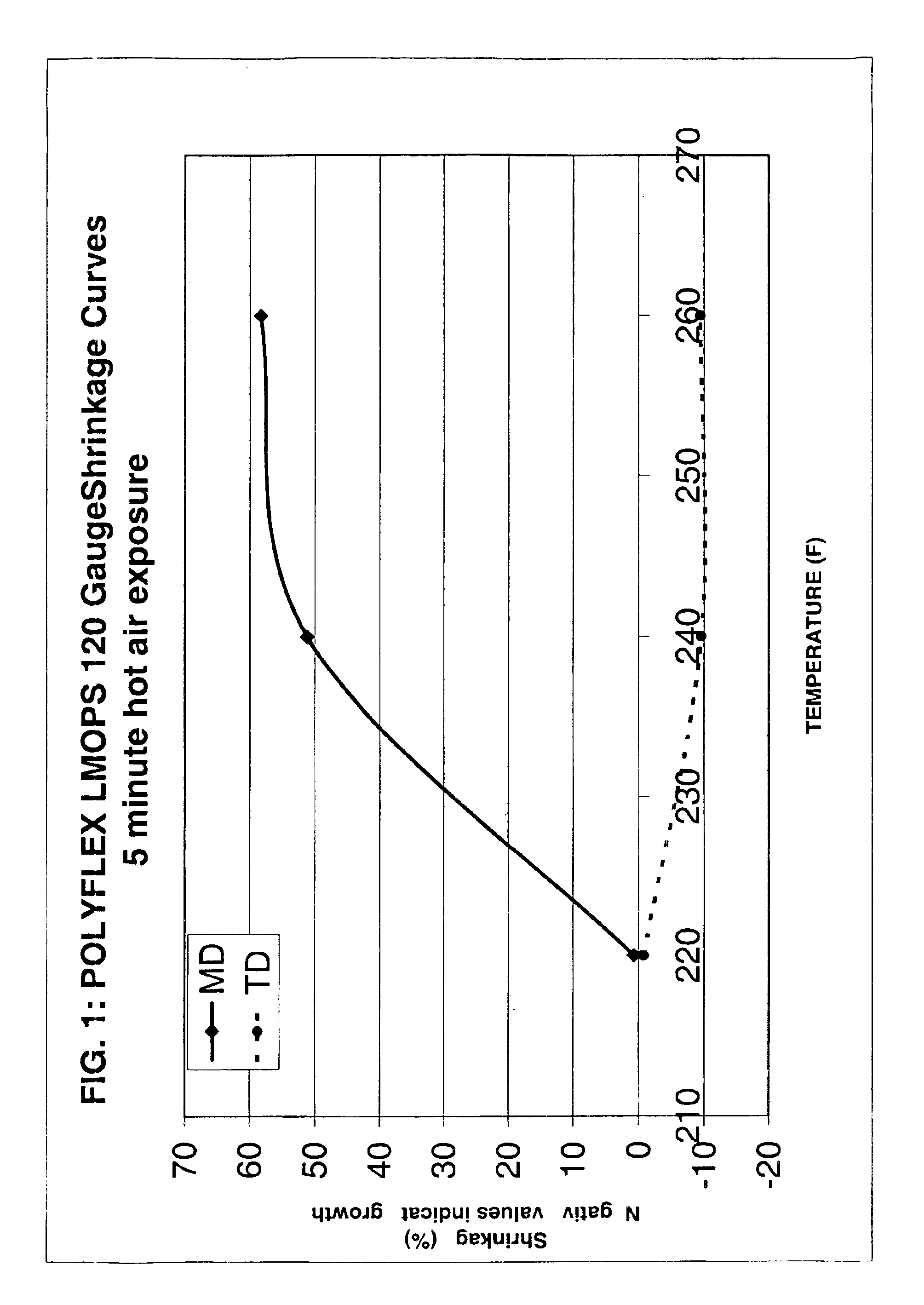

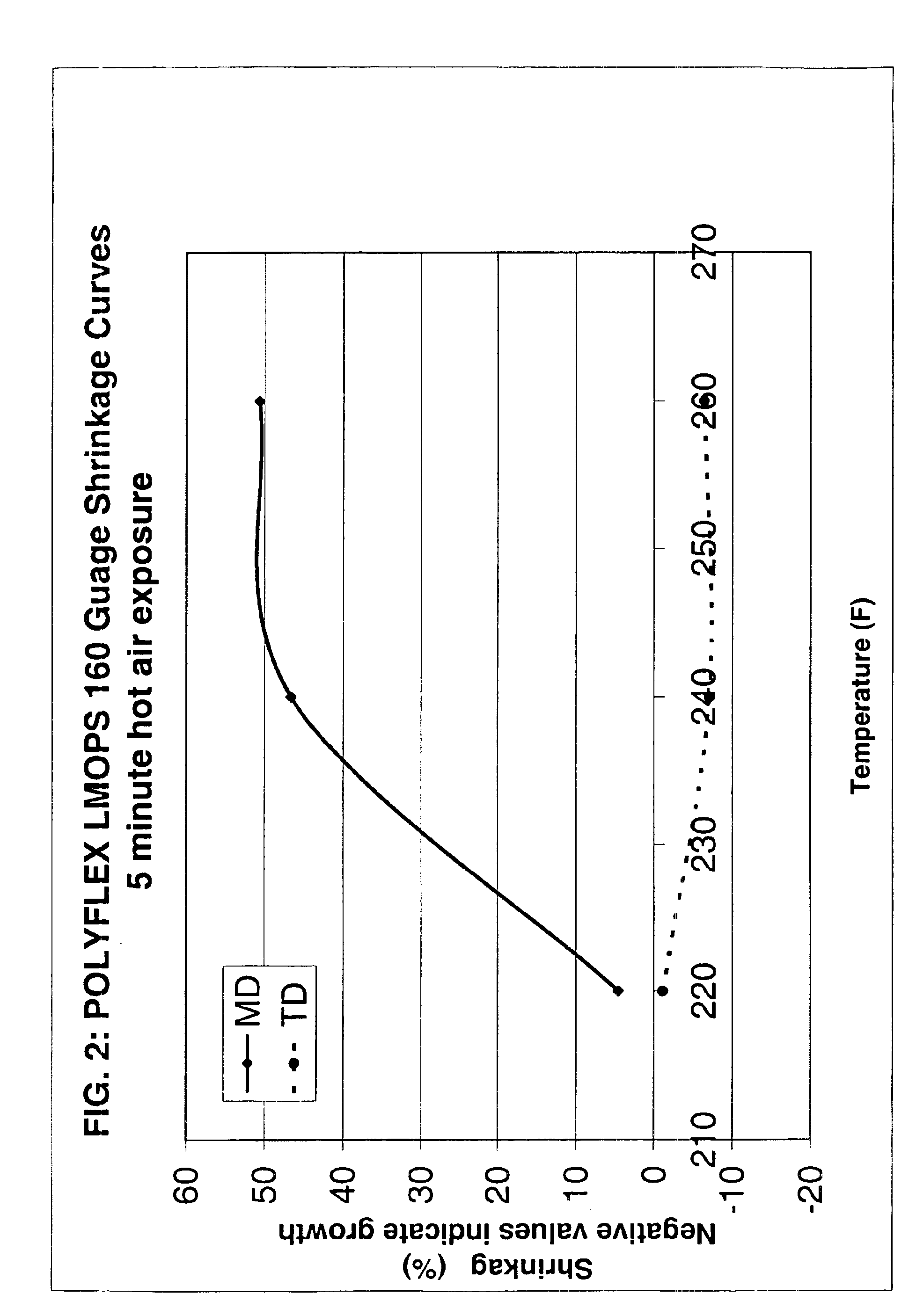

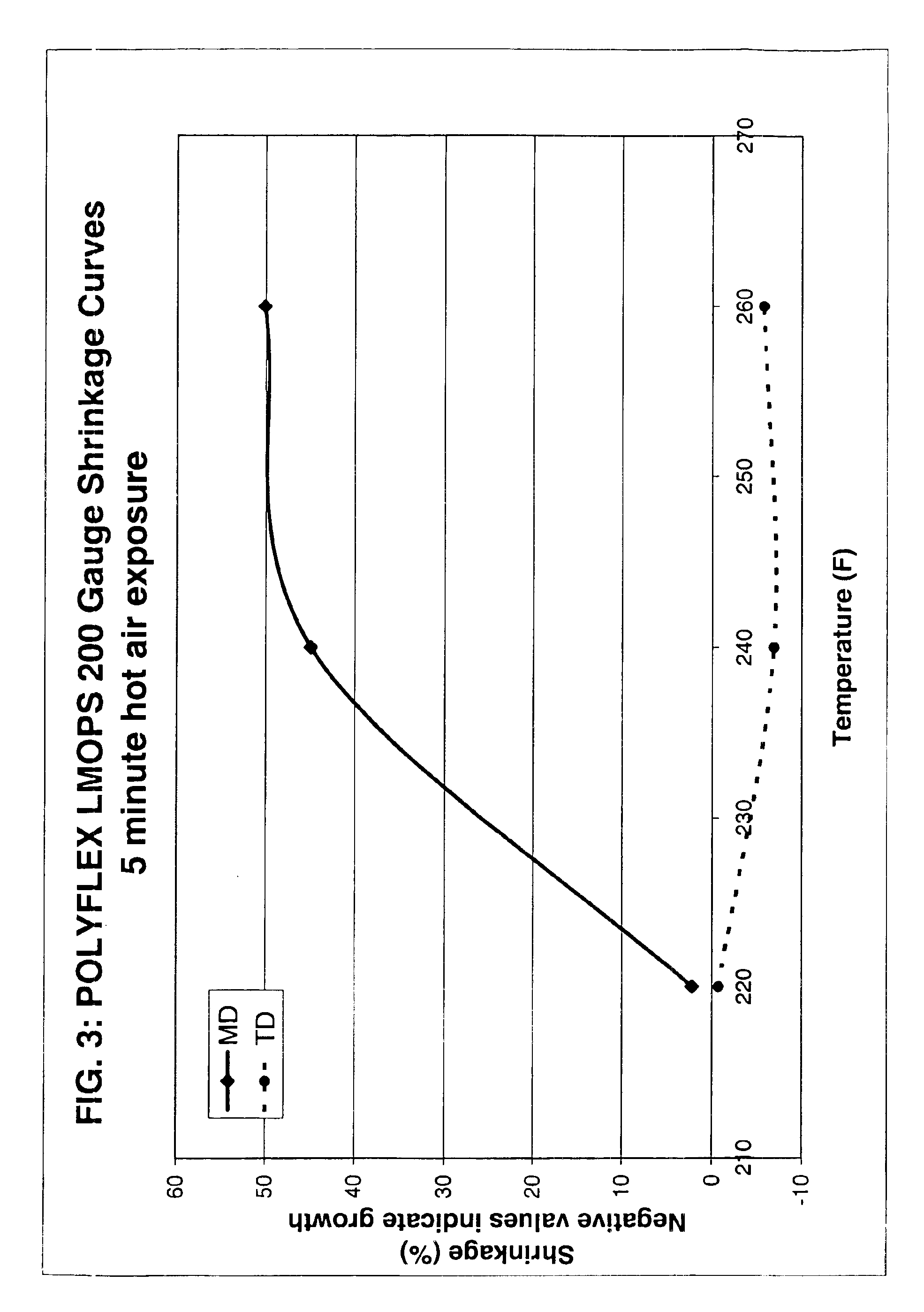

Longitudinal shrink films

A heat-shrinkable film and a method of its manufacture are provided. In an exemplary embodiment, a polystyrene film exhibits heat-induced growth in the cross direction of great than or equal to 5% with greater than or equal to 30% concomitant shrinkage in the machine direction. The films may comprise crystal polystyrene, high impact polystyrene, and / or elastomers. A method of manufacture is disclosed which includes a post-extrusion temperature conditioning step.

Owner:PLASTIC SUPPLIERS

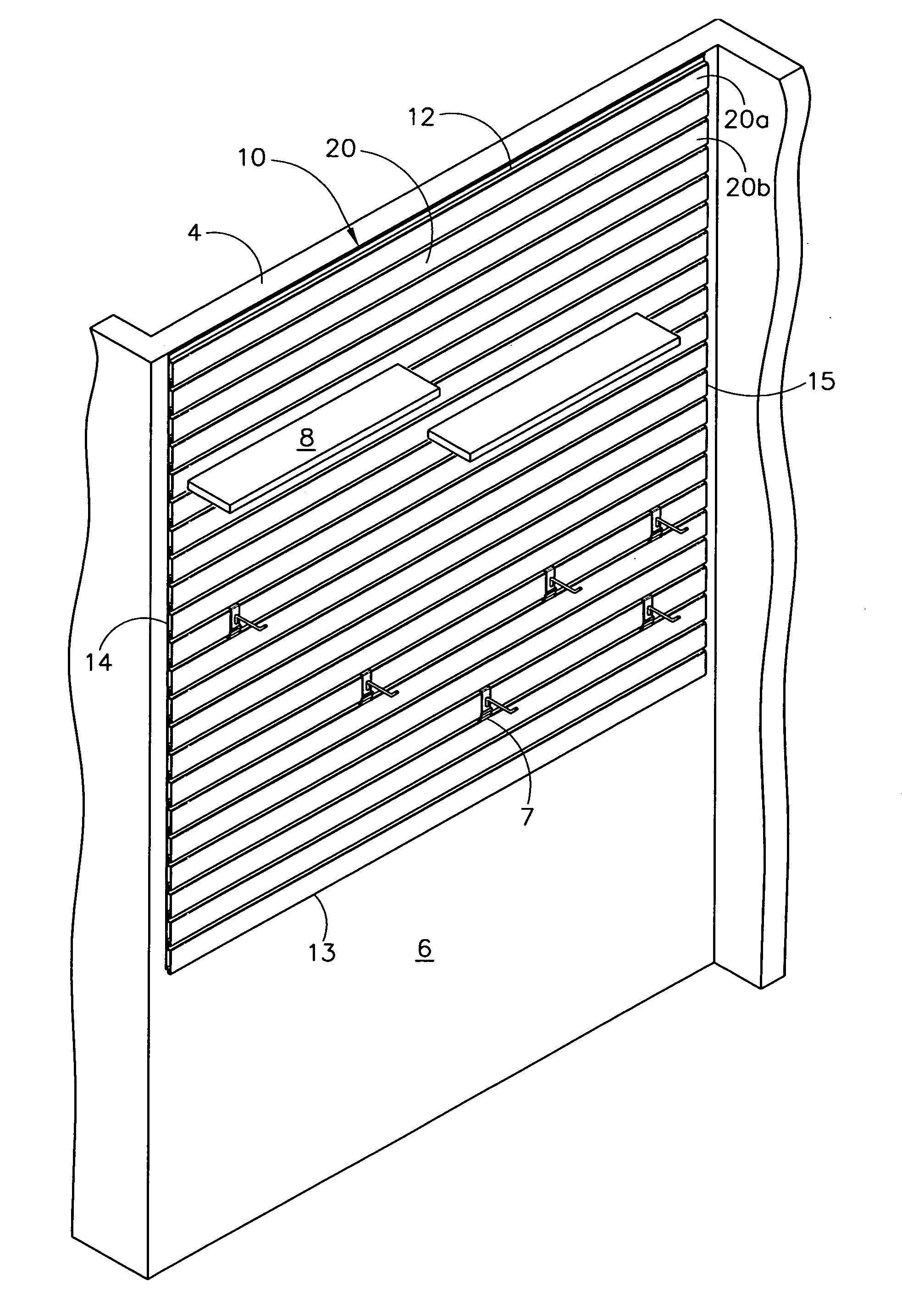

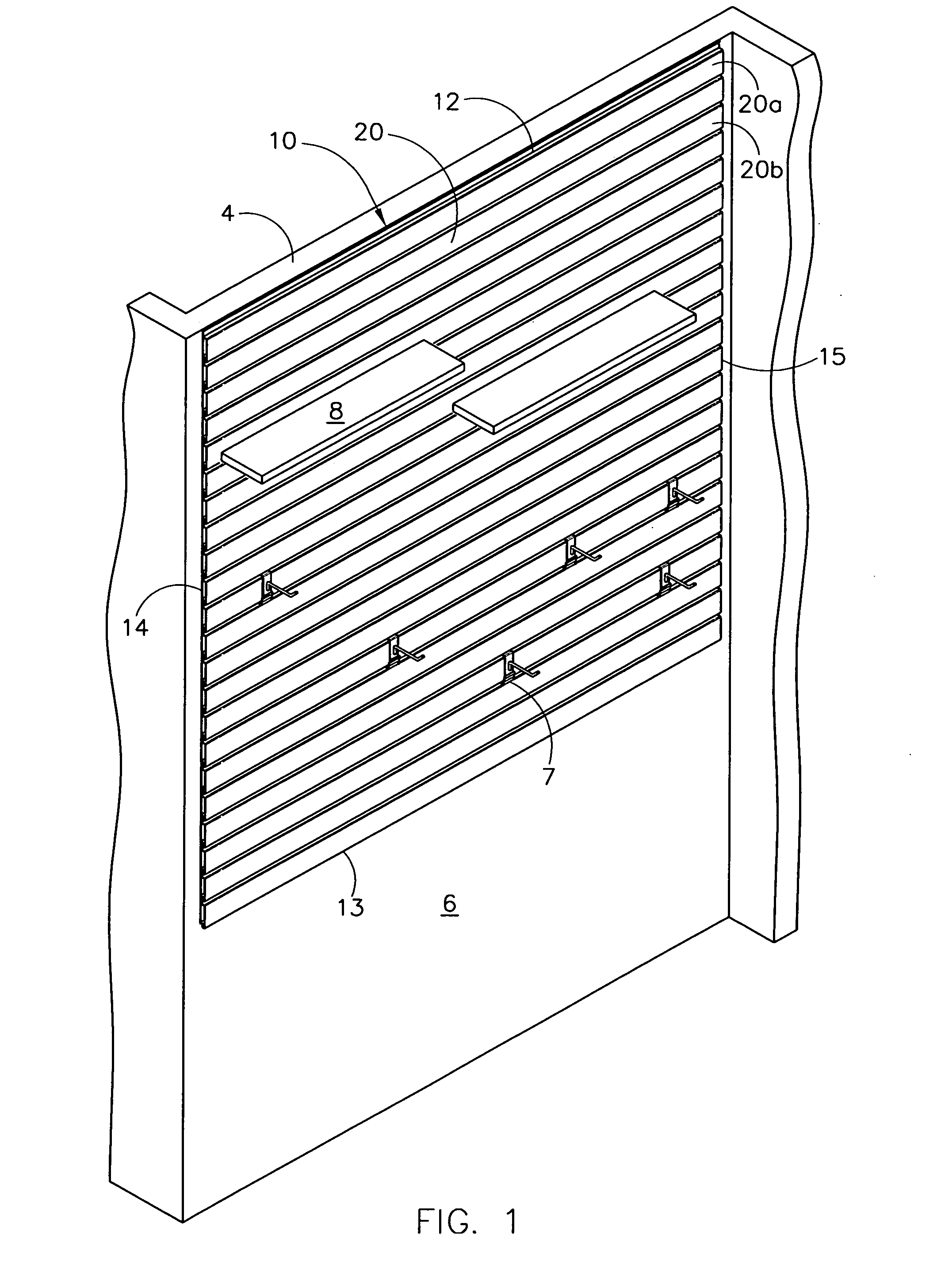

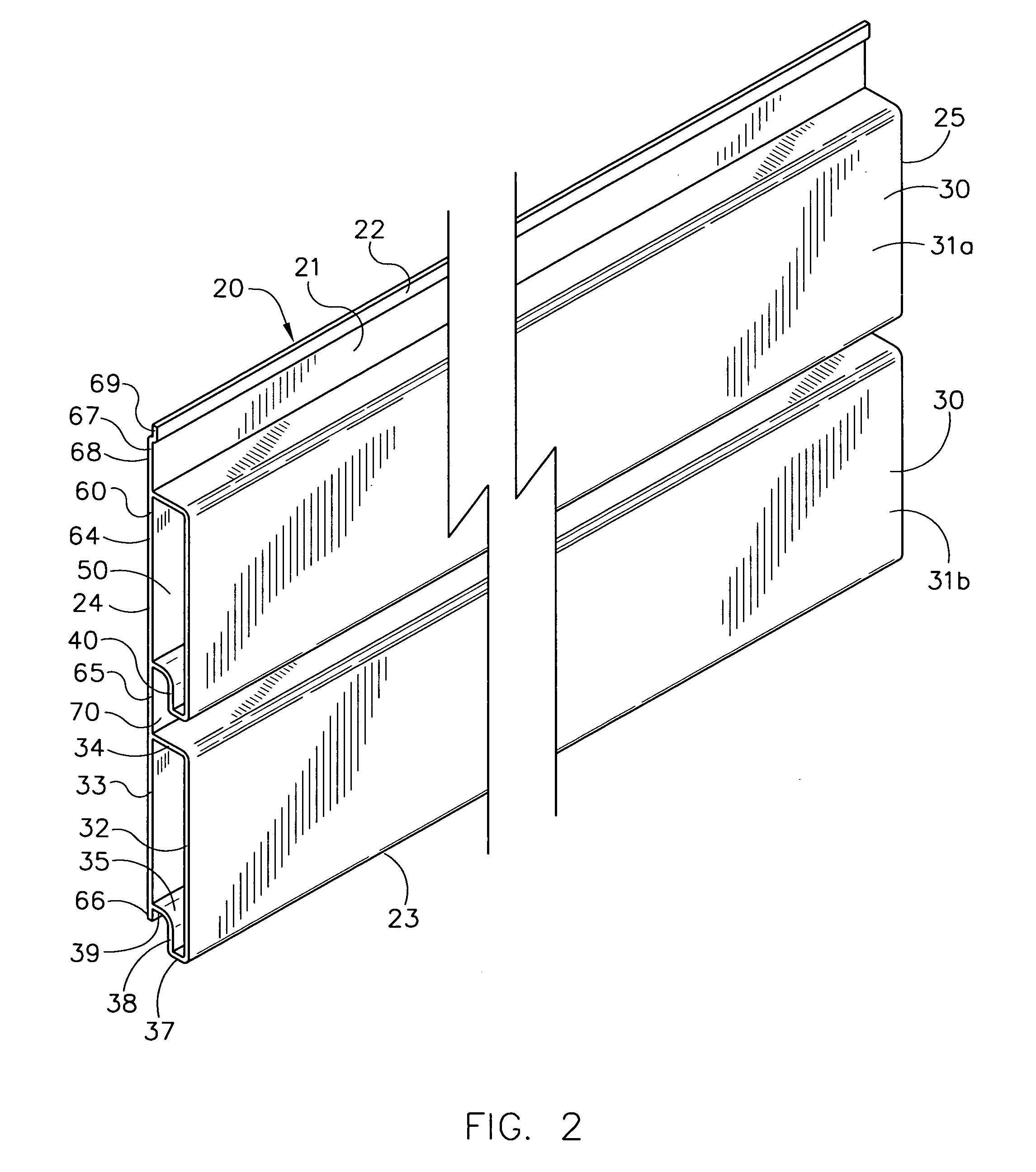

Slatwall extrusion and assembly

InactiveUS7198159B2Improve impact performanceLow costFolding cabinetsDismountable cabinetsEngineeringUltimate tensile strength

Owner:FISCHER JAMES R

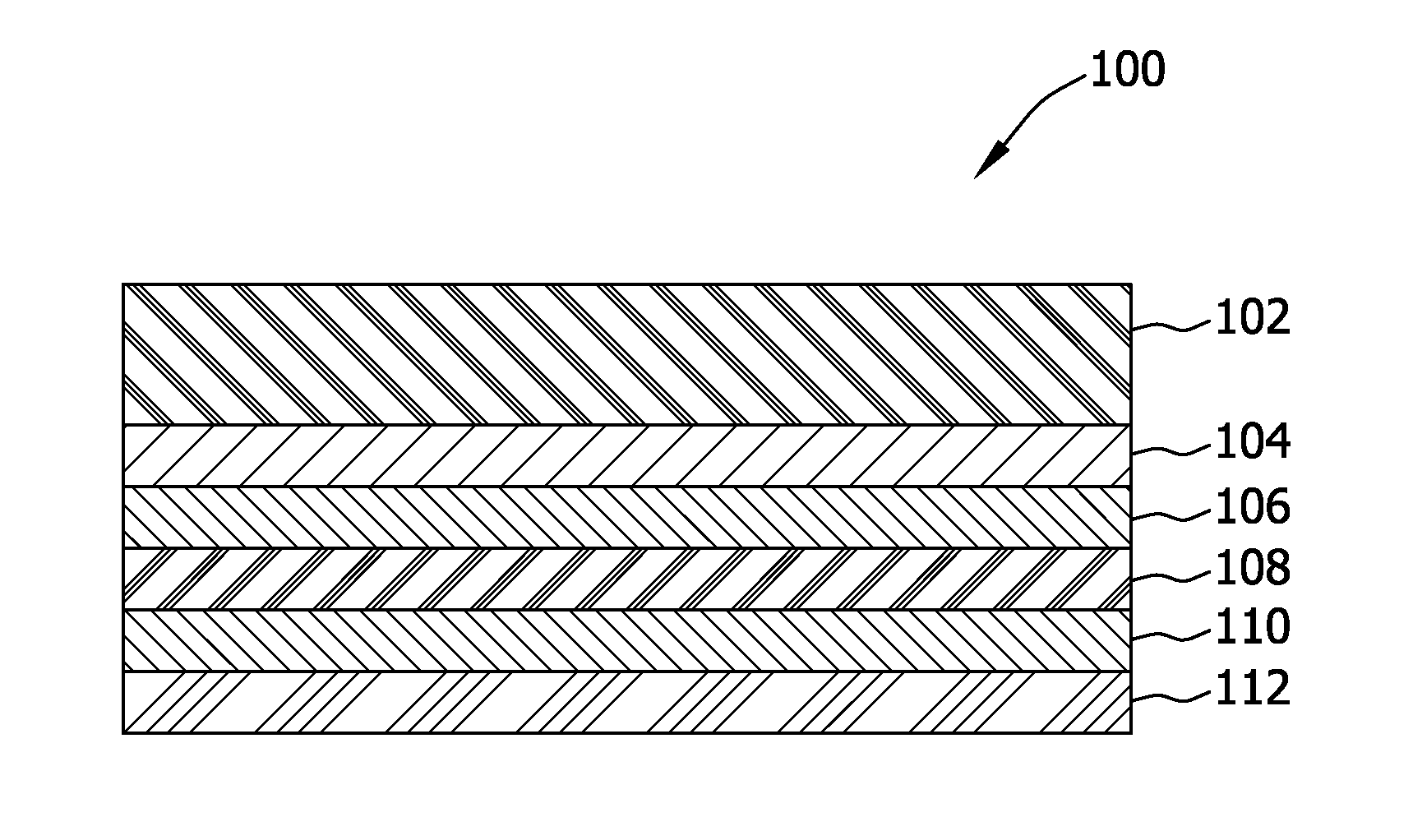

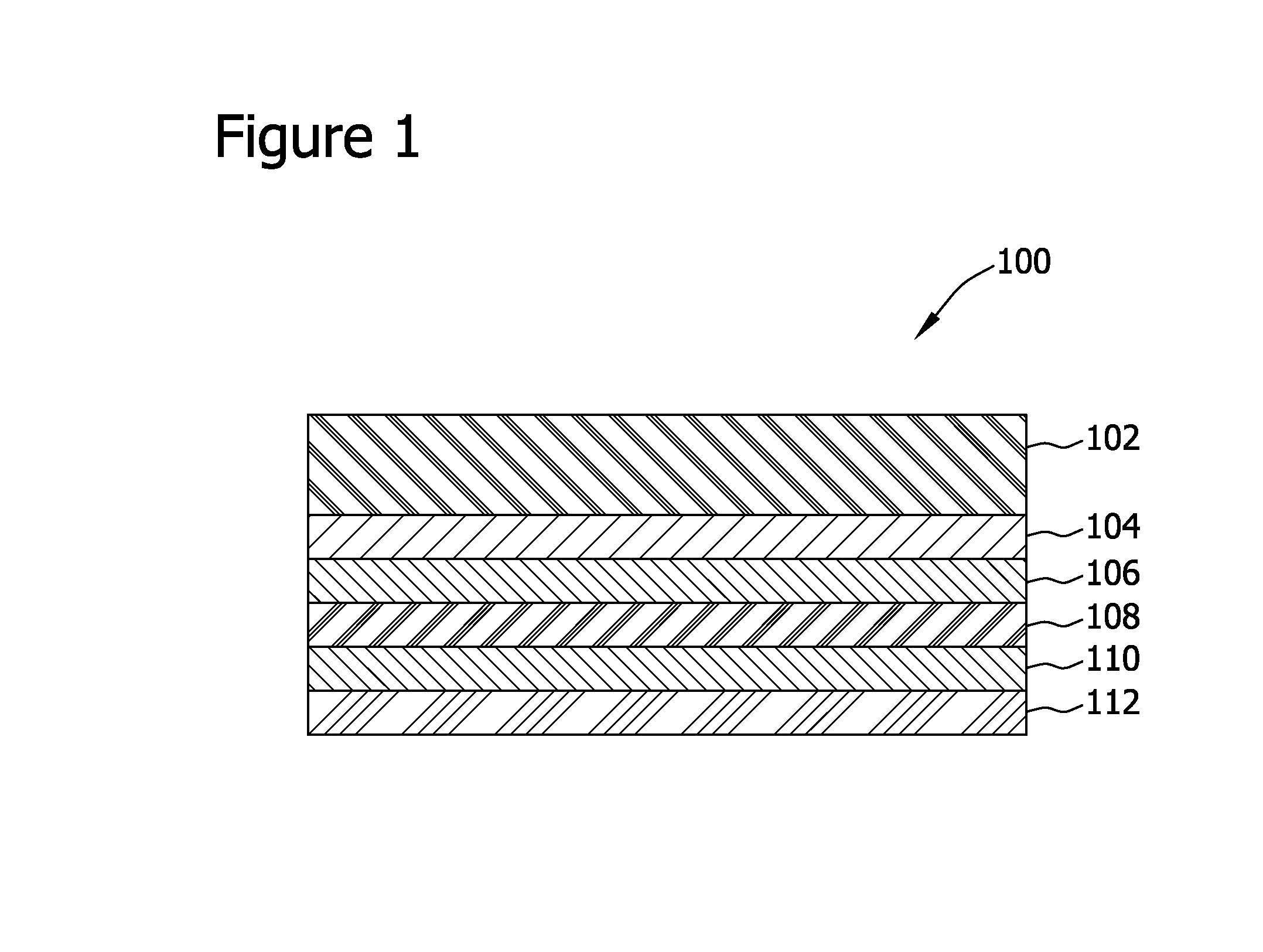

Multi-layer sheet structure having moisture barrier properties

InactiveUS20140170344A1Domestic containersGlass/slag layered productsCyclic olefin copolymerMoisture barrier

A multi-layer sheet structure is provided. The multi-layer sheet structure comprises at least one structural layer comprising high impact polystyrene and at least one moisture barrier layer comprising greater than about 30 percent cyclic olefin copolymer by weight of the at least one moisture barrier layer.

Owner:POLYONE DESIGNED STRUCTURES & SOLUTIONS LLC

PET (polyethylene glycol terephthalate) fiber/teflon fiber composite sound absorbing cotton and preparation method of PET fiber/teflon fiber composite sound absorbing cotton

InactiveCN102965843AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsNon-woven fabricsDiphenyl phosphatePolymer science

The invention discloses PET (polyethylene glycol terephthalate) fiber / teflon fiber composite sound absorbing cotton, which is prepared from the following ingredients in parts by weight: 70 to 80 parts of PET fibers, 40 to 50 parts of teflon fibers, 10 to 15 parts of emulsifying agents OP-30, 5 to 10 parts of peregal O-20, 80 to 100 parts of PP (propene polymer), 30 to 40 parts of HIPS (high impact polystyrene), 15 to 20 parts of activated clay, 10 to 15 parts of modified kieselguhr, 2 to 3 parts of stearic acid, 5 to 8 parts of dioctyl adipate, 4 to 6 parts of cresyl diphenyl phosphate, 2 to 3 parts of liquid paraffin, 1 to 2 parts of 3-aminopropyltrimethoxysilane, 2 to 3 parts of calcium stearate, 1 to 2 parts of barium stearate, 0.5 to 1.5 parts of anti-aging agents RD and 1 to 2 parts of antioxidants DLTP (dilauryl thiodipropionate). The sound absorbing cotton prepared by the invention has the advantages that the appearance evenness is good, the thickness is uniform, the hand feeling is soft, the product bonding degree is good, the tensile performance is high, the sound absorbing performance is excellent, the flame retardant effect is good, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

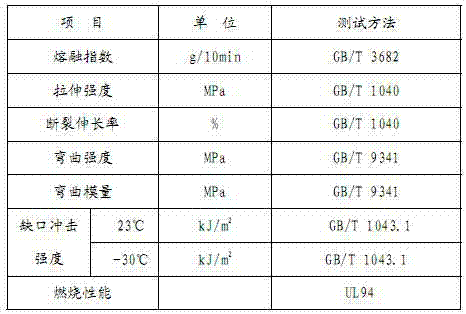

High-fluidity environmental protection halogen-free flame-retardant HIPS composite material and its preparation method

The invention belongs to the technical field of macromolecular compound combination and relates to a high-fluidity environmental protection halogen-free flame-retardant HIPS composite material, which is composed of the following components of: by weight, 29-50 parts of high impact polystyrene (HIPS), 15-35 parts of polyphenylene oxide (PPO), 3-12 parts of a flexibilizer, 5-20 parts of a phosphorus flame retardant, 1-7 parts of a flame-retardant synergistic agent, 0.2-1.0 part of a heat stabilizer, 0.2-0.8 part of an antioxidant and 0.5-1.2 parts of a processing aid. The invention also discloses a preparation method of the HIPS composite material. The composite material provided by the invention is a halogen-free flame retardation HIPS / PPO alloy with high fluidity and excellent mechanical properties.

Owner:深圳市比克新材科技有限公司

High-performance 3D printing supply alloy material

InactiveCN103804862AImprove impact performanceImprove the disadvantage of poor temperature resistanceGlycidyl methacrylateAcrylonitrile

The invention provides a high-performance 3D (Three Dimensional) printing supply alloy material. The high-performance 3D printing supply alloy material comprises, in parts by weight, 20.0-50.0 parts of polylactic acid, 50.0-80.0 parts of high impact polystyrene, 0.1-5.0 parts of compatilizer and 0.2-3.0 parts of auxiliaries, wherein the compatilizer comprises one or more than two, matched with each other in use, of a maleic anhydride grafted high polymer, a terpolymer copolymerized with styrene, acrylonitrile and glycidyl methacrylate (SAG), and a terpolymer copolymerized with methyl methacrylate, butadiene and a styrol copolymer (MBS). The high-performance 3D printing supply alloy plastics prepared from the high-performance 3D printing supply alloy material are non-toxic, low-carbon and environment-friendly, low in alloy material cost, excellent in combination properties, and very high in economic value and wide in market prospect.

Owner:芜湖瀚博电子科技有限公司

Modular, knock-down, light weight, thermally insulating, tamper proof shipping container and fire retardant shipping container bag

InactiveUS20070194019A1Lower the volumeEasy to disassembleContainer decorationsLevel indicationsUltravioletEngineering

The invention provides a knock-down, lightweight, thermally insulating, shipping container made at least in part from a polymer core covered by a thermoplastic sheet layer. In an embodiment of the invention, the shipping container is modular, being adjusted to suit the item(s) to be shipped. In an embodiment of the invention, the base, top panel and walls are made of expanded polystyrene core and combined with high impact polystyrene surface. In one embodiment, a mesh is introduced into the core to strengthen the core making the shipping container tamper proof. A shipping container bag that is light weight, strong, made of a fire retardant material and which forms an ultra violet light, weather and dust barrier can be used to store the shipping container. A system and method for supplying, dispensing, positioning, tracking, transporting, forwarding and storing the light weight shipping containers based on the shipping container bag is disclosed.

Owner:AIRDEX CORP

Halogen-free fire-resistant high anti-impact polystyrene/ polyphenyl ether complex containing modified polyphenyl ether and method for production thereof

The present invention is halogen-free fireproof polystyrene / polyphenyl ether composition with high shock strength and its preparation, and belongs to the field of polymer material. The composition contains polystyrene resin with high shock strength 40-65 wt%, polyphenyl ether 8-40 wt%, fire retardant 5-25 wt% and machining assistant 0.5-5 wt%, and is prepared through high speed pre-mixing and twice extrusion process. The composition has serial advantages of being fireproof, environment friendly, weatherproof, hot stable, high in mechanical performance, easy in machining, etc. It is suitable for use in display, video recorder, copying press, facsimile machine, printer, air conditioner, refrigerator, etc.

Owner:KINGFA SCI & TECH CO LTD

Flame-retardant PC/HIPS composite material and preparation method thereof

The invention discloses a flame-retardant PC / HIPS composite material and a preparation method thereof. The composite material is prepared by the following raw materials: polycarbonate, polystyrene, flame retardant, flame-retardant synergist, flexibilizer, compatilizer, antioxidant and other adjuvants; and the preparation method comprises the following steps of: a. forced air drying the polycarbonate and the polystyrene respectively at 100-130 DEG C and 70-90 DEG C for 4-8 hours; b. preparing high impact polystyrene grafting glycidyl methacrylate compatilizer; c. weighing the dried polycarbonate, the polystyrene, the flame retardant, the flame-retardant synergist, the flexibilizer, the compatilizer, the antioxidant and other adjuvants; d. putting the raw materials in the step c into a high-speed mixer for dry mixing for 3-5min;and e. putting the mixed raw materials into a twin-screw extruder for melt extruding and pelleting. The composite material has prominent toughness and excellent flame retardance; in addition, the preparation method is simple, the operation is convenient and the cost is low.

Owner:ANHUI KEJU NEW MATERIALS

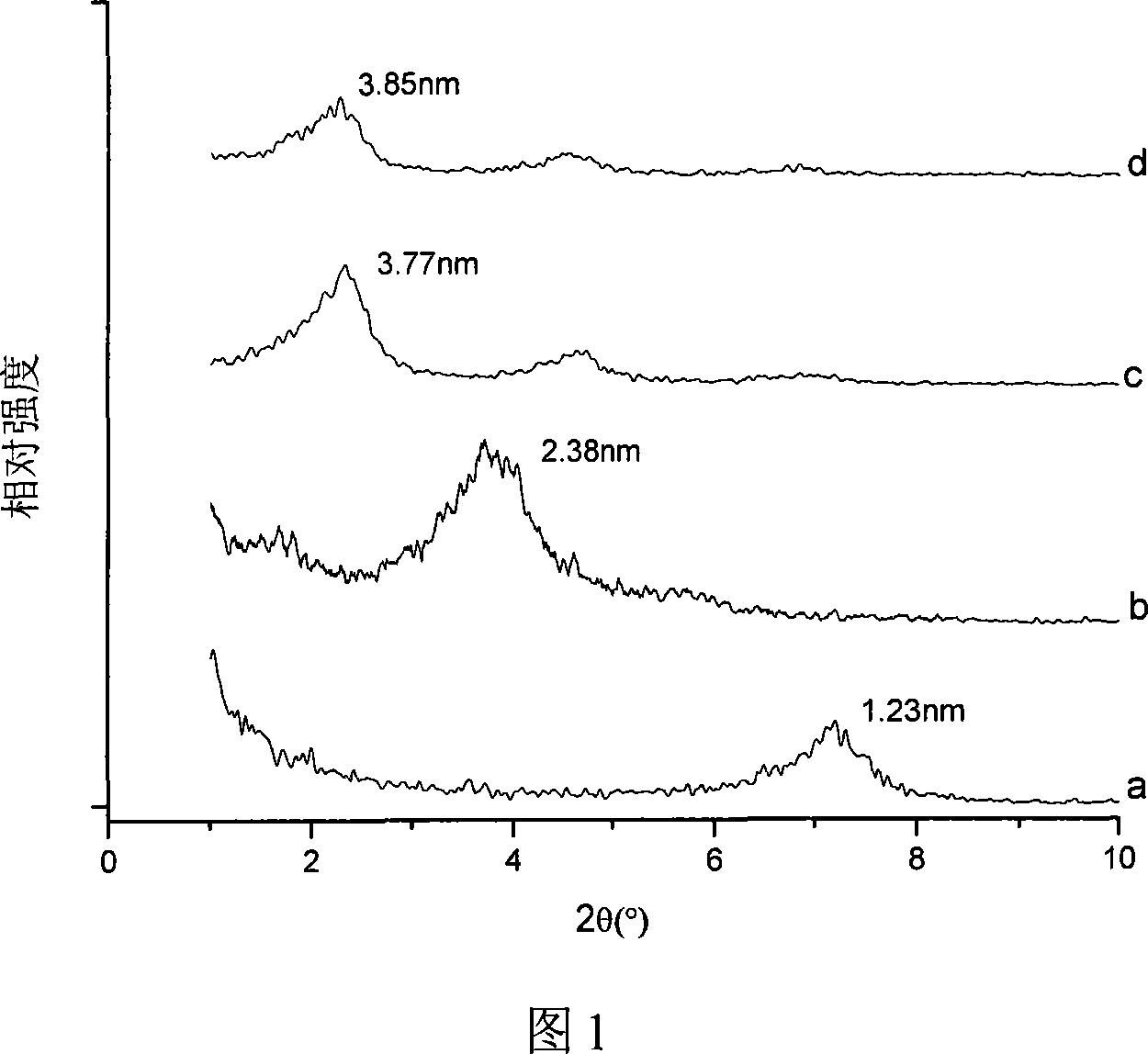

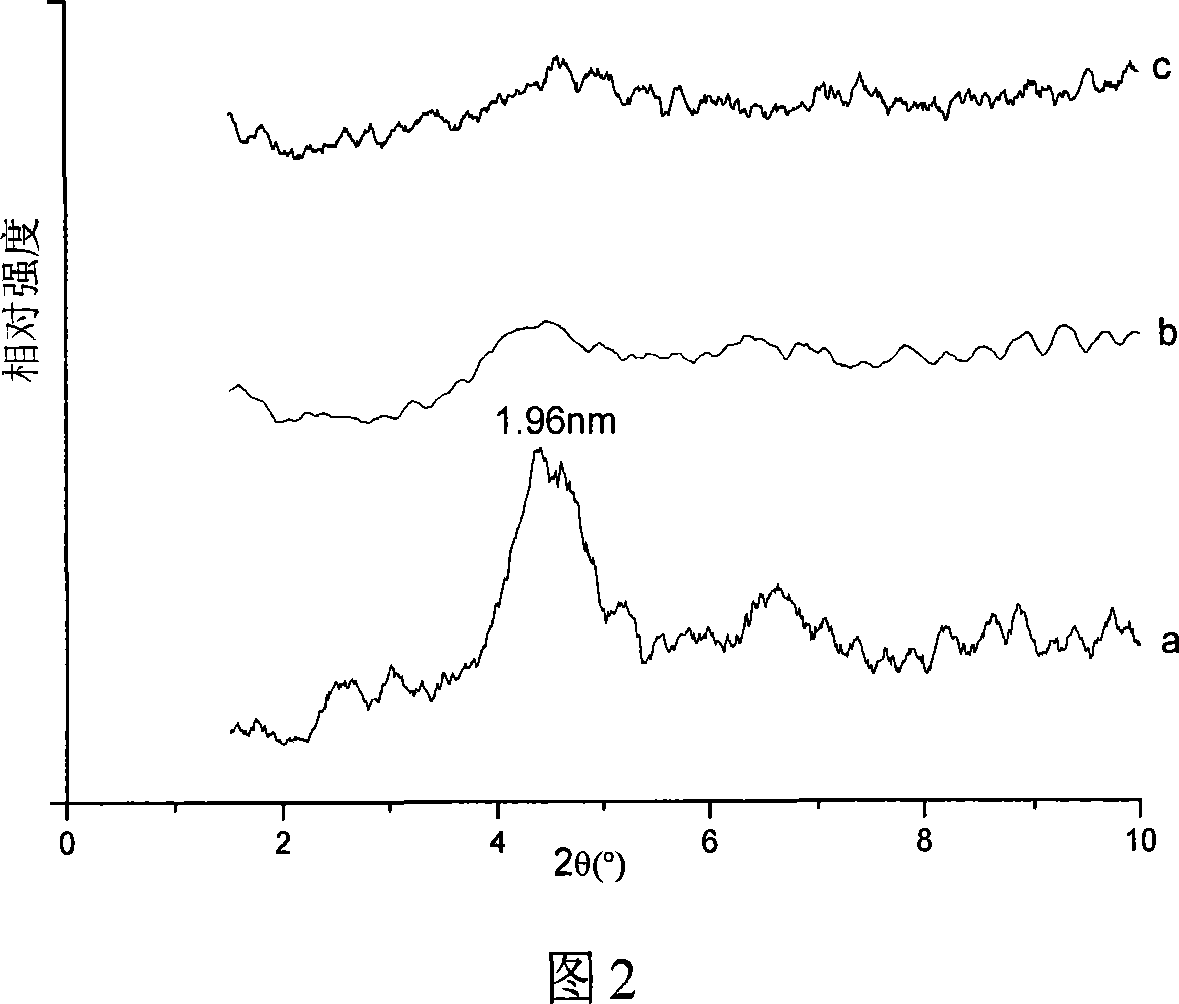

Polymer/organic montmorillonite nano composite flame-proof masterbatch, its preparing method and application

This invention relates to a polymer / organic montmorillonite nano-composite fire retardant material, its preparation and application, which takes water as the media, and under the condition of emulsifier, acrylic monomers or styrene monomers that enter organic montmorillonite layers through initiator conduct polymerization, obtaining the polymer / organic montmorillonite nano-composite fire retardant material. It can prepare flame-retardant plastic with good retardant and mechanical properties if this material is melt with acrylonitrile-butadiene-(ABS), HIPS or PP together.

Owner:SOUTH CHINA UNIV OF TECH

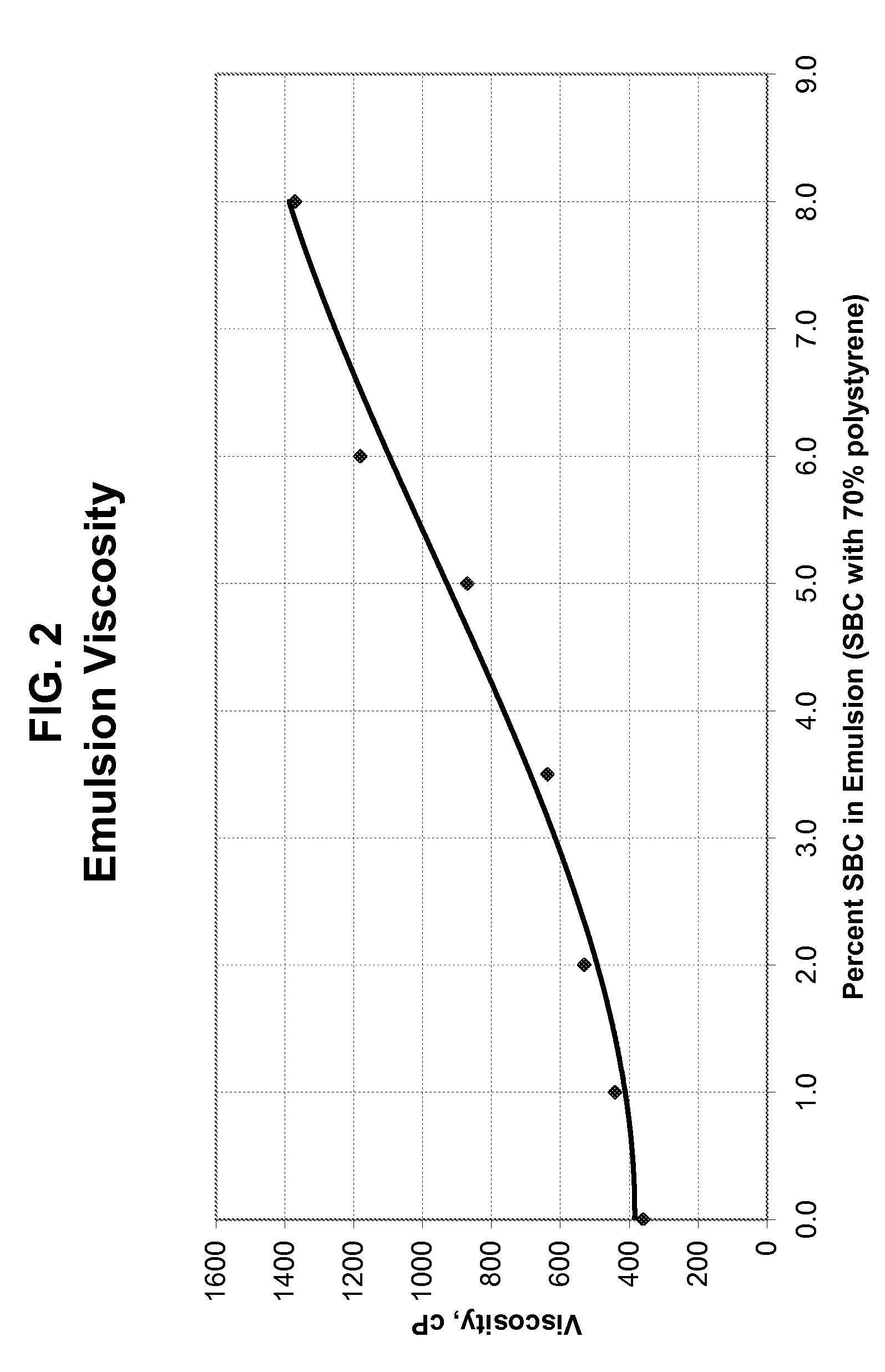

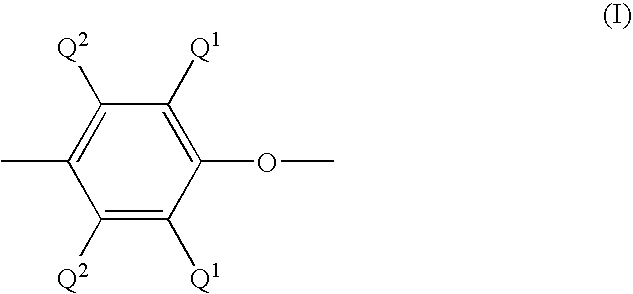

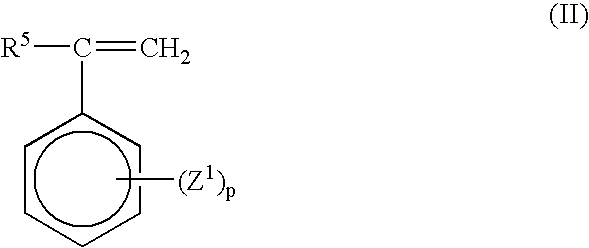

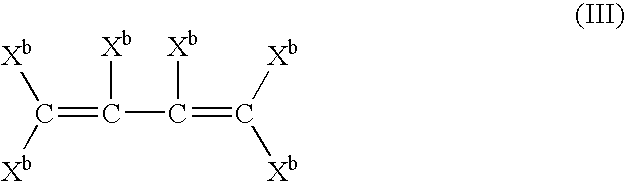

Process for making high impact strength polystyrene and related compositions

Compositions, processes, and methods are provided relating to styrenic polymers, including high impact polystyrene (HIPS), also referred to as rubber-modified polystyrene. In one aspect, a process is provided for making high impact polystyrenes, comprising the steps of combining a monovinylarene component, a monovinylarene-conjugated diene block copolymer, and a conjugated diene polymer. In another aspect, the feed components form an emulsion having a continuous phase and a dispersed phase. The continuous phase comprises at least a portion of the monovinylarene component and at least a portion of the conjugated diene polymer. The dispersed phase is suspended within the continuous phase, and comprises globules having at least a portion of the monovinylarene-conjugated diene block copolymer, a remaining portion of the monovinylarene component, and a remaining portion of the conjugated diene polymer. The monovinylarene component is polymerized in the presence of the emulsion alone or in the presence of other feedstocks.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Method for preparing functionalization polyolefin resin

The preparation process of functional polyolefin resin includes electronic beam or gamma-ray pre-irradiation treatment of functional polyolefin resin; mechanical mixing of polyolefin resin after pre-treatment, functional monomer and electron donor reagent; and reacting extrusion for the polyolefin resin in molten state and functional monomer to produce grafting reaction. The polyolefin resin includes polyethylene, polypropylene, ethylene-propylene copolymer, ethylene-styrene copolymer, polystyrene, etc; the functional monomer is unsaturated organic acid or its derivative with amino group, isocyanate, hydroxyl group or other reactive functional group; and the electron donor reagent includes electron-rich compound with P, N, S or O element, p-benzoquinone, triphenyl phosphite, triphenyl phosphate, etc.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

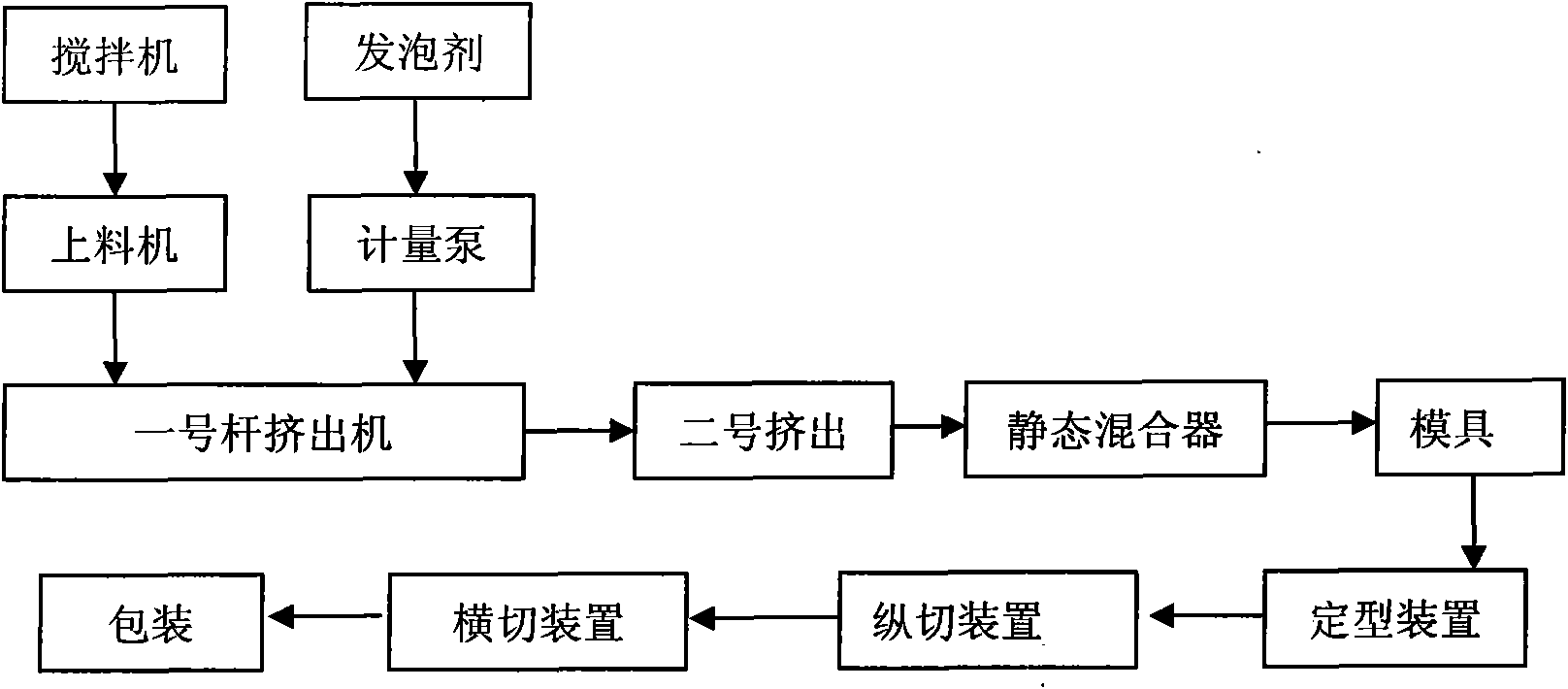

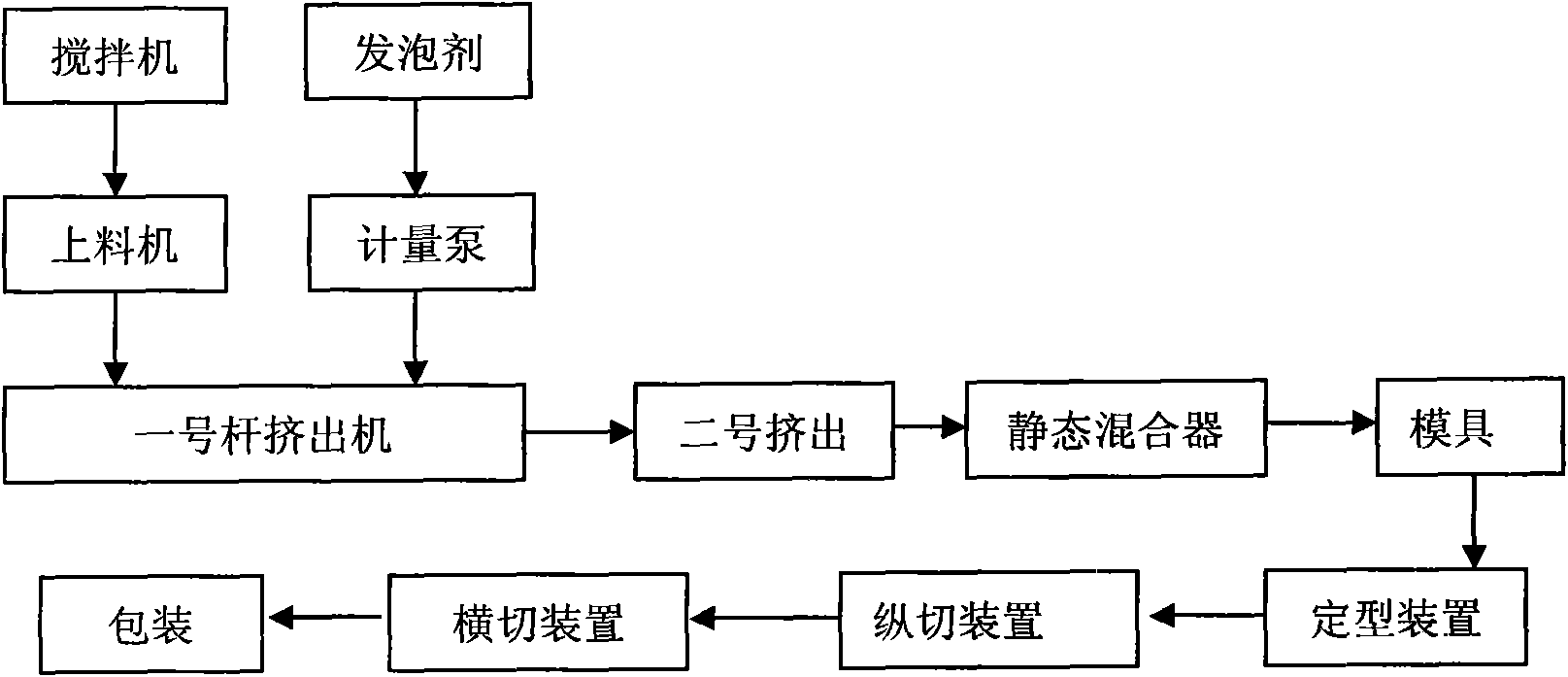

Method for producing polystyrene extruded sheet with compressive strength larger than 700 kPa

InactiveCN101890782AReasonable productivityReasonable design processFlat articlesPolymer scienceFire retardant

The invention relates to a method for producing a polystyrene extruded sheet with compressive strength larger than 700 kPa, in particular to a production formula and a process method for high-strength polystyrene extruded sheet (XPS) with compressive strength larger than 700 kPa. The method for producing the polystyrene extruded sheet with the compressive strength larger than 700 kPa of the invention is characterized by comprising the following steps: taking general purpose polystyrene (GPPS), high impact polystyrene (HIPS), a foaming agent, a nucleating agent, color master batches and a fire retardant in certain weight proportion as raw materials; utilizing a plastic extruding machine 1 to heat the raw materials so as to melt and mix polystyrene materials to form polymer melt; utilizing a plastic extruding machine 2 and a static mixer or a heat exchanger to carrying out mixing and cooling; enabling cooled gel to enter into a pressure lowered or decreased area through a die to form a foaming structure; leveling and typing by utilizing a bump-cutter machine; cooling by utilizing a cooling fan; and removing edges and carrying out fix-length cutting to prepare the high-strength polystyrene extruded sheet (XPS) with the compressive strength larger than 700 kPa.

Owner:南京法宁格节能科技股份有限公司

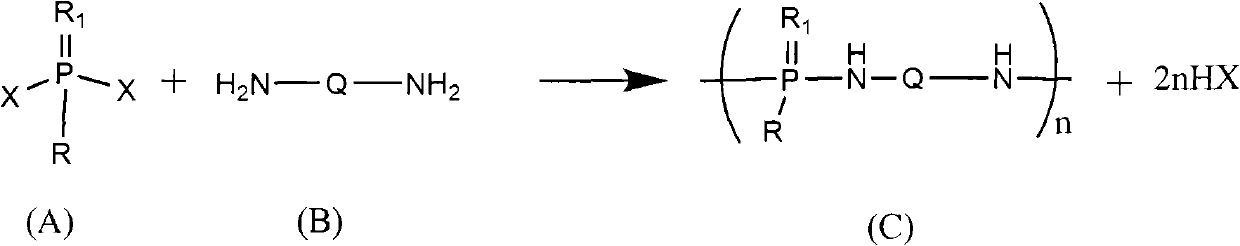

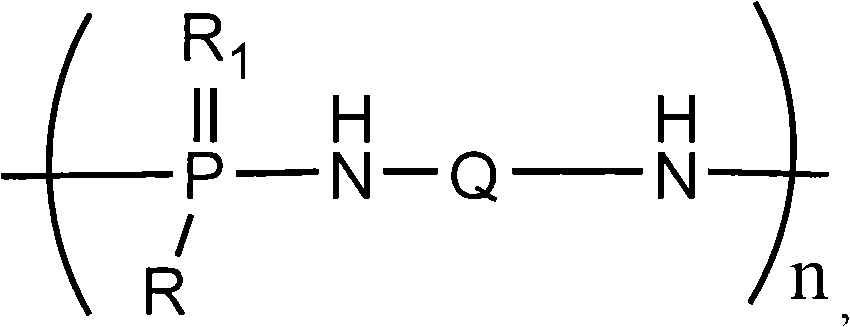

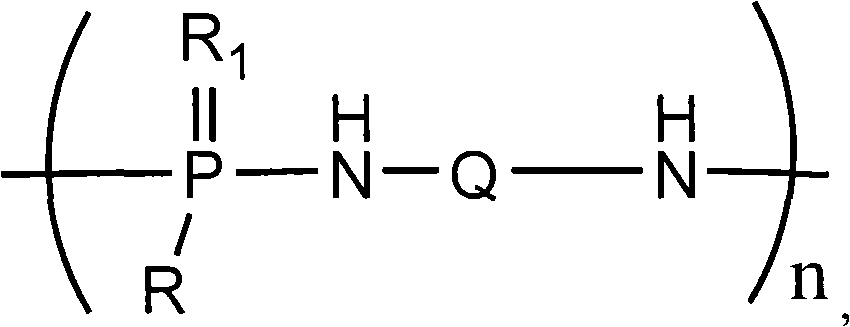

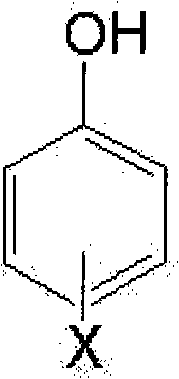

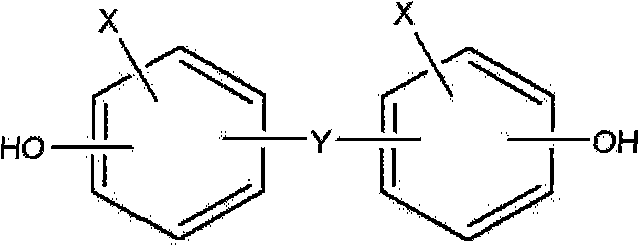

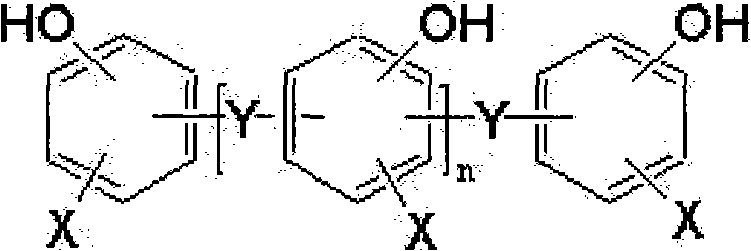

Phosphorus-containing and nitrogen-containing expansion type flame-retardant polymer and preparation method thereof

The invention discloses a phosphorus-containing and nitrogen-containing expansion type flame-retardant polymer and a preparation method thereof. The preparation method is characterized in that: the phosphorus-containing and nitrogen-containing expansion type flame-retardant polymer is prepared by solution polycondensation reaction or melt polycondensation reaction of diphosphorus acylchloride or diphosphorus acylbromide and a diamine functional group-containing compound. The expansion type flame-retardant polymer comprises phosphorus-containing and nitrogen-containing phosphamide with a structure unit formula shown in the specifications, wherein n is an integer of from 1 to 200; R1 is oxygen or sulphur; and R is alkoxy, alkylthio, aryloxy or arylthio. The product of the invention has high compatibility with a high molecular material matrix, difficult transfer and excellent durability. The preparation method has the advantages of simpleness, easy control, high yield, wide sources of the required raw materials and easy industrialized production. A high polymer with a flame-retardant function can be directly prepared, or the high polymer serving as a flame-retardant additive can be added into various polyesters, polyamide, polyolefin, epoxy resin, polystyrene, high impact polystyrene or acrylonitrile butadiene styrene (ABS) polymer.

Owner:UNIV OF SCI & TECH OF CHINA

Dunnage platform

A dunnage platform is in the general shape of a rectangular slab with legs extending form one side. The dunnage platform is made from an expanded polystyrene core. A chemical combination process is used to chemically combine portion of the core proximal to its surface with high impact polystyrene. In a first of two parts of the combination process, the core is placed in a forming mold with one of its two sides and two thirds of its thickness extending therefrom. A heated sheet of high impact polystyrene is brought into contact with the portion of the core extending from the mold. In a similar manner, the other of the two sides of the core is made to extend from the forming mold for contact with a heated sheet of high impact polystyrene.

Owner:AIRDEX CORP

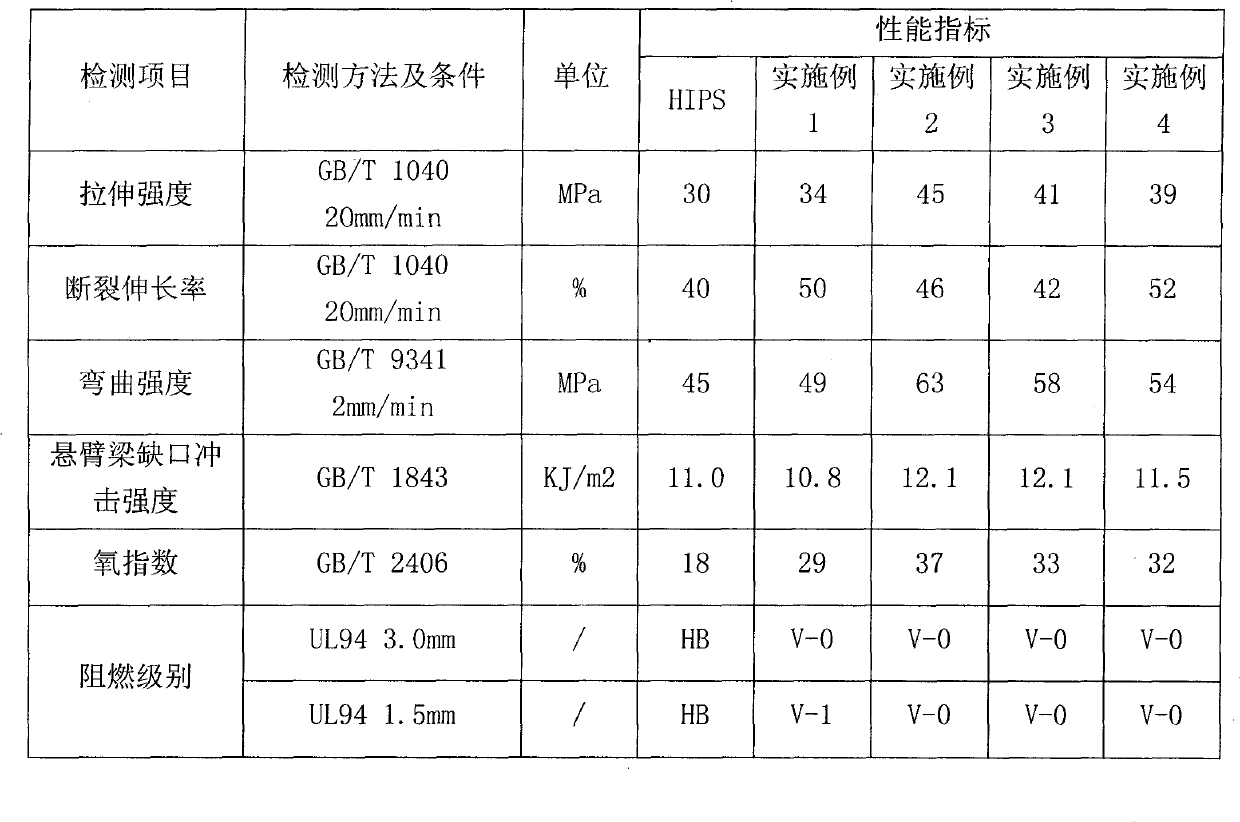

Halogen-free flame retarding high-impact polystyrene (HIPS) composite material and preparation method thereof

The invention discloses a halogen-free flame retarding high-impact polystyrene (HIPS) composite material and a preparation method thereof, belonging to the macromolecular material technical field. The halogen-free flame retarding HIPS composite material includes the following weight parts of components: 65-85 parts of HIPS, 15-35 parts of charring agent PPO, 5-20 parts of flame retardant MRP, 4-15 parts of toughener SEBS, 0.3-1.5 part(s) of assistant flame retardant PTFE, 0.3-1.5 part(s) of assistant flame retardant nano inorganic filling, and 0.1-0.5 part of antioxidant. The preparation method includes that firstly, the HIPS, the assistant flame retardant PTFE and the assistant flame retardant nano inorganic filling are stirred at high speed and mixed evenly in a certain weight proportion, melted and pelletized in a double-screw extruder to produce the HIPS and assistant flame retardant master batch; secondly, the HIPS, the charring agent, the flame retardant, the toughener, the HIPS and assistant flame retardant master batch and the antioxidant are stirred at high speed and mixed evenly in a certain weight proportion and then melted and pelletized in the double-screw extruder. The halogen-free flame retarding HIPS composite material includes no halogen and maintains excellent mechanical performances while reaching the high flame retarding level.

Owner:BEIJING UNIV OF CHEM TECH

Modified polyphenyl ether material and preparation method thereof

The invention provides a modified polyphenyl ether material, which has lower cost, good flame retardant property and good mechanical property at the same time. The modified polyphenyl ether material consists of the following raw materials in part by weight: 60 to 90 parts of polyphenyl ether, 5.6 to 8.4 parts of high impact polystyrene, 9 to 13.6 parts of flame retardant, 4.8 to 7.2 parts of toughening agent, 0.4 to 0.6 part of antioxidant, 0.16 to 0.24 part of light stabilizer and 0.48 to 0.72 part of toner. The flame retardant is phosphate flame retardant or the flame retardant compounded by phosphate flame retardant and nitrogen flame retardant; the flame retardant is bisphenol A bi(diphenyl phosphate); the toughening agent is SEBS or SBS; the light stabilizer is zinc oxide and / or sulfur oxide; and the toner is colorant such as carbon black powder.

Owner:重庆启蓝塑料有限公司

Moulded thermoplastic resin articles with travertine-like appearance

InactiveUS20070299179A1Synthetic resin layered productsPlastic recyclingPolymer scienceAcrylonitrile

The present invention relates to moulded thermoplastic resin articles with travertine-like appearance which exhibit shrinkage of not more than 0.5% upon cooling after moulding process and have a density of at least 1.5 g / cm3. The articles comprise 30-60% by weight of styrene-based resin and 40-50% by weight of stone powder. The styrene-based resin used is selected from the group comprising polystyrene (PS), high impact polystyrene (HIPS), styrene-acrylonitrile copolymer (SAN), acrylonitrile-butadiene-styrene terpolymer (ABS) and blends of two or more thereof. The stone powder used has an average size range of 600-2000 mesh and it preferably comprises limestone powder or calcium carbonate. The articles may further comprise 1-3% by weight of impact modifier and / or up to 2% by weight of lubricant. The articles also may further comprise 1-3% by weight of colour pigments or dyes.

Owner:GREENYIELD INDS M

Nylon composite material and preparation method thereof

The invention discloses a nylon composite material and a preparation method thereof. The nylon composite material comprises the following components, by mass, 20-90% of nylon 66, 3-20% of high impact polystyrene, 5-50% of an inorganic filler, 0.1-3% of a chain extender, 0.1-1% of an antioxidant, 0.1-1% of a coupling agent, 0.2-3% of a lubricant, and 0.5-3% of functional assistants. The recycled nylon 66 which is adopted as a main raw material allows a case of changing wastes into valuables and the resource recycle to be realized; the high impact polystyrene which is used as a compatilizer allows the comprehensive performance and the impact toughness of the material to be improved, and balanced physical and mechanical properties to be obtained; and the adopted chain extender allows the molecular weight and the relative viscosity of nylon to be effectively improved, and an abuse of the decrease of the physical and mechanical properties caused by the molecular chain rupture in the nylon regeneration process to be effectively prevented. The preparation method which is a one-step method has the advantages of simple production technology and low processing cost.

Owner:洪伟

Flame retardant resin compositions

InactiveUS6822025B2Improved flowabilityHigh strengthFireproof paintsPlastic/resin/waxes insulatorsAlcoholPhosphate

A flame retardant thermoplastic resin composition comprises a thermoplastic resin comprising a polyphenylene ether resin, a high impact polystyrene resin or an acrylontrile-butadiene-styrene resin; an organo phosphate compound in an amount less than or equal to about 20 parts by weight for every 100 parts by weight of the thermoplastic resin; and a polyhydric alcohol compound in an amount of about 0.5 to about 5.0 parts for every 100 parts by weight of the thermoplastic resin. A method for the manufacture of the thermoplastic resin composition is also disclosed. The thermoplastic resin composition exhibits high flow characteristics and improved impact strength while providing effective flame retardance.

Owner:SABIC INNOVATIVE PLASTICS IP BV

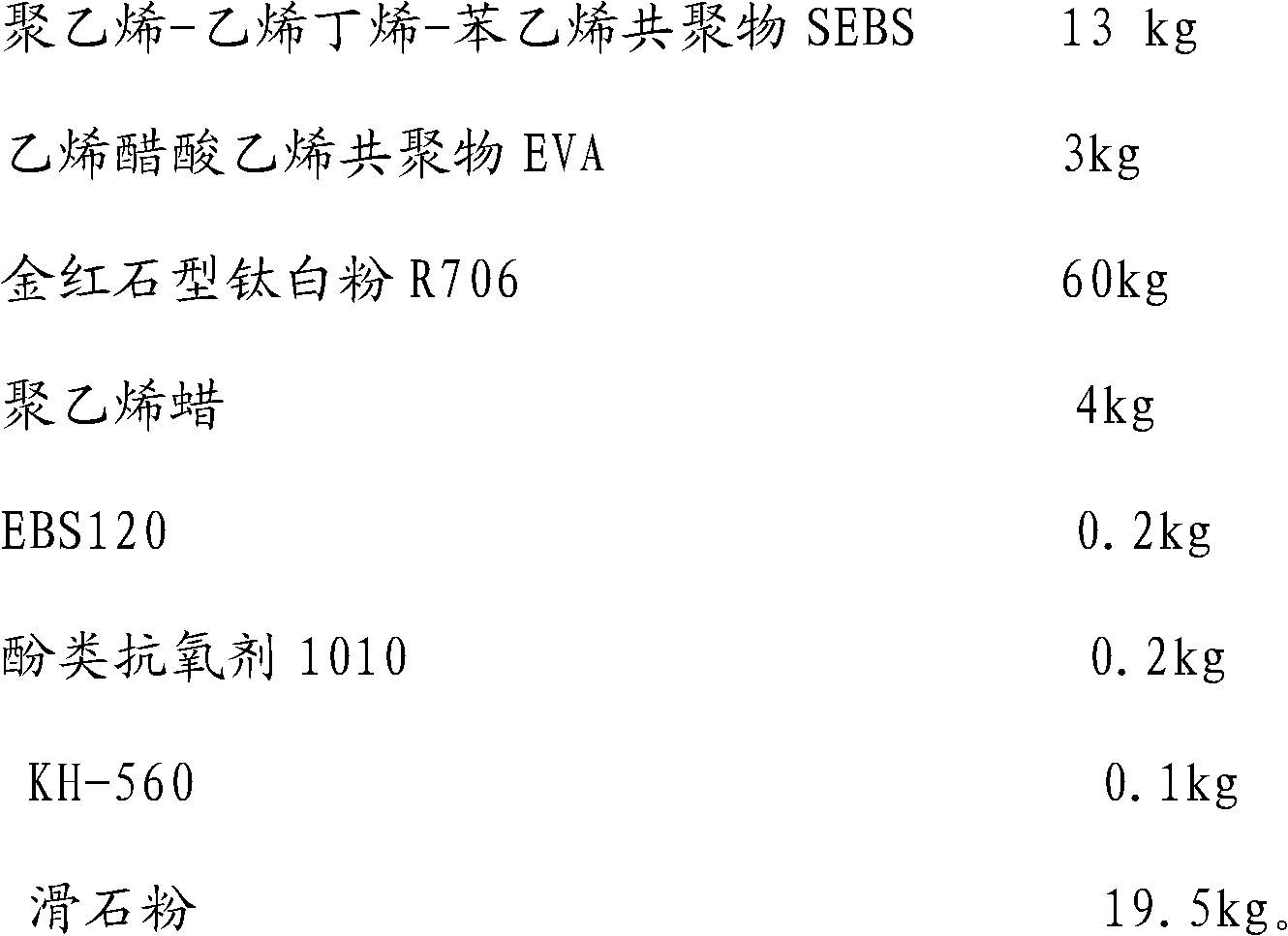

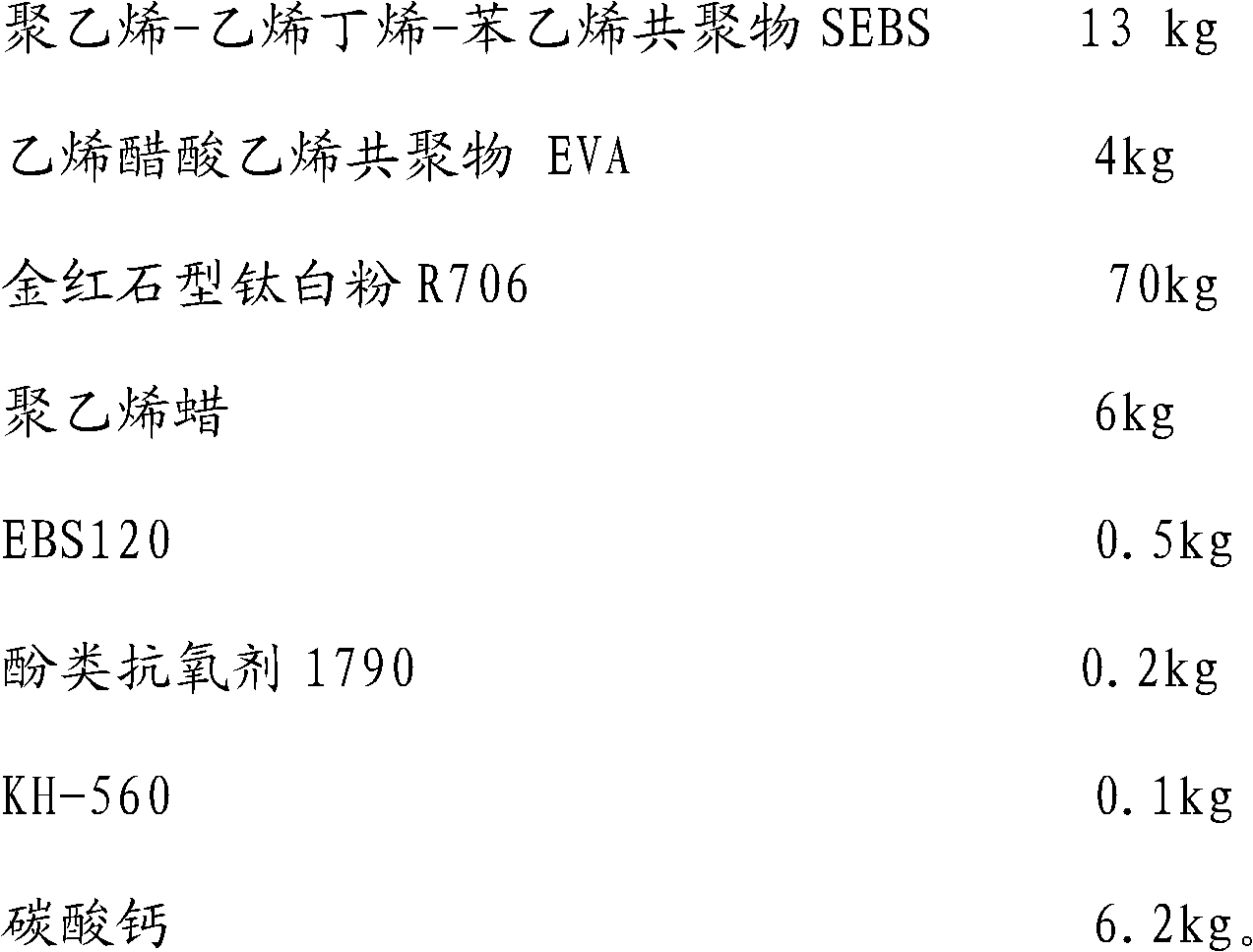

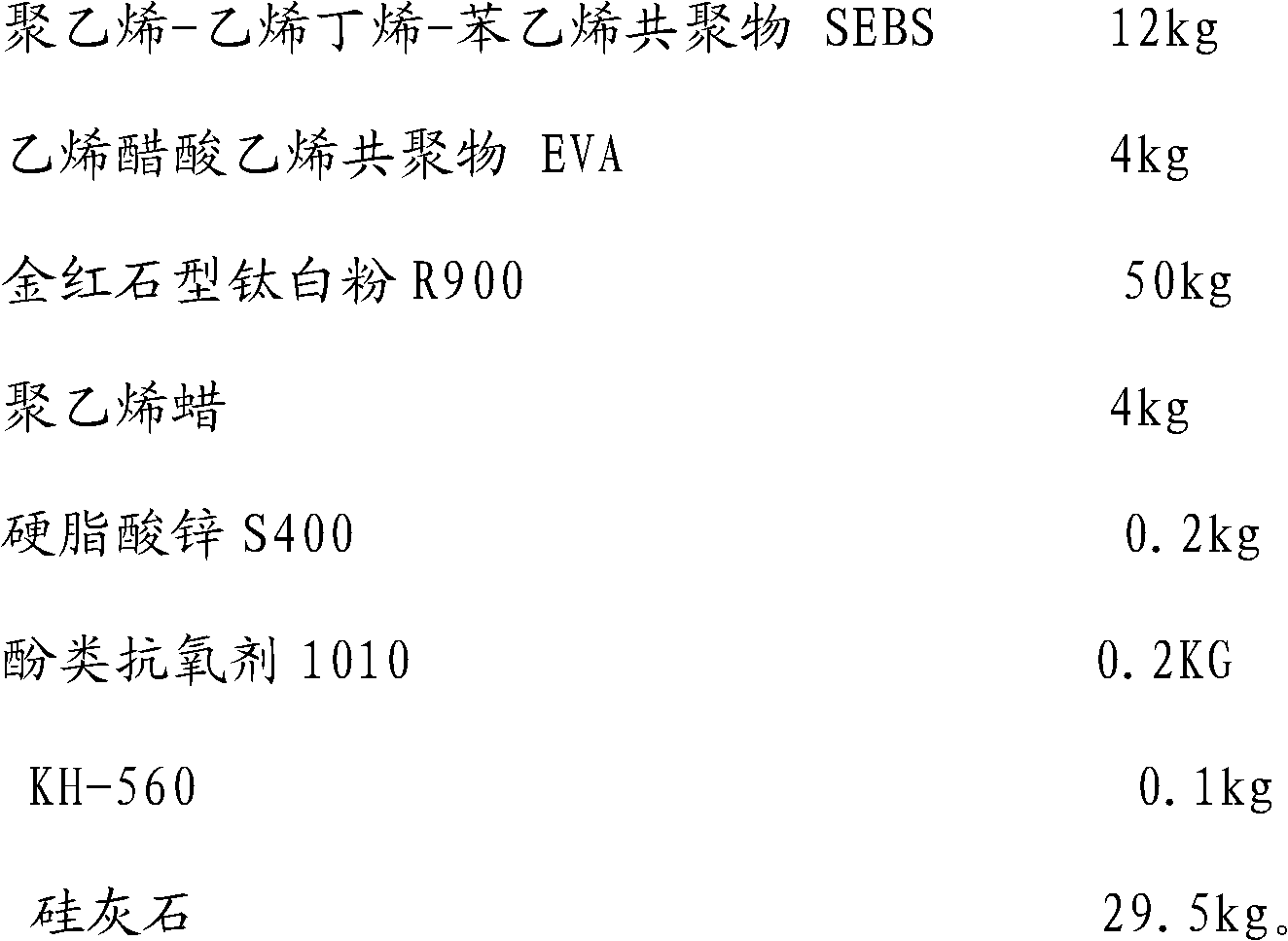

General white master batch and its preparation method

The invention discloses a general white master batch and its preparation method. The general white master batch is made from the following components of: by weight, 16-23% of a carrier resin; 50-75% of a pigment; 0-3% of a processing aid; 0-2.5% of a heat stabilizer; 4-7% of a dispersant; 0.1-3% of a coupling agent; and 0-40% of a filler. The general white master batch has good dispersibility and high whiteness, can be used for the coloring of a plurality of plastics such as polyethylene, polypropylene, polystyrene, high impact polystyrene, acrylonitrile-butadiene-styrol copolymer and the like, and has good compatibility with the colored plastics. Final products have no flow feeder liner, have high whiteness and have excellent impact performance. The general white master batch is especially applicable for white household electrical appliances which have high requirements on whiteness and surface glossiness.

Owner:SHENZHEN KEJU NEW MATERIAL

Method for preparing phosphor modified flame retardation stiffening agent

ActiveCN101928372AImprove flame retardant performanceImprove heat resistanceEngineering plasticCyanate compound

The invention discloses a method for preparing a phosphor modified flame retardation stiffening agent with excellent flame resistance and hear resistance. The prepared flame retardation stiffening agent has excellent flame resistance, hear resistance, physical properties and chemical properties, so the stiffening agent is sufficient for being used as polycarbonate or an additive of other engineering plastics such as acrylonitrile-butadiene-styrene (ABS) and high impact polystyrene (HIPS), and also used as raw material of epoxy resin, cyanate resin and acrylate resin and / or a stiffening agent of the epoxy resin. Especially the flame retardation stiffening agent can be applied to highly reliable electrical / electronic elements such as insulating material of EMC, and various composite materials such as printed circuit board (PCB) base material and insulation plate which need excellent flame resistance and thermal stability, adhesive, coating agent, paint and the like.

Owner:KANGNAM CHEM +1

Flame retardant polystyrene foamed hard wood-imitating material and preparation method thereof

The invention discloses a flame retardant polystyrene foamed hard wood-imitating material and a preparation method thereof. The hard wood-imitating material comprises, by weight, 50-70 parts of recovered polystyrene, 55-75 parts of high impact polystyrene, 35-45 parts of flame retardant masterbatch for a core layer, 30-40 parts of special flame retardant masterbatch for a surface layer, 0.5-0.9 parts of a foaming agent, 1-4 parts of a flexibilizer, 0.1-0.5 parts of a plasticizer, and 0.5-0.9 parts of a coloring agent. The flame retardant polystyrene foamed hard wood-imitating material of the present invention has high intensity flame retardation, is a hard foamed wood-imitating material with certain toughness and low density, and simultaneously has the advantages of fireproofing, waterproofing, oil resistance, insect prevention, mildew resistance, weatherproofing, light weight and the like.

Owner:SHANGHAI INTCO INDUSTRIES CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com