Patents

Literature

68results about How to "High flame retardant level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame-retardant heat-conducting double-component epoxy resin pouring sealant and preparation method thereof

InactiveCN104152093ALow coefficient of linear thermal expansionReduce packing settlingNon-macromolecular adhesive additivesMacromolecular adhesive additivesThermal conductivityPolymer chemistry

The invention relates to a flame-retardant heat-conducting double-component epoxy resin pouring sealant and a preparation method thereof. The pouring sealant is composed of a component A and a component B in a weight ratio of 100: 80 to 100: 120. The pouring sealant prepared in the invention has the advantages of a long operation period, a low thermal expansion coefficient after curing, a high flame retardation grade, reaching grade UL94-V0, good thermal conductivity and excellent electrical properties, and is applicable to high temperature electric packaging of power semiconductors, rectifiers, transformers, etc.

Owner:YANTAI DARBOND TECH

Nanometer enhanced type fluorosilicone rubber long-acting anti-fouling flashing coating

ActiveCN101338159AIncreased hydrophobic migration speedIncreased durability of hydrophobic migrationAntifouling/underwater paintsPaints with biocidesInsulation layerElectric power system

The invention provides a nanometer strengthening fluoride silicone rubber long-acting anti fouling and flashing coating material (nano PRTV coating material) which is used on an external insulation layer of a power system high pressure transmission and transformation device. The coating is composed of the following compositions (weight portion) of 20-40 percent of hydroxyl-fluoride containing polysiloxane, 2-5 percent of small molecular siloxane, 1-6 percent of cross linker, 0.02-1 percent of catalyst, 2-6 percent of nano silicon dioxide, 4-6 percent of decabromodiphenyl ethane, 1-2 percent of pigment and 30-50 percent of solvent. The coating provided by the invention is provided with perfect flame retardancy, solvent resistance, oil resistance, high and low temperature resistance and good self-cleaning performance. The surface of the coating material is smoother than dirt flash preventing coating material. Compared with the dirt flash preventing coating material, the coating material of the invention is greatly improved in aspects of hydrophobic migration speed, proportionality, sustainability, etc. Once filming can be realized. With the service life of more than 20 years, the coating material can be used permanently.

Owner:XIAN TAIPING ELECTRONICS TECH & DEVCO

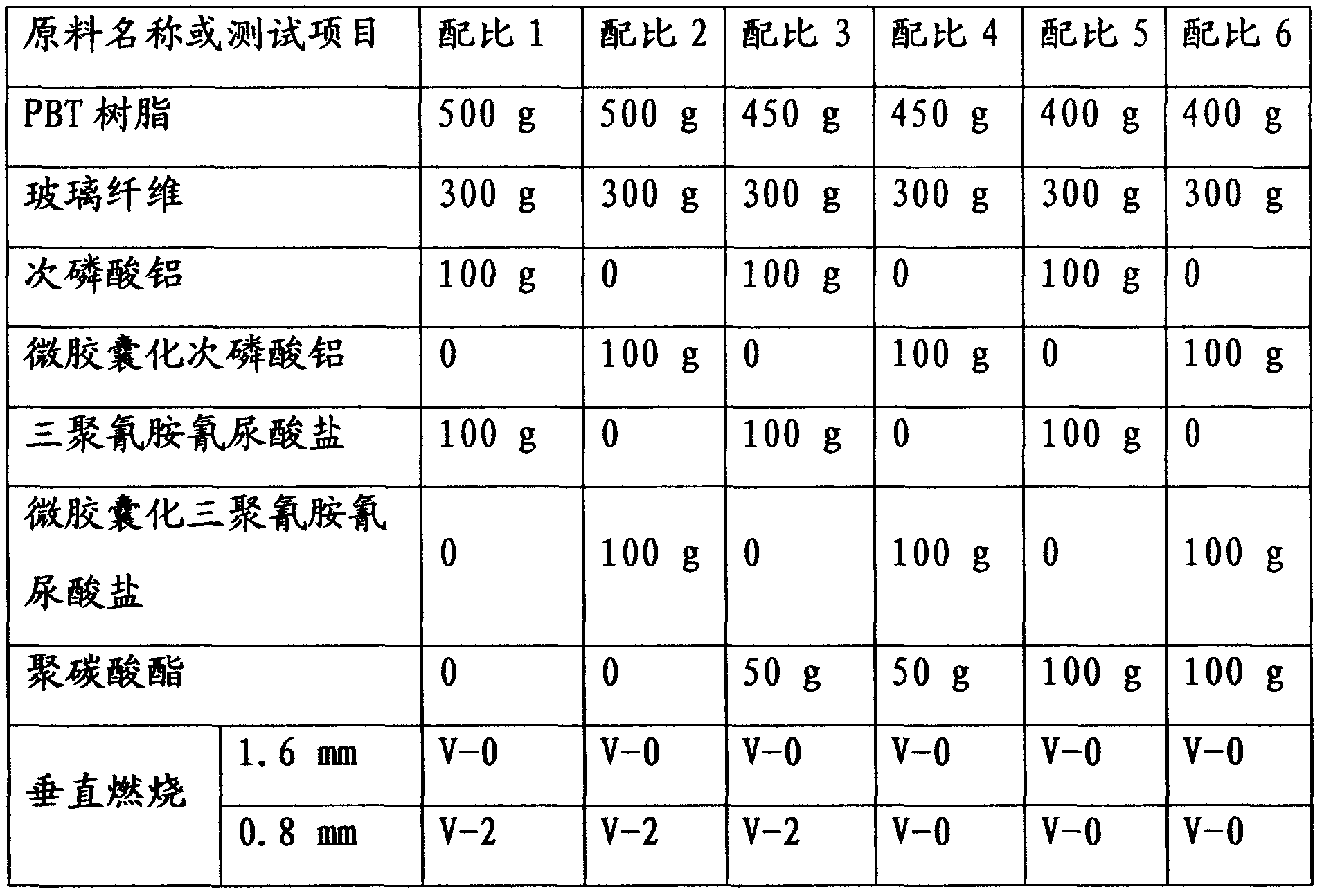

Halogen-free flame retardant glass fiber reinforced polyester composite and preparation method thereof

The invention discloses a halogen-free flame retardant glass fiber reinforced polyester composite and a preparation method thereof. The invention is characterized in that the preparation method of the composite comprises the following steps: mixing polyester, glass fiber, microencapsulated metal hypophosphite and microencapsulated nitrogen-containing flame retardant evenly, heating to 230-275 DEG C, and performing melt blending; and extruding, pulling, cooling, granulating and drying to obtain the composite, wherein the weight percentages of the polyester, glass fiber, microencapsulated metal hypophosphite and microencapsulated nitrogen-containing flame retardant to the total weight of the composite are 40-60%, 25-30%, 10-20% and 5-10% respectively. The halogen-free flame retardant glass fiber reinforced polyester composite has both good flame resistance and physical properties; the defects of the existing reinforced polyester material modification technology that the halogen-containing flame retardant inflicts great damage on the environment, the additional amount of the inorganic flame retardant is great and the material has poor physical properties and weather resistance can be overcome; and the composite has wide application prospect.

Owner:SUZHOU INST FOR ADVANCED STUDY USTC

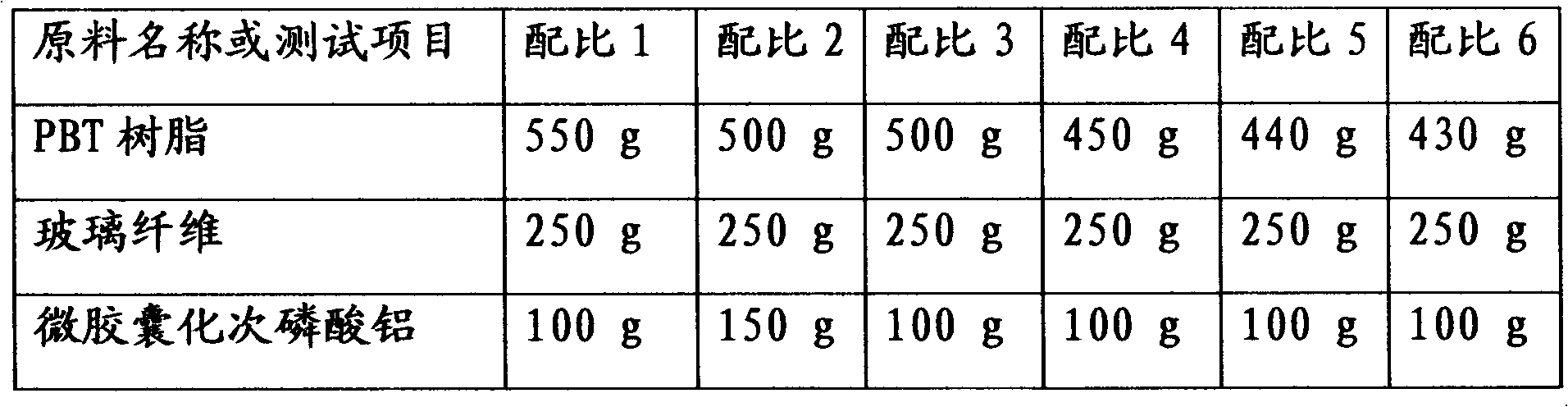

Halogen-free flame retarding high-impact polystyrene (HIPS) composite material and preparation method thereof

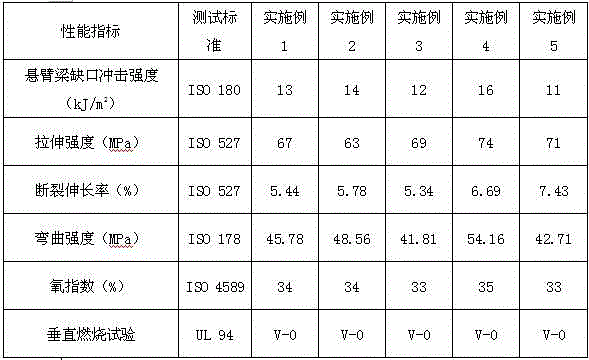

The invention discloses a halogen-free flame retarding high-impact polystyrene (HIPS) composite material and a preparation method thereof, belonging to the macromolecular material technical field. The halogen-free flame retarding HIPS composite material includes the following weight parts of components: 65-85 parts of HIPS, 15-35 parts of charring agent PPO, 5-20 parts of flame retardant MRP, 4-15 parts of toughener SEBS, 0.3-1.5 part(s) of assistant flame retardant PTFE, 0.3-1.5 part(s) of assistant flame retardant nano inorganic filling, and 0.1-0.5 part of antioxidant. The preparation method includes that firstly, the HIPS, the assistant flame retardant PTFE and the assistant flame retardant nano inorganic filling are stirred at high speed and mixed evenly in a certain weight proportion, melted and pelletized in a double-screw extruder to produce the HIPS and assistant flame retardant master batch; secondly, the HIPS, the charring agent, the flame retardant, the toughener, the HIPS and assistant flame retardant master batch and the antioxidant are stirred at high speed and mixed evenly in a certain weight proportion and then melted and pelletized in the double-screw extruder. The halogen-free flame retarding HIPS composite material includes no halogen and maintains excellent mechanical performances while reaching the high flame retarding level.

Owner:BEIJING UNIV OF CHEM TECH

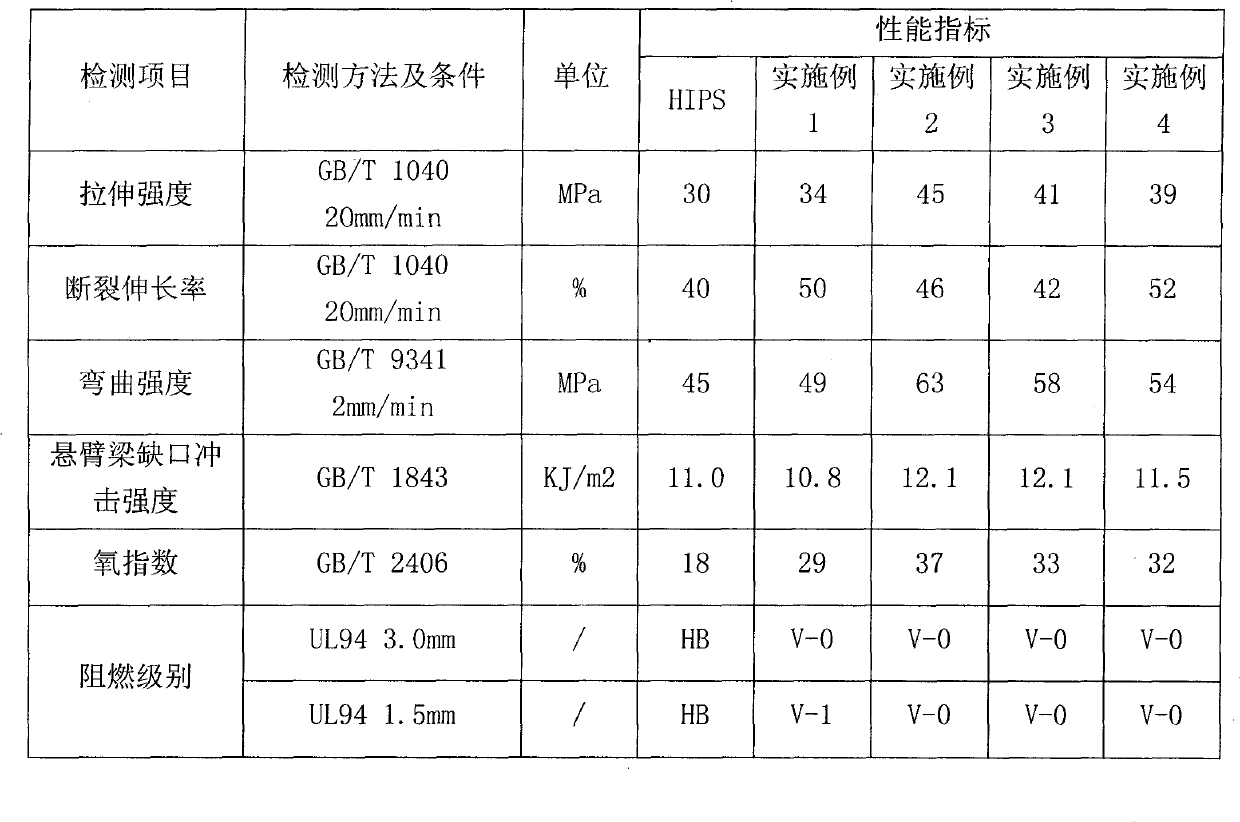

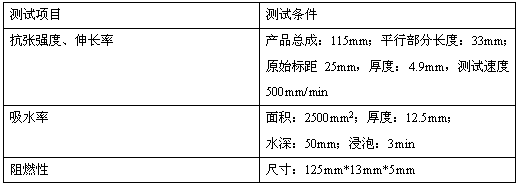

Heat-conduction electronic potting adhesive and preparation method thereof

InactiveCN102942895AMeet potting requirementsEffective protectionNon-macromolecular adhesive additivesAdhesiveUltimate tensile strength

The invention relates to the field of a potting adhesive and particularly relates to a low-viscosity heat-conduction electronic potting adhesive applicable to each electronic element and a preparation method thereof. The heat-conduction electronic potting adhesive is formed by a component A and a component B in a weight ratio from 100: 90 to 100: 110; the component A comprises the following raw materials in weight percentage of 39.20-79.60% of heat-conduction inflaming retarding powder, 0.80-2.00% of color matching agent, 0.40-1.00% of silane coupling agent, 16.20-43.80% of liquid silicon oil and 3.00-14.50% of silane cross-linking agent; and the component B comprises the following raw materials in weight percentage of 39.20-79.60% of heat-conduction inflaming retarding powder, 18.00-57.80% of liquid silicon oil, 0.20-1.00% of silane coupling agent, 1.00-1.96% of color matching agent and 0.04-1.00% of catalyst. The low-viscosity heat-conduction electronic potting adhesive has lower viscosity, excellent mobility, good heat-conduction performance and high inflaming retarding grade; the potting requirement of a seam less than 0.02 mm can be met and the construction is convenient; and after the heat-conduction electronic potting adhesive is cured, the strength is good, and the dustproof, moisture-proof and vibration-proof performances are good, the electronic element can be effectively protected and the service life of the electronic element is prolonged.

Owner:YANTAI DARBOND TECH

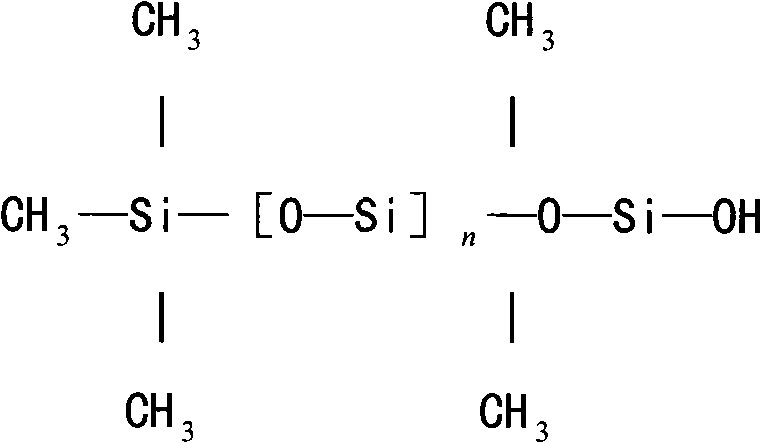

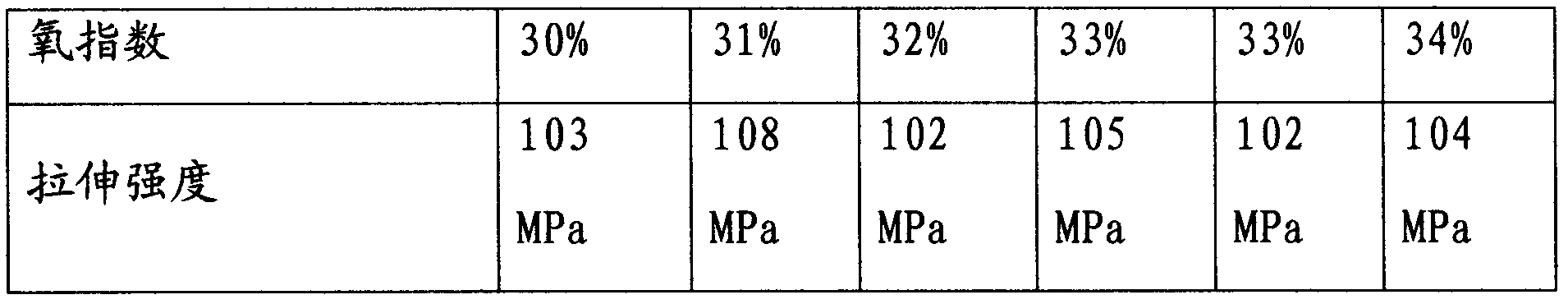

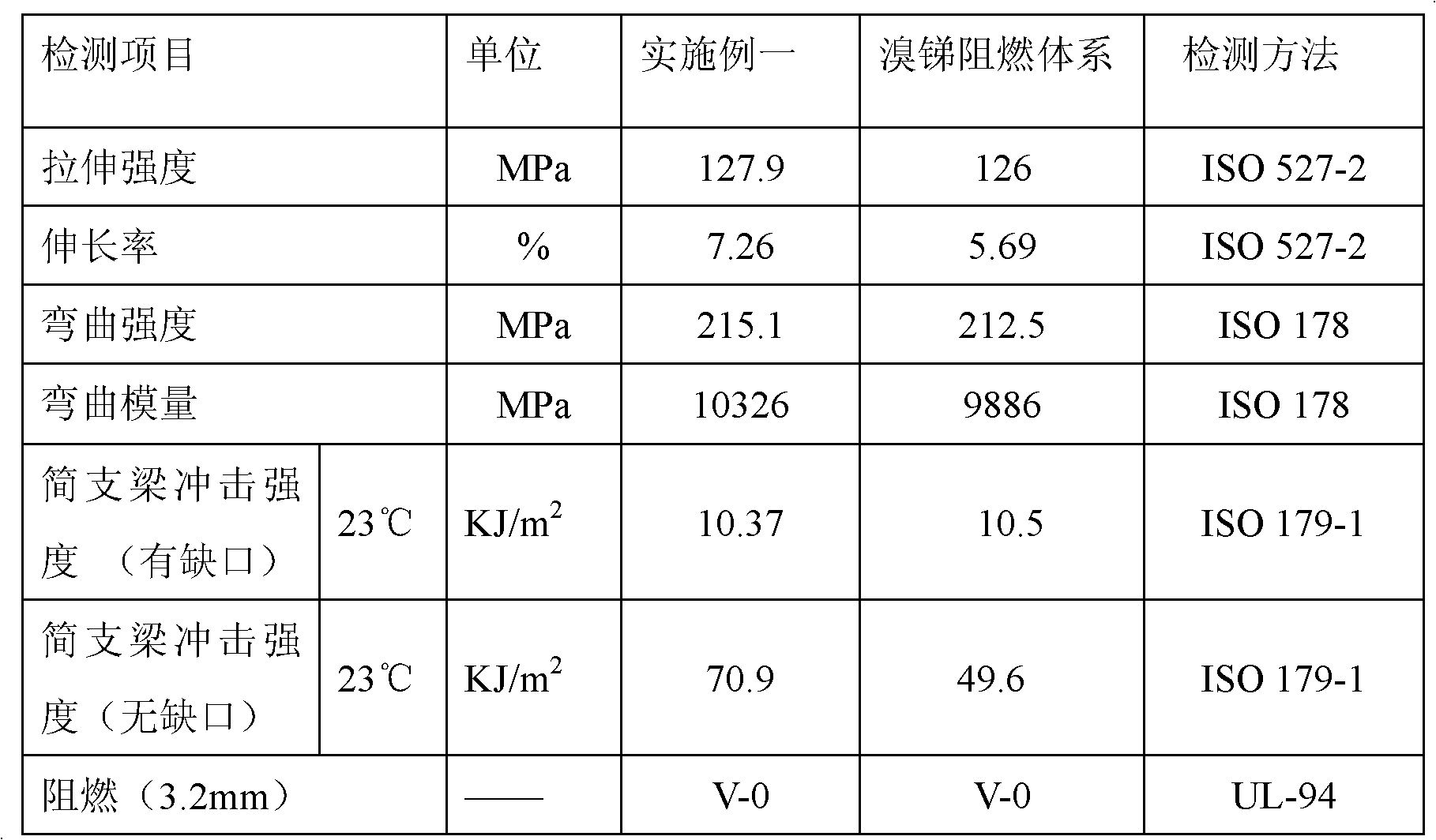

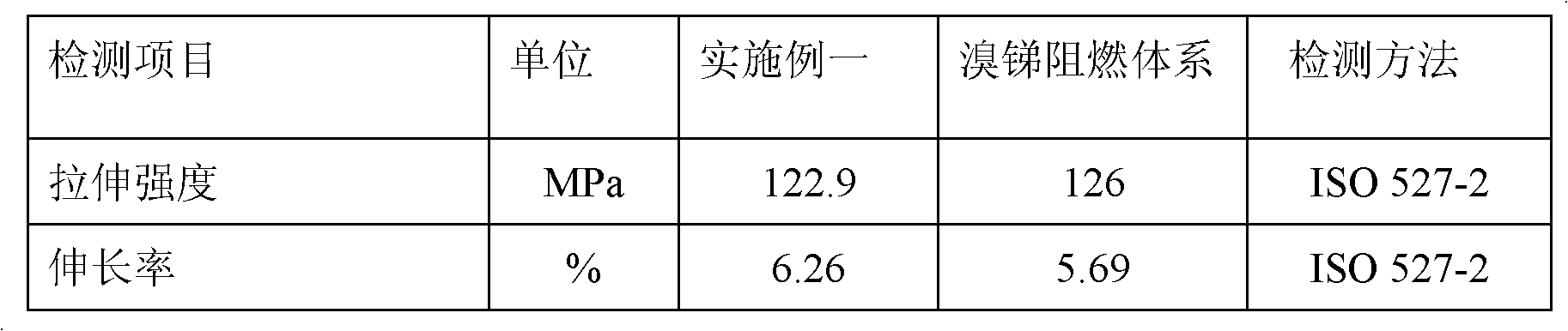

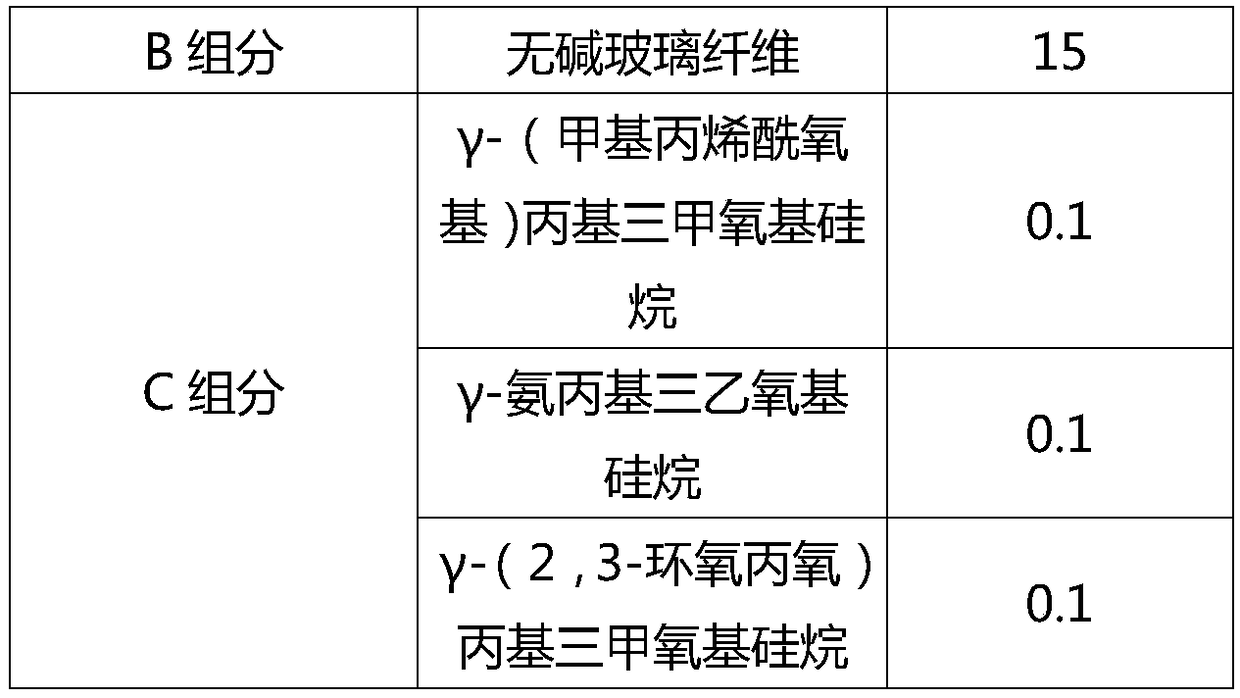

Halogen-free flame retarding and glass fiber reinforced resin and its preparation method

The invention relates to halogen-free flame retarding and glass fiber reinforced resin and its preparation method. The reinforced resin comprises the following components by weight percent (wt%): 30-75 of PBT (poly(butylene terephthalate)) resin, 0-50 of alkali-free glass fiber, 8-15 of a halogen-free fire retardant, 0-10 of a toughening agent, 0.2-0.6 of an anti-oxidant, 0-1 of a compatibilizer,and 0.5-1 of a processing aid. The preparation method consists of the steps of: conducting surface treatment to alkali-free glass fiber with a coupling agent, and adsorbing the halogen-free fire retardant on the surface of the alkali-free glass fiber, drying the PBT resin, and mixing it with the toughening agent, the anti-oxidant, the compatibilizer and the processing aid and placing the mixture in a double-screw extruder, adding alkali-free glass fiber in the downstream of the extruder, and carrying out fusing, mixing, extruding, cooling, drying and granulating, thus obtaining the product. The reinforced resin of the invention has the advantages of no halogen, low smoke, environmental protection, good flame retarding effect, and good disperse effect of the halogen-free fire retardant in a resin matrix. When heated, the halogen-free fire retardant can form a uniform, porous, expanded and compact carbon layer, which cooperates with the glass fiber so as to prevent the diffusion of heat, combustible volatile substances, and the like.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Regenerated polypropylene environment-friendly modified material and preparation method thereof

The invention relates to the technical field of recycling of polypropylene regenerated materials and particularly relates to a regenerated polypropylene environment-friendly modified material and a preparation method thereof. The regenerated polypropylene environment-friendly modified material comprises the following substances in parts by weight: 100 parts of polypropylene recycled materials, 10-15 parts of glass fibers, 30-40 parts of nitrogen-phosphor compounded expansion flame retardants, 0.3-0.8 part of a synergistic flame retardant, 4-10 parts of an anti-impact modifier, 1-2 parts of an antioxidant, and 0.1-0.5 part of a coupling agent, wherein the synergistic flame retardant is silicon dioxide, the anti-impact modifier is recycled rubber material, the coupling agent is a titanate coupling agent. According to the regenerated polypropylene environment-friendly modified material disclosed by the invention, the regenerated polypropylene is low in toxicity, low in smoke, free of melt drops and high in oxygen index, the material is high in mechanical performance and low in preparation cost, capable of saving the material cost, environmentally friendly, economical and efficient. The polypropylene recycled material obtained by the preparation method is high in polypropylene purity, less in impurity and simple in preparation process, and industrialization is easy to realize.

Owner:GUANGDONG GUOLI SCI & TECH CO LTD

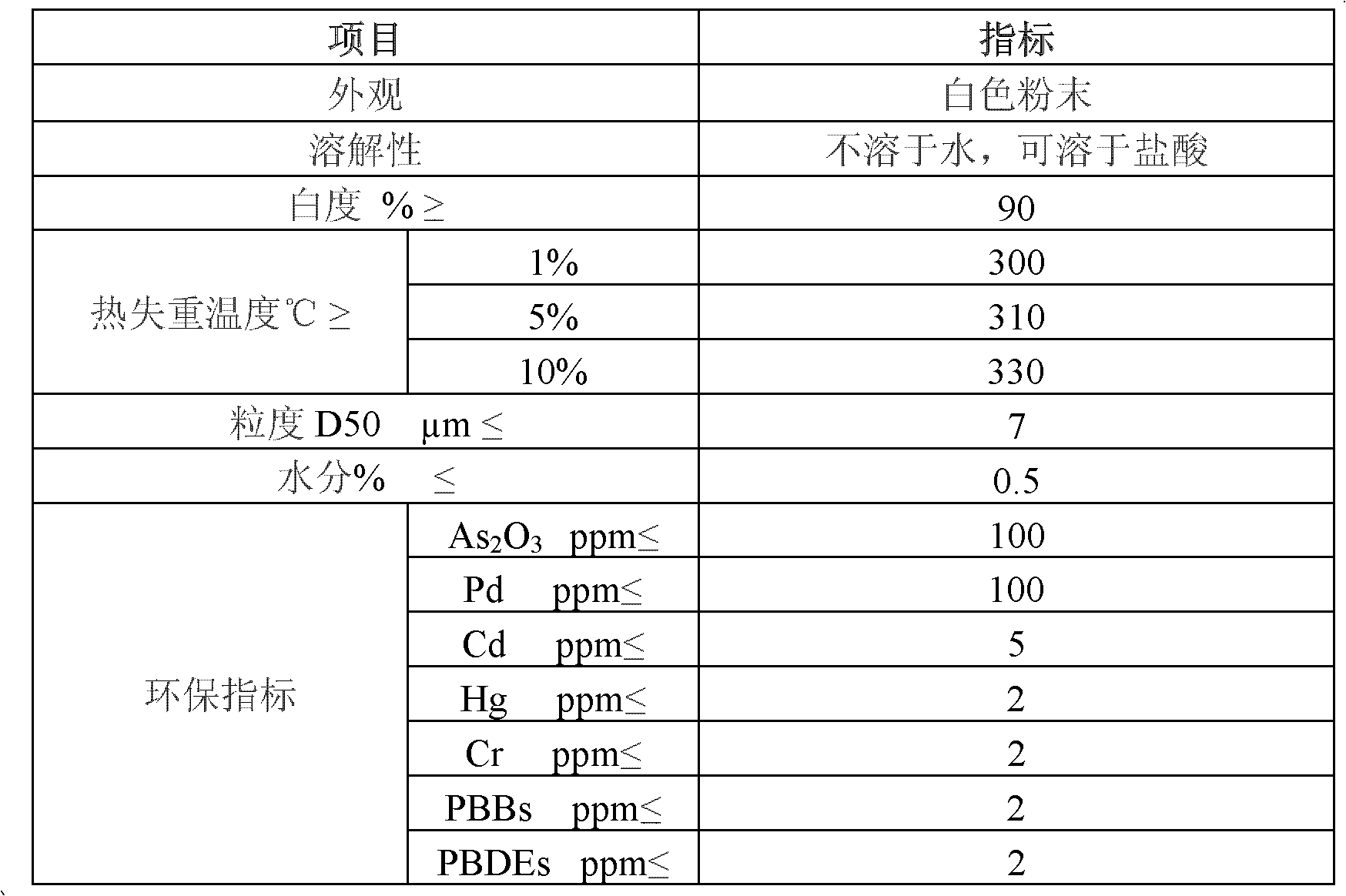

Environment-friendly halogen-free flame retardant for glass fiber reinforced PA6 (polyamide) and preparation method thereof

The invention discloses an environment-friendly halogen-free flame retardant for glass fiber reinforced PA6 (polyamide) and a preparation method thereof. The environment-friendly halogen-free flame retardant for glass fiber reinforced PA6 consists of the following raw materials, by weight, 10-12 parts of aluminum phosphate, 4-5 parts of melamine cyanurate, 1-3 parts of ammonium polyphosphate, 0.5-3.0 parts of association-effect carbonatic, 0.5-3.0 parts of flame-retardant association effect agent and 0.2-1.0 part of anti-oxidizer, wherein the aluminum phosphate is prepared by phosphoric acid and aluminum hydroxide. The environment-friendly halogen-free flame retardant has the advantages of excellent flame-retardant function and low fuming quantity, can be used for retarding the glass fiber reinforced PA6 by substituting for antimony and bromide flame retardant, and is higher in cost performance when being compared with the antimony and bromide flame retardant in the aspect of cost andlower in usage when in application as compared with antimony and bromide flame retardant and is prior to the like products of antimony and bromide in indexes of environment protection. Besides, the environment-friendly halogen-free flame retardant can completely substitute for the antimony and bromide flame retardant and has higher flame retardant level.

Owner:JINAN TAIXING FINE CHEM

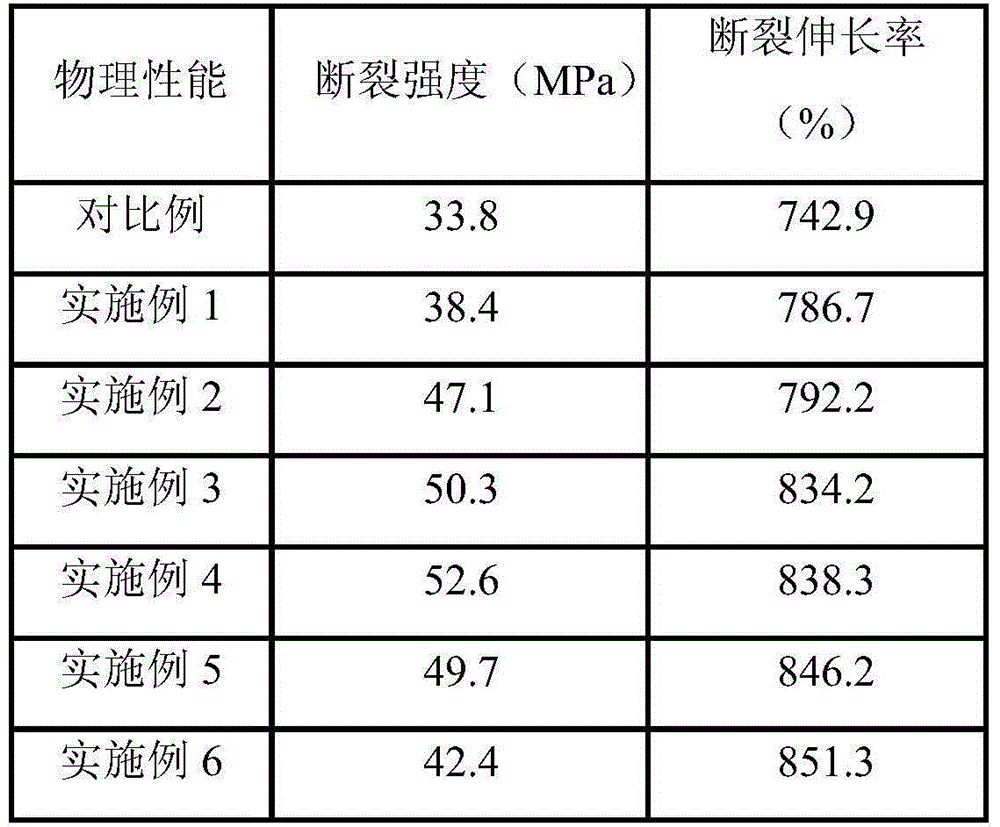

High-temperature vulcanized silicone rubber sealing strip and preparation method thereof

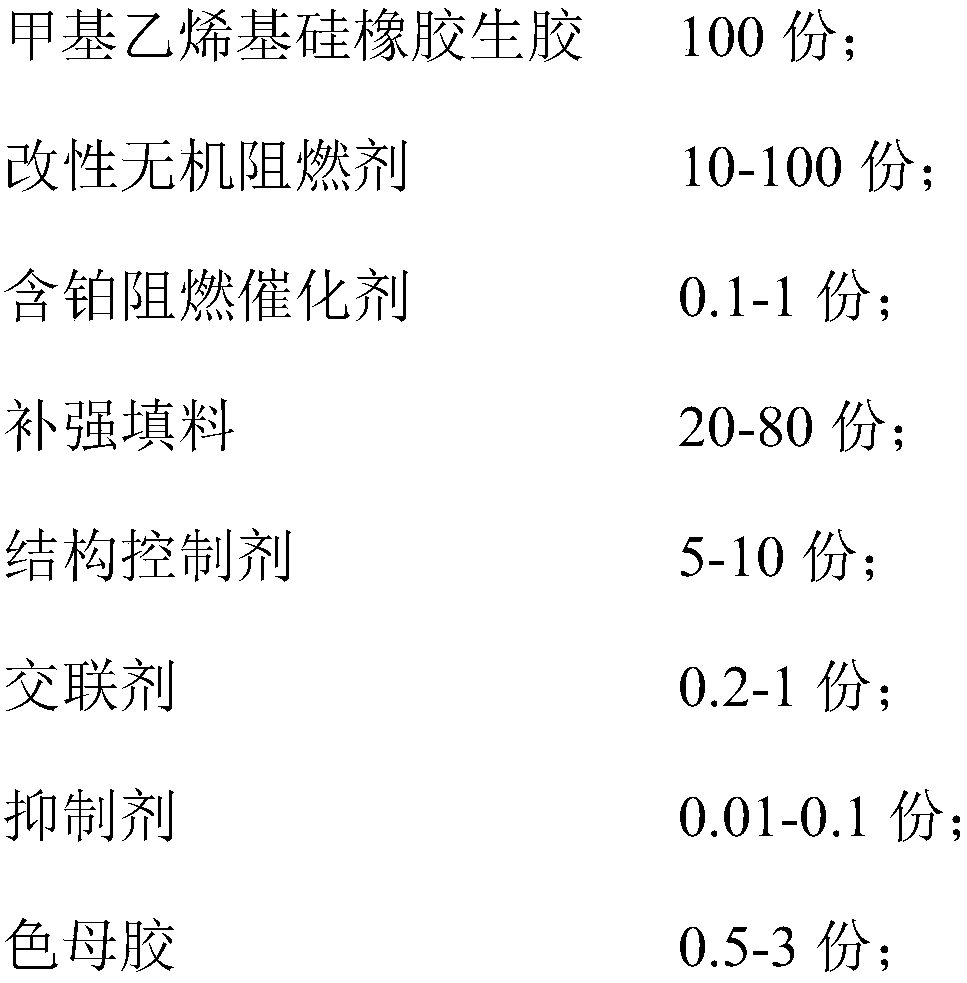

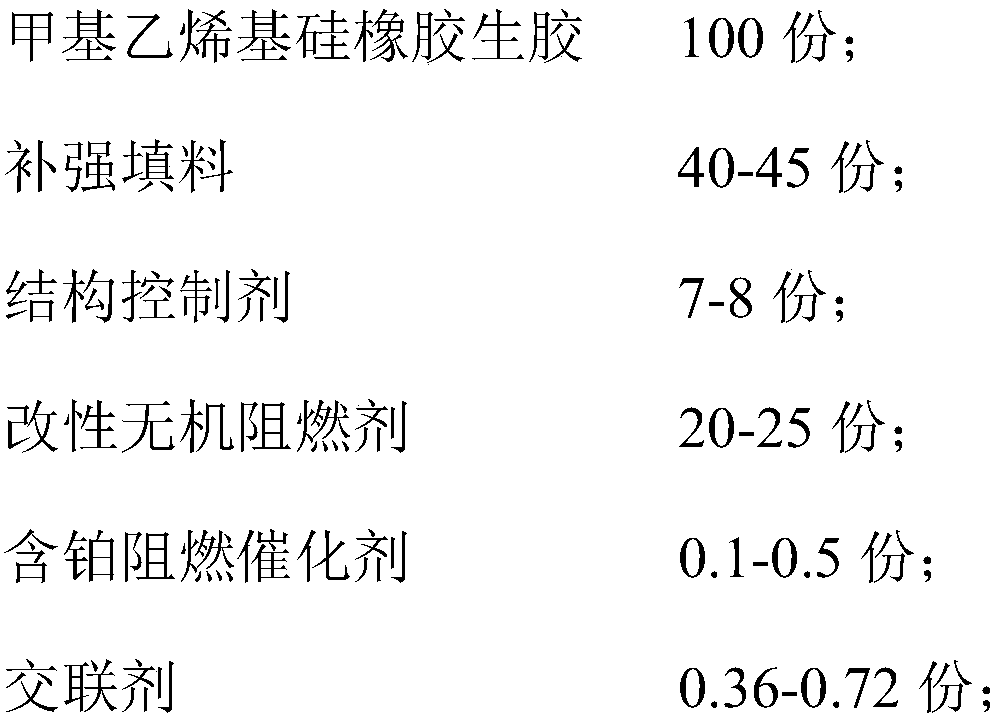

The invention relates to a high-temperature vulcanized silicone rubber sealing strip. The vulcanized silicone rubber sealing strip is mainly prepared from the following raw materials in parts by weight: 100 parts of methyl vinyl raw silicone rubber, 10-100 parts of a modified inorganic flame-retardant agent, 0.1-1 part of a platinum-containing flame-retardant catalyst, 20-80 parts of reinforcementfiller, 5-10 parts of a structure control agent, 0.2-1 part of a cross-linking agent, 0.01-0.1 part of an inhibitor and 0.5-3 parts of color masterbatch, wherein the modified inorganic flame-retardant agent is prepared from tetramethyldivinyldisilazane and aluminum hydroxide; the platinum-containing flame-retardant catalyst is prepared from chloroplatinic acid, octanol, fumed silica and vinyl-terminated polydimethylsiloxane. The high-temperature vulcanized silicone rubber is excellent in flame-retardant property and excellent in mechanical property.

Owner:GUANGZHOU BAIYUN CHEM IND

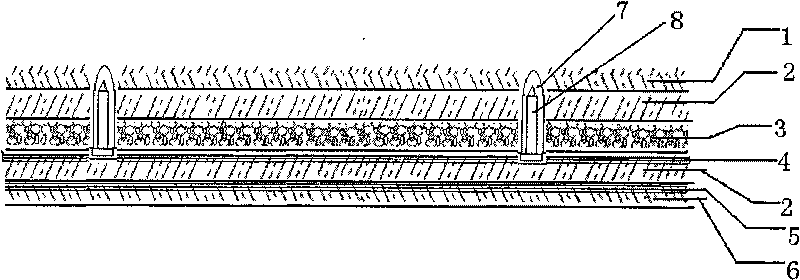

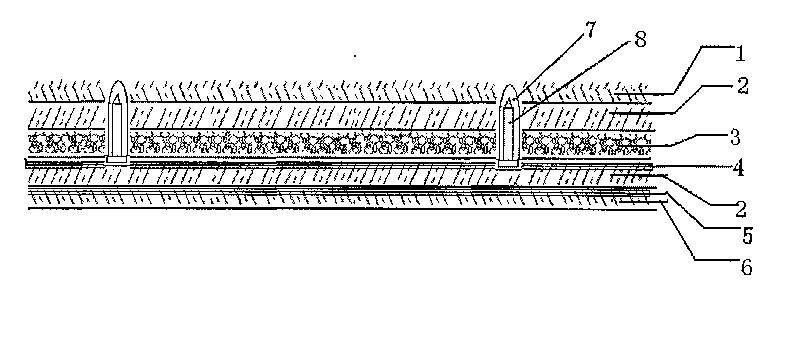

General insulation composite material for exterior wall and application method

InactiveCN101691800AImprove insulation performanceGood heat insulationCovering/liningsInsulation layerMicrosphere

The invention relates to an insulation composite material for an exterior wall and an application method. The composite material is characterized in that the interior and exterior surface layers of a rigid polyurethane layer are combined with inorganic hollow microsphere polymer composite insulation layers, an anti-crack mortar layer is arranged on the exterior inorganic hollow microsphere polymer composite insulation layer and a wall decoration layer is combined with the exterior surface layer of the anti-crack mortar layer. The application method is as follows: the exterior wall to be treated is sequentially coated with the interior hollow microsphere polymer composite insulation layer, rigid polyurethane and the exterior hollow microsphere polymer composite insulation layer, the anti-crack mortar layer is coated on the exterior hollow microsphere polymer composite insulation layer and the wall decoration surface layer is coated on the exterior surface layer of the anti-crack mortar layer. The composite material has good heat insulation property and quick construction method, is strongly adaptive to main structures, reaches higher flame retardant level, is energy-saving and environment-friendly, is suitable for insulation of various walls, especially exterior walls, and is applicable to floors.

Owner:东营丰力输送带有限公司

Master compound of fire-resistant color of highduty polyolefin

A high-efficiency flame-retarding color mother composition for polyolefin contains carrier (30-85 wt.%), flame-retarding agent (10-50), flame-retarding synergist (5-20), pigment powder (0-10) and assistant (1-5). It can be mixed with polyolefin resin to prepare variou s electric or electronic products by injection moulding. Its advantages are high flame-retarding performance, multiple colors and low cost.

Owner:KINGFA SCI & TECH CO LTD

Antibacterial halogen-free flame retardant reinforced PE/PET composite staple fiber and preparation method thereof

InactiveCN111850733AHigh fiber strengthImprove mechanical propertiesElectroconductive/antistatic filament manufactureFlame-proof filament manufacturePolymer scienceCarbon fibers

The invention discloses an antibacterial halogen-free flame retardant reinforced PE / PET composite staple fiber and a preparation method thereof. The antibacterial halogen-free flame retardant reinforced PE / PET composite staple fiber is prepared from the raw materials in parts by weight: 30-50 parts of PE, 35-50 parts of PET, 8-15 parts of graphene, 10-18 parts of modified carbon nanofibers, 8-15 parts of a composite antibacterial agent, 6-10 parts of a halogen-free flame retardant, 5-10 parts of a toughening agent, 3-8 parts of a compatibilizer, 2-5 parts of an antioxidant and 0.1-2.5 parts ofother additives. The antibacterial halogen-free flame retardant reinforced PE / PET composite staple fiber is composed of selected raw materials, the content of each raw material is optimized, the PE,PET, graphene, modified carbon nanofibers, composite antibacterial agent, halogen-free flame retardant, toughening agent, compatibilizer, antioxidant and other additives with appropriate proportion are selected, the respective advantages are fully played, and mutual complementation and promotion are achieved, so that the prepared antibacterial halogen-free flame retardant reinforced PE / PET composite staple fiber has advantages of high antibacterial property, high flame retardant level, high fiber strength, excellent mechanical properties and the like.

Owner:福建省福地化纤科技有限公司

Preparation of polylactic acid composite material with flame-retardant function

InactiveCN104194292AHigh flame retardant levelImprove anti-dripping performancePhosphatePolymethyl methacrylate

The invention discloses preparation of a polylactic acid composite material with a flame-retardant function. The preparation comprises the following steps: mixing polylactic acid, core / shell-methyl polysiloxane / polymethyl methacrylate particles and polyarylate phosphate; carrying out melt blending by adopting torque rheology at the temperature of 168-180 DEG C to obtain the polylactic acid composite material with the flame-retardant function, wherein the weight percent of the core / shell-methyl polysiloxane / polymethyl methacrylate particles is 0%-25%, the weight percent of the polyarylate phosphate is 0%-25%, and the core / shell-methyl polysiloxane / polymethyl methacrylate particles and the polyarylate phosphate can not be 0 simultaneously. Compared with the traditional polylactic acid flame-retardant material, the polylactic acid composite material has the advantages of better flame-retardant property, mechanical property, crystallization property and heat-resistant property.

Owner:NANJING UNIV OF SCI & TECH

Regenerated HIPS environmental-friendly modified material and preparation method thereof

The invention relates to the technical field of recycling of HIPS regenerated materials, and particularly relates to a regenerated HIPS environmental-friendly modified material and a preparation method thereof. The regenerated HIPS environmental-friendly modified material comprises the following substances in parts by weight: 100 parts of HIPS recovered materials, 3-6 parts of toughening agents, 15-20 parts of flame retardants, 1-2 parts of flame-retardant synergists, 10-12 parts of anti-impact modifying agents, 1-2 parts of antioxidants, 1-4 parts of coupling agents, 2-5 parts of lubricating agents and 2-5 parts of stabilizing agents, wherein the flame retardants are formed by mixing a compound flame retardant of ammonium polyphosphate, magnesium hydroxide and boric acid with montmorillonite-hexadecyl trimethyl ammonium bromide. The regenerated HIPS has the advantages of low toxicity, low smoke and no corrosion and is favorable to the flame retardance of HIPS. The regenerated HIPS environmental-friendly modified material disclosed by the invention is high in mechanical property, low in cost, capable of effectively saving the material cost, environmental-friendly, economic and effective. The preparation method disclosed by the invention has the advantages of high HIPS purity and few impurities of an obtained HIPS recovered material, simple preparation process and easiness for industrialization realization.

Owner:东莞国立高分子材料有限公司

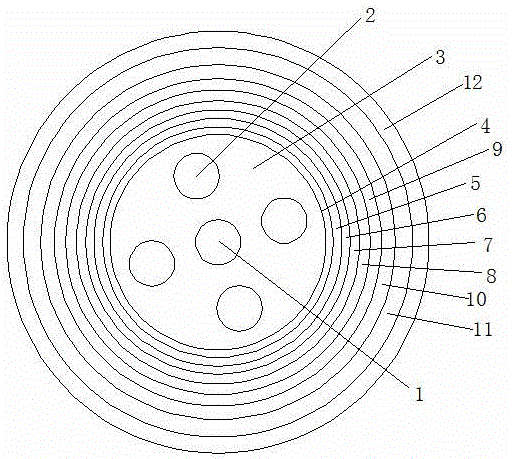

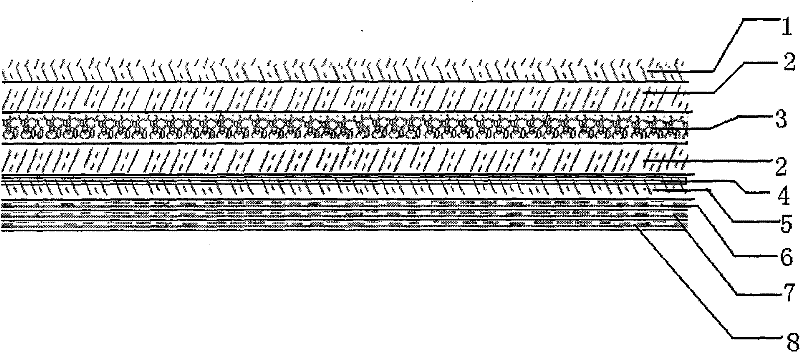

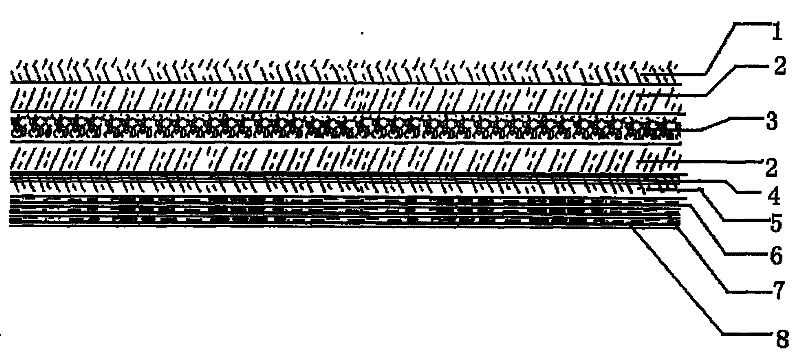

Environment-friendly cable with high compressive strength

InactiveCN104952539AHigh flame retardant levelImprove mechanical energyClimate change adaptationInsulated cablesInsulation layerEngineering

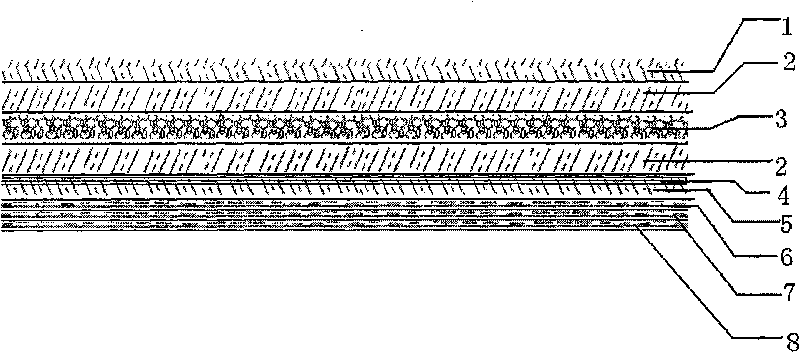

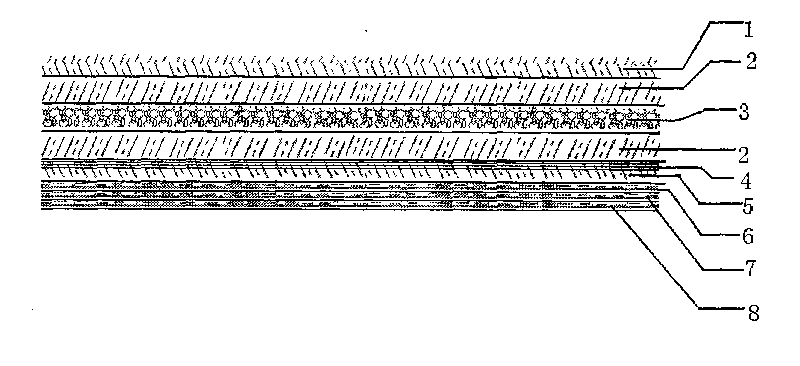

The invention discloses an environment-friendly cable with high compressive strength. The cable comprises an inner reinforcement core, power cables, a filling layer, a wrapping tape layer, an oxygen insulation layer, a steel tape layer, an inner jacket layer, a steel wire armor layer, a water-resistant factice layer, an outer jacket layer, a braided layer and a graphite coating, where the center of the filling layer is filled with the inner reinforcement core, the four power cables are circumferentially distributed on the outer circle of the inner reinforcement core, and the wrapping tape layer, the oxygen insulation layer, the steel tape layer, the inner jacket layer, the steel wire armor layer, the water-resistant factice layer, the outer jacket layer, the braided layer and the graphite coating are sequentially arranged outside the filling layer from inside to outside. The flame-retardant grade of the cable is increased due to the oxygen insulation layer, the steel tape layer and the wrapping tape layer, the cable can be prevented from being damaged by induced electromotive force during running and well protected due to the graphite coating, and the cable has the characteristics of good water resistance and fire resistance, high strength, deformation prevention, long service life and high-temperature resistance and is environment-friendly when being recycled.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY RIZHAOPOWER SUPPLY +1

Flame-retardant PC/ABS (Poly Carbonate/Acrylonitrile-Butadiene-Styrene) alloy containing no halogen-system flame retardant

The invention relates to a flame-retardant PC / ABS (Poly Carbonate / Acrylonitrile-Butadiene-Styrene) alloy containing no halogen-system flame retardant. The flame-retardant PC / ABS alloy comprises 80-150 parts of polycarbonate, 40-70 parts of ABS resin, 12-30 parts of flame retardant, 1-10 parts of compatilizer, 1-10 parts of toughening agent and 1-5 parts of lubricant. The flame-retardant PC / ABS alloy has the advantages of low production cost, good machining performance, high flame-retardant grade and environmental friendliness.

Owner:浙江赛日新材料科技有限公司

Reinforced insulation composite material for exterior wall and application method

InactiveCN101691798AGood insulation performanceLow thermal conductivityCovering/liningsPolymer compositesSurface layer

The invention relates to an insulation composite material for an exterior wall and an application method. The composite material is characterized in that the interior and exterior surface layers of a rigid polyurethane layer are combined with inorganic hollow microsphere polymer composite insulation layers, a wire mesh and an anchor bolt are arranged on the exterior inorganic hollow microsphere polymer composite insulation layer and wall tiles are combined with the exterior surface layer of the exterior inorganic hollow microsphere polymer composite insulation layer. The application method is as follows: the exterior wall to be treated is sequentially coated with the interior hollow microsphere polymer composite insulation layer, rigid polyurethane and the wire mesh, the wire mesh is fixed with the exterior wall by the anchor bolt, the exterior hollow microsphere polymer composite insulation layer is coated on the fixed wire mesh and the wall tiles are affixed to the exterior surface layer of the exterior hollow microsphere polymer composite insulation layer. The composite material has good heat insulation property and quick construction method, is strongly adaptive to main structures, reaches higher flame retardant level, is energy-saving and environment-friendly, is suitable for insulation of various walls, especially exterior walls, and is applicable to floors.

Owner:东营丰力输送带有限公司

Preparation method of flame-retardant polyurethane resin

InactiveCN105176061AThe method is simple and easy to controlImprove mechanical properties and flame retardancySolventDiphenyl phosphate

The invention relates to a preparation method of flame-retardant polyurethane resin. The preparation method comprises the steps of adding cyclodextrin and resorcinol bi(diphenyl) phosphate (RDP) to a solvent, conducting mixing, and obtaining a cyclodextrin / RDP compound; making the cyclodextrin / RDP compound be subjected to still standing for seimentation, filteration, vacuum drying and washing, and obtaining a cyclodextrin / RDP clathrate compound; adding the cyclodextrin / RDP clathrate compound to polyuretane resin, then adding the solvent, stirring the mixture uniformly, leaving the mixture still standing, conducting defoaming and formation, and obtaining the flame-retardant polyurethane resin. The preparation method of the flame-retardant polyurethane resin is simple and easy to control, the problems that resorcinol diphenyl phosphate is poor in dispersity in a base body and prone to migrating when serving as fire retardant can be solved, and meanwhile the mechanical property and the flame retardant property of polyurethane are substantially improved.

Owner:DONGHUA UNIV

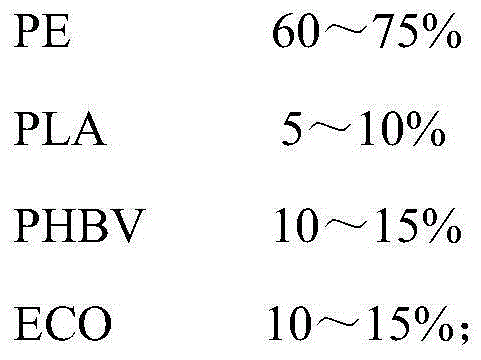

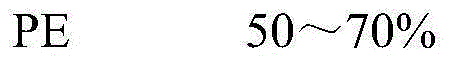

Medicinal flame-retardant plastic packaging material and preparation process thereof

ActiveCN105196667ASmall mechanical propertiesFast degradationSynthetic resin layered productsLaminationPlastic packagingMechanical property

The invention relates to a medicinal flame-retardant plastic packaging material and a preparation process thereof, belonging to the technical field of medicinal packaging materials. The medicinal flame-retardant plastic packaging material has a three-layer structure, an inner layer consists of PE, PLA, PHBV and ECO, a middle layer consists of PE, PLA, PHBV and EVA, and the outer layer consists of PE, PLA, PHBV and ECO. According to the preparation process, components are mixed uniformly according to the formula amount, film blowing is implemented by adopting a three-layer film blowing machine, and finally, rolling is implemented to form a film or cutting is implemented to prepare a bag. The degradable components contained in the plastic packaging material can be degraded gradually under the conditions of light, water and microorganisms in a short time to form a large-area hole, so that the mechanical properties of materials can be lowered, and the degradation of the materials can be accelerated; the contained flame-retardant components play the role of synergistic flame retardance, so that the medicinal flame-retardant plastic packaging materials can be applied to medicine packaging, particularly the packaging of medicines which are directly contacted, and the medicinal flame-retardant plastic packaging material provides a good, excellent and safe selection for the production and packaging of medicines.

Owner:ZIBO HUA ZHI LIN PACKING PROD CO LTD

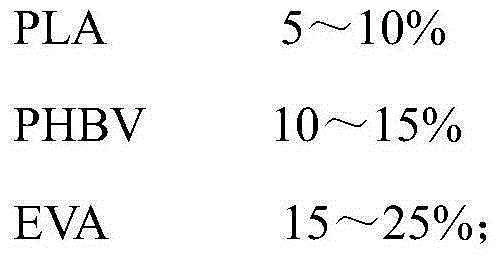

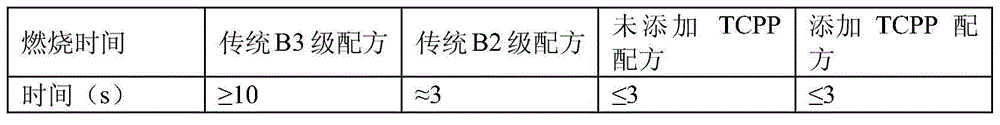

B2 grade flame retardation polyurethane foam material

ActiveCN105461892AHigh flame retardant levelImprove flame retardant performancePolyolPolymer science

The invention belongs to the field of foam gap fillers, and especially relates to a B2 grade flame retardation polyurethane foam material. The B2 grade flame retardation polyurethane foam material comprises, by mass, 10-70 parts of polyether polyol I, 10-50 parts of polyether polyol II, 20-40 parts of mixed flame retardation polyether polyol III, 20-80 parts of paraffin, 3-5 parts of polyether modified polysiloxane, 2-4 parts of a catalyst, 200-350 parts of isocyanate, 40-80 parts of methyl ether, 30-90 parts of liquefied petroleum gas and 0-30 parts of TCPP; the molecular weight of the polyether polyol I is 1000, and the functionality of the polyether polyol I is 3; the molecular weight of the polyether polyol II is 400, and the functionality of the polyether polyol II is 2; and the mixed flame retardation polyether polyol III, is a mixed flame retardation polyether, the average molecular weight of the mixed flame retardation polyether polyol III is 1000, and the average functionality of the mixed flame retardation polyether polyol III is 2.6. The mixed flame retardation polyether polyol III is used, and the formula is improved, so true B2 grade flame retardation is realized, the oxygen index is 26 or above, the flame retardation grade of foam is substantially improved, and the flame retardation performance is stable.

Owner:GUNUO TIANJIN IND

Sealing material and preparation method thereof

The invention discloses a sealing material and a preparation method thereof. The sealing material is prepared from the following raw materials in parts by weight: 40 to 66 parts of raw silicon rubber,10 to 20 parts of hydroxide polysiloxane, 10 to 23 parts of white carbon black, 20 to 30 parts of fire retardant, 5 to 30 parts of aluminum nitride, 1 to 6 parts of nanometer aluminum oxide, 1 to 6 parts of nanometer magnesia, 0.1 to 2 parts of paraffin and 0.1 to 2 parts of sulfurizing reagent. The sealing material is prepared by mixing, plastifying, milling, molding and vulcanizing in sequence.The sealing material disclosed by the invention has the advantages of high sealing performance, high flame-retardant level, high acid and alkali resistance, high stability and high oxidization resistance, particularly has high insulating performance and heat conductivity, has longer service life, does not deteriorate after long-time storage, and is safe and nontoxic to human body. The sealing material provided by the invention has the advantages of low price and environmental friendliness; the preparation method of the sealing material is simple, and has high operability.

Owner:上海良亿新能源科技有限公司

Halogen-free flame-retardant PBT resin with high CTI and preparation method of halogen-free flame-retardant PBT resin

InactiveCN109337305AComply with RoHS environmental directiveHigh flame retardant levelAntioxidantPre treatment

The invention provides halogen-free flame-retardant PBT resin with high CTI and a preparation method of the halogen-free flame-retardant PBT resin. The halogen-free flame-retardant PBT resin is prepared from components in parts by weight as follows: 40-70 parts of PBT resin, 18-24 parts of a composite flame retardant, 1-5 parts of a CTI synergist, 10-30 parts of reinforcing filler, 0.4-2 parts ofa lubricant, 0.2-1 part of an antioxidant and 0.2-2 parts of a coupling agent. The method comprises the following steps: (1) the reinforcing filler is subjected to pretreatment: 10-30 parts by weightof the reinforcing filler is weighed and subjected to surface treatment with the coupling agent mainly in a manner that the compound coupling agent and the reinforcing filler are premixed in a high-speed mixer for 10-30 min; (2) 40-70 parts of the PBT resin, 18-24 parts of the composite flame retardant, 1-5 parts of the CTI synergist, 10-30 parts of the reinforcing filler, 0.4-2 parts of the lubricant and 0.2-1 part of the antioxidant are added to the mixture in step (1) and mixed at a high speed for 5-8 min, the mixture is subjected to extrusion and granulation by a twin-screw extruder at 190-230 DEG C, and halogen-free flame-retardant PBT resin with high CTI is obtained; (3) injection molding is performed by an injection molding machine at 190-230 DEG C.

Owner:浙江富丽新材料有限公司

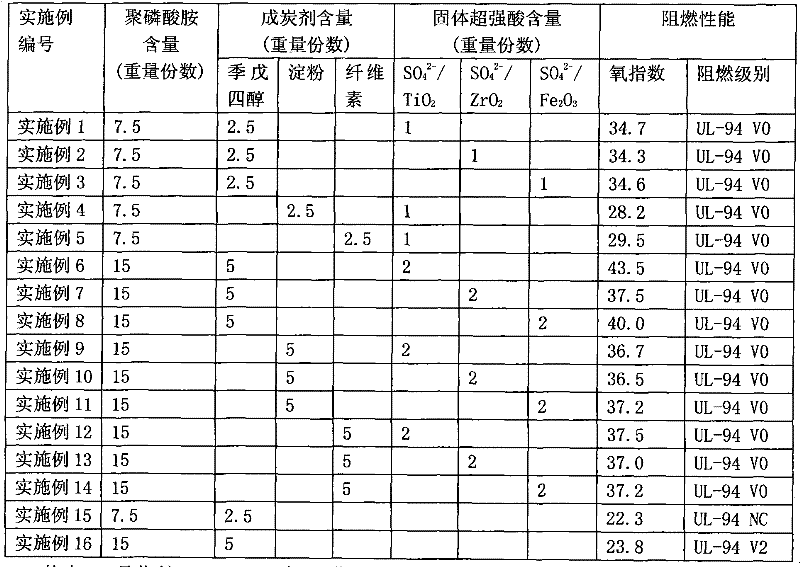

Halogen-free flame retardant polylactic acid composite material

The invention discloses a halogen-free flame retardant polylactic acid composite material which is formed by taking polylactic resin as a body, and adding a mixture of ammonium polyphosphate and a char forming agent, SO42- / MxOy type solid super-strong acid, an antioxidizer, a nucleating agent and an anti-melting drop agent through melt blending. The halogen-free flame retardant polylactic acid composite material comprises the following components in parts by weight: 70 to 95 parts of the polylactic resin, 3 to 25 parts of the mixture of the ammonium polyphosphate and the char forming agent, 0.1 to 5 parts of the SO42- / MxOy type solid super-strong acid, 0.01 part to 3 parts of the antioxidizer, 0.1 part to 2 parts of the nucleating agent and 0.1 part to 10 parts of the anti-melting drop agent. Compared with the prior art, the halogen-free flame retardant polylactic acid composite material synergistically promotes the fire retardation performance of the polylactic acid composite material through the catalytic action of the SO42- / MxOy type solid super-strong acid and the synergistic effect char forming fire retardation action of a nitrogen and phosphorus intumescent type fire retardant, has the advantages of environmental protection and high fire retardation level, and can furthest reduce the affect of addition of auxiliaries to the physical and mechanical performance of polylactic acid body materials simultaneously.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

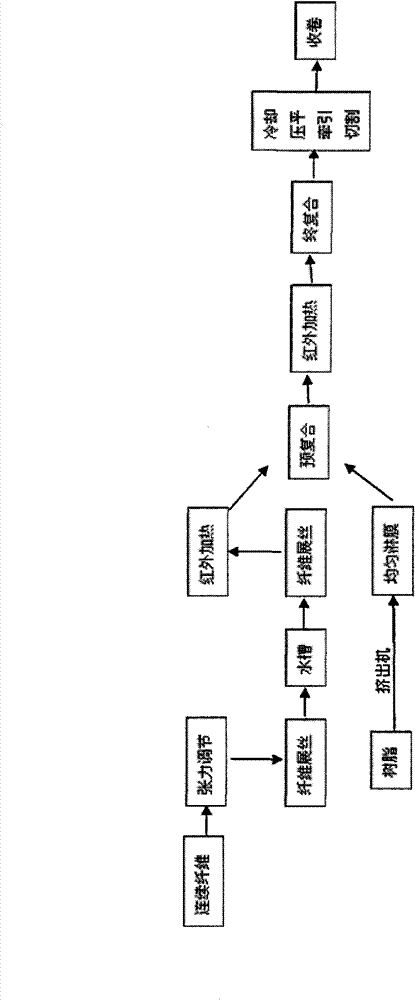

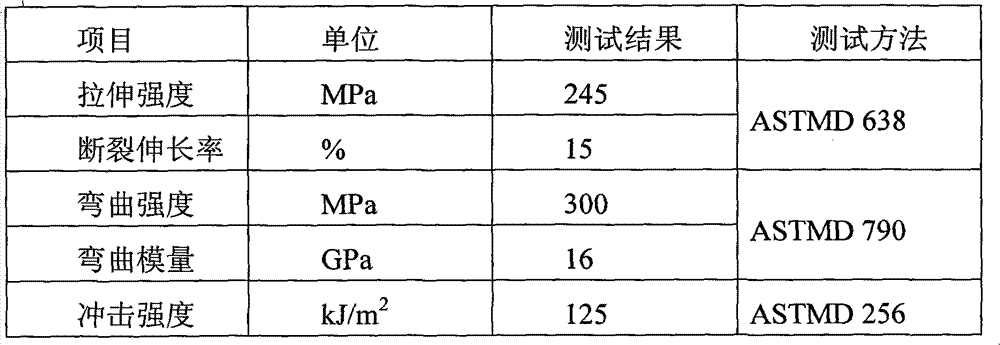

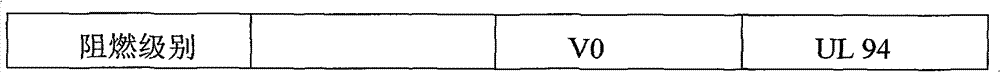

Continuous fiber enhanced thermoplastic antiflaming presoaking belt composite material and preparation method thereof

ActiveCN102295792BImprove impact resistanceSolve the problem of difficult impregnationPolymer scienceFire retardant

The invention relates to a continuous fiber enhanced thermoplastic antiflaming presoaking belt composite material and a preparation method thereof. The composite material is prepared from the following raw materials by weight percent: 45-55% of modified resin and 55-45% of continuous fiber. According to the preparation method in the invention, the composite material is obtained by reasonable fiber dispersion, resin impregnation and composite rolling processes based on the resin containing a flame retardant, a grafting agent, glass microsphere and other auxiliaries and the continuous fiber treated by an impregnating agent which are used as raw materials; compared with the prior art, by using the preparation method in the invention, the problem that the antiflaming resin is difficultly impregnated due to poor flowability is overcome, the produced continuous fiber enhanced thermoplastic antiflaming presoaking belt has extremely high strength, modules and impact property and has antiflaming characteristic, wherein the antiflaming grade can reach UL94 V0 grade.

Owner:LIAONING LIAOJIE SCI & TECH

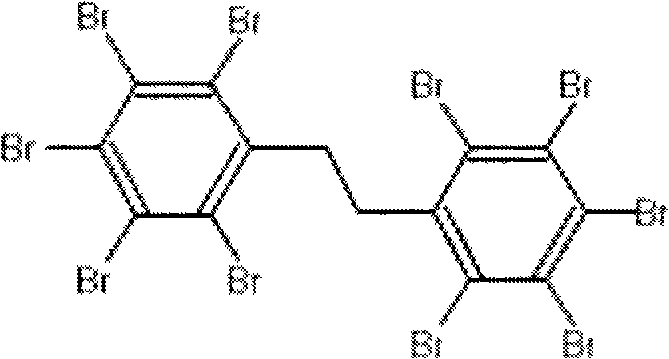

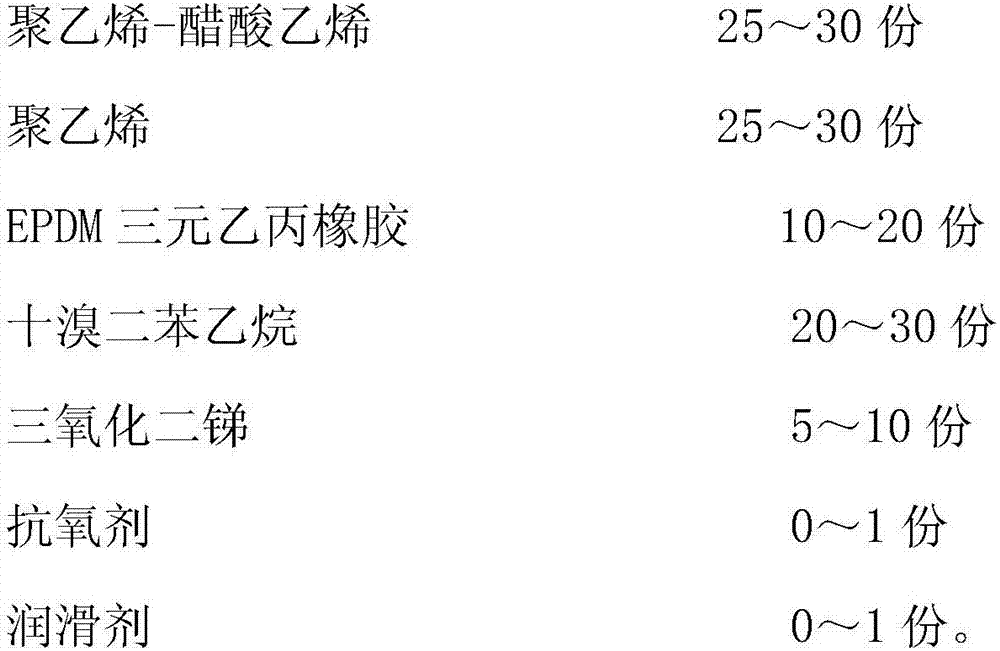

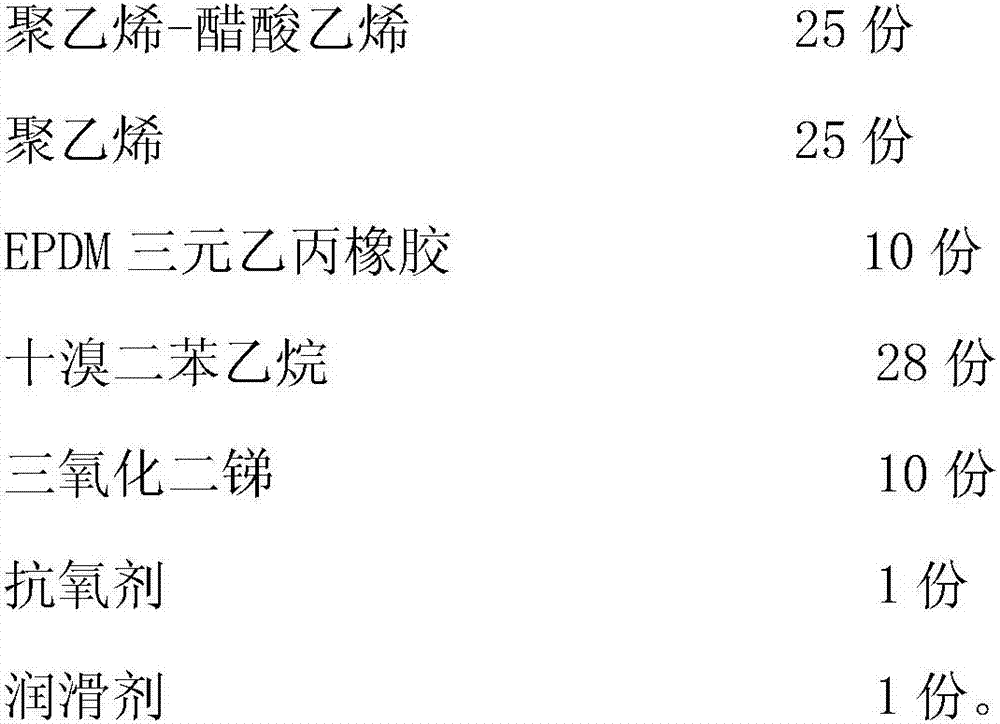

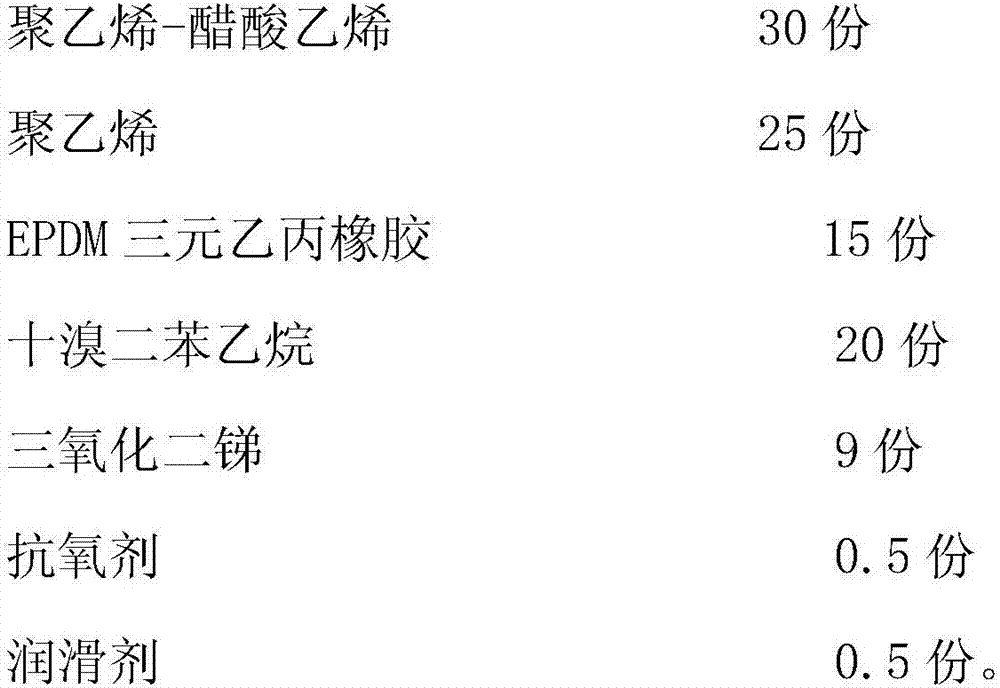

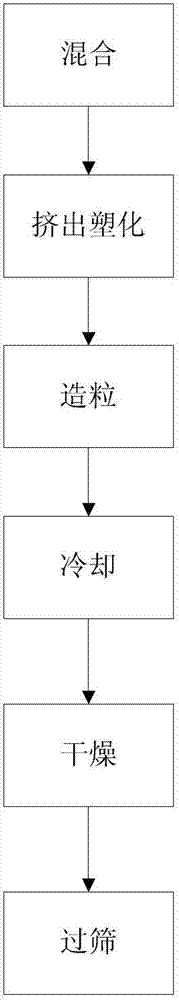

Heat shrink tube for automobile, and preparation method thereof

InactiveCN106893188AHigh flame retardant levelEliminates pungent odorsPolyethylene vinyl acetateAntioxidant

The invention discloses a heat shrink tube for an automobile, and a preparation method thereof. The heat shrink tube for the automobile is characterized by comprising the following raw materials in parts by weight: 25 to 30 parts of polyethylene-vinyl acetate, 25 to 30 parts of polyethylene, 10 to 20 parts of ethylene-propylene-diene monomer (EPDM), 20 to 30 parts of decabromodiphenyl ethane, 5 to 10 parts of antimonous oxide, 0 to 1 part of an antioxidant, and 0 to 1 part of a lubricating agent. The heat shrink tube for the automobile has the following beneficial effects: the new raw materials are added in the formula and the original proportion is adjusted, so that under the condition of not changing the original physical performance, the flame-retardant level is greatly increased, and the pungent smell is eliminated.

Owner:SHANGHAI HUALIU ELECTRONICS TECH CO LTD

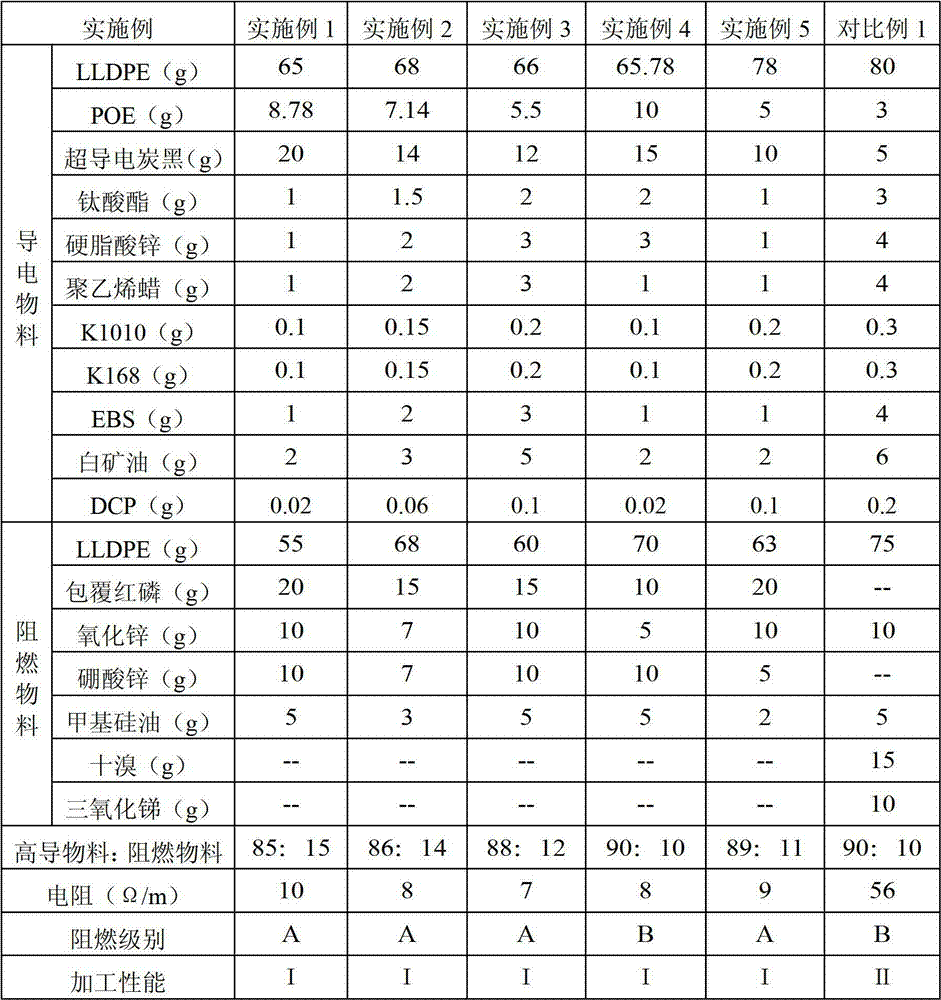

Composition for preparing highly-conductive flame retardant plastic, highly-conductive flame retardant plastic prepared thereby and preparation method thereof

The invention provides a composition for preparing highly-conductive flame retardant plastic. The composition comprises 85-90wt% of electric conductive material and 10-15wt% of flame retardant material, wherein the flame retardant material comprises 55-70wt% of low linear density polyethylene, 10-20wt% of encapsulated red phosphorous, 5-10wt% of zinc oxide, 5-10wt% of zinc borate and 2-5wt% of impregnating compound, according to the mass of the flame retardant material. With the adoption of the composition for preparing highly-conductive flame retardant plastic provided by the invention, the technical problems of the prior art that the highly-conductive flame retardant material is low in flame rating and dangerous in use are solved.

Owner:CHANGSHA QIANYUAN PLASTIC TECH DEV

Silicone sealant for stone curtain wall

InactiveCN105713524AImprove adhesionHigh flame retardant levelNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveAcetic acidPolymer science

The invention relates to a sealing material and particularly relates to a silicone sealant for a stone curtain wall. The silicone sealant is prepared from the following raw materials: a dimethyl siloxane polymer, (3-methyl butoxy)acetic acid-allyl alcohol ester, 2-(1,3-dimethyl-2,6-dioxo-2,3,6,7-tetrahydro-1H-purine-7-yl)acetic acid, hexamethyldisiloxane, 4-hydroxy-3-methoxy acetophenone and the like. The silicone sealant for the stone curtain wall has the advantages of good adhesive property, high flame retardance level and relatively long shelf life, facilitates long-time storage and is easy and convenient to construct with short time; and the preparation method is simple and easy to learn, the machine is convenient to operate, and large-scale production in a plant is promoted.

Owner:YANTAI TUWEN MARK CHEM TECH CO LTD

General insulation composite material for exterior wall and application method

InactiveCN101691800BImprove insulation performanceImprove insulation effectCovering/liningsSurface layerInsulation layer

The invention relates to an insulation composite material for an exterior wall and an application method. The composite material is characterized in that the interior and exterior surface layers of a rigid polyurethane layer are combined with inorganic hollow microsphere polymer composite insulation layers, an anti-crack mortar layer is arranged on the exterior inorganic hollow microsphere polymer composite insulation layer and a wall decoration layer is combined with the exterior surface layer of the anti-crack mortar layer. The application method is as follows: the exterior wall to be treated is sequentially coated with the interior hollow microsphere polymer composite insulation layer, rigid polyurethane and the exterior hollow microsphere polymer composite insulation layer, the anti-crack mortar layer is coated on the exterior hollow microsphere polymer composite insulation layer and the wall decoration surface layer is coated on the exterior surface layer of the anti-crack mortarlayer. The composite material has good heat insulation property and quick construction method, is strongly adaptive to main structures, reaches higher flame retardant level, is energy-saving and environment-friendly, is suitable for insulation of various walls, especially exterior walls, and is applicable to floors.

Owner:东营丰力输送带有限公司

Environment-friendly flame-retardant reinforced polypropylene resin and preparation method thereof

InactiveCN108570184AReduce the content of harmful substancesReduce security risksHeat deflection temperaturePolymer science

The invention discloses environment-friendly flame-retardant reinforced polypropylene resin and a preparation method thereof. The environment-friendly flame-retardant reinforced polypropylene resin comprises, by weight, 100 parts of polypropylene resin, 20-30 parts of flame retardant, 4-8 parts of flame retardant synergist, 10-30 parts of reinforcing filler, 0.4-2 parts of lubricating agent, 0.2-1part of antioxidant and 0.2-2 parts of coupling agent. The preparation method includes: using the coupling agent to perform surface pretreatment on the reinforcing filler, adding the polypropylene resin, the flame retardant, the flame retardant synergist, the lubricating agent and the antioxidant into the pretreated reinforcing filler, evenly mixing, and performing extrusion granulation. The environment-friendly flame-retardant reinforced polypropylene resin and the preparation method thereof have the advantages that the interaction between the reinforcing filler and the resin is increased byusing the coupling agent to pretreat the reinforcing filler, and material mechanical performance is further increased; the flame-retardant reinforced polypropylene resin is excellent in flame retardance and high in mechanical performance, the thermal deformation temperature of the flame-retardant reinforced polypropylene resin is increased, and accordingly the application range and operation performance stability of the flame-retardant reinforced polypropylene resin are increased.

Owner:浙江富丽新材料有限公司

Reclaimed ABS flame-retardant modified material and preparation method thereof

InactiveCN104448684AHigh flame retardant levelGood anti-aging performanceThermal deformationAnoxomer

The invention relates to the technical field of recycling of an ABS reclaimed material, and particularly relates to a reclaimed ABS flame-retardant modified material and a preparation method thereof. The reclaimed ABS flame-retardant modified material comprises the following substances: an ABS recycling material, a composite flame retardant, a flame-retardant synergist, a composite anti-aging agent, an antioxidant, a composite toughening agent and a coupling agent. The reclaimed ABS flame-retardant modified material prepared through the method disclosed by the invention has high flame-retardant grade as high as V-0 grade, is high in ageing resistance through the addition of the composite anti-aging agent, can be used for enhancing the tensile strength and the bending strength through the addition of the toughening agent, has the advantages of high anti-impact strength, good processing flowability, high glossiness of a finished product, stability in thermal deformation property, high char yield after combustion and no melting dropping and is greatly enhanced in flame retardance without being influenced in mechanical property. The preparation method disclosed by the invention has the advantages of high ABS purity, few impurities and simple preparation process of the obtained ABS recycling material and excellent property and easiness for industrialization realization of reclaimed ABS.

Owner:GUANGDONG GUOLI SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com