General insulation composite material for exterior wall and application method

An external wall insulation and composite material technology, which is applied in covering/lining, building, building structure, etc., can solve the problems of low flame retardant grade of polystyrene board, reduced thermal insulation effect, poor fire protection grade, etc., to avoid cold ( Thermal bridging phenomenon, easy maintenance, the effect of low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

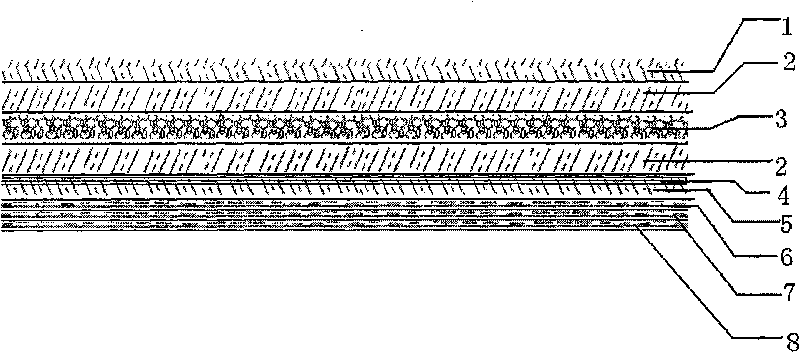

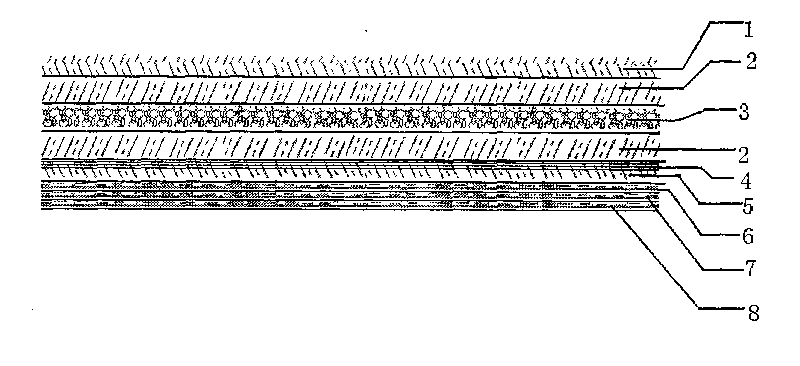

[0021] Referring to the accompanying drawings, a general-purpose external wall thermal insulation composite material is sequentially combined with an inorganic hollow microbead polymer composite thermal insulation layer 2 on the inner and outer layers of the rigid polyurethane foam layer 3, and an inorganic hollow microbead polymer composite thermal insulation layer 2 on the outer layer. The surface layer is combined with an anti-cracking mortar layer 4, and the outer layer of the anti-cracking mortar layer 4 is combined with a wall decoration surface layer 6. The wall decoration surface layer 6 is a mixed layer comprising a waterproof layer 7 formed by a polymer emulsion elastic primer and a flexible water-resistant putty layer 8 . Among them: the inorganic hollow microsphere polymer composite insulation layer material components include 70-80 parts by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com