Patents

Literature

2623 results about "Polymer emulsion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer emulsion means water-soluble polymers, such as certain polyvinyl alcohols or hydroxylate celluloses, can also be used to act as emulsifiers/stabilizers. Explanation: Emulsion polymerization is a type of radical polymerization that usually starts with an emulsion incorporating water, monomer, and surfactant.

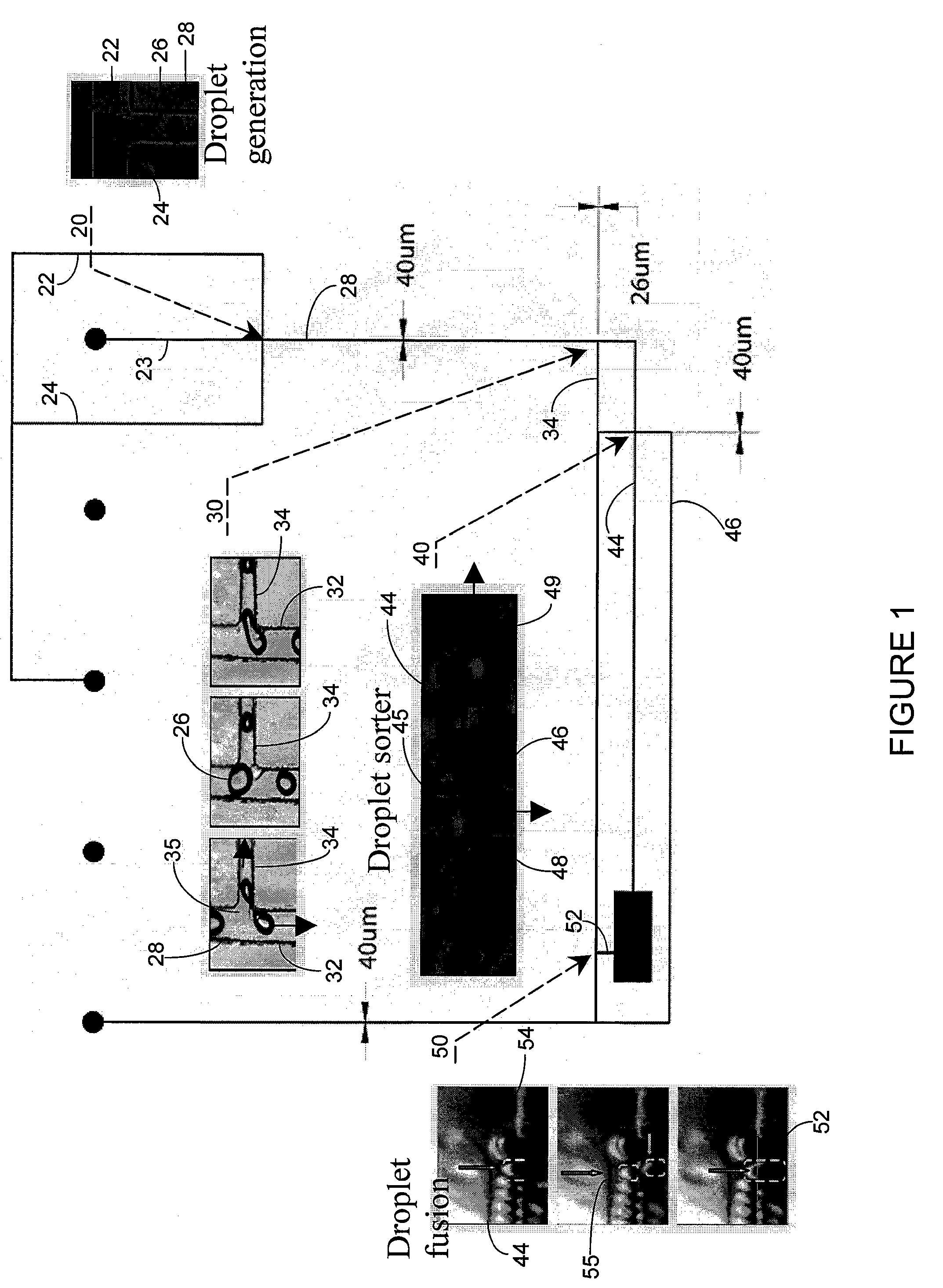

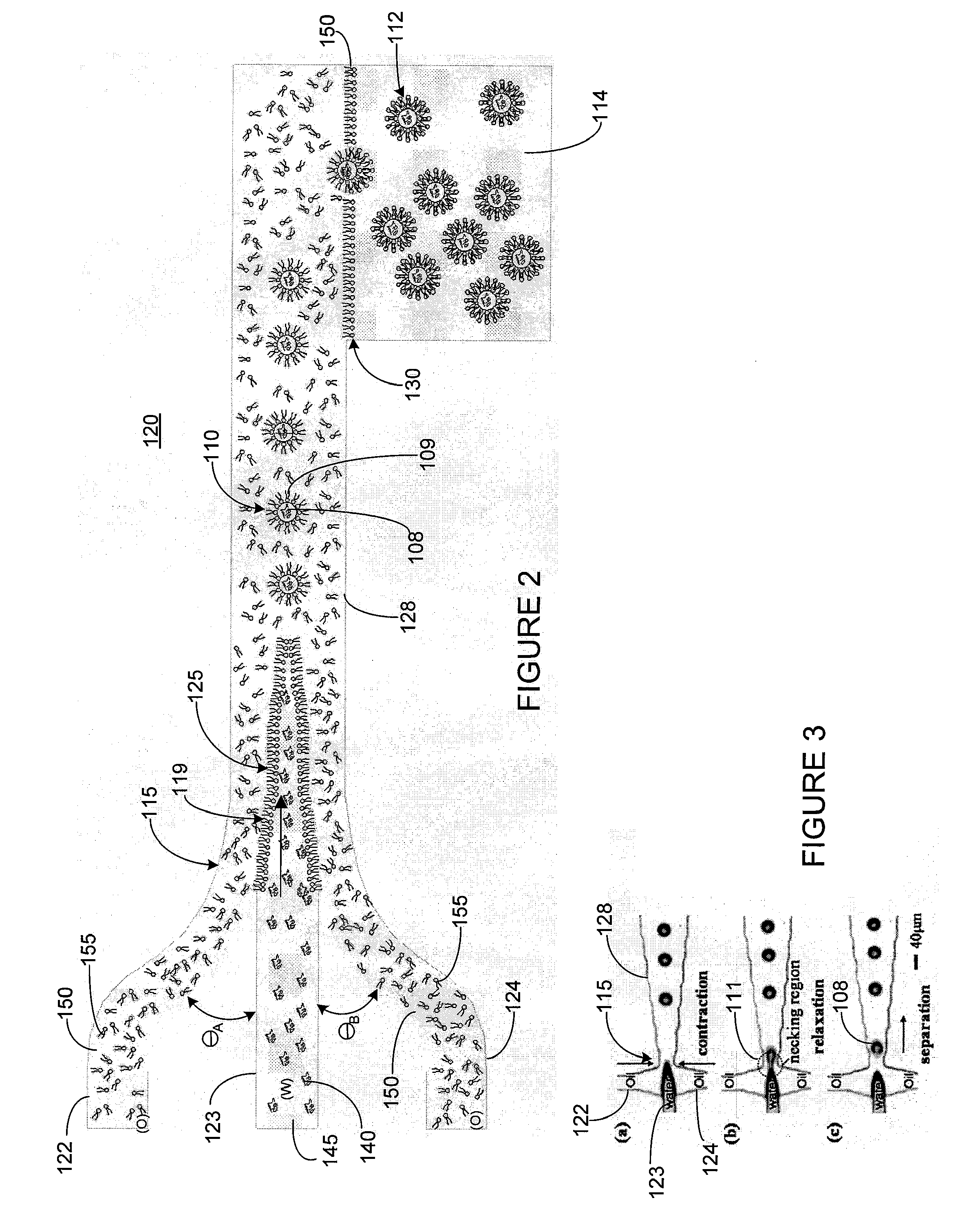

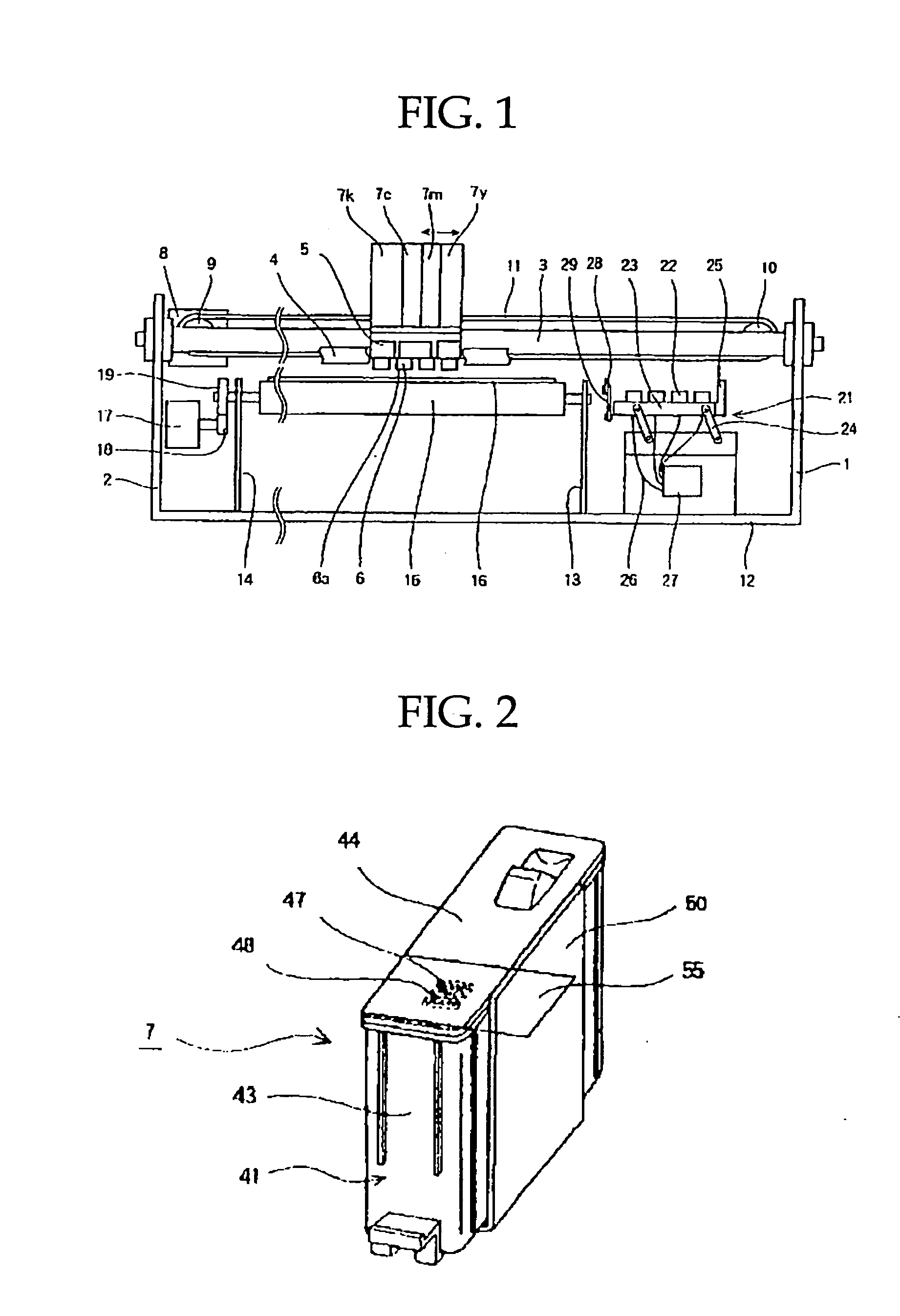

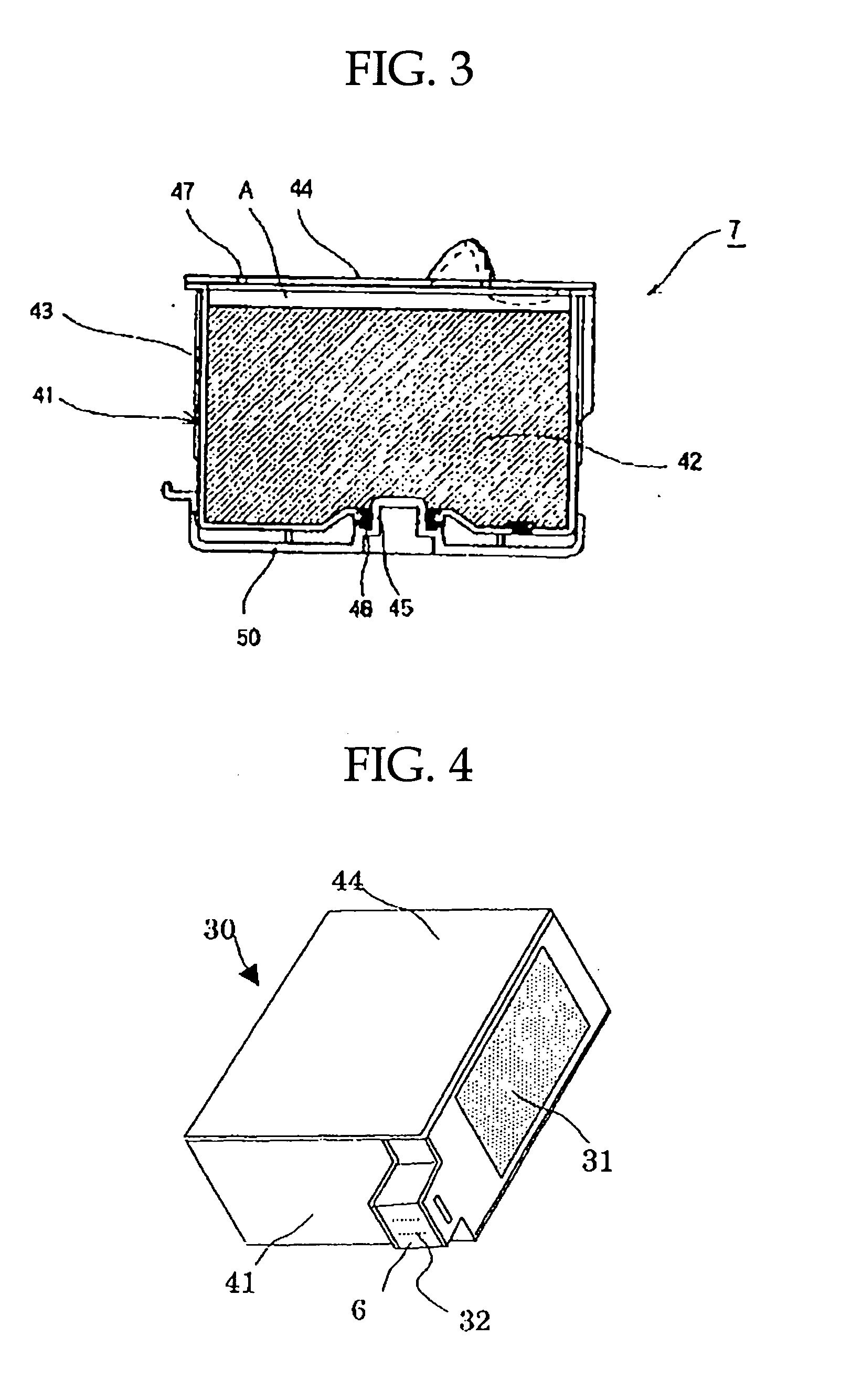

Microfluidic devices for controlled viscous shearing and formation of amphiphilic vesicles

ActiveUS20050032240A1Facilitates programmable control of sizeIncrease shear forceMixing methodsTransportation and packagingViscous shearEngineering

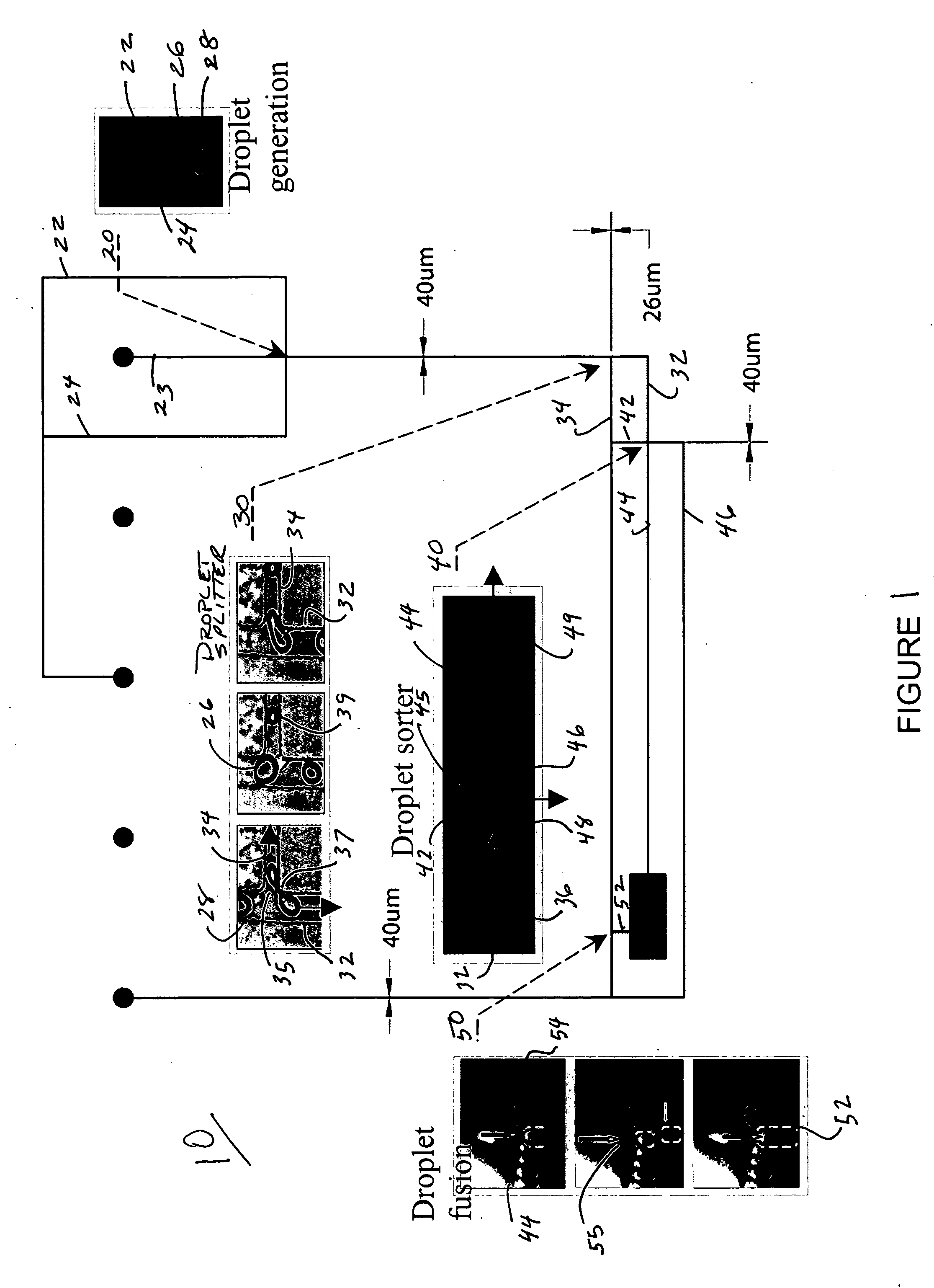

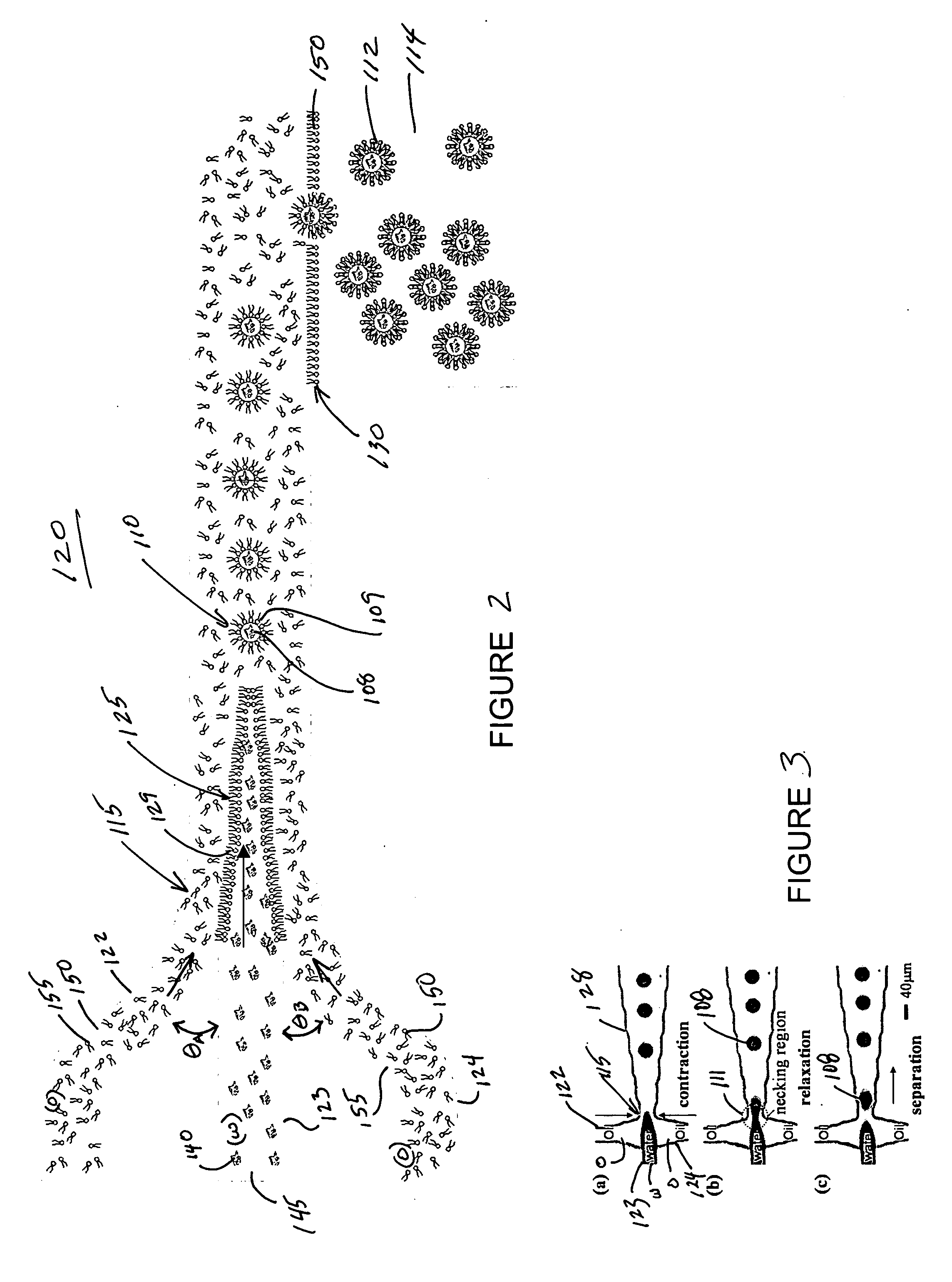

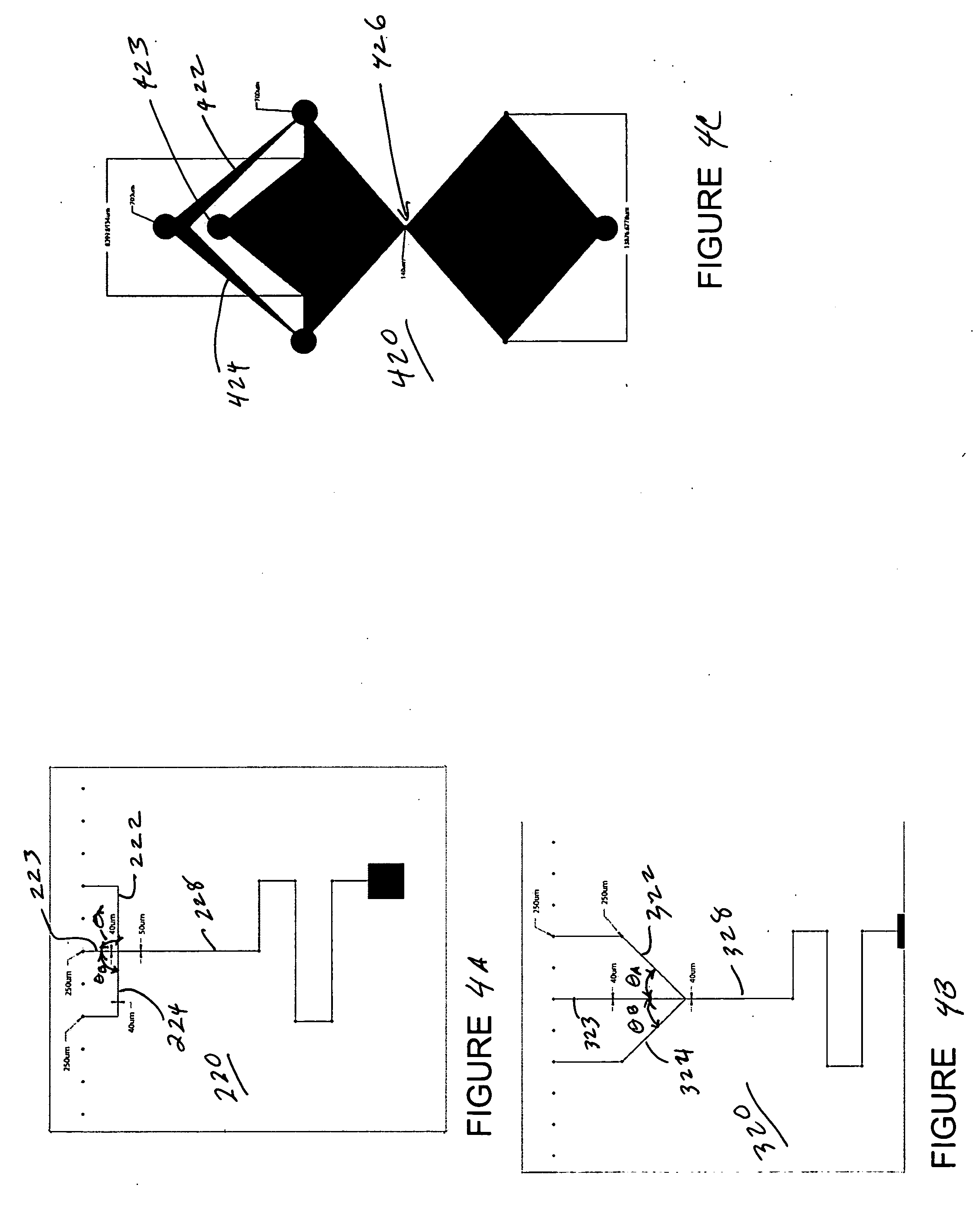

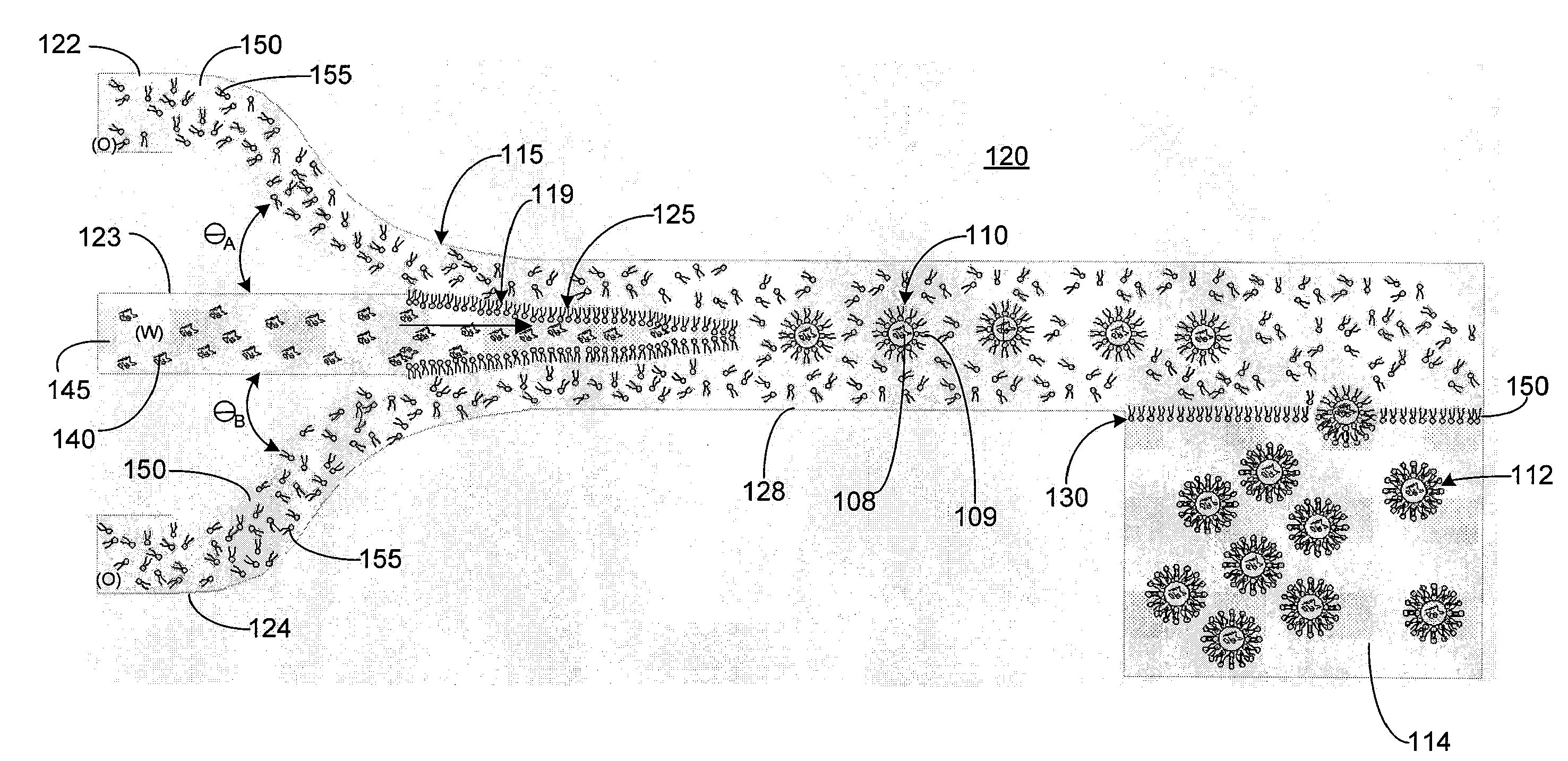

Systems and methods that control the size and composition of emulsified droplets, multi-lamellar and asymmetric vesicles, encapsulation of reagents, membrane proteins, and sorting of vesicles / droplets. More particularly, microfluidic devices for controlled viscous shearing of oil-water emulsions of micro- and nano-scale droplets, the subsequent formation of amphiphilic vesicles such as liposomes, polymer vesicles, micelles, and the like, the post-assembly and post-processing of the droplets including splitting, fusing, sorting and the like, polymer emulsions, and the integration of amphiphilic vesicle production-line on a single microfluidic chip. Preferably, the microfluidic device enables oil-water co-flows with tunable viscous shear forces higher than the immiscible interfacial tension forces that generate favorable conditions for droplet formation.

Owner:RGT UNIV OF CALIFORNIA

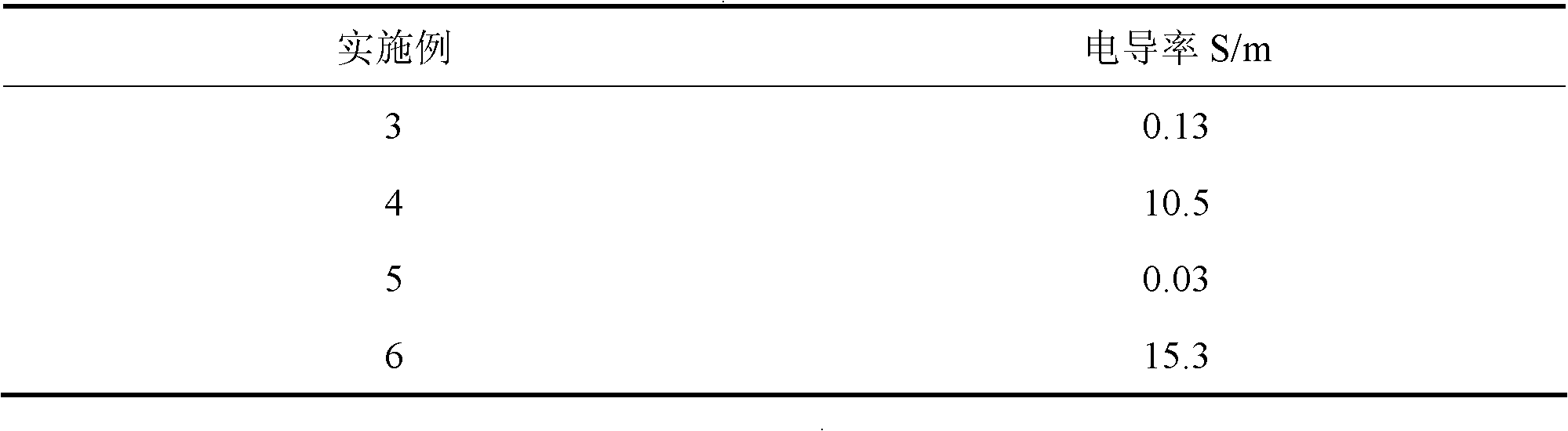

Waterborne conductive ink and preparation method thereof

The invention relates to waterborne conductive ink which comprises the following components in percentage by weight: 1-40 percent of polymer emulsion or dispersion liquid, 0.1-0.7 percent of dispersant, 0.1-0.3 percent of wetting agent, 0.2-1.8 percent of defoaming agent, 30-70 percent of conductive material, 0.5-3 percent of film-forming addition agent and 5-60 percent of water. The waterborne conductive ink disclosed by the invention has the advantages of no toxicity or odor, safety, environment friendliness, convenience in use, resource economization, favorable film forming performance and printing performance of ink, strong adhesive force and good weather resistance; the defects of toxicity, harm, inflammability and explosiveness of solvent ink are overcome; and water replaces organic solvent, so that a volatile organic compound (VOC) is reduced, and the production cost is also reduced.

Owner:SUZHOU NIUJIAN NEW MATERIAL

Microfluidic devices for controlled viscous shearing and formation of amphiphilic vesicles

ActiveUS7595195B2Facilitates programmable control of sizeIncrease shear forceMixing methodsTransportation and packagingViscous shearEngineering

Systems and methods that control the size and composition of emulsified droplets, multi-lamellar and asymmetric vesicles, encapsulation of reagents, membrane proteins, and sorting of vesicles / droplets. More particularly, microfluidic devices for controlled viscous shearing of oil-water emulsions of micro- and nano-scale droplets, the subsequent formation of amphiphilic vesicles such as liposomes, polymer vesicles, micelles, and the like, the post-assembly and post-processing of the droplets including splitting, fusing, sorting and the like, polymer emulsions, and the integration of amphiphilic vesicle production-line on a single microfluidic chip. Preferably, the microfluidic device enables oil-water co-flows with tunable viscous shear forces higher than the immiscible interfacial tension forces that generate favorable conditions for droplet formation.

Owner:RGT UNIV OF CALIFORNIA

Preparation method of graphene/polymer nano composite material

ActiveCN102161785AEvenly dispersedGood mechanical propertiesOther chemical processesMagnetic/electric field screeningUltrasonic dispersionVacuum drying

The invention discloses a preparation method of a graphene / polymer nano composite material, which is characterized by comprising the following steps: adding 0.1-30 parts by weight of graphite oxide into 10-3000 parts by weight of water, and dispersing and exfoliating by carrying out ultrasonic dispersion (the power is 50-500W, and the frequency is 10-100000Hz) at 10-100 DEG C for 15 minutes-5 hours or mechanical lapping for 15 minutes-5 hours or mechanical stirring for 1-48 hours to obtain a graphene oxide water solution; adding the graphene oxide water solution into 100 parts by weight of polymer emulsion of which the solid content is 10-70%; continuing the ultrasonic or mechanical stirring to carry out uniform mixing; demulsifying by adding 1-100 parts by weight of 5-100% demulsifier toobtain a graphene oxide / polymer granular suspension; adding 0.1-100 parts by weight of reducer into the graphene oxide / polymer granular suspension, reducing at 20-100 DEG C for 1-72 hours, filtering,and drying in a drying oven at 20-100 DEG C for 2-72 hours or drying in a vacuum drying oven at 20-120 DEG C under a vacuum degree of 0.1-0.01 MPa for 2-48 hours, thereby obtaining the graphene / polymer nano composite material.

Owner:SICHUAN UNIV

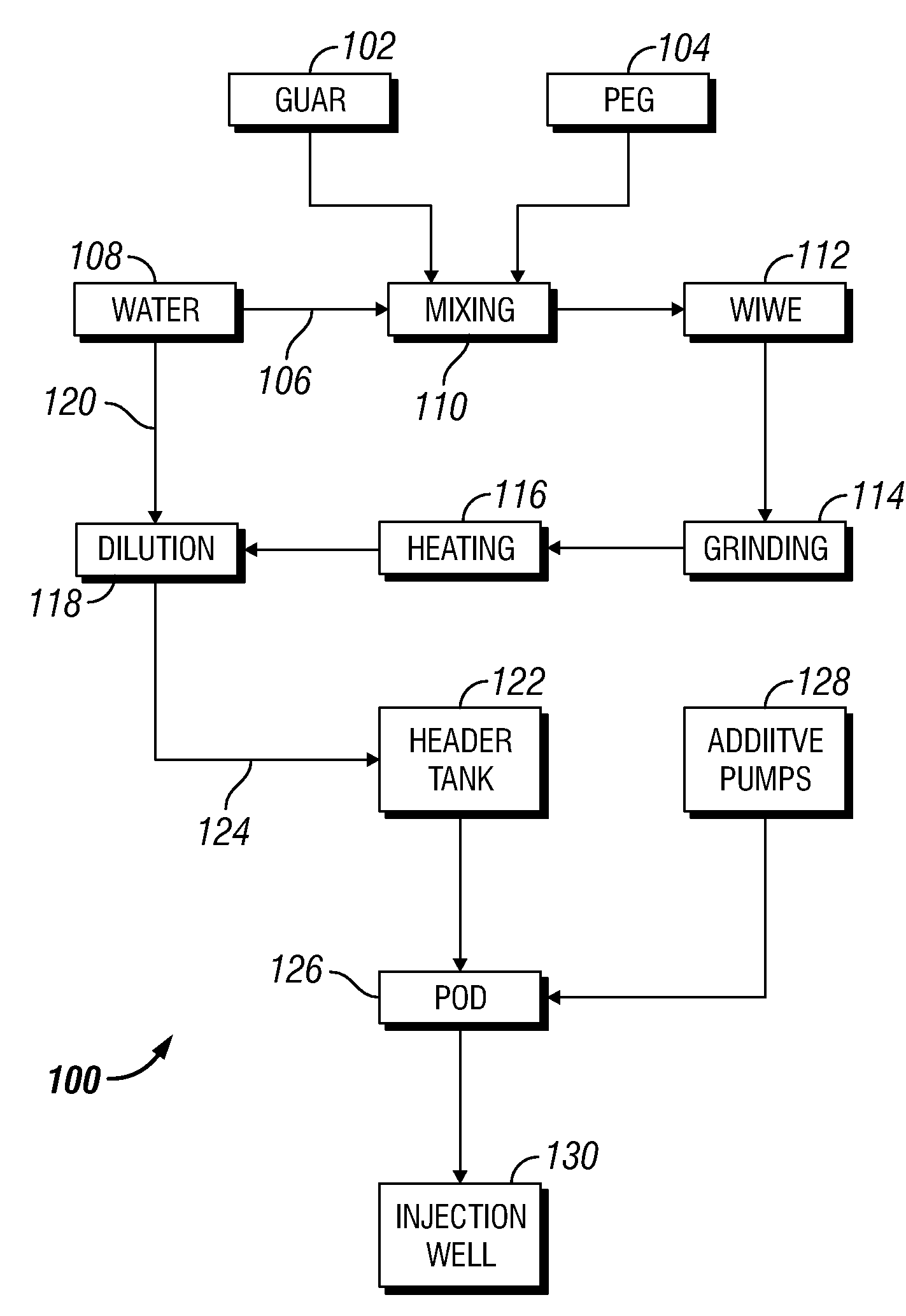

Polymer Delivery in Well Treatment Applications

InactiveUS20090023614A1Reduce solubilityEasy to pumpTransportation and packagingFluid removalActive polymerEmulsion

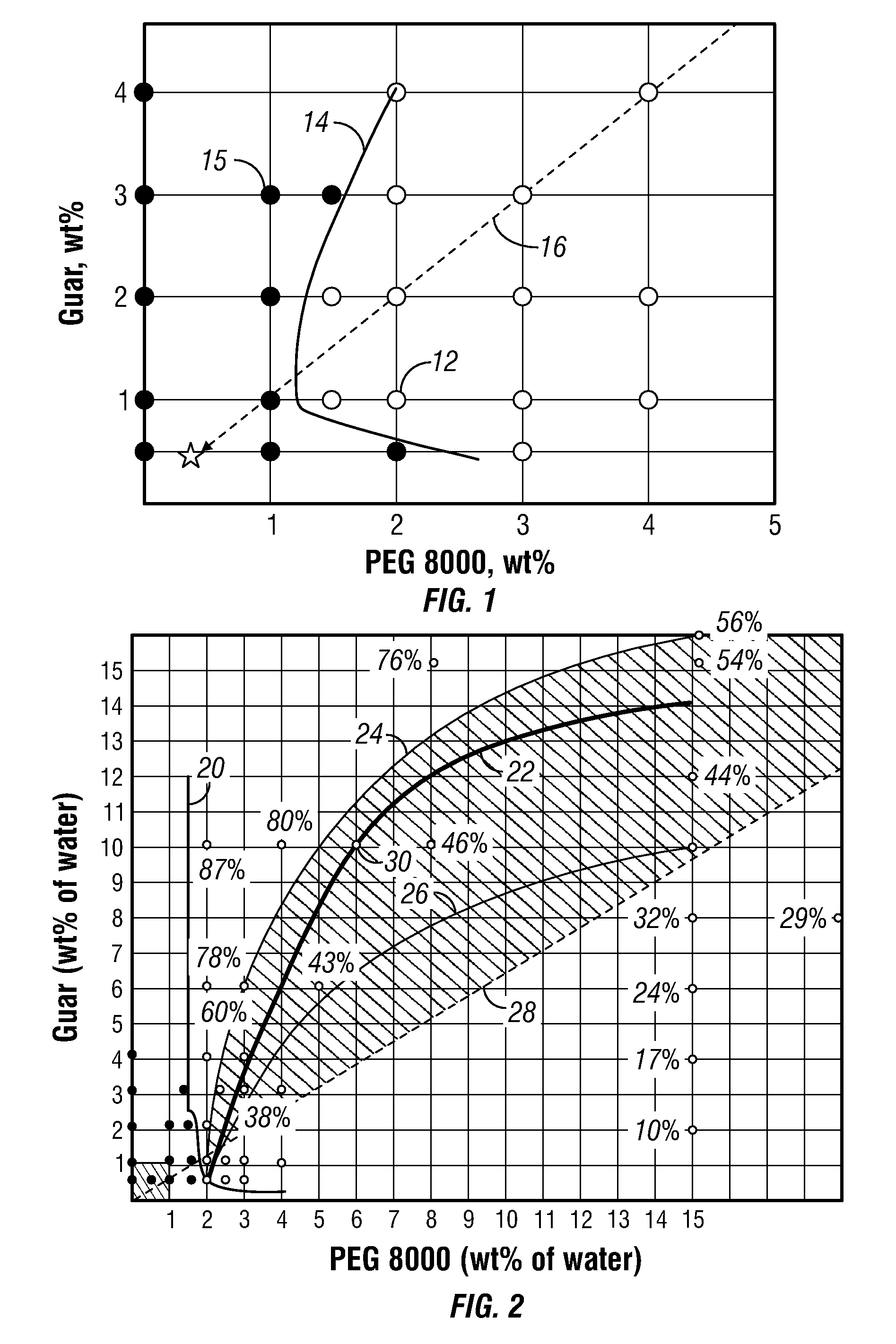

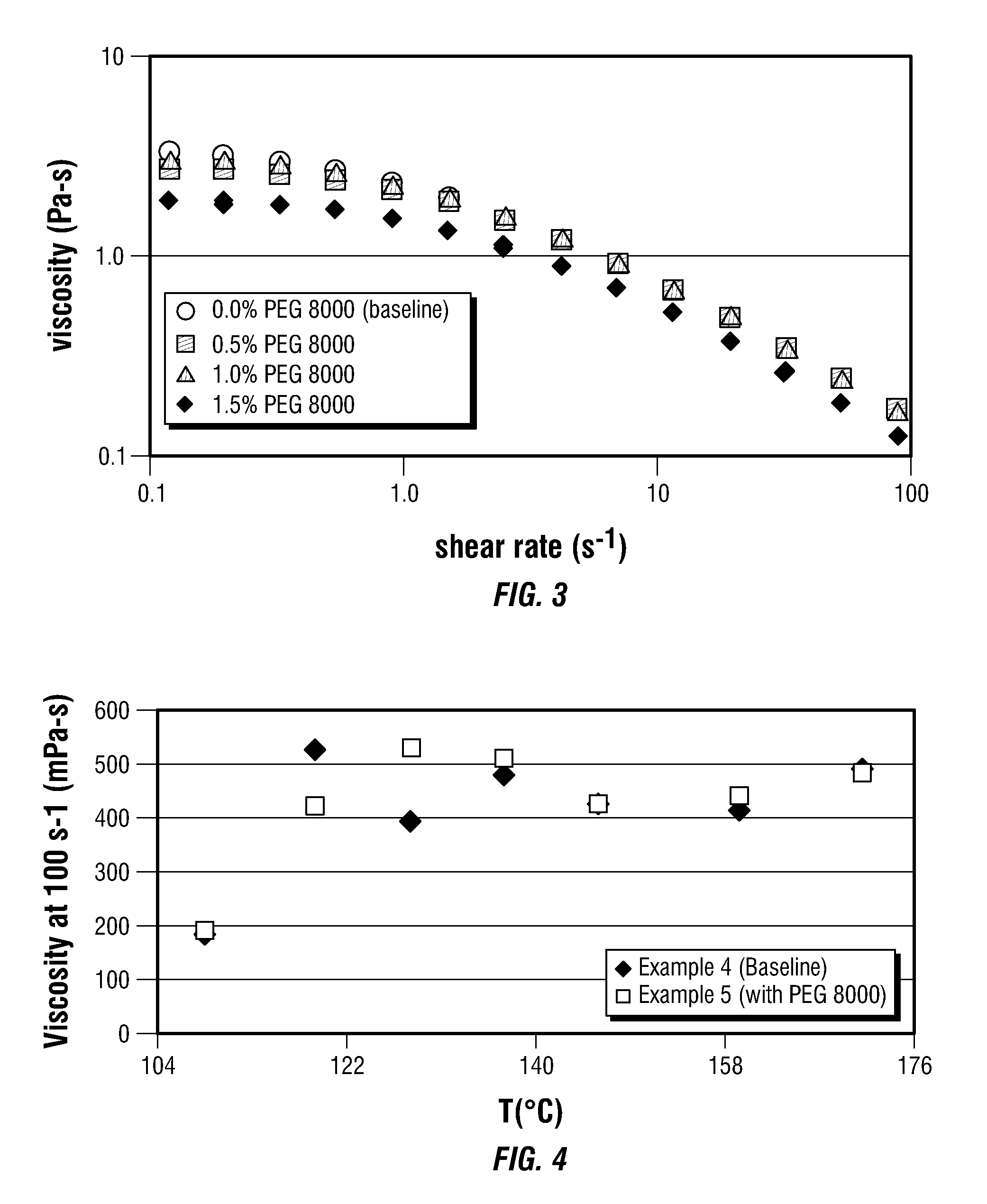

This invention relates to compositions and methods for treating subterranean formations, in particular, oilfield stimulation compositions and methods using water-in-water polymer emulsions to uniformly dissolve a rheologically active polymer, such as a thickener or friction reducer, in the treatment fluid. The emulsions have a low viscosity and are easily pumped for mixing into a treatment fluid, where upon dilution with an aqueous medium, the polymer is easily hydrated without forming fish-eyes. The partitioning agent in the water-in-water emulsion does not generally affect the rheology of the treatment fluid. The invention also relates to further processing of the emulsion by wet grinding, high shear mixing and / or heating to enhance the hydration rate in the preparation of the well treatment fluid.

Owner:SCHLUMBERGER TECH CORP

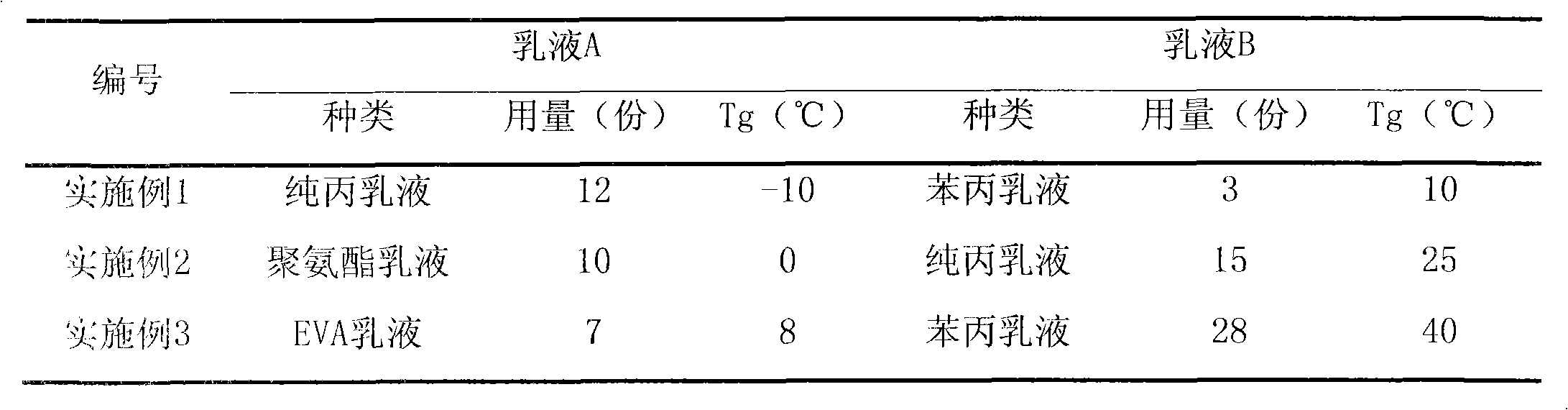

Water-based sound-proof damping coating and preparation method thereof

ActiveCN101891990AImprove performanceGood damping of vibrationPolyurea/polyurethane coatingsFiberWater based

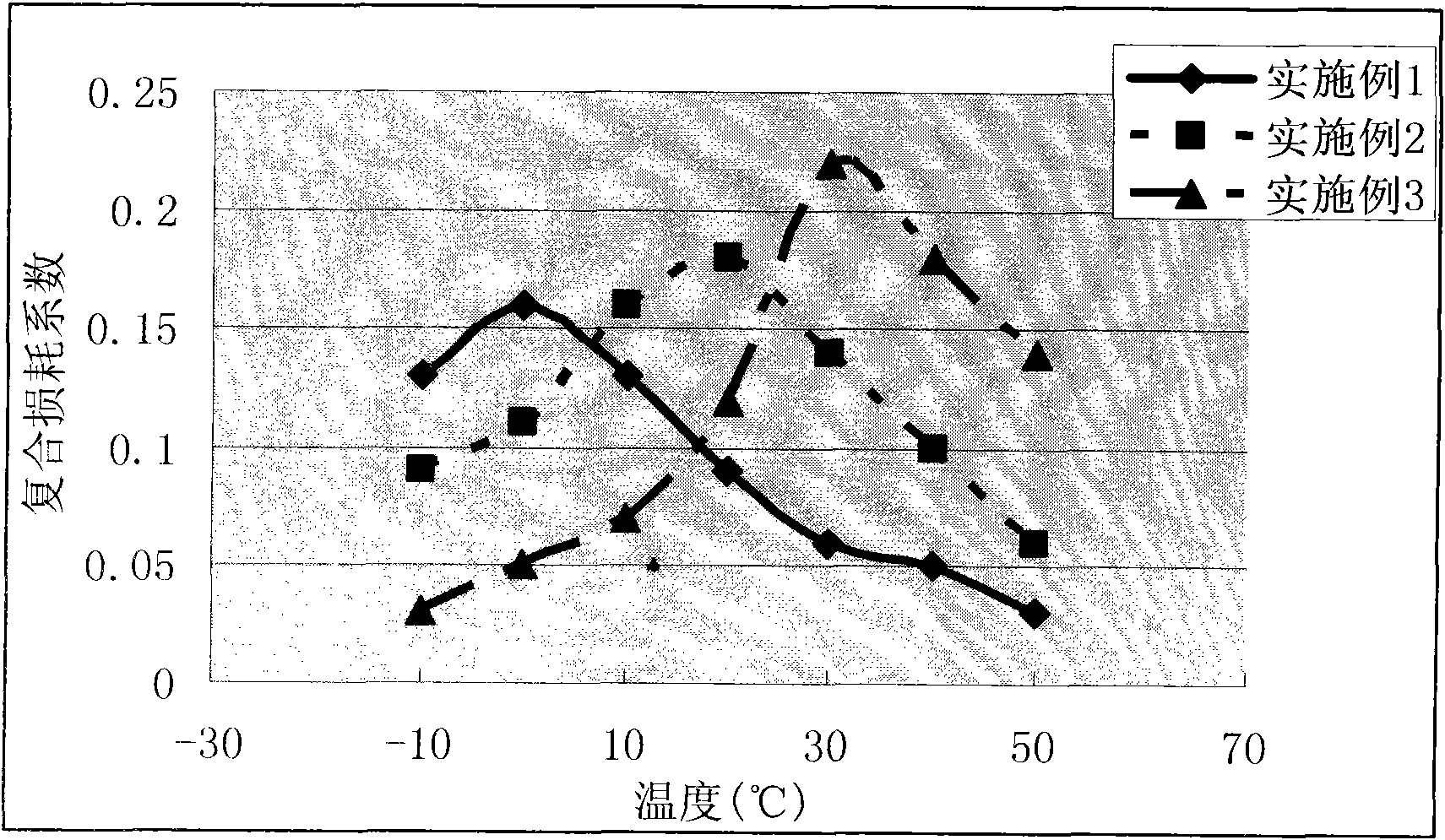

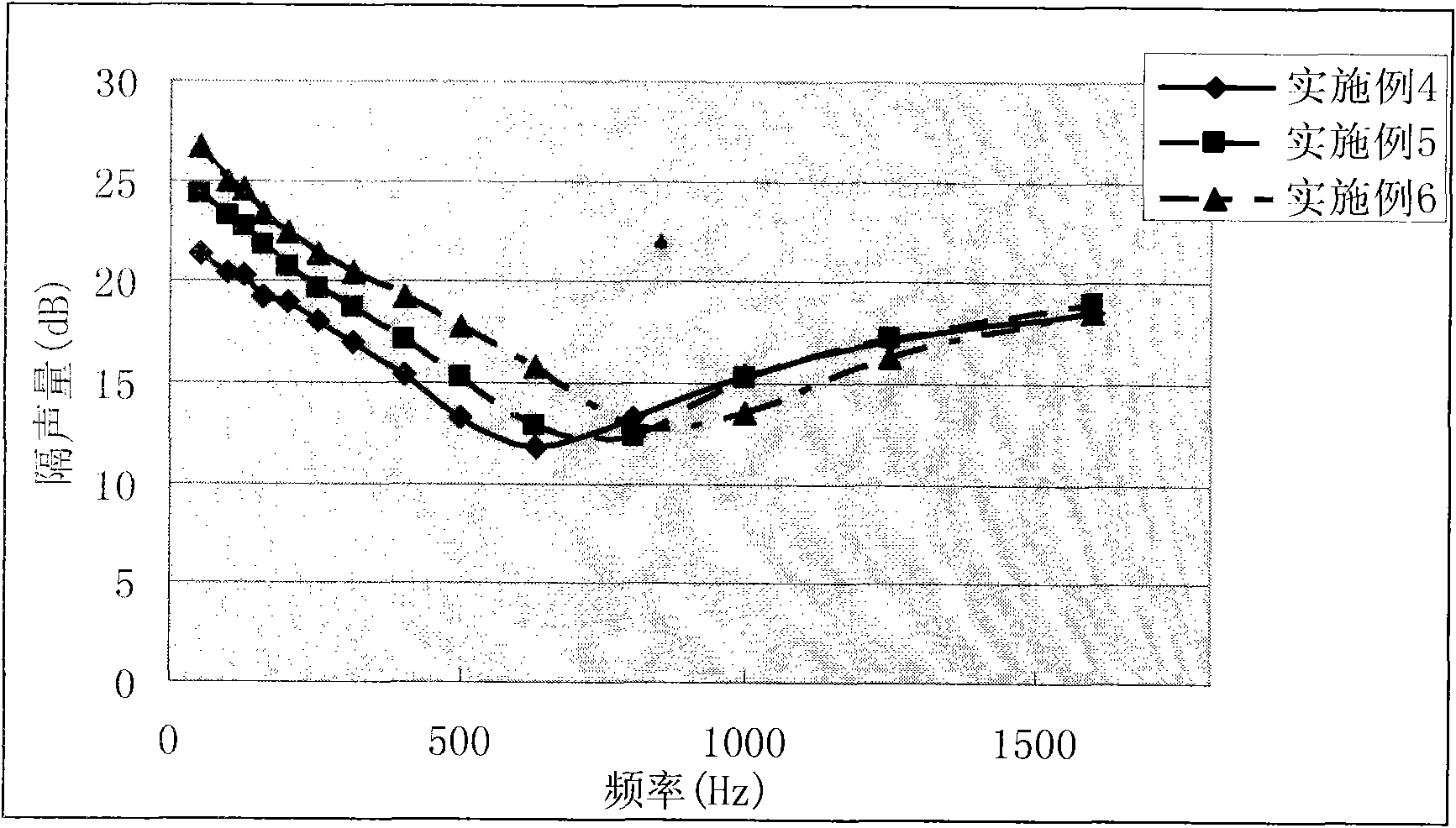

The invention discloses a water-based sound-proof damping coating and a preparation method thereof. The water-based sound-proof damping coating comprises the following raw materials in part by weight: 15 to 35 parts of polymer emulsion, 35 to 55 parts of inorganic filler, 10 to 20 parts of powdery flame retardant, 2 to 5 parts of auxiliary agent, and 10 to 20 parts of deionized water. The preparation method comprises the following steps of: uniformly mixing the deionized water and a wetting and dispersing agent, and adding part of inorganic filler with stirring at a high speed to prepare inorganic filler water dispersible slurry; and adding the polymer emulsion into the inorganic filler water dispersible slurry with stirring at the high speed, sequentially adding the powdery flame retardant, the rest part of inorganic filler, reinforcing fibers, a mould inhibitor and an antifoaming agent, and finally adding a thickening agent to adjust consistency. The coating of the invention has excellent vibration and noise reduction effect, is mainly used for internal coating of carriage floors, side walls and roofs of vehicles, and can play a good role in inhibiting vibration and reducing noise.

Owner:BOGE RUBBER&PLASTICS ZHUZHOU CO LTD

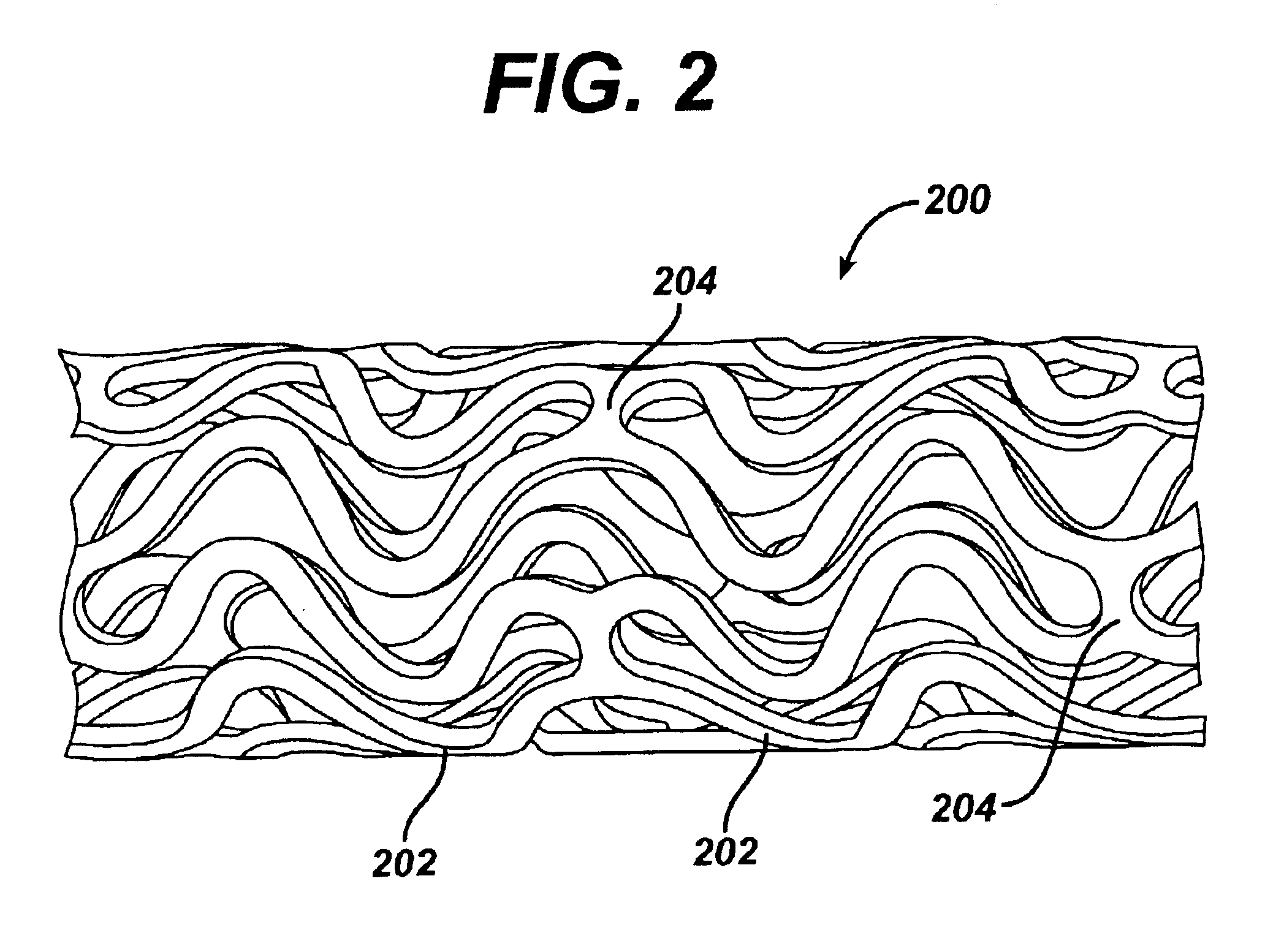

Latex glove with fabric-adherent cuff region

A dipped and cured latex glove article, the inner cuff surface of which is fabric-adherent, and a method of making such a glove comprising dipping a coagulant-coated glove former into an aqueous latex emulsion thereby forming a latex first layer on the former, partially coating the latex first layer on the former with a non-tacky aqueous polymeric emulsion, heating the former to cure the first layer with the second layer, stripping from the former and inverting the article, washing the article, dressing the inverted latex glove article on a glove former such that the fabric-adherent inner cuff surface contacts the former, treating the surface of the article to minimize tackiness, stripping the article from the former, washing the article, and drying the article, after which the article can be packaged and sterilized by exposing the packaged latex glove article to gamma radiation.

Owner:ANSELL HEALTHCARE PRODS

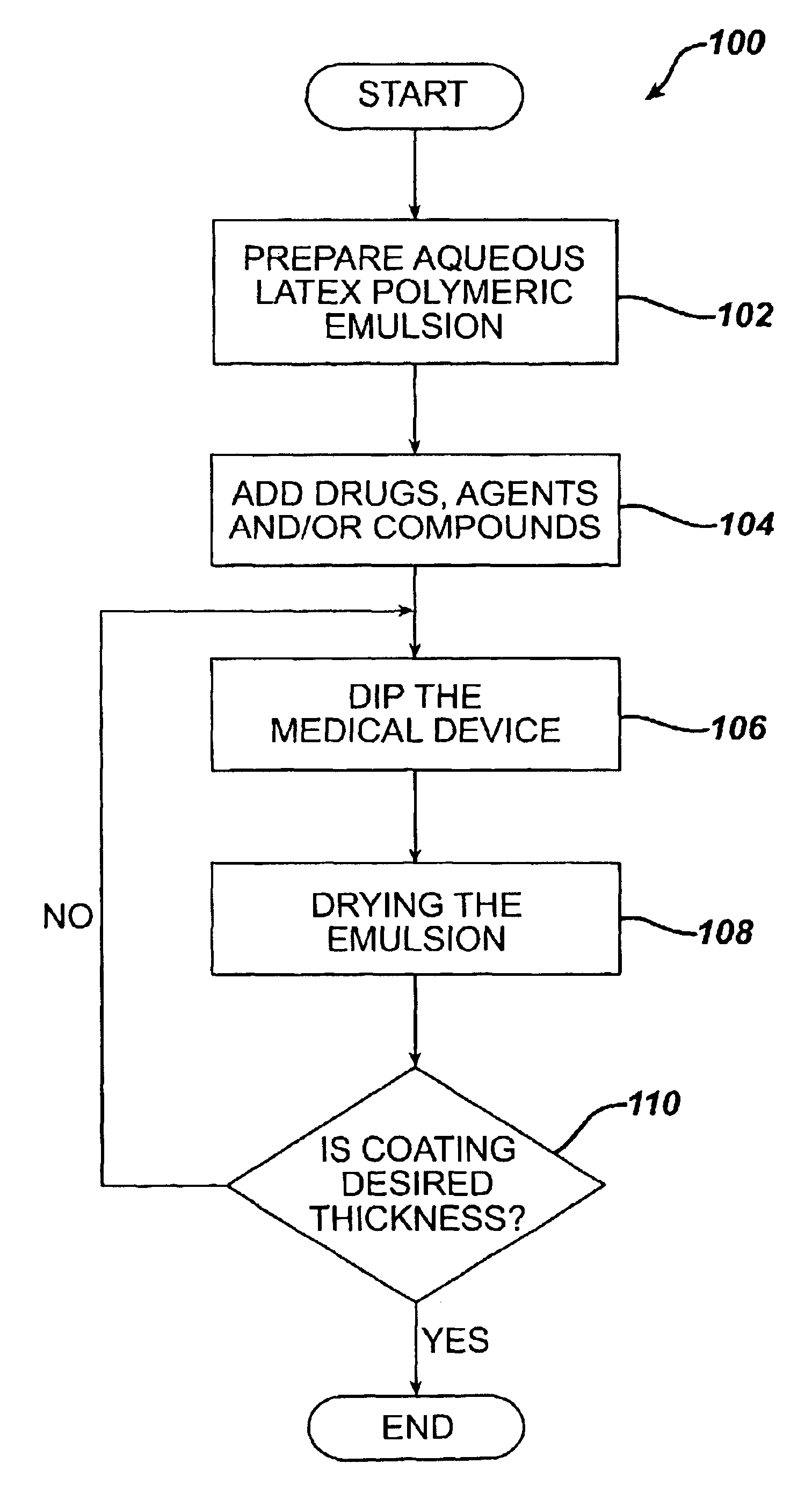

Method for coating medical devices

InactiveUS6919100B2Safe and efficient and effective processSimple and complex configurationOrganic active ingredientsImpression capsBiological bodyOrganic solvent

Medical devices, and in particular implantable medical devices, may be coated to minimize or substantially eliminate a biological organism's reaction to the introduction of the medical device to the organism or to treat a particular condition. A dip coating process is utilized to minimize waste. An aqueous latex polymeric emulsion is utilized to coat any medical device to a desired thickness by allowing for successive dipping and drying cycles. In addition, aqueous latex polymeric emulsions pose less of a chance of the bridging phenomenon associated with organic solvent based polymers.

Owner:WYETH LLC

Silica aerogel microsphere composite thermal insulation coating

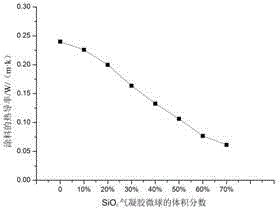

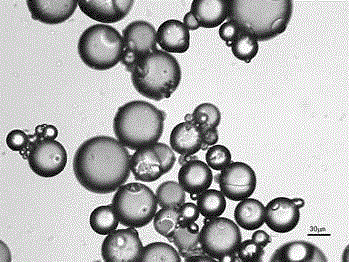

InactiveCN103333542ALow densityLow thermal conductivityEpoxy resin coatingsMicrosphereThermal insulation

The invention discloses a novel composite thermal insulation coating using silica aerogel microsphere as a thermal insulation filler. The main preparation process is as follows: mixing self-made silica aerogel microspheres with a polymer emulsion to obtain a silica aerogel composite thermal insulation coating with excellent heat insulation property. Compared with the existing coating in the market, the silica aerogel composite thermal insulation coating has greatly improved the thermal insulation property. The invention employs an atomization method to prepare the silica aerogel microspheres of micron size level, which have high filling rate of up to 70% in the coating. During the atomization process, the size of the silica aerogel microspheres is regulated by controlling the size of a nozzle. The invention also provides a method for preparing thermal insulation coating from silica aerogel microspheres with mixed grain size. Mixture of silica aerogel microspheres with different particle sizes is helpful to improving packing density of the silica aerogel microspheres in the coating, so as to reduce thermal conductivity of the coating to the minimum.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

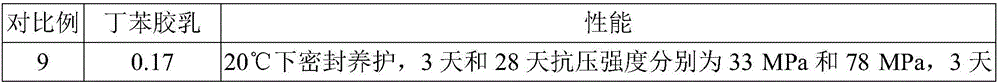

Cement-based composite material for powder-bonding three-dimensional (3D) printing, and powder-bonding 3D printing method applying cement-based composite material

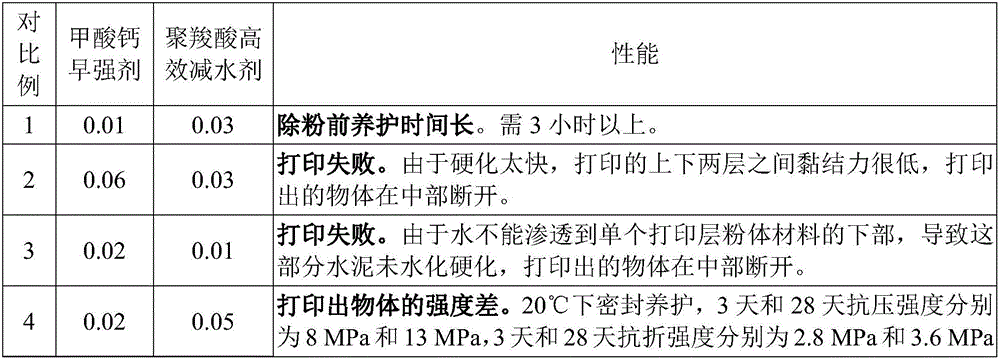

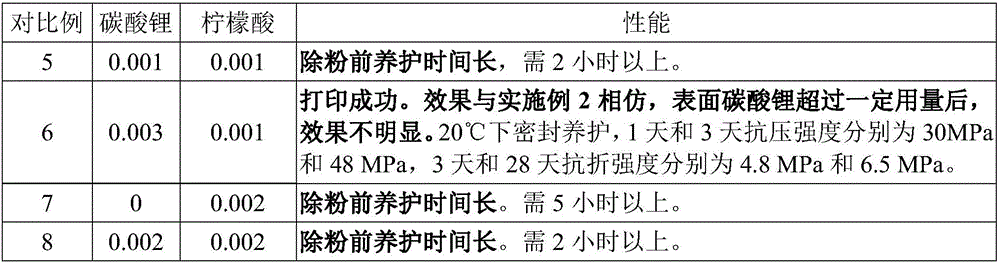

ActiveCN106800391AAppropriate hardening speedAppropriate water distribution effectAdditive manufacturing apparatusPolymer adhesivePhosphate

The invention provides a cement-based composite material for powder-bonding three-dimensional (3D) printing. The material is prepared from the following components in parts by weight: 1 part of cement, 0-5 parts of sand, 0-5 parts of a mineral admixture, 0-0.2 part of an expanding agent, 0-0.2 part of a toughening agent, 0-0.2 part of mineral pigment, 0.1-0.5 part of water, 0-0.25 part of polymer emulsion, 0.001-0.05 part of an additive and 0-0.03 part of fibers, wherein the cement is selected from one or a mixture of more in silicate cements, sulphoaluminate cement, high belite sulphoaluminate cement, aluminate cement, fluoroaluminate cement, aluminosilicate cement, phosphate cement or magnesium oxide cement; the additive is selected from one or a mixture of more in a water reducing agent, an early strength agent or a coagulating regulating agent. After being contacted with water, the cement-based composite material can be hardened, thus not needing a great deal of polymer adhesive; the cement-based composite material is rapid and controllable in hardening speed; the cement-based composite material is small in deformation in the hardening process, thus being suitable for a powder-bonding 3D printing technology. The invention also provides a method for carrying out powder-bonding 3D printing by using the cement-based composite material.

Owner:万玉君

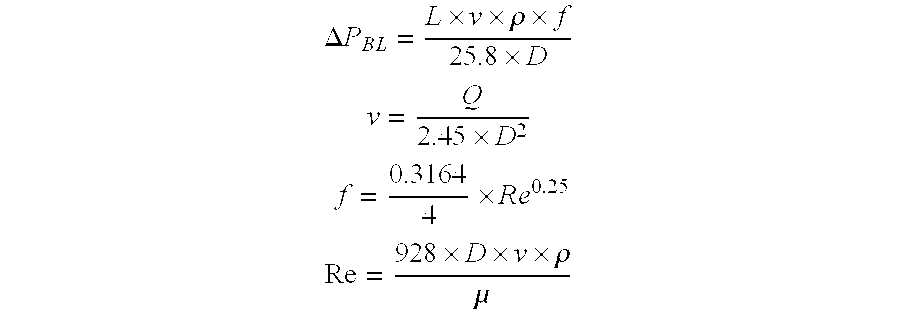

Drag-reducing copolymer compositions

A drag-reducing additive includes 40-85% by weight of a polymer emulsion that includes a polymer, a first surfactant, and a first solvent; 10-35% by weight of a second surfactant with an HLB greater than 8; and 5-30% by weight of a second solvent. In a preferred embodiment, the second solvent includes a terpene. In another preferred embodiment, the polymer is a copolymer that includes acrylamide and acrylic acid.

Owner:PNC BANK NAT ASSOC

Drag-reducing copolymer compositions

A method of preparing and using a drag-reducing composition in a well treatment operation includes the step of preparing the drag-reducing composition by mixing a polymer emulsion that includes a first surfactant and a first solvent, with a second surfactant and a second solvent. The method continues with the step of combining the drag-reducing composition with an aqueous treatment fluid. The method further includes the step of injecting the drag-reducing composition and aqueous treatment fluid into a subterranean formation, a pipeline or a gathering line.

Owner:PNC BANK NAT ASSOC

Thermal-insulating external-wall coating of nano-composite water and its production

InactiveCN101029206AImprove insulation performanceGood weather resistanceFireproof paintsEmulsion paintsRefractive indexSlurry

A water nan-composite thermal-insulating coating for external wall and its production are disclosed. The coating consists of water, polymer emulsion, high-refractive index pigment, filler, nano-tin-antimony oxide slurry, nano-SiO2, wet dispersant, filming accessory, pH adjuster, thickener, de-foaming agent, anti-freezing agent and mildew-proof bactericide. It's cheap and simple, has excellent wash and weather resistances, better thermal-insulating performance, safe storage and no environmental pollution. It can be used for apparatus surface and architecture external wall.

Owner:SOUTH CHINA UNIV OF TECH +1

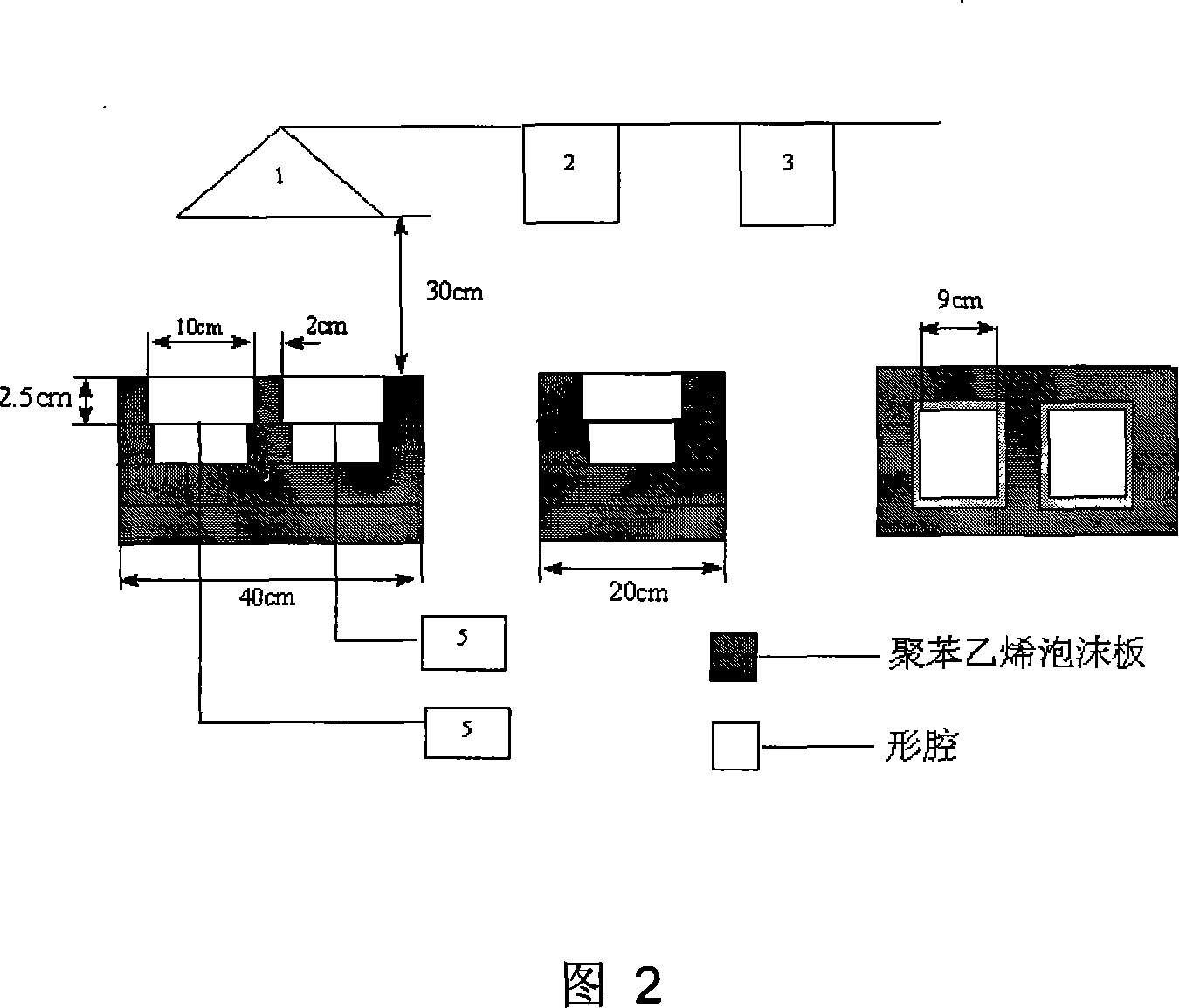

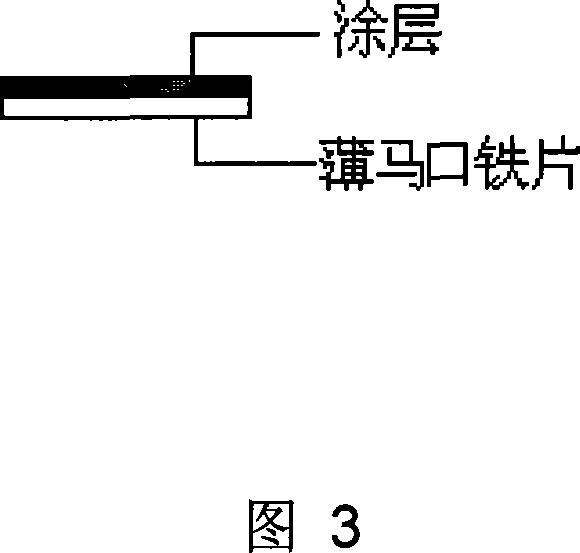

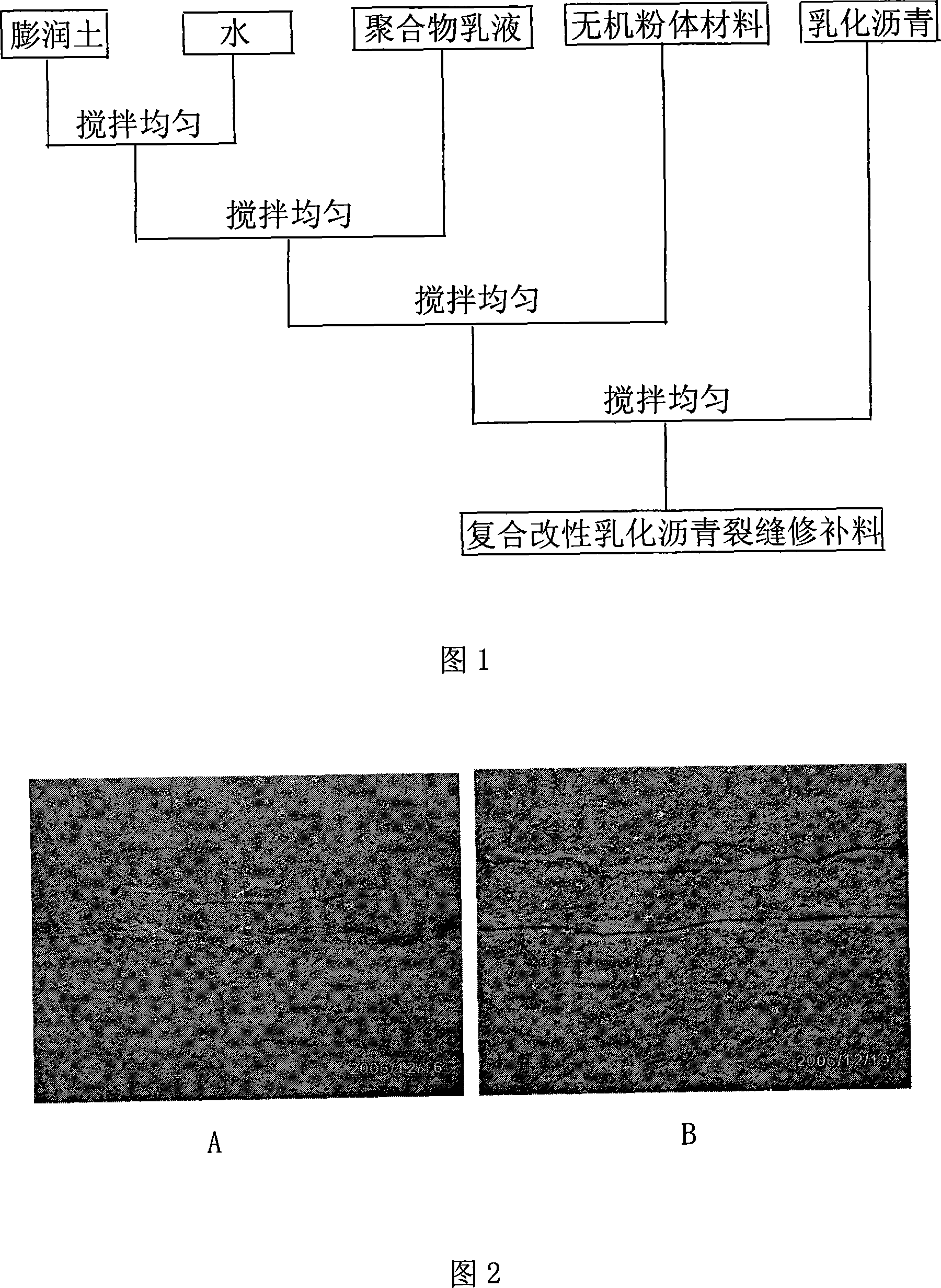

Environment-friendly type split mending material for polymer emulsion inorganic powder and nano material composite modified emulsified asphalt

InactiveCN101081933AImprove performanceImprove wear resistanceOther chemical processesSolid waste managementHigh wear resistanceInorganic materials

The present invention is one kind of environment friendly composite emulsified asphalt material for grouting and repairing cracks in highway and building. The composite emulsified asphalt material consists of emulsified asphalt40-90 weight portions, powdered inorganic material 50-90 weight portions, nanometer material 5-10 weight portions, polymer emulsion 20-40 weight portions and water 30-80 weight portions mainly. The composite emulsified asphalt material has nanometer particle component with unique surface effect, small size effect and tunnel effect, polymer emulsion component resulting in high interface combining force and high antiaging performance, and inorganic material powder component resulting in high wear resistance, high strength, etc., so that it has high comprehensive performance, good crack repairing effect and low cost.

Owner:HUNAN UNIV

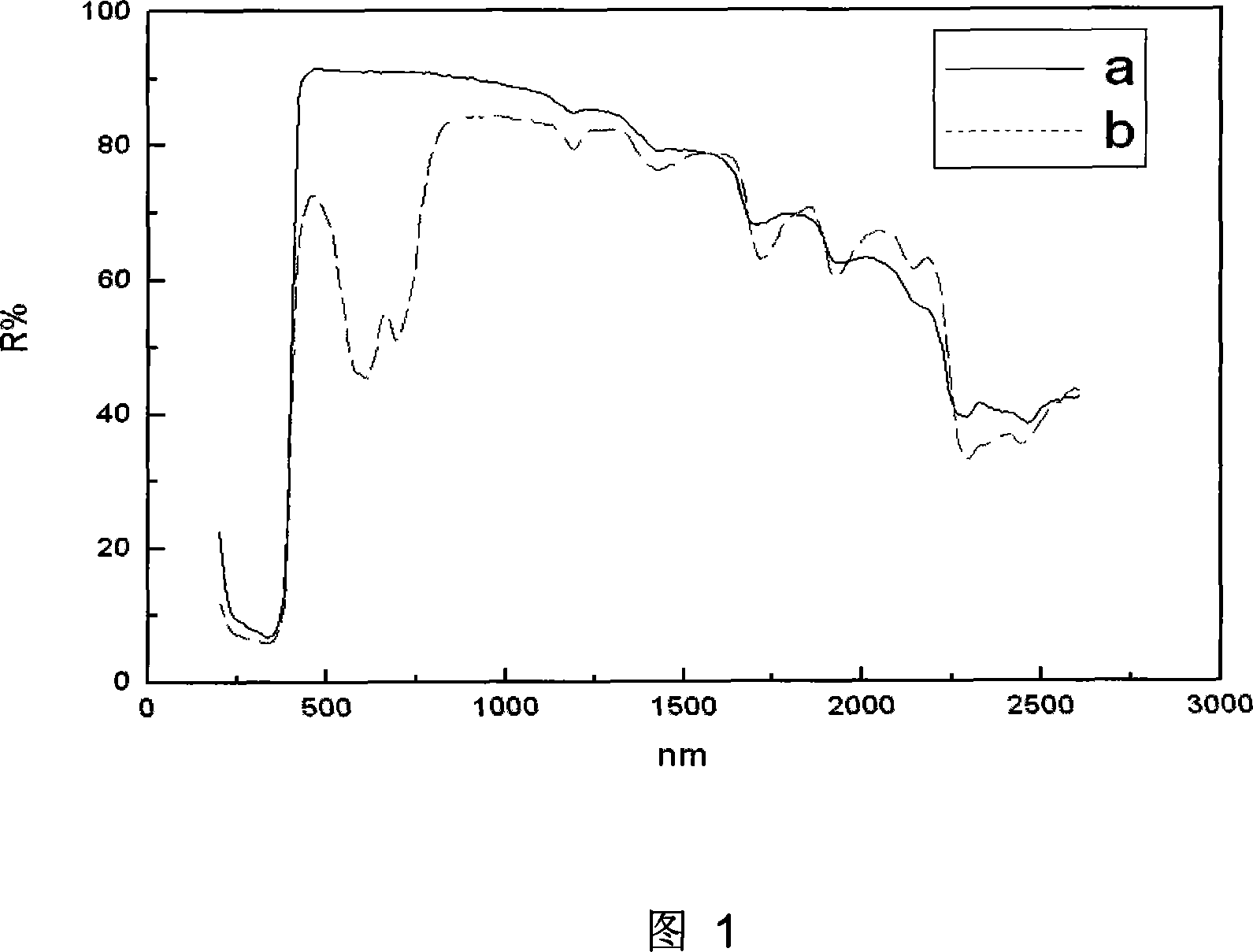

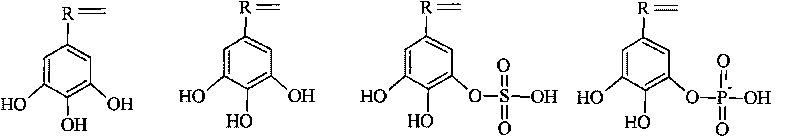

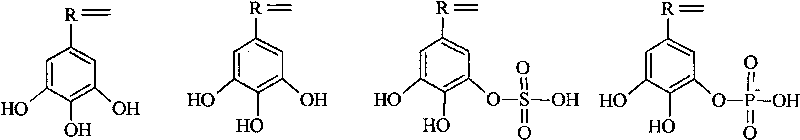

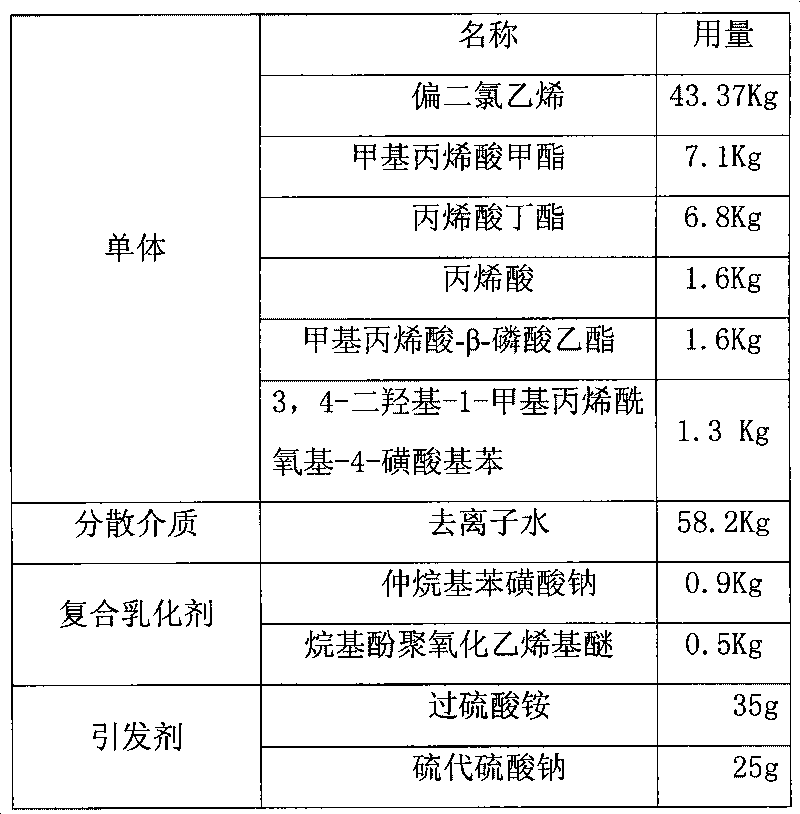

Waterborne rust conversion polymer emulsion, coating thereof and method for preparing same

The invention discloses a waterborne rust conversion polymer emulsion. The waterborne rust conversion polymer emulsion is prepared by the polyreaction of alkenyl halide monomers, monomers of (methyl)acrylic acid and esters of (methyl)acrylic acid, alkene phosphate ester monomers, a complexing agent, a compound emulsifying agent, an initiator and deionized water in an inert atmosphere at a pressure of 0.08 to 0.12MPa and a temperature of between 50 and 60 DEG C; and the percentages of dosages of all components on the basis of the total weight of all polyreaction monomers are: 75.0 to 95.0 percent of alkenyl halide monomers, 1.0 to 5.0 percent of alkene phosphate ester monomers, 5.0 to 10.0 percent of monomers of (methyl)acrylic acid and esters of (methyl)acrylic acid, 0.05 to 0.5 percent of initiator, 2 to 4 percent of compound emulsifying agent, 1.0 to 10.0 percent of complexing agent and 100 to 120 percent of deionized water. The coating prepared by the emulsion has the characteristics of good adhesive force, strong covering force, good stability, acid resistance, alkali resistance, salt spray corrosion resistance and long service life, and can be directly coated on the surfaces of metallic materials with a tight rusty layer without the rust removal treatment; and in a film-forming process, no volatile organic compounds are discharged, so that the coating of the invention is a green environmentally protected antirust coating.

Owner:深圳海润德添加剂有限公司

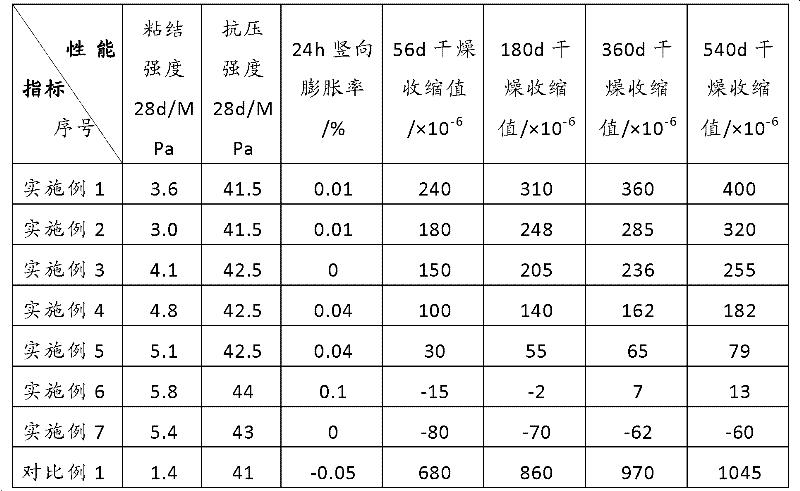

Super-high early-strength grouting material for repairing ballastless track structure of high speed railway

The invention discloses a super-high early-strength grouting material for repairing a ballastless track structure of a high speed railway, which is prepared by the following steps of: sequentially adding water, polymer emulsion, a water reducing agent, a rheology accessory agent and an antifoaming agent; adding admixture, cement, an expansion agent, a coagulator and a retarder, and stirring and blending the materials at a high speed. The parts by weight of the ingredients are as follows: 100 parts of superfine cement, 50-150 parts of admixture, 25-50 parts of redispersible emulsion powder, 3-10 parts of polymer emulsion, 5-25 parts of expansion agent, 0.1-1.0 part of carboxylic acid water reducing agent, 0.1-10 parts of coagulator, 0.1-5 parts of retarder, 0.001-0.005 parts of rheology accessory agent, 0.001 part of polyether-siloxane copolymer antifoaming agent and 20-70 parts of water. The material disclosed by the invention has the advantages of low viscosity, super-high early-strength, low cost, fatigue resistance, aging resistance and water erosion resistance, and the like, so that the material can be used for repairing the concrete gaps of ballastless tracks of high speed railways, gaps of cement asphalt mortar filling layers, cracks and damages.

Owner:四川昊龙高科轨道交通新材料科技股份有限公司

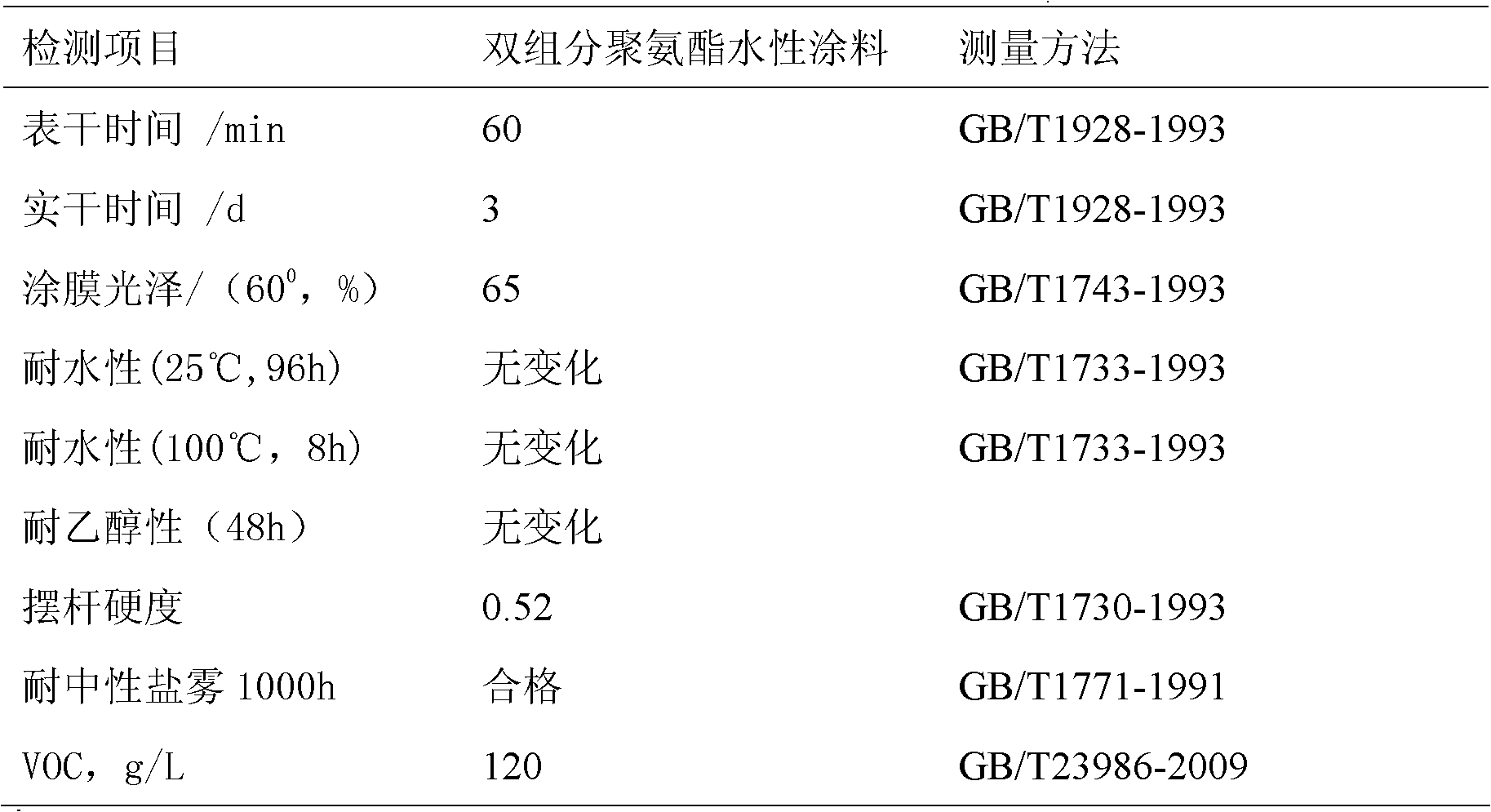

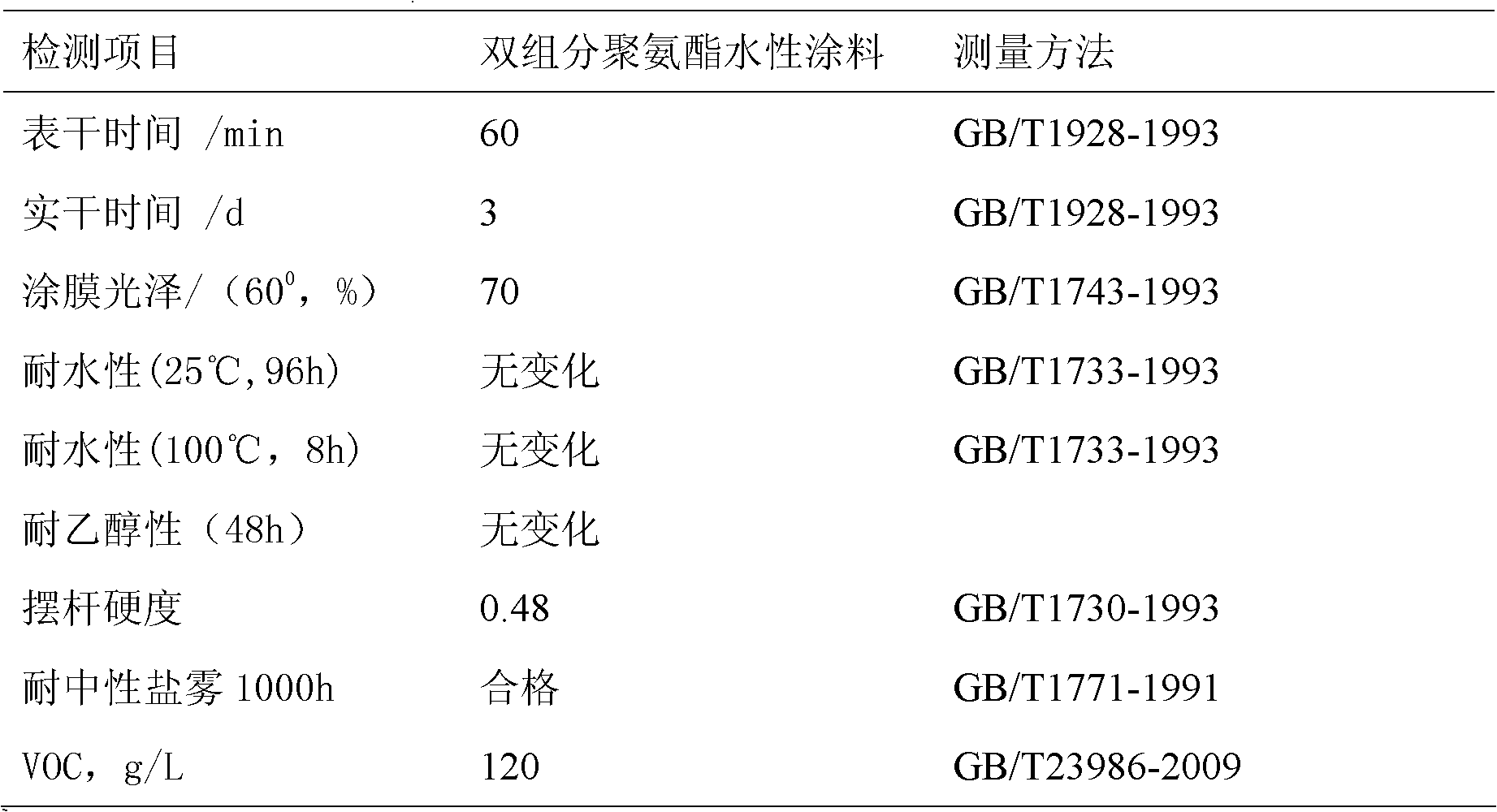

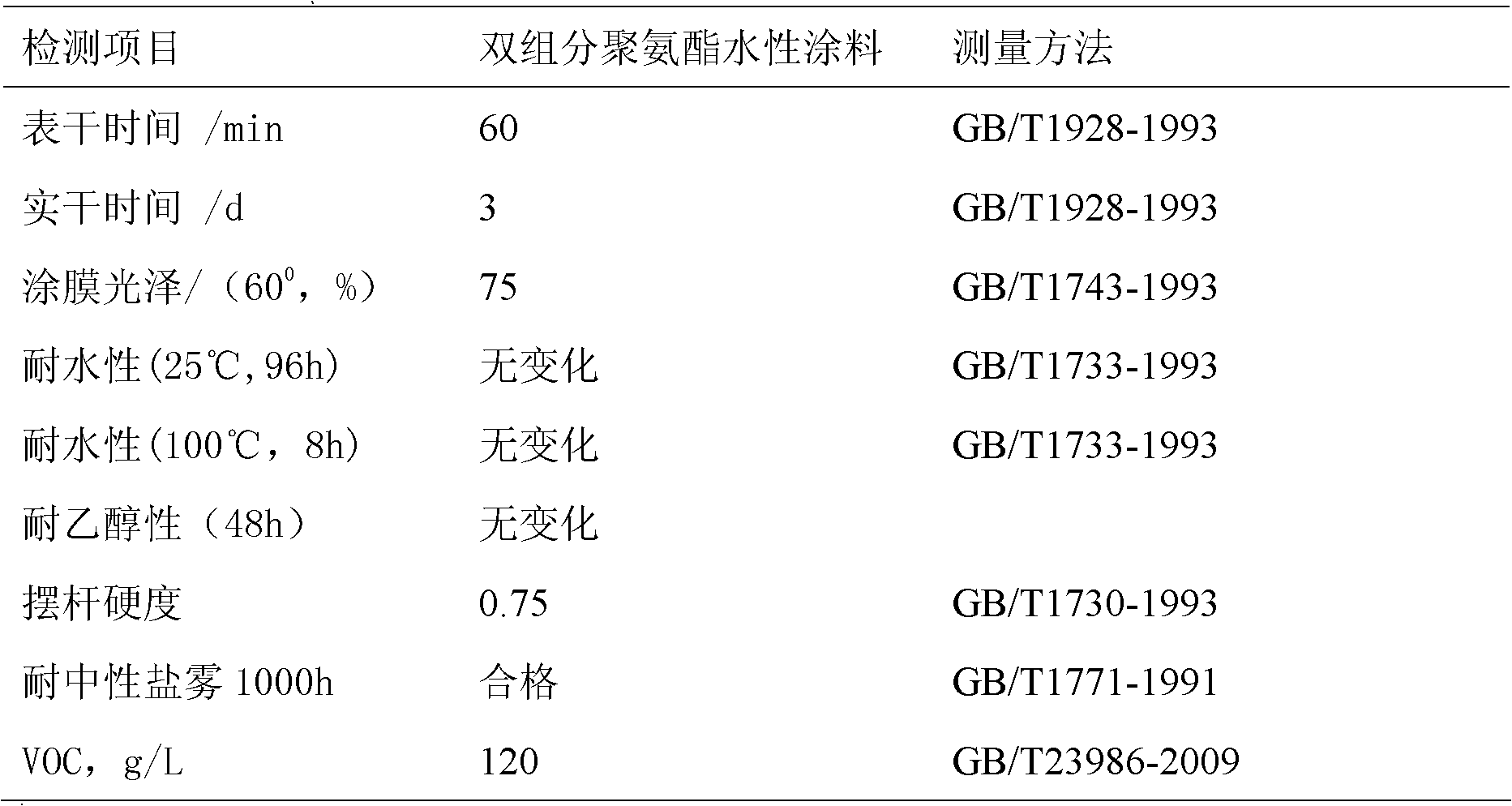

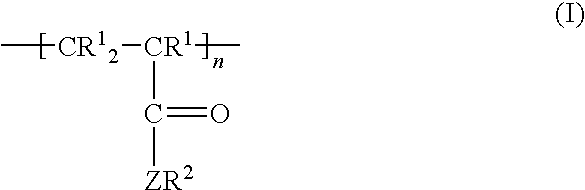

Double-component polyurethane water-based paint

InactiveCN102108246AIncrease roughnessImprove flatnessPolyurea/polyurethane coatingsWater basedPolymer science

The invention provides a double-component polyurethane water-based paint, belonging to the field of organic polymer compounds. The double-component polyurethane water-based paint comprises isocyanate curing agents component A and component B, wherein the molar ratio of OH groups of a polymer in the component A to NCO groups in the component B is 1: (1-2.2); and the component A contains polymer aqueous dispersion and polymer emulsion, wherein the content of OH in the polymer aqueous dispersion is 2.0-5.0% and the grain size of latex in the polymer aqueous dispersion is 10-100nm, the weight of the polymer emulsion is 0.05-16 times that of the polymer aqueous dispersion, the content of OH in the polymer emulsion is 0-2.0%, and the grain size of the latex in the polymer emulsion is 80-500nm. In the invention, the polymer aqueous dispersion which has small average grain size and contains -OH and the polymer emulsion which has large average grain size are compounded, wherein the latex with a large grain size can increase the roughness and unevenness of a film and reduce the gloss of the film, and the emulsion with small particles promotes the latex with the large grain size to aggregate, reduces the lowest film-forming temperature of the film, improves the film-forming capability of the film and decreases the usage amount of a film-forming additive; and the hardness, chemical-resistance and wear-resistance of the film are improved by using two different water-based polymers are used for compounding.

Owner:SOUTH CHINA UNIV OF TECH +1

Water-in-oil polymer emulsion containing microparticles

InactiveUS7531600B1Predictable and convenient and efficient preparationEasily metered into the fluid.Sludge treatment by de-watering/drying/thickeningWater treatment compoundsPolymer scienceFracturing fluid

A storage stable water-in-oil emulsion composition that includes 5% to 99% by weight of a water-in-oil emulsion polymer including a polymer or copolymer containing repeat units from an acrylamide monomer; 0.1% to 10% by weight of one or more inorganic microparticles; 0.5% to 90% by weight of a carrier solvent; and 0 to 90% by weight of a fluidizing agent. The compositions can be used to treat aqueous systems including paper processing, sludge dewatering and for fracturing fluids for subterranean formations.

Owner:KROFF CHEM

Emulsion compositions for use in printing inks

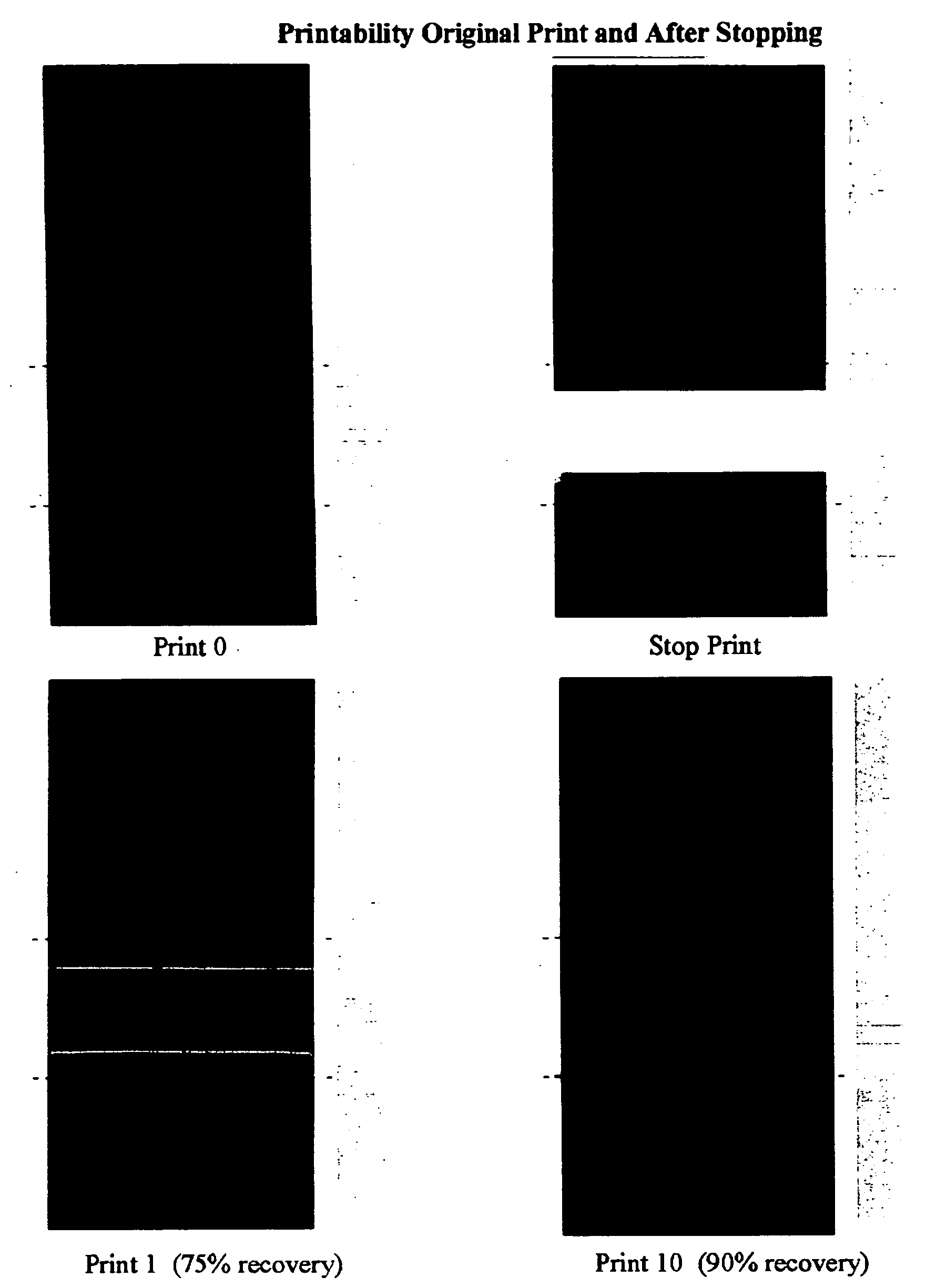

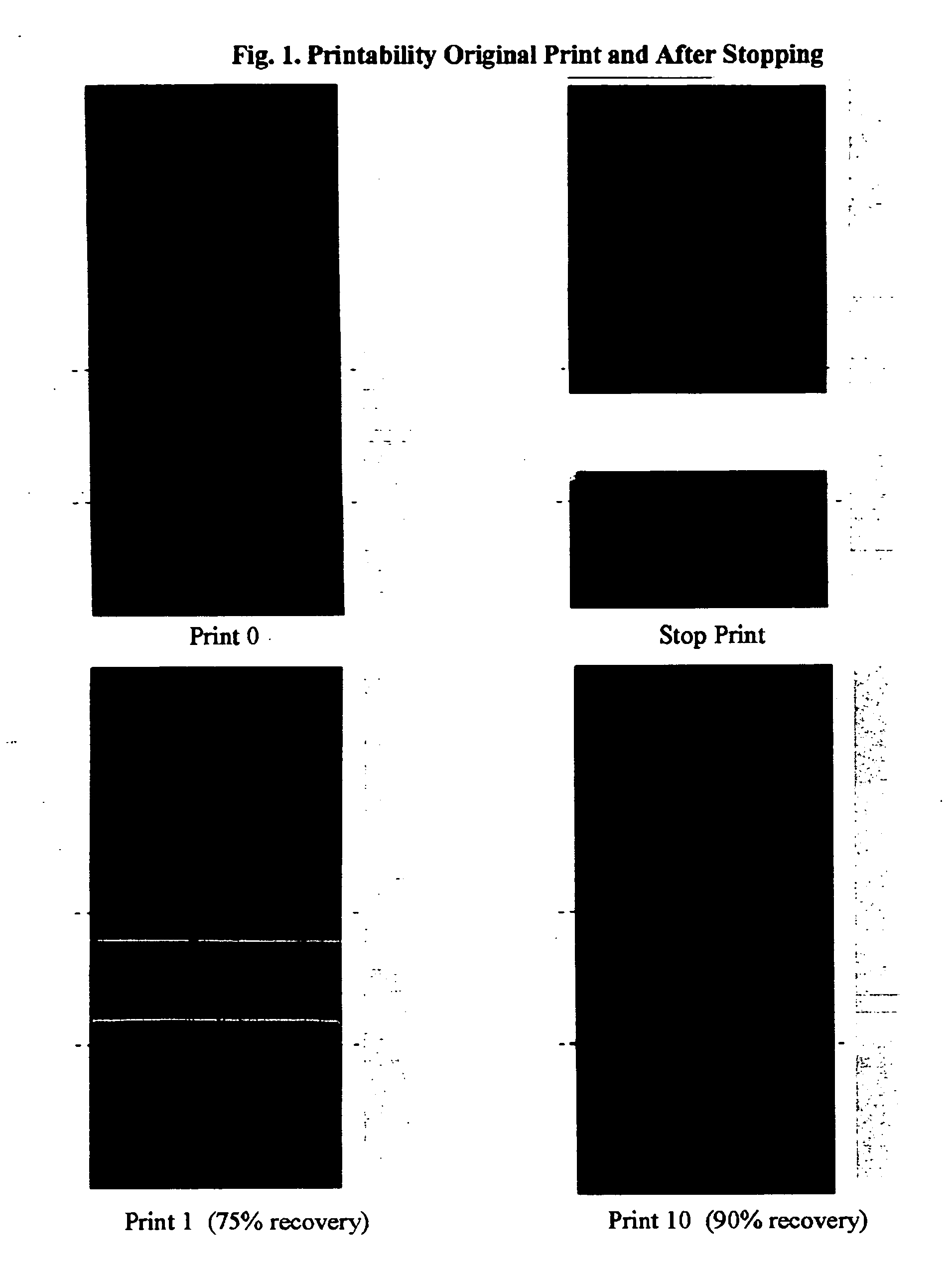

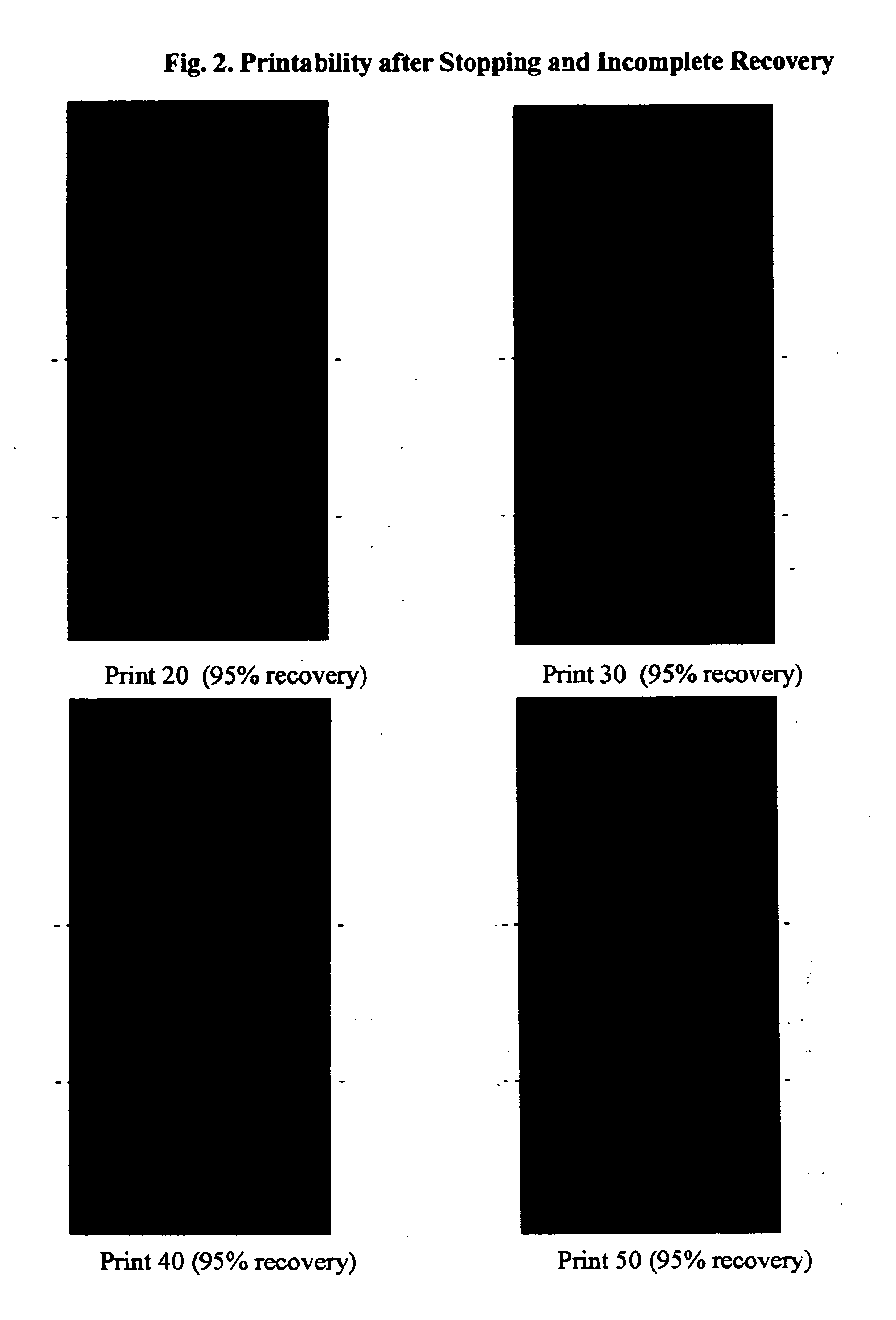

ActiveUS20060063868A1Good storage stabilityQuality improvementLiquid surface applicatorsInksEmulsionPrinting ink

Polymer emulsion compositions for use in printing inks and printing inks made from the compositions are provided. The emulsion compositions include an aqueous continuous phase containing water and a dissolved carboxylic acid-functional support polymer. The dispersed phase of the emulsion composition contains crosslinked, dispersed polymer particles. The emulsion compositions also include at least one multivalent metal crosslinker and at least one stabilizing agent. The polymer emulsion compositions display superior printability properties in inks and other coatings formulated with them, yet are stable at elevated temperatures for long periods of time.

Owner:BASF CORP

Light cast-in-situs concrete wallboard

InactiveCN1530501AStrong and durable connectionImprove the seismic performance of structuresSolid waste managementWallsFiberglass meshGlass fiber

A light concrete wall slab cast in-situ is composed of main body and welded reinforcing steel bar net in said main body. Said main body is made up of water, cement, powdered coal ash, slag powder, silicon powder, efficient composite water-reducing agent, polypropylene fibres, glass fibre fabric or alkali-resistant plastic-coated glass staple, modified cement polymer emulsion (or powder), haydite, and sand. Its advantages are light weight, high strength, low shrinkage, not deforming and cracking, and low cost.

Owner:张英保

Water adhesive for lithium ion battery, preparation method thereof and lithium ion battery positive plate

ActiveCN101260282AIncrease volumetric energy densityEasy to manufactureSecondary cellsActive material electrodesAdhesiveElectrical battery

The invention relates to aqueous bonding agent for lithium ion batteries, a preparation method and a positive plate for the lithium ion batteries, belonging to the energy storage device such as battery manufacturing field. The aqueous bonding agent for the lithium ion batteries provided by the invention is aqueous polymer emulsion formed after polyvinyl alcohol or ethylidene ether derivatives thereof is taken as a main polymer and two or more than two monomers with different polarities are taken as a graft comonomer to undergo a graft modification in water medium, the solid content of the emulsion is between 5 and 40 percent, and the viscosity is between 200 and 20000 centipoise (40 DEG C). The positive electrode prepared by the aqueous bonding agent for the lithium ion batteries of the invention has higher compacted density, so the volume energy density of the lithium ion batteries is improved; at the same time, the positive plate has good flexibleness after the drying, which contributes to the production of the batteries, improves the finished product rate of battery production, and solves the problems that the positive electrode of the lithium batteries has lower compacted density and the positive plate is brittle and has bad flexibleness after the drying.

Owner:SICHUAN INDIGO TECH CO LTD

Method for producing high-strength high damping concrete

InactiveCN101172820AHigh strengthImprove damping performanceSolid waste managementReduction treatmentSuperplasticizer

The invention relates to a preparation method of concrete with high strength and high damp. The invention is characterized in that the preparation method includes the following steps: firstly, the pretreatment of the light aggregate: (1) the feeding and vibration reduction treatment of the light aggregate: the light aggregate adsorbs the polymer to obtain feeding and vibration reduction treatment light aggregate; (2) sealing and reinforcing treatment on the surface of the feeding and vibration reduction treatment light aggregate: the feeding and vibration reduction treatment light aggregate obtained at the first step is put into sealing and reinforcing treatment slurry to mix for 1 to 3 minutes, then being fished out, and then conserved for 3 days in the condition of 85 percent to 95 percent of relative humidity and the temperature of 23 DEG C to 27 DEG C, wherein, pretreatment light aggregate is obtained; secondly, preparation for the concrete with high strength and high toughness: the concrete with high strength and high toughness is formed by evenly mixing water, common coarse aggregate, the pretreatment light aggregate, cement, fine aggregate, mineral addition, fibre, emulsified polymer and high efficiency water reducing agent. The invention can effectively increase the strength and the damp performance of the concrete.

Owner:WUHAN UNIV OF TECH

Method for preparing functional composite microsphere with multi-layer core-shell structure and application thereof

InactiveCN101735413ADifferent Surface ElectricityWith strengthDrilling compositionPolymer scienceMicrosphere

The invention discloses a method for preparing functional composite microsphere with a multi-layer core-shell structure and application thereof, and relates to the technical fields of functional macromolecular microsphere preparation and petroleum exploitation, in particular to the technical field of deep profile control water shutoff during high water-cut period of petroleum exploitation. The functional composite microsphere is prepared by a dispersion polymerization method which comprises the following steps: forming a core part by polymerization of a styrene monomer, and forming a cation shell part by copolymerization of acrylamide, the cation monomer and a crosslinking agent; and forming an anion shell part by copolymerization of acrylamide, anion monomer and the crosslinking agent. The functional composite microsphere is characterized in that the size of the microsphere is between 1,500 and 2,000nm and the microsphere is white solid powder or polymer emulsion; the expansion multiplying power of the microsphere is improved by 20 to 50 times after 5-day hydration; and therefore, the functional composite microsphere can be used for effective plugging at the pore throat of a bottom high permeability zone during high water-cut period of the petroleum exploitation.

Owner:JIANGNAN UNIV

Seed Treatment Formulations and Methods of Use

The present invention generally relates to aqueous seed treatment formulations comprising a pesticidal agent, a polyvinyl alcohol (PVA), a graft copolymer, and a plasticizer. In one embodiment of the invention, PVA-compatible polymer emulsions are employed. The present invention also relates to uses of the disclosed compositions for protecting seeds from pests.

Owner:VALENT USA CORP

Acrylic acid series nucleocapsid polymer emulsion and re-dispersible emulsion powder, and method for producing thereof

InactiveCN101173021AImprove performanceMeet the redispersion performanceAnticaking agentPolymer chemistry

The invention relates to a crylic acid nucleocapsid polymer emulsion and subdividable emulsion powder and the preparation method thereof. The emulsion is prepared by methacrylic acid alkyl ester, crylic acid alkyl ester, hydroxyalkyl ester, methacrylic acid, N-methylol acrylamide, an emulsifying agent and an initiator through the method of emulsion polymerization. The subdividable emulsion powder is prepared by the crylic acid nucleocapsid polymer emulsion, a protective colloid, and an anticaking agent through the spray method of emulsion. The subdividable emulsion powder of the invention has high fixed content (approximating 100 percent) and can reduce the difficulty of transportation and storage, and can be packed by using paper to reduce the packing cost, moreover, the storage stability is good and the storage period is long, and the subdividable emulsion powder of the invention can not go bad due to the water freezing or volatilization; the invention has the important thing that the subdividable emulsion powder can be rapidly dissolved in water and evenly distributed to repeatedly form the emulsion having the same performance as the primary matrix polymer emulsion, thereby being widely applied to zero VOC dry powder paint, terrace patch mortar, artesian flow flat plateau mortar, wall and floor tile bonding agent, sealed mortar, construction luting powder, plastering material, plastering gypsum, heat insulation and heated board bonding material, concrete interface agent, powder binding agent, powder paint, etc.

Owner:SHANGHAI UNIV +1

Heat resistant and fire retardant materials and methods for preparing same

InactiveUS8172938B2Increased durabilityHigh strengthFireproof paintsSolid waste managementWater basedFluoropolymer

A silica cement blend having an insulating, fire retarding and high temperature characteristic capable of withstanding temperatures ranging from ambient to greater than 40000 F without degradation of the concrete structure. In addition to its high temperature capabilities the blend can be produced as ultra light weight to heavy weight concrete. The silica based mixture when added to cementitious materials such as Portland cement, Class C Fly Ash, silica fume and other cementitious materials. Presented also are methods for reducing fire damage by coating interior / exterior walls, ceiling, and roofs of a building with a water based latex coating containing a fire retardant material and low heat conductivity silicas. Methods for painting internal / external walls, ceilings, and roof are also presented. This coating retains thermal blocking properties comprised of processed, expanded and / or finely milled, pyrogenic silicas and micro spheres in combination of but not limited to, one, two or more component water based polymer / copolymer latex binders and a water born fluoropolymer emulsion. The combined properties of these elements create a coating similar to paint with a high level of thermatic resistance which slows the composition break-down from fire, extreme temperatures, and restricts the thermal conductivity which helps to preserve the integrity of the substructure or underlying materials. The properties of this coating reduce or slow the potential of catastrophic fire by retarding flashover and protecting the under structure; which in turn assist fire fighters and rescue personnel by helping to retard the potential of a catastrophic fire.

Owner:SPECIALTY CONCRETE DESIGN

Self-densifying concrete as well as preparation method and application thereof

The invention provides self-densifying concrete, which is prepared from 100 parts by weight of cement, 20-100 parts by weight of coal ash, 20-120 parts by weight of porous fine aggregate, 150-250 parts by weight of non-porous fine aggregate, 150-300 parts by weight of coarse aggregate, 0.1-3 parts by weight of water-absorbing resin, 5-40 parts by weight of polymer emulsion, 1-12 parts by weight of expanding agent, 0.5-3 parts of water reducing agent, 10-90 parts by weight of water, 5-50 parts by weight of steel slag, 0-2 parts by weight of air entraining agent and 0-2 parts by weight of defoaming agent. The invention also provides a method for preparing the self-densifying concrete and the application of the self-densifying concrete in preparing a filling layer which is laid under plates of ballastless tracks.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +1

Full-color colloid photonic crystal film and its preparation method and use

ActiveCN1808214AThe monodispersity index is smallThe size is easy to controlNon-linear opticsPolymer chemistryPolymer

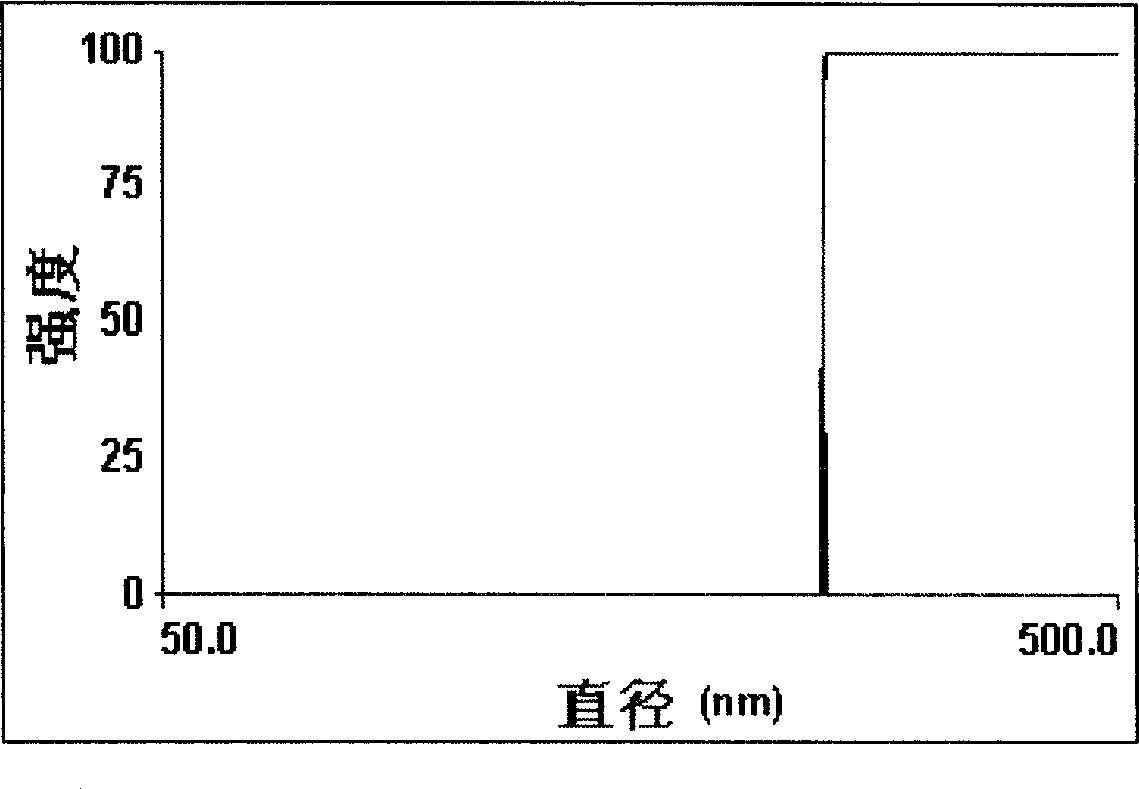

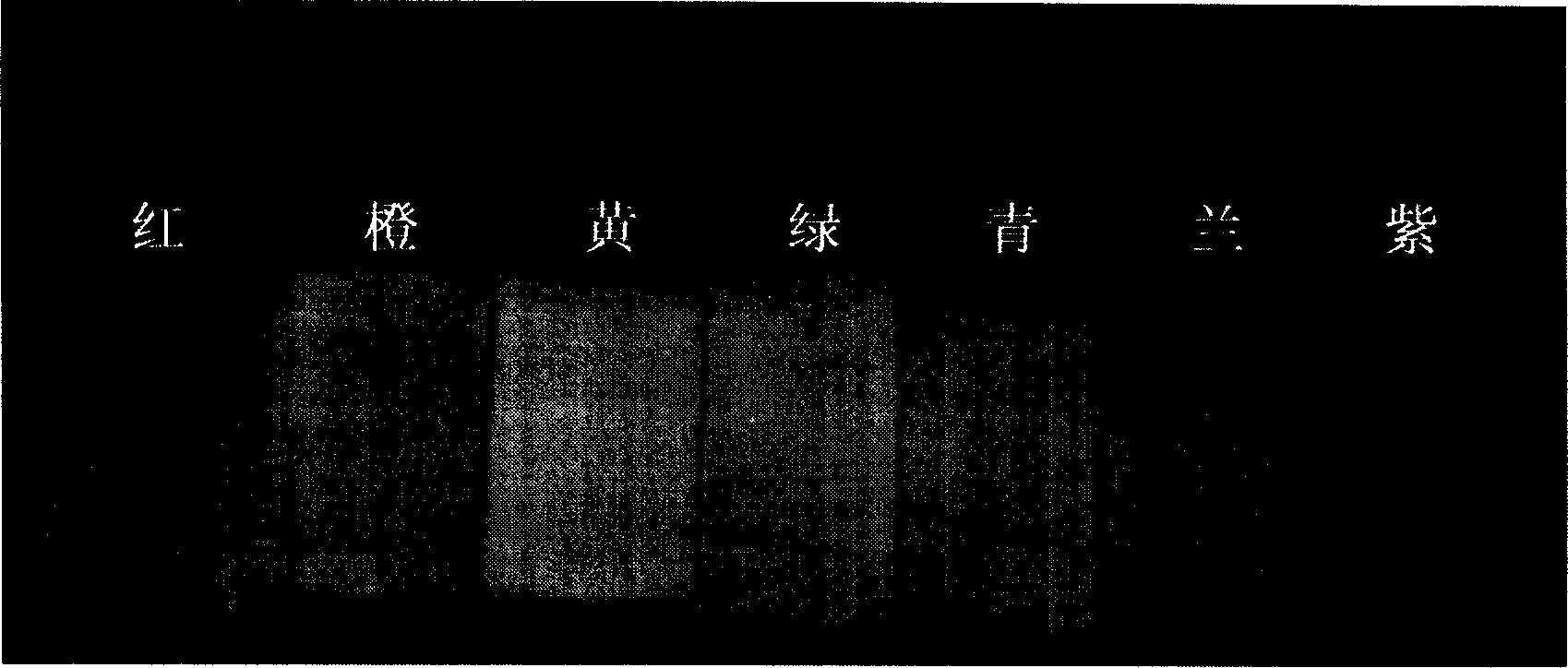

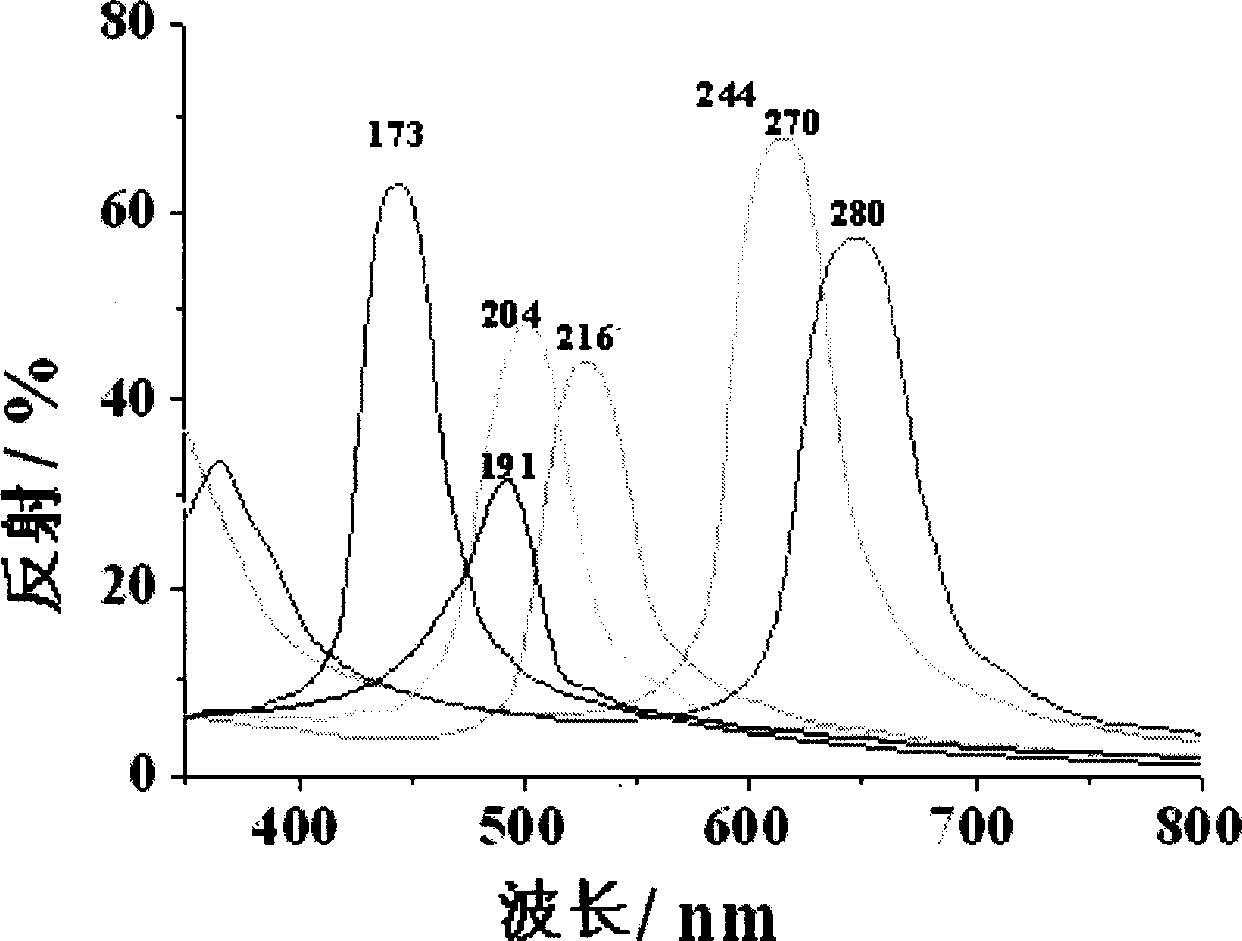

The invention relates to a large size full color colloid photon crystal membrane and the method for making the same. The method comprises: covering monodisperse polymer emulsion particle with hard shell-soft shell structures on the flat base material to form full color colloid photon crystal membrane after dispersion volatilizing, the model having cellular structure; the thickness of the single dispersion polyaromatics emulsion particle shell is 20-50nm, the range of the diameter of emulsion particle is 170í½300nm, and the multi dispersion index is less or equal to 0.005.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Ink Jet Recording Method, Recording Device, Ink/Recording Medium Set, Recording Matter

ActiveUS20080273045A1Excellent toneSatisfied with stabilityMeasurement apparatus componentsInksWater insolublePolymer chemistry

An ink-jet recording process which conducts recording by imparting ink onto the surface of a recording medium according to recording information, where the recording medium has a base material and a porous ink receiving layer thereon containing inorganic particles having a BET specific surface area of at least 150 m2 / g, and the ink contains a polymer emulsion having a water-insoluble or hardly-soluble colorant contained in polymer fine particles and at least one wetting agent, 8-11 C polyol or glycol ether, anionic or nonionic surfactant, water-soluble organic solvent, and water; and has a surface tension of 40 mN / m or less at 25° C. This process can provide high-grade images excellent in ink absorbing and fixing properties and satisfactory in color tone, produce images excellent in image fastness such as water resistance and light resistance, and implement ink-jet recording excellent in storage stability and discharge stability and free from head clogging at printing.

Owner:RICOH KK

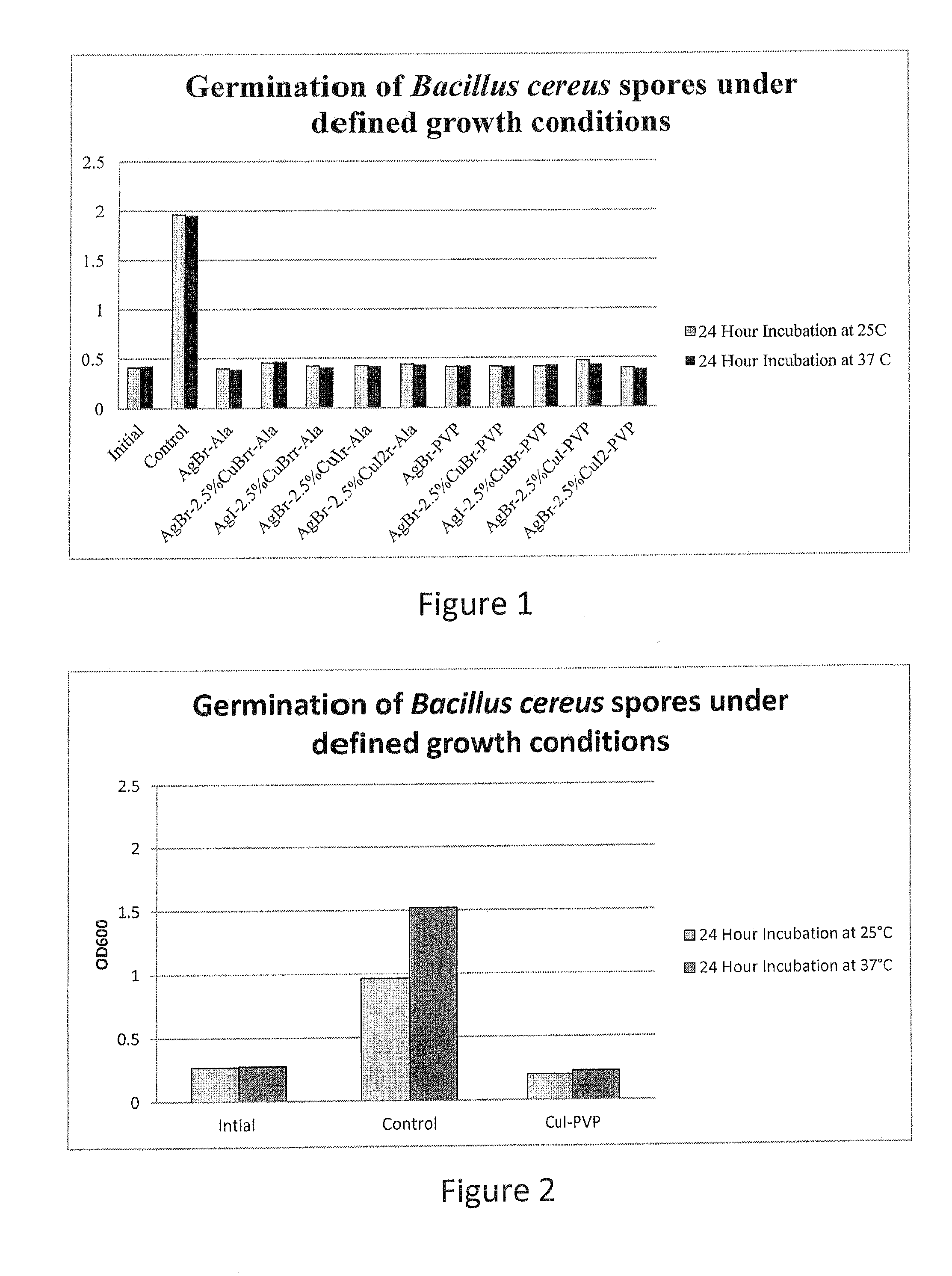

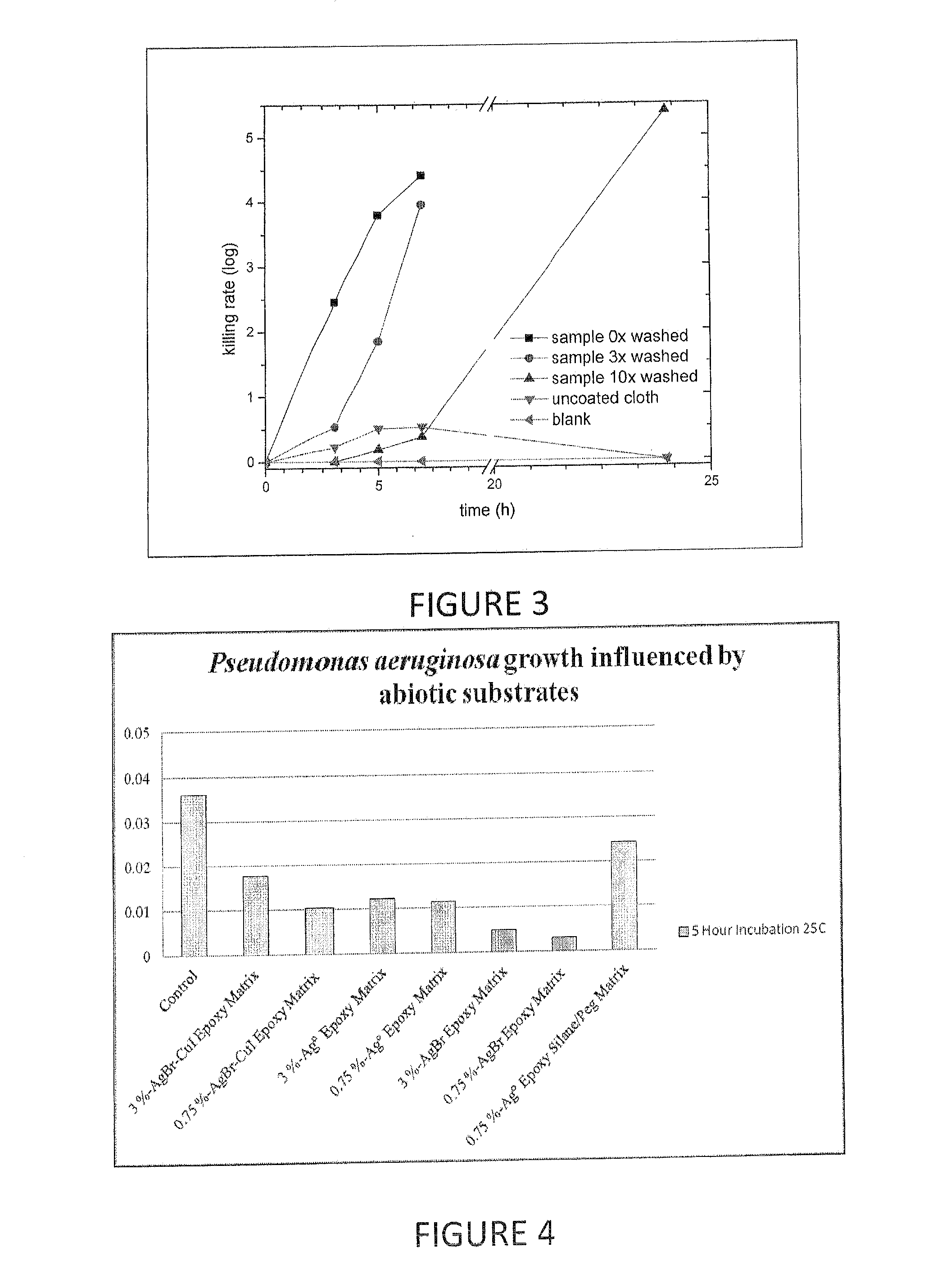

Compositions and methods for antimicrobial metal nanoparticles

InactiveUS20120301531A1Good effectAntibacterial agentsBiocideHydrophilic polymersHydrophobic polymer

Embodiments of the invention are directed to a composition having antimicrobial activity comprising particles comprising at least one inorganic copper salt; and at least one functionalizing agent in contact with the particles, the functionalizing agent stabilizing the particle in a carrier such that an antimicrobially effective amount of ions are released into the environment of a microbe. The average size of the particles ranges from about 1000 nm to about 4 nm. Preferred copper salts include copper iodide, copper bromide and copper chloride. Preferred functionalizing agents include amino acids, thiols, hydrophilic polymers emulsions of hydrophobic polymers and surfactants.

Owner:UHLMANN DONALD R +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com