Preparation method of graphene/polymer nano composite material

A nanocomposite material and graphene technology, which is applied in the field of preparation of graphene/polymer nanocomposite materials, can solve problems such as unfavorable graphene dispersion, and achieve the effects of low cost, simple preparation process and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

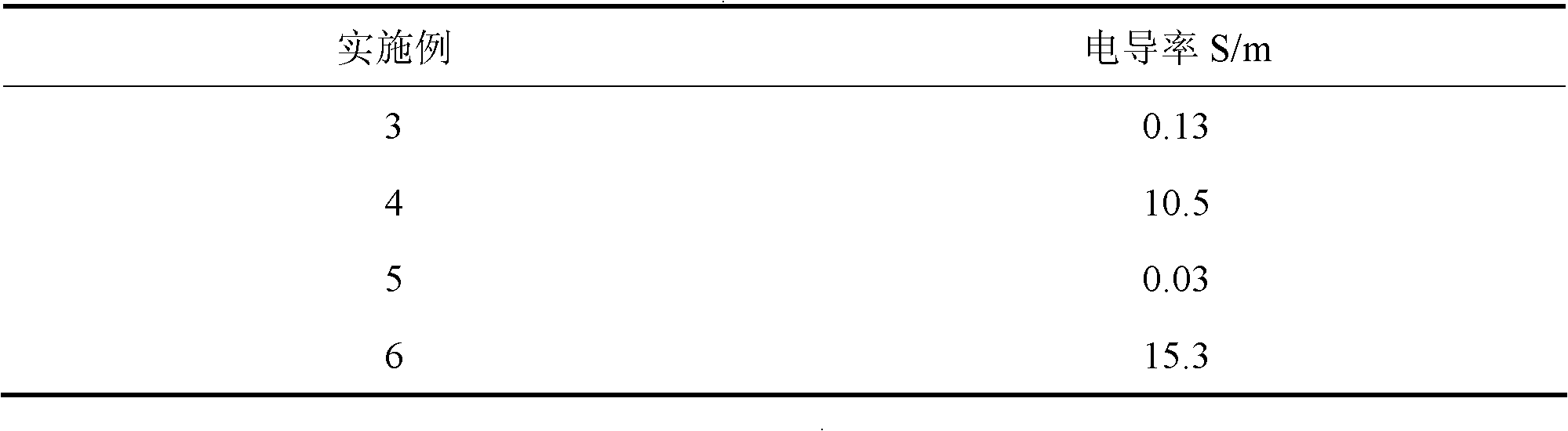

Examples

Embodiment 1

[0029] Disperse 0.1g of graphite oxide in 100g of water with a power of 50W and a frequency of 10Hz for 5 hours at a temperature of 10°C to obtain an aqueous solution of graphene oxide, and then add the aqueous solution of graphene oxide to natural latex containing 100g of natural rubber. After mixing evenly, add 5g of sodium sulfate solution with a concentration of 5% to break the emulsion to obtain a graphene oxide / natural rubber particle suspension, add 0.1g of hydrazine hydrate to reduce the graphene oxide, and reduce at a temperature of 100°C for 2 hours. After filtering, the product was dried in an oven at a temperature of 60° C. for 48 hours to obtain a graphene / natural rubber nanocomposite material. The composite material is formed by traditional rubber vulcanization method, and the gas permeability of the obtained sheet is reduced by 46%.

Embodiment 2

[0031] 0.5g of graphite oxide is mechanically ground in 200g of water for 1 hour to obtain an aqueous solution of graphene oxide, and the aqueous solution of graphene oxide is added to the natural rubber latex containing 100g of natural rubber. After mixing evenly, add sodium chloride and chlorine with a concentration of 25%. 10g of potassium chloride mixed solution was demulsified to obtain a suspension of graphene oxide / natural rubber particles, and 1g of sodium borohydride was added to pre-reduce graphene oxide, and the temperature was reduced at 20°C for 2 hours, then 3g of hydrazine hydrate was added, and at a temperature of 100°C, After reduction for 24 hours, the product was filtered and dried in a vacuum oven with a vacuum degree of 0.01 MPa and a temperature of 60° C. for 48 hours to obtain a graphene / natural rubber nanocomposite material. The composite material is molded by a traditional rubber vulcanization method, and the tensile strength of the prepared sheet is 24...

Embodiment 3

[0033]Disperse 7g of graphite oxide in 400g of water, using ultrasound with a power of 100W and a frequency of 10000Hz, at a temperature of 80°C for 15 minutes to obtain an aqueous solution of graphene oxide. Add the aqueous solution of graphene oxide to the latex containing 100g of styrene-butadiene rubber, and mix well Finally, add 100 g of magnesium chloride solution with a concentration of 15% to break the emulsion, obtain a suspension of graphene oxide / styrene-butadiene rubber particles, add 10 g of dimethylhydrazine to reduce graphene oxide, and reduce it for 24 hours at a temperature of 90 ° C. After filtering, the product is in The degree of vacuum is 0.1 MPa, and the temperature is 70° C. in a vacuum oven for 24 hours to obtain a graphene / styrene-butadiene rubber nanocomposite material. The composite is molded using conventional rubber vulcanization methods.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com