Patents

Literature

826 results about "Natural rubber latex" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Natural rubber master batch, production method thereof, and natural rubber composition

InactiveUS6841606B2Easy to processImprove propertiesPigmenting treatmentSpecial tyresPolymer scienceSlurry

The natural rubber master batch of the present invention is prepared by mixing a natural rubber latex having its amide linkages cleaved and an aqueous slurry having a filler dispersed in water. Alternatively, the natural rubber master batch is prepared by a method including a step for mixing a natural rubber latex and an aqueous slurry containing dispersed fillers having a specific particle size distribution and a limited range of 24M4DBP absorption. The natural rubber composition of the present invention is prepared by compounding natural rubber, which contains non-rubber components prepared by cleaving amide linkages of natural rubber latex, with silica and / or a particular inorganic filler.

Owner:BRIDGESTONE CORP

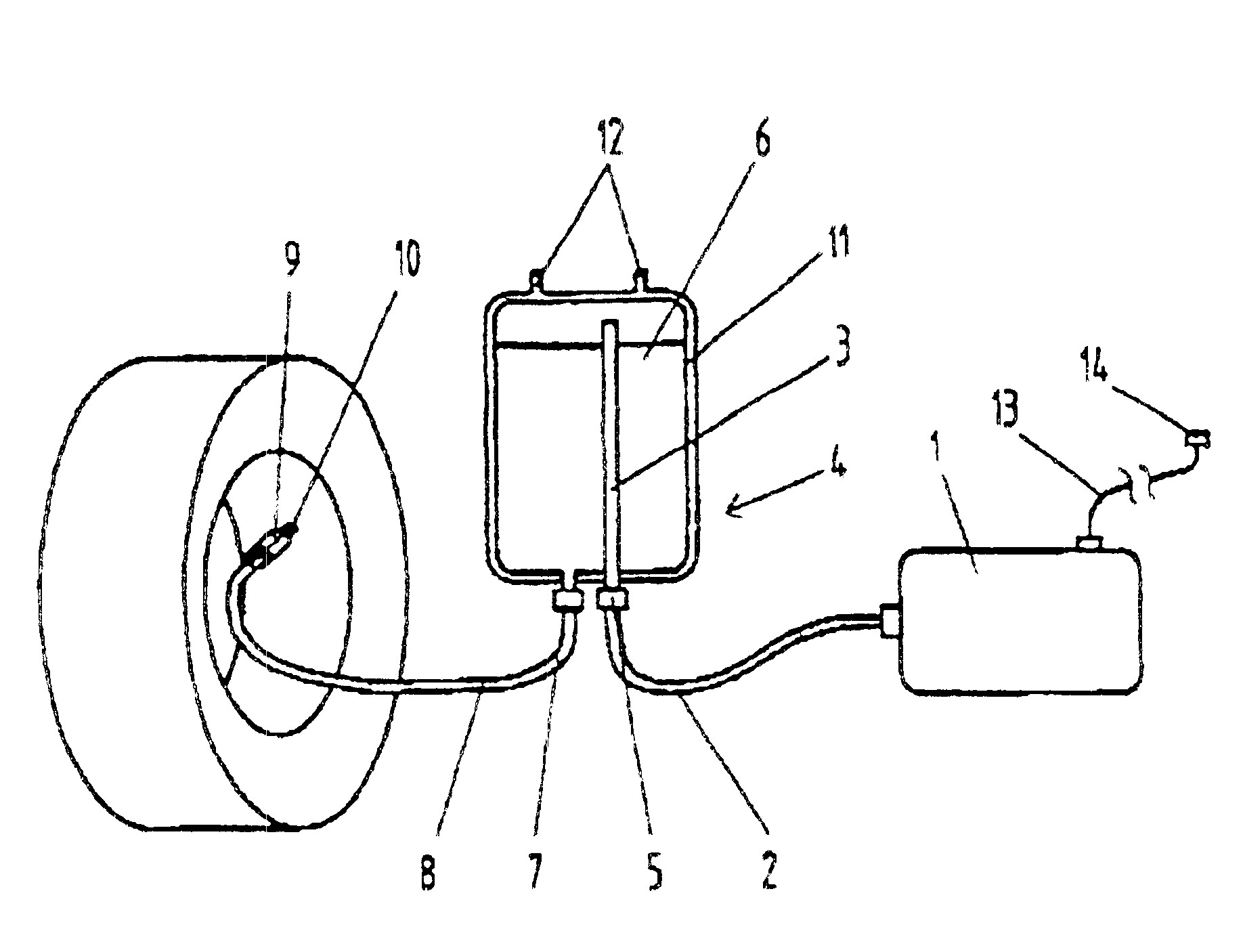

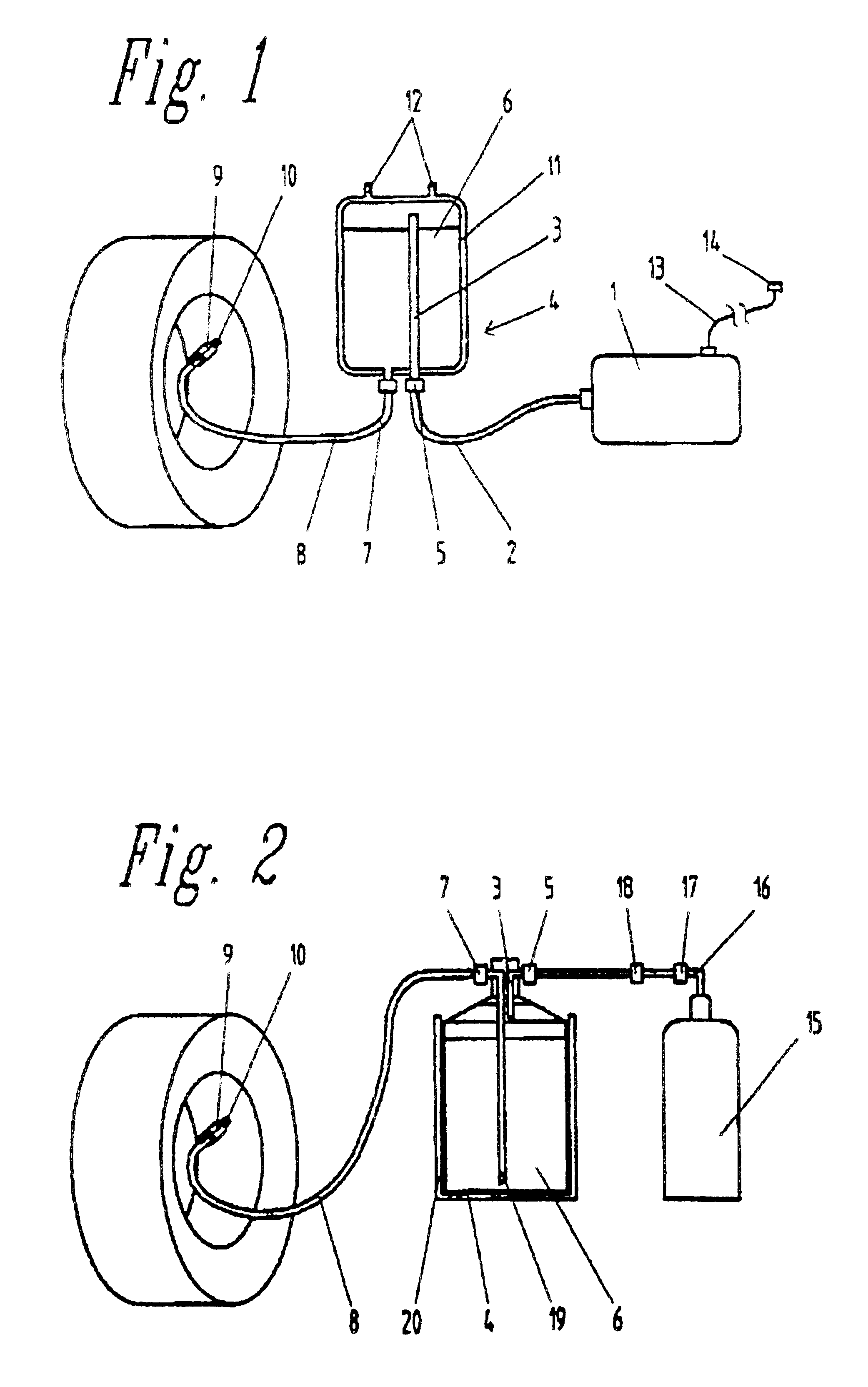

Preparation for sealing punctured tires and apparatus for the sealing and pumping up of tires

InactiveUS6889723B2Avoid easy removalImprove sealingLiquid surface applicatorsTyresSulfur hexafluorideEngineering

A sealing preparation for tire problems is proposed which seals in wet conditions, at low and high temperatures and with defects at the transition between the tread and the side wall of the tire. The sealing preparation contains natural rubber latex or a combination of rubber latex and compatible adhesive resin. Furthermore, various devices are proposed for introducing the sealing preparation into the tire and for the pumping up. An air compressor, or liquefied dinitrogenoxide, or sulphur hexafluoride are preferably used with these devices as a pressure source.

Owner:SUMITOMO RUBBER IND LTD

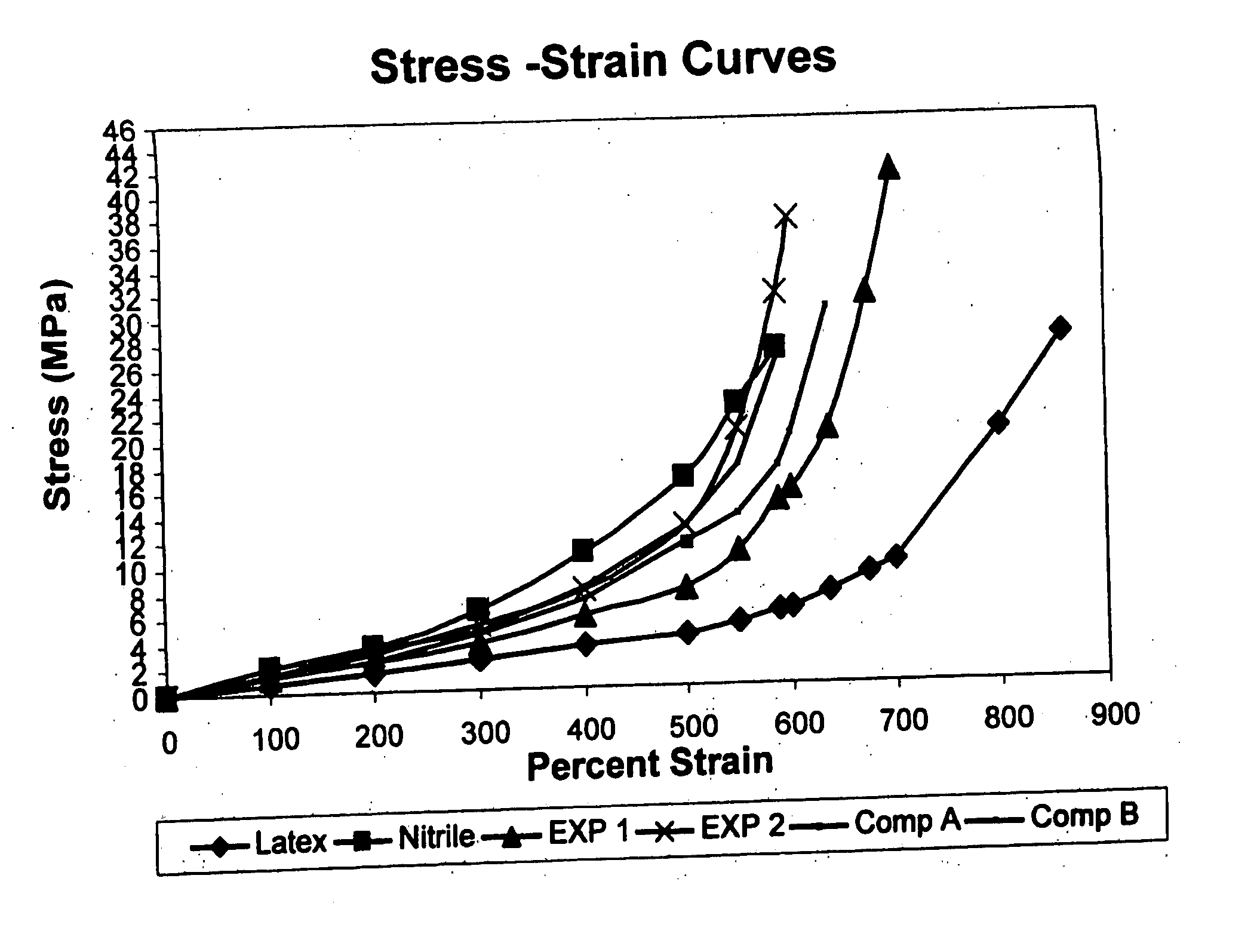

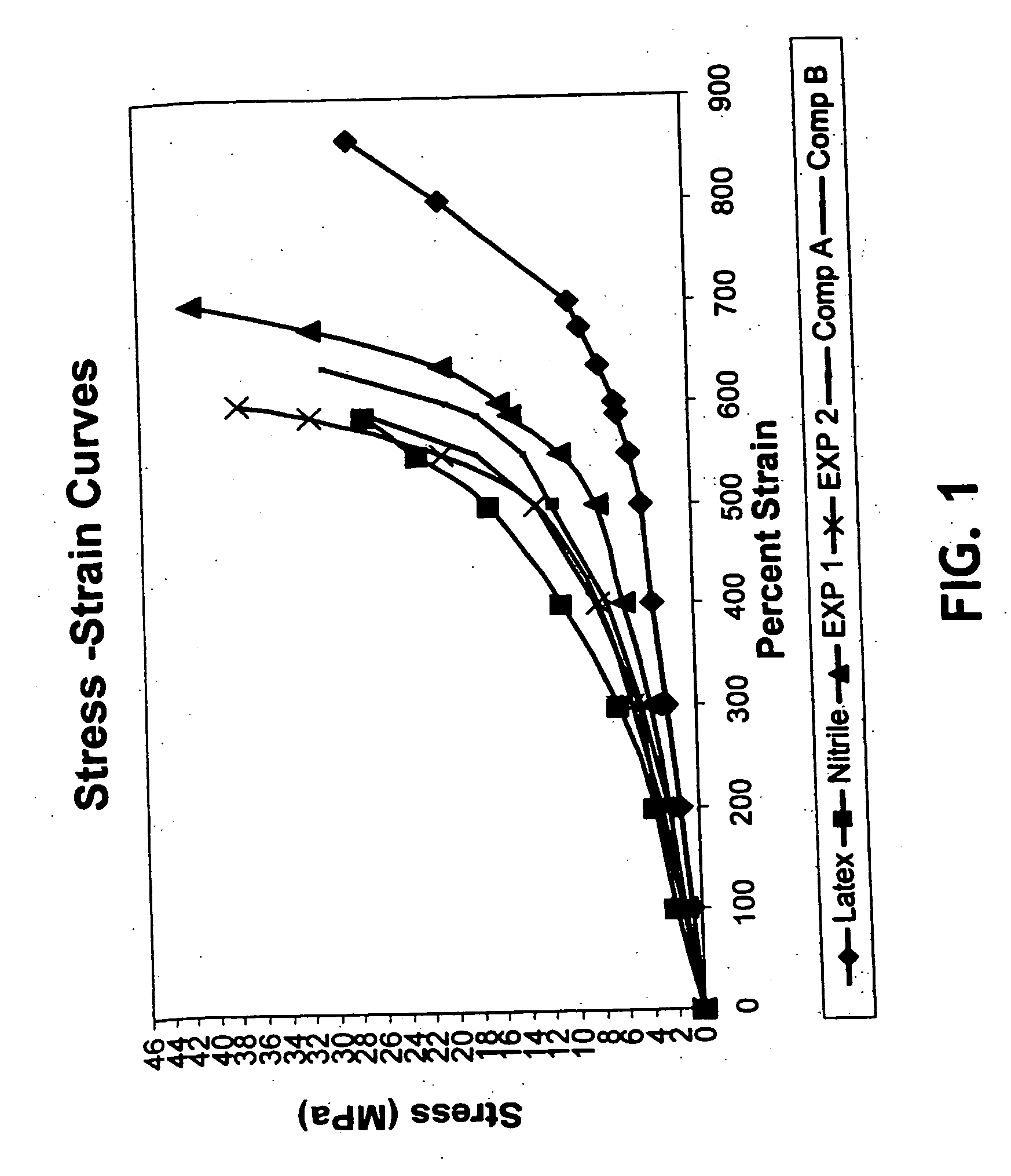

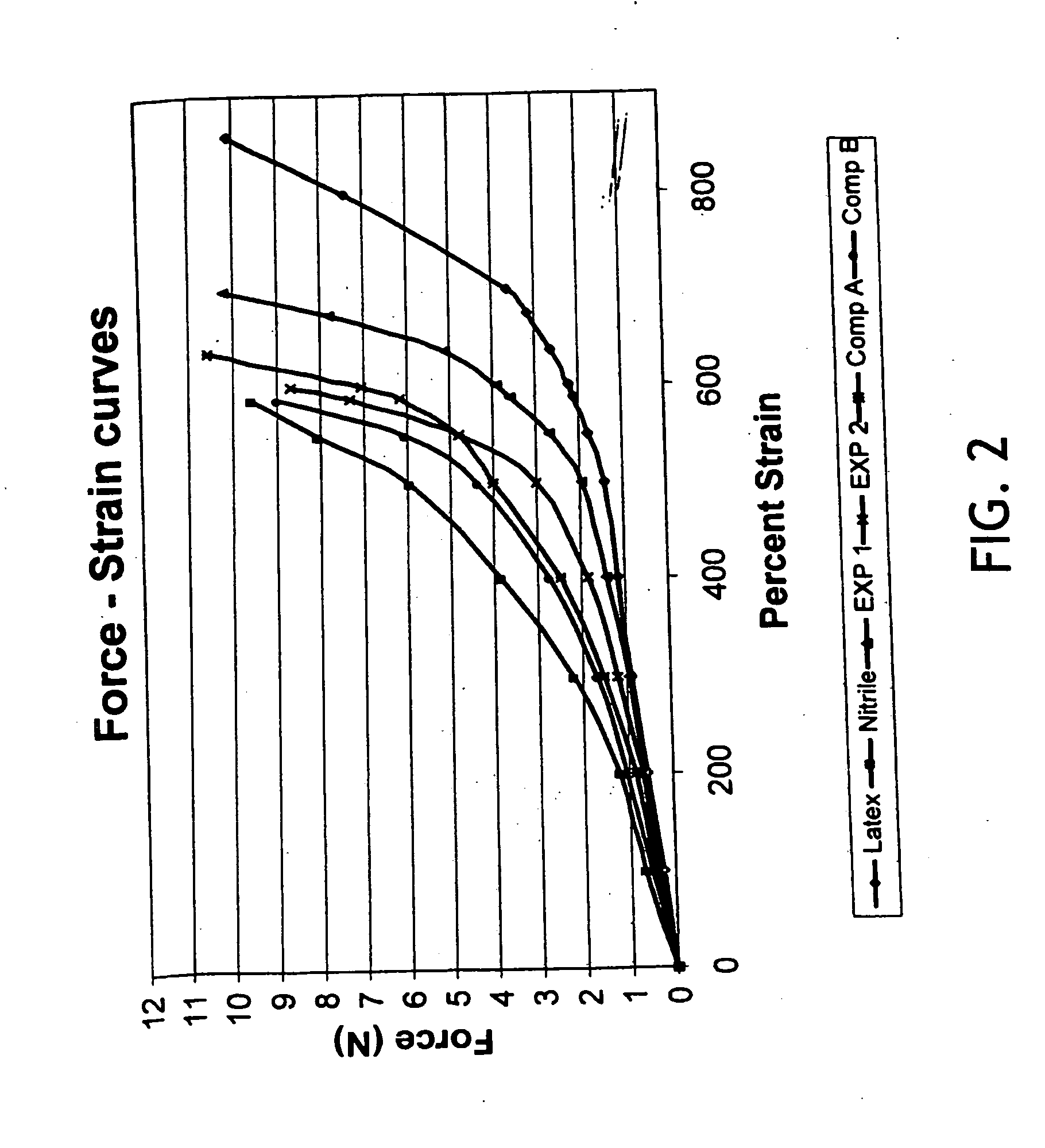

Exterior-coated nitrile rubber article having natural rubber characteristics

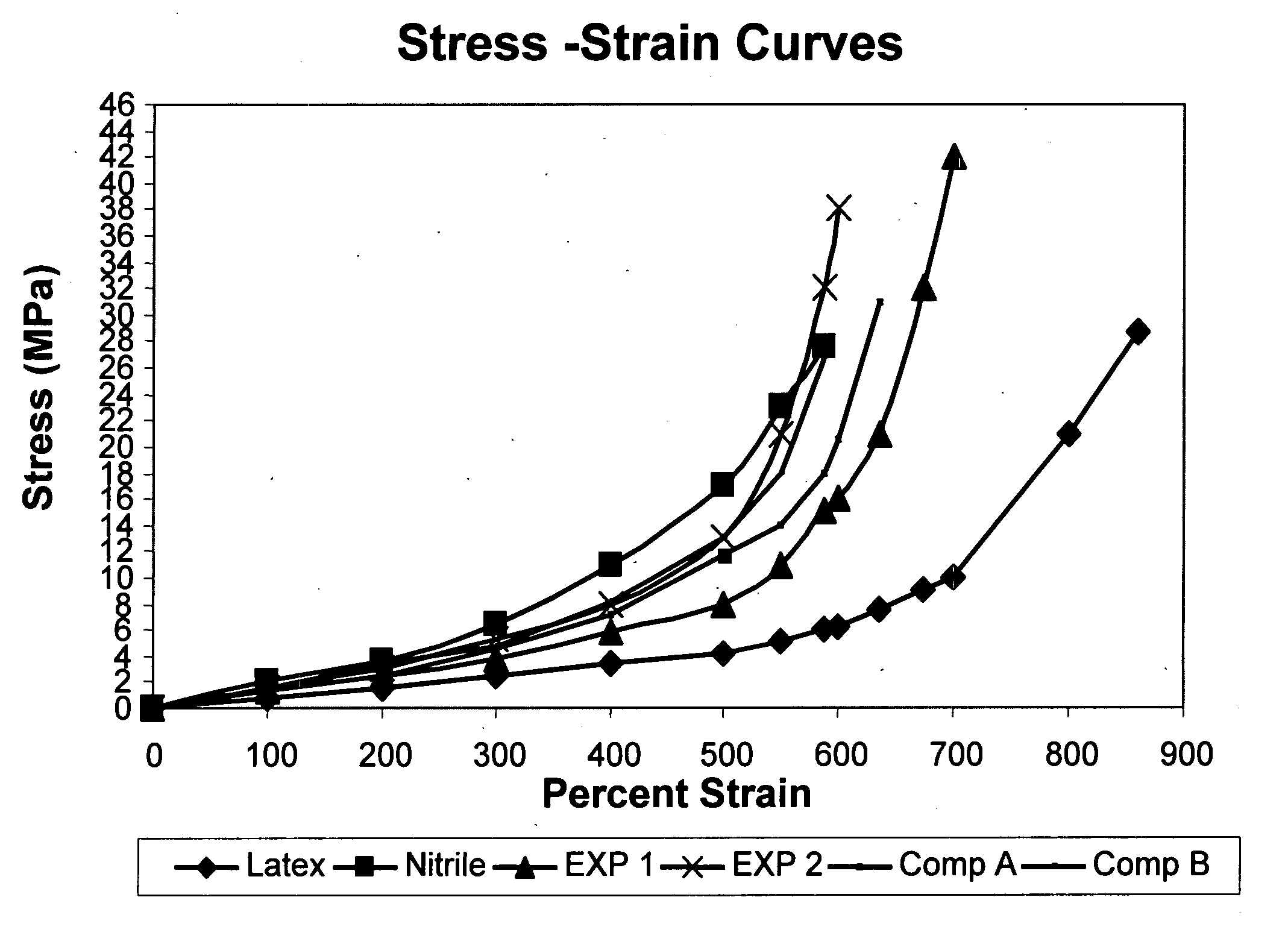

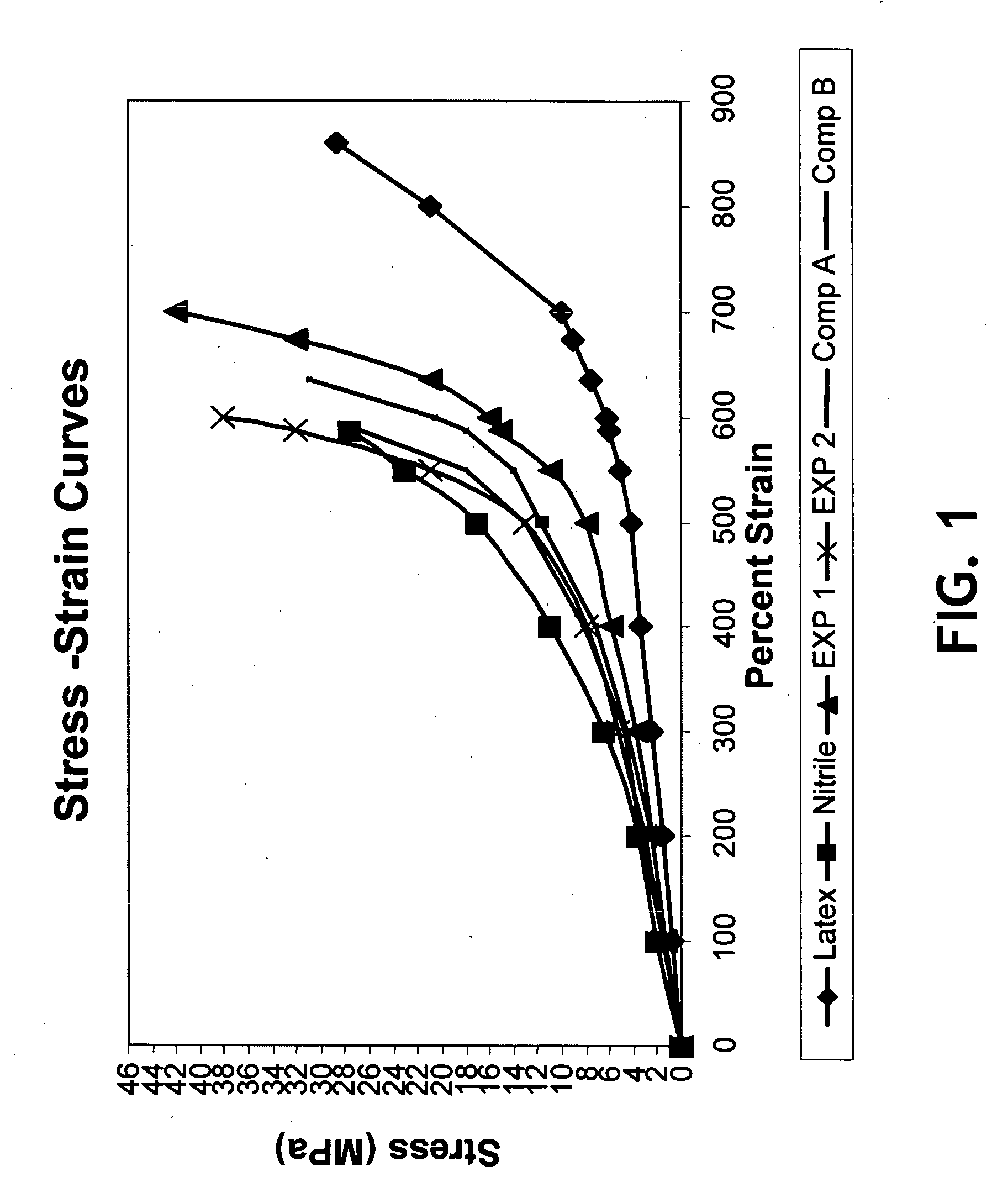

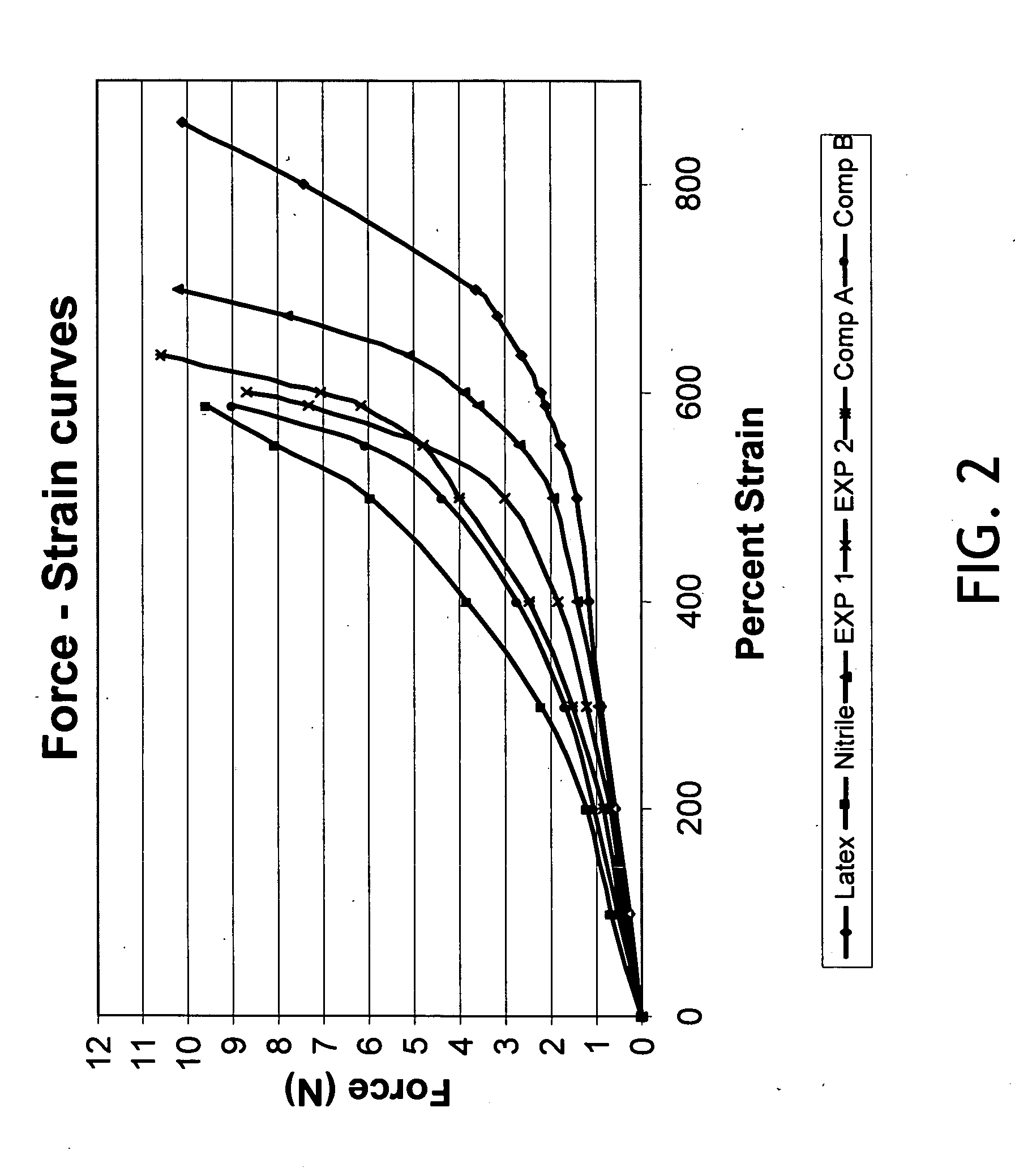

ActiveUS20060257674A1Maximize material strengthMinimize forceCosmetic preparationsBiocideRubber materialPolymer science

A material for making elastomeric nitrile rubber articles is disclosed. In particular, the process and material formulation can produce nitrile rubber based articles, which exhibit force-strain characteristics that are comparable to those of natural rubber latex articles, while maintaining the tensile strength properties of nitrile rubber. The process includes an accelerator composition at the pre-cure stage having a dithiocarbamate, a thiazole, and a guanidine compound. The invention also includes an elastomeric nitrile rubber product made by the process, such as examination, surgical, or work gloves, which can have an exterior coating over naked rubber selected from either a silicone emulsion or oil, glycerin solution, a combined mixture of silicone and glycerin / glycerol, a fluorocarbon release agent, or a natural or synthetic hydrocarbon-based oil in amounts that do not degrade said substrate rubber material.

Owner:O&M HALYARD INC

Carbon nanotube modified powder natural rubber and method for preparing same

Disclosed is a powder natural rubber modified by carbon nanostructured pipe and the preparing method, relating to the field of modifying macromolecular material with CNTs. Said powder natural rubber is characterized in that it possesses carbon nanostructured pipe which is 1%~50% of the glue of natural latex in mass.The method comprises conducting surface treatment forCNTs to make it hydrophilism: mixing it with dispersant and deionized water and getting the CNTs-water slurry; modifying the pH value to 9~12; mixing with natural latex and getting the natural rubber liquid latex added with CNTs. Then preparing modified powder natural rubber containing CNTs with the method of spray-drying, the quantity of input is 5%~30%, the temperature is 100~180DEG C. The prepared powder rubber is characterized by the adequate distribution of the CNTs in the product, the small size, and the dramatically increased mechanics property compared with the traditional powder rubber.

Owner:TSINGHUA UNIV

Latex products

InactiveUS20050031884A1Reduce in quantitySynthetic resin layered productsCarboxyl rubber coatingsPolymer scienceLatex rubber

The present invention finds that a detackified natural rubber latex product can be provided by a combination of treatment with a hydrophilic group sealant, coating with a detackifying polymer, halogenation and the like. The present invention also finds that a detackified natural rubber latex product which causes no discoloration of a metallic product surface can be provided by coating it with a detackifying, carboxylated latex vulcanized without using sulfur. The present invention also finds that a detackified natural rubber latex product of controlled protein elution can be provided by chemically modifying protein present in the natural rubber latex with an anionic group, cationic group or the like.

Owner:SUZUKI LATEX IND

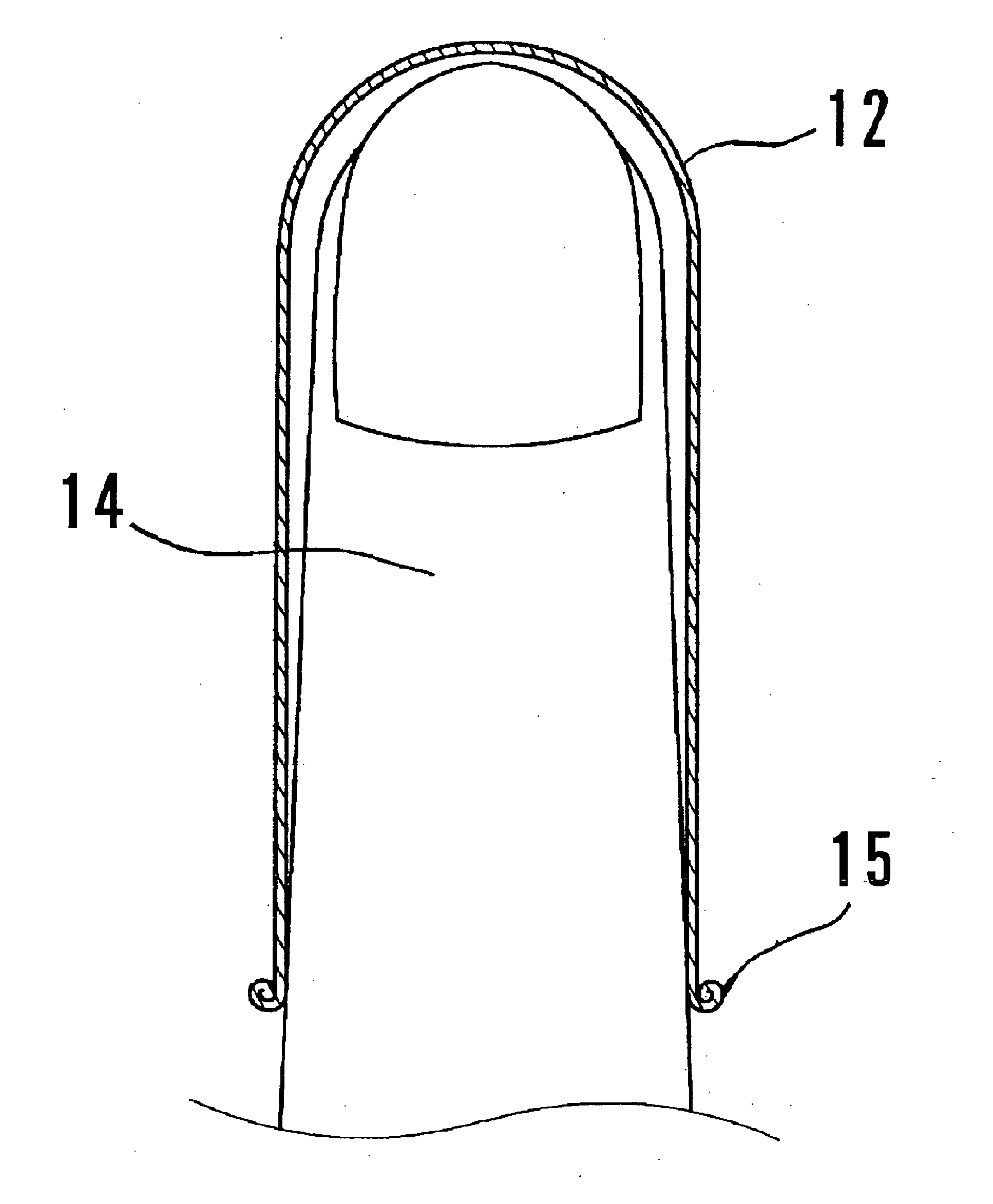

Thin-walled natural rubber latex material substantially free of sulfur and nitrosamines

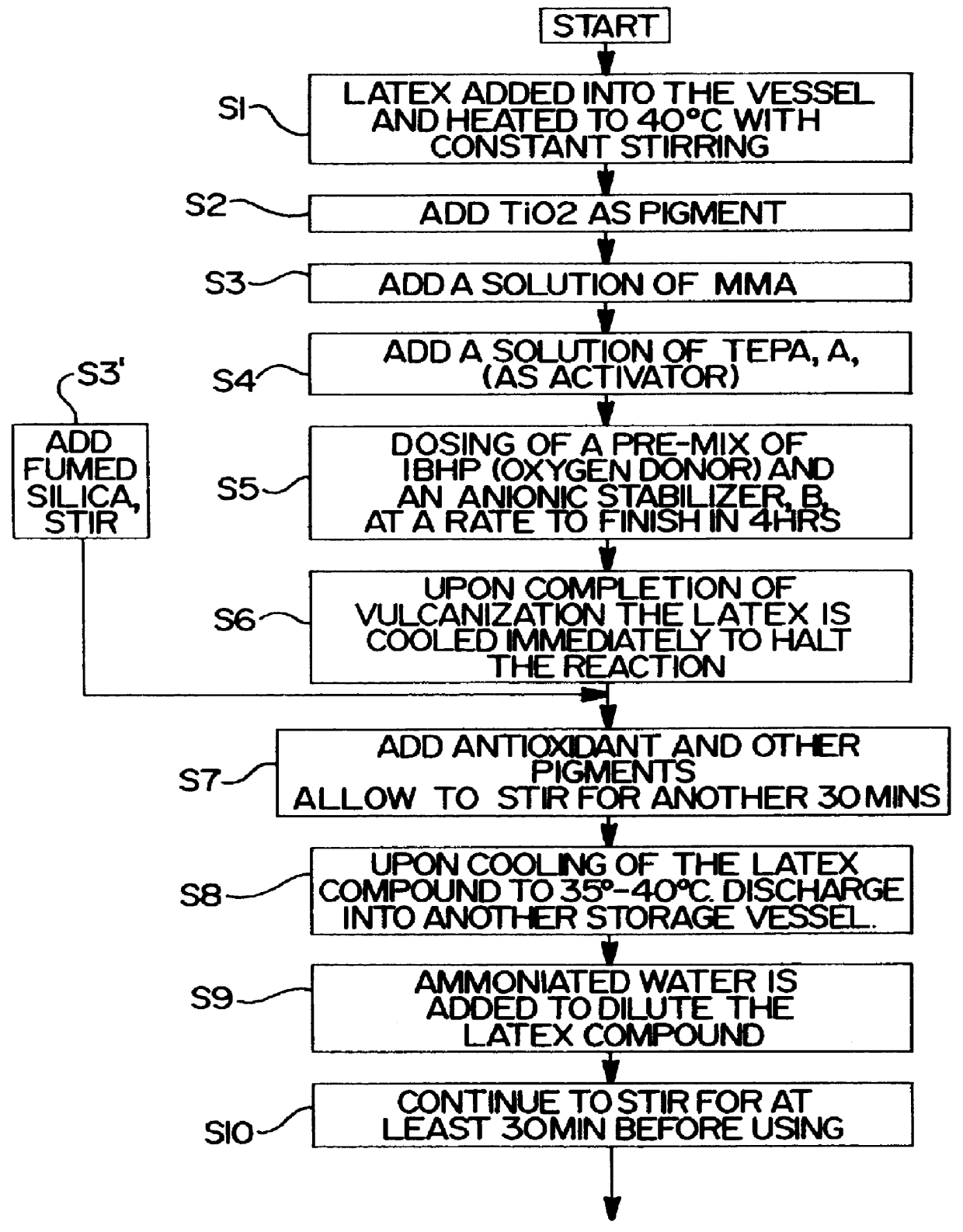

InactiveUS6051320AEfficient processingEasy to useLayered productsGlovesMicrocrystalline waxGas phase

A thin walled natural rubber latex material is disclosed suitable for forming thin walled products including gloves, dental dams and shields, catheter tubing, penrose surgical drains, finger cots, coverings for body parts, and the like. The thin walled material is formed from a latex emulsion containing natural rubber, sulphur-free, oxygen-donating curing agents, and a strength enhancing agent which may be an inorganic substance such as fumed silica and / or an organic substance such as monomers and polymers of families of acrylics and esters. The emulsion also preferably includes microcrystaline wax as an oxygen barrier, and the material is also provided with a heat resistant and water resistant coating which blocks transfer of latex proteins from the material and enhances slip of the material.

Owner:HAU HO TEON +1

Nitrile rubber article having natural rubber characteristics

ActiveUS20060253956A1Maximize material strengthMinimization requirementsCosmetic preparationsBiocidePolymer scienceCarbamate

An improved process and material for making elastomeric nitrile rubber articles is disclosed. In particular, the process and material formulation can produce nitrile rubber based articles, which exhibit force-strain characteristics that are comparable to those of natural rubber latex articles, while maintaining the tensile strength properties of nitrile rubber. The process includes an accelerator composition at the pre-cure stage having a dithiocarbamate, a thiazole, and a guanidine compound. The invention also includes an elastomeric nitrile rubber product made by the process, such as examination, surgical, or work gloves.

Owner:O&M HALYARD INC

Preparation process of oil extended rubber for tire, oil extended rubber for tire, and rubber composition and tire using the same

InactiveUS8044118B2High strengthReduce supplySynthetic resin layered productsSpecial tyresVegetable oilPetroleum

The present invention provides a process for preparing an oil extended rubber, in which an effect on environments can be taken into consideration, provision for the future decrease of petroleum supply can be satisfied, and further, strength is excellent without molecular breakage, an oil extended rubber obtained by the preparation process, and a tire using the oil extended rubber. A process for preparing an oil extended rubber, comprising (a) a step of preparing an oil-in-water type emulsion by emulsifying a vegetable oil having an iodine value of not less than 135 with a surfactant, (b) a step of mixing said emulsion and a modified natural rubber latex, and then aging the mixture, and (c) a step of coagulating the mixture obtained in the step (b) to obtain a lump of a rubber, an oil extended rubber obtained by the preparation process, and a rubber composition for a tire and a tire which use the oil extended rubber.

Owner:SUMITOMO RUBBER IND LTD

Cationic deproteinized natural rubber latex, method of preparing the same, and treating agent used in the method

Disclosed are a cationic deproteinized natural rubber latex, in which rubber particles are positively charged and the concentration of said rubber particles is from 40 to 65% by weight and that the viscosity at 25.degree. C. of said latex is 200 mPa.multidot.s or less, a method of preparing said latex which comprises subjecting to a deprotenization treatment using a proteolytic enzyme and a deproteinizing agent made of one or more surfactant selected from cationic and nonionic surfactants, and optionally adding a post additive comprising a cationic or nonionic surfactant as an active component, thereby to enable both surfactants described above to coexist, and a treating agent used in the same.

Owner:SUMITOMO RUBBER IND LTD +1

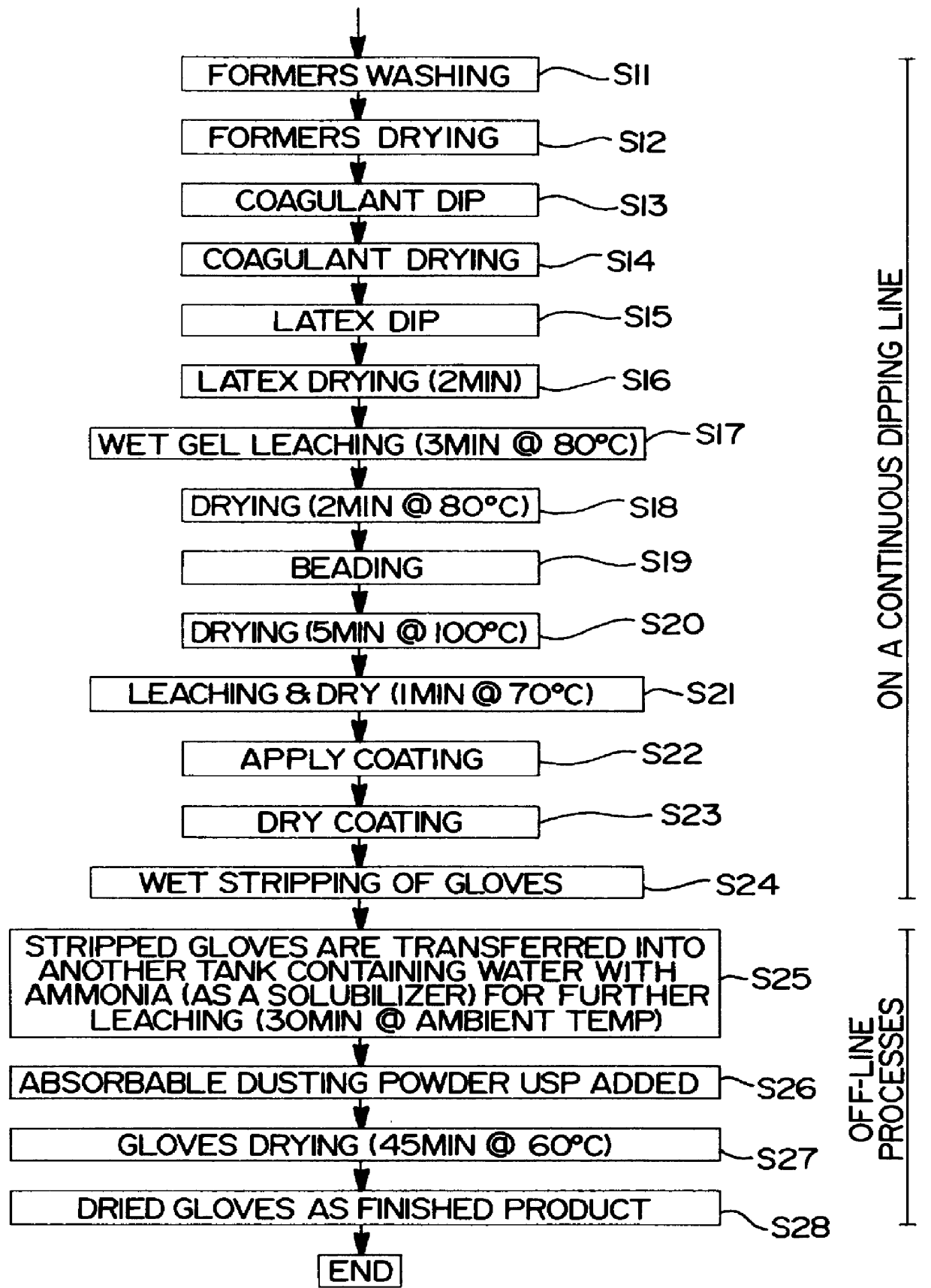

Elastomeric rubber and rubber products without the use of vulcanizing accelerators and sulfur

A composition for producing an elastomeric thin film comprising a carboxylated acrylonitrile polybutadiene latex which is vulcanized without the use of conventional sulphur and accelerators thereby reducing the possibility of contacting immediate Type I hypersensitivity and delay Type IV hypersensitivity caused by the presence of natural rubber latex proteins and accelerators respectively. The dipping process for making gloves by using a latex composition provided by: premixing carboxylated acrylonitrile polybutadiene latex with methacrylic acid, or alternatively using a self-crosslinked latex, adding zinc oxide, adjusted to 9 to 10 of the pH level, and diluted with water to obtain 18% to 30% by weight of total solid content; dipping the glove former into the composition to form a layer of thin film of the latex composition on the former; drying the thin latex film on the former and crosslinking the latex film on the former.

Owner:KOSSAN +1

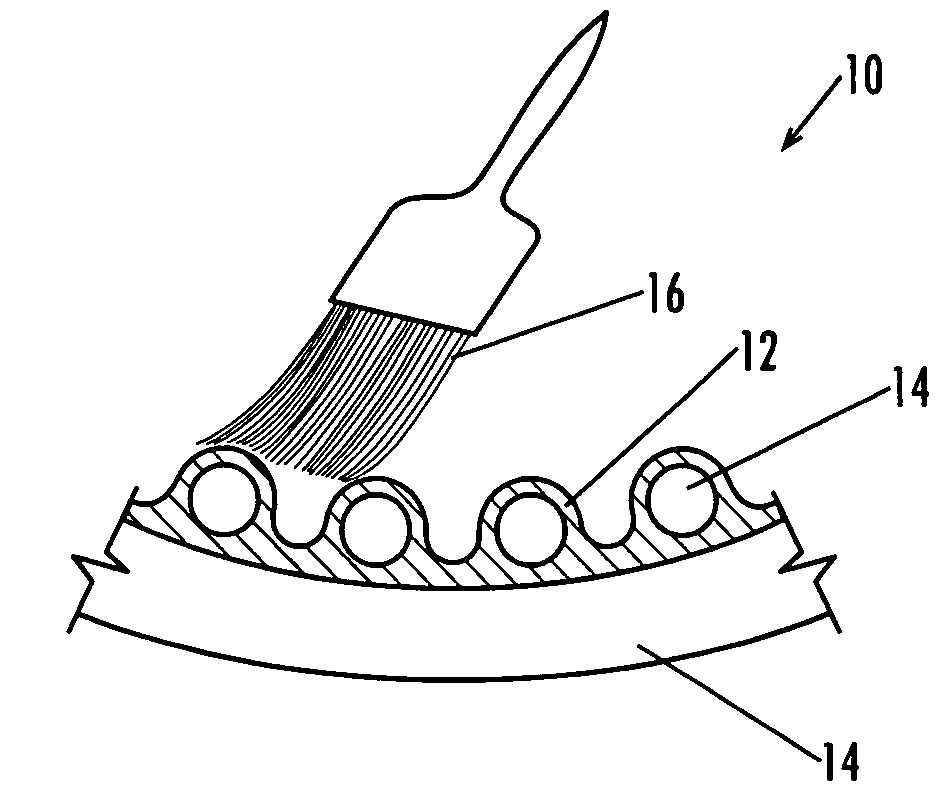

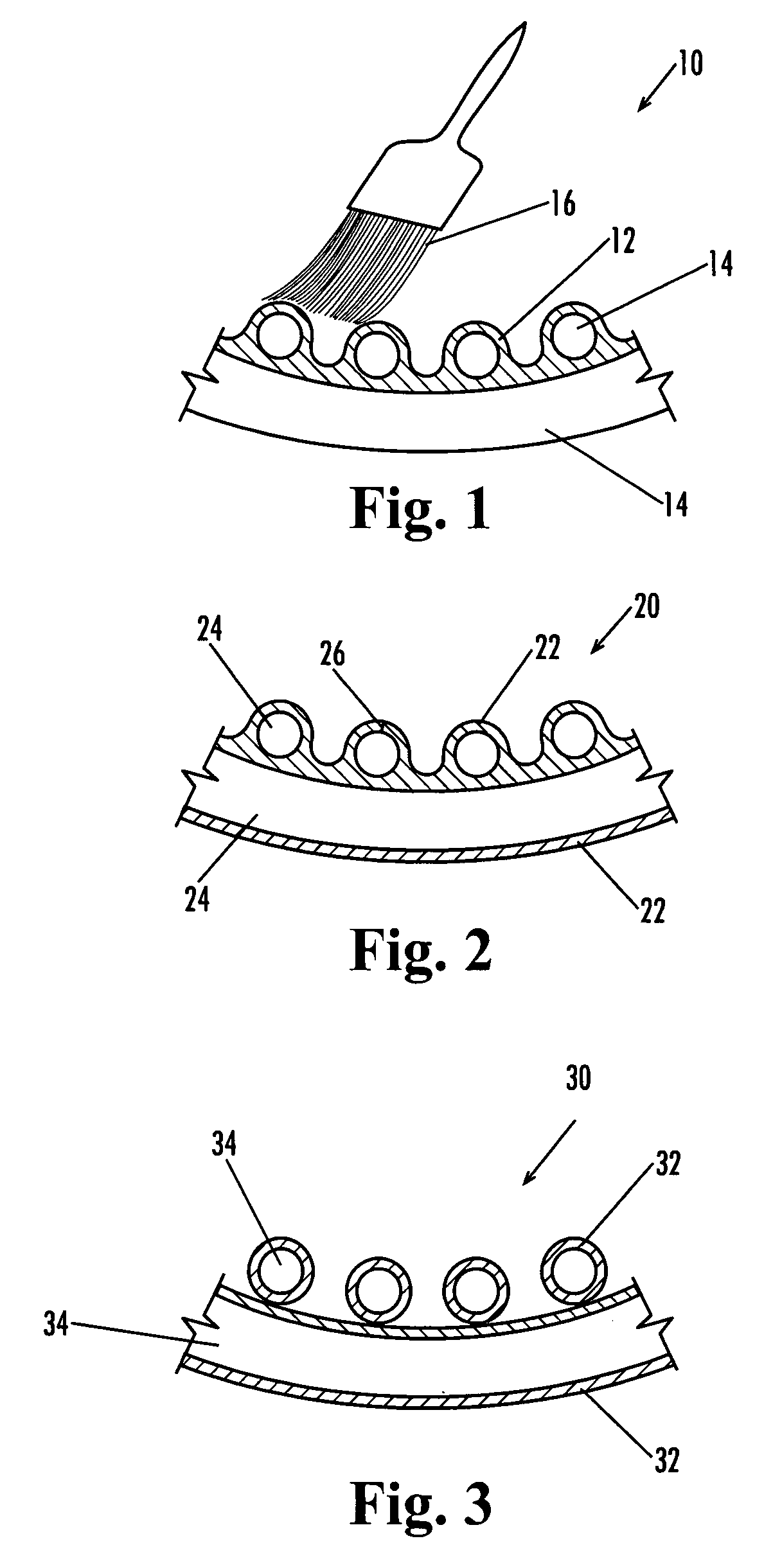

Lacrosse net

InactiveUS20080146385A1Improve adhesionImprove integrityThrow gamesCoatingsElastomerThermoplastic elastomer

A modified form of a lacrosse net provides increased adherence, integrity, and “give” as a result of a coating applied to the fibers. In one form, the fibers are manually coated by brushing them with a natural latex mixture followed by evaporation of the volatile components, which gives the coated fibers a tacky and energy absorbent nature. The soft nature of the coating may also aid in dissipating energy during impact with the ball, and this could contribute to the sense of increased “feel.” There are many natural and synthetic polymers that might be capable of delivering similar benefits, including conventional synthetic elastomers, e.g., butyl rubber. Thermoplastic elastomers are a growing field of interest in coating technologies, and with the appropriate tuning, they can be made with all of the same properties as the natural rubber coating. A brush-on method delivers the desired coating thickness and properties, but other methods, such as dip coating and spray coating, may increase feasibility for scaling-up the process. In one arrangement, the entire fiber is composed of a rubbery material. The resulting properties may not be exactly what is desired, however, because the underlying integrity of the nylon fiber would be absent, and this might result in netting with a “springy” feel.

Owner:LUNDBERG STEPHEN F

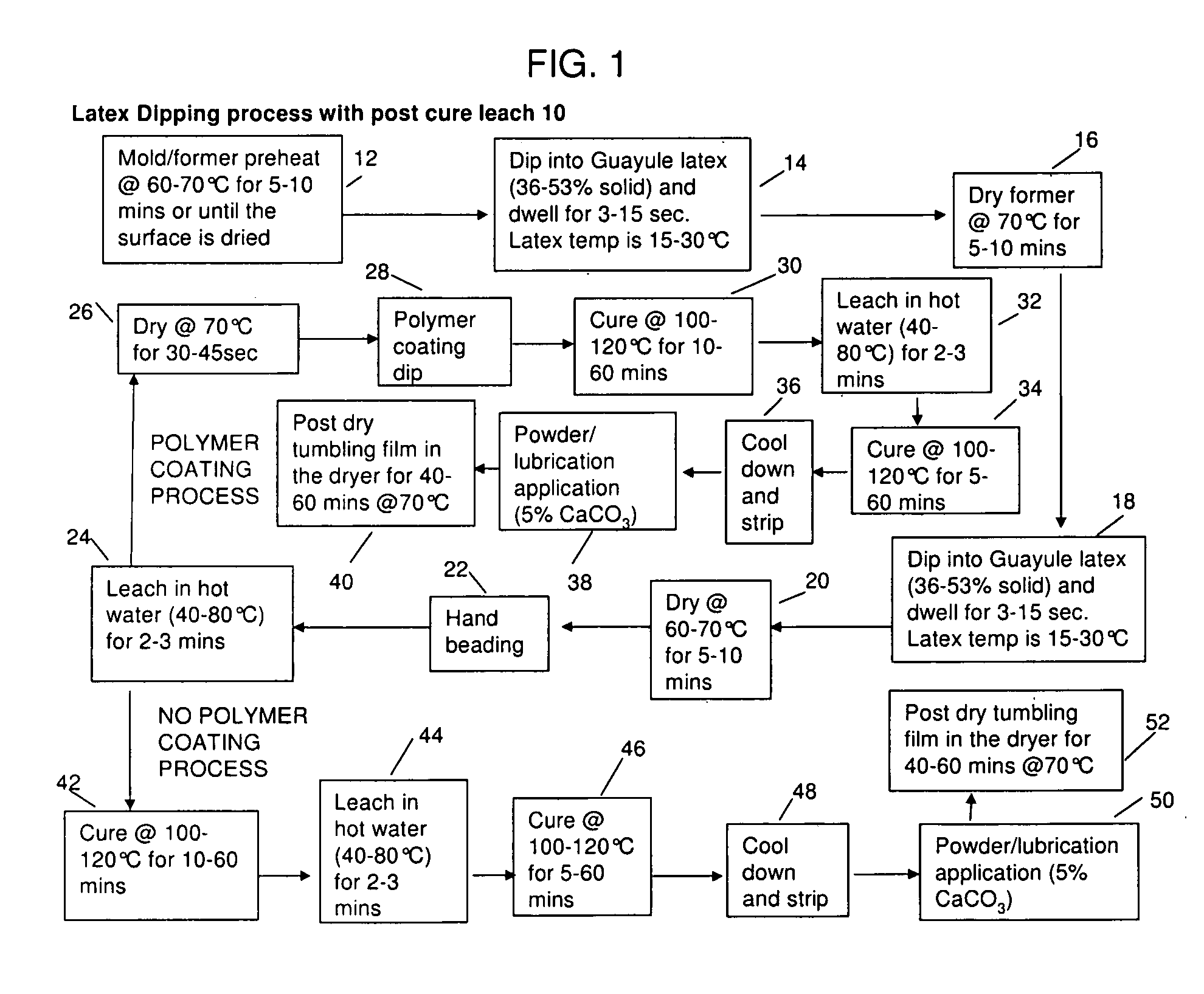

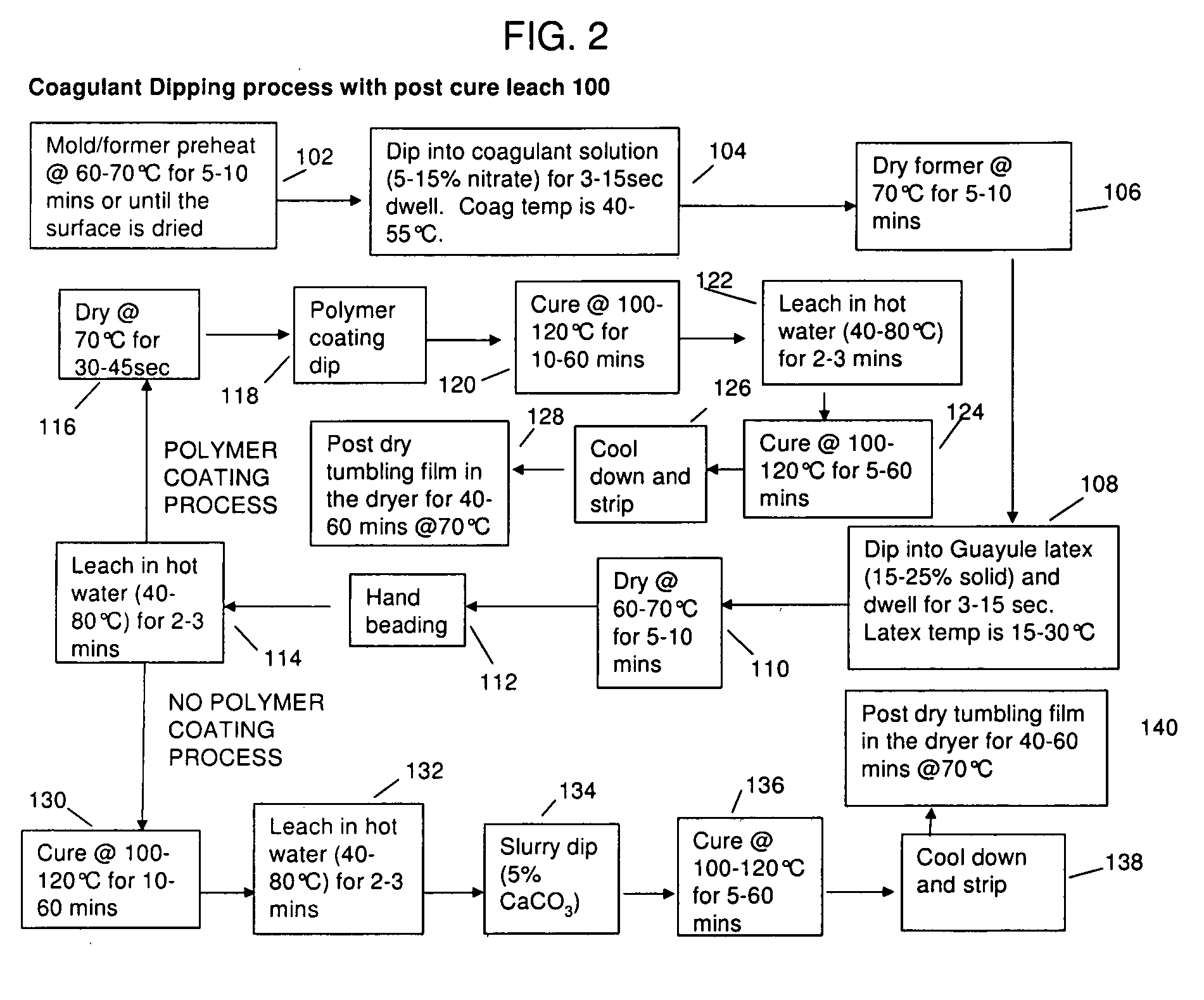

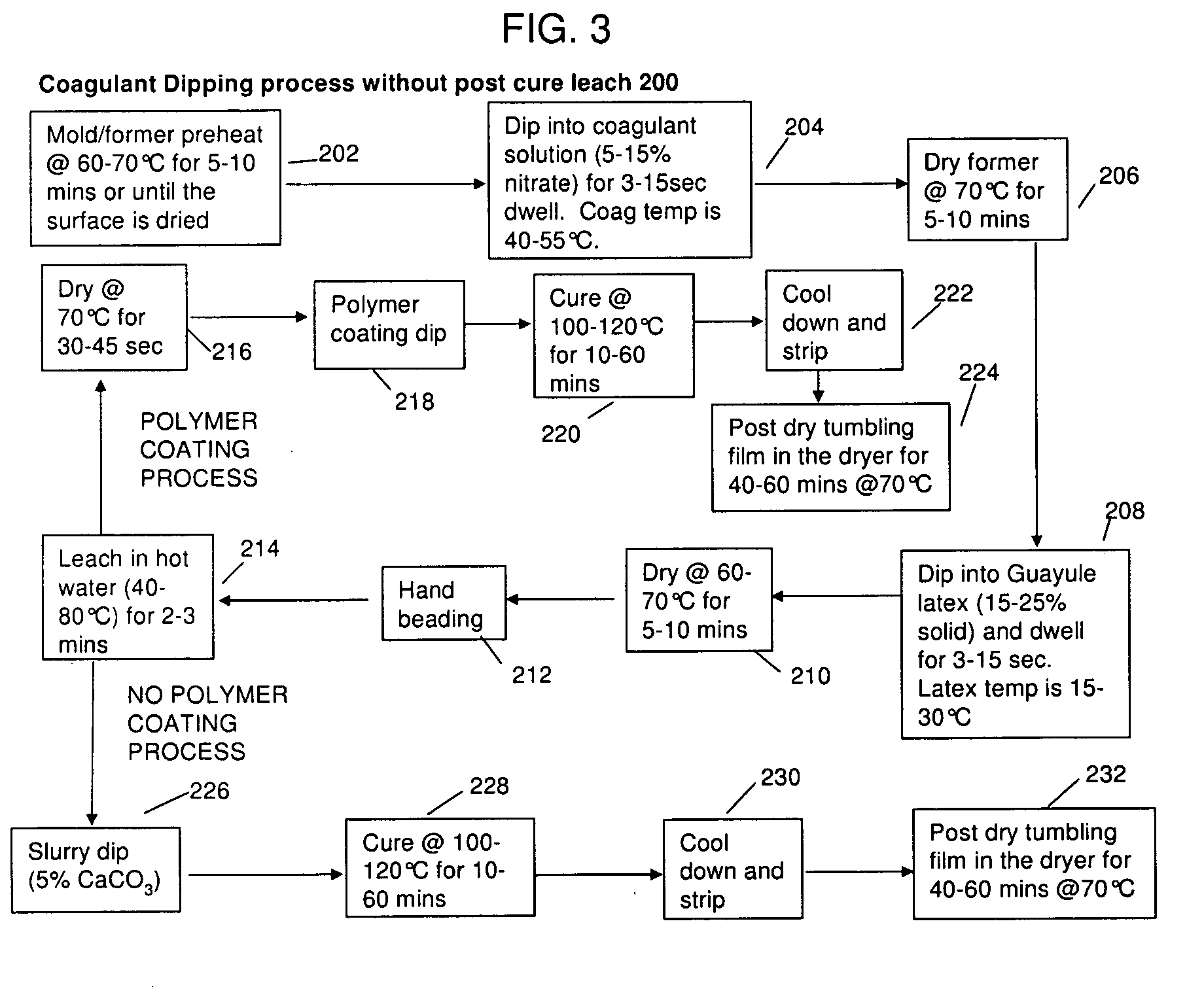

Guayule natural rubber latex thin film articles

The present disclosure provides for a formula and process for making elastomeric rubber thin film articles. In particular, the formula and process is a system which produces non-Hevea or Guayule natural rubber latex (GNRL) thin film articles which have a thickness of 30-80 microns (0.03-0.08 mm), and preferably less than 40 microns (0.04 mm). These thin film articles exhibit physical strength properties similar to that of Hevea brazilensis natural rubber latex (NRL). More specifically, the disclosed thin rubber thin film articles exhibit unaged tensile strength of at least 24 MPa (about 3500 psi) and aged tensile strength of at least 19 MPa (about 2800 psi).

Owner:YULEX LLC

Composite leather material

InactiveUS20070184742A1Improve propertiesHigh strengthDomestic upholsteryLeather websNatural rubber latexCalcium carbonate

Engineered leather substrates, methods of making the substrates, engineered leather composites including the substrates, and articles of manufacture which include the engineered leather substrates or composites are disclosed. The substrate includes leather, non-leather fibers, a binding agent and one or more additional components such as cushioning agents, softeners, processing aids, and colorants. A composite material can be formed including the substrate and one or more additional layers, such as top coat layers, reinforcing layers, and cushioning layers. The substrate and or the composite can be chemically or mechanically embossed. The leather used to form the engineered leather substrate can be derived from post-industrial and / or post-consumer materials. The non-leather fibers can be organic or inorganic, and the composition can also include inorganic fillers, such as calcium carbonate, and clays. The cushioning agents can include polymeric microbubbles, foam, rubber particles, and other low density cushioning agents. The binding agents can be synthetic or natural, such as synthetic latex, natural latex, PVA, and starch.

Owner:MALLARD CREEK POLYMERS

Modified natural rubber or modified natural rubber latex, and rubber composition and pneumatic tire

ActiveUS20070010610A1Improve frost resistanceMaintain physical propertiesSpecial tyresPolymer scienceSilicon dioxide

There are provided a modified natural rubber made from a modified natural rubber latex, in which a polar group-containing monomer is graft-polymerized to natural rubber latex, and a rubber composition comprising such a modified natural rubber and carbon black and / or silica. Also, there are provided a modified natural rubber latex in which a tin-containing monomer or an alkoxysilyl group-containing monomer is graft-polymerized to natural rubber latex and a modified natural rubber made therefrom and a rubber composition comprising such a modified natural rubber.

Owner:BRIDGESTONE CORP

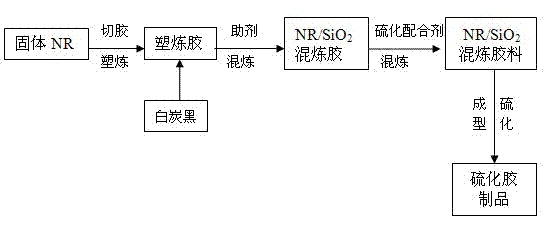

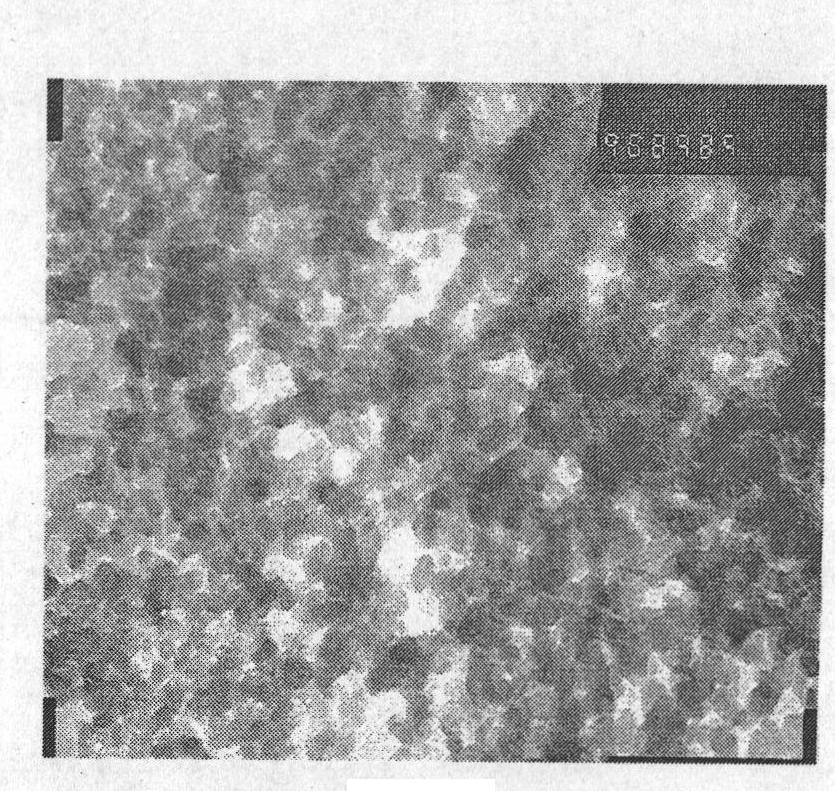

Wet smelting method for preparing natural rubber/nanometer silicon dioxide rubber compound

ActiveCN102775618AGrowth inhibitionImprove adsorption capacityRolling resistance optimizationRolling resistanceEmulsion

The invention discloses a wet smelting method for preparing a natural rubber / nanometer silicon dioxide rubber compound, which comprises the following steps of: mixing natural rubber latex with silicon sol solution to form a wet smelting system; heating the silica sol to generate condensation reaction to generate the SiO2 gel with properties, heating the wet smelting system to generate the silica sol into nanometer silicon dioxide particles in situ and uniformly dispersing the nanometer silicon dioxide particles into NR (Natural Rubber) emulsion to form the NR / nanometer silicon dioxide rubber compound after condensation and co-precipitation; and mixing the natural rubber latex with a nanometer silicon dioxide dispersing body to form the NR / nanometer silicon dioxide rubber compound after condensation and co-precipitation. The wet smelting method has the beneficial effects that the mass ratio of natural rubber / nanometer silicon dioxide prepared by the wet smelting method is 100 / 30-90, and vulcanized rubber of the nanometer silicon dioxide has excellent physical and mechanical properties and is high-quality rubber for preparing truck radial tire tread rubber with high wet skid resistance and low rolling resistance, i.e. green tire.

Owner:SOUTH CHINA UNIV OF TECH

Method for producing a natural rubber master batch and a synthetic isoprene rubber master batch using biodegraded powder, a method for producing a natural rubber master batch and a synthetic isoprene rubber master batch using rubber powder and a filling agent and a method for producing a natural rubber master batch and a synthetic isoprene rubber master batch using biodegraded rubber powder and a filling agent

InactiveUS20070173567A1High physical propertyReduce energy costsSpecial tyresEmulsion paintsPolymer scienceCombined method

The present invention makes it possible (1) to produce a natural rubber wet master batch and / or a synthetic isoprene rubber wet master batch by mixing a slurry solution of biodegraded rubber powder dispersed in water with a natural rubber latex solution and / or a synthetic isoprene rubber latex solution. Further, the present invention makes it possible (2) to produce a natural rubber wet master batch and / or a synthetic isoprene rubber wet master batch by mixing a slurry solution of dispersed carbon black and / or silica and rubber powder with a natural rubber latex solution and / or a synthetic isoprene rubber latex solution. A rubber composition having high physical properties can be obtained by adding a natural rubber master batch and / or a synthetic isoprene rubber master batch obtained by drying the natural rubber wet master batch and / or the synthetic isoprene rubber wet master batch. Further, the rubber composition containing the wet master batch obtained by the method in combination of above (1) and (2) also exhibits high physical properties.

Owner:BRIDGESTONE CORP

Preparation method of epoxidized natural rubber masterbatch with highly dispersed nano-silicon dioxide/carbon black

The invention discloses a preparation method of an epoxidized natural rubber masterbatch with highly dispersed nano-silicon dioxide / carbon black, which comprises the following steps: performing ultrasonic dispersion on nano-silicon dioxide modified by a silane coupling agent and carbon block after liquid phase oxidation by an oxidant by using deionized water, then adding the nano-silicon dioxide into epoxidized natural rubber latex, stirring, finally performing steam solidification or solidification by a solidifying agent, drying, and getting the epoxidized natural rubber masterbatch with the highly dispersed nano-silicon dioxide / carbon black. Compared with the mechanical properties of the masterbatch prepared by adding the same parts of the nano-silicon dioxide / carbon black powder, the mechanical properties of the masterbatch are as follows: the 100% modulus is improved from 2.3MPa to 3.1-3.4MPa, the 300% modulus is improved from 9.2MPa to 10.1-11.6MPa, the tensile strength is improved from 31.2MPa to 33.5-36.8 MPa, the elongation at break is improved from 625% to 647%-688%, and the tearing strength is improved from 48.3N / mm to 53.8-58.3N / mm; furthermore, the process is simple, and the large-scale production is easy.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

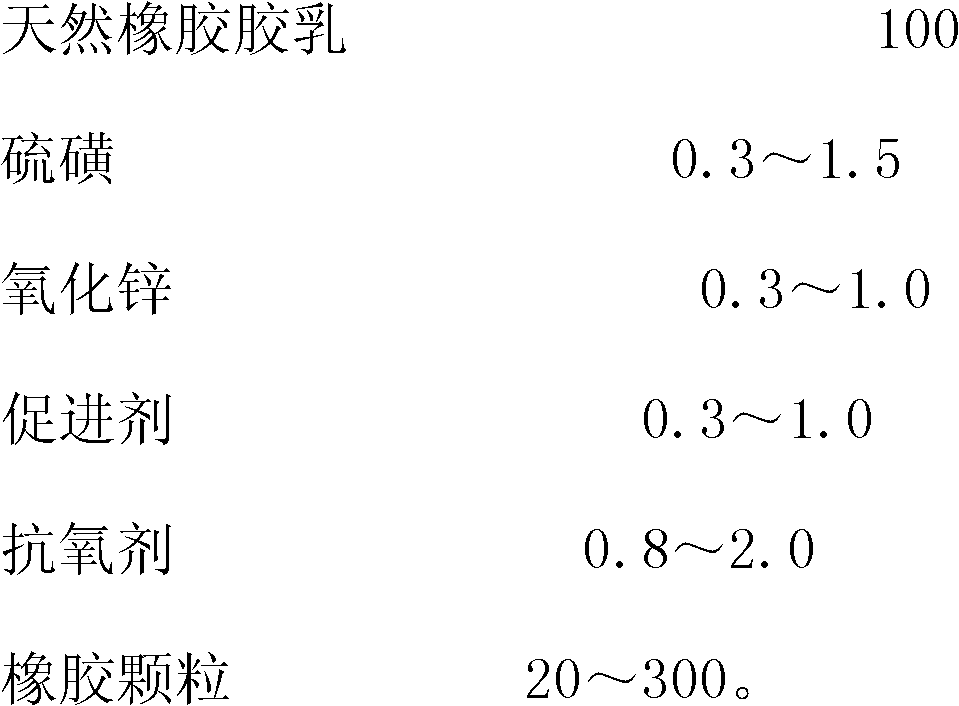

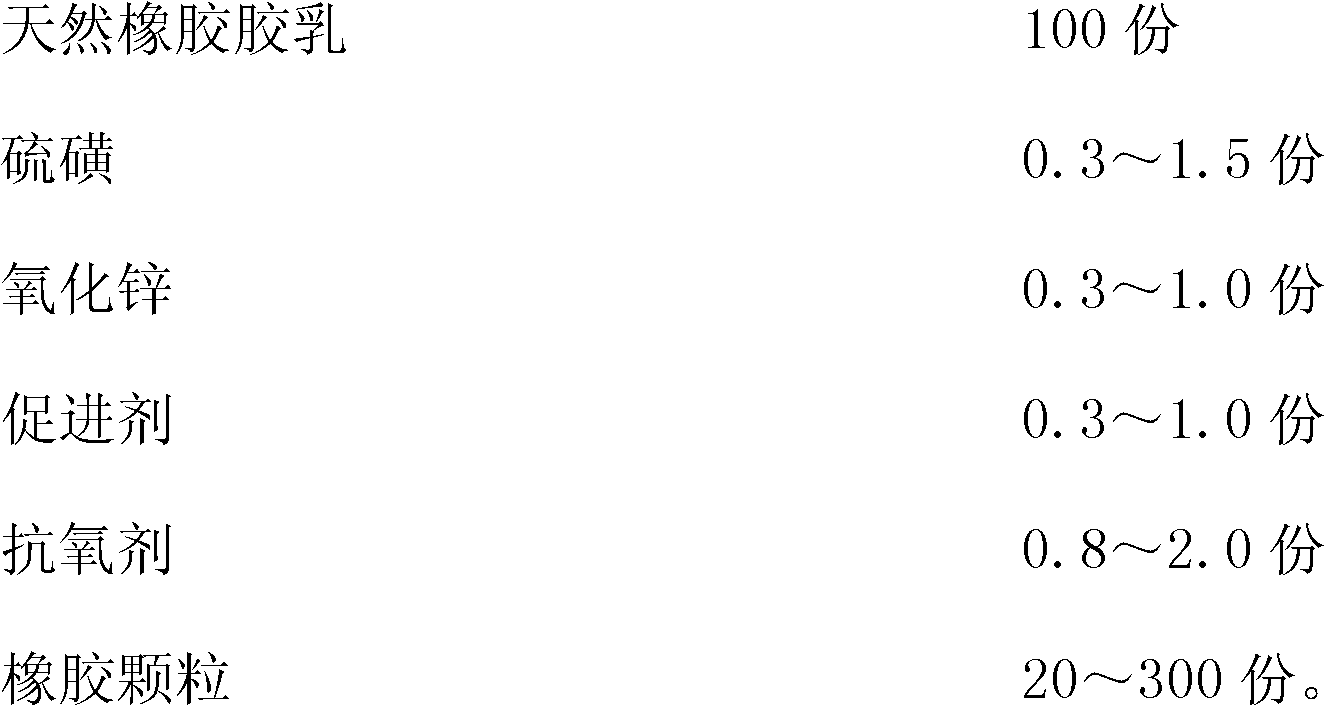

Antiskid rubber gloves and processing method thereof

InactiveCN102488340AIncrease coefficient of frictionImprove grip performanceCoatingsProtective garmentPolymer scienceSulfur

The invention discloses a pair of antiskid rubber gloves and a processing method thereof. Each antiskid rubber glove comprises rubber latex forming a glove body and antiskid rubber latex forming an antiskid layer, wherein the antiskid rubber latex consists of natural rubber latex, sulfur, zinc oxide, an accelerator, an antioxidant and rubber particles. According to the antiskid rubber gloves disclosed by the invention, rubber particles are arranged on the outer surfaces of the gloves in a processing course of the gloves so as to increase the friction coefficient of the gloves, enhance the catching power of the gloves and largely improve the antiskid effect of the gloves; in addition, the gloves have no special requirement on production moulds and equipment and only the traditional production mould is needed in a production process, therefore the production input is low and the production cost of enterprises can be reduced greatly. The gloves processed with the processing method disclosed by the invention have the advantages of good antiskid effect, capability of solving the problem that defective holes possibly appear on the gloves caused by mould bumps in the production process and high yield; and the processing method disclosed by the invention has the advantage of simple operation.

Owner:ZHENJIANG SUHUI LATEX PROD

Process for preparing a pressure-sensitive self-adhesive composition wherein tackifiers in dispersed, melted or solid form are mixed with natural rubber latex

Process for preparing a pressure-sensitive adhesive composition, characterized in that tackifiers in dispersed, melted or solid form are mixed with natural rubber latex, the water content being not more than 45% by weight.

Owner:TESA SE

Meteorologic balloon and production method thereof

ActiveCN101526630AImprove anti-aging performanceImprove overall machining performanceInstrumentsPotassium hydroxideCasein

The invention relates to a meteorological balloon and a production method thereof. The meteorological balloon has the quality of 700g to 800g, the length of a balloon body is 205 cm to 255 cm, and a balloon handle has a width of 9 cm to 10 cm and a length of 10 cm to 14 cm. The meteorological balloon comprises a solid raw material, an oil raw material and a colloid raw material, wherein the solid raw material comprises the ingredients by weight ratio: 100 parts of centrifugal concentrated natural latex, 0 part to 0.30 part of potassium hydroxide, 0 part to 0.15 part of casein, 0 part to 0.10 part of leveling agent O, 1.00 part to 3 parts of sulfur, 1.00 part to 2 parts of antioxidant D, 1.00 part to 2 parts of 4010NA, 1.50 part to 3 parts of rubber accelerator PX and 0.20 parts to 5 parts of zinc oxide; the oil raw material comprises 7.00 parts to 10.0 parts of mechanical oil by weight ratio; and the colloid raw material comprises neoprene latex which is added by the mixed weight ratio of the mixture of the solid raw material and the oil raw material to the neoprene latex, namely 1 to 10. The neoprene latex is added in a raw material formulation so as to improve the anti-aging performance and the whole processing performance of the meteorological balloon, ensure the streamlined appearance of the meteorological balloon, improve the evenness degree of a balloon surface and enable the balloon surface to swell evenly in the discharge process.

Owner:CHEMCHINA ZHUZHOU RUBBER RES & DESIGN INST

Rubber composition

InactiveCN101107296AImprove resistance to damageImprove crack growth resistanceMasterbatchPolymer science

A natural rubber wet masterbatch rubber composition comprising a mixture of a natural rubber latex with a slurry solution containing a carbon black dispersed therein, which satisfies the followings: (1) a CATB specific surface area (m<2> / g) in the range of 60 < CTAB < 110, (2) a 24M4DBP (m<3> / 100g) in the range of 55 < 24M4DBP < 75, (3) a CATB specific surface area and a tint strength (TINT) having the relationship of TINT > 0.41 x CTAB + 81, and (4) a compounding amount of 10 to 100 parts by mass relative to 100 parts by mass of natural rubber. The natural rubber wet masterbatch rubber composition can be suitably used for improving the resistance to fracture and to crack propagation of a tire, a steel coating rubber for a rubber product for industrial use, and the like.

Owner:BRIDGESTONE CORP

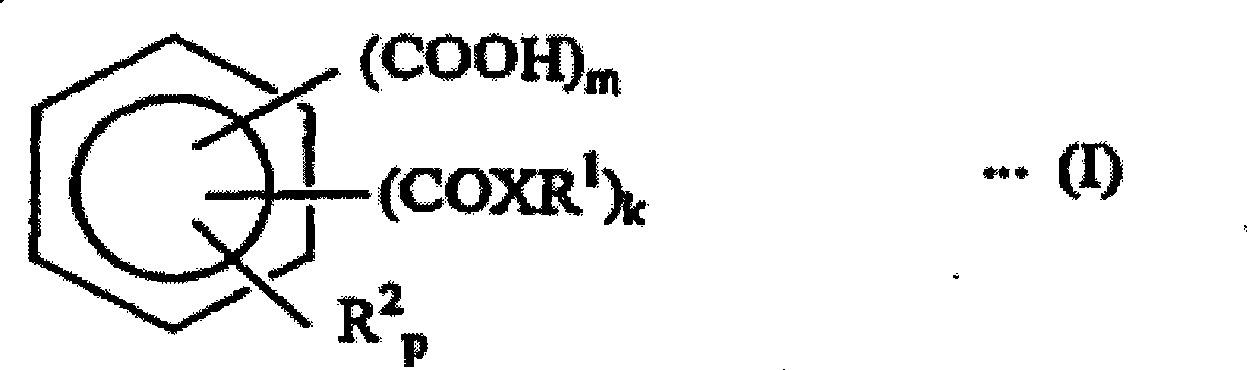

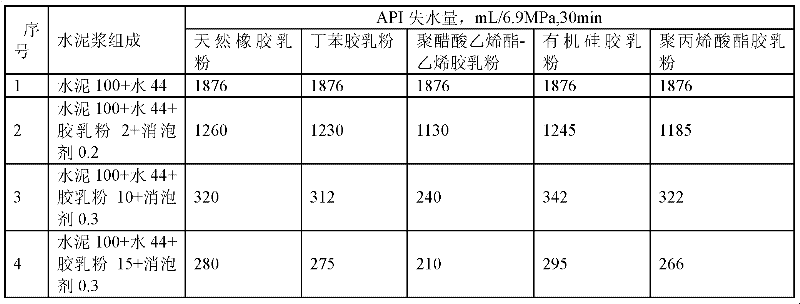

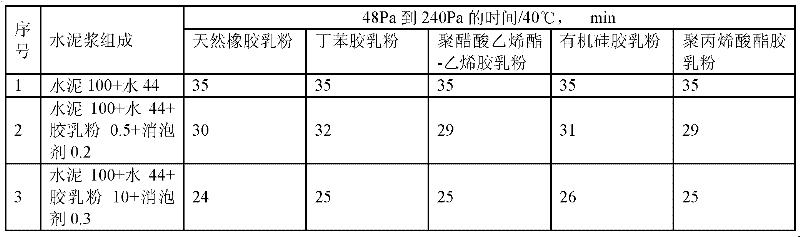

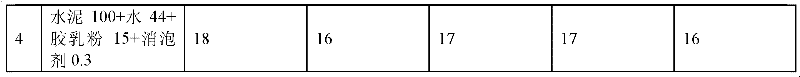

Novel cement paste for well cementation

InactiveCN102250596AExcellent mechanical propertiesIncreased durabilityDrilling compositionCarvacryl acetateMechanical property

The invention relates to novel cement paste for well cementation. The novel cement paste for well cementation is made from the following components of: by weight, 100 parts of hydraulic cement, 44 parts of water, 0.5-30 parts of a reversible latex powder and 0.2-0.5 parts of an antifoaming agent, wherein the reversible latex powder is prepared by spray drying of one component which can be selected from the group consisting of a natural rubber latex, SBR latex, a vinyl acetate-ethene emulsion, an organosilicon emulsion and a polyacrylate emulsion. The cement paste provided by the invention has excellent properties of controlling dehydration, preventing fluid channeling, improving mechanical properties of cement stone to prolong the endurance of the cement stone, reducing the permeability of the cement stone and raising the corrosion resistance of the cement stone. The above properties of the cement paste enable the cement paste to be applied in a plurality of cementing operations. The cement paste can be used to effectively improve the cementing job quality and raise the service life of the cement stone, and has an extensive application prospect.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

Meteorologic balloon and production method thereof

ActiveCN101592742AThere will be no problem of uneven distributionAgainst destructive powerInstrumentsPotassium hydroxideDioctyl sebacate

The invention discloses a meteorologic balloon and a production method thereof. The raw materials consist of a solid raw material, an oily raw material and a gluey raw material; the solid raw material comprises the following components by weight: 0 to 0.30 portion of potassium hydroxide, 0 to 0.15 portion of casein, 0 to 0.10 portion of peregal O, 1.00 to 3 portions of sulfur, 1.00 to 2 portions of N-phenyl-2-naphthylamine, 1.00 to 2 portions of N-phenyl-N'-isopropyl-ursol, 1.50 to 3 portions of ethyl-phenyl-zinc dithiocarbamate, 0.20 to 5 portions of zinc oxide, and 5 to 30 portions of chloroprene polymer; the oily raw material is dioctyl sebacate, and the weight rate of the dioctyl sebacate is 5.00 to 10.0 portions; and the gluey raw material is centrifugally-concentrated natural latex, and the adding amount of the centrifugal concentrated natural latex is 100 portions. The weight of the meteorologic balloon is 1,600 to 1,700 grams, the length of the balloon body is 3.05 to 3.55 meters, the width of the ball handle is 10 to 11 centimeters, and the length of the ball handle is 12 to 16 centimeters. The meteorologic balloon can adapt to the requirement of probing high-altitude meteorological elements of more than 35,000 meters, has the advantages of good aging resistance, high blastoff height, long balloon service time and the like, and can effectively overcome the morning-evening difference.

Owner:CHEMCHINA ZHUZHOU RUBBER RES & DESIGN INST

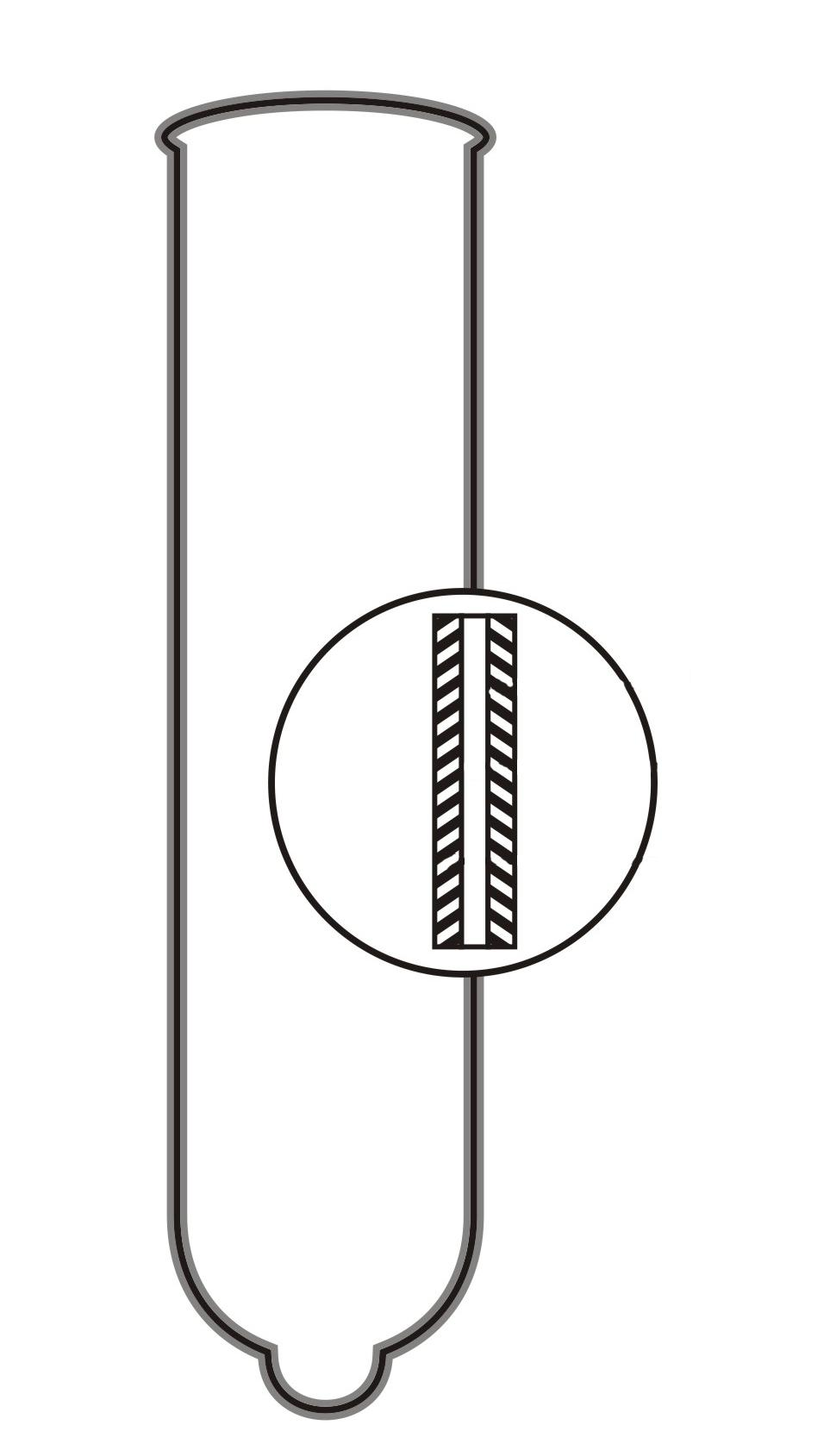

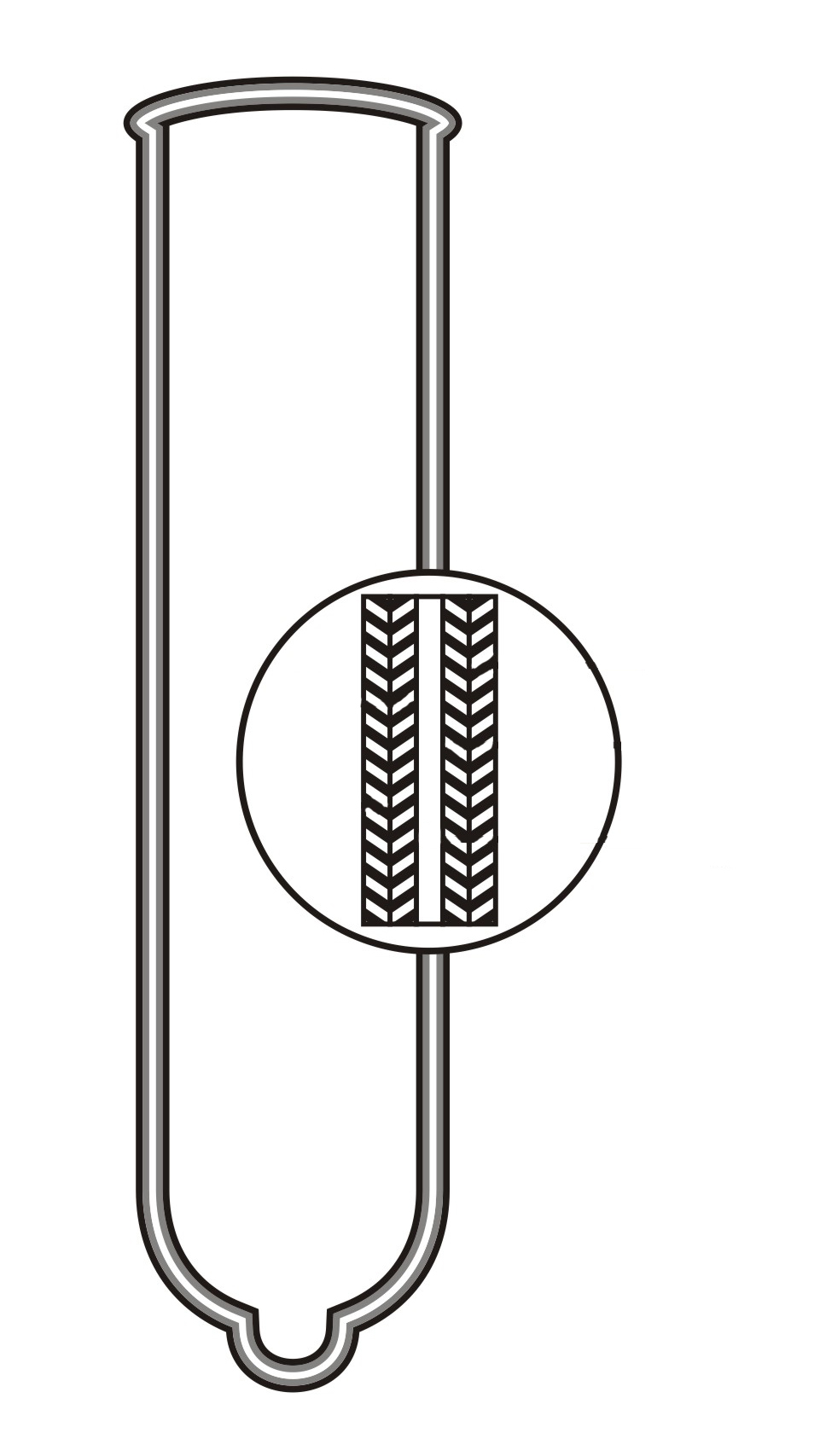

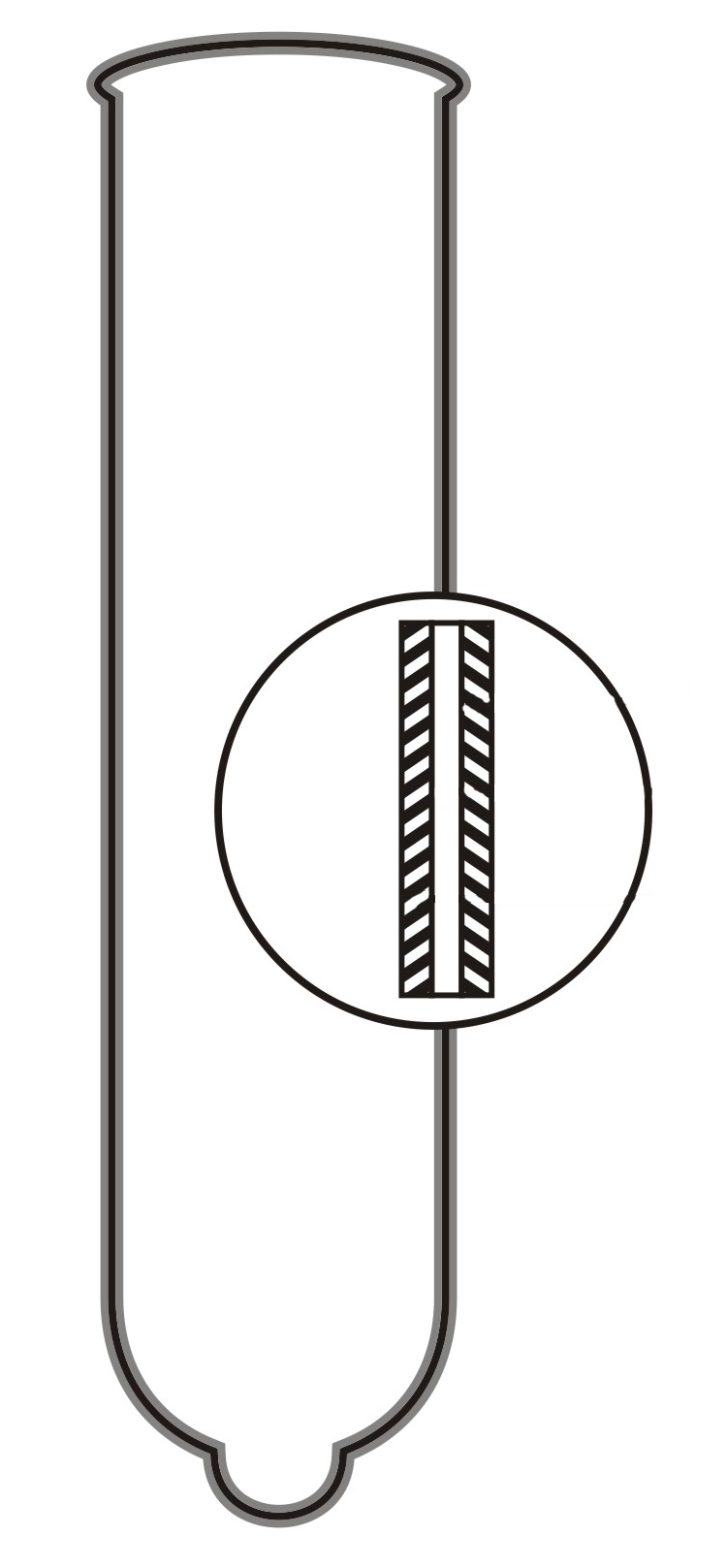

Double-layer sandwich or multi-layer sandwich multi-latex condom and preparation method thereof

ActiveCN101961279APermeation barrierImprove compactnessContraceptive devicesPolymer scienceStretch rate

The invention provides a double-layer sandwich or multi-layer sandwich multi-latex condom and a preparation method thereof. The preparation method of the condom comprises the following steps: vulcanizing natural latex; emulsifying and dispersing polymer materials such as polyurethane or polyisoprene or butyronitrile or other non-natural latex and making the polymer materials into synthetic latex; and dipping a condom die in the natural latex and the synthetic latex respectively and then drying to finally obtain the double-layer sandwich or multi-layer sandwich multi-latex condom the middle layer of which is made from the natural latex or the synthetic latex, wherein, the innermost layer and the outermost layer of the condom can be made from the same material or different materials. The double-layer sandwich or multi-layer sandwich multi-latex condom of the invention has stretch rate and comfortability of the natural latex as well as high compactness of the synthetic latex, thus being applicable to obstructing penetration of small molecules such as hepatitis, AIDS virus and the like.

Owner:桂林恒保健康防护有限公司

Environmental-friendly ventilation type composite natural emulsion product as well as preparation method and application thereof

ActiveCN104987551AImprove toughnessImprove wear resistanceInsolesBrassieresPotassium hydroxideOleic Acid Triglyceride

The invention relates to an environmental-friendly ventilation type composite natural emulsion product as well as a preparation method and application thereof, and belongs to the technical field of emulsion products. The environmental-friendly ventilation type composite natural emulsion product is prepared from the following raw materials in parts by weight: 190-210 parts of natural emulsion, 20-24 parts of sulphur, 11-13 parts of an oxidizer, 1-1.7 parts of a dispersing agent, 95-105 parts of an accelerant, 36-39 parts of a hardener, 2-3 parts of castor oil, 5-7 parts of oleic acid, 1.6-2.4 parts of potassium hydroxide, 14-16 parts of styrene-butadiene co-polymerized rubber emulsion and 130-142 parts of water. The environmental-friendly ventilation type composite natural emulsion product disclosed by the invention not only has favorable ventilation perspiration properties and favorable bacterial inhibition, but also has excellent toughness, excellent wear resistance and favorable density and hardness, so that emulsion products are soft and comfortable, are favorable in hand feel, can effectively protect skins and are environmental-friendly and healthy.

Owner:晋江金飞鞋材有限公司

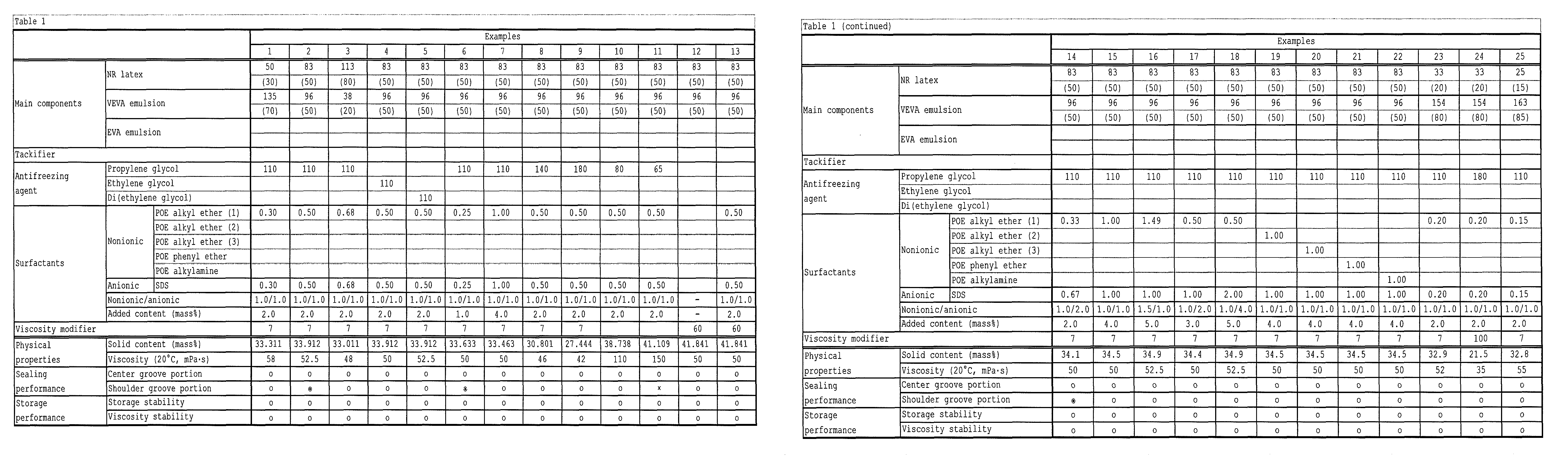

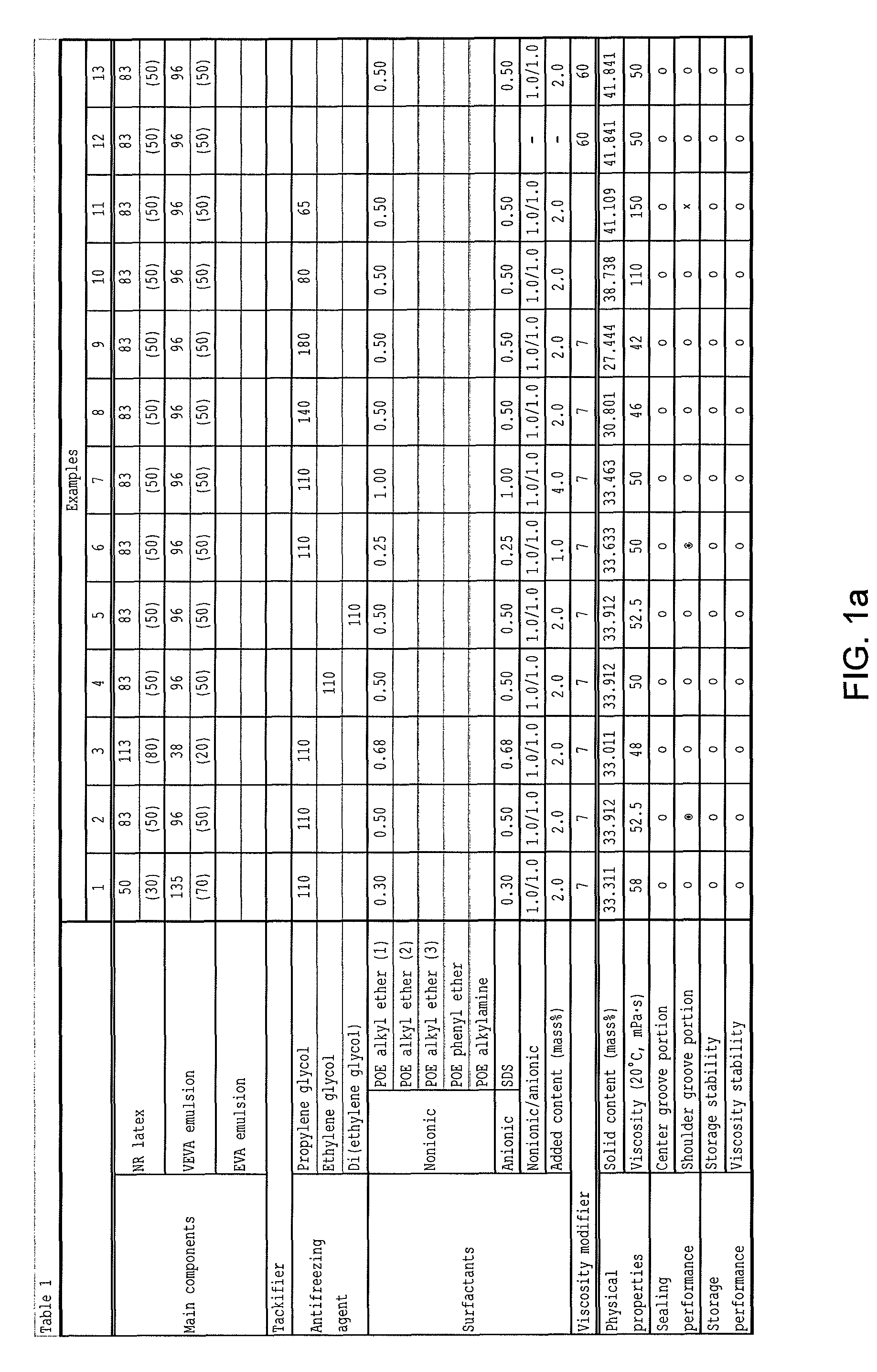

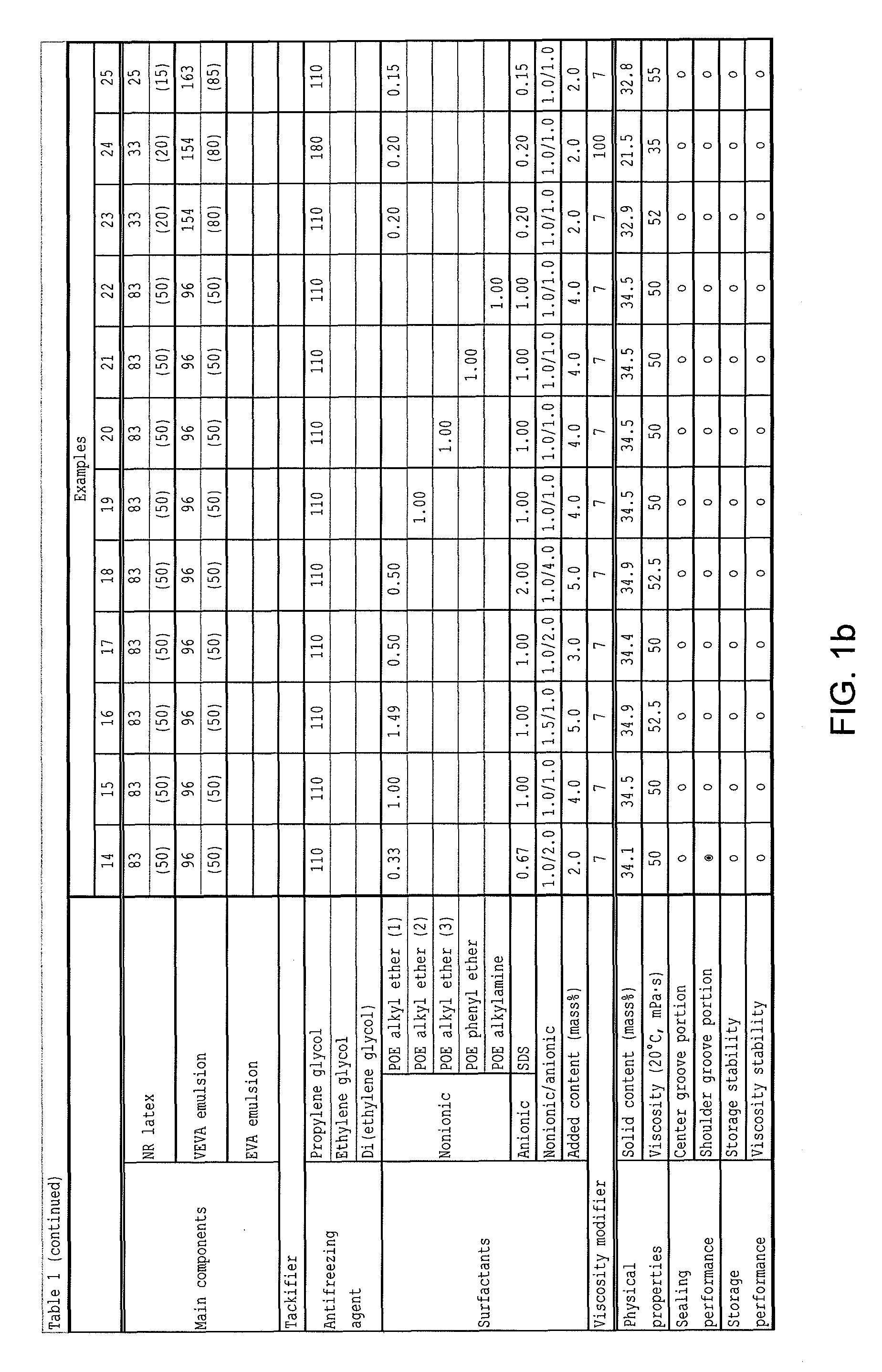

Tire puncture sealant

ActiveUS8148448B2Excellent sealing performance and storage performanceImprove performancePaper coatingOrganic dyesEmulsionSolid content

A tire puncture sealant having both excellent sealing performance and excellent storage performance, specifically a tire puncture sealant containing a natural rubber latex (A) and a VEVA copolymer resin emulsion (B), wherein the solid content mass of the natural rubber latex (A) / solid content mass of the VEVA copolymer resin emulsion (B) is between 80 / 20 and 15 / 85.

Owner:THE YOKOHAMA RUBBER CO LTD

Topical Formulation Containing Latex of Fraction Thereof, and Cosmetic Treatment Method

ActiveUS20080279885A1Organic active ingredientsCosmetic preparationsPapaya familyOrthosiphon stamineus

The present invention refers to a topical formulation containing natural latex or fraction thereof, for topical application, aiming to provide skin regeneration. It particularly refers to a formulation comprising latex from plants of the families Euphorbiaceae, such as Hevea brasiliensis, Apocinaceae, such as guava and sorb, Compositae such as guayule, Caricaceae such as papaya, or one of its fractions, whose topical application provides the skin with regeneration benefits, such as whitening or elimination of senile spots, increase in turgor, improved texture, shine and resilience

Owner:PELE NOVA BIOTECNOLOGIA

Natural rubber latex having reduced allergenicity and method of making

ActiveUS20090192244A1Reduce allergiesLower Level RequirementsSpecial tyresPaper coatingPolymer scienceNatural rubber latex

Owner:VYSTAR CORP

Phenol formaldehyde-rubber copolymerized emulsion and its preparation method

The present invention discloses a phenolic aldehyde-rubber copolymer emulsion and its preparation method. Said emulsion is made up by using resorcinol formaldehyde (RF) resin and one or several kinds of butadiene-vinylpyridine latex and / or neoprene latex, carboxy styrene-butadiene latex, acrylate latex, natural rubber latex, chlorosulfonated polyethylene latex and hydrobutadiene-acrylonitrile latex, making them undergo the process of copolymerization and adding formaldehyde. Said invention also provides the concrete steps of its preparation method.

Owner:HOHAI UNIV

Pressure sensitive adhesive tape containing natural rubber latex

InactiveUS6489024B2Film/foil adhesive primer layersThin material handlingPolymer sciencePolymer thin films

Owner:ROHM & HAAS CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com