Tire puncture sealant

a puncture sealant and tire technology, applied in the field of tire puncture sealant, can solve the problems of repeated vibration of the puncture repair kit, and the puncture sealant described in japanese patent no. 3210863 will not exhibit satisfactory sealing performance, and achieve excellent sealing performance and excellent storage performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

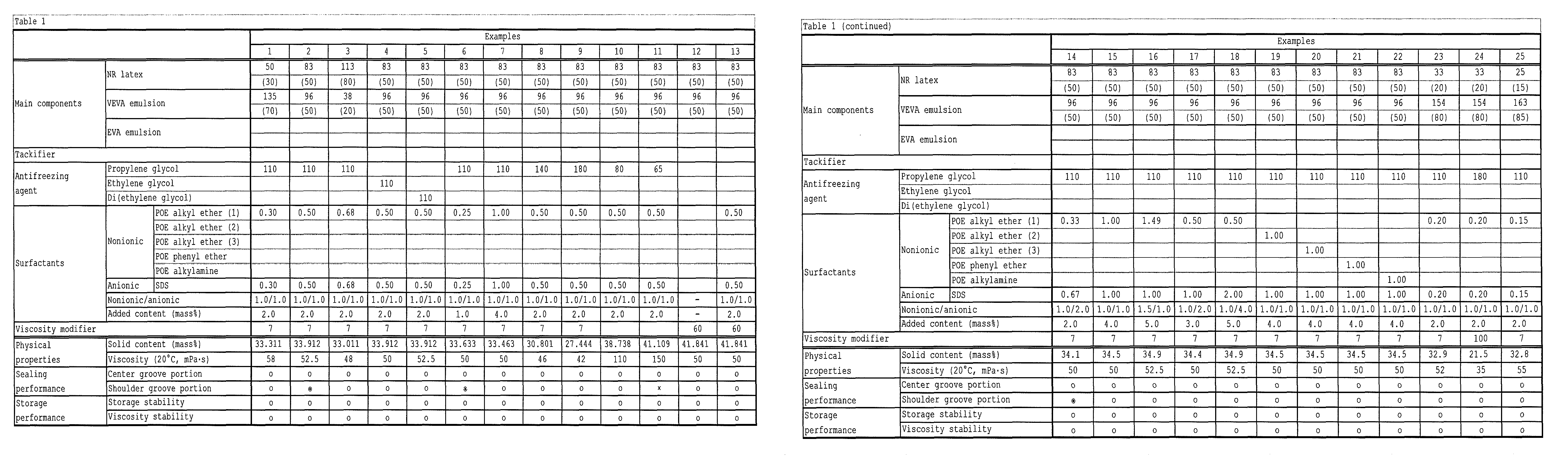

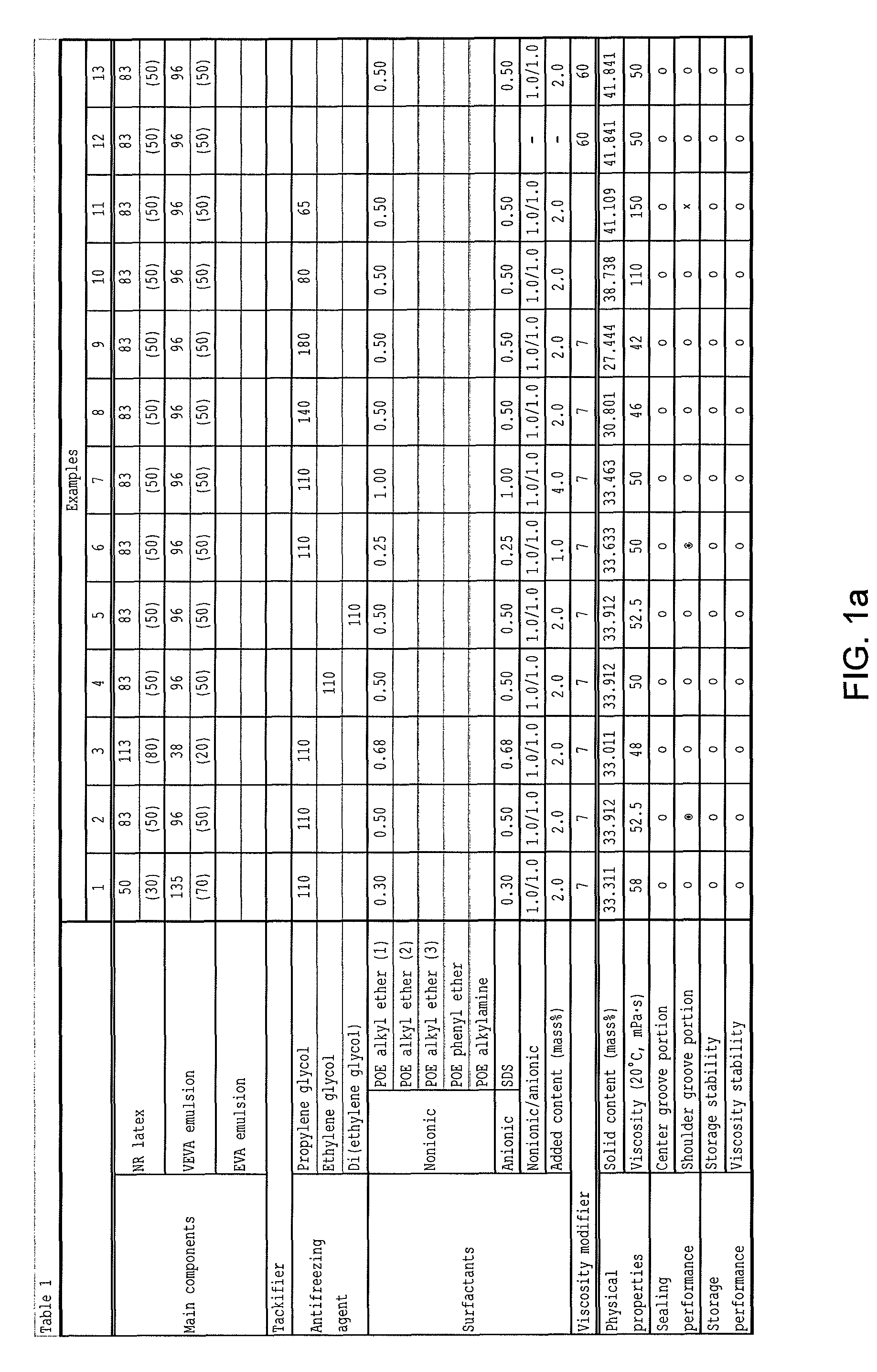

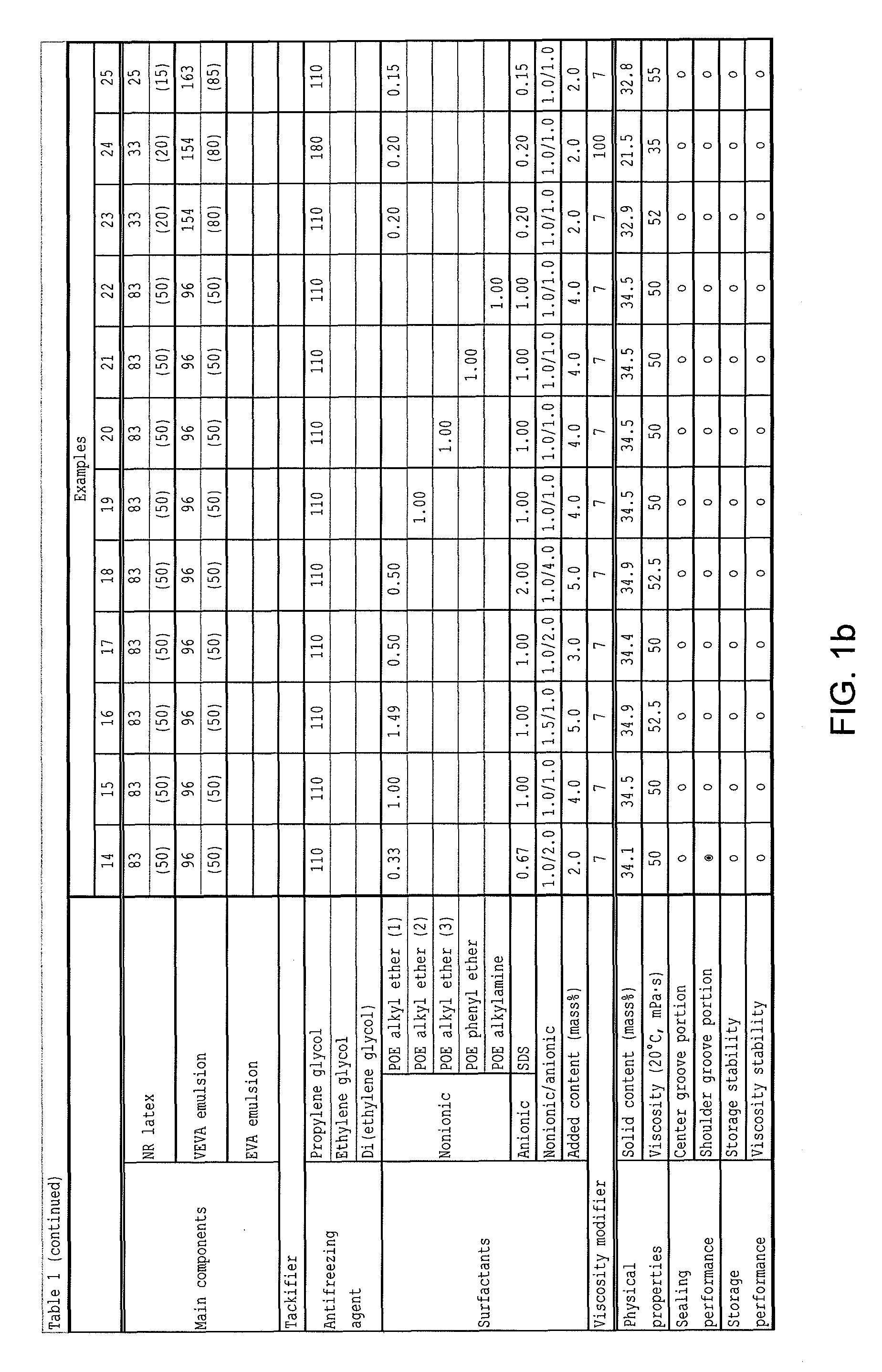

[0110]The present invention will now be described in greater detail using the following examples, but is in noway restricted to these examples.

1. Manufacturing the Tire Puncture Sealant

(1) Components

[0111]Details of the components indicated in Table 1 (Examples 1 to 25) and Table 2 (Comparative examples 1 to 7) are as follows.

Main Components

[0112]NR latex: Natural rubber latex (Hytex HA, manufactured by Fulflex and available from Nomura Trading Co., Ltd.; Solid content=60 mass %)[0113]VEVA emulsion: Ethylene-vinyl acetate-VEOVA copolymer resin emulsion (Product name: Sumikaflex 950HQ, manufactured by Sumitomo Chemtex; Solid content=approximately 53 mass %)[0114]EVA emulsion: Ethylene-vinyl acetate copolymer resin emulsion (product name: Sumikaflex 408HQE, manufactured by Sumitomo Chemtex; Solid content=approximately 50 mass %)

Tackifier[0115]Terpene phenol resin emulsion (product name: R1050, manufactured by Yasuhara Chemical Co., Ltd.)

Antifreezing Agents[0116]Propylene glycol (manuf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com