Patents

Literature

4259 results about "Vinyl alcohol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vinyl alcohol, also called ethenol (IUPAC name), is the simplest enol. With the formula CH₂CHOH, it is a labile compound that converts to acetaldehyde. It is not a precursor to polyvinyl alcohol.

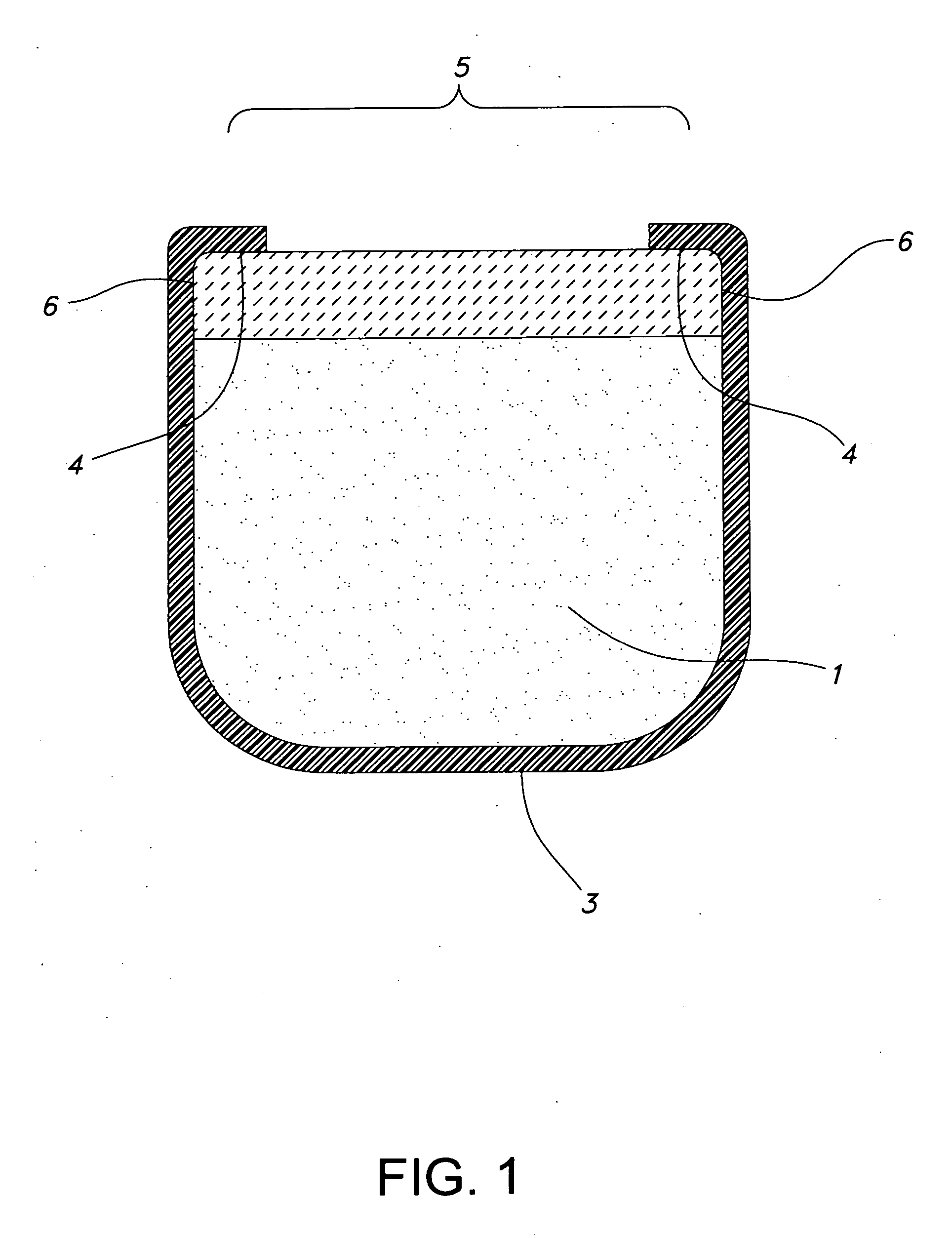

Water-soluble copolymer film packet

Owner:MONOSOL LLC +1

Hydrogels and methods of making and using same

The invention is directed to methods of making novel porous and solid polyvinyl alcohol hydrogels. These hydrogels are particularly suited for use in the replacement and augmentation of soft tissue or non-load bearing bone of the face, head and cranium.

Owner:POREX CORP

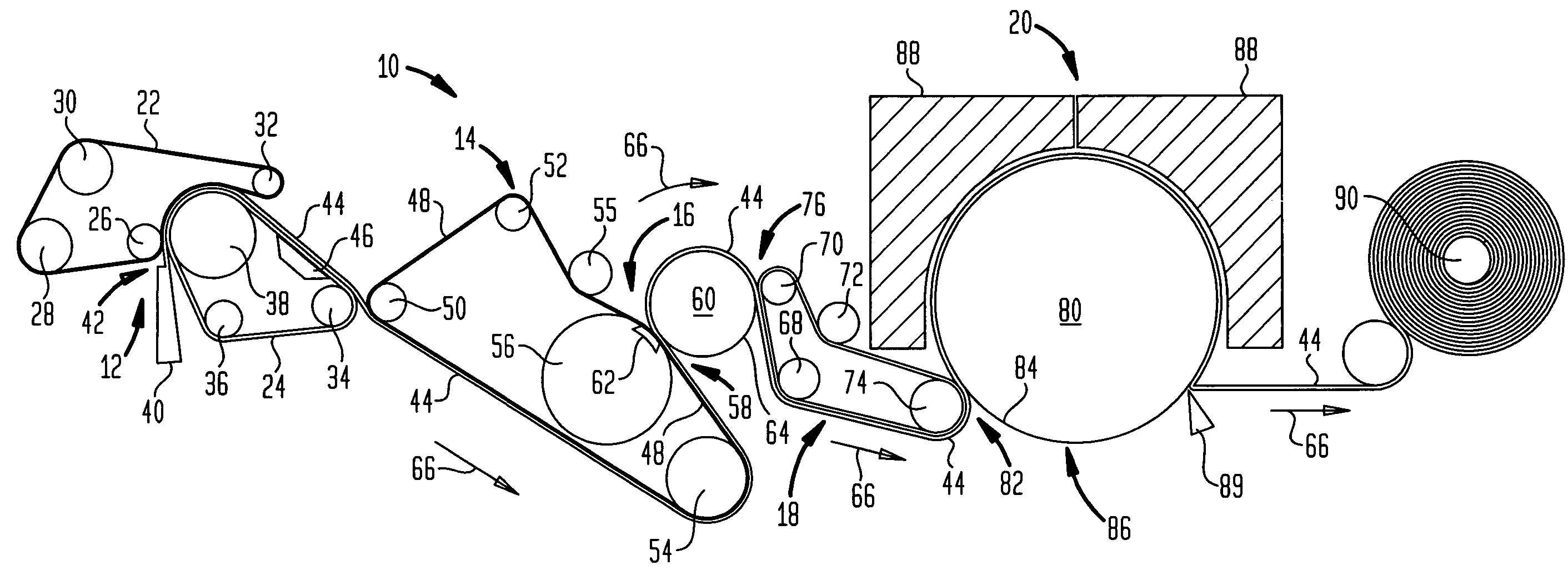

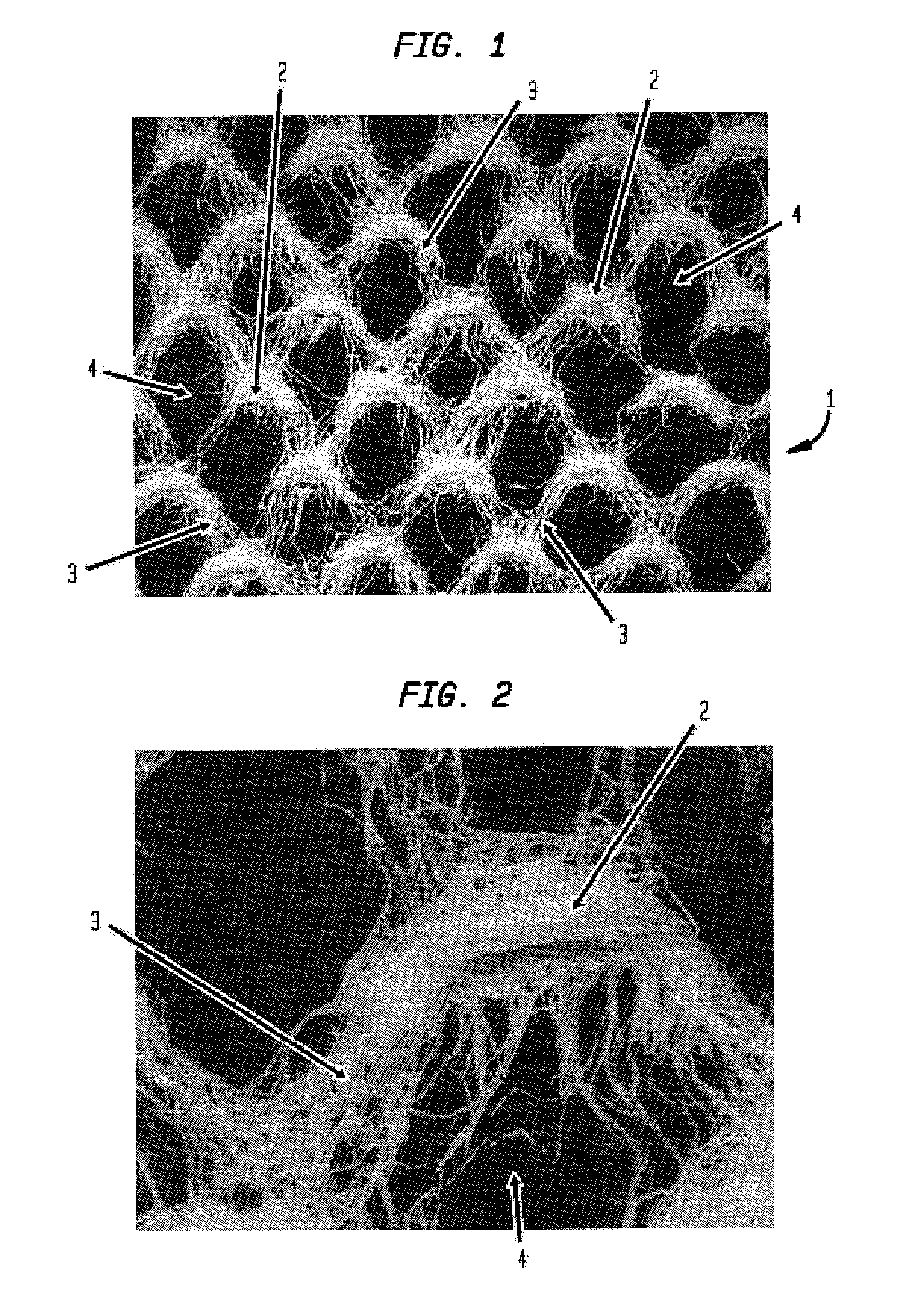

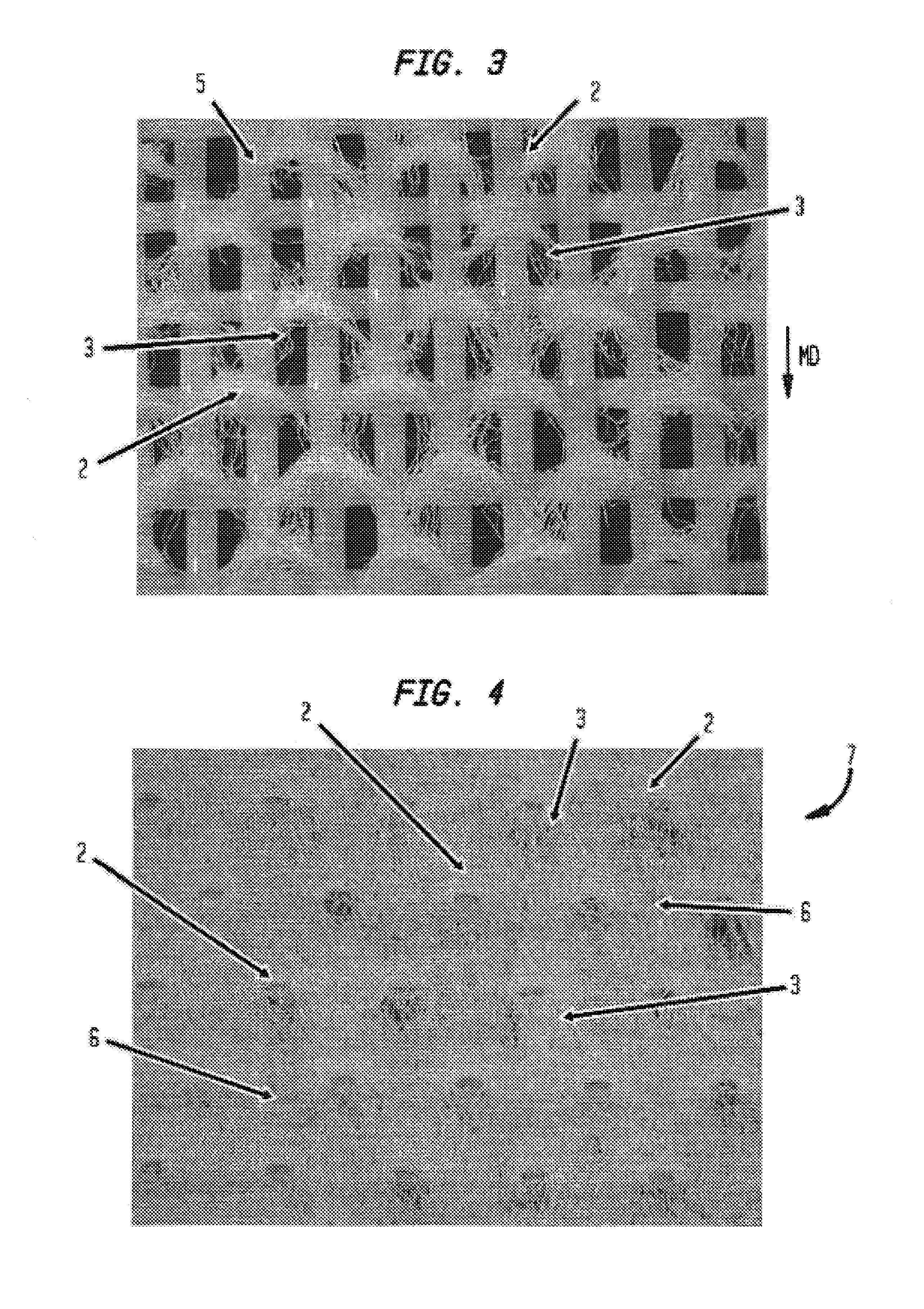

Fabric crepe process for making absorbent sheet

ActiveUS7399378B2High speed transmissionGuaranteed high speed operationNatural cellulose pulp/paperMechanical working/deformationFiberAdhesive

A process for making absorbent cellulosic paper products such as sheet for towel, tissue and the like, includes compactively dewatering a nascent web followed by wet belt creping the web at an intermediate consistency of anywhere from about 30 to about 60 percent under conditions operative to redistribute the fiber on the belt, which is preferably a fabric. In preferred embodiments, the web is thereafter adhesively applied to a Yankee dryer using a creping adhesive operative to enable high speed transfer of the web of intermediate consistency such as a poly(vinyl alcohol) / polyamide adhesive. An absorbent sheet so prepared from a papermaking furnish exhibits an absorbency of at least about 5 g / g, a CD stretch of at least about 4 percent, and an MD / CD tensile ratio of less than about 1.1, and also exhibits a maximum CD modulus at a CD strain of less than 1 percent and sustains a CD modulus of at least 50 percent of its maximum CD modulus to a CD strain of at least about 4 percent. Products of the invention may also exhibit an MD modulus at break 1.5 to 2 times their initial MD modulus.

Owner:GPCP IP HLDG LLC

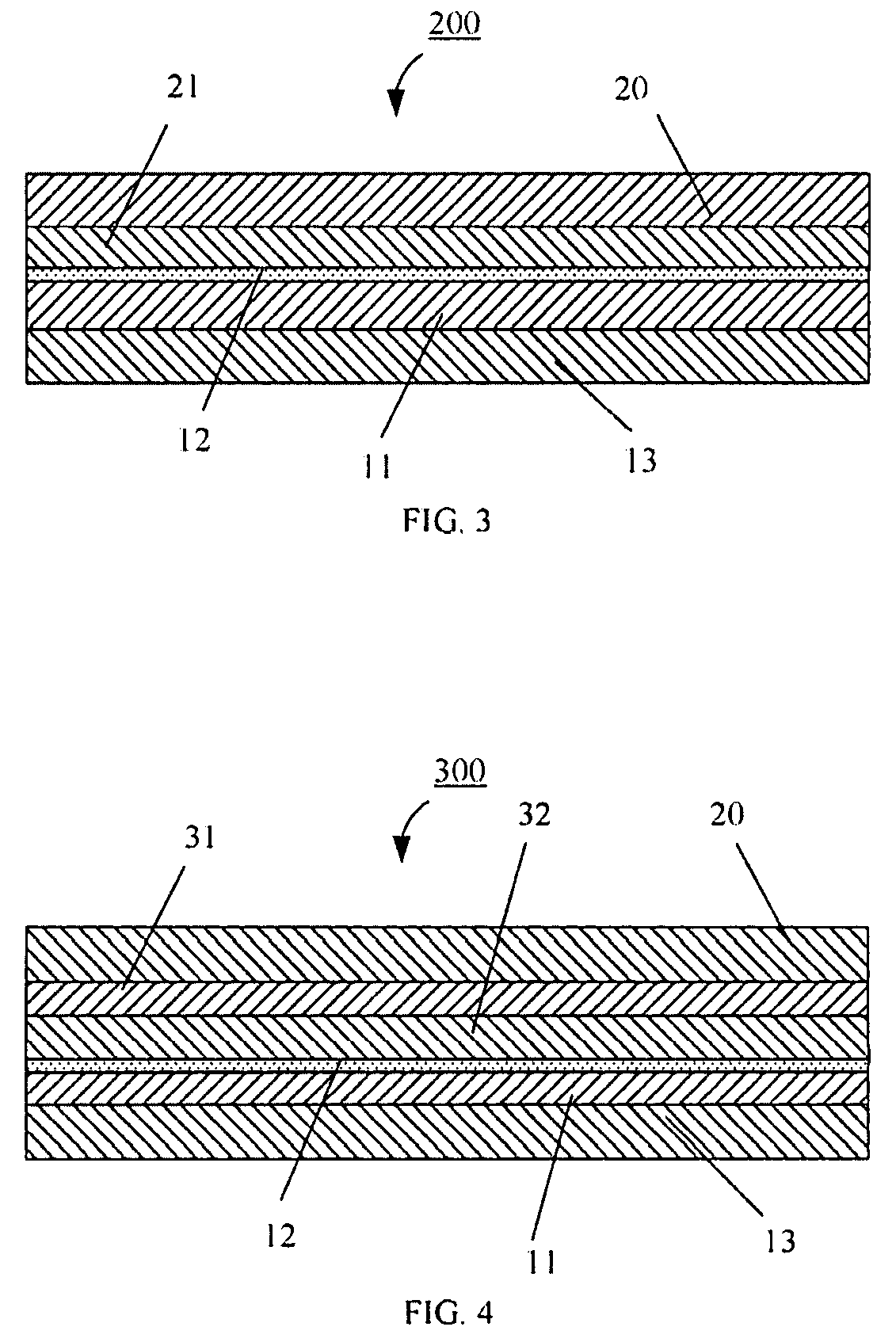

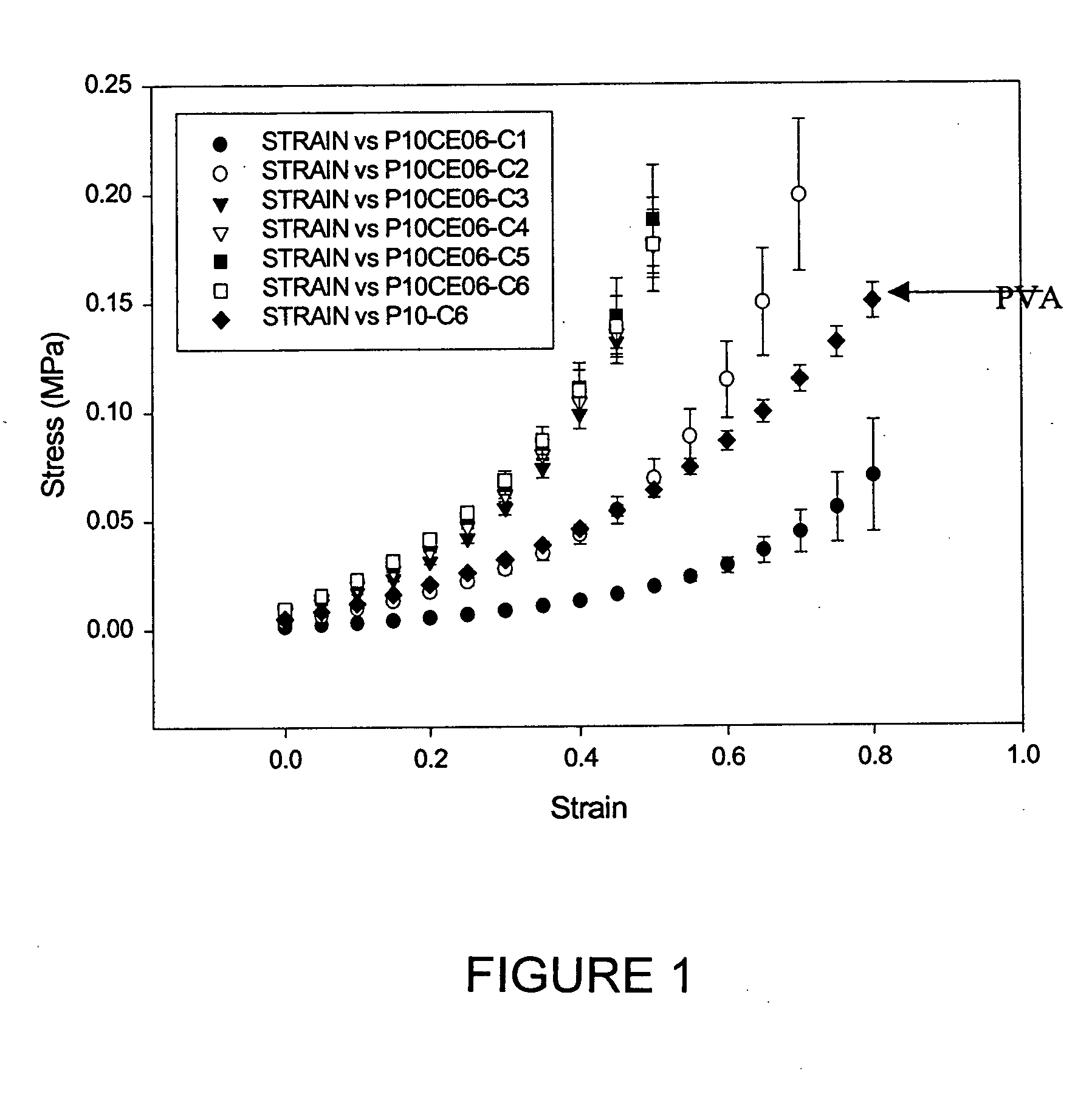

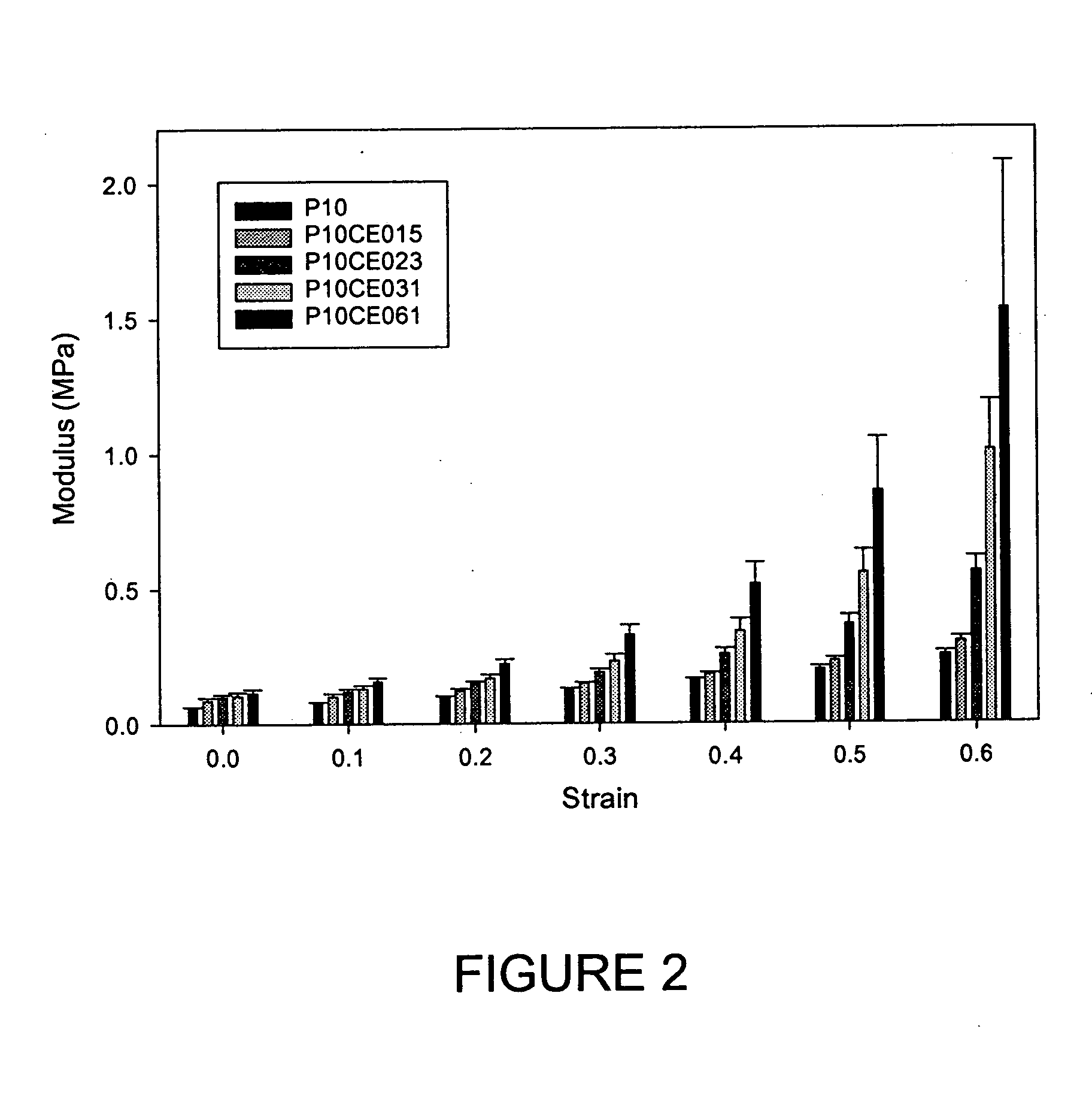

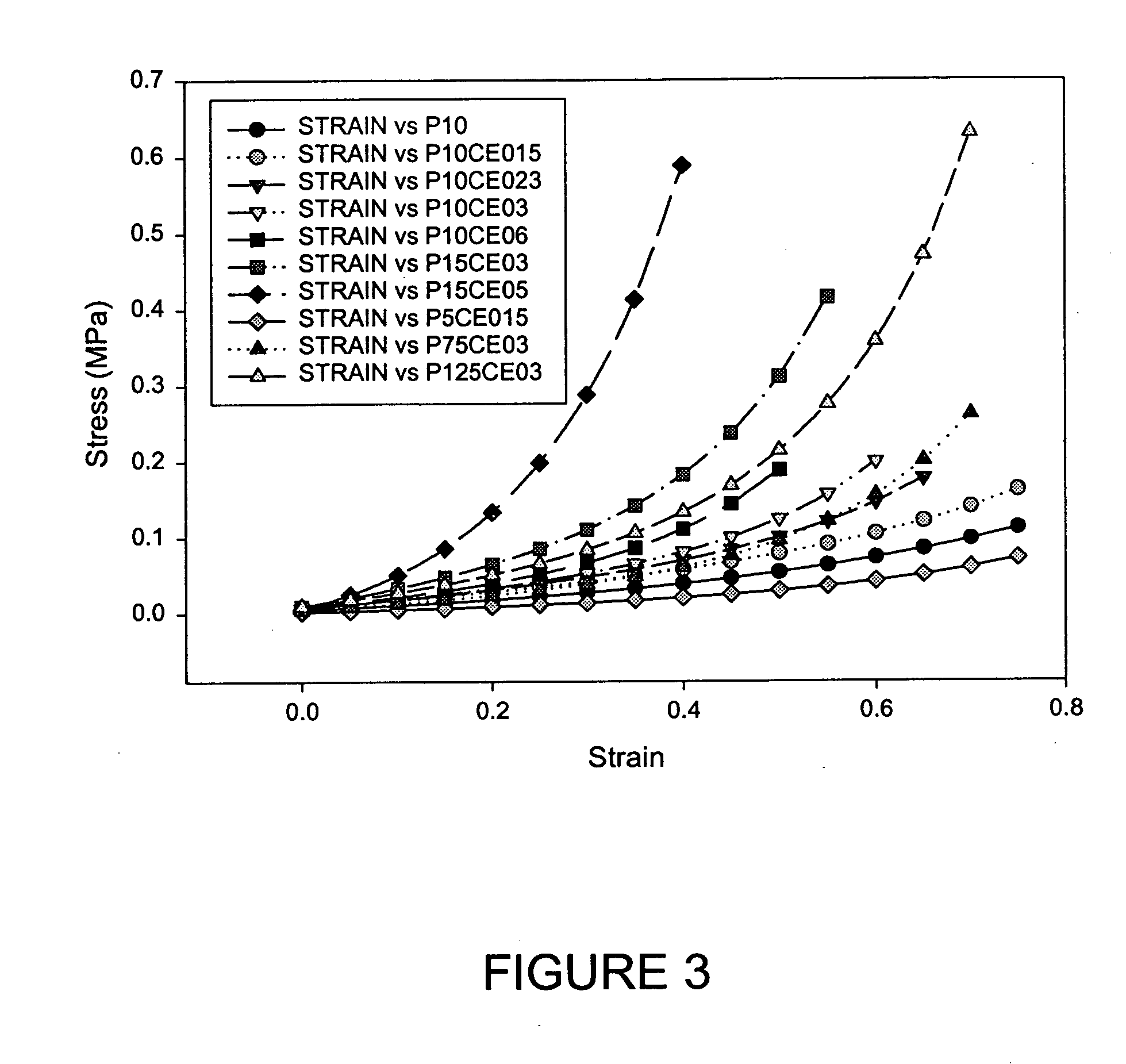

Poly(vinyl alcohol) hydrogel

InactiveUS6231605B1Exemption stepsLow biocompatibilityOrganic active ingredientsBone implantBearing surfaceSacroiliac joint

The present invention relate to a poly(vinyl alcohol) hydrogel construct having a wide range of mechanical strengths for use as a human tissue replacement. The hydrogel construct may include a tissue scaffolding, a low bearing surface within a joint, or any other structure which is suitable for supporting the growth of tissue.

Owner:GEORGIA TECH RES CORP

Polyacrylates coatings for implantable medical devices

A coating for a medical device, particularly for a drug eluting stent, is described. The coating can include a polyacrylate, a blend of polyacrylates, or a blend of the polyacrylate with other polymers, for example, poly(ethylene-co-vinyl alcohol).

Owner:ABBOTT CARDIOVASCULAR

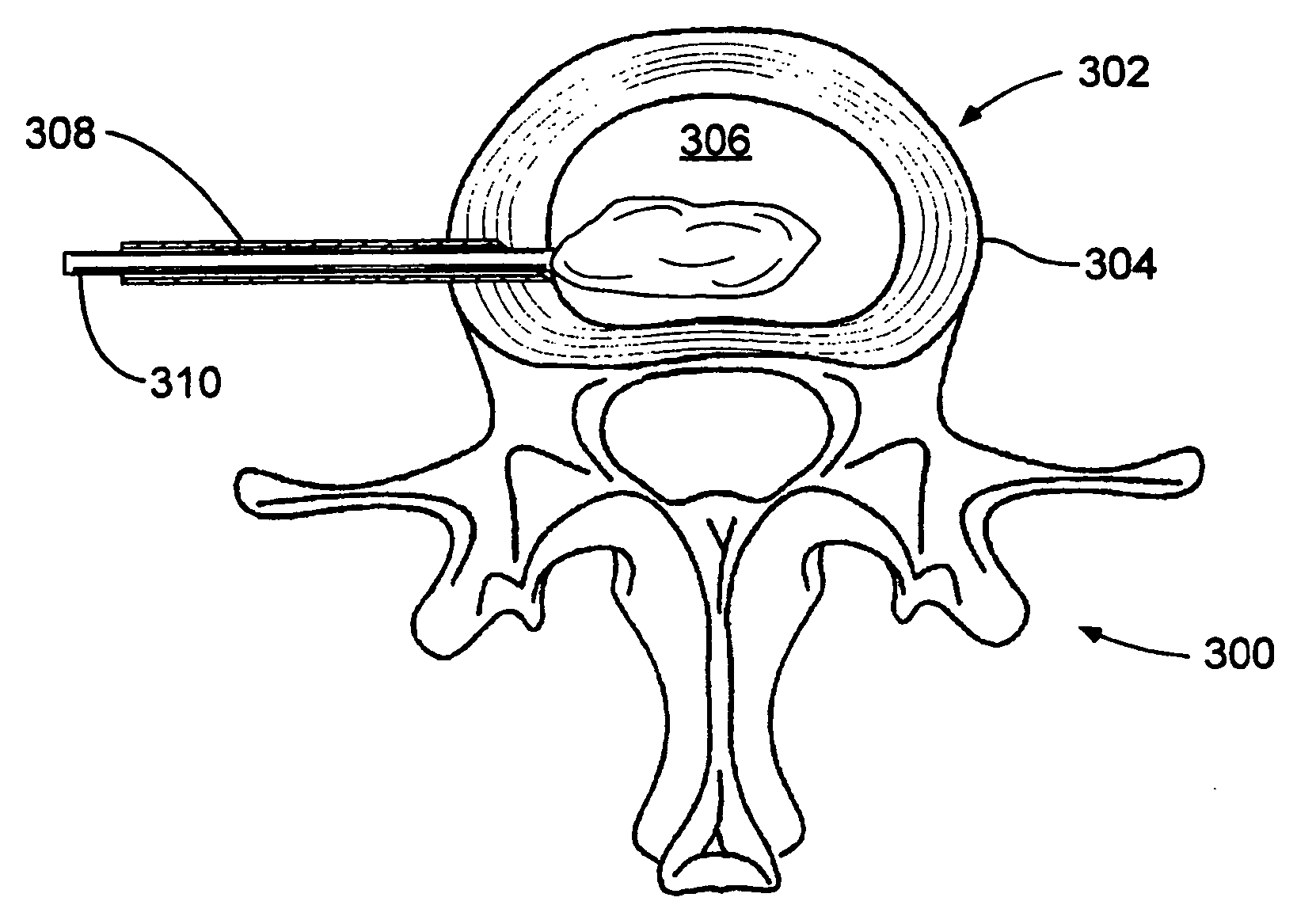

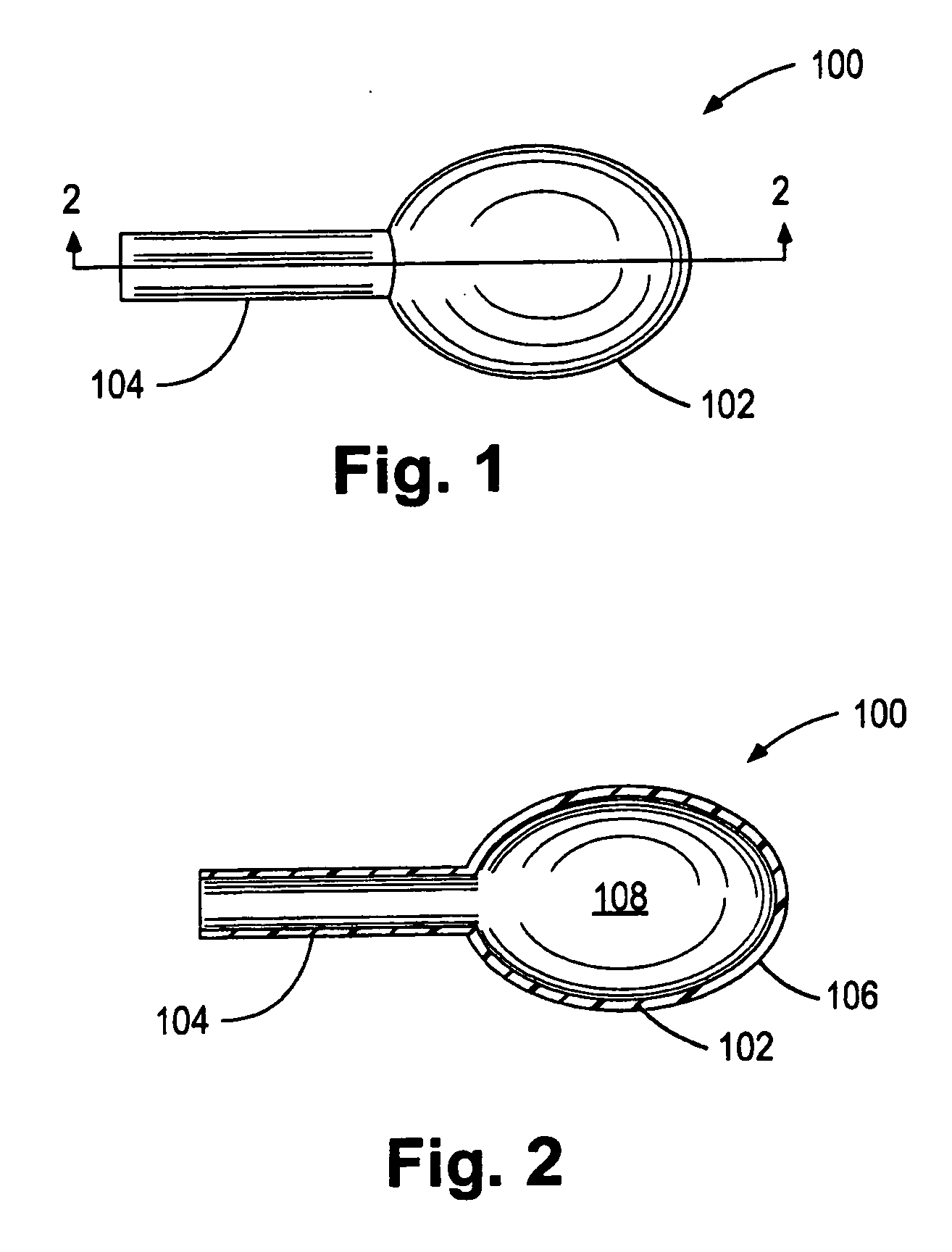

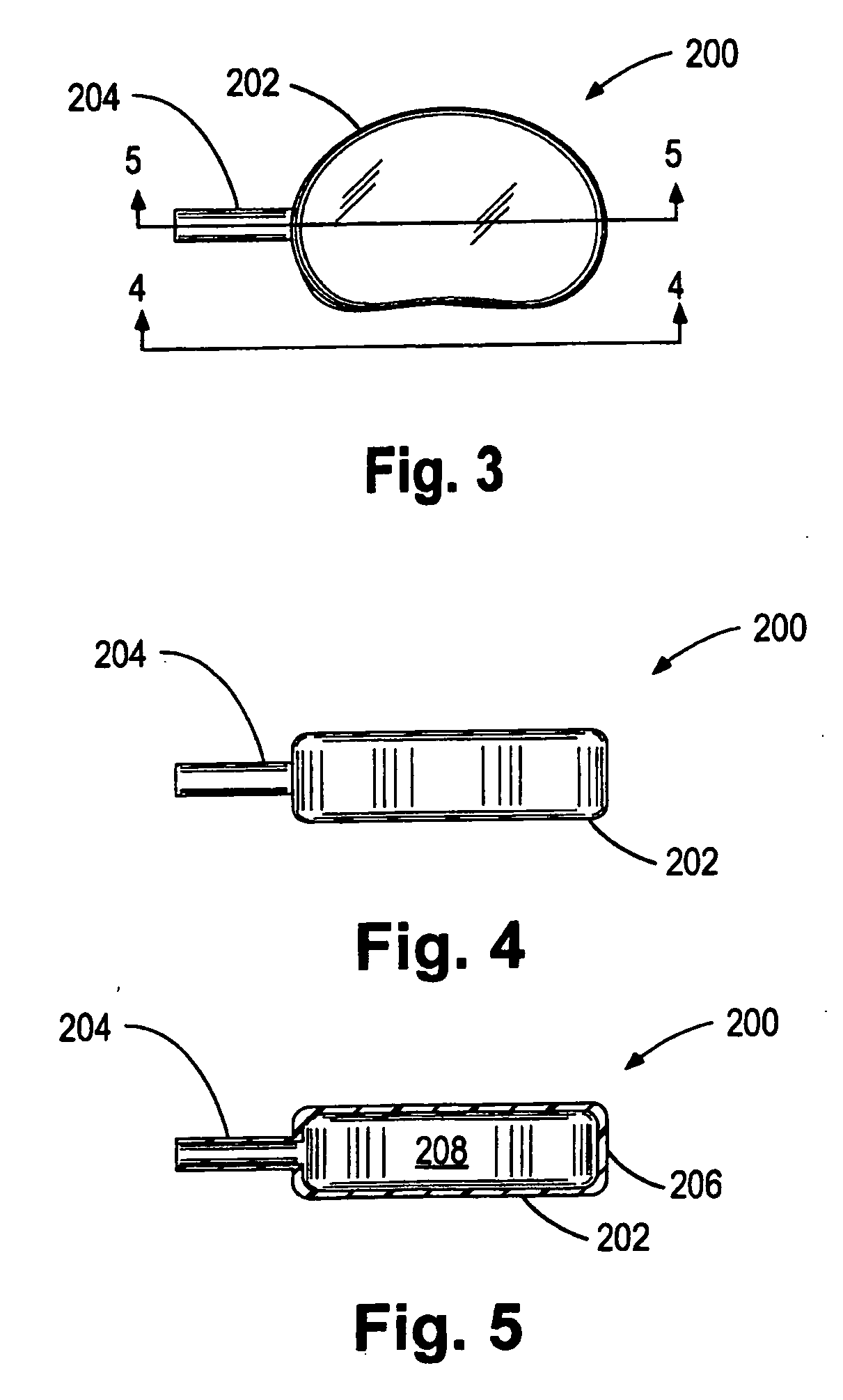

Hydrogel balloon prosthesis for nucleus pulposus

Owner:SYNTHES USA +1

Poly (vinyl alcohol) - based formaldehyde-free curable aqueous composition

A formaldehyde-free curable aqueous composition containing polyvinyl alcohol, a multi-functional crosslinking agent, and, optionally, a catalyst. The composition may be used as a binder for non-woven products such as fiberglass insulation. The non-woven products are formed by contacting the formaldehyde-free curable aqueous composition with fibrous components and the mixture is cured to form a rigid thermoset polymer providing excellent strength and water resistance of the cured nonwoven product.

Owner:ARCLIN USA

Composite materials comprising polar polymers and single-wall carbon nanotubes

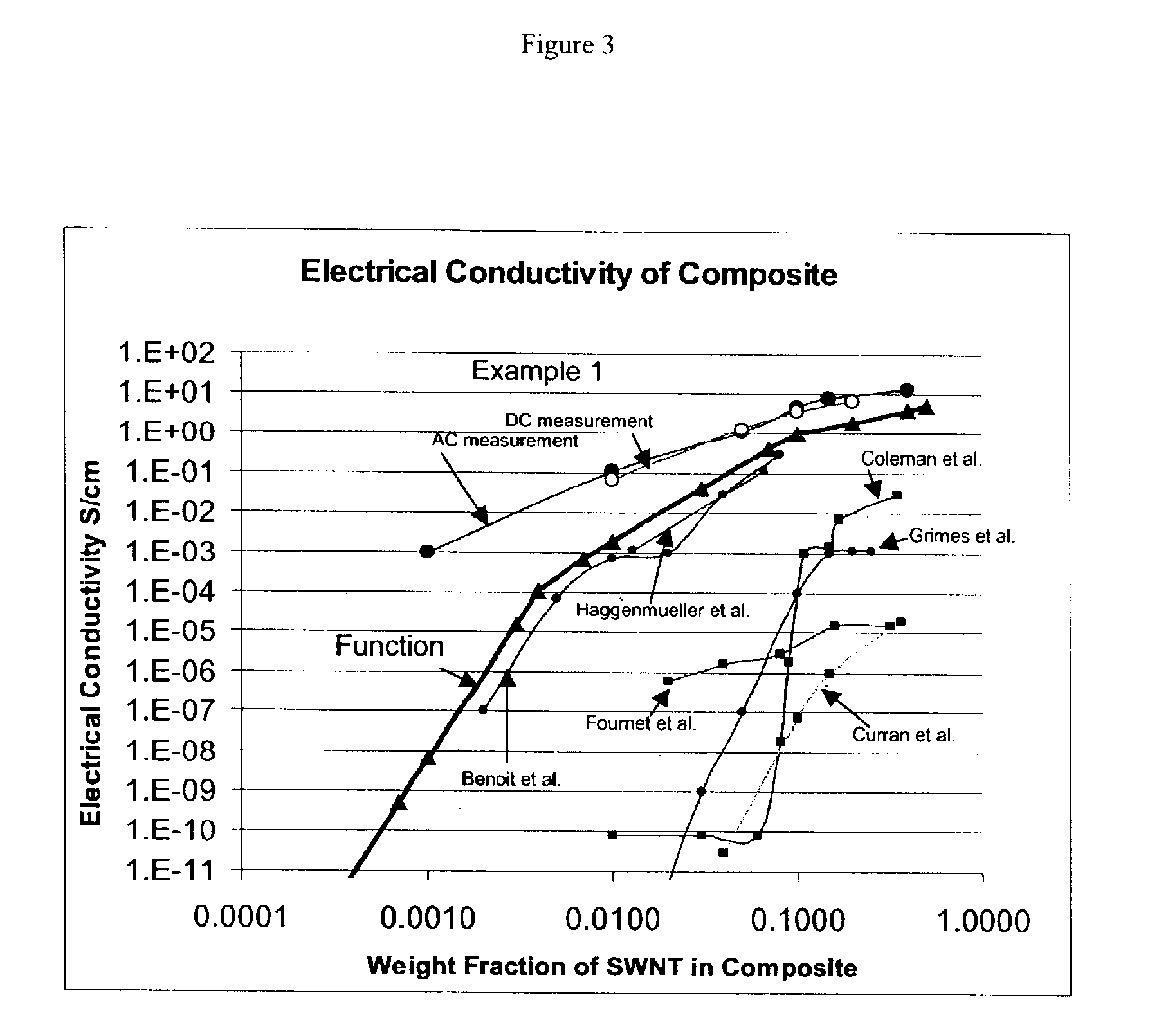

InactiveUS6936653B2Improve conductivityMaterial nanotechnologyIndividual molecule manipulationPolyesterPolymer science

The invention relates to a composite comprising a weight fraction of single-wall carbon nanotubes and at least one polar polymer wherein the composite has an electrical and / or thermal conductivity enhanced over that of the polymer alone. The invention also comprises a method for making this polymer composition. The present application provides composite compositions that, over a wide range of single-wall carbon nanotube loading, have electrical conductivities exceeding those known in the art by more than one order of magnitude. The electrical conductivity enhancement depends on the weight fraction (F) of the single-wall carbon nanotubes in the composite. The electrical conductivity of the composite of this invention is at least 5 Siemens per centimeter (S / cm) at (F) of 0.5 (i.e. where single-wall carbon nanotube loading weight represents half of the total composite weight), at least 1 S / cm at a F of 0.1, at least 1×10−4 S / cm at (F) of 0.004, at least 6×10−9 S / cm at (F) of 0.001 and at least 3×10−16 S / cm (F) plus the intrinsic conductivity of the polymer matrix material at of 0.0001. The thermal conductivity enhancement is in excess of 1 Watt / m-° K. The polar polymer can be polycarbonate, poly(acrylic acid), poly(acrylic acid), poly(methacrylic acid), polyoxide, polysulfide, polysulfone, polyamides, polyester, polyurethane, polyimide, poly(vinyl acetate), poly(vinyl alcohol), poly(vinyl chloride), poly(vinyl pyridine), poly(vinyl pyrrolidone), copolymers thereof and combinations thereof. The composite can further comprise a nonpolar polymer, such as, a polyolefin polymer, polyethylene, polypropylene, polybutene, polyisobutene, polyisoprene, polystyrene, copolymers thereof and combinations thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

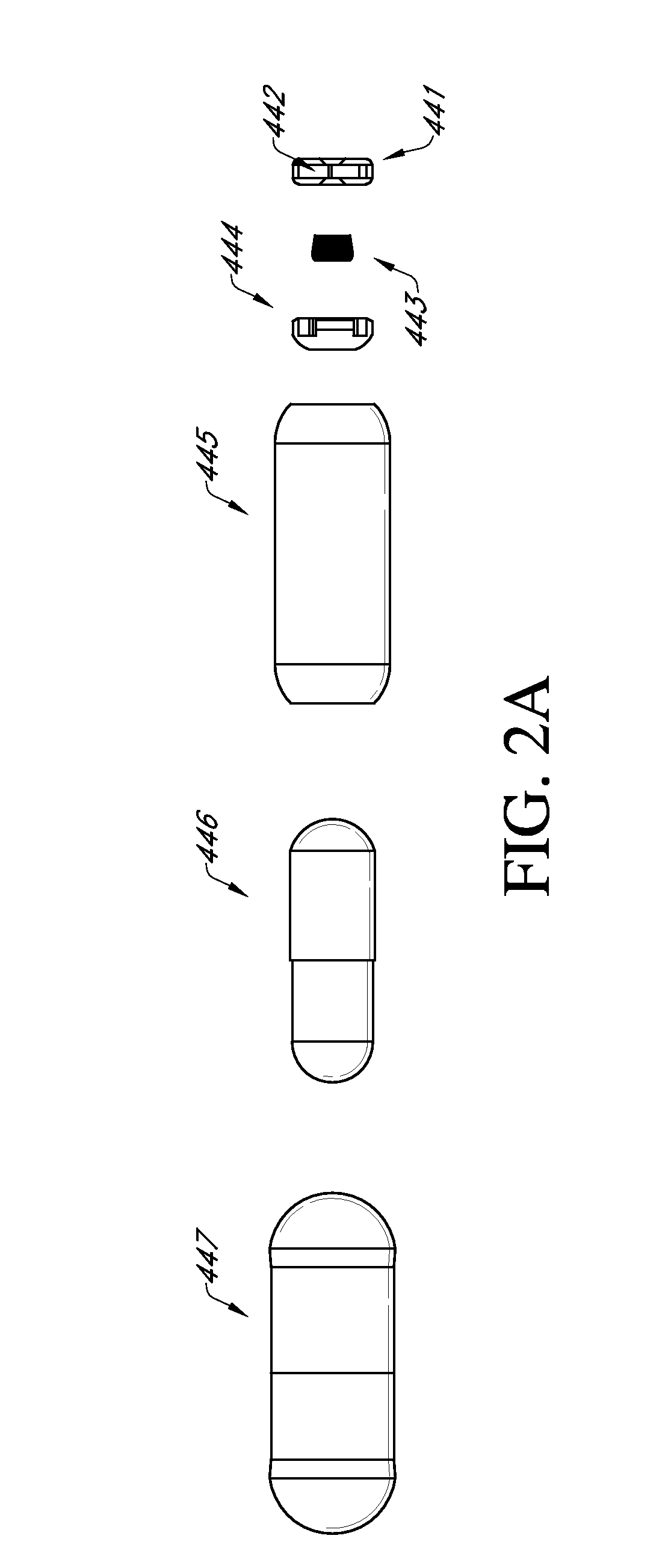

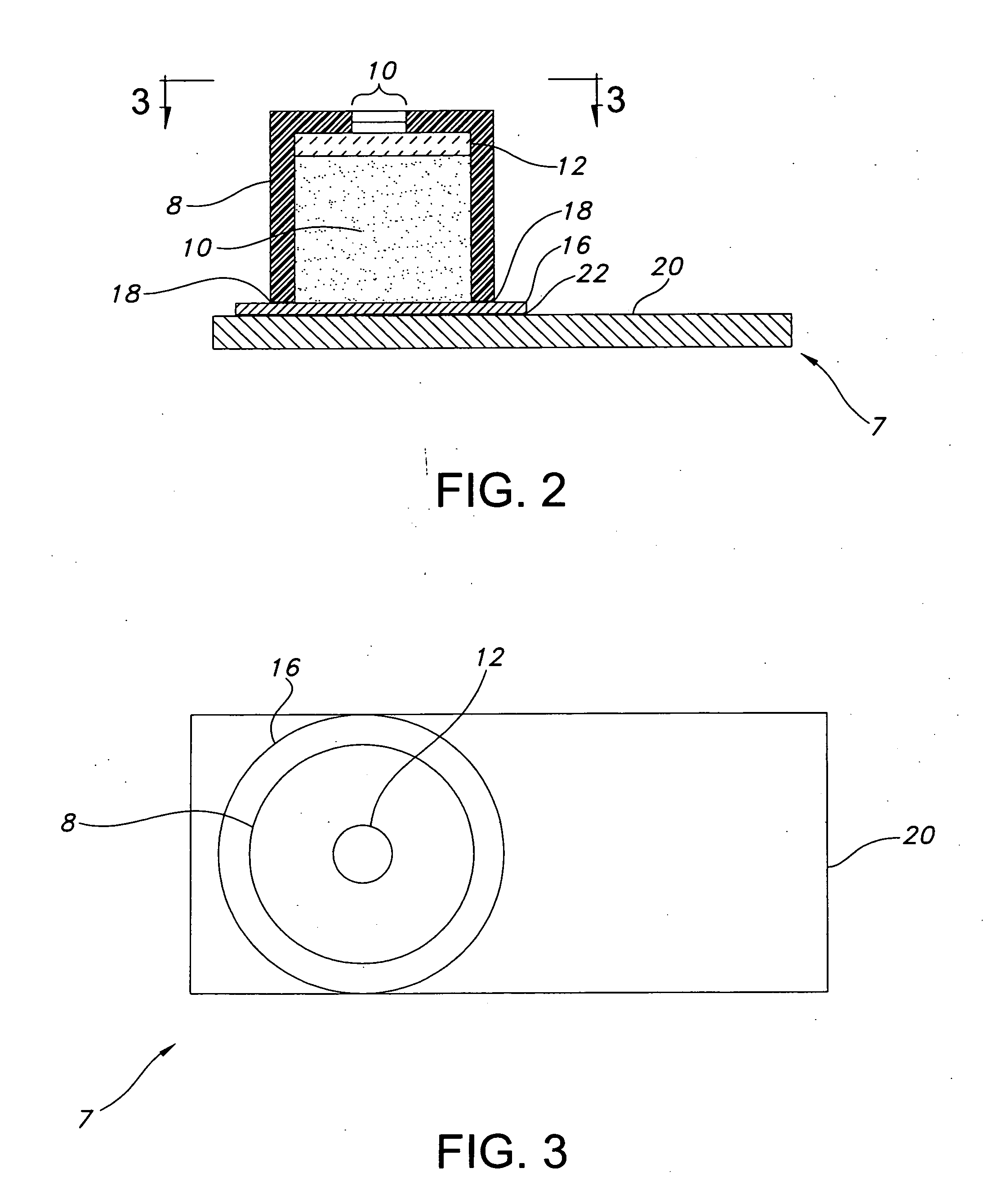

Intragastric volume-occupying device and method for fabricating same

ActiveUS20100100116A1Smooth outer surfaceHollow inflatable ballsHollow non-inflatable ballsSilicon oxideIn vivo

Intragastric volume-occupying devices and methods for treating obesity are provided. The devices, which are inflated by carbon dioxide, include an aluminum or silicon oxide barrier layer providing carbon dioxide retention and an alkylene vinyl alcohol polymer layer providing structural integrity in vivo.

Owner:RESHAPE LIFESCIENCES INC

Biodegradable and biocompatible crosslinked polymer hydrogel prepared from PVA and/or PEG macromer mixtures

InactiveUS20050271727A1High elastic modulusLow elongationPowder deliverySurgical adhesivesWound dressingBlood vessel

Biodegradable and biocompatible polymeric hydrogels based on the mixtures of poly(vinyl alcohol) and poly(ethylene glycol) macromers, and methods for their preparation and use, are disclosed. The polymerization may be carried out in situ on organs or tissues or outside the body. Applications for such biocompatible crosslinked hydrogels include prevention of post-operative adhesions, surgical sealants, embolic therapies, controlled delivery of drugs, coating of medical devices such as vascular grafts, wound dressings and other medical applications.

Owner:CALLISYN PHARMA

Poly(vinyl alcohol) hydrogel

InactiveUS20030008396A1Exemption stepsBone implantPharmaceutical delivery mechanismUltimate tensile strengthBearing surface

The present invention comprises a poly (vinyl alcohol) hydrogel construct having a wide range of mechanical strengths for use as a human tissue replacement. The hydrogel construct may comprise a tissue scaffolding, a low bearing surface within a joint, or any other structure which is suitable for supporting the growth of tissue.

Owner:GEORGIA TECH RES CORP

Nanometer cellulose/polyvinyl alcohol gel composite material

ActiveCN102786642ALarge specific surface areaHigh porosityChemical industryChemical industryPolyvinyl alcohol

The invention relates to a nanometer cellulose / polyvinyl alcohol gel composite material, which is characterized by comprising hydrogel and aerogel. A preparation method of the nanometer cellulose / polyvinyl alcohol gel composite material comprises the following process steps of 1, nanometer cellulose preparation by a chemical combination mechanical treatment method; 2, composite hydrogel preparation; and 3, composite aerogel preparation. The nanometer cellulose / polyvinyl alcohol gel composite material has the advantages that the composite aerogel belongs to a porous amorphous solid material consisting of nanometer level colloid particles or high-polymer molecules, and a unique open nanometer level porous structure and a continuous three-dimensional reticular structure are adopted, so the density is extremely low, the specific surface area is high, and the porosity is high, wherein the solid phase of the aerogel accounts for 0.2 percent to 20 percent of the total volume percentage, the characteristics of high adsorption catalytic capability, low thermal conductivity, low sound resistance, low refractive index and the like are shown, and wide application prospects are realized in the fields of aviation, spaceflight, chemical industry, metallurgy, energy-saving building and the like.

Owner:SHANDONG LVSEN WOOD PLASTIC COMPOSITE

Barrier Packaging Webs Having Metallized Non-Oriented Film

ActiveUS20090110888A1Improve sealingImprove barrier propertiesFlexible coversWrappersThermoplasticFiber

Owner:BEMIS COMPANY INC

Poly(vinyl alcohol)-bacterial cellulose nanocomposite

Hydrogel-bacterial cellulose nano-composite materials are created using a hydrogel and never dried bacterial cellulose fibers. Such materials are suitable for a broad range of soft tissue replacement applications. In addition controlled release of bioactive agents properties can be designed into medical devices fabricated from such composite materials.

Owner:AXCELON BIOPOLYMERS COPRORATION

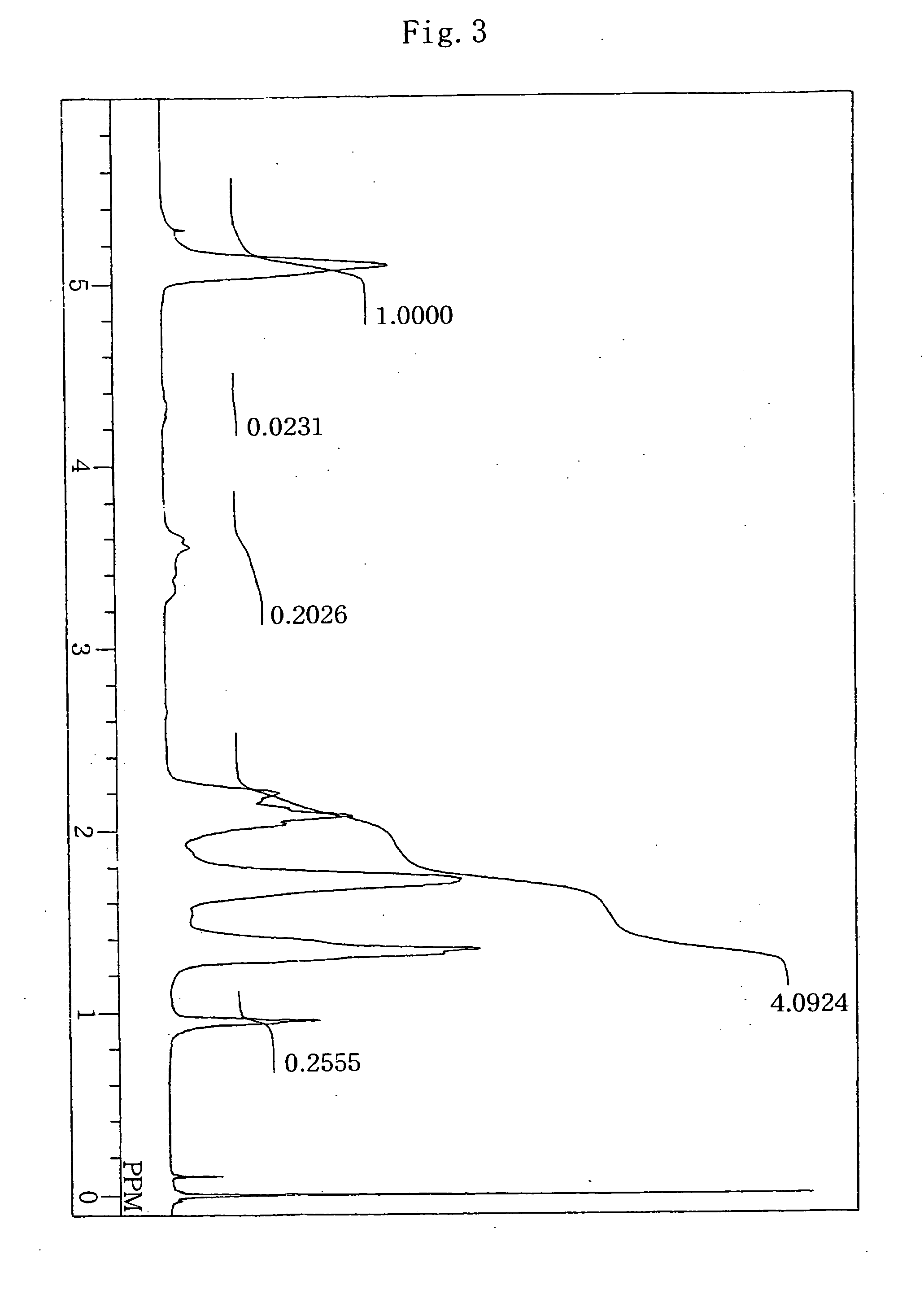

Adhesive polyethylene compositions and multi-layer laminated films using the same

InactiveUS6210765B1Improve adhesion strengthHigh heat sealing strength heatWrappers shrinkageShrinkage connectionsElastomerPolyamide

Disclosed is a specific adhesive polyethylene composition comprising [1] a modified ethylene / alpha-olefin copolymer resin or elastomer obtained by modifying a specific ethylene / alpha-olefin copolymer resin or elastomer, each of which comprises ethylene and an alpha-olefin of 3 to 20 carbon atoms, with an unsaturated carboxylic acid or anhydride, ester, amide, imide or metallic salt derivative of a unsaturated carboxylic acid thereof, [2] an unmodified ethylene / alpha-olefin copolymer resin and / or an unmodified ethylene / alpha-olefin copolymer elastomer and [3] a tackifier. Also disclosed is a multi-layer laminated film of 3 or more layers in which a layer of the above composition is interposed between an ethylene polymer layer and either a polyamide resin layer, an ethylene / vinyl alcohol copolymer layer or a layer of a mixture of polyamide resin and ethylene / vinyl alcohol copolymer. The adhesive polyethylene composition shows excellent adhesion strength to ethylene polymers, polyamide resins and ethylene / vinyl alcohol copolymers, high heat-sealing strength and heat resistance. The multi-layer laminated film shows excellent strength, heat resistance and gas barrier properties, and besides this film has heat shrinkability, so that the film is suitably used as a shrink film.

Owner:MITSUI CHEM INC

Wiping sheet

InactiveUS20060009106A1Improve wiping effectPromote stratificationCarpet cleanersFloor cleanersNonwoven fabricFiber structure

A wiping sheet is provided, which presents excellent in handling during wiping, high wiping ability for greasy dirt, and less liquid remains on an object after wiping. A wiping sheet having a fiber structure (such as a woven fabric, a knitted fabric and a nonwoven) is obtained, which includes an ultrafine fiber layer containing ultrafine fibers having a fineness of at most 0.9 dtex which result from at least two types of ultrafine fiber-generating conjugate fibers, at least one conjugate fiber giving ultrafine fibers containing a modified vinyl alcohol resin, and the other conjugate fibers giving ultrafine fibers containing another resin(s). The ultrafine fibers can be obtained by a first splittable conjugate fiber including a component containing the modified vinyl alcohol resin and a second splittable conjugate fiber composed of components of other resins. In the ultrafine fiber layer, the fibers are preferably bonded by thermoadhesive resin-containing ultrafine fibers.

Owner:DAIWABO HLDG +1

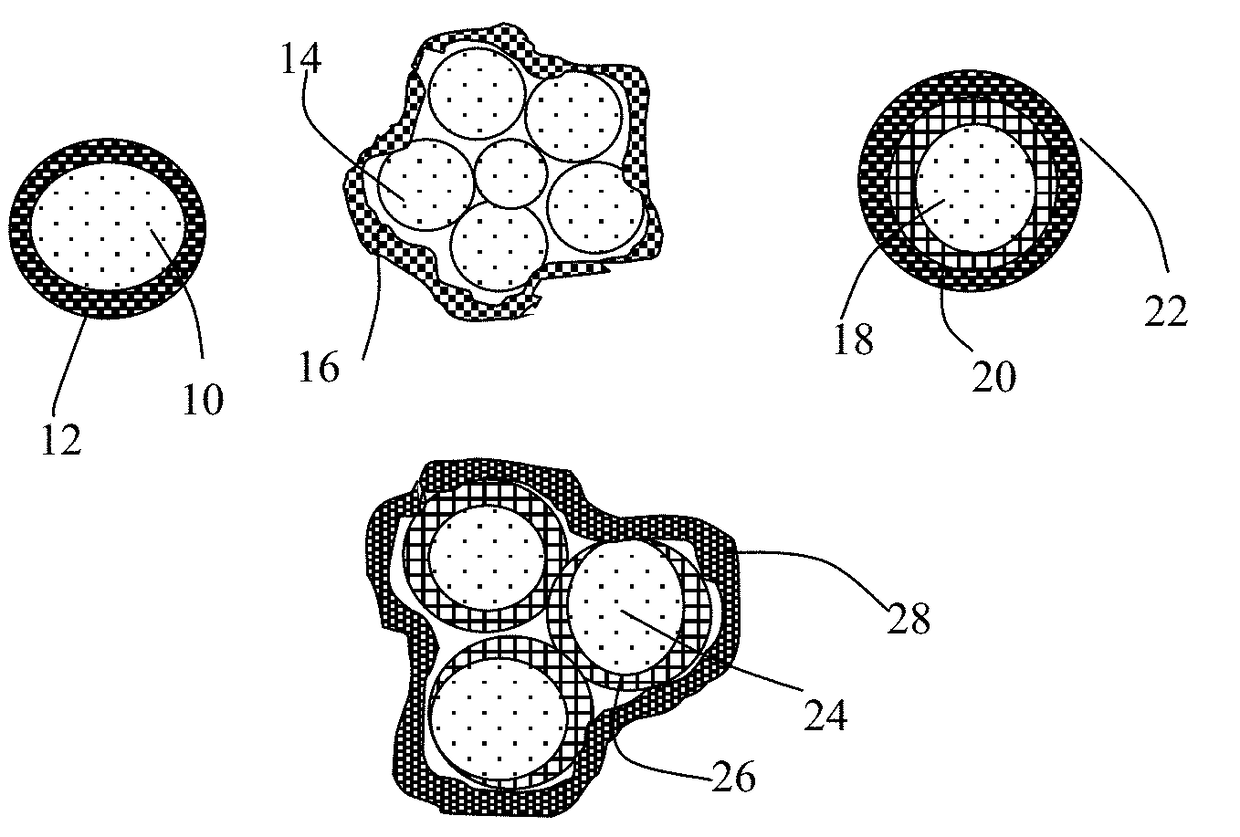

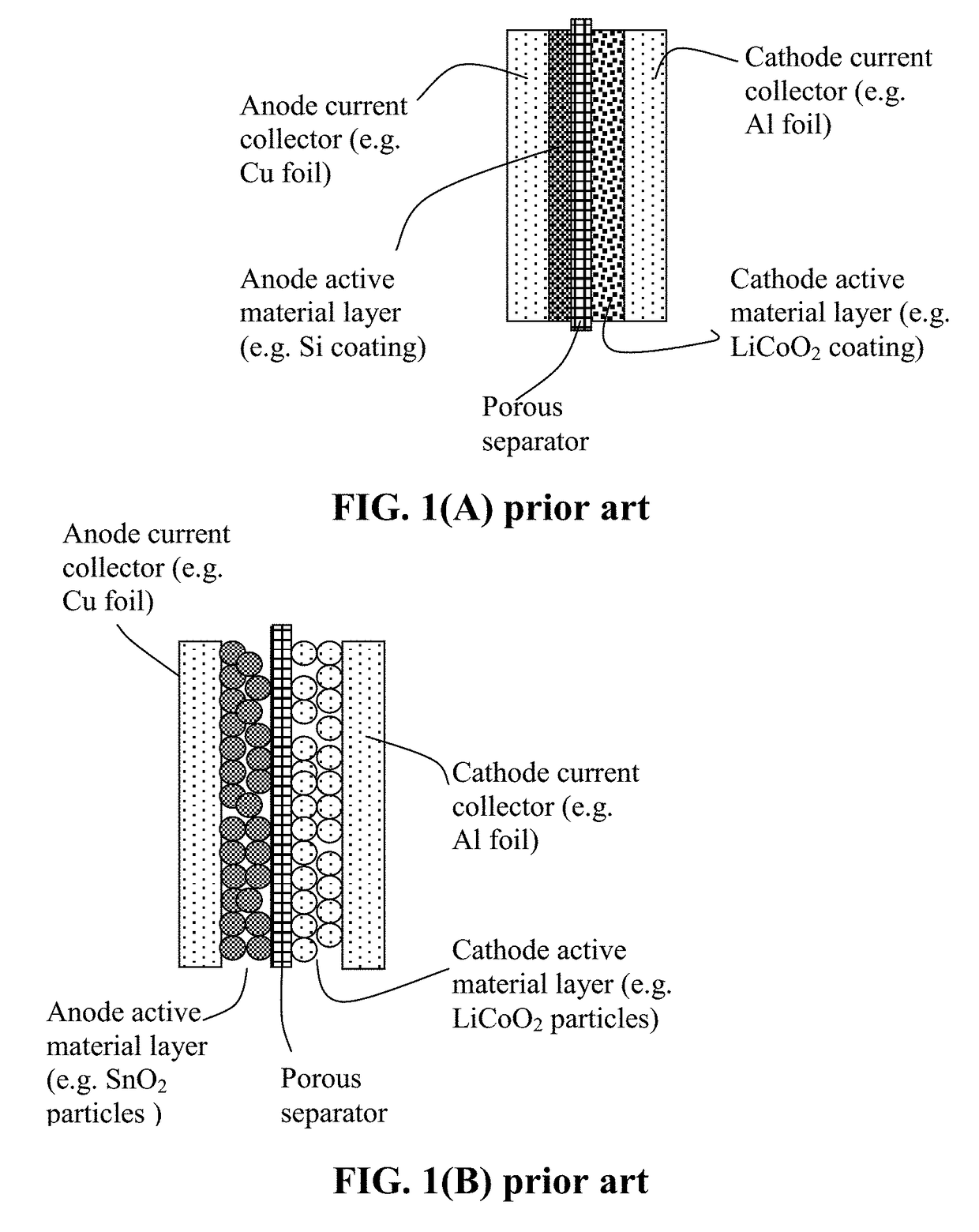

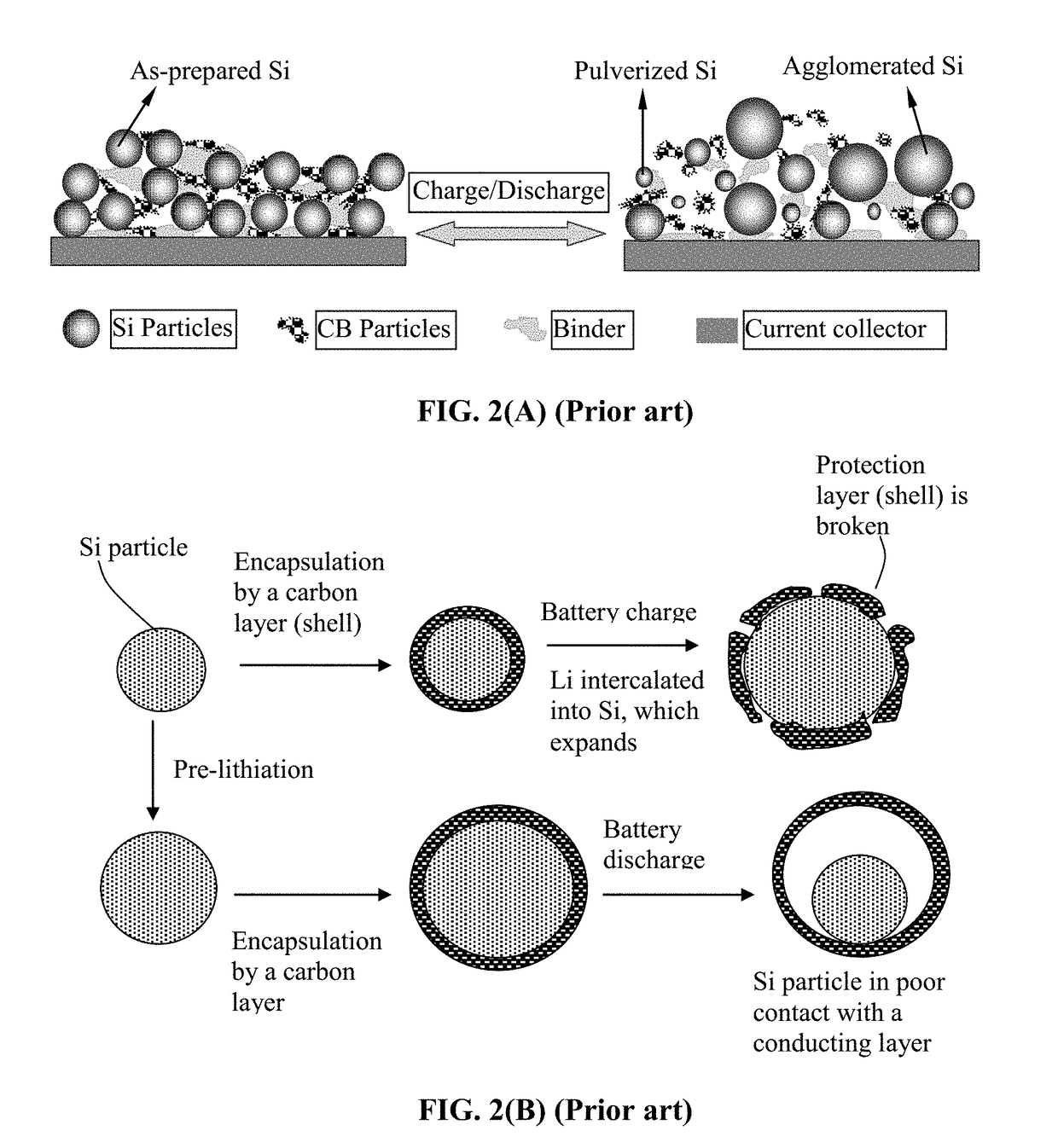

Encapsulated Anode Active Material Particles, Lithium Secondary Batteries Containing Same, and Method of Manufacturing

ActiveUS20180287142A1Improve lithium ion conductivitySolid electrolytesNegative electrodesParticulatesPolyethylene oxide

Provided is particulate of an anode active material for a lithium battery, comprising one or a plurality of anode active material particles being embraced or encapsulated by a thin layer of a high-elasticity polymer having a recoverable tensile strain no less than 5%, a lithium ion conductivity no less than 10−6 S / cm at room temperature, and a thickness from 0.5 nm to 10 μm, wherein the polymer contains an ultrahigh molecular weight (UHMW) polymer having a molecular weight from 0.5×106 to 9×106 grams / mole. The UHMW polymer is preferably selected from polyacrylonitrile, polyethylene oxide, polypropylene oxide, polyethylene glycol, polyvinyl alcohol, polyacrylamide, poly(methyl methacrylate), poly(methyl ether acrylate), a copolymer thereof, a sulfonated derivative thereof, a chemical derivative thereof, or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

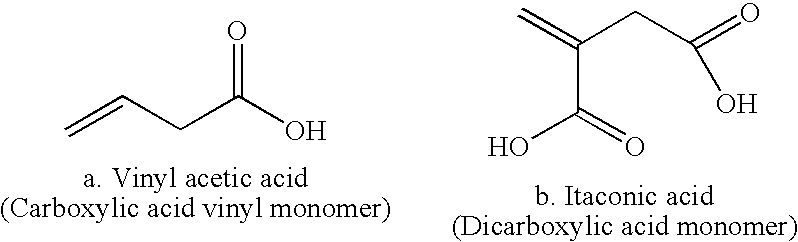

Pvp copolymer for harsh chemical packaging

A water soluble film useful in unit-dose chemical packaging is disclosed. The film may include: a water soluble saccharide and a polyvinyl alcohol copolymer consisting essentially of: (a) from 80 to 99 mole percent of vinyl alcohol and vinyl ester monomer; and (b) from 1 to 20 mole percent of a pyrrolidone comonomer. Such compositions may be used to provide a water-soluble film simultaneously satisfying requirements in regard to water solubility, biodegradability, and physical properties, even when used for packaging of harsh, oxidizing chemicals.

Owner:SEKISUI SPECIALTY CHEM AMERICA

Heat-shrinkable film with improved inter-ply adhesion

A heat shrinkable film suitable for use in cook-in applications is provided which exhibits a transverse direction free shrink at 50° C. of less than about 2% and a transverse direction free shrink at 57° C. of at least about 3%. The film has at least two layers. The first layer includes an ethylene / vinyl alcohol copolymer and the film has a second layer directly adhered to the first layer, the second layer including at least one member selected from the group consisting of polyester, polyamide and polyurethane. Preferably, the desired shrink properties are attained by annealing the film under controlled conditions.

Owner:CRYOVAC INC

Coatings for implantable medical devices

InactiveUS20060121089A1Improve hydrophobicityLong-term biocompatibilityBiocideSurgeryPropanolBiocompatibility

The present application teaches a coating having a biologically compatible compound conjugated to, or blended with, a polymer, wherein the polymer includes at least one olefin-derived unit and at least one unit derived from a vinyl alcohol, an allyl alcohol, or derivatives thereof.

Owner:ABBOTT CARDIOVASCULAR

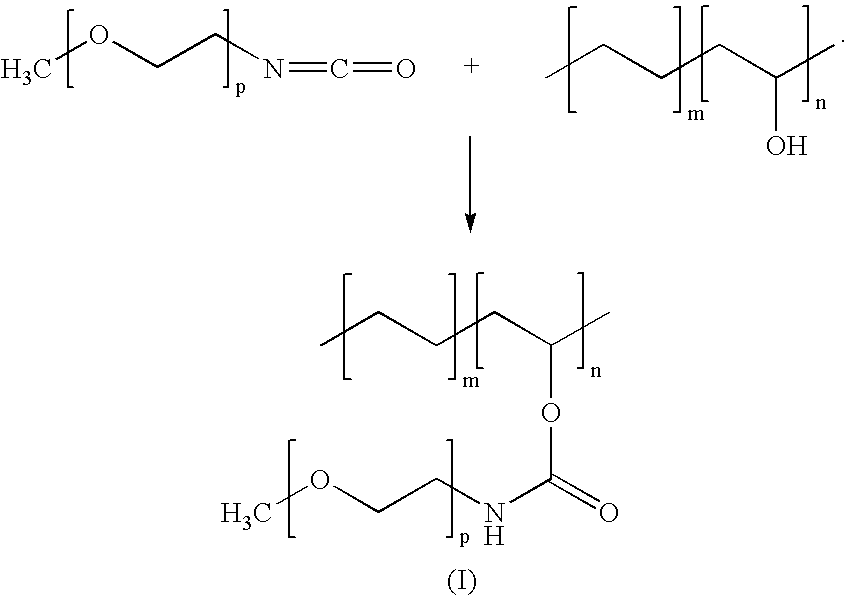

Use and provision of an amorphous vinyl alcohol polymer for forming a structure

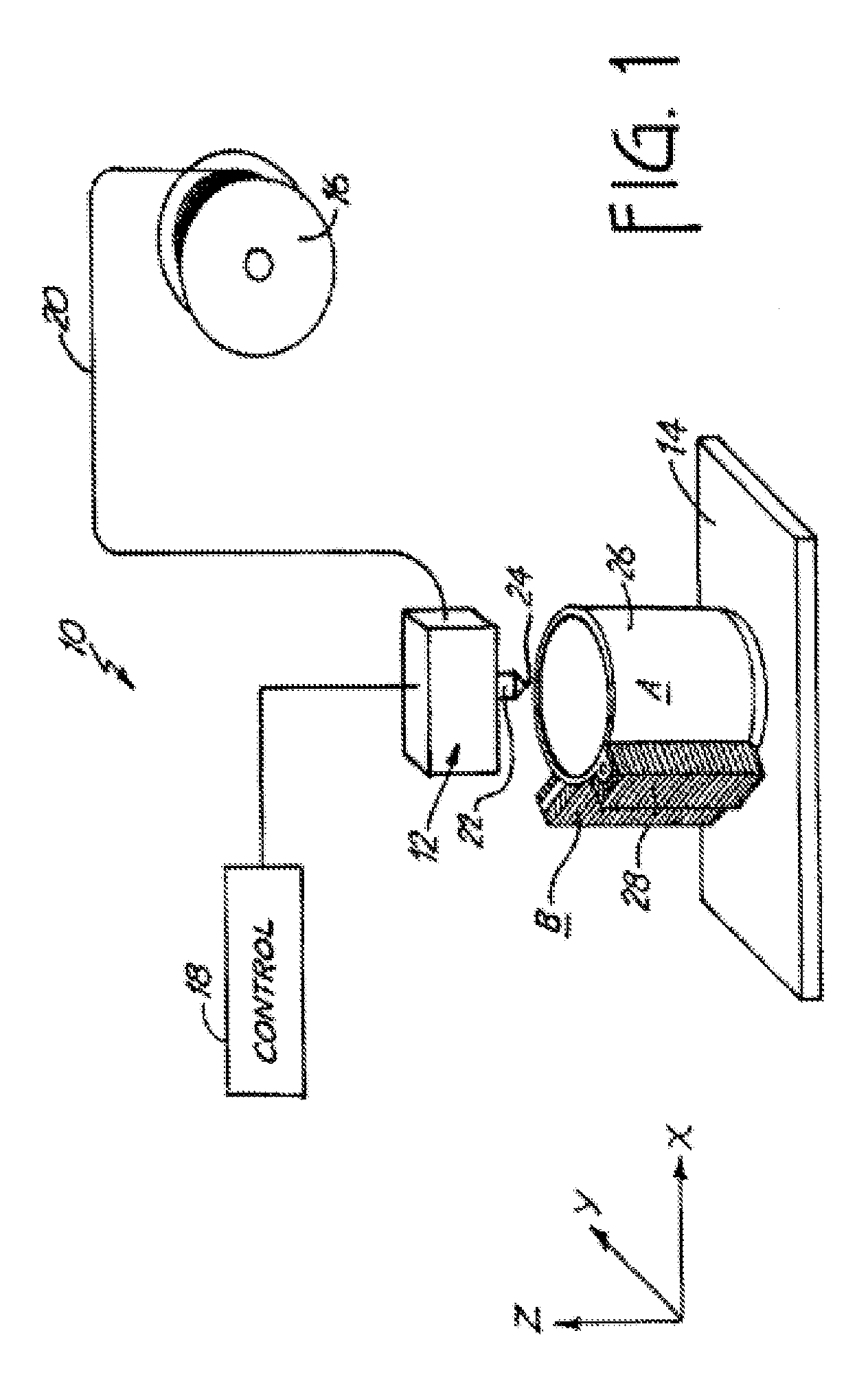

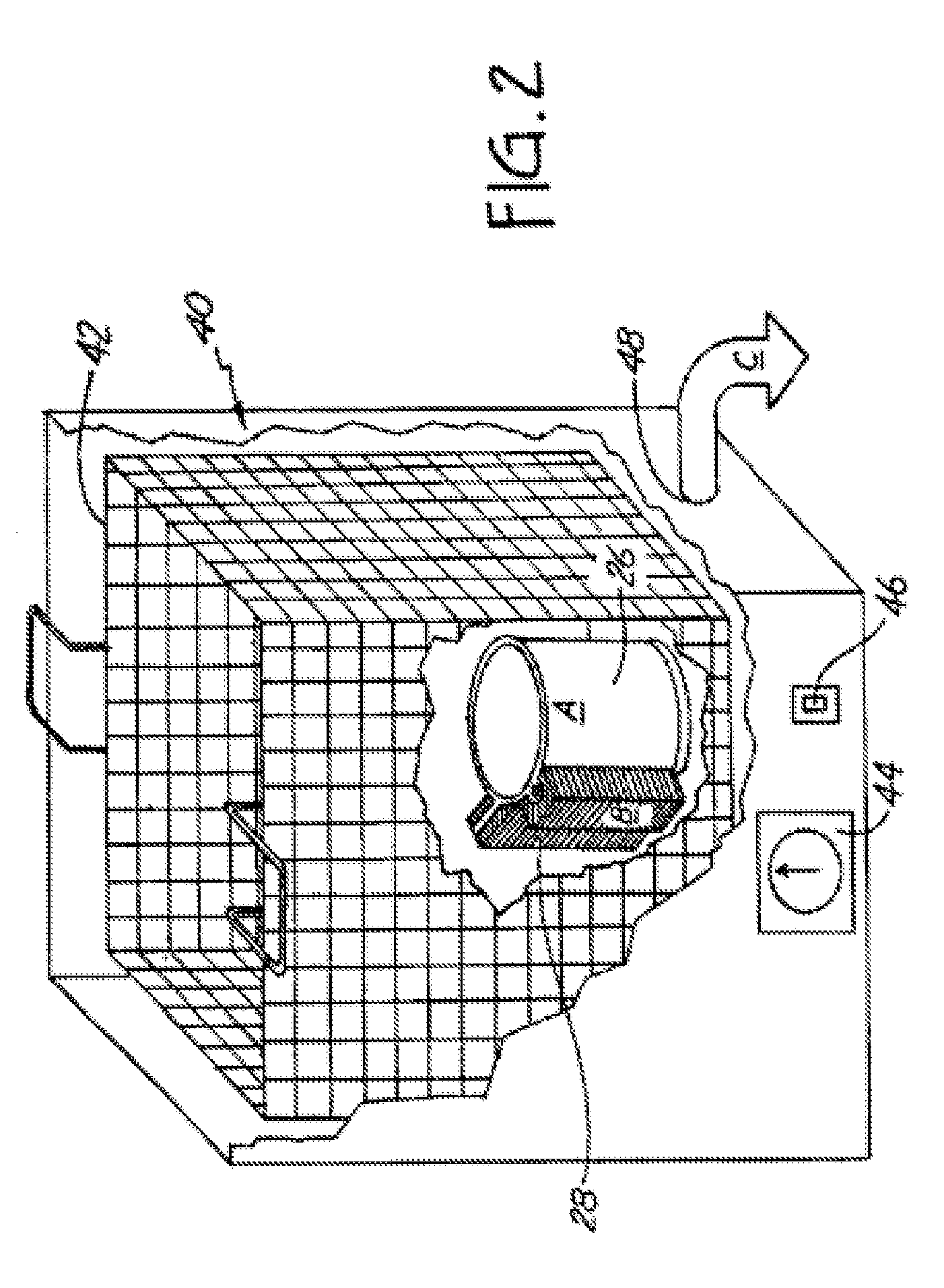

A process for three-dimensional modeling in which water soluble thermoplastic material is used in an additive deposition process to form a soluble support structure for a three-dimensional model formed via layer-by-layer deposition of the model's geometry. The water-soluble thermoplastic material includes a base of vinyl alcohol. Following the completion of the model, the model is placed in a cold water bath to dissolve the support structure. The water-soluble material can also be used to form soluble model directly.

Owner:BOLSON MATERIALS INTL

Resin composition and multi-layer structures

ActiveUS20050147778A1Improved melt stabilityInhibit deteriorationNon-fibrous pulp additionSynthetic resin layered productsStructural unitEthylene

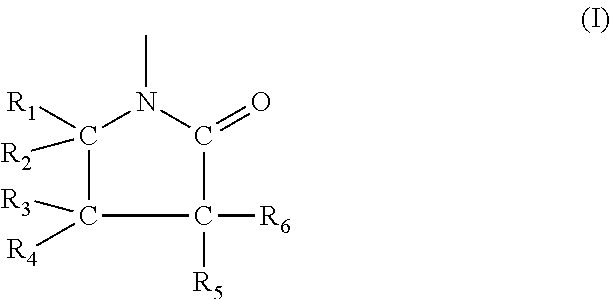

Provided is a resin composition comprising 1-99% by weight of a modified ethylene-vinyl alcohol copolymer (C) having an ethylene content of 5-55 mol %, which contains a specific structural unit (I) in an amount of 0.3-40 mol % and can be obtained by reacting an ethylene-vinyl alcohol copolymer (A) with a monofunctional epoxy compound (B) having a molecular weight of not more than 500, and 1-99% by weight of a thermoplastic resin (T1) other than (C). Moreover, a multilayer structure in which the resin composition and a thermoplastic resin (T2) are laminated is also provided. Thus, a resin composition superior in barrier properties, transparency, stretchability, flexibility, flexing resistance and interlayer adhesiveness and various kinds of molded articles made thereof are provided.

Owner:KURARAY CO LTD

Polymeric films

ActiveUS20090312462A1Excellent oxygen barrier propertiesSuitable for usePaper coatingDomestic articlesMolten statePolymer science

A polymer composition and its use for thin film packaging applications including on a dry basis: a) from 45 to 90% by weight of starch; b) from 0.1 to 15% by weight of a water soluble polymer selected from polyvinyl alcohol, polyvinylacetate, and copolymers of ethylene and vinyl alcohol which have a melting point compatible with the molten state of the starch component; and c) from 5 to 45% by weight of one or more plasticizers having a molecular weight in the range of 50-6000, more preferably 50-2500 and more preferably still 100-400 and desirably selected from the group consisting of sorbitol, glycerol, maltitol, xylitol, mannitol, erythritol, glycerol trioleate, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate, polyethylene oxide, ethylene glycol, diethylene glycol or polyethylene glycol.

Owner:PLANTIC TECH

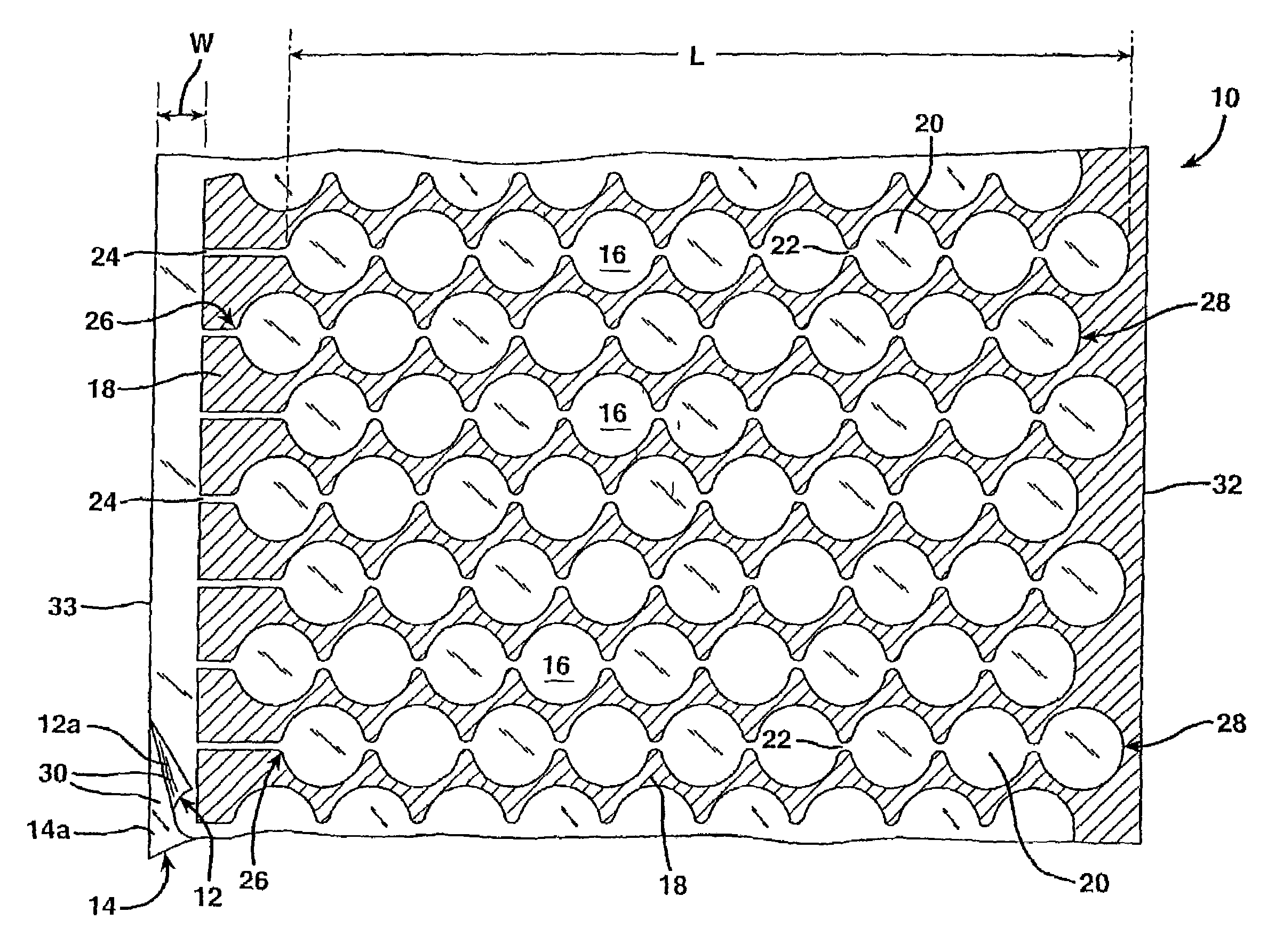

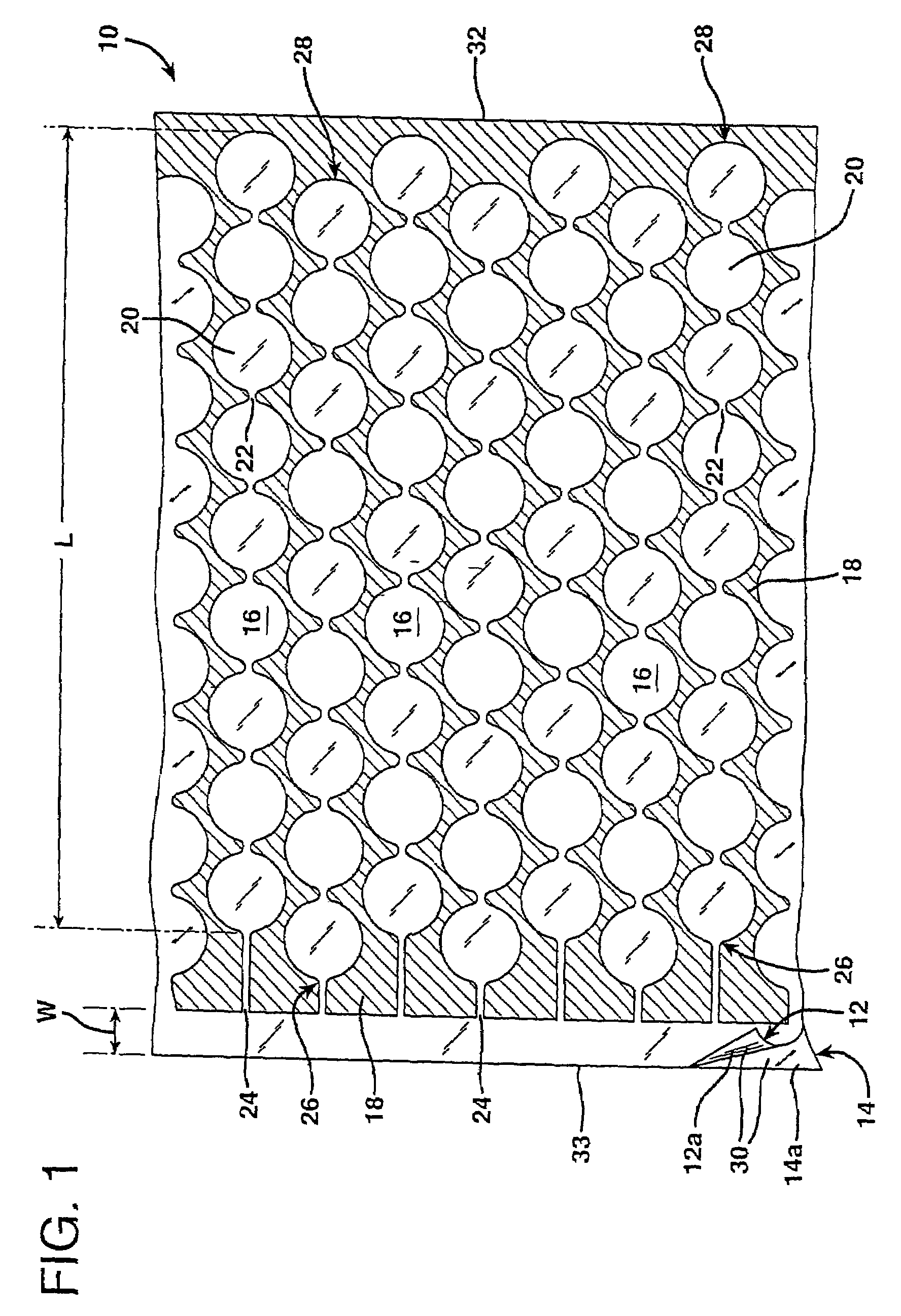

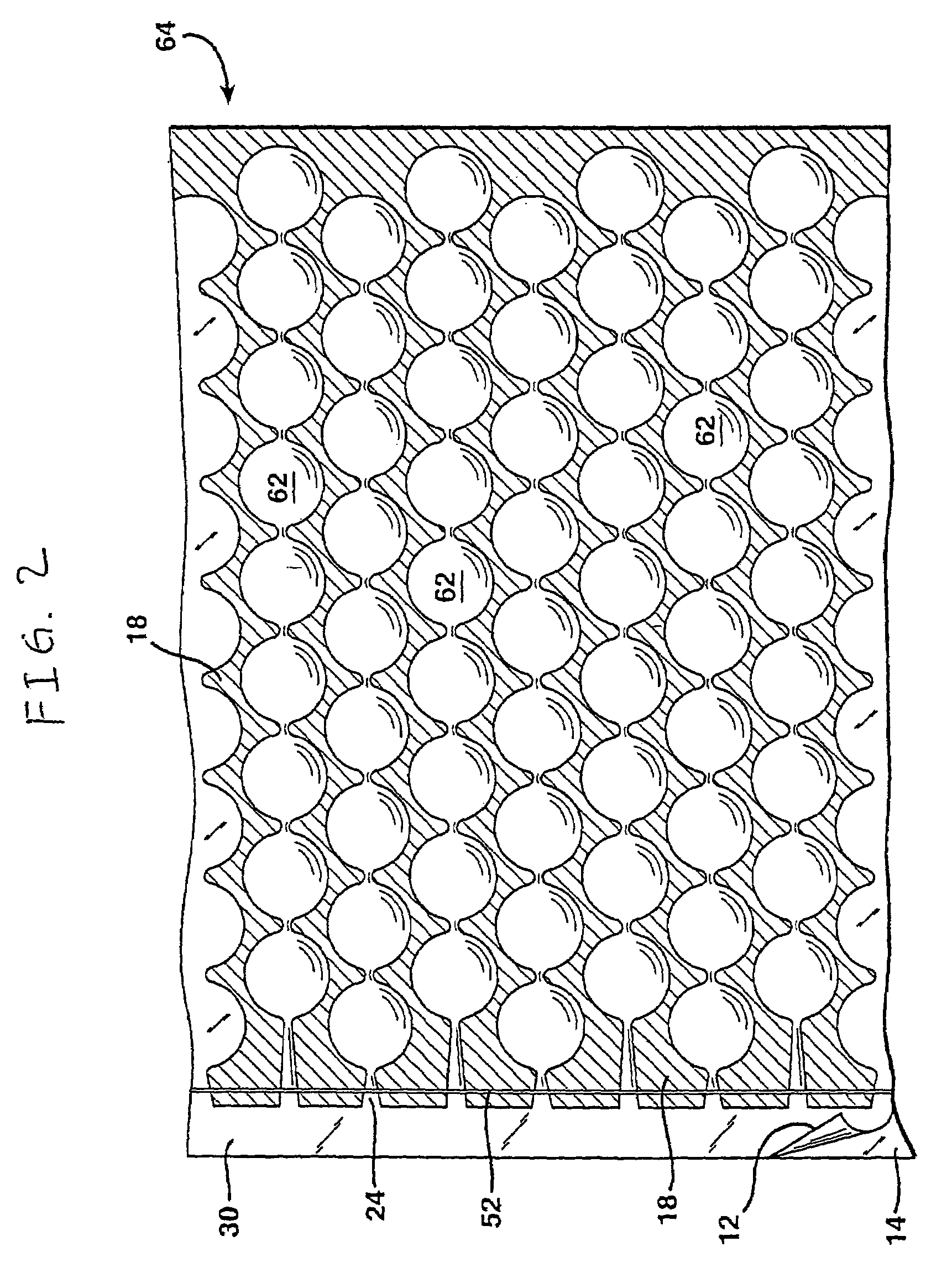

Process for making and aging high strength high gas barrier cellular cushioning product

ActiveUS7018495B2Reduce and eliminate film delaminationLower bursting pressurePaper/cardboard articlesHollow inflatable ballsPolyesterPolymer science

An inflatable cushioning article is made by a process of extruding two multilayer films (or extruding one film which is either annular or folded over) each having (a) a seal layer, (b) a tie layer containing an anhydride modified olefin polymer containing anhydride at a level of at least 150 ppm, based on the weight of the modified olefin polymer, and (c) an oxygen barrier layer comprising crystalline polyamide, crystalline polyester, ethylene / vinyl alcohol copolymer, polyacrylonitrile, and / or crystalline polycycloolefin. Selected portions of the films are heat sealed to one another in a selected area providing a heat seal pattern which leaves inflatable chambers between the films, whereby an inflatable cellular cushioning article is produced. At some point after extrusion, at least one of the multilayer films are aged for a time and at a temperature in accordance with at least one member selected from the group consisting of: (i) 141° F. to 250° F. for a period of at least 1 second; (ii) 101° F. to 140° F. for a period of at least 10 minutes; (iii) 61° F. to 100° F. for a period of at least 1 hour; and (iv) 30° F. to 60° F. for a period of at least 1 day. After aging, the cellular cushioning article is inflated. Preferably, the article is inflated to an internal pressure of at least 1.5 psi.

Owner:SEALED AIR U S

Poly (vinyl alcohol) hydrogel

InactiveUS20010029399A1Exemption stepsOrganic active ingredientsEar treatmentEngineeringSacroiliac joint

The present invention comprises a poly (vinyl alcohol) hydrogel construct having a wide range of mechanical strengths for use as a human tissue replacement. The hydrogel construct may comprise a tissue scaffolding, a low bearing surface within a joint, or any other structure which is suitable for supporting the growth of tissue.

Owner:GEORGIA TECH RES CORP

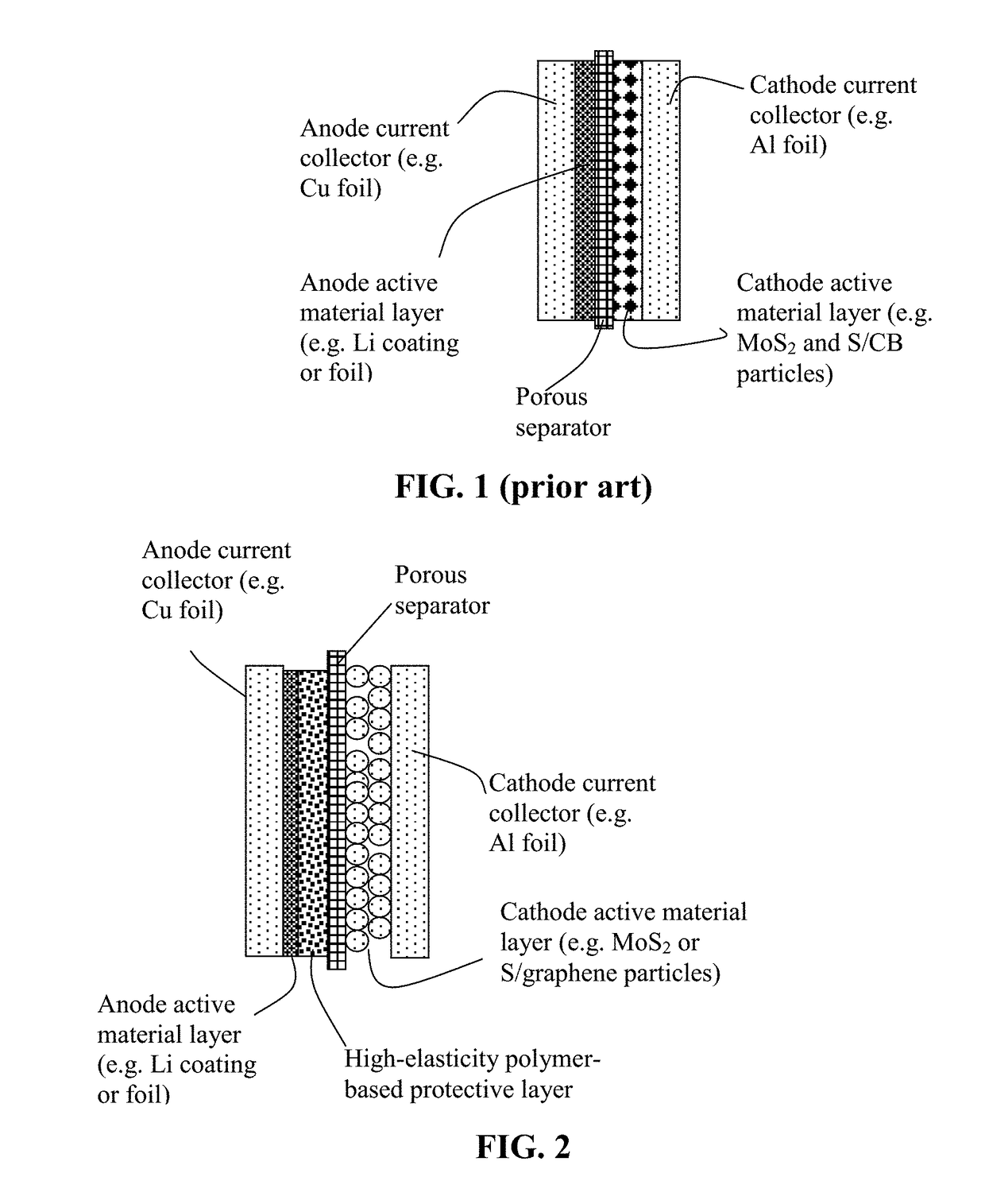

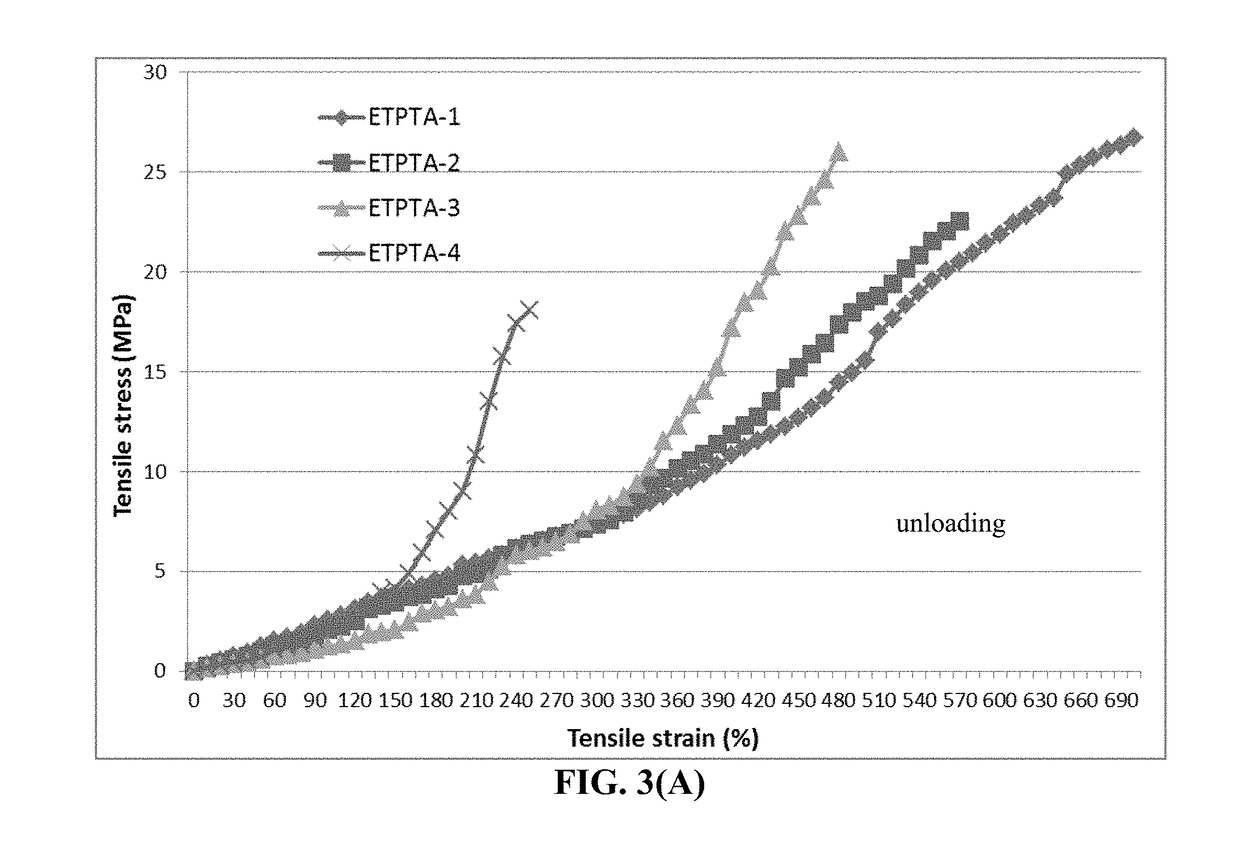

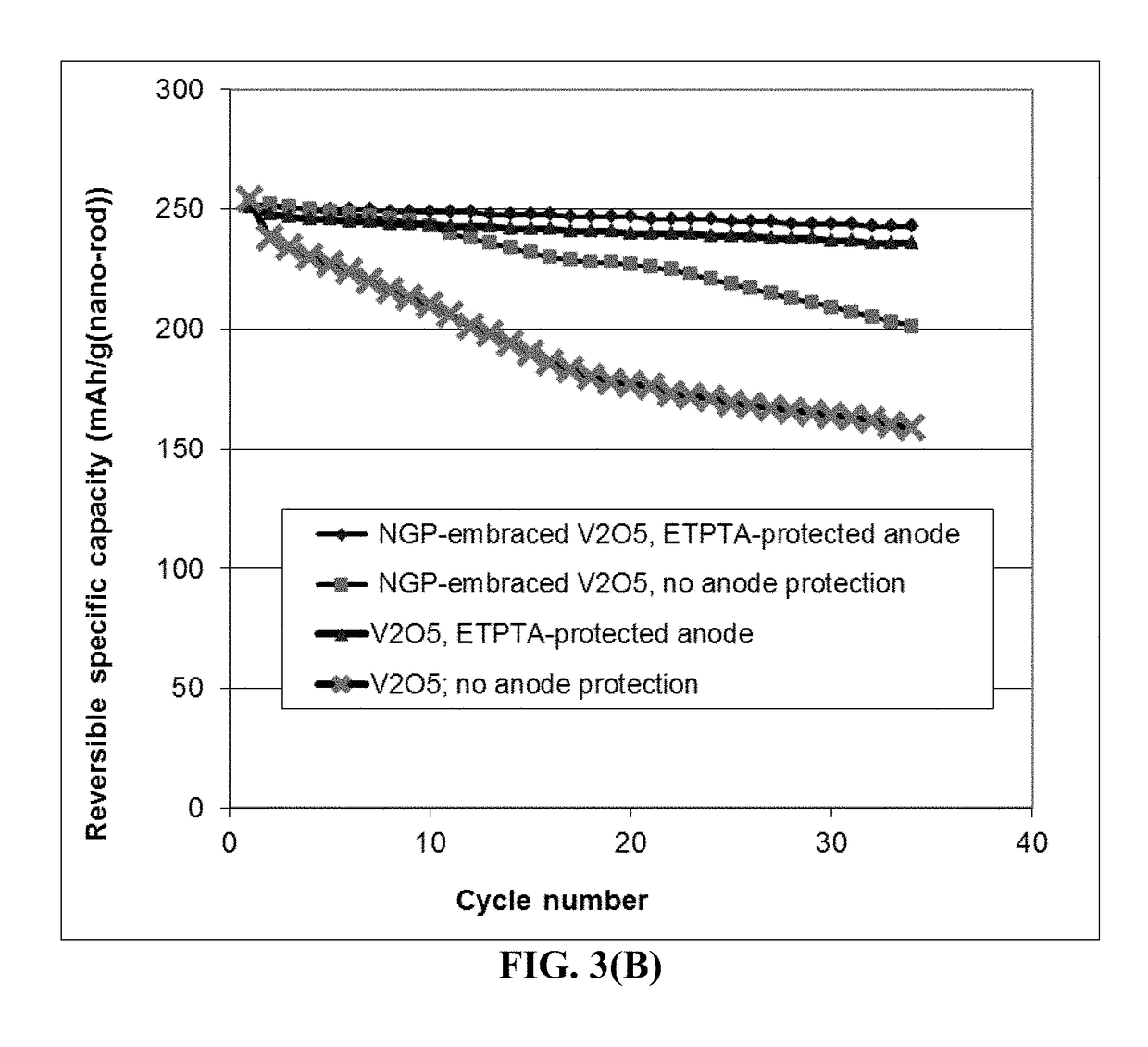

Lithium Anode-Protecting Polymer Layer for a Lithium Metal Secondary Battery and Manufacturing Method

ActiveUS20180301707A1Improve lithium ion conductivityIncrease elasticityFuel and secondary cellsCell electrodesCross-linkLithium metal

Provided is lithium secondary battery comprising a cathode, an anode, and an electrolyte or separator-electrolyte assembly disposed between the cathode and the anode, wherein the anode comprises: (a) a foil or coating of lithium or lithium alloy; and (b) a thin layer of a high-elasticity polymer disposed between the foil / coating and the electrolyte (or separator-electrolyte assembly), having a recoverable tensile strain no less than 2%, a lithium ion conductivity no less than 10−6 S / cm at room temperature, and a thickness from 1 nm to 10 μm, wherein the high-elasticity polymer contains a cross-linked network of polymer chains having an ether linkage, nitrile-derived linkage, benzo peroxide-derived linkage, ethylene oxide linkage, propylene oxide linkage, vinyl alcohol linkage, cyano-resin linkage, triacrylate monomer-derived linkage, tetraacrylate monomer-derived linkage, or a combination thereof in the cross-linked network of polymer chains.

Owner:GLOBAL GRAPHENE GRP INC

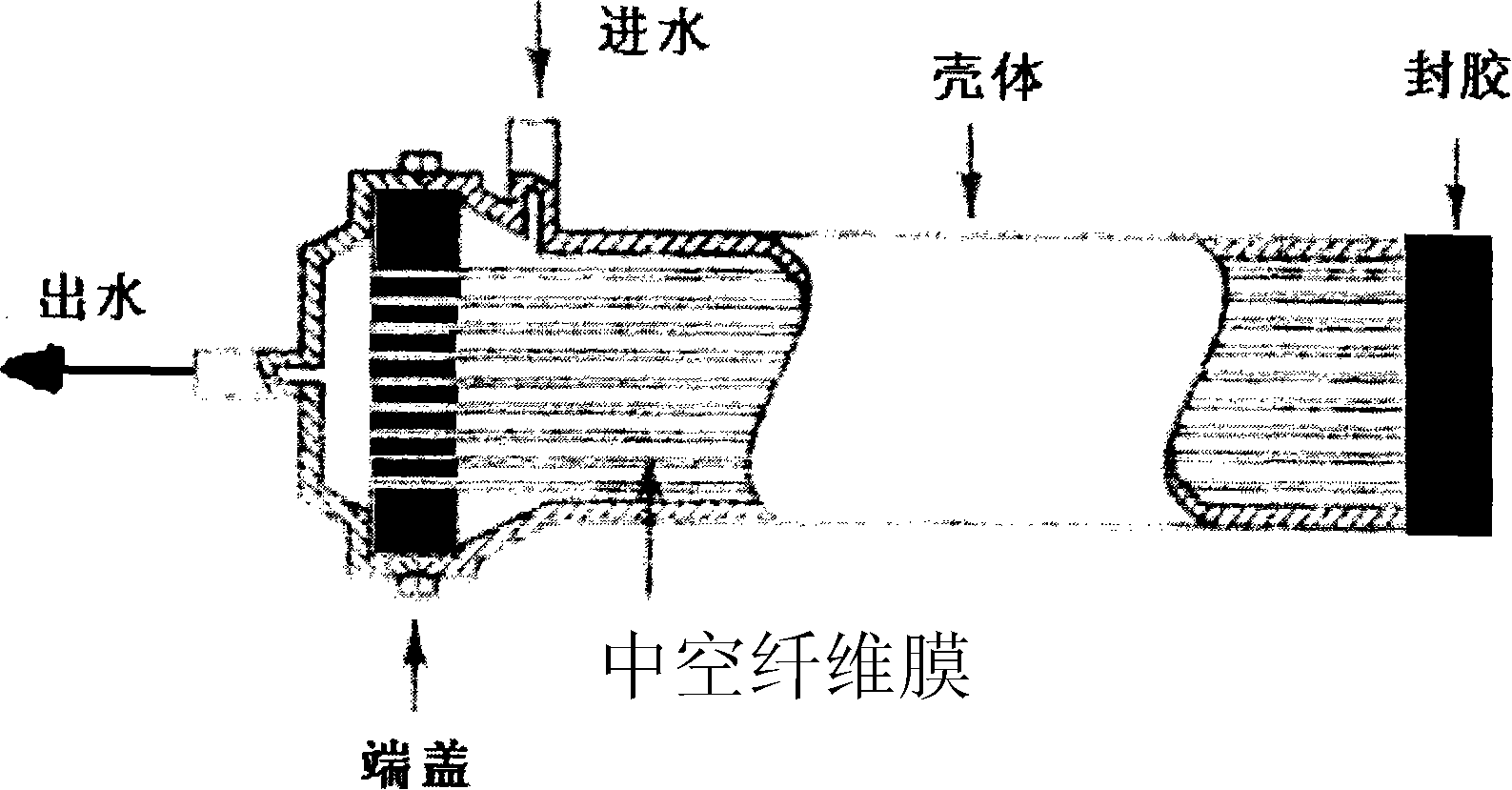

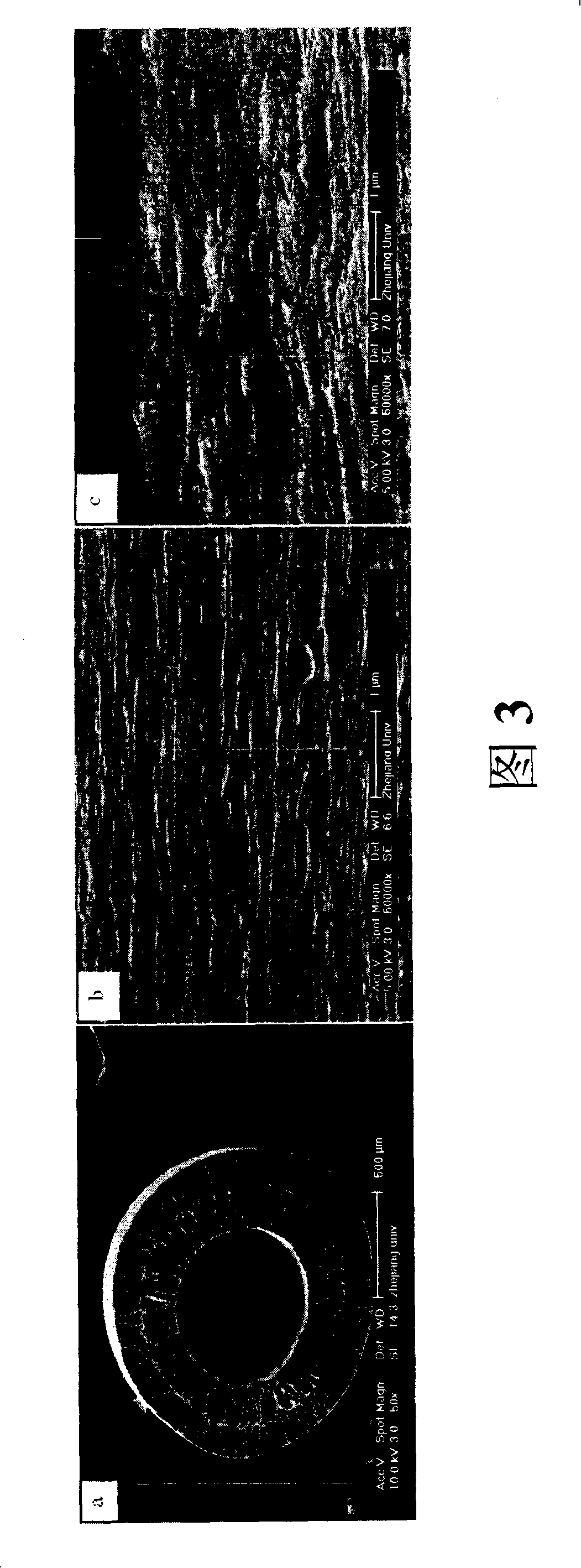

Hydrophilicity kynoar hollow fiber microporous membrane and preparation method thereof

ActiveCN101190401AImprove anti-pollution performanceAvoid adsorptionSemi-permeable membranesHollow fibrePorosity

The invention discloses a hydrophilic polyvinylidene fluoride hollow fiber microporous membrane and the preparation method thereof. The main composition and the mass content of the membrane are 70% to 90% of polyvinylidene fluoride, amphiphilic poly-(propylene oxide-oxirane), 5% to 29% of poly-(methacrylic acid- acrylic acid) or poly-(methacrylic acid methyl ester-vinyl alcohol) copolymer and 1% to 5% of nano-silicon dioxide. The membrane preparation method is that all the components are mixed and dissolved with aperture regulator, thickener and solvent to obtain the membrane preparation liquid; after that, the hollow fiber forming is carried out through a dry-wet spinning technique, and finally cleaning and drying are implemented. The obtained membrane has adjustable internal diameter and external diameter, 60% to 80% of porosity and the aperture ranging from 0.01micron to 0.2micron. As a water disposal separating membrane material with excellent performance, the invention has the advantages of being able to be fully humid, organic adsorption resistance and great water flux, etc.

Owner:HAINAN LITREE PURIFYING TECH CO LTD

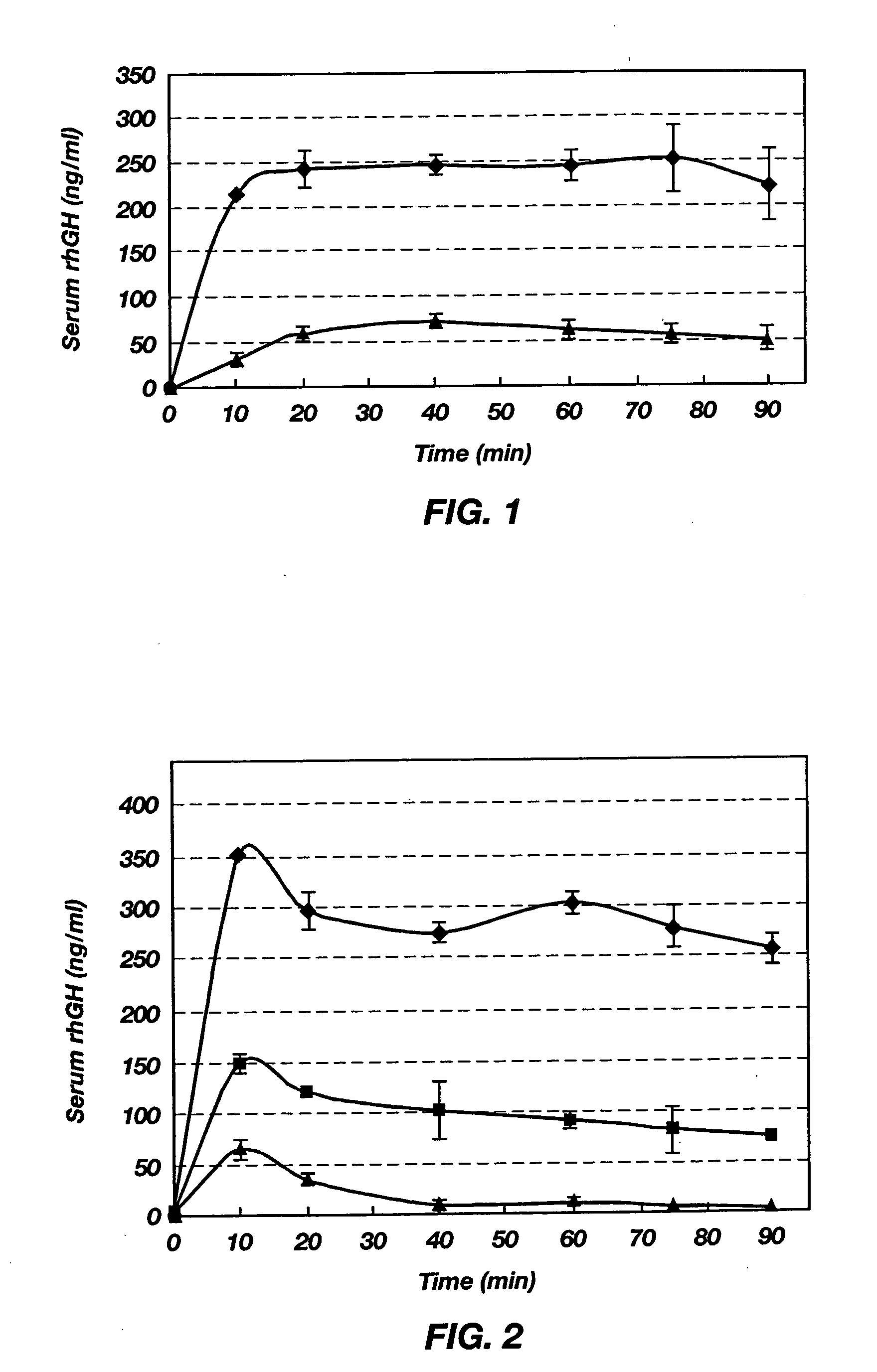

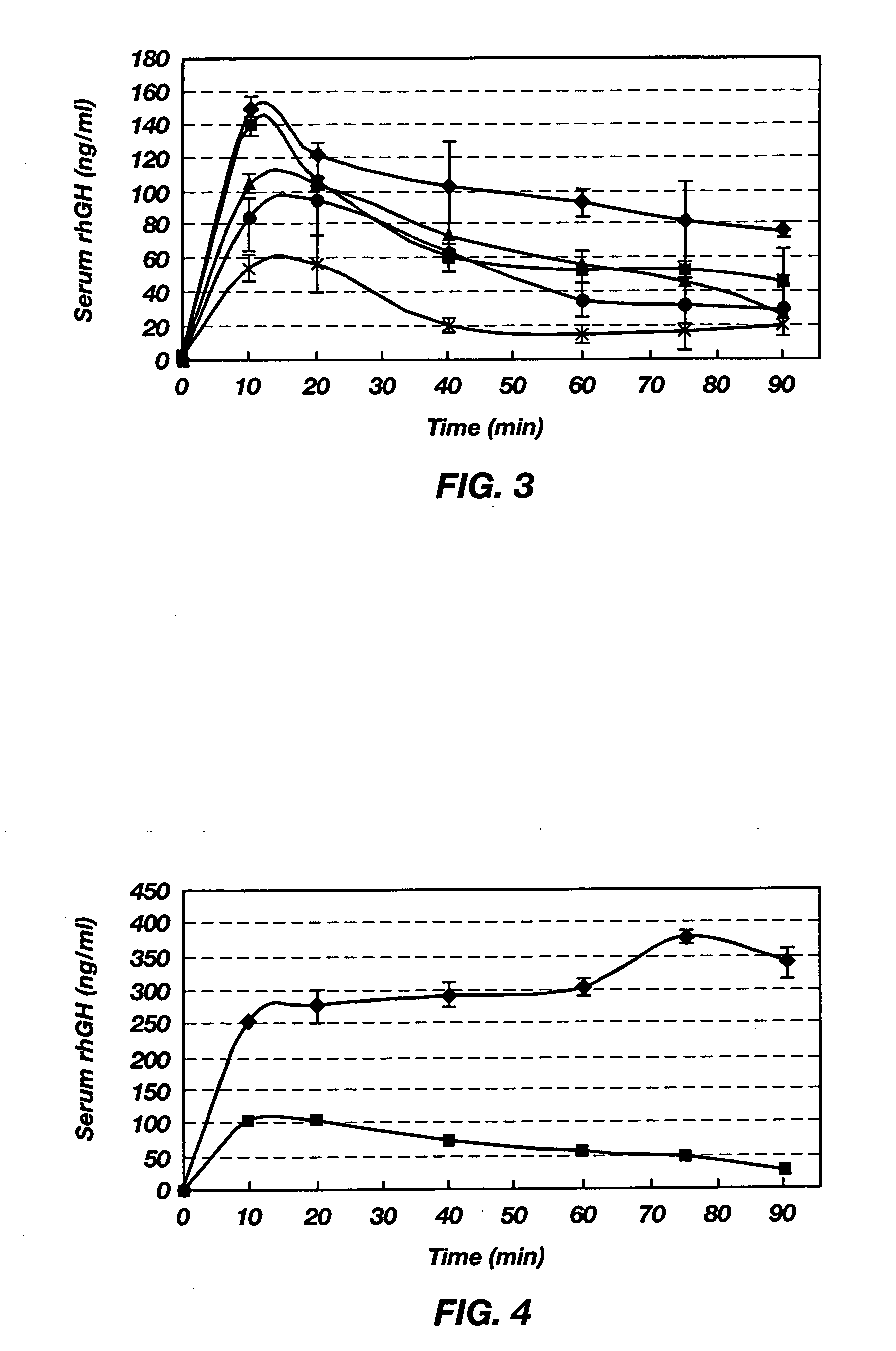

Oral formulation for delivery of poorly absorbed drugs

InactiveUS20060088592A1Promote absorptionReduce inactivationHeavy metal active ingredientsMultiple-port networksSucrosePolyvinyl alcohol

A composition for oral delivery of a poorly absorbed drug is disclosed. The composition includes the drug, an enhancer for increasing absorption of the drug through the intestinal mucosa, a promoter, which alone does not increase absorption of the drug through the intestinal mucosa, but which further increases the absorption of the drug in the presence of the enhancer, and optionally a protector for protecting the drug from physical or chemical decomposition or inactivation in the gastrointestinal tract. Illustrative enhancers include sucrose fatty acid esters, and illustrative promoters include aminosugars and amino acid derivatives, such as poly(amino acids). Illustrative protectors include methylcellulose, poly(vinyl alcohol), and poly(vinyl pyrrolidone).

Owner:PROCARRIER

Process for co-producing olefins and esters by ethenolysis of unsaturated fats in non-aqueous ionic liquids

A process is described in which an unsaturated fat is reacted with ethylene in a metathesis reaction in the presence of at least one non-aqueous ionic liquid to produce both an olefinic fraction and a composition of monoalcohol or polyol esters. Particular application to an oleic sunflower seed oil, an oleic rapeseed oil or to a mixture of monoalcohol esters of said oils, the process producing both an olefinic fraction and a monoalcohol or glycerol esters composition generally having more than half of its chains constituted by unsaturated C10 chains.

Owner:INST FR DU PETROLE

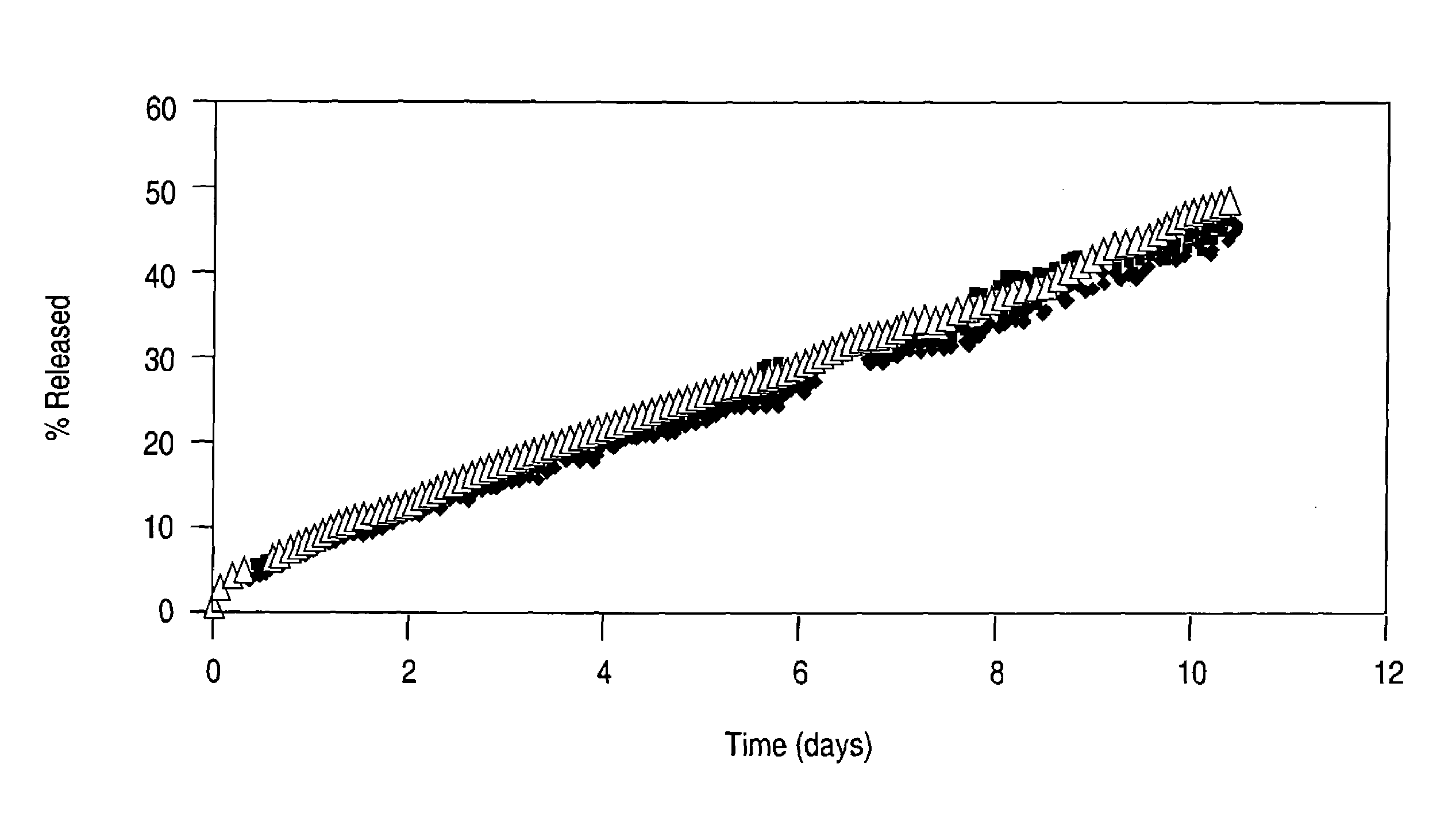

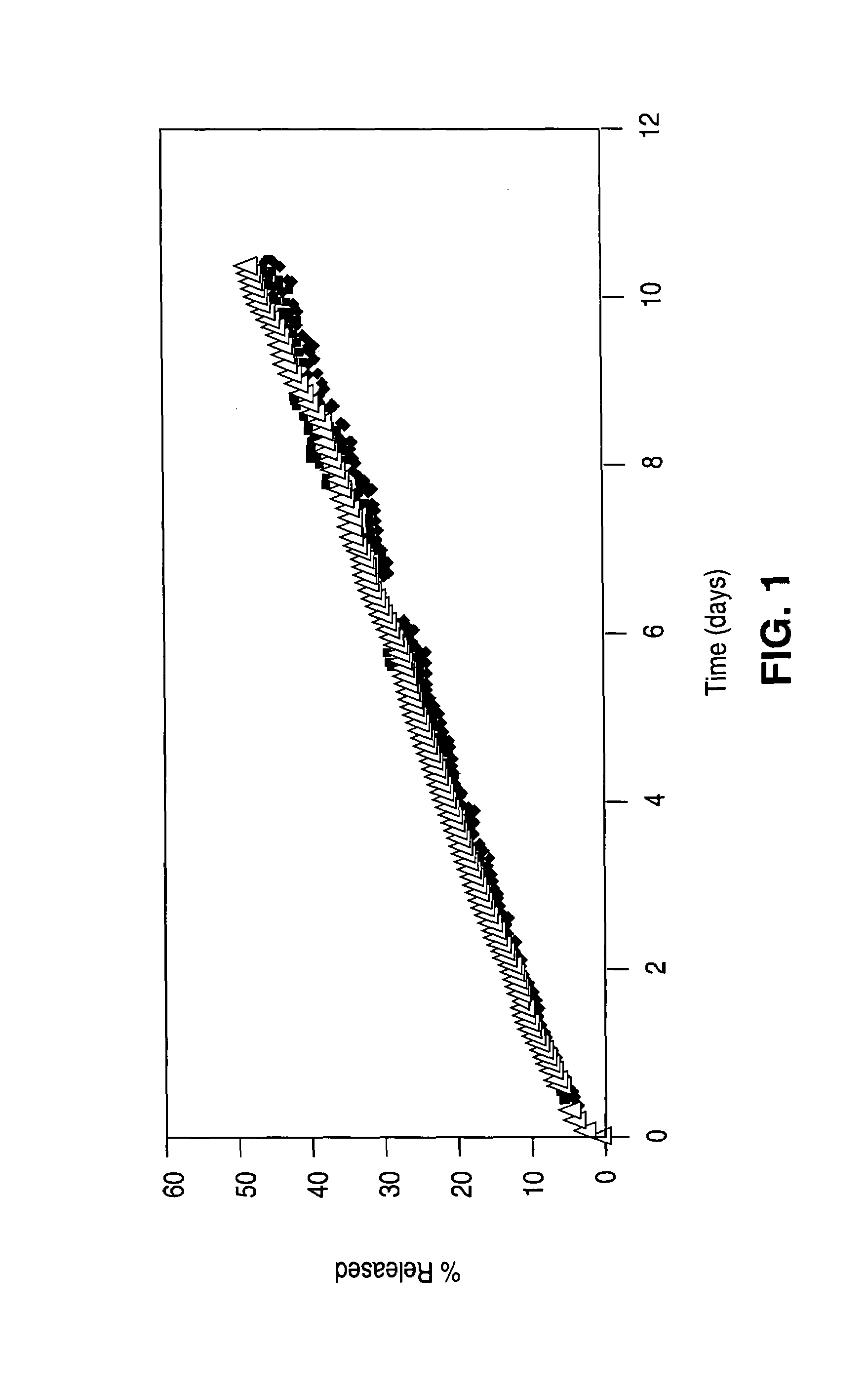

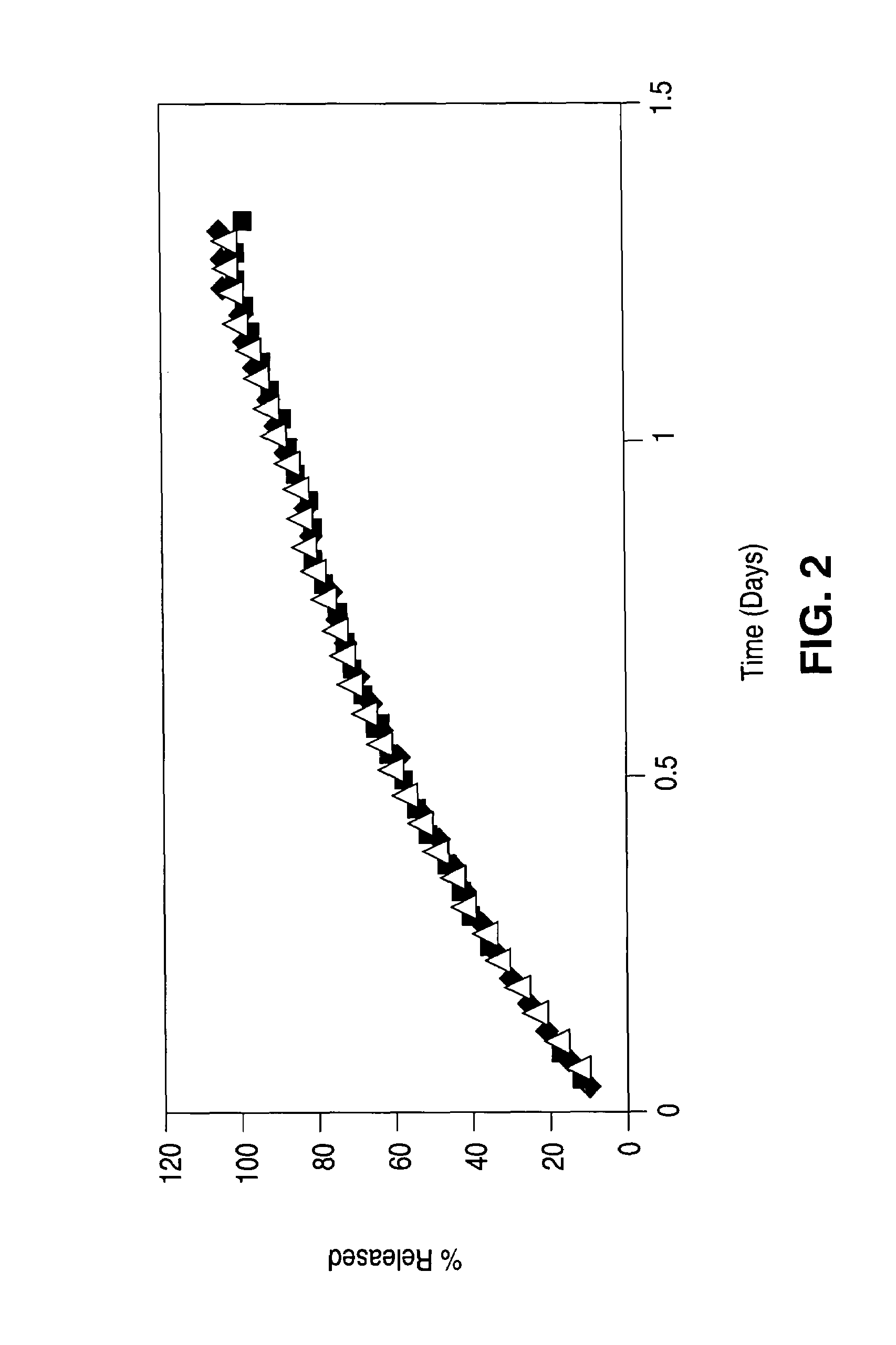

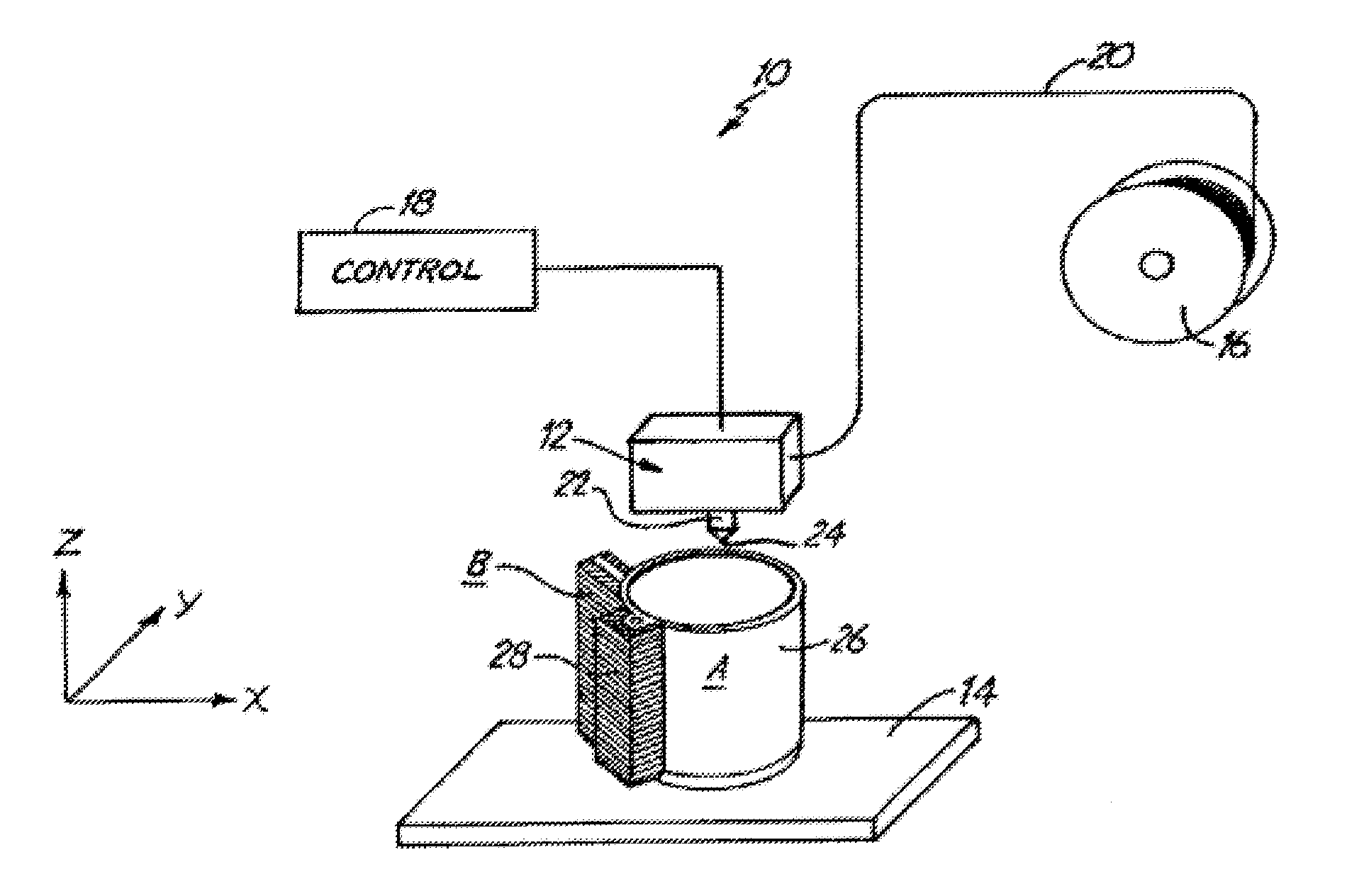

Process for preparing poly(vinyl alcohol) drug delivery devices

InactiveUS20060067978A1Pharmaceutical containersPharmaceutical delivery mechanismPolyvinyl alcoholMedicine

The present invention is a process for making a plurality of drug delivery devices for implantation in the eye of a patient. The plurality of drug delivery devices are made in part of poly(vinyl alcohol). During the manufacturing process the poly(vinyl alcohol) is cured. The poly(vinyl alcohol) may be in the form of separate pieces, a unitary sheet or may be incorporated into the drug delivery device at the time of curing. During the step of curing the humidity is controlled to ensure improved consistency during the curing process. The improved consistency results in inventories of drug delivery devices that have different cure times.

Owner:BAUSCH & LOMB INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com