Patents

Literature

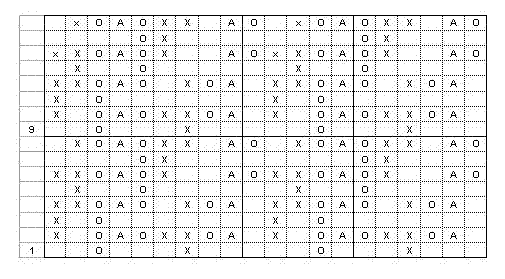

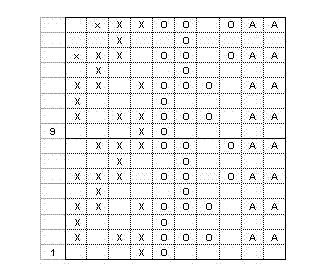

486 results about "Vinyl pyridine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

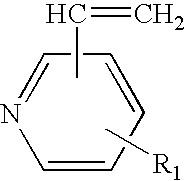

2-Vinylpyridine is an organic compound with the formula CH2CHC5H4N. It is a derivative of pyridine with a vinyl group in the 2-position, next to the nitrogen. It is a colorless liquid although samples are often brown.

Composite materials comprising polar polymers and single-wall carbon nanotubes

InactiveUS6936653B2Improve conductivityMaterial nanotechnologyIndividual molecule manipulationPolyesterPolymer science

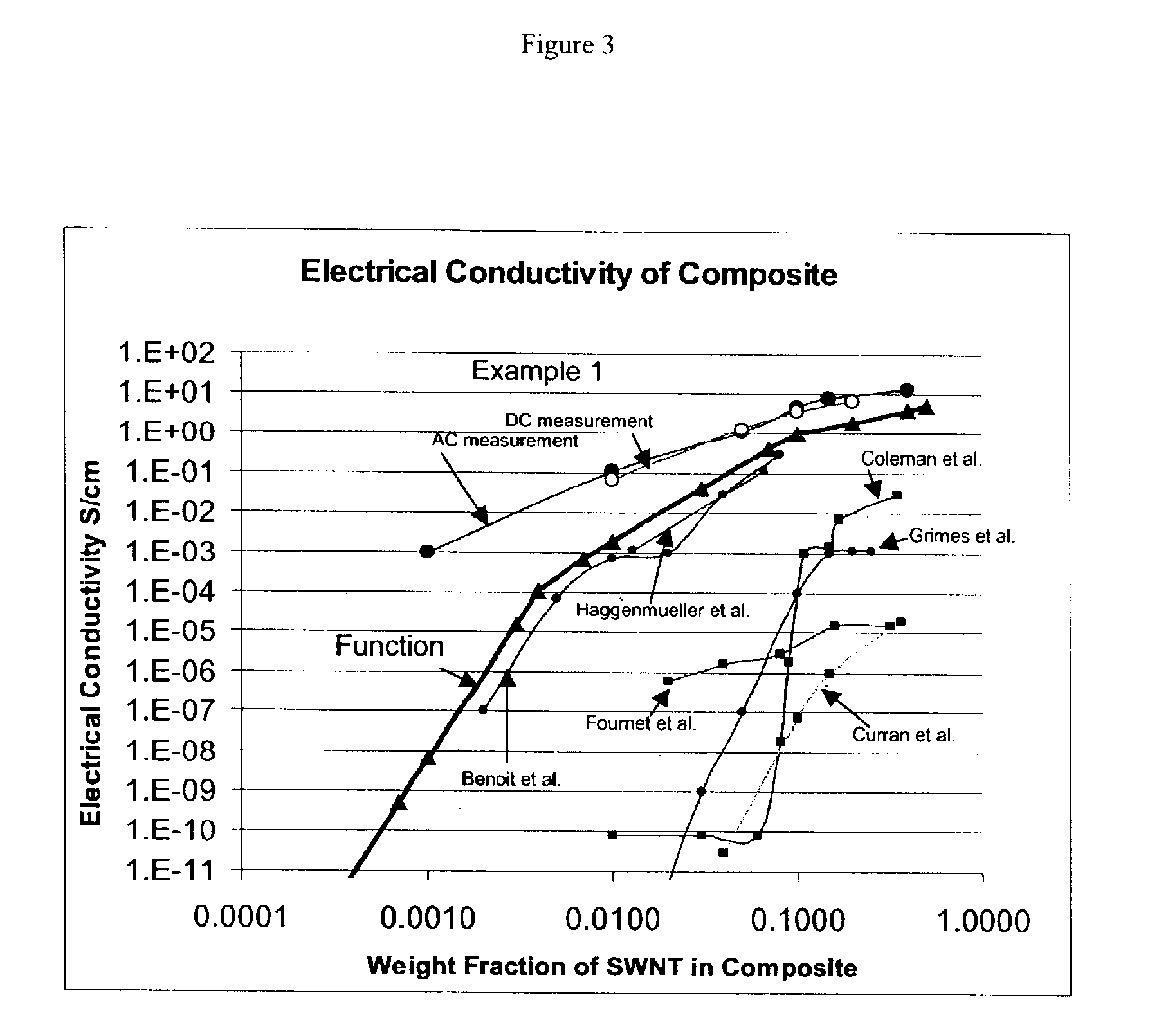

The invention relates to a composite comprising a weight fraction of single-wall carbon nanotubes and at least one polar polymer wherein the composite has an electrical and / or thermal conductivity enhanced over that of the polymer alone. The invention also comprises a method for making this polymer composition. The present application provides composite compositions that, over a wide range of single-wall carbon nanotube loading, have electrical conductivities exceeding those known in the art by more than one order of magnitude. The electrical conductivity enhancement depends on the weight fraction (F) of the single-wall carbon nanotubes in the composite. The electrical conductivity of the composite of this invention is at least 5 Siemens per centimeter (S / cm) at (F) of 0.5 (i.e. where single-wall carbon nanotube loading weight represents half of the total composite weight), at least 1 S / cm at a F of 0.1, at least 1×10−4 S / cm at (F) of 0.004, at least 6×10−9 S / cm at (F) of 0.001 and at least 3×10−16 S / cm (F) plus the intrinsic conductivity of the polymer matrix material at of 0.0001. The thermal conductivity enhancement is in excess of 1 Watt / m-° K. The polar polymer can be polycarbonate, poly(acrylic acid), poly(acrylic acid), poly(methacrylic acid), polyoxide, polysulfide, polysulfone, polyamides, polyester, polyurethane, polyimide, poly(vinyl acetate), poly(vinyl alcohol), poly(vinyl chloride), poly(vinyl pyridine), poly(vinyl pyrrolidone), copolymers thereof and combinations thereof. The composite can further comprise a nonpolar polymer, such as, a polyolefin polymer, polyethylene, polypropylene, polybutene, polyisobutene, polyisoprene, polystyrene, copolymers thereof and combinations thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

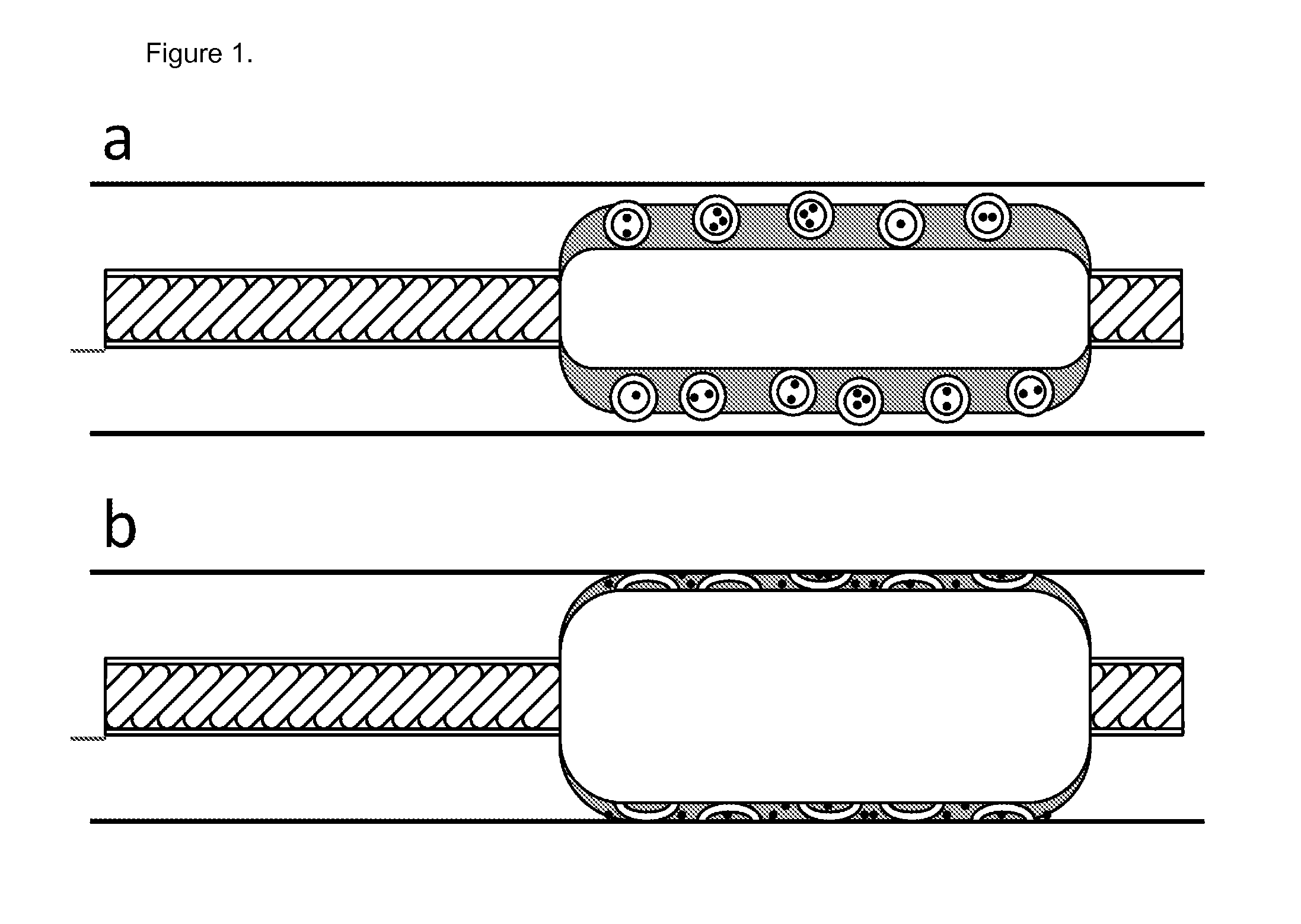

Balloon catheter comprising pressure sensitive microparticles

InactiveUS20120083734A1Improve brittlenessEffective treatmentSurgeryDilatorsPolyesterPoly(N-isopropylacrylamide)

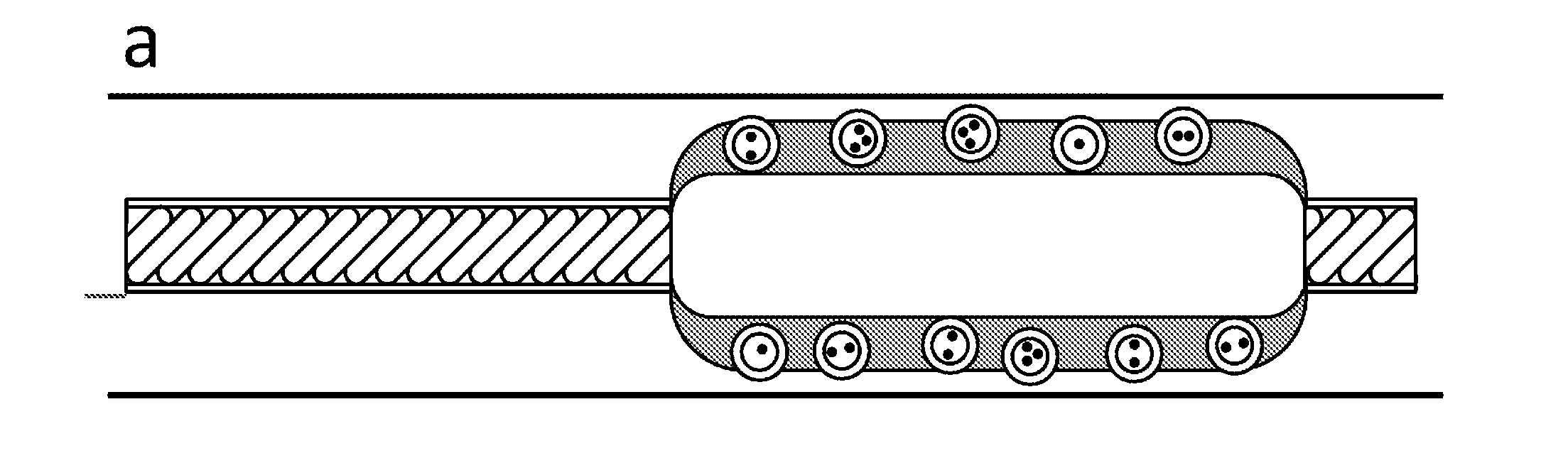

The invention provides a solution to the above mentioned problem in that it provides a catheter balloon comprising a flexible coating on its outer surface wherein a plurality of microparticles are contained wherein said coating comprises a material selected from the group consisting of poly(N-vinyl-pirrolidone, poly(N-vinyl-pirrolidone-co-butylacrylate), poly(-vinyl pyridine), polyacrylamides, e.g. poly(N-isopropylacrylamide), poly(amido-amines), poly(ethylene imine), poly(ethylene oxide-block-propylene oxide), poly(ethylene oxide-block-propylene oxide-block-ethylene oxide), poly(styrene-block-isobutylene-block-styrene), poly(hydroxystyrene-block-isobutylene-block-hydroxystyrene), polydialkylsiloxanes, polysaccharides, polyacrylates and polyalkylmethacrylates, e.g. polymethylmethacrylate and poly(2-hydroxyethylmethacrylate) and wherein said microparticles comprise a material selected from the group consisting of polyesters, e.g. poly(lactic acid), poly(lactic-co-glycol acid), poly(glycolic acid), poly(3-hydroxybutyrate), poly(3-hydroxyvalerate), poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and polycaprolactone, polyamides, polysaccharides, polyurethanes, polyalkylmethacrylates and polyacrylates, e.g. polymethylmethacrylate and poly(2-hydroxyethylmethacrylate) and wherein the microparticles comprise a pharmaceutically active compound.

Owner:ENCAPSON

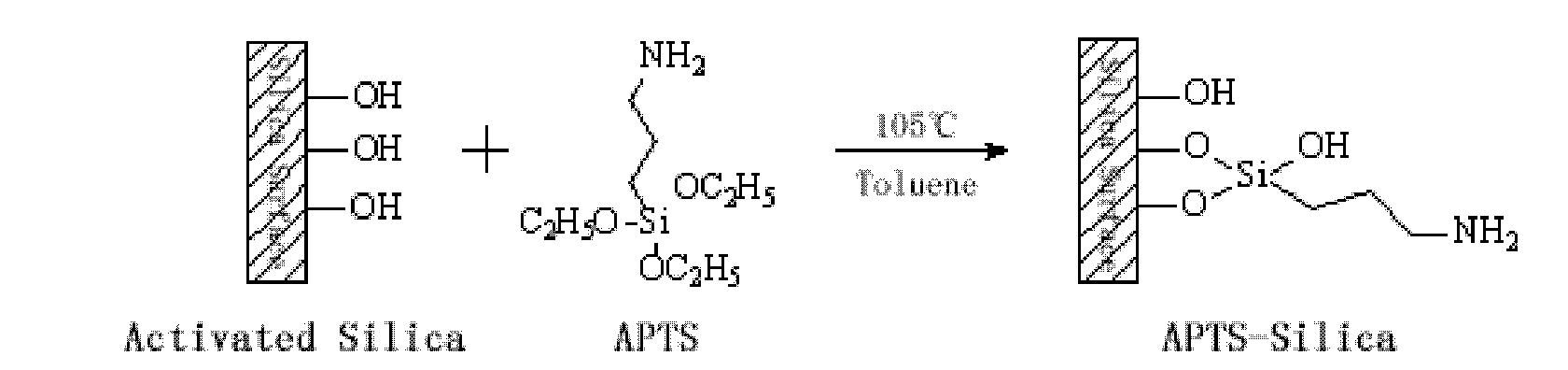

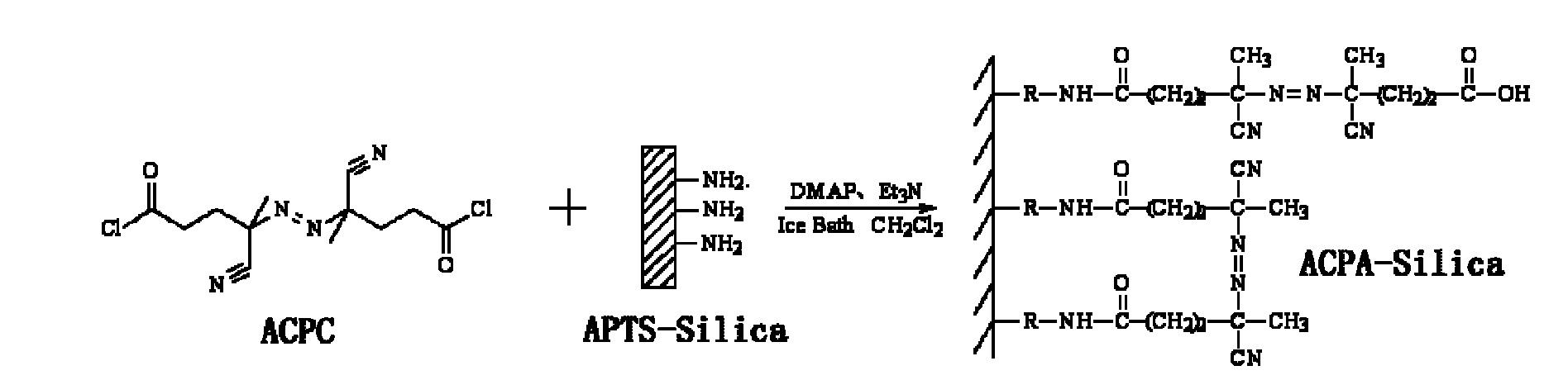

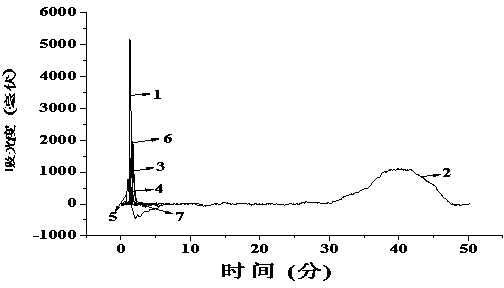

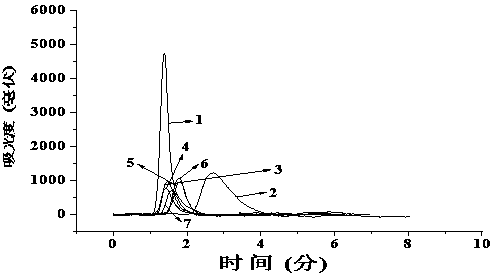

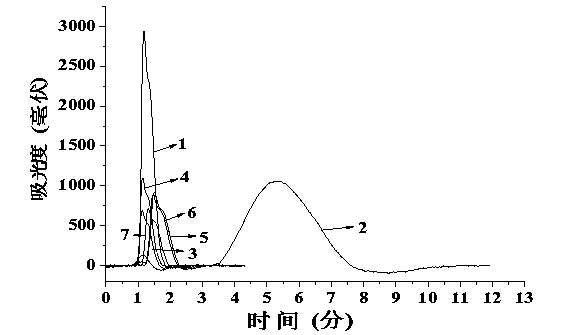

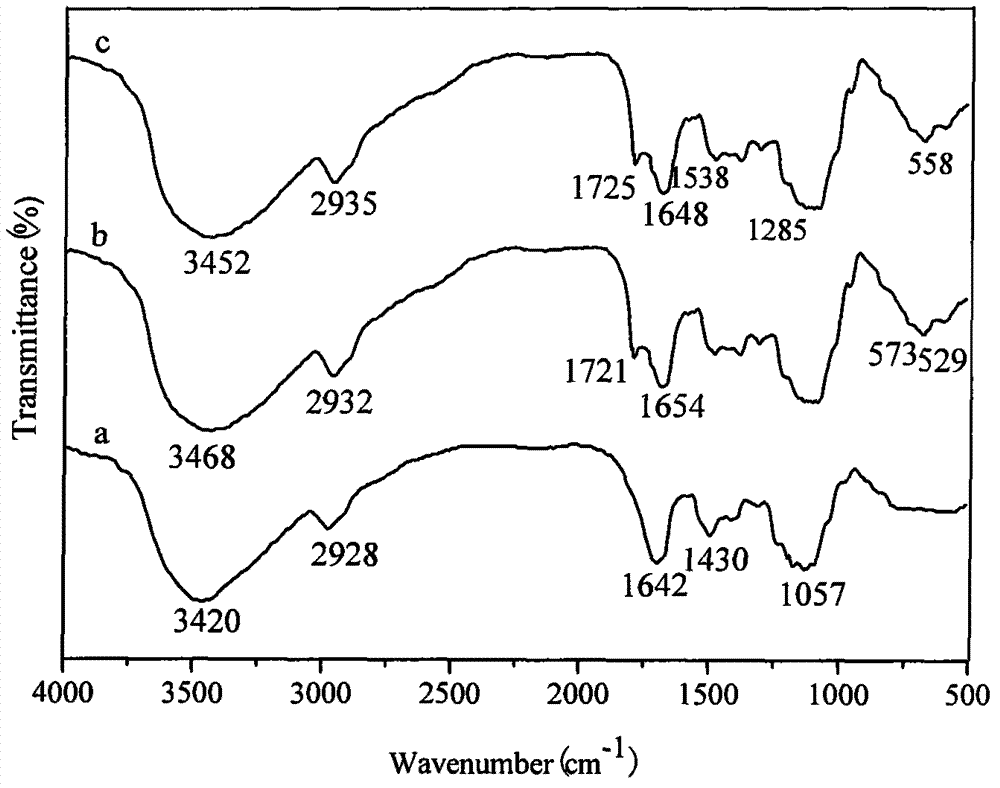

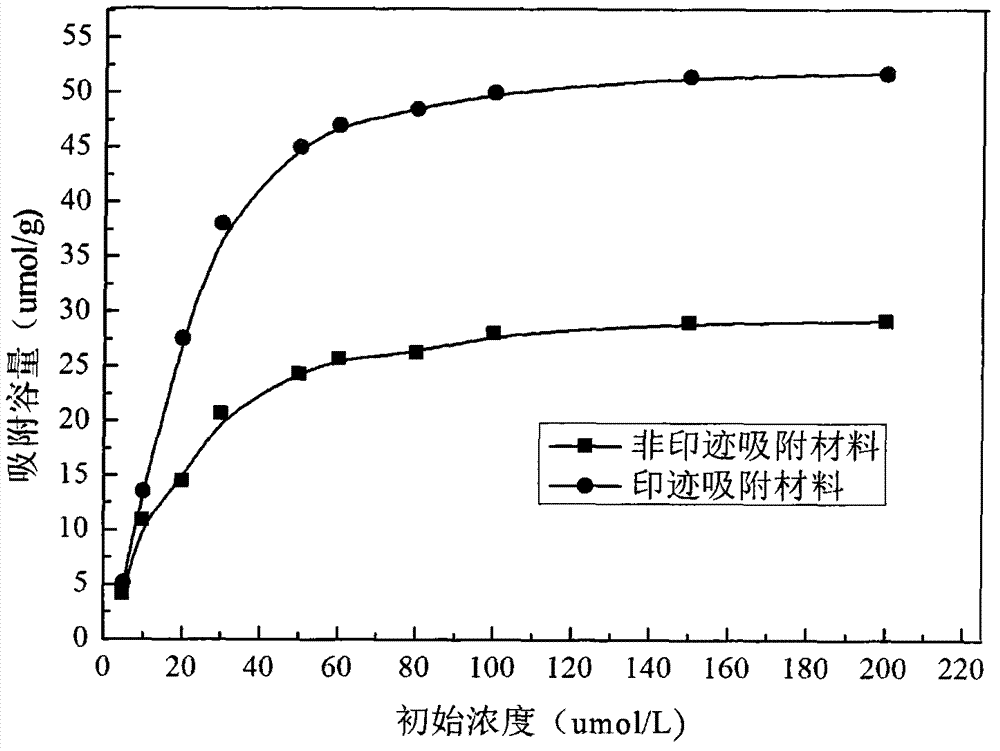

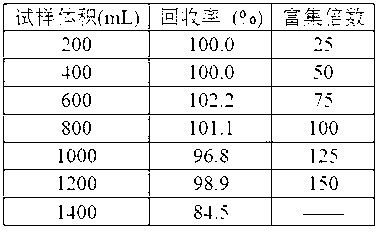

Preparation method and application of molecular imprinted polymer on silica surface for specifically adsorbing patulin

A preparation method and application of a molecular imprinted polymer on the silica surface for specifically adsorbing patulin belong to the technical field of bioassay. The method comprises the following steps: firstly pretreating the silica surface; siliconizing the silica surface to prepare APTS-silica and introducing amino groups; preparing ACPA-silica by dewatering and esterifying or an acyl chloride intermediate method and grafting an azo initiator on the silica surface; and finally taking the patulin analog 2-hydroxynicotinic acid as a template to replace molecules, taking acrylamide, methylacrylic acid, 4-vinyl pyridine and trifluoromethyl acrylic acid as the functional monomers and taking ethylene glycol dimethacrylate (EDMA) as a cross-linking agent to obtain the molecular imprinted polymer on the silica surface in acetonitrile and pyridine solvents by thermal initiation. The invention has the following advantages: as the pretreatment method for liquid chromatography of trace patulin in apple juice and related products, the polymer prepared by the invention can specifically adsorb the enriched patulin, the sample is simply and quickly treated and can be reused multiple times, and the polymer is resistant to acid and alkali treatment and is preserved under normal temperature, at the same time, the invention avoids the recovery loss caused by the traditional steps of removing impurities by alkaline washing by liquid-liquid extraction and removing organic solvents by rotary evaporation and reduces the usage amount of the organic solvents.

Owner:SHANGHAI JIAO TONG UNIV

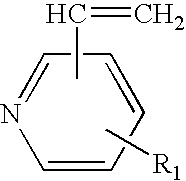

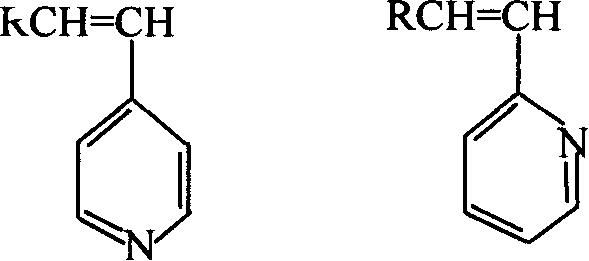

Process for production of clay nanocomposite

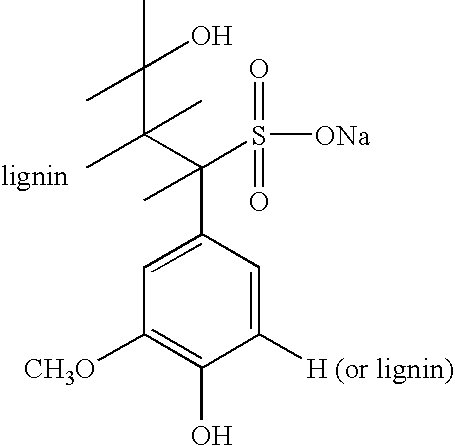

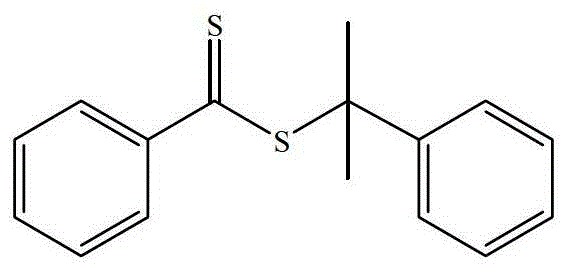

A process of preparing a nanocomposite comprised of an elastomer and at least partially exfoliated, intercalated water-swellable clay, comprising the steps of(A) forming a first blend of water-swelled clay and anionic polymer particle emulsion by blending:(1) an aqueous mixture comprised of water and a multilayered water-swellable clay, exclusive of an intercalant for said clay, wherein said water-swellable clay is comprised of a plurality of stacked platelets with water-expanded galleries between said platelets, wherein said galleries contain naturally occurring cationic ion exchangeable ions therein, and(2) an emulsion of anionic synthetic vinylpyridine-styrene-butadiene terpolymer (VPSBR) elastomer particles as an aqueous pre-formed elastomer emulsion having a pH in a range of from about 6 to about 11, comprised of anionic elastomer particles (elastomer particles having anions on the surface derived from an anionic surfactant) prepared by aqueous free radical induced polymerization of monomers in the presence of a free radical generating polymerization initiator and non-polymerizable anionic surfactant,wherein said synthetic elastomer particles are derived from an aqueous polymerization of said monomers comprising from about 0.1 to about 40 weight percent of styrene, from about 60 to about 100 weight percent of 1,3-butadiene, and from about 0.1 to about 8 percent by weight of vinylpyridine monomers which have the structural formula:wherein R1 represents a hydrogen atom or a straight chain or branched alkyl group containing 1 to 4 carbon atoms; and(B) blending with said first blend an aqueous mixture comprised of water and inorganic acid having a pH in a range of about 1 to about 4.

Owner:THE GOODYEAR TIRE & RUBBER CO

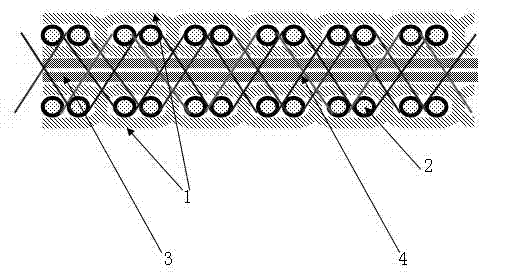

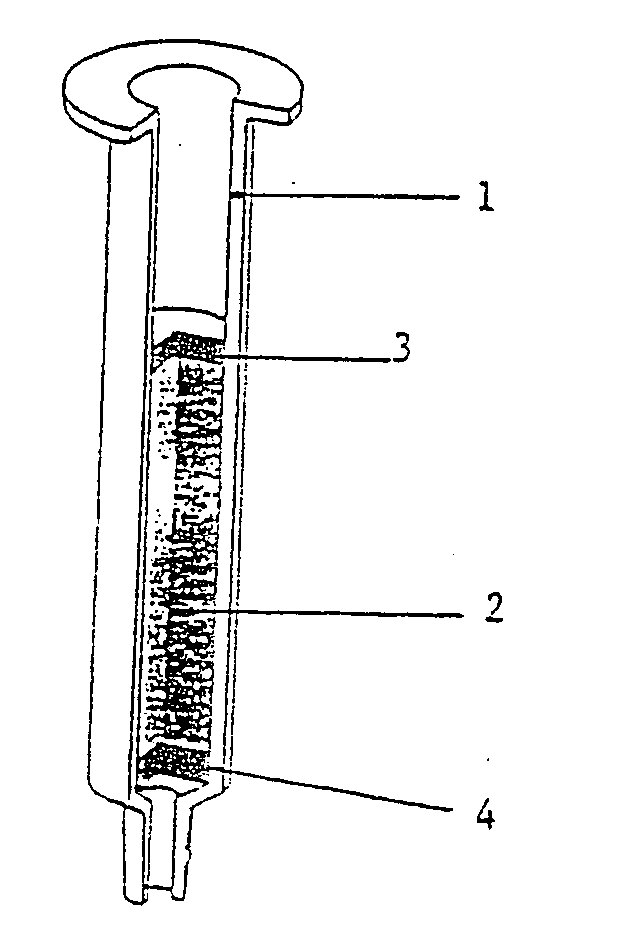

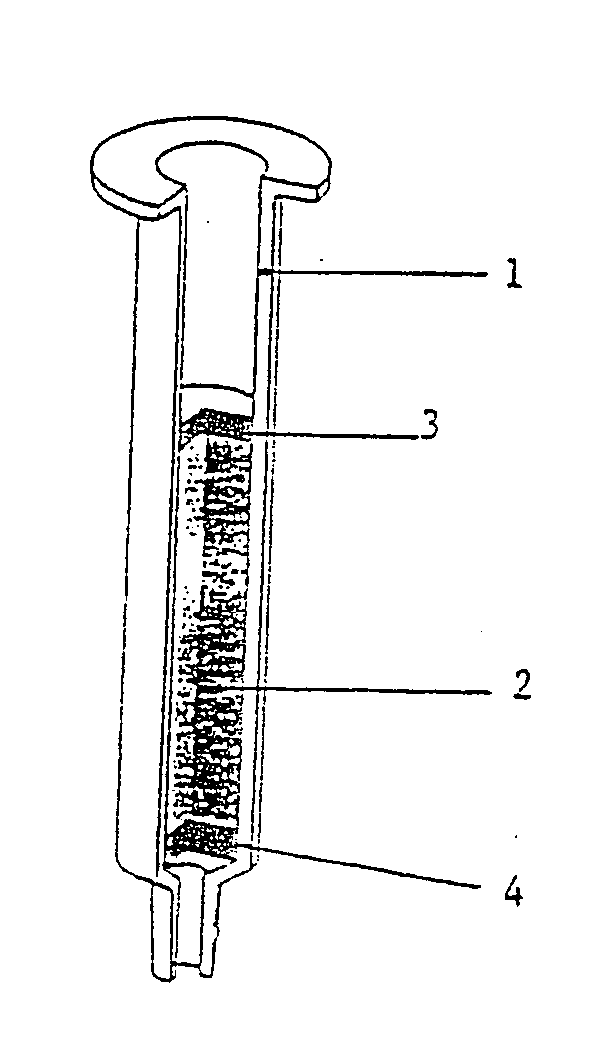

Dipped canvas fabric structure in three-dimensional structure for heavy-duty conveyor belt and production process thereof

ActiveCN102212917ASolve production technical problemsGood physical and mechanical propertiesFibre treatmentTwo or more solvent application treatmentPolyesterEngineering

The invention discloses a dipped canvas fabric structure in a three-dimensional structure for a heavy-duty conveyor belt and a production process thereof. The dipped fabric structure is characterized in that an upper layer and a bottom layer adopt ground-facing warps (1) in the plain weave structure and weft (2) interwoven with the ground-facing warp, a straight warp (3) in the straight warp structure is utilized as an intermediate layer, a bundling warp (4) is connected with the weft (2), and the upper layer, the intermediate layer, the bottom layer and the bundling warp form the three-dimensional structure. The production process comprises the following processes: the process of weaving a fabric on a machine: adopting double warp shafts to send a warp woven cloth; and the process of stipulating a dipping formula and preparing, wherein a dipping solution is a mixture of an RF (resorcinol-formaldehyde) resin water solution generated by virtue of condensation polymerization of hydroxyphenol and formaldehyde and VP (vinyl pyridine) latex (L), the total content of solids is 18-22%, the pH value is 9-11, and the ratio of the RF to the L is (1:5)-(1:7). Polyester dipped canvas in the three-dimensional structure is especially applicable to production of the heavy-duty rubber conveyor belts and has the characteristics of tear resistance, puncture resistance and impact resistance.

Owner:浙江尤夫科技工业有限公司

Ink-jet printing methods and systems providing improved image durability

InactiveUS7157504B2Good image permanenceGood smudge resistanceDuplicating/marking methodsInksMethacrylateVolumetric Mass Density

Owner:HEWLETT PACKARD DEV CO LP

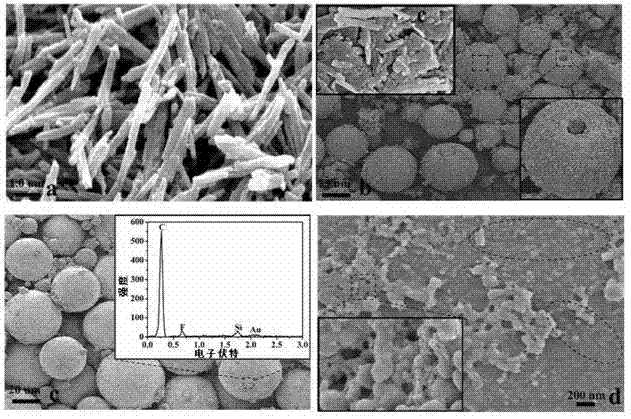

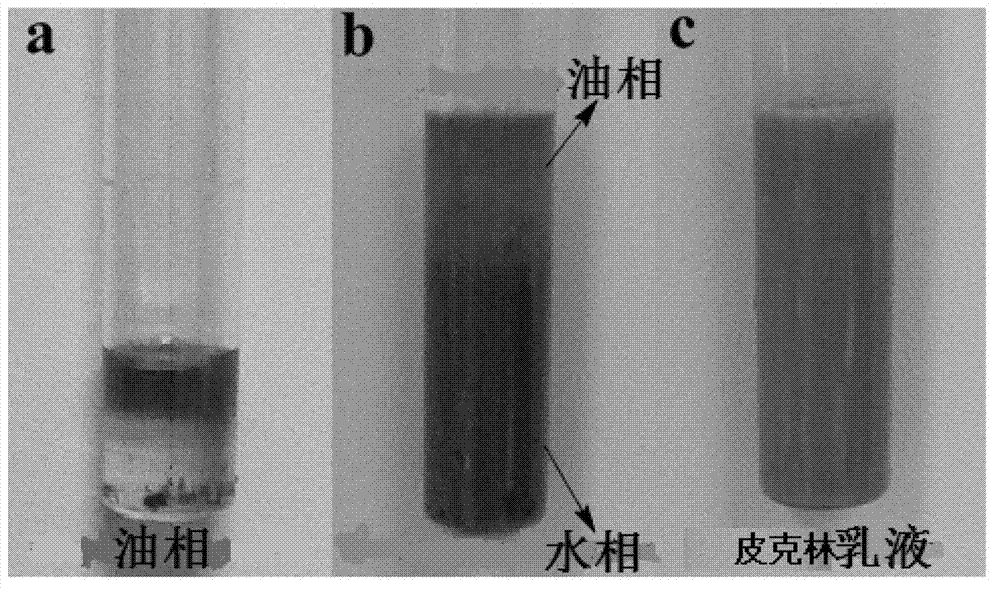

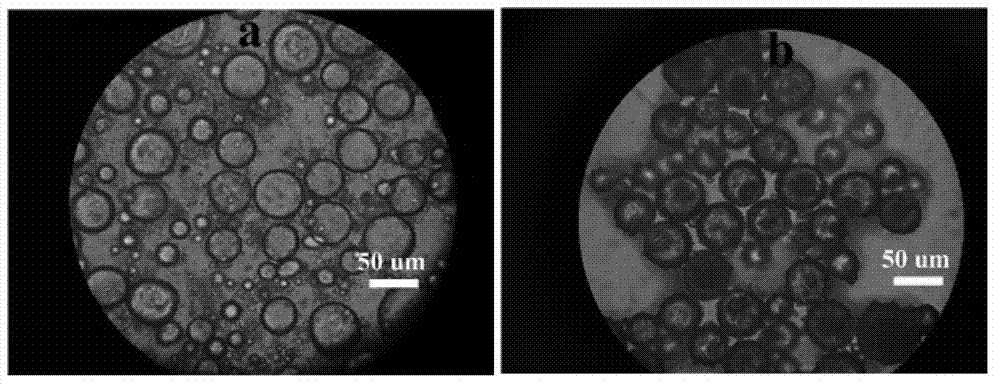

Method for preparing magnetic/hollow double-shell layer print adsorbent by emulsion polymerization

InactiveCN103204966AGood magnetic response propertiesEasy to separateOther chemical processesAlkali metal oxides/hydroxidesHexadecaneCross-link

The invention relates to a method for preparing magnetic / hollow double-shell layer print adsorbent by emulsion polymerization and belongs to the technical field of the preparation of environment function materials. Attapulgite is used as stabilizer; a few Fe3O4 nanometer particles are used as a magnetic separation carrier; a dispersion solution of hydrophilic Fe3O4 nanometer particles and attapulgite is used as a water phase; and a mixture of organic solvent hexadecane, cross-linking agent styrene, template molecule cyhalothrin, initiator azo isobutyric dimethyl ester and functional monomers acrylamide and tetra-vinyl pyridine is used as an oil phase. The water phase and the oil phase are mixed to prepare stable oil-in-water emulsion in an ultrasonic manner; and the magnetic hollow double-shell layer print polymer is prepared by emulsion polymerization. The magnetic hollow double-shell layer print polymer can be applied to selective recognition and separation of cyhalothrin in an aqueous solution. The magnetic hollow double-shell layer print polymer has a hollow double-layer structure, wherein the hollow structure can be used for effectively increasing adsorption capacity; the strength of the obtained printer polymer is enabled to be high by the inorganic particle layer in the shell layer; and the recognition points are unlikely to be damaged.

Owner:JIANGSU UNIV

Use of polymers in dishwashing compositions for the removal of grease and oil from plastic dishware, and dishwashing compositions

InactiveUS20070272277A1Easy to cleanHigh molecular weightOrganic detergent compounding agentsAnionic surface-active compoundsAdditive ingredientPyridine-N-oxide

Owner:THE PROCTER & GAMBLE COMPANY

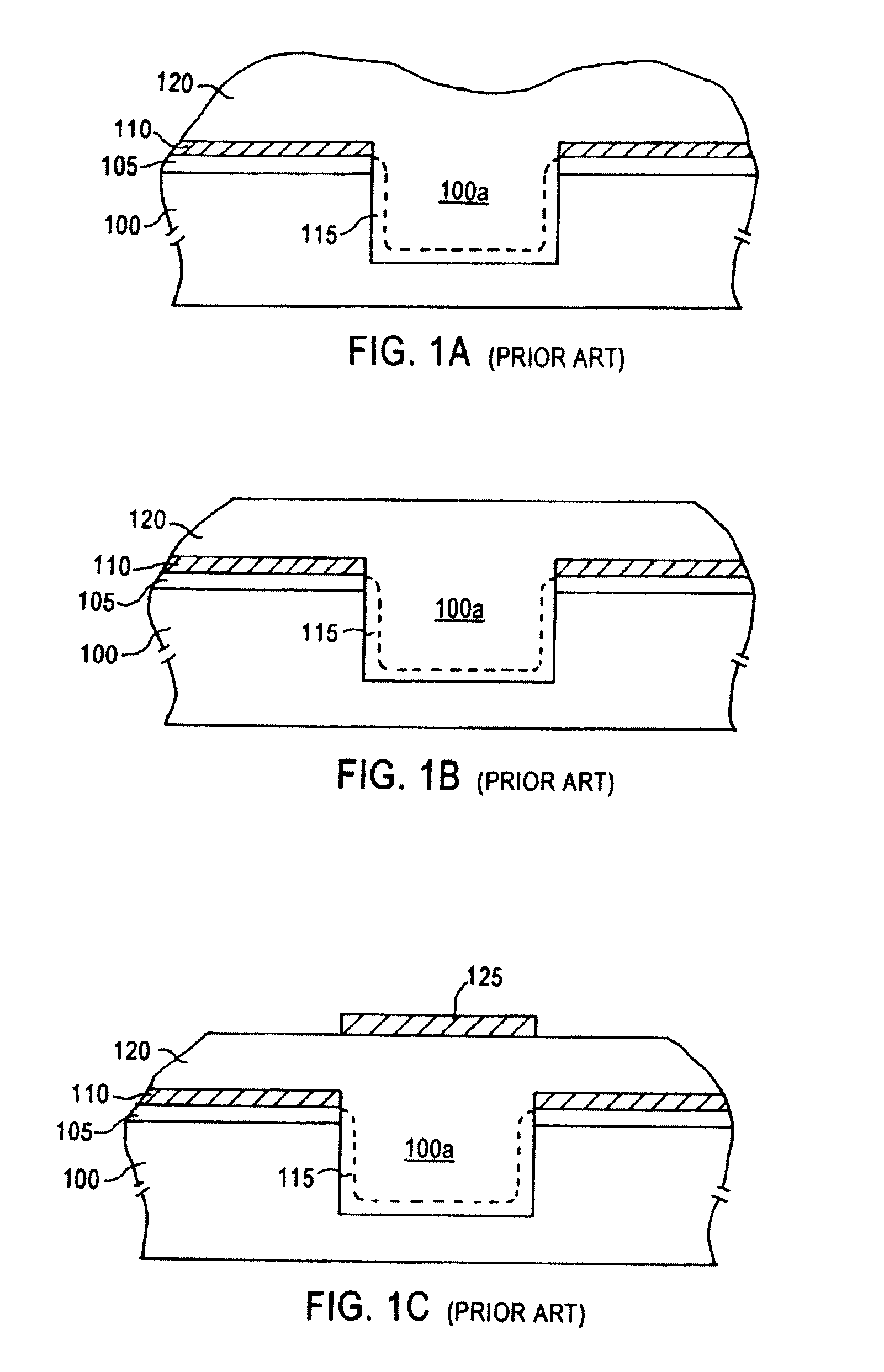

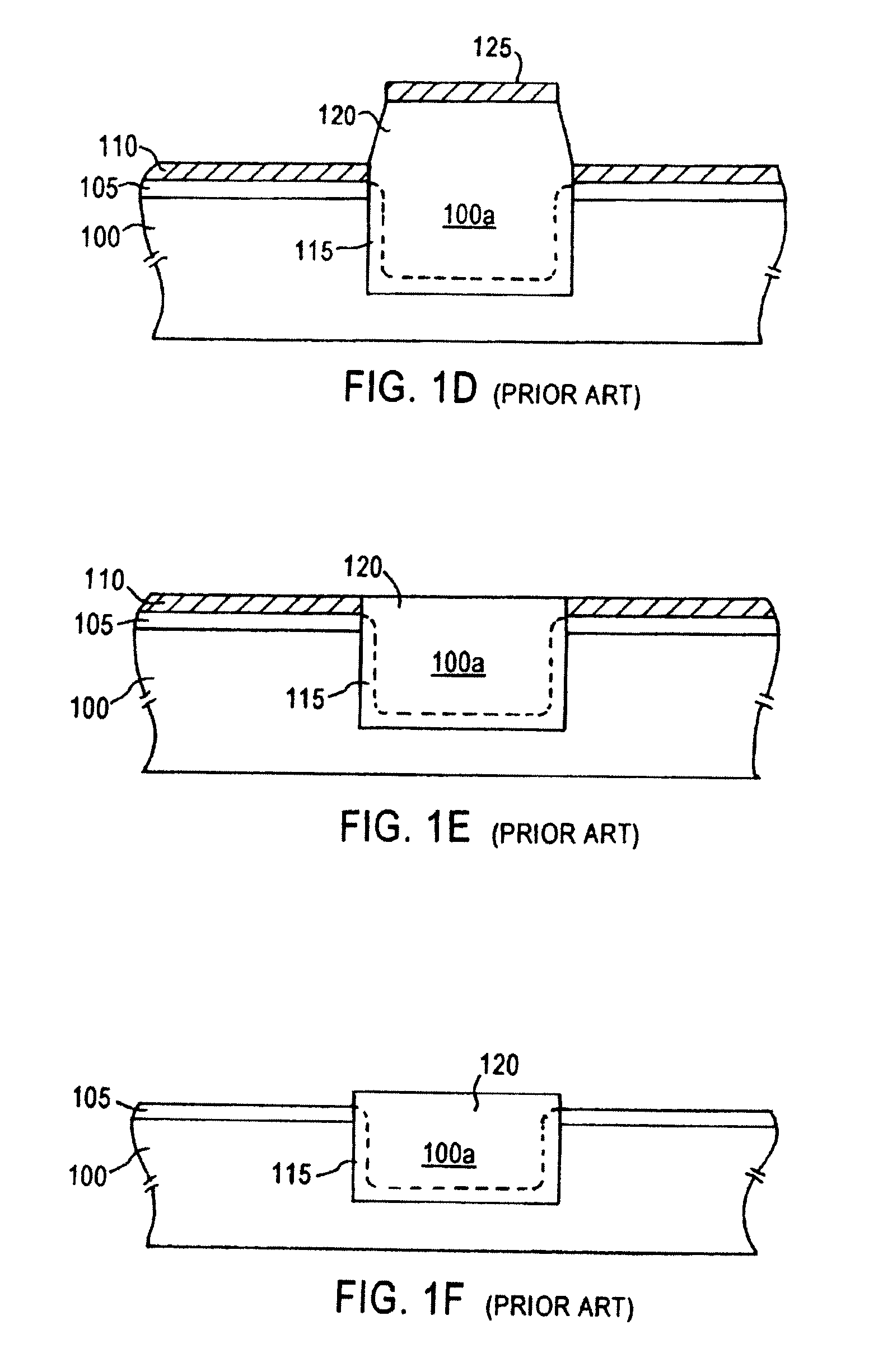

Reverse Shallow Trench Isolation Process

InactiveUS20090047870A1Suppressing TEOS rateGood continuityPolishing machinesLapping machinesSilicon oxideVinyl pyridine

A method of polishing a substrate surface containing silicon nitride and silicon oxide or silicon dioxide, comprising movably contacting the surface with a polishing pad and having a polishing composition disposed between the polishing pad and the surface, said polishing composition comprising 1) hydrous ceria abrasive; 2) polyvinylpyridine, vinyl pyridine copolymers, or both, and 3) water, wherein at 2 psi downpressure the silicon nitride removal rate is at least 500 angstroms per minute and the selectivity of silicon nitride to silicon oxide is at least 30.

Owner:AIR PROD & CHEM INC

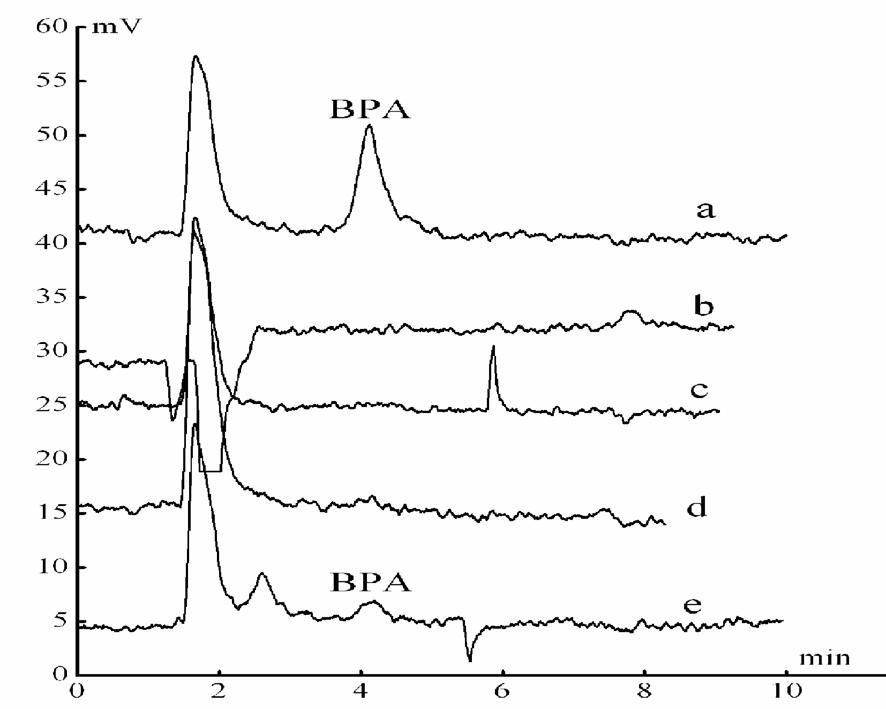

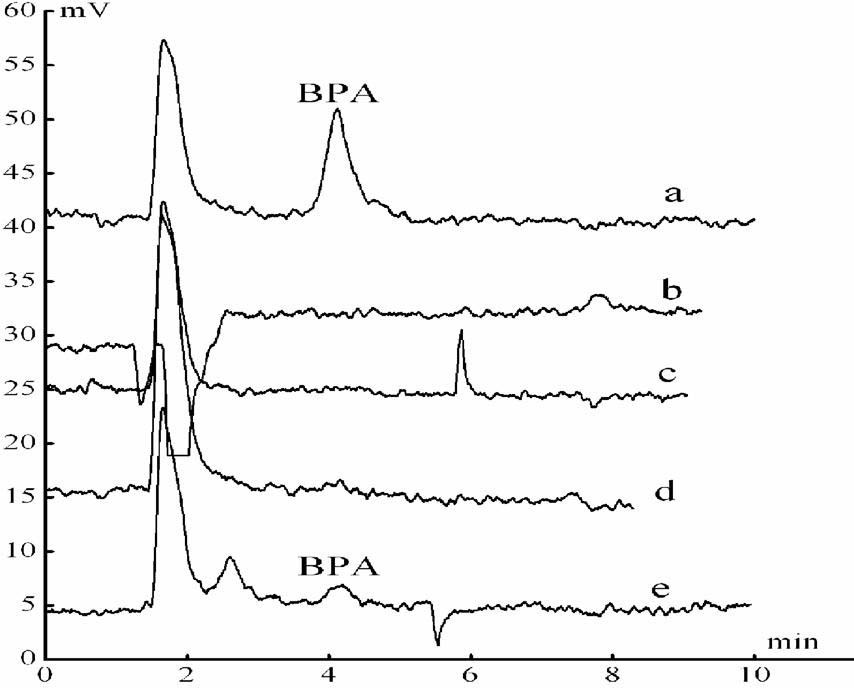

Bisphenol A dummy template molecularly imprinted stir bar and preparation method thereof

InactiveCN102416313AIncrease the number ofHigh sensitivityOther chemical processesPreparing sample for investigationMolecularly imprinted polymerBisphenol

The invention relates to a bisphenol A dummy template molecularly imprinted stir bar and a preparation method thereof. The stir bar is a glass bar containing an iron core, wherein the glass bar is coated by a polymer coating; the polymer coating is a bisphenol A dummy template molecularly imprinted polymer; modified silica microspheres with grain size being 400nm are taken as the carriers for synthesizing the imprinted polymer; and biphenyl diphenol is taken as a dummy template molecule. The bisphenol A dummy template molecularly imprinted polymer is prepared by carrying out surface grafting on the surfaces of silica microspheres with grain size being 400nm with vinyltrimethoxysilane to obtain the modified silica microspheres, then subjecting the modified silica microspheres to react withbiphenyl diphenol, 4-vinyl pyridine, ethylene glycol dimethacrylate and azodiisobutyronitrile and using a methanol-glacial acetic acid mixed solution to wash off the template molecule. The stir bar and the preparation method have the following beneficial effect that: SiO2 is taken as the carrier for synthesizing the imprinted polymer, thus greatly adding the number of the effective binding sites and improving the sensitivity.

Owner:NANJING MEDICAL UNIV

Cetirizine molecularly imprinted polymer monolithic column and preparation method thereof

InactiveCN104209104AEasy to makeSimple experimentOther chemical processesSolid sorbent liquid separationTetrafluoroborateGlycol synthesis

The invention relates to a cetirizine molecularly imprinted polymer monolithic column and a preparation method thereof. The cetirizine molecularly imprinted polymer monolithic column is composed of raw materials of, by mass, 1-3% of cetirizine, 3-4% of 4-vinyl pyridine, 20-25% of ethylene gylcol dimethacrylate, 42-45% of mixed solution (eutectic solvent) of ethylene glycol and choline chloride, 4-5% of dimethylformamide, 13-22% of 1-butyl-3-methylimidazolium tetrafluoro borate and 0.5-1% of azobisisobutyronitrile. The method includes the steps of adding ionic liquid and the eutectic solvent of ethylene glycol and choline chloride to a polymerization system, using cobalt ions as a metal ion hub to enhance the effect of imprinting recognition, and preparing molecularly imprinted polymer (MIP) of a successive rod shape in a stainless steel column. The cetirizine molecularly imprinted polymer (MIP) monolithic column obtained through the preparation method has the advantages of good permeability and obvious imprinting effects and can have the model cetirizine imprinting factors up to 31.54, and meanwhile, the method is simple in preparation process and avoids the use of volatile liquid, thereby reducing harmful gas emission to the environment.

Owner:TIANJIN MEDICAL UNIV

Preparation method of chloramphenicol molecular imprinted adsorbing material on surface of magnetic carbon microsphere

ActiveCN104741097AEasy to identifyHigh selectivityIon-exchange process apparatusOther chemical processesCross-linkFunctional monomer

The invention relates to a preparation method of a chloramphenicol molecular imprinted adsorbing material on the surface of a magnetic carbon microsphere. The magnetic carbon microsphere is prepared from shaddock peel by adopting a solvent thermal synthesis method, the surface of the magnetic carbon microsphere is subjected to ethylene functional modification by KH570, the treated magnetic carbon microsphere is used as a matrix material, chloramphenicol is used as a template, hydroxyethyl methylacrylate and 4-vinylpyridine are used as functional monomers, N-isopropyl acrylamide is used as a thermosensitive monomer, ethylene glycol dimethacrylate and N,N-methylene bisacrylamide are used as cross-linking agents, 2,2'-azobis[2-methylpropionamidine] dihydrochloride is used as an initiator, and the magnetic carbon microsphere surface imprinted thermosensitive adsorbing material is prepared in a methanol / water mixed system, and the adsorbing material is used for selective recognition and selective separation of chloramphenicol in a water environment. The prepared molecular imprinted adsorbing material on the surface of the magnetic carbon microsphere is low in cost, can be prepared easily, has the high recognition and selectivity properties, high separation and enrichment ability and high adsorption rate of target molecules, and is high in adsorption speed.

Owner:HENAN UNIV OF URBAN CONSTR

Modified pyridine styrene butadiene rubber latex and preparation method and application thereof

The invention provides modified pyridine styrene butadiene rubber latex and a preparation method and application thereof. The modified pyridine styrene butadiene rubber latex is prepared from raw materials, namely mixed monomers, an initiator, an emulsifying agent, a dispersing agent and water, wherein the dosage of the initiator is 0.2 to 0.6 percent of the weight of the mixed monomers; the dosage of the emulsifying agent is 1 to 2 percent of the weight of the mixed monomers; the dosage of the dispersing agent is 2 to 4 percent of the weight of the mixed monomers; the dosage of the water is 95 to 105 percent of the weight of the mixed monomers; the mixed monomers comprise the following components in percentage by weight: 20 to 80 percent of isoprene, 0 to 50 percent of butadiene, 10 to 30percent of styrene or acrylonitrile, and 2 to 9 percent of 2-vinylpyridine. The modified pyridine styrene butadiene rubber latex has high solid content and percent conversion of the rubber latex, uniform latex particles and low content of residual dialkene, is nontoxic and odorless, has simple, convenient and safe operations in production and use, has better chemical stability, heat resistance and cold resistance than the conventional pyridine styrene butadiene rubber latex, and has low production cost.

Owner:SHANDONG HEYI GAS CO LTD DONGYING CITY

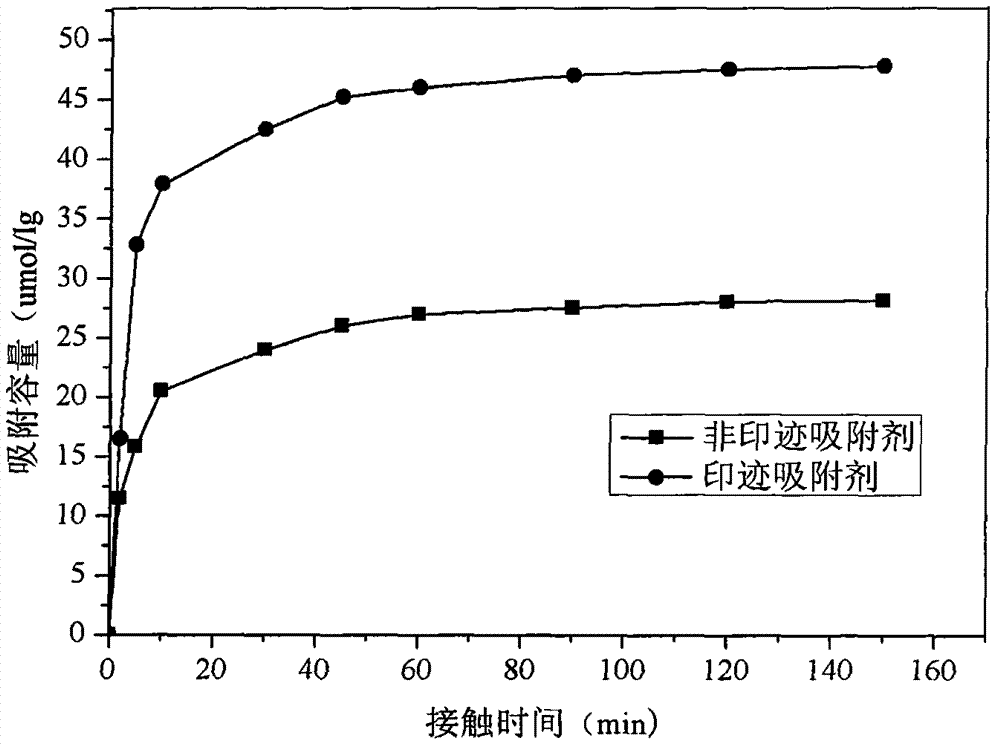

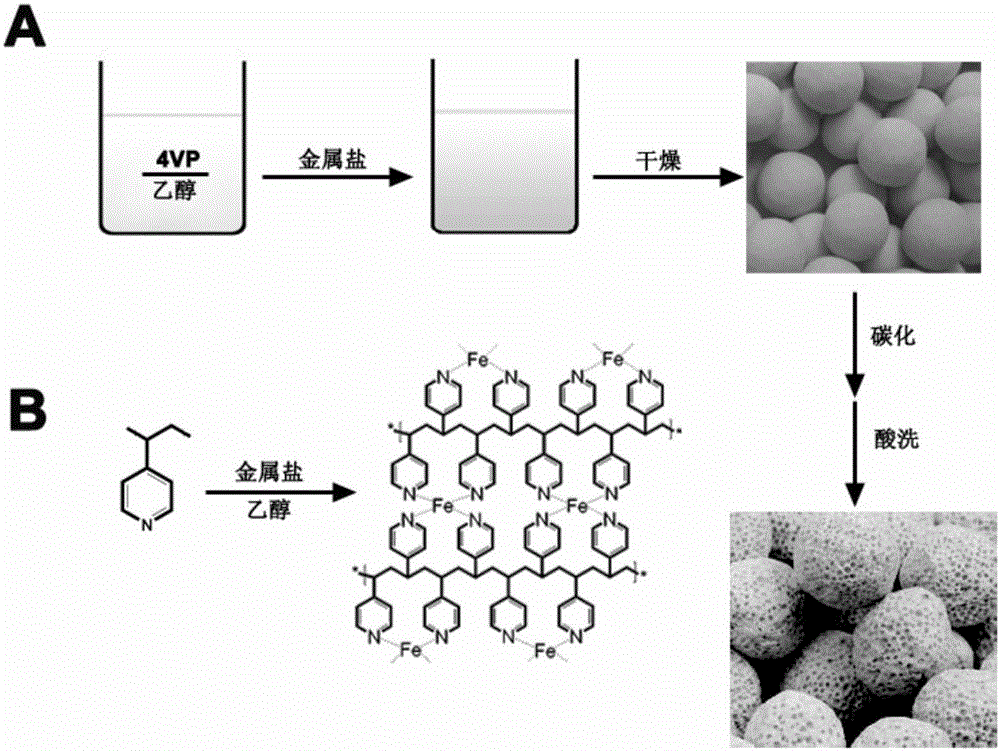

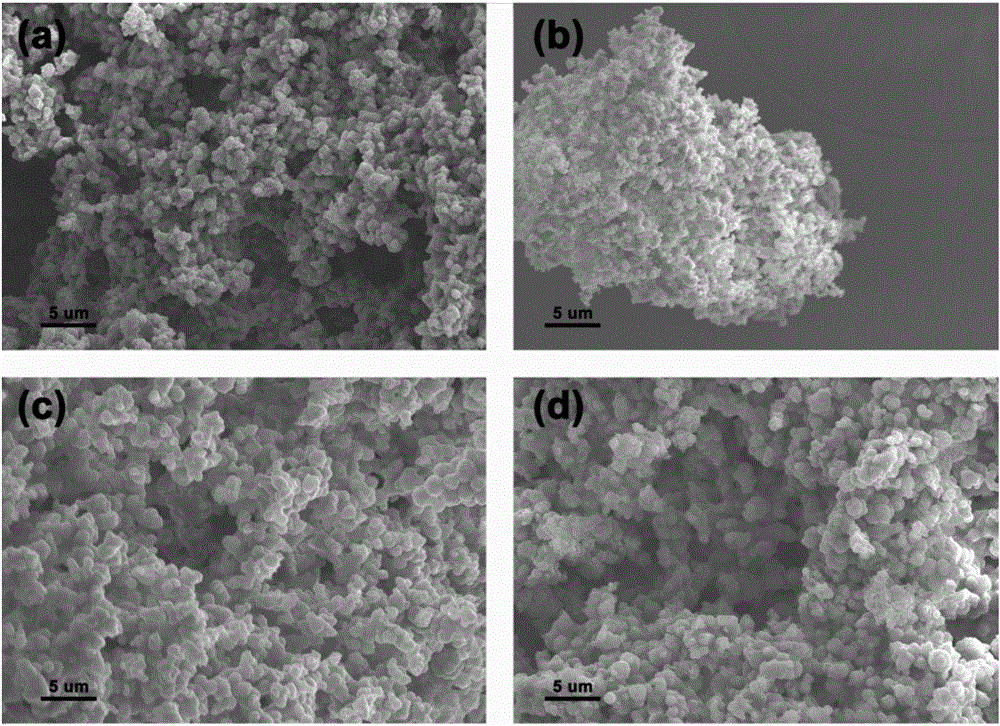

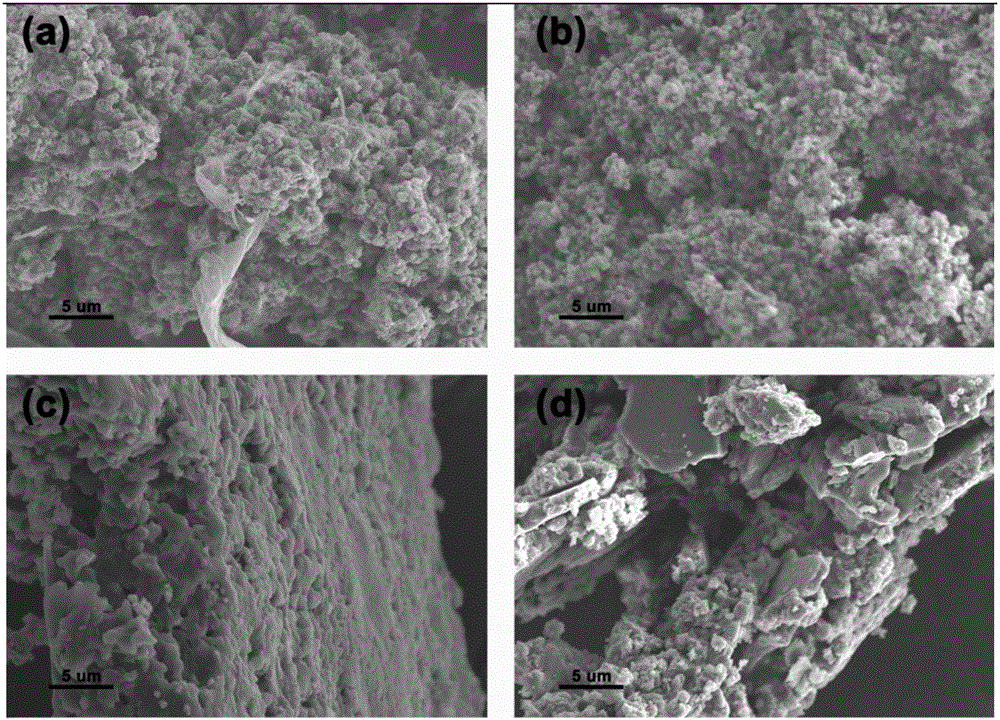

Preparation method of metal-nitrogen-doped porous carbon microspheres

ActiveCN106744786ALarge specific surface areaHigh nitrogen contentCarbon preparation/purificationMicrosphereNitrogen doped

The invention discloses a preparation method of metal-nitrogen-doped porous carbon microspheres. According to the preparation method, a 4VP (4-vinyl pyridine) monomer is taken as a carbon and nitrogen source, different metal salts are taken as an initiator, a coordination agent, a catalyst and a template agent, firstly, the 4VP monomer is polymerized at the normal temperature by utilizing the metal salts as the initiating agent, a metal-coordination structure is formed by metal ions and nitrogen atoms in 4VP molecules, and metal-organic matter microspheres are formed; then metal in the microspheres has functions of the catalyst and the template agent at the high temperature, so that organic matter is converted into carbon, a spherical structure is reserved, and the metal-nitrogen-doped porous carbon microspheres are obtained after acid pickling. Selectivity of metal sources is high, steps are simple, and the prepared nitrogen-doped porous carbon material is large in specific surface area and high in nitrogen content. By means of large specific surface area and high nitrogen content, the material has huge application prospect in the fields of energy storage and conversion, catalysis and environment protection.

Owner:SHANGHAI INST OF TECH

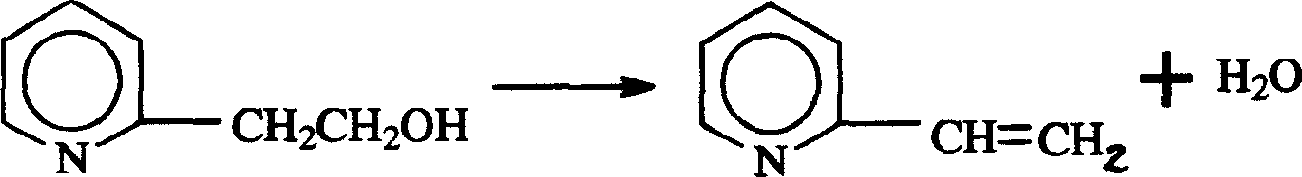

Process for large-scale preparation of 2-vinyl pyridine

ActiveCN1580045AGeneral equipment requirementsSimple production processOrganic chemistryState of artPotassium hydroxide

The invention refers to the technique to produce 2- vinyl pyridine with the scale of industrial production. It chooses the 2-ethoxyl pyridine as the starting material, dehydrates a molecule of water to produce 2-vinyl pyridine with the existence of the catalyzer; keep the weight ratio of 2-ethoxyl pyridine:catalyzer=1:0.05-1.0 and chooses the vitriol, phosphoric acid, sodium hydroxide or potassium hydroxide as the catalyzer. The reaction condition is as follows: whisk it for between 5min and 30min at the temperature of between 100deg.C and 190deg.C, collect the fractions with boiling range of 60-100deg.C / 10-150mm / Hg, separate the water of the imputities by alkaliingout method or saltingout method to get the crude product; distill it with lower pressure, collect the fractions with boiling range of 60-100deg.C / 90-150mm / Hg and get the turnoff of the 2- vinyl pyridine. Compared with today's technology, the invention is featured by the following aspects: normal pressure, tank reactor, ecumenic requirements to the equipments, simpler production technique and higher yield.

Owner:淄博张店东方化学股份有限公司

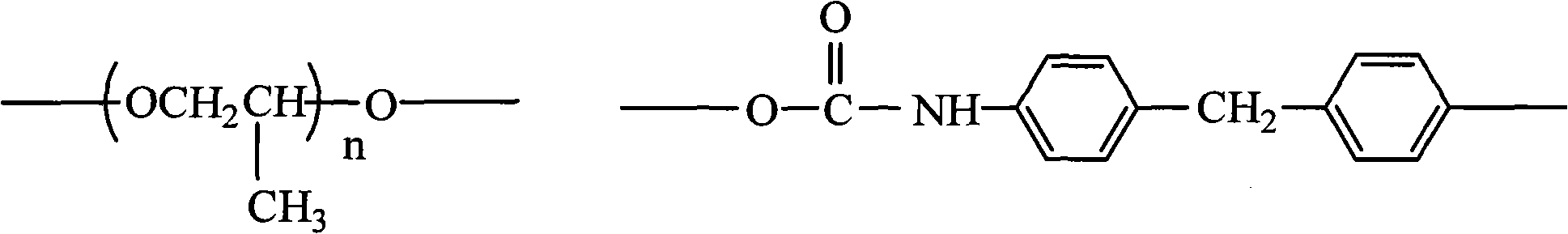

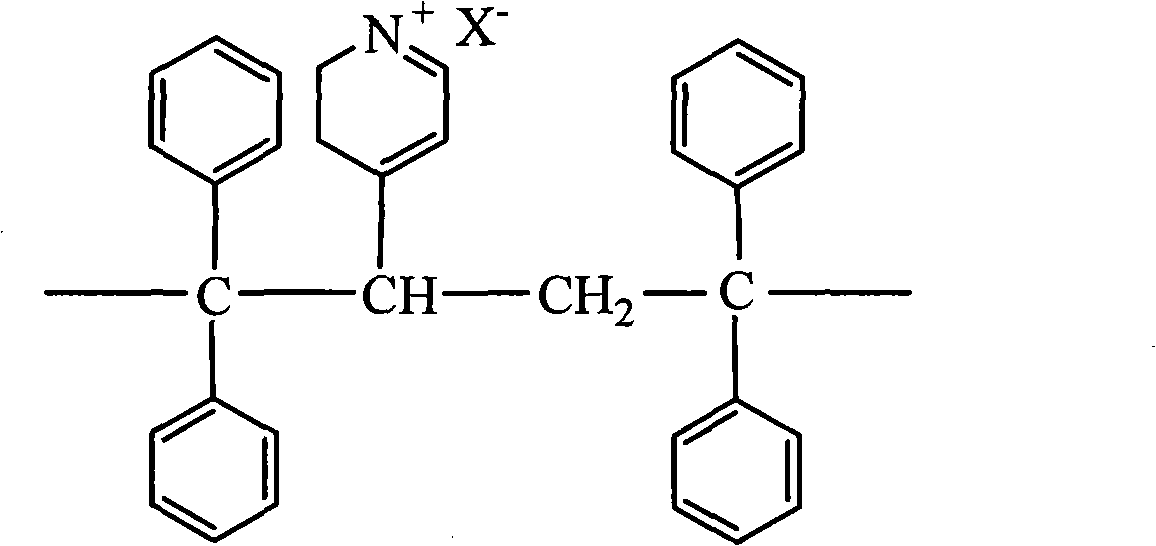

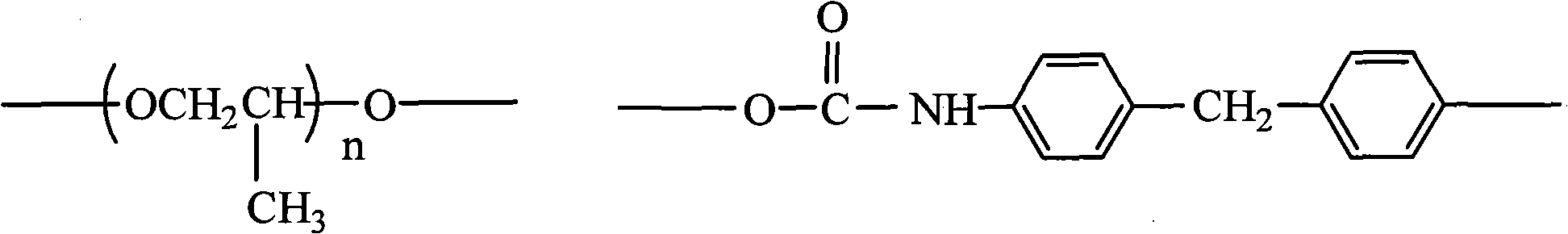

Pyridine quaternary ammonium salt polyurethane and preparation method thereof

The invention provides pyridine quaternary ammonium salt polyurethane, which comprises constitutional units shown in formulas 1, 2 and 3, wherein n is an integer from 20 to 80, and X is halogen atom; and the molecular weight of the pyridine quaternary ammonium salt polyurethane is 10,000 to 80,000. The invention also provides a preparation method for the pyridine quaternary ammonium salt polyurethane, which comprises the following steps of: performing condensation on polypropylene glycol and 4,4'-diphenylmethane diisocyanate to obtain prepolymer 1 taking isocyanate as a terminal group; performing chain extension on resin by adopting 1,1,2,2-tetraphenyl-1,2-ethanediol, and adding vinyl pyridine; and performing quaternary ammonium. The pyridine quaternary ammonium salt polyurethane has lipophilicity and hydrophily, and improves antibiotic property on the premise of keeping better ageing resistance and scratch resistance.

Owner:BYD CO LTD

Dipping adhesive for flexible industrial canvas and preparation method of dipping adhesive

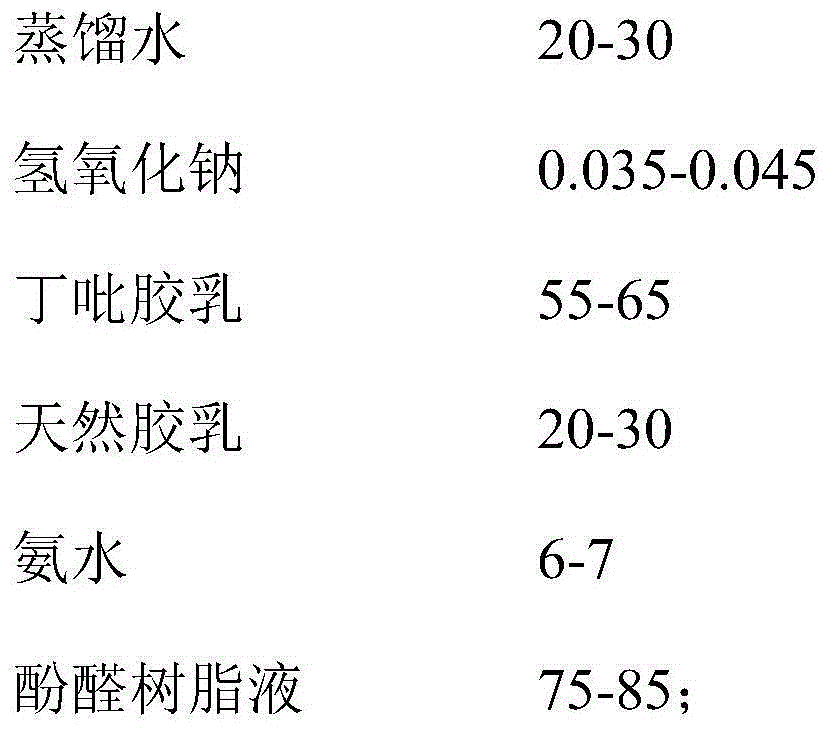

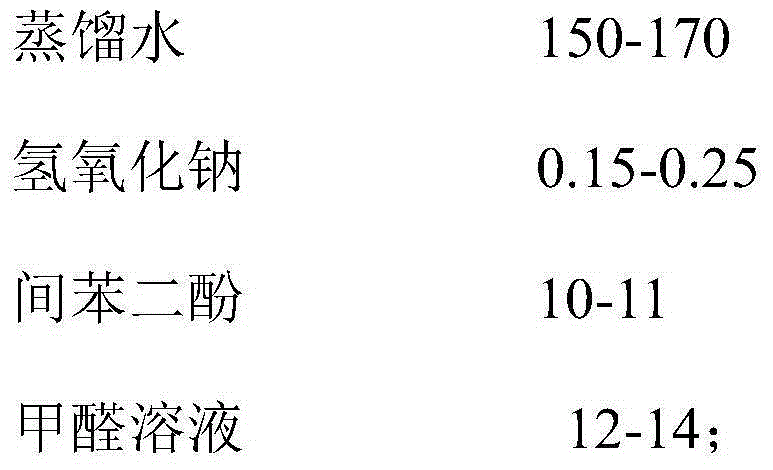

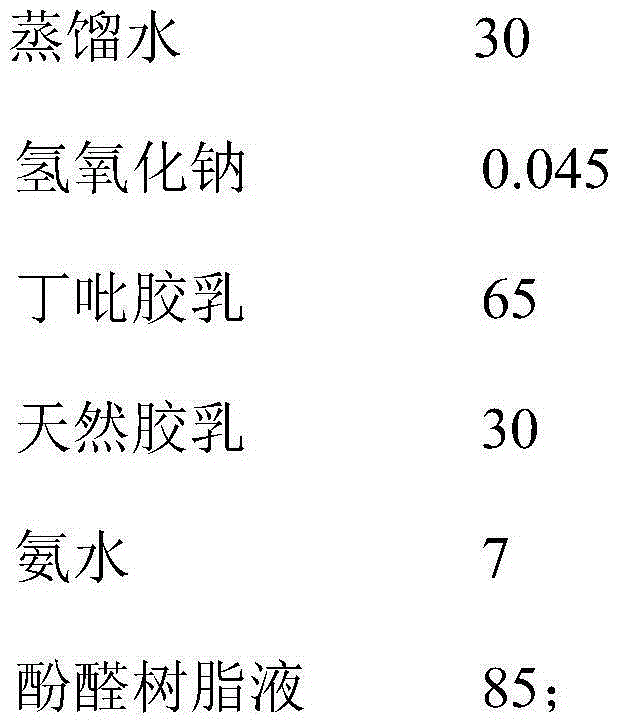

The invention discloses a dipping adhesive for flexible industrial canvas and a preparation method of the dipping adhesive. The dipping adhesive comprises raw materials in parts by weight as follows: 20-30 parts of distilled water, 0.035-0.045 parts of sodium hydroxide, 55-65 parts of butadiene-vinyl pyridine latex, 20-30 parts of natural latex, 6-7 parts of ammonium water and 75-85 parts of a phenolic resin solution, wherein the phenolic resin solution comprises raw materials in parts by weight as follows: 150-170 parts of distilled water, 0.15-0.25 parts of sodium hydroxide, 10-11 parts of resorcinol and 12-14 parts of formaldehyde. Compared with the prior art, the dipping adhesive adopts phenolic resin prepared from resorcinol and the formaldehyde solution as well as butadiene-vinyl pyridine latex and natural latex as main raw materials, so that the canvas has better flexibility, the adhesion performance between a framework layer and a rubber layer is improved, the service life of a conveyor belt is prolonged, and the conveying accuracy of the conveyor belt is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

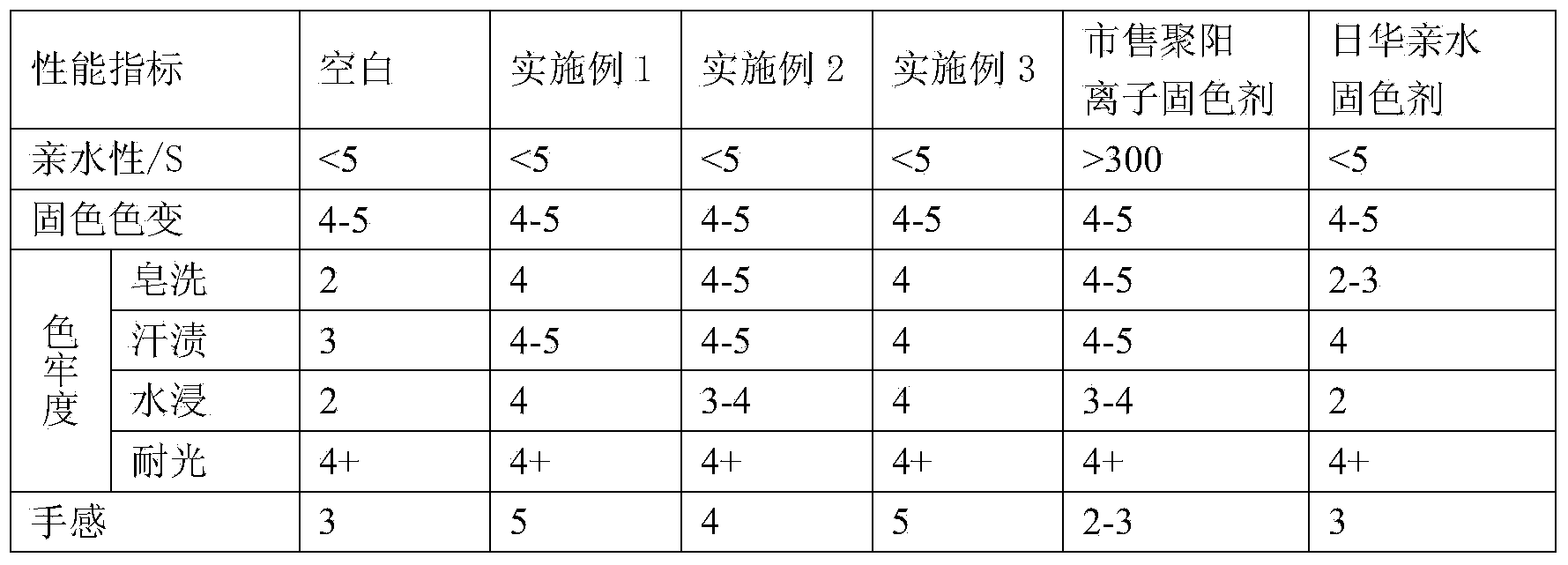

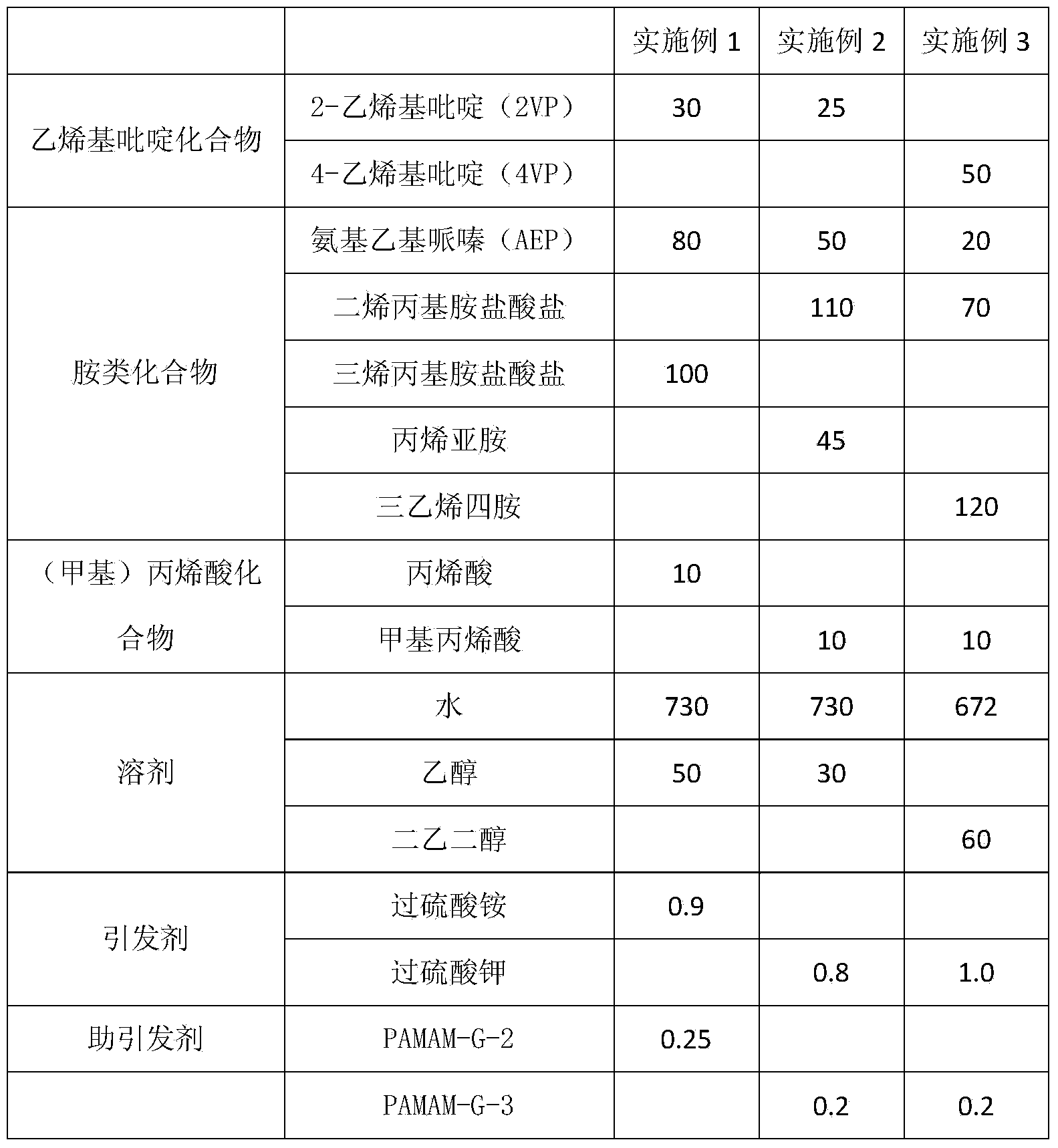

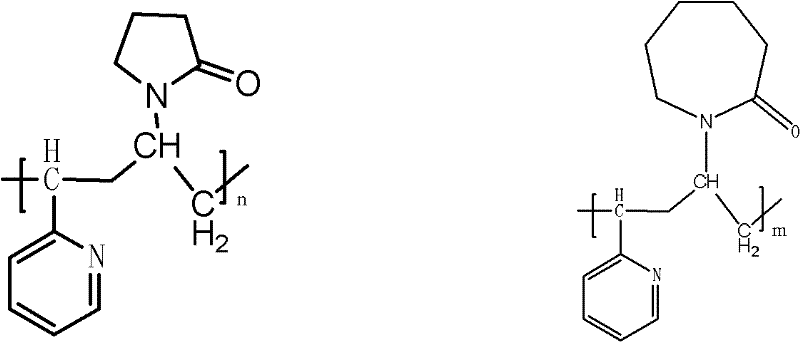

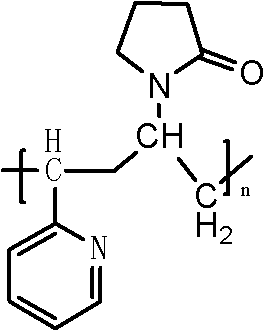

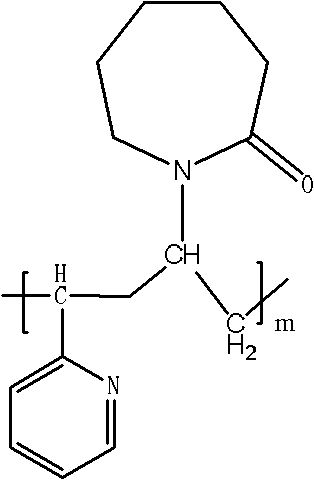

Preparation method for hydrophilic dye-fixing agent for reactive dyeing

ActiveCN104313926ADoes not affect hydrophilicityDoes not affect the feelDyeing processRadical initiatorDyeing

The invention relates to a preparation method for a hydrophilic dye-fixing agent for reactive dyeing. According to the method, vinylpyridine, amine monomers and acrylate monomers have a polymerization reaction when radical initiators and assisting initiators exist, and the hydrophilic dye-fixing agent is obtained. The hydrophilic dye-fixing agent prepared with the method has an excellent dye-fixing effect, meanwhile, the hygroscopicity and the hydrophilia of cotton fabric are not affected, and a good hand feeling is achieved.

Owner:SHANGHAI ARGUS NEW MATERIAL CO LTD

Composite hydrate inhibitor and application thereof

ActiveCN102181275ANon-volatileGood chemical stabilityPipeline systemsDrilling compositionSuper cooling2-Vinylpyridine

The invention discloses a composite hydrate inhibitor and application thereof. The provided composite hydrate inhibitor comprises a copolymer and an anti-aggregation agent; the copolymer is selected from at least one of the following substances: poly (N-vinyl pyrrolidone-2-vinyl pyridine) and poly (N-vinyl caprolactam-2-vinyl pyridine); and the anti-aggregation agent is a quaternary ammonium saltcompound. When the series of copolymer and the anti-aggregation agent are interacted, the composite hydrate inhibitor has good hydrate generation inhibiting performance. The hydrate inhibitor is in aliquid state, and can be used in the range that the water content is 10 to 80 weight percent, the pressure is 1.5 to 70MPa and the temperature is 20 DEG C below zero to 25 DEG C. The hydrate inhibitor cannot be limited by super-cooling degree, and is suitable for oil and water coexistence or oil-gas field and crude oil recovery; and particularly under the condition of high water content, the hydrate nucleation and aggregation inhibiting effects of the inhibitor can be fully exerted. The inhibitor has the advantages of high efficiency, economical efficiency, low dose and good biodegradability,and has good application prospect.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Water-wettable chromatographic media for solid phase extraction

InactiveUS20050133424A1Simple methodReduce sample preparation timeIon-exchange process apparatusAnalysis using chemical indicatorsHydrophilic monomerOrganic solvent

A method for removing an organic solute from a solution comprises contacting the solution with a polymer formed by copolymerizing one or more hydrophobic monomers and one or more hydrophilic monomers, whereby the solute is adsorbed onto the polymer. The solution can comprise a polar solvent such as a polar organic solvent or water or an aqueous buffer. The hydrophobic monomer can be, for example, divinylbenzene. The hydrophilic monomer can be, for example, a heterocyclic monomer, such as a vinylpyridine or N-vinylpyrrolidone.

Owner:WATERS TECH CORP

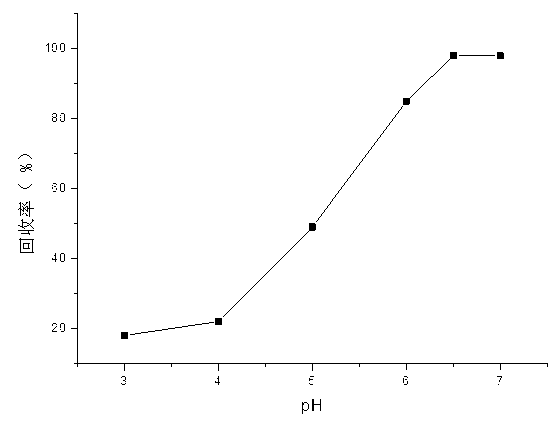

Preparation and application of Sudan red I molecular imprinted polymeric adsorbent

InactiveCN101880355ASpecific recognition abilityHigh selectivityOther chemical processesOxygenHigh selectivity

The invention discloses a method for preparing a Sudan red I molecular imprinted polymeric adsorbent and application thereof. The method has the main technical characteristics of : adding Sudan red I, 4-vinyl pyridine, azodiisobutyronitrile and ethylene glycol dimethacrylate into a reactor in a certain molar ratio; introducing argon to remove oxygen in a chloroform medium; reacting for 24h at the constant temperature of 60 DEG C to obtain a bulk polymer; grinding the bulk polymer into fine particles; carrying out Soxhlet extraction for 24h with mixed solution of acetic acid and methanol in a volume ratio of 1:9 to remove template Sudan red I molecules; washing off residual organic matter with the methanol; finally eluting the fine particles with water and the methanol; filtering the fine particles to remove superfine particles; and drying the fine particles in vacuum at the temperature of 60 DEG C. The obtained Sudan red I molecular imprinted polymeric adsorbent has the advantages of specific identification ability to Sudan red I, high selectivity, high adsorption rate, high deabsorption performance, high physicochemical stability, high mechanical stability, and regeneration capacity.

Owner:UNIV OF JINAN

Stability of covert pigments

ActiveUS20060011730A1Difficult to manufactureInksRecord carriers used with machinesPolyesterPolyolefin

Owner:L 1 SECURE CREDENTIALING

Cement composition and process therewith

A composition comprising a polymer which comprises repeat units derived from a first unsaturated amide, a hydroxy acrylate, and at least two monomers selected from the group consisting of (1) a vinyl pyridine or derivative thereof and acrylic acid or salt thereof; (2) a vinyl morpholine and a second unsaturated amide; (3) acrylic acid or salt thereof and a second unsaturated amide; (4) acrylic acid or salt thereof, a vinyl pyridine, and a vinyl morpholine; and combination of two or more thereof wherein said first unsaturated amide is not the same as said second unsaturated amide.

Owner:PHILLIPS PETROLEUM CO

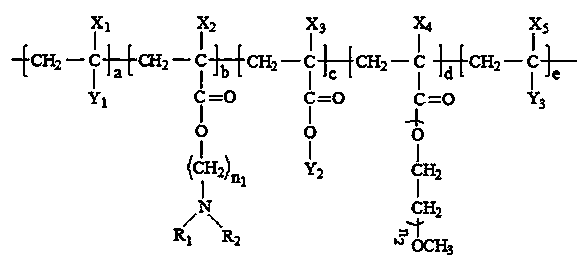

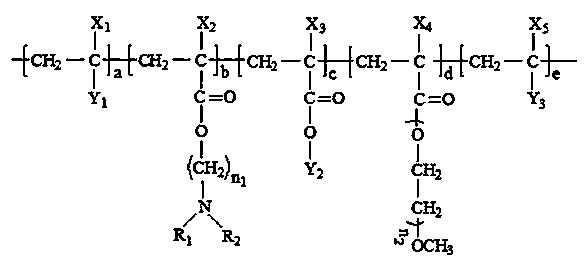

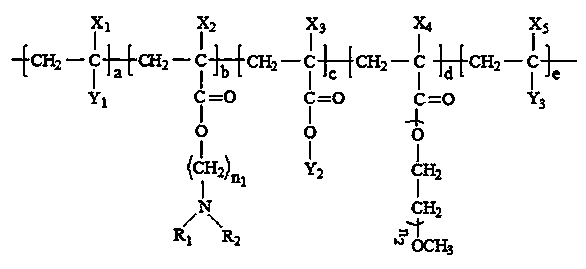

Solventtype block polymer dispersant

ActiveCN103897441AHigh purityHigh hiding powerOrganic dyesPigment treatment with macromolecular organic compoundsAcrylonitrileEthylene Homopolymers

The invention relates to a solvent type block polymer dispersant and a preparation method thereof, the molecular chain of the dispersant comprises an anchoring chain segment and a solvation chain segment, and has a structural formula shown in the specification. The solvent type block polymer dispersant fundamentally solves the defects of traditional dispersants, the molecular chain of the dispersant comprises the anchoring chain segment and the solvation chain segment, a homopolymer or copolymer of vinyl pyridine, vinyl imidazole, amino acrylate and other nitrogen-containing vinyl monomers is used as the pigment anchoring chain segment, a homopolymer or copolymer of nitrogen-free vinyl monomer such as acrylate, acrylonitrile and styrene is used as the solvation chain segment, and pigment flocculation and sedimentation during storage can be prevented.

Owner:NANTONG HANTAI CHEM

Copper nanofluid solar cooling liquid and preparation method thereof

InactiveCN103045181ASolve Oxidation ProblemsDoes not affect thermal conductivityHeat-exchange elementsPhosphatePropanediol

The invention provides a copper nanofluid solar cooling liquid and a preparation method thereof, and belongs to the field of synthesis technologies of inorganic materials. The copper nanofluid solar cooling liquid comprises deionized water, glycol and propylene glycol, nano-copper powder, vinylpyridine, azodiisobutyronitrile, acylamino compound, phosphates and benzotriazole. The preparation method comprises the following steps of: uniformly dispersing the nano-copper powder into alcoholic solution by rapid dispersing; polymerizing on the nanometer copper surface to obtain a monomolecular film; adding a dispersing agent; mixing the obtained alcoholic solution with phosphate aqueous solution; dispersing and mixing at a medium speed again; dispersing by an ultrasonic oscillating instrument; and then homogenizing through a fold-type reducer pipe, so as to obtain the copper nanofluid solar cooling liquid. The prepared copper nanofluid has the characteristics that the thermal conductivity is four times higher than that of the deionized water, the uniformity in dispersing is realized, the stability is excellent, the stability is remained after placing for 2400 hours at the normal state, the freezing point is low, no icing occurs at the temperature of -40 DEG C, the corrosion resistance is excellent, and the copper nanofluid is suitable for an anti-freezing liquid, and the material source is rich; the raw materials are directly sourced, low in price and easy to obtain; low requirement is brought to the running of the equipment; and the massive industrial production can be easily realized.

Owner:济南道生一新能源科技有限公司

Polarized SEBS and its preparing mthod

The present invention provides a kind of polarized SEBS and its preparation process. The product may be expressed as SEBS-P, where S expresses polystyrene block, EB hydrogenated polybutadiene block, and P polarized block formed via polymerizing polar vinyl pyridine or methacrylate monomer. The preparation process adopts butyl lithium as initiator, tetrahydrofuran as activator and cyclohexane as solvent and includes the steps of the first preparing four block SBS-P polymer, and the subsequent selective hydrogenation to obtain polar SEBS. The present invention produces and polarizes SEBS simultaneously, and thus has high polar monomer converting rate, no need of single treatment of un-converted monomer, simple operation and low production cost. The prepared polar SEBS has obvious polarity, excellent performance, and expanded application field.

Owner:BALING PETRO CHEM CO LTD SINOPEC +1

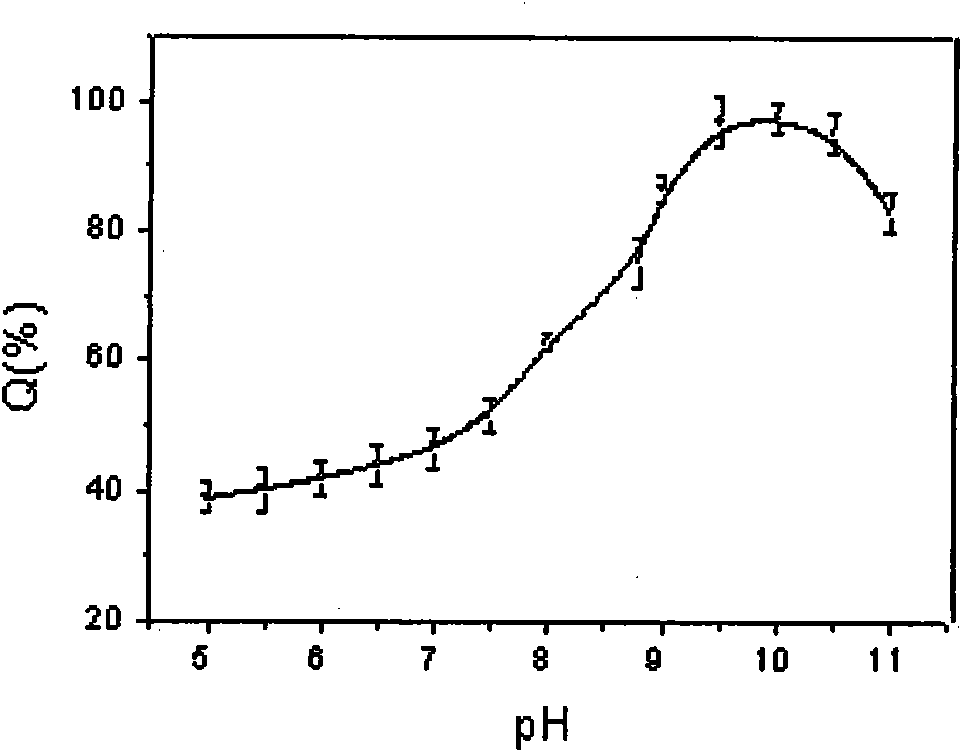

Preparation method and use of loofah sponge surface lead ion imprinted absorbing material

InactiveCN101992067ASpecific recognition abilityHigh selectivityOther chemical processesWater/sewage treatment by sorptionWater bathsHigh absorption

The invention discloses a preparation method of a loofah sponge surface lead ion imprinted absorbing material and the use of the loofah sponge surface lead ion imprinted absorbing material in metal ion absorption and belongs to natural high polymer material modification. In the method, the loofah sponge natural high polymer material is used as a support, and the surface of the material is modified with a lead ion imprinted polymer. The main technical characteristics of the method include: adding acylated loofah sponge, lead-dithizone complex, 4-vinylpyridine, ethylene dimethacrylate and azodiisobutyronitrile into a chloroform medium, removing oxygen by argon in a certain proportion; introducing argon to expel oxygen; reacting in a water bath at a constant temperature of 50 to 70 DEG C, filtering and washing; and performing Soxhlet extraction by using 0.10mol / L solution of HNO3 for 12 hours, removing template lead ions, washing, drying and obtaining the material. The material has specific lead ion identification capacity, high selectivity, high absorption speed and high desorption capacity, is widely available and biodegradable, can be prepared by a simple process and has regeneration capacity and the advantages of environmental friendliness and the like.

Owner:UNIV OF JINAN

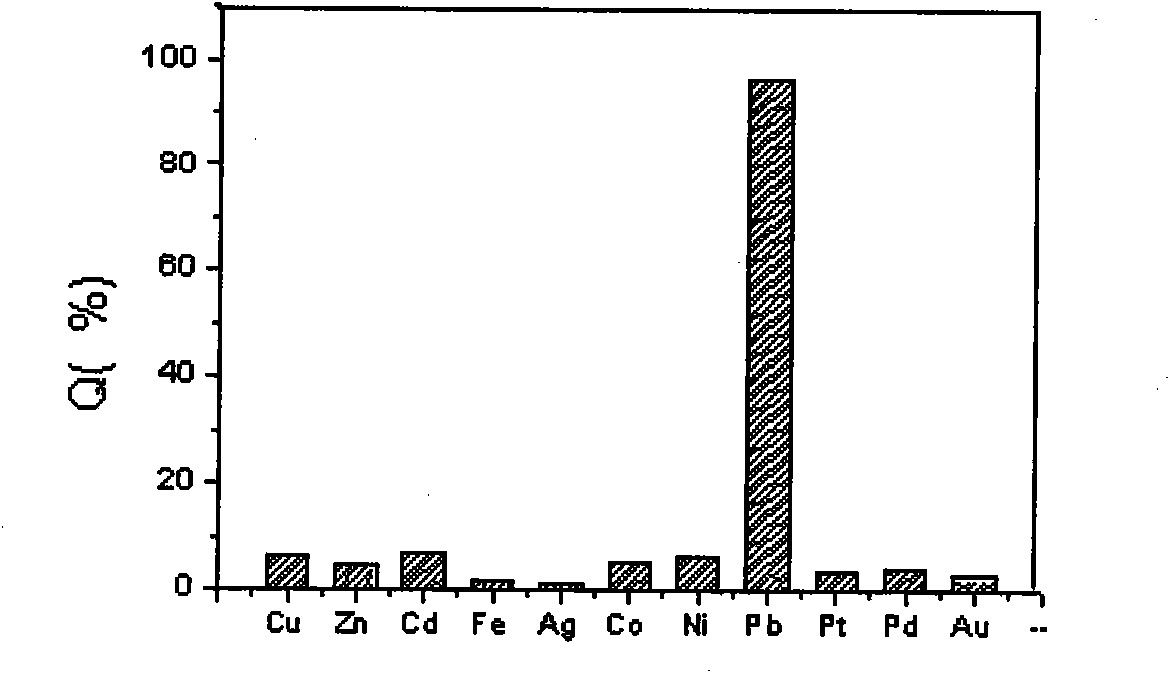

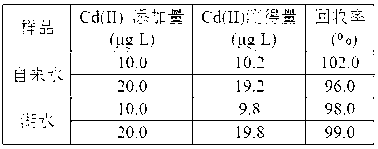

Cadmium ion imprinted adsorbent, and preparation method and application thereof

InactiveCN103254354AImprove stabilityHigh selectivityOther chemical processesWater/sewage treatment by sorptionAmbient waterFunctional monomer

The invention discloses a cadmium ion imprinted adsorbent, and a preparation method and application thereof, belonging to the technical field of preparation adsorbing materials. The preparation method comprises the following steps: (1) forming a chelate from cadmium ions and functional monomers; (2) crosslinking the chelate into a polymer under the action of a crosslinking agent; and (3) washing the polymer with an eluate to remove the cadmium ions to form the cadmium ion imprinted adsorbent. The cadmium ion imprinted adsorbent disclosed by the invention is prepared by a mass polymerization method, and synthesizes a solid-phase extraction material by using methacrylic acid and 4-vinyl pyridine as the functional monomers and ethylene glycol dimethyl acrylate as the crosslinking agent; and the solid-phase extraction material has the advantages of high bonding firmness, stable properties, favorable reproducibility and high selectivity. The adsorbent can be used in enrichment pretreatment of trace amounts of Cd (II) in an ambient water sample.

Owner:FUZHOU UNIV

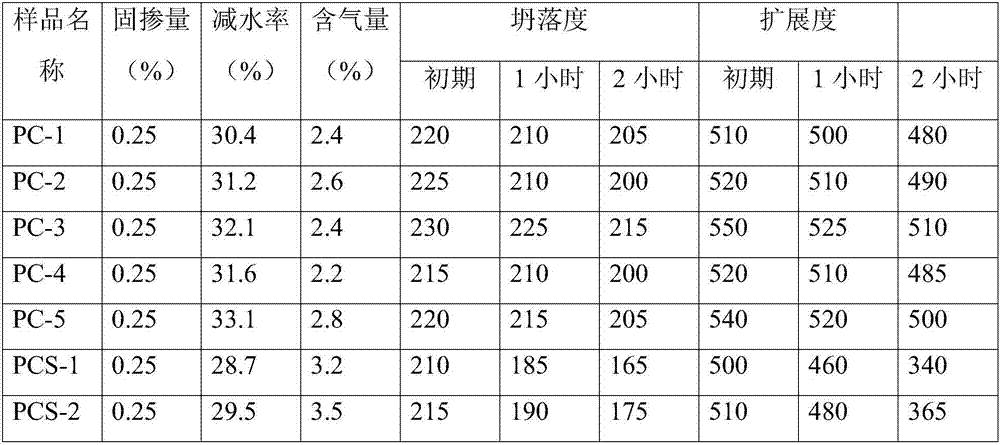

High-performance polycarboxylic acid water reducing agent and preparation method therefor

The invention discloses a high-performance polycarboxylic acid water reducing agent and a preparation method therefor. The water reducing agent comprises the following ingredients in parts by weight: 300-350 parts of macromonomer, 38-50 parts of agent A, 2.5-5.5 parts of agent B, 4.8-5.8 parts of agent C and 550-650 parts of deionized water, wherein the macromonomer is any one or a mixture of both of methyl allyl alcohol polyoxyethylene ether and isopentenol polyoxyethylene ether; the agent A comprises acrylic acid or a mixture of acrylic acid and at least one of micromonomers; the micromonomers comprise one or several of acrylamide, methacrylic acid, maleic acid, N-vinyl pyrrolidone, 4-vinyl pyridine, fumaric acid, vinyl acetate, 2-acrylamide-2-methyl propanesulfonic acid and sodium methylallylsulfonate; the agent B comprises 1.2-1.8 parts by weight of reducing agent and 1.5-3.6 parts by weight of chain transfer agent; and the agent C is an initiator. The high-performance polycarboxylic acid water reducing agent disclosed by the invention has high water reducing rate and good slump retaining capability, the entrained air volume is lower than that of commercially available products, and the whole production process has no need of heating and is energy-saving and environmentally friendly.

Owner:南宁新泰瑞科建材股份有限公司

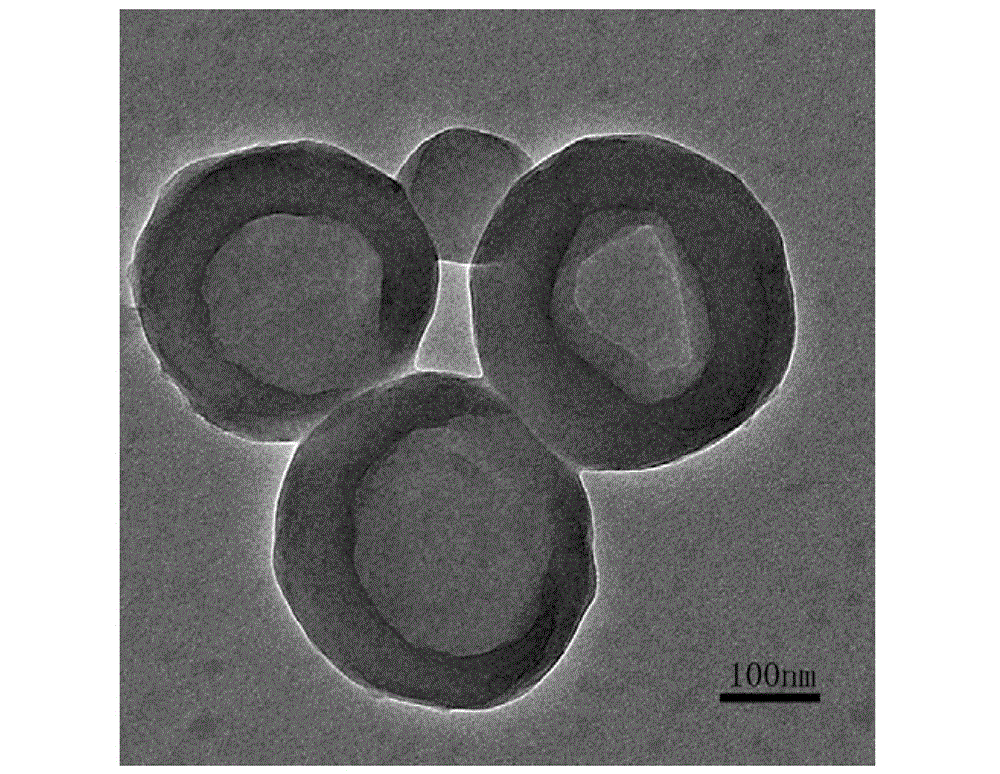

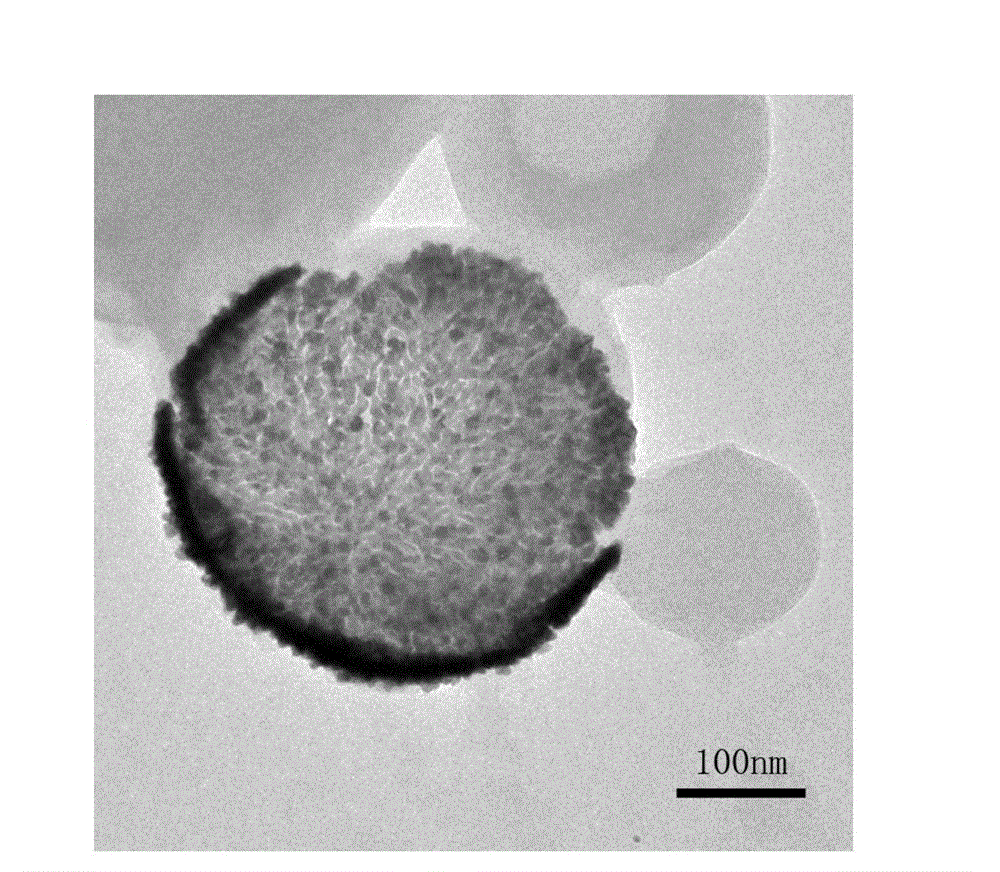

Polyhedral oligomeric silasesquioxane (POSS)-based load metal nanoparticle and preparation method thereof

InactiveCN103146115AShape is easy to controlControllable block length ratioFreeze thawingMicrosphere

Provided is a polyhedral oligomeric silasesquioxane (POSS)-based load metal nanoparticle and a preparation method thereof. A reversible addition fragmentation free radical polymerization (RAFT) method is utilized to compound propyl methyl acryloyl oxygen isobutyl POSS monomers, chain transfer agent and initiator into solution according to dosages. Liquid nitrogen is utilized to achieve freeze thawing and degassing, and then argon is filled to protect reaction. PMAiBuPOSS is obtained. The PMAiBuPOSS, 4-vinyl pyridine (4VP) monomers and the initiator are compounded into the solution. Through the RAFT method, POSS-based amphiphilic block copolymers, namely, PMAiBuPOSS-b-P4VP, are polymerized. The POSS-based amphiphilic block copolymers are dissolved in volatility co-solvent, and then selective solvent is added to enable the POSS-based amphiphilic block copolymers to form the nanoparticle dissolved in the solution in a self-assembly mode. A certain dosage of chloroauric acid (HAuCl4) is further added dropwise. Finally, the POSS-based load metal nanoparticle is obtained after in-situ reduction.

Owner:XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com