Patents

Literature

1086results about How to "Non-volatile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

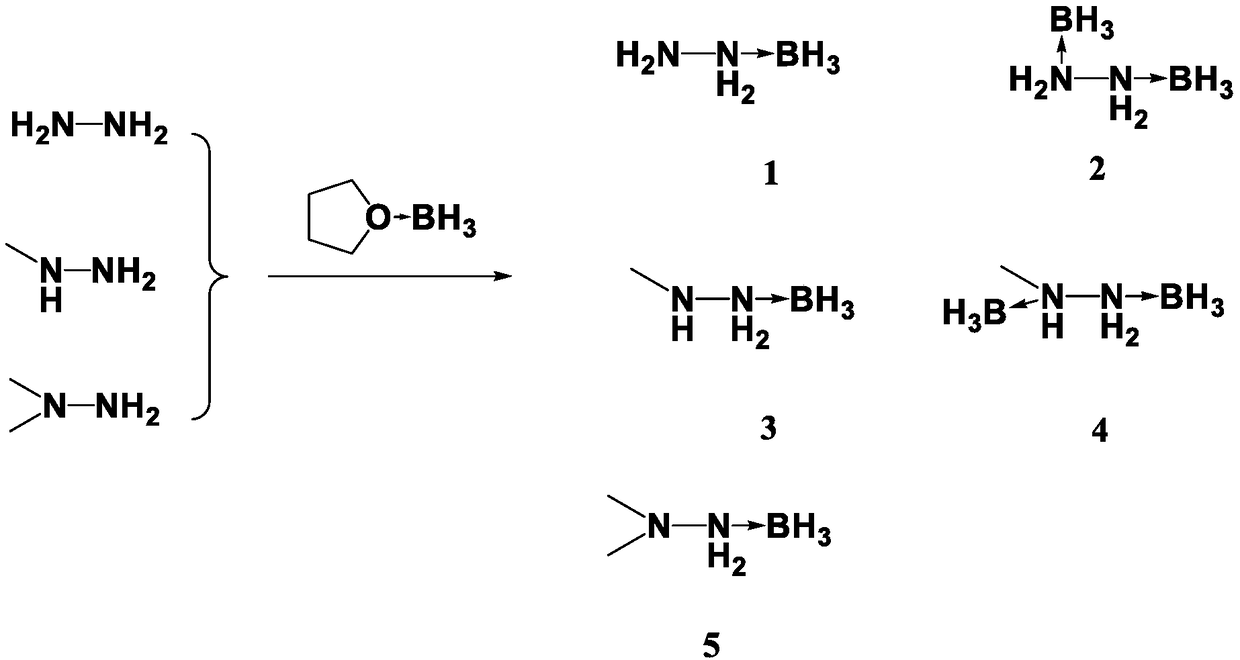

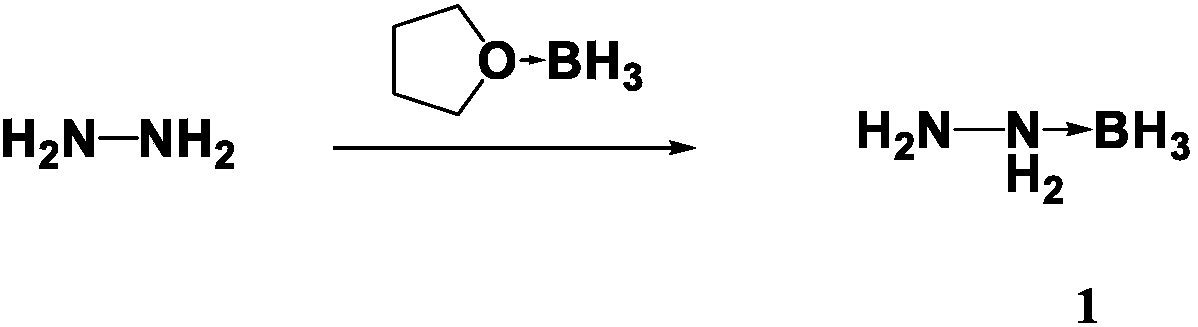

Preparation method for propellant fuel

InactiveCN108910843AShorter ignition delay timeHazard reductionOrganic chemistryHydrazineEvaporationIgnition delay

The invention discloses a preparation method for propellant fuel. The preparation method comprises the following steps: uniformly mixing hydrazine or a methyl derivative thereof with a tetrahydrofuransolution of borane to perform a reaction, and after the reaction, performing rotary evaporation on the tetrahydrofuran solution to obtain a first product; adding a first solvent into the first product, then performing washing, and then performing rotary evaporation to remove the first solvent, so as to obtain a hydrazinoborane derivative. According to the method, hydroboration is carried out on ahighly-volatile hydrazine fuel and a methylated derivative of hydrazine, the obtained borohydride of the hydrazine is a colorless non-volatile liquid or a white solid, has no volatility and greatly reduces hazard of the hydrazine fuel, and is a novel aerospace propellant fuel since the ignition delay time of the hydrazine borofluoride is extremely short.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

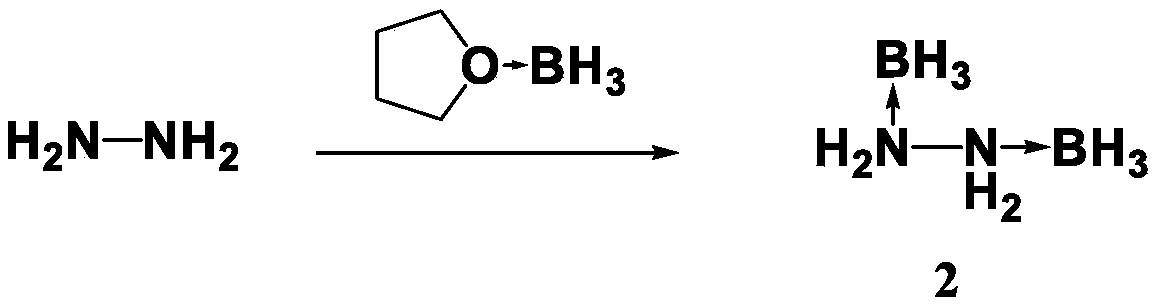

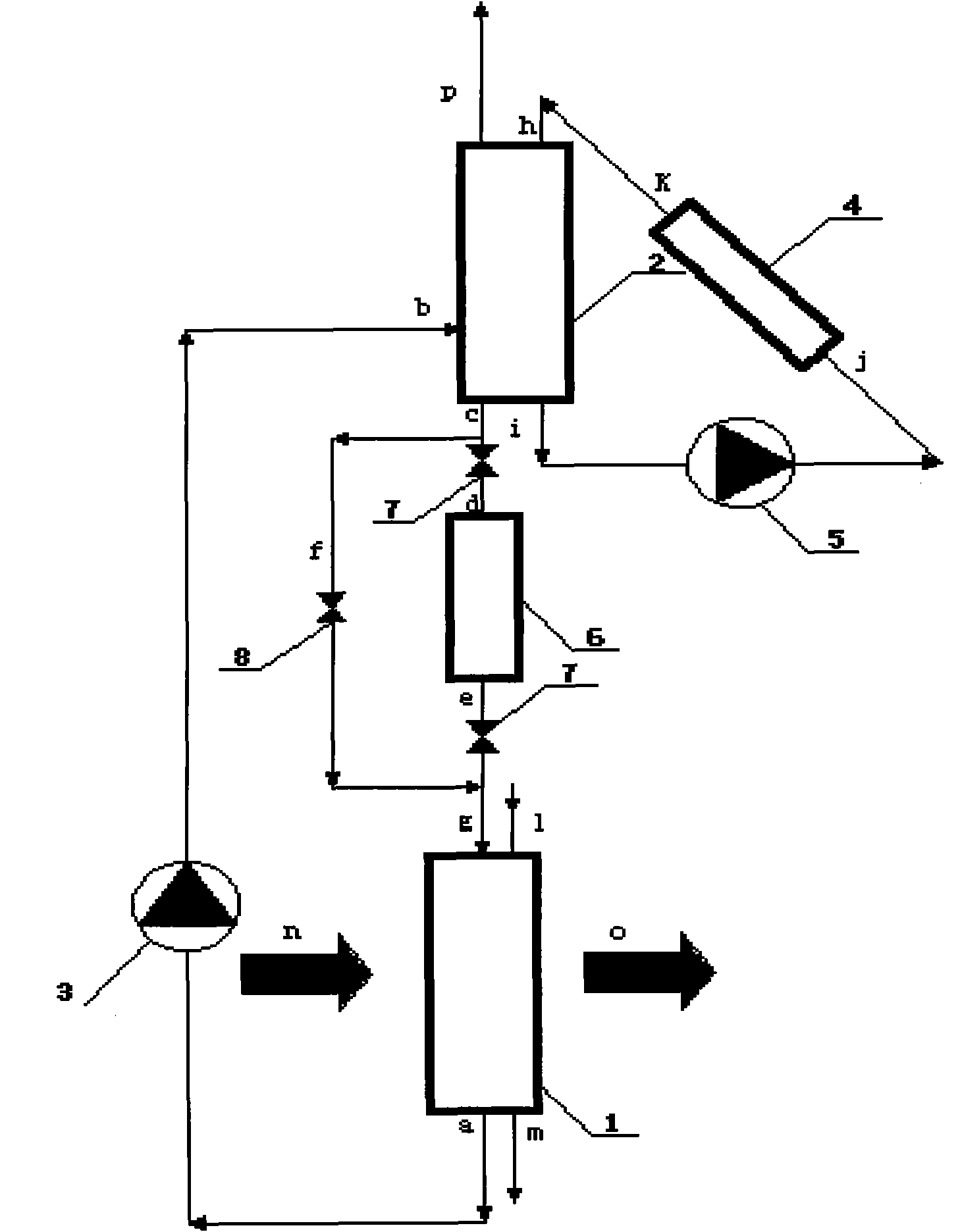

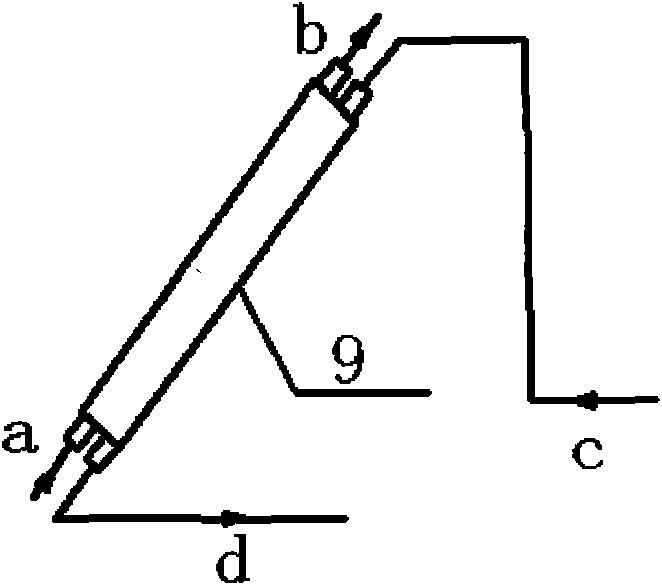

Dehumidizer for air dehumidification, air dehumidification method and device

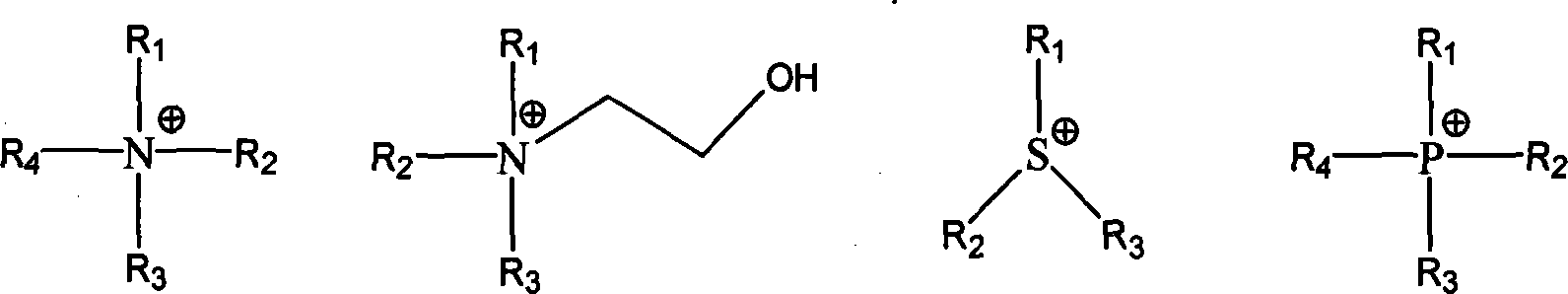

InactiveCN102335545AEfficient removalQuick removalLighting and heating apparatusDispersed particle separationLithium chlorideWater vapor

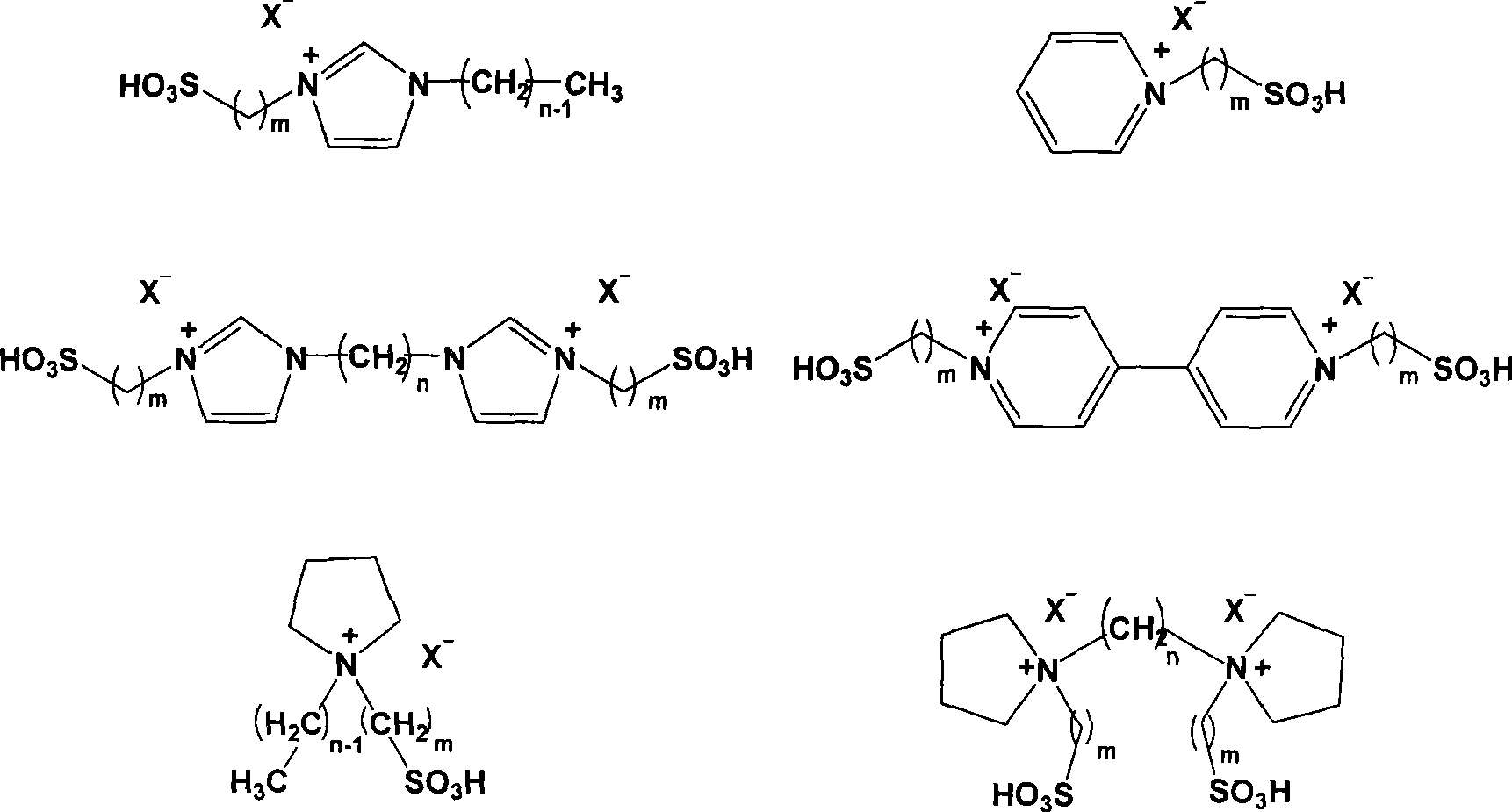

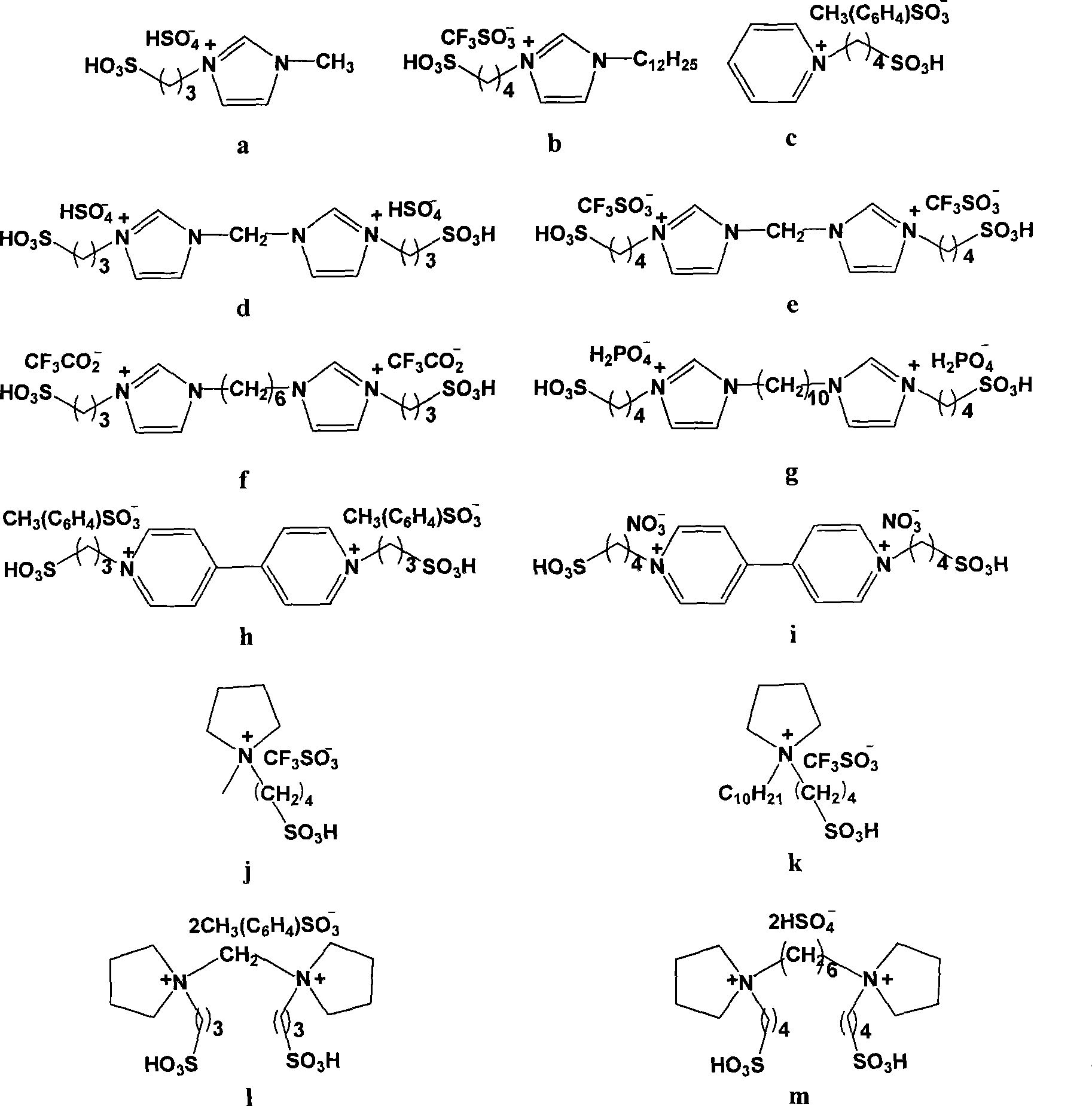

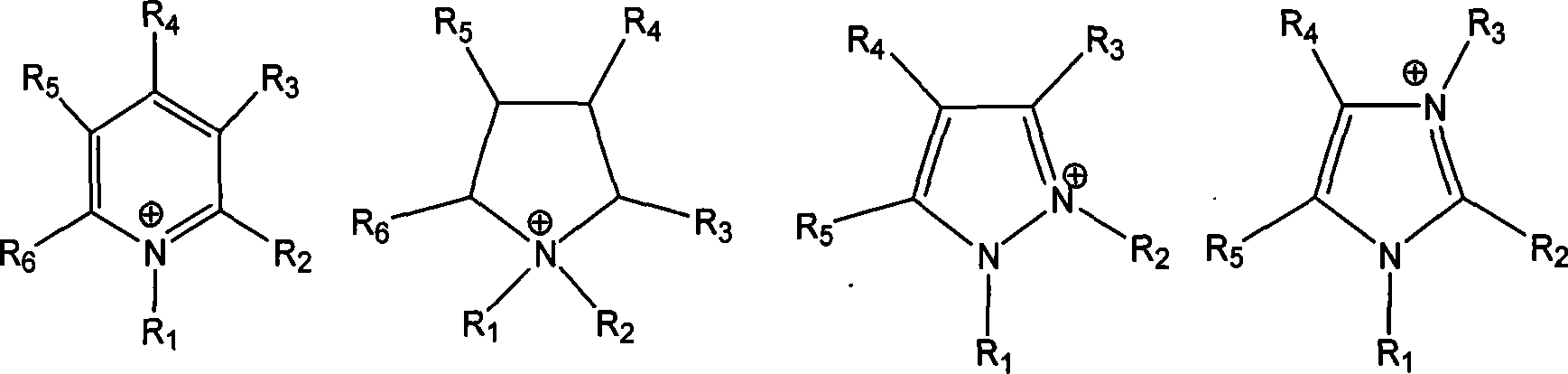

The invention discloses a dehumidizer for air dehumidification. The dehumidizer provided by the invention is an ionic liquid solution formed by dissolving an ionic liquid in water, wherein the ionic liquid is formed by organic positive ions and inorganic negative ions, and the melting point of the ionic liquid is close to or is lower than room temperature. In addition, the invention further discloses a method and a device for air dehumidification by the adoption of the above dehumidizer. In comparison with traditional salting liquids (lithium bromide, lithium chloride and calcium chloride aqueous solutions and the like), the dehumidizer provided by the invention has the following advantages: 1) the applied ionic liquid solution is in the liquid state at normal temperature, is intermiscible with water, and will not be crystallized during operation, so as to guarantee the reliable operation of a system; 2) the applied ionic liquid solution has similar or lower water vapor pressure than a traditional dehumidifying salting liquid so as to raise the dehumidifying efficiency; 3) the applied ionic liquid solution will not corrode metal equipment such as steel equipment such that the equipment has low cost and long service life; 4) the dehumidizer has nonvolatility so as to reduce the environmental pollution.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Phosphorus-free water-based metal cleaning agent

The invention relates to a phosphorus-free metal cleaning agent comprising the components of, by weight, 2-20% of a cleaning aid, 1-20% of a surfactant, 1-10% of a chelating agent, 1-20% of an emulsifier, 1-10% of an antirust agent, 0.2-4% of a copper alloy corrosion inhibitor, 1-10% of a penetration agent, 1-6% of a solubilizing agent, 0.1-0.6% of a defoaming agent, and balance of water. The cleaning agent provided by the invention has excellent cleaning capacity, long rust proof period, low foam, long service life, and the like. The cleaning agent is suitable for ferrous metal and non-ferrous metal processing industries. The agent has the advantages of no volatilization, no irritation, no toxic or harmful substance such as nitrite, no damage to health, and no environment pollution.

Owner:SHENYANG PARKERIZING

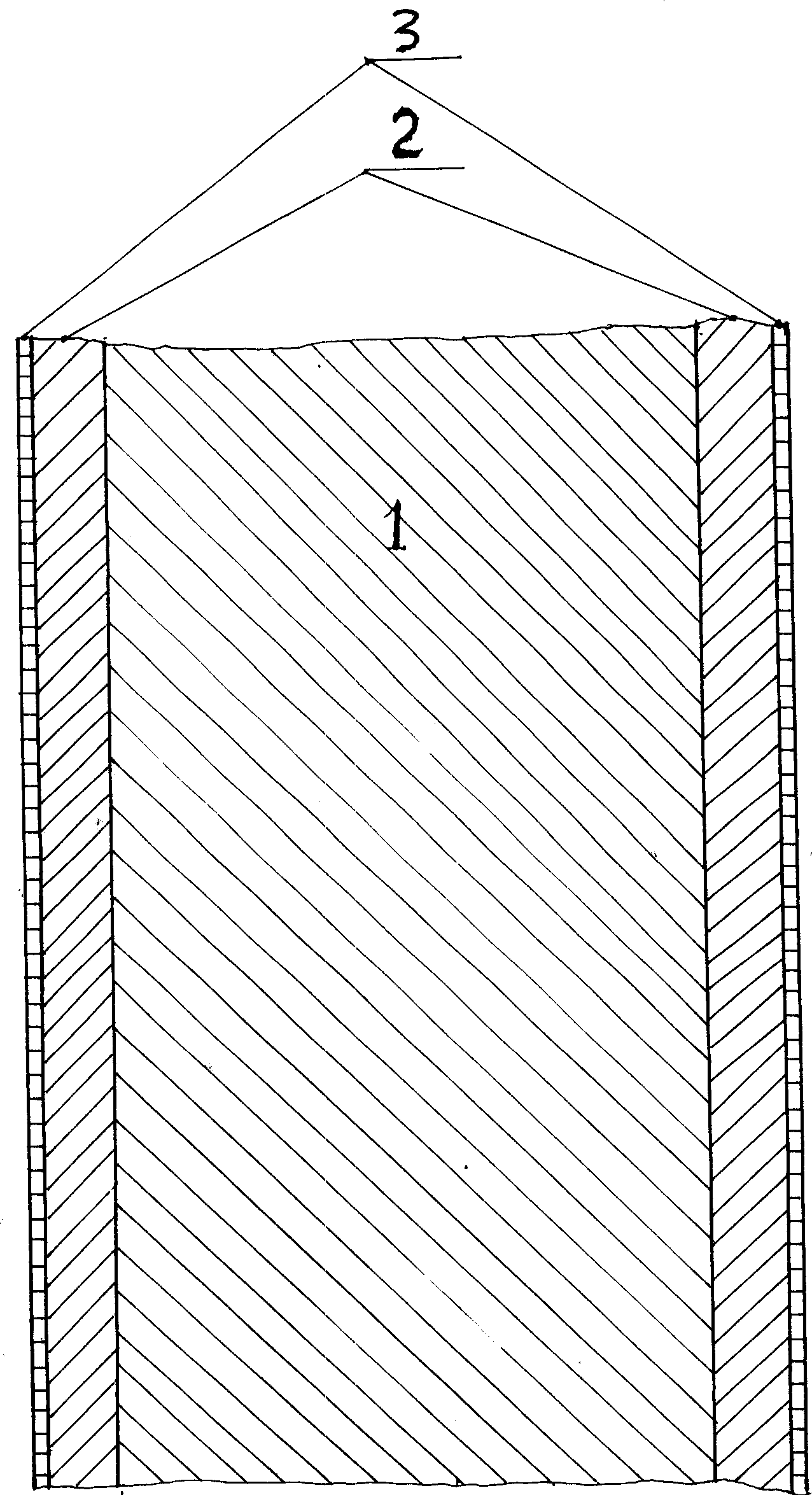

Interface paint with high hydrophobicity, heat conductivity and adhesion

A high-hydrophobicity, heat conductivity and adhesivity pigment of interface is prepared by taking methyl chloroform and butanone as medium, liquid-phase treating ordinary carbon black by silicone oil to hydrophobic activate, forming coating into dense methyl surface by polyester modified dimethylsilicone and agitation dispersing by supersonic homogenizer. The formed coating (2) is three-dimensional cross-linking network of cured polyphenylene methyl resin, which contains nanometer carbon black and silicon dioxide, and it forms dense methyl thin layer (3) on coating surface. It can be used to treat heat exchanger surface (1) of indoor apparatus and outer tube fin of household air conditioner. It has good hardness and is non- toxic.

Owner:李跃

Oily high-temperature resistant protective coating material, application thereof and titanium ingot production method

The invention discloses an oily high-temperature resistant protective coating material. The oily high-temperature resistant protective coating material is obtained after a raw material mixture is uniformly mixed, wherein the raw material mixture contains an oxidation protecting agent and an oily film forming agent; the oxidation protecting agent contains Al powder and Fe powder which are in the weight ratio of 1: (0.01-0.1). The invention further discloses an application of the oily high-temperature resistant protective coating material in titanium ingot production and a titanium ingot production method. The oily high-temperature resistant protective coating material disclosed by the invention has the advantages that the condition that the surface of a titanium ingot is not subjected to oxidation cracking under the condition that the titanium ingot undergoes constant temperature for 8 hours at the high temperature of 1,000 DEG C can be guaranteed, the forming possibility of an oxygen dissolved layer can be greatly reduced, and the yield and production efficiency of a titanium material are increased; the construction environment is not affected; the preparation process is simple; a variety of coating manners, such as pneumatic spraying, vacuum spraying and brushing, can be adopted. The titanium ingot production method disclosed by the invention has good economic and social benefits and has relatively broad popularization and application prospects in titanium plate and titanium tube production industries.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for synthesizing fatty acid ester by ester exchange reaction

InactiveCN101456810ASpecial solubilityWell mixedPreparation by ester-hydroxy reactionOrganic-compounds/hydrides/coordination-complexes catalystsReaction temperatureIonic liquid

The invention discloses a method for synthesizing fatty acid ester through ester exchange reaction. The method comprises: adding grease, methanol and ionic liquid catalyst to a reactor, and controlling the reaction temperature to be between 45 and 85 DEG C for the ester exchange reaction for 1 to 10 hours. The method has the advantages of mild reaction condition, wide material applicability, high fatty acid yield, good quality, long service life of the catalyst and the like. Compared with the prior acid-alkali catalyst for industrial use, the catalyst of the method has the advantages of low corrosivity, high catalytic activity, no pollution and repeated use, and has the potential for industrial application.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

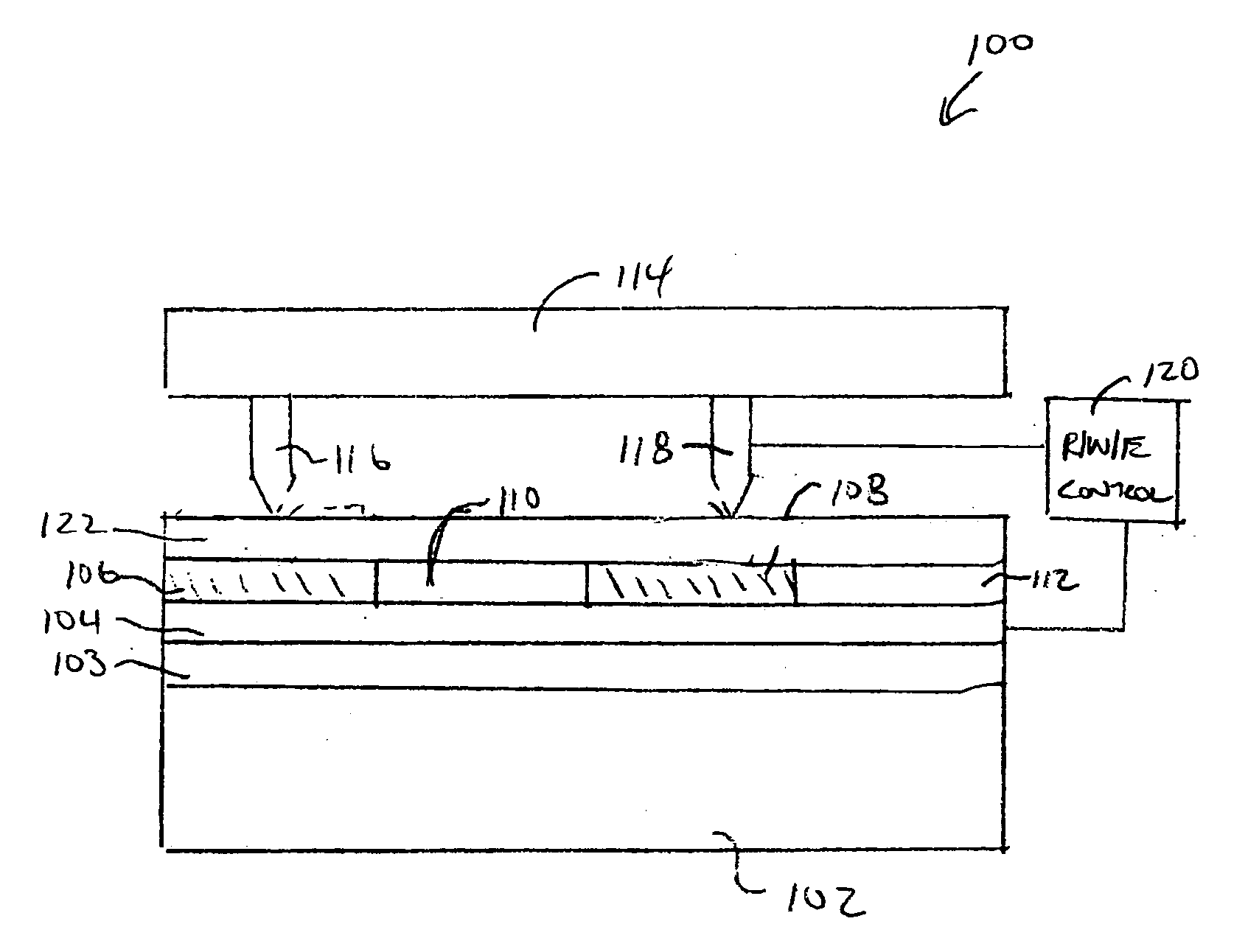

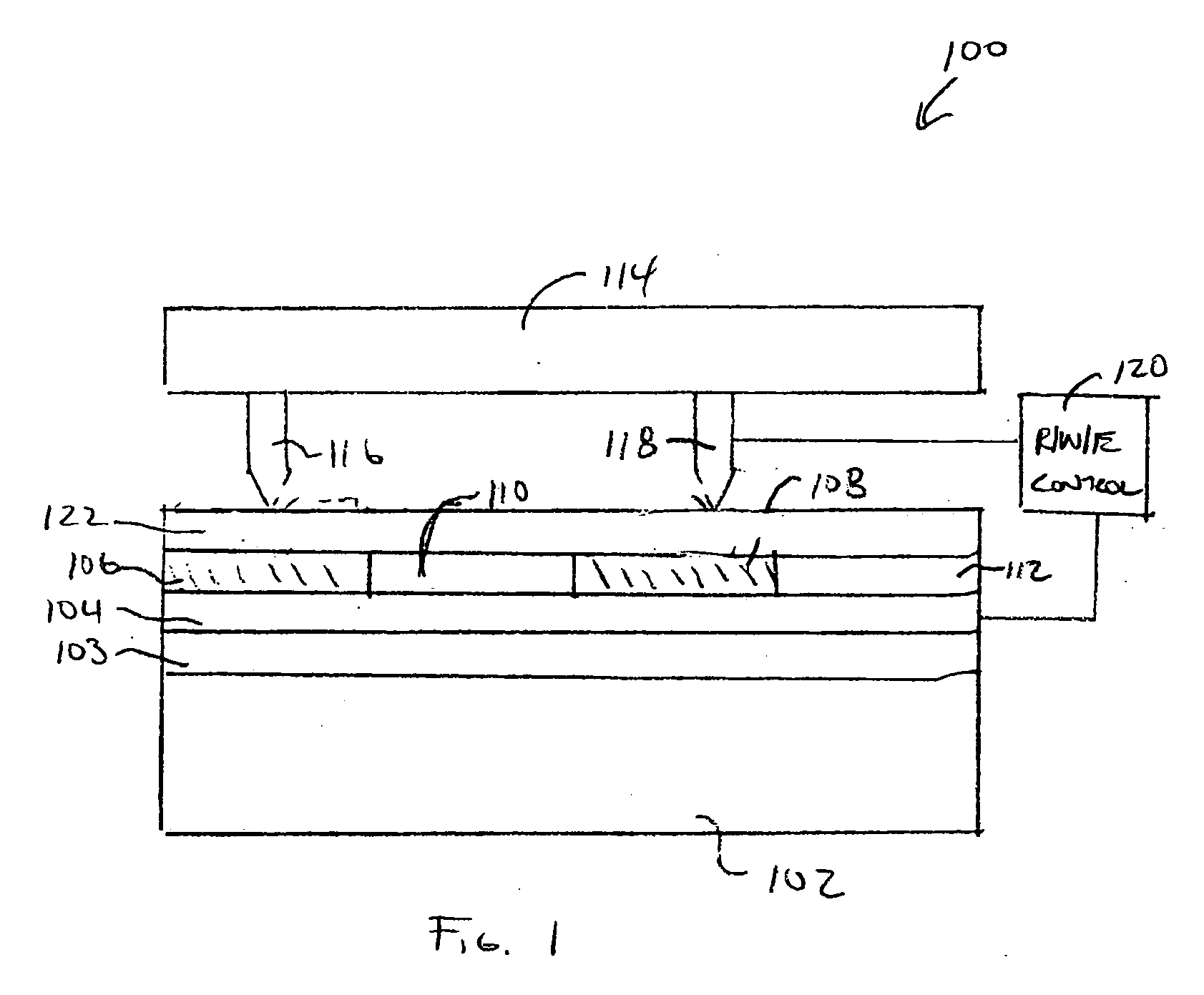

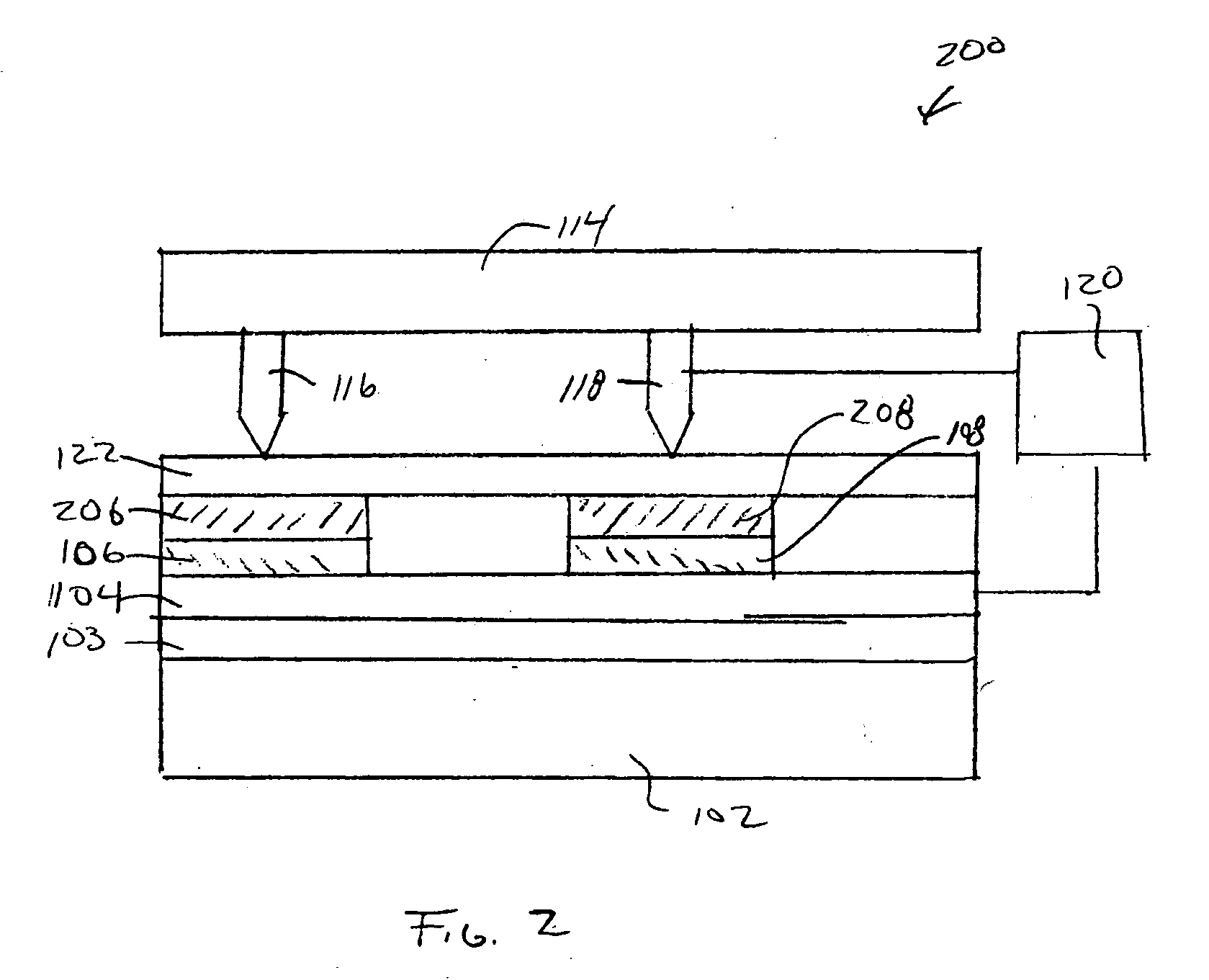

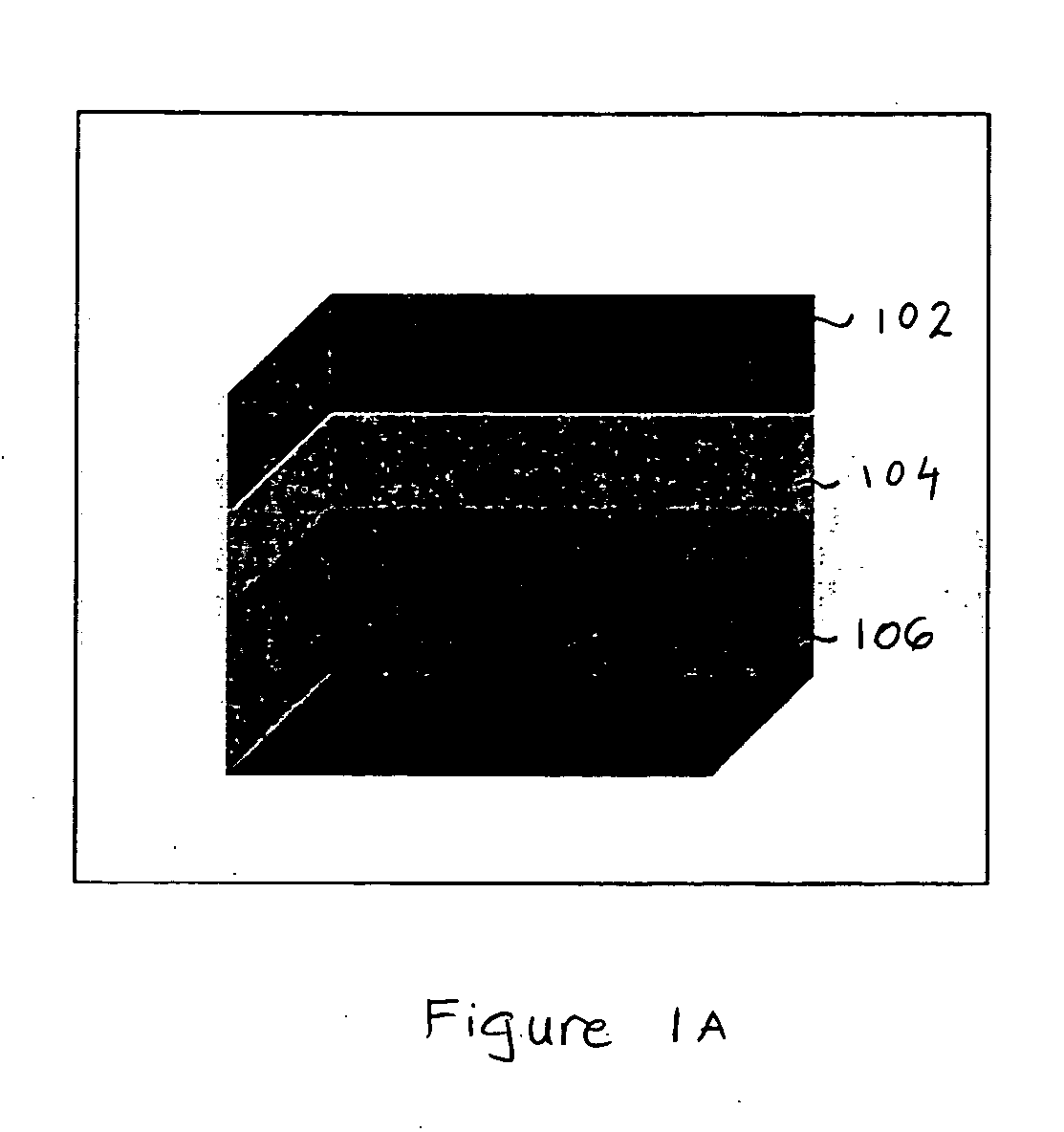

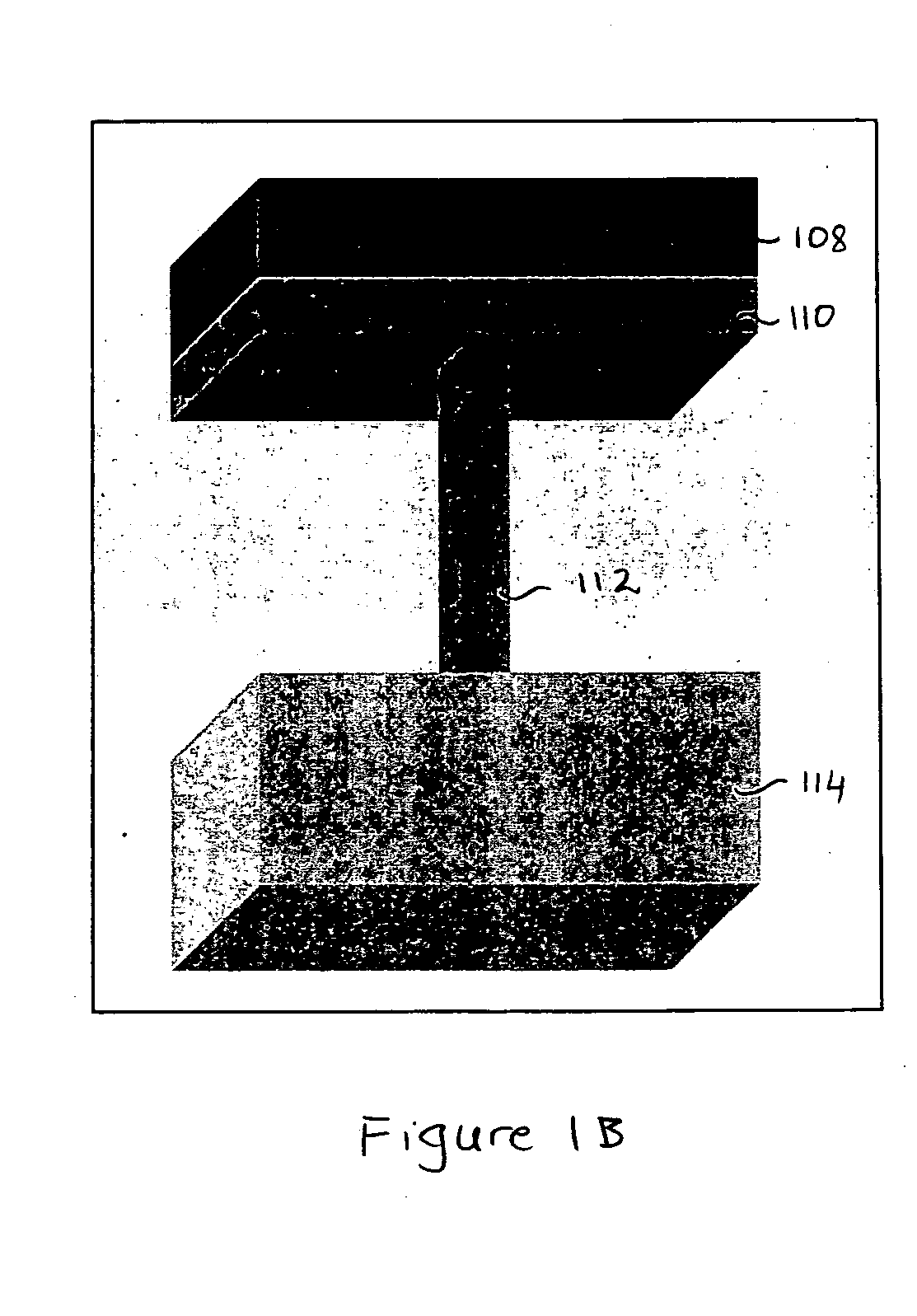

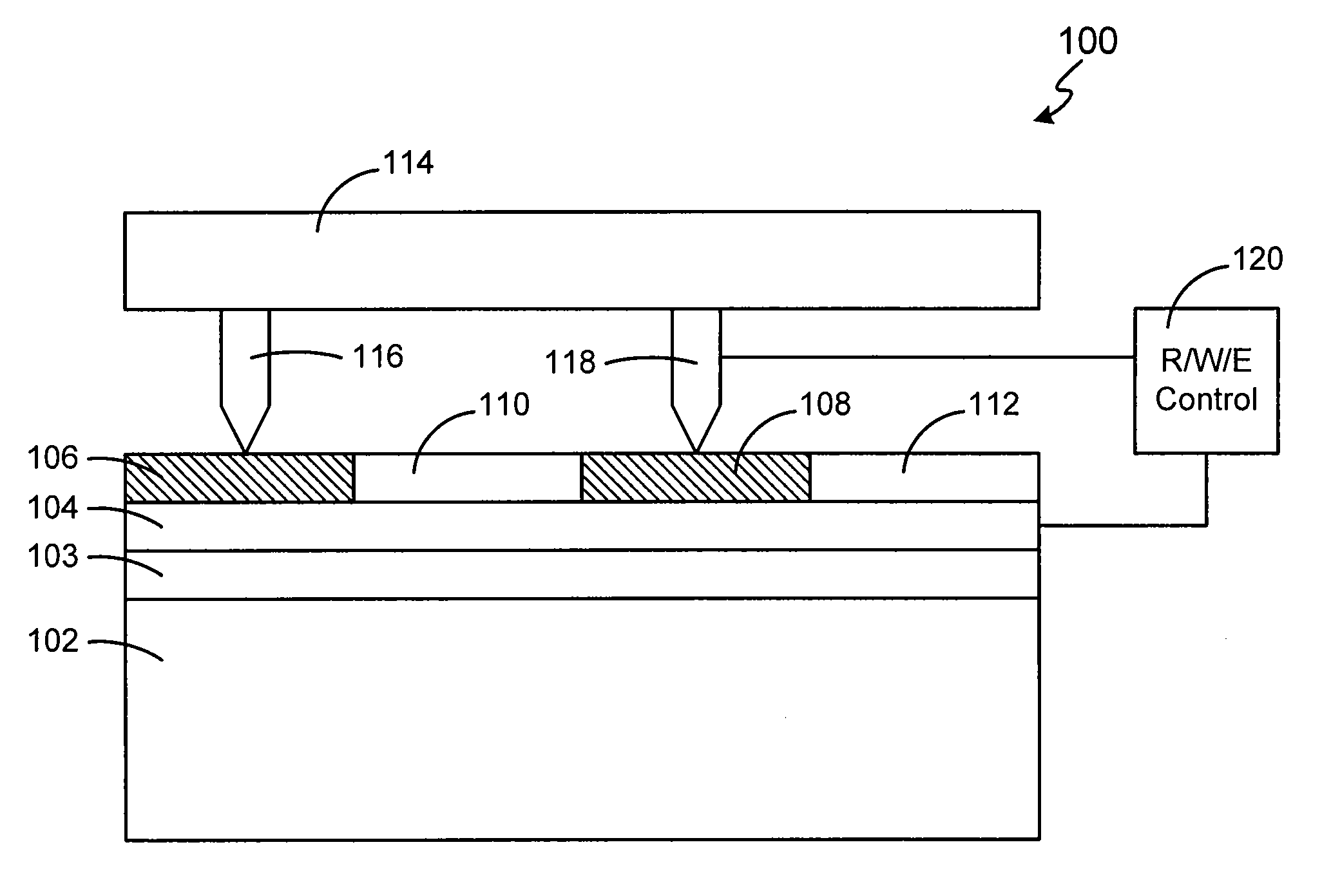

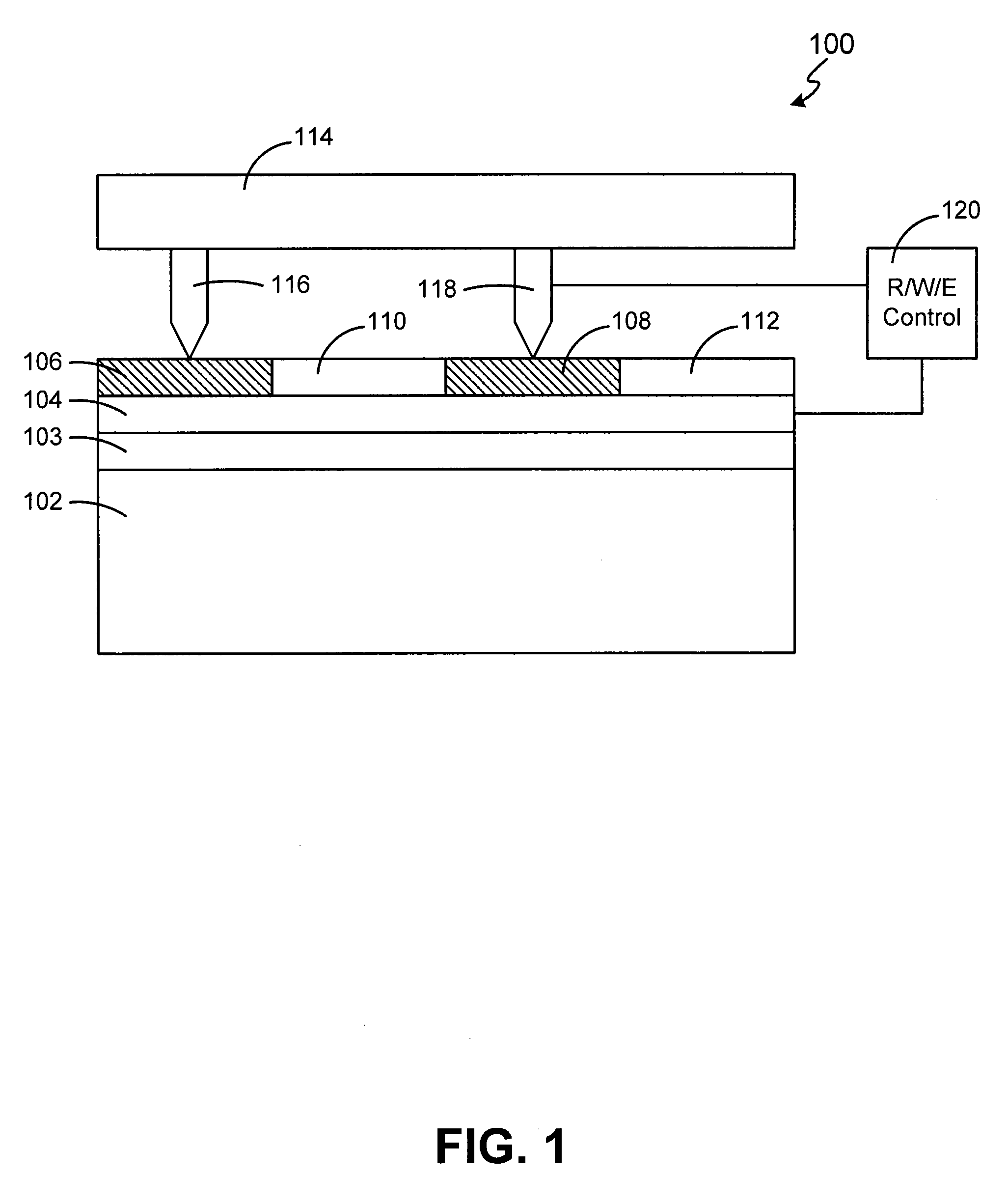

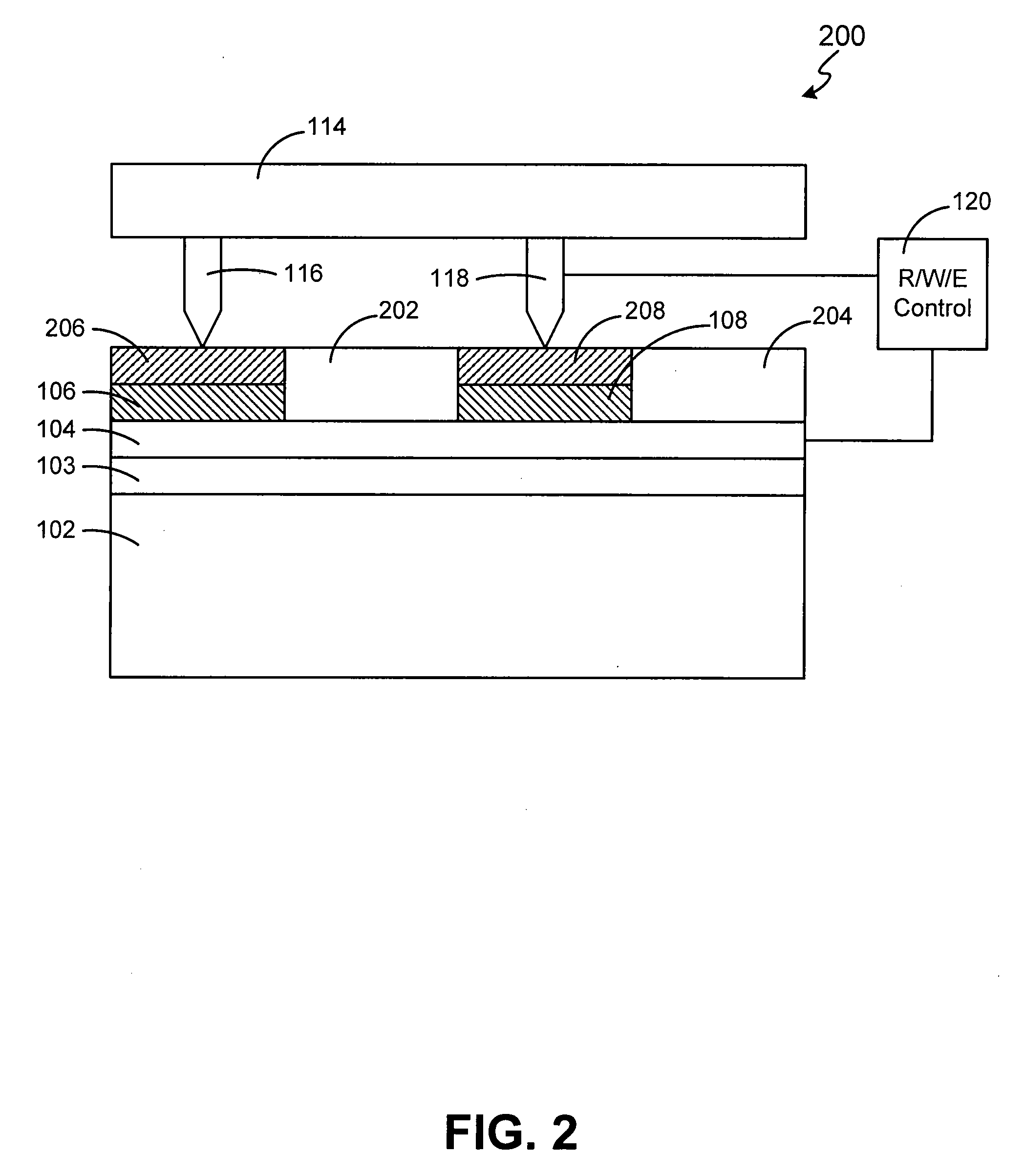

Solid electrolyte probe storage device, system including the device, and methods of forming and using same

InactiveUS20060291364A1Easy and inexpensive to manufactureKeep energy smallVariable resistance carrier recordingNanoinformaticsElectrical conductorElectrical battery

A probe storage system, including programmable cells suitable for storing information, and methods of forming and programming the cells are disclosed. The programmable cells generally include an ion conductor, a plurality of electrodes, and a protective layer between the ion conductor and at least one of the electrodes, wherein one of the electrodes may be in the form of a probe. Electrical properties of the cells may be altered by applying energy to the structure, and thus information may be stored using the system.

Owner:AXON TECH

Solar battery back plate adopting ultraviolet (UV) curing weather-proof coating and manufacture method of solar battery back plate

ActiveCN102610680AGood insulation of the materialLow water vapor transmission rateCoatingsPhotovoltaic energy generationFilling materialsUV curing

The invention discloses a solar battery back plate adopting an ultraviolet (UV) curing weather-proof coating and a manufacture method of the solar battery back plate. The solar battery back plate comprises a substrate, wherein at least one side of the substrate is coated with the UV curing weather-proof coating, the UV curing weather-proof coating is prepared from the following materials: 50 to 80 weight percent of weather-proof photosensitive resin, 10 to 20 weight percent of reactive diluent, 2 to 15 weight percent of initiating agent, 5 to 30 weight percent of filling material, 0.5 to 2 weight percent of dispersing agent, 0.5 to 2 weight percent of antioxidant, 0.5 to 2 weight percent of hydrolysis-resistant agent and 0.5 to 2 weight percent of anti-aging agent. The UV curing weather-proof coating is adopted and directly coated onto the substrate, the coating curing efficiency is high, the production efficiency of the solar battery back plate is improved, and meanwhile, the use of organic solvents causing serious pollution to the environment is avoided, so the organic solvent volatilization is avoided in the whole production process, and the solar battery back plate conforms to the green and environmental friendly standard.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD

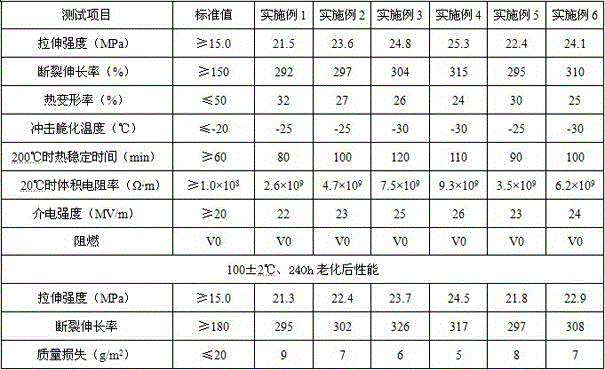

High-abrasion-resistant and environment-friendly polyvinyl chloride (PVC) modified materials and preparation method thereof

ActiveCN103059470AImprove wear resistanceImprove wet skid resistancePolymer sciencePolyvinyl chloride

The invention relates to the technical field of polyvinyl chloride composite materials, in particular to a high-abrasion-resistant and environment-friendly polyvinyl chloride (PVC) modified materials and a preparation method of the high-abrasion-resistant and environment-friendly PVC modified materials. The modified materials comprise following raw materials, by weight, 80-120 parts of PVC resin, 5-15 parts of stuffing bulking agents, 31-70 parts of plasticizer, 1-10 parts of abrasion resistant modifying agents, 1-10 parts of fire retardant, 1-10 parts of stabilizer, 10-20 parts of impact modifier and 0.2-2 parts of lubricating agents. The raw materials are weighed according to the weight and are blended, after the raw materials are stirred, the stirred raw materials are extruded to be granulated into particles through a double-screw extruder to produce the modified materials. The prepared modified materials are good in abrasion resistant property, environment-friendly, high in strength, good in flame retardant efficiency, strong in compression property and toughness, good in processing property, and good in comprehensive property. The preparation method of the high-abrasion-resistant and environment-friendly PVC modified materials is simple in craft, convenient to operate and control, stable in quality and high in production efficiency and can be produced in a large scale industrialization mode.

Owner:广东祺龙科技有限公司

High-temperature resistant flame-retardant environment-friendly PVC (polyvinyl chloride) modified material and preparation method thereof

Owner:广东祺龙科技有限公司

Preparation method of cellulose membrane by using ion liquid as solvent

The invention provides a method for making a cellulose membrane taking ionic liquid as a solvent. The method comprises the following steps that: (1) floccosem or crushed cellulose is mixed with the ionic liquid and is dissolved for 0.5 to 120 hours at a temperature of between 50 and 160 DEG C to prepare a membrane making stock solution, the concentration is between 5 and 35 percent; (2) after the membrane making stock solution is filtered and deaerated, the membrane is made, wherein, a solidification solution is an ionic liquid aqueous solution with a temperature of between 0 and 95 DEG C and a concentration of between 0 and 90 percent. The method is convenient and simple as well as economic, protects the environment and satisfies the industry needs. The cellulose membrane made by the method can be taken as a packaging material, a decorating material and a printing material or a filter membrane and a reverse osmosis membrane.

Owner:高小山

Chalcogenide memory

InactiveUS20050041467A1Easy to manufactureReduce voltageSolid-state devicesRead-only memoriesEngineeringChalcogenide

A memory core includes a top electrode, a bottom electrode. The memory core also includes a threshold-switching material disposed between the top electrode and the bottom electrode. The threshold-switching material serves as both a steering and a storage element. The memory cores are stacked to make the memory a 3D memory.

Owner:MACRONIX INT CO LTD

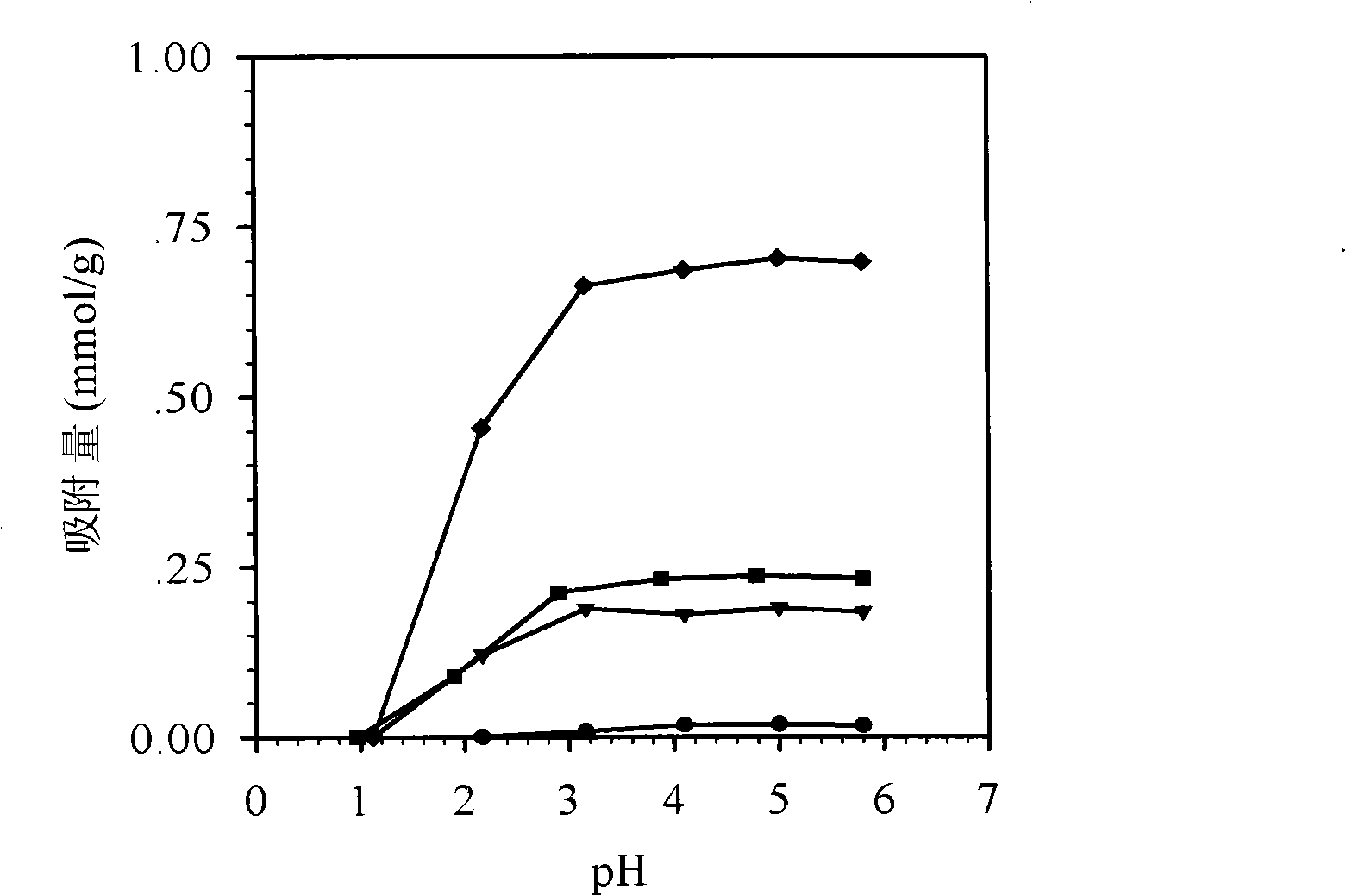

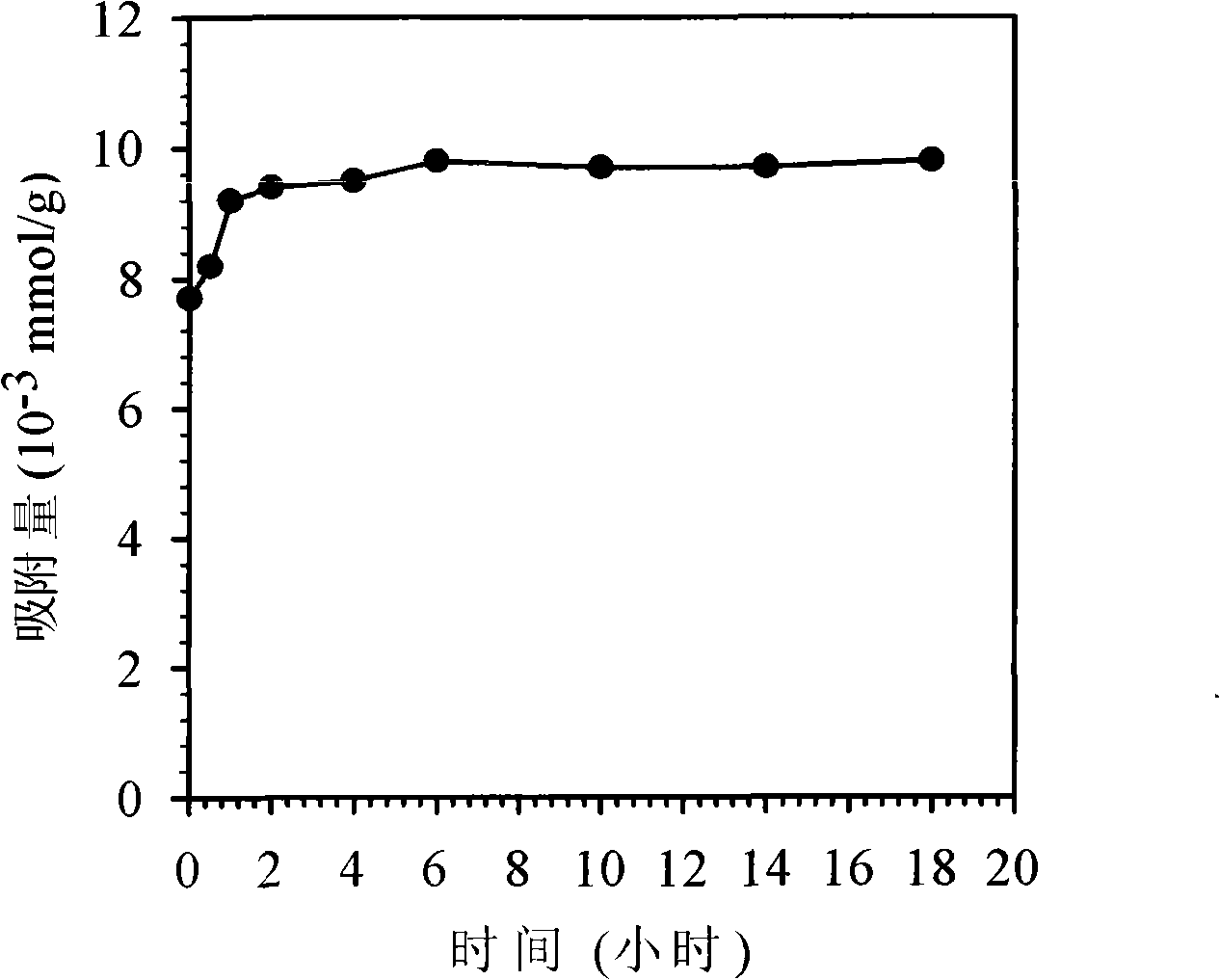

Biological adsorbing agent with adsorption capacity of heavy metal ion, and producing method and application thereof

ActiveCN101274268ANot easy to dissolveReduce crystallinityOther chemical processesWater/sewage treatment by sorptionSorbentEnvironmental engineering

The invention relates to a biology adsorbent and a preparation method thereof as well as application of the preparation method in heavy metal ion adsorption. The biology adsorbent is characterized in that hybrid blending material which has heavy metal ion adsorption capability is prepared by the capability of biological polymer such as microcrystalline cellulose, chitin, chitosan, etc. which can be dissolved in ionic liquid; the ionic liquid is chloridized 1-butyl-3-methyl imidazole salt and chloridized 1-allyl-3-methyl imidazole salt; the preparation of the adsorbent adopts two types: a drying type and a freeze-drying type; the ionic liquid used in the method can be recovered; the prepared adsorbent can be automatically degraded in environment; the preparation method and the prepared adsorbent in the method cause no secondary environmental pollution.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Solvent recovery method for cellulose fiber preparation with ion liquid as solvent

InactiveCN1804161AImprove protectionGood for healthArtificial filament recoveryTextile/flexible product manufactureRecovery methodFiltration

The invention provides a solvent recovery method in the cellulose fiber preparation process by using ionic liquid as the solvent, which comprises subjecting coagulating bath components to precipitation, filtration, vacuum distillation and normal atmosphere distillation.

Owner:DONGHUA UNIV

High heat resisting and high abrasion resistant polyvinyl chloride (PVC) modified material and preparation method thereof

ActiveCN103059465AImprove wear resistance and heat resistanceImprove surface gloss and surface smoothnessPelletizingPlasticizer

The invention relates to the technical field of polyvinyl chloride composite materials, in particular to high heat resisting and high abrasion resistant polyvinyl chloride (PVC) modified materials and a preparation method of the high heat resisting and high abrasion resistant PVC modified materials. The modified materials comprise the following raw materials, by weight, 80-120 parts of PVC resin, 25-60 parts of stuffing bulking agents, 21-60 parts of plasticizer, 1-10 parts of chlorinated polyvinyl chloride, 1-10 parts of fire retardant, 1-10 parts of stabilizer, 1-10 parts of impact modifier and 0.2-2 parts of lubricating agents. The raw materials are weighed according to parts by weight and are blended. After being blended, the raw materials are extruded out to be granulated through a double-screw extruder to produce the modified materials. The modified materials are good in heat resisting property and abrasion resistant property, environment-friendly, high in strength, good in flame retardant effect, strong in compressing property and toughness, good in processing property and good in comprehensive property. The preparation method is simple in craft, convenient to operate and control, stable in quality and high in production efficiency, and can be produced in a large scale industrialization mode.

Owner:广东祺龙科技有限公司

High temperature and wear resistant graphene coating and preparation method thereof

The invention relates to a high temperature and wear resistant graphene coating, and the graphene coating is characterized by comprising the following components by weight percent: 35.0-60.0wt% of silicate, 0.01-20.0wt% of graphene, 0.1-25.0wt% of additive, and the balance of water as a solvent. The invention further provides a method for preparing the coating. The high temperature and wear resistant graphene coating disclosed by the invention can be used for well protecting matrixes by coating on pipelines, chemical equipment, storage, kiln furnace, medicine, aerospace and sewage, the service life of the matrix is prolonged, and the performance of the coating is much greater than that of a common material.

Owner:ZHUHAI LETONG NEW MATERIAL TECH CO LTD

Preparation method of defoaming agent for waterborne system

ActiveCN105148571AActive ingredient reductionReduce manufacturing costCoatingsFoam dispersion/preventionAdjuvantNitrogen gas

The invention relates to a preparation method of a defoaming agent for a waterborne system. The preparation method of the defoaming agent for the waterborne system comprises the following steps: a) adding silicon oil, gaseous silicon dioxide and catalyst into a reaction container according to proportions, and preparing silicon cream under an agitating condition protected by nitrogen; b) adding hydrogen-containing silicon oil and allyl polyether into the reaction container, agitating under the protection of nitrogen, increasing temperature and adding an initiator for reaction to obtain polyether modified organic silicon; c) jading the silicon cream obtained in step a), the polyether modified organic silicon obtained in step b) and an emulsifier into the reaction container, adding water for emulsification under a high-speed agitating condition, and adding a thickening agent to regulate viscosity to obtain a product. The defoaming agent prepared by adopting the preparation method provided by the invention has the advantages that the active components are low, the manufacturing cost is low and the environmental friendliness is better; the emulsification is stable, the compatibility in the waterborne system is good, the defoaming agent is easy to disperse, the surface tension is low, the defoaming speed is quick, the foam inhibiting time is long, the thermal resistance, shear resistance and acid and alkali resistance thereof are good, and the defoaming agent can adapt to various places; the defoaming agent can be separately used and can also be jointly used with other adjuvants, the stability is good, the phenomenon of oil floating due to demulsification does not occur, no sediment is produced and shrinkage cavities during coating are not caused; and the defoaming agent is also very effective to non-waterborne systems.

Owner:KITO CHEM CO LTD

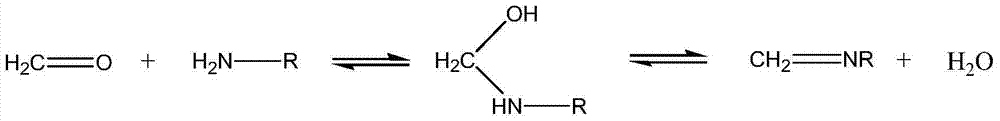

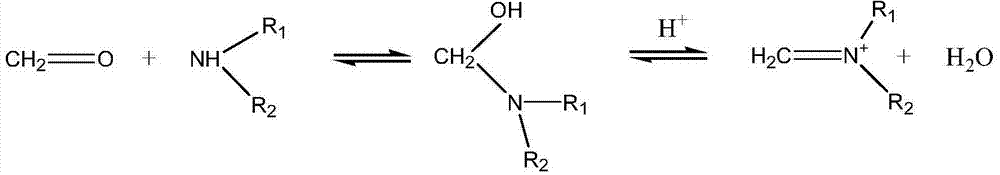

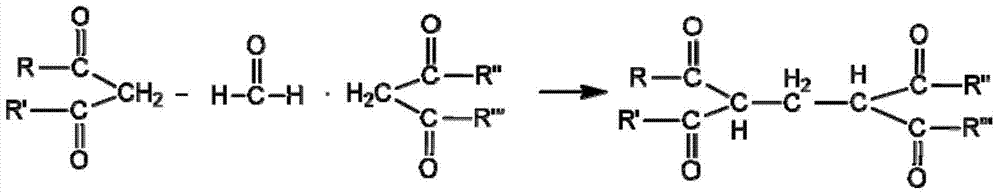

Wood lacquer for purifying formaldehyde and preparation method thereof

The invention discloses wood lacquer for purifying formaldehyde and a preparation method thereof. The wood lacquer is prepared by mixing a component A with a component B in a mass ratio of (1:0.25)-(1:0.5), and then stirring the mixture uniformly, wherein the component A is prepared by putting alkyd resin and alcohol solvents into a reaction kettle under the protection of nitrogen, stirring the materials uniformly and heating the materials to 50-75 DEG C, adding first diluents, fillers, driers, wax powder, formaldehyde removal agents and an anti-settling agent in sequence, continuing stirring, maintaining the temperature at 40-70 DEG C and reacting for 15-60 minutes, and discharging the material after returning to the room temperature; the component B is prepared by putting second diluents into the reaction kettle under the protection of nitrogen, stirring and insulating the materials, putting curing agents, a levelling agent and a defoaming agent into the reaction kettle, insulating and stirring the materials, and discharging the material after returning to the room temperature. The wood lacquer has high formaldehyde removal efficiency and good durability, dispenses with recoating films, and is convenient to use.

Owner:SOUTH CHINA UNIV OF TECH

Low temperature resistant environment-friendly polyvinyl chloride (PVC) modified material and preparing method thereof

ActiveCN103059468AGood flexibility and electrical insulation propertiesImprove low temperature resistancePelletizingPlasticizer

The invention relates to the technical field of polyvinyl chloride composite materials, in particular to a low temperature resistant environment-friendly polyvinyl chloride (PVC) modified material and a preparing method thereof. The modified material comprises by weight, 80-120 parts of PVC resin, 20-45 parts of filling agent, 41-80 parts of plasticizer, 1-10 parts of cold-resistant modifying agent, 1-10 parts of fire retardant, 1-10 parts of stabilizing agent, 5-15 parts of impact modifier and 0.2-2 parts of lubricating agent. Each raw material is weighed by weight and mixed, after being stirred; the raw material is squeezed out of prilling through a double-screw extruder and the modified material is available. The low temperature resistant performance of the modified material manufactured by the preparing method is fine; the minimum usage temperature can reach below 65 DEG C. The modified material is environment-friendly and has the advantages of high intensity, good flame retardant effects, strong compression performance and toughness, excellent processing performance and better comprehensive performance. The preparing method of the low temperature resistant environment-friendly polyvinyl chloride (PVC) modified material has the advantages of being simple in technology, convenient to control and operate, stable in quality, high in production efficiency. In addition, the preparation method of the low temperature resistant environment-friendly polyvinyl chloride (PVC) modified material can be used for a large scale industrial production.

Owner:广东祺龙科技有限公司

Green alkaline paint remover for eliminating coating from electronic circuit board and its prepn and usage

InactiveCN1887979AReduce poisonNo corrosionChemical paints/ink removersAqueous sodium hydroxideEngineering

The present invention is green alkaline paint remover for eliminating coating from electronic circuit board and its preparation and usage, and belongs to the field of paint remover technology. The paint remover consists of NaOH in 40-150 g / L, surfactant in 0.5-50 g / L, additive in 0-50 g / L, corrosion retardant 0.1-2.5 g / L, and water for the rest. It is prepared through mixing and heating at 50-80 for dissolving completely. When the paint remover is used, the electronic circuit board is soaked in the paint remover and heated at 50-100 deg.c for 10-60 min to eliminate its paint layer. The present invention has the advantages of low cost, fast paint eliminating speed, low toxicity, use safety and capacity of being used repeatedly.

Owner:UNIV OF SCI & TECH BEIJING

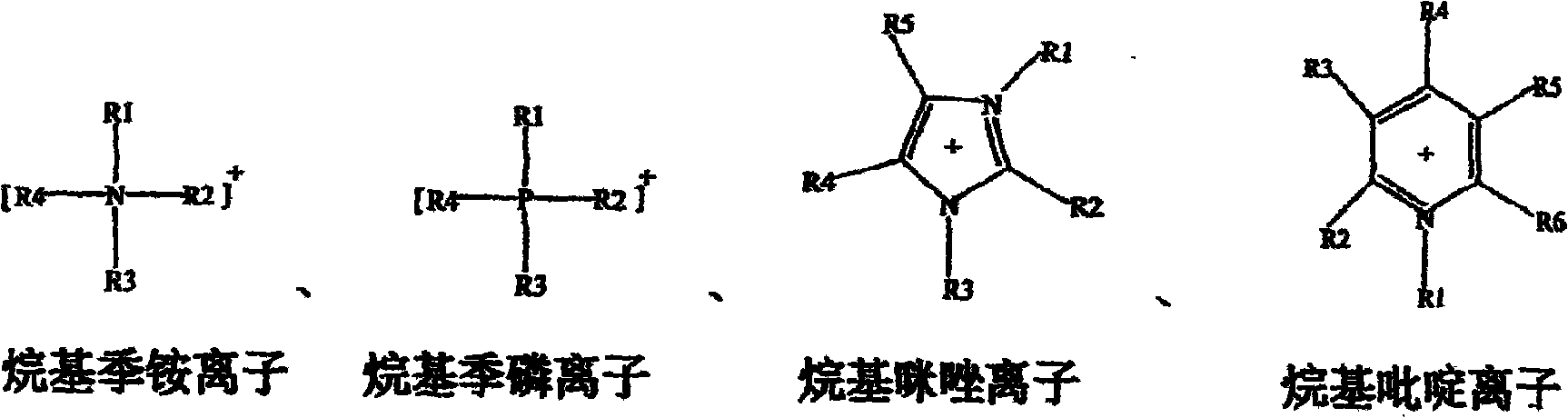

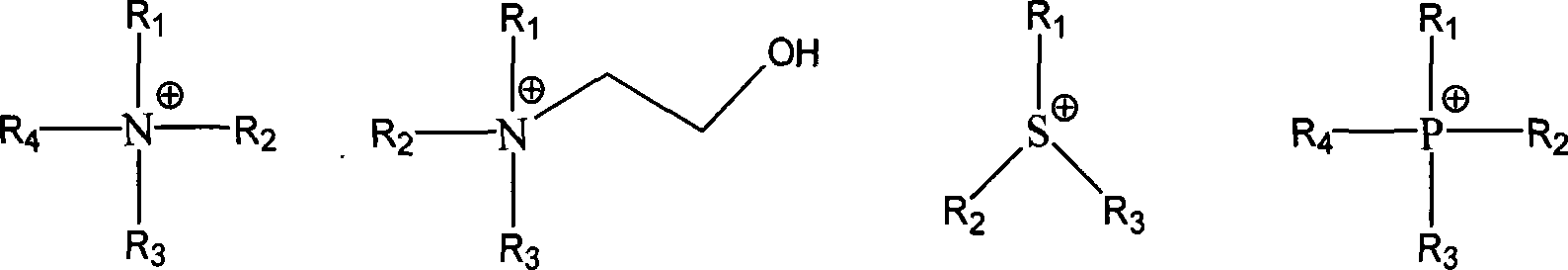

Method for synthesizing biologic diesel oil based on ion liquid

ActiveCN1696248ASimple processWell mixedLiquid hydrocarbon mixture productionBio-feedstockSolventIon

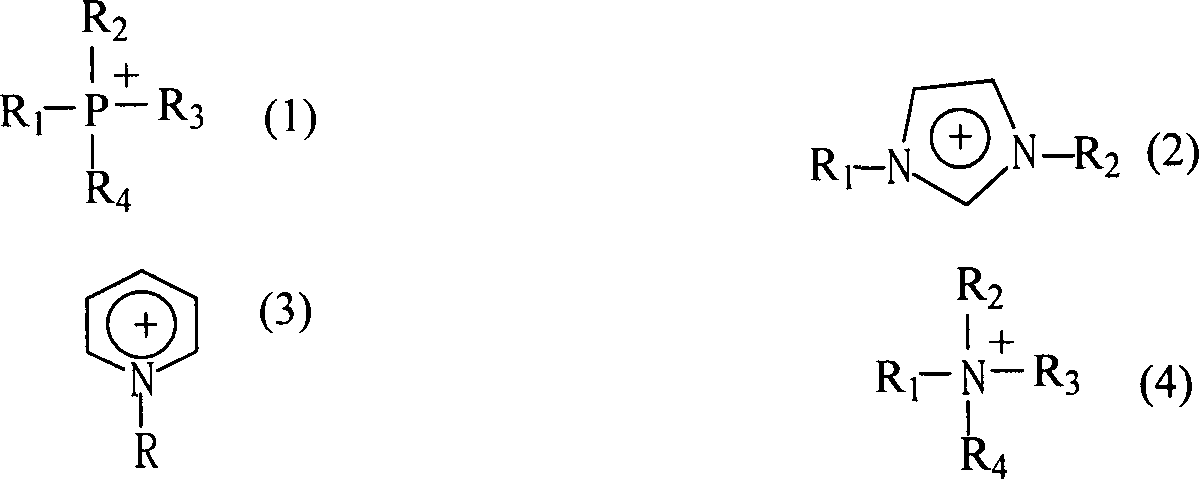

A process based on ionic liquid for synthesizing biologic diesel oil features that the ionic liquid can be used as both catalyst and solvent, so speeding up the reaction. Said ionic liquid is prepared from the N or P contained compound (alkylimidazole, alkylpyredine, quaternary ammonium salt, etc) and the halide (or acidic salt) of metal or non-metal.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Acrylate grafted aqueous polyurethane emulsion and preparation method thereof

ActiveCN102558460AImprove stabilitySmall particle sizeFibre treatmentCoatingsHydrophilic monomerPolymer science

The invention discloses acrylate grafted aqueous polyurethane emulsion and a preparation method thereof. The emulsion is characterized is prepared from polyether polyol, dimethylol propionic acid, isophorone diisocyanate, ethylenediamine, hydroxyethyl acrylate and the like. The preparation method comprises the following steps: carrying out prepolymerization on polyether polyol, dimethylol propionic acid and isophorone diisocyanate so as to introduce a hydrophilic monomer; adding ethylenediamine and hydroxyethyl acrylate to carry out chain extension so as to introduce a functional monomer; adding an acrylate mixed monomer so as to reduce system viscosity; adding triethylamine for neutralization; adding deionized water for emulsification and dispersion under the condition of high-speed shearing to obtain emulsion; then dropwise adding the acrylate mixed monomer and an initiator, raising the temperature and carrying out reaction; and cooling to obtain the PUA (polyurethane-acrylate) emulsion. The emulsion prepared by the method has small grain size and excellent performances such as mechanical performance, is narrowly distributed and can be widely applied to industry fields such as leather finish, coatings, adhesives and fabric coatings.

Owner:顶立新材料科技股份有限公司

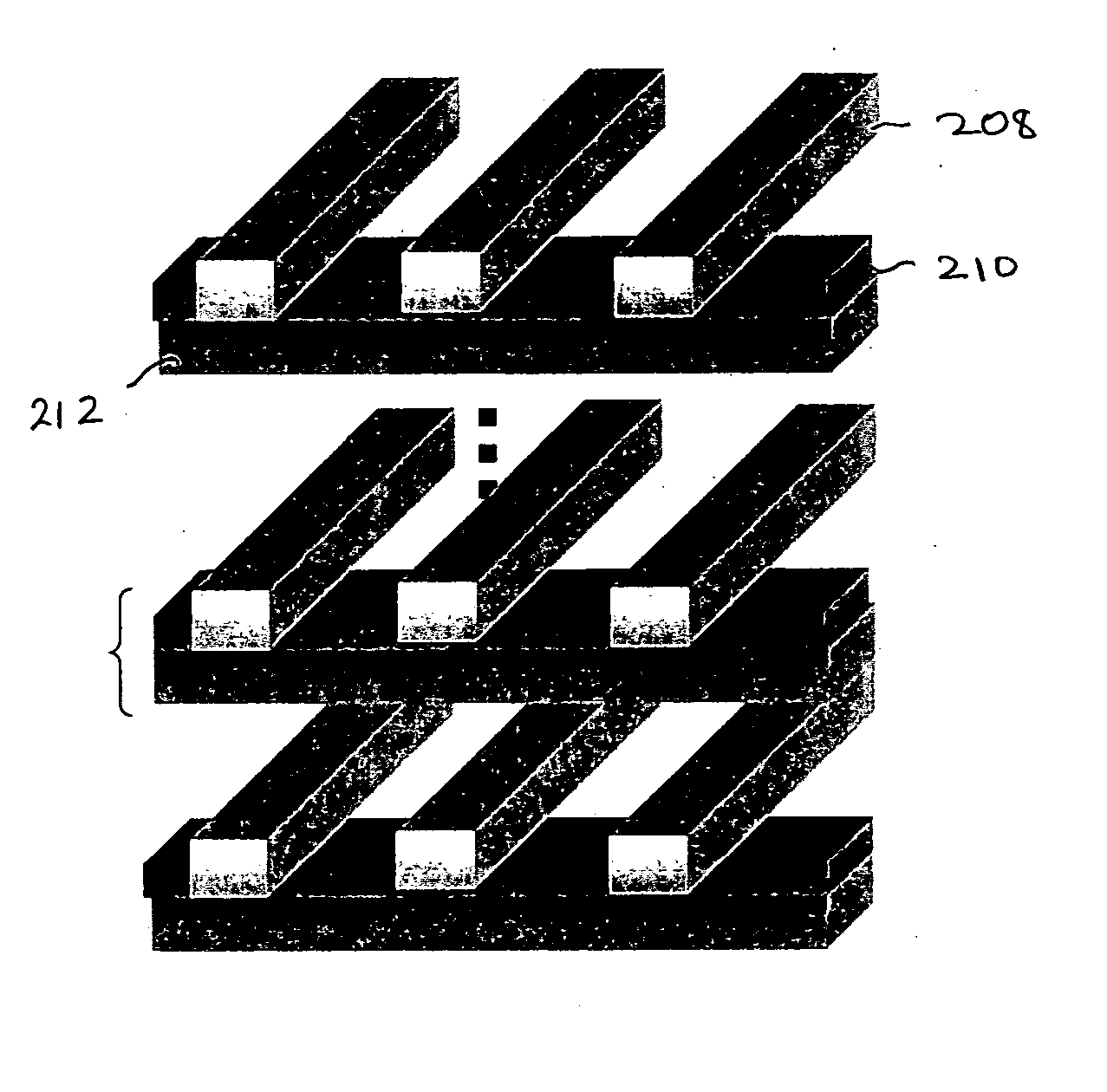

Probe storage device, system including the device, and methods of forming and using same

InactiveUS20060238185A1Easy and inexpensive to manufactureKeep energy smallCurrent/voltage measurementNanoinformaticsElectrical conductorElectrical battery

A probe storage system, including programmable cells suitable for storing information, and methods of forming and programming the cells are disclosed. The programmable cells generally include an ion conductor and a plurality of electrodes, wherein one of the electrodes may be in the form of a probe. Electrical properties of the cells may be altered by applying energy to the structure, and thus information may be stored using the system.

Owner:KOZICKI MICHAEL N

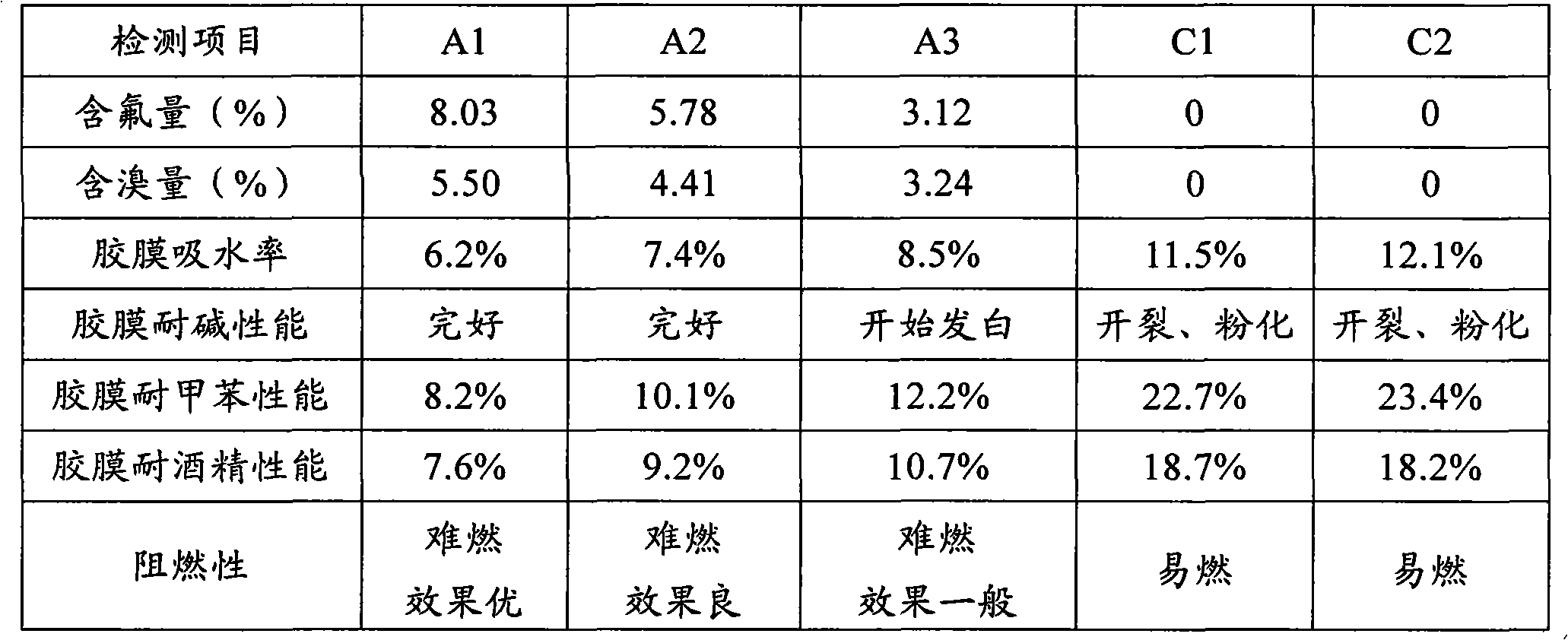

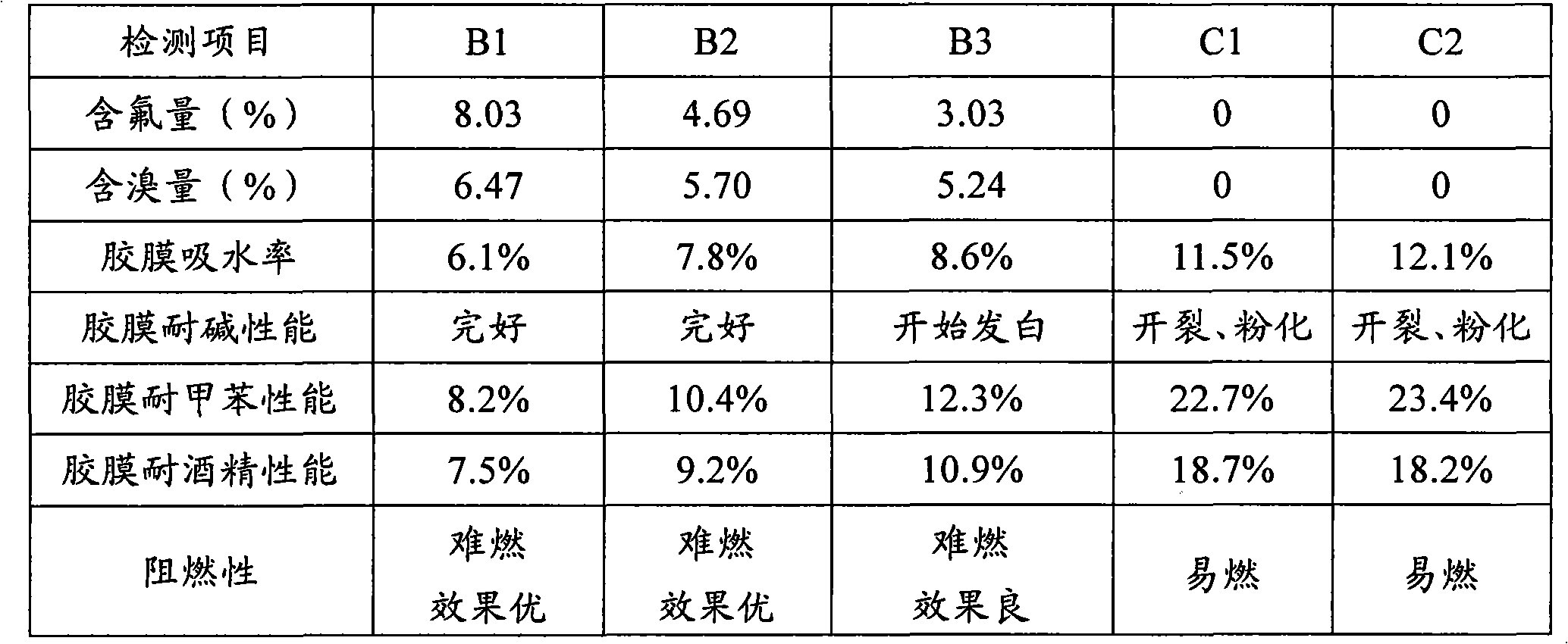

Method for preparing water-based polyurethane resin and water-based polyurethane resin

InactiveCN101935449AImprove stabilityLower surface energyFibre treatmentPolyurethane dispersionWater based

The invention provides a method for preparing a water-based polyurethane resin. The method comprises the following steps of: (1) reacting polyisocyanate, polyether diol and fluorine-containing diol to obtain prepolymer; (2) performing chain extension reaction on the prepolymer, bromine-containing diol and hydrophilic chain extender; and (3) neutralizing the solution by using a salt forming agent, and dispersing and emulsifying the solution by adding water to obtain water-based polyurethane dispersion. The invention also provides the water-based polyurethane resin prepared by the method. The water-based polyurethane resin solves the problems of poor dirt resistance and flame-retardant property of oil-based polyurethane resin and common water-based polyurethane resin.

Owner:丽水市优耐克水性树脂科技有限公司

Method for preparing protein modified cellulose fibre

InactiveCN101113535AImprove protectionGood for healthConjugated cellulose/protein artificial filamentsWet spinning methodsYarnCellulose fiber

The invention relates to a preparation method of a protein modified cellulose fiber, comprising the steps that: (1) a protein and a cellulose are dissolved in ion solution to prepare homogeneous mixing spinning solution; (2) the spinning solution is deaerated, filtered, measured, and extruded out through spinning jet to form spinning rills, and the spinning rills pass through a wet air layer and enter into a solidification bath to be solidified and molded; (3) the yarn is extended, cleaned by water, dried and heat molded, and formed into fiber to prepare the protein modified cellulose fiber. The method has the advantages of environmental protective, low cost, fast spinning speed and high production efficiency, and the prepared fiber has the advantages of comfort and health care, etc.

Owner:DONGHUA UNIV

Water-based organic silicon waterproof agent

InactiveCN101580355AGive full play to the effect of waterproofImprove impermeabilityOther chemical processesWater basedBrick

The invention relates to a water-based organic silicon waterproof agent by taking sodium methylsilanolate as a main raw material, and is particularly suitable for moving penetration waterproof processing of a porous structure, such as bricks, stone materials, concrete, mortar, cement slurry and the like.

Owner:郭元华

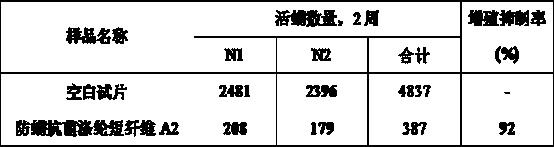

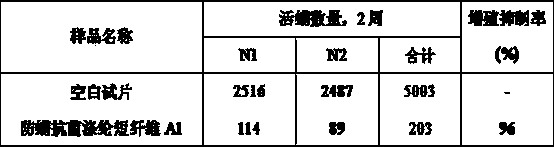

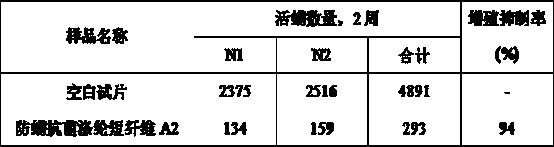

Anti-mite antibacterial polyester staple fiber and preparation method thereof

The invention relates to insoluble inorganic anti-mite antibacterial polyester staple fiber which is prepared from micron-scale heat accumulation anti-mite ceramic powder and silver-loaded nano titanium dioxide composite antibacterial powder through an esterification polymerization spinning mode or prepared by making the powder into masterbatch and mixing with polyether slices and spinning, wherein the micron-scale heat accumulation anti-mite ceramic powder is prepared from 2-6 parts of Tai Chi stone, 5-12 parts of boric acid, 8-30 parts of clayed soil and 3-8 parts of silicic acid by mass by grinding, tabletting, calcining and high-temperature compounding; the silver-loaded nano titanium dioxide composite antibacterial powder is prepared from 1-1.5 parts of silver nitrate and sodium chloride and 3-5 parts of metatitanic acid by mass by precipitation, suction filtration, washing, drying and calcining; the anti-mite antibacterial polyester staple fiber obtained by spinning has a relatively strong antibacterial effect on staphylococcus aureus and escherichia coli, wherein the antibacterial rate is greater than or equal to 95%, and the mite proliferation inhibition rate is greater than 92%.

Owner:SHANGHAI DEFULUN CHEM FIBER

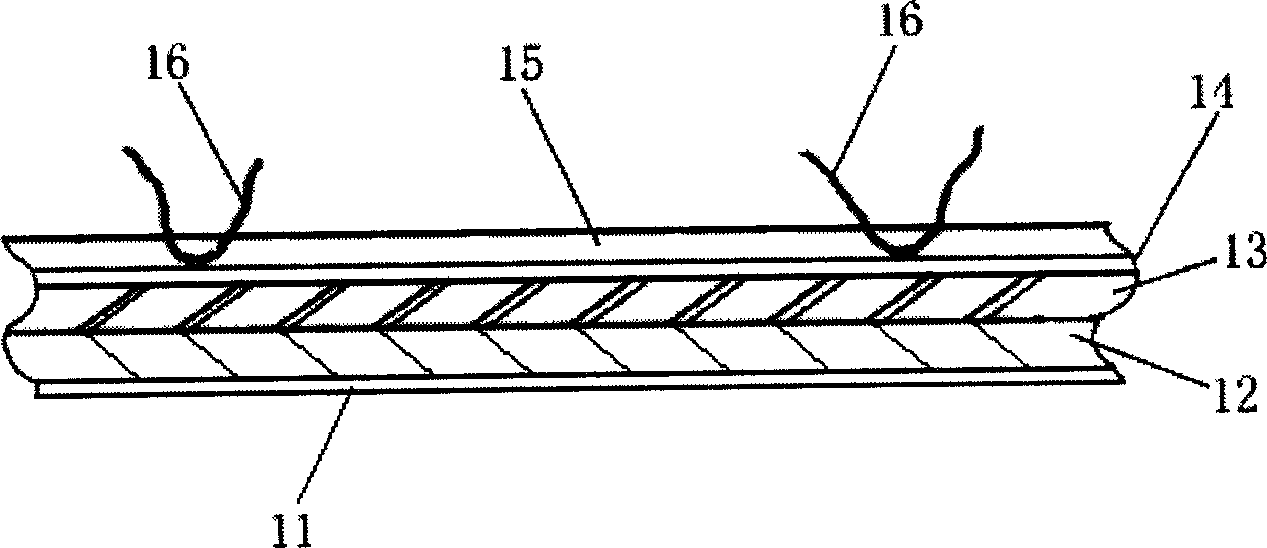

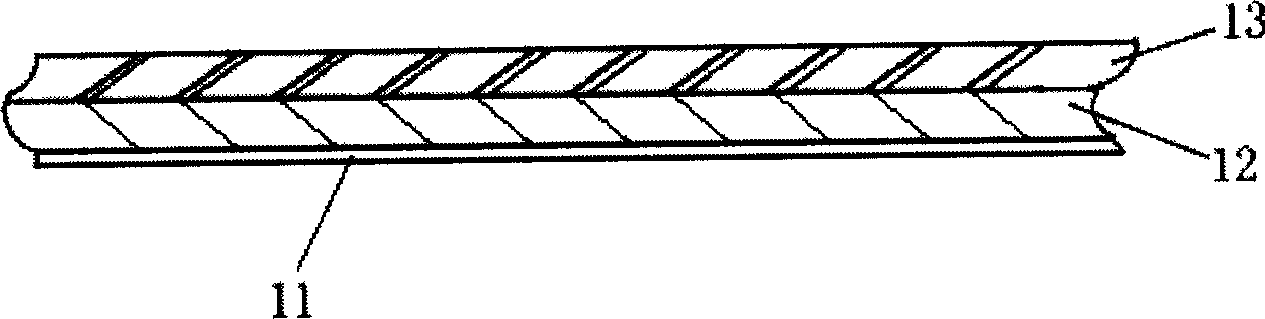

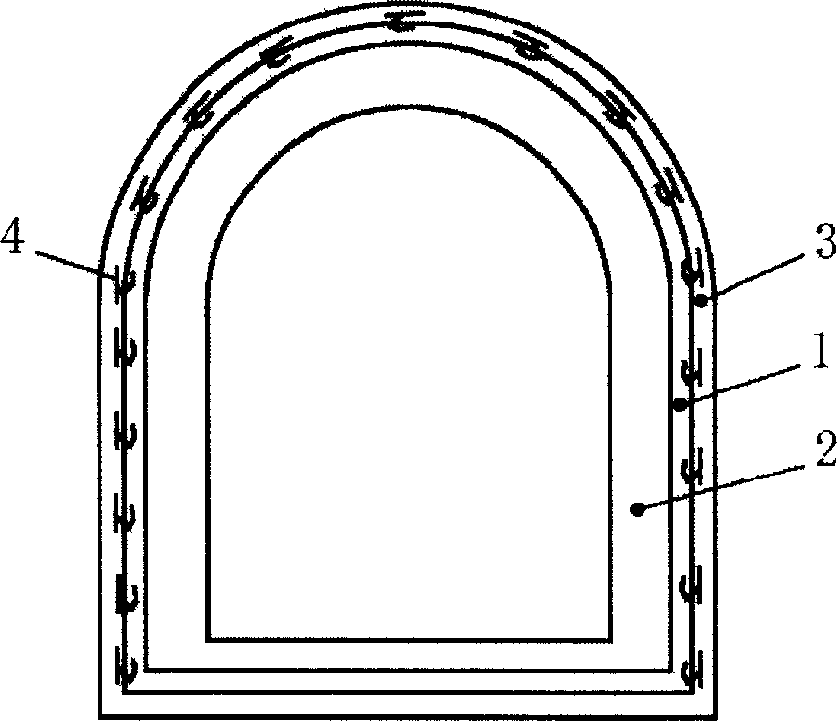

Wet coating self-adhering waterproof coiled material and producing method and construction method thereof

InactiveCN1888350AGood waterproof performanceHigh strengthLamination ancillary operationsRoof covering using flexible materialsSolventAsphalt

The present invention relates to a wet-stickable self-adhesive water-proof sheet material, its production method and construction method. It is characterized by that said invention uses butyl rubber and high-grade oxidated asphalt, makes them undergo the process of high-temperature mixing treatment, adds acryl water-absorbing resin, operation oil, filler and flow-resisting agent, makes them undergo the process of high-speed dispersion treatment so as to obtain self-adhesive seal water-proof material, dip-coating said self-adhesive seal water-proof material onto one surface of high-molecular water-proof sheet material carrier, then makes the above-mentioned material undergo the processes of calendaring, extruding and layering isolating layer as anti-adhesion layer, then makes a flexible protective layer be stuck on another surface of the above-mentioned high-molecular water-roof sheet material, so that the invented wet-stickable self-adhesive water-proof sheet material can be obtained.

Owner:北京中联天盛建筑工程有限公司

Production of spinning stoste with cellulose base fibre

InactiveCN1818160AImprove protectionGood for healthArtificial filaments from viscoseCELLULOSE FLOURCellulose fiber

The invention opened a preparing method of the cellulose fibre spinning stock solution. The solvent is the intermixture of the [BMIM]Cl and the [BMIM]BF4. The cellulose dissolves in the solvent after breaking up to get the uniform and transparent liquid. So it can save the energy, decrease the pollution and improve the quality of the stock solution.

Owner:DONGHUA UNIV

Method for producing aluminium and aluminium alloy by low temperature electrolysis

InactiveCN1664170ALight in massNon-volatilePhotography auxillary processesProcess efficiency improvementMetallic materialsIonic liquid

The invention relates to a method of making aluminum and aluminum alloy through electrolyzing in low temperature, which belongs to the metal material field, characterized in that it uses the alumina or silicate mineral containing aluminum as raw materials, and gets anhydrous aluminum chloride after chloridization, then prepares AlCl3 ionic liquid with anhydrous aluminum chloride, and uses the AlCl3 ionic liquid as ionogen, the aluminum will be produced in the cathode while the chlorine will be discharged from the anode. When producing the aluminum alloy, preparing the alloy elements chloridate-AlCl3 ionic liquid through adding alloy elements chloridate MeCln to the AlCl3 ionic liquid, Using the direct current to electrolyzing, wherein the voltage is above the higher decomposition voltage of the aluminium chloride and chloridate and below the electrochemistry window of the ionic liquid, and the aluminum will be produced in the cathode while the chlorine will be discharged from the anode.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com