Patents

Literature

438results about How to "Not easy to dissolve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biosensor

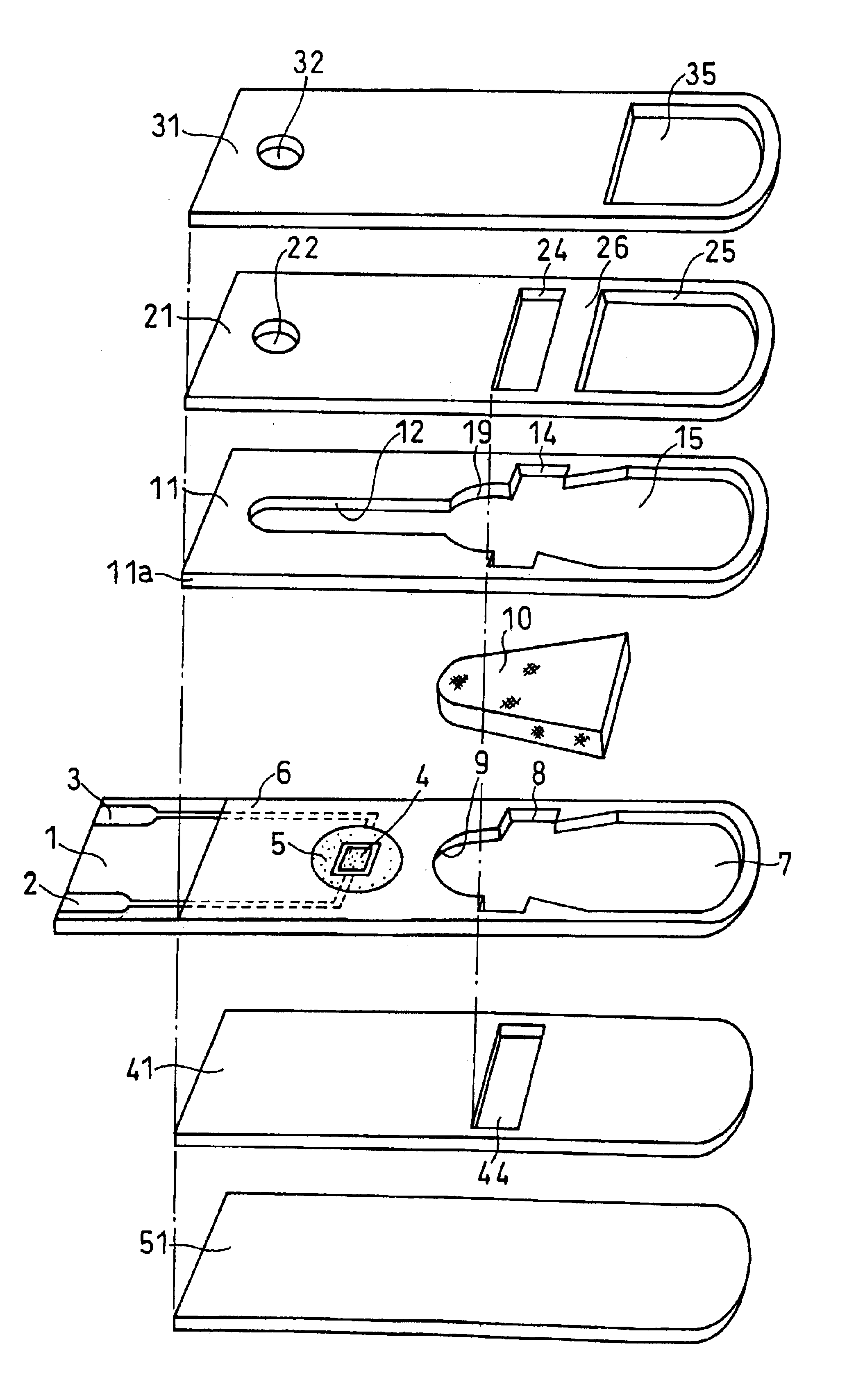

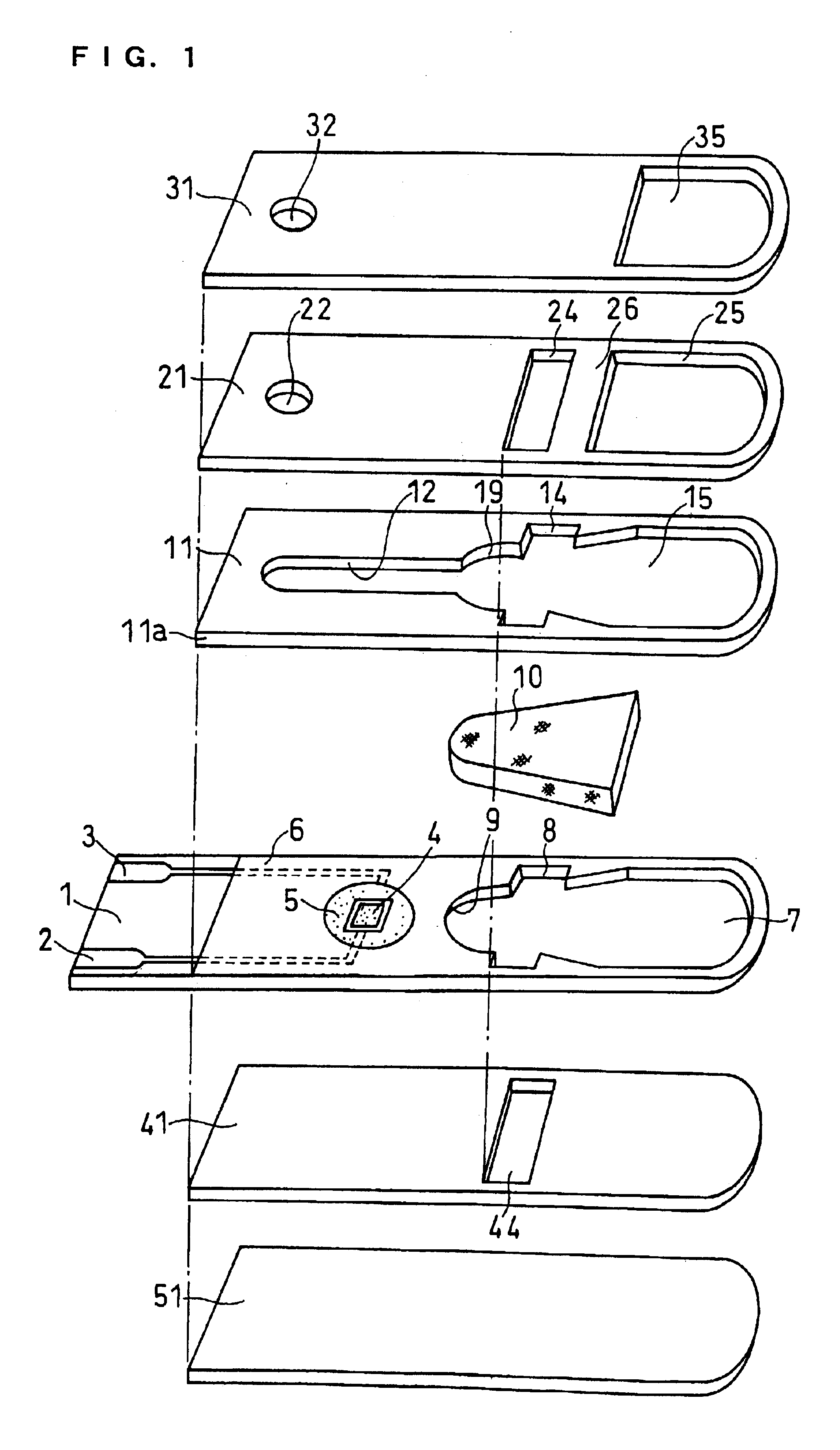

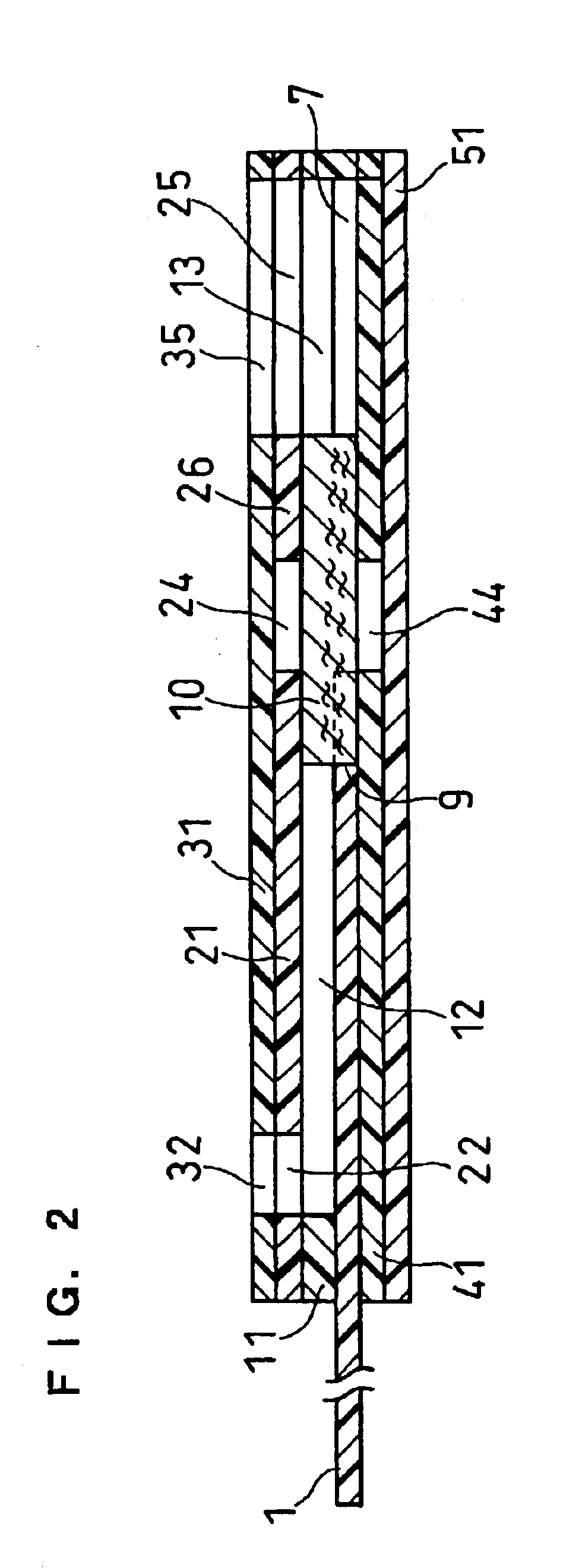

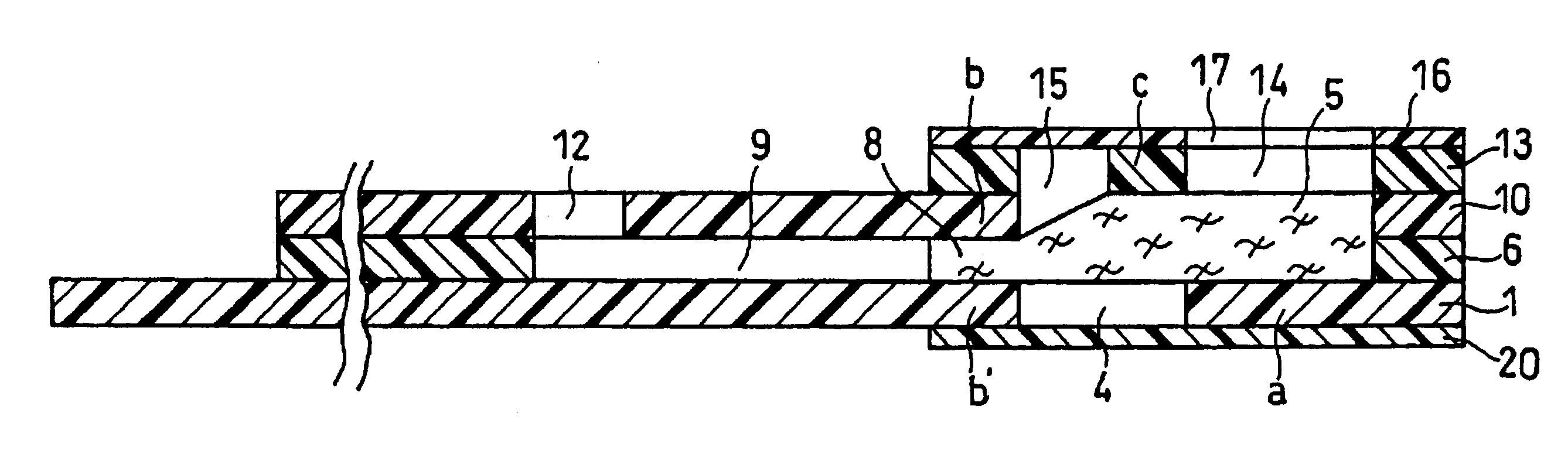

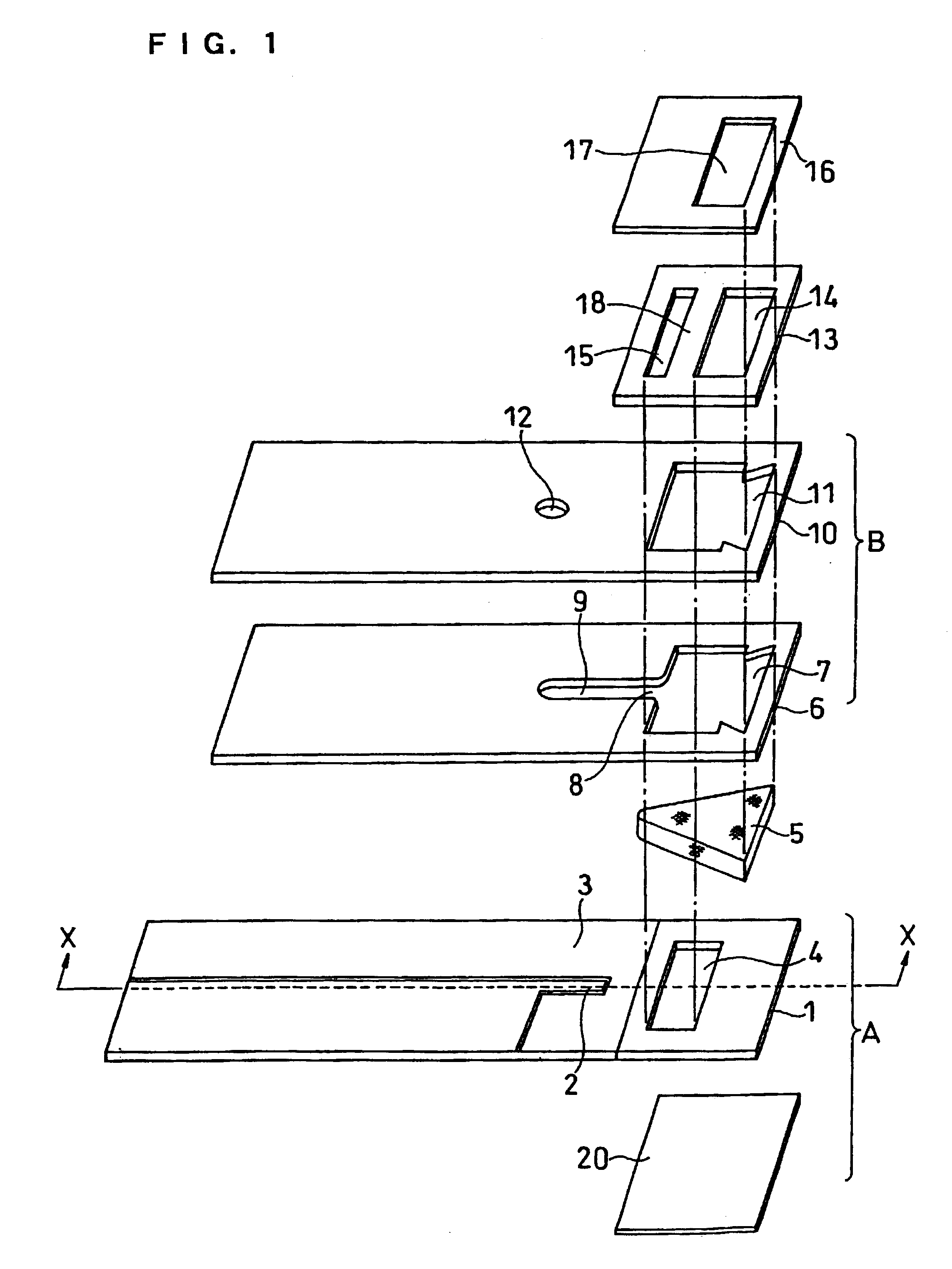

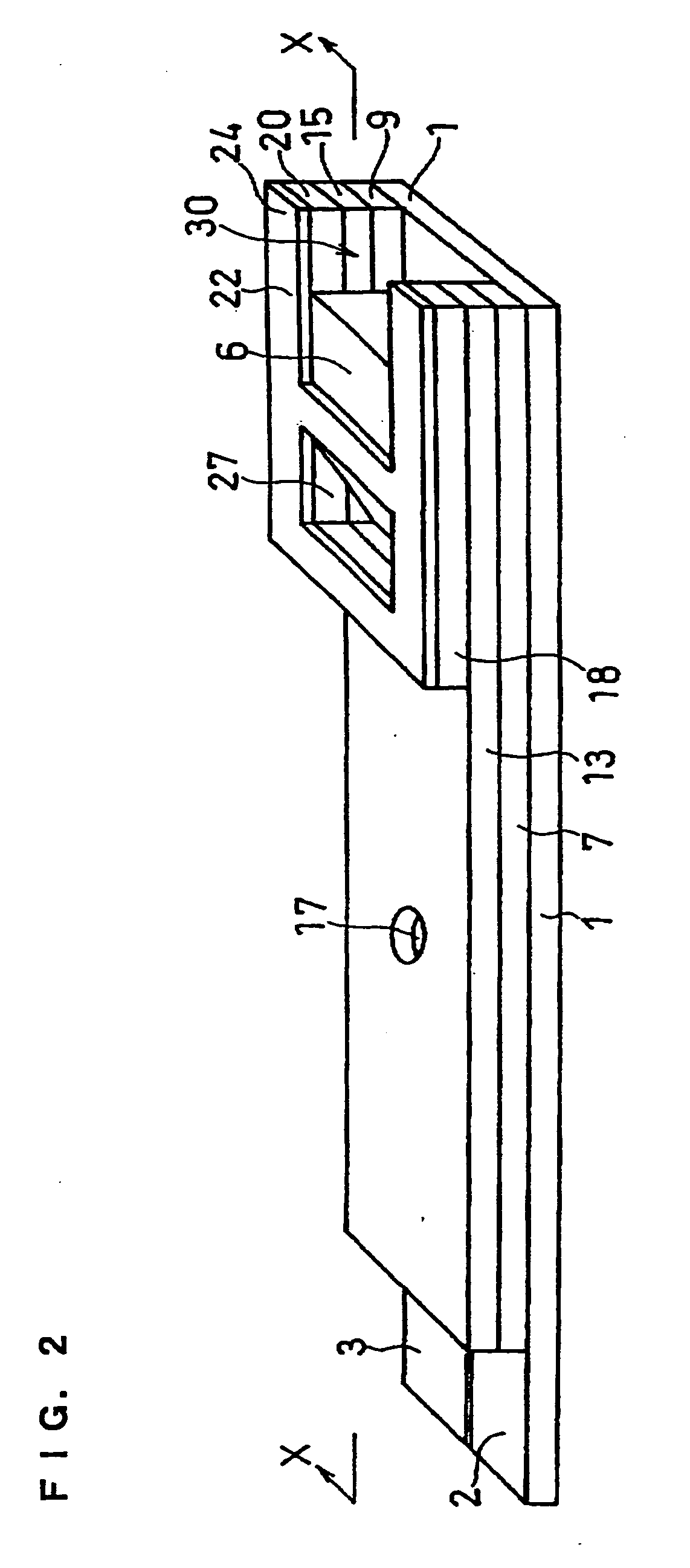

InactiveUS6719887B2Improve solubilityNot easy to dissolveImmobilised enzymesBioreactor/fermenter combinationsReaction layerEngineering

Owner:PHC HLDG CORP

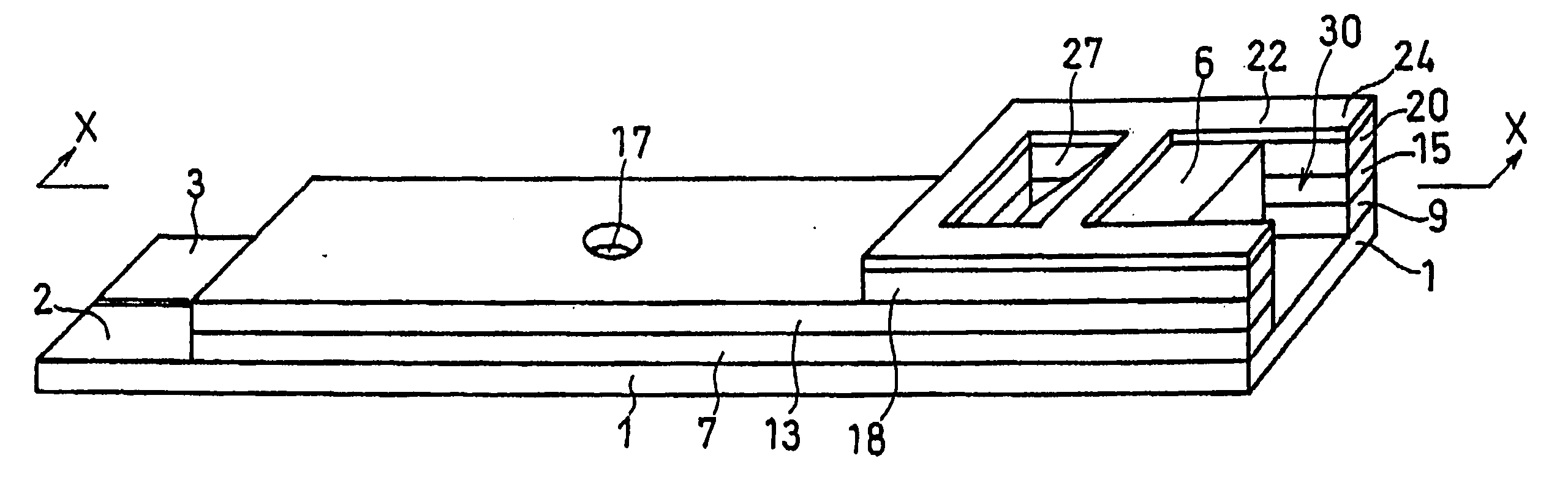

Biosensor

InactiveUS6706232B2Avoid destructionNot easy to dissolveImmobilised enzymesBioreactor/fermenter combinationsWhole blood unitsEngineering

There is provided a cholesterol sensor with high-accuracy and excellent response, whose object to be measured is whole blood, where plasma with hemocytes therein filtered can rapidly reach an electrode system. In a biosensor where plasma with hemocytes therein filtered with a filter is sucked into a sample solution supply pathway due to capillarity, there are formed: a first pressing part for holding a primary side portion of the filter from the bottom; a second pressing part for holding a secondary side portion of the filter from the top and the bottom; a third pressing part for holding the central portion of the filter from the top; and a void for surrounding the filter between the second pressing part and third pressing part.

Owner:PANASONIC CORP

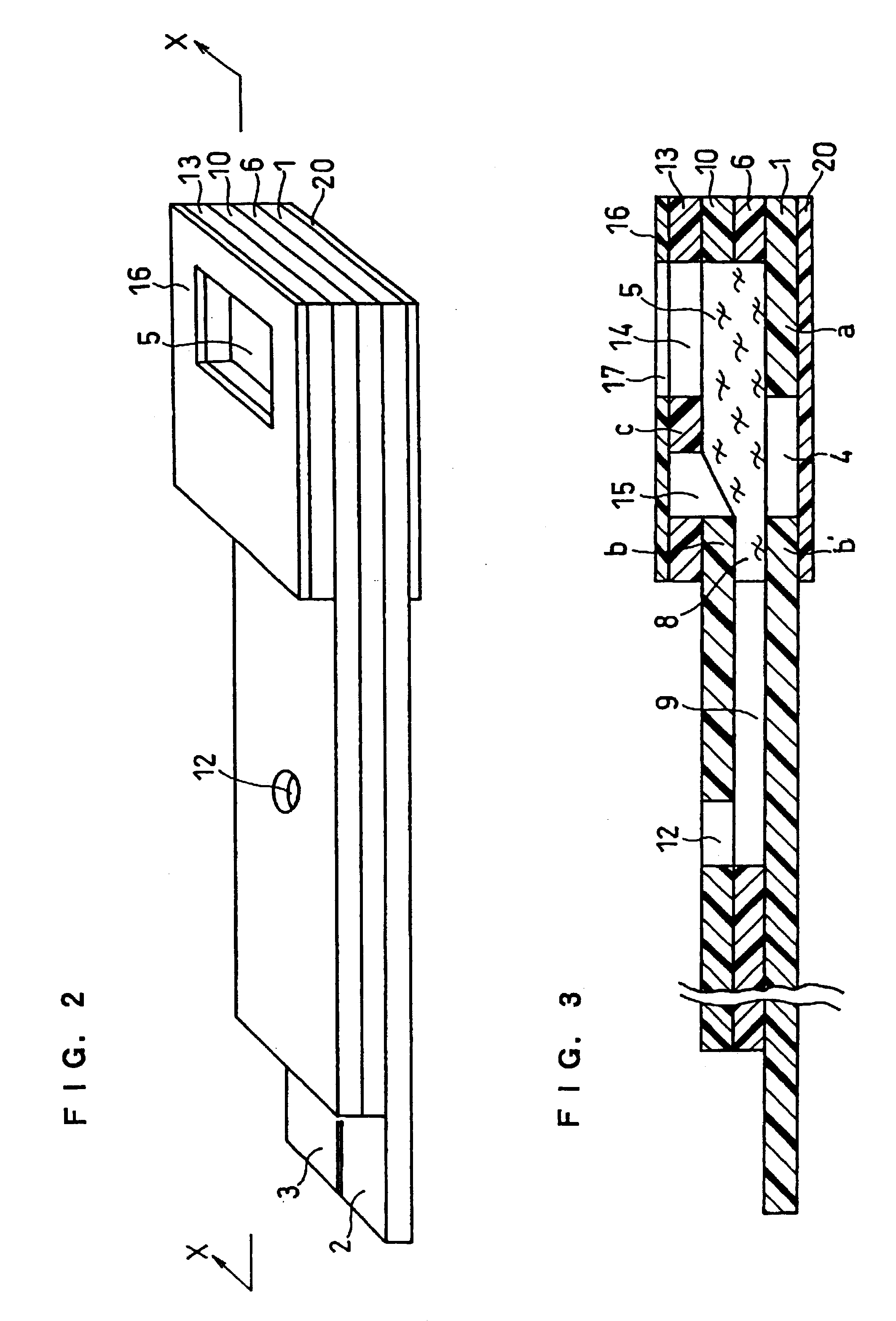

Preparation method of high-viscosity organic silicon defoamer

InactiveCN104069654AIncrease the molecular chain lengthGood defoaming performanceFoam dispersion/preventionRoom temperatureOil phase

The invention discloses a preparation method of a high-viscosity organic silicon defoamer. The preparation method comprises the following steps of preparing a silicon grease by using organopolysiloxane, dewatering particles, catalysts and silicon resin under 180-240 DEG C, and stirring and uniformly mixing the silicon grease, polyether modified silicone oil and an emulsifying agent under 72-78 DEG C so as to obtain an oil phase mixture, dissolving a dispersing thickening agent in water; then adding a sodium hydroxide solution to uniformly stir to obtain emulsifying thickening water, adding the emulsifying thickening water into an oil-phase mixture, and carrying out emulsifying stir on the oil-phase mixture under 72-78 DEG C to obtain a coarse emulsifying object; and homogenizing the coarse emulsifying object under 50-55 DEG C to obtain a fine emulsifying object, adding residue water into the fine emulsifying object, stirring and uniformly mixing the fine emulsifying object under room temperature so as to obtain the high-viscosity organic silicon defoamer. The preparation method provided by the invention has the advantages that high-viscosity simethicone is utilized as an emulsifying main raw material, and thus, the obtained high-viscosity organic silicon defoamer has an ultra-strong defoaming speed and an anti-foam effect.

Owner:道尔达(西安)新材料有限公司

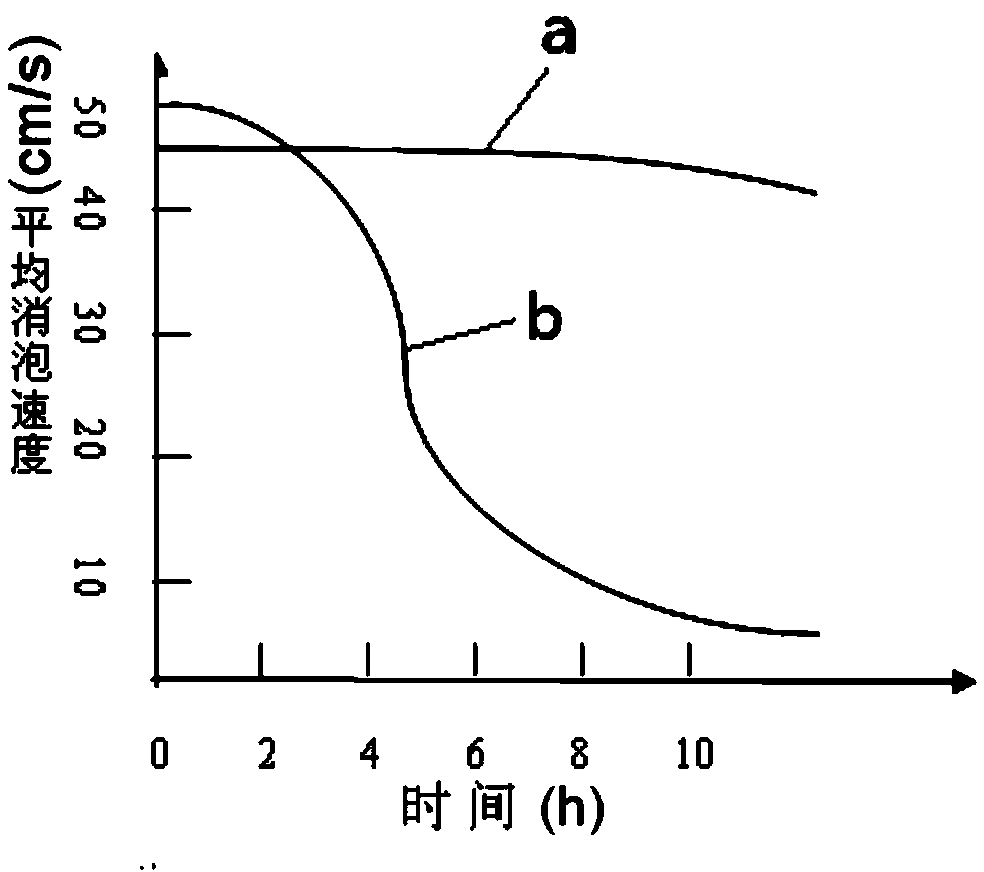

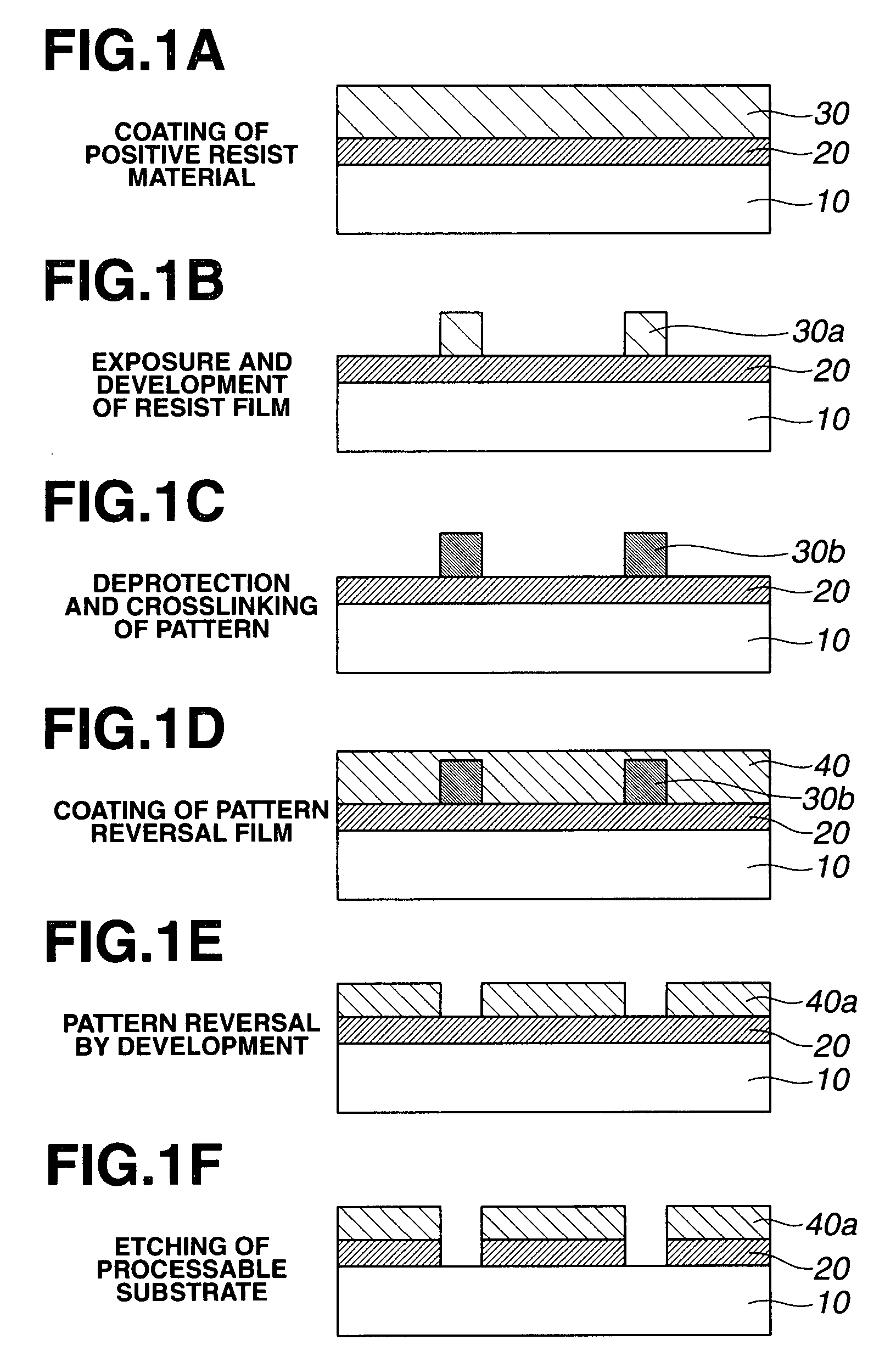

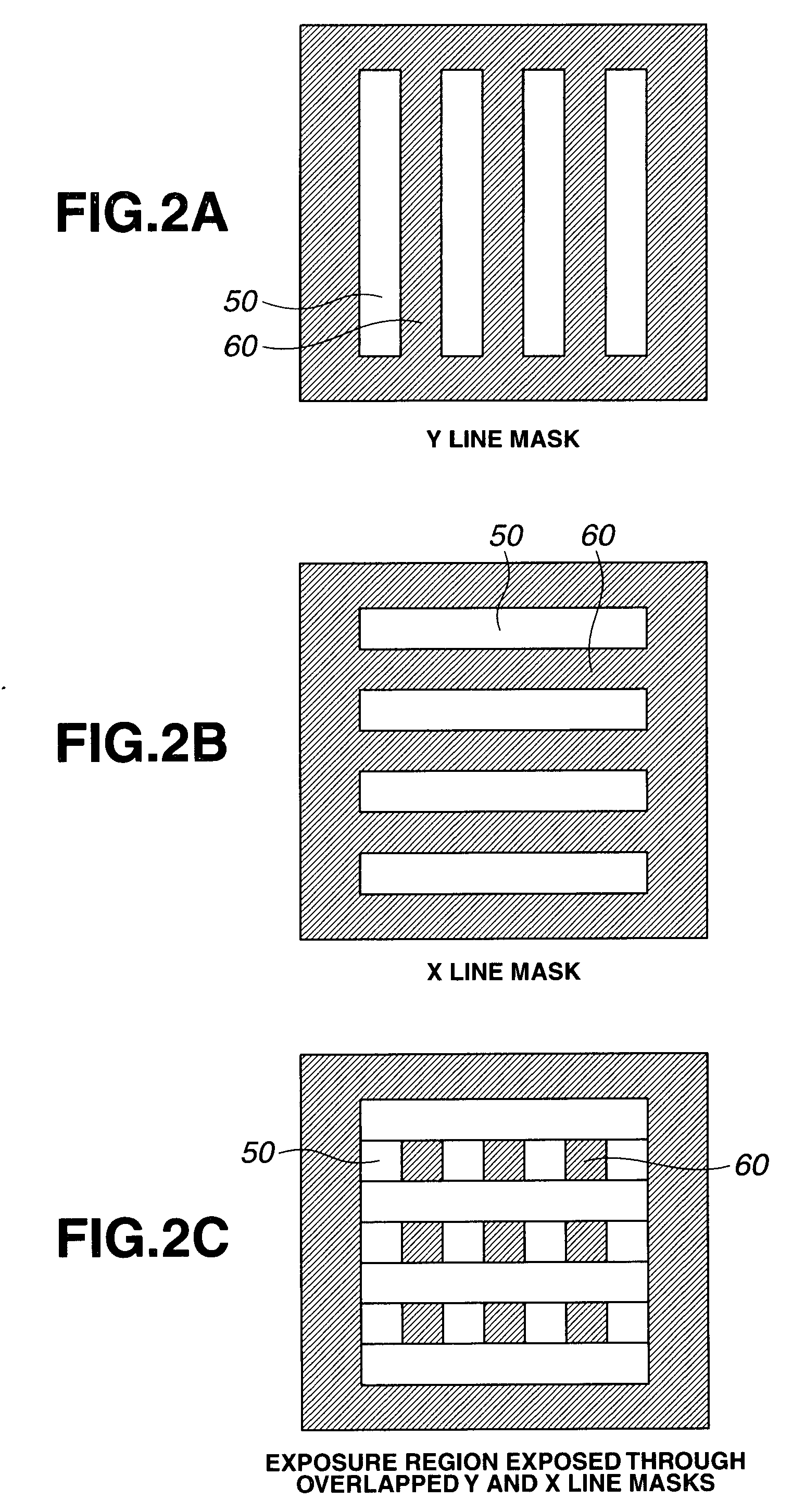

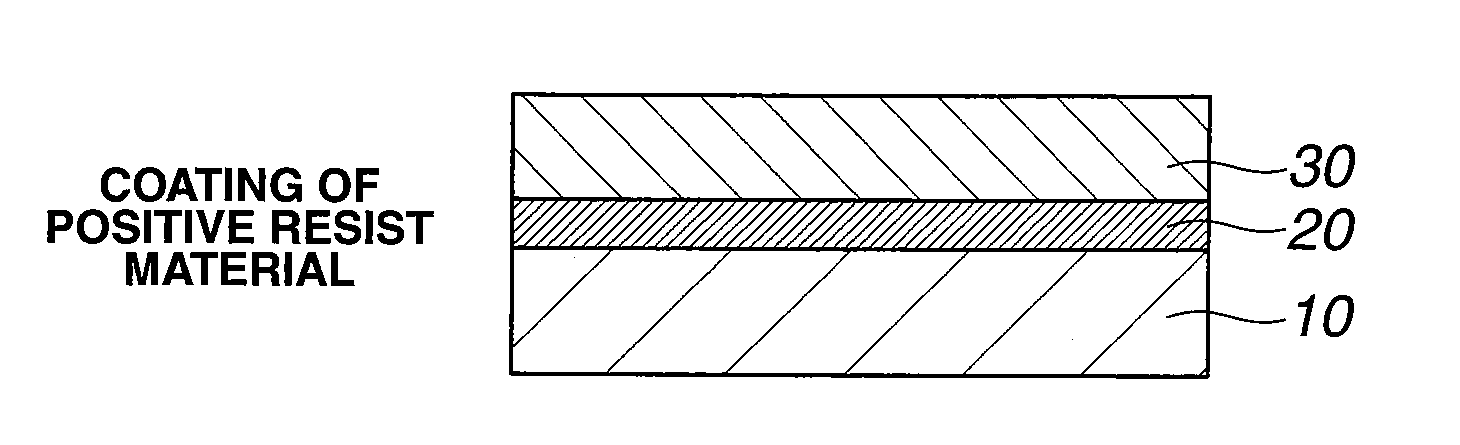

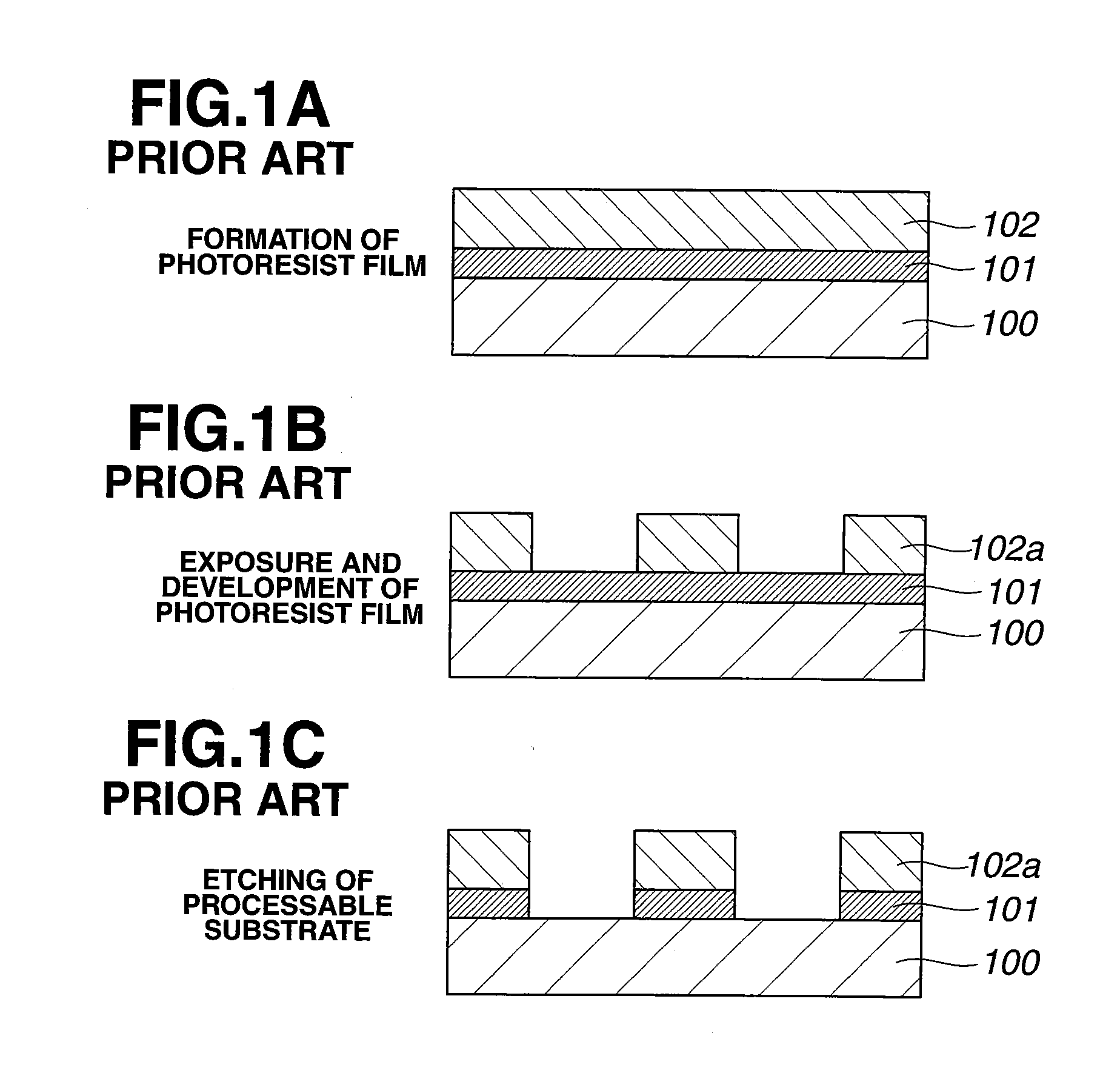

Patterning process

ActiveUS20090081595A1Increase contrastFunction increaseResist coatingPhotosensitive materialsSolubilityResist

A pattern is formed through positive / negative reversal by coating a chemically amplified positive resist composition comprising an acid labile group-bearing resin, a photoacid generator, and an organic solvent onto a substrate, prebaking the resist composition, exposing the resist film to high-energy radiation, post-exposure heating, and developing the exposed resist film with an alkaline developer to form a positive pattern; irradiating or heating the positive pattern to facilitate elimination of acid labile groups and crosslinking for improving alkali solubility and imparting solvent resistance; coating a reversal film-forming composition thereon to form a reversal film; and applying an alkaline wet etchant thereto for dissolving away the positive pattern.

Owner:SHIN ETSU CHEM IND CO LTD

Acidic compositon for external use and agent for accelerating infiltration of cosmetic preparation, hair-growing agent, and preparation for external use each containing the composition into skin or the like

InactiveUS20050074421A1Reduce mixingIncrease absorption rateCosmetic preparationsHair cosmeticsOtic AgentsTreatment effect

An acidic composition for external use which contains an acidic polysaccharide and water as essential ingredients, and an agent for accelerating the penetration into skin or the like of a cosmetic preparation, hair-growing agent or preparation for external use, each containing the composition. The composition is easy to manufacture, and shows a stronger cosmetic or therapeutic effects than conventional compositions.

Owner:NEOCHEMIR INC

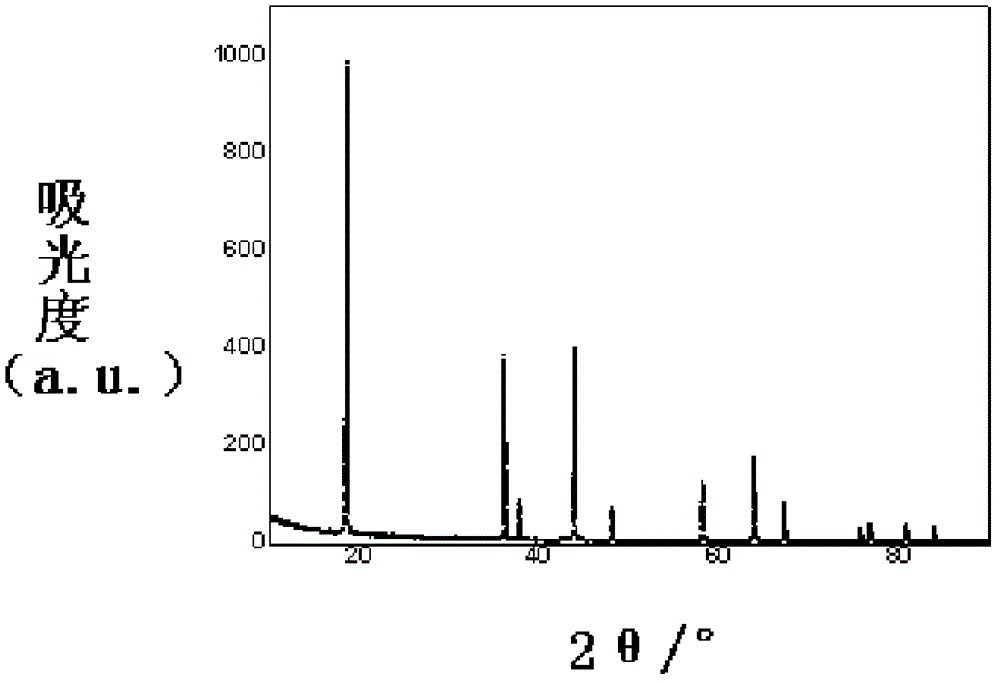

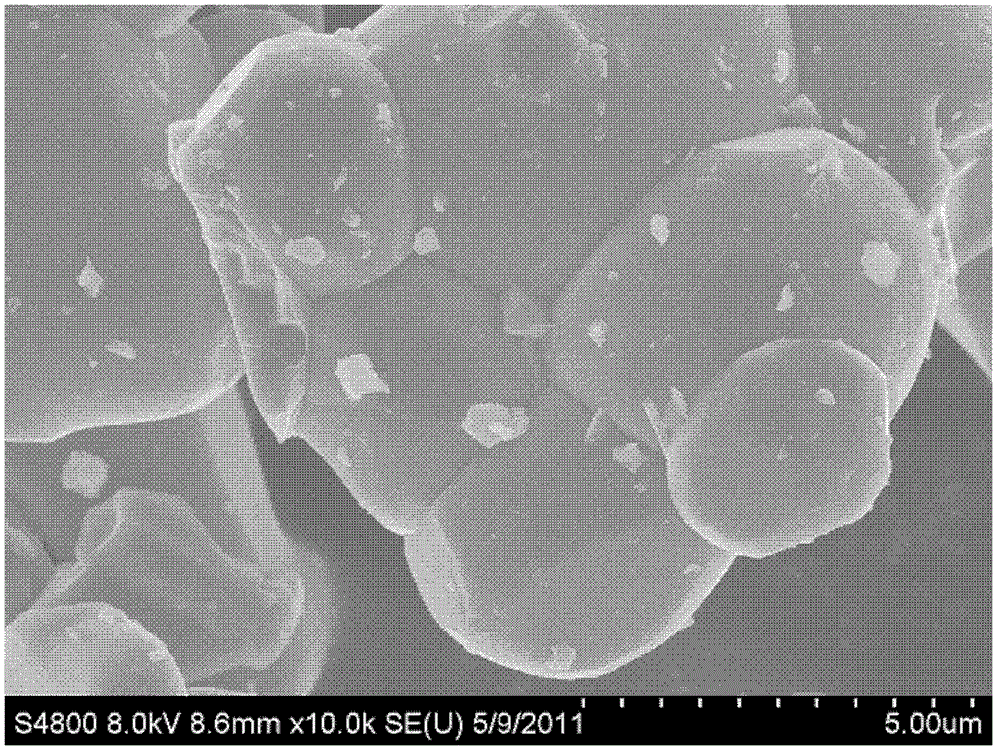

Cathode material of lithium ion battery, and preparation method thereof and lithium ion battery

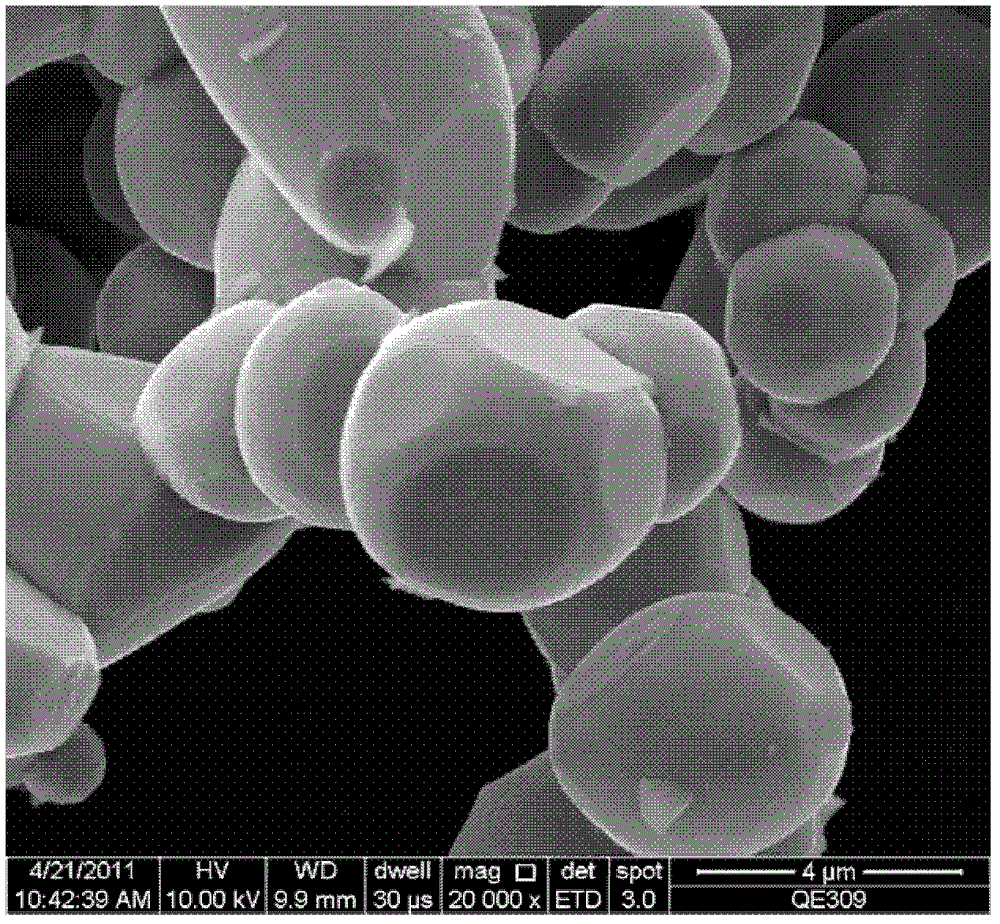

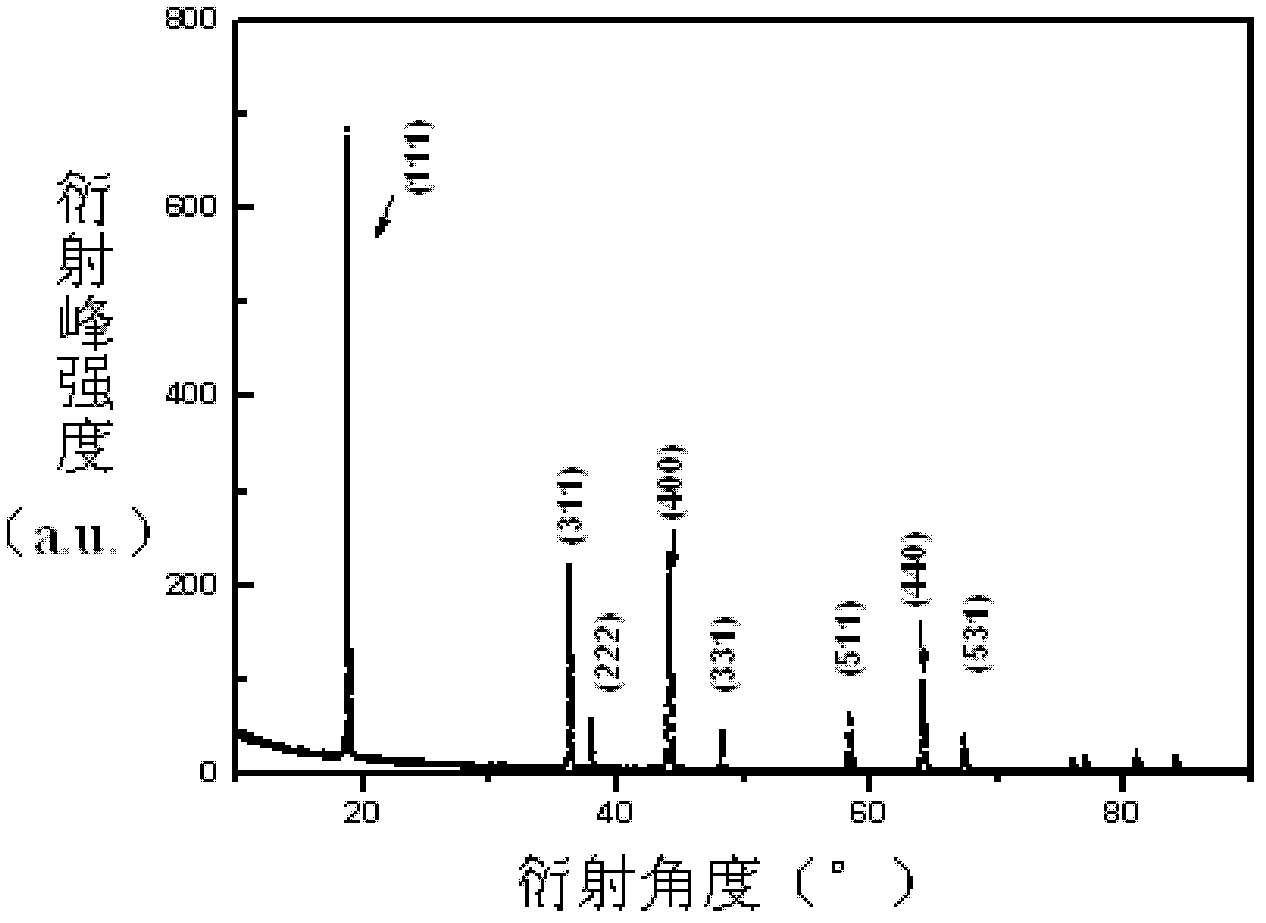

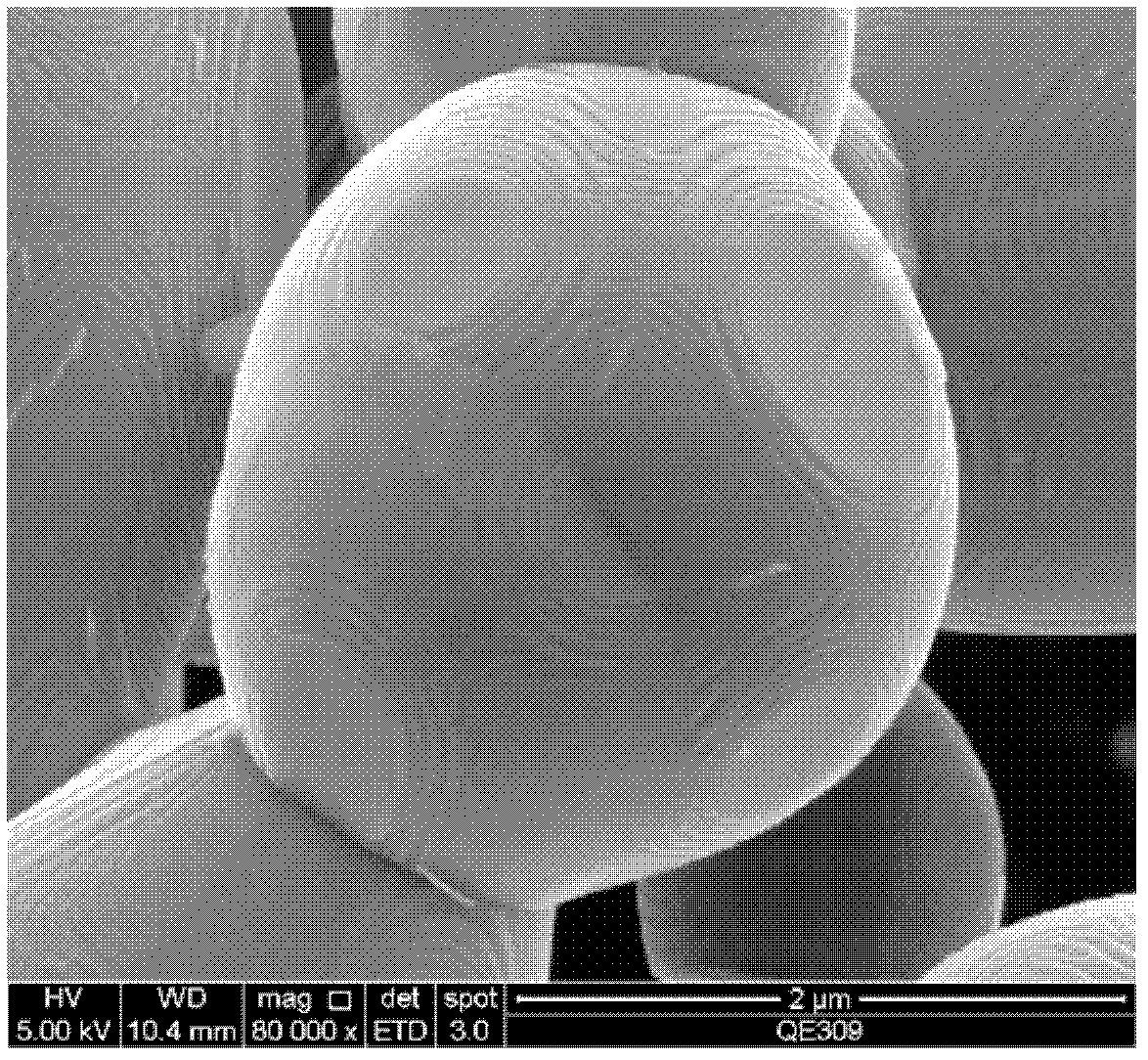

ActiveCN102800840ANot easy to dissolveGood high temperature cycle performanceCell electrodesSecondary cellsTemperature cyclingLithium electrode

The invention provides a cathode material of a lithium ion battery. The cathode material is composed by the atomic ratio shown in formula (I): Lia(MxMn2-x)(O4-yZy), wherein a is greater than or equal to 0.8 and less than or equal to 1.2; x is greater than or equal to 0 and less than or equal to 1; y is greater than or equal to 0 and less than or equal to 1; M is one or more selected from Li, Na, K, Ca, Mg, Al, Ti, Sc, Ge, V, Cr, Zr, Co, Ni, Zn, Cu, La, Ce, Mn, Hf, Nb, Ta, Mo, W, Ru, Ag, Sn, Pb and Si; and Z is one or more selected from OH, halogens, N, P, S and O. Primary particles of the cathode material have sphere-like morphologies, wherein (111) face is connected with adjacent equivalent crystal face through a curved surface having no clear edges. The invention also provides a preparation method for the cathode material of the lithium ion battery and the lithium ion battery. The cathode material provided by the invention has good high-temperature cycling performance and good filling property.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

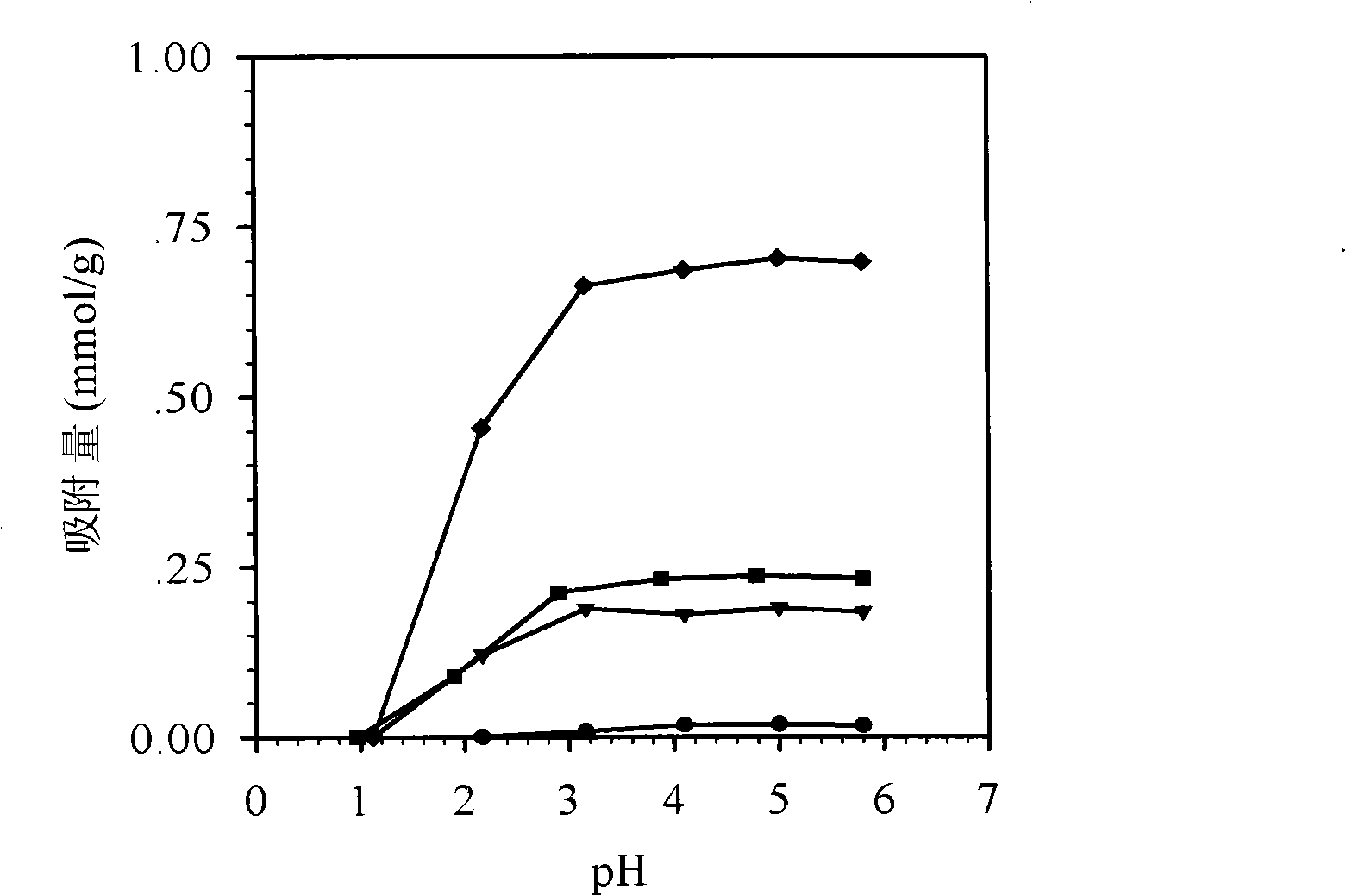

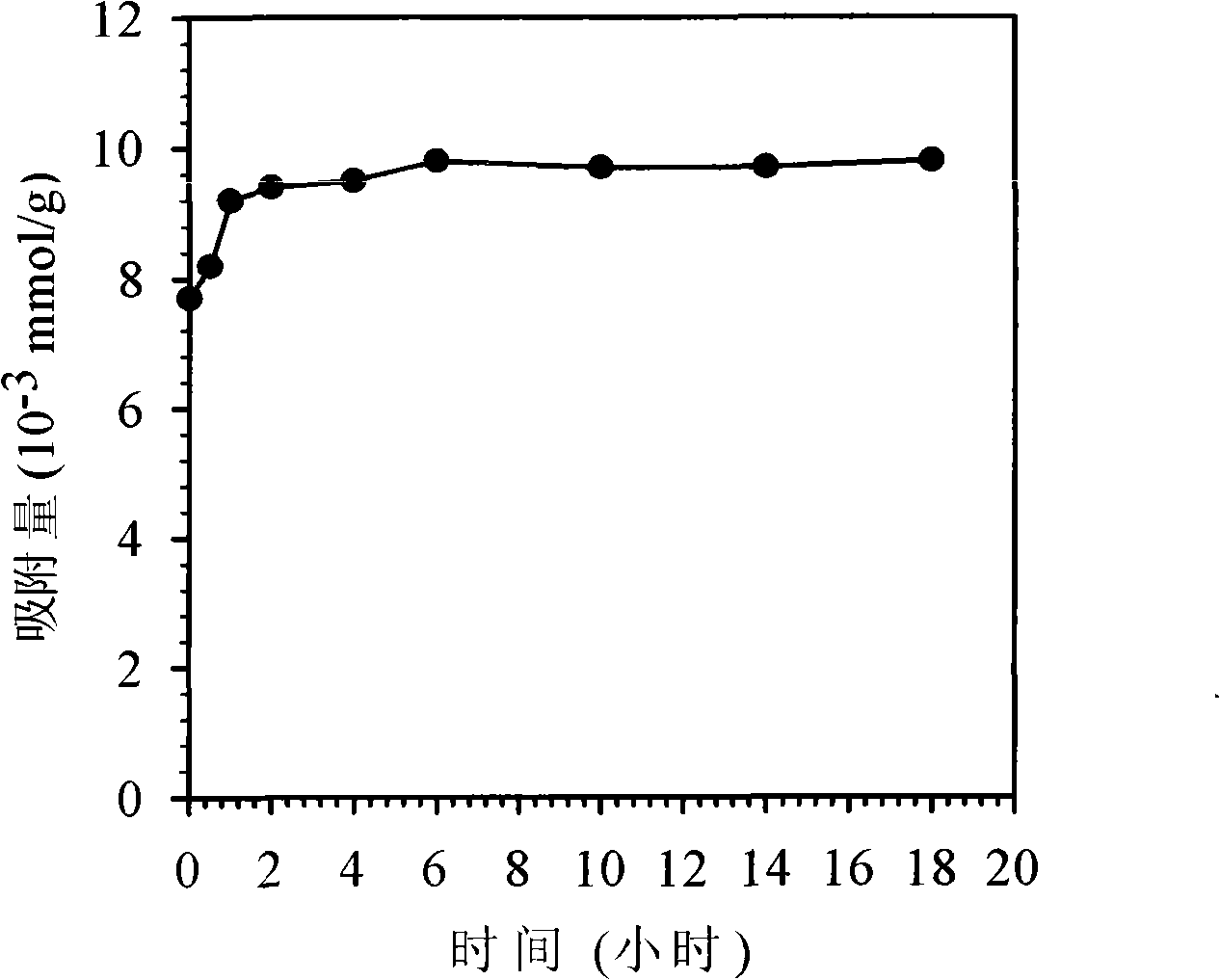

Biological adsorbing agent with adsorption capacity of heavy metal ion, and producing method and application thereof

ActiveCN101274268ANot easy to dissolveReduce crystallinityOther chemical processesWater/sewage treatment by sorptionSorbentEnvironmental engineering

The invention relates to a biology adsorbent and a preparation method thereof as well as application of the preparation method in heavy metal ion adsorption. The biology adsorbent is characterized in that hybrid blending material which has heavy metal ion adsorption capability is prepared by the capability of biological polymer such as microcrystalline cellulose, chitin, chitosan, etc. which can be dissolved in ionic liquid; the ionic liquid is chloridized 1-butyl-3-methyl imidazole salt and chloridized 1-allyl-3-methyl imidazole salt; the preparation of the adsorbent adopts two types: a drying type and a freeze-drying type; the ionic liquid used in the method can be recovered; the prepared adsorbent can be automatically degraded in environment; the preparation method and the prepared adsorbent in the method cause no secondary environmental pollution.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

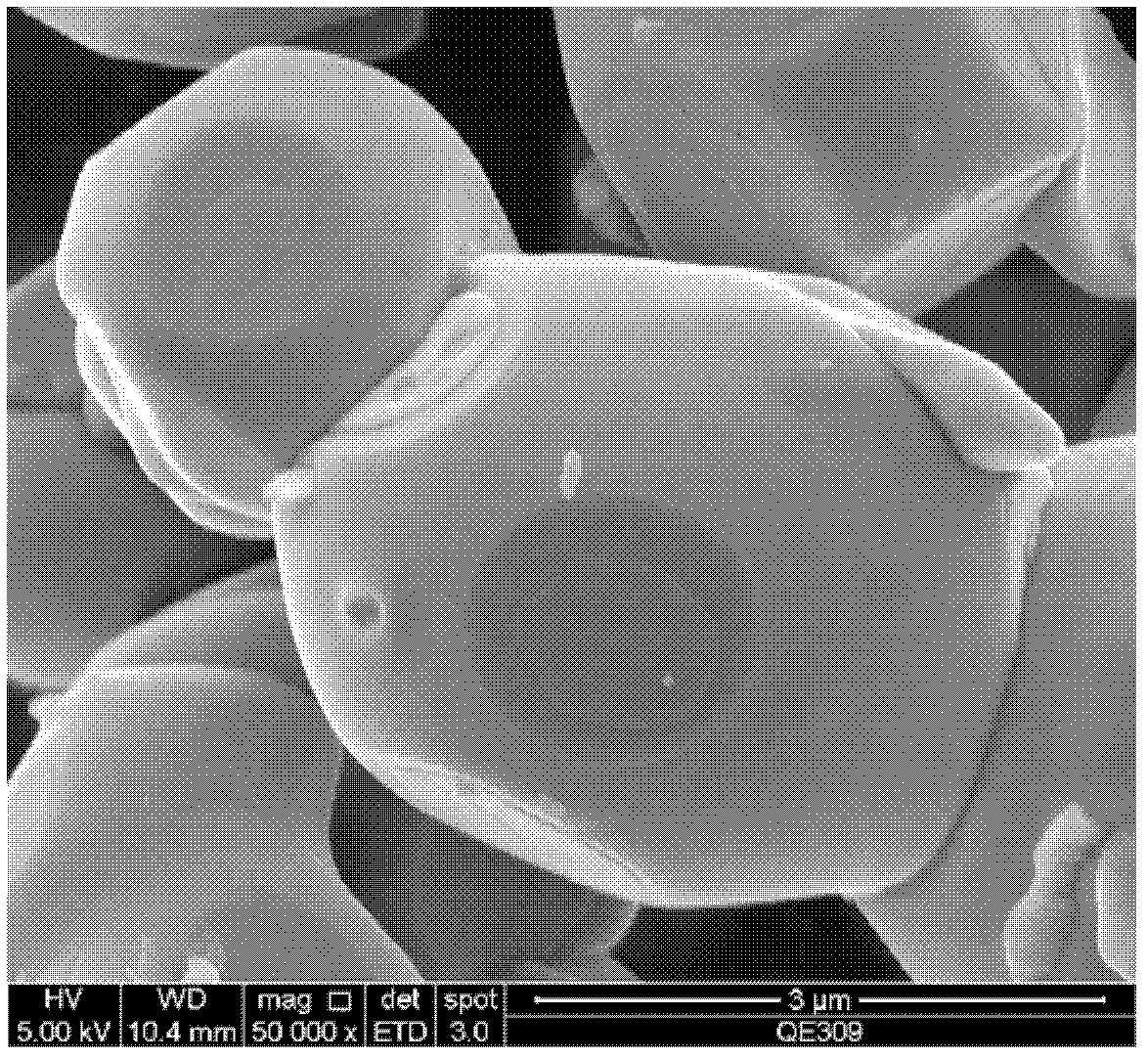

Cathode material of lithium ion battery and preparation method of cathode material

ActiveCN102683669ASmall specific surface areaGood high temperature cycle performanceCell electrodesManganesePhysical chemistry

The invention discloses a cathode material of a lithium ion battery. The cathode material has an atomic ratio of LiaMxMn(2-x)O(4-y)Zy. Primary particles of the cathode material of the lithium ion battery are substantially spherical, and the surface of each primary particle consists of 2 to 120 multilayer crystal dislocation frustums. The invention provides a preparation method of the cathode material of the lithium ion battery. The cathode material of the lithium ion battery is prepared by annealing, cooling and grinding a lithium manganate precursor in a roasting treatment mode of repeatedly changing roasting temperature. The invention has the advantages that by repeatedly changing the roasting temperature in the roasting process, the prepared cathode material of the lithium ion battery has a dislocation structure, and the mobility of ions and electrons from the inner part of the material to the outer part of the material is improved, and the magnification performance of a lithium manganate material is improved. Because the cathode material is substantially spherical, the specific surface area of the lithium manganate material is reduced, and manganese is difficult to dissolve, so the cathode material of the lithium ion battery is high in high-temperature cycle performance.

Owner:宁波富理电池材料科技有限公司

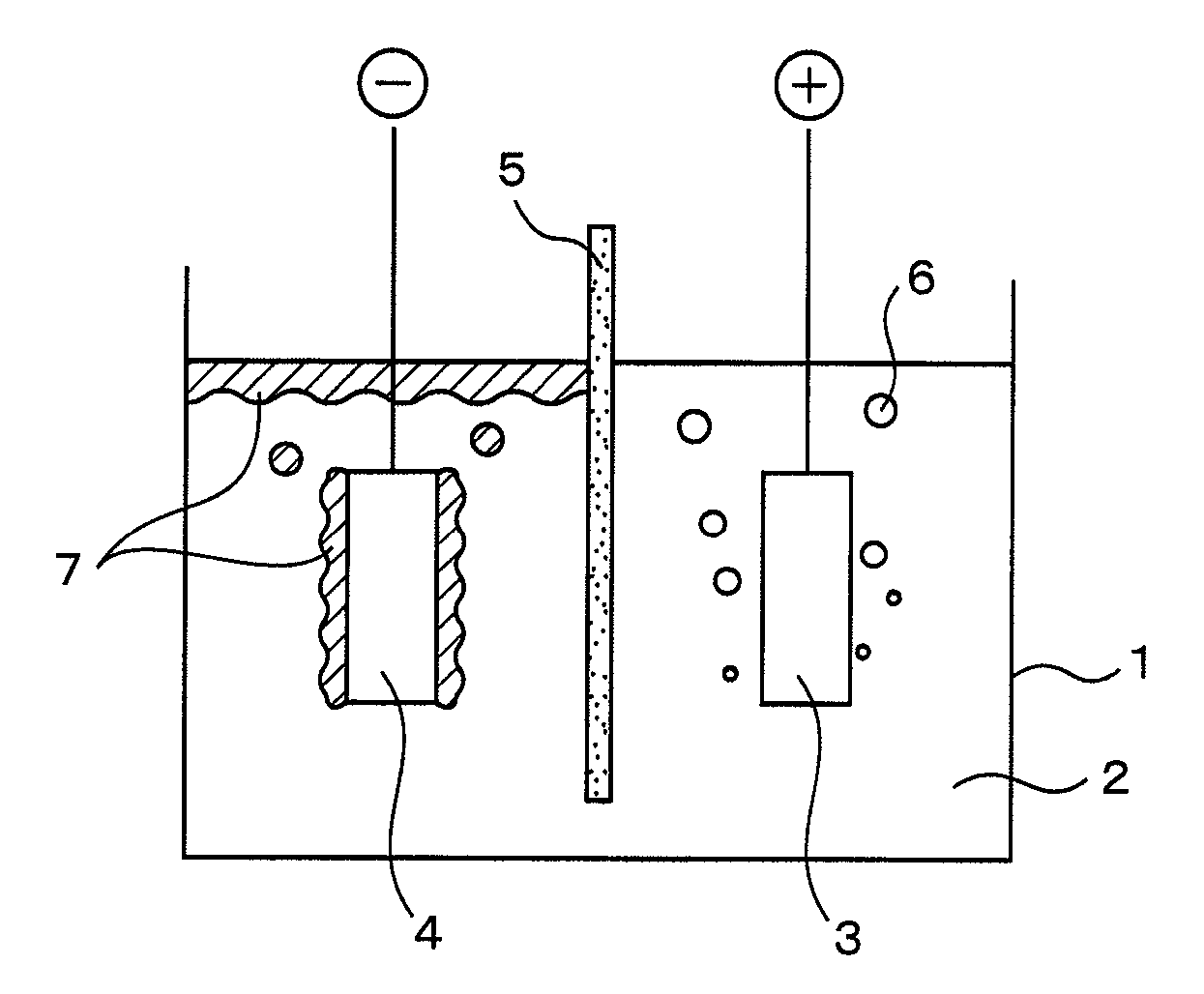

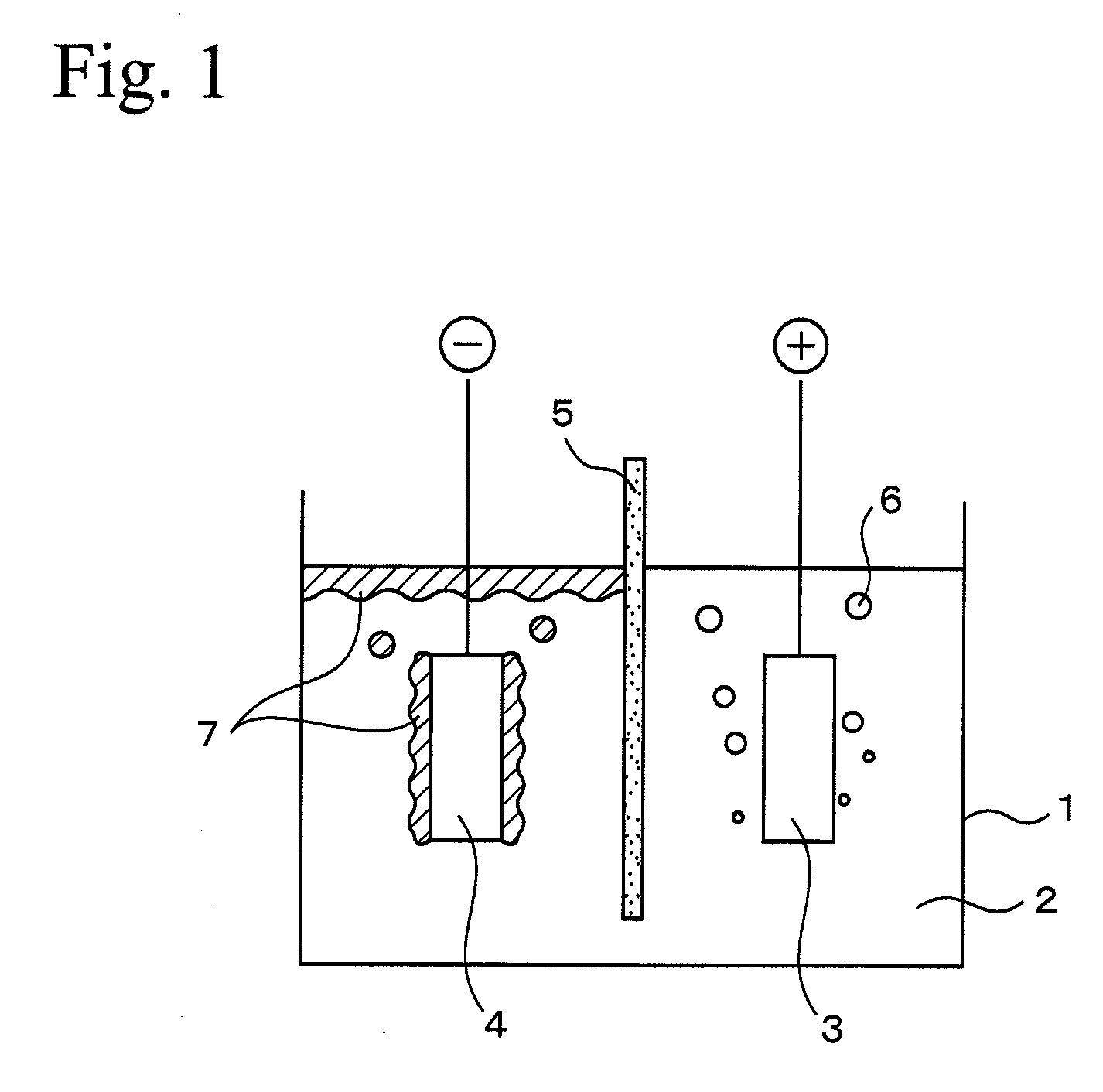

Method for Production of Metal by Molten-Salt Electrolysis and Method for Production of Titanium Metal

InactiveUS20080053838A1Effective recoveryReduce solubilityElectrolysis componentsMetal chlorideElectrolysis

A method for production of metal by molten-salt electrolysis is a method for production of metal by molten-salt electrolysis which is performed by filling molten salt of a metal chloride in an electrolysis vessel having an anode and a cathode, and a molten salt which reduces solubility of the metal in the molten salt is used.

Owner:TOHO TITANIUM CO LTD +1

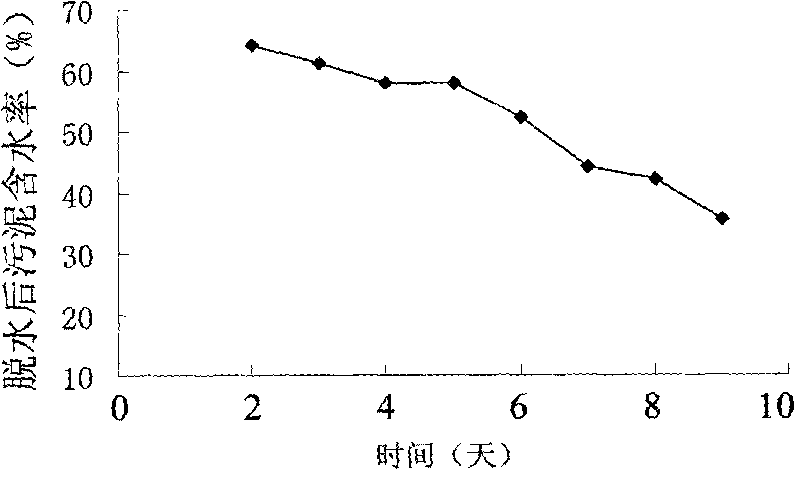

Sludge dewatering method

ActiveCN101691272ANo smellReduce volumeSludge treatment by de-watering/drying/thickeningClimate change adaptationWater contentSludge dewatering

The invention discloses a sludge dewatering method and relates to a sludge treatment method. The invention provides the sludge dewatering method which can significantly reduce the water content in sludge, reduce the volume of the sludge, solve the difficulties in sludge transport and storage, reduce the sludge treatment fee, complete the advance-phase preparation for the follow-up treatment of the sludge and lay a foundation for the final disposal and the utilization of the sludge. The sludge dewatering method comprises the steps of first-stage liquid gravity concentration of the sludge, conditioning and plate-and-frame mechanical dewatering.

Owner:厦门市政环境科技股份有限公司

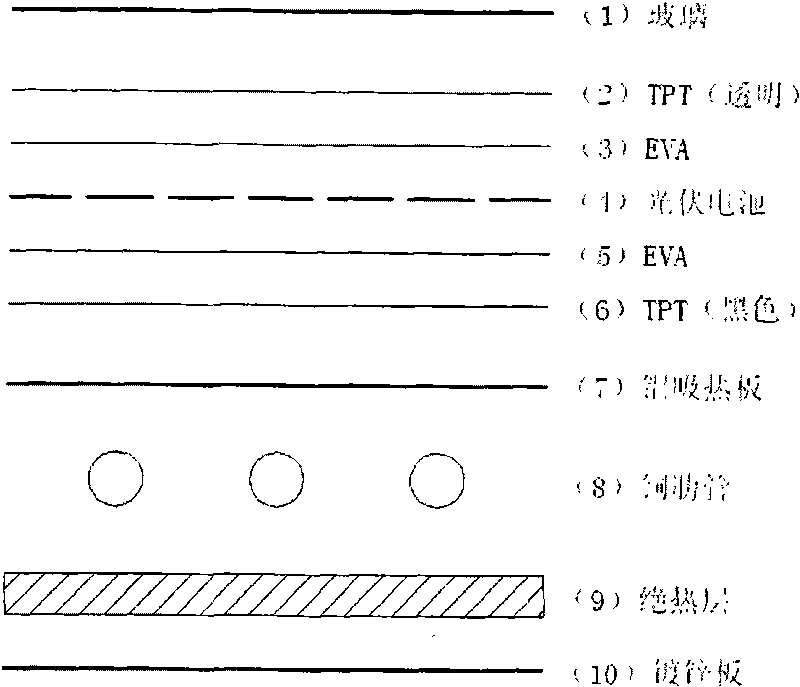

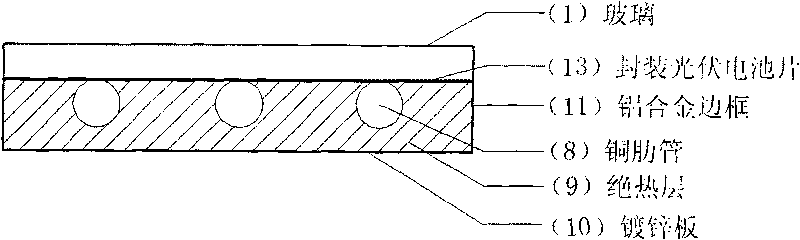

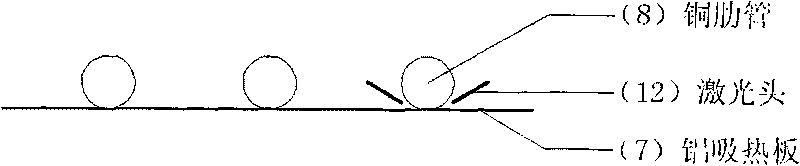

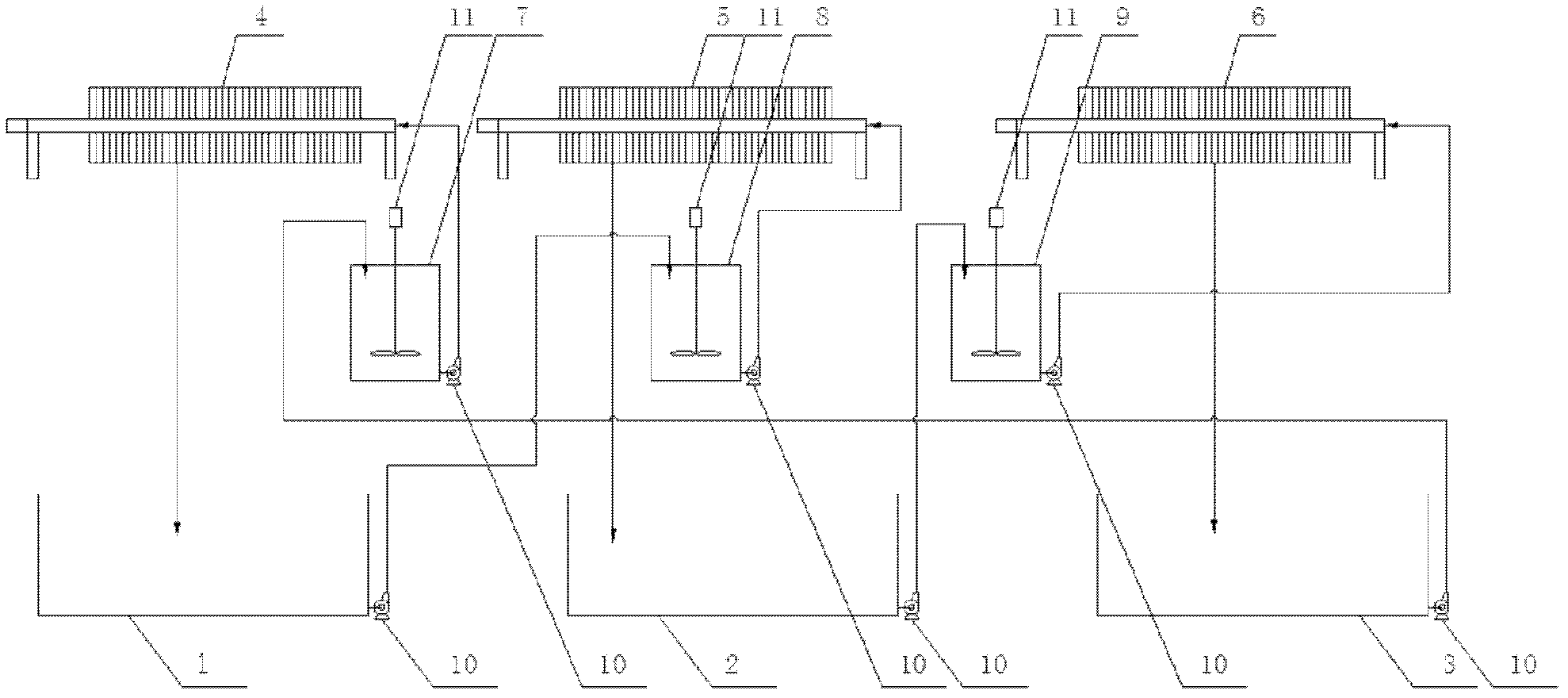

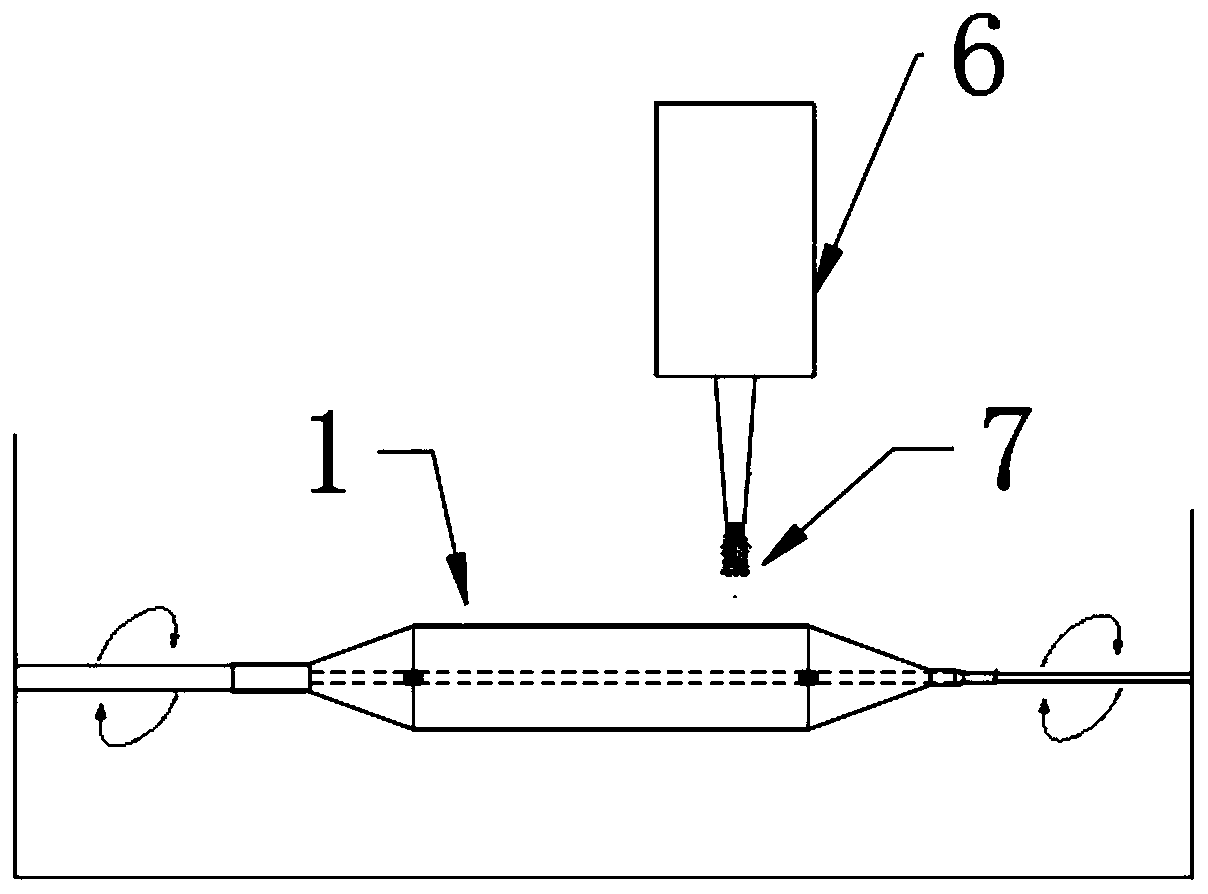

Complete plate tube-sheet type photovoltaic hot-water module

InactiveCN101740650AImprove utilization efficiencyImprove heat collection efficiencyRoof covering using slabs/sheetsRoof covering using tiles/slatesEngineeringCarvacryl acetate

The invention discloses a complete plate tube-sheet type photovoltaic hot-water module, which comprises glass, an encapsulated photovoltaic cell, a copper ribbed tube, an insulating layer and a galvanized sheet. The encapsulated photovoltaic cell consists of a photovoltaic cell, ethylene vinyl acetate (EVA) coated on the upper and lower surfaces of the photovoltaic cell, a transparent composite fluorine plastic film TPT on an upper layer of the EVA, a black TPT on a lower layer of the EVA, and an aluminum absorber plate under the black TPT. The copper ribbed tube is welded at the back of the aluminum absorber plate through spot welding by a laser head; and the insulating layer and the galvanized sheet cover below the photovoltaic cell. A glass plate covers on the encapsulated photovoltaic cell; an air gap is formed between the upper part of the encapsulated photovoltaic cell and the glass plate; and the periphery is fixed by adopting an aluminum alloy frame. The complete plate tube-sheet type photovoltaic hot-water module can generate electricity and hot water simultaneously, and improve the overall efficiency of solar utilization.

Owner:UNIV OF SCI & TECH OF CHINA

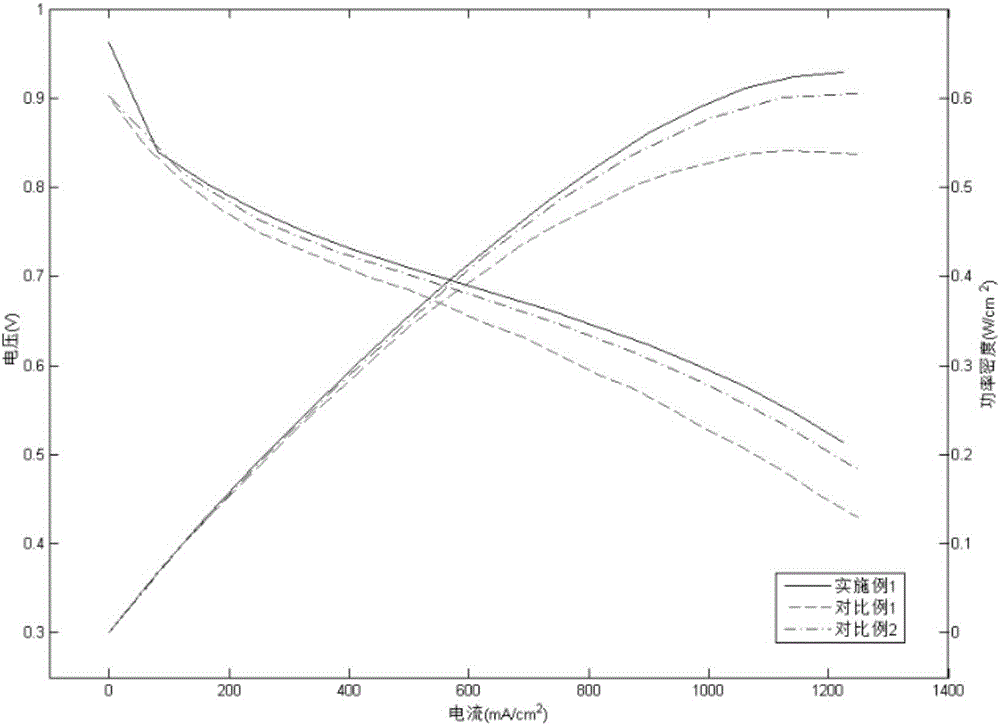

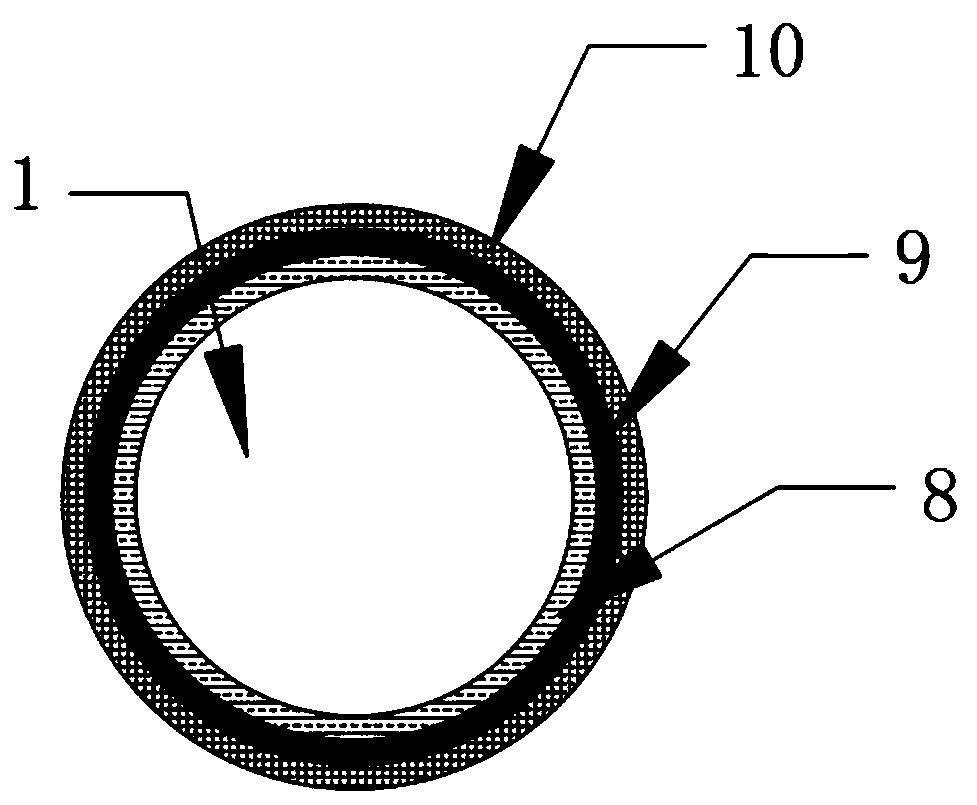

Preparation process of hydrogen fuel battery membrane electrode

ActiveCN106784944AIncrease profitReduce utilizationFinal product manufactureFuel cellsHydrogen fuel cellSlurry

The invention discloses a preparation process of a hydrogen fuel battery membrane electrode, and belongs to the field of battery membrane electrodes. The membrane electrode is prepared by the aid of an ultrasonic spraying process and a heat transfer printing process. The preparation process includes the steps: firstly, sequentially spraying a transfer printing medium with carbon powder slurry, electric catalyst slurry and binding agent slurry by the aid of the ultrasonic spraying process; secondly, loading a catalyst layer on a proton exchange membrane by the aid of the heat transfer printing process; finally, performing hot-pressing for self-made diffusion layers by the aid of the ultrasonic spraying process to obtain the membrane electrode. According to the preparation process, the diffusion layers are closely combined by the aid of actions among Nafion slurry, the proton exchange membrane and carbon powder slurry and the diffusion layers, electrochemical performance of the membrane electrode is greatly improved by the aid of the heat transfer printing process, the service life of the membrane electrode is prolonged, the problems such as wrinkle and swelling of the proton exchange membrane are solved, a lot of time for paving and treating the membrane is saved, and mass production of the membrane electrode is facilitated.

Owner:KUSN INNOVATION INST OF NANJING UNIV

Oil-based ink composition for inkjet recording

ActiveUS20070167538A1Outstanding propertyNot easy to dissolveFilm/foil adhesivesDuplicating/marking methodsSolubilityAcrylic resin

An oil-based ink composition for inkjet recording capable of exhibiting desired properties of drying after print, rubfastness and re-solubility is achieved by performing solubilization on an acrylic resin which is not easily dissolved conventionally. The oil-based ink composition for inkjet printing comprises glycol ether dialkyl ethers as a prime solvent; and an acrylic resin that results from solution polymerization in a solvent of the glycol ether dialkyl ethers by use of a radical polymerization initiator.

Owner:SEIKO EPSON CORP +1

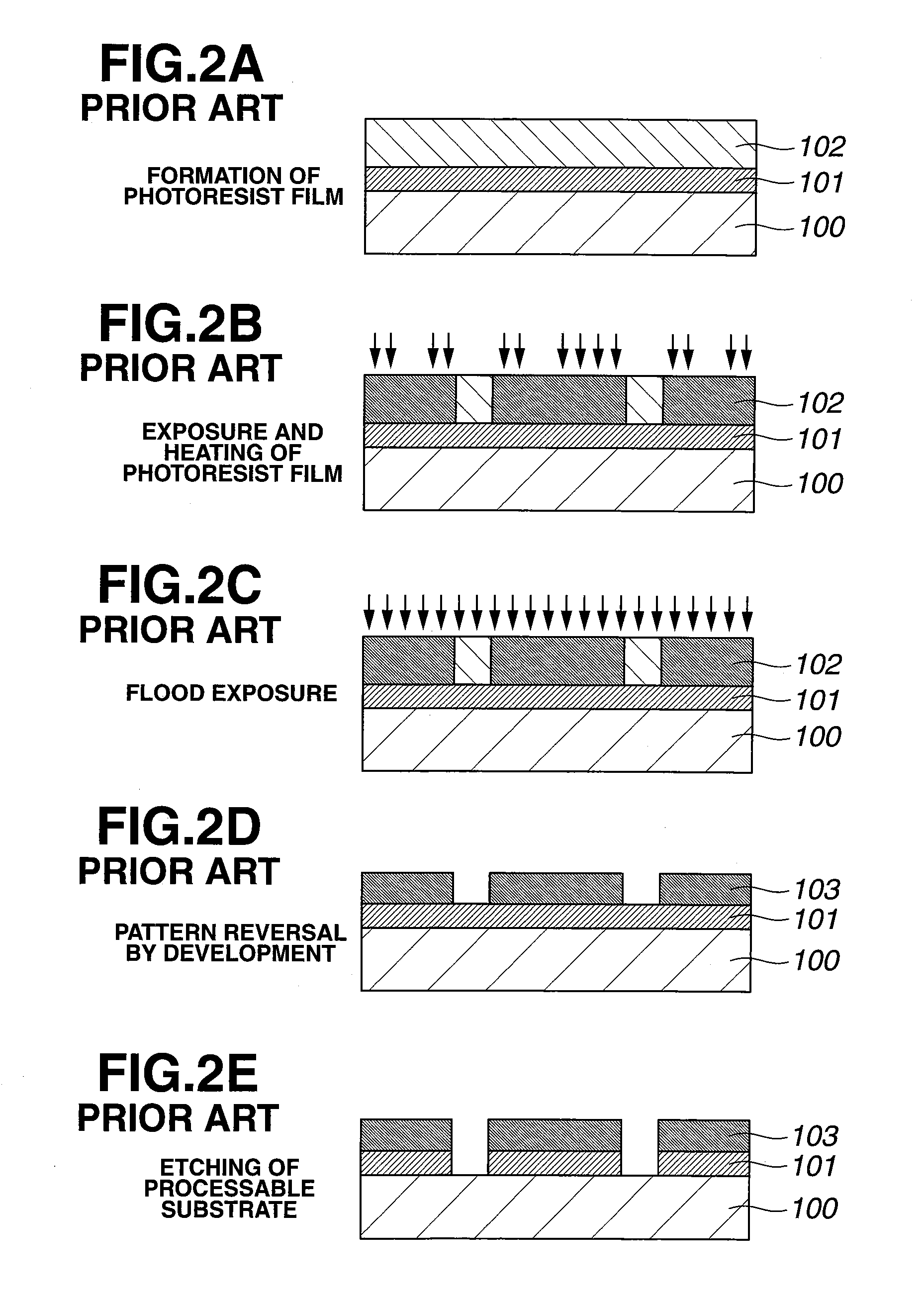

Patterning process

ActiveUS20100178617A1Improve adhesionImprove accuracyPhotosensitive materialsSemiconductor/solid-state device manufacturingSolubilityResist

A pattern is formed by coating a chemically amplified positive resist composition comprising a resin comprising acid labile group-containing recurring units and a photoacid generator onto a substrate, drying to form a resist film, exposing the resist film to high-energy radiation, PEB, developing to form a positive pattern, illuminating or heating the positive pattern to eliminate acid labile groups for increasing alkaline solubility and to induce crosslinking for imparting solvent resistance, coating a reversal film, forming a space pattern, and shrinking the space pattern.

Owner:SHIN ETSU CHEM IND CO LTD

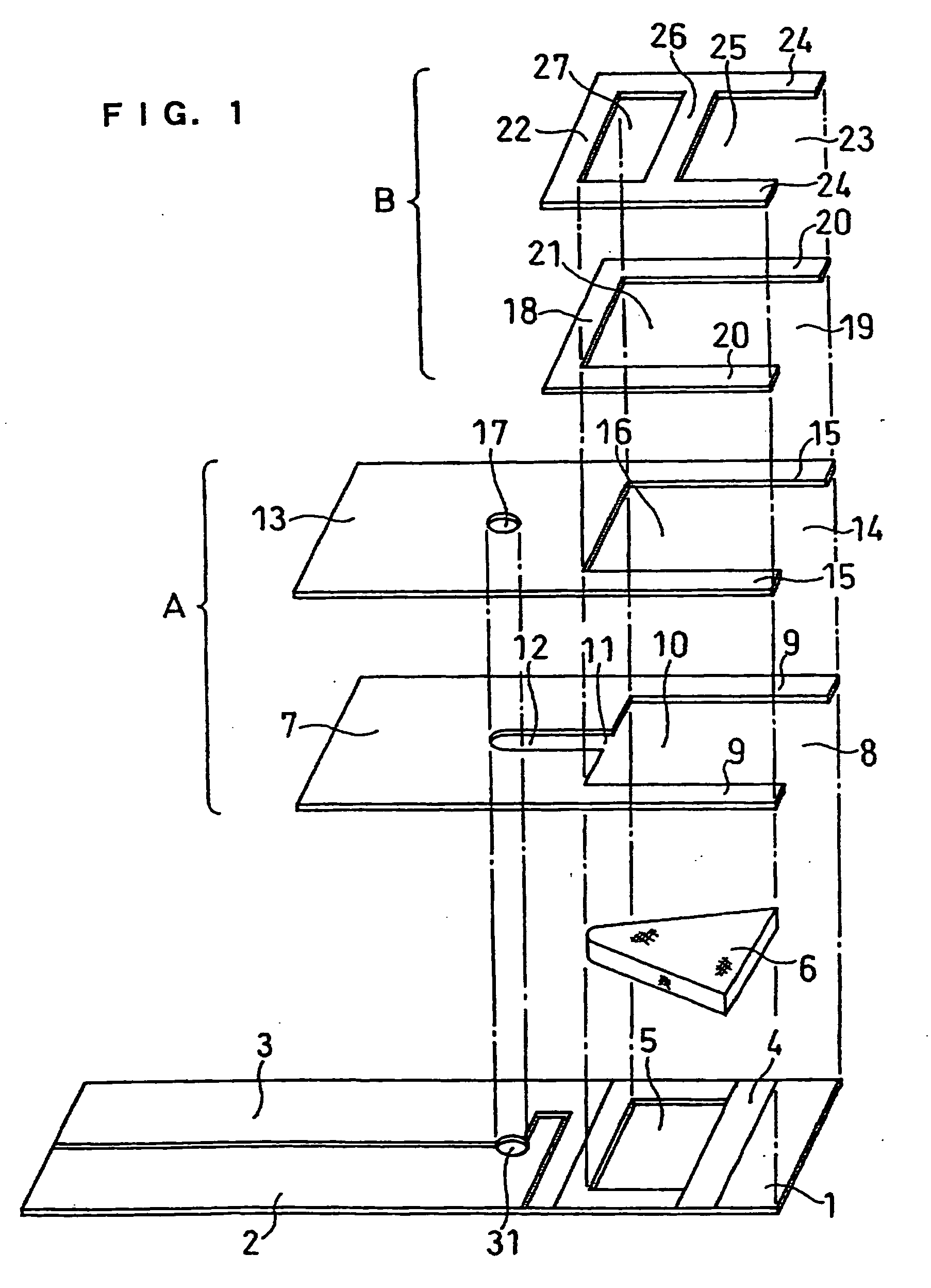

Biosensor

InactiveUS20040096928A1Rapidly be flown into sensorImprove solubilityMicrobiological testing/measurementMaterial analysis by electric/magnetic meansReaction layerEngineering

In a biosensor comprising an insulating base plate, an electrode system including a measuring electrode and a counter electrode provided on said base plate, a cover for covering said insulating base plate, at least one reaction layer containing oxidoreductase and / or an electron mediator, a sample solution supply pathway including said electrode system and said reaction layer and communicating with an air aperture at a terminal end side, a sample solution supply part and a filter provided between said sample solution supply pathway and said sample solution supply part to filter hemocytes, an end face and a top face of a primary portion of the filter are exposed and the sample solution supply part is provided adjacently to the primary side portion so as to provide an improved biosensor which allows easy addition of whole blood to the sensor and rapid supply of the added whole blood to a filter even in the case of collecting blood by fingertip centesis for measurement.

Owner:PANASONIC CORP

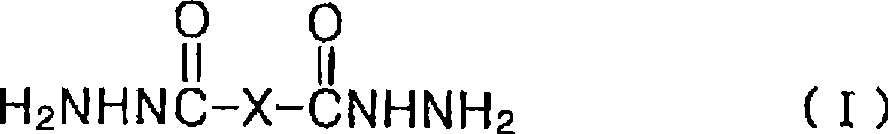

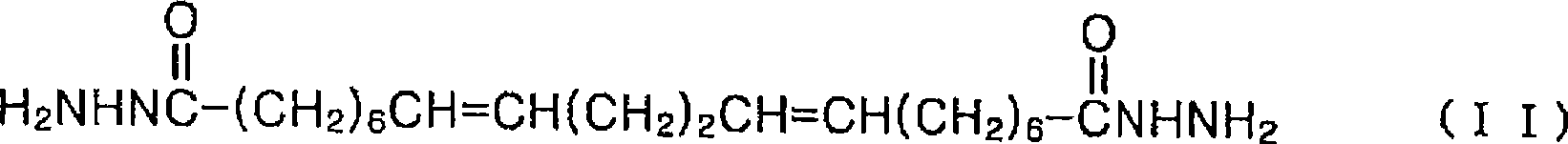

Epoxy resin composition for fiber-reinforced composite material

Provided is an epoxy resin composition for fiber-reinforced composite materials, which serves as a matrix resin for a prepreg. This epoxy resin composition is improved in tackiness stability during storage, while maintaining mechanical characteristics. The epoxy resin composition for fiber-reinforced composite materials is characterized by containing 25 to 50 parts by weight of an amine curing agent (B) selected from aliphatic polyamines, alicyclic polyamines and aromatic polyamines, and 1 to 20 parts by weight of an organic acid dihydrazide compound (C) having a melting point of not less than 150 DEG C, per 100 parts by weight of an epoxy resin (A).

Owner:YOKOHAMA RUBBER CO LTD

Method for preparing sustained-release fertilizer

ActiveCN101948352AFacilitate inhalationImprove solubilityFertiliser formsFertilizer mixturesPollutionPorous microspheres

The invention relates to a method for preparing a sustained-release fertilizer, and belongs to a method for preparing the sustained-release fertilizer by embedding a fertilizer into the pores of a carrier, in particular a method for preparing the sustained-release fertilizer by embedding the fertilizer into the pores of porous microspheres puffed by mountain flour in a larger amount than that in the prior art. The method comprises the following steps of: putting the porous microspheres puffed by the mountain flour in a vacuum container which is vacuumized; stopping vacuumizing after the air in the pores of the porous microspheres puffed by the mountain flour is pumped out completely; pouring the fertilizer into the vacuum container; uniformly mixing the porous microspheres puffed by the mountain flour and the fertilizer; gradually reducing the vacuum to normal pressure to ensure that the fertilizer is absorbed into the pores of the porous microspheres puffed by the mountain flour as much as possible; and thus, obtaining a sustained-release fertilizer primary product. Compared with the method of simply mixing the porous microspheres puffed by the mountain flour and the fertilizer, the method not only increases the vacuumization process and the cost, but prolongs the utilizable time of the fertilizer in the soil, increases the utilization rate of the fertilizer and reduces the fertilizer pollution.

Owner:河北硅谷肥业有限公司

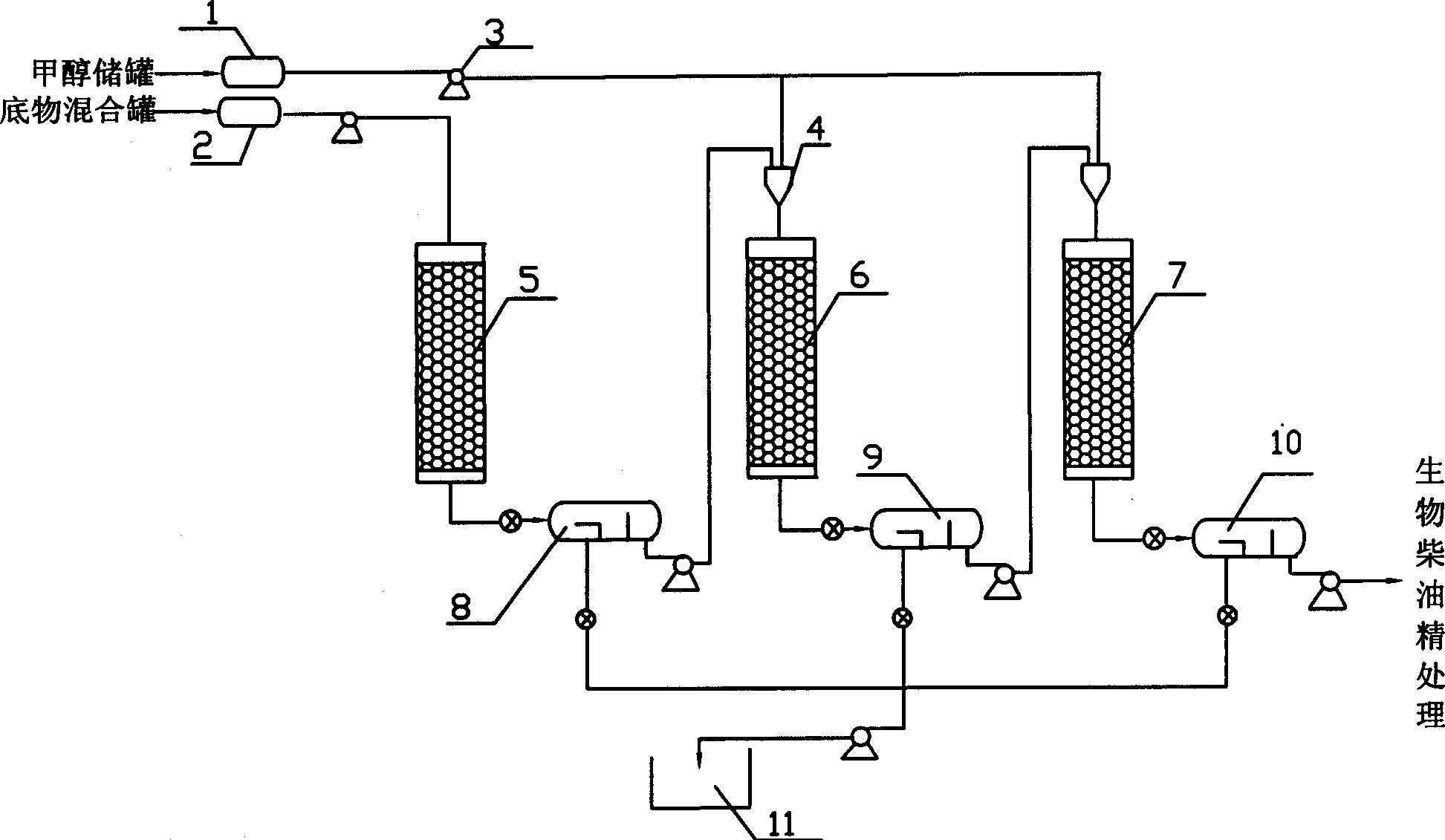

Production of biological diesel oil by fixed enzyme method

ActiveCN1818026AEnzyme stabilityExtended half-lifeBiofuelsLiquid hydrocarbon mixture productionOil and greaseBiodiesel

A process for producing biological diesel oil by fixed enzyme method is carried out by taking sodium alginate, kaoline, glutaraldehyde, gelatin and lactose as co-fixer, fixing the lipase, piling the spherical fixed enzyme in filled bed columnar reactor naturally, alcoholyzing animal and plant oil fatty with biological diesel oil as solvent and producing biological diesel oil. It is cheap, has less consumption and by product and better quality. It can be used for continuous production.

Owner:茂名市泓宇能源科技有限公司

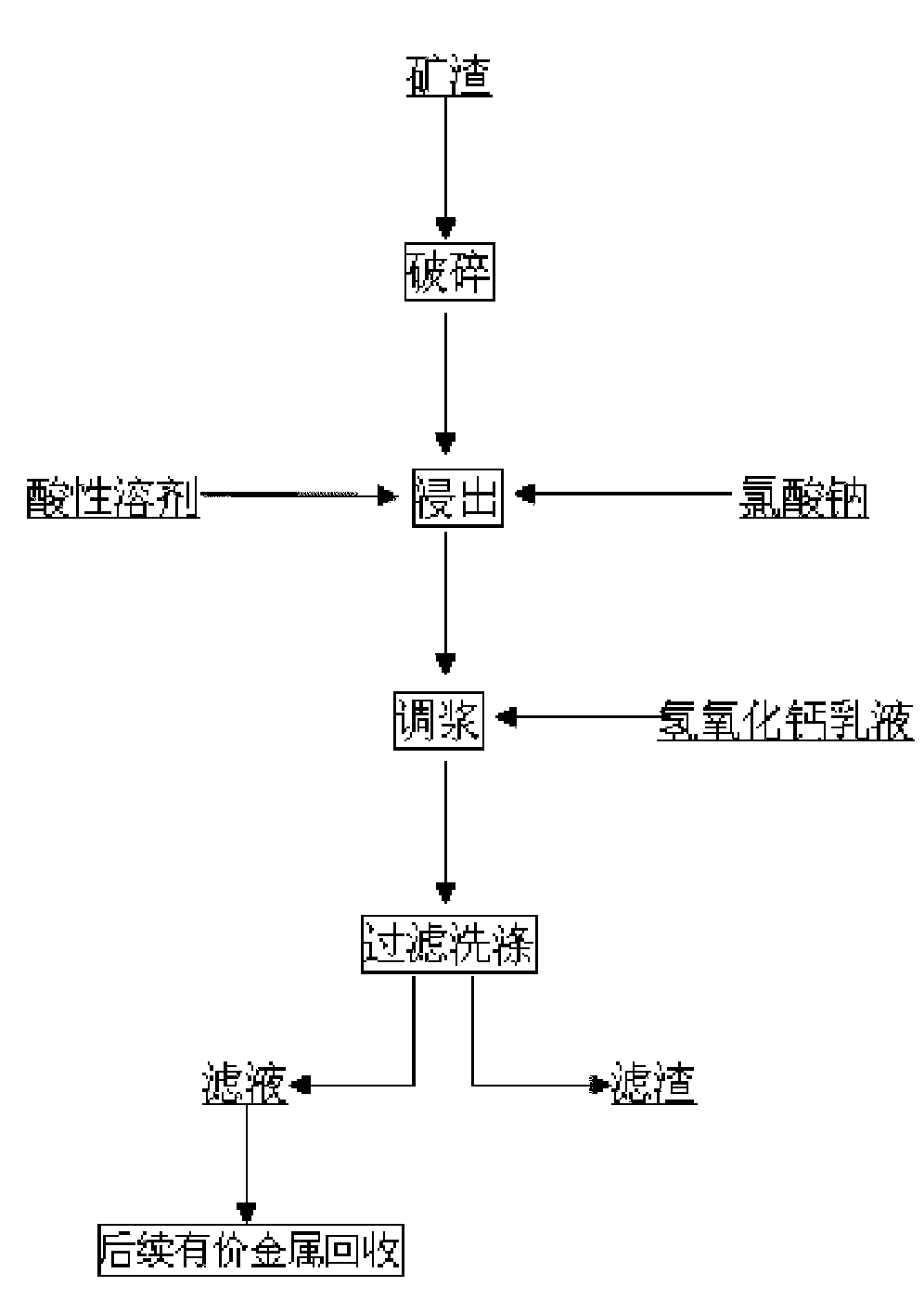

Method for selectively leaching voluble metal in copper refinery cinder

The invention provides a method for selectively leaching voluble metal in copper refinery cinder, which comprises the steps of crushing, acid fusion, size mixing and ageing, and the concrete steps are as follows: crushing and sieving the copper refinery cinder, and adding an oxidizer in slag; then stirring and leaching the mixture with 0.5-1.5 mol / L dilute sulphuric acid; after leaching, adding a size mixing agent which is calvital emulsion to neutralize excessive acid in the neutralization reaction; controlling the pH value of the reaction end point to 1.6-2.3; ageing the leaching agent; and carrying out filtering and washing to obtain filtrate containing the leached valuable metal. The method can effectively leach out copper, cobalt and zinc, inhibit the dissolution of silicon and ferrum to the maximum extent and obtain filter residue with favorable filtering performance. The method has simple and convenient size mixing scheme, less equipment investment, low raw material and small environment pollution, changes copper smelting waste residue into developable resources and has huge environment and economic benefits.

Owner:CENT SOUTH UNIV

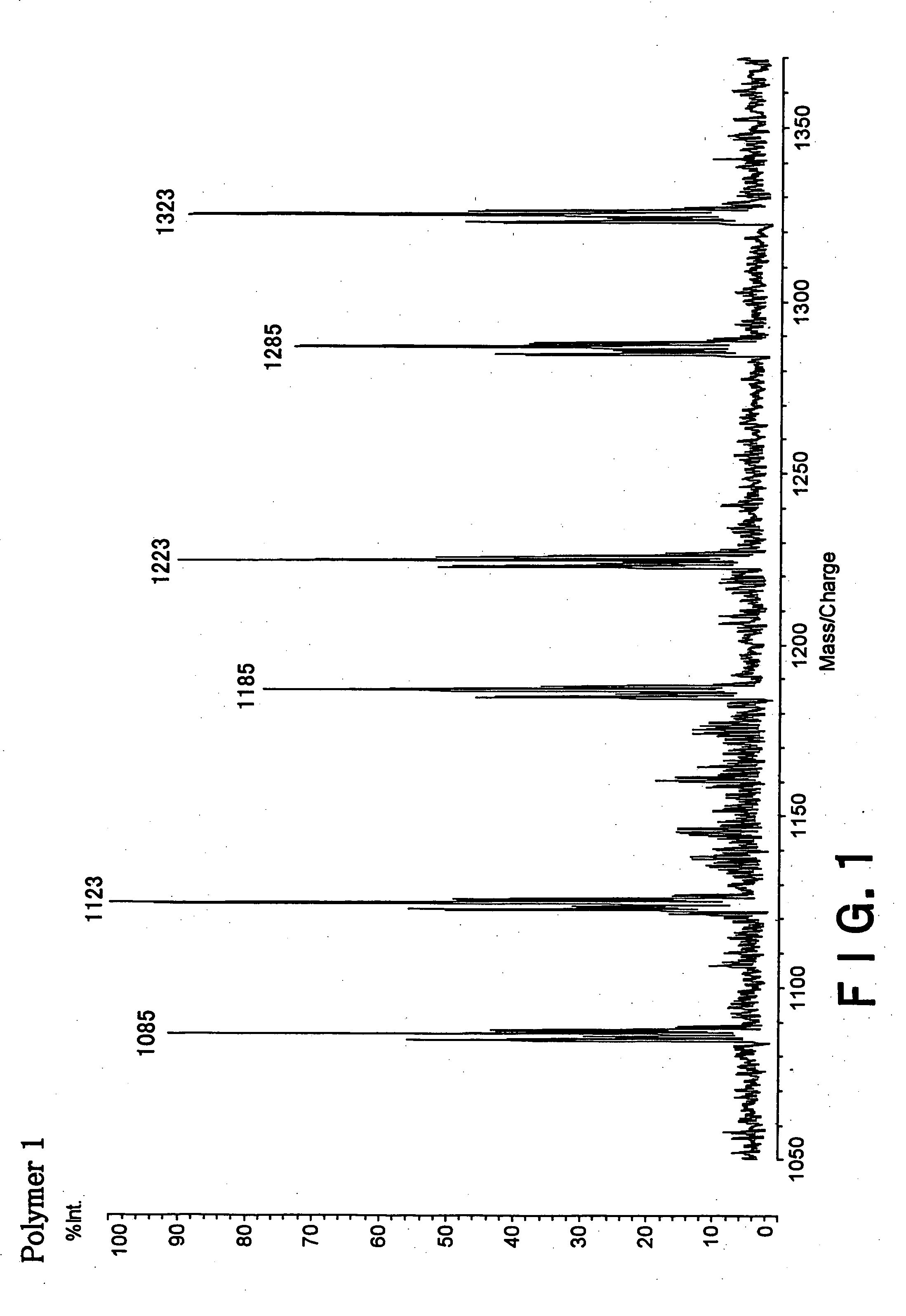

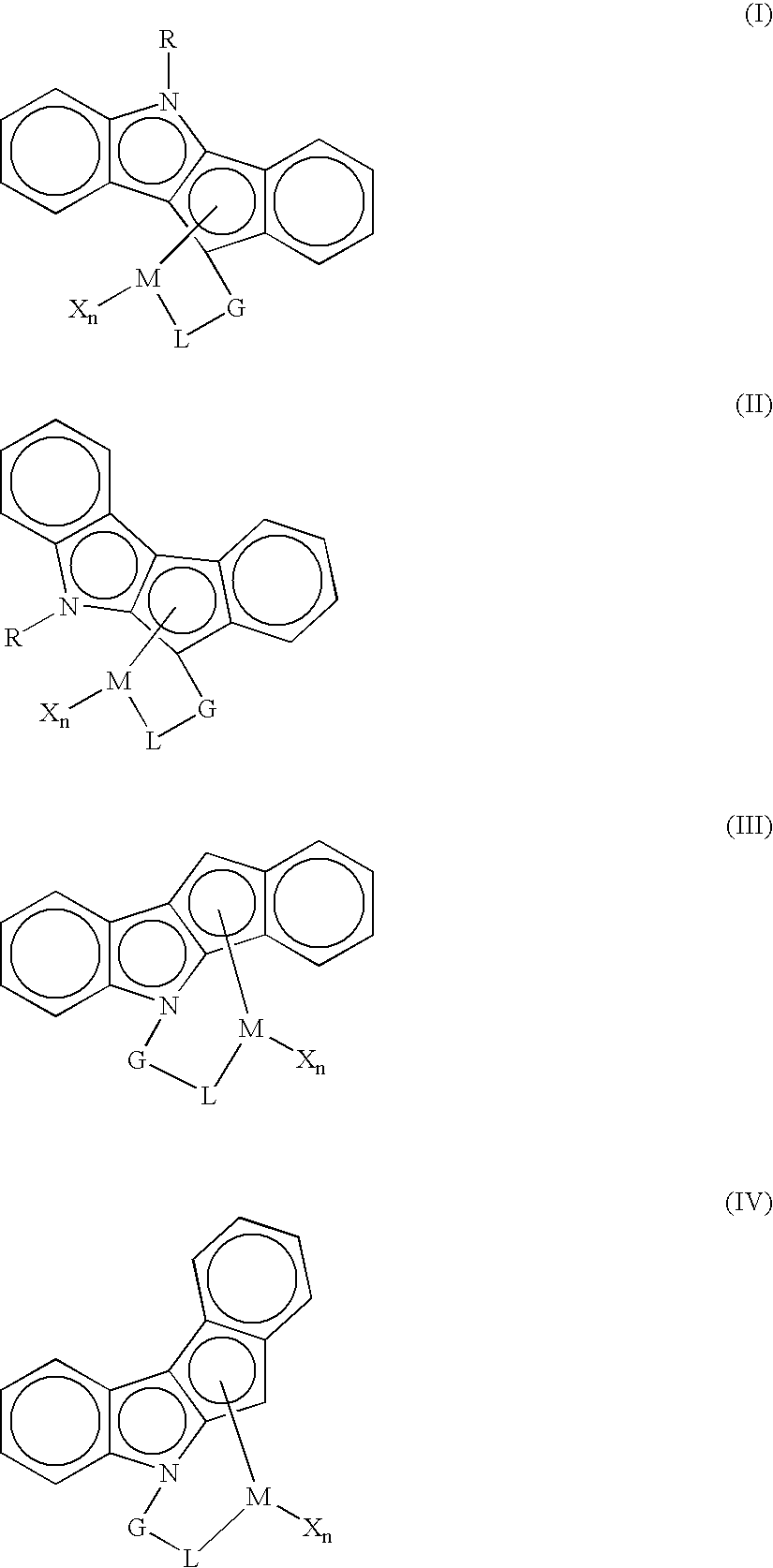

Polymer bound single-site catalysts

InactiveUS20050090384A1Not easy to dissolveHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolymer scienceAllylic alcohol

A single-site catalyst is disclosed. The catalyst comprises a transition metal complex, an activator, and an allylic alcohol-containing polymer. The catalyst has high activity and great capability to incorporate higher α-olefins into polyethylene. The polyethylene produced has high molecular weight and low density.

Owner:EQUSR CHEM LP

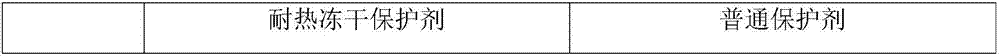

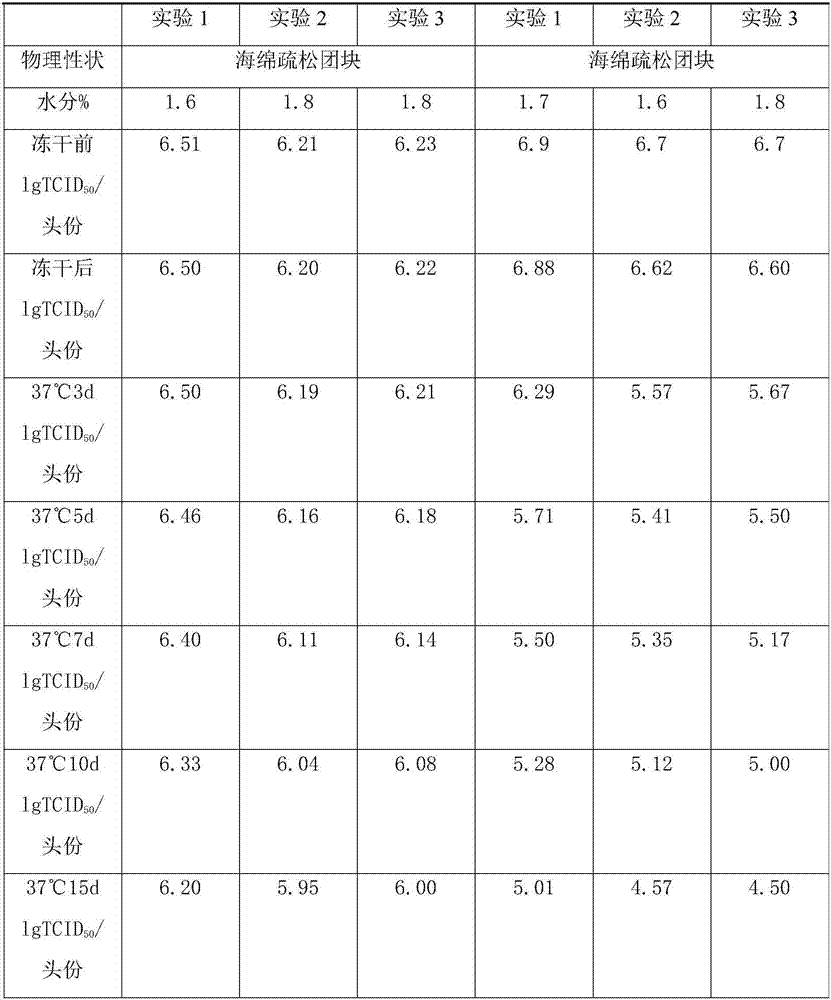

Heatproof lyoprotectant for live vaccine against pseudorabies and preparation method thereof, and lyophilized vaccine and preparation method thereof

ActiveCN107281481AFunction increaseImprove protectionViral antigen ingredientsAntiviralsMonosodium glutamateSucrose

The invention provides a heatproof lyoprotectant for a live vaccine against pseudorabies. The heatproof lyoprotectant comprises, by weight, 3 to 10 parts of gelatin, 1 to 5 parts of trehalose, 5 to 15 parts of sucrose, 0.1 to 2 parts bovine serum albumin, 1 to 8 parts of tryptone, 2 to 10 parts of enzyme-hydrolyzed casein, 1 to 5 parts of thiourea, 0.8 to 2 parts of L-monosodium glutamate, 0.1 to 3 parts of arginine, 0.5 to 5 parts of polyvinylpyrrolidone (PVP-K30) and 0.1 to 2 parts of mannitol. The invention also discloses a preparation method of the heatproof lyoprotectant and a lyophilized vaccine prepared from the heatproof lyoprotectant. When the heatproof lyoprotectant is used for protecting the vaccine and a specific lyophilization process is employed, lyophilization loss of viruses can be effectively reduced, the temperature tolerance of the viruses can be improved, and the vaccine can still maintain good physical properties and titer after long-term storage; i.e., the vaccine has stable characters and has the characteristics of heat resistance and long storage time.

Owner:SICHUAN HUAPAI BIO PHARMA

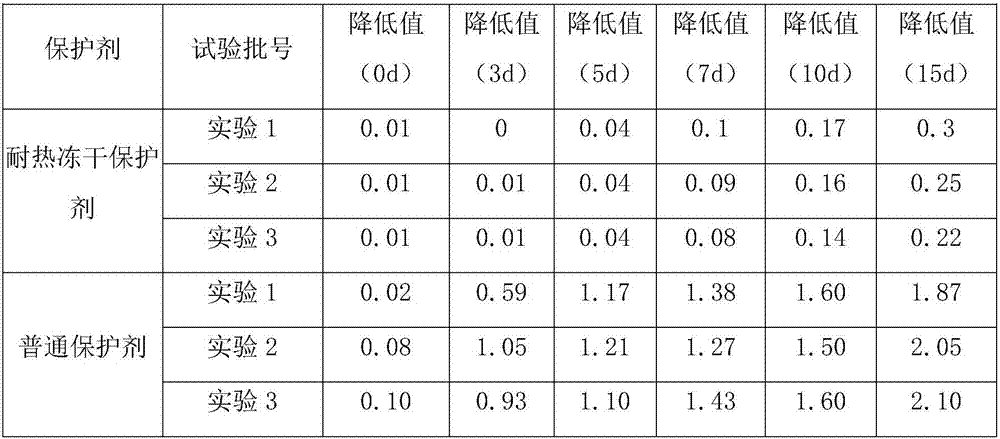

Hydrophobic gel composite cement and plugging method thereof

ActiveCN101863643AOvercoming the fatal flaw of not repelling waterReach hydrophobicCement slurryUltimate tensile strength

The invention discloses hydrophobic gel composite cement, and relates to the technical field of cement slurry plugging in petroleum drilling. The composite cement comprises the following components in percentage by weight: 0.15 to 0.25 percent of hydrophobic gel, 10 to 30 percent of hydrophobic curing agent, 8 to 15 percent of coagulant, and the balance of cement. The invention provides a preparation method for the composite cement at the same time. By introducing the hydrophobic gel into a cement system, the water repellency of the cement slurry system is improved, the strength of a plugginglayer is improved, the mixing alternation of stratum water and cement slurry can be effectively inhibited, the tendency of gradual enhancement along with the time after the composite cement is injected into a leakage layer is ensured, the pressure bearing capacity of the leakage layer is improved, the loss problem of a loss return leakage well is solved, and the one-time plugging success rate is improved and exceeds 50 percent.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Stub-leaving no-tillage spring-manure wheat sowing and cultivation method

The invention relates to a sowing technique, in particular to a stub-leaving no-tillage mechanical sowing cultivation method. The stub-leaving no-tillage mechanical spring-manure wheat sowing cultivation method comprises the steps of harvesting wheat, irrigating in winter, performing medical treatment on selected spring-manure wheat seeds, mixing the selected spring-manure wheat seeds with chemical fertilizer, performing stub-leaving no-tillage mechanical spring-manure wheat sowing, performing field management of stub-leaving no-tillage spring-manure wheat, and performing stub-leaving no-tillage spring-manure wheat harvesting and the like. The method has the advantages of increasing moisture in soil, reducing wind corrosion and waster and soil loss, regulating ground temperature, increasing nutrients in soil, improving activity of soil enzymes and the like.

Owner:GANSU AGRI UNIV

Transparent and environment-friendly underwater consolidated solvent-free epoxy grouting material and preparation method and application thereof

The invention discloses a transparent and environment-friendly underwater consolidated solvent-free epoxy grouting material. The transparent and environment-friendly underwater consolidated solvent-free epoxy grouting material is prepared from a first component and a second component. The weight ratio of the first component to the second component is 100:(0.5-100). The first component is prepared from, by weight, 20-85 parts of epoxy resin, 25-80 parts of reactive diluent and 0.5-5 parts of interfacial modifier. The second component is prepared from, by weight, 10-95 parts of amine curing agent, 0-40 parts of waterproof dispersant and 0-20 parts of accelerant. The invention further discloses a preparation method and application of the transparent and environment-friendly underwater consolidated solvent-free epoxy grouting material. The grouting material is high in strength, good in water plugging and leakage preventing effect, good in waterproof performance and comprehensive mechanical property and low in toxicity, the preparation method is simple, and the application range is wide.

Owner:GUANGZHOU YINGTIAN BUILDING MATERIAL TECH CO LTD

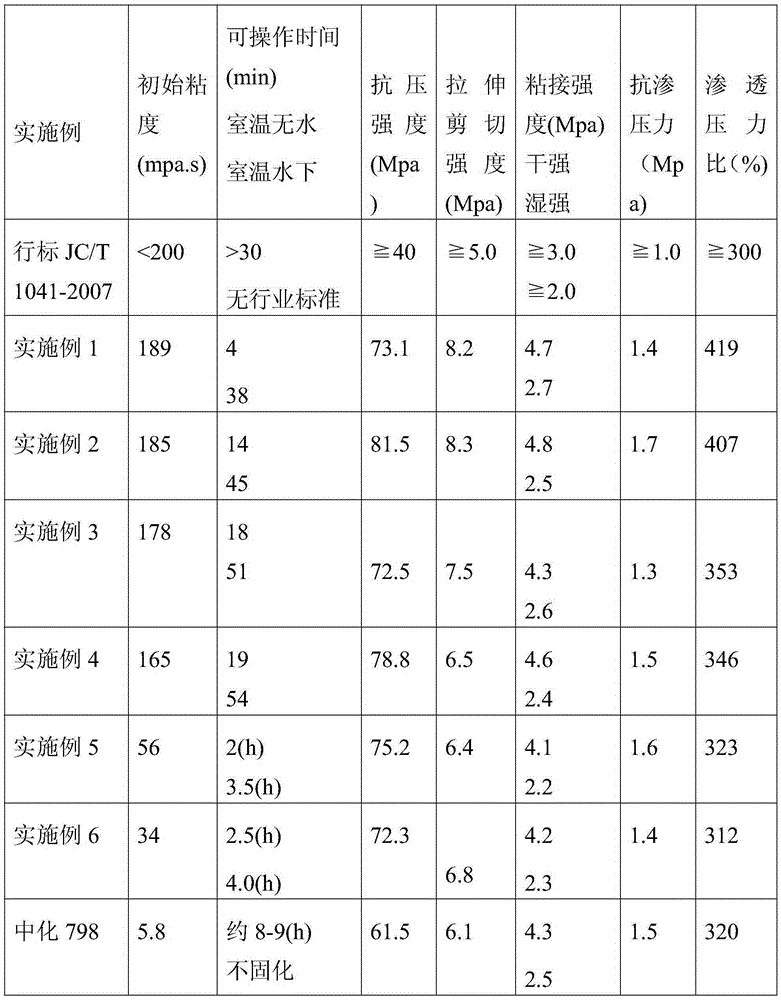

Method for recovering bismuth from bismuth slag

ActiveCN102586627AAvoid safety hazardsReduce labor intensityProcess efficiency improvementElectrolysisSlag

The invention relates to a method for recovering bismuth from bismuth slag, which includes steps of: firstly, smelting silver-refining converter oxidizing slag in high-temperature restoring mode to obtain lead-bismuth alloy, performing silico-fluoric acid system lead-bismuth alloy electrolysis to obtain electric lead products and high-bismuth anode mud; secondly performing hydrochloric acid leaching on the high-bismuth anode mud, filtering to obtain bismuth-contained leaching liquid, wherein the leaching condition is that: liquid-solid ratio (weight ratio) is 3-6:1, process temperature is 40-70 DEG C, hydrochloric acid concentration is 150-200g / L, and reaction time is1.5-2.5h; and thirdly, replacing bismuth in the leaching liquid through reduced iron powder to obtain sponge bismuth and obtain refined bismuth with high purity in pyro-refining electrolysis. Sodium sulfide for sedimenting silver is added in the leaching process to obtain bismuth leaching liquid, silver can be prevented from immersing into the liquid as much as possible, when return washing liquid is used for leaching high-bismuth anode mud, a part of hydrochloric acid is refilled to maintain necessary potential of hydrogen (pH) value, concentration of Cl- is controlled to be 150-200g / L, and simultaneously bismuth ion hydrolysis can be avoided. Compared with the prior art, the method has no operations of water quenching, ball milling, hydrolysis, neutralization and the like of coarse bismuth alloy, has less procedures, is low in cost and free of pollution, simultaneously achieves double-metal electrolysis of the lead-bismuth alloy and does not influence the electric-lead main system.

Owner:蒙自矿冶有限责任公司

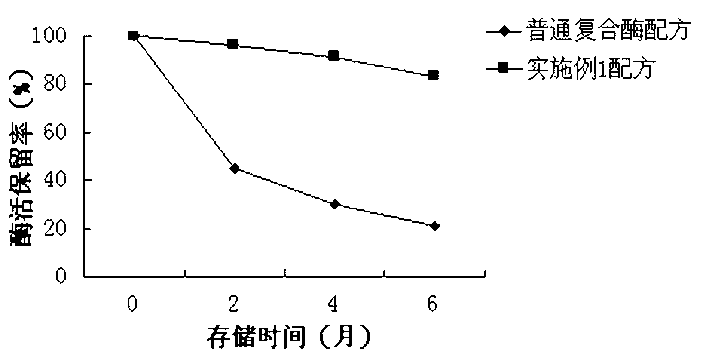

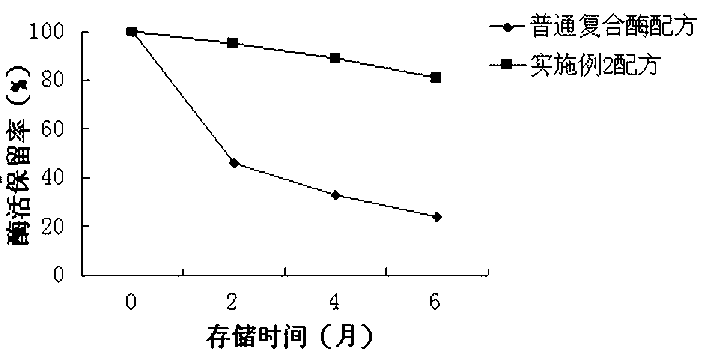

Multi-enzyme complex preparation containing microcapsule and preparation method and application thereof

Provided are a multi-enzyme complex preparation containing microcapsule and a preparation method and an application thereof. The preparation method includes placing 20.7%-22.9% of amylase, 8.4%-11.3% of saccharifying enzyme, 7.6%-9.8% of cellulose, 10.9%-13.1% of pectinase, 11.4%-15.3% of catalase, 6.4%-9.7% of laccase, 0.2%-8.5% of enzyme stabilizer and 0.01%-0.5% of preservative by weight into water, stirring the mixture to enable the mixture to be dissolved completely and form water solution, dispersing 8.6%-12.5% of microencapsulation protease into the water solution to obtain the multi-enzyme complex preparation containing the microcapsule. The multi-enzyme complex preparation containing the microcapsule is added into tobacco raw materials in a feeding mode according to 0.5%-1% of the weight of the tobacco raw materials in a tobacco threshing re-baking line or a tobacco storage alcoholization or formula tobacco thread making line. The microencapsulation protease in the multi-enzyme complex preparation contains a high polymer material wall material, the protease wrapped by the wall material is not easy to dissolve in the low water solution state and can be dispersed and dissolved quickly in the diluted high water solution state, so that activity loss of the protease and other enzymes caused by the fact that the protease reacts with other enzymes is avoided.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Vanadium-contained semimetallic brake block

ActiveCN105240429ANot easy to produceReduce wear rateOther chemical processesFriction liningAluminum silicateCellulose fiber

The invention discloses a vanadium-contained semimetallic brake block. The vanadium-contained semimetallic brake block includes, by weight, 5-7 parts of red copper fibers, 3-6 parts of potassium hexatitanate whiskers, 4-5 parts of barium sulfate, 15-25 parts of ferrovanadium powder, 4-6 parts of frictional powder, 13-15 parts of short stainless steel fibers, 6-10 parts of graphite, 2-4 parts of cellulosic fibers, 7-9 parts of coke blacking, 1-5 parts of modified resin nitrile fibers, 3-7 parts of chromite ore fine, 1-5 parts of nitrile rubber, 5-9 parts of ceramic adhesive agents and 8-10 parts of spray-bounded aluminum silicate fibers. The brake block obtained by material mixing, steel backing treatment, press molding, heat treatment, packaging and storage is low in wear rate, not prone to being dusty, high in density, good in heat dissipation, small in vibration, low in noise and high in corrosion resistance. The whole manufacturing process is simple, stability is good, cost is low and the cost-performance ratio is high.

Owner:盐城加能汽车部件有限公司

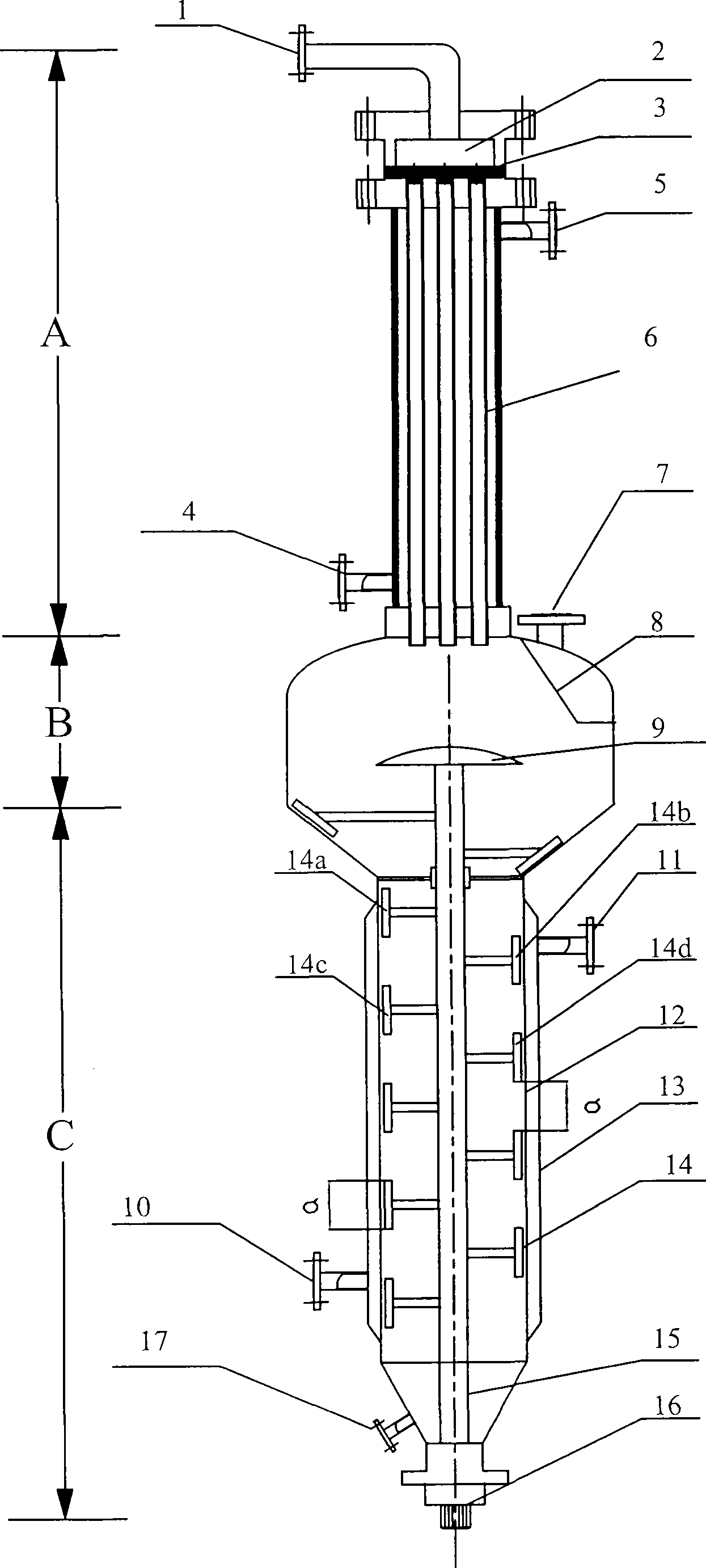

Dry process of dodecyl sodium sulfate

InactiveCN101456829AReasonable process designLower the preheat temperatureDrying using combination processesDrying solid materials with heatOrganic compoundSodium sulfate

The invention provides a process for drying lauryl sodium sulfate, which belongs to the technical field of preparation of a surfactant in an organic compound. The method is carried out in a compound vacuum drier formed by a vacuum tube type spray drying part (A), an adapting tank (B) and a vacuum scraper drying part (C), and comprises the following steps: (1) preheating a lauryl sodium sulfate material in a preheater to the temperature of between 50 and 100 DEG C, and making the material be in a half atomized state and enter a vacuum drying tube with vapor in the vacuum tube type spray drying part (A) at a pressure of between 0.2 and 1.0MPa by a conveying pump, so that the moisture content of the material is reduced to 50 to 10 percent; (2) introducing the material into the vacuum scraper drying part (C) through the adapting tank (B) for secondary drying, so that the moisture content of the dried material is lower than 3 percent; and (3) according to the prior process, granulating the dried materials through a double screw extruder to manufacture an acicular product. The process has reasonable design, and can effectively improve the drying efficiency and product quality.

Owner:ZANYU TECH GRP CO LTD

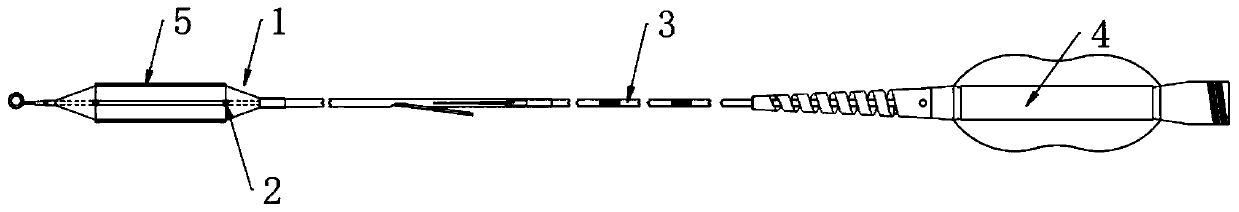

Composite medicine coating balloon, preparation method thereof, and composite medicine coating balloon dilatation catheter

The invention discloses a composite medicine coating balloon. The composite medicine coating balloon comprises a balloon body and a composite medicine coating covering the surface of the balloon body,wherein the composite medicine coating comprises a bottom-layer coating, a middle-layer coating and an outer-layer coating; the bottom-layer coating is used for coating the surface of the balloon body, and consists of medicines A and a hydrophilic excipient; the middle-layer coating consists of a medicine B packed with a packing agent and hydrophilic excipients / lipophilic excipients / amphipathic excipients; and the outer-layer coating consists of a medicine C and lipophilic excipients / amphipathic excipients. The invention further discloses a preparation method of the composite medicine coatingballoon and a composite medicine coating balloon dilatation catheter. According to the composite medicine coating balloon, the loss of traditional Chinese medicines in the balloon transporting process can be reduced, besides, the vasculopathy position can have effective medicine concentration within a short term, vascular restenosis is restrained, long-time medicine release can be provided, durable medicine action time can be maintained, and the restenosis rate can be reduced.

Owner:KOSSEL MEDTECH SUZHOU

Sustained-release pesticide fertilizer granula and production method thereof

InactiveCN109320340AFast fertilizerImprove fertilizer efficiencyLayered/coated fertilisersFertilizer mixturesCyclodextrinMesoporous silica

The invention relates to the technical field of pesticide preparations and specifically relates to a sustained-release pesticide fertilizer granula and a production method thereof. The pesticide fertilizer granula is prepared from a sustained-release coating layer and an inner effective matter, wherein the sustained-release coating layer is prepared from talcum powder, neutral bentonite, hydroxymethyl cellulose and chitosan which are mixed according to the mass ratio of 8 to 5 to 2 to 1; the effective matter is prepared from sustained-release medicine, compound fertilizer, a wetting expandingagent and a filling agent; the sustained-release medicine is a coated systematic type pharmaceutical preparation; the systematic type pharmaceutical preparation and a mesoporous AcF micro powder carrier are mixed and then coated; a coating material is prepared from the following ingredients of polyglycolic acid, talcum powder, mesoporous silica, cyclodextrin, liquid paraffin, polyvinyl alcohol, calcium dodecyl benzene sulfonate and deionized water. The pesticide fertilizer granula is treated by a special coating technology, has the characteristics of quick and stable fertilizer efficiency andslow and durable insect killing pesticide effect and is suitable for synchronous pesticide fertilizer application of flowers and nursery stock plants.

Owner:JIXI NONGHUA BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com