Patents

Literature

100results about How to "Reduce mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

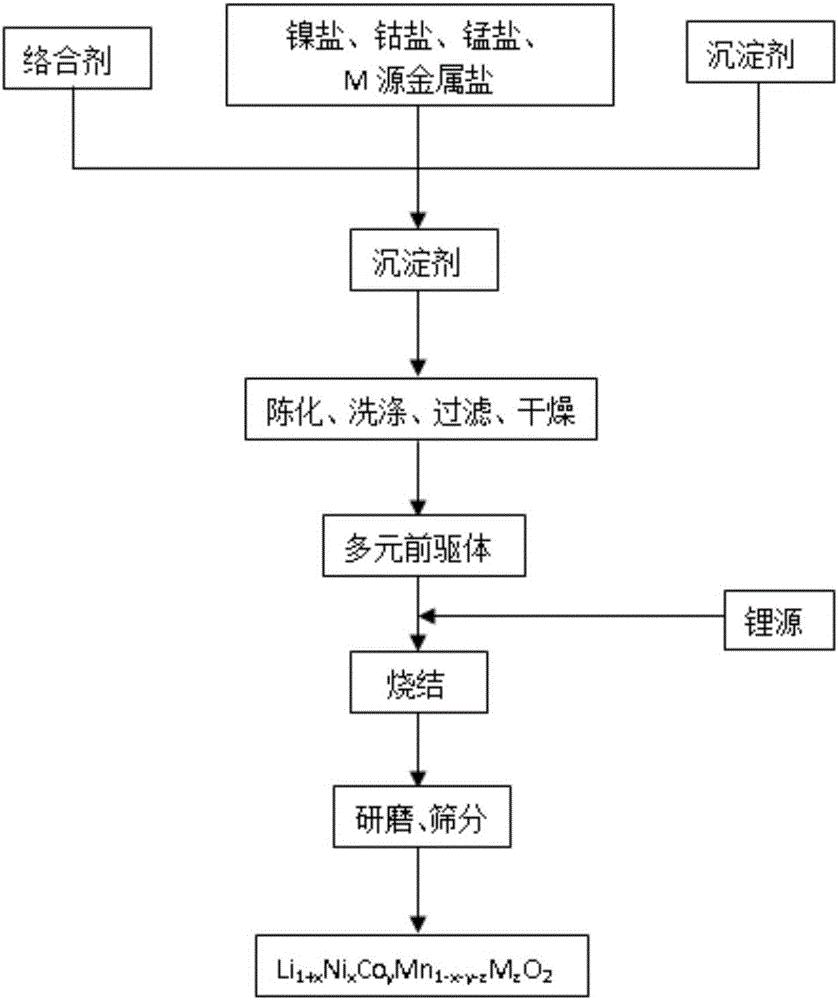

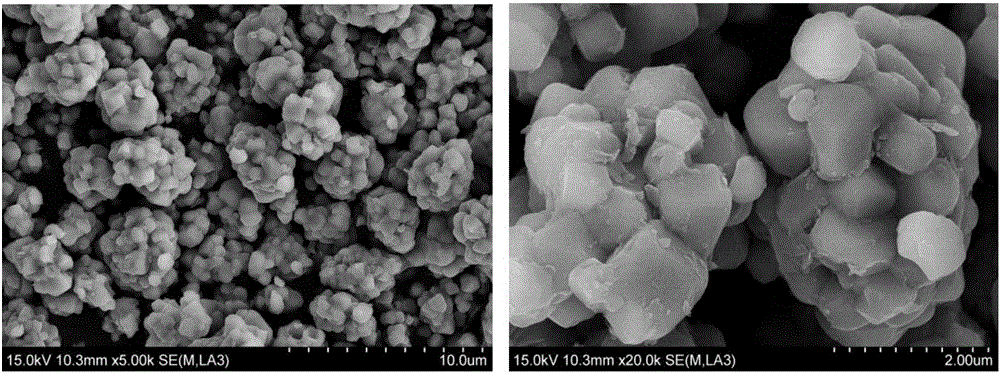

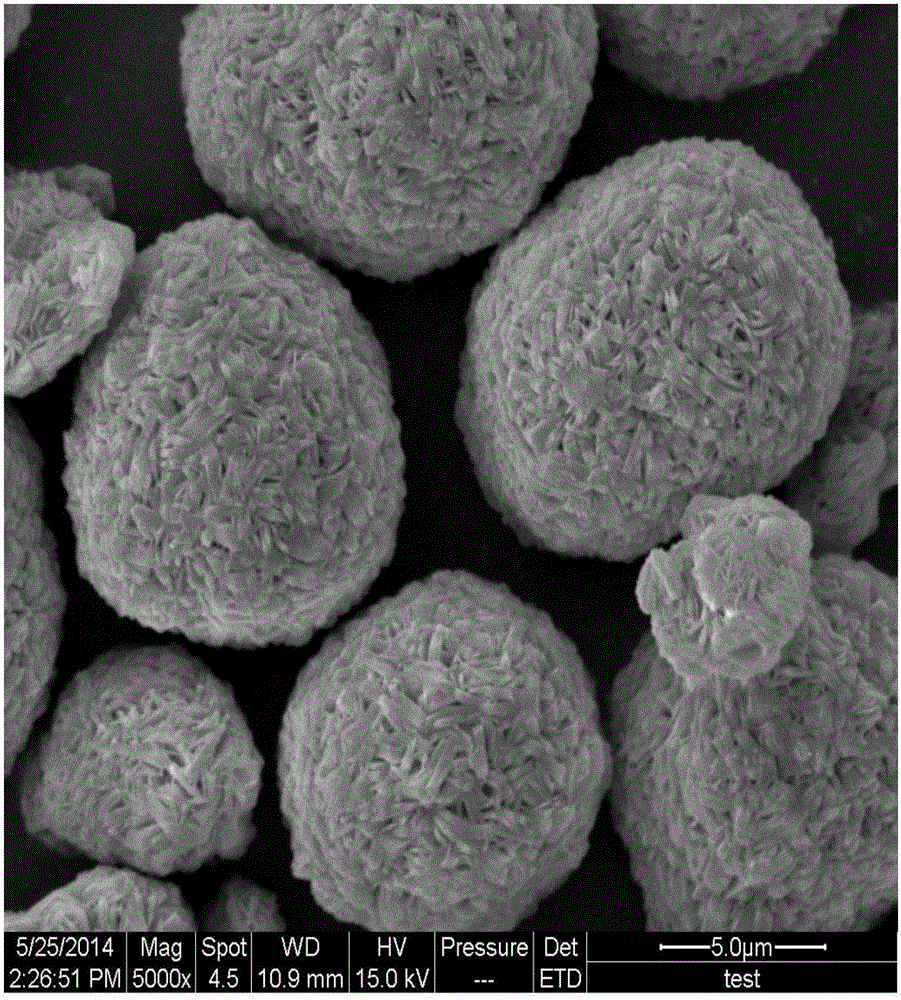

Doped monocrystal multi-component material for lithium ion batteries and preparation method of such doped monocrystal multi-component material

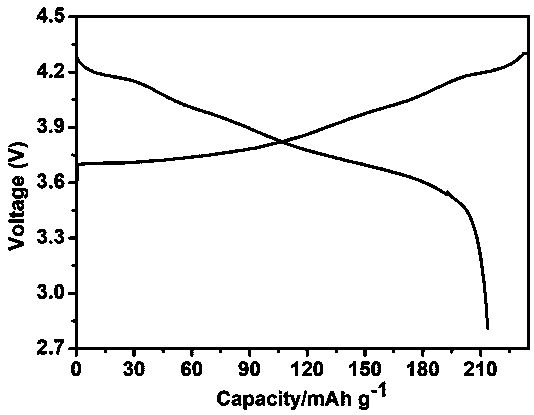

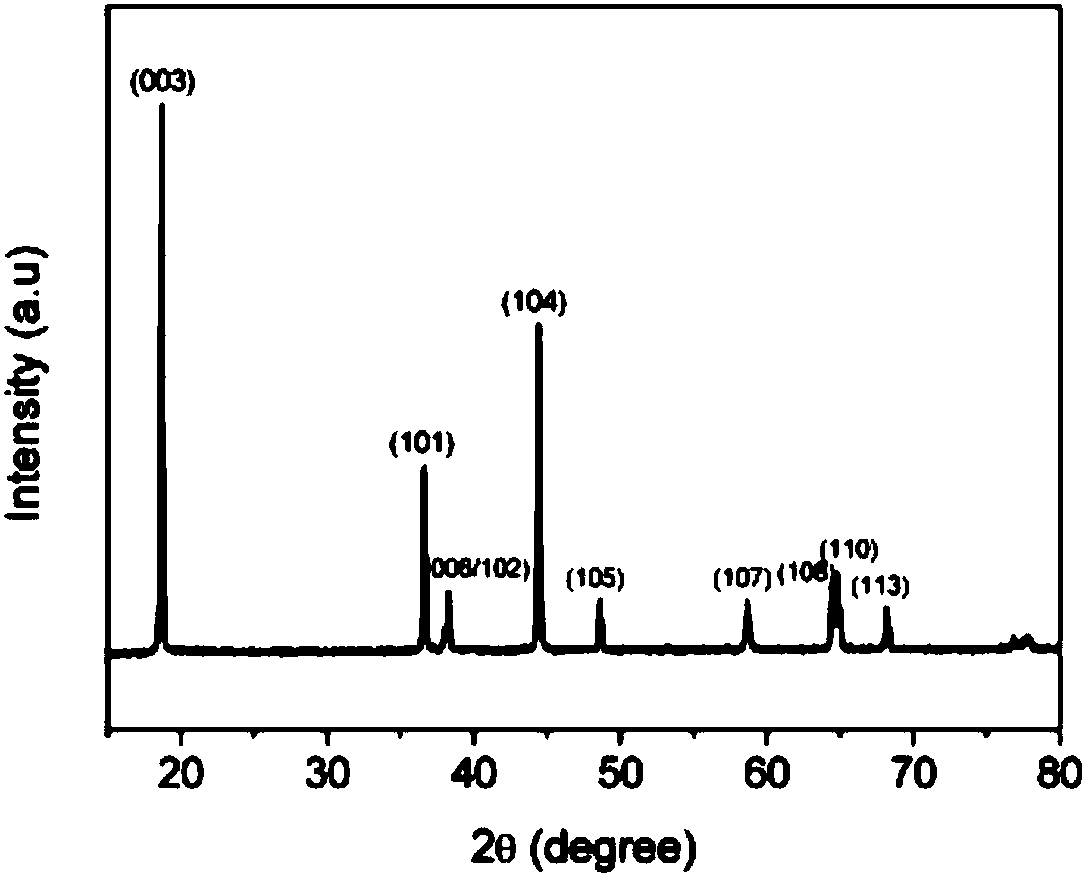

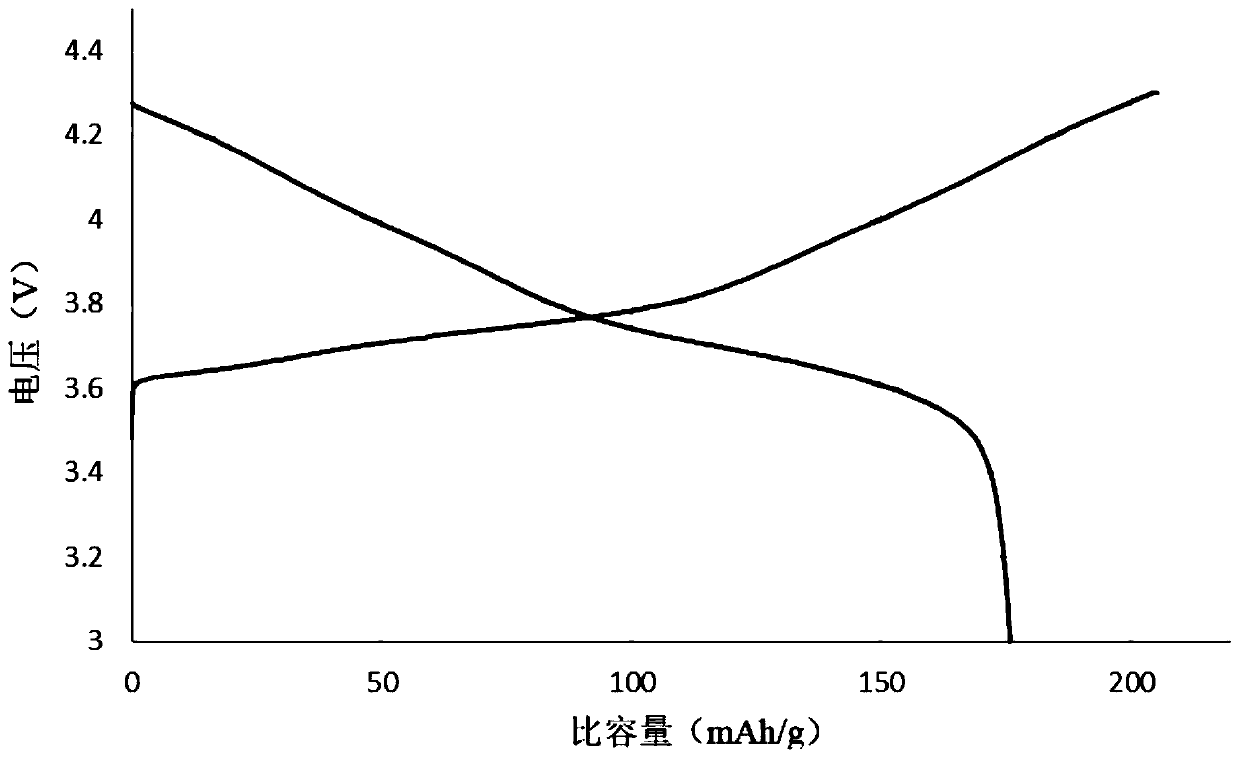

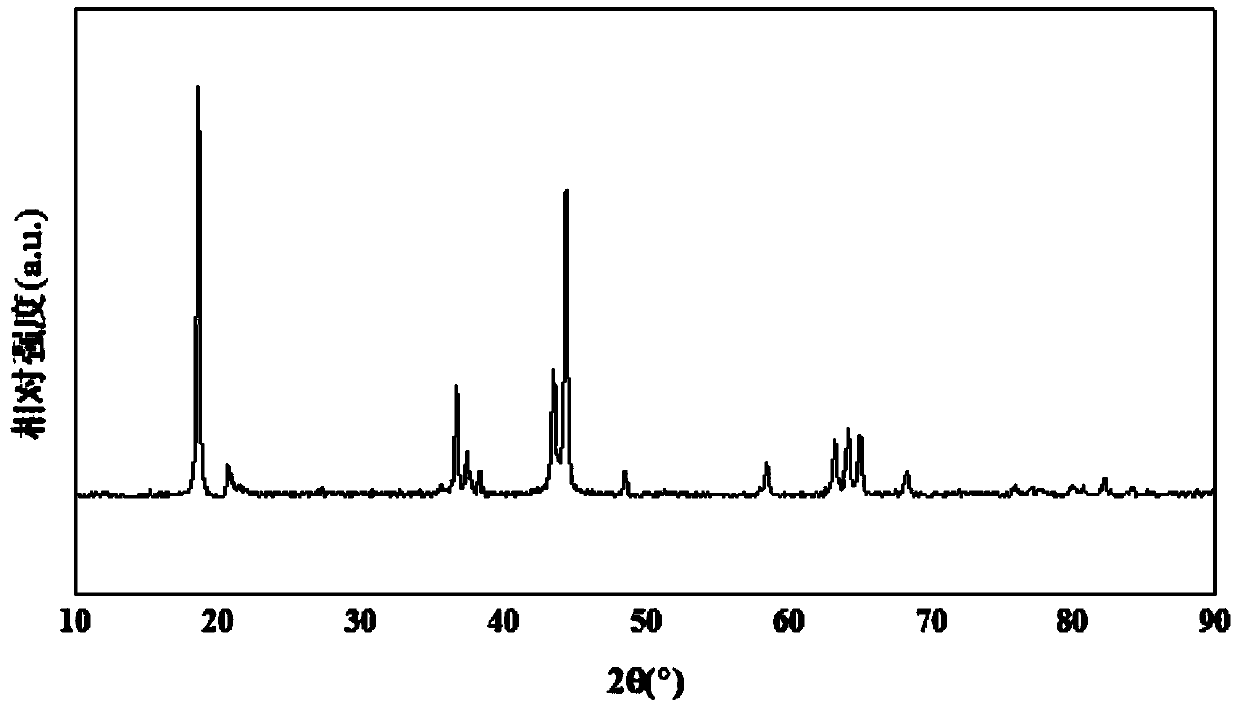

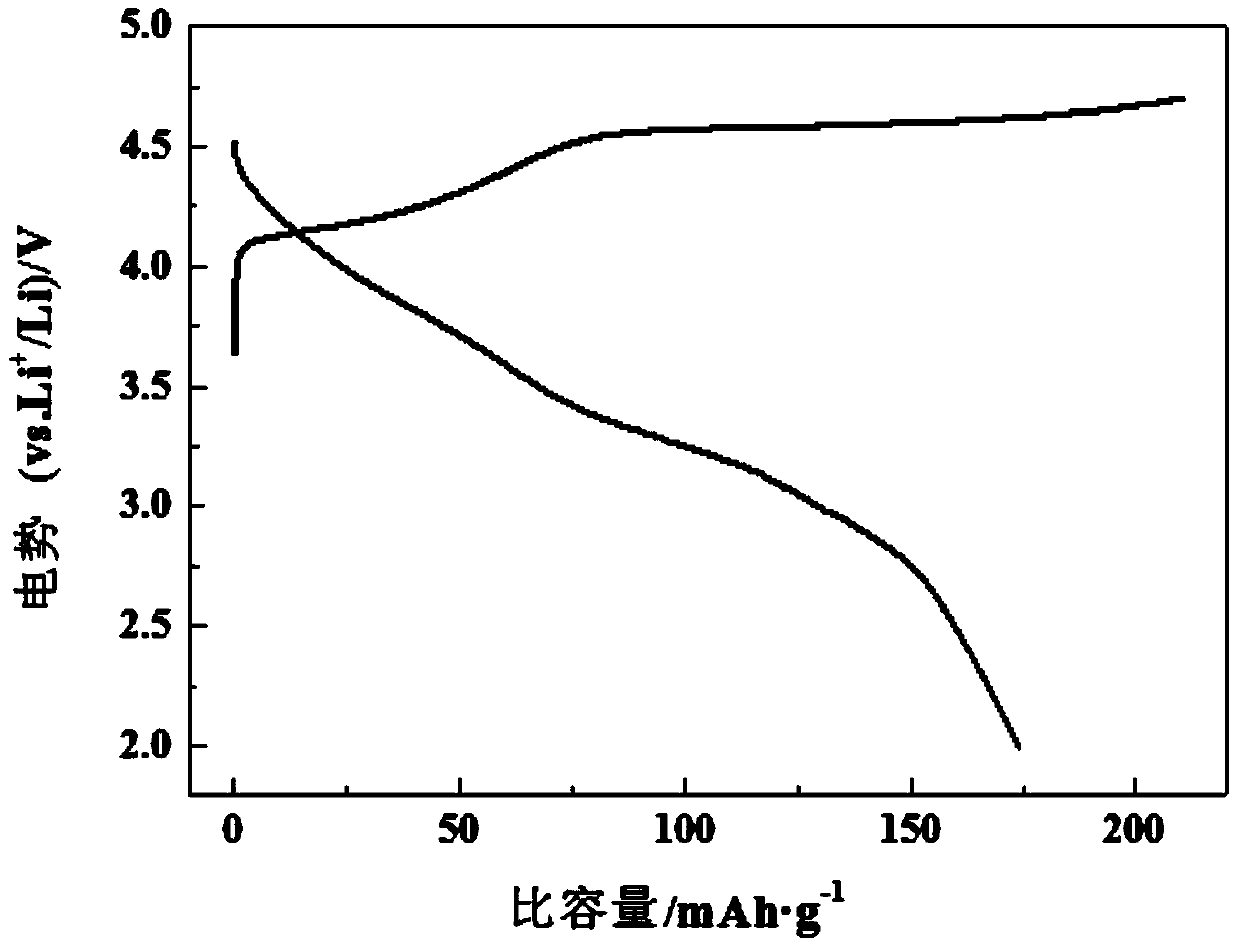

InactiveCN106784686AIncrease energy densityHigh tap densityHybrid capacitor electrodesCell electrodesManganeseCharge discharge

The invention belongs to the technical field of anode materials for lithium ion batteries and particularly discloses a doped monocrystal multi-component material for lithium ion batteries and a preparation method of such doped monocrystal multi-component material. The doped monocrystal multi-component material and the preparation method thereof have the advantages that nickel-cobalt-manganese ternary materials are modified, and M-source metals are doped when a precursor is prepared to decrease the material sintering temperature and improve material tapping density, so that the mixed arrangement degree of Ni<2+> in a Li<+> layer is weakened obviously; through high-temperature sintering and tempering processes, the precursor of the multi-composite material, prepared through a coprecipitation method, is more stable in crystal structure, metal ions in the material are inhibited from dissolving through surface coating, side reaction between the metal ions and electrolyte is inhibited, and stability and electrochemical performance of an active material are further enhanced; a doped monocrystal multi-component material finished product is stable in crystal structure, high in safety and compaction density and excellent in rate capability and cycle performance, so that specific capacity and charge-discharge voltage of the material are further enhanced; the preparation method is small in doping quantity, simple to operate, easy to control, widely applicable and suitable for large-scale production.

Owner:烟台卓能锂电池有限公司

Acidic compositon for external use and agent for accelerating infiltration of cosmetic preparation, hair-growing agent, and preparation for external use each containing the composition into skin or the like

InactiveUS20050074421A1Reduce mixingIncrease absorption rateCosmetic preparationsHair cosmeticsOtic AgentsTreatment effect

An acidic composition for external use which contains an acidic polysaccharide and water as essential ingredients, and an agent for accelerating the penetration into skin or the like of a cosmetic preparation, hair-growing agent or preparation for external use, each containing the composition. The composition is easy to manufacture, and shows a stronger cosmetic or therapeutic effects than conventional compositions.

Owner:NEOCHEMIR INC

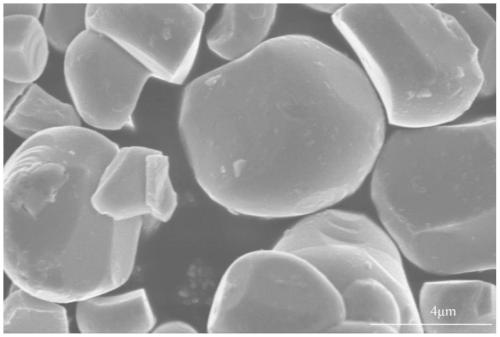

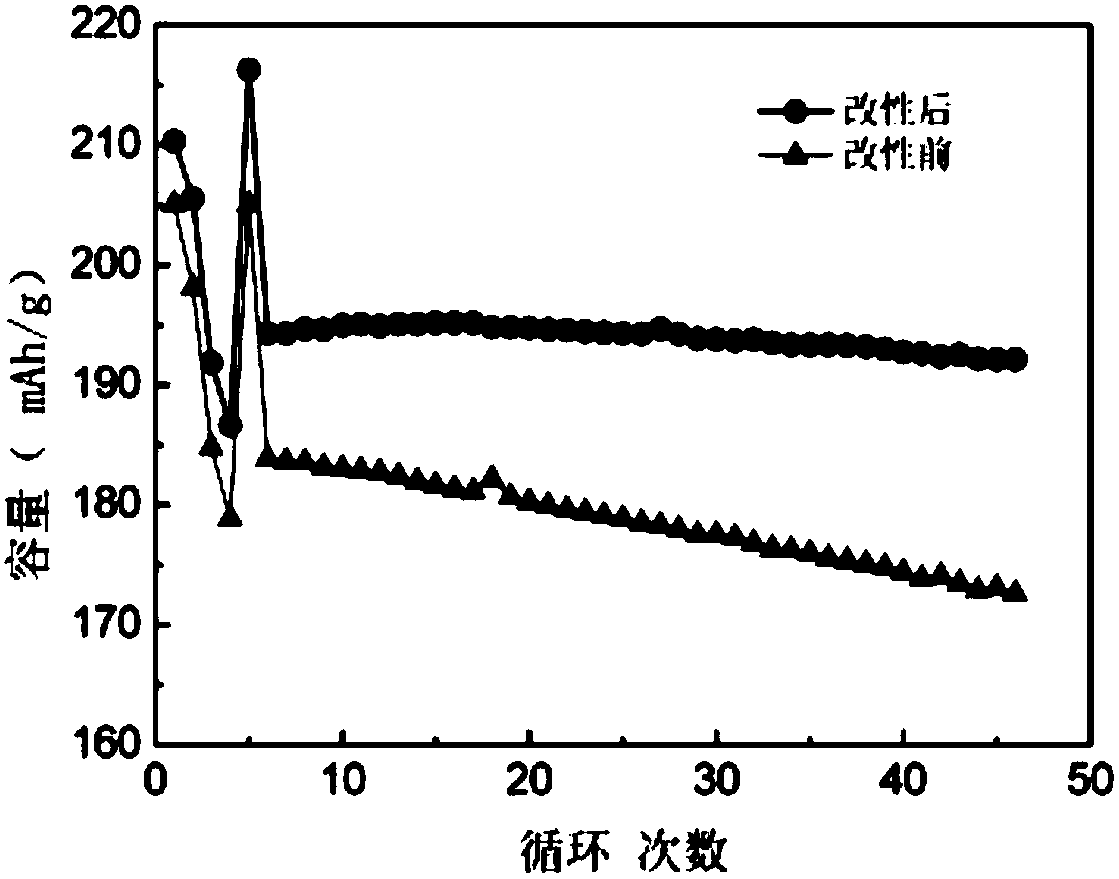

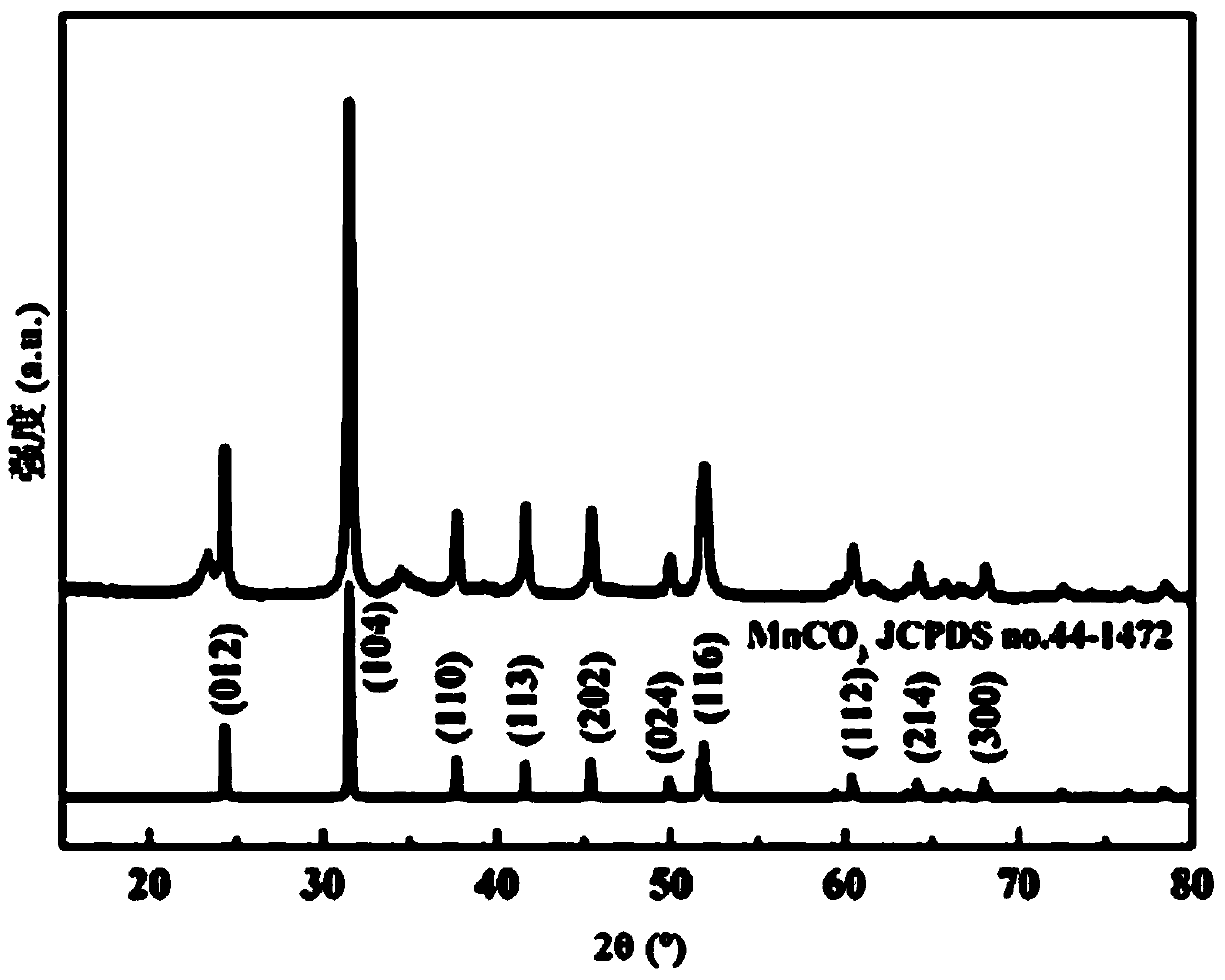

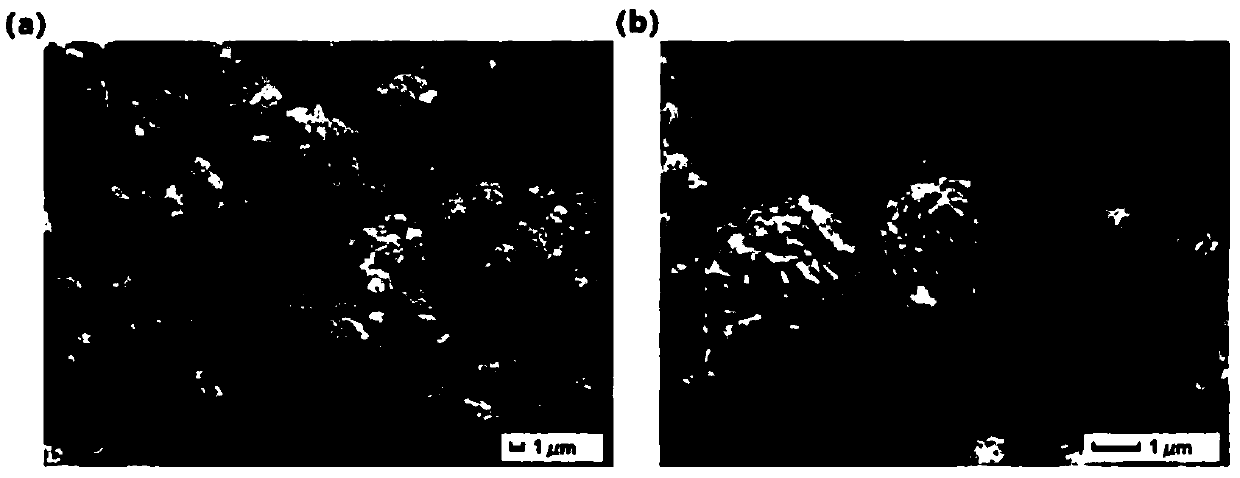

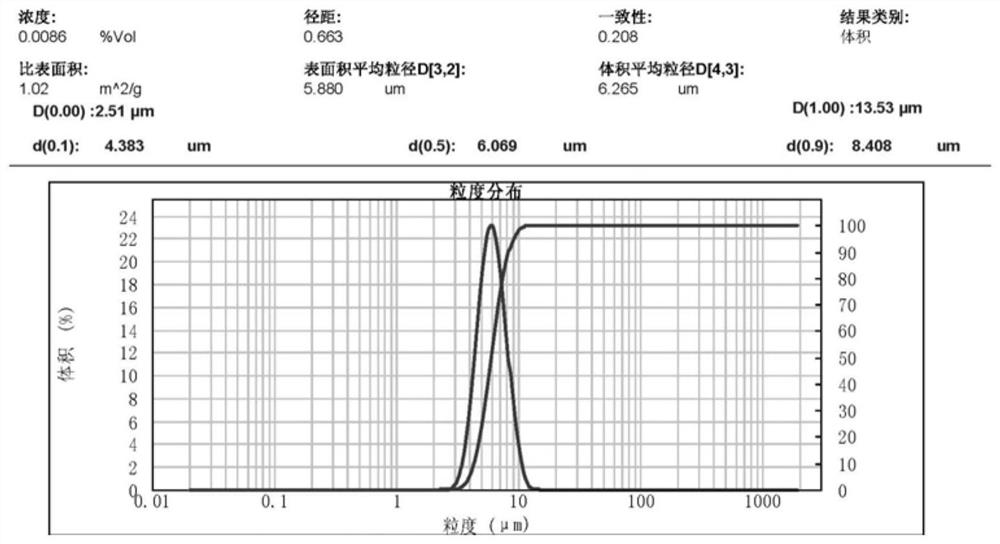

Single-crystal appearance layered nickel lithium manganate positive electrode material and preparation method thereof

ActiveCN109811412ALow cost of preparationReduce mixingPolycrystalline material growthCell electrodesOxideLithium electrode

The invention discloses a single-crystal appearance layered nickel lithium manganate positive electrode material and a preparation method thereof. The single-crystal appearance layered nickel lithiummanganate positive electrode material is prepared by the following preparation method with the steps of (1) performing preparation to obtain nickel manganese precursors by using nickel salts and manganese salts by a wet chemical method, wherein the mol ratio of the Ni to Mn is 1:1; (2) performing pre-sintering on the nickel manganese precursors to obtain the nickel manganese oxide precursors; (3)mixing the nickel manganese oxide precursors with Li source and M source additives; then, performing calcination to obtain the single-crystal appearance layered nickel lithium manganate positive electrode material. The advantage that the single crystal particle has the theory density is sufficiently achieved, so that the compaction density of an electrode plate made of positive electrode materialscan be improved, so that the volume energy density of a lithium ion battery is improved. The defects inside the single crystal particles can be greatly reduced; the structure stability of the positive electrode material in the charging and discharging process can be effectively improved, so that the service life of the lithium ion battery is prolonged.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

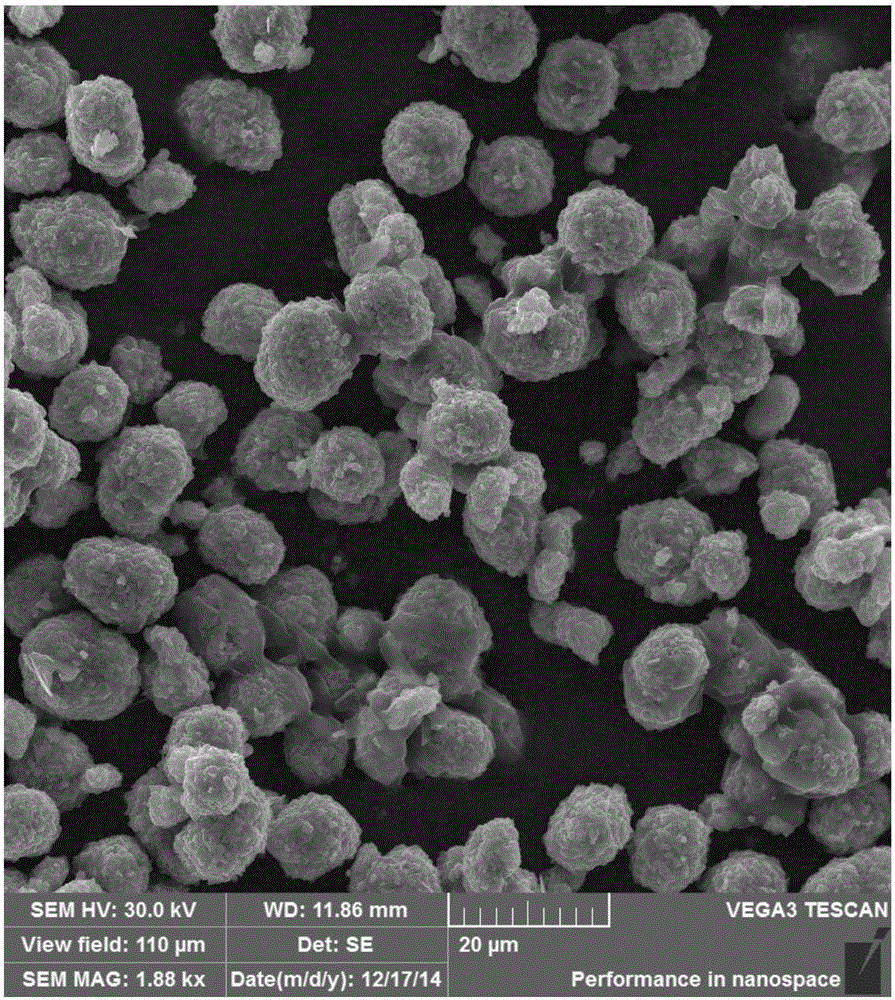

Preparation method of high-nickel ternary cathode material

InactiveCN109461907AReduce mixingReduce residual alkali contentCell electrodesSecondary cellsPower batteryPhysical chemistry

The invention discloses a preparation method of a high-nickel ternary cathode material. The method comprises the steps of 1) pre-oxidizing a high-nickel ternary cathode material precursor with an oxidizing agent to obtain an oxidized high-nickel ternary precursor; 2) uniformly mixing the pre-oxidized high-nickel ternary precursor with a lithium source and a modified assistant, and performing calcining to obtain an oxidized and modified high-nickel ternary cathode material; 3) carrying out coating modification of a lithium-containing compound on the oxidized and modified high-nickel ternary cathode material to obtain a coated and modified high-nickel ternary cathode material for a power battery. According to the method disclosed by the invention, the material precursor is pre-oxidized withthe oxidizing agent, so that Ni<2+> can be fully oxidized into Ni<3+>, the cation mixing degree of the material is reduced, and the capacity of the material is expanded; and through the coating modification of the lithium-containing compound, the content of residual alkali on the surface of the material can be reduced, the generation of side reactions can be effectively inhibited, the embedding and separation of lithium ions are improved, and finally the cycling performance and the rate performance of the material are improved.

Owner:郑州中科新兴产业技术研究院 +1

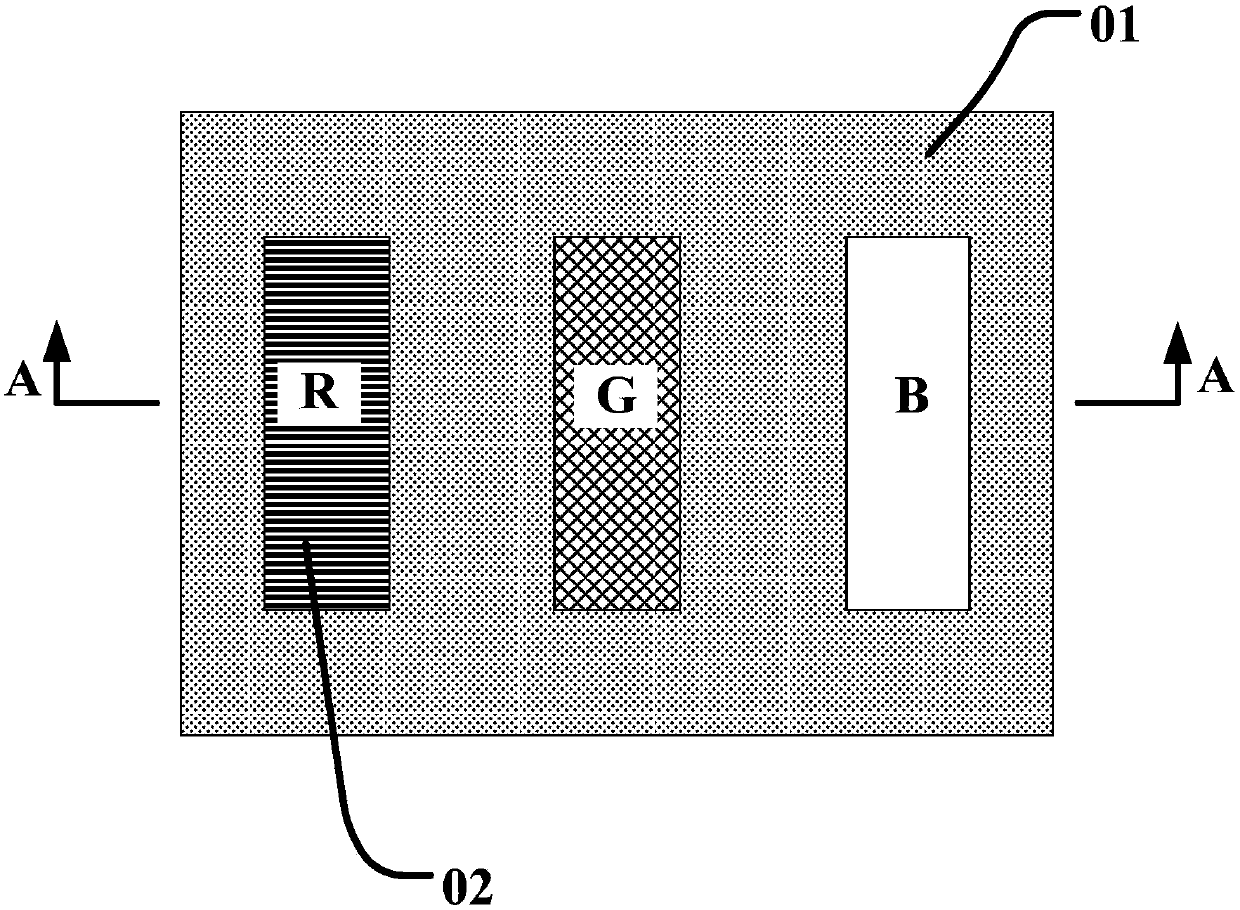

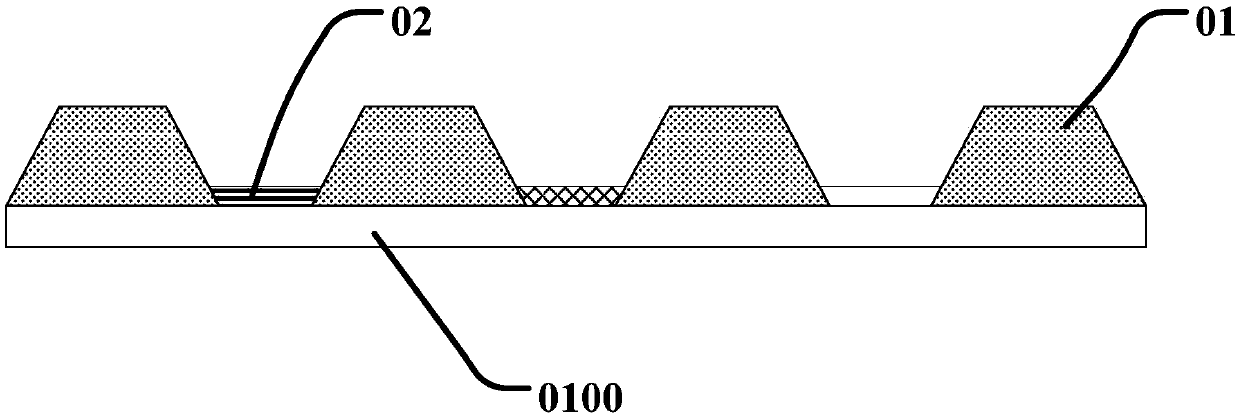

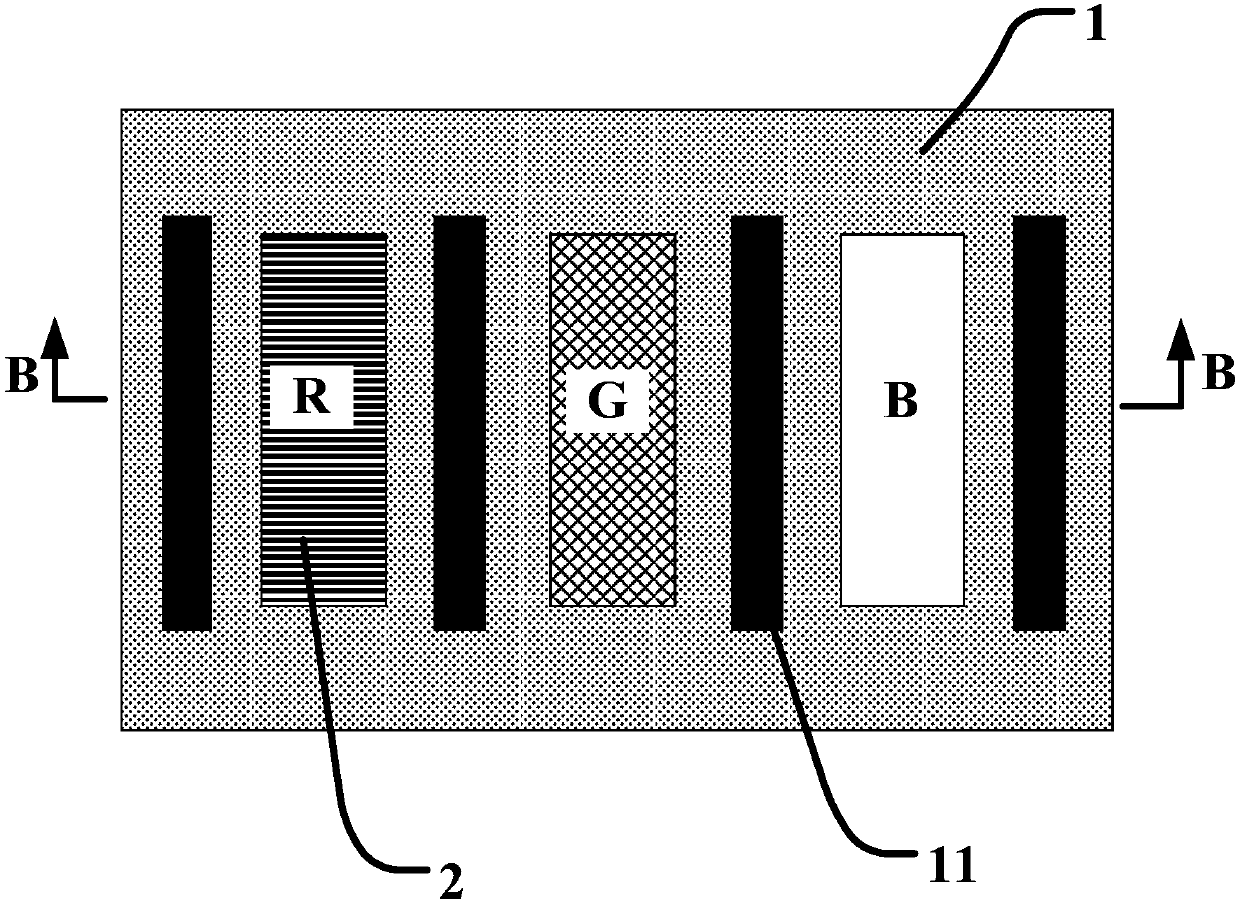

Organic electroluminescent display panel and manufacturing method thereof, and display device

ActiveCN107623082AReduce the risk of color mixingImprove the display effectSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceComputer science

The invention discloses an organic electroluminescent display panel and a manufacturing method thereof, and a display device, so that the color mixing risk of the organic electroluminescent display panel is reduced and the display effect of the organic electroluminescent display panel is improved. The organic electroluminescent display panel comprises a substrate and a pixel defining barrier wallarranged on the substrate. The pixel defining barrier wall defines a plurality of pixel regions for accommodating organic electroluminescent devices; and an accommodation groove structure is arrangedat one side, far away from the substrate, of the pixel defining barrier wall. The side wall, facing the pixel regions, of the pixel defining barrier wall includes a hydrophilic side wall part approaching the substrate and a hydrophobic side wall part adjacent to the hydrophilic side wall part; the inner wall of the accommodation groove structure is a hydrophilic inner wall; and the top, except theaccommodation groove structure, of the pixel defining barrier wall is a hydrophobic top wall.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Preparation method of preoxidation modified high-nickel ternary cathode material

InactiveCN108511746AReduce mixingReduce the mixing degree of lithium and nickelSecondary cellsPositive electrodesNitrateSlurry

The invention discloses a preparation method of a preoxidation modified high-nickel ternary cathode material. The preparation method comprises the following steps of mixing a high-nickel ternary precursor material, nitrate and a solvent to obtain slurry; sequentially performing drying and presintering on the slurry to obtain a pre-oxidized high-nickel ternary precursor material, wherein a chemicalformula of the pre-oxidized high-nickel ternary precursor material is NixCoyM1-x-y(OH)2, and x is greater than or equal to 0.80; and mixing the pre-oxidized high-nickel ternary precursor material anda lithium source, and performing sintering to obtain the preoxidation modified high-nickel ternary cathode material LiNixCoyM1-x-yO2, wherein x is greater than or equal to 0.80. By adopting the preparation method of the preoxidation modified high-nickel ternary cathode material provided by the invention, a cation mixed arrangement degree in a layered structure of the high-nickel ternary cathode material is lowered, and the initial effect, the capacity and the cycle performance of the high-nickel ternary cathode material are improved at the same time.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Method for manufacturing cobalt nickel lithium manganate oxide as gradient anode active material of lithium ion battery

ActiveCN102214819AThe lattice structure is stableHigh charge and discharge capacityCell electrodesNickel compoundsManganateCharge discharge

The invention relates to a method for manufacturing a cobalt nickel lithium manganate oxide as a gradient anode active material of a lithium ion battery, belonging to the technical field of manufacturing the anode material of the lithium ion battery. In the method, a metal ion mixed solution with incremental Co<2+> concentrations is divided into multiple liquid-phase systems to realize coprecipitation for many times so as to manufacture NixCoyMn(l-x-y)(OH)2; the NixCoyMn(l-x-y)(OH)2 is taken as a precursor; and a high-temperature solid-phase reaction is utilized to obtain layered LiNixCoyMn(l-x-y)O2 with gradient Co content. The crystal lattice framework of the anode material with the gradient Co content manufactured by the method is more stable and the cation syncopation degree is reduced, so that the charge-discharge capacity and the cycle efficiency of the anode material are improved, thus the anode material has good electrochemical performances and can be applied to lithium ion batteries widely.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing linear polyurethane phase change material

The invention discloses a method for preparing a linear polyurethane phase change material. The method comprises the following steps: dissolving polyethylene glycol and diisocyanate into solvent in inert atmosphere, reacting in the presence of optional catalyst, adding tertiary amine type chain extender containing hydroxyl for chain extension, adding an optional neutralizer for salt formation so as to obtain the linear polyurethane phase change material, wherein the molar ratio of the sum of hydroxyl of polyethylene glycol and hydroxyl of chain extender to the isocyanate group of diisocyanate is 1:1, the add amount of the catalyst accounts for 0-1% the total weight of the polyethylene glycol, diisocyanate and chain extender, the molar ratio of neutralizer to tertiary amine type chain extender is 0-1, and the molecular weight of the polyethylene glycol is higher than 2000. The linear polyurethane phase change material prepared by the method has a linear structure and large enthalpy of phase change, has a simple preparation method, is low in cost, has stable property, can be stored for long time, is not solidified and cross-linked, is easy to process and shape, and is beneficial to large-scale popularization and application.

Owner:温州东润新材料科技有限公司

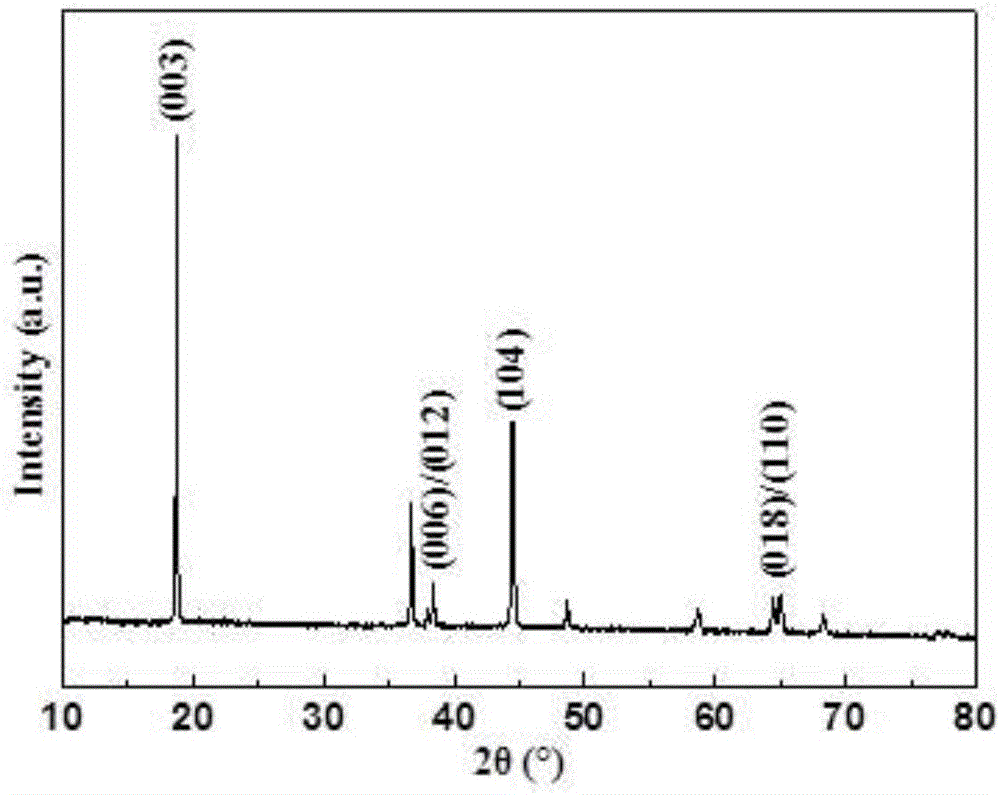

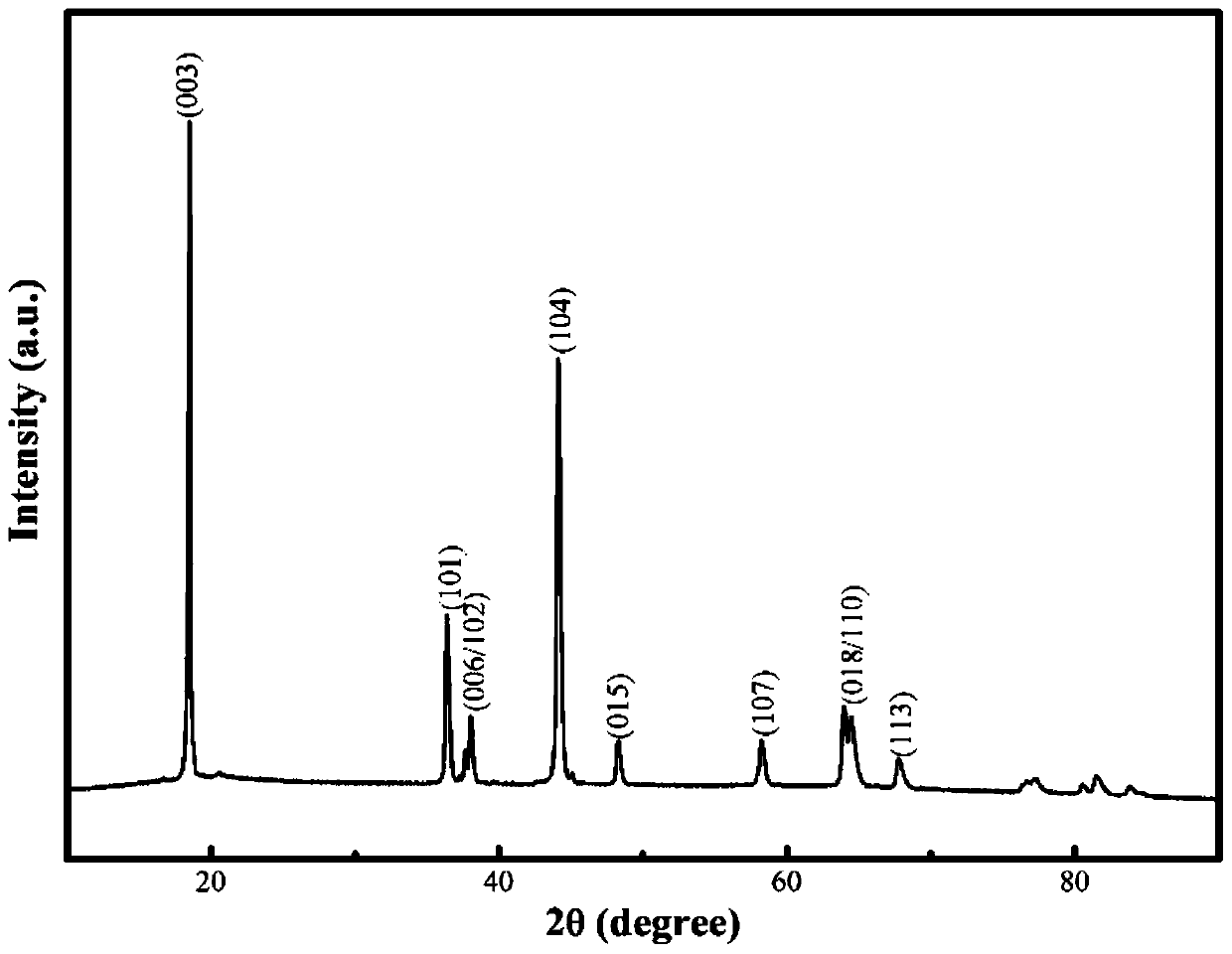

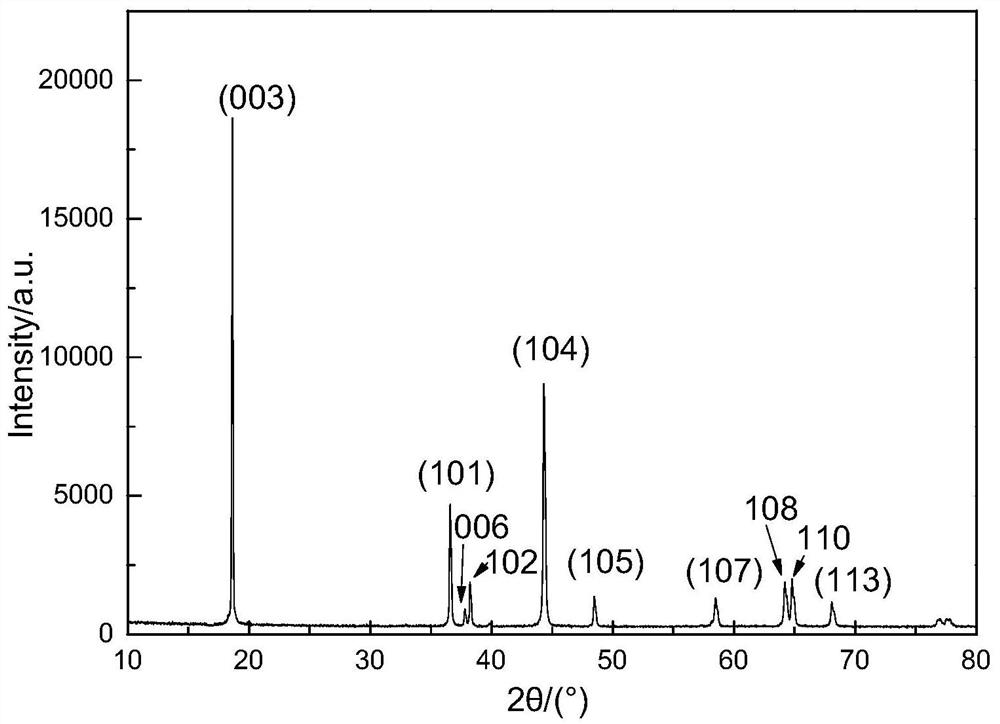

Cathode material for lithium ion battery and preparation method thereof, cathode and lithium ion battery

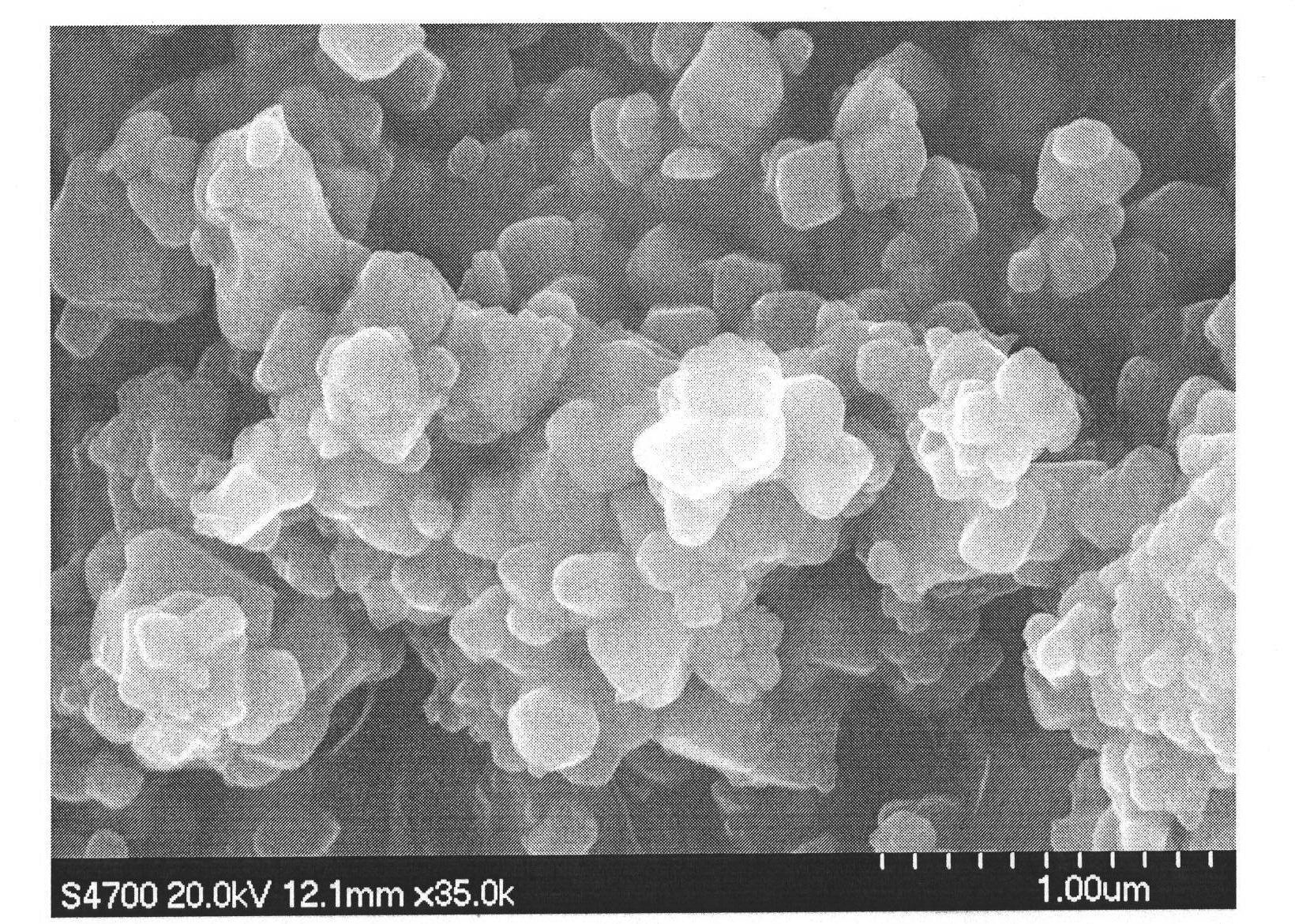

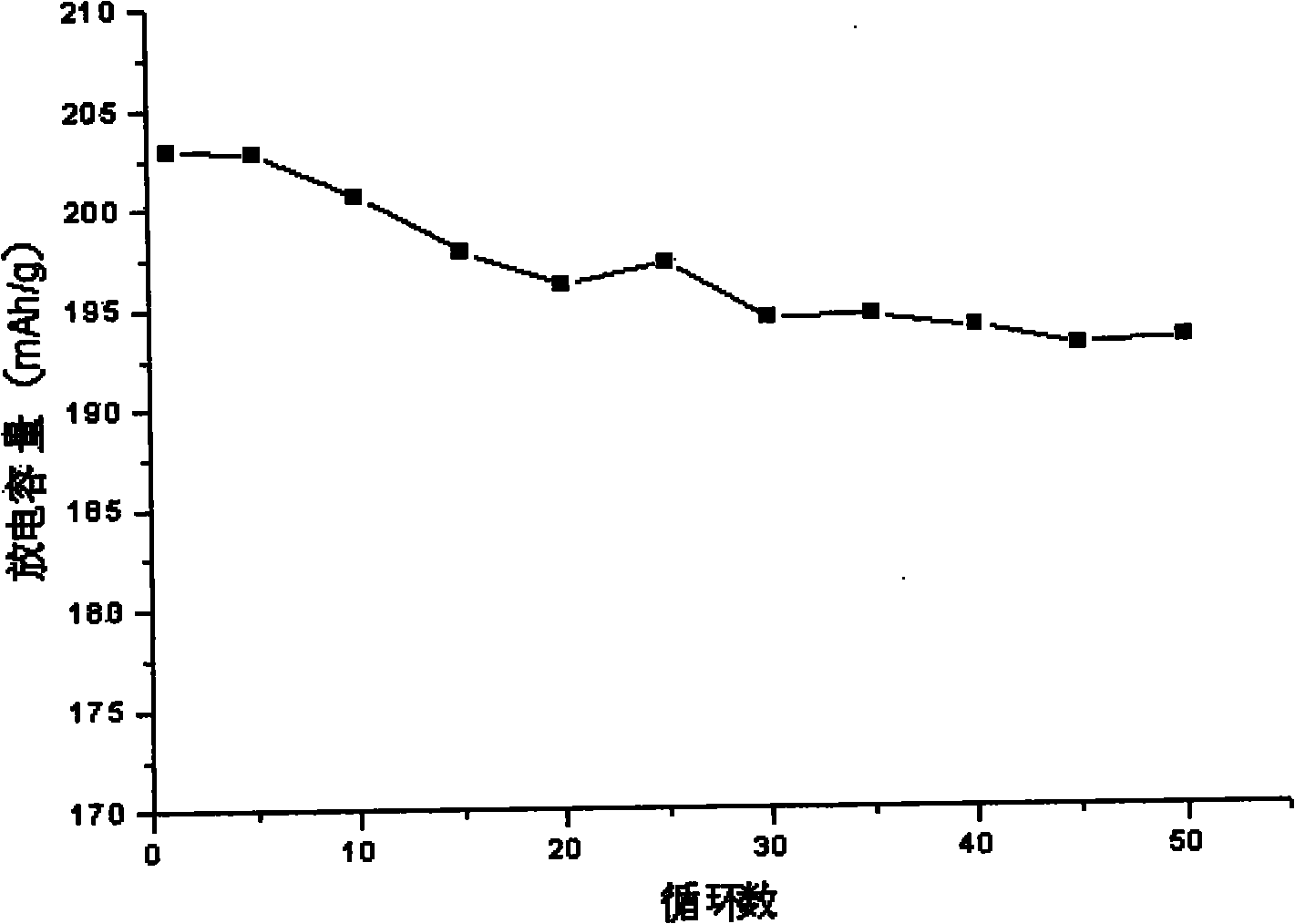

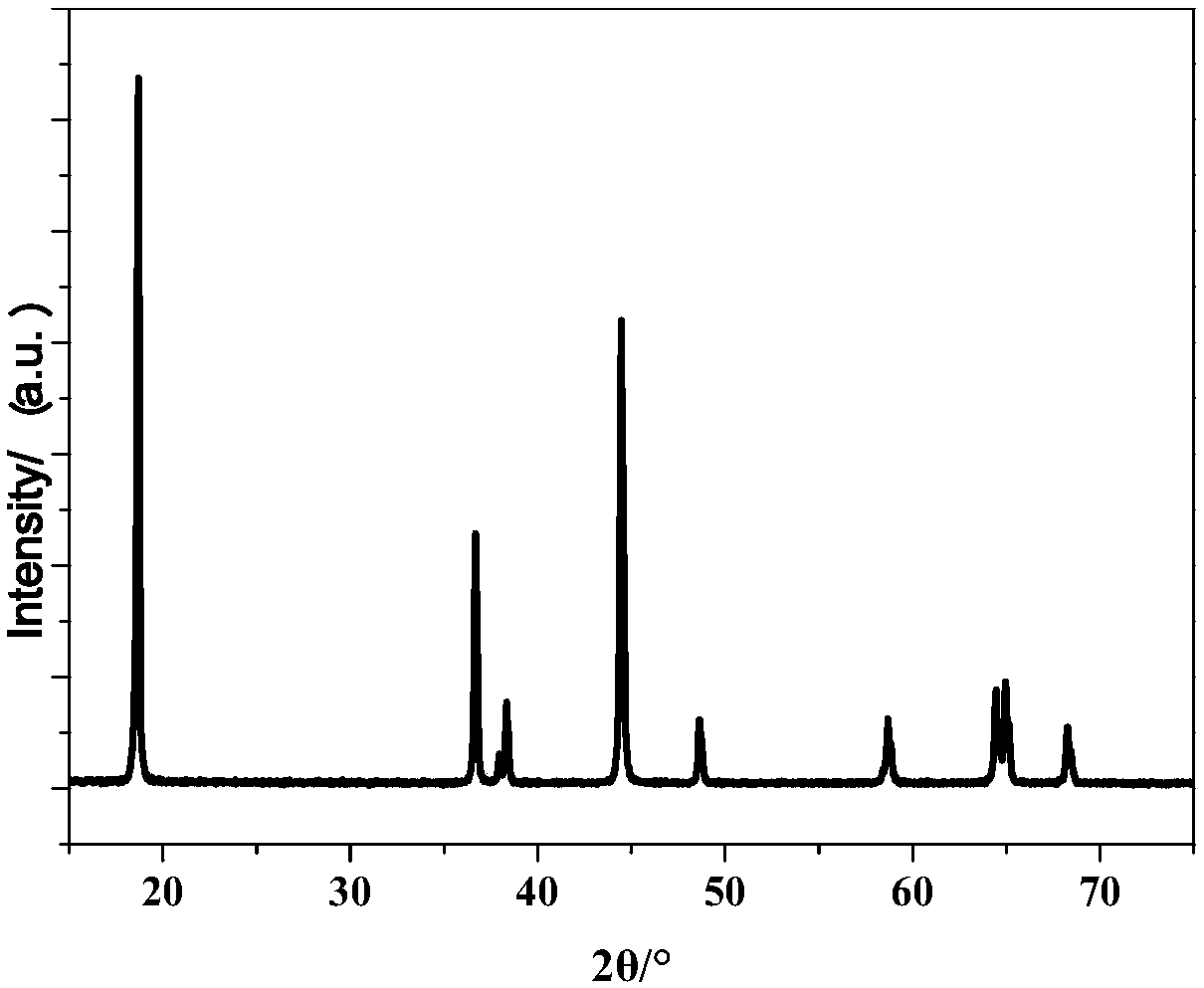

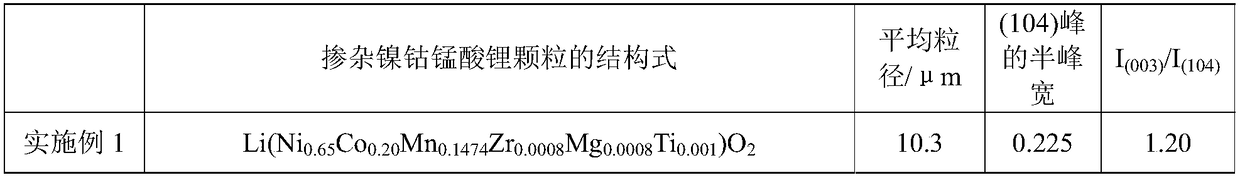

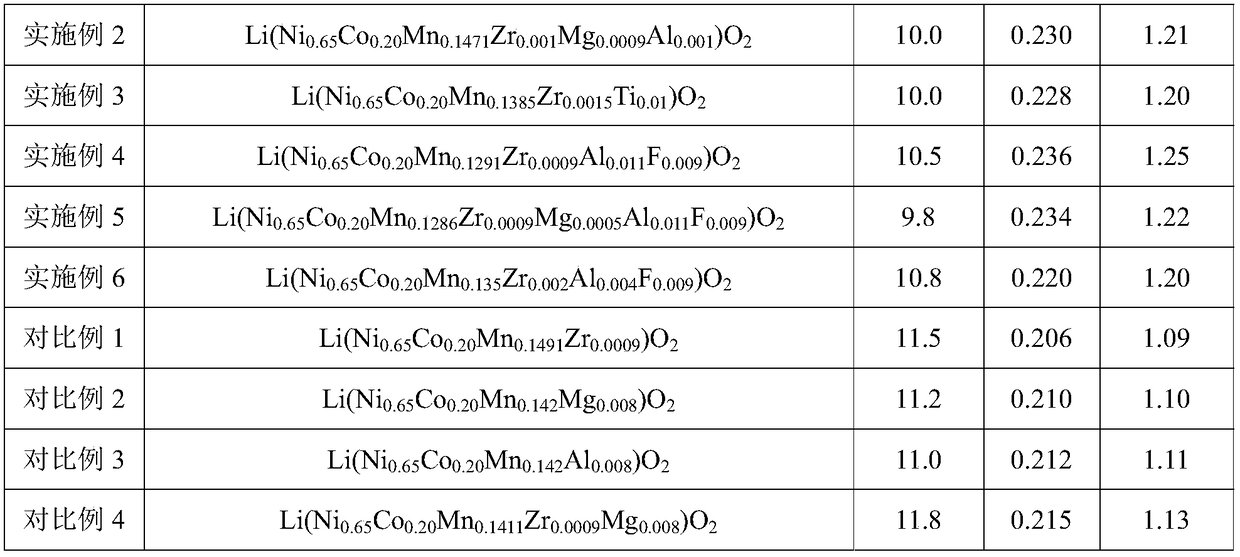

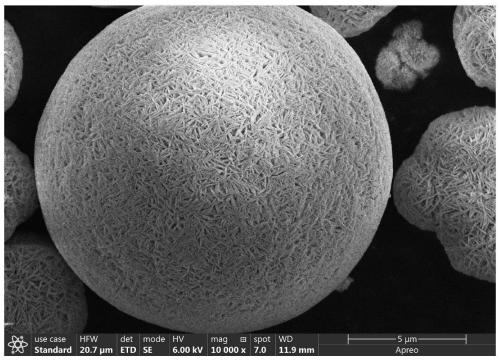

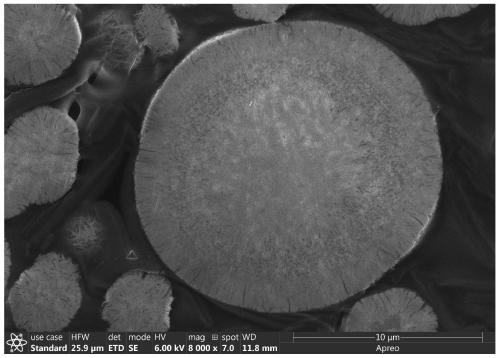

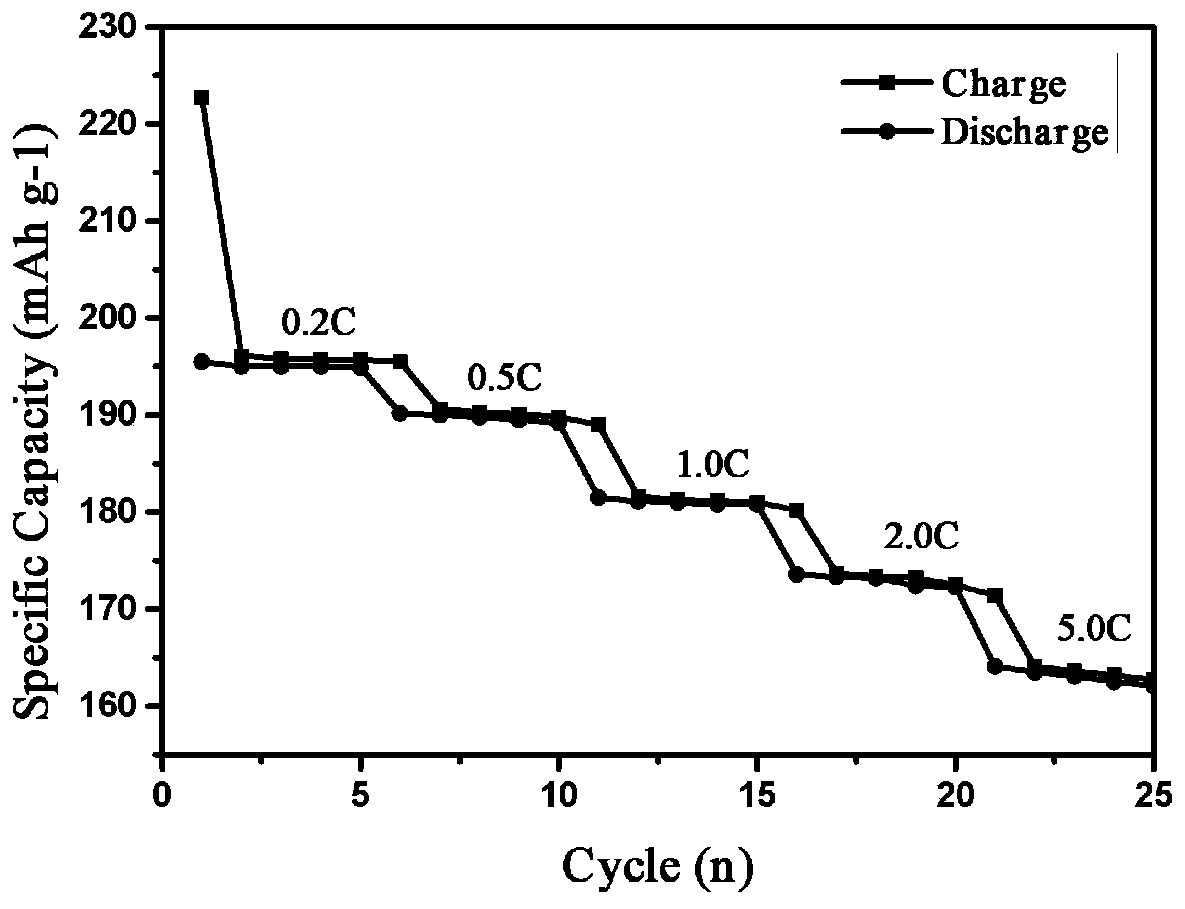

ActiveCN109244365AHigh specific capacityImproved magnification performanceCell electrodesSecondary cellsFull width at half maximumManganate

The invention relates to a lithium ion battery cathode material and a preparation method thereof, a cathode and a lithium ion battery. The cathode material comprises doped lithium nickel cobalt manganate particles, wherein the structural formula of the doped lithium nickel cobalt manganate particles is Li (NixCoyMn1-x-y-p-qM1pM2q)O2, M1 is a metal element comprising Zr and / or Mg, M2 is Al, Ti, La,B, F or Mo, or a combination of two or three or four of them, wherein 0.6<=x<=0.8, 0.1<=y<= 0.2, 0.0006<=p<= 0.0018, 0.0055<=q<=0.013; The ratio of the peak intensity I (003) of the peak (003) and the peak intensity I (104) of the peak (104) of the XRD spectrum of the doped nickel cobalt manganate lithium particles is 1.20<=I (003) / I (104)<= 1.30; The (104) diffraction peak of the doped lithium nickel cobalt manganate particles has a full width at half maximum of 0.22 to 0.25. The cathode material of the lithium ion battery disclosed by the invention has high specific capacity, and also improves the rate performance, cycle performance and safety performance of the cathode material. The method disclosed by the invention has the advantages of small doping amount, simple operation, easy control and low production cost, and is suitable for industrial large-scale production.

Owner:WANHUA CHEM GRP CO LTD

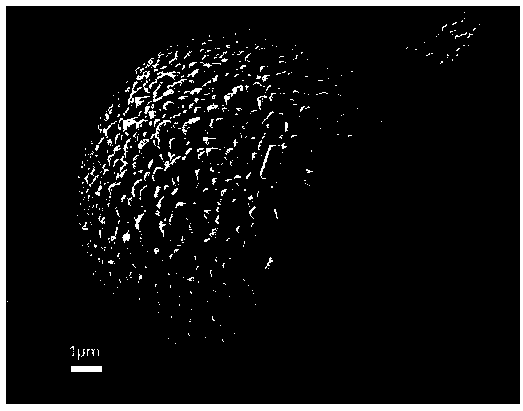

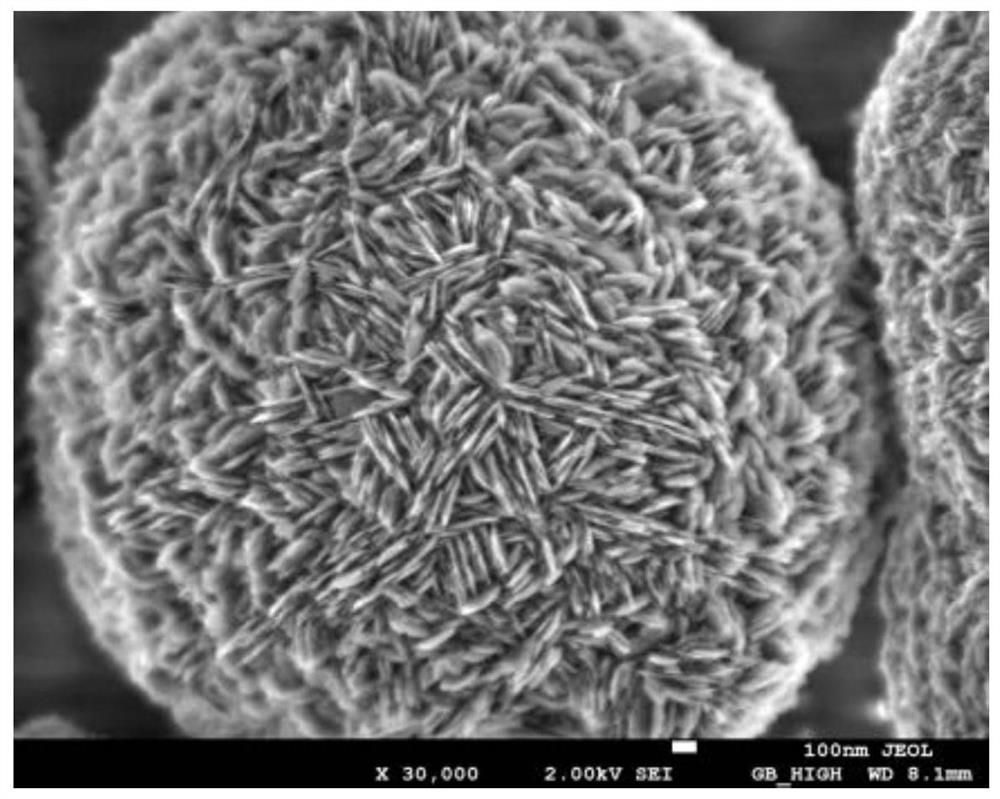

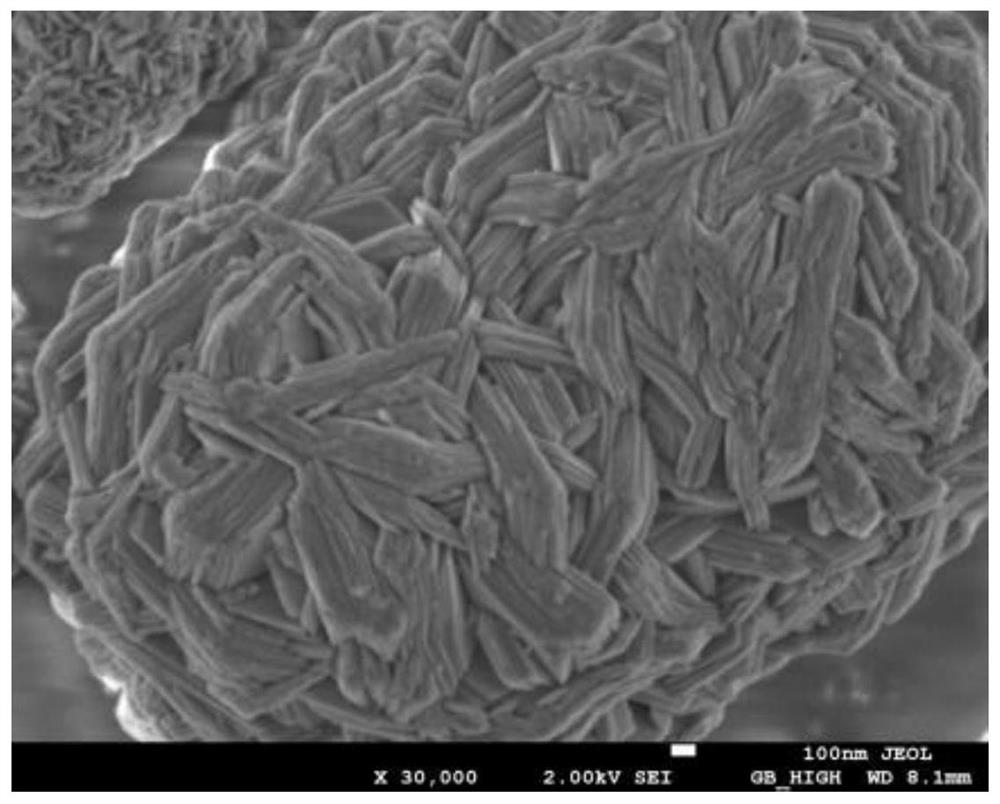

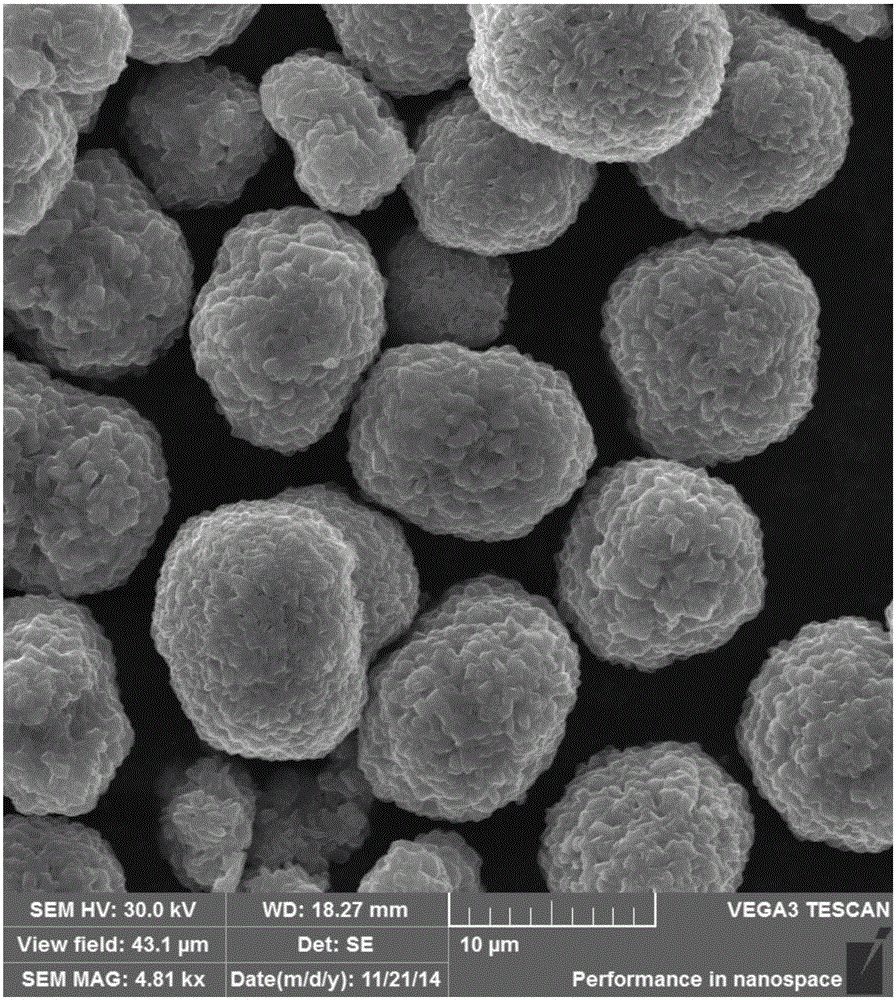

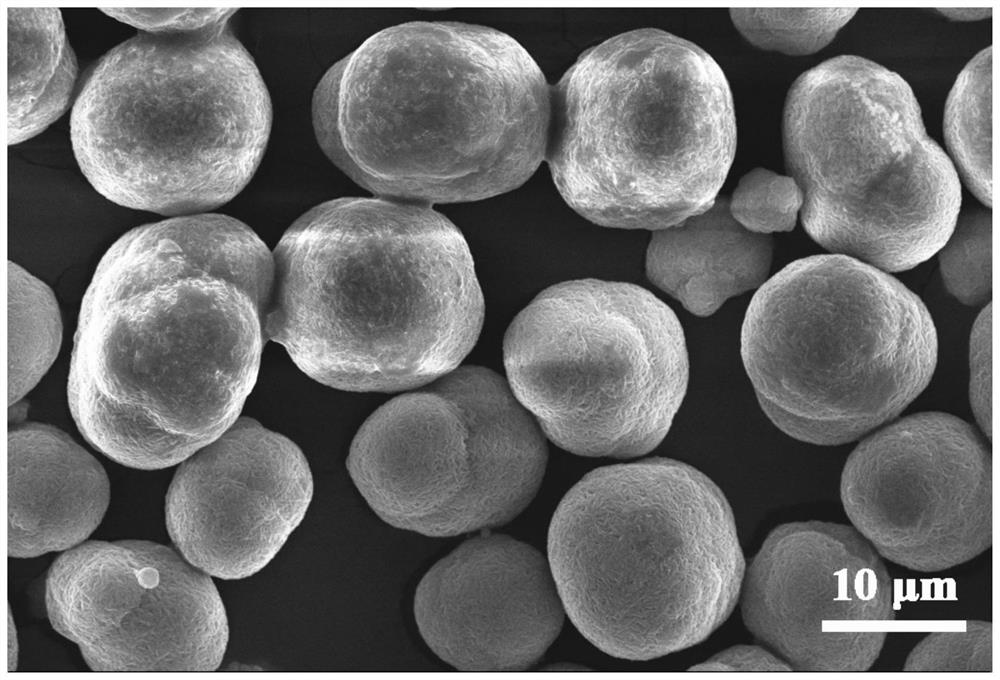

Al/La co-doped high-nickel ternary precursor with core-shell structure and preparation method thereof, and positive electrode material

ActiveCN111422926AImprove cycle performanceSmall sizeCell electrodesSecondary cellsManganeseLithium-ion battery

The invention relates to the field of lithium ion battery materials, and provides an Al / La co-doped high-nickel ternary precursor with a core-shell structure and a preparation method thereof, and a positive electrode material prepared from the precursor. The preparation method mainly comprises the following three steps: step 1, synthesizing an Al-doped high-nickel ternary precursor with rod-like primary particles under the condition of a low pH value; 2, increasing the pH value on the basis of the step 1, growing a La-doped high-nickel ternary precursor shell with needle-shaped primary particles by taking the Al-doped high-nickel ternary precursor as an inner core so as to synthesize an Al / La co-doped high-nickel ternary precursor with a core-shell structure; and 3, mixing the Al / La co-doped high-nickel ternary precursor with the core-shell structure and a lithium salt, and carrying out high-temperature calcination in an oxygen atmosphere to obtain the Al / La co-doped ternary positive electrode material with the core-shell structure. Due to the unique co-doped core-shell structure, the stability of an internal structure is effectively enhanced, the generation of mixed phases such ascation mixing and rock salt structures is inhibited, the breakage of grain boundaries is reduced, the average oxidation state of manganese ions is improved, the Jahn-Teller effect is effectively inhibited, the rapid attenuation of the capacity in a cycle process is reduced, the cycle stability of the material is remarkably improved, and the cycle life of the material is remarkably prolonged. Theproduct synthesized by adopting a coprecipitation method is uniform in component, good in sphericity, good in reproducibility, easy in condition control, low in preparation cost, high in economic value and wide in application prospect.

Owner:ZHUJI PAWA NEW ENERGY

Control method for continuous casting of different steel grade

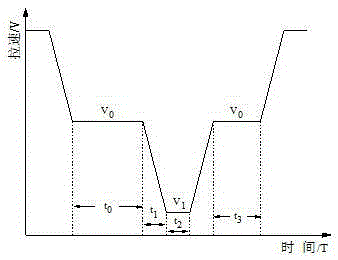

The invention relates to a control method for continuous casting of the different steel grade. The method comprises the following steps: firstly, according to the shape and structural parameters of a tundish flow control device, the mixed casting tonnage M is determined, and the value is the molten steel amount correspondingly when the height of the liquid level of the molten steel in a tundish is the height of a retaining dam; according to following formulas, the remaining steel amount of the previous steel grade is determined as Mo (shown in the specification), and when casting of a molten steel large ladle of a previous furnace is finished, speed begins to be slowly reduced; the mixed casting initial tonnage of the tundish is M1, the pull speed is reduced to the lowest pull speed V0 during normal production of the steel grade, and the retaining time is t0; thirdly, according to the casting cross section, the large ladle cast-on tonnage is selected, when the remaining weight of the tundish is M2, the pull speed is reduced to V1 from V0, and large ladle cast-on operation is carried out; fourthly, after large ladle cast-on operation, the amount of molten steel of the tundish is kept M, the pull speed is kept V1, after t2, the pull speed rises to V0, the reference formula of t2 is shown in the specification, the pull speed rises to V0, meanwhile, the molten steel amount of the tundish is kept M, after the retaining time t3 is equal to 5 min to 8 min, the opening degree of a sliding plate of the large ladle is gradually increased, the tonnage of the tundish rises to the normal casting tonnage, and the pull speed rises to the normal production target value.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

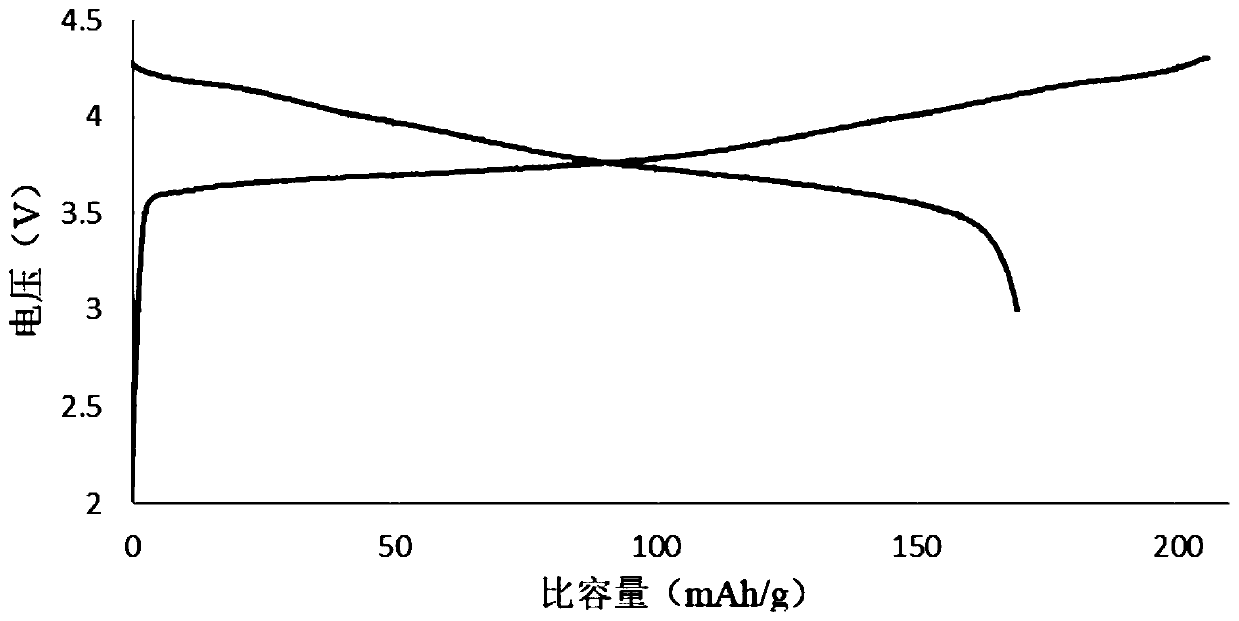

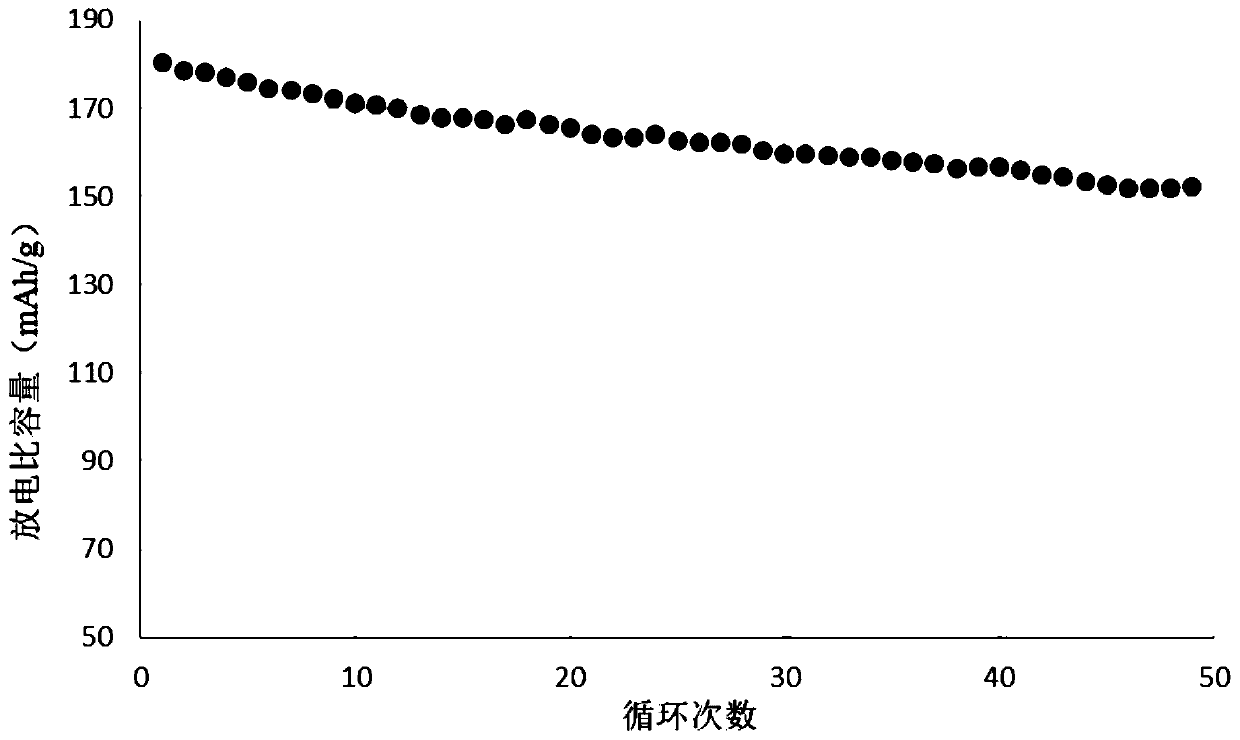

Lithium battery anode material and preparation method and application thereof

ActiveCN110085814AImprove cycle performanceImprove securityFinal product manufactureCylindrical casing cells/batteryBorideLithium metal

The invention provides a lithium battery anode material and a preparation method and an application thereof. The lithium battery anode material includes a lithium metal composite oxide having a layered structure and a boron coating layer formed on the surface of the lithium metal composite oxide, wherein the lithium metal composite oxide includes Li, Ni and a doping element M1, the doping elementM1 is at least one selected from the group consisting of Zr, Mg, Al, Ni, Mn, Zn, Fe, Cr, Mo, and W, a molar ratio of the sum of Ni and the doping element M1 to the Li is less than 1, and the boron coating layer includes boron and / or boride. The lithium battery anode material has advantages of good structure stability and stable electrochemical performance, and the lithium battery anode material donot easily react with the electrolyte.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

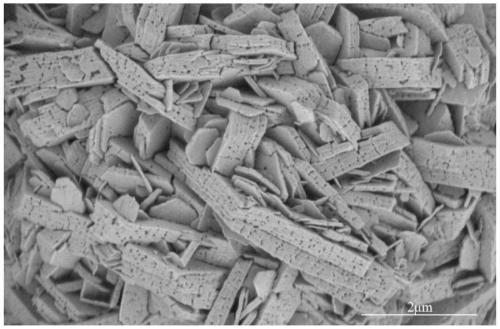

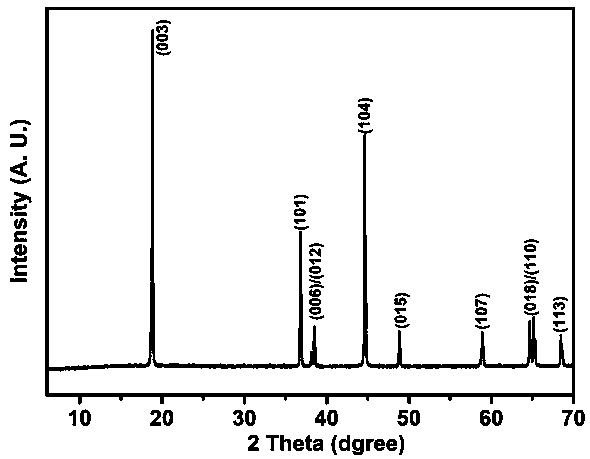

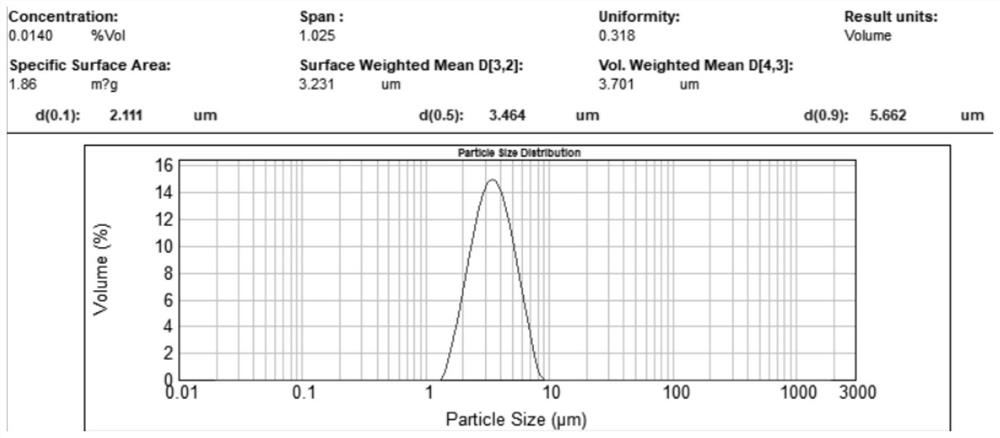

High-nickel single-crystal small-particle ternary precursor and continuous preparation method thereof

ActiveCN113373517AHigh solid contentIncrease collisionPolycrystalline material growthFrom normal temperature solutionsPhysical chemistrySingle crystal

The invention discloses a high-nickel single-crystal small-particle ternary precursor and a continuous preparation method thereof. The method comprises the following steps of: preparing a soluble ternary mixed salt solution, and adding H2O2 and an additive to obtain a mixed solution; adding a part of the mixed solution and a precipitant solution into a first reaction kettle for nucleation reaction, and continuously overflowing a reaction product to a second reaction kettle; when the addition amount of the ternary precursor crystal nucleus slurry accounts for 40-60% of the volume of the second reaction kettle, starting stirring in the second reaction kettle; adding the other part of the mixed solution and the precipitant solution into the second reaction kettle for growth reaction, starting overflow, continuously overflowing a reaction product to a concentration machine for concentration, and returning the product to the second reaction kettle; and carrying out aging, filter-pressing, washing and drying to obtain the high-nickel single-crystal small-particle ternary precursor. The technical problems that an existing intermittent method for preparing the high-nickel single-crystal small-particle ternary precursor is low in yield, low in production efficiency, high in cost and poor in batch stability, and nickel and lithium cations are mixed in the subsequent calcination process are solved.

Owner:南通金通储能动力新材料有限公司

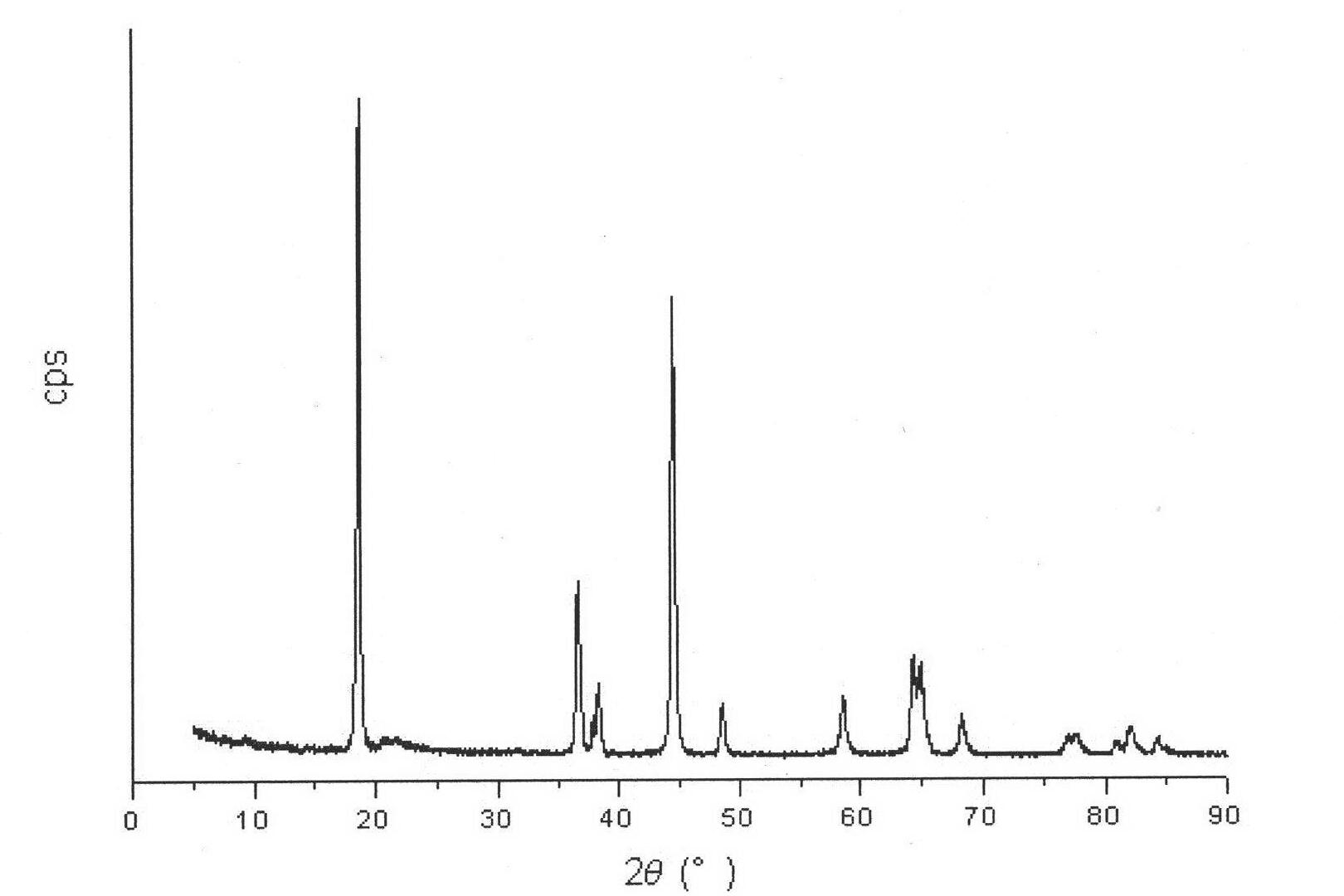

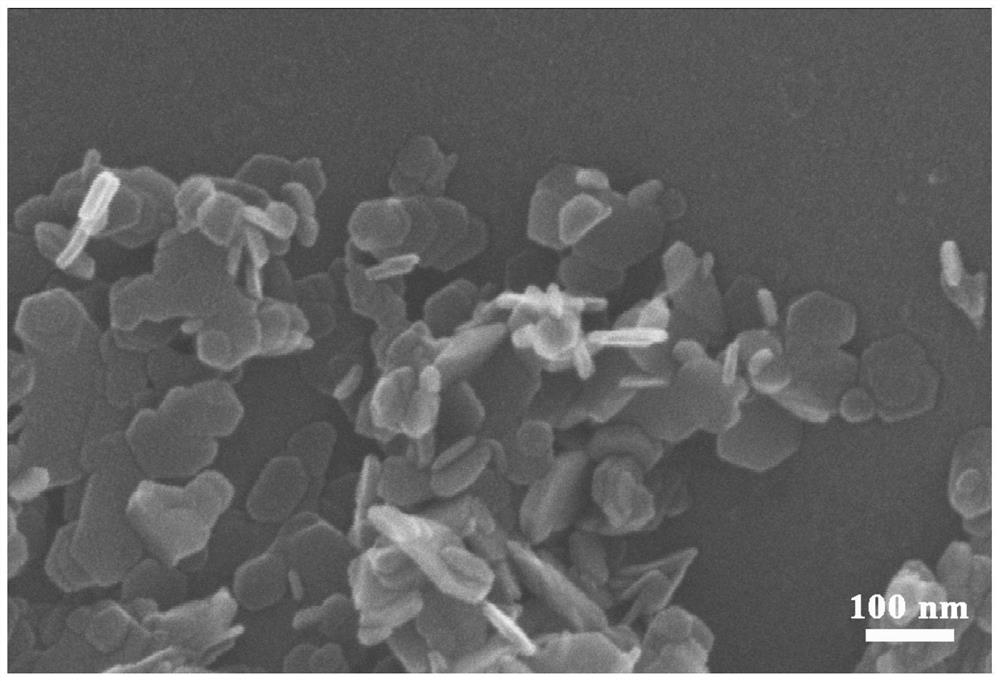

Preparing method for submicron particles of nickel-manganese-base lithium ion battery anode material

InactiveCN104009217AShorten the pathway of diffusionIncreased lattice stabilityMaterial nanotechnologyCell electrodesFiberManganese

The invention relates to a preparing method of a nickel-manganese-base lithium ion battery anode material, in particular to a preparing method for submicron particles for the nickel-manganese-base lithium ion battery anode material. The technical problems that a material obtained through an existing preparing method for the nickel-manganese-base lithium ion battery anode material is large in particle size and poor in electrical property are solved. The preparing method includes the steps that according to the chemical formula Li (MxNiyMn1-x-y) O2, a electrostatic spinning precursor solution is prepared through metal nitrates, N, N-dimethyl formamide and polyvinylpyrrolidone; the electrostatic spinning precursor solution is spun into nano-fibers through an electrostatic spinning machine, and the nano-fibers are calcinated to obtain the submicron particles for the nickel-manganese-base lithium ion battery anode material. The particle diameter of the submicron particles is 50 nm-200 nm, the specific discharge capacity under the condition of 1000 mA / g large current reaches 110 mAh / g, and only differs from that under the condition of 20 mA / g current by 39.3 mAh / g. The submicron particles for the nickel-manganese-base lithium ion battery anode material can be used in a high-power lithium ion battery.

Owner:HARBIN INST OF TECH

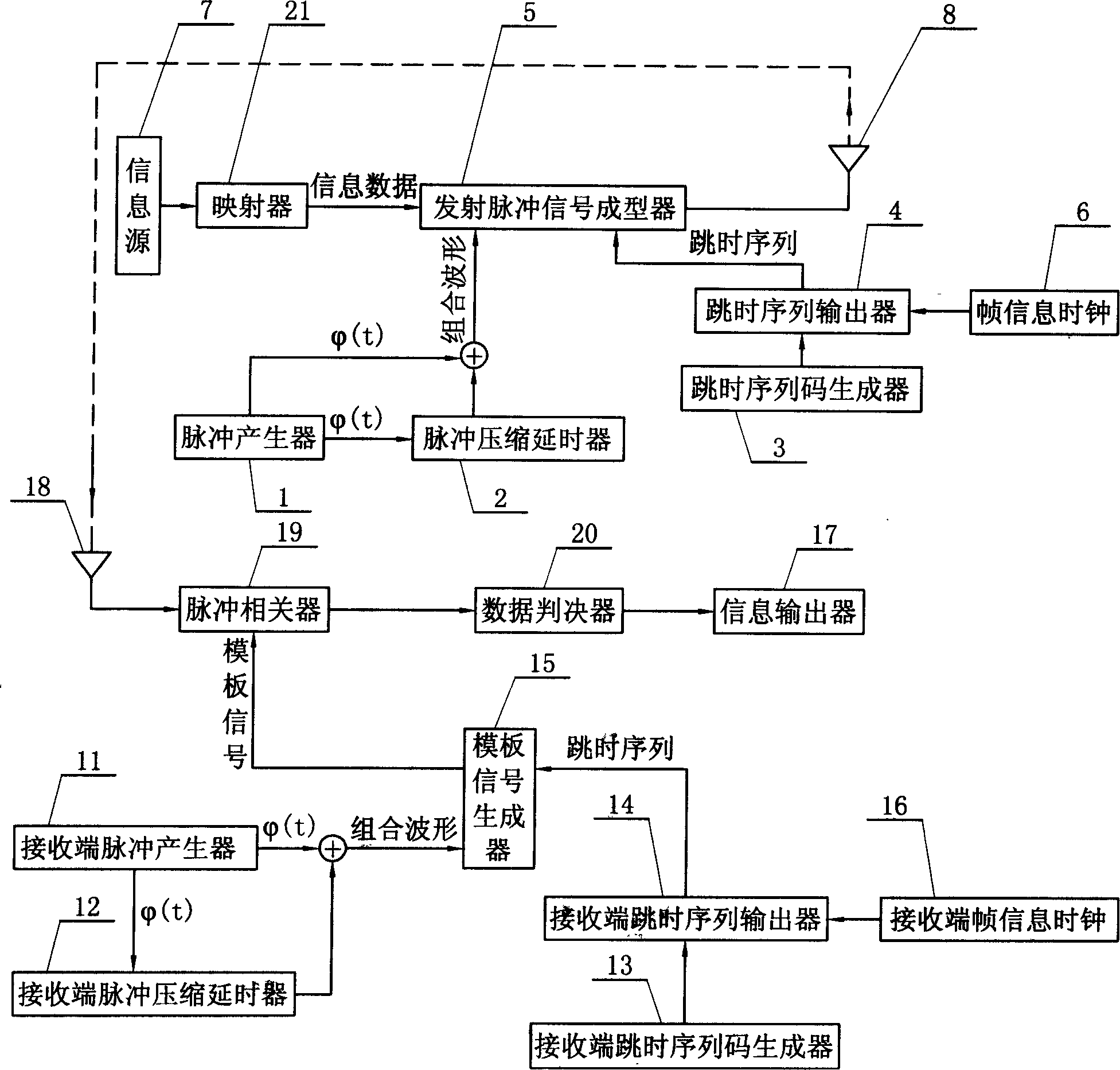

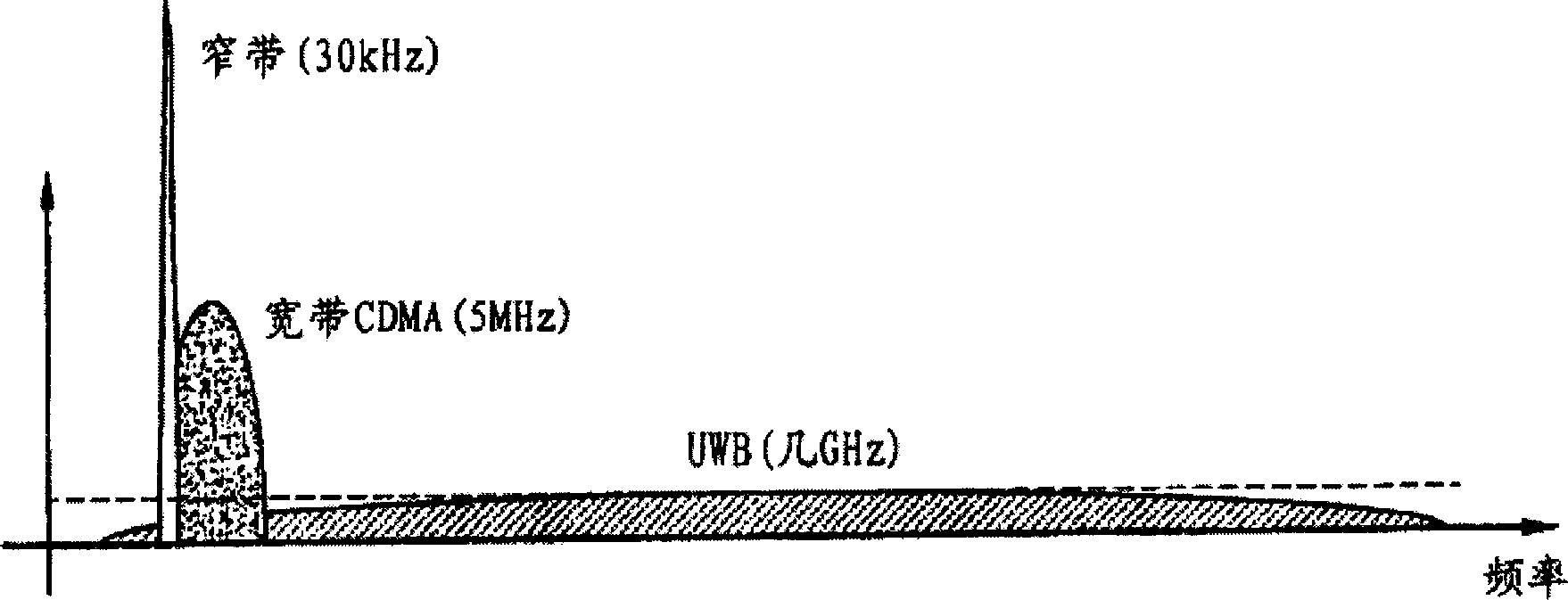

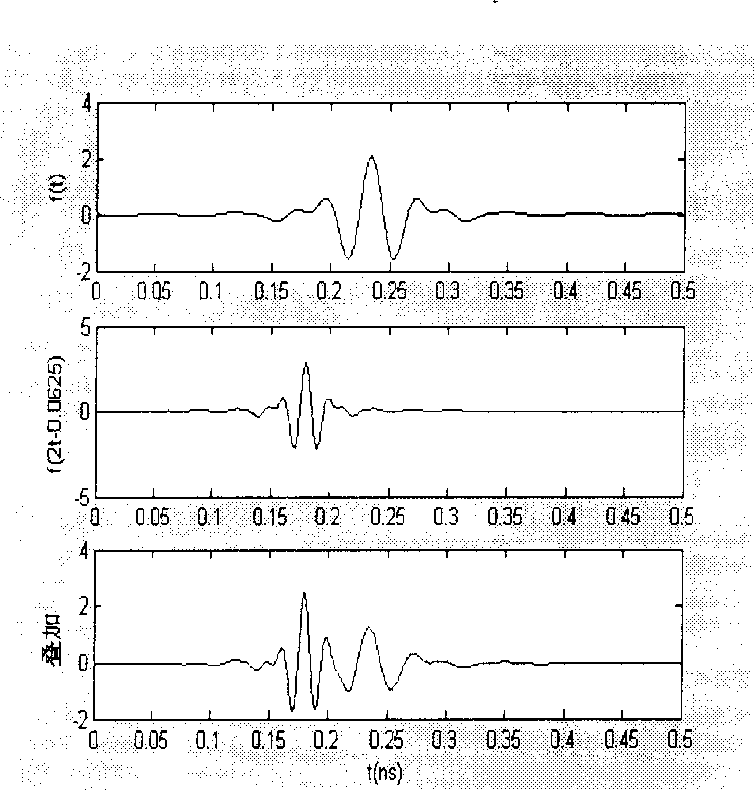

Construction and receiving method of superwide band pulse wave signal

InactiveCN1694372AReduce energy valueImprove bit error characteristicsTransmissionWave shapeBroadband

This invention discloses a structure of a super-wide band pulse waveform signal and receive method, which sets up a pulse first, then compresses said pulse for times then carries out translation on time finally to weigh the original waveform and compressed waveform to make up of a new combined waveform to transmit data in terms of the present super wide band wireless communication way, besides, various modulations and multiple address ways are added.

Owner:HARBIN INST OF TECH

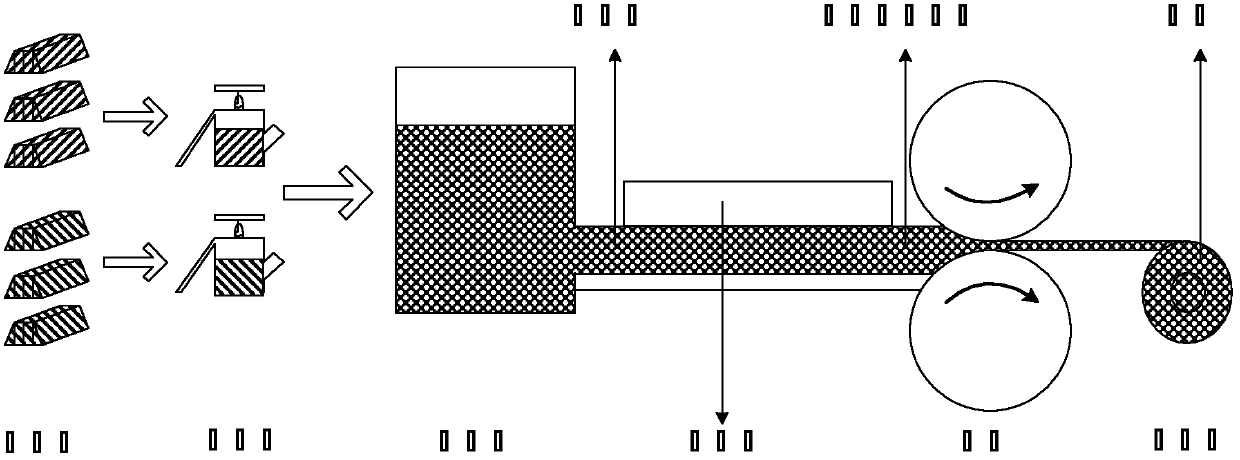

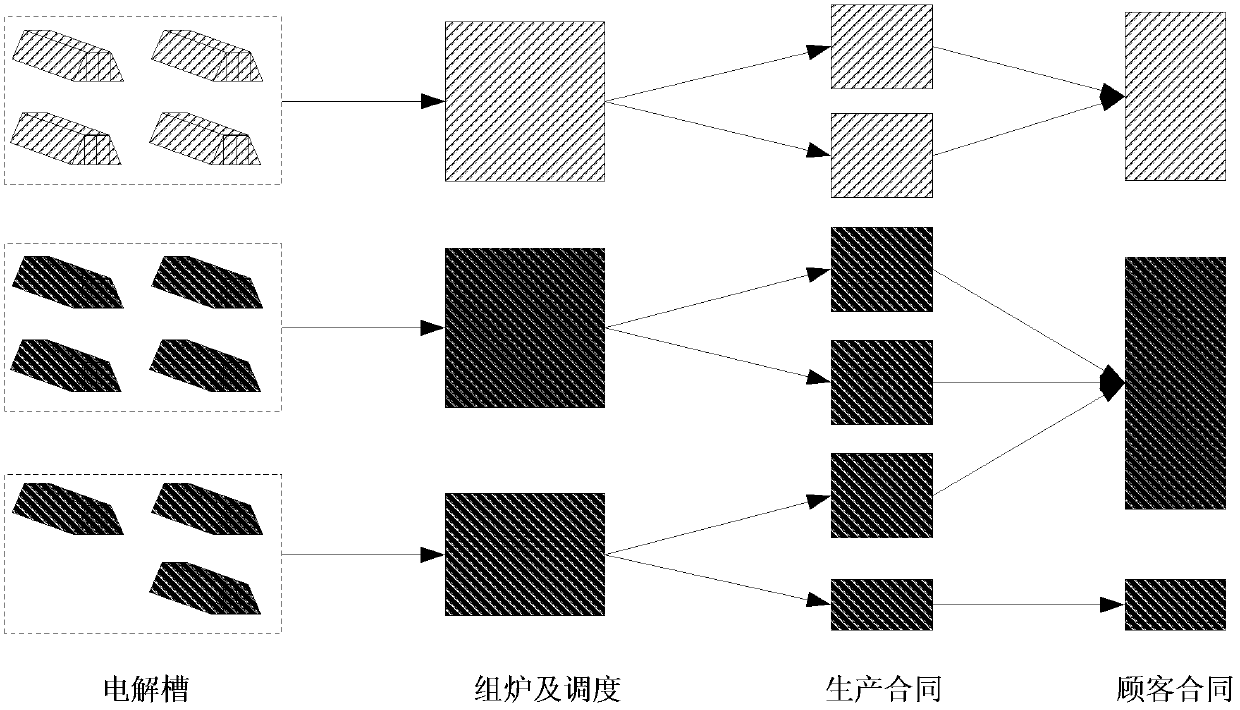

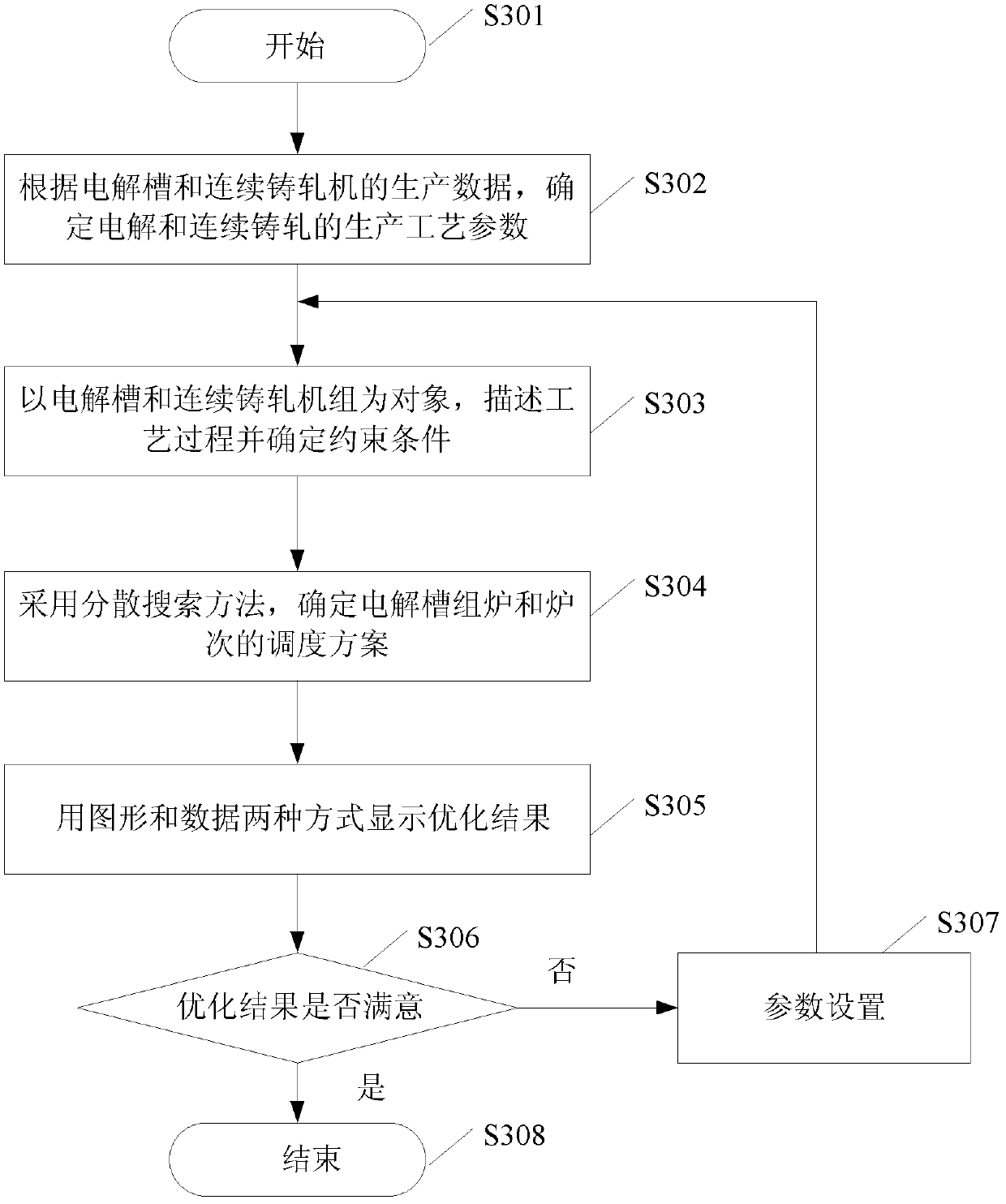

Furnace, dispatching method and device for aluminum continuous cast-rolling production

ActiveCN102699027AEasy to use and maintainReduce mixingRoll mill control devicesMetal rolling arrangementsAluminium industryProcess engineering

The invention relates to a furnace, a dispatching method and a device for aluminum continuous cast-rolling production and belongs to the technical field of aluminum industrial plate processing information. Manufacturing processes are described and constraint conditions are determined by utilizing production process parameters, taking electrolytic tanks and a continuous cast-rolling unit as objects and taking minimization of the electrolytic tanks, purity difference among furnace orders distributed by the electrolytic tanks, purity and position difference among the electrolytic tanks with the same distributed furnace order, manufacturing period and idle production capacity of the furnace orders in the whole plan as objectives, and furnaces and furnace order dispatching of the electrolytic tanks are determined by adopting the scatter search. Established product tasks are completed while production time of an aluminum continuous cast-rolling process is reduced, so that operation efficiency of the machine is improved; operations of furnace cleaning caused by different purities of adjacent furnace orders and halt for adjusting a crystallizer caused by different widths and thicknesses of the adjacent furnace orders are reduced, so that loss of materials can be reduced; and production task planning of the unit is more rational, so that production quality of aluminum coils can be improved.

Owner:NORTHEASTERN UNIV

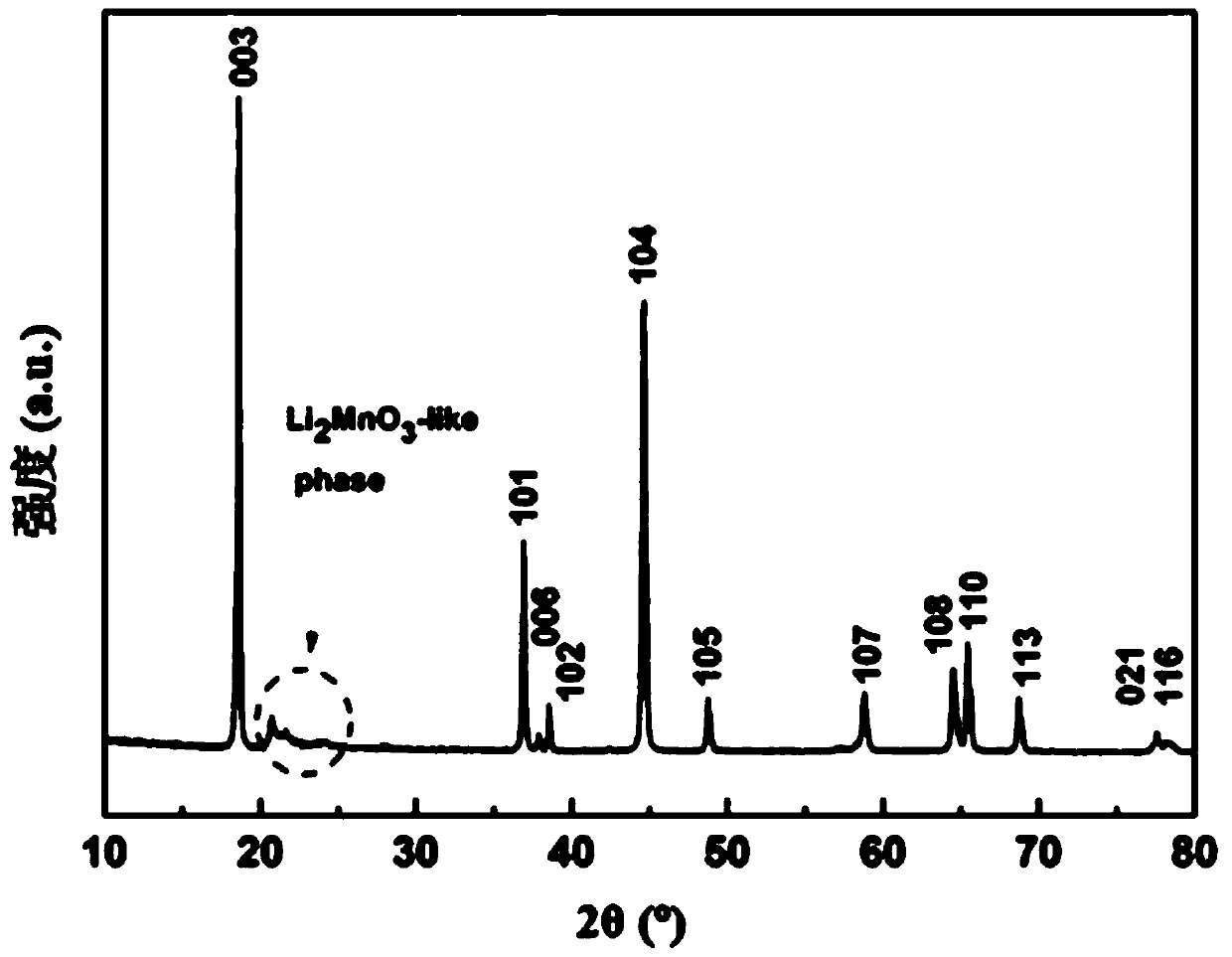

Lithium-enriched manganese-based positive electrode material and preparation method thereof

InactiveCN109686967AImprove electrochemical performanceStable interface structureCell electrodesSecondary cellsManganeseSodium salt

The invention belongs to the field of positive electrode materials of electrochemistry, and particularly relates to a lithium-enriched manganese-based positive electrode material and a preparation method thereof. Three kinds of material liquid containing different metal ion proportions are subjected to reaction precipitation successively, weak acid sodium salt is taken as a precipitator, an alkaline salt solution is taken as a complexing agent, and a weak acid salt precursor of a stable interface structure with three layers of different metal ion concentrations is generated; the weak acid saltprecursor is fully mixed with a certain number of lithium sources, and after the high-temperature solid-phase reaction, the lithium-enriched manganese-based positive electrode material of a three-layer core shell sphere structure is prepared; components of the three-layer core shell structure are subjected to gradient from inside to outside, so that the difference between metal ion concentrationsof adjacent layers is smaller, the interface structure is more stable, and therefore the electrochemical performance of the material is effectively improved; the prepared material has quite excellentcirculation stability performance, quite excellent multiplying power performance and long cycle life performance.

Owner:JIANGSU UNIV

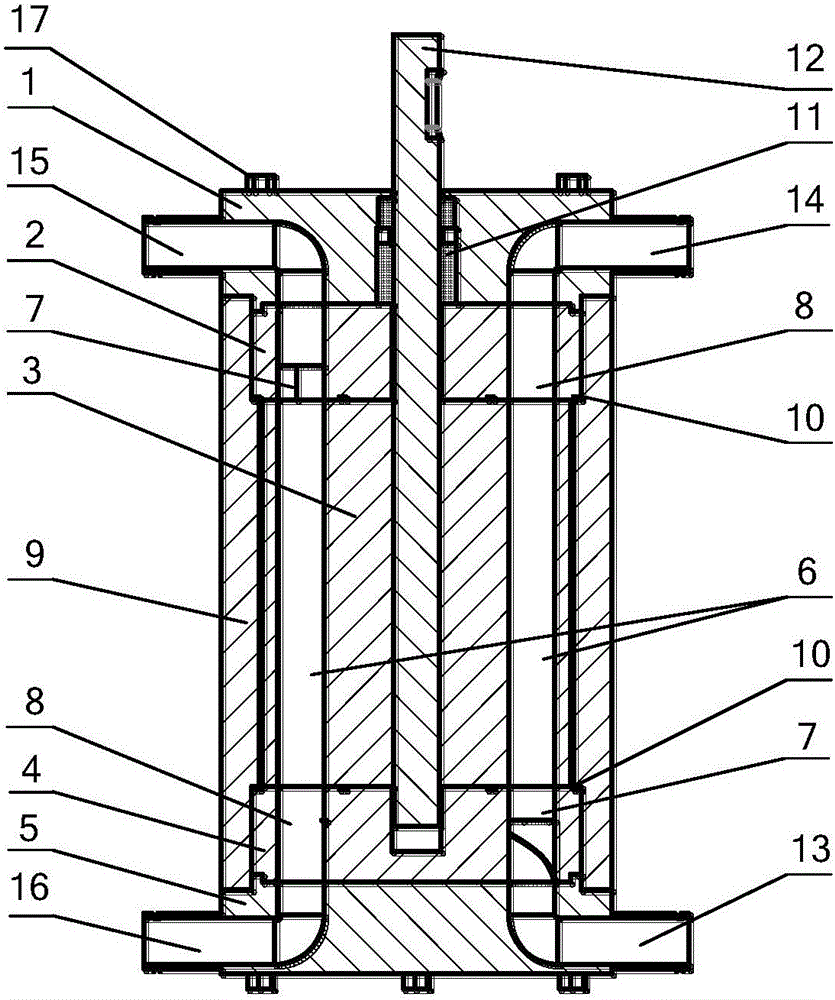

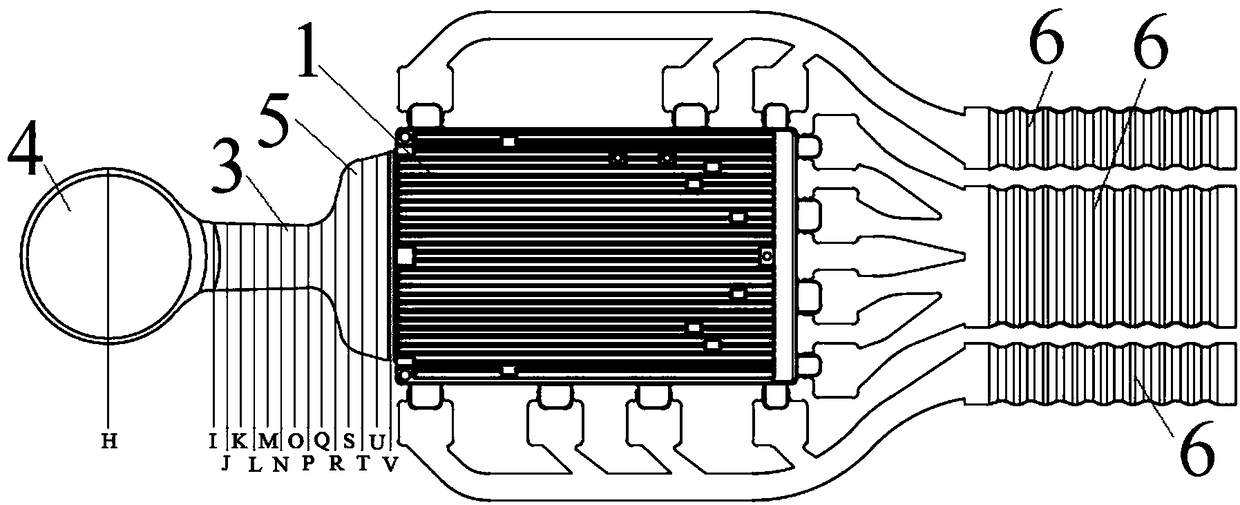

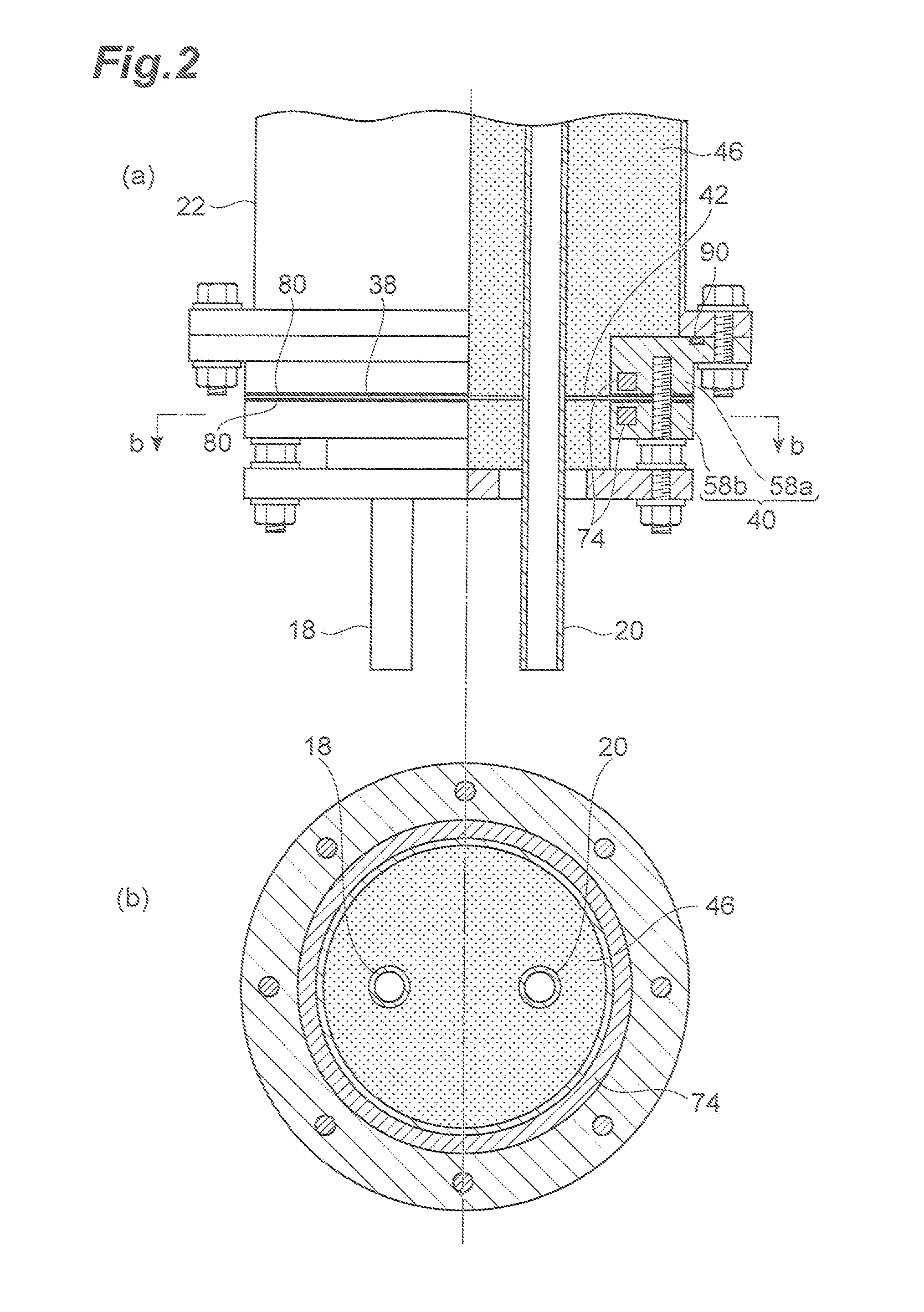

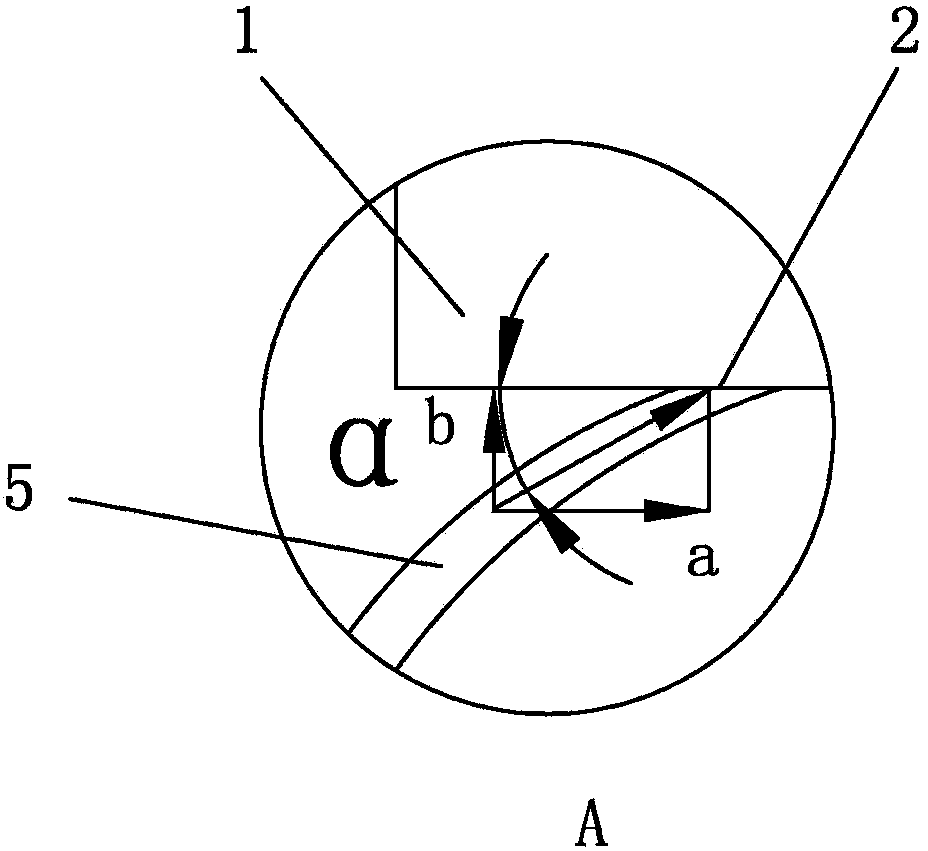

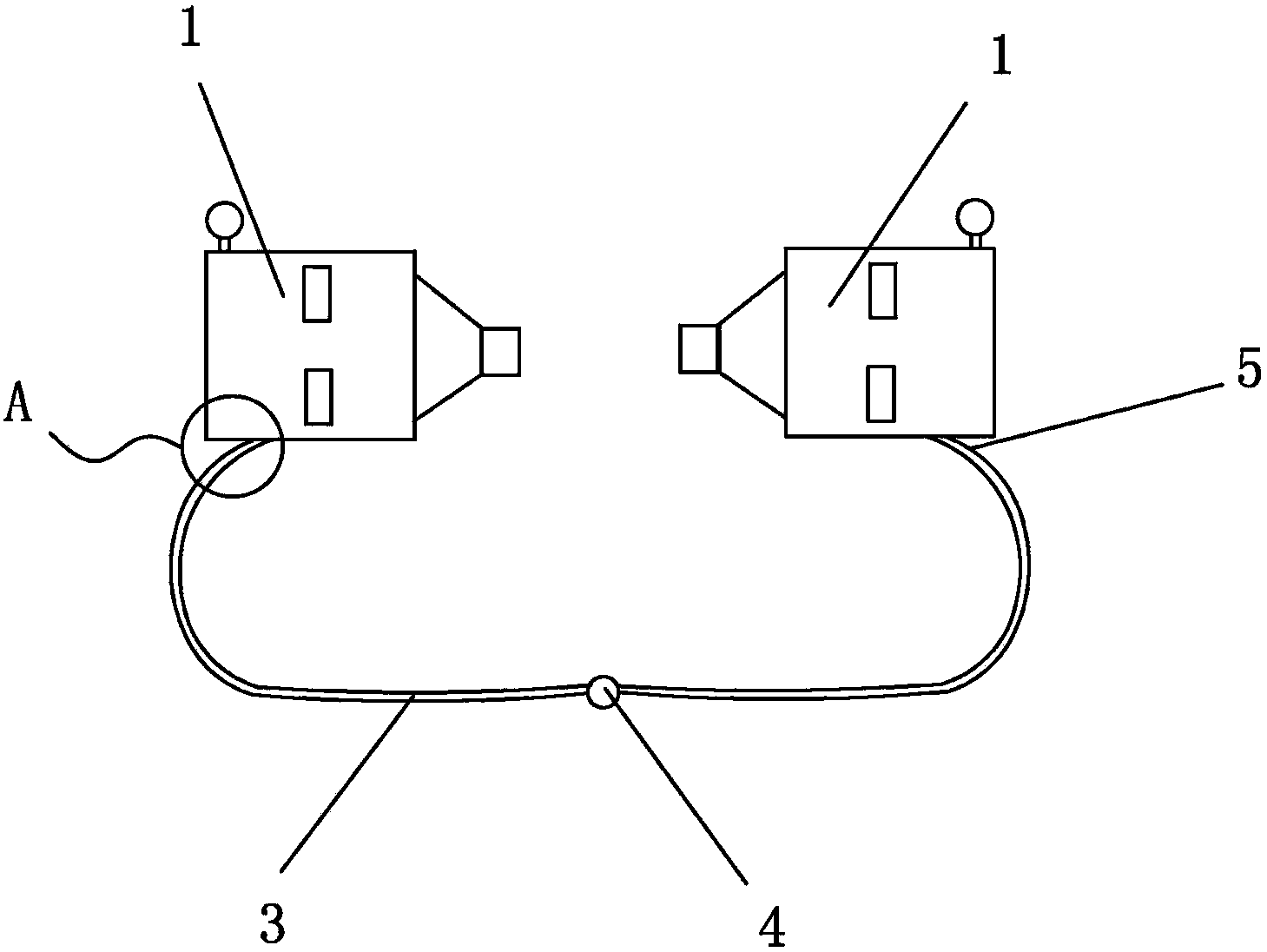

Rotary power exchanger with extended inflow angle structure

ActiveCN105114368AReduce Jet BlendingReduce the average velocityMachines/enginesEngineeringPore pressure gradient

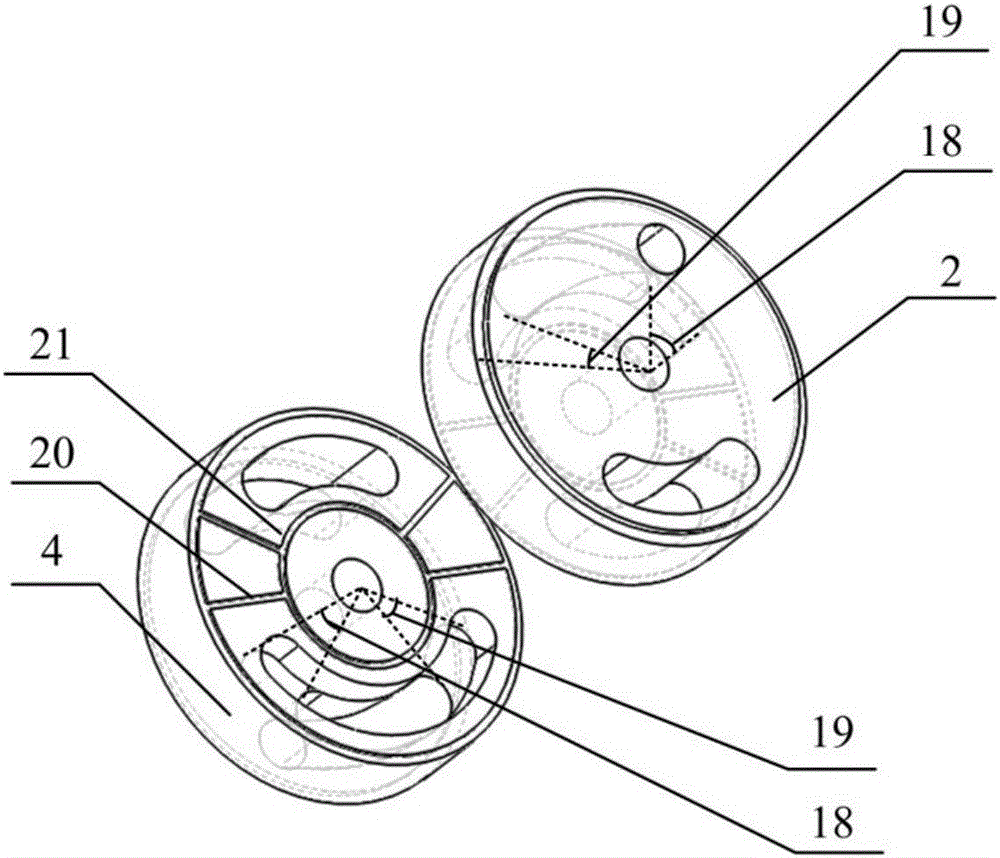

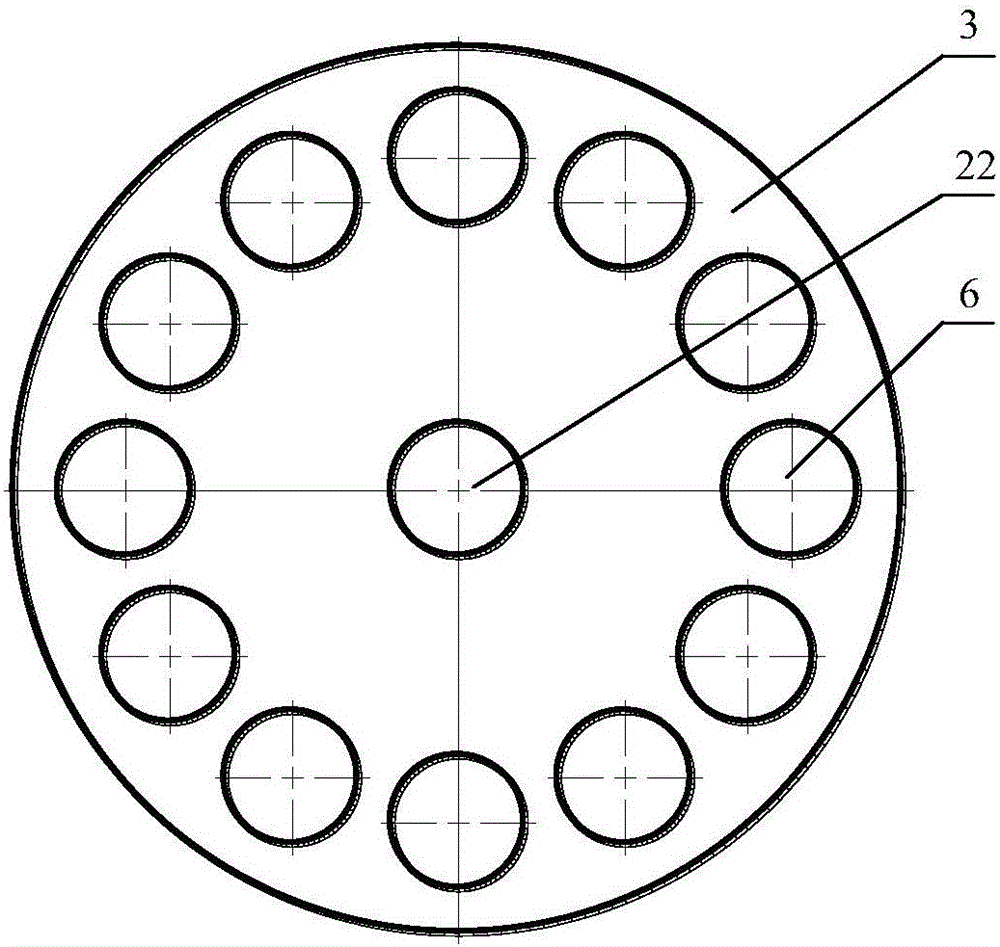

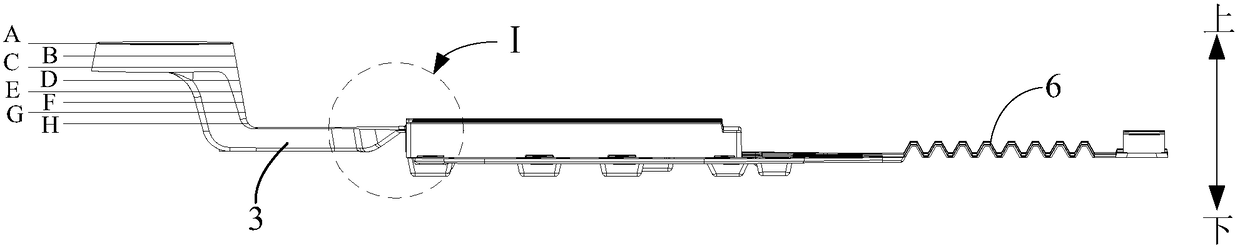

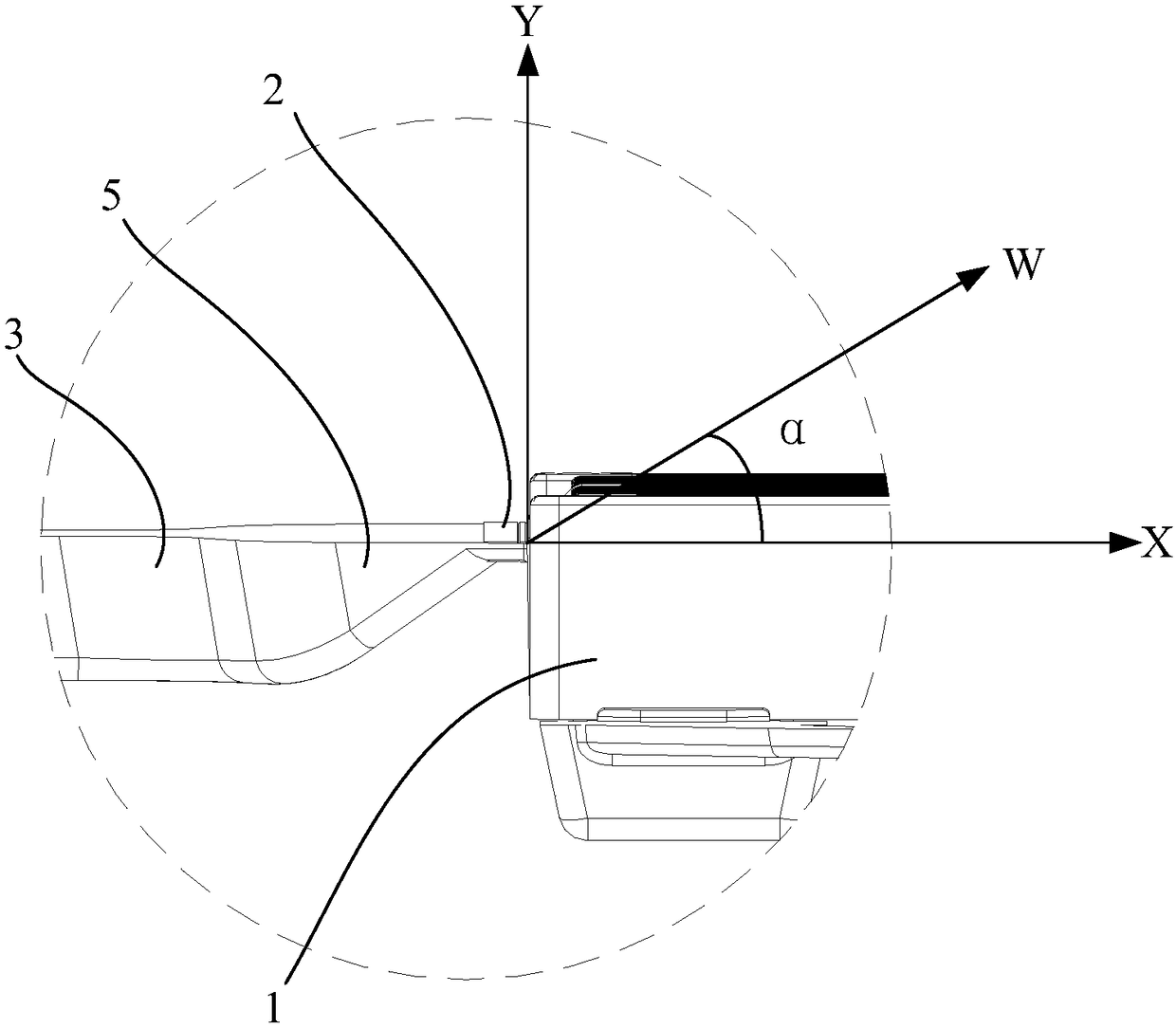

The invention discloses a rotary power exchanger with an extended inflow angle structure, and belongs to the technical field of fluid residual pressure recycling. The exchanger comprises a rotor, an upper stator and a lower stator which are positioned at the two ends of the rotor, and a rotor sleeve, wherein the stators are provided with inflow liquid collecting slots with extended angle structures, so that pressure gradient is remarkably reduced when speed is in gradient change in a switching process among a high-pressure communication region, a sealing region and a low-pressure communication region of a duct, and therefore, jet-flow mixing of the liquid can be effectively reduced. The rotary power exchanger disclosed by the invention is reasonable in inflow structure design, simple and convenient to manufacture, and capable of effectively restraining jet-flow mixing in the duct and guaranteeing concentration quality of a first liquid pressurized in a pressure energy transmission process, so that a concentration value at a high-pressure outlet is within a stable range, and the efficient operation of the power exchanger and a membrane system is guaranteed.

Owner:XI AN JIAOTONG UNIV

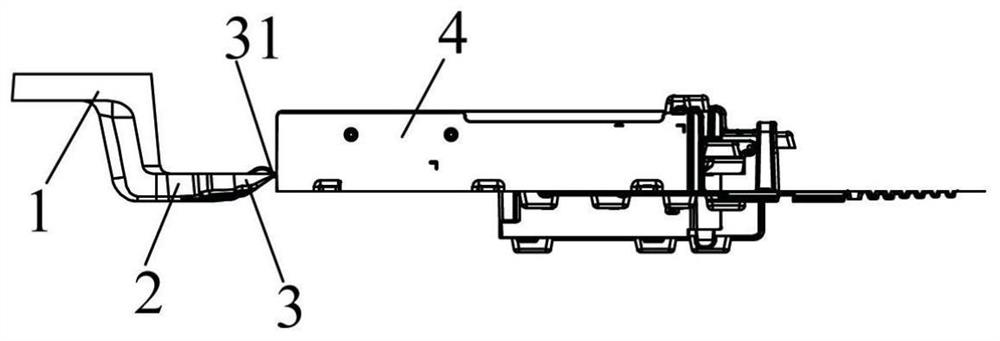

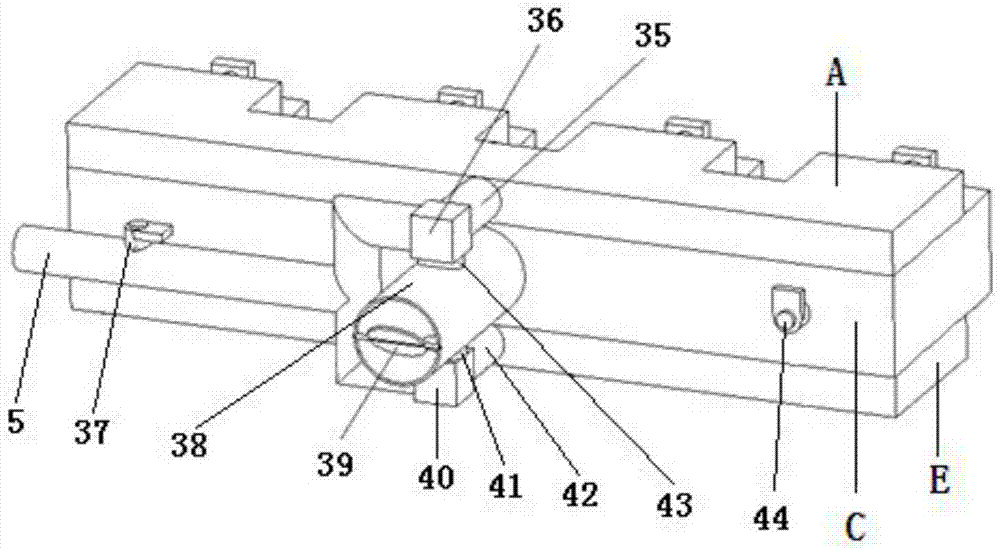

Pouring system for vacuum die casting of profiled optical fiber module and die casting process of pouring system

The invention discloses a pouring system for vacuum die casting of a profiled optical fiber module and a die casting process of the pouring system. The pouring system and the die casting process comprise (1) calculation and simulation of the pouring system; (2), design of a vacuum-pumping system; (3), selection of an aluminum alloy material; (4), alloy smelting; (5), design of a mold heating system; (6), design of the die casting process. The process steps are simple, operability is high, and the service life of a mold is prolonged; by means of the process, the uniformity of poured molten metal is further improved through improvement of a pouring mouth, the situation that the molten metal cannot enter a cavity smoothly for die casting due to accumulation of the metal liquid is prevented, the die casting efficiency is improved, and a casting generated through die casting in a vacuum state is high in quality; and the direction that the molten metal enters the mold cavity is controlled, the flowing process that the molten metal enters the mold cavity through the pouring system is effectively controlled, the mixed degree between the molten metal and the air is lowered, the overall filling of the molten metal in the mold is good, the proportions of surface bubbling, surface flow liner, loose structure, low intensity and decrease of electric conductivity of an aluminum alloy thin-walled workpiece product are lowered, and the qualified rate of the product is increased.

Owner:深圳市奥力压铸五金制品有限公司

Method for reducing surface tension of molten-state lithium source so as to improve high-temperature solid phase sintering process of cathode material of lithium ion battery

ActiveCN105789621AReduce surface tensionReduce mixingCell electrodesSecondary cellsMolten stateElectrical battery

The invention discloses a method for reducing surface tension of a molten-state lithium source so as to improve a high-temperature solid phase sintering process of a cathode material of a lithium ion battery, relating to a method for improving the high-temperature solid phase sintering process of the cathode material of the lithium ion battery and belonging to the technical field of a lithium ion battery material and a fabrication process thereof. The invention aims to solve the problems of unbalanced reaction and inadequate reaction caused by non-uniform molten-state lithium source distribution and incomplete immersion during the high-temperature solid phase sintering process of the cathode material of the lithium ion battery so that the problems such as rate performance, cycle stability and thermal stability of the material during the charge-discharge cycle process are improved. The improvement process is achieved according to the following steps of 1, pre-processing the lithium source; 2, mixing the lithium source and a precursor material; 3, fully immersing the lithium source and the precursor material; and 4, carrying out high-temperature sintering. The material fabricated according to the method is used for the cathode material of the lithium ion battery.

Owner:HARBIN INST OF TECH

Five-element lithium ion battery positive electrode material, preparation method and lithium battery prepared from five-element lithium ion battery positive electrode material

ActiveCN111668475AStrong structural stabilityImproved magnification performanceCell electrodesSecondary cellsChemical physicsPhysical chemistry

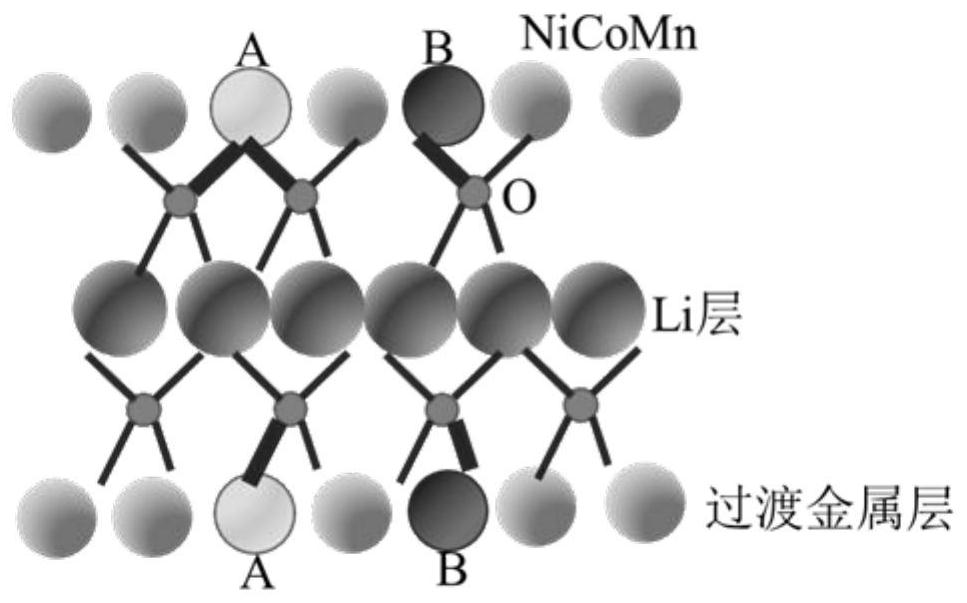

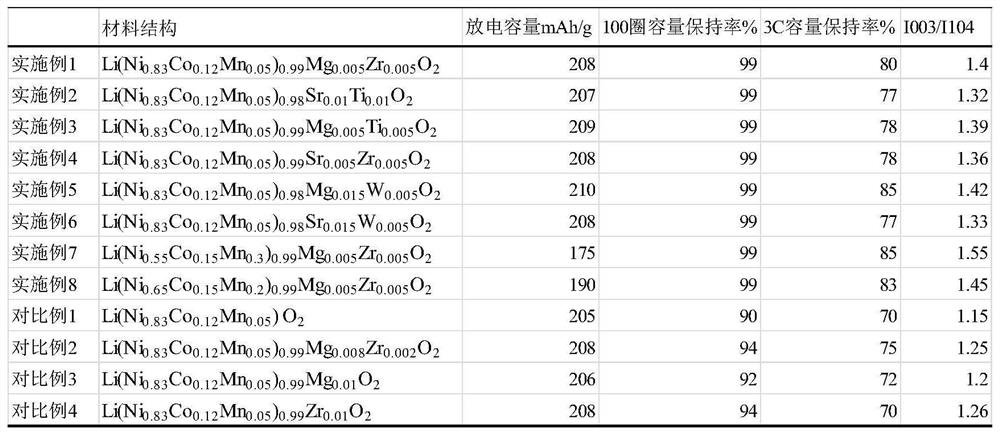

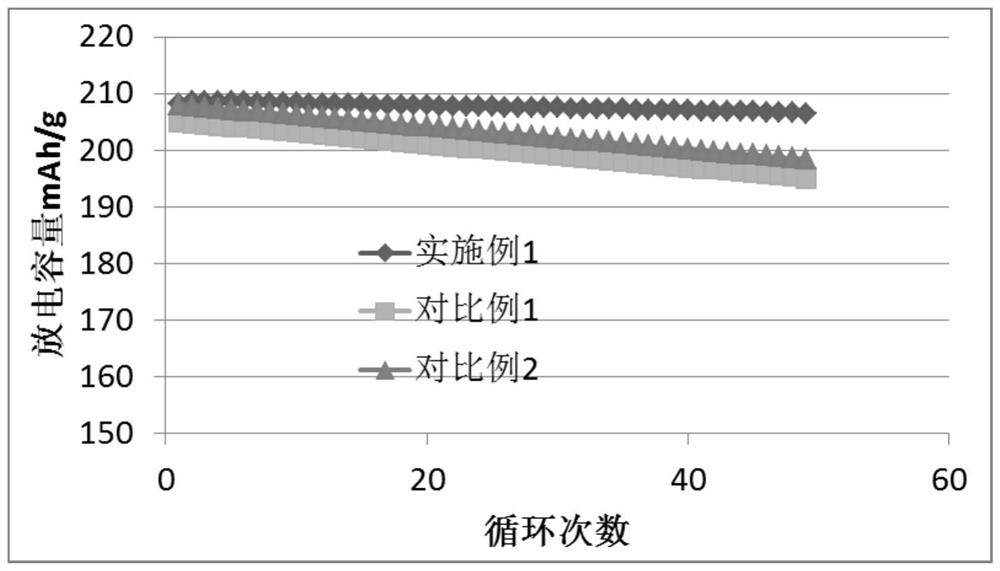

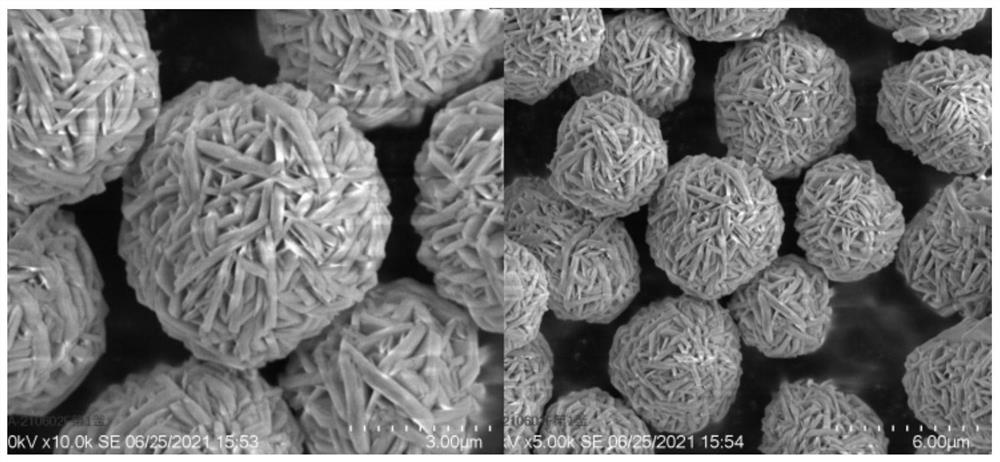

The invention discloses a five-element lithium ion battery positive electrode material with an equivalent valence ratio, high stability and long cycle, a preparation method and a lithium battery prepared from the five-element lithium ion battery positive electrode material. The five-element positive electrode material has the following structure: Li(NiCoMn)xAyBzO2, wherein x is greater than or equal to 0.98, the element A comprises one of Mg and Sr, the element B is one of Zr, Ti and W, and the ratio of the element A to the element B needs to meet the following equation: (3-A valence)*y=(B valence-3)*z, and x+y+z=1. Compared with traditional ternary and other non-equal-proportion system materials, the five-element lithium ion battery positive electrode material has higher structural stability, and the cycle performance is obviously improved; and material defects are few, Li / Ni mixed arrangement is low, and the rate capability is more excellent.

Owner:WANHUA CHEM GRP CO LTD

High-voltage nickel-cobalt-manganese ternary precursor and preparation method thereof

ActiveCN113603154AHold capacityImprove high pressure performanceCell electrodesSecondary cellsPhysical chemistryManganese

The invention relates to the field of nickel-cobalt-manganese ternary precursor manufacturing, and in particular, relates to a high-voltage nickel-cobalt-manganese ternary precursor and a preparation method thereof. The preparation method comprises the steps: mixing a nickel-cobalt-manganese ternary metal salt solution, a carbonate solution, a complexing agent solution and a first base solution, carrying out a co-precipitation reaction, and carrying out solid-liquid separation after precipitate reaches a required particle size range to obtain a nickel-cobalt-manganese composite basic carbonate seed crystal; and mixing the nickel-cobalt-manganese ternary metal salt solution, a precipitant solution, the ammonia water solution and a second base solution containing the nickel-cobalt-manganese composite basic carbonate seed crystal, enabling the nickel-cobalt-manganese composite basic carbonate seed crystal to continuously grow, and after the seed crystal reaches the required particle size range, carrying out solid-liquid separation, drying, batch mixing, sieving and demagnetizing to obtain the ternary precursor, wherein the core of the ternary precursor is nickel-cobalt-manganese composite basic carbonate, and the shell of the ternary precursor is nickel-cobalt-manganese composite hydroxide. A battery assembled by a ternary positive electrode material prepared from the precursor shows high discharge capacity, high first coulombic efficiency and excellent rate capability under 4.5 V high cut-off voltage.

Owner:GUANGDONG JIANA ENERGY TECH CO LTD +1

Die casting system for preparing aluminum alloy die castings and die casting process

The invention belongs to the technical field of aluminum alloy part forming machining, and particularly relates to a die casting system for preparing aluminum alloy die castings. The die casting system comprises a straight pouring gate, a cross pouring gate, an inner pouring gate and a die cavity which sequentially communicate with one another, the die cavity is connected with an exhaust passage,the exhaust passage communicates with a vacuumizing device, an inner pouring gate connected with the die cavity is arranged on the end part of the inner pouring gate, the lower end surface of the inner pouring gate inclines upwards, a jet angle is formed between molten metal and the plane where the inner pouring gate is located in the direction of the inner pouring gate, and the jet angle is 30-60degrees. In addition, the invention further relates to a die casting process. Compared with the prior art, vortexes and air entrapment generated by mixing of the molten metal and air in the mold filling process can be effectively reduced, so that product mold filling is complete, surface bubbles and flow lines are few, the surface smoothness is high, and the product percent of pass is high.

Owner:东莞市兴茂压铸有限公司

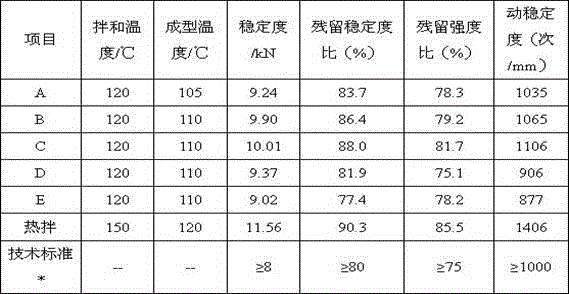

Zwitter-ion and nonionic composite asphalt warm-mixing agent and preparation method thereof

ActiveCN104559251AReduce high temperature viscosityImprove performanceClimate change adaptationBuilding insulationsHydrogenAsphalt

The invention discloses a zwitter-ion and nonionic composite asphalt warm-mixing agent and a preparation method thereof. The zwitter-ion and nonionic composite asphalt warm-mixing agent comprises in percentage by weight: 0.1-20% of zwitter-ion components, 0.1-20% of macromolecule nonionic components, 0.1-15% of low-molecular-weight nonionic components, 0.1-3% of acid catalysts and 42-99.6% of water. The preparation method comprises the following steps: the water is added into a container in the proportion, the temperature is controlled to range from 40 DEG C to 60 DEG C, the macromolecule nonionic components are added, a mixture is stirred for 0.5-2 hours at a constant temperature and then heated to 60-80 DEG C, the low-molecular-weight nonionic components and the zwitter-ion components are added in the proportion and are respectively stirred for 0.5-1 hours, the acid catalysts are added so that a pH (potential of hydrogen) can be adjusted to be 5-7, and the composite asphalt warm-mixing agent is obtained. The zwitter-ion and nonionic composite asphalt warm-mixing agent can effectively reduce high-temperature viscosity of the asphalt, improves the anti-peeling performance of the asphalt and stone and has the advantages of good compounding performance, stable performance, easiness of collection of the raw materials, low production cost, simple and convenient preparation method, wide application range and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

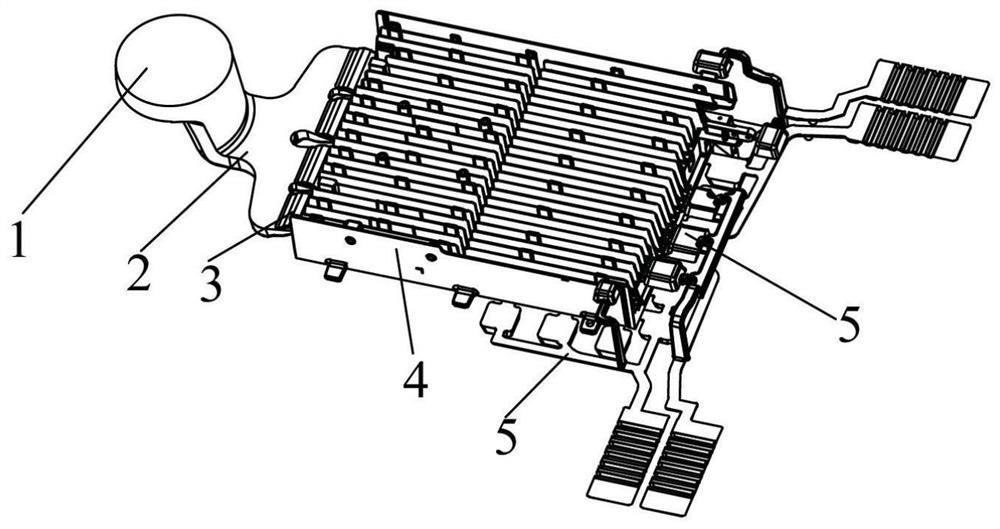

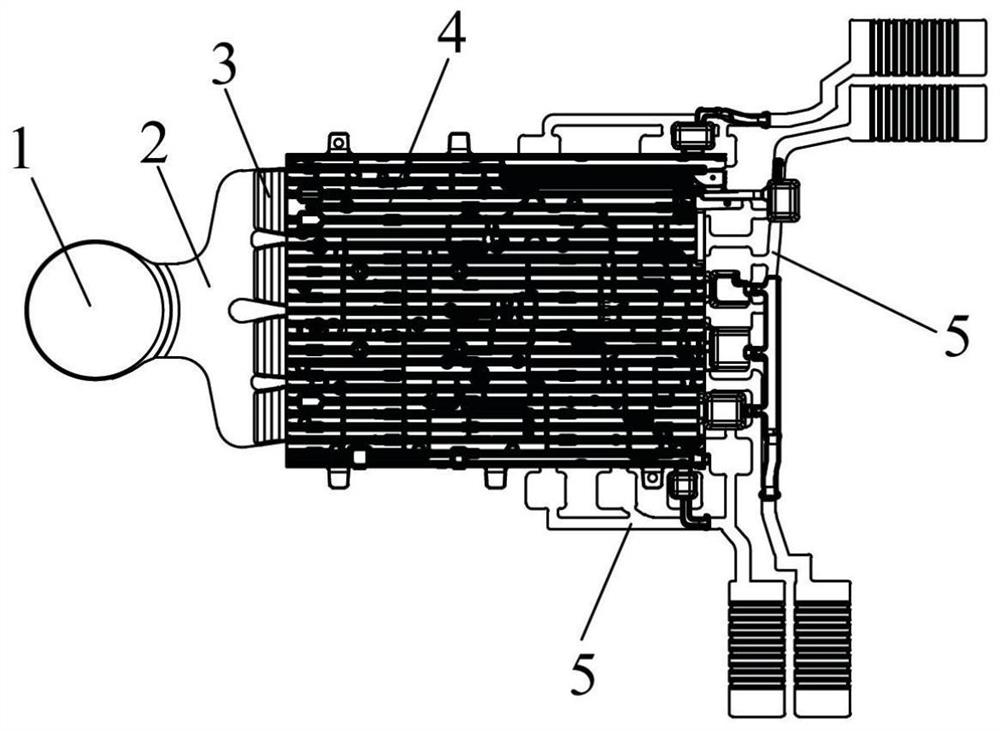

Gasoline engine EGR stratified charge system based on flow guiding plate

InactiveCN103670815ALarge openingReduce lossesNon-fuel substance addition to fuelExhaust gas recirculationCombustion chamberGasoline

The invention discloses a gasoline engine EGR stratified charge system based on a flow guiding plate, and belongs to the technical field of engines. An exhaust pipe is fixedly connected with an intake manifold through a bypass pipe, an EGR valve, an EGR cooler and an EGR loop. An airflow cavity in the air inlet side of a cylinder cover part is respectively and correspondingly connected with an airflow cavity of an air inlet diverting cavity part, an air inlet of the cylinder cover part corresponds to branch pipes of the air inlet diverting cavity part, a throttle valve is fixedly connected with an intake manifold hole through the intake manifold, and the exhaust branch pipes of the exhaust pipe are correspondingly connected with four exhaust ways of the cylinder cover part respectively. Waste gas and fresh air can be prevented from being early mixed outside a combustion chamber and can also be prevented from being accumulated and mixed when an air inlet door is closed, the equipressure air intake of the fresh air and the pressure can be achieved, the mixed degree of the fresh air and the waste gas can be reduced, the load control of an engine can be achieved, the circulation thermal efficiency of a gasoline engine is improved, high EGR efficiency can be achieved, and the combustion economical efficiency of the gasoline engine is effectively improved.

Owner:JILIN UNIV

Flow dividing plate and cold tank for water dispenser and water dispenser

ActiveCN104739244AWarm water outlet temperature is reliableReduce energy consumptionBeverage vesselsEngineeringWarm water

The invention discloses a flow dividing plate and a cold tank for a water dispenser and the water dispenser. The flow dividing plate for the water dispenser comprises a transverse clapboard, a longitudinal clapboard and a hot tank water inlet pipe, and the lower space of the transverse clapboard forms a cold water region; the longitudinal clapboard is arranged on the upper surface of the transverse clapboard and divides the upper space of the transverse clapboard into a warm water region and a mixed water region communicated with the cold water region, and the longitudinal clapboard is provided with a water hole communicated with the mixed water region and the warm water region and a warm water discharge passage for communicating the warm water region with the outside; the hot tank water inlet pipe runs through the transverse clapboard and is communicated with the warm water region. The flow dividing plate for the water dispenser is capable of reducing the cold water and warm water mixing degree so as to guarantee the warm water discharge temperature.

Owner:FOSHAN MIDEA CHUNGHO WATER PURIFICATION MFG +1

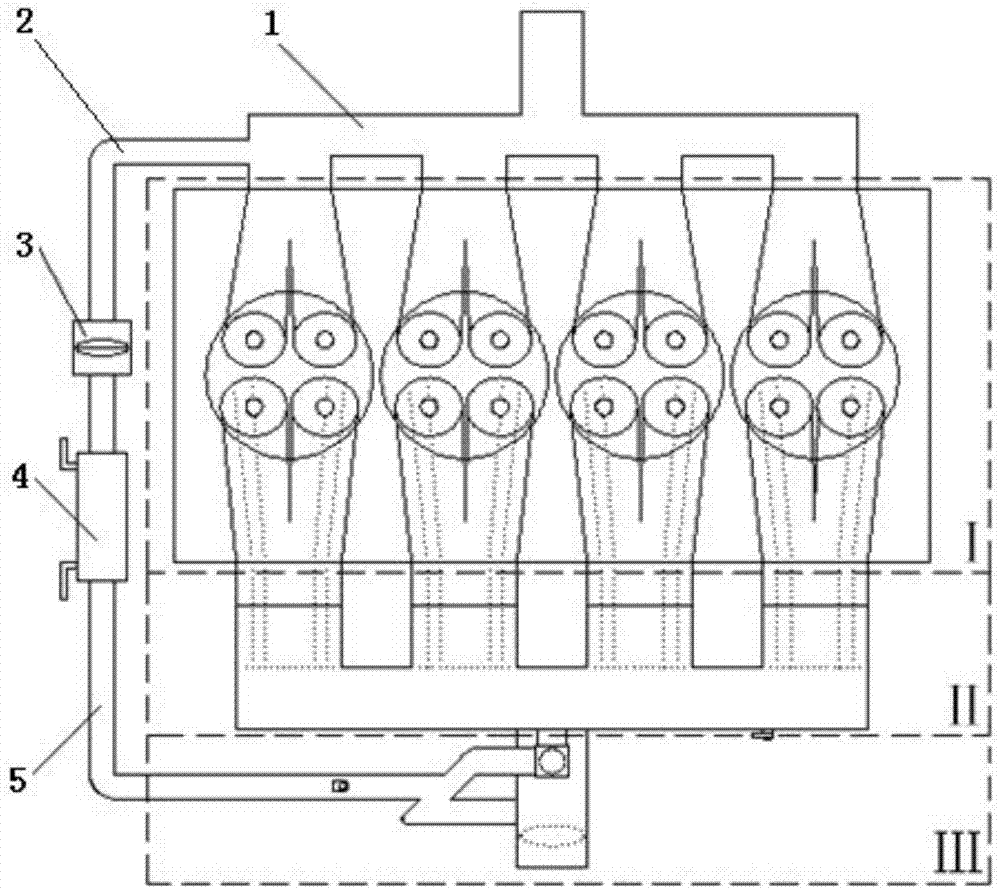

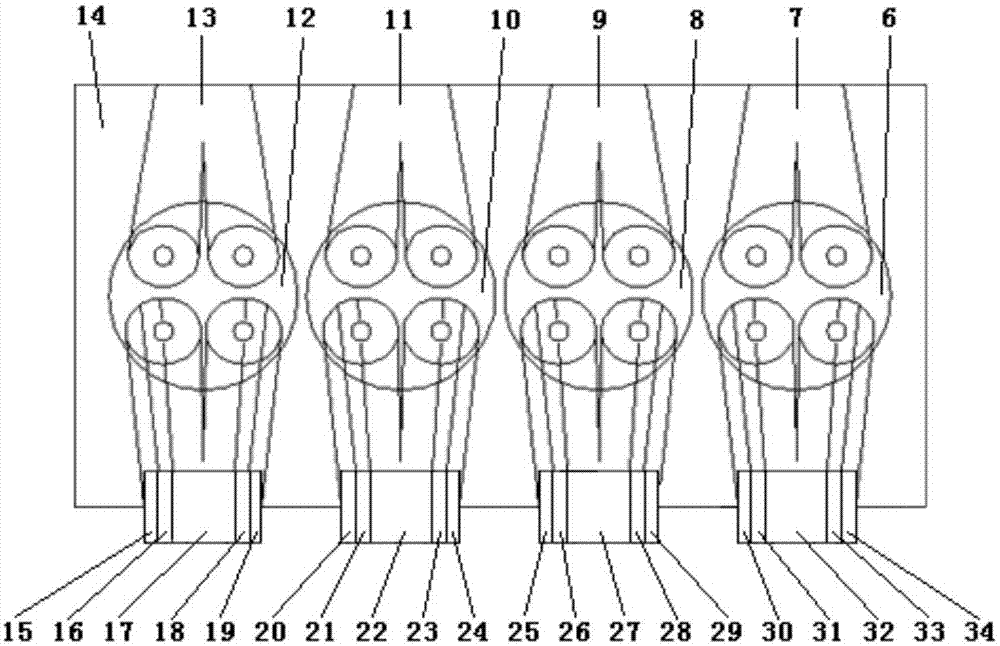

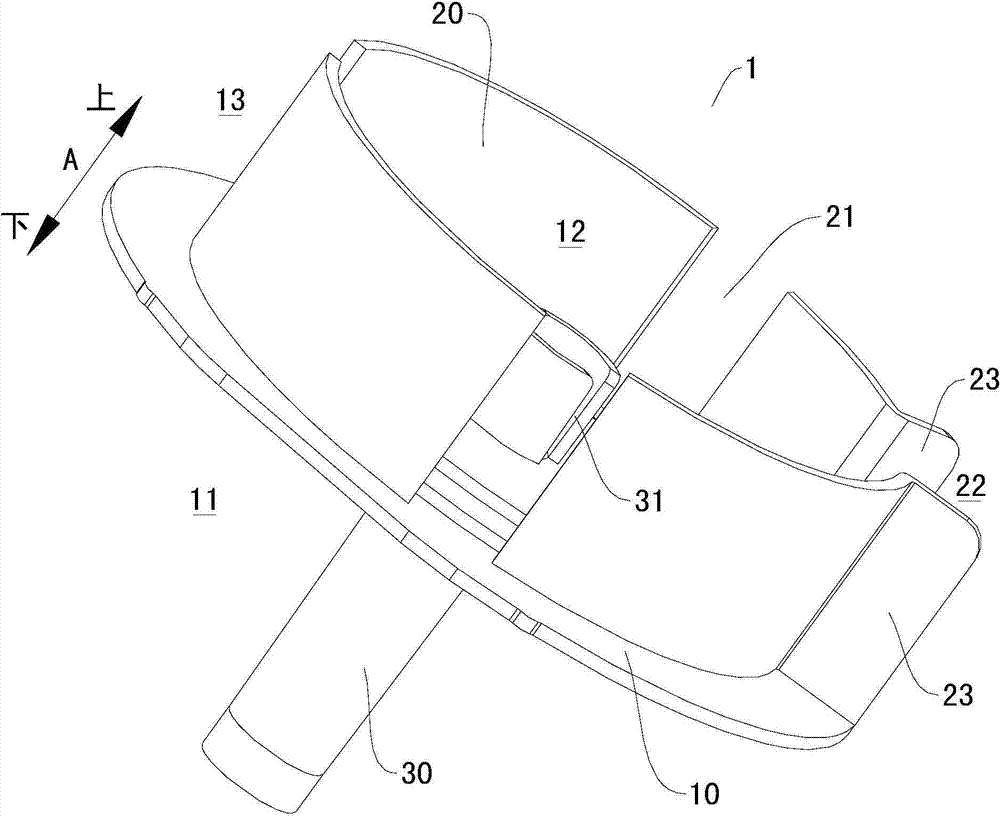

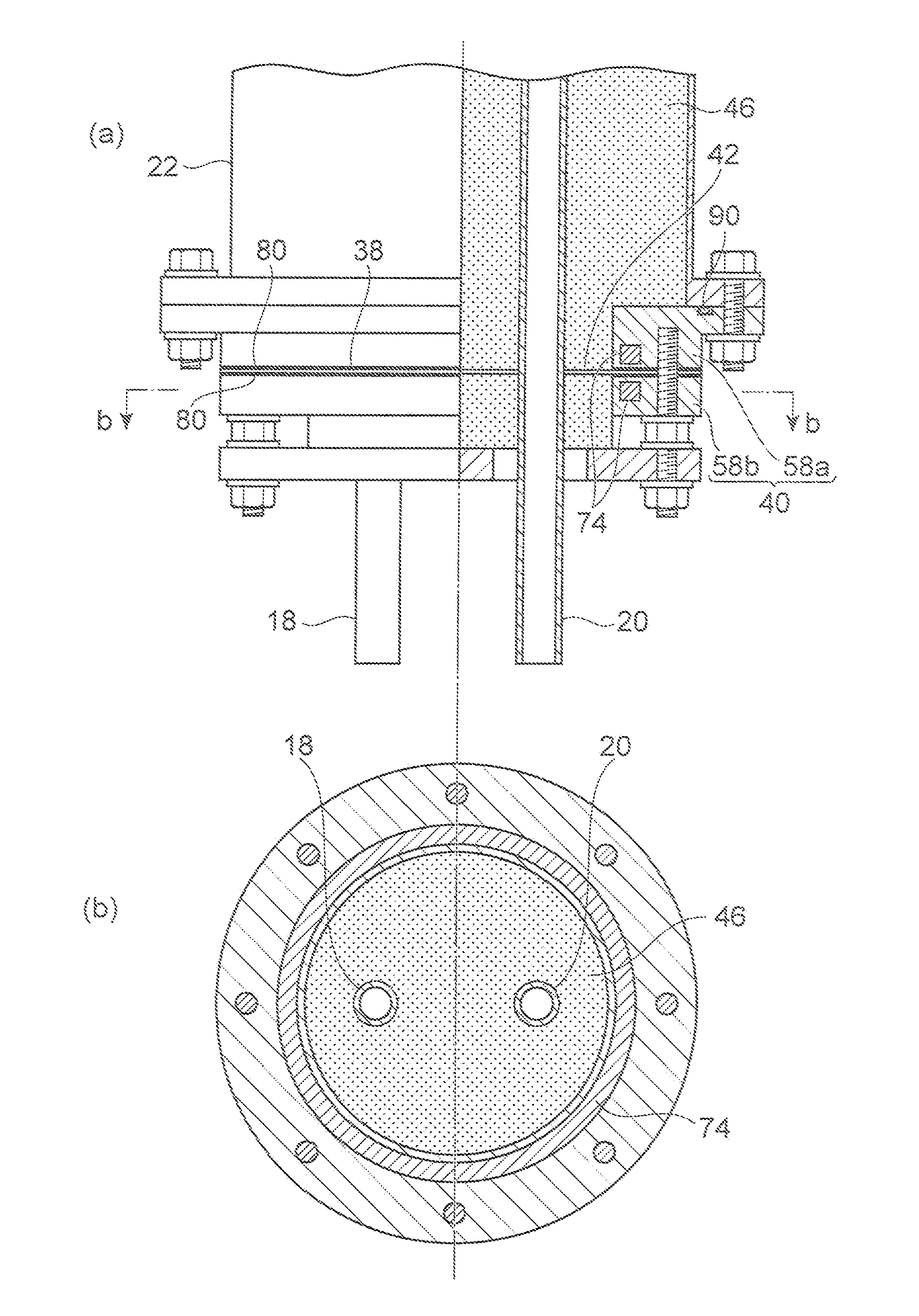

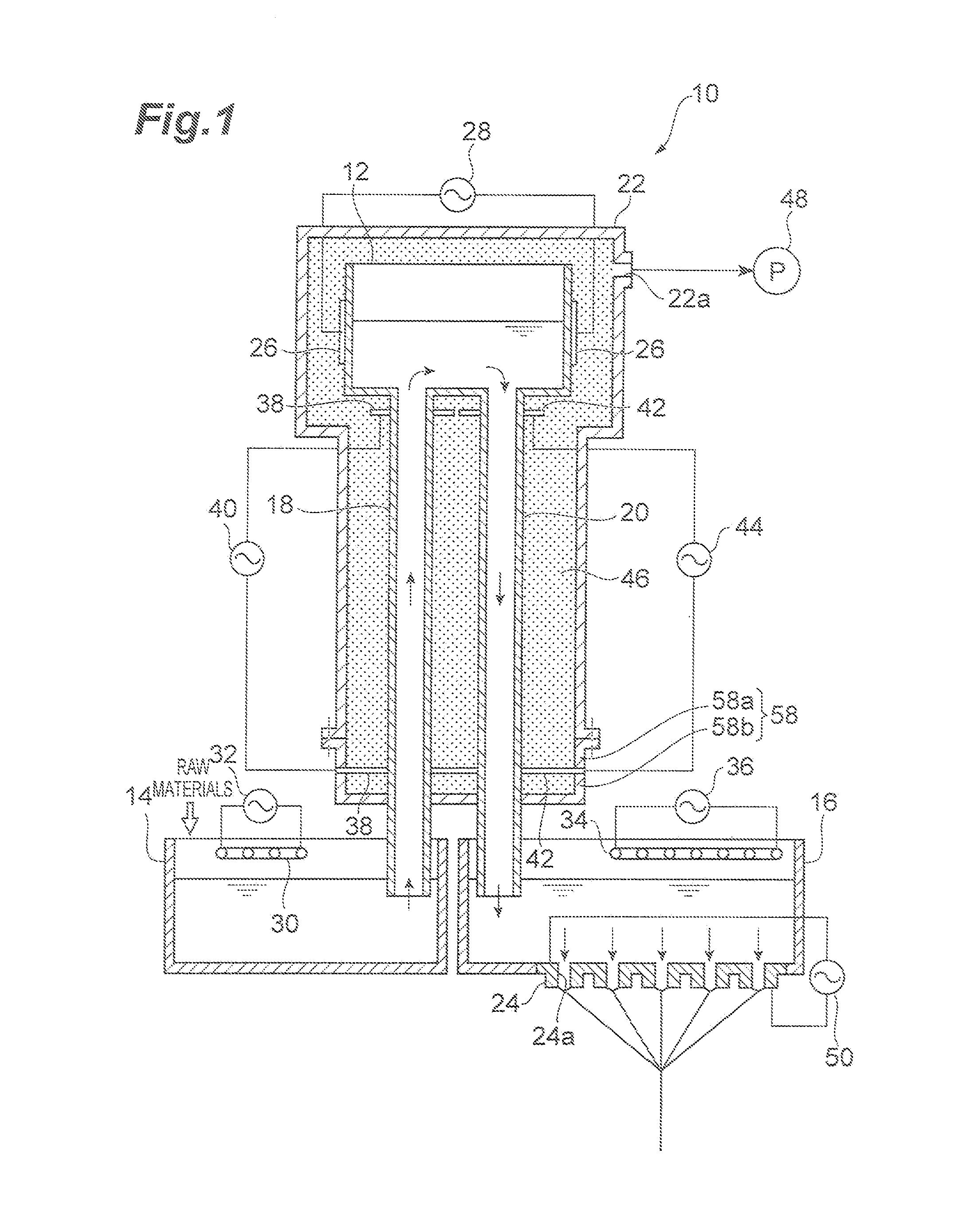

Glass-Melting Device for Producing Glass Fiber and Method for Producing Glass Fiber Using Same

ActiveUS20120055200A1Reduce mixingReduce mixGlass furnace apparatusRotary drum furnacesGlass meltingMolten glass

An object of the present invention is to effectively reduce mixing of bubbles into a spun glass fiber.A glass-melting device 10 for producing glass fibers includes: a first glass-melting tank 12 exposed to a reduced-pressure atmosphere; a second glass-melting tank 14 and a third glass-melting tank 16 arranged below the first glass-melting tank 12; an ascending conduit 18 that sends up molten glass resulting from melting in the second glass-melting tank 14 to deliver the molten glass to the first glass-melting tank 12; a descending conduit 20 that sends the molten glass down from the first glass-melting tank 12 to deliver the molten glass to the third glass-melting tank 16; a decompression housing 22; and a bushing 24. The glass-melting device 10 further includes heating means for separately heating the first glass-melting tank 12, the second glass-melting tank 14, the third glass-melting tank 16, the ascending conduit 18, the descending conduit 20 and the bushing 24.

Owner:NITTO BOSEIKI CO LTD

Zinc-alloy USB (universal serial bus) thin-walled workpiece die-casting die structure

Owner:YONG TAI ELECTRONICSDONGGUAN LTD

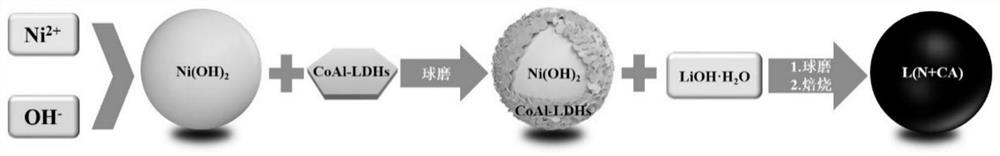

Method for preparing lithium nickel cobalt aluminate positive electrode material

ActiveCN111777103AEvenly distributedReduced diffusion rateMaterial nanotechnologyCell electrodesElectrical batteryLithium aluminate

The invention discloses a method for preparing a lithium nickel cobalt aluminate positive electrode material, and belongs to the technical field of preparation of lithium ion battery positive electrode materials. The preparation method comprises the following steps of: firstly, respectively preparing spherical nickel hydroxide and cobalt-aluminum hydrotalcite nanosheets, then coating the surface of the spherical nickel hydroxide with the cobalt-aluminum hydrotalcite nanosheets through solid-phase ball milling, cobalt-aluminum hydrotalcite nanosheet coated spherical nickel hydroxide is used asa precursor to be mixed and roasted with a lithium compound to obtain the lithium nickel cobalt aluminate LiNi1-x-yCoxAlyO2 positive electrode material, wherein 1-x-y is greater than or equal to 0.8 and smaller than 1, x is greater than 0 and smaller than or equal to 0.15, and y is greater than 0 and smaller than or equal to 0.06. The method has the advantages that nickel, cobalt and aluminum elements are uniformly distributed in the product, the Li<+> / Ni<2+> mixed arrangement degree can be reduced by utilizing the LiCo1-xAlxO2 intermediate phase buffer layer effect, and a more regular layeredstructure is obtained. The prepared lithium nickel cobalt aluminate positive electrode material has high tap density, high specific capacity, good rate capability, high cycling stability and other excellent electrochemical properties; and moreover, the process is simple, the controllability is high, and large-scale production is facilitated.

Owner:BEIJING UNIV OF CHEM TECH

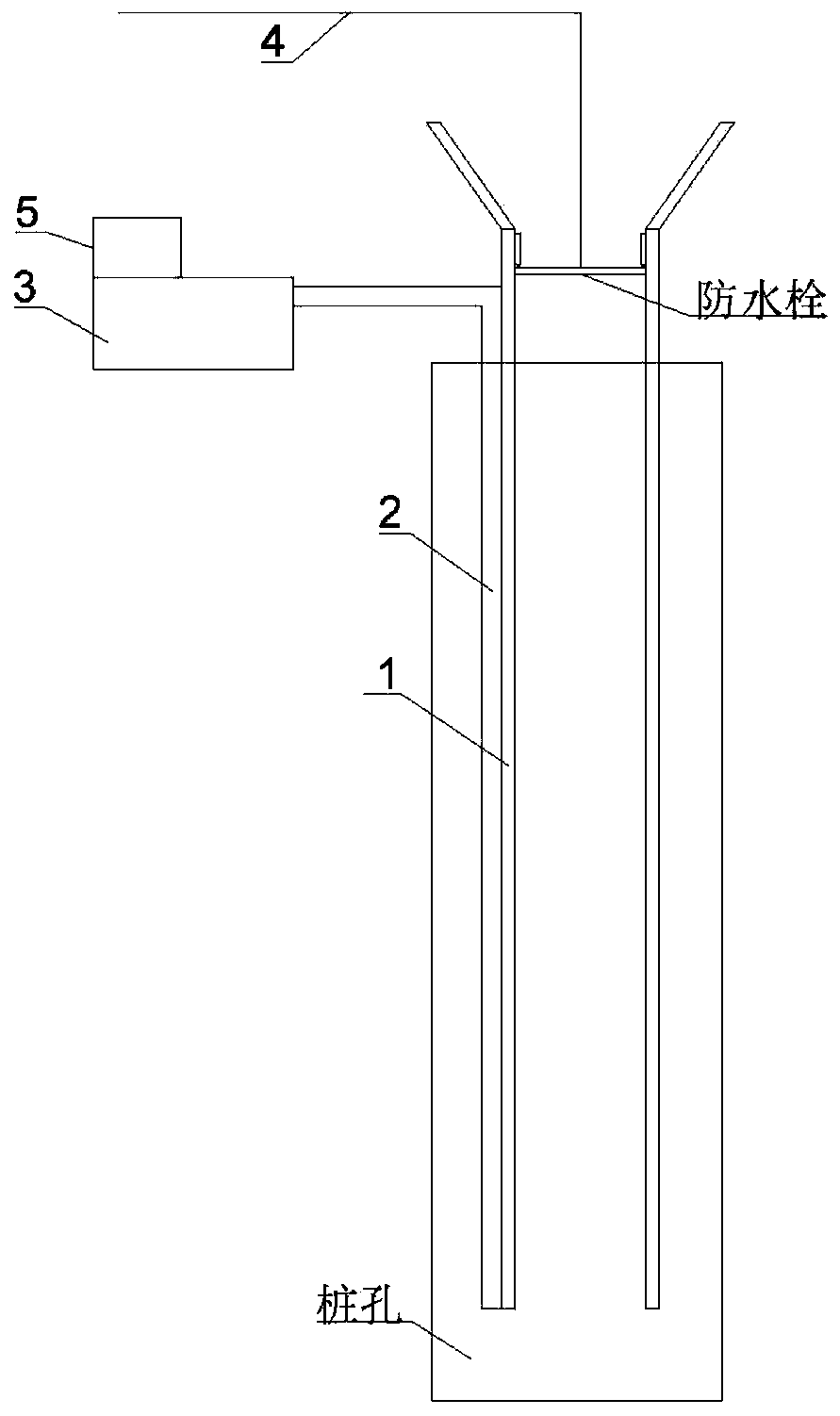

Sediment-free construction device for cast-in-place bored pile

PendingCN111424668AReduce distanceImprove the perturbation effectBulkheads/pilesEnvironmental geologyStructural engineering

The invention discloses a sediment-free construction device for a cast-in-place bored pile, and relates to a cast-in-place structure. The sediment-free construction device for the cast-in-place boredpile comprises a cast-in-place pile with the top communicating with a pouring hopper; a high-pressure pipe is arranged on the outer wall of the cast-in-place pile; the top end of the high-pressure pipe is connected with an air pump; a waterproof bolt capable of sliding up and down inside the cast-in-place pile is arranged in the cast-in-place pile; the waterproof bolt is hung at the top of an inner cavity of the cast-in-place pile through a hanging structure; the air pump is in signal control with a controller; the waterproof bolt specifically comprises a base and a cylindrical coaming with the outer diameter identical with the inner diameter of the cast-in-place pile; the cylindrical coaming specifically comprises multiple arc-shaped coamings; and the center of the bottom end of each arc-shaped coaming is hinged to the base. By the aid of the device, the strength of a pile foundation bottom formed by the cast-in-place pile can be improved effectively, and the influence caused by high-pressure air flow and turbid solutions on a pile body can be avoided.

Owner:安徽省建设工程测试研究院有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com