Lithium-enriched manganese-based positive electrode material and preparation method thereof

A cathode material, lithium-rich manganese-based technology, applied in the field of lithium-rich manganese-based cathode materials and their preparation, can solve problems such as insufficient stability and performance degradation, achieve good charge-discharge specific capacity, complete development of layered structure, and improve The effect of high rate and long cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

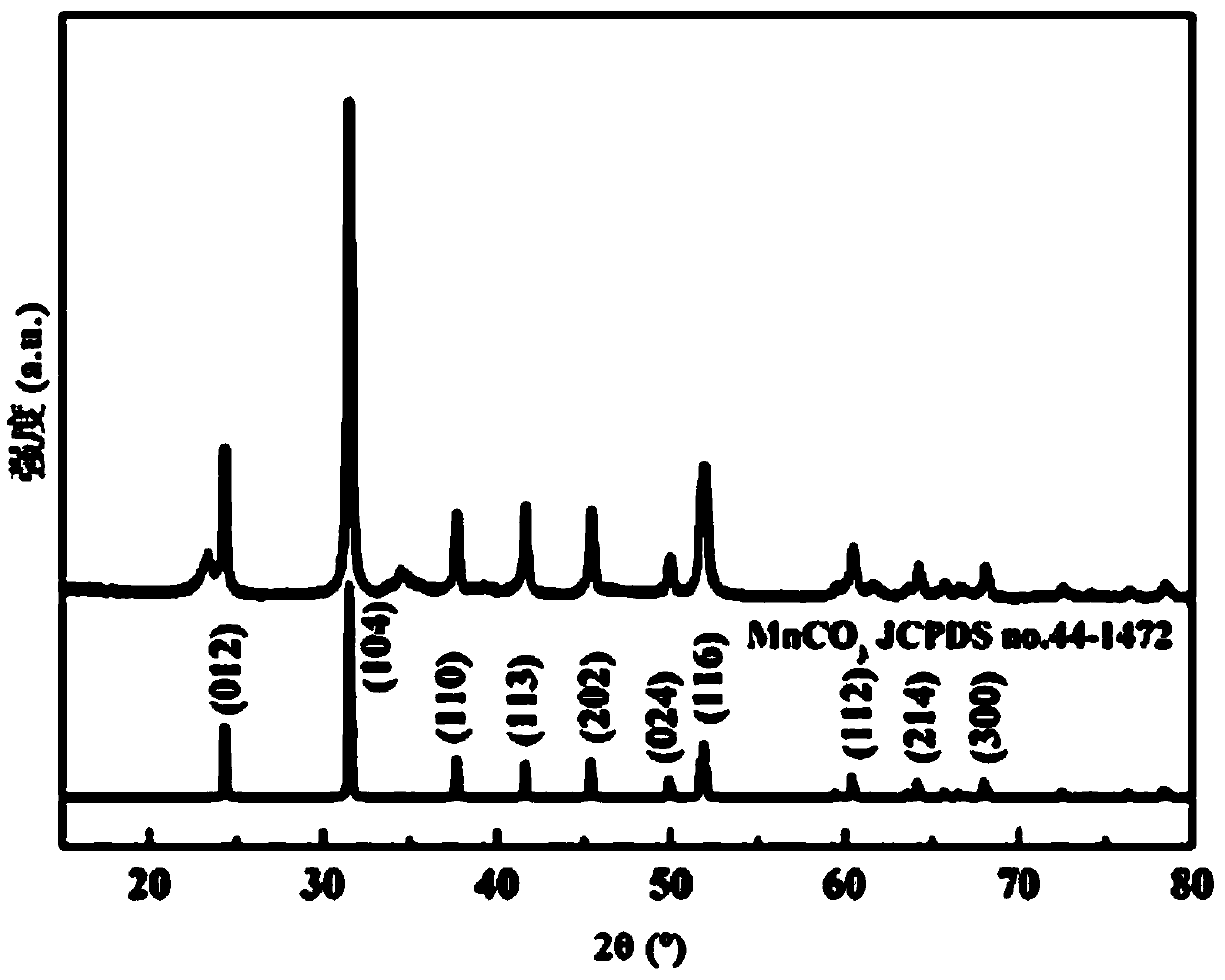

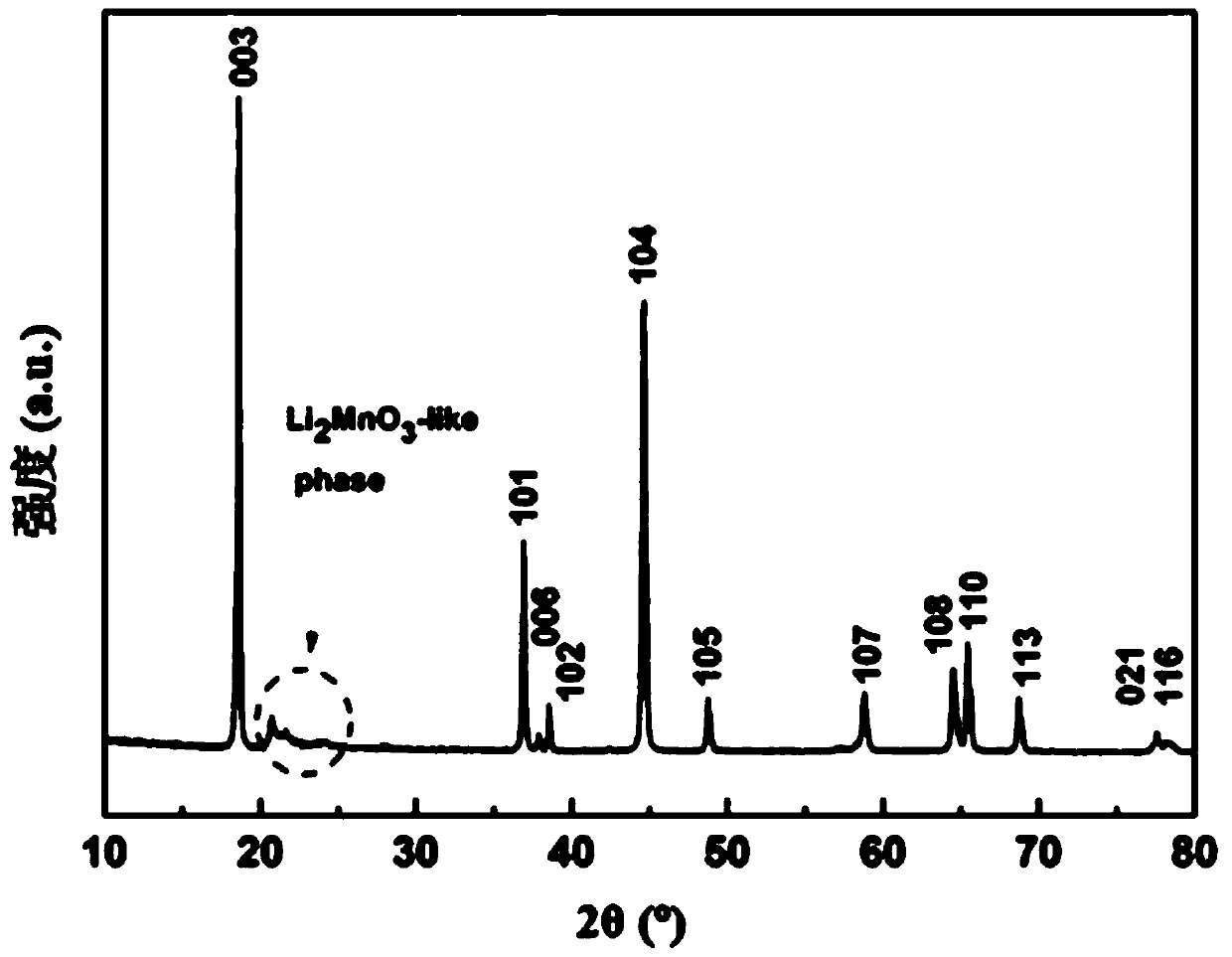

[0029] According to the proportion of metal ions, nickel sulfate, cobalt sulfate and manganese sulfate are respectively configured into bottom liquid, feed liquid 1, feed liquid 2 and feed liquid 3; the ratio of Ni, Co and Mn metal ions in the bottom liquid is 1:1:3.5, and the feed liquid The ratio of Ni, Co and Mn metal ions in solution 1 is 1:1:3.5, the ratio of Ni, Co and Mn metal ions in material solution 2 is 1:1:4, and the ratio of Ni, Co and Mn metal ions in material solution 3 is 1:1:4.5;

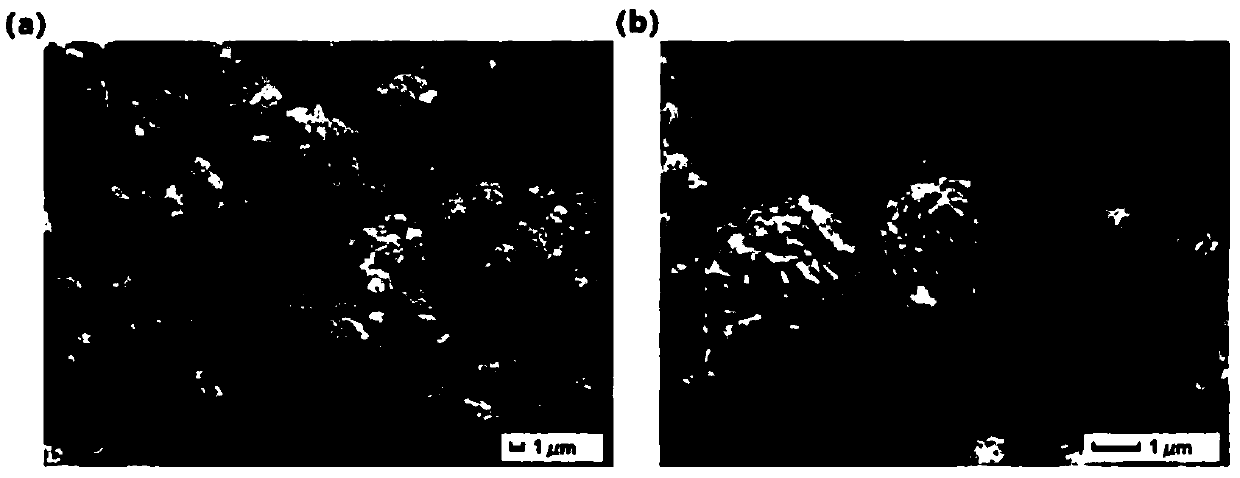

[0030] Put 6L of the bottom liquid into the reaction kettle and stir at a stirring speed of 450rpm. When the temperature in the kettle is 45°C, add 2mol / L of sodium carbonate solution as a precipitant and 0.3mol / L of ammonia as a complexing agent to adjust the bottom liquid. pH value to 8.0; Feed liquids 1, 2, and 3 are put into the reaction kettle in turn, and sodium carbonate solution and ammonia water are used to keep the pH value in the reaction kettle unchanged during the addit...

Embodiment 2

[0040] According to the proportion of metal ions, nickel sulfate, cobalt sulfate and manganese sulfate are respectively configured into bottom liquid, feed liquid 1, feed liquid 2 and feed liquid 3; the ratio of Ni, Co and Mn metal ions in the bottom liquid is 1:1:1, and the feed liquid The ratio of Ni, Co and Mn metal ions in solution 1 is 1:1:1, the ratio of Ni, Co and Mn metal ions in material solution 2 is 1:1:1.3, and the ratio of Ni, Co and Mn metal ions in material solution 3 is 1:1:4;

[0041] Put 6L of the bottom solution into the reactor and stir at a stirring speed of 550rpm. When the temperature in the reactor is 55°C, add 3mol / L of sodium carbonate solution as a precipitant and 0.4mol / L of ammonia as a complexing agent to adjust the bottom. The pH value in the liquid reaches 9.0; Feed liquids 1, 2, and 3 are sequentially entered into the reactor, and sodium carbonate solution and ammonia water are used to keep the pH value in the reactor constant during the additi...

Embodiment 3

[0045] According to the ratio of metal ions, nickel nitrate, cobalt nitrate, and manganese nitrate are respectively configured into bottom liquid, feed liquid 1, feed liquid 2, and feed liquid 3; the ratio of Ni, Co and Mn metal ions in the bottom liquid is 1:1:4, and the feed liquid The ratio of Ni, Co and Mn metal ions in solution 1 is 1:1:5, the ratio of Ni, Co and Mn metal ions in material solution 2 is 1:1:5, and the ratio of Ni, Co and Mn metal ions in material solution 3 is 1:1:7;

[0046] Put 6L of bottom liquid into the reaction kettle and stir at a stirring speed of 500rpm. When the temperature in the kettle is 50°C, add 3mol / L sodium carbonate solution as a precipitant and 0.4mol / L ammonia water as a complexing agent to adjust the bottom liquid. pH value to 8.5; Feed liquids 1, 2, and 3 are put into the reaction kettle in turn, and sodium carbonate solution and ammonia water are used to keep the pH value in the reaction kettle unchanged during the addition process; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com