Patents

Literature

8766 results about "Core shell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Posted by on October 11, 2017 The “shell and core” building concept involves the building owner or landlord planning and constructing the core, or inside, of a building surrounded by the exterior shell. The term fit-out refers to everything you need to outfit the interior of a building, such as furnishings, decorations, and other interiors.

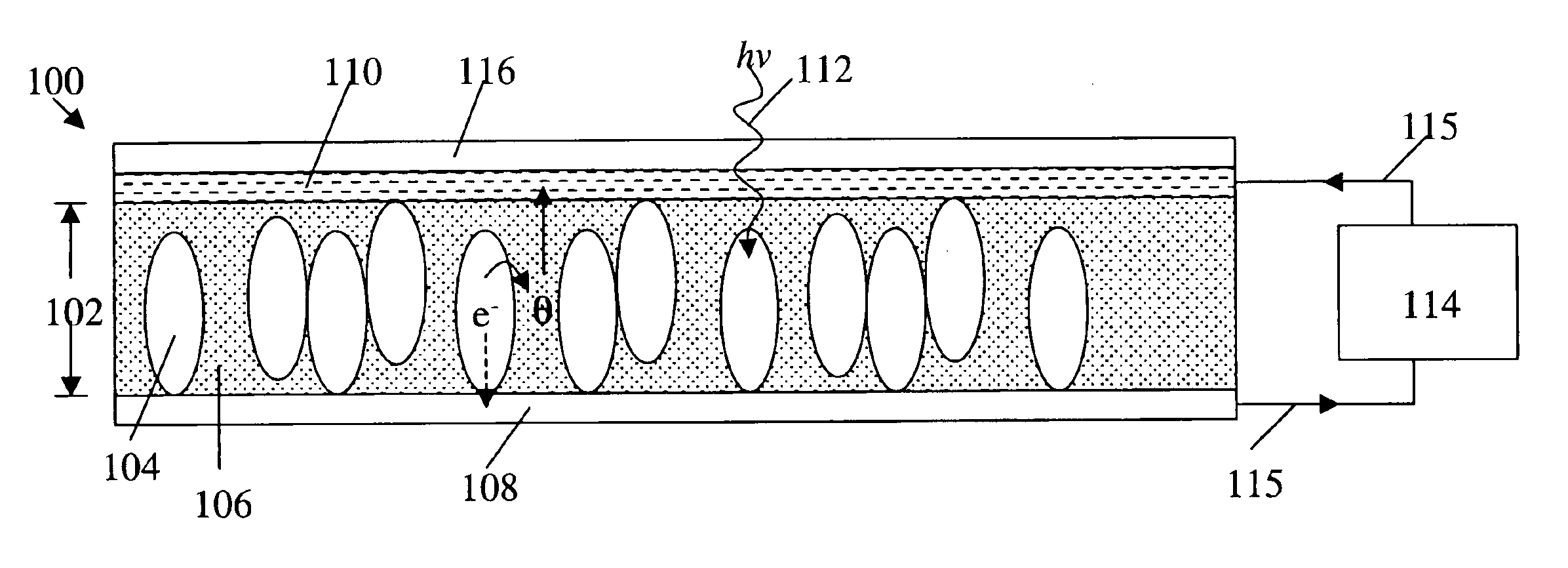

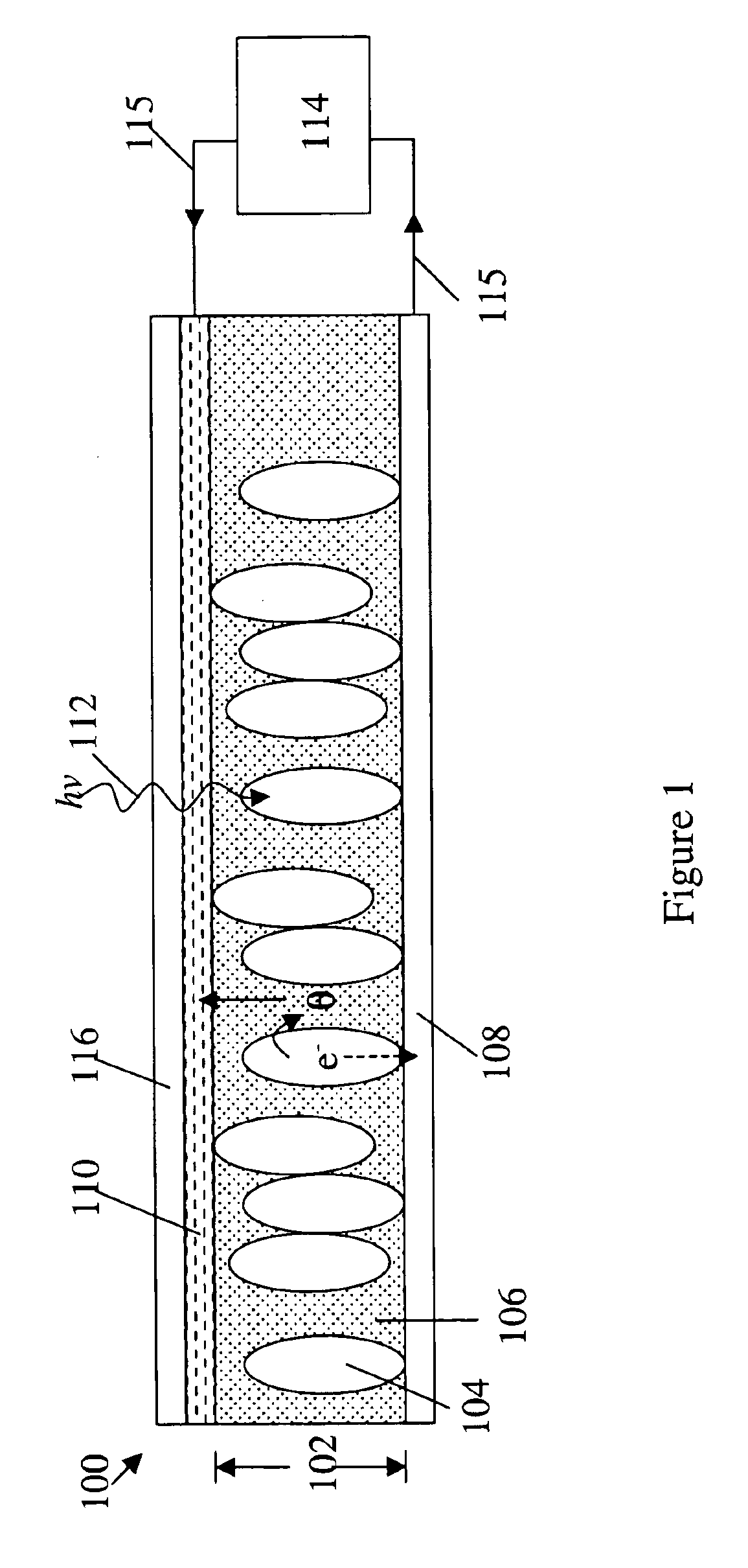

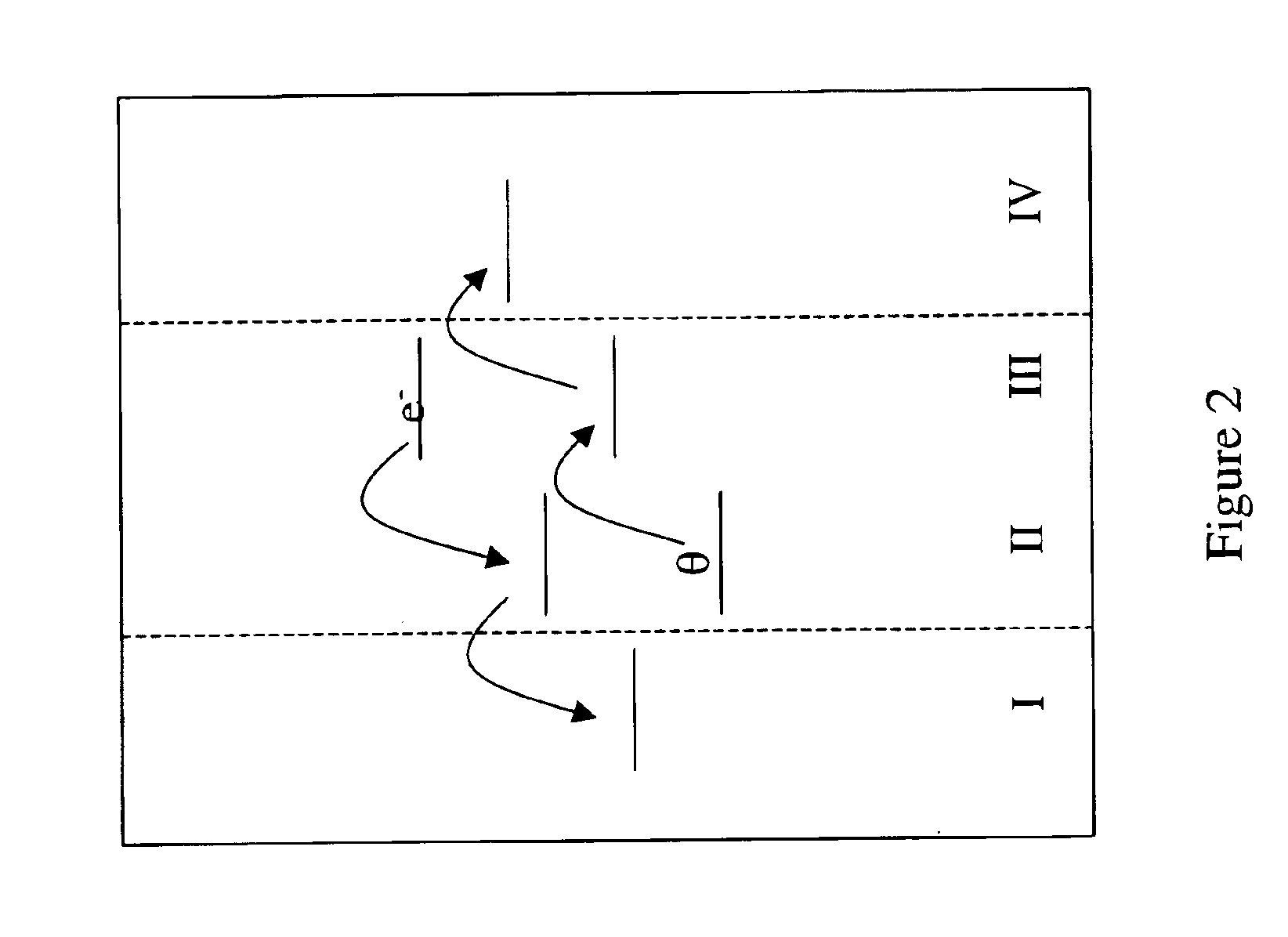

Nanostructure and nanocomposite based compositions and photovoltaic devices

InactiveUS6878871B2Improve equipment efficiencyMaterial nanotechnologyFinal product manufactureSemiconductor nanocrystalsNanostructure

Nanocomposite photovoltaic devices are provided that generally include semiconductor nanocrystals as at least a portion of a photoactive layer. Photovoltaic devices and other layered devices that comprise core-shell nanostructures and / or two populations of nanostructures, where the nanostructures are not necessarily part of a nanocomposite, are also features of the invention. Varied architectures for such devices are also provided including flexible and rigid architectures, planar and non-planar architectures and the like, as are systems incorporating such devices, and methods and systems for fabricating such devices. Compositions comprising two populations of nanostructures of different materials are also a feature of the invention.

Owner:NANOSYS INC

Ferromagnetic powder for dust core

InactiveUS7498080B2Increase resistanceTotal current dropLiquid surface applicatorsInductances/transformers/magnets manufactureElectrical resistance and conductanceEddy current

Owner:HON HAI PRECISION IND CO LTD

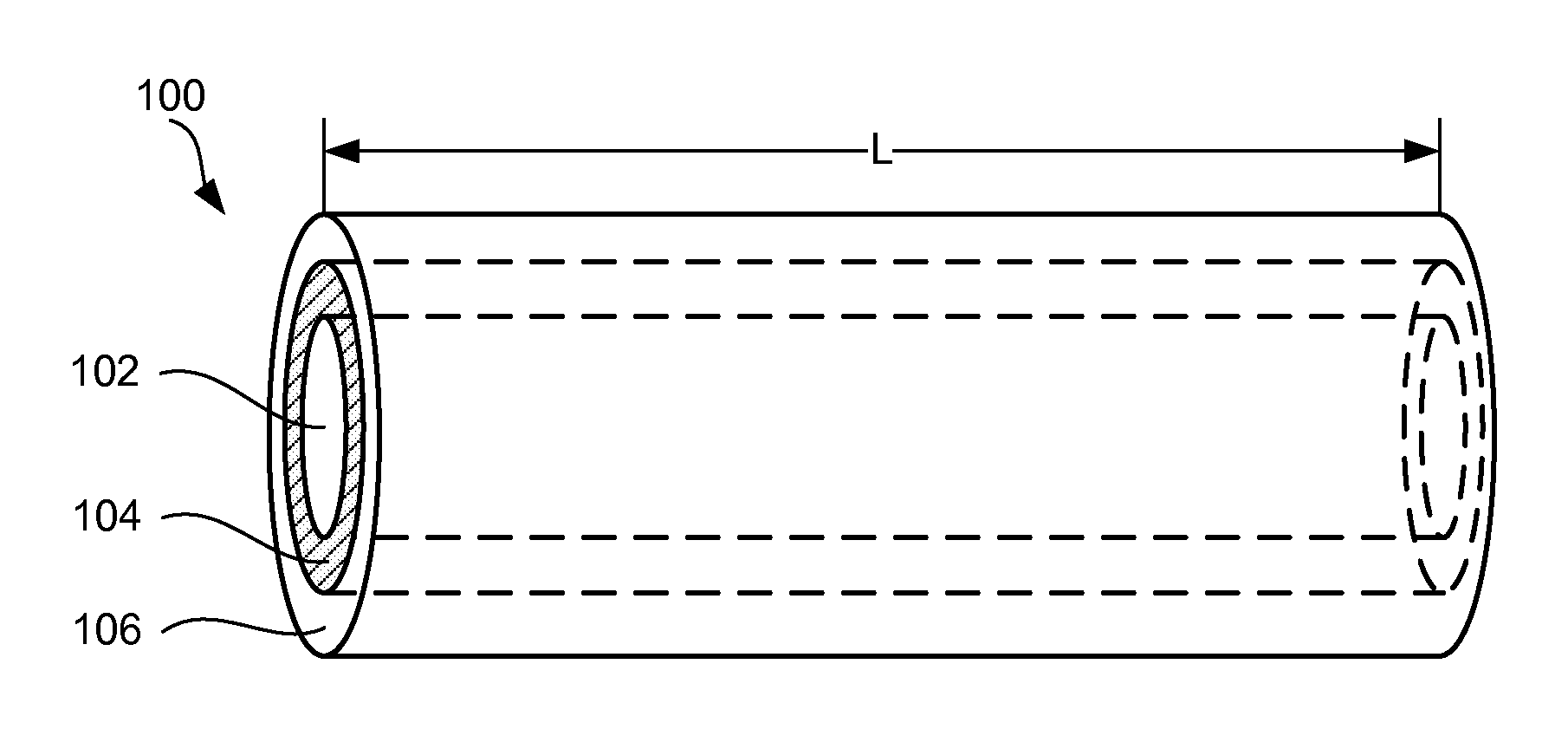

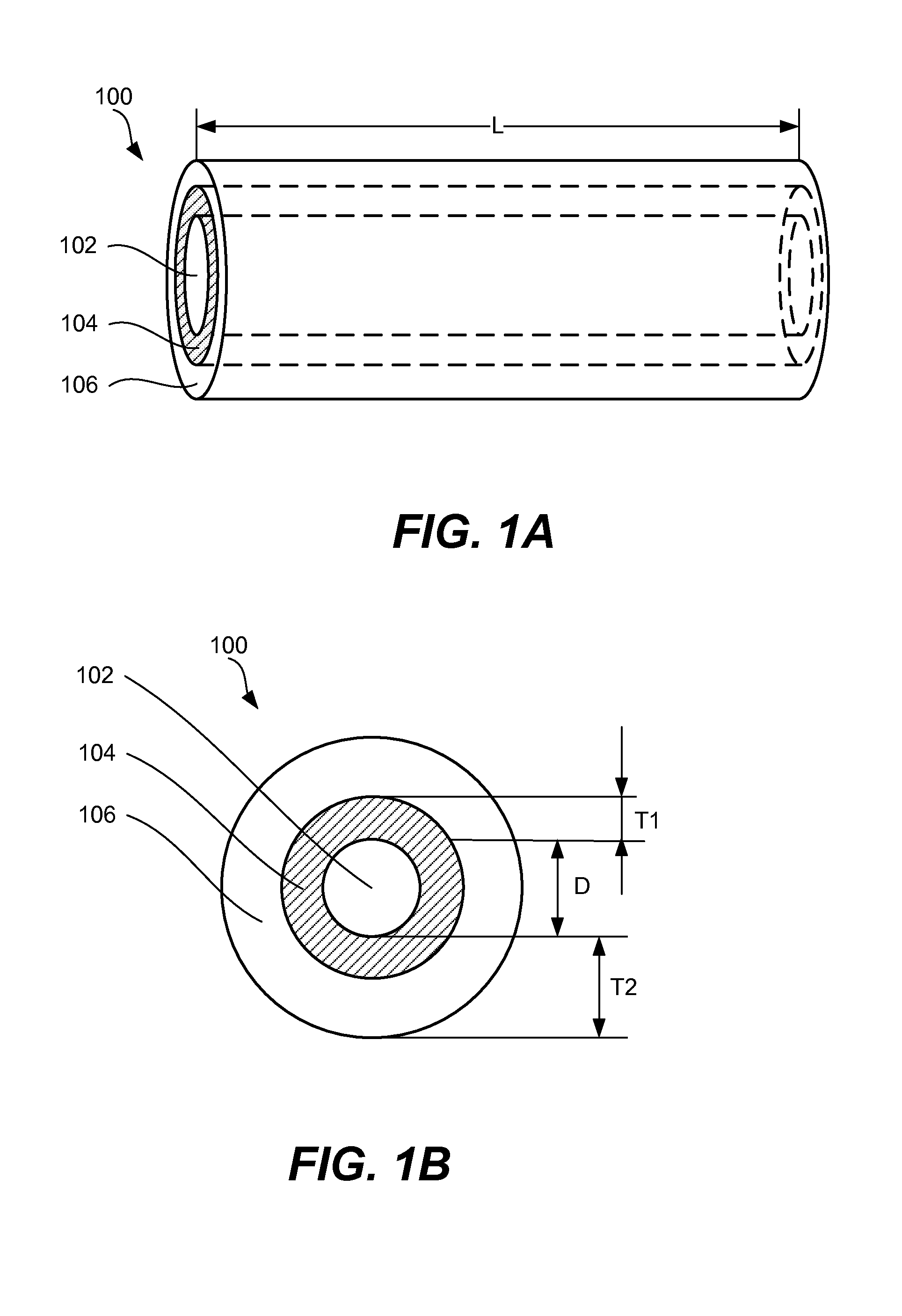

Core-shell high capacity nanowires for battery electrodes

InactiveUS20100330421A1Large capacityInhibition formationMaterial nanotechnologyNanostructure manufactureNanowireElectrochemistry

Provided are nanostructures containing electrochemically active materials, battery electrodes containing these nanostructures for use in electrochemical batteries, such as lithium ion batteries, and methods of forming the nanostructures and battery electrodes. The nanostructures include conductive cores, inner shells containing active materials, and outer shells partially coating the inner shells. The high capacity active materials having a stable capacity of at least about 1000 mAh / g can be used. Some examples include silicon, tin, and / or germanium. The outer shells may be configured to substantially prevent formation of Solid Electrolyte lnterphase (SEI) layers directly on the inner shells. The conductive cores and / or outer shells may include carbon containing materials. The nanostructures are used to form battery electrodes, in which the nanostructures that are in electronic communication with conductive substrates of the electrodes.

Owner:AMPRIUS INC

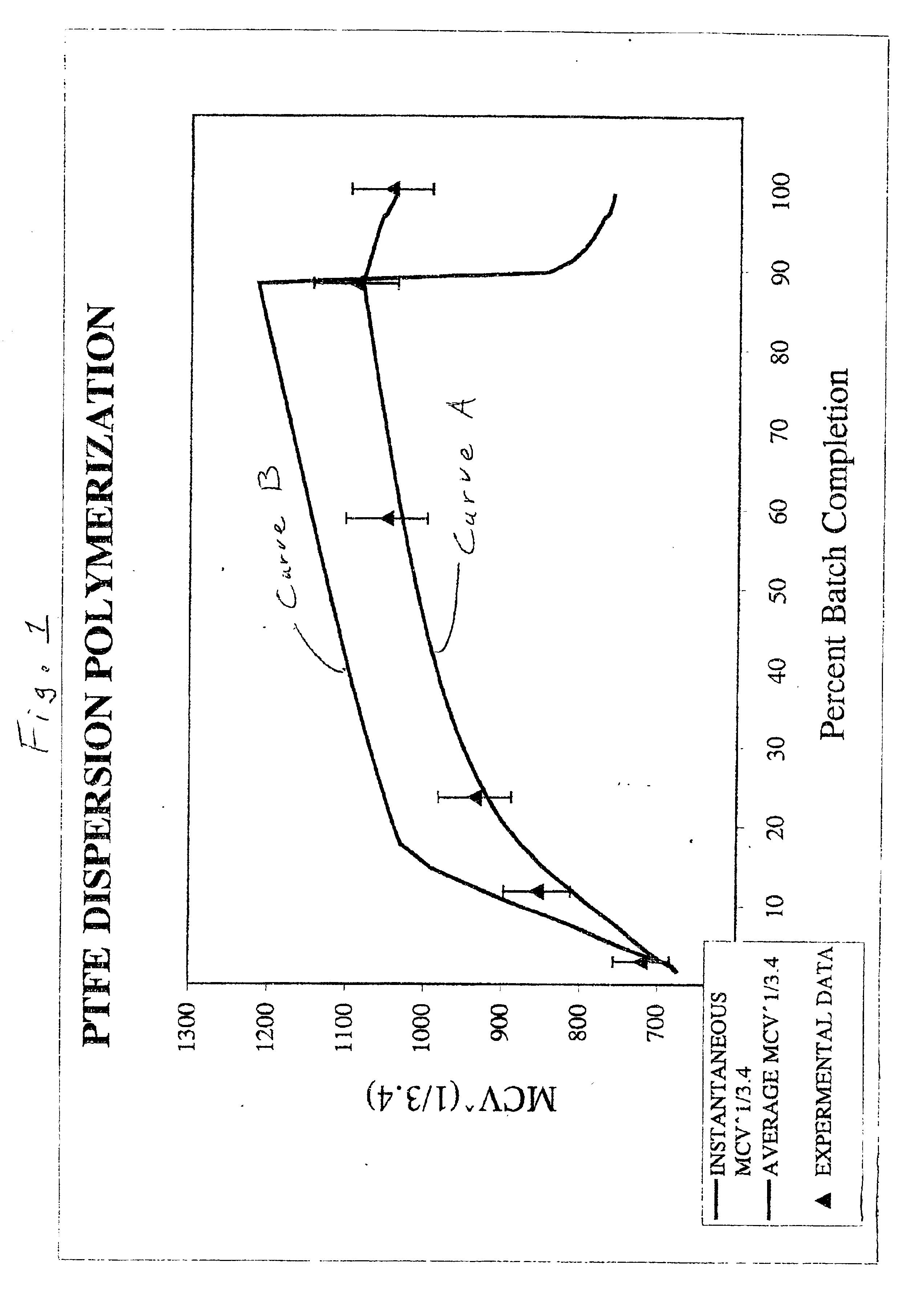

Core-shell fluoropolymer dispersions

InactiveUS6841594B2High shear stabilityExtend elastic lifeSynthetic resin layered productsCellulosic plastic layered productsTetrafluoroethylenePolymer science

A dispersion of non-melt-processible fluoropolymer particles having an SSG of less than about 2.225 in aqueous medium. The fluoropolymer particles comprise a core of high molecular weight polytetrafluoroethylene having an average melt creep viscosity greater than about 1.5×1010 Pa·s and a shell of lower molecular weight polytetrafluoroethylene or modified polytetrafluoroethylene. The shell has an average melt creep viscosity greater than about 9×109 Pa·s and comprises about 5 to about 30% by weight of the particles. The fluoropolymer in the dispersion of the invention is fibrillating.

Owner:THE CHEMOURS CO FC LLC

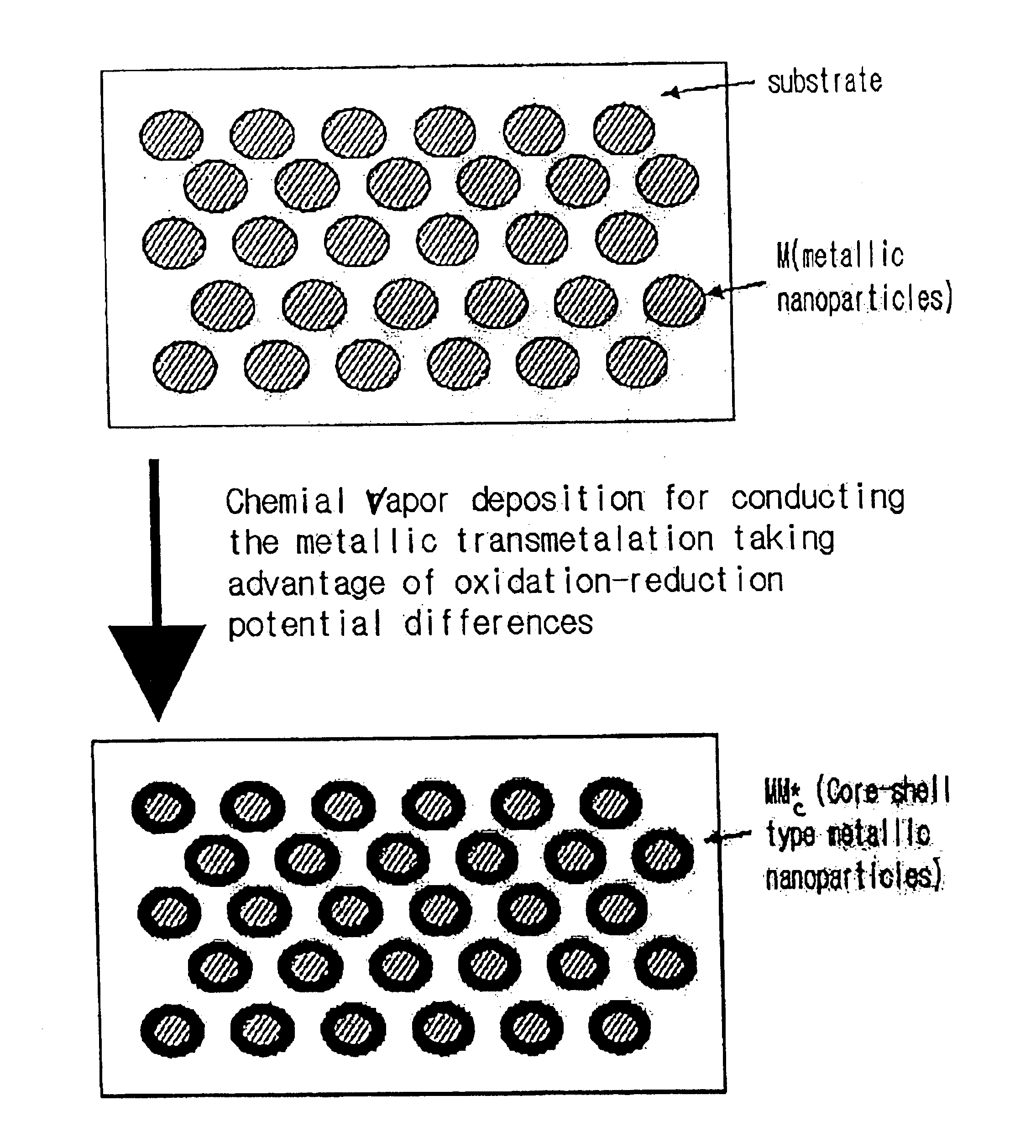

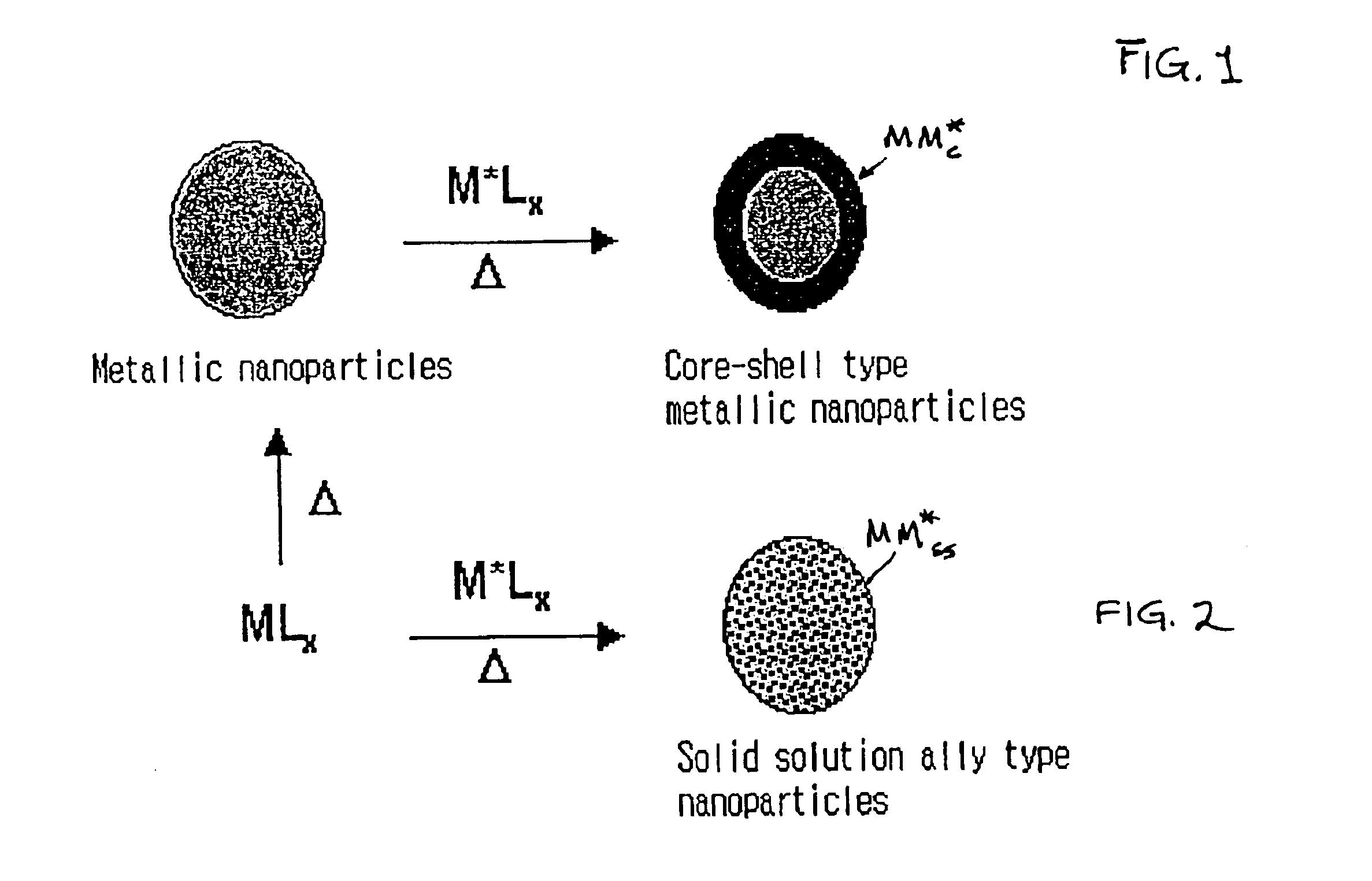

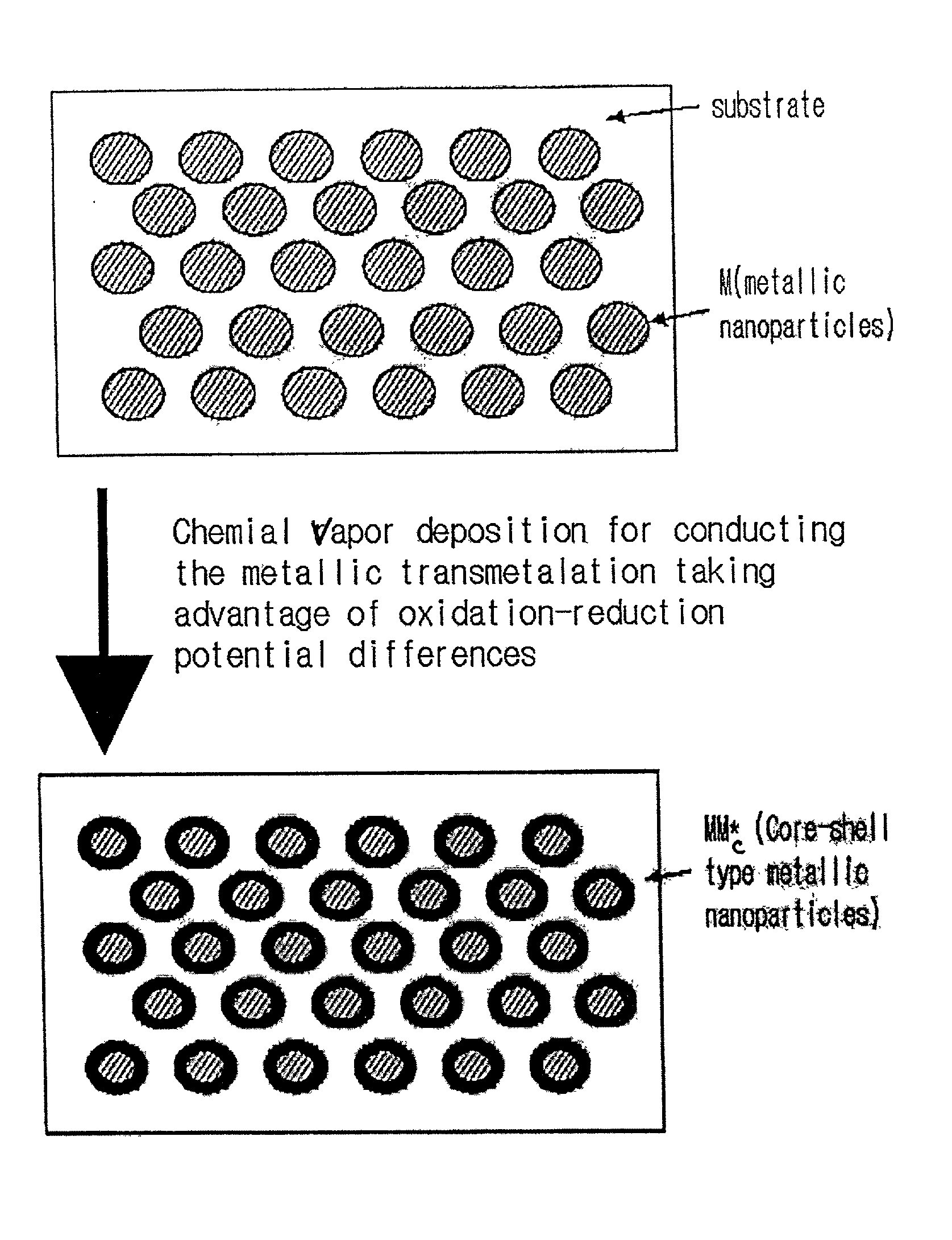

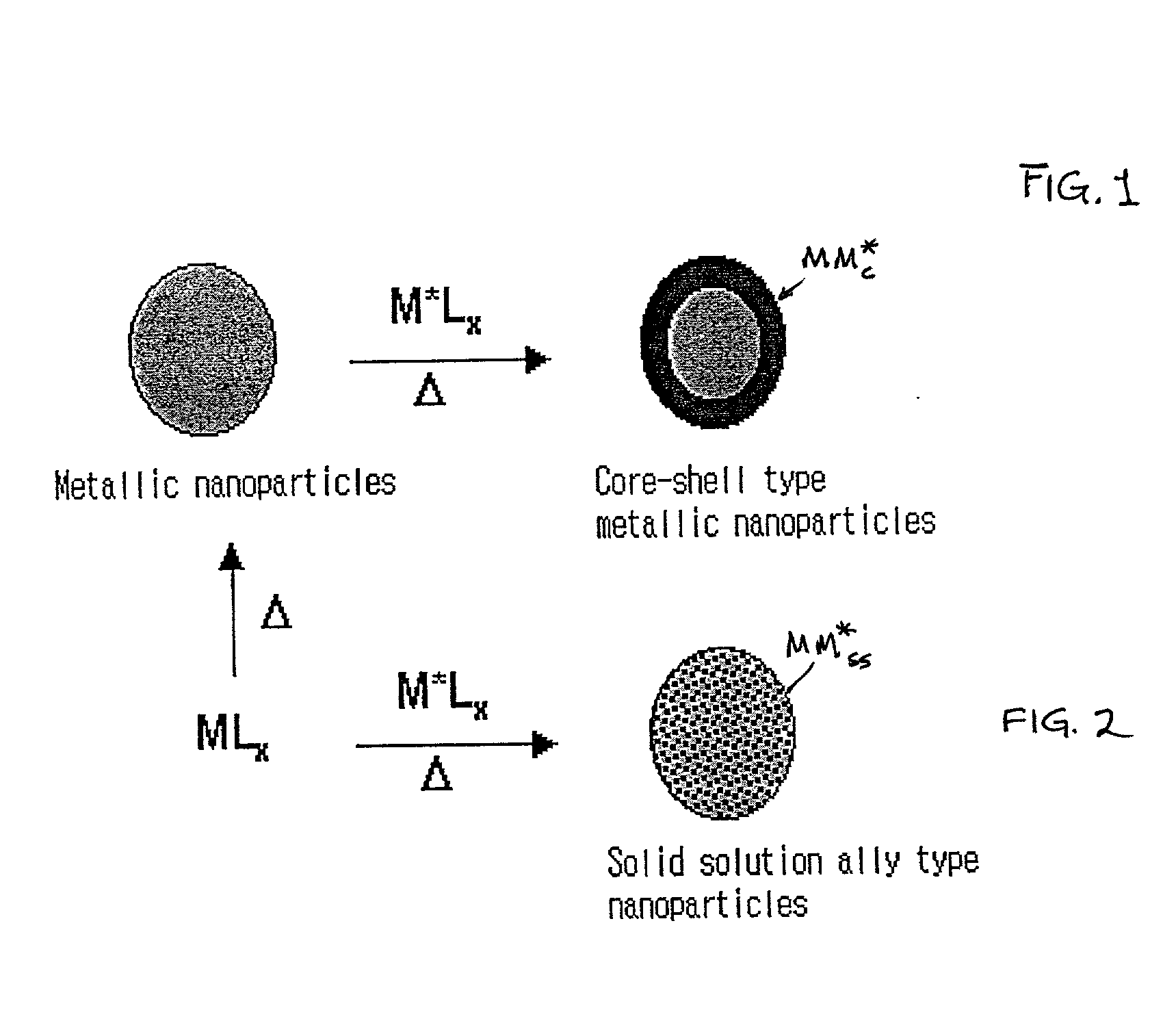

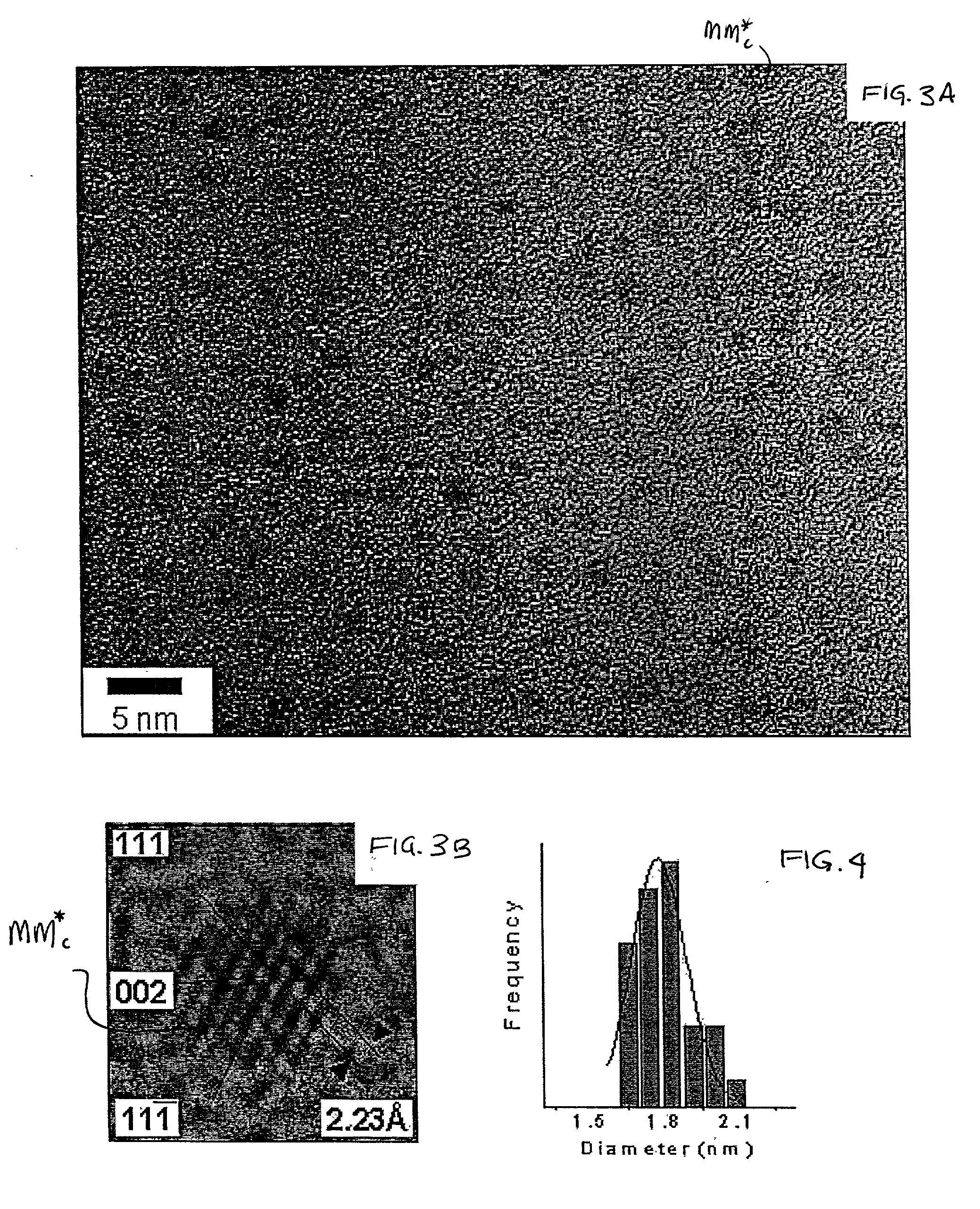

Method for synthesis of core-shell type and solid solution alloy type metallic nanoparticles via transmetalation reactions and applications of same

Disclosed is a method for producing core-shell type metallic nanoparticles involving (i) providing a dispersion of a first metal as nanoparticles in an appropriate organic solvent; (ii) providing a solution of a metallic precursor containing a second metal in an appropriate organic solvent, in which the second metal has a reduction potential higher than that of the first metal; and (iii) combining the dispersion from (i) and the solution from (ii) together to carry out the transmetalation reaction of the first and second metals, thereby forming core-shell type metallic nanoparticles.

Owner:KOREA ADVANCED INST OF SCI & TECH

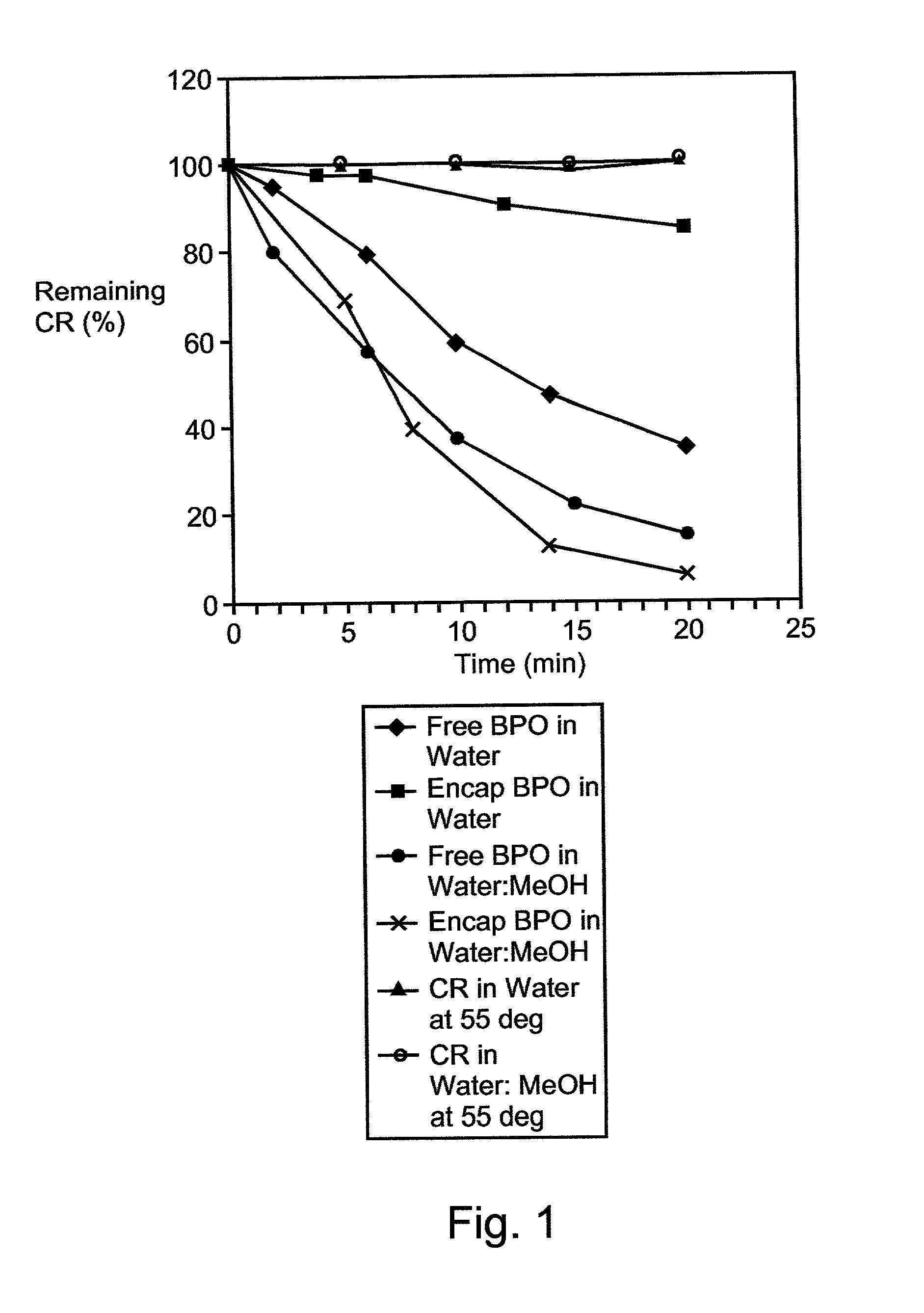

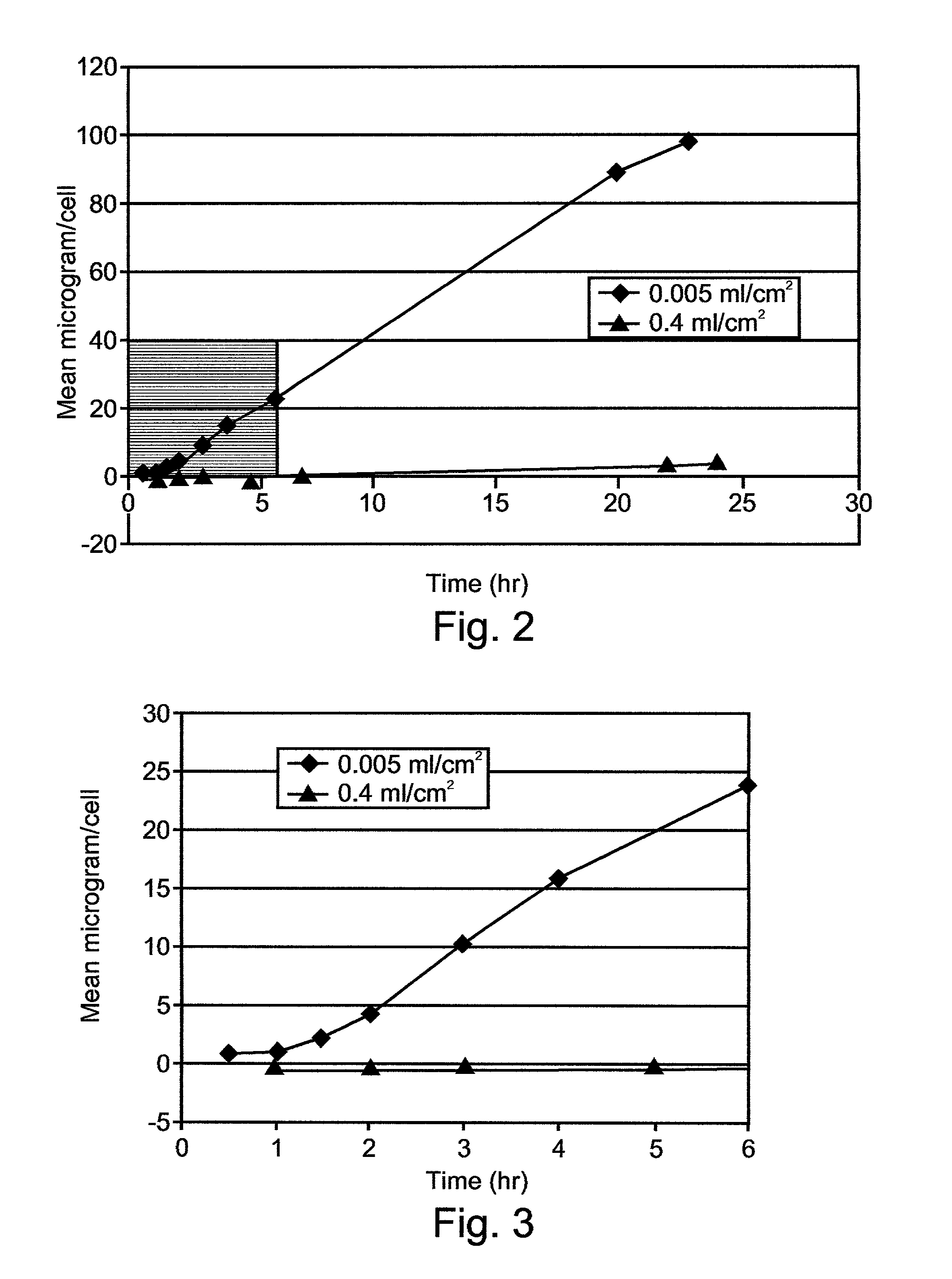

Composition exhibiting enhanced formulation stability and delivery of topical active ingredients

InactiveUS7758888B2Improve stabilityExtended shelf lifeAntibacterial agentsCosmetic preparationsBenzoyl peroxideMedicine

A therapeutic, cosmetic or cosmeceutic composition for topical application, capable of stabilizing an active ingredient and delivering the active ingredient, comprising a plurality of microcapsules having a core-shell structure. The microcapsules have a diameter of approximately 0.1 to 100 micron. The core of each microcapsule includes at least one active ingredient and is encapsulated within a microcapsular shell. The shell is comprised of at least one inorganic polymer obtained by a sol-gel process, and the shell protects the active ingredient before topical application and is designed to release the active ingredient from the microcapsules following application. The composition is useful in encapsulating active ingredients, such as benzoyl peroxide, that are unstable in other formulation, or are irritating to the skin.

Owner:SOL GEL TECH

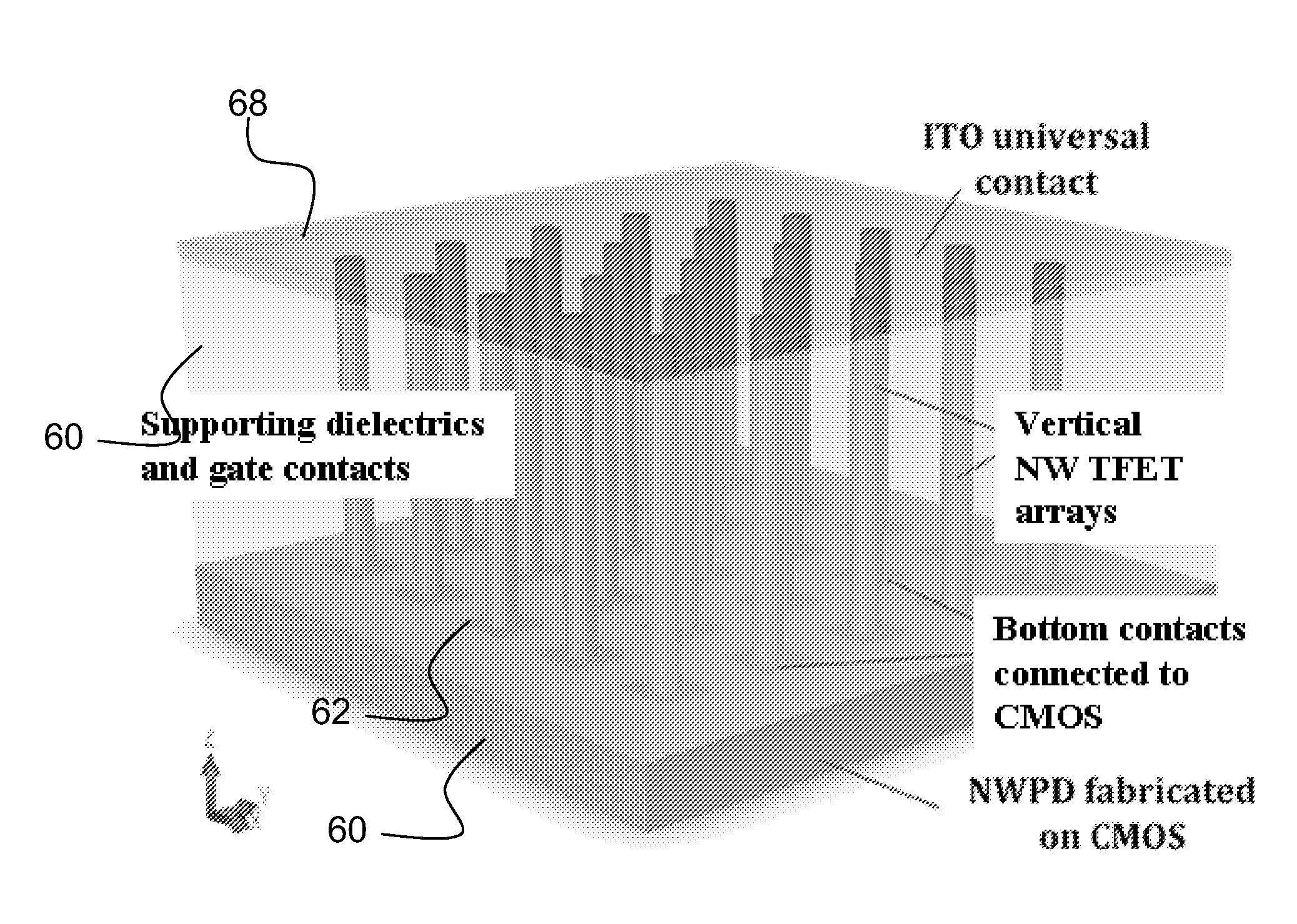

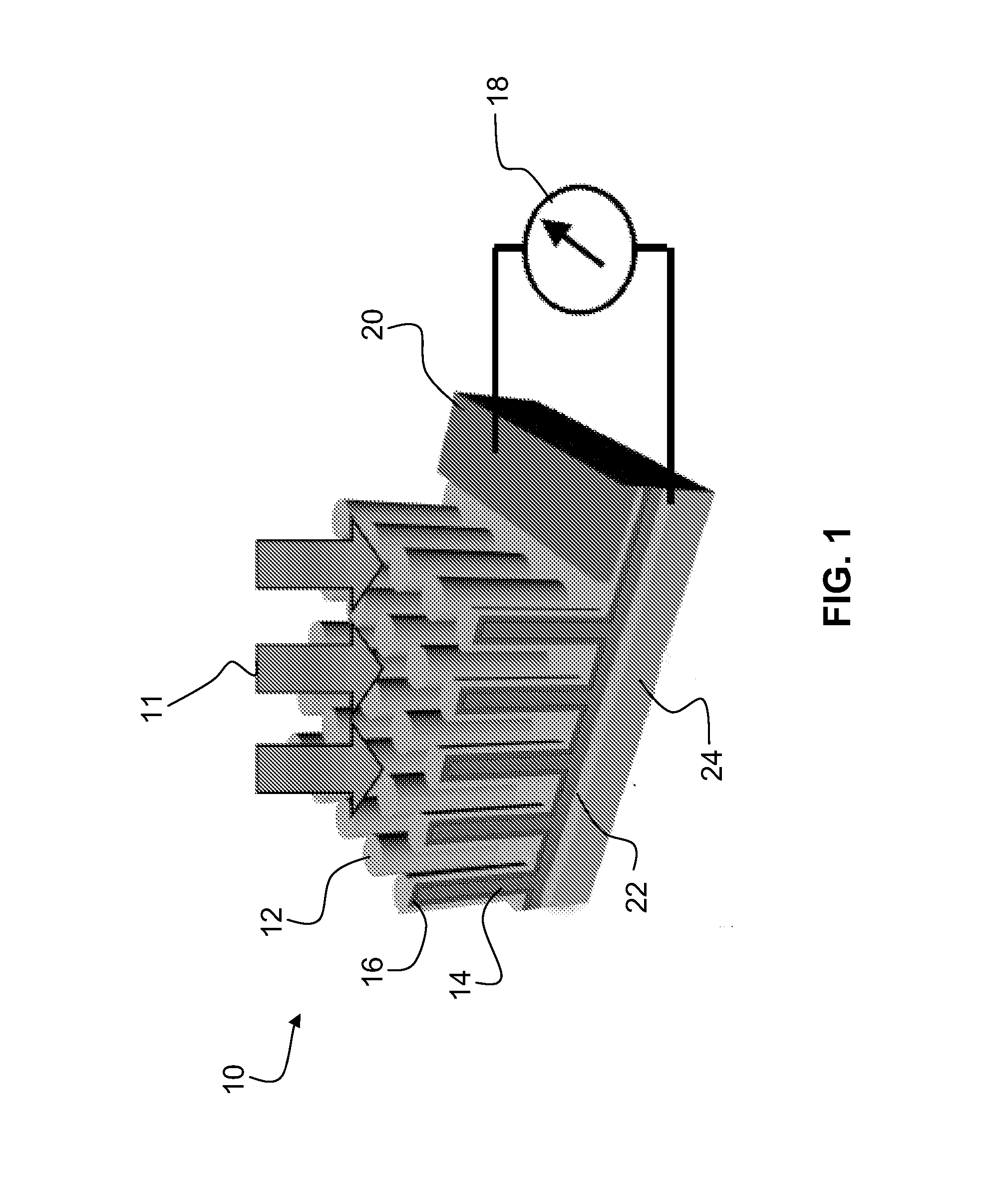

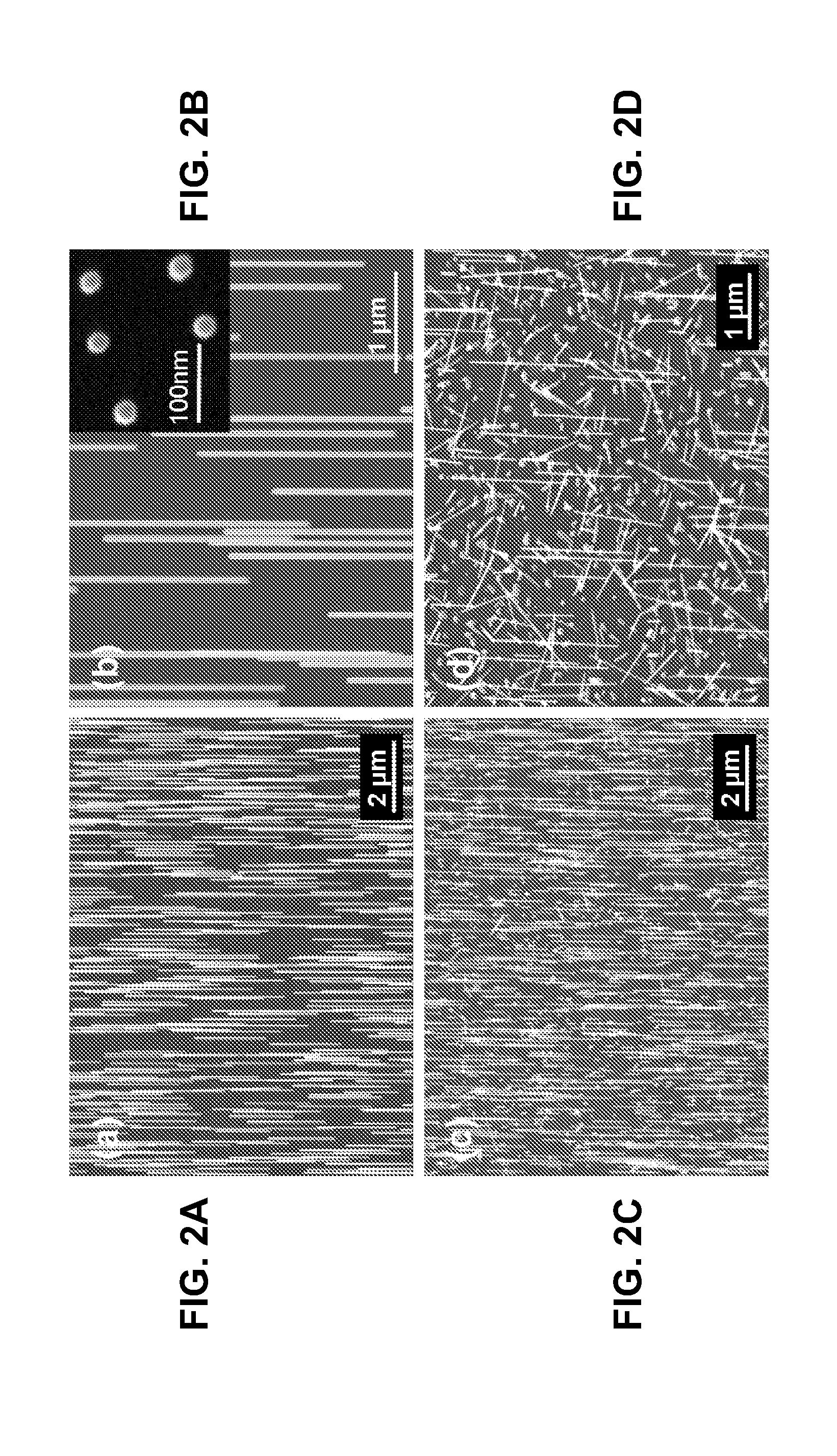

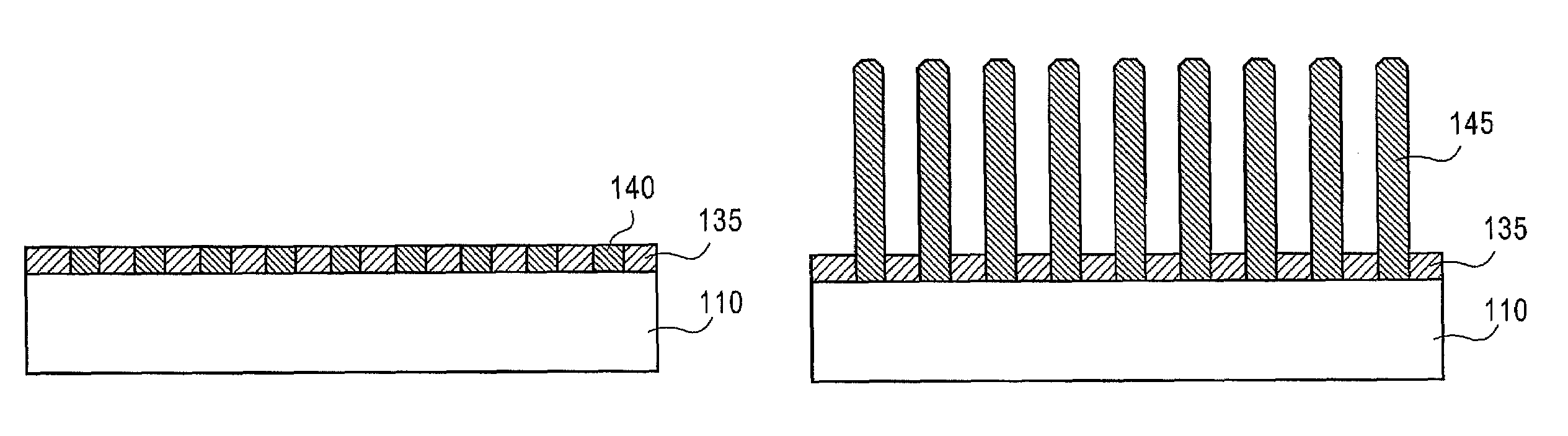

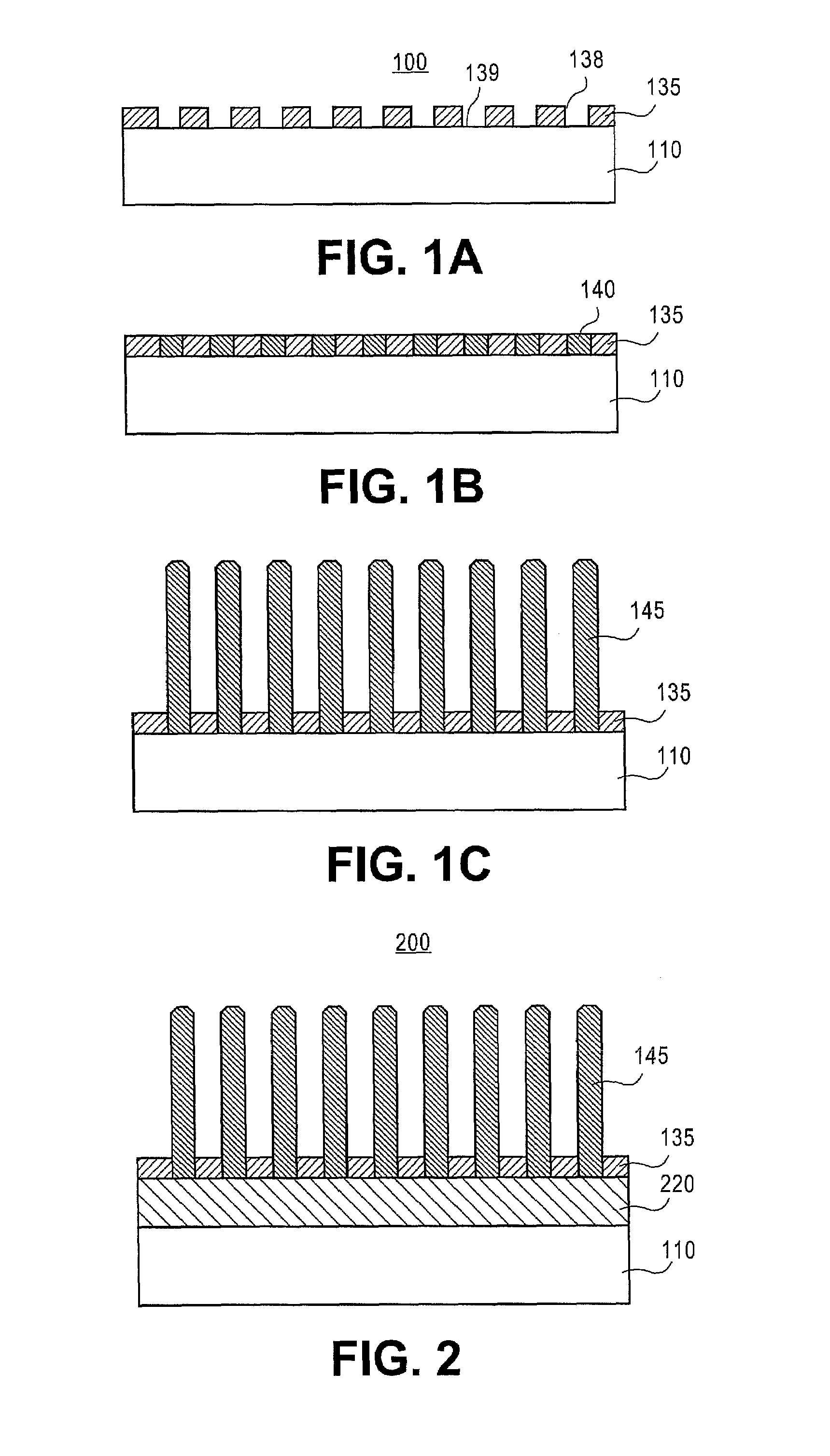

Vertical group iii-v nanowires on si, heterostructures, flexible arrays and fabrication

ActiveUS20110253982A1Promote absorptionReduce distanceNanoinformaticsSolid-state devicesNanowire arrayCore shell

Embodiments of the invention provide a method for direct heteroepitaxial growth of vertical III-V semiconductor nanowires on a silicon substrate. The silicon substrate is etched to substantially completely remove native oxide. It is promptly placed in a reaction chamber. The substrate is heated and maintained at a growth temperature. Group III-V precursors are flowed for a growth time. Preferred embodiment vertical Group III-V nanowires on silicon have a core-shell structure, which provides a radial homojunction or heterojunction. A doped nanowire core is surrounded by a shell with complementary doping. Such can provide high optical absorption due to the long optical path in the axial direction of the vertical nanowires, while reducing considerably the distance over which carriers must diffuse before being collected in the radial direction. Alloy composition can also be varied. Radial and axial homojunctions and heterojunctions can be realized. Embodiments provide for flexible Group III-V nanowire structures. An array of Group III-V nanowire structures is embedded in polymer. A fabrication method forms the vertical nanowires on a substrate, e.g., a silicon substrate. Preferably, the nanowires are formed by the preferred methods for fabrication of Group III-V nanowires on silicon. Devices can be formed with core / shell and core / multi-shell nanowires and the devices are released from the substrate upon which the nanowires were formed to create a flexible structure that includes an array of vertical nanowires embedded in polymer.

Owner:RGT UNIV OF CALIFORNIA

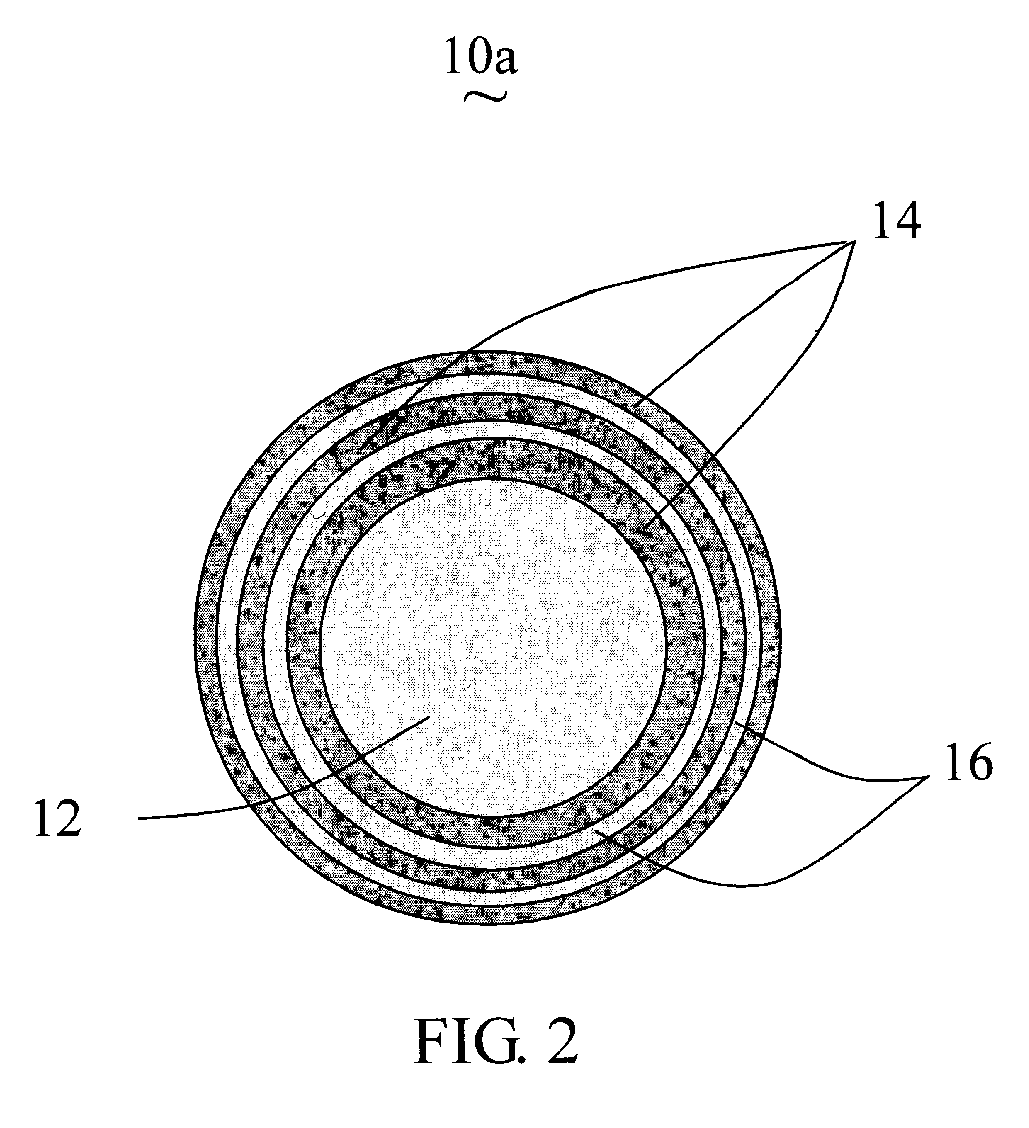

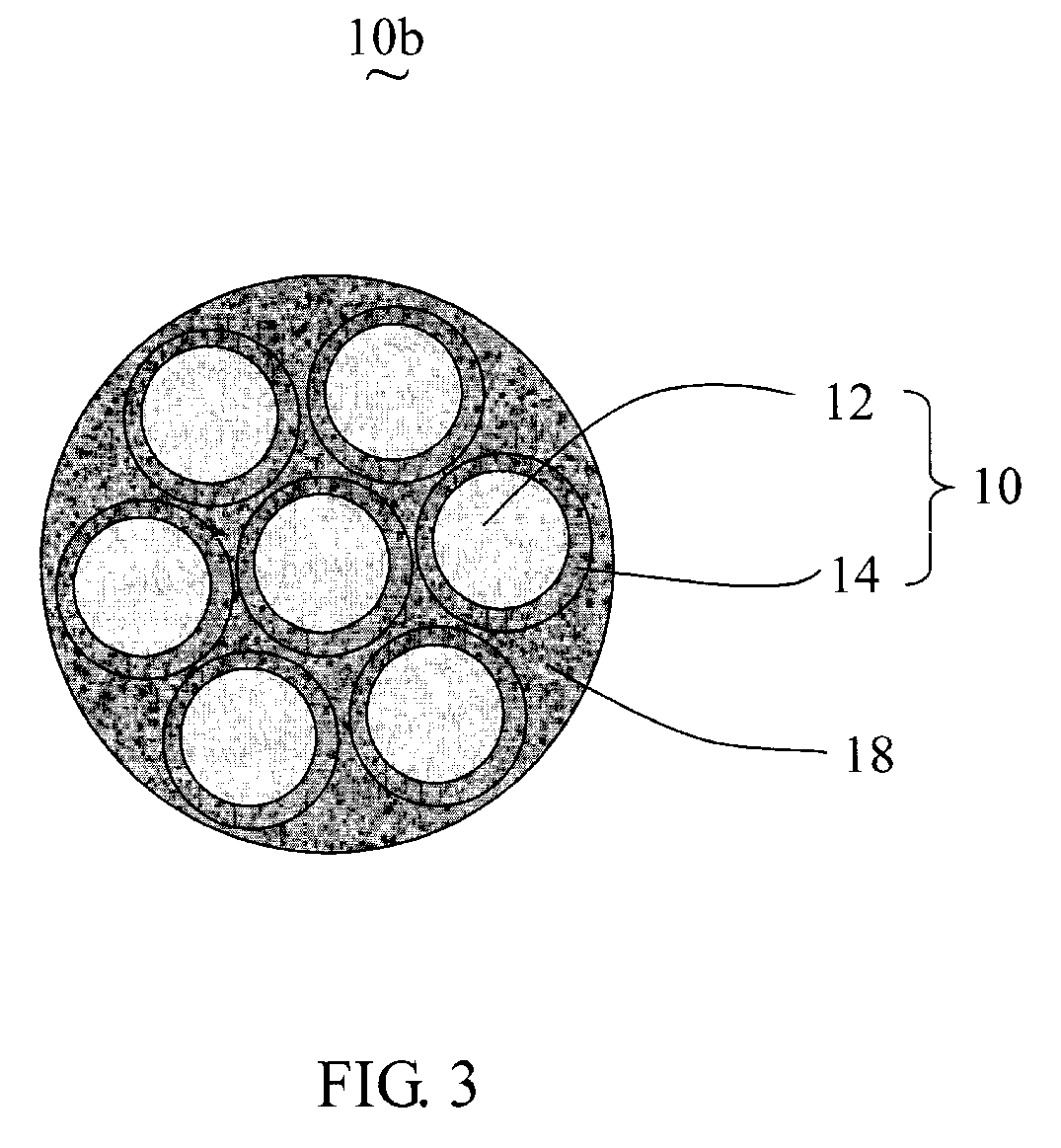

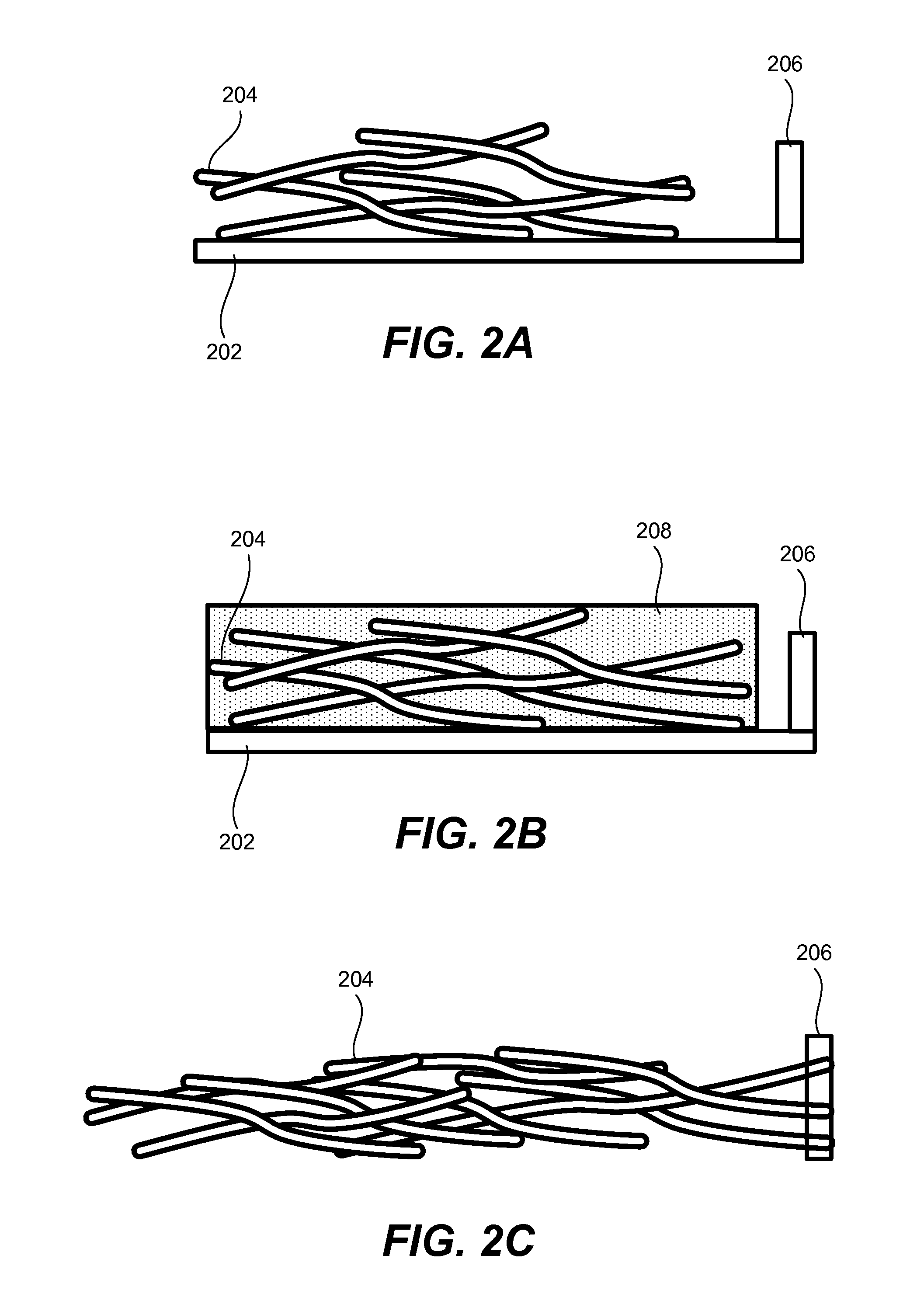

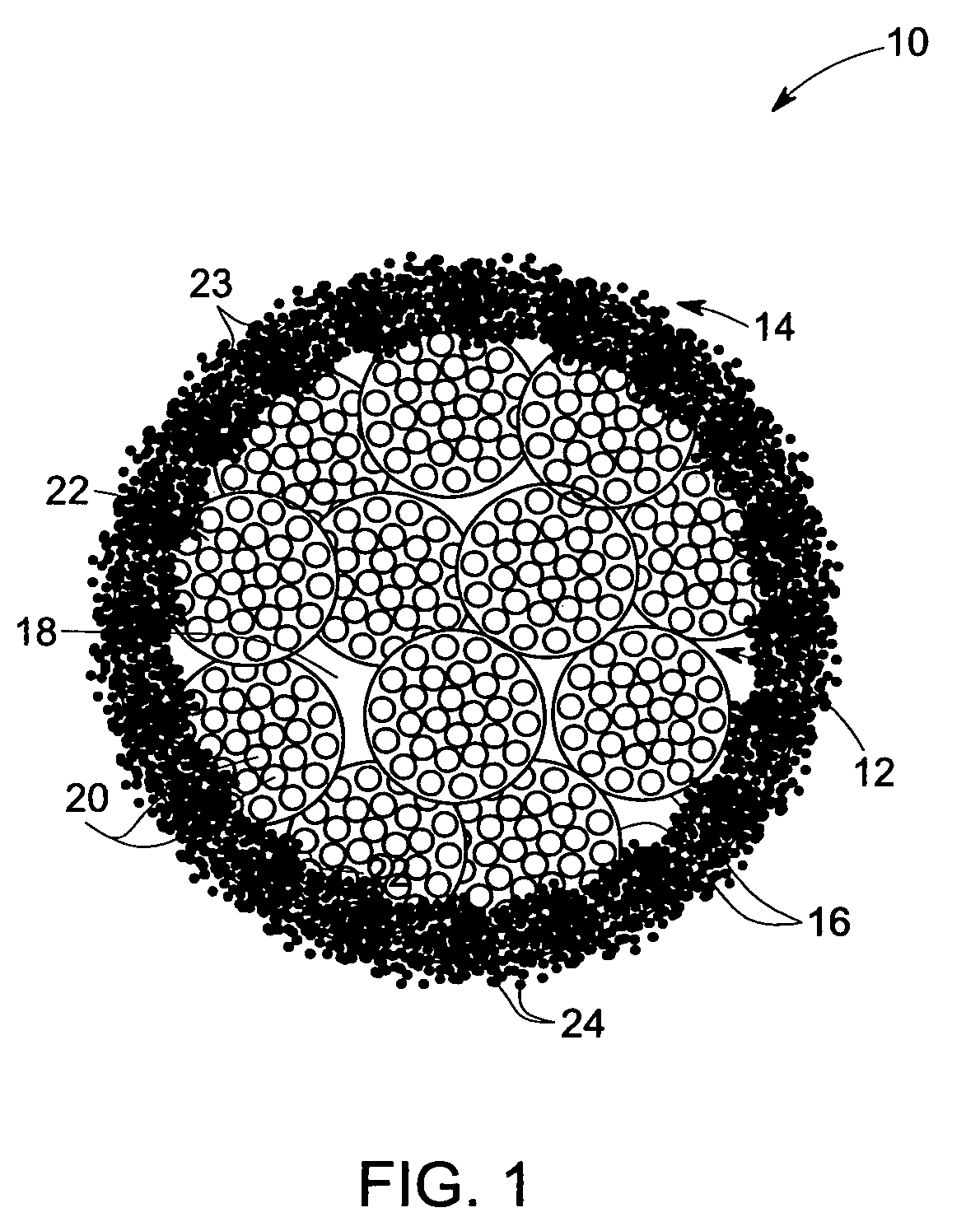

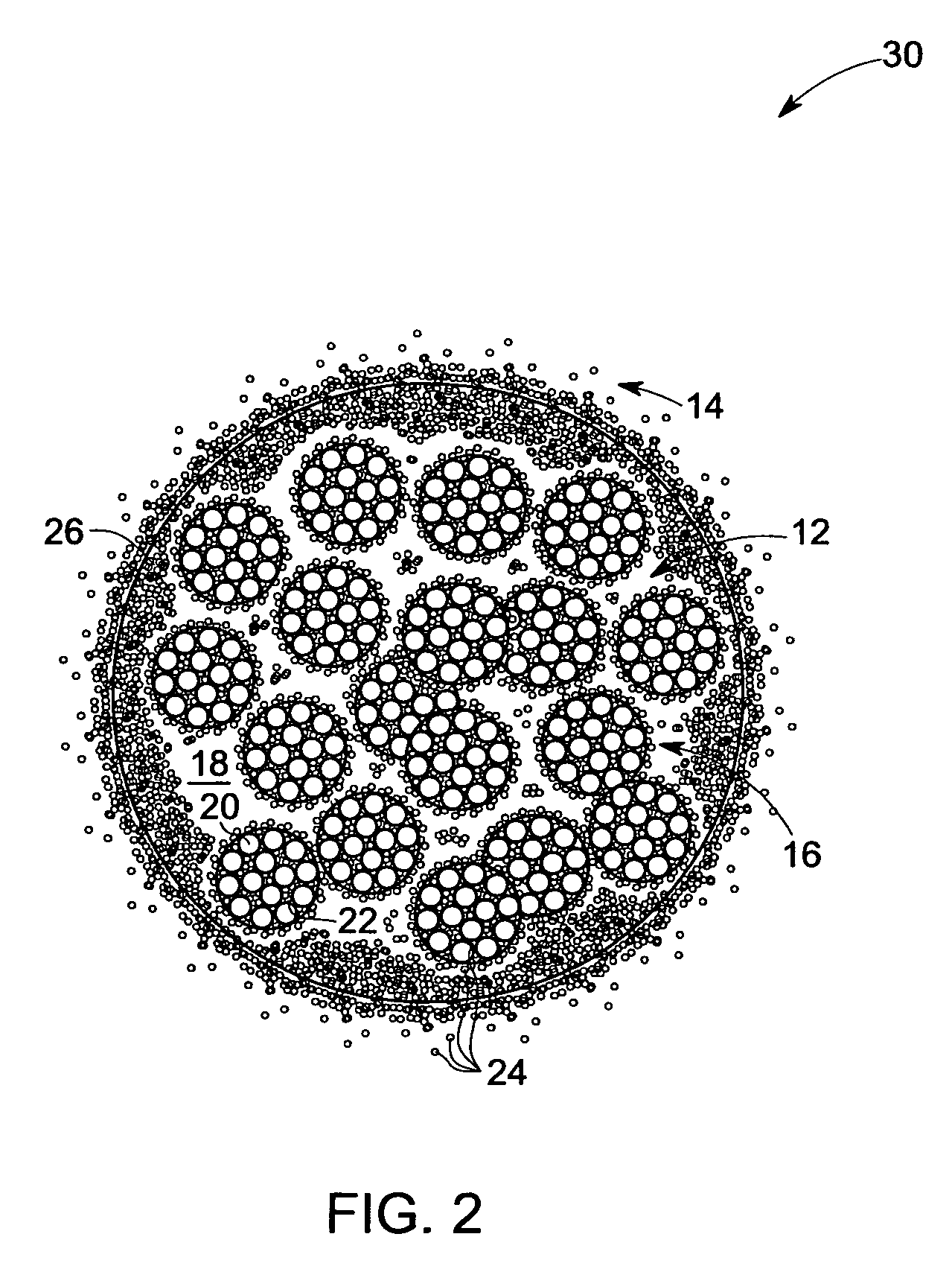

Toughened fiber reinforced polymer composite with core-shell particles

Embodiments disclosed herein include a resin composition comprising two or more different kinds of thermosetting resins, wherein at least one of the two or more different kinds of the thermosetting resins is a multifunctional resin, and a core-shell particle having a core and a shell, wherein a composition of the core is different from a composition of the shell and the composition of the shell has a branched polymer structure comprising at least one main chain and at least one side chain, the main chain or the side chain containing at least one functional group that reacts with the thermosetting resin, a method of manufacturing the resin composition, and a composite comprising a reinforcing fiber and the resin composition.

Owner:TORAY IND INC

Smooth, flexible powder coatings

The present invention, a powder composition for making powder coatings comprising one or more than one curable polymer or resin and an agglomerate of a core-shell polymer, wherein the agglomerate of a core-shell polymer has an average particle size of from 5 to 190 microns, preferably from 10 to 127 microns. The powders in accordance with the present invention provide a cured powder coating that is flexible, smooth, and which may be applied in a thickness of only from 0.3 to 8 mils. In a preferred embodiment of making a powder in accordance with the present invention, the agglomerate is cryoground to form a reduced agglomerate prior to adding it into a powder as a post-blend or a powder-forming mixture as a preblend. The preferred core-shell polymer for use in accordance with the present invention comprises an acrylic impact modifier having a poly(methyl methacrylate) shell and a poly(butyl acrylate) core. Further, the preferred curable polymer or resin powder is an epoxy resin, wherein the powder composition is a low temperature curing one component powder composition which cures at from 107 to 149 degrees C.

Owner:ROHM & HAAS CO

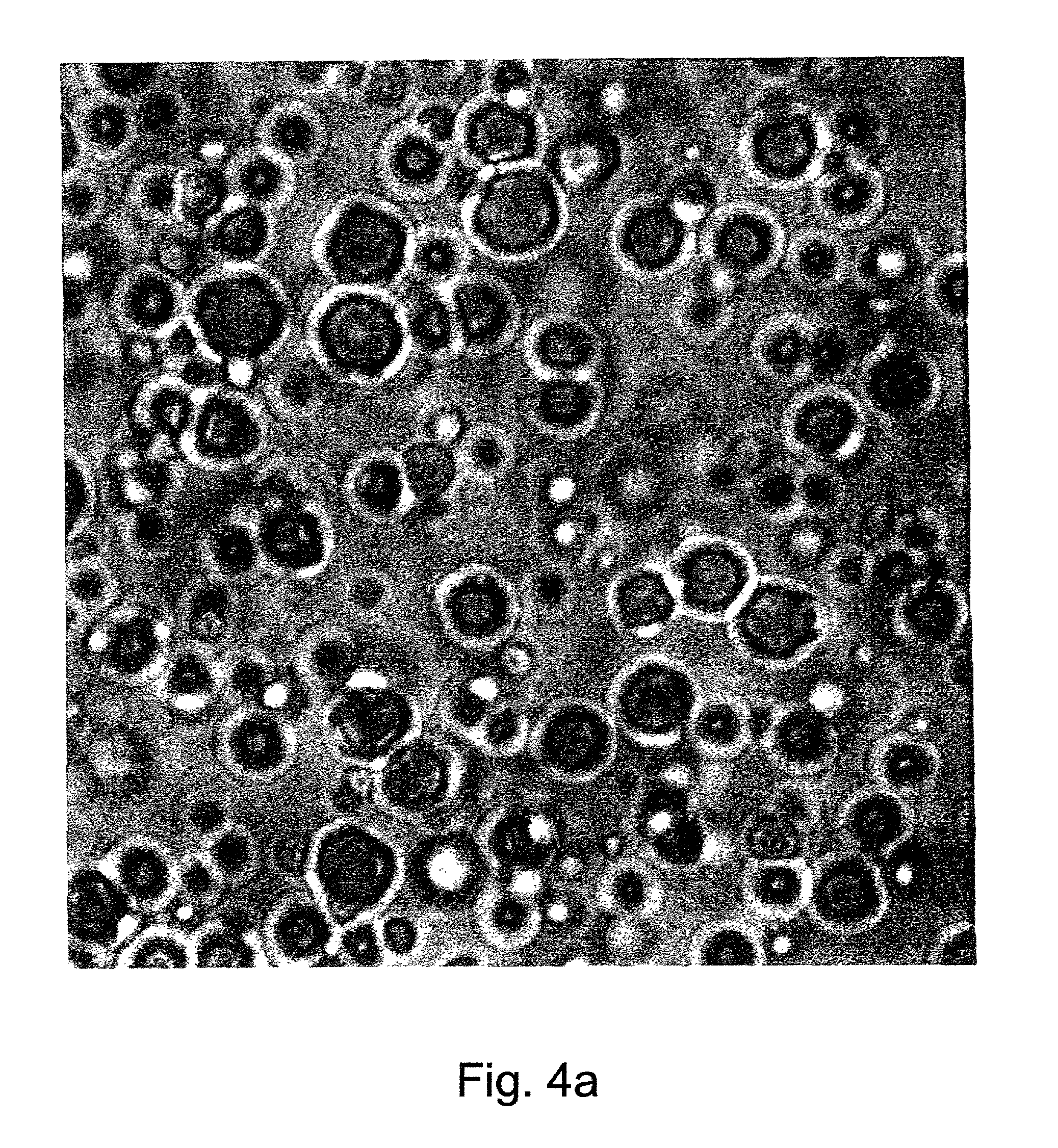

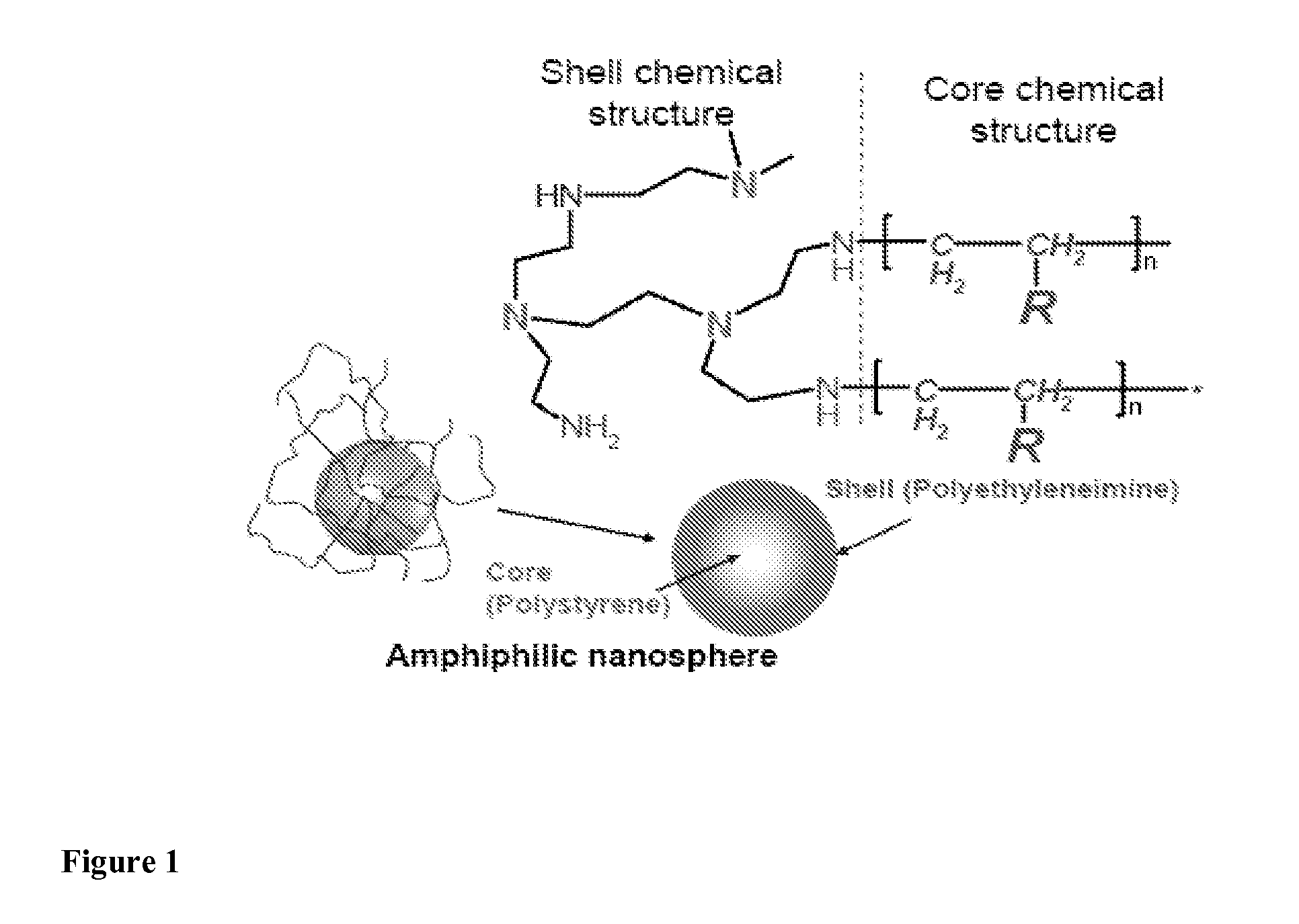

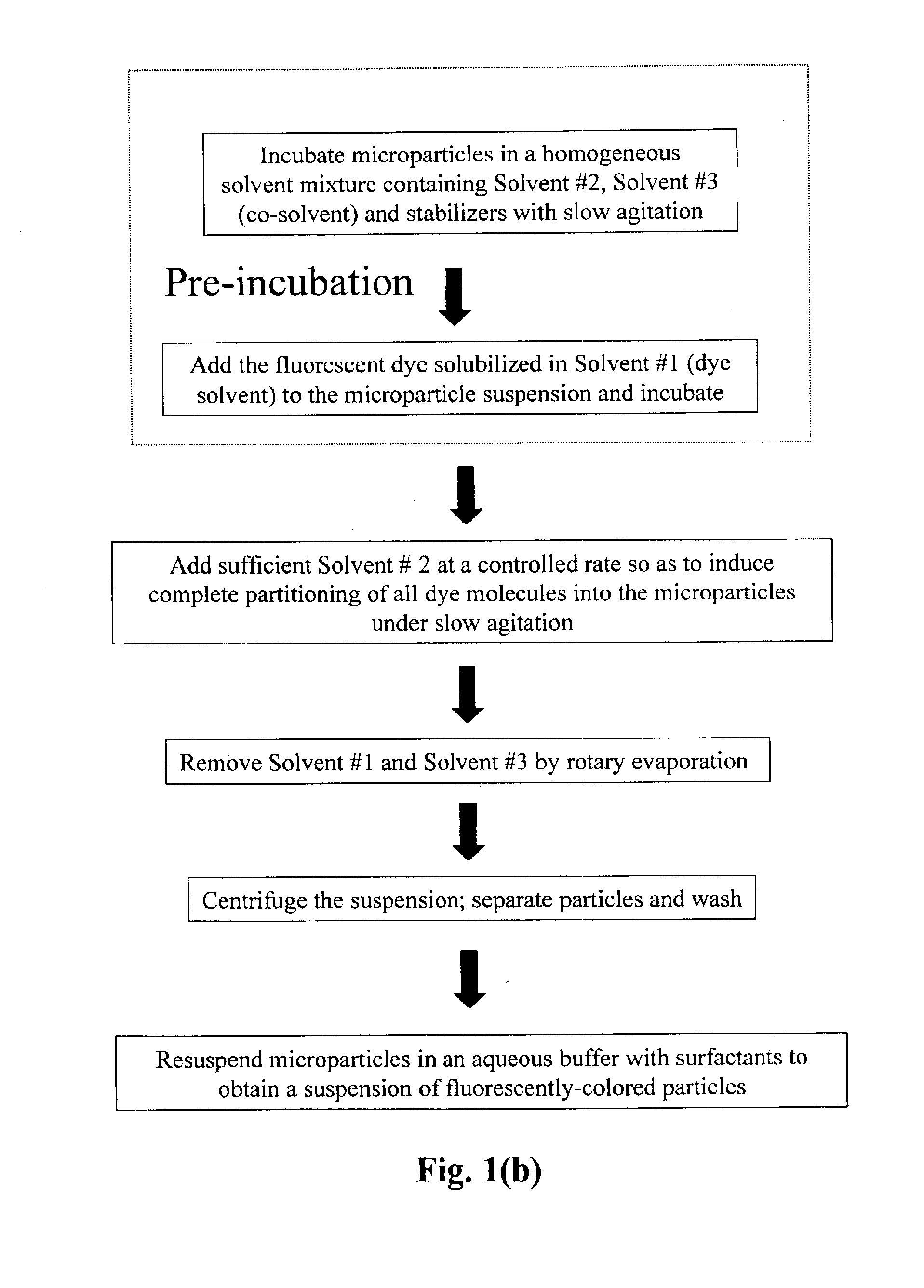

Production of dyed polymer microparticles

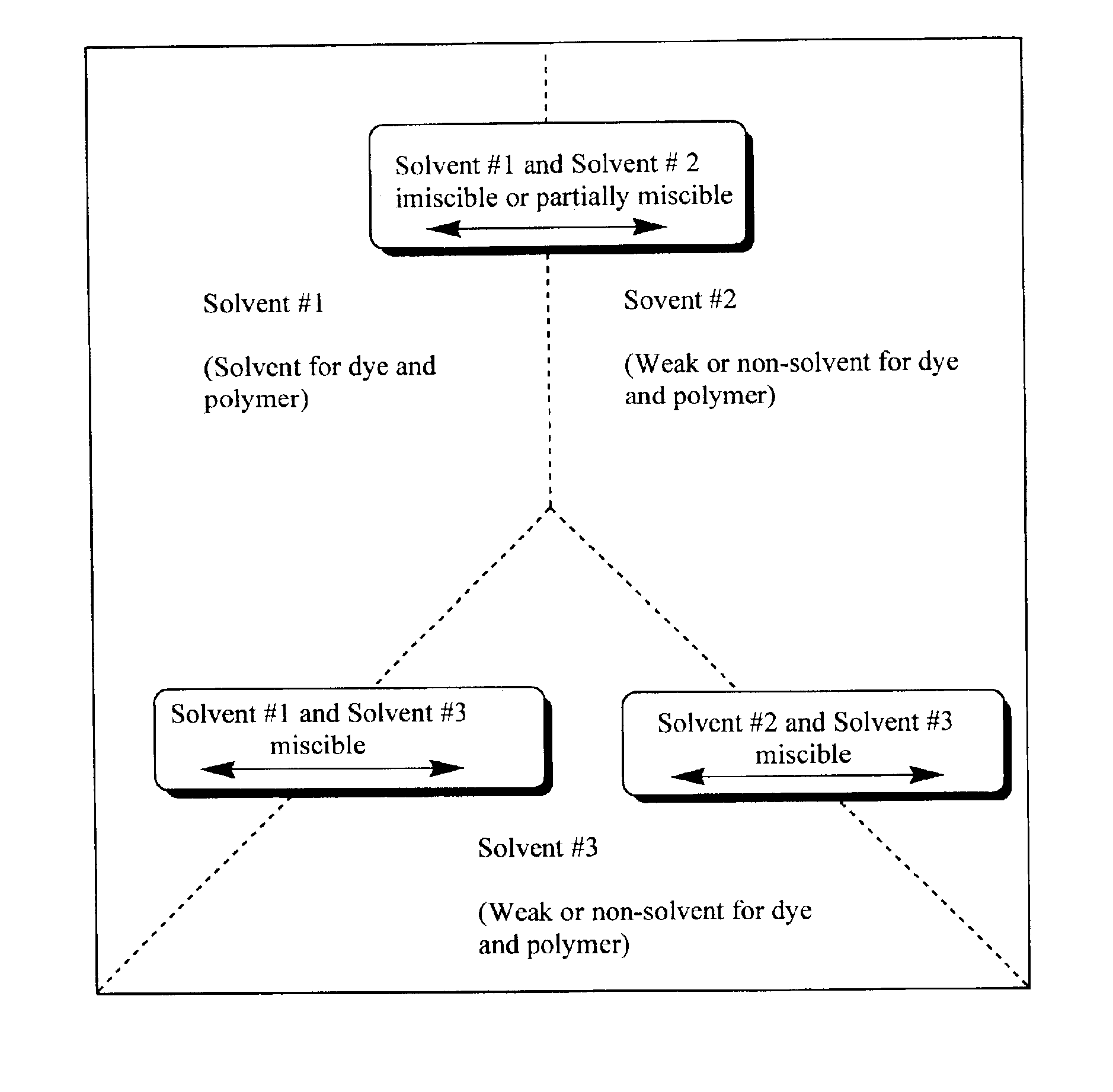

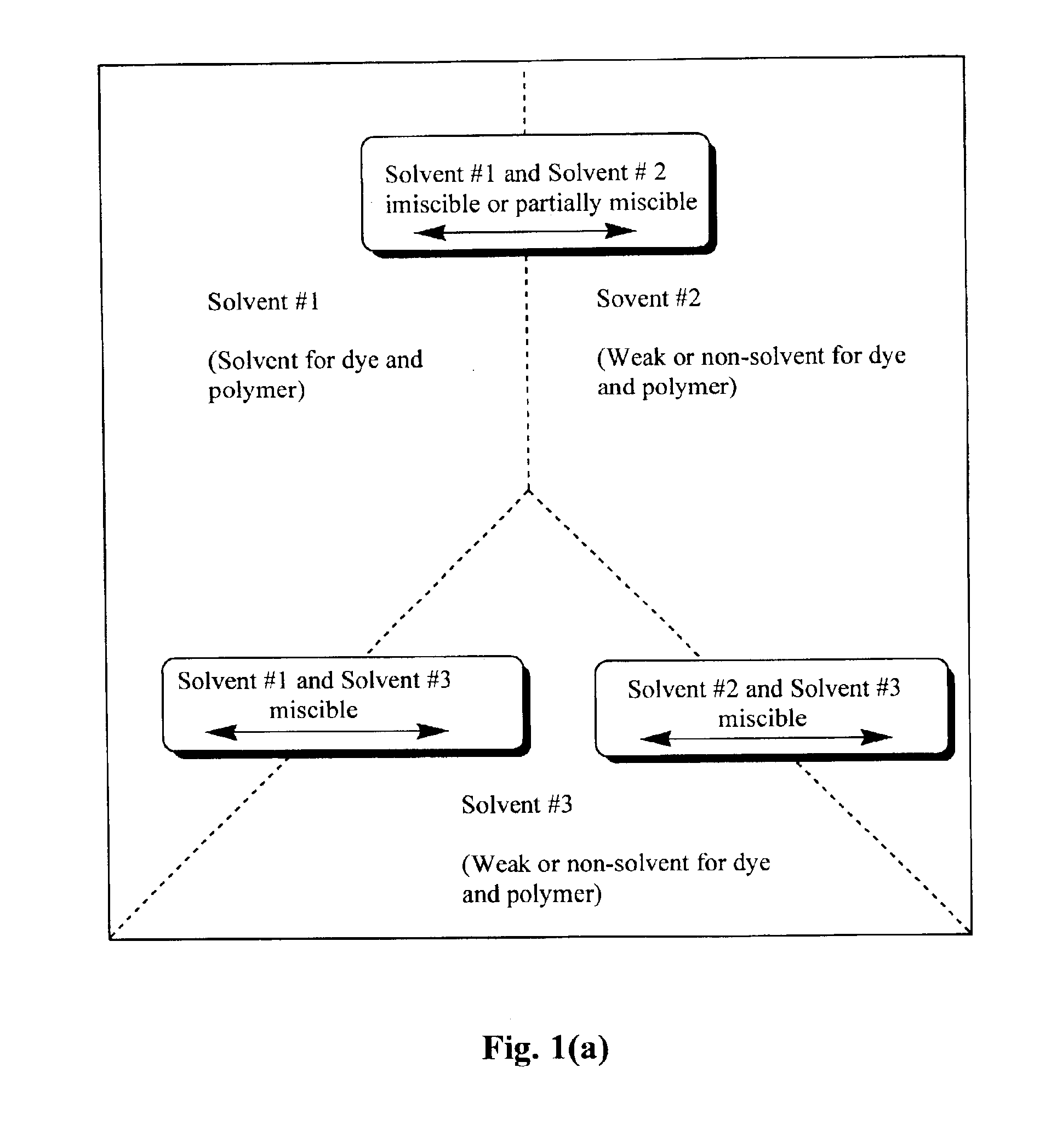

A dye, such as a fluorescent dye, is incorporated into polymer microparticles using a solvent system composed of a first solvent in which the dye and the microparticle polymer are soluble, a second solvent in which the dye and the microparticle polymer are not or only weakly soluble, and a third solvent in which the dye and the microparticle polymer are not or only weakly soluble. The first and second solvents are immiscible with each other, or at most partially miscible. The third solvent is miscible with the first and second solvents. The formulation provides substantially complete partitioning of the dye to the microparticles. The method may be used to obtain dyed polymer microparticle formed of cross-linked or non-cross-linked polymers. Libraries are provided comprising two or more sets of microparticles of different dye loadings. Fluorescent core-shell microparticles are produced from a mixture of microparticle cores incorporating one or more fluorescent dyes, a polymerization mixture comprising at least one polymerizable shell monomer, at least one free radical polymerization initiator comprising a water-insoluble oxidizing agent, and at least one water-soluble reducing agent.

Owner:BIOARRAY SOLUTIONS

Method for synthesis of core-shell type and solid solution alloy type metallic nanoparticles via transmetalation reactions and applications of same

Disclosed is a method for producing core-shell type metallic nanoparticles involving (i) providing a dispersion of a first metal as nanoparticles in an appropriate organic solvent; (ii) providing a solution of a metallic precursor containing a second metal in an appropriate organic solvent, in which the second metal has a reduction potential higher than that of the first metal; and (iii) combining the dispersion from (i) and the solution from (ii) together to carry out the transmetalation reaction of the first and second metals, thereby forming core-shell type metallic nanoparticles.

Owner:KOREA ADVANCED INST OF SCI & TECH

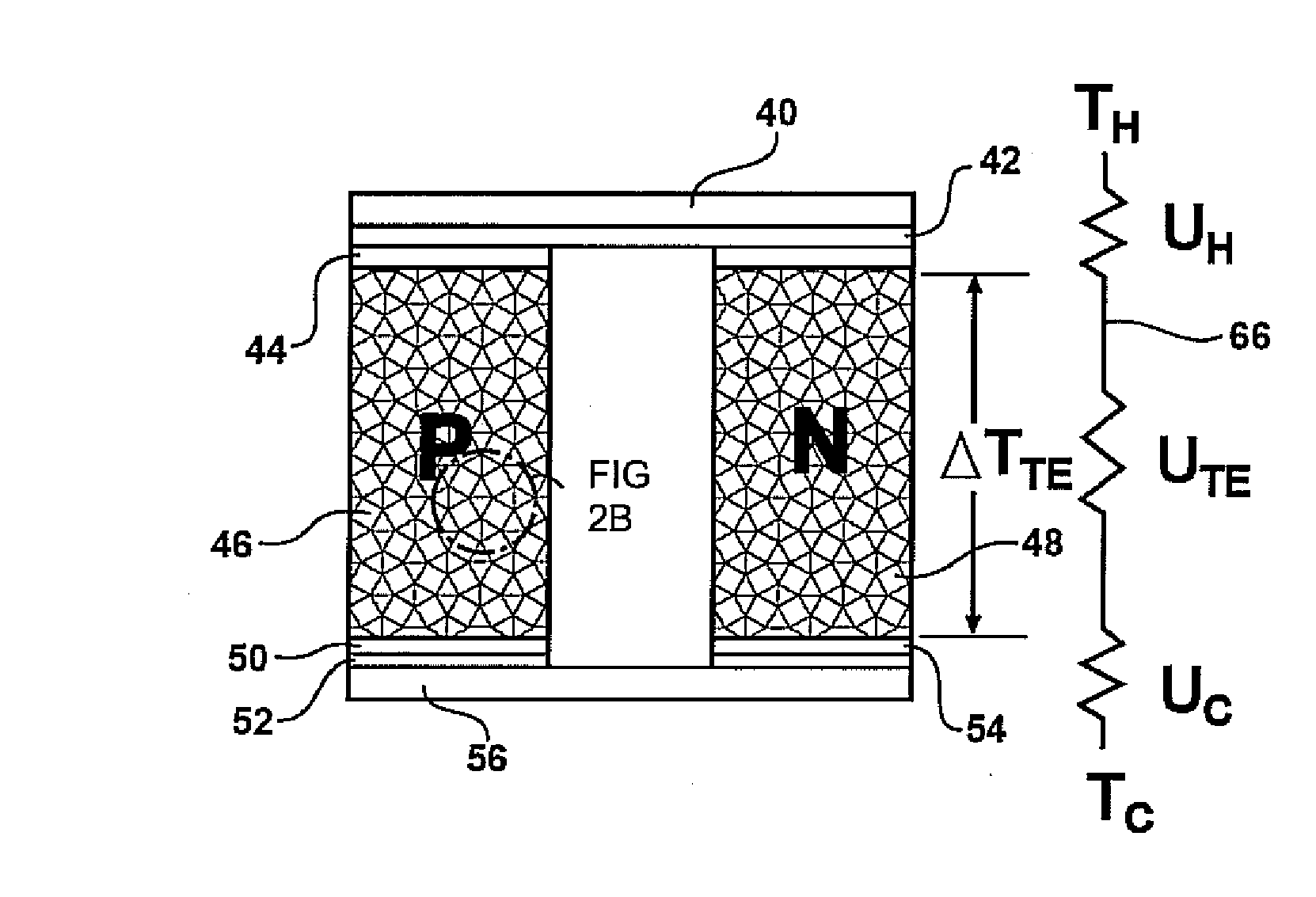

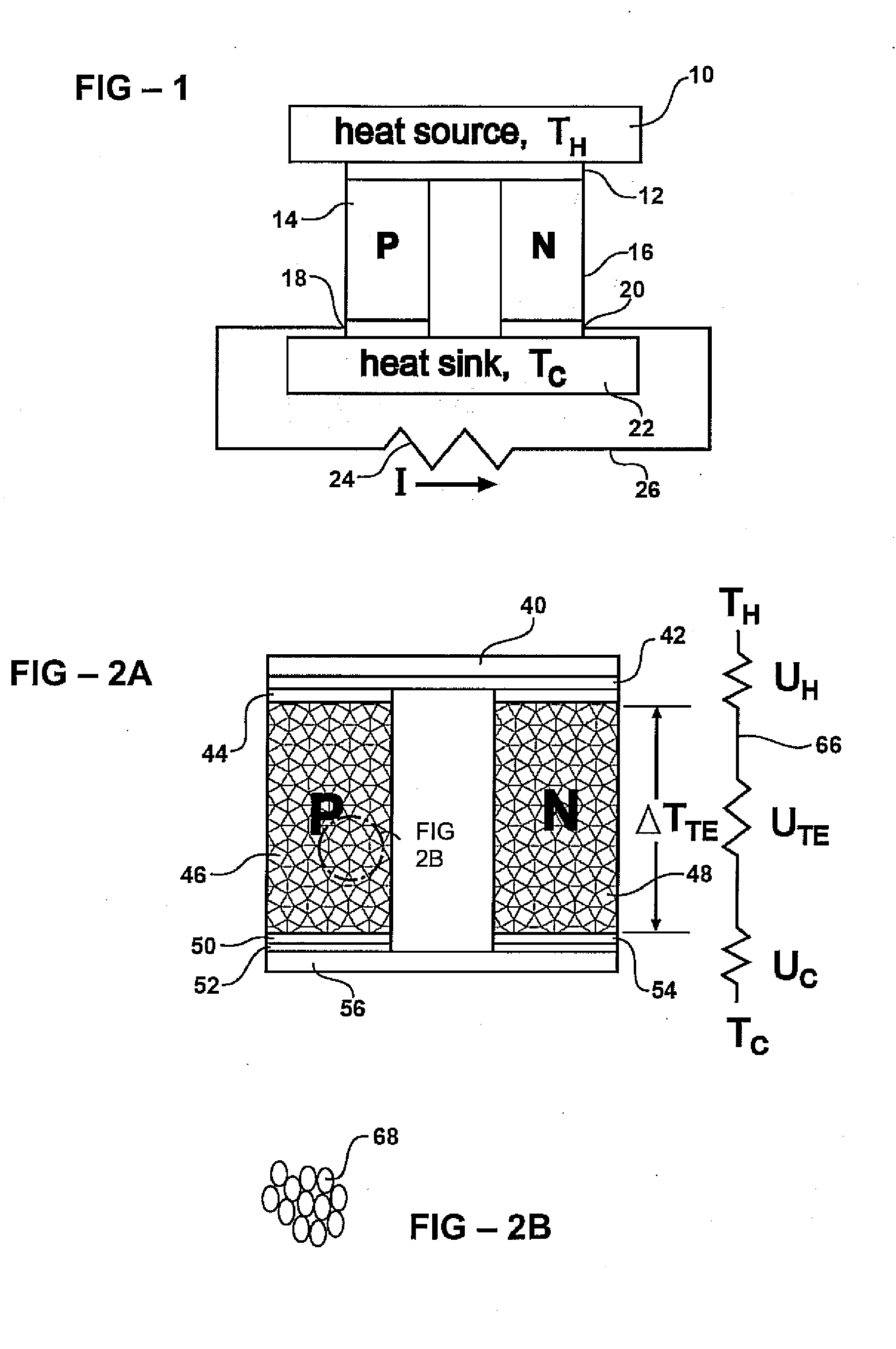

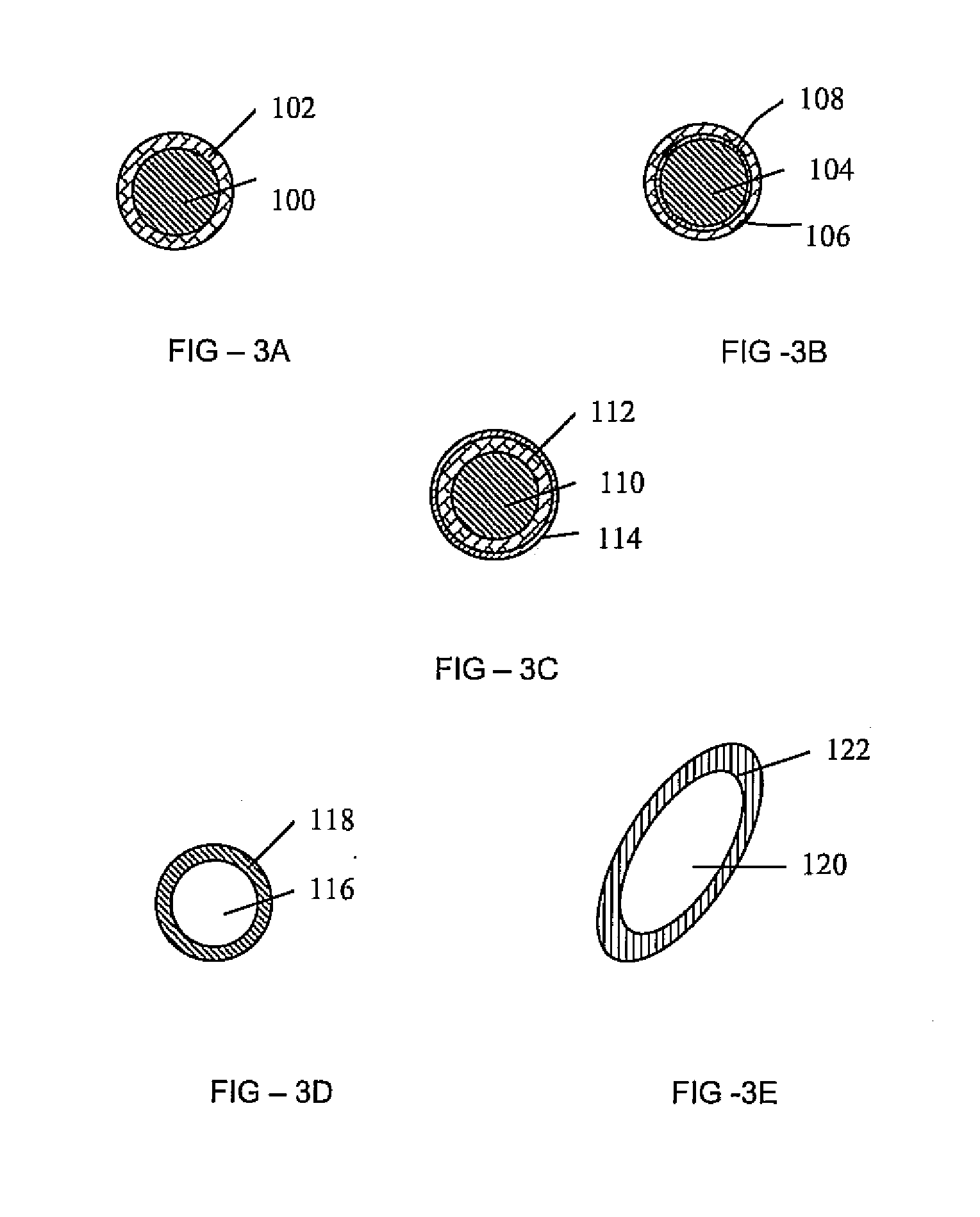

Homogeneous thermoelectric nanocomposite using core-shell nanoparticles

ActiveUS20080087314A1Uniform and improved thermoelectricThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentBismuth tellurideSilicon dioxide

A thermoelectric material comprises core-shell particles having a core formed from a core material and a shell formed from a shell material. In representative examples, the shell material is a material showing an appreciable thermoelectric effect in bulk. The core material preferably has a lower thermal conductivity than the shell material. In representative examples, the core material is an inorganic oxide such as silica or alumina, and the shell material is a chalcogenide semiconductor such as a telluride, for example bismuth telluride. A thermoelectric material including such core-shell particles may have an improved thermoelectric figure of merit compared with a bulk sample of the shell material alone. Embodiments of the invention further include thermoelectric devices using such thermoelectric materials, and preparation techniques. The use of core-shell nanoparticles allows highly uniform nanocomposites to be formed, and embodiments of the invention also includes other materials and devices using core-shell particles.

Owner:TOYOTA MOTOR CO LTD +1

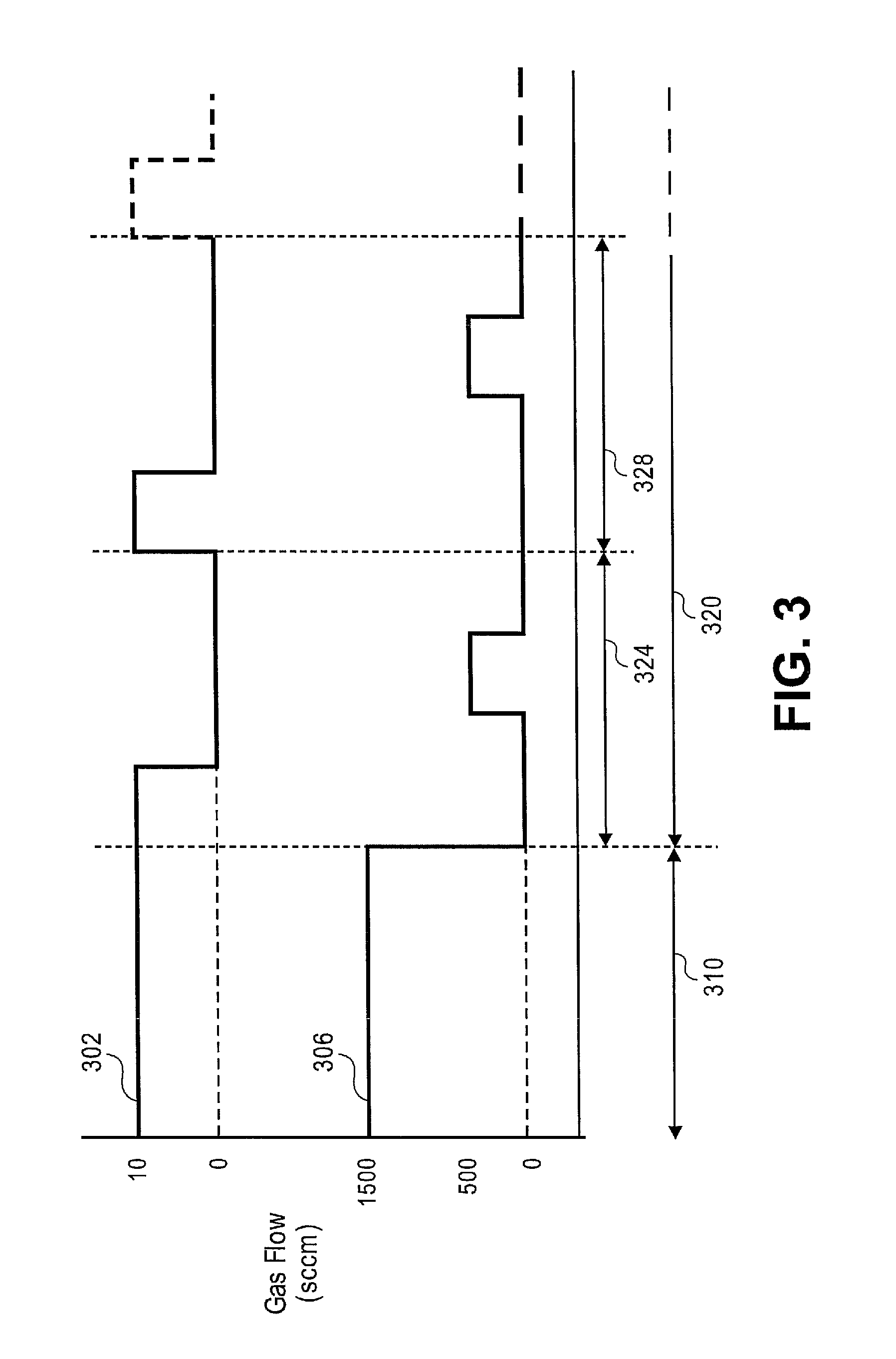

Pulsed growth of catalyst-free growth of GaN nanowires and application in group III nitride semiconductor bulk material

Exemplary embodiments provide semiconductor devices including high-quality (i.e., defect free) group III-N nanowires and uniform group III-N nanowire arrays as well as their scalable processes for manufacturing, where the position, orientation, cross-sectional features, length and the crystallinity of each nanowire can be precisely controlled. A pulsed growth mode can be used to fabricate the disclosed group III-N nanowires and / or nanowire arrays providing a uniform length of about 10 nm to about 1000 microns with constant cross-sectional features including an exemplary diameter of about 10-1000 nm. In addition, high-quality GaN substrate structures can be formed by coalescing the plurality of GaN nanowires and / or nanowire arrays to facilitate the fabrication of visible LEDs and lasers. Furthermore, core-shell nanowire / MQW active structures can be formed by a core-shell growth on the nonpolar sidewalls of each nanowire.

Owner:STC UNM

Core-shell composite micron/nano fiber and preparation method thereof

ActiveCN1807707AAvoid sex changeStable structure and performanceOther chemical processesFilament/thread formingFiberPolymer science

The invention discloses a core-shell structure composite fiber and preparing method in the functional fibre preparing technique domain, which is characterized by the following: the material of composite fiber is functional microballoon / microcapsule; the shell material is oil soluble high molecular polymer or water-soluble high molecular polymer; the embedded functional microballoon / microcapsule is distributed over the inner fibre of high molecular polymer to form core-shell structure composite fiber; the polymer fluid of multiphase component forms composite embedding structure directly by the action of high-voltage electric field.

Owner:重庆大清医疗器械有限公司

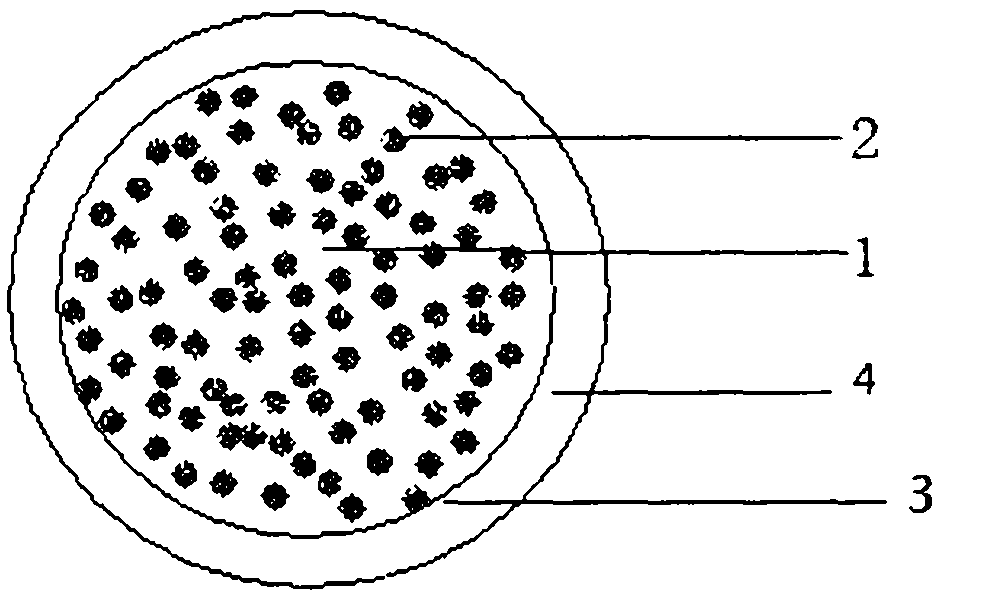

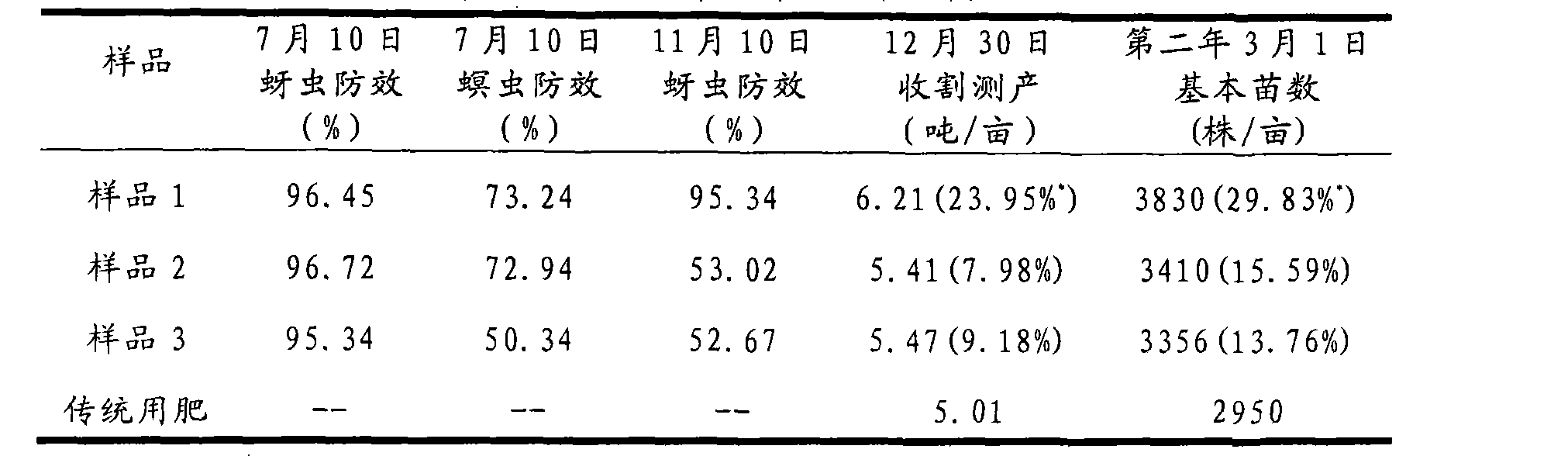

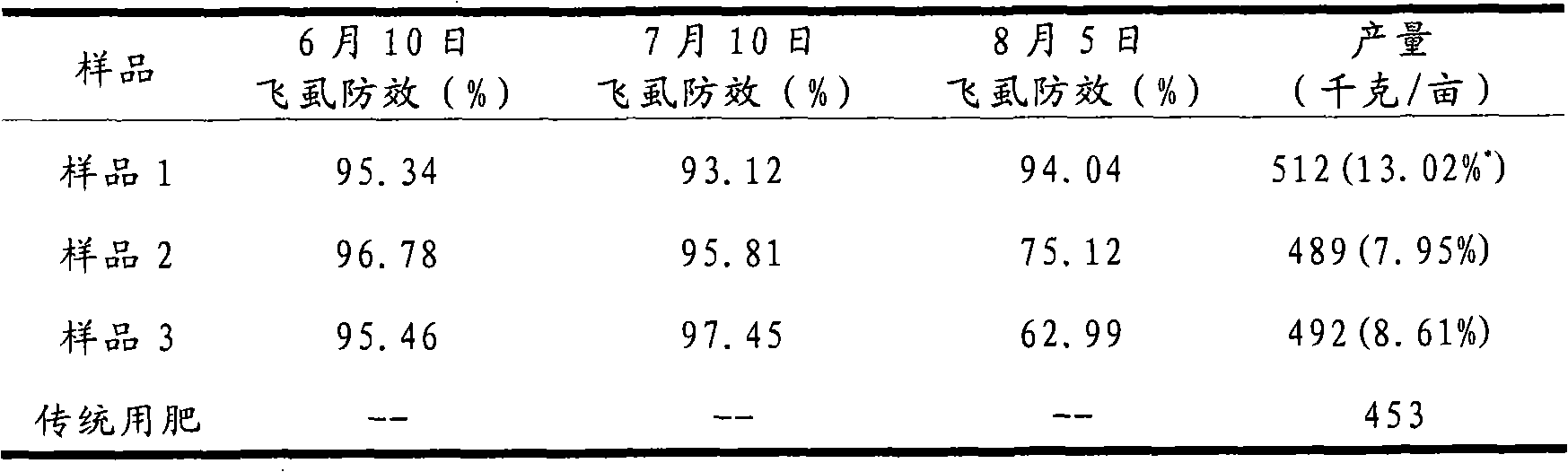

A kind of stable controlled-release granular medicinal fertilizer

ActiveCN102276356AAvoid stabilityAchieve controlled releaseFertilizer mixturesControl releaseCore shell

The invention relates to a stable controlled release particle pesticide-containing fertilizer. The pesticide-containing fertilizer has a core-shell structure, is granular and comprises a core which is composed of a fertilizer and a microcapsule pesticide or pesticide pulvis adsorbed by a porous material, and a shell which is used as a controlled release layer. The invention enables the pesticide and the fertilizer to stably exist and to be slowly released, frequency of pesticide application and fertilizer application in growth stages of crops to be reduced and field labor to be saved.

Owner:GAUNGXI TIANYUAN BIOCHEM

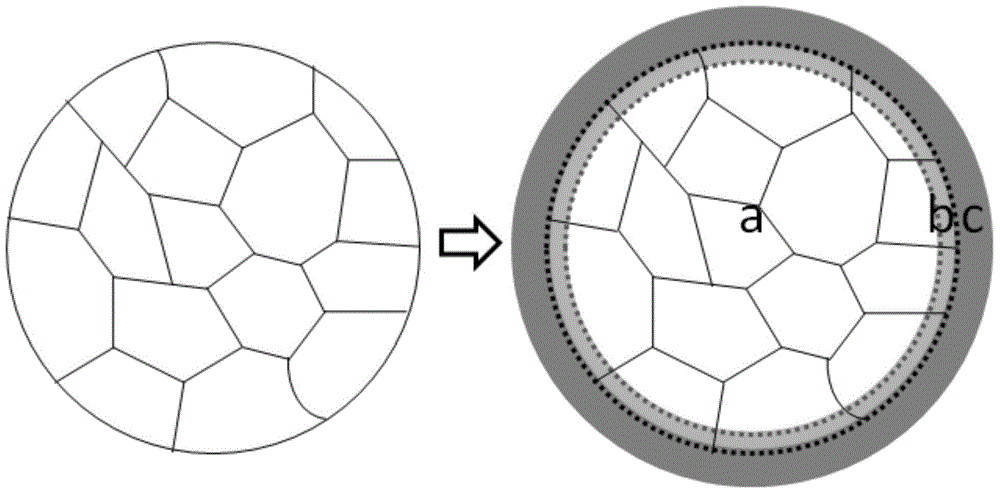

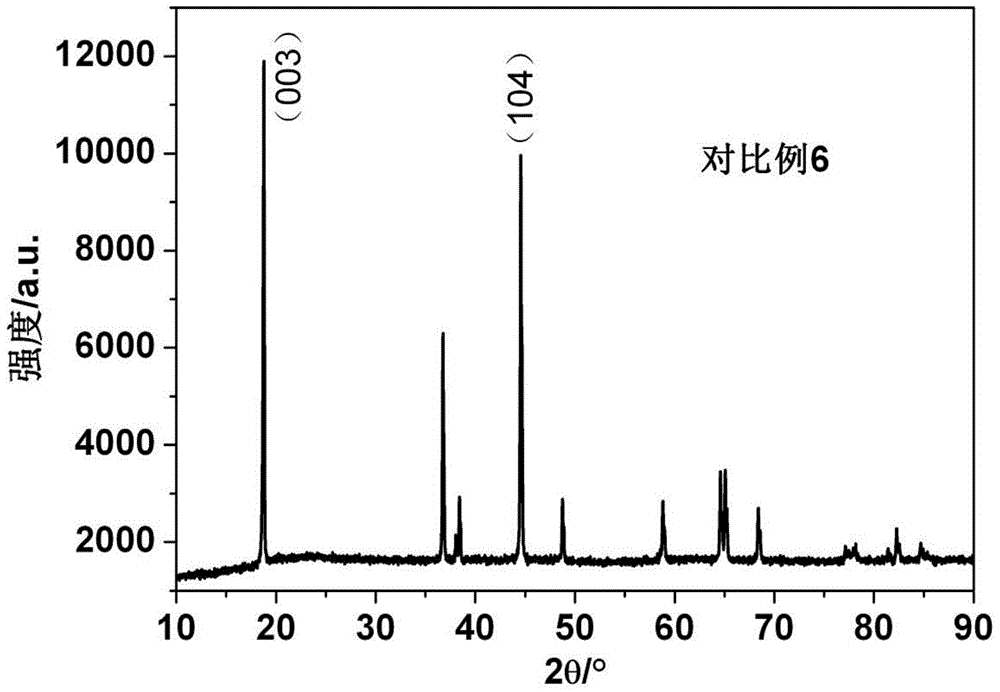

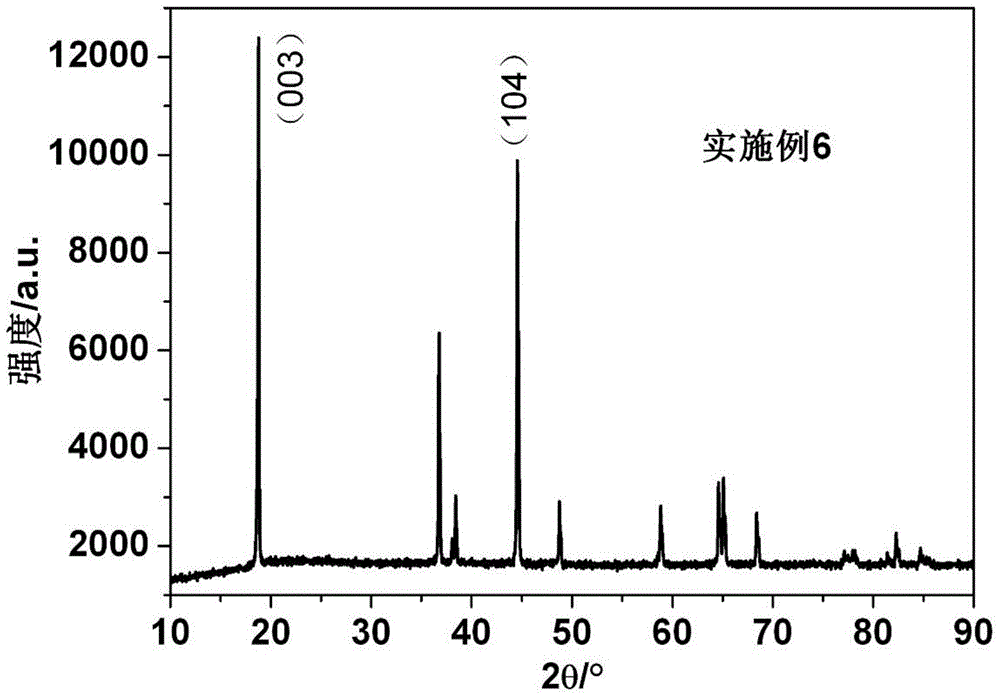

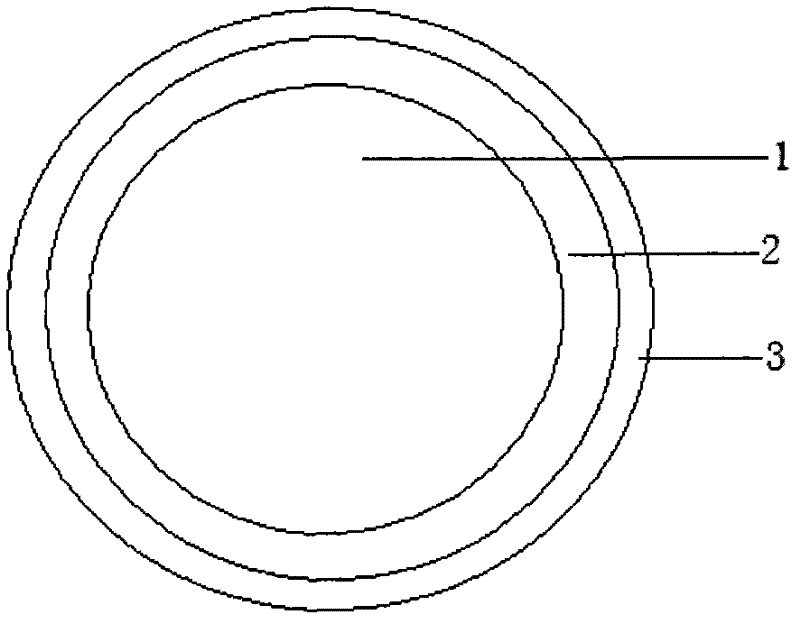

Anode material for nickel-base lithium ion battery and preparation method of anode material

ActiveCN104409700AEasy to operateSuitable for industrial productionCell electrodesSecondary cellsOptoelectronicsOxygen

The invention provides an anode material for a nickel-base lithium ion battery and a preparation method of the anode material. The anode material comprises an inner core, a doping layer and a cladding layer, wherein the chemical formula of the inner core is LiaNixCoyMzO2; the doping layer is another inner core containing M'; at least M' and oxygen elements are contained in the cladding layer; the anode material is of a core-shell structure, and comprises the inner core, the doping layer and the cladding layer from inside to outside. The anode material for the nickel-base lithium ion battery provided by the invention is little in lithium-nickel mixing, and the cycling stability of the material is obviously improved.

Owner:BTR NEW MATERIAL GRP CO LTD

Profile control oil-displacement agent for core-shell type inorganic/organic polymer composite microballoon

InactiveCN102485830AGood expansion performanceGood temperature and salt resistanceDrilling compositionCross-linkMicrosphere

The invention discloses a profile control oil-displacement agent for a core-shell type inorganic / organic polymer composite microballoon. A preparation method of the core-shell type inorganic / organic polymer composite microballoon comprises the following steps of carrying out surface modification of inorganic cores of inorganic nano-particles such as silica particles and magnetic particles, and carrying out graft polymerisation by a dispersion polymerization method or an inverse emulsion polymerization method to form polymer shells (such as polyacrylamide cross-linked copolymers) on the surfaces of the inorganic cores. The inorganic components and the organic components bind by chemical bonds so that the core-shell type inorganic / organic polymer composite microballoon has very stale structure. The core-shell type inorganic / organic polymer composite microballoon retains the advantages of polymer microballoons and inorganic particles, and has strong heat-resistant and mineralization-resistant capabilities, high plugging strength and good dilatancy. The core-shell type inorganic / organic polymer composite microballoon can move in rock pores and can plug the rock pores. When a plugging pressure difference is improved to a certain degree, elastic deformation of the core-shell type inorganic / organic polymer composite microballoon can be produced and the deformed core-shell type inorganic / organic polymer composite microballoon sequentially moves to a deep rock stratum part so that a liquid flow direction is changed gradually and a crude oil yield is improved. The profile control oil-displacement agent provided by the invention has a large potential.

Owner:BEIJING UNIV OF CHEM TECH

Controlled release particle fertilizer used for controlling crop insect disease

The invention relates to a controlled release particle fertilizer used for controlling crop insect diseases. The fertilizer has a double layer core shell structure and is in a granular shape and comprised of a core, an interface layer cladding the core and a controlled release layer as a casing cladding the interface layer. The core contains fertilizers required by a crop, and the interface layer cladding the core contains pesticide; or according to production requirement, the core contains particles with pesticide, and the interface layer cladding the core contains fertilizers; and an outermost layer is a controlled release layer controlling dissolving of pesticide and fertilizers. According to the invention, pesticide and fertilizer can coexist stably and release slowly, so as to reduce drug application and fertilizing times during a crop fertility stage and save field labor.

Owner:GAUNGXI TIANYUAN BIOCHEM

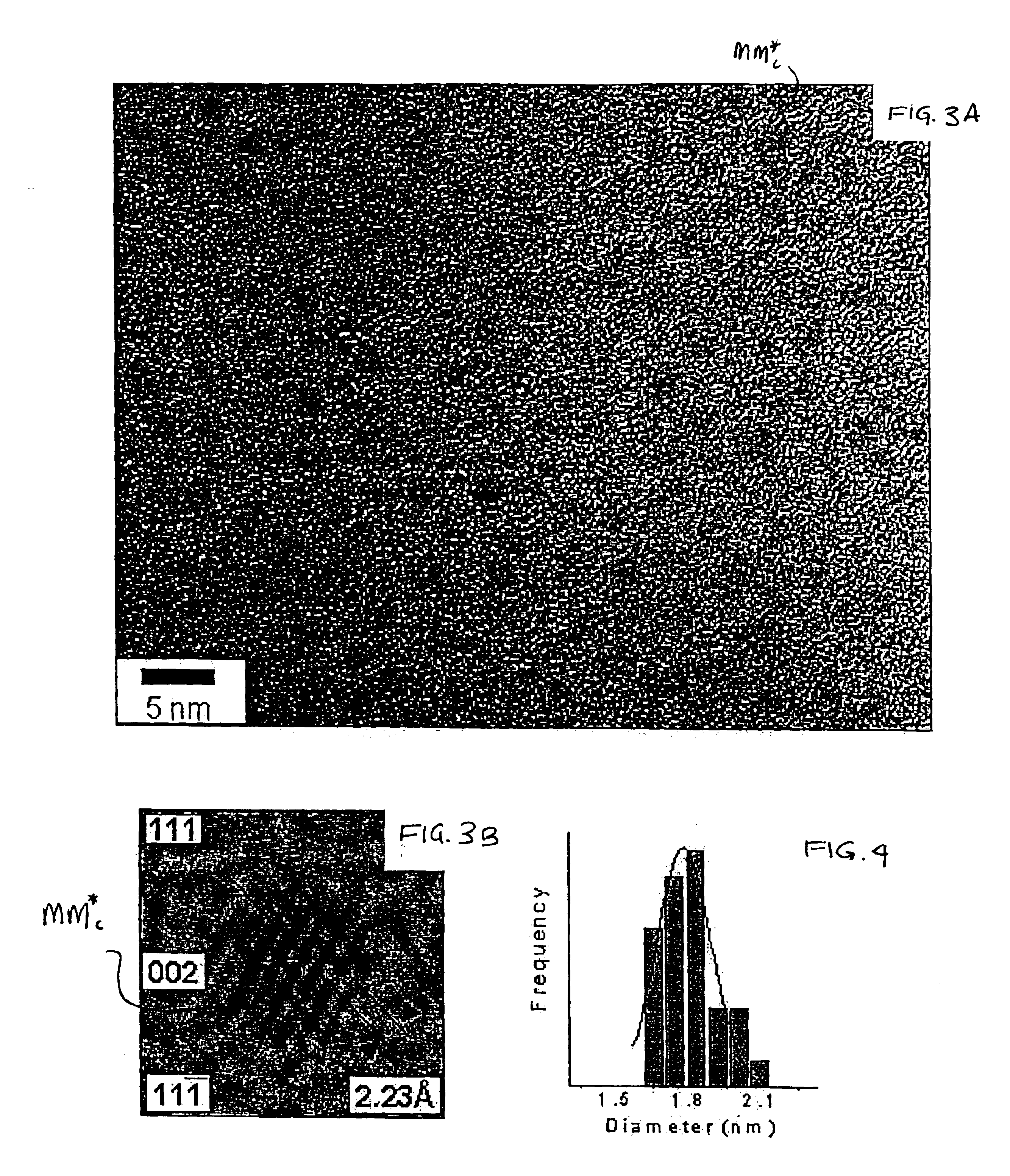

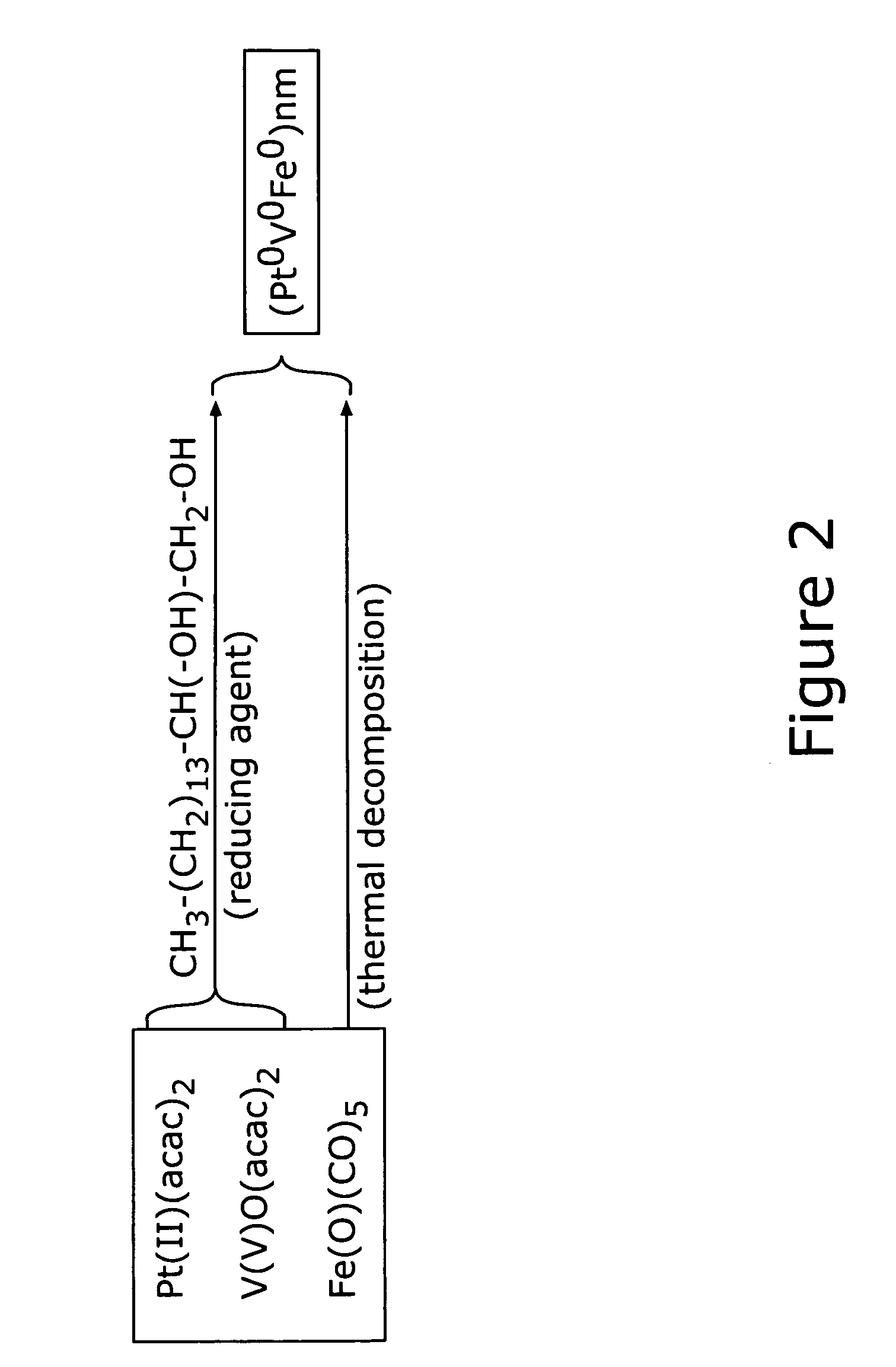

Core-shell synthesis of carbon-supported alloy nanoparticle catalysts

InactiveUS7053021B1Good monodispersityEfficient activationMaterial nanotechnologyTransportation and packagingFuel cellsBiological activation

There is provided a method of preparing carbon supported, ternary alloy composition core-shell PtVFe nanoparticles for use as fuel cell electrocatalysts. These catalysts have been found particularly useful for oxygen reduction reactions. The alloy nanoparticles can be assembled on carbon supports which then may undergo subsequent activation and / or calcination treatments. The method, combined with new synthetic feed and processing conditions, provides core-shell PtVFe alloy nanoparticles of 1–3 nm size. The catalyst-produced high monodispersity, controlled composition are highly dispersed, and have a uniform distribution. Finally, the correlation of the preparation and treatment parameters to the ORR catalytic activities of the prepared nanoparticles is described. The catalysts exhibit ORR in the range of 2 to 4 times more than a standard Pt / carbon catalyst.

Owner:HONDA MOTOR CO LTD +1

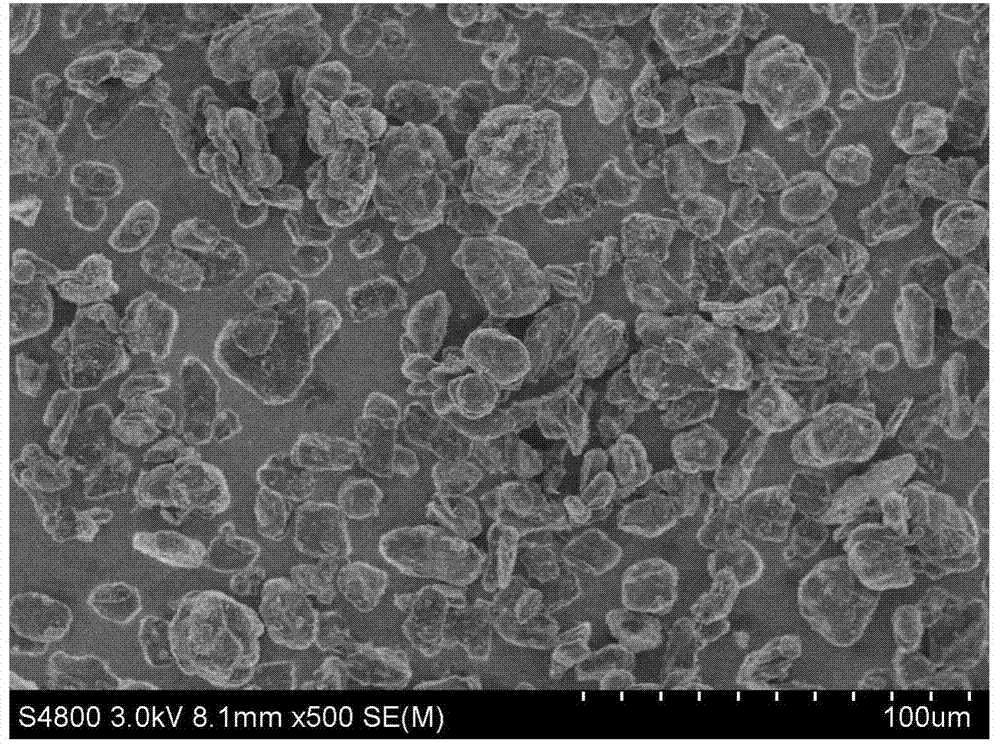

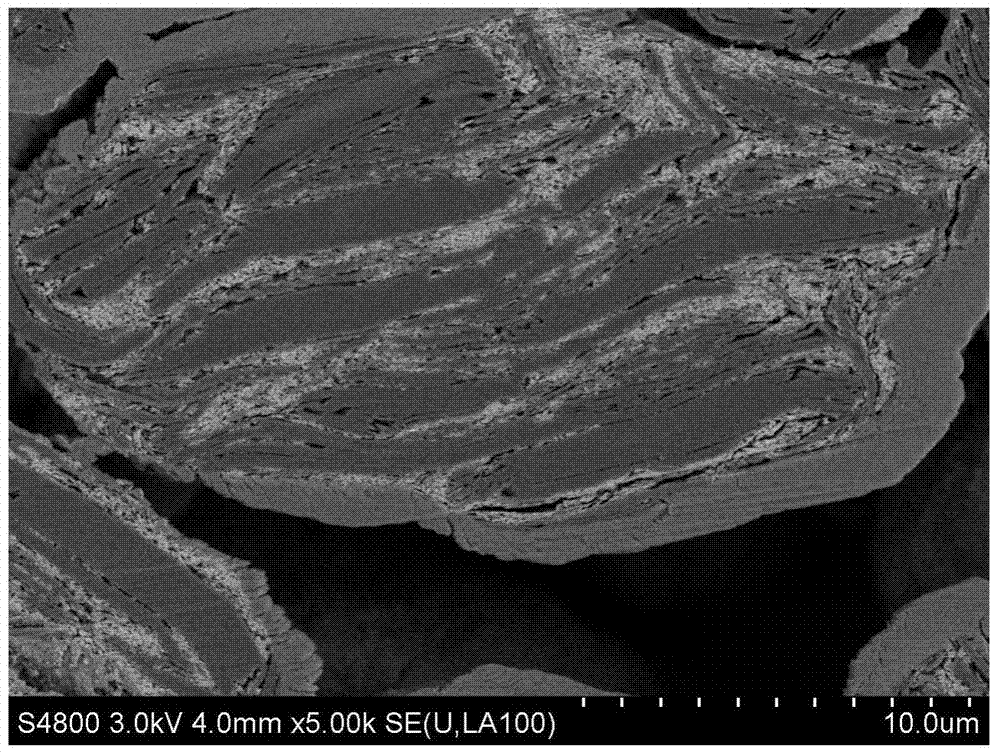

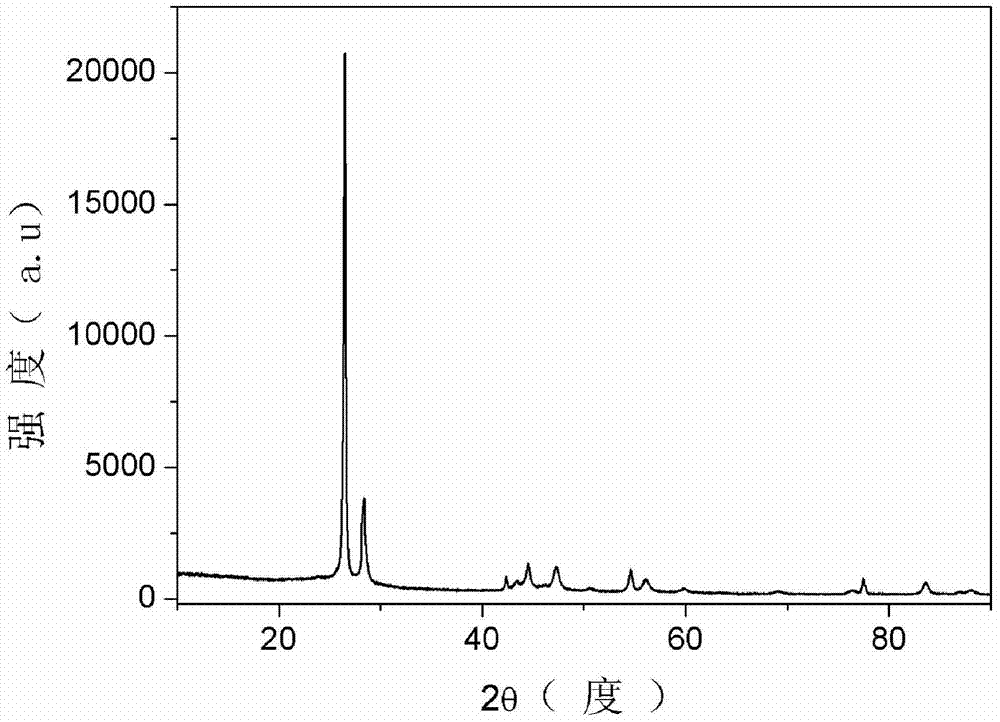

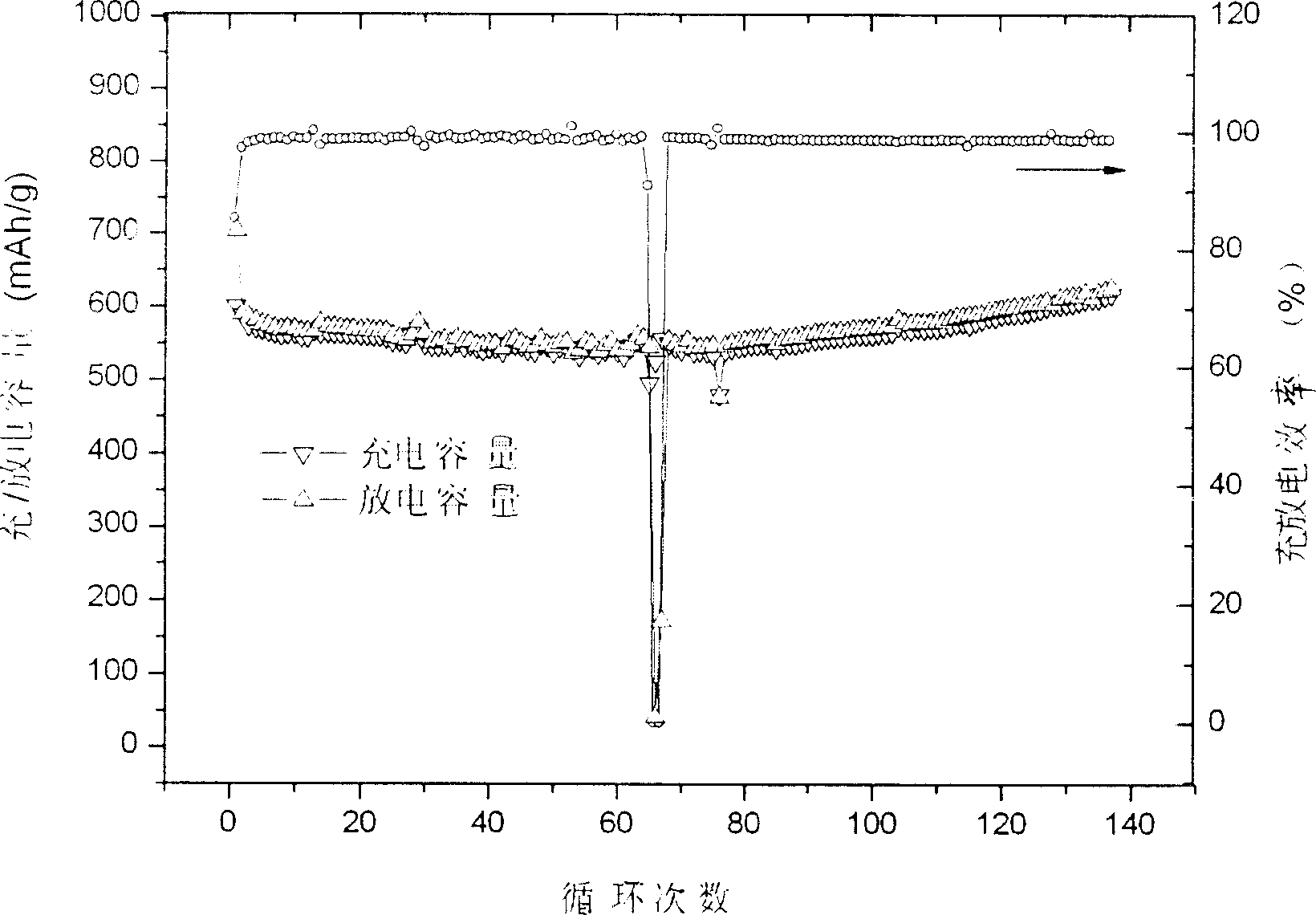

Lithium ion battery silicon-based composite anode material, preparation method thereof and battery

ActiveCN103682287AGood dispersionInhibit swellingCell electrodesSecondary cellsCarbon coatingRetention ratio

The invention relates to a lithium ion battery silicon-based composite anode material, a preparation method of the lithium ion battery silicon-based composite anode material, and a battery. The lithium ion battery silicon-based composite anode material adopts an embedded composite core-shell structure, a core has a structure formed by embedding nano silicon particles into a gap of an inner layer of hollowed graphite, and a shell is made from a non-graphite carbon material. According to the silicon-based composite anode material, mechanical grinding, mechanical fusing, isotropic compression processing and carbon coating technologies are combined, so that the nano silicon particles can be successfully embedded into the inner layer of the graphite and the surfaces of graphite particles are uniformly coated; the high-performance silicon-based composite anode material is obtained and is excellent in cycle performance (the 300-times cycle capacity retention ratio is more than 90%) and high in first efficiency (more than 90%); in addition, the silicon-based composite anode material is high in specific energy and compaction density, and can meet the requirements of a high-power density lithium ion battery; the preparation process is simple, the raw material cost is low, and the environment is protected.

Owner:BTR NEW MATERIAL GRP CO LTD

MBS impact modifiers

A process and composition for MBS modifiers having (A) a rubbery core, (B) an inner graft stage comprised mainly of a hard polymer, (C) an intermediate sealer stage comprised mainly of an alkyl acrylate monomer and / or a polyunsaturated crosslinker, and (D) an outer shell to provide compatibility of the core-shell polymer with the matrix polymer, is disclosed. A process for preparing MBS impact modifiers having suprisingly improved impact performance in matrix polymers is also disclosed. Articles prepared from blends of matrix polymers and the MBS core-shell polymers described herein are also disclosed.

Owner:ROHM & HAAS CO

Core-shell ceramic particulate and method of making

InactiveUS7670679B2High-temperature mechanical and structural stabilityLiquid surface applicatorsCell electrodesParticulatesCore shell

Owner:BHA ALTAIR

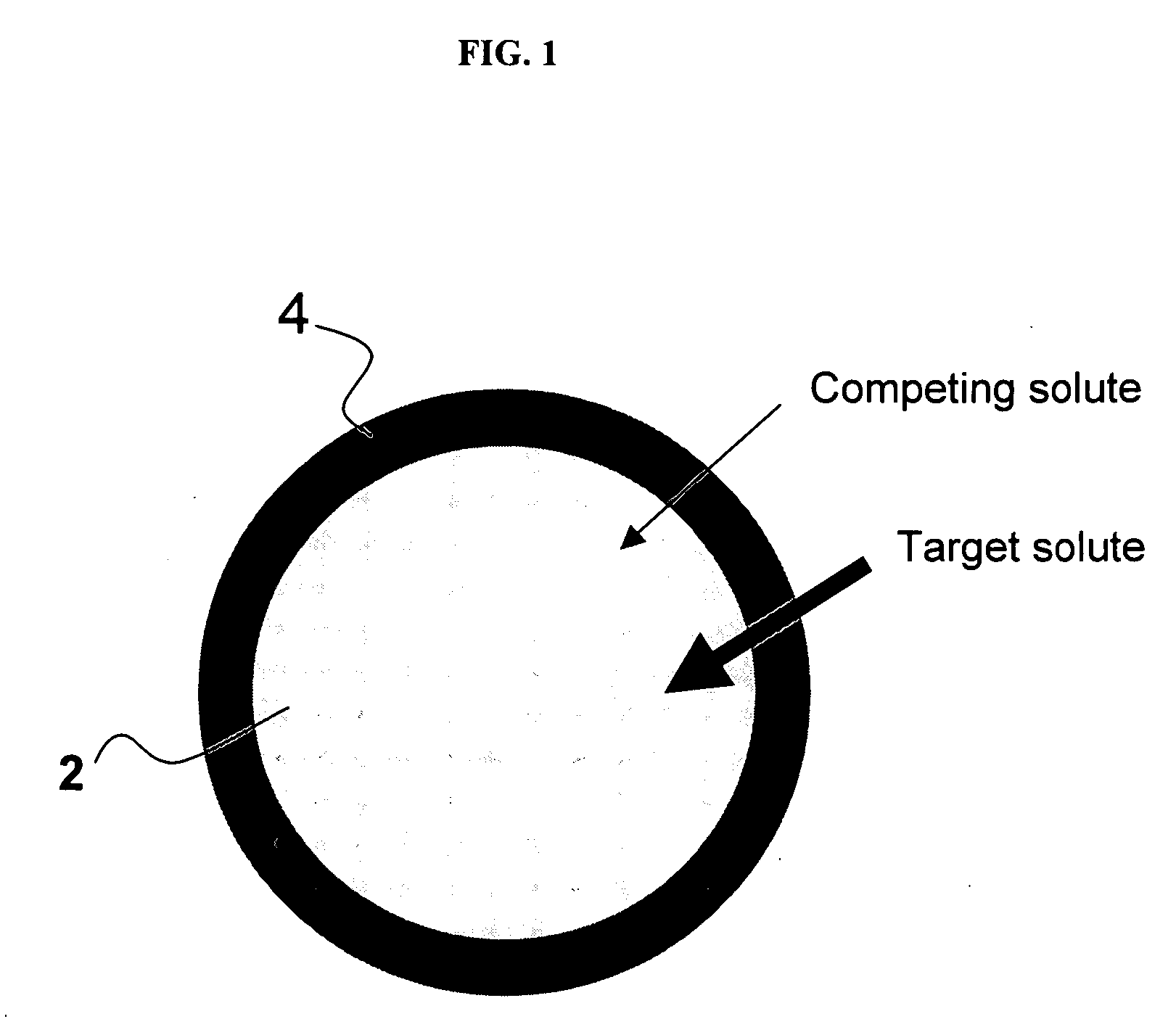

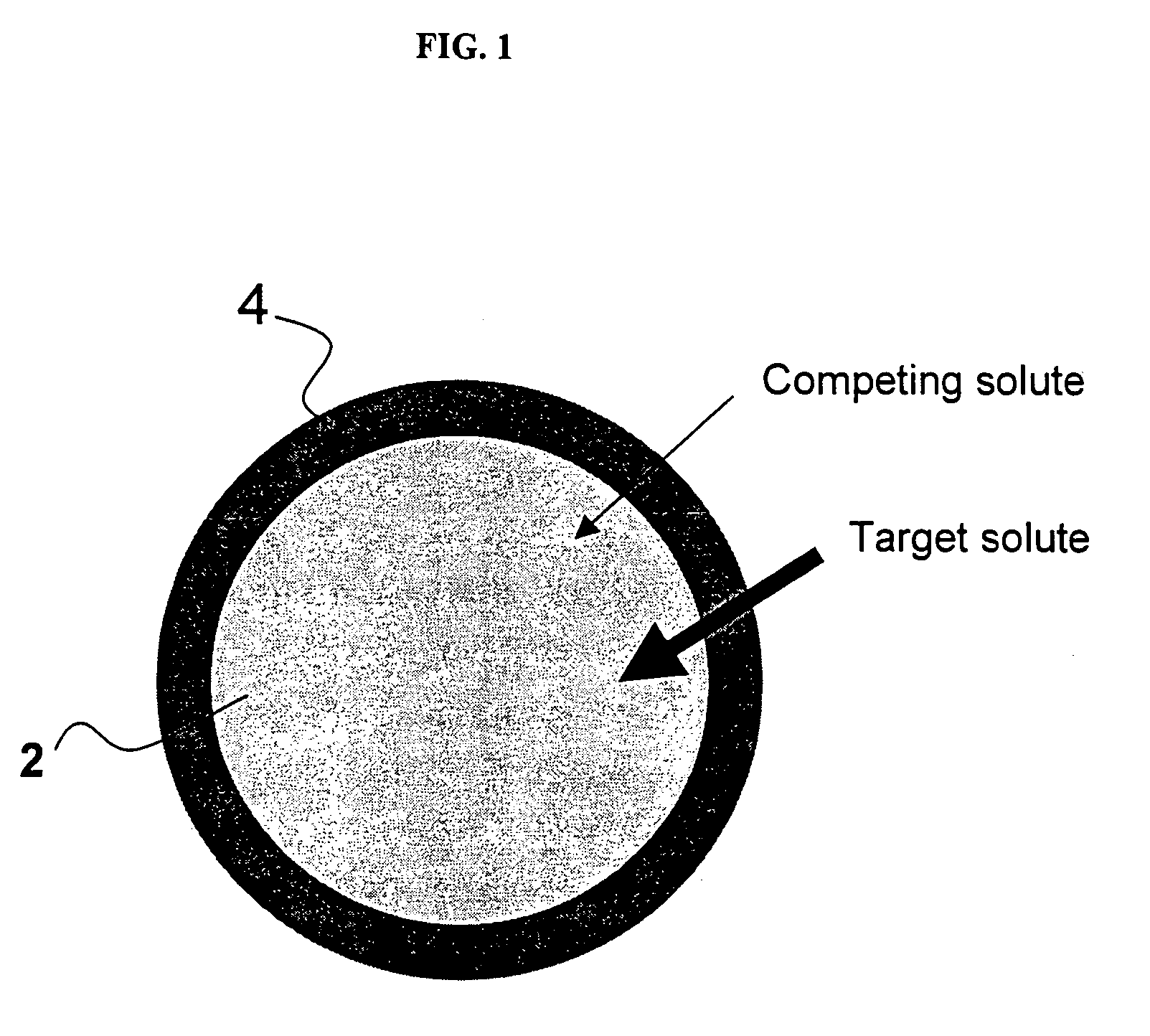

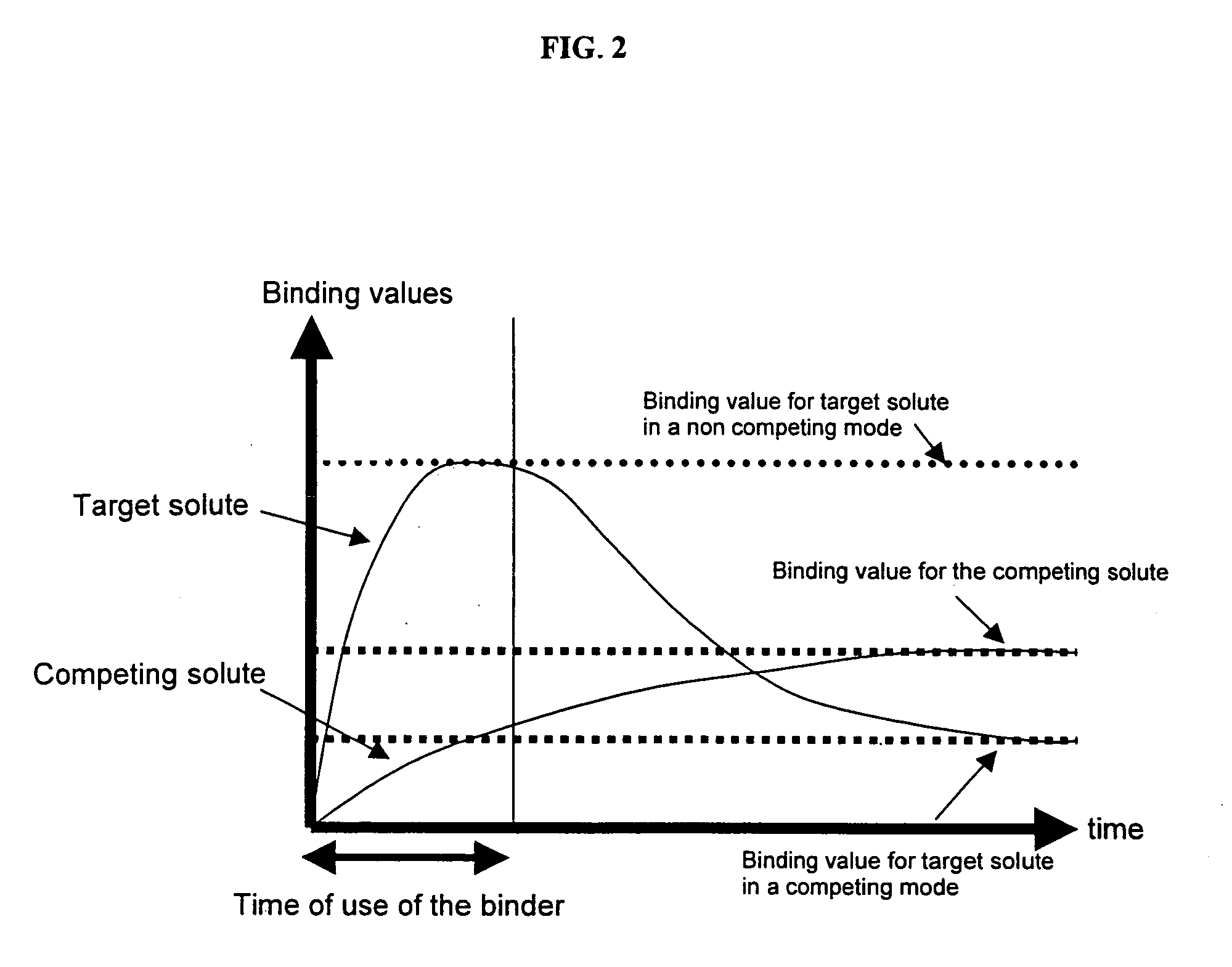

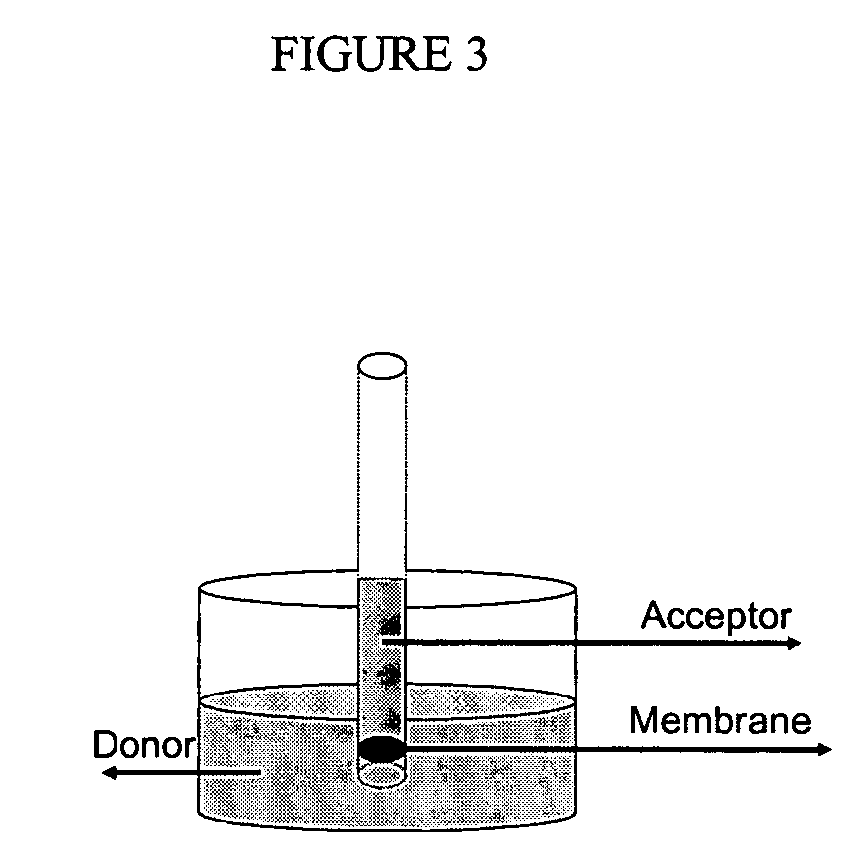

Ion binding compositions

The present invention provides methods and compositions for the treatment of ion imbalances. In particular, the invention provides core-shell compositions and pharmaceutical compositions thereof. Methods of use of the core-shell compositions for therapeutic and / or prophylactic benefits are disclosed herein. Examples of these methods include the treatment of phosphate imbalance disorders, hypertension, chronic heart failure, end stage renal disease, liver cirrhosis, chronic renal insufficiency, fluid overload, or sodium overload.

Owner:VIFOR INT AG

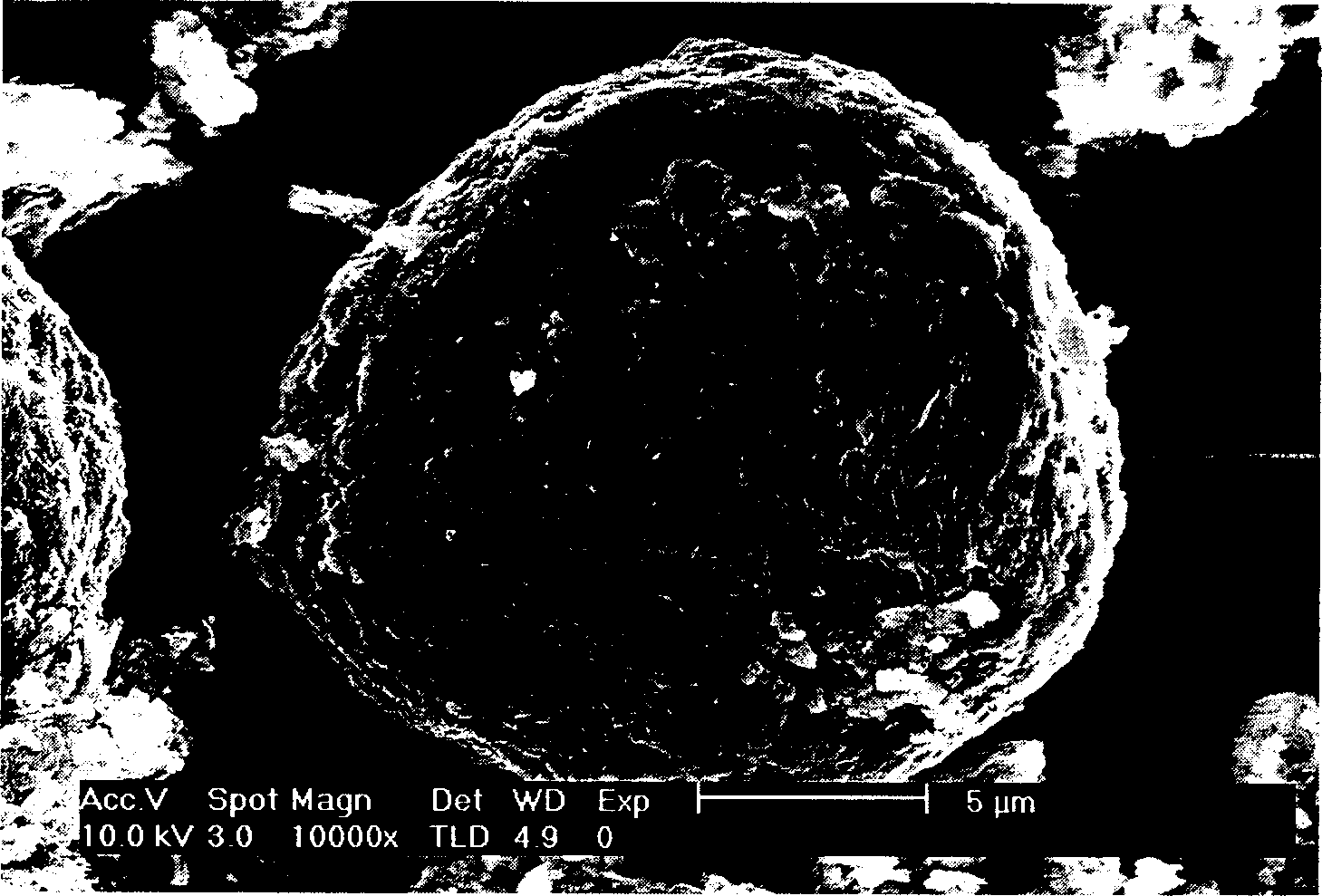

Carbon-silicon composite material with spherical nucleocapsid, and its preparing method and use

This invention relates to a kind of silicon&carbon composite material with a spherical appearance and core-shell structure in spherical particles with a mean diameter of 1.2~53 micron and a 'core-shell' structure, there are silicon particles 5~50wt% and carbon particles 50~95wt%, the core of which is spherical carbon particles with a mean diameter of 1~45 micron. The carbon particles are the mixture of one, two or three kinds of mesophase carbon graphite balls, hard carbon balls and spherical graphite ball. The thickness of the shell is 0.1~4 microns composed of carbon and silicon grains with the average size of 10 nm~4 micron. The carbon&silicon composite materials are achieved through thermal decomposition and chemical vapor deposition after the spherical carbon particles are coated with silicon and carbon composite ultrafine silica slurry.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD

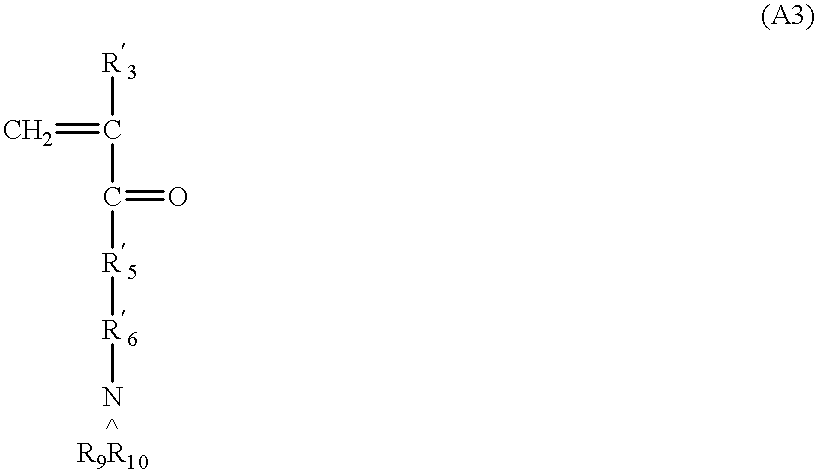

Ink-jet printing ink compositions having magnetic properties and specific core/shell binder

InactiveUS6248805B1Improve propertiesImprove magnetic propertiesIron oxides/hydroxidesDuplicating/marking methodsCharge-transfer complexPrinting ink

Specific core-shell binders and magnetic additives for use in ink-jet printing ink compositions are provided. One class of specific core / shell binders has the general formula [AmBnC'p]x, where A and B are hydrophobic components in which A exhibits a glass transition temperature Tg between about -150° and +25° C. and B exhibits a glass transition temperature greater than 25° C., C' is a component that forms hydrophilic or water-soluble component in the polymer chain, and has an ionic or non-ionic structure, m<30 wt %, n>40 wt %, and p<30 wt %, with the total of m+n+p=100 wt %, and x=1 to 100,000. The molecular weight (weight average) of the polymer is between about 1,000 and 2,000,000. The polymers useful in the practice of the invention are prepared by emulsifying the monomers and then conducting a free-radical polymerization in water. The foregoing binder polymer is used in conjunction with magnetic additives comprising either (a) inorganic magnetic compound containing at least one of iron, cobalt, and nickel or (b) organic magnetic complexes containing at least one of iron, cobalt, and nickel or (c) organic charge transfer complexes that exhibit magnetic properties. The ratio of binder (I) to colorant (pigment) is greater that 1 to 10. The concentration of the magnetice additive is within the range of 1 to 30 wt %. The general ink formulation comprises: 5 to 50 wt % water-miscible solvent; 0.5 to 10 wt % colorant; 1 to 30 wt % magnetice additive; and water.

Owner:HEWLETT PACKARD DEV CO LP

Ion binding compositions

ActiveUS20060024336A1Powder deliveryPharmaceutical non-active ingredientsEnd stage renal diseaseChronic renal insufficiency

The present invention provides methods and compositions for the treatment of ion imbalances. In particular, the invention provides core-shell compositions and pharmaceutical compositions thereof. Methods of use of the core-shell compositions for therapeutic and / or prophylactic benefits are disclosed herein. Examples of these methods include the treatment of phosphate imbalance disorders, hypertension, chronic heart failure, end stage renal disease, liver cirrhosis, chronic renal insufficiency, fluid overload, or sodium overload.

Owner:VIFOR INT AG

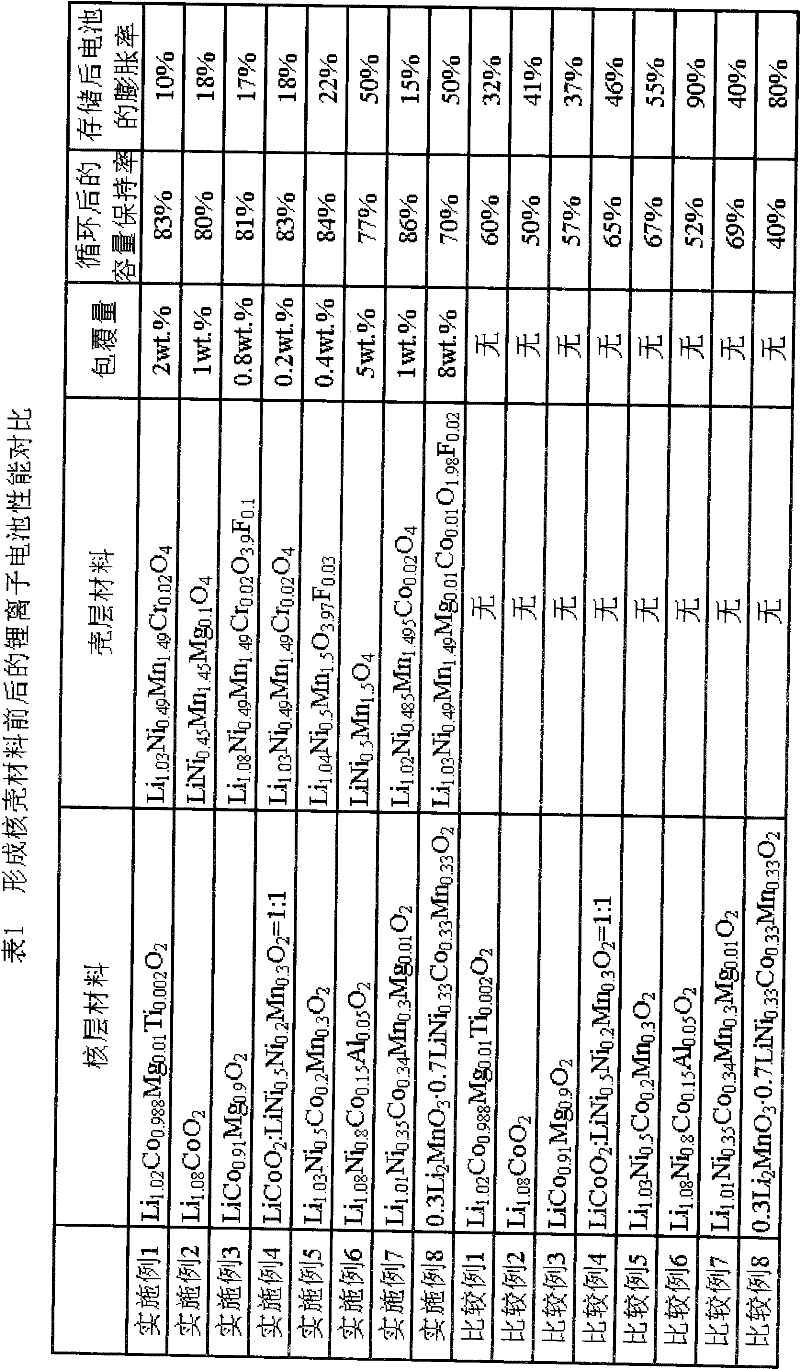

Lithium ion battery and its positive material

ActiveCN102394295AImprove cycle performanceIncrease storage capacityCell electrodesSecondary cellsHigh temperature storageManganese

The invention discloses a lithium ion battery and a positive material, the positive material possesses a core-shell structure, the material of a core layer is at least one of lithium cobaltate, a ternary material and a lithium manganese material, the material of a shell layer is lithium nickel manganese spinel. The preparation method comprises the following steps: preparing the sol shell layer material, then adding the core layer material in the sol, stirring, drying and calcining to prepare the lithium ion battery positive material with the core-shell structure. In addition, the invention also discloses the lithium ion battery prepared by the positive material with the core-shell structure, the end of charge voltage is 4.3-4.7V(vs. Li), the lithium ion battery has excellent charge and discharge cycling performance and high temperature storage performance under high voltage.

Owner:DONGGUAN AMPEREX TECH +1

Preparation method of core-shell structured synthetic polymer-natural polymer composite fiber

InactiveCN102817105ASimple and fast operationMild reaction conditionsConjugated cellulose/protein artificial filamentsFilament/thread formingFiberPolymer science

The invention discloses a preparation method of a core-shell structured synthetic polymer-natural polymer composite fiber, and the method comprises the steps of: (1) selecting one or several of synthetic polymers to dissolve in a solvent, and conducting stirring until complete dissolution; (2) selecting a natural polymer to dissolve in a solvent, or adding a spinning assistant, and carrying out stirring until complete dissolution; and (3) taking the solution prepared in step (1) as an outer tube spinning solution, adopting the solution prepared in step (2) as an inner tube spinning solution, injecting them into the inner tube and the outer tube of a coaxial spinneret, and performing coaxial electrospinning at room temperature. The core-shell structured nano-fiber prepared by the invention selects the synthetic polymer as the shell layer, and can inhibit water molecules from penetrating the natural polymer as the core layer. The natural polymer as the core layer can more effectively encapsulate active substances to avoid inactivation of the active substances in the presence of an organic solvent, so that the core-shell structured composite fiber can play a good drug sustained release role in the drug carrier field, and an integral activity can be maintained.

Owner:SHANGHAI JIAO TONG UNIV +1

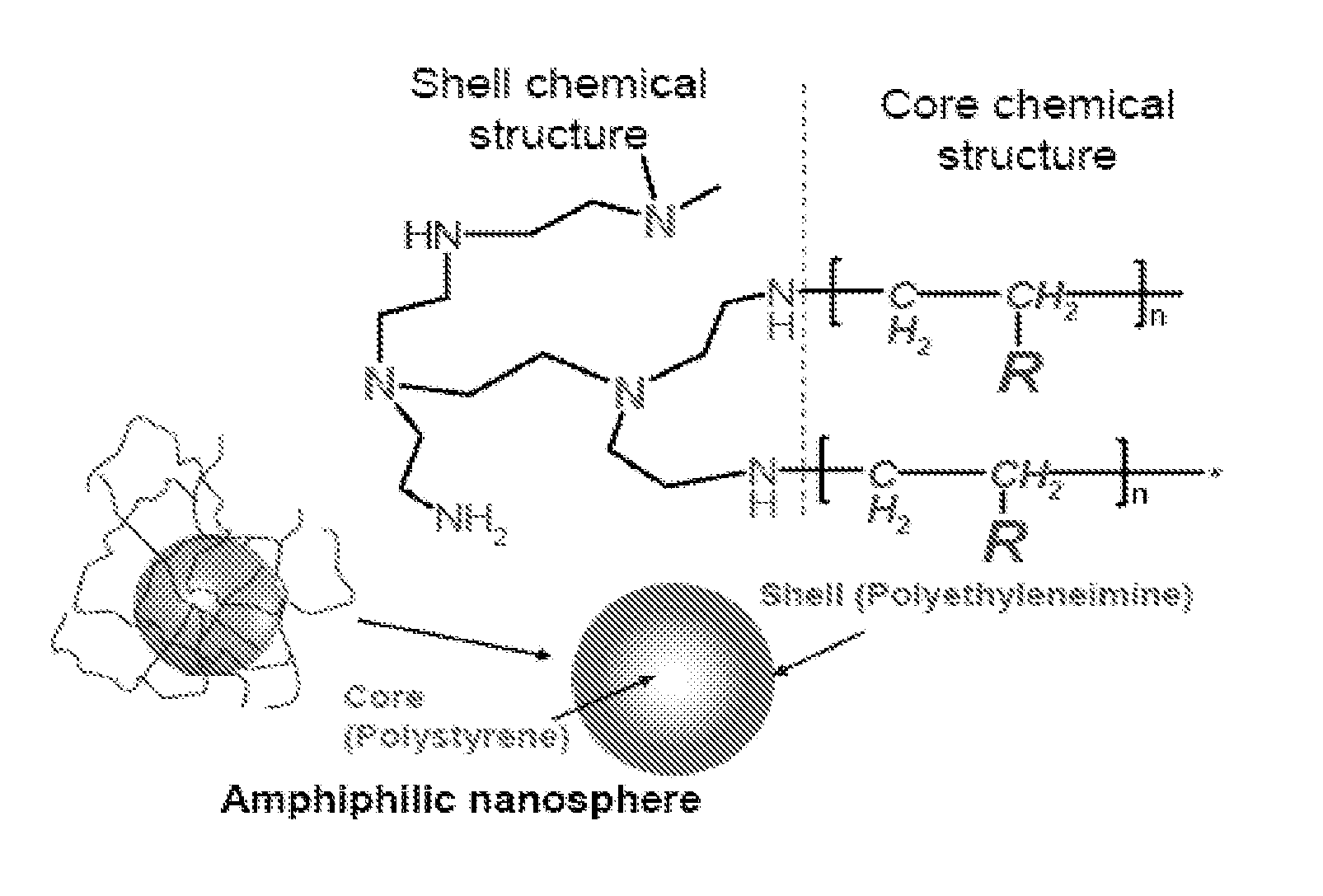

Water dispersions of non-uniform polyurethane particles

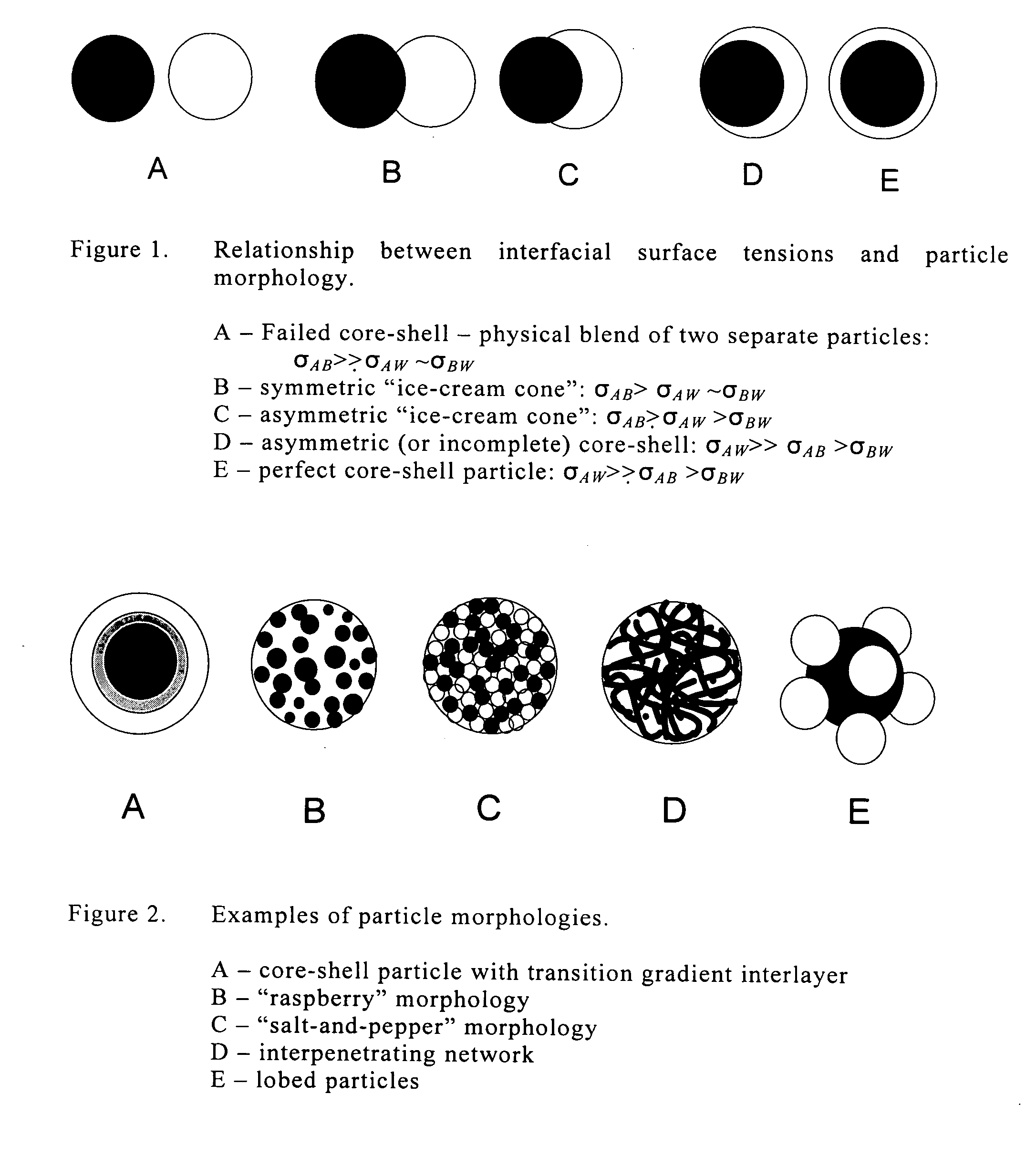

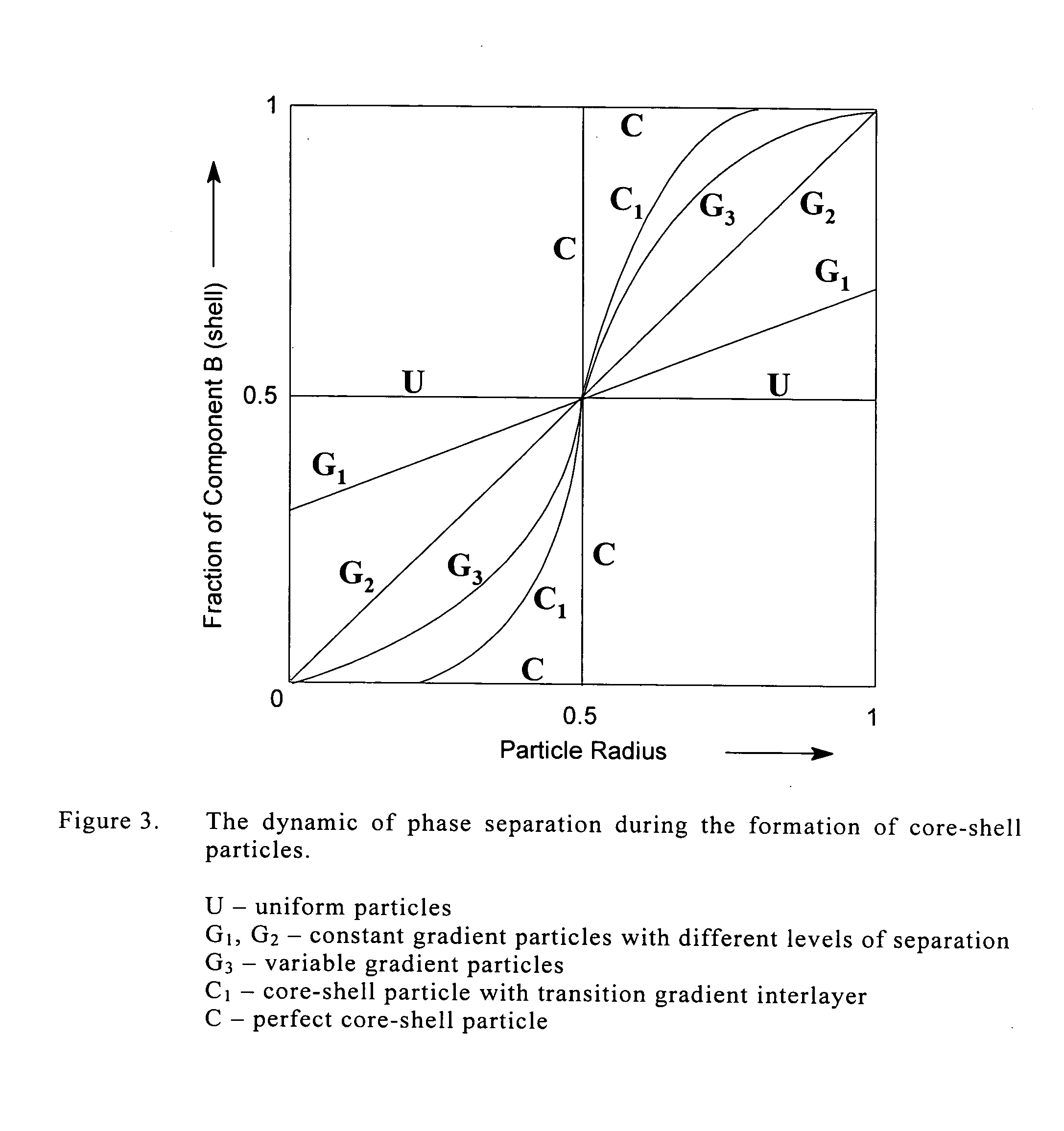

A novel method of preparing an aqueous dispersion of non-uniform polyurethane particles which comprises (a) preparing at least two isocyanate-terminated polyurethane prepolymers having different hydrophilicities; (b) preparing a uniform mixture of said prepolymers; and (c) dispersing the mixed prepolymers in an aqueous medium. The resulting dispersion of the prepolymers may optionally be chain extended. This method enables the preparation of core-shell particles as well as particles of other morphologies, including “raspberry”, interpenetrating network, “salt-and-pepper”, “ice-cream cone” and particles of gradient composition. Similarly, an aqueous dispersion of two different polyurethane polymers may be obtained by first preparing at least two different isocyanate-terminated polyurethane prepolymers, preparing a uniform mixture of such prepolymers and thereafter dispersing the mixture in an aqueous medium.

Owner:LUBRIZOL ADVANCED MATERIALS INC

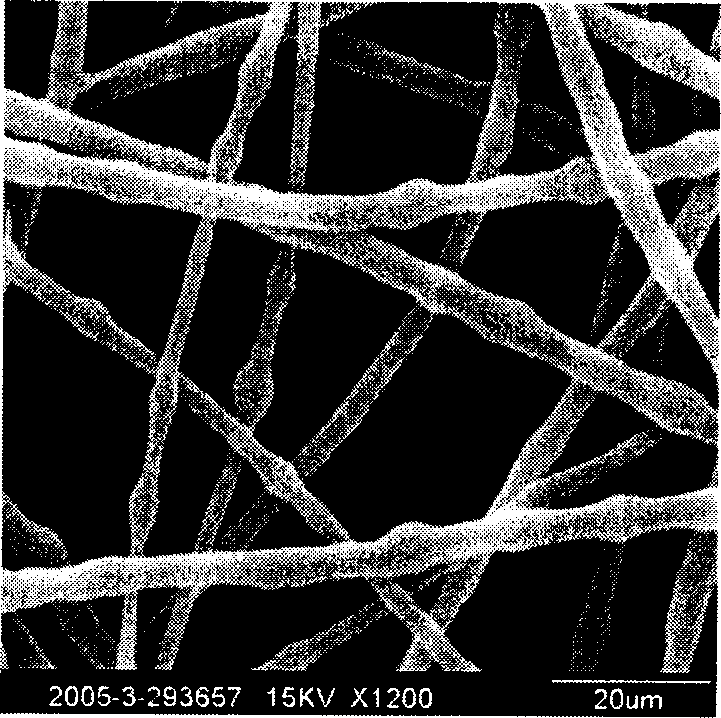

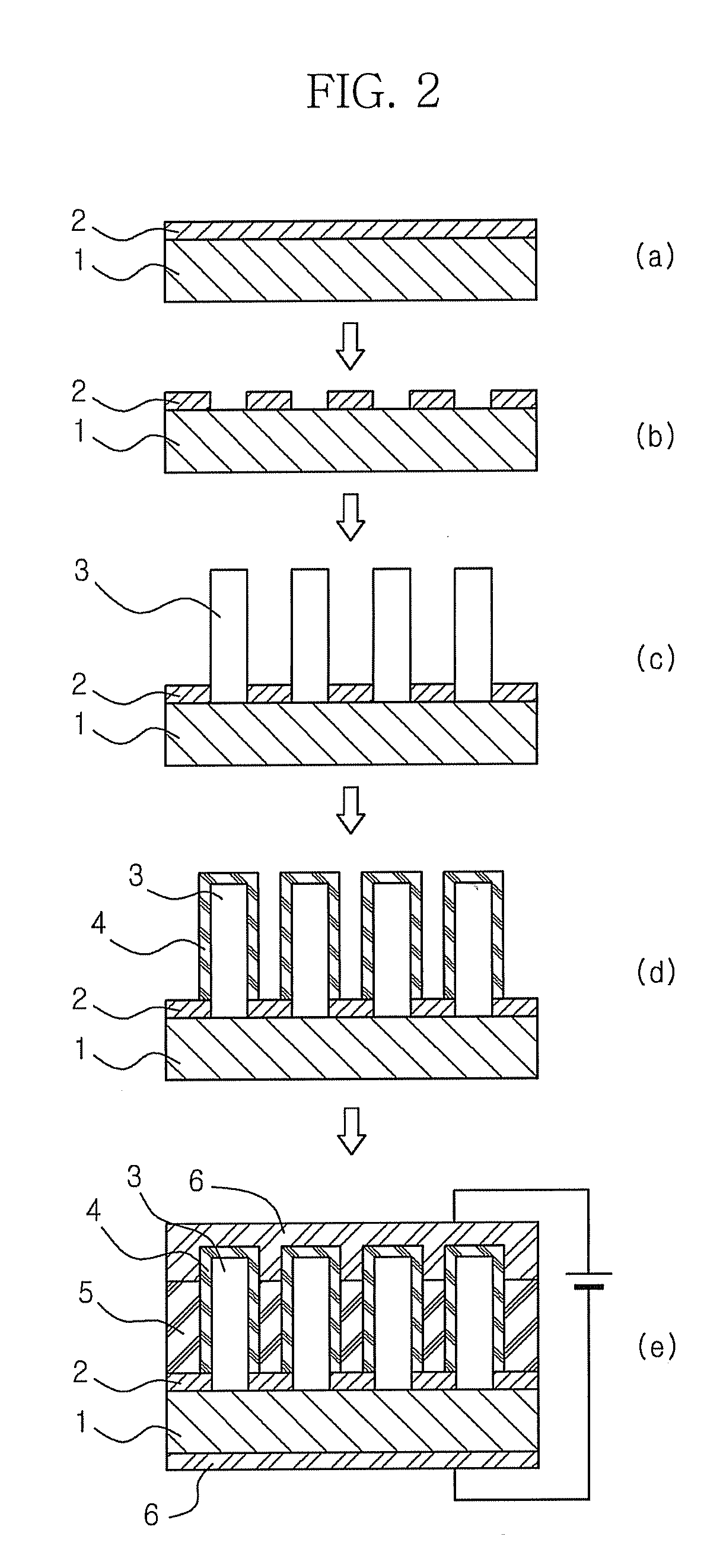

Method for producing core-shell nanowires, nanowires produced by the method and nanowire device comprising the nanowires

Disclosed is a method for producing core-shell nanowires in which an insulating film is previously patterned to block the contacts between nanowire cores and nanowire shells. According to the method, core-shell nanowires whose density and position is controllable can be produced in a simple manner. Further disclosed are nanowires produced by the method and a nanowire device comprising the nanowires. The use of the nanowires leads to an increase in the light emitting / receiving area of the device. Therefore, the device exhibits high luminance / efficiency characteristics.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com