Patents

Literature

15442results about "Duplicating/marking methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-swellable copolymers and articles and coatings made therefrom

Owner:TYCO HEALTHCARE GRP LP

Method of hydrophilizing materials

InactiveUS6863933B2Easy to controlGood removal effectInorganic/elemental detergent compounding agentsRadiation applicationsPolymer scienceNanoparticle

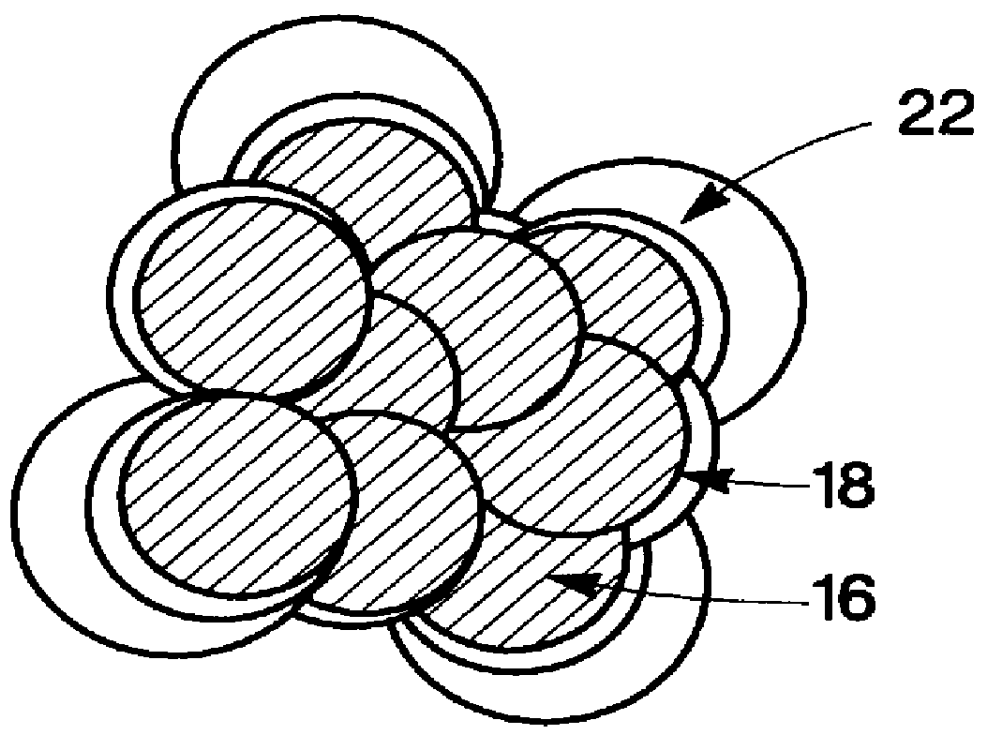

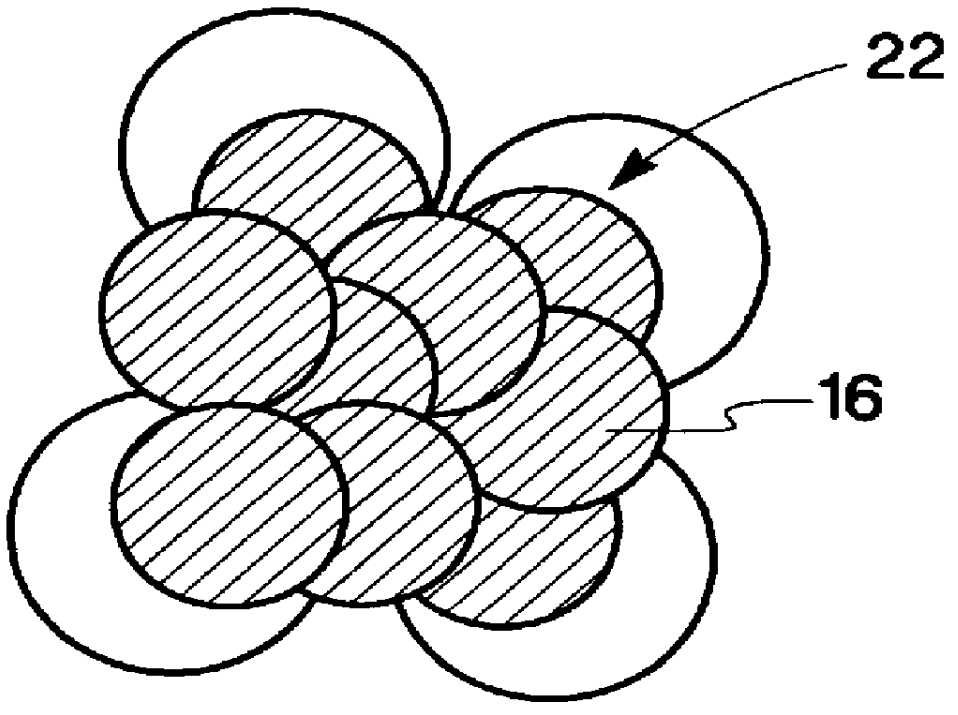

Coating compositions, methods and articles of manufacture comprising a nanoparticle system employing same to impart surface modifying benefits for all types of soft surfaces, and in some cases, hard surfaces, are disclosed. In some embodiments, dispersement of nanoparticles in a suitable carrier medium allows for the creation of coating compositions, methods and articles of manufacture that create multi-use benefits to the modified surfaces. These surface modifications can produce long lasting or semi-permanent multi-use benefits that, in some embodiments, may include at least one of the following improved surface properties: cleaning, wettability, liquid strike-through, comfort, stain resistance, soil removal, malodor control, modification of surface friction, reduced damage to abrasion and color enhancement, relative to the surfaces unmodified with such nanoparticle systems.

Owner:THE PROCTER & GAMBLE COMPANY

Lithographic apparatus, device manufacturing method, and device manufactured thereby

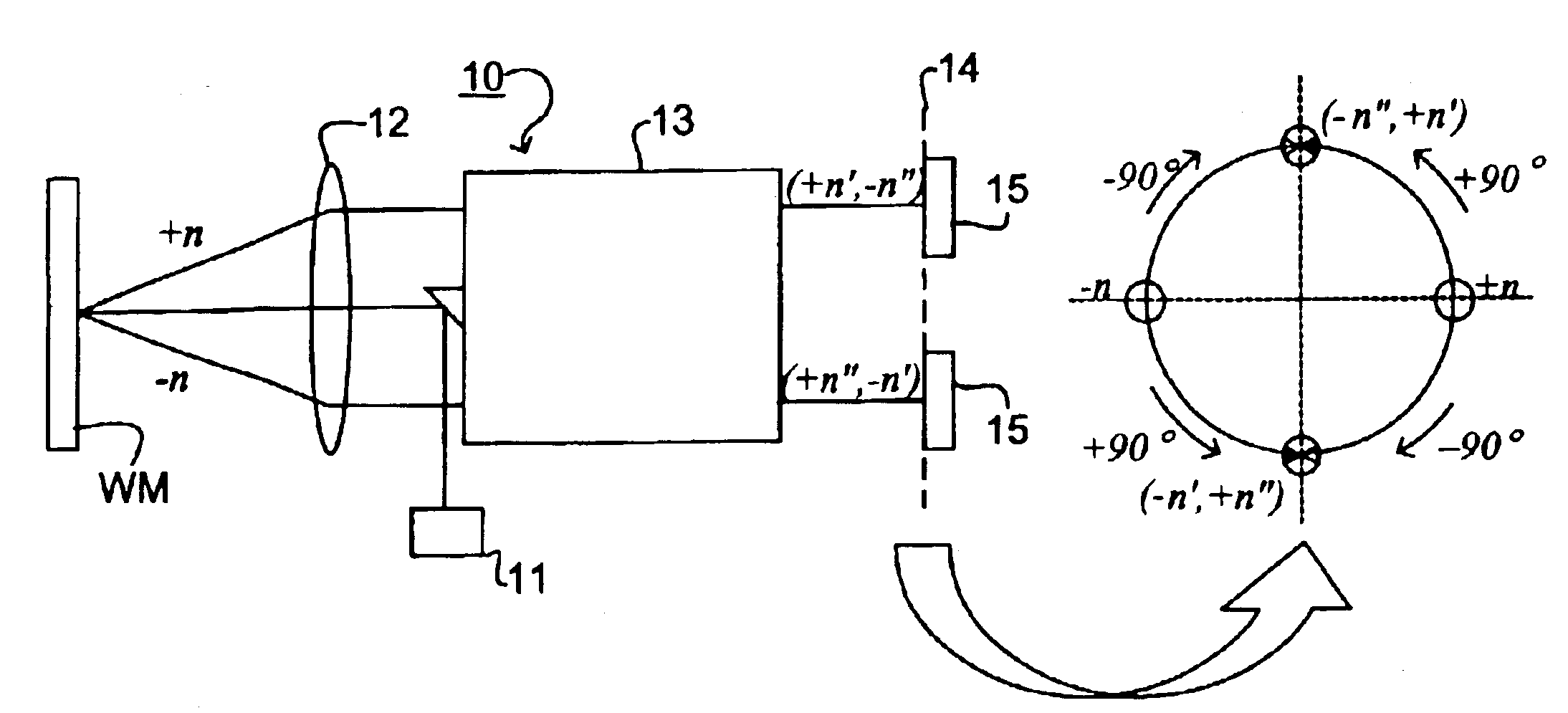

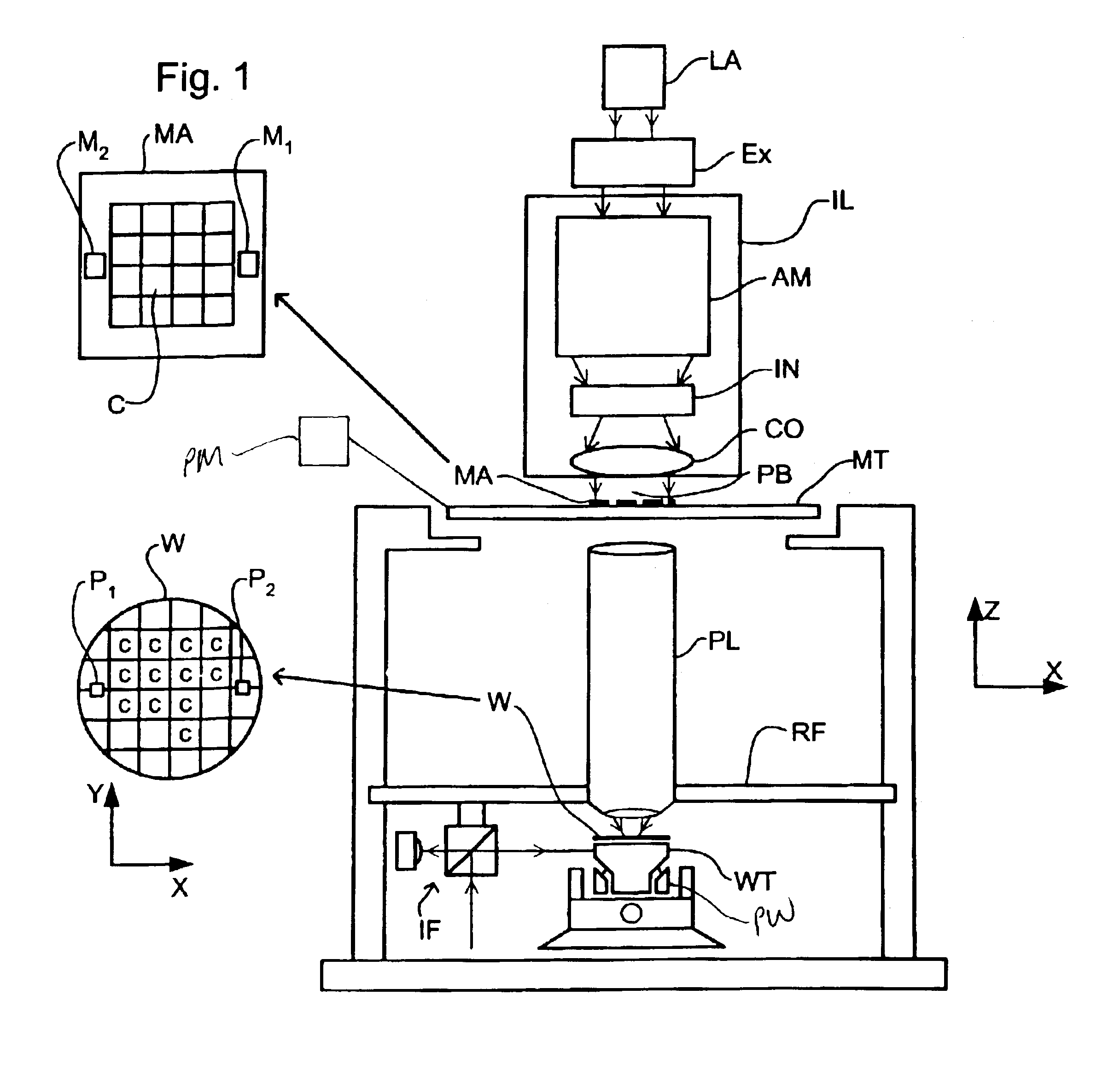

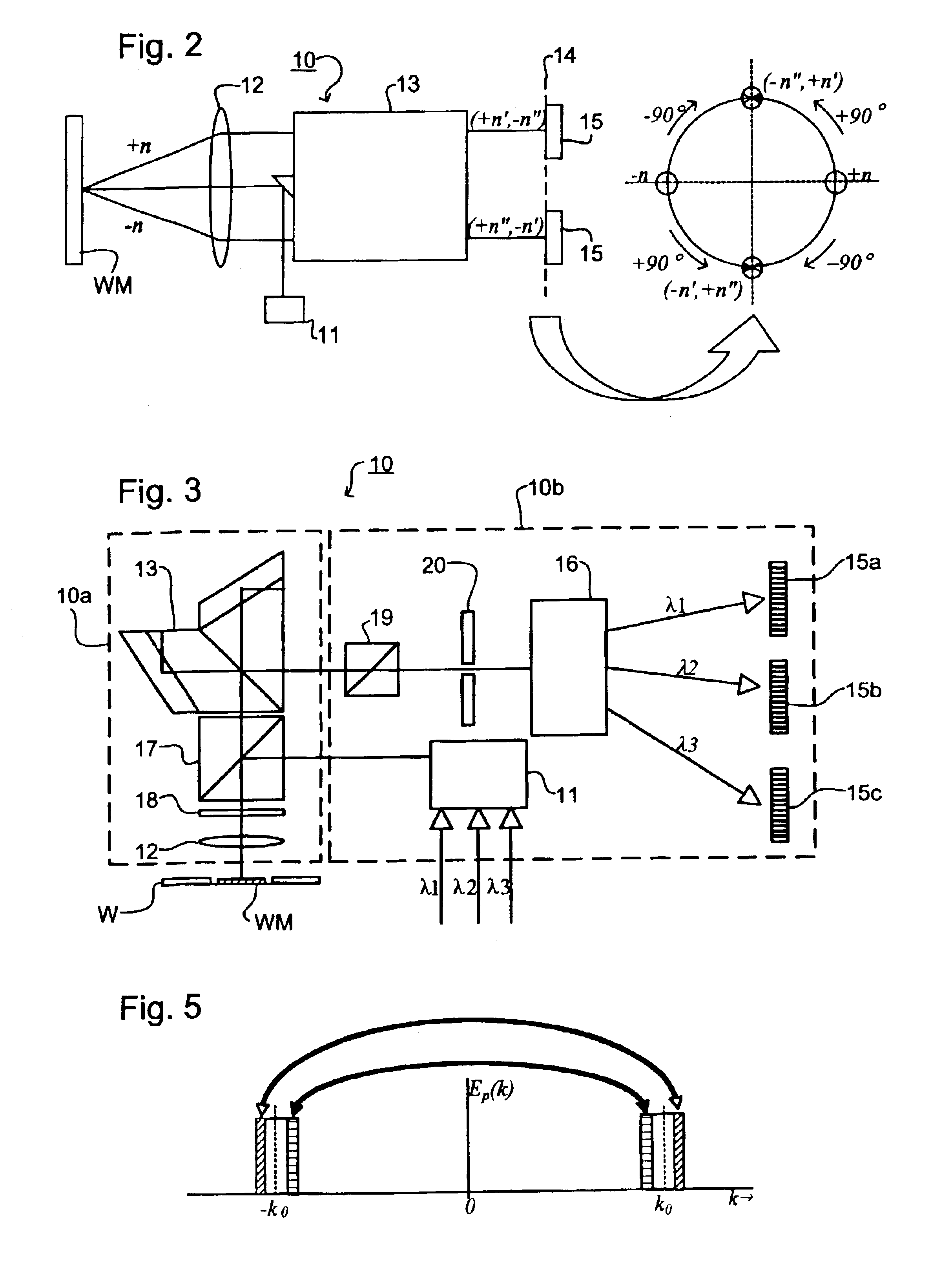

InactiveUS6961116B2Fine positioning informationLarge capture rangeDecorative surface effectsDuplicating/marking methodsDiffraction orderPhase difference

An alignment system uses a self-referencing interferometer that produces two overlapping and relatively rotated images of an alignment markers. Detectors detect intensities in a pupil plane where Fourier transforms of the images are caused to interfere. The positional information is derived from the phase difference between diffraction orders of the two images which manifests as intensity variations in the interfered orders. Asymmetry can also be measured by measuring intensities at two positions either side of a diffraction order.

Owner:ASML NETHERLANDS BV

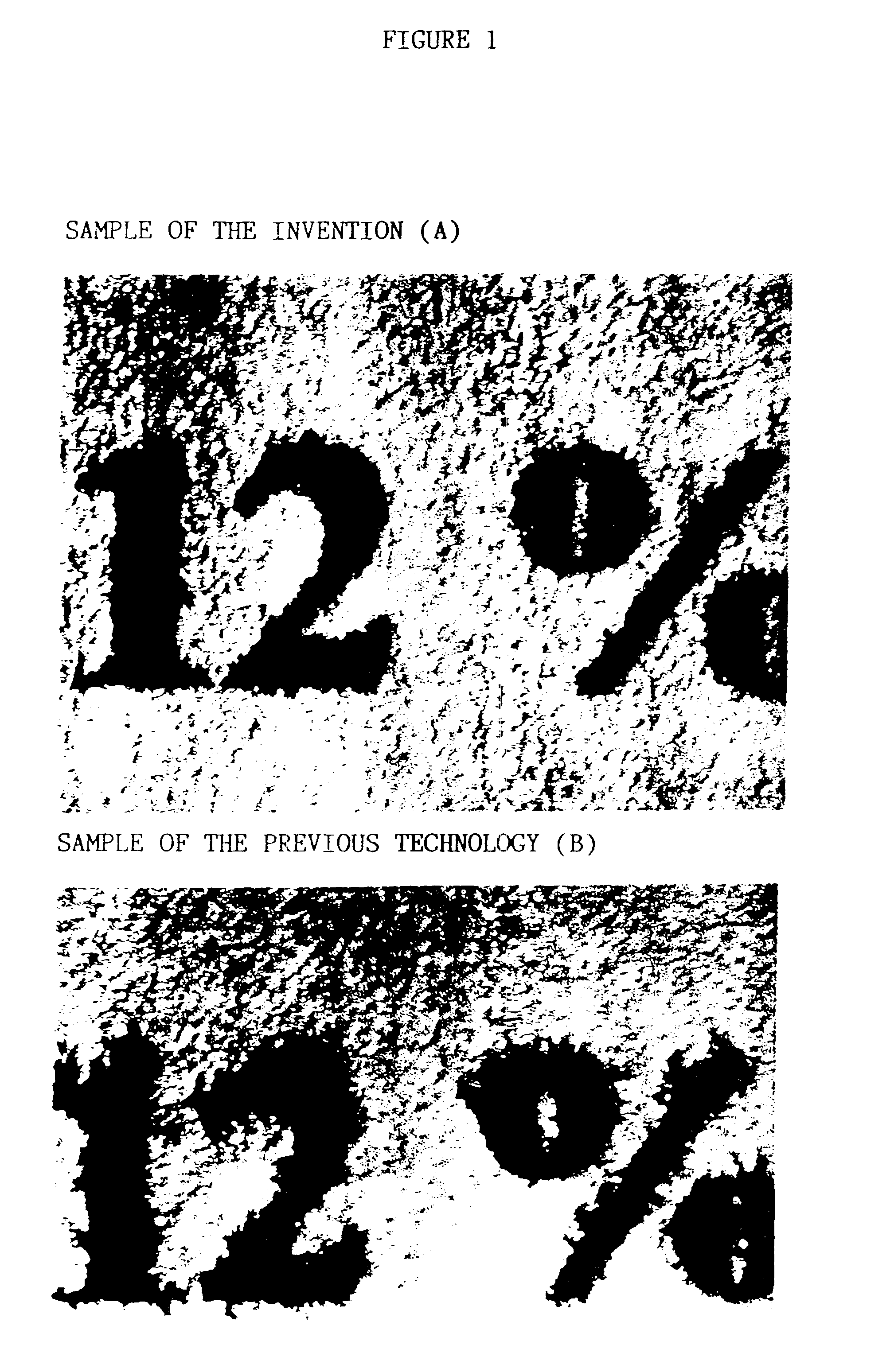

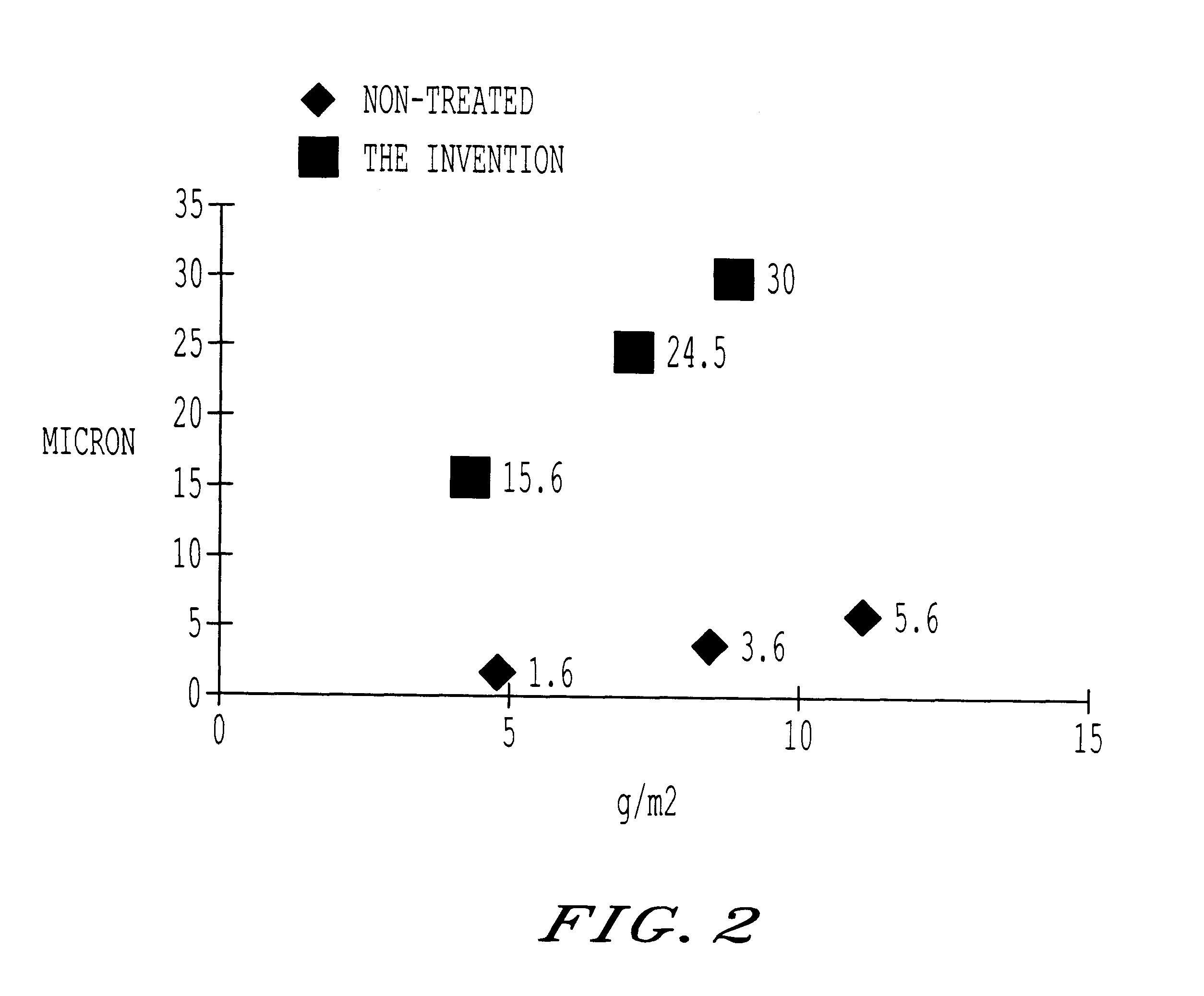

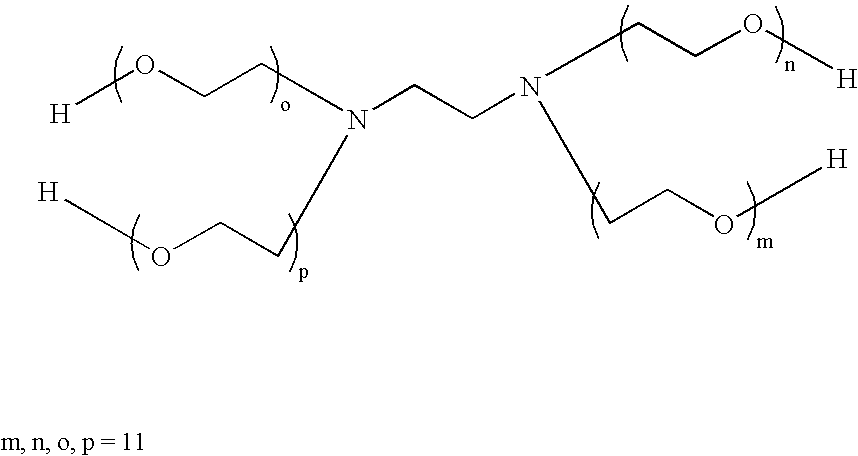

Nonwoven Having Durable Hydrophilic Coating

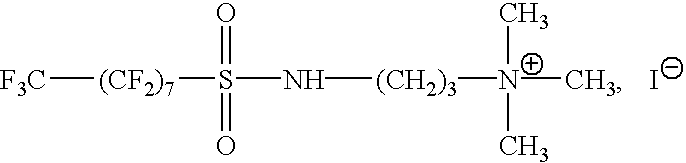

InactiveUS20110268932A1Promote migrationLamination ancillary operationsDecorative surface effectsHydrophilic coatingTrace Amounts

A nonwoven material coated with an amine-polyether silicone. The coating composition may include a wetting agent, an acid, and / or a defoamer. The nonwoven may be incorporated into a disposable absorbent article. The disposable absorbent article may include at least trace amounts of a mineral oil. The coating of the nonwoven may be durable even in the presence of mineral oil.

Owner:THE PROCTER & GAMBLE COMPANY

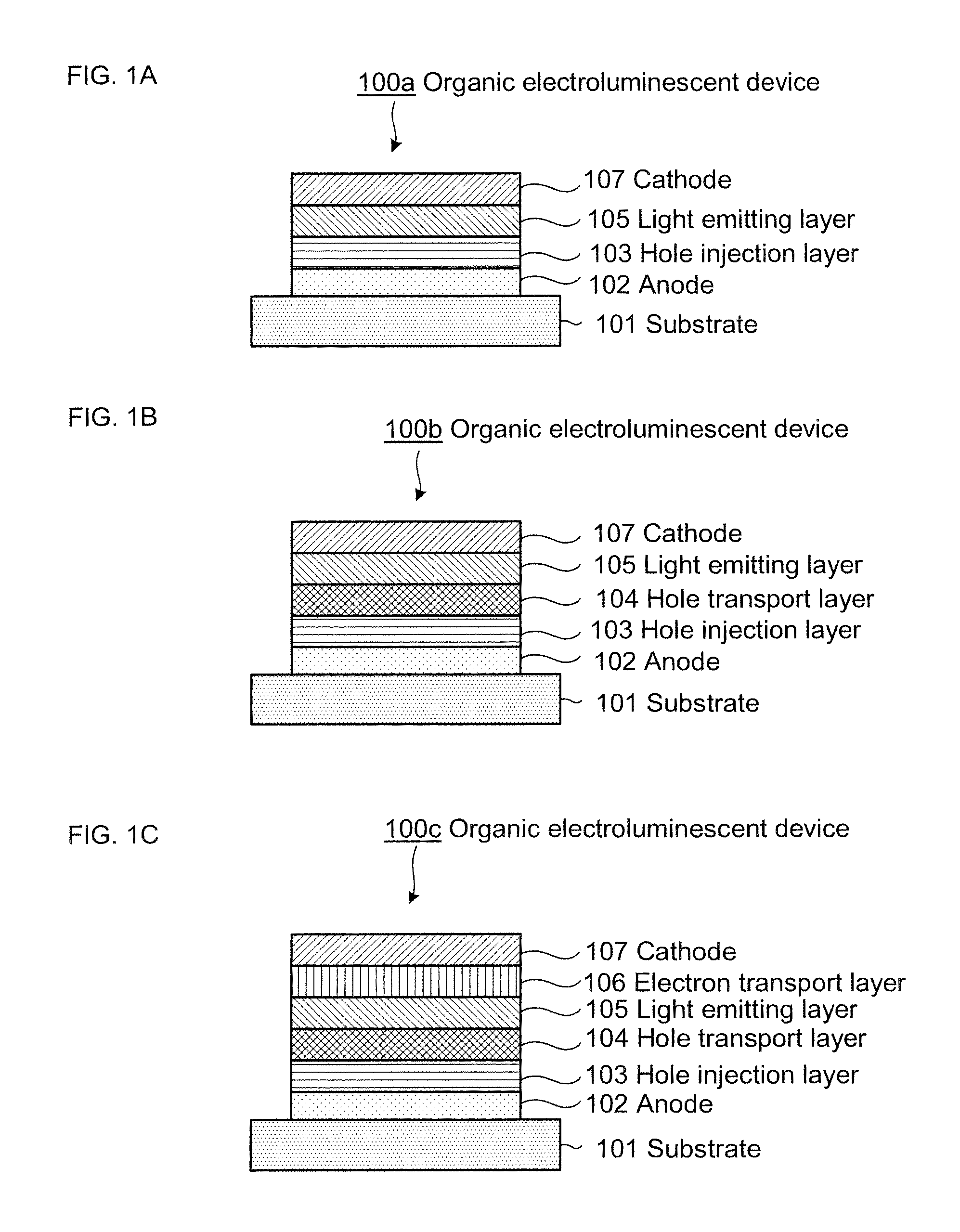

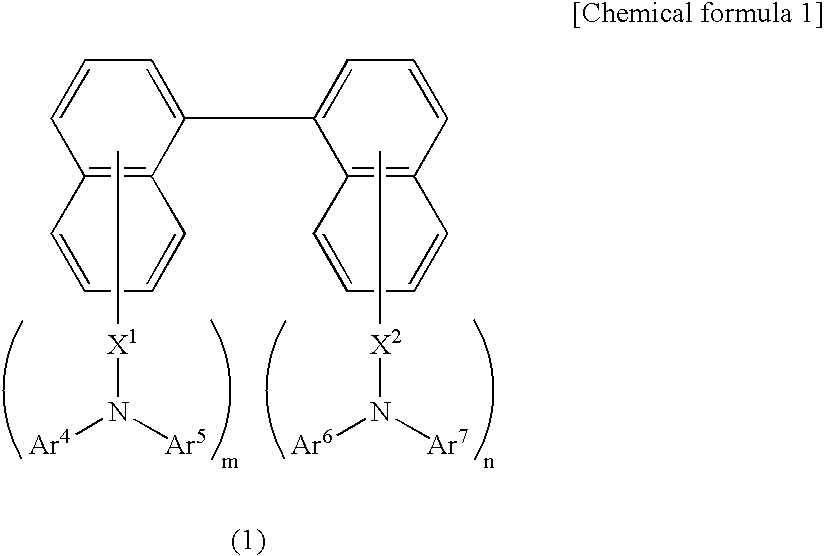

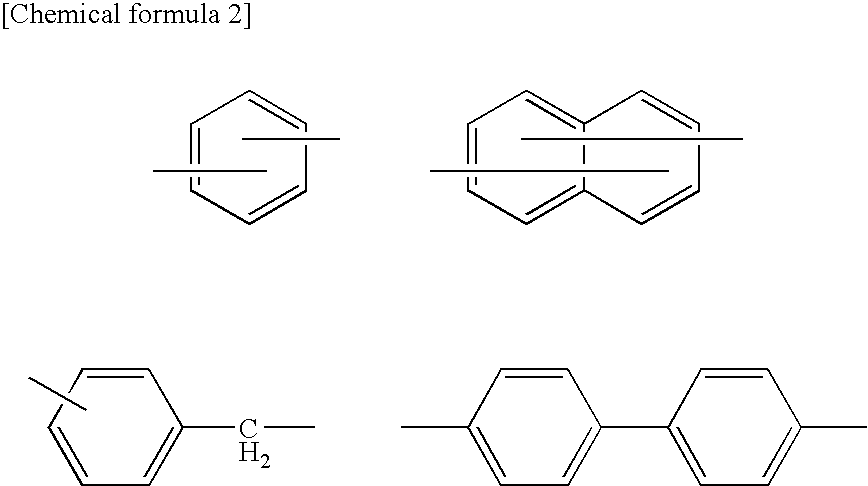

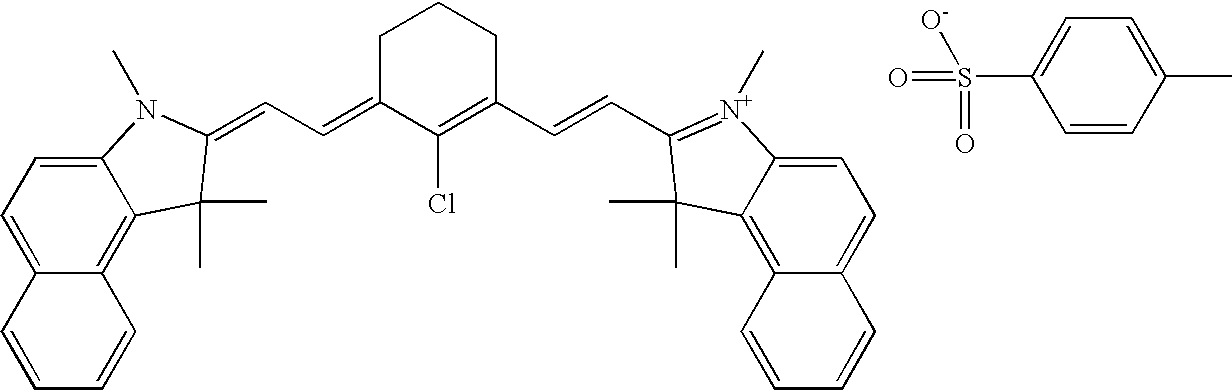

Compositions for organic electroluminescent device and organic electroluminescent device

InactiveUS20060182993A1Reduce inactivationChange propertiesDischarge tube luminescnet screensDuplicating/marking methodsSolubilityHole injection layer

Disclosed are compositions for an organic electroluminescent device favorably used for forming a hole injection layer and a hole transport layer of the organic electroluminescent device by a wet film forming method. The compositions for the organic electroluminescent device, which are composite solutions prepared by dissolving hole transport materials such as aromatic diamine compounds and an electron acceptor such as tri(pentafluorophenyl)boron in a solvent that contains an ether solvent and / or an ester solvent whose water solubility at 25° C. is 1 weight % or less in the solvent, with a concentration of 10 weight % or higher in the compositions.

Owner:MITSUBISHI CHEM CORP

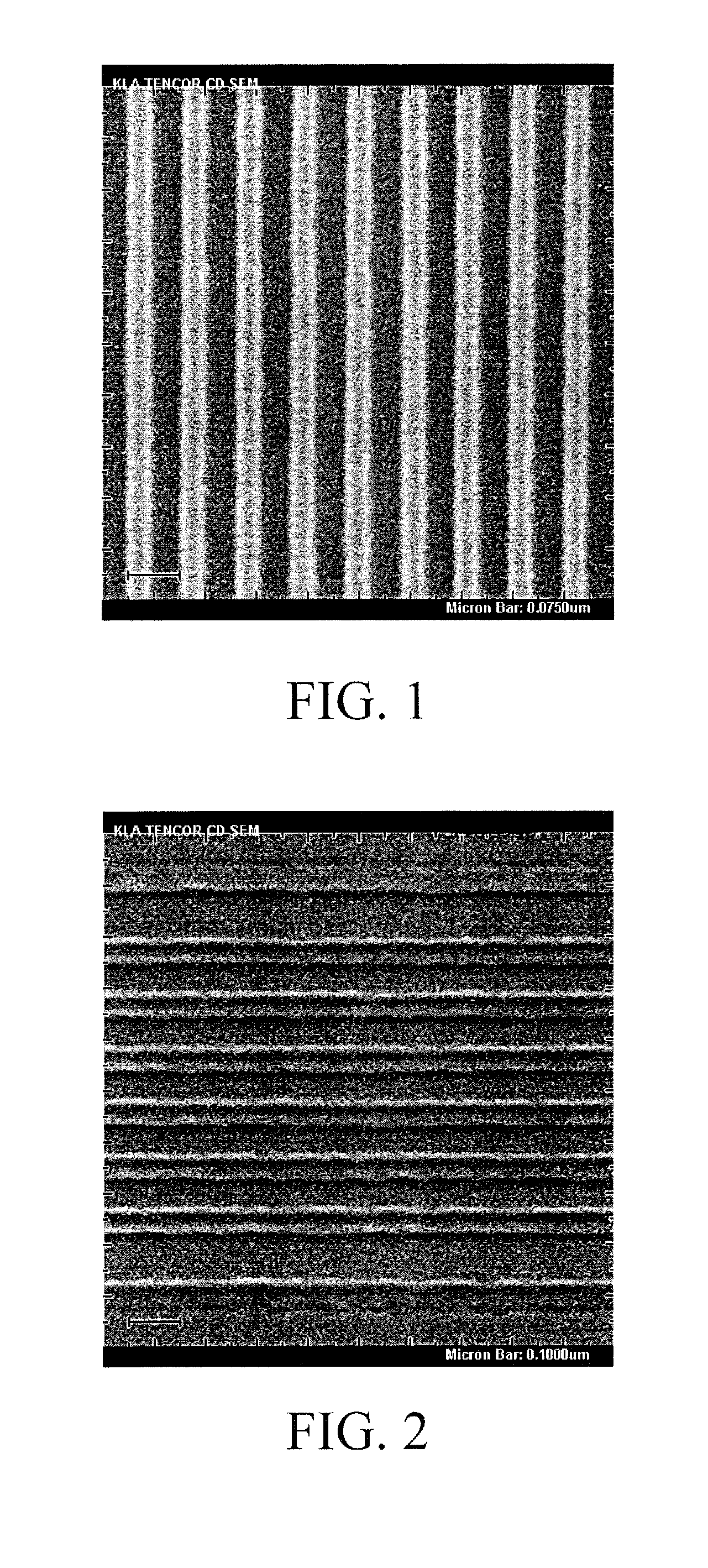

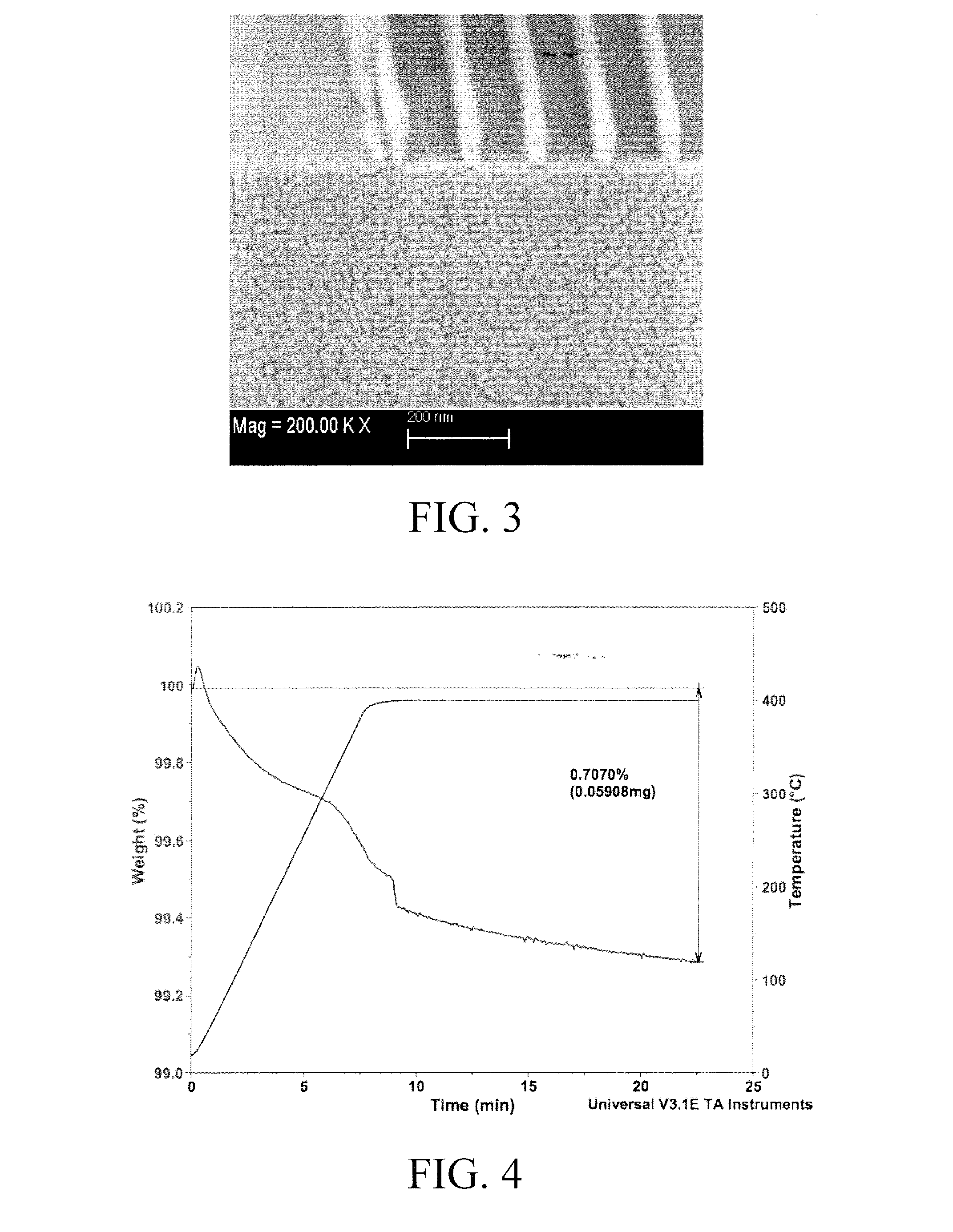

Spin-on carbon compositions for lithographic processing

The invention described herein is directed towards spin-on carbon materials comprising polyamic acid compositions and a crosslinker in a solvent system. The materials are useful in trilayer photolithography processes. Films made with the inventive compositions are not soluble in solvents commonly used in lithographic materials, such as, but not limited to PGME, PGMEA, and cyclohexanone. However, the films can be dissolved in developers commonly used in photolithography. In one embodiment, the films can be heated at high temperatures to improve the thermal stability for high temperature processing. Regardless of the embodiment, the material can be applied to a flat / planar or patterned surface. Advantageously, the material exhibits a wiggling resistance during pattern transfer to silicon substrate using fluorocarbon etch.

Owner:BREWER SCI

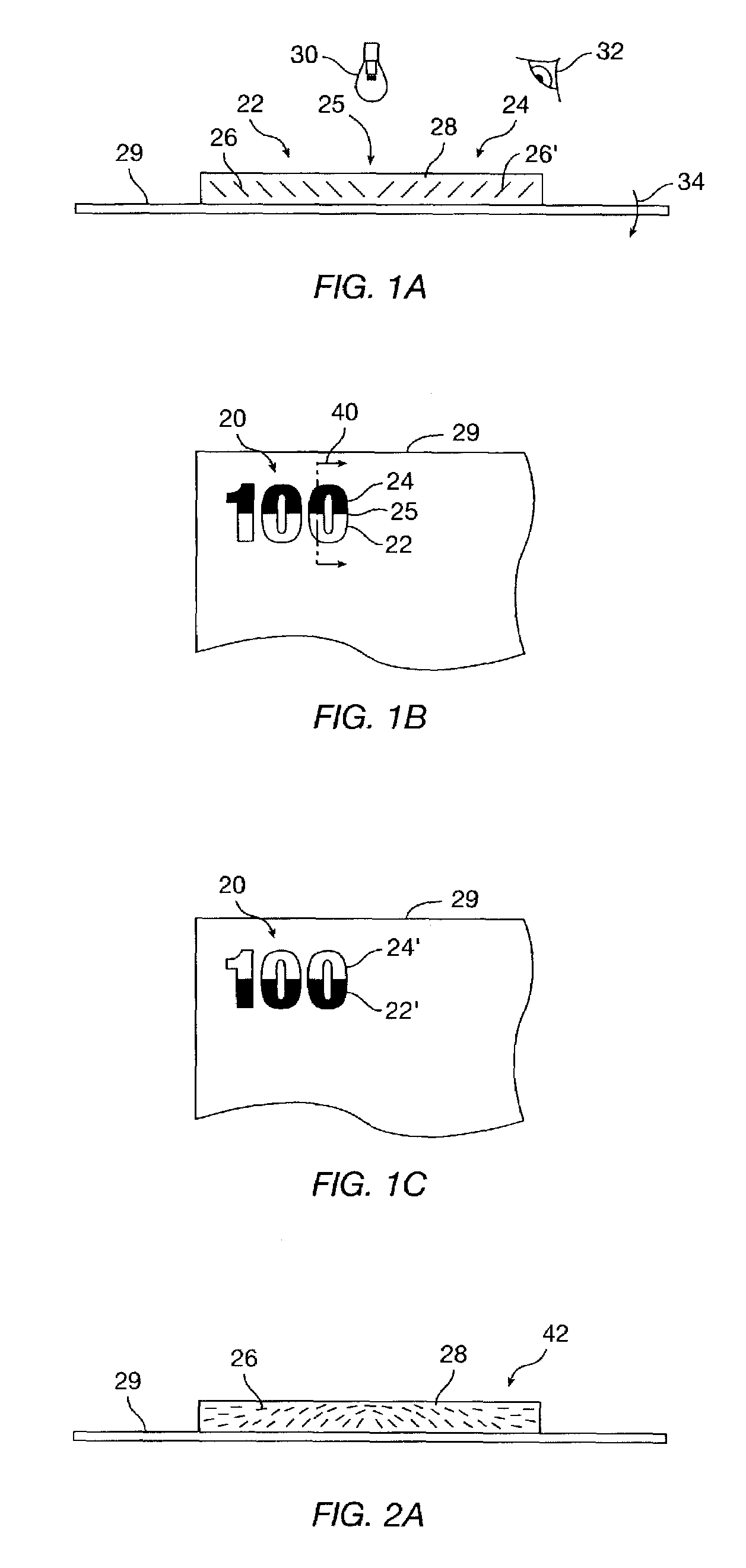

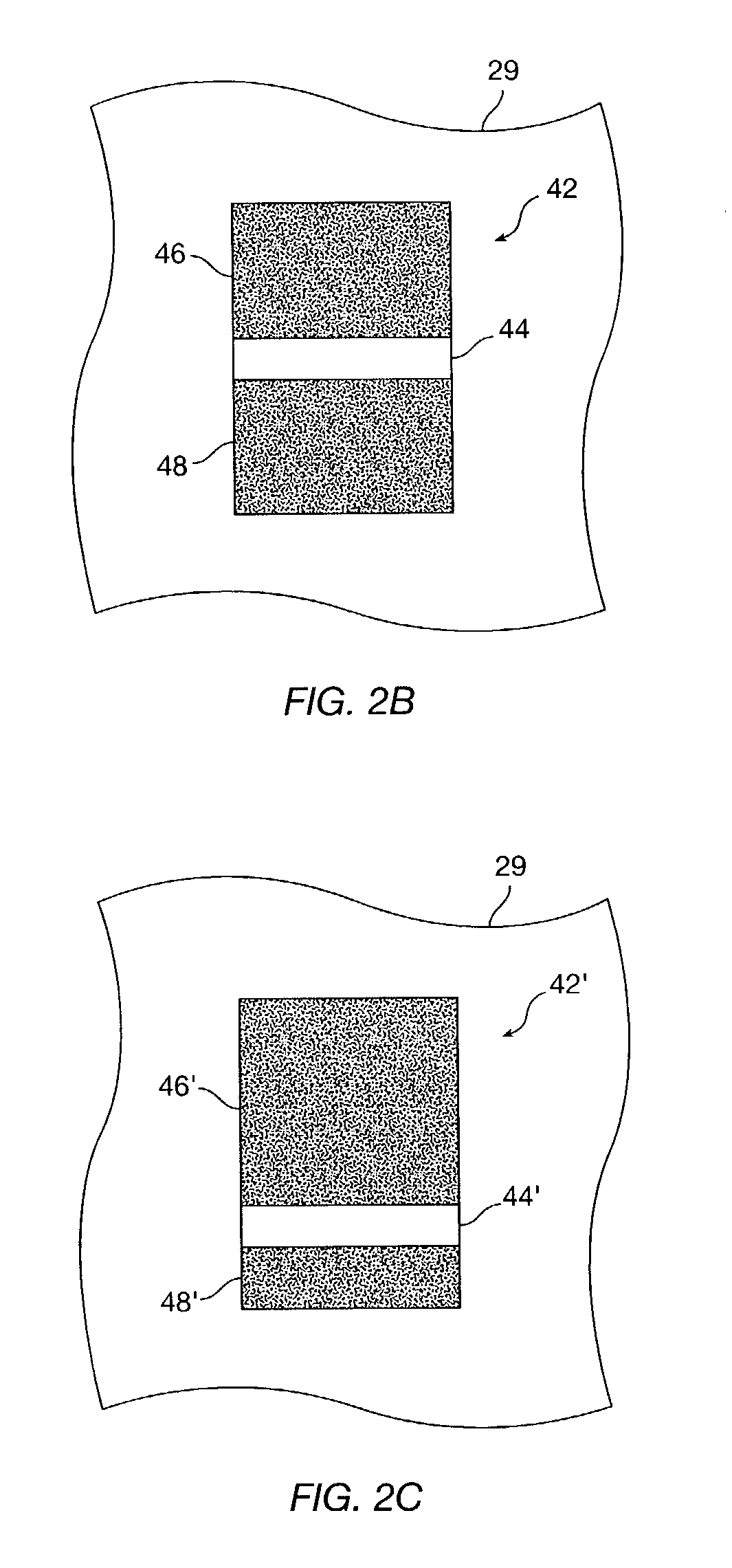

Alignable diffractive pigment flakes

Diffractive pigment flakes are selectively aligned to form an image. In one embodiment, flakes having a magnetic layer are shaped to facilitate alignment in a magnetic field. In another embodiment, the flakes include a magnetically discontinuous layer. In a particular embodiment, deposition of nickel on a diffraction grating pattern produces magnetic needles along the grating pattern that allow magnetic alignment of the resulting diffractive pigment flakes. Color scans of test samples of magnetically aligned flakes show high differentiation between illumination parallel and perpendicular to the direction of alignment of the magnetic diffractive pigment flakes.

Owner:VIAVI SOLUTIONS INC

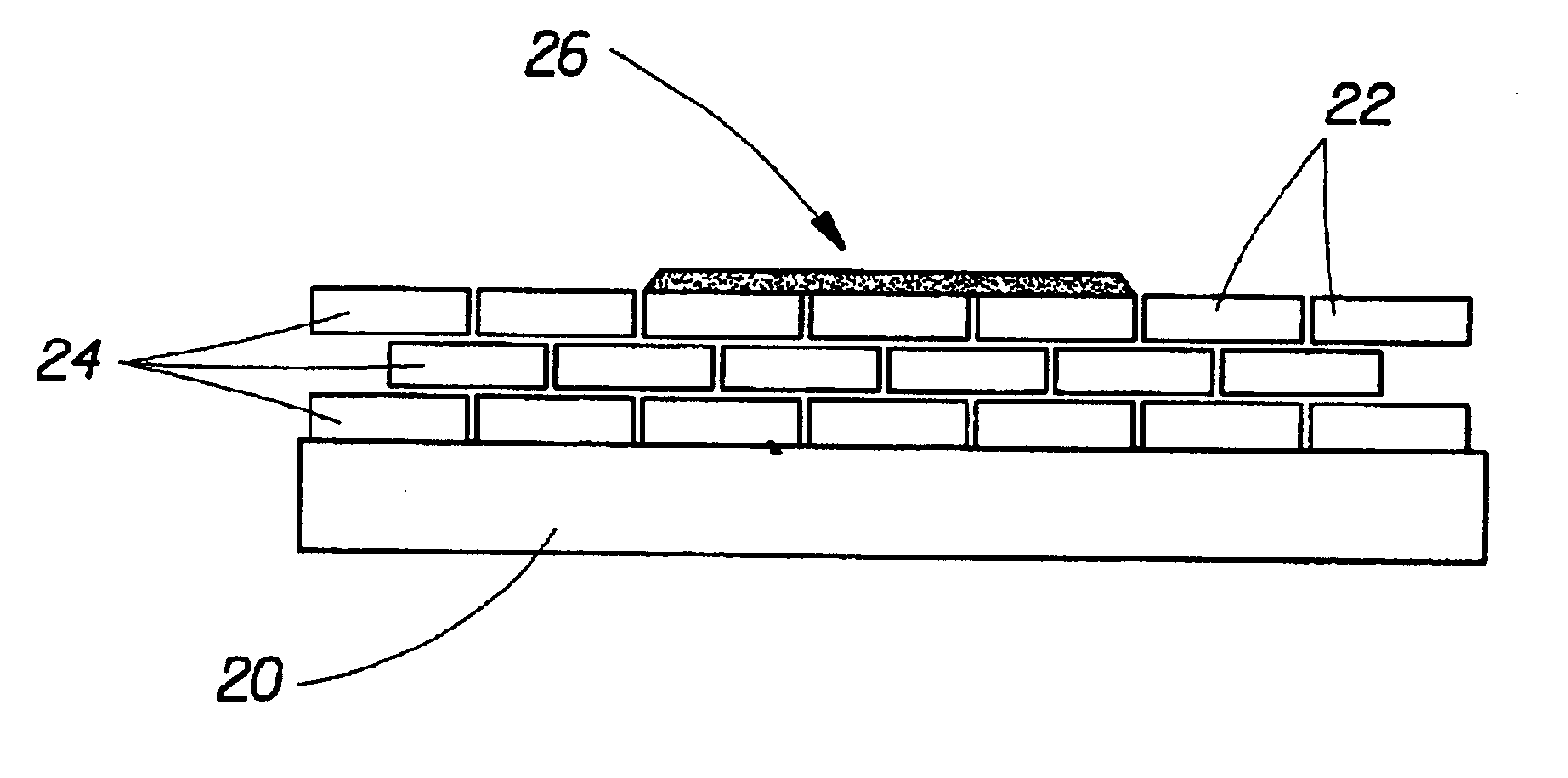

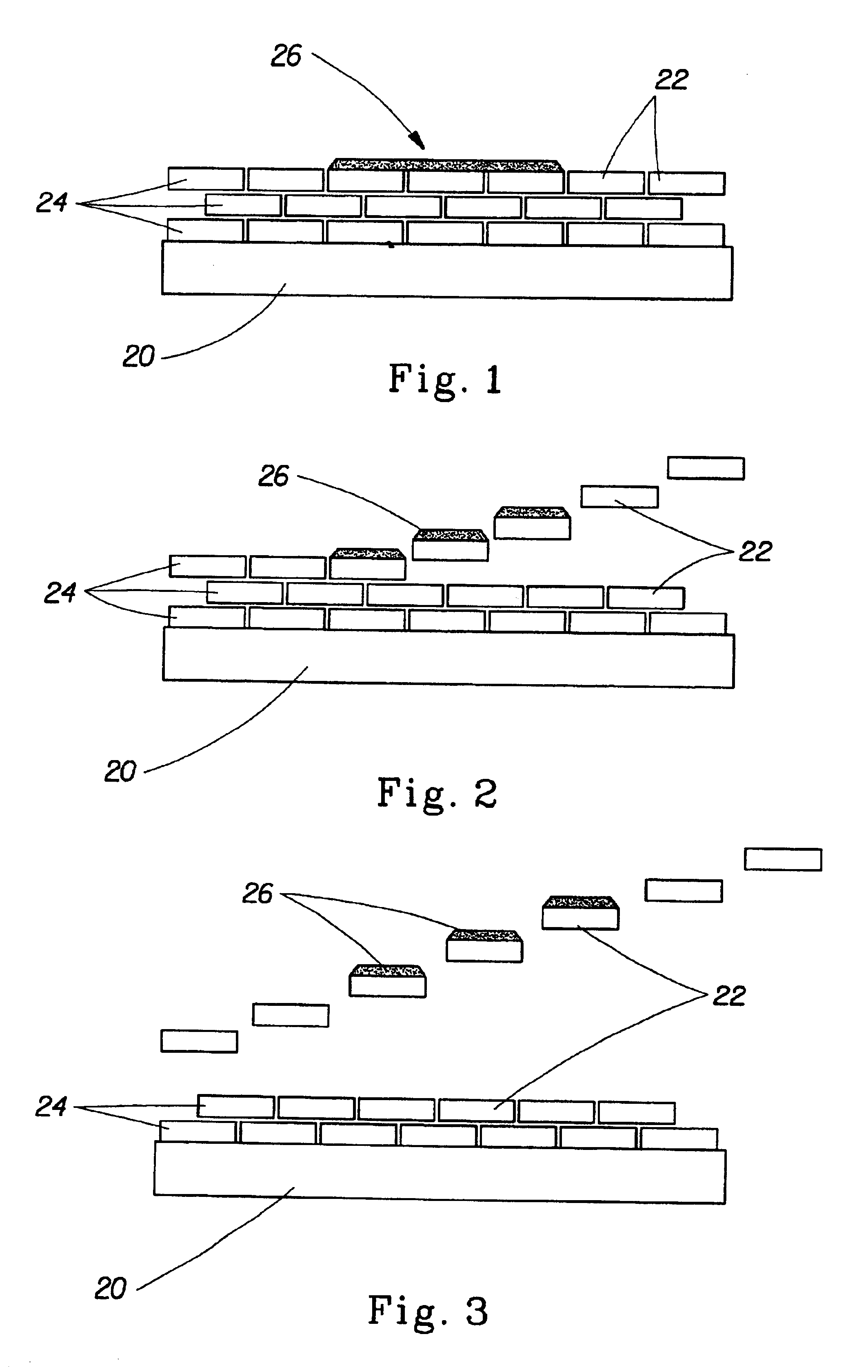

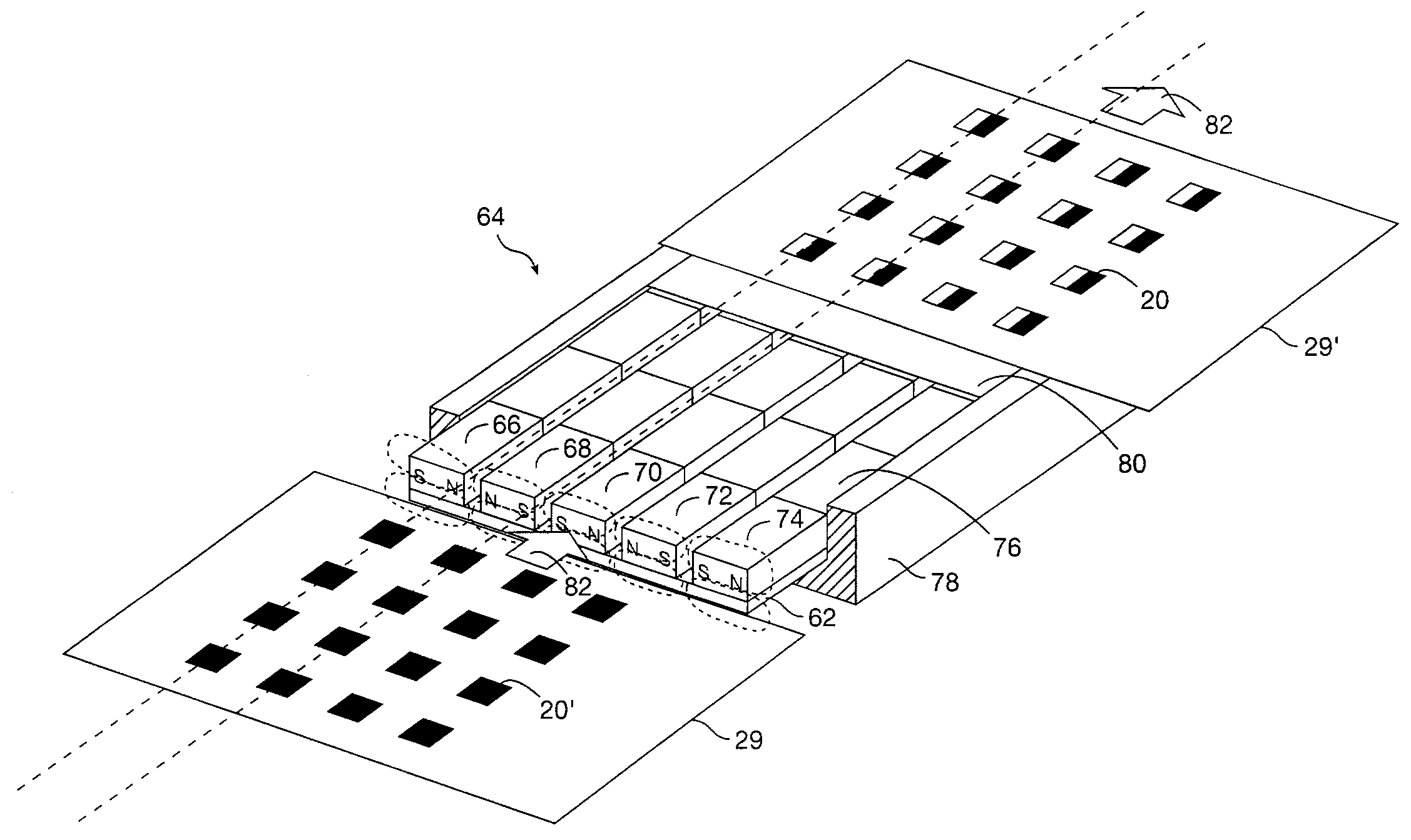

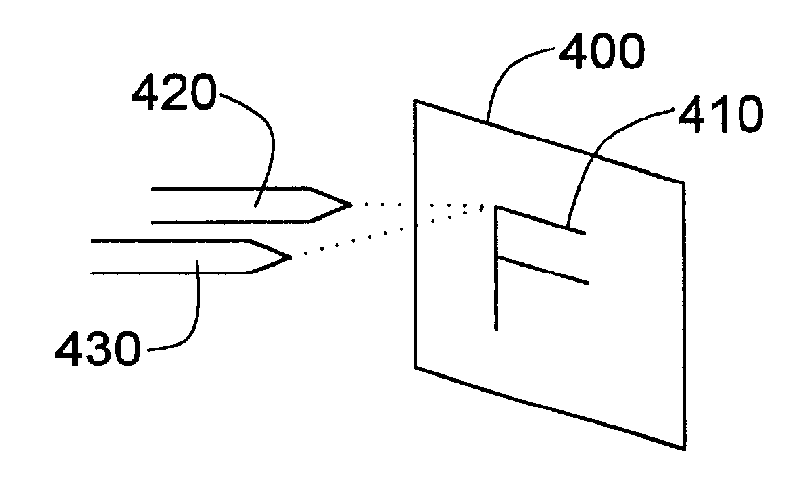

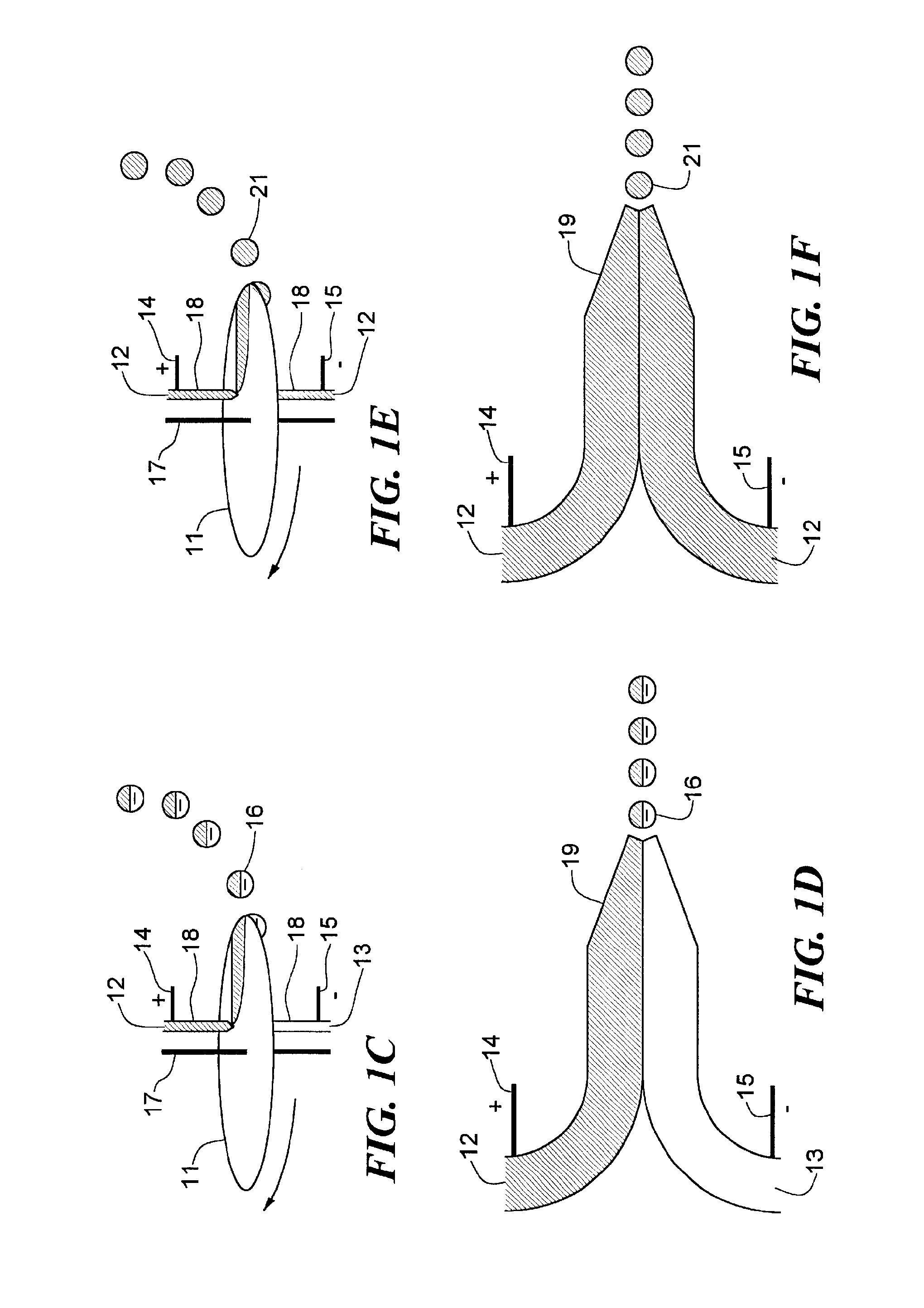

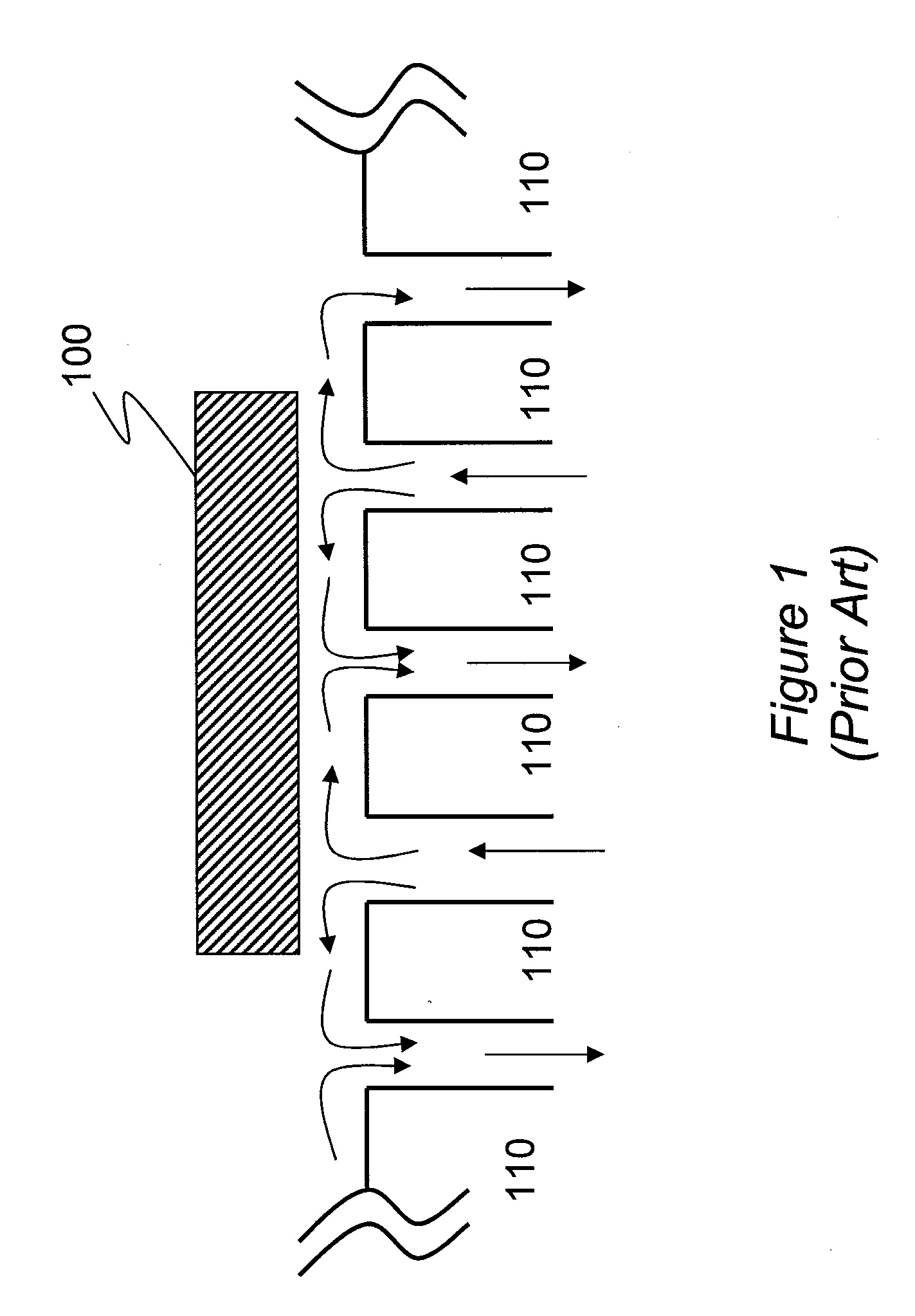

Method and apparatus for orienting magnetic flakes

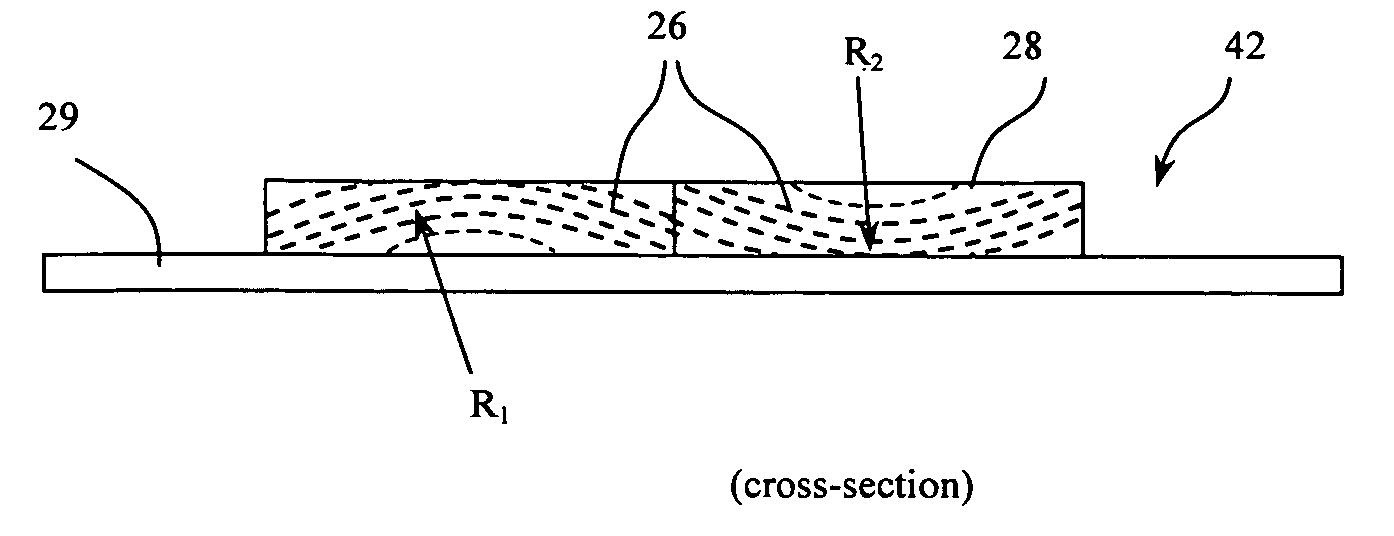

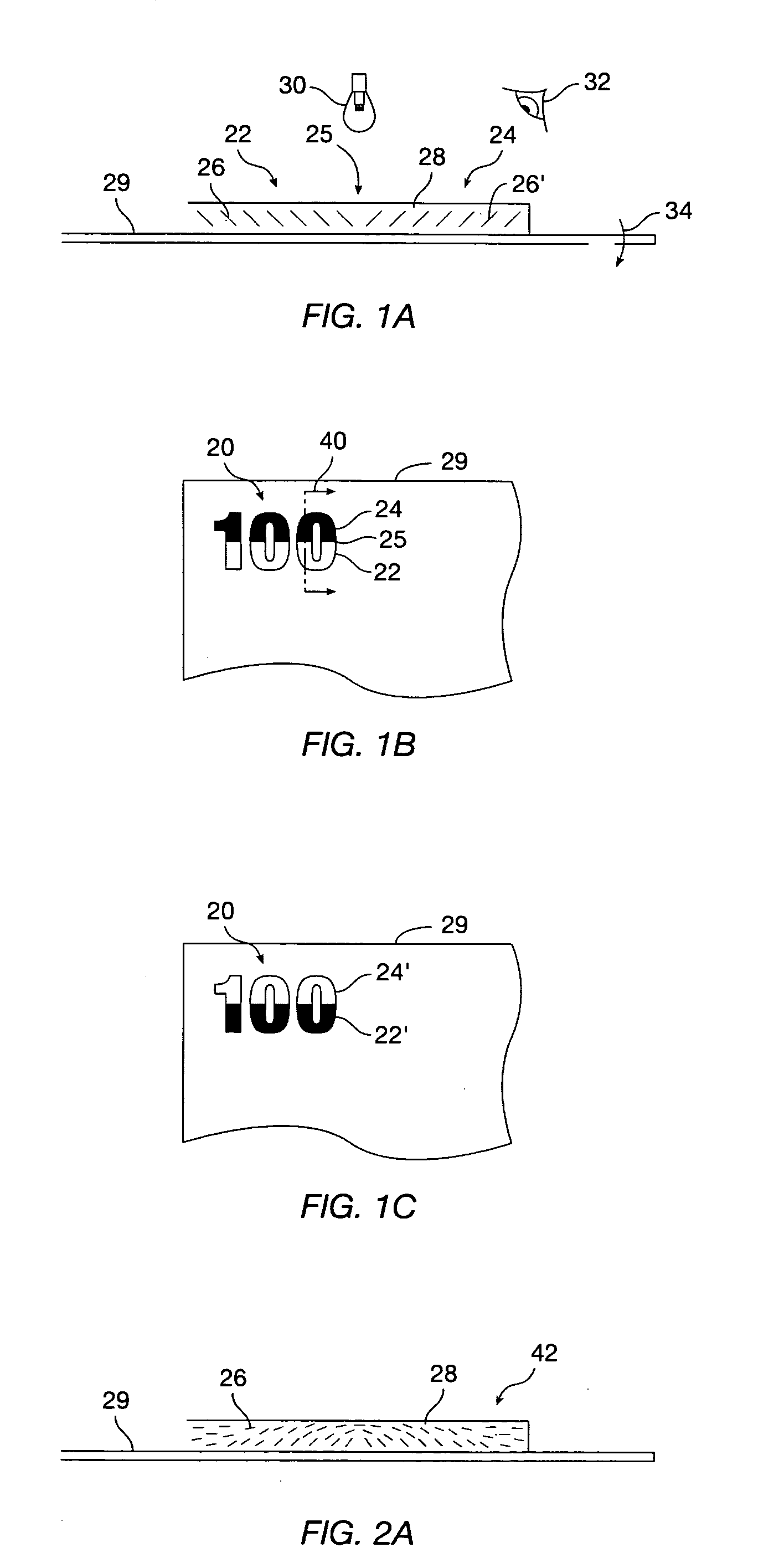

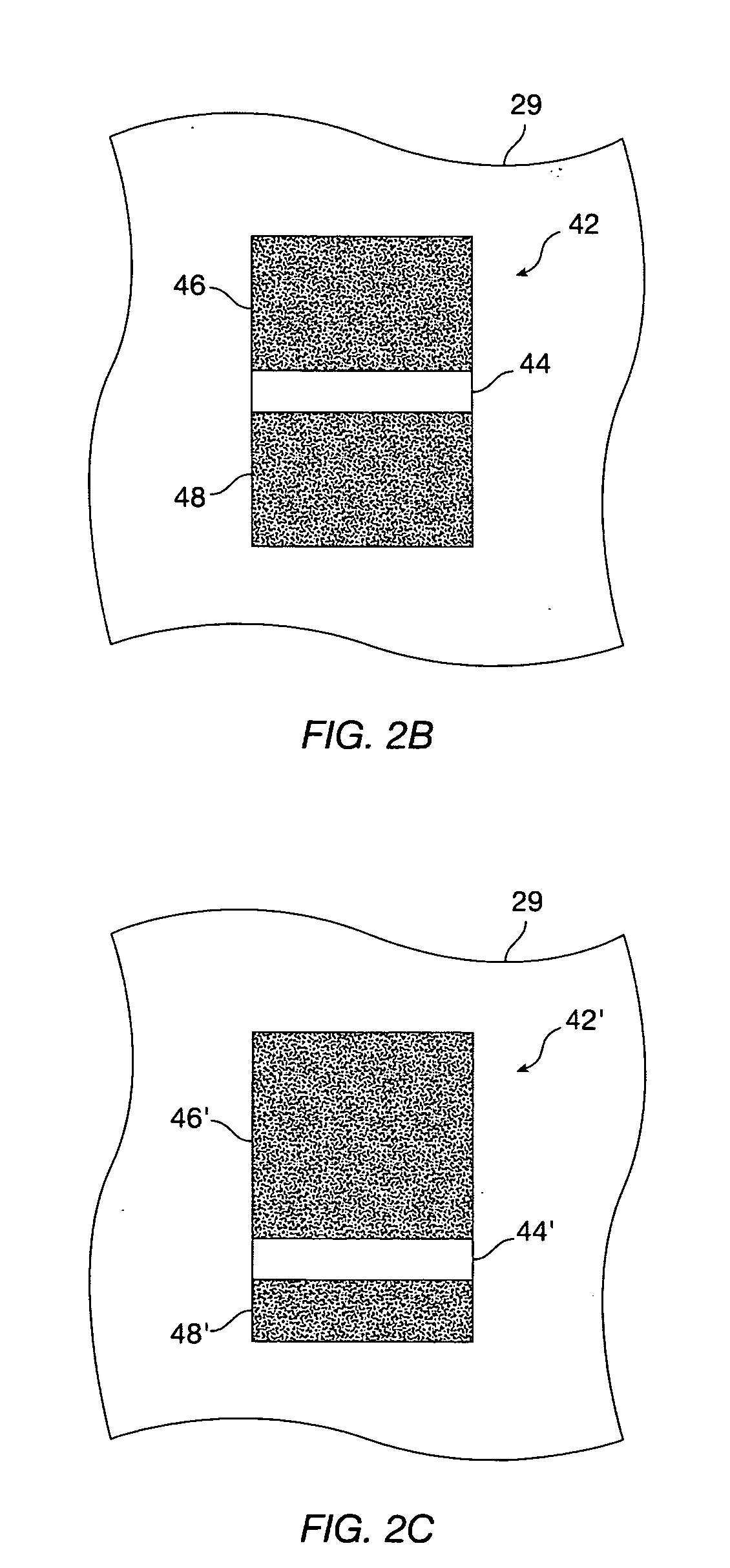

InactiveUS20050106367A1Non-fibrous pulp additionDecorative surface effectsPaper documentDocument preparation

Apparatus and related methods align magnetic flakes in a carrier, such as an ink vehicle or a paint vehicle to create optically variable images in a high-speed, linear printing operation. Images can provide security features on high-value documents, such as bank notes. Magnetic flakes in the ink are aligned using magnets in a linear printing operation. Selected orientation of the magnetic pigment flakes can achieve a variety of illusive optical effects that are useful for decorative or security applications.

Owner:VIAVI SOLUTIONS INC

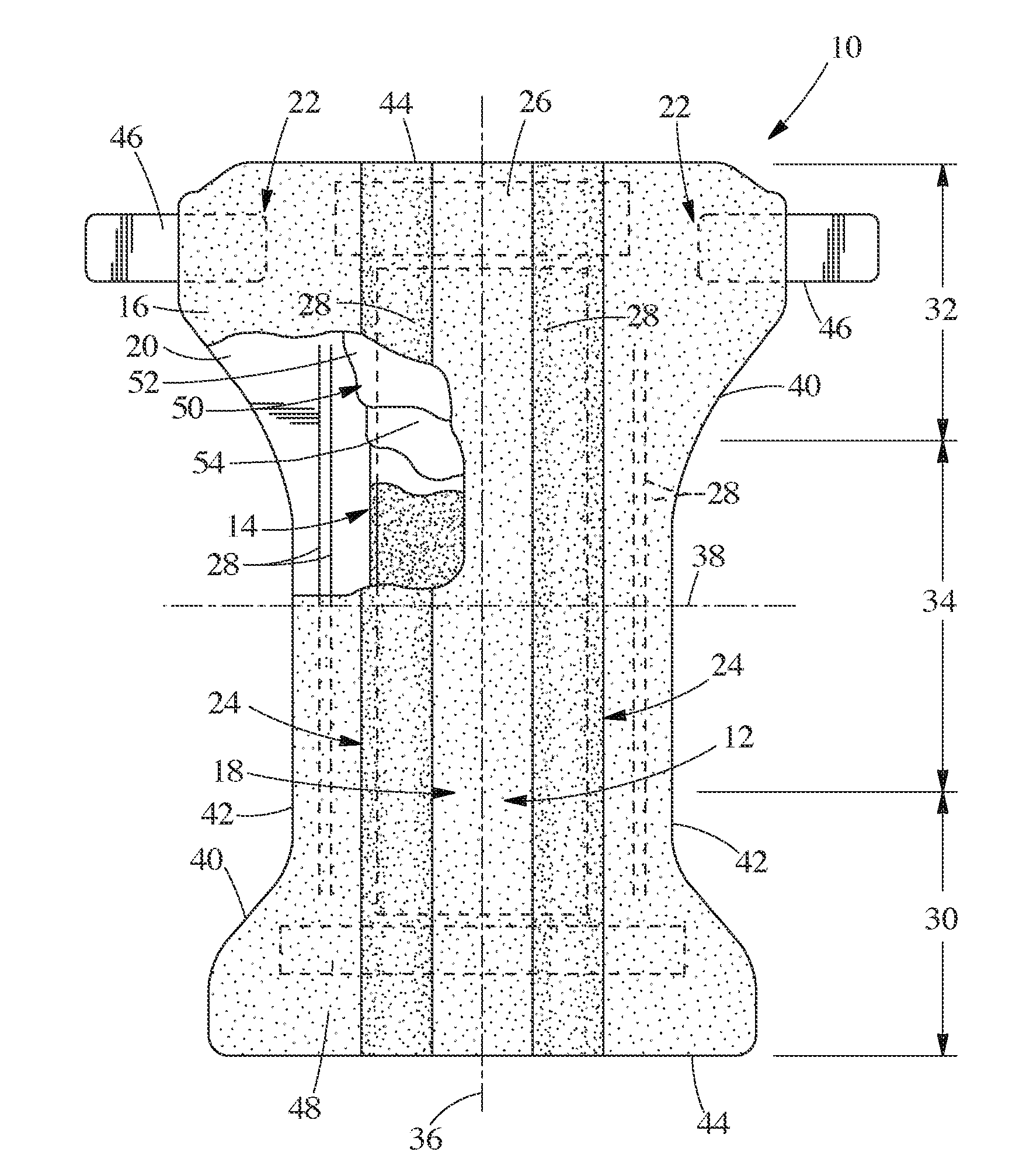

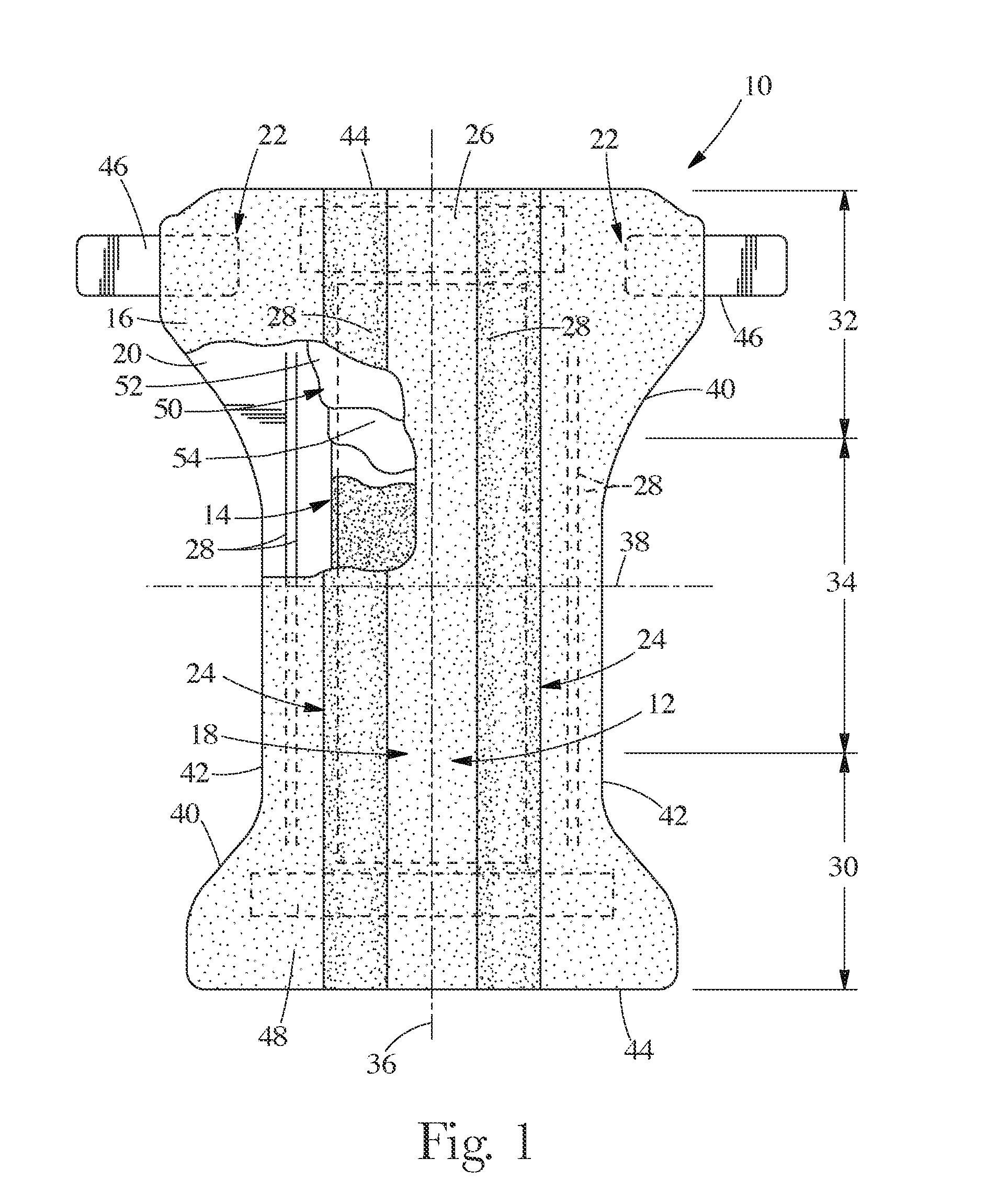

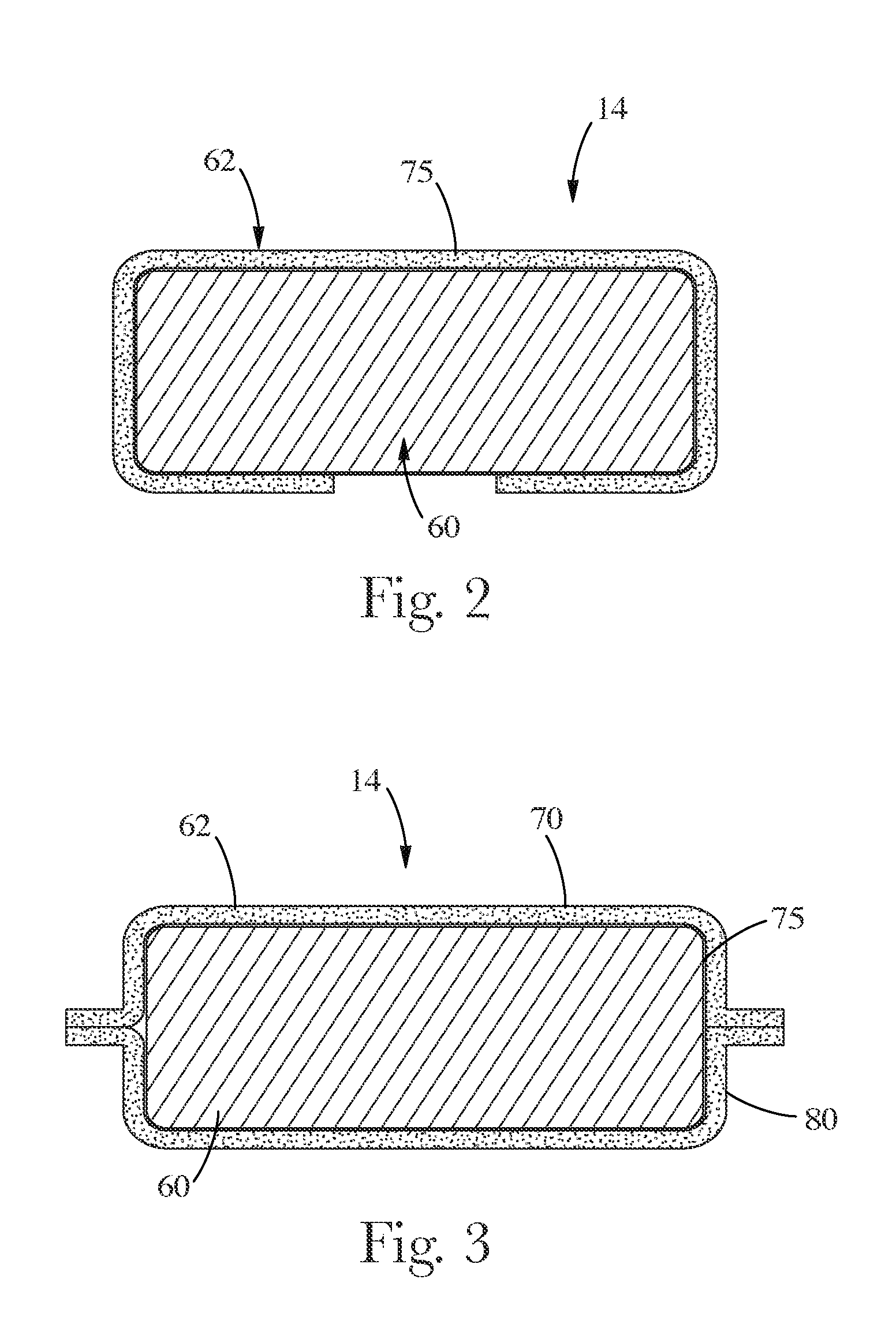

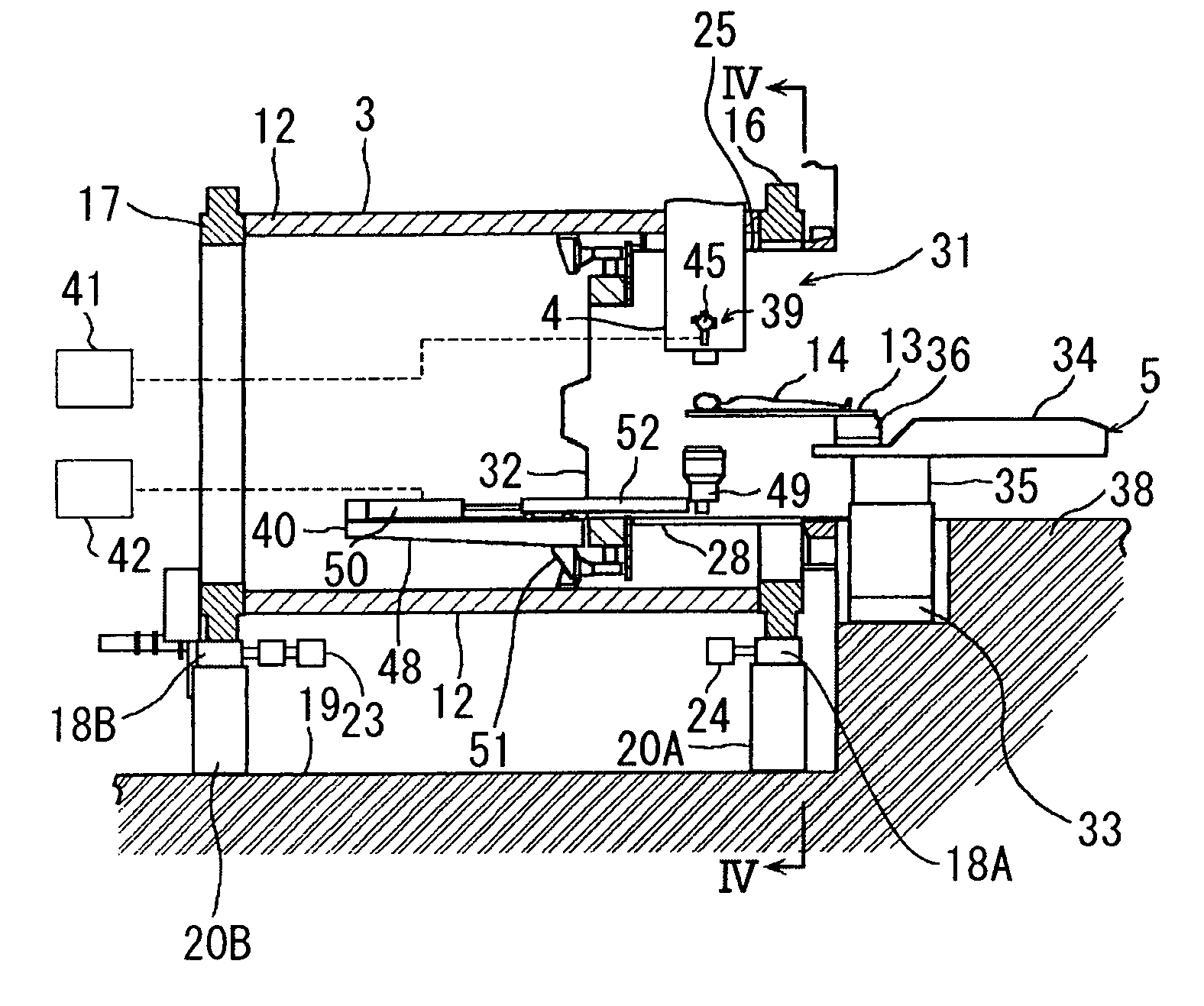

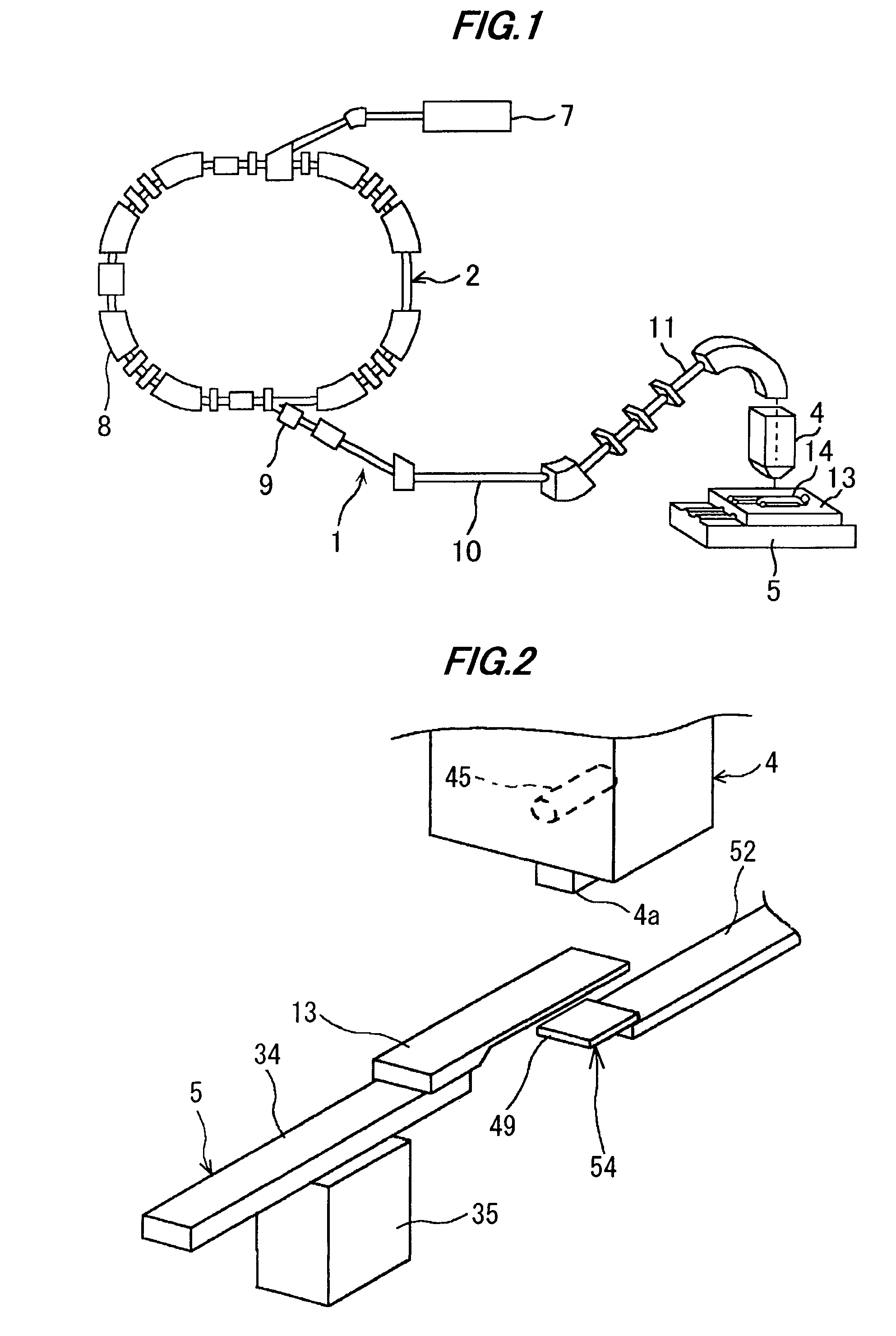

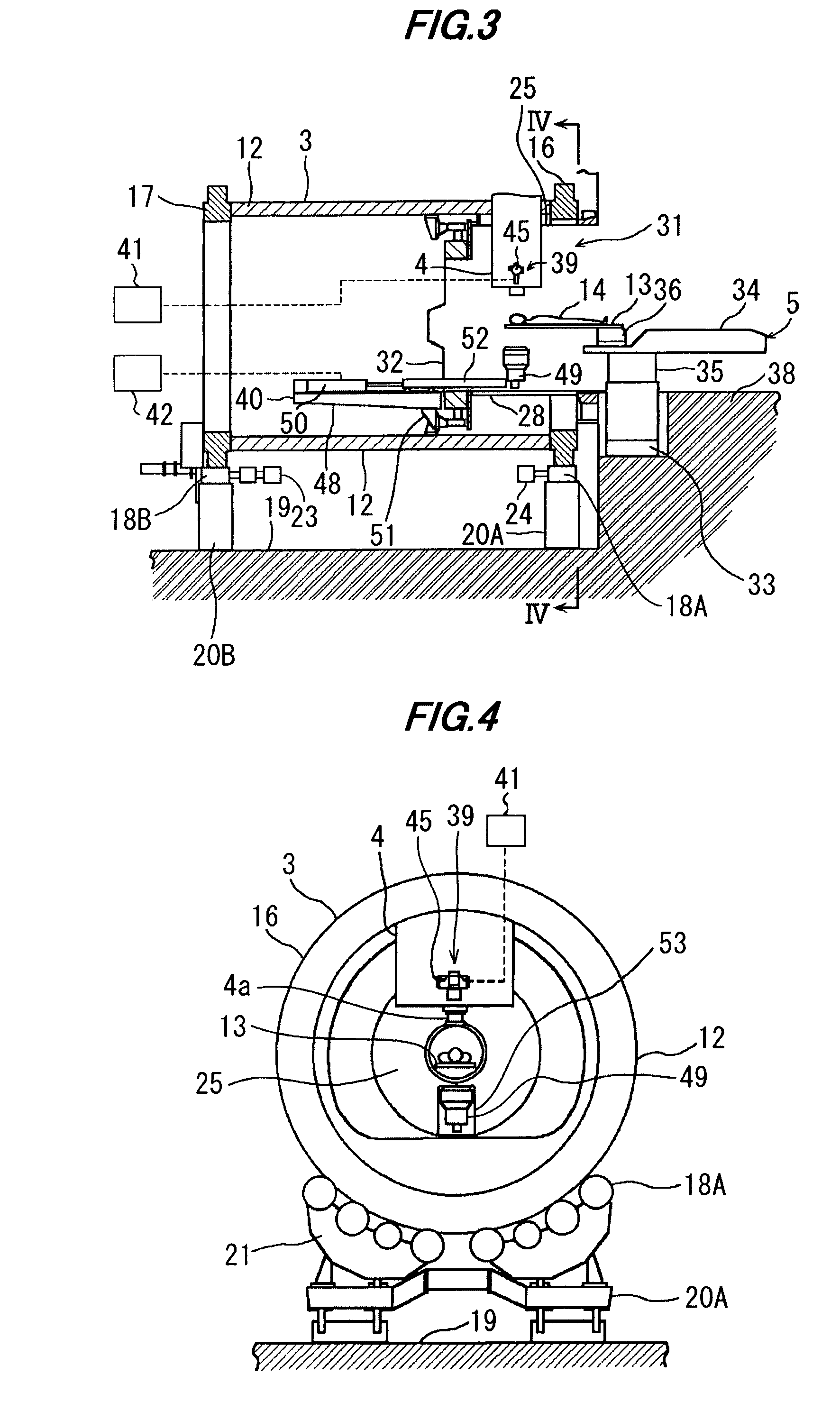

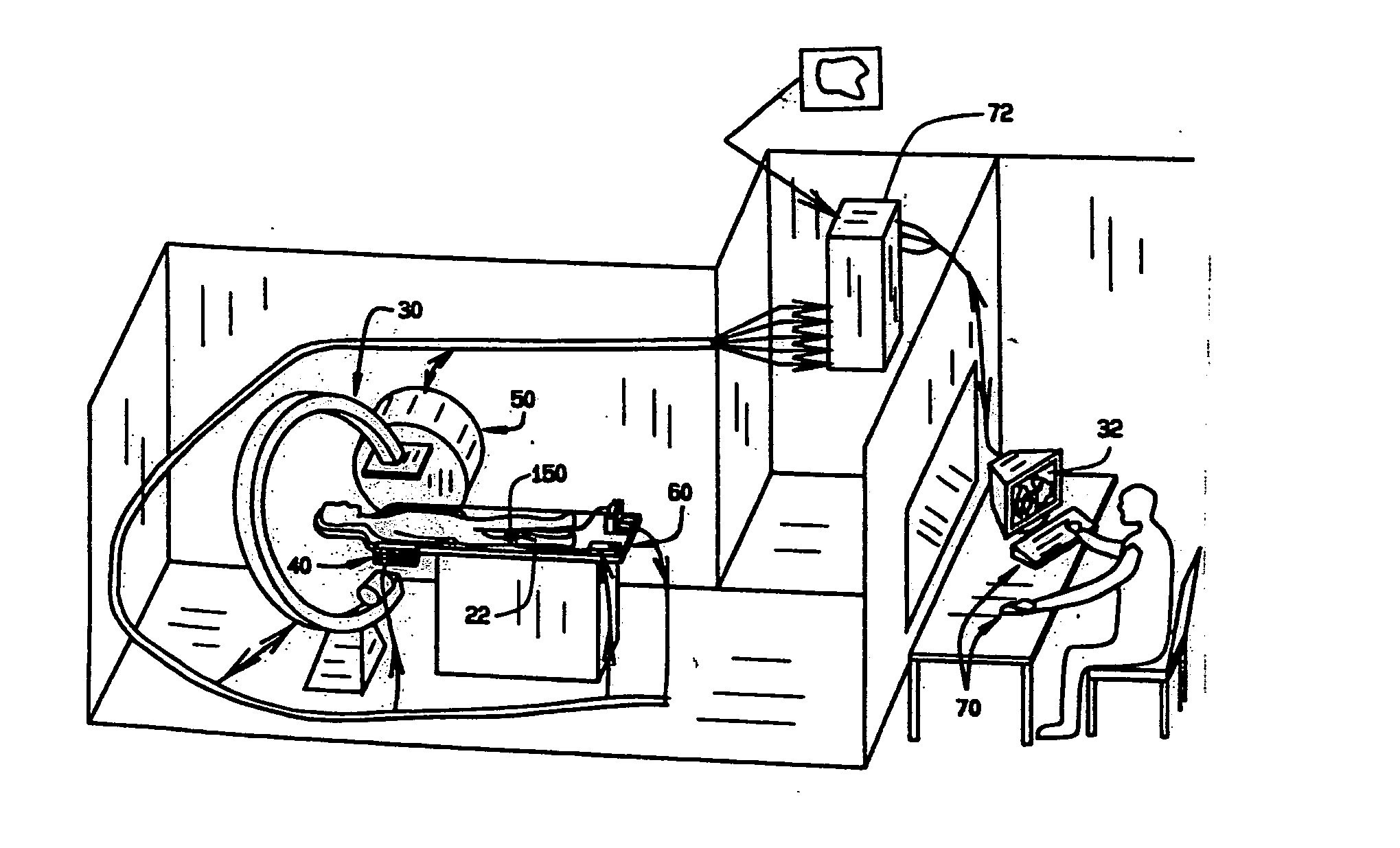

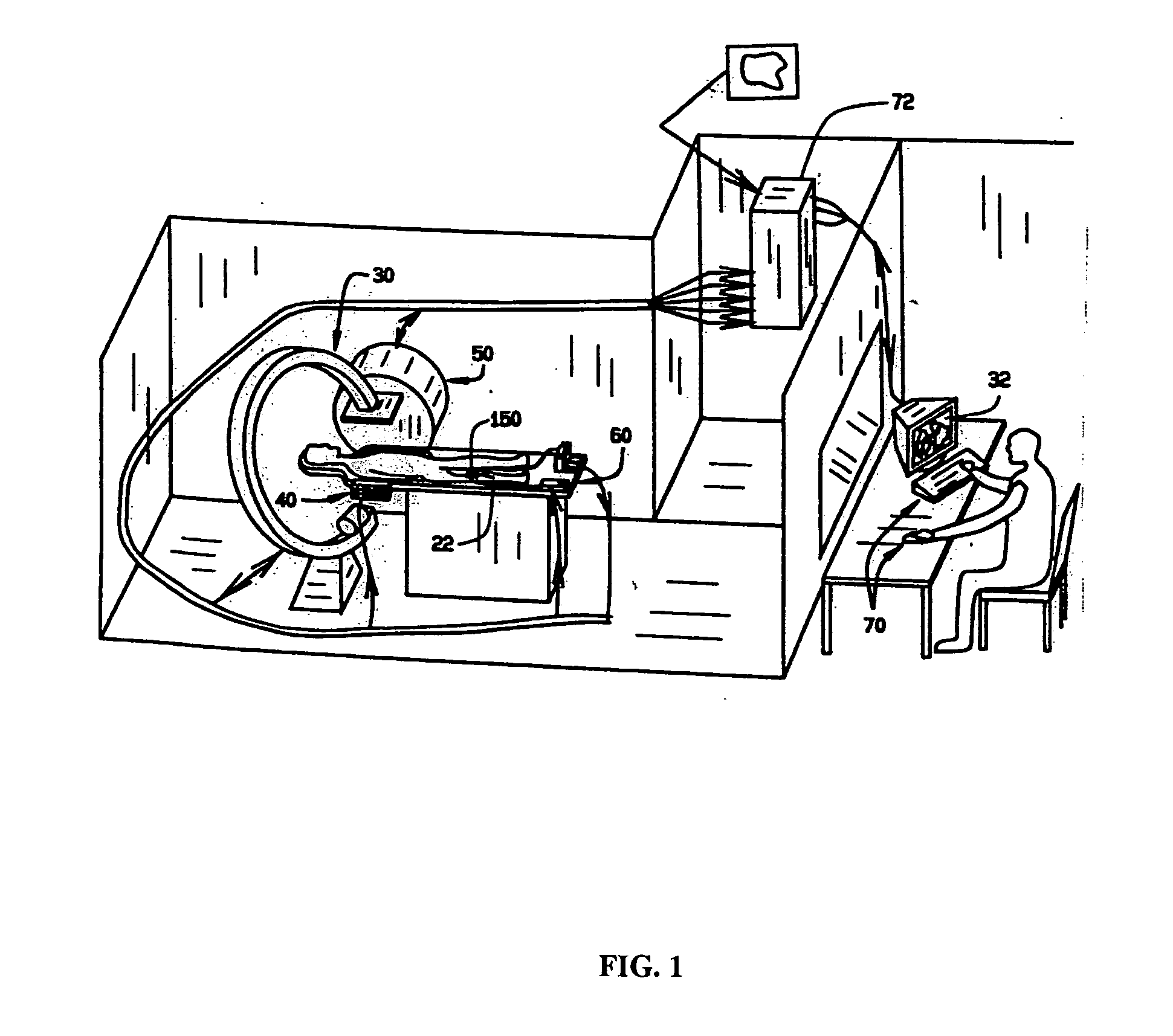

Ion beam therapy system and its couch positioning method

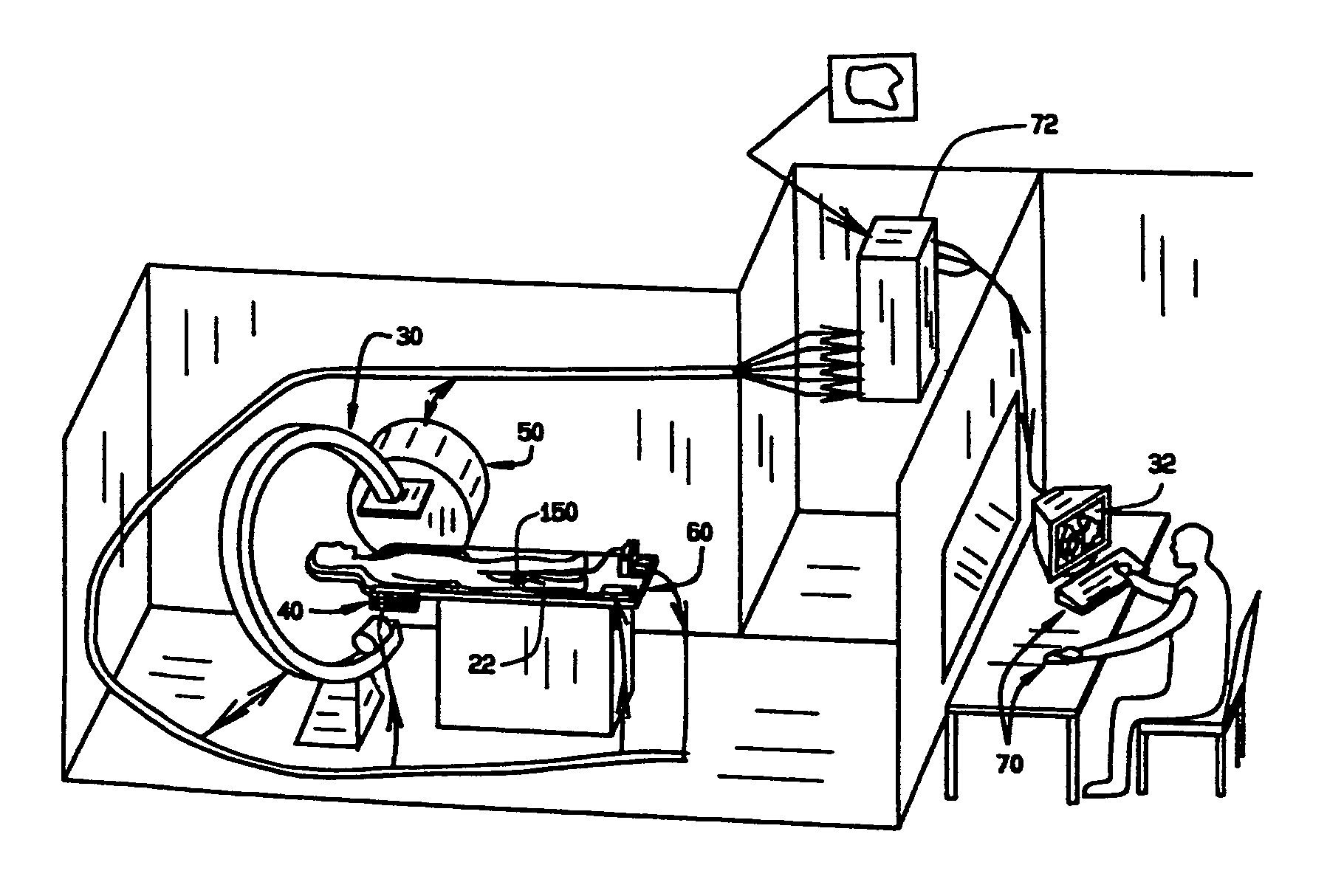

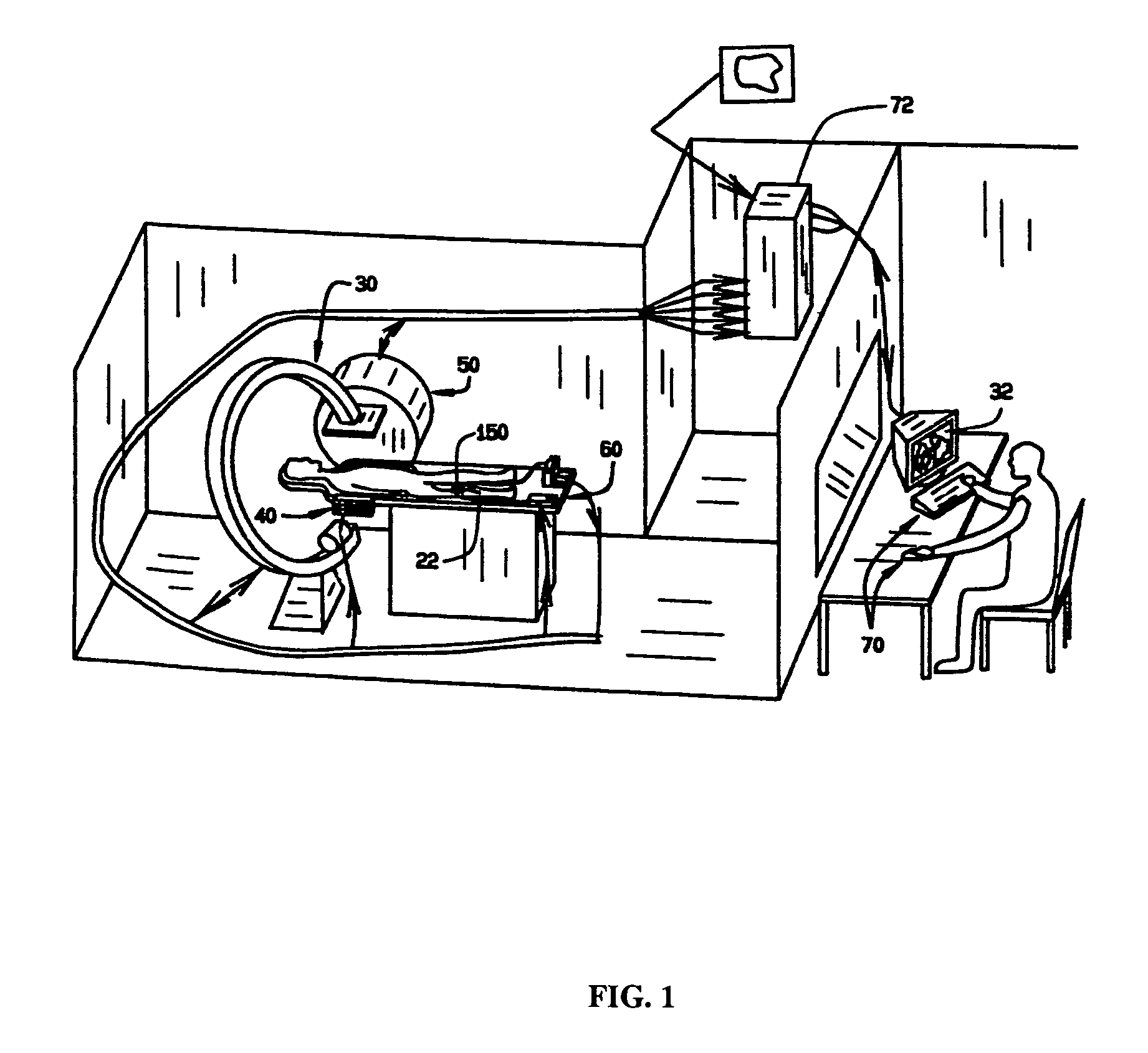

ActiveUS7193227B2Improve accuracyExtension of timeRadiation/particle handlingElectric discharge tubesIon beamX-ray

A therapy system using an ion beam, which can shorten the time required for positioning a couch (patient). The therapy system using the ion beam comprises a rotating gantry provided with an ion beam delivery unit including an X-ray tube. An X-ray detecting device having a plurality of X-ray detectors can be moved in the direction of a rotation axis of the rotating gantry. A couch on which a patient is lying is moved until a tumor substantially reaches an extension of an ion beam path in the irradiating unit. The X-ray tube is positioned on the ion beam path and the X-ray detecting device is positioned on the extension of the ion beam path. With rotation of the rotating gantry, both the X-ray tube emitting an X-ray and the X-ray detecting device revolve around the patient. The X-ray is emitted to the patient and detected by the X-ray detectors after penetrating the patient. Tomographic information of the patient is formed based on signals outputted from the X-ray detectors. Information for positioning the couch is generated by using the tomographic information.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST +1

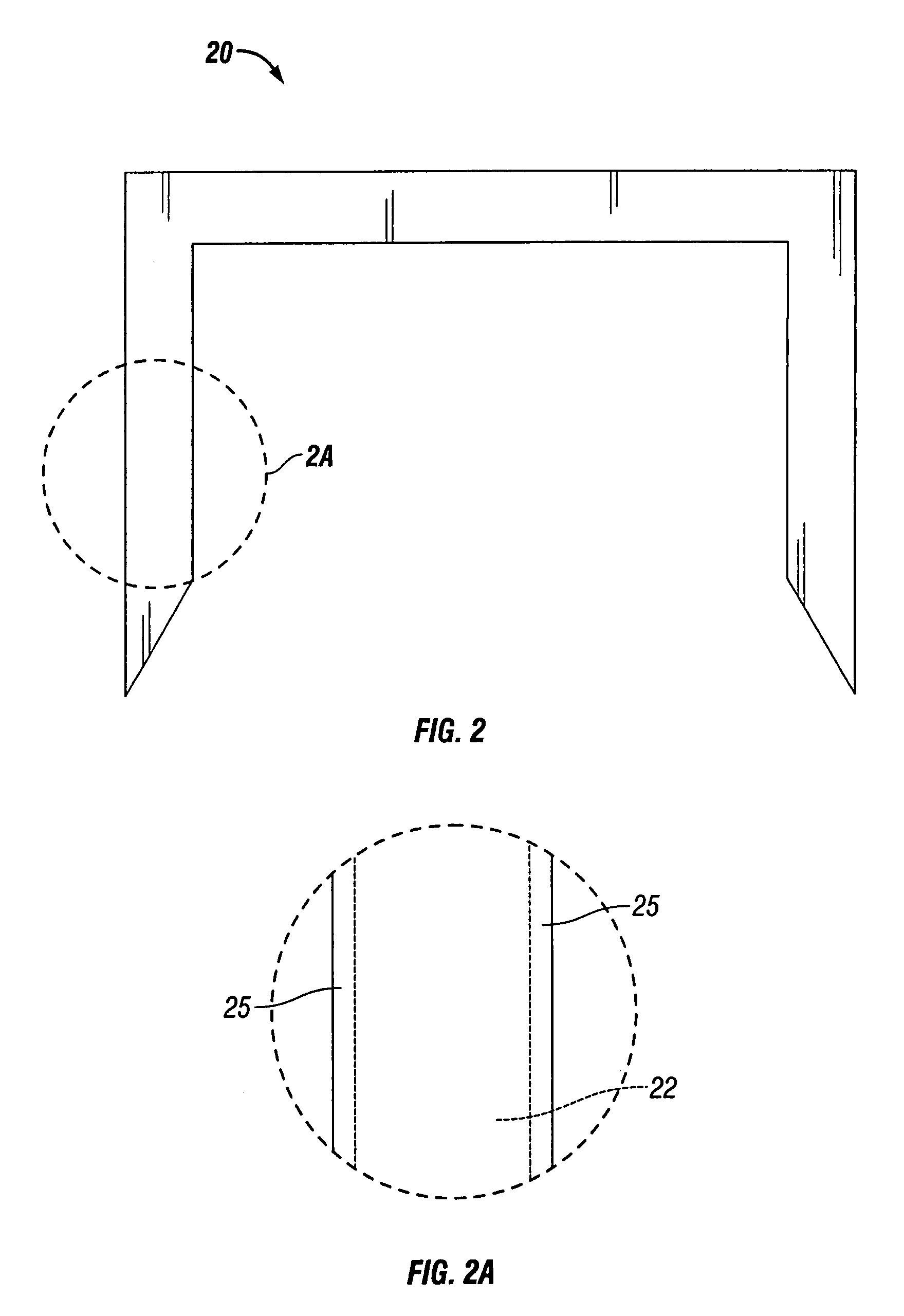

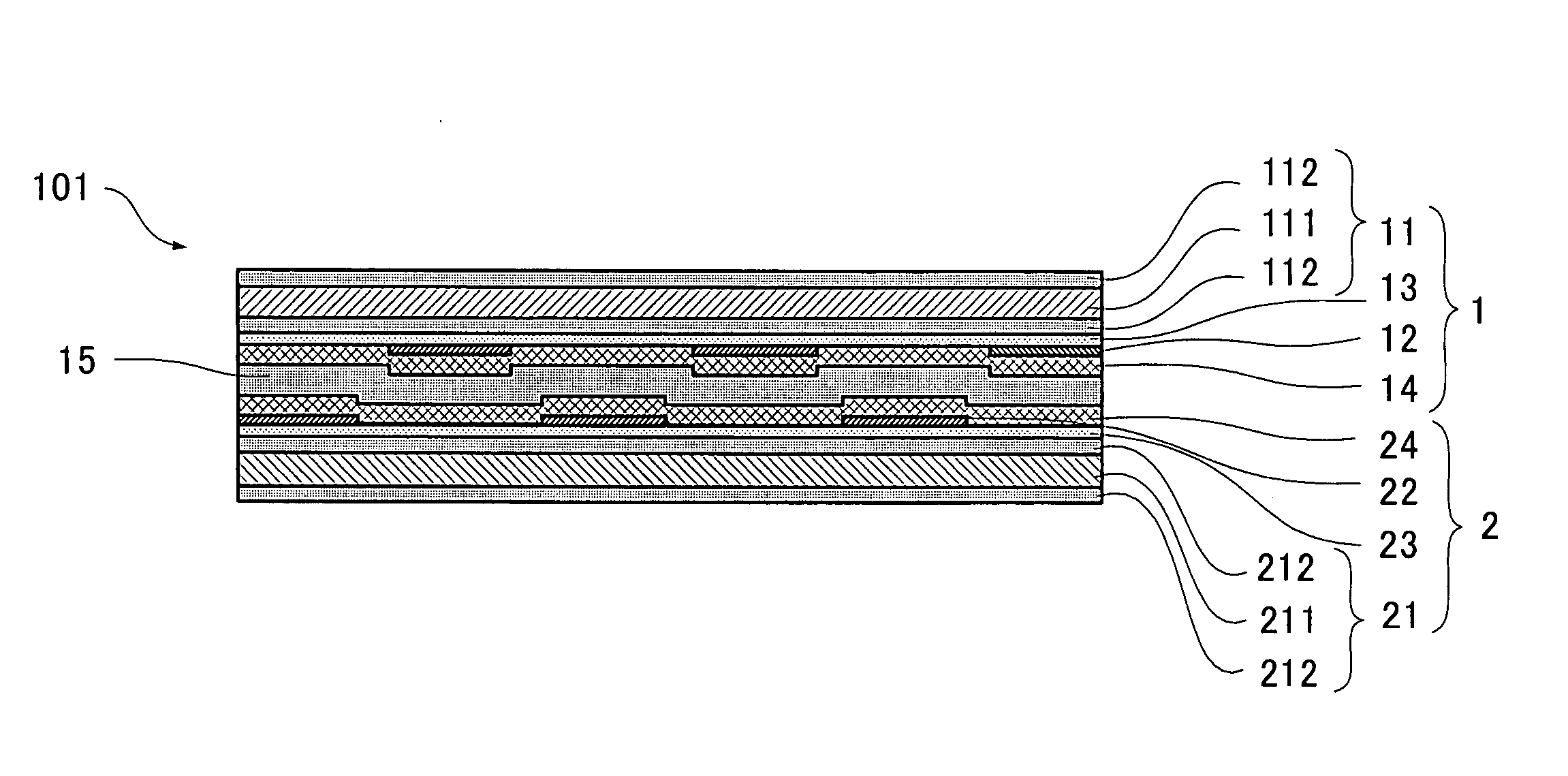

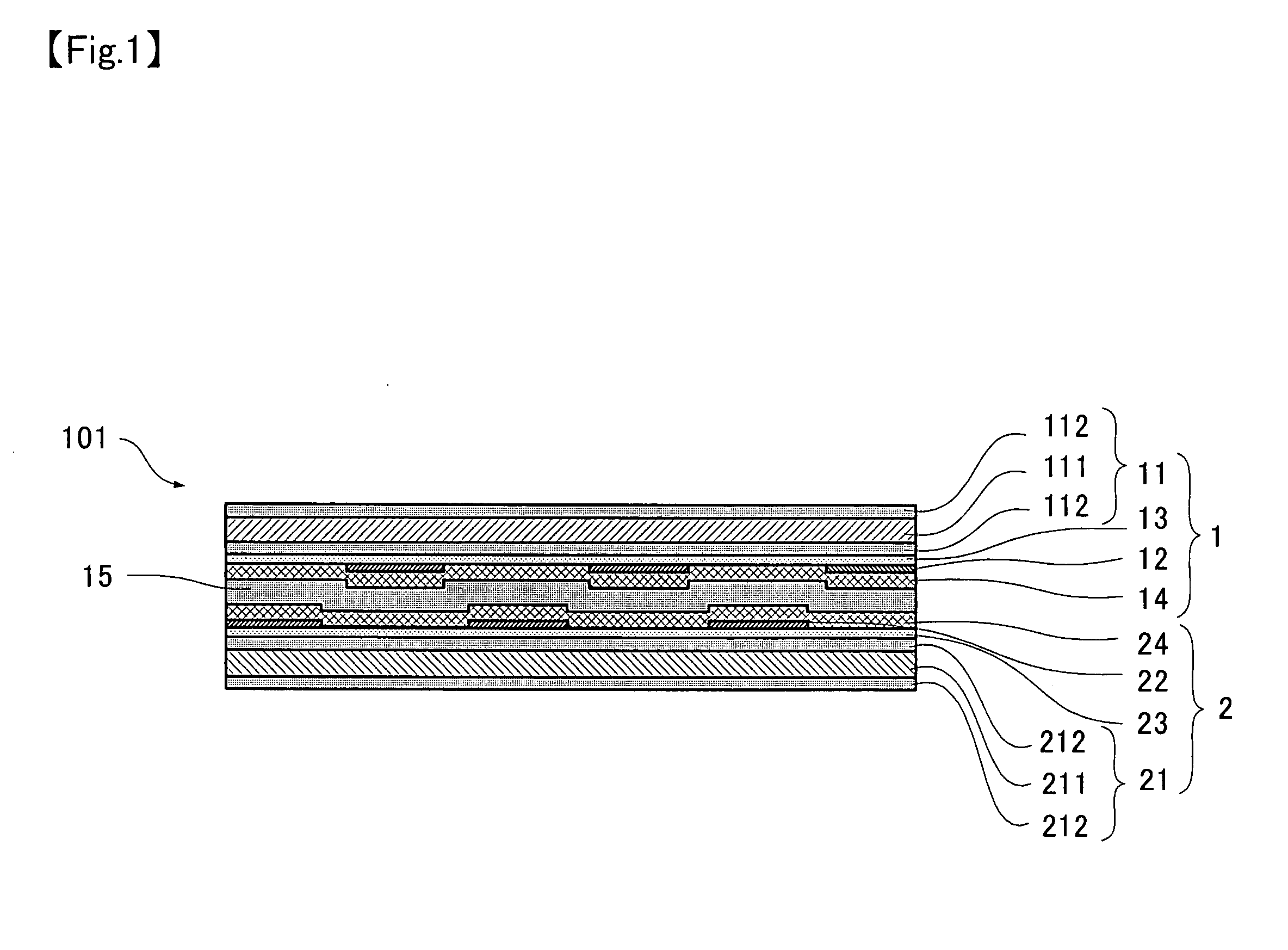

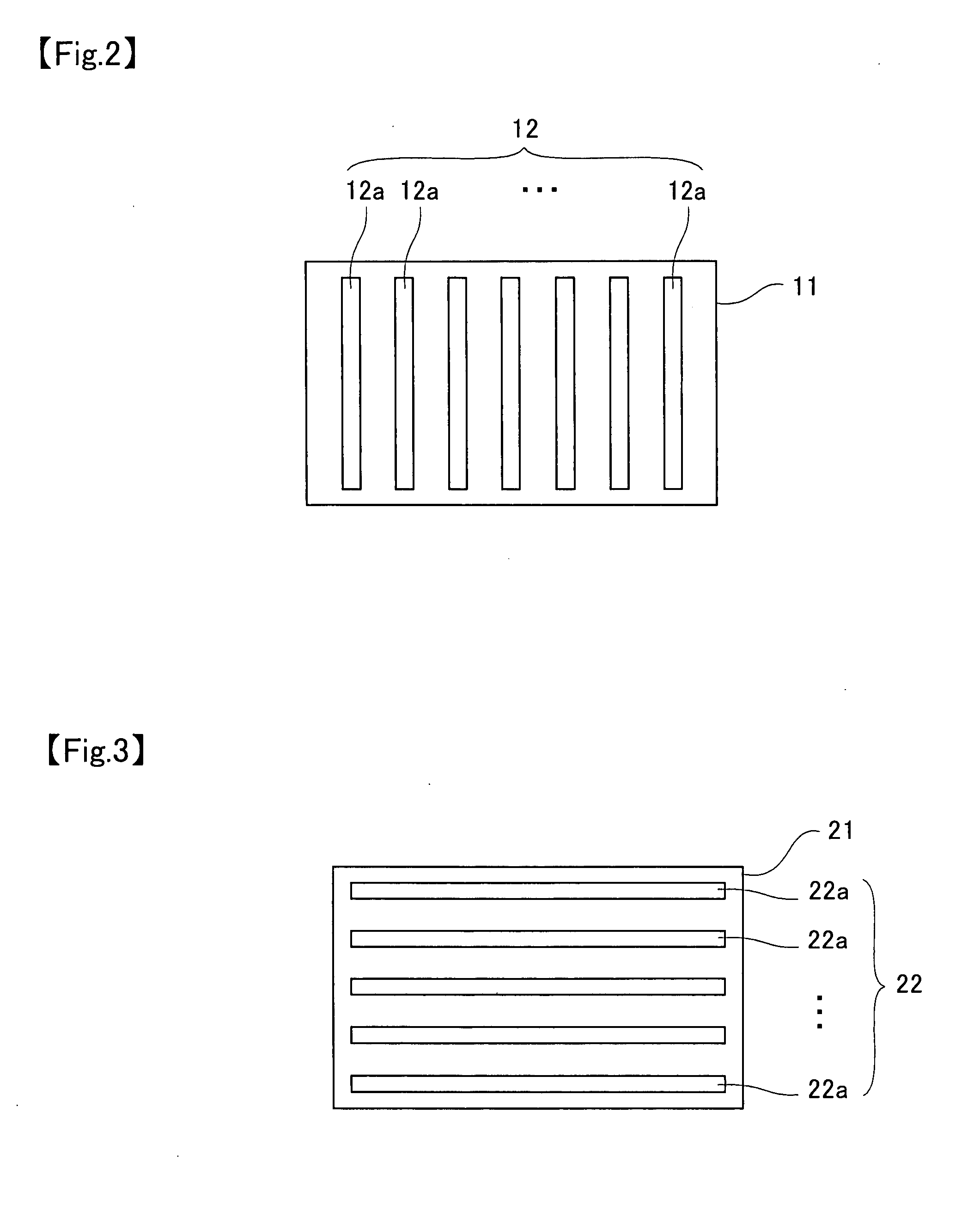

Transparent Planar Body and Transparent Touch Switch

ActiveUS20080138589A1Increase awarenessConductive layers on insulating-supportsDecorative surface effectsVisibilityTransmittance

The present invention provides a transparent planar body and a transparent touch switch that can improve visibility. Specifically, the transparent planar body (1) has a patterned transparent conductive film (12) on at least one surface of a transparent substrate (11). This transparent planar body (1) comprises a transmittance-adjusting layer for equalizing the transmission spectrum of light transmitted through a patterned region wherein the transparent conductive film (12) is provided via the transparent substrate (11) with that transmitted through a non-patterned region wherein the transparent conductive film (12) is not provided via the transparent substrate (11).

Owner:GUNZE LTD

Method and apparatus for orienting magnetic flakes

Apparatus and related methods align magnetic flakes in a carrier, such as an ink vehicle or a paint vehicle to create optically variable images in a high-speed, linear printing operation. Images can provide security features on high-value documents, such as bank notes. Magnetic flakes in the ink are aligned using magnets in a linear printing operation. Selected orientation of the magnetic pigment flakes can achieve a variety of illusive optical effects that are useful for decorative or security applications.

Owner:VIAVI SOLUTIONS INC

Jettable compositions

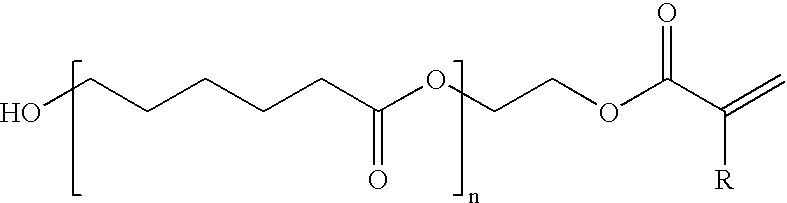

ActiveUS20050171237A1Prevent long-term corrosionReaction is slowAdditive manufacturing apparatusLiquid surface applicatorsMeth-Oligomer

A fully curable jettable composition having a viscosity less than 30 cps at a temperature within the range of 15-180° C., more preferably at a temperature of 15-100° C., e.g. 60-80° C. the composition comprising: (A) at least one low viscosity reactive resin selected from the group consisting of compounds containing an oxetane ring, cycloaliphatic epoxy resins, tetrahydrofurans, hexahydropyrans and mono-functional (meth)acrylates, said resin having a molecular weight of not greater than 300 Daltons, e.g. 250 Daltons or less, and a viscosity at a temperature in the said range of less than 30 cps, e.g. 5 to 15 cps; (B) at least one higher viscosity resin selected from the group consisting of epoxy resins, compounds containing an oxetane ring and acrylates, which resin acts to thicken the low viscosity resin and strengthen a jetted deposit of the composition, the higher viscosity resin having: a viscosity greater than twice that of the low viscosity resin at the said temperature in the range stated above, and a functionality of greater than or equal to 2; (C) at least one curable toughener, preferably having a functionality of at least 2, such as hydroxy, epoxy, acrylic or other reactive functionalised polymer / oligomer (e.g. derived by functionalising poly(tetrahydrofuran), polycaprolactone, polycarbonate diol, or a dendrimeric polyol; (D) at least one initiator for the polymerisation of the resins, and (E) at least one stabiliser for delaying the curing of the resins of the composition; wherein the low viscosity resin is slower to react than the higher viscosity resin and acts to solvate the higher viscosity resin prior to curing and at least partly during curing and wherein at least 30% of the components A and B are cationically curable resins. The composition can be jetted from piezo electric printing heads under the control of a computer program to form a multi-layered article, e.g. a three dimensional article, in which the adjacent droplets merge and are cured homogeneously together.

Owner:3D SYST INC +1

Image making medium

InactiveUS8921473B1Improve aestheticsEnhance and enable bondingDuplicating/marking methodsSpecial tyresEngineeringSmart material

The invention relates to an image support medium for creation of an aesthetic image that is a work or object for display. This support medium is made from a smart or intelligent material so that the medium provides or enables formation of an image having at least one aesthetic element that can be responsive, interactive, controlled, changed, programmed, and / or modulated. The support medium can further comprise stimuli, triggers or influences that cause the smart or intelligent material to respond to change shape, size, volume, density, light properties, color, appearance, and / or another physical property of the aesthetic element. In a preferred embodiment, the smart or intelligent material is reversibly responsive to the stimuli, triggers or influences.

Owner:HYMAN SYDNEY

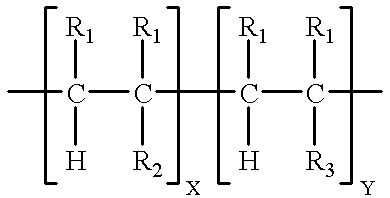

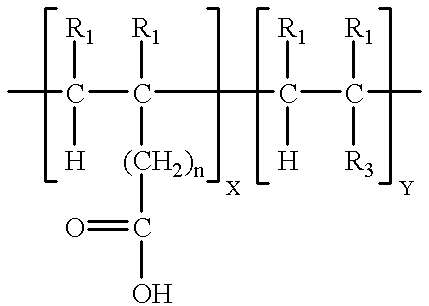

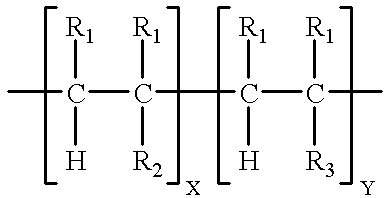

Latex polymer blends for improving the permanence of ink-jet inks

InactiveUS6057384AImprove adhesionPromotes increased adhesionDuplicating/marking methodsInksGlass transitionPolymer chemistry

Ink-jet inks for ink-jet printing are provided which include a vehicle and a colorant, the colorant associated with a primer core / shell polymer to form a primer / colorant combination, and the primer / colorant combination, upon printing on a print medium, encapsulated by a durable core / shell polymer. The primer core / shell polymer serves to promote adhesion of the durable core / shell polymer to the colorant and to disperse the colorant in the ink and the durable core / shell polymer serves to provide a smear-fast film upon drying of the ink on a print medium. The primer core / shell polymer comprises a hydrophobic core and a hydrophilic shell comprising a polar component, while the durable core / shell polymer comprises a hydrophobic core comprising a first Tg component, which, when homopolymerized, has a glass trnnsition temperature, Tg, between -150 DEG C. to +25 DEG C. and a second Tg component, which, when homopolymerized, has a glass transition temperature above +25 DEG C. and a hydrophilic shell selected from the group consisting of neutral shells, cationic shells, and anionic shells.

Owner:HEWLETT PACKARD DEV CO LP

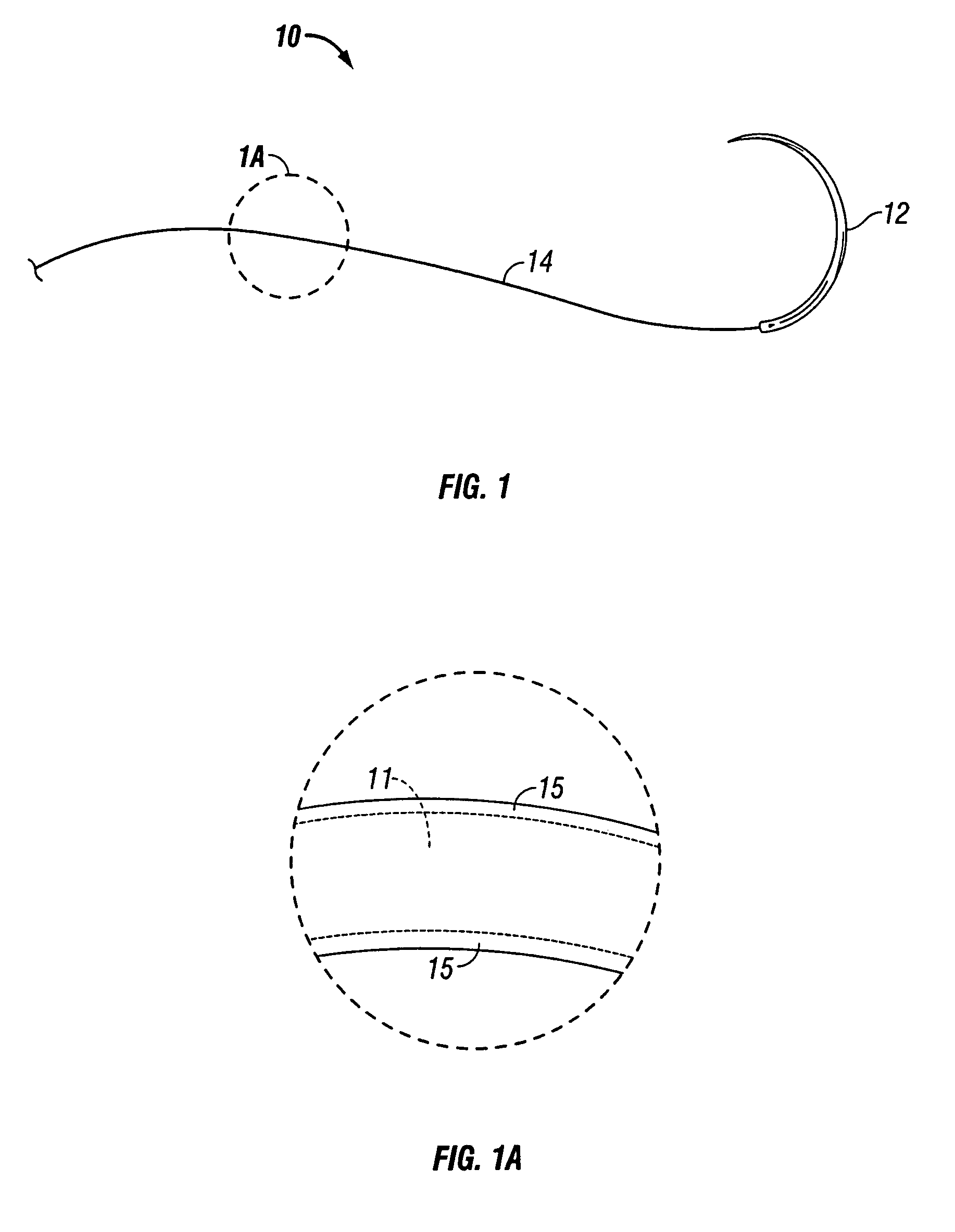

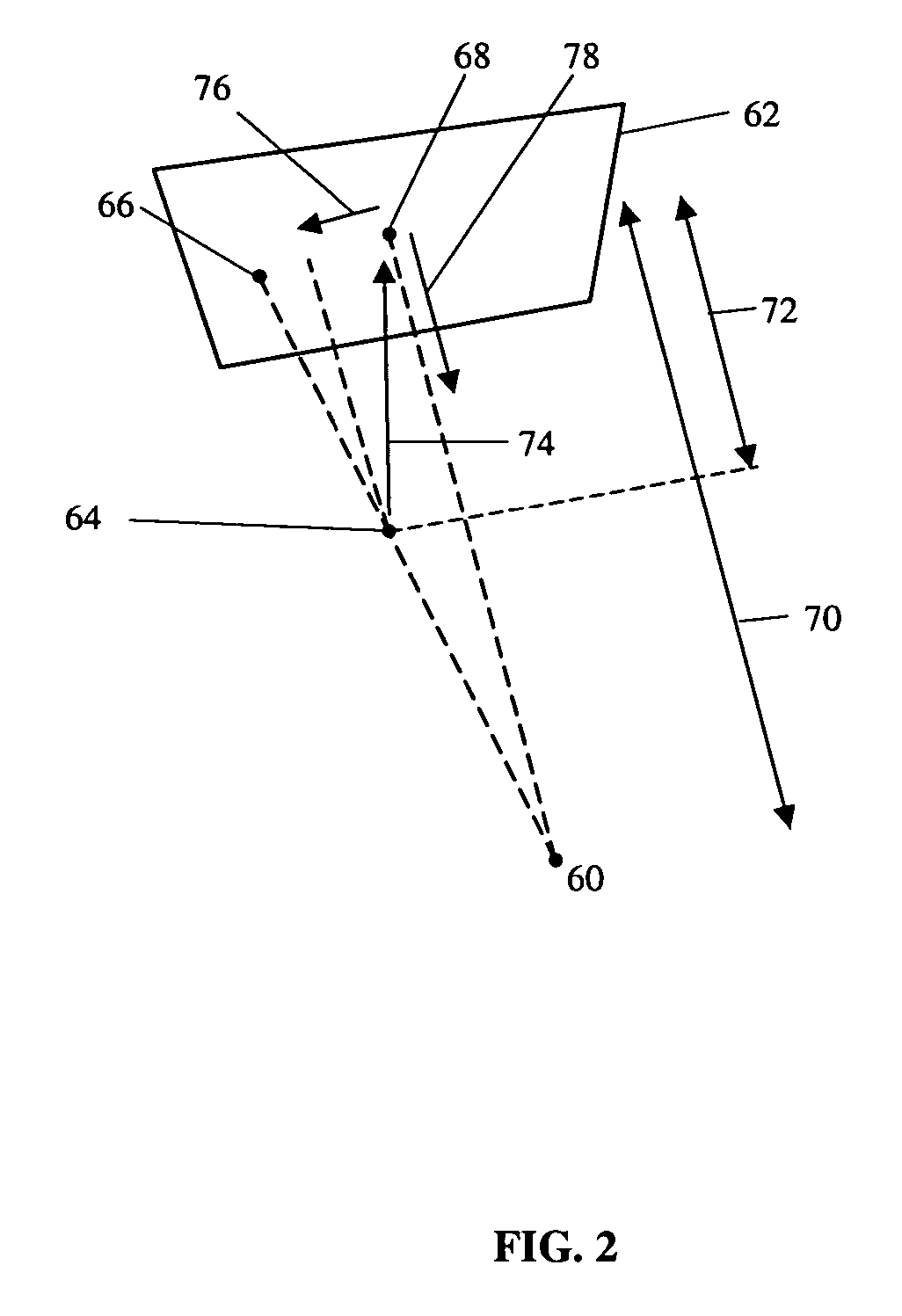

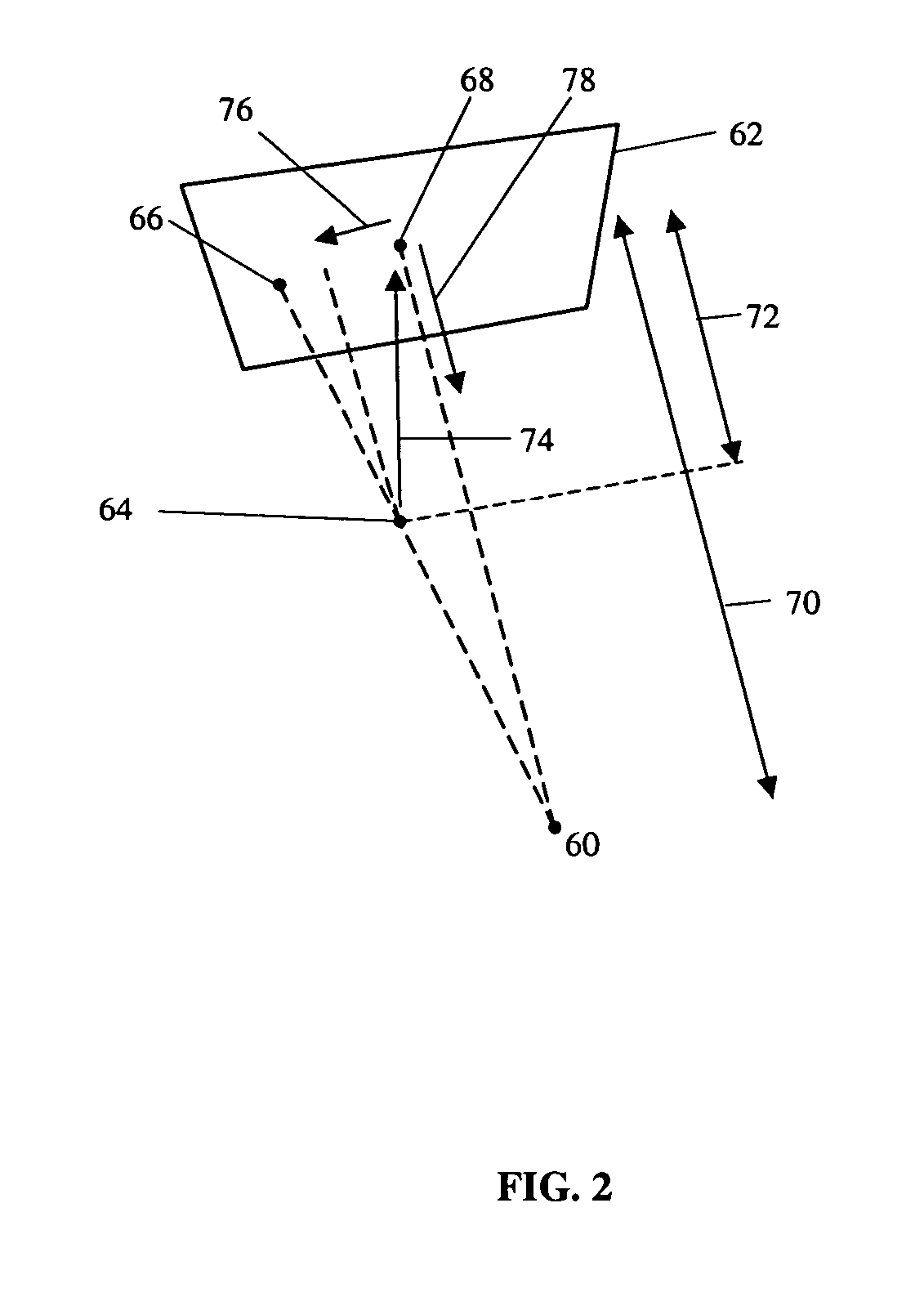

System and method of surgical imagining with anatomical overlay for navigation of surgical devices

ActiveUS7831294B2Improve the display effectPrecise positioningMaterial analysis using wave/particle radiationRadiation/particle handlingX-rayDisplay device

A system and method are provided for control of a navigation system for deploying a medical device within a subject, and for enhancement of a display image of anatomical features for viewing the projected location and movement of medical devices, and projected locations of a variety of anatomical features and other spatial markers in the operating region. The display of the X-ray imaging system information is augmented in a manner such that a physician can more easily become oriented in three dimensions with the use of a single-plane X-ray display. The projection of points and geometrical shapes within the subject body onto a known imaging plane can be obtained using associated imaging parameters and projective geometry.

Owner:STEREOTAXIS

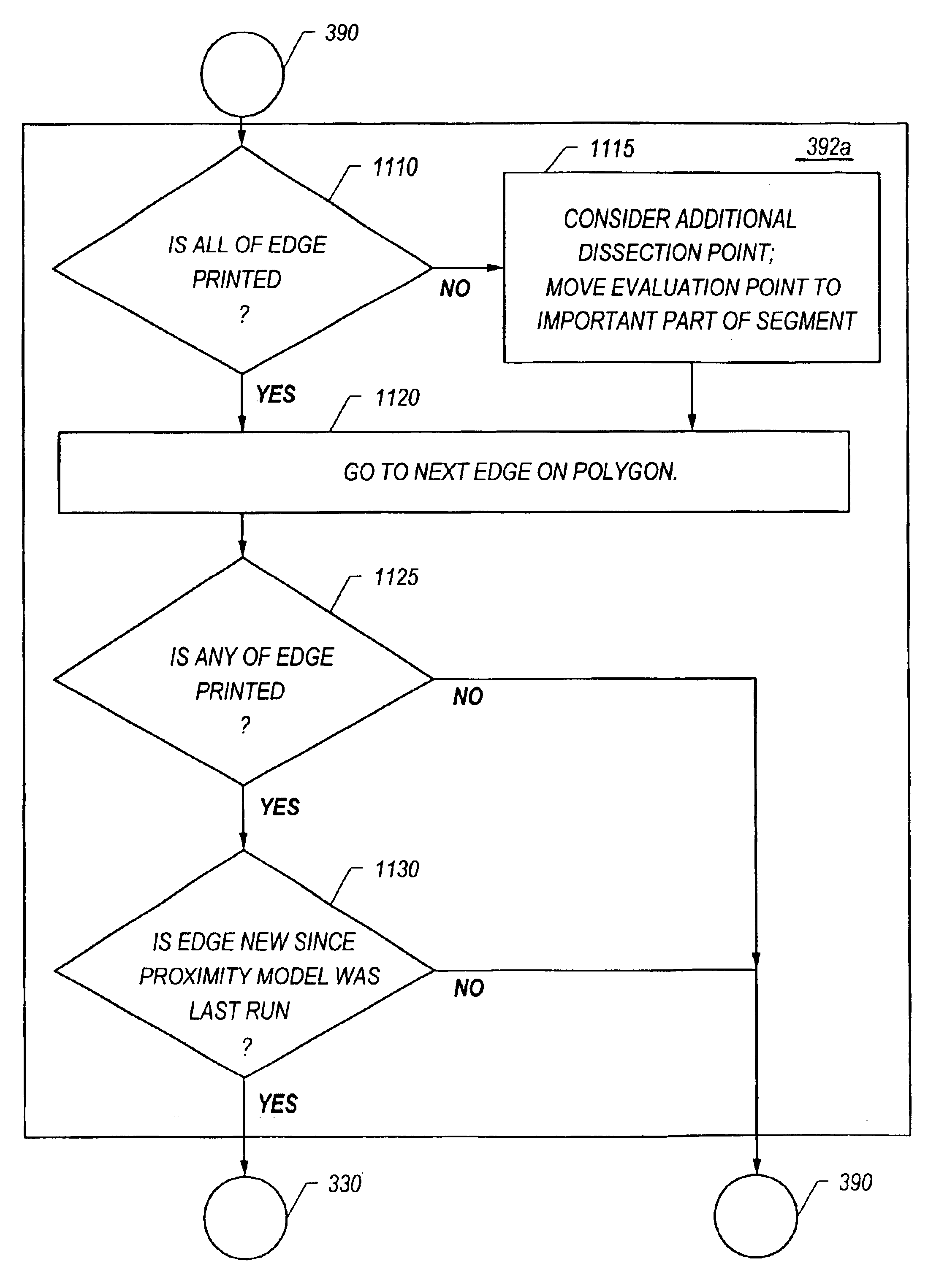

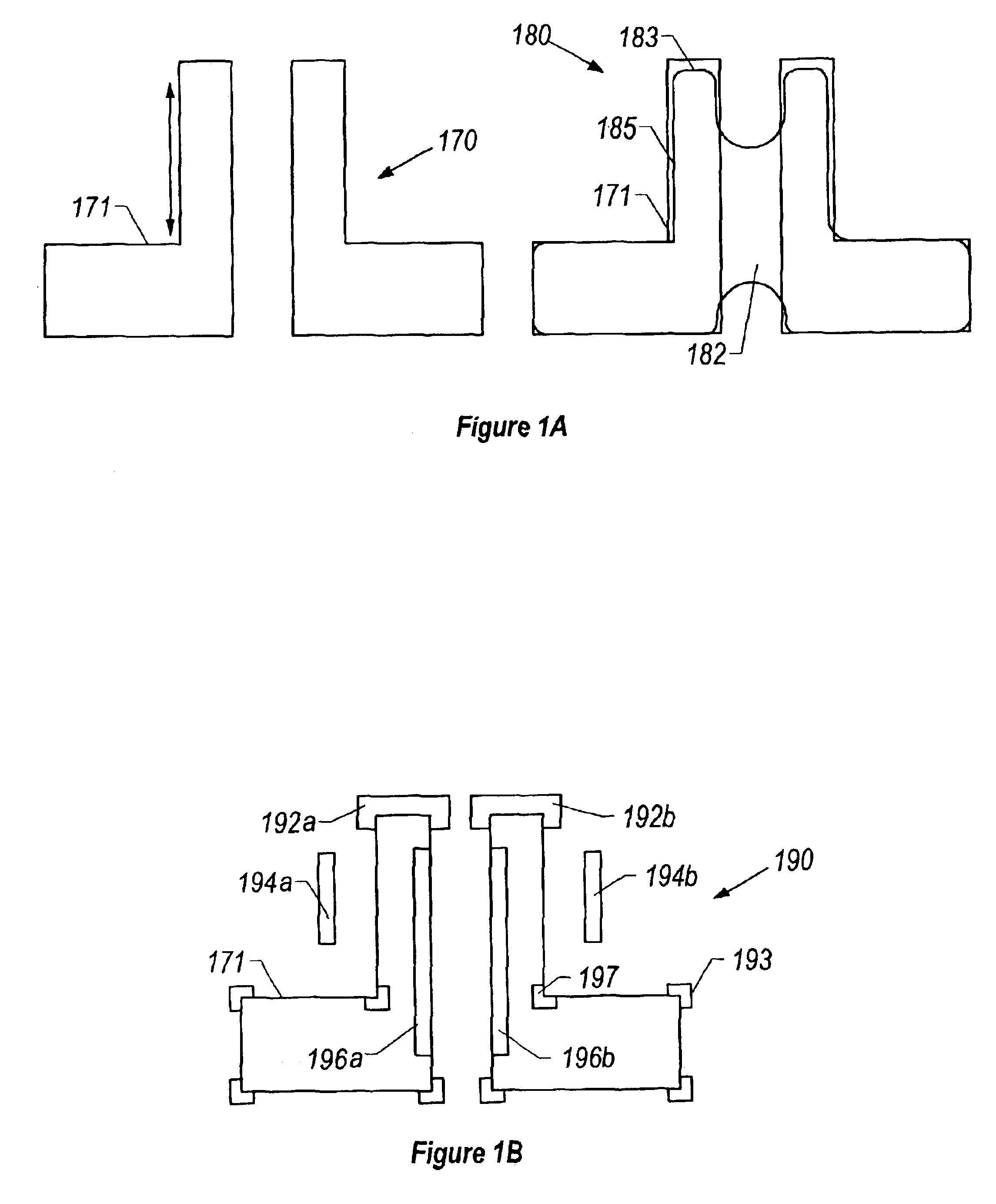

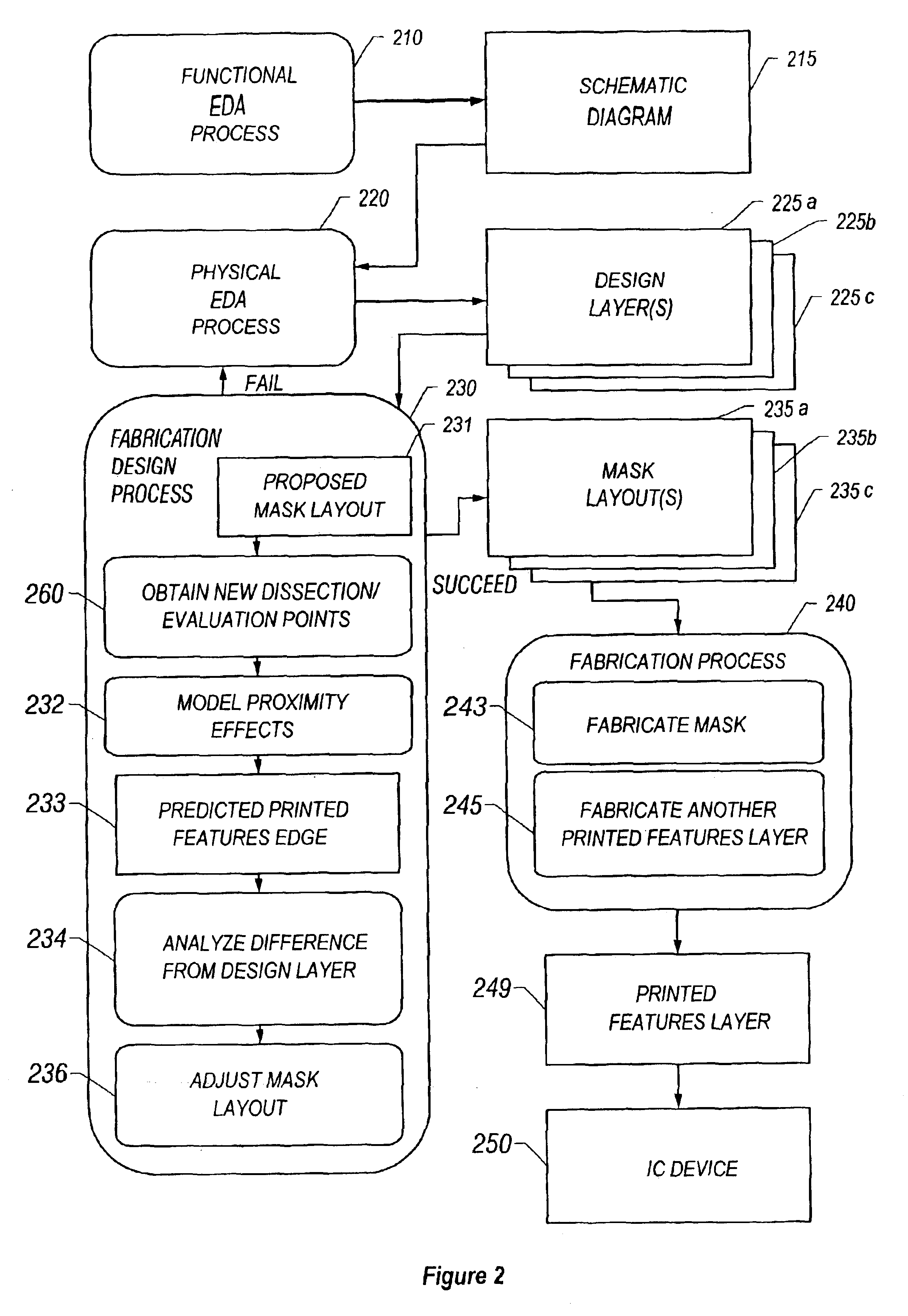

Dissection of printed edges from a fabrication layout for correcting proximity effects

InactiveUS6918104B2SpeedGood dissectionDecorative surface effectsLayered productsEngineeringDissection

Techniques for fabricating a device include forming a fabrication layout, such as a mask layout, for a physical design layer, such as a design for an integrated circuit, and identifying evaluation points on an edge of a polygon corresponding to the design layer for correcting proximity effects. Techniques include correcting for proximity effects associated with an edge in a first fabrication layout by determining whether any portion of the edge corresponds to a target edge in a design layer. The first fabrication layout corresponds to the design layer that indicates target edges for a printed features layer. If any portion of the edge corresponds to the target edge, then it is determined whether to establish an evaluation point on the edge. Then it is determined how to correct the edge for proximity effects based on the evaluation point. In case it is determined that no portion of the edge corresponds to the target edge, then no evaluation point is selected on the edge.

Owner:SYNOPSYS INC

Negative Working, Heat-Sensitive, Lithographic Printing Plate Precursor

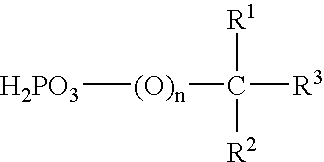

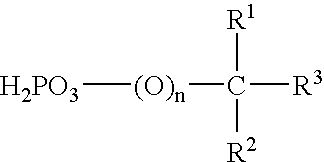

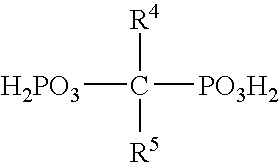

ActiveUS20080213696A1Number of defectSize of defectPhotosensitive materialsDuplicating/marking methodsSimple Organic CompoundsPhosphoric acid

A heat-sensitive negative-working lithographic printing plate precursor includes on a grained and anodized aluminum support a coating including hydrophobic thermoplastic polymer particles, a hydrophilic binder, and an organic compound, wherein the organic compound includes at least one phosphonic acid group or at least one phosphoric acid group or a salt thereof.

Owner:AGFA OFFSET BV

Surgical navigation with overlay on anatomical images

ActiveUS20060079745A1Enhance displayed imagePrecise positioningMaterial analysis using wave/particle radiationRadiation/particle handlingX-rayDisplay device

A system and method are provided for control of a navigation system for deploying a medical device within a subject, and for enhancement of a display image of anatomical features for viewing the projected location and movement of medical devices, and projected locations of a variety of anatomical features and other spatial markers in the operating region. The display of the X-ray imaging system information is augmented in a manner such that a physician can more easily become oriented in three dimensions with the use of a single-plane X-ray display. The projection of points and geometrical shapes within the subject body onto a known imaging plane can be obtained using associated imaging parameters and projective geometry.

Owner:STEREOTAXIS

Electronically addressable microencapsulated ink and display thereof

InactiveUS20070052757A1Inexpensive displayMechanical clocksVisual indicationsElectrical conductorSemiconductor materials

A system of electronically active inks is described which may include electronically addressable contrast media, conductors, insulators, resistors, semiconductive materials, magnetic materials, spin materials, piezoelectric materials, optoelectronic, thermoelectric or radio frequency materials. We further describe a printing system capable of laying down said materials in a definite pattern. Such a system may be used for instance to: print a flat panel display complete with onboard drive logic; print a working logic circuit onto any of a large class of substrates; print an electrostatic or piezoelectric motor with onboard logic and feedback or print a working radio transmitter or receiver.

Owner:E INK CORPORATION

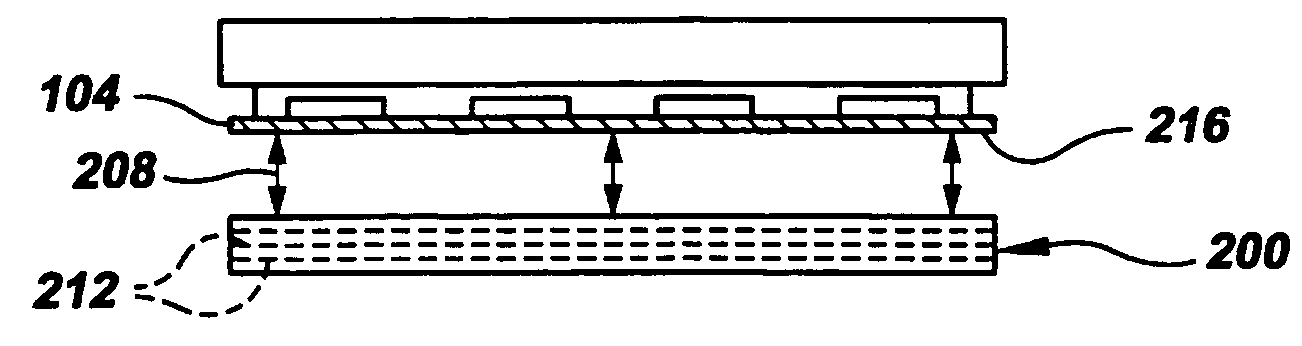

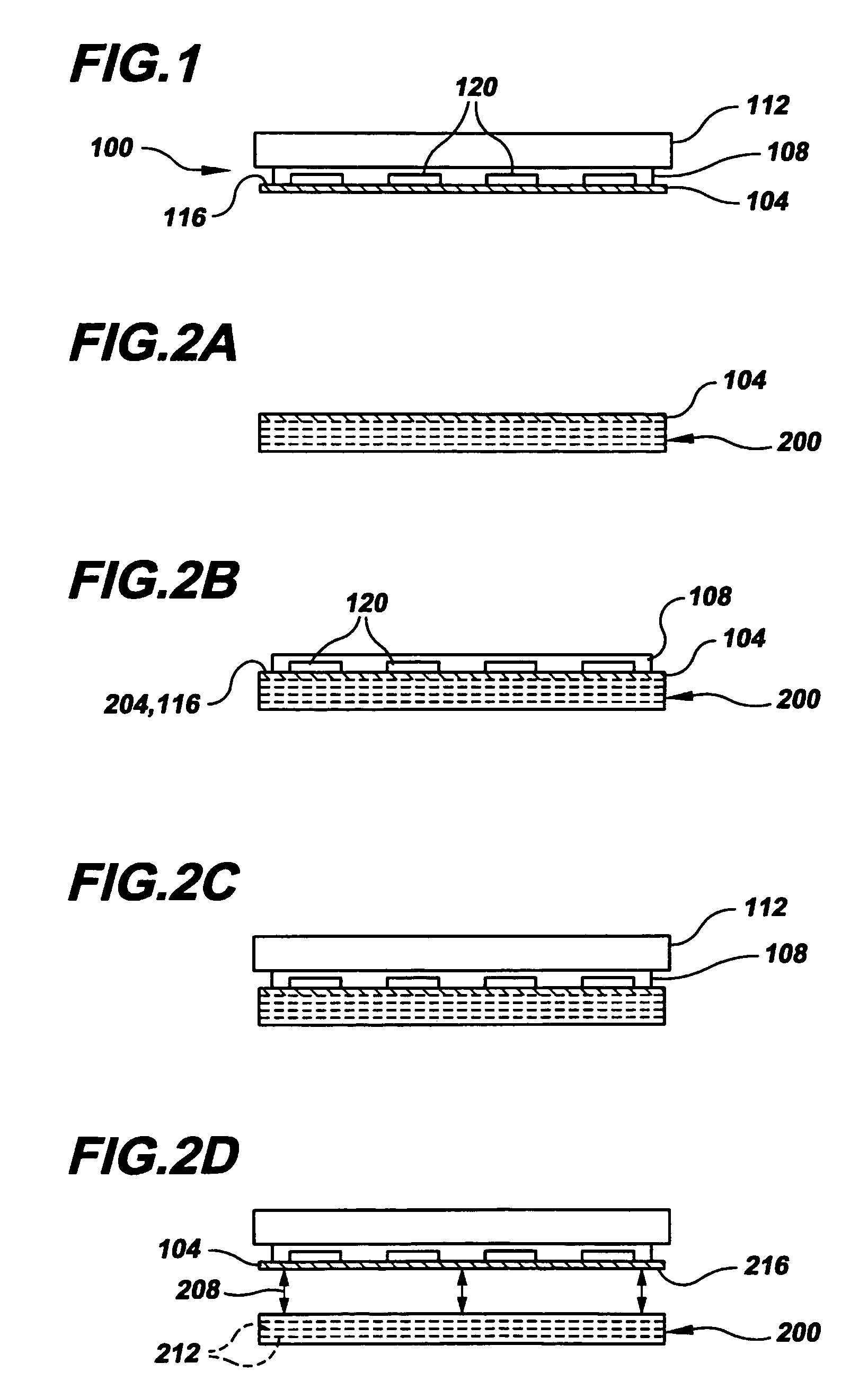

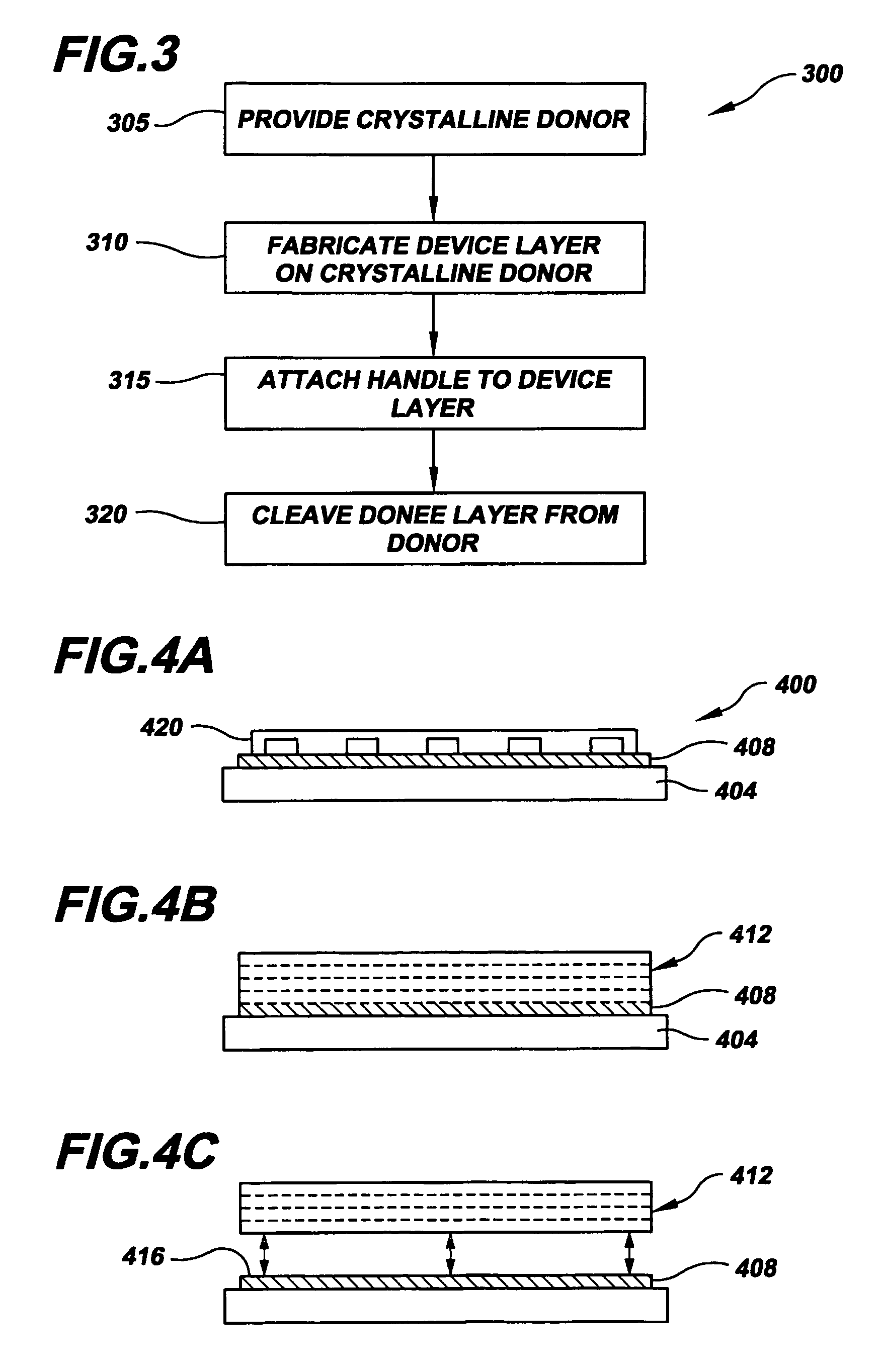

System and method for manufacturing thick and thin film devices using a donee layer cleaved from a crystalline donor

Various embodiments of fabricated crystalline-based structures for the electronics, optoelectronics and optics industries are disclosed. Each of these structures is created in part by cleaving a donee layer from a crystalline donor, such as a micaceous / lamellar mass comprising a plurality of lamelliform sheets separable from each other along relatively weak cleavage planes. Once cleaved, one or more of these lamelliform sheets become the donee layer. The donee layer may be used for a variety of purposes, including a crystalline layer for supporting heteroepitaxial growth of one or more semiconductor layers thereon, an insulating layer, a barrier layer, a planarizing layer and a platform for creating useful structures, among others.

Owner:VERSATILIS

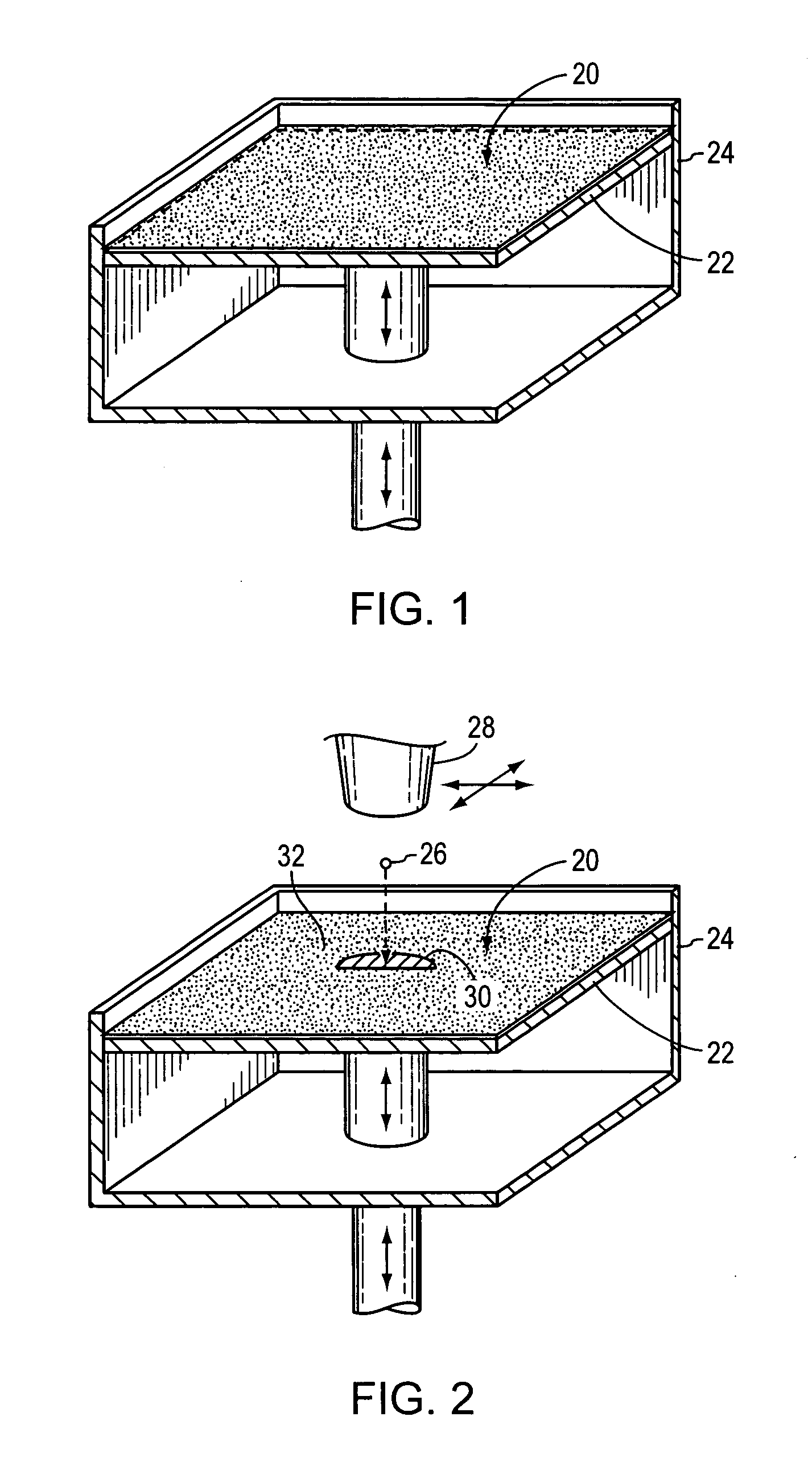

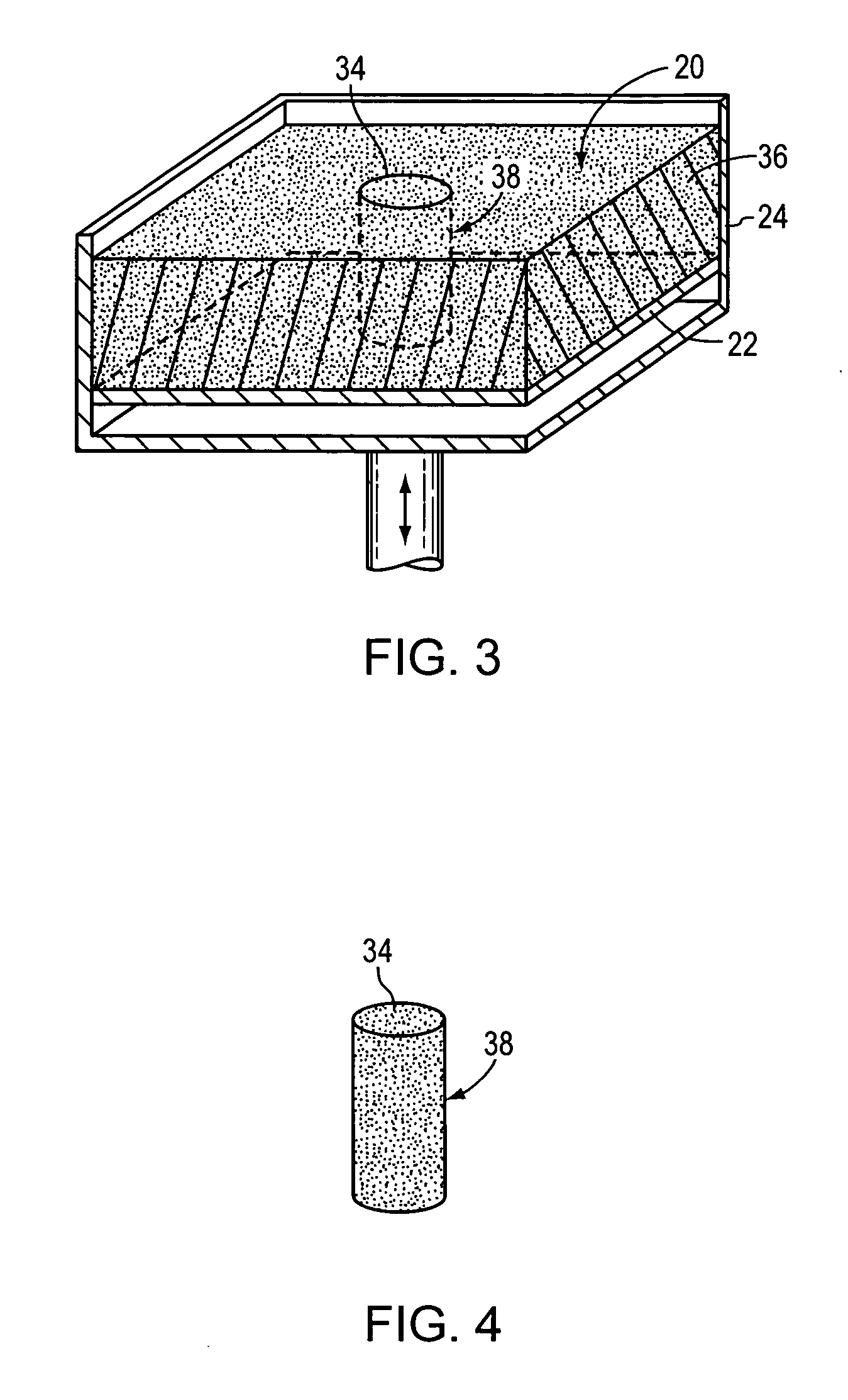

Absorbent fillers for three-dimensional printing

InactiveUS20050059757A1Quick and reliable and safe and inexpensiveSmooth surface finishPigmenting treatmentAdditive manufacturing apparatusParticulatesEngineering

A materials system and methods are provided to enable the formation of articles by three-dimensional printing. The materials system includes an absorbent particulate filler that facilitates absorption of infiltrants, thereby allowing the accurate definition of articles with enhanced mechanical and structural characteristics. The methods include the use of phase-change materials to bind a powder, as well as the formation of support structures to improve the control of the shape of the articles.

Owner:Z CORPORATION

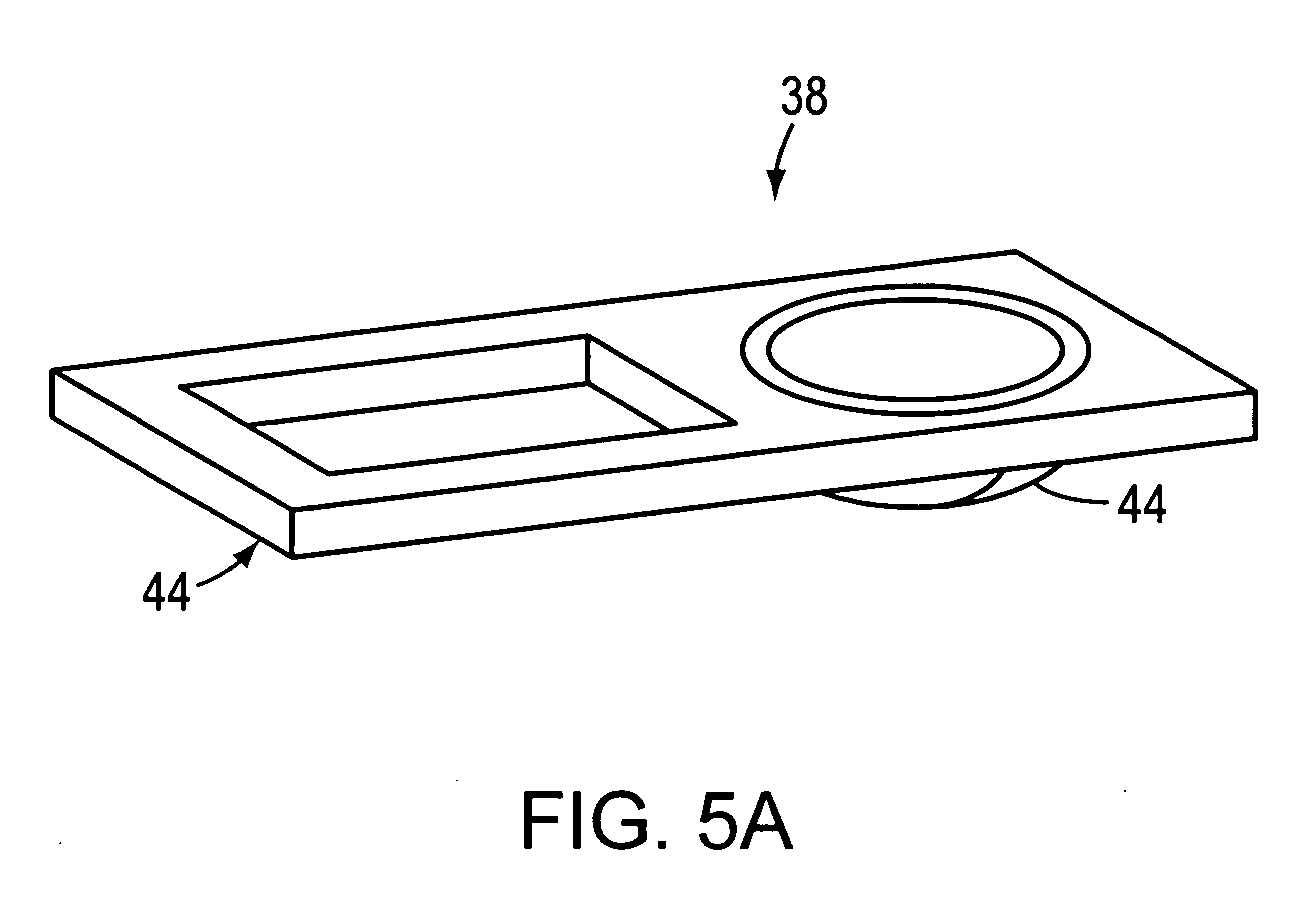

Ink-jet inks containing metal nanoparticles

ActiveUS20050078158A1Slow sedimentation rateLow and viscosity gradeMeasurement apparatus componentsConductive materialWater basedNanometre

Compositions for use in ink jet printing onto a substrate comprising a water based dispersion including metallic nanoparticles and appropriate stabilizers. Also disclosed are methods for the production of said compositions and methods for their use in ink jet printing onto suitable substrates.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

Primed substrates comprising radiation cured ink jetted images

Owner:3M INNOVATIVE PROPERTIES CO

Treated filler or pigment containing natural carbonate

InactiveUS6666953B1Reduce weightReduce wearNatural cellulose pulp/paperSpecial paperPhysical chemistryKaolin clay

The invention concerns a pigment, filler or mineral containing a natural calcium carbonate, treated with one of more providers of H3O<+> ions and gaseous CO2, allowing a reduction in the weight of paper for a constant surface area without loss of physical properties when it is used as a pigment or coating filler for the said paper. In particular, the invention concerns a pigment, filler or mineral containing a natural calcium carbonate or dolomite or mixtures of talc and calcium carbonate, of kaolin and carbonate or carbonate alone or in combination with natural and / or synthetic fibers or similar, treated with one or more medium-strong or strong providers of H3O<+> ions in the presence of gaseous CO2. Applications are particularly in the paper industry, obtaining in particular good sheet properties i.e. a reduction its weight for a given surface area.

Owner:OMYA DEV AG

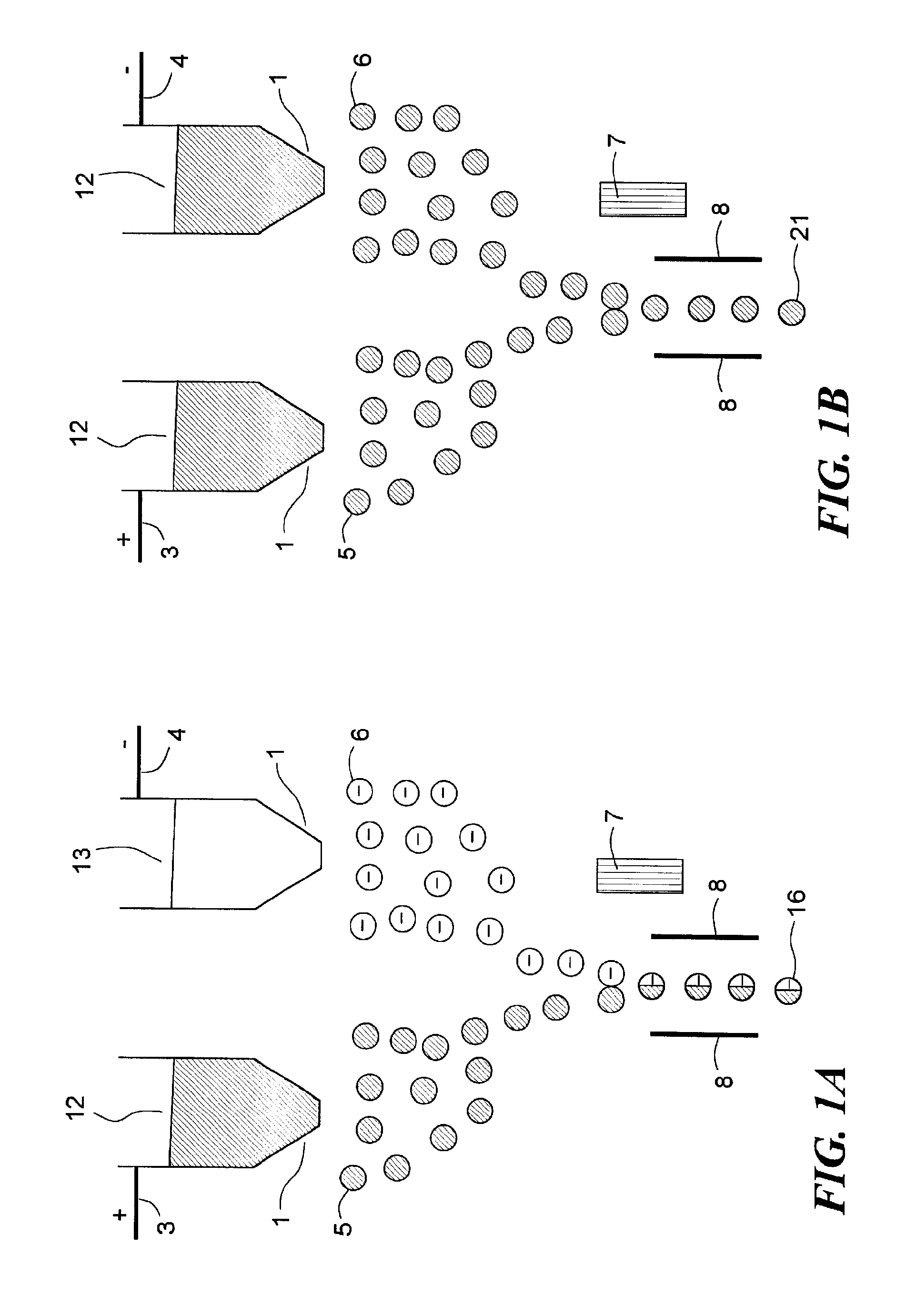

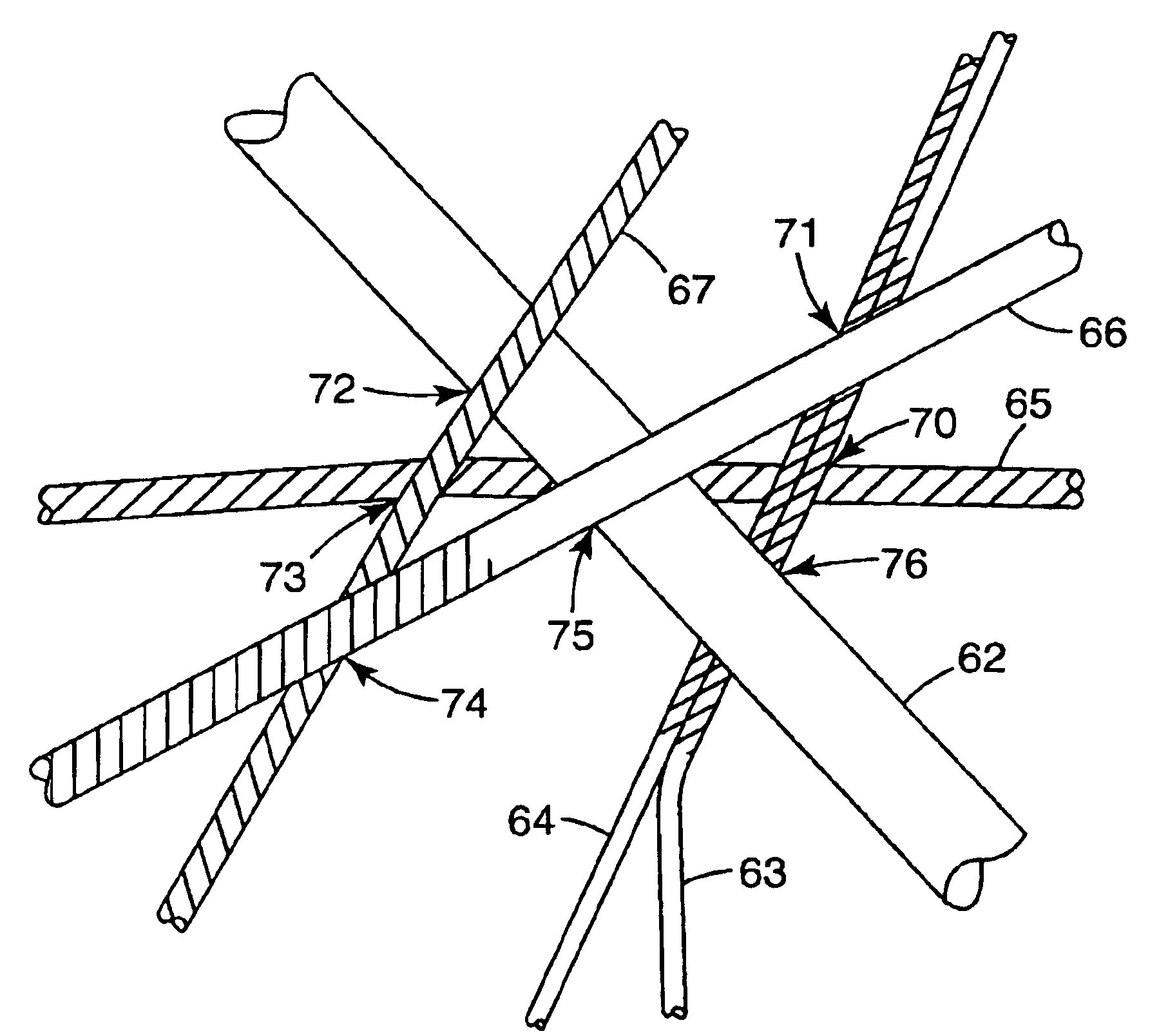

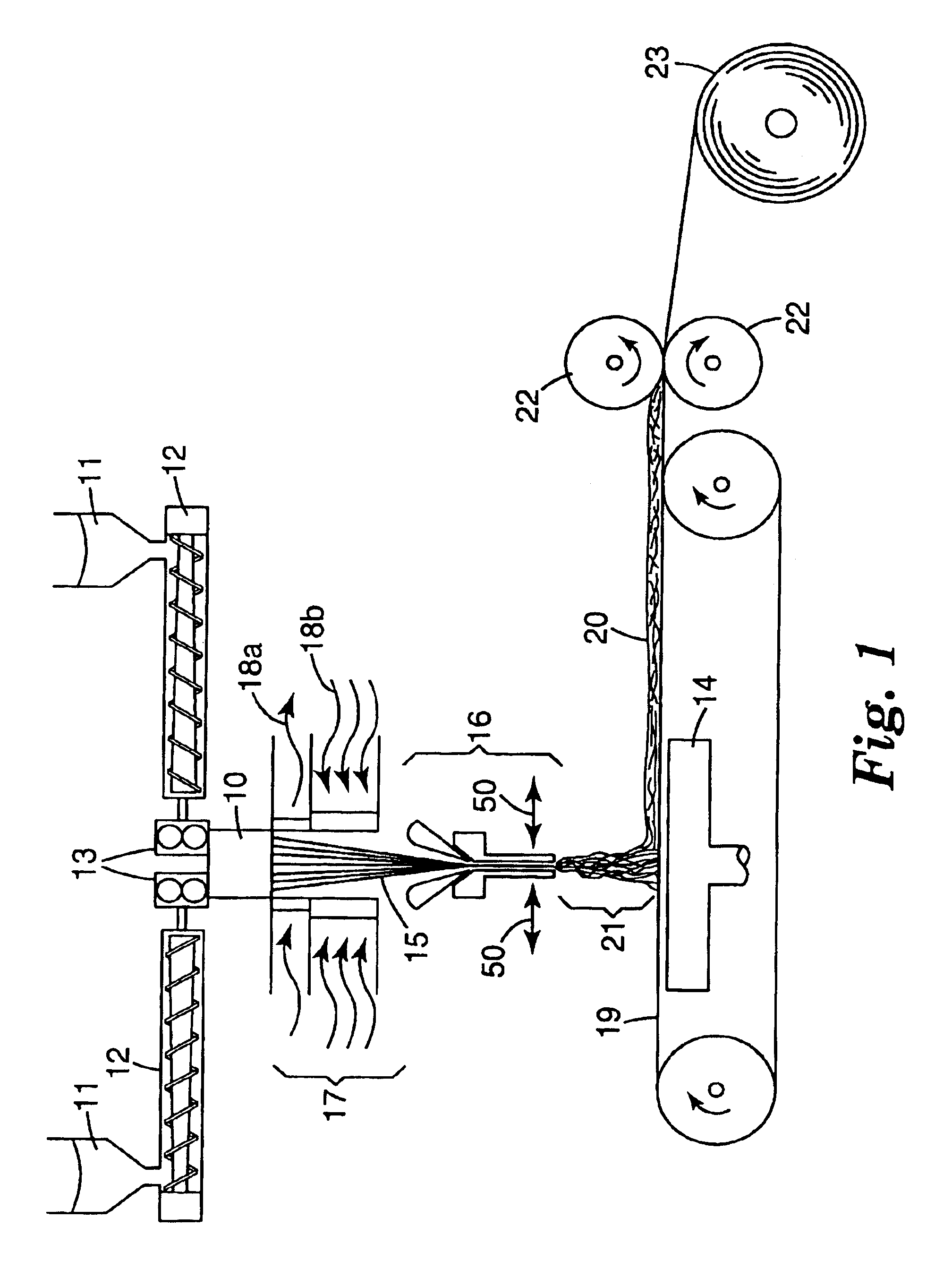

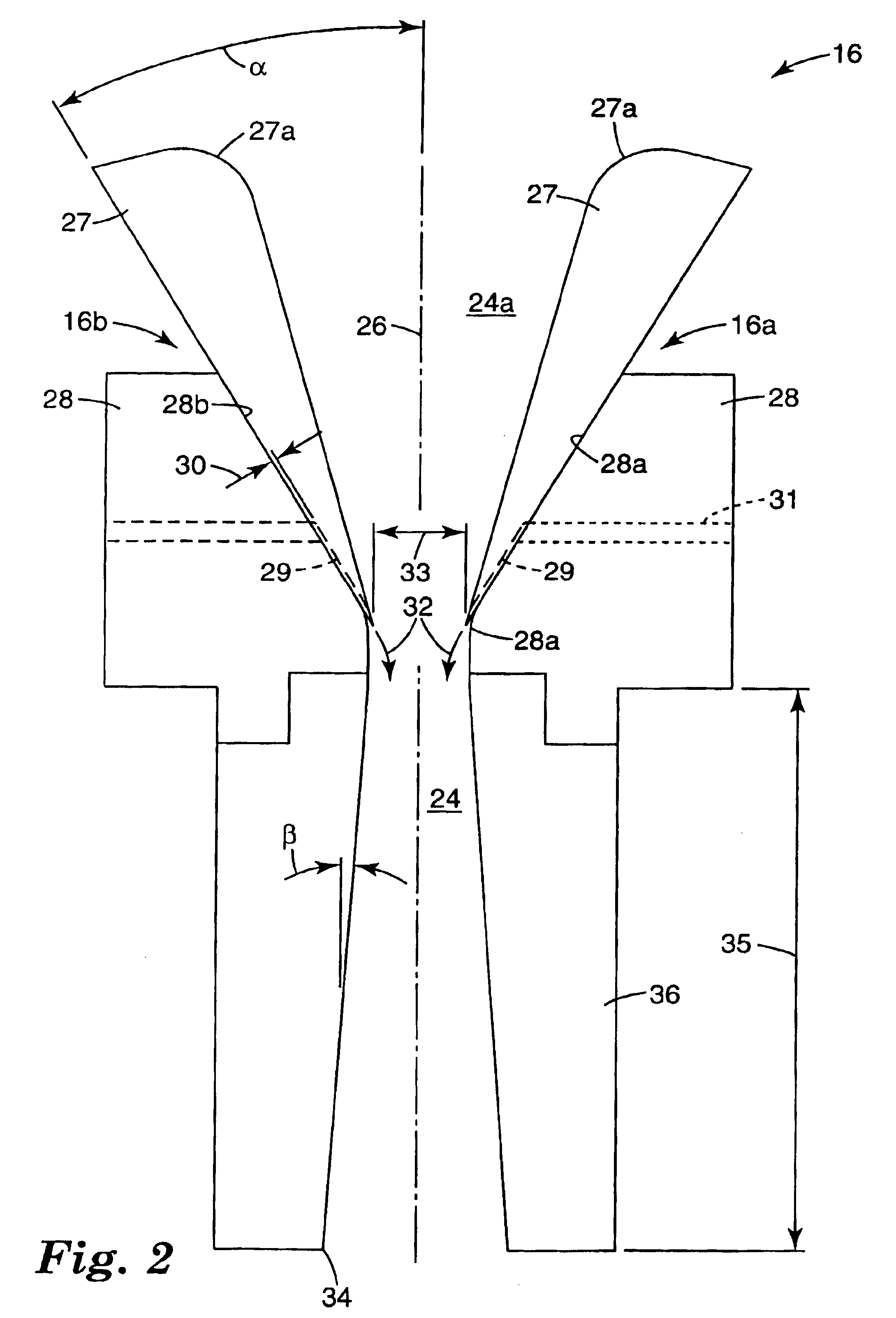

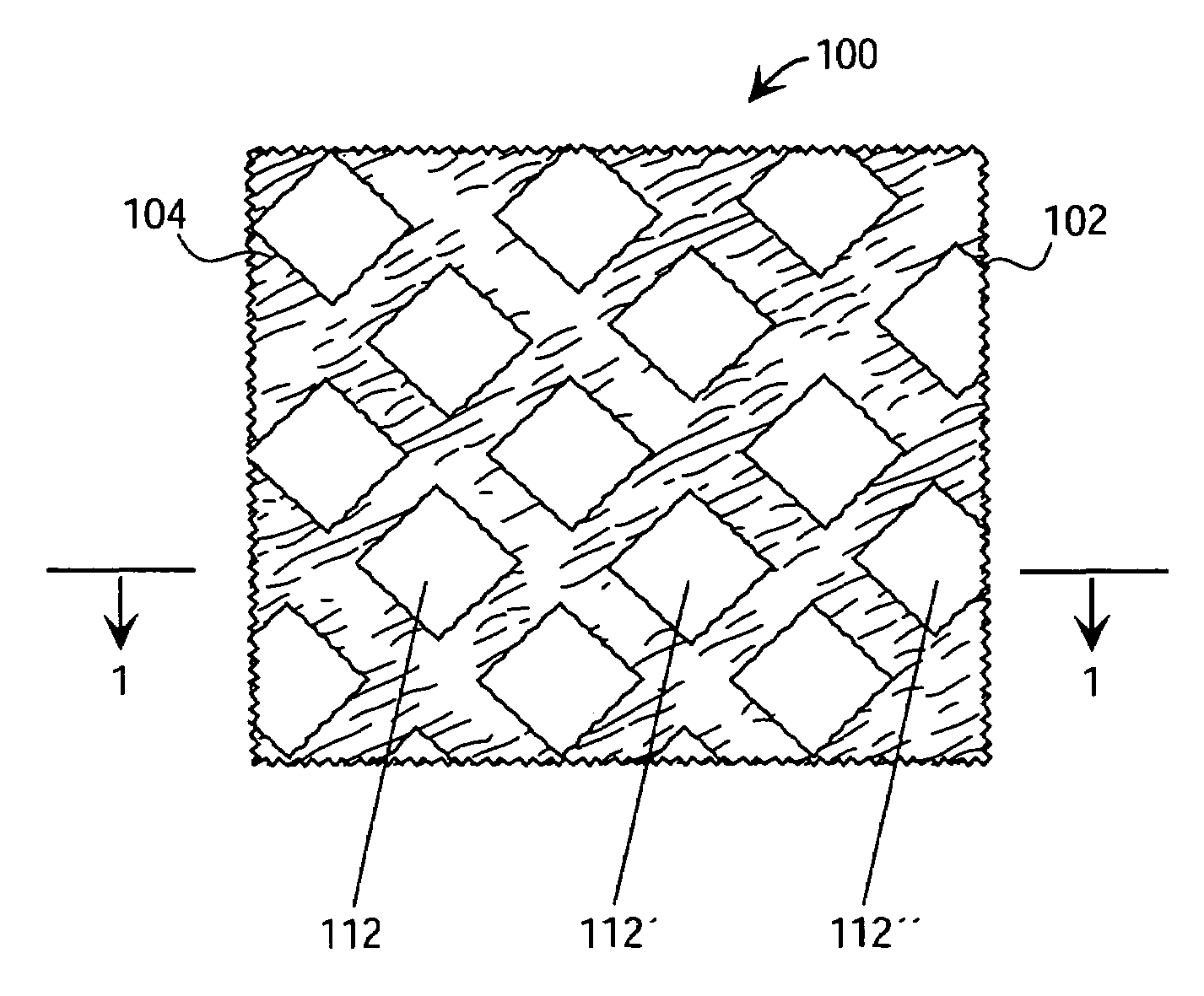

Bondable, oriented, nonwoven fibrous webs and methods for making them

InactiveUS6916752B2Improve adhesionImprove strength propertiesDecorative surface effectsDuplicating/marking methodsFiberEngineering

Nonwoven fibrous webs comprise fibers of uniform diameter that vary in morphology along their length. The variation provides longitudinal segments that exhibit distinctive softening characteristics during a bonding operation. Some segments soften under the conditions of the bonding operation and bond to other fibers of the web, and other segments are passive during the bonding operation. Webs as described can be formed by a method that comprises a) extruding filaments of fiber-forming material; b) directing the filaments through a processing chamber in which the filaments are subjected to longitudinal stress; c) subjecting the filaments to turbulent flow conditions after they exit the processing chamber; and d) collecting the processed filaments; the temperature of the filaments being controlled so that at least some of the filaments solidify while in the turbulent field.

Owner:3M INNOVATIVE PROPERTIES CO

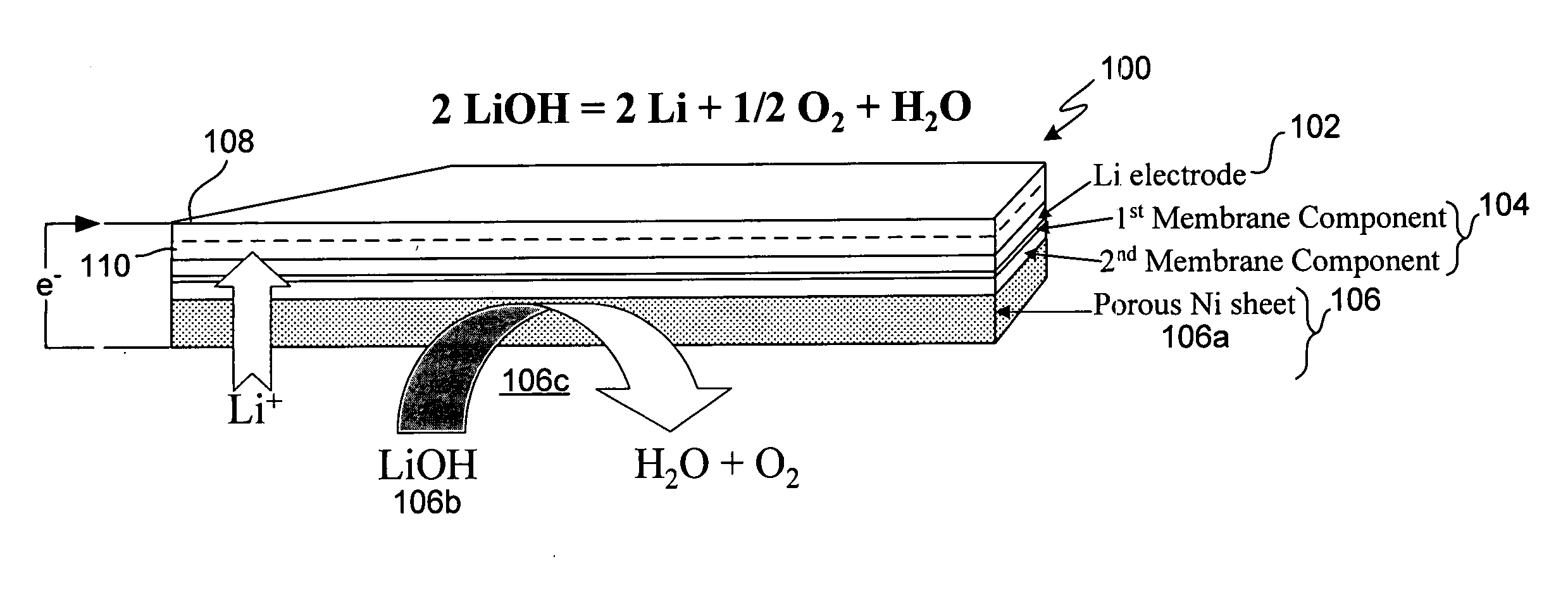

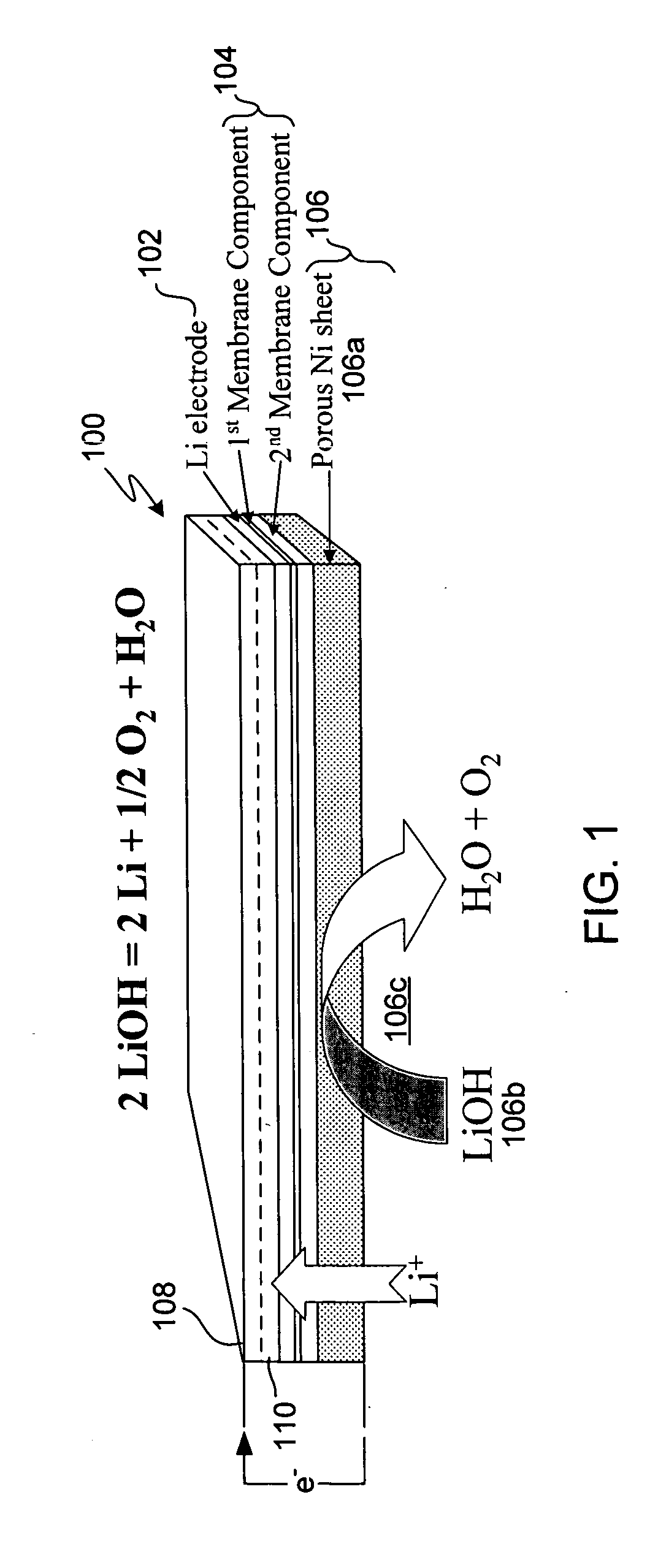

Active metal electrolyzer

InactiveUS20050100793A1Effective isolationReduce environmental pollutionPhotography auxillary processesElectrode manufacturing processesElectrolysisAqueous electrolyte

Electro-winning of active metal (e.g., lithium) ions from a variety of sources including industrial waste, and recycled lithium and lithium-ion batteries is accomplished with an electrolyzer having a protected cathode that is stable against aggressive solvents, including water, aqueous electrolytes, acid, base, and a broad range of protic and aprotic solvents. The electrolyzer has a highly ionically conductive protective membrane adjacent to the alkali metal cathode that effectively isolates (de-couples) the alkali metal electrode from solvent, electrolyte processing and / or cathode environments, and at the same time allows ion transport in and out of these environments. Isolation of the cathode from other components of a battery cell or other electrochemical cell in this way allows the use of virtually any solvent, electrolyte and / or anode material in conjunction with the cathode. The electrolyzer can be configured and operated to claim or reclaim lithium or other active metals from such sources.

Owner:POLYPLUS BATTERY CO INC

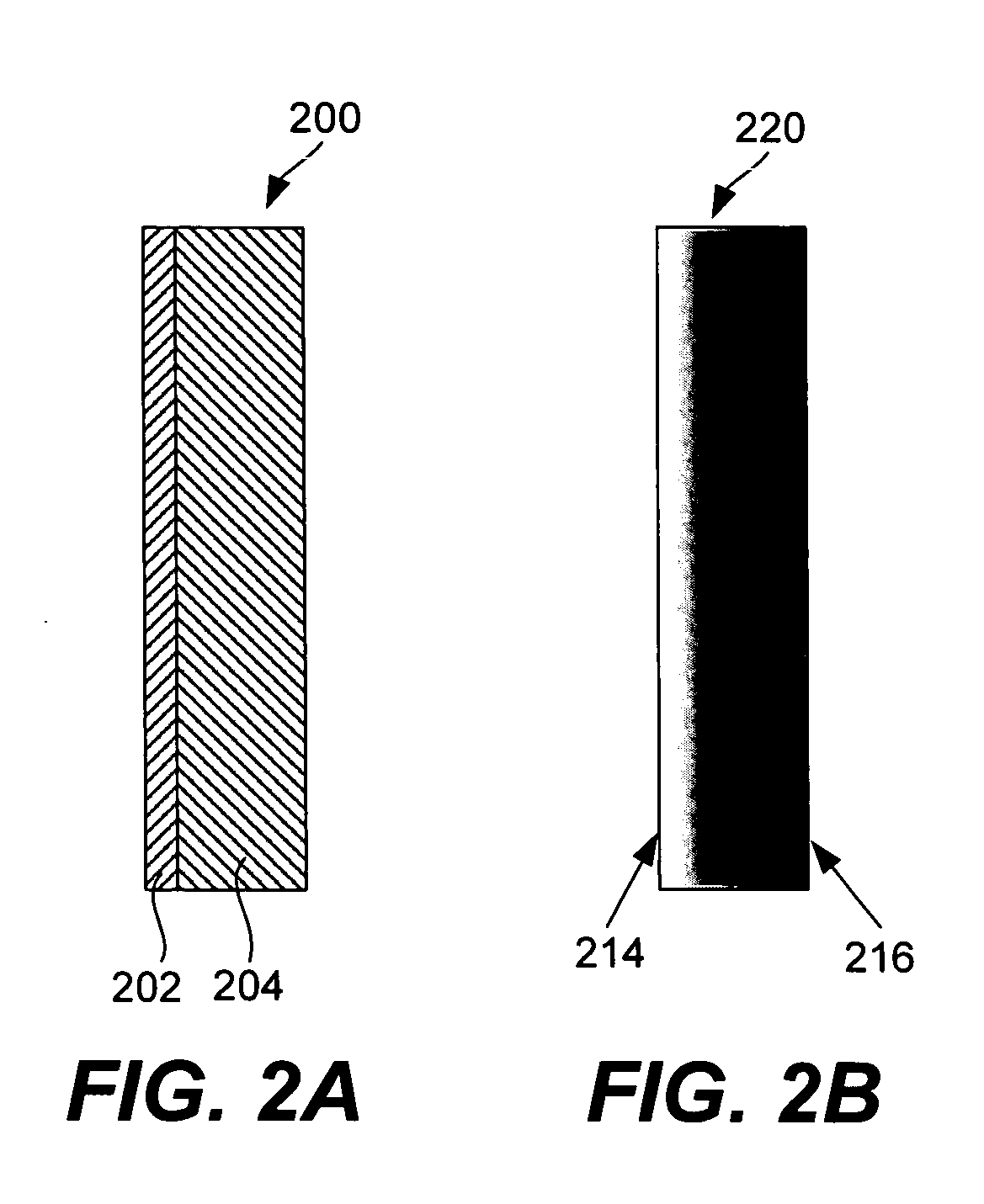

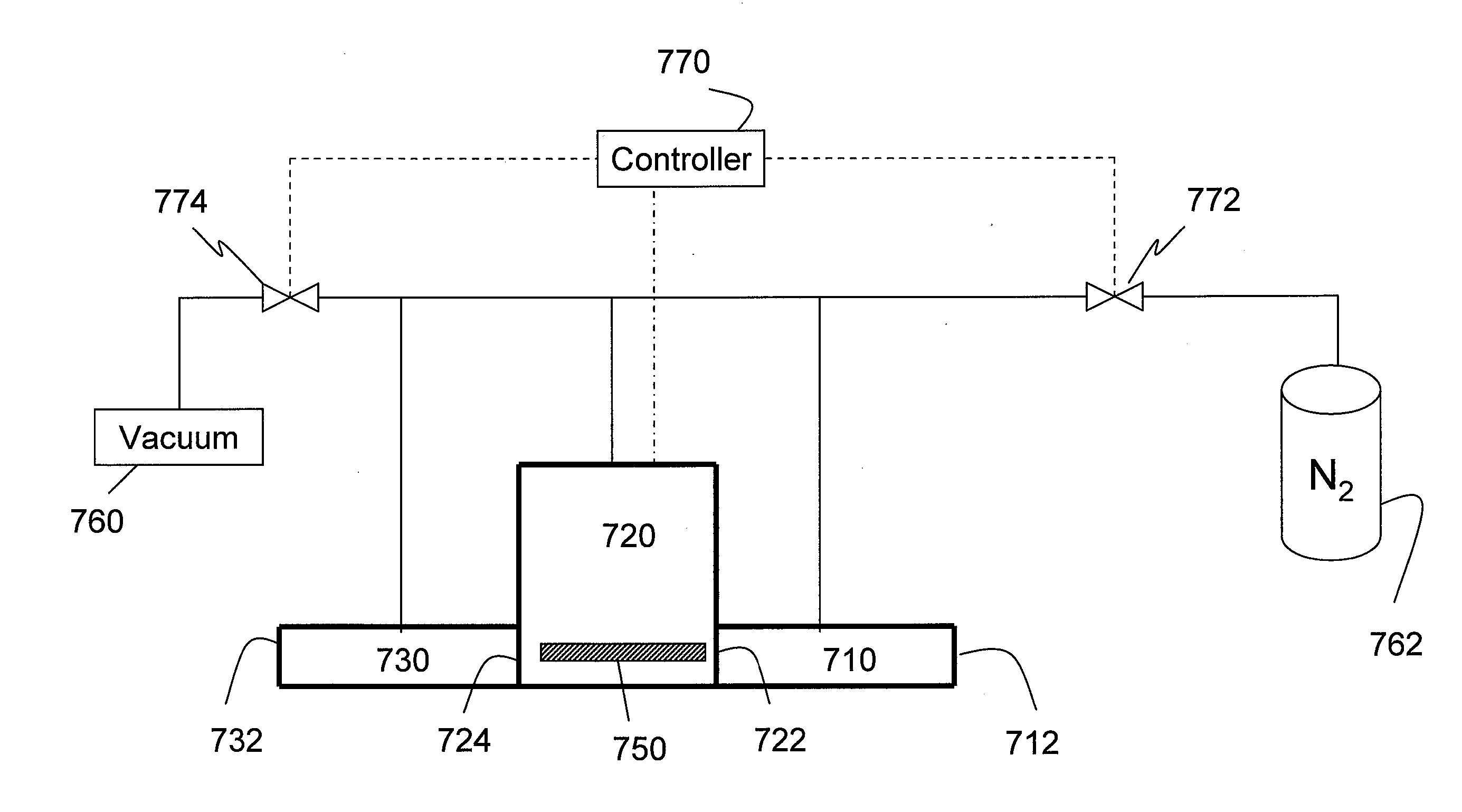

Method And Apparatus for Load-Locked Printing

ActiveUS20100201749A1Prevent oxidationAvoid contaminationInking apparatusMolten spray coatingElectrical and Electronics engineering3D printing

The disclosure relates to a method and apparatus for preventing oxidation or contamination during a circuit printing operation. The circuit printing operation can be directed to OLED-type printing. In an exemplary embodiment, the printing process is conducted at a load-locked printer housing having one or more of chambers. Each chamber is partitioned from the other chambers by physical gates or fluidic curtains. A controller coordinates transportation of a substrate through the system and purges the system by timely opening appropriate gates. The controller may also control the printing operation by energizing the print-head at a time when the substrate is positioned substantially thereunder.

Owner:KATEEVA

Method of making a photopolymer printing plate

ActiveUS20050266349A1High degree of polymerizationImage deteriorationPhotosensitive materialsDuplicating/marking methodsPhotopolymerEngineering

A method of making a lithographic printing plate comprising the steps of: a) providing a lithographic printing plate precursor comprising (i) a support having a hydrophilic surface or which is provided with a hydrophilic layer, (ii) a photopolymerizable coating on said support, b) image-wise exposing said coating in a plate setter, c) developing the precursor, thereby removing the non-exposed areas of the coating from the support, whereby the developing step is carried out off-press in a gumming unit by treating the coating of the precursor with a gum solution.

Owner:AGFA OFFSET BV

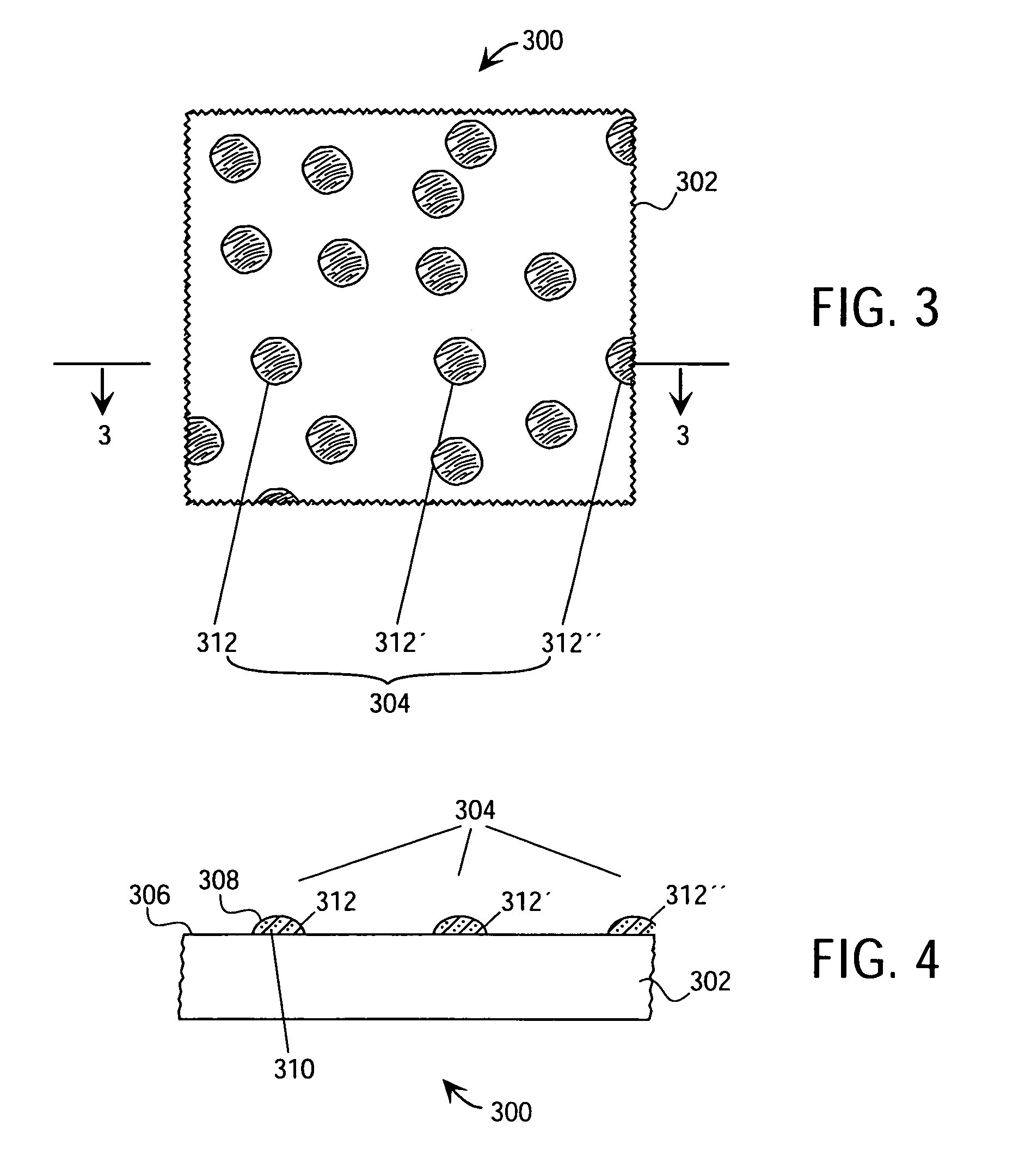

Coated articles having enhanced reversible thermal properties and exhibiting improved flexibility, softness, air permeability, or water vapor transport properties

InactiveUS7135424B2Enhanced reversible thermal propertyImprove breathabilityHeat storage plantsDecorative surface effectsWater vaporMedical product

The invention relates to a coated article having enhanced reversible thermal properties. The coated article comprises a substrate having a surface and a coating covering a portion of the surface and comprising a polymeric material and a temperature regulating material dispersed in the polymeric material. The coating is formed with a plurality of regions of discontinuity that are separated from one another and expose a remaining portion of the surface to provide improved flexibility, softness, air permeability, or water vapor transport properties. The coated article may be used in apparel, footwear, medical products, containers and packagings, building materials, appliances, and other products.

Owner:OUTLAST TECH LLC

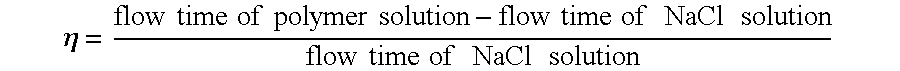

Ink to ink bleed and halo control using specific polymers in ink-jet printing inks

InactiveUS6281267B2Reduce bleedingReduce haloDuplicating/marking methodsInksPH-sensitive polymersPrinting ink

The ink set of this invention comprises at least two inks, one of which contains a pH sensitive polymer and preferably a self-dispersing pigment colorant. A second ink is provided which comprises incompatible inorganic or organic salts or has an appropriate pH. The polymer precipitates onto a medium upon contact with the second ink, thereby providing improved bleed and halo control.

Owner:HEWLETT PACKARD DEV CO LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com