Patents

Literature

379results about How to "Reduce inactivation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

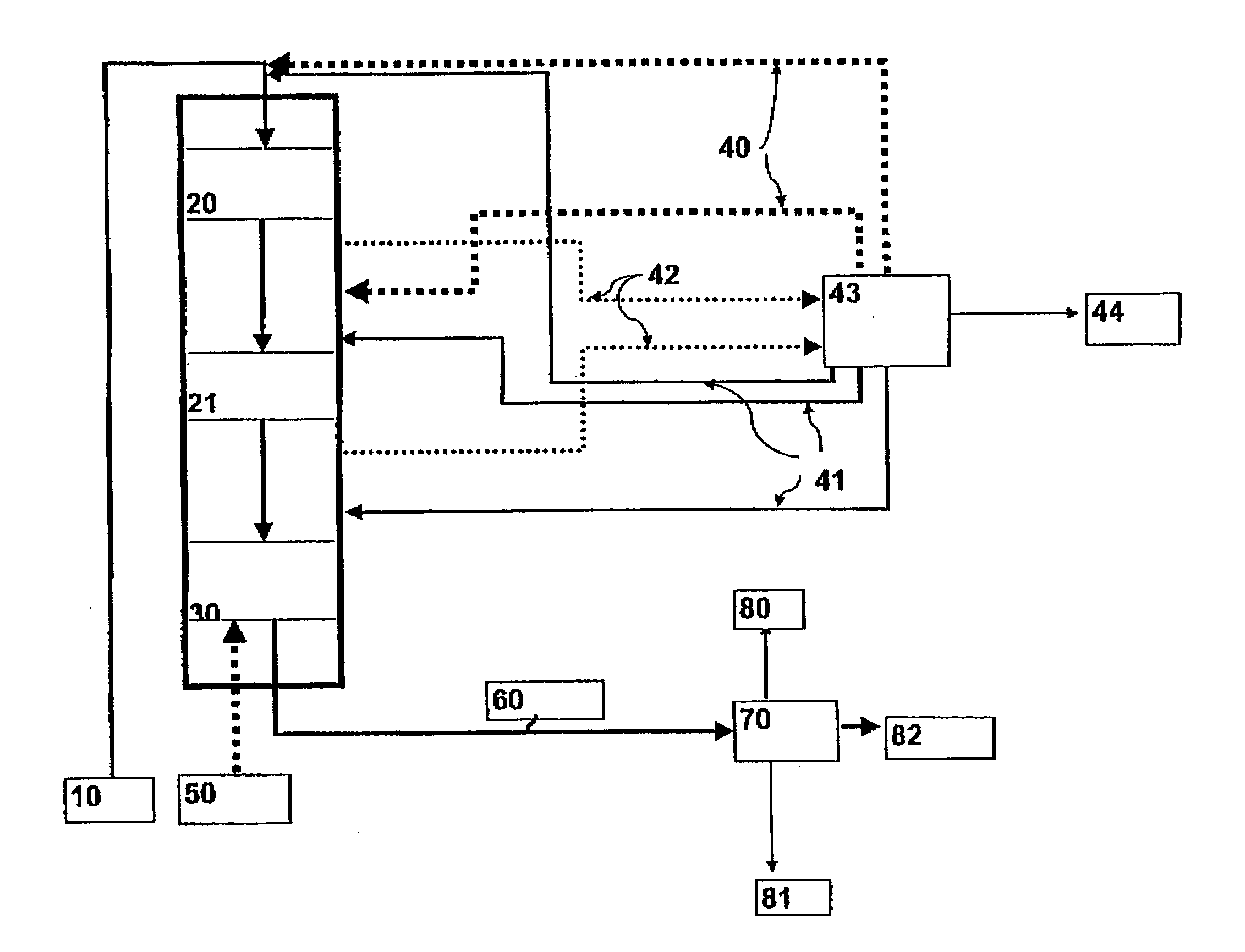

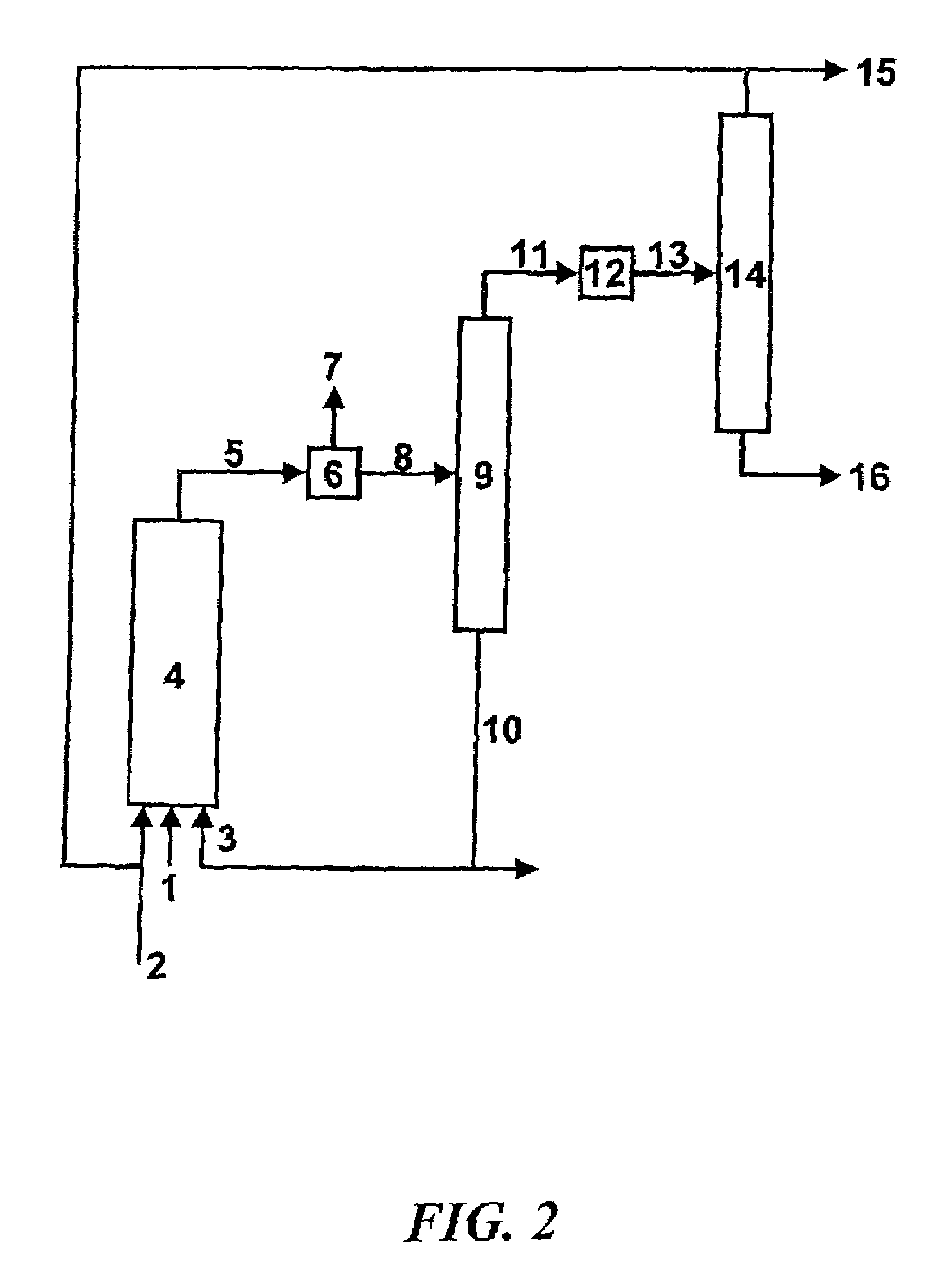

Process for producing a hydrocarbon component of biological origin

ActiveUS20040230085A1Improve performanceLow densityLiquid hydrocarbon mixture productionHydrocarbonsIsomerizationHydrocarbon

The invention relates to a process for producing a hydrocarbon component of biological origin. The process comprises at least two steps, the first one of which is a HDO step and the second one is an isomerization step operated using the counter-current flow principle. A biological raw material containing fatty acids and / or fatty acid esters serves as the feed stock.

Owner:OYJ NESTE OIL +1

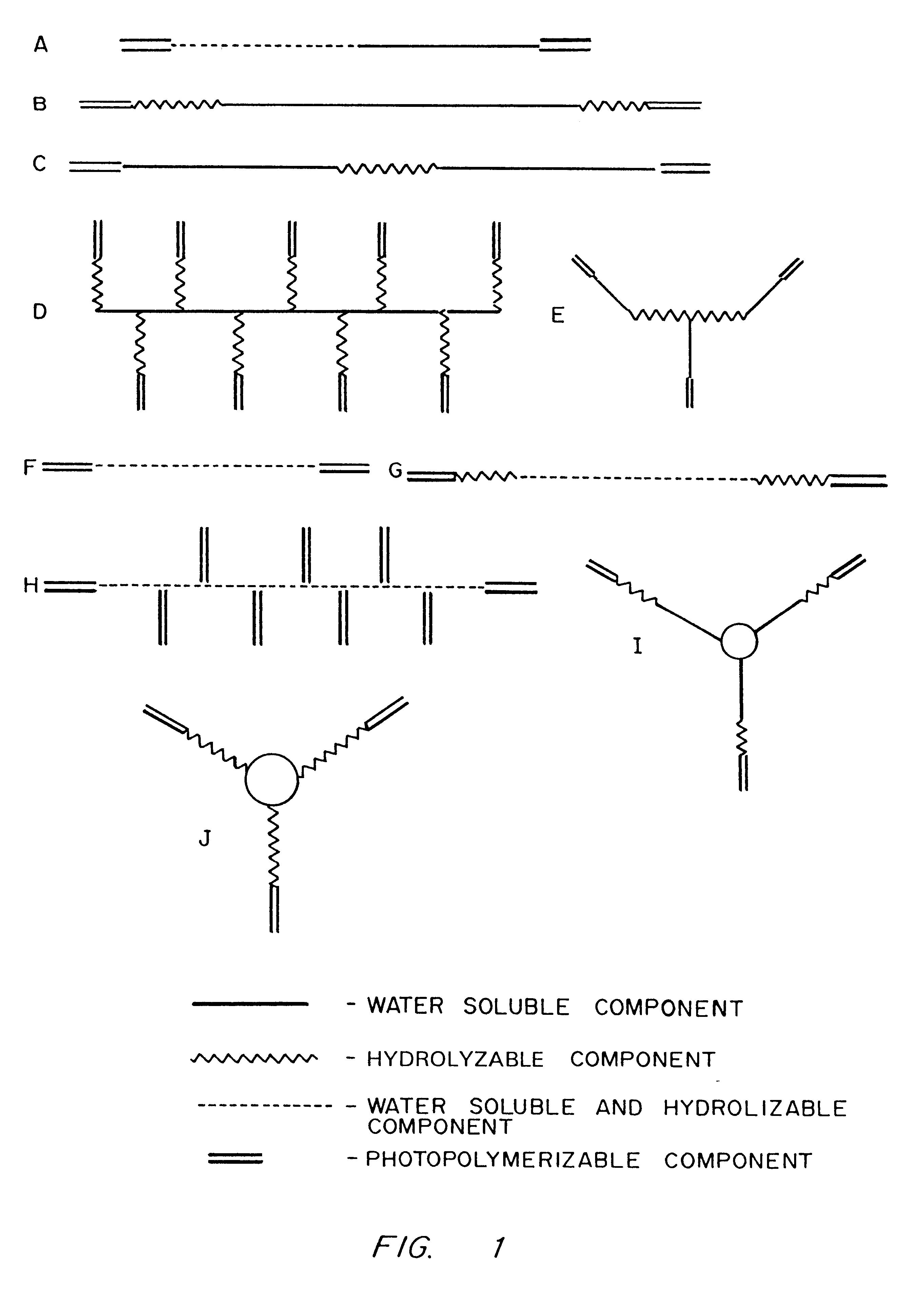

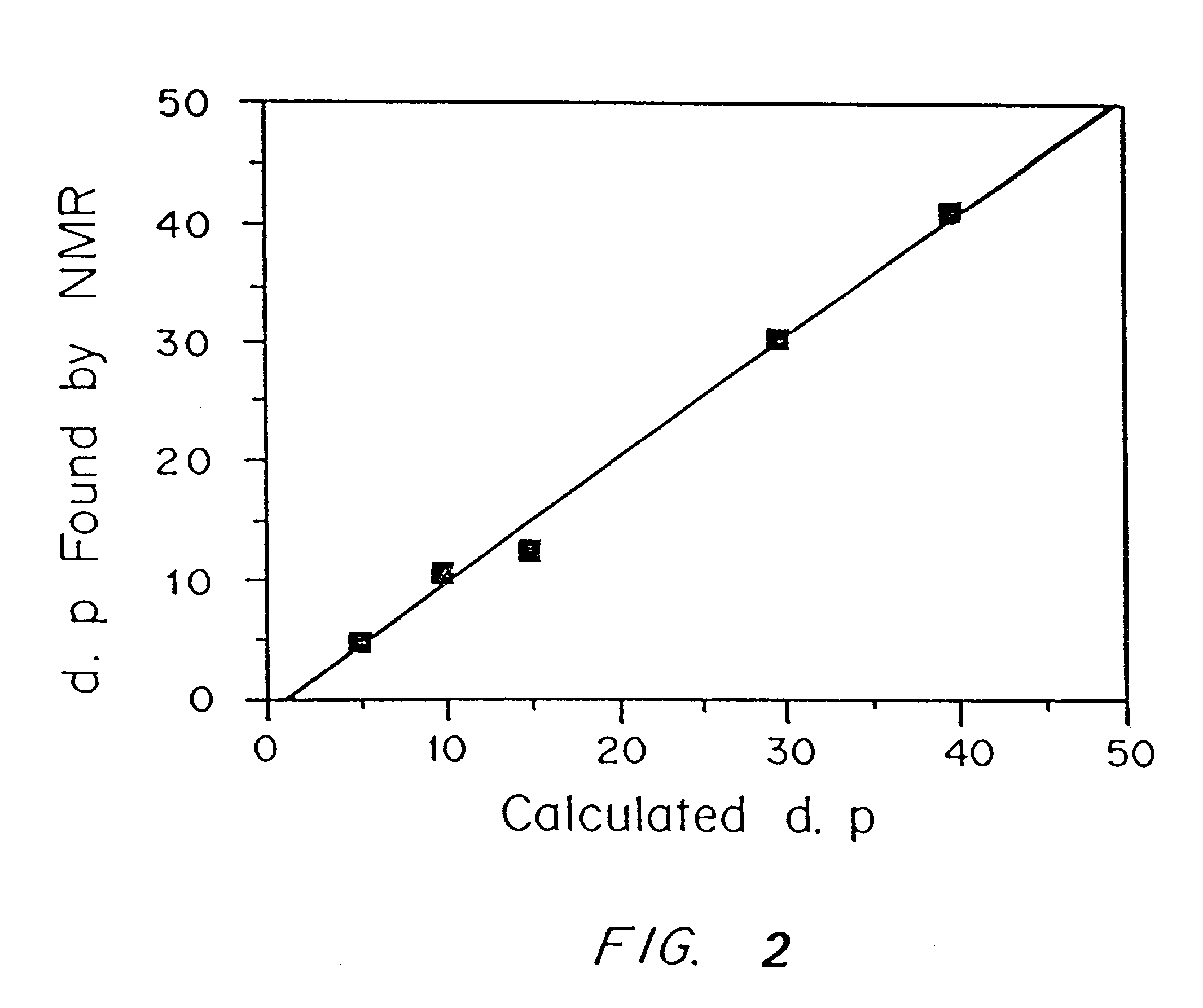

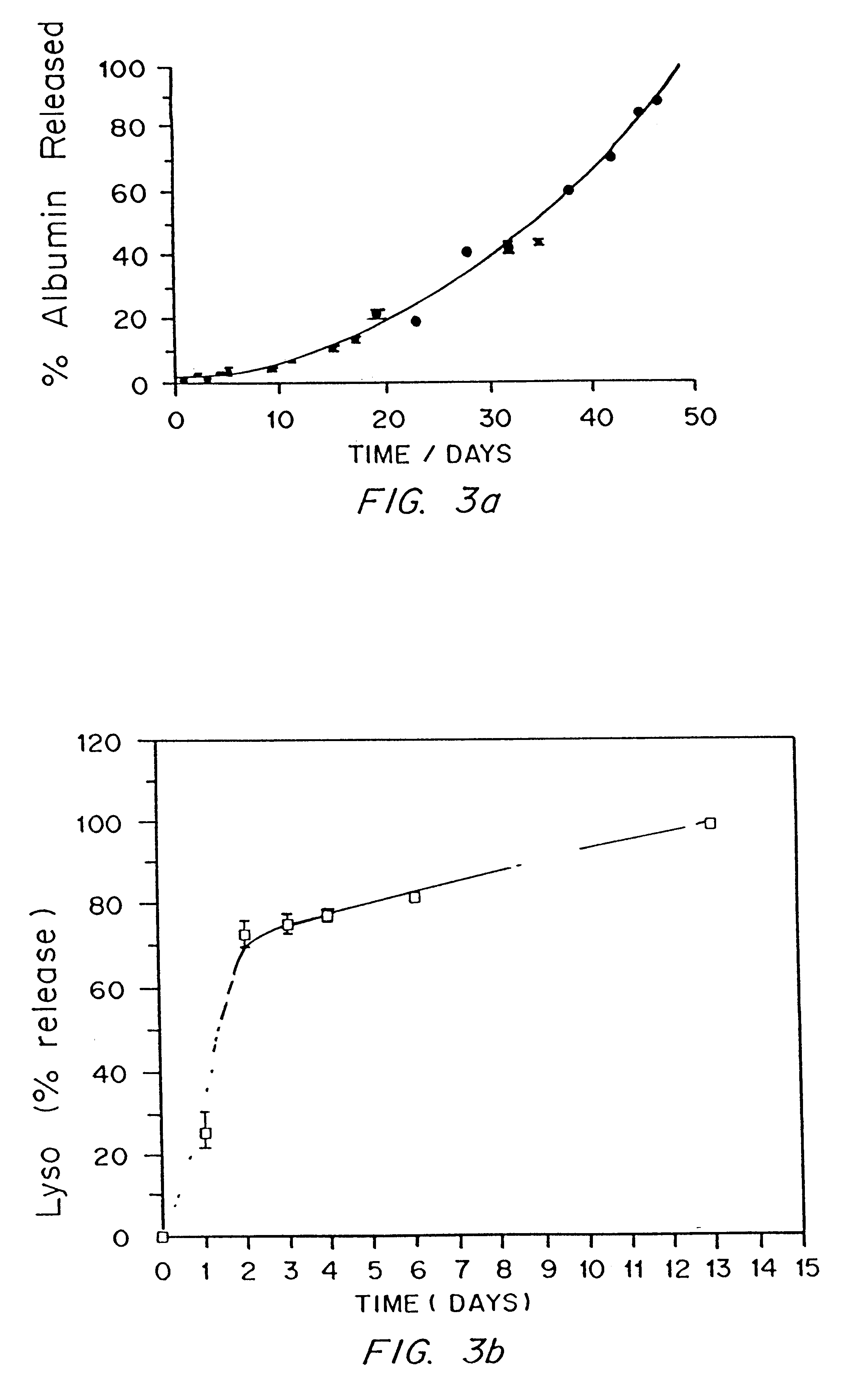

Photopolymerizable biodegradable hydrogels as tissue contacting materials and controlled-release carriers

InactiveUS6306922B1Fast gelationRapid polymerizationImmobilised enzymesPowder deliveryThermal energyUltraviolet lights

Hydrogels of polymerized and crosslinked macromers comprising hydrophilic oligomers having biodegradable monomeric or oligomeric extensions, which biodegradable extensions are terminated on free ends with end cap monomers or oligomers capable of polymerization and cross linking are described. The hydrophilic core itself may be degradable, thus combining the core and extension functions. Macromers are polymerized using free radical initiators under the influence of long wavelength ultraviolet light, visible light excitation or thermal energy. Biodegradation occurs at the linkages within the extension oligomers and results in fragments which are non-toxic and easily removed from the body. Preferred applications for the hydrogels include prevention of adhesion formation after surgical procedures, controlled release of drugs and other bioactive species, temporary protection or separation of tissue surfaces, adhering of sealing tissues together, and preventing the attachment of cells to tissue surfaces.

Owner:BOARD OF REGENTS

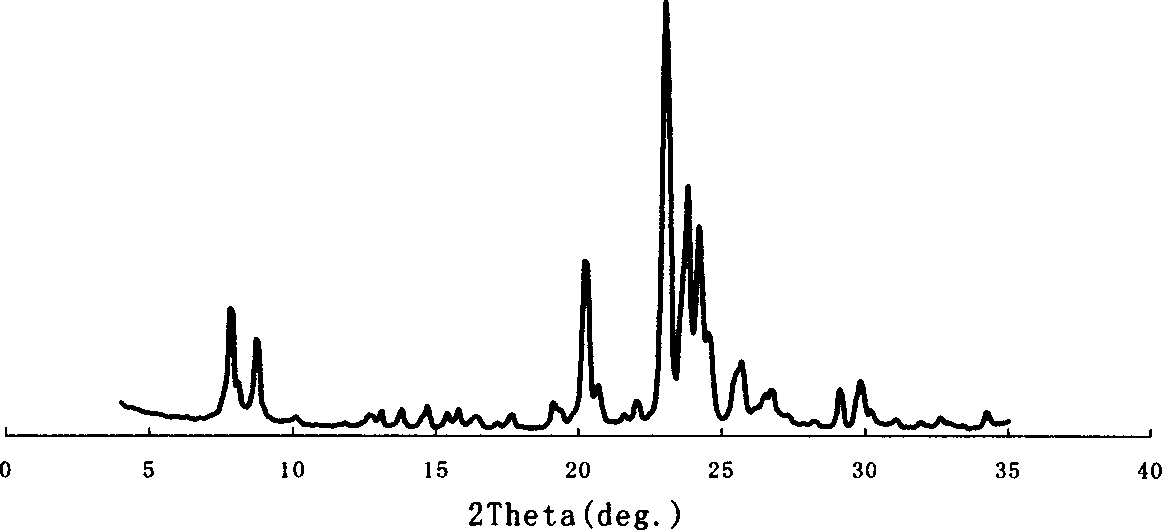

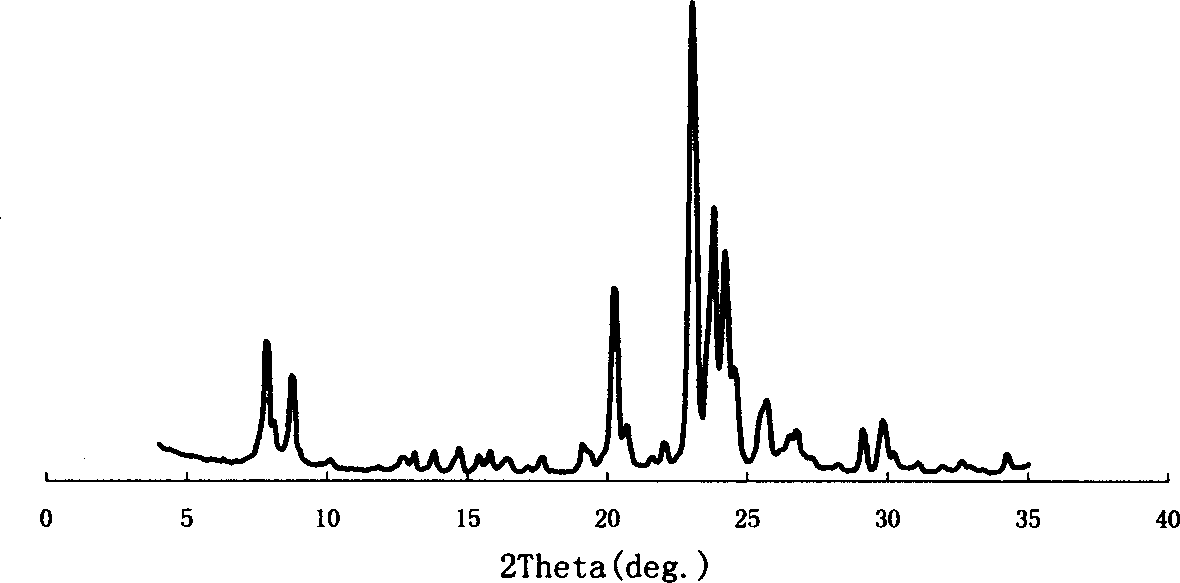

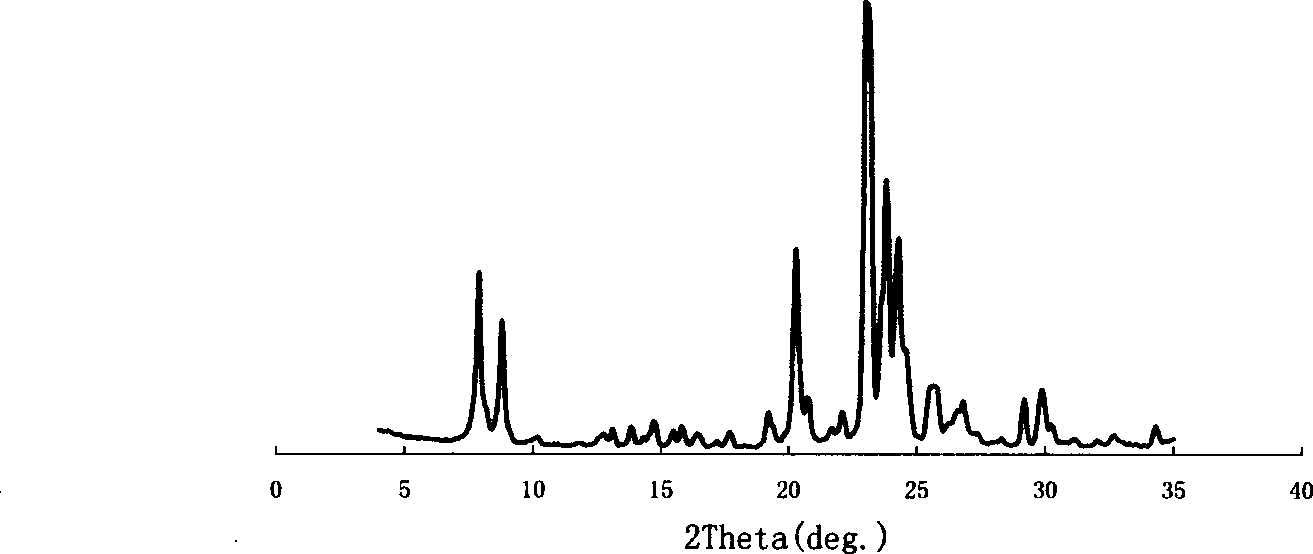

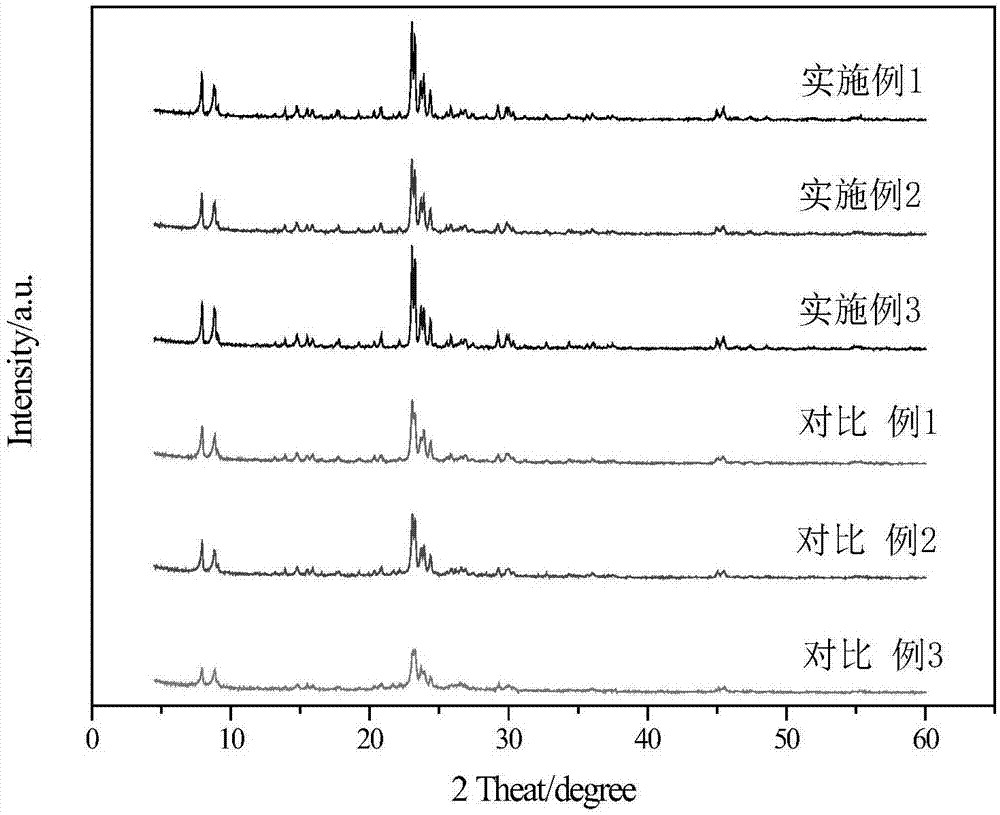

Mole cular sieve with composite structure and preparing method thereof

InactiveCN1552625AHigh activityHigh selectivityCrystalline aluminosilicate zeolitesMolecular sieveCrystallization

A composite molecular sieve with TON and MFI structures is prepared in static crystallizing condition. In the procedure of preparing gel, less crystal seeds and salt are added. The Si / Al ratio on its crystal lattice is greater than 50.

Owner:CHINA PETROLEUM & CHEM CORP +1

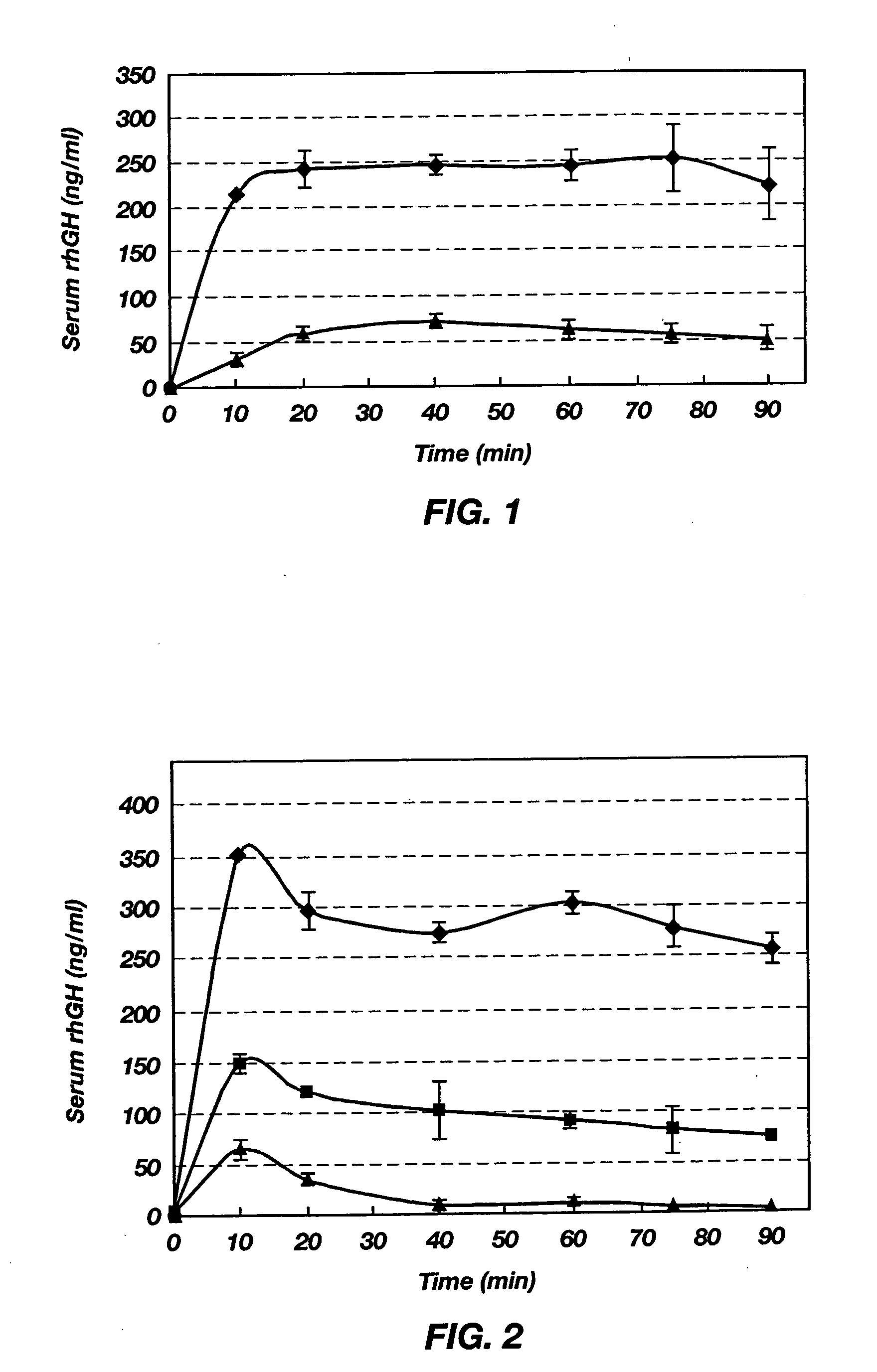

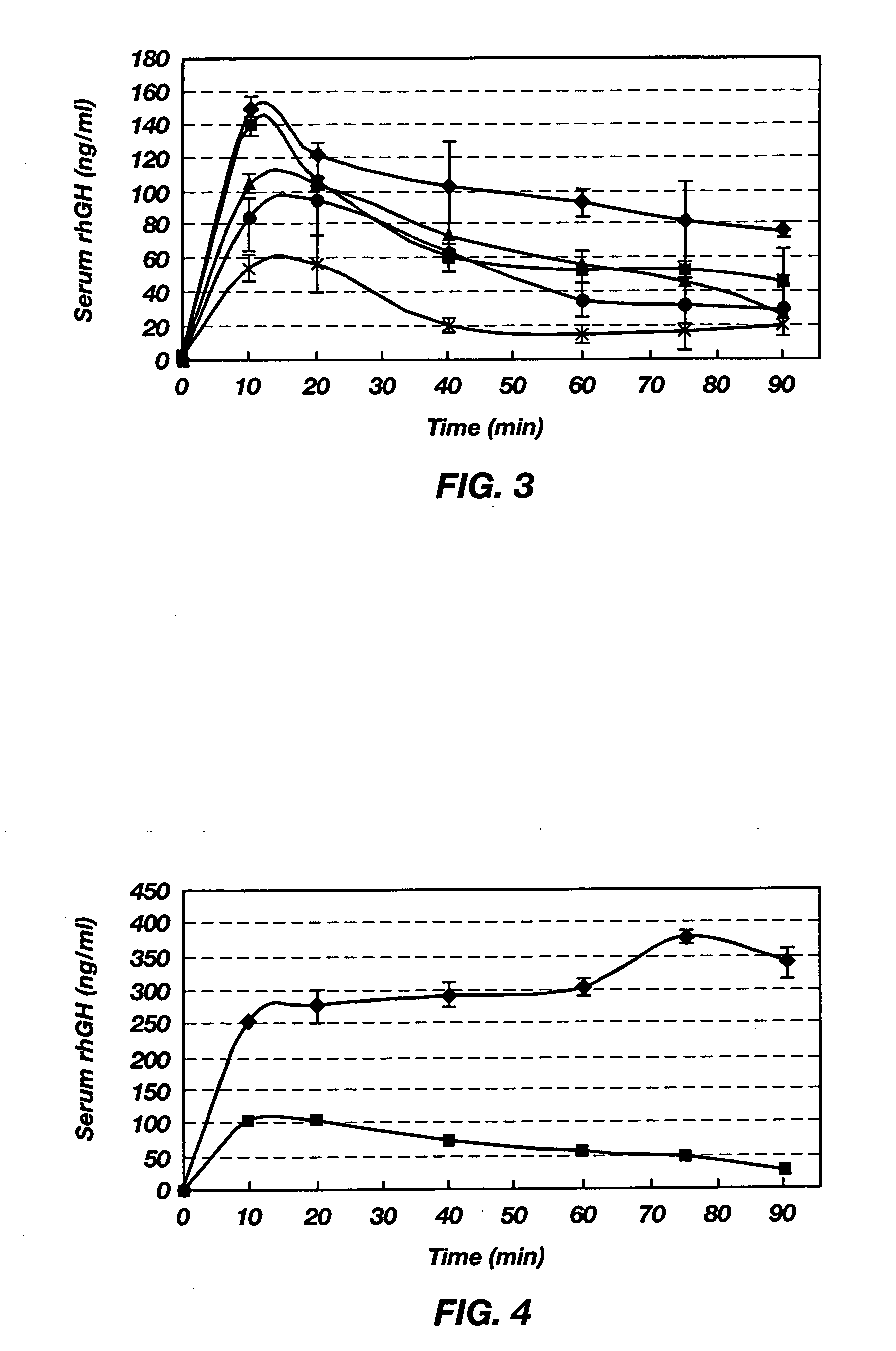

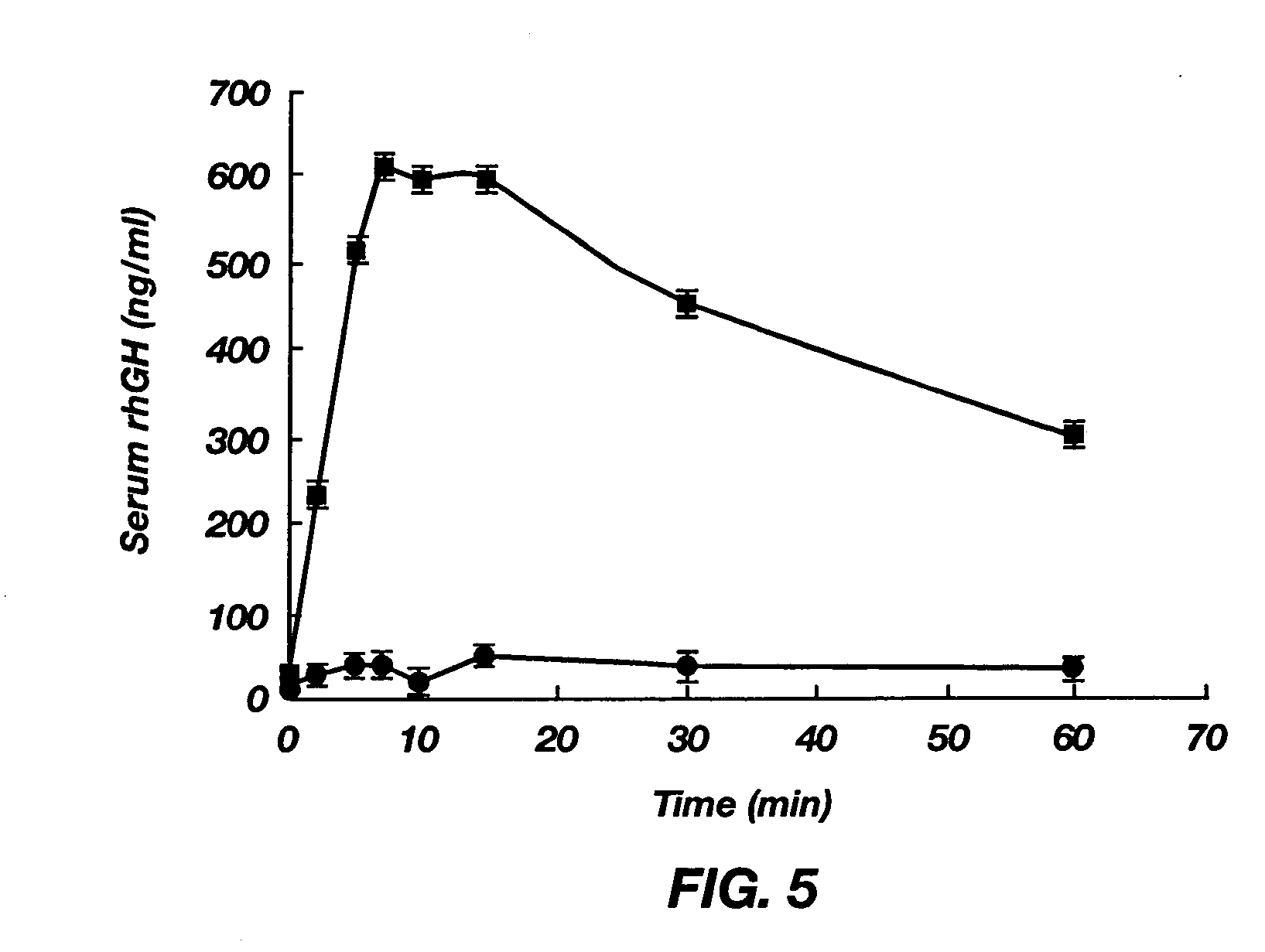

Oral formulation for delivery of poorly absorbed drugs

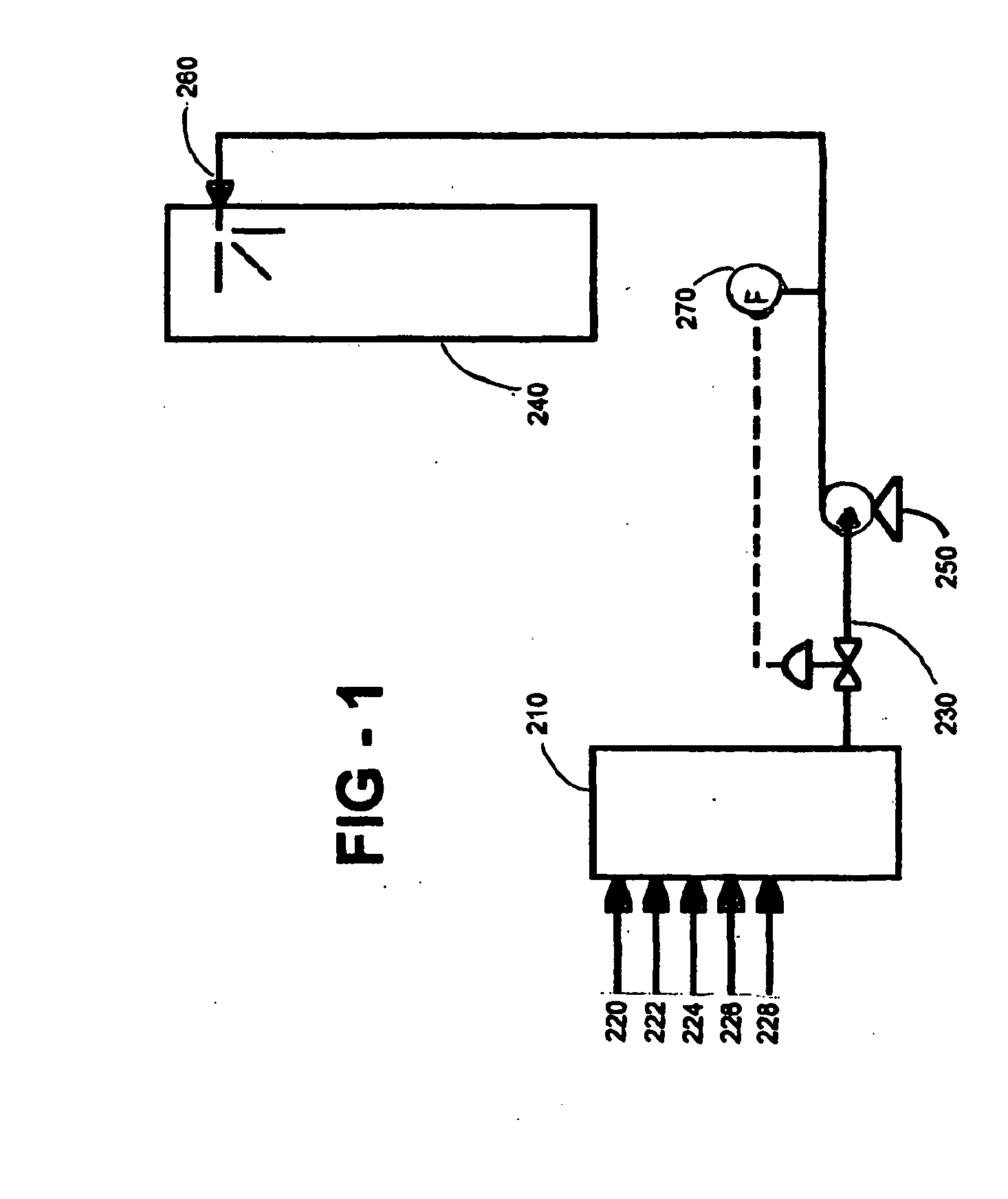

InactiveUS20060088592A1Promote absorptionReduce inactivationHeavy metal active ingredientsMultiple-port networksSucrosePolyvinyl alcohol

A composition for oral delivery of a poorly absorbed drug is disclosed. The composition includes the drug, an enhancer for increasing absorption of the drug through the intestinal mucosa, a promoter, which alone does not increase absorption of the drug through the intestinal mucosa, but which further increases the absorption of the drug in the presence of the enhancer, and optionally a protector for protecting the drug from physical or chemical decomposition or inactivation in the gastrointestinal tract. Illustrative enhancers include sucrose fatty acid esters, and illustrative promoters include aminosugars and amino acid derivatives, such as poly(amino acids). Illustrative protectors include methylcellulose, poly(vinyl alcohol), and poly(vinyl pyrrolidone).

Owner:PROCARRIER

Cs-supported silica-based catalyst and preparation method and application thereof

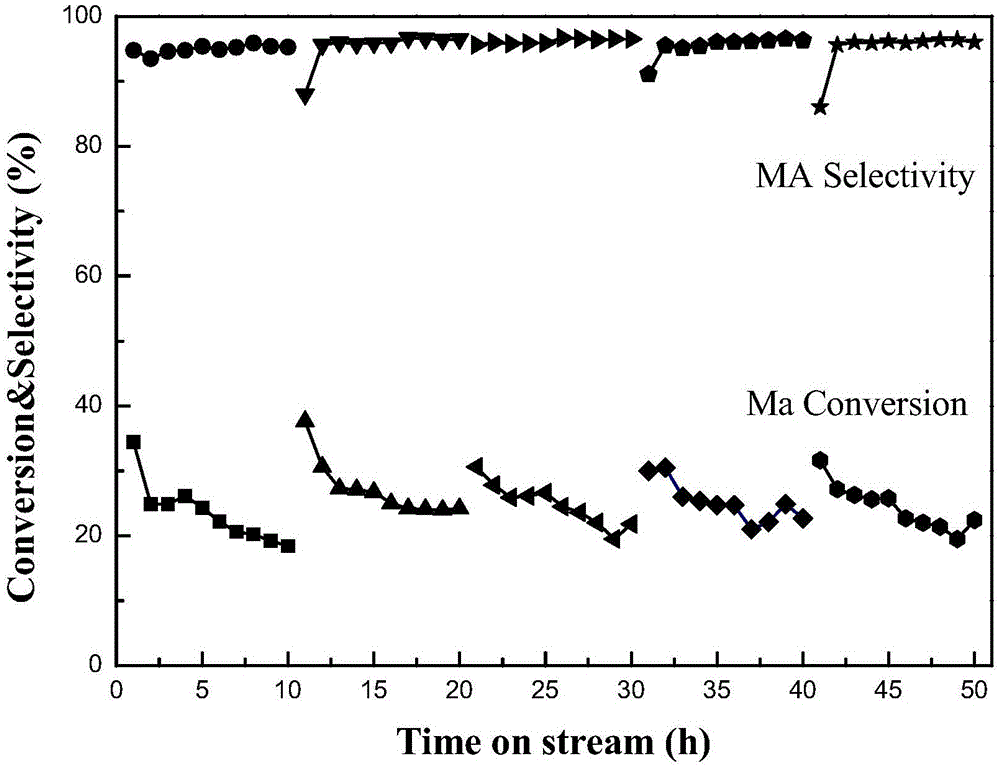

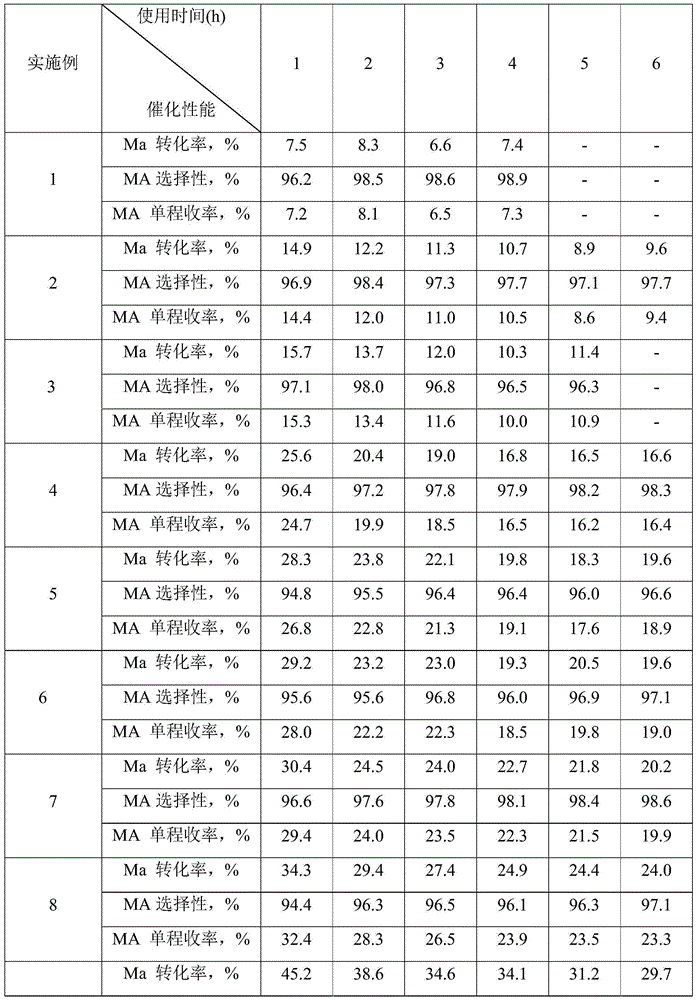

InactiveCN103801280AImprove stabilityContinuous productionMolecular sieve catalystsOrganic compound preparationGas phaseMethyl acetate

The invention provides a Cs-supported silica-based catalyst. One of SBA-15, SiO2 or silicon dioxide prepared by a silica sol method is used as a carrier, the support is selected from one of Cs salt and a mixture of Cs and modified elements, the catalyst is prepared by a dipping method, the Cs content is 0.1wt%-10wt%, and the content of the modified elements is 0-2wt%. Meanwhile, the invention further provides a preparation method of the Cs-supported silica-based catalyst and application of the Cs-supported silica-based catalyst to the process of preparing methyl acrylate by catalyzing condensation reaction of methyl acetate and a methanal gas phase. The prepared catalyst is capable of realizing the aldol condensation of the methyl acetate and the methanal gas phase under proper conditions so as to prepare the methyl acrylate, wherein the activity of the Cs / SBA-15 catalyst is higher than that of other Cs-supported silica-based catalysts, and the selectivity on the methyl acrylate is good.

Owner:SHANGHAI HUAYI GRP CO

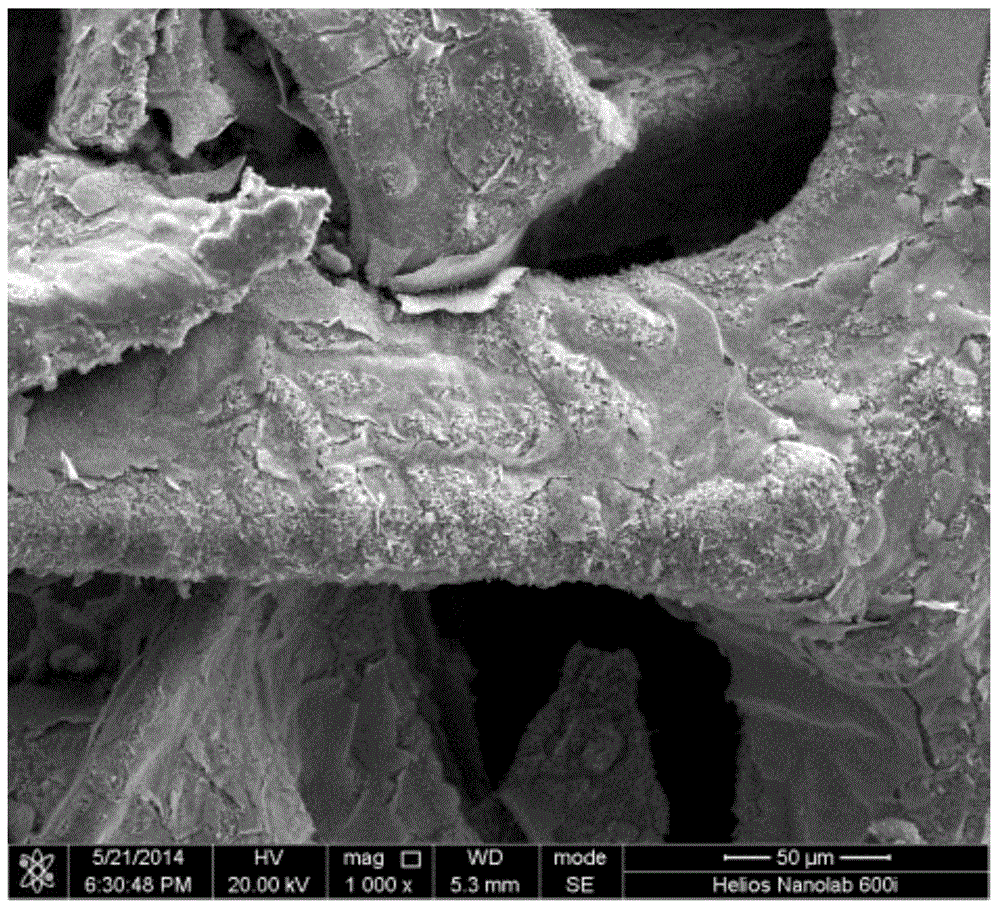

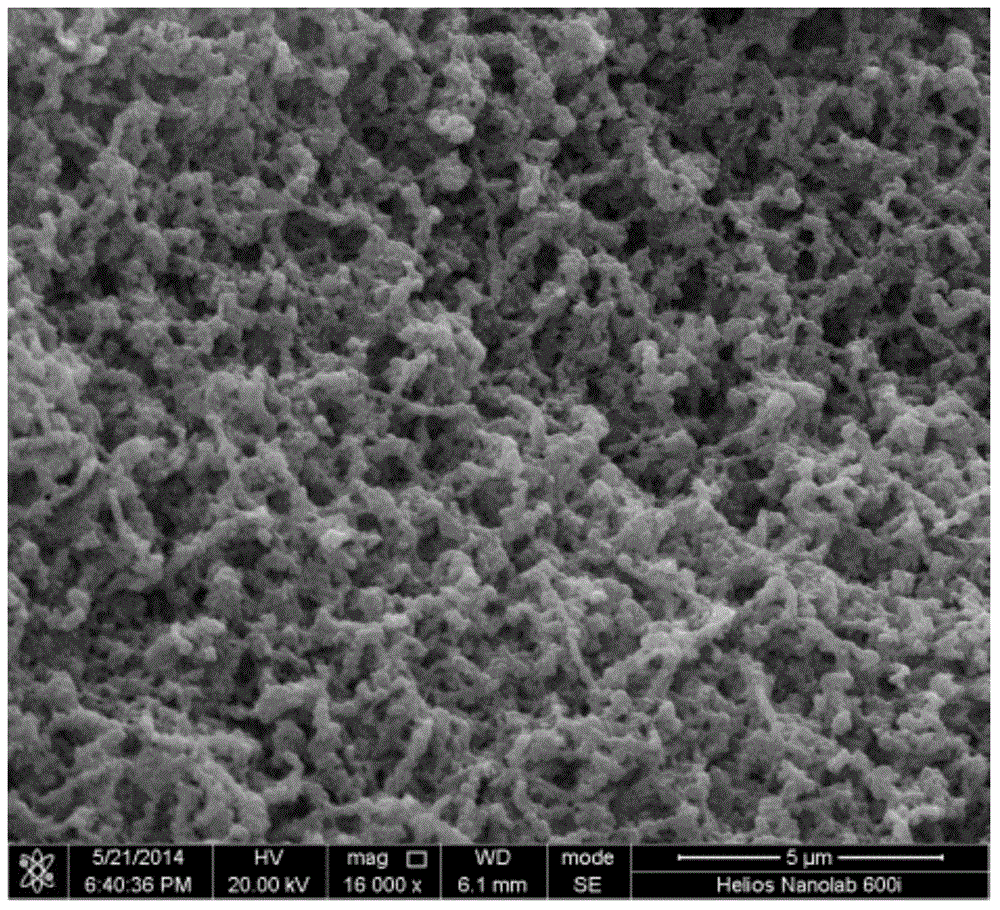

Three-dimensional macroporous graphene, carbon nano tube and molybdenum disulfide composite material, and preparation method and application of composite material

The invention discloses a three-dimensional macroporous graphene, carbon nano tube and molybdenum disulfide composite material, and a preparation method and an application of the composite material, and relates to a nano composite material, and a preparation method and an application of the nano composite material. The composite material, the preparation method and the application aim at solving the problems of poor stability and too low first cycle efficiency of existing molybdenum disulfide serving as a cathode active substance of a lithium ion battery. The method comprises the steps of 1, preparing a three-dimensional macroporous graphene / foam metal composite, 2, preparing a three-dimensional macroporous graphene / carbon nano tube / foam metal composite, 3, preparing a three-dimensional macroporous graphene / carbon nano tube, 4, loading molybdenum disulfide by a hydrothermal method, and 5, annealing the three-dimensional macroporous graphene / carbon nano tube loaded with molybdenum disulfide to obtain the three-dimensional macroporous graphene, carbon nano tube and molybdenum disulfide composite material.

Owner:HARBIN INST OF TECH

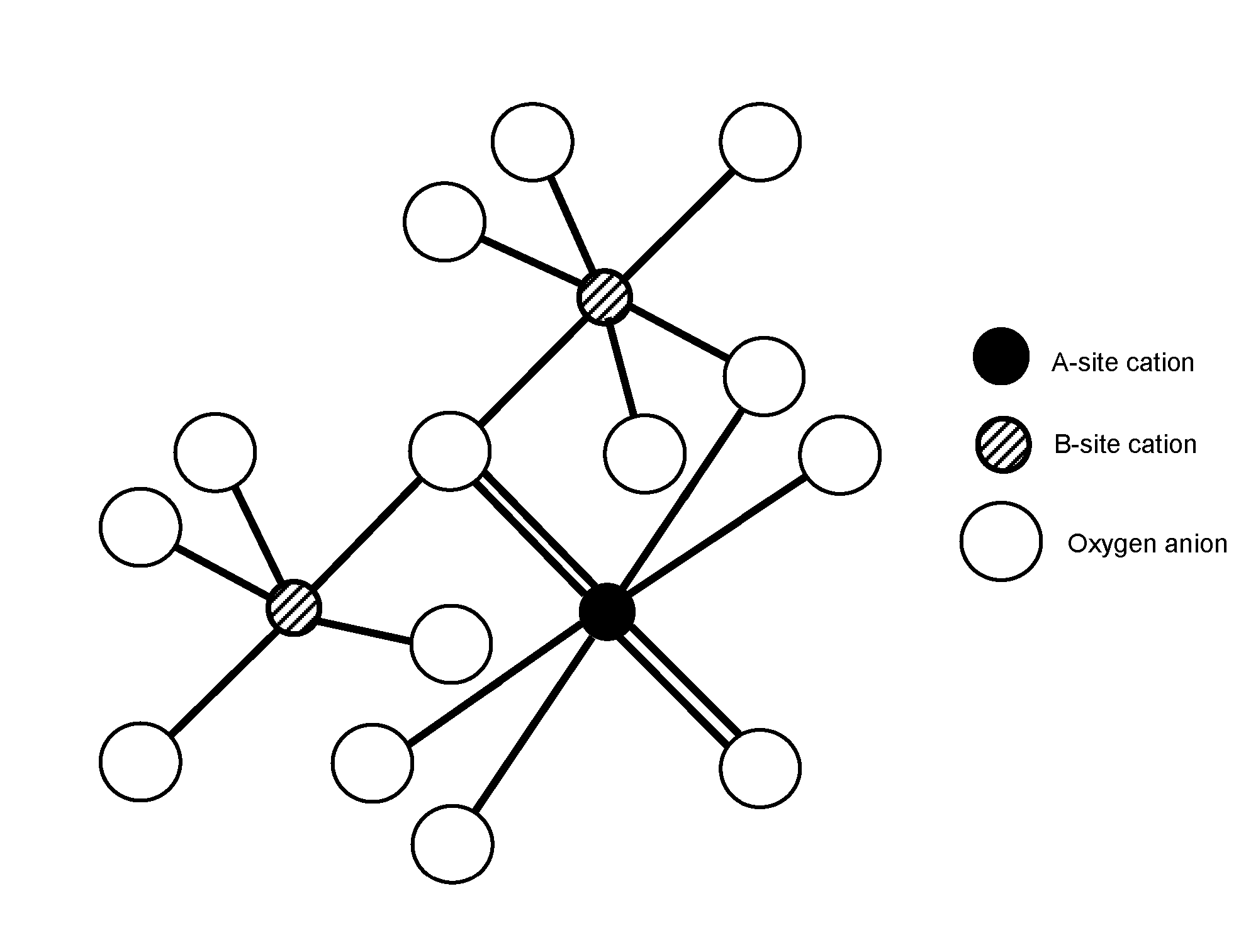

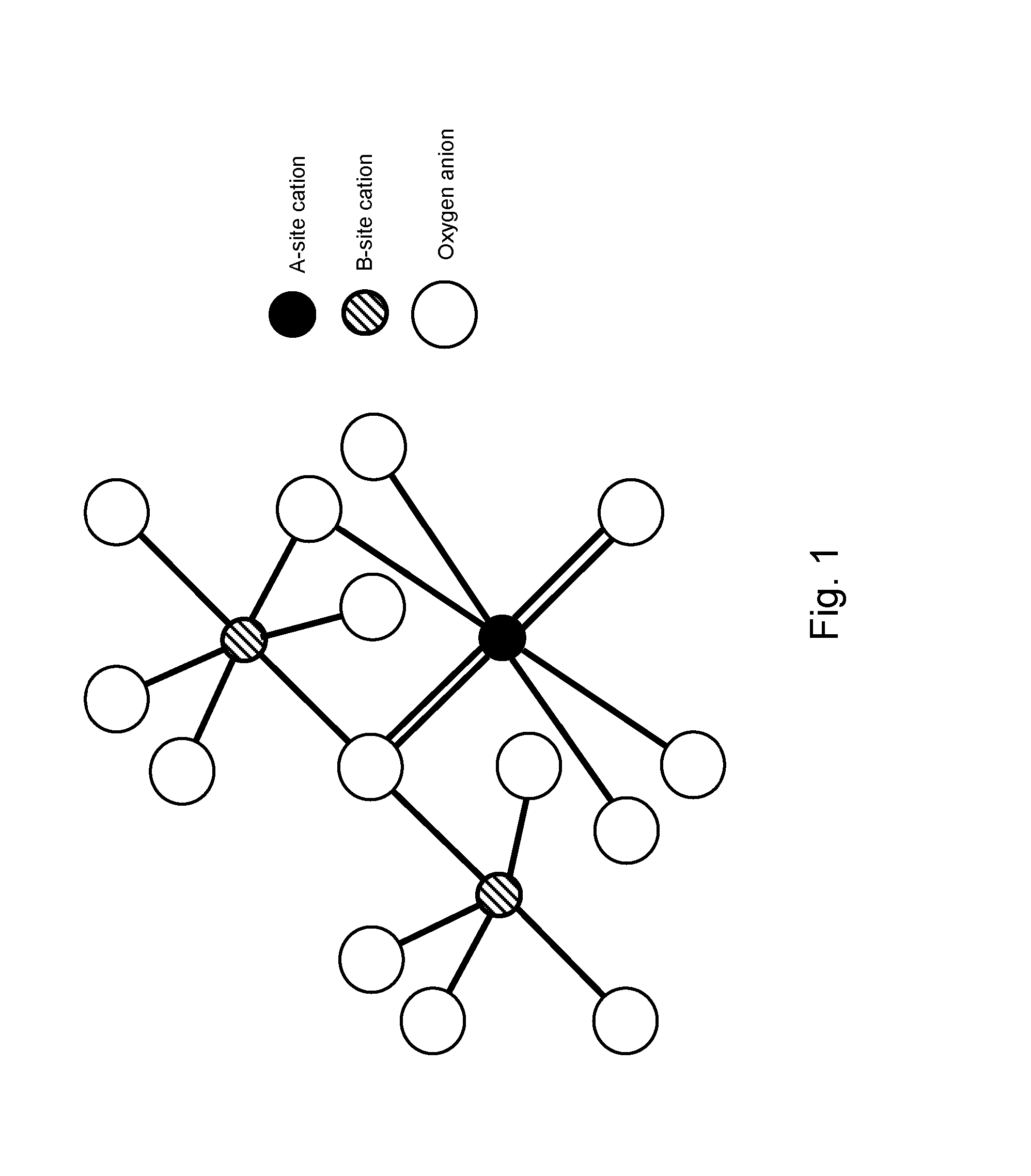

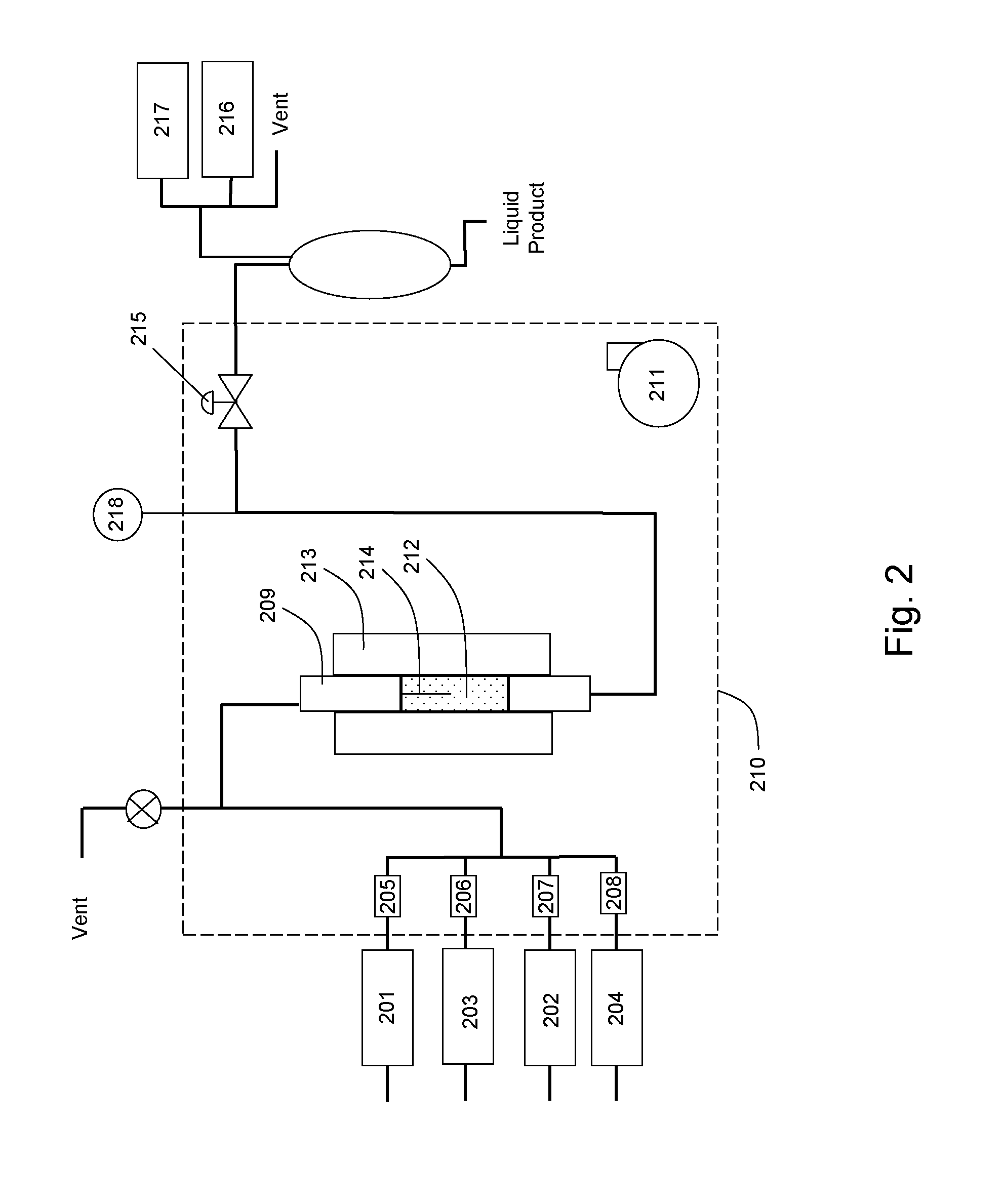

Pyrochlore-type catalysts for the reforming of hydrocarbon fuels

ActiveUS8133463B1Reducing metal sinteringReduce catalyst deactivationHydrogenHydrocarbon from carbon oxidesCatalytic reformingFuel cells

A method of catalytically reforming a reactant gas mixture using a pyrochlore catalyst material comprised of one or more pyrochlores having the composition A2-w-xA′wA″xB2-y-zB′yB″zO7-Δ. Distribution of catalytically active metals throughout the structure at the B site creates an active and well dispersed metal locked into place in the crystal structure. This greatly reduces the metal sintering that typically occurs on supported catalysts used in reforming reactions, and reduces deactivation by sulfur and carbon. Further, oxygen mobility may also be enhanced by elemental exchange of promoters at sites in the pyrochlore. The pyrochlore catalyst material may be utilized in catalytic reforming reactions for the conversion of hydrocarbon fuels into synthesis gas (H2+CO) for fuel cells, among other uses.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

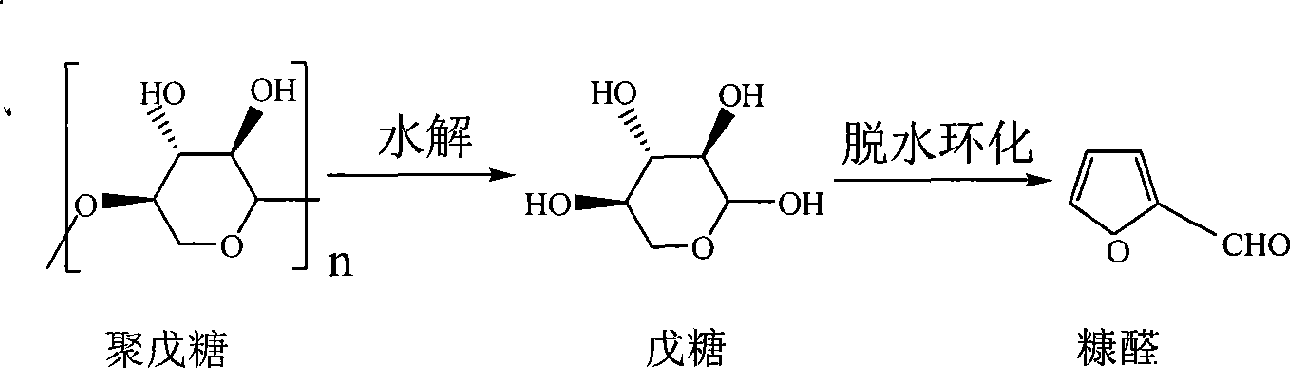

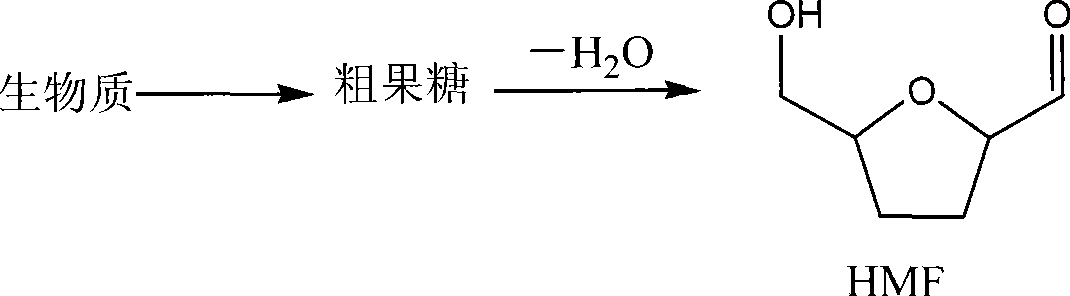

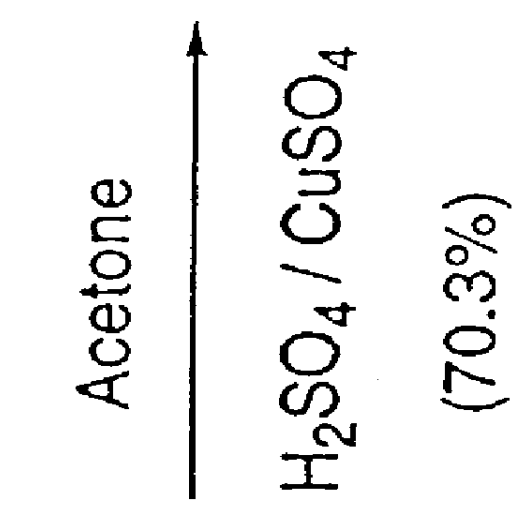

Method for catalytic preparation of 5-hydroxymethyl furfural from carbohydrates

InactiveCN102101851ALow costGood choiceOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsNiobiumSolid acid

The invention relates to a niobium-containing compound catalyst for efficiently converting carbohydrates into 5-hydroxymethyl furfural, which has high activity and selectivity for preparing hydroxymethyl furfural (HMF) by dehydrolyzing saccharides and is an ideal catalyst for preparing HMF. When the reaction is performed under moderate conditions, the target product HMF can have a high yield. The catalyst is environment-friendly, is easy to separate and recycle, can be reused, is convenient and practical to operate, and can not corrode the equipment, thereby being an ideal solid acid catalyst for preparing HMF, and having significant industrial application meanings.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Selective Cracking and Coking of Undesirable Components in Coker Recycle and Gas Oils

InactiveUS20100170827A1High processing capacityReduce deactivationThermal non-catalytic crackingTreatment with plural serial cracking stages onlyCycle oilEngineering

Undesirable gas oil components are selectively cracked or coked in a coking vessel by injecting an additive into the vapors of traditional coking processes in the coking vessel prior to fractionation. The additive contains catalyst(s), seeding agent(s), excess reactant(s), quenching agent(s), carrier(s), or any combination thereof to modify reaction kinetics to preferentially crack or coke these undesirable components that typically have a high propensity to coke. Exemplary embodiments of the present invention also provide methods to control the (1) coke crystalline structure and (2) the quantity and quality of volatile combustible materials (VCMs) in the resulting coke. That is, by varying the quantity and quality of the catalyst, seeding agent, and / or excess reactant the process may affect the quality and quantity of the coke produced, particularly with respect to the crystalline structure (or morphology) of the coke and the quantity & quality of the VCMs in the coke.

Owner:ETTER ROGER G

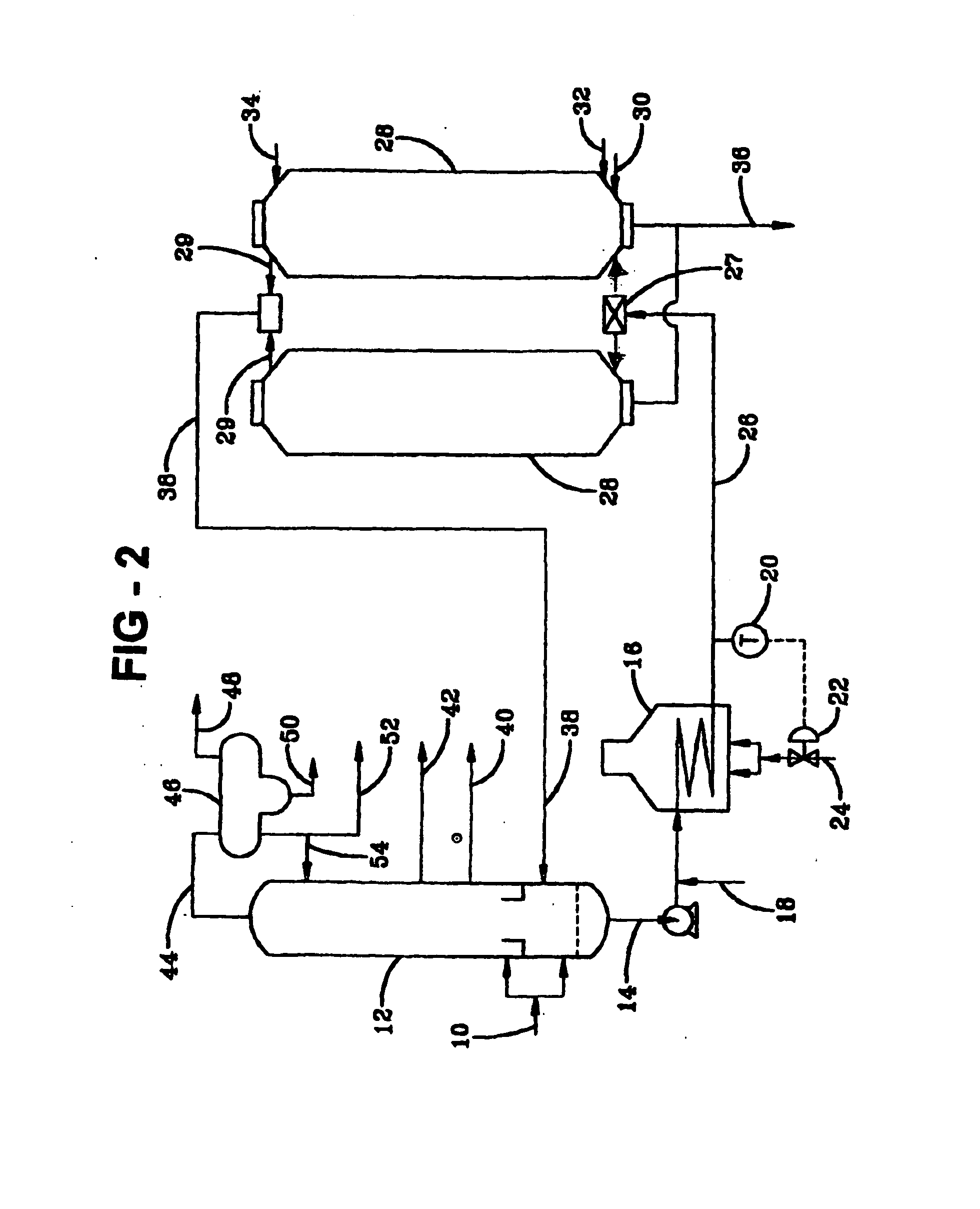

Hydrogenation and refining method of gasoline with poor quality

ActiveCN101591565AThe method flow is simpleEasy and flexible operationTreatment with hydrotreatment processesSolventPoor quality

The invention discloses a hydrogenation and refining method of gasoline with poor quality, comprising the following steps: the base oil of gasoline contacts and reacts with hydrogenation protective agent at low temperature; after reaction effluent is mixed with circulation oil, the mixture sequentially contacts and reacts with hydrogenation desilication solvent and hyrorefining catalyst at high temperature; the reaction product is cooled and separated to obtain hydrogen-rich gas and refined gasoline fraction; and parts of refined gasoline fraction serves as circulation oil to return to the outlet of a first hydrogenation reaction area. The method can handle coker gasoline with high content of sulphur, nitrogen and olefin, and refined gasoline fraction can satisfy charging requirements of reforming pre-hydrogenation devices and steam cracking ethene preparing devices. The method of the invention can effectively slow coking speed of heating furnace tubes, greatly lowers pressure drop generation frequency of a main hydrogenation reactor, improves the operating severity of the main hydrogenation reactor and retards the deactivation speed of catalyst at the bottom of a refined reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

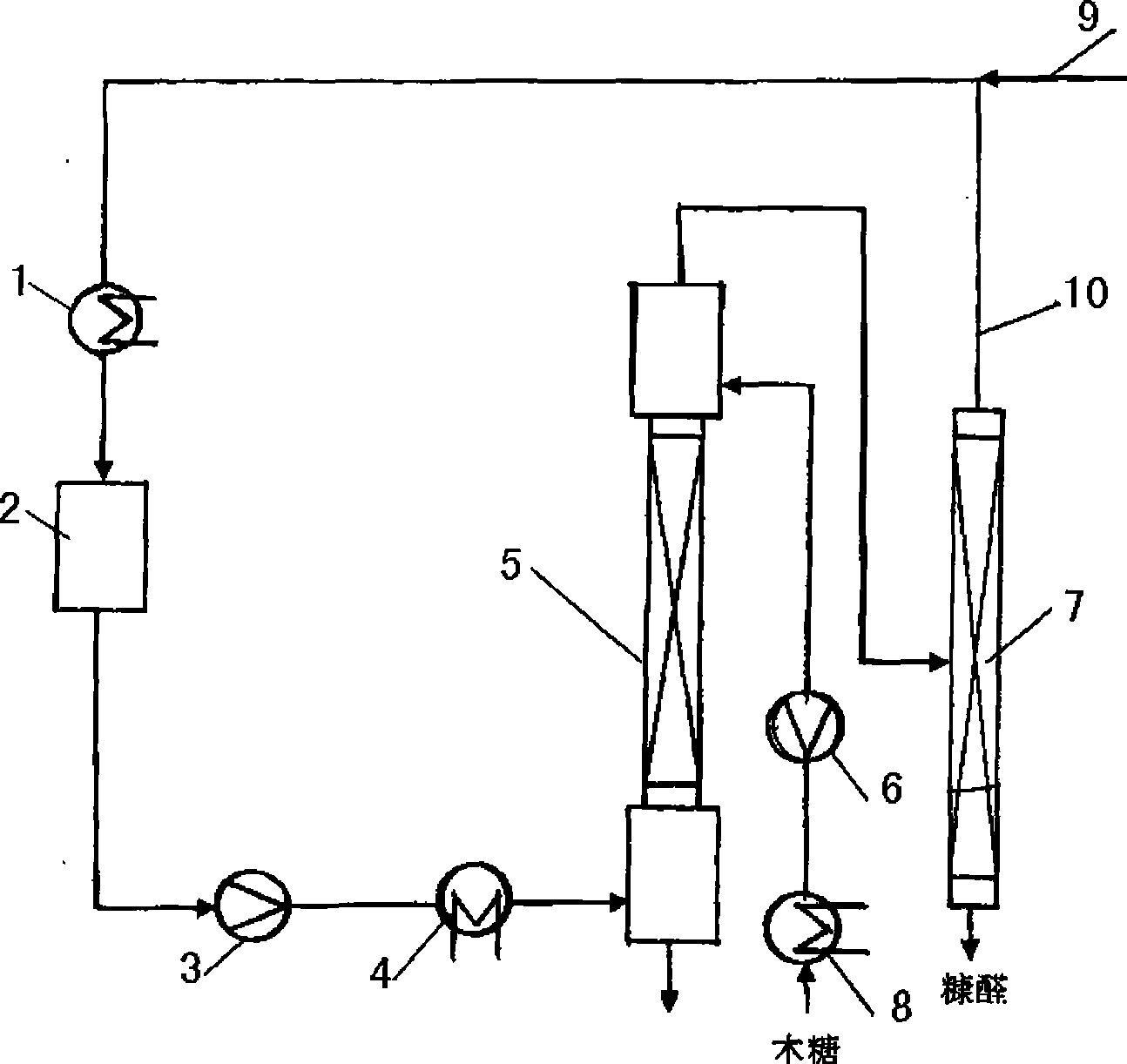

Solid acid catalysis and supercritical extraction coupled furfural preparation and apparatus

InactiveCN101486695AEasy to separateReduce pollutionOrganic chemistryMolecular sieve catalystsSolubilitySolid acid

The invention discloses a solid-acid catalysis and supercritical extraction coupling preparation method of furfural and a device thereof, pertaining to the technical field of the preparation of biobased chemicals. The method adopts solid acid as a catalyst, such as superacid or molecular sieve, and uses supercritical CO2 (SCCO2) for on-line extraction and separation of products. In the whole preparation process of the furfural, raw material aqueous phase and supercritical fluid phase successively enter a tower for realizing the countercurrent contact multiple-extraction which is carried out in a catalysis filling extracting tower. In the whole process, the solid acid is easily separated from the product, can be recycled and has little corrosion to equipment. Discharge amount of the three wastes is small and operation is convenient and safe. Furthermore, the SCCO2 has low cost, no toxicity, good diffusivity performance and easily controllable solubility, and such a defect as mass transmission efficiency reduction in a heterogeneous catalytic reaction after the use of the solid acid can be overcome when the SCCO2 is used for on-line extraction of the furfural, so as to immediately remove coking precursors from a catalyst pore passage, thereby deferring the inactivation of the catalyst, realizing green and clean production technology and wide application prospect.

Owner:TSINGHUA UNIV

High water content tolerant process for the production of polyethers

The present invention provides a process for the production of a polyether involving establishing oxyalkylation conditions in an oxyalkylation reactor in the presence of from about 5 ppm to about 1,000 ppm, based on the final polyether weight, of a double metal cyanide (DMC) catalyst, continuously introducing into the reactor at least one alkylene oxide and a low molecular weight starter having a number average molecular weight of less than about 300 Daltons (Da) containing from about 200 ppm to about 5,000 ppm water and acidified with from about 10 ppm to about 2,000 ppm of at least one of an inorganic protic mineral acid and an organic acid, and recovering a polyether product having a number average molecular weight of from about 200 Da to about 4,000 Da, wherein the ppm (parts per million) of water and acid are based on the weight of the low molecular weight starter. The inventive process may allow for the use of low molecular weight starters containing higher levels of water at lower DMC catalyst levels than current processes.

Owner:BAYER MATERIALSCIENCE AG

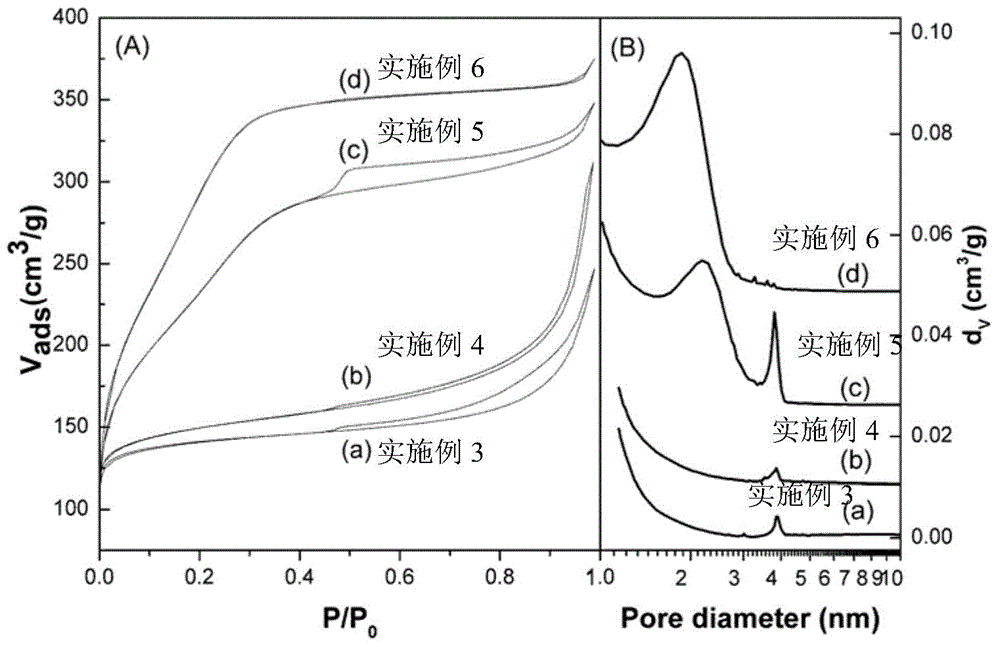

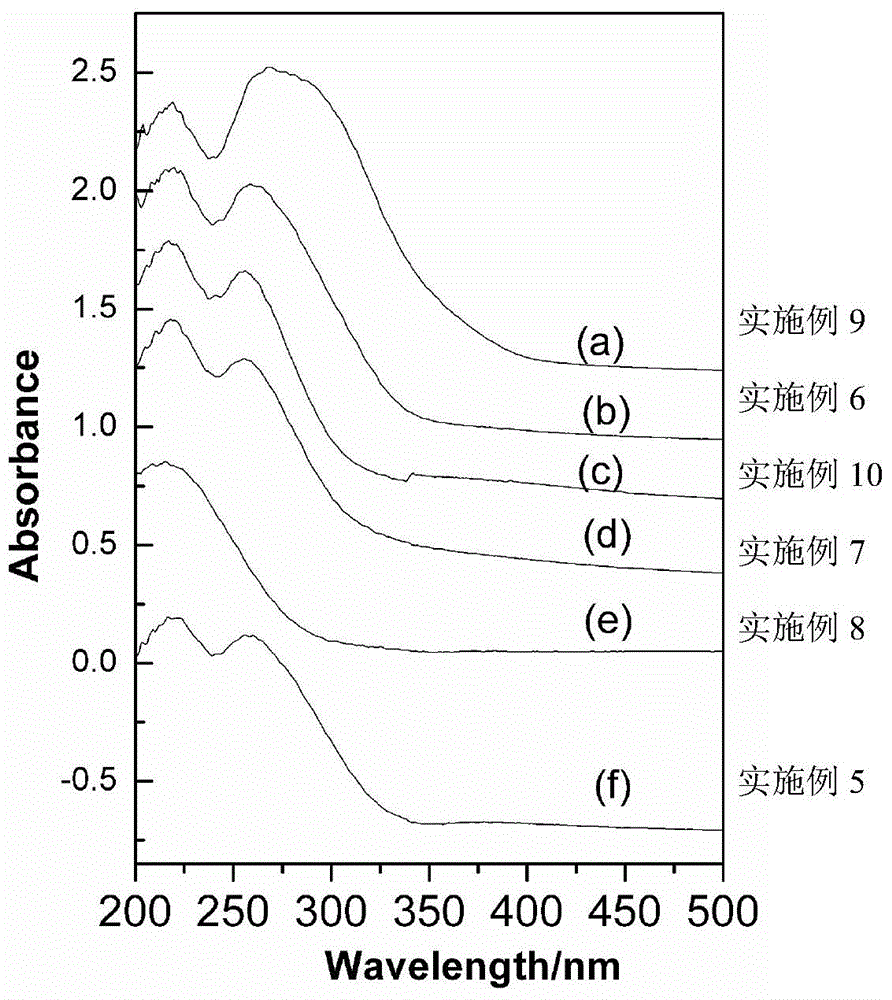

Lamellar catalyst containing mesoporous titanium-silicate molecular sieves and preparation method and application of lamellar catalyst

InactiveCN104437616AReduce inactivationExtend your lifeMolecular sieve catalystsOximes preparationMolecular sieveTitanium

The invention relates to a lamellar catalyst containing mesoporous titanium-silicate molecular sieves and a preparation method and application of the stratiform catalyst. The stratiform catalyst is provided with a 12-membered ring hole and sine reticulation hole system of an MWW high-silicon molecular sieve, wherein the interlayer is provided with a 2-10 nm mesoporous structure, 4-coordinated titanium or 4-coordinated and 6-coordinated titanium. The preparation method comprises the following steps: an MWW high-silicon molecular sieve containing a template agent serves as a precursor for swelling, then filtering, washing and drying are carried out, pillaring, filtering and drying are performed, then hydrolysis reaction is realized to form an inorganic wall and a mesoporous structure in the interlayer of the MWW high-silicon molecular sieve, re-filtering, re-washing and re-drying are carried out, and high-temperature calcination is carried out to obtain titanium-containing MCM-36 of a microporous-mesoporous composite structure. According to the invention, as a new silicone source and titanium source hybrid pillaring agent is used for pillaring to prepare the titanium-containing mesoporous pure titanium silicate molecular sieve, Bronsted acid site of boron or aluminium in the molecular sieve precursor is eliminated.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Non-mercury catalyst for production of vinyl chloride and preparation method thereof

InactiveCN102069000AAvoid pollutionEase of mass productionPhysical/chemical process catalystsPreparation by halogen halide additionBarium dichlorideCopper chloride

The invention discloses a non-mercury catalyst for the production of vinyl chloride and a preparation method thereof, belonging to the fields of chemical catalyst and the preparation thereof. The non-mercury catalyst of the invention uses cocoanut active charcoal as carrier and stannous chloride as main active substance, wherein the weight percentage of stannous chloride is 15%-30%; and at least one additive of barium chloride, zinc chloride and copper chloride is added and the total additive weight percentage is 0.5-2%. By using the non-mercury catalyst, the environmental pollution caused by the mercury-containing catalyst can be avoided; the large-scale production can be benefited, the conversion rate and selectivity of the catalyst can be increased, the yield of the product can be increased; by increasing the quality of the carrier, technical guarantee can be provided for the large-scale production device of vinyl chloride, the loss of the active matter can be slowed down, the service life of the catalyst can be prolonged; and the use efficiency of the catalyst can be increased by 500%.

Owner:YIBIN TIANYUAN GRP CO LTD

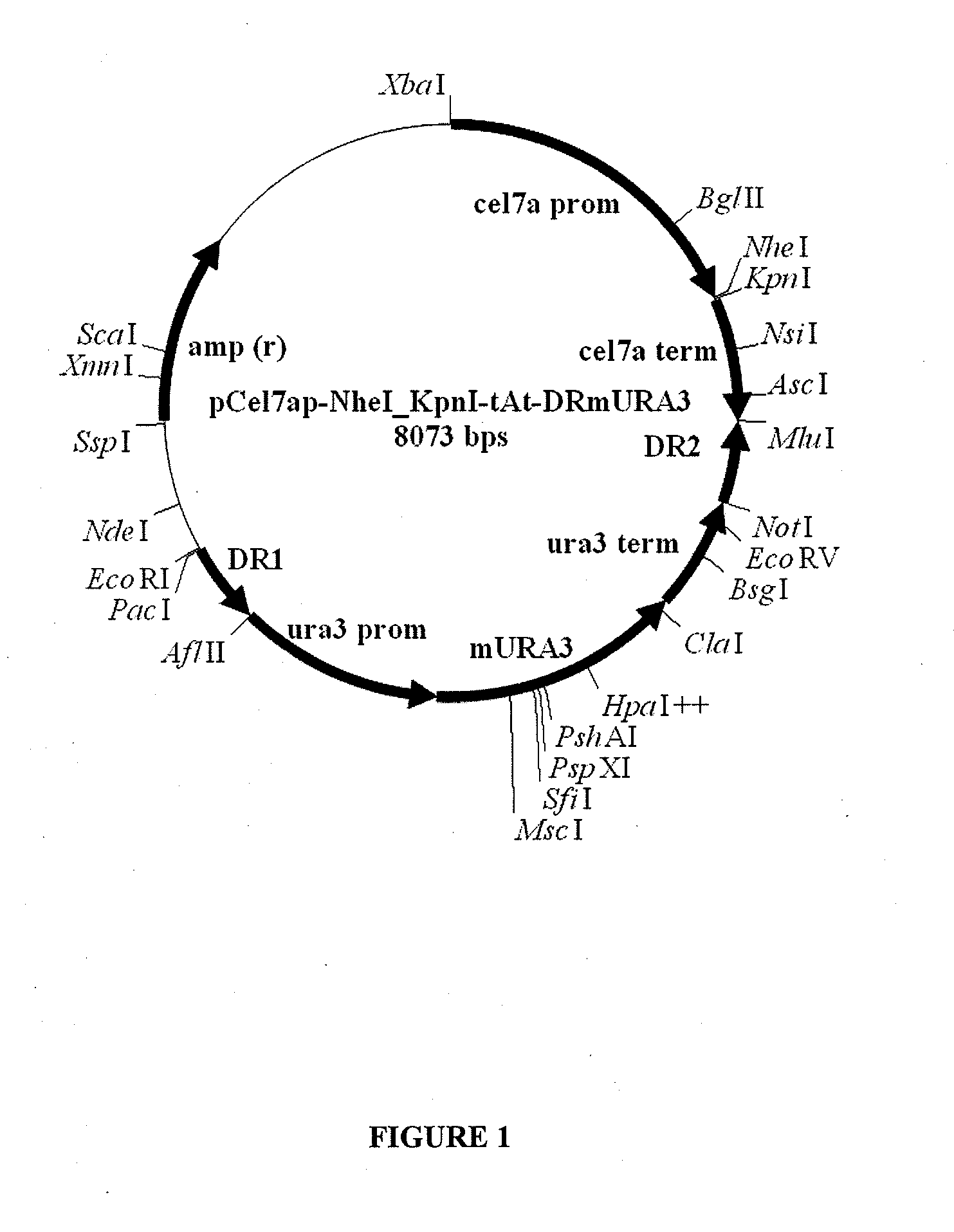

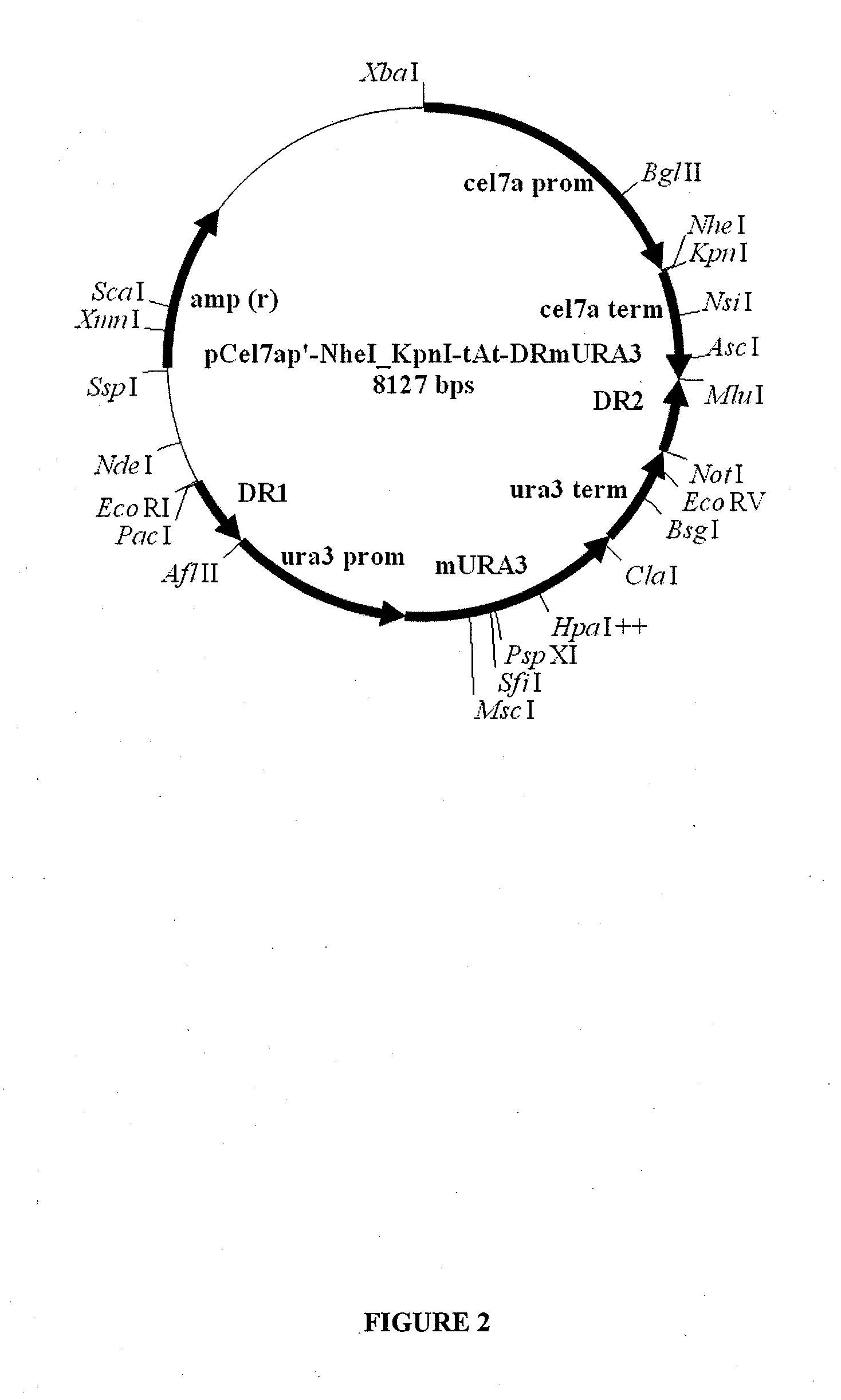

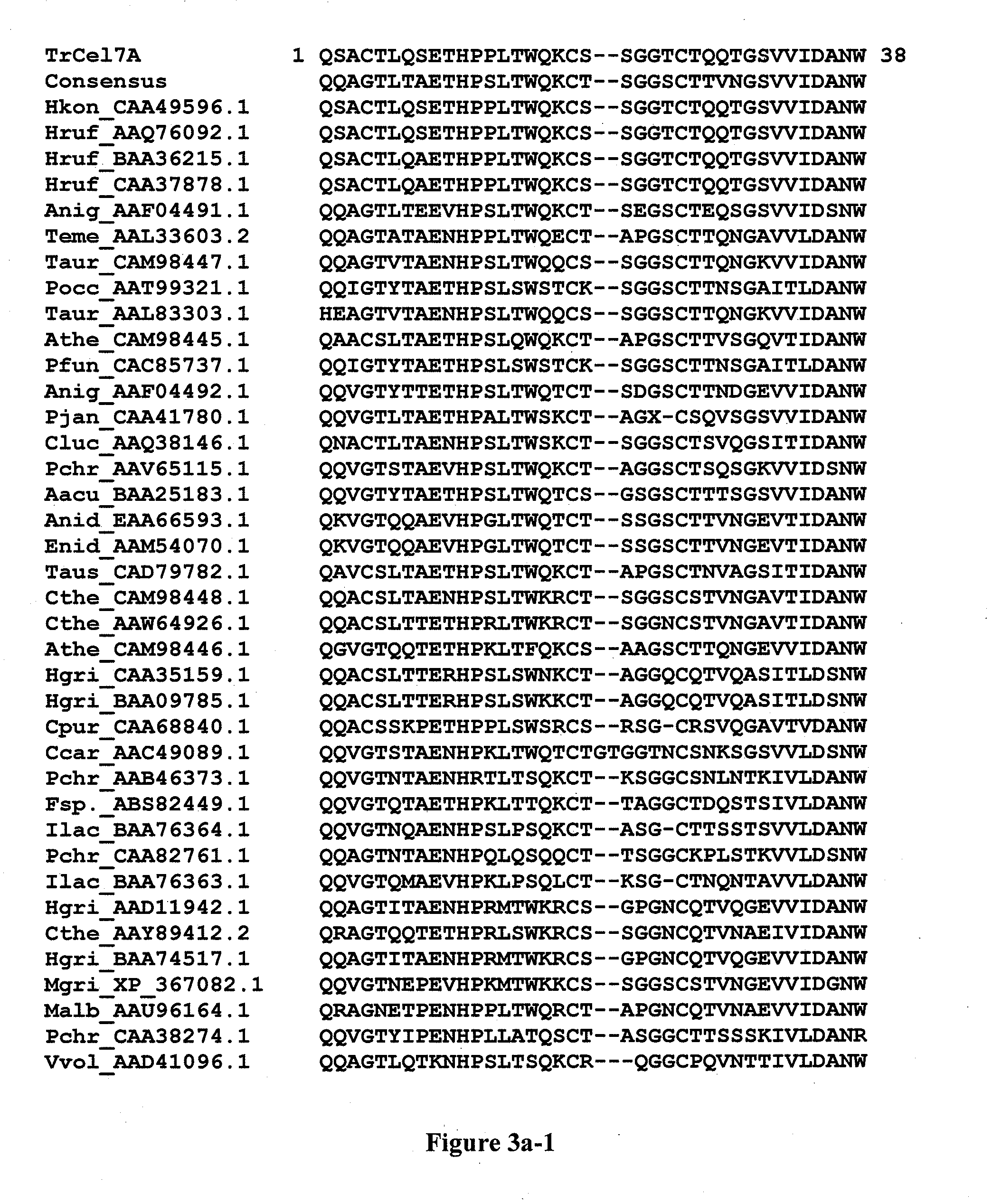

Novel cellobiohydrolase enzymes

Provided are isolated cellobiohydrolases comprising a modified Glycoside Hydrolase (GH) Family 7 catalytic domain, a GH Family 7 catalytic domain and a modified Family 1 carbohydrate binding module (CBM), or both a modified Family 7 catalytic domain and a modified Family 1 CBM. Such isolated cellobiohydrolases exhibit from 45% to about 99.9% amino acid sequence identity to amino acids 1-436 of SEQ ID NO: 1 or to amino acids 1-438 of SEQ ID NO: 2 and improved activity on process substrates. Also provided are genetic constructs and genetically modified microbes for expressing the isolated cellobiohydrolases, a process for producing the isolated cellobiohydrolases, cellulase enzyme mixtures comprising the isolated cellobiohydrolase and a process for hydrolysing a cellulosic substrate with such cellulase enzyme mixtures.

Owner:IOGEN ENERGY CORP

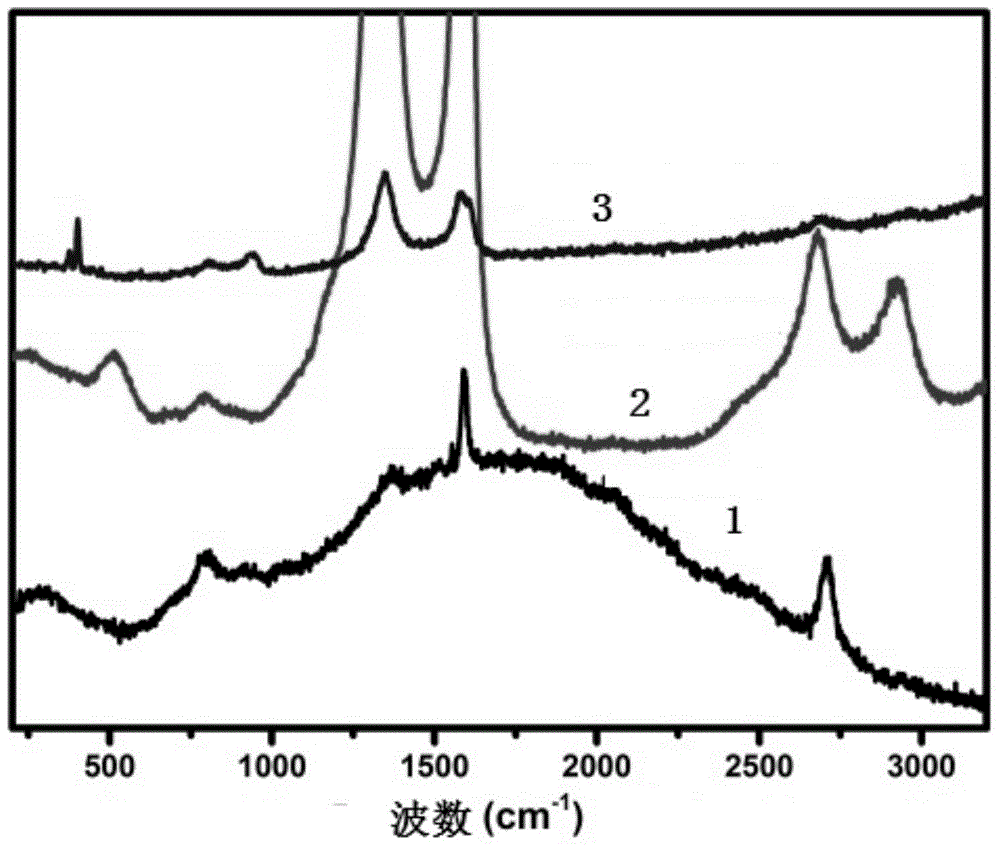

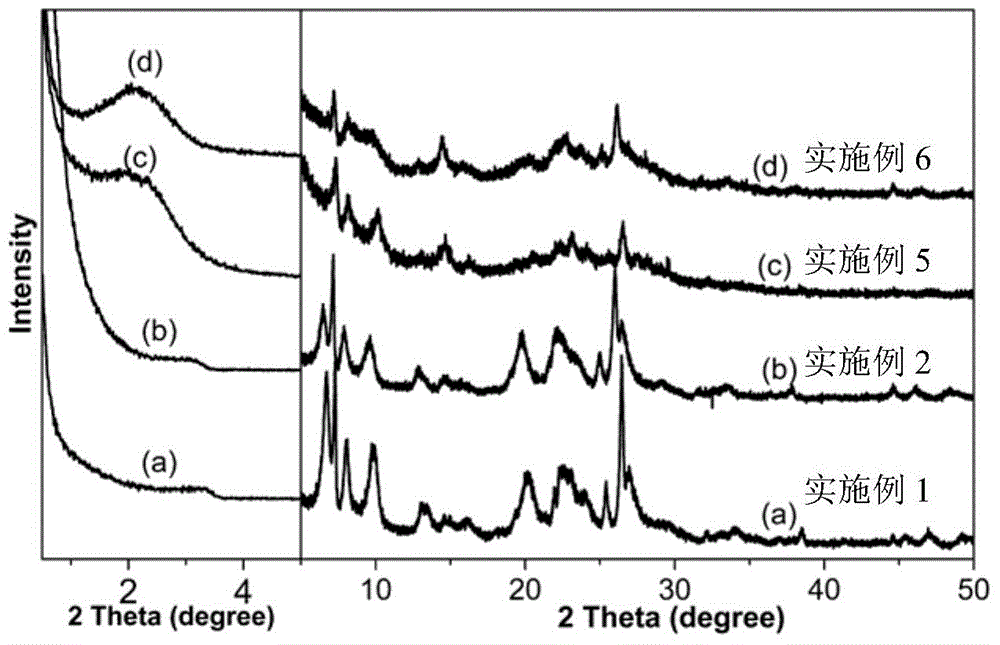

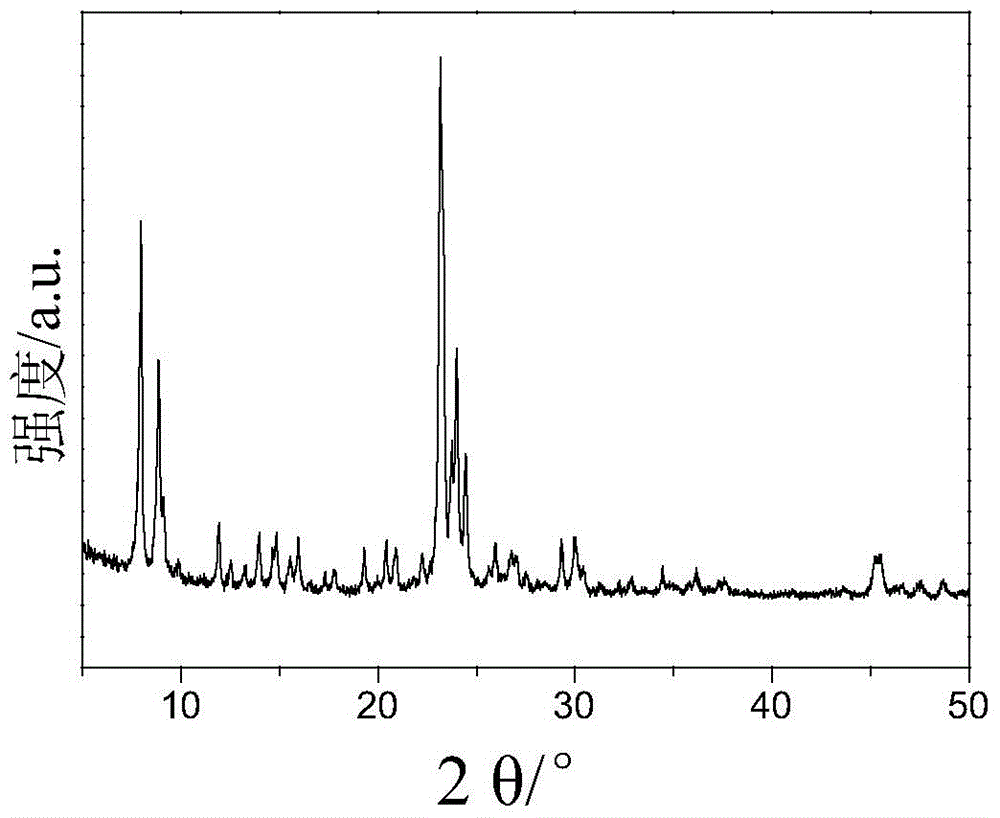

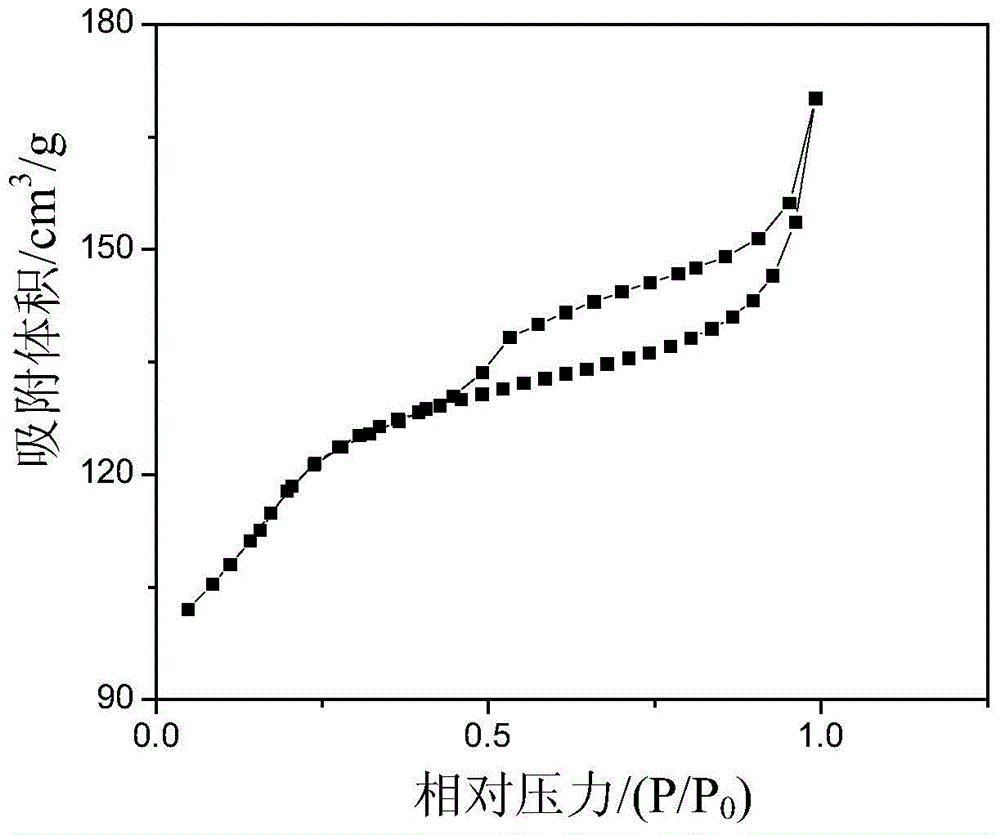

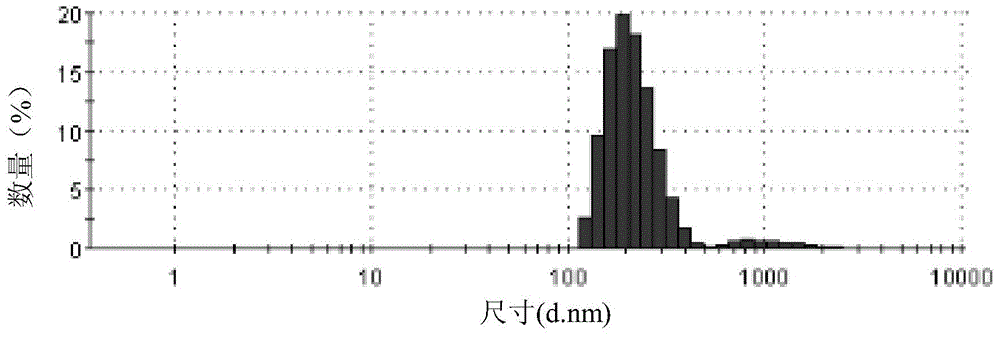

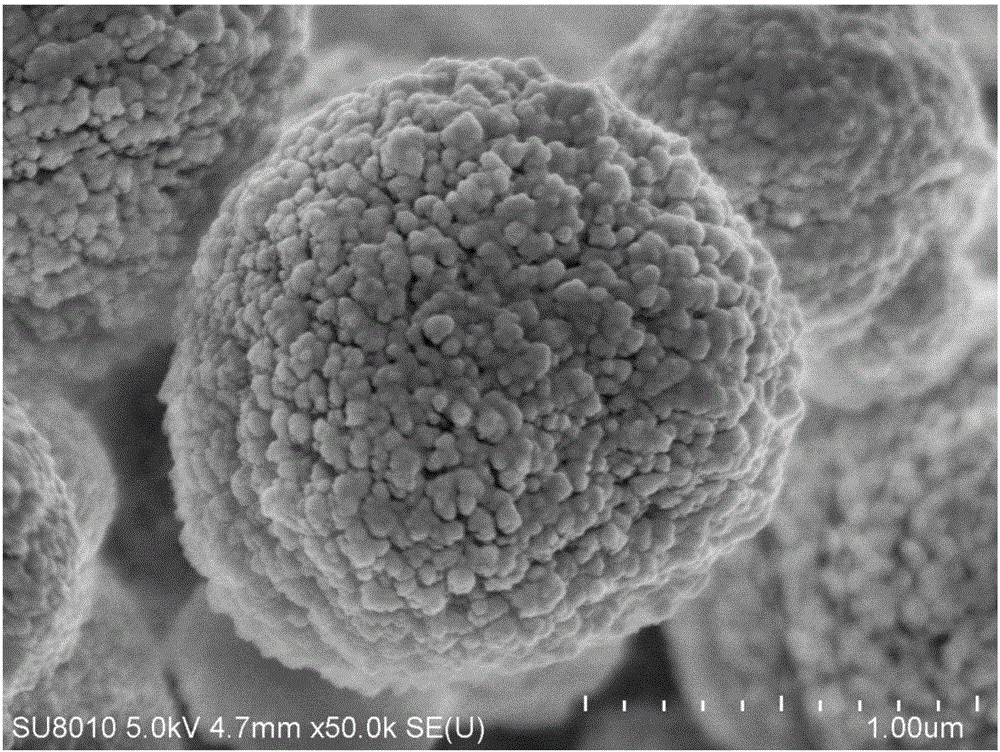

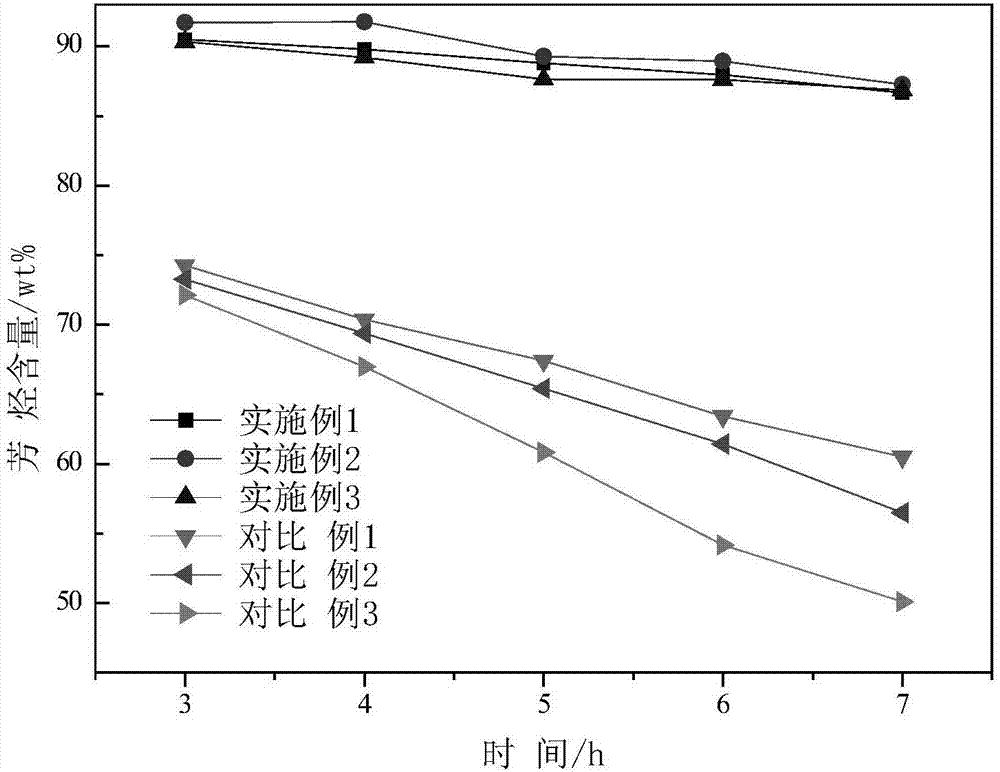

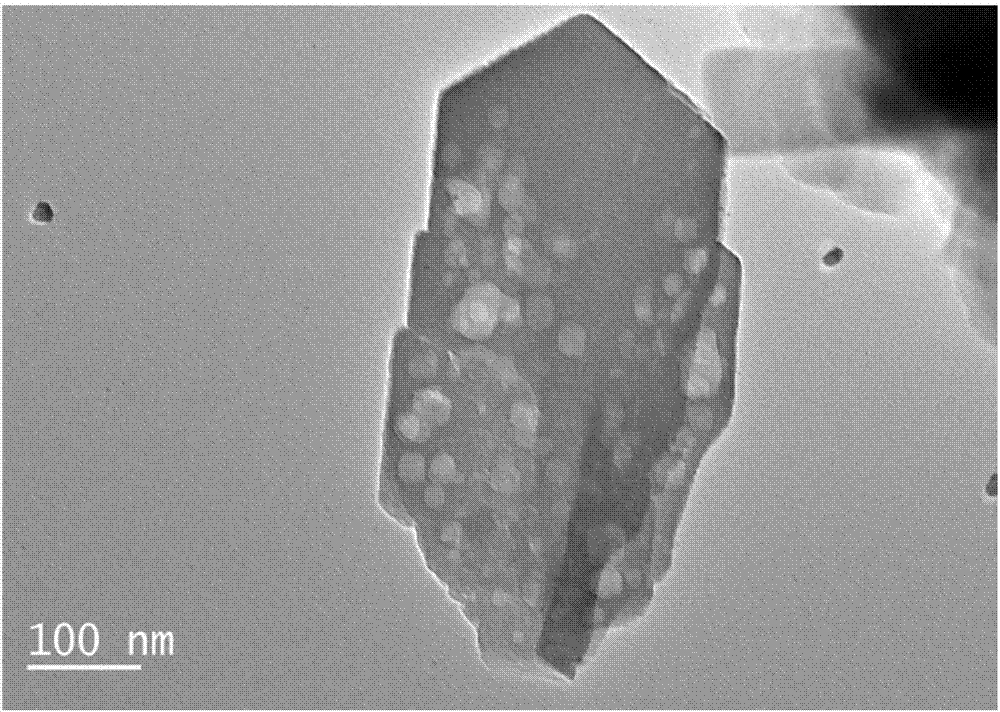

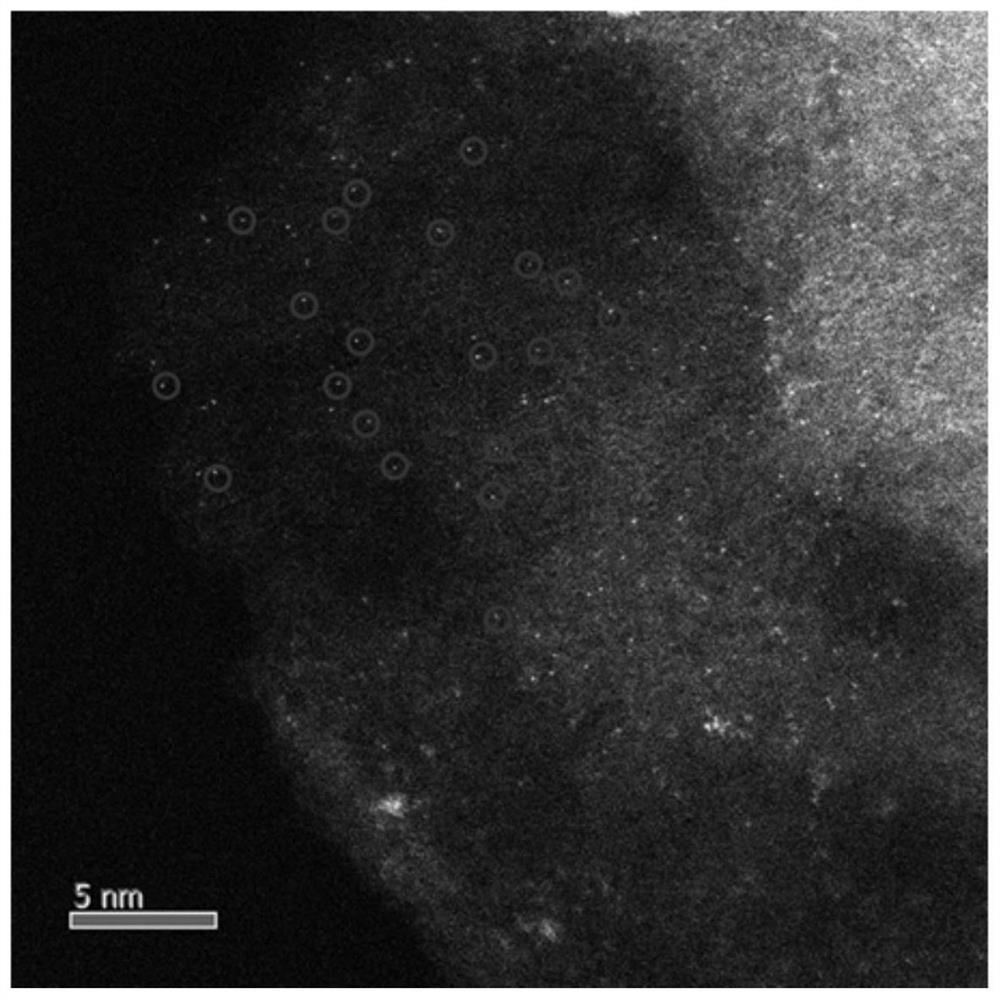

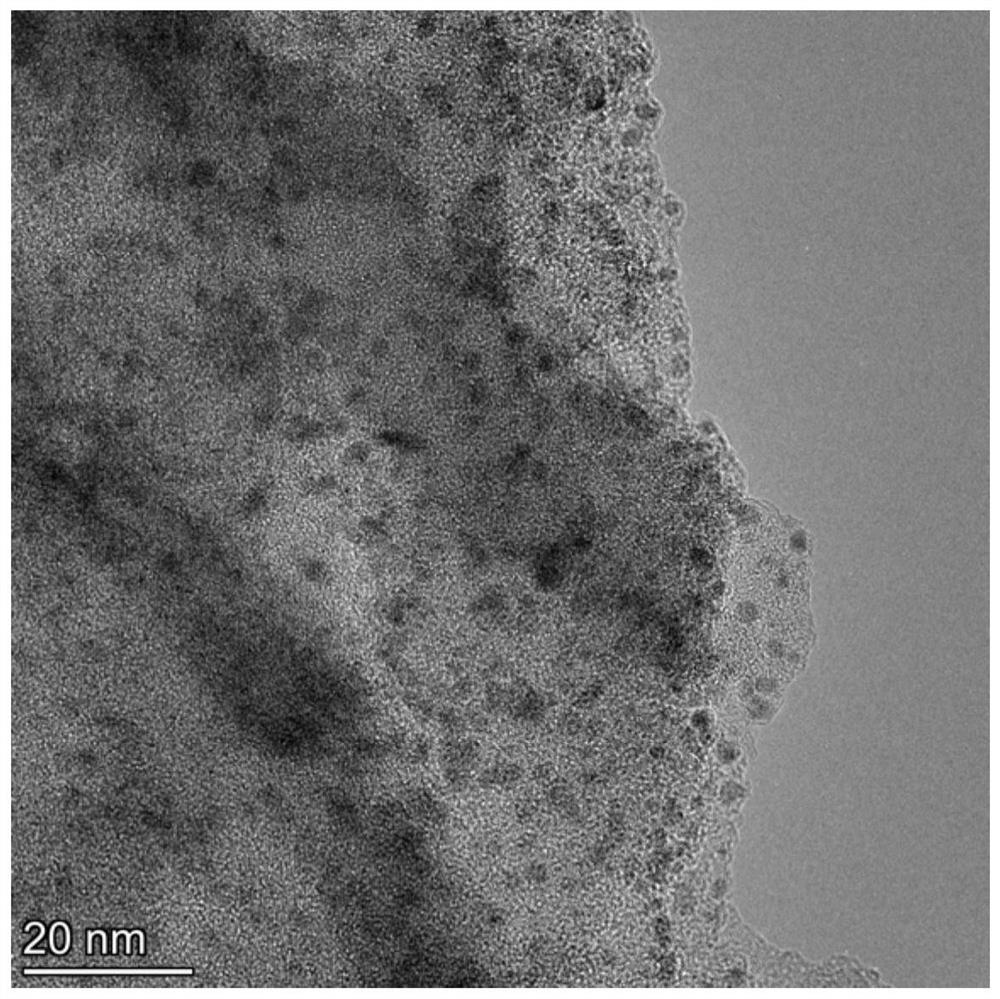

Nanocrystalline accumulation meso-microporous ZSM-5 catalyst and preparation and application

ActiveCN104525245APropylene selectivity is highLong catalyst lifeMaterial nanotechnologyMolecular sieve catalystsMolecular sieveCrystallite

The invention provides a nanocrystalline accumulation meso-microporous ZSM-5 catalyst and preparation and application thereof. The catalyst is aggregated by small grains with particle sizes of 20-100 nm to an aggregation state with a particle size of 200-2000 nm, the aggregation state forms the catalyst, the specific surface area of the catalyst is 350-420 m<2> / g, and the pore volume of the catalyst is 0.25-0.35 cm<3> / g. According to the invention, a mesoporous-microporous composite nanocrystalline accumulation state ZSM-5 molecular sieve is directly synthesized; under the condition of adding no second template, a solid silicon source is pretreated to generate different degrees of depolymerization, the material ratio of the synthesis system is further adjusted, a sodium salt is added to adjust the growth speed in a crystallization process of the molecular sieve, and meanwhile, a two-stage crystallization method is adopted to promote the generation of a crystal nucleus at a low temperature and promote the growth of a crystal at a high temperature, so as to synthesize a serial grain aggregation state ZSM-5 molecular sieve.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for preparing 5-hydroxymethyl furfural from fructose source biomass

InactiveCN101434589AReduce inactivationImprove conversion and yieldOrganic chemistryFermentationBiomassChemistry

The invention relates to a method for preparing 5-hydroxymethyl furfural (HMF), an important platform compound, by directly using a fructose source biomass. The method for preparing the HMF is mainly divided into two steps: firstly, a monosaccharide solution is obtained by the transformation of polysaccharide in the fructose source biomass; under the condition that catalysts such as protonic acid, cation exchange resin, zeolite, Lewis acid and the like are added in a system of an aqueous-organic phase to exchange, a salt for salting out and stabilizing the HMF is added in the aqueous phase and the HMF is prepared by heating at proper temperature.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

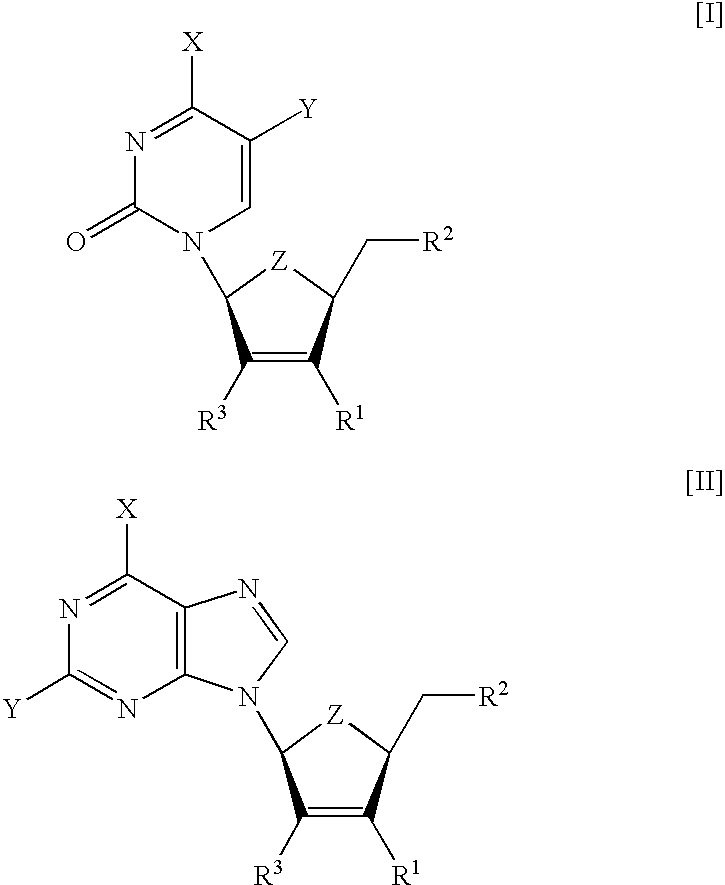

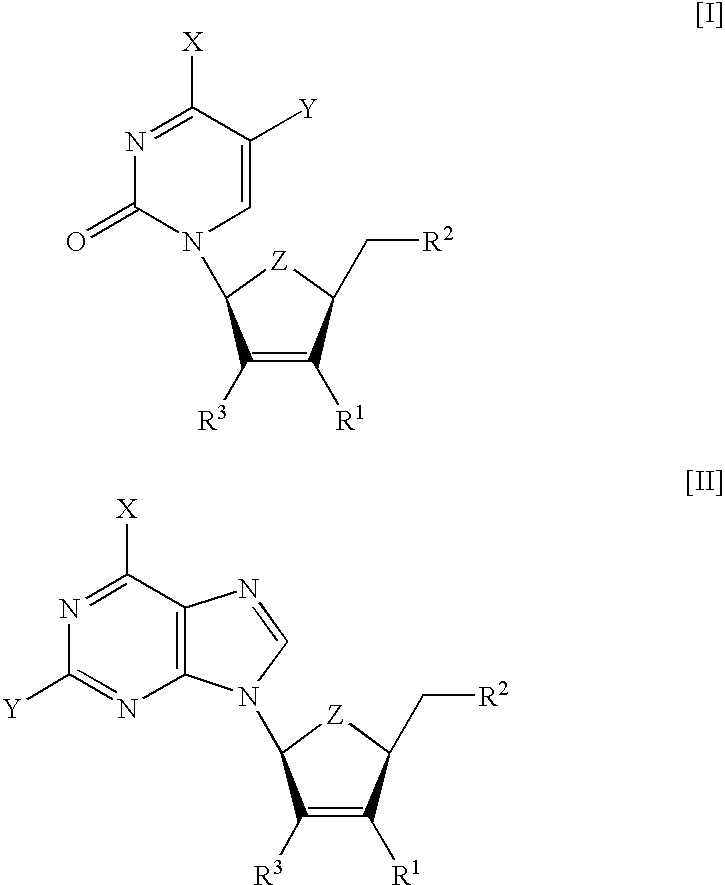

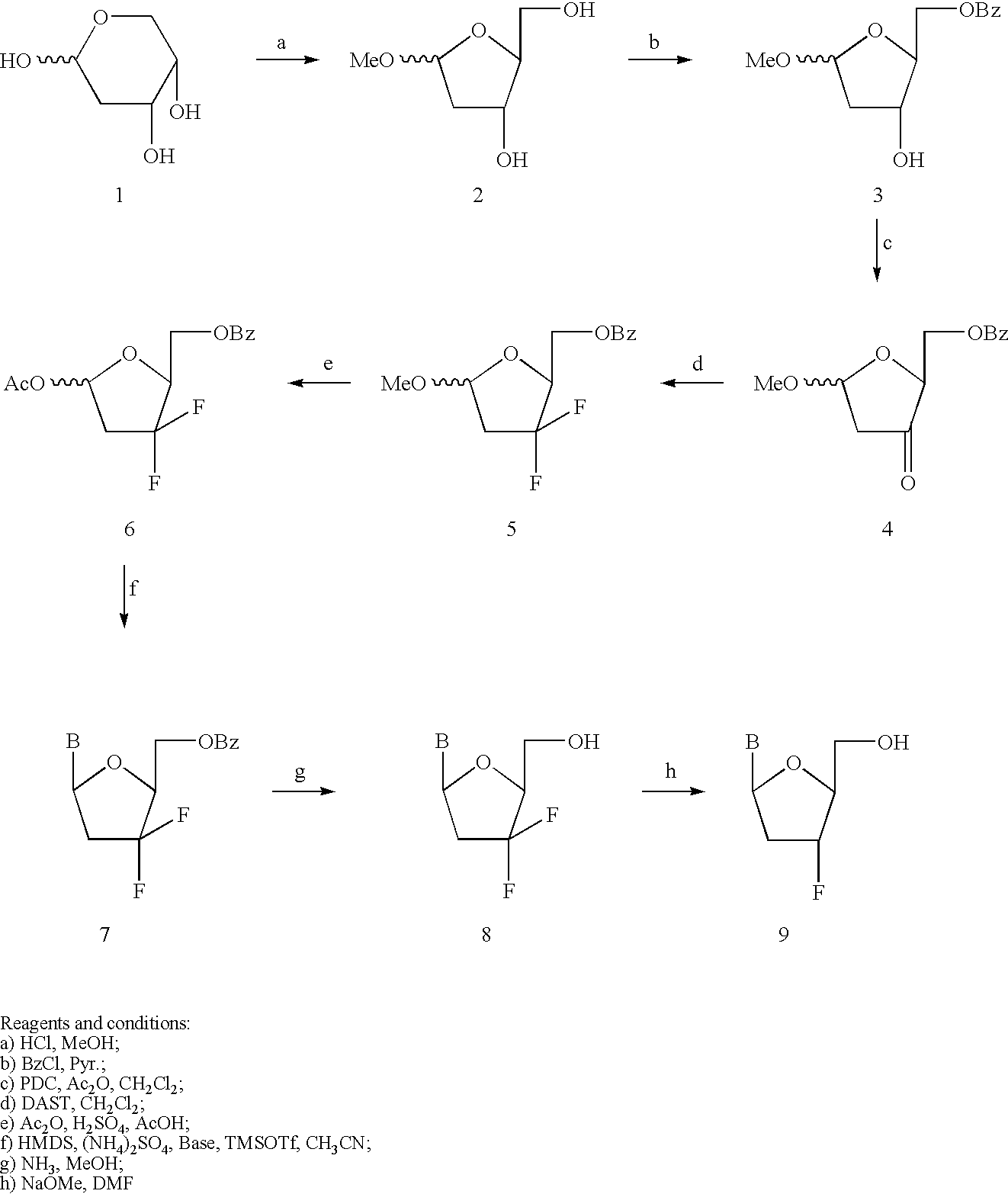

Modified nucleosides as antiviral agents

InactiveUS20040157793A1Improve bioavailabilityImprove stabilityBiocideSugar derivativesAntiviral drugViral disease

Owner:UNIV OF GEORGIA RES FOUND INC +1

Devices And Processes For Deasphalting And/Or Reducing Metals In A Crude Oil With A Desalter Unit

ActiveUS20100089797A1Easy to processReduce dirtDewatering/demulsification with chemical meansDewatering/demulsification with mechanical meansDesalterWater soluble

This invention relates to devices and processes for removing asphaltenes and / or metals from crude oil to increase refinery processing of heavy materials. The desalters of this invention reduce and / or remove at least a portion of asphaltenes and / or metals form the crude oil. The separation occurs by mixing water with the crude oil to result in an aqueous phase having water and water soluble salts, an interface phase having asphaltenes and / or metals along with water, and a hydrocarbon phase having desalted, deasphalted and / or reduced metal crude oil.

Owner:BP CORP NORTH AMERICA INC

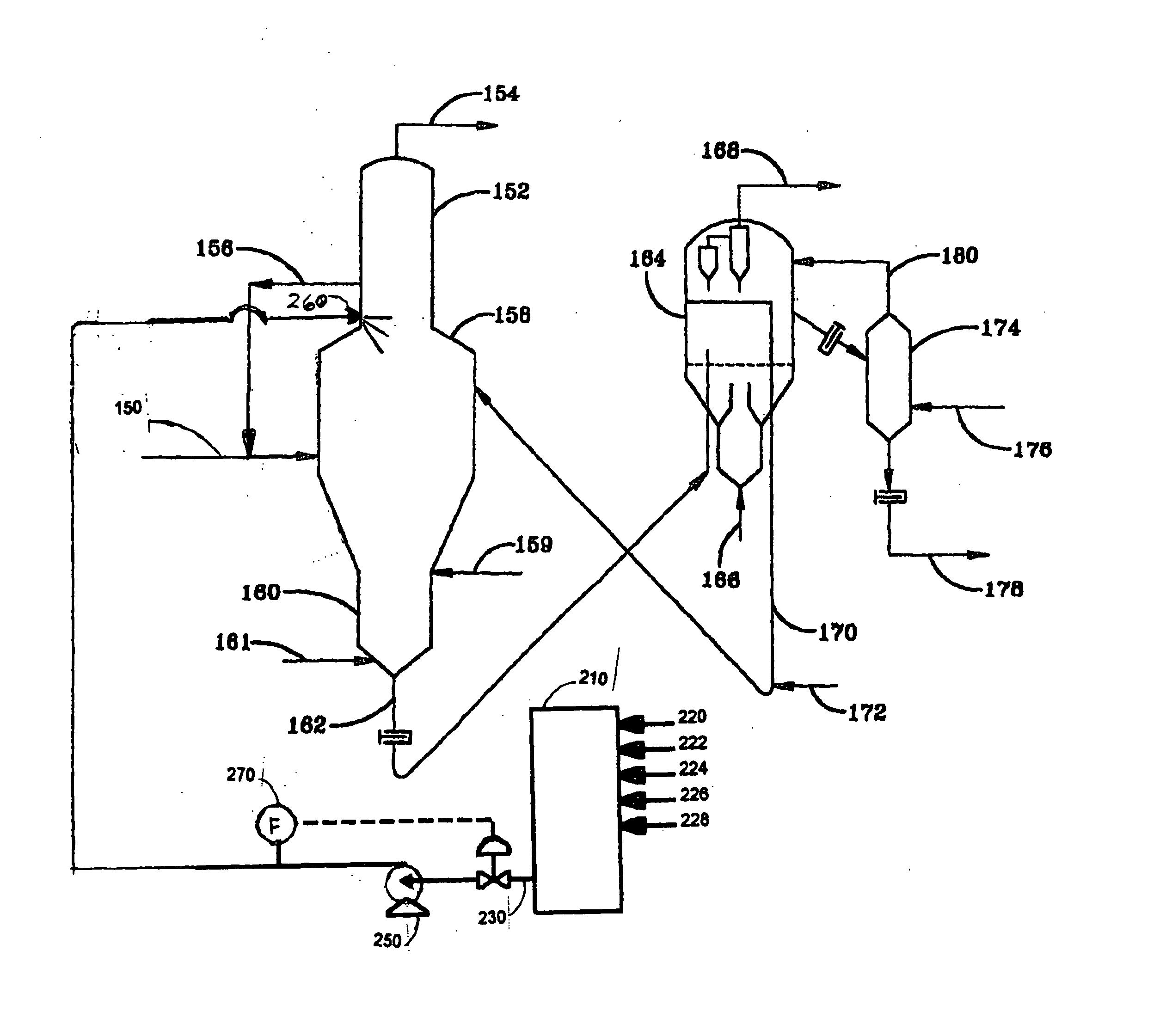

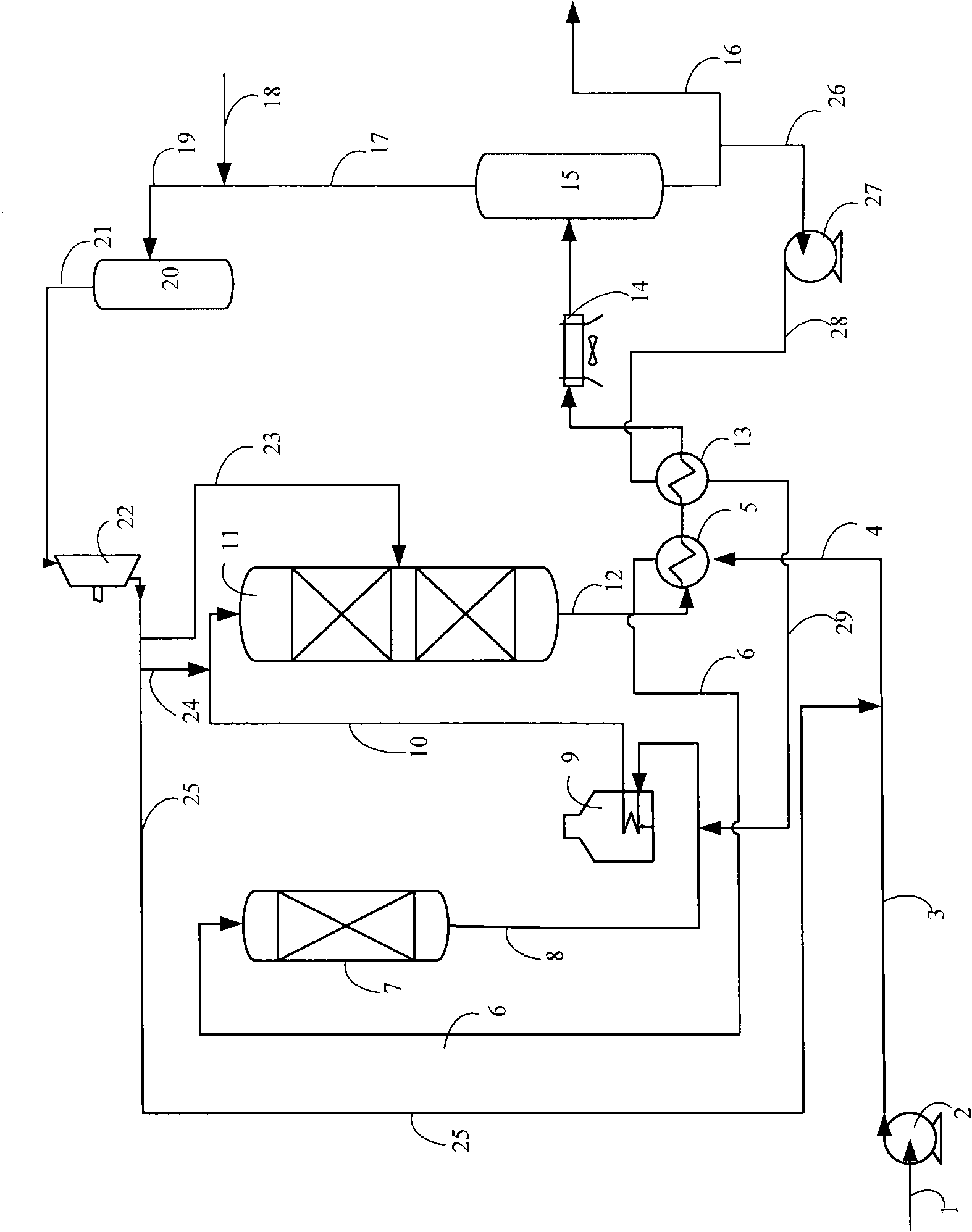

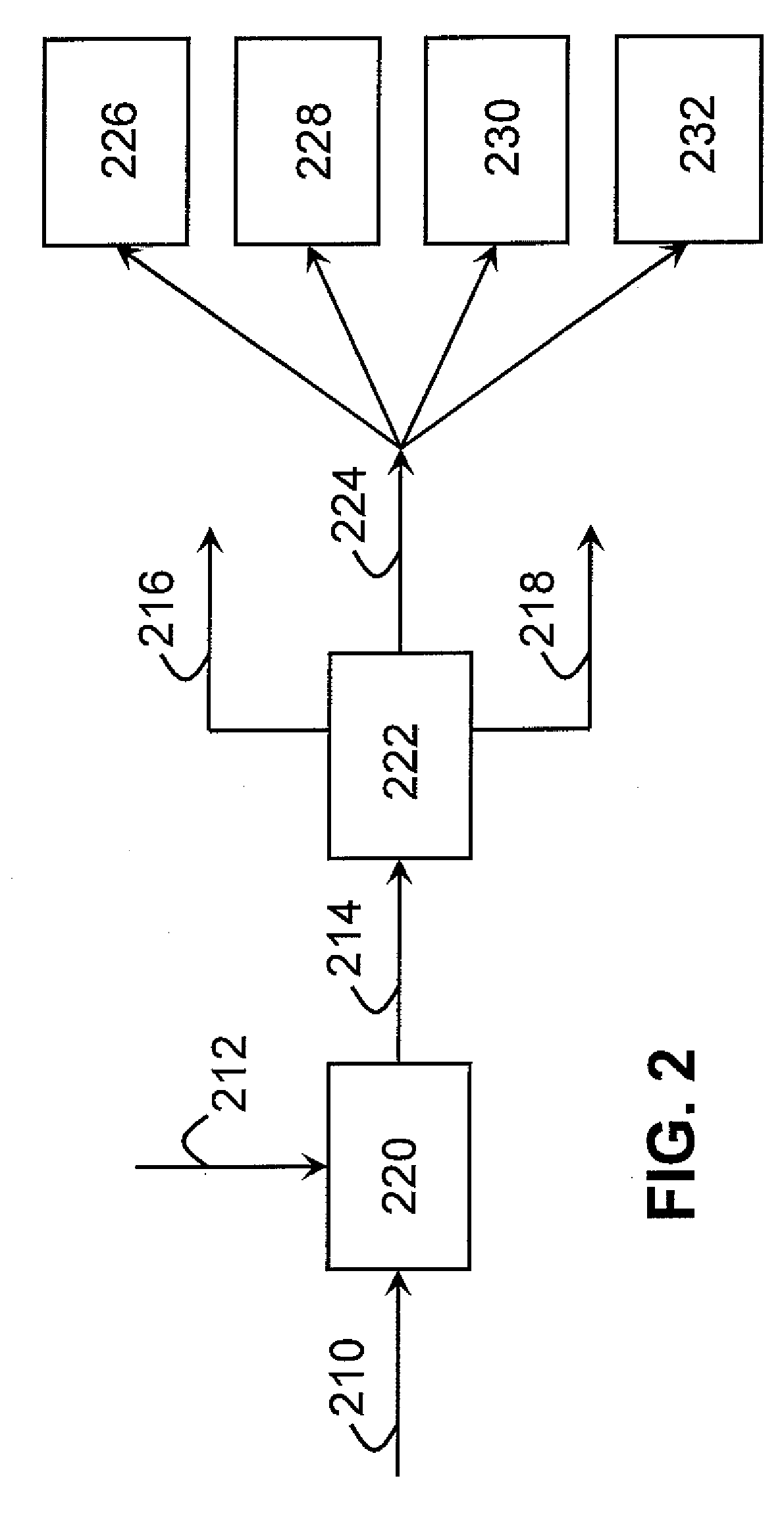

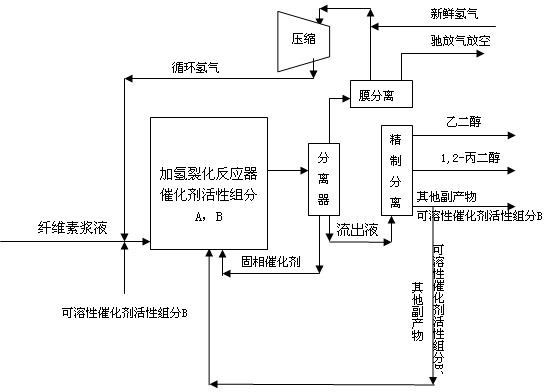

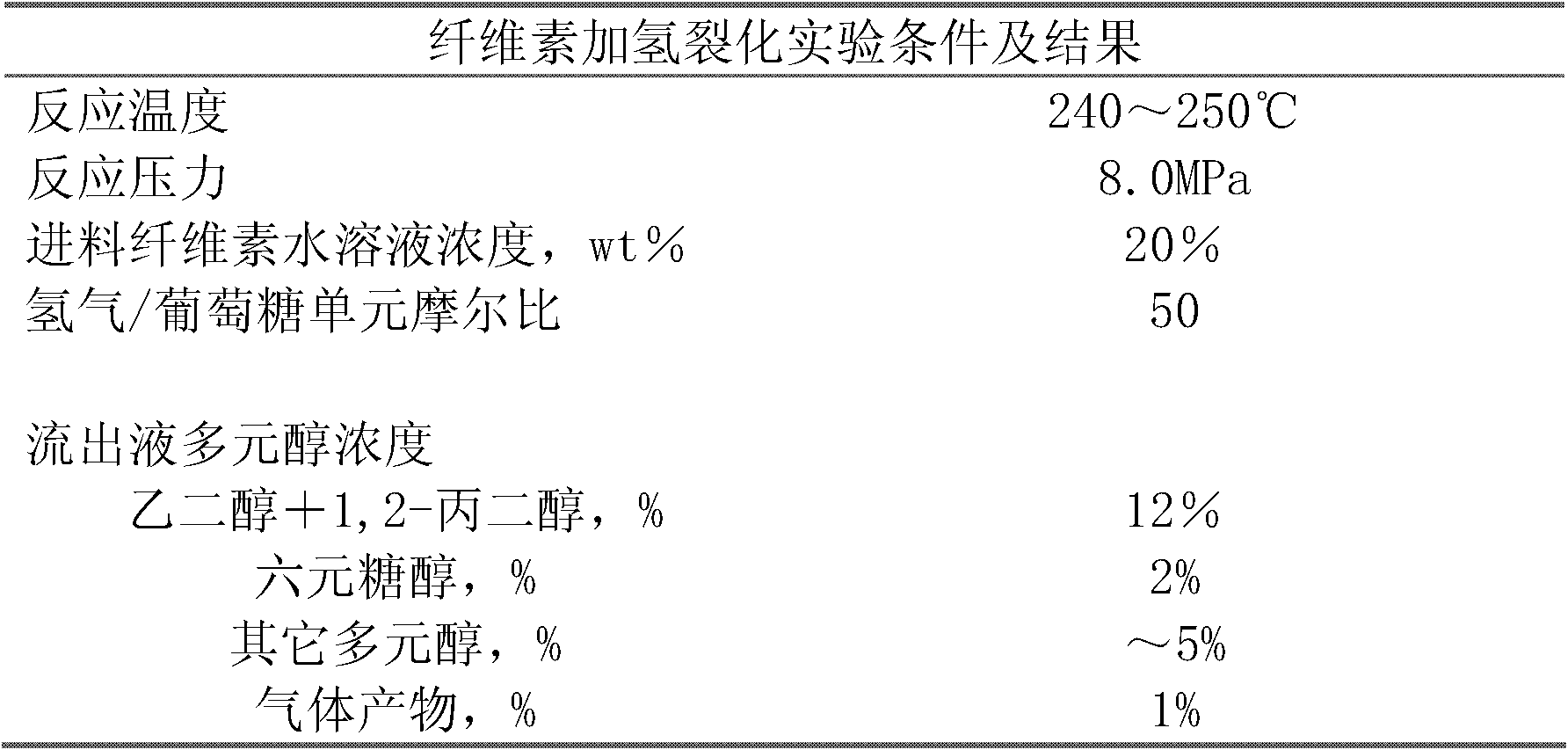

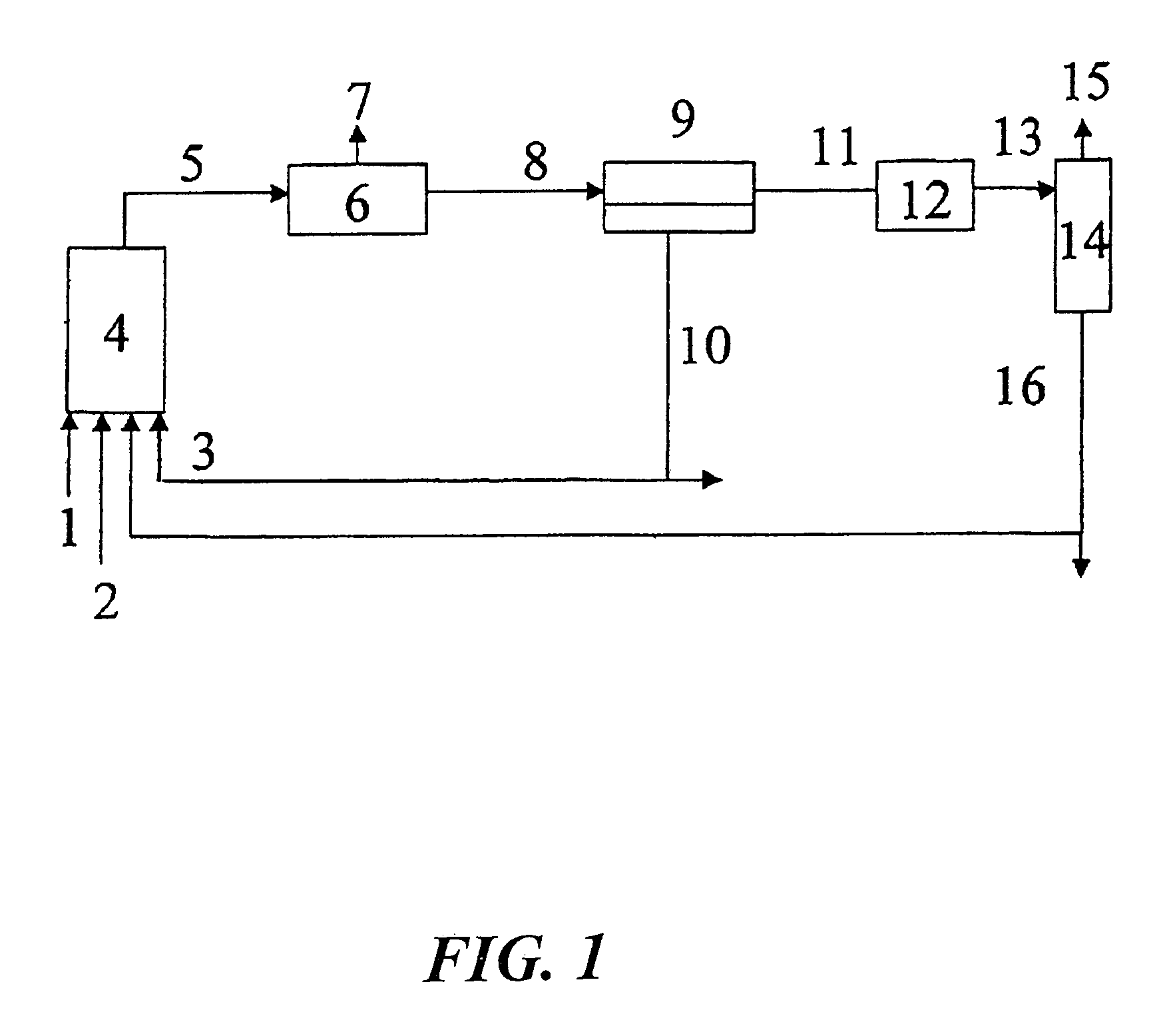

Method for producing ethylene glycol and 1,2-propylene glycol by continuously hydrocracking cellulose

ActiveCN102643164ARealize continuous inputReduce consumptionOrganic compound preparationPreparation by OH group eliminationCelluloseHydrogen

The invention provides a method for producing ethylene glycol and 1,2-propylene glycol by continuously hydrocracking cellulose and particularly relates to a continuous reaction technological process for producing ethylene glycol and 1,2-propylene glycol by virtue of transformation of semi-homogeneous catalyzed and hydrocracked cellulose. In the technological process, the cellulose is hydrocracked in the presence of a catalyst in a reactor and then enters into a separation system; hydrogen in a gas phase is recycled by separation and recovery; a liquid-phase product part is refluxed to the reactor, the other liquid-phase products are refined so as to separate out glycol, propylene glycol and other polyatomic; and the concentrated soluble catalyst component existing in the refined and separated residual heavy component liquid phase can be partially circulated to the reactor.

Owner:中科柏易金(郑州)新能源科技有限责任公司

Catalyst for coal tar hydrogenation modification and its preparation method and use

InactiveCN101507929AHigh asphaltenesReduce carbon depositionMolecular sieve catalystsRefining to eliminate hetero atomsActive componentHydrogenation reaction

The invention discloses a catalyst for hydrogenation modification of coal tar and a preparation method thereof and the application thereof. The catalyst consists of a mixture of active components of WO3, NiO and P2O5 and a catalyst carrier, wherein the weight of WO3 is 27 to 30 percent of the total weight of the catalyst, the weight of NiO is 4 to 7 percent of the total weight of the catalyst, the weight of P2O5 is 2 to 3 percent of the total weight of the catalyst, and the balance being the catalyst carrier; the catalyst carrier consists of aluminum oxide and a ZSM-5 molecular sieve, of which the weight ratio is between 8-13:1; and the specific surface area of the catalyst is 210 to 230m / g, and the pore volume is 0.44 to 0.48ml / g. the catalyst has proper acid center, better water resistance and bigger specific surface, pore volume and pore size, and can reduce the carbon deposit and inactivation of the catalyst and the plugging of a bed. In the hydrogenation reaction, the proper acid center and active center can maximally make the arene saturated and ring opening under the condition of reducing the broken chain as far as possible, and the cetane number of the diesel oil component is increased, so that the catalyst possesses of good selectivity, stability and mechanical strength.

Owner:FUSHUN XINRUI CATALYST +1

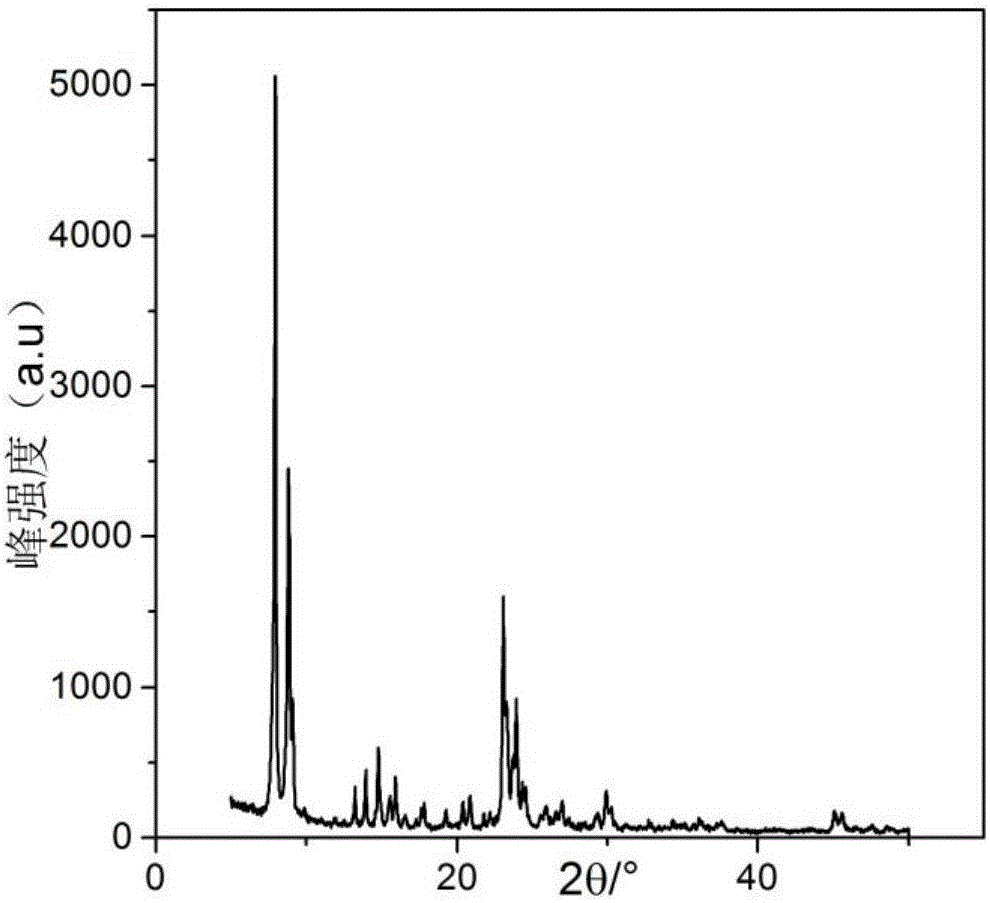

Multilevel structure ZSM-5 zeolite molecular sieve, as well as synthetic method and application thereof

ActiveCN106673008AImprove diffusion abilityHigh catalytic activityMolecular sieve catalystsOrganic compound preparationMolecular sieveSide reaction

The invention relates to a synthesized multilevel structure ZSM-5 zeolite molecular sieve with intracrystalline meso pores and intercrystalline meso pores, as well as a synthetic method and an application thereof. Except micropores of the zeolite structure, the multilevel structure ZSM-5 zeolite molecular sieve comprises the intracrystalline mesoporous and intercrystalline mesoporous structure, wherein primary nanometer crystal grain size is 40-500nm, and secondary accumulated particle size is 500nm-5[mu]m. The structure greatly improves diffusion performance and the catalyst activity of the molecular sieve, reduces possibility of generation of side reaction and carbon deposit, improves carbon accommodating capability of the molecular sieve catalyst, and prolongs life of the catalyst.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

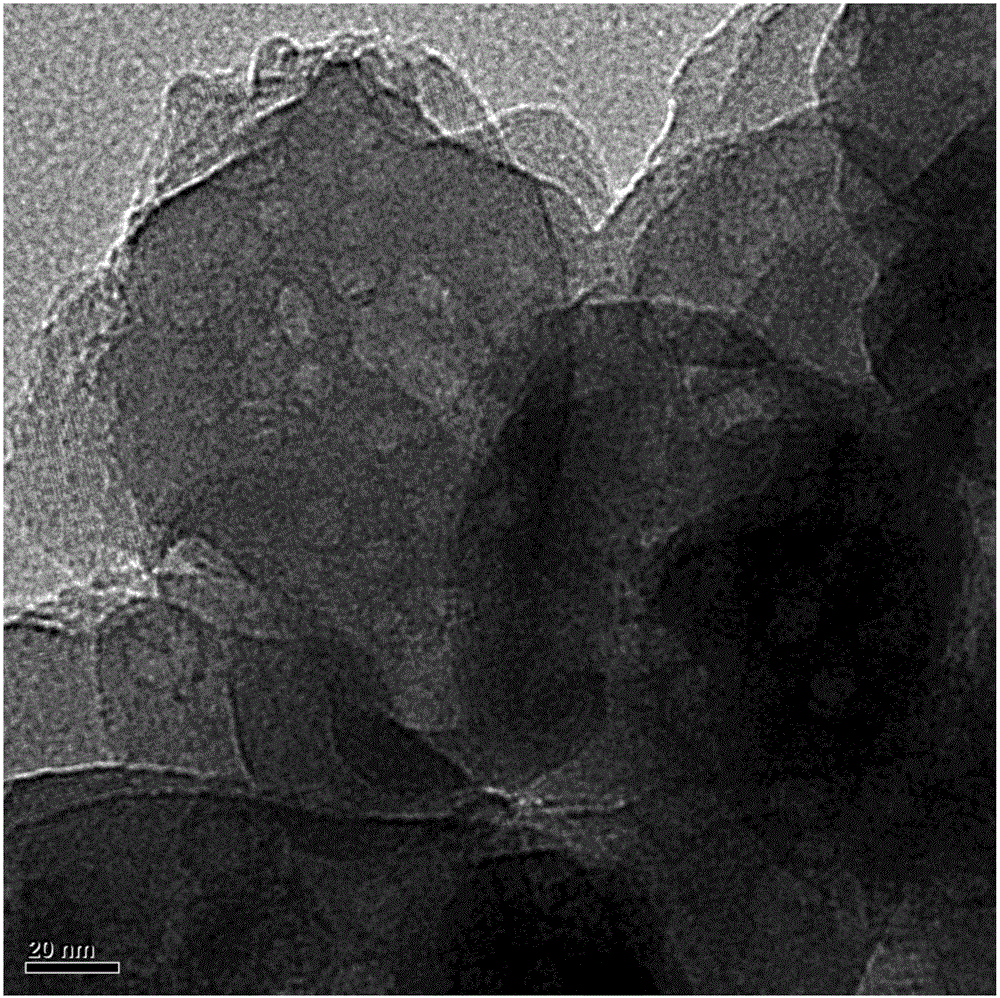

Alkali-modified ZSM-5 molecular sieve, preparation method and application thereof

InactiveCN107876082AReduced Diffusion ResistanceExtend your lifeMolecular sieve catalystsHydrocarbonsAromatizationOrganic chemistry

The invention relates to a preparation method of an alkali-modified ZSM-5 molecular sieve, which includes the steps of: mixing ZSM-5 molecular sieve with an alkali solution, performing a reaction andperforming post-treatment, wherein the reaction is carried out at 150-200 DEG C. The invention also relates to an application of the alkali-modified ZSM-5 molecular sieve in an aromatization reactionof hexene. The alkali-modified ZSM-5 molecular sieve is low in micropore ratio, wherein the micropores are enlarged into the range of mesopores and macropores (5-110 nm); the molecular sieve also is higher in crystalline degree, can effectively delay deactivation due to coking, thus increasing service life of a catalyst; without damage on the appearance of the ZSM-5 molecular sieve, grain size canbe controlled and acidity of the ZSM-5 molecular sieve can be regulated; in addition, pore structure in the molecular sieve is regulated, so that catalytic performance and service life of the catalyst are improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

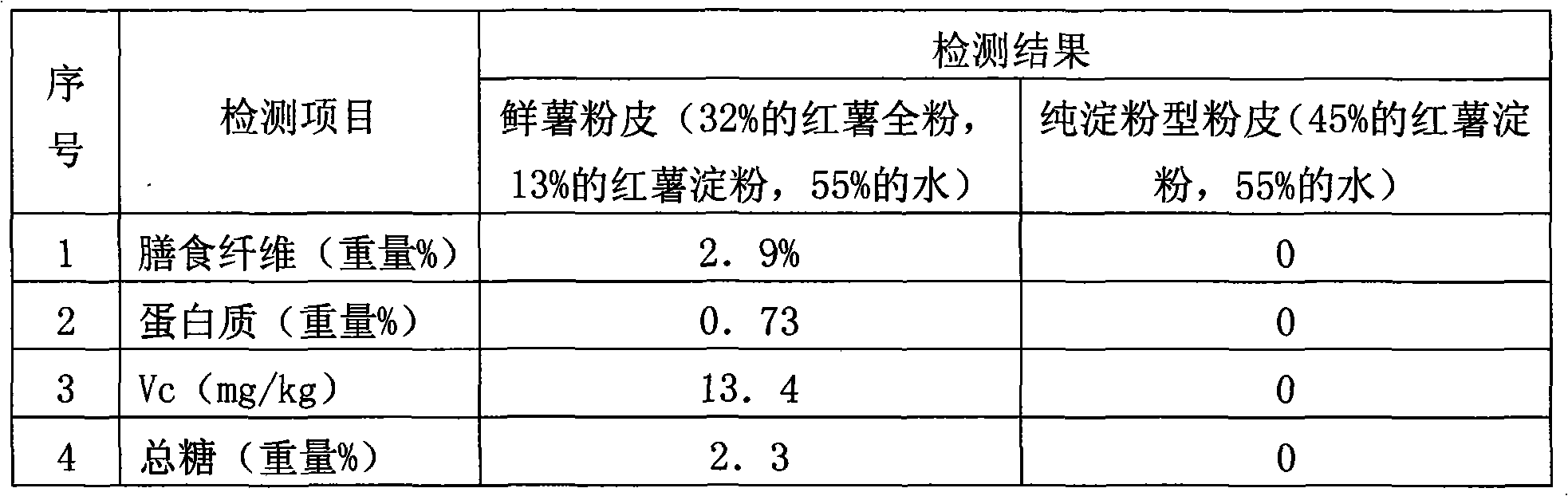

Processing method of sweet potato sheet jelly

A processing method of sweet potato sheet jelly, comprising the following steps of cleaning raw material sweet potatoes by water, and then continuously conveying the sweet potatoes to a crusher for crushing into sweet potato slurry with the particle size smaller than 3mm, weighing the sweet potato slurry, sweet potato graham flour or / and sweet potato starch in a weight ratio of the sweet potato slurry, the sweet potato graham flour or / and the sweet potato starch, which is 1: 0-100, adding water, mixing uniformly to prepare mixed slurry, wherein the water is added so that the water content in the mixed slurry is 48-65% by weight percentage, sending the mixed slurry to a spiral extrusion molding machine for curing and molding to form the sheet jelly, conveying the sheet jelly by a continuous conveyer, automatically cutting the sheet jelly according to a fixed length, and packing through an automatic packing machine or a vacuum packing machine so as to prepare the sheet jelly product. The invention uses mechanical continuous production and has a simple processing technology. The prepared sweet potato sheet jelly product maintains the nutrient components in the sweet potatoes and the active components capable of improving human immunity, and is excellent green health food.

Owner:SICHUAN GUANGYOU SWEET POTATO & FOOD PROD CO LTD

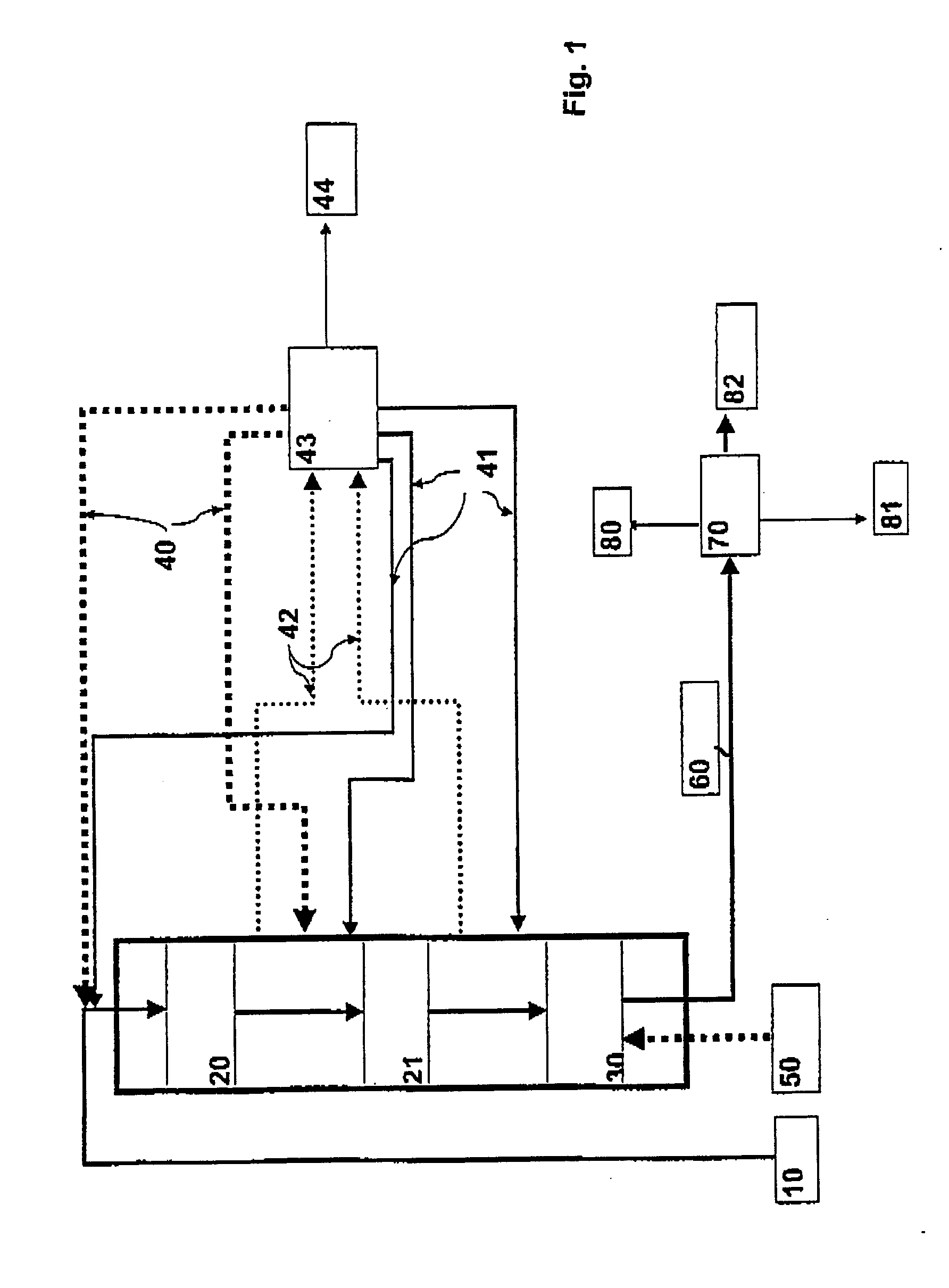

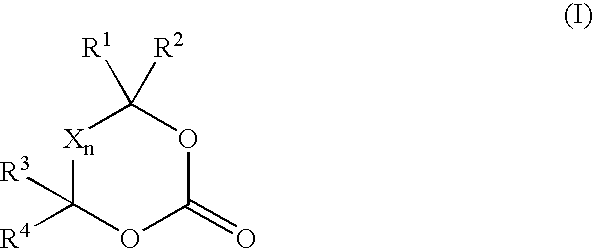

Method for producing aldehydes by means of hydroformylation of olefinically unsaturated compounds, said hydroformylation being catalyzed by unmodified metal complexes in the presence of cyclic carbonic acid esters

ActiveUS7193116B2Reduce catalyst deactivationSpeed up the processPreparation by oxo-reaction and reductionOrganic compound preparationChemistryAldehyde

The present invention relates to a process for preparing aldehydes by hydroformylation catalyzed by metals of groups 8 to 10 of the Periodic Table of the Elements in the presence of cyclic carbonic esters.

Owner:EVONIK DEGUSSA GMBH

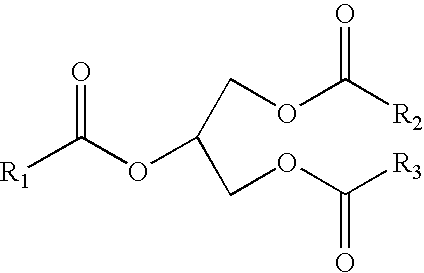

L- beta -dioxolane uridine analogs and methods for treating and preventing Epstein-Barr virus infections

InactiveUS6022876ALow toxicityMinimal toxicityBiocideGroup 5/15 element organic compoundsHigh activityUridine Nucleotides

The present invention relates to the discovery that certain beta -L-dioxolane nucleoside analogs which contain a uracil base, and preferably, a 5-halosubstituted uracil base, exhibit unexpectedly high activity against Epstein-Barr virus (EBV), Varciella-Zoster virus (VZV) and Herpes Virus 8 (HV-8). In particular, the compounds according to the present invention show potent inhibition of the replication of the virus (viral growth) in combination with very low toxicity to the host cells (i.e., animal or human tissue). Compounds are useful for treating EBV, VZV and HV-8 infections in humans.

Owner:GEORGIA UNVERSITY OF RES FOUND INC THE +1

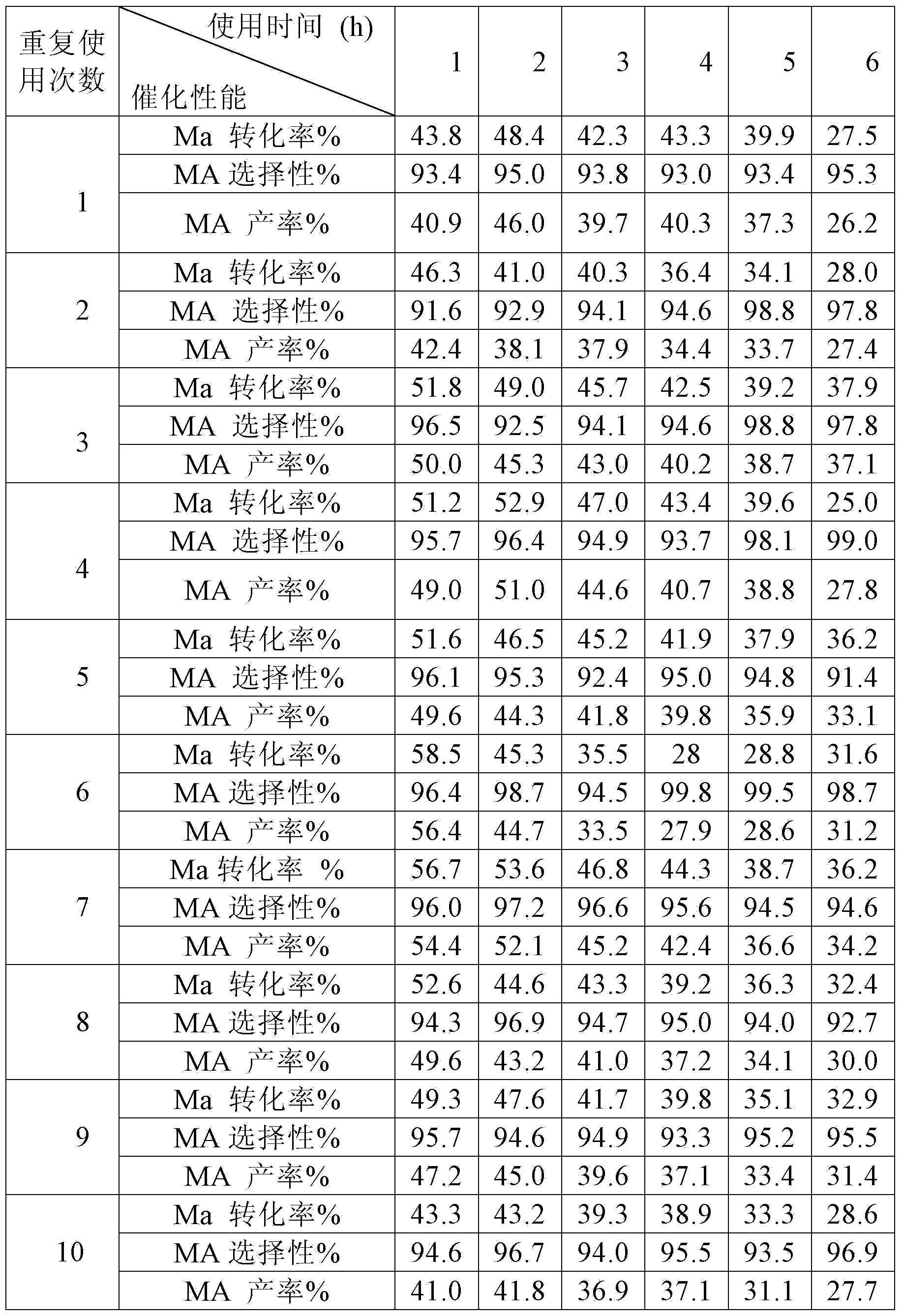

Catalyst for preparing methyl acrylate and acrylic acid, and preparation method and application thereof

InactiveCN106693941AHigh activityHigh selectivityOrganic compound preparationCarboxylic acid esters preparationAluminateAlkaline earth metal

The invention relates to a catalyst for preparing methyl acrylate and acrylic acid, and a preparation method and an application thereof, and is used for mainly solving the problems in the prior art. The problems are relatively well solved by the technical schemes comprising that the catalyst for preparing methyl acrylate and acrylic acid is composed of a main active component, an active auxiliary agent and a carrier, wherein the main active component comprises nitrate, carbonate, aluminate, sulfate and chloride of alkali metals or alkaline earth metals, an active auxiliary agent element is selected from at least one of IIA, IIIA, VA, VIA and VIIA main group elements, IB, IIB, IIIB, IV, VB, VIB and VIII transition metal elements and lanthanides in the periodic table of elements, and the carrier is Al2O3, TiO2, ZrO2 or SiO2; for the catalyst, based on oxide, the mass percentage content of the main active component is 0.1%-50%, and the mass percentage content of the active auxiliary agent is 0.1%-20%; and the preparation method and the application of the catalyst are provided. The catalyst can be used for preparing methyl acrylate and acrylic acid by condensation reaction of methyl acetate with formaldehyde or methanol.

Owner:SHANGHAI HUAYI GRP CO +1

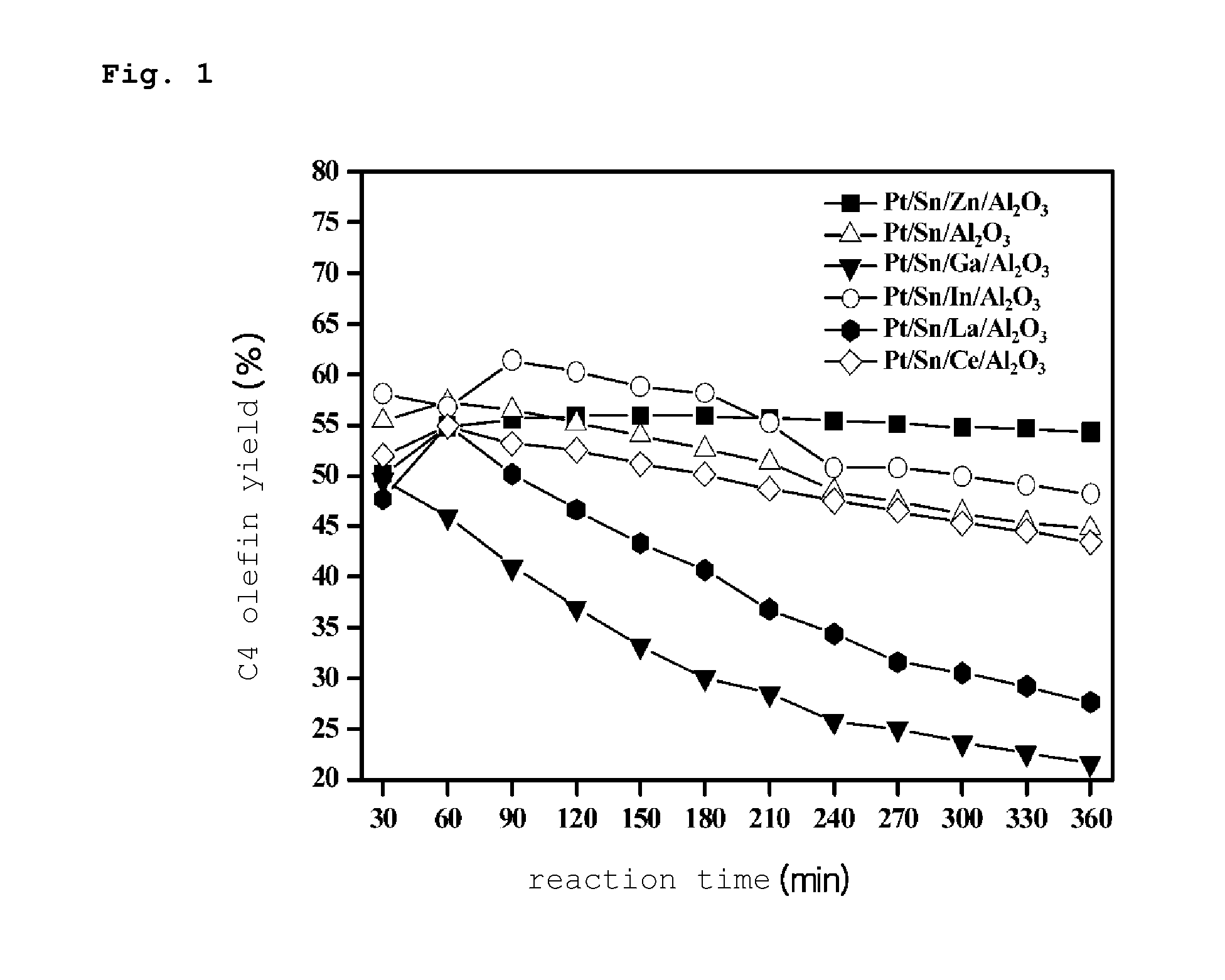

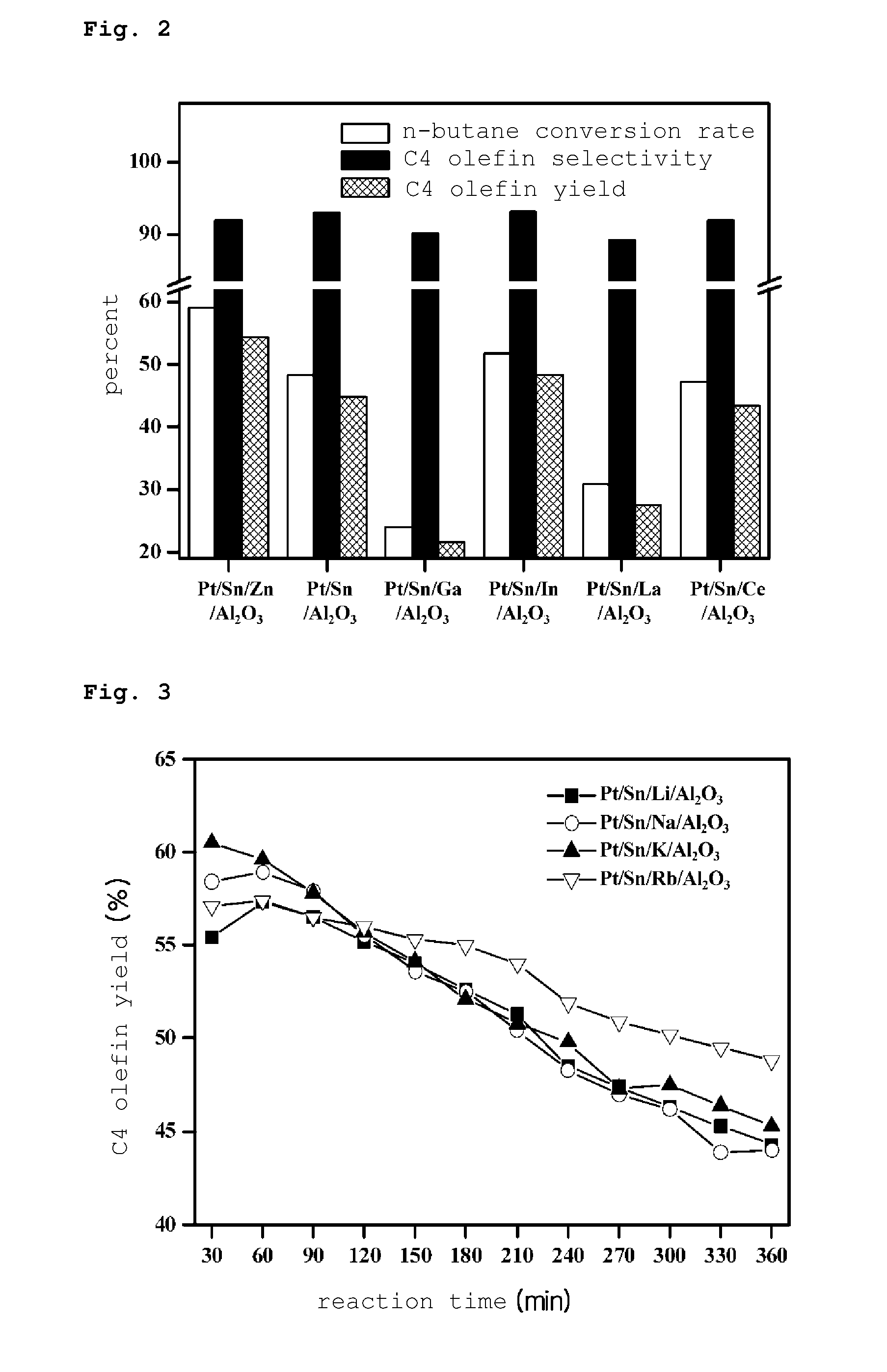

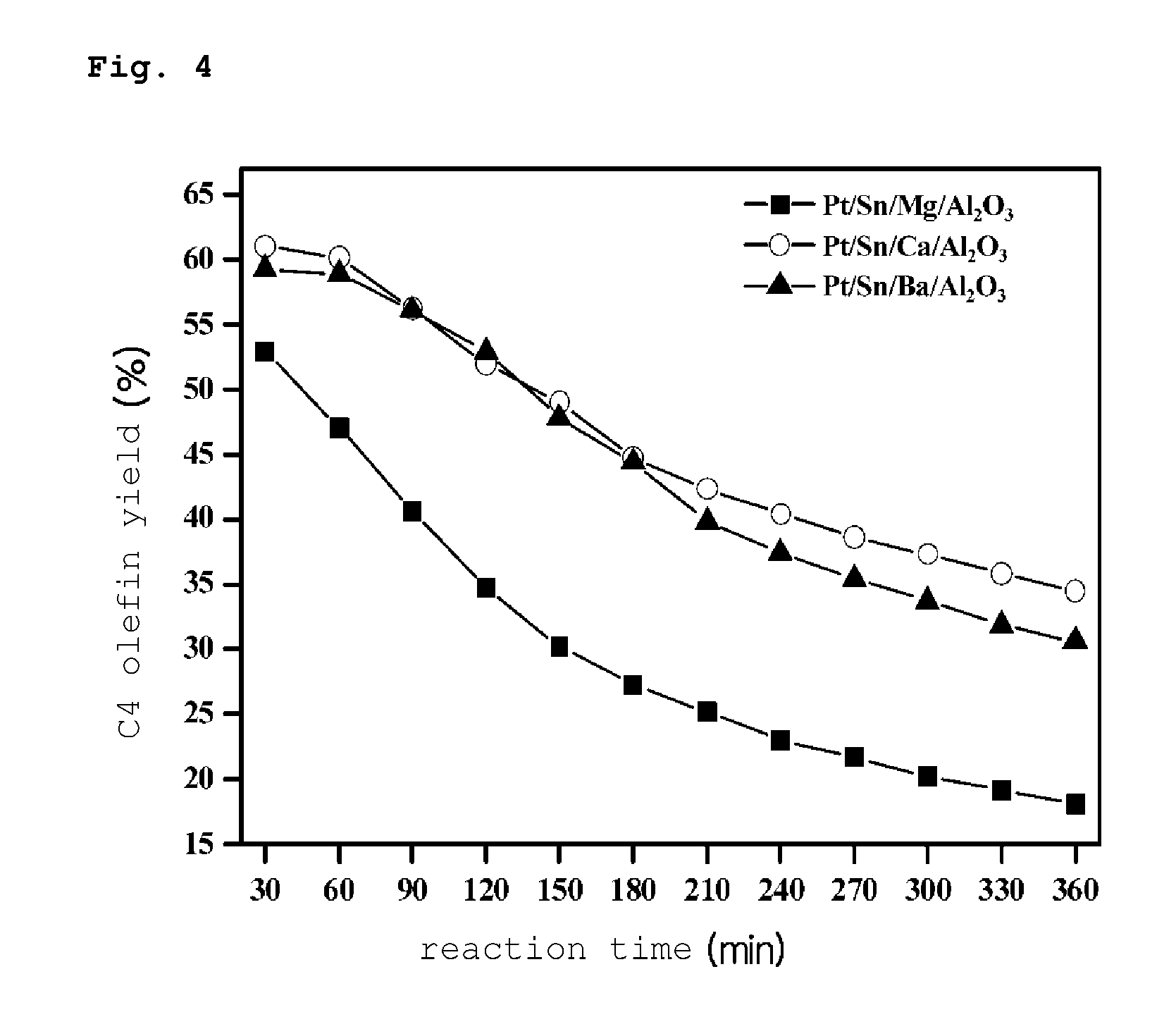

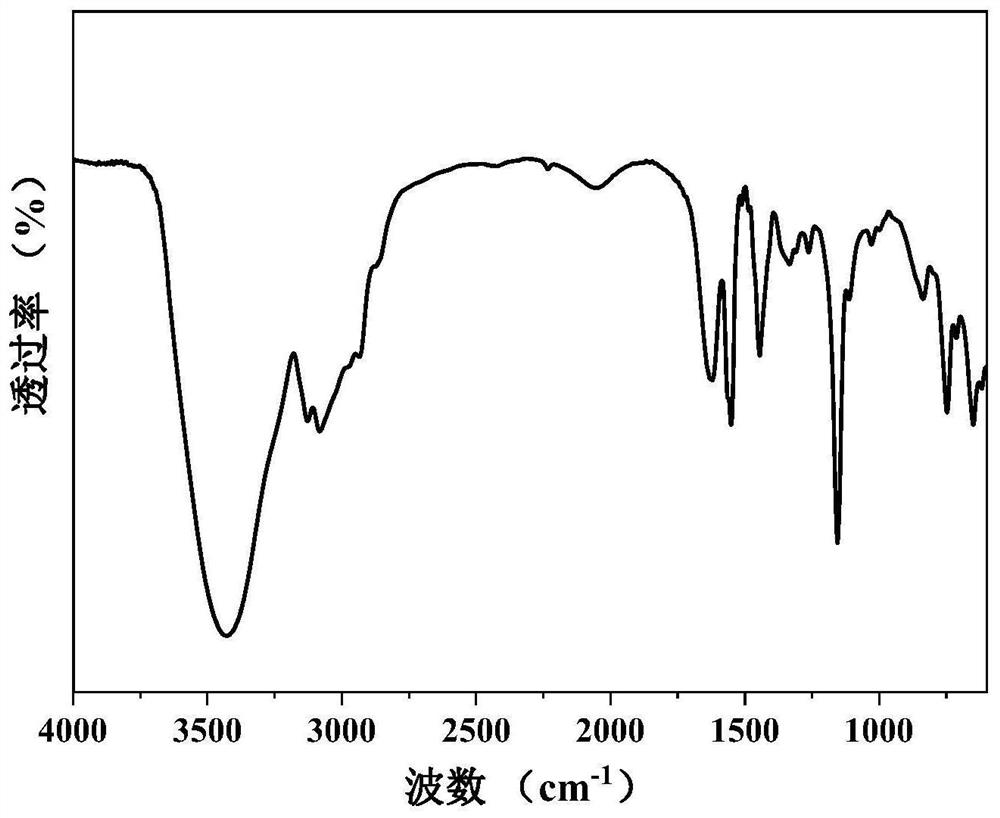

PREPARATION METHOD OF PLATINUM/TIN/METAL/ALUMINA CATALYST FOR DIRECT DEHYDROGENATION OF n-BUTANE AND METHOD FOR PRODUCING C4 OLEFINS USING SAID CATALYST

InactiveUS20150038758A1Reduce catalytic activityImprove production yieldHydrocarbon by dehydrogenationCatalystsPlatinumDehydrogenation

The provided is a method for preparing a platinum-tin-metal-alumina catalyst by comprising: as an active ingredient, platinum which has a high activity in a direct dehydrogenation reaction of n-butane, tin which can increase the catalyst stability by preventing carbon deposition; additionally metal for reducing the level of catalyst inactivation over the reaction time; and an alumina carrier for supporting said components. Further, provided is a method for producing a high value product, C4 olefins from low cost n-butane by using the catalyst prepared by the method according to the present invention in a direct dehydrogenation reaction.

Owner:HANWHA TOTAL PETROCHEMICAL CO LTD

Nitrogen-doped carbon-loaded ruthenium monatomic catalyst as well as preparation method and application thereof

ActiveCN112387295AHigh activityHigh selectivityPhysical/chemical process catalystsOrganic compound preparationPtru catalystAromatization

The invention relates to a nitrogen-doped carbon supported ruthenium monatomic catalyst which is characterized by comprising a carrier and an active component supported on the carrier, wherein the carrier is nitrogen-doped carbon, and the active component is a metal ruthenium single atom; and the mass percentage of the metal ruthenium single atoms in the nitrogen-doped carbon-loaded ruthenium single atom catalyst is 0.01-1.2%. The catalyst takes nitrogen-doped carbon as the carrier and the metal ruthenium single atoms as the active component, and compared with the prior art, the catalyst can greatly improve the utilization rate of precious metal ruthenium in the reaction of preparing alicyclic amine through one-step hydrogenation of a nitro aromatic compound, does not introduce an alkalineauxiliary agent, and does not need subsequent separation operation. The production cost is greatly reduced, and the high-activity and high-selectivity one-step hydro-conversion of the nitro aromaticcompound into alicyclic amine is realized under mild conditions.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

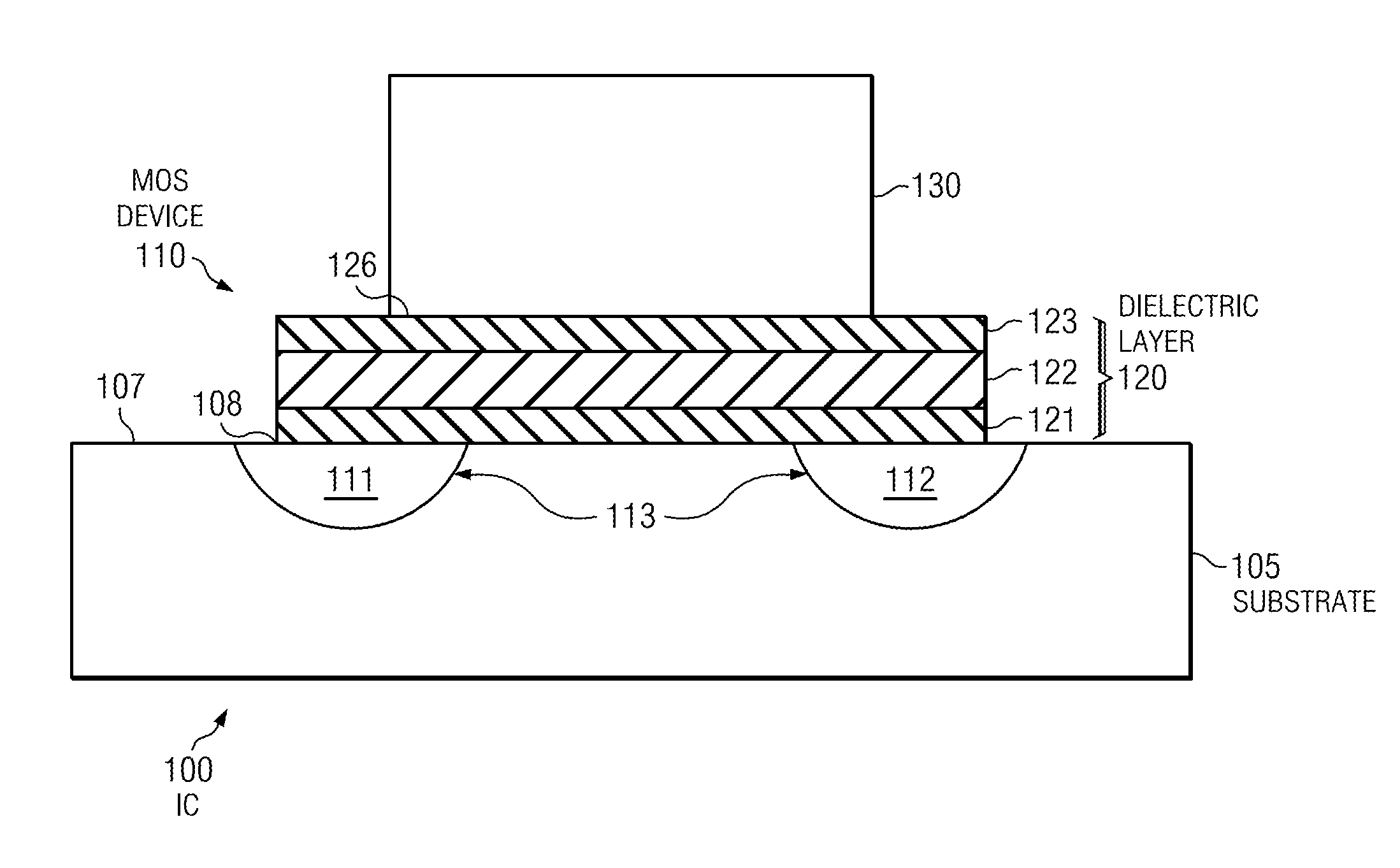

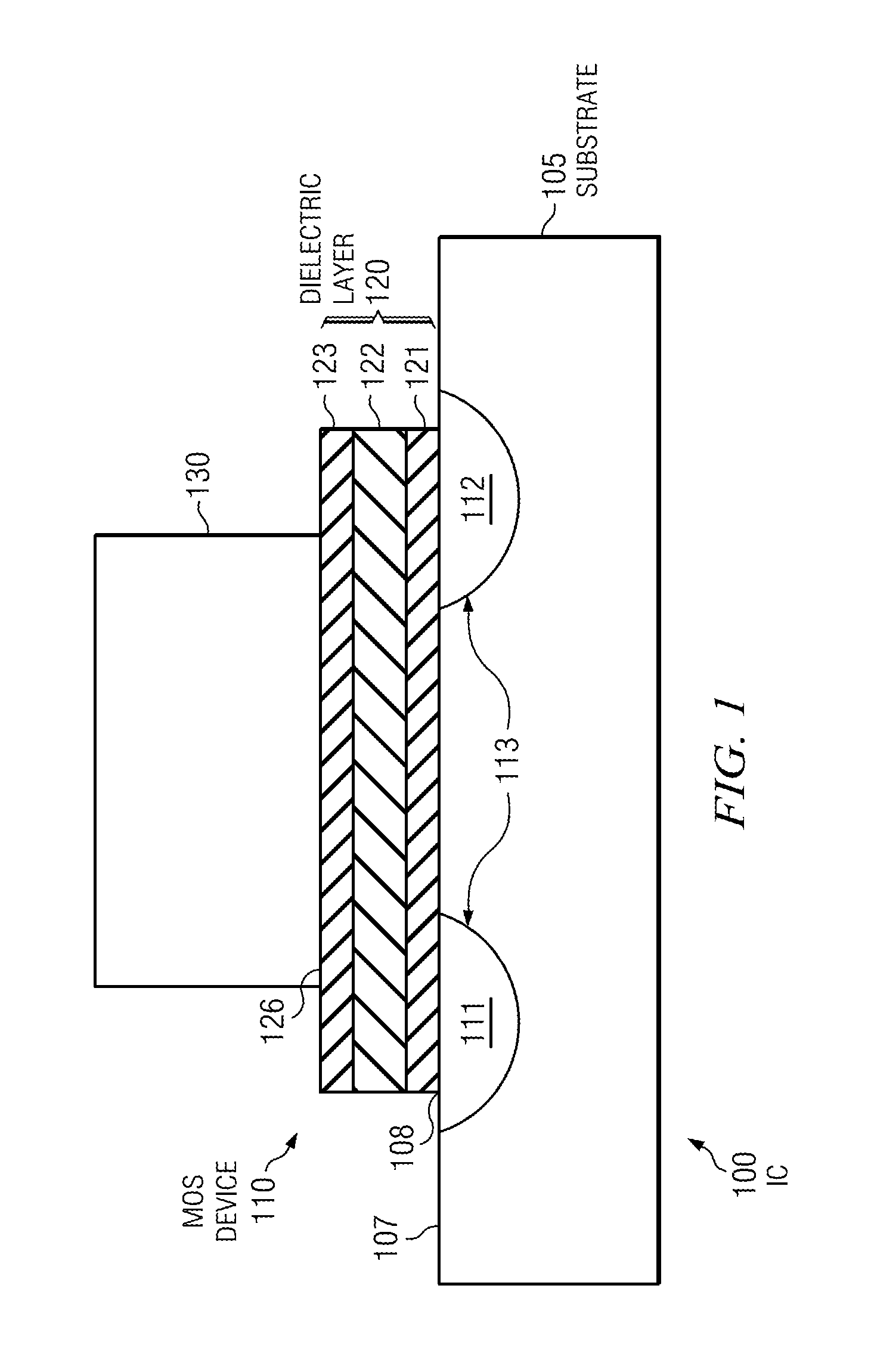

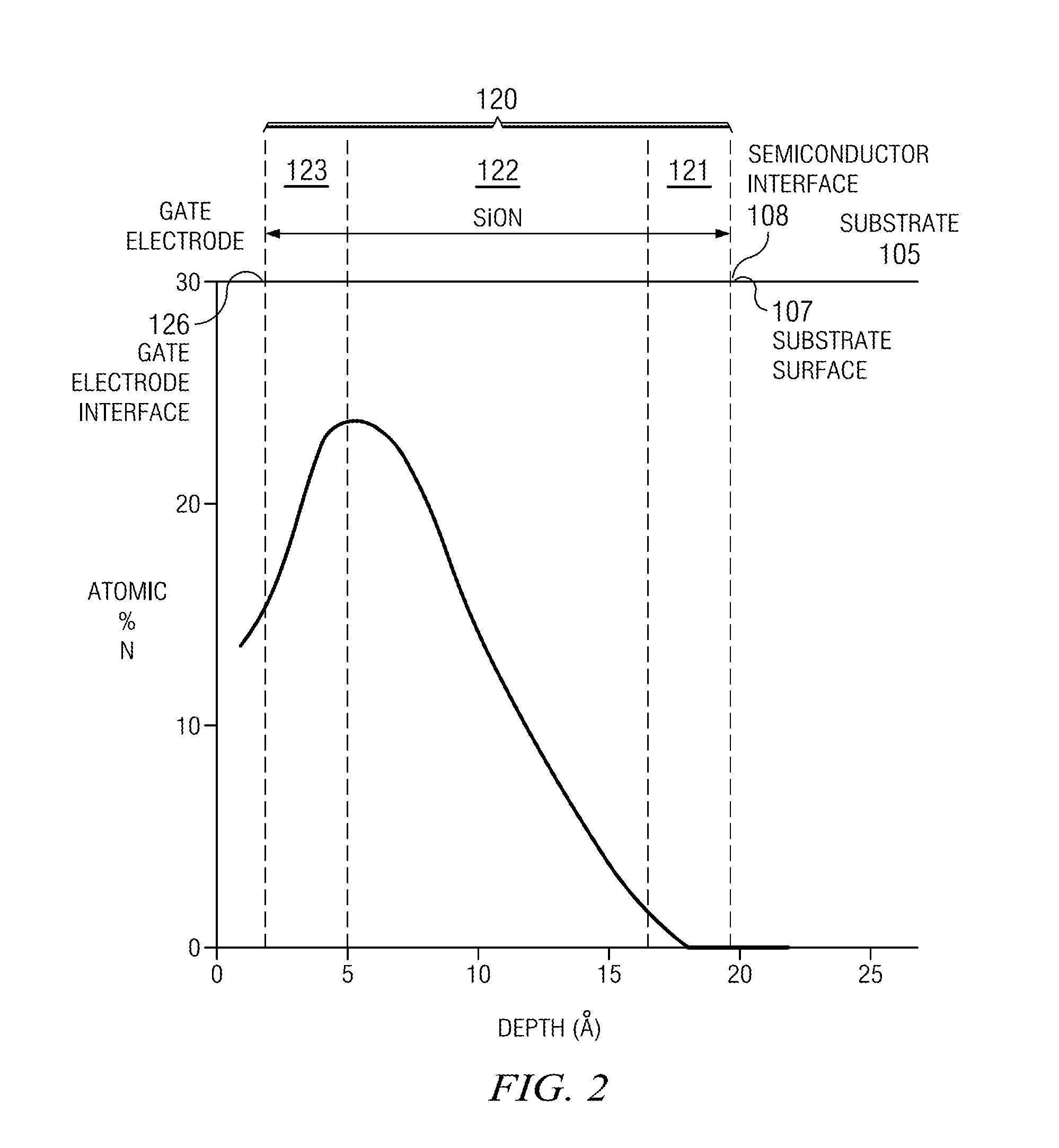

Semiconductor device including sion gate dielectric with portions having different nitrogen concentrations

ActiveUS20110204454A1Reduce B deactivationMinimize poly depletionTransistorSolid-state devicesGate dielectricDevice material

An integrated circuit (IC) includes a substrate having a top semiconductor surface including at least one MOS device including a source and a drain region spaced apart to define a channel region. A SiON gate dielectric layer that has a plurality of different N concentration portions is formed on the top semiconductor surface. A gate electrode is on the SiON layer. The plurality of different N concentration portions include (i) a bottom portion extending to the semiconductor interface having an average N concentration of <2 atomic %, (ii) a bulk portion having an average N concentration >10 atomic %, and (iii) a top portion on the bulk portion extending to a gate electrode interface having an average N concentration that is ≧2 atomic % less than a peak N concentration of the bulk portion.

Owner:TEXAS INSTR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com