Patents

Literature

386 results about "Cycle efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The formula for process cycle efficiency is value-added time divided by total lead time. For instance, if the total lead time for a process is 4 hours and the value-added time equals 1.2 hours, you get a process cycle efficiency of 30 percent – a figure generally viewed as very good.

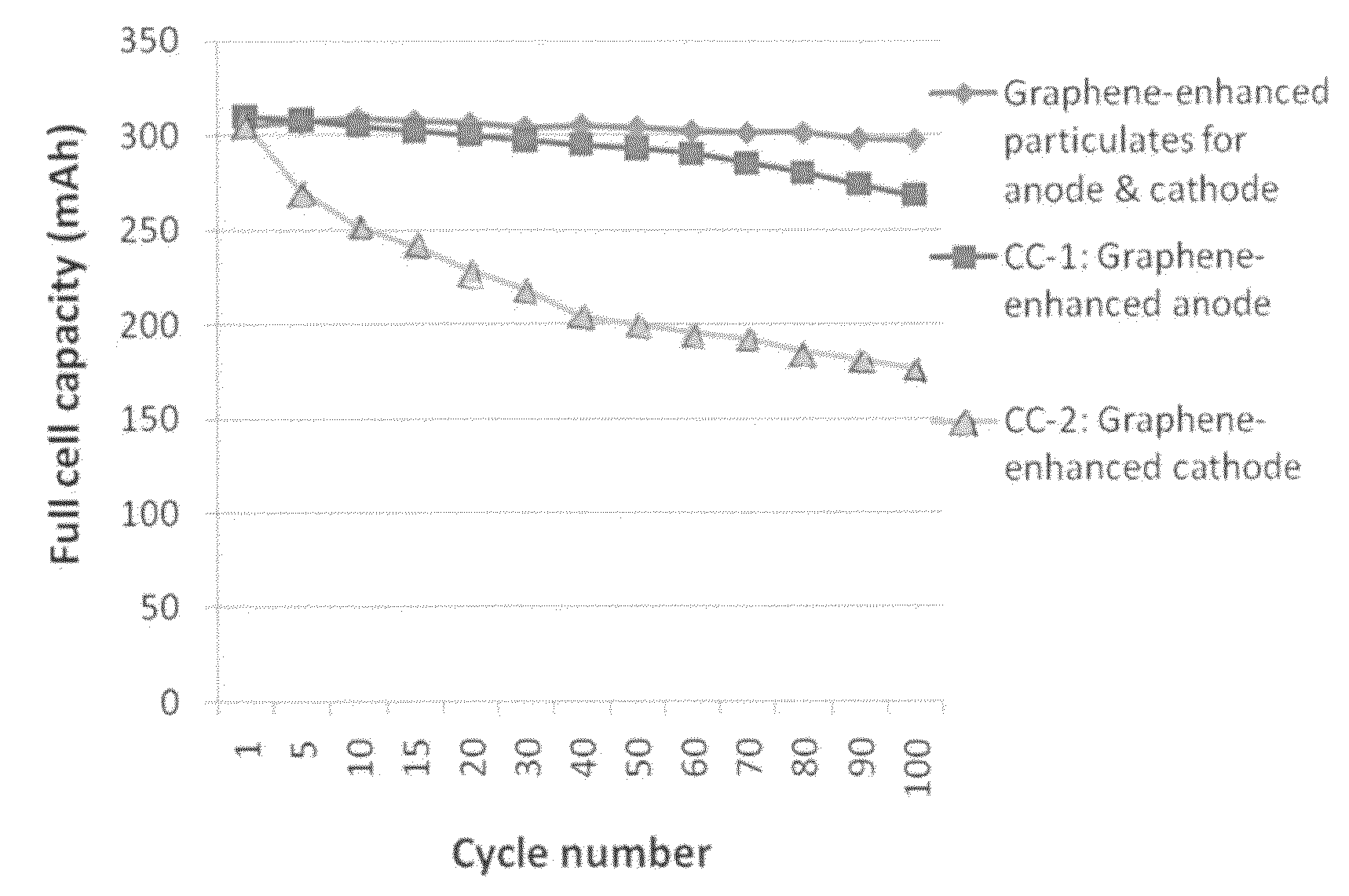

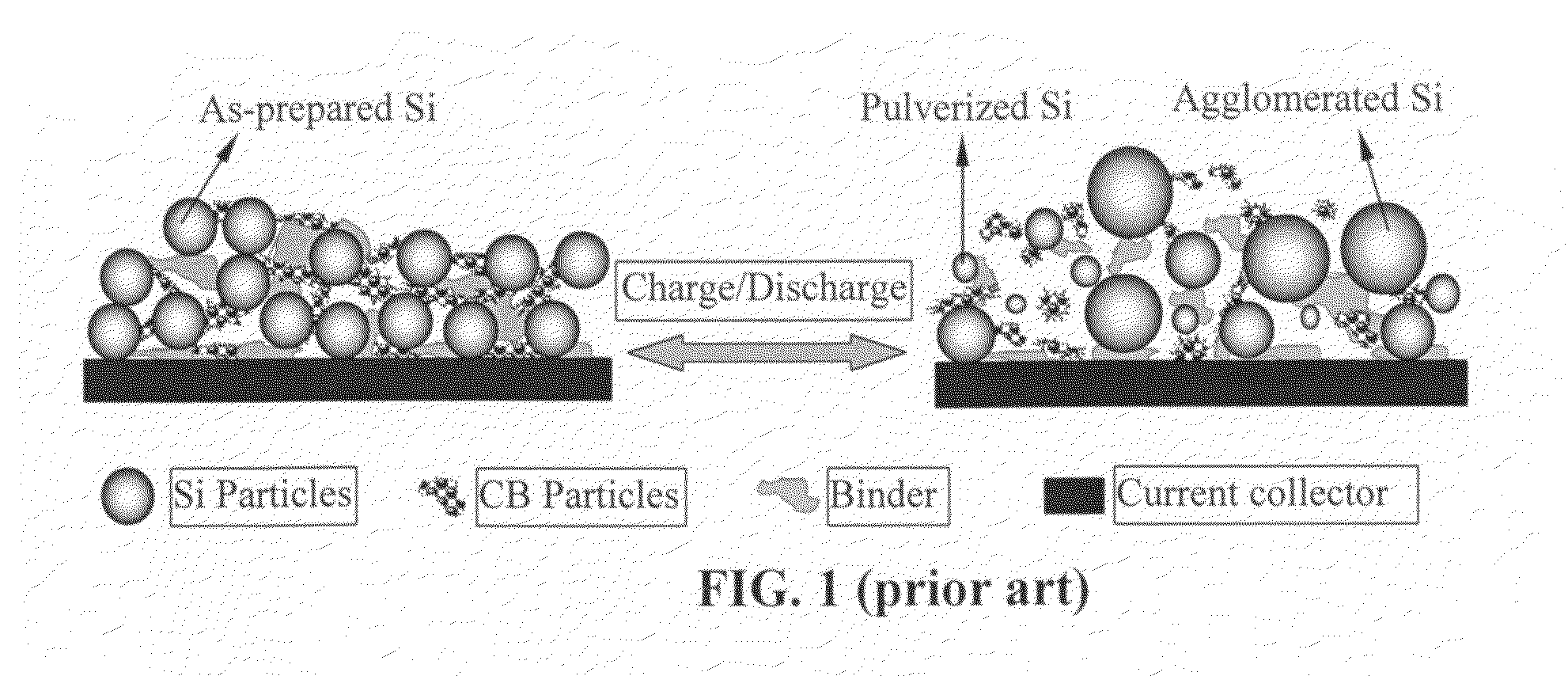

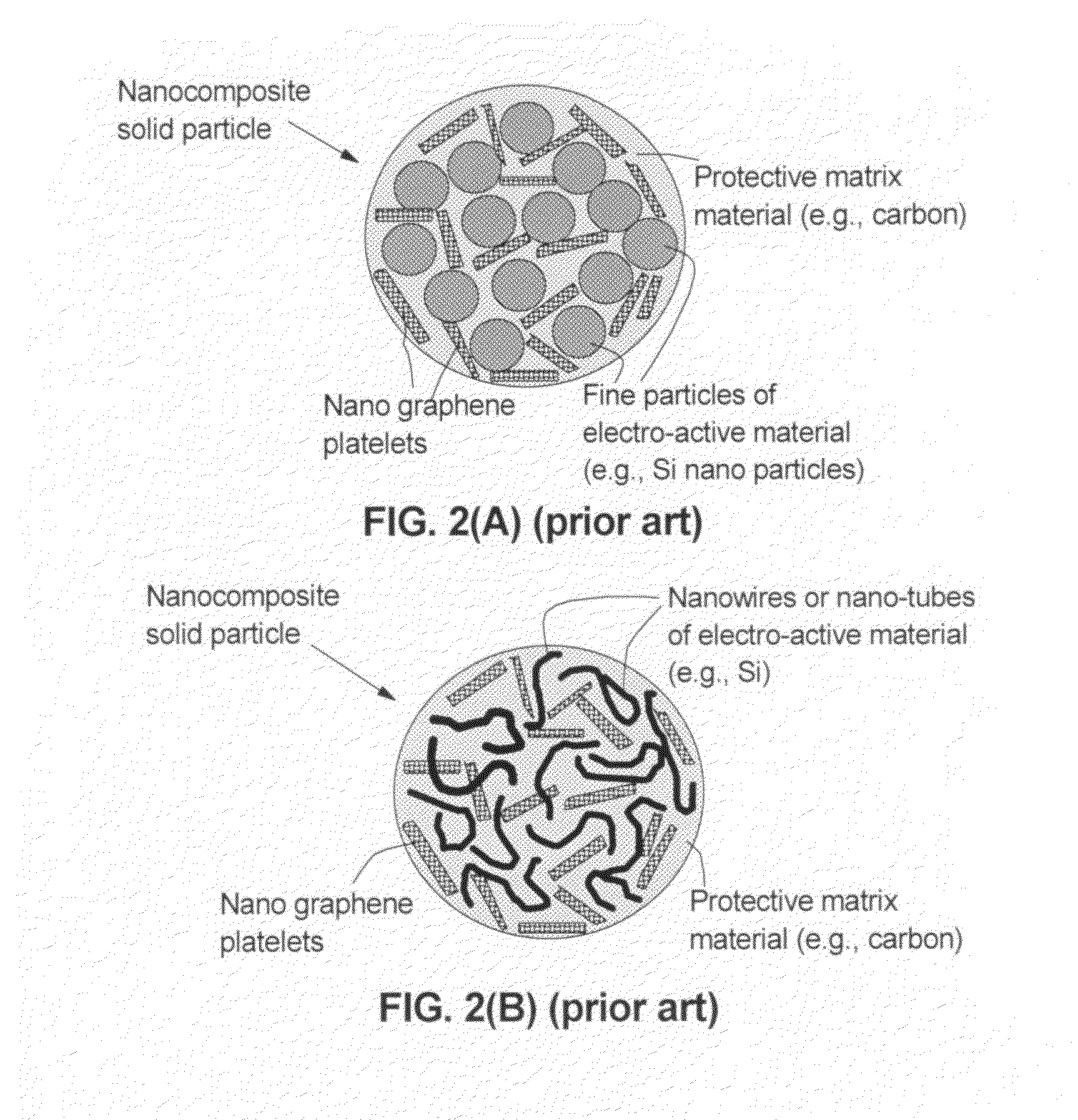

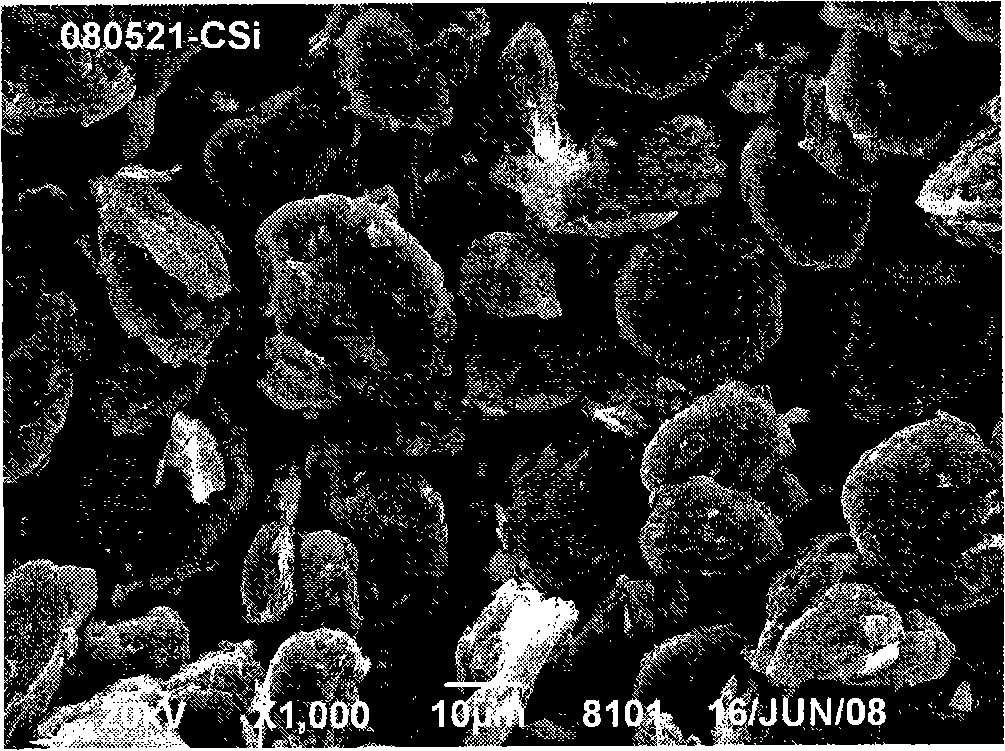

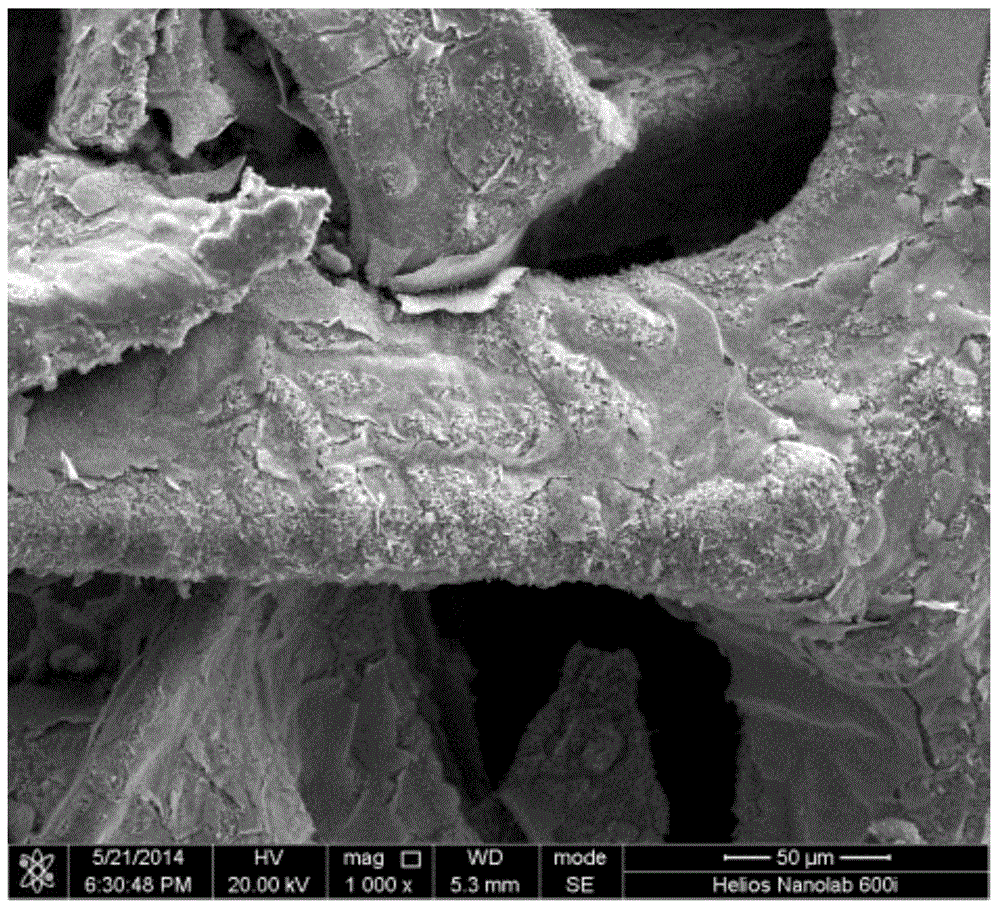

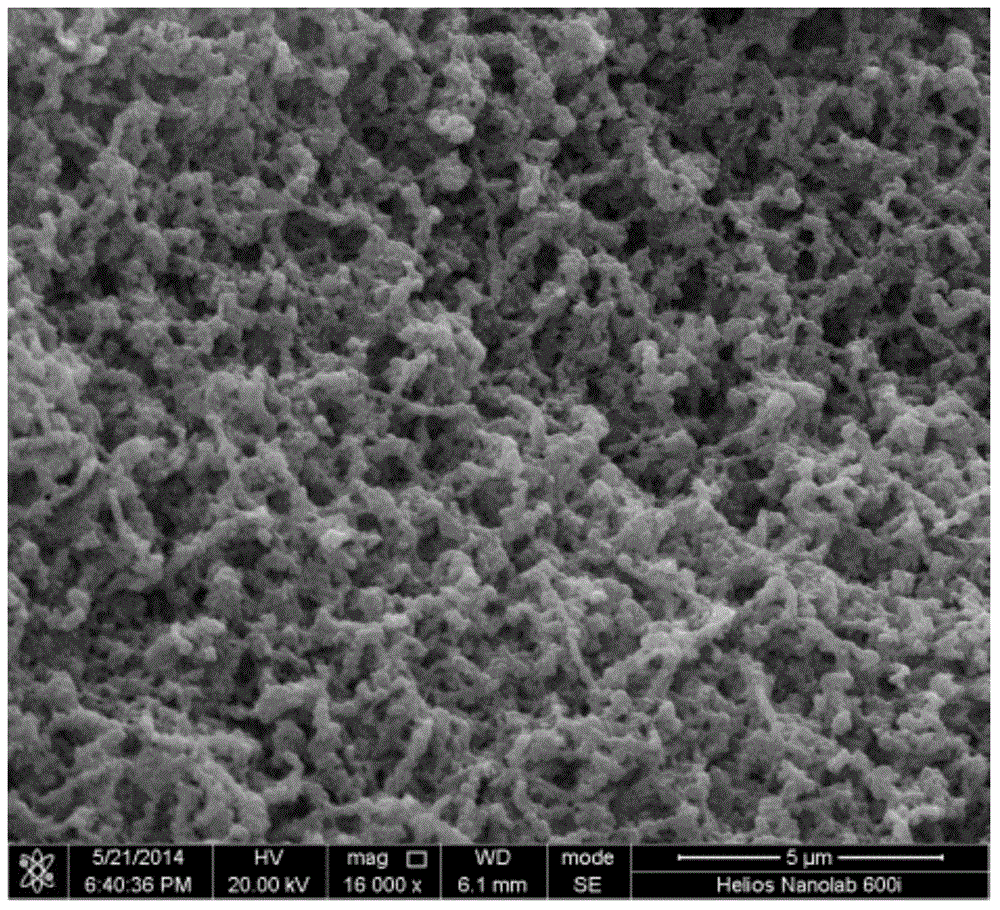

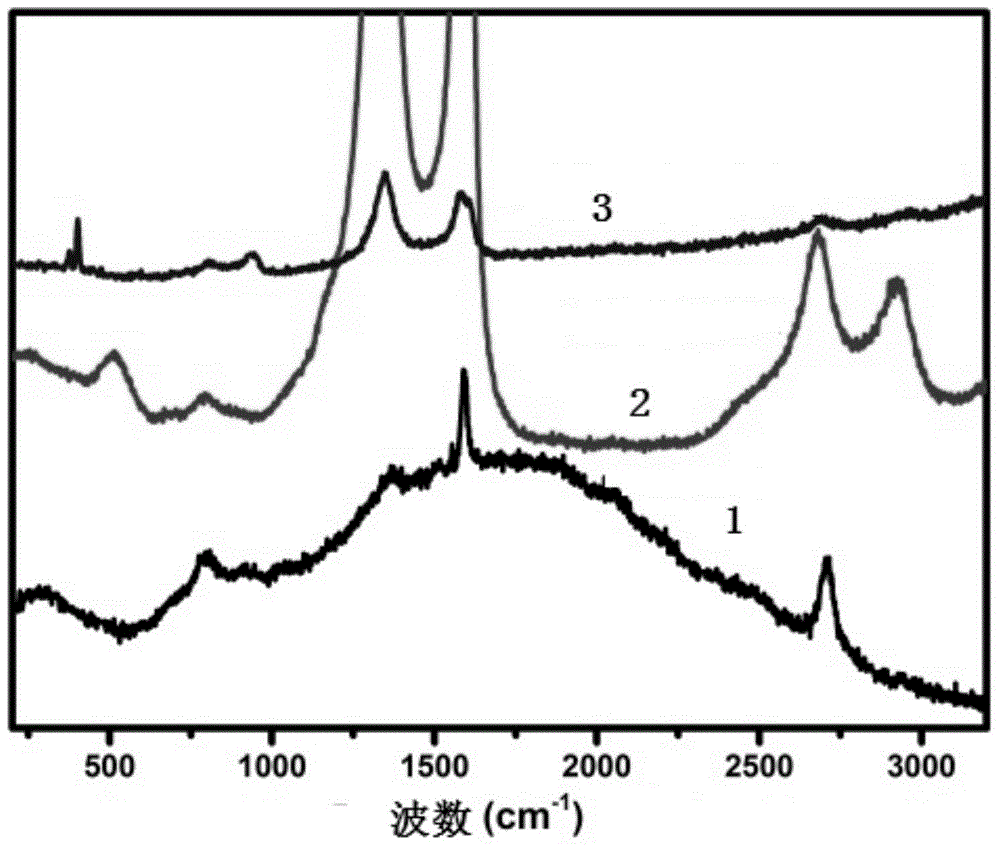

Graphene-enhanced anode particulates for lithium ion batteries

ActiveUS20120064409A1Enhanced Li-ion insertionIncrease capacityNon-metal conductorsMaterial nanotechnologyParticulatesMicroparticle

A nano graphene-enhanced particulate for use as a lithium-ion battery anode active material, wherein the particulate is formed of a single sheet of graphene or a plurality of graphene sheets and a plurality of fine anode active material particles with a size smaller than 10 μm. The graphene sheets and the particles are mutually bonded or agglomerated into the particulate with at least a graphene sheet embracing the anode active material particles. The amount of graphene is at least 0.01% by weight and the amount of the anode active material is at least 0.1% by weight, all based on the total weight of the particulate. A lithium-ion battery having an anode containing these graphene-enhanced particulates exhibits a stable charge and discharge cycling response, a high specific capacity per unit mass, a high first-cycle efficiency, a high capacity per electrode volume, and a long cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD +1

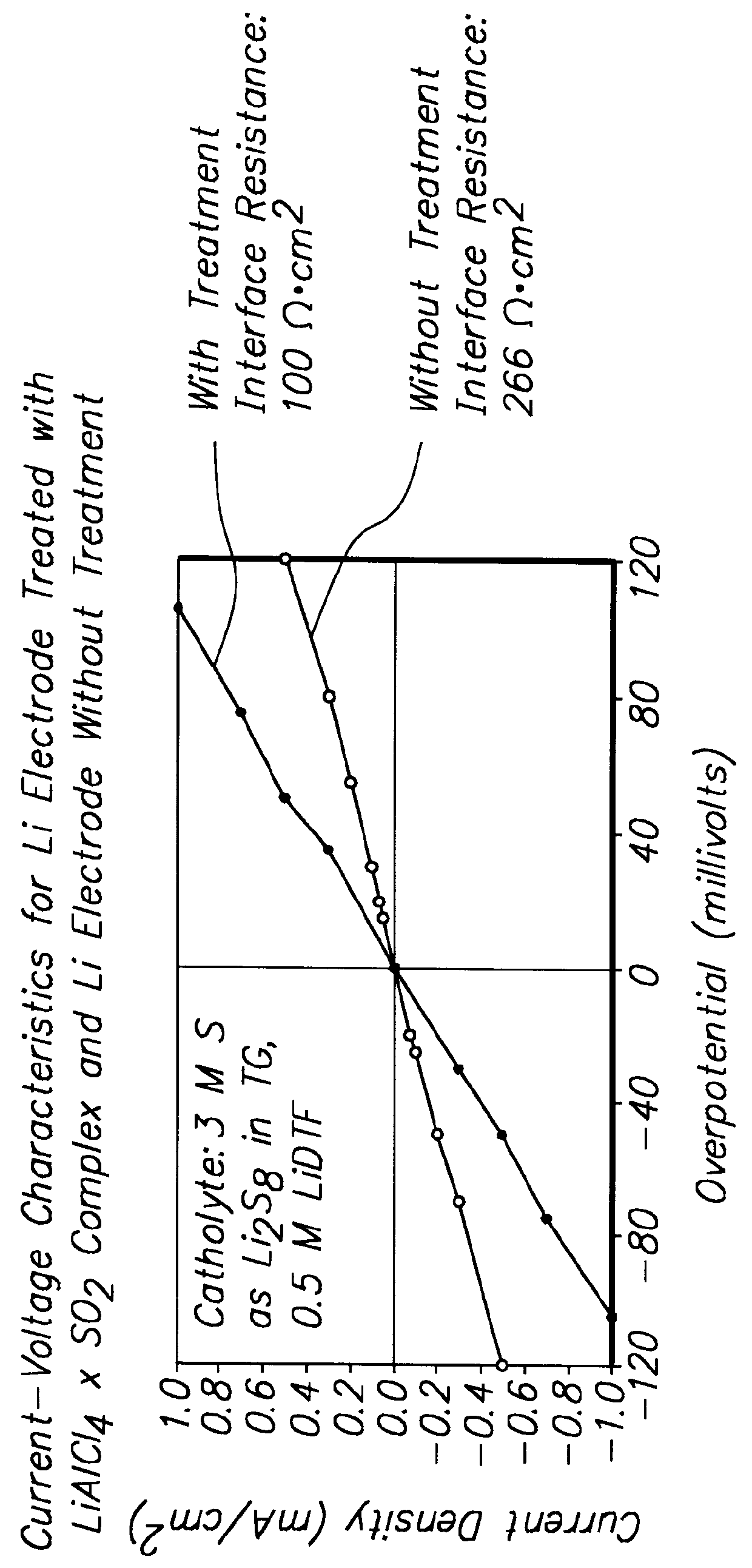

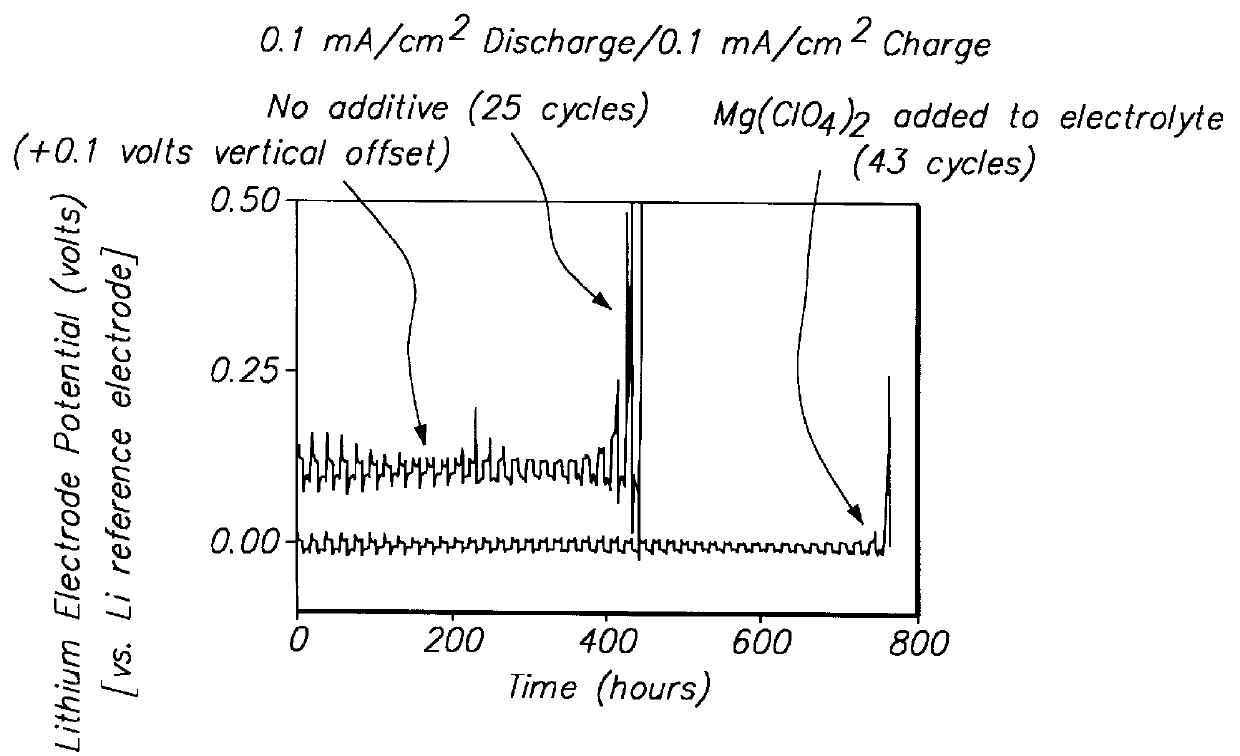

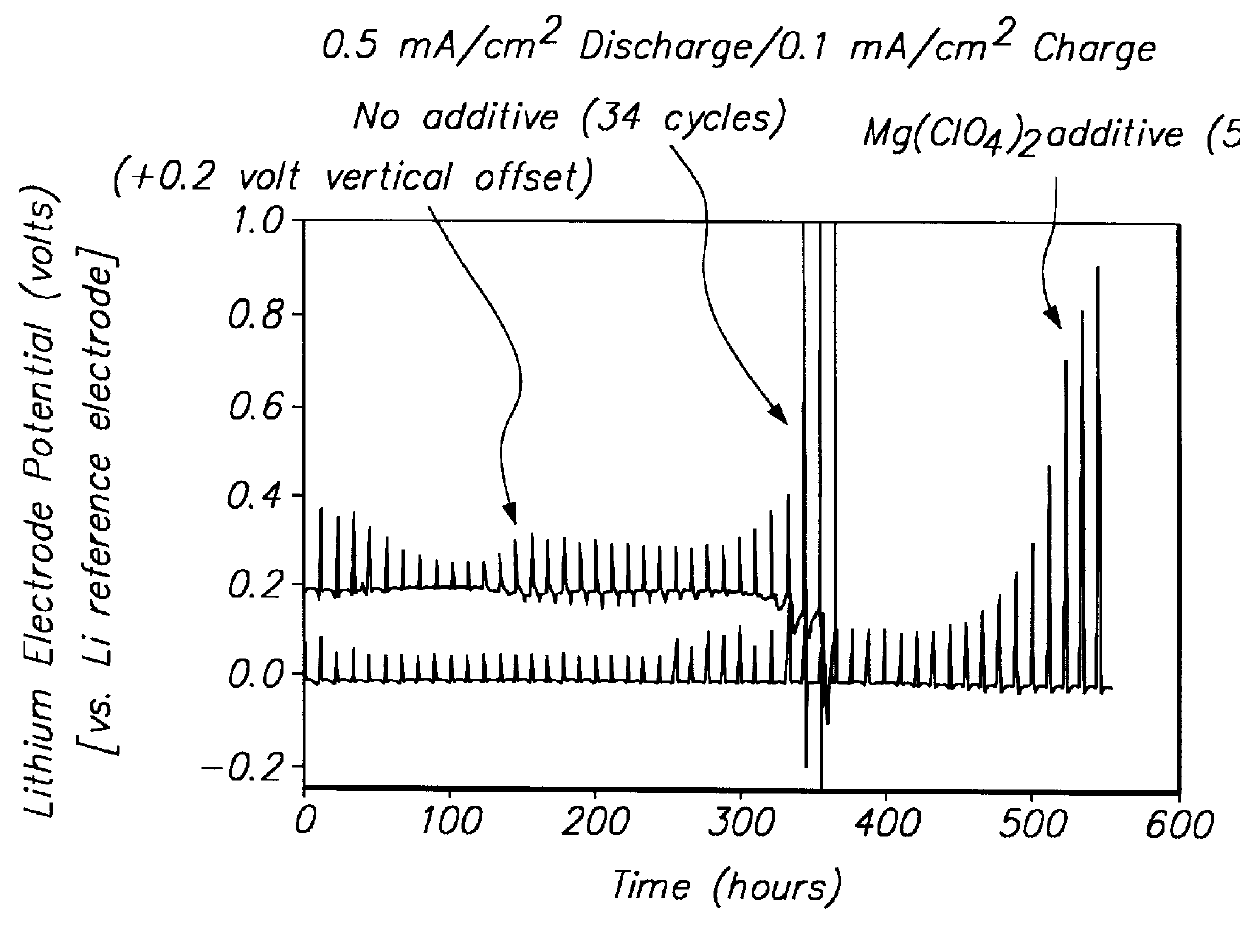

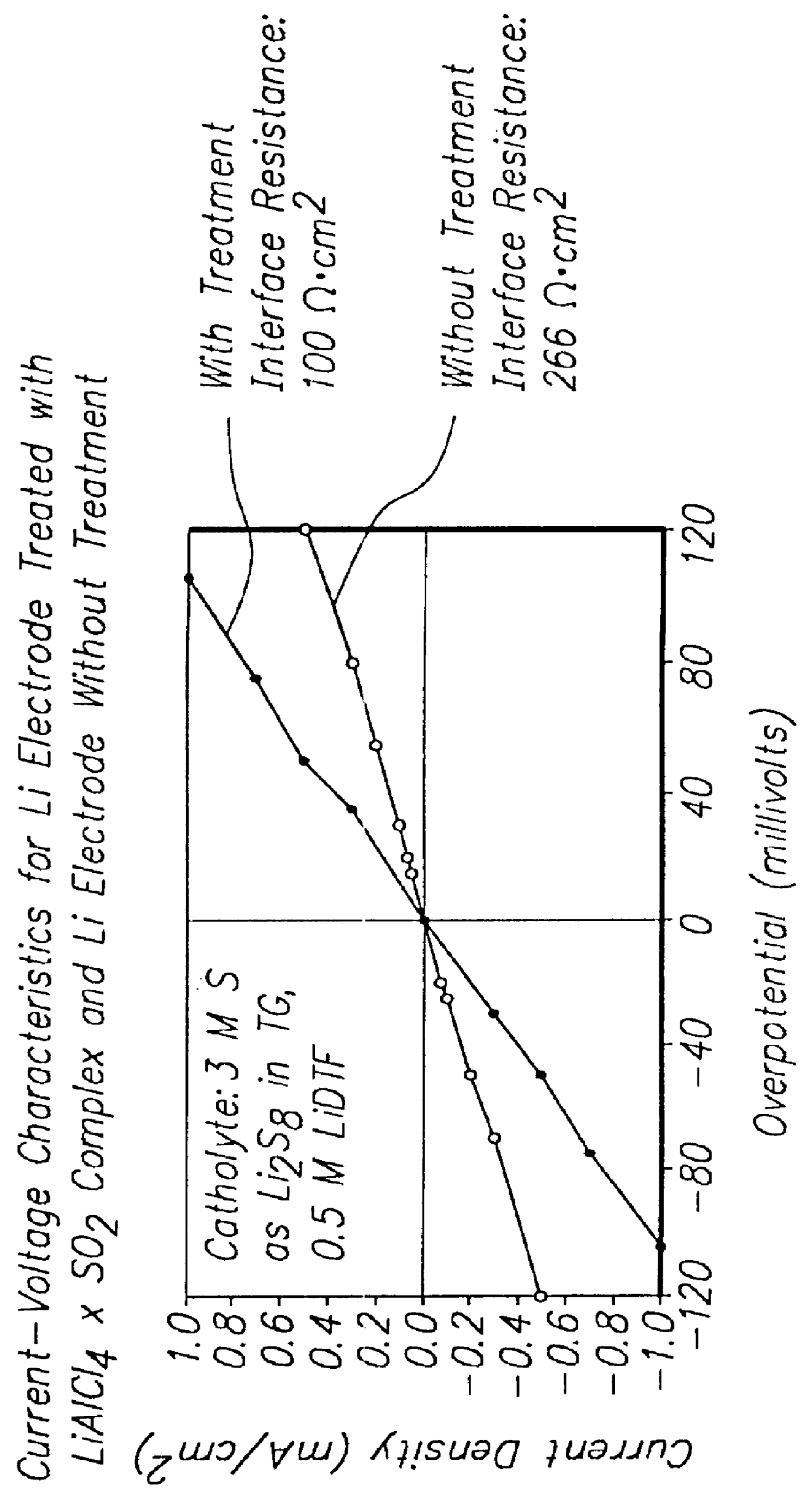

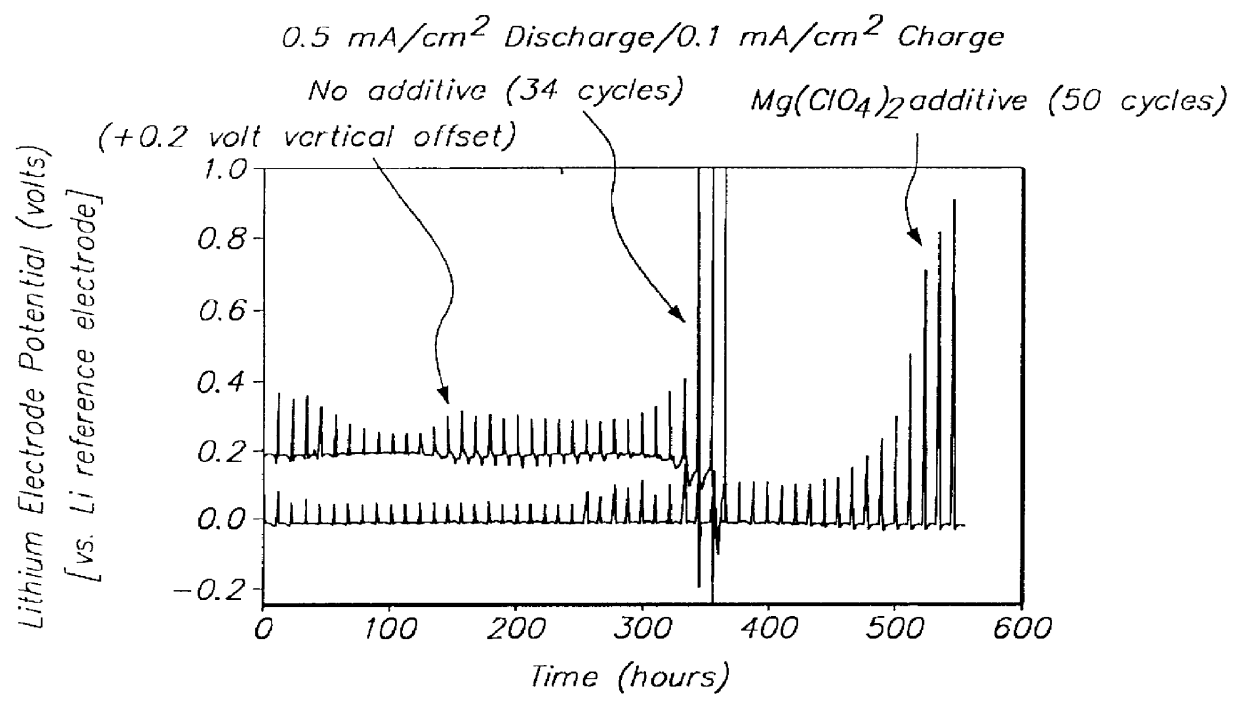

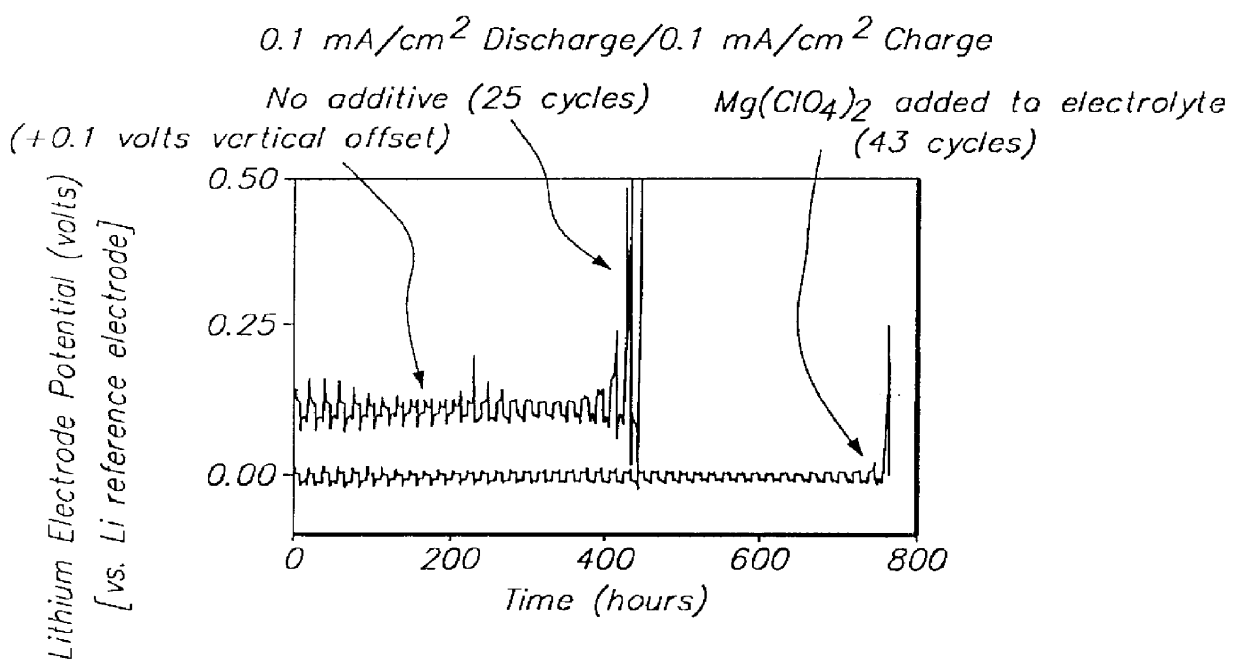

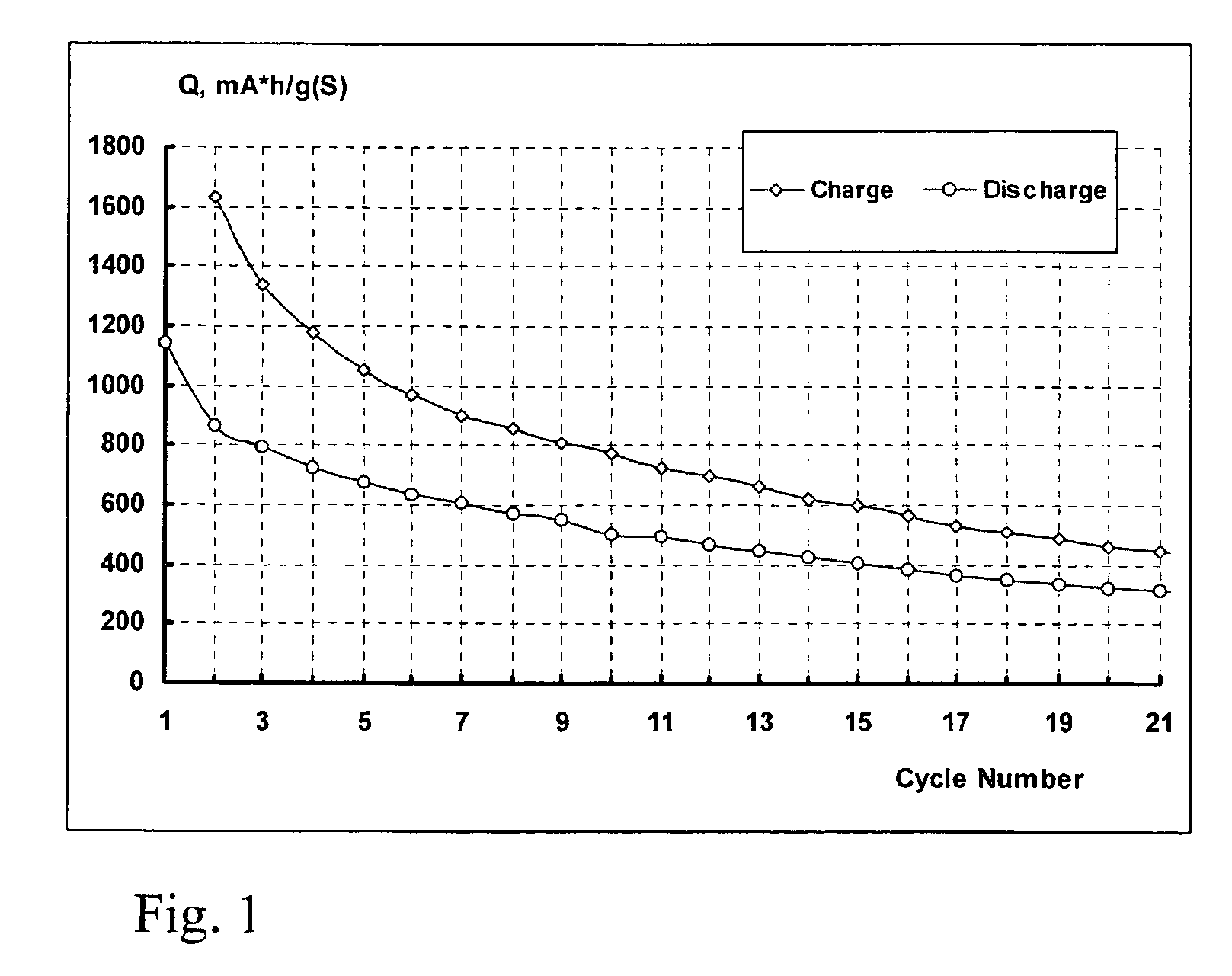

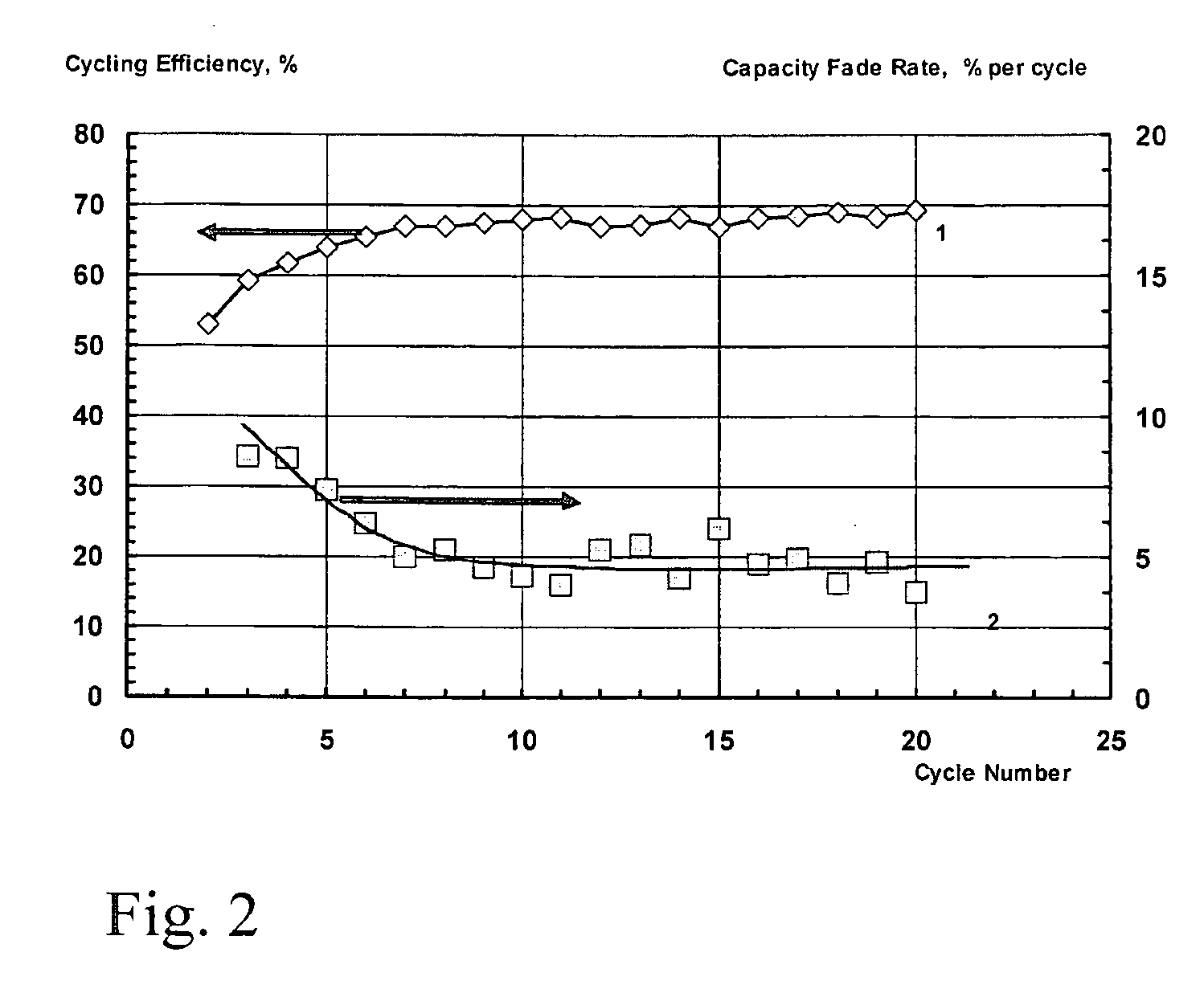

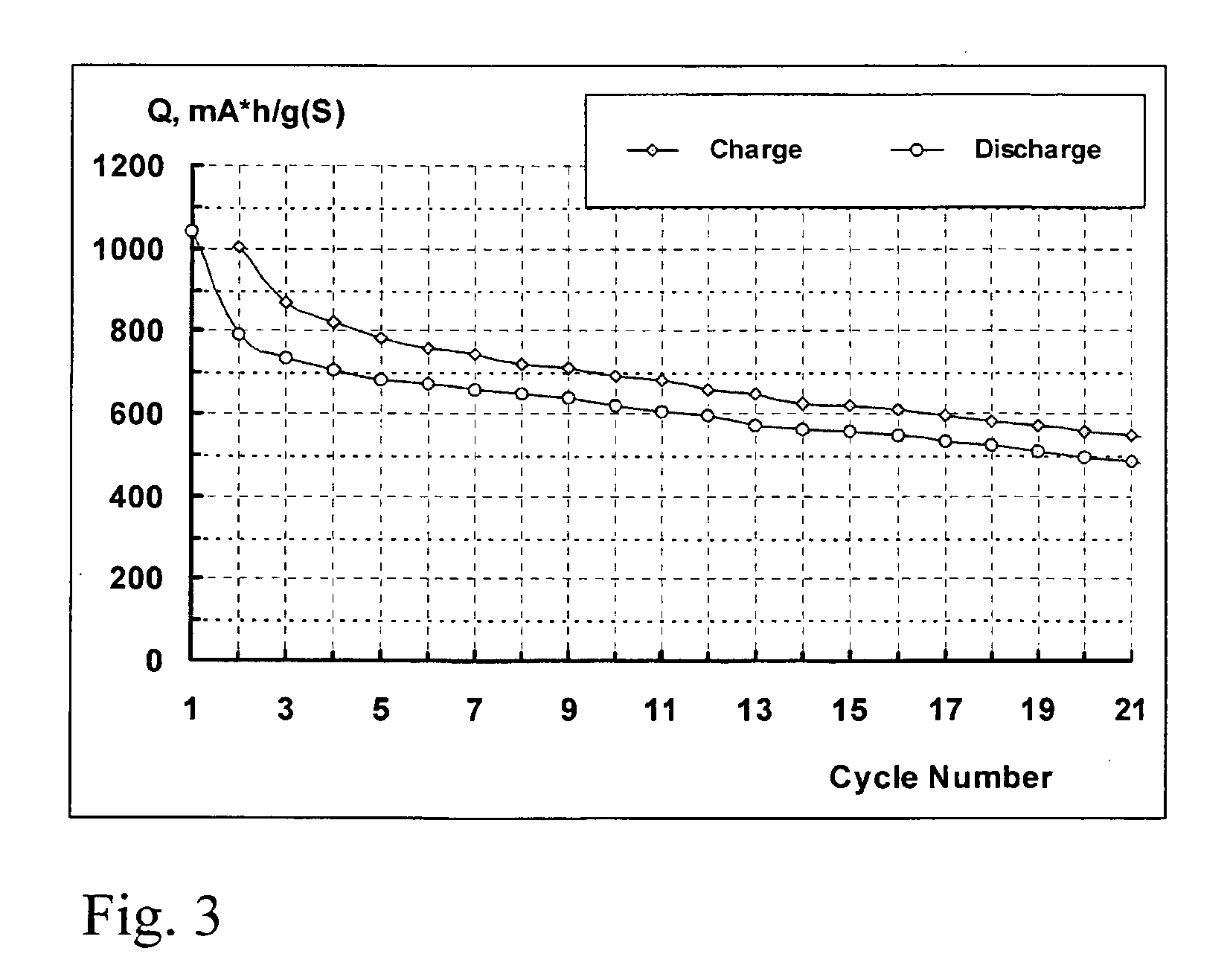

Methods and reagents for enhancing the cycling efficiency of lithium polymer batteries

InactiveUS6017651AImprove efficiencyElectrode rolling/calenderingElectrochemical processing of electrodesLithium metalSulfur electrode

Batteries including a lithium electrode and a sulfur counter electrode that demonstrate improved cycling efficiencies are described. In one embodiment, an electrochemical cell having a lithium electrode and a sulfur electrode including at least one of elemental sulfur, lithium sulfide, and a lithium polysulfide is provided. The lithium electrode includes a surface coating that is effective to increase the cycling efficiency of said electrochemical cell. In a more particular embodiment, the lithium electrode is in an electrolyte solution, and, more particularly, an electrolyte solution including either elemental sulfur, a sulfide, or a polysulfide. In another embodiment, the coating is formed after the lithium electrode is contacted with the electrolyte. In a more particular embodiment, the coating is formed by a reaction between the lithium metal of the lithium electrode and a chemical species present in the electrolyte.

Owner:POLYPLUS BATTERY CO INC

Methods and reagents for enhancing the cycling efficiency of lithium polymer batteries

InactiveUS6165644AImprove efficiencyElectrode rolling/calenderingElectrochemical processing of electrodesLithium metalSulfur electrode

Batteries including a lithium electrode and a sulfur counter electrode that demonstrate improved cycling efficiencies are described. In one embodiment, an electrochemical cell having a lithium electrode and a sulfur electrode including at least one of elemental sulfur, lithium sulfide, and a lithium polysulfide is provided. The lithium electrode includes a surface coating that is effective to increase the cycling efficiency of said electrochemical cell. In a more particular embodiment, the lithium electrode is in an electrolyte solution, and, more particularly, an electrolyte solution including either elemental sulfur, a sulfide, or a polysulfide. In another embodiment, the coating is formed after the lithium electrode is contacted with the electrolyte. In a more particular embodiment, the coating is formed by a reaction between the lithium metal of the lithium electrode and a chemical species present in the electrolyte.

Owner:POLYPLUS BATTERY CO INC

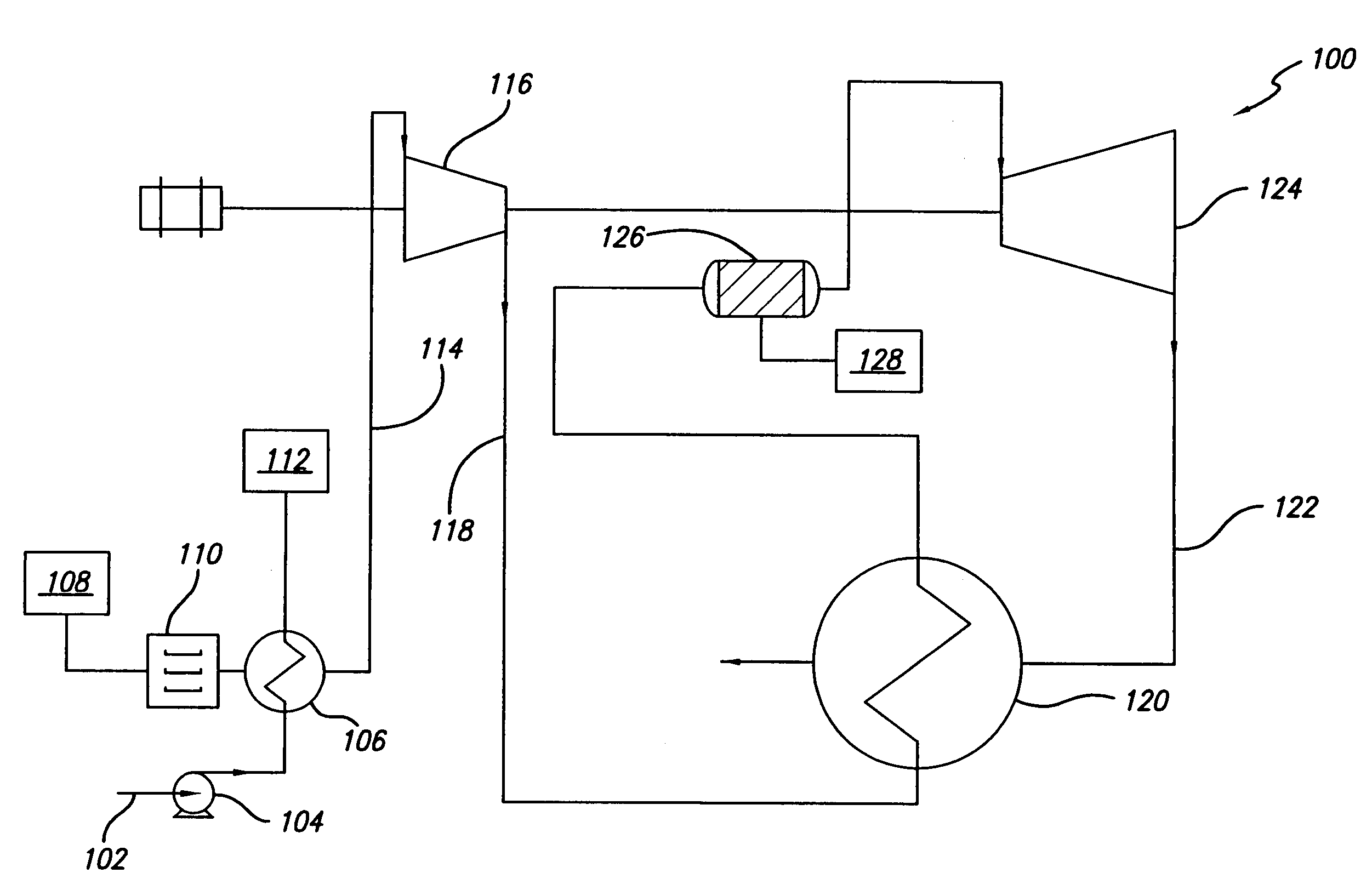

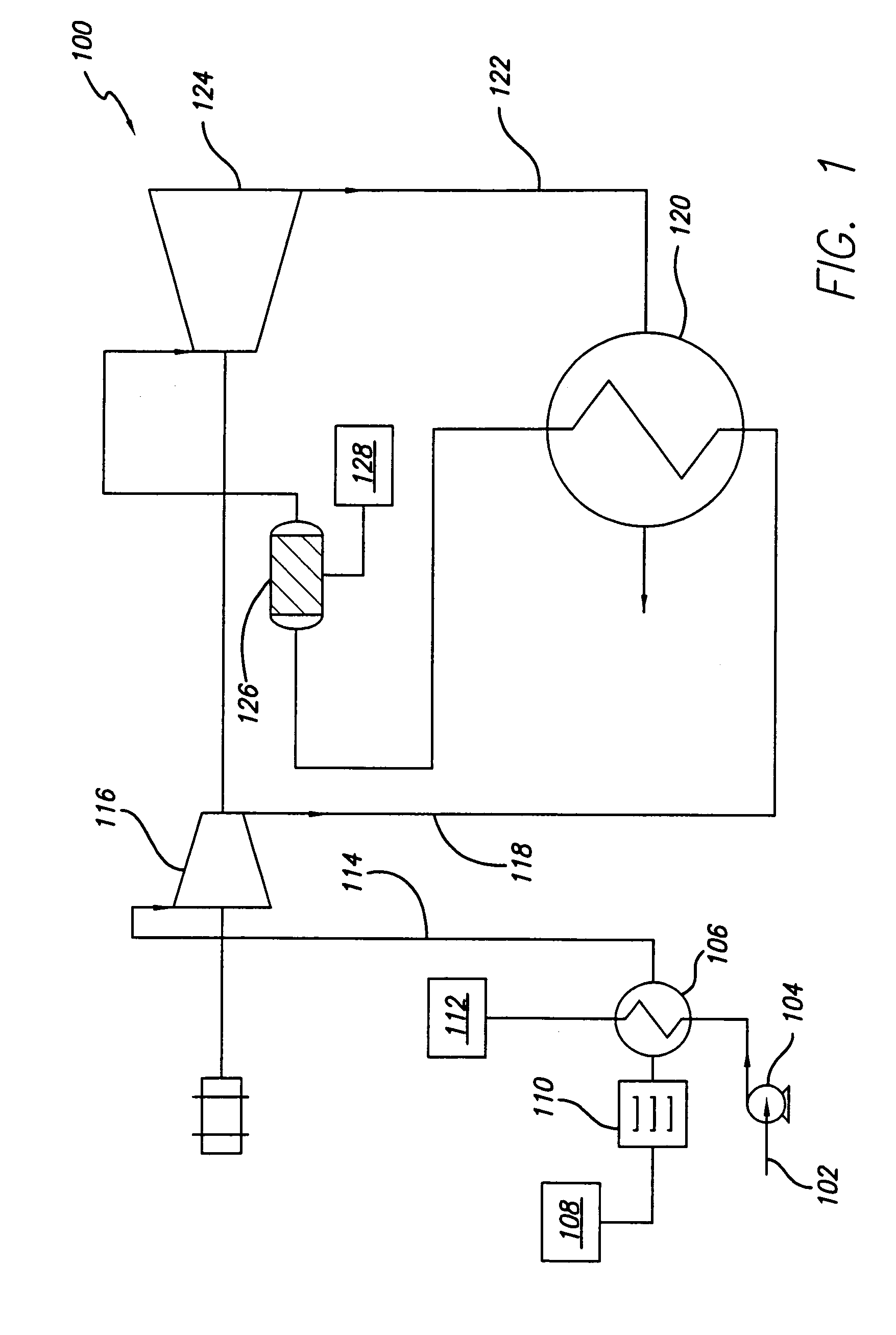

Vaporization of liquefied natural gas for increased efficiency in power cycles

InactiveUS7299619B2Easy to compressLess contaminantGas turbine plantsJet propulsion plantsCombustion chamberPower cycle

Owner:SIEMENS ENERGY INC

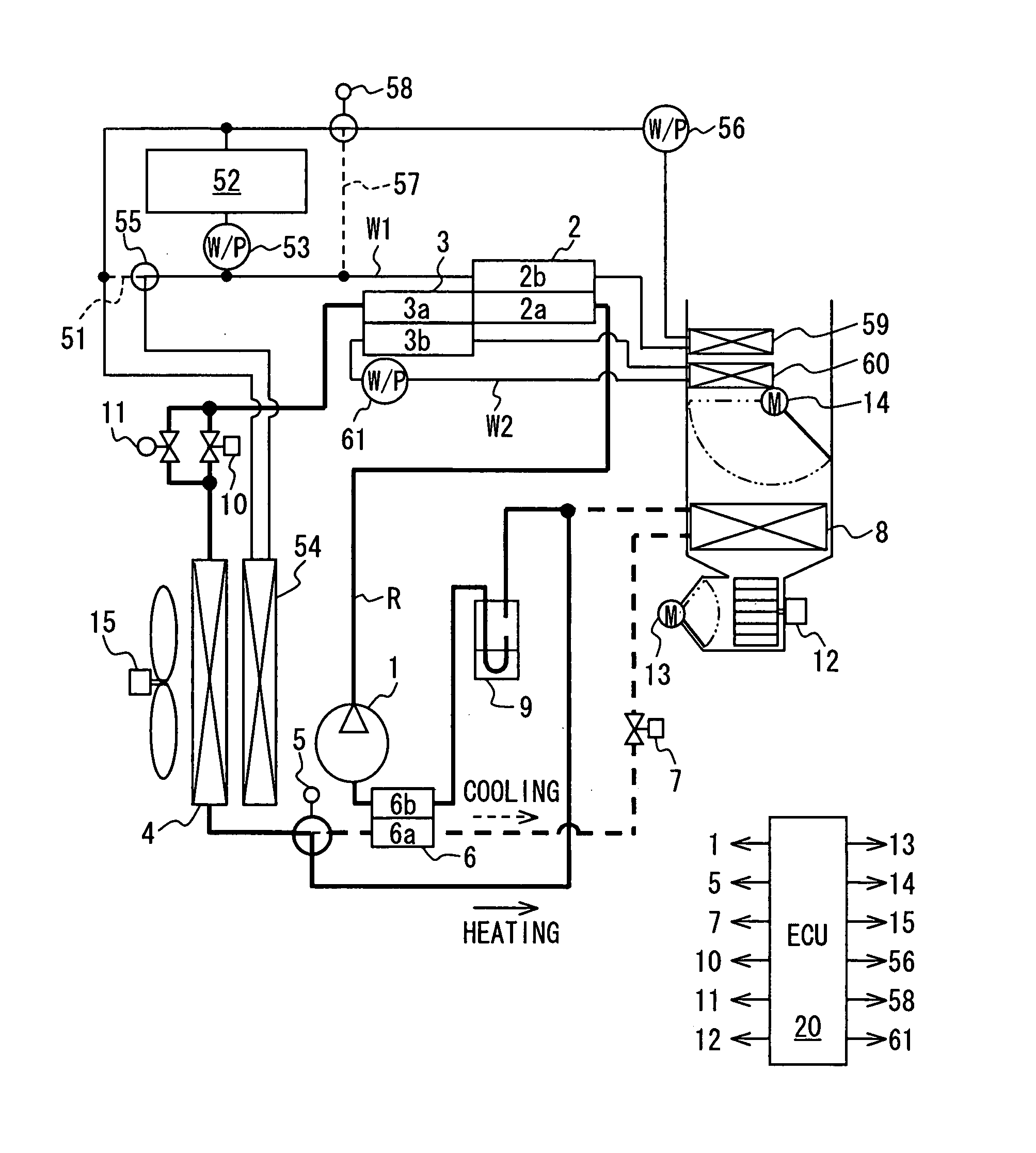

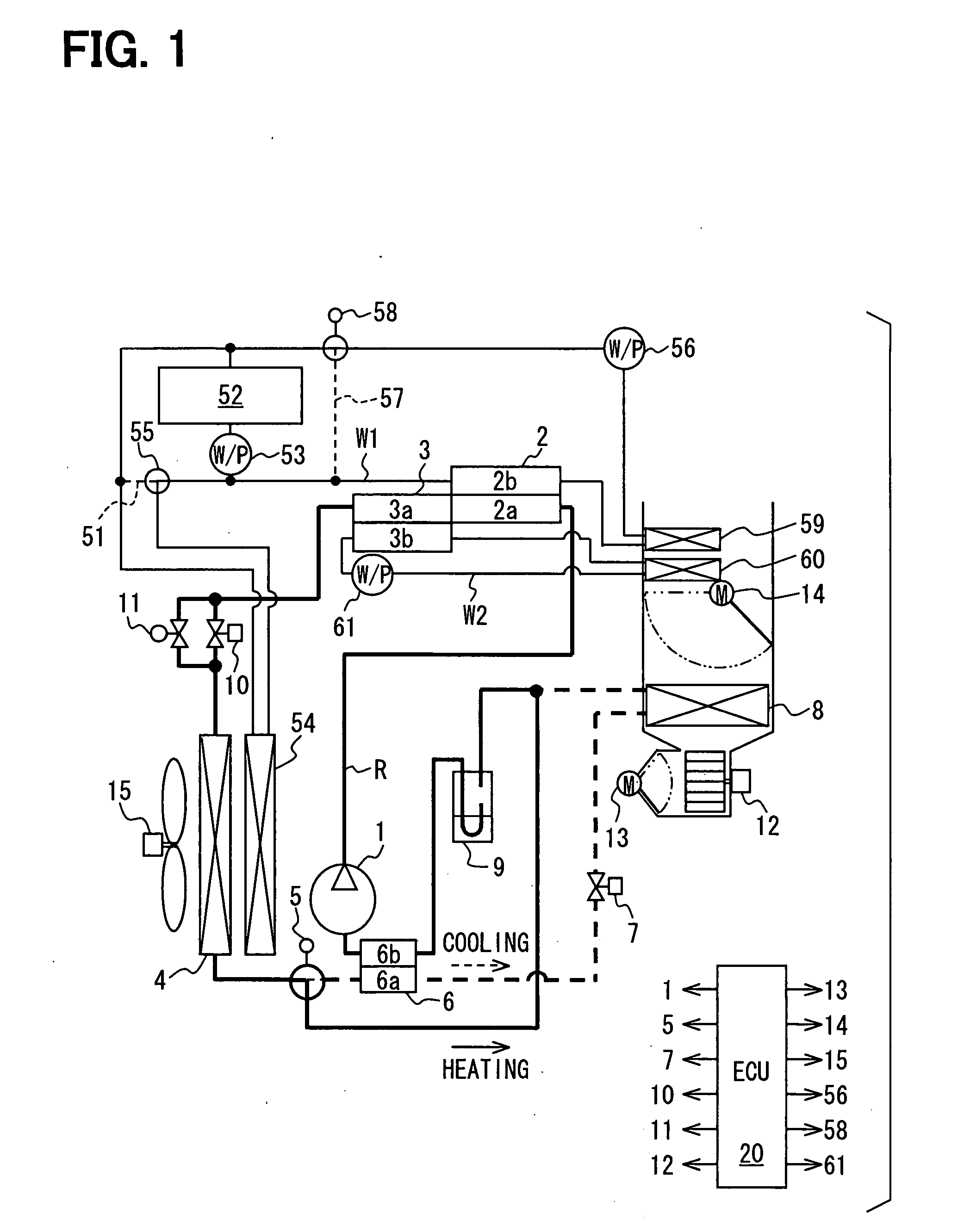

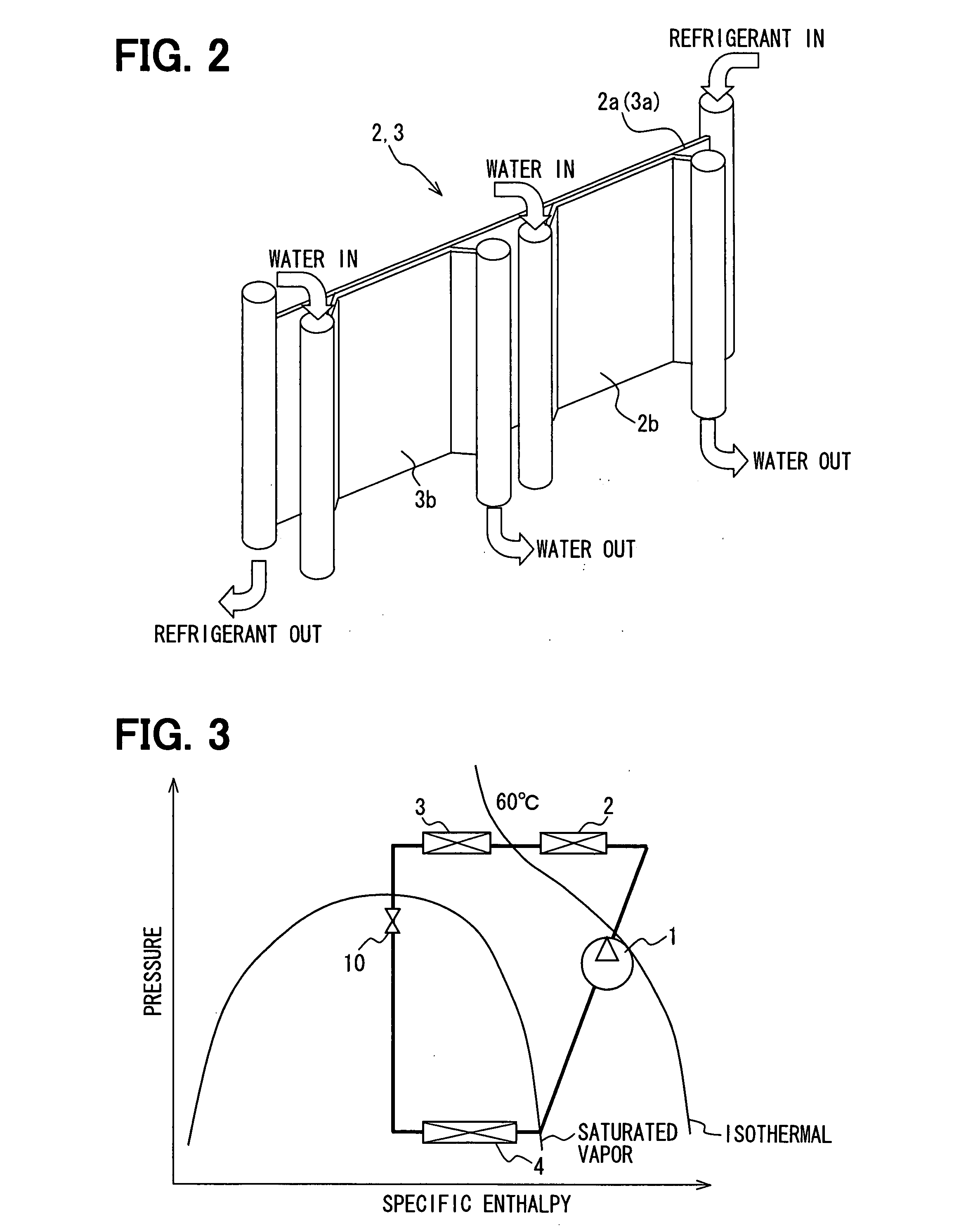

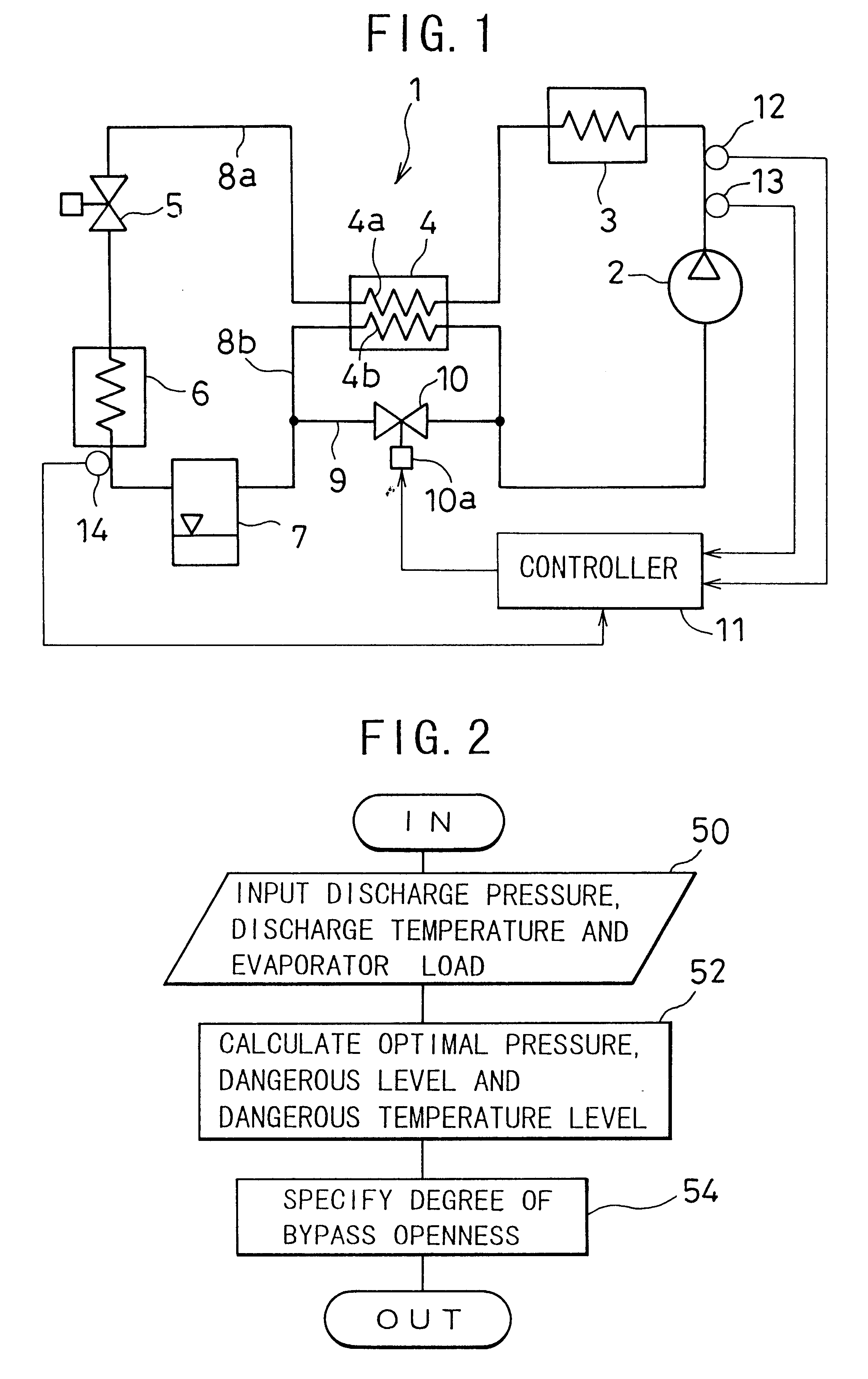

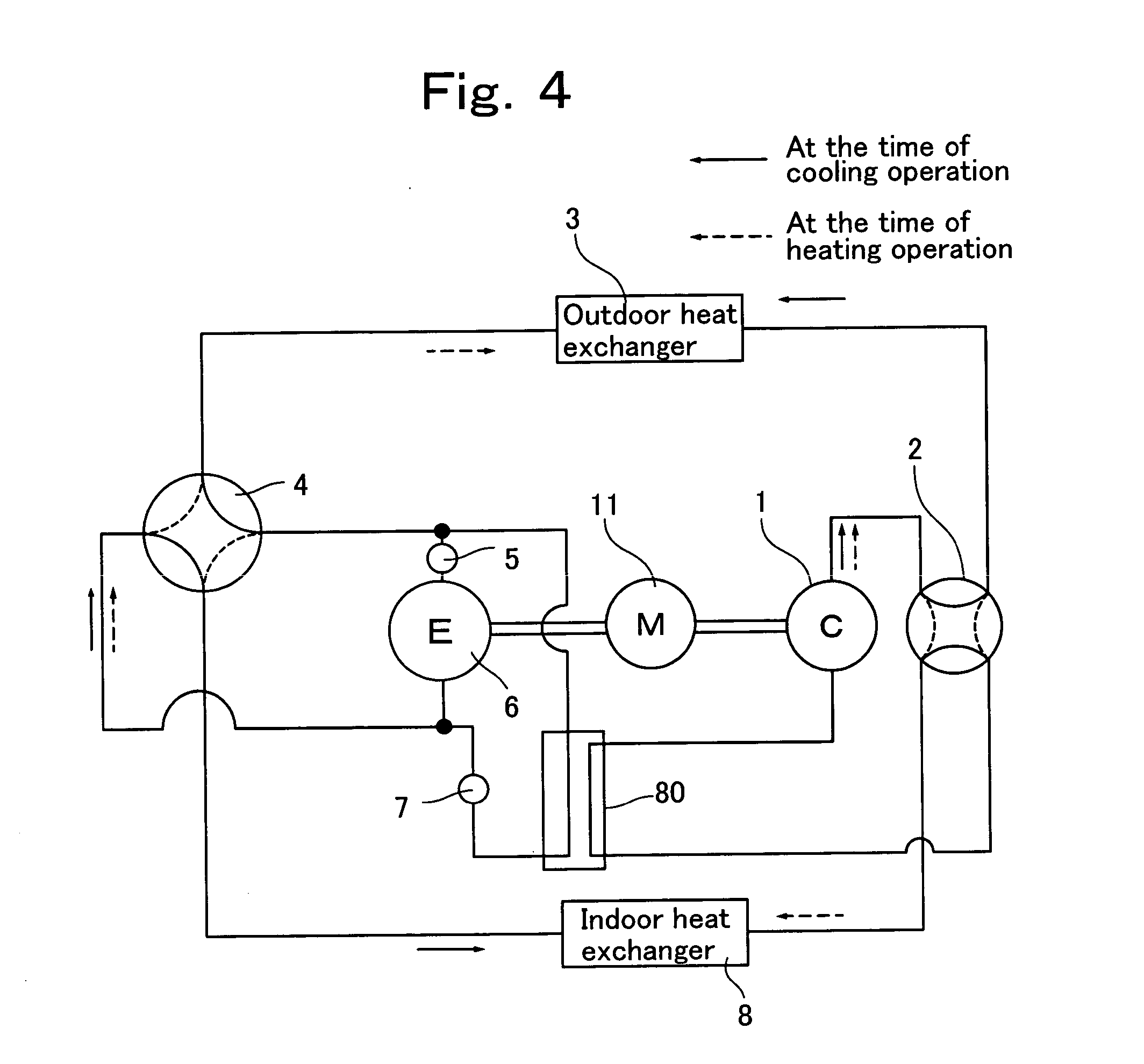

Heat pump cycle device

InactiveUS20080041071A1Improve cycle efficiencyPrevent foggingHeat pumpsEvaporators/condensersEngineeringCycle efficiency

A heat pump cycle device includes a compressor for drawing and compressing refrigerant, a first high-pressure heat exchanger located for heating a first fluid circulating in a first fluid circuit using high-pressure refrigerant discharged from the compressor, a second high-pressure heat exchanger for heating a second fluid circulating in a second fluid circuit using the high-pressure refrigerant flowing out of the first high-pressure heat exchanger, a first heating heat exchanger located to heat a third fluid using the first fluid, a second heating heat exchanger located to heat the third fluid using the second fluid, a decompression unit located to decompress the high-pressure refrigerant flowing out of the second high-pressure heat exchanger, and a low-pressure heat exchanger for evaporating low-pressure refrigerant decompressed by the decompression unit. Because the first and second high-pressure heat exchangers are located, cycle efficiency can be improved.

Owner:DENSO CORP

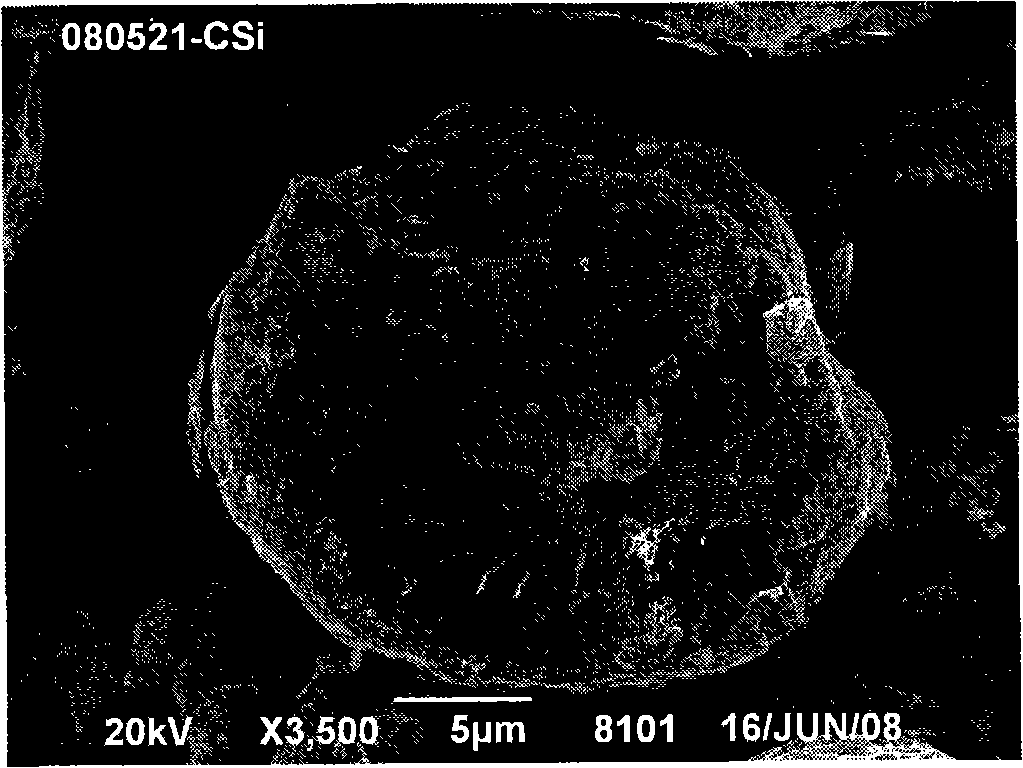

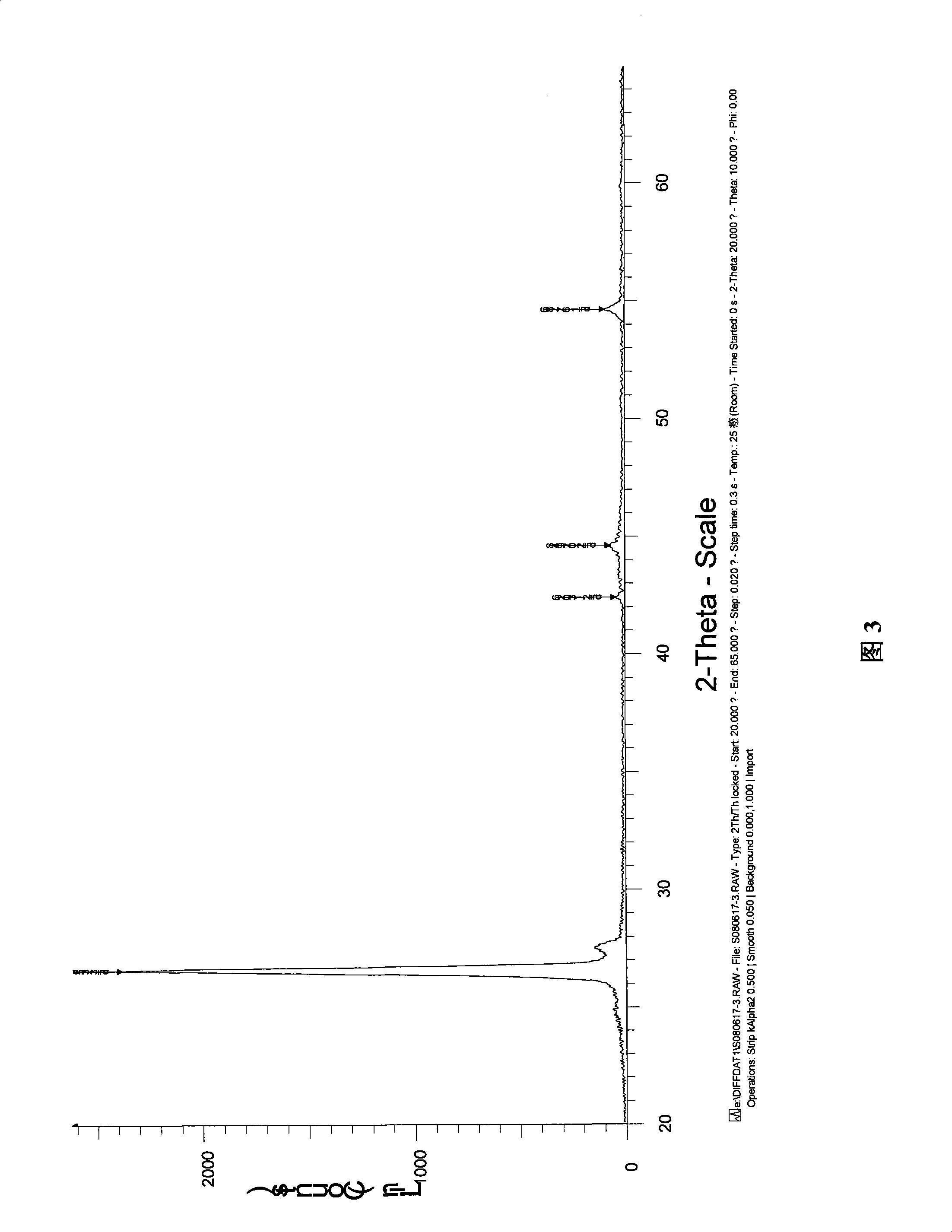

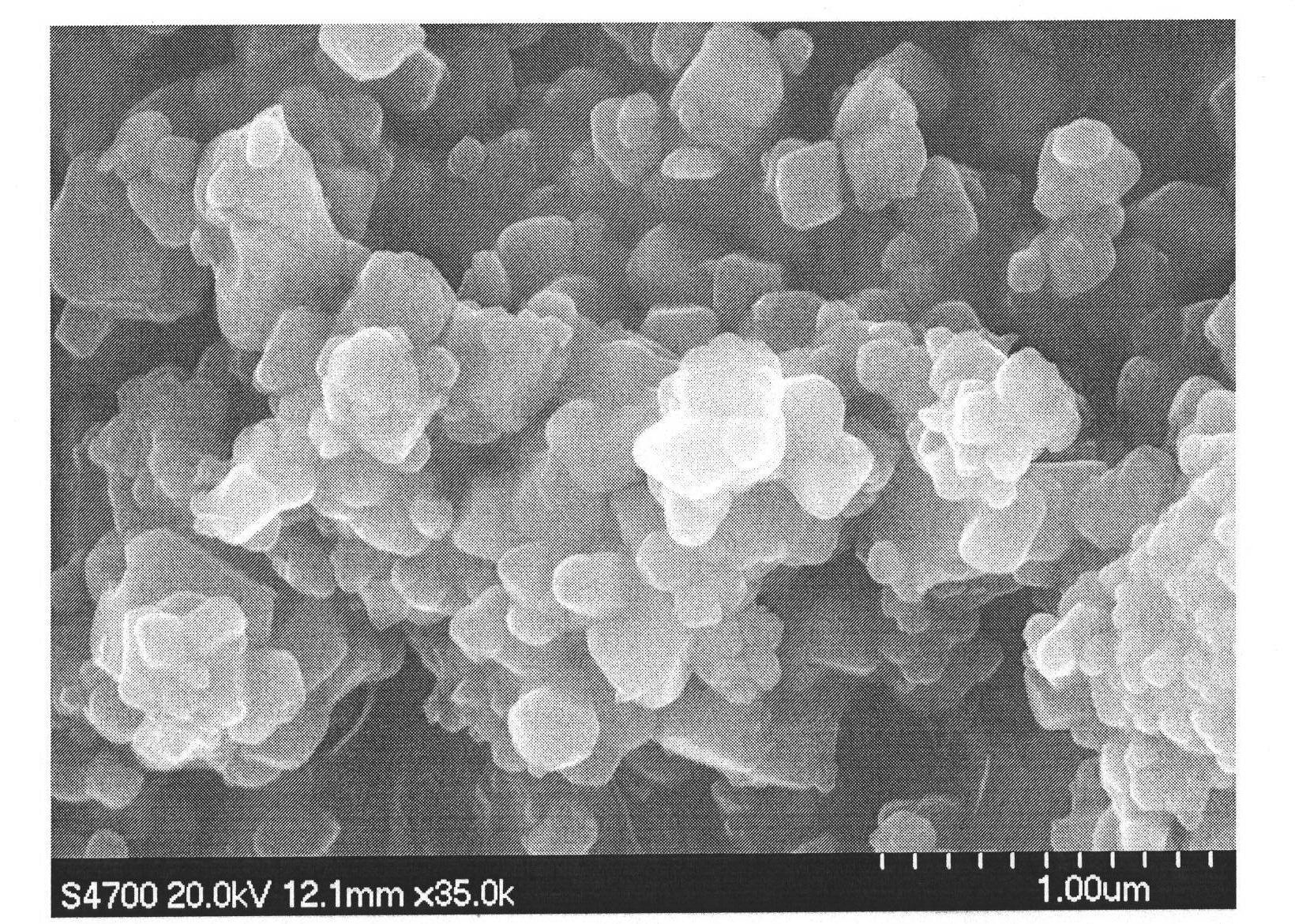

Silicon-carbon composite cathode material of lithium ion battery and preparation thereof

InactiveCN101339987AImprove battery energy densityImprove cycle performanceElectrode manufacturing processesChemical/physical/physico-chemical processesCarbon compositesCarbonization

The invention provides a silicon-carbon composite cathode material for preparing a lithium-ion battery at the room temperature and a preparation method thereof. The composite cathode material is a material with a nuclear shell structure and comprises the following proportional elements: 0.01-10% of simple substance silicon and 90-99.9% of carbon. With regard to the preparation method, silicon powder and graphite are mixed for ball grinding and then added with bitumen or polymer cladding material for ball grinding again, after the treatment of carbonization, the mixture is crushed and sieved to obtain the material containing 0.01-10wt% of silicon and 10-99.9% of carbon. The capacity of the material is more than 350mAh / g, the cycle efficiency of the material is larger than 90% for the first time, and keeps larger than 80% after 200 cycles, and the material has good charging and discharging property.

Owner:湖南海容新材料有限责任公司

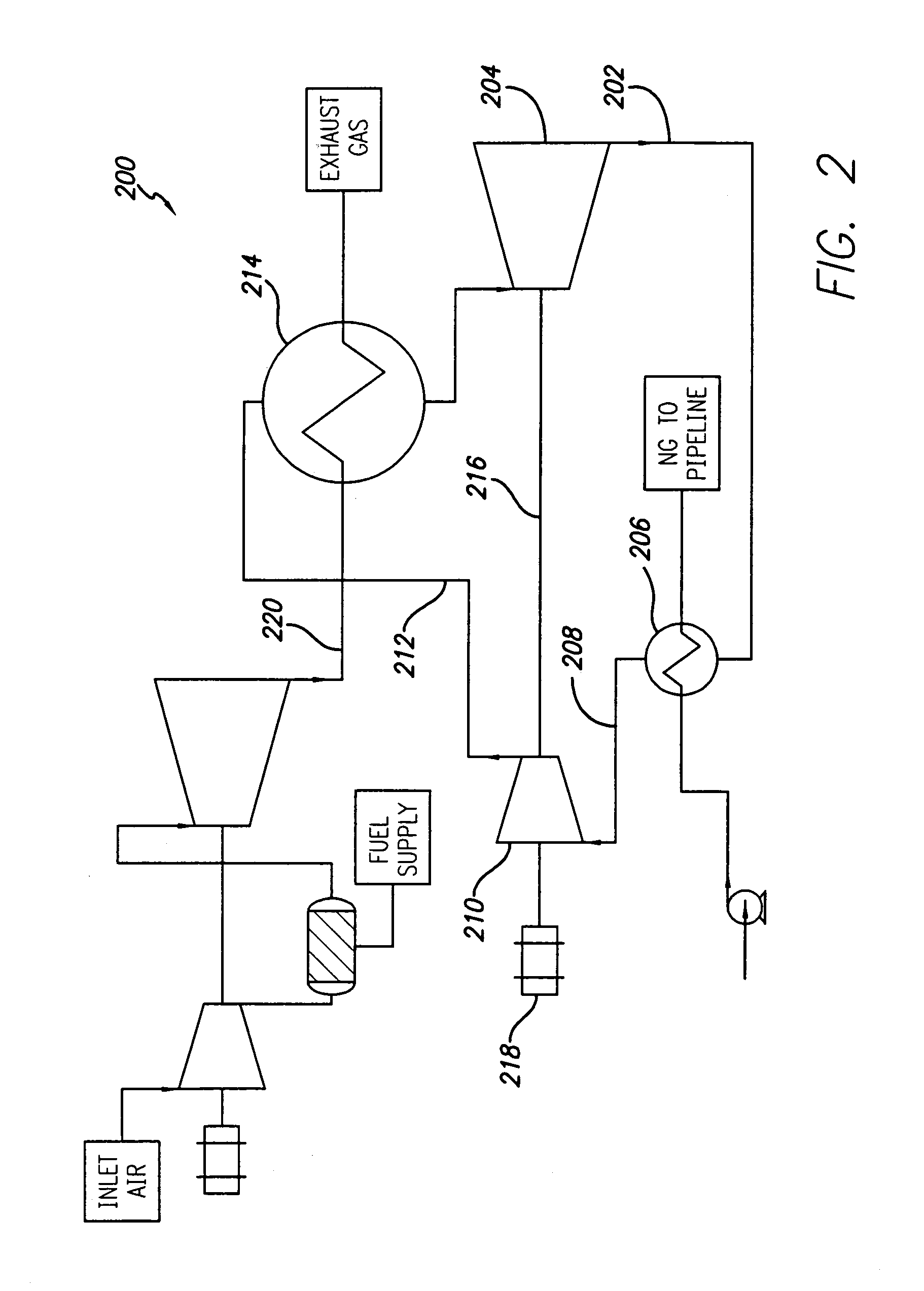

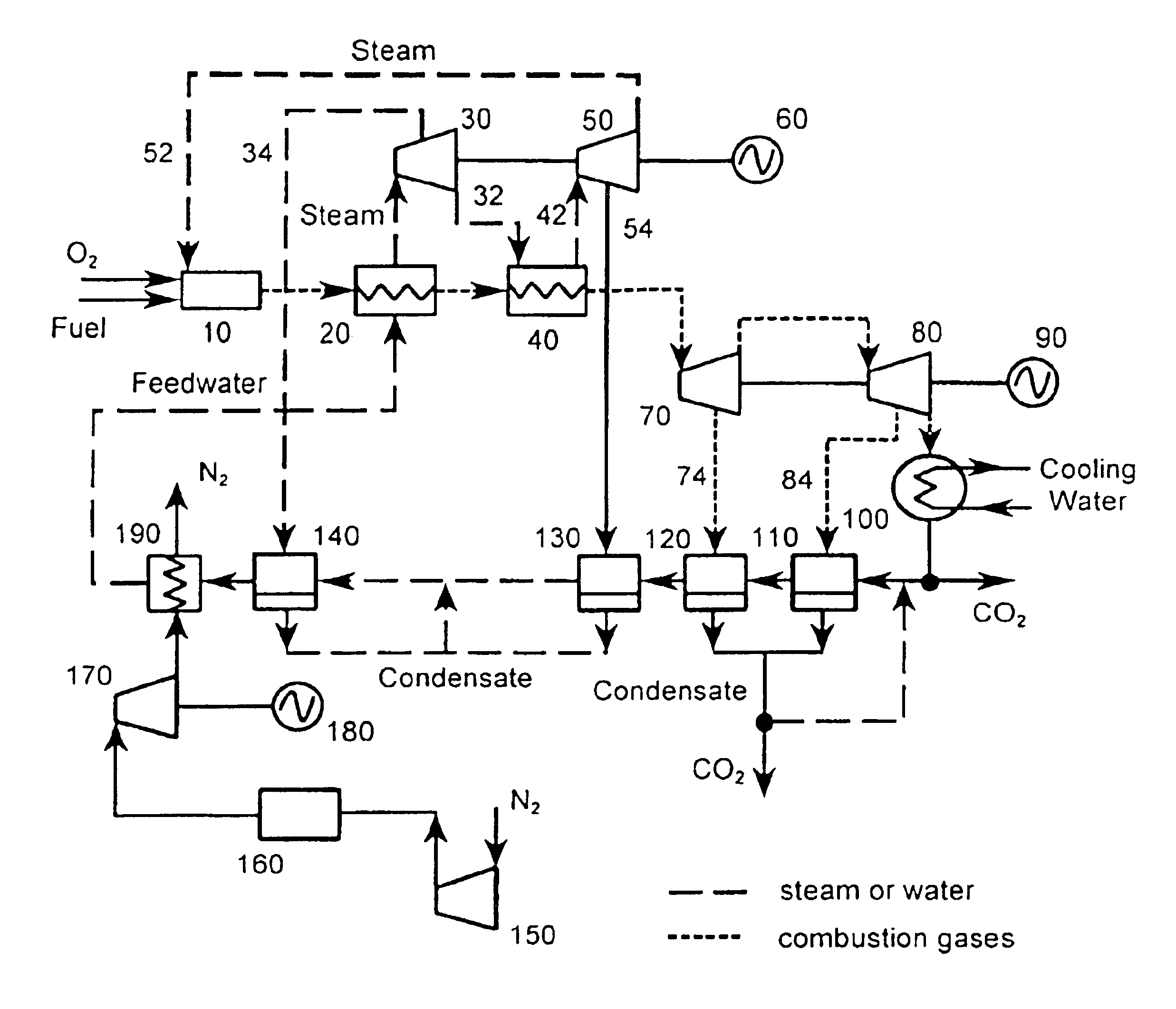

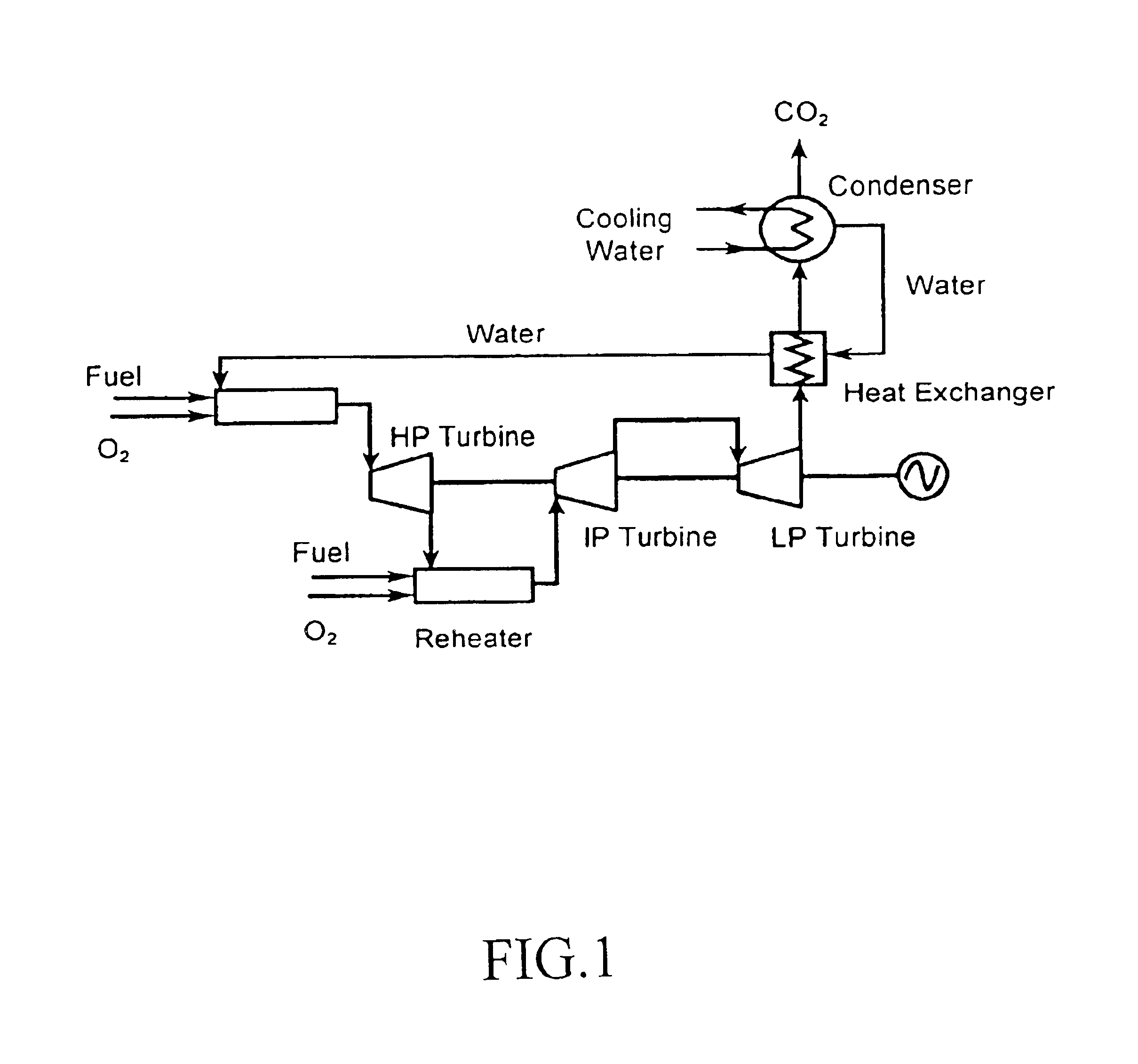

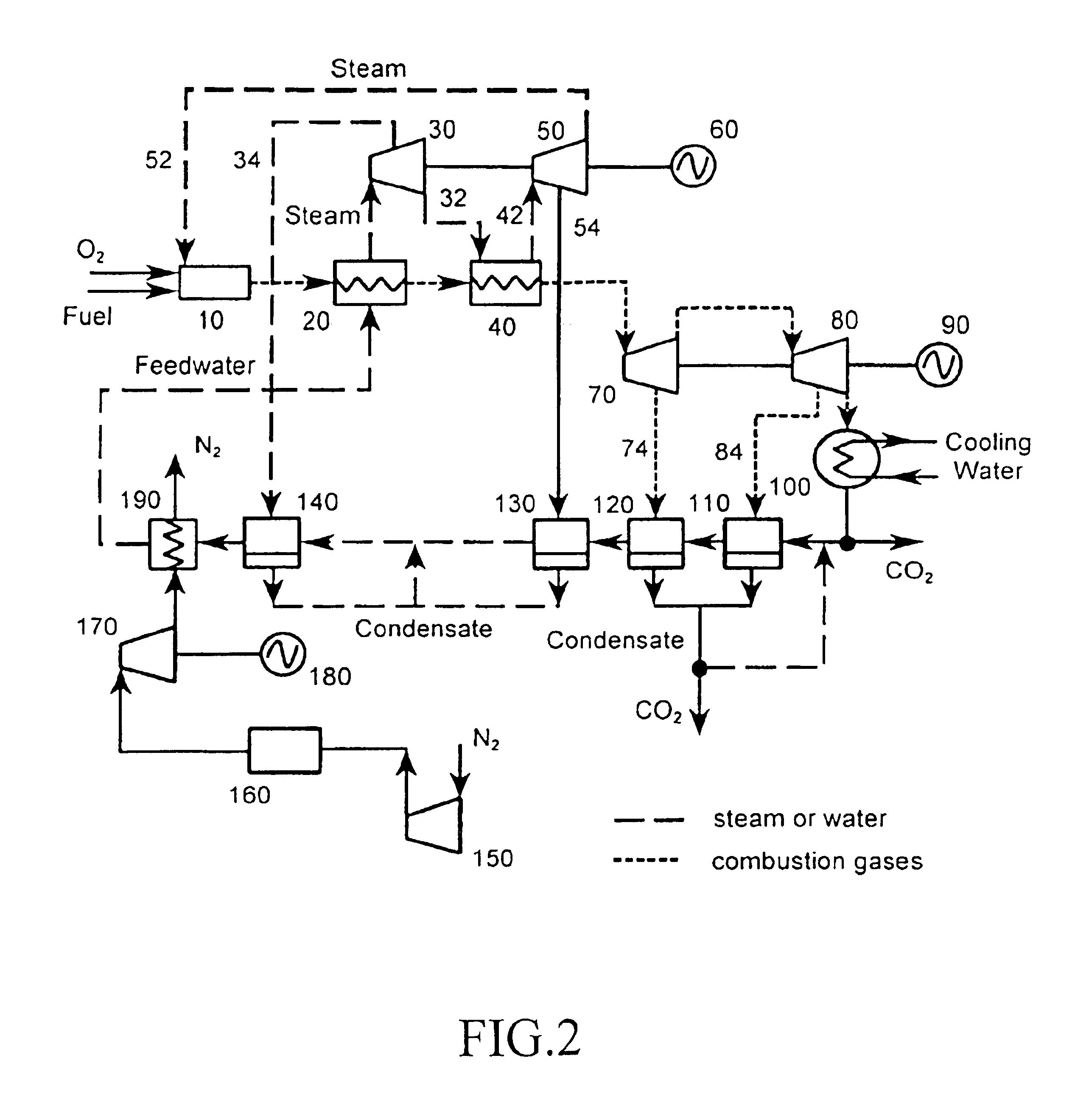

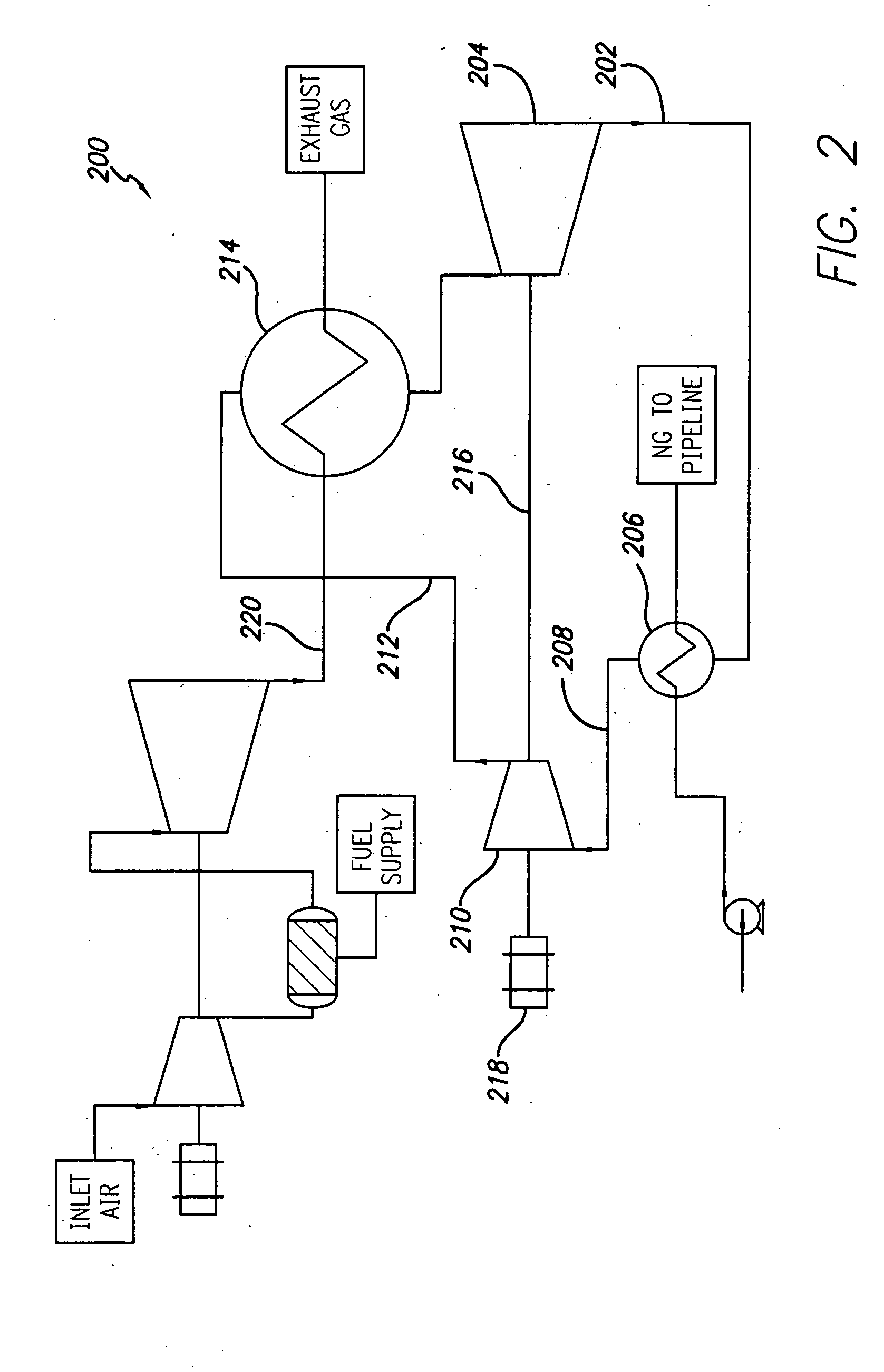

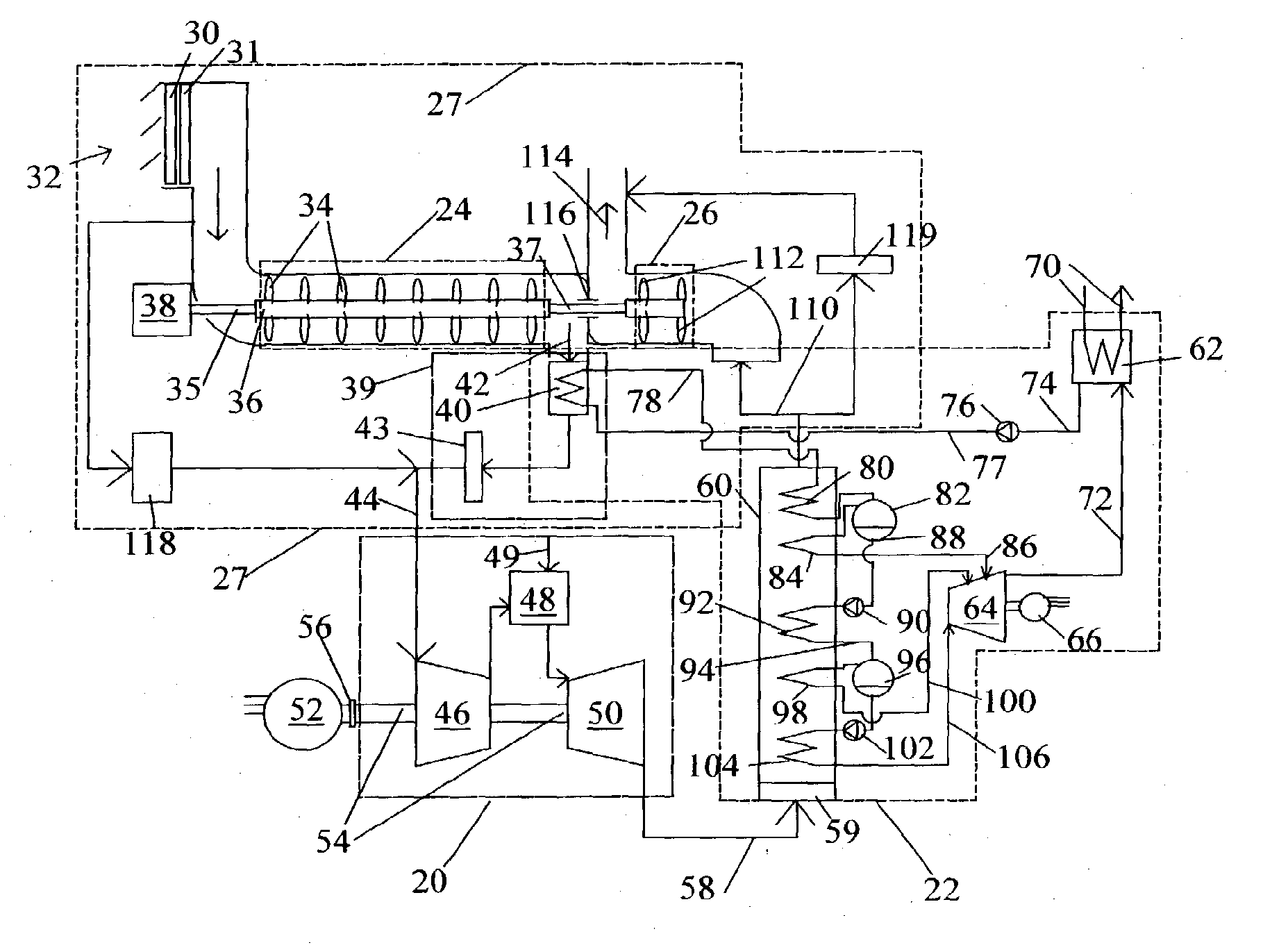

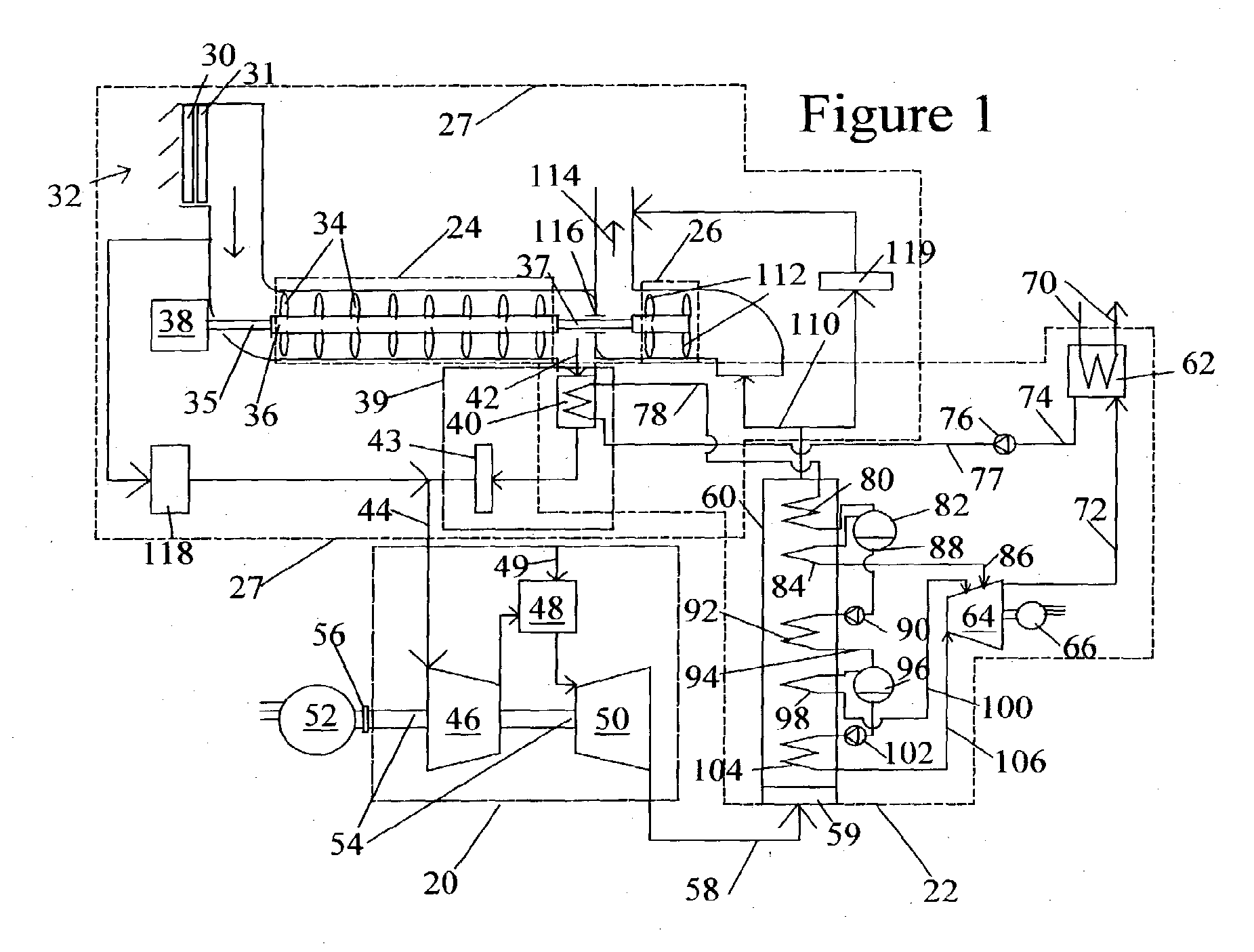

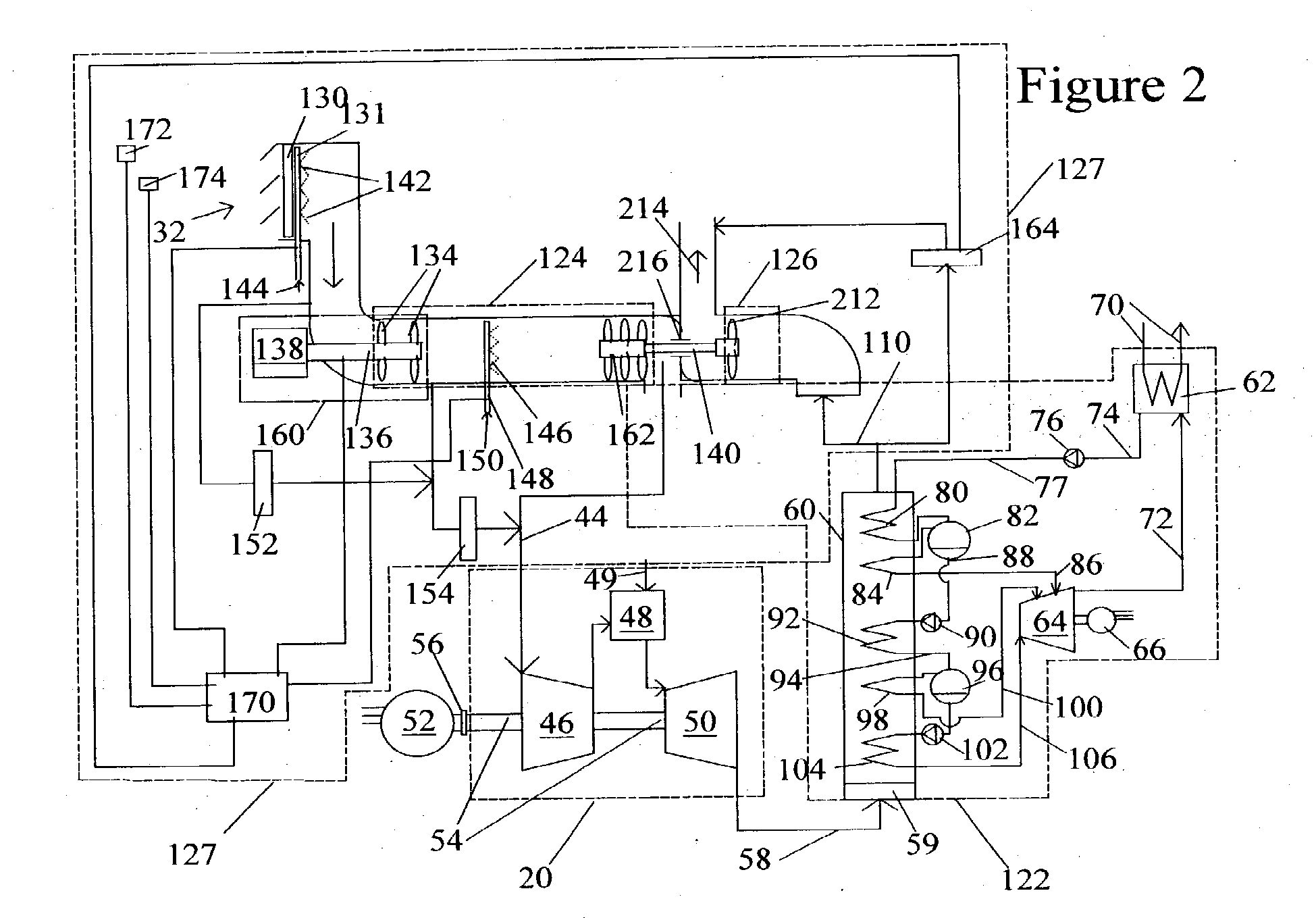

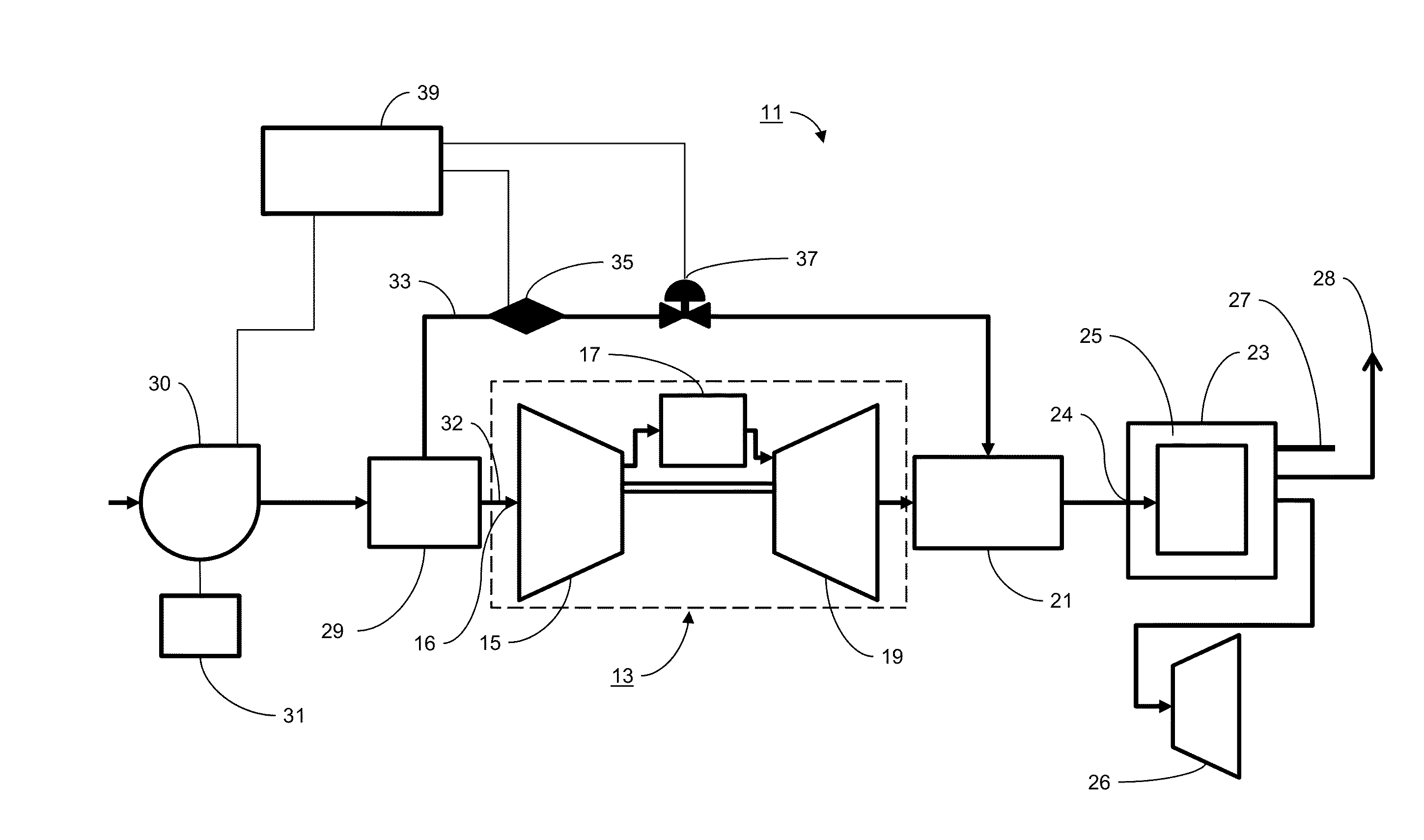

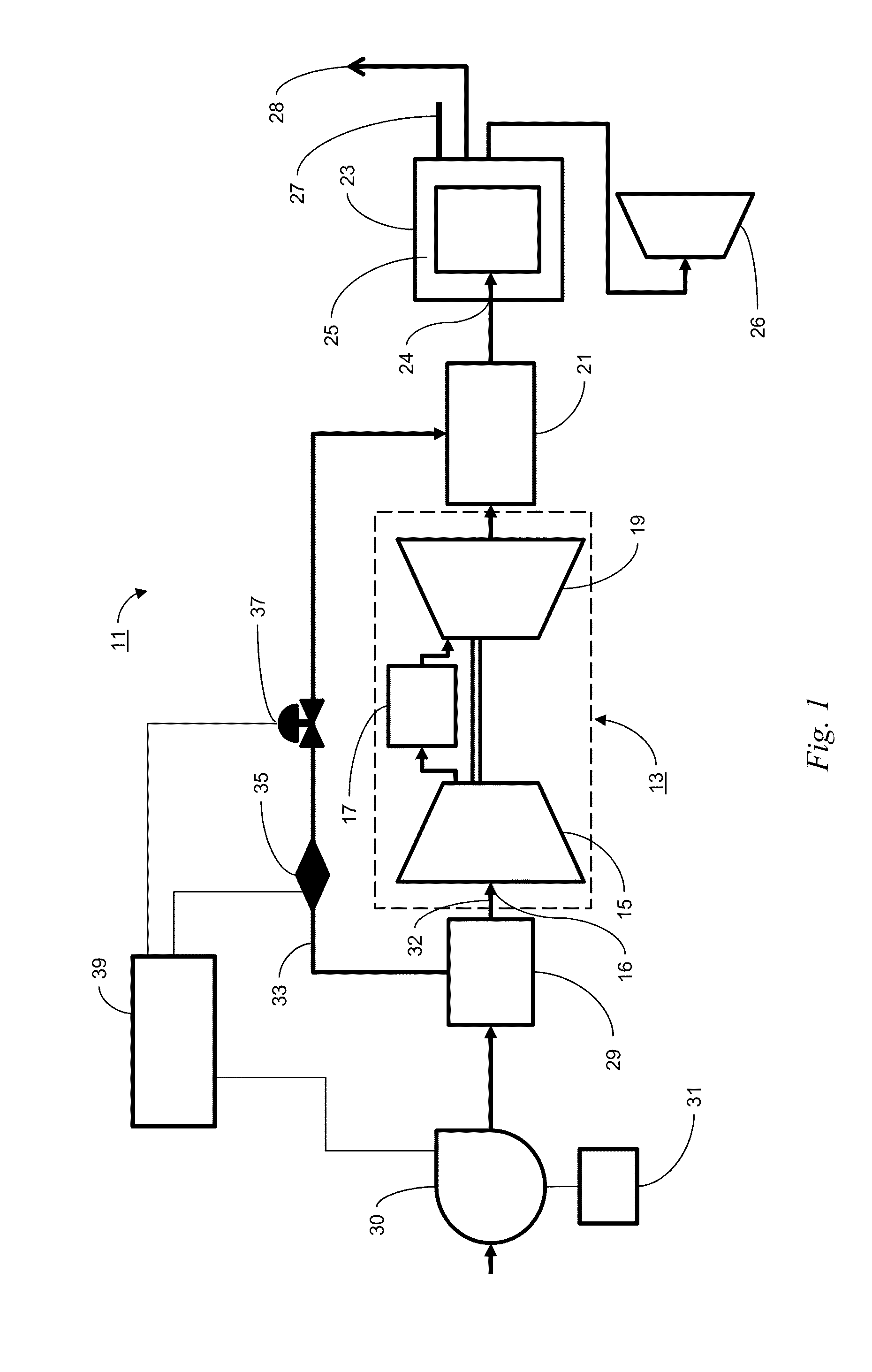

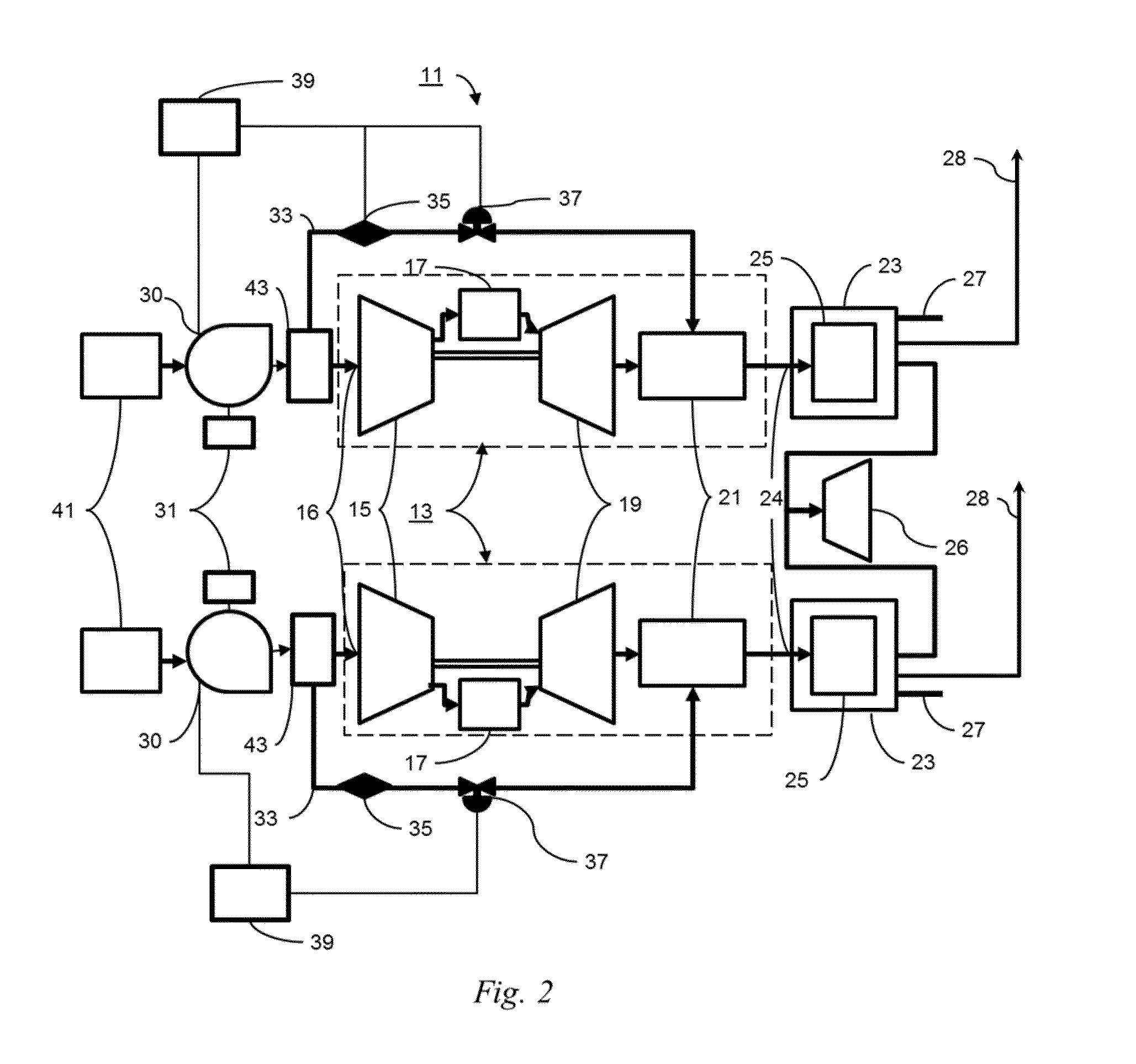

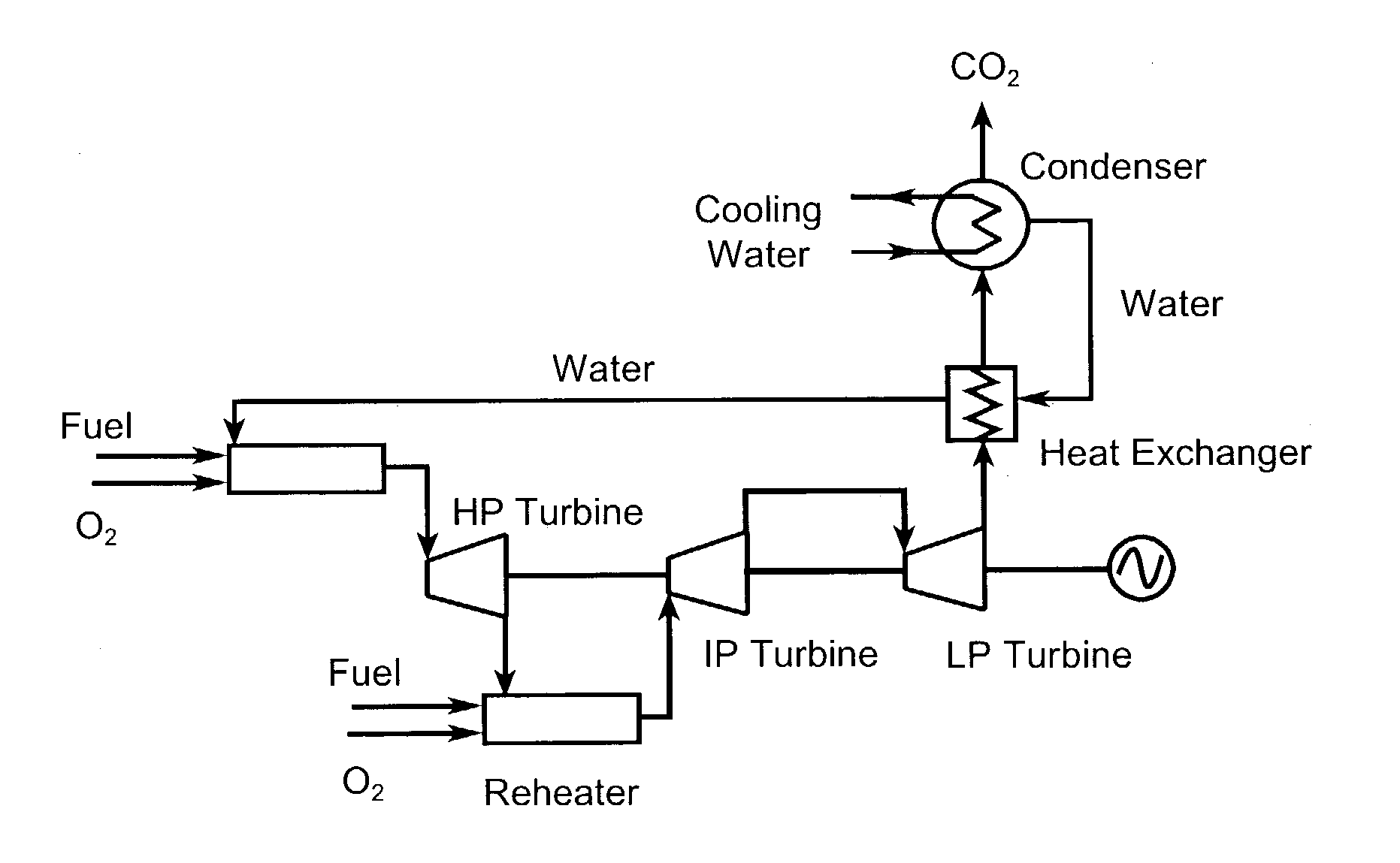

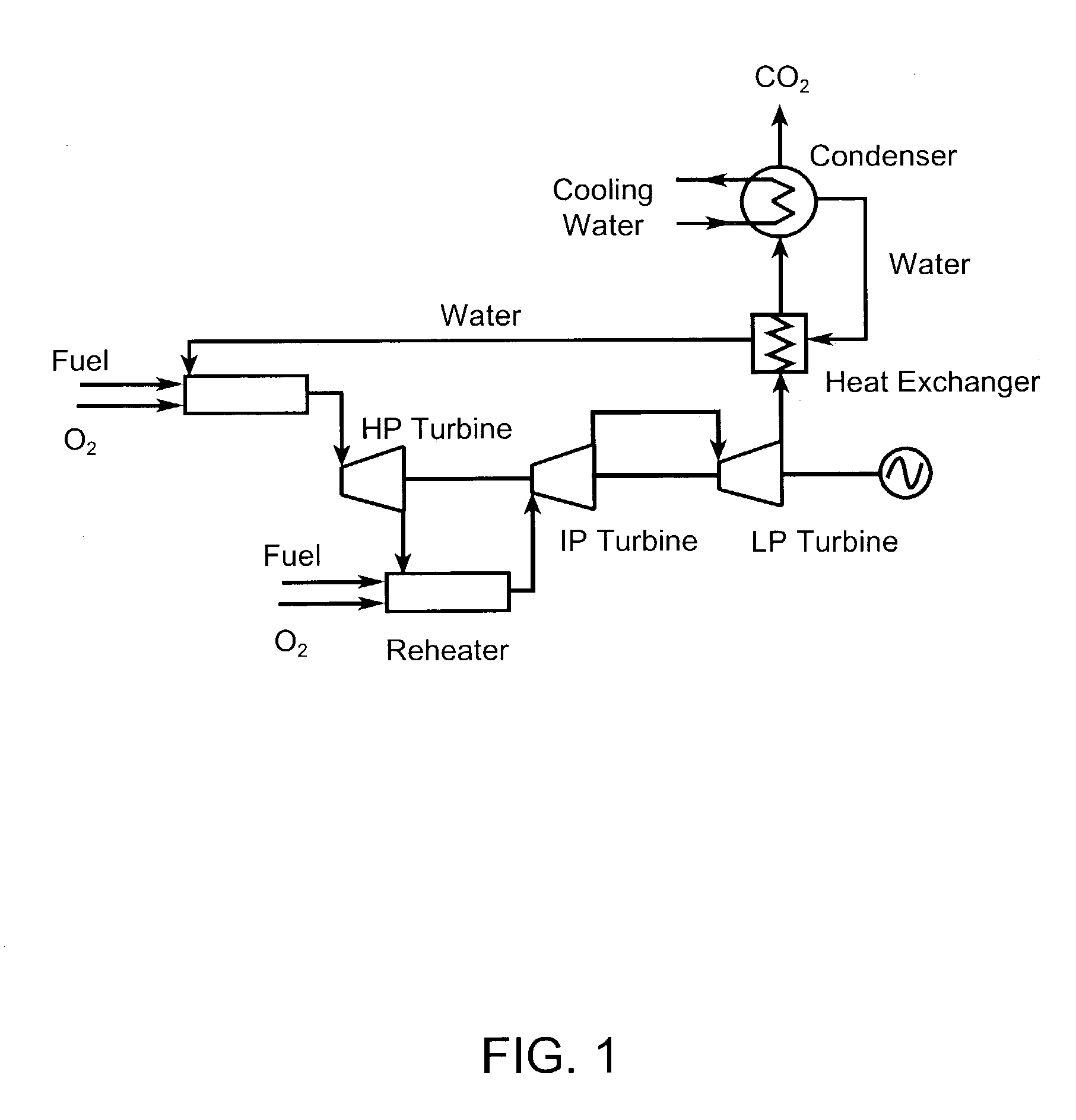

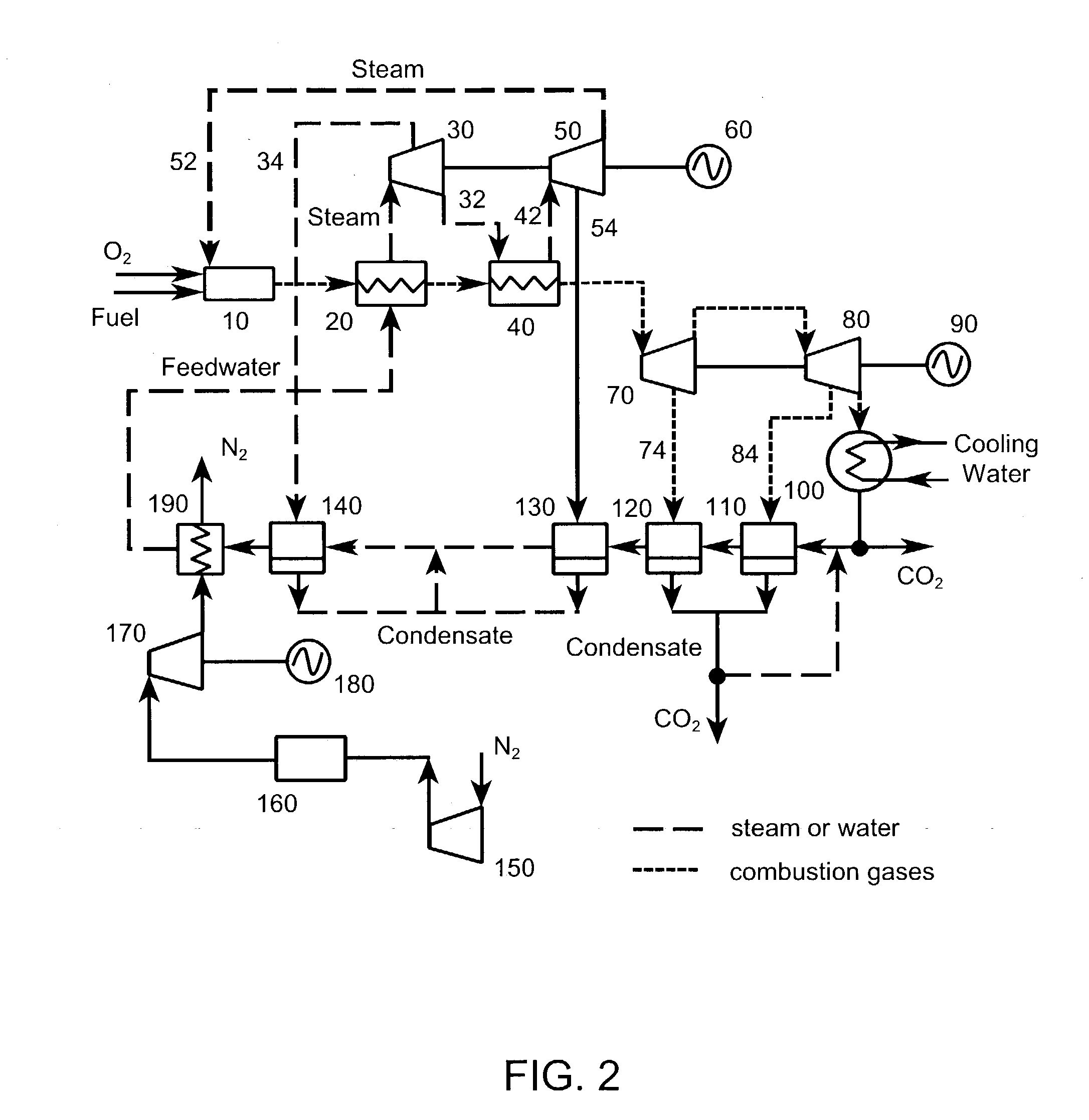

Optimized power generation system comprising an oxygen-fired combustor integrated with an air separation unit

InactiveUS6871502B2Maximize efficiencyImprove efficiencySolidificationLiquefactionHigh pressureCycle efficiency

A novel power generation system, more specifically an integrated power generation and air separation system and an integrated power generation and air separation process is provided. A key component of the system and process is an oxygen-fired combustor designed for gas turbine operating pressures. The combustor produces a high-temperature gas stream that enters one or more heat exchangers to generate / heat steam, and then enters one or more turbines to generate power. The steam from the heat exchanger drives one or more steam turbines to generate power, and the discharged steam is admitted to the combustor. To maximize cycle efficiency, steam extraction and reheat is incorporated in the process. Additional power is generated from a high-pressure nitrogen stream produced by an air separation unit (ASU). This process has the potential to attain high cycle efficiencies with zero emissions, while utilizing existing or near-term steam turbines, and moderate-pressure combustion systems.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

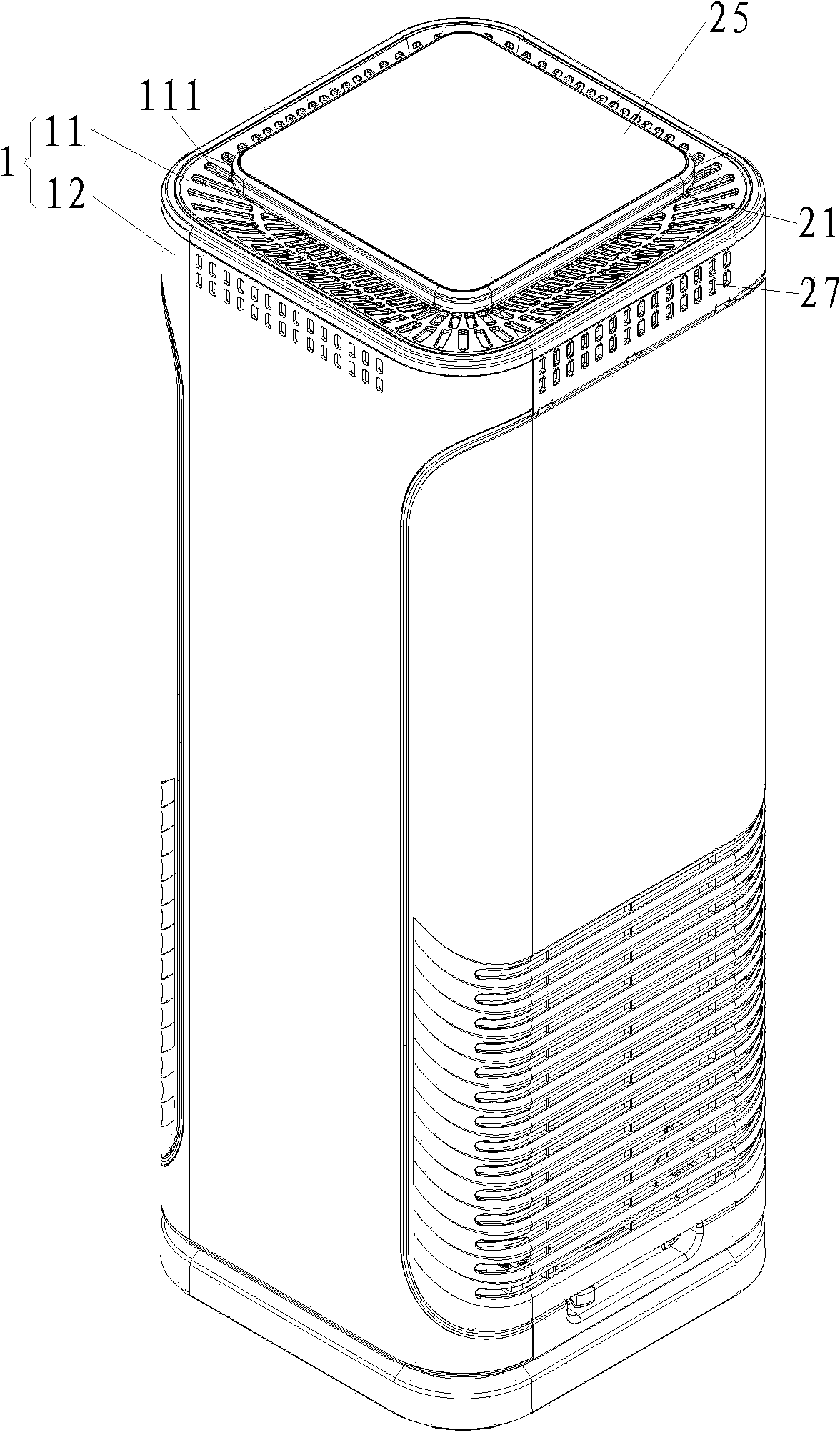

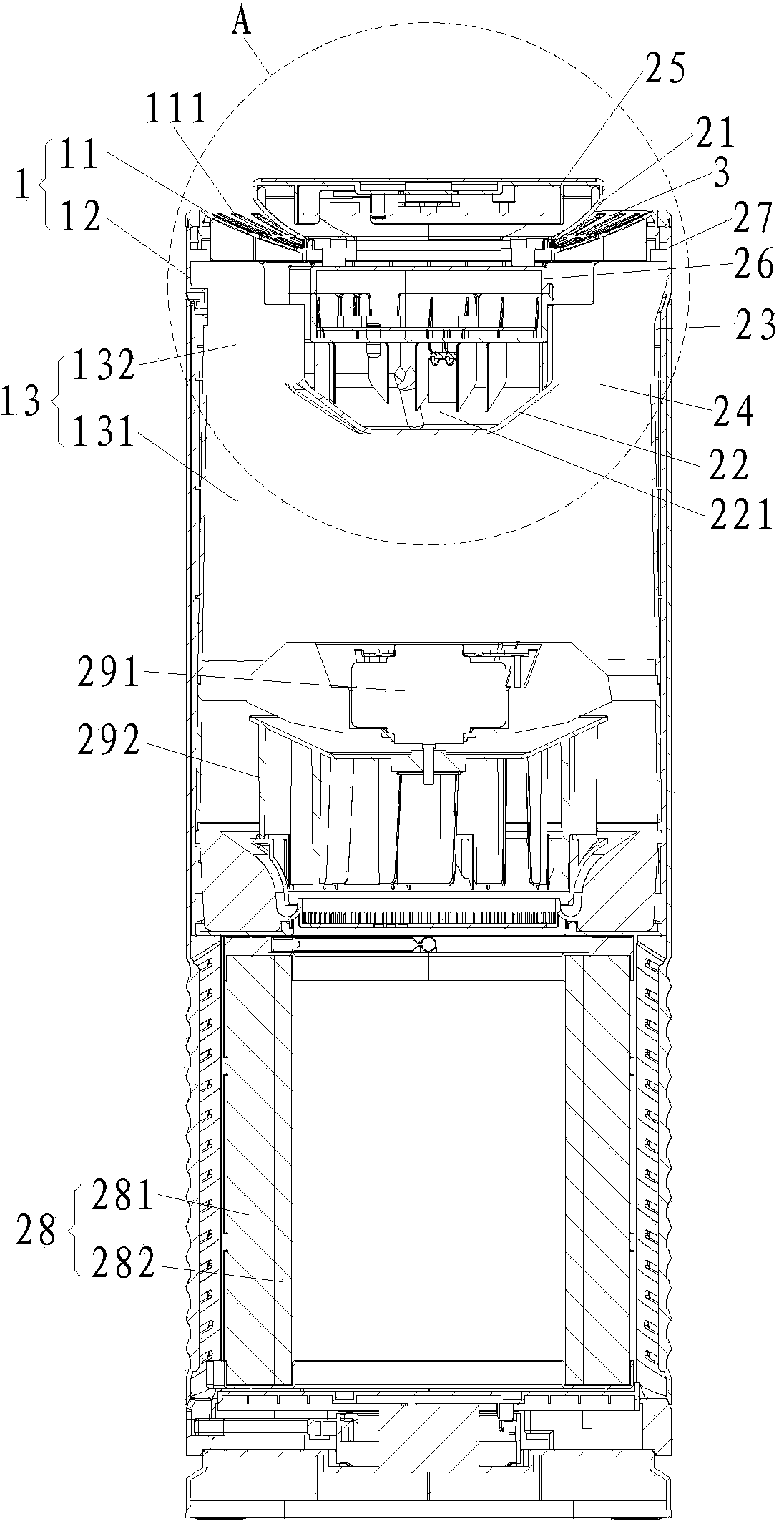

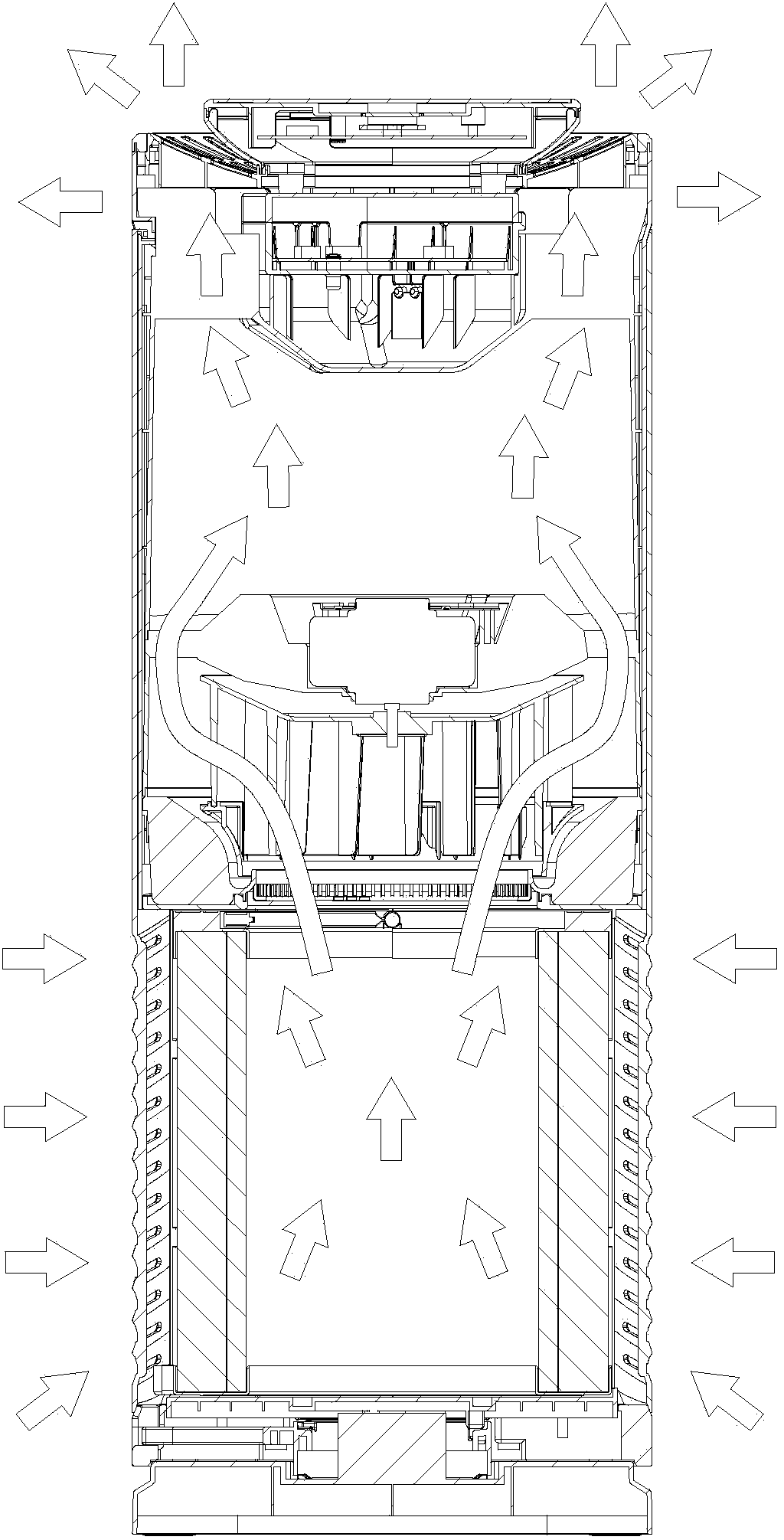

Air purifier

ActiveCN103982994AFast diffusionEffective diffusionSpace heating and ventilation safety systemsLighting and heating apparatusAir purifiersEngineering

The invention discloses an air purifier. The air purifier comprises a shell; an air cavity for air to circulate is formed in the shell; the shell comprises a top wall and a peripheral wall; the top wall of the shell is provided with an upper air outlet communicated with the air cavity; the purifier also comprises a distributing component fixed to the shell; the distributing component comprises an air blocking piece covering above the upper air outlet; the air blocking piece diffuses air blown out of the air outlet upwards to the periphery. The air purifier is omni-directional in air outlet, so that the purified air is more quickly and more efficiently diffused indoors, and the cycle efficiency of the purified air is improved.

Owner:MIDEA GRP CO LTD

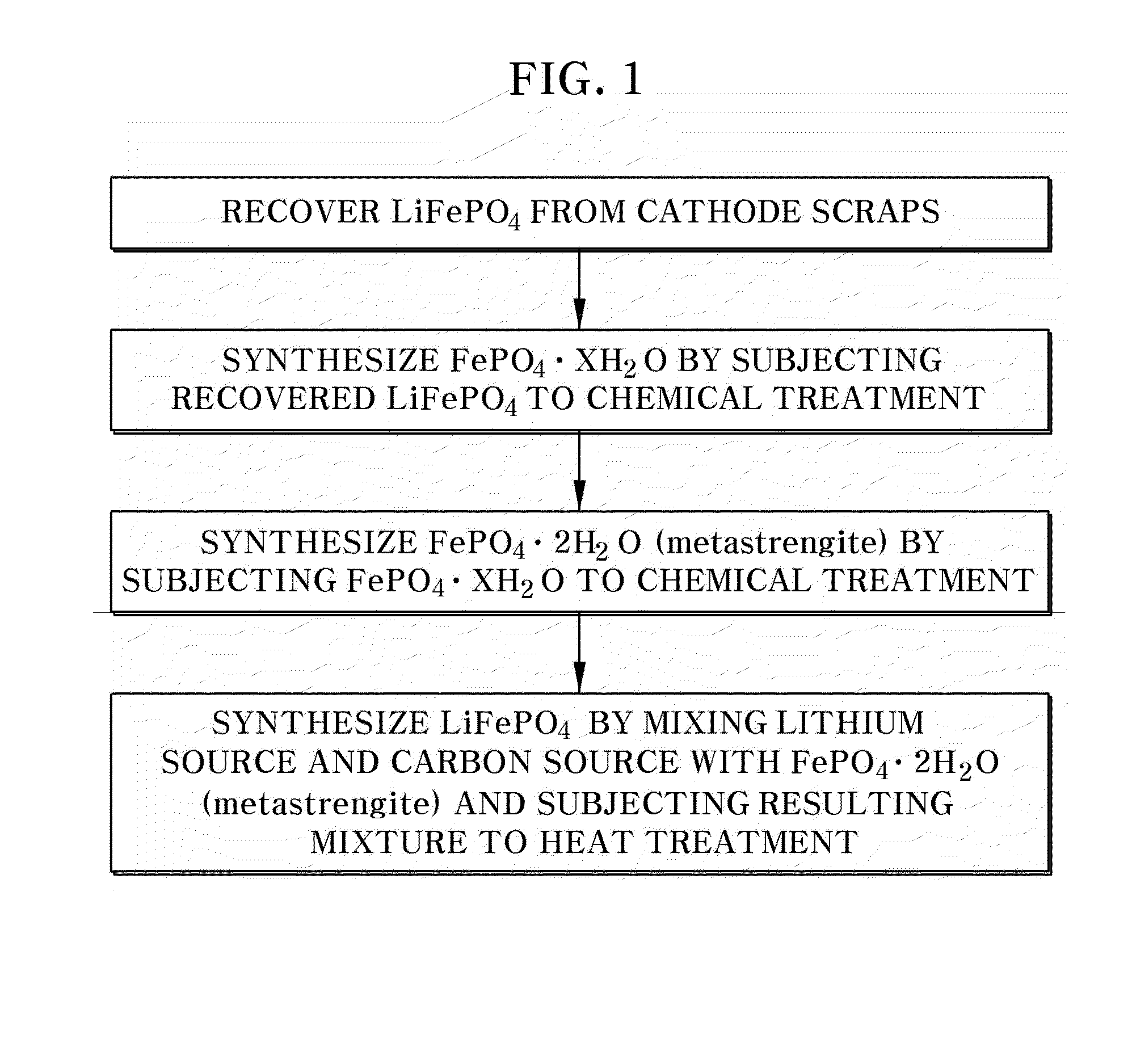

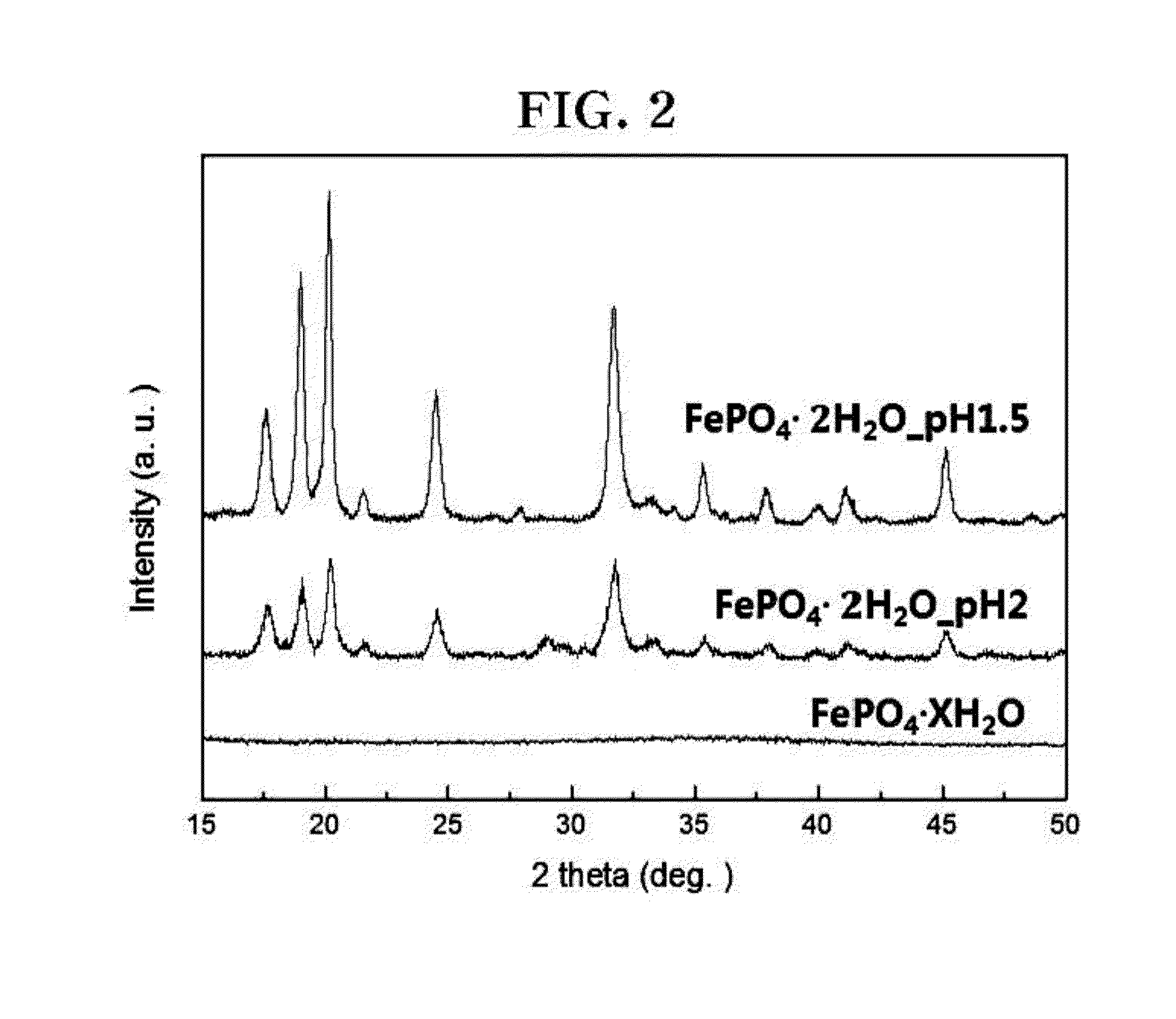

Recycling method of olivine-based cathode material for lithium secondary battery, cathode material fabricated therefrom, and cathode and lithium secondary battery including the same

ActiveUS20140264185A1Deterioration in performanceReduce manufacturing costNon-metal conductorsPhosphatesCycle efficiencyOlivine

Owner:KOREA INST OF SCI & TECH

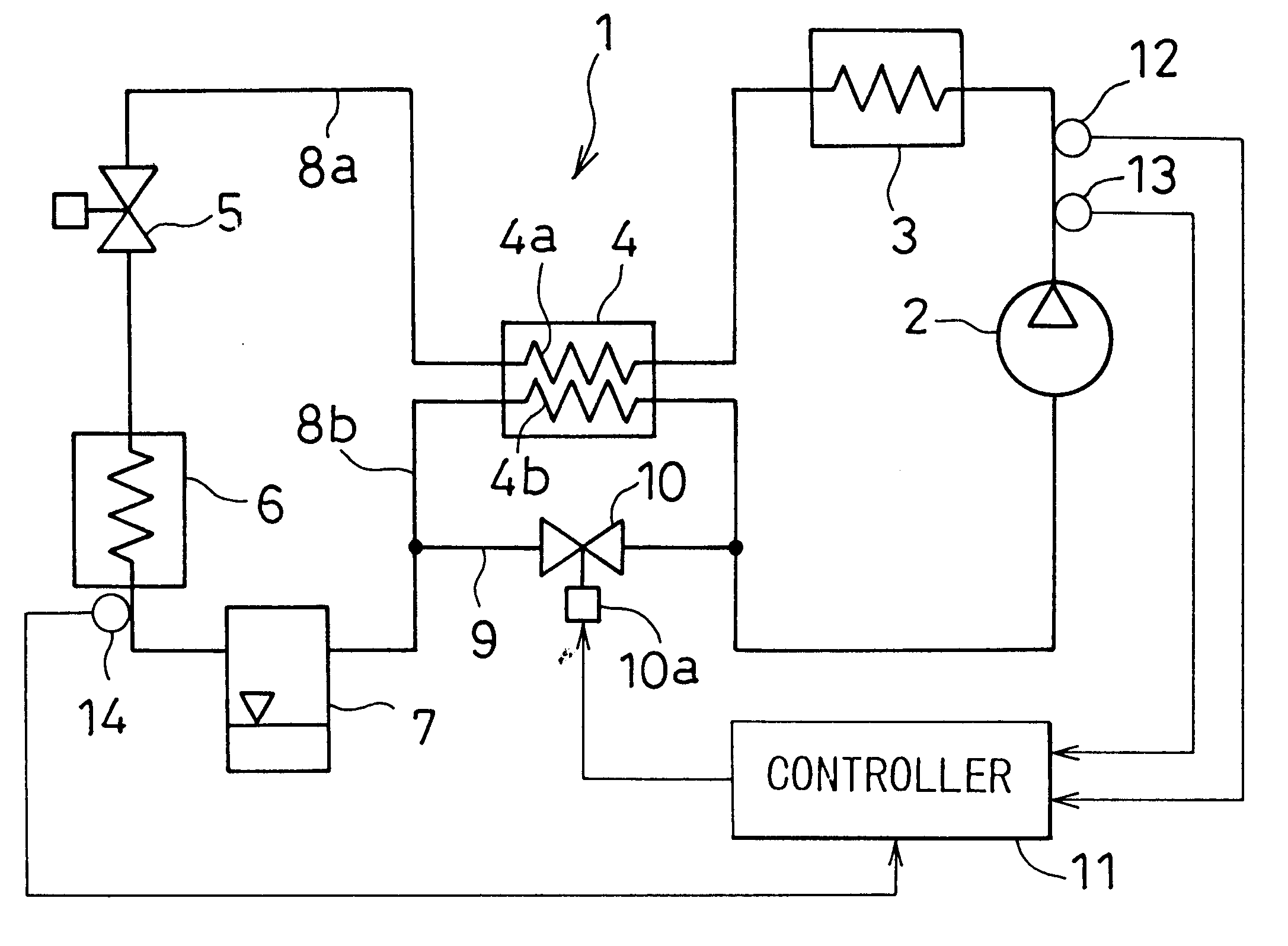

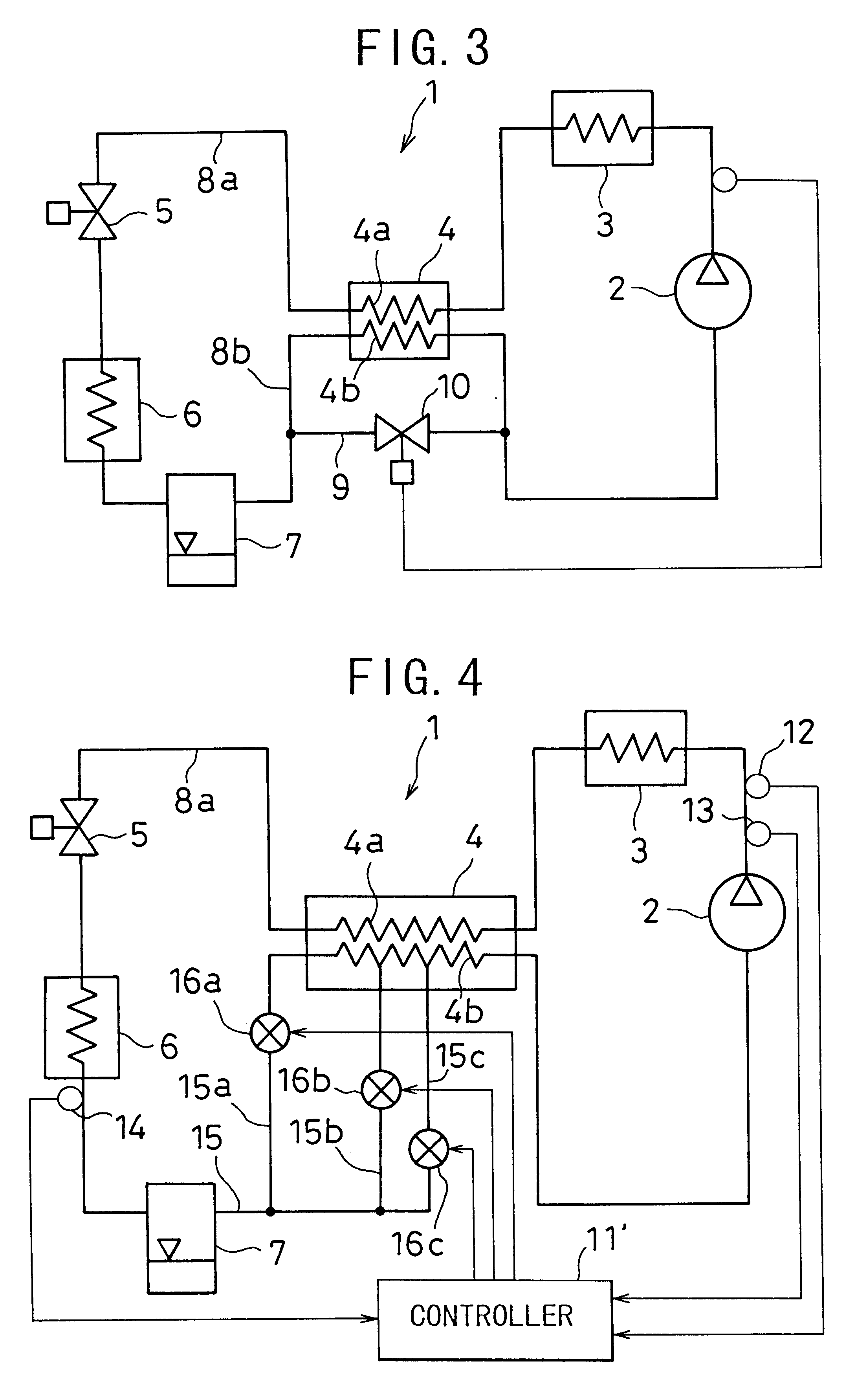

Refrigerating cycle

InactiveUS6260367B1Mechanical apparatusCompression machines with non-reversible cycleSolenoid valveCoolant flow

In a freezing cycle that utilizes a supercritical fluid as its coolant and employs an internal heat exchanger that performs heat exchange on the coolant on the outlet side of a gas cooler and on the intake side of a compressor, a means for adjustment that adjusts the quantity of heat exchange performed by the internal heat exchanger (4) is provided. The means for adjustment is constituted of a bypass passage (9) that bypasses the internal heat exchanger (4) and a flow-regulating valve (10) that adjusts the coolant flow rate in the bypass passage (9). The flow-regulating valve (10) is constituted of an electromagnetic valve, the degree of openness of which is determined based upon information with respect to the cycle state, or a bellows regulating valve that operates in correspondence to the pressure on the high-pressure side. Alternatively, the means for adjustment may perform adjustment by varying the passage length over which heat exchange is performed by the internal heat exchanger (4). Good cycle efficiency is achieved by maintaining the optimal high-pressure through cycle balance control. The freezing cycle can be temporarily protected against excessively high-pressure or excessively high discharge temperature at the compressor.

Owner:ZEXEL VALEO CLIMATE CONTROL CORP SAITAMA

Three-dimensional macroporous graphene, carbon nano tube and molybdenum disulfide composite material, and preparation method and application of composite material

The invention discloses a three-dimensional macroporous graphene, carbon nano tube and molybdenum disulfide composite material, and a preparation method and an application of the composite material, and relates to a nano composite material, and a preparation method and an application of the nano composite material. The composite material, the preparation method and the application aim at solving the problems of poor stability and too low first cycle efficiency of existing molybdenum disulfide serving as a cathode active substance of a lithium ion battery. The method comprises the steps of 1, preparing a three-dimensional macroporous graphene / foam metal composite, 2, preparing a three-dimensional macroporous graphene / carbon nano tube / foam metal composite, 3, preparing a three-dimensional macroporous graphene / carbon nano tube, 4, loading molybdenum disulfide by a hydrothermal method, and 5, annealing the three-dimensional macroporous graphene / carbon nano tube loaded with molybdenum disulfide to obtain the three-dimensional macroporous graphene, carbon nano tube and molybdenum disulfide composite material.

Owner:HARBIN INST OF TECH

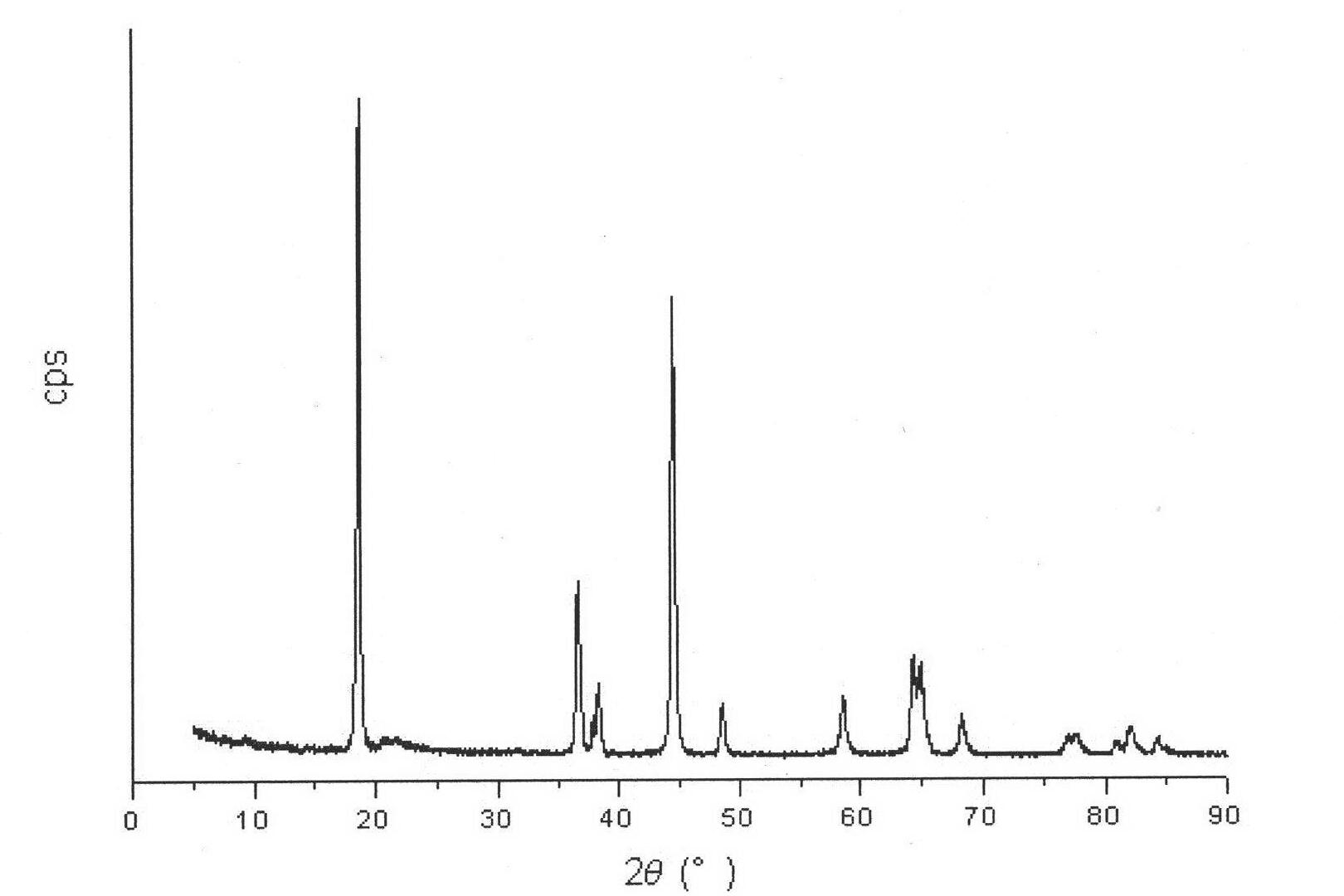

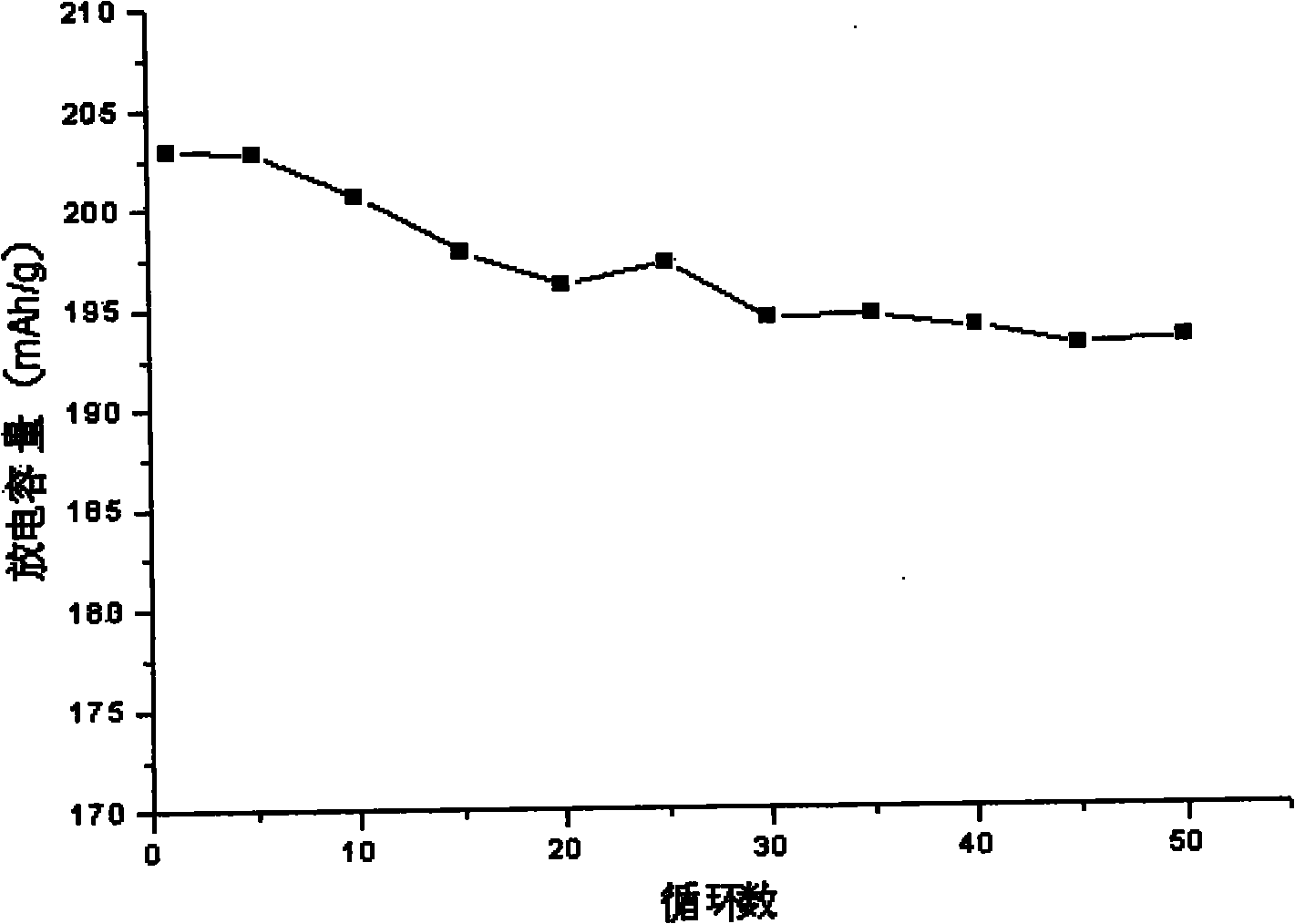

Lithium ion battery composite anode material LiFePO4-Li3V2(PO4)3/C and method for making same

InactiveCN101114709ARich sourcesLow priceElectrode manufacturing processesPhosphorus compoundsHigh rateChemical compound

The invention discloses a composite anode material LiFePO4-Li3V2(PO4)3 / C for lithium ion batteries and a preparation method for the composite anode material, wherein, the LiFePO4 and the Li3V2(PO4)3 of the complex chemical compound LiFePO4-Li3V2(PO4)3 / C are stoichiometrie compounds; the substance quantity ratio of the LiFePO4 and the Li3V2(PO4)3 is that LiFePO4 / Li3V2(PO4)3 is equal to an 1 / x, and the x is more than zero and less than or equal to 1; the LiOH®qH2O, Li2CO3 or CH3COOLi®q2H2O is mixed uniformly with FePO4, 4H2O,V2O5, NH4H2PO4 and the polyethylene glycol to be blended to be the rheological phase after being added with water, and an obtained rheological phase precursor is roasted in the inert atmosphere for three to twenty hours under the temperature of 600-800 DEG C, which produces the composite anode material LiFePO4-Li3V2 (PO4)3 / C for lithium ion batteries. The prepared composite anode material for lithium ion batteries has the advantages of large capacity, high efficiency of charge-discharge, good cycle efficiency, good high-rate performance, which is suitable for industrial production.

Owner:WUHAN UNIV

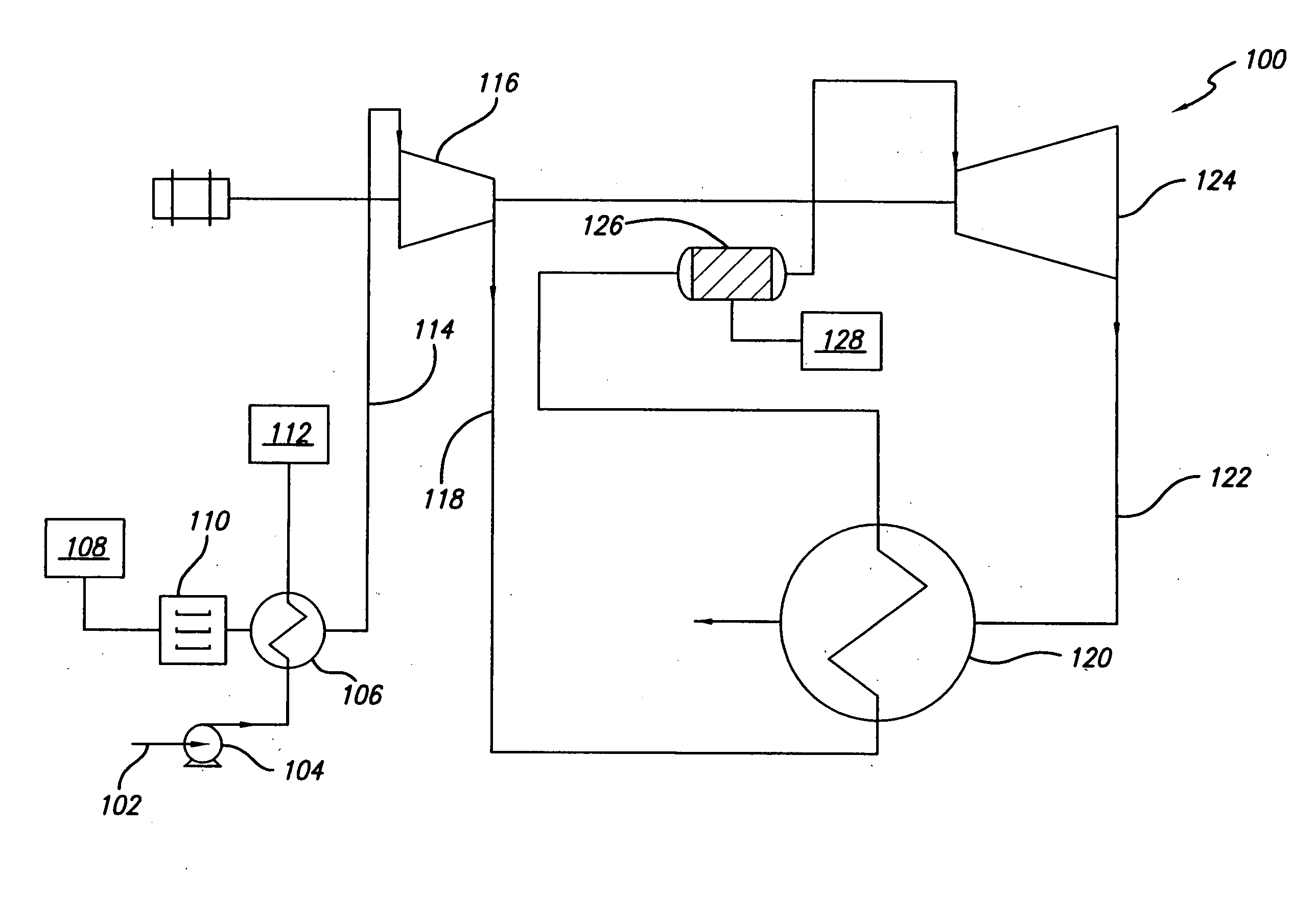

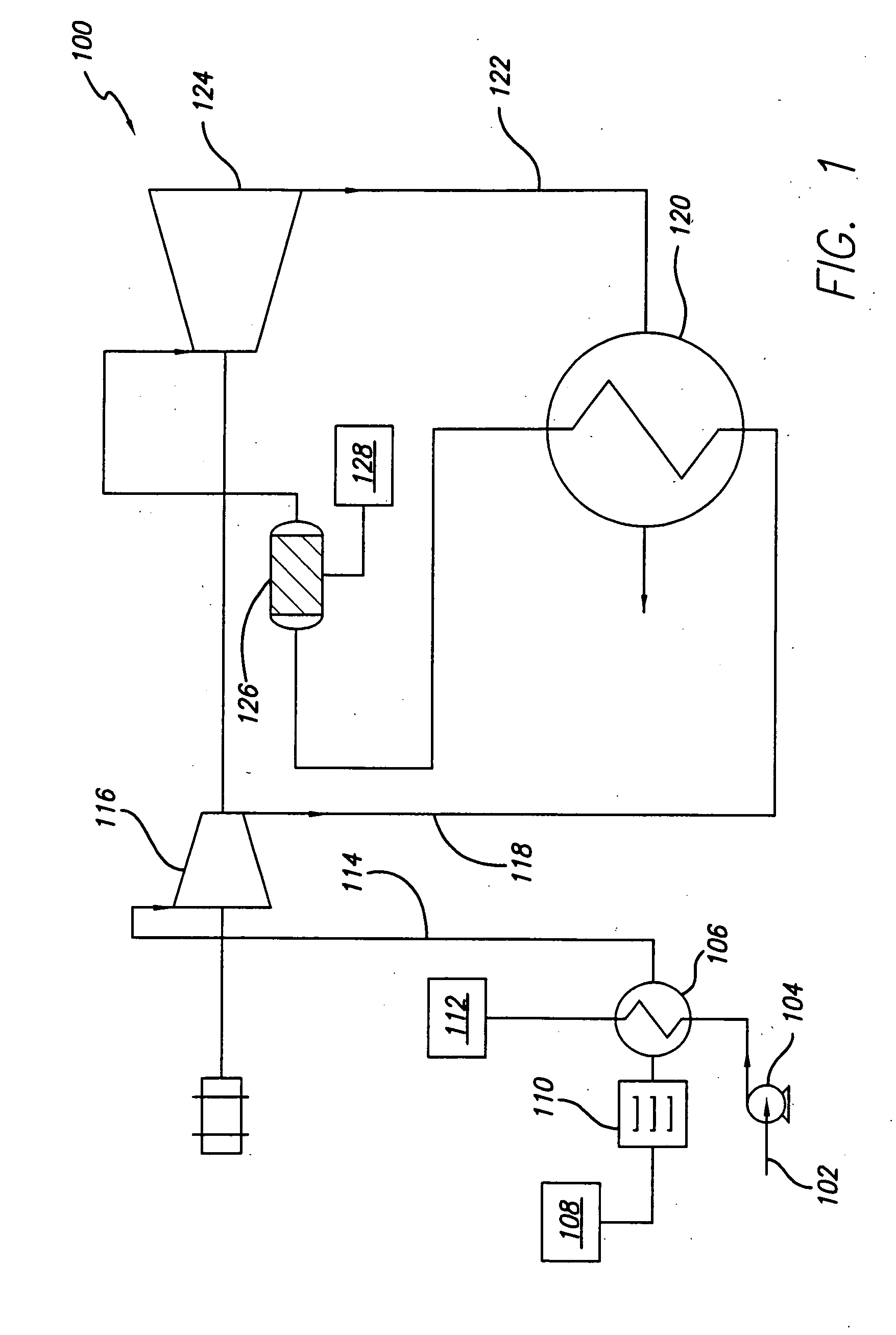

Vaporization of liquefied natural gas for increased efficiency in power cycles

InactiveUS20050223712A1Easy to compressLess contaminantGas turbine plantsJet propulsion plantsPower cycleCycle efficiency

A gas turbine cycle that utilizes the vaporization of liquefied natural gas as a source of inlet air chilling for a gas turbine. The cycle uses regeneration for preheating of combustor air and offers the potential of gas turbine cycle efficiencies in excess of 60%. The systems and methods permit the vaporization of LNG using ambient air, with the resulting super cooled air being easier to compress and / or having fewer contaminants therein. As the air is easier to compress, less energy is needed to operate the compressor, thereby increasing the efficiency of the system. A portion of the vaporized natural gas may be used as the combustion fuel for the gas turbine system, thereby permitting multiple turbines to be operated using a single topping cycle. In alternative embodiments, the vaporization of the LNG may be used as part of a bottoming cycle to increase the efficiencies of the gas turbine system.

Owner:SIEMENS ENERGY INC

Highly Supercharged Gas Turbine Generating System

InactiveUS20080304954A1Improve power output capabilityIncrease wind speedWind motor controlGas turbine plantsTransformerInlet pressure

A highly supercharged gas-turbine generation system include a gas turbine power plant that is supercharged to a high inlet pressure, preferably over about 1.15 pressure ratio and preferably includes a transmission system with refrigerated transformers for increased output. The gas turbine power plant includes a precompressor that supercharges to a design pressure ratio of about 1.20 to 10, with a preferred pressure ratio of about 2. For high supercharging pressures, a pressure-reducer is located downstream of the gas turbine to maintain turbine outlet pressure that is close to the inlet pressure. The pressure-reducer is preferably an expander, but can alternatively be an orifice. A torque-limiting coupling on the shaft between the gas turbine and the generator prevents transient overload of the shaft. Capacity of the gas turbine plant is preferably controlled by varying supercharging pressure. The expander preferably has variable-pitch blades to allow efficient variation of turbine outlet pressure. For combined-cycle embodiments, a heat-recovery steam generator (HRSG) may be placed between the gas turbine and a downstream expander. For highest combined cycle output, a single-pressure steam system with high inlet temperature to the HRSG is preferred. The high temperature is preferably provided by supplemental firing between the gas turbine and the HRSG. An expander may be inserted between the supplemental firing and the HRSG to further improve cycle efficiency and to reduce pressure in the HRSG. For retrofit applications with limited supercharging, a refrigeration system for generator cooling may be added to increase generator output to match that available from the supercharged gas turbine.

Owner:HOFFMAN JOHN S +1

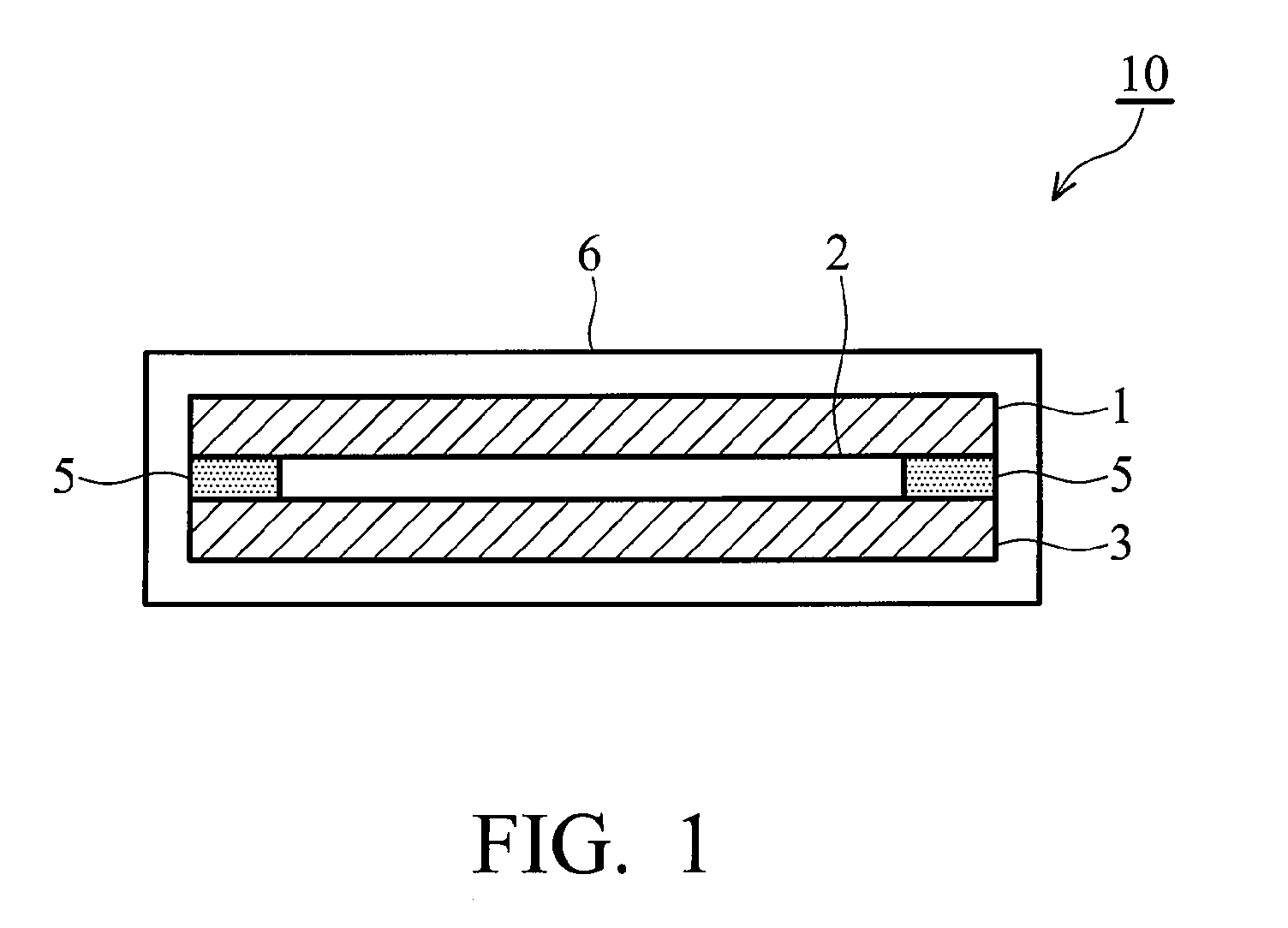

Electrolytic solution and lithium battery employing the same

Disclosed is an electrolytic solution including an organic solvent, a lithium salt, and an additive. The additive includes maleimide compound and vinylene carbonate. The maleimide compound can be maleimide, bismaleimide, polymaleimide, polybismaleimide, maleimide-bismaleimide copolymer, or combinations thereof. The lithium battery employing the described electrolytic solution has a higher capacity of confirmation, higher cycle efficiency, and longer operational lifespan.

Owner:IND TECH RES INST

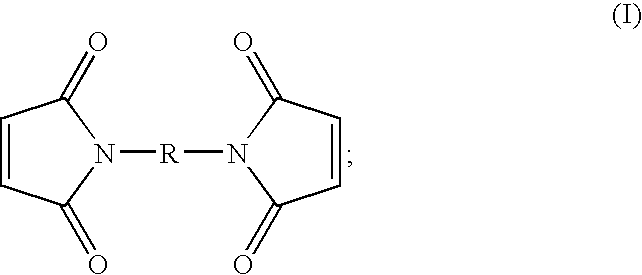

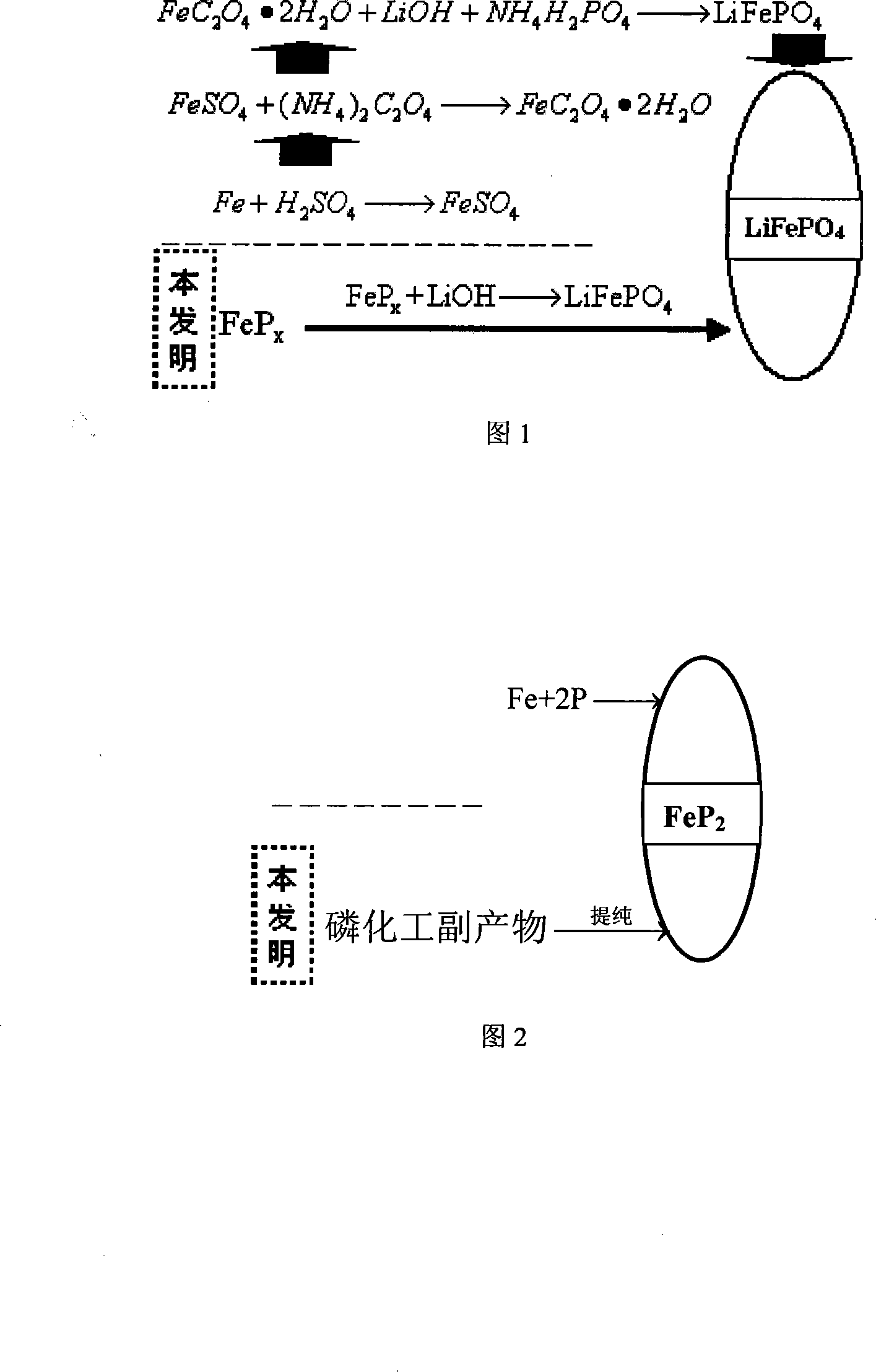

Method for producing electrode material with ferrophosphorus

ActiveCN101219783AImprove cycle efficiencyLow costCell electrodesPhosphidesChemical industryState of art

The invention relates to a method for applying ferro phosphorus to manufacture electrode material with low cost, belonging to a material and electrochemical field. The ferro phosphorus at least comprises P and Fe elements at the same time, thus providing part or all sources of phosphorus and ferro for the electrode material; the ferro phosphorus can be mineral, the smelt products thereof, byproducts of phosphorus chemical industry or silicate chemical industry, or self-made. Compared with the prior art, the method has rich source, low cost, simple manufacture method and process, short production flow; the impurity elements inside the material can be used for carrying out in-situ self-doping modification the invention can effectively increase cycling efficiency and utilization rate of resources, and reduce electrode material cost from the source; the invention is practical and easy for large-scale industrial clean production to realize consumption reduction, energy conservation and comprehensive utilization of resources.

Owner:SICHUAN UNIV

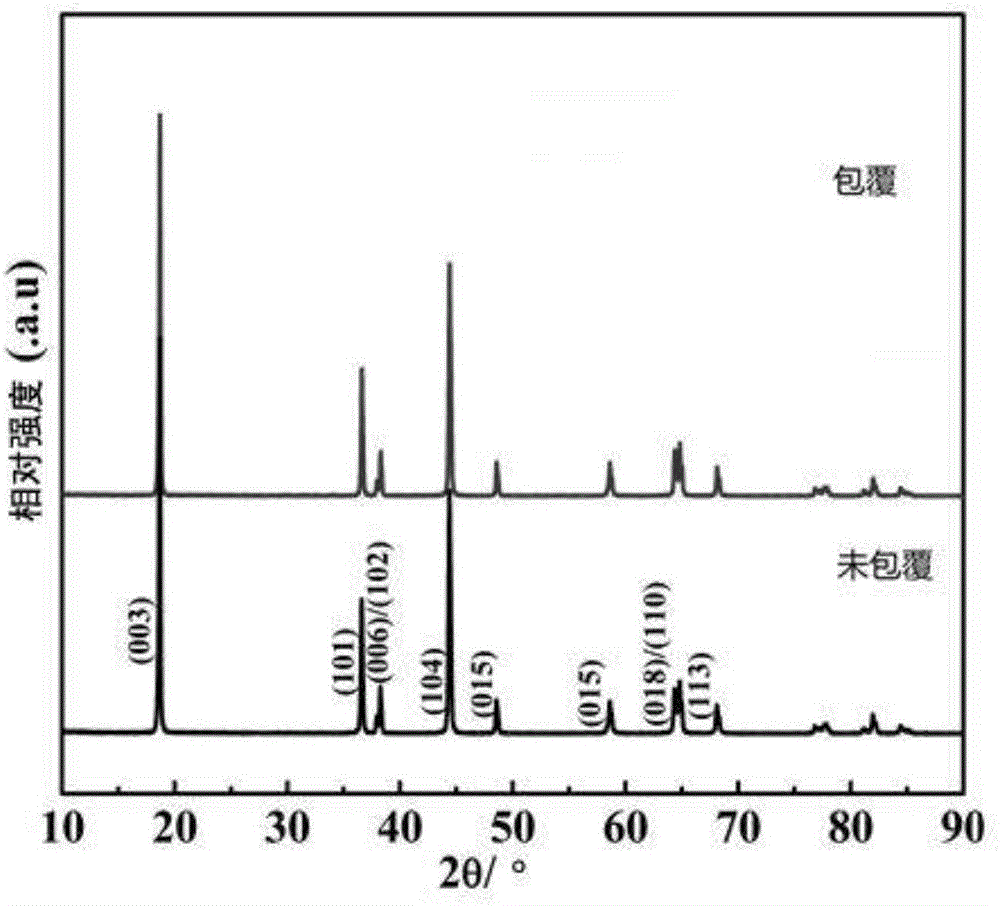

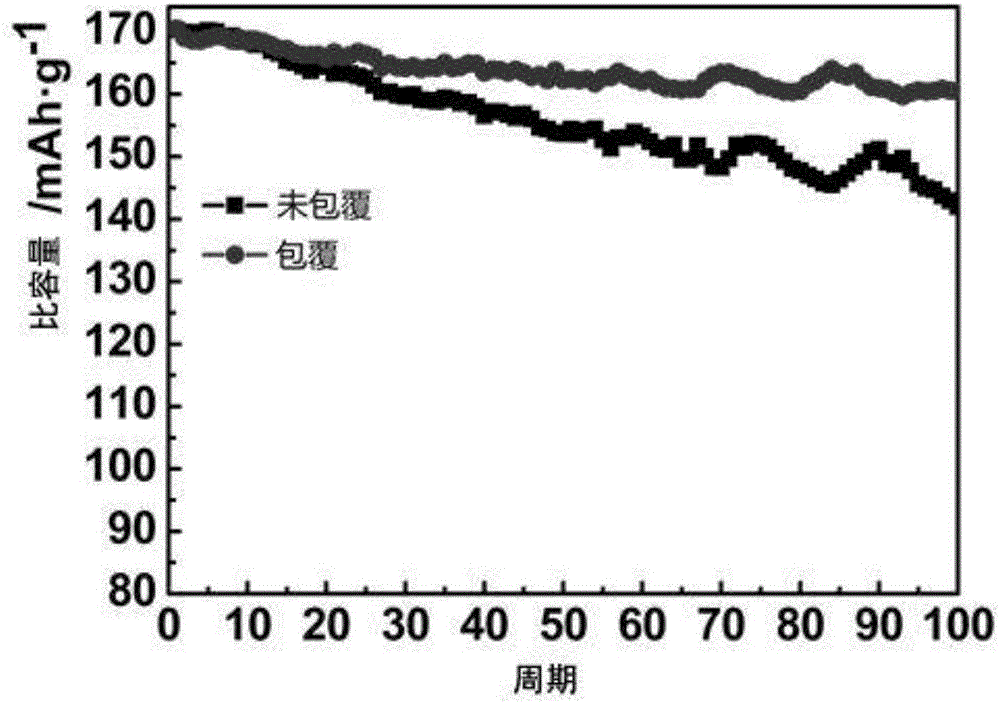

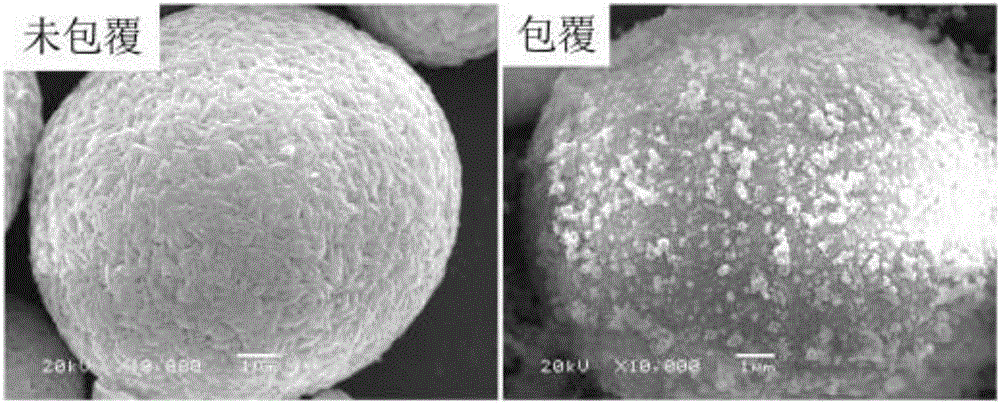

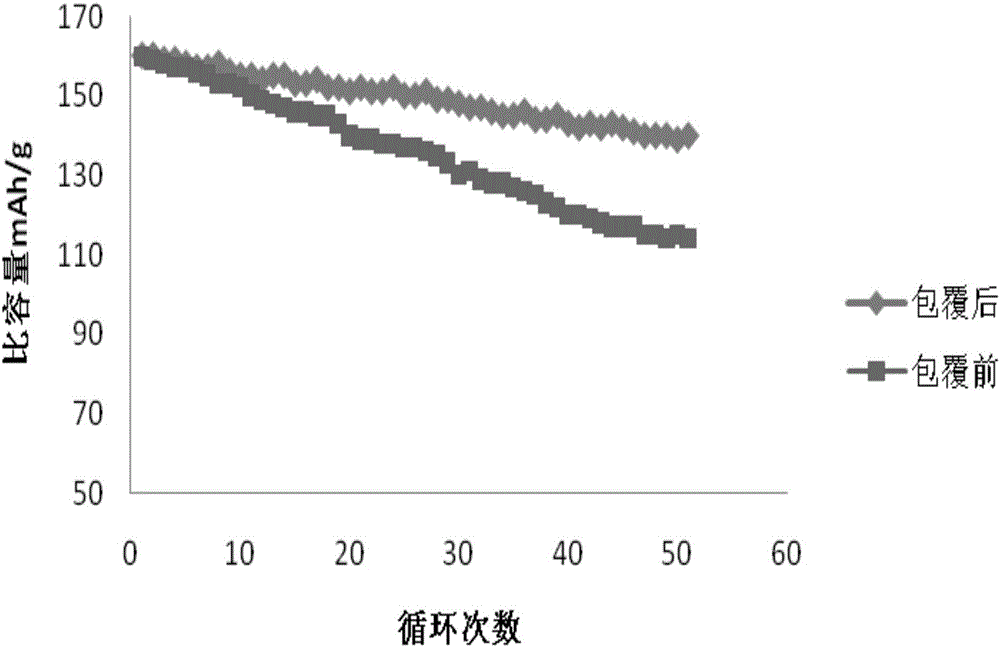

Preparation method of aluminum oxide-coated positive electrode material for lithium-ion battery

InactiveCN106784837AImprove structural stabilityAvoid stabilityCell electrodesBatteriesSlurryCycle efficiency

The invention discloses a preparation method of an aluminum oxide-coated positive electrode material for a lithium-ion battery. The method comprises the following steps of (1) adding water to a hydroxide precursor of a positive electrode material for stirring to obtain positive electrode material precursor slurry; (2) dissolving sodium metaaluminate into water to obtain an aluminum salt solution; (3) adding the aluminum salt solution to the positive electrode material precursor slurry, stirring and introducing CO2 to obtain an aluminum hydroxide-coated positive electrode material precursor; (4) filtering, washing and drying slurry of the aluminum hydroxide-coated positive electrode material precursor to obtain aluminum hydroxide-coated positive electrode material precursor powder; (5) mixing the aluminum hydroxide-coated positive electrode material precursor powder with a lithium salt to obtain mixed powder; and (6) carrying out thermal treatment on the mixed powder to obtain the aluminum oxide-coated positive electrode material for the lithium-ion battery. The method is carried out in a water solution, an organic solvent is not used, and the discharge capacity and the cycle efficiency of the lithium-ion battery are improved through the method.

Owner:CENT SOUTH UNIV

Method for manufacturing cobalt nickel lithium manganate oxide as gradient anode active material of lithium ion battery

ActiveCN102214819AThe lattice structure is stableHigh charge and discharge capacityCell electrodesNickel compoundsManganateCharge discharge

The invention relates to a method for manufacturing a cobalt nickel lithium manganate oxide as a gradient anode active material of a lithium ion battery, belonging to the technical field of manufacturing the anode material of the lithium ion battery. In the method, a metal ion mixed solution with incremental Co<2+> concentrations is divided into multiple liquid-phase systems to realize coprecipitation for many times so as to manufacture NixCoyMn(l-x-y)(OH)2; the NixCoyMn(l-x-y)(OH)2 is taken as a precursor; and a high-temperature solid-phase reaction is utilized to obtain layered LiNixCoyMn(l-x-y)O2 with gradient Co content. The crystal lattice framework of the anode material with the gradient Co content manufactured by the method is more stable and the cation syncopation degree is reduced, so that the charge-discharge capacity and the cycle efficiency of the anode material are improved, thus the anode material has good electrochemical performances and can be applied to lithium ion batteries widely.

Owner:BEIJING UNIV OF CHEM TECH

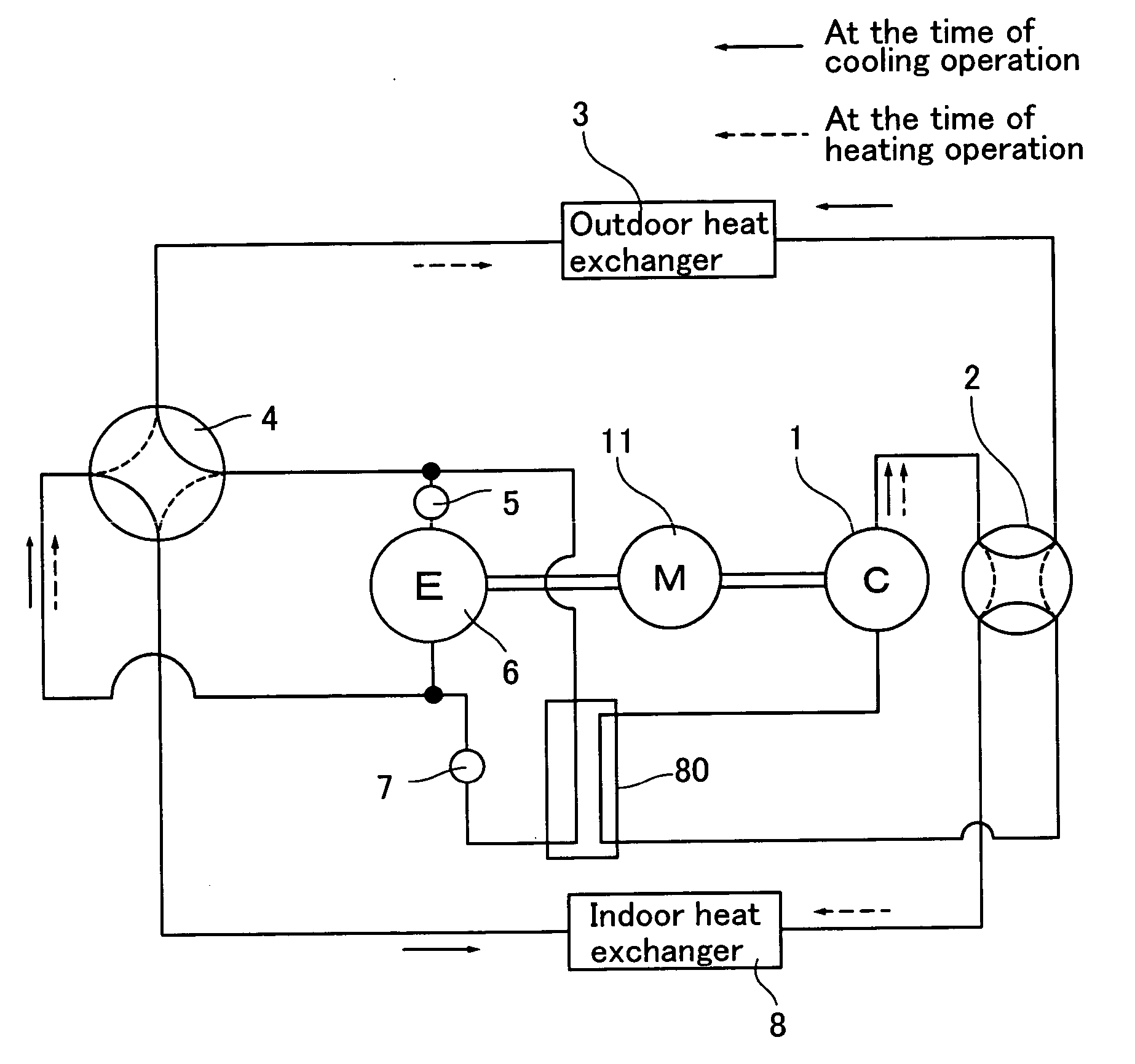

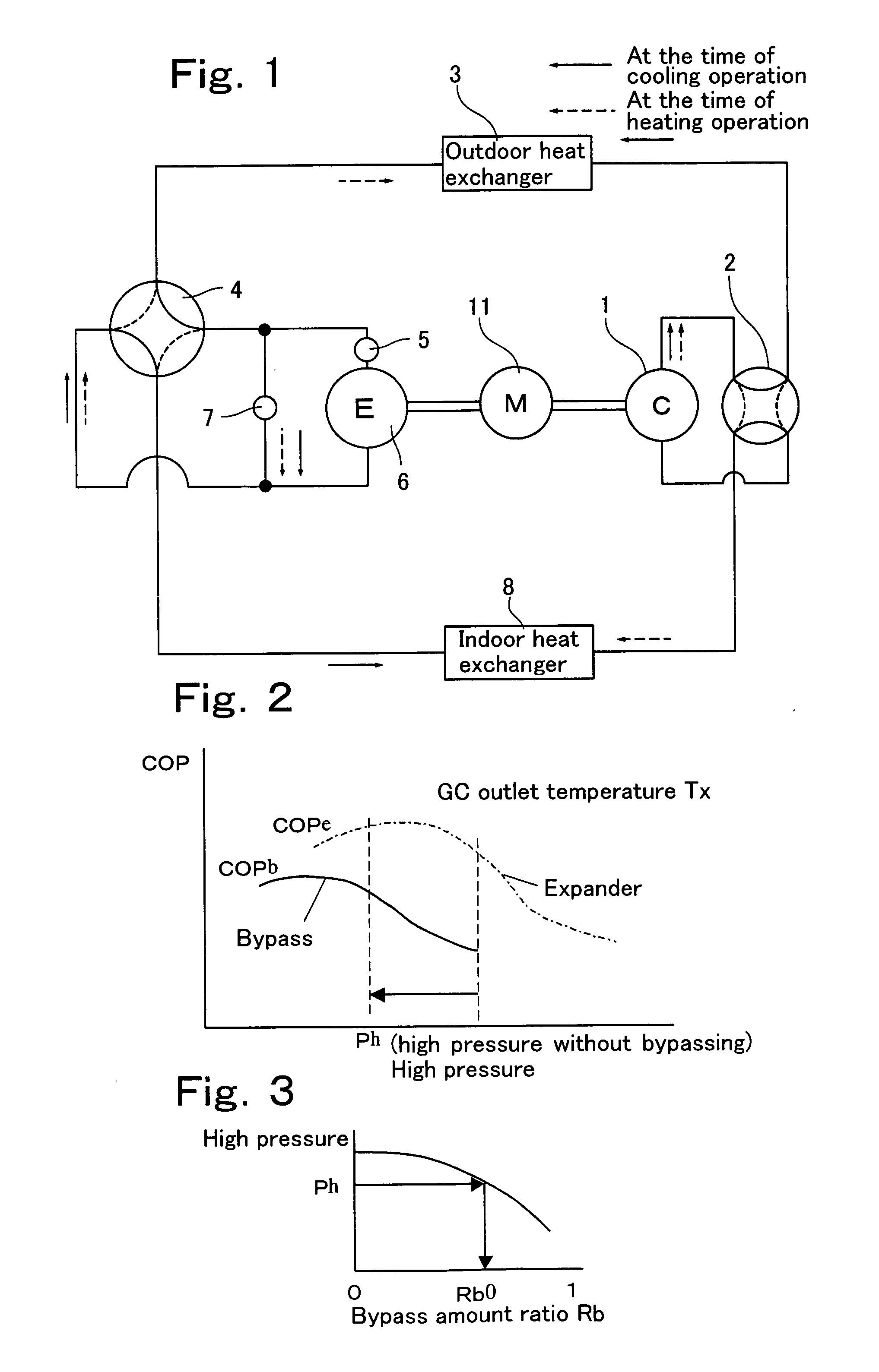

Determining method of high pressure of refrigeration cycle apparatus

InactiveUS20040118138A1Domestic cooling apparatusCompression machines with non-reversible cycleDensity ratioProcess engineering

It is an object of the present invention to reduce the constraint that the density ratio is constant as small as possible, and to obtain high power recovering effect in a wide operation range by using an expander which is operated in accordance with a flowing direction of refrigerant. A determining method of a high pressure of a refrigeration cycle apparatus in which a refrigeration cycle uses carbon dioxide as refrigerant and has a compressor, an outdoor heat exchanger, an expander and an indoor heat exchanger, and the refrigeration cycle including a bypass circuit provided in parallel to said expander, and a control valve which adjusts a flow rate of refrigerant flowing through said bypass circuit, said compressor being driven by power recover by said expander, wherein if an optimal high pressure of a first refrigeration cycle flowing through said expander and a second refrigeration cycle flowing through said bypass circuit is defined as Ph, and a bypass amount ratio flowing through said bypass circuit in said Ph is defined as Rb0, and a maximum refrigeration cycle efficiency of said first refrigeration cycle in said Ph is defined as COPe, and a maximum refrigeration cycle efficiency of said second refrigeration cycle in said Ph is defined as COPb, the optimal high pressure Ph which maximizes (1-Rb0)xCOPe+Rb0xCOPb is determined.

Owner:PANASONIC CORP

Modified nickel, cobalt and lithium manganite three-element material and preparation method thereof

ActiveCN106299320AImprove cycle performanceLittle changeCell electrodesSecondary cellsCyclic processLithium

The invention provides a modified nickel, cobalt and lithium manganite three-element material and a titanium dioxide layer compounded on the surface of the nickel, cobalt and lithium manganite three-element material. The titanium dioxide layer is creatively compounded on the surface of the nickel, cobalt and lithium manganite three-element material, the surface microstructure change of the NCM three-element material in the first-time charging process is effectively decreased, and the first-cycle efficiency is improved. In addition, due to the fact that titanium dioxide serves as a shell layer and form a core-shell structure with the NCM material, only lithium ions can pass through the titanium dioxide layer, and nickel and manganese ions cannot pass through, dissolution of Ni and Mn in the three-element material in the cycling process is reduced, and the cycle performance of the three-element material is optimized.

Owner:GREE ELECTRIC APPLIANCES INC

Systems And Methods To Extend Gas Turbine Hot Gas Path Parts With Supercharged Air Flow Bypass

ActiveUS20140208765A1Prolong lifeGas turbine plantsTurbine/propulsion fuel controlControl systemEngineering

A system and method for supercharging a combined cycle system includes a forced draft fan providing a variable air flow. At least a first portion of the air flow is directed to a compressor and a second portion of the airflow is diverted to a heat recovery steam generator. A control system controls the airflows provided to the compressor and the heat recovery steam generator. The system allows a combined cycle system to be operated at a desired operating state, balancing cycle efficiency and component life, by controlling the flow of air from the forced draft fan to the compressor and the heat recovery steam generator.

Owner:GENERAL ELECTRIC CO

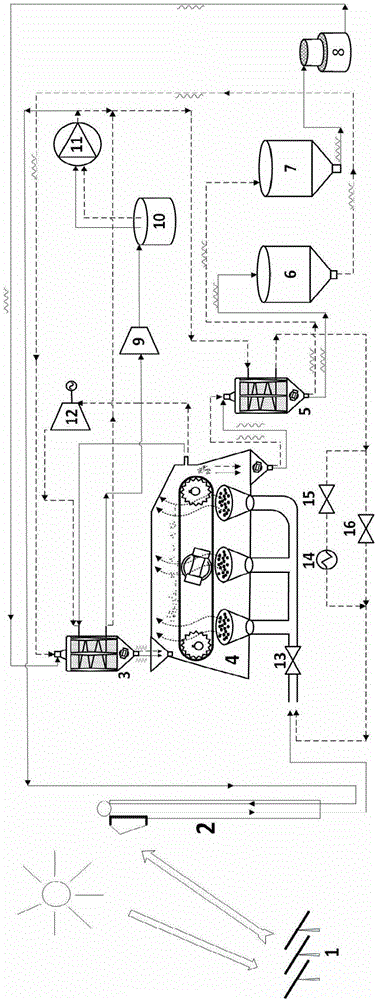

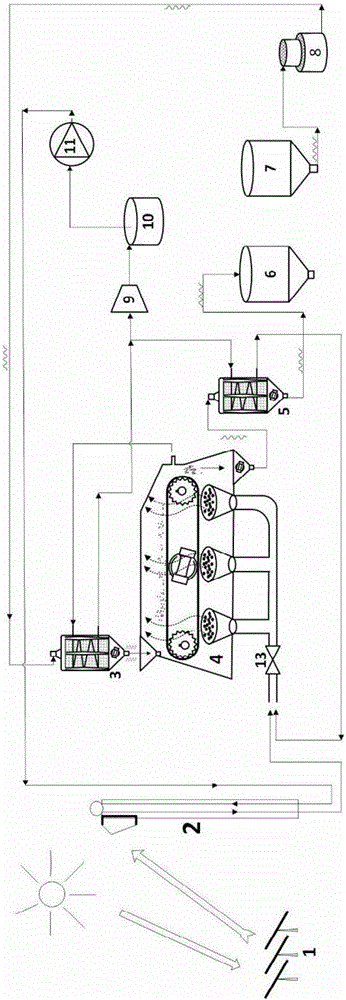

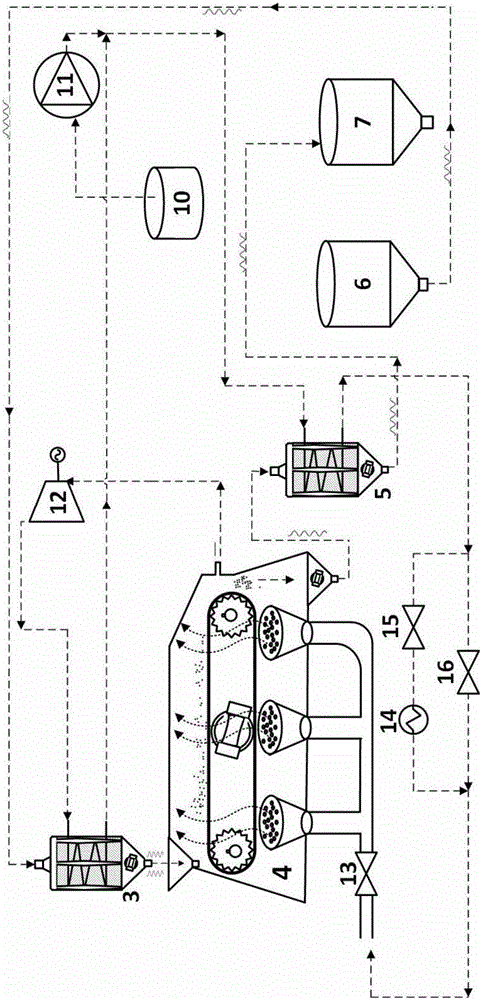

Medium-and-low temperature calcium cycling thermochemical energy storage device and method

ActiveCN106813402AAchieve regenerationAchieve continuous power supplySolar heating energySolar heat devicesThermal energyChemical reaction

The invention relates to a medium-and-low temperature calcium cycling thermochemical energy storage device and method. The device comprises a solar heat collection device, an energy storage system and a power generation system. According to the Ca(OH)2 / CaO thermochemical energy storage system, energy storage is conducted through interconversion between thermal energy and chemical energy, when solar irradiation is sufficient, Ca(OH)2 solid particles are subjected to an endothermic decomposition reaction under the action of high-temperature water vapor generated by solar energy, and received heat is stored in decomposition products, namely CaO and H2O, in a chemical energy form; when the heat is released, CaO and H2O are subjected to a backward thermochemical reaction at normal pressure, and the chemical energy stored in CaO and H2O are inversely converted into the thermal energy and released out. The device and method are high in energy storage density, high in cycle efficiency and environmentally friendly, the structure is simple, and flexible control and application under variable working conditions are achieved.

Owner:NANJING UNIV OF TECH

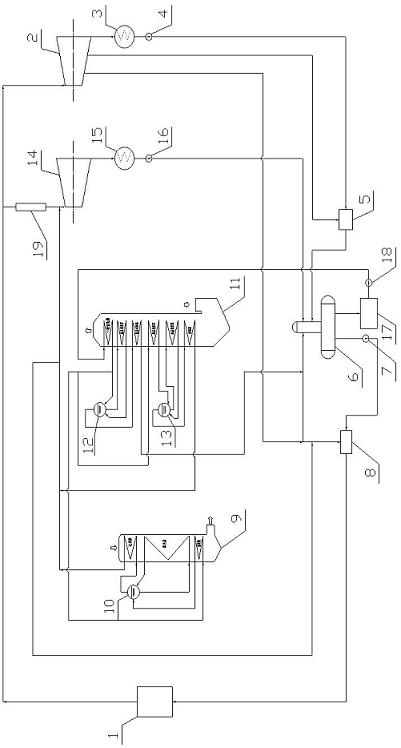

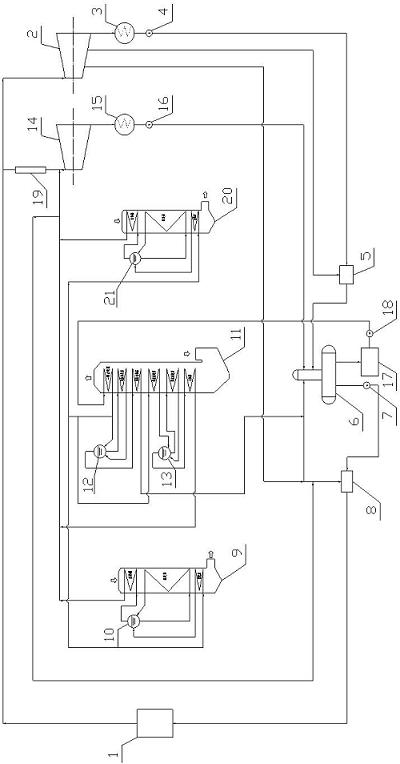

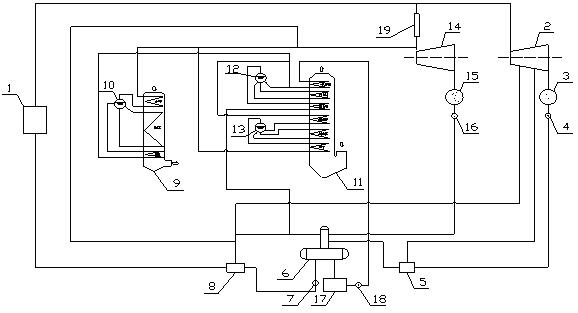

Coal-fired power generation and waste heat power generation coupling system for private station of cement kiln

ActiveCN102080582AReduce non-adjusted steam extractionImprove stabilityEnergy industryIncreasing energy efficiencyEngineeringDeaerator

The invention discloses a coal-fired power generation and waste heat power generation coupling system for a private station of a cement kiln, comprising a coal-fired boiler, a kiln head waste heat boiler, a kiln tail waste heat boiler, a kiln head steam pocket, a kiln tail steam pocket, a condensing steam turbine, a condensate pump, a heater, a deaerator, a water feeding pump and related auxiliary devices, wherein the kiln head waste heat boiler utilizes a dual-pressure system; a primary economizer of the low-pressure system is used as a public economizer for the waste heat power generation; the high-pressure steam and the steam generated by the kiln tail waste heat boiler are collected to the main steam pipeline of the waste heat power generation system; one path of the main steam pipeline is connected with a steam turbine of the waste heat power generation system while the other path thereof is connected with non-adjustable extraction steam of a coal-fired steam turbine; one path ofthe main steam pipeline of the coal-fired unit is connected with the coal-fired steam turbine while the other path thereof is connected with the waste heat steam turbine. In the invention, the coal-fired power generation is rationally coupled with waste heat power generation system so that the problem that the stability of the waste heat power generation system of the cement kiln is low is solved, and the whole thermal circulating efficiency of the private station can be largely increased.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

Electrolyte compositions for batteries using sulphur or sulphur compounds

InactiveUS20060177741A1Improve conductivityImprove temperature stabilityNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsLithiumElectrolyte composition

There are disclosed electrolytes comprising solutions of lithium salts with large anions in polar aprotic solvents with a particular concentration of background salts. The concentration of the background salts is selected to be equal or close to the concentration of a saturated solution of these salts in the aprotic solvents used. The electrolytes disclosed can be used in chemical sources of electric energy such as secondary (rechargeable) cells and batteries comprising sulphur-based positive active materials. The use of such electrolytes increases cycling efficiency and cycle life of the cells and batteries.

Owner:OXIS ENERGY

High-security metallic lithium cathode and preparation method thereof

ActiveCN104966814ALarge specific surface areaIncrease current densityCell electrodesCell component detailsMetallic lithiumHigh current density

The invention provides a high-security metallic lithium cathode and a preparation method thereof. The high-safety metallic lithium cathode comprises a lithium powder porous electrode and a silicon-based protecting layer, wherein the silicon-based protecting layer is arranged on the lithium powder porous electrode in an evaporation manner; the silicon-based protecting layer is 0.02-0.2 micrometers thick. Through the adoption of the technical scheme, the silicon-based protecting film with a lithium storage function is arranged on the metal lithium powder electrode in the evaporation manner, so that the security of the metallic lithium cathode is greatly improved; the high-security metallic lithium has relatively high current density and relatively small inner resistance; meanwhile, the cycle efficiency is improved, and a development space is provided for application of the metallic lithium cathode in the field of high-energy batteries.

Owner:李震祺 +1

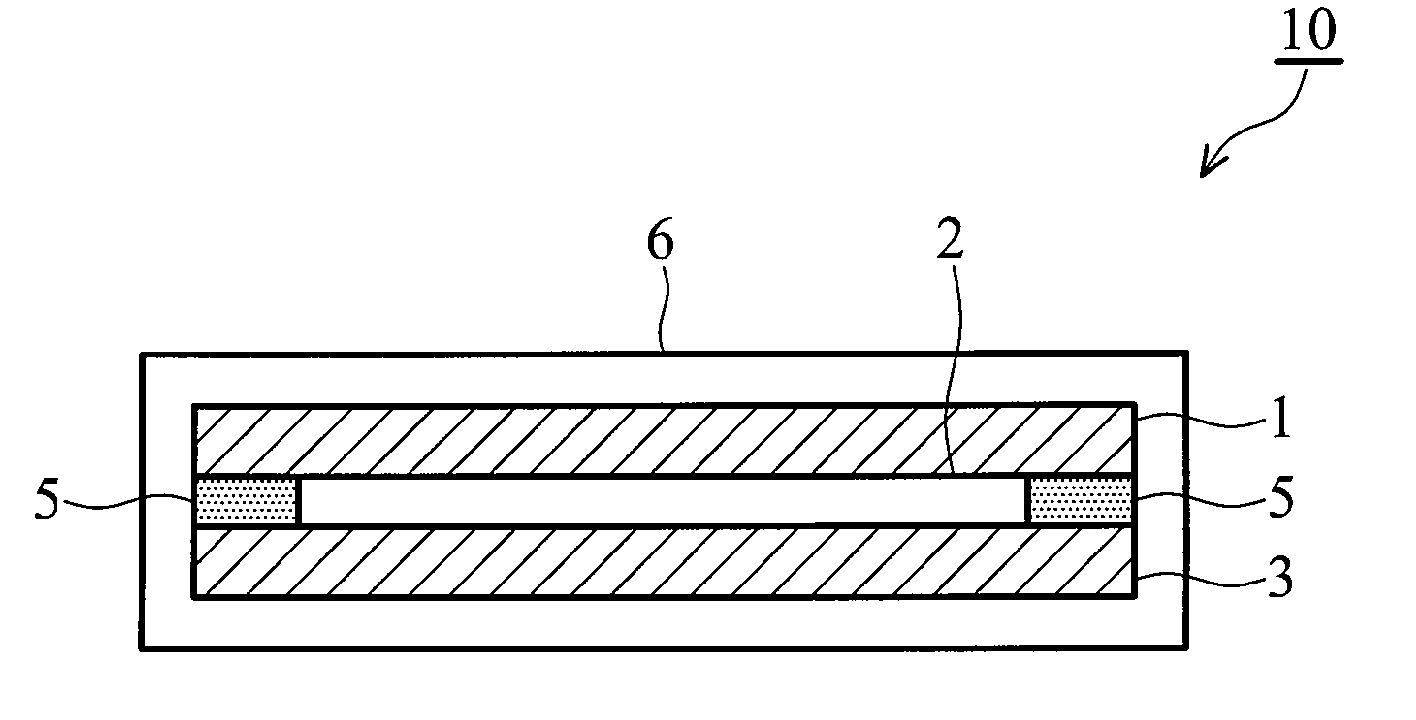

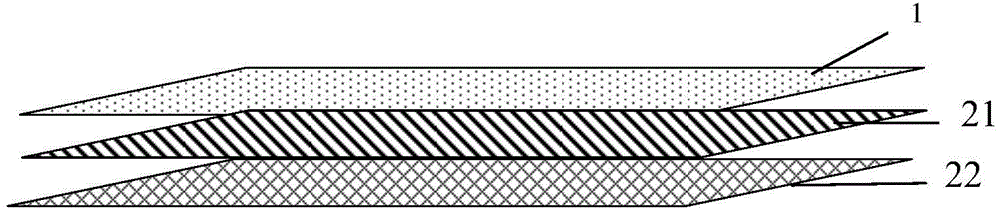

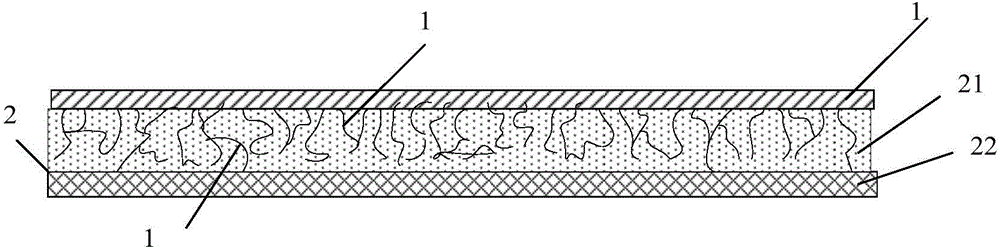

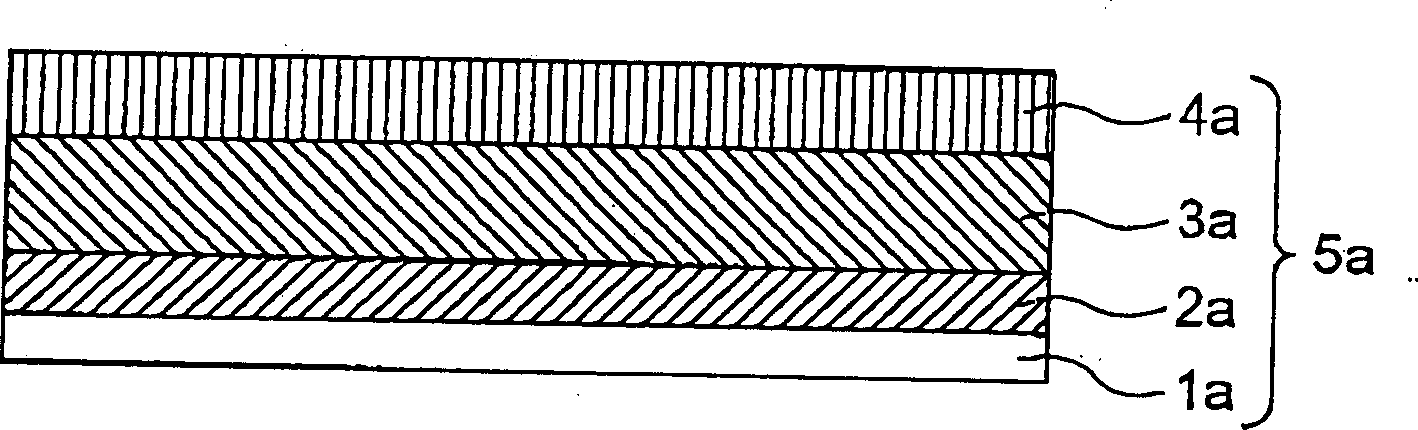

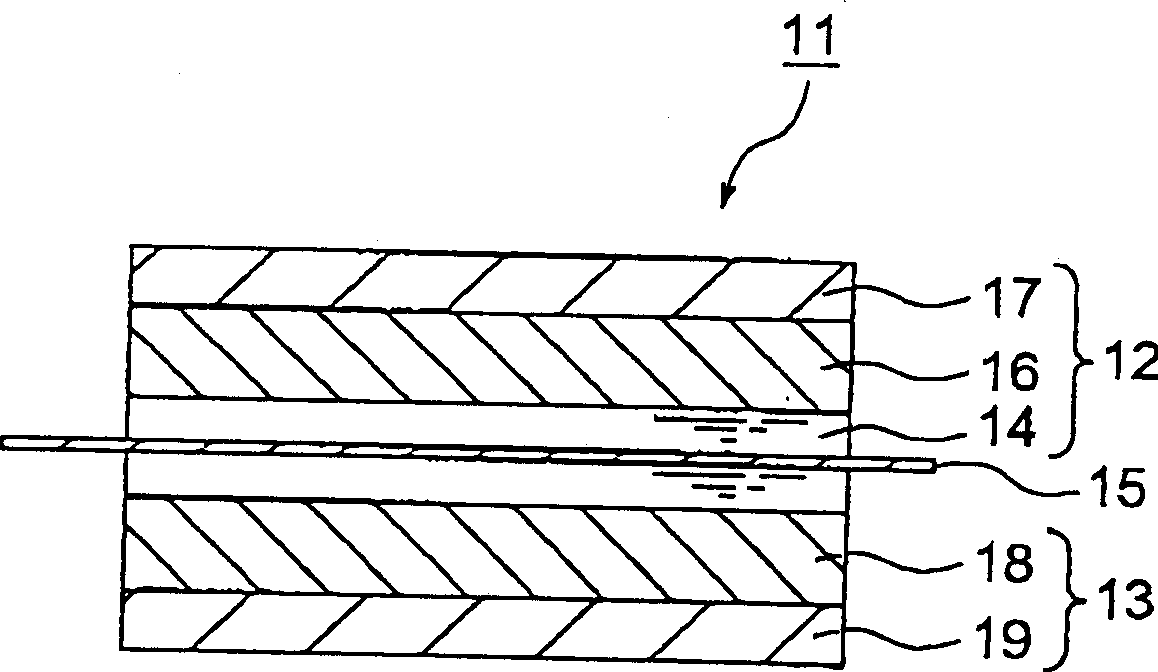

Negative electrode of rechargeable battery

InactiveCN1400680AAvoid formingImprove cycle lifeElectrode manufacturing processesNon-aqueous electrolyte accumulatorsLithiumRechargeable cell

A negative electrode for a rechargeable battery includes: a current collector, a first layer containing a conductive material to occlude and release lithium ion, the first layer formed on the current collector, a second layer containing a metal selected from lithium and lithium alloy, the second layer formed on the first layer, and a third layer containing a lithium ion. conductive material, the third layer formed on the second layer. The third layer prevents the lithium and / or the lithium alloy in the second layer from being in contact with the electrolyte and smoothly feeds the lithium to the second layer to improve the efficiency of the negative electrode. The first layer can occlude and release the part of the lithium to be occluded and released, thereby reducing the volume change of the second layer. Such a structure of the negative electrode enables us to enhance cycling efficiency, and to attain long cycle life and good safety.

Owner:NEC CORP

Optimized power generation system comprising an oxygen-fired combustor integrated with an air separation unit

InactiveUS20030233830A1Maximize cycle efficiencyZero emissionSolidificationLiquefactionHigh pressureCycle efficiency

A novel power generation system, more specifically an integrated power generation and air separation system and an integrated power generation and air separation process is provided. A key component of the system and process is an oxygen-fired combustor designed for gas turbine operating pressures. The combustor produces a high-temperature gas stream that enters one or more heat exchangers to generate / heat steam, and then enters one or more turbines to generate power. The steam from the heat exchanger drives one or more steam turbines to generate power, and the discharged steam is admitted to the combustor. To maximize cycle efficiency, steam extraction and reheat is incorporated in the process. Additional power is generated from a high-pressure nitrogen stream produced by an air separation unit (ASU). This process has the potential to attain high cycle efficiencies with zero emissions, while utilizing existing or near-term steam turbines, and moderate-pressure combustion systems.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

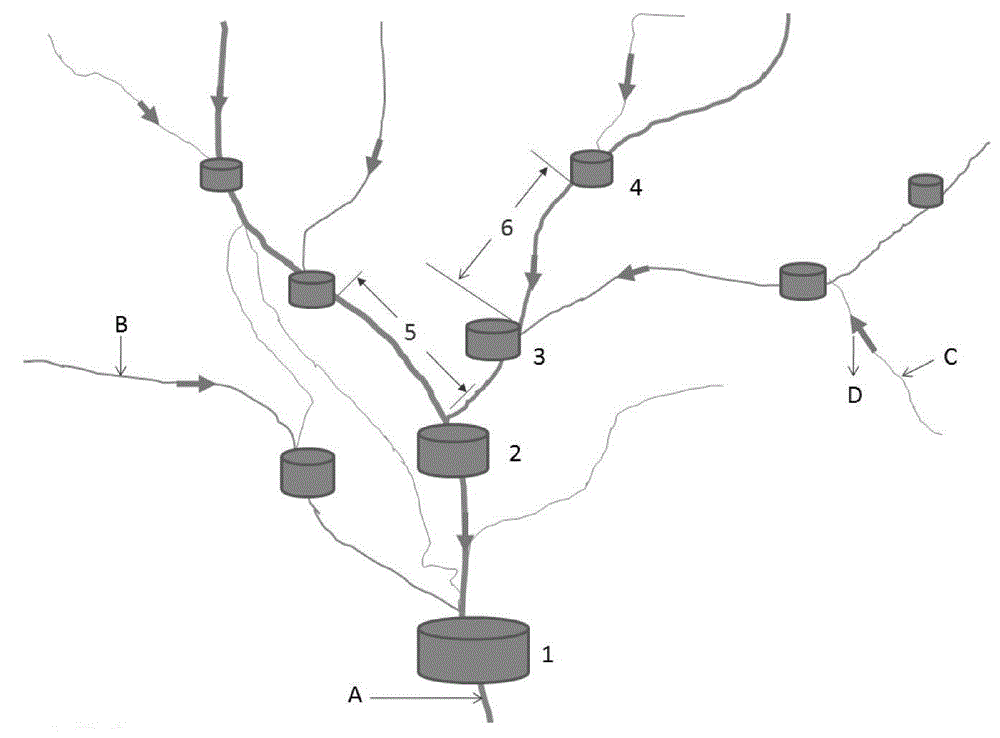

Method for preventing and treating regional farmland non-point source pollution through farmland ditch and pond system

ActiveCN104480920AImprove runoff recycling capacityRealize comprehensive pollution prevention and controlConstructionsSoil drainageWater sourceAgricultural engineering

The invention provides a method for preventing and treating regional farmland non-point source pollution through a farmland ditch and pond system. According to the method for preventing and treating the regional farmland non-point source pollution through the farmland ditch and pond system, an ecological pond is added to a farmland irrigation and drainage ditch based on arrangement and improvement of the farmland irrigation and drainage ditch according to a farmland surface runoff confluence track, the water flow speed of the farmland ditch is rapidly slowed down, the buffering capacity of a farmland system against water is reinforced, the cycle efficiency of farmland interior water sources and nitrogen and phosphorus nutrients is improved, the farmland non-point source sewage discharge is reduced, farmland nitrogen and phosphorus pollutant discharge is effectively cut down, and the method plays a greater role in protecting regional water environment.

Owner:INST OF AGRI ENVIRONMENT & RESOURCES YUNNAN ACAD OF AGRI SCI +2

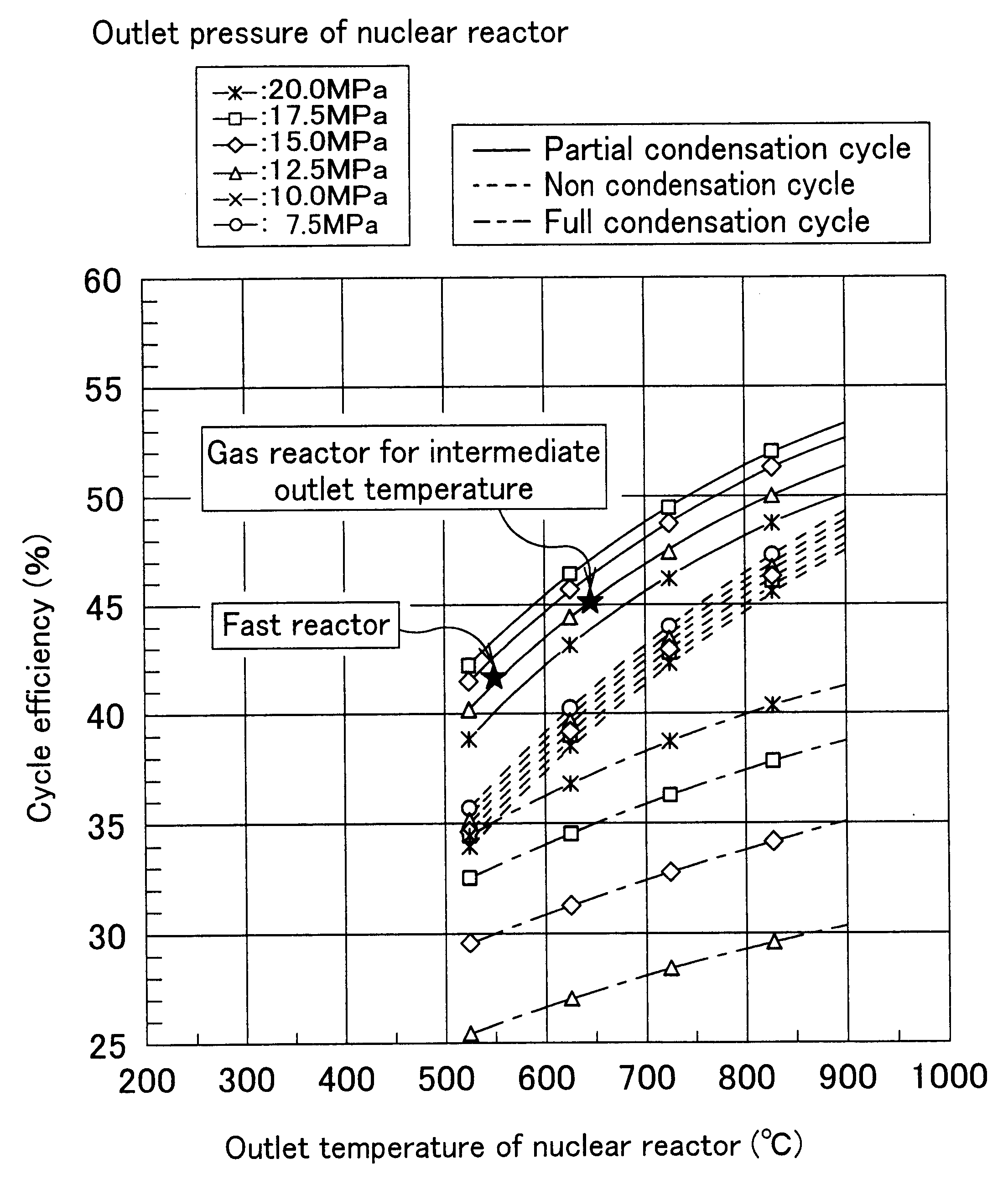

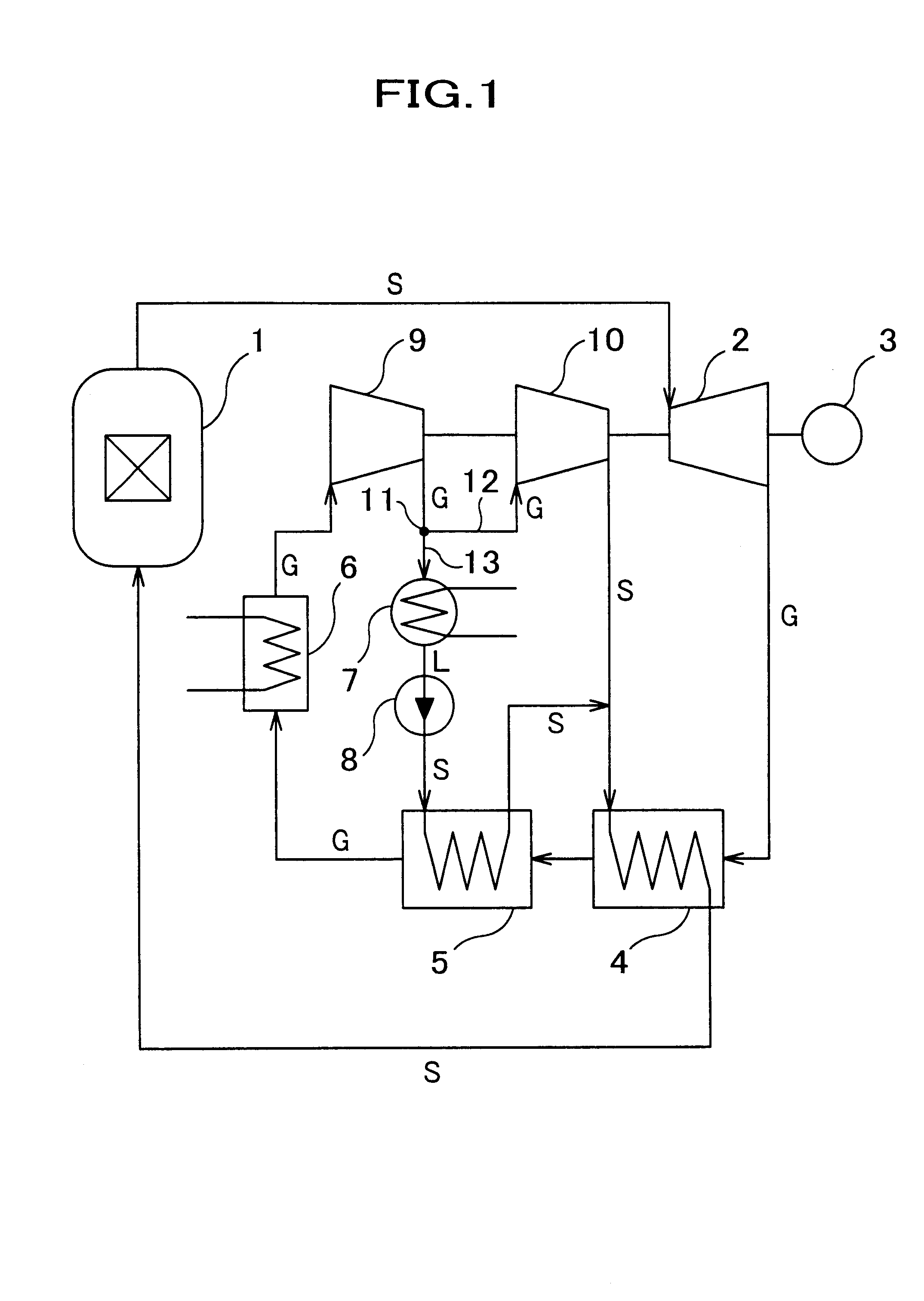

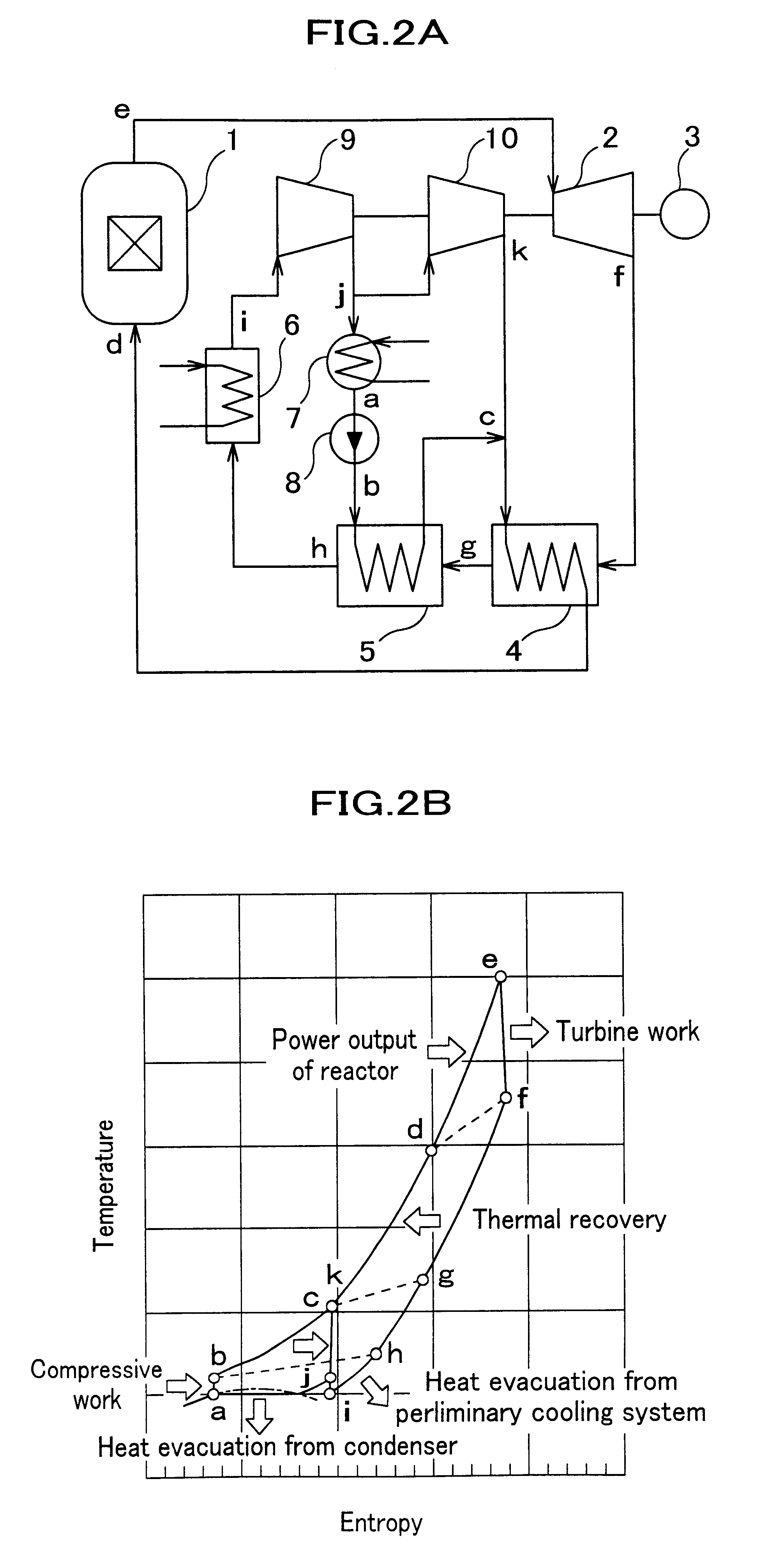

Nuclear reactor plant

InactiveUS6674830B2Nuclear energy generationWorking fluid for enginesNuclear reactor coreNuclear reactor

The subject of the present invention is to provide a nuclear reactor plant of which is a direct cycle nuclear reactor using a carbon dioxide as a coolant such that a heat evacuation for liquefying coolant is reduced while a compressive work is reduced by using a condensation capability of a carbon dioxide for enhancing a cycle efficiency.The nuclear reactor plant is comprised of a nuclear reactor 1, a turbine 2, and wherein, the coolant of supper critical state is heated by a heat of a nuclear reactor to directly drive a turbine, a gaseous coolant discharged from said turbine is chilled and compressed after said turbine is driven for keeping in a critical state, and then said coolant is circulated again into said nuclear reactor, and wherein, a carbon dioxide is used as said coolant, and a predetermined ratio of gaseous coolant discharged from said turbine is liquefied for being compressed in a liquid state while a rest of gaseous coolant is compressed in a gaseous state.

Owner:PRESIDENT OF TOKYIO INST OF TECH THE A JAPANESE NAT INST

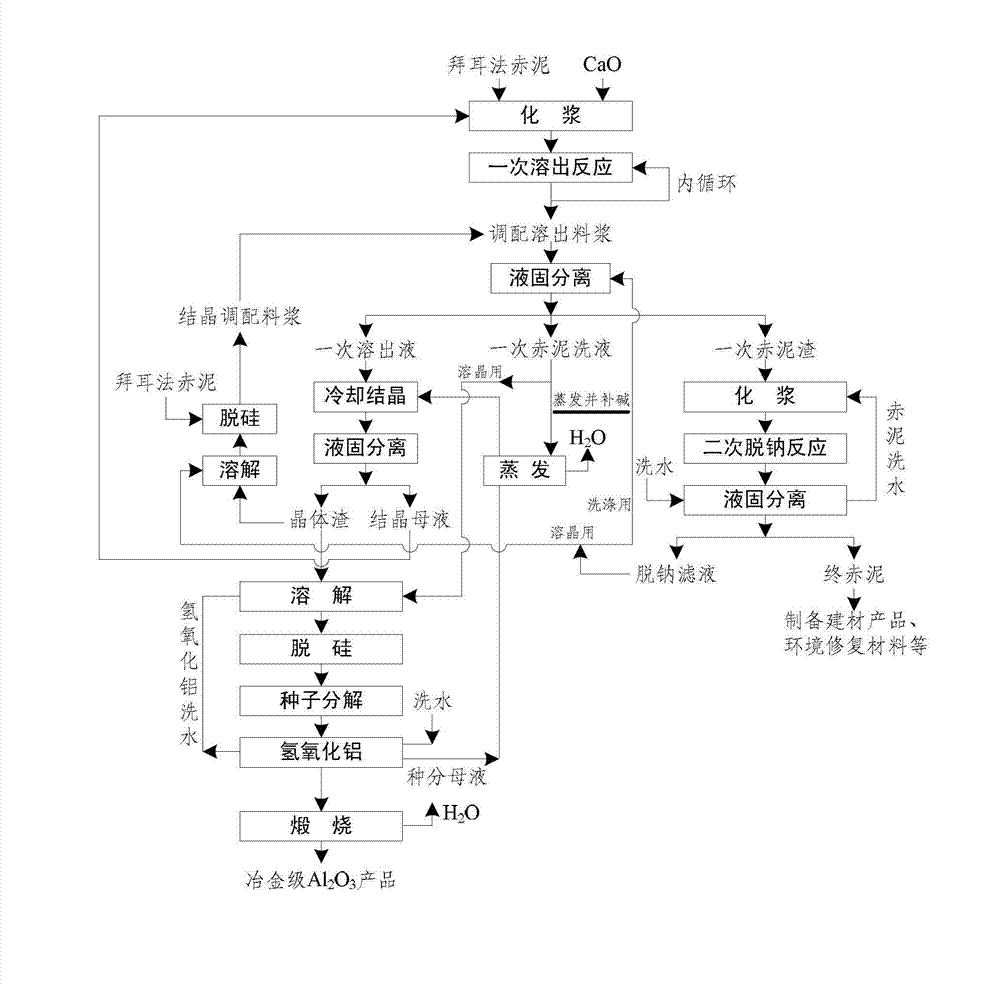

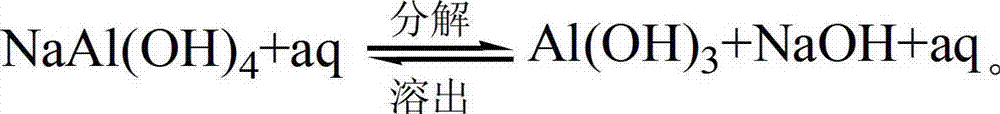

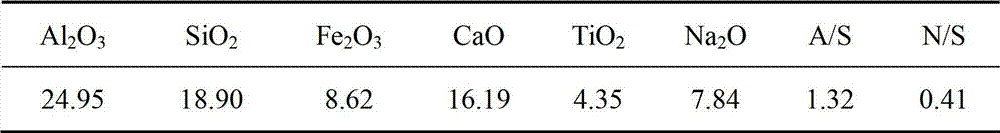

Method for recycling alumina and sodium oxide from bayer process red mud

ActiveCN103030160AHigh dissolution rateEfficient cycleAlkali metal oxidesAluminium oxides/hydroxidesBrickRed mud

The invention relates to a method for recycling alumina and sodium oxide from bayer process red mud. In the method, by adopting a high molecular ratio and high alkali concentration sodium aluminate solution, aluminum extracting reaction can be rapidly carried out under mild operating conditions, so that the recovery rate of alumina in the red mud reaches more than 85%, and the defects, such as equipment scabbing and the like can be effectively prevented and even eliminated; by implementing an efficient crystallization process of an intermediate product of hydrated sodium aluminate, the cycle efficiency of a dissolution medium is greatly improved; due to complete transformation of a phase in the aluminum extracting reaction, a reaction process of recycling sodium oxide can be performed at low temperature and normal pressure; and after secondary sodium removal reaction, the sodium oxide content in final red mud is not more than 1% and is far less than 6-8% of the bayer process red mud. Therefore, the red mud can be doped in large proportion for preparing cement, brick and roadbed materials, concrete additives, environmental remediation materials and other fillers, and the problems such as resource utilization of the red mud, potential environment hazard and the like are hopefully solved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com