Patents

Literature

781 results about "Steam system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

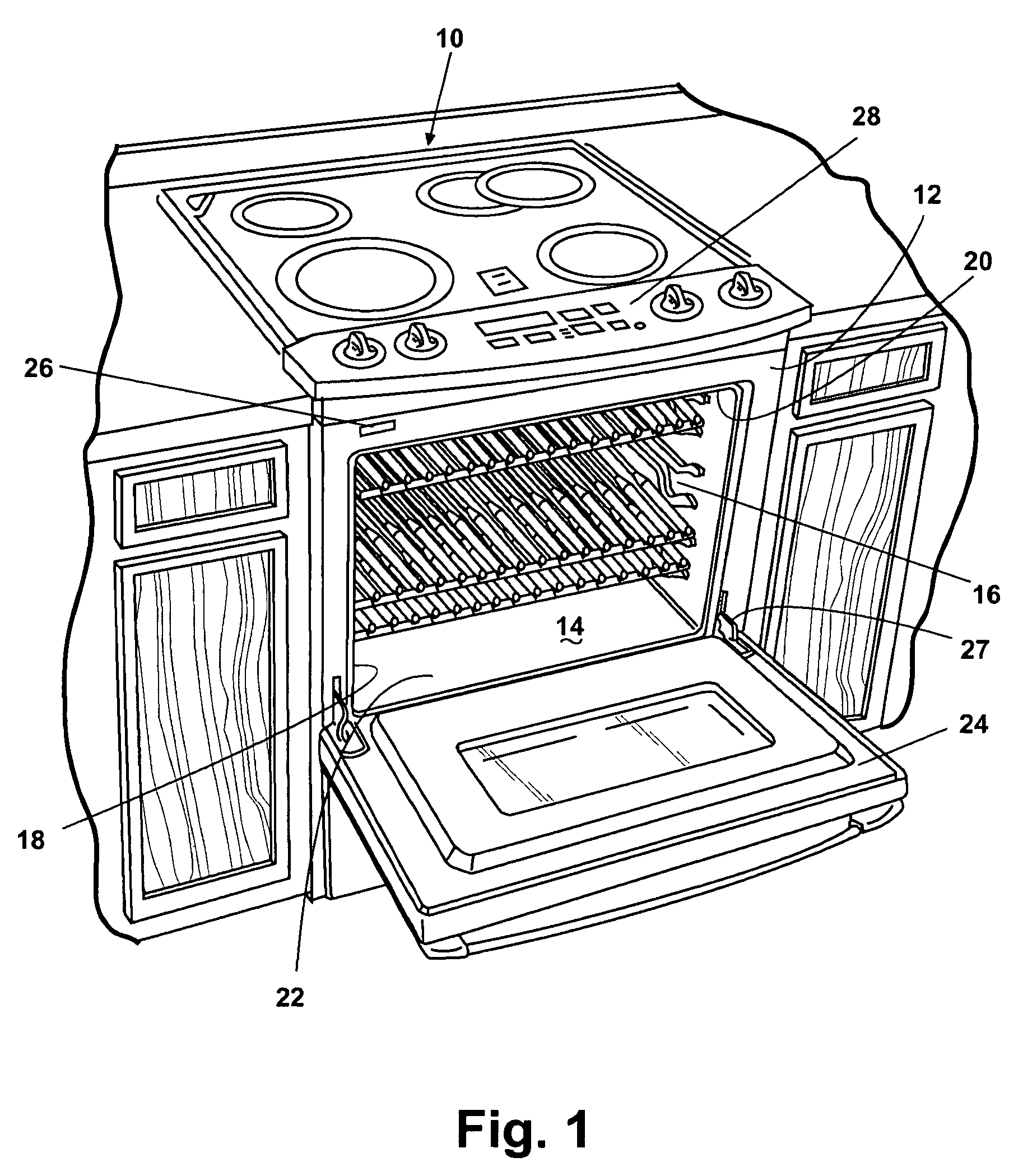

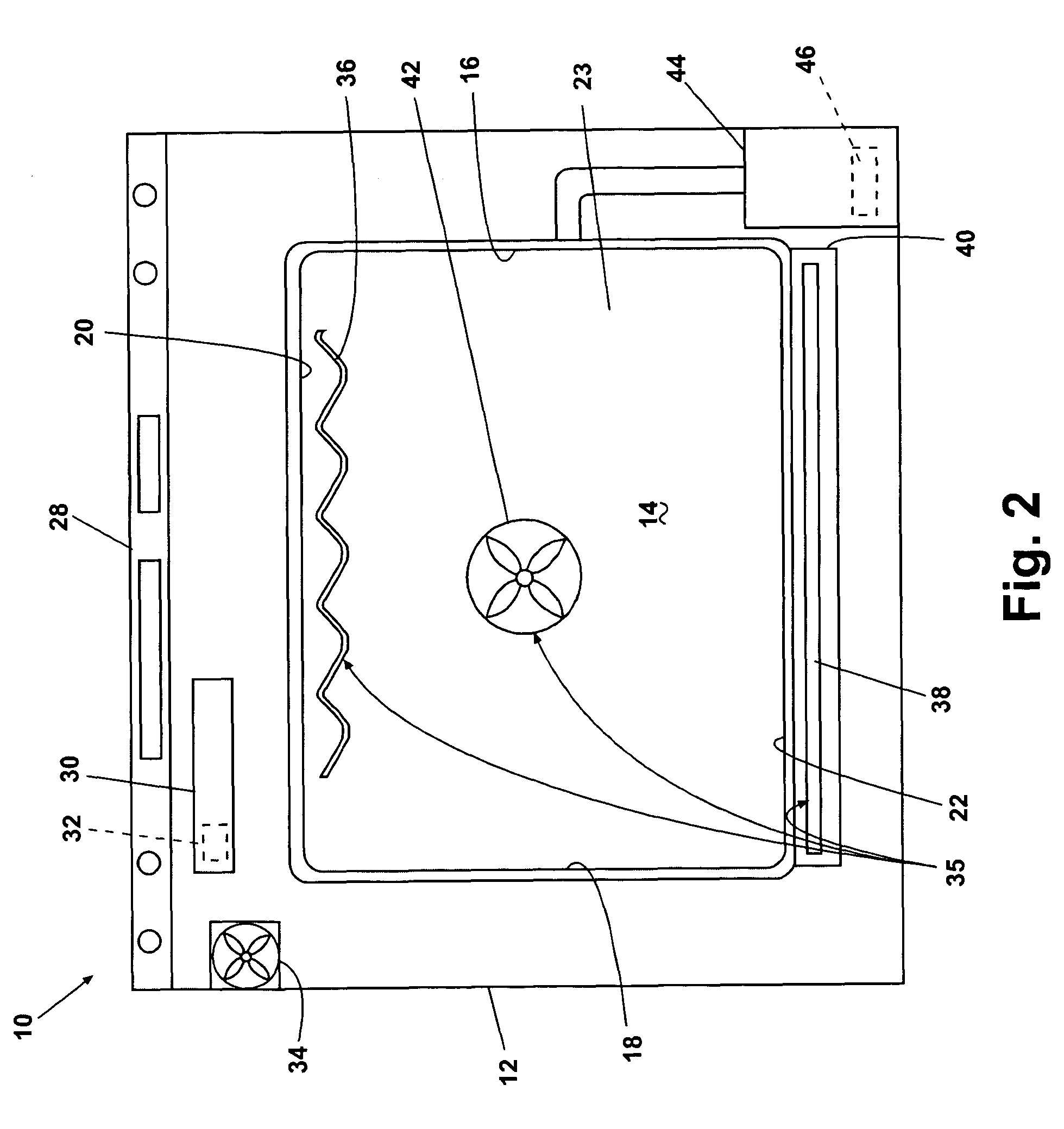

Method for baking a dessert using steam

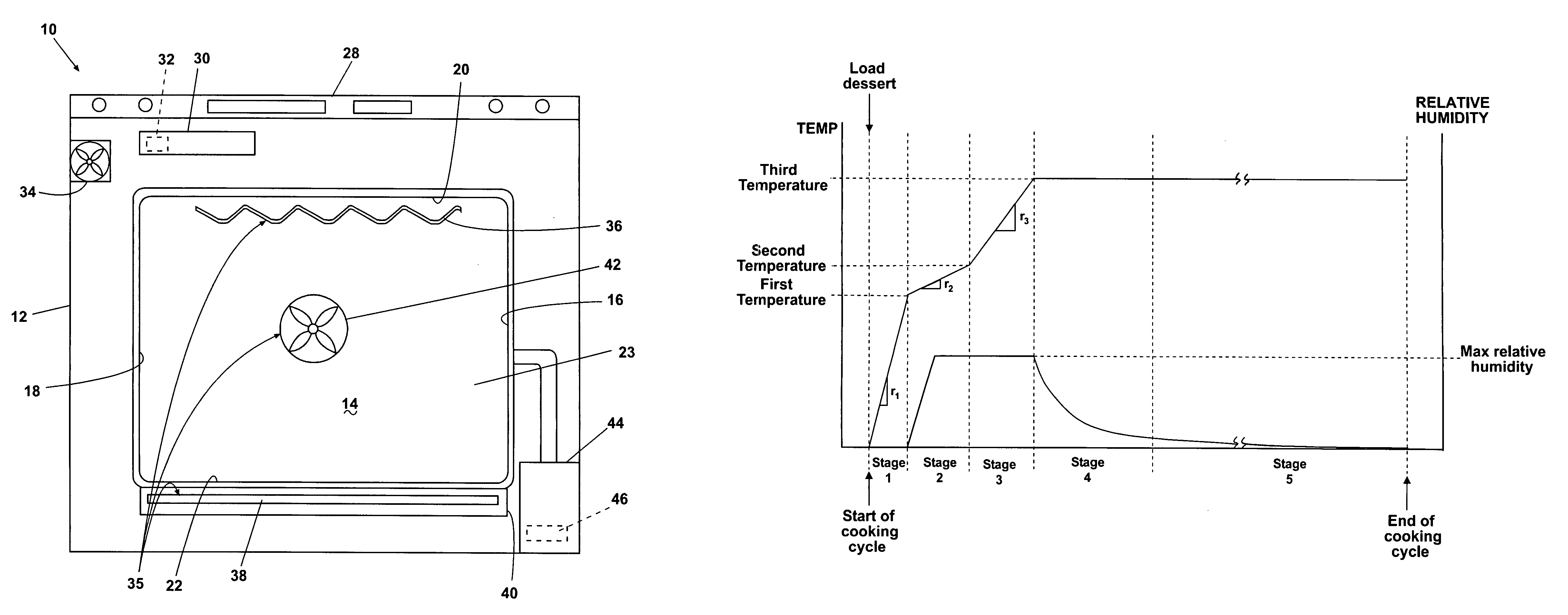

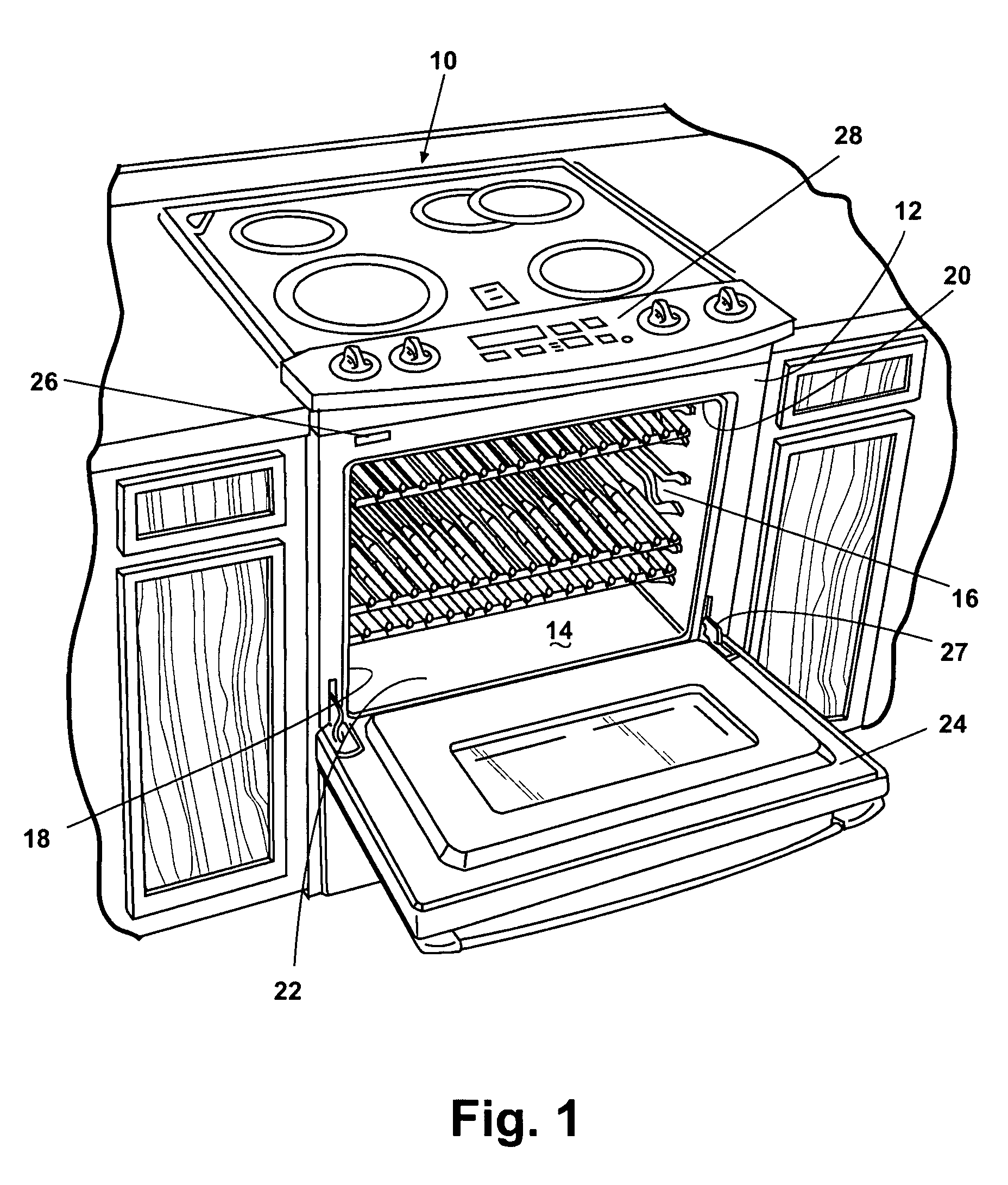

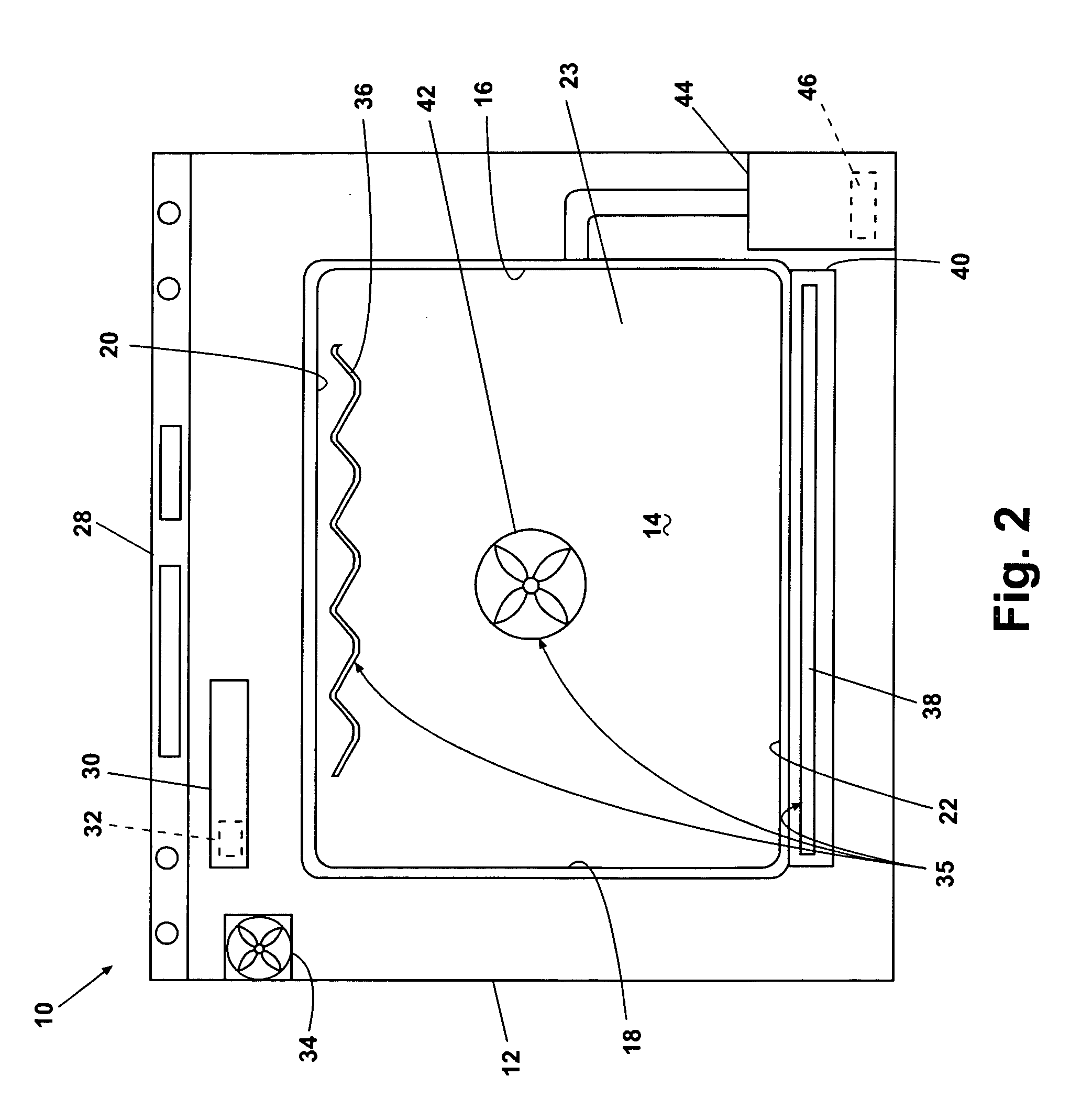

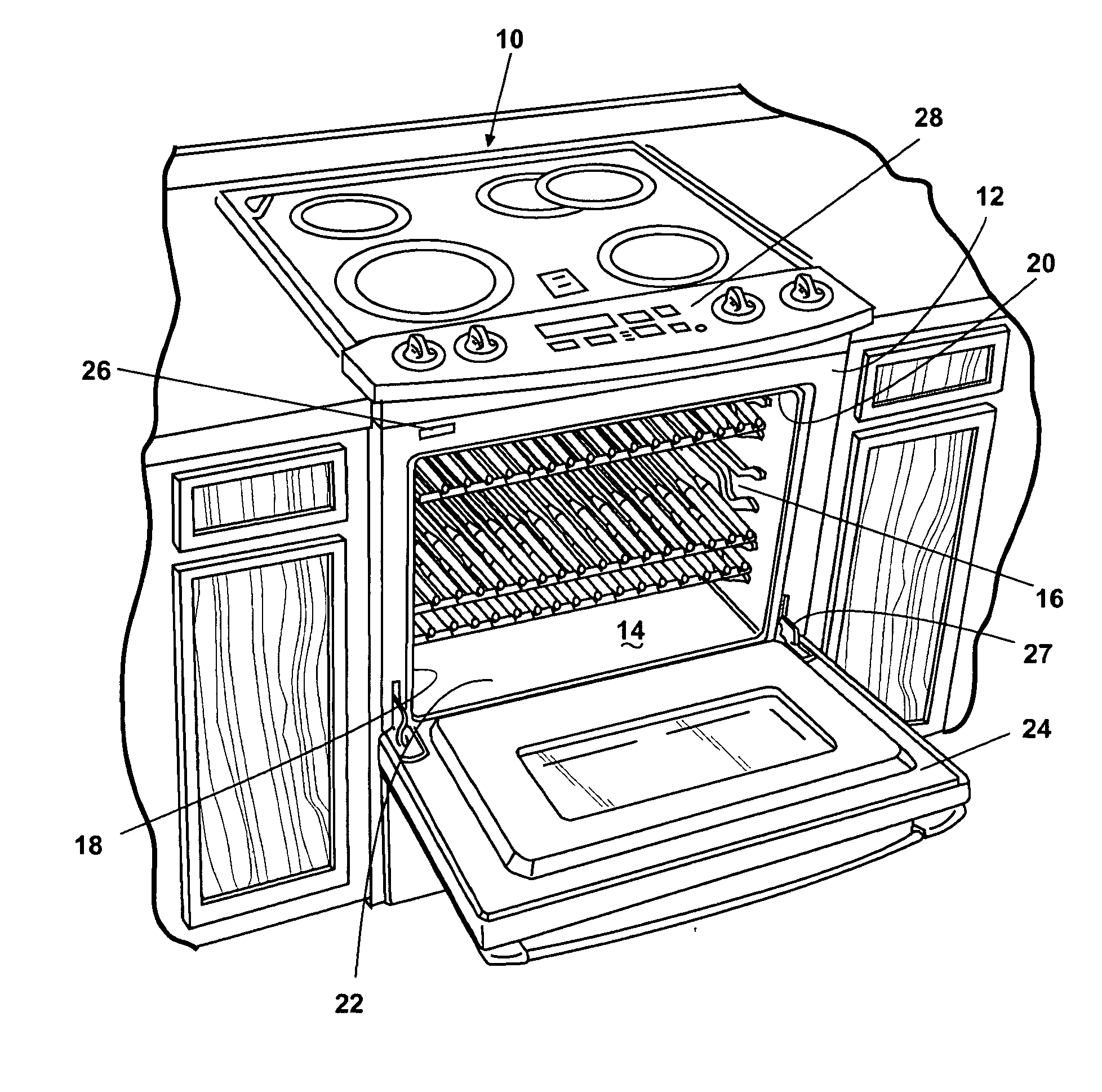

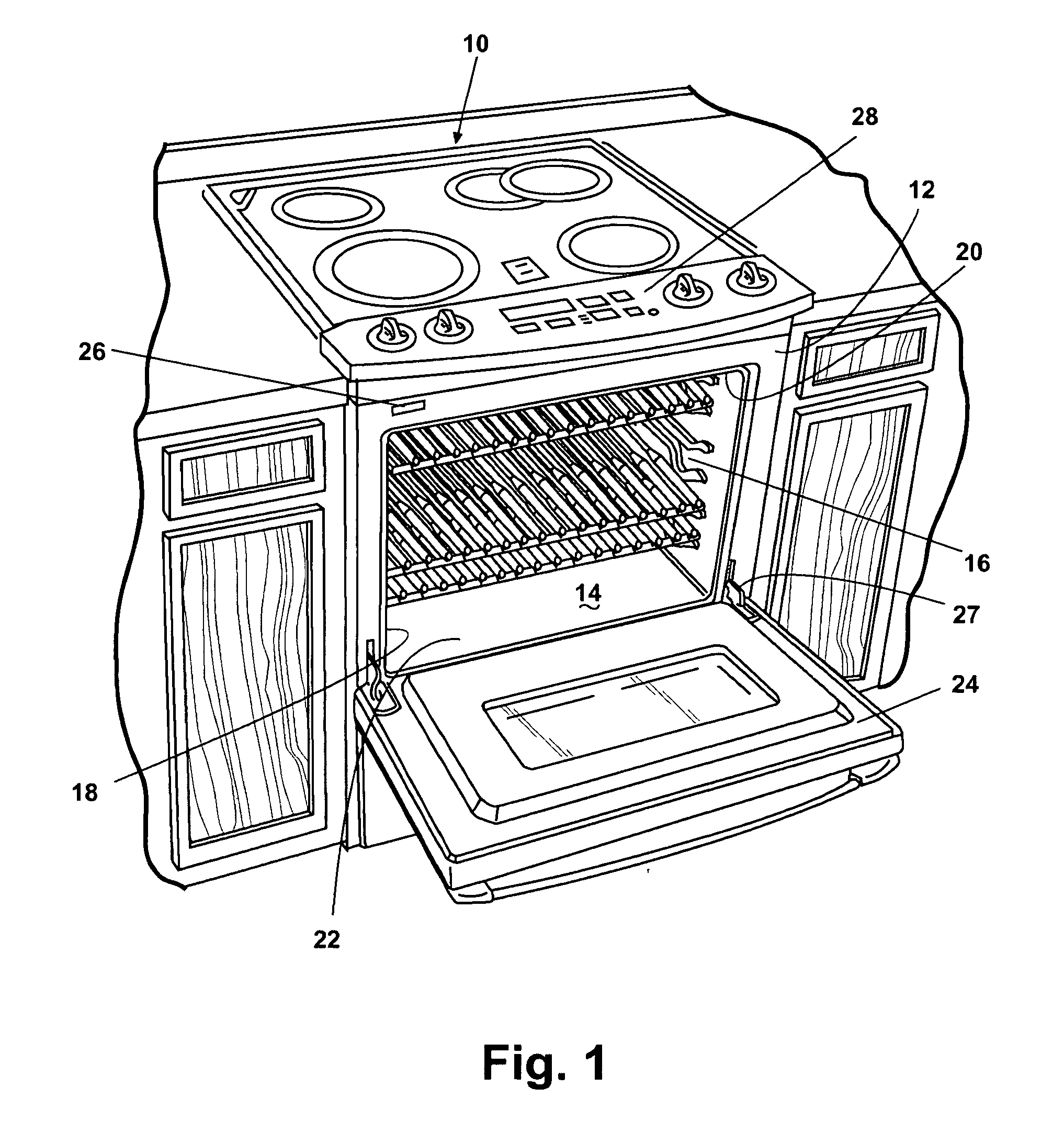

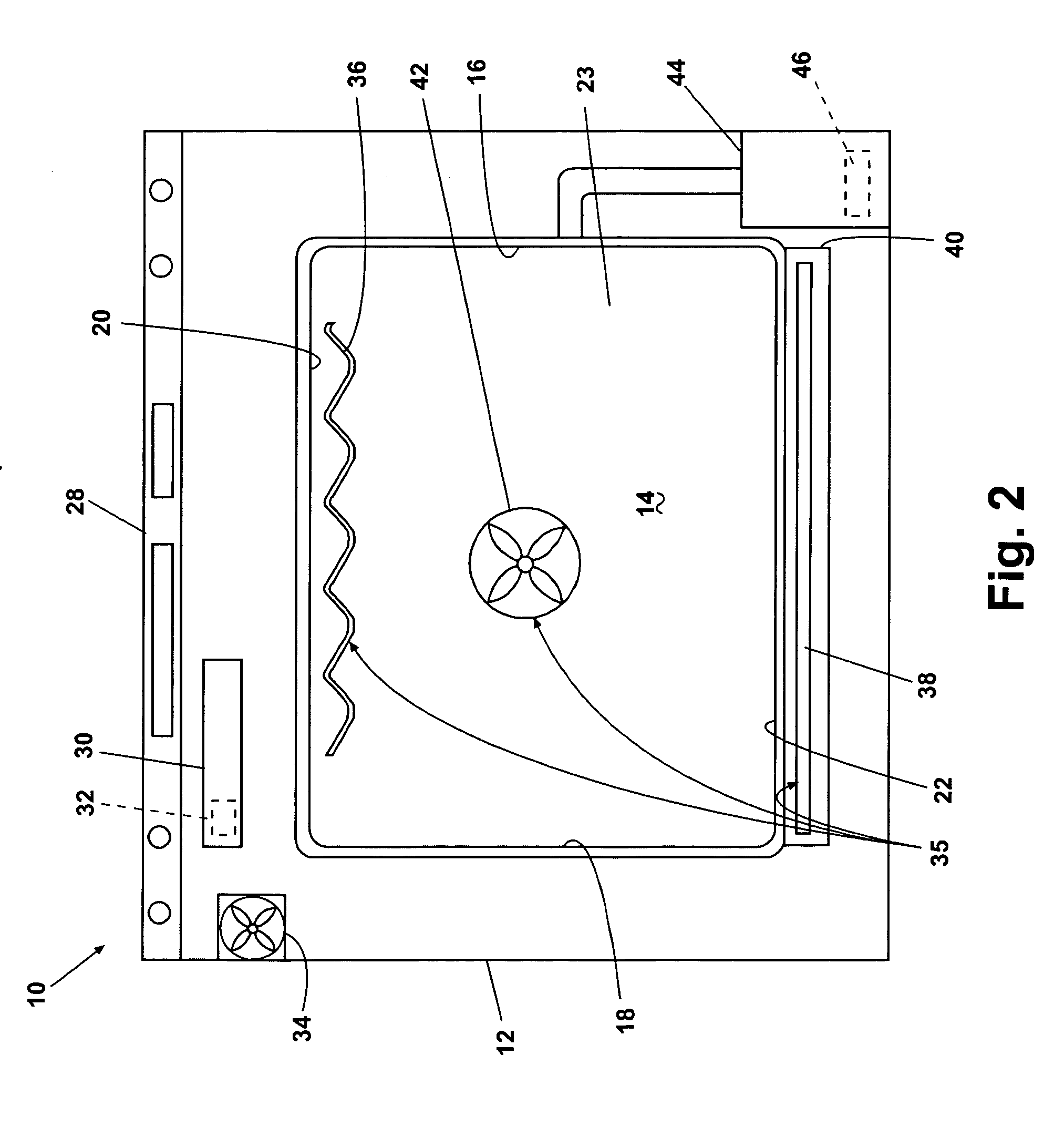

A method of baking a dessert using steam in an automated household oven comprises a first heating step where a heating system preheats a cooking cavity to a first temperature at a first heating rate and a second heating step where the heating system preheats the cooking cavity from the first temperature to a second temperature at a second heating rate less than the first heating rate. The first temperature is preferably about the boiling point of water, and a steam system introduces steam into the cooking cavity to facilitate baking of the dessert after the cooking cavity reaches the first temperature. A convection fan of the heating system is active during the first and second heating steps to help circulate air and steam in the cooking cavity and becomes inactive later in the baking method.

Owner:WHIRLPOOL CORP

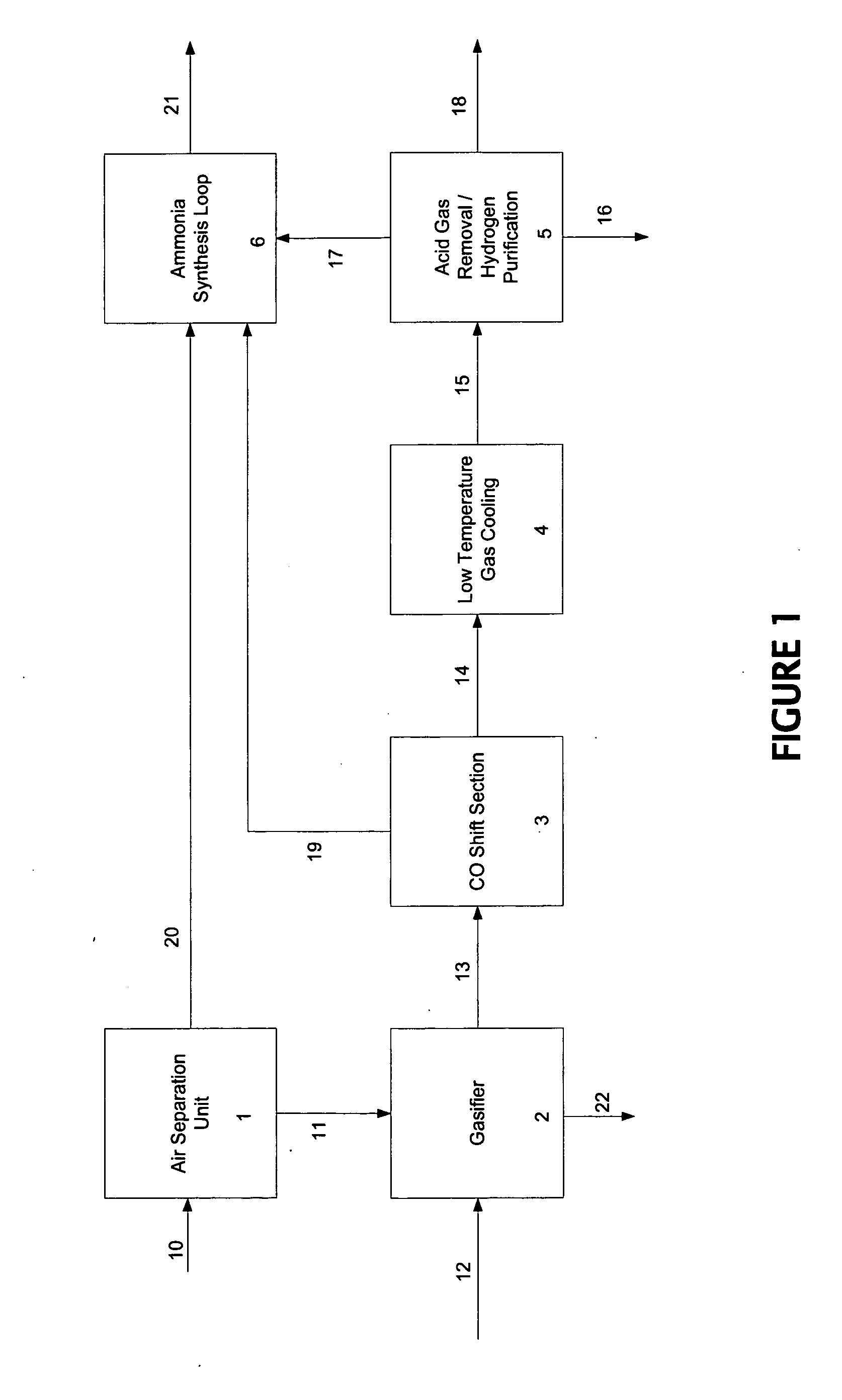

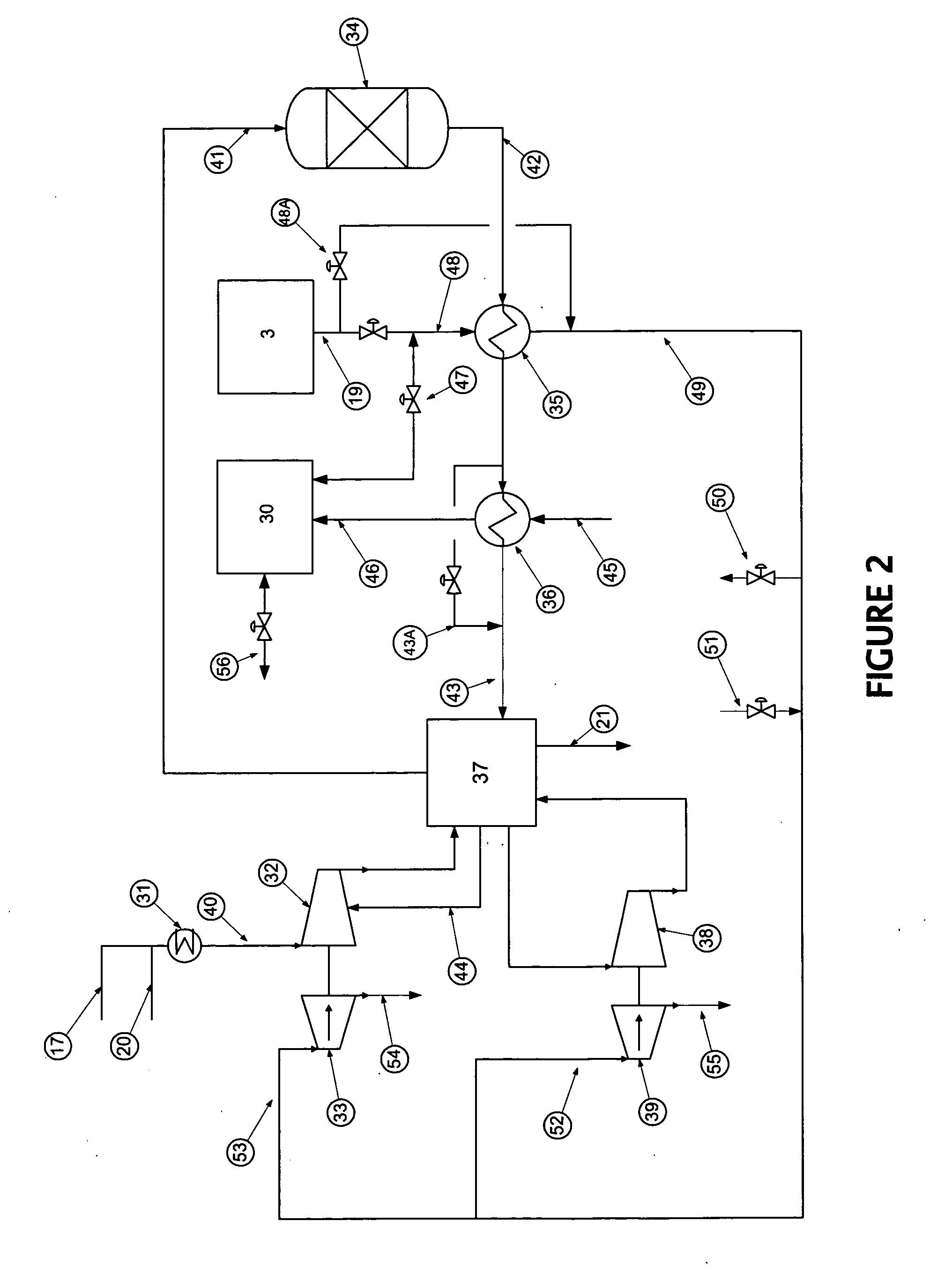

Integration of gasification and ammonia production

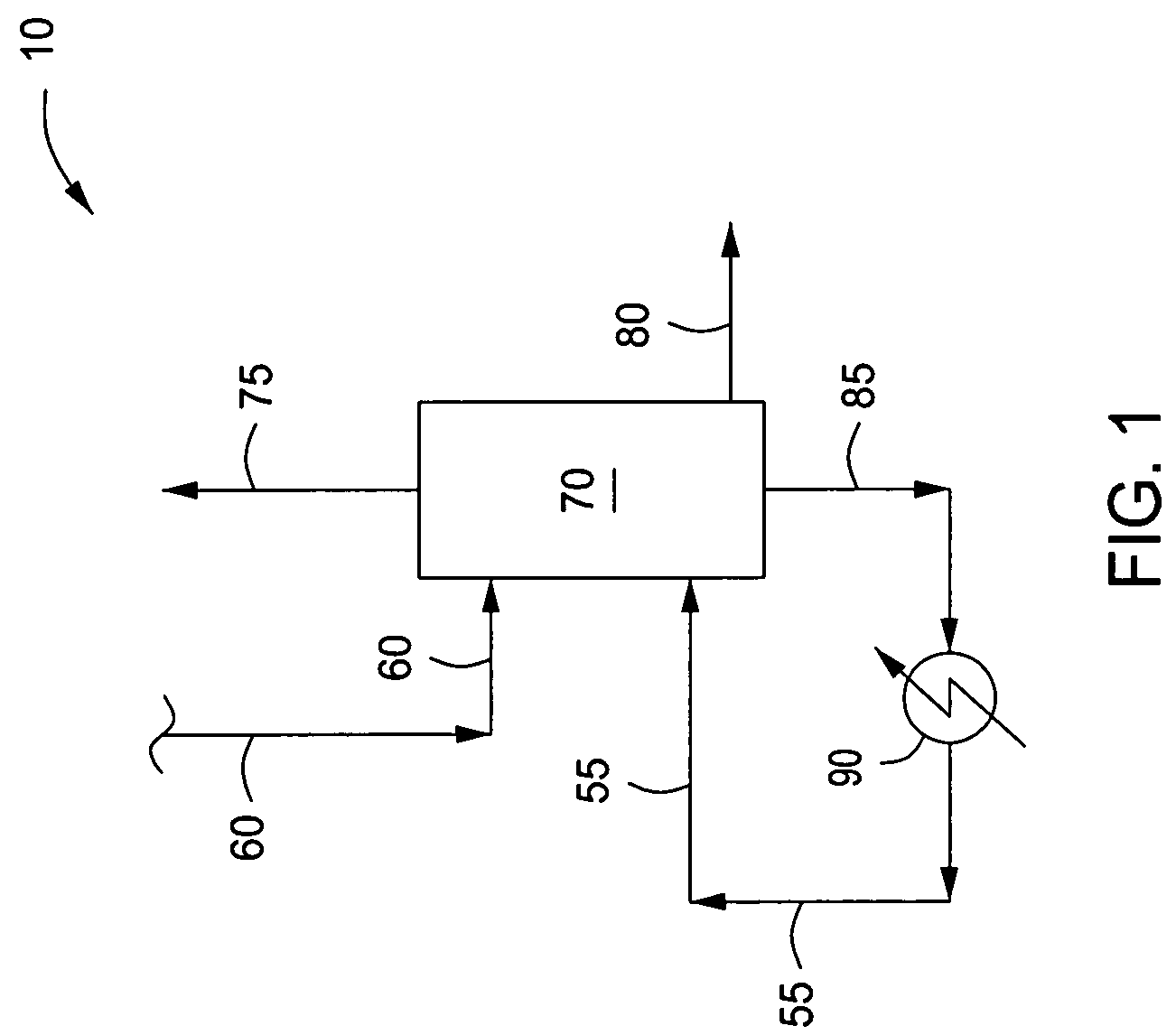

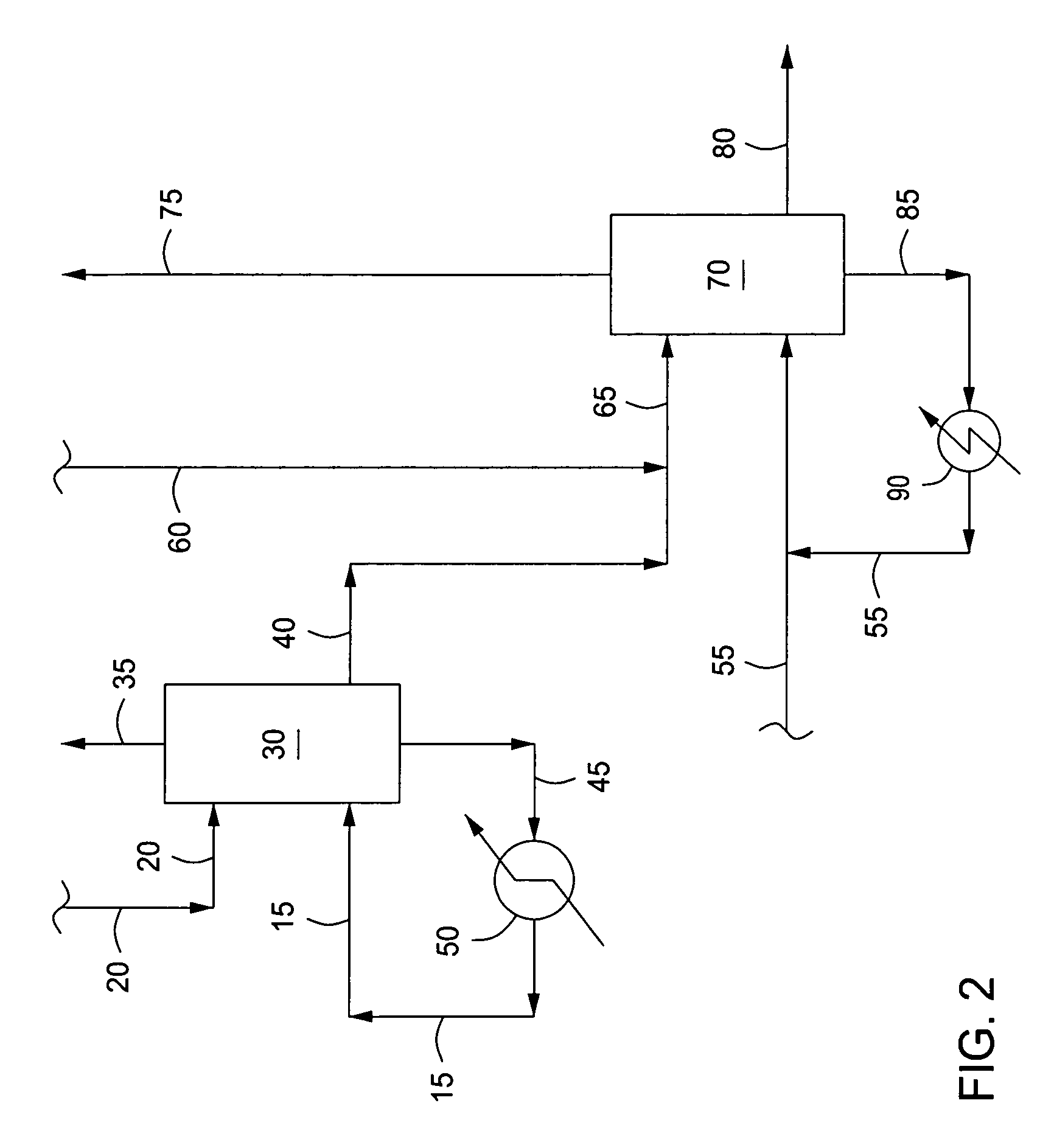

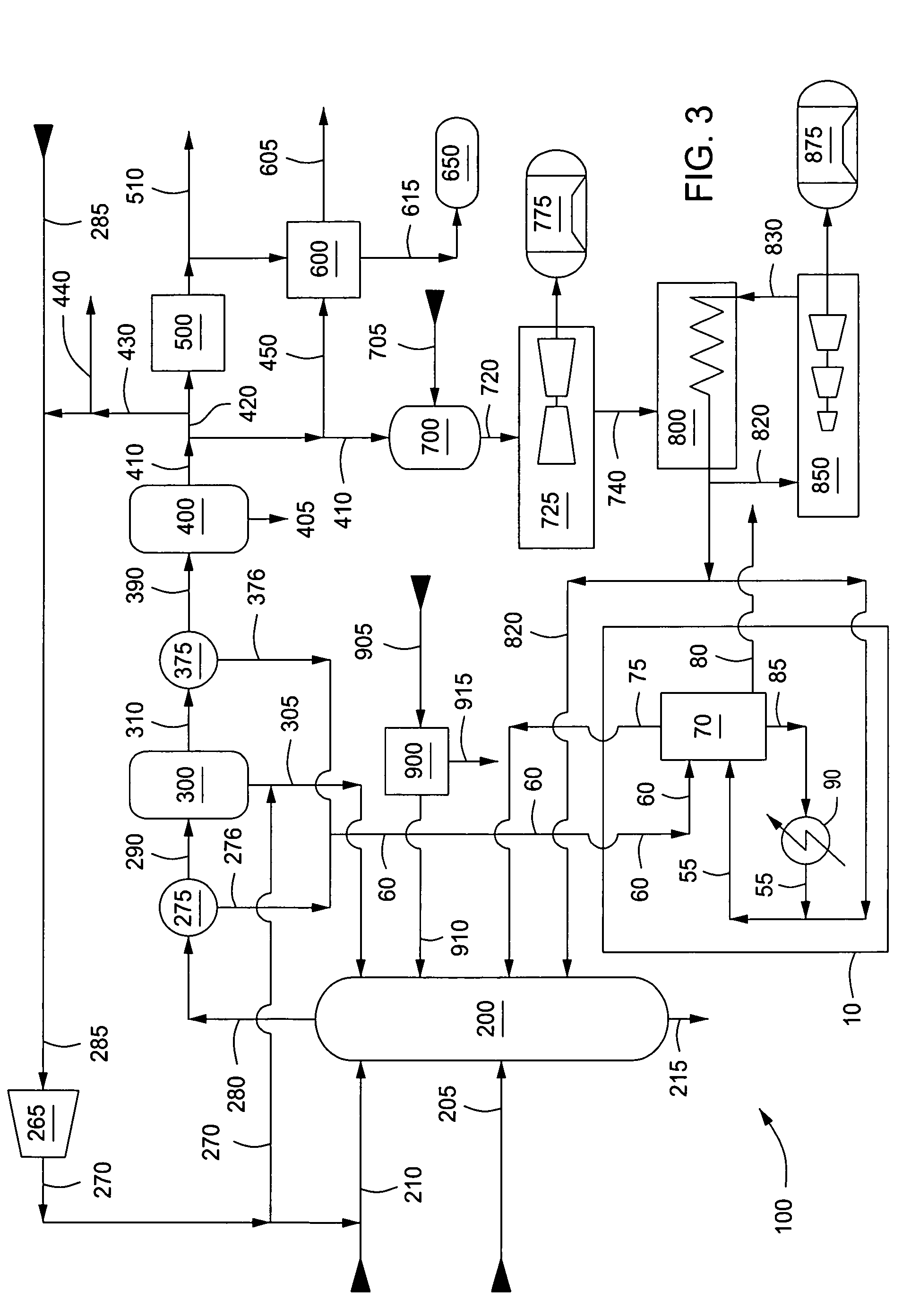

A method and system are described for making ammonia using hydrogen from a gasification process and for integrating the steam systems of the two processes. The gasification process provides high-pressure, purified hydrogen and high-pressure, saturated steam. The high pressure hydrogen lowers the overall compression requirement for the ammonia process. In addition, the high-pressure, saturated steam can be converted into superheated steam by recovering heat from ammonia synthesis and used to power steam turbines for compression and refrigeration needs.

Owner:EASTMAN CHEM CO

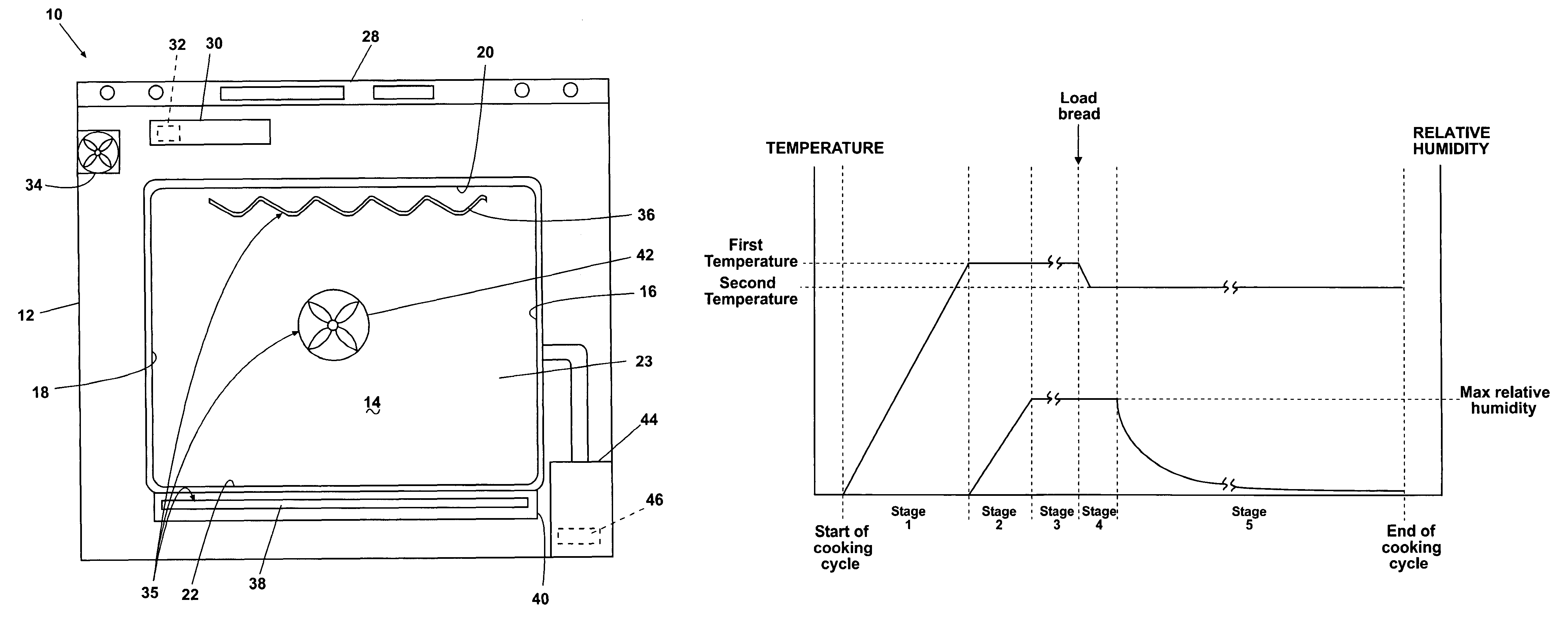

Method for baking bread using steam

A method of baking bread using steam in an automated household oven with a cooking cavity and a steam system for introducing steam into the cooking cavity comprises determining a presence of bread in the cooking cavity and introducing steam into the cooking cavity upon a positive determination of the presence of bread. After the positive determination, the steam is introduced into the cavity to maintain a desired relative humidity in the cavity for a predetermined period of time to aid in formation of a moist, flexible crust on the bread, and the amount of steam introduced into the cavity decreases after the predetermined period of time. The cavity can be preheated and prehumidified prior to the determining of the presence of the bread in the cooking cavity.

Owner:WHIRLPOOL CORP

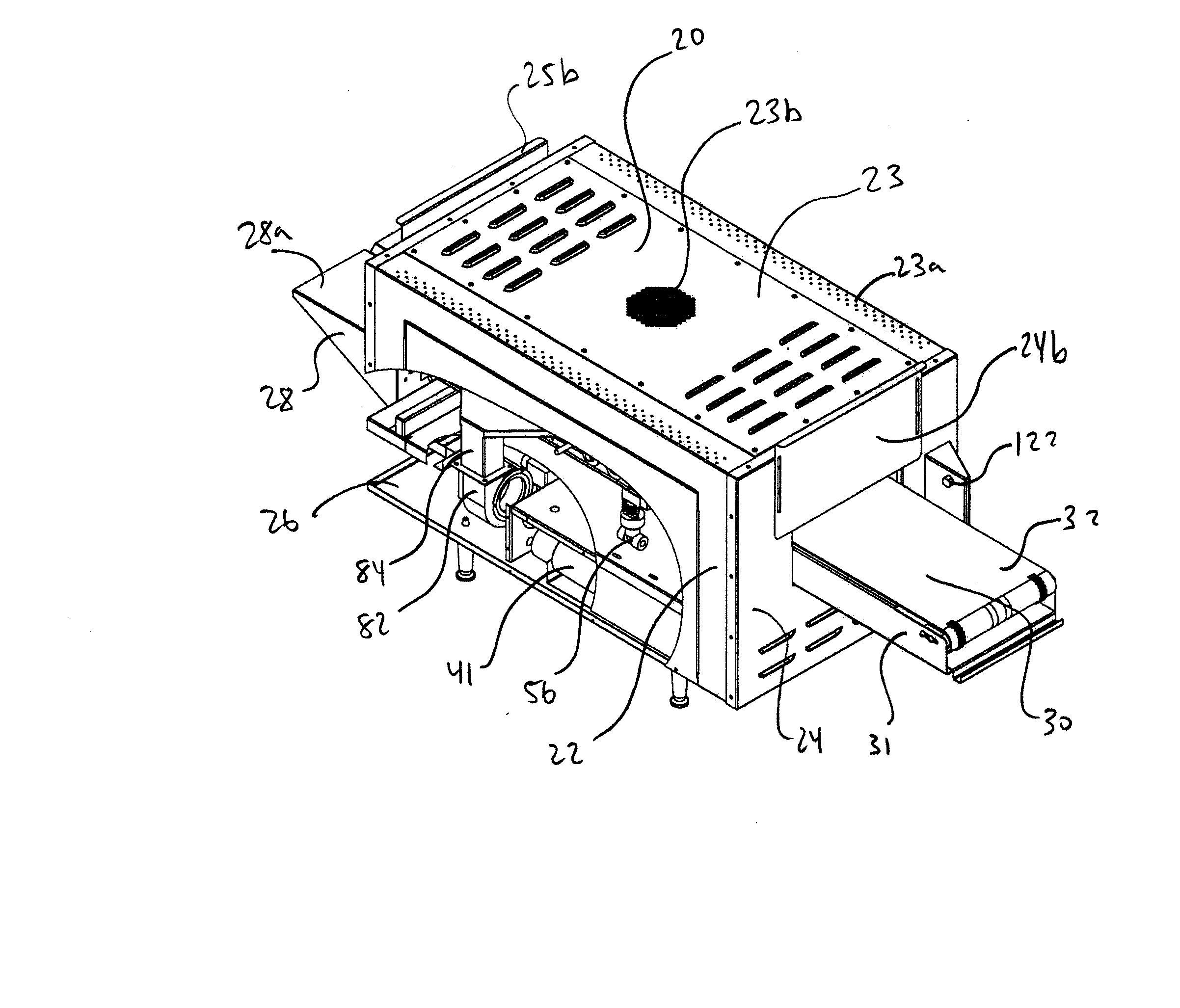

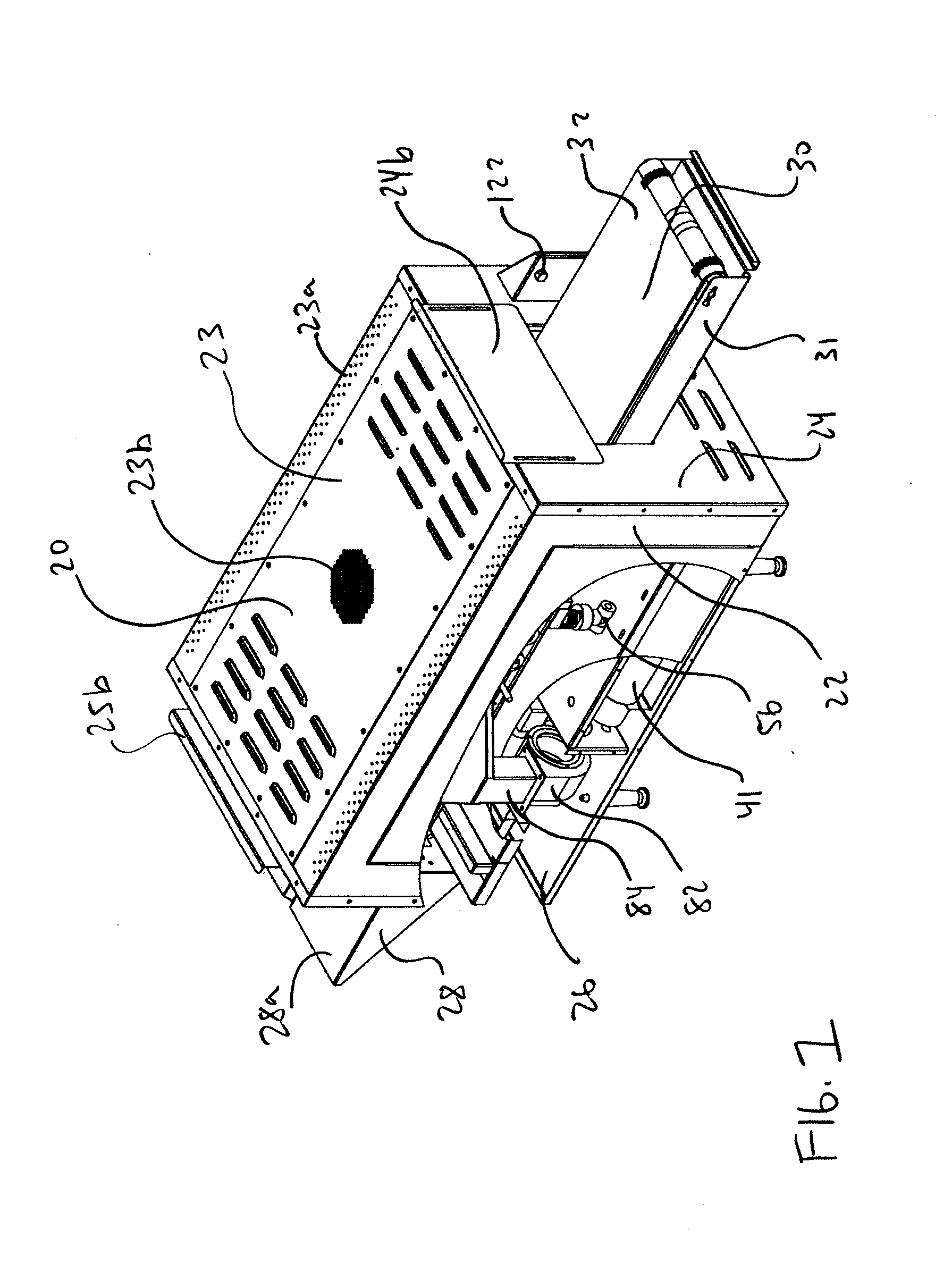

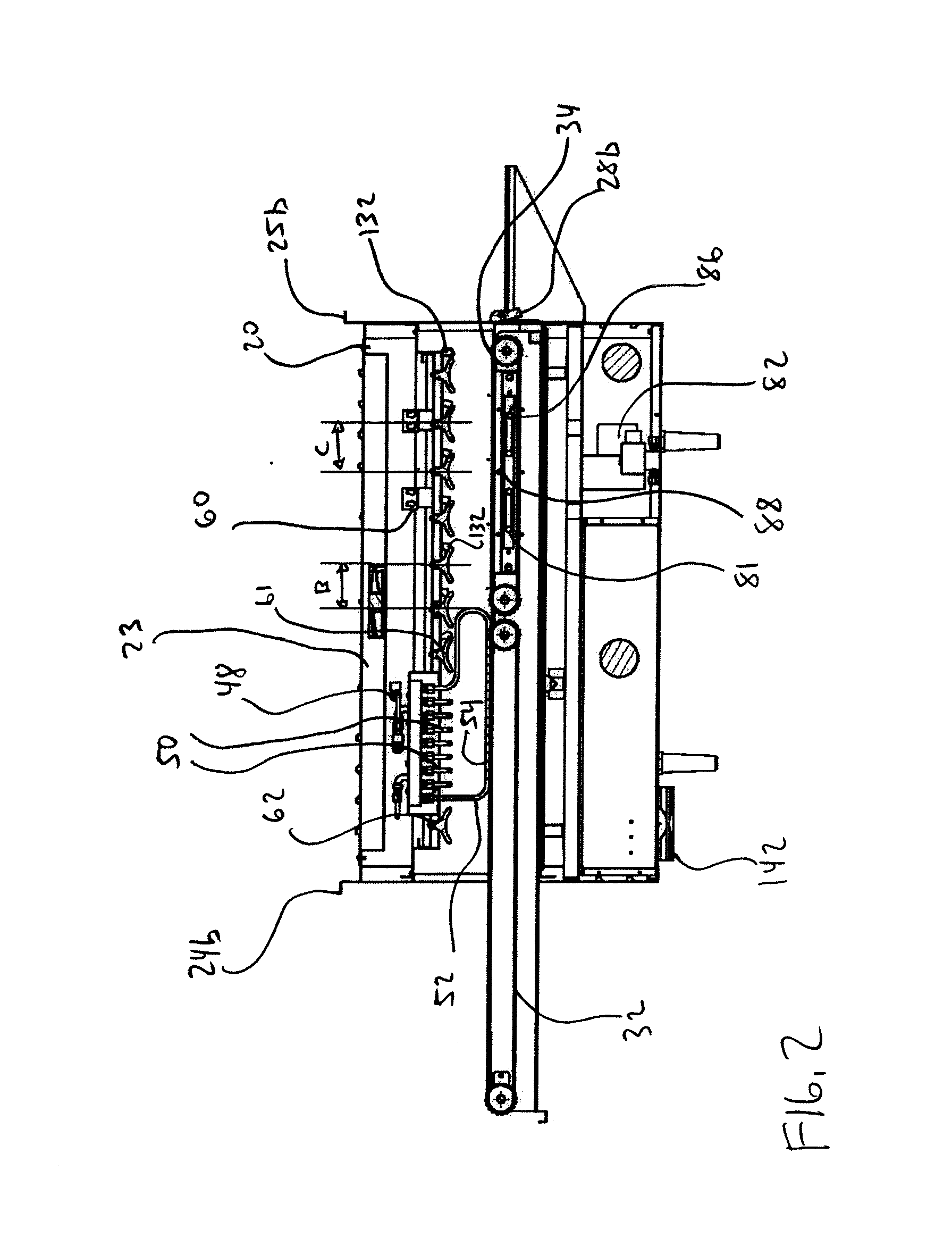

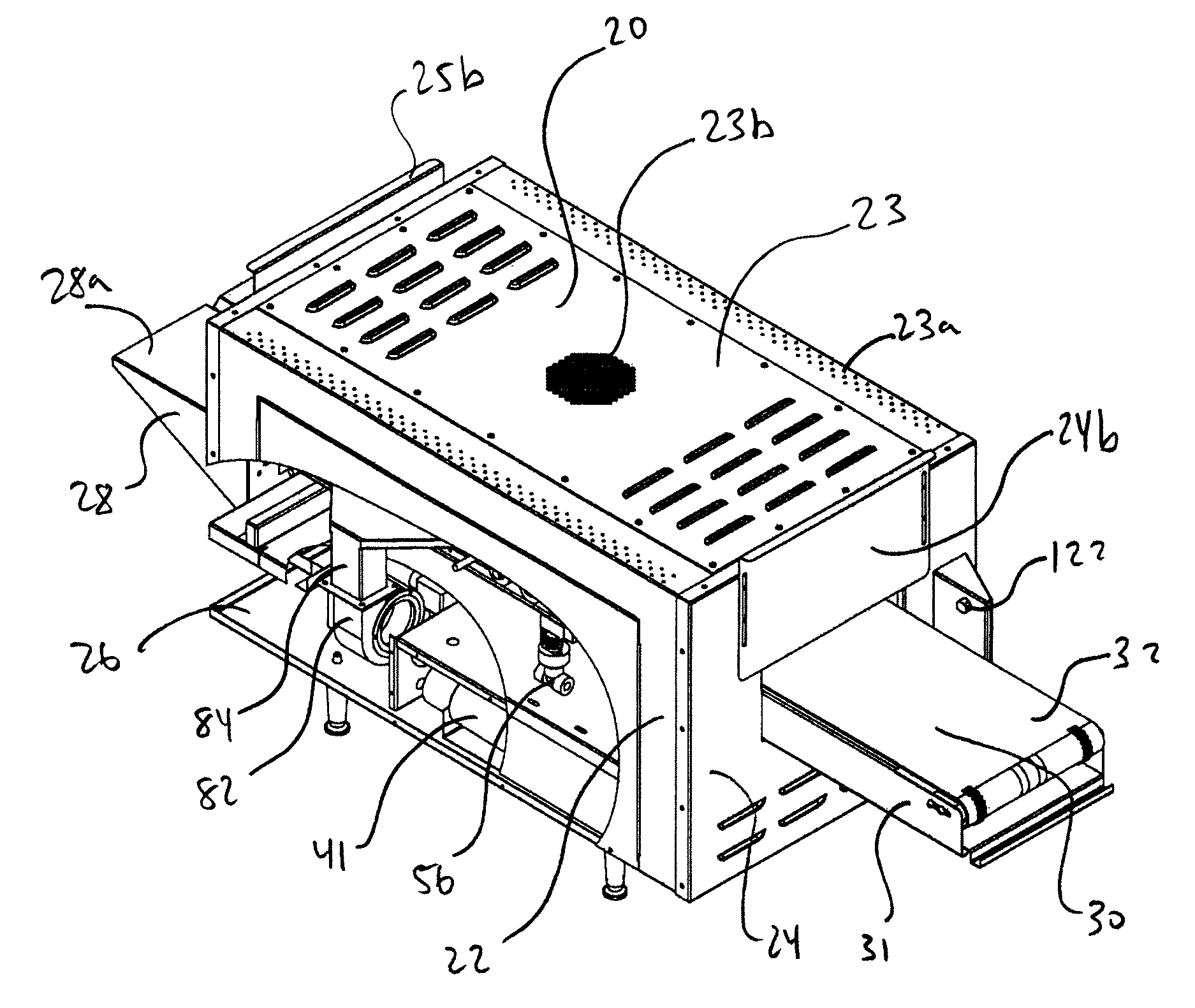

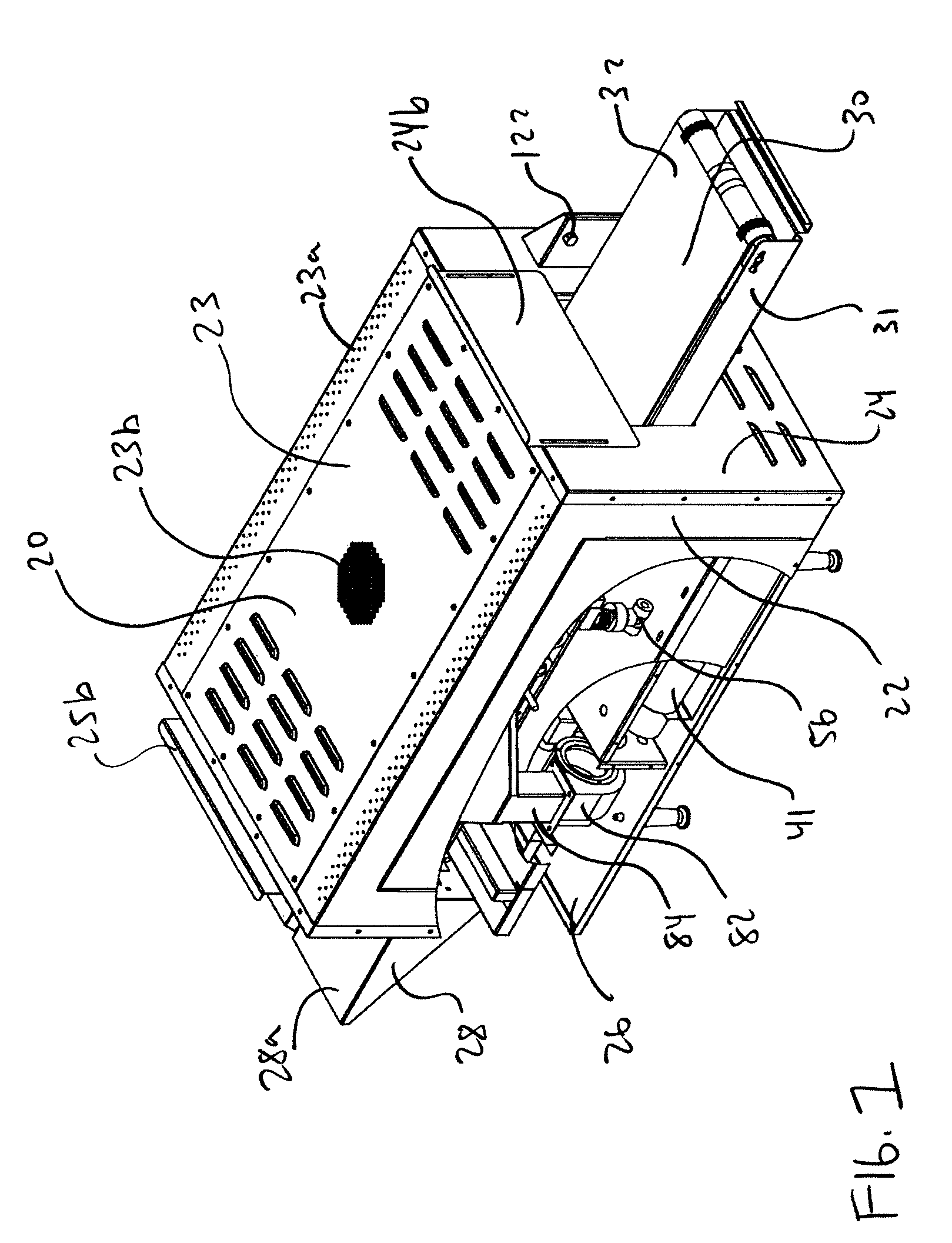

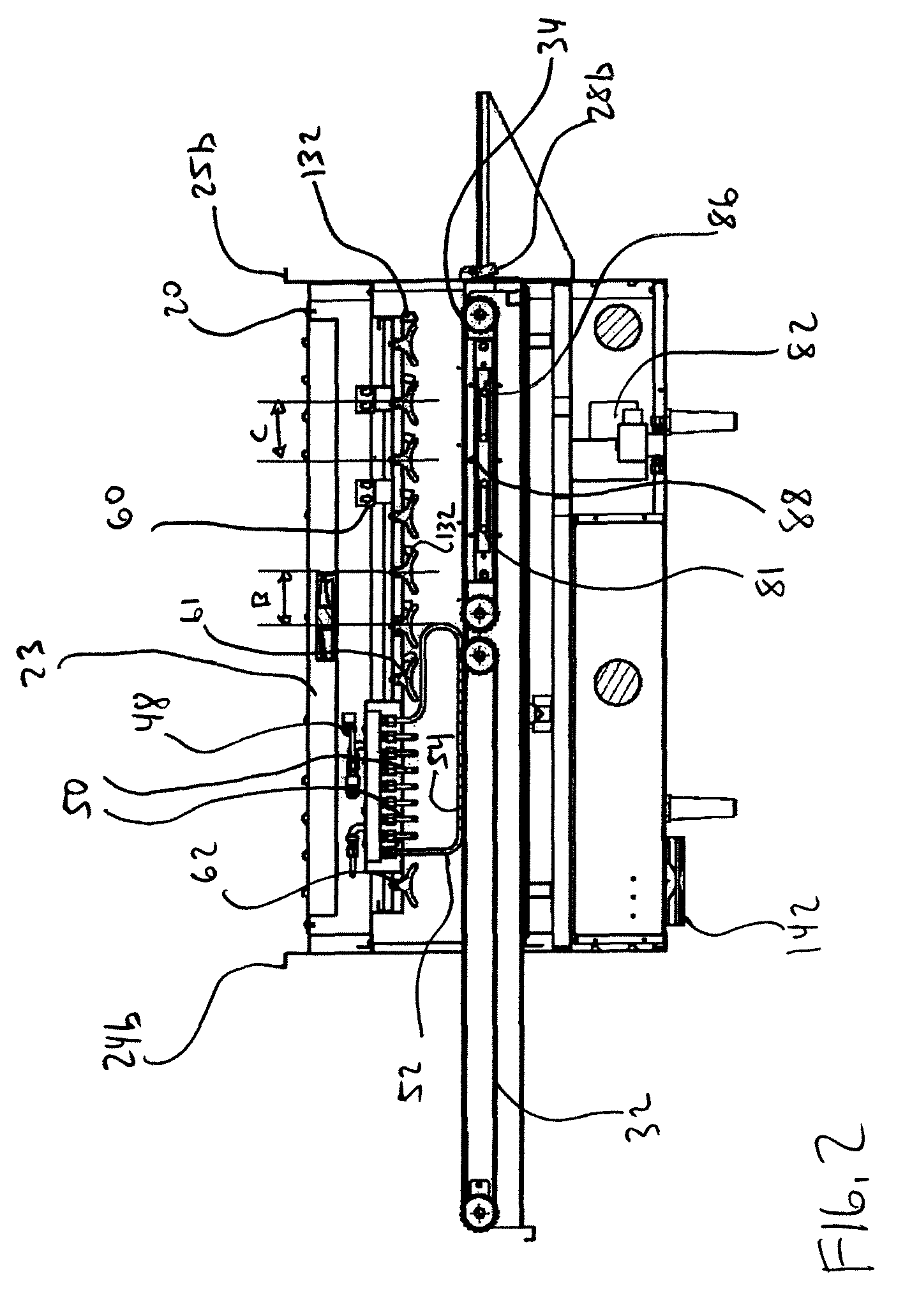

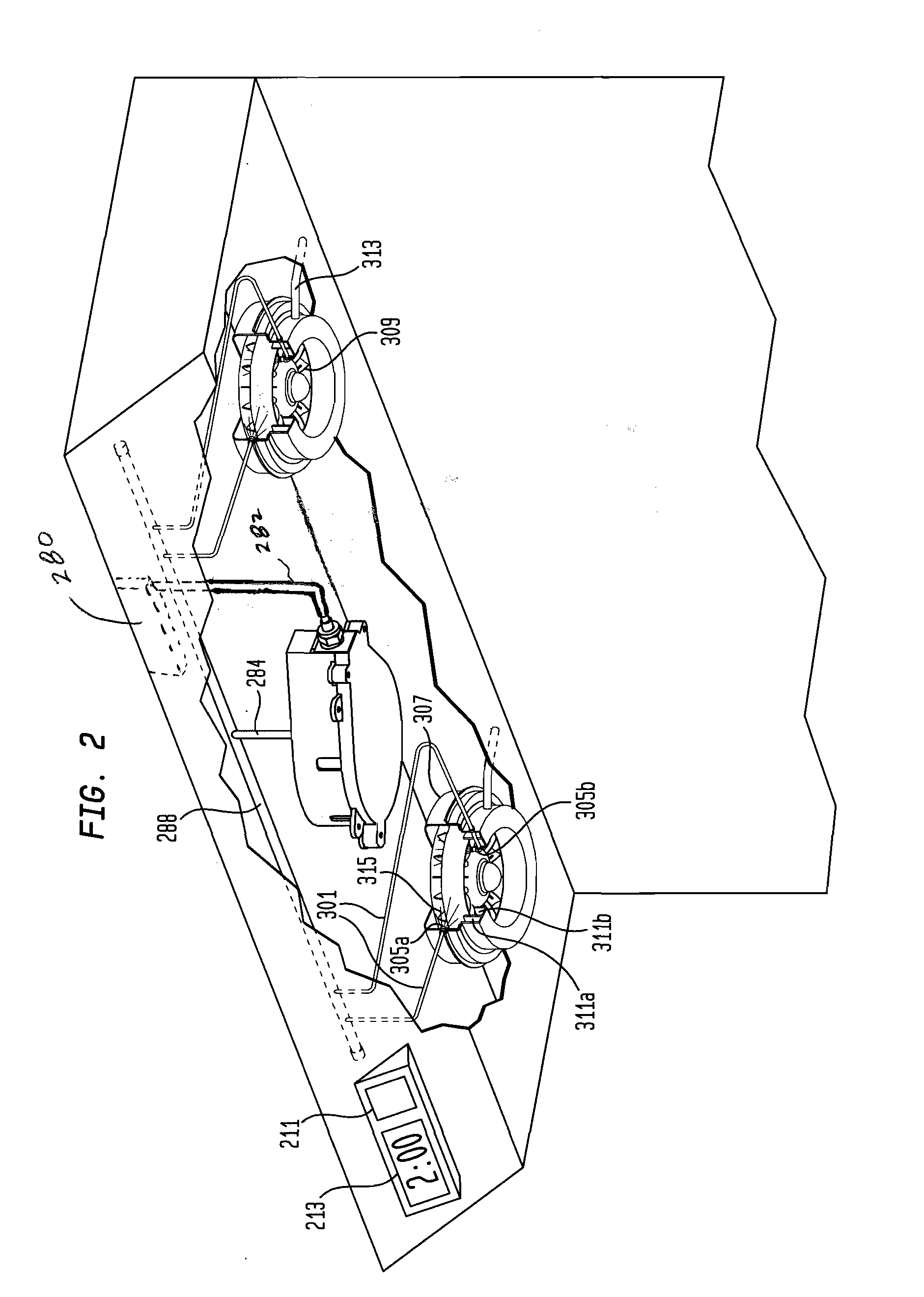

Combination Conveyor Oven

InactiveUS20080032018A1Save energyReduce the amount requiredOven air-treatment devicesDielectric heating circuitsProcess engineeringPartial closure

An oven for heating a product is provided. The oven includes a partially enclosed housing with an inlet opening and an outlet opening and a conveyor to move a product through the housing. The oven additionally includes a steam system for boiling liquid with an associated steam pipe and a heating element provided within the housing.

Owner:NU VU FOOD SERVICE SYST

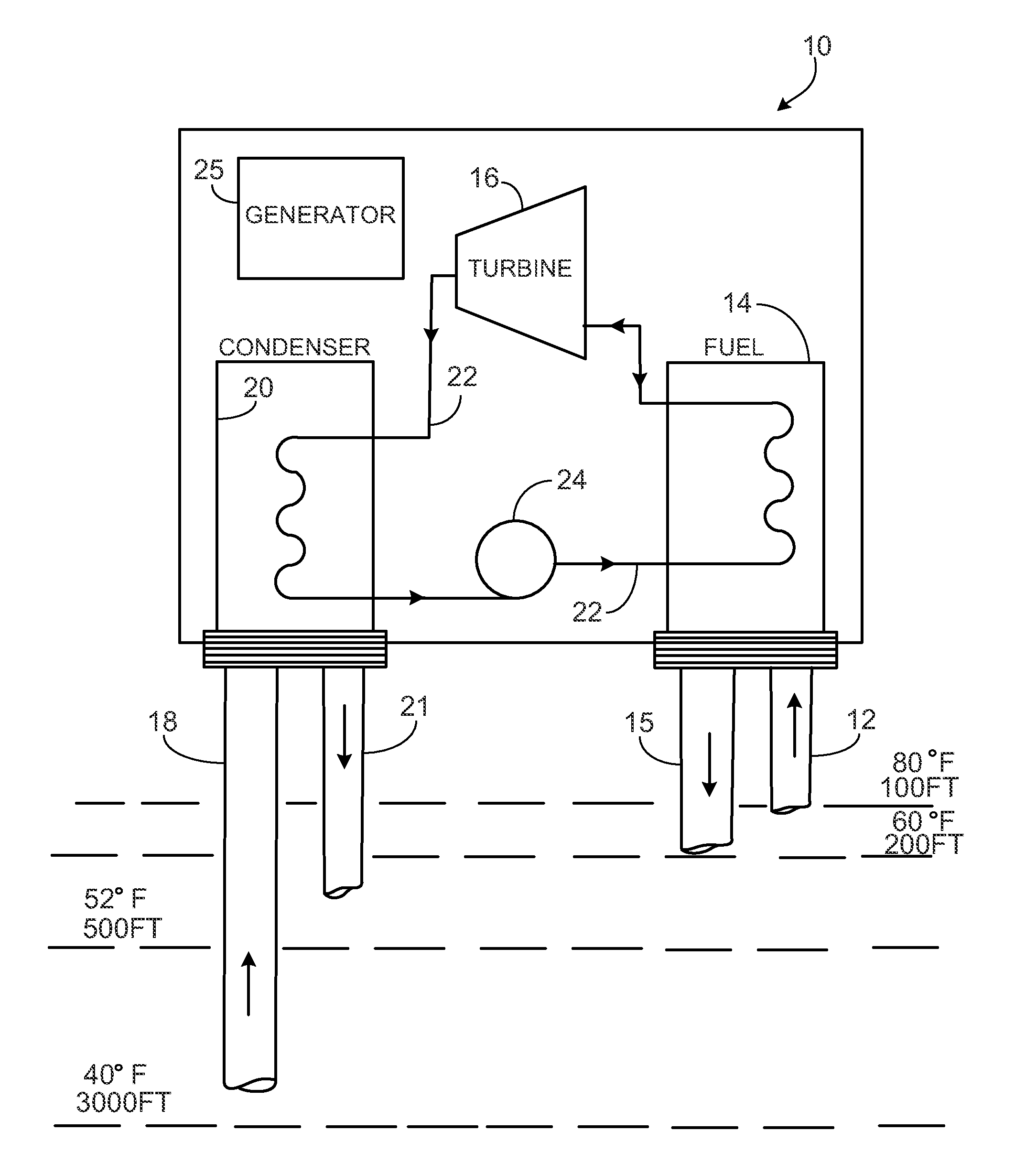

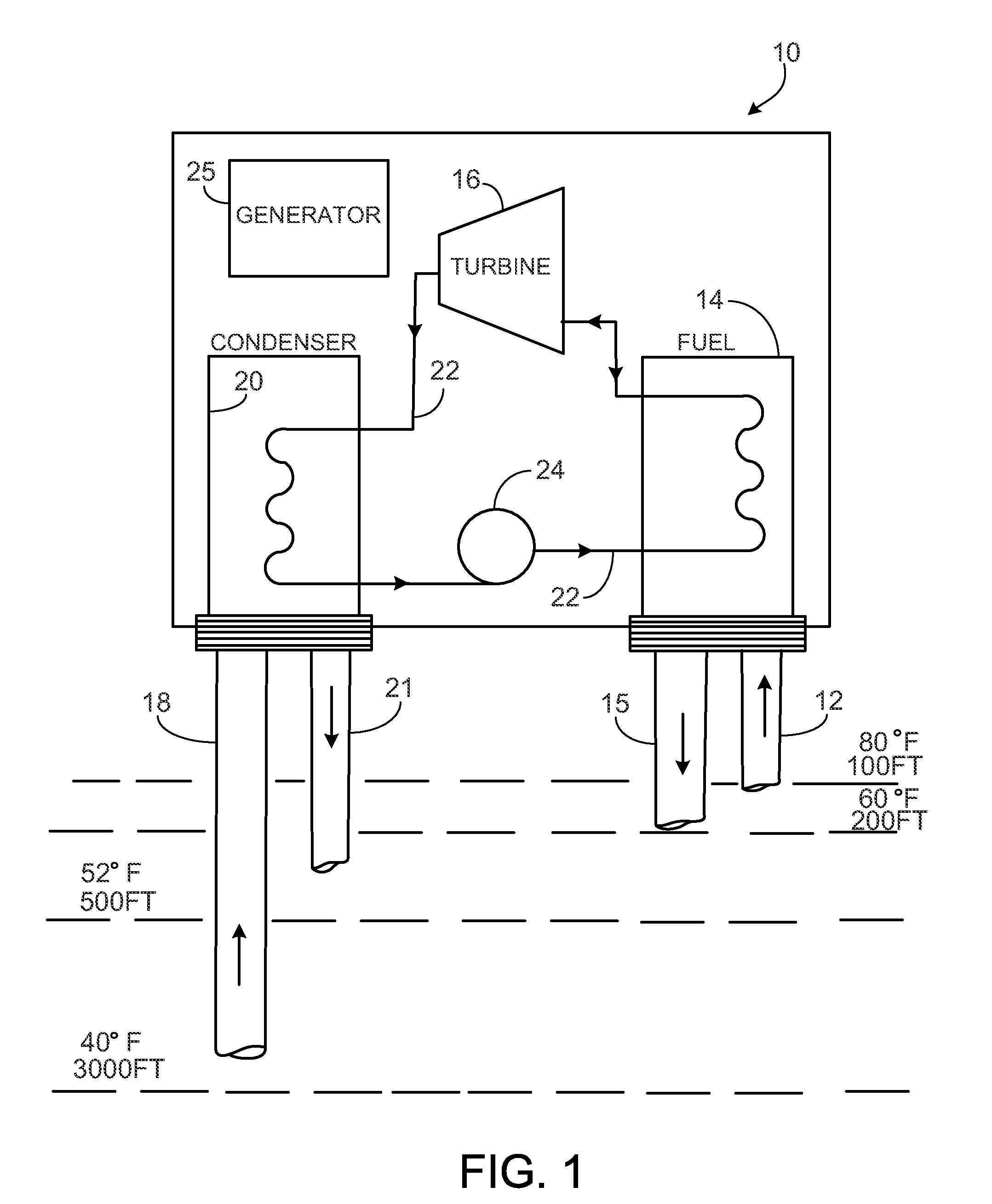

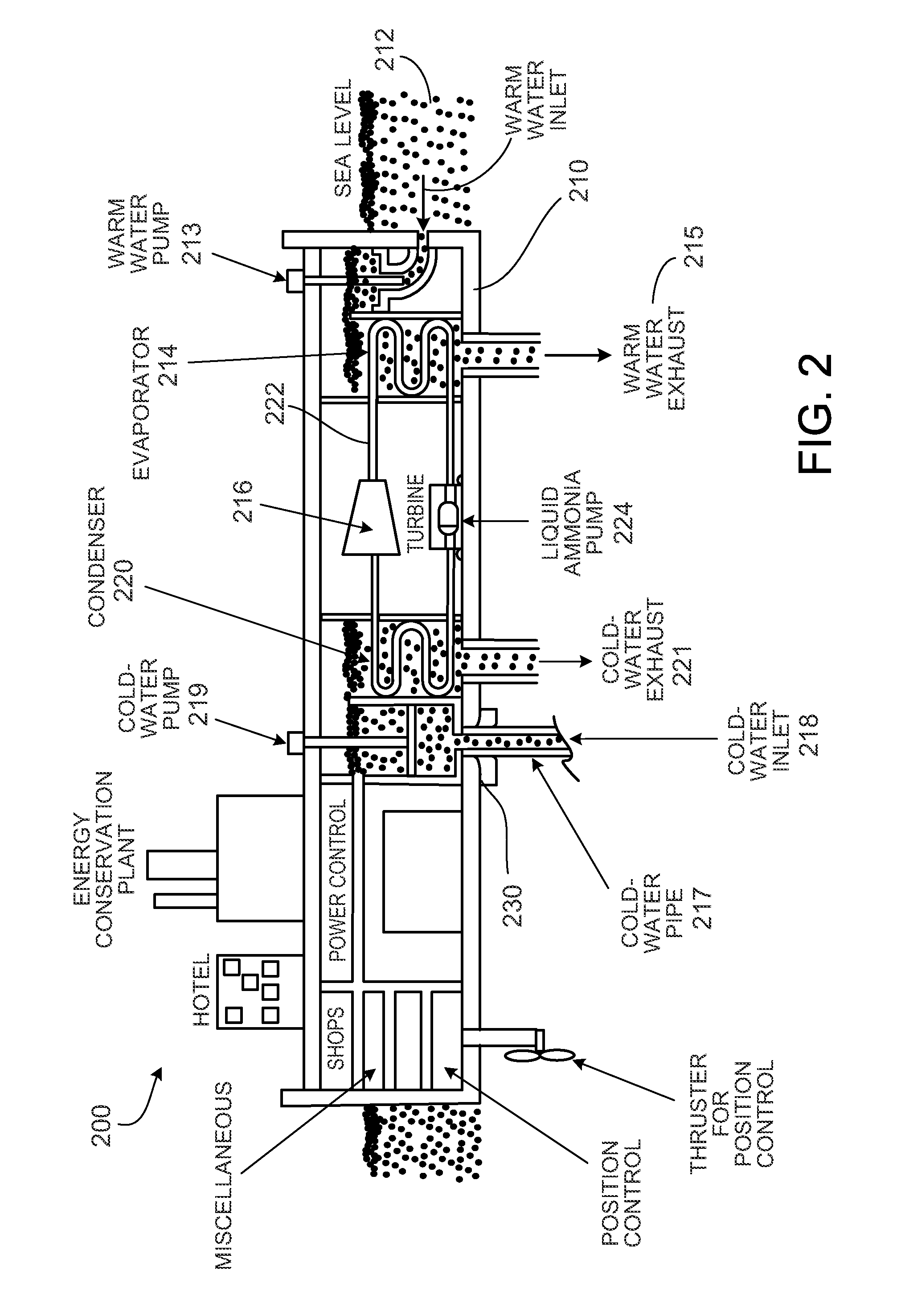

Industrial Ocean Thermal Energy Conversion Processes

InactiveUS20120073291A1Increase net efficiencyShorten construction timeSteam generation plantsSteam engine plantsThermal energyOcean thermal energy conversion

A combined OTEC and steam system having an OTEC power generation system including a multistage condensing system in fluid communication with a cold water system and a steam system comprising a steam condenser, wherein the steam condenser is in fluid communication with the cold water system.

Owner:THE ABELL FOUND INC

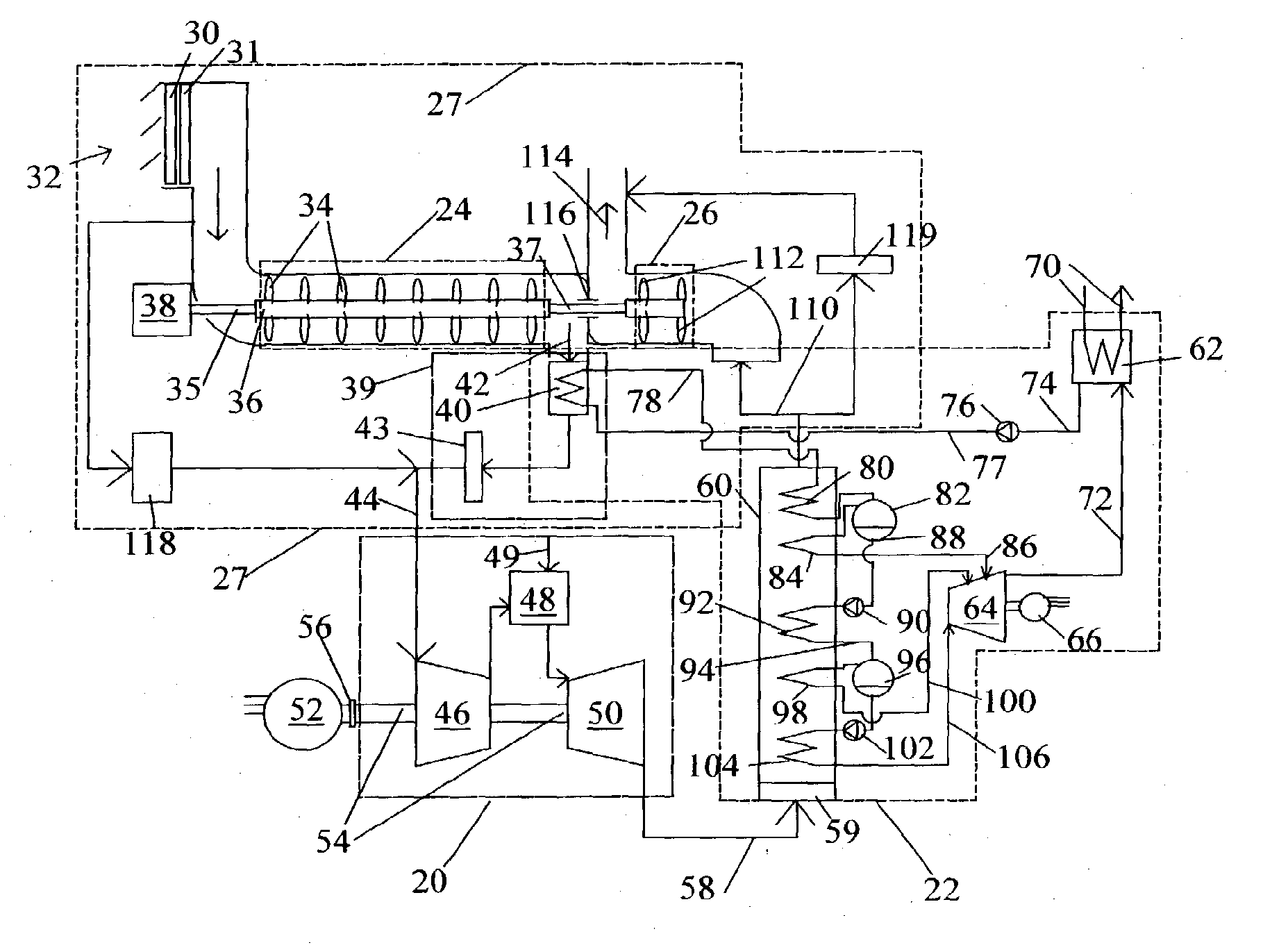

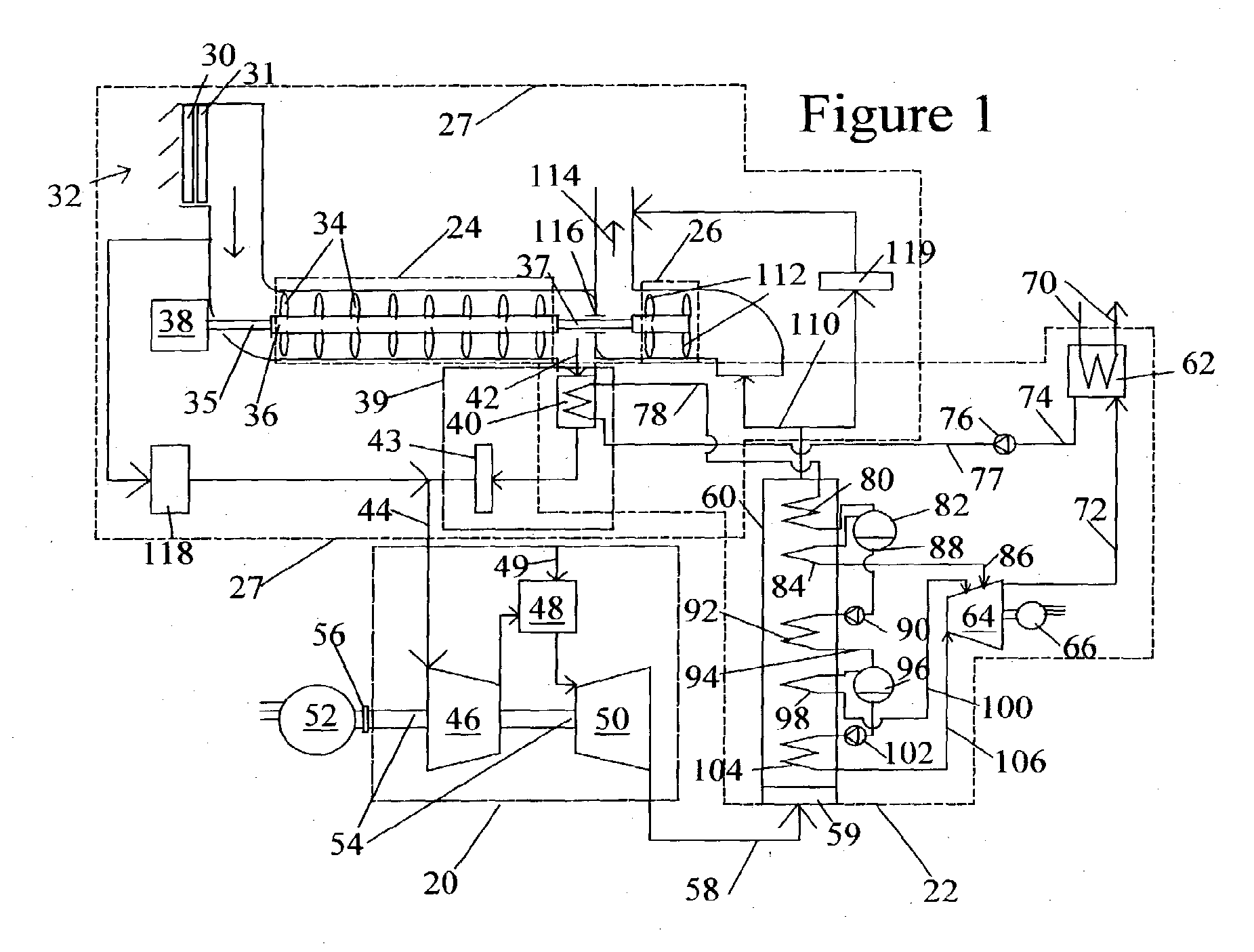

Highly Supercharged Gas Turbine Generating System

InactiveUS20080304954A1Improve power output capabilityIncrease wind speedWind motor controlGas turbine plantsTransformerInlet pressure

A highly supercharged gas-turbine generation system include a gas turbine power plant that is supercharged to a high inlet pressure, preferably over about 1.15 pressure ratio and preferably includes a transmission system with refrigerated transformers for increased output. The gas turbine power plant includes a precompressor that supercharges to a design pressure ratio of about 1.20 to 10, with a preferred pressure ratio of about 2. For high supercharging pressures, a pressure-reducer is located downstream of the gas turbine to maintain turbine outlet pressure that is close to the inlet pressure. The pressure-reducer is preferably an expander, but can alternatively be an orifice. A torque-limiting coupling on the shaft between the gas turbine and the generator prevents transient overload of the shaft. Capacity of the gas turbine plant is preferably controlled by varying supercharging pressure. The expander preferably has variable-pitch blades to allow efficient variation of turbine outlet pressure. For combined-cycle embodiments, a heat-recovery steam generator (HRSG) may be placed between the gas turbine and a downstream expander. For highest combined cycle output, a single-pressure steam system with high inlet temperature to the HRSG is preferred. The high temperature is preferably provided by supplemental firing between the gas turbine and the HRSG. An expander may be inserted between the supplemental firing and the HRSG to further improve cycle efficiency and to reduce pressure in the HRSG. For retrofit applications with limited supercharging, a refrigeration system for generator cooling may be added to increase generator output to match that available from the supercharged gas turbine.

Owner:HOFFMAN JOHN S +1

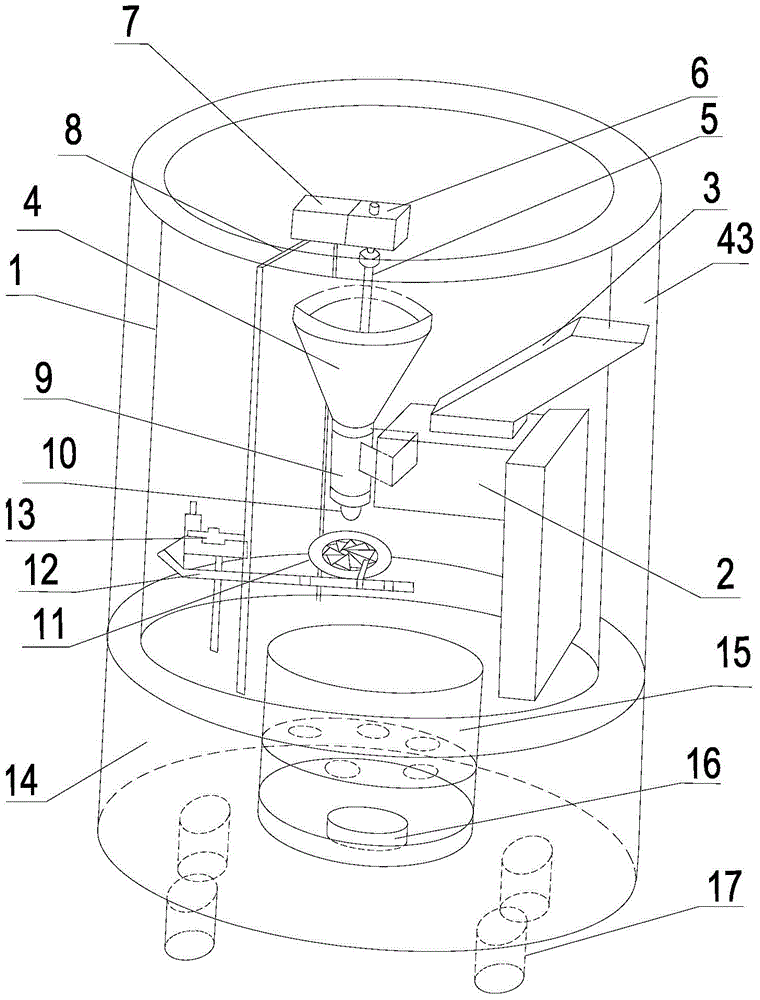

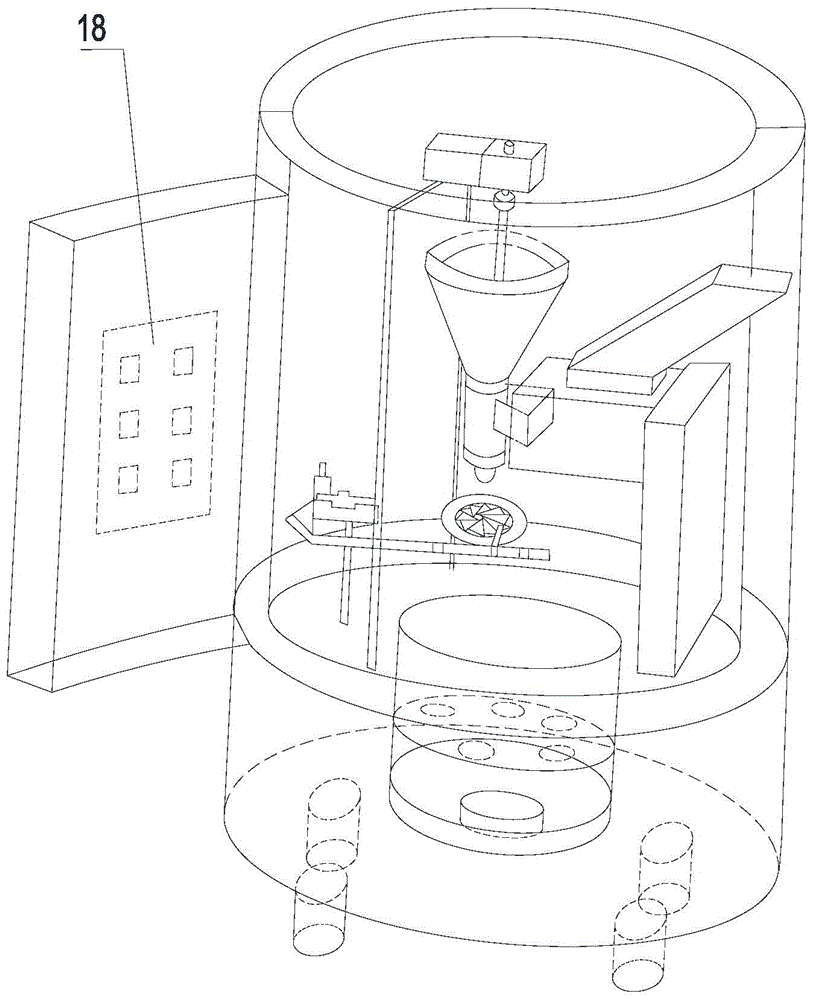

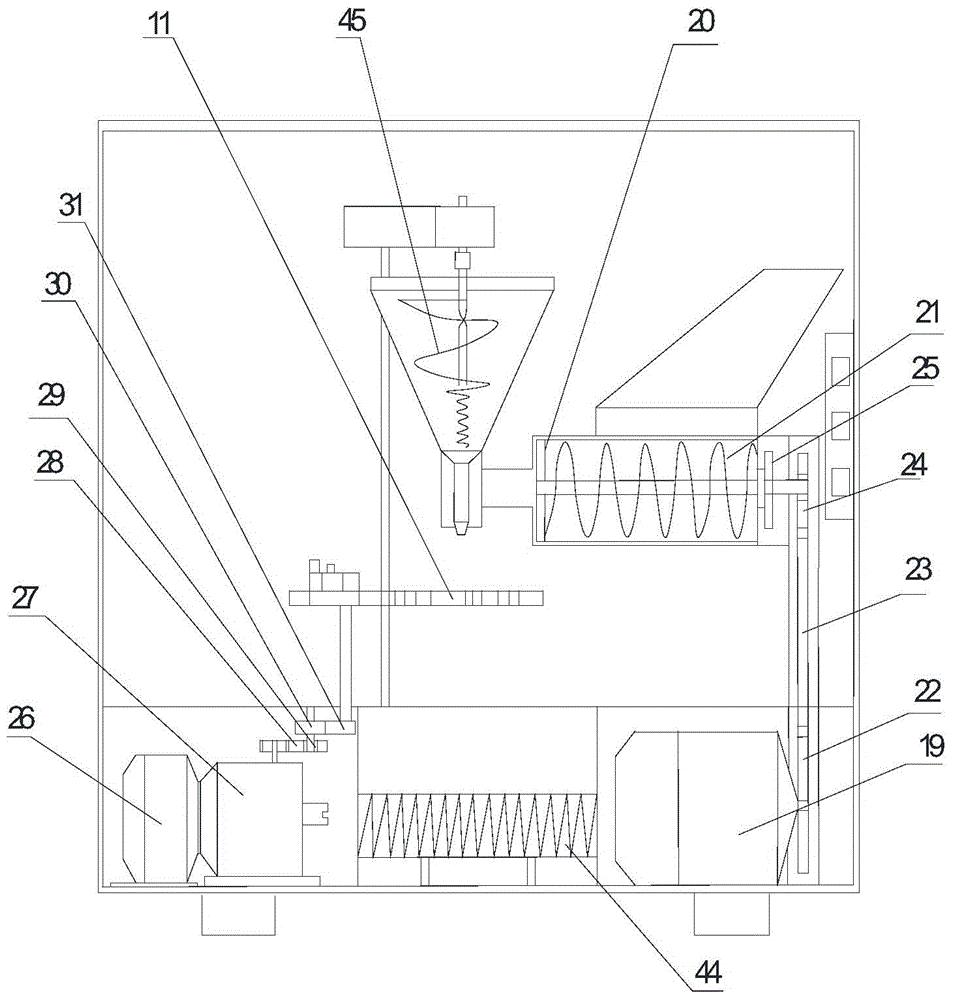

Household fully automatic steamed stuffed bun making machine

ActiveCN104798845ABeautiful shapeReduce demandDough shapingDough processingControl systemEngineering

The invention discloses a household fully automatic steamed stuffed bun making machine. The machine comprises a body, a flour delivery system, a stuffing delivery system, a forming device, a steaming system, a control system and an annular base, wherein the body is of a hollow structure; the annular base is of a hollow structure; the lower part of the body is connected with the annular base; the flour delivery system comprises a flour mixing box, a flour feed hopper, a flour mixing screw, a head and a second motor; a side face of the flour mixing box is fixedly provided with the head; a hole is formed in the middle of the head; one side of the hole is communicated with the flour mixing box; the lower end of the hole is communicated with a stuffing nozzle; a supporting pattern plate is fixedly arranged in the flour mixing box; the flour mixing screw is arranged on the supporting pattern plate and is connected with the second motor through a first transmission device; the control system mainly comprises a control panel; the control panel is controlled by using a single-chip microprocessor; the single-chip microprocessor is connected with the first motor, the second motor, a third motor and a variable frequency motor respectively. According to the machine, fully automatic flour mixing, skin making, material mixing, forming and steaming are realized; the machine has the advantages of cook and serve, small-scale making, attractive steamed stuffed bun shape and the like.

Owner:GUANGDONG HENGLIAN FOOD MACHINERY

Method for treatment of process waters using steam

Systems and methods for treating water. Water containing one or more thermally destructible contaminants can be contacted with steam to provide an effluent containing essentially contaminant-free water and a recycle containing the steam and at least a portion of the one or more thermally destructible contaminants. The one or more thermally destructible contaminants in the recycle can be thermally destroyed using one or more combustion processes.

Owner:KELLOGG BROWN & ROOT LLC

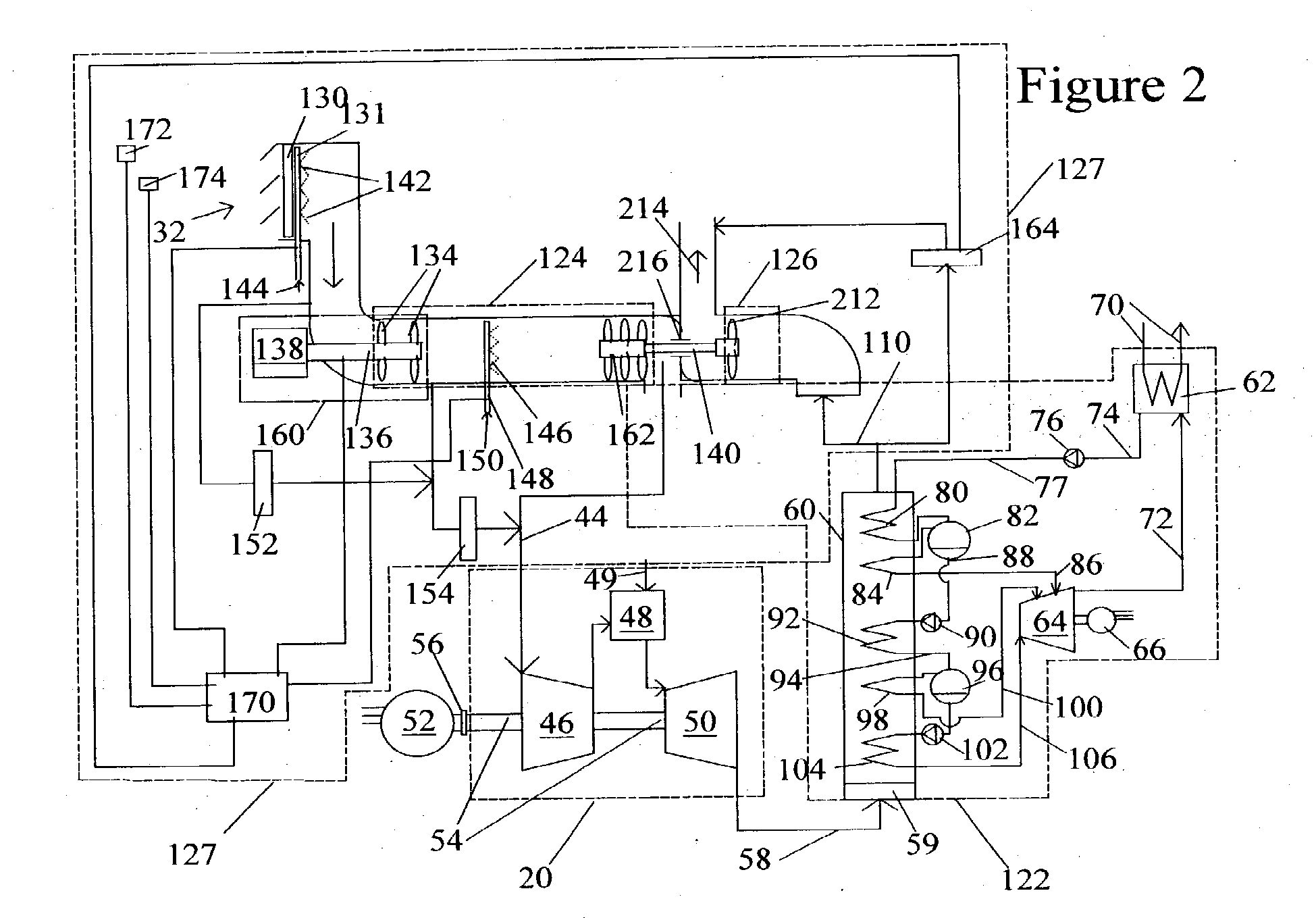

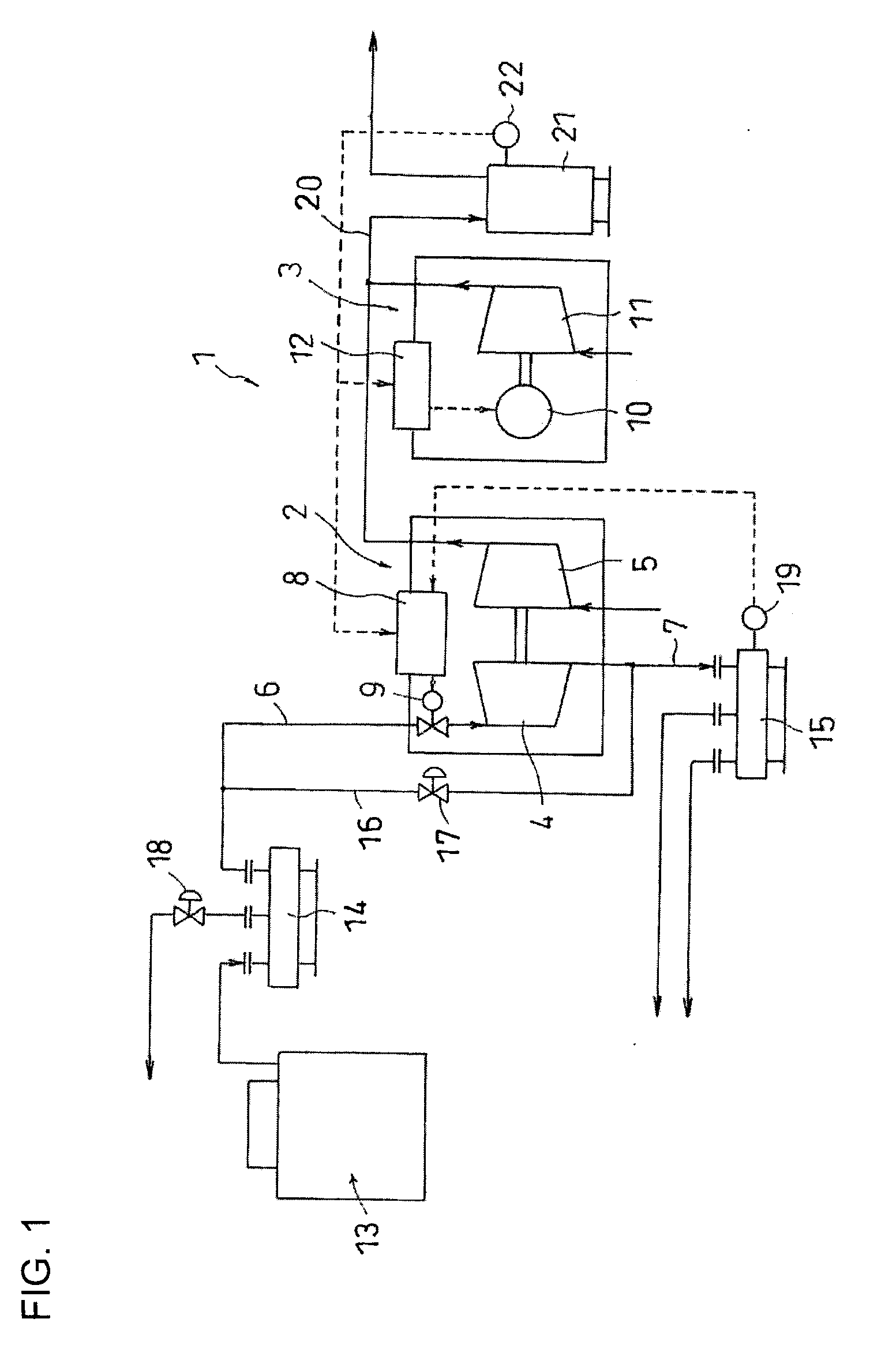

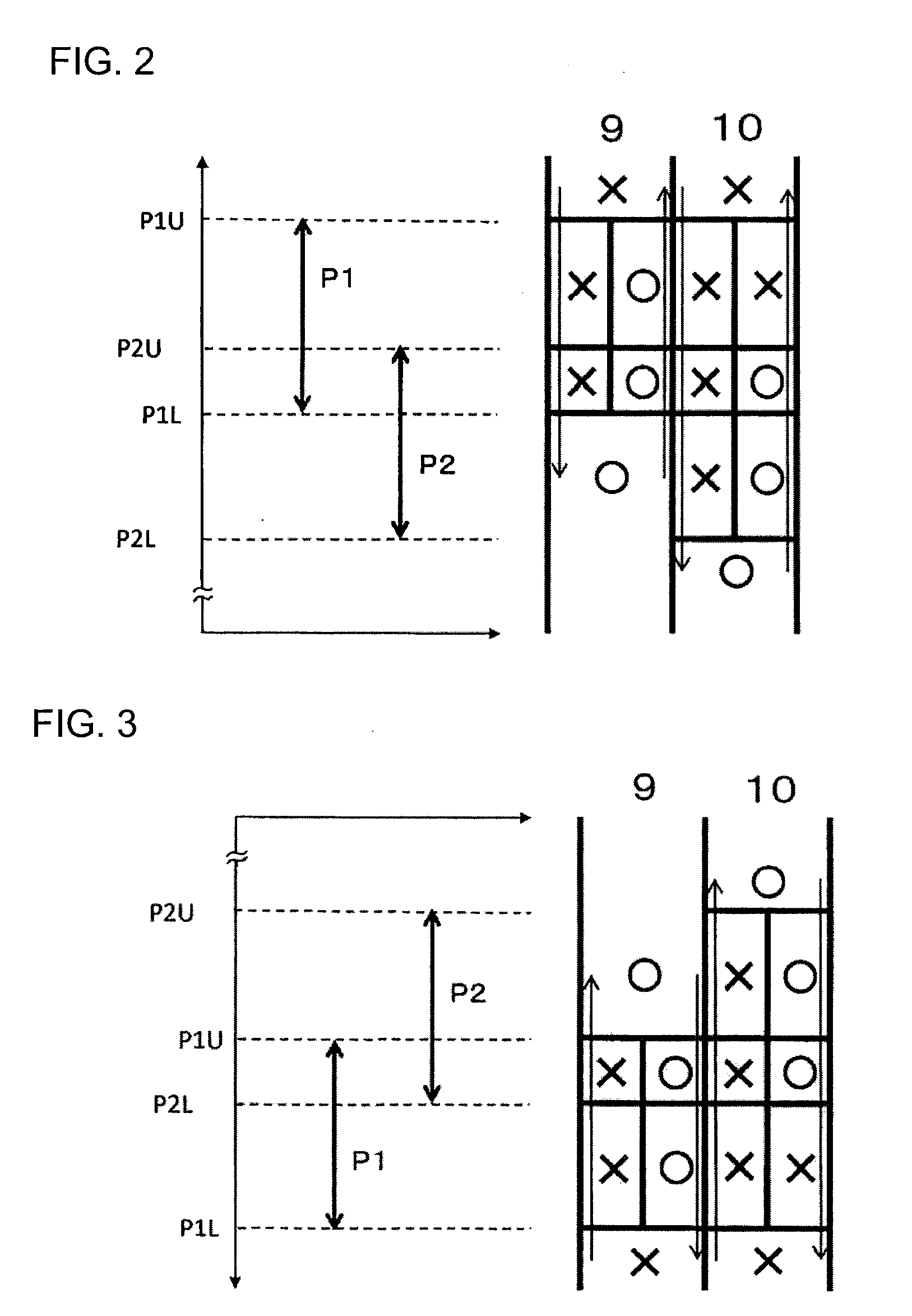

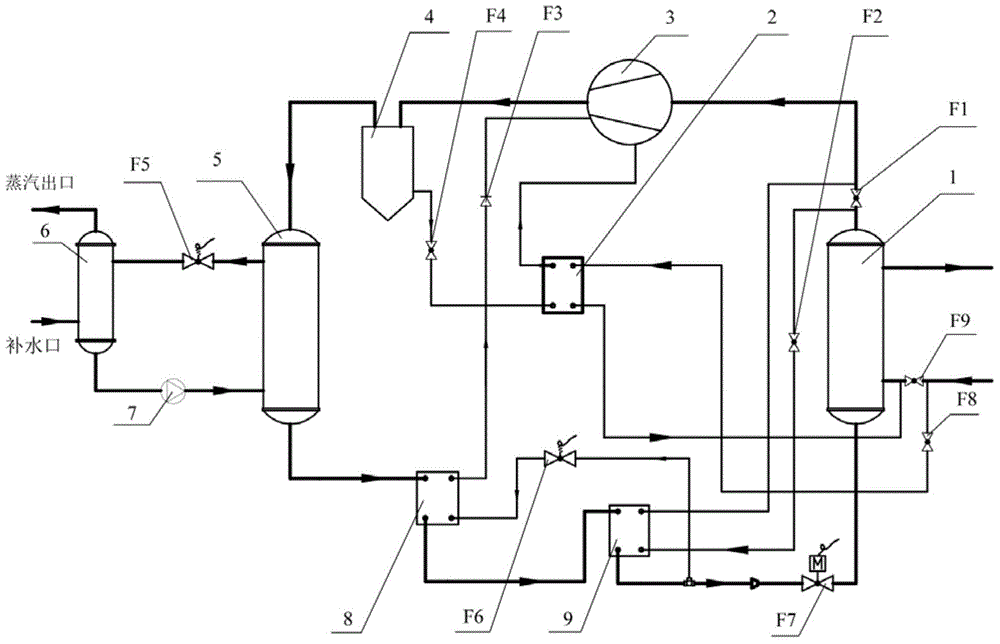

Steam system

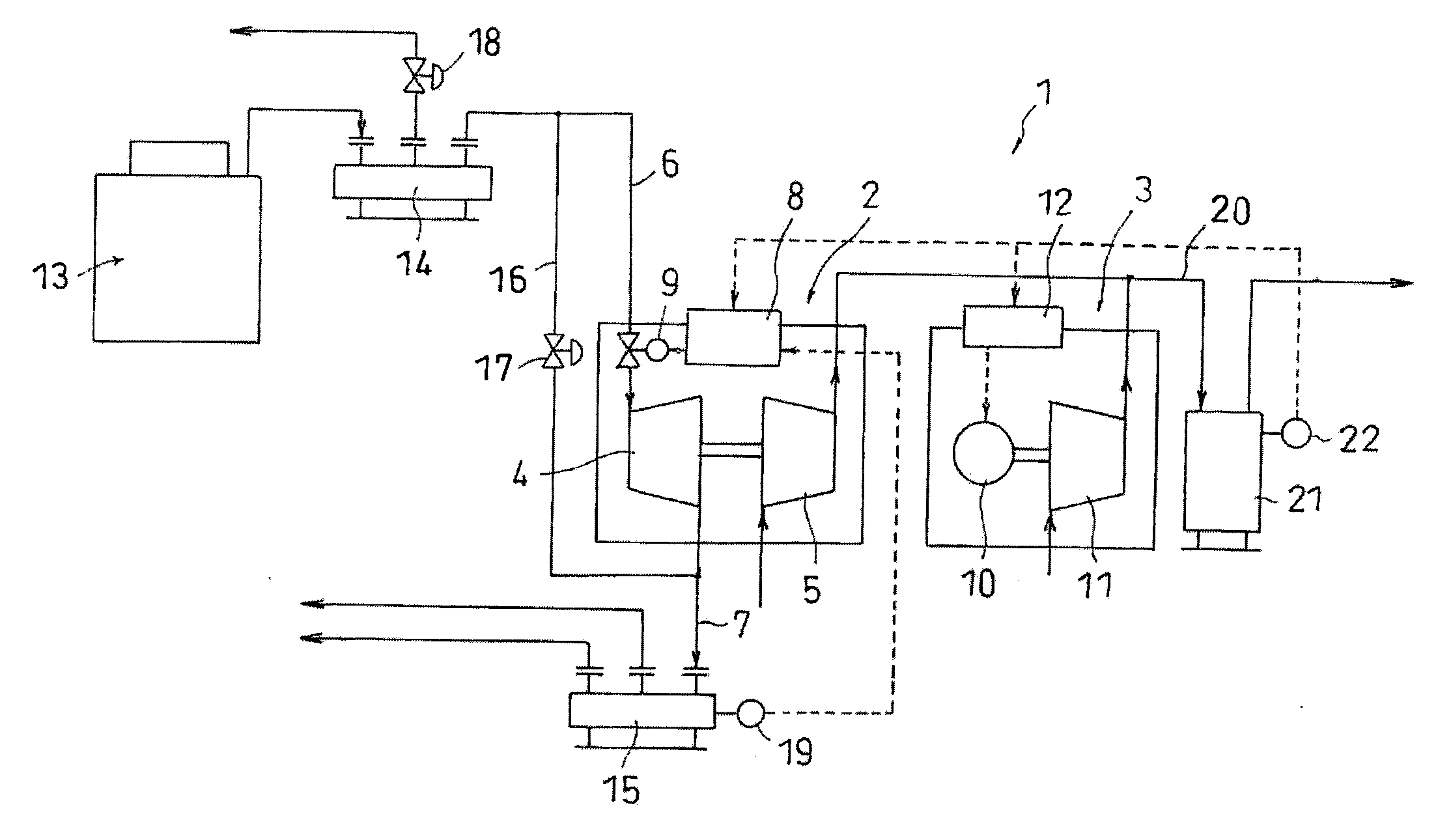

ActiveUS20110005228A1Conducive to stable operationSave energyReciprocating combination enginesCombination enginesSteam pressureEngineering

A steam engine and an electric motor are arranged, which respectively drives an air compressor. The compressed air from the air compressor is supplied to a compressed air using device through a common air tank. The steam is supplied to the steam engine through a steam supply path, and the steam used in the steam engine is supplied to a steam using device through a steam exhaust path. The steam pressure is monitored by a pressure sensor arranged in a steam header ahead of the steam exhaust path. The air pressure is monitored by a pressure sensor arranged in an air tank. A steam supply valve is controlled based on the steam pressure and the air pressure, and the electric motor is controlled based on the air pressure. The steam engine is preferentially driven over the electric motor by shifting the target value of the air pressure.

Owner:MIURA COMPANY LIMITED

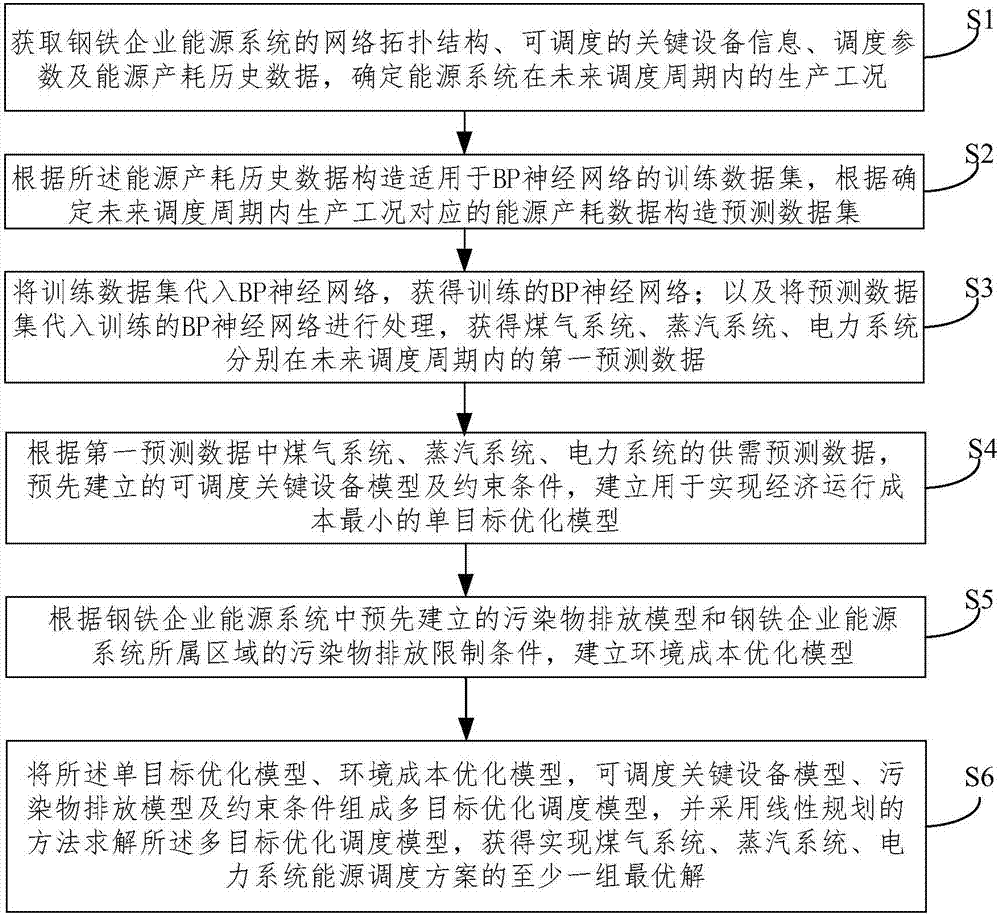

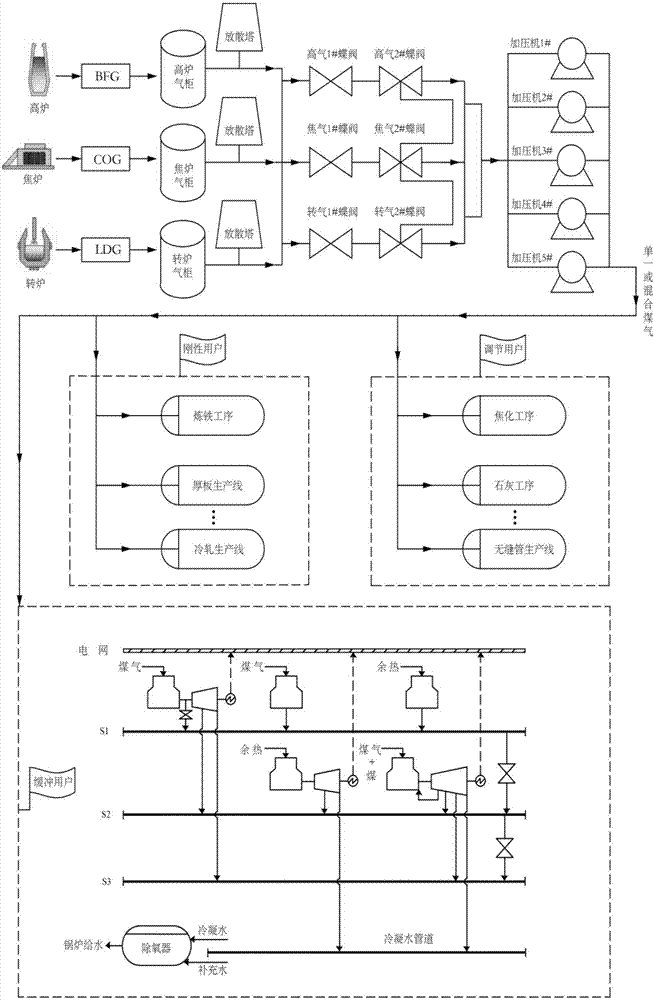

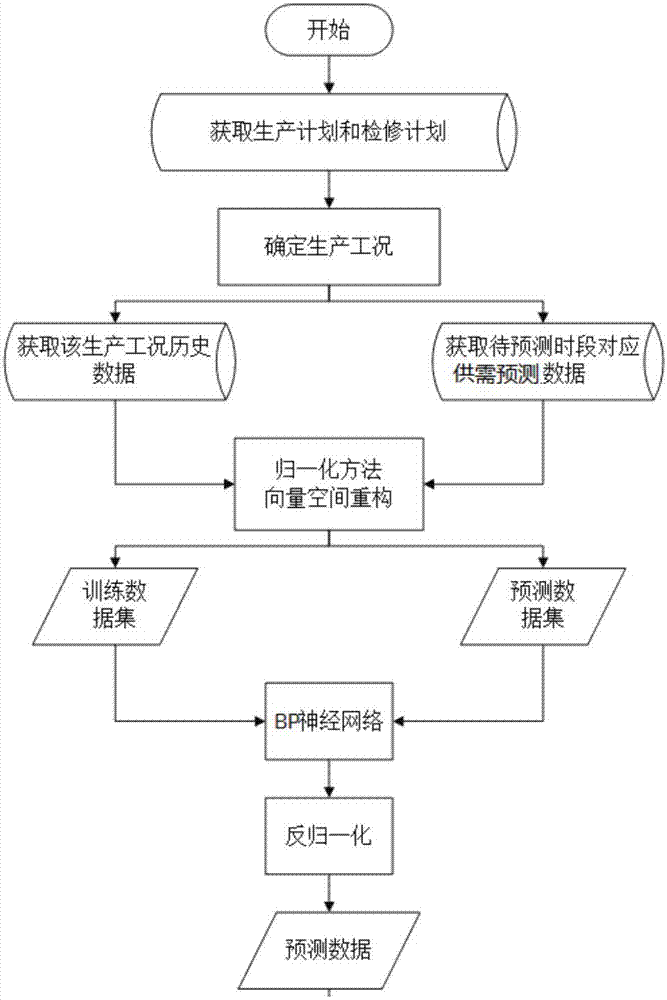

Multi-objective optimization scheduling method based on iron and steel enterprise energy system

ActiveCN107169599AGuaranteed calculation process convergenceImprove balanceEnergy industryForecastingData setOptimal scheduling

The invention provides a multi-objective optimization scheduling method based on an iron and steel enterprise energy system. The method comprises steps: the network topology of the iron and steel enterprise energy system, schedulability key device information and energy production and consumption historical data in a past scheduling period are acquired; according to the energy production and consumption historical data, a training data set is built, and according to energy production and consumption data corresponding to a production working condition in a future scheduling period, a prediction data set is built; through the training data set, a trained BP neural network is acquired; the prediction data set is substituted to the trained BP neural network for processing to acquire first prediction data for supply and demand for a gas system, a steam system, and a power system in the future scheduling period; and according to the first prediction data, an economic scheduling model, an environment cost model, a schedulability key device model and constraints, a multi-objective optimization scheduling model is built, the multi-objective optimization scheduling model is solved, and the optimal solution for the energy system is acquired. The above method ensures convergence of the calculation process, and the optimal scheduling scheme can be acquired.

Owner:NORTHEASTERN UNIV

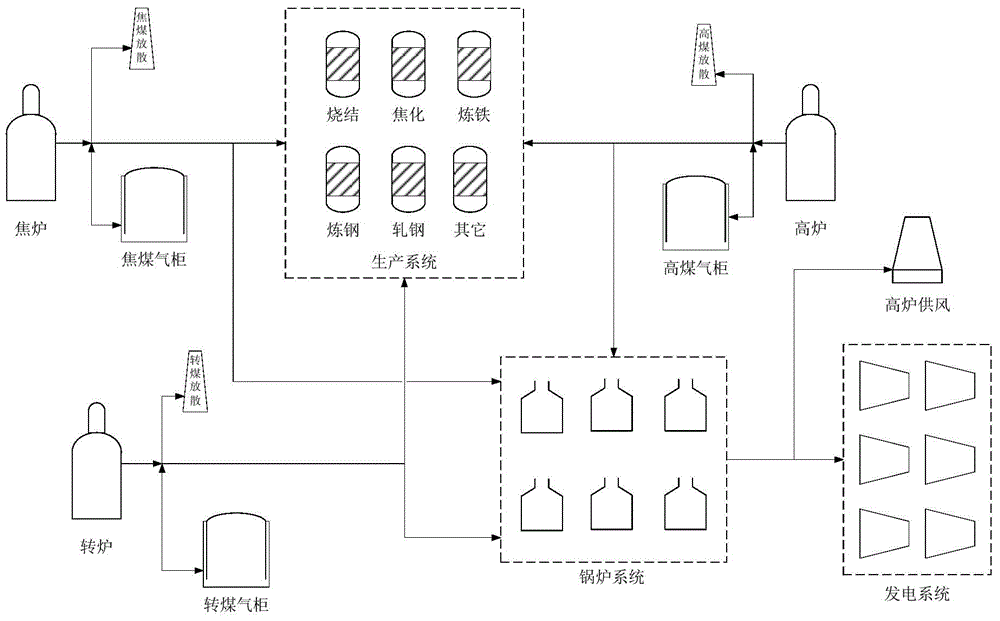

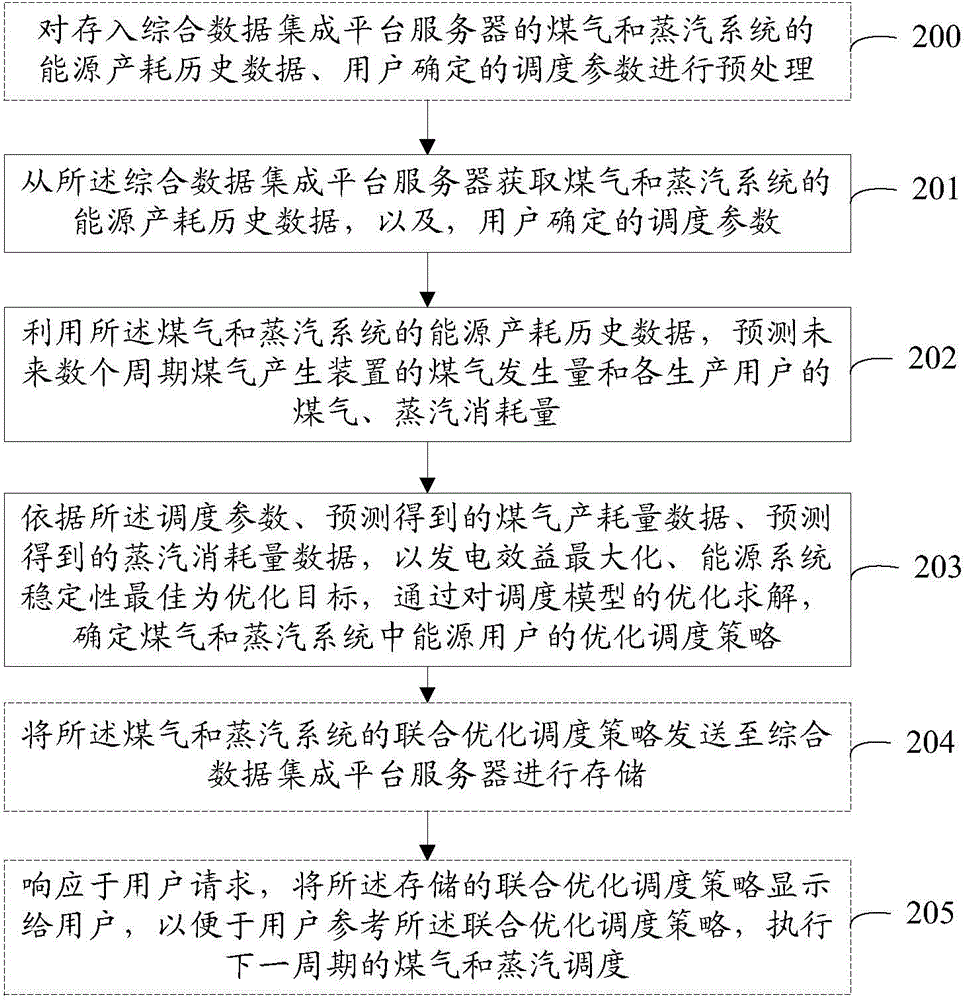

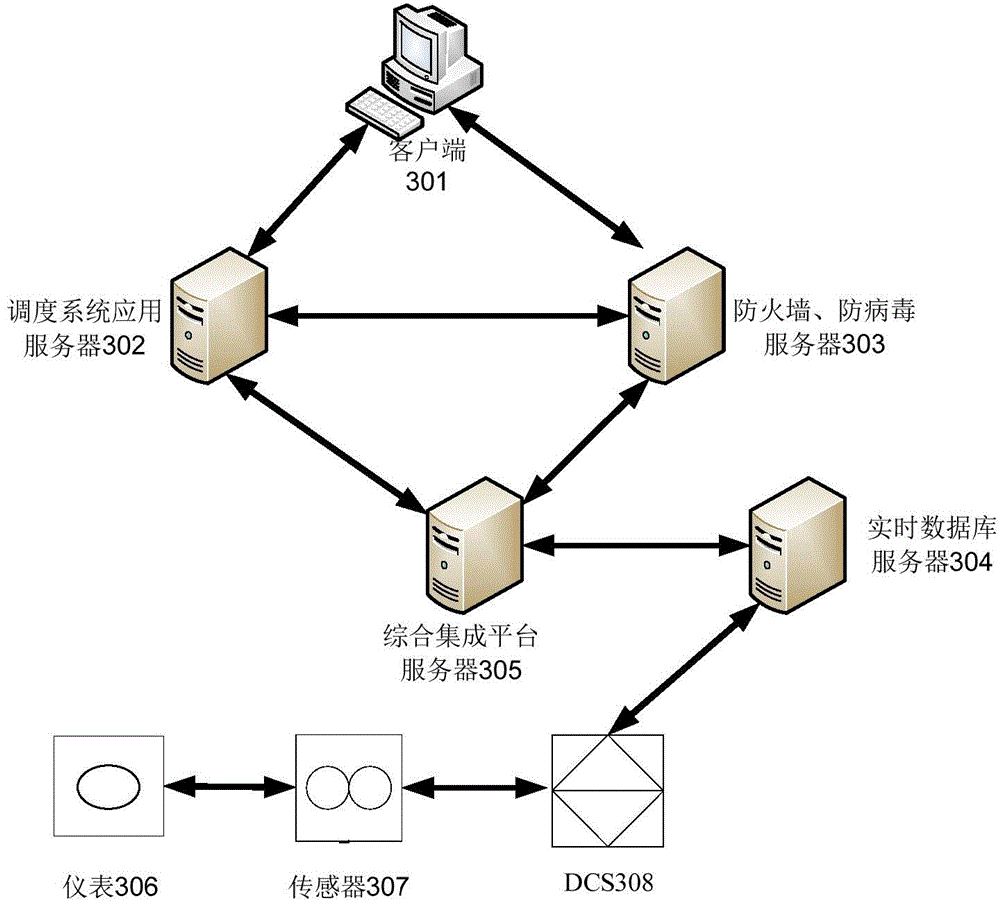

Dispatching method, apparatus and system for gas and steam system in iron and steel enterprises

ActiveCN104102212AImprove management levelEnergy industryTechnology managementApplication serverSynthetic data

The invention provides a dispatching method, apparatus and system for a gas and steam system in iron and steel enterprises. The dispatching method is deployed in a dispatching application server of the gas and steam system in the iron and steel enterprises and includes acquiring historical data of energy production and consumption of the gas and steam system as well as dispatching parameters determined by a user from a synthetic data integration platform server; predicting gas production amount of a gas production device and gas and steam consumption amount of each production user in several cycles in the future by means of the historical data of energy production and consumption of the gas and steam system; determining optimized dispatching policies of each energy user in the gas and steam system through optimization solution of a dispatching model with the optimization object of maximizing electricity generation benefits and optimizing stability of an energy system according to the dispatching parameters, predicted gas production and consumption amount data, and predicted steam consumption amount data.

Owner:ZHEJIANG SUPCON SOFTWARE +1

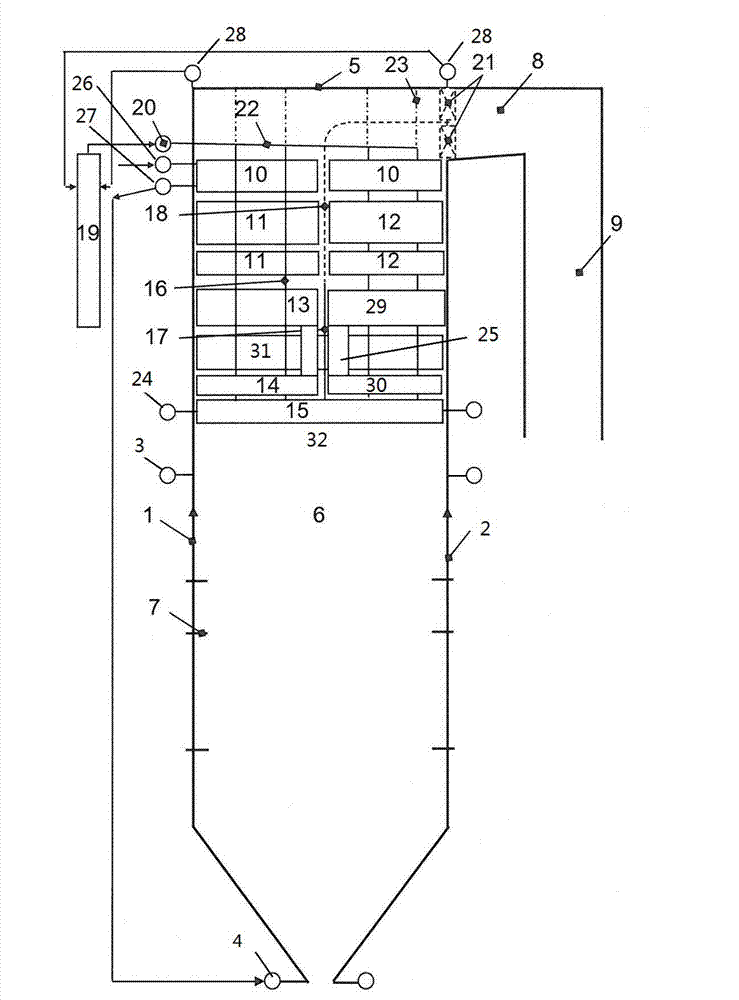

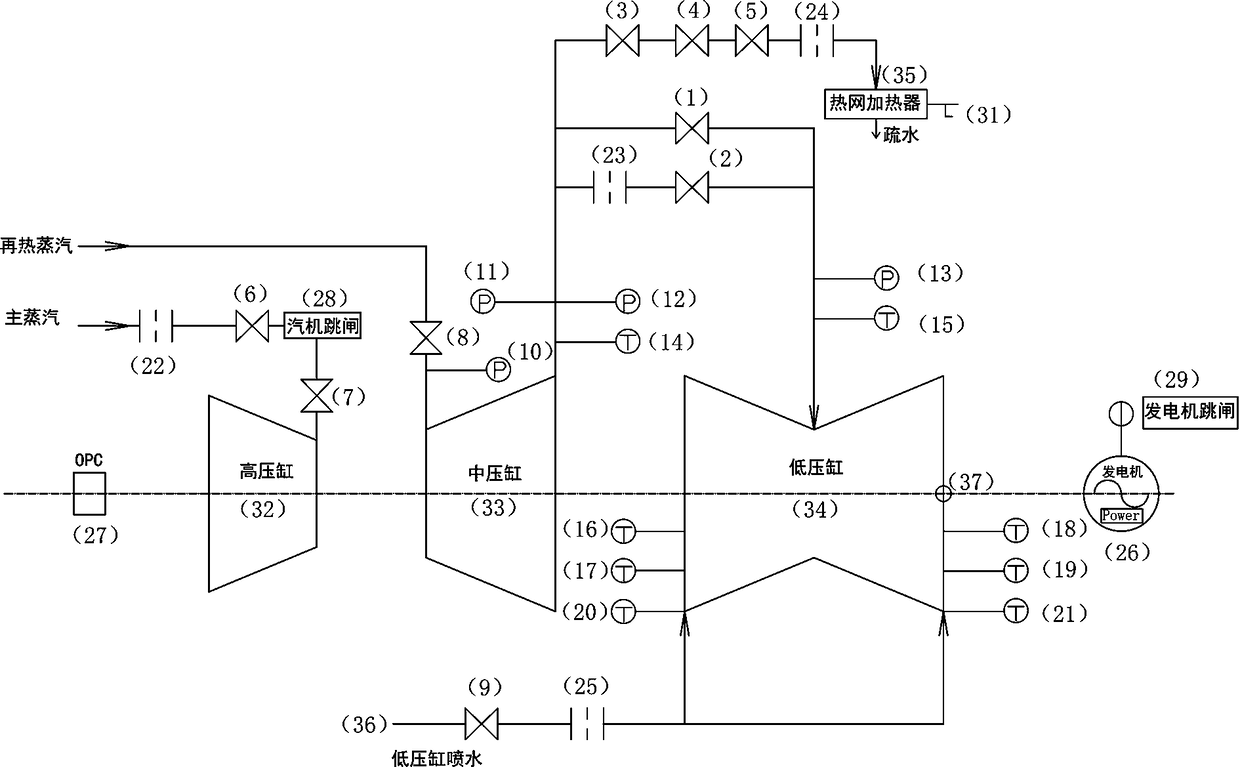

Tower-type boiler with primary reheater and secondary reheater

ActiveCN102889570AImprove heat transfer characteristicsImprove heat transfer efficiencySuperheating controlBoiler flue tubes/fire tubesEngineeringSuperheater

The invention discloses a tower-type boiler with a primary reheater and a secondary reheater. A superheater of the boiler comprises a low-temperature superheater and a high-temperature superheater; a technological process of a main steam system comprises the following steps that: feeding water enters a front flue coal economizer and a rear flue coal economizer which are arranged in parallel; water from outlets of the coal economizers enters water-cooling walls from the lower part of a hearth; outlets of the water-cooling walls are connected with a separator; and steam of an outlet of the separator enters the low-temperature superheater and the high-temperature superheater sequentially. According to a low-to-high flow direction of temperatures on a steam side, the primary reheater sequentially comprises primary reheating low-temperature reheaters and a primary reheating high-temperature reheater, the secondary reheater sequentially comprises secondary reheating low-temperature reheaters and a secondary reheating high-temperature reheater, and the primary reheater and the secondary reheater are connected with each other in parallel in a perpendicular flue.

Owner:SHANGHAI BOILER WORKS

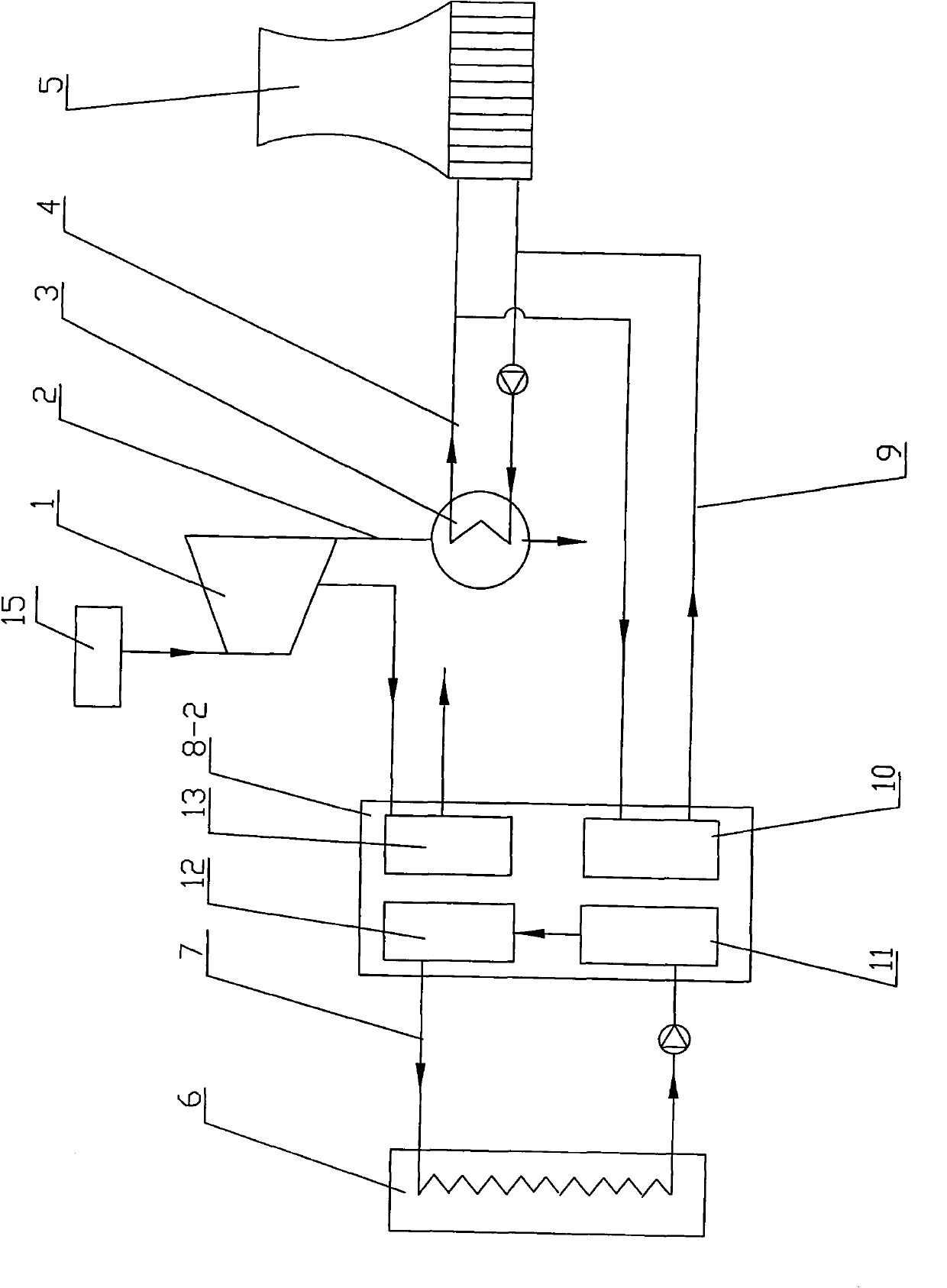

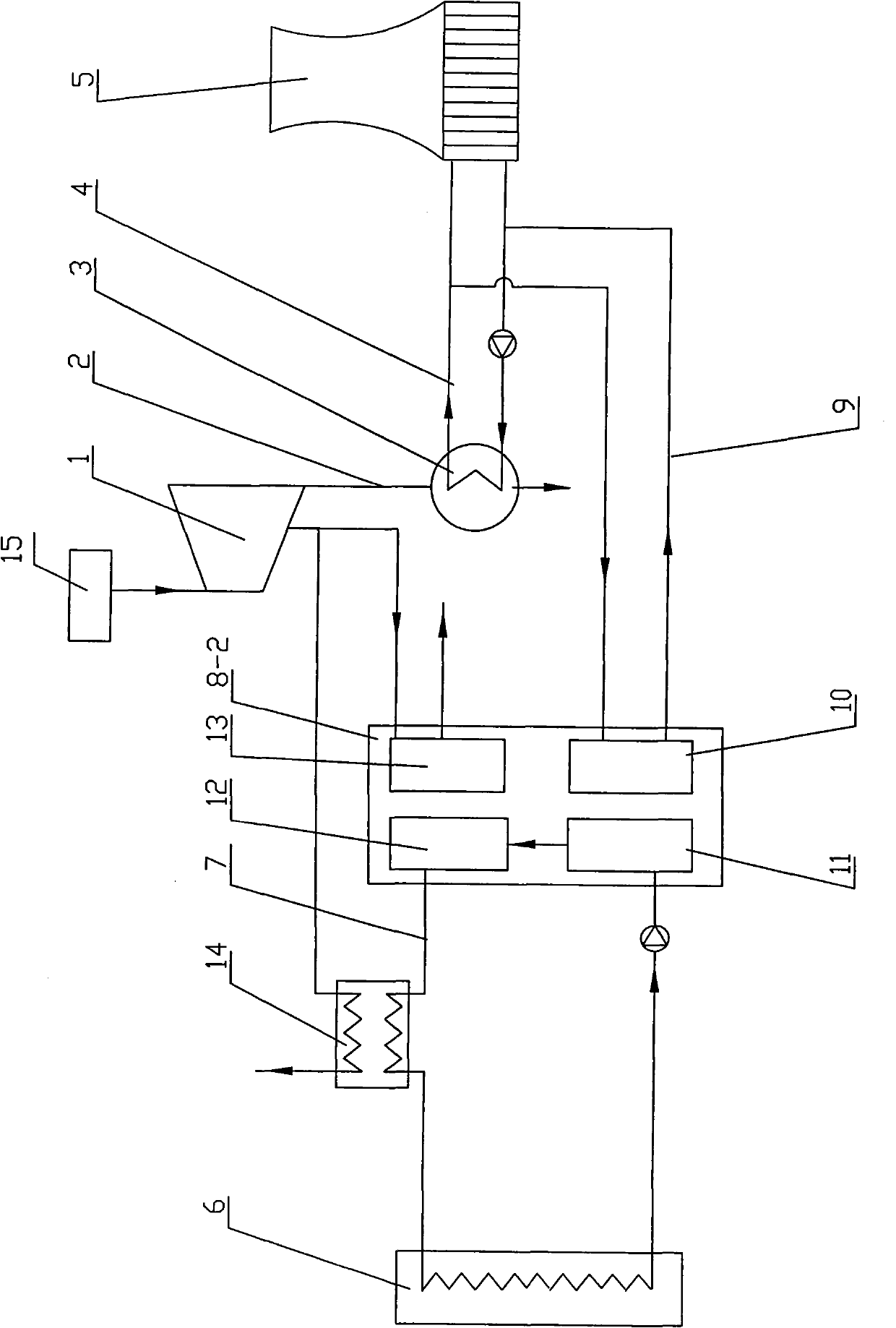

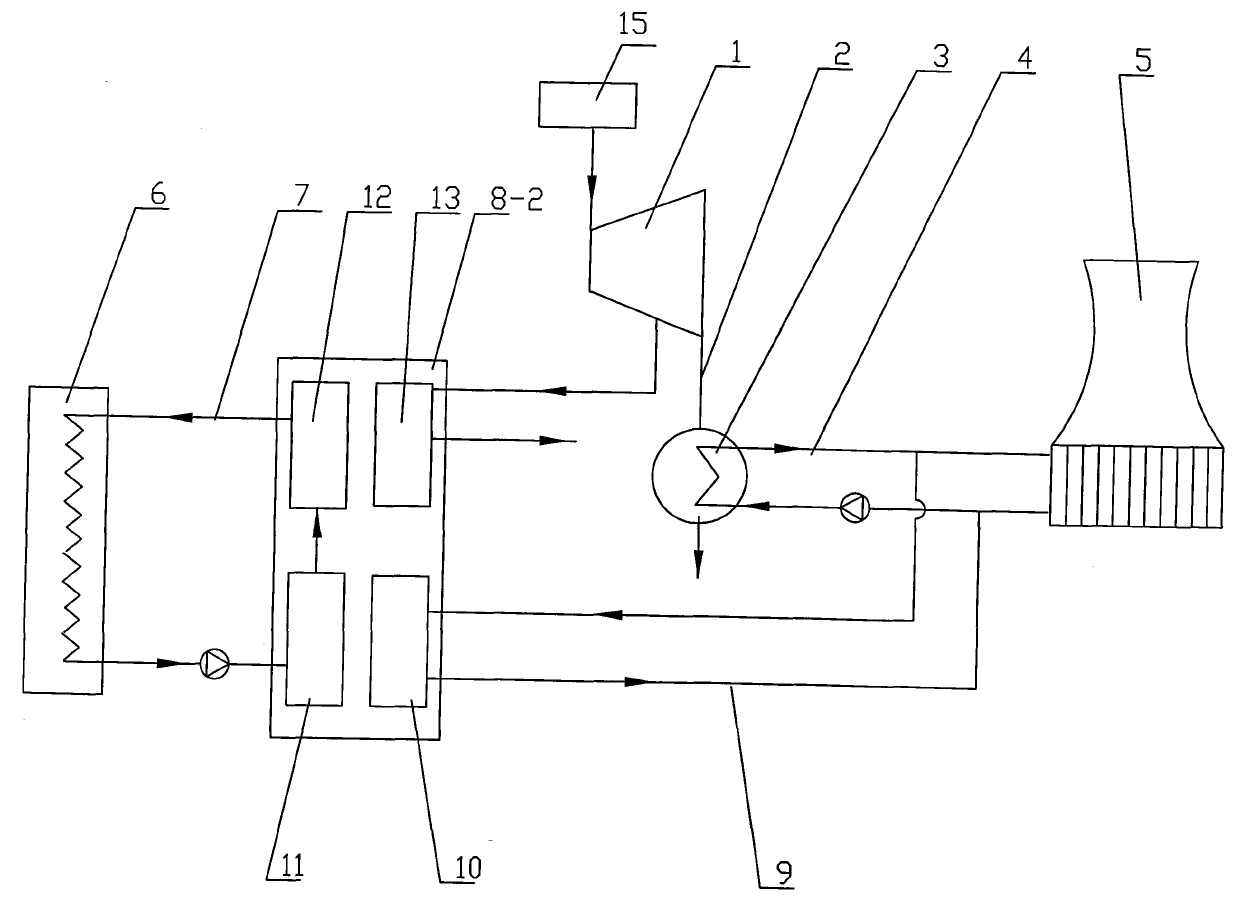

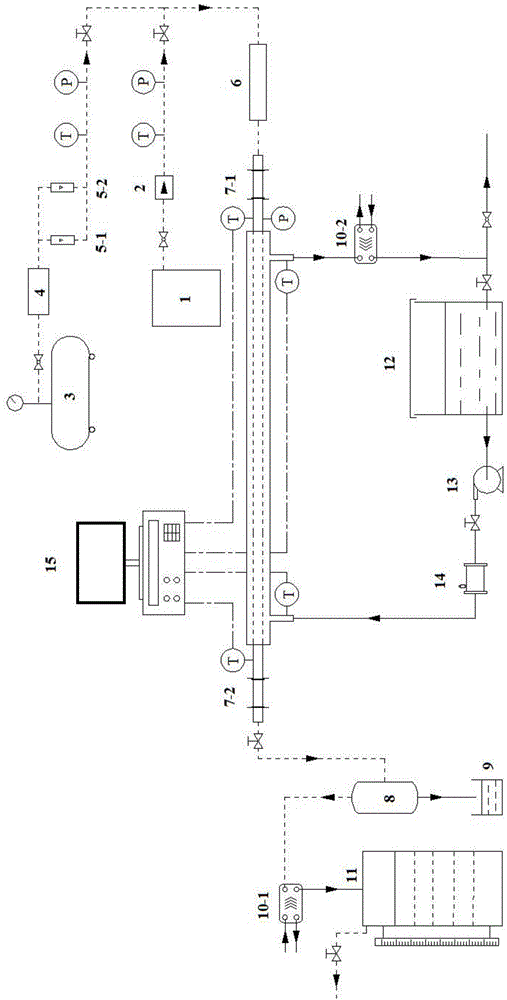

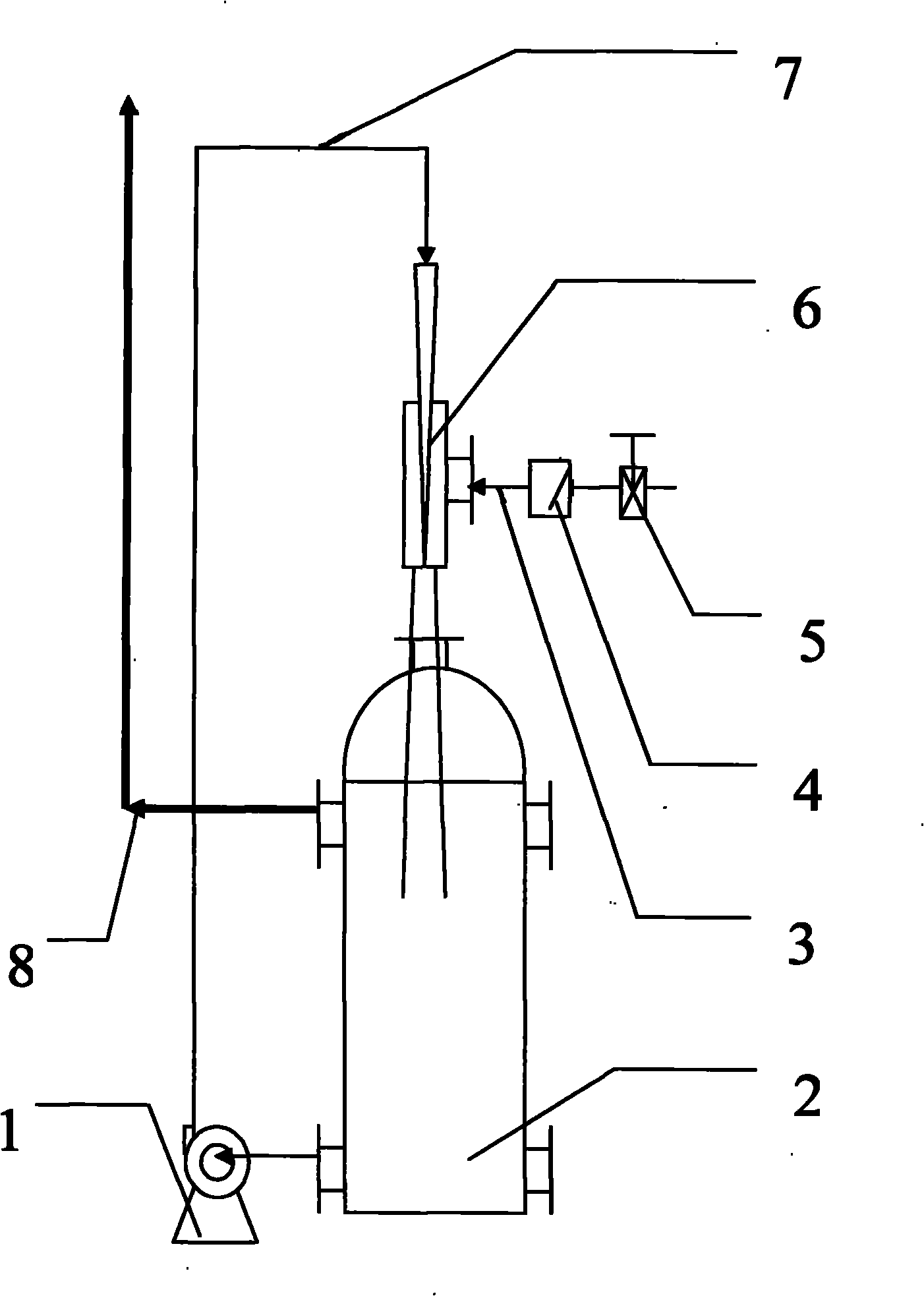

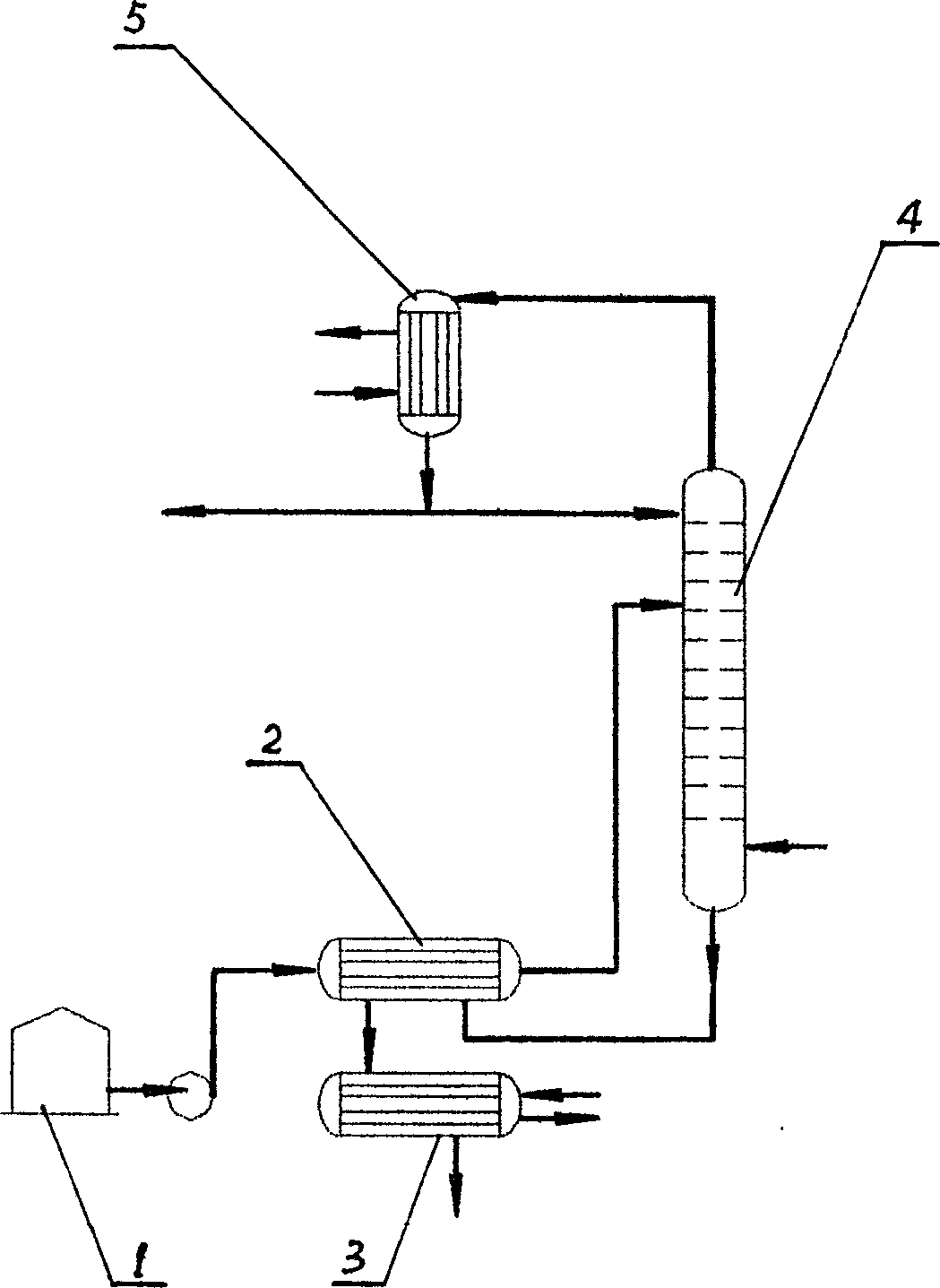

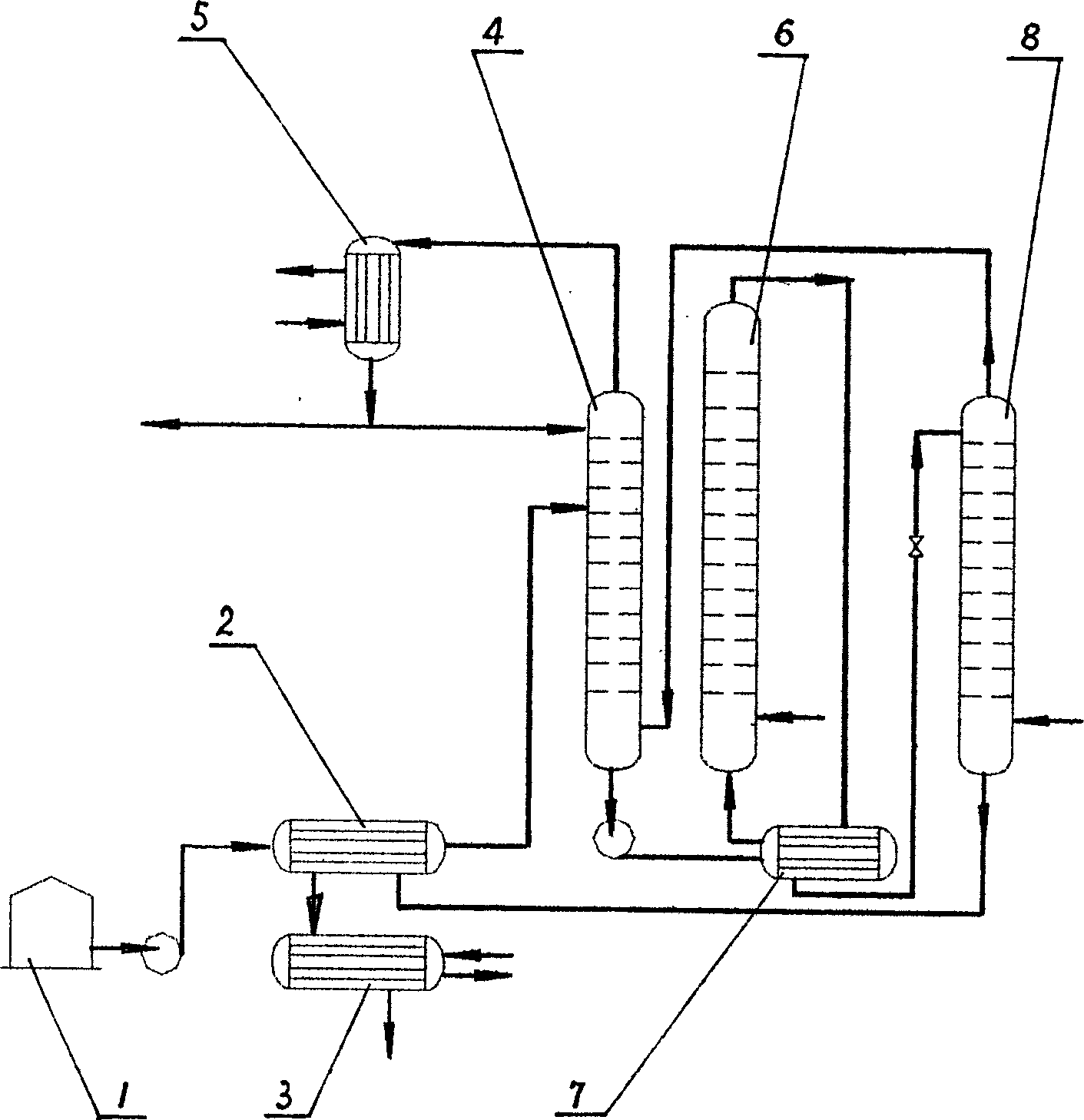

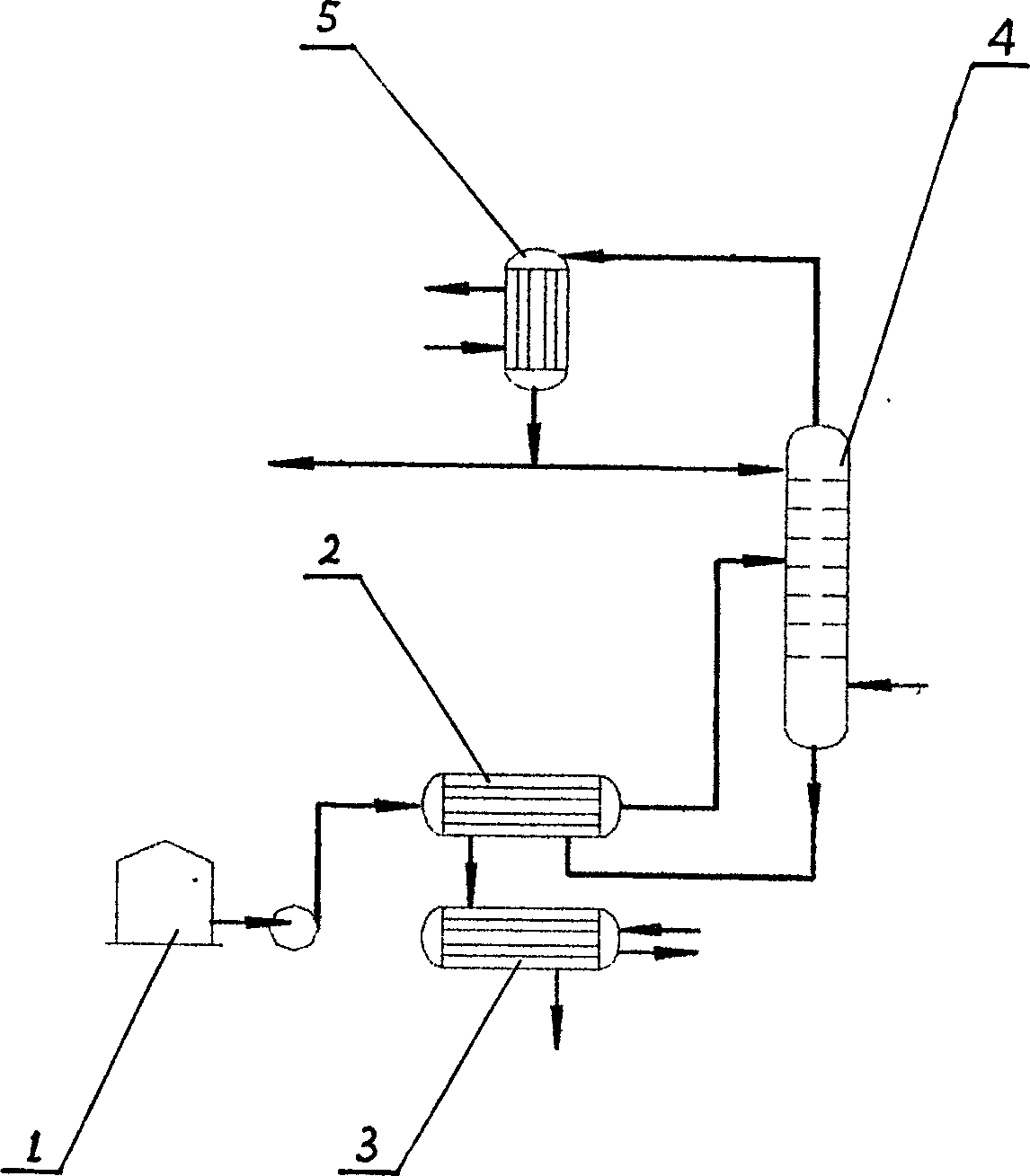

Condensation heat recovery central heating system of power plant indirect air cooling machine set

InactiveCN101906997AIncrease maximum heating capacityImprove utilization efficiencySteam useCombined combustion mitigationWater circulationAbsorption heat pump

The invention relates to a condensation heat recovery central heating system of a power plant indirect air cooling machine set. The invention is used for recovering surplus heat of exhaust steam of a power plant steam turbine. The system comprises a steam outlet turbine (1), a turbine steam exhaust header pipe (2), a water-cooled condenser (3), a closed cooling circulation water system (4), an indirect air condensation steam system (5), a heat utilization place (6) and a hot water supply pipeline system (7), wherein the exhaust steam of the steam outlet turbine (1) is connected with the water-cooled condenser (3) through the turbine steam exhaust header pipe (2). The system is characterized in that the heating system also comprises an absorption type heat pump machine set (8-2) and a surplus heat water circulation pipeline system (9); the closed cooled circulation water of the water-cooled condenser (3) is divided into two paths, one path is connected with an evaporator of the absorption type heat pump machine set (8-2) through the surplus heat water circulation pipeline system (9), and the other path is connected with the indirect air condensation steam system (5); and a hot water supply outlet of the absorption type heat pump machine set (8-2) is connected with the heat utilization place (6) through the hot water supply pipeline system (7). The heating system can efficiently recover and utilize the low-grade condensation heat of exhaust steam of an indirect air cooling power plant.

Owner:SHUANGLIANG ECO ENERGY SYST CO LTD

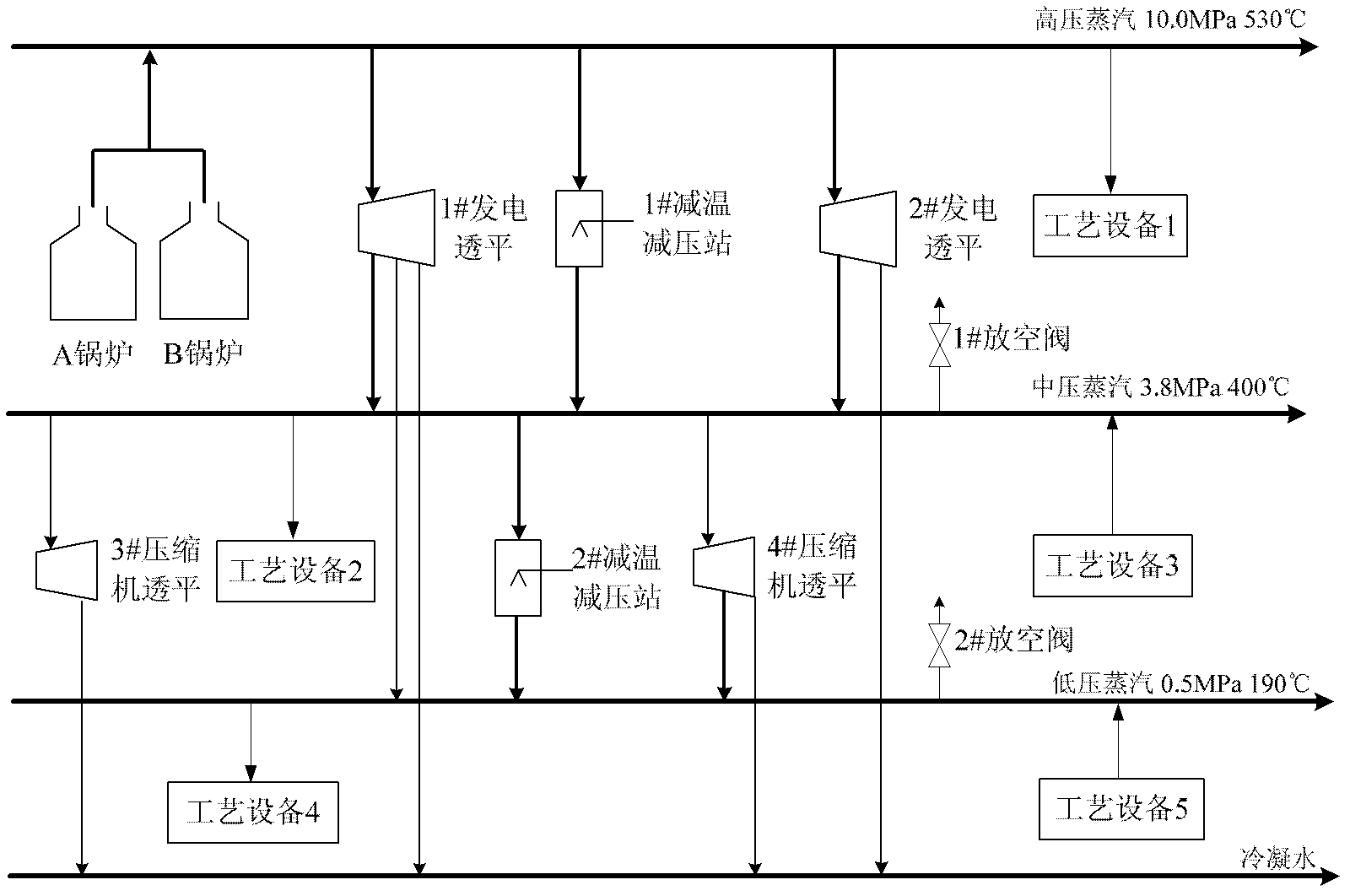

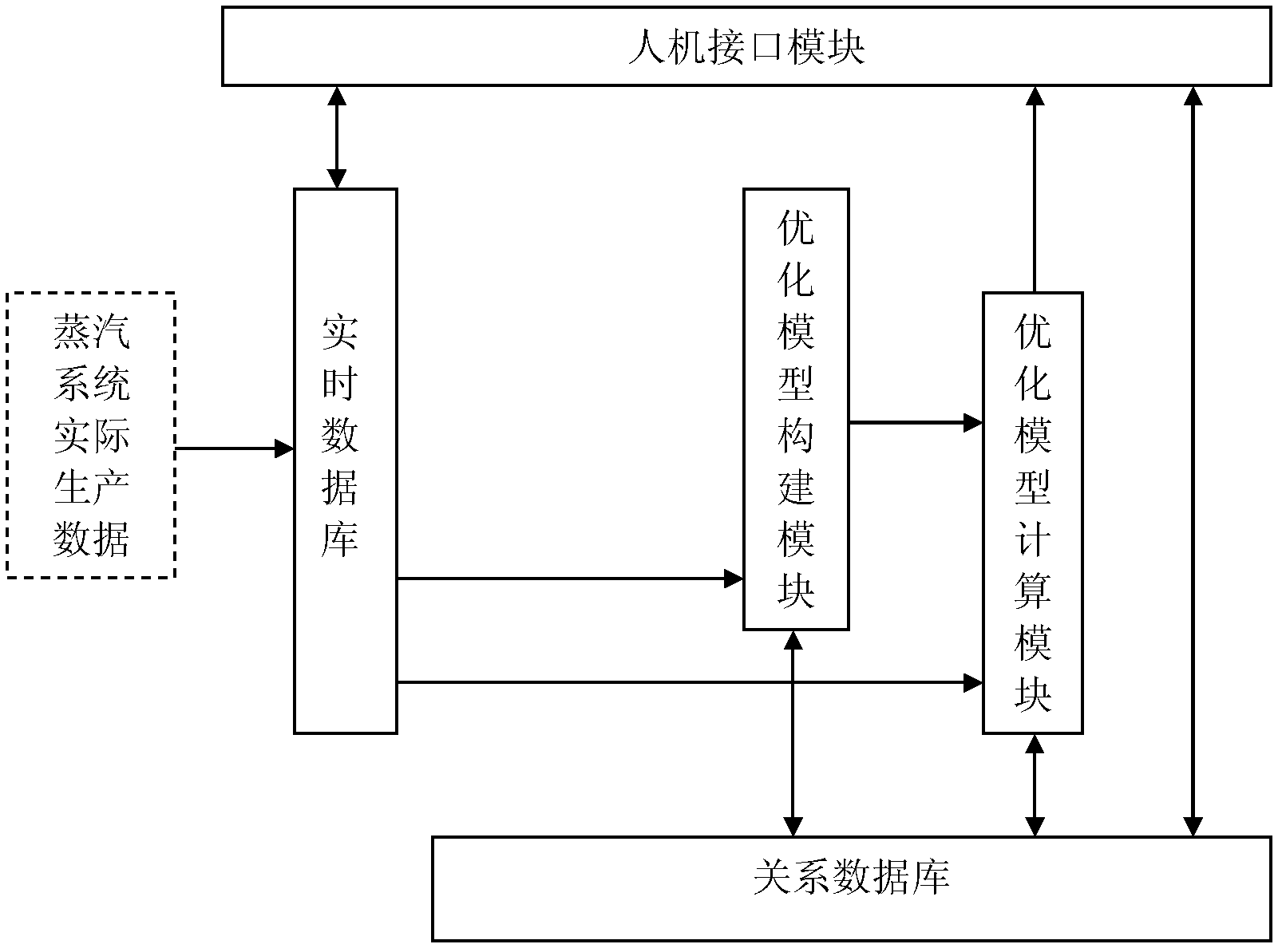

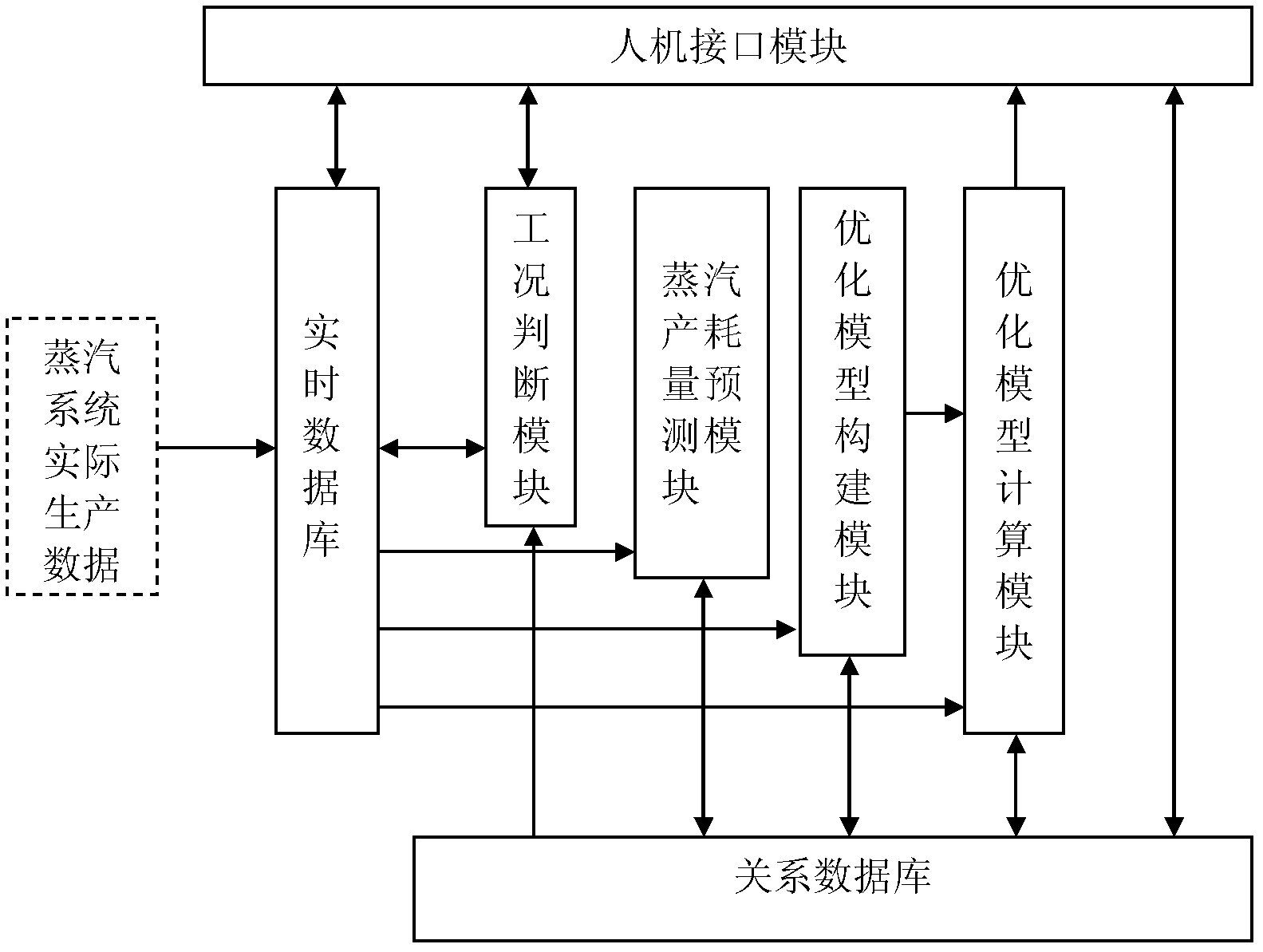

Operation optimizing system and method of steam system

InactiveCN102830616AReduce manufacturing costReduce consumptionAdaptive controlChemical industryRelational database

The invention relates to a steam system in field of chemical industry, metallurgy and the like and in particular relates to an operation optimizing system and an operation optimizing method of a steam system of the fields. The operation optimizing system of the steam system comprises a real-time database, a relation database, an optimization model constructing model, an optimization model calculating model and a man-machine interface module. The invention further provides the operation optimizing method of the steam system, which can construct an optimized model according to actual conditions of the steam system and can utilize an optimization algorithm to calculate to obtain an optimization operation scheme, so that field scheduling personnel and managers can schedule according to the optimization scheme, the economical efficiency of the operation of the steam system is improved, the energy consumption of an enterprise is reduced and the production cost of the enterprise is reduced.

Owner:北京三博中自科技有限公司

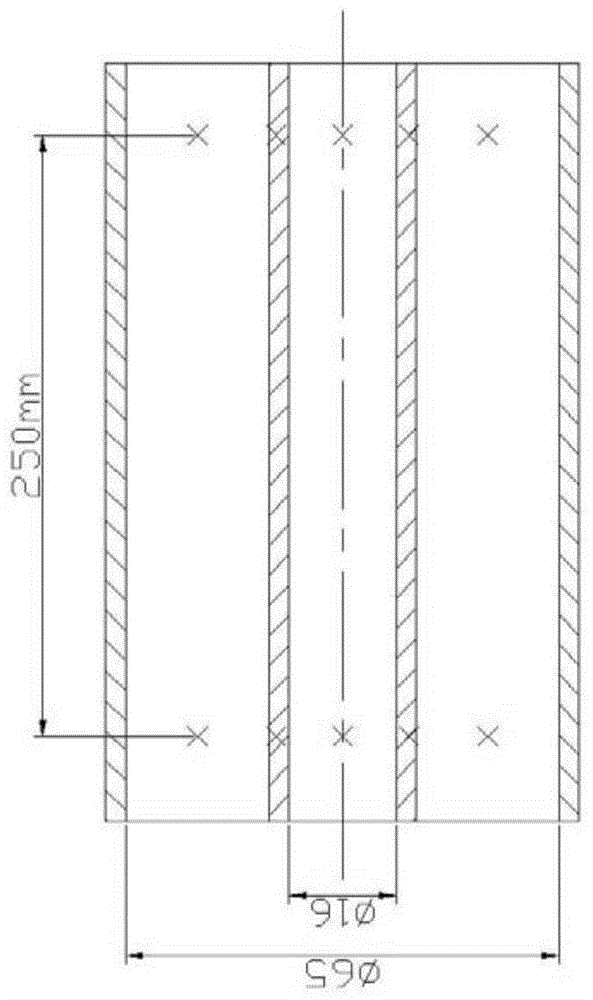

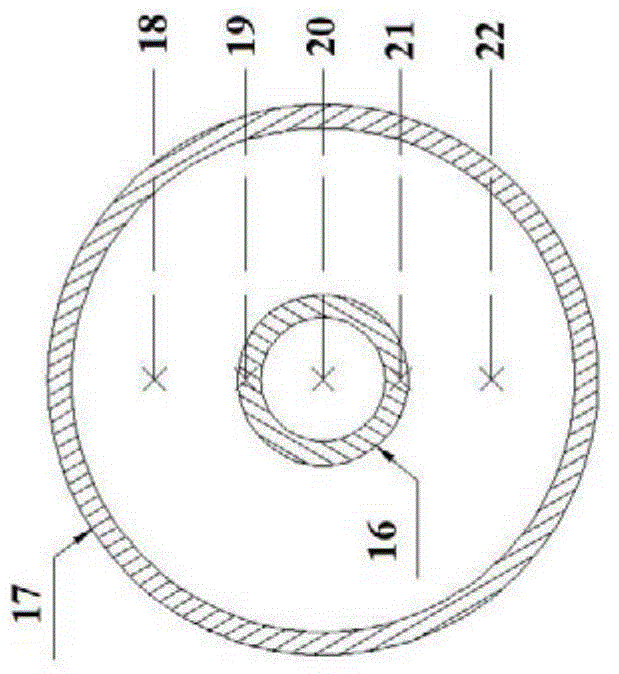

Test system for evaluating local condensing heat transfer performance of mixed steam

ActiveCN104407008ALocal condensation heat transfer coefficient observationReal-time observation of cooling formMaterial thermal conductivityMaterial heat developmentLight pipeWater channel

The invention relates to a test system for evaluating the local condensing heat transfer performance of mixed steam. The test system comprises a steam system, a cooling water loop and a data collection system, wherein an air compressor and an air drier of the steam system are connected, air enters a gas mixer together with steam in a boiler after passing through the air drier, and mixed gas enters a test section after being sufficiently mixed in the gas mixer; a water pump of the cooling water loop is used for conveying cooling water to the test section through a flowmeter from a water channel, a cooling water outlet of the test section is connected with an auxiliary cooling device, and the auxiliary cooling device is then connected with the water channel; four valves are arranged at the inlets and outlets of the test section, and are used for controlling the flow rates and pressures of the steam and cooling water respectively. The influence of non-condensable gas on condensation inside a horizontal light pipe can be evaluated by contrasting local condensing heat transfer coefficients.

Owner:EAST CHINA UNIV OF SCI & TECH

Combination conveyor oven

InactiveUS7765918B2Save energyReduce the amount requiredDomestic stoves or rangesOven air-treatment devicesProcess engineeringPartial closure

An oven for heating a product is provided. The oven includes a partially enclosed housing with an inlet opening and an outlet opening and a conveyor to move a product through the housing. The oven additionally includes a steam system for boiling liquid with an associated steam pipe and a heating element provided within the housing.

Owner:NU VU FOOD SERVICE SYST

Method for drying materials by utilizing superheated steam

ActiveCN101968299AAvoid lostAvoid pollutionDrying solid materials with heatHearth type furnacesEvaporationEngineering

The invention discloses a method for drying materials by utilizing superheated steam, which is characterized in that the superheated steam is added into a sealed container in which materials to be dried are arranged, the superheated steam is used for evaporating the moisture in the materials to be dried to generate steam, and the superheated steam is cooled into low-temperature steam; the low-temperature steam enters a low-temperature steam system from the sealed container under the condition that the flow rate of the low-temperature steam is controlled; a mechanical pressurizing device is used by the low-temperature steam system for pressurizing the low-temperature steam to obtain the boosted steam; and the boosted steam is used for indirectly heating the steam in the sealed container, the boosted steam discharges the latent heat of vaporization to generate condensed water, and the steam in the sealed container receives the heat to become the superheated steam for continuously drying the materials to be dried. In the invention, the moisture of the materials to be dried is similar to the moisture of a multiple-effect evaporation system and is discharged in a form of the condensed water. The invention has the advantages of high drying efficiency, low energy consumption and simple processes, and has an industrial base of large-scale implementation.

Owner:武善东 +1

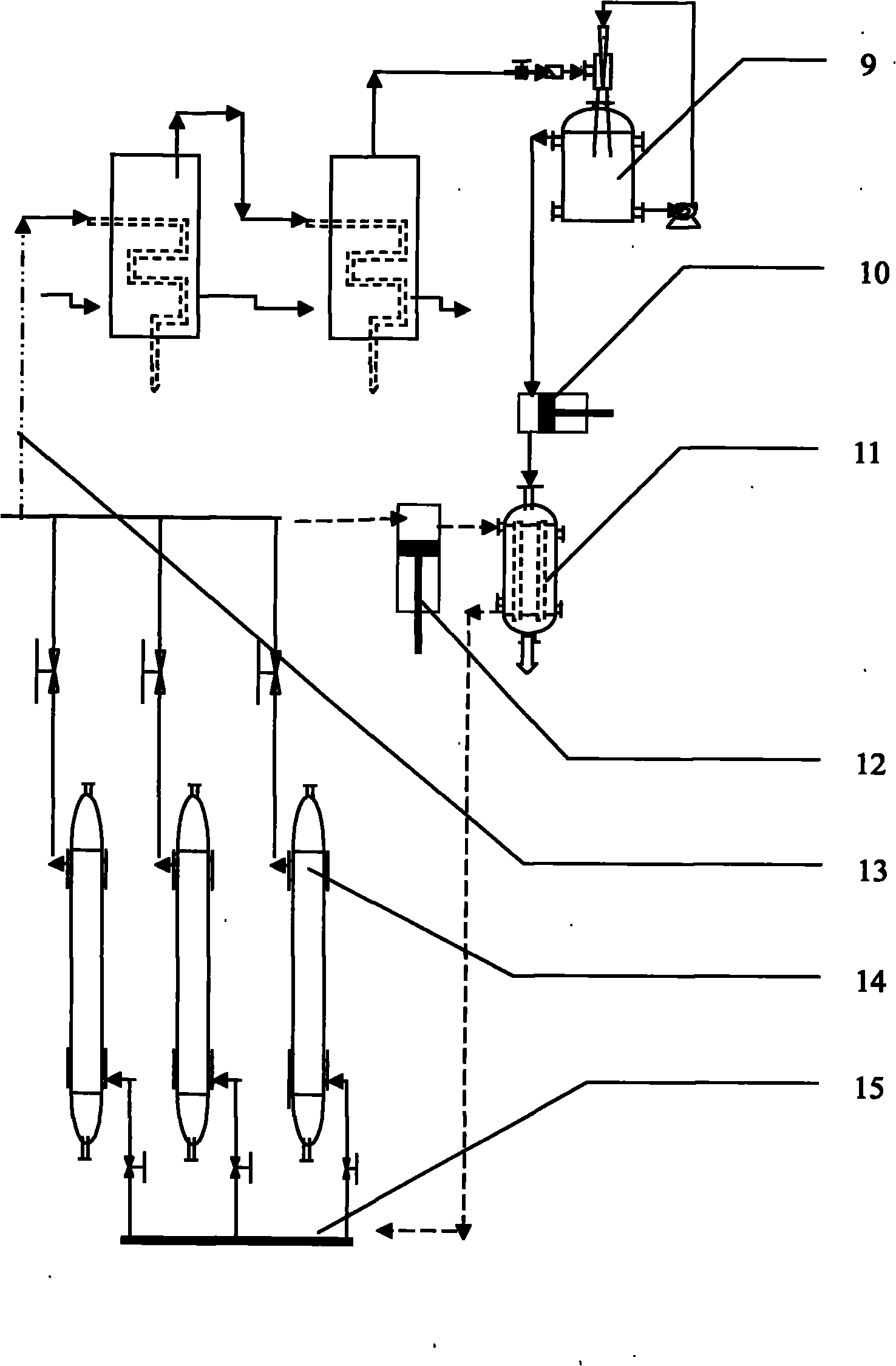

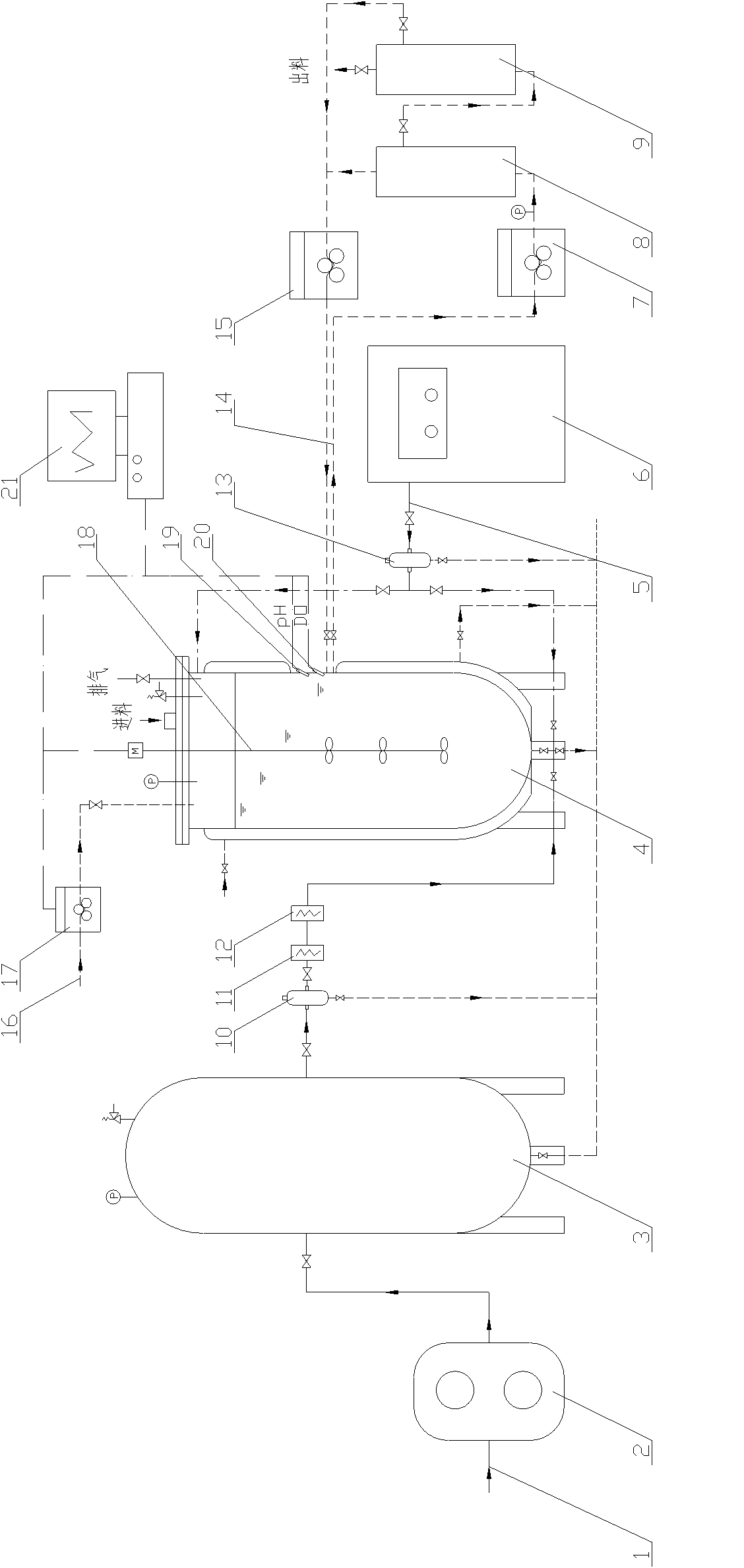

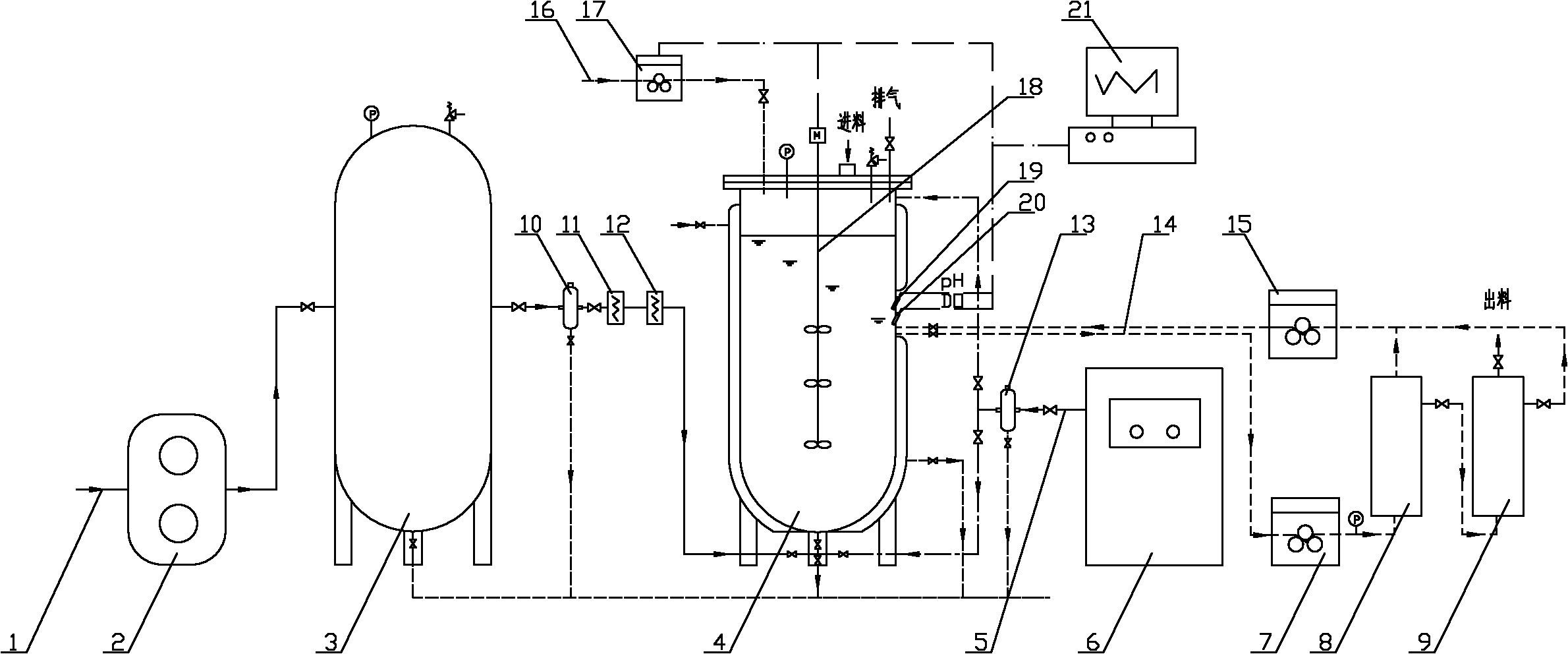

Sclerotium rolfssii scleroglucan online fermentation extraction method and system

ActiveCN102154408AHigh yieldInhibit synthesisBioreactor/fermenter combinationsBiological substance pretreatmentsFermentationGlucan

The invention relates to a Sclerotium rolfssii scleroglucan online fermentation extraction method, which comprises the following steps: (1) culturing a strain; (2) fermenting the Sclerotium rolfssii by using a fermentation tank; and (3) extracting polysaccharide liquid on line by ceramic membrane separation. The invention also relates to a Sclerotium rolfssii scleroglucan online fermentation extraction system, which comprises the fermentation tank, a feeding system, an oxygen supply system, a steam system, a control system and a ceramic membrane separation system. In the Sclerotium rolfssii scleroglucan online fermentation extraction method and the Sclerotium rolfssii scleroglucan online fermentation extraction system, a Sclerotium rolfssii glucan product is continuously extracted from fermentation liquor by ceramic membrane separation in a fermentation process, the Sclerotium rolfssii glucan does not accumulated in the fermentation liquor, and thus, the inhibition of the synthesis ofthe Sclerotium rolfssii glucan product due to problems of increases in viscosity of fermentation liquor, reduction in dissolved oxygen, reduction in pH value and the like. Meanwhile, post treatment is not required, the yield is high, the production process is simplified, the equipment cost is low, and the operation cost is low.

Owner:天津实发中科百奥工业生物技术有限公司

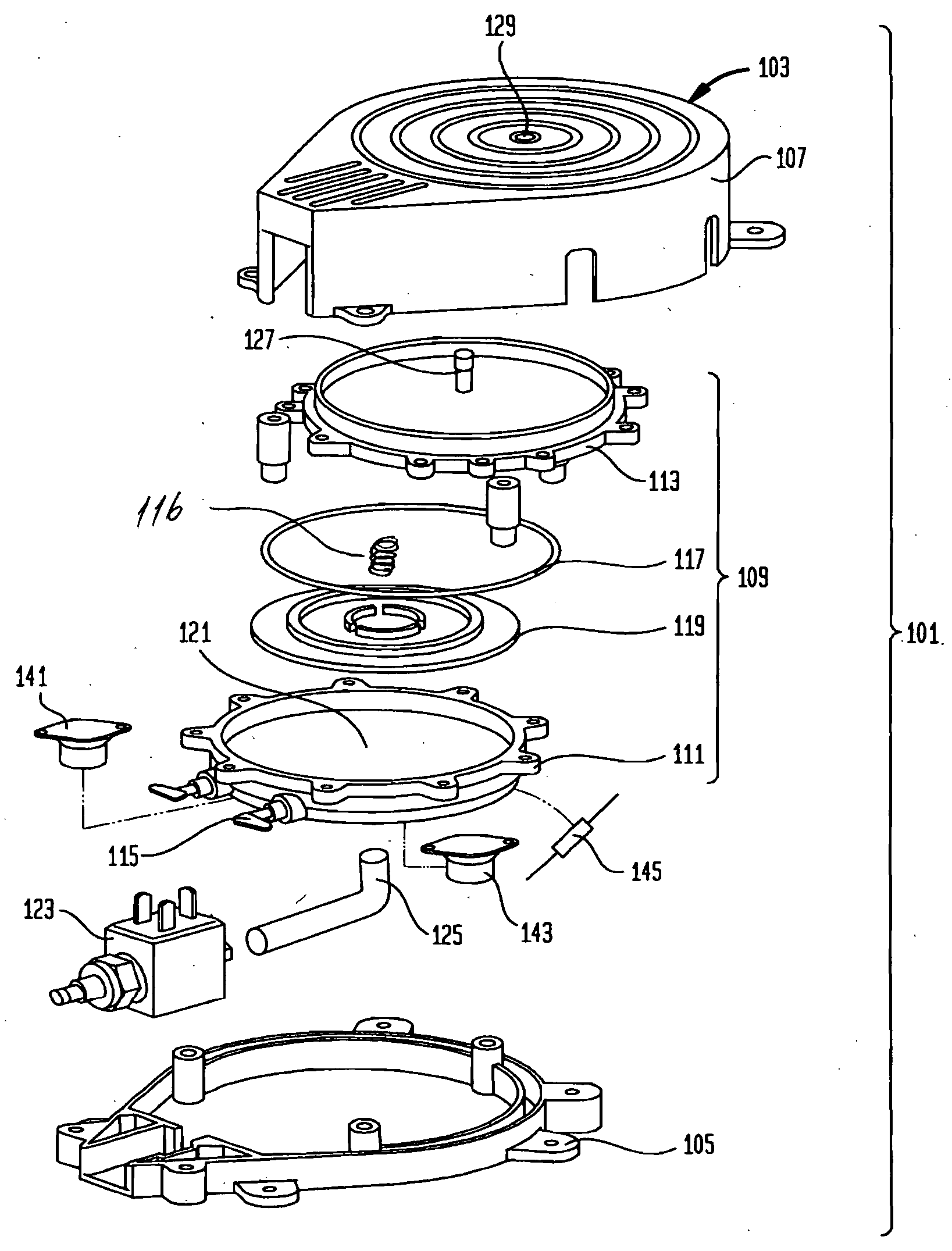

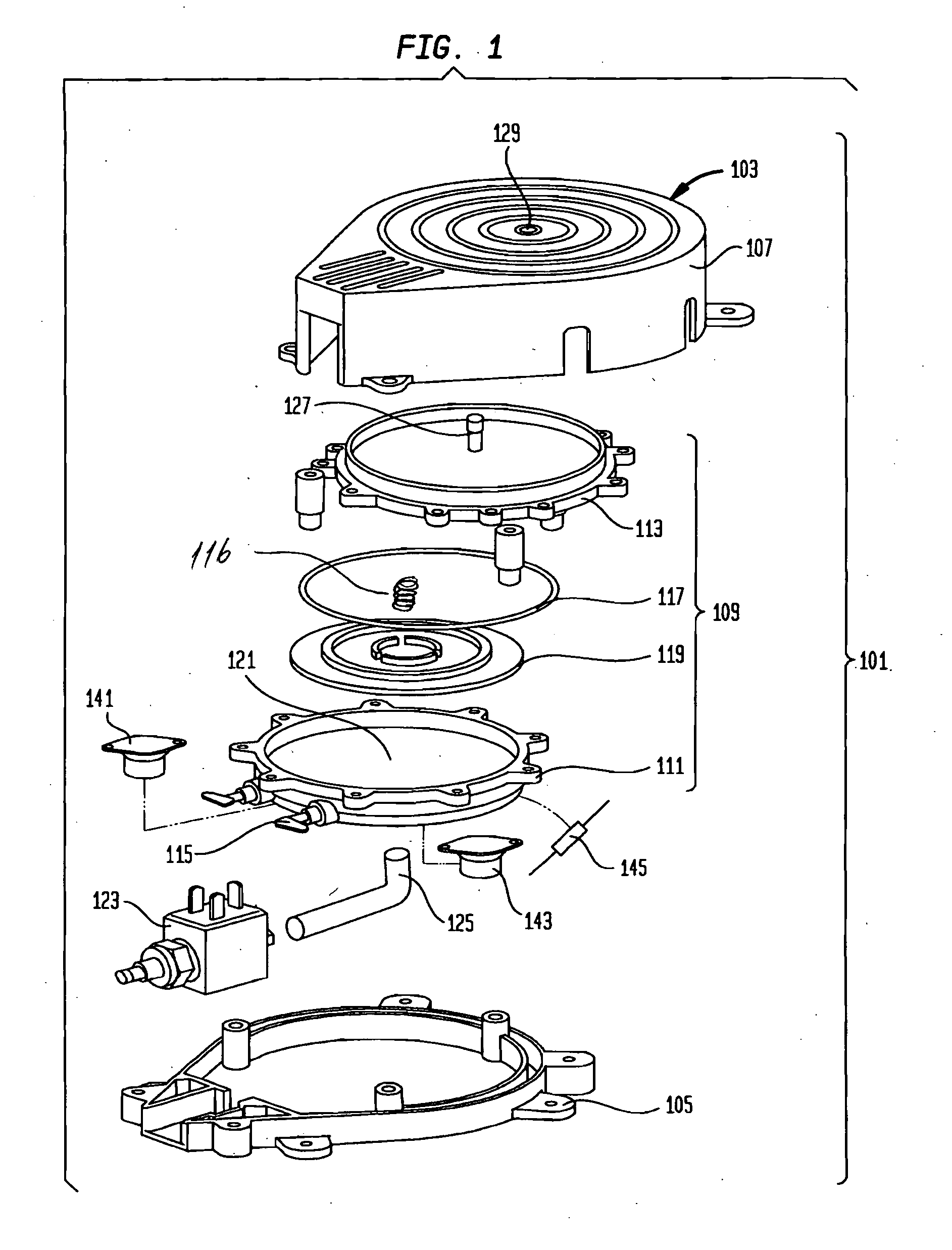

Steam system for continuous cleaning of hood fans

InactiveUS20070204855A1Cleaning systemEasy to disassembleDomestic stoves or rangesLighting and heating apparatusImpellerEngineering

A device and method for cleaning fans in range or stove hoods by spraying steam onto the fan impeller area on which soot and cooking fumes condense to clean the impeller and wash the accumulated condensates down a drain. By using steam above atmospheric pressure as the cleaning fluid, the device uses significantly less water that other devices that spray water or an aqueous solution to clean the fan blades.

Owner:CHENG JASON +1

Solar steam system

ActiveCN110285587AIncrease heat transfer rateMeet absorptive capacitySolar heating energySolar heat collector detailsAbsorption capacityEngineering

The invention provides a solar steam device. The solar steam device comprises a box body and a heat collection device, wherein the heat collection device comprises a heat collection component and a heat release component, wherein the heat release component is arranged inside the box body, the heat collection component is arranged outside the box body, the heat collection component can absorbs solar energy, and then heat is released into the box body through the heat release component. According to a solar steam generator with a novel heat pipe structure, the heat collection component and the heat release component are arranged, so that the heat transfer speed is high, the heat transfer speed of solar energy is increased, and the heat absorption capacity can be further met.

Owner:济南长城空调公司

Steam system for continuous cleaning of hood fan

InactiveUS20070204853A1Cleaning systemEasy to disassembleSelf-cleaning stoves/rangesLighting and heating apparatusImpellerEngineering

A device and method for cleaning fans in range or stove hoods by spraying steam onto the fan impeller area on which soot and cooking fumes condense to clean the impeller and wash the accumulated condensates down a drain. By using steam above atmospheric pressure as the cleaning fluid, the device uses significantly less water that other devices that spray water or an aqueous solution to clean the fan blades.

Owner:CHENG JASON +1

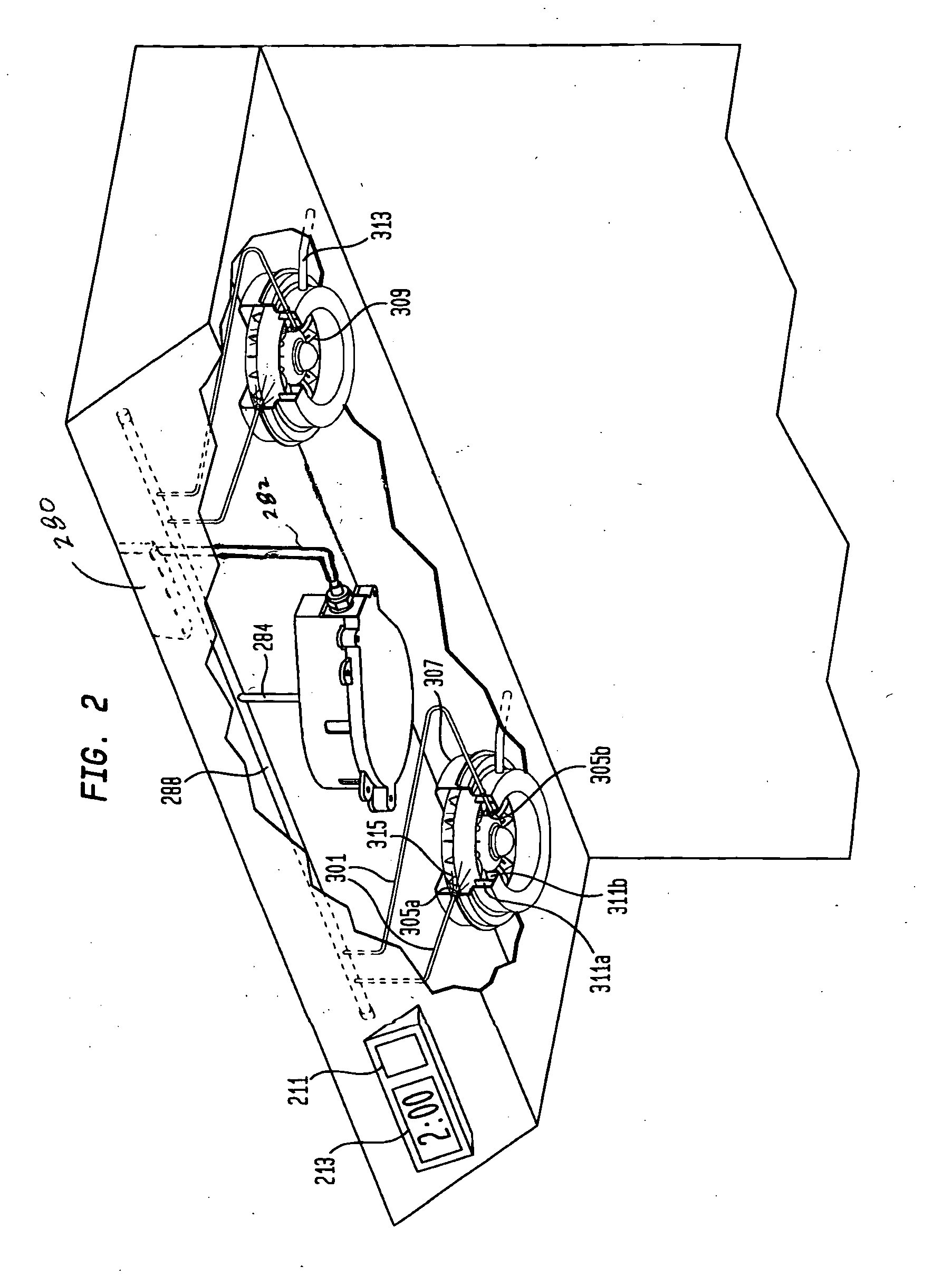

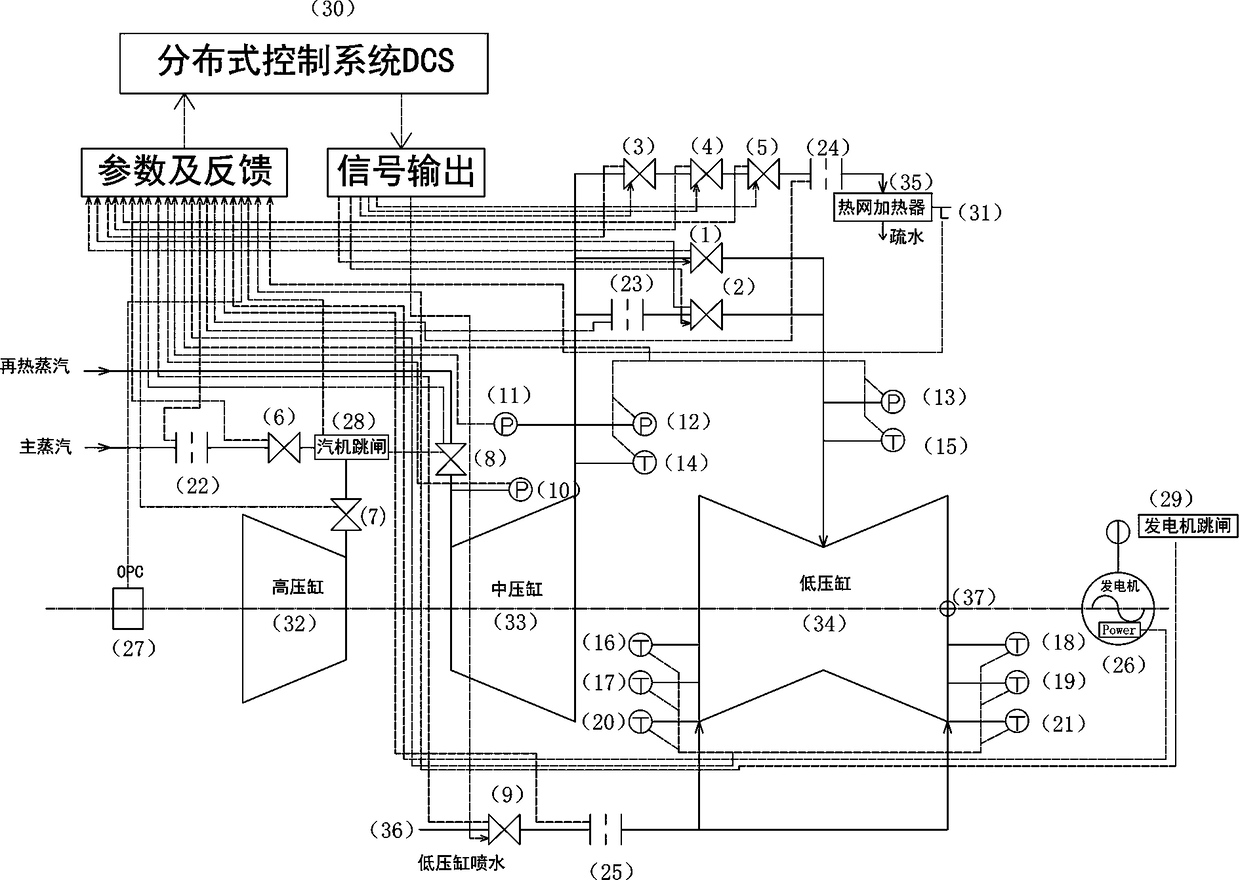

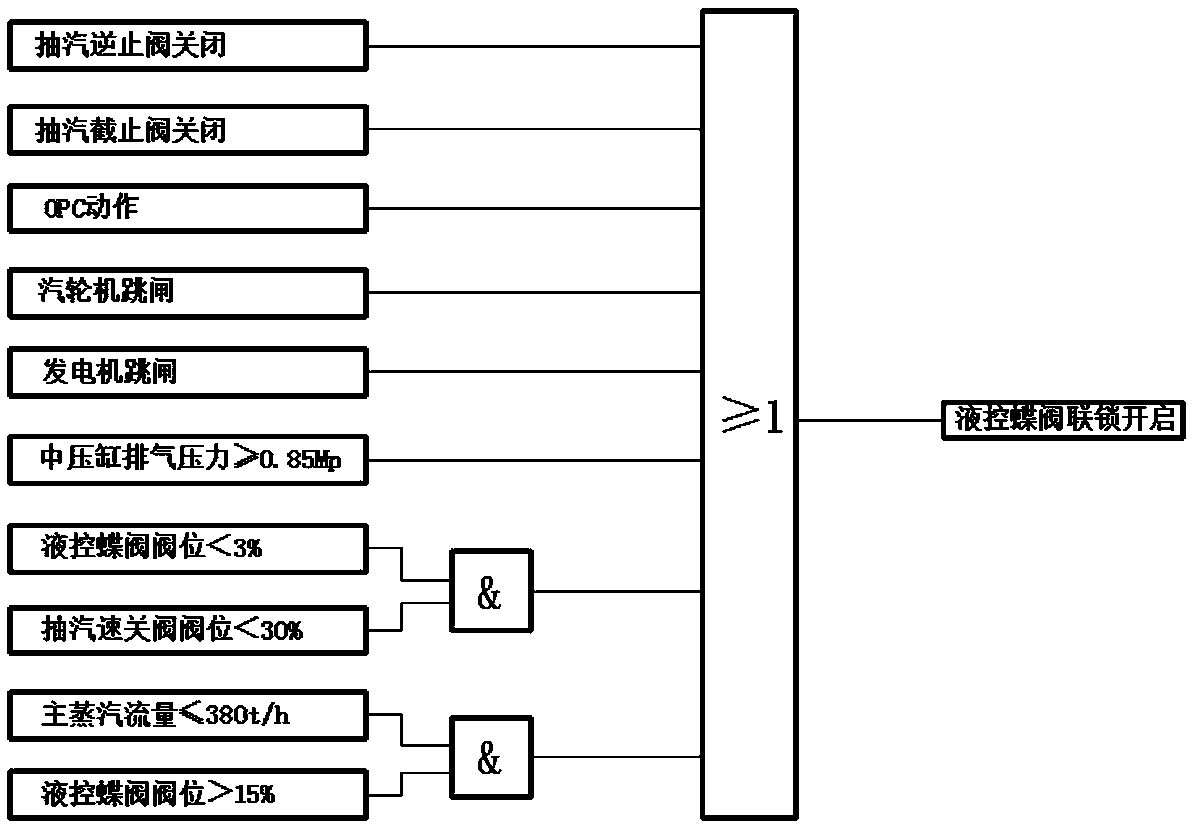

Safety protection system and method for cutting low-pressure cylinder operation of thermal power unit

PendingCN108561196AReduce steam intakeEnsure safe shutdownSteam engine plantsSafety/regulatory devicesEngineeringButterfly valve

The invention belongs to the technical field of thermal power unit operation and relates to a safety protection system and method for the cutting low-pressure cylinder operation of a thermal power unit. The system comprises equipment of an original unit, and a hydraulic control butterfly valve of a middle-low cylinder steam guide pipe which can be completely closed is reformed; and a cooling steamsystem of a low-pressure cylinder is additionally arranged, a water spray desuperheating system of the low-pressure cylinder is reformed, and various pressure sensors, a flow measuring device and a galvanic couple resistor are additionally arranged. According to the safety protection method, a protection method for interlocking opening and allowing closing of the hydraulic control butterfly valveis designed; a protection method for interlocking closing of an extraction stop valve and an extraction check valve and a protection method for manual closing are designed; a protection method for interlocking opening and allowing closing of an extraction quick closing regulating valve is designed; a protection method for interlocking opening and interlocking closing of a cooling steam regulatingvalve is designed; and a protection method for interlocking opening and interlocking closing of a low-pressure cylinder water spray regulating valve and a protection method for high or low exhaust pressure of a medium-pressure cylinder are designed, so that the operation safety of a steam turbine unit is protected during the cutting cylinder process of the thermal power unit.

Owner:辽宁东方发电有限公司 +1

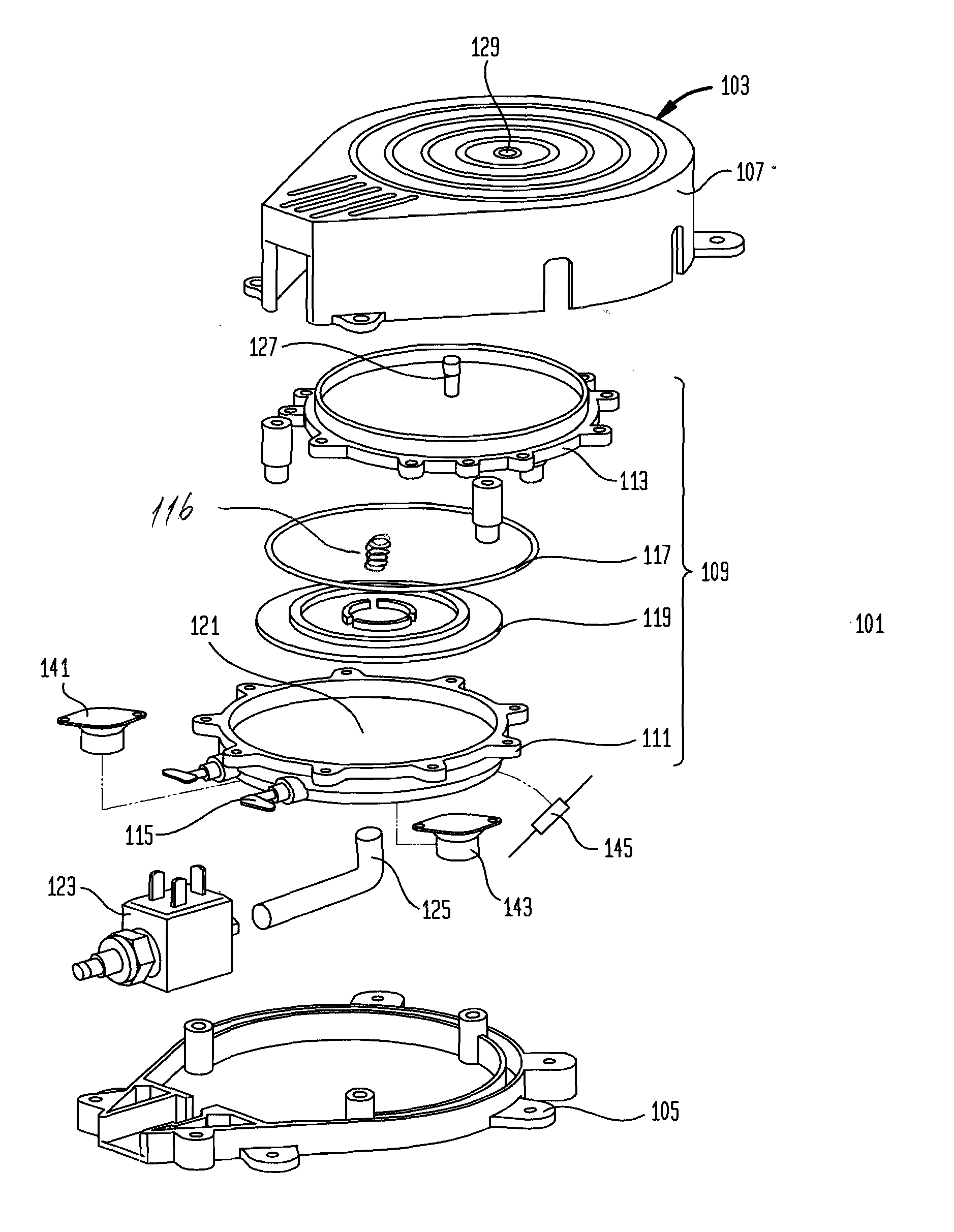

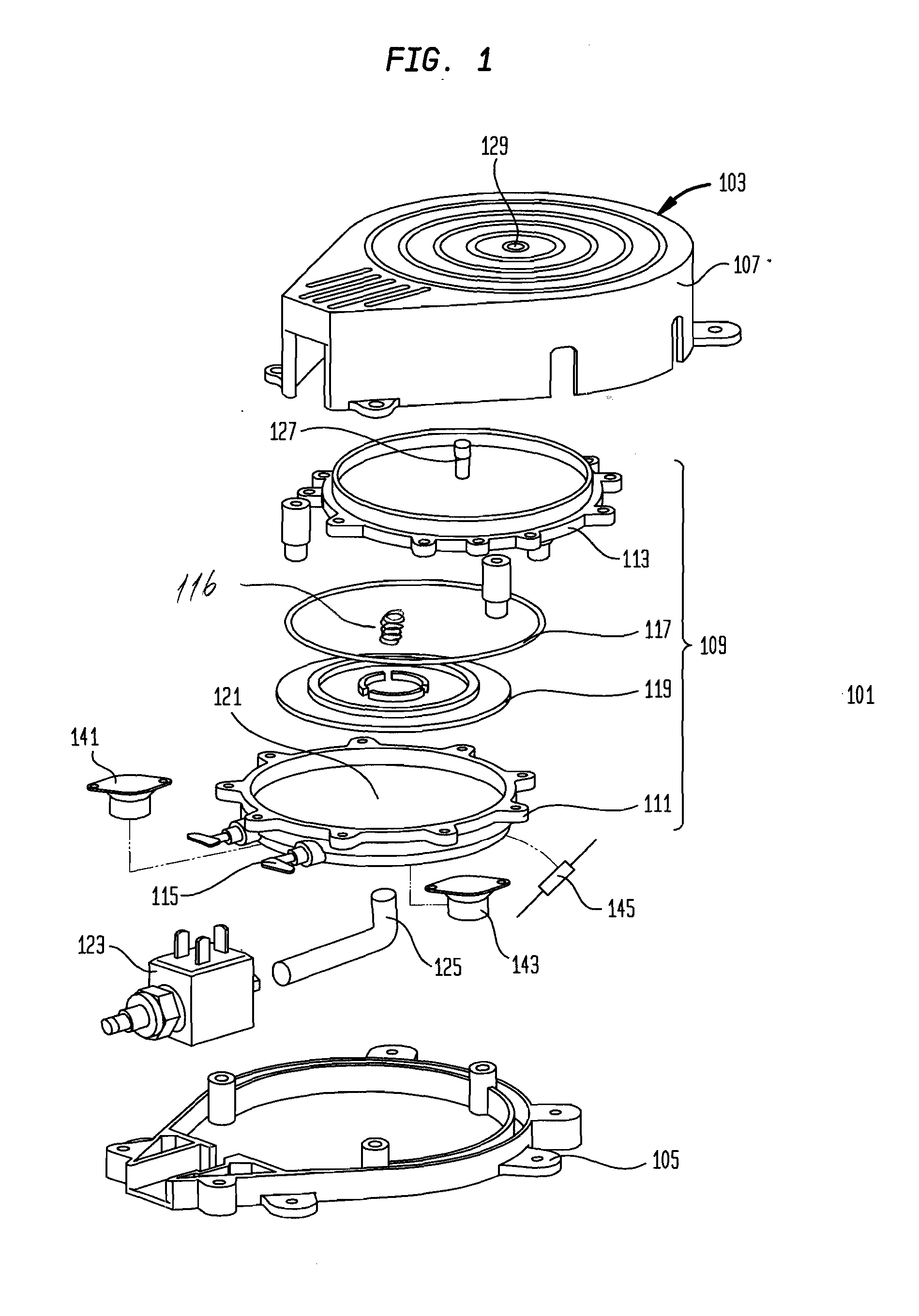

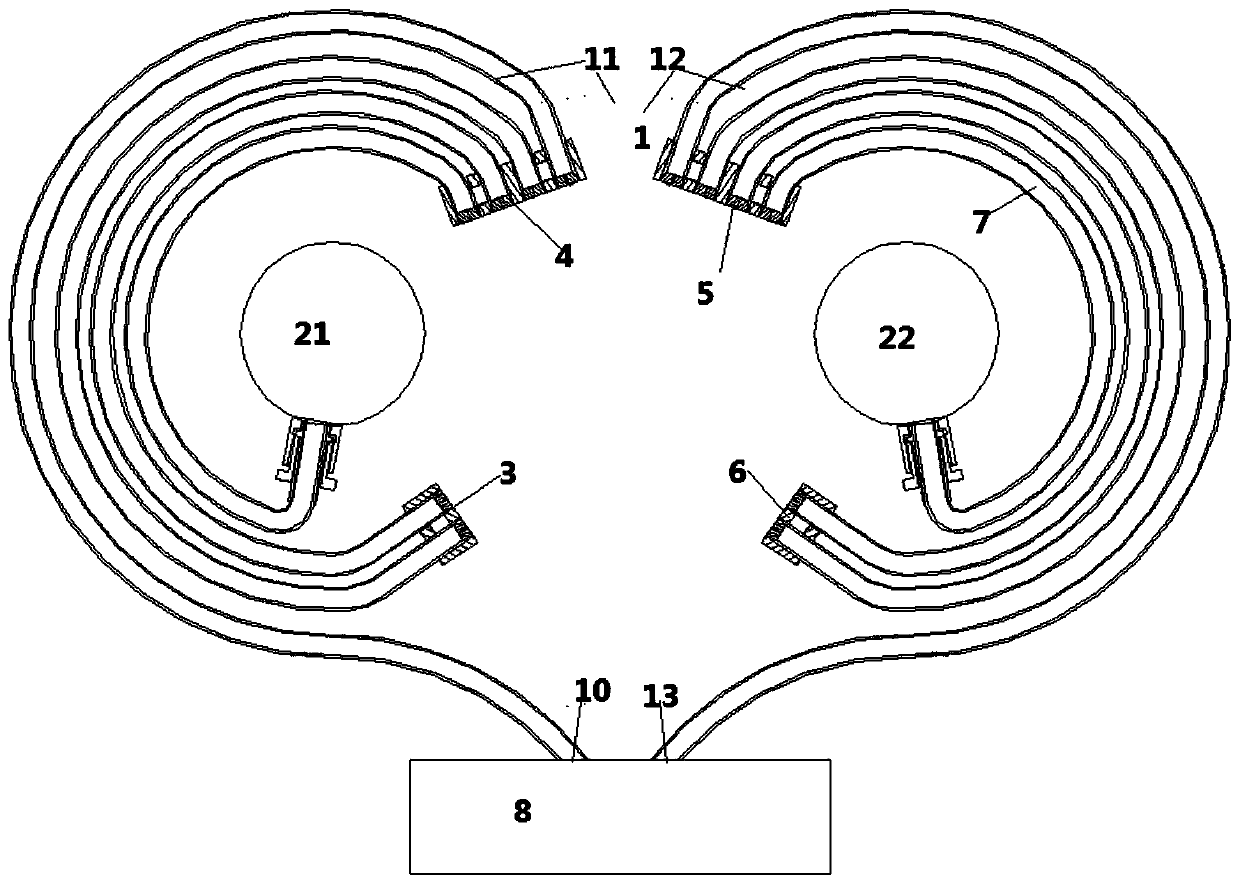

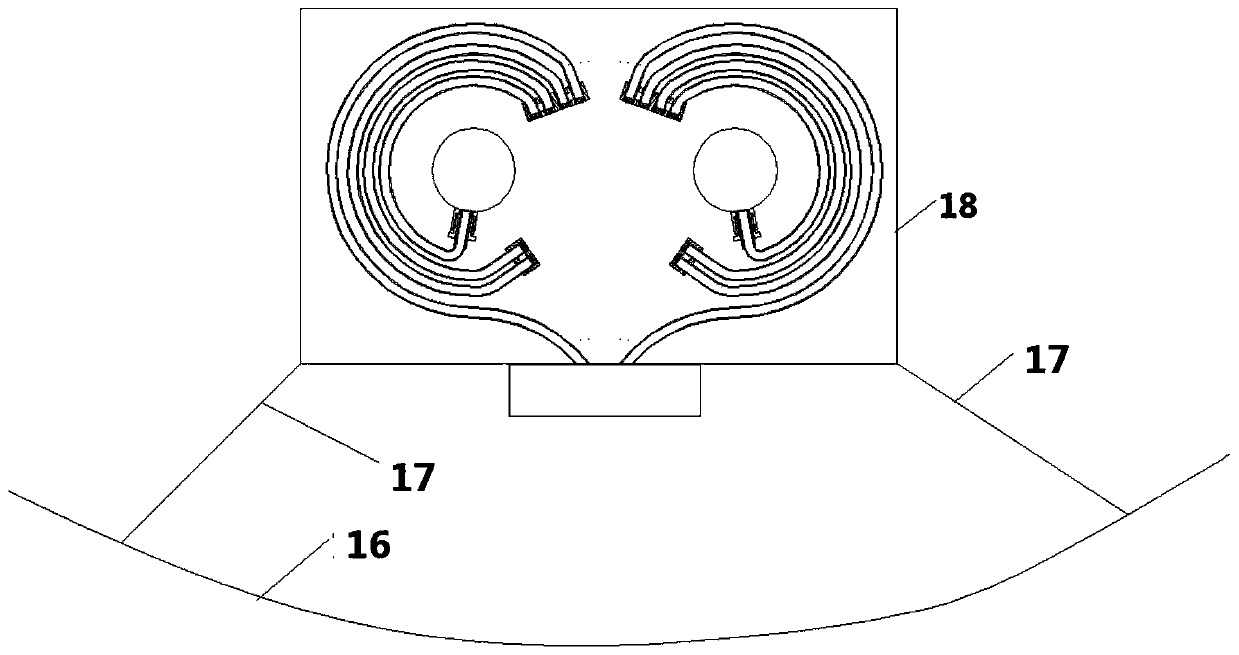

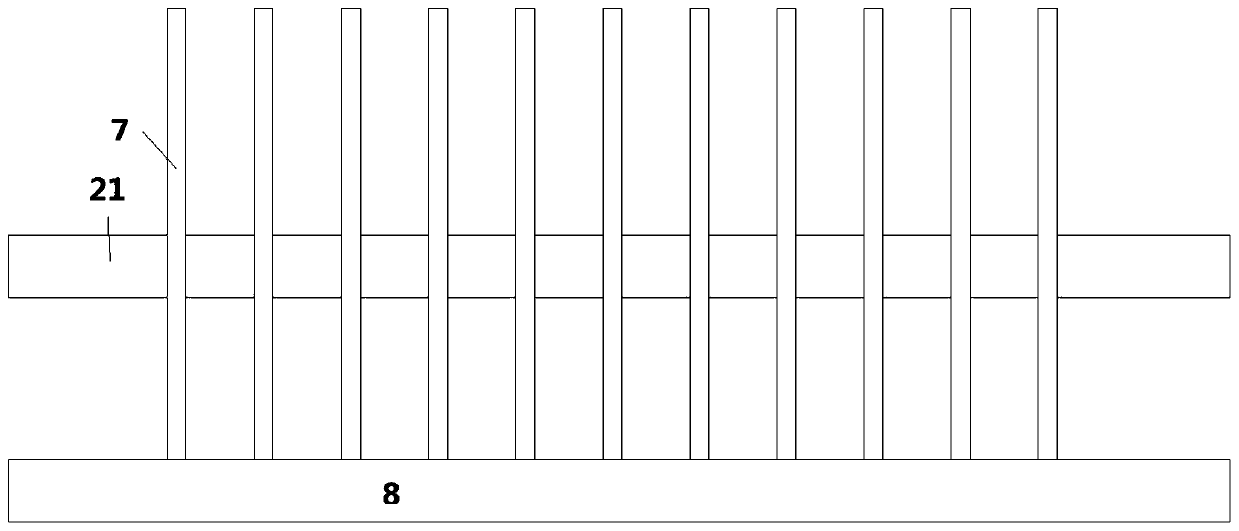

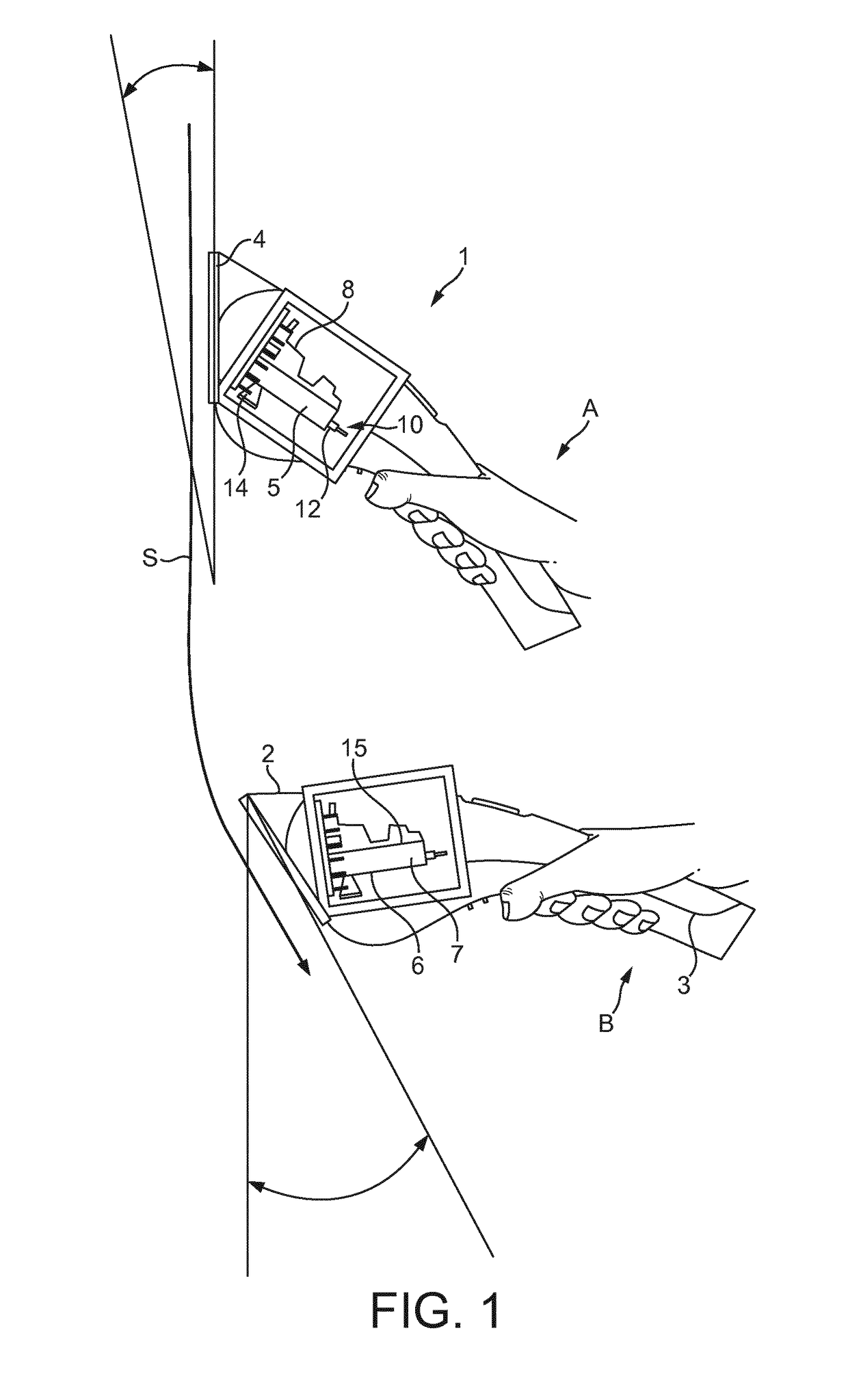

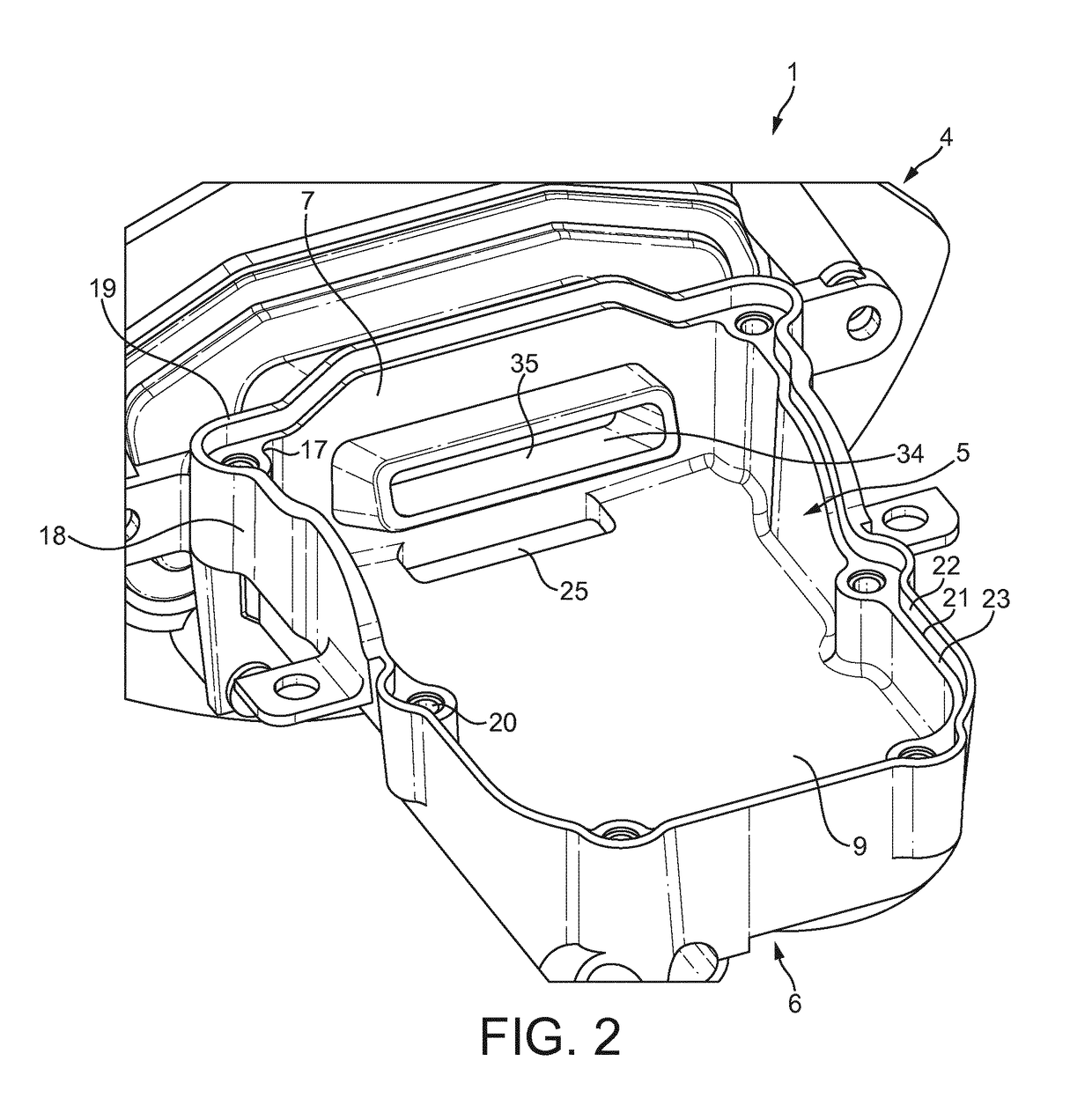

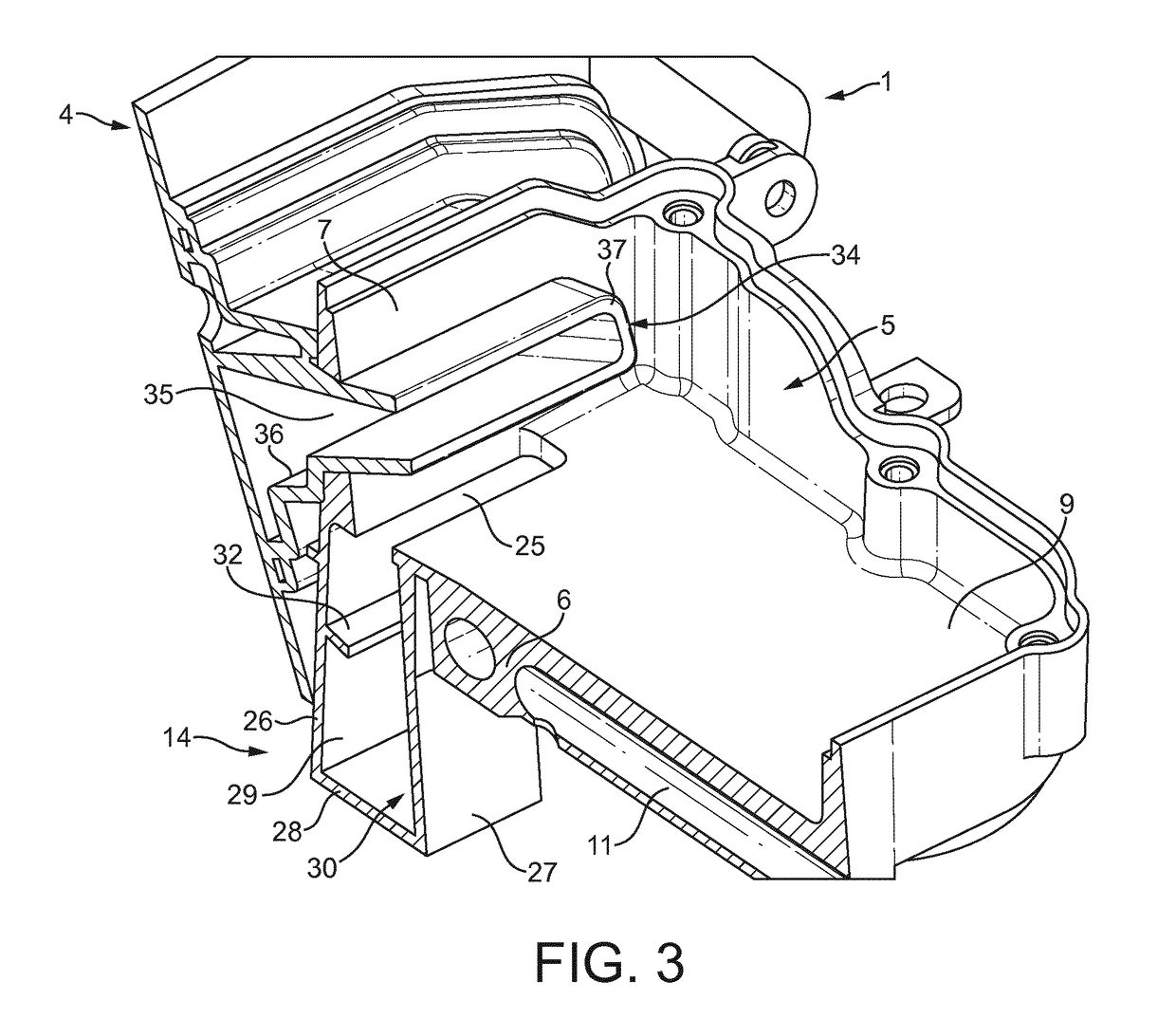

A hand-held garment steamer with scale collection chamber

The present application relates to a hand-held garment steamer (1) comprising a steam generating chamber (5) having a surface (9) and a heater (10) to heat the surface (9) such that water fed onto the surface (9) is converted into steam. The hand-held garment steamer (1) further comprises a scale collection chamber (14) having an opening (25). The surface (9) and opening (25) are positioned relative to each other and configured so that when the garment steamer (1) is in a first orientation (A) in which the surface (9) extends downwardly away from the opening (25), water fed onto the surface (9) flows away from the opening (25) to be evaporated from the surface (9). When the garment steamer (1) is in a second orientation (B) in which the surface (9) extends downwardly towards the opening (25), scale dislodged from the surface (9) falls into the scale collection chamber (14) through the opening (25). The scale collection chamber (14) is located below the steam generating chamber (5) in both the first orientation (A) and the second orientation (B). The present application also relates to a garment steaming system (40) comprising the hand-held garment steamer (1).

Owner:VERSUNI HLDG BV

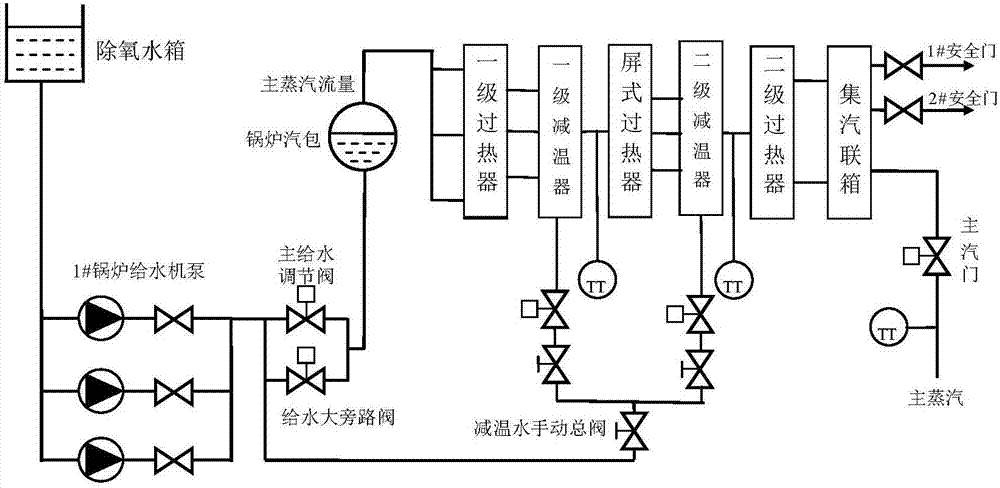

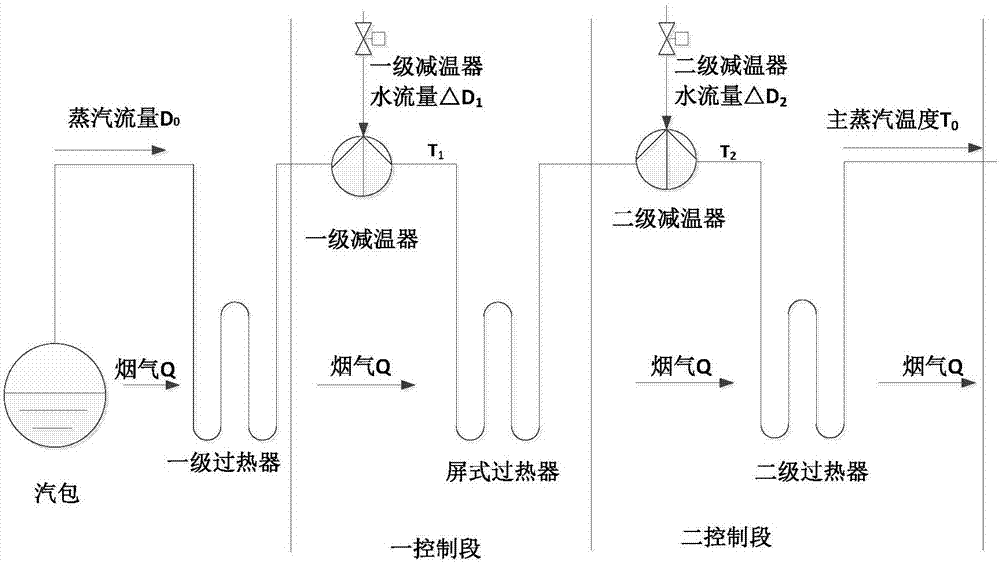

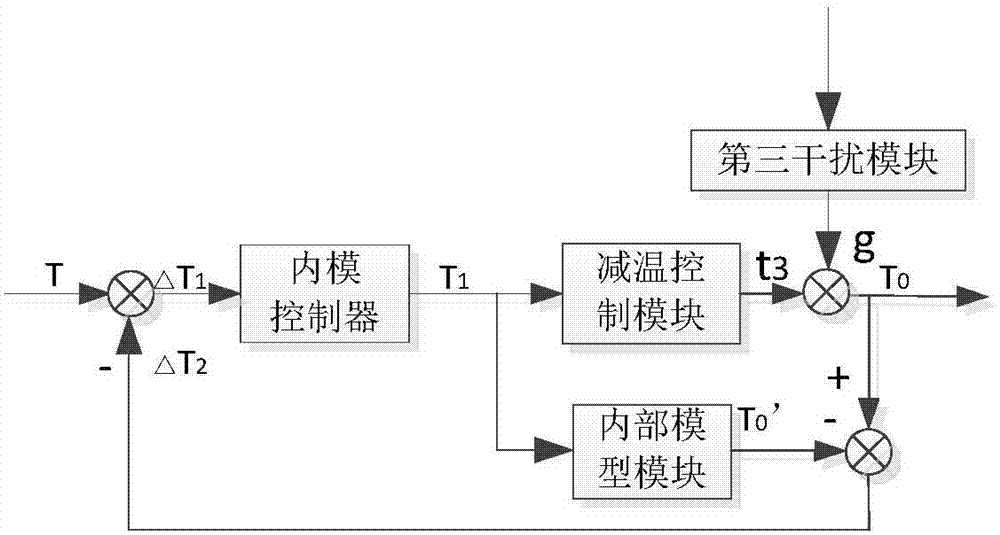

Multi-parameter intelligent control system for controlling boiler main steam temperature

InactiveCN107218594AEnhanced desuperheating control stabilityRealize online real-time correctionSuperheating controlSuperheaterEngineering

The invention discloses a multi-parameter intelligent control system for controlling the boiler main steam temperature. The multi-parameter intelligent control system for controlling the boiler main steam temperature comprises a water supply system and a main steam system. The main steam system is provided with a boiler steam pocket, a first level superheater, a first level desuperheater, a platen superheater, a second level desuperheater, a second level superheater and a steam collecting header, wherein the first level superheater, the first level desuperheater, the platen superheater, the second level desuperheater, the second level superheater and the steam collecting header are sequentially arranged on a steam output gas channel of the boiler steam pocket. Through mutual effect and cooperation of an internal model controller, a temperature reduction control system, a third disturbance module, an internal model module and a self-adapting PID correction module, control over the main steam temperature is achieved, the main steam temperature is stabilized, and cumulative deviation of the main steam temperature is reduced. The multi-parameter intelligent control system for controlling the boiler main steam temperature has the beneficial effects that the main steam temperature is stable, response to disturbance signals is rapid, the influence on main steam by disturbance is reduced, and the cumulative deviation of the main steam is small.

Owner:CHONGQING UNIV

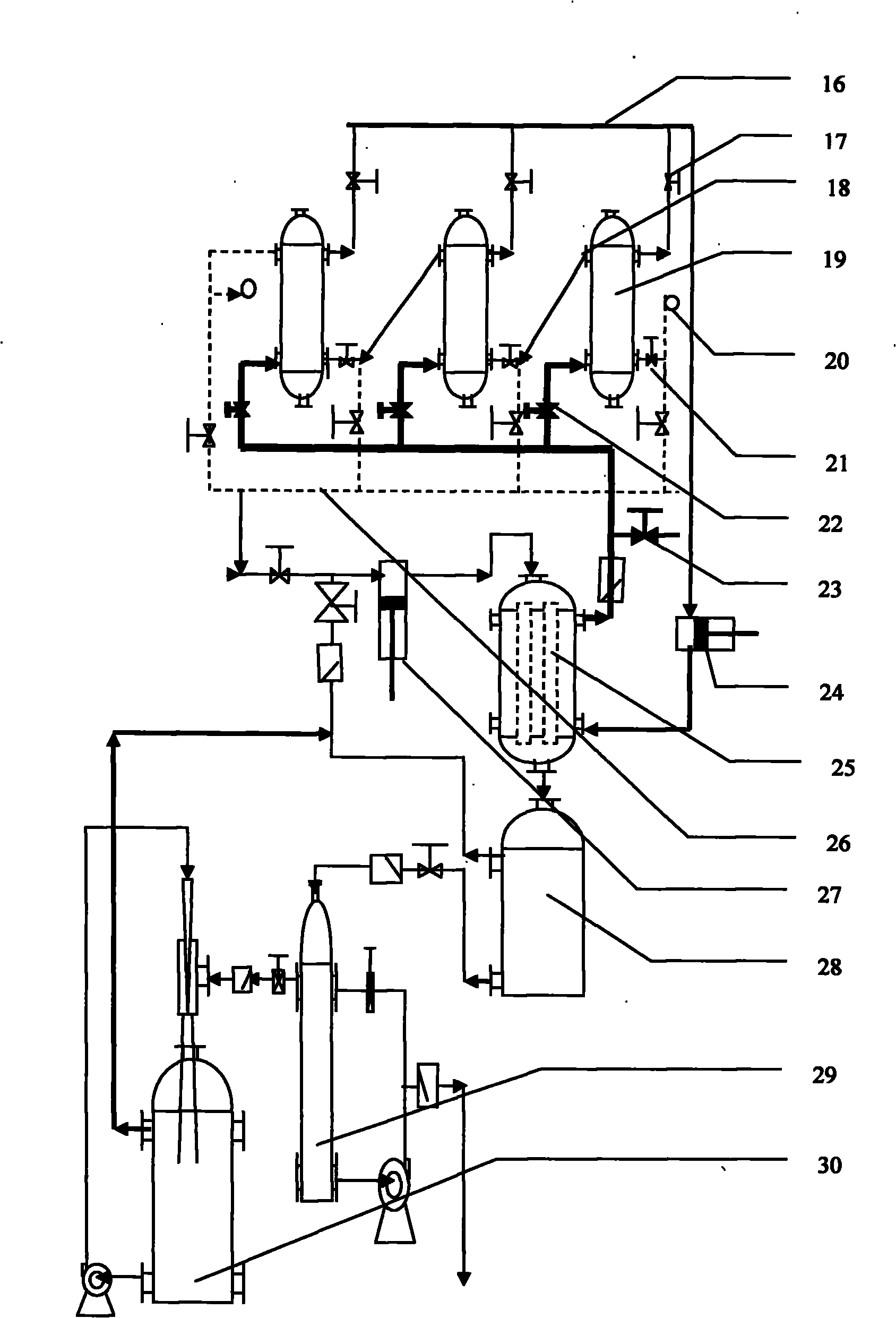

Technique for recycling waste fluid containing urea

InactiveCN1539748ALess investmentNo increase in circulationWater/sewage treatment by heatingWater/sewage treatment by degassingLiquid wasteDesorption

A process for reclaiming the sewage containing urea includes desorbing said sewage by desorption tower, condensing the desorbed gas by condenser, refluxing part of condensed liquid to tower top, returning rest back to production system of urea, concentrating the urea solution discharged from absorption tower by medium-pressure steam, returning the concentrated solution back to urea evaporating system, and delivering the generated secondary steam to low-pressure steam system. Its advantages are less investment in equipment and no environmental pollution.

Owner:河北阳煤正元化工集团有限公司

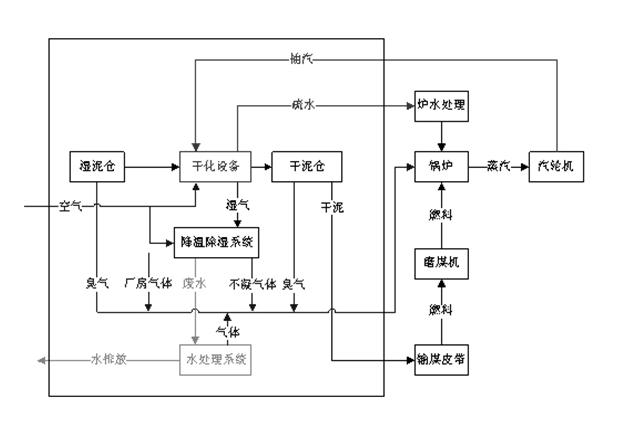

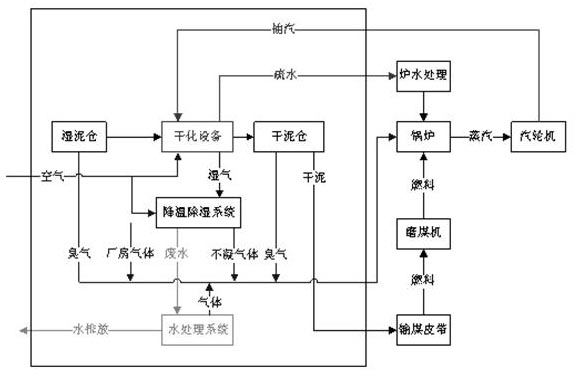

Municipal sludge drying method

ActiveCN102351399AReduce pollutionAvoid secondary pollutionSludge treatment by de-watering/drying/thickeningLiquid wasteDecomposition

The invention discloses a municipal sludge drying method, which is applicable to the treatment disposal of municipal dewatered sludge of municipal sewage treatment plants in combined use with electric plants. The method comprises the following flow processes of: (1) wet sludge drying flow process: pouring wet sludge to a wet sludge storage cabin through a sludge conveying vehicle, installing two double-spiral pre-pressing conveyors at the bottom of the sludge cabin and connecting a sludge pump under a material outlet of each double-spiral conveyor; (2) drying gas load flow process: sucking waste gas (steam) generated through the drying into a condenser, pumping and pressuring waste liquid after condensing, temperature reduction and dehumidification by a water pump, conveying the waste liquid to a sewage treatment system, simultaneously conveying defogged uncondensed gas and odor in the cabin into a boiler and carrying out burning decomposition at a high temperature; and (3) drying medium flow process: using the steam introduced from a low-pressure steam system of the electric plant as a heat source of a sludge drying system after the temperature reduction and pressure reduction.

Owner:NANJING GUONENG ENVIRONMENTAL PROTECTION ENG

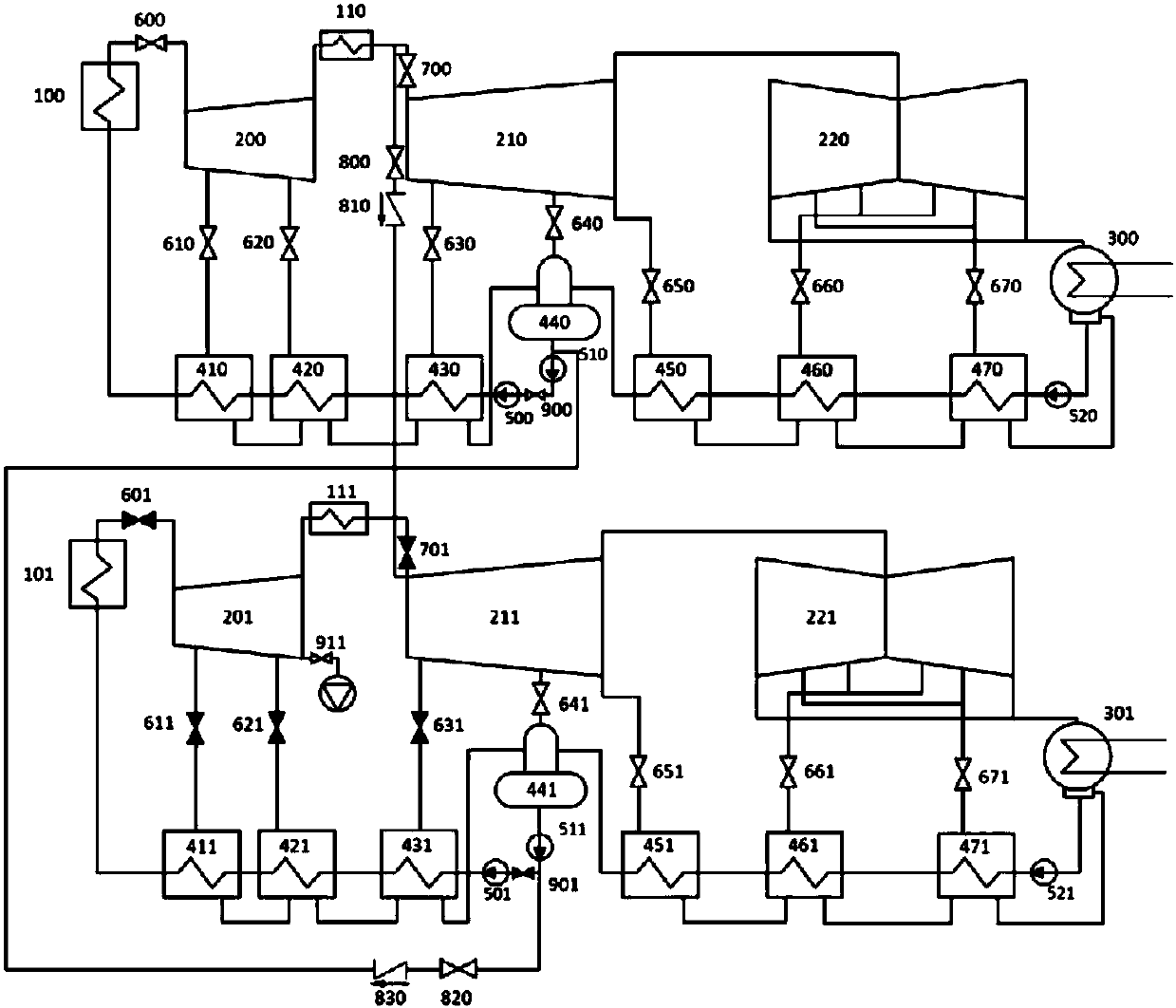

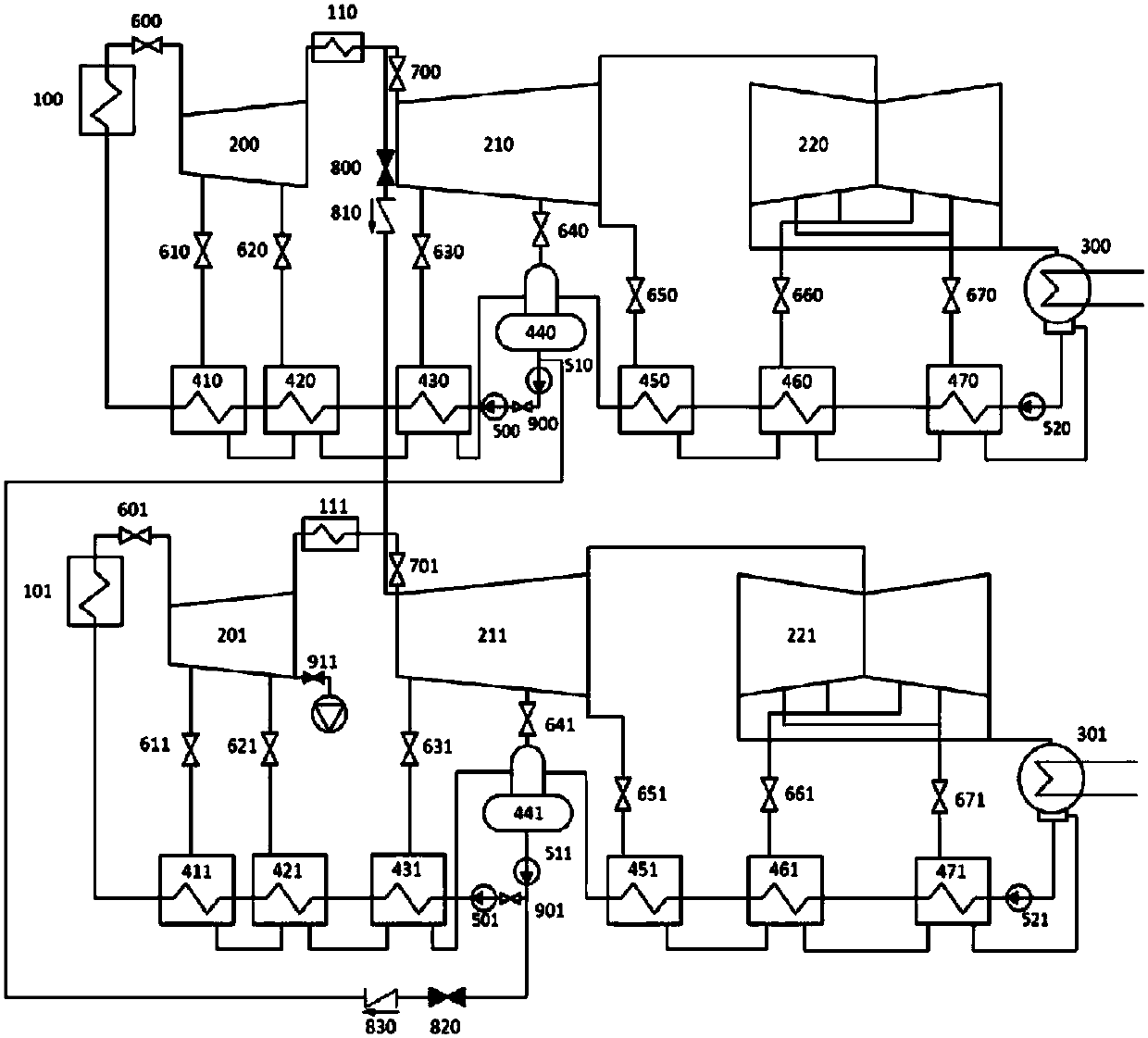

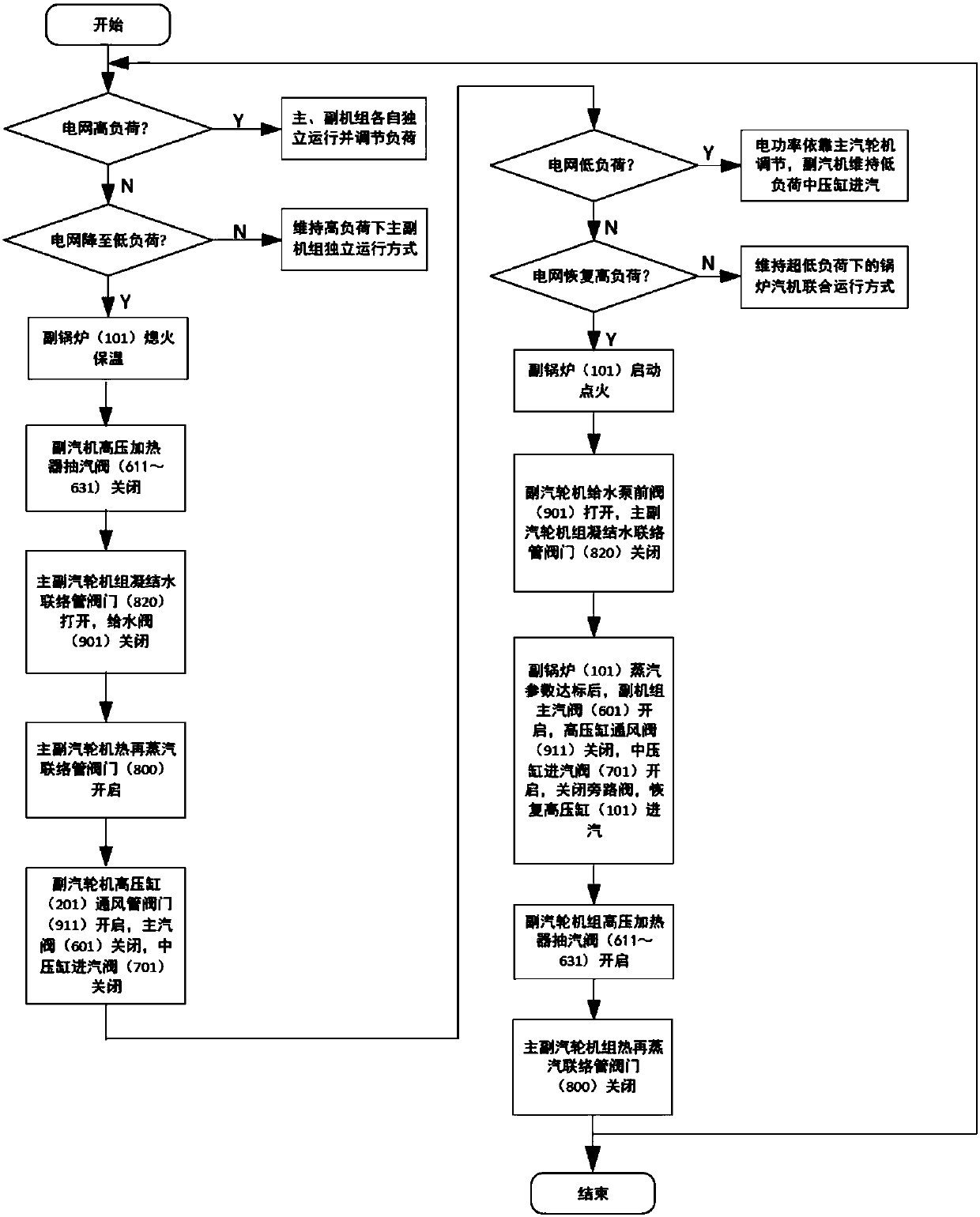

Ultra-low-load operation system and operation method for coal-fired generating units

InactiveCN107747503AIncrease peak shaving depthImprove peak shaving performanceSteam engine plantsProcess engineeringSteam system

The invention discloses an ultra-low-load operation system and an operation method for coal-fired generating units. The system is composed of two coal-fired generating units which operate in a unifiedmode, and each coal-fired generating unit consists of a steam turbine, a steam system, a vacuum air exhaust system, a condensed water system and a water feeding system; the steam systems of the generating units are connected through a heat steam connecting tube; and the water feeding systems of the generating units are connected through a water feeding connecting tube. The ultra-low-load operation system concentrates steam outlet force when the two units operate under ultra-low load on a main boiler, and solves the problems that boiler consumption is unstable, a coal mill, a fan and a denitrification reactor are unstable and the like when current coal-fired generating unit operates under the ultra-low load, and greatly improves safety and reliability of boiler operation control.

Owner:SOUTHEAST UNIV +1

Medium-low-temperature hot source heat pump steam system

InactiveCN105042943ASimple structureIncrease profitHeat pumpsSteam generation heating methodsLower gradeLow graded

A medium-low-temperature hot source heat pump steam system comprises a heat pump circulating loop allowing a refrigerant to pass and a flash evaporation circulating loop allowing flash evaporation water to pass, wherein an evaporator, a high-temperature compressor, an oil separator, a condenser, an economizer, a subcooler and an electronic expansion valve are sequentially arranged on the heat pump circulating loop, a medium-low-temperature hot source pipeline is communicated to the evaporator, an oil return pipe of the oil separator is communicated to an oil bath of the high-temperature compressor, a flash evaporator and a pressurizing water pump are arranged on the flash evaporation circulating loop, the flash evaporation circulating loop passes the condenser, the condenser is positioned between an outlet of the pressurizing water pump and an inlet of the flash evaporator, a first bypass pipeline is bypassed on a refrigerant outlet pipeline of the evaporator, and the first bypass pipeline passes the subcooler and serves as the cold source of the subcooler. The system can utilize low-grade residual heat to produce steam higher than 100 DEG C, is simple in structure, and can fully recycle waste heat and fully utilize resources.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

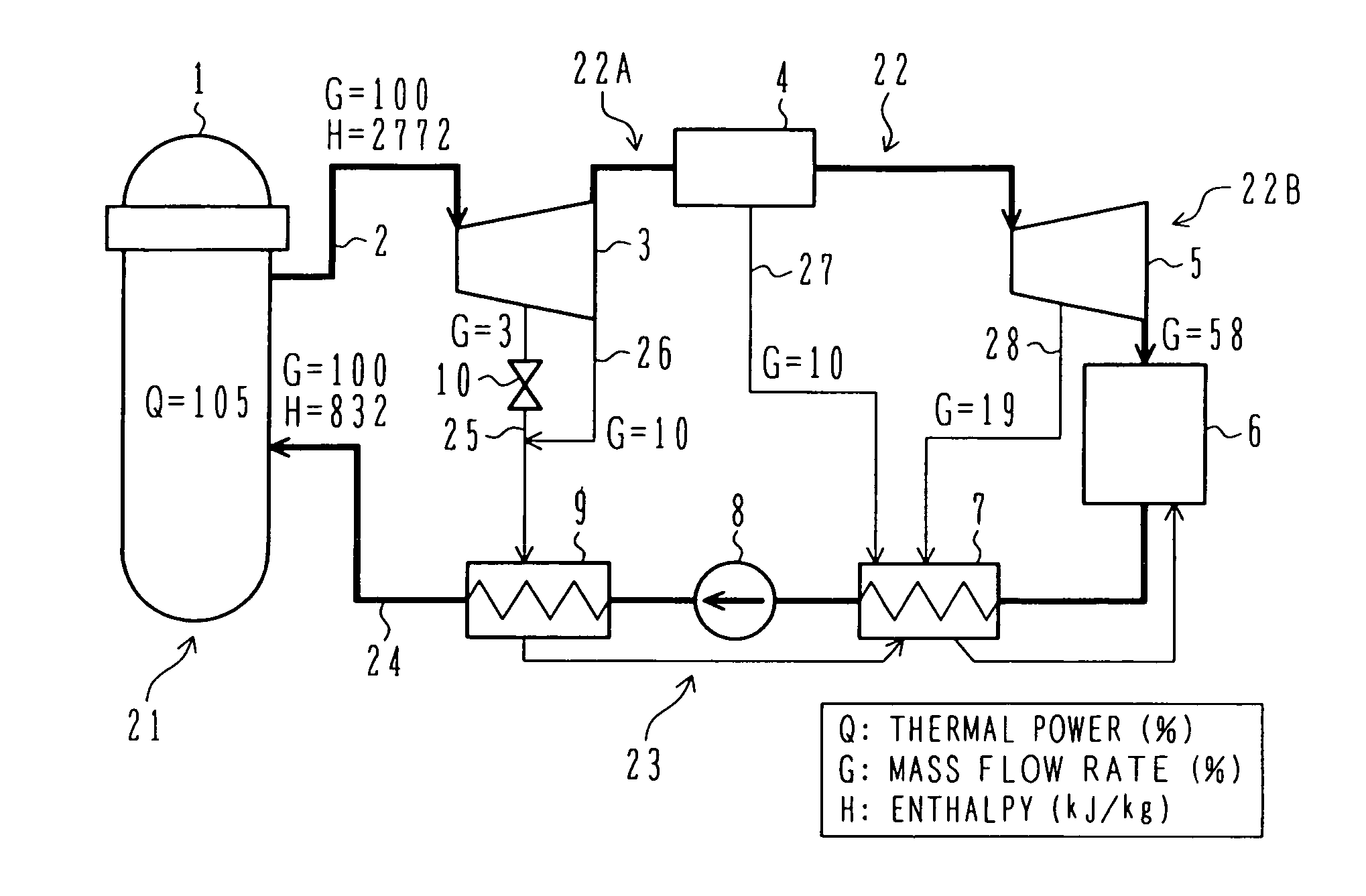

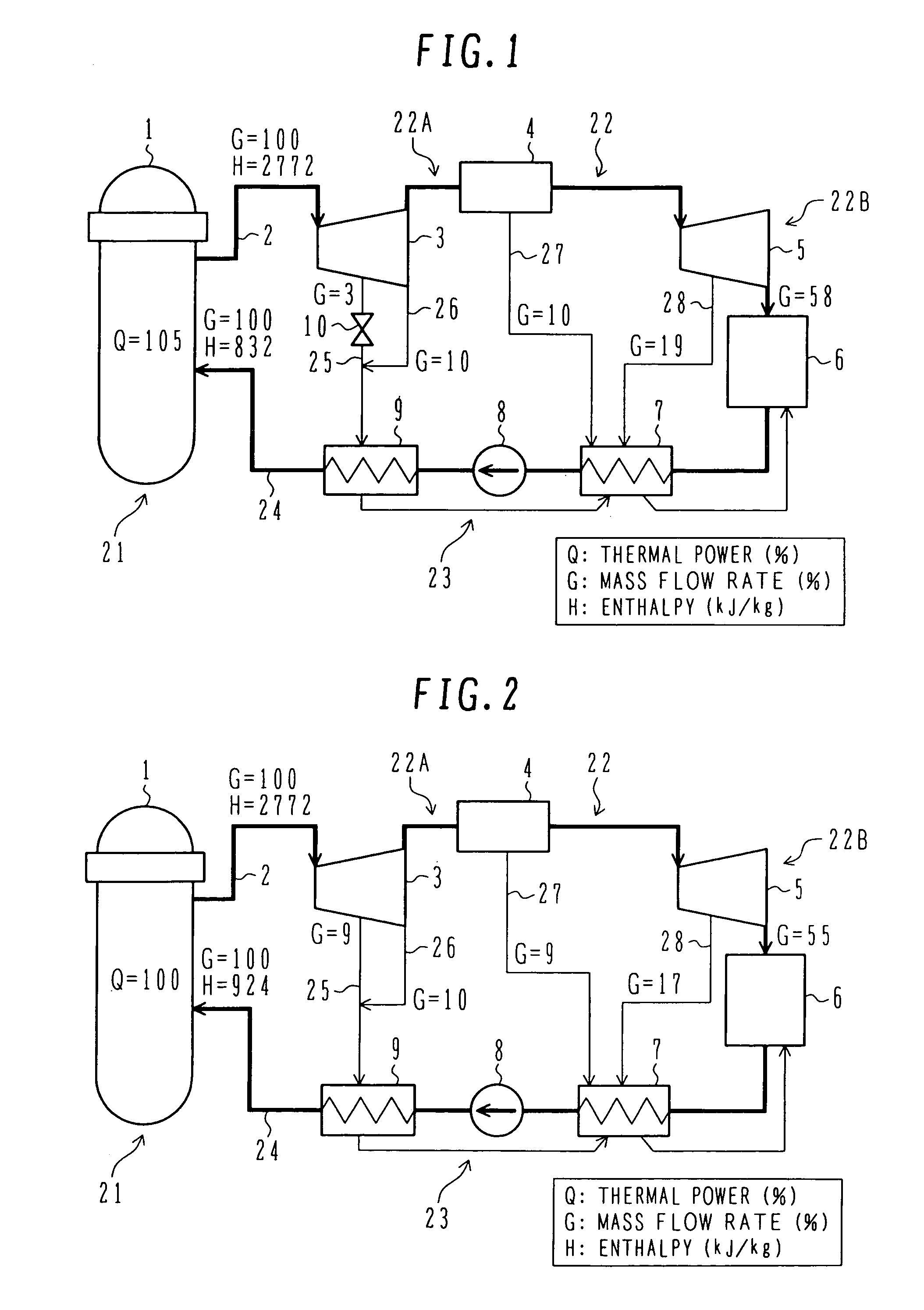

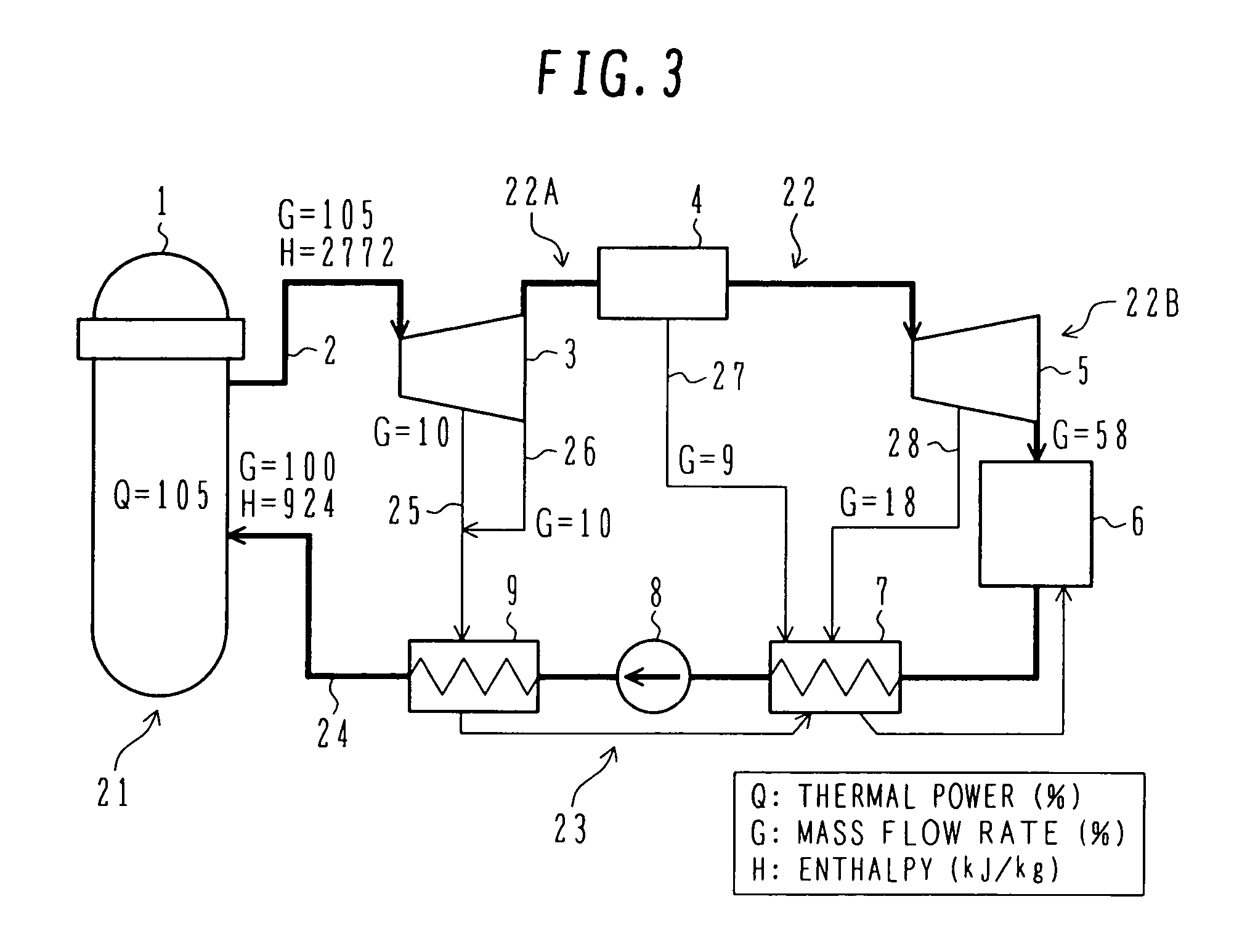

Operation method of nuclear power plant

ActiveUS7614233B2Increase thermal powerIncrease flow rateNuclear energy generationNuclear power plant controlNuclear reactorNuclear power

In a nuclear power plant, thermal power in a second operation cycle of a nuclear reactor is uprated from thermal power in a first operation cycle preceding the second operation cycle by at least one operation cycle. A proportion of steam extracted from a steam system and introduced to a feedwater heater, which is in particular extracted from an intermediate point and an outlet of a high pressure turbine, with respect to a flow rate of main steam, is reduced in the second operation cycle from that in the first operation cycle such that the temperature of feedwater discharged from the feedwater heater is lowered by 1° C. to 40° C. in the second operation cycle.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

Method for baking bread using steam

ActiveUS20070104844A1Reduce the cooking temperatureReduce the amount requiredDough treatmentDomestic stoves or rangesProcess engineeringRelative humidity

A method of baking bread using steam in an automated household oven with a cooking cavity and a steam system for introducing steam into the cooking cavity comprises determining a presence of bread in the cooking cavity and introducing steam into the cooking cavity upon a positive determination of the presence of bread. After the positive determination, the steam is introduced into the cavity to maintain a desired relative humidity in the cavity for a predetermined period of time to aid in formation of a moist, flexible crust on the bread, and the amount of steam introduced into the cavity decreases after the predetermined period of time. The cavity can be preheated and prehumidified prior to the determining of the presence of the bread in the cooking cavity.

Owner:WHIRLPOOL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com