Patents

Literature

258results about How to "Improve heat transfer characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

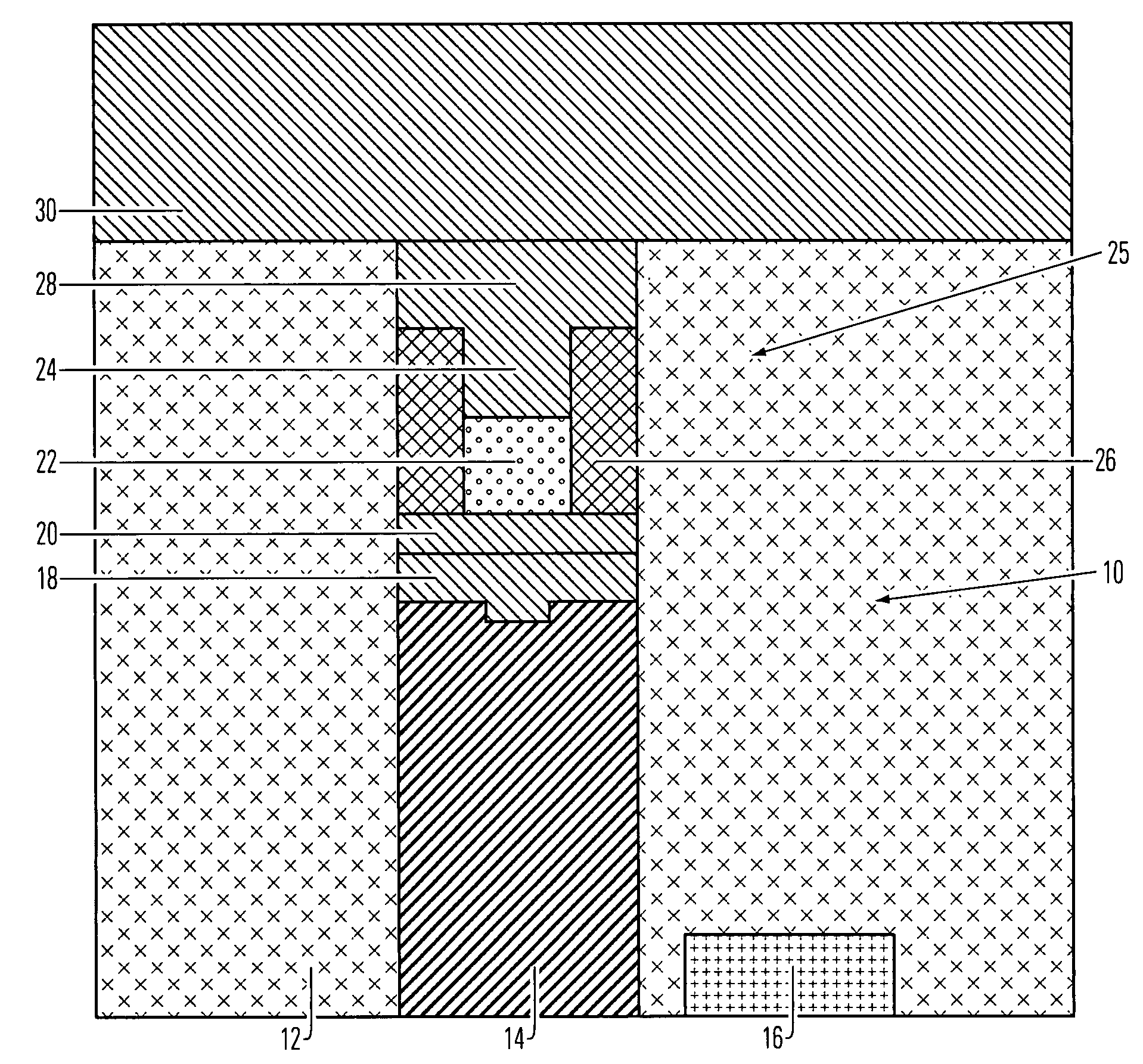

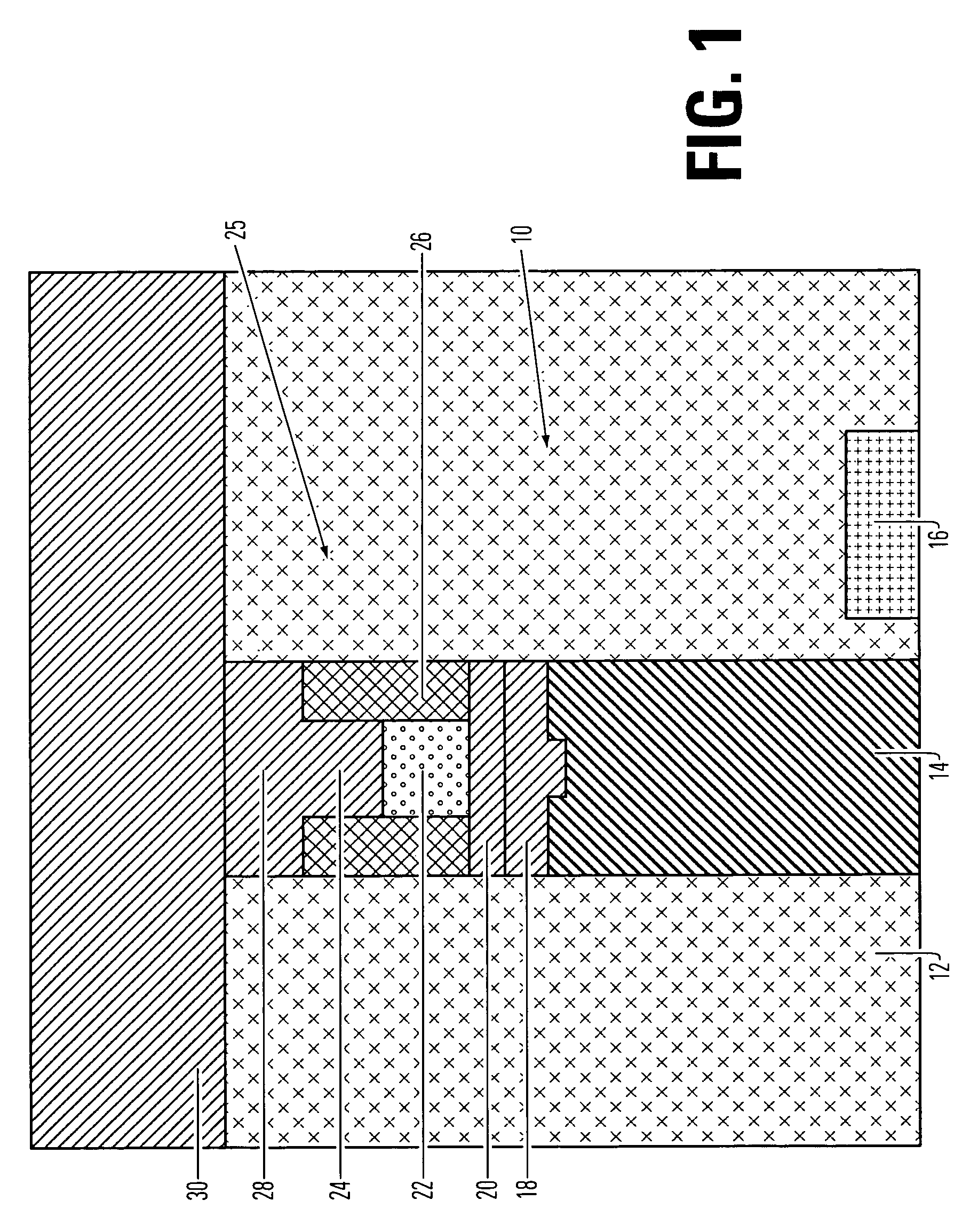

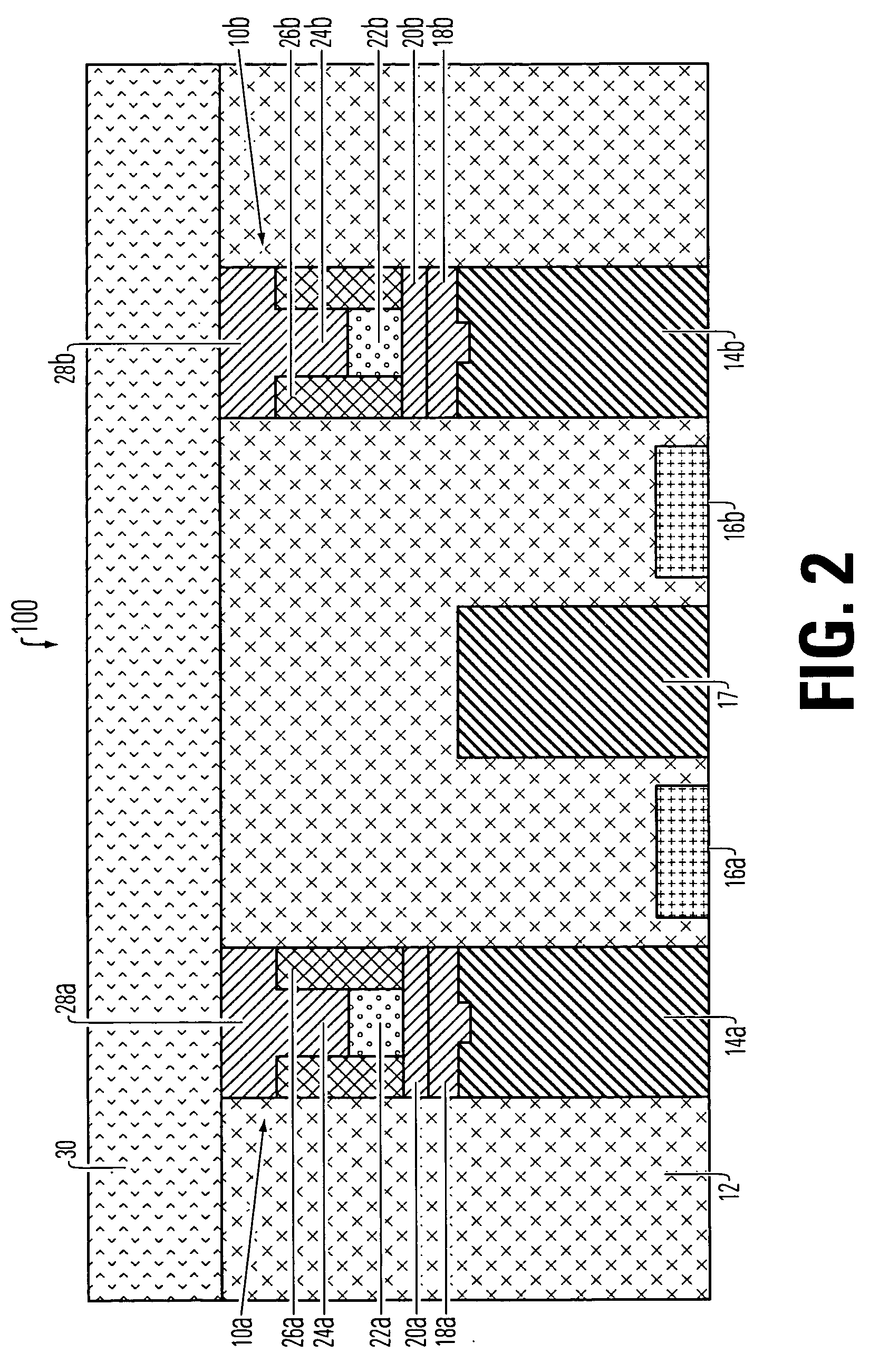

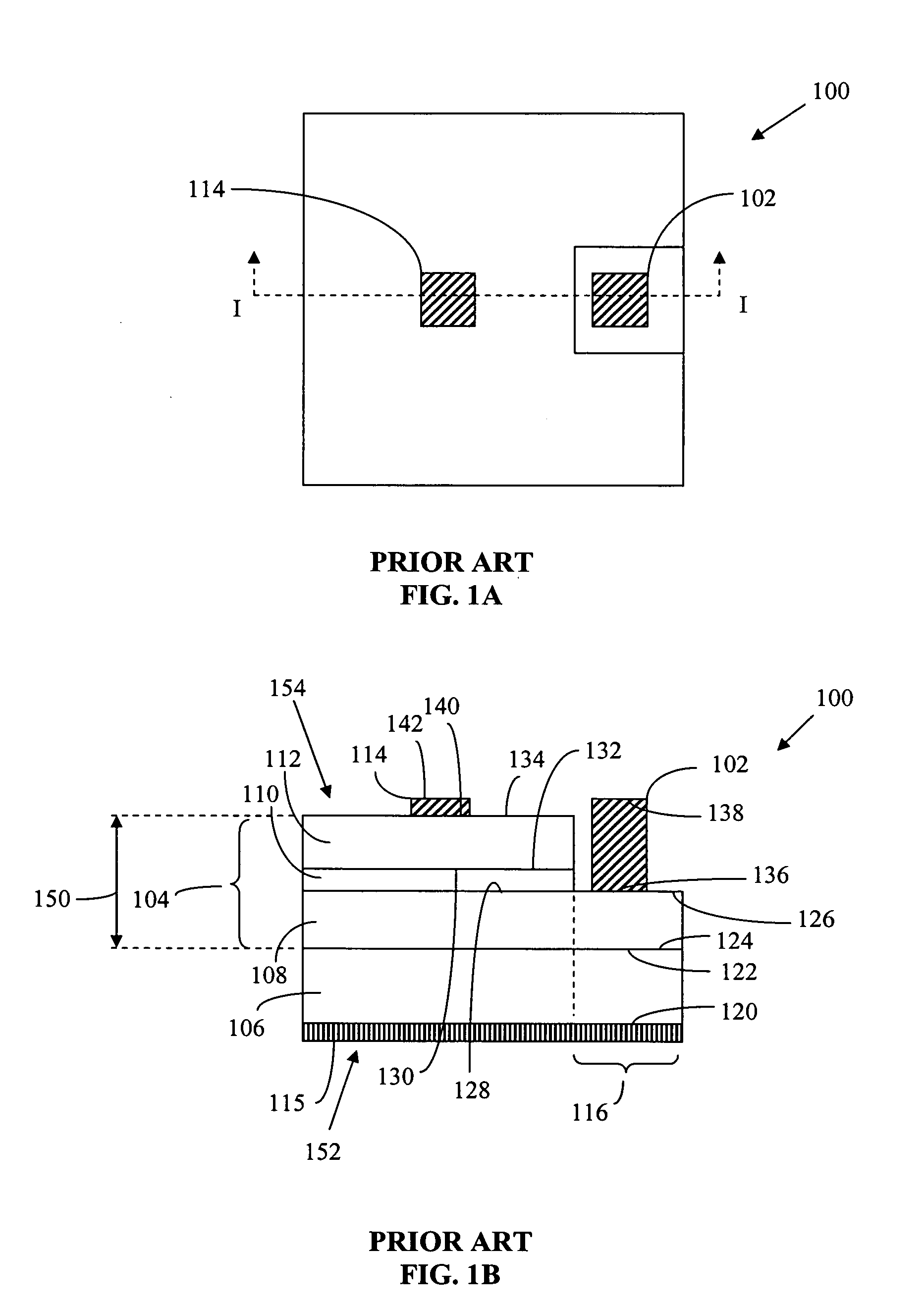

Thermally contained/insulated phase change memory device and method (combined)

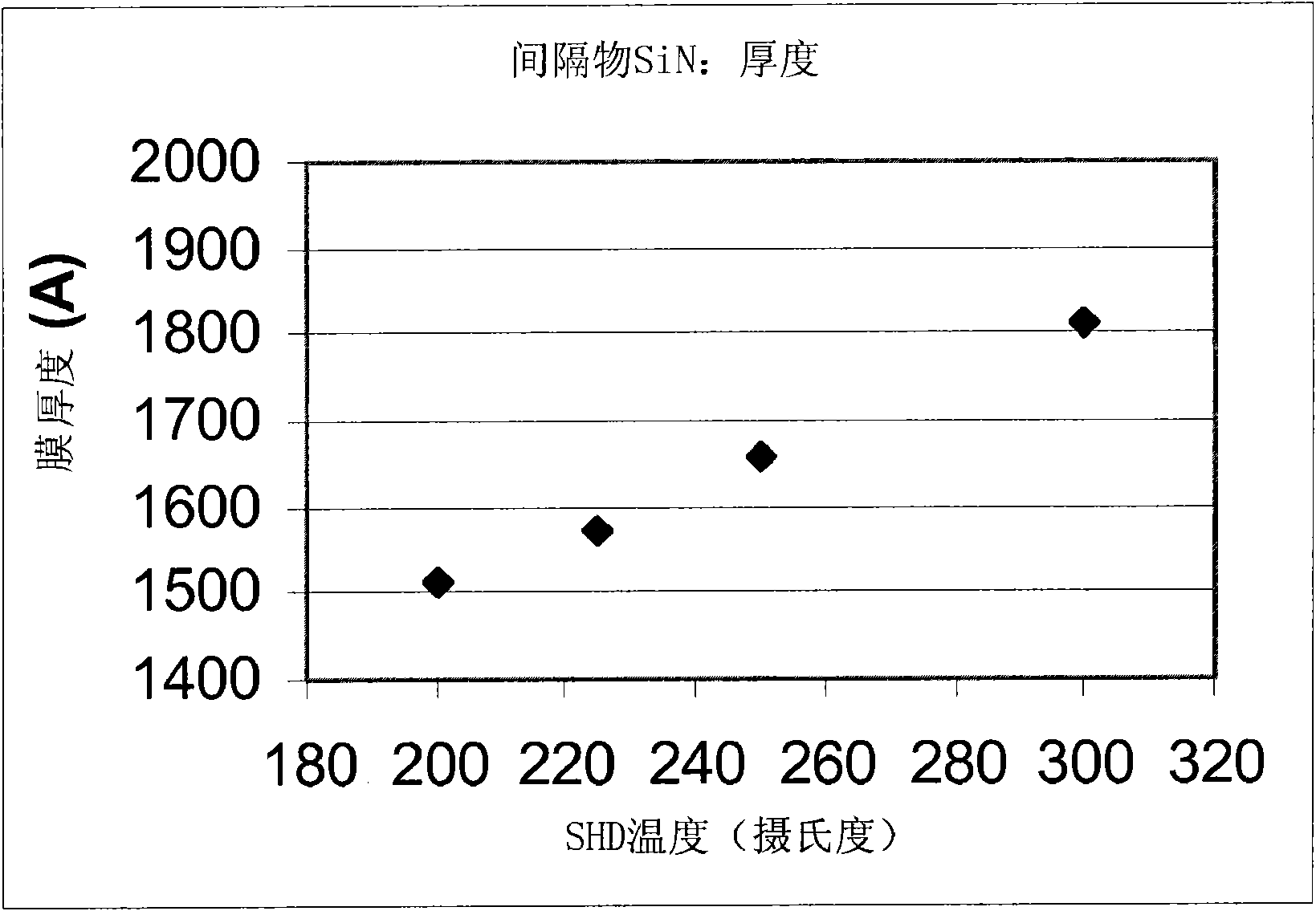

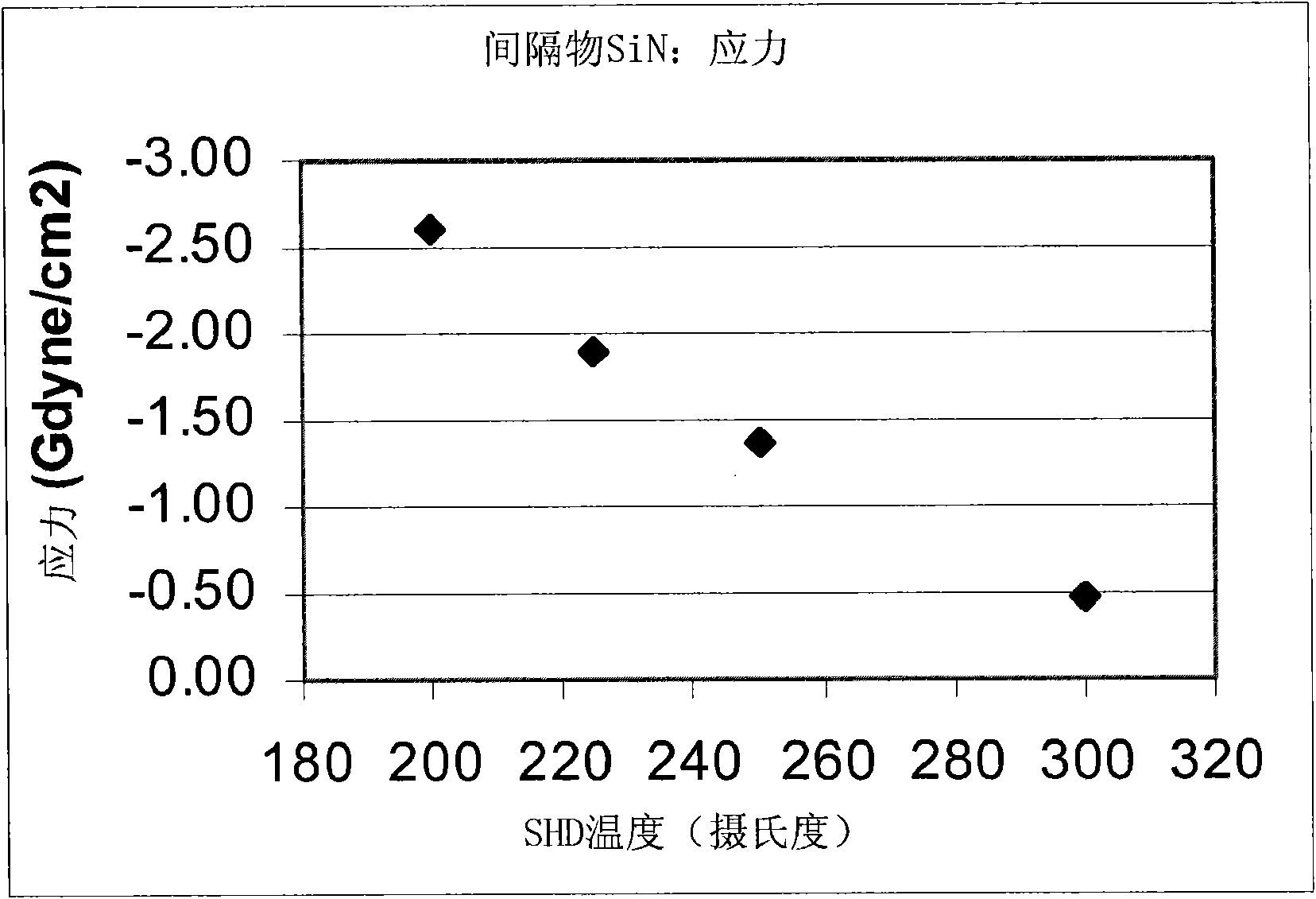

ActiveUS7394088B2Improve heat transfer characteristicsImprove insulation performanceTransistorSemiconductor/solid-state device detailsPhase-change memoryDielectric layer

Owner:MACRONIX INT CO LTD

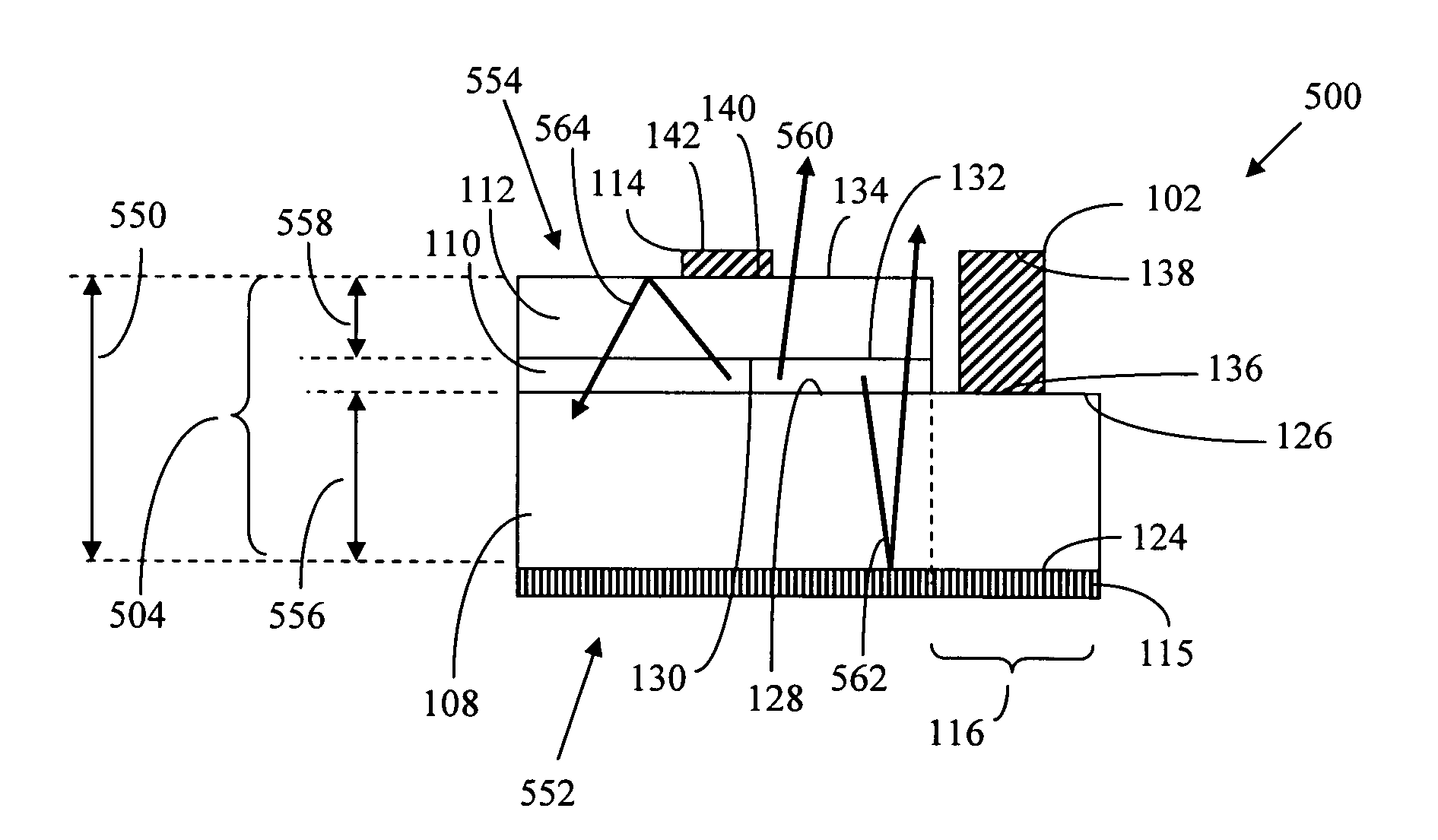

Substrate-free light emitting diode chip

InactiveUS20090140279A1Improve structural strengthIncreasing the thicknessSolid-state devicesSemiconductor devicesStructural rigidityVapor phase

A light emitting diode (LED) chip has a multilayer semiconductor structure that is at least 10 microns thick and does not require an attached growth substrate or transfer substrate for structural rigidity or support. The multilayer semiconductor structure includes a first doped layer, a second doped layer and an active region interposed between the first doped layer and the second doped layer. Optionally, the multilayer semiconductor structure includes an undoped layer. At least one of the layers of the multilayer semiconductor structure is at least 5 microns thick and is preferably deposited by hydride vapor phase epitaxy.

Owner:GOLDENEYE

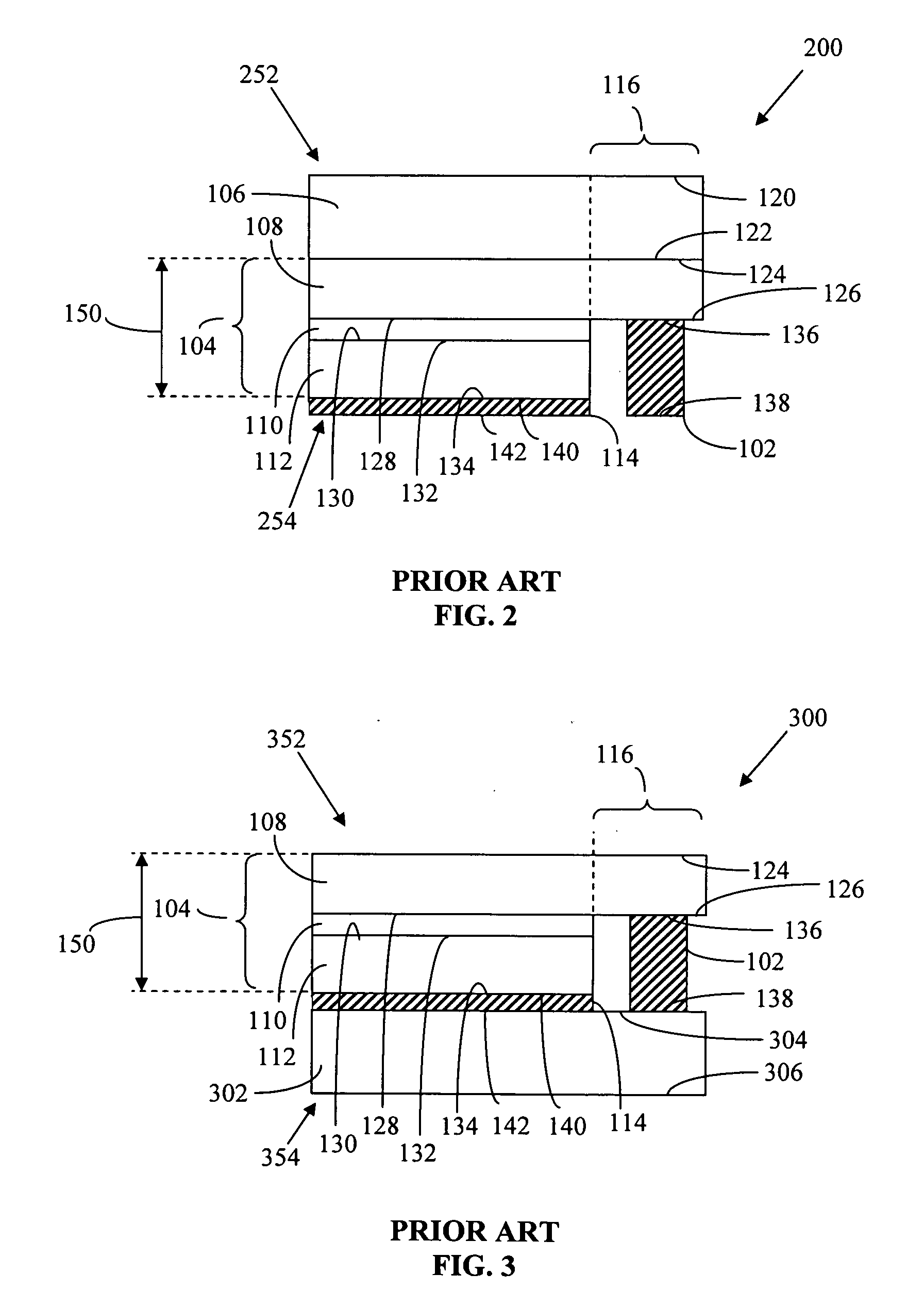

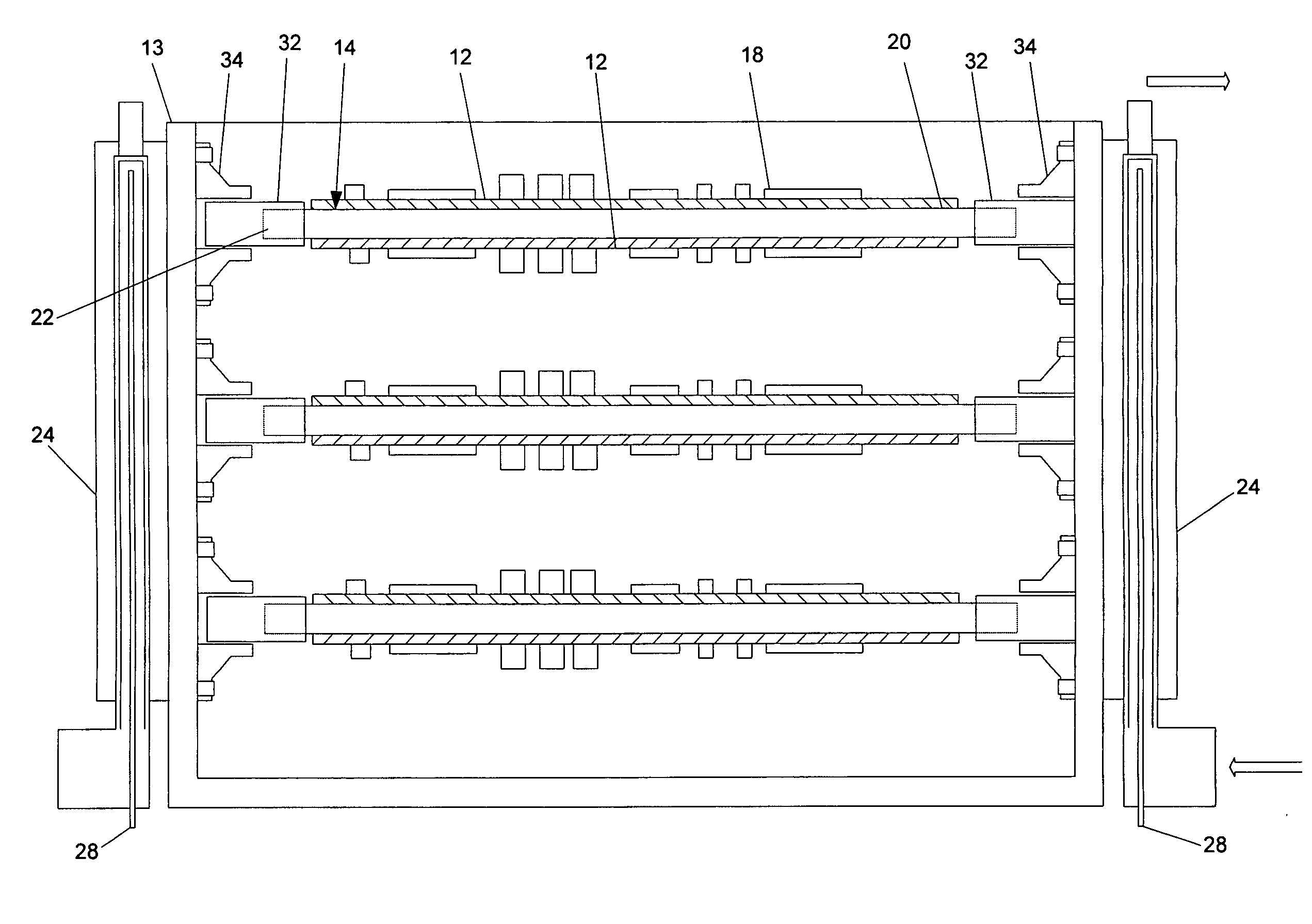

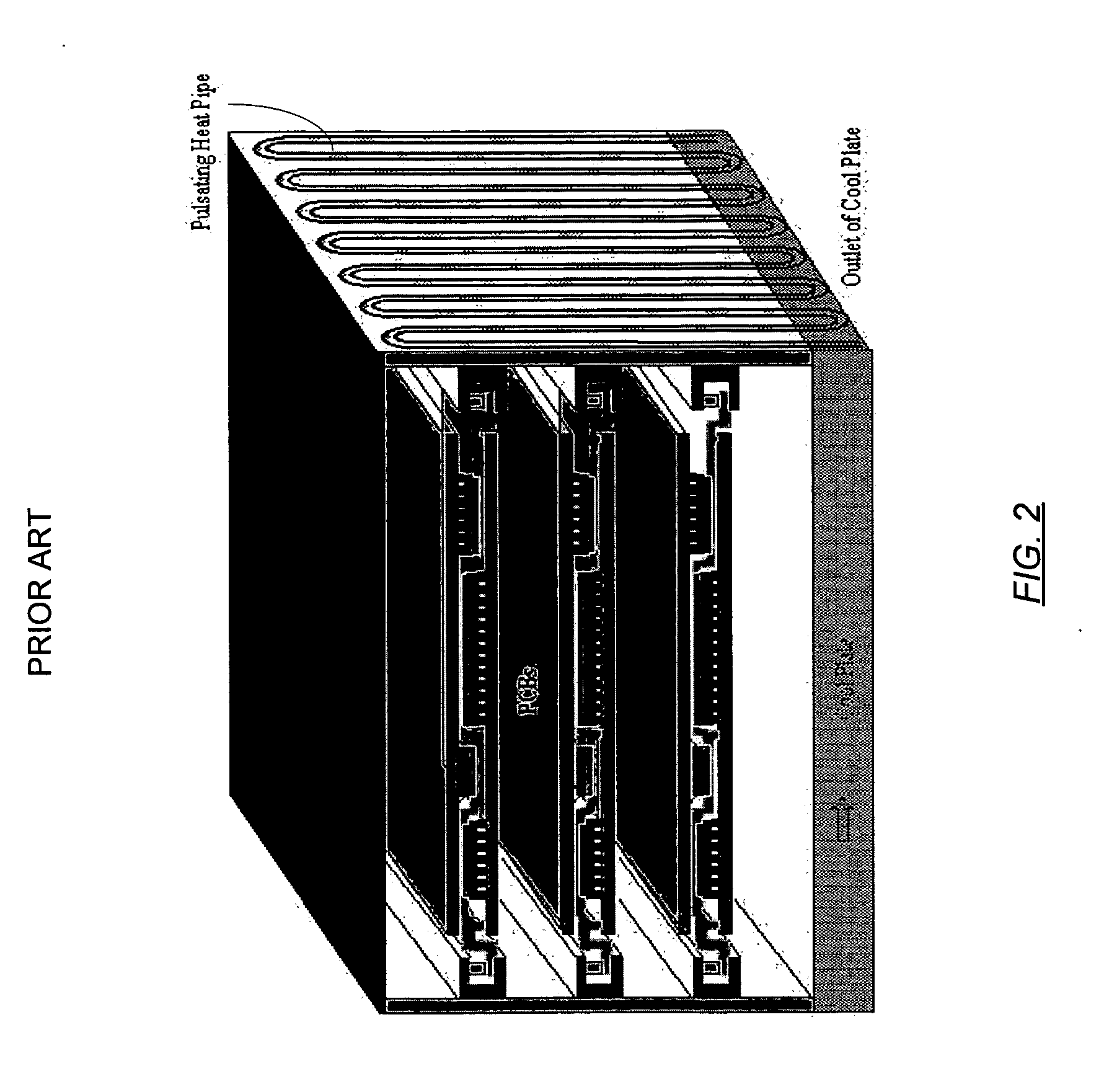

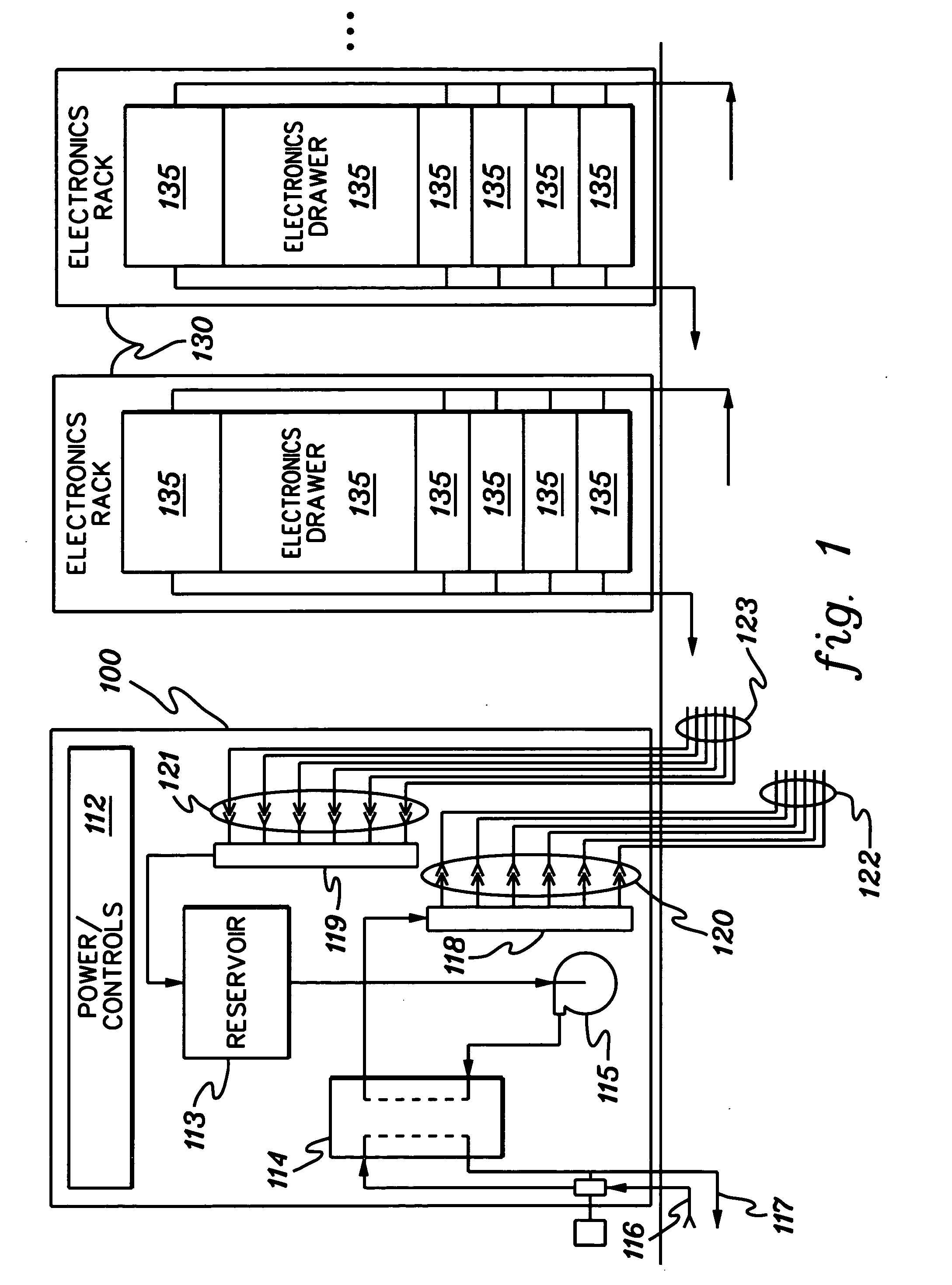

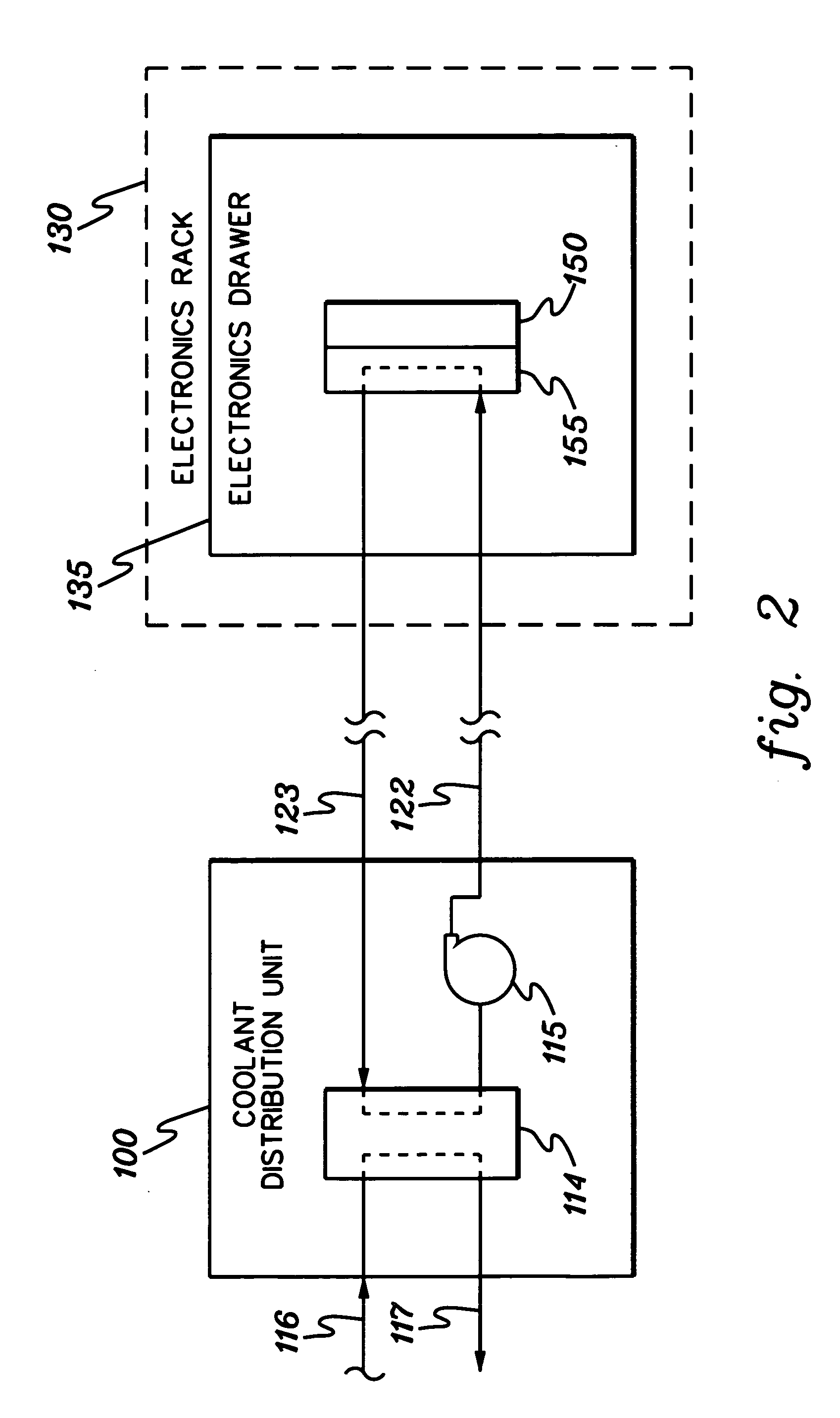

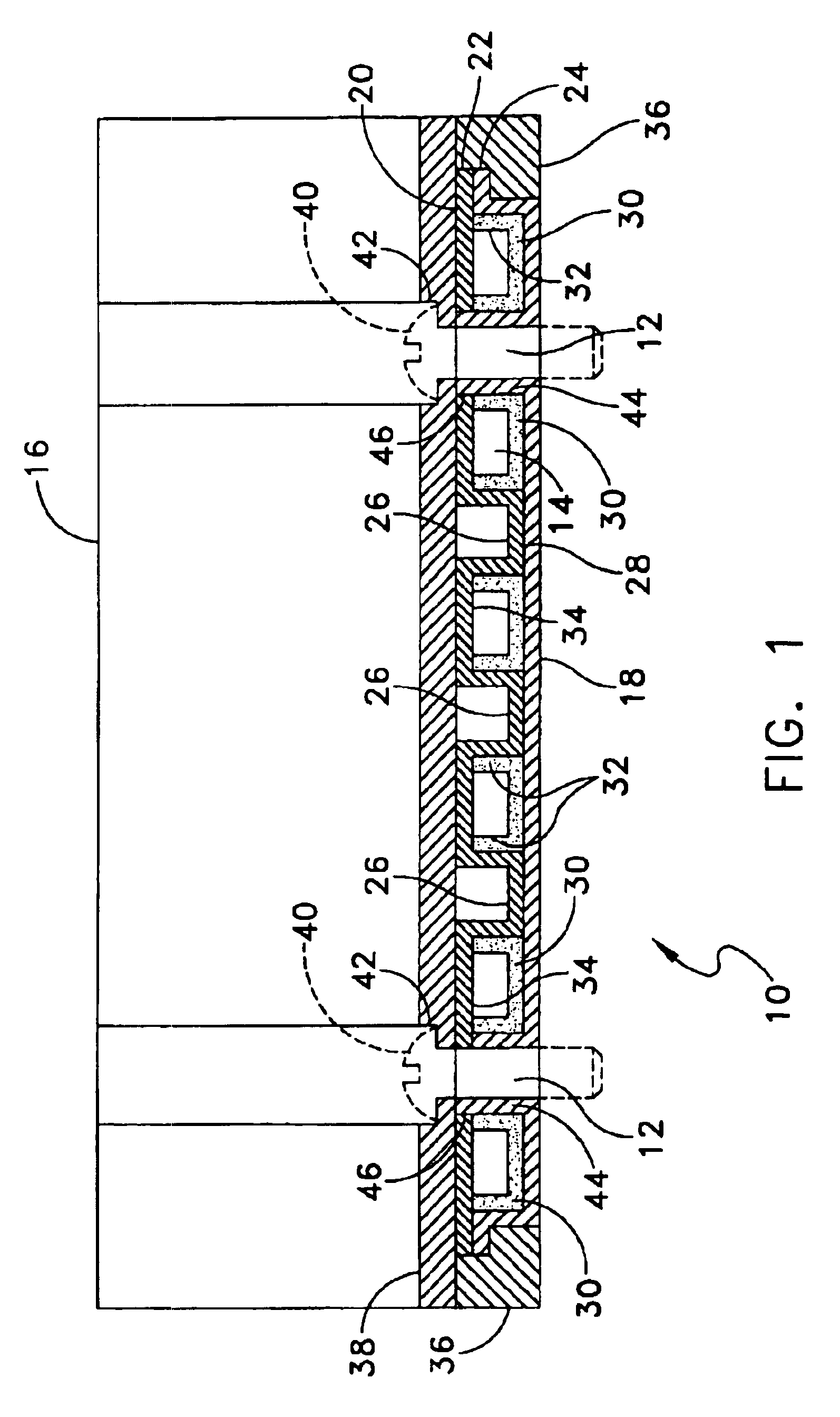

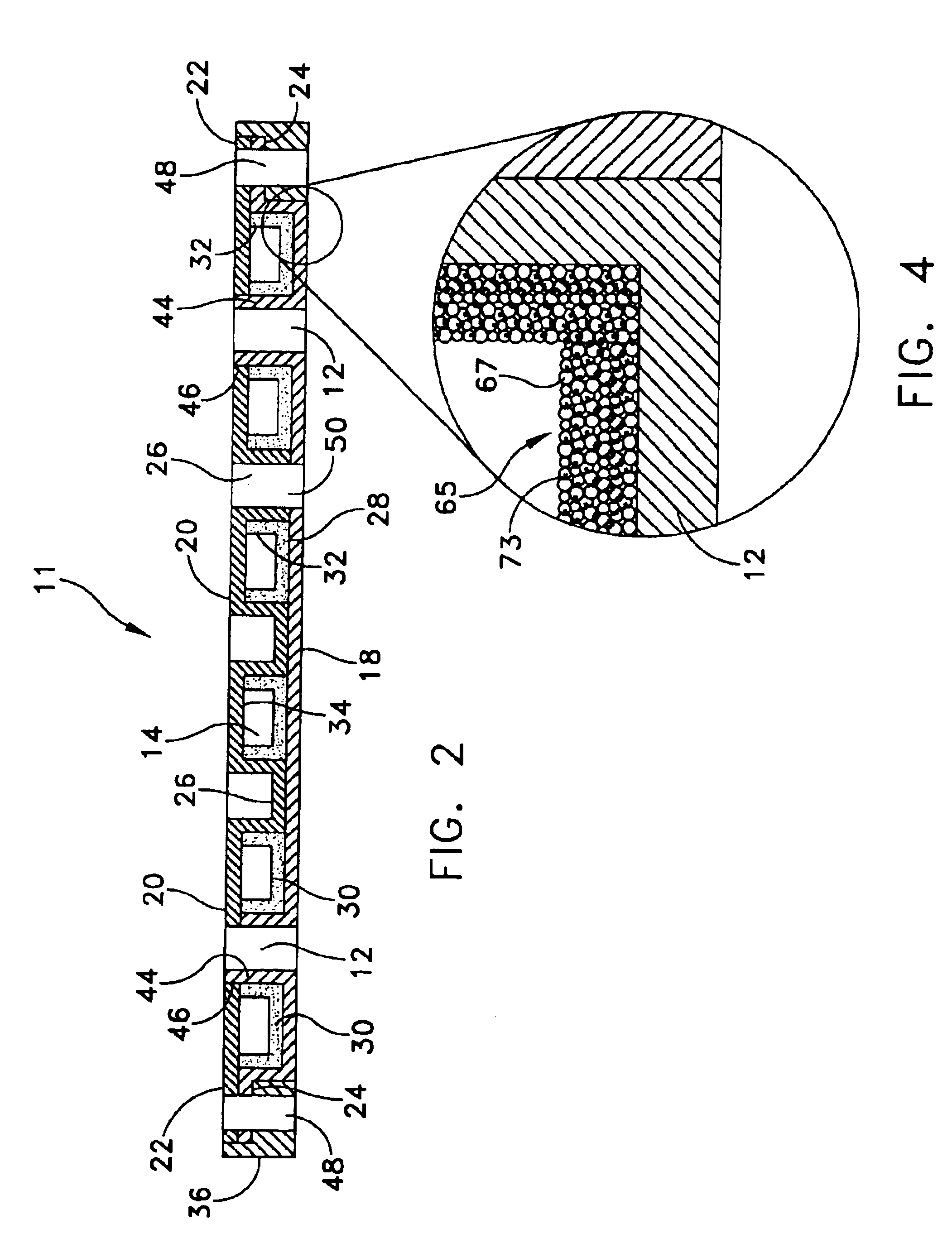

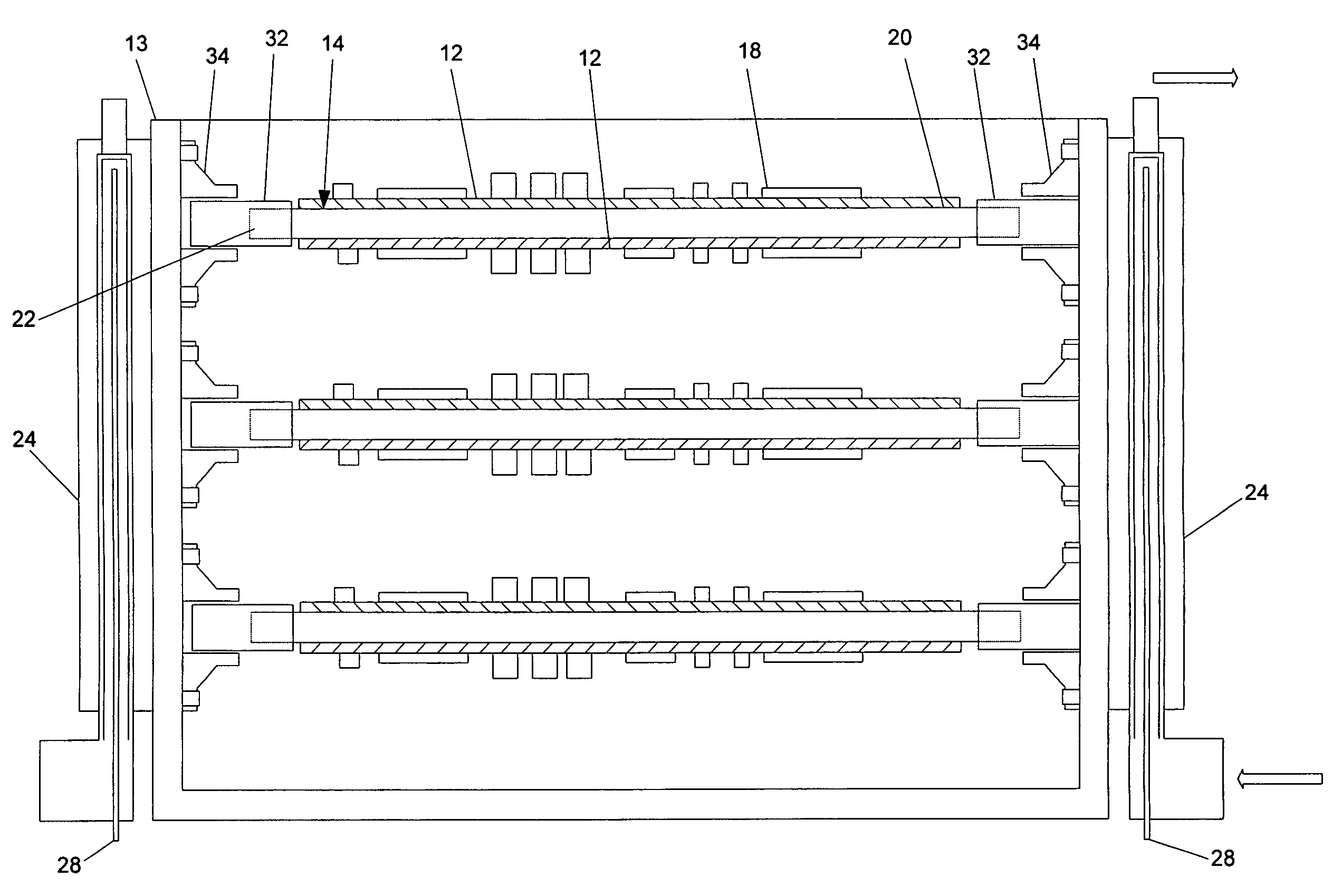

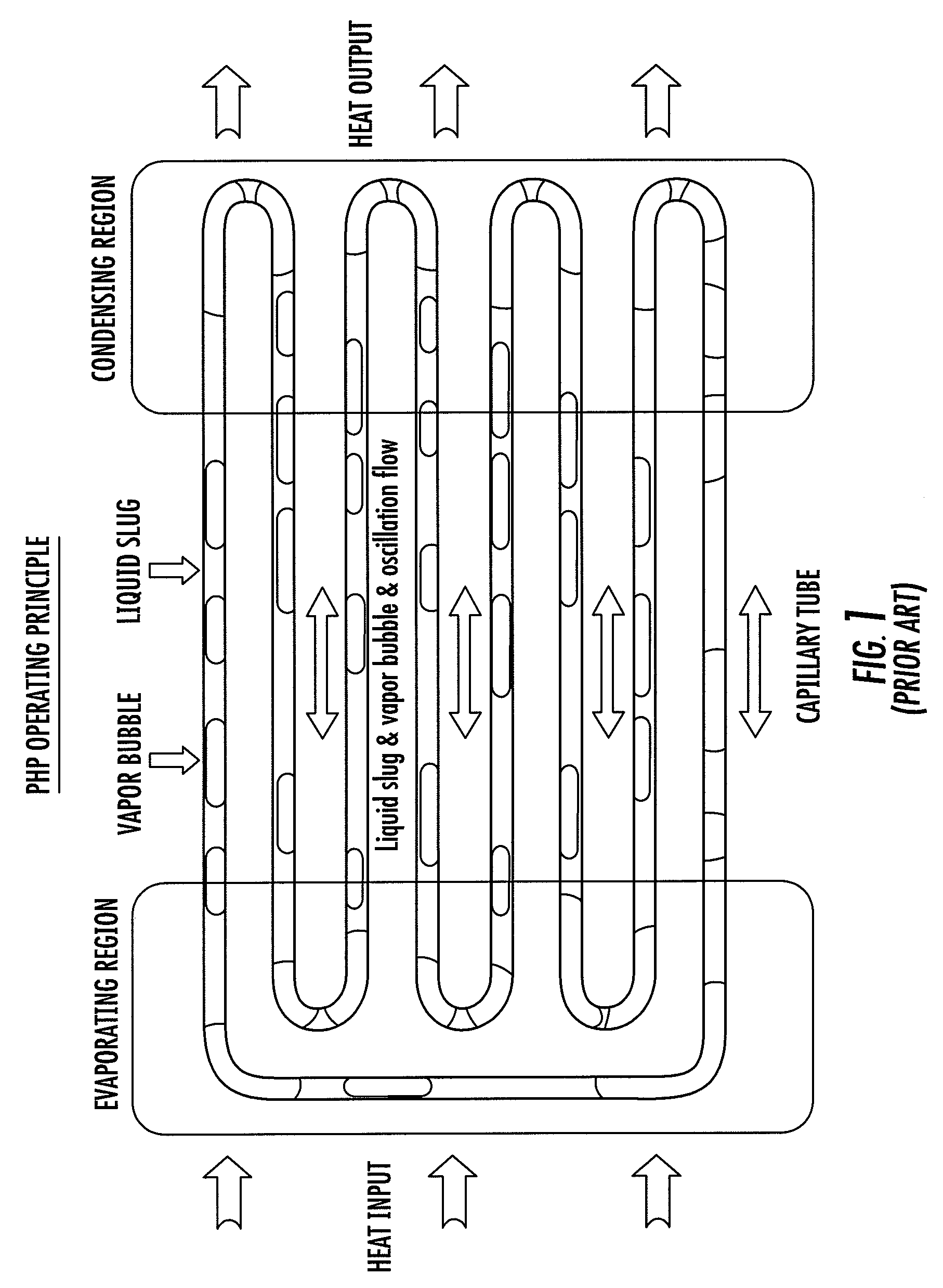

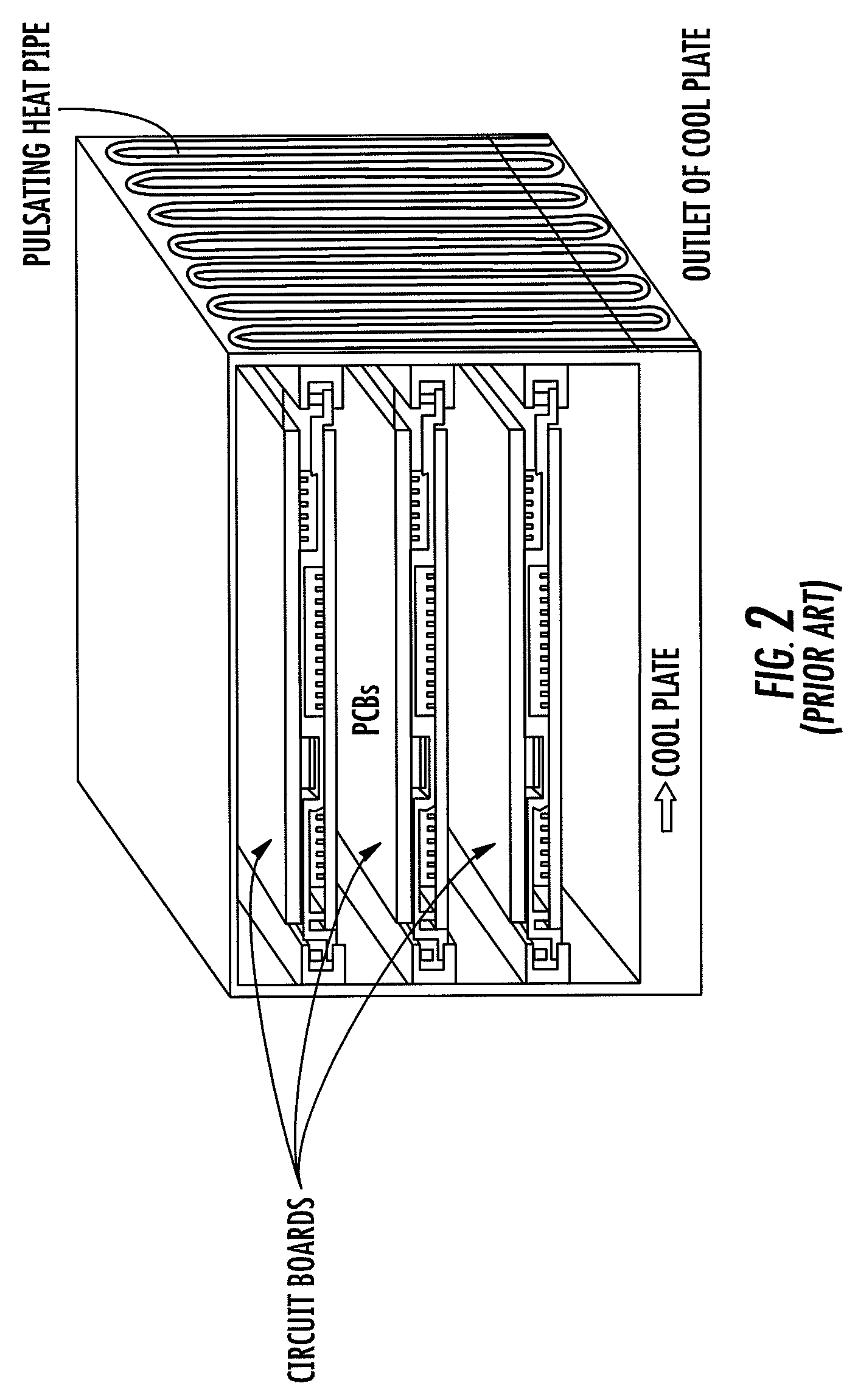

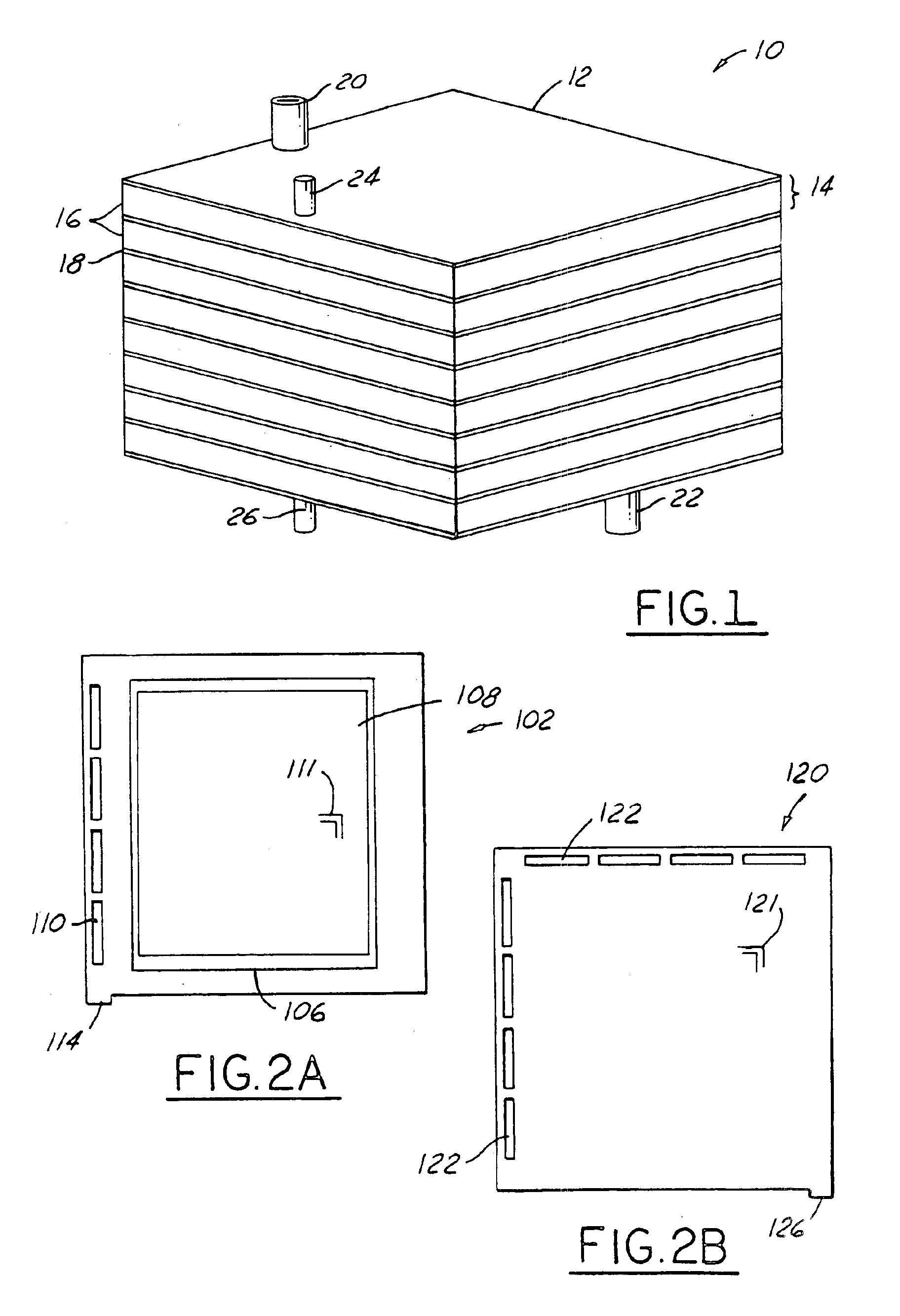

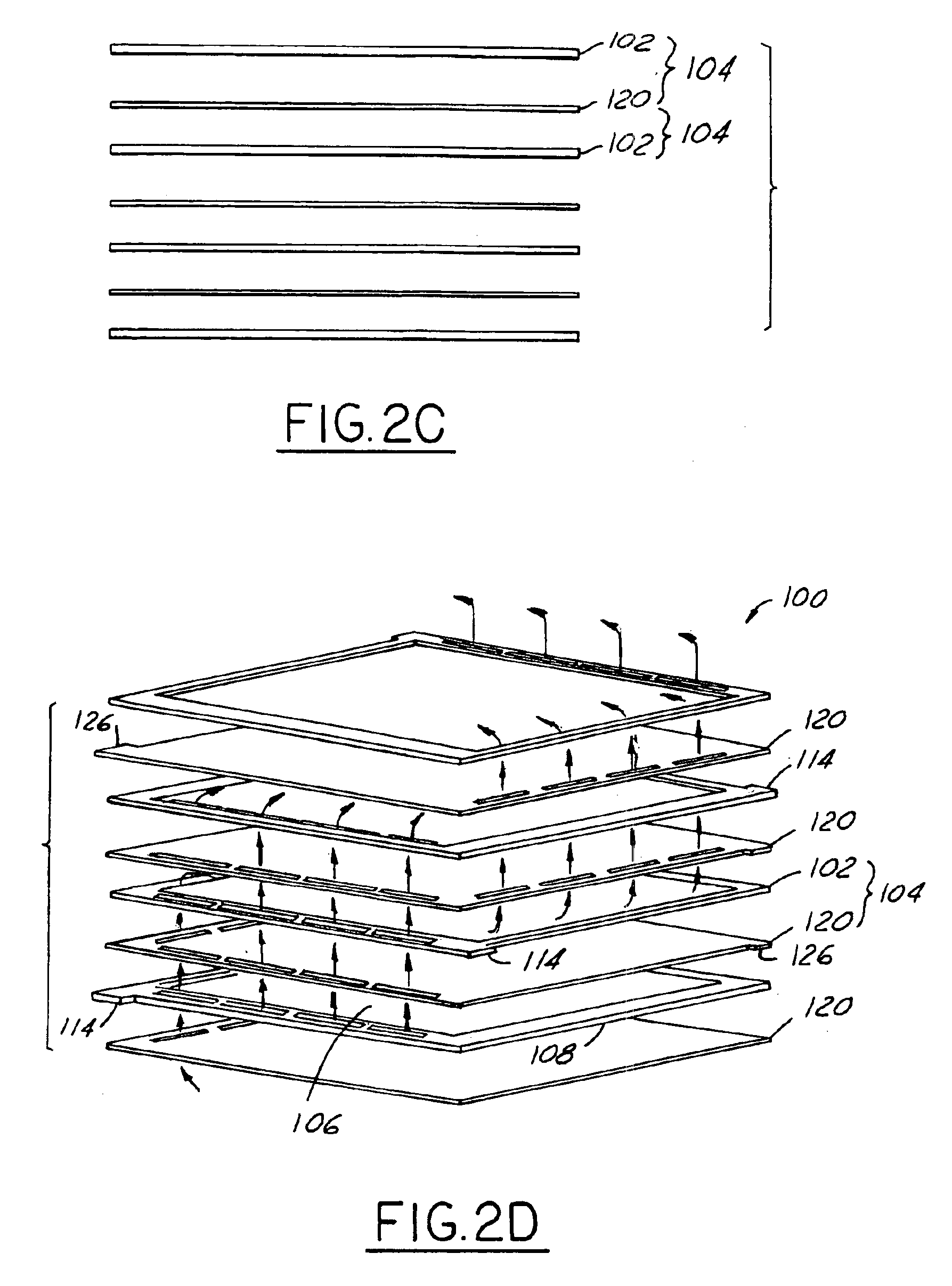

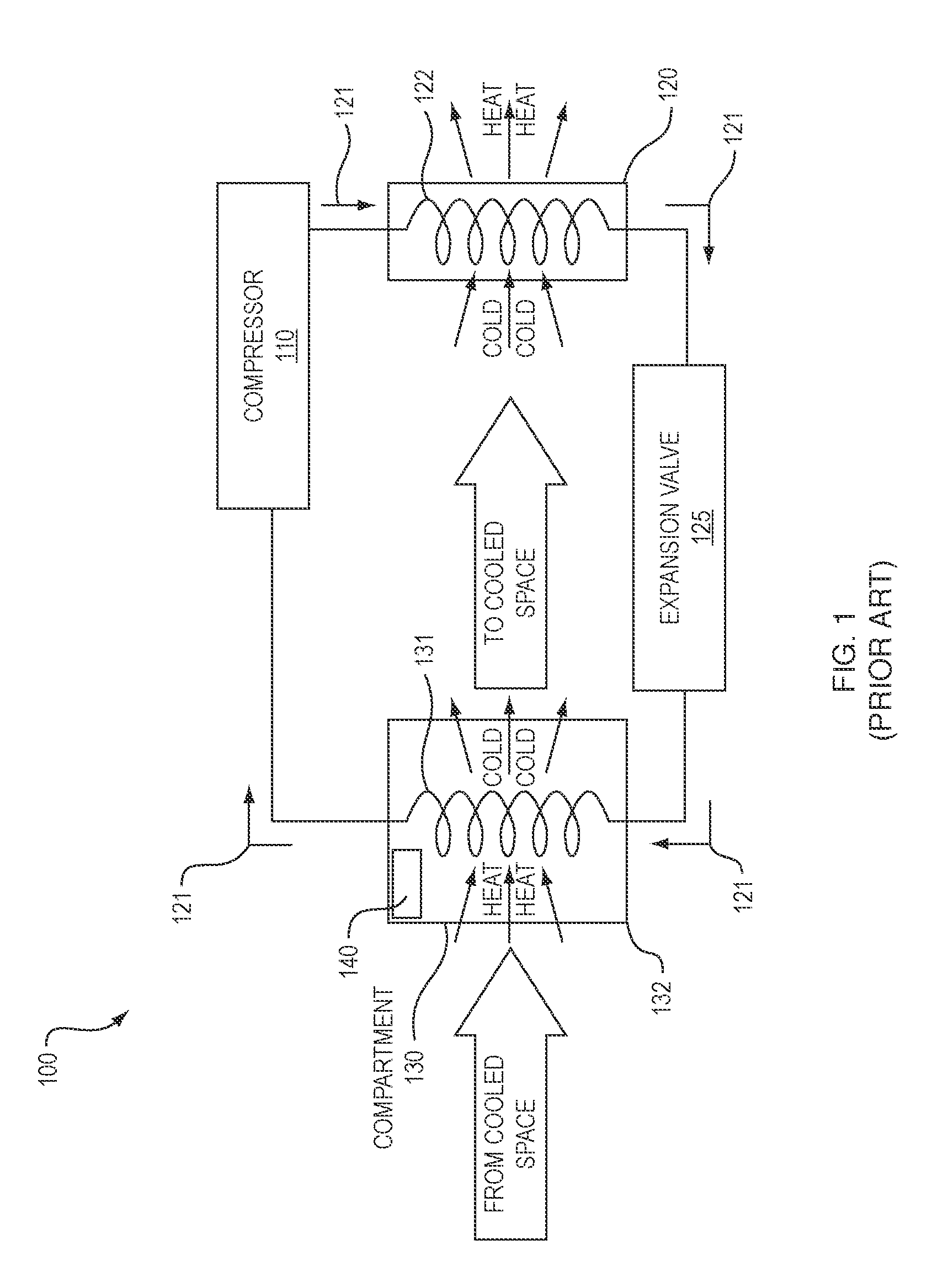

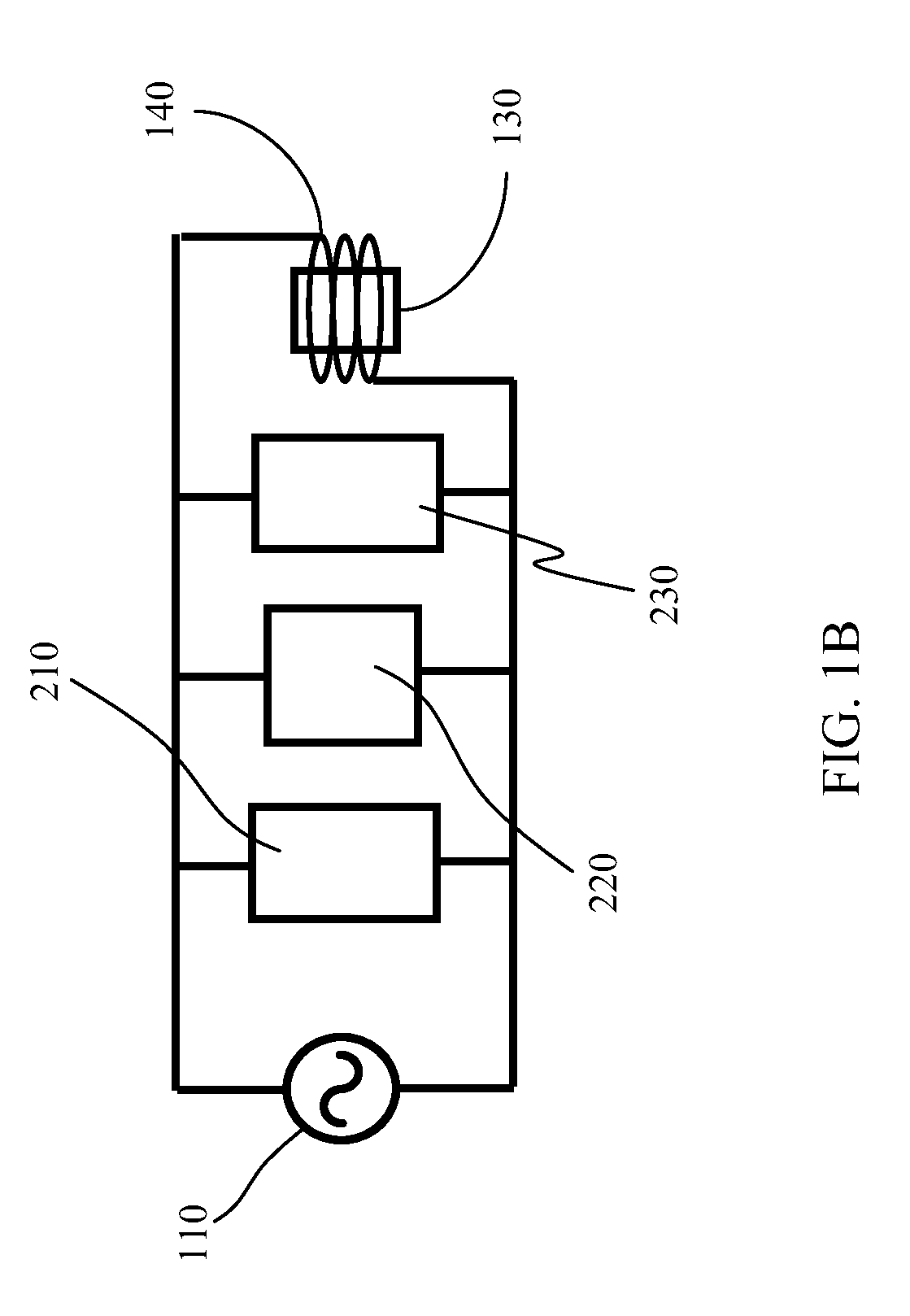

Cooling apparatus, system, and associated method

ActiveUS20060146496A1Readily and effectively transfer heat away from printed circuit boardMinimal amount of spaceCircuit fluid transportIndirect heat exchangersEngineeringPrinted circuit board

A cooling apparatus, system, and method are provided. The cooling apparatus includes at least one printed circuit board having opposed major surfaces, and at least one electrical component or other heat source positioned on one major surface of the printed circuit board. The cooling apparatus also includes a pulsating heat pipe having at least a portion that is positioned to either extend along and proximate to one of the major surfaces or be embedded within the printed circuit board. As such, the pulsating heat pipe is capable of transferring heat from the printed circuit board.

Owner:THE BOEING CO

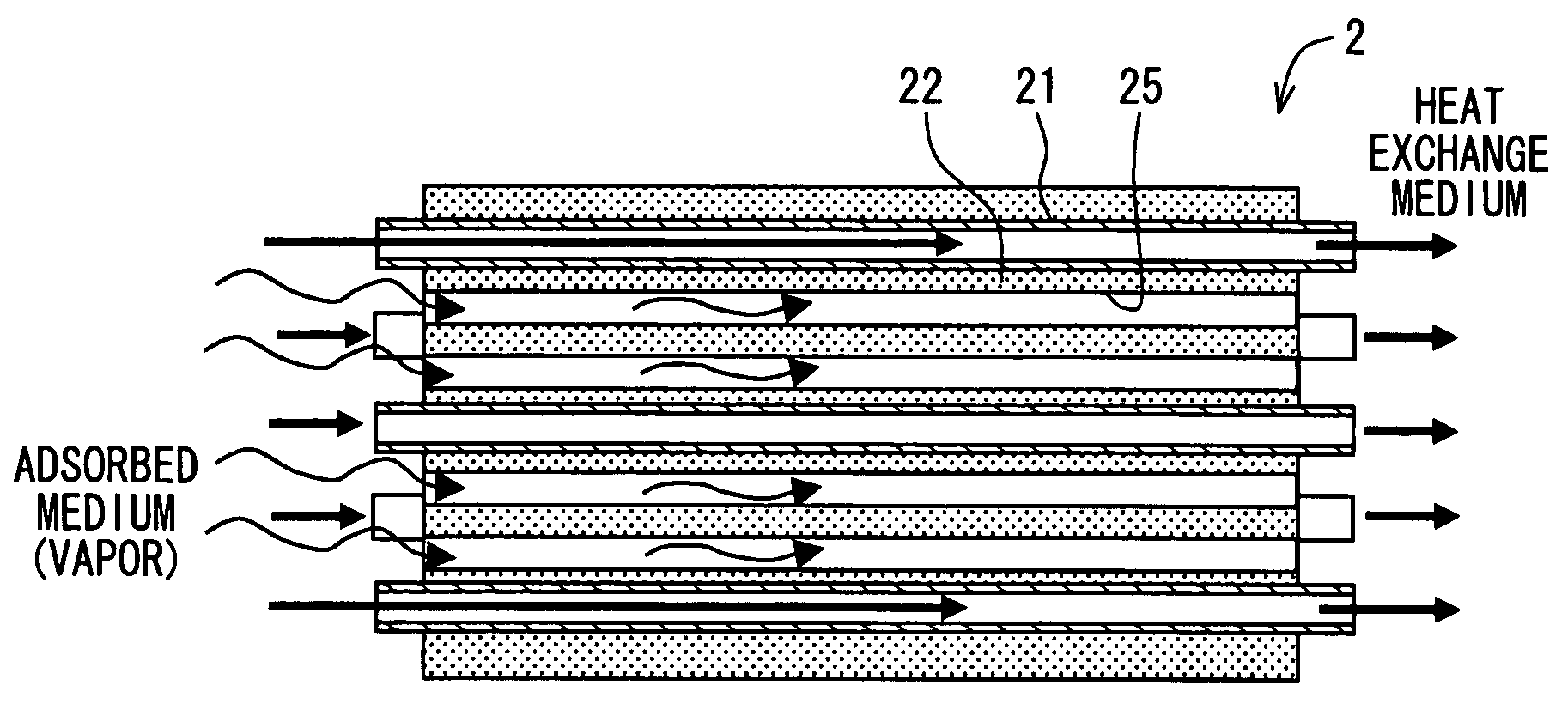

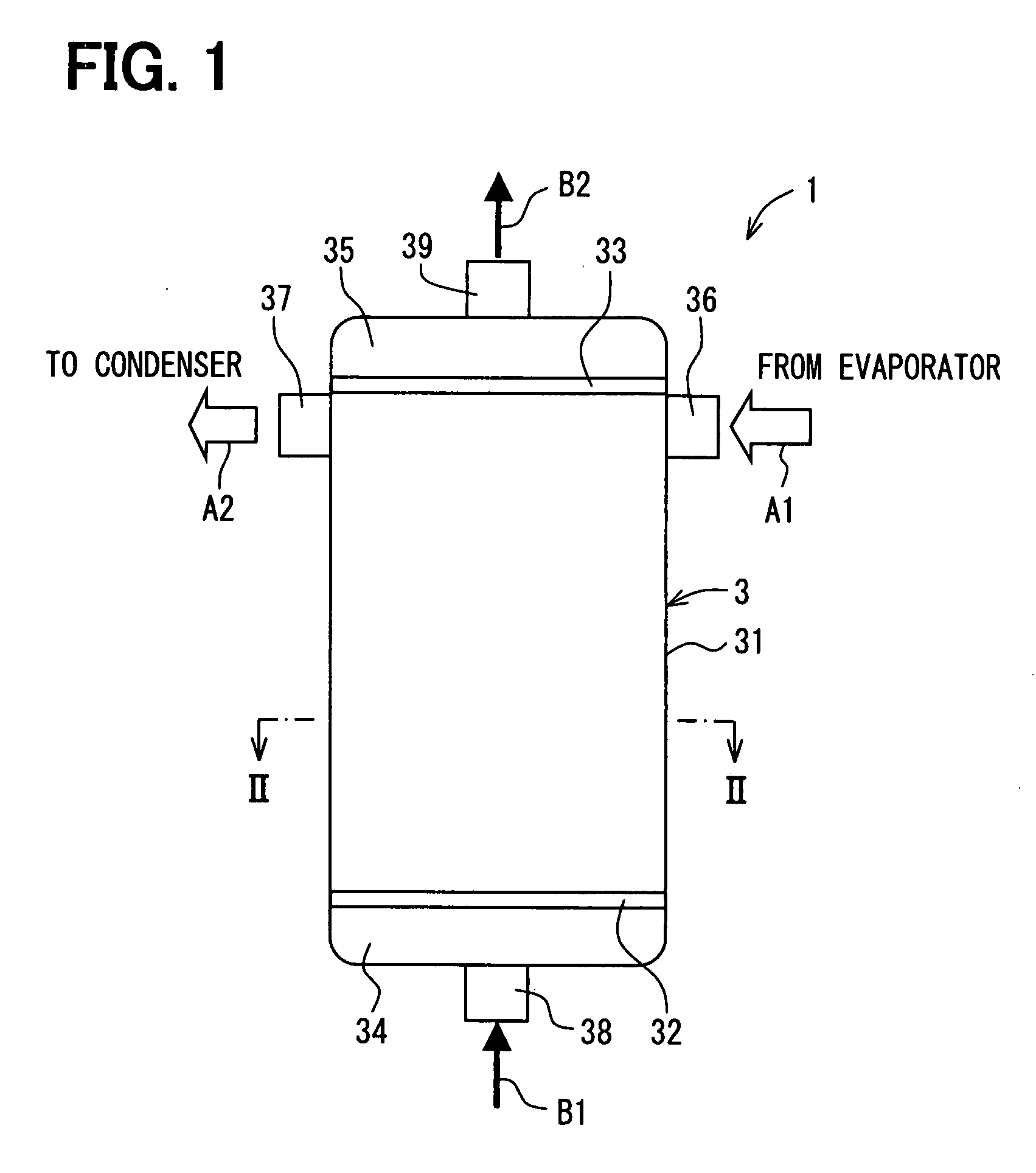

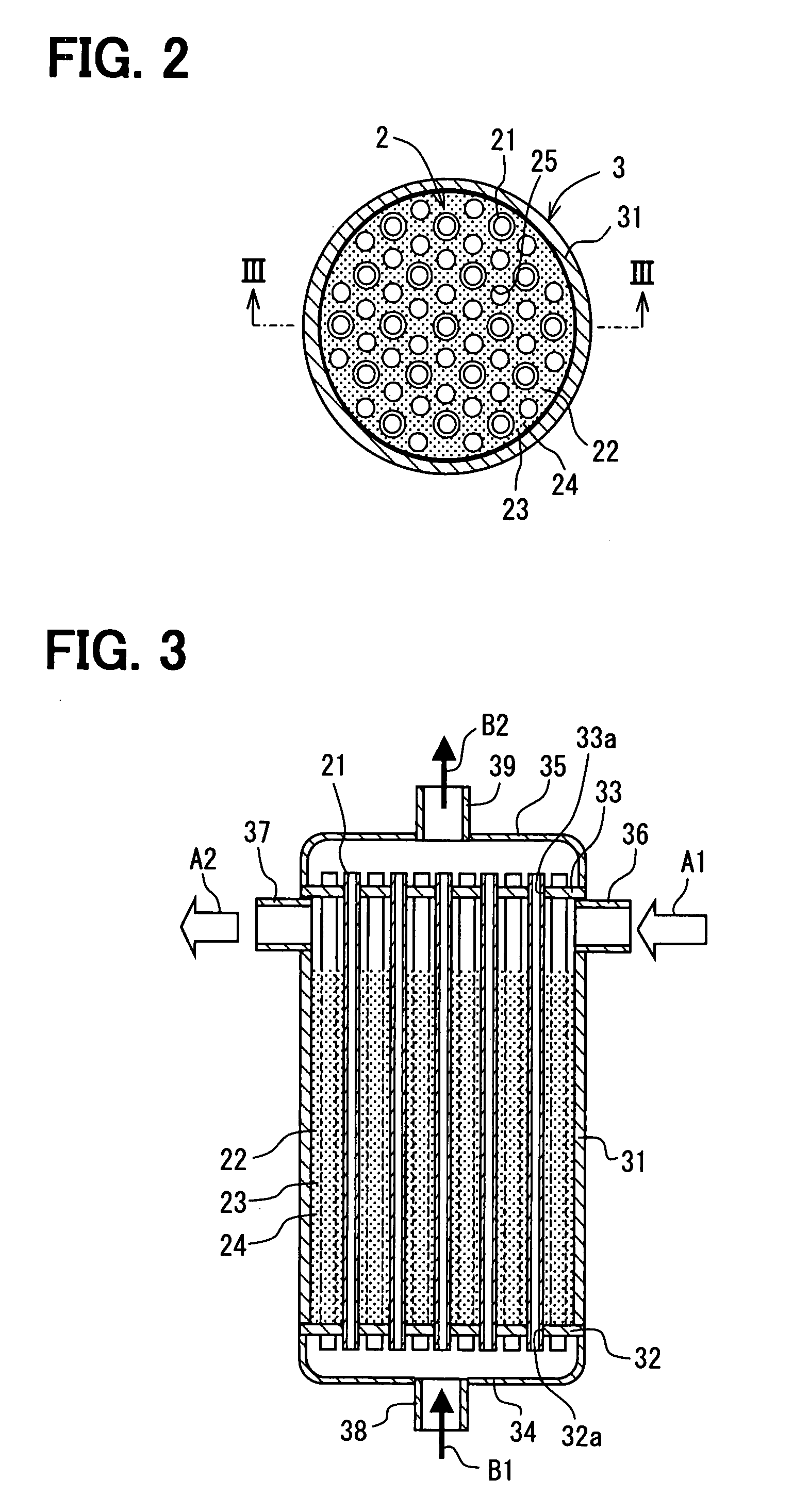

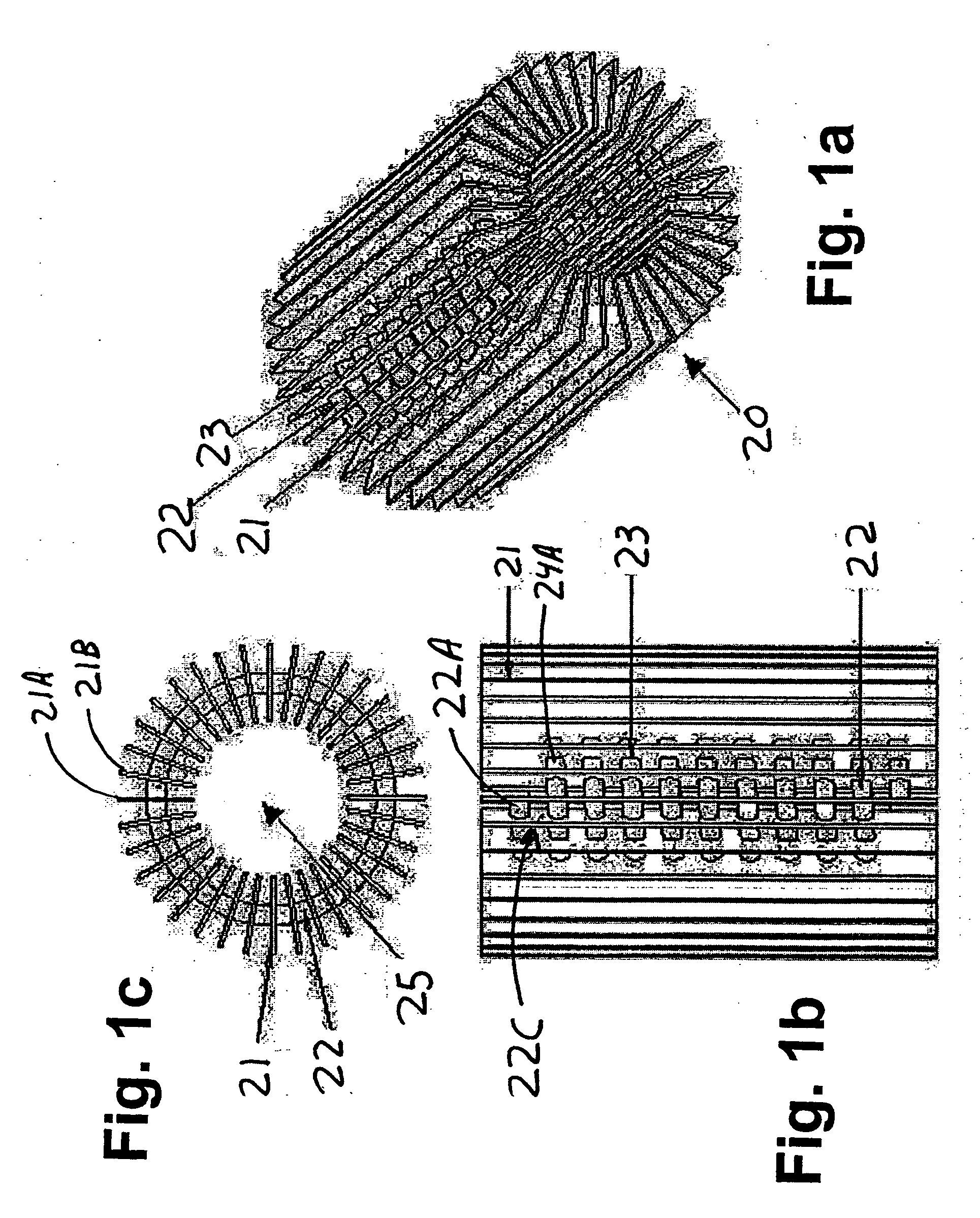

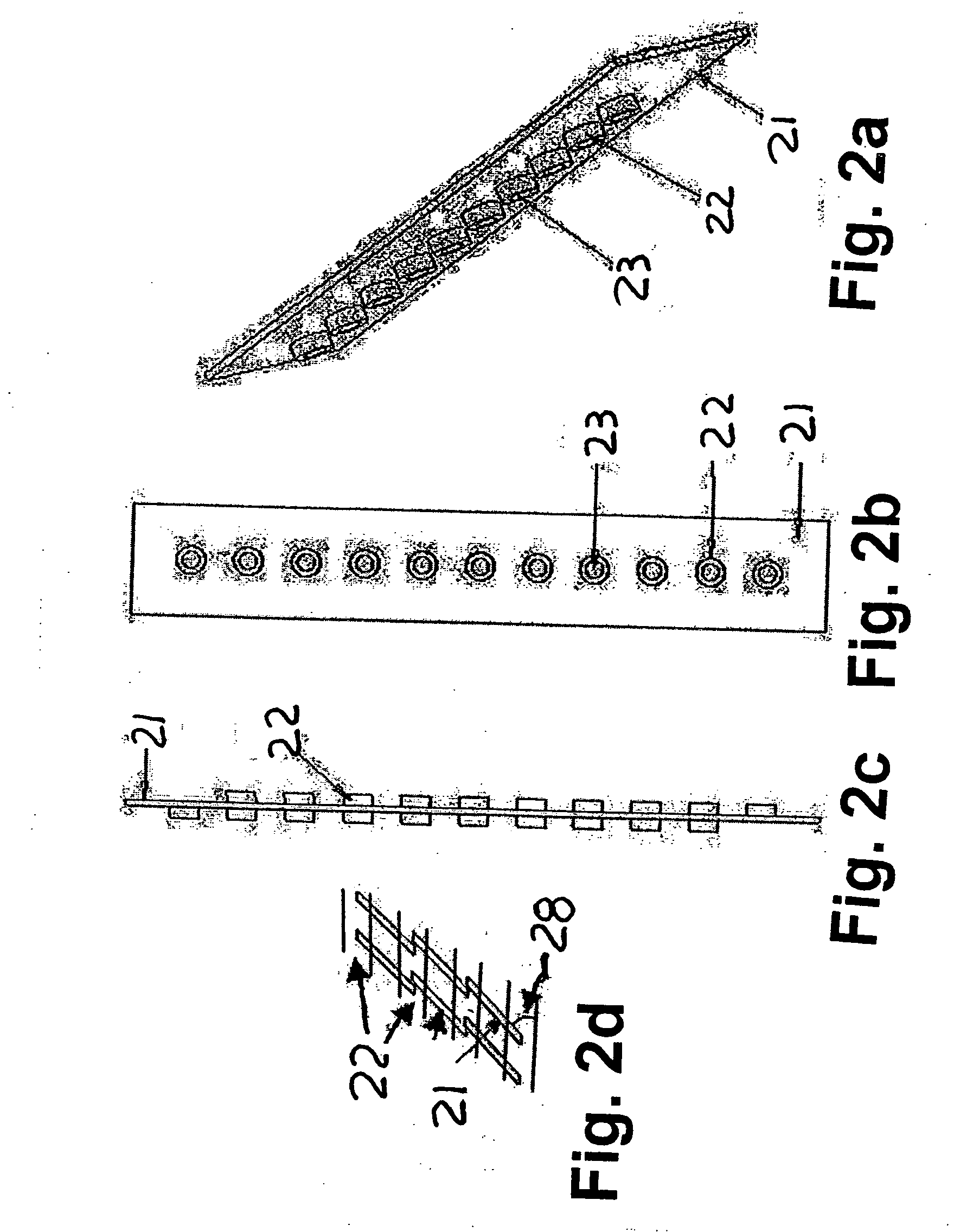

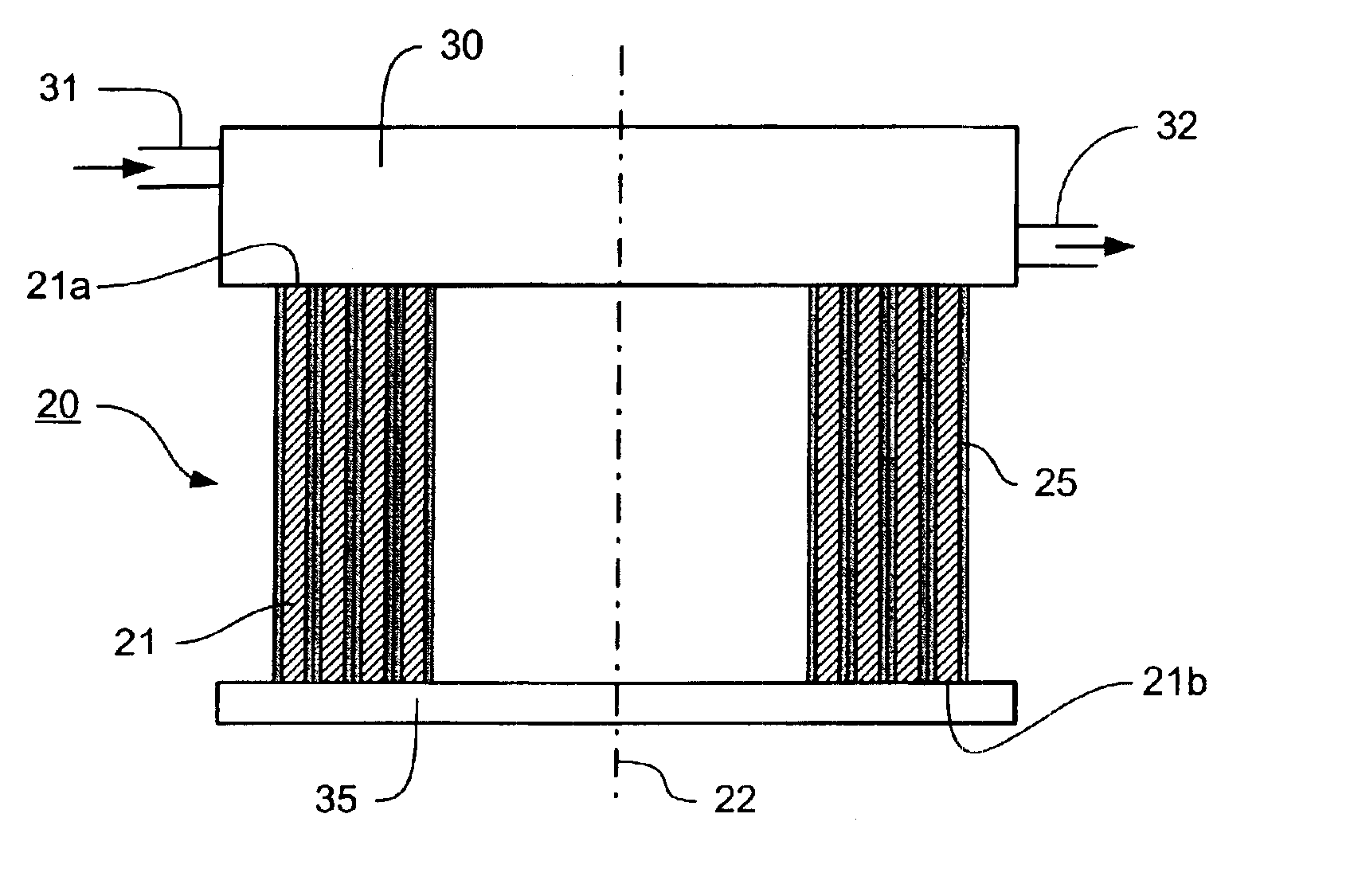

Adsorption module and method of manufacturing the same

InactiveUS20080078532A1Reduce the number of stepsReduce in quantityBoiler absorbersStationary tubular conduit assembliesFiberMetallic materials

An adsorption module has heat medium pipes through which a fluid flows, a porous heat transferring member, and adsorbent. The porous heat transferring member is a sintered body formed by sintering a metallic material that is in a form of one of powders, particles and fibers, and has pores for allowing an adsorbed medium to pass through. The porous heat transferring member is disposed on peripheries of the heat medium pipes and bonded to outer surfaces of the heat medium pipes by sintering. The adsorbent is disposed in the pores. The porous heat transferring member further has an adsorbed medium passage for allowing the adsorbed medium to pass through. The adsorbed medium passage is located between the heat medium pipes, and extends straight and parallel to axes of the heat medium pipes.

Owner:DENSO CORP

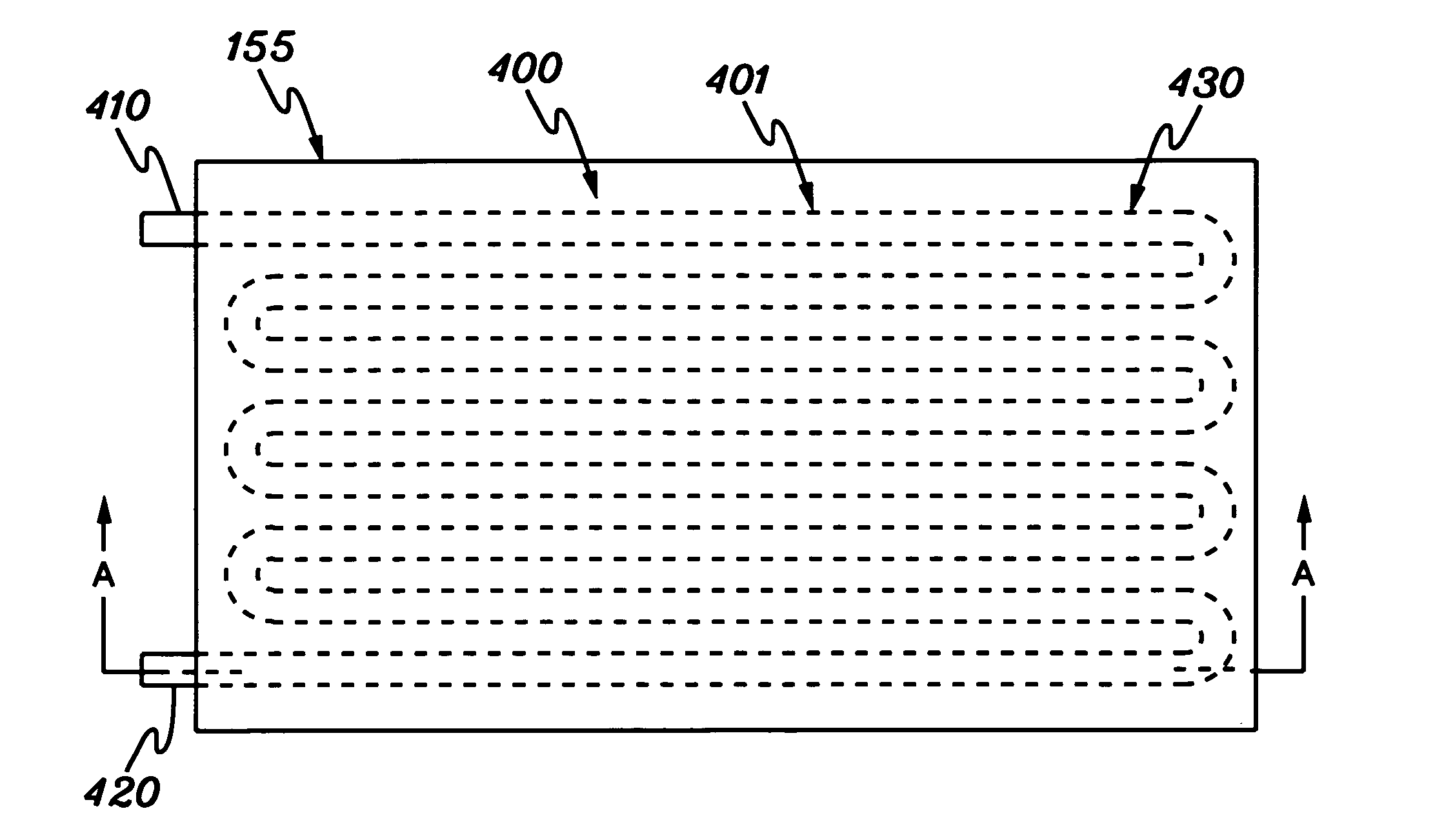

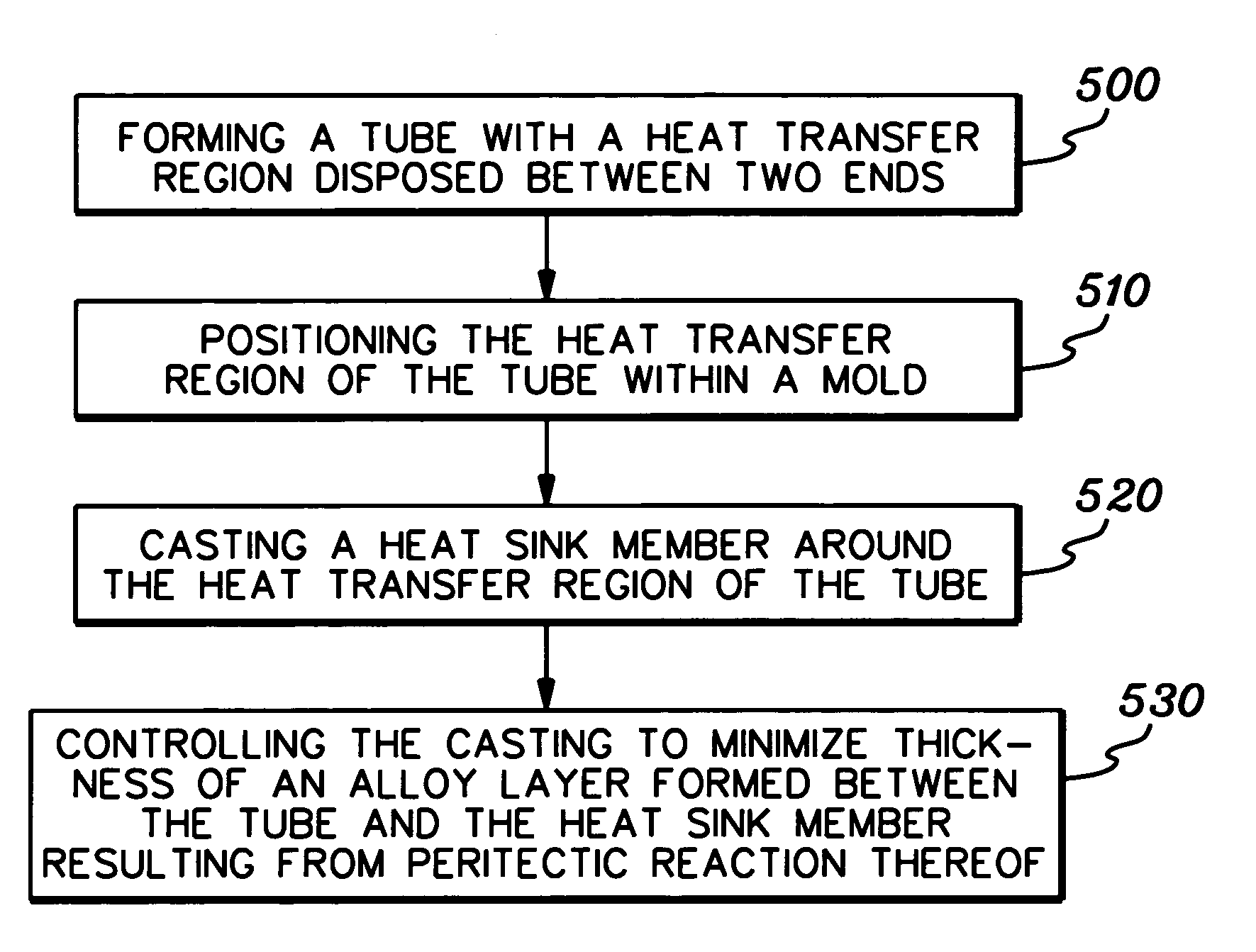

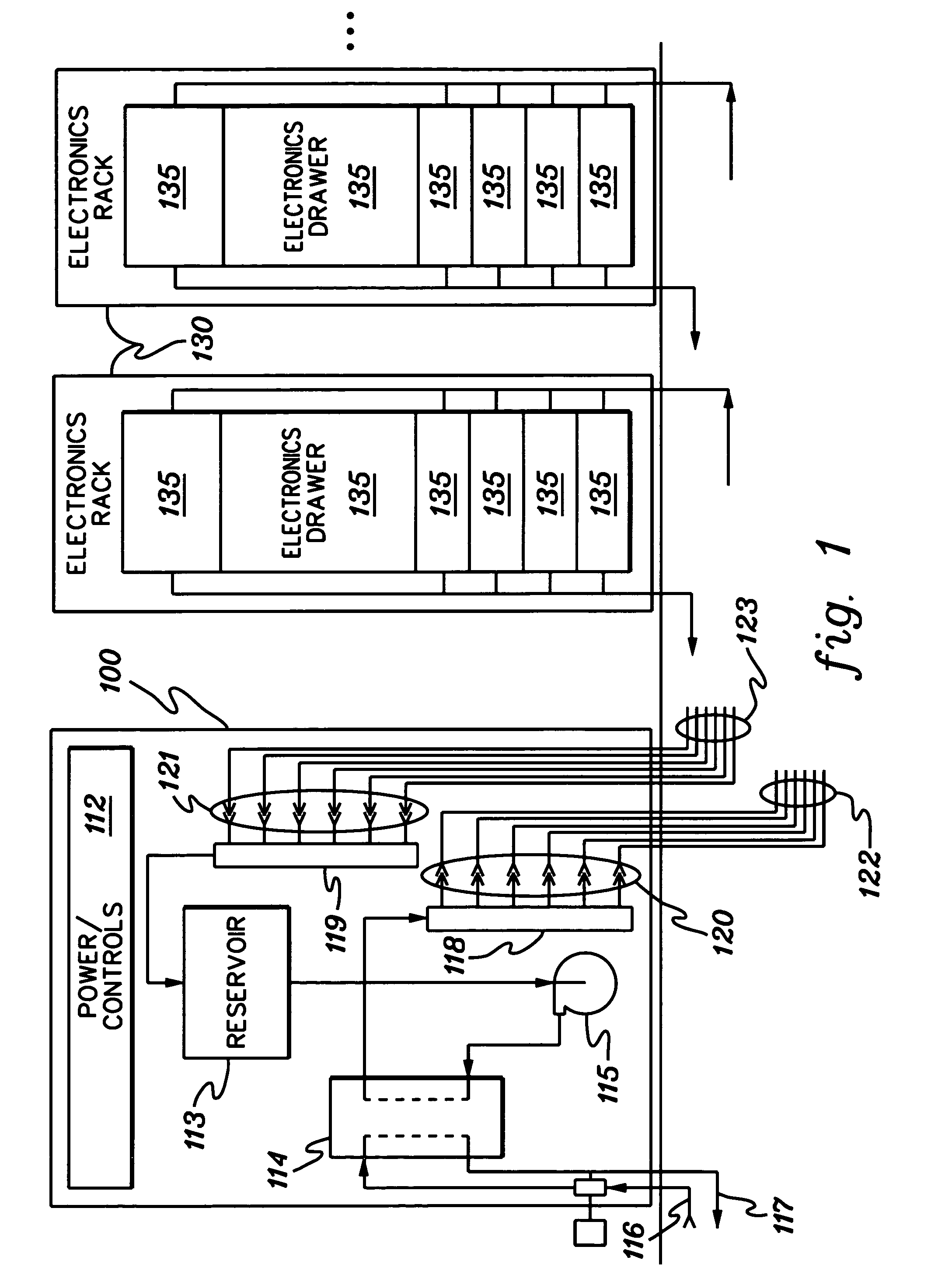

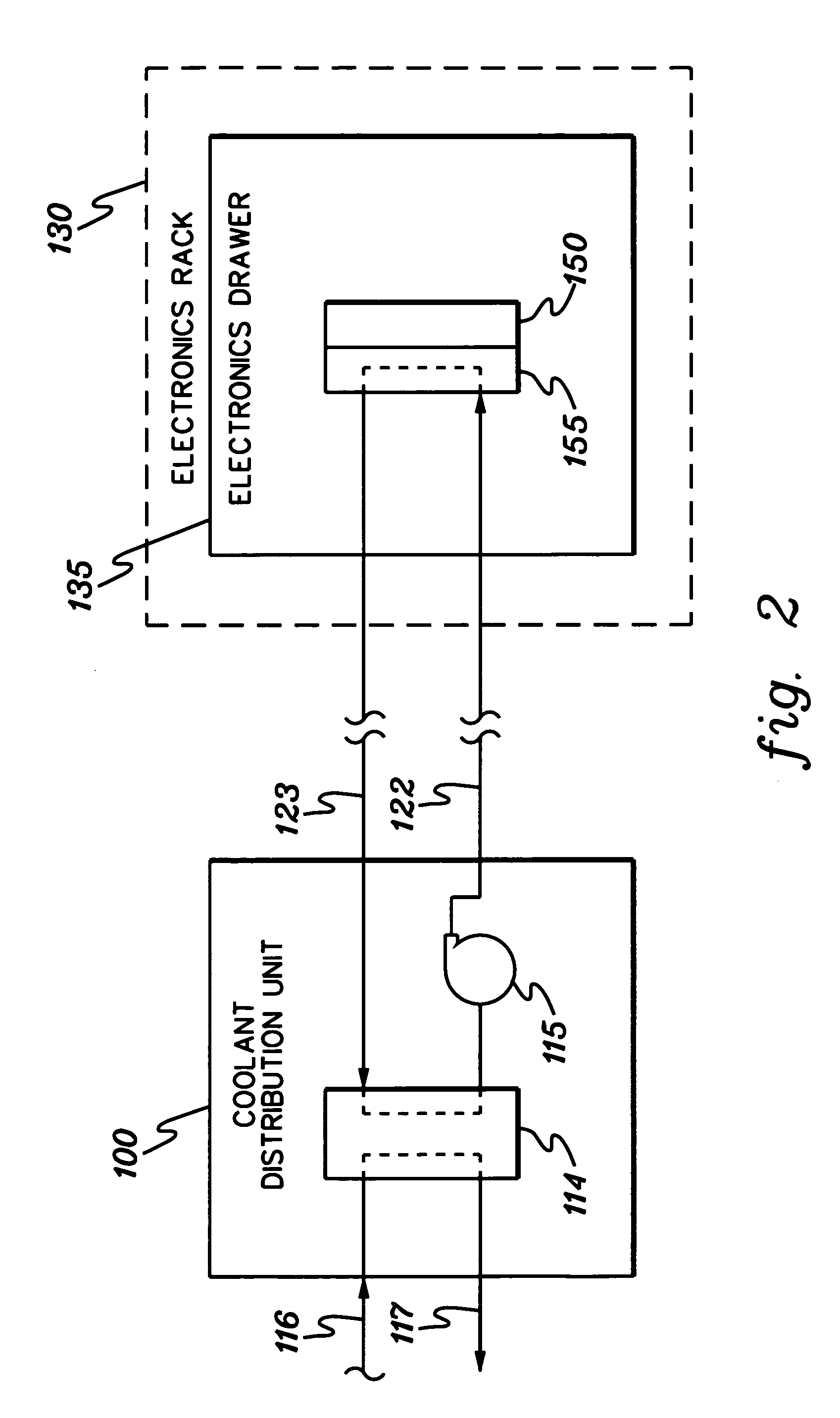

Cold plate apparatus and method of fabrication thereof with a controlled heat transfer characteristic between a metallurgically bonded tube and heat sink for facilitating cooling of an electronics component

InactiveUS20070017658A1Avoid corrosionLow costCooling/ventilation/heating modificationsLaminated elementsAlloyCold plate

Cold plate apparatuses and methods of fabrication are provided for facilitating cooling of an electronics component. The fabrication approach includes: forming a tube with a first metal and having first and second ends with a heat transfer region disposed therebetween; positioning the heat transfer region of the tube within a mold and casting a heat sink member around the tube by contacting a second metal in molten form over the tube, wherein the first and second metals react peritectically to form an alloy layer between the tube and the heat sink member, and a metallurgical bond is formed between the tube and heat sink member with cooling of the molten second metal; and controlling casting of the heat sink member to minimize a thickness of the alloy layer to enhance a heat transfer characteristic of the metallurgical bond formed between the tube and the heat sink member.

Owner:IBM CORP

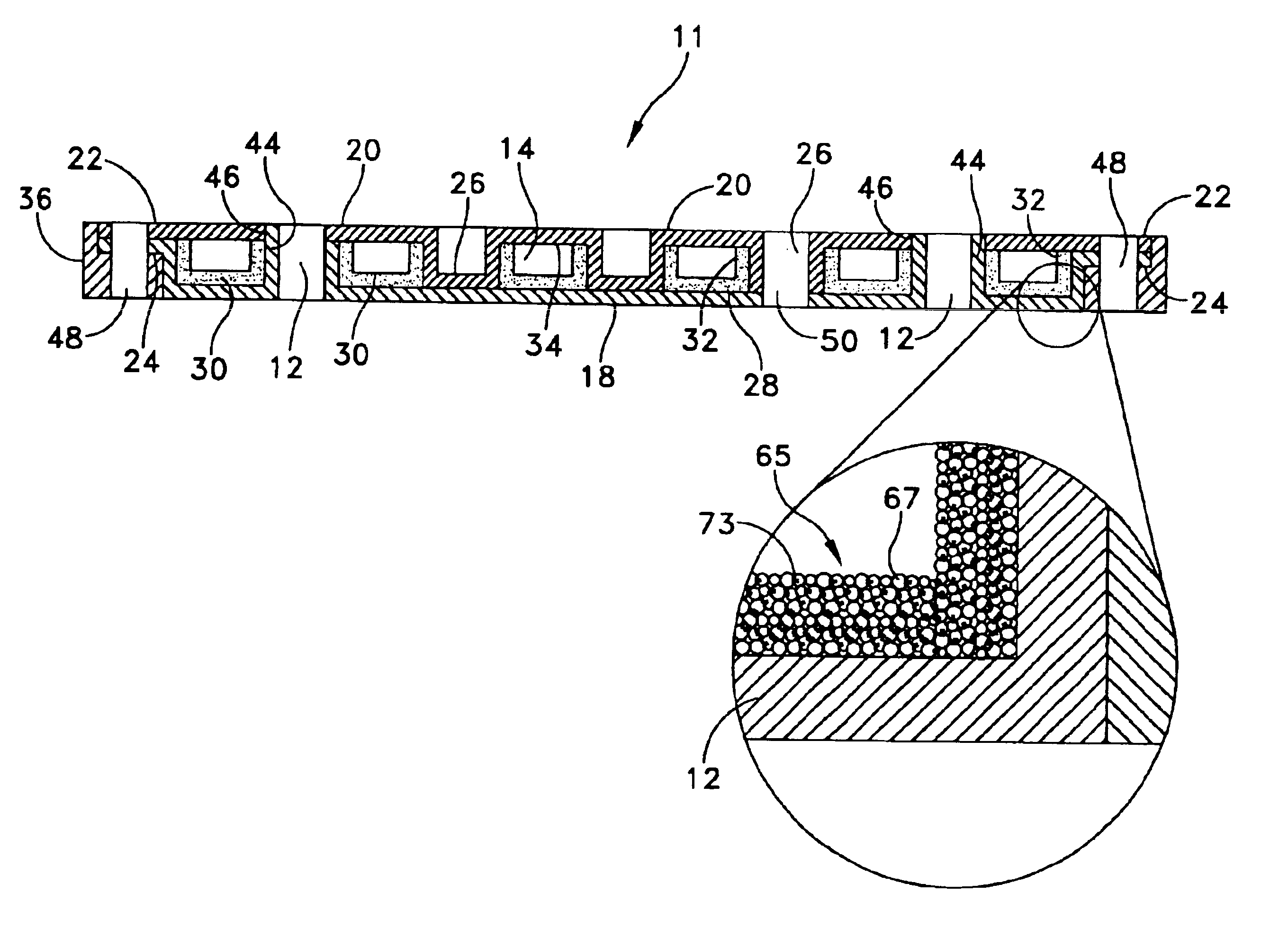

Integrated circuit heat pipe heat spreader with through mounting holes

InactiveUS6896039B2Improve heat transfer performanceImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat pipe

A heat pipe with superior heat transfer between the heat pipe and the heat source and heat sink is provided. The heat pipe is held tightly against the heat source by mounting holes which penetrate the structure of the heat pipe but are sealed off from the vapor chamber because they each are located within a sealed structure such as a pillar or the solid layers of the casing surrounding the vapor chamber. Another feature of the heat pipe is the use of a plurality of particles joined together by a brazing compound such that fillets of the brazing compound are formed between adjacent ones of the plurality of particles so as to form a network of capillary passageways between the particles of the wick.

Owner:AAVID THERMALLOY LLV

Cooling apparatus, system, and associated method

ActiveUS7345877B2Readily and effectively transfer heat away from printed circuit boardMinimal amount of spaceCircuit fluid transportIndirect heat exchangersEngineeringPrinted circuit board

A cooling apparatus, system, and method are provided. The cooling apparatus includes at least one printed circuit board having opposed major surfaces, and at least one electrical component or other heat source positioned on one major surface of the printed circuit board. The cooling apparatus also includes a pulsating heat pipe having at least a portion that is positioned to either extend along and proximate to one of the major surfaces or be embedded within the printed circuit board. As such, the pulsating heat pipe is capable of transferring heat from the printed circuit board.

Owner:THE BOEING CO

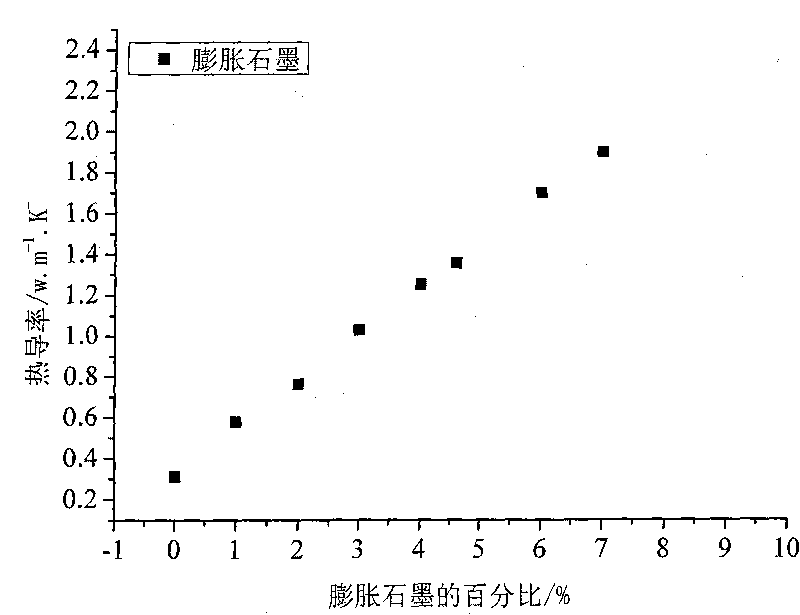

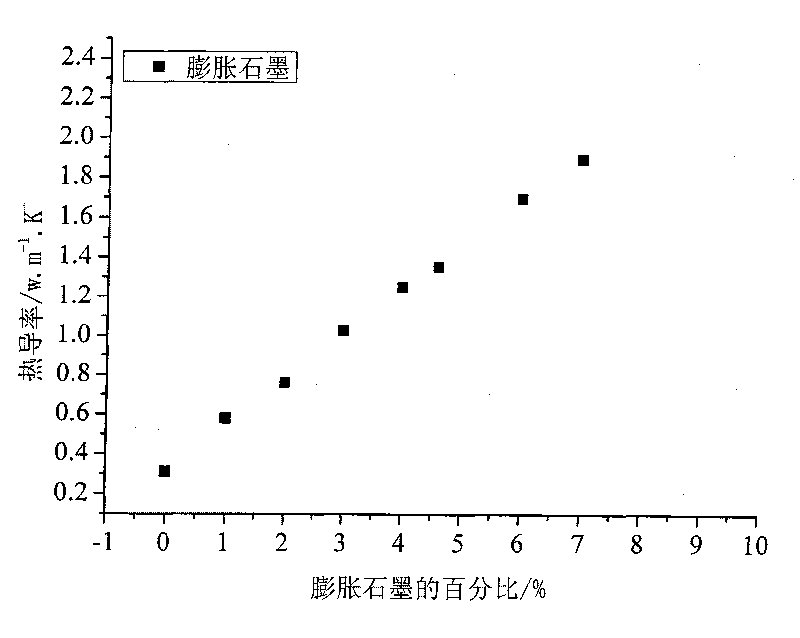

Setting phase change energy storage material with high-thermal conductivity and preparation method thereof

InactiveCN101724381AImprove thermal conductivityImprove heat transfer characteristicsHeat-exchange elementsMolten stateMaterials science

The invention relates to a setting phase change energy storage material with high-thermal conductivity and a preparation method thereof, belonging to the field of phase change heat storage materials. The setting phase change energy storage material with high-thermal conductivity is characterized by containing 65-90 percent by mass of paraffin substances as a phase-change material, 9-34 percent by mass of high-density polyethylene as a support material and 1-7 percent by mass of expanded graphite as a heat conduction intensifier; a method for adding a proper amount of expanded graphite to paraffin / high-density polyethylene in a molten state is adopted to enable the heat conductivity of the setting phase change material to be increased to 1.35W / (m.K) or higher. The method comprises the following steps of: heating to melt the paraffin substances with the mass percent of 65-90 percent, and heating to enable the temperature of the liquid paraffin to reach 120-190 DEG C; adding high-density polyethylene with the mass percent of 9-34 percent and the expanded graphite with the mass percent of 1-7 percent to the liquid paraffin, and then melting and evenly stirring in vacuum; putting the mixture in a hot mould for pressing and molding; taking the mixture from the mould after naturally cooling. The setting phase change material has high thermal conductivity, does not need to be packaged in containers and can directly contact heat-transfer media.

Owner:UNIV OF SCI & TECH OF CHINA

Finned helicoidal heat exchanger

InactiveUS20070125528A1Additional exchangeHigh densityStationary conduit assembliesStationary tubular conduit assembliesWorking fluidEngineering

Heat exchanger having a plurality of heat transfer tubes arranged substantially in the shape of a helicoidal tube with the individual coils running parallel to one another, and a plurality of fins secured to the external surfaces of the heat transfer tubes and arranged perpendicular to the tube to extend outwardly therefrom. The first working fluid flows inside the heat transfer tubes, and air flows through a passage defined between the adjacent fins and at right angles to the axis of each heat transfer tube. The blower is placed co-axial with the helicoid's axis to further enhance the heat exchange.

Owner:FAKHERI AHMAD

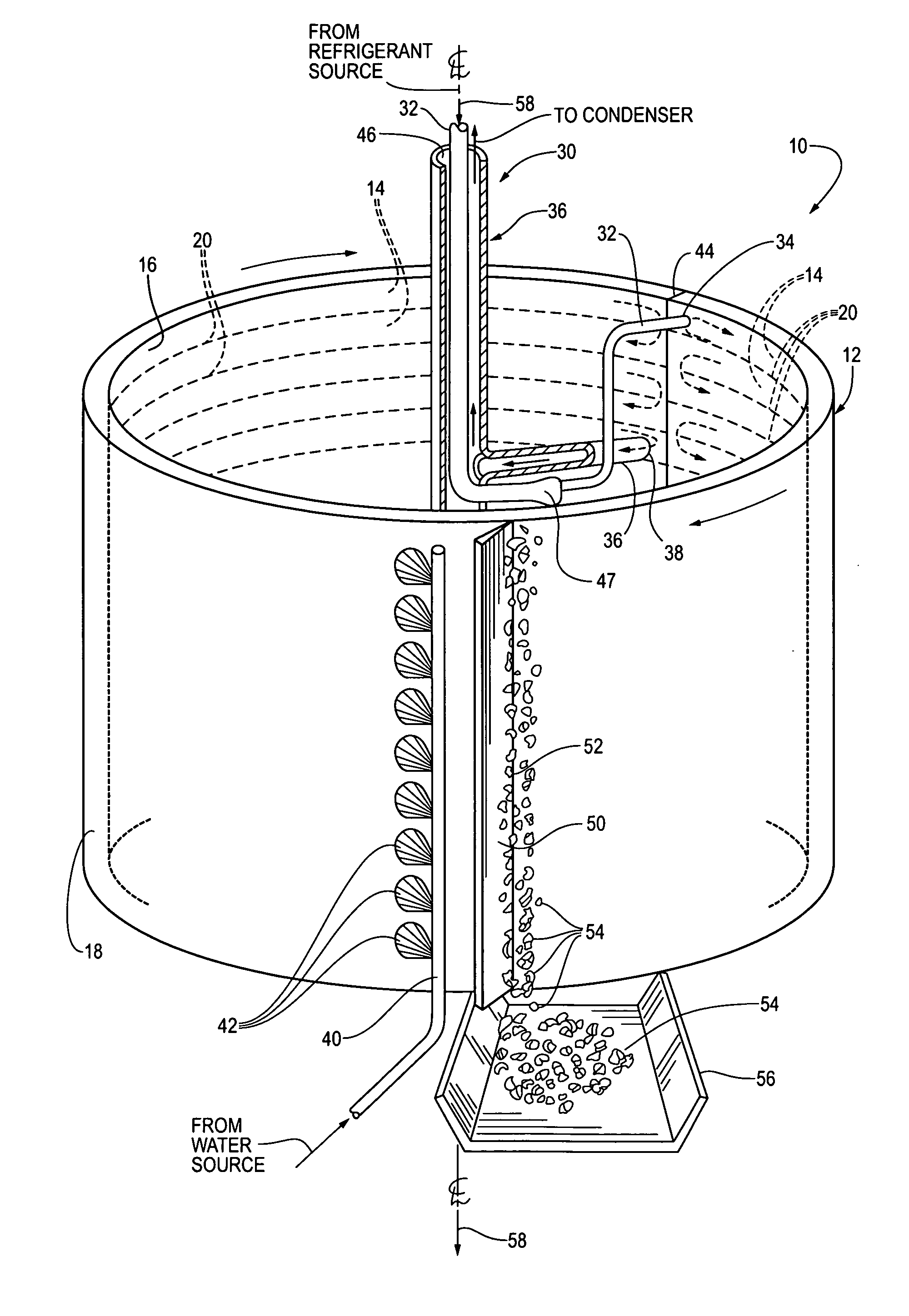

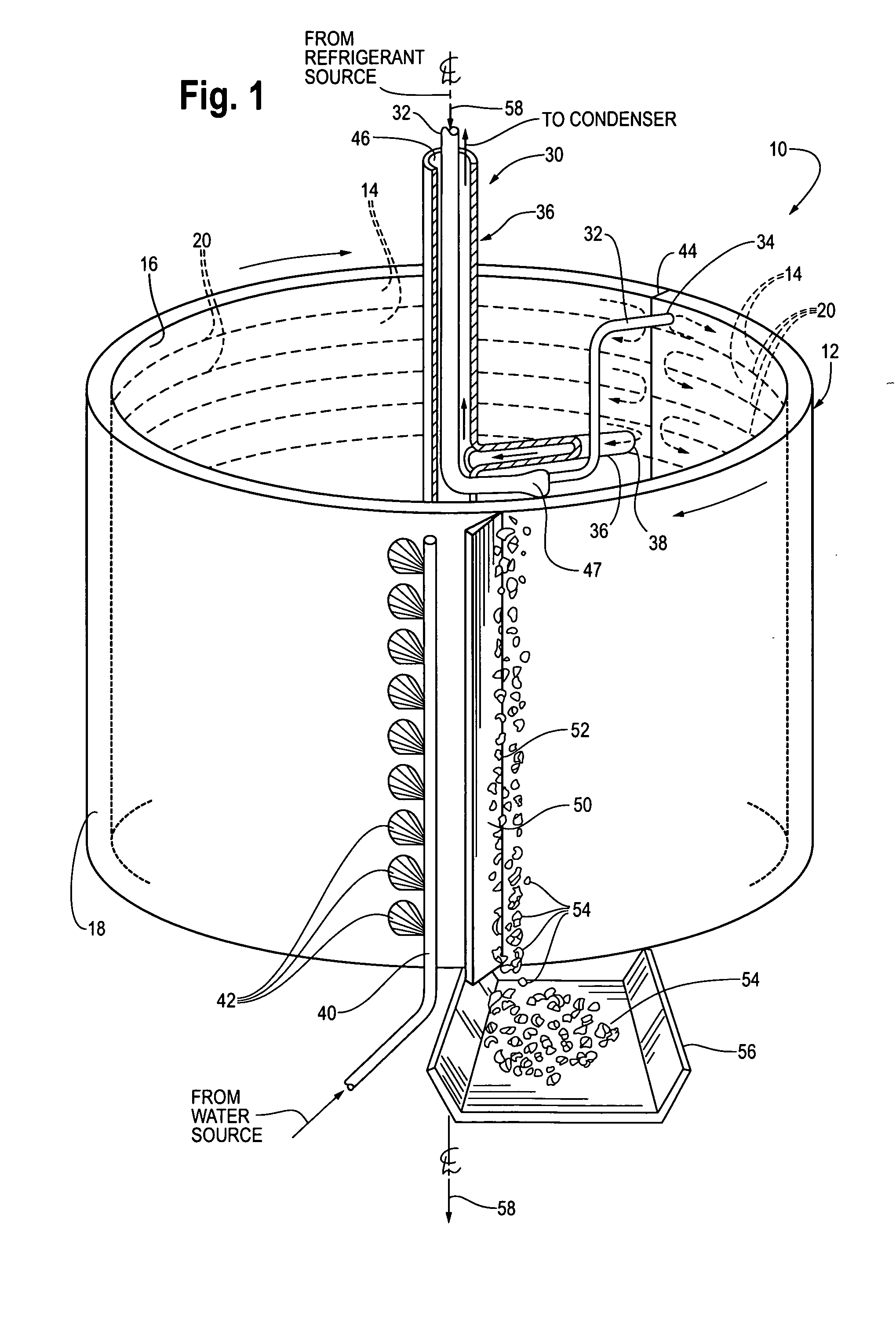

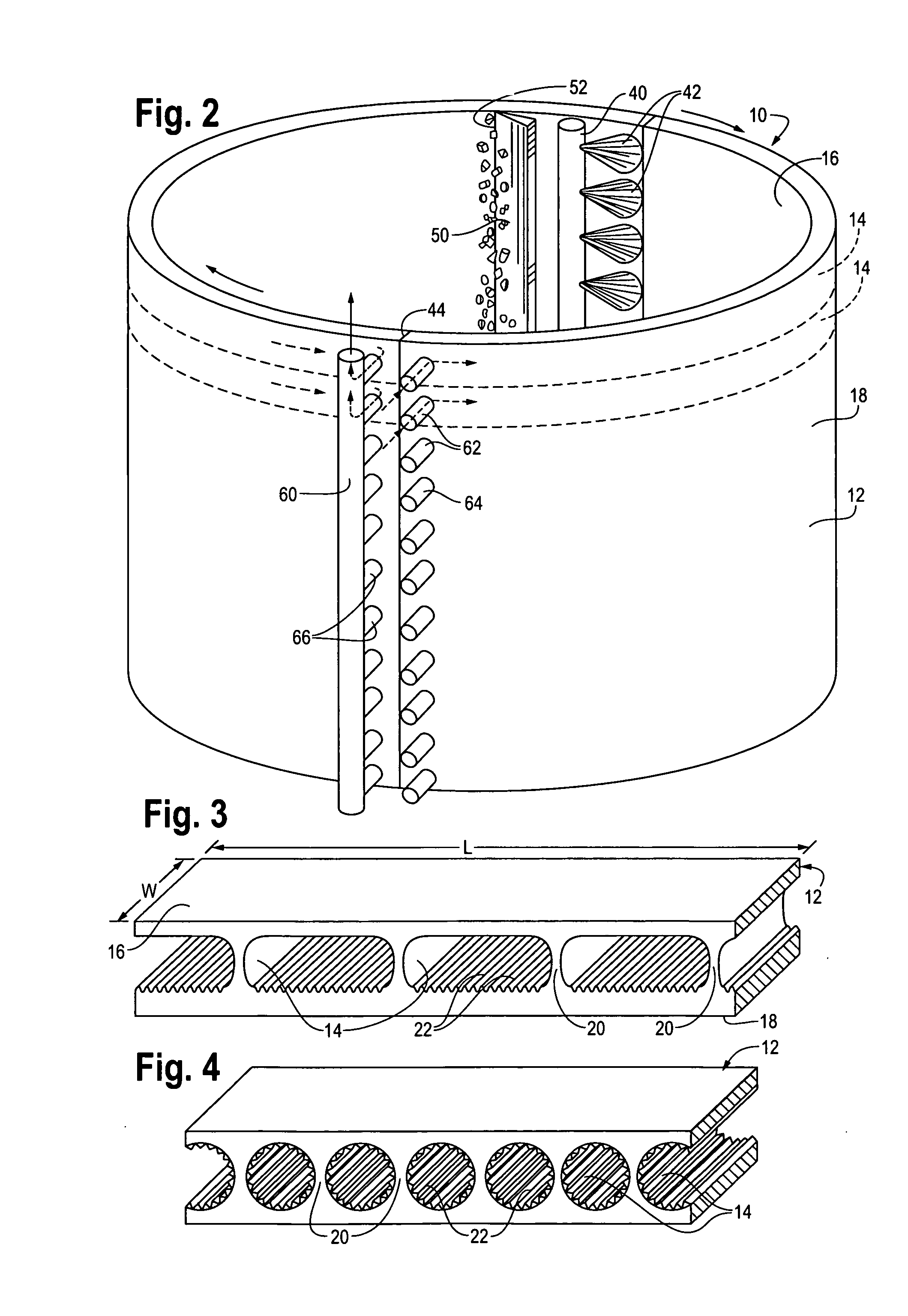

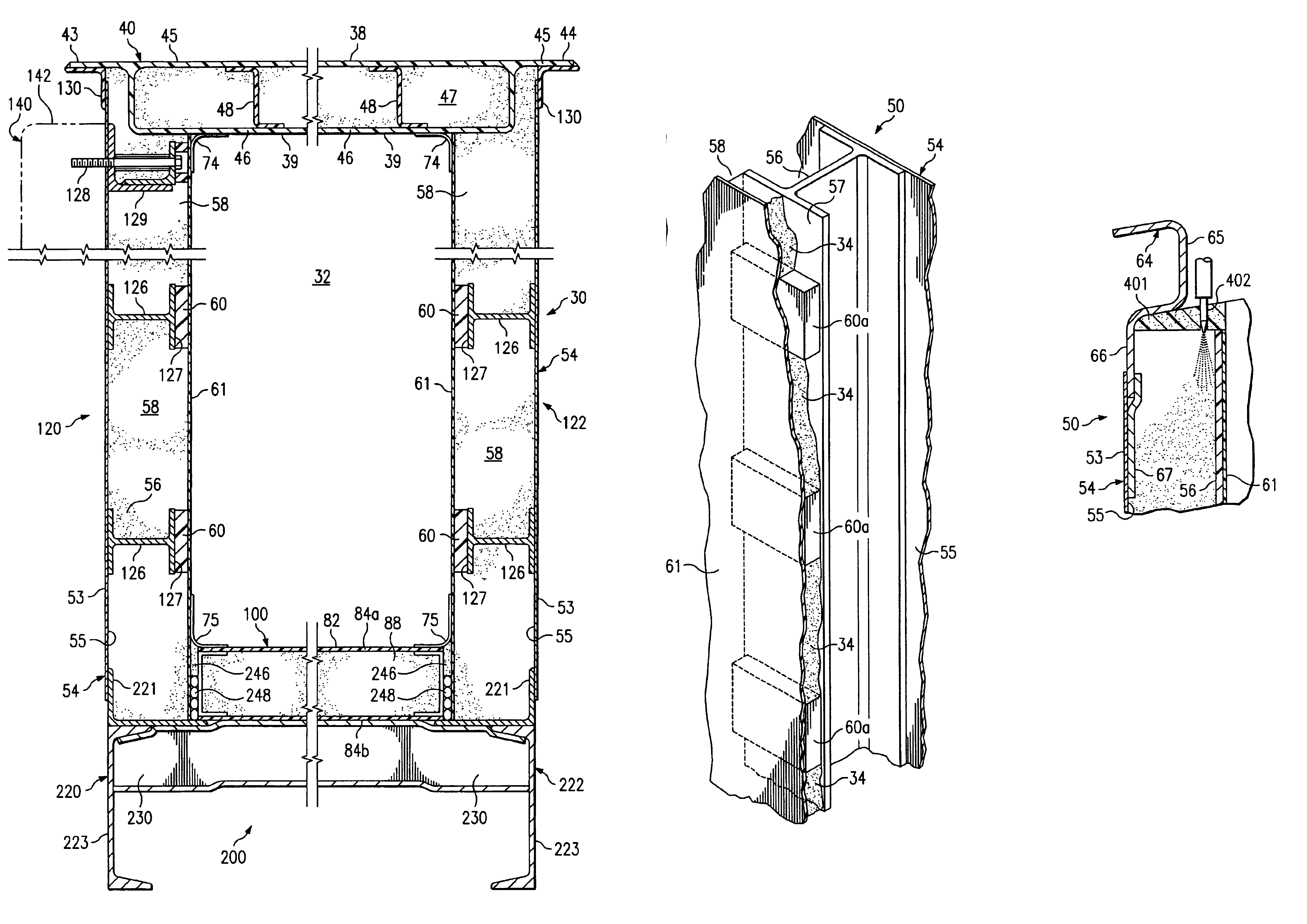

Ice machines with extruded heat exchanger

ActiveUS20100064717A1Increase surface areaEnhance heat transfer characteristicIce productionFrozen sweetsEngineeringIce formation

A heat exchanger for an ice machine has the form of a cylinder. In some embodiments, the cylinder is made from an extrusion of a metal such as an aluminum alloy. The heat exchanger includes inner and outer cylindrical walls and one or more refrigeration passages positioned between the inner and outer walls. The inner and outer walls are separated from each other by connecting structures defining the refrigeration passages. The heat exchanger can be extruded as a rectangular panel and subsequently formed into a cylindrical form. Alternatively, the heat exchanger can be extruded as a cylinder, or as an arcuate cylindrical segment in which several of such segments are subsequently joined together (as by welding) into a cylinder. Ice machines that feature ice formation on both the inner and outer walls of the cylinder are also disclosed.

Owner:INTEGRATED MARINE SYST

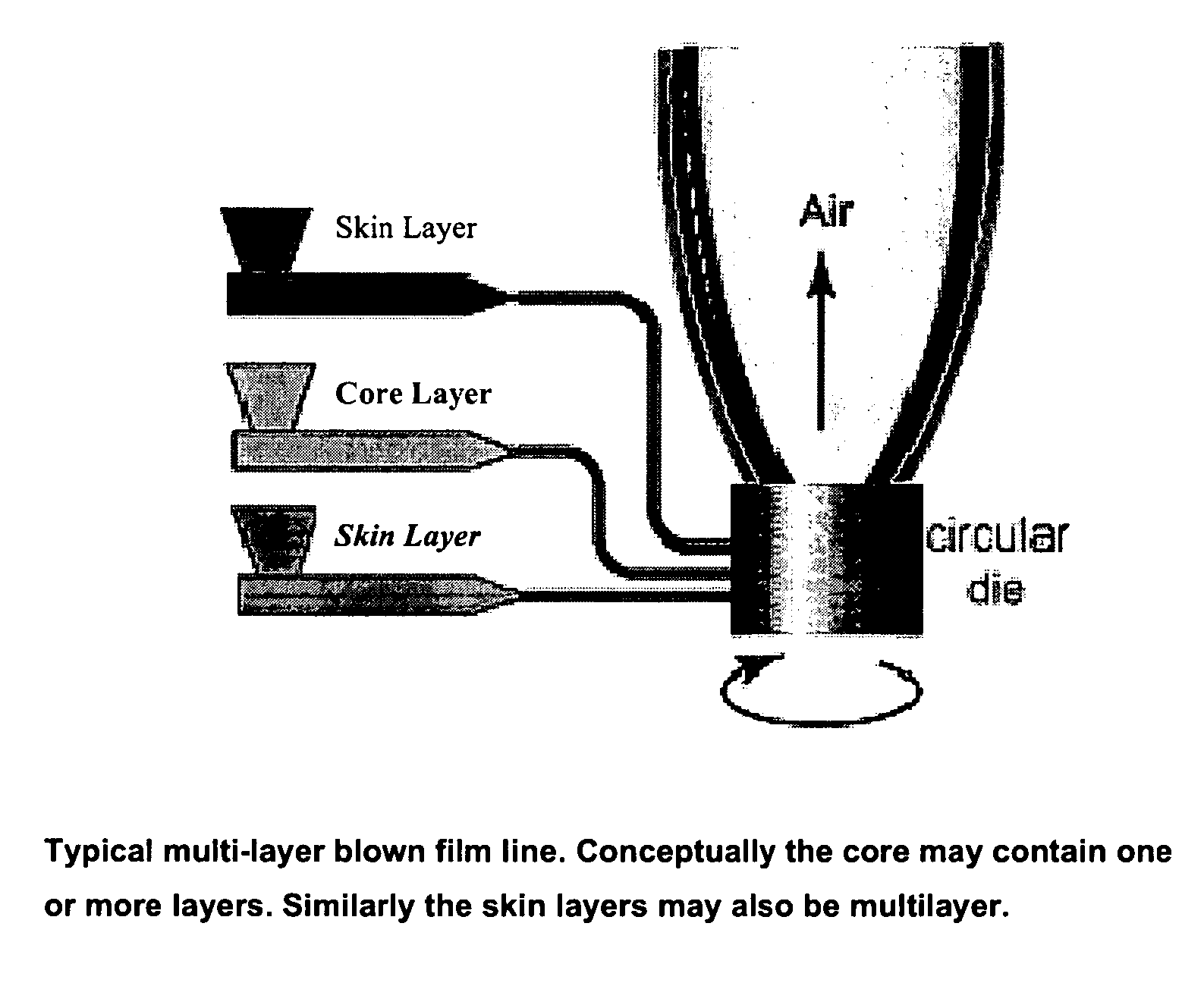

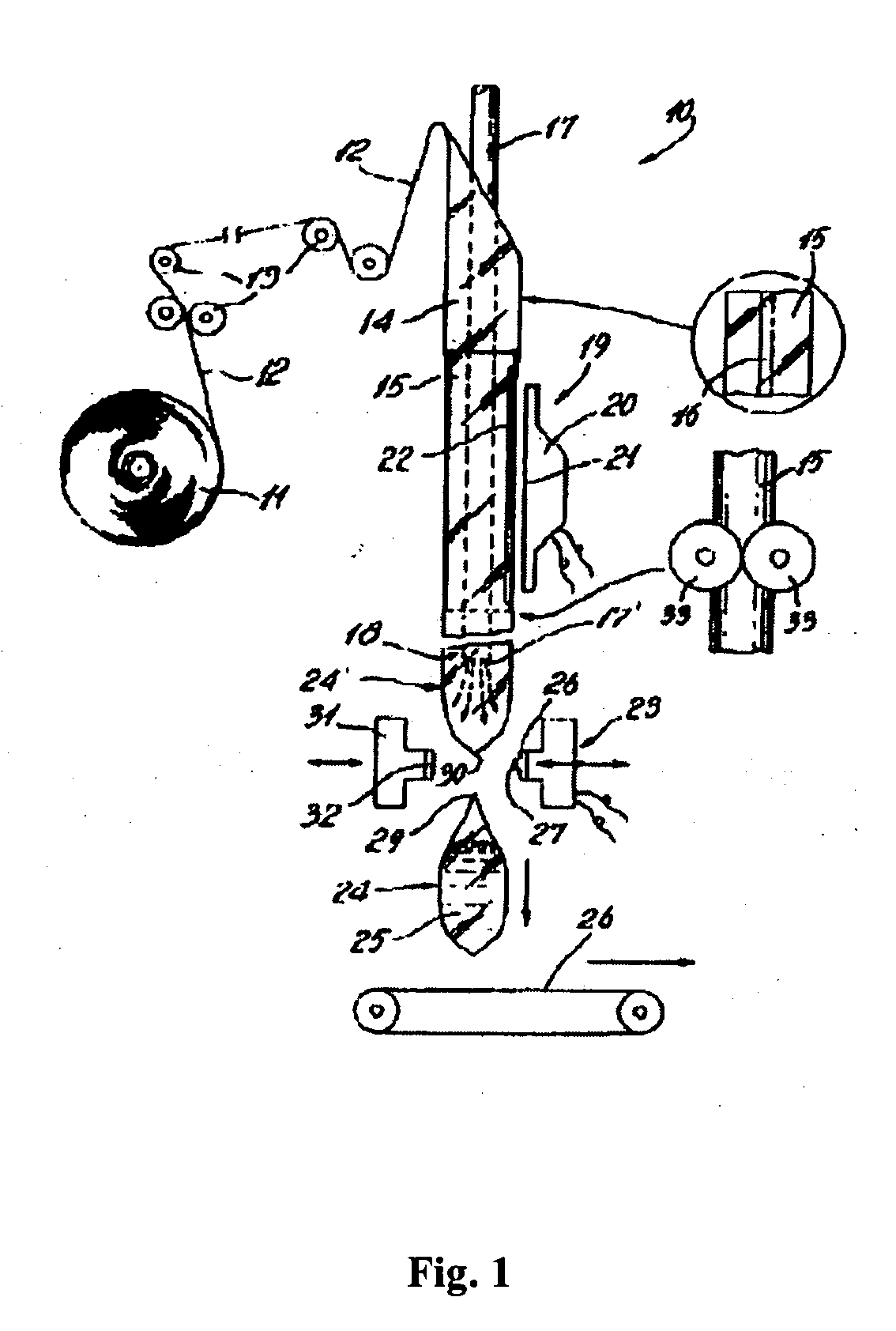

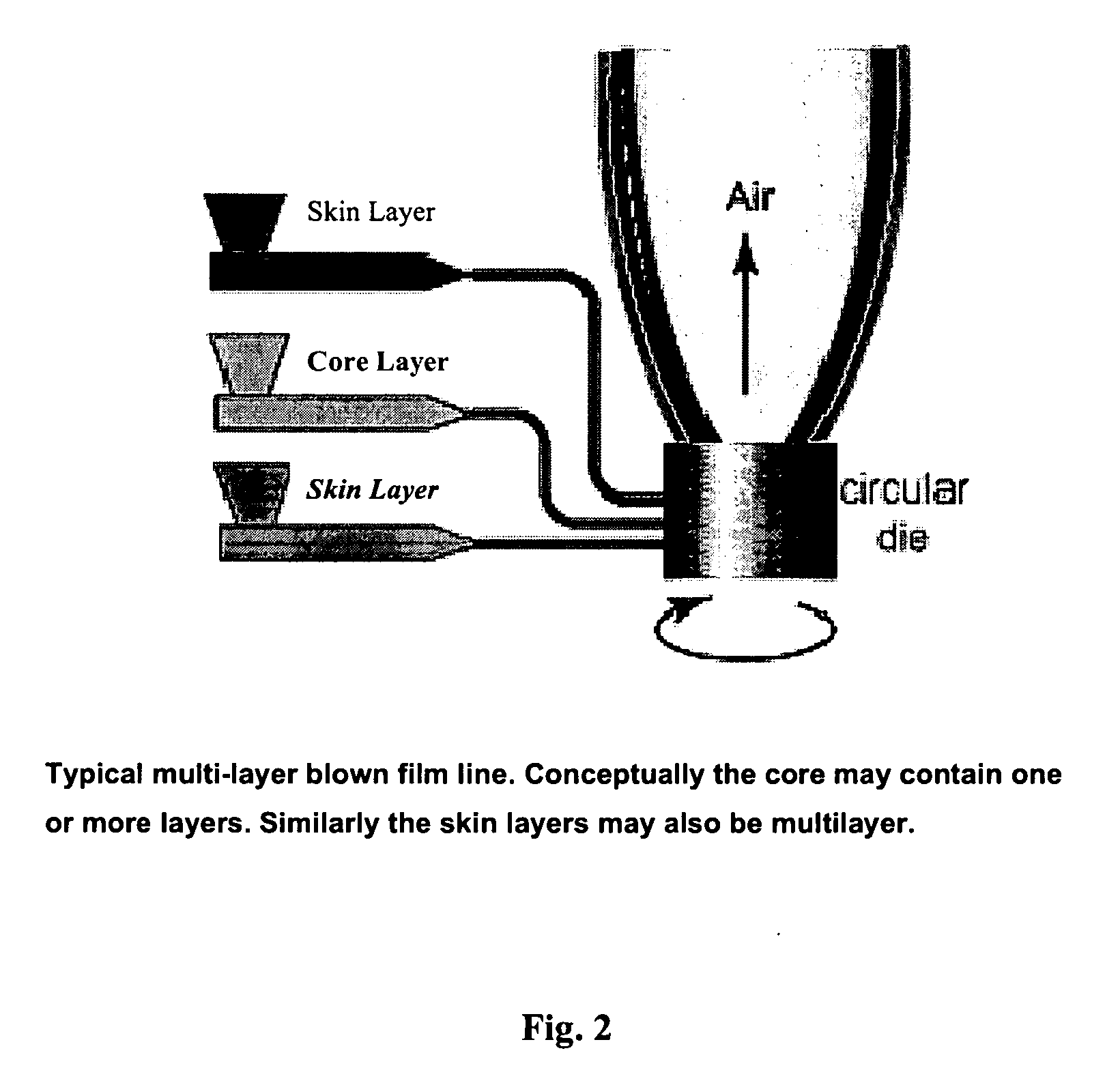

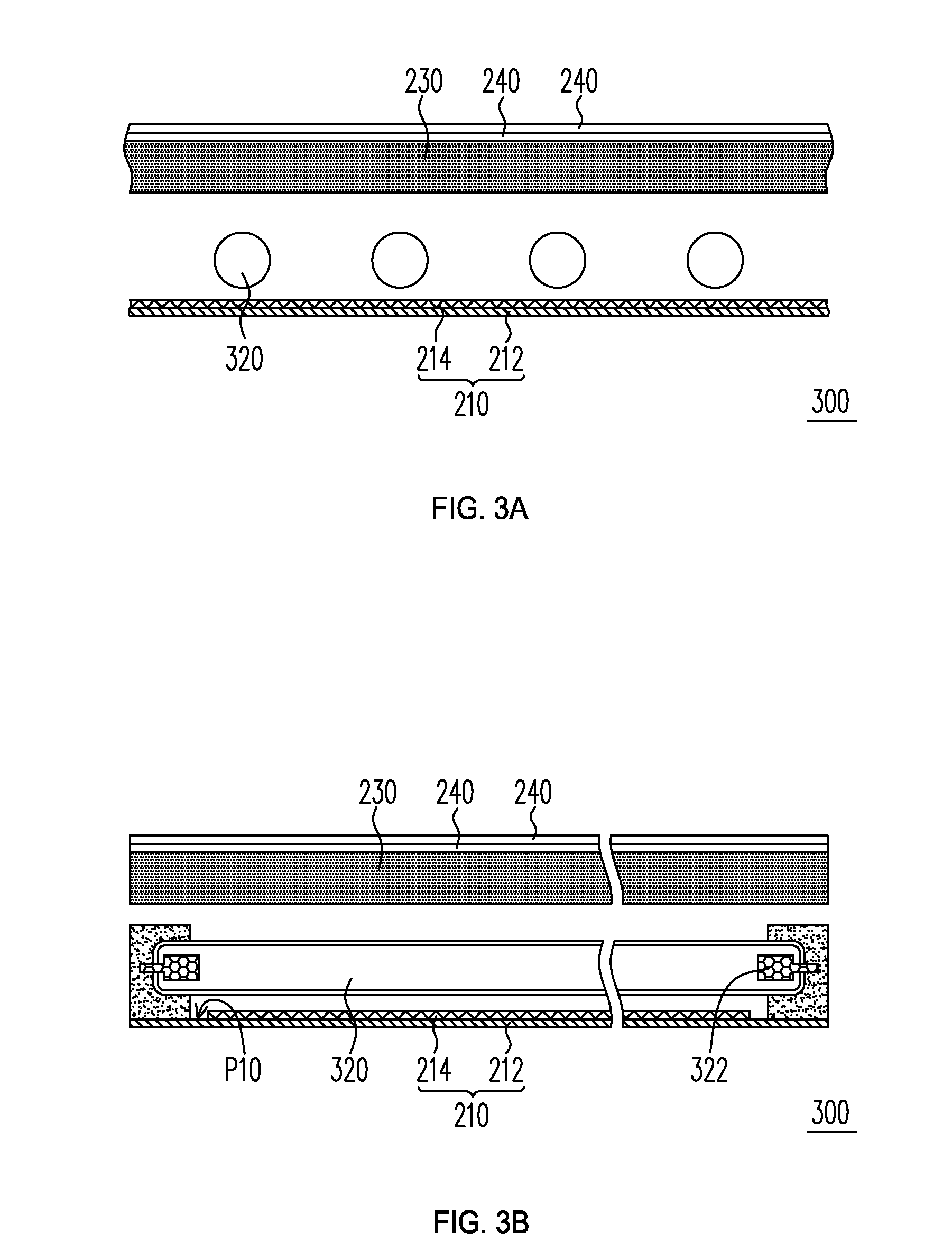

Thin film for vertical form fill and seal packaging of flowable materials

InactiveUS20070252276A1Quick sealImprove heat transfer characteristicsSemiconductor/solid-state device detailsSynthetic resin layered productsPolypropyleneLow-density polyethylene

A multi-layer film for vertical form, film and seal systems for liquid, powder, granules and / or other flowables packaging, said multi-layer comprising: an inner layer made of polyethylene, a blend of polyethylenes or ethylene copolymers; a core, comprising one or more than one layer, made from a blend of polypropylene, linear low density polyethylene, a polymer compatibilizer or tie-layer resin, and / or low density polyethylene, said core being applied against the inner layer; and an outer layer (same or different from the inner layer or the core layer) is made of a polyethylene or a blend of polyethylenes with or without ethylene copolymers, said outer layer being applied against the core and opposite the inner layer; said multi-layer film having an overall thickness of lower or equal to 2.5 mil and at least one of the properties listed hereinafter: a stiffness (as measured by 1% secant modulus in the film direction) varying from 79000 psi to 140000 psi; a tensile strength at yield of from 2100 psi to 3300 psi; (measured in film machine direction) and a tensile strength at break of from 4700 to 6700 psi (measured in film machine direction). A method of forming, sealing and filling a pouch with said film, a pouch formed with said film and use of said film to form a pouch.

Owner:LLOYD GEORGE IAN

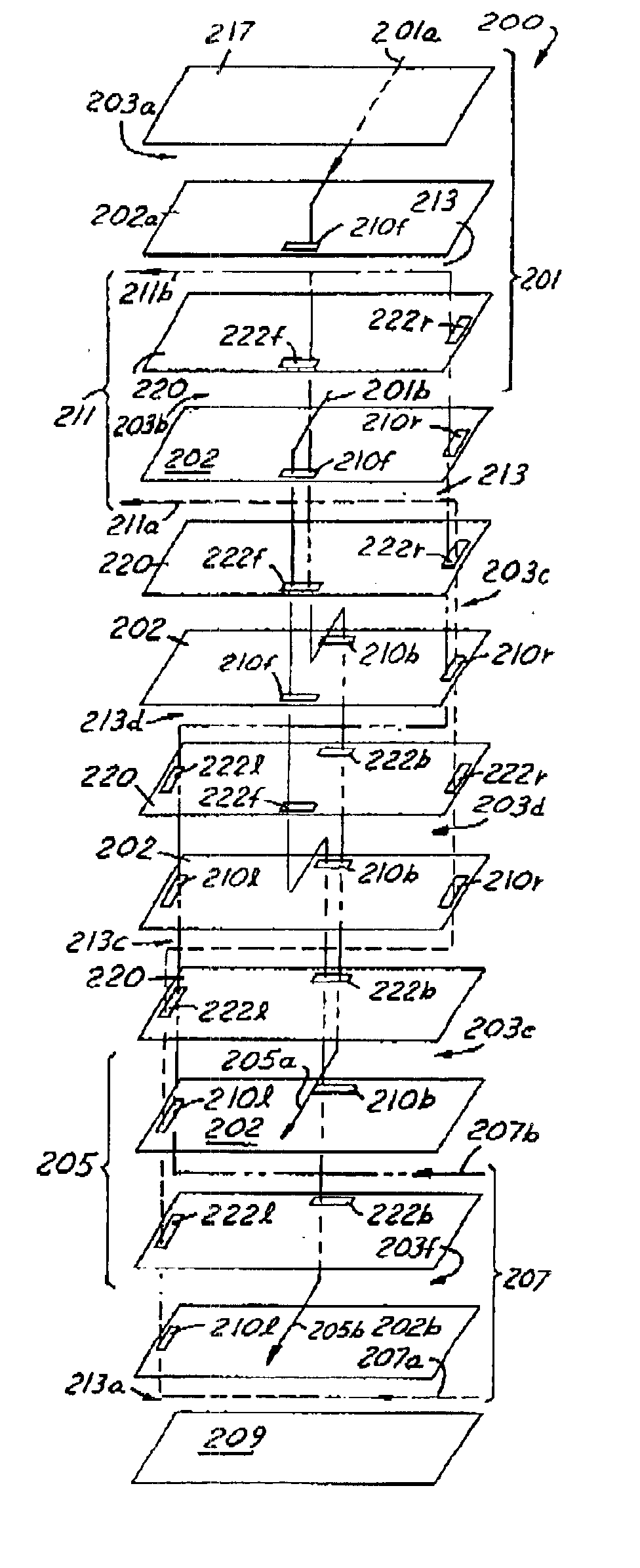

Plate-frame heat exchange reactor with serial cross-flow geometry

InactiveUS6893619B1Improve heat transfer characteristicsImprove characteristic reactant mixingVapor condensationChemical/physical/physico-chemical processesProcess engineeringAirflow

A plate-frame heat exchange reactor having a serial cross-flow geometry. This is accomplished by designing a plate-frame heat exchanger wherein the flow of feed gas in one cell of the reactor flows perpendicular to the flow of burner exhaust within the next adjacent cell. The improved reactor increases the Reynold's number of the flows as compared with a massively parallel design to improve heat transfer and reactant mixing characteristics, thereby reducing reactor size by half or more. The serial cross-flow arrangement allows for constructing reactors where feed gas addition is possible at many distinct points along the serial flow in order to control hot spots or other undesirable chemical reactions. The new arrangement also greatly reduces manifolding of the flows and reduces the distinct components of the reactor.

Owner:FORD GLOBAL TECH LLC

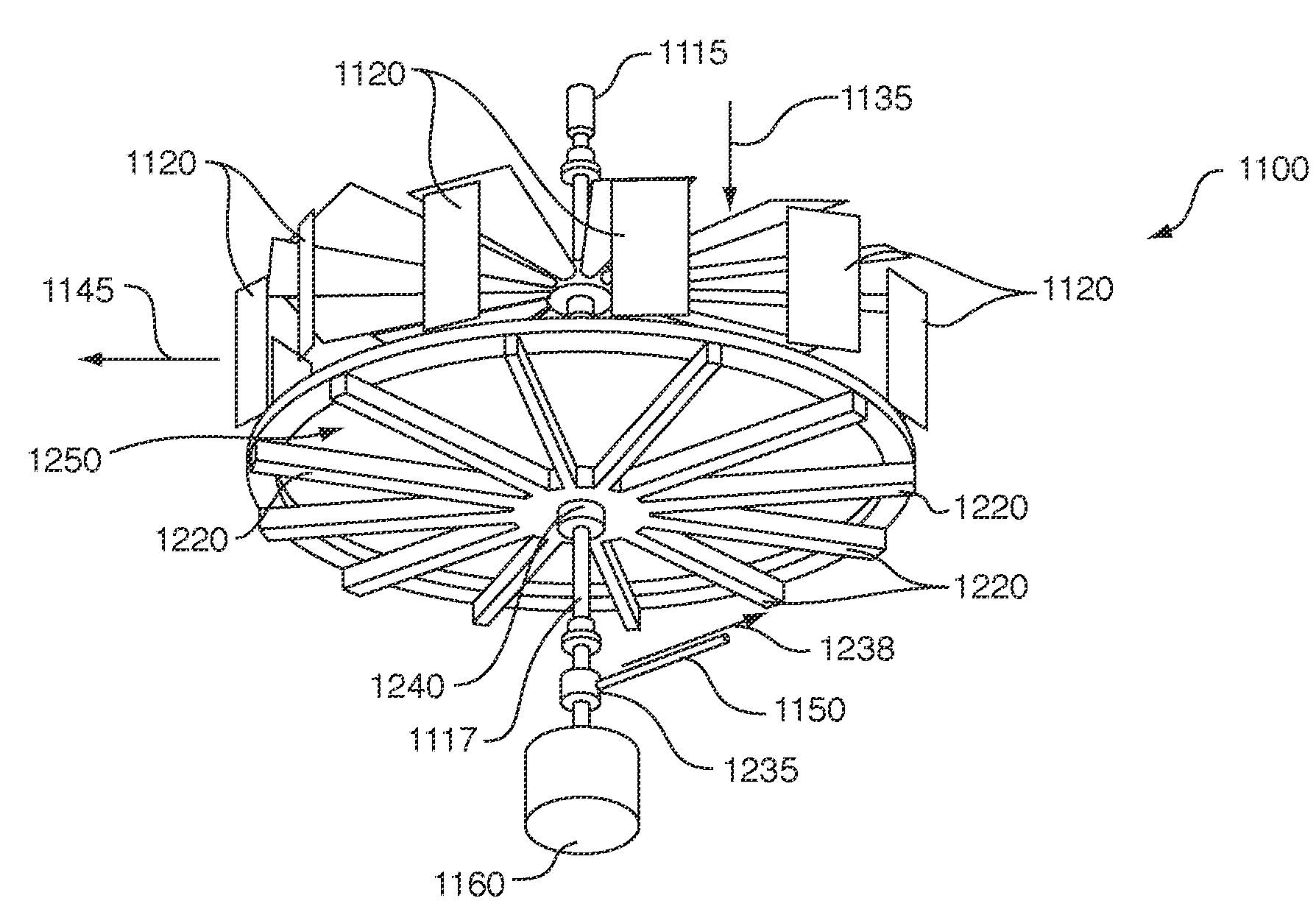

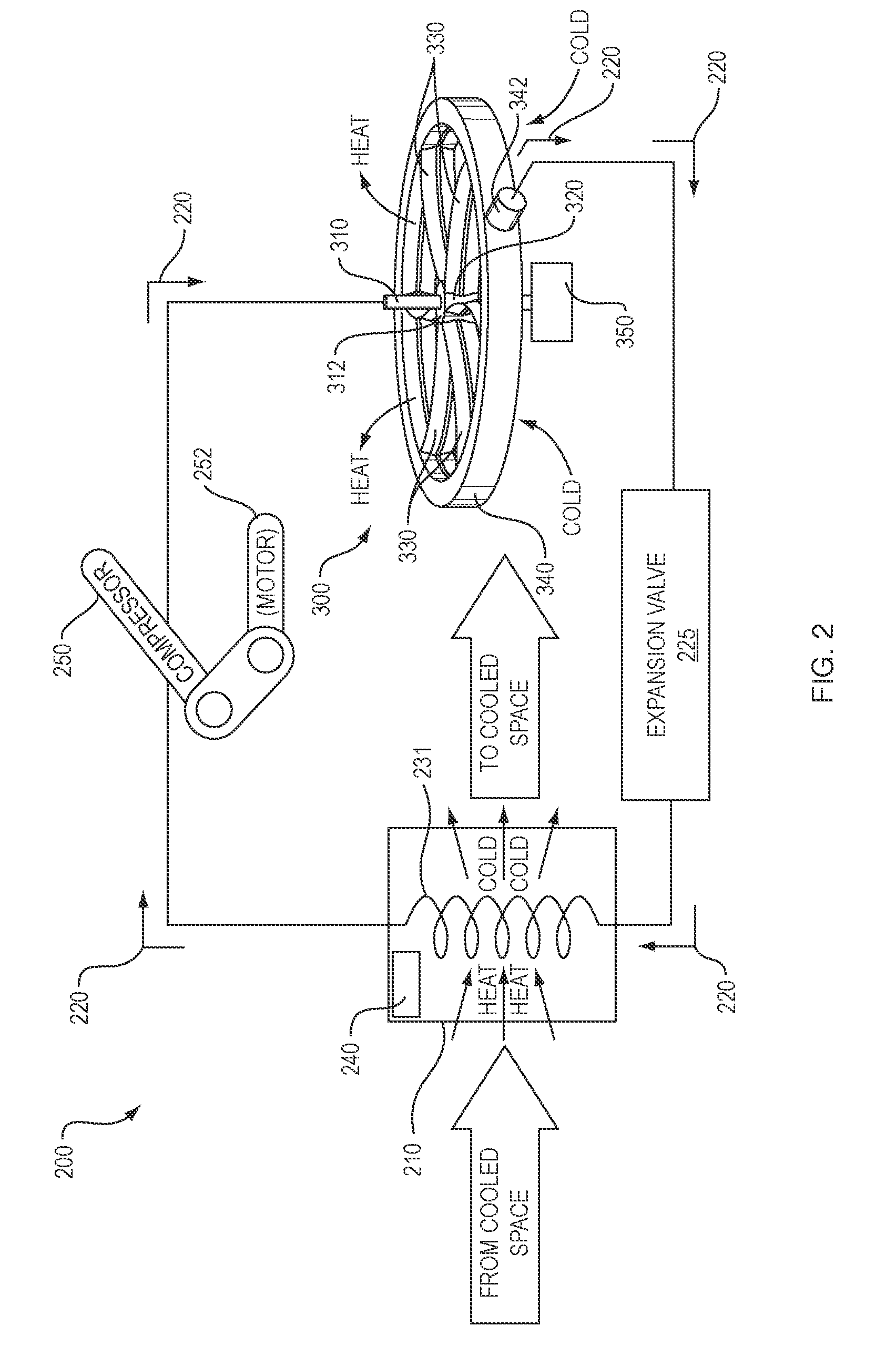

Turbo-compressor-condenser-expander

ActiveUS20100180631A1Improve featuresImprove heat transfer characteristicsCompressorPump componentsOpen frameworkEngineering

This invention provides an isothermal turbocompressor and a combined turbo-compressor-condenser-expander arrangement, which includes heat-transferring blades that are mounted on, or surround, individual conduits to promote air exchange and heat transfer. In operation, the open framework rotates in free air to promote heat exchange. This optimizes contact with free air during rotation. The assembly includes a first plurality of spokes extending radially outwardly from a first central hub to an outer perimeter with first radial conduits that transport refrigerant under centrifugal force and compression from the hub to the outer perimeter. The first radial conduits include heat exchanging blades. A second plurality of spokes extend radially outwardly from a second central hub at an axial spacing from the first central hub. This second plurality of spokes each includes a second thermally-insulated conduit that transports refrigerant from the outer perimeter to the second central hub. Axial conduits extend axially at the outer perimeter, and each interconnects each first radial conduit and each second radial conduit. At least some of the plurality of axial conduits include an axial blade in thermal communication with the conduit that promotes heat exchange radially. A motor rotates a central axis of the turbo-compressor-condenser-expander.

Owner:APPOLLO WIND TECH

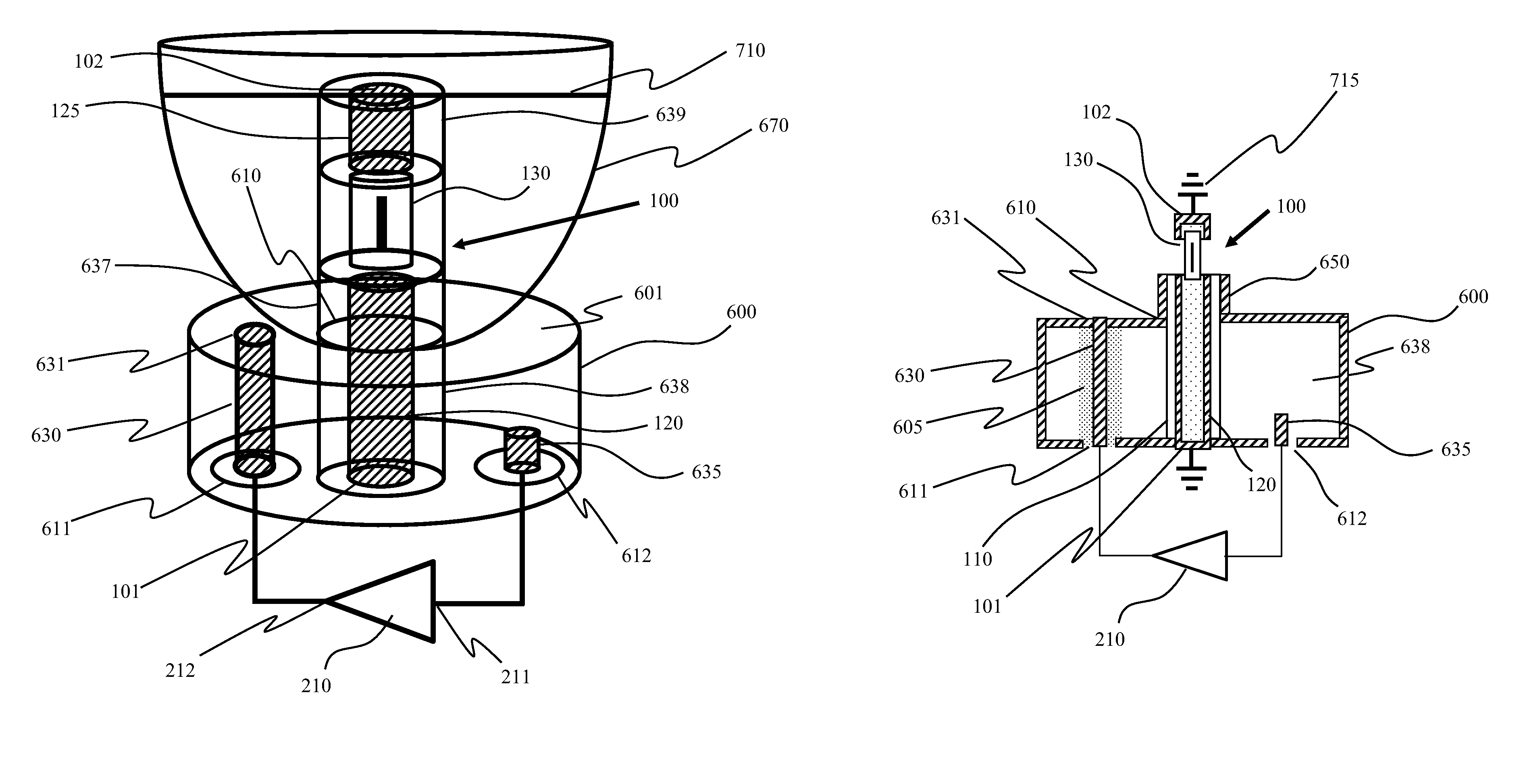

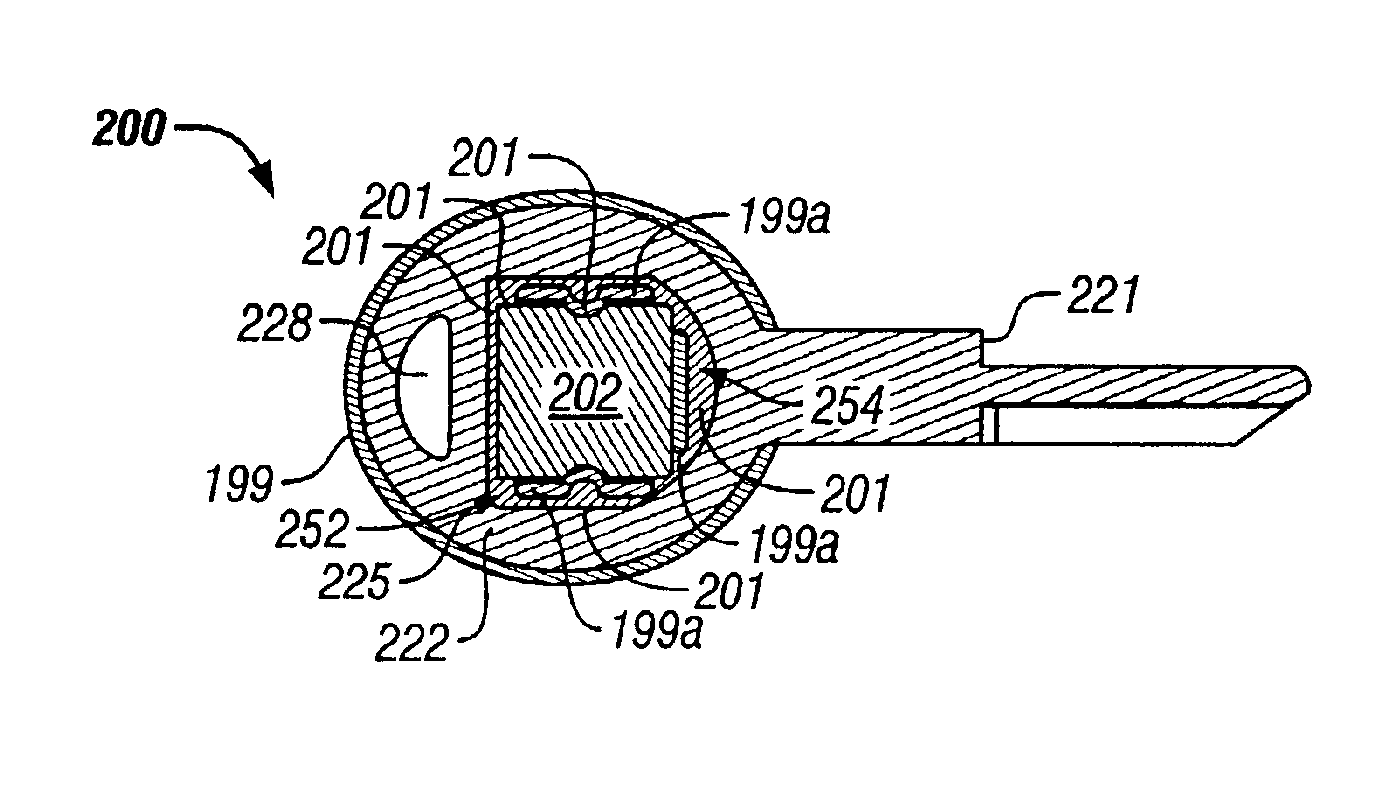

Electrodeless lamps with externally-grounded probes and improved bulb assemblies

InactiveUS7830092B2Simple designImprove manufacturabilityBeam/ray focussing/reflecting arrangementsBeam/ray deflecting arrangementsCouplingEngineering

An electrode-less plasma lamps, comprising generally of a bulb containing a gas-fill that is excited to produce light using radio-frequency (RF) energy. In specific embodiments, the use of grounded coupling-elements with integrated bulb assemblies simplifies manufacturability, improves resonant frequency control, and enables the use of solid, partially filled, and hollow lamp bodies.

Owner:TOPANGA USA

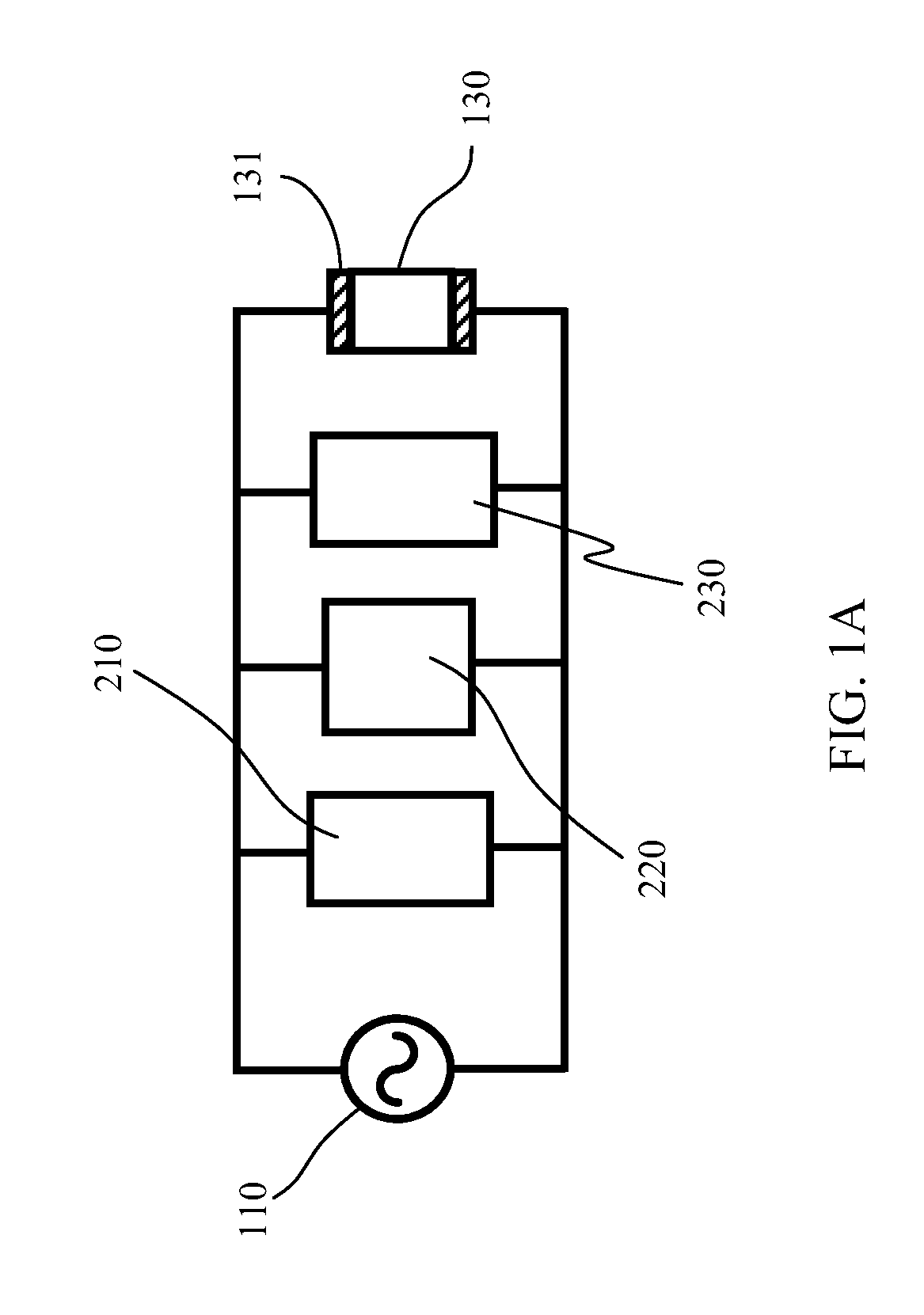

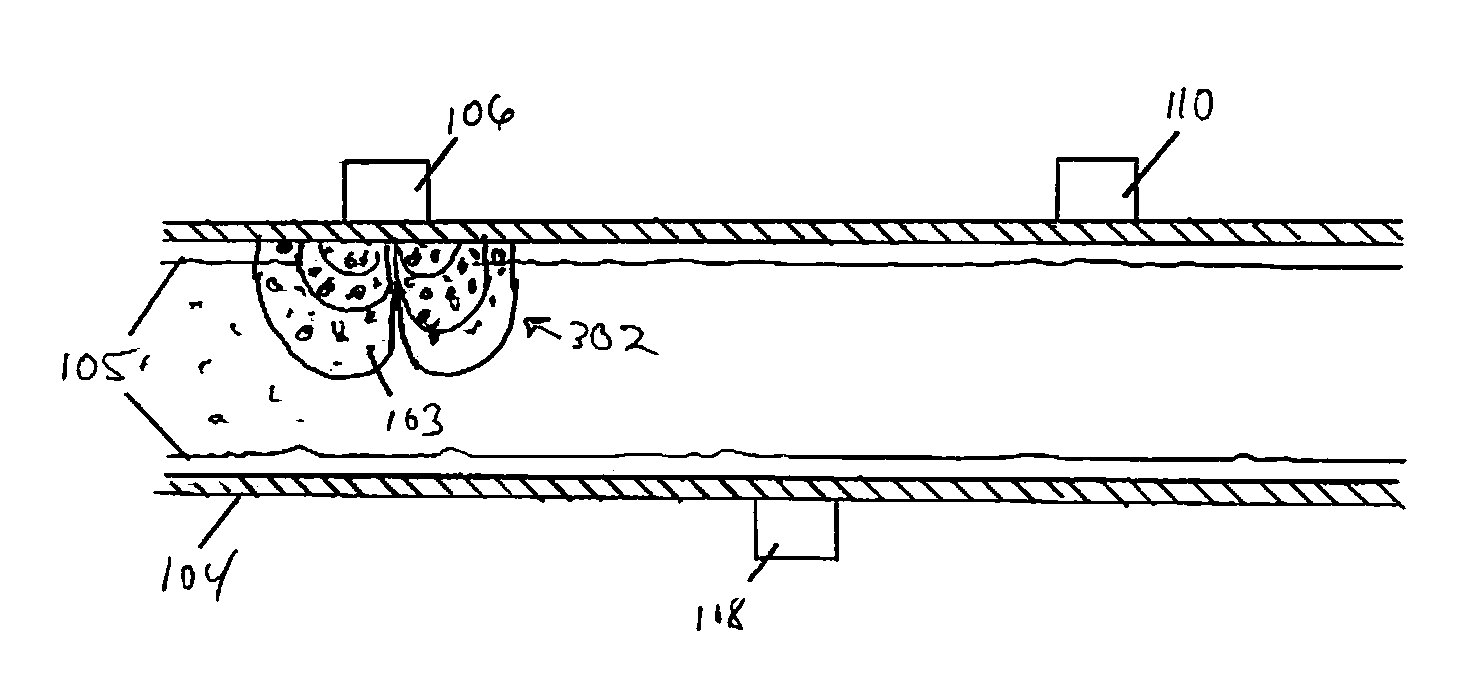

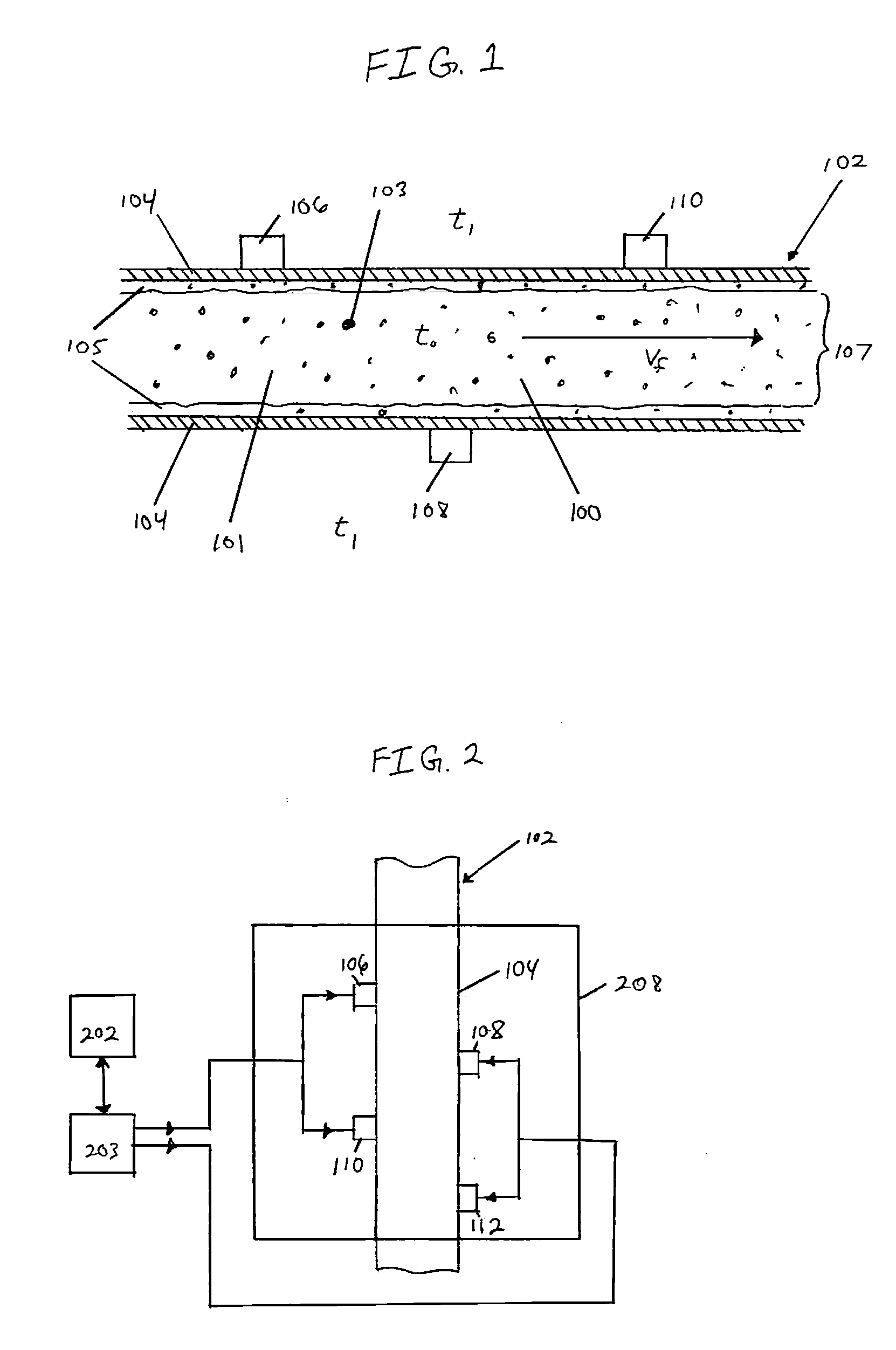

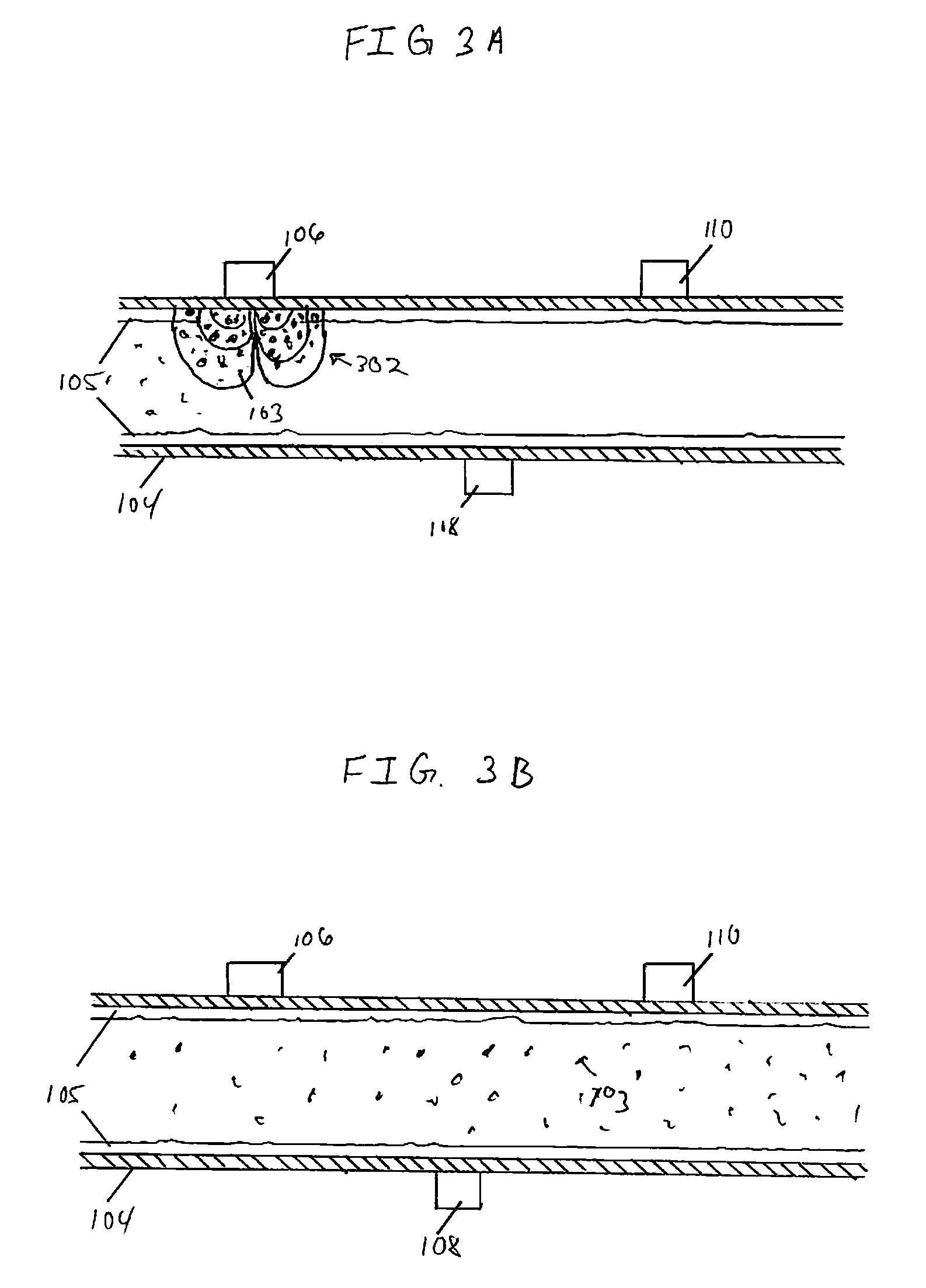

System and method for convective heat transfer utilizing a particulate solution in a time varying field

InactiveUS20070039721A1Improve thermal conductivityImprove conductivitySemiconductor/solid-state device detailsSolid-state devicesParticulatesEnhanced heat transfer

A system combines the thermal conductivity characteristics of certain solids with the high specific heat values of appropriate fluids to enhance the overall heat transfer characteristics of a heat exchanger. The system comprises a fluid channel disposed in a heat exchanger unit with a slurry as the convective heat transfer medium. The slurry comprises an appropriate fluid with field reactive particles suspended therein. Field emitters are located along the walls of the fluid channel whereby the distribution of particles within the slurry is manipulated to achieve enhanced heat transfer characteristics.

Owner:UNITED STATES OF AMERICA

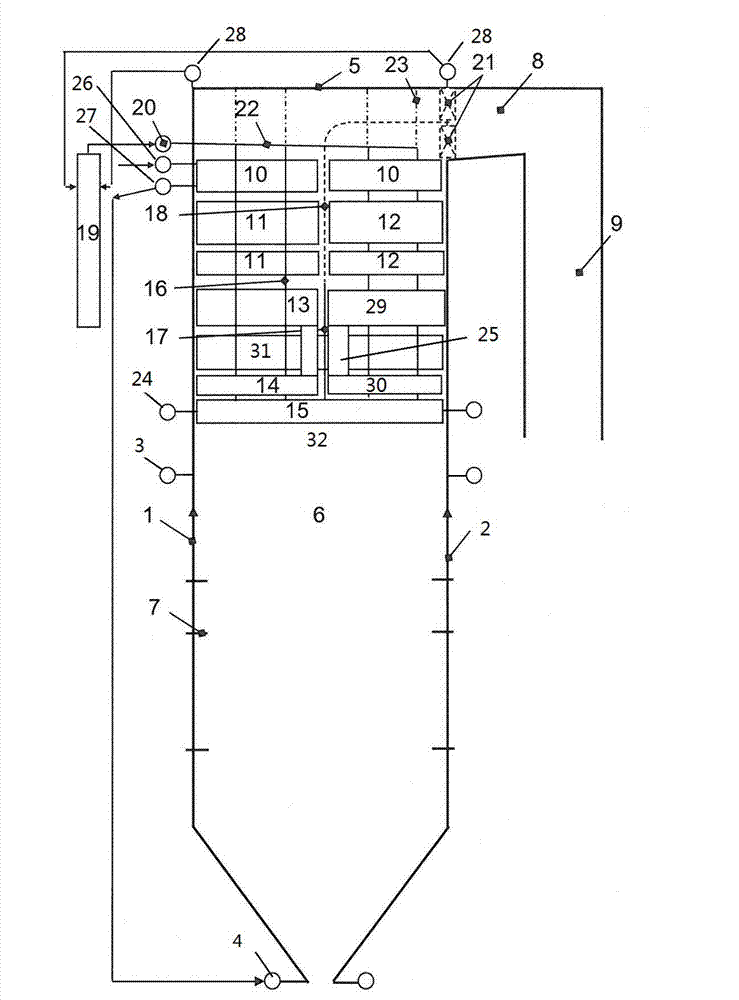

Tower-type boiler with primary reheater and secondary reheater

ActiveCN102889570AImprove heat transfer characteristicsImprove heat transfer efficiencySuperheating controlBoiler flue tubes/fire tubesEngineeringSuperheater

The invention discloses a tower-type boiler with a primary reheater and a secondary reheater. A superheater of the boiler comprises a low-temperature superheater and a high-temperature superheater; a technological process of a main steam system comprises the following steps that: feeding water enters a front flue coal economizer and a rear flue coal economizer which are arranged in parallel; water from outlets of the coal economizers enters water-cooling walls from the lower part of a hearth; outlets of the water-cooling walls are connected with a separator; and steam of an outlet of the separator enters the low-temperature superheater and the high-temperature superheater sequentially. According to a low-to-high flow direction of temperatures on a steam side, the primary reheater sequentially comprises primary reheating low-temperature reheaters and a primary reheating high-temperature reheater, the secondary reheater sequentially comprises secondary reheating low-temperature reheaters and a secondary reheating high-temperature reheater, and the primary reheater and the secondary reheater are connected with each other in parallel in a perpendicular flue.

Owner:SHANGHAI BOILER WORKS

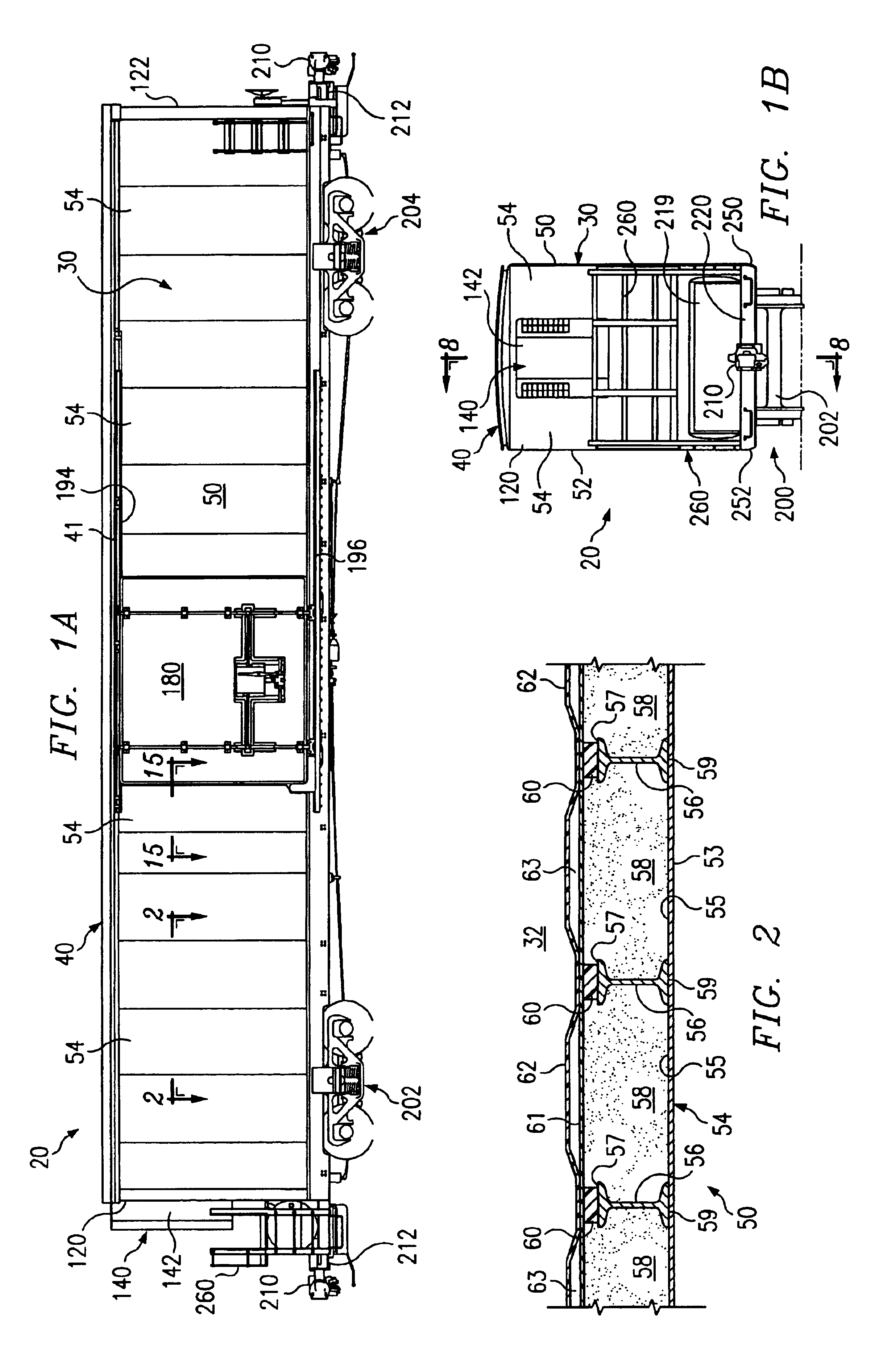

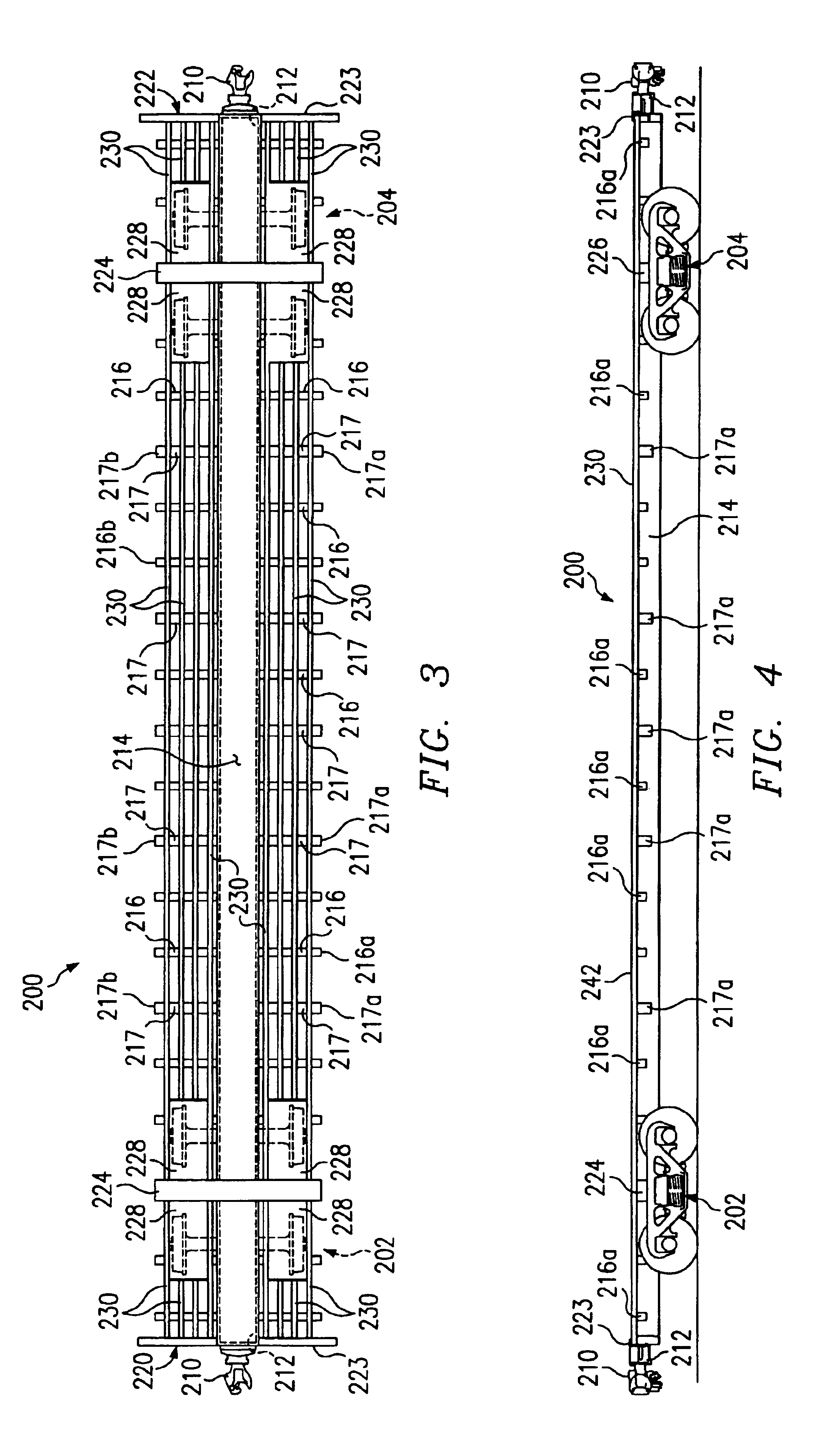

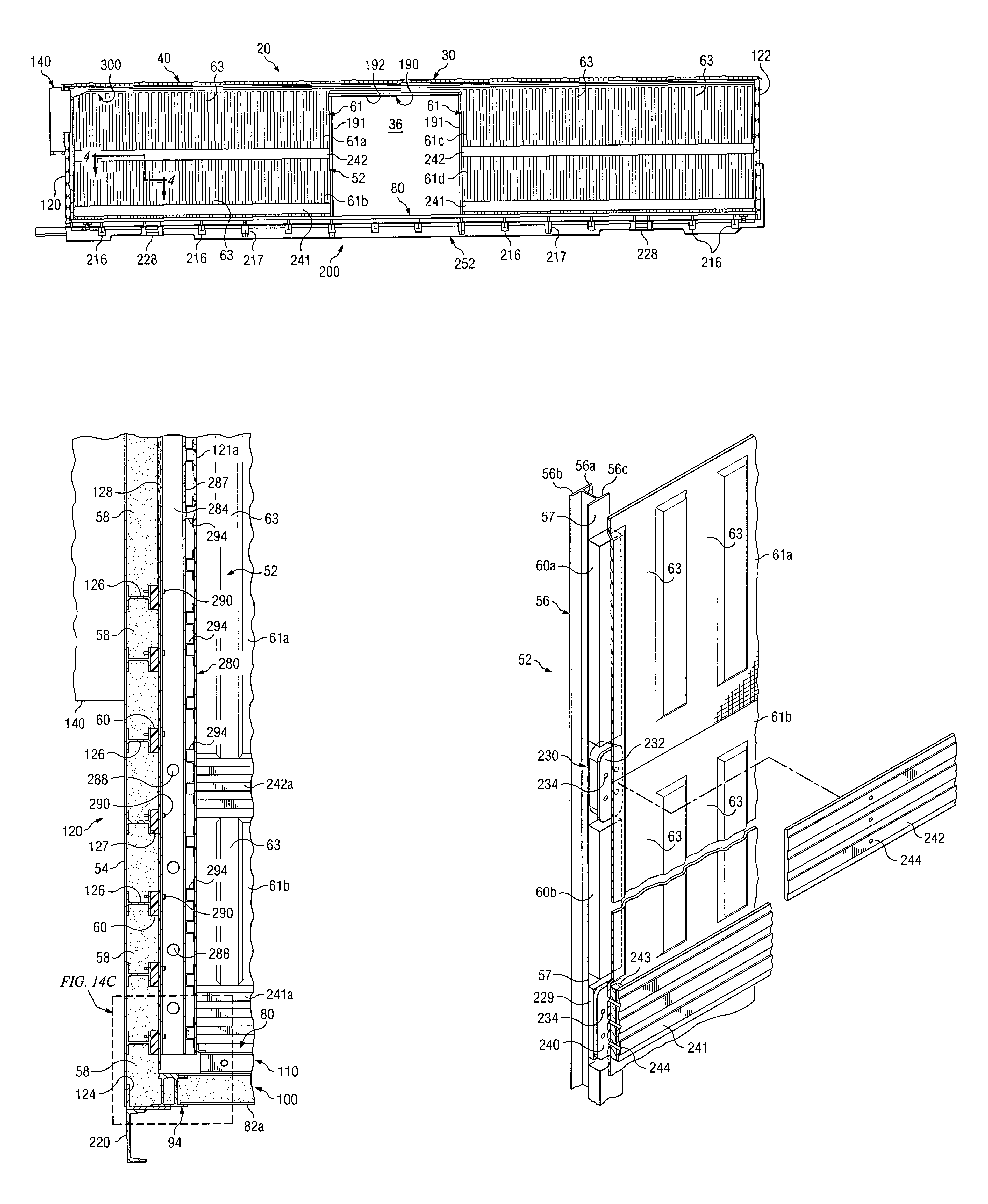

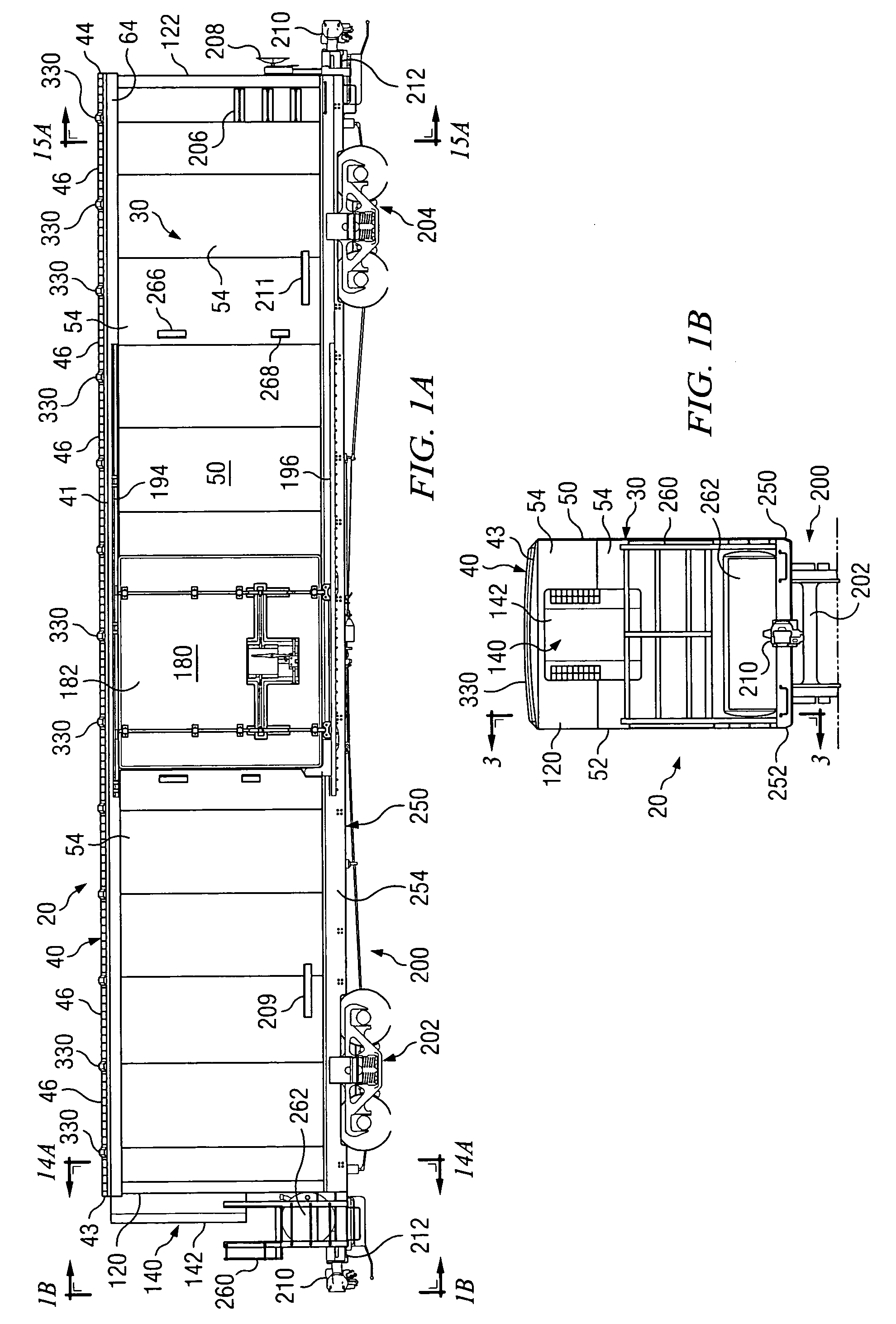

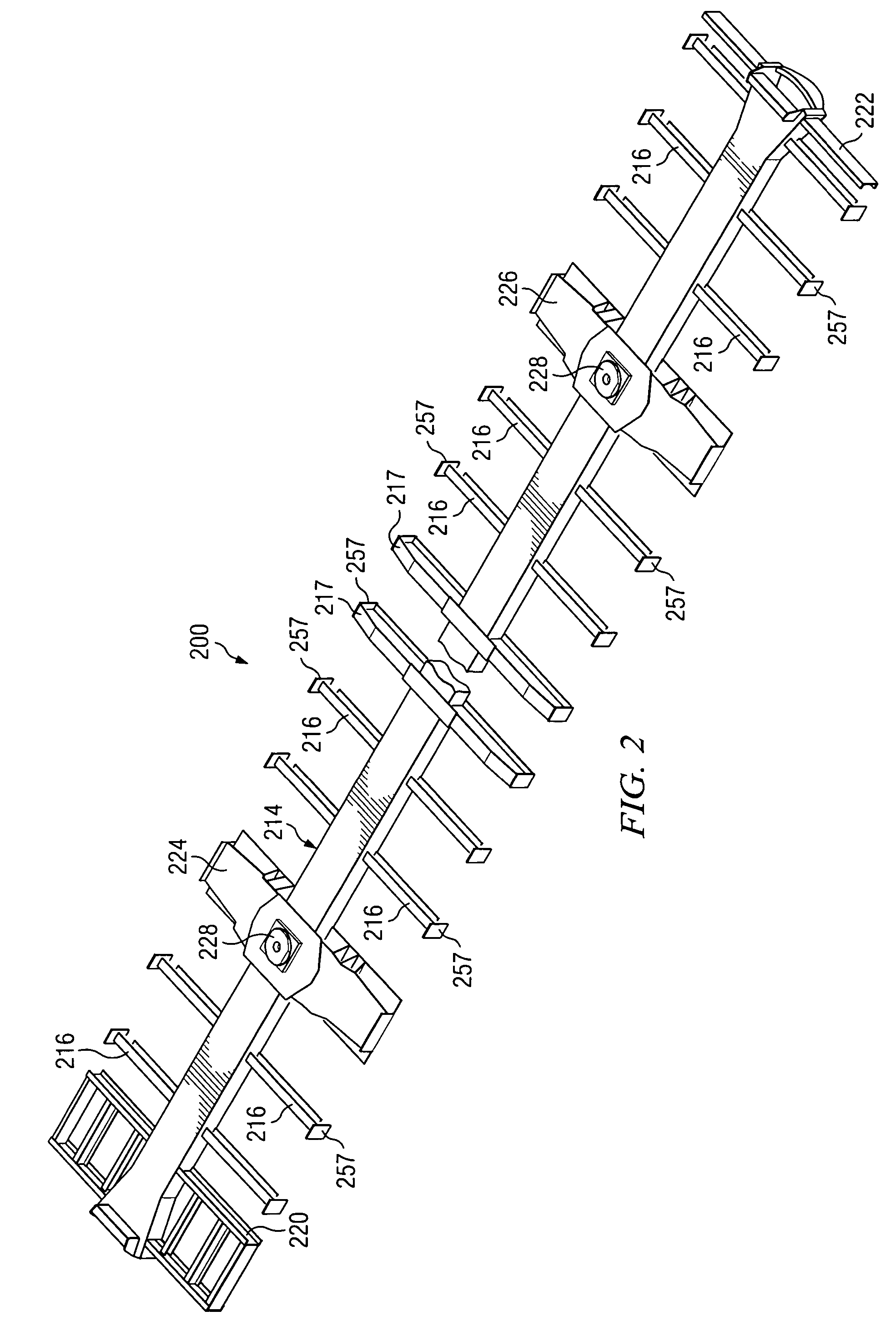

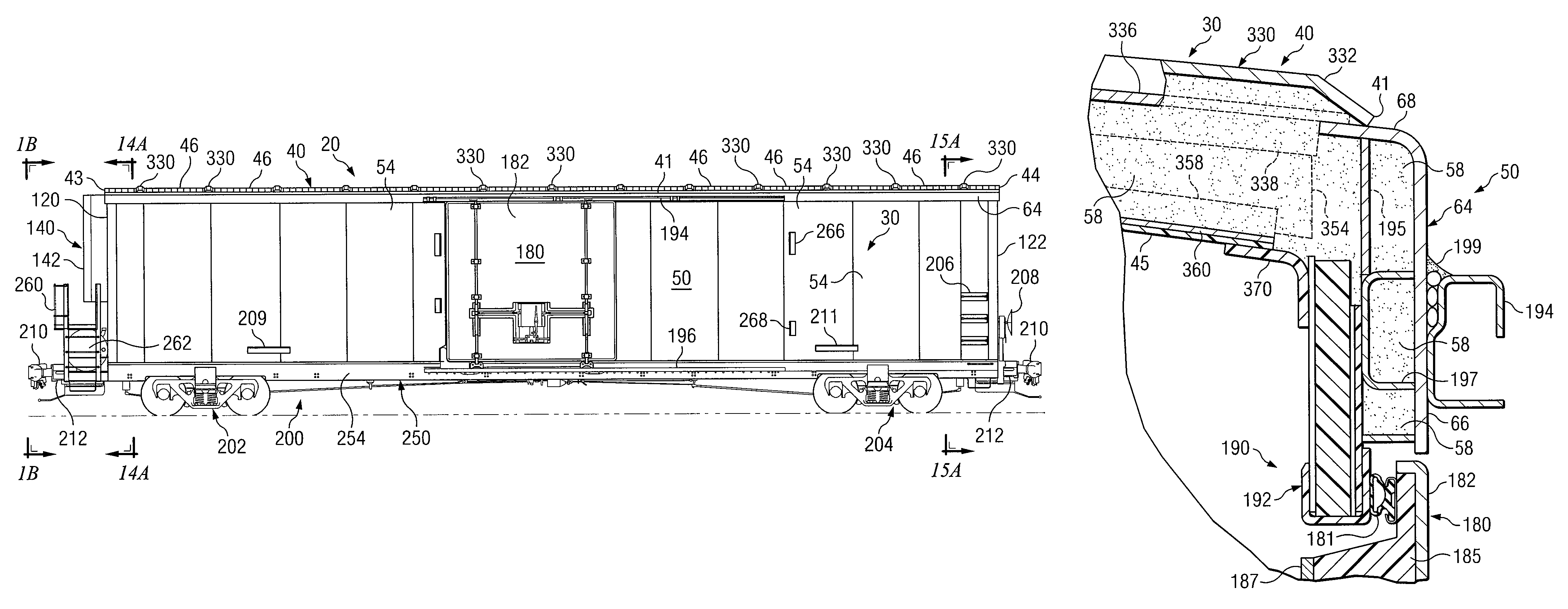

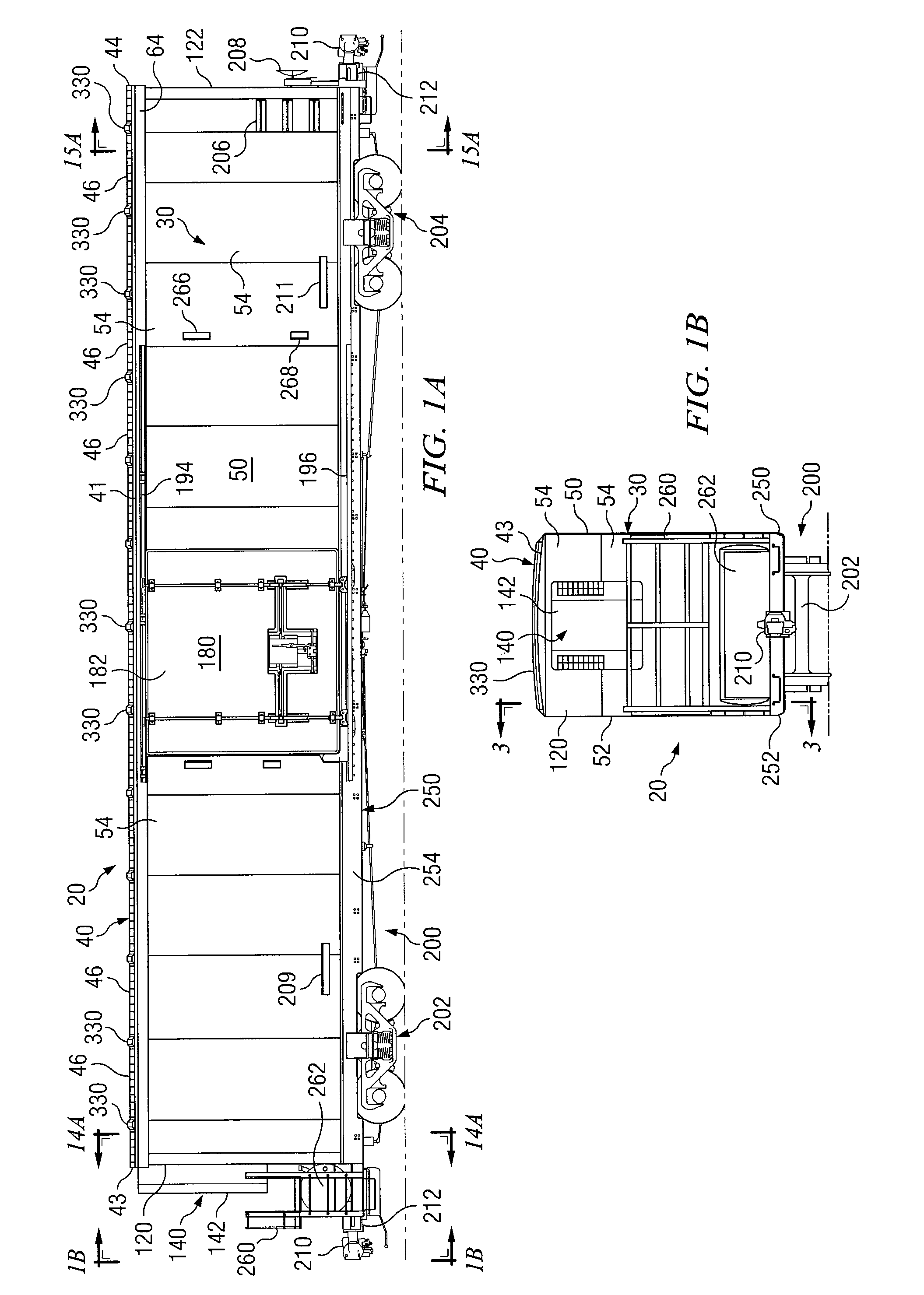

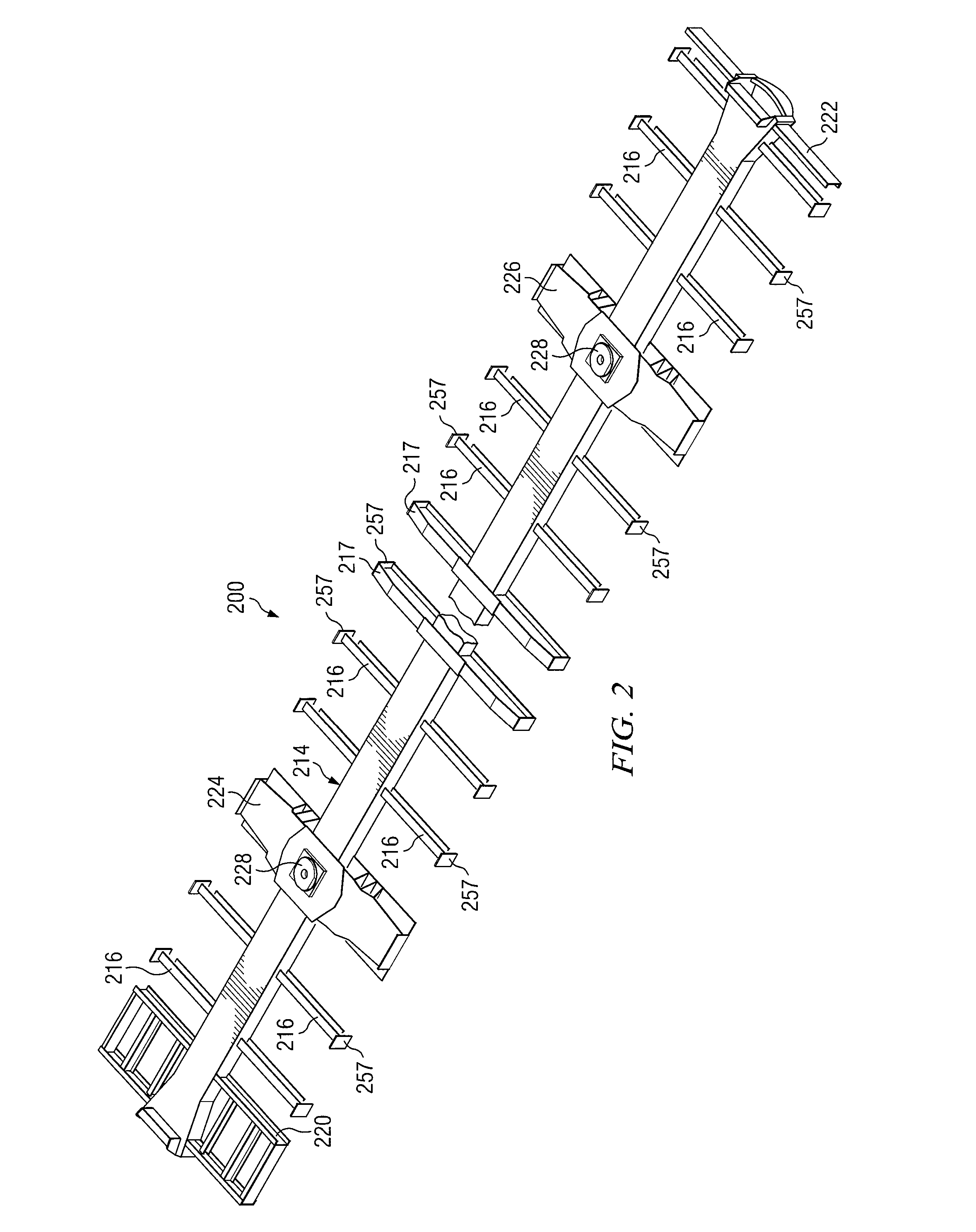

Temperature controlled railway car

A composite box structure assembled on and securely attached to a railway car underframe to form a temperature controlled railway car or on insulated boxcar. The composite box structure defined in part by an exterior metal surface, interior side stakes and at least one layer of fiber reinforced plastic attached to the side stakes. Foam insulation may be disposed between the side stakes, the exterior metal surface and the at least one layer of fiber reinforced plastic. The foam insulation provides improved resistance to heat transfer between the interior and the exterior of the composite box structure. An airflow management system may be incorporated into the composite box structure.

Owner:TRINITY IND INC

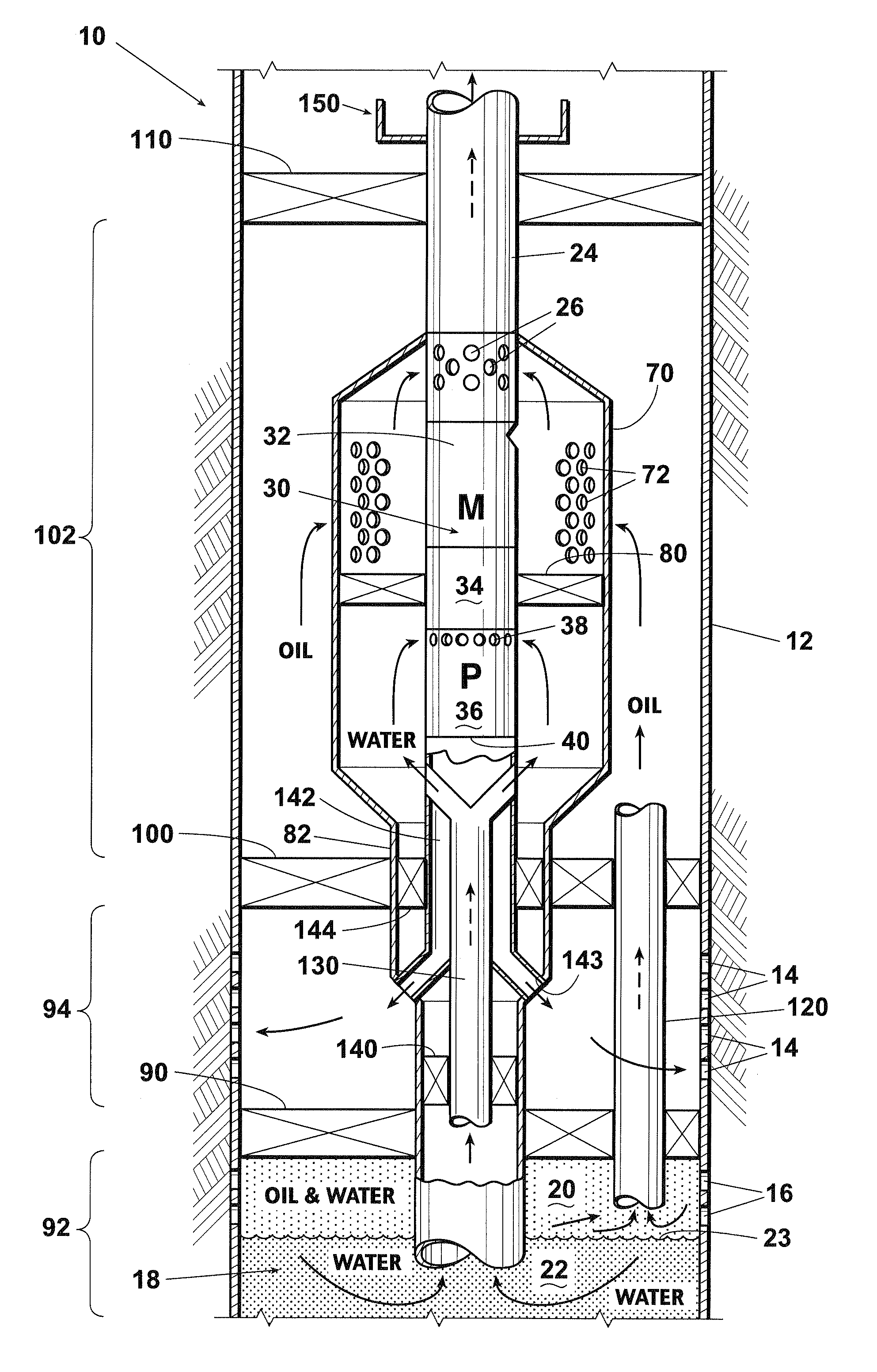

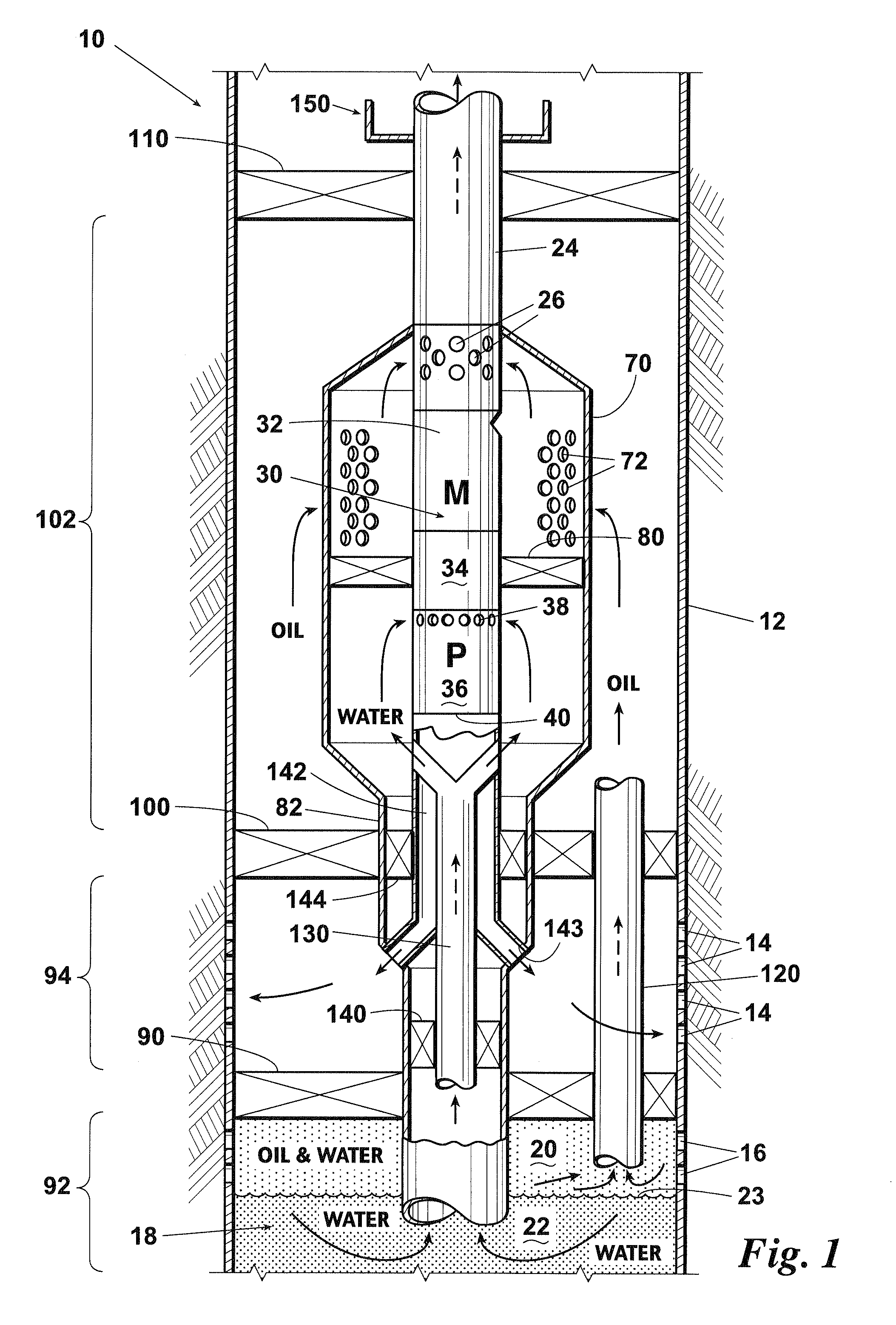

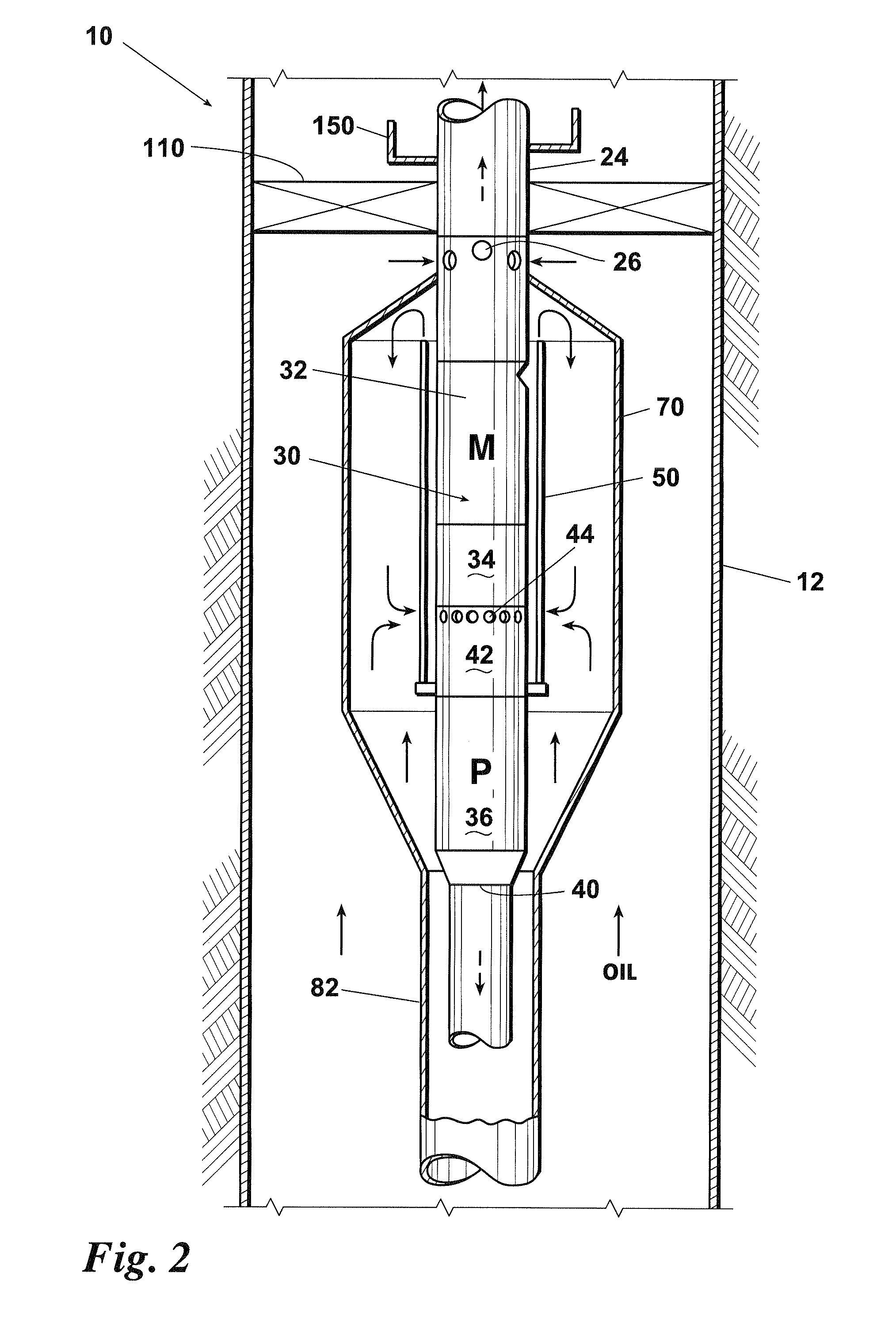

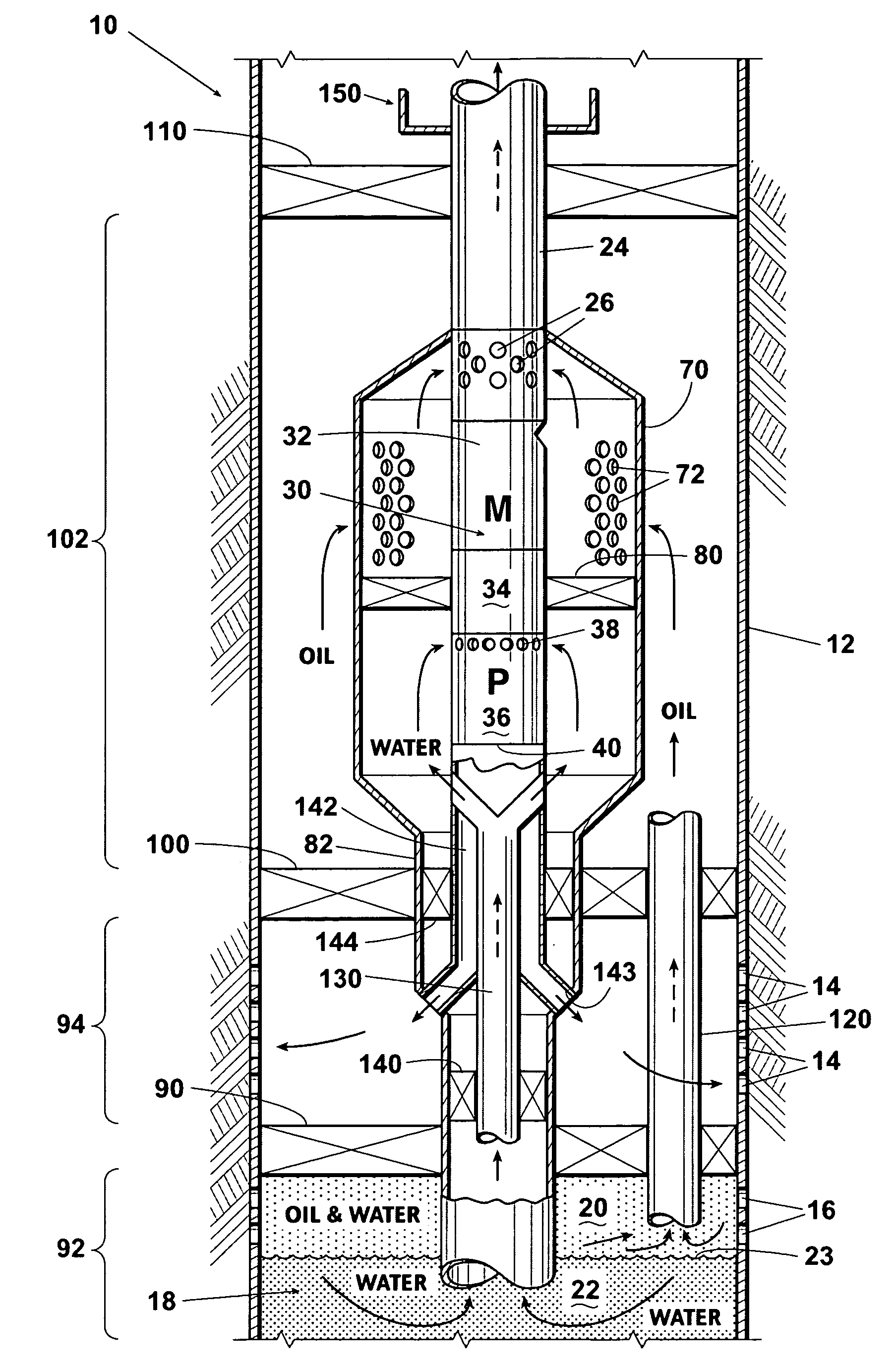

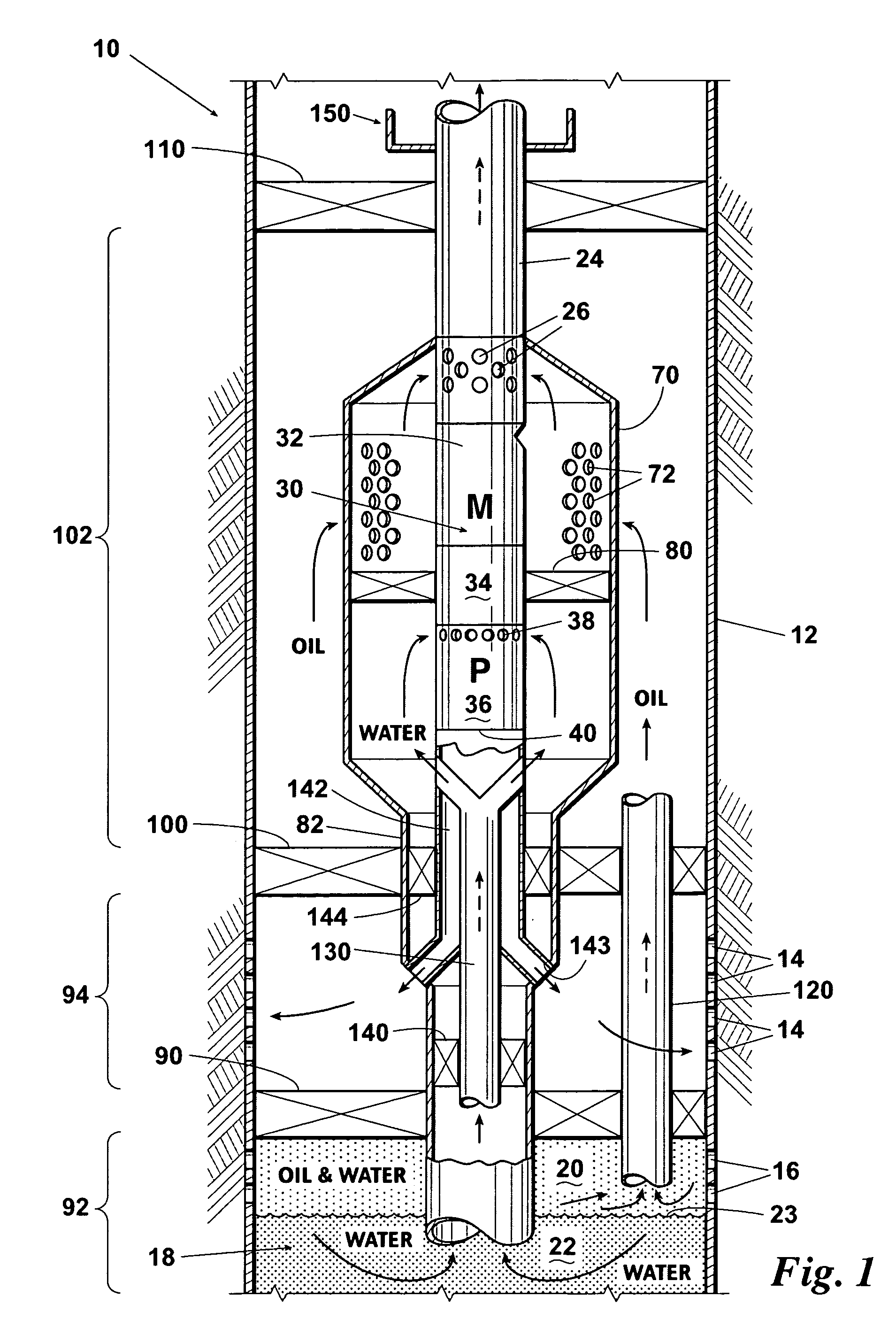

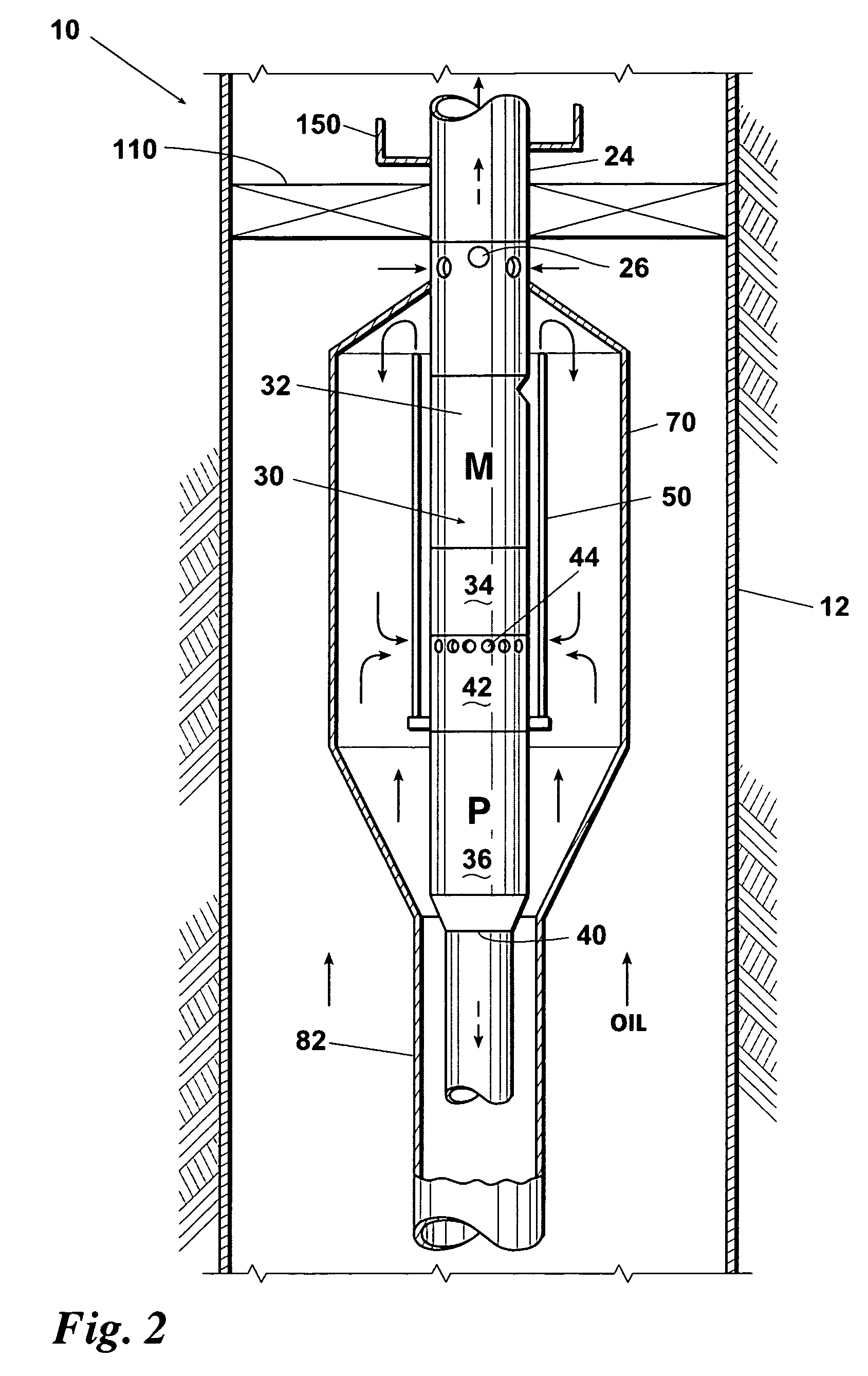

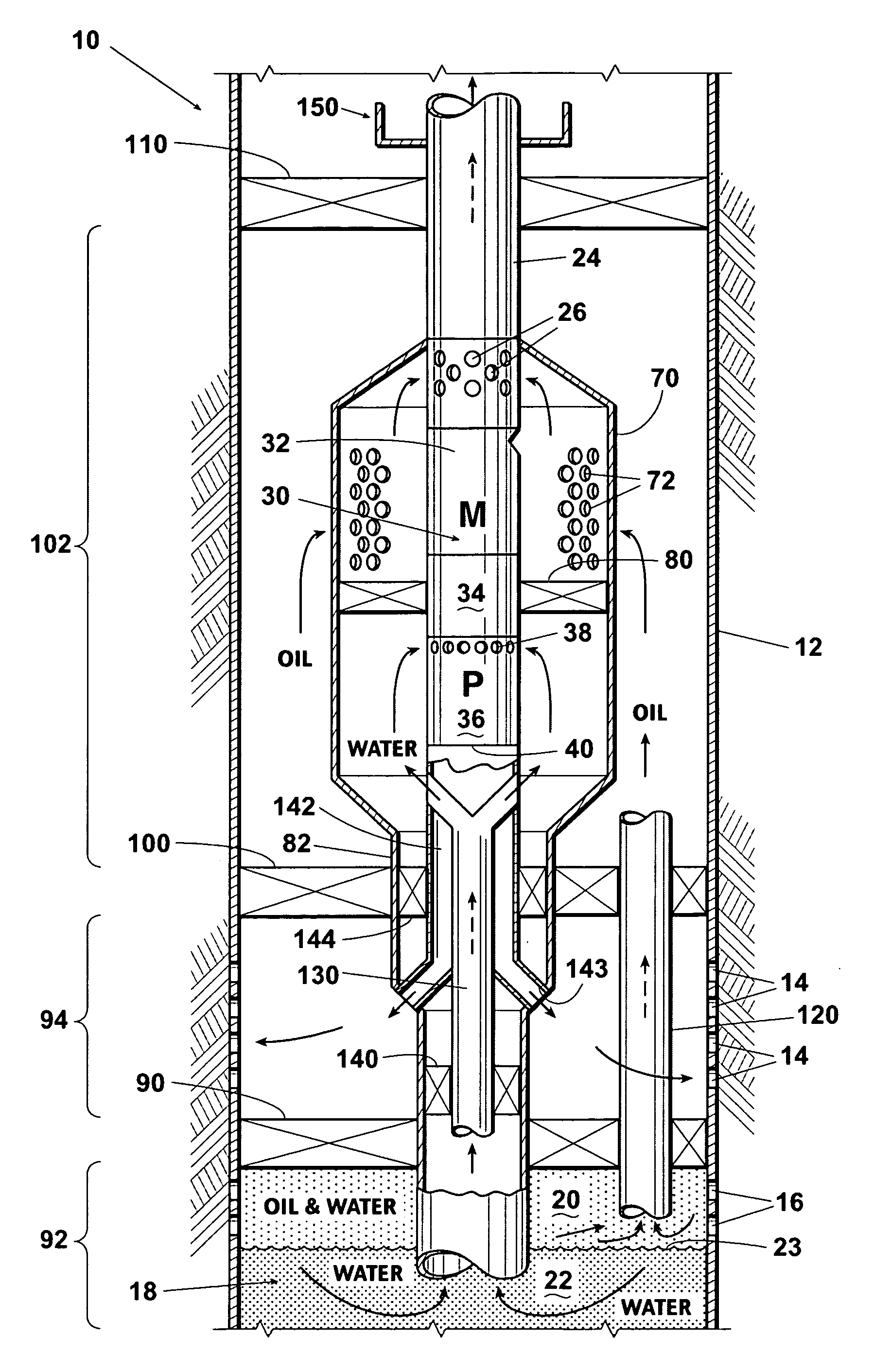

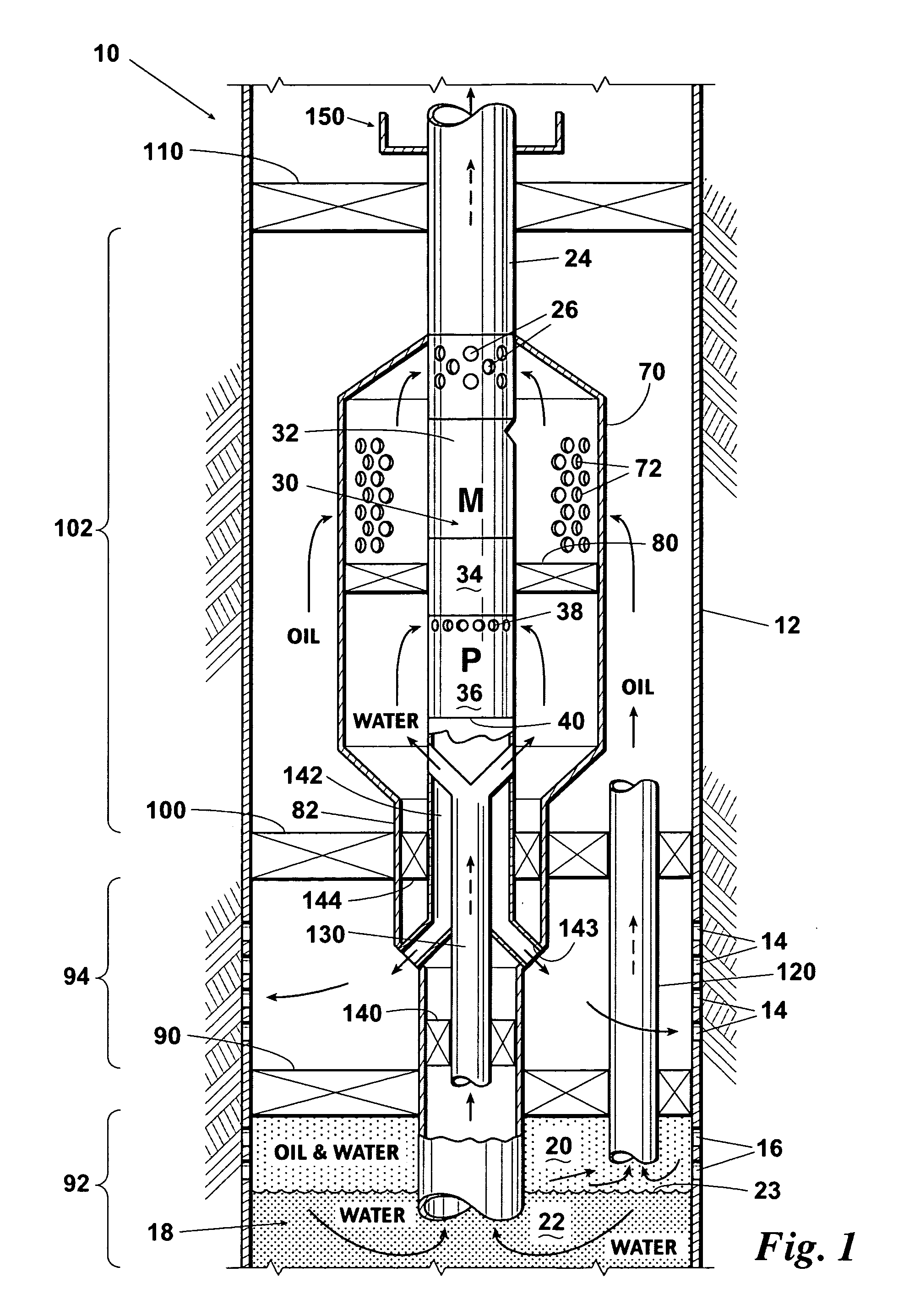

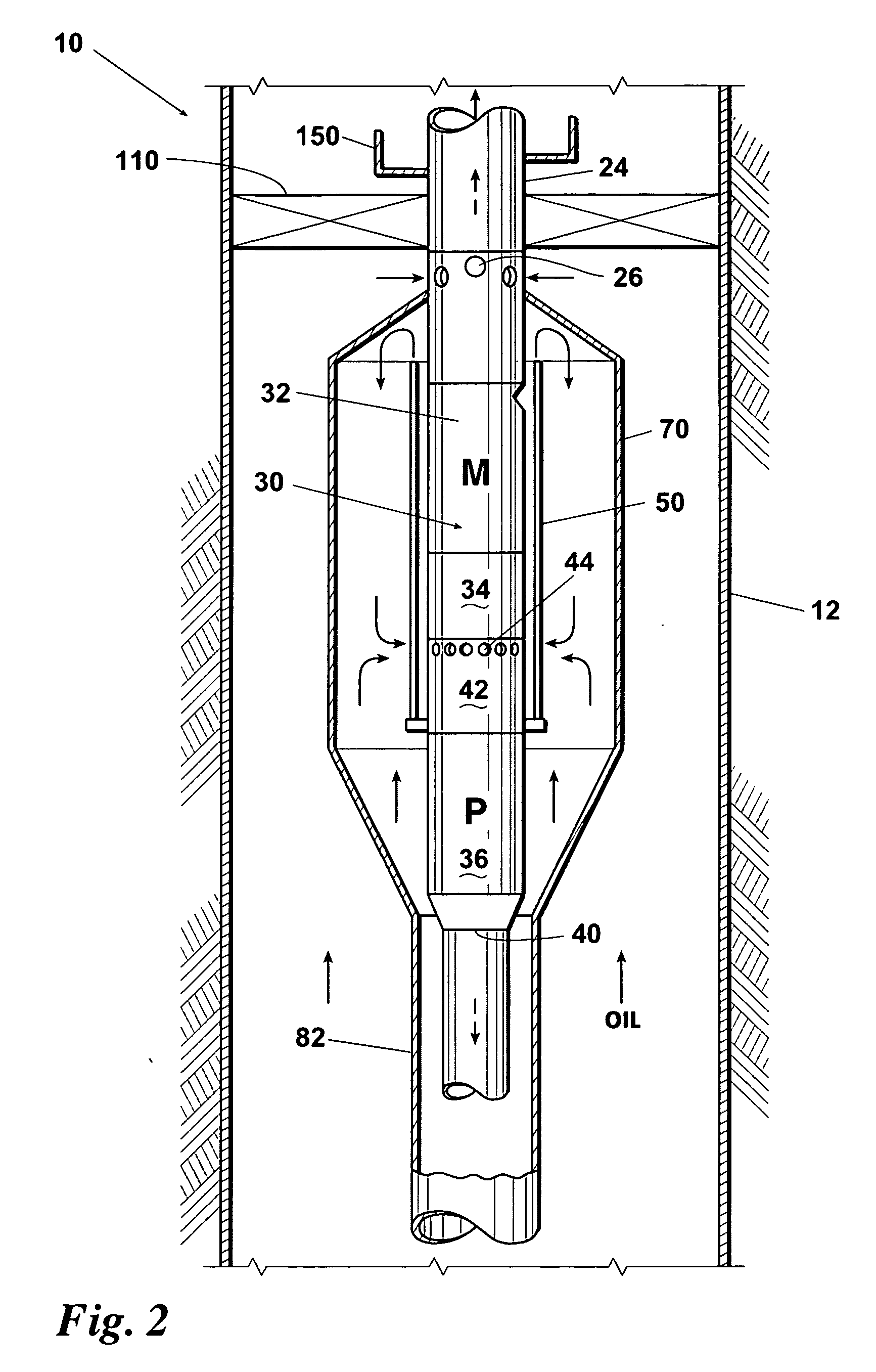

Inverted electrical submersible pump completion to maintain fluid segregation and ensure motor cooling in dual-stream well

InactiveUS20080093085A1Improve heat transfer characteristicsReduce necessityFluid removalProduction packerElectric machinery

An electrical submersible pump (ESP) completion installed in casing perforated for water disposal and production. A packer separates the disposal zone and the production zone. An inverted ESP assembly is located inside of a canister. The ESP and canister are lowered on a tubing string into the casing. The canister has a downwardly extending canister extension flow-directing member that communicates with water in the casing and which passes through the disposal zone. Water is pumped down the canister extension member into the disposal zone and formation. Well fluids are drawn up the extension from the production zone. Various configurations are disclosed to facilitate flowing well fluids, e.g., oil-rich mixture or water passed the motor for cooling the motor of the inverted ESP while maintaining fluid segregation. The completion is particularly suited for production wells wherein the oil and water have a strong tendency to naturally segregate within the wellbore.

Owner:BAKER HUGHES INC

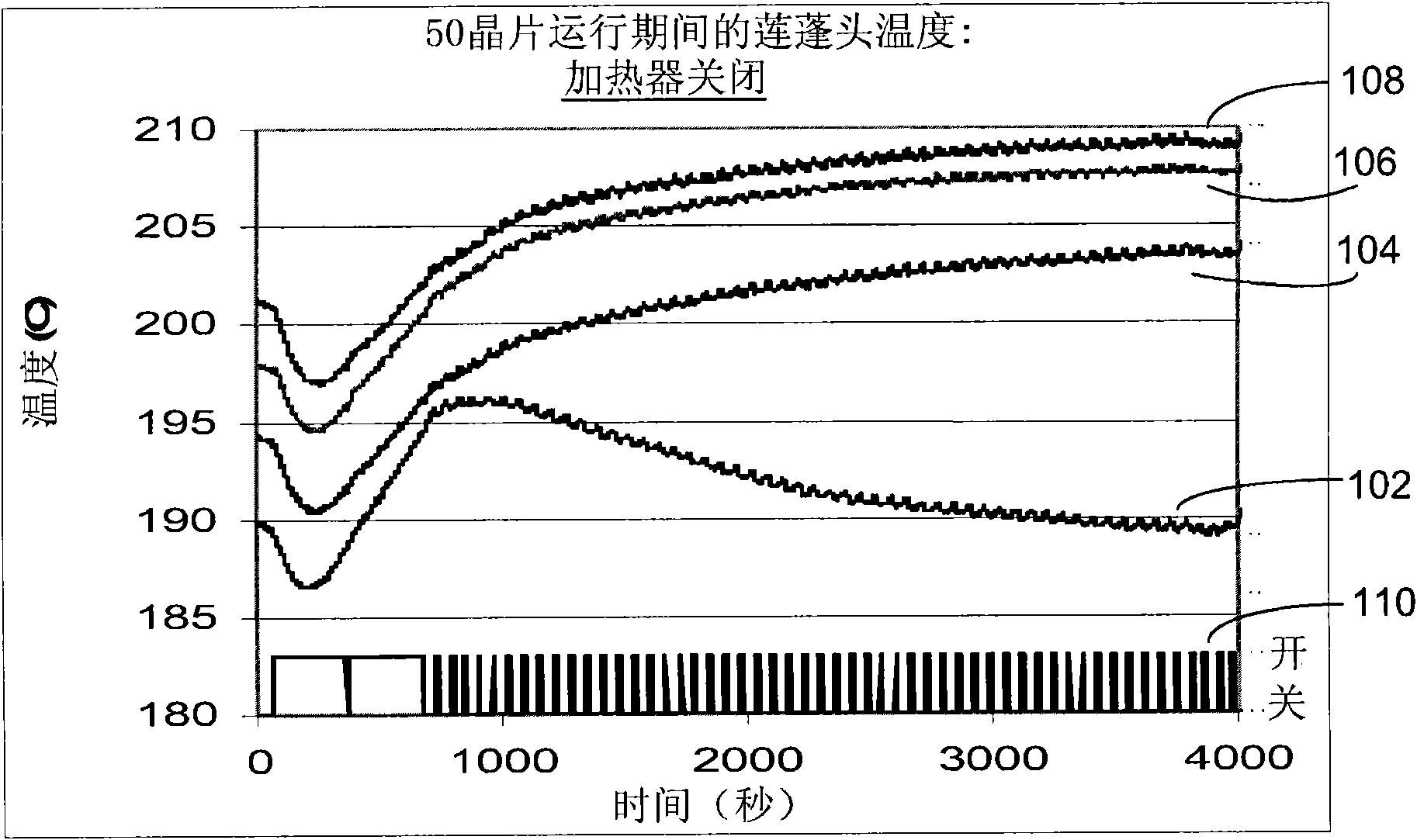

Temperature controlled showerhead for high temperature operations

ActiveCN102102194AImprove uniformityEnhanced heat transfer characteristicsChemical vapor deposition coatingEngineeringThermal contact

A temperature controlled showerhead assembly for chemical vapor deposition (CVD) chambers enhances heat dissipation to provide accurate temperature control of the showerhead face plate and maintain temperatures substantially lower than surrounding components. Heat dissipates by conduction through a showerhead stem and removed by the heat exchanger mounted outside of the vacuum environment. Heat is supplied by a heating element inserted into the steam of the showerhead. Temperature is controlled using feedback supplied by a temperature sensor installed in the stem and in thermal contact with the face plate.

Owner:NOVELLUS SYSTEMS

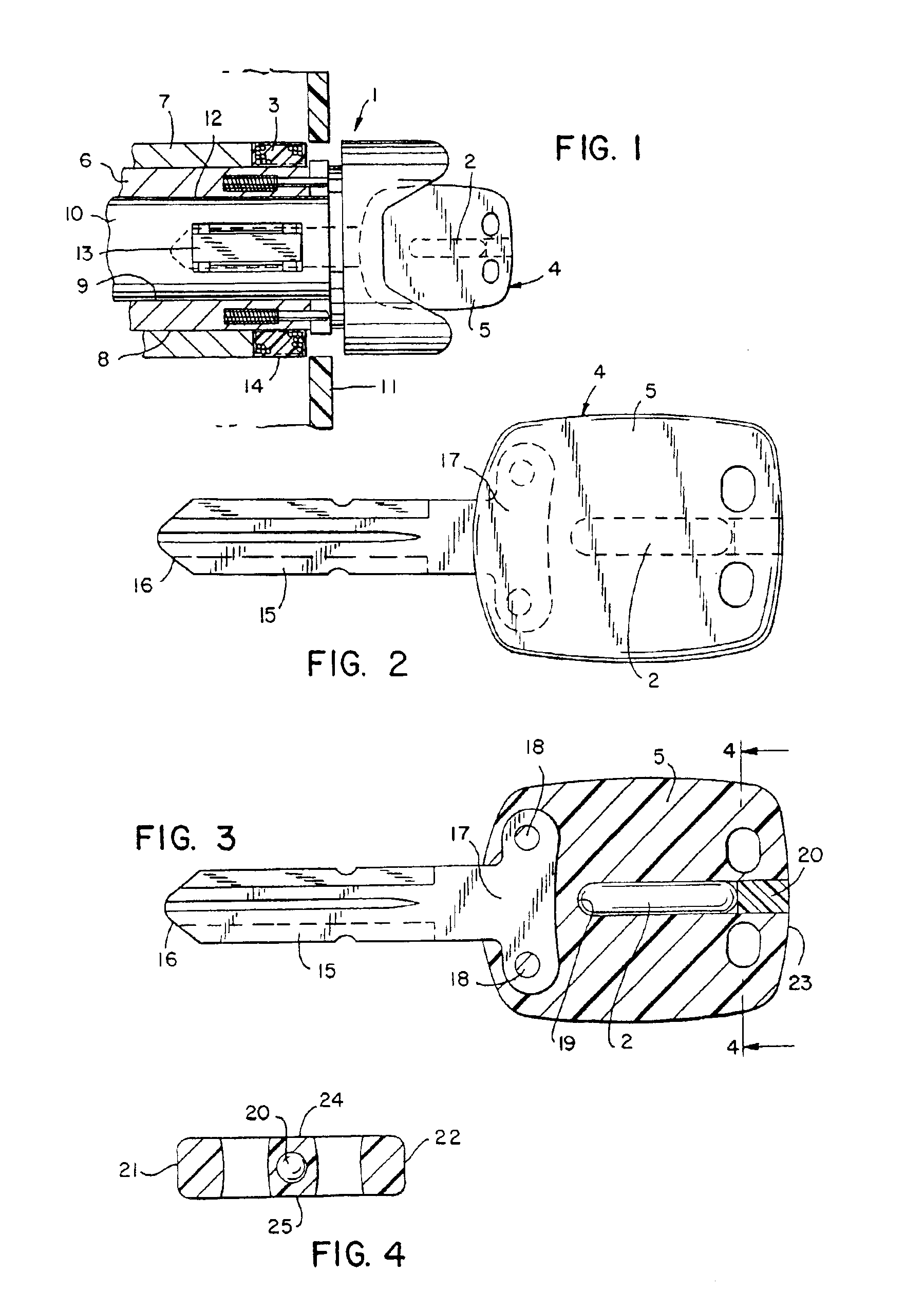

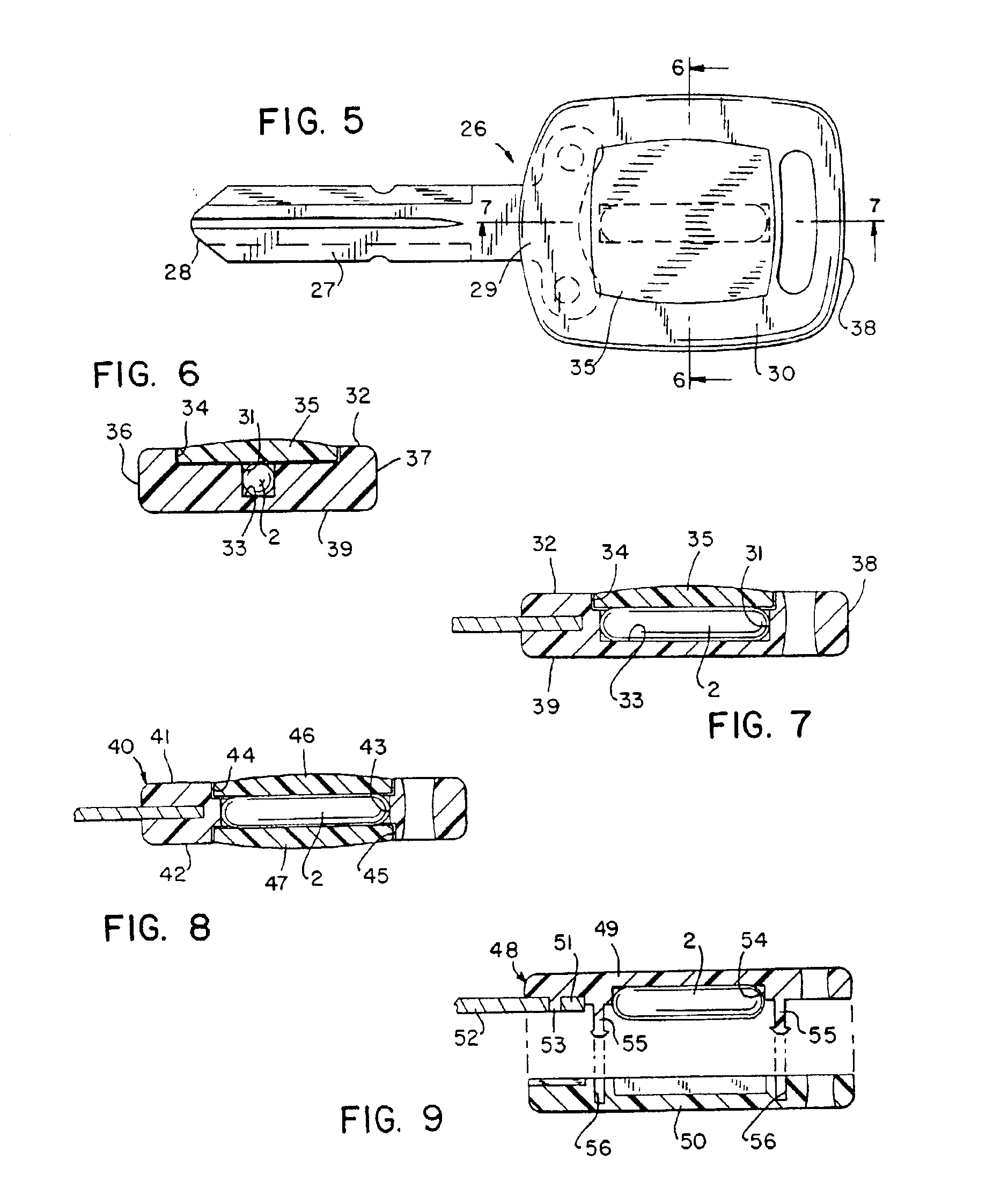

Key assembly for vehicle ignition locks

InactiveUS6948344B2Minimize impactLower potentialNon-mechanical controlsKeysElectricityMetallic materials

A method of decreasing resonant frequency shifting of an electrical circuit mounted on a vehicle key includes providing a frame in an opening in the head portion of a vehicle key and locating the transponder in the frame. The frame comprises substantially rigid non-metallic material, and the frame includes a support structure for supporting the transponder while decreasing forces produced on the transponder by thermal expansion and contraction of the head portion of the key, thereby decreasing shift in the resonance of the electrical circuit of the transponder. The frame, the transponder and the head portion of the key are overmolded providing an outer covering that encloses and protects the transponder.

Owner:STRATTEC SECURITY

Inverted electrical submersible pump completion to maintain fluid segregation and ensure motor cooling in dual-stream well

InactiveUS7487838B2Improve heat transfer characteristicsReduce necessityFluid removalElectric machineryEngineering

An electrical submersible pump (ESP) completion installed in casing perforated for water disposal and production. A packer separates the disposal zone and the production zone. An inverted ESP assembly is located inside of a canister. The ESP and canister are lowered on a tubing string into the casing. The canister has a downwardly extending canister extension flow-directing member that communicates with water in the casing and which passes through the disposal zone. Water is pumped down the canister extension member into the disposal zone and formation. Well fluids are drawn up the extension from the production zone. Various configurations are disclosed to facilitate flowing well fluids, e.g., oil-rich mixture or water, past the motor for cooling the motor of the inverted ESP while maintaining fluid segregation. The completion is particularly suited for production wells wherein the oil and water have a strong tendency to naturally segregate within the wellbore.

Owner:BAKER HUGHES INC

Cold plate apparatus and method of fabrication thereof with a controlled heat transfer characteristic between a metallurgically bonded tube and heat sink for facilitating cooling of an electronics component

InactiveUS7673389B2Cost-effectiveAvoid corrosionMetal-working apparatusCooling/ventilation/heating modificationsAlloyElectronic component

Cold plate apparatuses and methods of fabrication are provided for facilitating cooling of an electronics component. The fabrication approach includes: forming a tube with a first metal and having first and second ends with a heat transfer region disposed therebetween; positioning the heat transfer region of the tube within a mold and casting a heat sink member around the tube by contacting a second metal in molten form over the tube, wherein the first and second metals react peritectically to form an alloy layer between the tube and the heat sink member, and a metallurgical bond is formed between the tube and heat sink member with cooling of the molten second metal; and controlling casting of the heat sink member to minimize a thickness of the alloy layer to enhance a heat transfer characteristic of the metallurgical bond formed between the tube and the heat sink member.

Owner:INT BUSINESS MASCH CORP

Temperature controlled railway car

InactiveUS7228805B2Improve insulation performanceImprove carrying capacityRailway roofsRailway heating/coolingFiberTemperature control

A composite box structure mounted on and attached to a railway car underframe to form a temperature controlled railway car. The composite box structure defined in part by an exterior metal surface, interior side stakes and at least one layer of fiber reinforced material attached to the side stakes. Insulating material may be disposed between the side stakes, the exterior metal surface and the at least one fiber reinforced layer of fiber reinforced material. The insulating materials provide resistance to heat transfer between the interior and the exterior of the composite box structure. A primary floor assembly and a secondary floor assembly may be mounted on the railway car underframe.

Owner:TRINITY IND INC

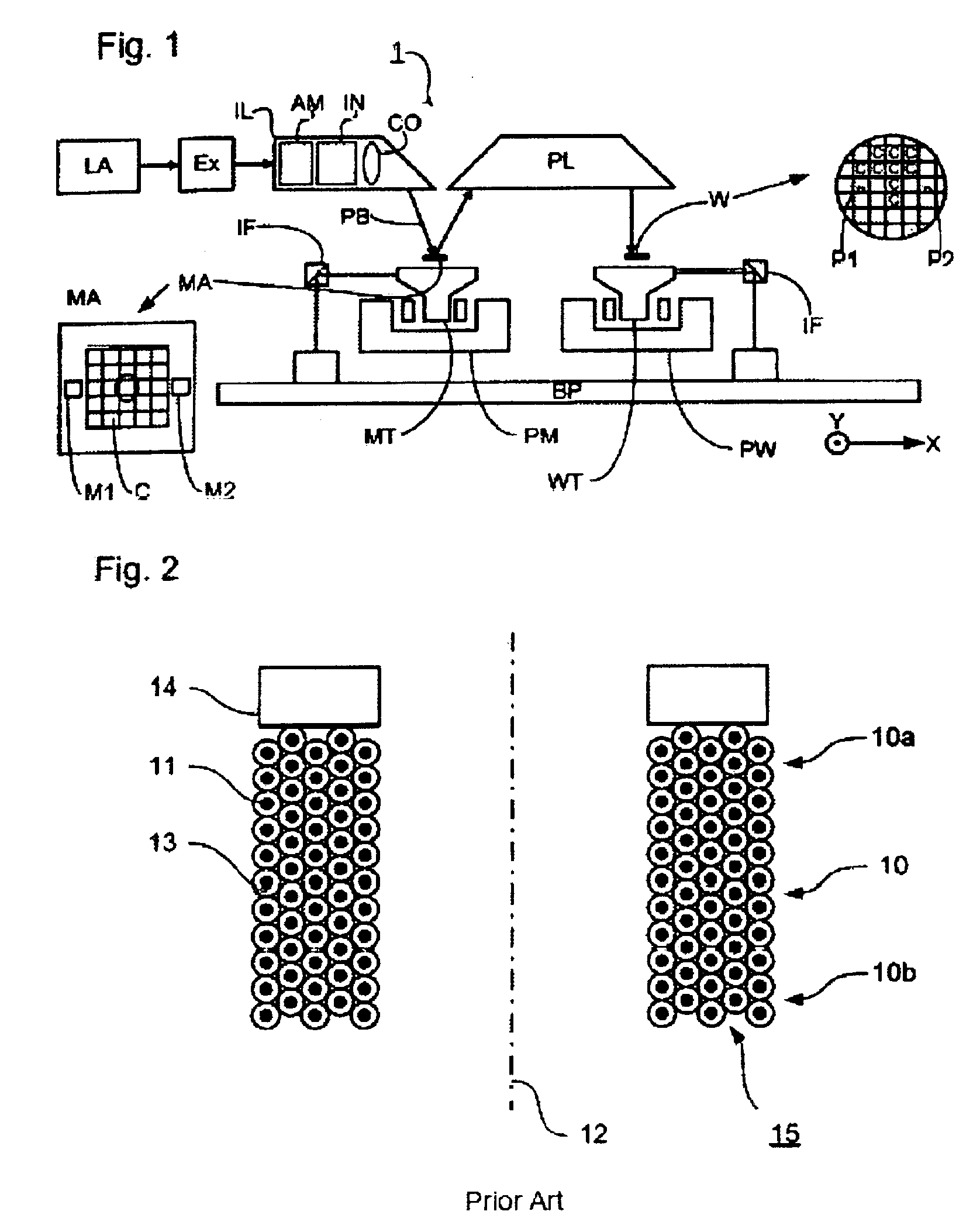

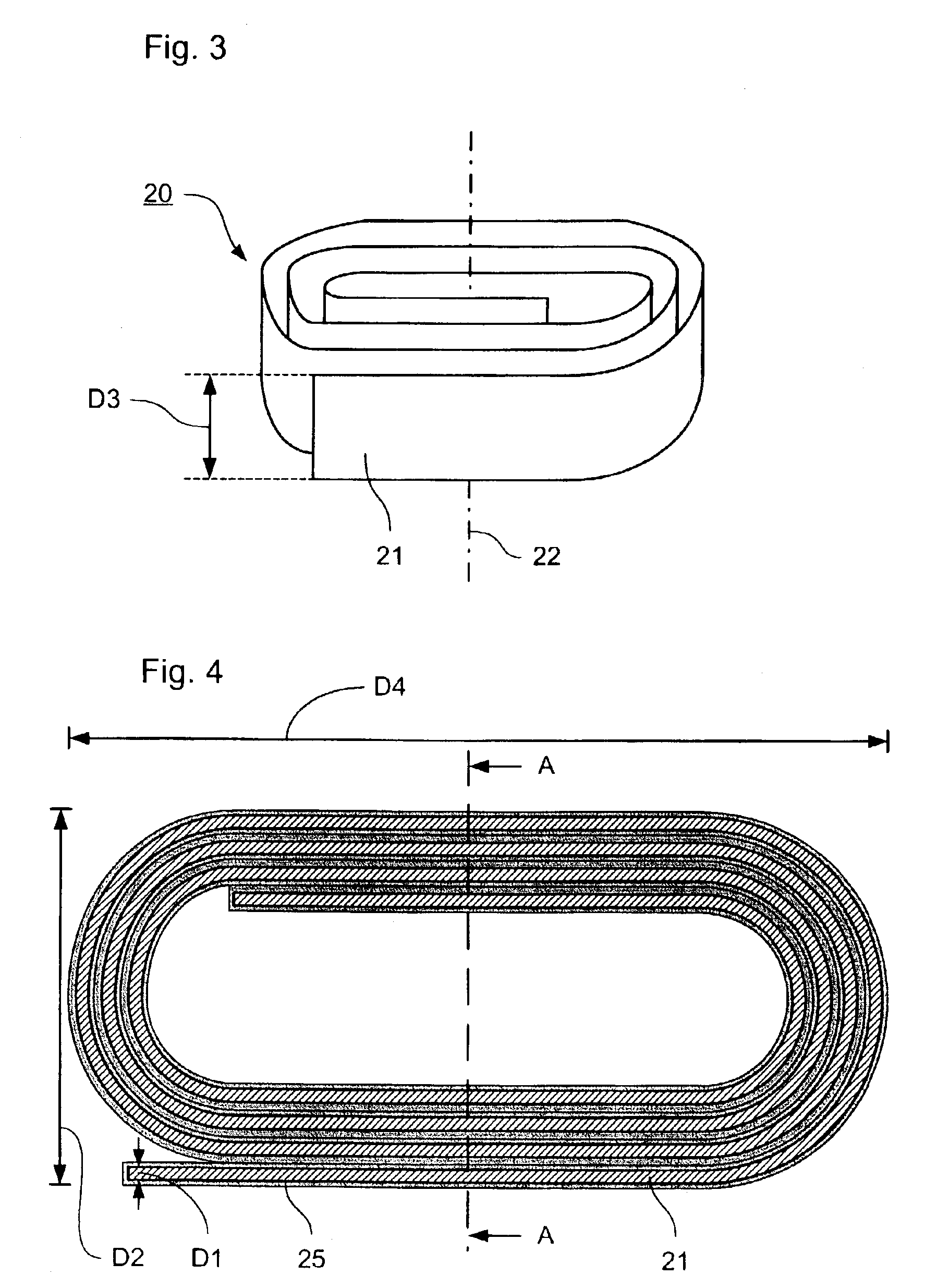

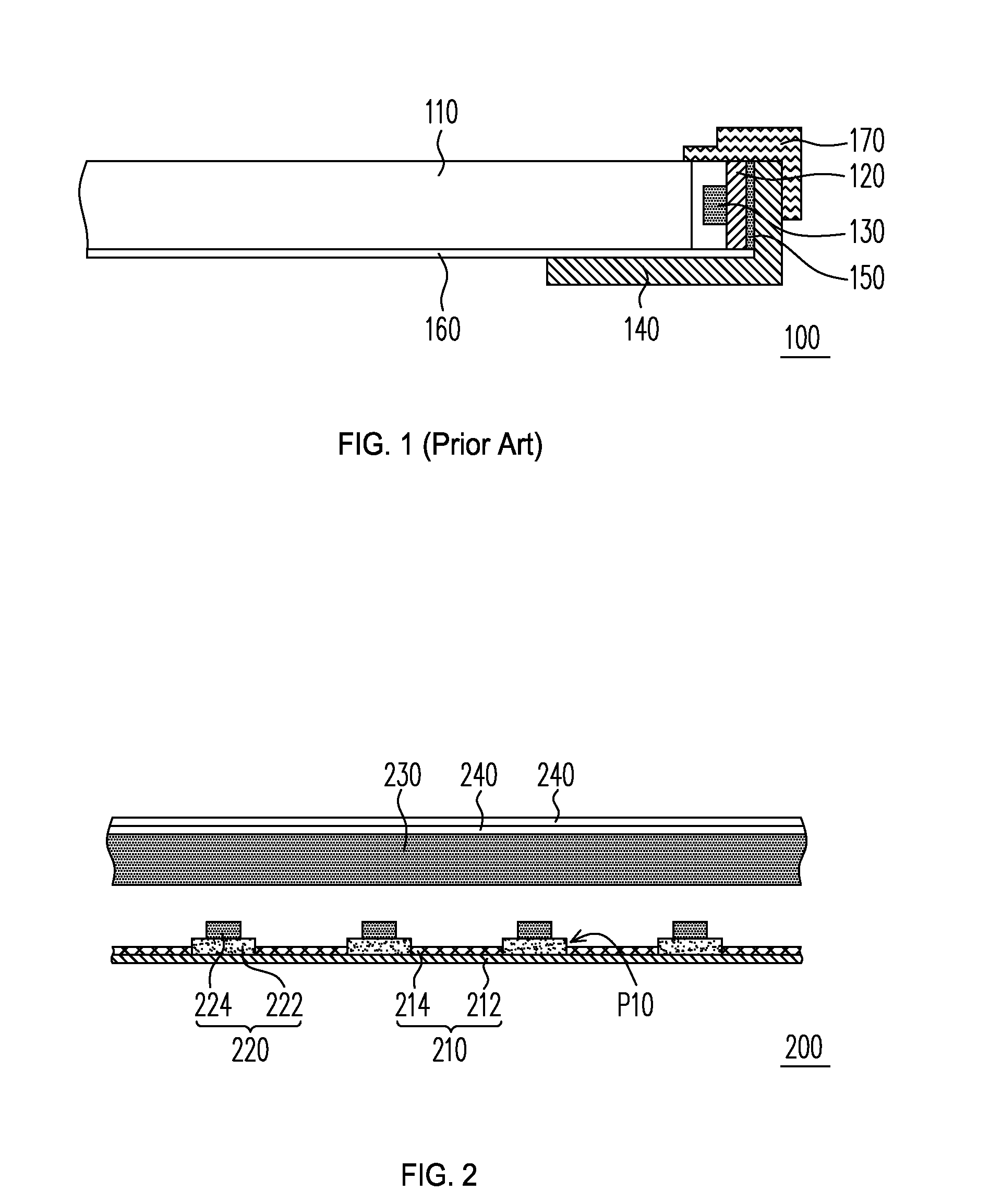

Lithographic apparatus and device manufacturing method

InactiveUS6891600B2Improve heat transfer characteristicsWindings insulation shape/form/constructionMagnetic circuitEngineeringActuator

A coil for use in an actuator in a lithographic projection apparatus. The coil is formed of a strip of electrically conducting sheet-material that is wound round a winding axis. Respective turns of the strip of sheet-material are separated by an electrically non-conducting layer.

Owner:ASML NETHERLANDS BV

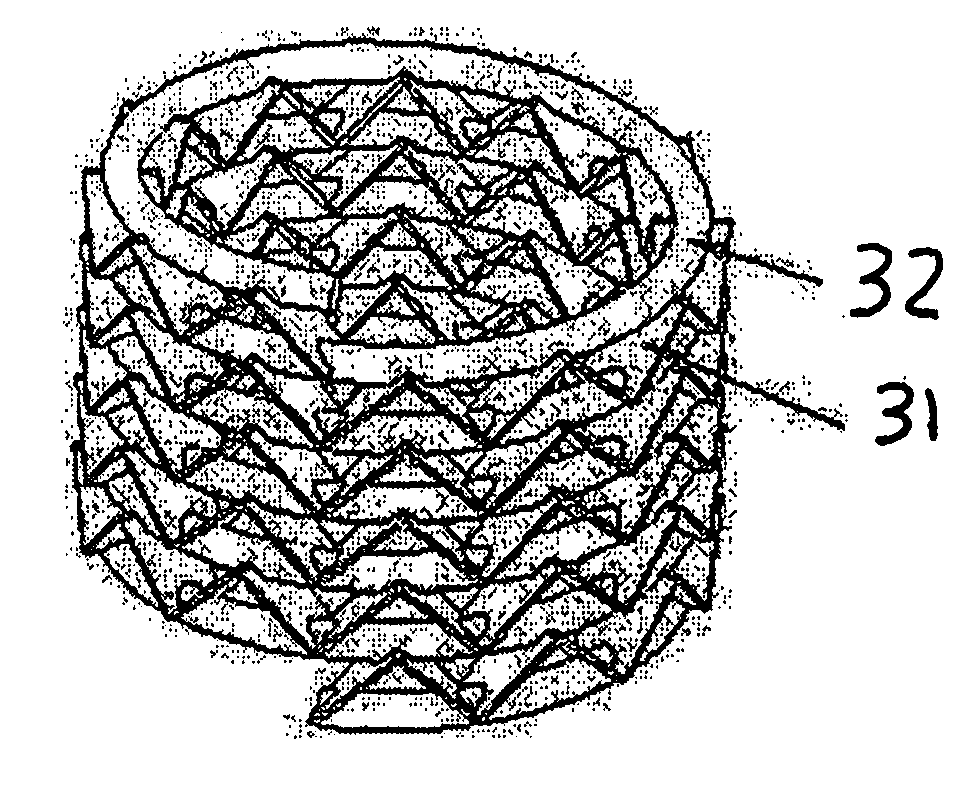

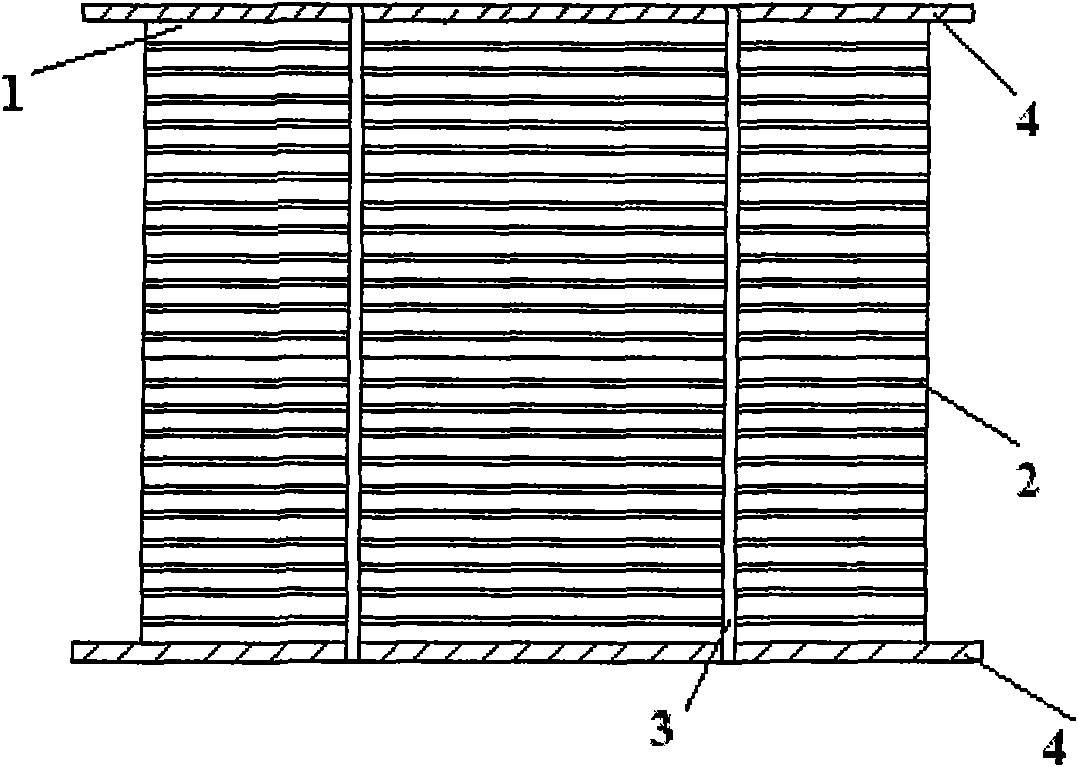

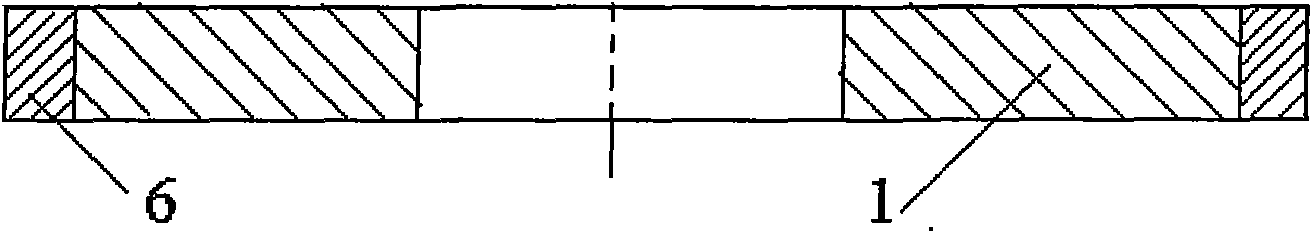

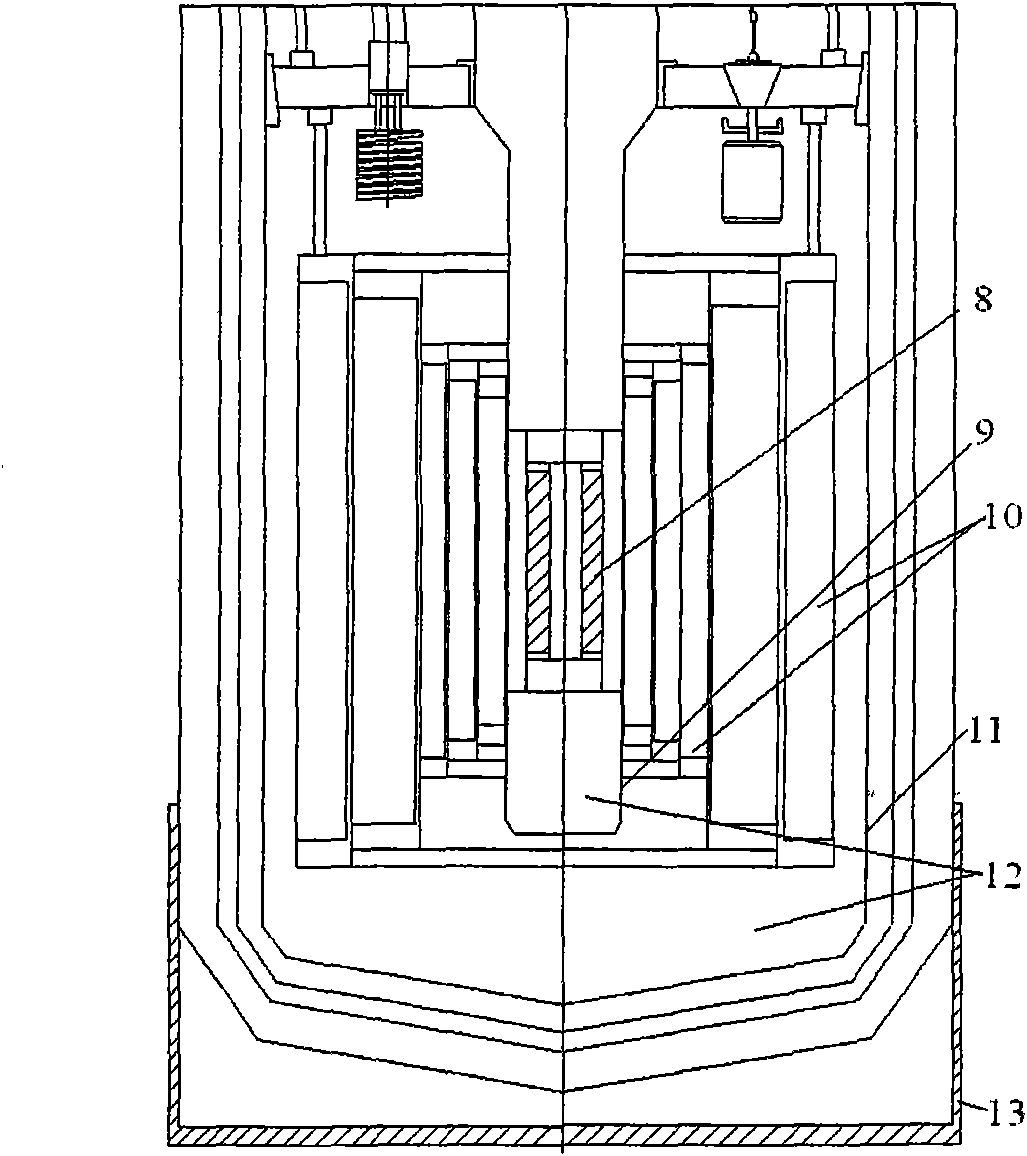

Superconducting magnet system of inserted YBCO-Bitter type high-temperature superconducting coil

ActiveCN101577165AQuench preventionSimple structureInductances/transformers/magnets manufactureSuperconducting magnets/coilsEpoxyHigh-temperature superconductivity

The invention relates to a superconducting magnet system of an inserted YBCO-Bitter type high-temperature coil. The inserted YBCO-Bitter type high-temperature superconducting coil (8) is inserted into an inner hole of a peripheral superconducting coil (10) formed by NbTi and Nb3Sn. The inserted YBCO-Bitter type high-temperature superconducting coil (8) is positioned in a low-temperature container (9); the peripheral superconducting coil (10) is arranged in a low-temperature container (11); and the low-temperature containers (9 and 11) are filled with liquid helium (12). The inserted YBCO-Bitter type high-temperature superconducting coil (8) is formed by superposing of multiple YBCO ring pieces (1) which are embedded in a stainless steel ring (6). High-purity copper ring pieces (2) plated with an aluminum nitride film are arranged between the YBCO ring pieces (1). The multiple YBCO ring pieces (1) and the multiple high-purity copper ring pieces (2) are superposed along the same shaft, are assembled together by a stainless steel central hole tube (3) and an end flange (4), and are cured into a whole body after being soaked by epoxy resin. The superconducting magnet system has simplified structure, little heat leakage of system and stable generated magnetic field.

Owner:NINGBO JANSEN NMR TECH CO LTD

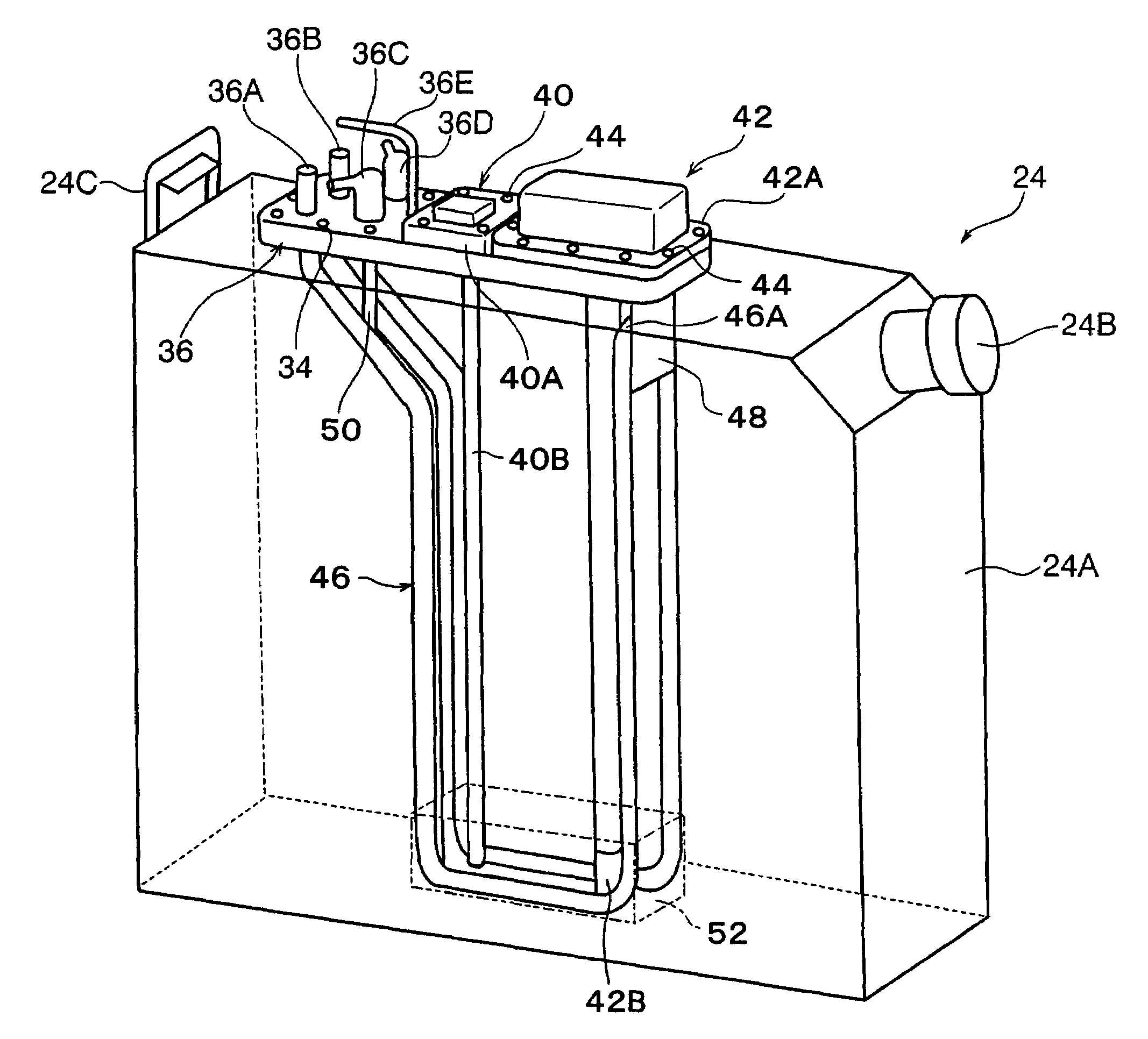

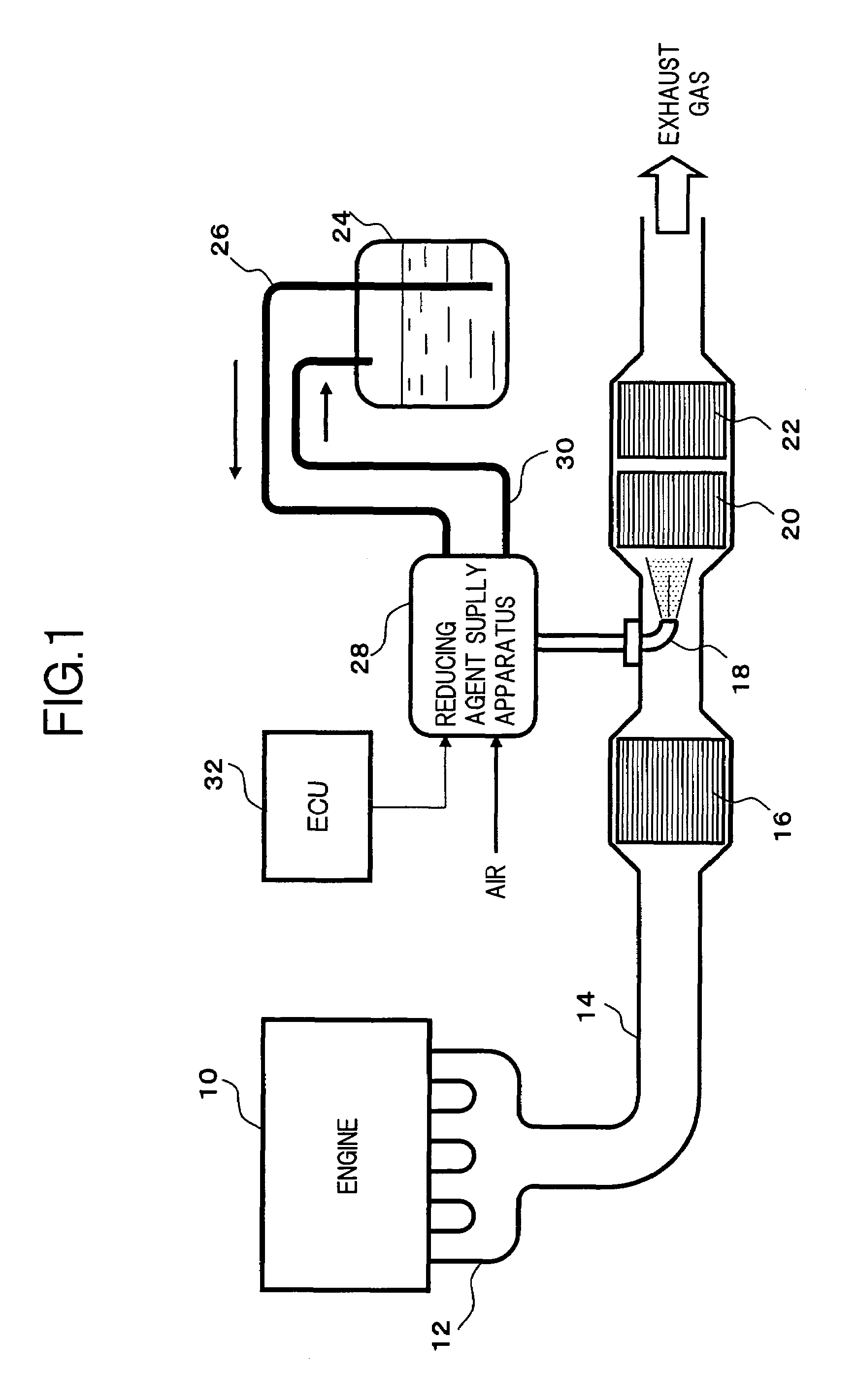

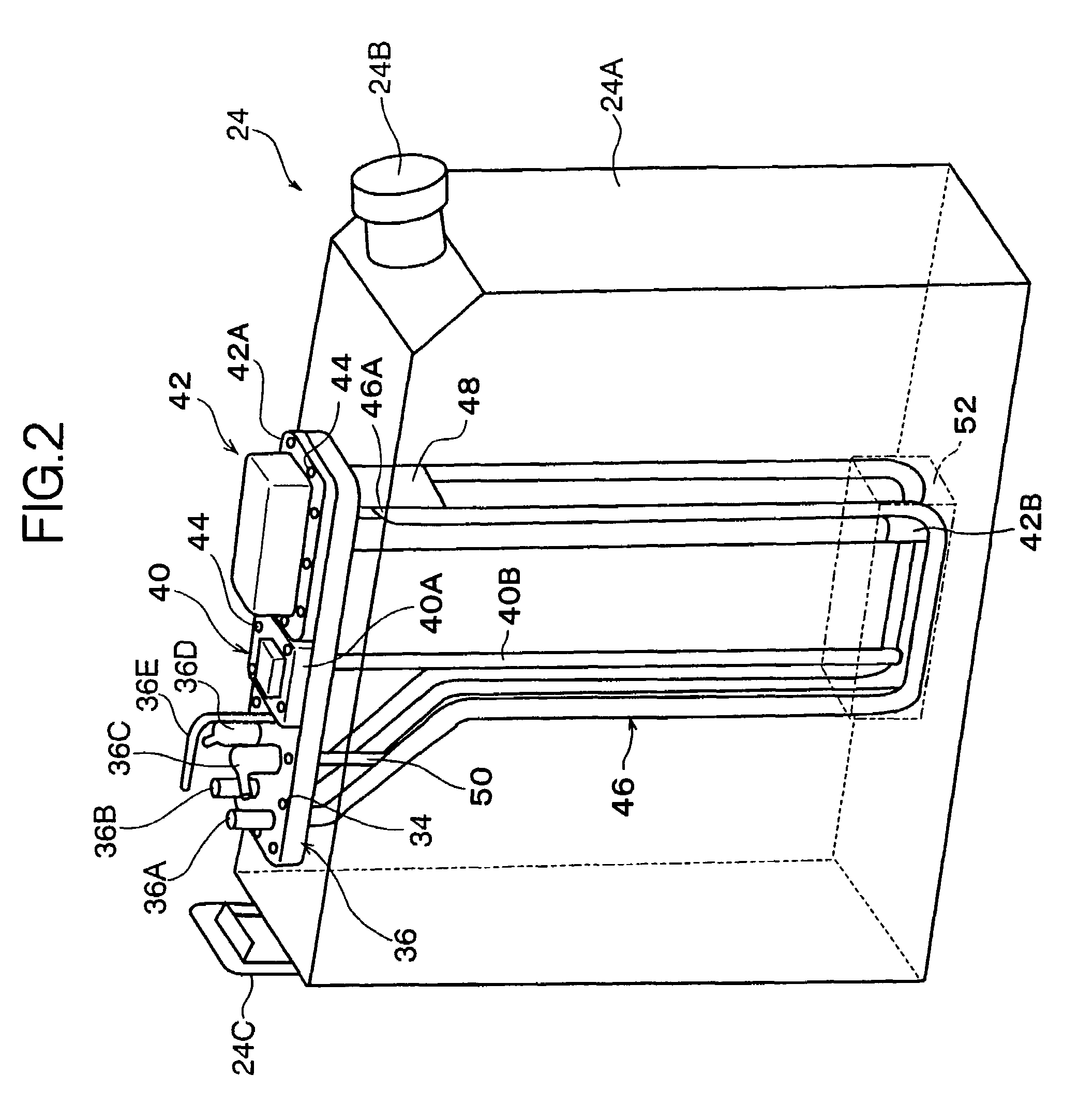

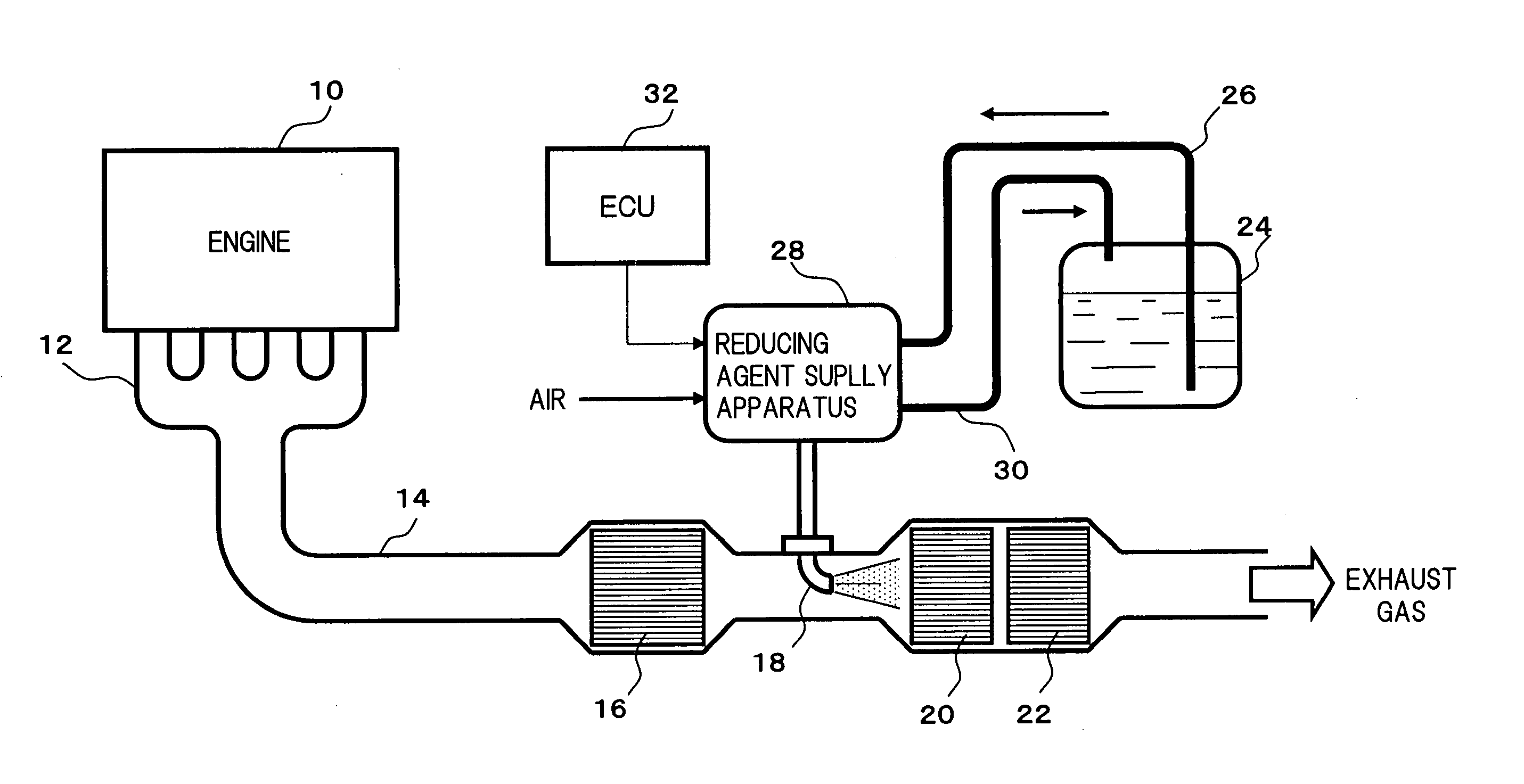

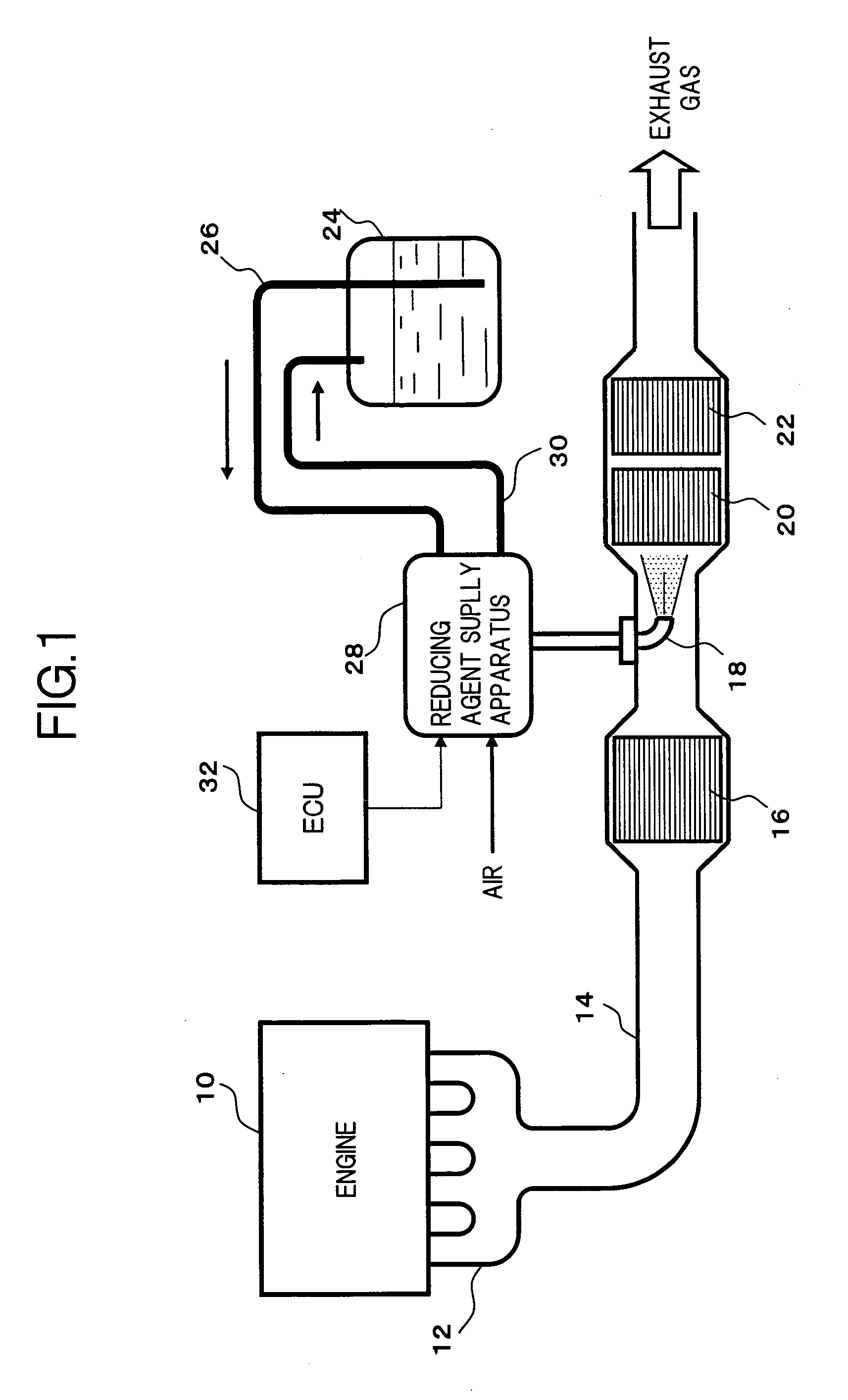

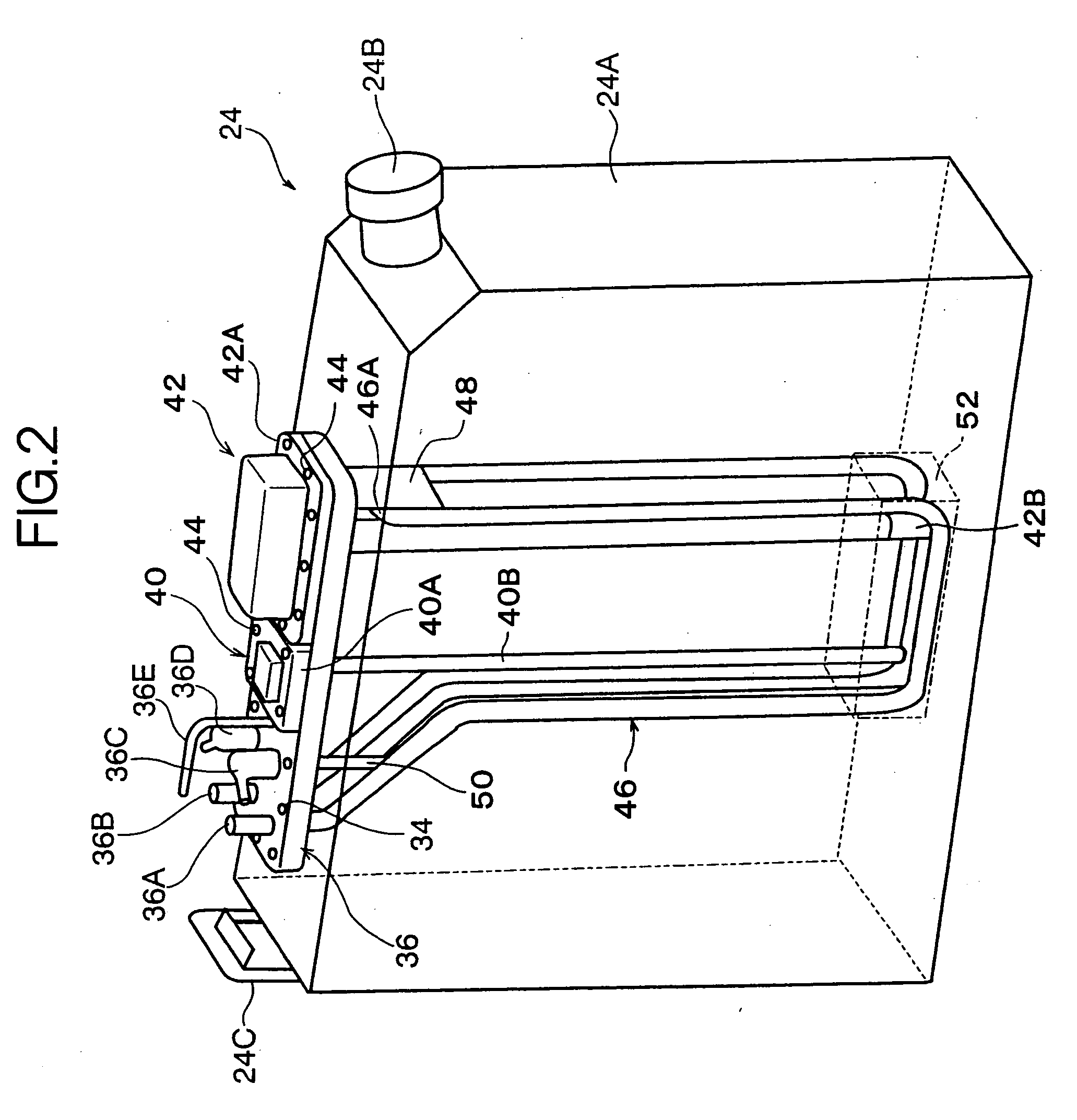

Structure for reducing agent container

ActiveUS7544328B2Reduce inspectionReduce maintenanceTesting/calibration apparatusNitrogen compoundsEngineeringTank container

Owner:NISSAN DIESEL MOTOR CO

Structure for reducing agent container

ActiveUS20070075467A1Good heat transfer characteristicReduce inspectionTesting/calibration apparatusNitrogen compoundsEngineeringDensitometer

A canopy is removably secured to the container body, is respectively fitted with: a base of a water level indicator for detecting a remaining amount of liquid reducing agent; a base of a densitometer for detecting a concentration of a liquid reducing agent; and a heat exchanger which surrounds detection portions respectively suspended from the bases of the water level indicator and the densitometer, and through which is circulated engine coolant, to perform heat exchange with the liquid reducing agent, and a supply port and a return port for the liquid reducing agent are respectively formed in the canopy. The water level indicator, the densitometer, the heat exchanger, and the supply port and the return port for the liquid reducing agent are formed integrally with the canopy, so that the water level indicator and the densitometer can be dismounted together with the canopy at the same time.

Owner:NISSAN DIESEL MOTOR CO

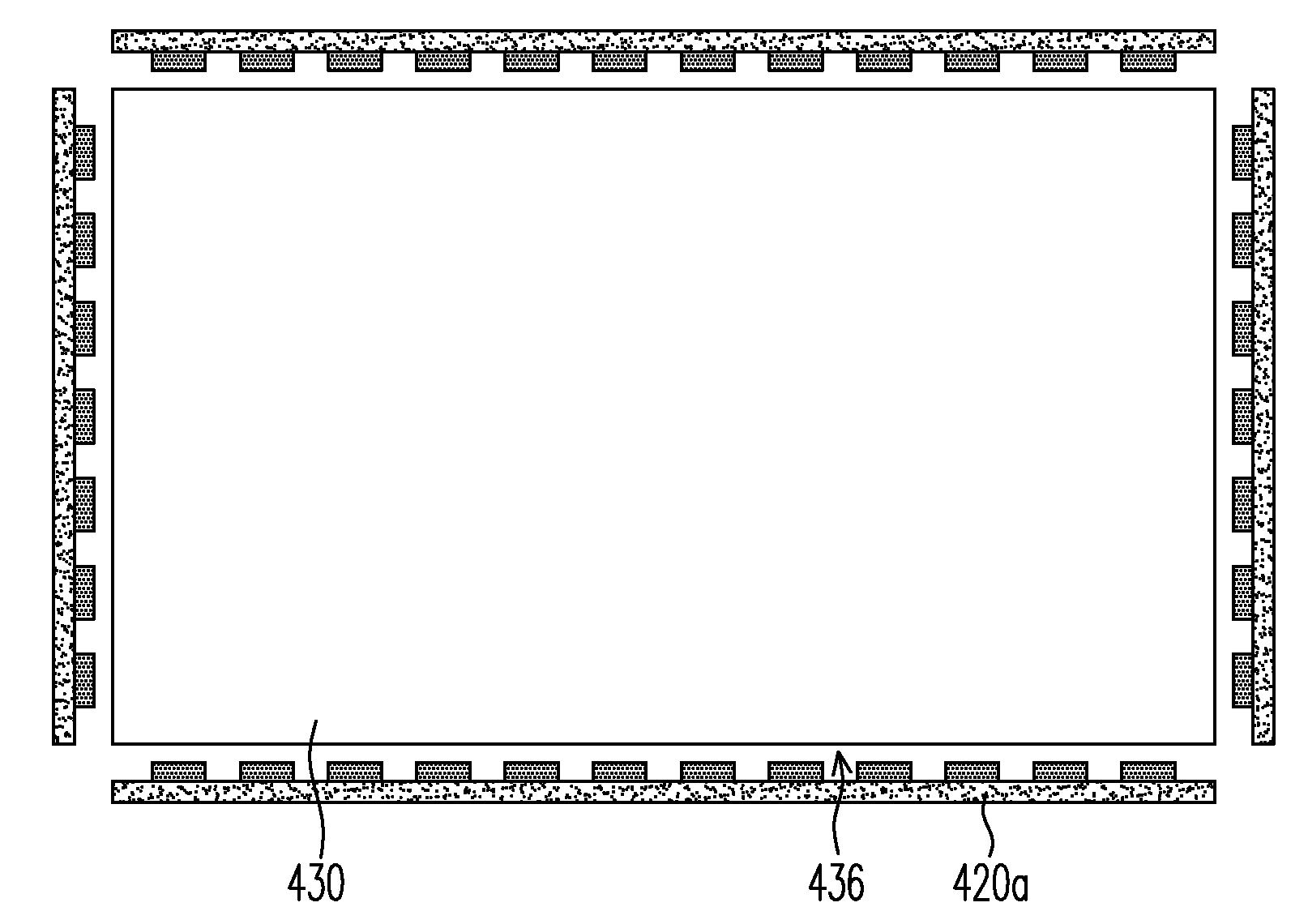

Backlight Module and Liquid Crystal Display using the same

InactiveUS20080170177A1Fast transferRapidly dismissNon-electric lightingPoint-like light sourceComposite filmLiquid-crystal display

A backlight module includes a composite film, and at least one light source unit adjacent to at least one opening. The composite film has a thermal transferring layer and a reflecting layer, the reflecting layer being disposed at the thermal transferring layer and having the at least one opening exposing part of the thermal transferring layer. The backlight module can be used in a liquid crystal display. The liquid crystal display has the aforementioned backlight module and a liquid crystal panel, the backlight module being disposed under the liquid crystal panel.

Owner:INNOLUX CORP

Inverted electrical submersible pump completion to maintain fluid segregation and ensure motor cooling in dual-stream well

InactiveUS20080093084A1Improve heat transfer characteristicsReduce necessityFluid removalElectric machineryEngineering

An electrical submersible pump (ESP) completion installed in casing perforated for water disposal and production. A packer separates the disposal zone and the production zone. An inverted ESP assembly is located inside of a canister. The ESP and canister are lowered on a tubing string into the casing. The canister has a downwardly extending canister extension flow-directing member that communicates with water in the casing and which passes through the disposal zone. Water is pumped down the canister extension member into the disposal zone and formation. Well fluids are drawn up the extension from the production zone. Various configurations are disclosed to facilitate flowing well fluids, e.g., oil-rich mixture or water, past the motor for cooling the motor of the inverted ESP while maintaining fluid segregation. The completion is particularly suited for production wells wherein the oil and water have a strong tendency to naturally segregate within the wellbore.

Owner:BAKER HUGHES INC

Temperature controlled railway car

InactiveUS7478600B2Improve insulation performanceImprove carrying capacityRailway roofsRailway heating/coolingFiberTemperature control

Owner:TRINITY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com