Patents

Literature

559 results about "Tank container" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tank container or tanktainer is an intermodal container for the transport of liquids, gases and powders as bulk cargo.

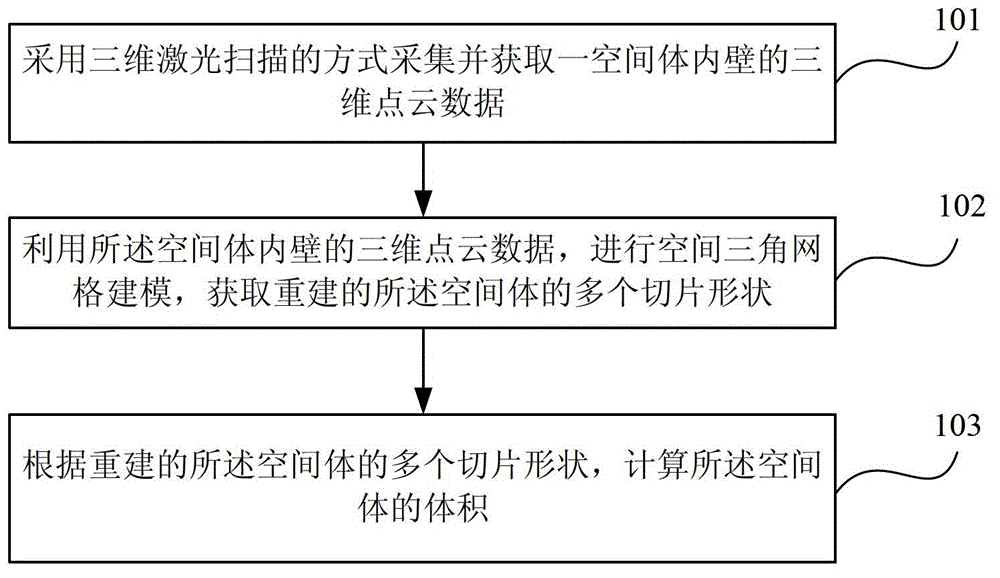

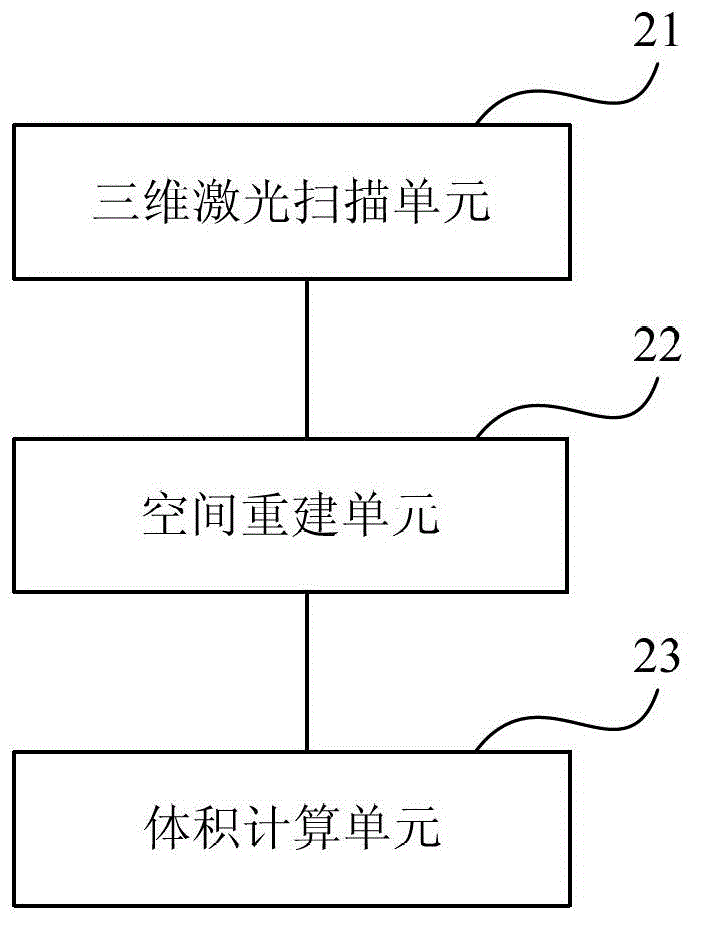

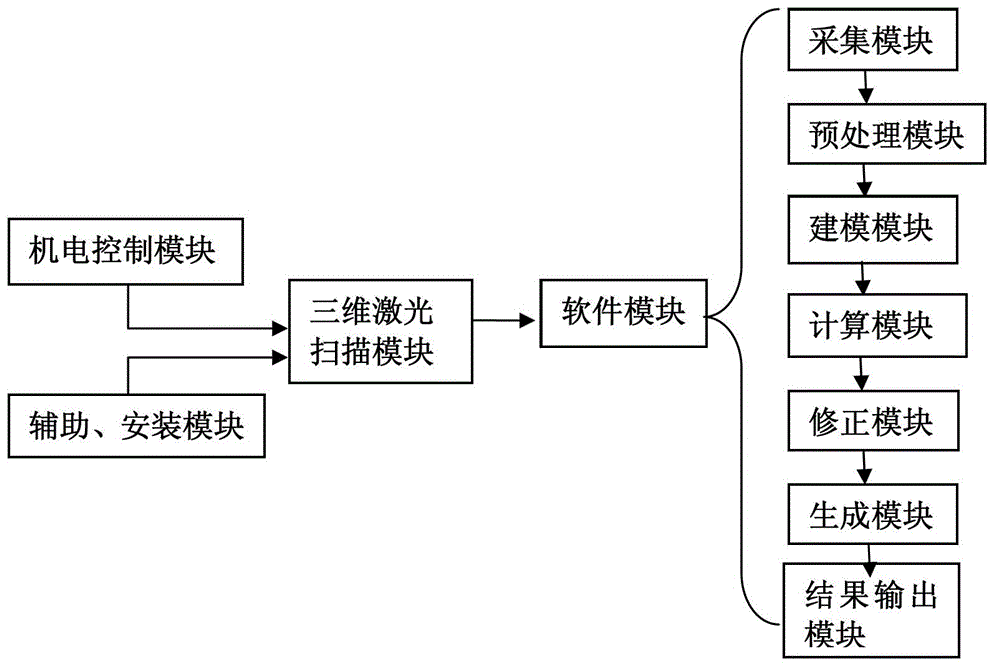

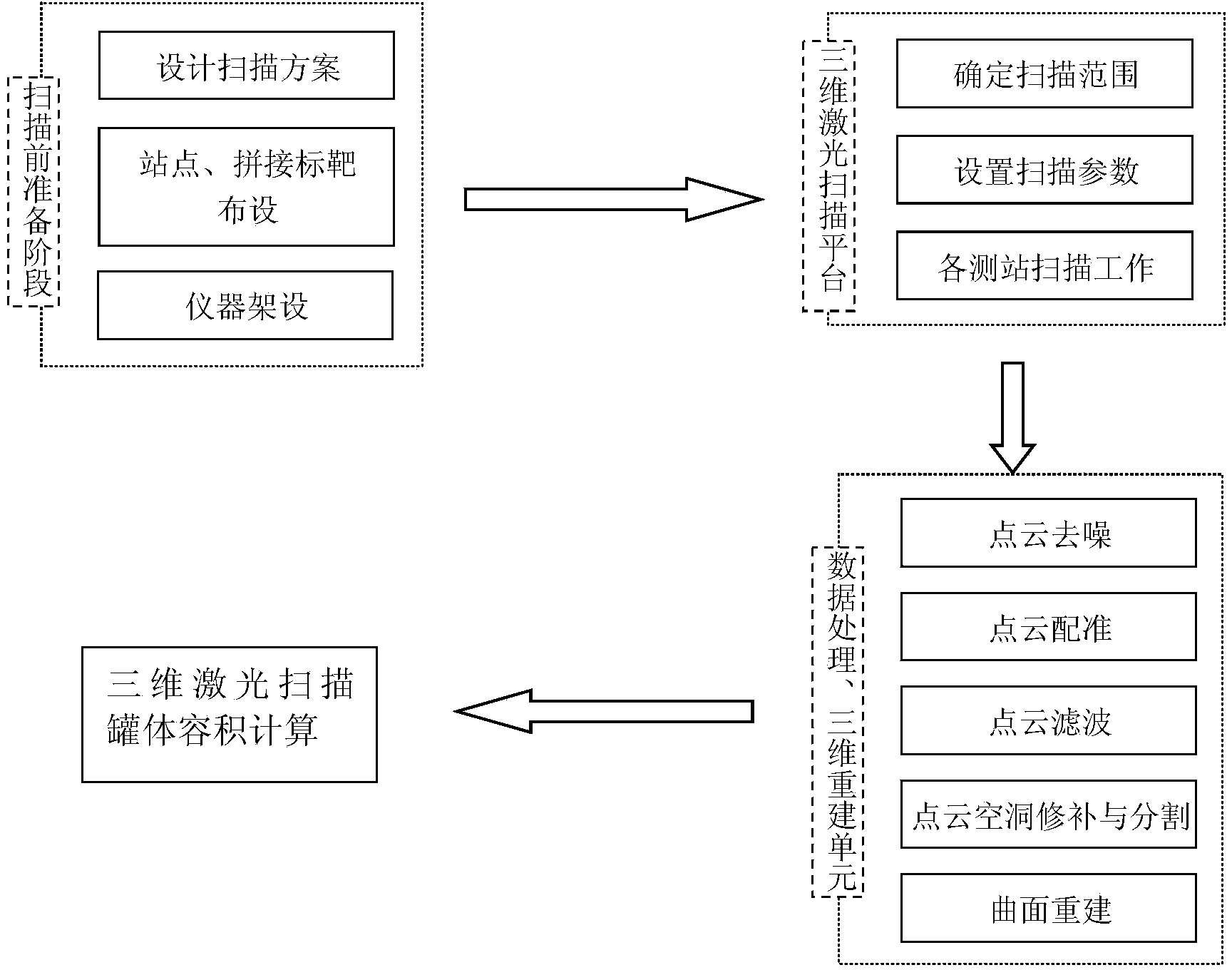

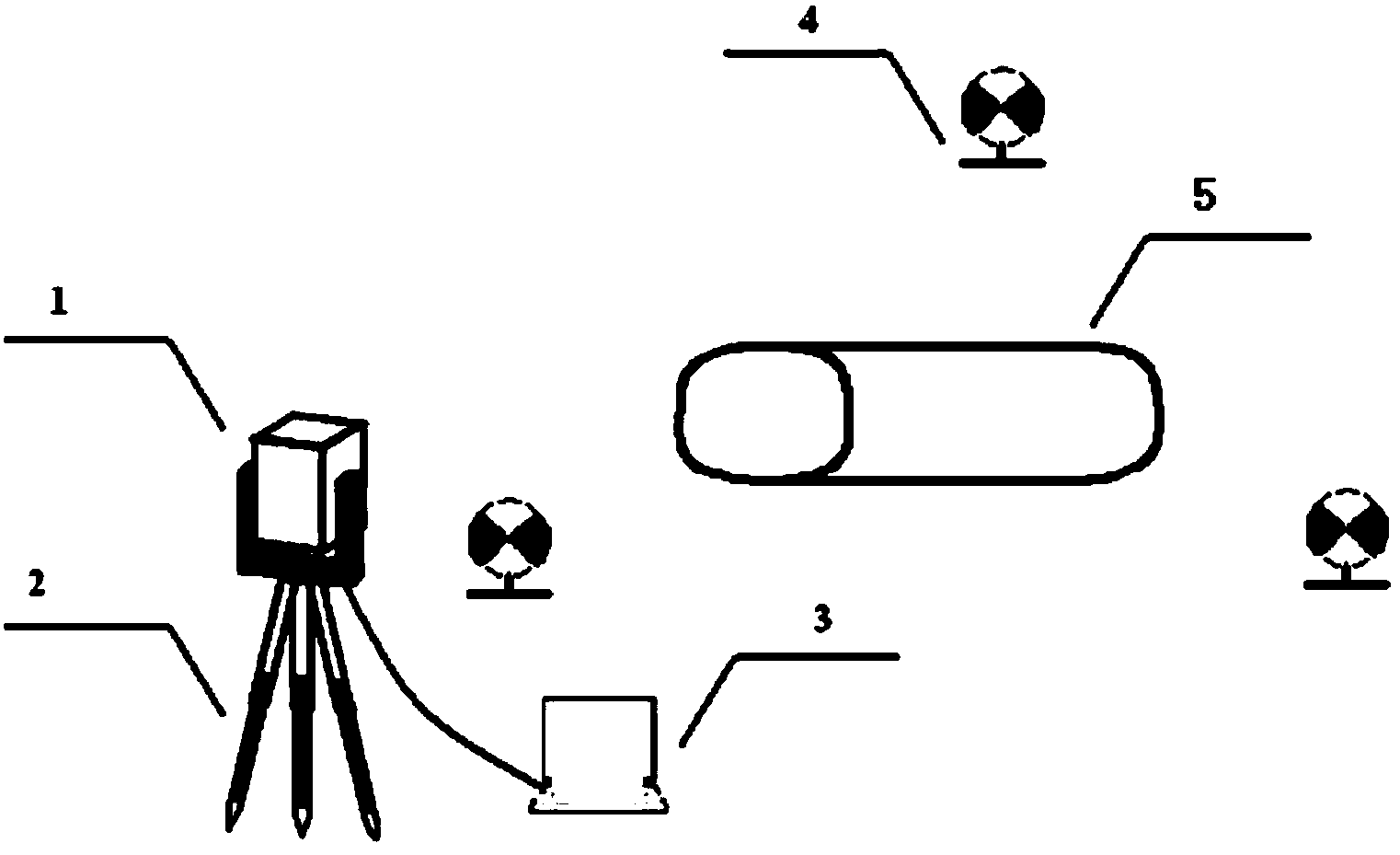

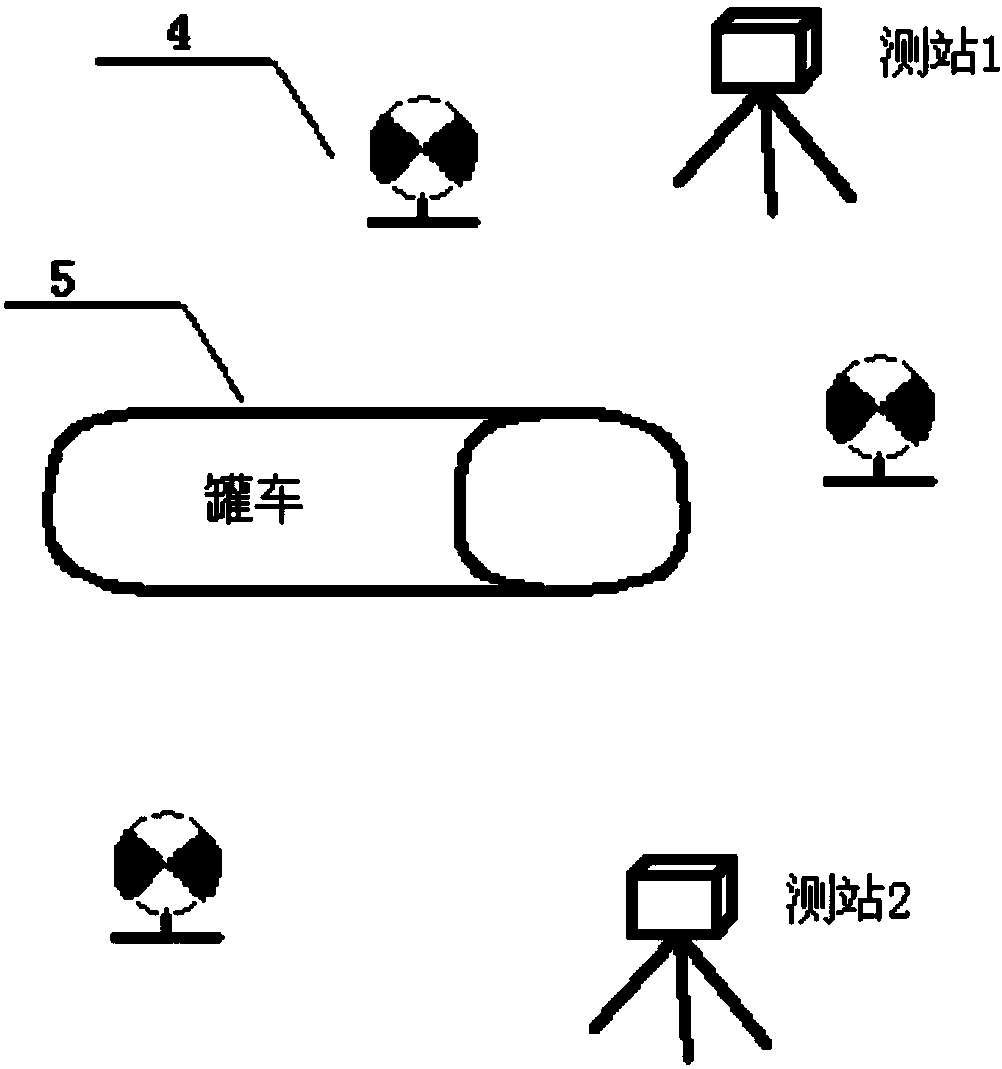

Volume measurement method and device based on three-dimensional laser scanning

ActiveCN102980531AEasy to calculateReduce the influence of materials, etc.Using optical meansPoint cloudWorking environment

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +1

High-speed and high-precision tank volume measurement method and device based on three-dimensional laser scanning

InactiveCN104180771AQuick measurementAccurate measurementUsing optical meansLaser scanningTank truck

The invention discloses a high-speed and high-precision tank volume measurement method and device based on three-dimensional laser scanning. The method comprises the steps of making an experimental scheme and controlling the data collection quality; collecting and acquiring three-dimensional point cloud data of the outer surface of a tank through a three-dimensional laser scanning platform; carrying out spatial three-dimensional modeling and establishing a three-dimensional model of the tank through the acquired three-dimensional point cloud data of the outer surface of the tank; analyzing the three-dimensional model of the tank and calculating the volume of the tank through the section method. According to the method, the volume of tanks such as tank trucks, storage tanks and tank containers can be quickly and accurately measured, operation is simple, the safety is high, the labor intensity is low, the data processing time is greatly shortened, influence of materials of the tanks and the like is reduced, and data calculation is convenient. The method can adapt to different work environments and is particularly suitable for the quality supervision department to calibrate and retest the volume of the tanks quickly.

Owner:南京金创有色金属科技发展有限公司 +1

Tank container for petroleum asphalt

InactiveCN102001500AReasonable structural designIncrease loading capacityDomestic cooling apparatusLighting and heating apparatusTank containerAsphalt

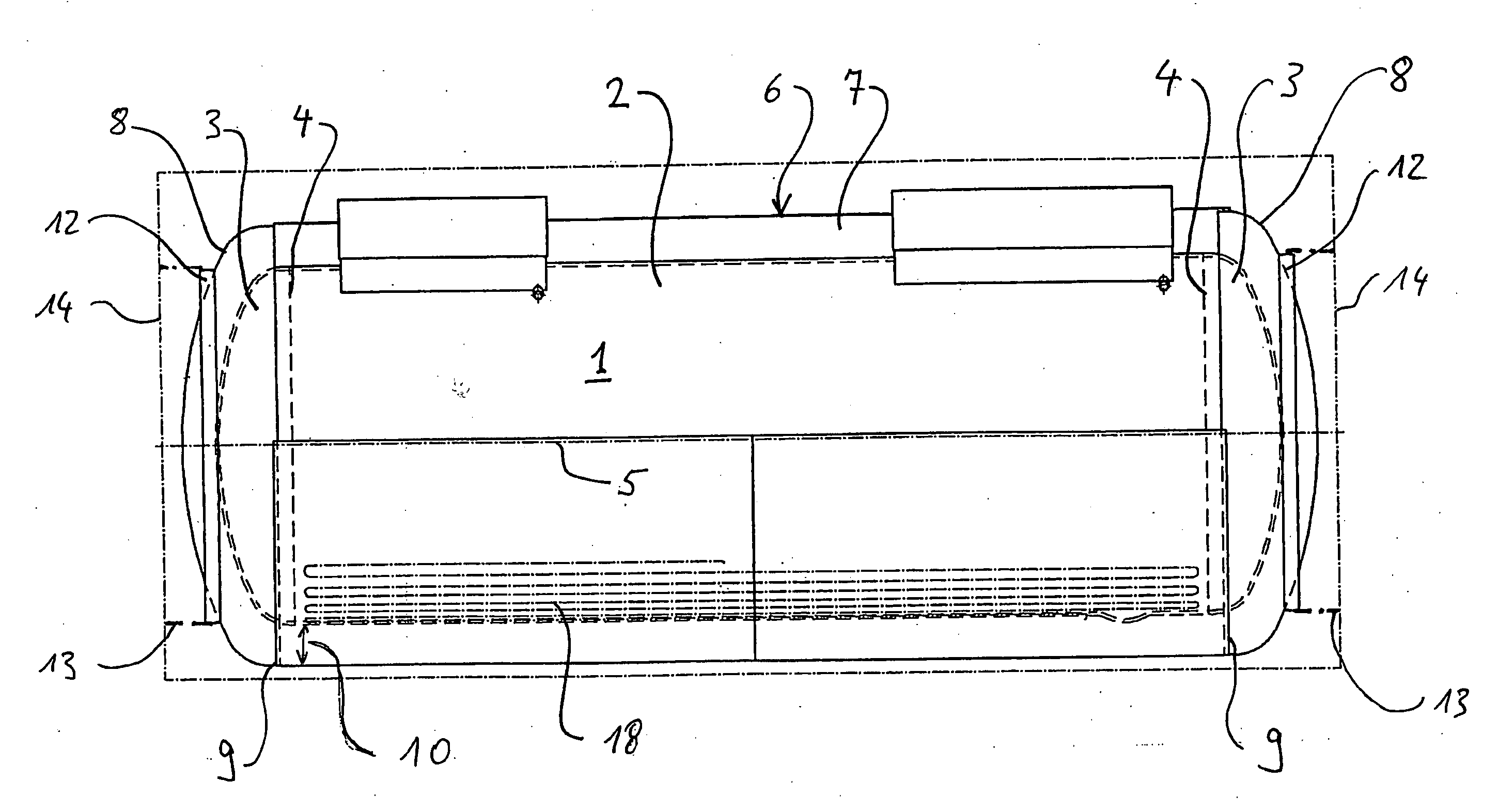

The invention discloses a tank container for petroleum asphalt and relates to a device for naval, land or railway transportation of petroleum asphalt. The invention aims to solve the problem that the conventional tank container for petroleum asphalt is low in loading capacity, unreasonable in frame structure and low in safety performance. End frames are connected through a longitudinal beam; a tank body is connected with the frame through an end barrel; the bottom surface of the tank body is connected with the frame through a supporting saddle; a manhole, a pressure reducing valve and a one-way valve are arranged on the top of the tank body; two anti-wave devices are arranged along the longitudinal direction inside the tank body; each anti-wave device consists of two anti-wave plates; two heating tubes are arranged inside the tank body and are arranged at the bottom of the tank body; one end of each heating tube penetrates the tank body to be arranged outside the tank body, and the other end of the heating tube is communicated with one end of a flue; the other end of the flue penetrates the tank body; and a discharging valve is arranged at the lowest part of the end part of the tank body and is positioned between the two heating tubes. The tank container for the petroleum asphalt is applied to transporting petroleum asphalt.

Owner:哈尔滨建成北方专用车有限公司

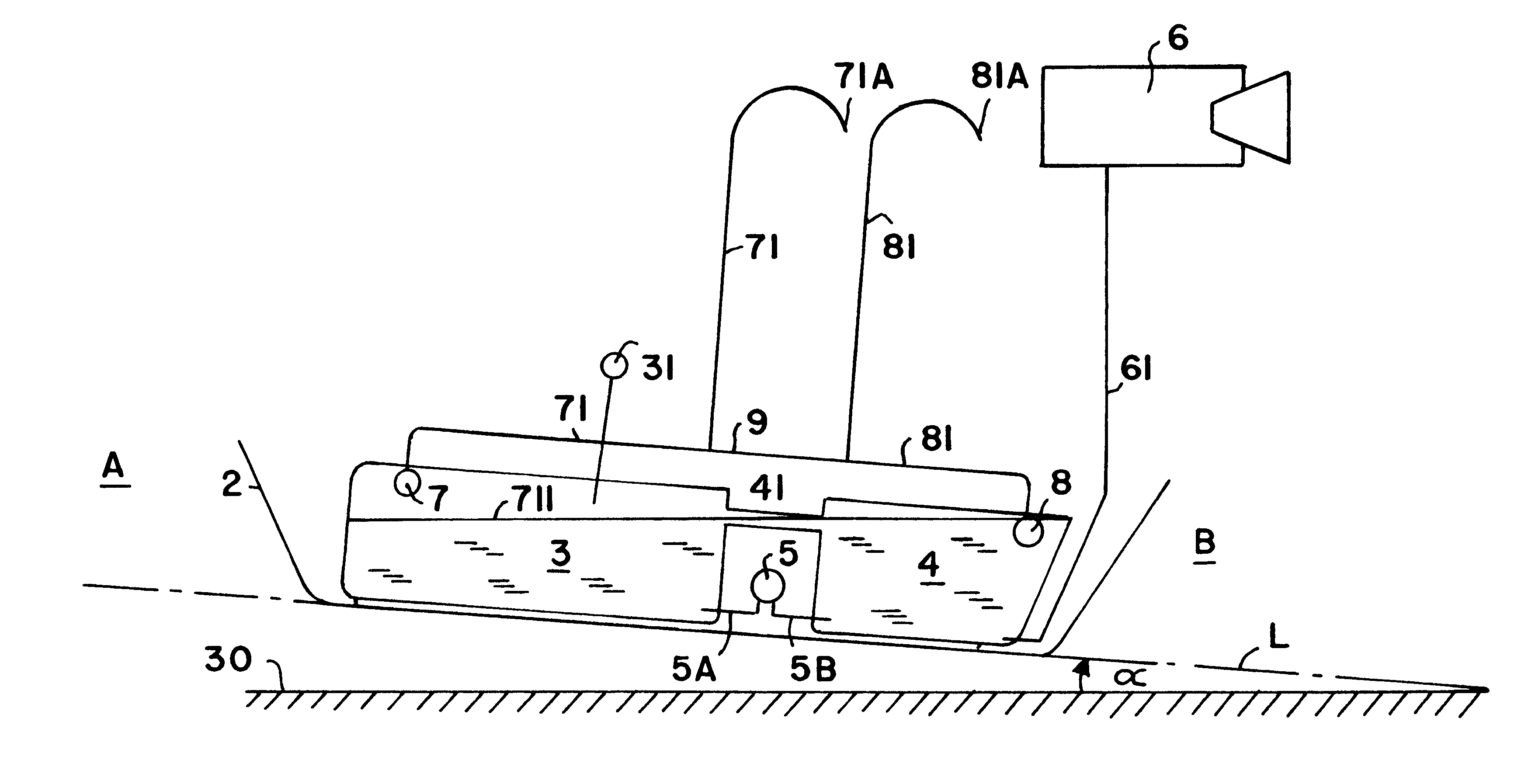

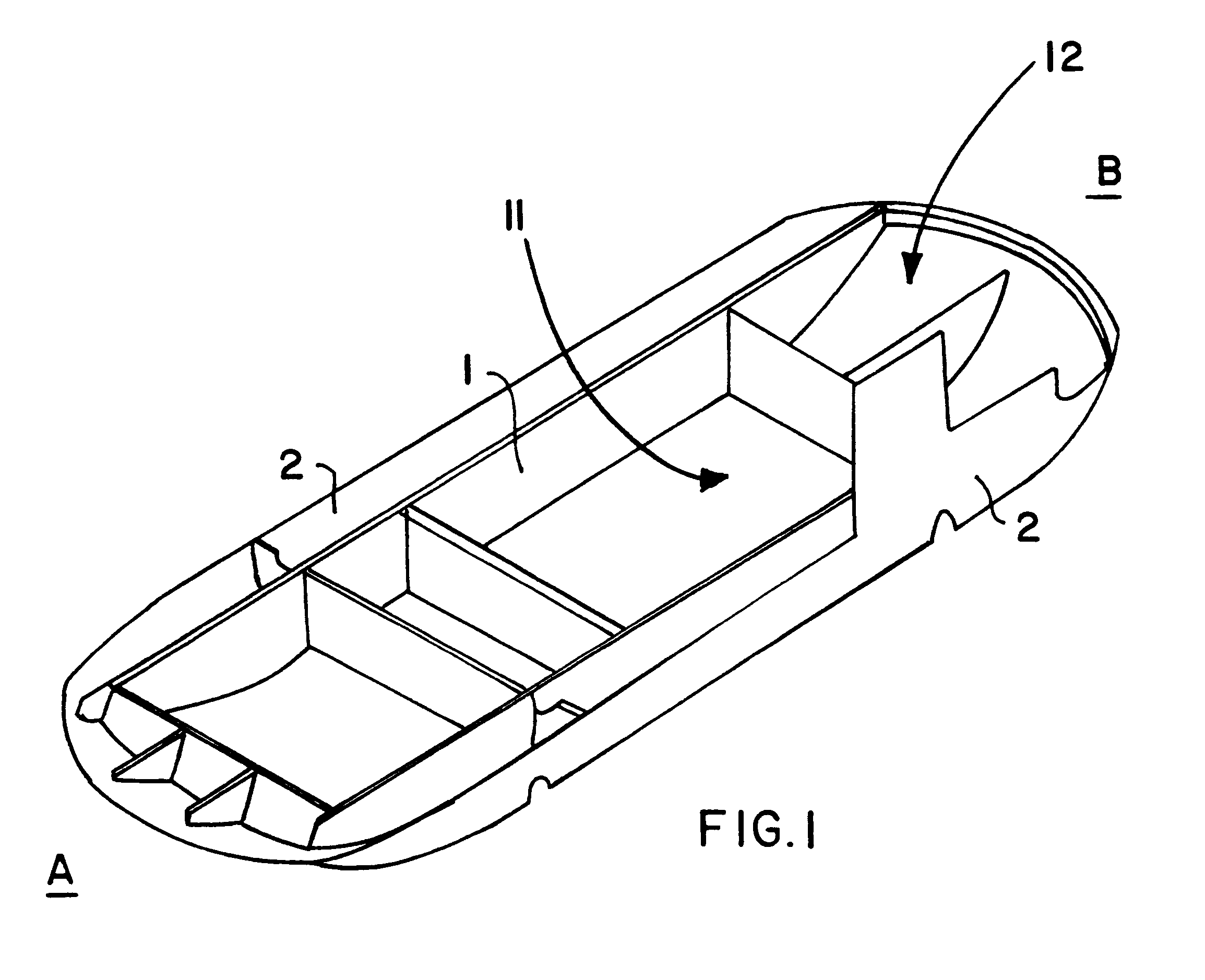

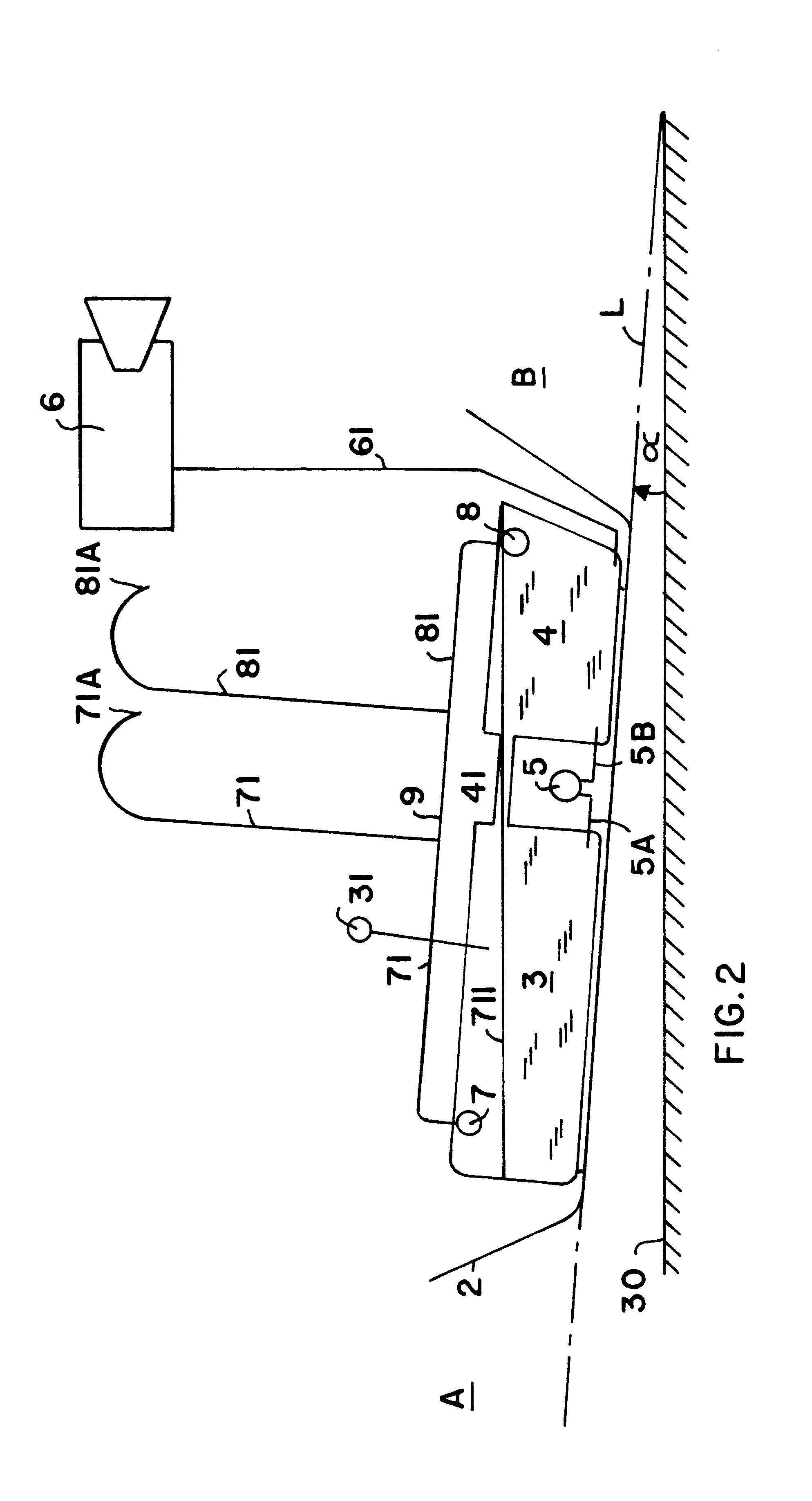

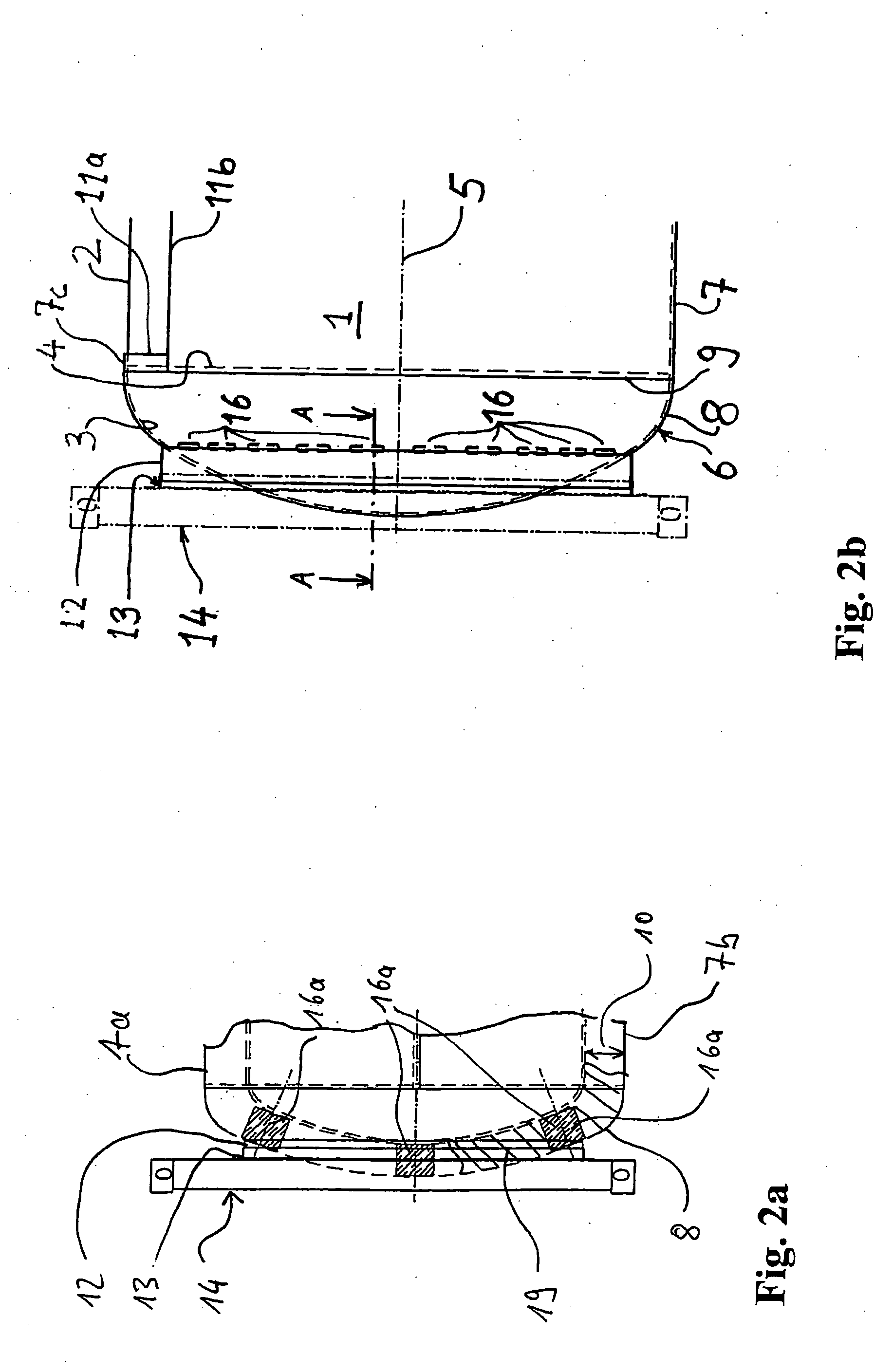

Ventilation valve with a breathing channel for a tank container of a helicopter

A ventilation valve cooperating with a breathing channel for a fuel tank of a helicopter has a safety device arranged in a valve housing of the ventilation valve. To seal the breathing channel from the tank when a connection between the fuselage cell and the tank is released or disrupted, e.g. in a crash, the safety device includes a spring-loaded plunger (15), a retainer (22), and a movable seal element (10). To allow the tank container to be filled essentially full, and to ensure the ongoing reliable functioning of the breathing channel, the seal element (10) is a buoyant valve ball (10) that seals the breathing channel (81) of the fuel extraction or discharge tank (4) if the fuel level (711) in the tank (4) rises up into the valve (8). Also, the breathing channel (81) is connected with the breathing channel (71) of a main fuel tank (3) by a connecting channel (9).

Owner:AIRBUS HELICOPTERS DEUT GMBH

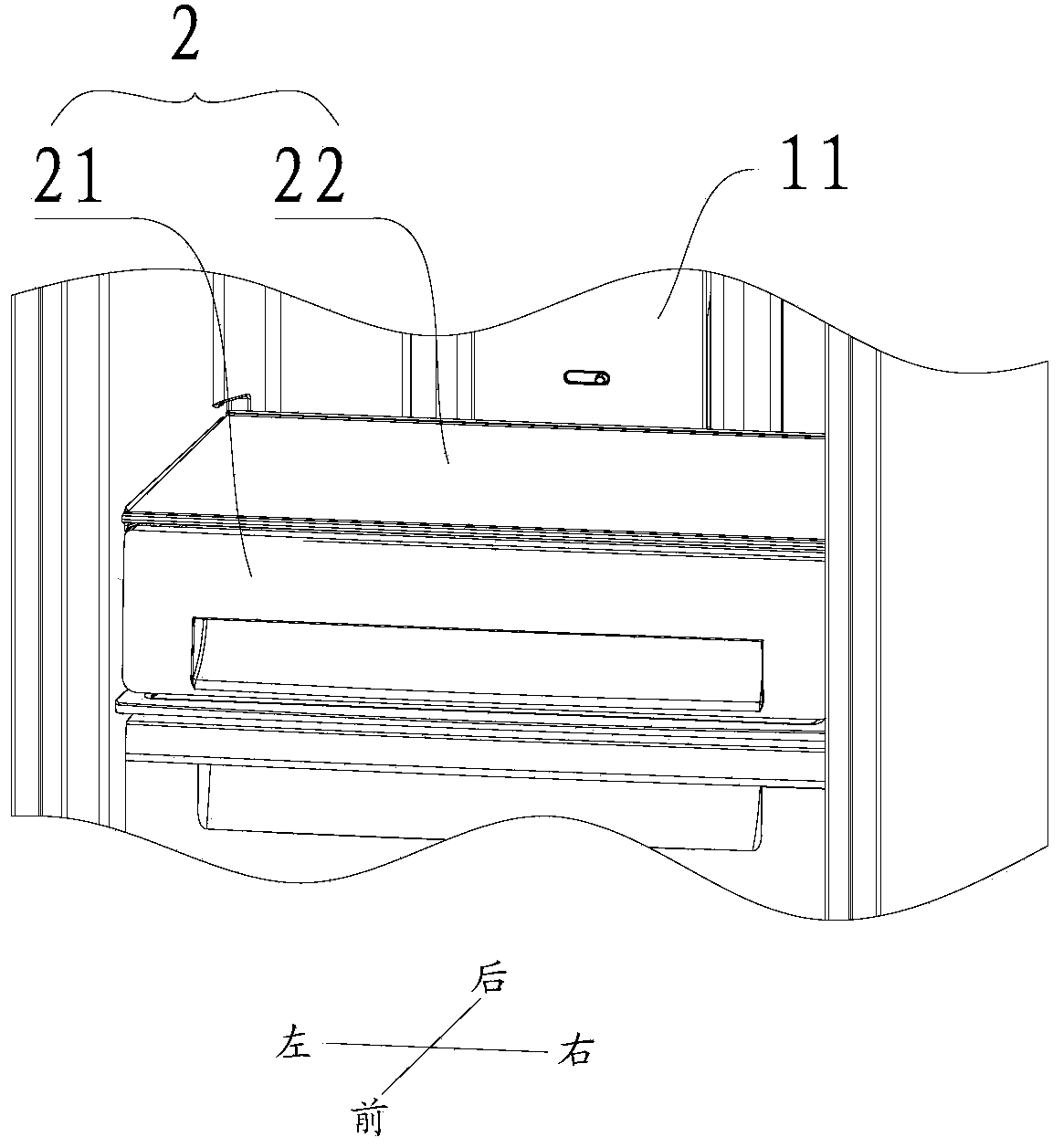

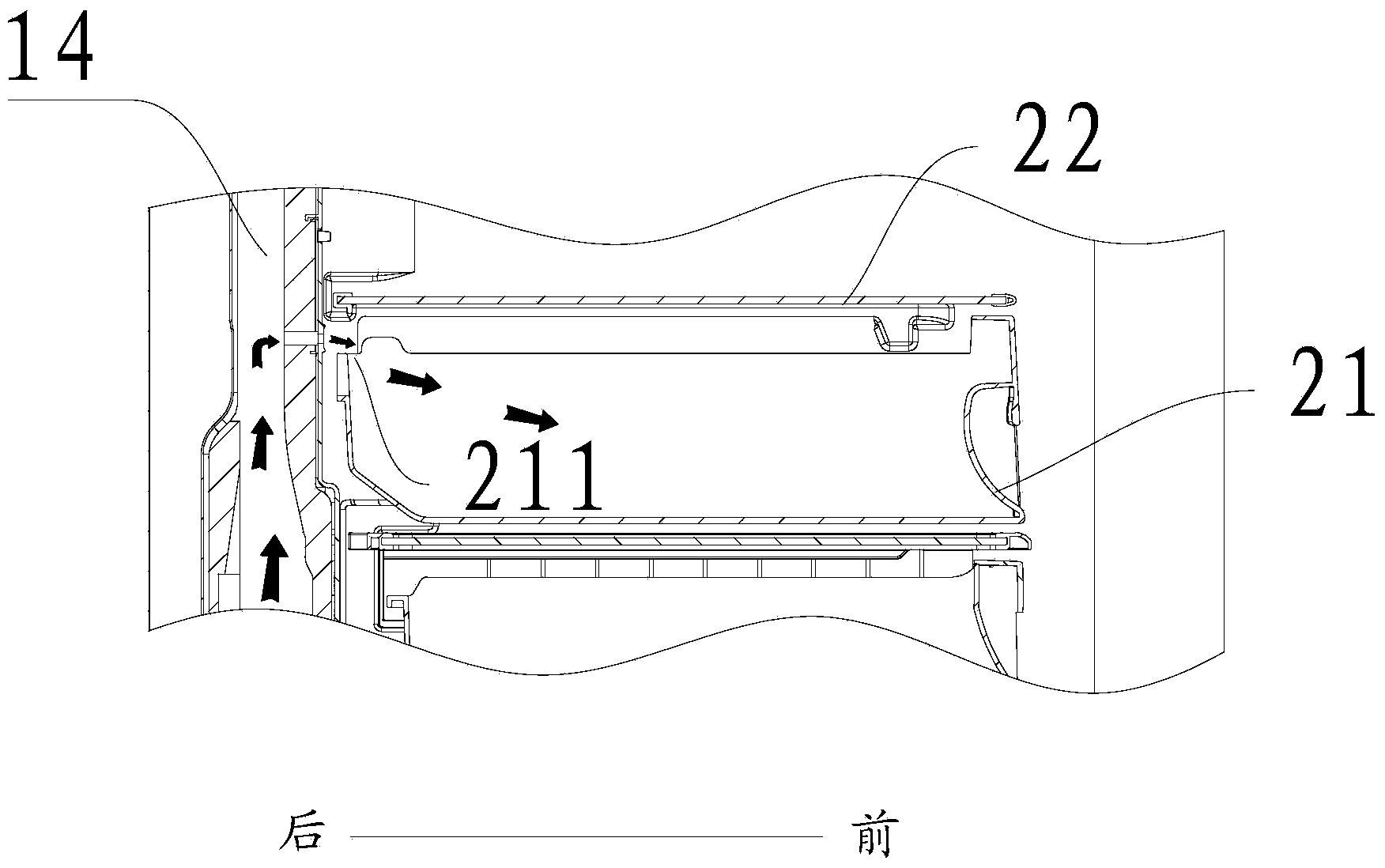

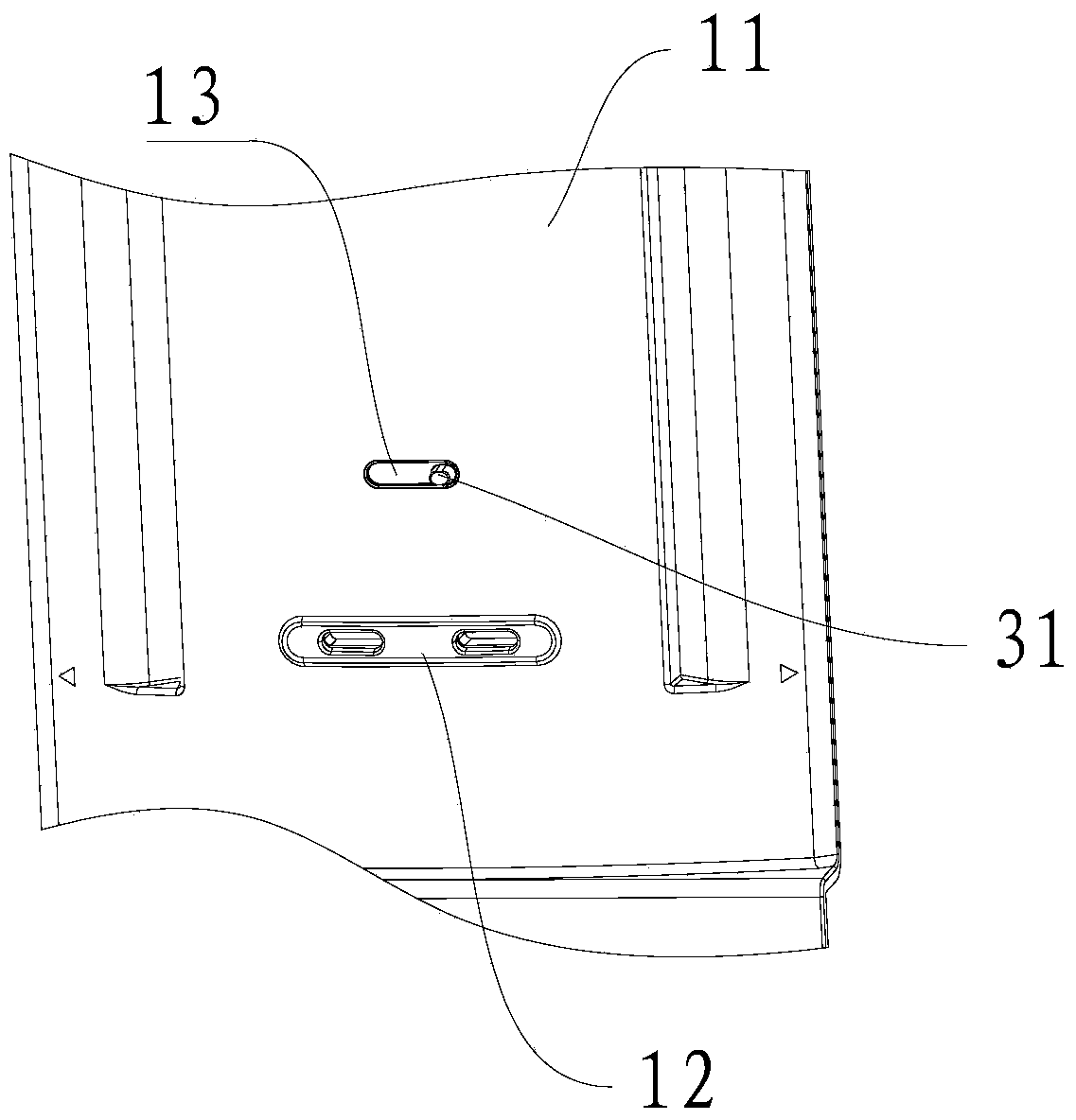

Air cooling refrigerator

ActiveCN103471317AEasy to adjustSimple structureLighting and heating apparatusDomestic refrigeratorsTank containerRefrigerated temperature

The invention discloses an air cooling refrigerator, which comprises a tank body, a temperature alternating chamber, and an adjusting plate, wherein the tank body is provided with a tank container and an air channel; the temperature alternating chamber is arranged in the tank body; an air supply outlet which is communicated with the air channel and used for supplying air into the temperature alternating chamber is arranged on a rear wall of the tank container corresponding to the temperature alternating chamber; the adjusting plate can be movably arranged at the air supply outlet and is used for adjusting the opening of the air supply outlet; and the adjusting plate is suitable to be adjusted by a user manually. According to the air cooling refrigerator disclosed by the embodiment of the invention, the user operates the adjusting plate manually, so that the opening of the air supply outlet can be adjusted. The air cooling refrigerator is simple in structure, low in cost and convenient to adjust.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

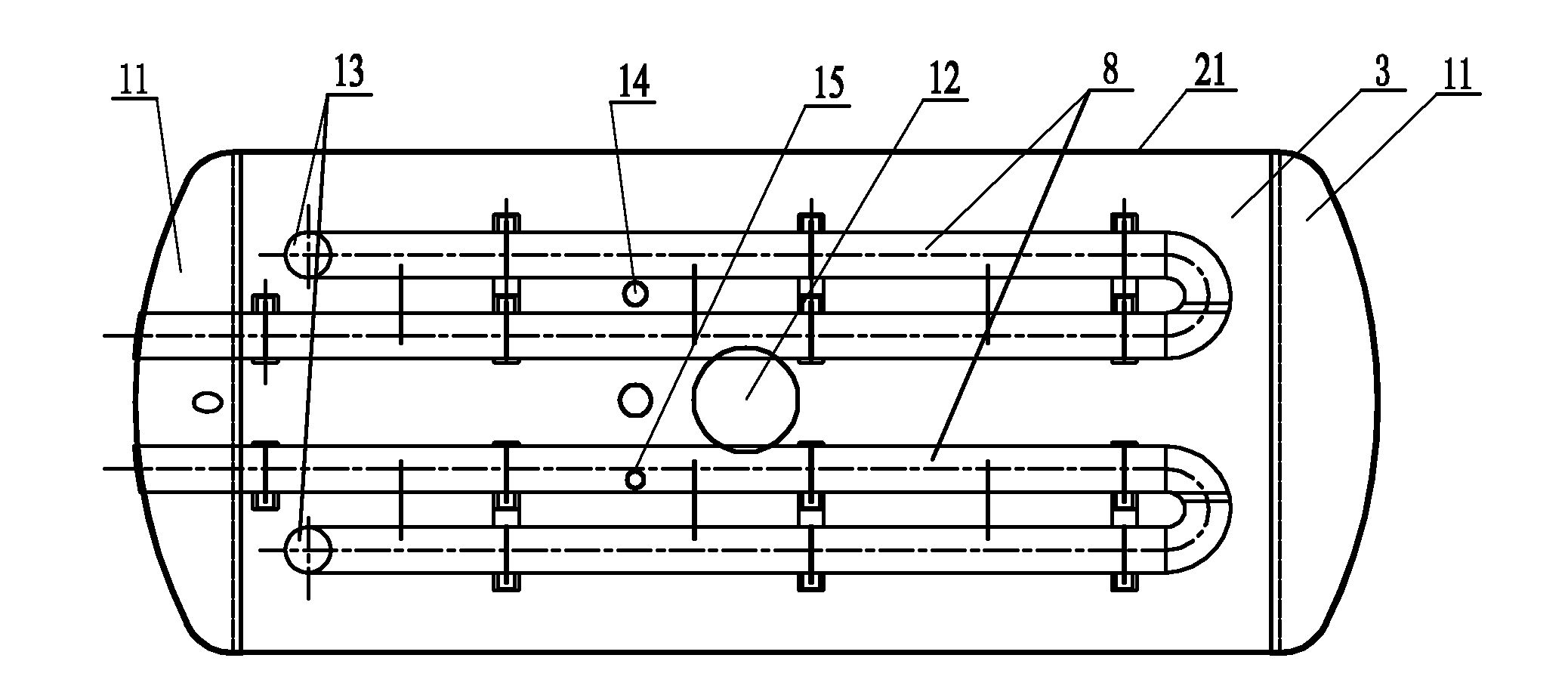

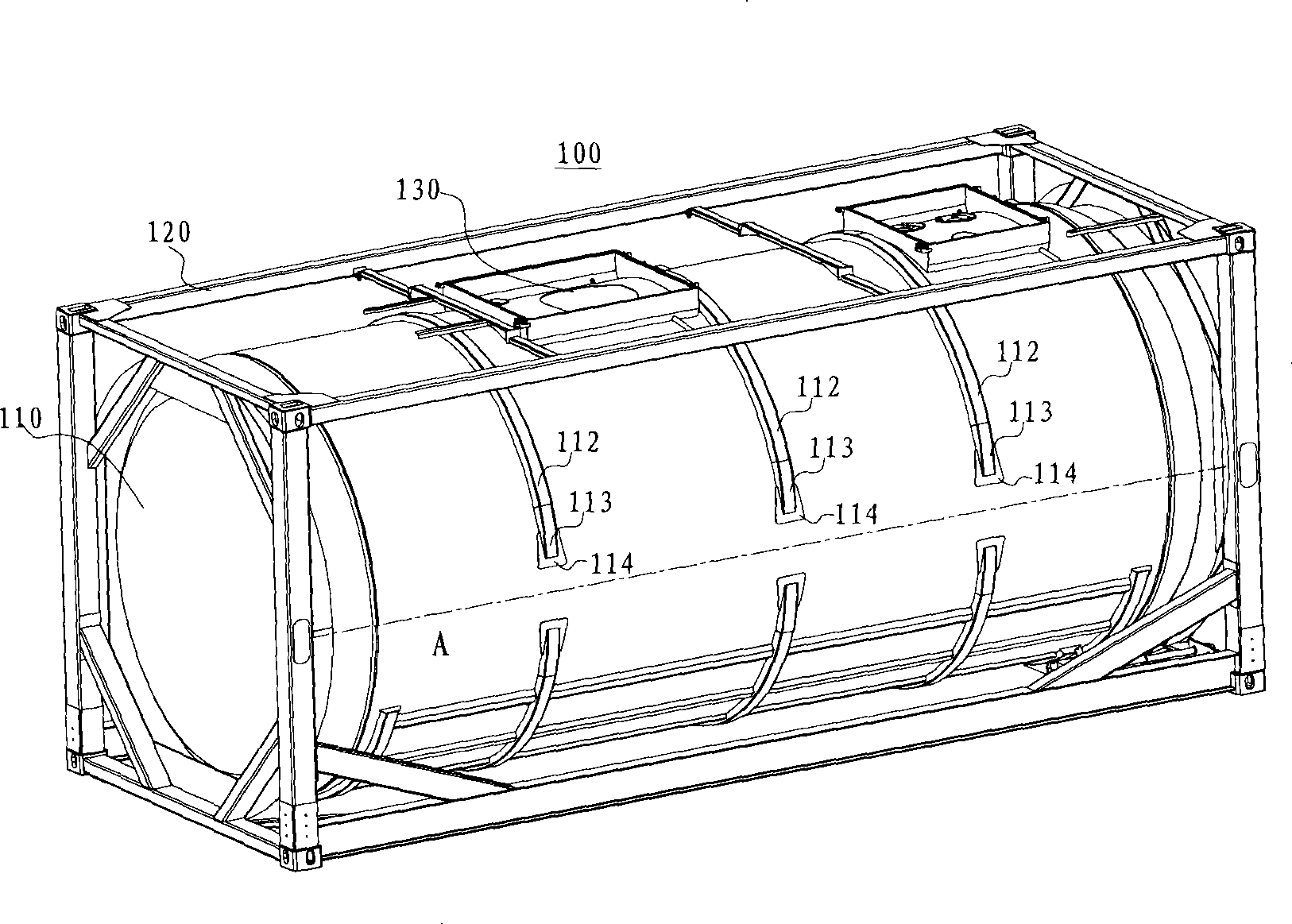

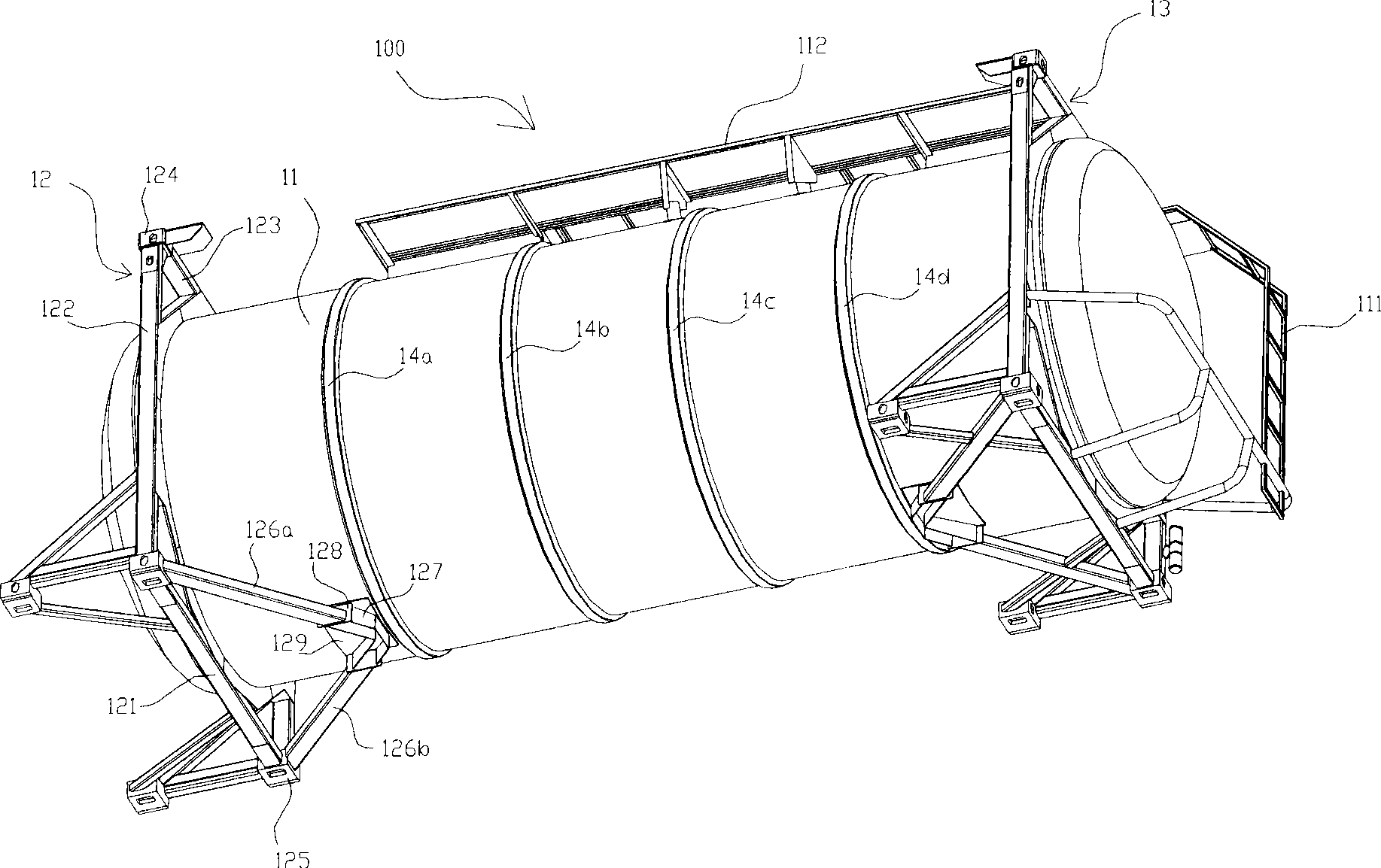

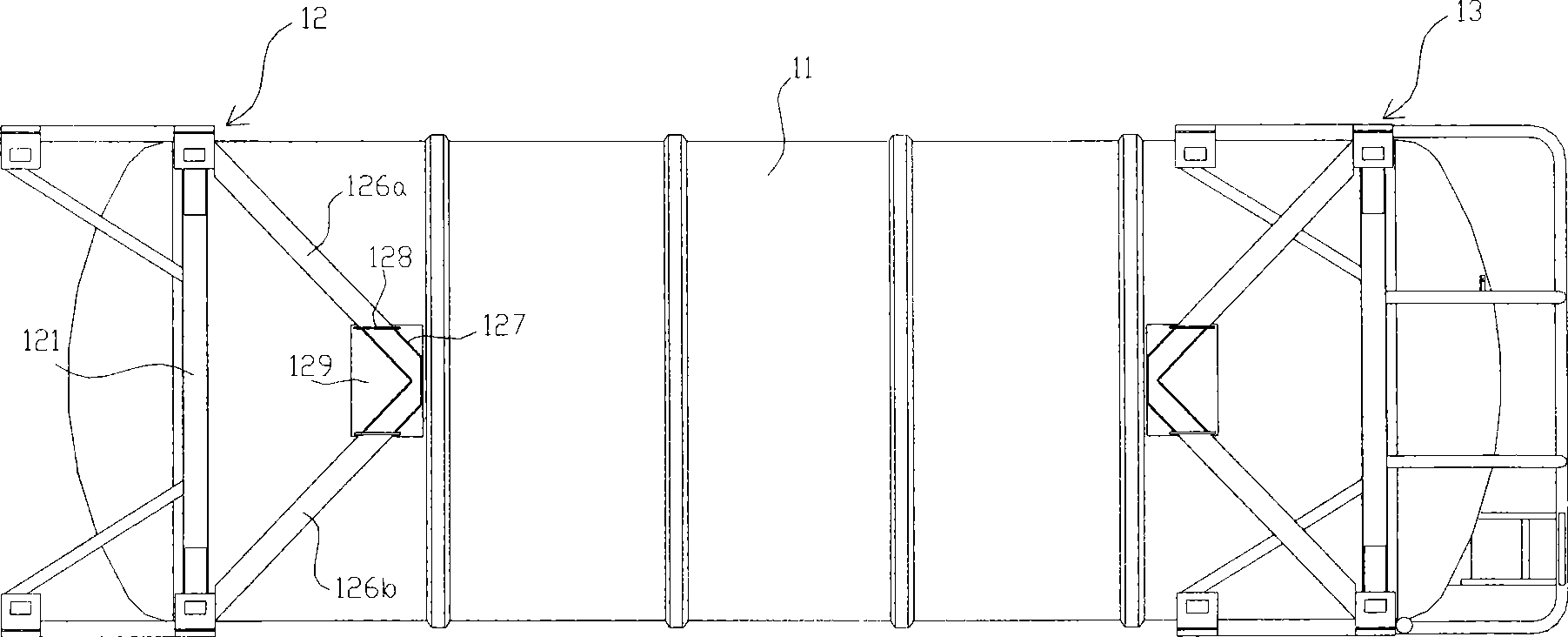

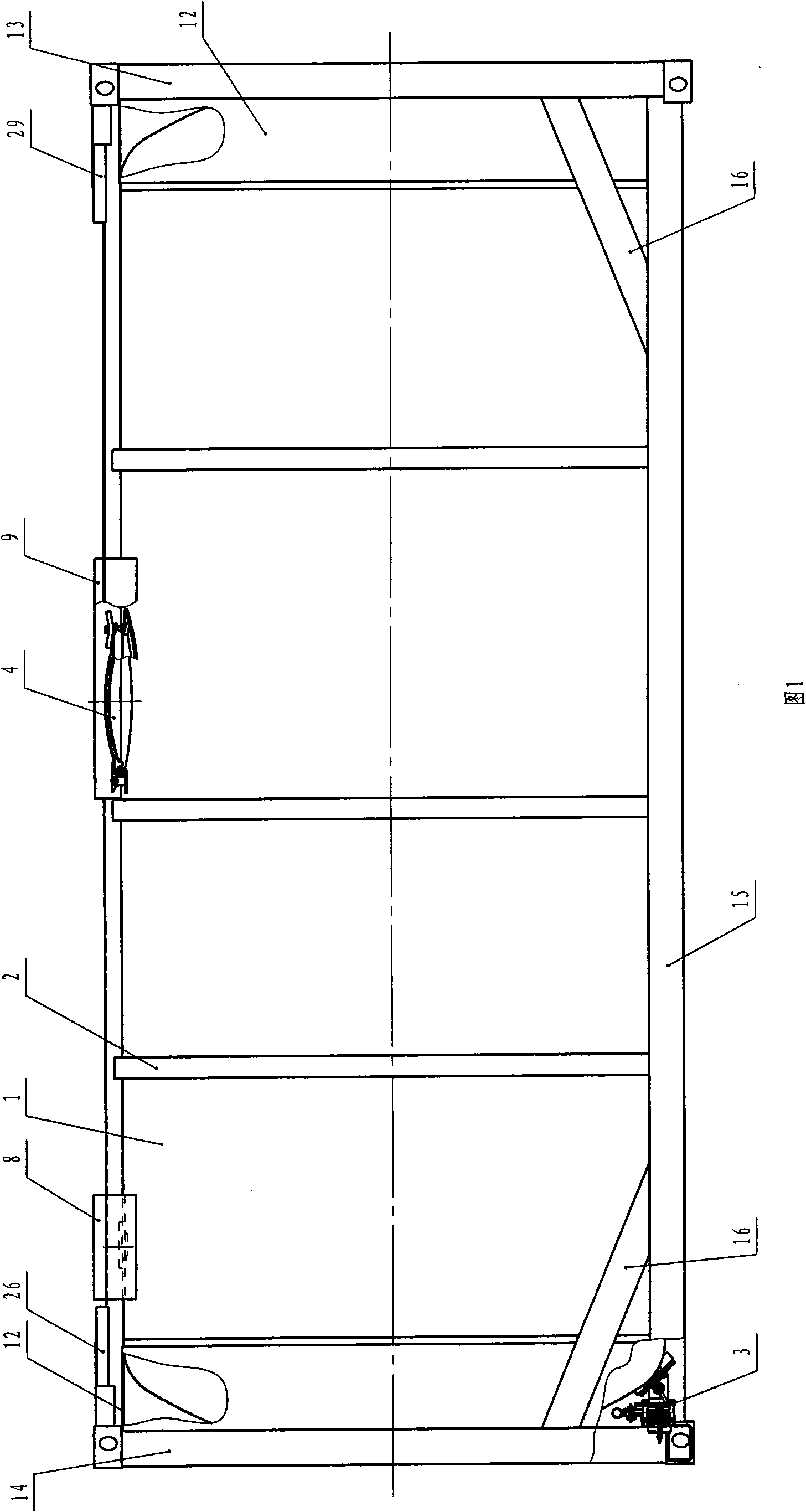

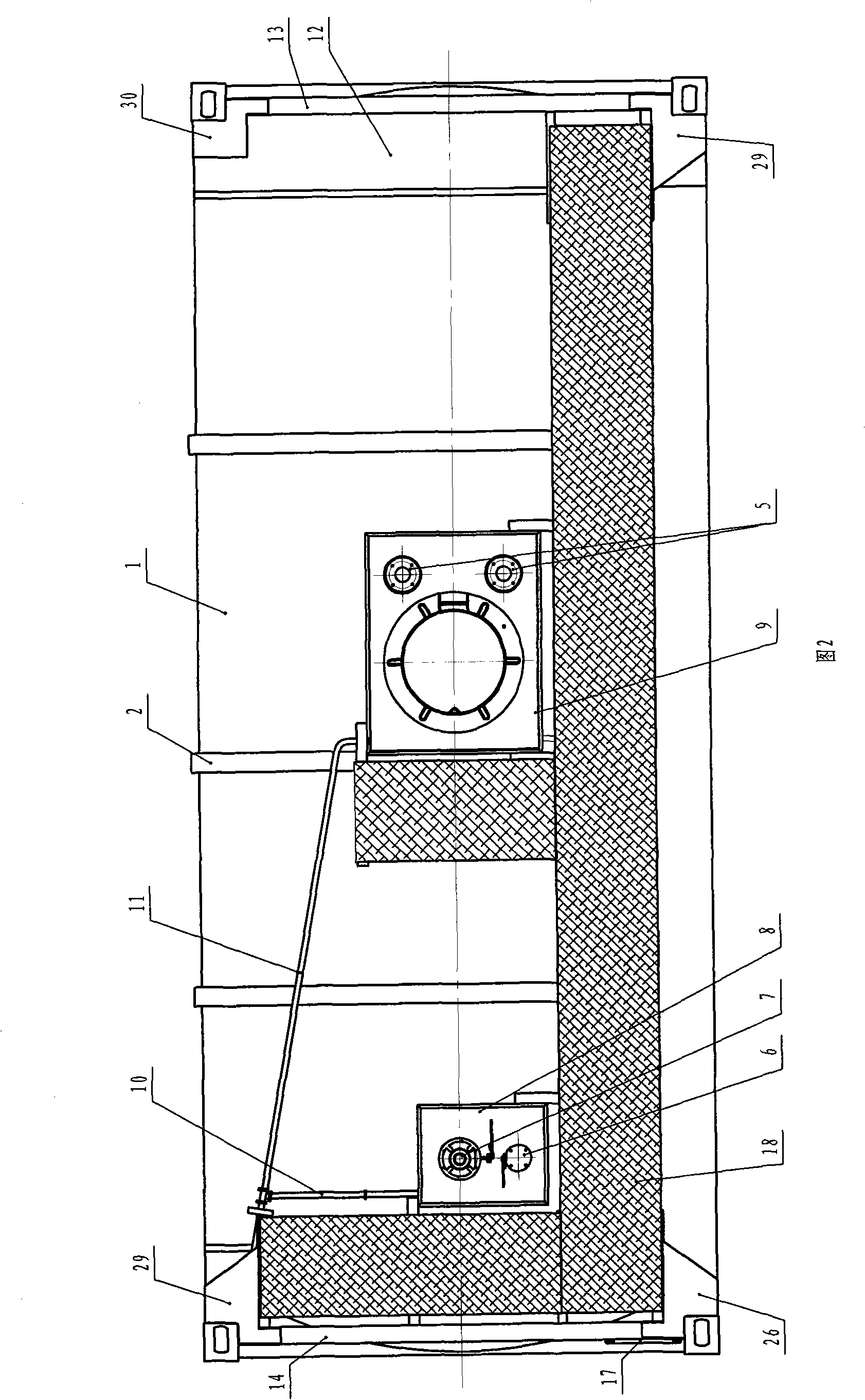

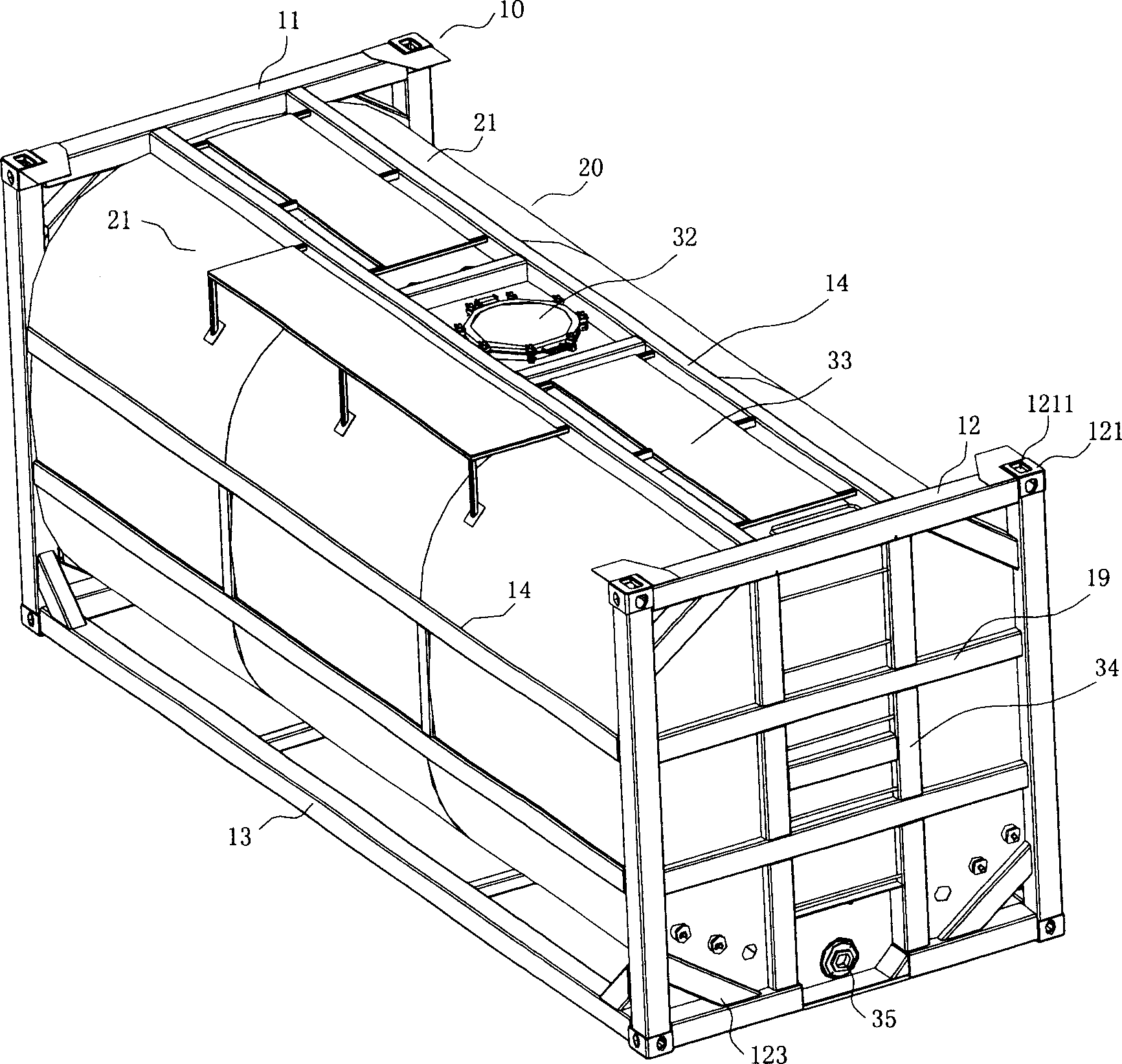

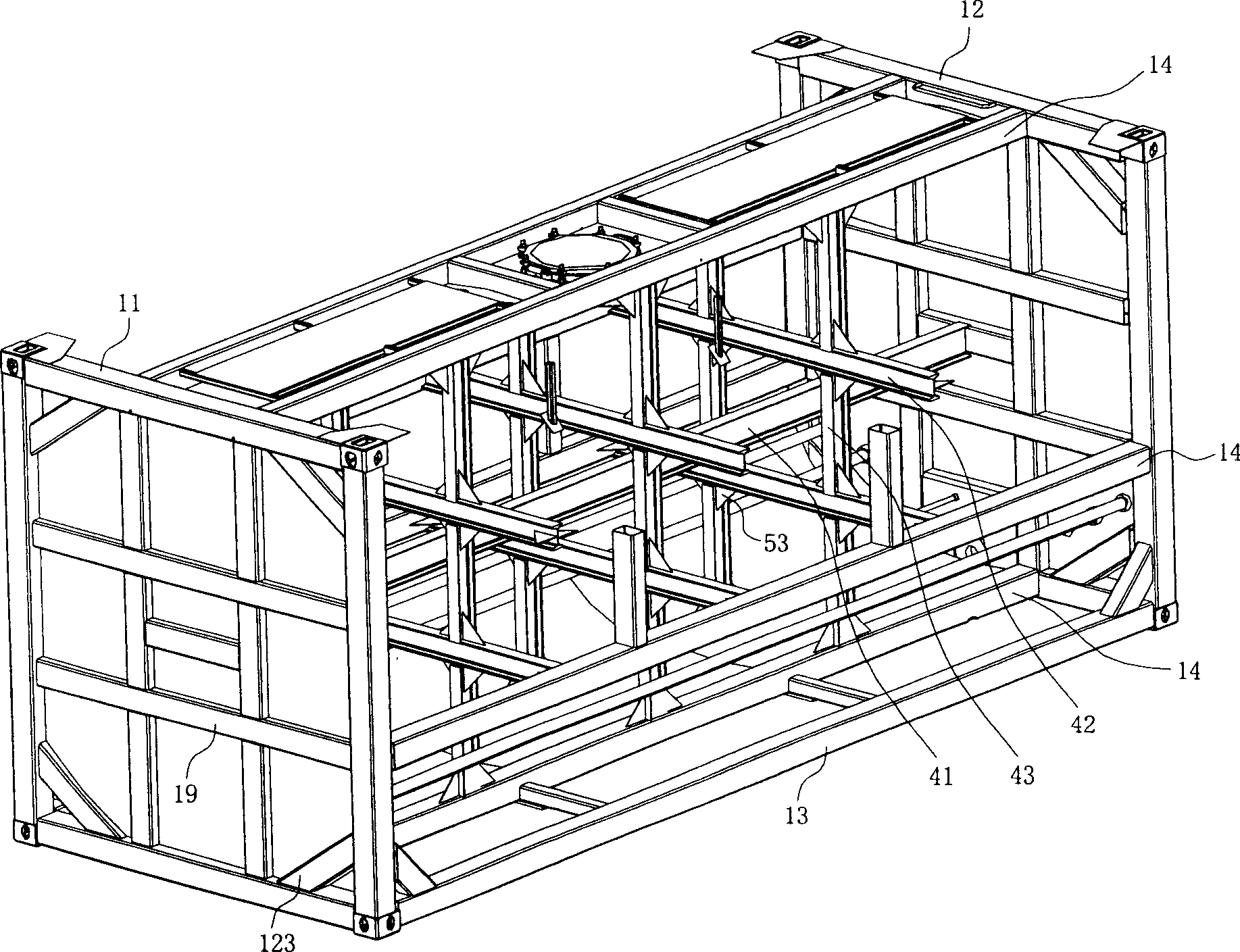

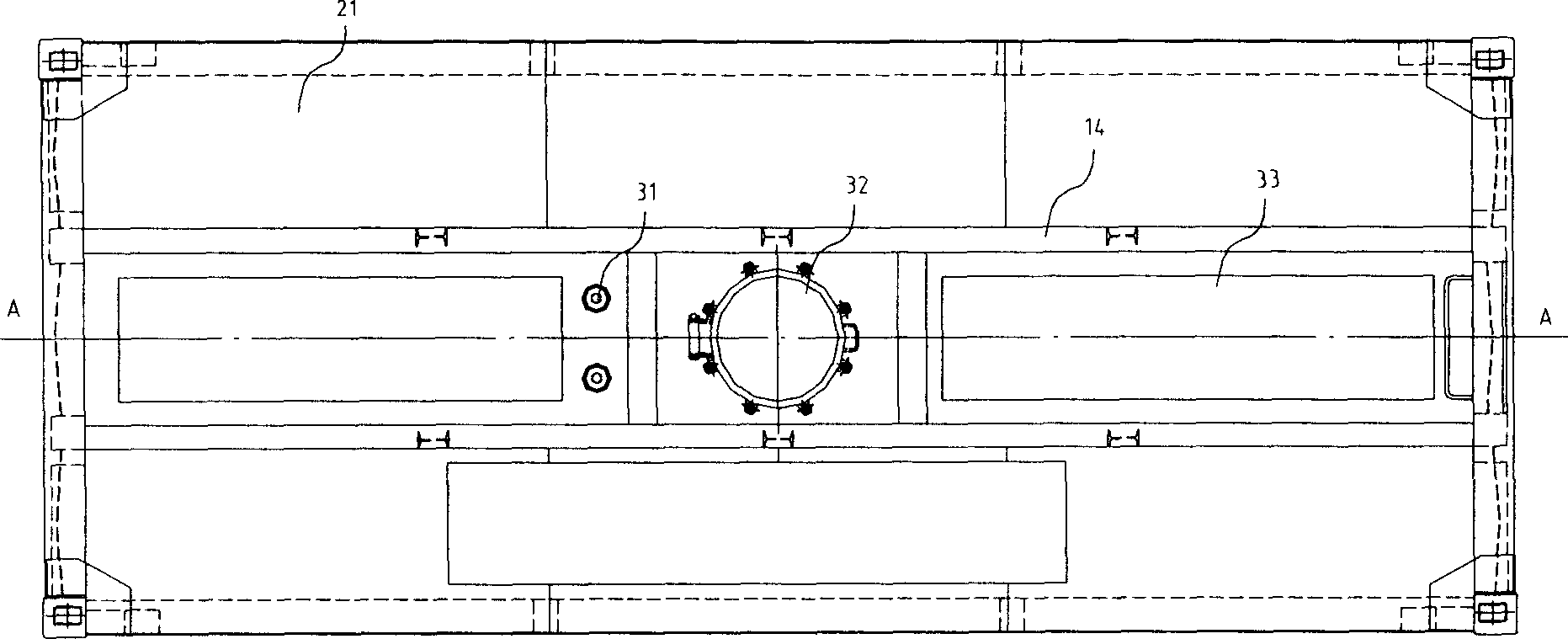

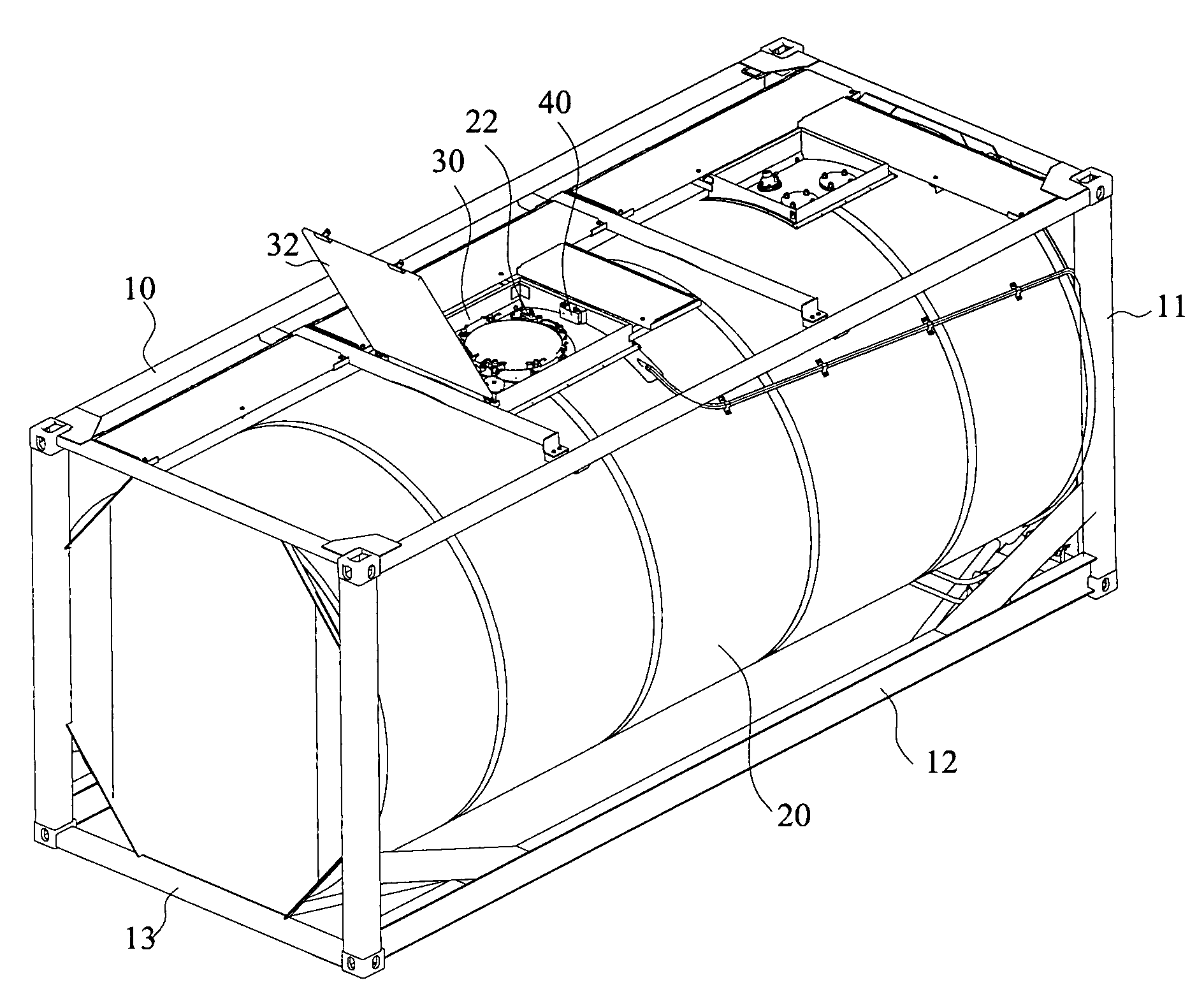

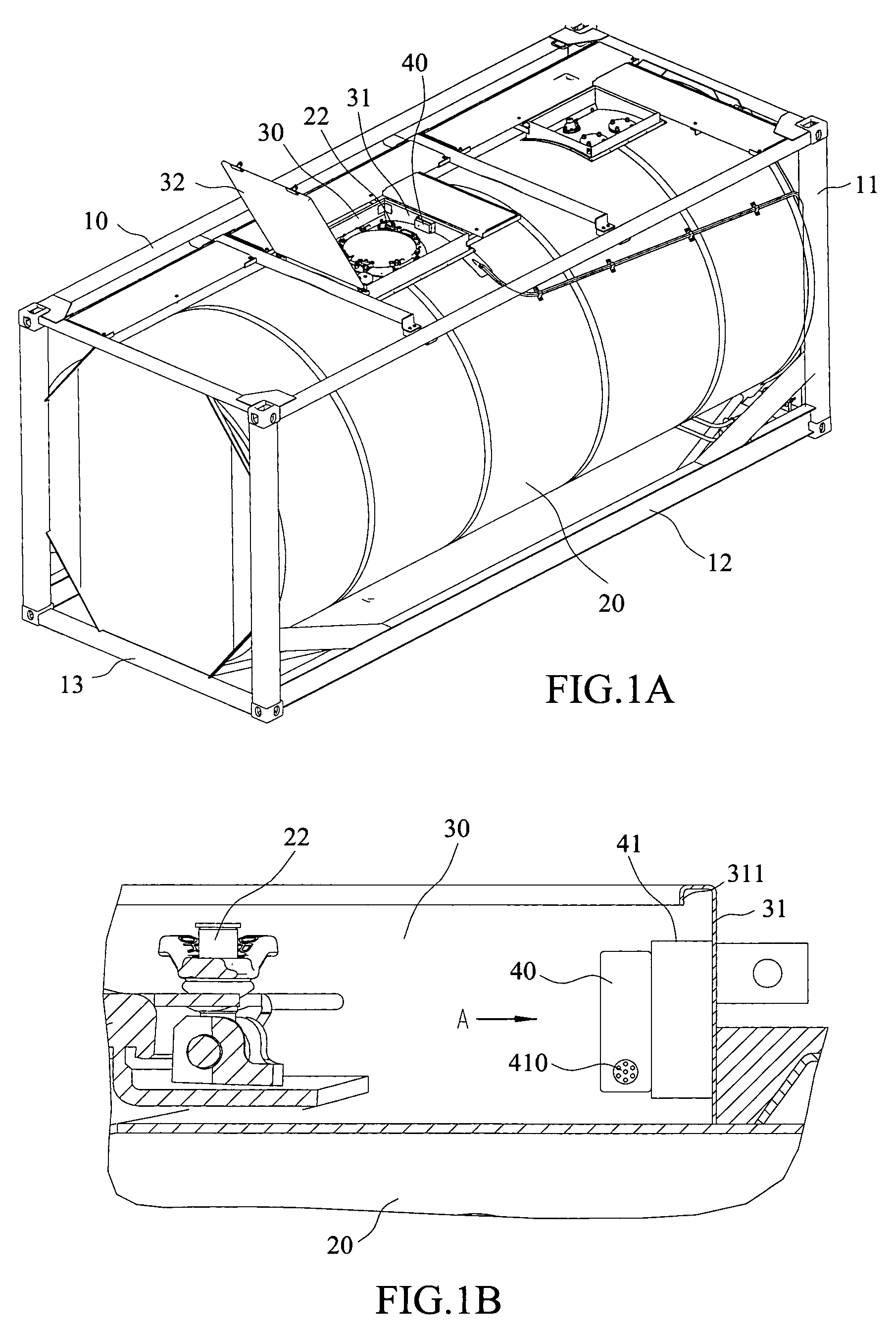

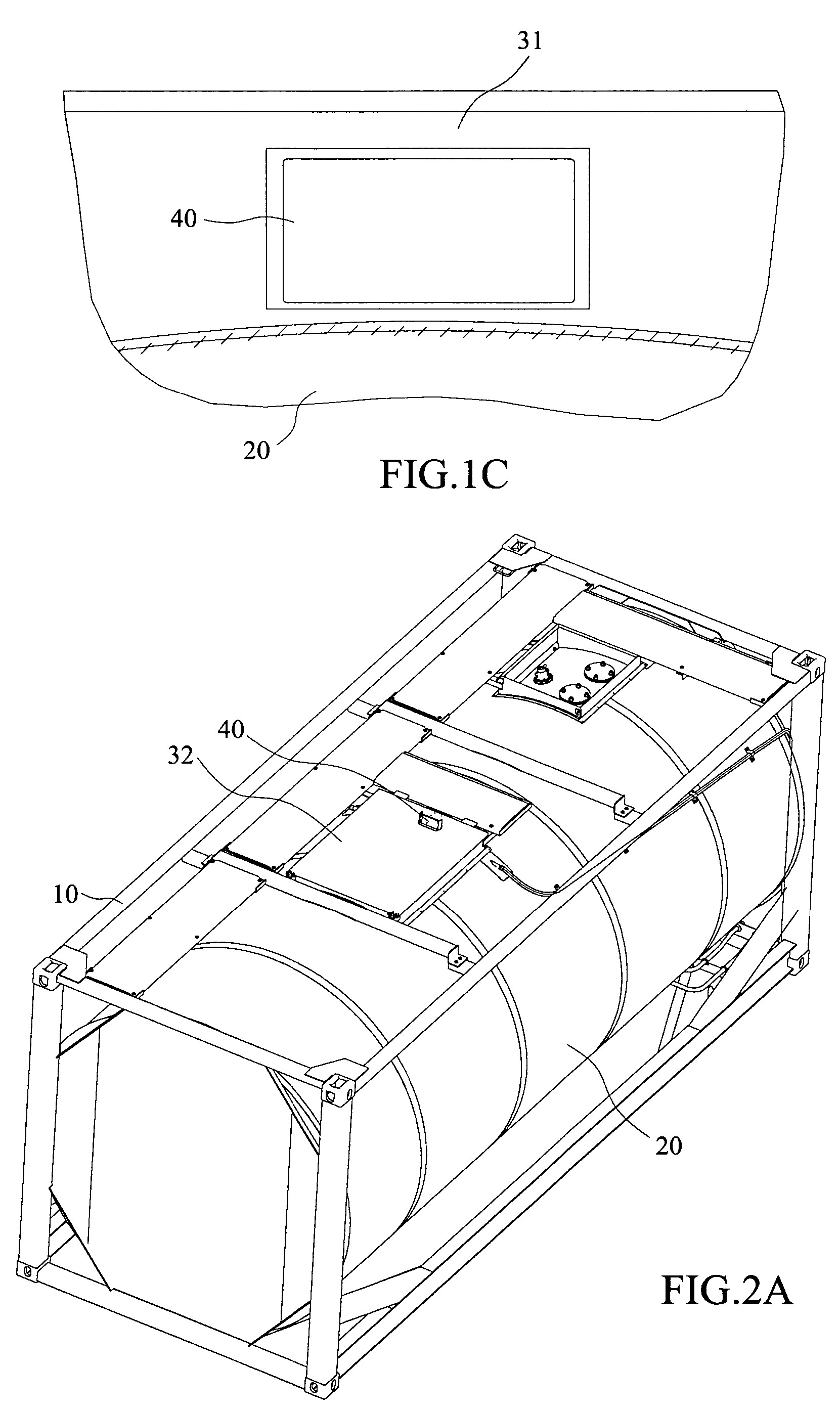

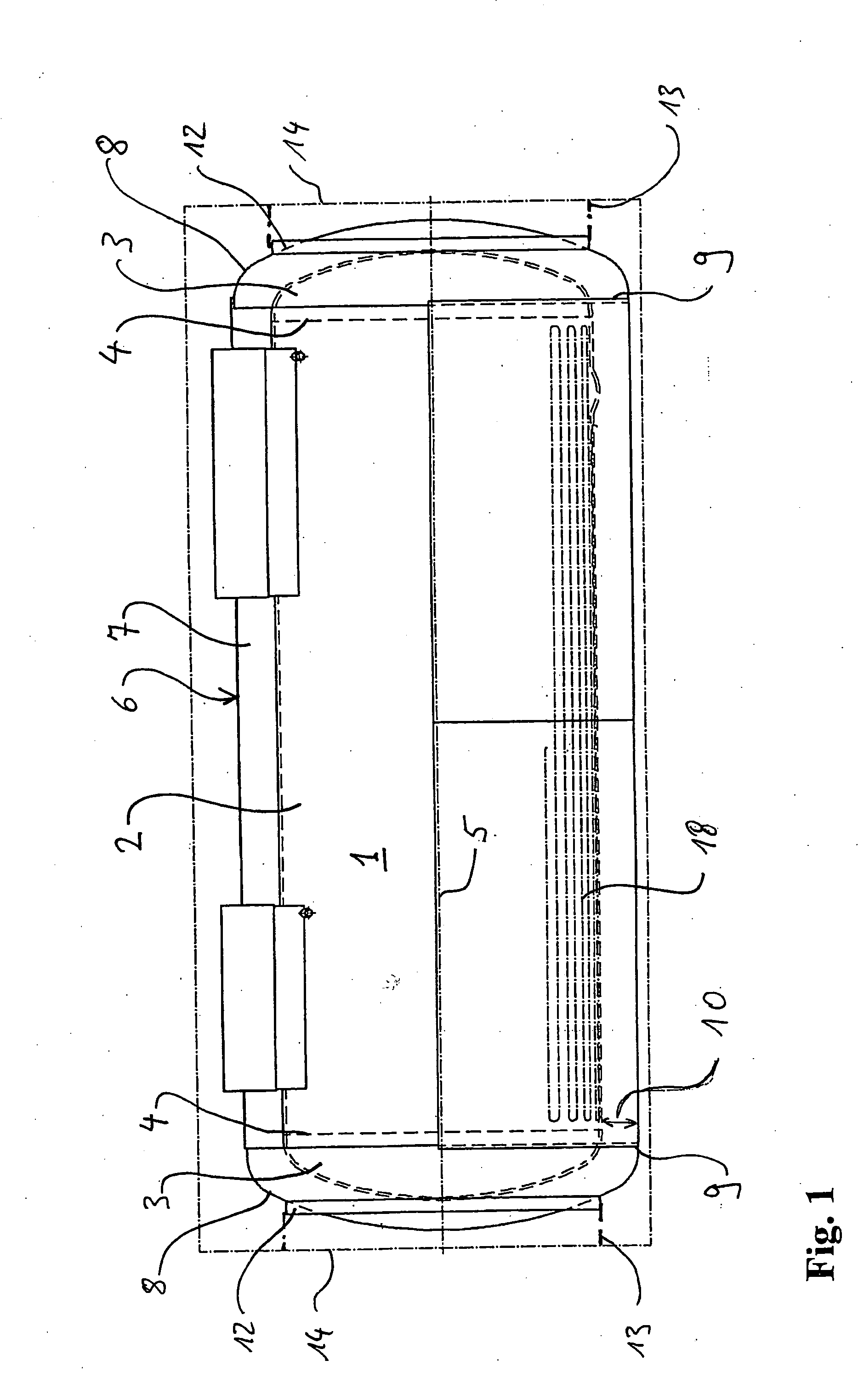

Large volume tank container

ActiveCN101362543ALose weightGuaranteed StrengthLarge containersBiochemical engineeringTank container

The invention relates to a high volume tank container, which comprises a framework, a tank body arranged in the framework, at least one reinforcing ring arranged on the periphery of the tank body and used for reinforcing the intensity of the tank body to better resist the external pressure; wherein, the reinforcing ring is broken in the position closed to the central line on the side of the tank body, and a wedge-shaped reinforcing ring is arranged at the broken end part of the reinforcing ring and connected with the tank on the both sides of the central line on the side of the tank body. A discharging system is installed at the bottom part at the rear end of the tank body, the lower beam corresponding to the position of the discharging system is disconnected into two sections, and a discharging bottom board is connected at the lower end of each lower beam in the disconnecting position. Simultaneously, the central line of the tank body is arranged lower than that of the framework, therefore, not only the dimension of the side surface of the high volume tank container is ensured to be within the ISO dimension, but also a larger operating space exists in the discharging positions at the top part and the bottom part, thus being convenient for the operation.

Owner:NANTONG CIMC TANK EQUIP CO LTD

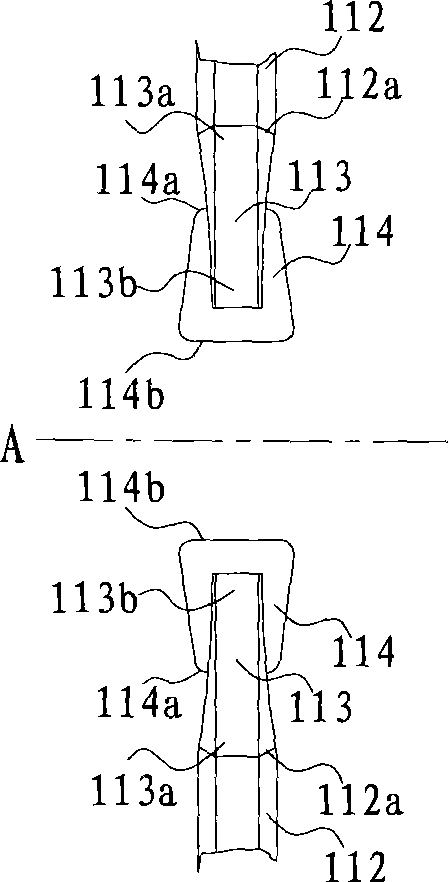

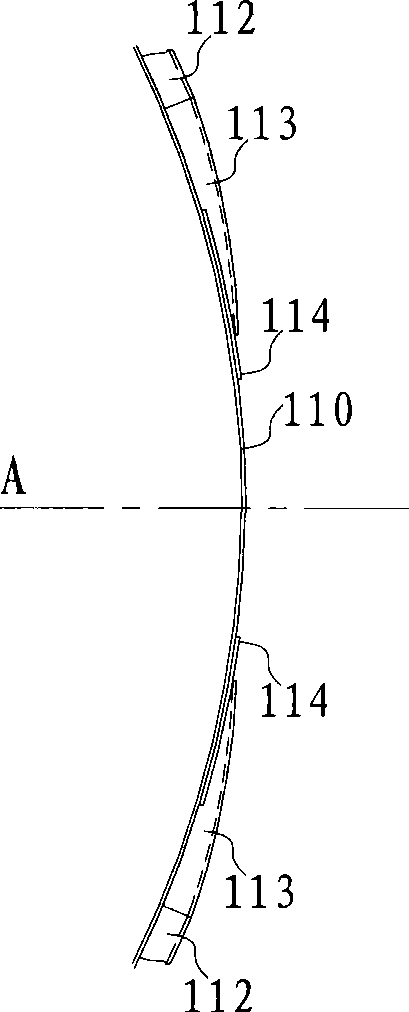

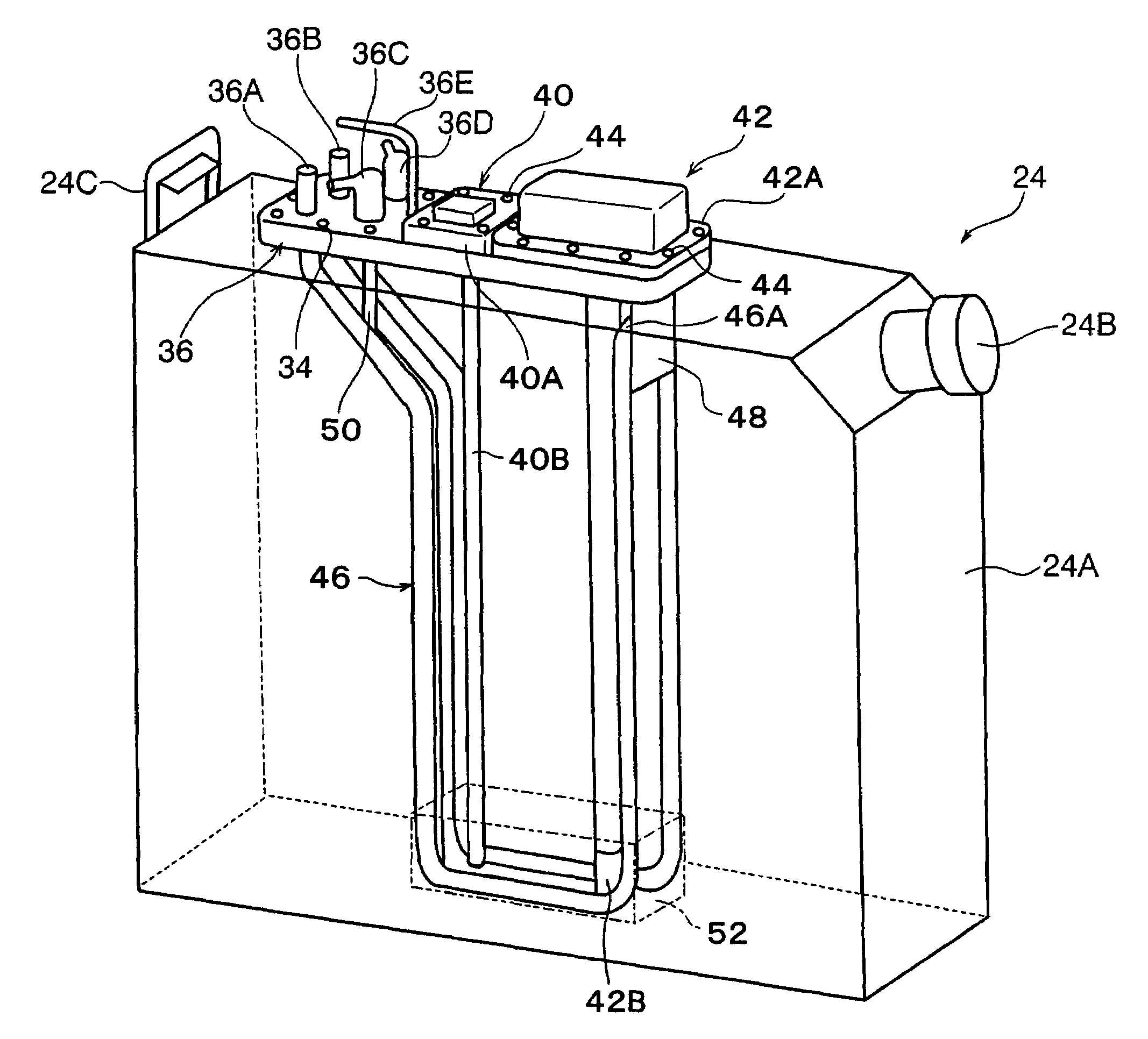

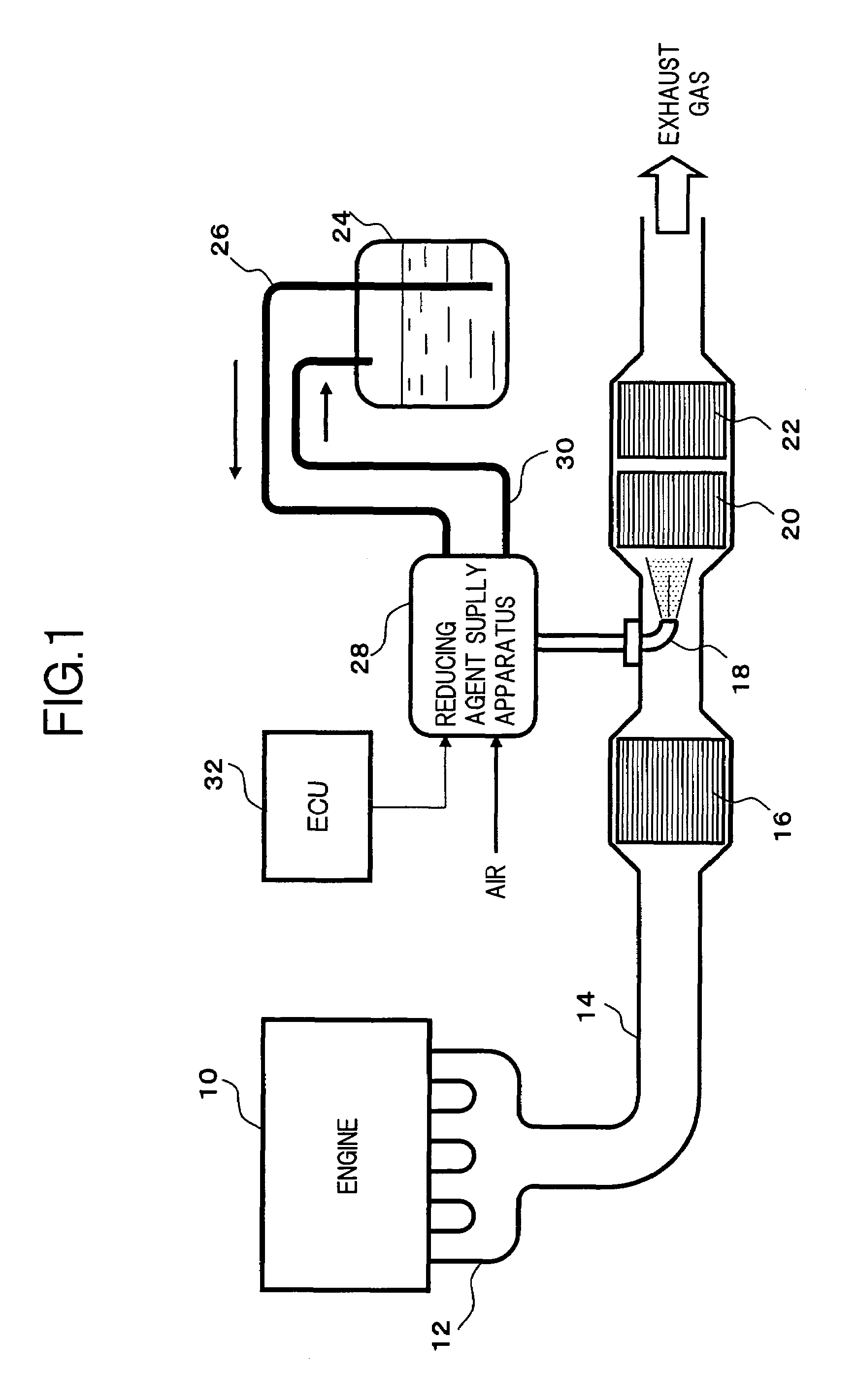

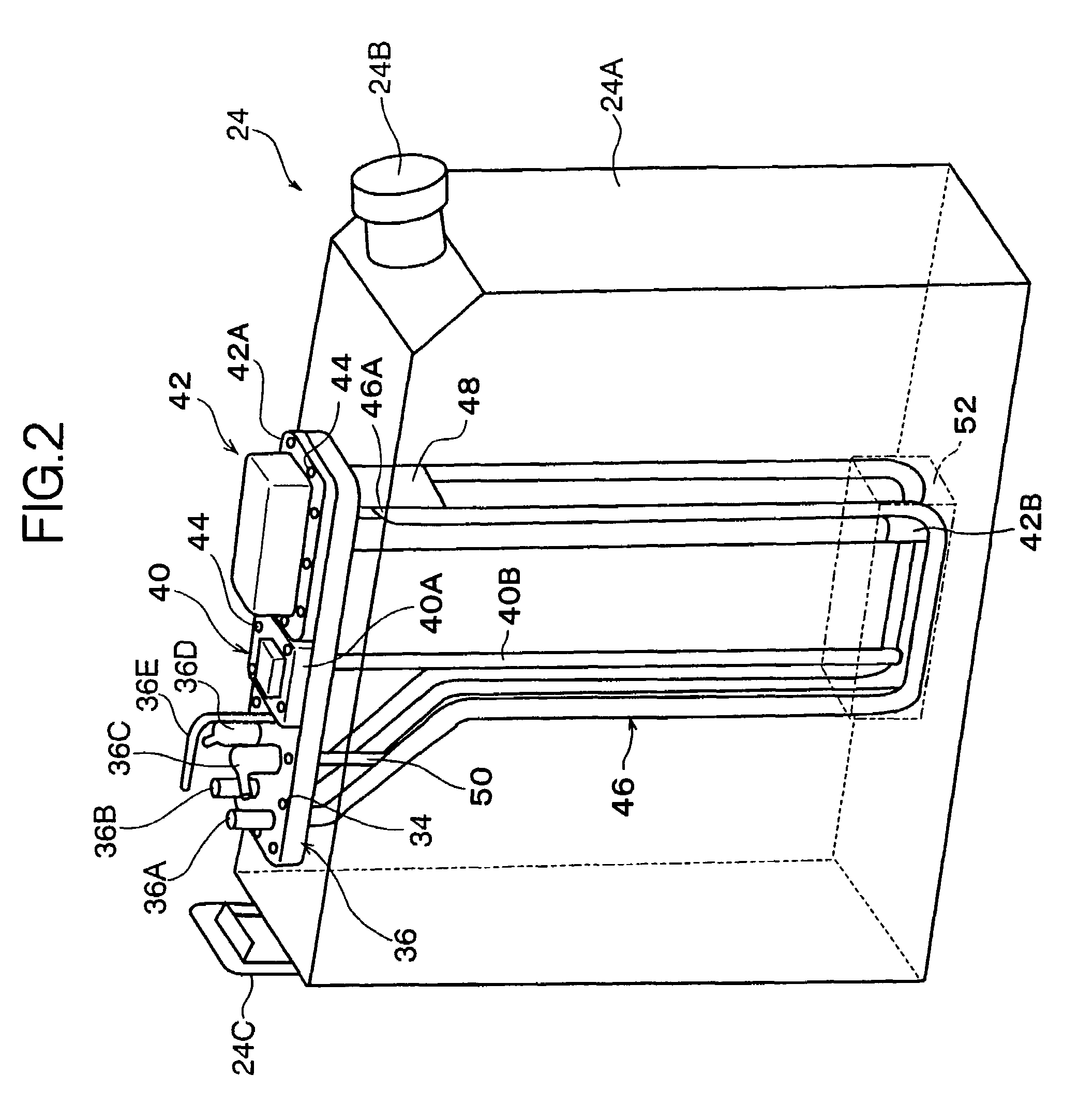

Structure for reducing agent container

ActiveUS7544328B2Reduce inspectionReduce maintenanceTesting/calibration apparatusNitrogen compoundsEngineeringTank container

Owner:NISSAN DIESEL MOTOR CO

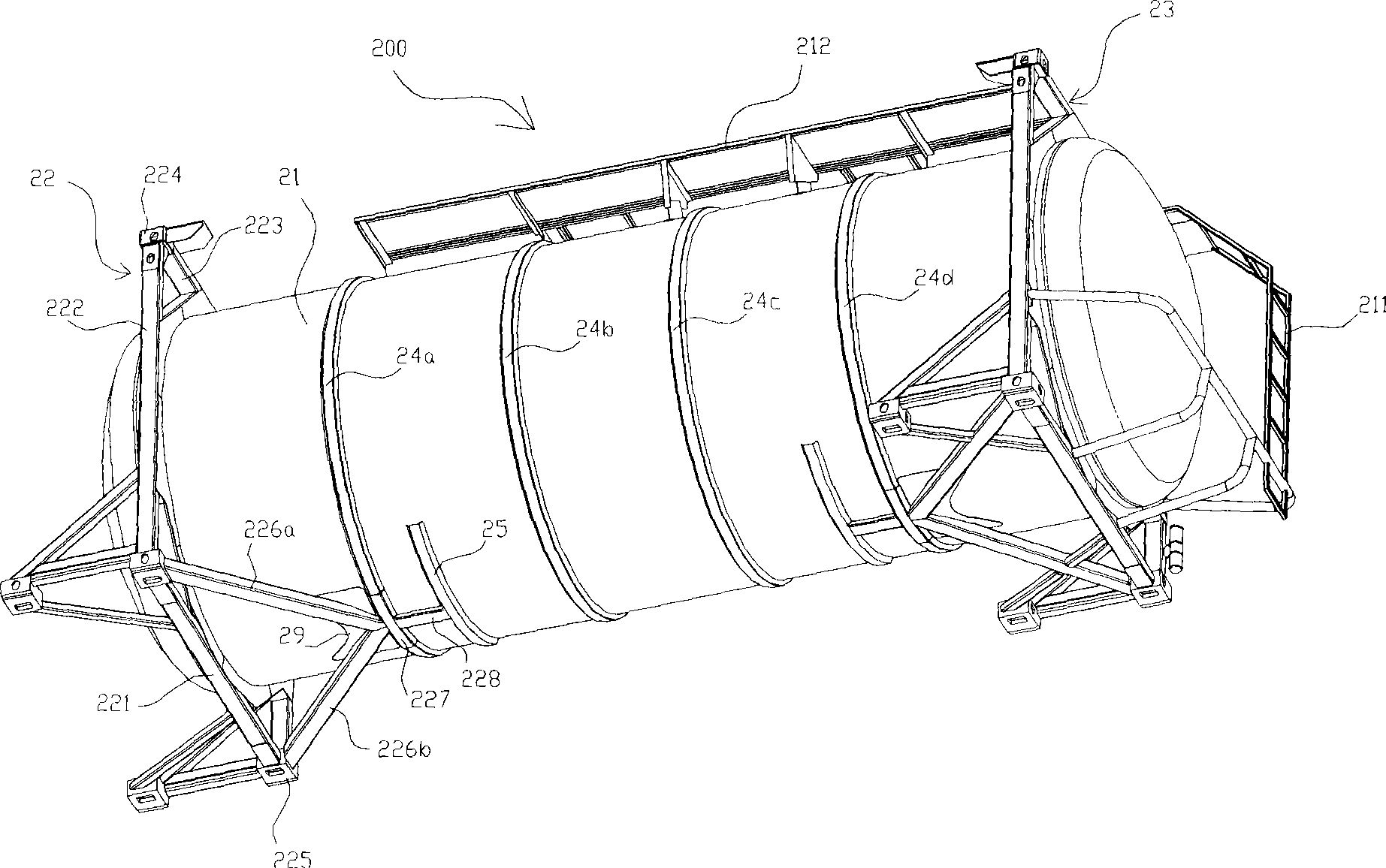

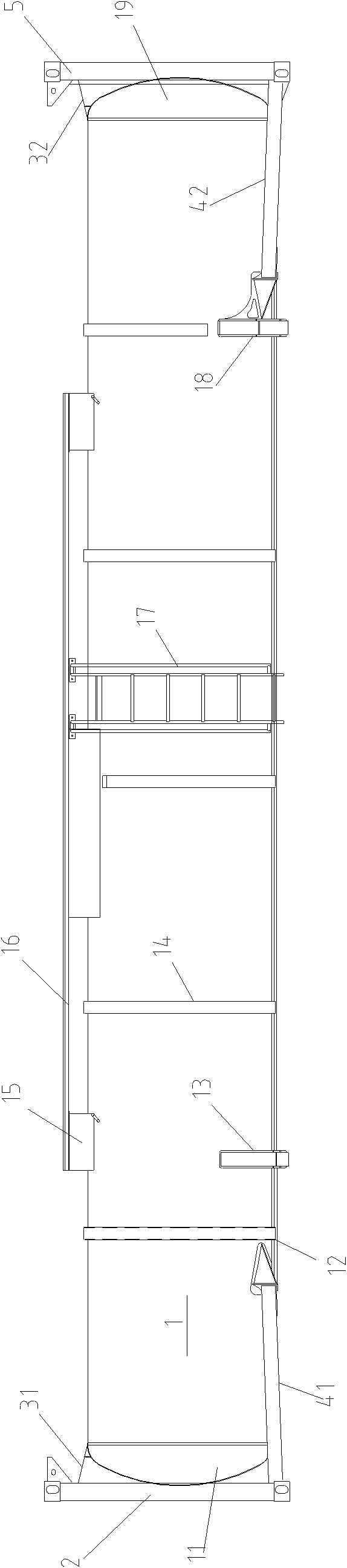

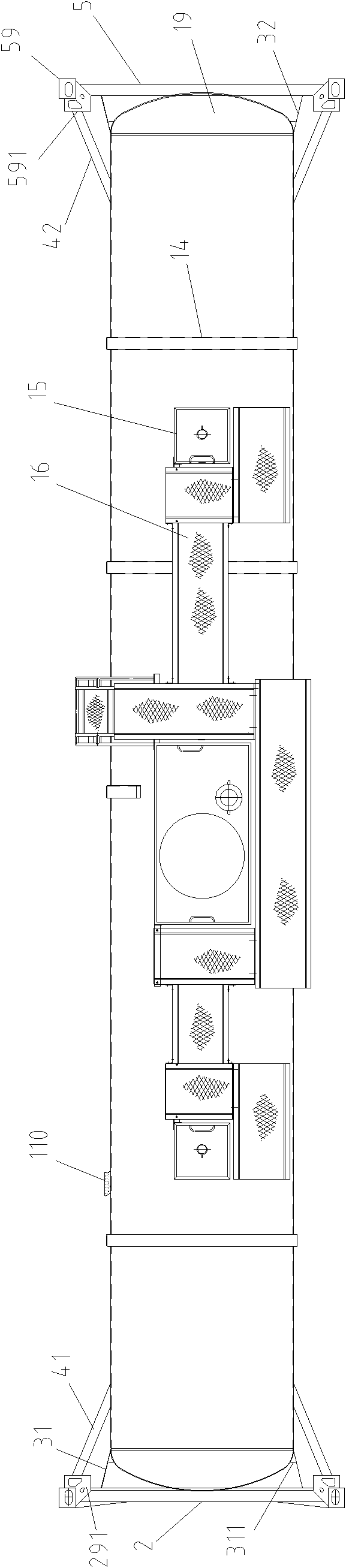

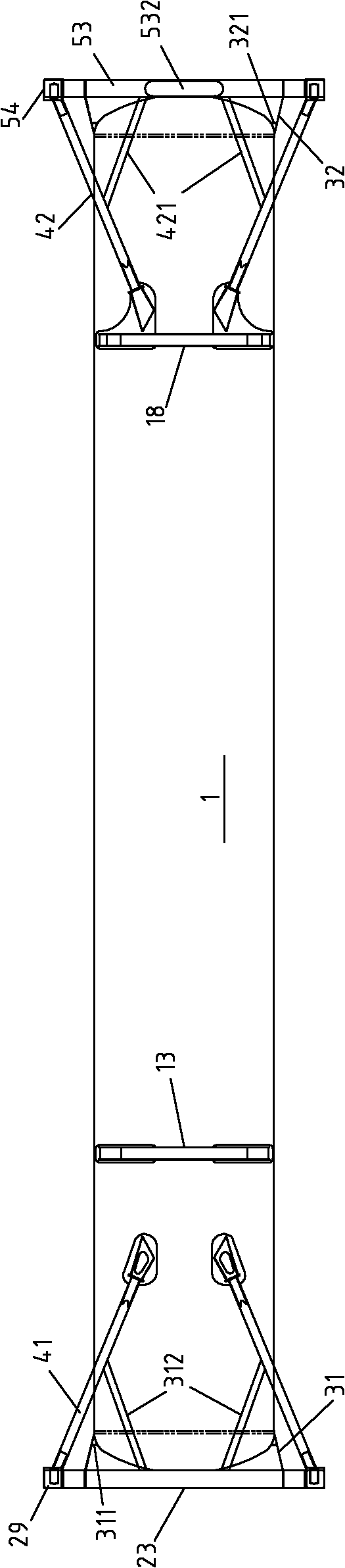

Exchange vehicle body tank container

The invention relates to an exchange vehicle tank container; the exchange vehicle tank container consists of a tank body, a front end frame and a rear end frame which are respectively arranged at the front end and the rear end of the tank body, as well as a plurality of reinforcing rings which are arranged on the outer surface of the tank body; both the front end frame and the rear end frame are provided with a top corner fitting and a bottom corner fitting, wherein both the frond end frame and the rear end frame are provided with at least one auxiliary supporting pipe; and the auxiliary supporting pipe leans upwards from the bottom corner fitting, stretches to a reinforcing ring nearest to the bottom corner fitting and is welded with the tank body and the reinforcing ring. The exchange vehicle tank container has simple structure and is safe and reliable.

Owner:NANTONG CIMC TANK EQUIP CO LTD

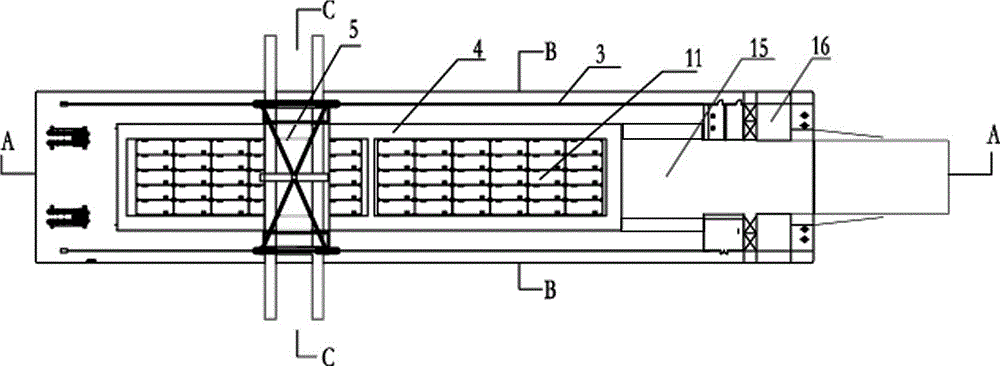

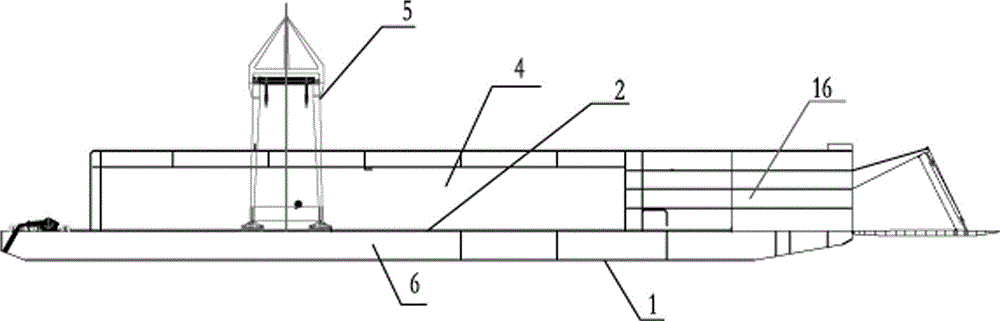

LNG tank container reloading ship

An LNG tank container reloading ship comprises a ship body, wherein a main deck is arranged on the upper surface of the ship body; two parallel tracks are arranged on the main deck; a portal bridge type special crane for LNG tank containers runs along the two tracks; an enclosed dock wall type protective wall is arranged between the two tracks; and a head springboard and a hoisting system for driving the head springboard to ascend and descend are arranged at the front end of the main deck. The LNG tank container reloading ship has the advantage that the seamless multimodal transportation water reloading new transportation mode for LNG tank containers of which tanks are not changed in the whole transportation process is implemented.

Owner:YICHANG DONGJIANG SHIPBUILDING CO LTD

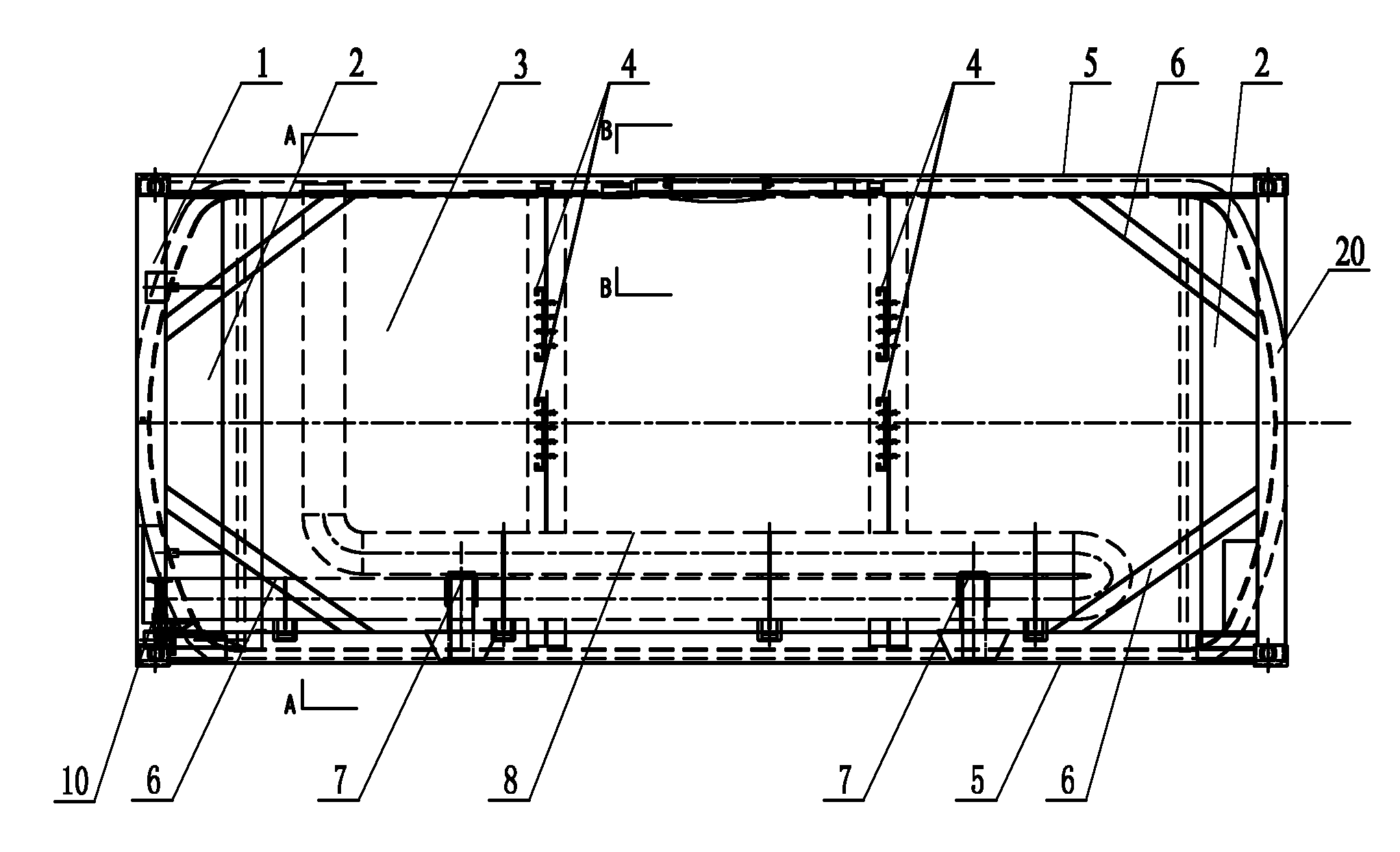

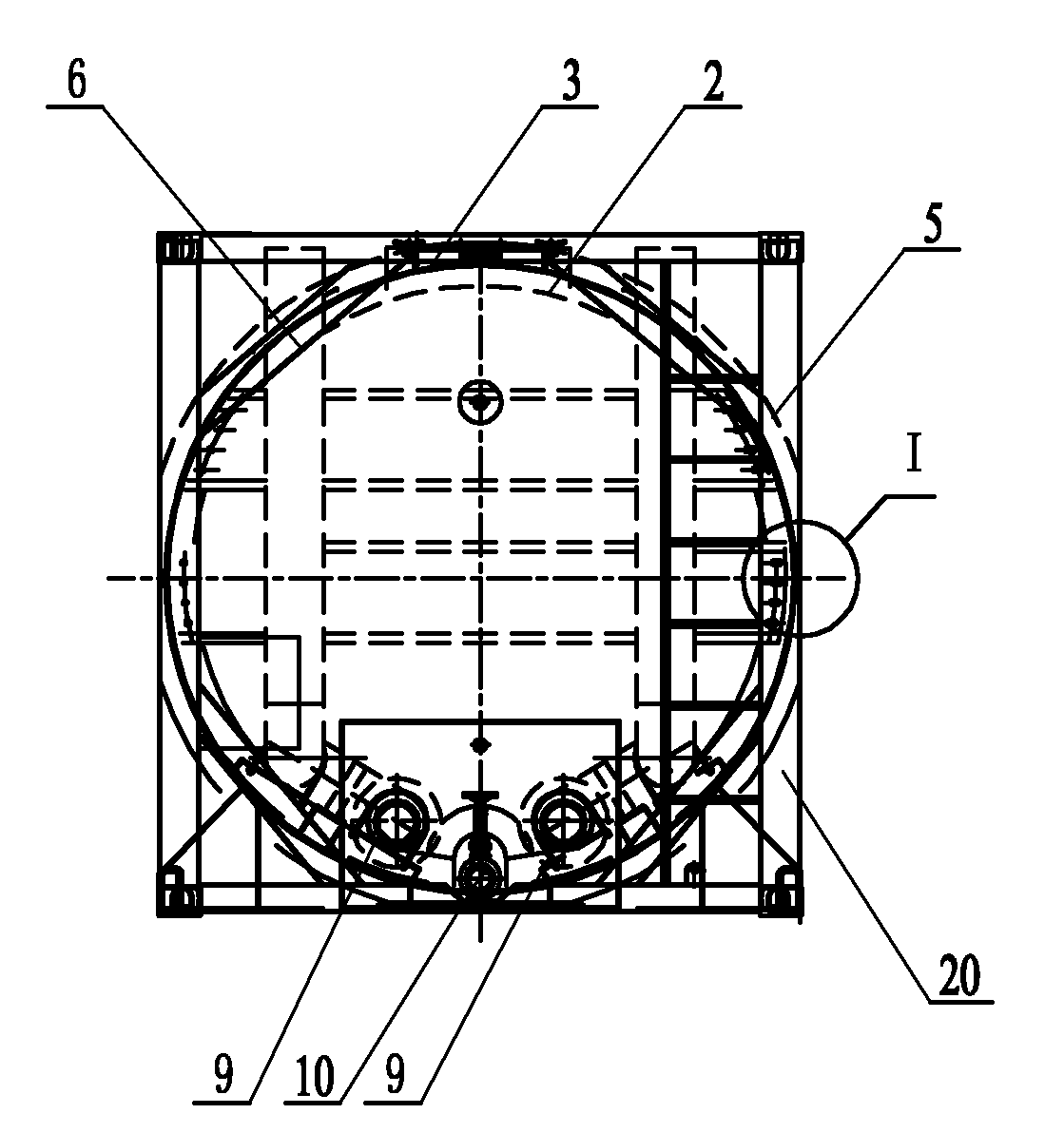

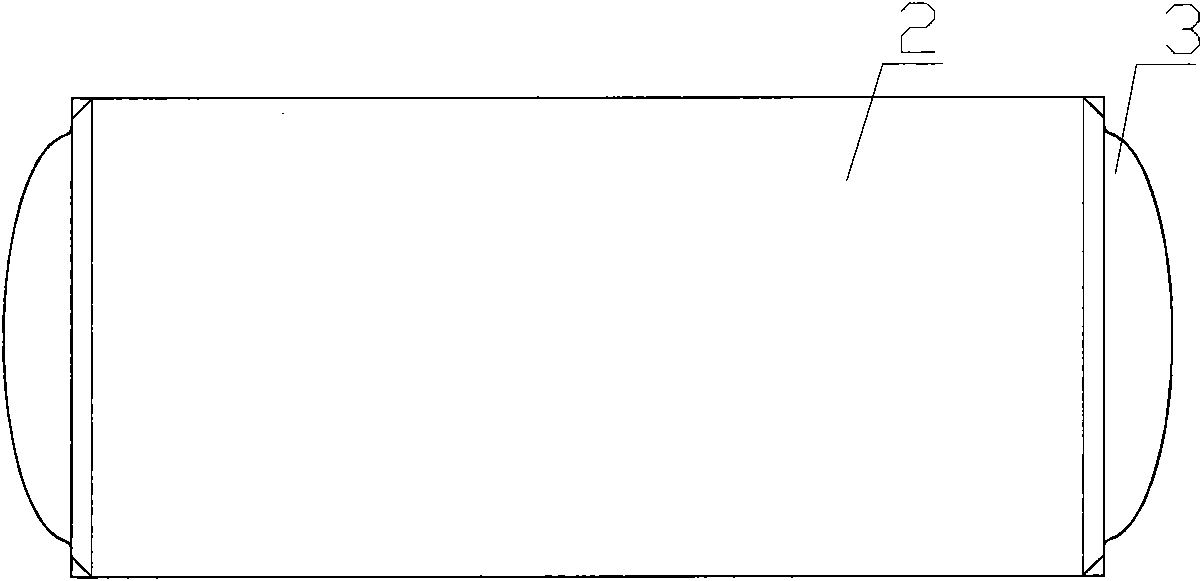

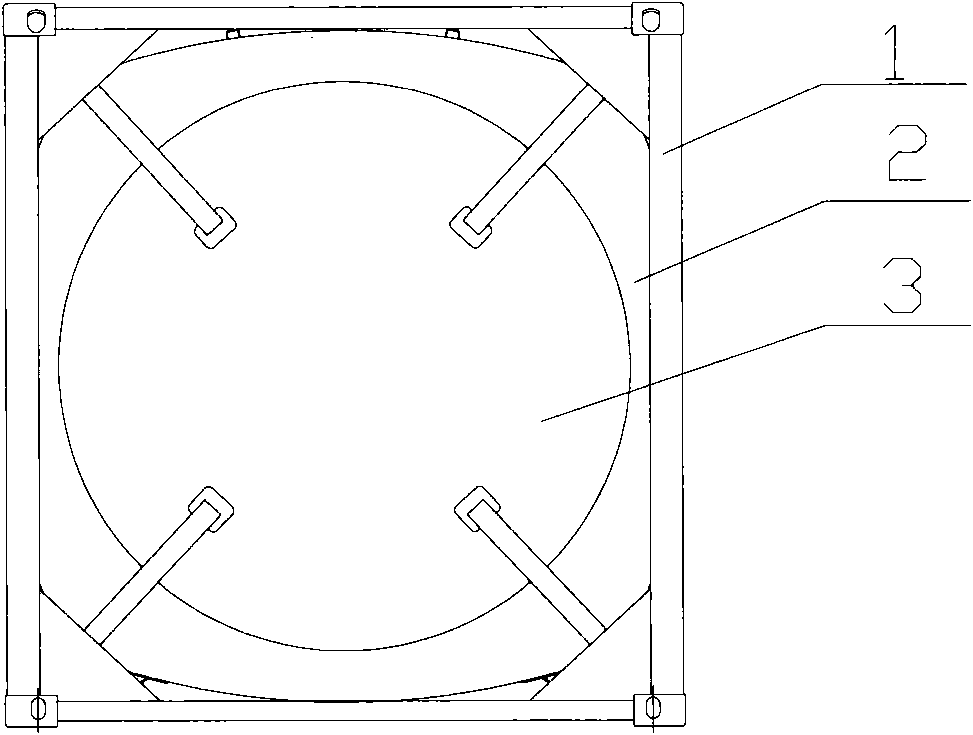

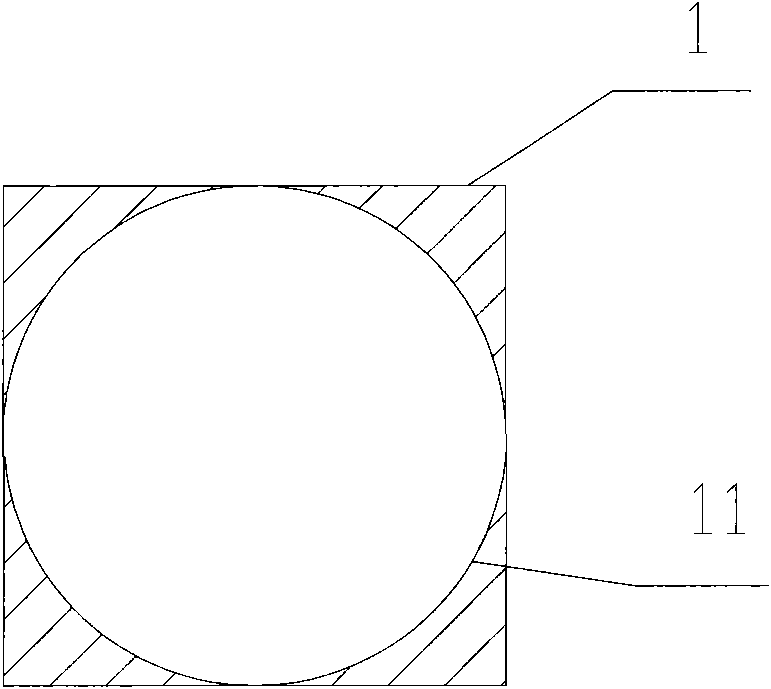

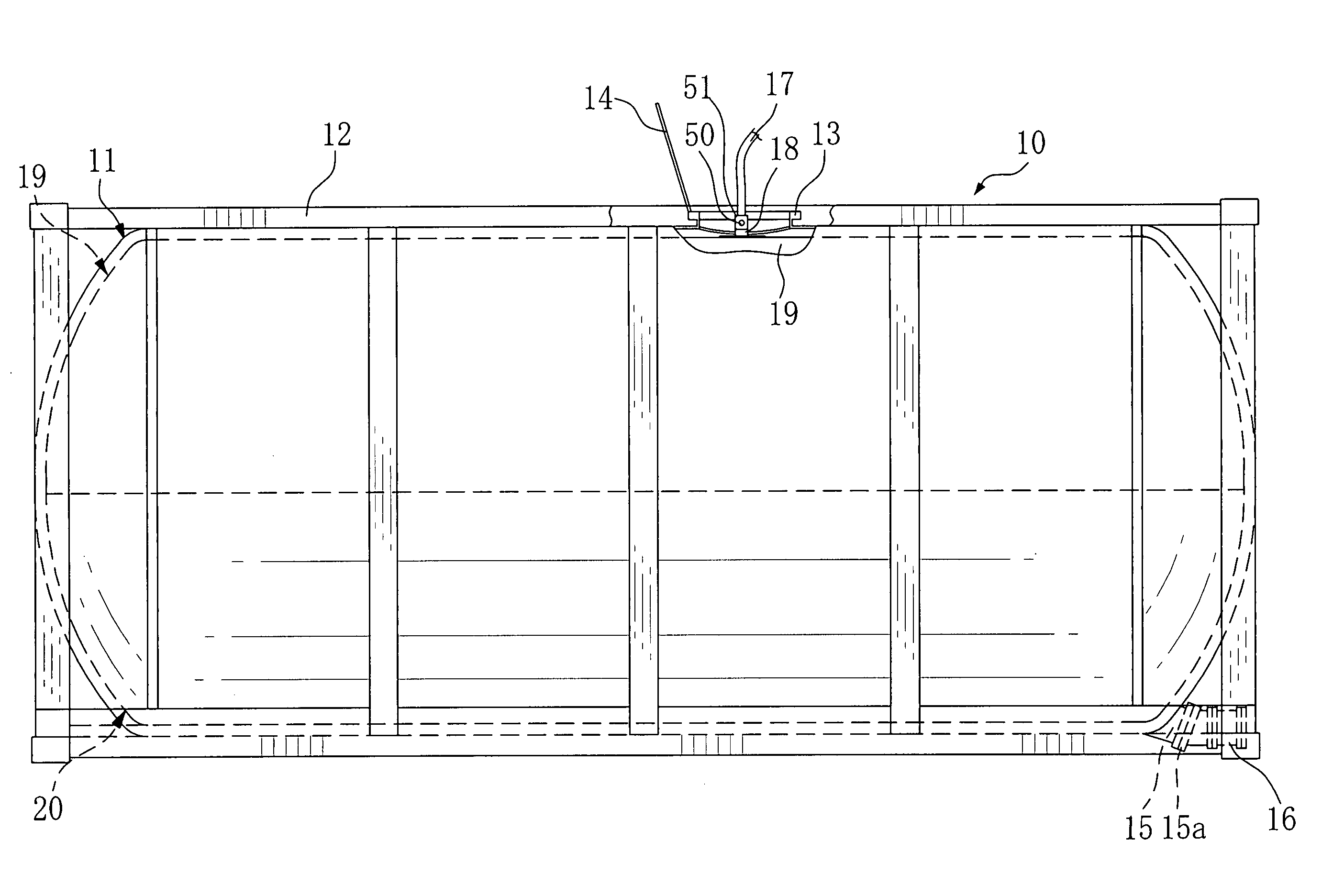

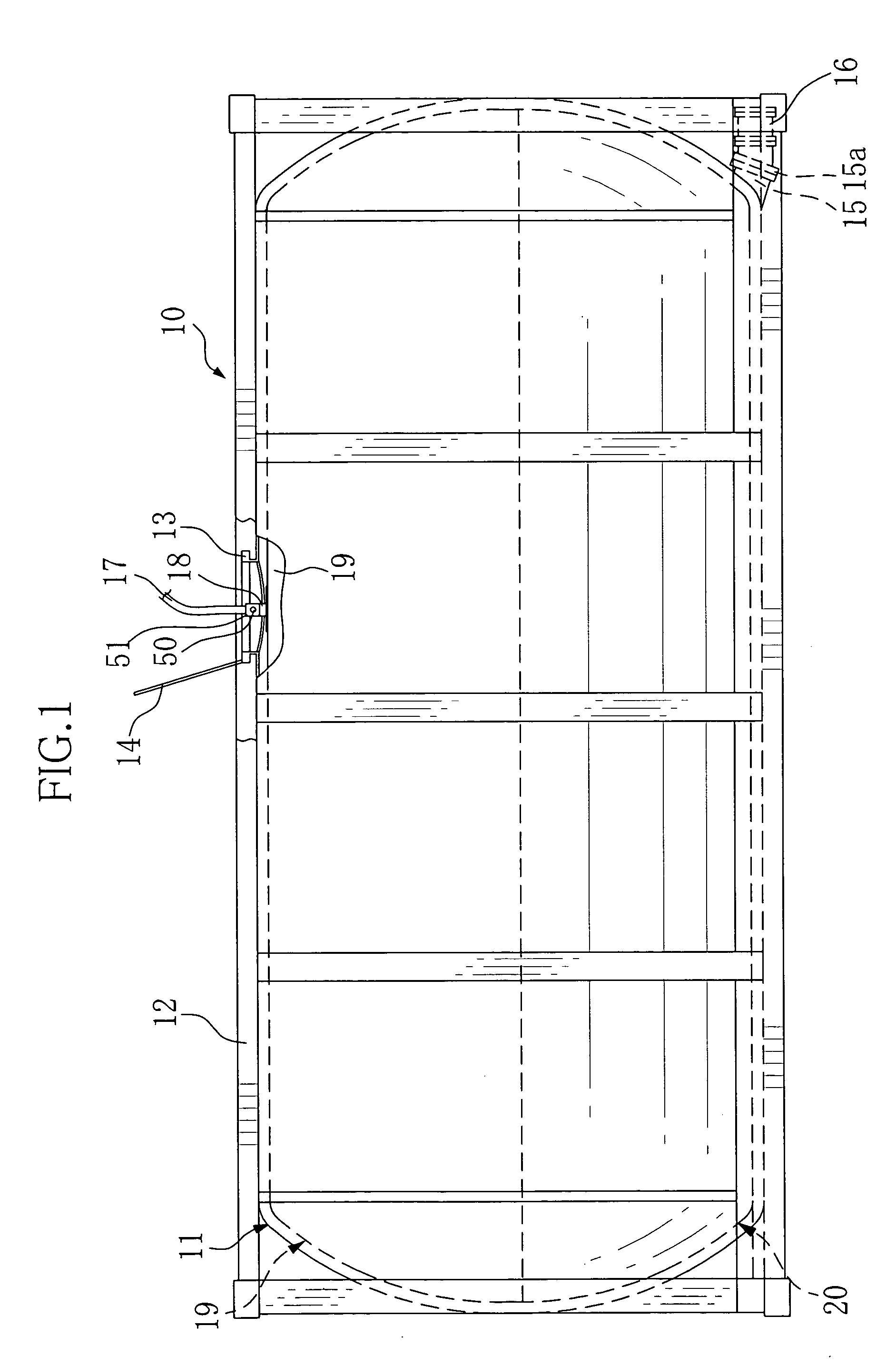

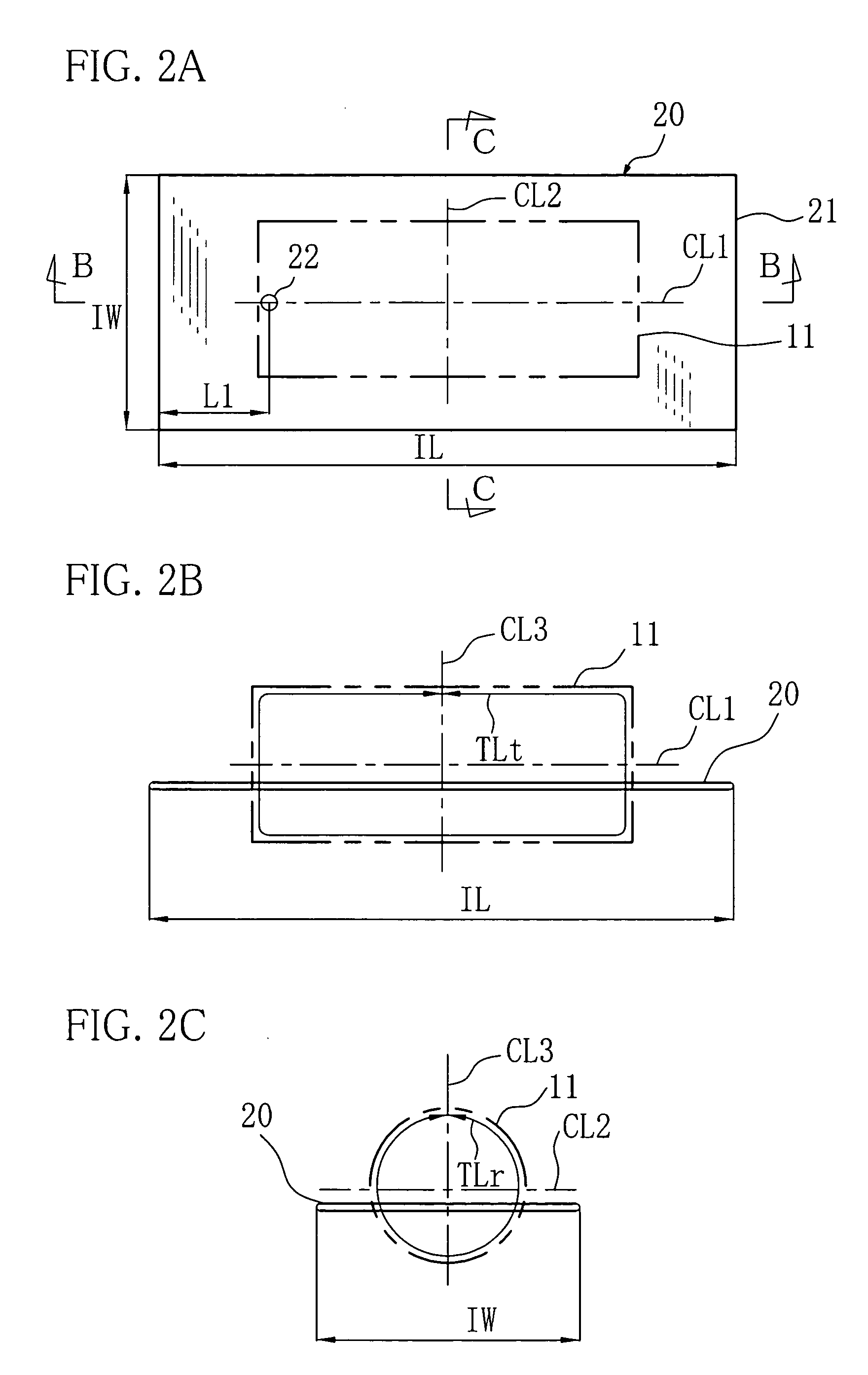

Tank container, tank body and processing method of tank body

ActiveCN101554948AImprove reliabilityLose weightLarge containersDomestic vesselsFuel tankTank container

The invention discloses a container tank body and a processing method thereof. The tank body is arranged in a frame with a square-shaped cross section and comprises a cylindrical main body part, end enclosures arranged at the two ends of the cylindrical main body part and fixedly connected with the cylindrical main body part, and a tank body strengthening device; the cylindrical main body part comprises a plurality of parts with an arc-shaped cross section, the parts are formed by the bending and welding of a same panel, and the cross section of the cylindrical main body part of the tank body is generally arranged between the square-shaped cross section of the frame and an inscribed circle of the square-shaped cross section. The invention also discloses a tank container comprising the tank body. As the cylindrical main body part is made by continuously bending a whole panel, the molding process is simplified so that the cylindrical main body part is only provided with one welding line, thereby remarkably lowering the leakage risk of the container tank body in use and improving the reliability of the container tank body in work; and the structure has quite strong self-anti-load capacity, thereby decreasing the number of the used tank strengthening devices and reducing own weight.

Owner:CRRC QIQIHAR ROLLING CO LTD

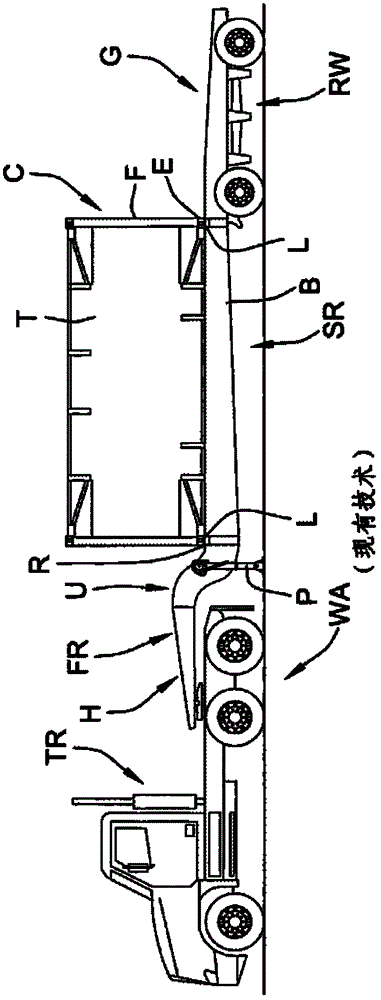

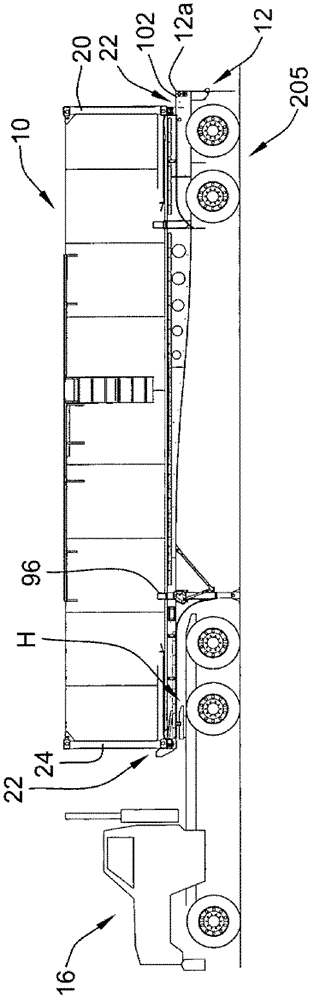

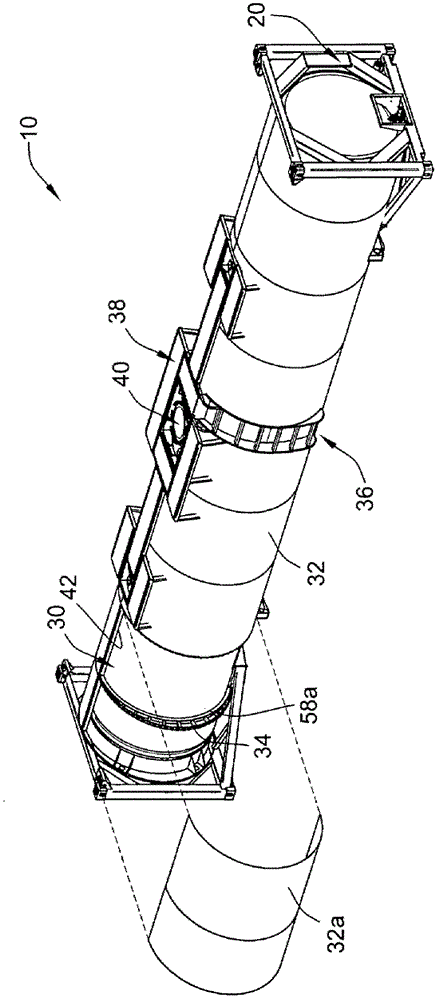

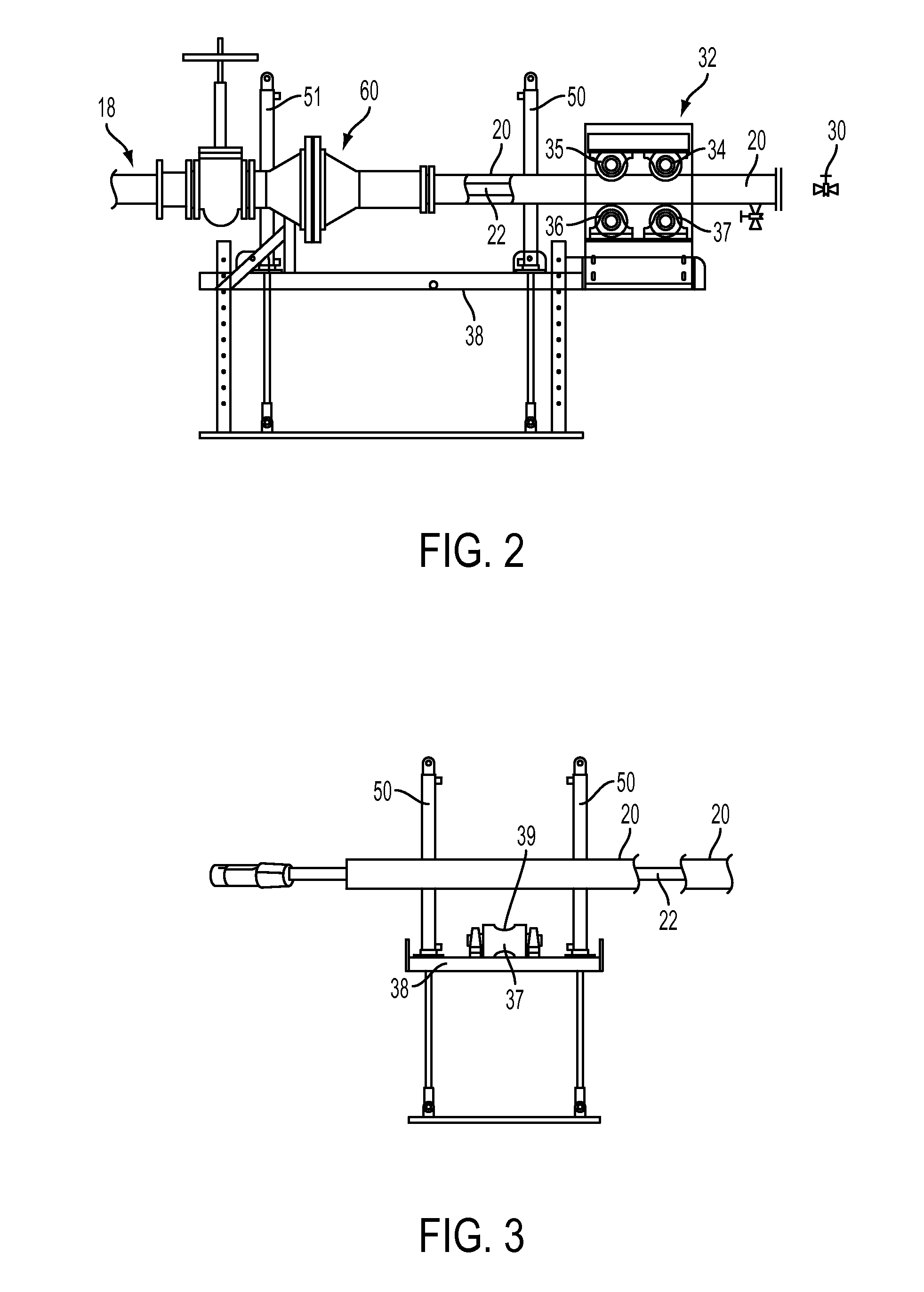

Intermodal tank transport system, components, and methods

An intermodal tank container and complementary chassis, and features and methods for use thereof, are disclosed. The intermodal tank container and chassis has an appearance and length substantially similar to a non-intermodal OTR tank trailer, while affording the same capacity as an intermodal tank container. The design of the tank container allows for an improved, lighter design for the chassis and for improved usability of the tank container in intermodal environments such as with rail cars. The reduced weight of the chassis allows for a greater payload while remaining within various applicable legal restrictions for gross vehicle weight, axle weight, etc.

Owner:INT TRANSPORT EQUIP CORP

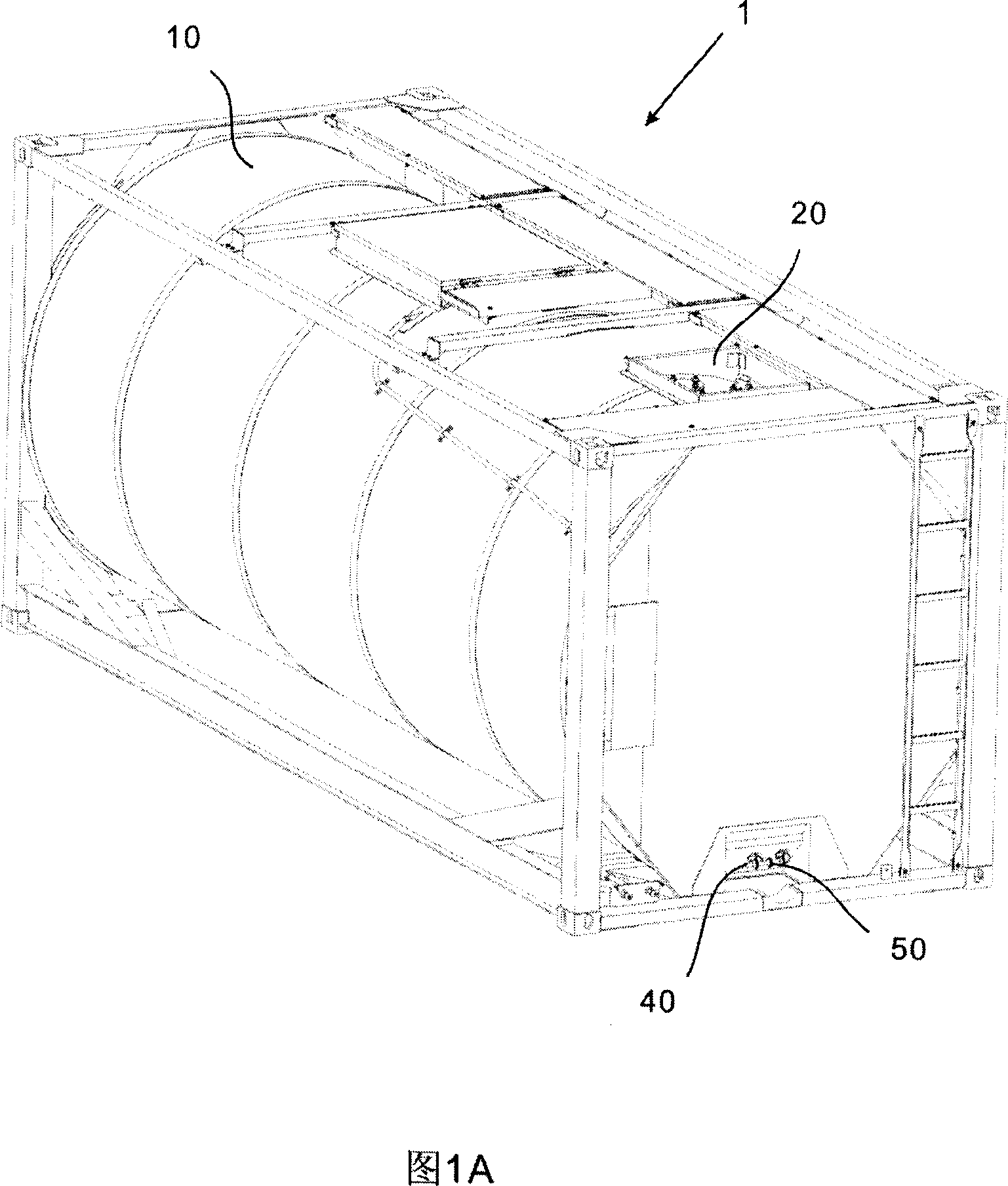

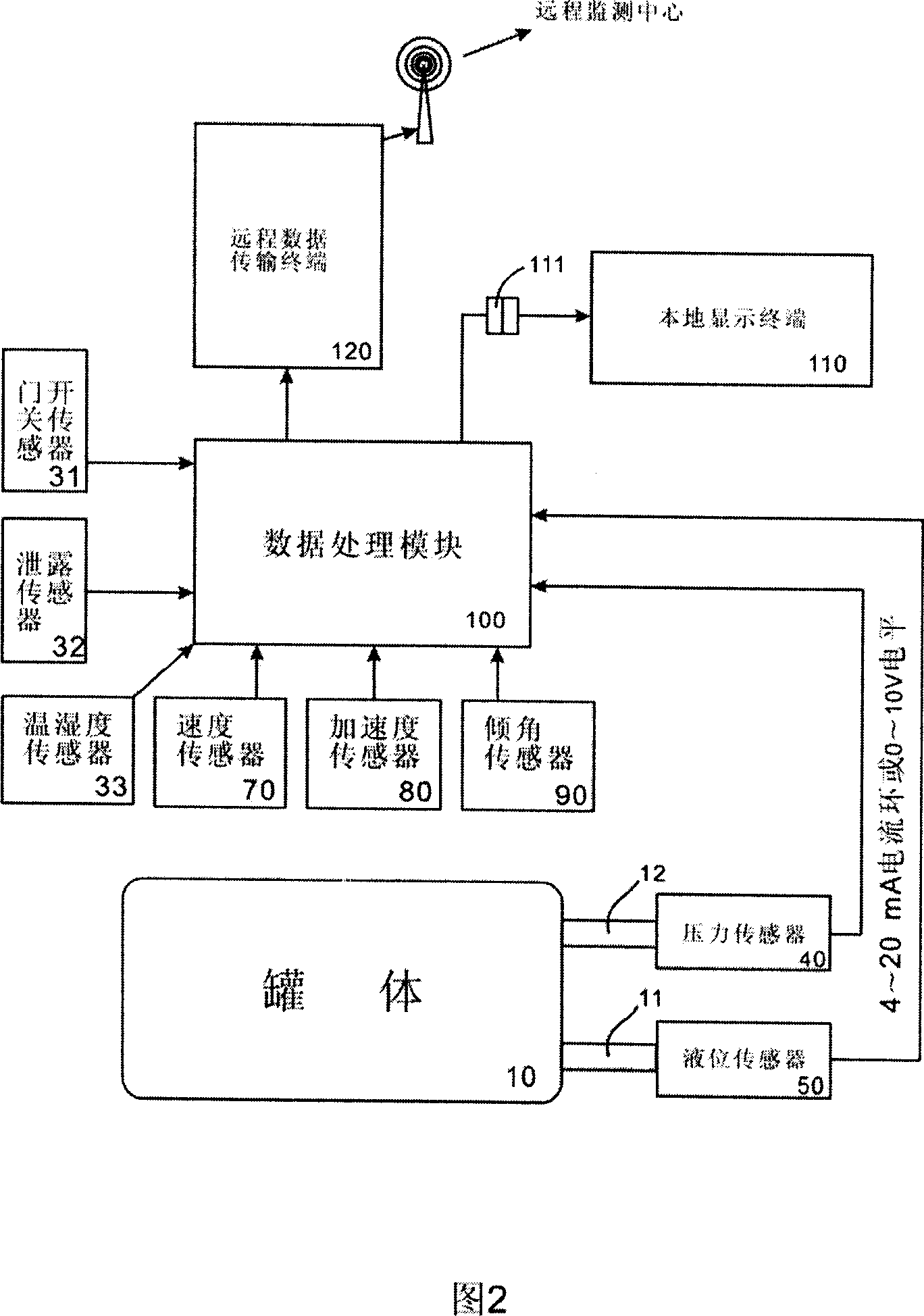

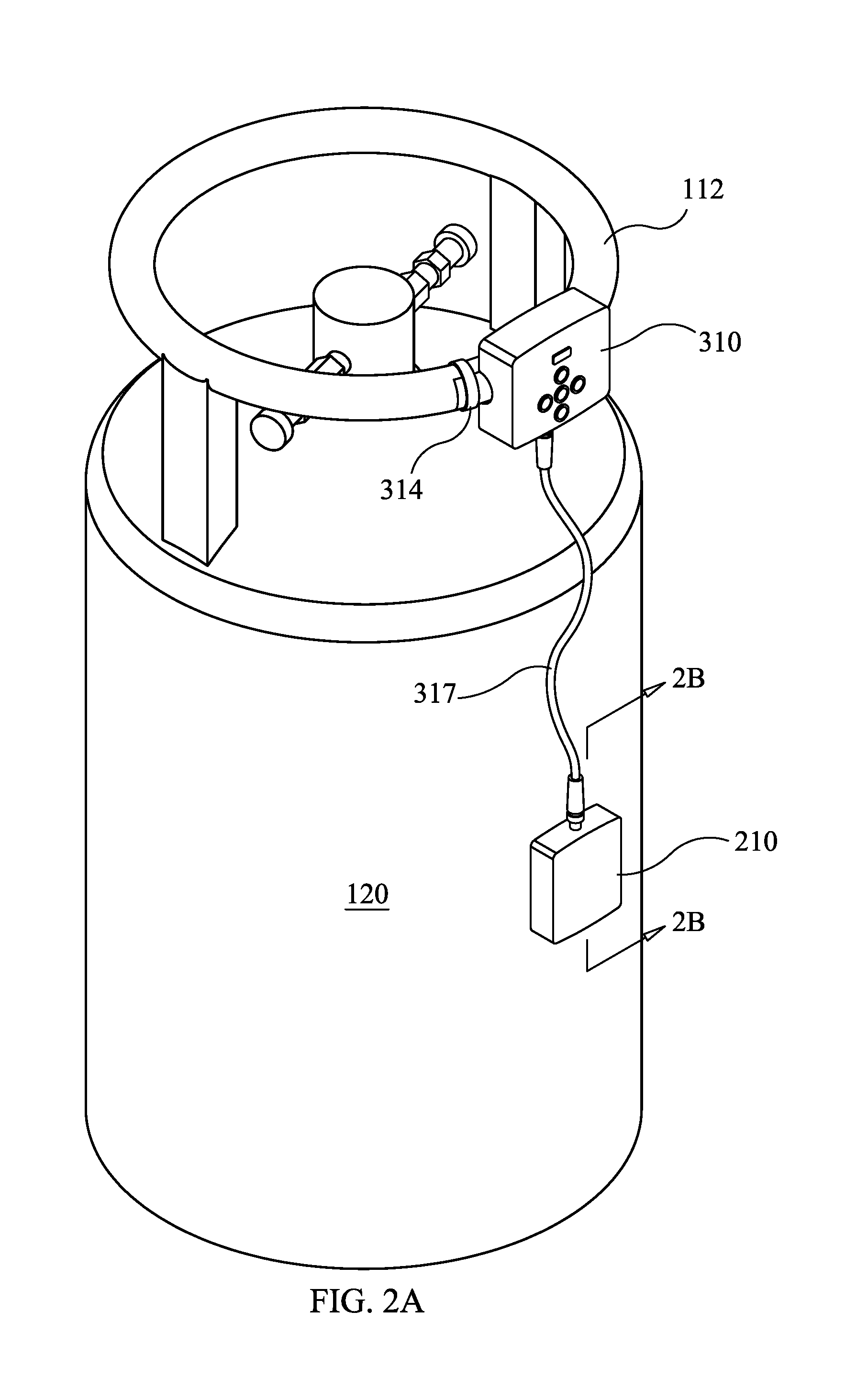

Pot type container with digital electronic monitoring device

ActiveCN101045498ARealize remote tracking and monitoringImplement trackingLarge containersComputer terminalTank container

A tank-type container with digital electronic monitor features that said digital electronic monitor arranged in a valve protecting box is composed of data processing module, liquid level sensor, pressure sensor, inclination sensor, acceleration sensor, speed sensor, leakage sensor, gate state sensor, and local display terminal and / or remote data transmission terminal.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +1

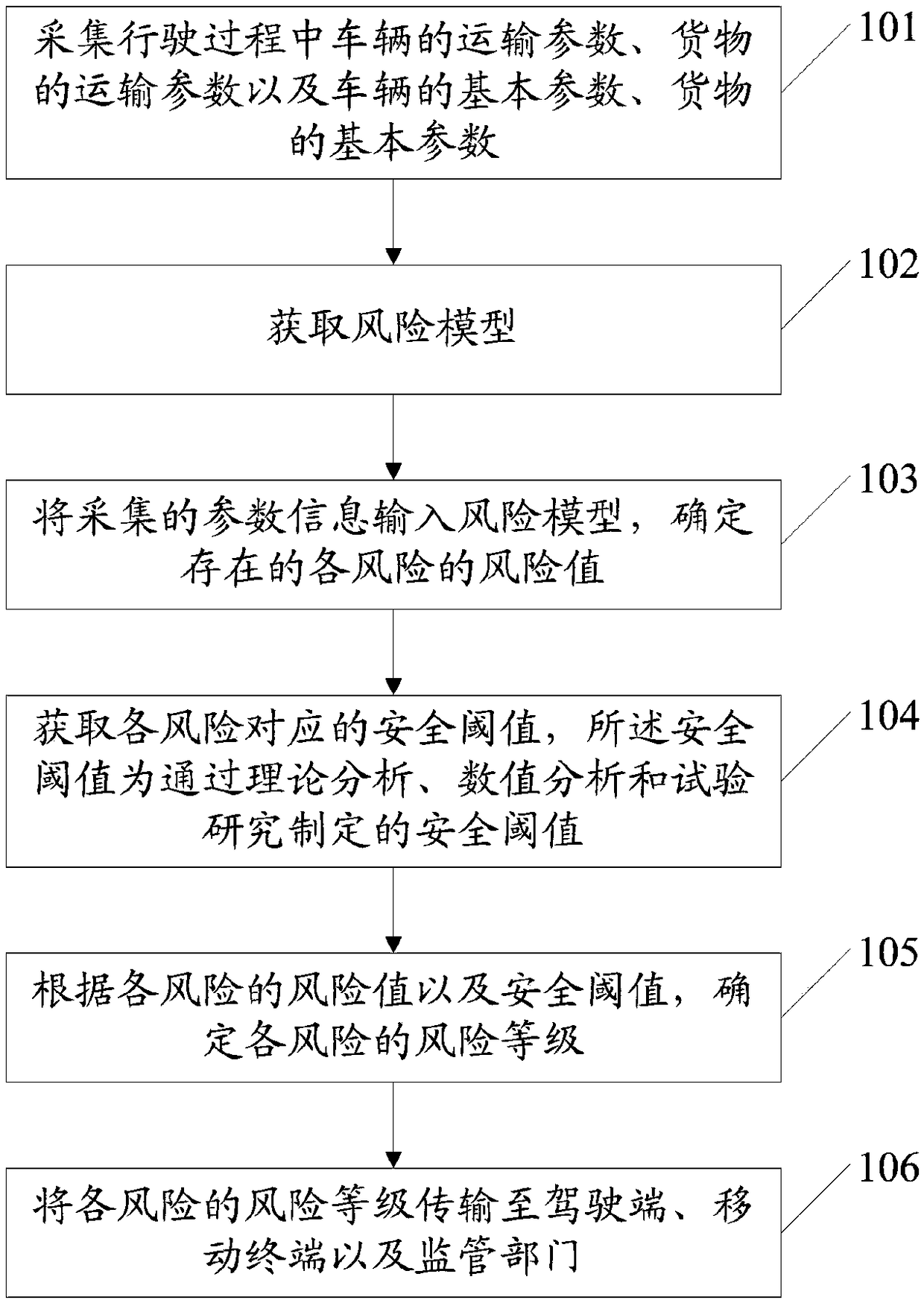

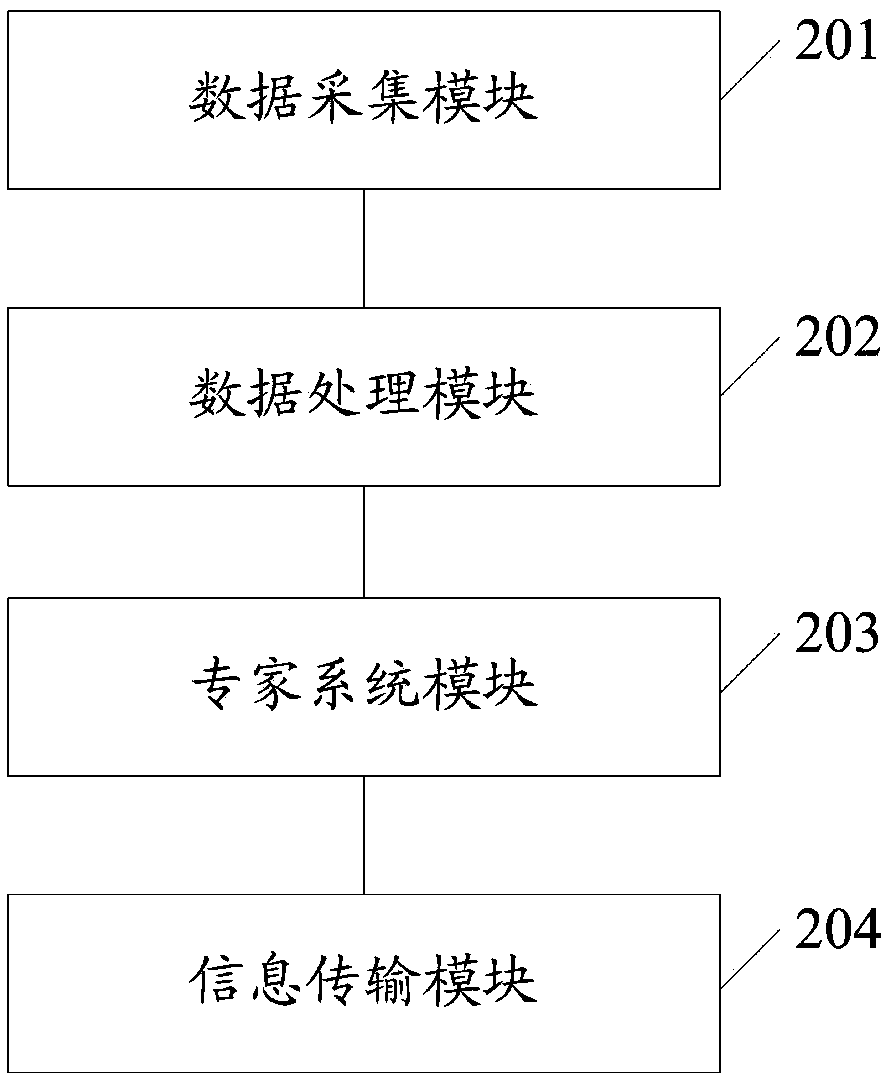

Tank container highway transportation early warning method and system

PendingCN108805472AReal-time monitoring statusAvoid dangerRegistering/indicating working of vehiclesSignalling/lighting devicesRisk levelExperimental research

The invention discloses a tank container highway transportation early warning method and system. The method comprises the steps that the transportation parameter of the vehicle in the driving process,the transportation parameter of the cargo and the basic parameter of the vehicle and the basic parameter of the cargo are acquired; a risk model is acquired; the acquired parameter information is inputted to the risk model, and the risk value of each existing risk is determined; the corresponding safety threshold of each risk is acquired, wherein the safety threshold is the safety threshold madeby theoretical analysis, numerical analysis and experimental research; the risk level of each risk is determined according to the risk value of each risk and the safety threshold; and the risk level of each risk is transmitted to the driving side, the mobile terminal and the supervision department. According to the tank container highway transportation early warning method and system, real-time monitoring and risk prediction of the vehicle state and the cargo state in the tank container can be performed so as to perform better risk prevention.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

Tank type container

ActiveCN101301952AImprove the forceOptimize usage efficiencyLarge containersStress conditionsEngineering

The invention relates to a tank-shaped container, comprising a tank body, a reinforcing ring arranged on the outer side of the tank body and a bottom discharging valve arranged below one end of the tank body. A manhole, a safety valve, an air-phase valve, a top discharging hole and an overflowing box are arranged on the top of the tank body. An overflowing tube used for guiding liquid in the overflowing box to the outside of the tank-shaped container is arranged at the bottom of the overflowing box. The two ends of the tank body are respectively welded onto the end frames of the two ends by apron rings, and the end frames of the two ends are respectively connected with a vertical bottom beam and a reinforcing inclined support. A stair fixedly arranged on the end frame of one end is led to a path board fixedly arranged on the top of the tank-shaped container. An angle part, an angle column, a top beam, a bottom beam, the reinforcing inclined support and a top angle board are connected to form the end frame. A reinforcing plate is welded on the internal surface of the lower wall of a rectangular tube of the bottom beam. The tank-shaped container has the main advantages that the distance between the lower surface of the end part of the bottom beam of the end frame and the lower surface of the angle part of the end frame is enlarged, therefore, the stressing condition of the bottom beam of the end frame during conveying is enhanced and the service efficiency of the tank-shaped container is improved.

Owner:NANTONG TANK CONTAINER CO LTD

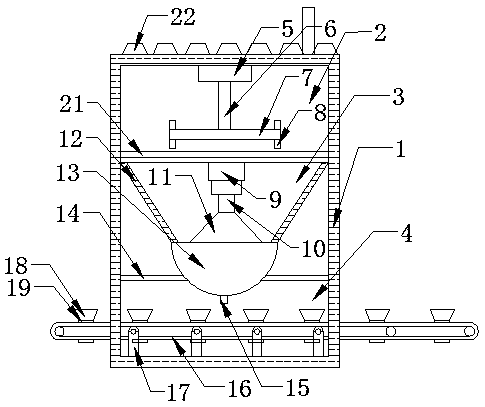

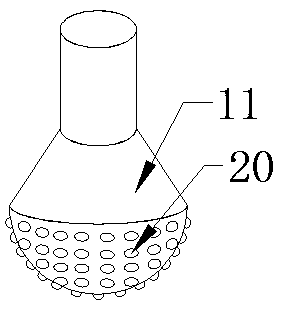

Traditional Chinese medicine grinding equipment

InactiveCN107737647AGuarantees a high degree of grindingReduce labor intensityGrain treatmentsTank containerConveyor belt

The invention discloses a grinding equipment for traditional Chinese medicine, which comprises a casing. The interior of the casing is provided with a crushing box, a grinding box and a discharge box from top to bottom. The filter screen is separated from the partition, and the top of the crushing box is provided with a feeding port to pass through the shell to connect with the outside world. The top inside the crushing box is fixed with a first motor, and one end of the output shaft of the first motor is fixedly connected with a turntable. The present invention is equipped with a pulverizing box on the top of the grinding box. First, the medicine is pulverized, and the medicine with a relatively high degree of pulverization is filtered through the filter plate, and the medicine is guided into the mortar by the baffle plate. Driven by the second motor Turn the grinding rod down, and there is a discharge port and a conveyor belt at the bottom, and an infrared sensor is installed at the electronic scale and the discharge port. The worker controls it through the infrared sensor control button, and the conveyor belt rotates for the next medicine bowl The process of holding medicine.

Owner:杨晓彬

Transport tank and transporting method thereof

InactiveUS20050189357A1Avoid fillingPrevent movementLarge containersItem transportation vehiclesEngineeringTank container

A transport inner bag and a pressure inner bag are loaded in a tank body of a tank container. A supply-discharge opening for the transport inner bag is provided in a position corresponding to a tank supply-discharge opening, and cargo is filled through the opening. A supply-discharge opening for the pressure inner bag is provided in a position corresponding to a hatch of the tank body, and air is filled through the opening to expand the pressure inner bag, so that a space between the transport inner bag and an inner surface of the tank body is filled as well as the gap in between. This prevents the transport inner bag from moving in the tank body in transporting in a state that the cargo is not fully loaded in the transport inner bag, so that the breakage of the transport inner bag caused by the movement is prevented.

Owner:FUJIFILM CORP

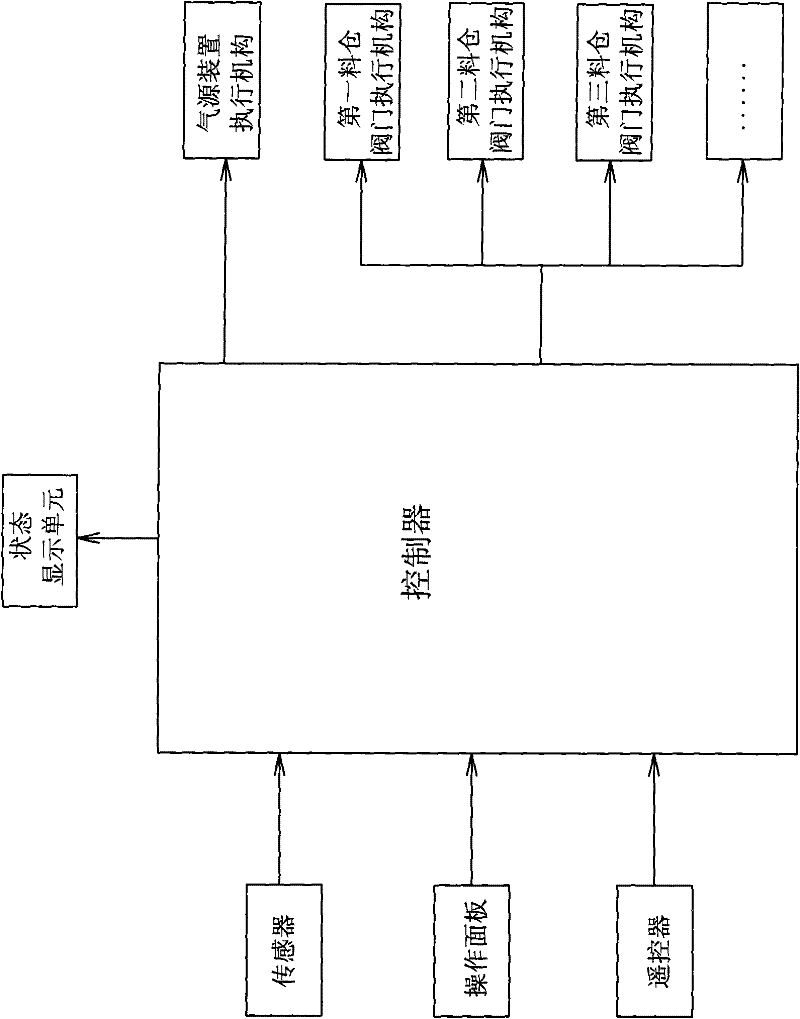

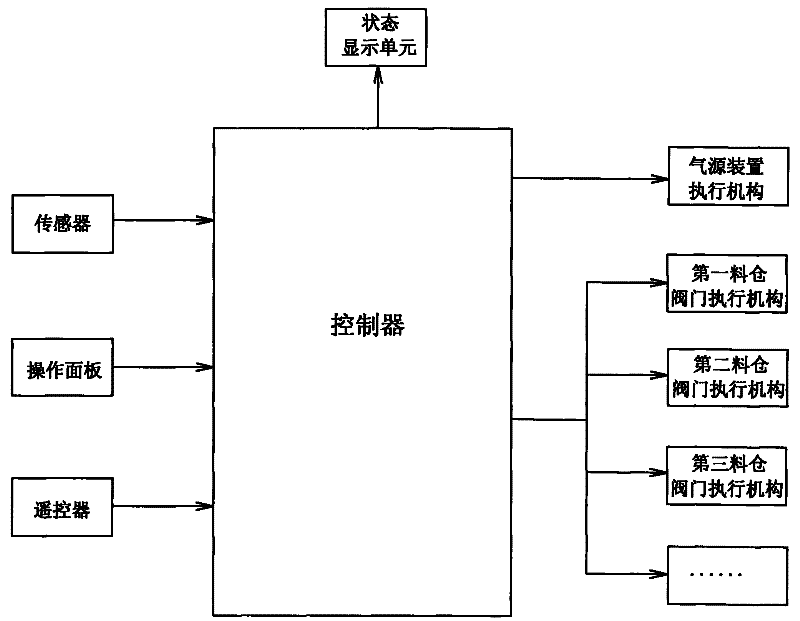

Intelligent unloading system, multi-silo tank container and multi-silo tank car

ActiveCN102234027AReduce labor intensityImprove unloading efficiencyLoading/unloadingControl signalValve actuator

The invention discloses an intelligent unloading system, a multi-silo tank container and a multi-silo tank car. The intelligent unloading system comprises a sensor which is arranged in a tank body and is used for timely acquiring a pressure signal in the tank body, multiple valve actuators which are respectively connected with multiple unloading valves of multiple silos and are used for opening or closing the unloading valves, a controller and an input unit, wherein the controller is used for receiving the pressure signal input by the sensor, comparing a pressure value with multiple opening pressure set values and multiple closing pressure set values in the controller and then controlling multiple actuators to sequentially open and close the unloading valves of all the silos according to the comparison result, thus all the silos sequentially unload; and the input unit is connected with the controller and is used for inputting a control signal to the controller. By adopting the intelligent unloading system disclosed by the invention, the labour intensity can be greatly reduced, and the unloading efficiency can be improved. A tank container or tank car provided with the intelligent unloading system disclosed by the invention is convenient and rapid to unload.

Owner:CIMC VEHICLES (GROUP) CO LTD +1

Pot container

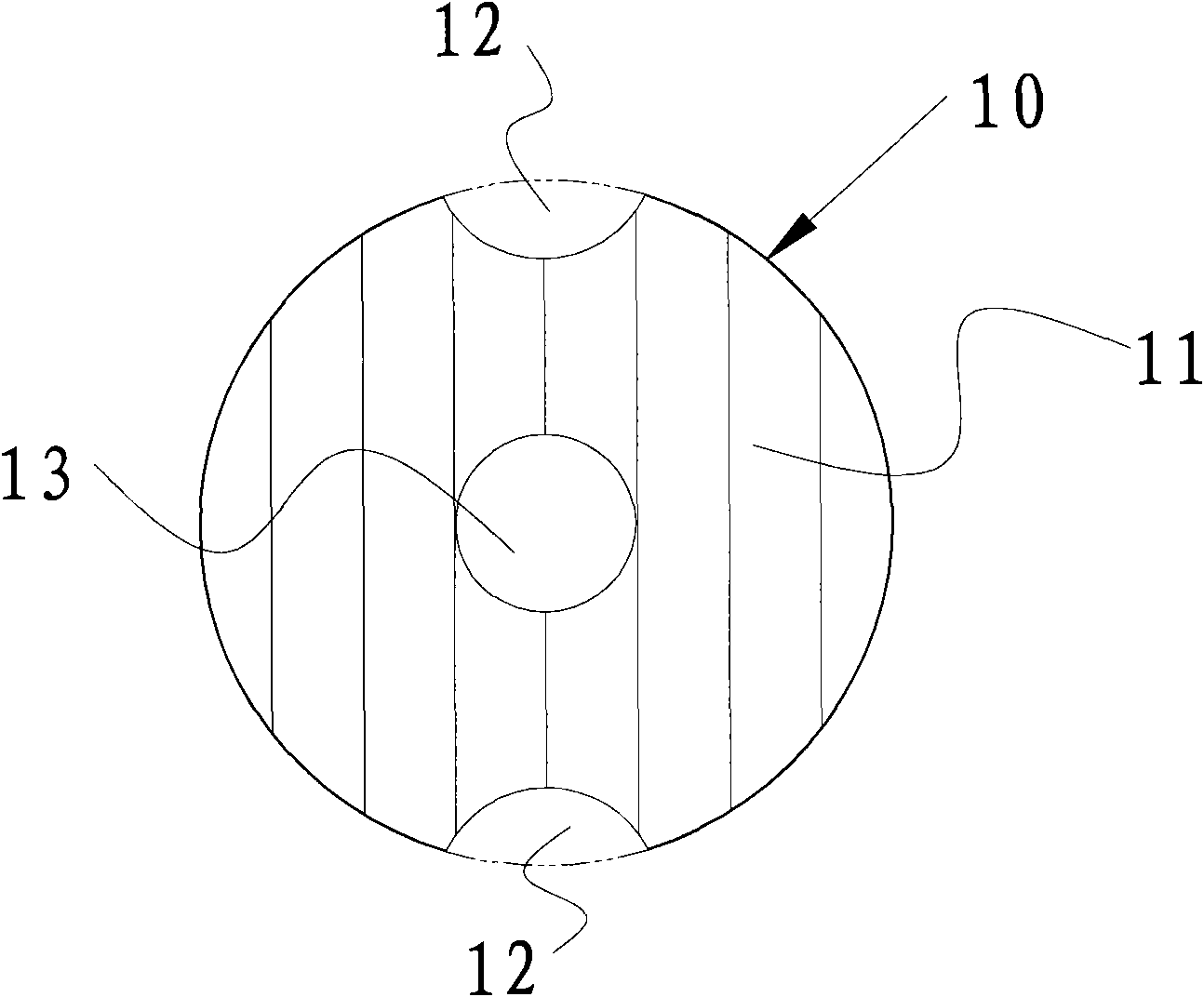

InactiveCN1803546ALarge loading volumeGood strengthLarge containersTank wagonsInternal pressureLongitude

The invention discloses a can-type container, which consists of frame structure and can body in the frame structure, wherein the frame structure contains the opposing front end frame and back end frame and side beam in connection with coroner part between front and back end frames, which concludes multiple longitude beams on the periphery of can; two ends of longitude beam connects the corresponding frame of front and back end frame; the can body is a sealing can with multiple arc blocks connected by longitude beams. The invention can bear certain inner-pressure and guarantee the bulk need as large as possible, which improves the transportation efficiency and economical benefit.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +1

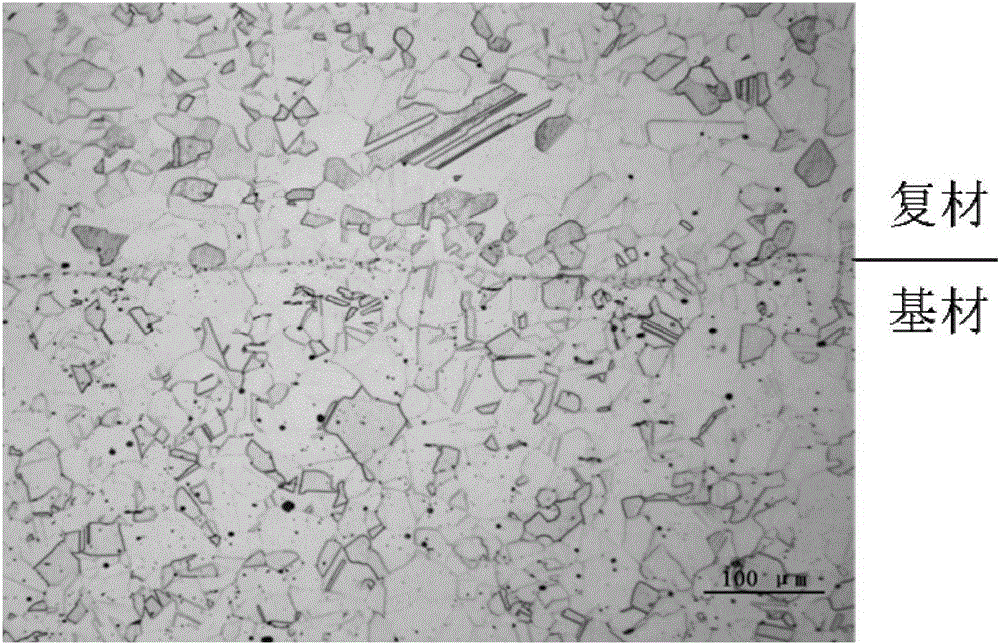

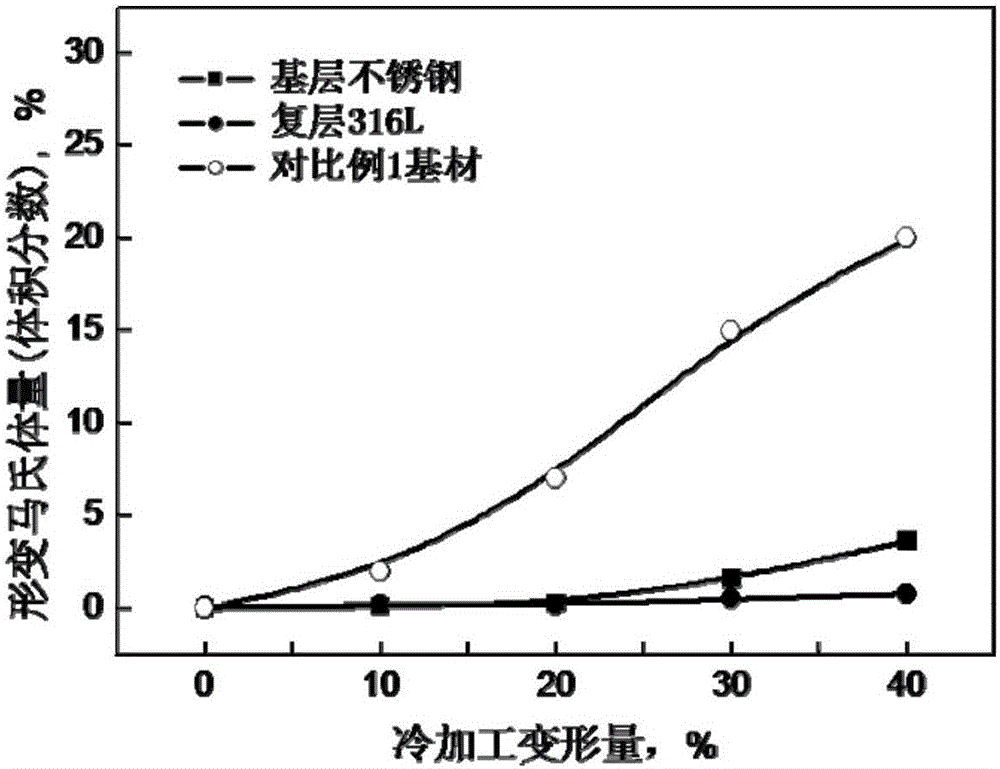

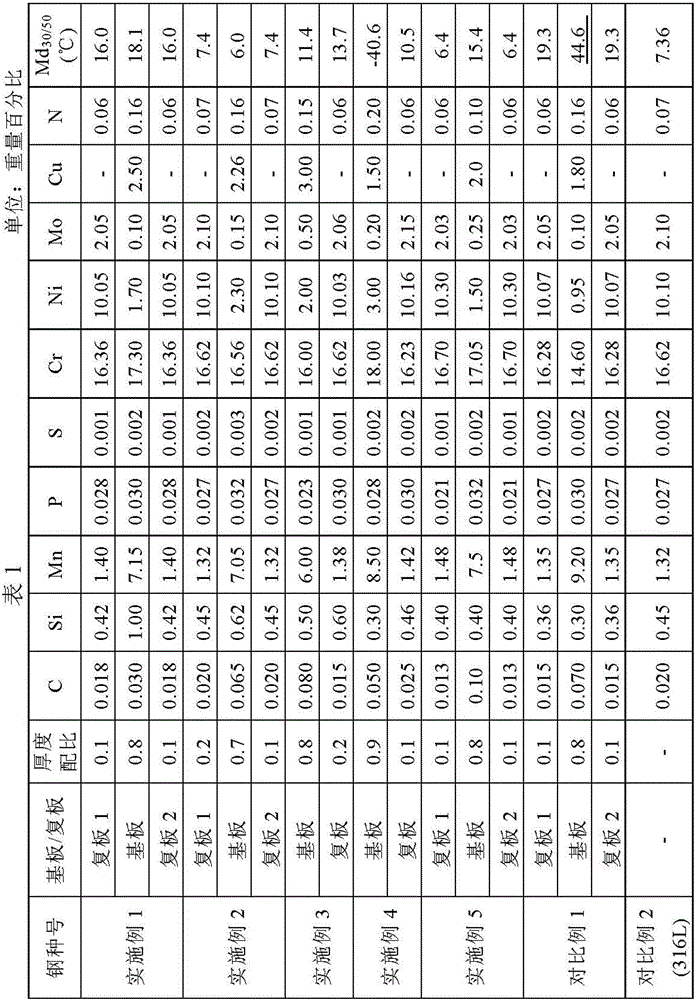

High-strength and high-plasticity stainless steel composite plate and manufacturing method thereof

ActiveCN106222539AHigh strength and high plasticityImprove low temperature impact toughnessMetal layered productsChemical compositionRoom temperature

The invention discloses a high-strength and high-plasticity stainless steel composite plate and a manufacturing method thereof. The composite plate comprises a substrate and a compound plate; the single surface or double surfaces of the substrate is totally and continuously coated with the compound plate; the substrate comprises the following chemical components in percentage by mass: 0.03-0.10% of C, 0.2-1.0% of Si, 6.0-8.5% of Mn, 16.0-18.0% of Cr, 1.5-3.0% of Ni, 0.1-0.5% of Mo, 1.5-3.0% of Cu, 0.10-0.25% of N, 0.005-0.40% of P, 0.001-0.01% of S, and the balance of Fe and inevitable impurities; the compound plate is 316L stainless steel; and the components of the substrate and the compound plate both request that Md30 / 50(alpha') is not more than 20 DEG C. The manufactured composite plate has no magnetism in room-temperature cold working process of the room-temperature tensile strength of not less than 650 MPa, the ductility of not less than 50%, -196 DEG C impact power of not less than 27 J and deformation of not more than 20%, is high in strength and corrosion resistance, is excellent in plastic toughness and machining performance, can replace the 316L stainless steel, and is applied to such manufacturing fields as tank containers.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

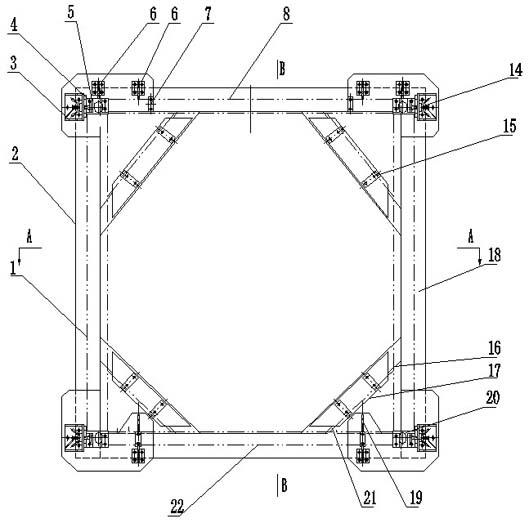

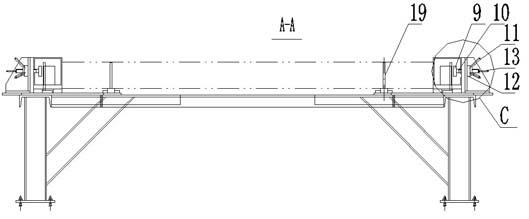

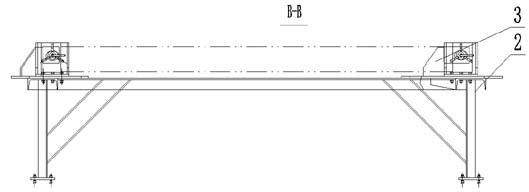

Tank container end frame assembling tooling

ActiveCN102513766AEasy to useEasy to use and maintainWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringTank container

The invention relates to a tooling, in particular to a tank container end frame assembling tooling, which comprises a worktable. Two groups of paired limit components which are respectively used for limiting positions of an upper end beam and a lower end beam are fixed on the worktable. Each limit component includes an angular bracket and a locking unit fixed on the angular bracket, wherein the angular bracket is fixed on an upper end face of the worktable, and the worktable is provided with a plurality of positioning plates used for regulating heights of angle parts, the upper end beam and the lower end beam. The tank container end frame assembling tooling can position relative dimension and location of various workpieces of a tank container end frame quickly and conveniently, avoids the operation process of repeated measuring and positioning and has the advantages of simplicity and convenience in operation, easiness in meeting requirements for dimension design and the like.

Owner:ZHEJIANG KIN SHINE TECH

Skirt and frame of tank container

InactiveCN106185069AMeet the transportation conditionsSimple pathLarge containersStress concentrationButt joint

The invention relates to a skirt and frame of a tank container. The skirt comprises a box body and two rear sealing plates. The box body comprises a top straight-barrel arc section, a bottom straight-barrel arc section, a first connection section and a second connection section. One end of the top straight-barrel arc section is connected with one end of the bottom straight-barrel arc section through the first connection section. The other end of the top straight-barrel arc section is connected with the other end of the bottom straight-barrel arc section through the second connection section. The outer diameter of the top straight-barrel arc section and the outer diameter of the bottom straight-barrel arc section are both the same as the outer diameter of a tank body. The upper arc section and the lower arc section are both connected with the tank body through butt joint welding seams. By means of the design of the structure of the skirt, the longitudinal impact force borne by the tank container can be uniformly dispersed and transmitted through multiple routes, each transmission route is simple and direct, the whole frame is reasonable in force bearing, no large stress concentration can be generated, and the railway transportation working conditions can be completely met.

Owner:XI AN RAILWAY TRANSPORTATION EQUIP

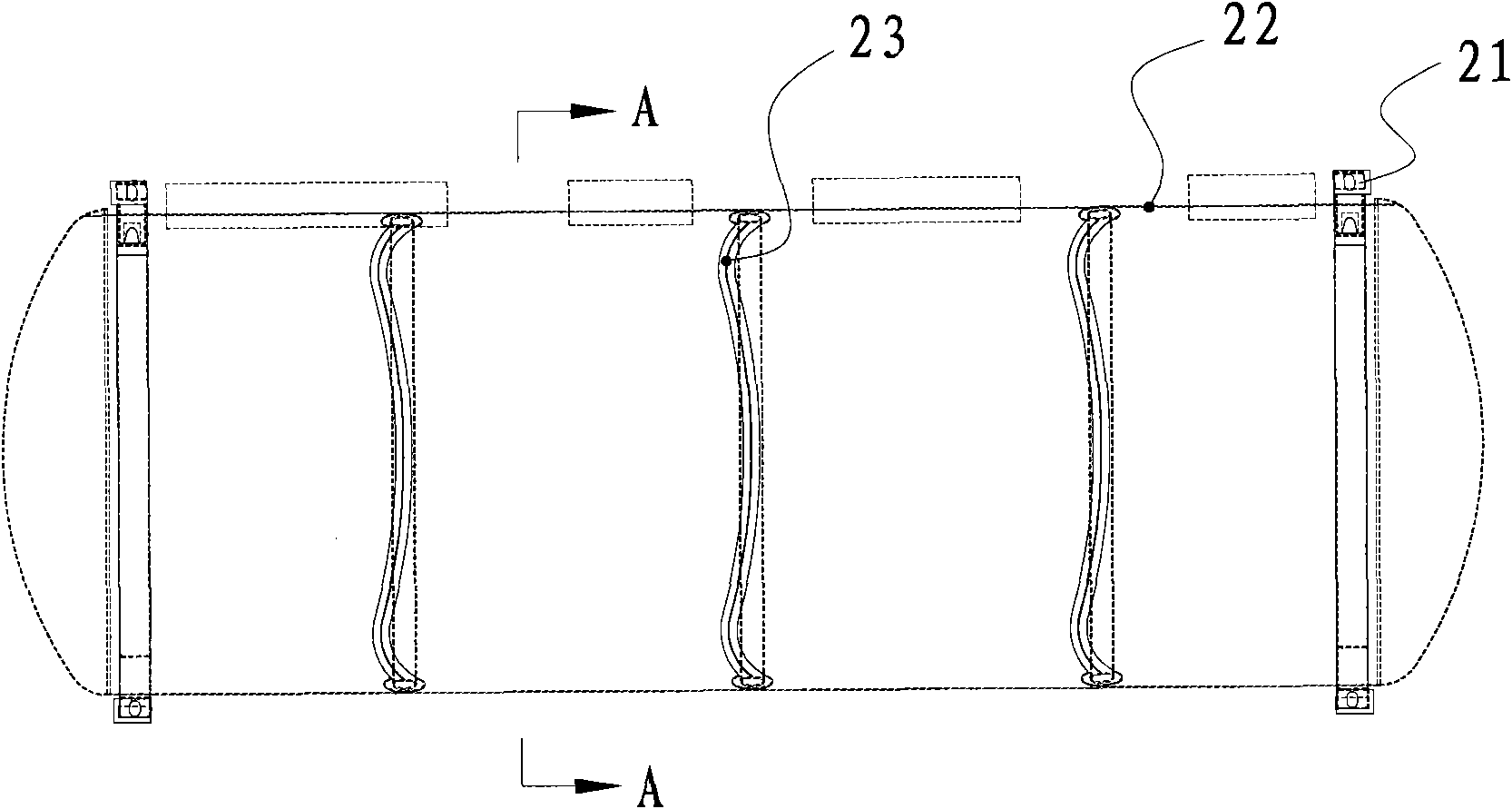

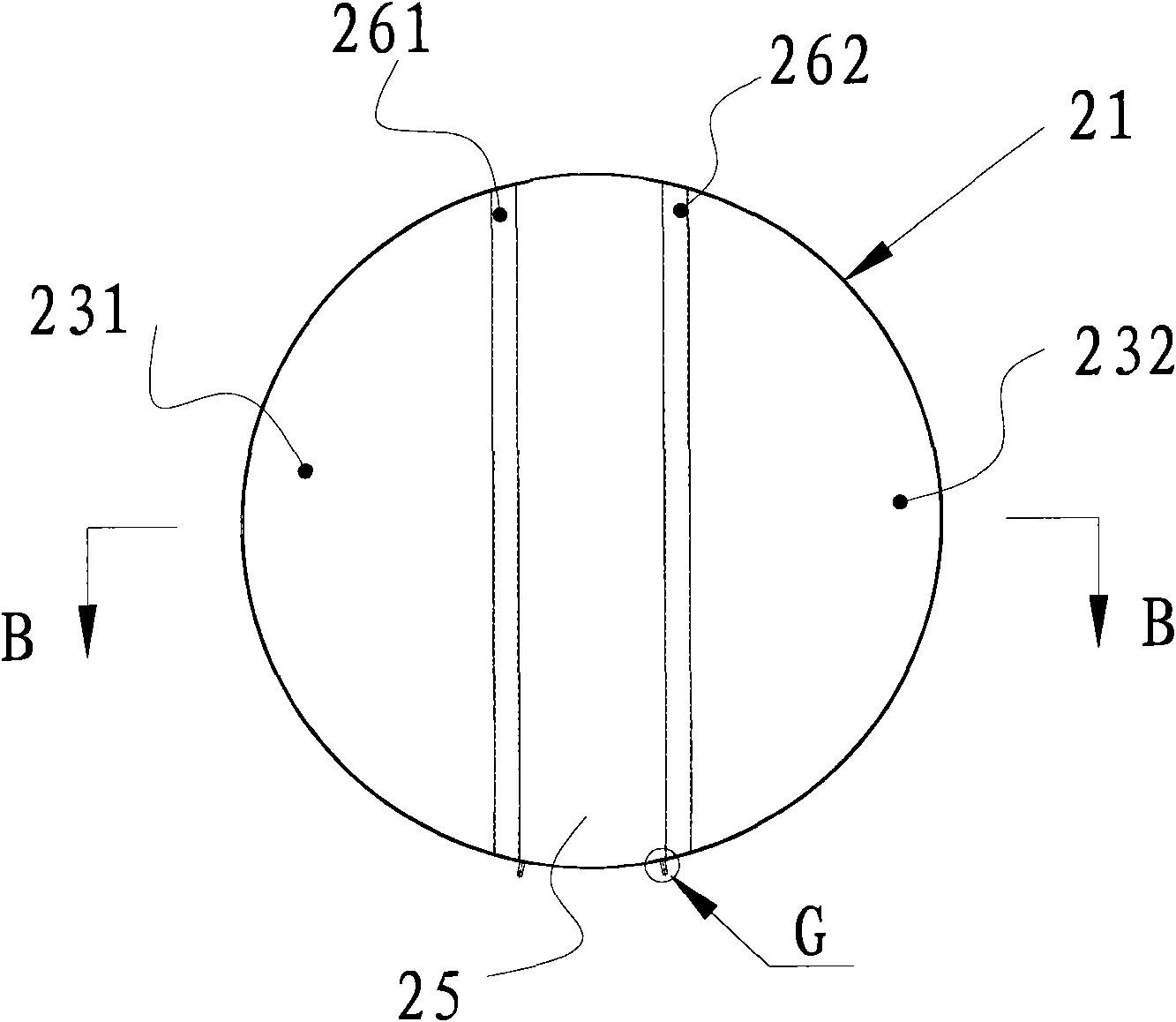

Liquid tank container

The invention discloses a liquid tank container, comprising a framework body and a tank body which is fixedly connected with the framework body, wherein at least one group of breakwaters are laterally and fixedly arranged in the tank body along the tank body and comprise at least two breakwater units, a gap between at least two unit breakwaters can at least allow one person to pass through, and the bottom of the tank body is communicated at least. Compared with the prior art, the liquid tank container has simple and reliable structure, easy processing and manufacturing and convenient maintenance in the tank body by the maintenance personnel.

Owner:SHENGSHI CONTAINER MANAGEMENT SHANGHAI

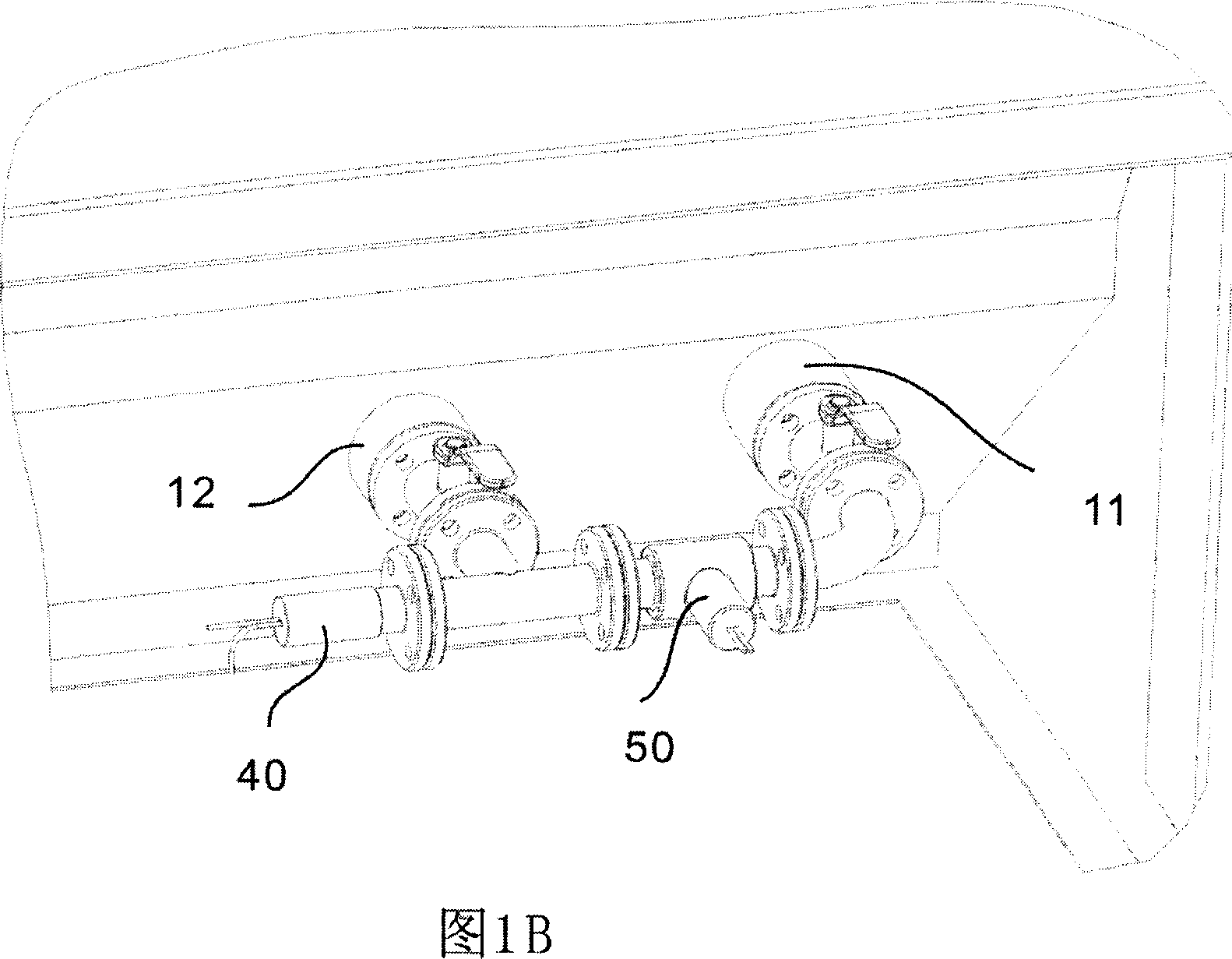

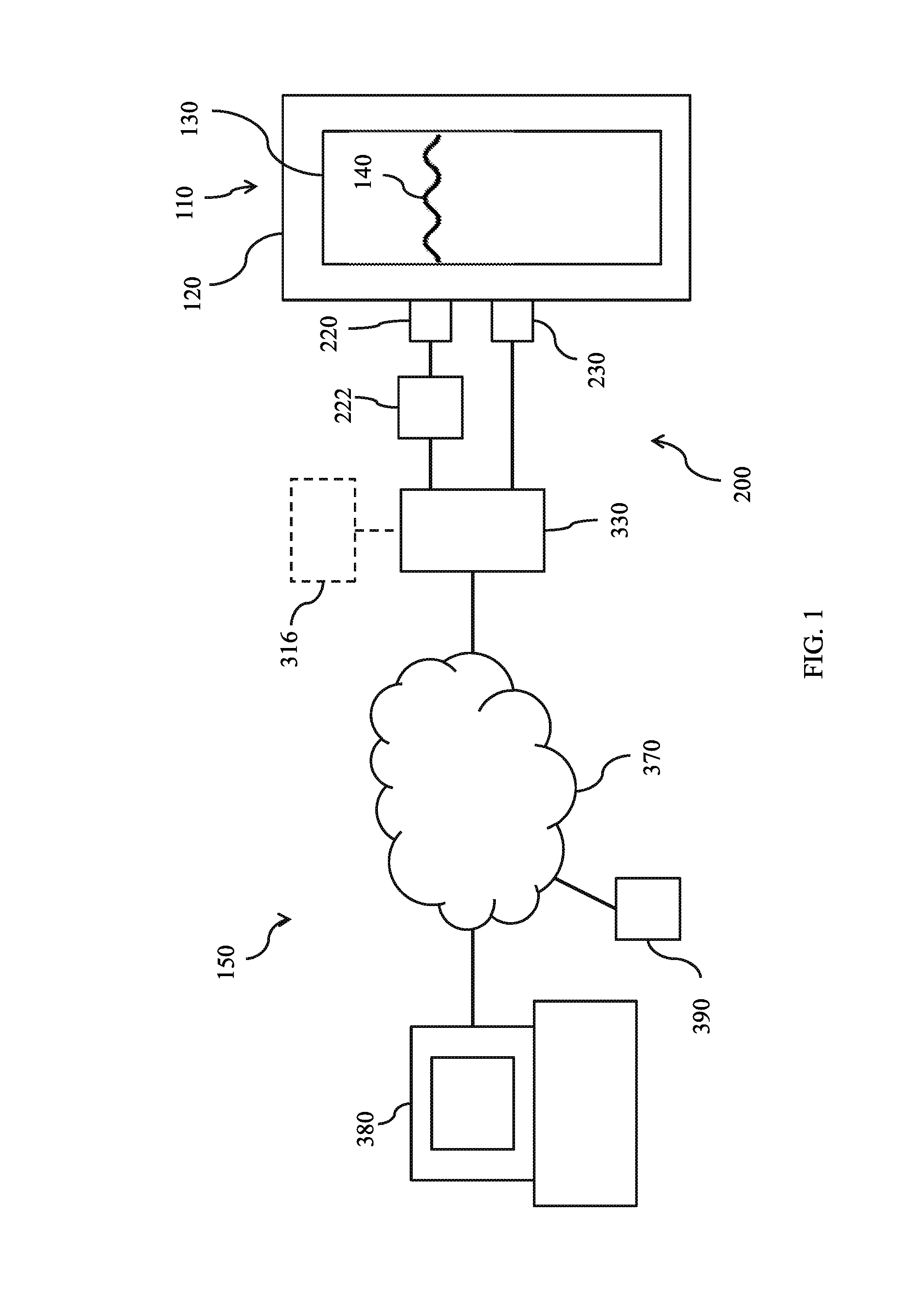

Tank container with electronic monitoring device

ActiveUS7322227B2Transportation safetyEfficient detectionDetection of fluid at leakage pointLiquid dispensingComputer moduleTank container

A tank container with electronic monitoring device includes a tank barrel and a container frame supporting the same. The tank barrel includes a valve assembly and a valve assembly protection box. The electronic monitoring device is installed inside the valve assembly protection box, or on a sealing surface of the tank barrel, or in a range of the container frame outside the tank barrel. The electronic monitoring device includes a sensor for detecting a leakage condition of the cargoes contained in the tank container and transmitting an information data related to the leakage condition, and a data processing module connected with the sensor for processing the data. The invention can be used for detecting a sealing condition of a sealing surface and an illegal open of a lid of the valve assembly protection box as well as for realizing a global tracking, whereby ensuring a safe transport for containers.

Owner:NANTONG CIMC TANK EQUIP CO LTD

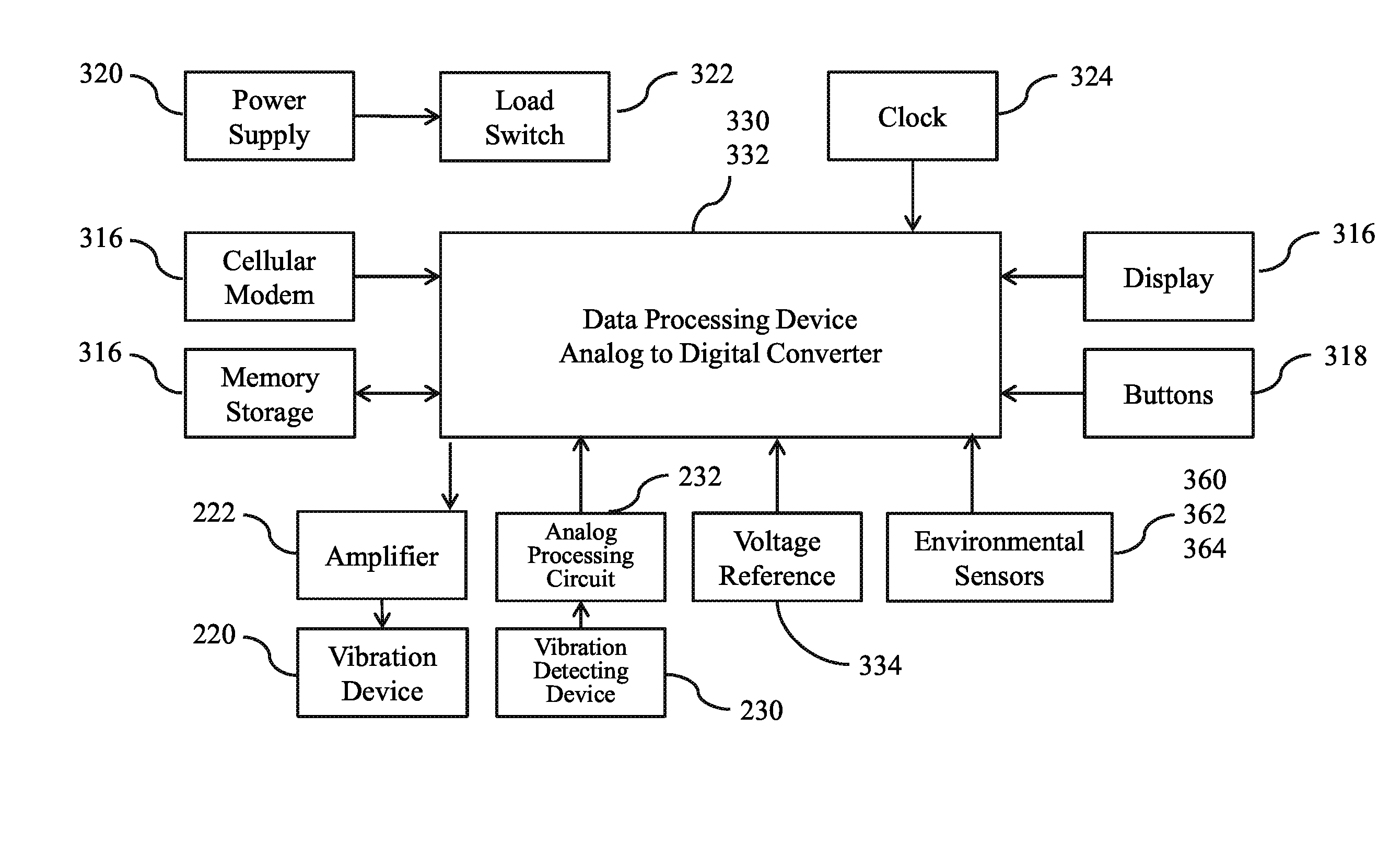

Tank-in-tank container fill level indicator

ActiveUS20160349097A1Accurate measurementContainer filling methodsFluid-tightness measurementMicrocontrollerAccelerometer

A tank-in-tank fill level indicator, making use of noninvasive tank-in-tank measuring techniques. A vibration device, such as an exciter or resonator, vibrates the outer tank at its natural frequency of vibration, thereby inducing the vibration of the inner tank and a beating effect as a result of the interaction of the vibrations of the two tanks. A vibration detection device, such as an accelerometer, detects the resultant beating effect of the two tanks' induced vibrations. A data processing device, such as a microcontroller, processes the detection data to obtain the liquid volume. A display, wired or wireless data transmission device, or combination thereof, is then used to provide tank or container fill-level information.

Owner:TUTTLE NICHOLAS L

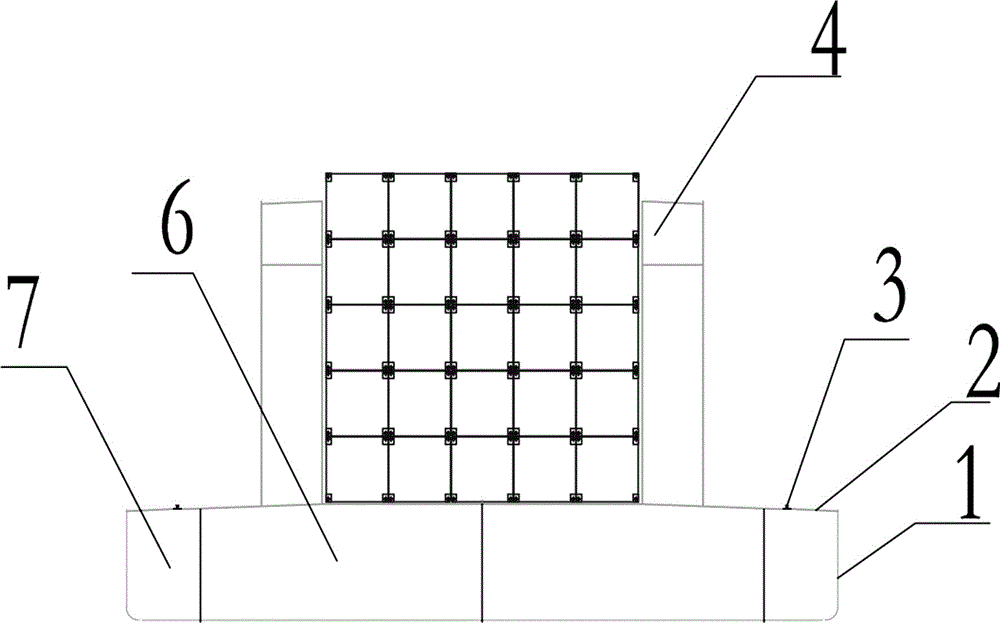

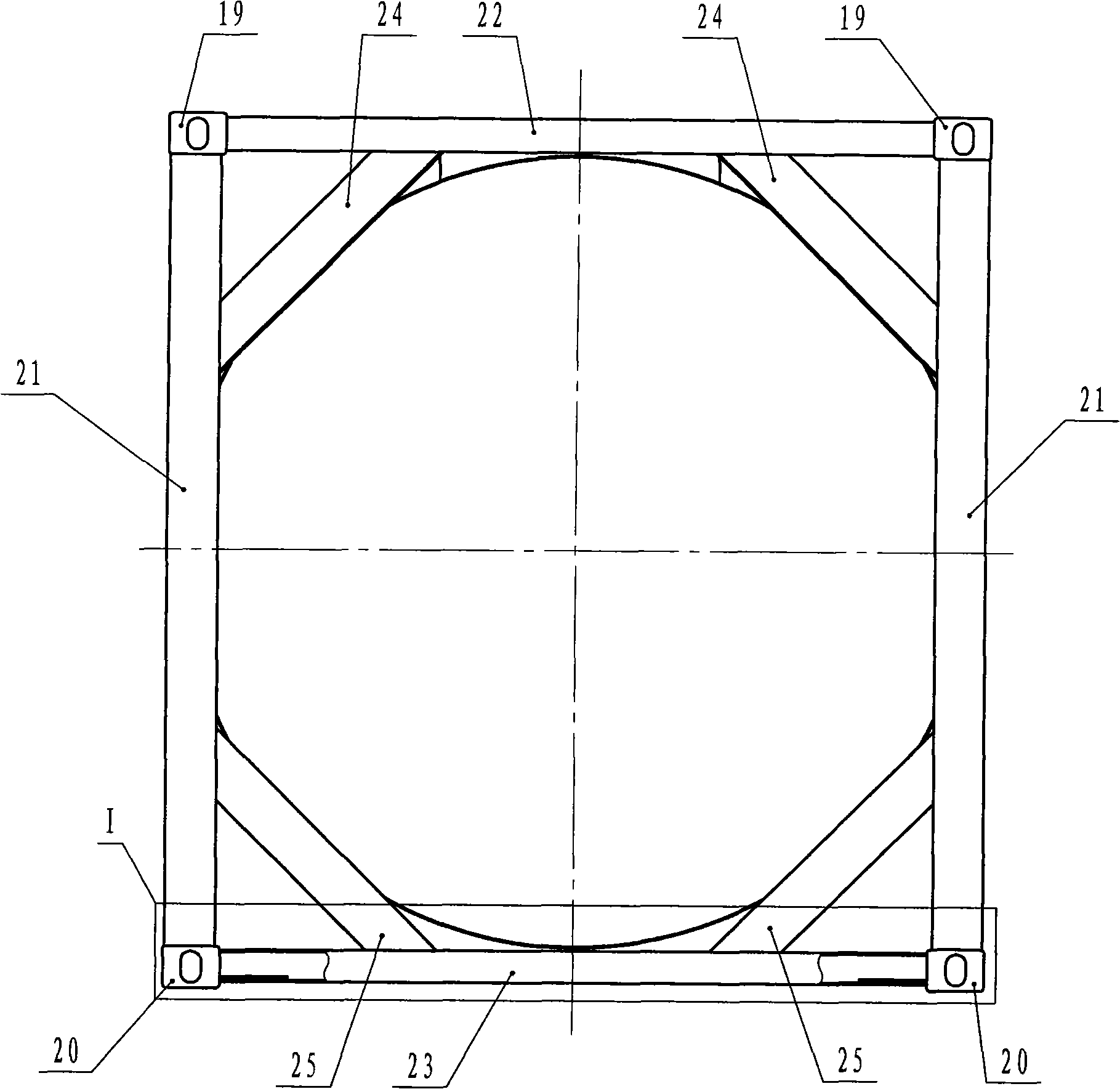

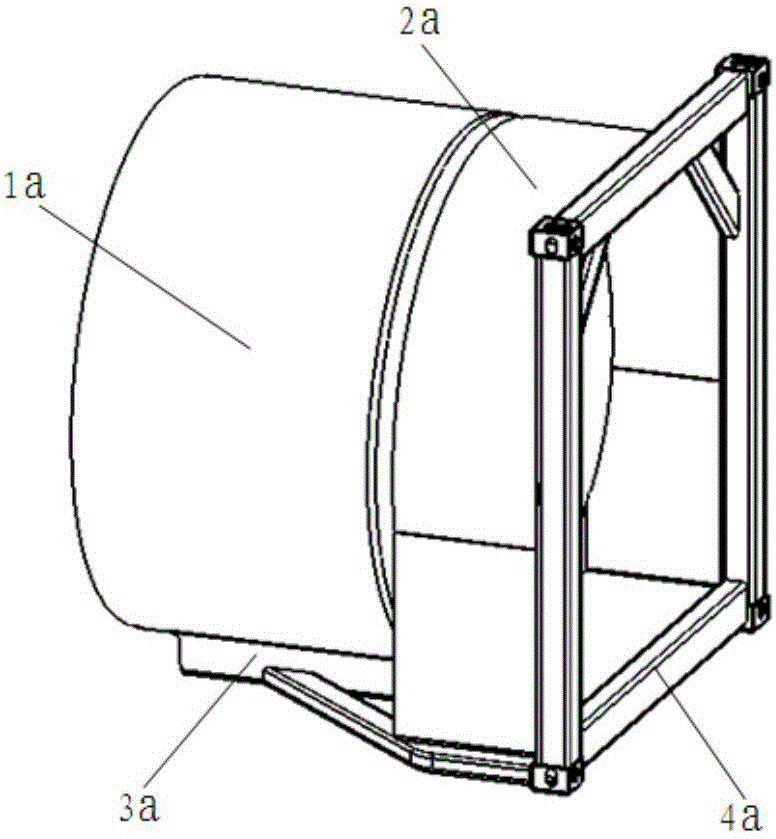

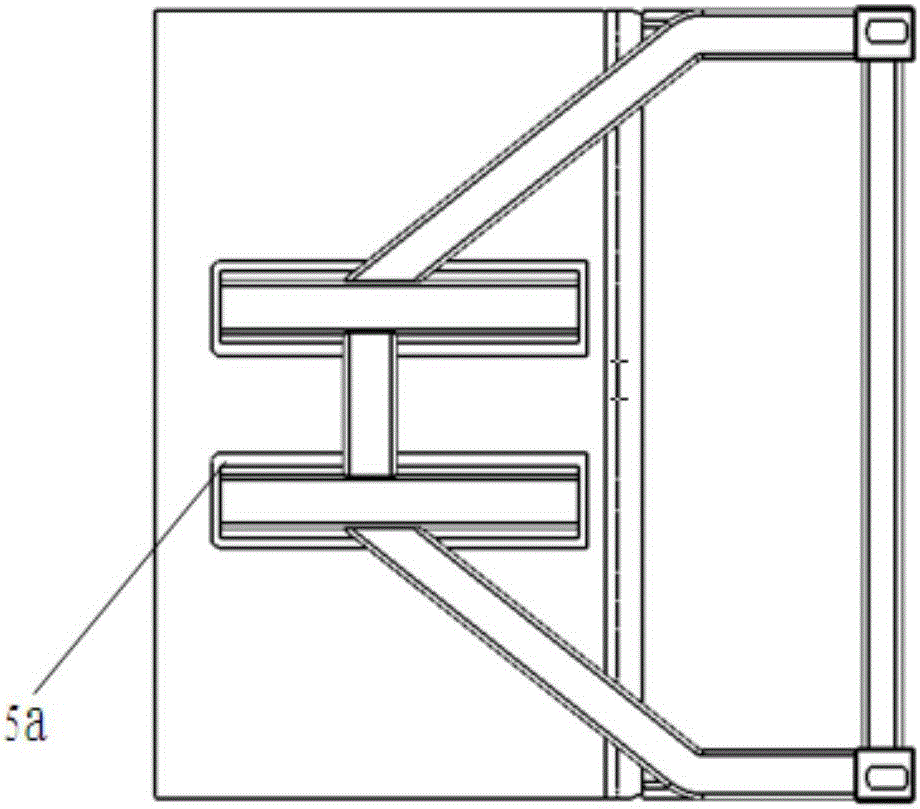

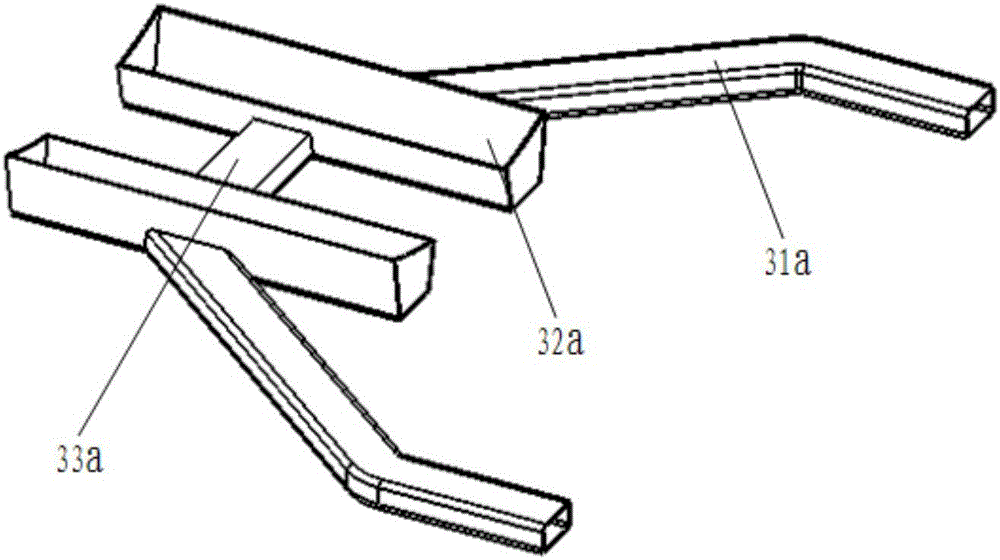

Tank container and end frame thereof

The invention discloses a tank container and an end frame of the tank container. The end frame comprises an upper beam, a lower beam, a first corner post and a second corner post; corner pieces are arranged at the upper and lower ends of the first corner post, as well as the upper and lower ends of the second corner post; and the upper beam and the lower beam are vertically connected between the first corner post and the second corner post. The tank container is characterized in that the two ends of a first support pipe are connected with the middle part of the upper beam and the middle part of the first corner post respectively; the two ends of a second support pipe are connected with the middle part of the upper beam and the middle part of the second corner post respectively; the two ends of a third support pipe are connected with the middle part of the lower beam and the middle part of the first corner post respectively; the two ends of a fourth support pipe are connected with the middle part of the lower beam and the middle part of the second corner post respectively; the two ends of a fifth support pipe are connected with the middle part of the first support pipe and the middle part of the third support pipe respectively; and the two ends of a sixth support pipe are connected with the middle part of the second support pipe and the middle part of the fourth support pipe respectively. The tank container and the end frame of the tank container disclosed by the invention at least have the advantages that the structures are simplified, and the transportation efficiency is improved.

Owner:NANTONG CIMC TANK EQUIP CO LTD

Steel plate for low-temperature spherical tank container and production method thereof

The invention discloses a steel plate for a low-temperature spherical tank container and a heat treatment production method thereof. The steel plate is prepared from less than or equal to 0.12wt% of C, 0.15-0.50wt% of Si, 1.2-1.6wt% of Mn, 0.3-0.8wt% of Ni, less than or equal to 0.010wt% of P, less than or equal to 0.005wt% of S, 0.020-0.045wt% of Al, less than or equal to 0.040wt% of Nb and the balance Fe and unavoidable impurities by melting. The steel plate utilizes low-price carbon and manganese solid solution reinforcement, and through adjustment optimization of a ratio of other elements in the steel plate, good steel plate mechanical properties are ensured under conditions of low carbon equivalent, the steel plate has a good microstructure, good comprehensive performances and welding performances, a cost is reduced and market competitiveness is improved. Through a reasonable heat treatment technology, a uniform ferrite-tempered sorbite microstructure is obtained and impact toughness of a large-thickness steel plate is improved. The steel plate has high purity, impact energy greater than 170J at a temperature of -70 DEG C, an elongation rate of more than 25%, good simulation of performances after welding and welding performances, and good mechanical properties.

Owner:WUYANG IRON & STEEL

Double-walled tank container

ActiveUS20060096991A1Smooth stress transitionGood effectTank vehiclesLarge containersThermal insulationDouble wall

The present invention concerns a double-walled tank container, whereby the inner container is stored at the bottom inside the outer enclosure by a spacer consisting of several spacer pieces. The spacer provided, which is preferably placed near a front saddle ring, imparts transportation and storage stresses between the inner tank and the outer enclosure and consequently between the inner container and the frame of the tank container. The spacer can be laid out in such a way that it absorbs shocks and / or defines a hollow space. This hollow space can serve as a thermal insulation or for the installation of temperature equalization devices, mediums or a leak detector fluid.

Owner:THIELMANN

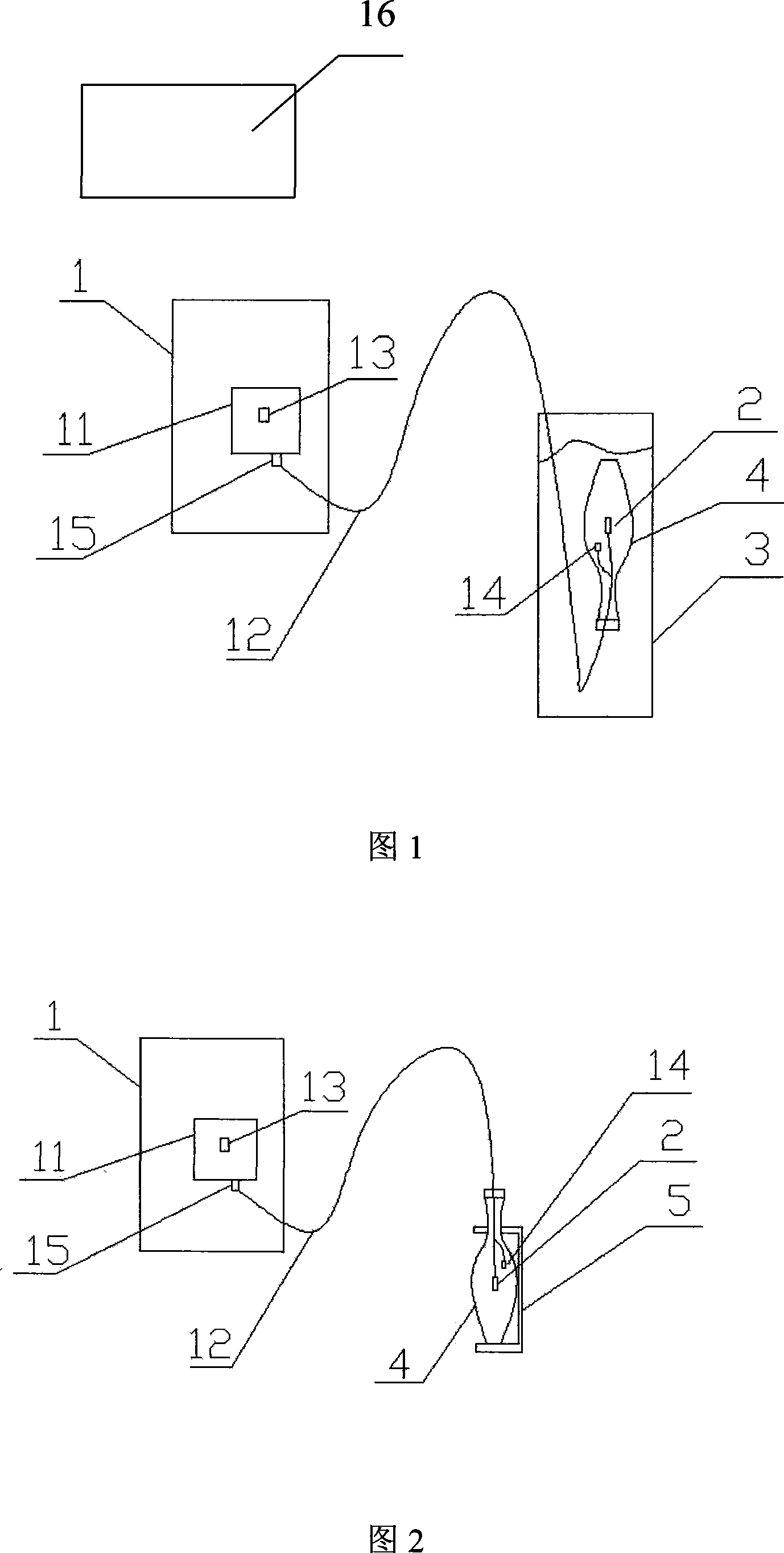

Bottle, bottle cap and detector for detecting airtightness of sealed pot

InactiveCN101183037ATest stress levelsTest connection integrityMeasurement of fluid loss/gain rateMaterial strength using tensile/compressive forcesEngineeringTank container

The invention provides a sealing detection instrument for a bottle, a bottle cover and a sealed tank container and comprises a host, a testing head and a testing water tank. The host is provided with a pressure control device and the pressure control device is connected with one end of a gas path pipeline through a controllable electro-magnetic valve; the other end of the gas road pipeline is connected with the testing head; the gas path pipeline, the testing head as well as the pressure control device are sealed in an air-tight way; the host is also provided with an adjusting valve which can adjust the gas pressure outputted by the pressure control device; the host is also provided with a pressure sensor to sense the pressure in the tested container; a PLC liquid crystal display programmable controller can control and display the tested data. When in test, a small hole is drilled on the cover of the tested bottle base and the testing head is inserted into the hole while the hole is sealed in an air-tight way; the pressure control device outputs pressure and the pressure sensor tests the pressure in the bottle; a PLC display screen displays the tested data; the tested container is put into the testing water tank under the water level for observation of the phenomenon of leakage and pressurization. Therefore, the sealing and the firmness of the connection between the bottle body and the bottle cover as well as the anti-pressure level of the bottle body can be tested. The invention can be applied in the field of the leak tightness test of the bottle, the bottle cover and the sealed container.

Owner:HEBEI FANGYUAN INSTR EQUIP

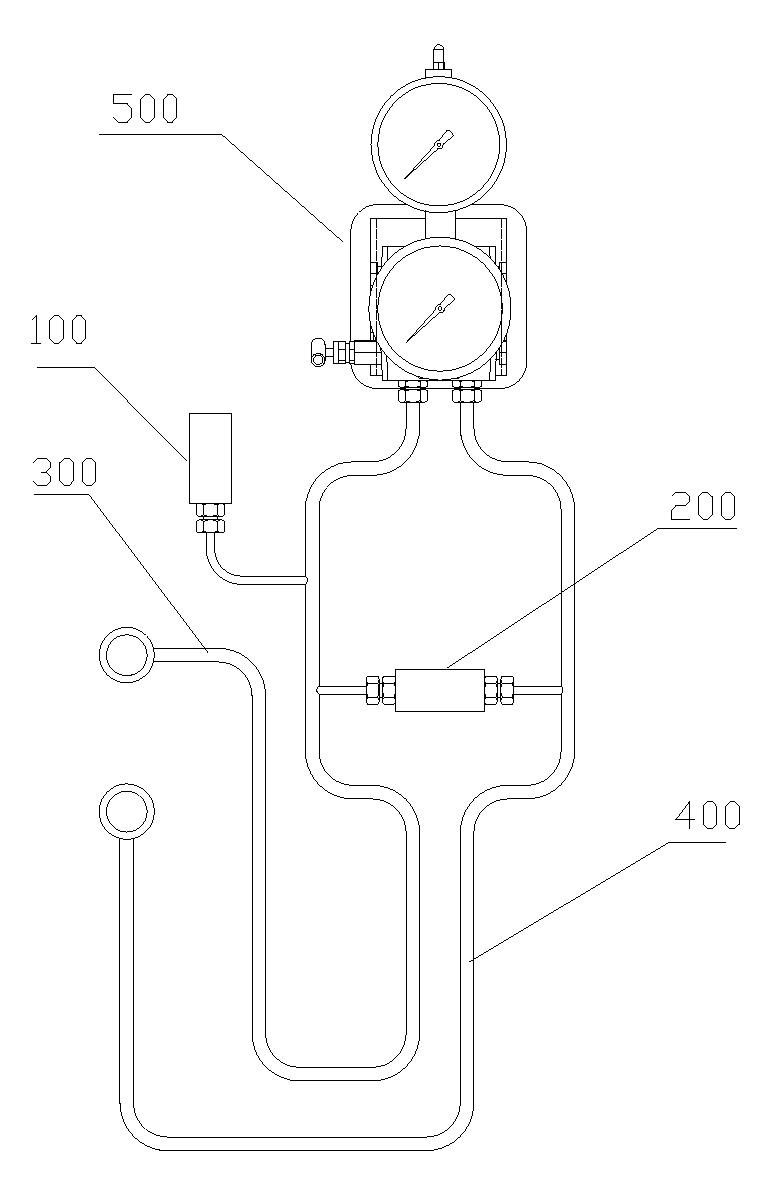

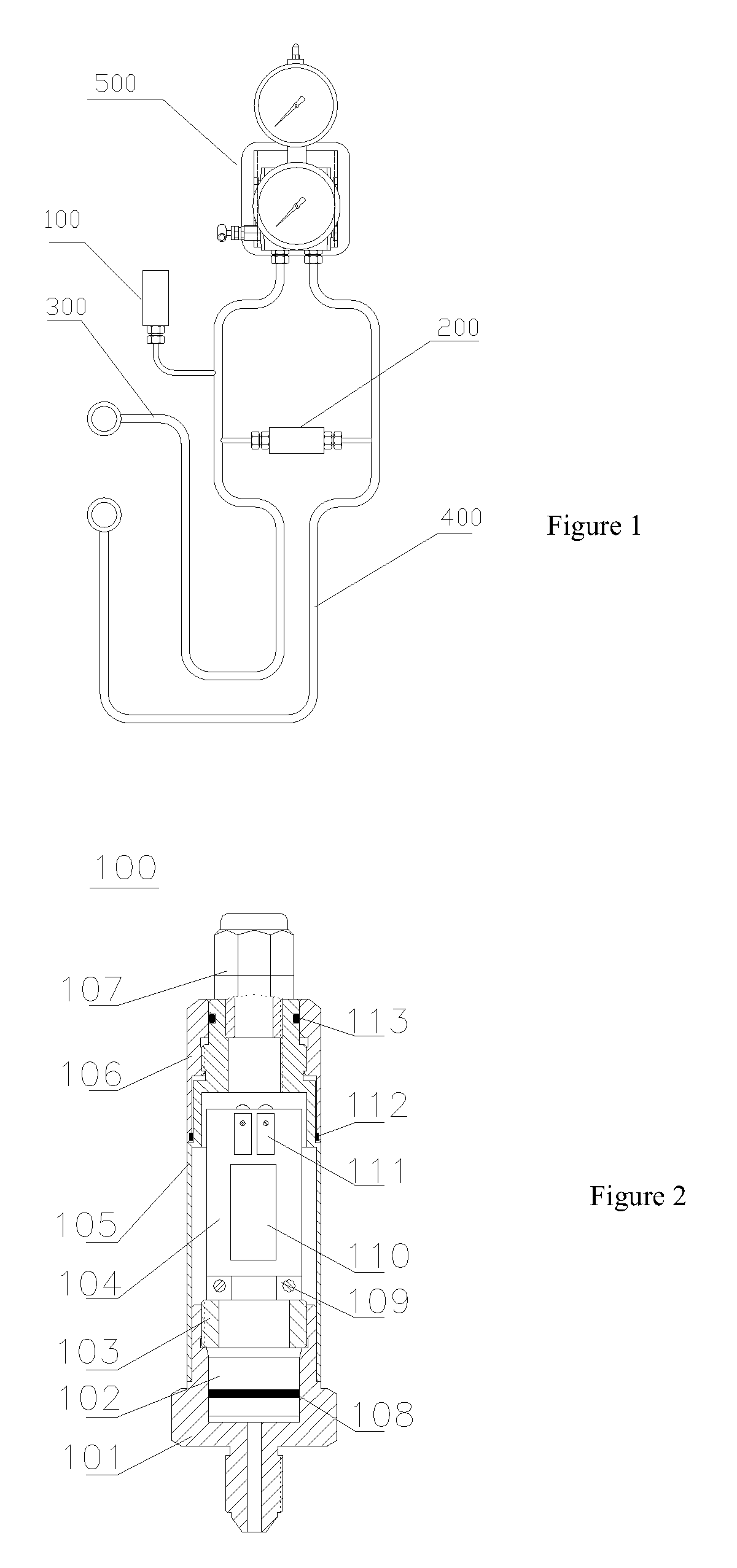

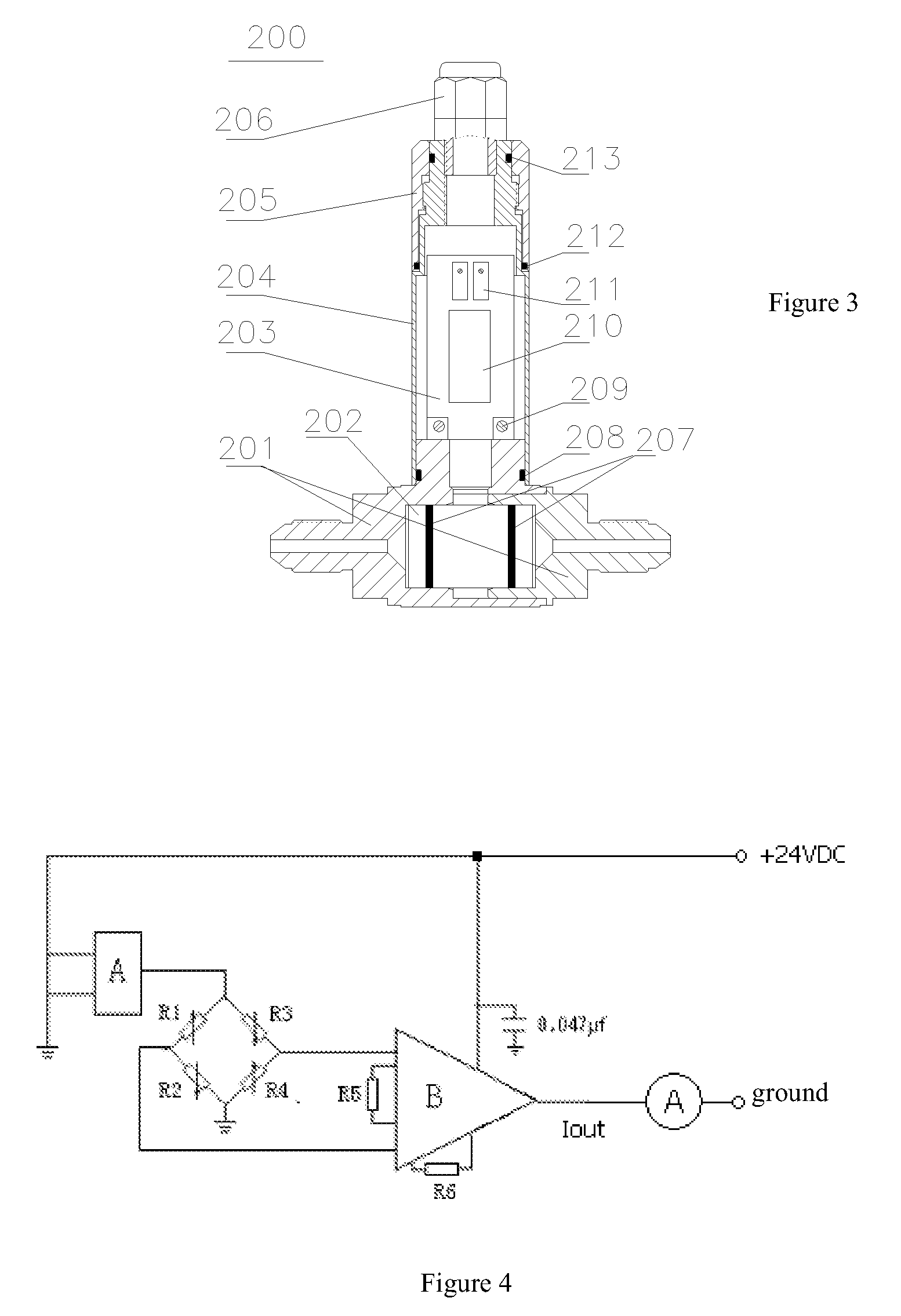

Pressure and liquid level sensing system for tank containers and tank vehicles

InactiveUS20080134776A1Improve transport safetyAccurate measurementMachines/enginesLubrication indication devicesDriver/operatorGas phase

A pressure and liquid level sensing system for a tank container or tank vehicle comprising a vessel for containing a liquid substance, such as Liquified Natural Gas (LNG), etc. The pressure and liquid level sensing system comprises a pressure sensor for measuring a gas pressure inside the vessel and a liquid level sensor for measuring a liquid level inside the vessel, the pressure sensor and the liquid level sensor comprises a first and a second pressure sensitive elements and a first and a second printed circuit boards respectively. A circuit on the first printed circuit board converts a pressure signal into an electric signal, a circuit on the second printed circuit board converts pressure signals of a gas-phase space and a liquid-phase space into electric signals of 4-20 mA or 0-10V standard. In this way, the pressure and the liquid level can be accurately measured. Furthermore, the measured values are digitalized, such that both driver and remote control center can know variation conditions of the pressure and the liquid level of the transported medium in real time, thereby transportation safety is improved.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD

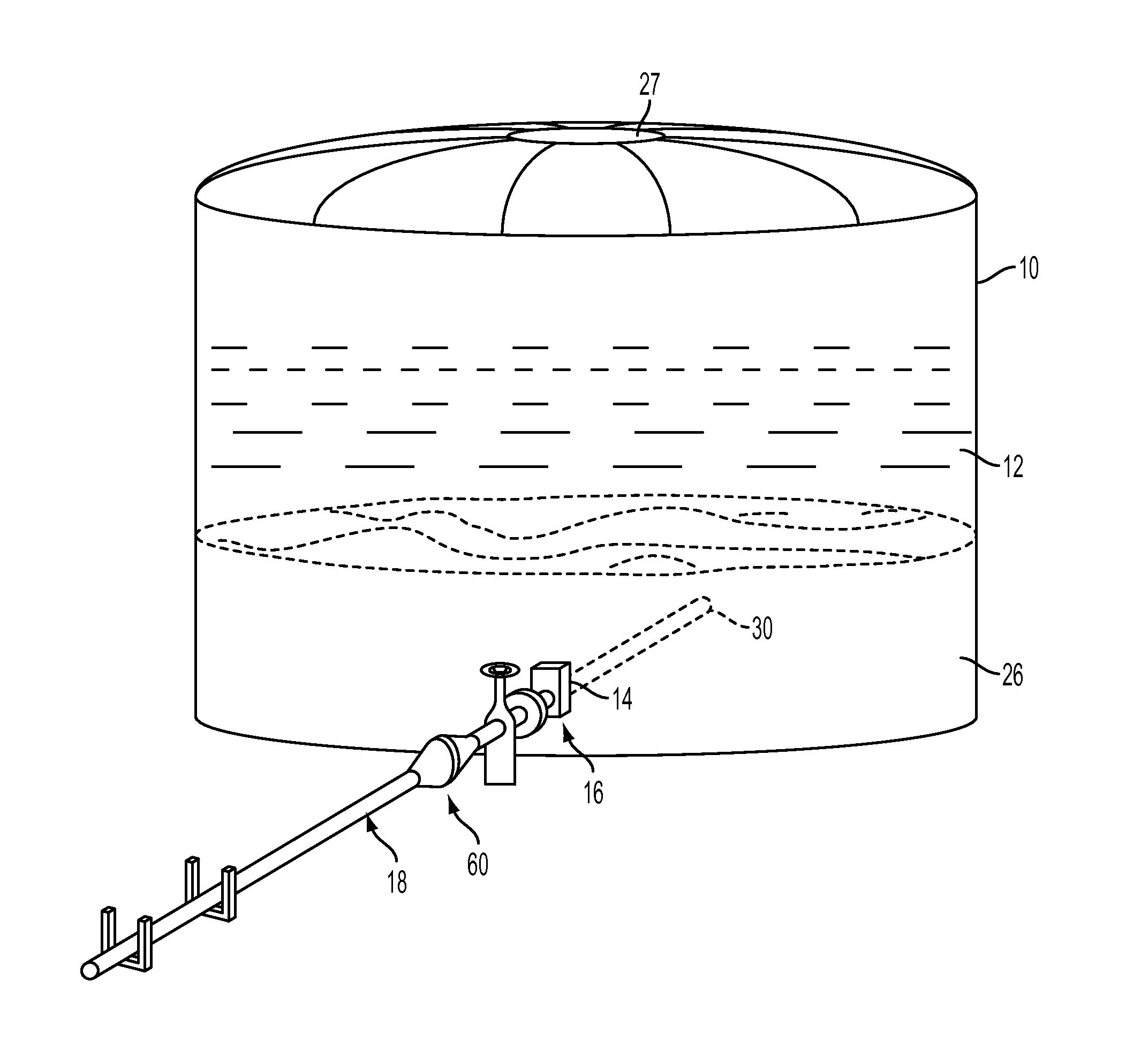

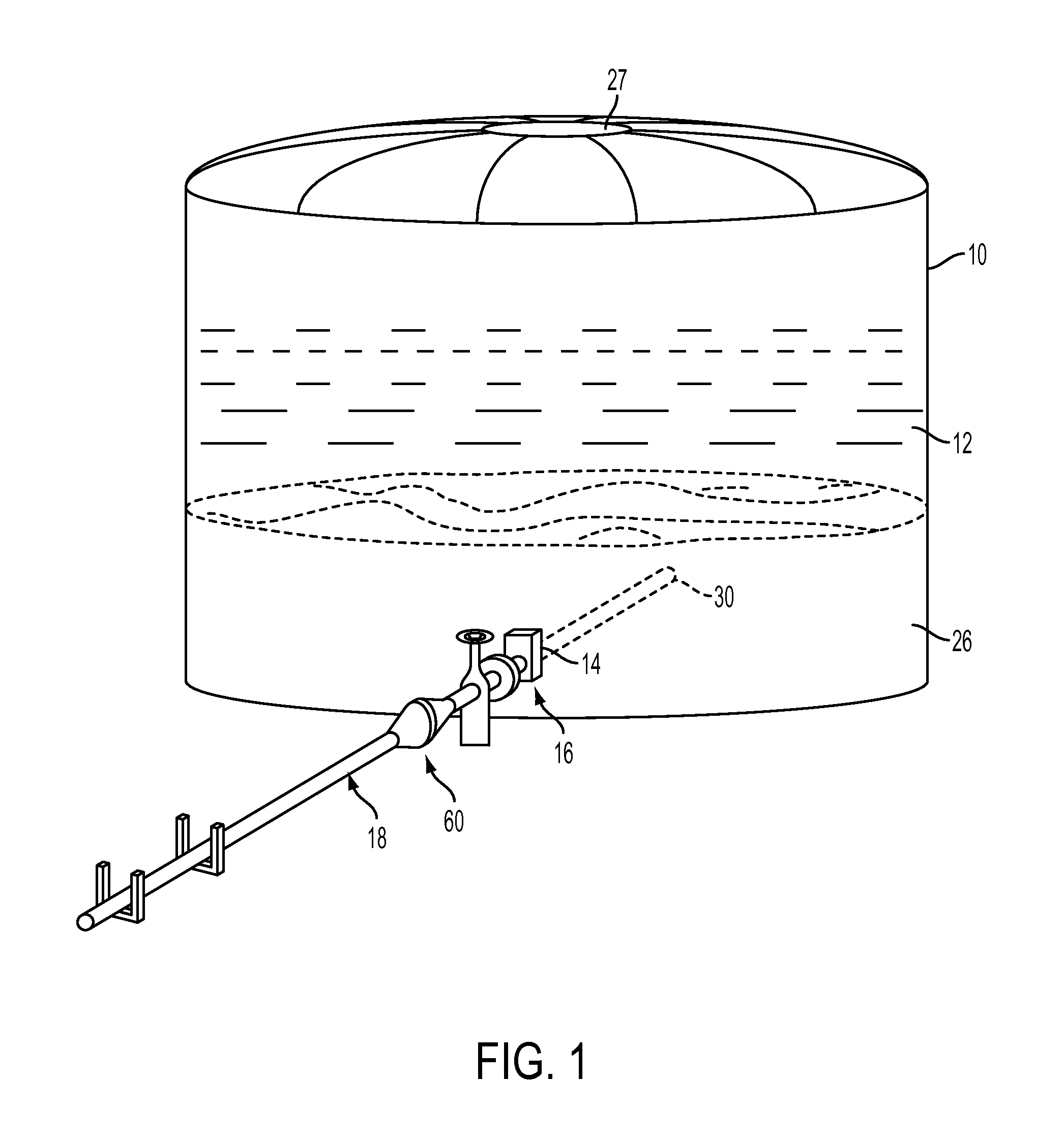

System and method for removing sludge from a storage tank

InactiveUS20140190517A1Improve abrasivenessDifficult to fluidizeHollow article cleaningSedimentation separationVertical planeSludge

The system and method permits the use of equipment that is located exterior to a container, such as a tank container liquid hydrocarbon material within which a sludge deposit has accumulated, and then inserted, as through an access opening in the side of the tank. In addition to other innovations, an improved hydraulic equipment positioning arrangement is provided, for both positioning, inserting and withdrawing the conduit structure and end effectors for accessing the sludge or sediment, which may include a leveling element preferably in the form of an hydraulic system that operates to move the assembly in a vertical plane as well as a rotary driven hydraulic system for driving the conduit structure along a long axis.

Owner:TRADEBE ENVIRONMENTAL SERVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com