Transport tank and transporting method thereof

a technology of transport tank and container, which is applied in the field of transport tank, can solve the problems of no practical application, difficulty in producing appropriate inner bags for large tanks including 20 foot containers, and difficulty in producing the inner bags fitting in the cylindrical b>20/b> foot containers easily and affordably, so as to prevent the failure of filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

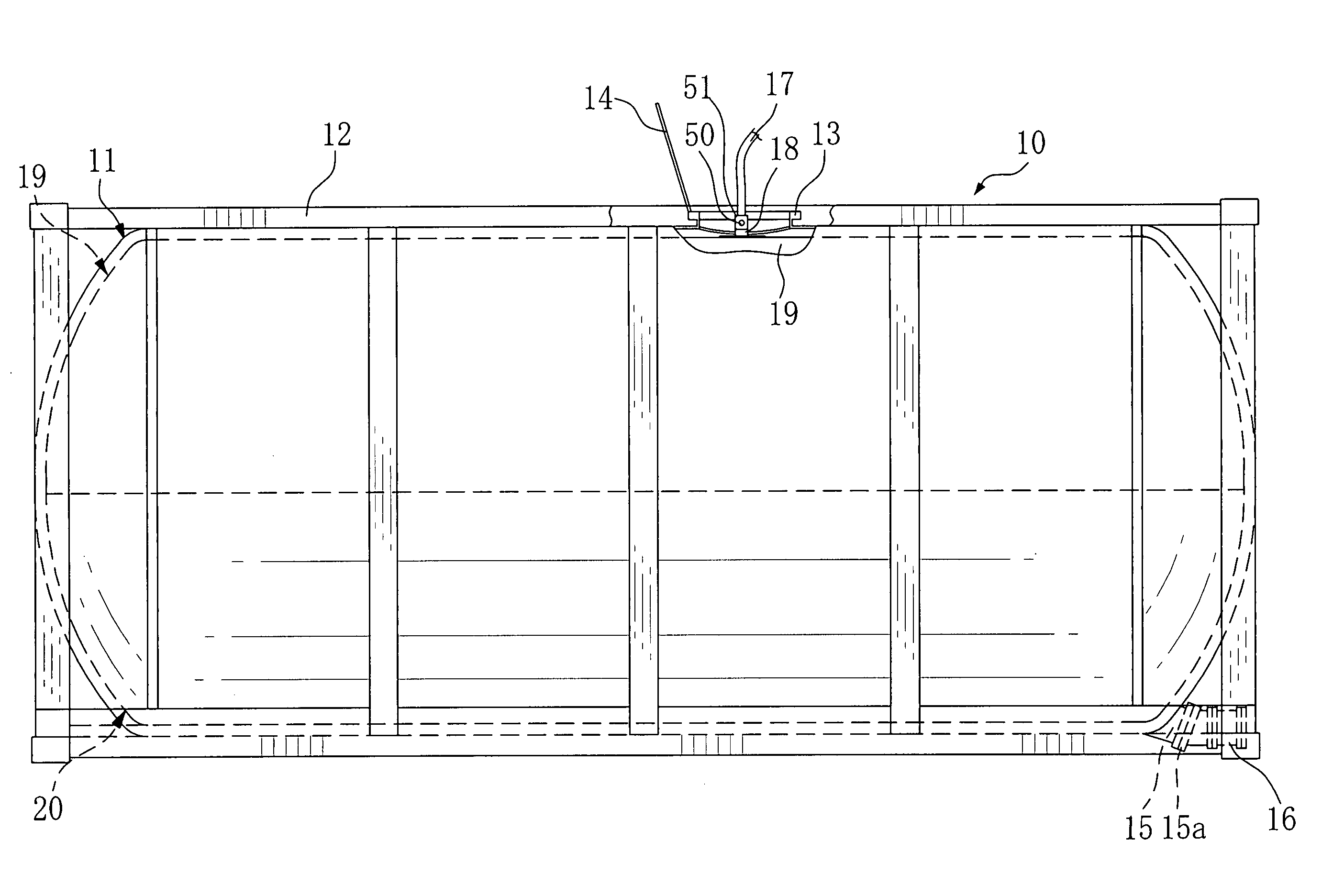

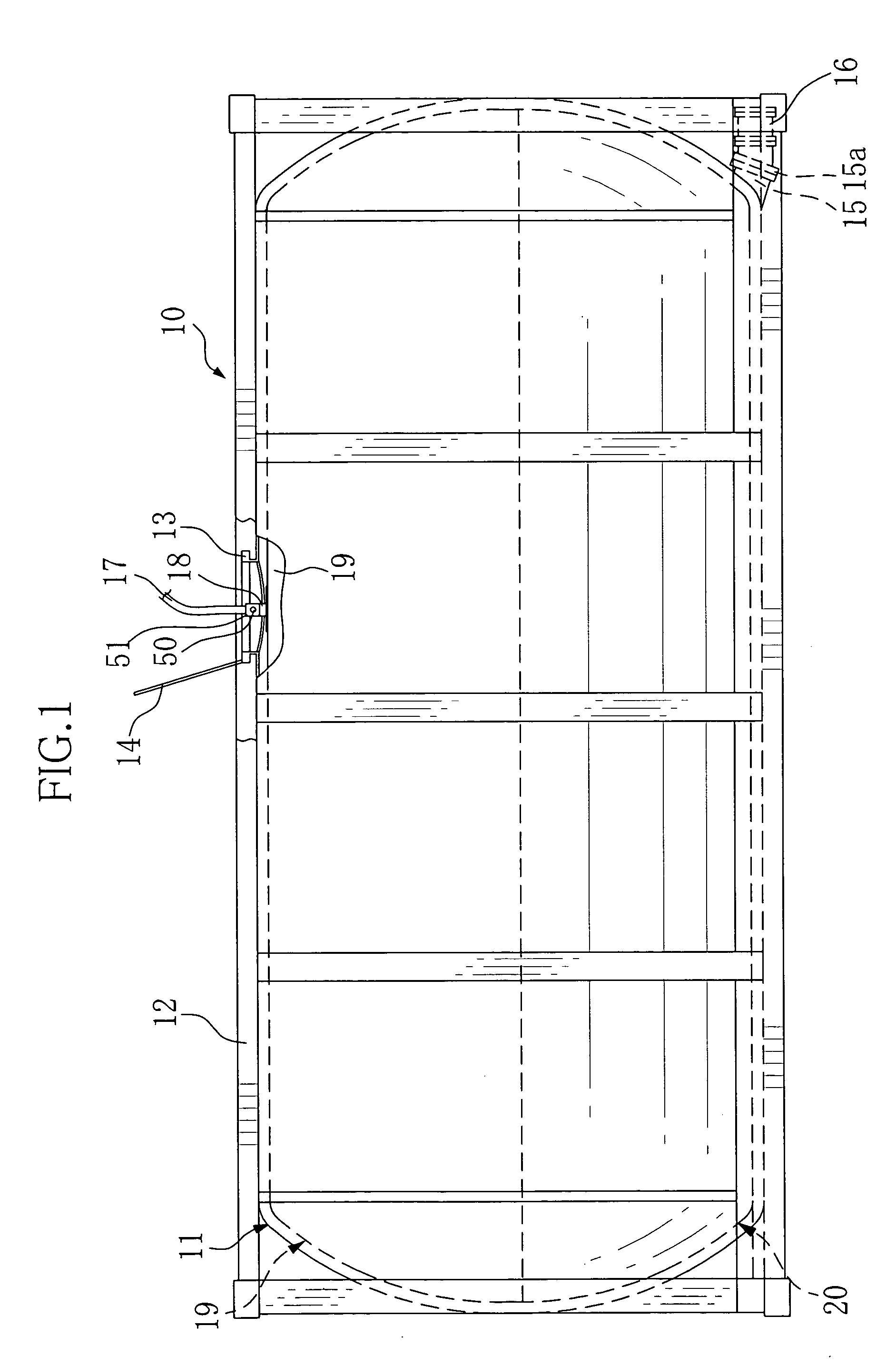

[0031] In FIG. 1, a twenty-foot ISO container 10 is constituted of a tank body 11 and a rectangular parallelepiped frame 12 for holding the tank body 11. A hatch 13 is formed at the top face of the tank body 11. The maintenance and filling of liquid are performed through the hatch 13. At the time of transporting, a lid 14 is locked by a locking member in order to prevent the lid 14 covering the hatch 13 from opening. A tank supply-discharge opening 15 is formed in one end of a lower portion of the tank body 11. A foot valve 16 is fixed through a flange 15a of the tank supply-discharge opening 15.

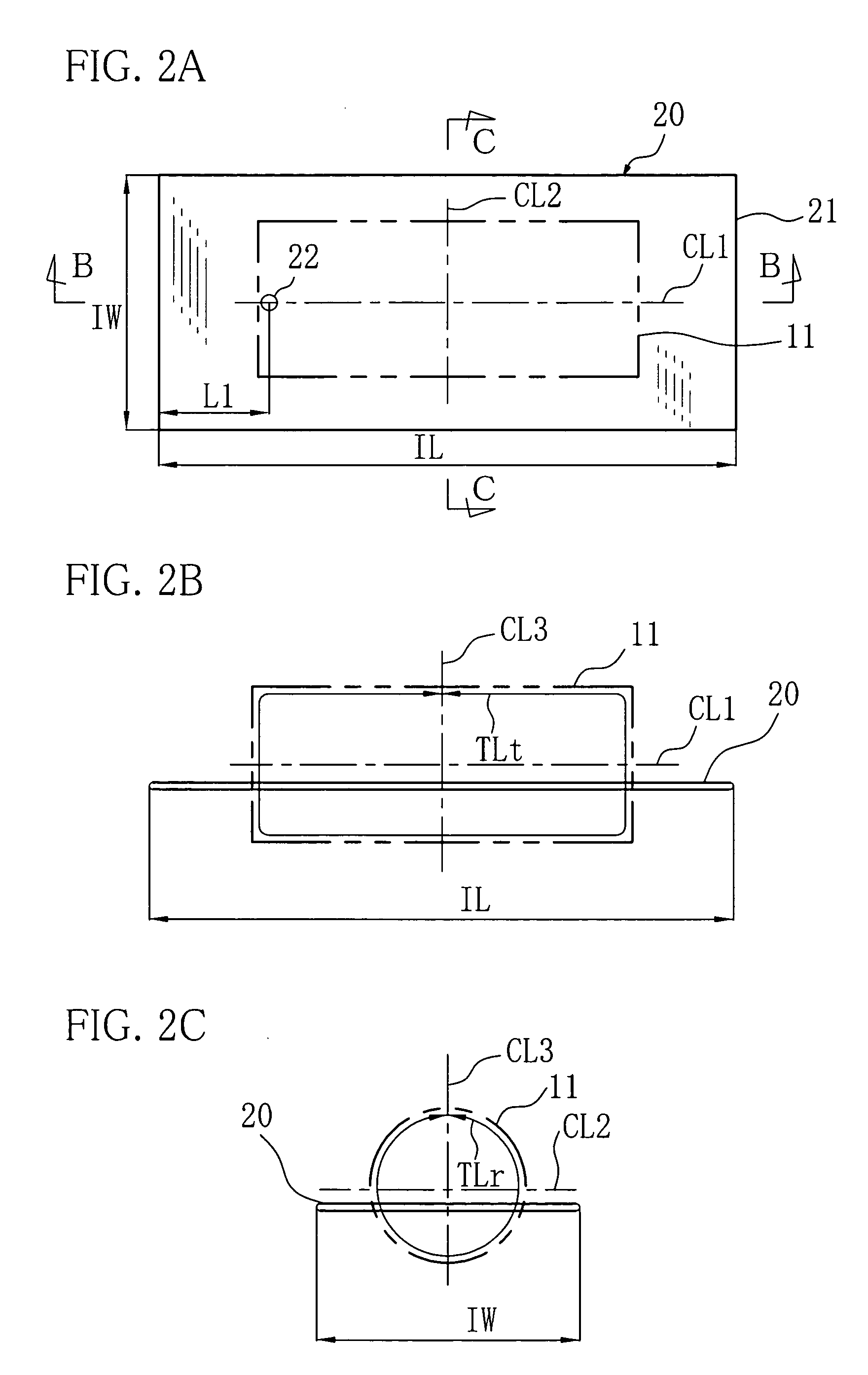

[0032] A transport inner bag 20 is loaded in a lower portion of the tank body 11, while a pressure inner bag 19 is loaded in an upper portion thereof. These inner bags 19, 20 are brought into the tank body 11 from the hatch 13 by an operating person to set in the tank body 11. The transport inner bag 20 upswells in the tank body 11 by pouring the liquid as cargo therein from the tank supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com