Patents

Literature

4231 results about "Manufactured material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing material means any material or substance used in or used to facilitate the manufacturing process, a concomitant constituent, or a byproduct constituent produced during the manufacturing process, which is present in or on the finished device as a residue or impurity not by design or intent of the manufacturer. FK Reading Ease.

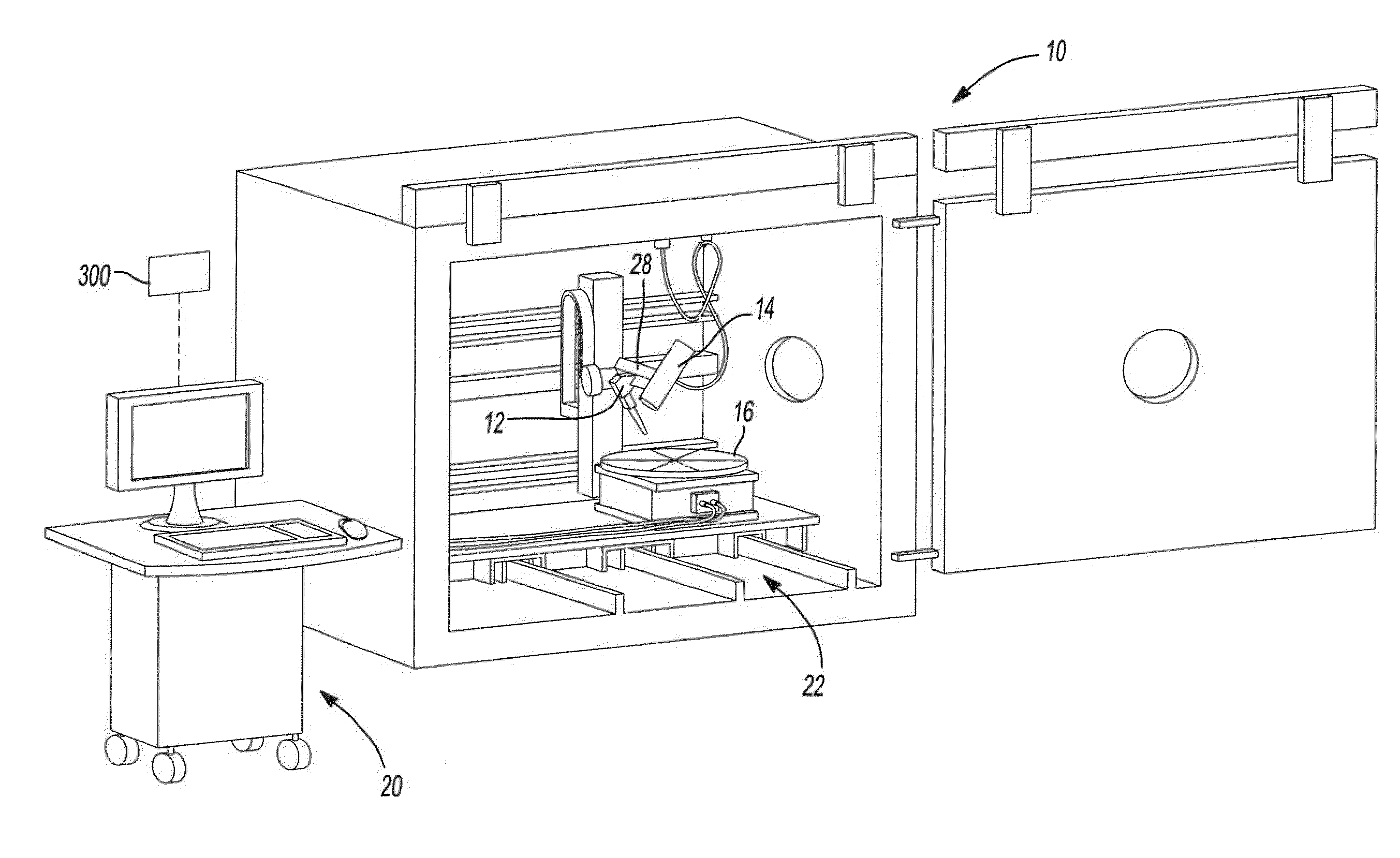

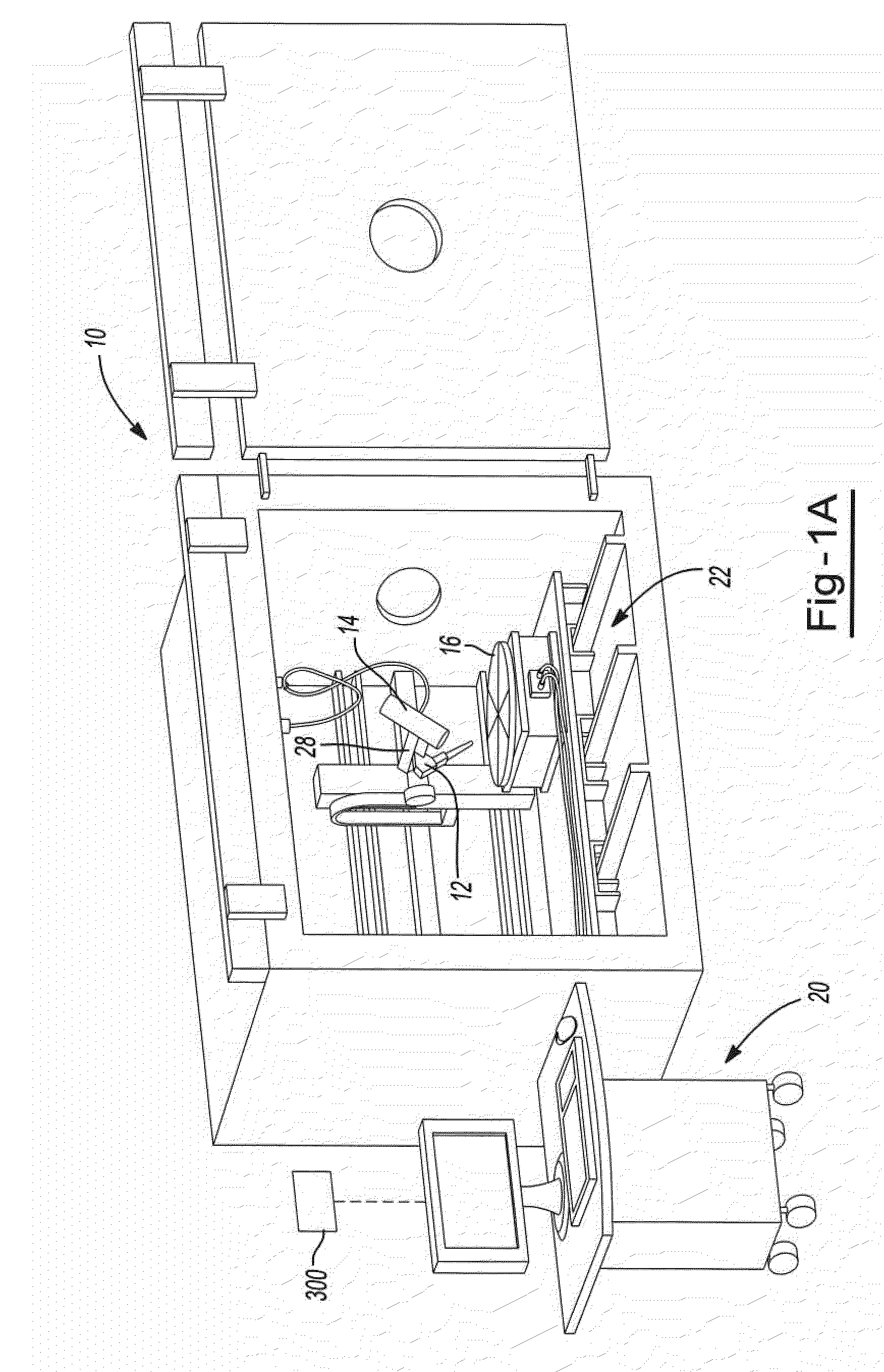

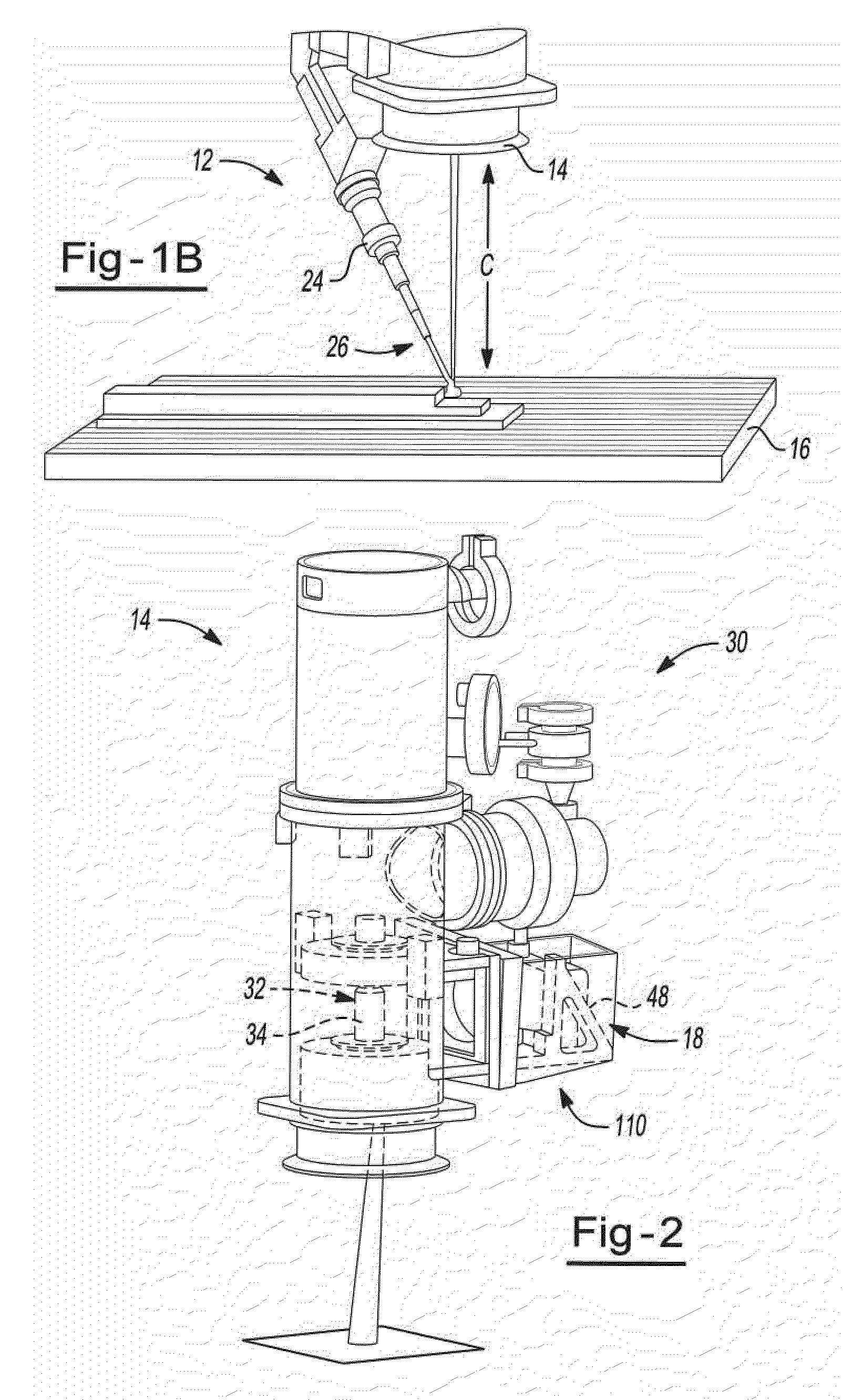

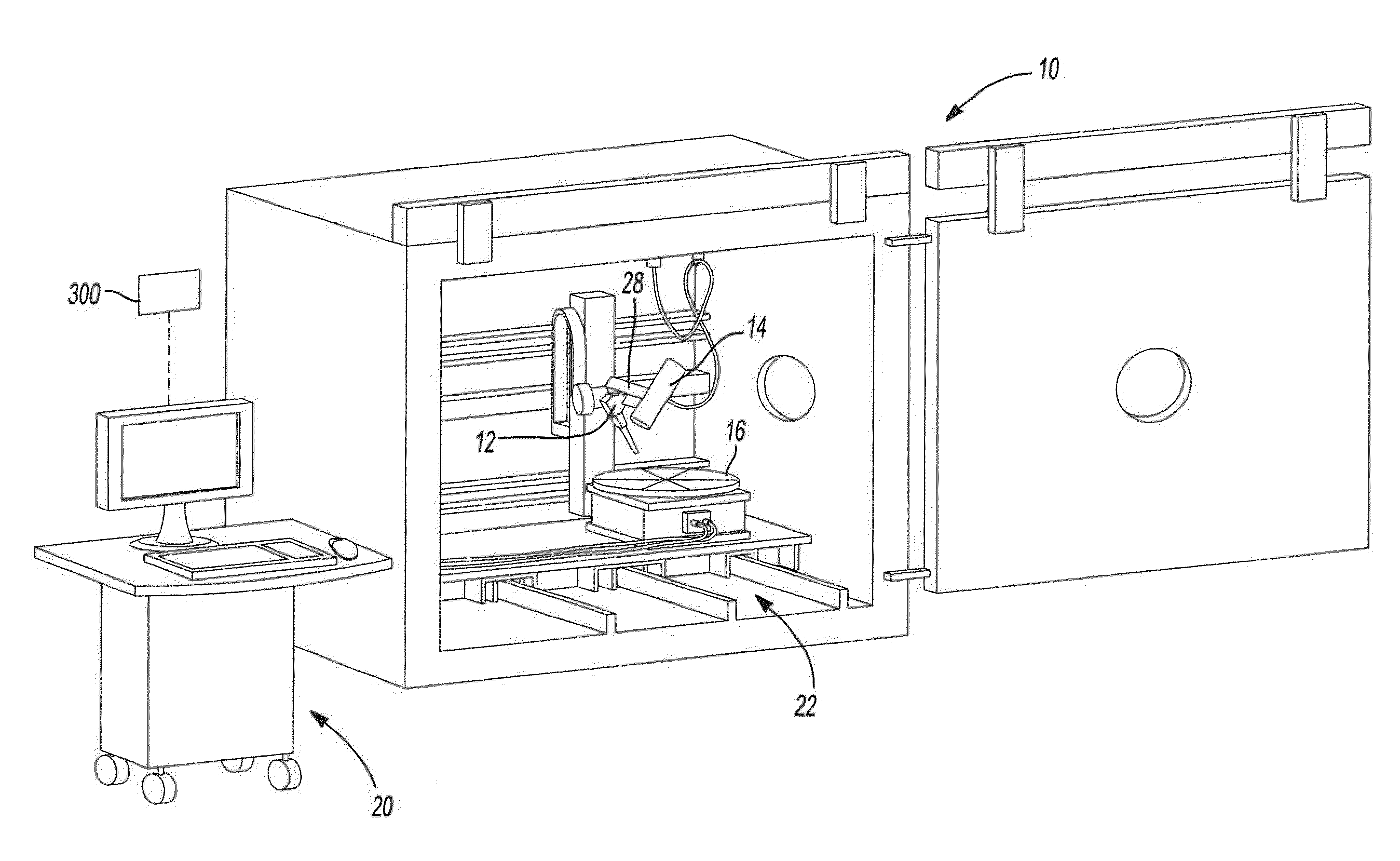

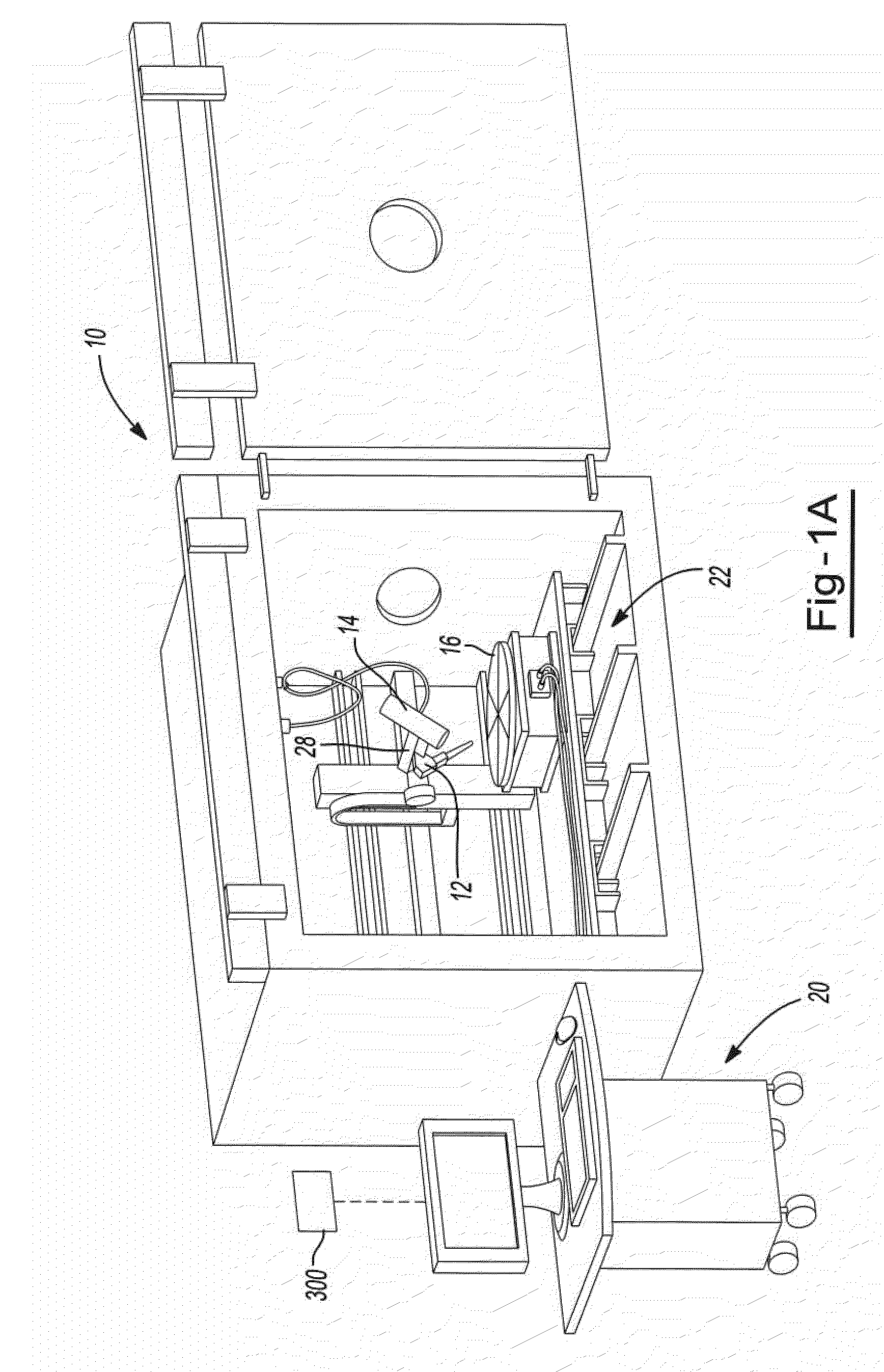

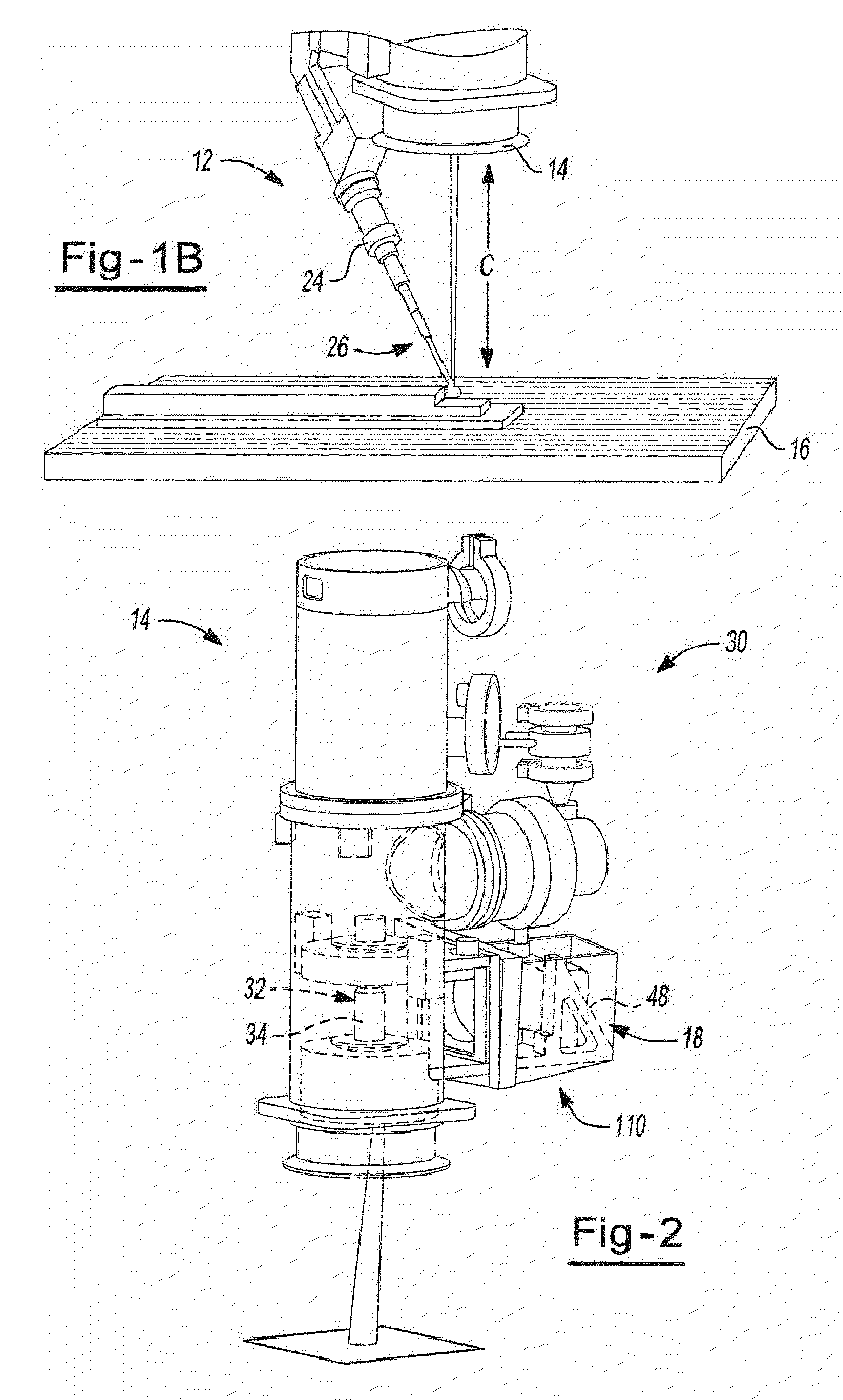

Electron beam layer manufacturing

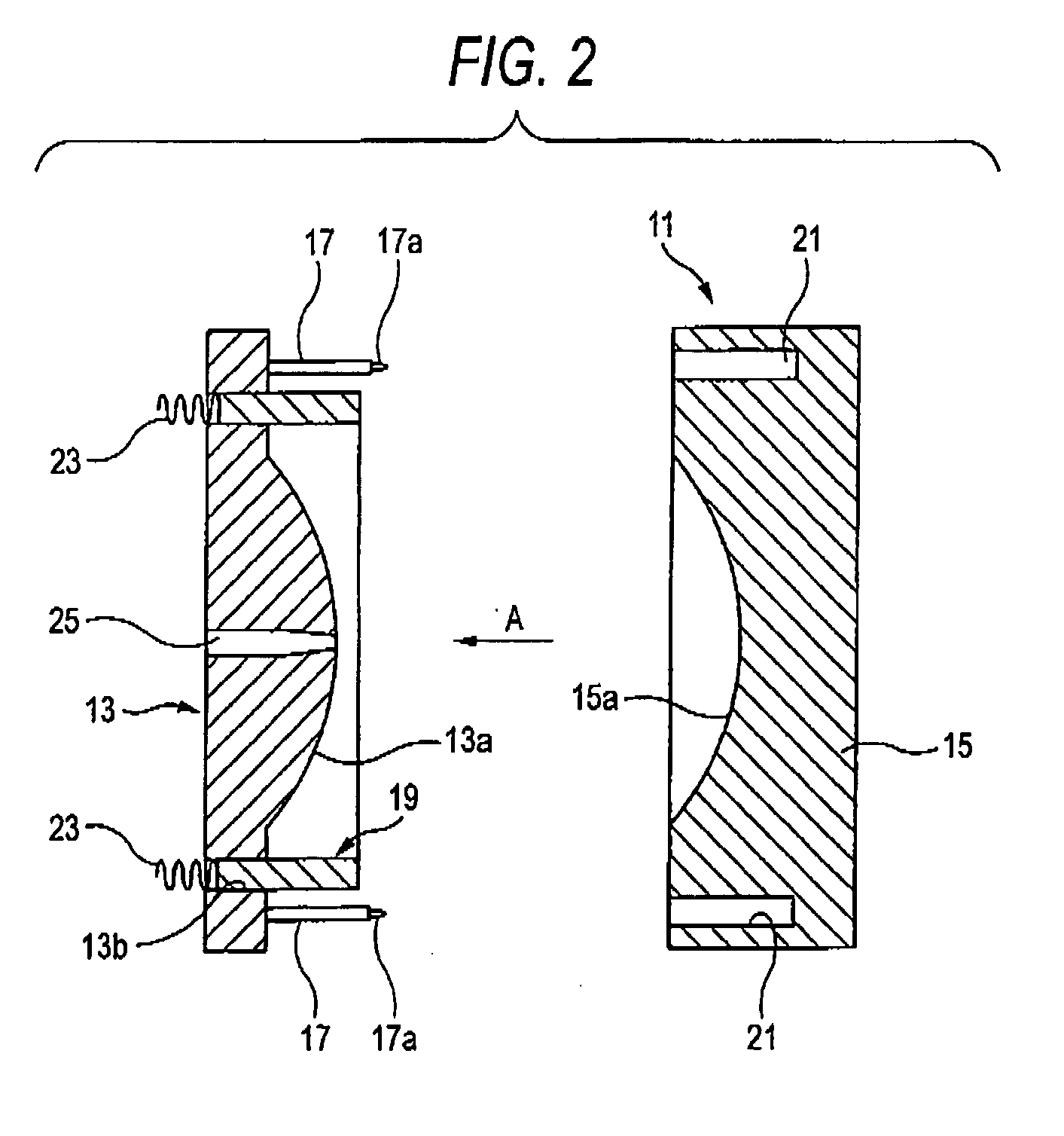

ActiveUS20110061591A1Obstruct passageProgramme controlAdditive manufacturing apparatusFree formClosed loop

A process and apparatus for free form fabrication of a three-dimensional work piece comprising (a) feeding raw material in a solid state to a first predetermined location; (b) depositing the raw material onto a substrate as a molten pool deposit under a first processing condition; (c) monitoring the molten pool deposit for a preselected condition; (d) comparing information about the preselected condition of the monitored molten pool deposit with a predetermined desired value for the preselected condition of the monitored molten pool deposit; (e) solidifying the molten pool deposit; (f) automatically altering the first processing condition to a different processing condition based upon information obtained from the comparing step (d); and repeating steps (a) through (f) at one or more second locations for building up layer by layer a three-dimensional work piece. The apparatus is characterized by a detector that monitors a preselected condition of the deposited material and a closed loop electronic control device for controlling operation of one or more components of the apparatus in response to a detected condition by the detector.

Owner:SCIAKY SA

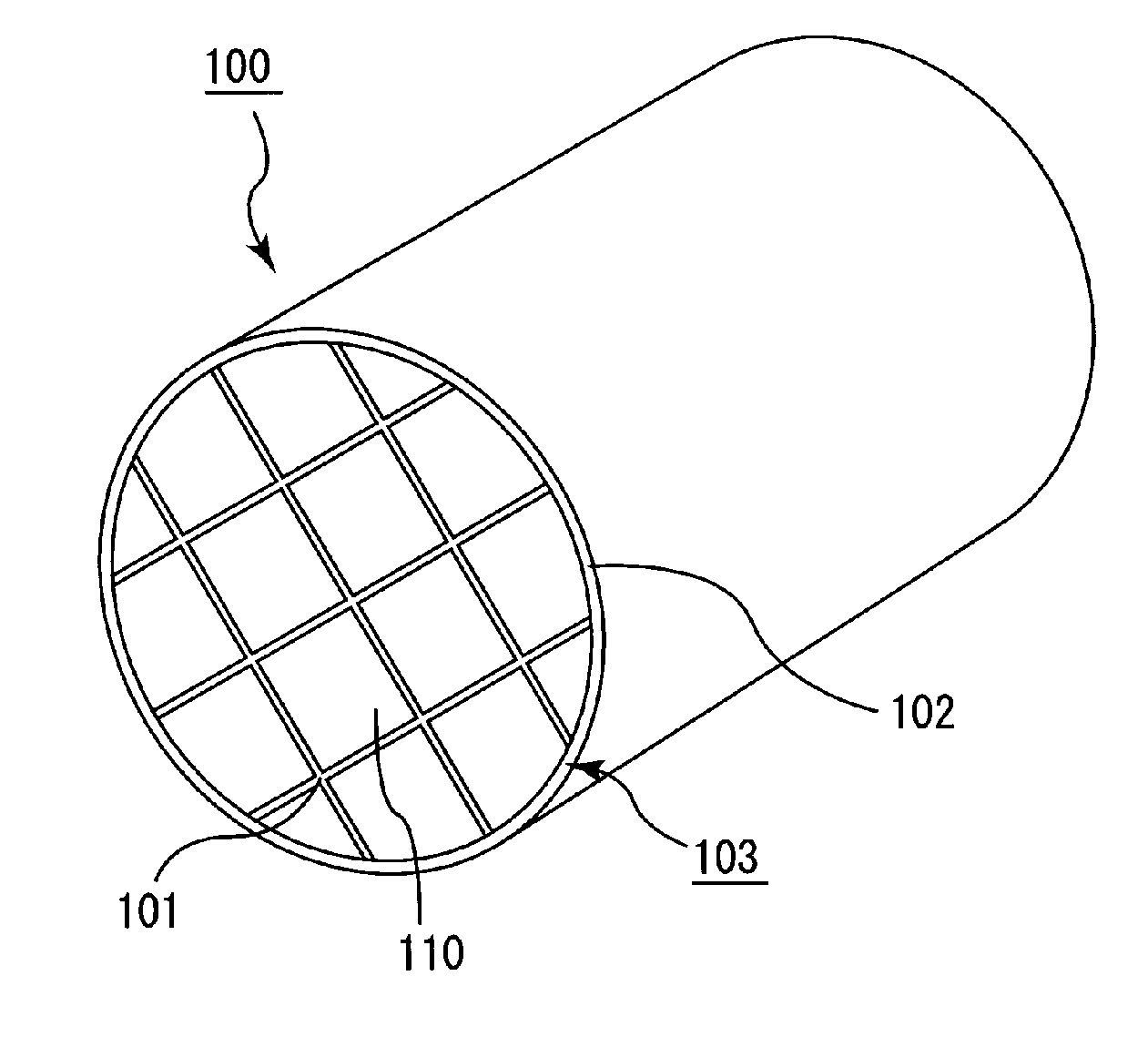

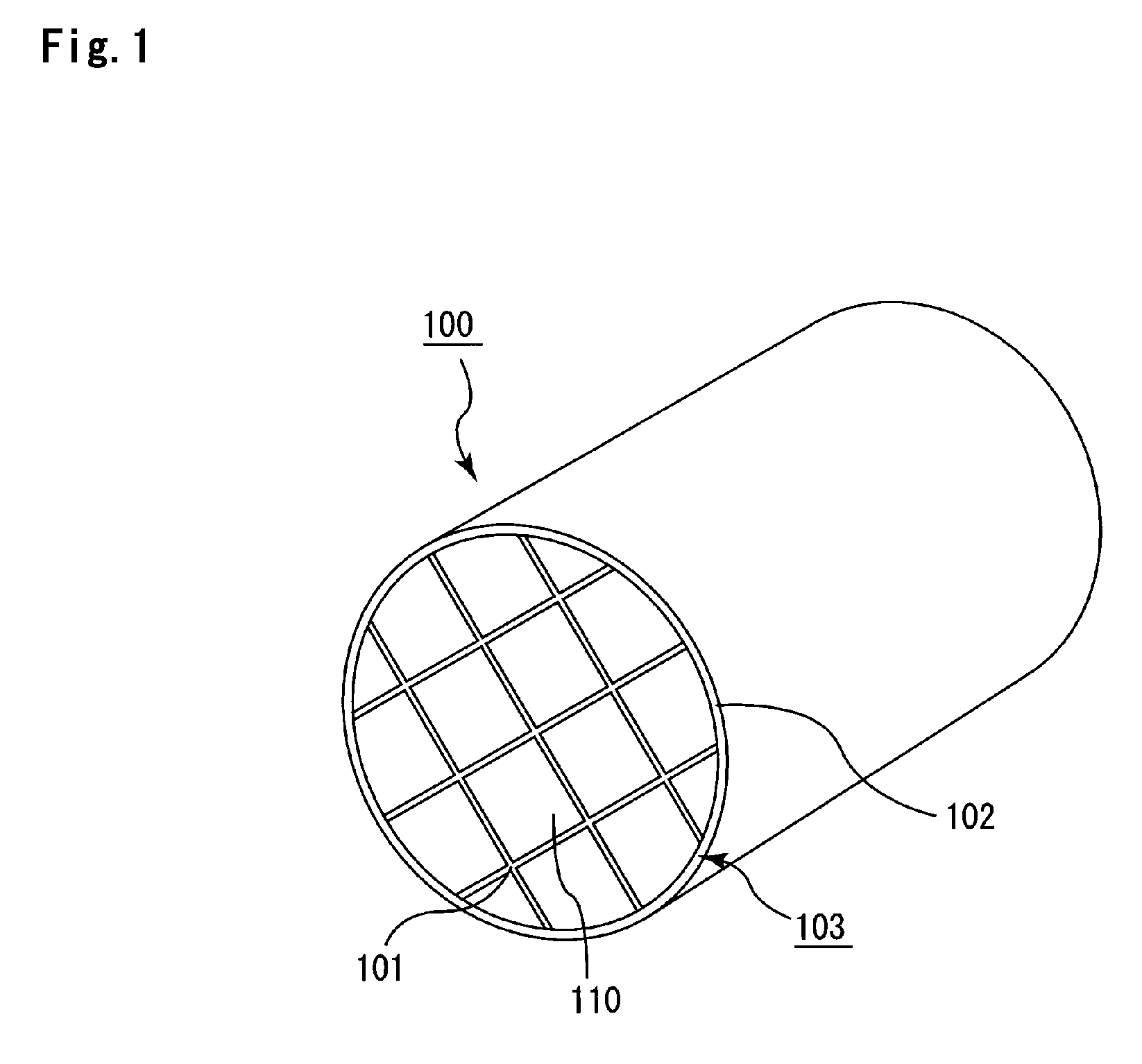

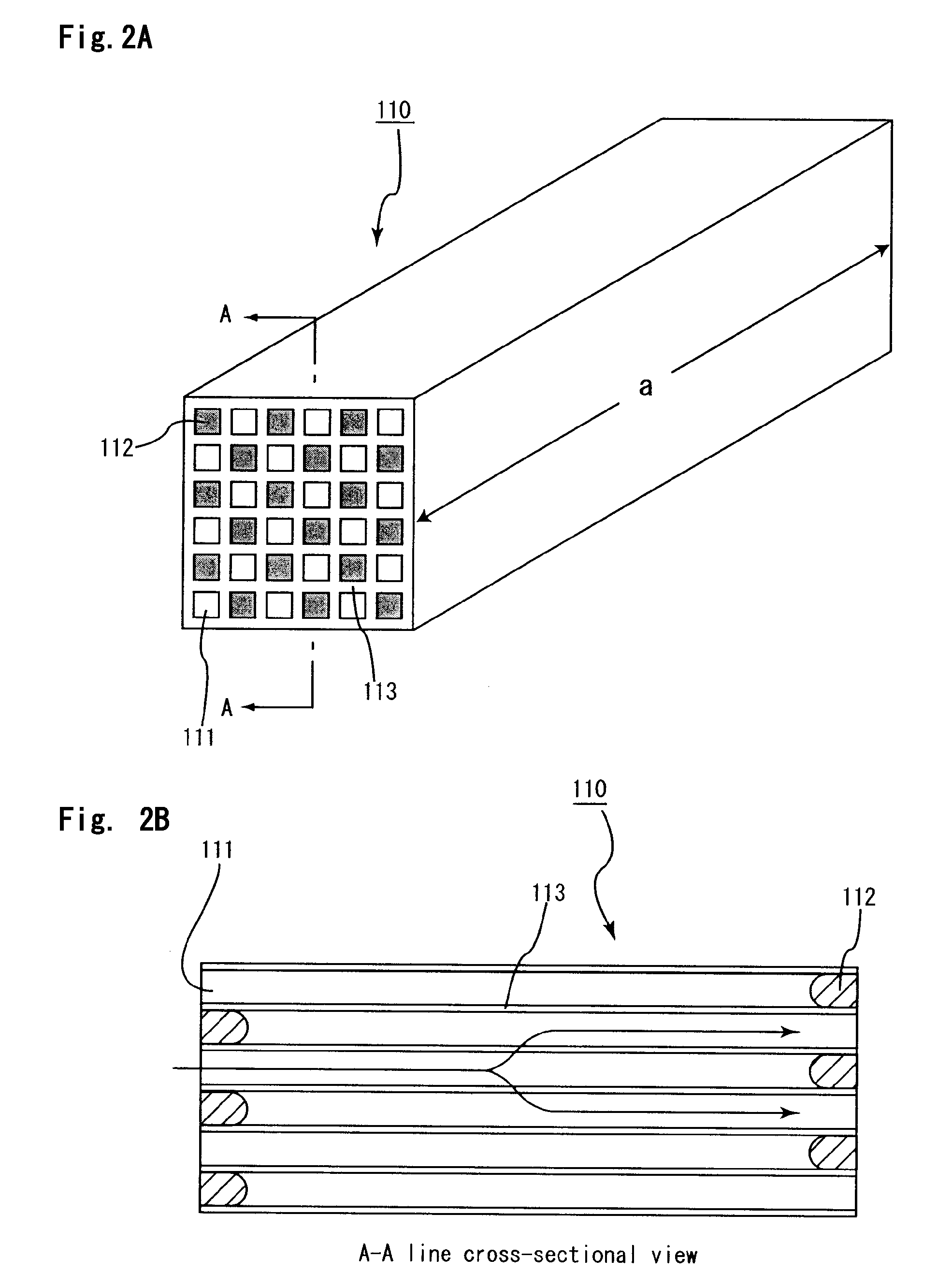

Method for manufacturing material for silicon carbide fired body and method for manufacturing honeycomb structure

InactiveUS20080284067A1Mixing operation control apparatusCeramic shaping apparatusManufactured materialHoneycomb structure

A material for a silicon carbide fired body is manufactured by wet mixing at least a silicon carbide powder and an iron compound powder. A honeycomb structure is manufactured by molding a raw material composition containing the material for a silicon carbide fired body and an additive to manufacture a honeycomb molded body which has cell walls extending along a longitudinal direction of the honeycomb molded body to define a plurality of cells extending along the longitudinal direction. The honeycomb molded body is degreased to manufacture a honeycomb degreased body. The honeycomb degreased body is fired to manufacture a honeycomb structure including a honeycomb fired body.

Owner:IBIDEN CO LTD

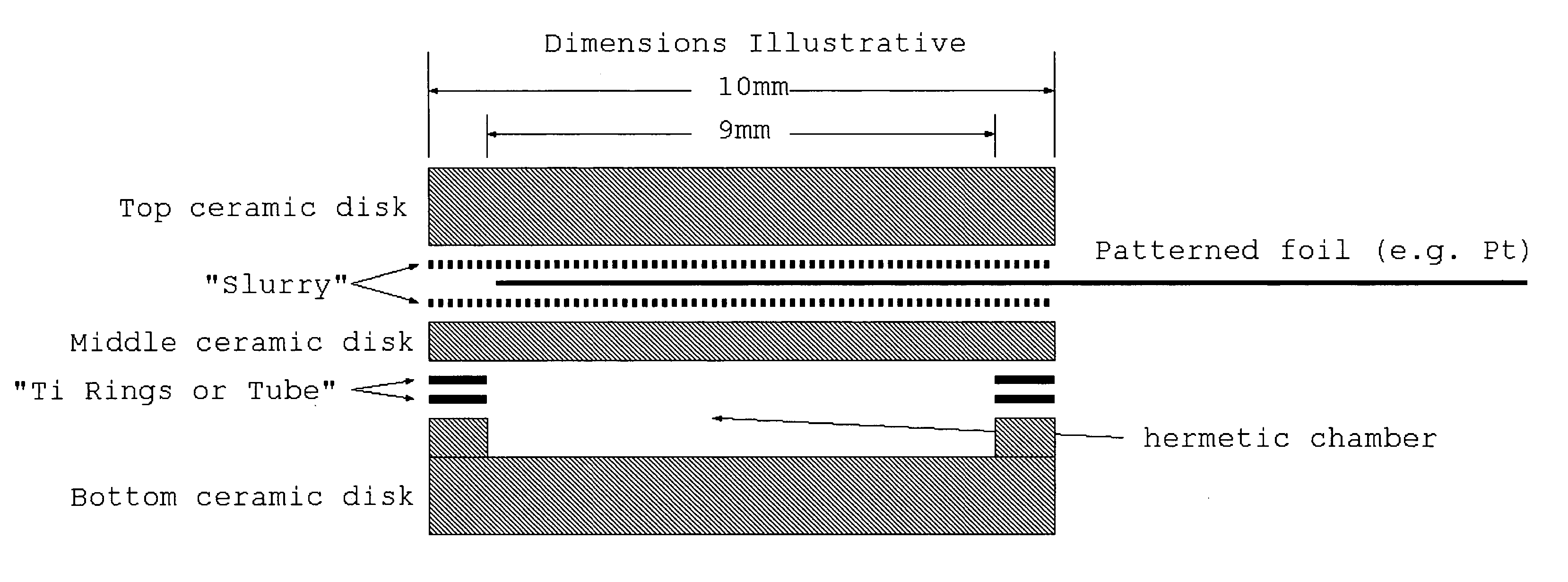

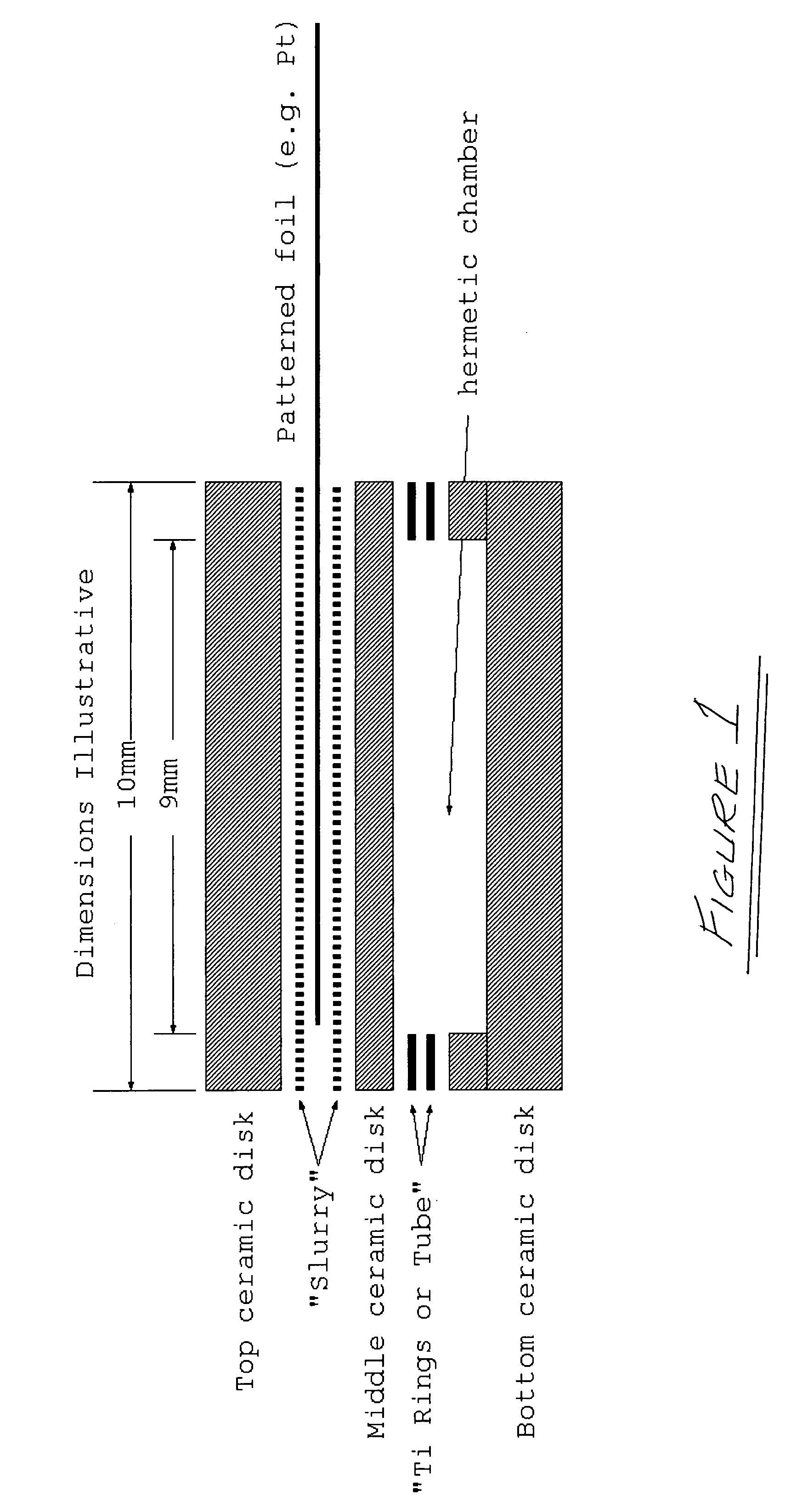

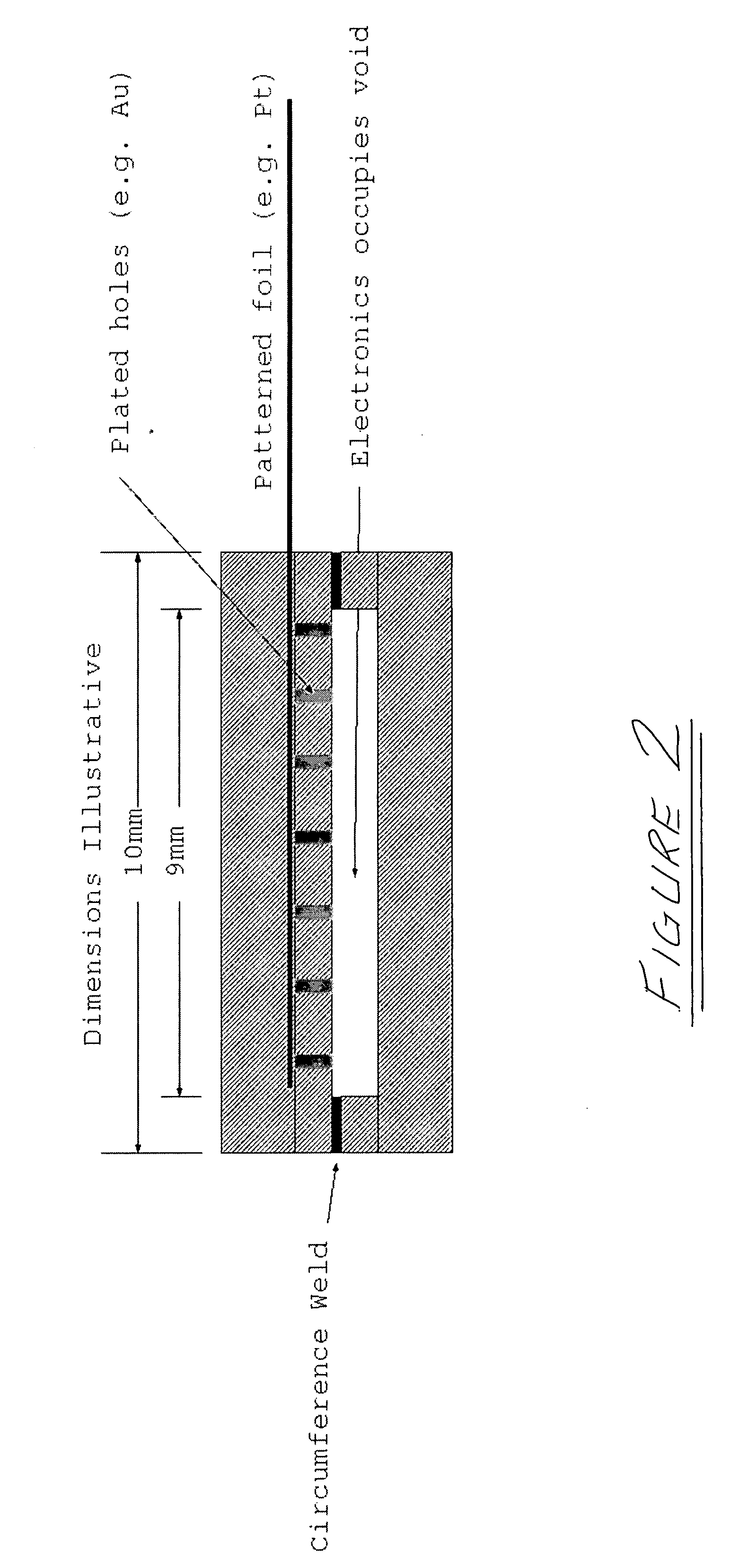

Method for fabrication of hermetic electrical conductor feedthroughs

InactiveUS20070277374A1High bonding strengthComplicated in fabrication procedurePrinted circuit assemblingLine/current collector detailsOxide ceramicPlatinum

A method is disclosed for the fabrication of feedthrough devices that can transmit a single or plurality of electrical signal(s) to or from within a leak-tight (hermetic) chamber from or to the outside of said leak-tight (hermetic) chamber. The invention allows materials known to be well-tolerated within the human body such as alumina-oxide ceramic and platinum to be used as raw materials in the fabrication of body-compatible, single or multi-channel leak-tight (hermetic) feedthroughs.

Owner:NEWSOUTH INNOVATIONS PTY LTD

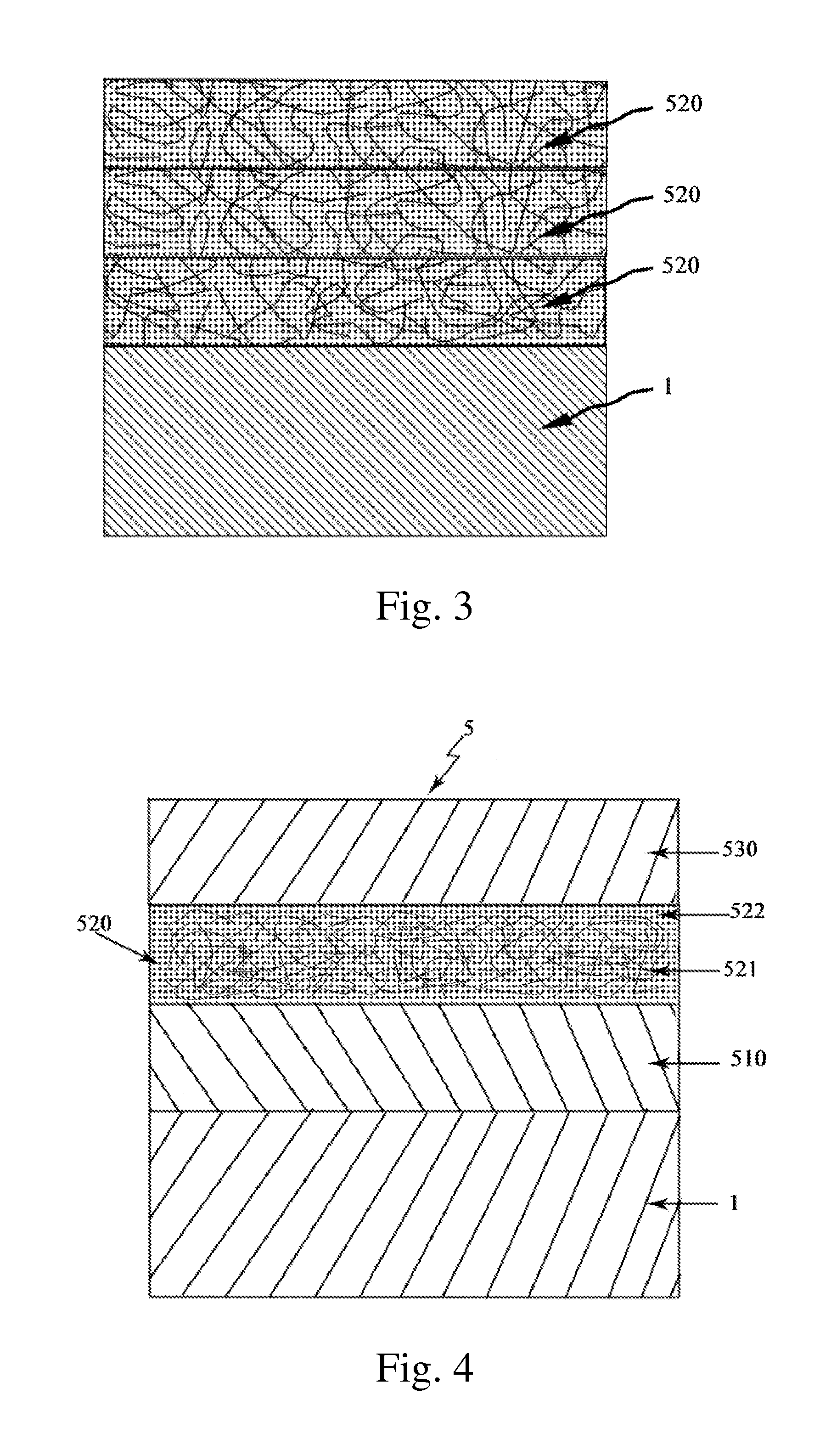

Method for manufacturing high thermal conductivity graphite film

InactiveCN103011141AEasy to separateImprove cooling effectCarbon compoundsThin membraneManufactured material

The invention discloses a method for manufacturing a high thermal conductivity graphite film, which adopts polyimide films as raw materials and is formed through two processes of carbonization and graphitization. The technological processes of the high thermal conductivity graphite film comprise the steps as follows: a, the polyimide films are selected as the raw materials, and a piece of graphite paper is clamped between each layer of the polyimide films; b, the polyimide films which are provided with the graphite paper at intervals, crossed and stacked are placed into a carbonization furnace to be carbonized in an environment of nitrogen or argon, the carbonized temperature ranges from 1000 DEG C to 1400 DEG C, and the time is controlled from 1 hour to 6 hours; and c, after the carbonization, the graphitization is performed also in the environment of nitrogen or argon, the temperature is controlled in a range from about 2500 DEG C to 3000 DEG C, and the time is controlled within 12 hours. The method for manufacturing the high thermal conductivity graphite film has a simple manufacturing process, the high heat dissipation capacity of the graphite film is guaranteed, the bending-resistant performance is enhanced, and a requirement for a thin and light electronic product of a consumer is met to a certain extent.

Owner:NINGBO JINSHAN NEW MATERIAL

Electron beam layer manufacturing

ActiveUS8546717B2Obstruct passageProgramme controlAdditive manufacturing apparatusFree formClosed loop

A process and apparatus for free form fabrication of a three-dimensional work piece comprising (a) feeding raw material in a solid state to a first predetermined location; (b) depositing the raw material onto a substrate as a molten pool deposit under a first processing condition; (c) monitoring the molten pool deposit for a preselected condition; (d) comparing information about the preselected condition of the monitored molten pool deposit with a predetermined desired value for the preselected condition of the monitored molten pool deposit; (e) solidifying the molten pool deposit; (f) automatically altering the first processing condition to a different processing condition based upon information obtained from the comparing step (d); and repeating steps (a) through (f) at one or more second locations for building up layer by layer a three-dimensional work piece. The apparatus is characterized by a detector that monitors a preselected condition of the deposited material and a closed loop electronic control device for controlling operation of one or more components of the apparatus in response to a detected condition by the detector.

Owner:SCIAKY SA

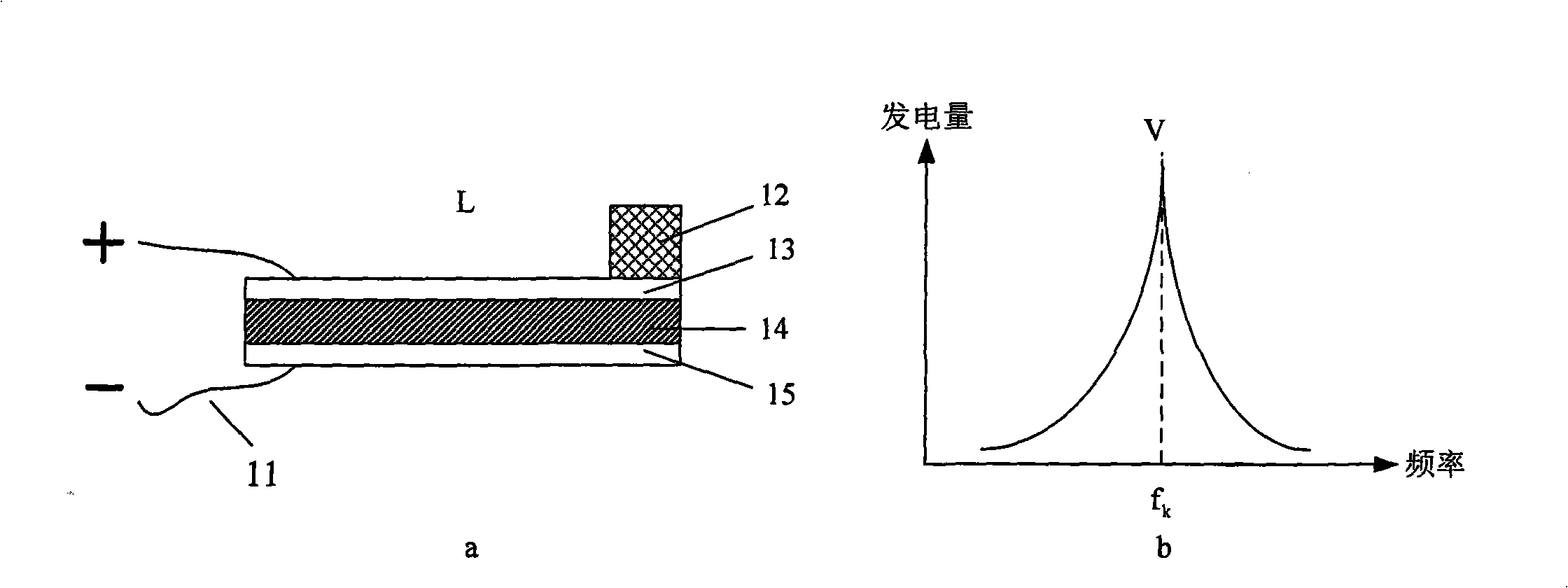

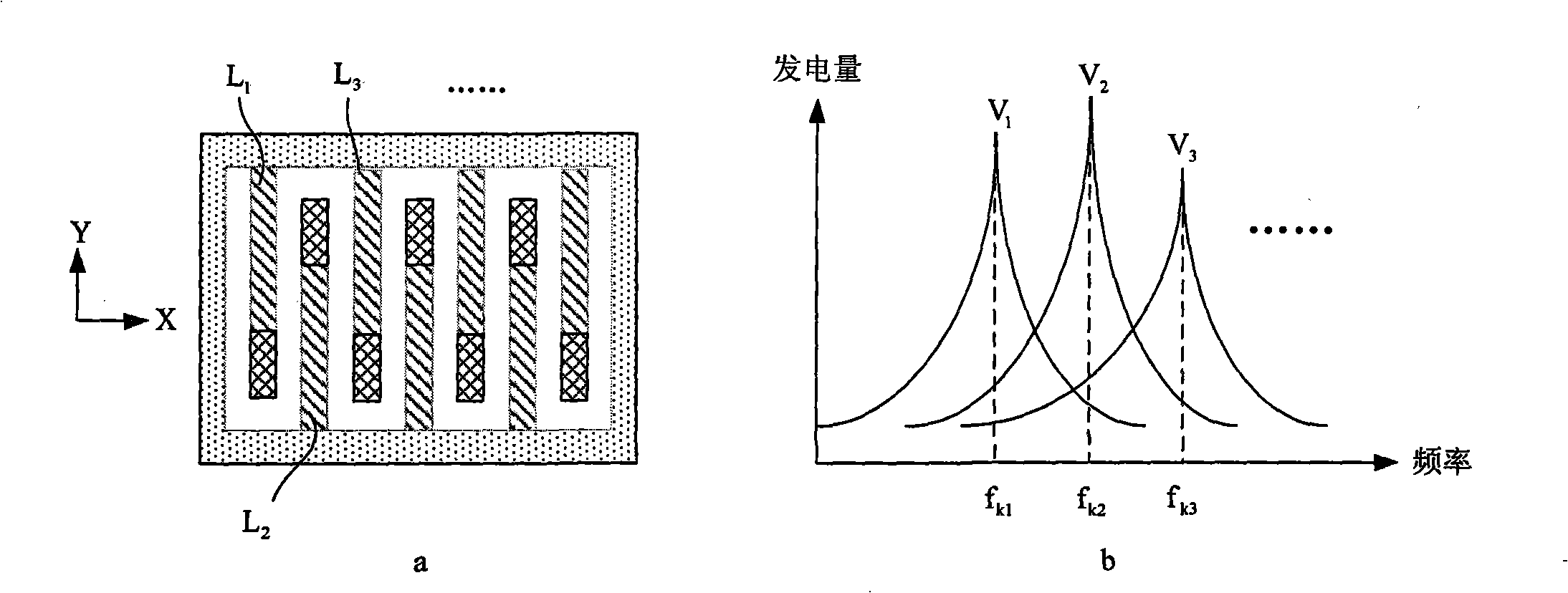

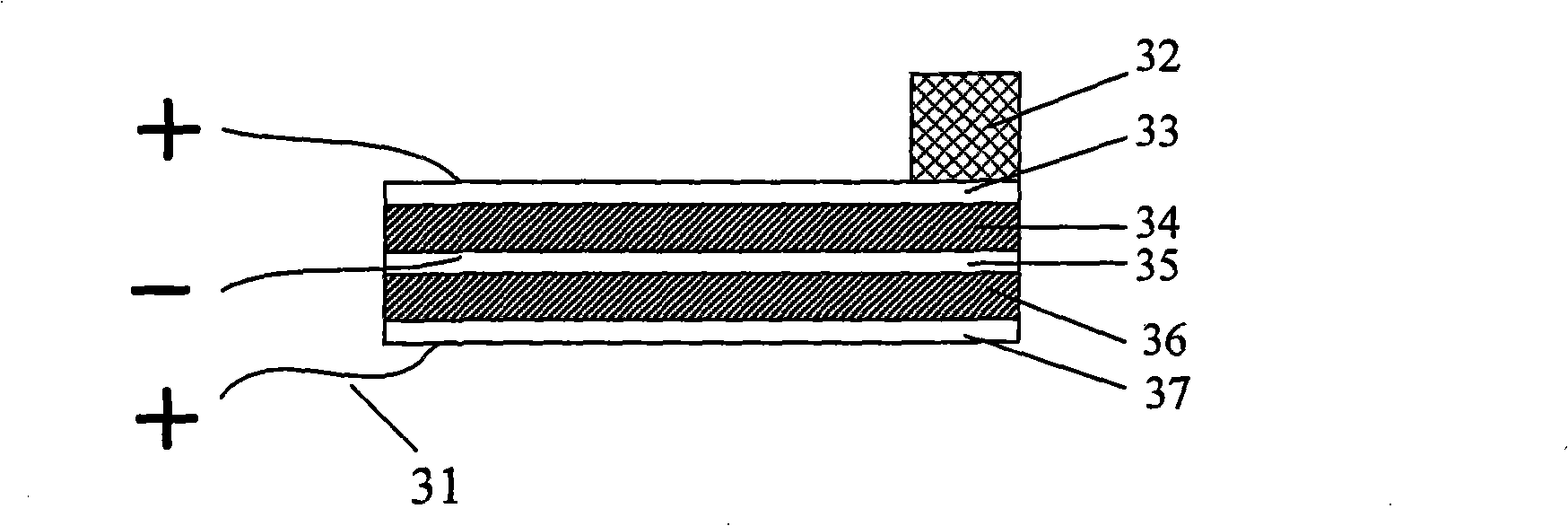

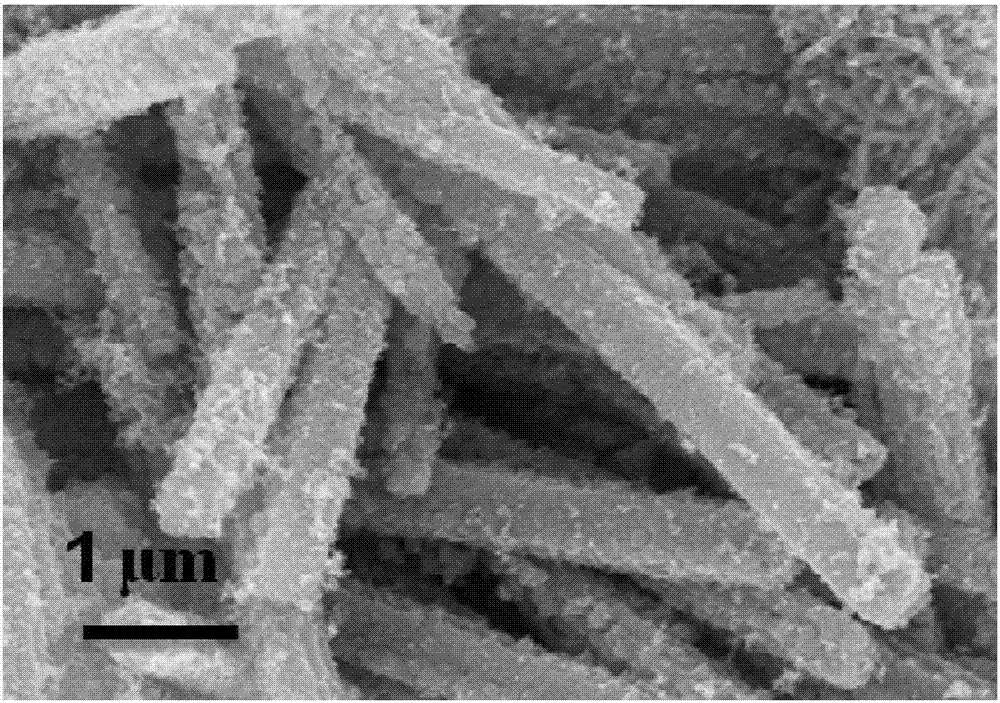

Broad-band piezoelectricity oscillating generating set

InactiveCN101272109ARealize piezoelectric power generationTake advantage ofPiezoelectric/electrostriction/magnetostriction machinesIn planeElectricity

The invention relates to a board band piezoelectric generating set. A plurality of socle beams L1, L2, L3 are divided into two groups; one end of each socle beam is fixed and the other end keeps free; the socle beams keep parallel with each other; a crossing section is arranged between the two groups of the socle beams; wherein, the socle beam consists of piezoelectric transduction elements (34, 36), a down-lead (31), a metal block (32) and electrodes (33, 35, 37). The electrodes and the transduction elements are alternately arranged; the down-lead (31) is arranged at the fixed end of the socle beam; the metal block (32) is arranged at the free end of the socle beam. The sizes and the structures of the socle beams L1, L2, L3 are different, the manufacture materials of the piezoelectric transduction elements are different and the qualities of the metal blocks are different, therefore, the resonance frequency of each beam is different. The two groups of the socle beams L1, L2, L3 are arranged in an interdigital structure in plane or an interdigital structure in space. The board band piezoelectric generating set can absorb the mechanical vibration or noise of a plurality of frequency components in the environment and realize the transformation from mechanical energy to electricity energy by the piezoelectric transduction elements so as to increase the generating capacity and improve the generating efficiency.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

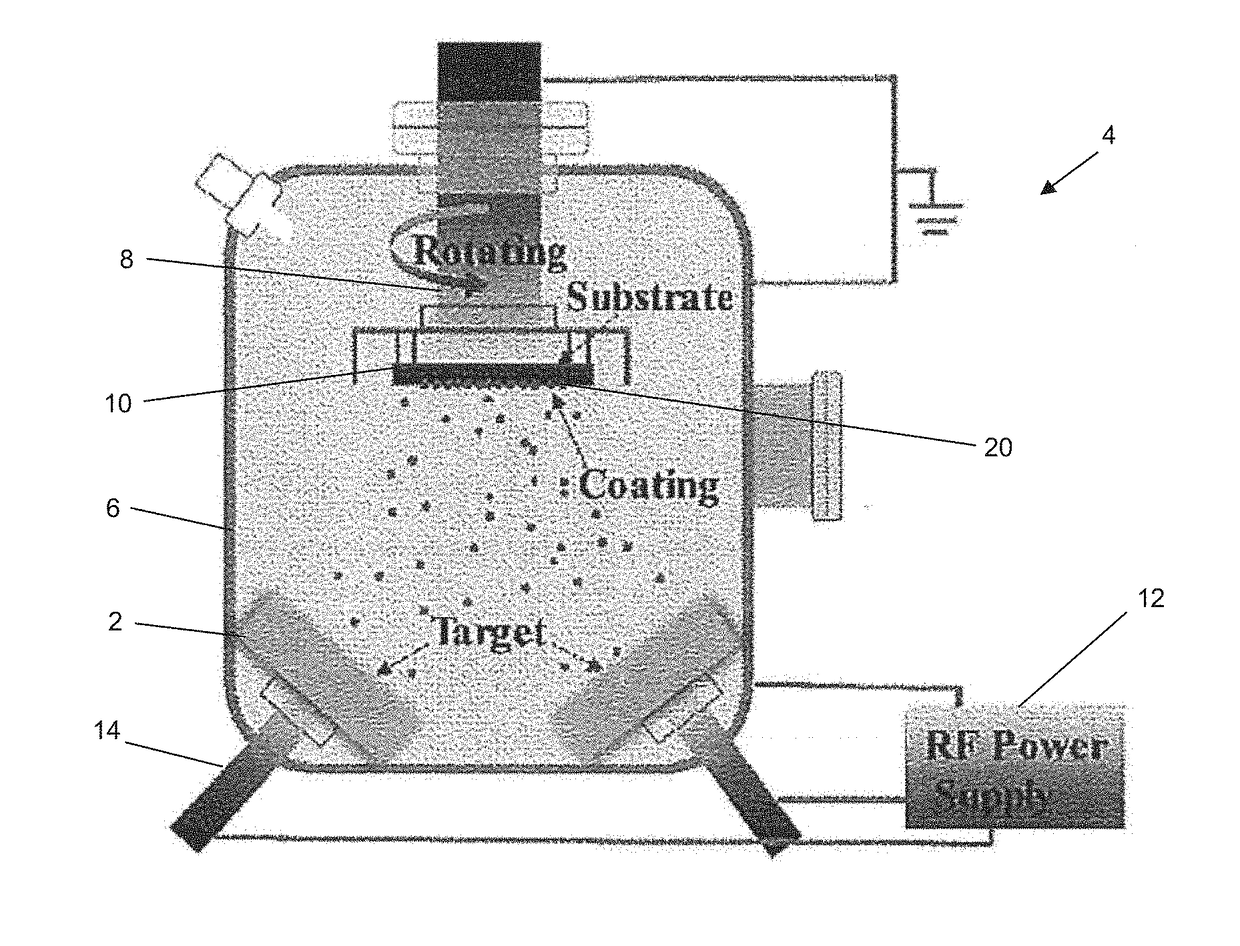

High entropy alloy thin film coating and method for preparing the same

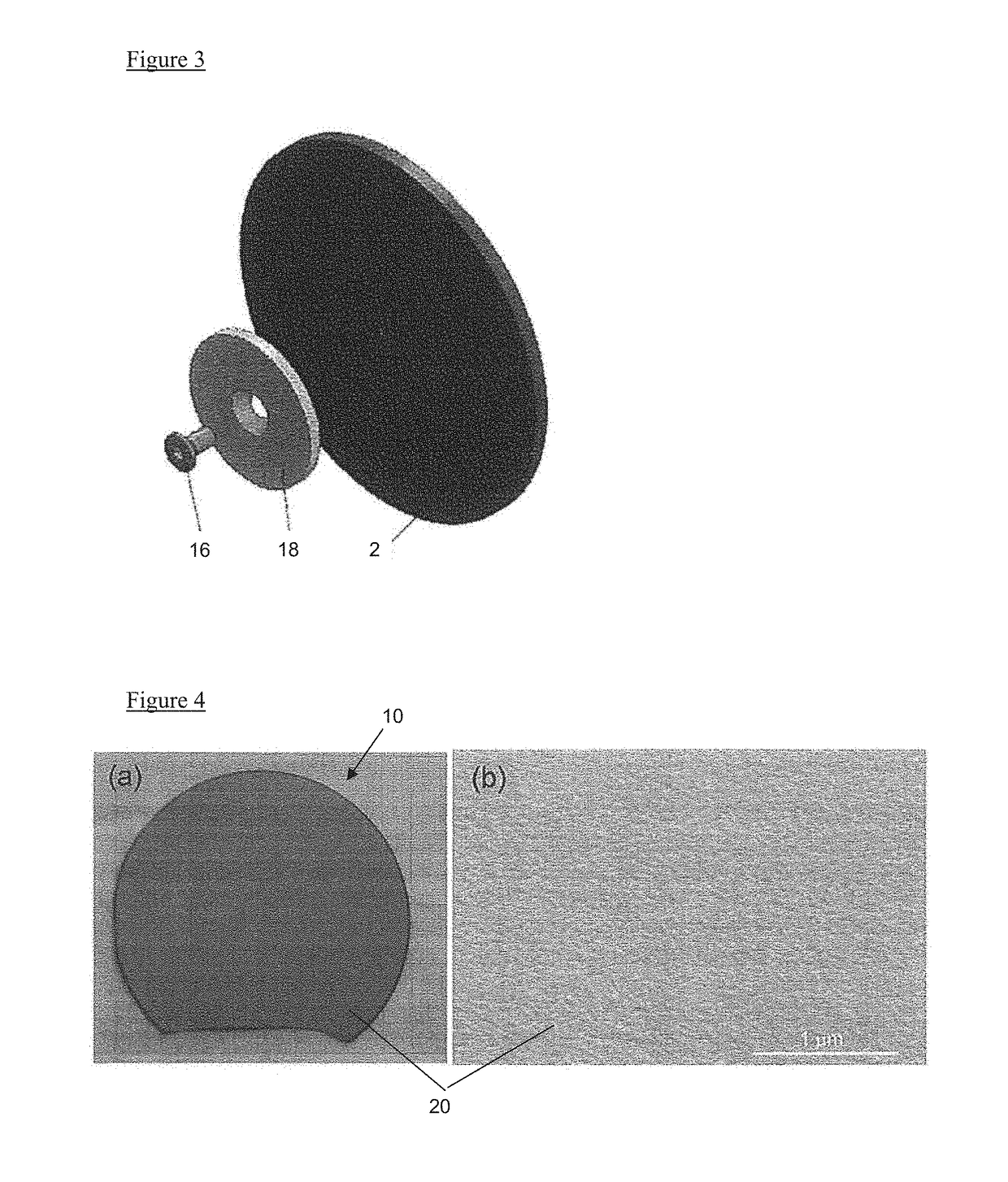

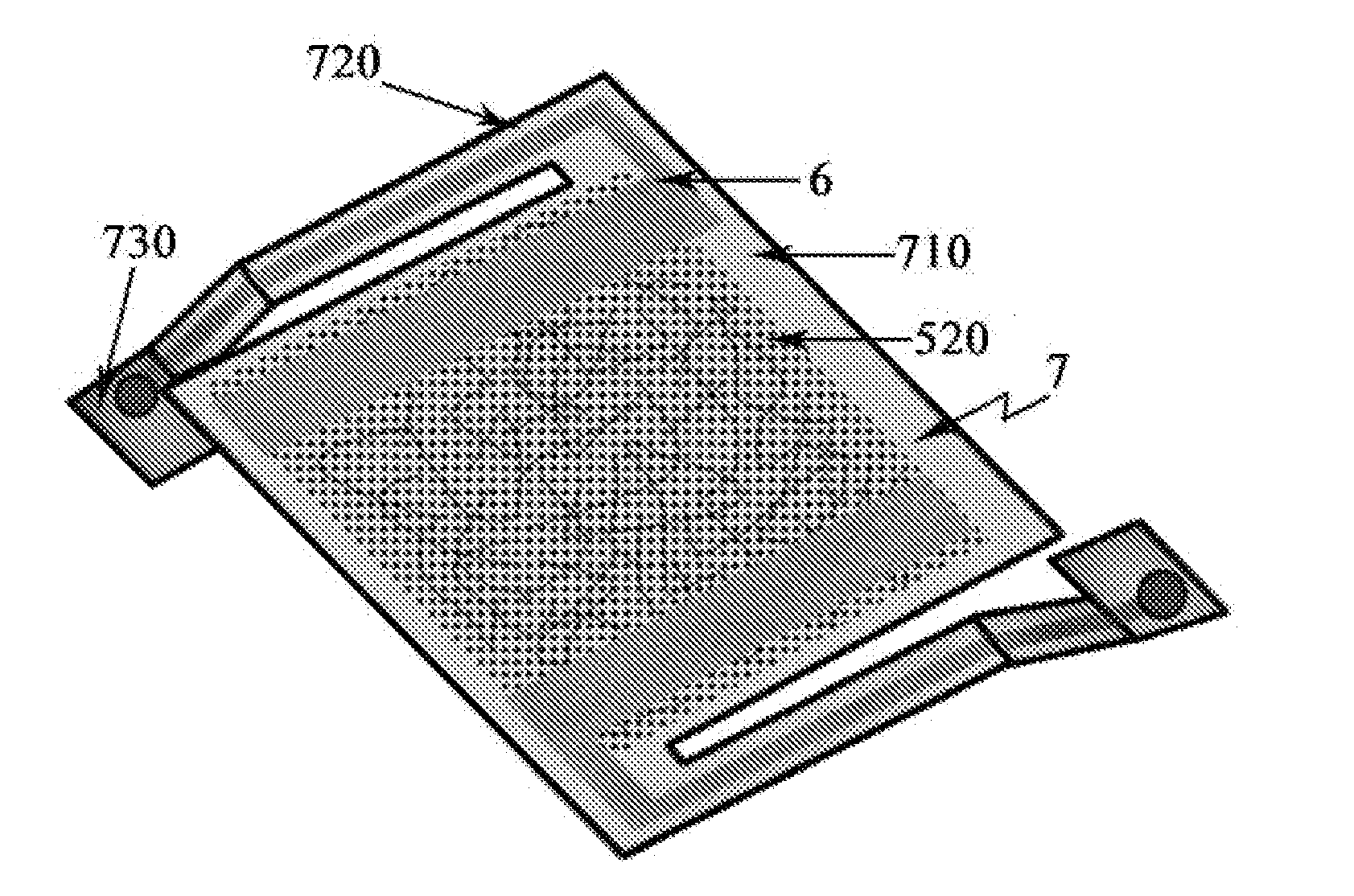

ActiveUS20180223417A1High hardnessImprove wear resistanceVacuum evaporation coatingSputtering coatingHigh entropy alloysRadio frequency sputtering

A method for preparing a high entropy alloy thin film coating includes preparing a melt alloy by arc melting raw materials including five or more elements, casting the melt alloy into a mold to form a target, placing the target inside a vacuum chamber of a magnetron sputtering system, and rotatably fixing a substrate inside the vacuum chamber, spaced apart from the target. A high entropy alloy thin film is deposited on the substrate by high vacuum radio frequency sputtering inside the vacuum chamber.

Owner:CITY UNIVERSITY OF HONG KONG

Microbolometer for infrared detector or Terahertz detector and method for manufacturing the same

InactiveUS20110315981A1Improve business performanceLow costSemiconductor/solid-state device manufacturingPyrometry using electric radation detectorsComposite filmMicrobolometer

A microbolometer includes a micro-bridge structure for uncooling infrared or terahertz detectors. The thermistor and light absorbing materials of the micro-bridge structure are the vanadium oxide-carbon nanotube composite film formed by one-dimensional carbon nanotubes and two-dimensional vanadium oxide film. The micro-bridge is a three-layer sandwich structure consisting of a layer of amorphous silicon nitride base film as the supporting and insulating layer of the micro-bridge, a layer or multi-layer of vanadium oxide-carbon nanotube composite film in the middle of the micro-bridge as the heat sensitive and light absorbing layer of the microbolometer, and a layer of amorphous silicon nitride top film as the stress control layer and passivation of the heat sensitive film. The microbolometer and method for manufacturing the same can overcome the shortcomings of the prior art, improve the performance of the device, reduce the cost of raw materials and is suitable for large-scale industrial production.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

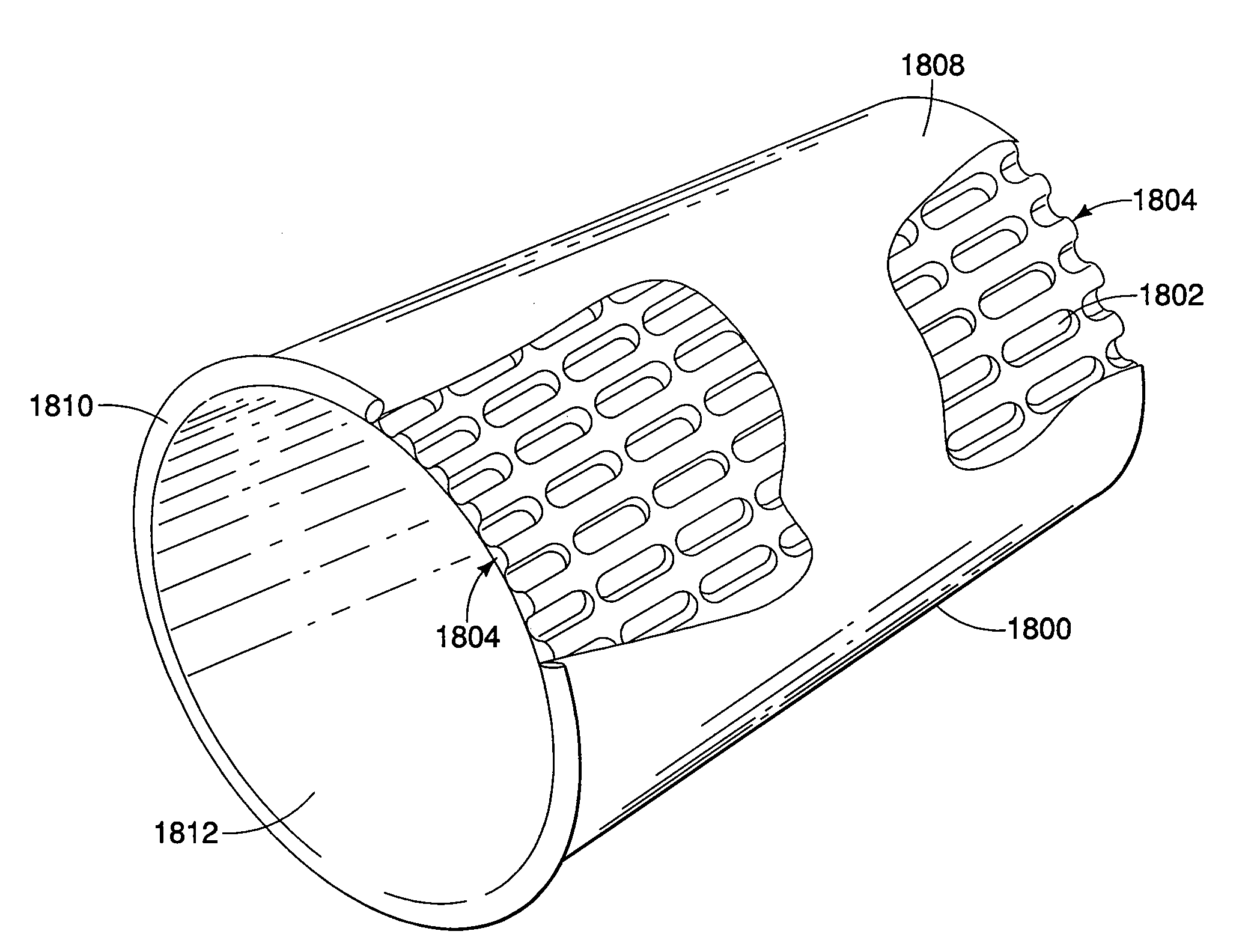

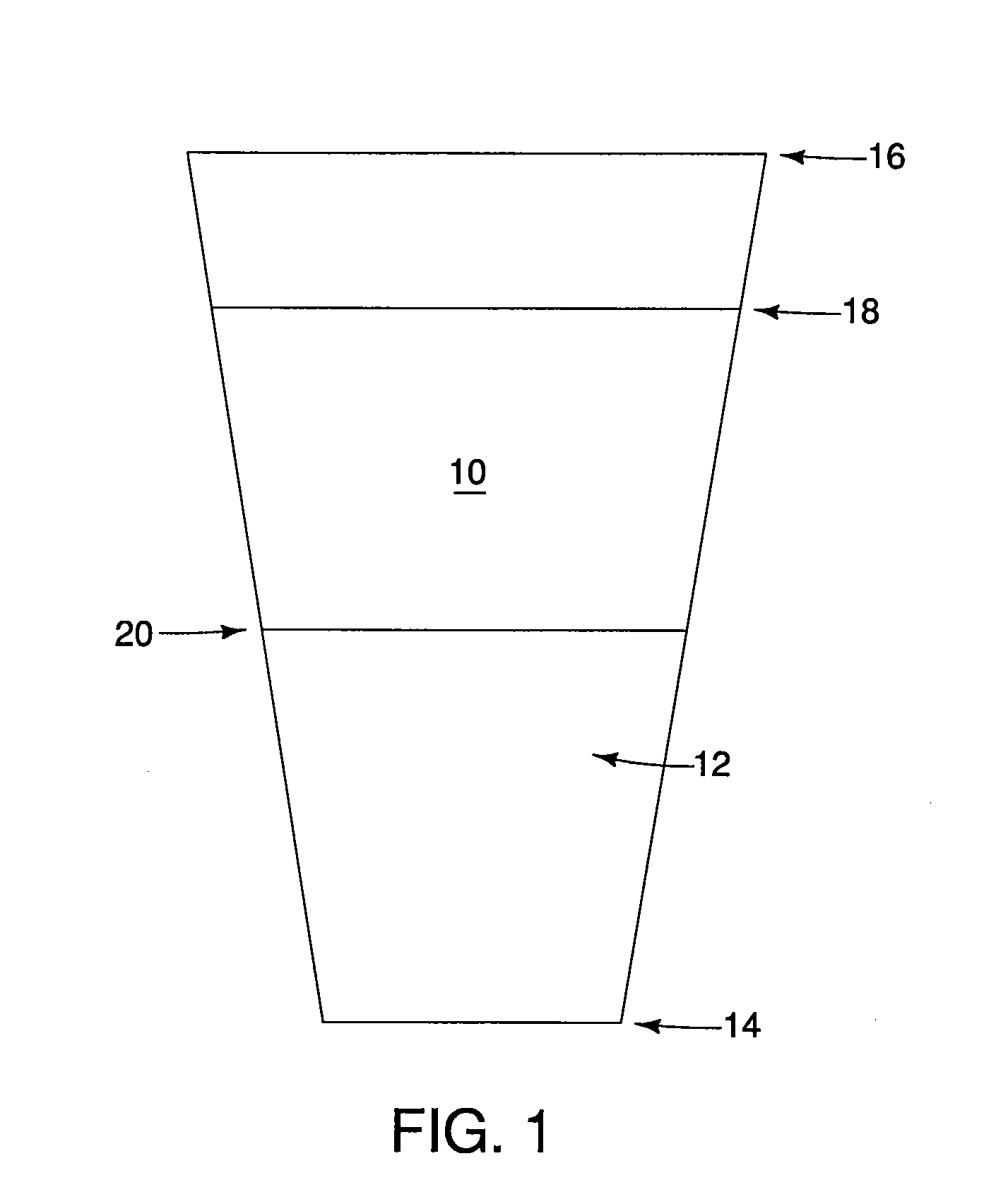

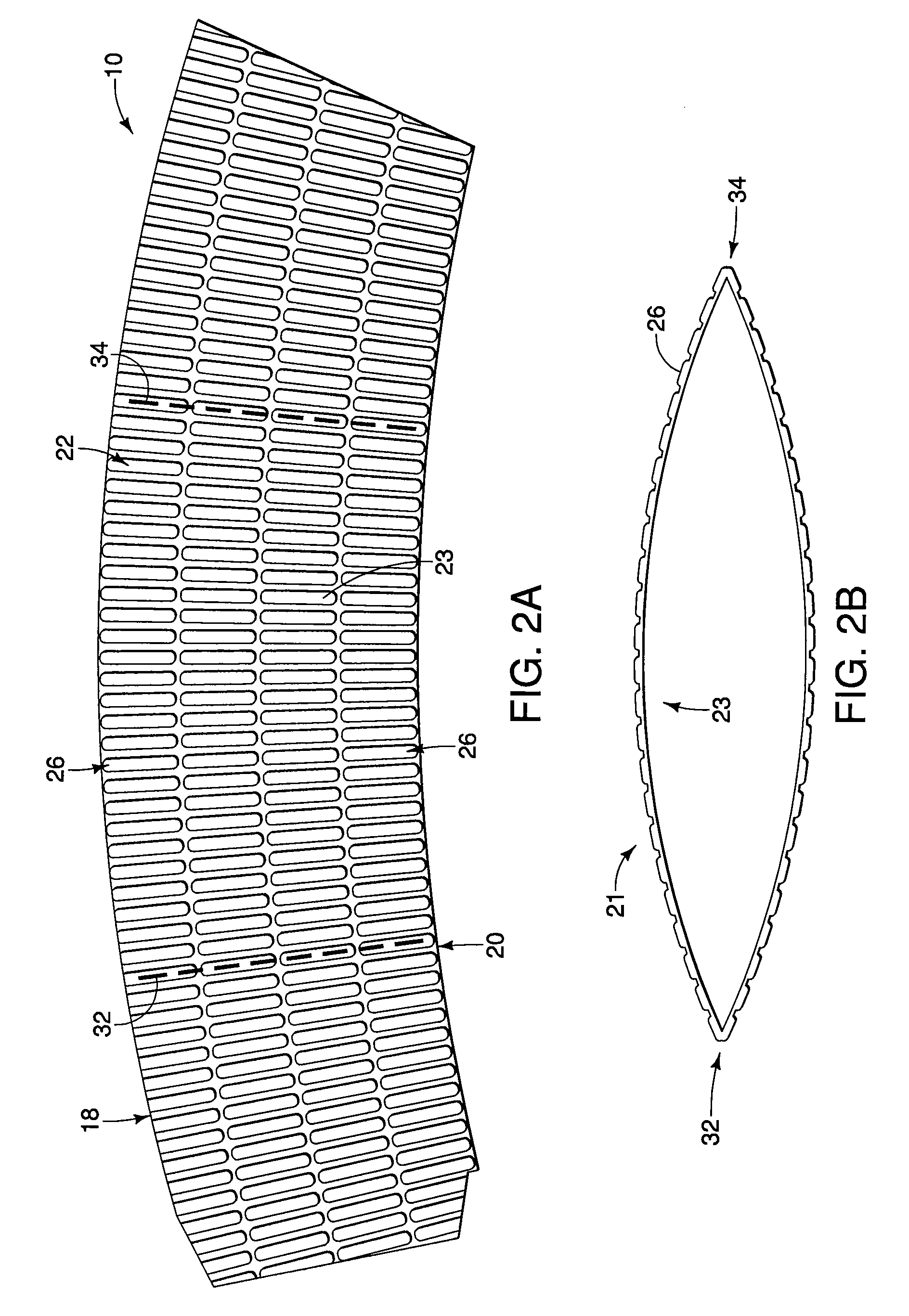

Protective sleeve

A container and a sleeve for a container are disclosed that employ unique air channels to divert heat from a hot beverage via hot air escaping upward and downward. The surface of the container and sleeve include raised images, depressed images, or a combination of both which are generally aligned in substantially vertical columns. The space between the columns defines the air channels. The air channels are substantially uninterrupted and facilitate the upward and downward escape of hot air. The images are applied, such as by embossing and / or debossing, which facilitates manufacturing material efficiency and therefore reduces material costs and environmental waste. A blank for a container or sleeve and a method of making a sleeve are also disclosed.

Owner:LBP MANUFACTURING INC

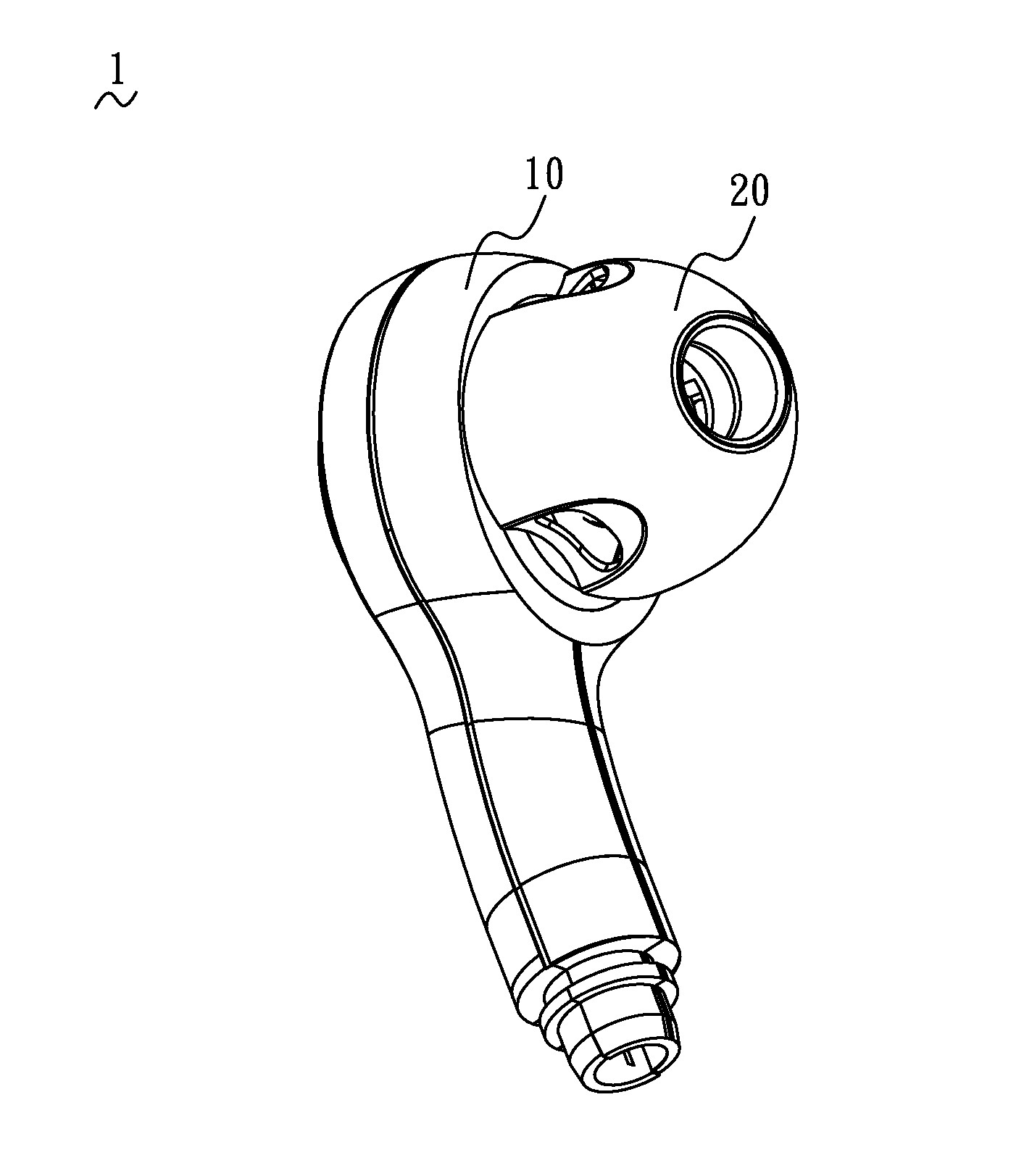

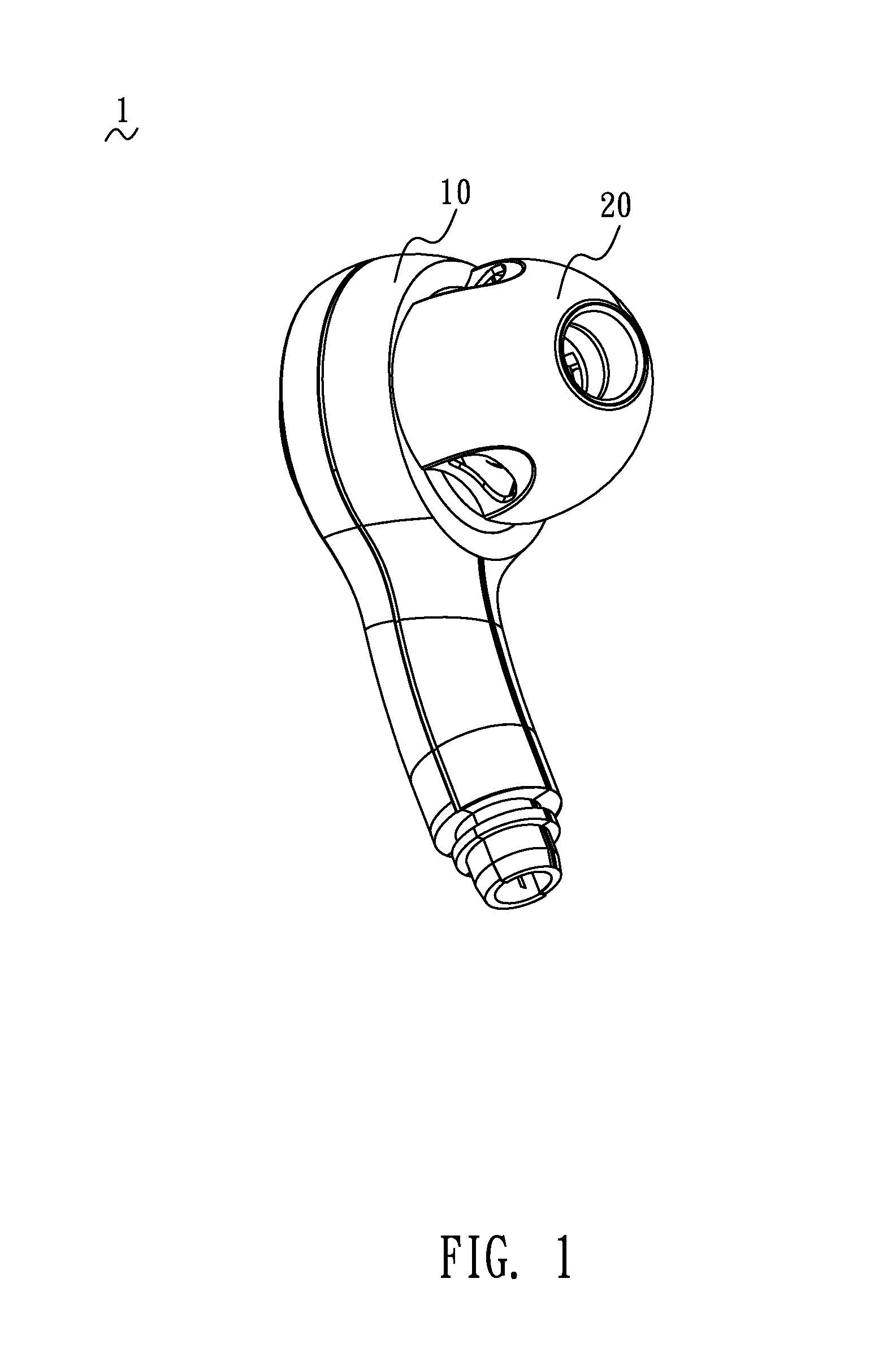

Physiological function detecting earphone and detecting method thereof

ActiveUS20150257662A1Improve accuracyEliminate the effects ofSignal processingCatheterLight sensingTransmittance

A physiological function detecting earphone includes an earphone body, an earplug mounted at one side of the earphone body and defining a window, a light processing module including a light sensing module towards the window, and a signal processing module. A detecting method includes steps: the participant inserts the earplug in the ear canal thereof; the light sensing module senses the changes of light emitted through the window and then reflected by the wall of the ear canal; the light processing module processes the reflected light of changes to get PPG signals; the signal processing module receives and processes the PPG signals to get physiological information of the participant. The window opened in the earplug can gather the light in a narrow area of the ear canal so that reduces effect of manufacturing material on transmittance of light and improves accuracy of the PPG signals and the physiological information.

Owner:CHENG UEI PRECISION IND CO LTD

Printing decoration metallic plate capable of panel beating and manufacturing method thereof

ActiveCN101077676AGood decorative effectImprove product gradeSpecial ornamental structuresCoatingsSheet steelSurface tension

The present invention is printed metal plate and its making process. On the surface of coated steel sheet, patterns are first printed with ink fitting the surface coating of steel sheet and through intaglio offset printing, and high temperature cured paint or UV cured paint is then roller coated to the surface of the patterns. The printed metal plate has high decorating effect. Compared with available technology, the present invention has the advantages of environment friendship and low cost.

Owner:青岛河钢复合新材料科技有限公司 +1

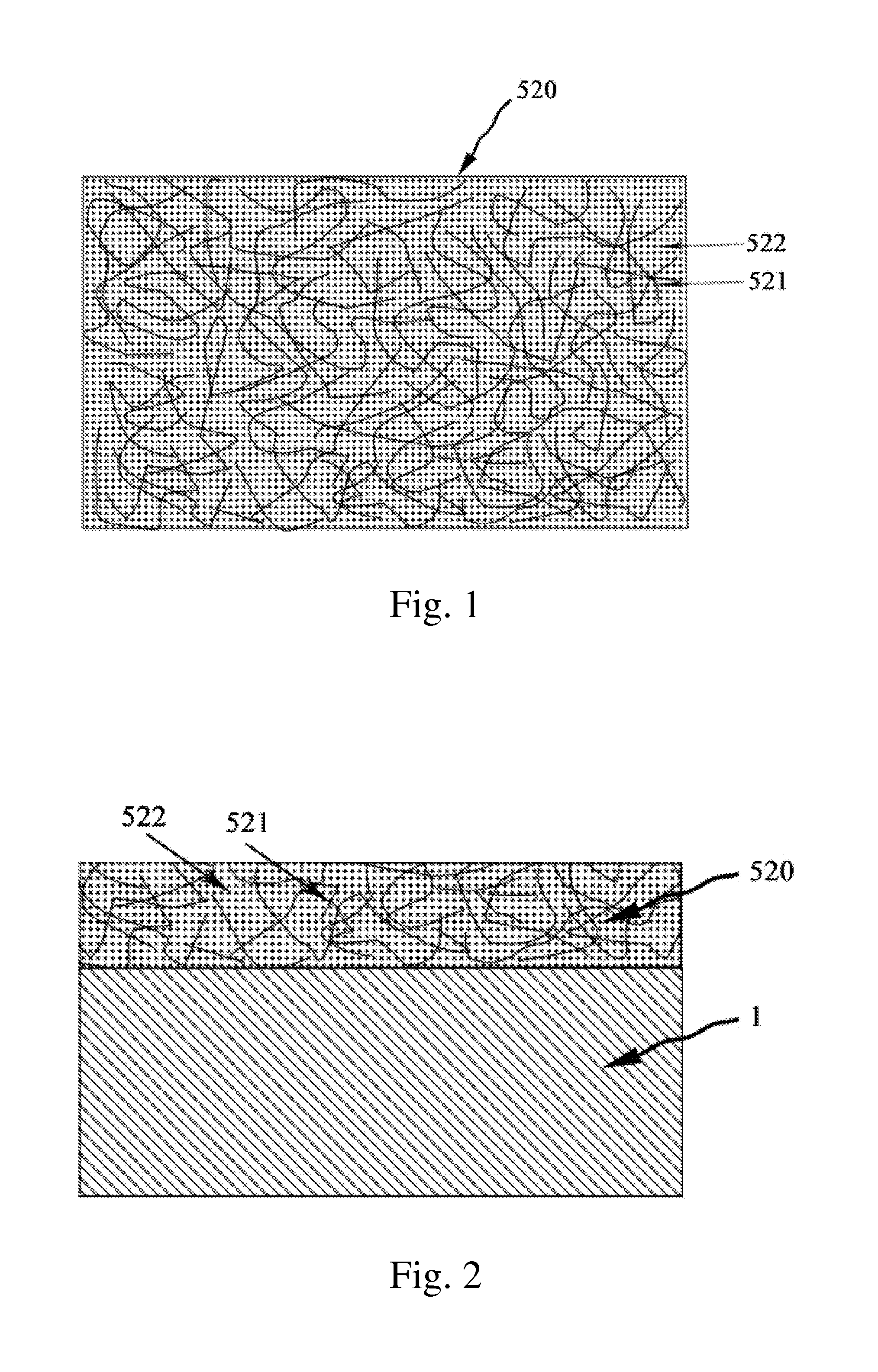

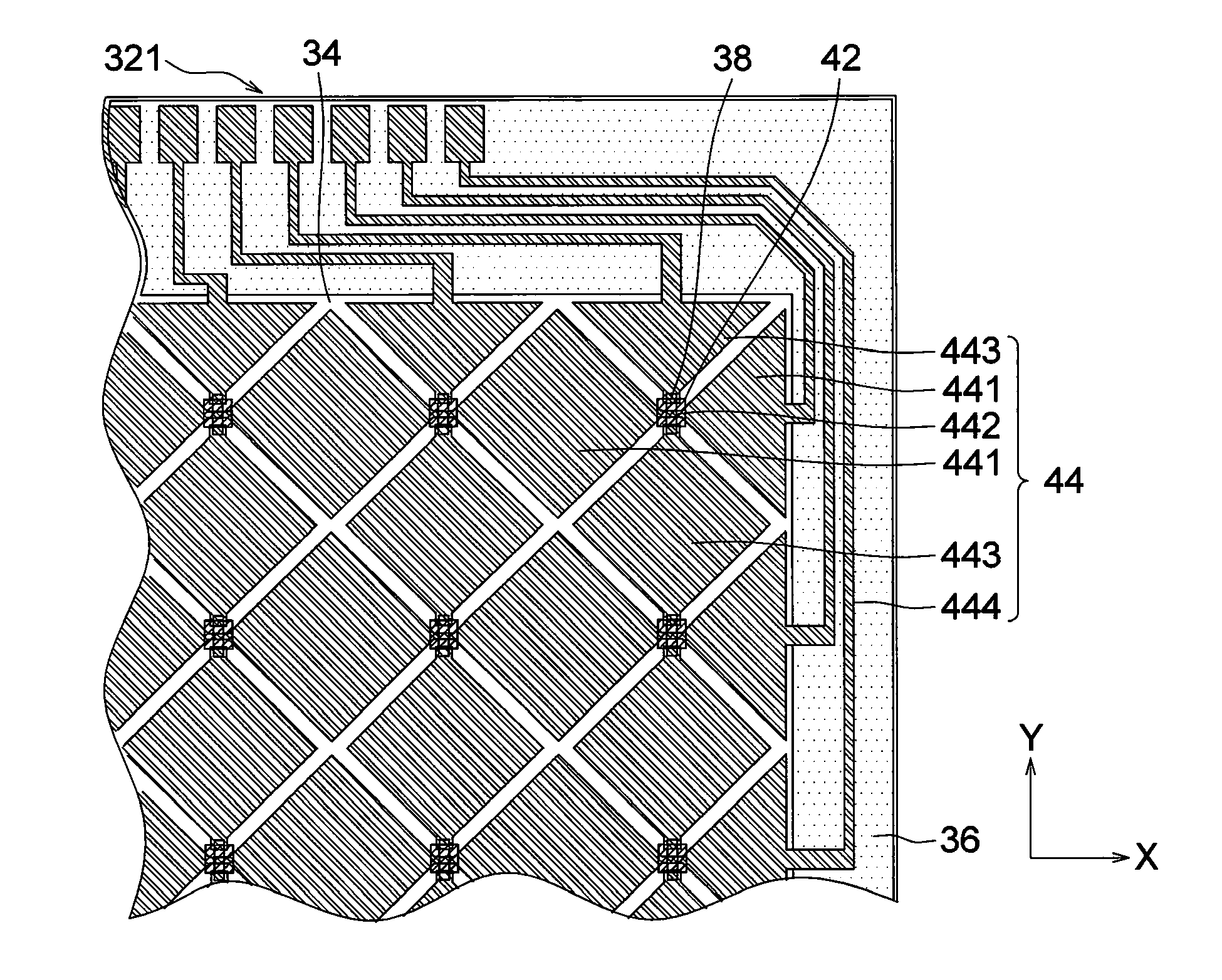

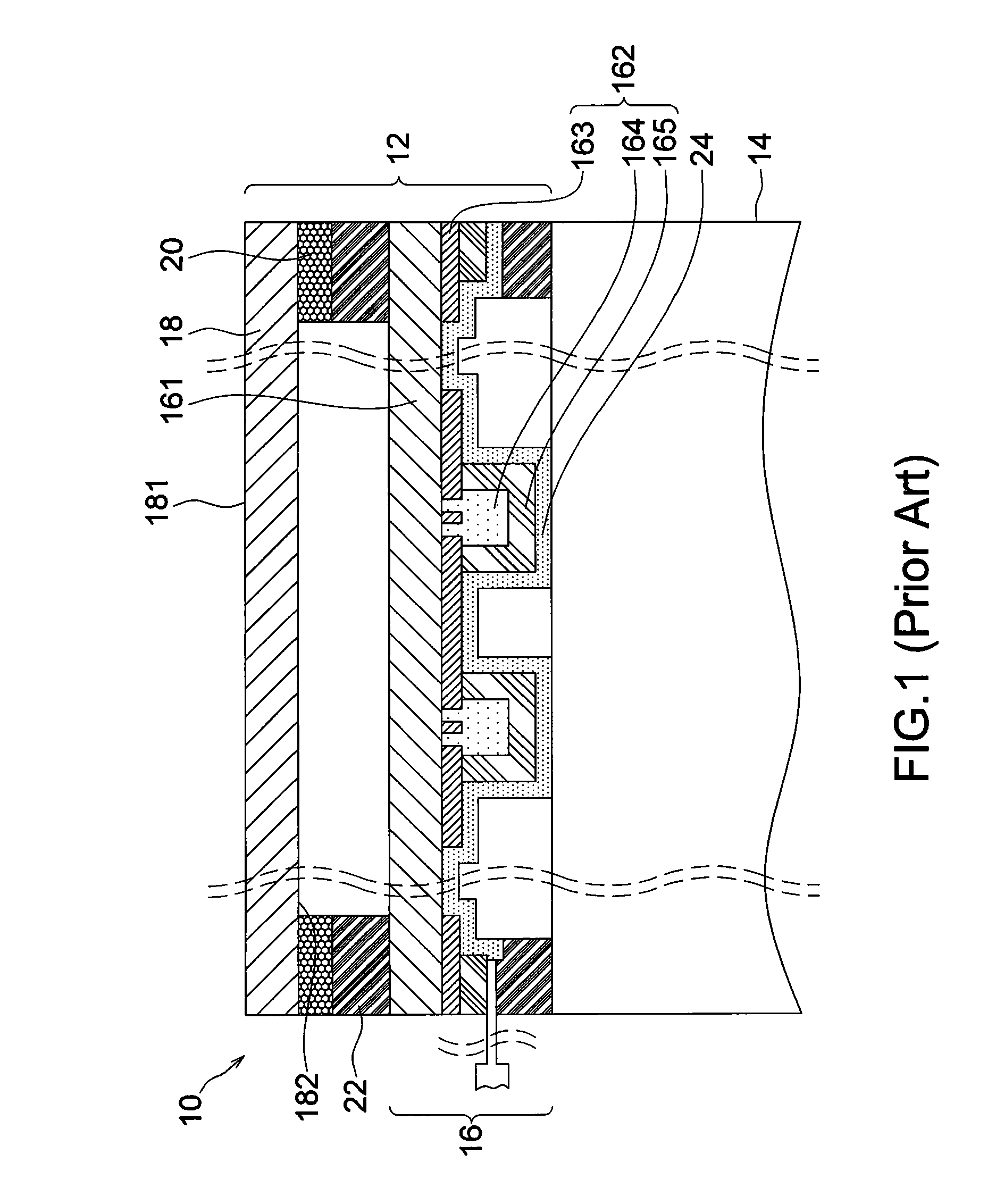

Thin touch panel

ActiveUS20110007005A1Reduce material consumptionHigh transparencyNon-linear opticsInput/output processes for data processingManufacturing cost reductionOptical bonding

A thin touch panel includes a transparent substrate with a black bordering around the inner surface of the transparent substrate. A plurality of metal connecting structures, metal guiding lines, transparent insulating structures and a transparent sensing layer are formed on the inner surface, so that the transparent substrate not only provides a touch surface, but also has the touch sensing ability, to decrease the manufacture material and increase the transmittance of the touch panel. Besides, the manufacture of the thin touch panel may not use any optical adhesive to decrease the manufacture cost and improve the yield. Further, the thin touch panel may satisfy the trend of thin design.

Owner:BUWON PRECISION SCI

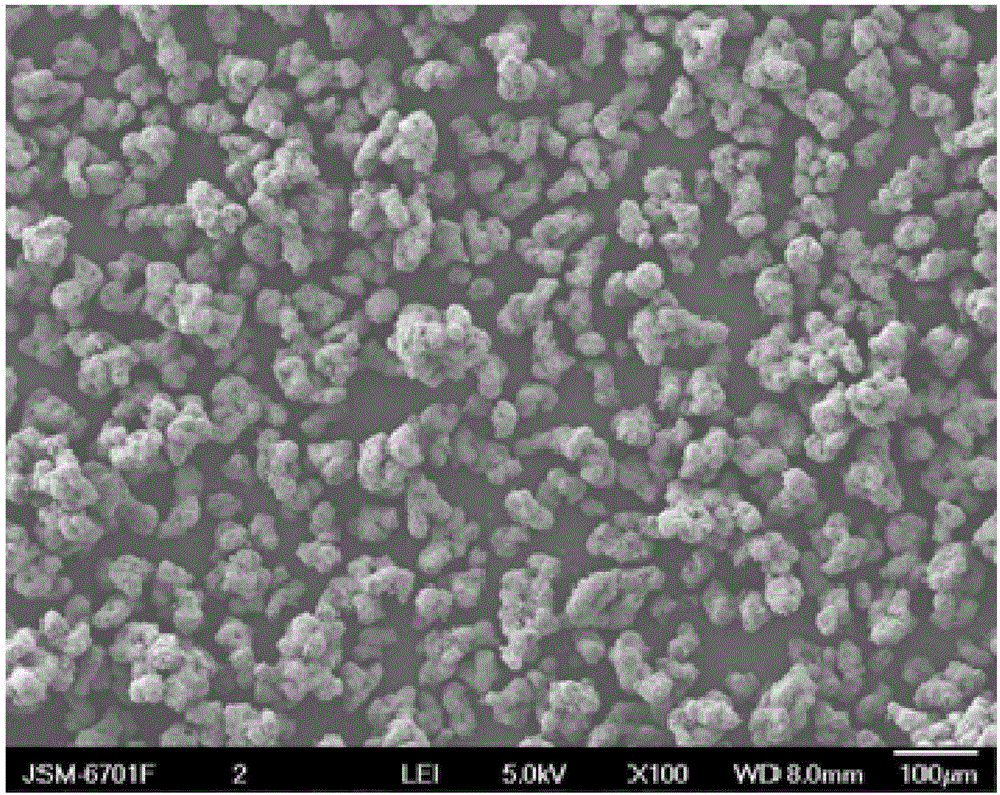

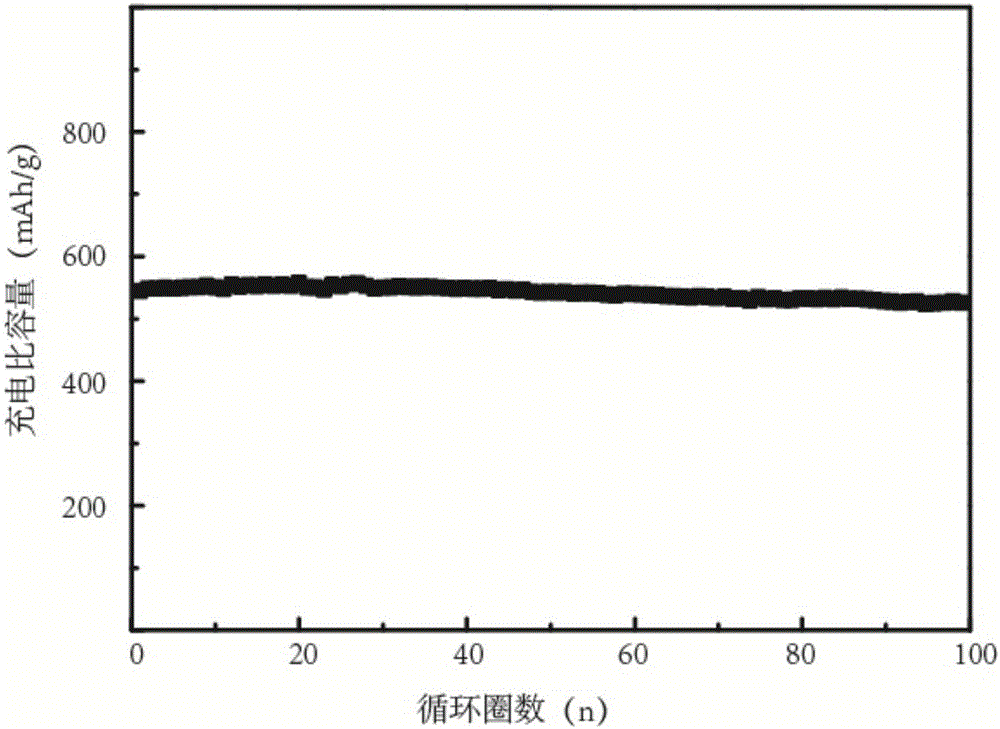

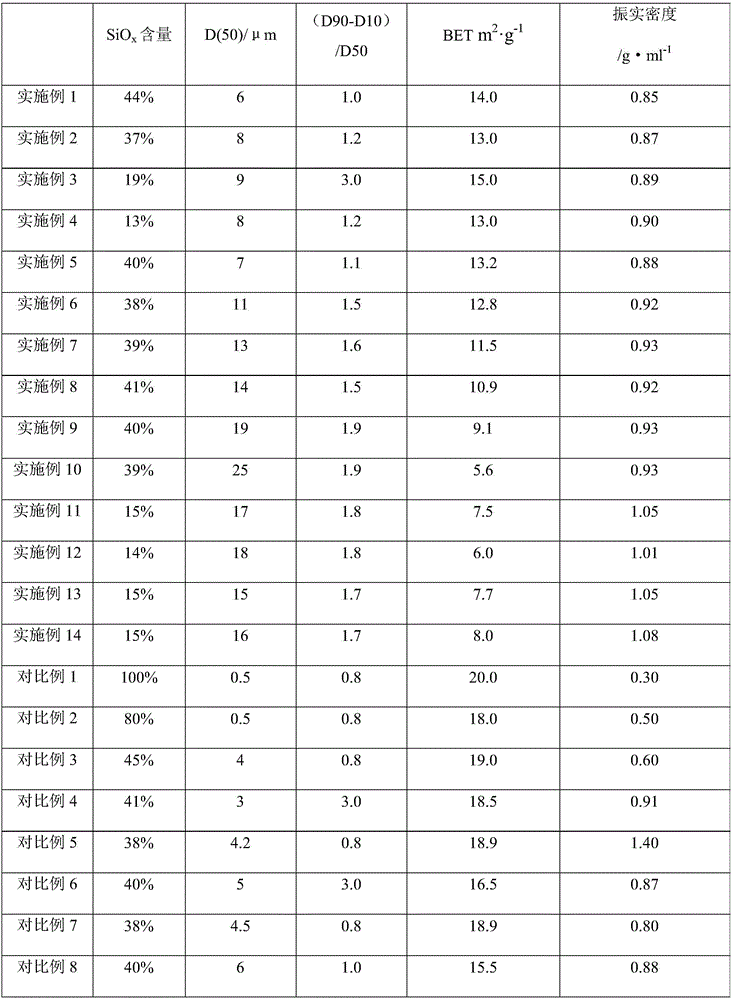

Graphene modified silicon monoxide and carbon composite microsphere, and preparation method and application thereof

ActiveCN106410158AAlleviate volume expansionActive connectionCell electrodesBatteriesCarbon compositesSilicon monoxide

The invention provides a graphene modified silicon monoxide and carbon composite microsphere prepared from graphene, asphalt and silicon monoxide, and a preparation method and an application thereof. Asphalt and silicon monoxide bulk are adopted as raw materials, so the cost is low; a high temperature and high pressure reaction is adopted to obtain a silicon monoxide and carbon composite material in a liquid phase, so the technology is simple; and a dispersant can be recycled, so no waste liquid is generated, and no toxic substances are discharged. The above obtained material has a small specific surface area, and is in favor of forming a stable SEI film; a graphene two-dimensional material has an obvious modification effect, effectively connects active substances, and alleviates volume expansion of an electrode, and good dispersion and reasonable cavity of silicon monoxide make the material have excellent cycle performances.

Owner:BEIJING IAMETAL NEW ENERGY TECH CO LTD

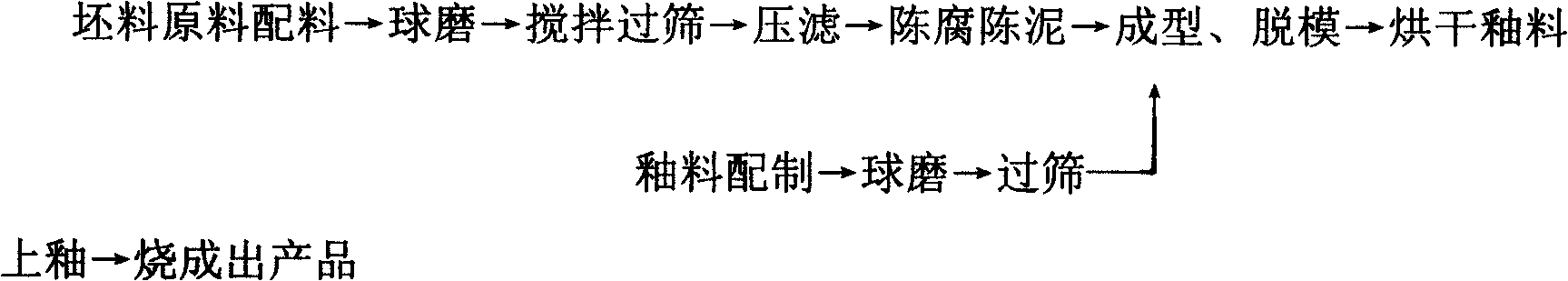

Heat resisting red porcelain chinaware

The invention discloses a heat-resistant purple sand ceramic tool. The manufacture material includes stock and glaze; wherein, the stock is formed by the following components according to weight percentage: 1 to 15 percent of purple sand soil, 25 to 38 percent of triphane, 5 to 30 percent of bauxite clay, 5 to 30 percent of kaolin, 2 to 6 percent of talc, 5 to 20 percent of alum clay, 5 to 20 percent of grog and 5 to 25 percent of attaclay; the glaze is formed by the following components according to weight percentage: 20 to 35 percent of paste, 10 to 25 percent of petalite, 15 to 25 percent of grog, 8 to 15 percent of clinker, 12 to 25 percent of yellow earth, 6 to 9 percent of iron red, 0 to 0.15 percent of trimeric sodium phosphate and 1 to 2 percent of water glass. The adoption of triphane in the material of ceramics can largely enhance the heat-resistant capability, and the ceramics can be heated by electricity or fire and even the firing without water causes no crack. The heat-resistant purple sand ceramics can be adopted either as tableware or as drinking vessel.

Owner:熊禄生

PVC material and preparation thereof

InactiveCN101486820AReduce foulingHigh low temperature impact resistanceProcedure AgentsFood sanitation

The invention discloses a PVC material and a preparation method thereof. The PVC material comprises the following substances according to parts by weight: 100 parts of PVC, 2-8 parts of stabilizer, 2-6 parts of processing agent, 1.5-2.5 parts of lubricants, 4-12 parts of filler, and 0.05-1 part of colorant. Compared with the prior art, the invention adopts food sanitation-level or nontoxic raw materials; the mobility of the manufactured material is good, and the molding temperature and molding pressure of tubular products and pipe fittings can be reduced, thus preventing the PVC material from pyrolyzing. The PVC-U water supply tubular products, pipe fittings and pressure-proof ball valves made from the material have good acid and alkali resistance, inoxidability and ageing resistance, and the pressure resistance of the pressure-proof ball valve is more than or equal to 2.5MPa (the pressure resistance of similar products is only more than 1.6MPa), thus fully meeting food and chemical use requirements.

Owner:黄山琦源塑管阀门有限公司

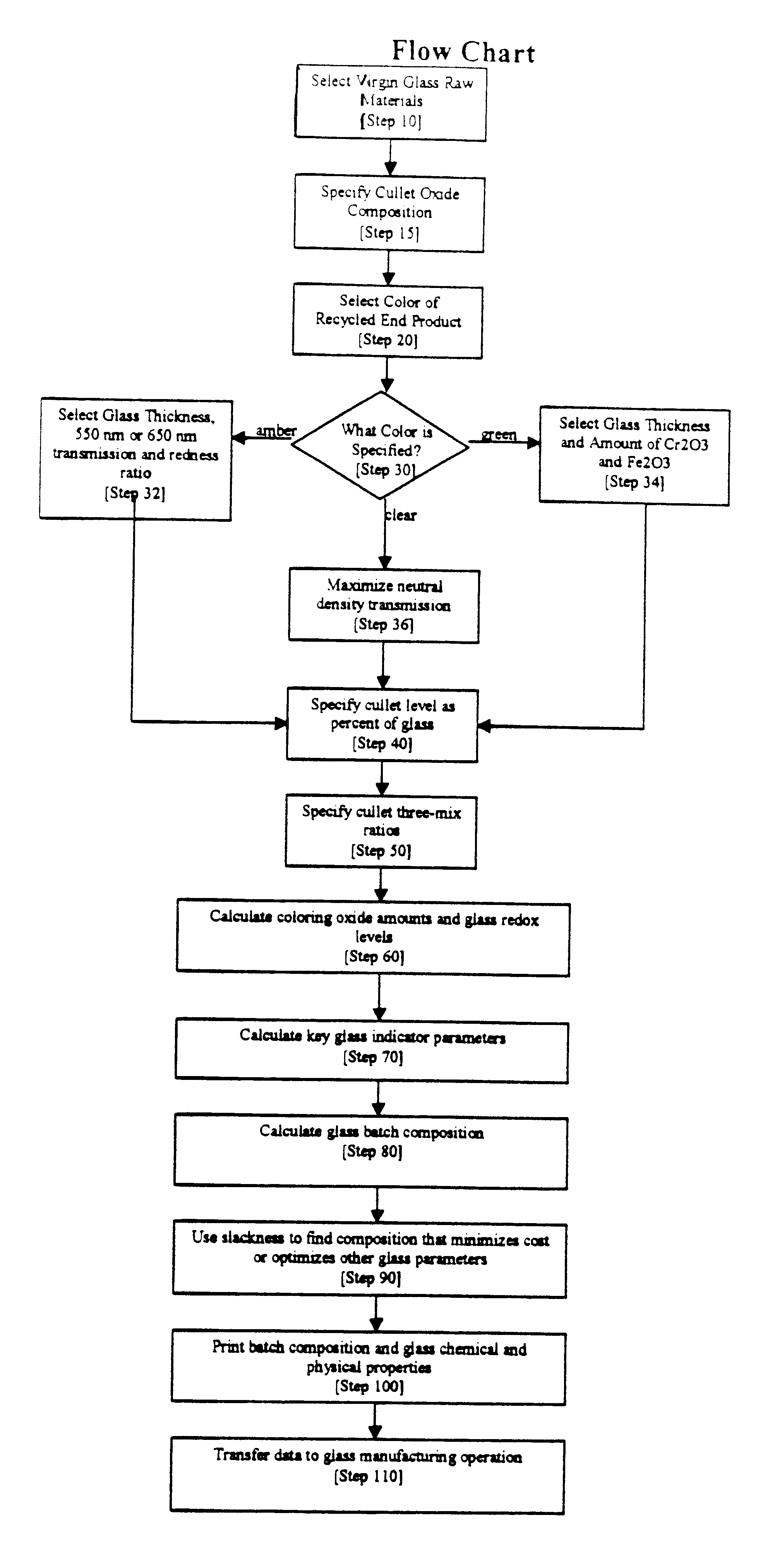

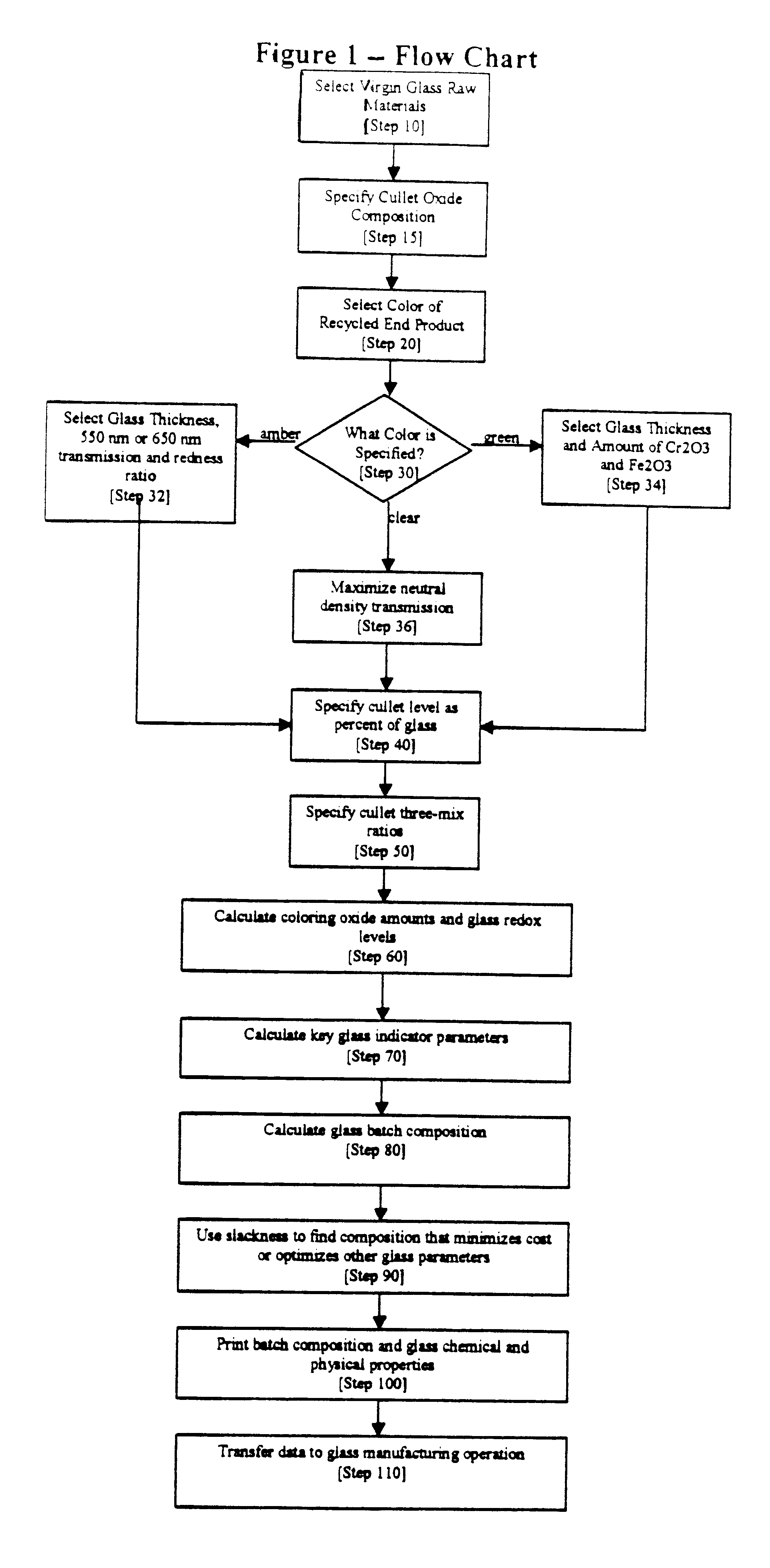

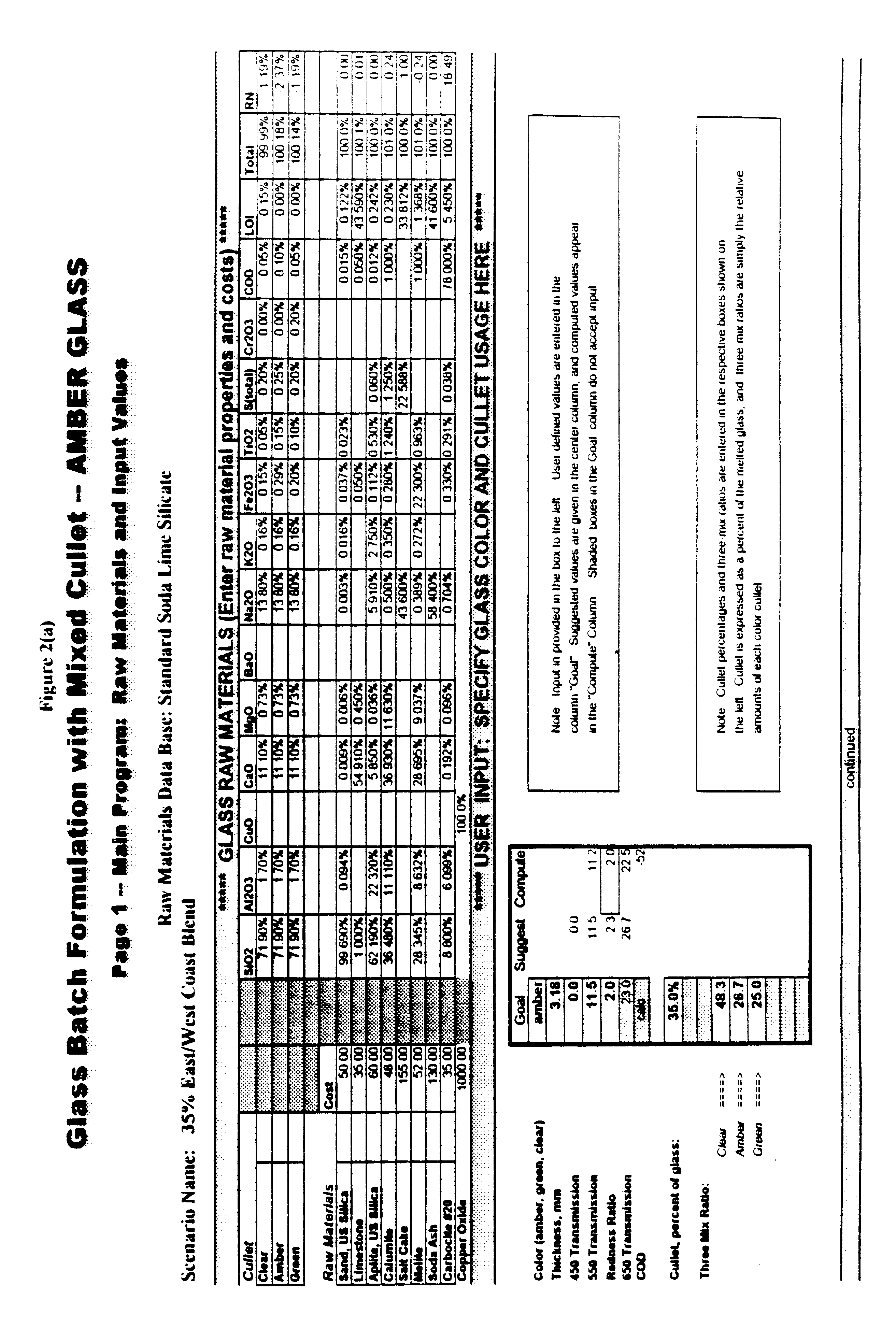

Automated process for recycling batches of mixed color cullet into amber, green, or flint glass with selected properties

InactiveUS6763280B1Low costMinimize iron levelCharging furnaceBlowing machine gearingsManufactured materialRedox

An automated method for recycling mixed colored cullet glass (i.e., broken pieces of glass of mixed colors and types) into new glass products. A computer controlled process identifies the virgin glass raw materials, the desired target glass properties, the composition of a batch of mixed colored cullet, and the quantity of cullet to be used in the glass melt, and the computer controlled process automatically determines the proper amounts of raw materials to add to the batch of mixed colored cullet so that recycled glass is produced having the desired coloring oxides, redox agents, and glass structural oxides in the proper proportion. The recycled glass is then used to make glass products such as beer bottles.

Owner:CULCHROME LLC

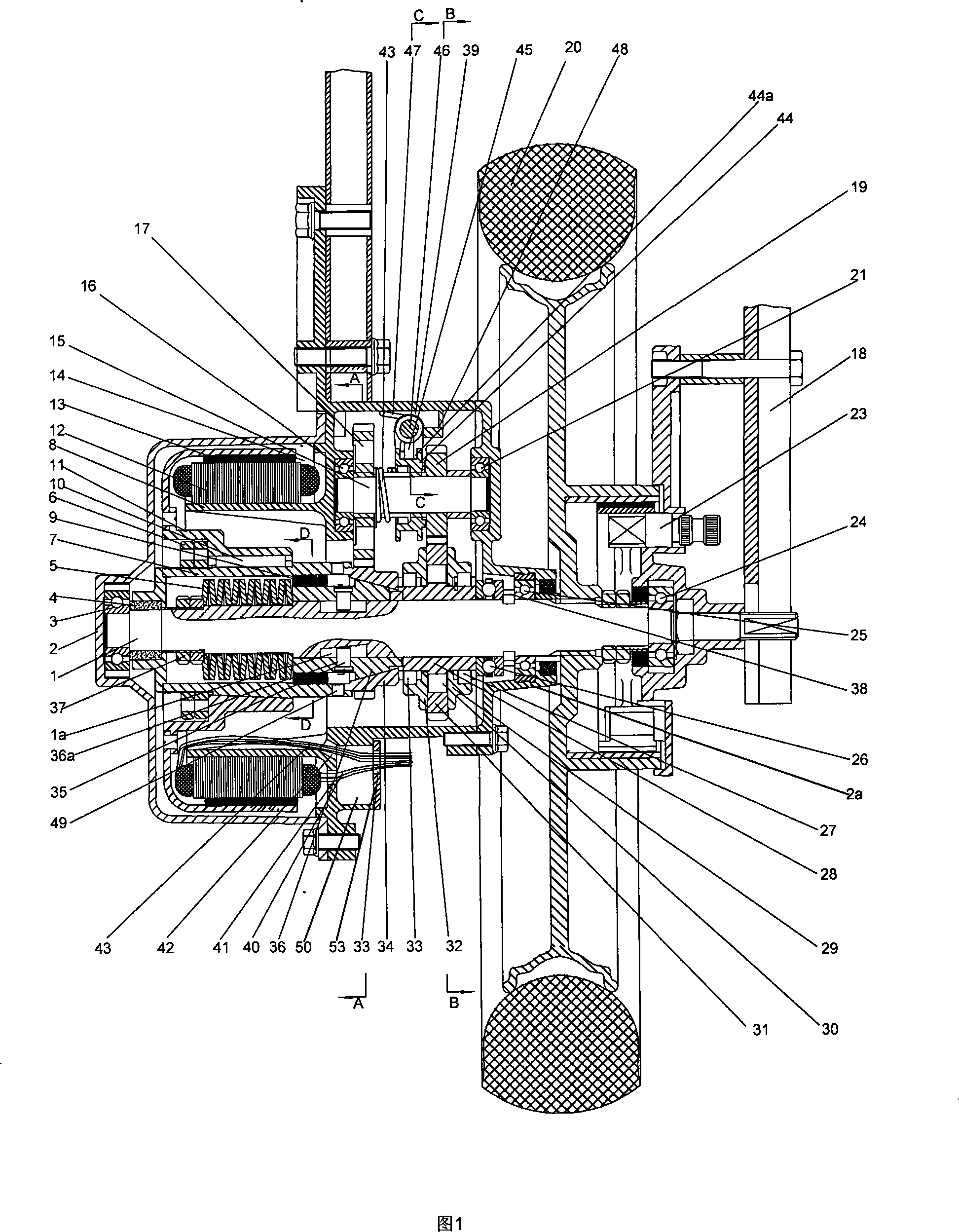

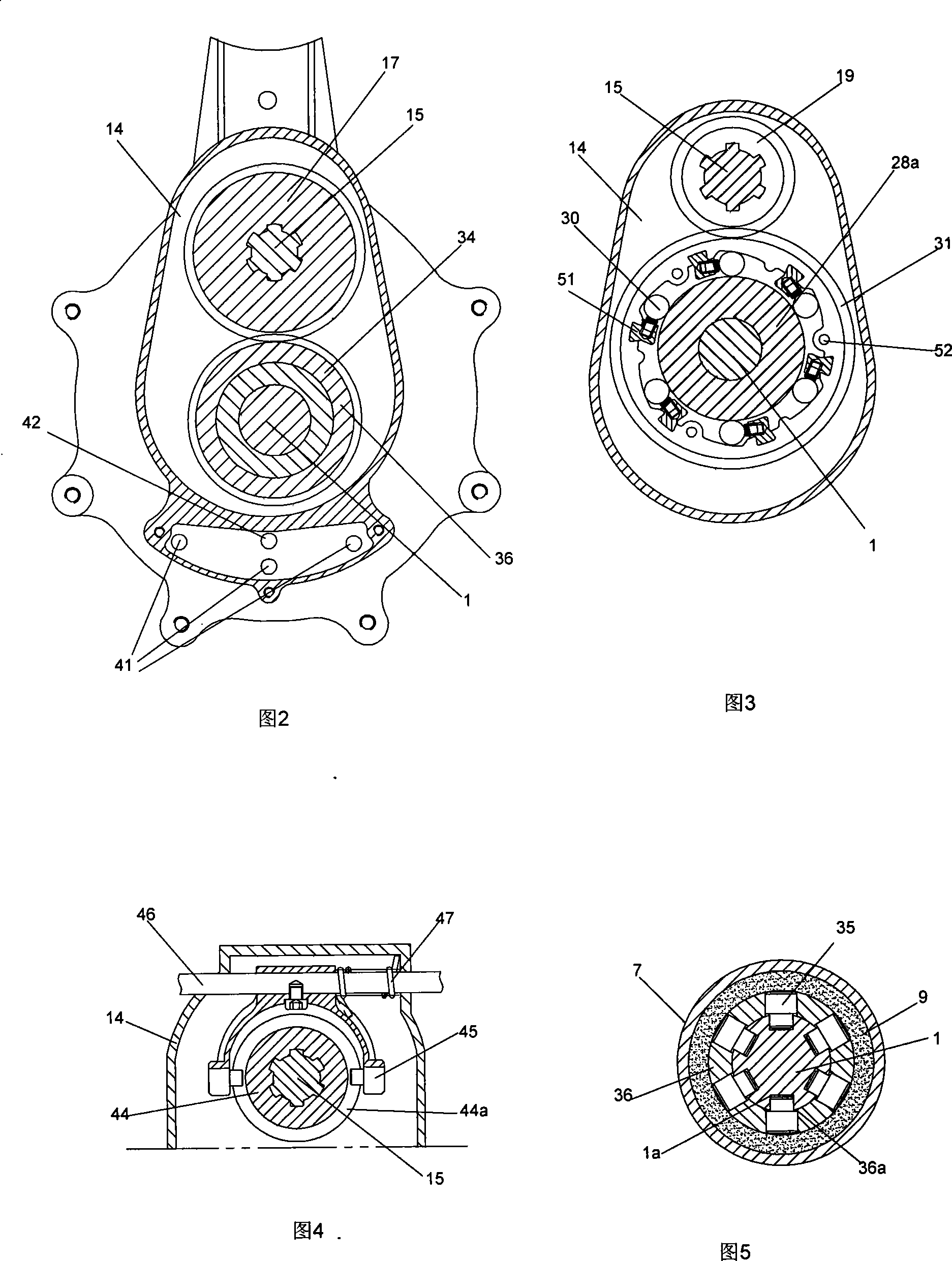

Automatic speed changing electric driven hub

InactiveCN101244747AReduce volumeIncrease in sizeWheel based transmissionMechanical energy handlingDrive shaftElectric machine

The invention discloses an automatic speed-change electrical wheel hub, comprising a left wheel hub frame, a right wheel hub frame, a housing, a motor, a transmission shaft, a wheel, a brake device arranged on the transmission shaft, and a self-adaptive two-speed automatic speed-change assembly driven by the motor rotor via a transmission device. The transmission device is arranged in the intracavity of the motor stator. The automatic speed-change electrical wheel hub has the advantages that the motor transmission device is arranged reasonably, the consumption of the manufacture materials of the housing is lowered, the whole wheel hub has a compact size and a light weight, the manufacturing cost is reduced, and the invention can enable the output power of the motor and the driving status of vehicles to always be in an optimum matching status to achieve the balancing control of the driving moment of the vehicles and the synthesized driving resistance; the speed change can be operated automatically along with the change of the driving resistance by the self adaptive without cutting off the driving force, so that the invention is beneficial to the energy-efficiency of the vehicles and the mechanical power equipment, and can satisfy the usage under the conditions of mountain areas, hills and heavy loads; and the transmission of the invention has a light weight and a compact structure.

Owner:SOUTHWEST UNIVERSITY

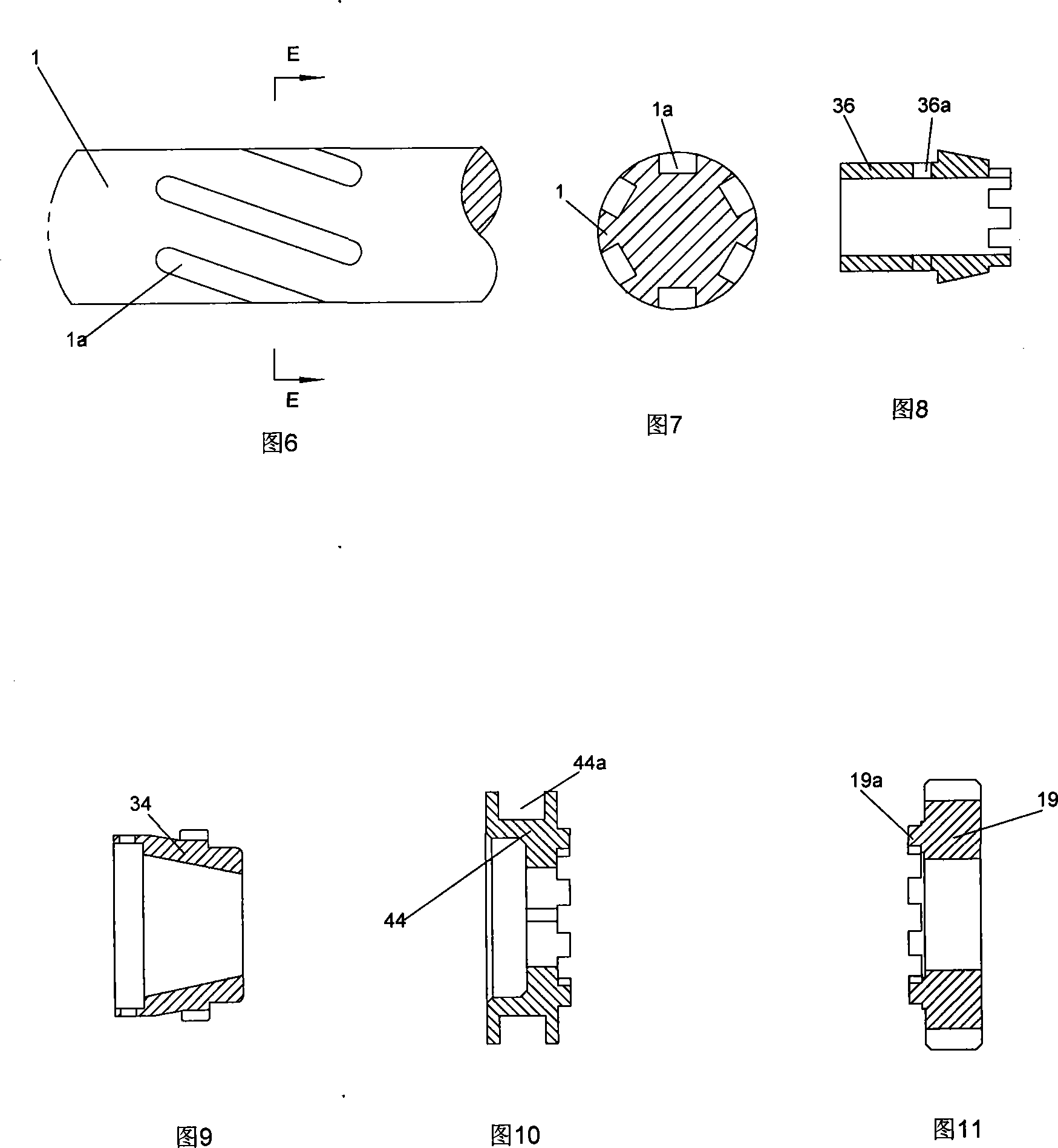

Forming method of thin-wall nut

The invention discloses a forming method of a thin-wall nut. The forming method comprises the following steps: (1) treatment of raw materials, namely aligning wires used as the raw materials by virtue of a cold upsetting machine, conveying the aligned wires to a material cutting mechanism and cutting the wires into small sections of wire blanks; (2) primary upsettig, namely putting the small sections of wire blanks into a female die, performing end surface reshaping on the wire blanks by virtue of a reshaping punch and the female die, so as to obtain a cylinder and frustum combination body; (3) pre-upsetting, namely overturning the blank subjected to primary upsetting so as to enter into a cavity of the female die, and reshaping the blank as a mushroom shape; (3) semi fine supsetting, namely forming a tray part by use of a semi fine upsetting die and forming pre-upset holes; (5) fine upsetting, namely deepening the hole by virtue of a fine upsetting die; (6) punching; (7) threading. According to the forming method disclosed by the invention, a wire upsetting process is used for replacing a sheet material deep-drawing process, area deformation is replaced by volume deformation, and various problems such as drawing breakage and wrinkling caused by area formation in the deep-drawing process can be effectively avoided.

Owner:AVIC STANDARD PARTS MFG

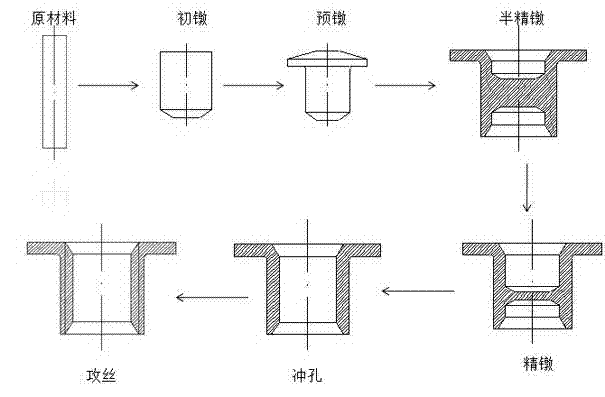

MoSe2/Co0.85Se composite material for electrocatalytic water decomposition as well as preparation method and application thereof

InactiveCN107051550AFor subsequent applicationFacilitate catalytic performance testingPhysical/chemical process catalystsElectrodesDecompositionCobalt

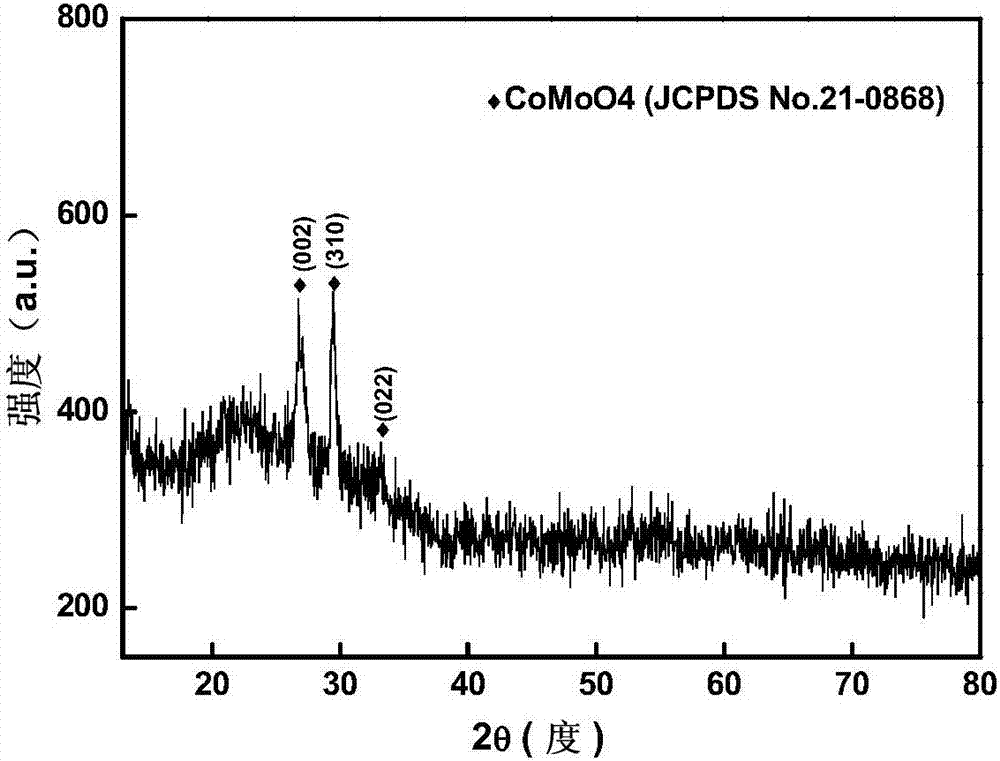

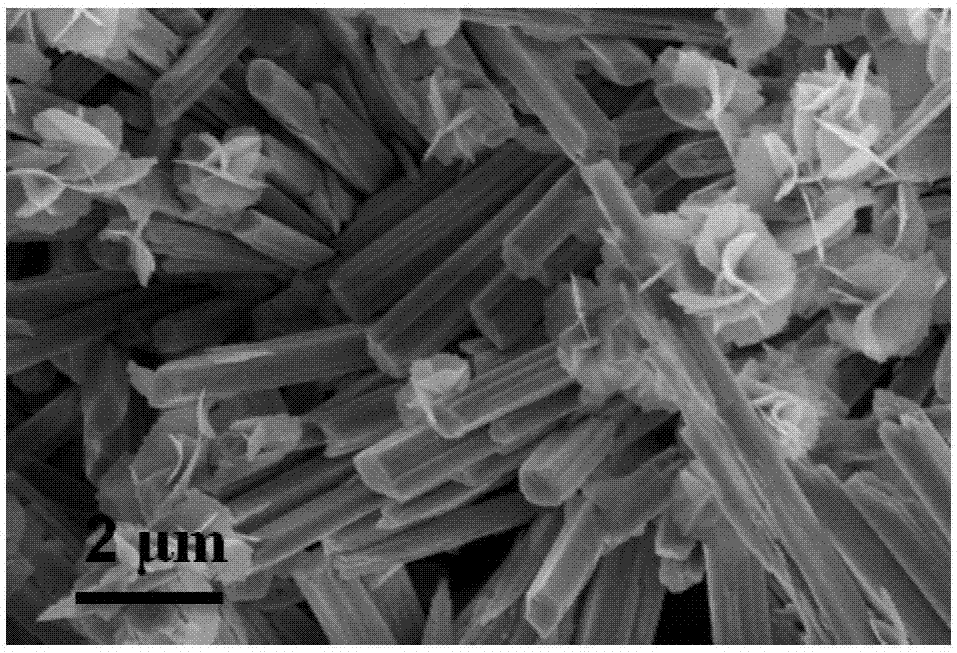

The invention relates to a MoSe2 / Co0.85Se composite material for electrocatalytic water decomposition. The microtopography of the composite material is that a micron / nano rod of a MoSe2 / Co0.85Se compound is loaded with a nano sheet of a molybdenum selenide / cobaltous selenide compound; the micron / nano rod has the length of is 1.5 to 3.5 microns and a diameter of 0.2 to 0.5 micron. A composite-material precursor CoMoO4 is firstly prepared and obtained through a hydrothermal reaction by using cobalt nitrate and sodium molybdate as reactive raw materials; afterwards, the composite material is made through the hydrothermal reaction by using sodium borohydride, selenium powder and the prepared composite-material precursor as raw materials. A preparation method of the MoSe2 / Co0.85Se composite material is simple; the raw materials are easily obtained; the cost is low; the industrialized production is easily realized; the prepared and obtained composite material is good in electrocatalytic effect, and further, has favorable stability.

Owner:SHANDONG UNIV

Preparation method for composite material of cellulose nanofiber and reinforced polyurethane

InactiveCN103436002AHigh strengthReduce forcePaper recyclingWaste paper working-upCelluloseChemical treatment

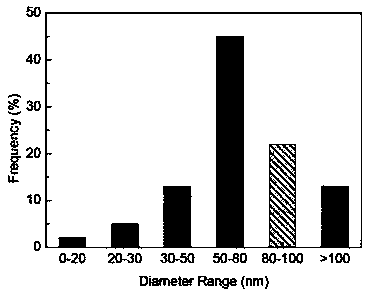

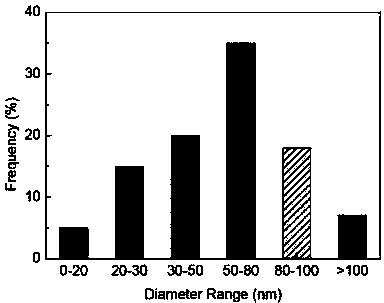

The invention discloses a preparation method for a composite material of cellulose nanofiber and reinforced polyurethane. The method comprises the following steps: 1) pretreating in a chemical method; 2) unfastening fibers in a mechanical method. According to the invention, chemical treatment and mechanical treatment are adopted to separate the cellulose nanofiber, which has a high length diameter ratio and is used for reinforced polyurethane, from newspaper; the transparent nano composite material with high-intensity is prepared; wood meal and newspaper are adopted as raw materials to prepare cellulose nanofiber through the chemical treatment combined with the mechanical treatment; the diameter range of the cellulose nanofiber is 30-100 nm, and the length diameter ratio is higher than 1000.

Owner:NANJING FORESTRY UNIV

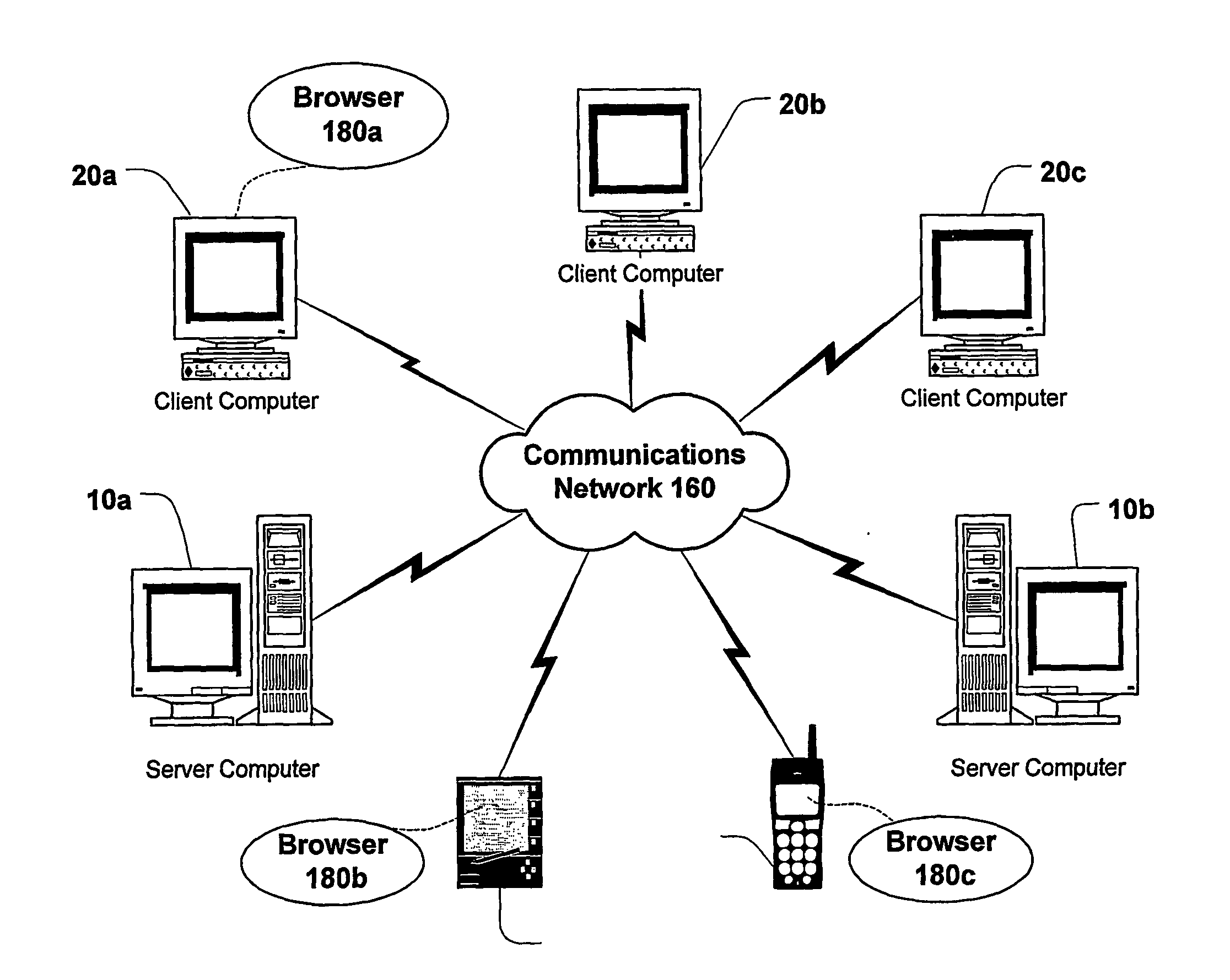

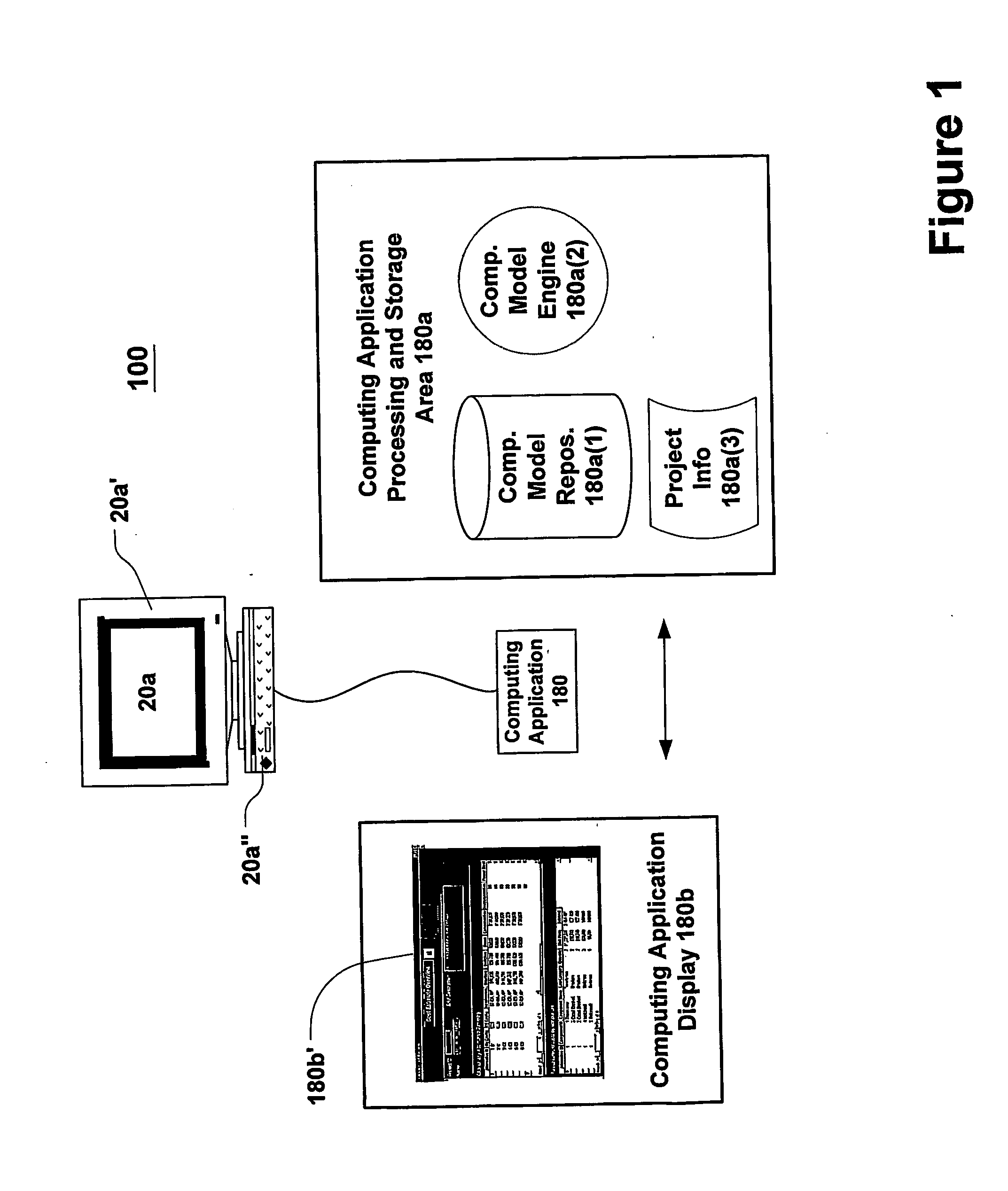

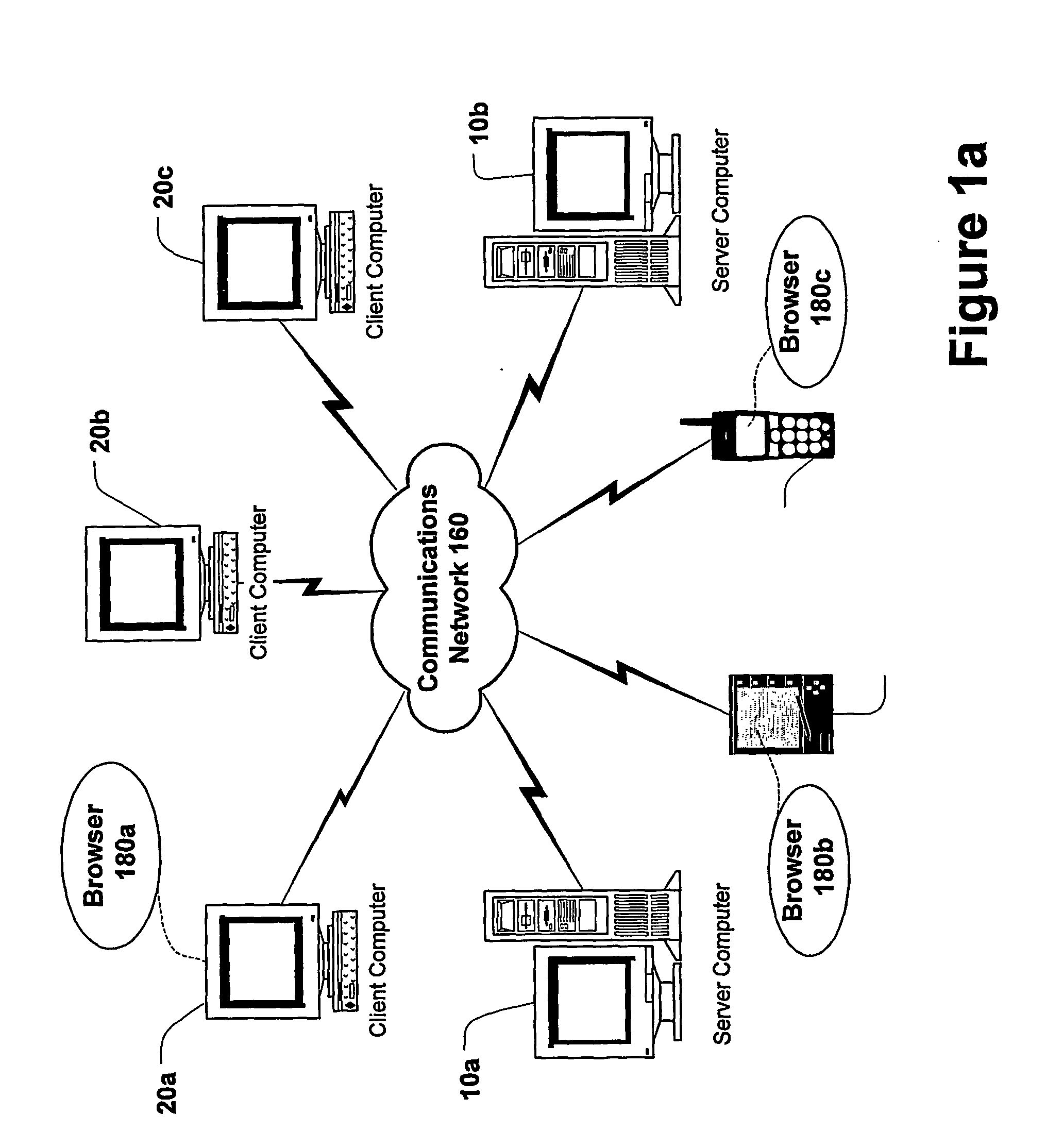

Industrial it system for distribution power transformers manufacturing material control with suppliers systems integration

InactiveUS20060052888A1ResourcesSpecial data processing applicationsDistribution transformerIndustrial systems

The invention contemplates a system and method for communicating among entities of a manufacturing process. The System (100) comprises a process tracking and workflow engine and a communications network. The process tracking and workflow engine (180a) includes at least one processing rule operating on manufacturing processing information. The communications network (160) cooperates with the process tracking and workflow engine to transmit and receive data representative of manufacturing communication information. The inventive system also may include a sales system (801) for receiving a product request, where the product request is received from a customer and / or a field sales representative.

Owner:ABB RES LTD

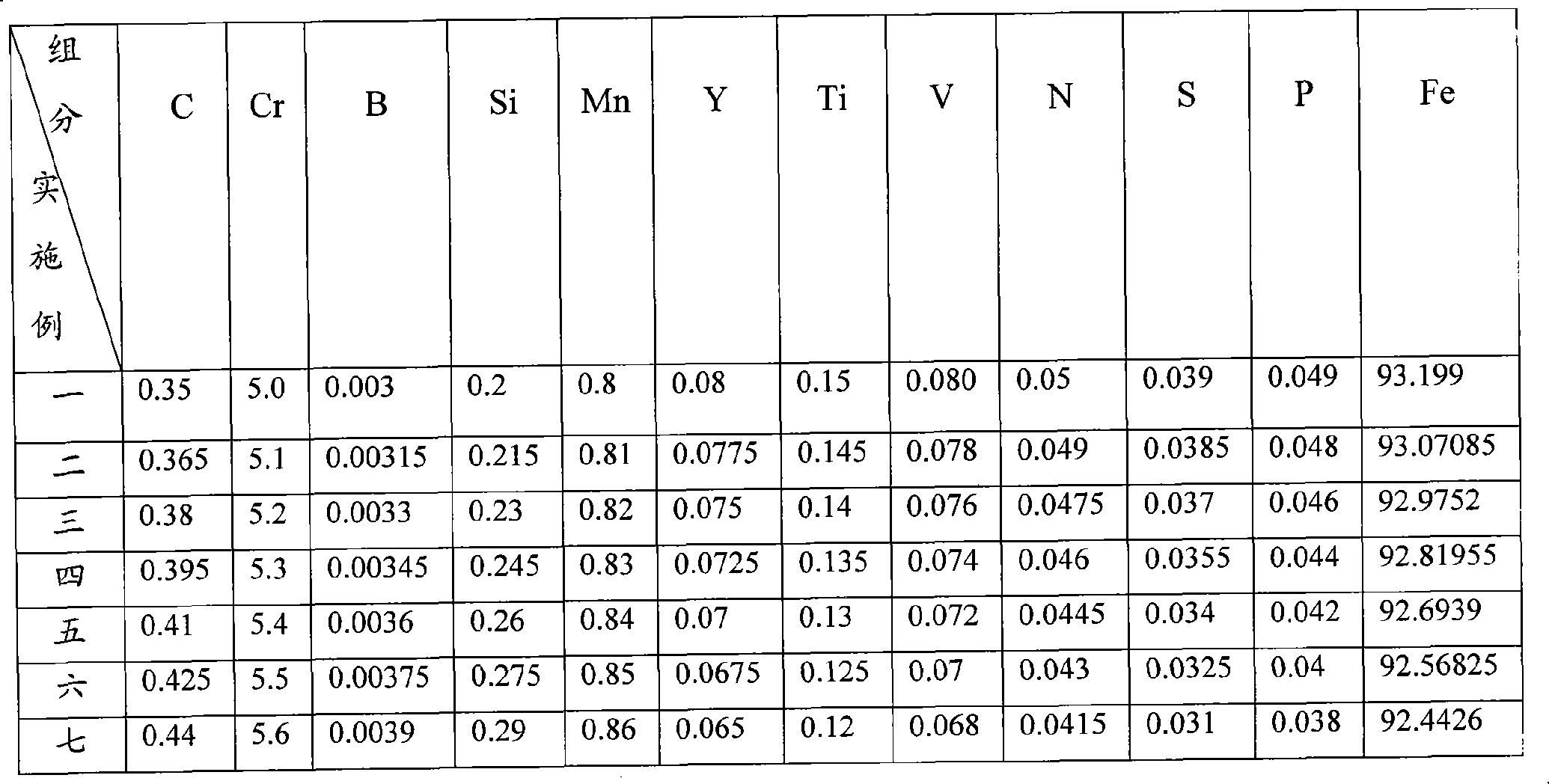

Non-molybdenum non-nickel middle chrome wear resistant steel casting and heat treatment method thereof

The invention belongs to the technical field of metal wear-resistant materials and particularly relates to a wear-resistant casting steel part which is free of molybdenum-nickel and medium-chromium and a heat treatment method thereof. The wear-resistant casting steel part which is free of molybdenum-nickel and medium-chromium comprises the components of the following mass percentages: 0.35 to 0.65 wt percent of C, 5.0 to 7.0 wt percent of Cr, 0.003 to 0.006 wt percent of B, 0.2 to 0.5 wt percent of Si, 0.8 to 1.0 wt percent of Mn, 0.03 to 0.08 wt percent of Y, 0.05 to 0.15 wt percent of Ti, 0.04 to 0.08 wt percent of V, 0.02 to 0.05 wt percent of N, less than 0.04 wt percent of S, less than 0.05 wt percent of P and the balance of ferrite. The wear-resistant casting steel part which is free of molybdenum-nickel and medium-chromium can be manufactured by an electric furnace using a sand casting. The invention carries out step quenching by using two types of quenching oils with different temperatures, thus leading to depth of more than 60mm of the quenching full hardening layer of the cast steel, high hardness, good uniformity of the hardness, and no cracks in the heat treatment. The casting steel is free of expensive alloying elements such as molybdenum or nickel, raw materials resource is rich, the manufacture cost is low and economic benefit is good.

Owner:SHENZHEN UNIV

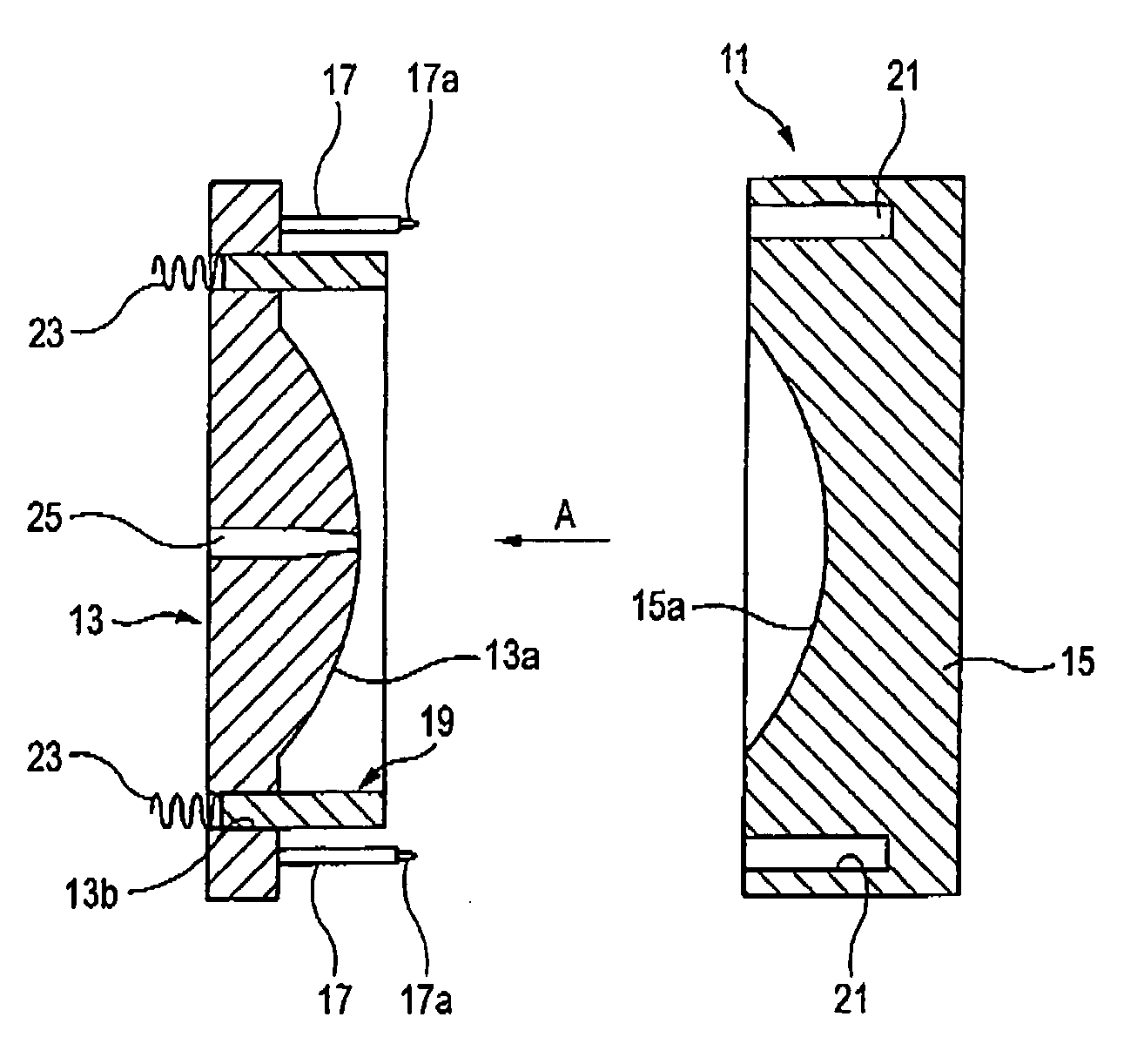

Method for manufacturing speaker-use center cap

InactiveUS20050257998A1Increase production costNumber of manufacturing step is increasedLoudspeaker screensDomestic articlesManufactured materialSynthetic resin

A method is for manufacturing a speaker-use center cap provided with a first cap member layer of synthetic resin and a second cap member layer layered in intimate contact with the first cap member layer and made of a material different from that of the first cap member layer. The method includes: a pre-molding step of attaching a non-molded sheet-like material which is a raw material of the second cap member layer to a mating surface of one of die parts of an injection molding die and thereafter closing the injection molding die to apply a predetermined cap shape to the sheet-like material; and an injection molding step of injecting the synthetic resin material into the injection molding die closed by the pre-molding step to form the first cap member layer to be intimate contact with the second cap member layer.

Owner:PIONEER CORP +1

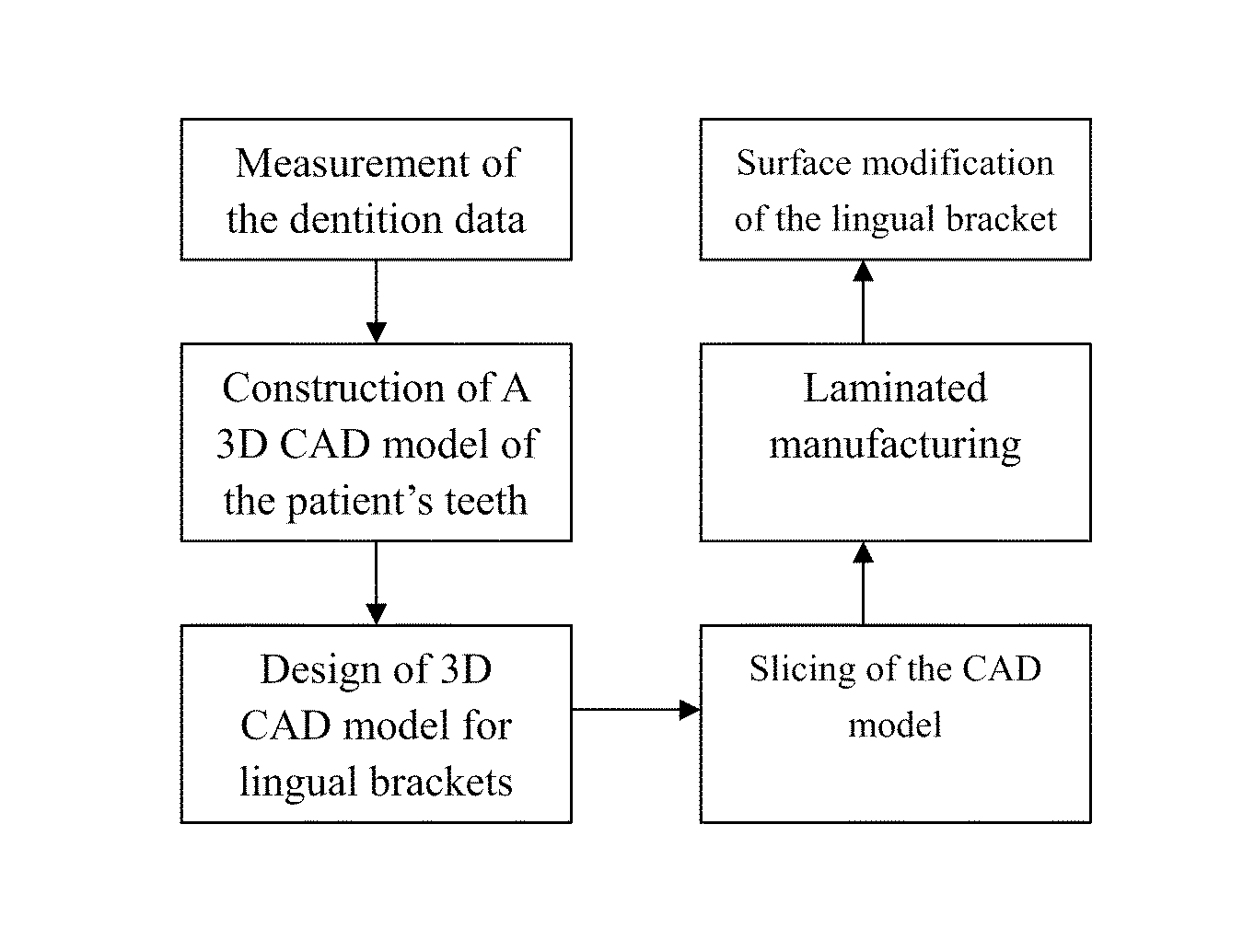

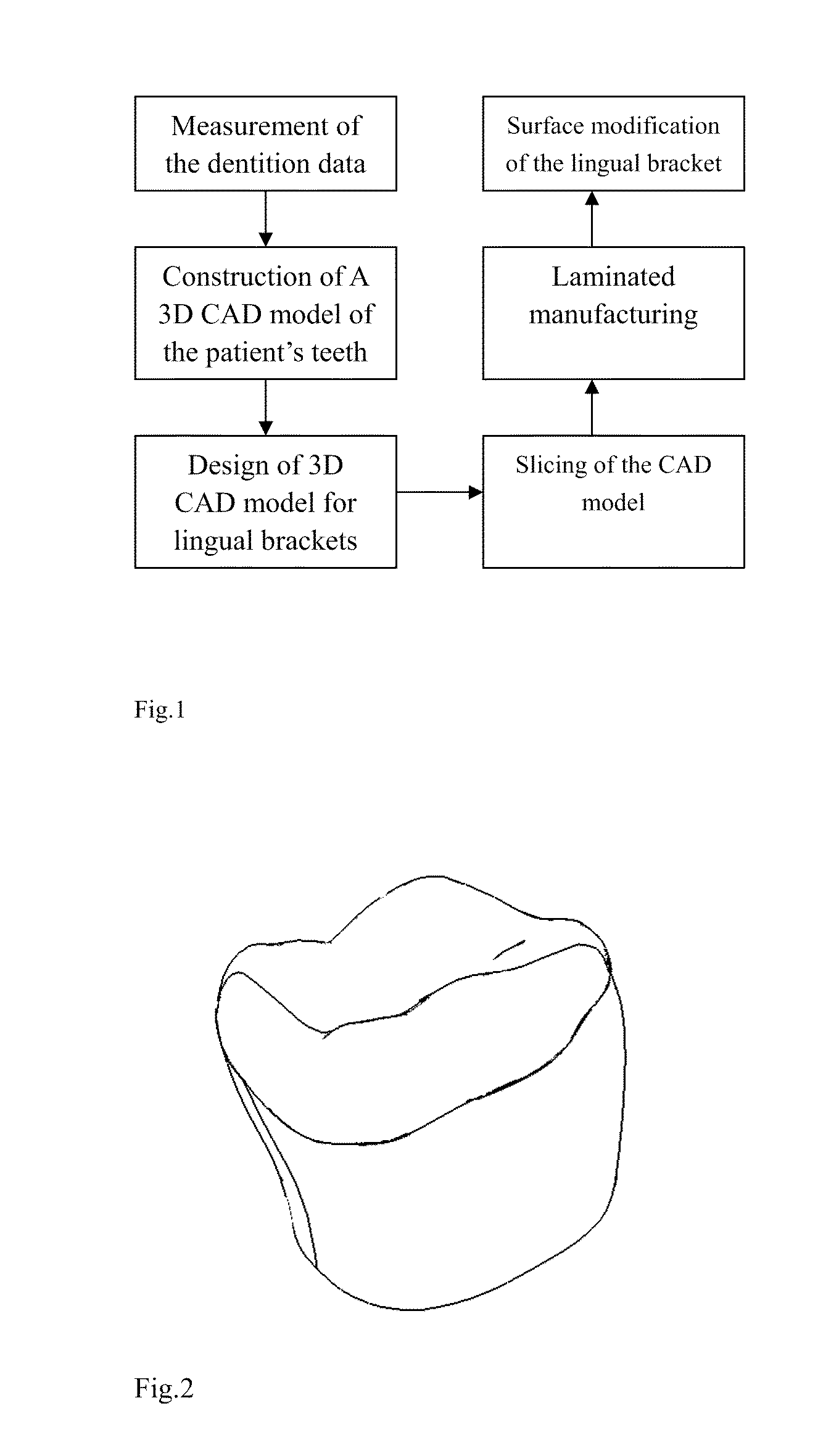

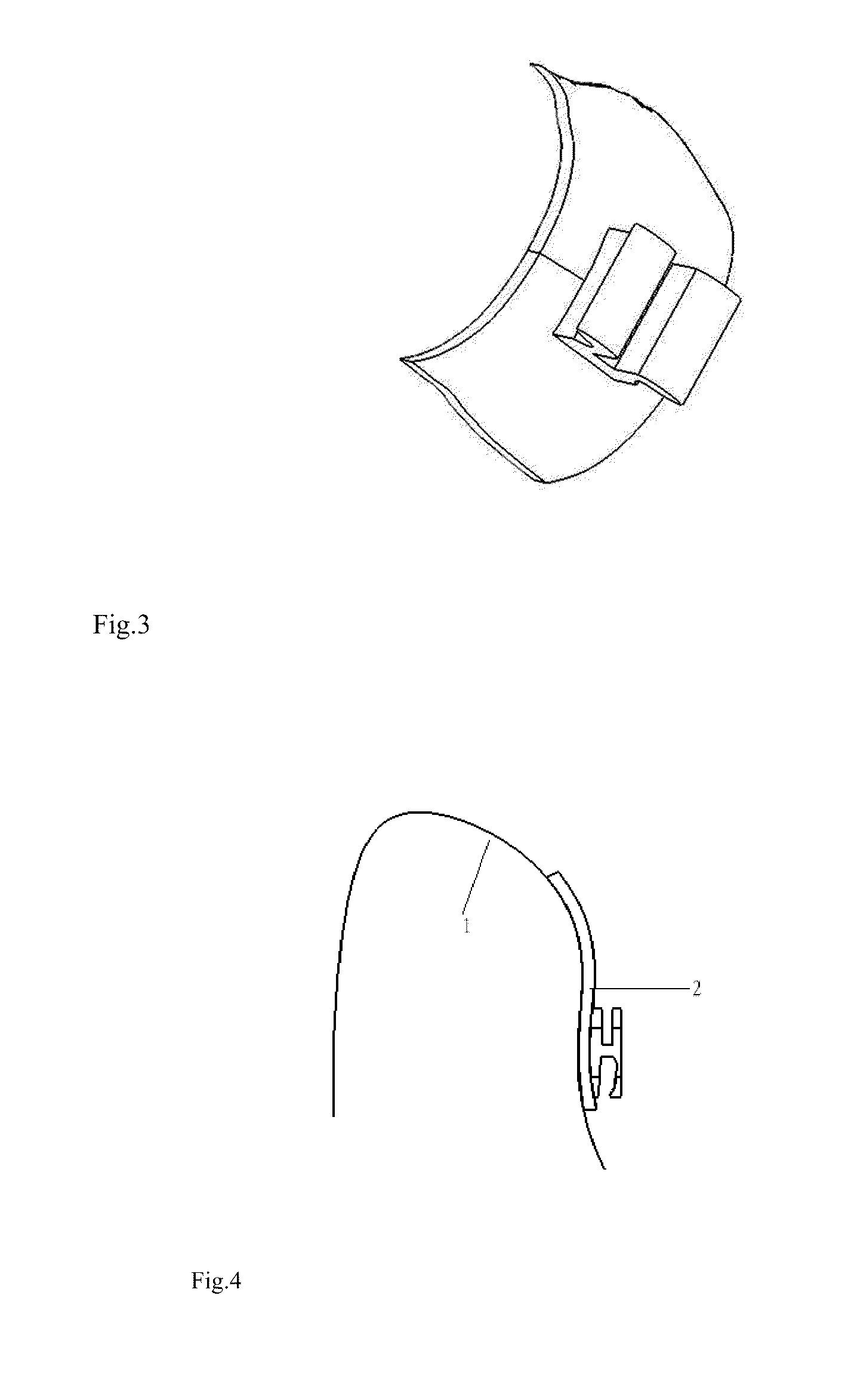

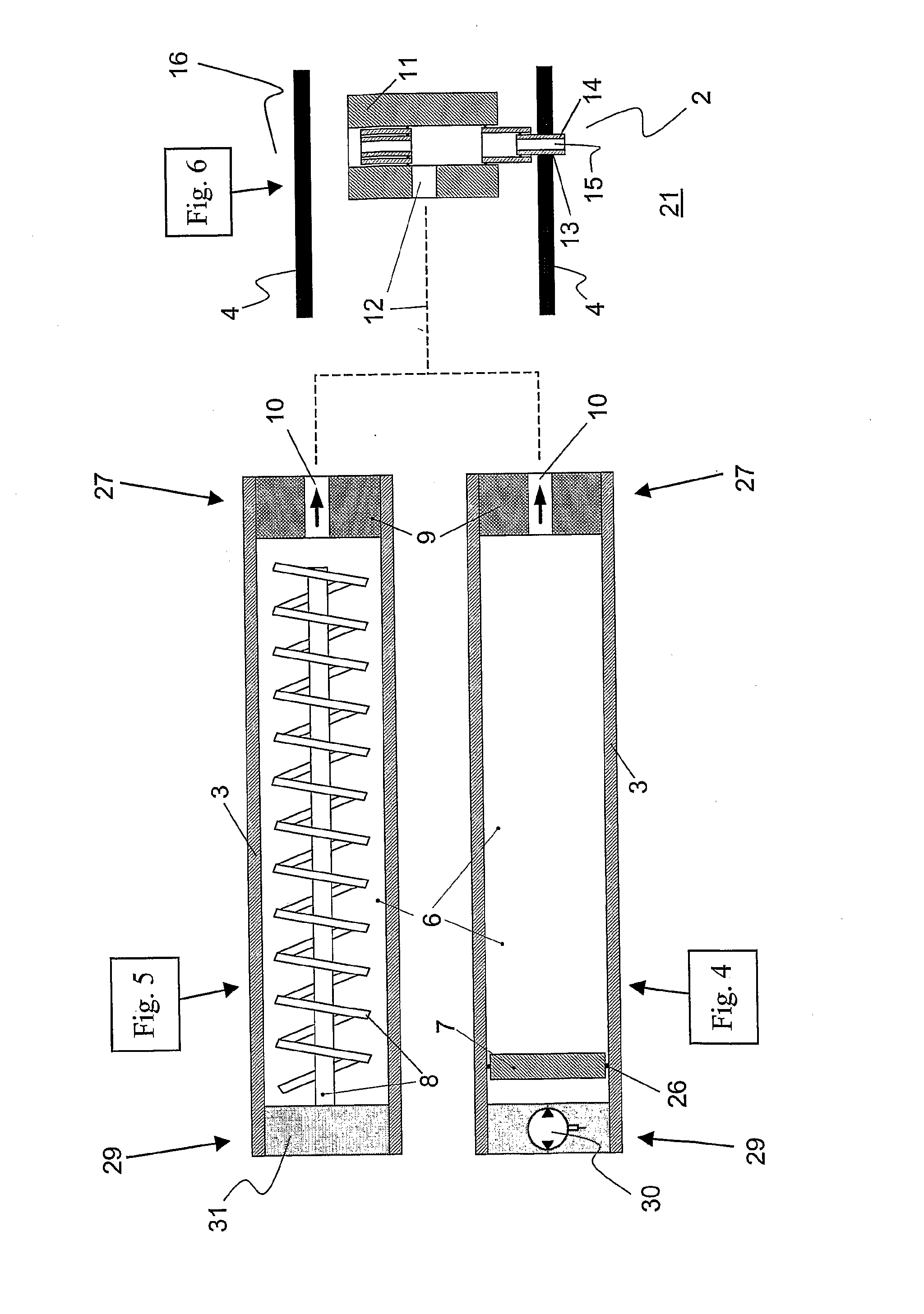

Direct manufacturing method of selective laser melting of customized tongue-side orthodontic support grooves

ActiveUS20100324715A1Improve Manufacturing AccuracyImprove accuracyAdditive manufacturing apparatusBracketsSelective laser meltingEngineering

This invention has provided a direct manufacturing methodology of customized lingual orthodontic brackets by selective laser melting. The procedure is as follows. First of all, measure the dentition data and construct the 3D CAD model of the teeth through reverse engineering. Then a single soleplate of the lingual bracket contacting the tooth surface, as well as the ideal slot position is designed based on the teeth features. The designed models are later imported into the SLM machine and used to produce the brackets with desired materials directly. This method can actualize customized manufacture with highly accuracy, producing highly matched brackets all at once. The invention not only saves time and cost, but also has wide adaptation range and is able to adopt various raw materials. Different raw materials can be utilized in one step to accommodate specific capacity requirement of different parts of the brackets.

Owner:SOUTH CHINA UNIV OF TECH

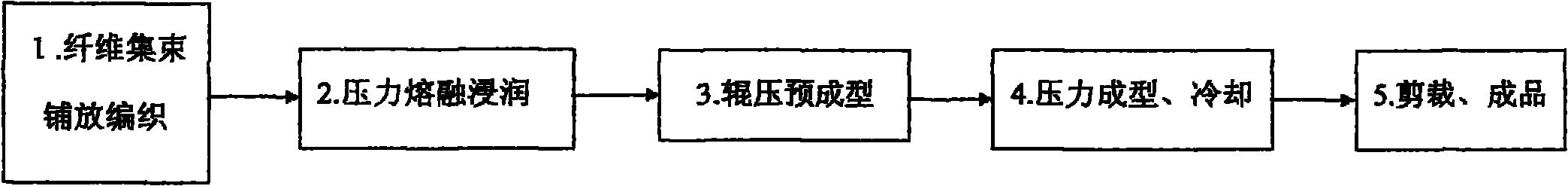

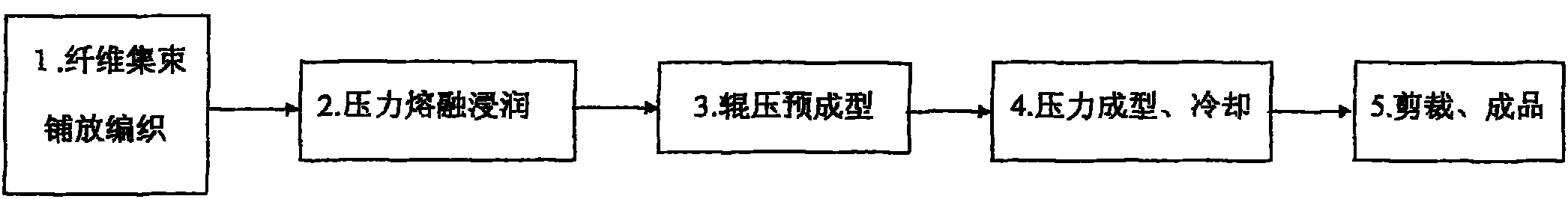

Fiber reinforced thermoplastics composite material section bar and molding technology

The invention discloses a fiber reinforced thermoplastics composite material section bar relating to a new molding technology for producing continuous fiber thermoplastics composite material section bar. Glass fiber yarn, fiber glass cloth and a glass fiber mat form a fiber preimpregnating board in a fiber laying and weaving area (1) by a beam concentration weaving device. The fiber preimpregnating board which is in beam concentration weaving forms a composite blank board after fully rolled and infiltrated by a material pressing roller in a constant-temperature gum dipping slot. The compositeblank plate is successively subject to pressure preforming (3) and pressure forming (4), is cooled by a cooling device to form continuous finished product section bar and is cut into required finished product section bar by a board shearing device. The product of the invention can automatically determine material and proportioning according to different requirements of the product, and burdening degree of freedom is high; in the molding process, the product of the invention has extra low abrasion degree on fiber, and all glass fiber in the product is continuous filament; according to different using requirements, the fiber is laid to be designed and adjusted to ensure that the final finished product has excellent mechanical property and appearance; and the product has smaller abrasion on molding equipment and is easier to recycle and reuse the recycled scrap.

Owner:SHANDONG GRAD GROUP

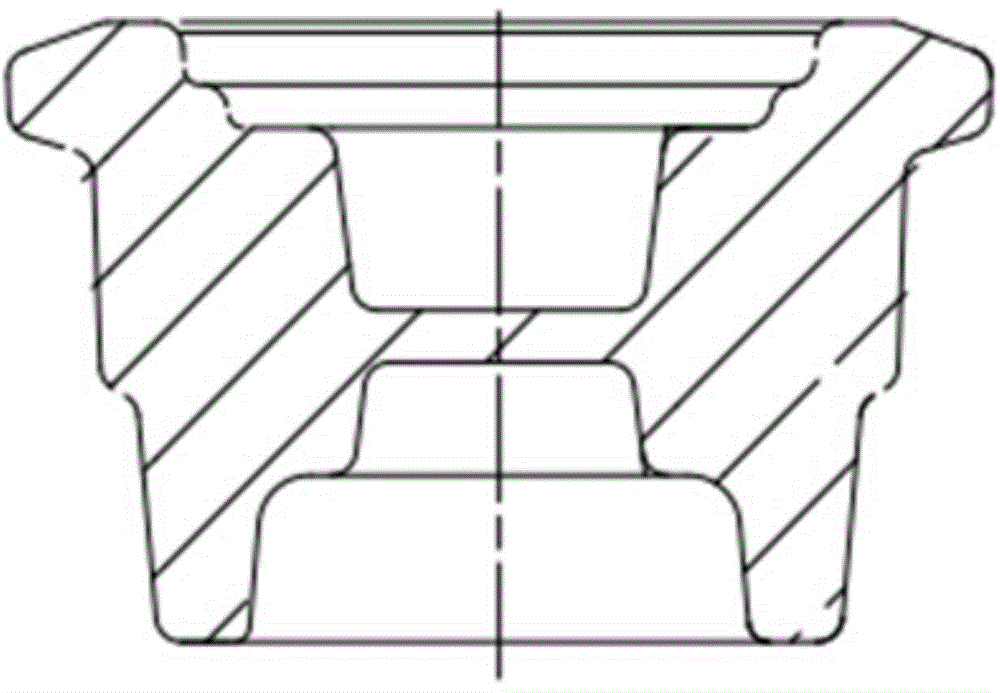

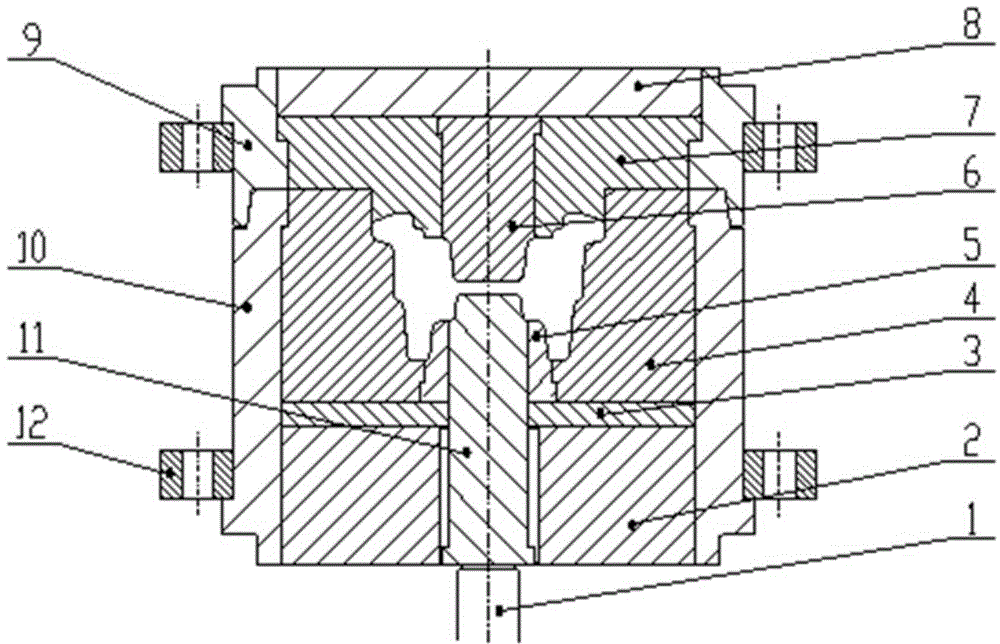

Supporting wheel closed forging process and forging die

InactiveCN104907471AThere is no flash phenomenonTotal deformation area reductionForging/hammering/pressing machinesWheelsPunchingMedium frequency

The invention discloses a supporting wheel closed forging process and a forging die, and belongs to the technical field of forging. Blanking is conducted on round steel through a band sawing machine; heating is conducted on a bar material through a medium frequency induction heating furnace; jumping-up and preforging are conducted on the hot bar material on a l600T electric screw press, then the hot bar material is transferred to a 2500T electric screw press to be subjected to finish forging and forming through the closed forging die, and finally punching is finished on a 400T mechanical press; normalizing treatment is conducted on a forge piece generated after punching is conducted; the closed forging die adopted for the process comprises a lower cushion block (2), a lower male die (11), a lower base plate (3), a lower female die insert (5), a lower female die (4), an upper male die (6), an upper female die (7) and an upper cushion block (8). By means of the supporting wheel closed forging process and the forging die, burrs do not exist in the forged forge piece, and the total forge piece deformation area is reduced, so that the forging deformation force is lowered, the raw material utilization rate is increased, the subsequent trimming process is omitted, the product cost is lowered greatly, and product efficiency is improved remarkably.

Owner:XUZHOU XCMG CRAWLER CHASSIS CO LTD

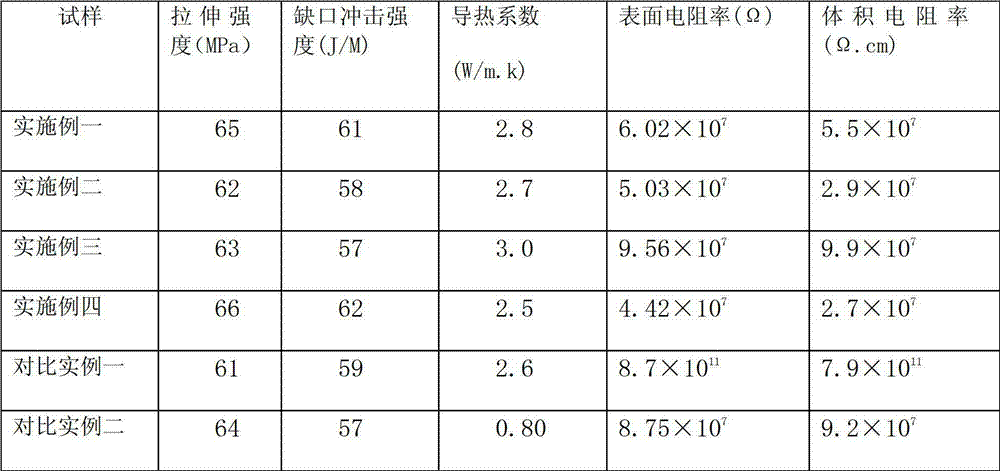

Nylon 66 composite material, preparation method thereof and electronic device

The invention is suitable for the technical field of high polymer materials and provides a nylon 66 composite material, a preparation method thereof and an electronic device. the nylon 66 composite material comprises the raw materials in percentage by weight as follows: 40%-65% of PA 66 resins, 8%-12% of a roughening agent, 20%-35% of heat conduction powder; 10%-15% of an antistatic agent, 2.5%-5.5% of a compatilizer, 0.1%-0.5% of a lubricating agent, 0.1%-1% of an antioxidant agent, 0.1%-2% of a coupling agent and 0.2%-0.5% of a nucleating agent, wherein the heat conduction powder is processed by the coupling agent. According to the invention, when the nylon 66 composite material is prepared, the coupling agent is used for processing the heat conduction powder, and two fillers of the heat conduction powder and a conductive agent are mutually matched and coordinated, so that the excellent heat conductivity and antistatic property can be obtained with low filler consumption, and simultaneously the prepared nylon 66 composite material has excellent physical and mechanical properties.

Owner:SHENZHEN YATAIXING IND

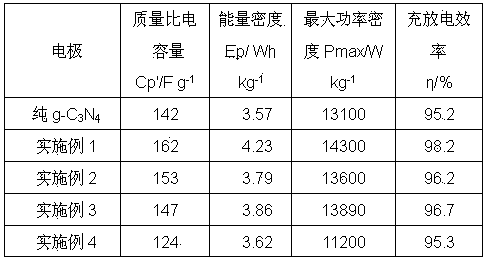

A method for preparing a g-C3N4/carbon quantum dot composite electrode

ActiveCN103745836AImprove performanceNot easy to decomposeHybrid/EDL manufactureCapacitanceElectron transfer

Provided is a method for preparing a g-C3N4 / carbon quantum dot composite electrode. The method comprises: adding carbon quantum dots into ethanol in order to prepare carbon quantum dot ethanol solution; mixing urea with the carbon quantum dot ethanol solution, performing ultrasonic dispersion on the mixed solution and then transferring the mixed solution to a crucible; warming the mixed solution to 350 to 700 degree centigrade with a muffle furnace step by step, maintaining the temperature for one to three hours and then decreasing the temperature of the mixed solution to room temperature; and grinding the obtained substance with ethanol and filtering the same so as to obtain g-C3N4 / carbon quantum dot composite material. The method has advantages of simpleness, no by-products, raw material easy to obtain, and low price. The obtained composite material is stable in performance, uneasy to decompose, and nontoxic. The method may increase the electron transfer rate of the g-C3N4 material, has good conductive performance, enhances electrode specific area, improves the electron adsorption capability of an electrode surface, and effectively increases the specific capacitance of a capacitor.

Owner:BOHAI UNIV

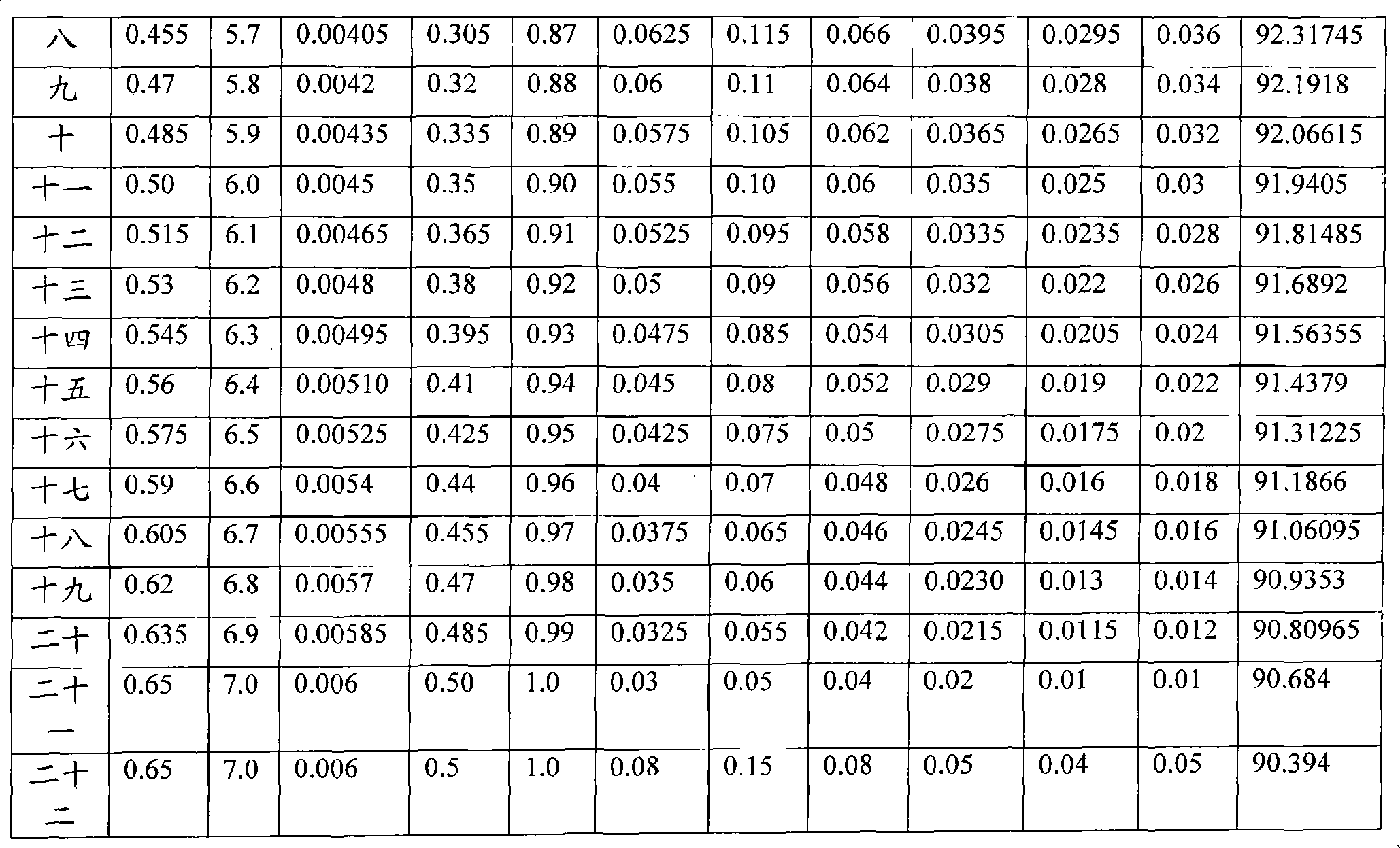

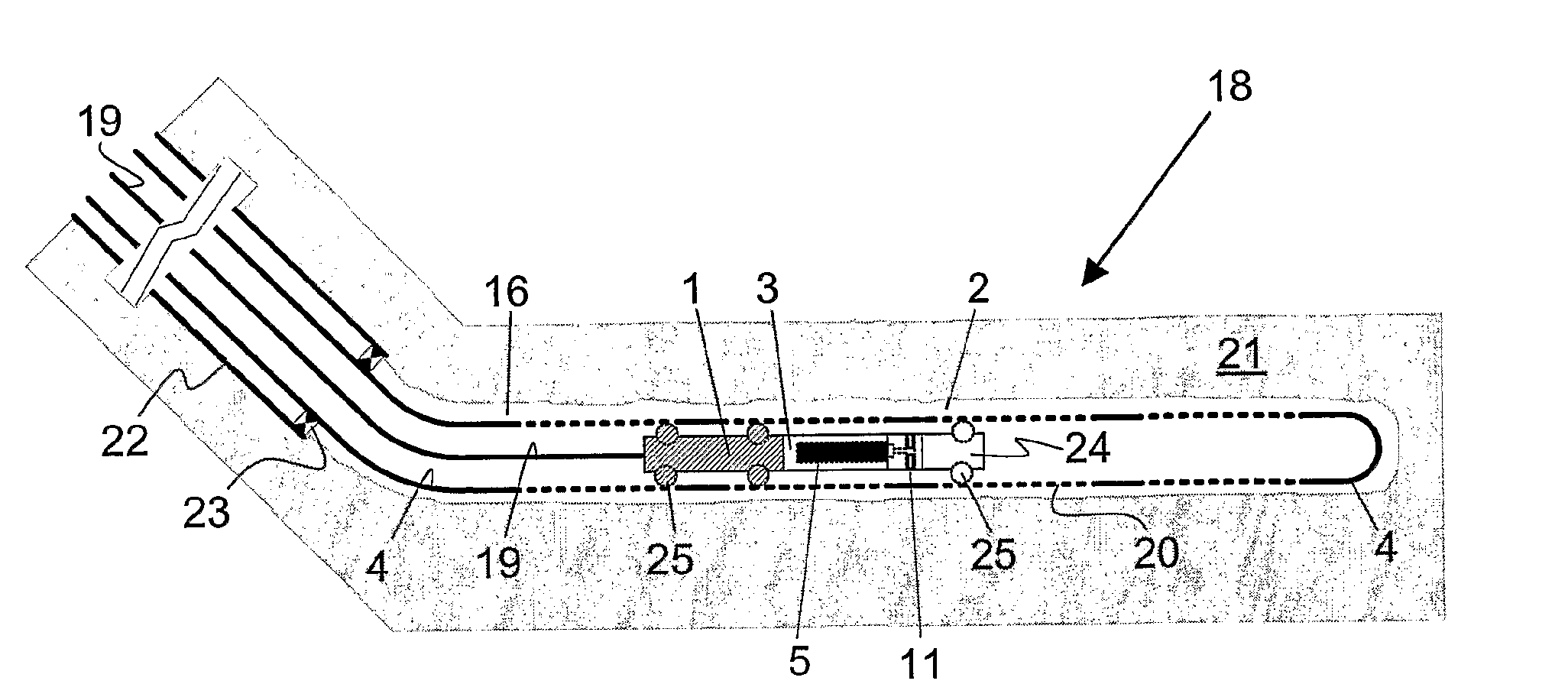

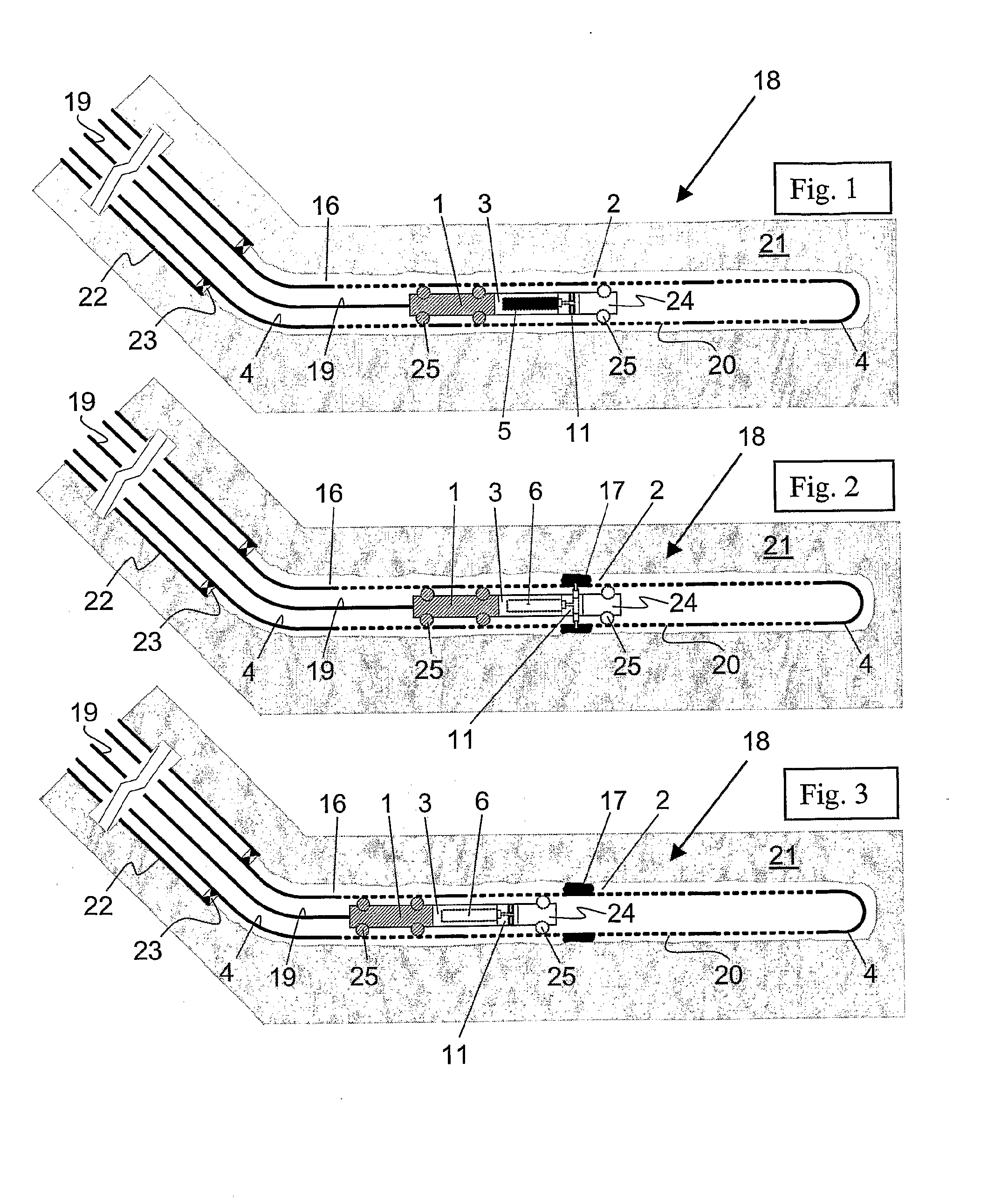

Method and a Device for in Situ Formation of a Seal in an Annulus in a Well

ActiveUS20080190612A1Restrict fluid flowOperative complexity be increaseConstructionsInsulationSolid-stateEngineering

A method and a device for in situ formation of a seal (17) in a region (2) of an annulus (18) located around a pipe structure (4) in a well (18), in which the method comprises the following steps: (A) to convey a perforation device into the pipe structure (4) to a location vis-a-vis said region (2) of the annulus (16); (B) by means of the perforation device, to make at least one hole (13) through the pipe wall of the pipe structure (4) at said annulus region (2); (C) to force a liquid sealing material, which is capable of entering into solid state, through said hole (13) and further into the annulus region (2) for the filling thereof, where-upon the sealing material enters into solid state and forms said seal (17). The distinctive characteristic of the method is that step (C) thereof also comprises:—to choose a fusible, solid-state packer material (5) as raw material for said seal material;—to heat and melt at least a part of the solid-state packer material (5); and—subsequently, to force liquid packer material (5) into the annulus region (2) via the at least one hole (13) through said pipe wall, whereupon the liquid packer material (5) enters into solid state and forms said seal (17) in the annulus region (2).

Owner:AGR CANNSEAL

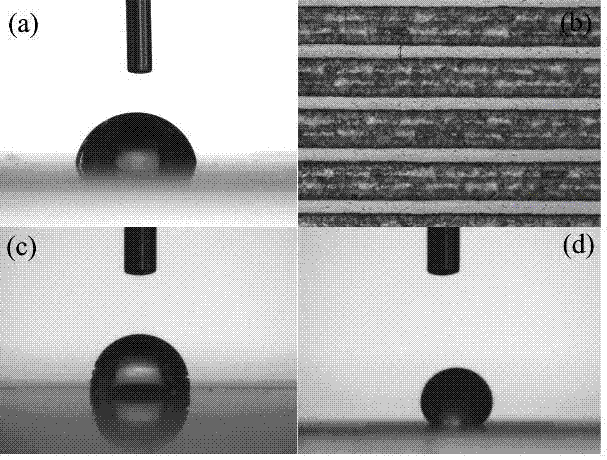

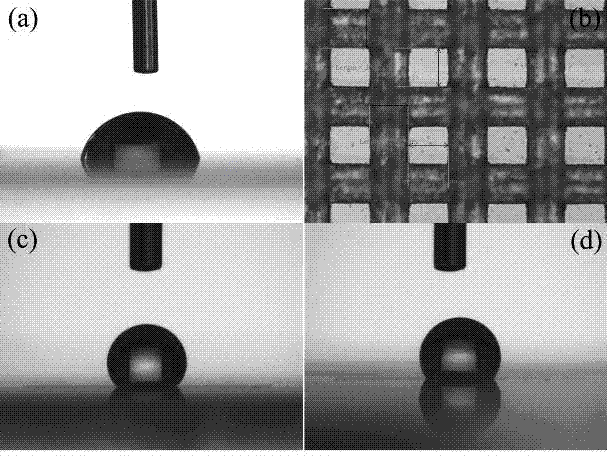

Method for preparing hydrophobic micro-structure on surface of organic glass through femtosecond laser

InactiveCN102336393ALow costHigh selectivityDecorative surface effectsChemical vapor deposition coatingFemto second laserLight spot

The invention relates to a method for preparing a hydrophobic micro-structure on the surface of organic glass through a femtosecond laser, and the main process is as follows: a light beam transmitted by the femtosecond laser is irradiated to the surface of the organic glass after being focused by a microscope objective, as a light spot after focusing is very small and the power density is very high, and an ablation region which is equivalent to the scale of the light spot can be formed in an irradiation region; and furthermore, three-dimensional precision control can be further performed on a platform for placing a sample through a computer program, so that the periodic micron dimension micro-structure can be generated on the organic glass surface by utilizing the laser processing technology. Through the detection by a contact angle tester, the micro-structure has a very obvious hydrophobic characteristic; and furthermore, the wetness degree of water drops on the surface is related to the period and the type of the micro-structure. The manufacturing process of the invention is simple, raw materials are low in cost, the parameter selectivity and the controllability are very high, and the hydrophobic micro-structures in different sizes and patterns can be prepared on the surface of the organic glass.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com