Patents

Literature

762 results about "Screw press" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A screw press is a type of machine press in which the ram is driven up and down by a screw. The screw shaft can be driven by a handle or a wheel. It works by using a coarse screw to convert the rotation of the handle or drive-wheel into a small downward movement of greater force. The overhead handle usually incorporates balls as flyweights. The weights helps to maintain the momentum and thrust of the tool to make it easier to operate.

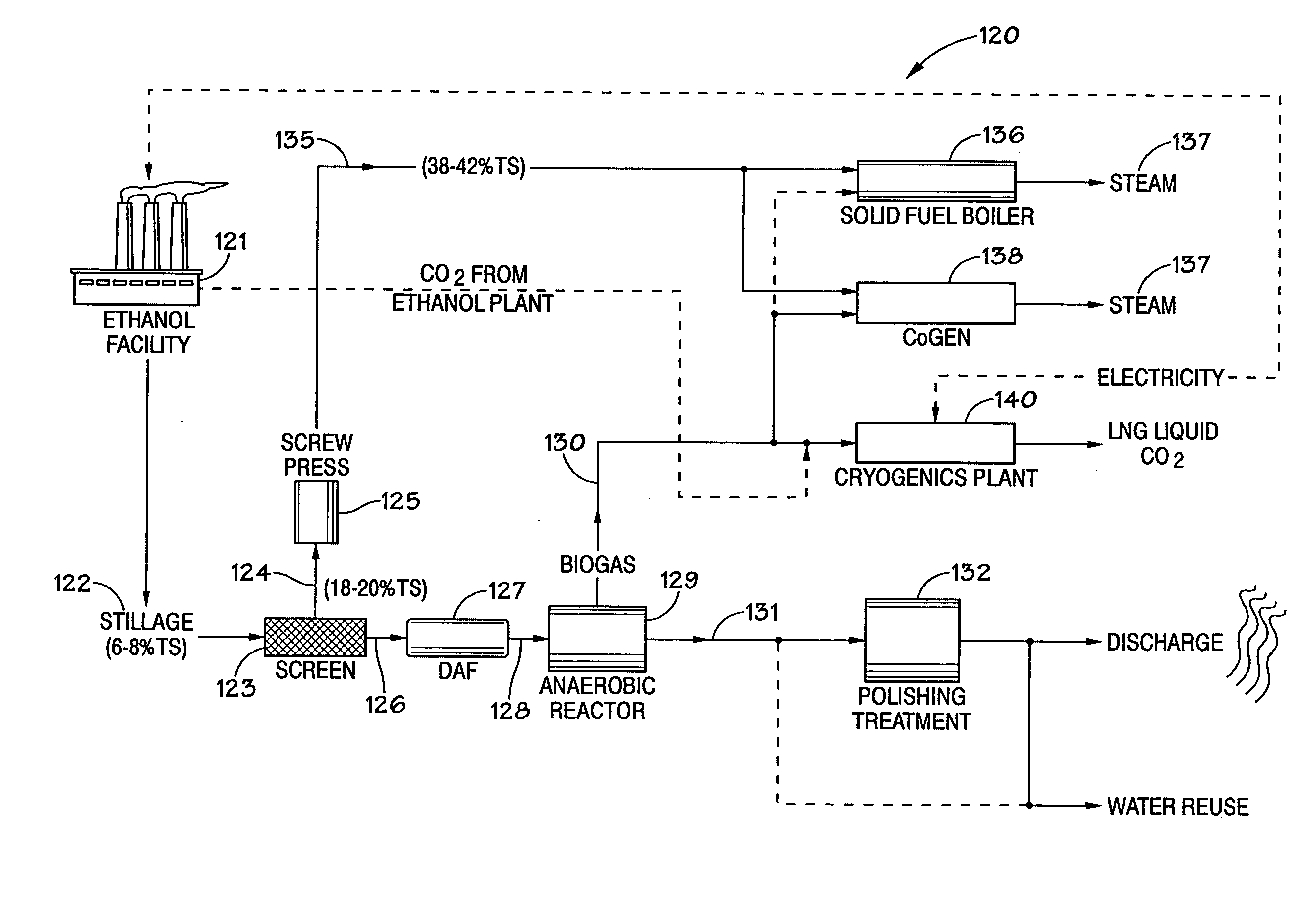

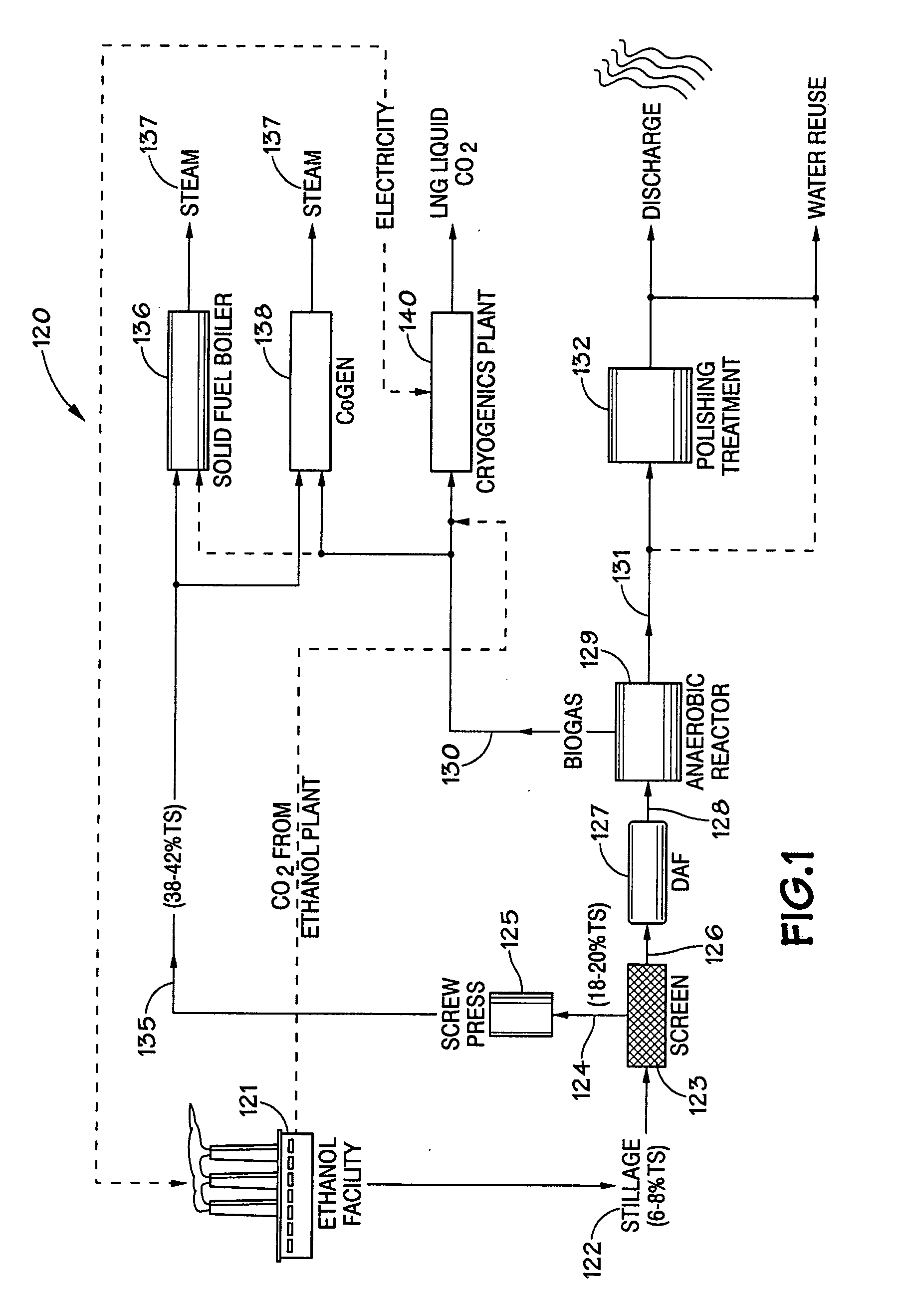

Method and apparatus for the treatment of byproducts from ethanol and spirits production

A method and system for the treatment of byproducts from the production of ethanol or alcohol spirits may include: a screw press to dewater the byproducts to produce a wet cake product and a filtrate product; and an anaerobic reactor to treat to filtrate product.

Owner:ECOVATION

Method for extracting and refining paeonia rockii seed oil

InactiveCN101649246AImprove oil yieldNo solvent residueCosmetic preparationsToilet preparationsAdditive ingredientAntioxidant

The invention relates to a method for extracting and refining paeonia rockii seed oil. The method comprises the following steps: collecting seeds, unshelling, baking and frying, carrying out screw press, filtering, deacidifying, degumming, drying, decoloring, deodorizing in vacuum, adding an antioxidant and filling. After solid impurities and residues obtained by the screw press are broken up, ethylacetate is added, then refluxing extraction is carried out, and a solvent is recovered so as to obtain the paeonia rockii seed oil for cosmetics. A two-step method is used for extracting the paeonia rockii seed oil, wherein in the first step: primary pressed oil used for eating is obtained by physical pressing, and the produced paeonia rockii seed oil has higher oil recovery rate and no residual solvents and can be securely eaten; in the second step, the ethyl acetate is adopted for extraction, and ingredients for antioxidation, inflammation resistance, sun block, and the like in the paeonia rockii seed oil can be extracted and used for producing the cosmetics. The invention not only improves the oil recovery rate of paeonia rockii seeds, but also ensures that the effective ingredients in the paeonia rockii seeds are sufficiently utilized.

Owner:兰州牡丹园艺开发公司

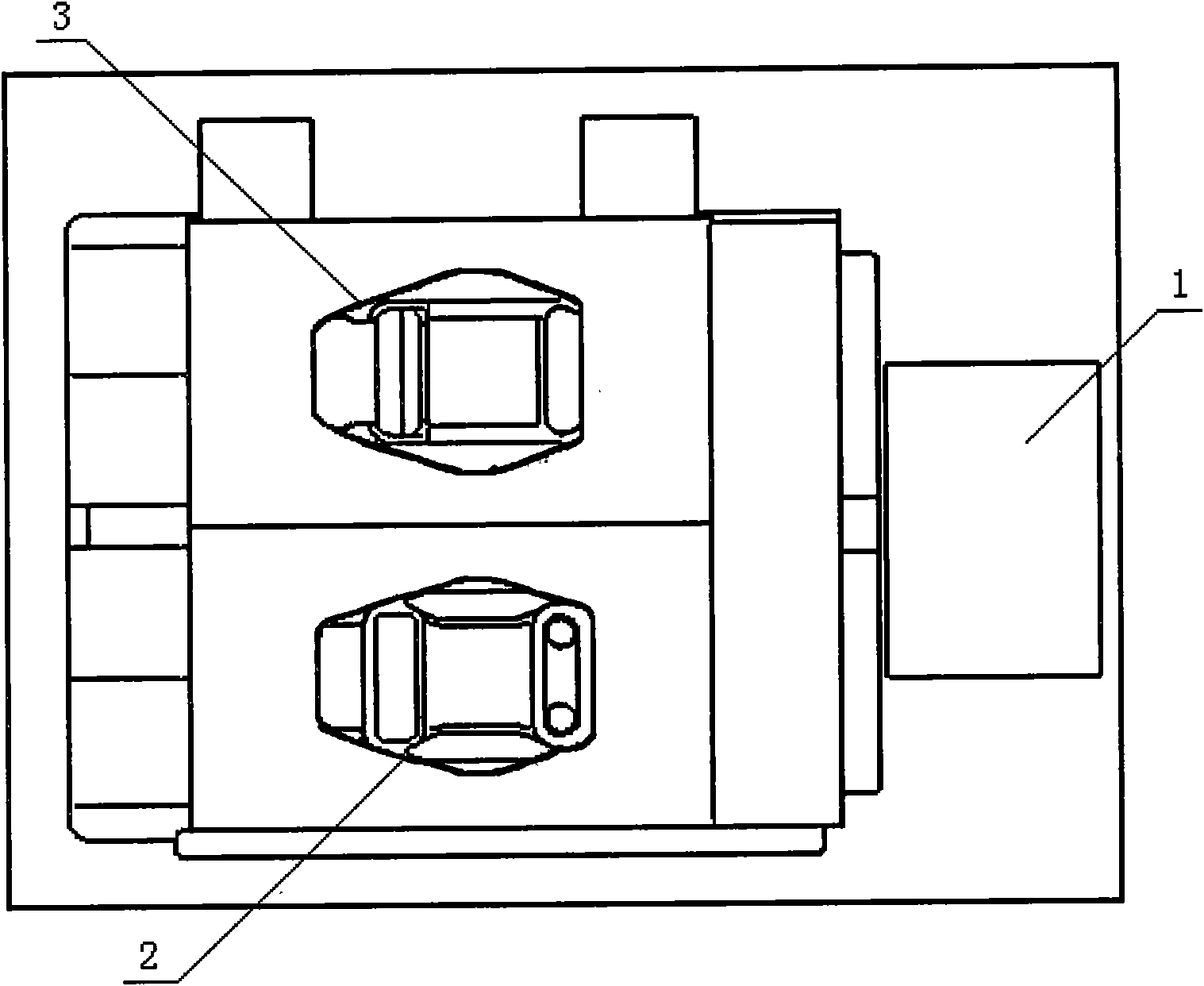

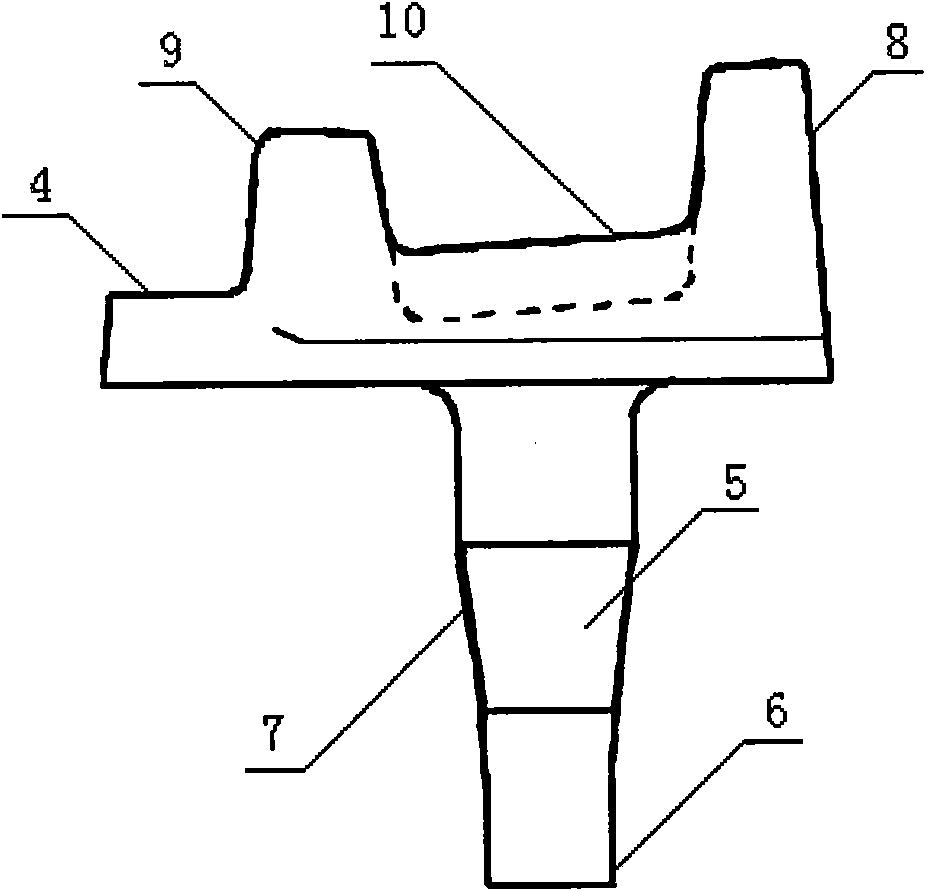

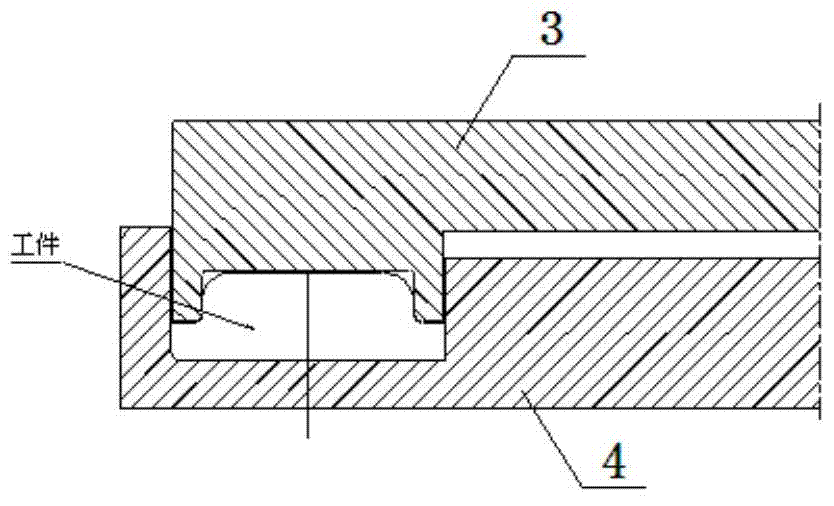

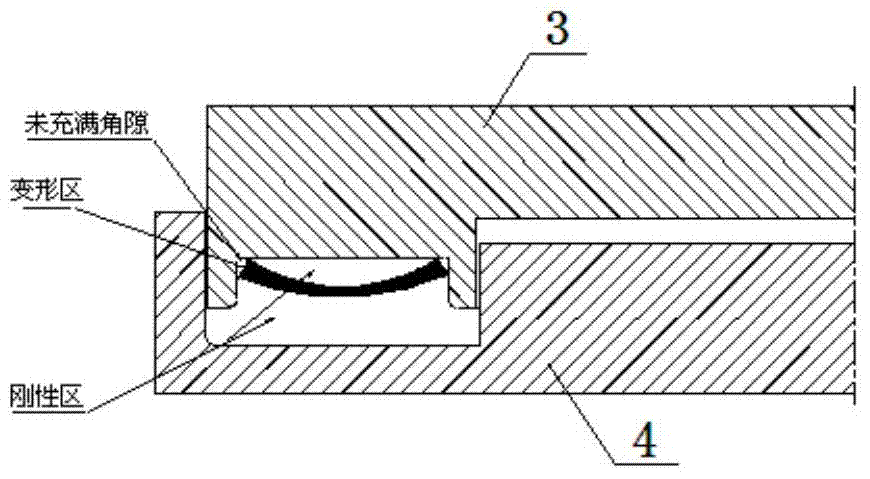

Closed forging technique for steering knuckle

ActiveCN101972835AReduce investmentAchieve flash-free forgingMetal-working drilling toolsRailway componentsControl theoryScrew press

The invention discloses a closed forging technique for a steering knuckle, belongs to automotive steering knuckle forging in the machining field, and overcomes the defects of need of procedures, such as trimming and the like, large metal consumption, low use ratio of a material and the like. The steering knuckle is forged on an electric straight direct drive spindle press by the closed forging technique; an extrusion blanking mould and a final forging mould both have a closed structure; a rod part of the steering knuckle is placed on an upper mould, and an ear part is placed on a lower mould; extrusion blanking and final forging forming can be tried; required blow energy is determined by actually debugging, a procedure of the blow energy is stored and used in the process of mass production; and in a series of technical schemes, the flashless forging of the steering knuckle is realized by three forging process steps, the procedures, such as preforging, trimming, revising and the like are saved, the use ratio of a forging material of the steering knuckle is increased, mould input is reduced, working efficiency is improved, and production cost is reduced.

Owner:HUBEI TRI RING FORGING

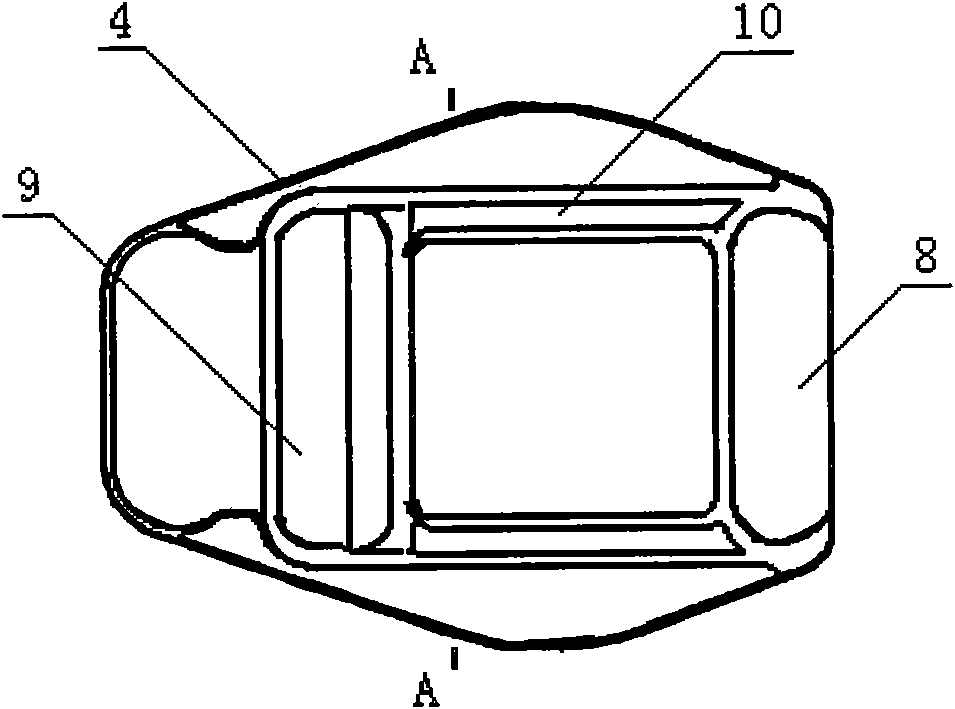

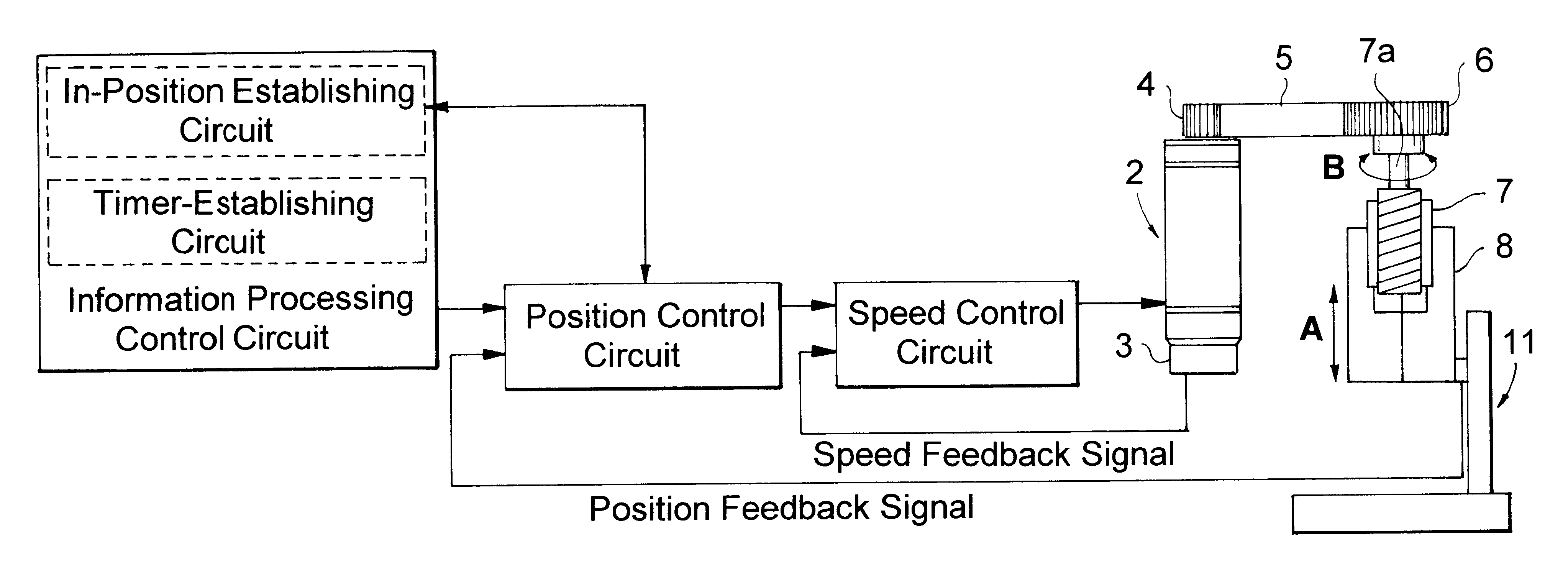

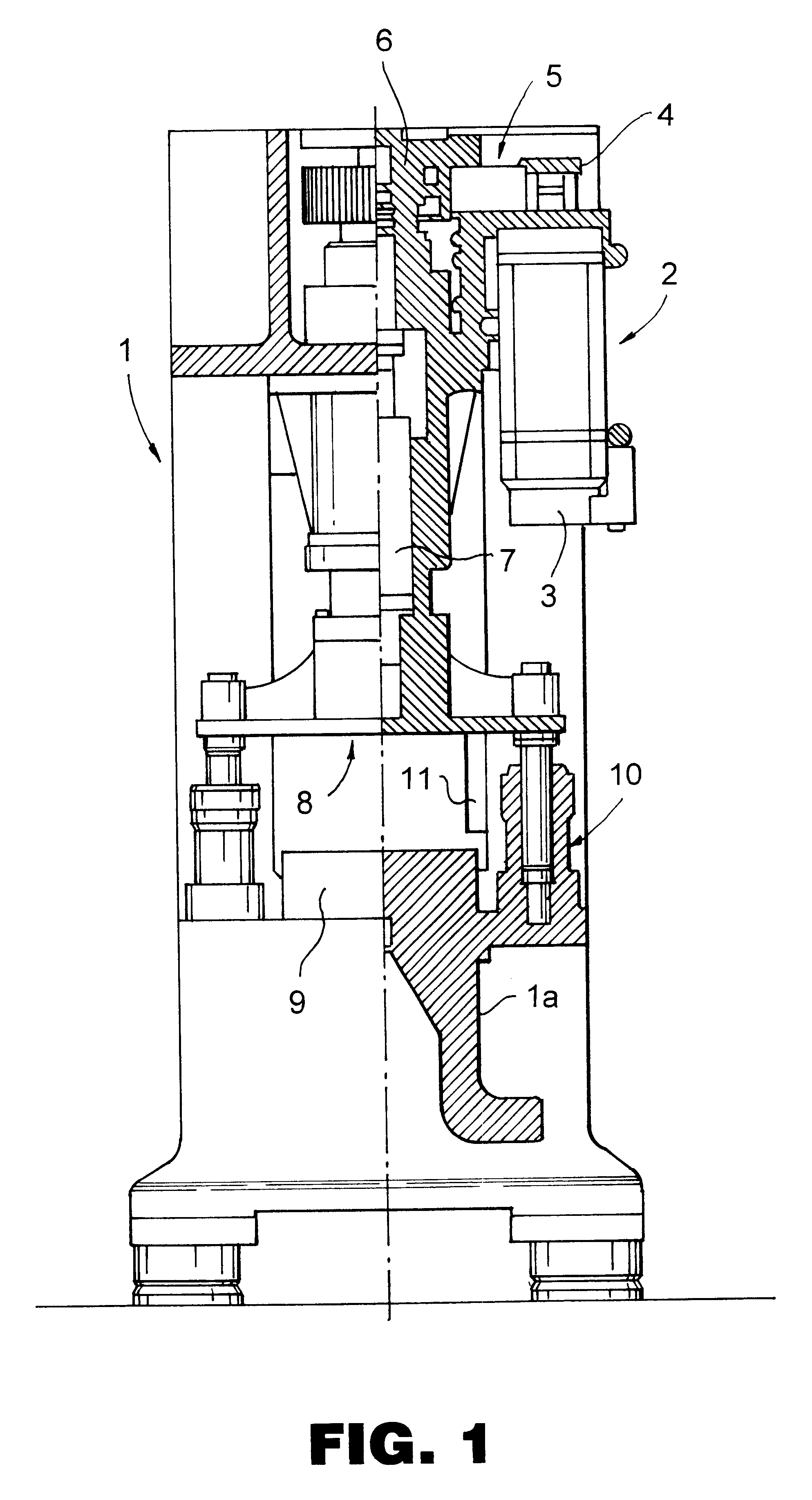

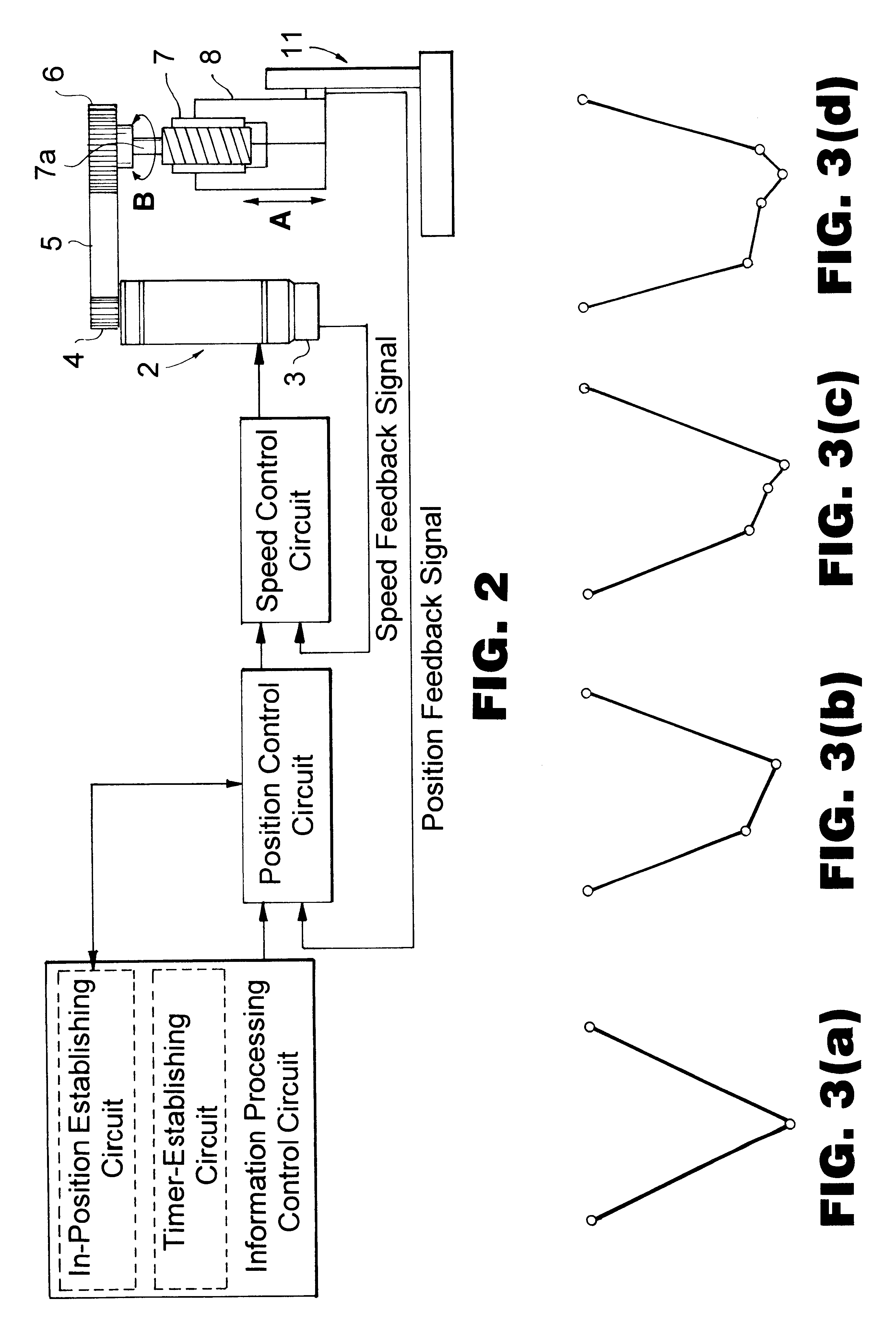

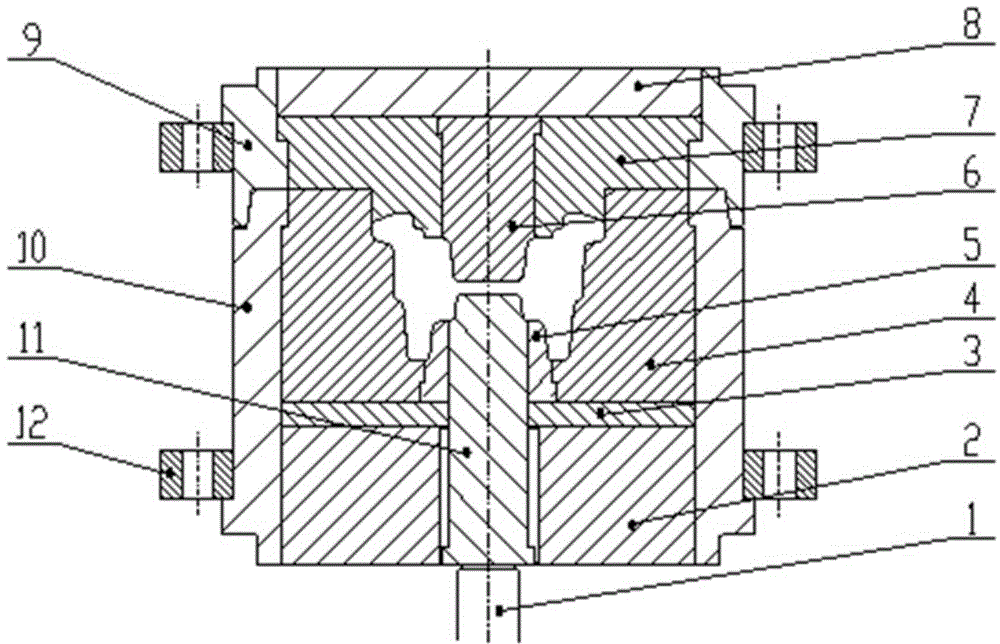

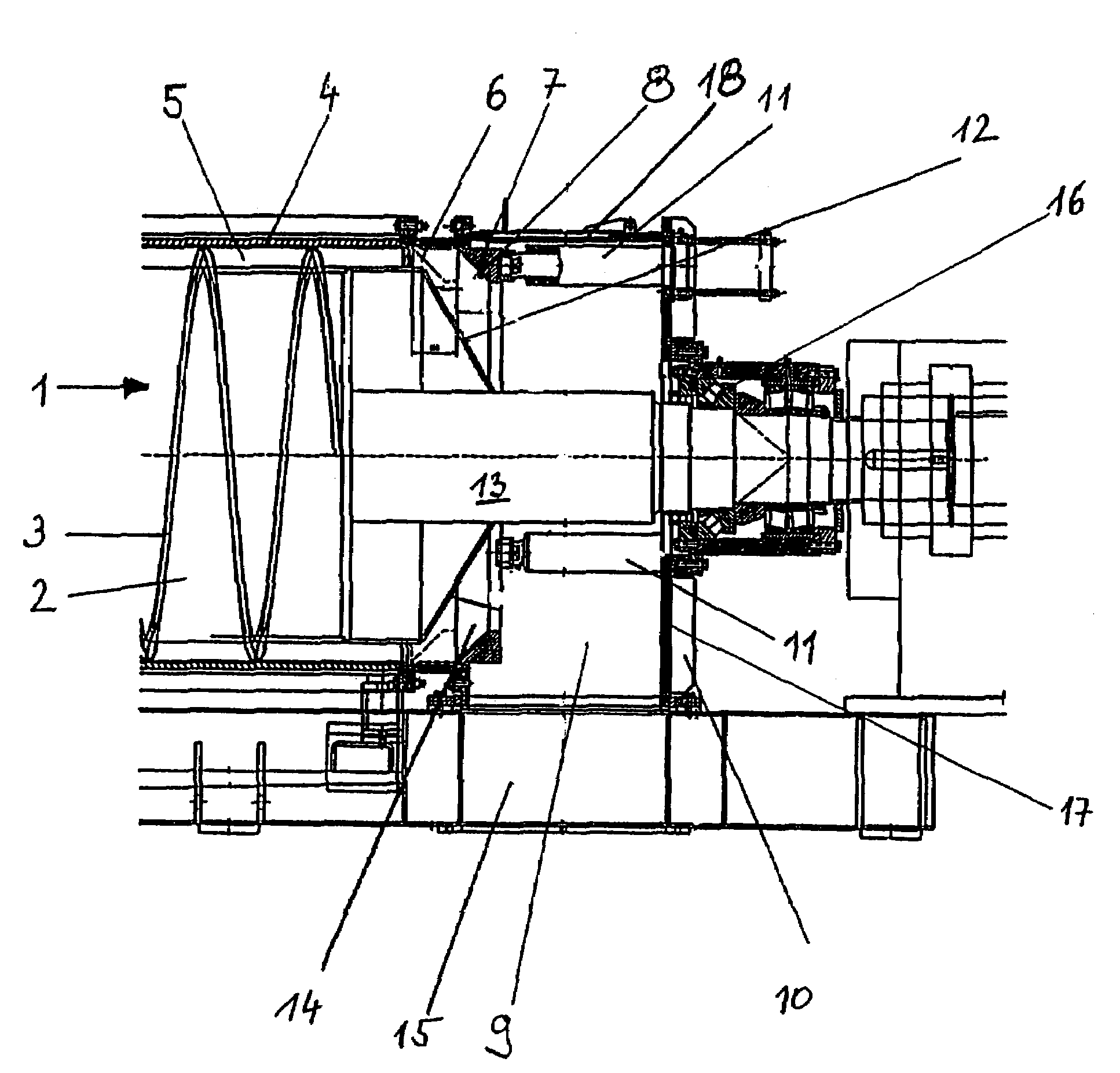

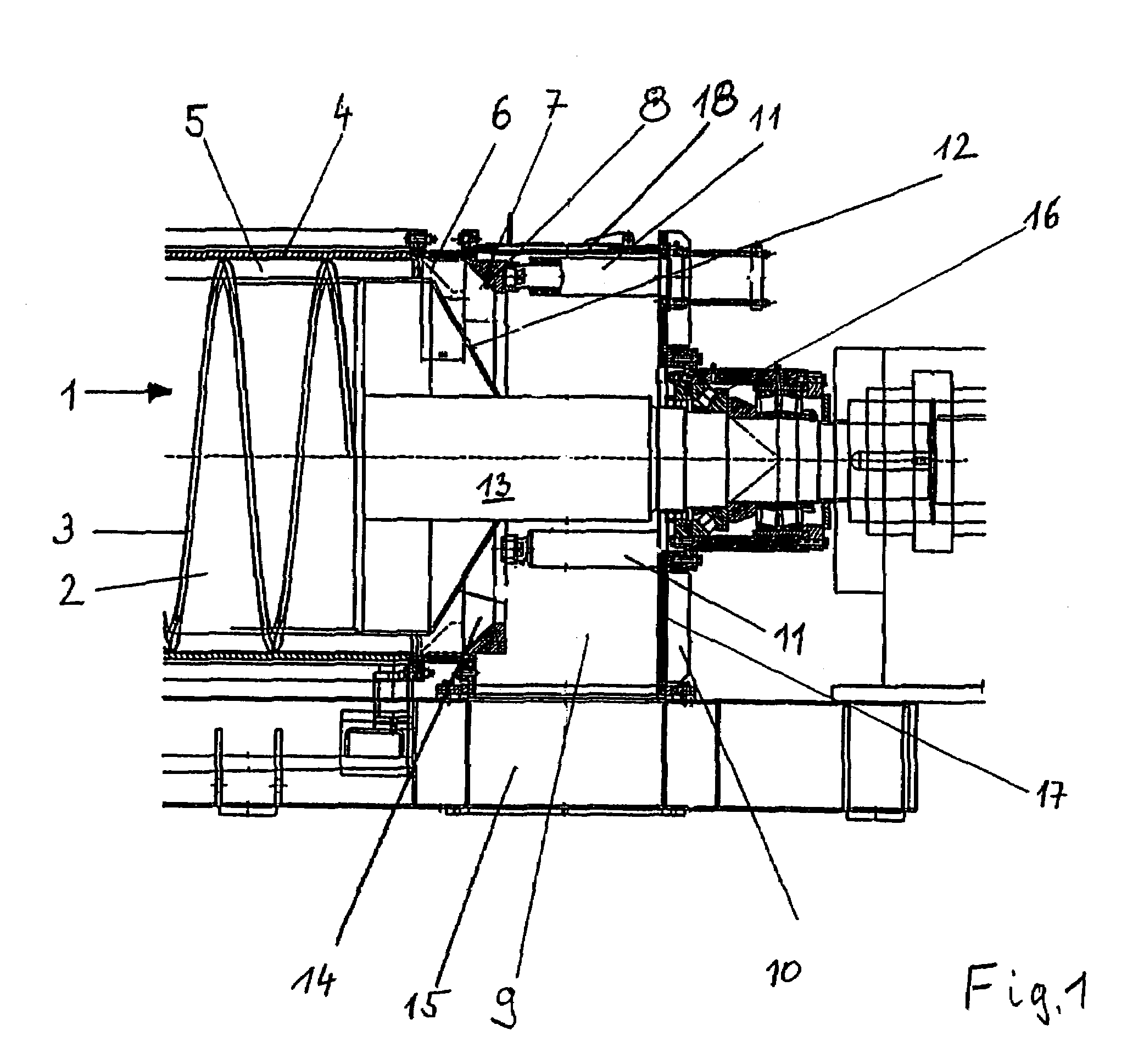

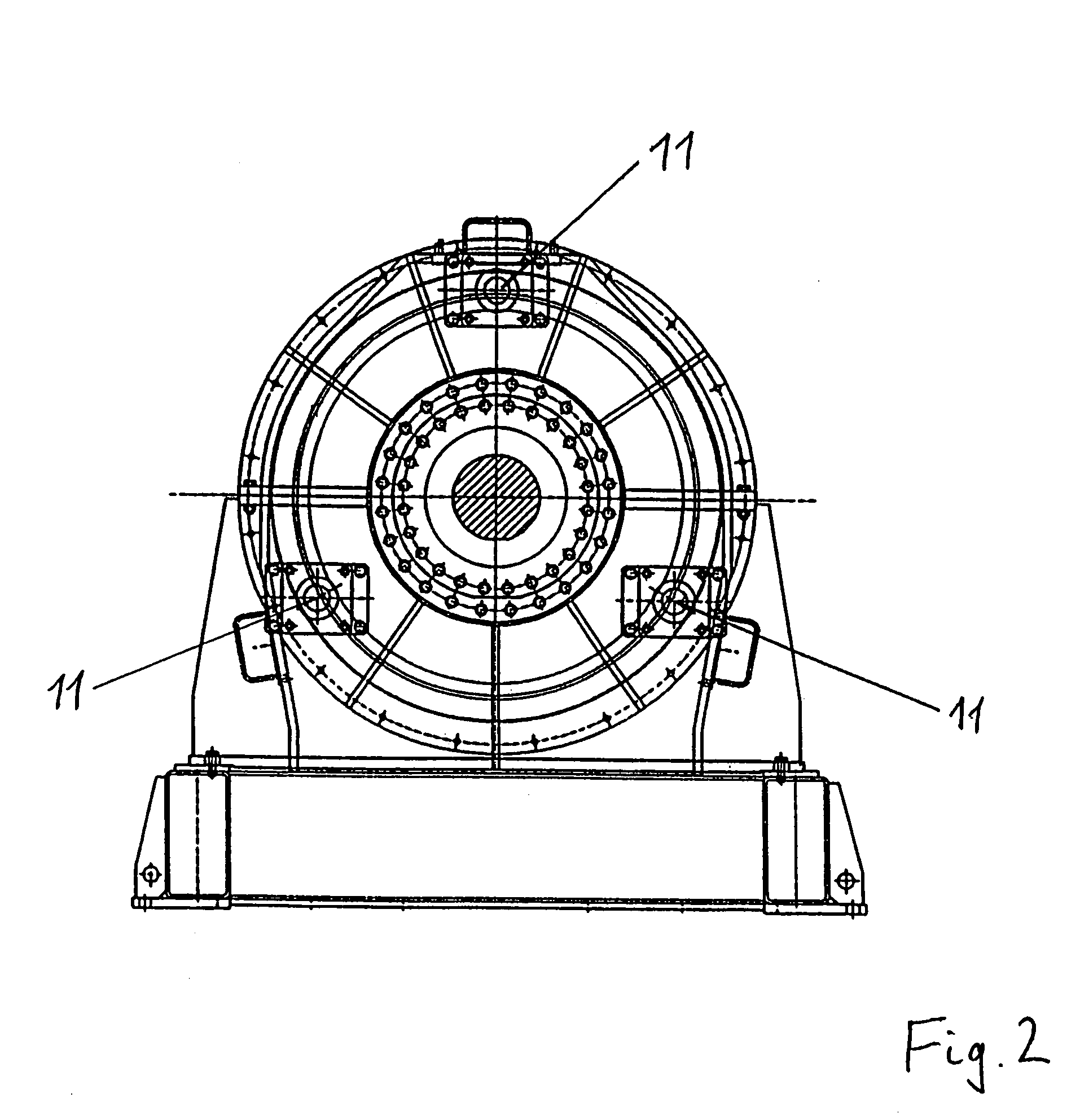

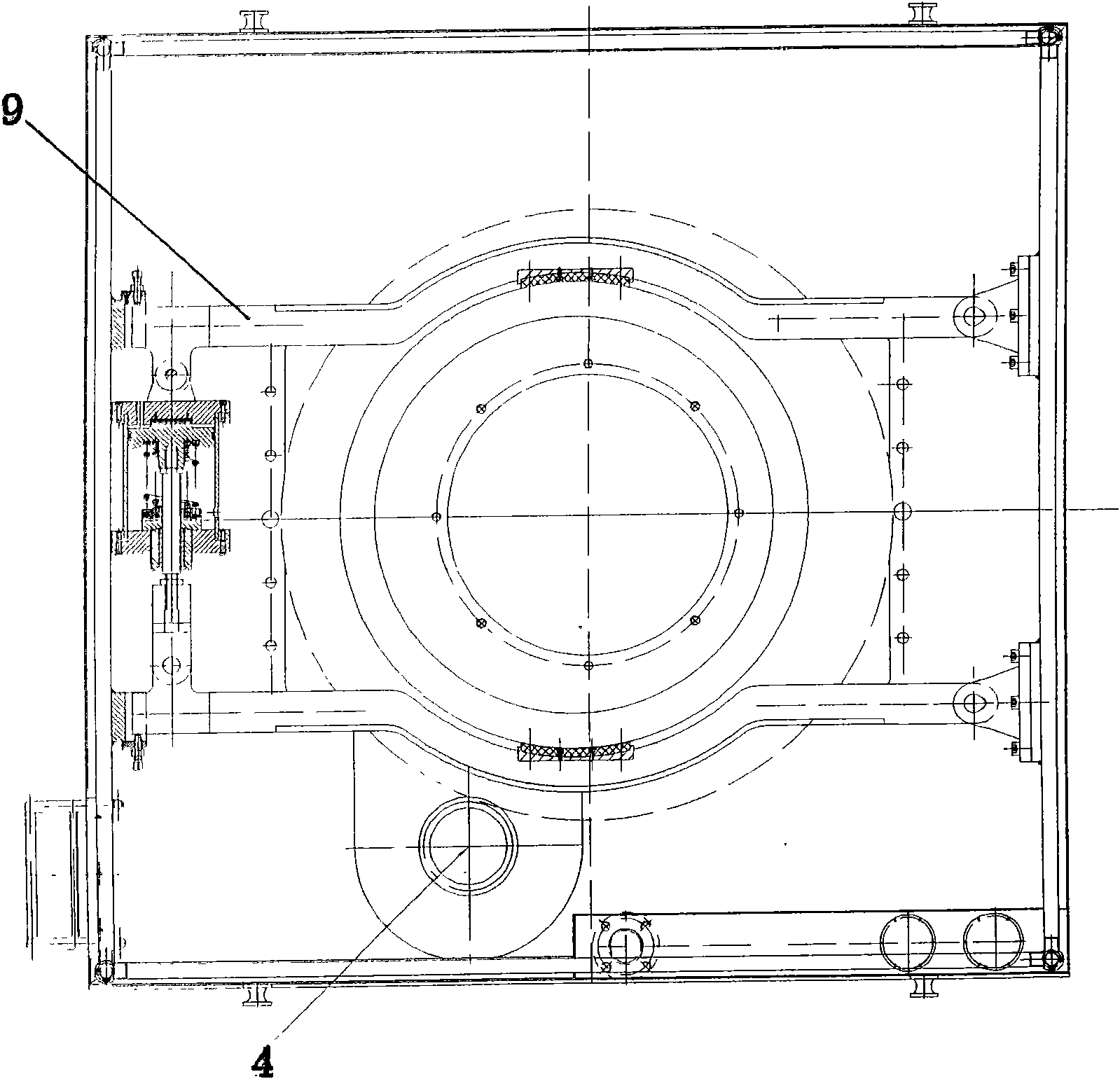

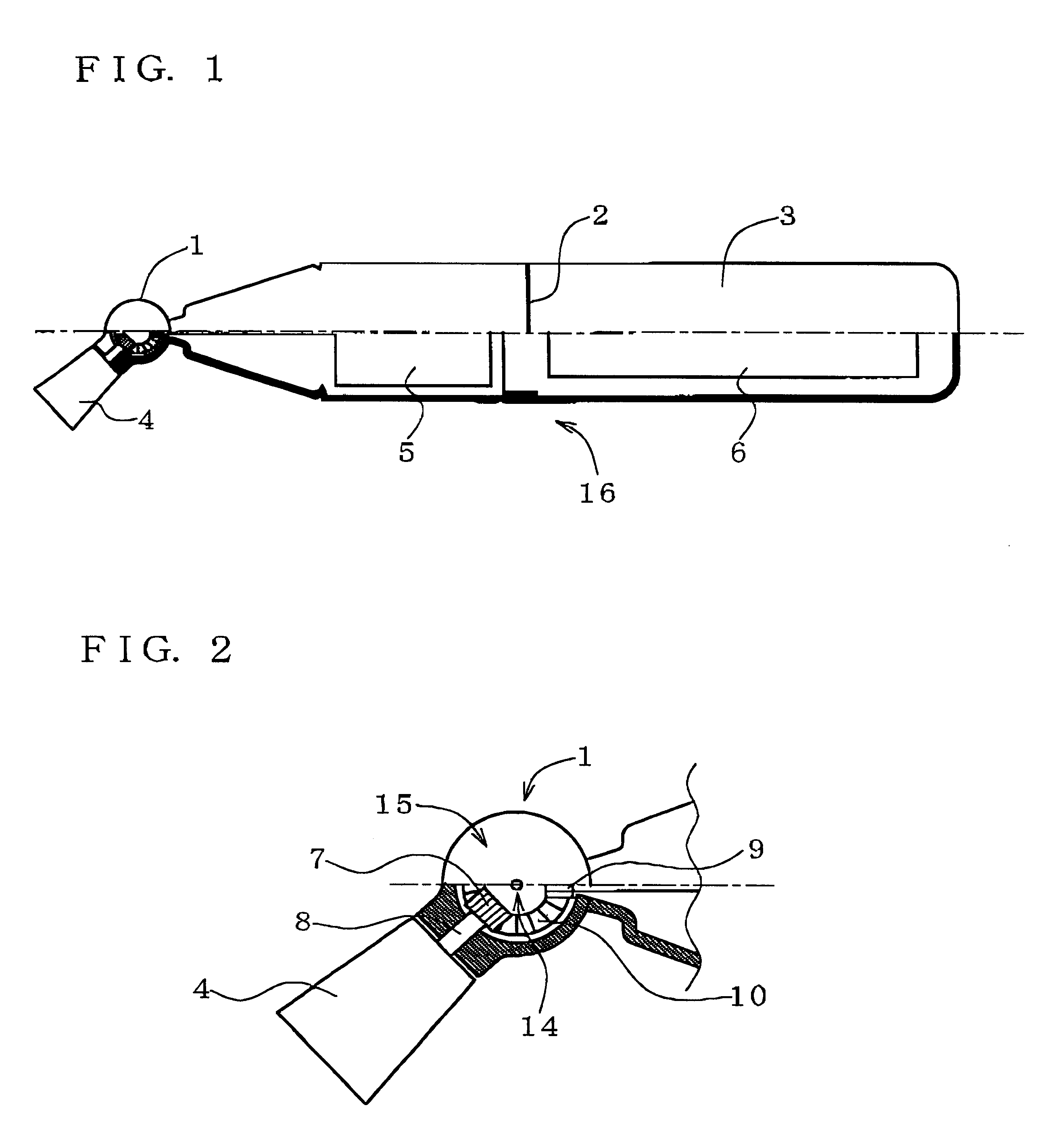

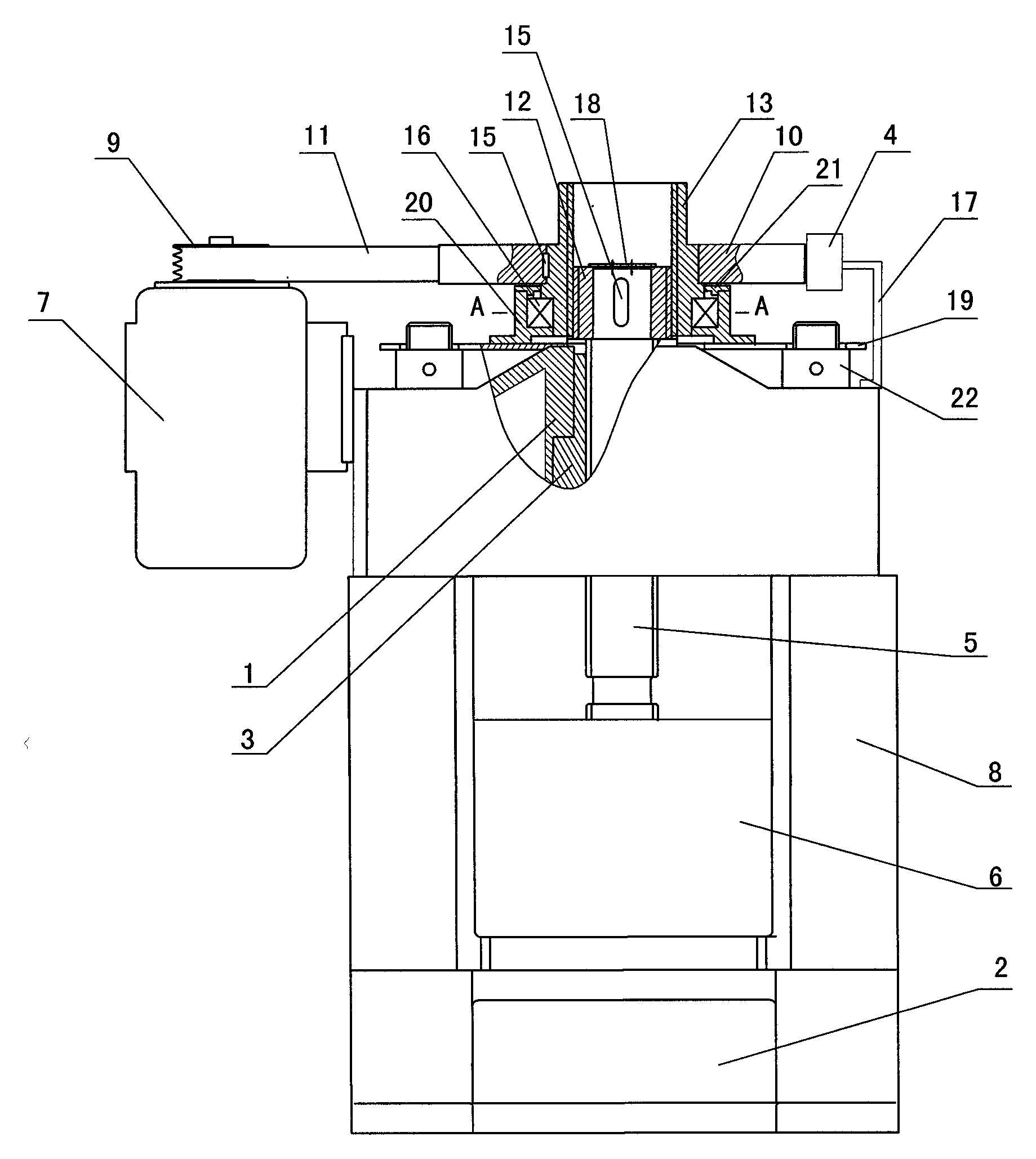

Screw press

InactiveUS6520077B1Precise positioningShaping safety devicesForging press detailsReduction driveControl theory

A screw press which can ensure the positional precision of the ram when the rotation amount of the press motor does not directly translate into the position of the ram because there is other machinery, such as a decelerator and the like, present between the motor (servo motor) and the screw mechanism, has a construction in which a position detection sensor, which detects the position of the ram, is provided, and the position of the ram is controlled by the output from this sensor.

Owner:AIDA ENG LTD

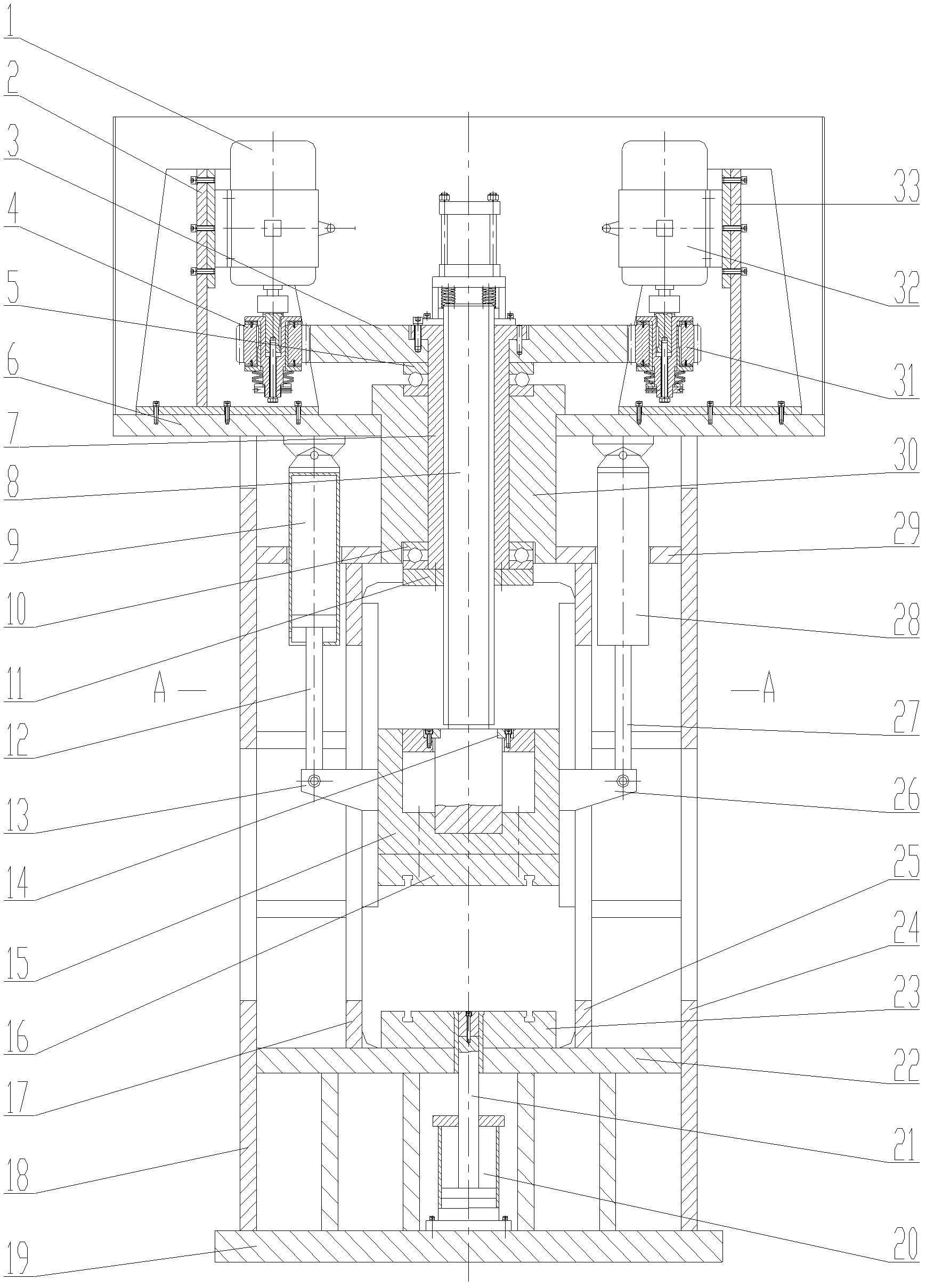

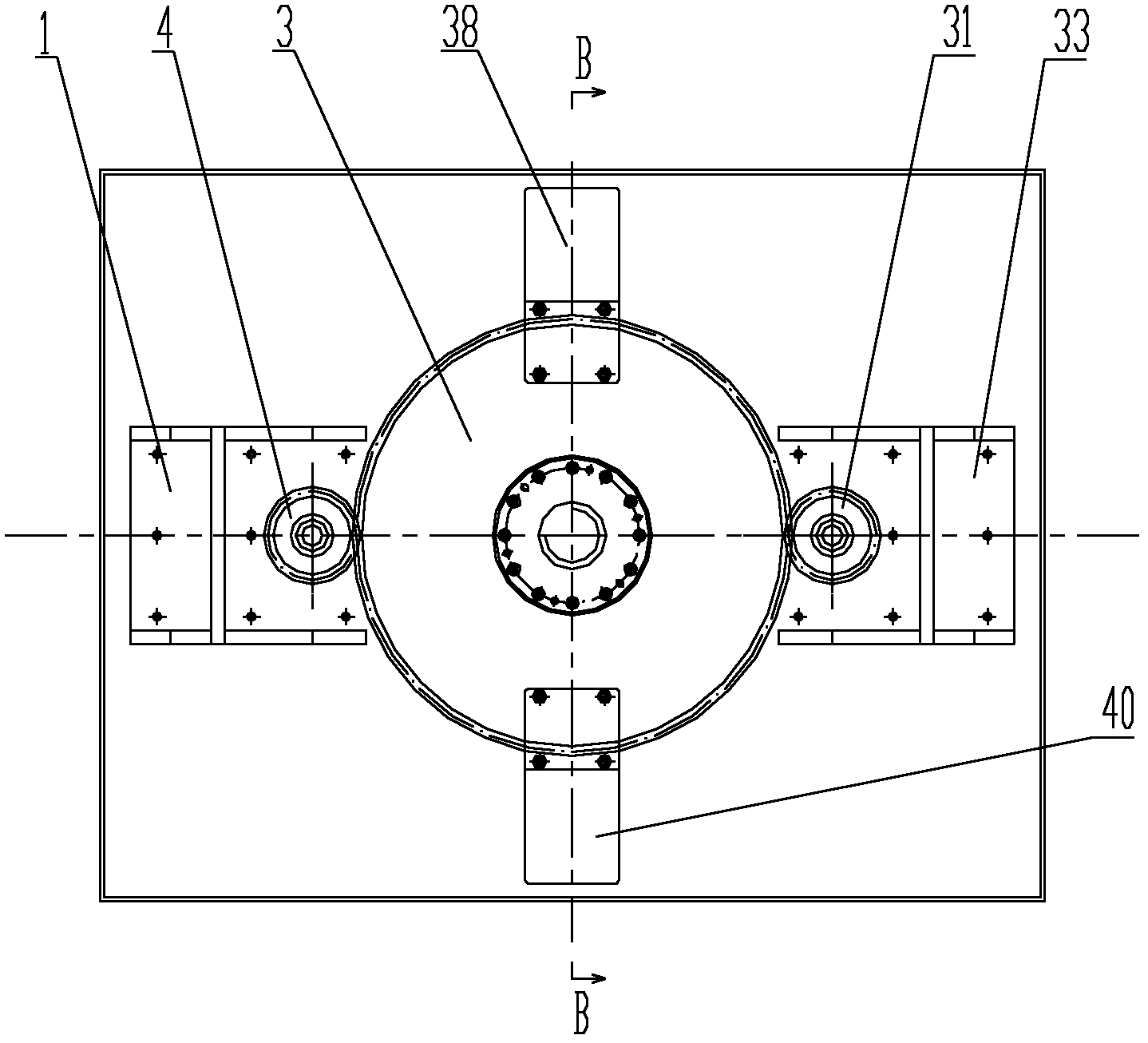

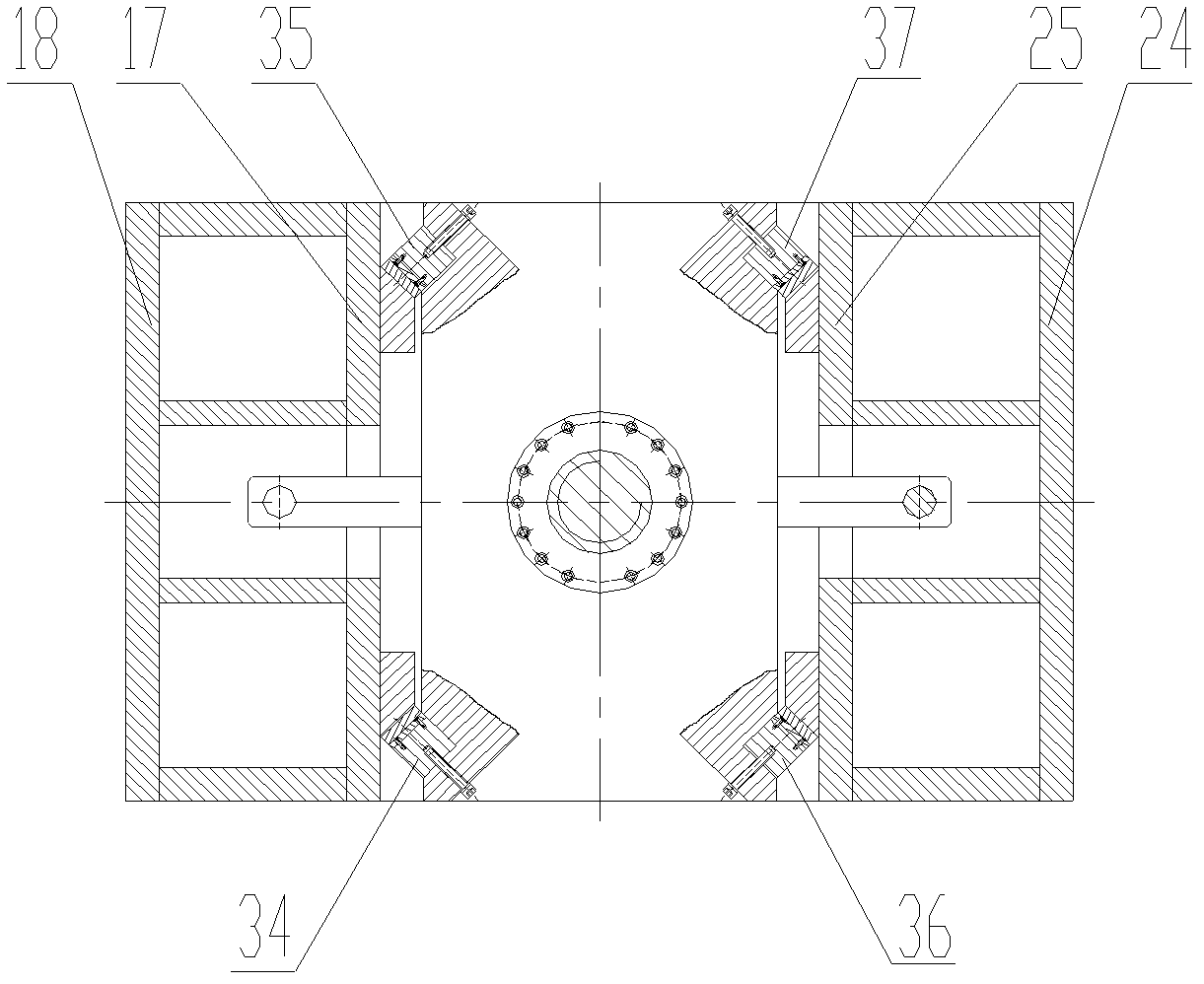

Electric screw press

InactiveCN102990957AContact friction resistance is smallReturn speedForging press drivesPress ramBrickGear wheel

The invention discloses an electric screw press, belongs to forging forming equipment, solves the problem that a slider is long and has a small travel in the conventional electric screw press, and is used for producing clay bricks, refractory bricks, common die forgings and precision die forgings. The electric screw press comprises a press body, a main gear, a nut, a screw, a slider body, an ejection cylinder, a left motor, a right motor, a front brake cylinder and a rear brake cylinder; and a left piston cylinder and a right piston cylinder which are bilaterally symmetrical are fixed in the press body. The nut and the main gear are tightened and rotate under the drive of the left and right motors; and the screw and the slider body are connected into a whole and driven by the nut to linearly move vertically, the screw can extend out of the upper end face of the main gear, the length of the slider body is consistent with or is even less than the height of a slider of a friction screw press with the same nominal pressure and body dimensions, the travel of the slider body can be increased by more than 100mm, the hammering energy of the slider body is correspondingly increased, and the application range can be widened obviously.

Owner:HUBEI NAFU GEARING MACHINERY +1

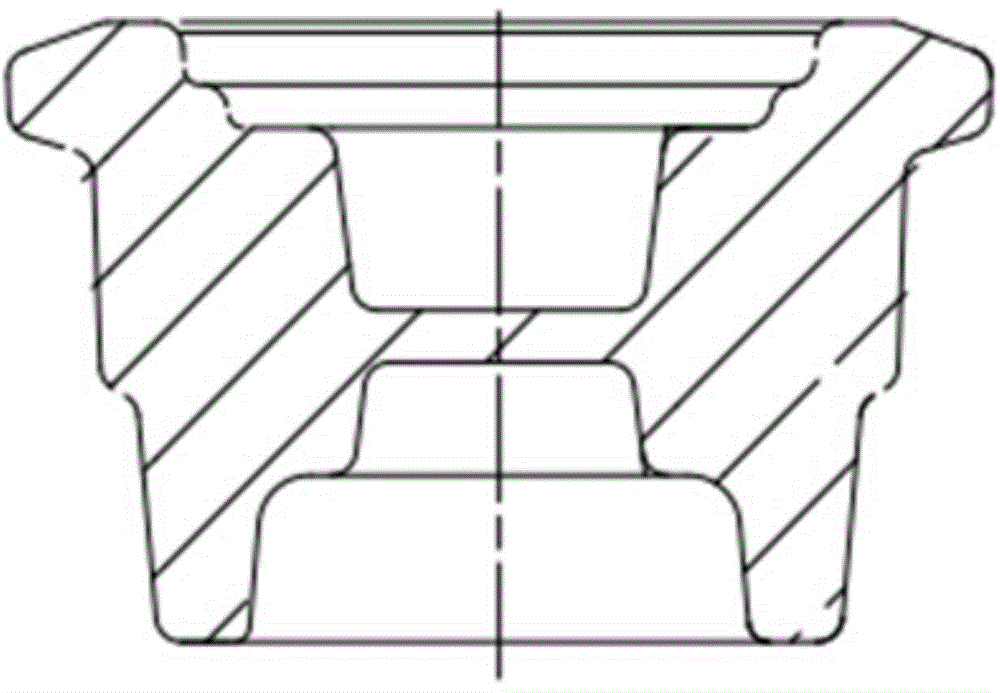

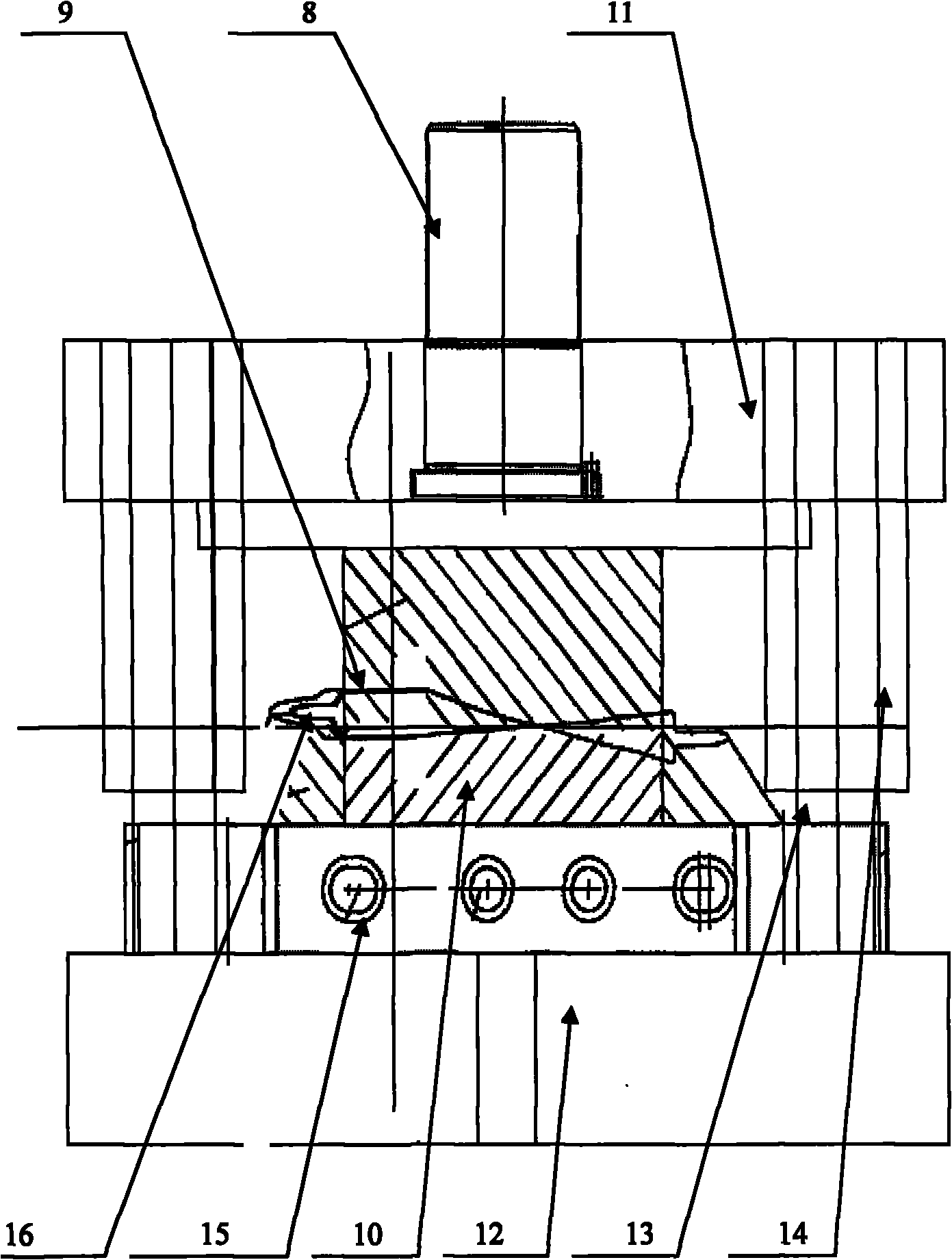

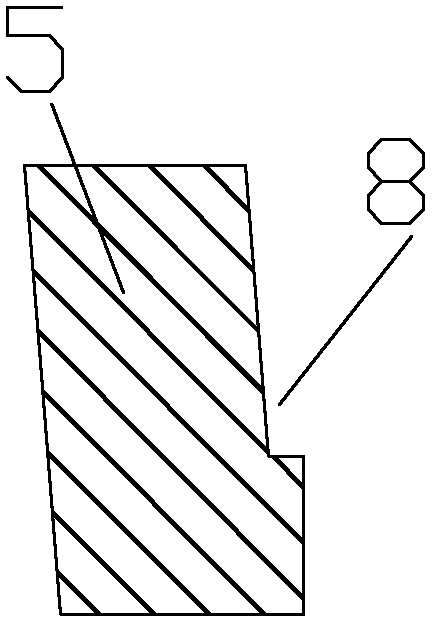

Supporting wheel closed forging process and forging die

InactiveCN104907471AThere is no flash phenomenonTotal deformation area reductionForging/hammering/pressing machinesWheelsPunchingMedium frequency

The invention discloses a supporting wheel closed forging process and a forging die, and belongs to the technical field of forging. Blanking is conducted on round steel through a band sawing machine; heating is conducted on a bar material through a medium frequency induction heating furnace; jumping-up and preforging are conducted on the hot bar material on a l600T electric screw press, then the hot bar material is transferred to a 2500T electric screw press to be subjected to finish forging and forming through the closed forging die, and finally punching is finished on a 400T mechanical press; normalizing treatment is conducted on a forge piece generated after punching is conducted; the closed forging die adopted for the process comprises a lower cushion block (2), a lower male die (11), a lower base plate (3), a lower female die insert (5), a lower female die (4), an upper male die (6), an upper female die (7) and an upper cushion block (8). By means of the supporting wheel closed forging process and the forging die, burrs do not exist in the forged forge piece, and the total forge piece deformation area is reduced, so that the forging deformation force is lowered, the raw material utilization rate is increased, the subsequent trimming process is omitted, the product cost is lowered greatly, and product efficiency is improved remarkably.

Owner:XUZHOU XCMG CRAWLER CHASSIS CO LTD

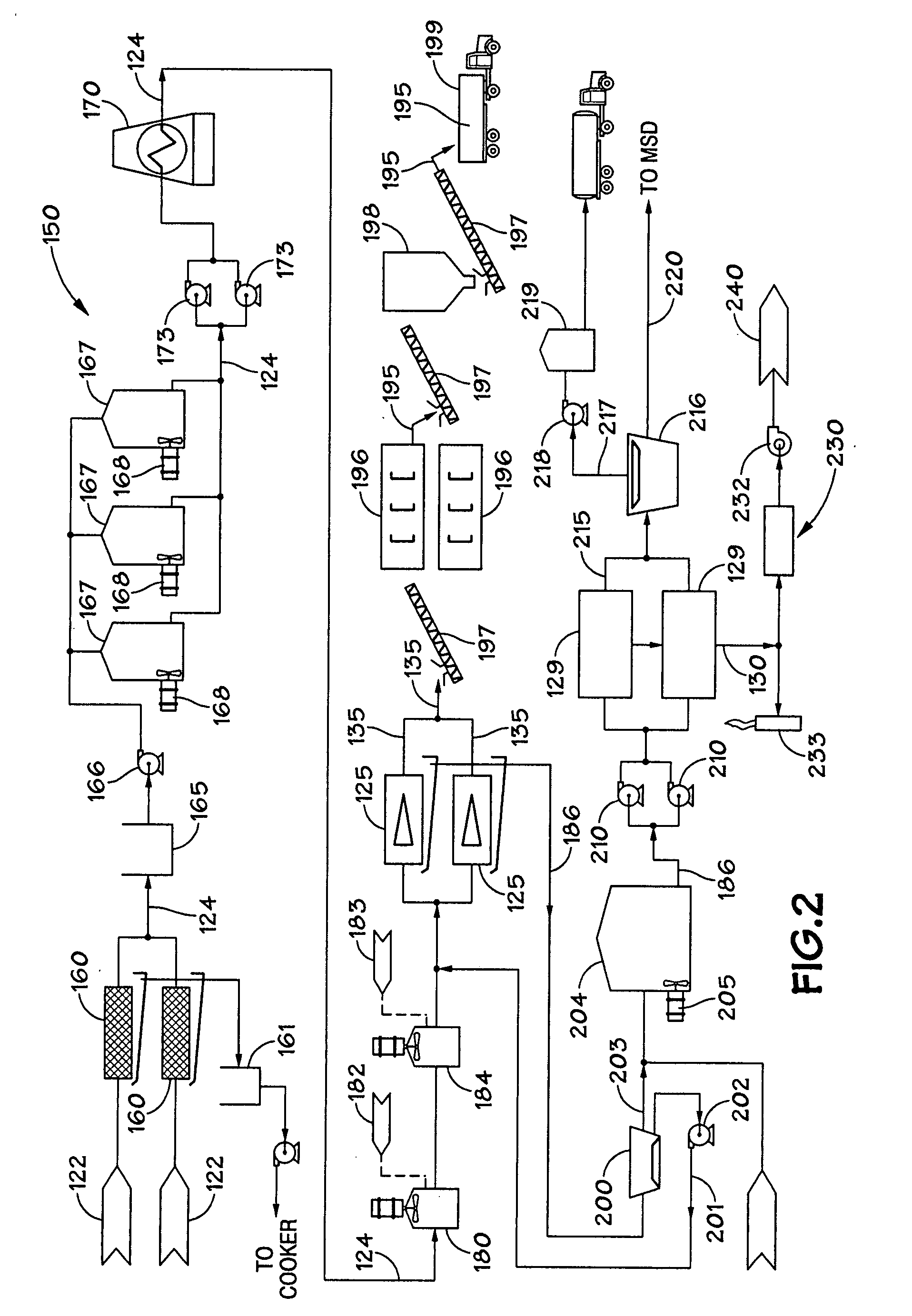

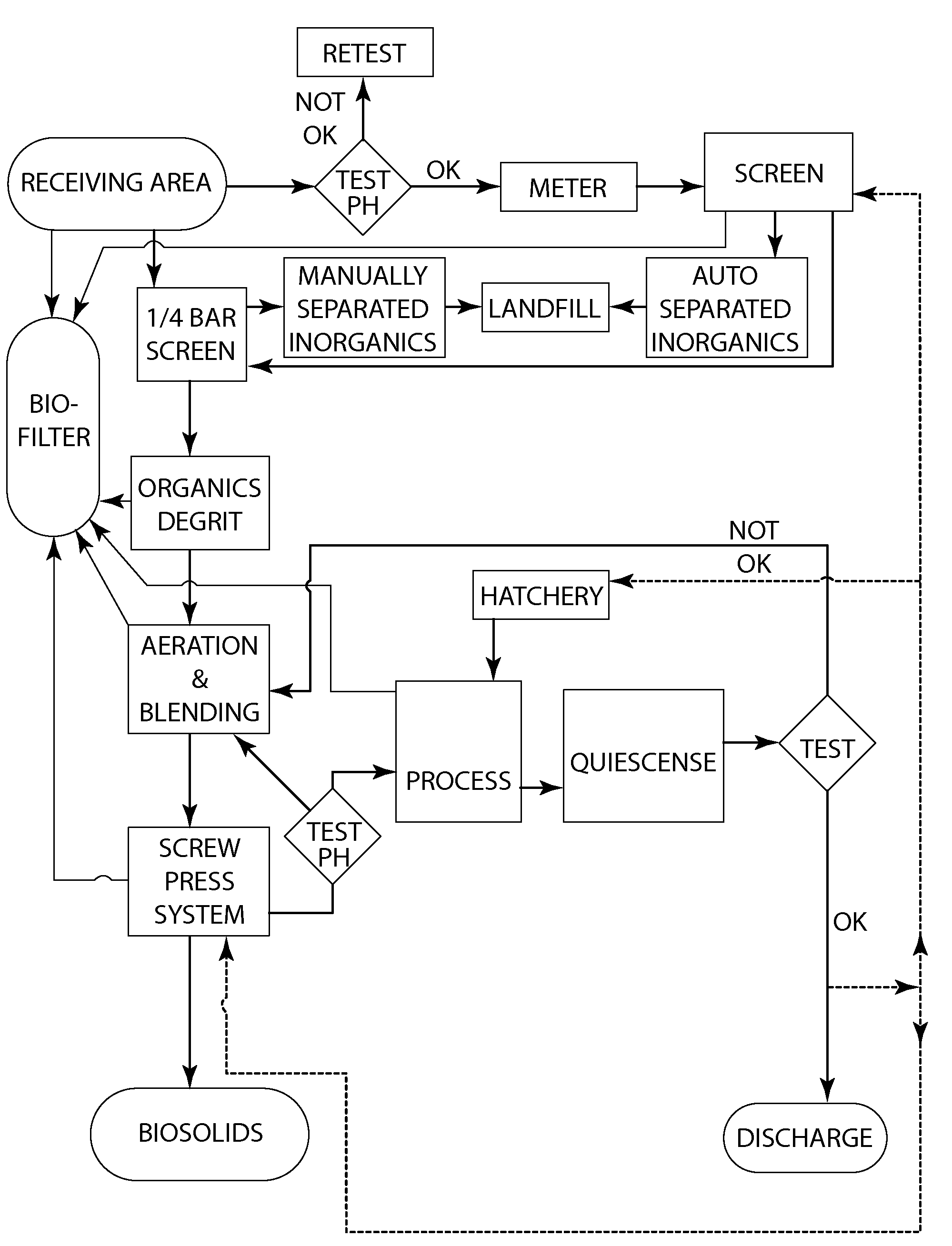

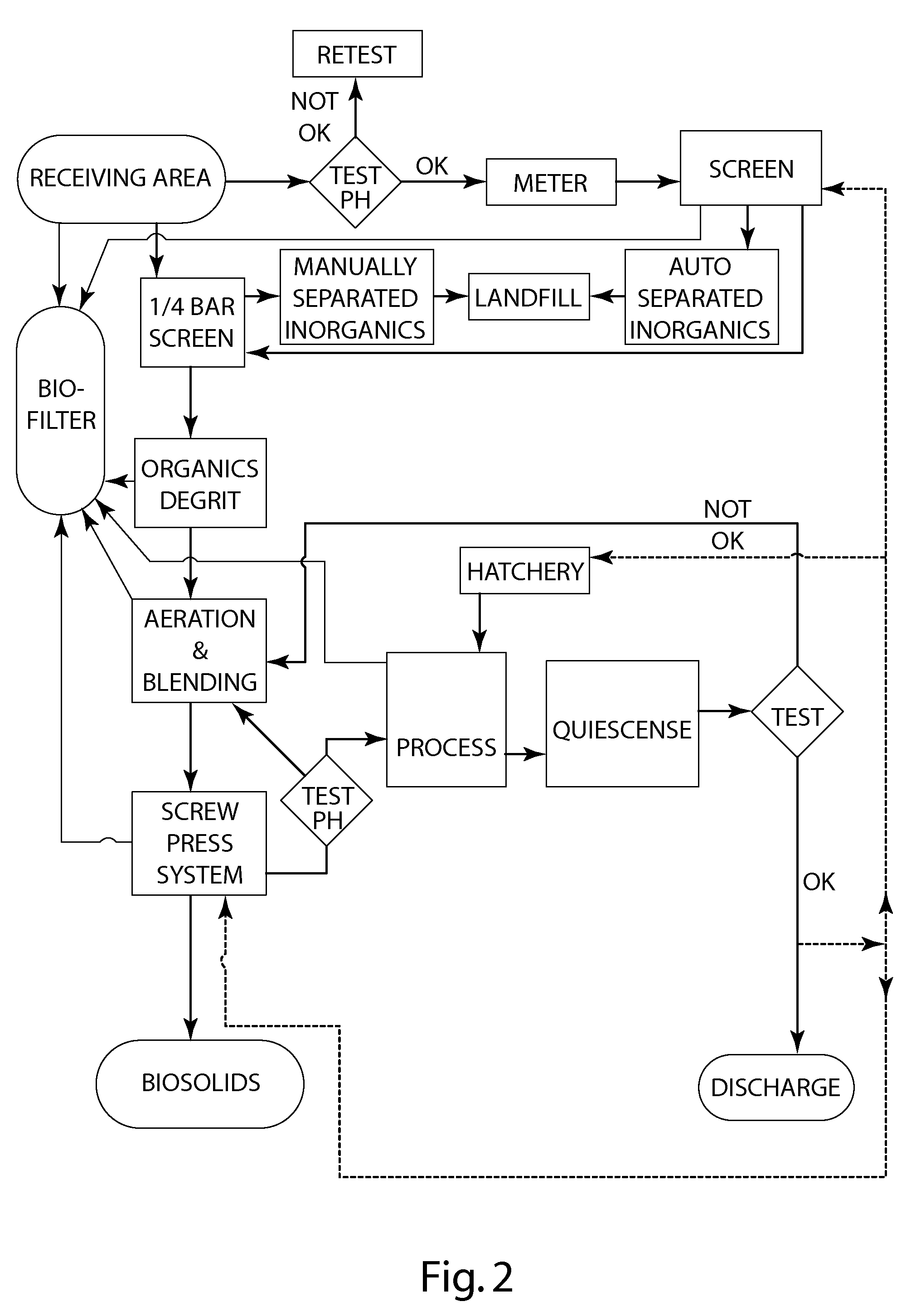

Apparatus and method for the treatment of waste

A facility for treating solid and liquid waste includes a receiving station, a screening station, a preprocessing station, a press station and a processing station. The screening station is connected to an inlet capable of receiving liquid and solid waste and includes a screen for capturing at least some of the solid waste. The preprocessing station is in fluid communication with the screening station, and includes a degrit chamber for settling out an additional amount of the solids. The press station included at least one alkali mixing tank and a screw press for separating out an additional portion of the solids. The processing station includes at least one aerobic microorganism generating unit for converting nitrites into nitrogen gas and consuming carbon-based waste material.

Owner:BIG FISH ENVIRONMENTAL

Full insurance type artificial rain bullet detonator

A full-insurance rain bomb fuze relates to an artificial hail-suppressing rain bomb fuze for antiaircraft guns. The present invention mainly includes a fuze body, an upper drug tray, a lower drug tray, a rotary body, a bracket, a pressure screw, and a detonator tube. There is a 134-136° circular groove on the bottom surface of the medicine tray and the top surface of the medicine tray respectively. The gunpowder column is installed on the side, and the gyratory body is installed in the medicine feeding tray. The left and right sides of the medicine feeding tray and the gyratory body are respectively equipped with centrifugal safety screw plugs, centrifugal springs, centrifugal pins and safety pins, and gunpowder safety screw plugs. The dimensions of the booster tube have also been improved. The invention has the advantages of small fragments, sufficient explosion, safe use, good delay reliability and more complete detonation.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

Production method and forge die of high-speed train brake disc

ActiveCN103831386AAvoid missingPrevent shrinkage deformationRailway componentsForging/hammering/pressing machinesEngineeringForge

Owner:胡谦 +1

Continuous sludge treatment device

InactiveCN107176780AAvoid cloggingEfficient heatingSludge treatment by de-watering/drying/thickeningSludgePulp and paper industry

The invention discloses a continuous sludge treatment device. The continuous sludge treatment device comprises a feeding hopper, a first driving motor and a second driving motor, wherein the feeding hopper is communicated with a dewatering box, a screen drum is arranged in the dewatering box and sleeved with a rack ring, and the rack ring is rotationally connected with the screen drum through a bearing; strip-shaped brushes which are symmetrically arranged are fixedly connected with the right side wall of the rack ring; a drying box is communicated with the right side of the screen drum through a sludge pipe. With the arrangement of a screw extrusion dewatering device provided with the rotating brushes, sieve meshes are prevented from being blocked, continuous dewatering work is guaranteed, and the continuous sludge treatment device has higher dewatering efficiency; the continuous sludge treatment device is equipped with a drying device consisting of a heating plate, flat spreading rollers and scrapers, therefore, sludge is efficiently and uniformly heated, and drying efficiency is improved; an auxiliary drying device consisting of hot air spray nozzles, smashing blades and a turning plate is arranged, so that the sludge is thoroughly dried, and the drying effect is guaranteed.

Owner:李群珍

Precision forging method of titanium alloy blade

ActiveCN101791671AAchieve uniformityTo achieve the effect of adjustable gapForging/hammering/pressing machinesRoom temperatureTitanium alloy

The invention relates to a precision forging method of titanium alloy blade. The forging method comprises a finish forging process and a trimming process, wherein the finish forging process comprises the following steps: (1) coating glass lubricant on the surface of a pre-forged blade forging, then heating the blade forging to the forming temperature, and maintaining the temperature for 15-30 minutes; (2) coating die lubricant on dies, respectively placing the upper die and the lower die on an upper die holder and a lower die holder, and arranging the blade forging in the upper die and the lower die; and (3) forging the blade forging by using a screw press based on the dimension requirements. The trimming process comprises the following steps: arranging the finish-forged blade forging in a trimming die, and trimming the blade forging at room temperature. The forging method has the advantages of low raw material consumption, good combination property and long service life of the obtained blade and the like.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

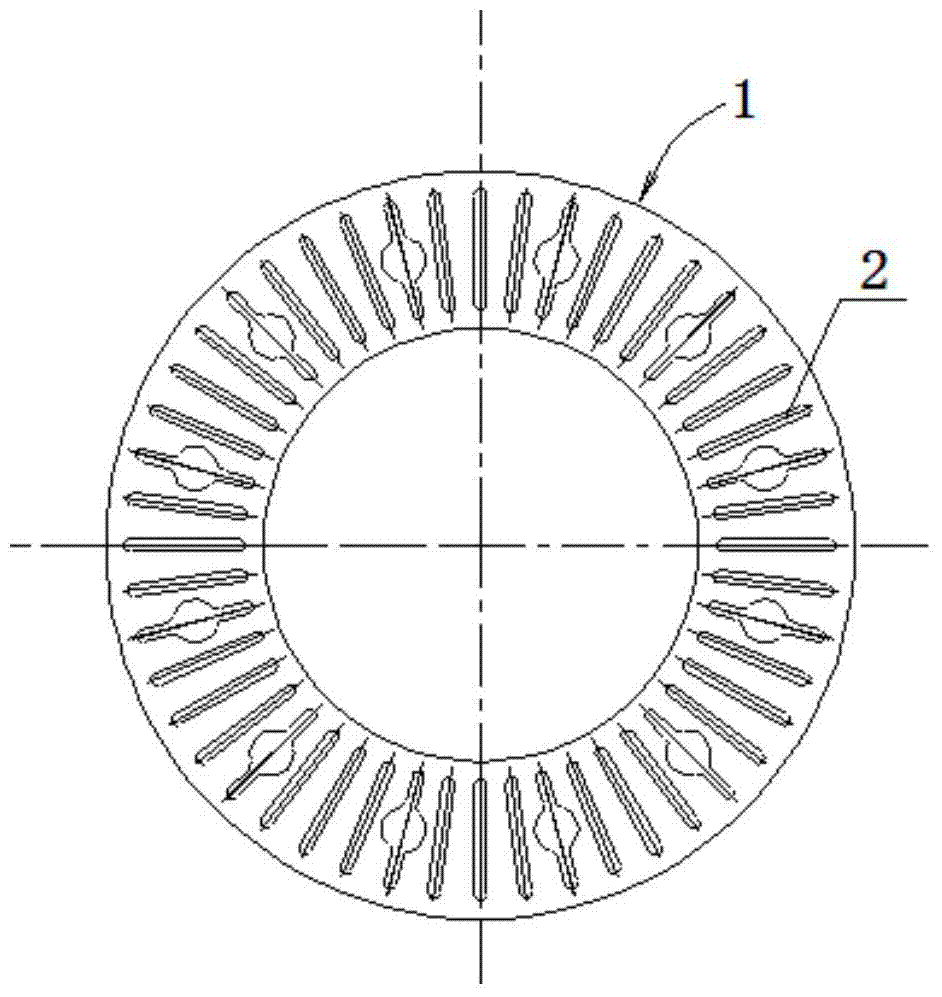

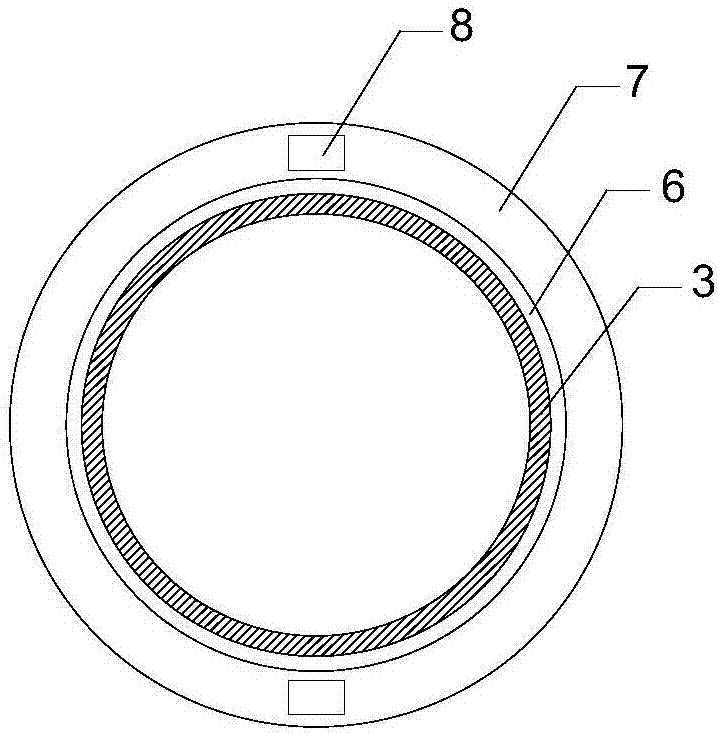

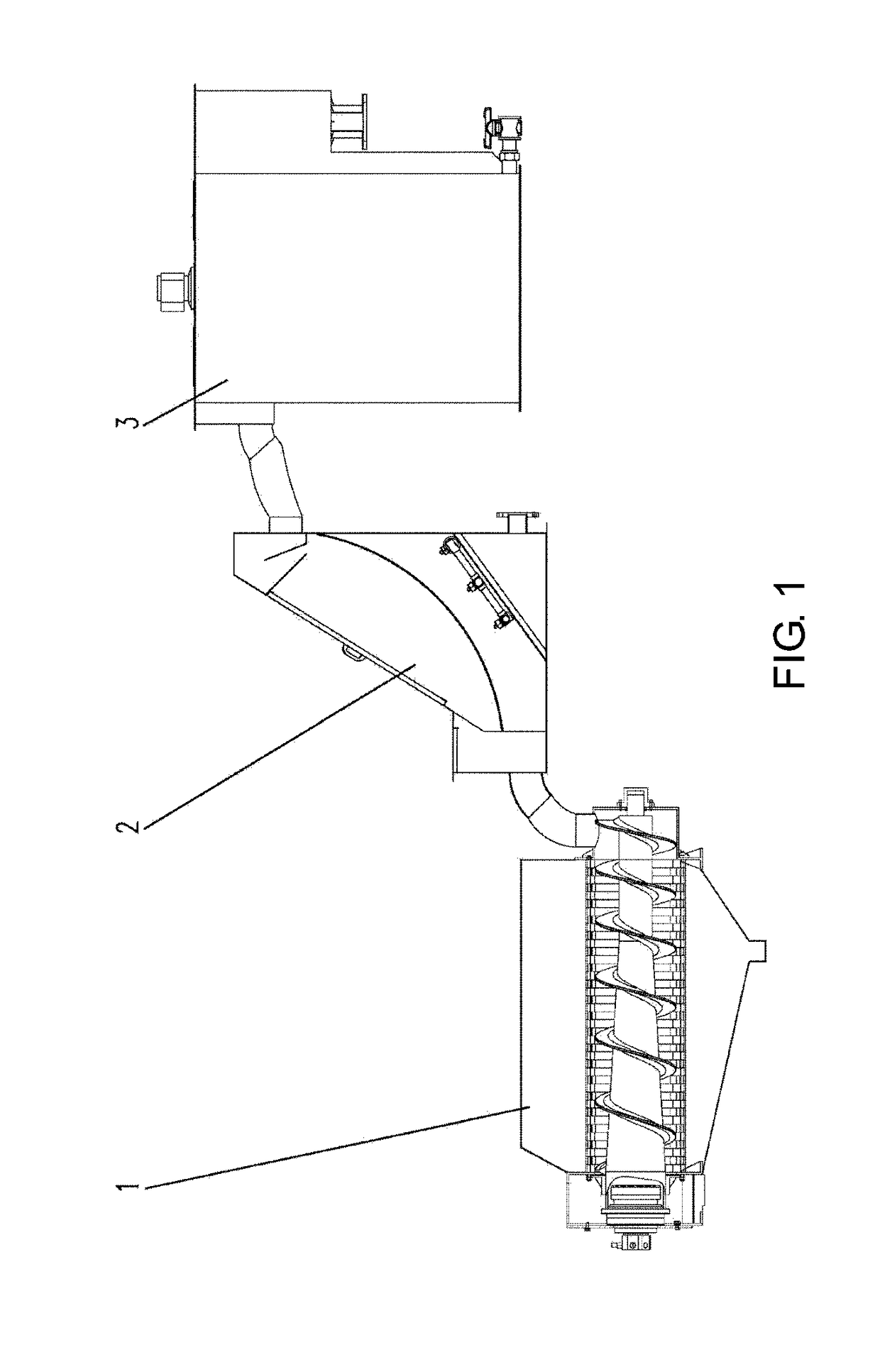

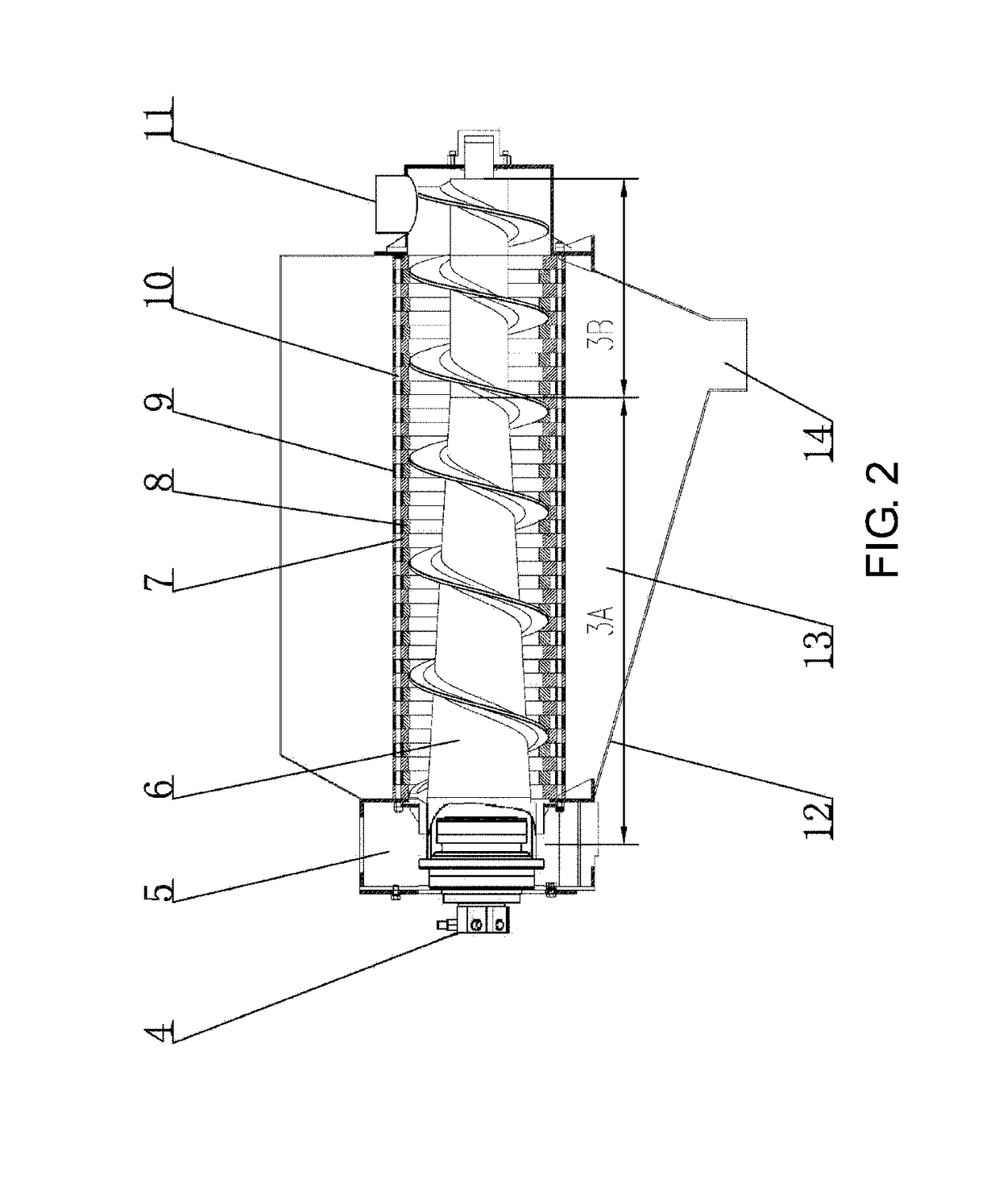

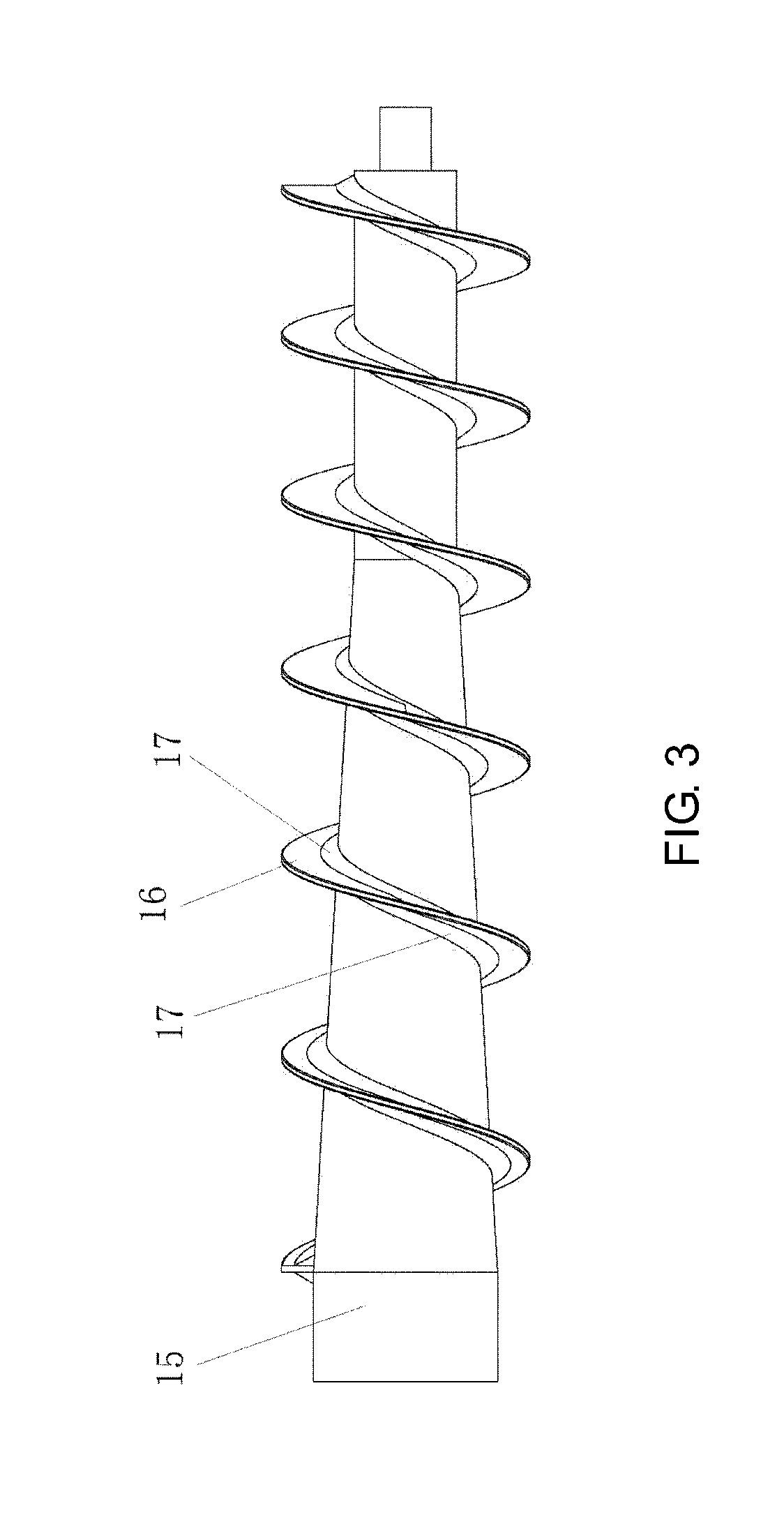

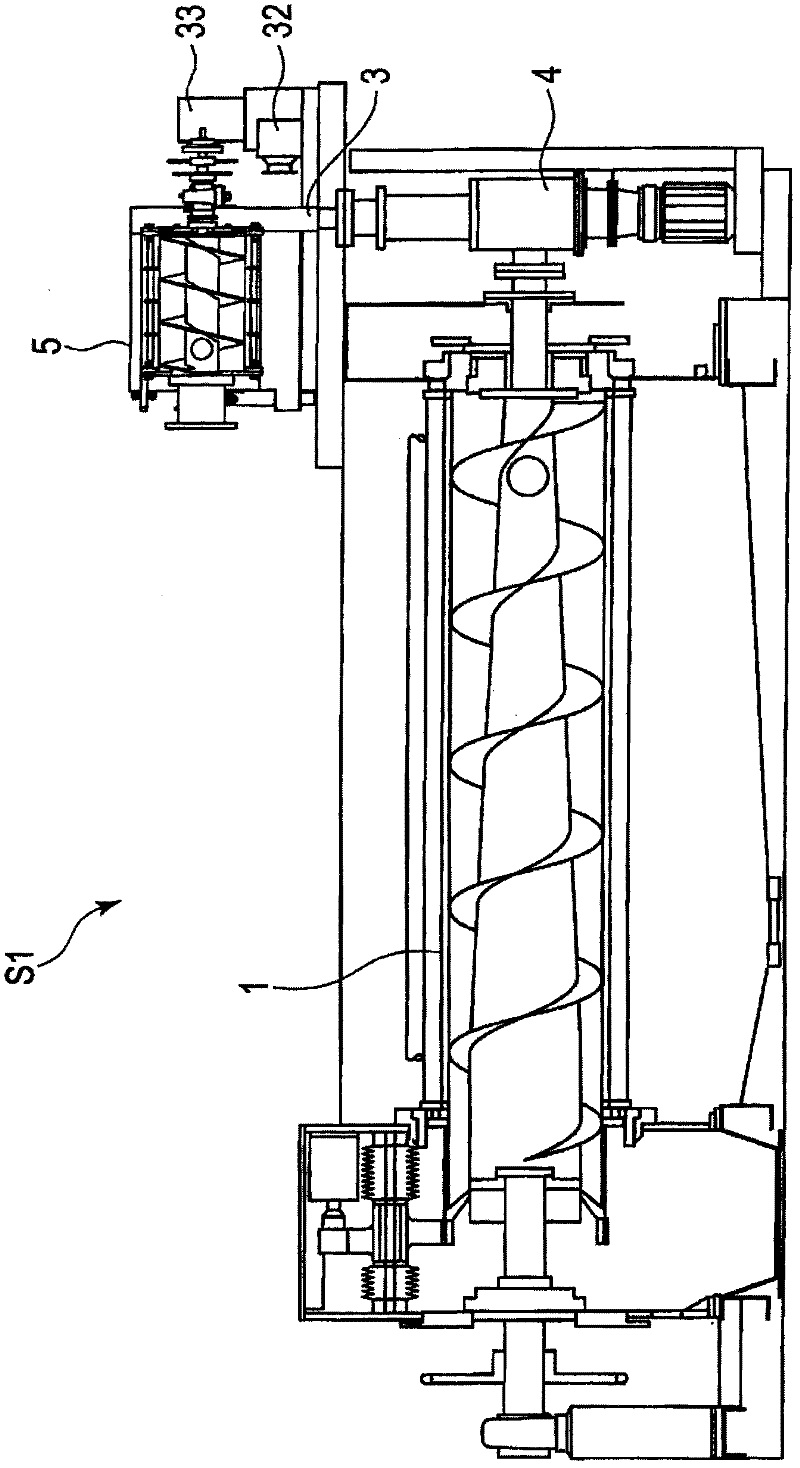

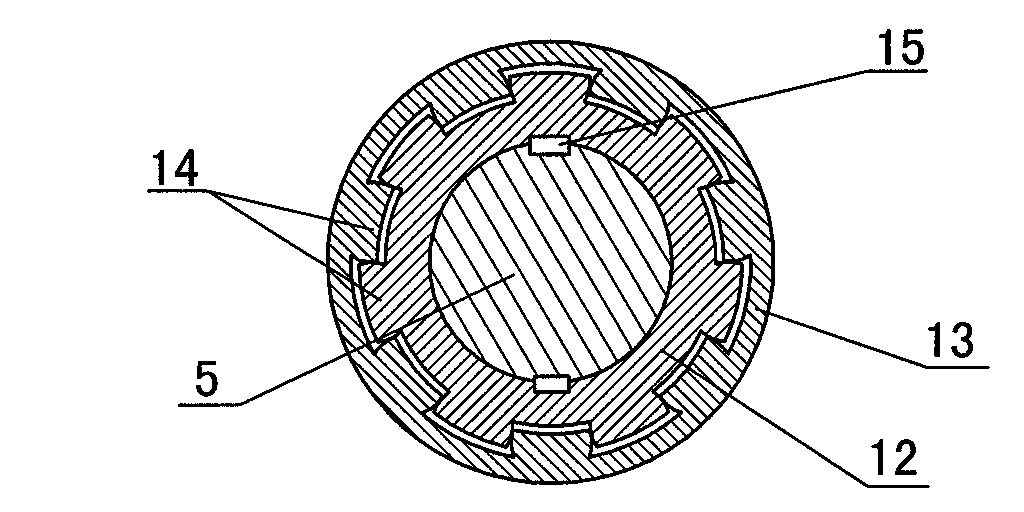

Multi plate screw press sludge dewatering machine

ActiveUS20180346362A1Convenience to workReduced footprintSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesHelical scanHelical blade

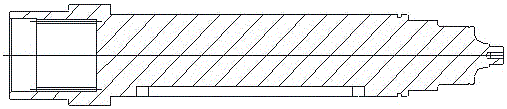

The present invention provides a multi plate screw press sludge dewatering machine and a helical shaft thereof. The multi plate screw press sludge dewatering machine includes fixed rings, movable rings, the helical shaft, a sludge inlet tank and a sludge discharging tank; the helical shaft adopts a variable diameter variable pitch helical shaft, a lead angle arrangement sequence of a helical blade of the whole helical shaft is gradual reduction from the sludge discharging tank to the sludge inlet tank, and the lead angle arrangement sequence is gradually reduced from 16°-22° to 6°-14°; a pitch of the helical shaft is gradually increased along a direction from the sludge inlet tank to the sludge discharging tank; a diameter of a shaft body of the helical shaft is gradually increased along with a direction of the sludge discharging tank from a ⅓ position of a shaft length; and blockage prevention plates are arranged on two sides of the bottom of the helical blade. The helical shaft in the present invention is specially designed, so that the pitch is more reasonable, a helical angle is gentler, frictional resistance when sludge passes through the helical shaft may be effectively reduced, and phenomena of shaft blockage and shaft sticking of the sludge may be reduced.

Owner:SHANGHAI TECHASE ENVIRONMENT PROTECTION

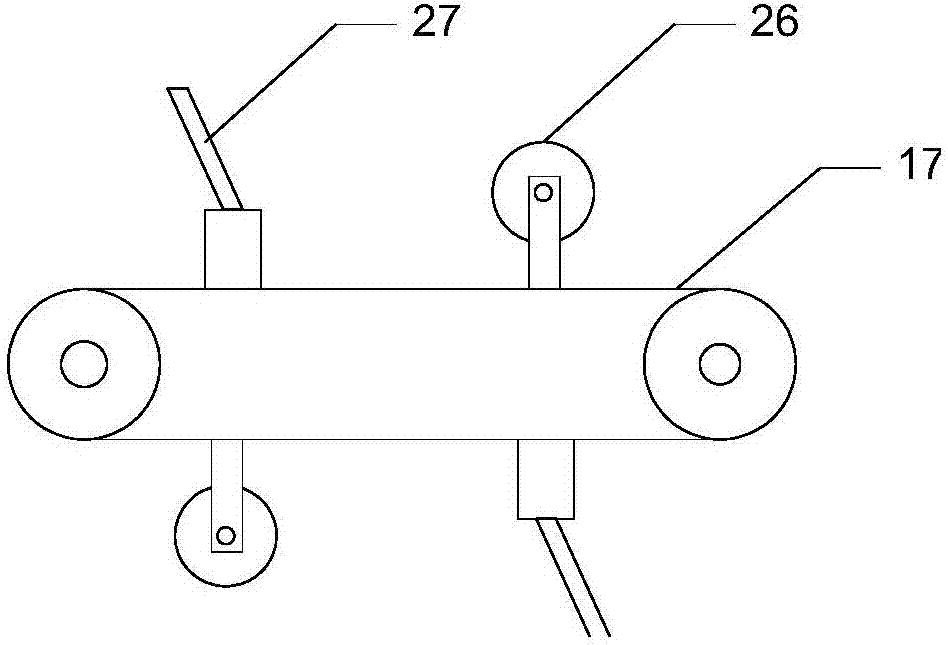

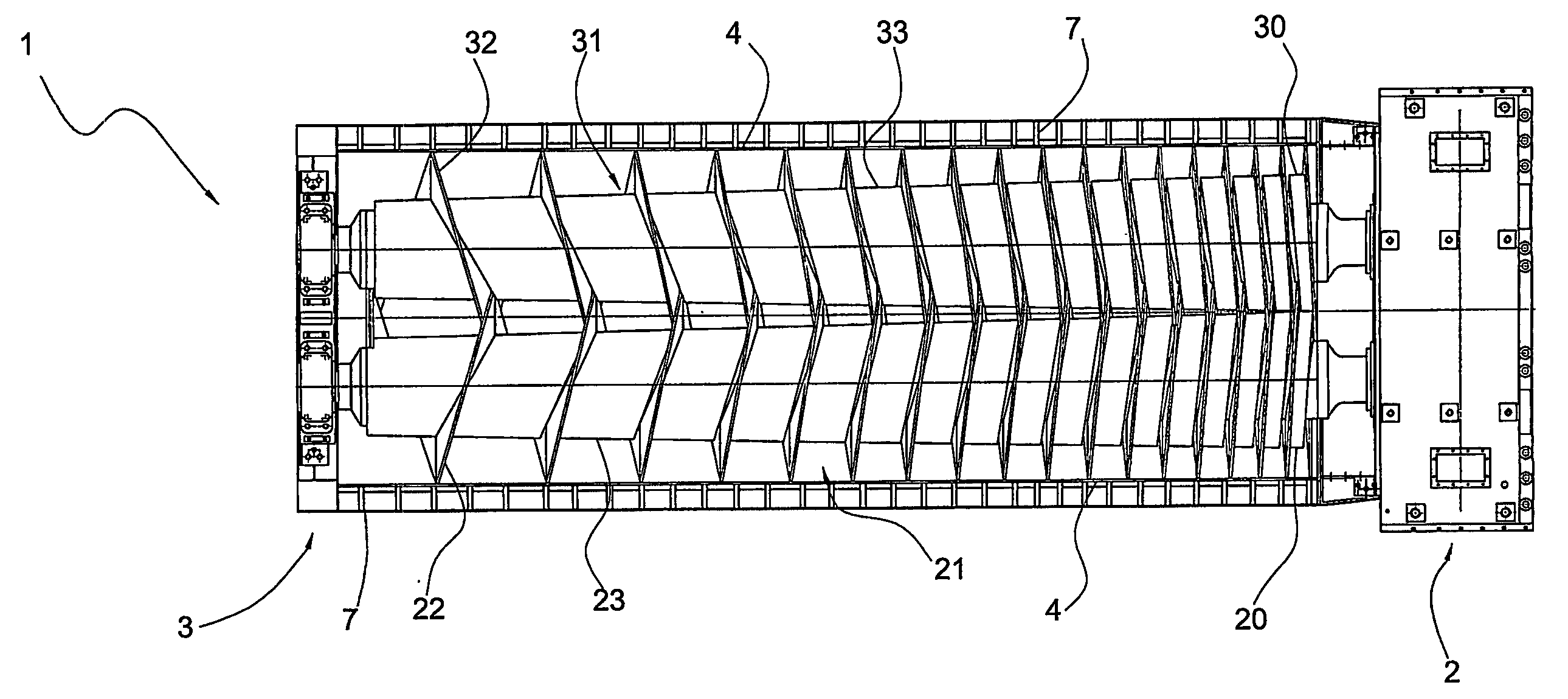

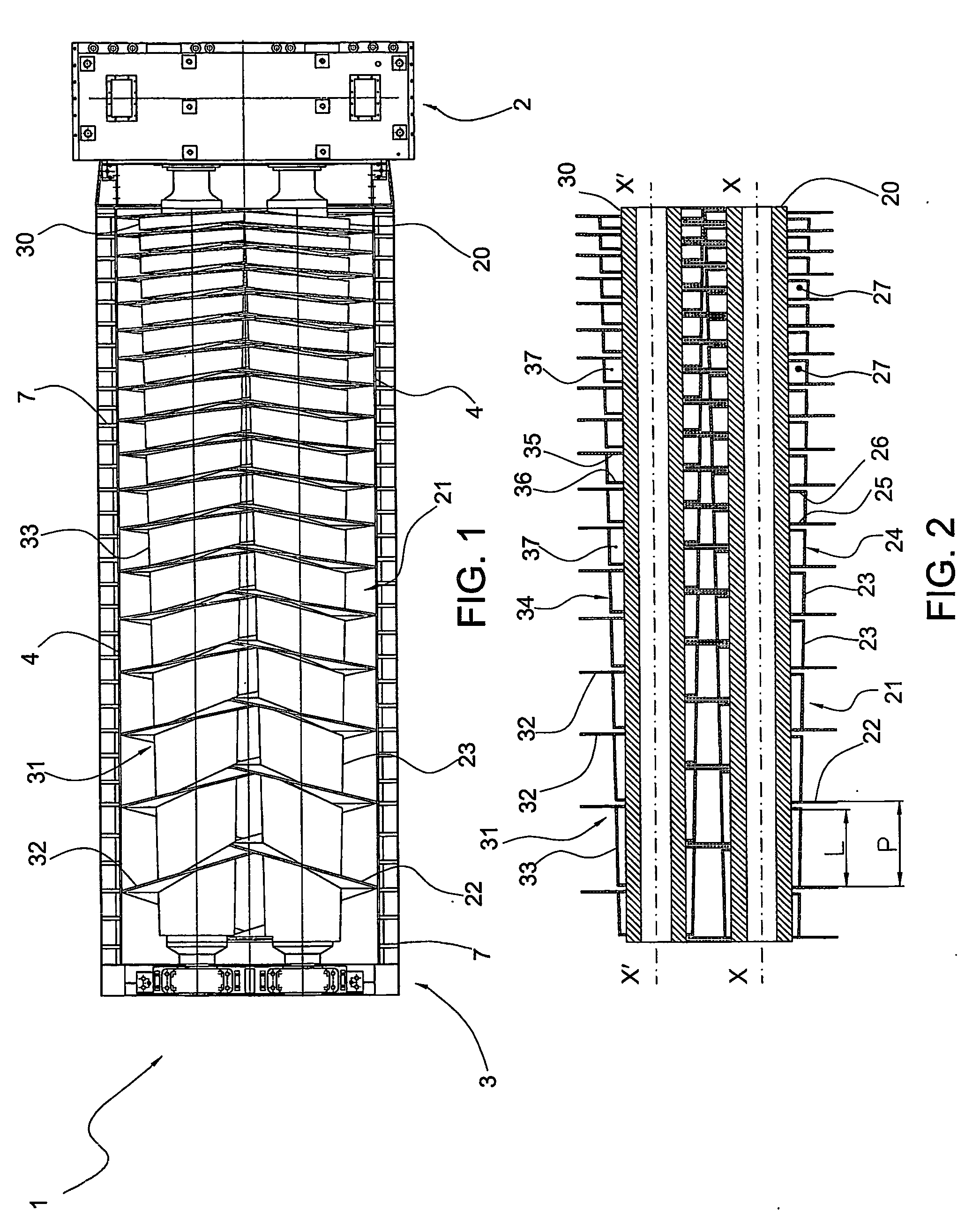

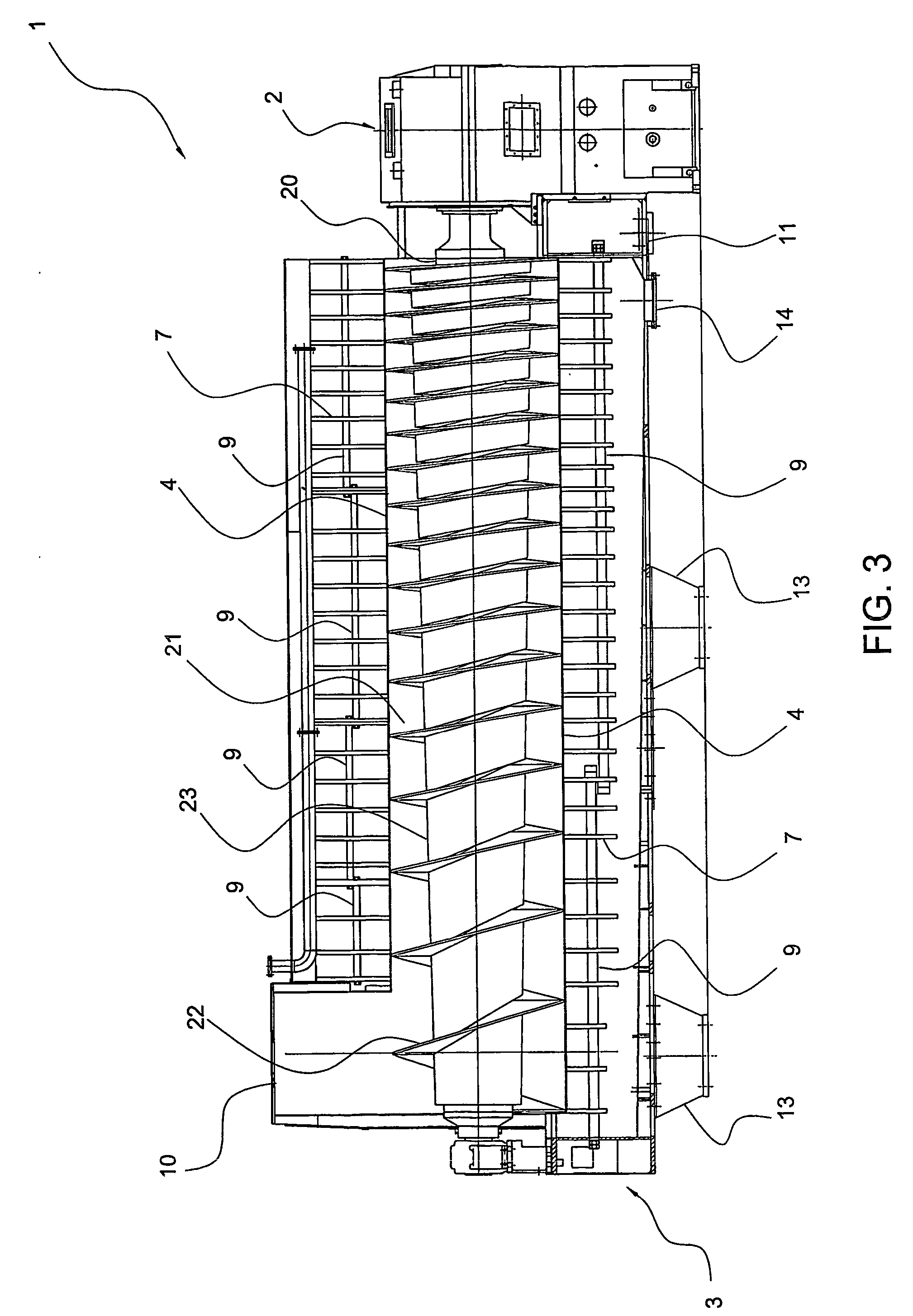

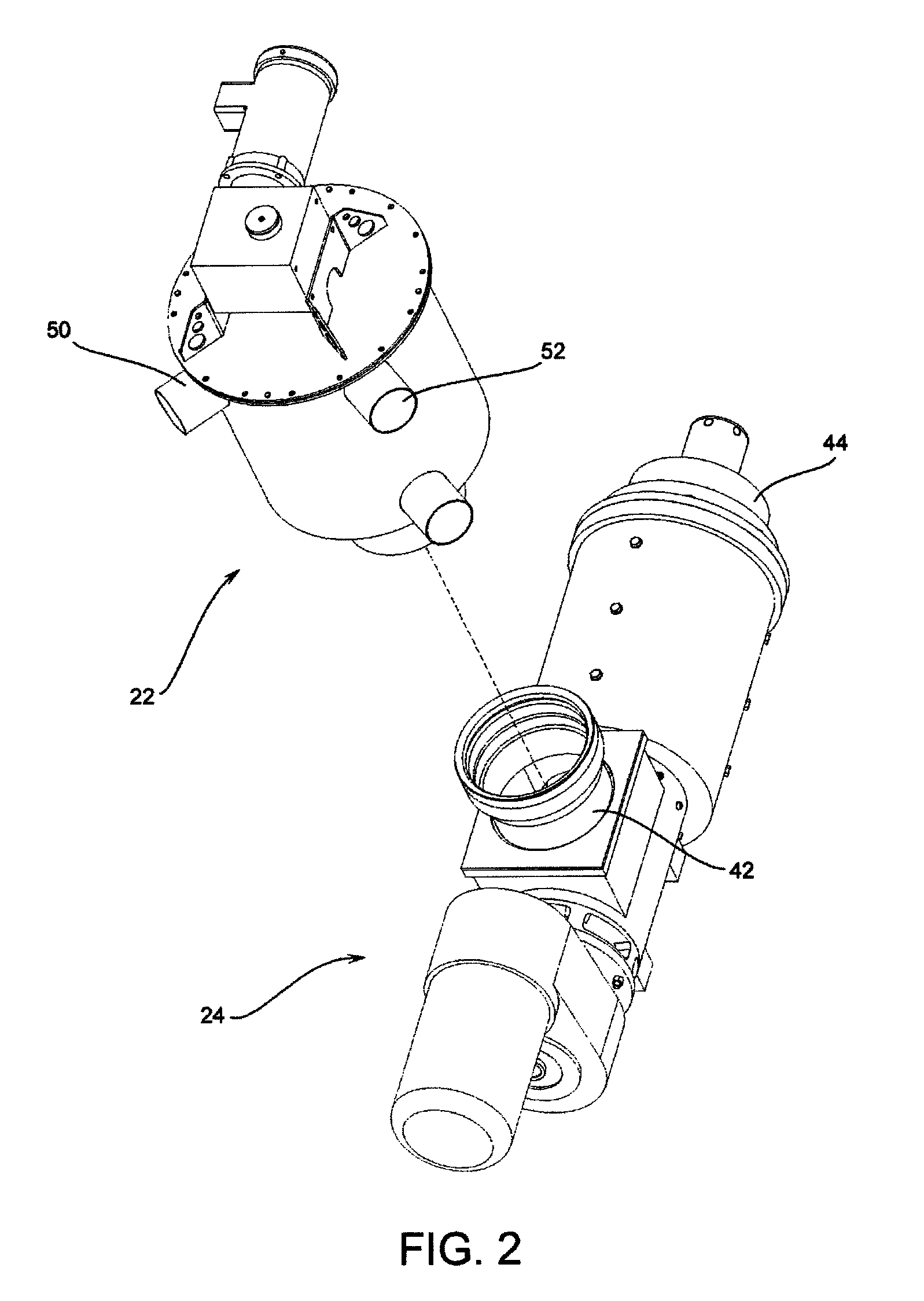

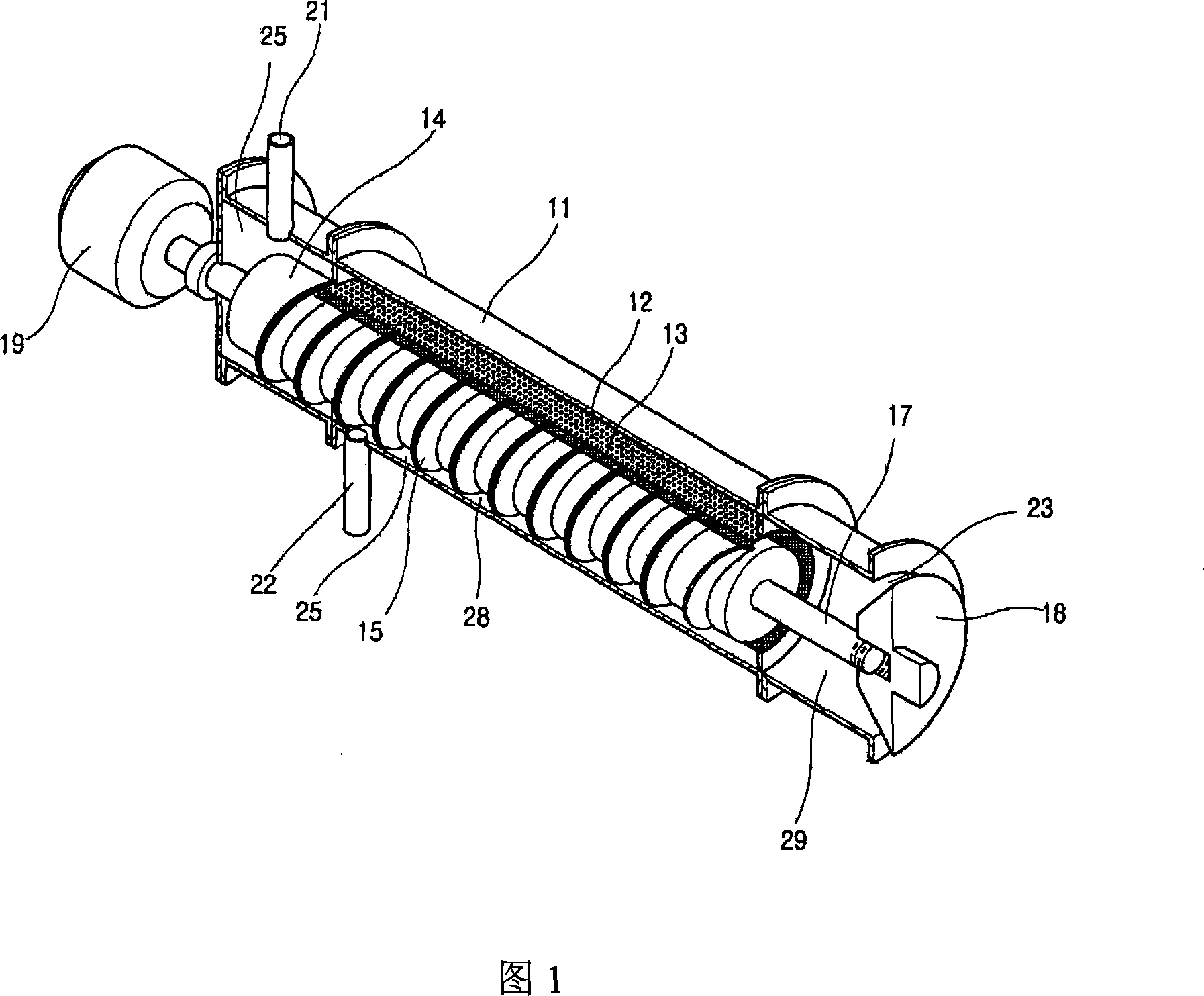

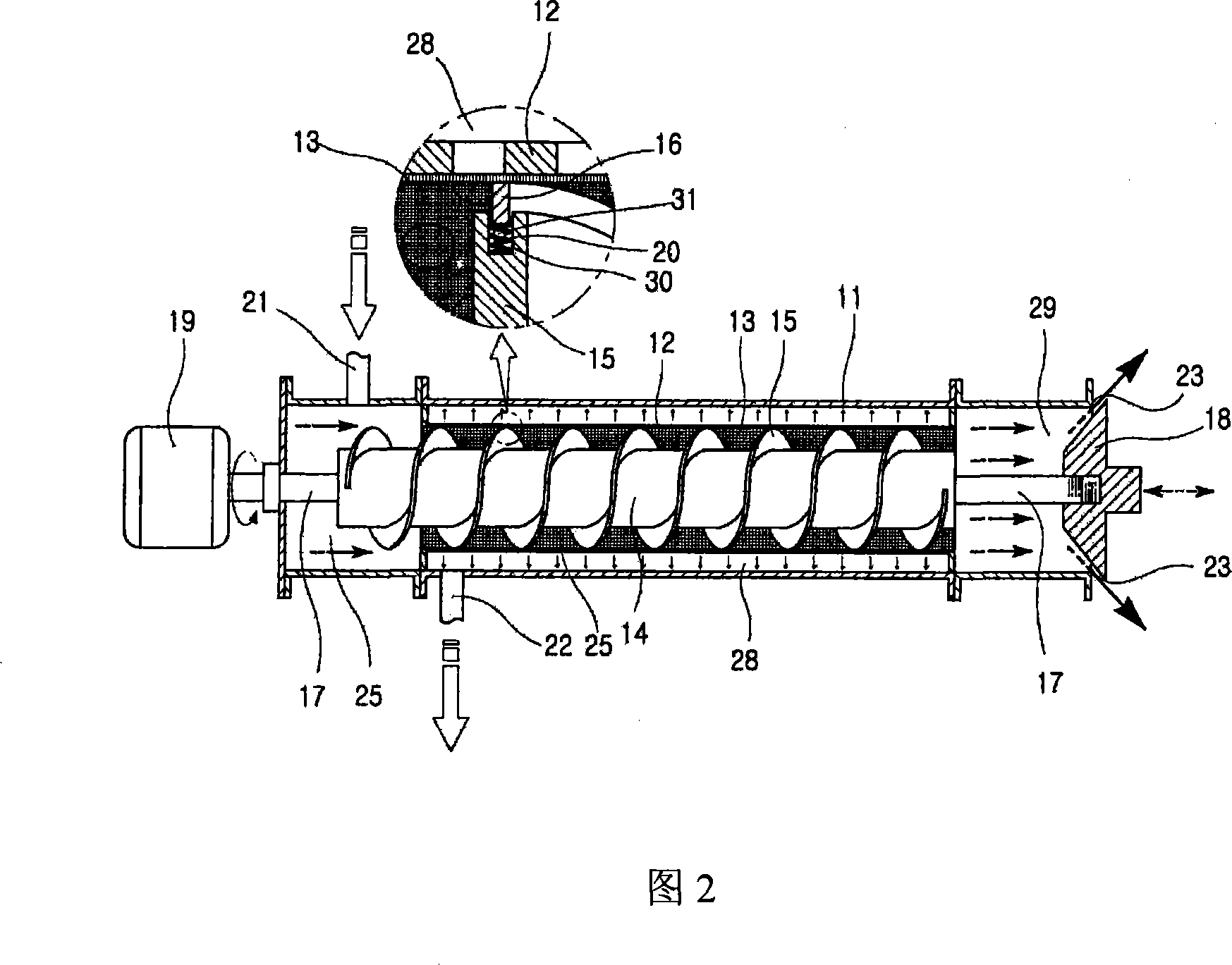

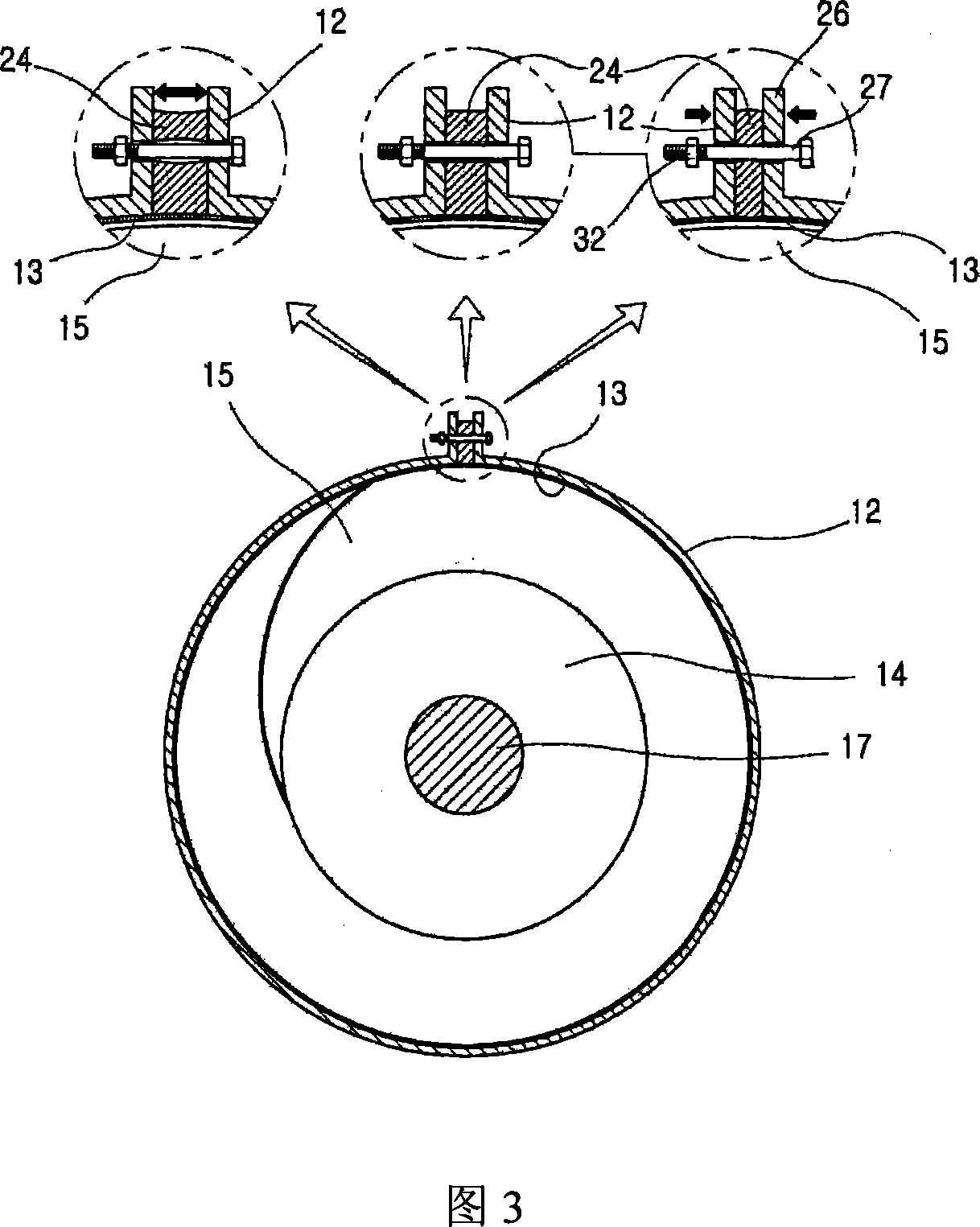

Screw press for squeezing out fibrous material

A screw press (1) for pressing fibrous material, in particular sugar beet pulp, comprising:—a pair of adjacent counter-rotating shafts (20, 30) having their axes (X-X, X′-X′), disposed parallel to each other, said shafts (20, 30) each being provided externally with a helical structure winding in the opposite direction to the helical structure of the other shaft;—a perforated walled filtering cage (4) enclosing said helical structures (21, 31) as an exact fit;—a loading hopper (10) for feeding the fibrous material to the press (1);—a discharge aperture (11) for the exit of the pressed material;—a collection sump (12) positioned externally to said filtering cage (4); in which each box-like helical structure (21, 31) comprises a helix (22, 32) and a helical element (23, 33), comprising at least one perforated surface (24, 34) and forming a helical interspace (27, 37) with the outer surface of the shaft (20, 30), said perforated surface (24, 34) having a length (L) along the axis (X-X, X′-X′) of the shaft (20, 30) which at every point is less than the pitch (P) of the helix (22, 32) by an amount sufficient to receive the helix (32, 33) of the adjacent shaft (30, 20).

Owner:DOMUS INT

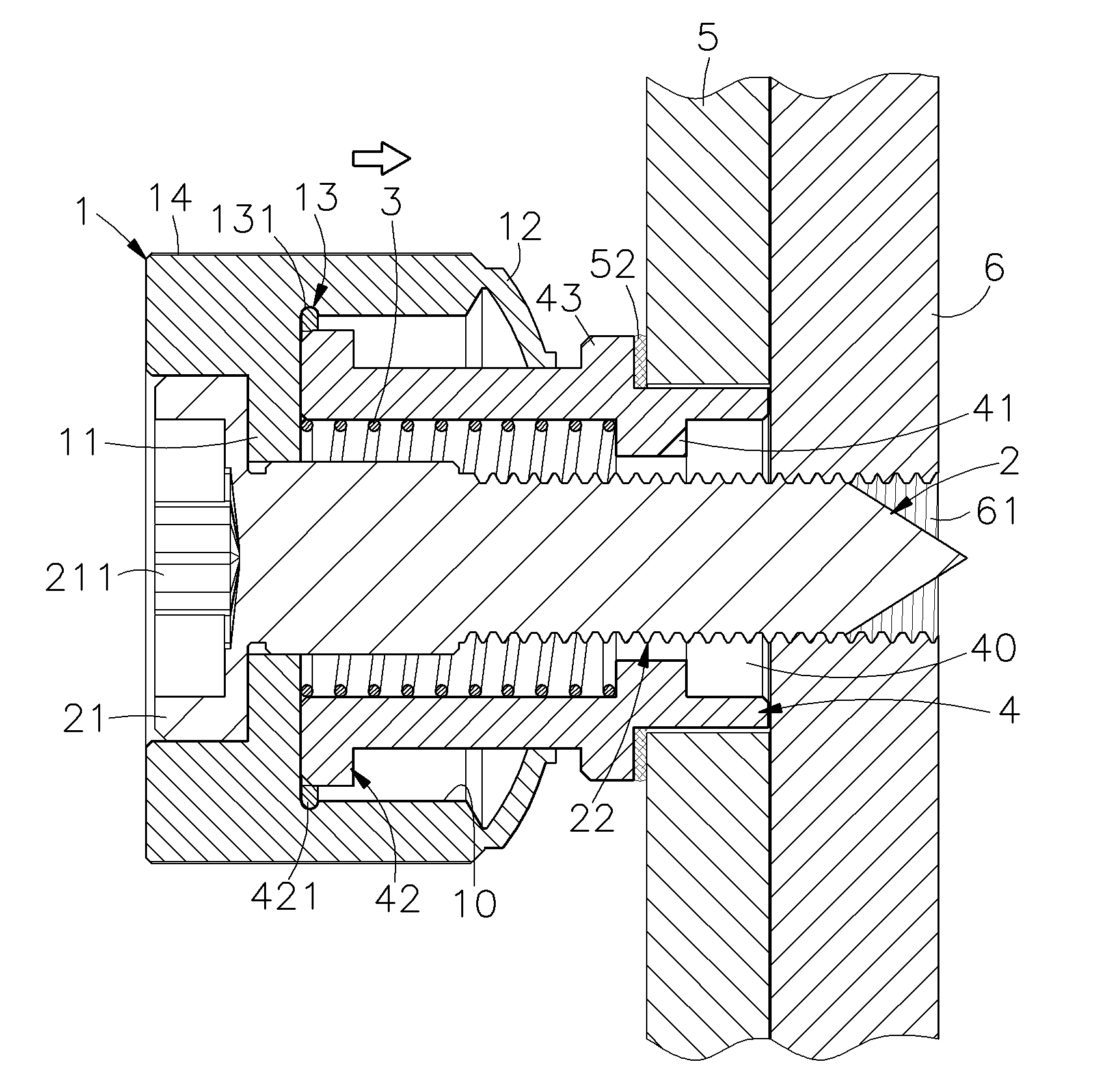

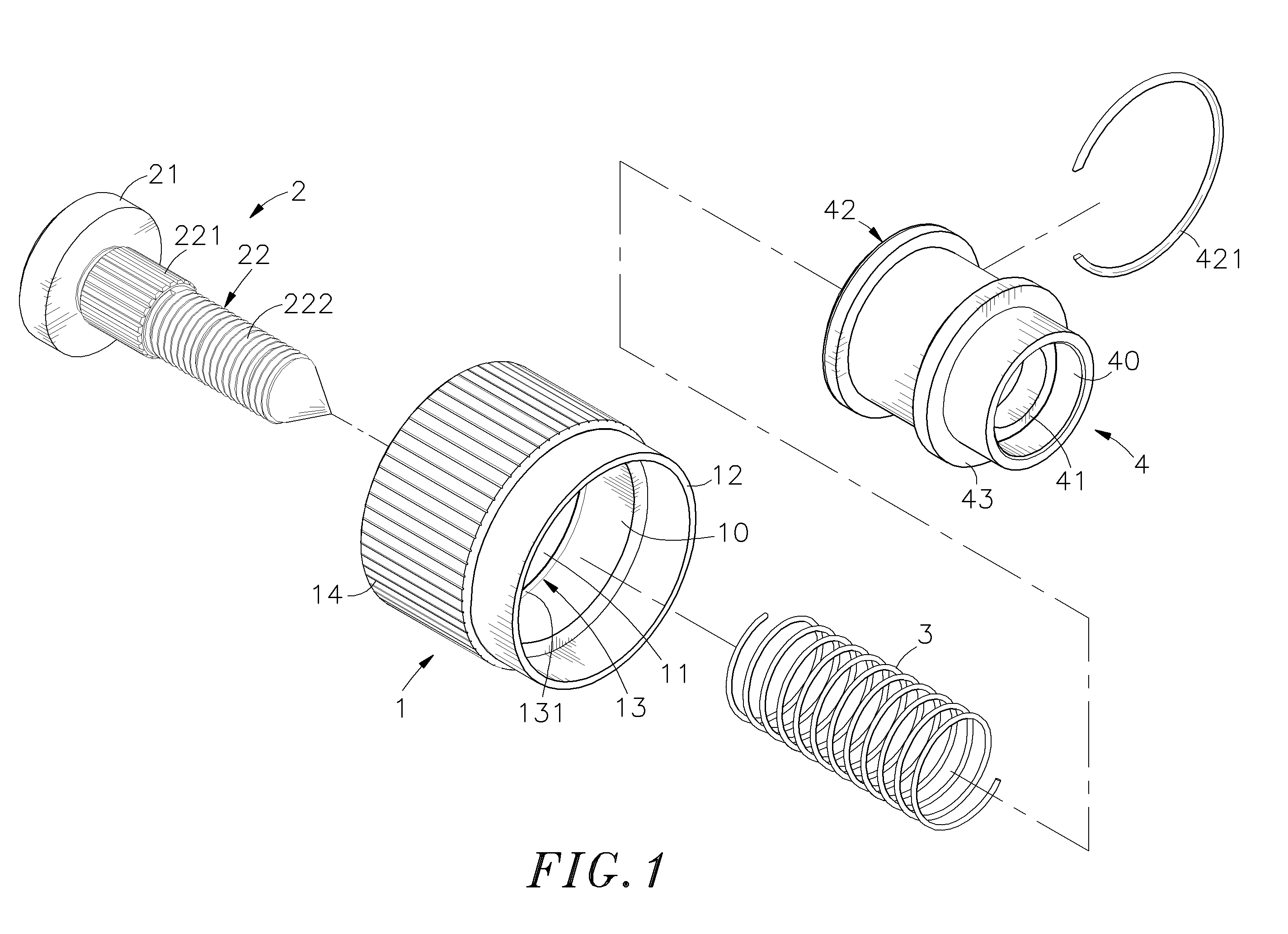

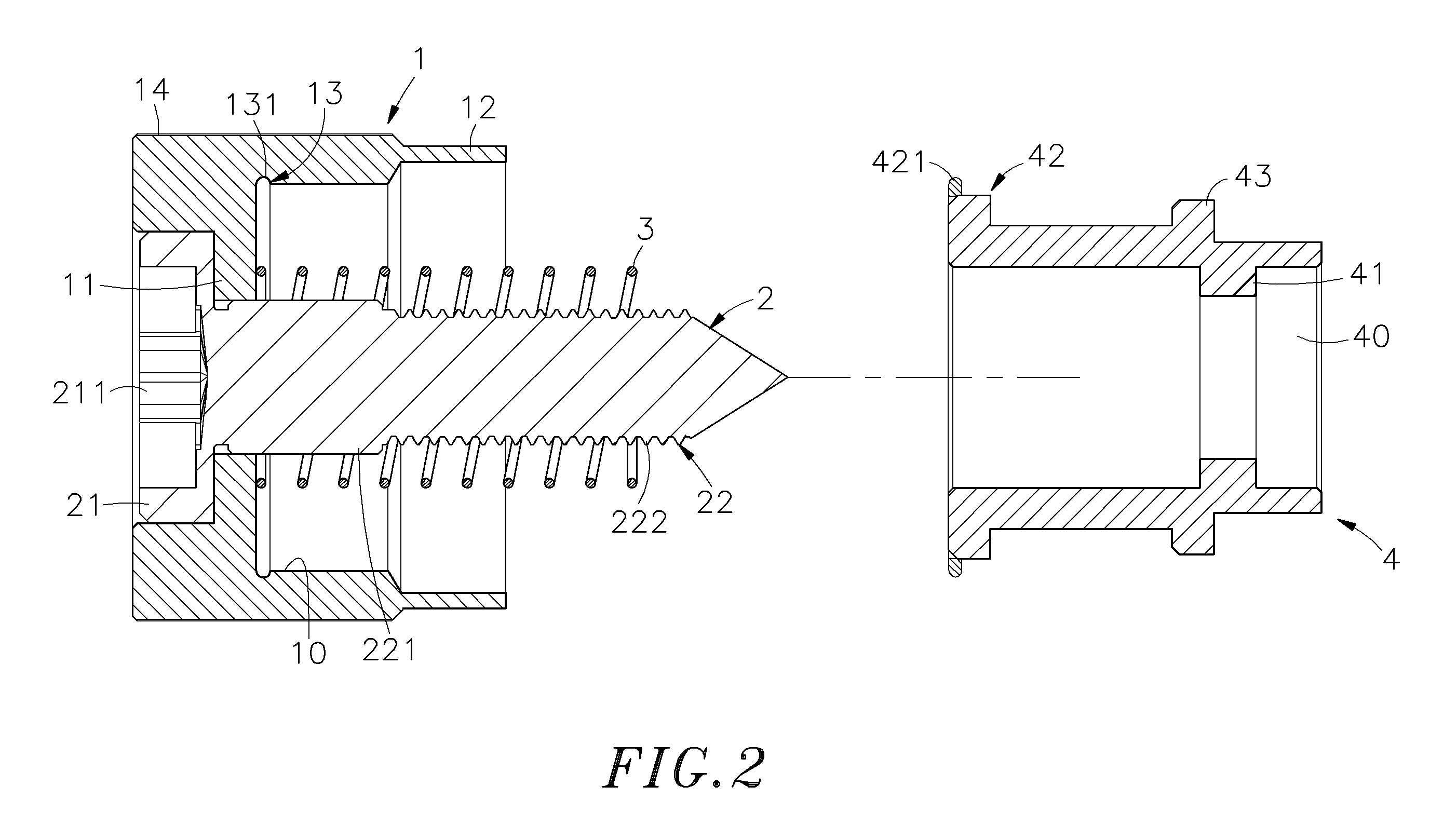

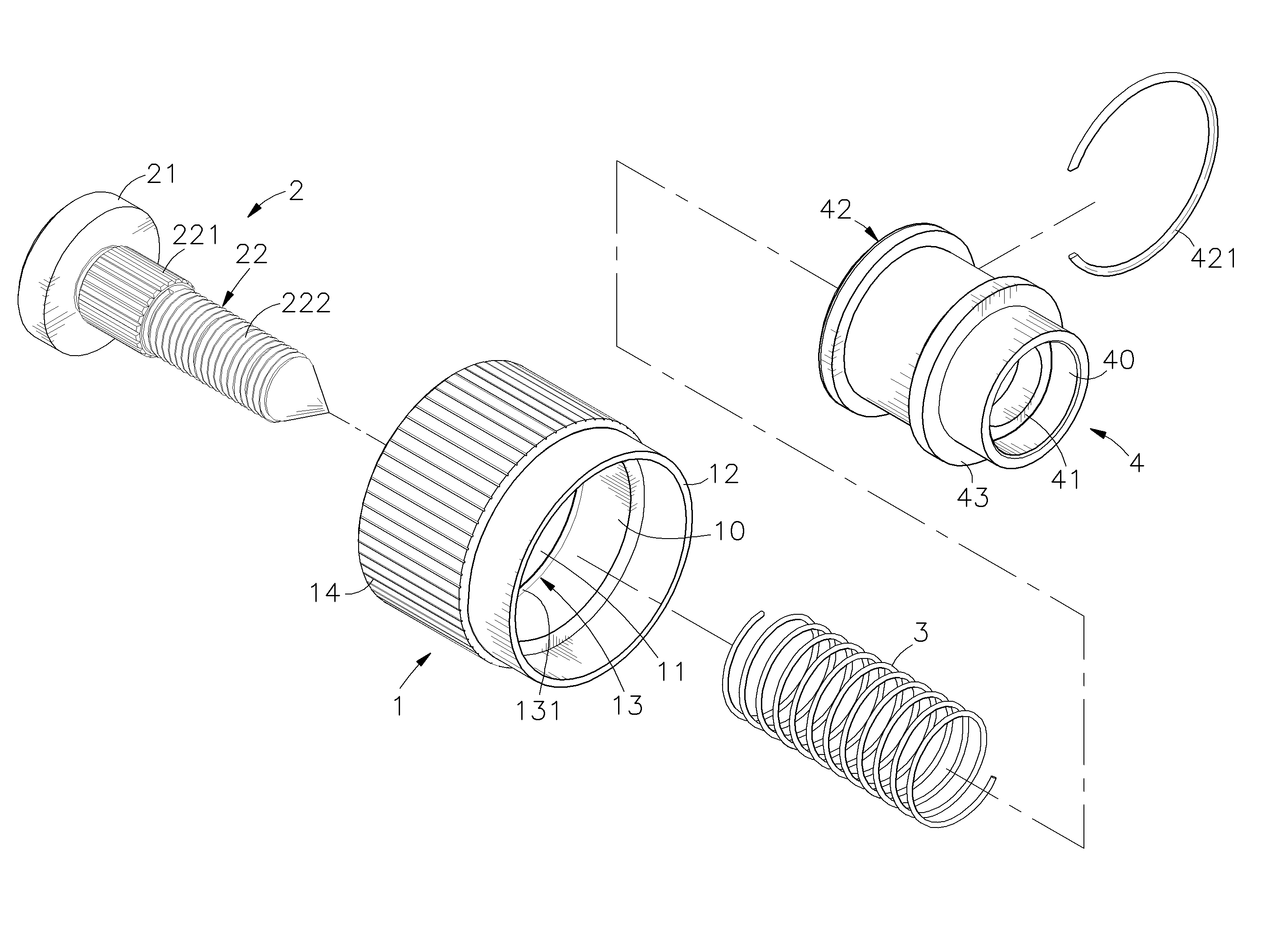

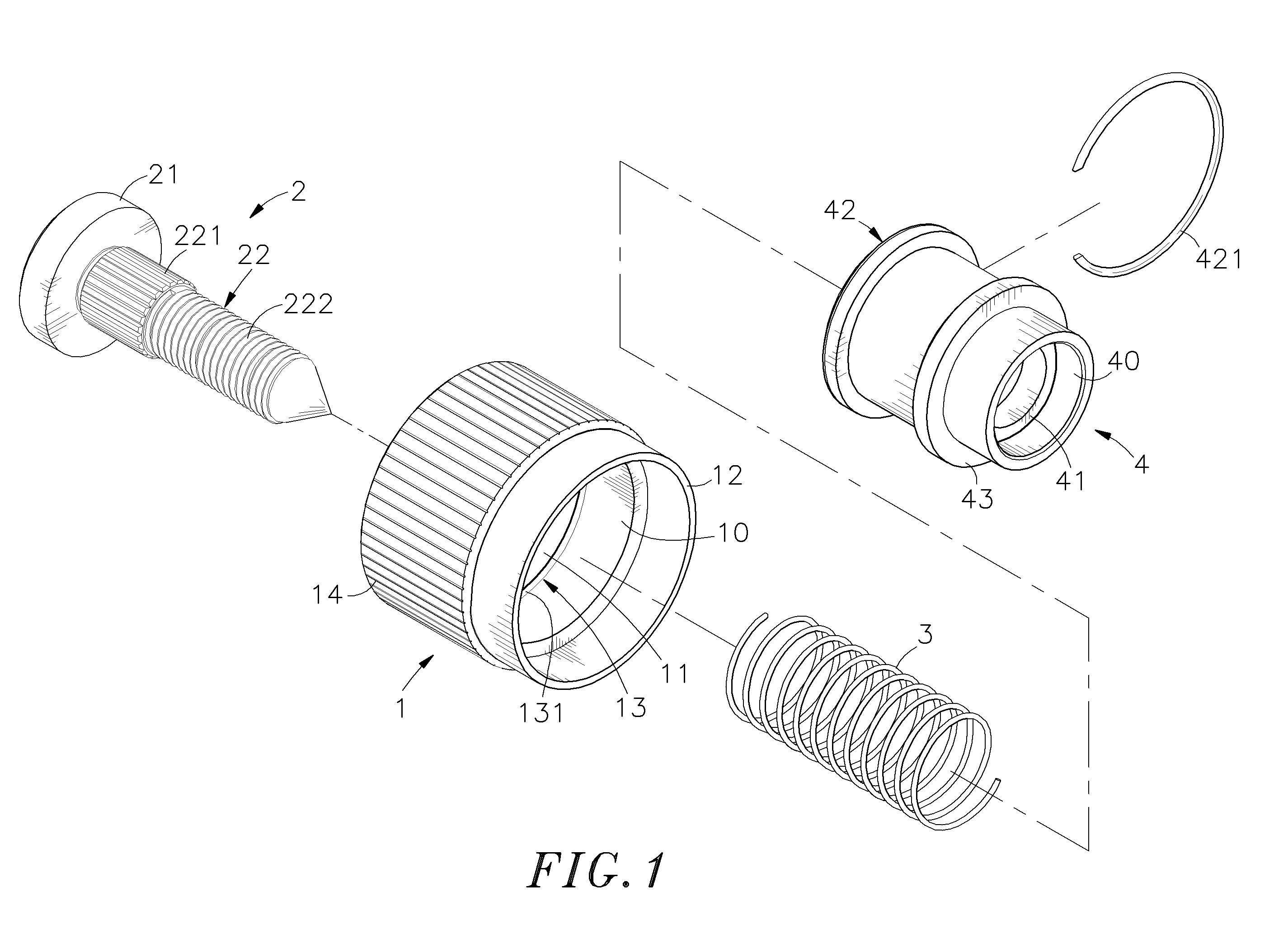

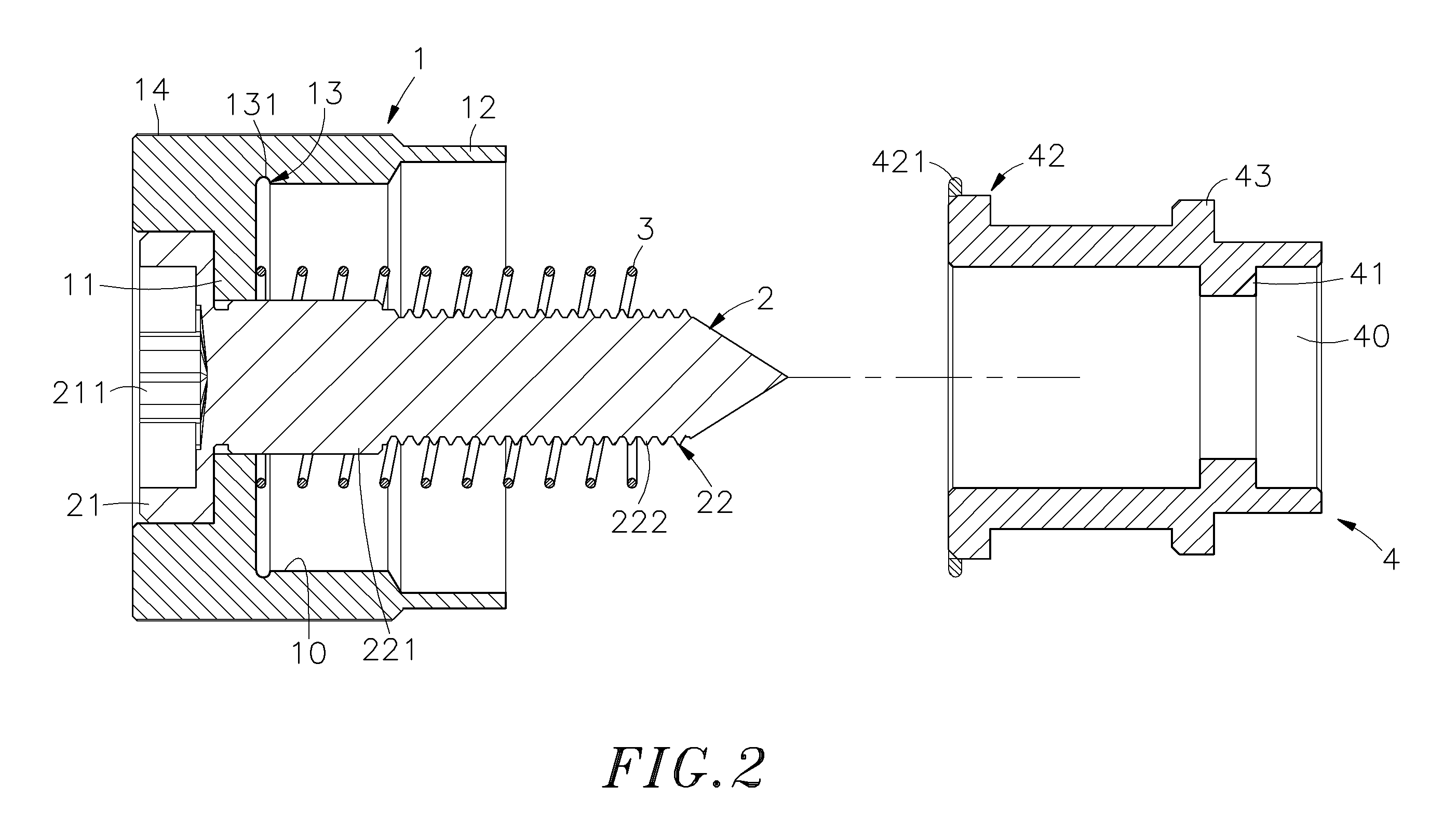

Quick-positioning screw assembly

InactiveUS20100132178A1Quick and accurate installationPrevent fallingNutsBoltsEngineeringScrew press

A quick-positioning screw assembly includes a cap having an inside annular flange and a locating groove or locating rib extending around the inside wall, a mounting socket bonded to a mounting through hole of a first plate member and having a top positioning flange extending around the periphery and detachably forced into engagement with the locating groove or locating rib of the cap, a screw press-fitted into the inner diameter of the inside annular flange of the cap for threading into a screw hole on a second plate member to secure the first plate member to the second plate member, and a compression spring mounted in the cap around the screw and stopped between the inside annular flange of the cap and an inside annular flange of the mounting socket.

Owner:HANWIT PRECISION IND LTD

Quick-positioning screw assembly

A quick-positioning screw assembly includes a cap having an inside annular flange and a locating groove or locating rib extending around the inside wall, a mounting socket bonded to a mounting through hole of a first plate member and having a top positioning flange extending around the periphery and detachably forced into engagement with the locating groove or locating rib of the cap, a screw press-fitted into the inner diameter of the inside annular flange of the cap for threading into a screw hole on a second plate member to secure the first plate member to the second plate member, and a compression spring mounted in the cap around the screw and stopped between the inside annular flange of the cap and an inside annular flange of the mounting socket.

Owner:HANWIT PRECISION IND LTD

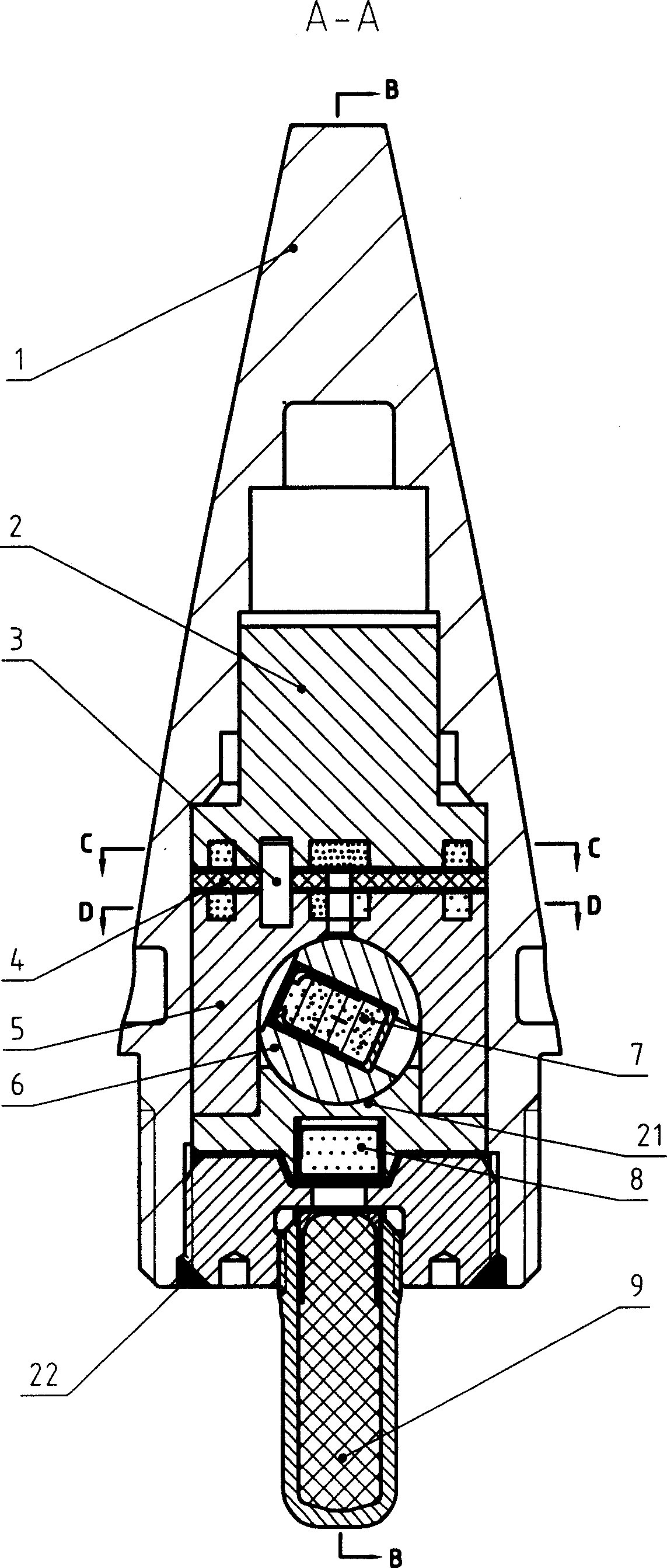

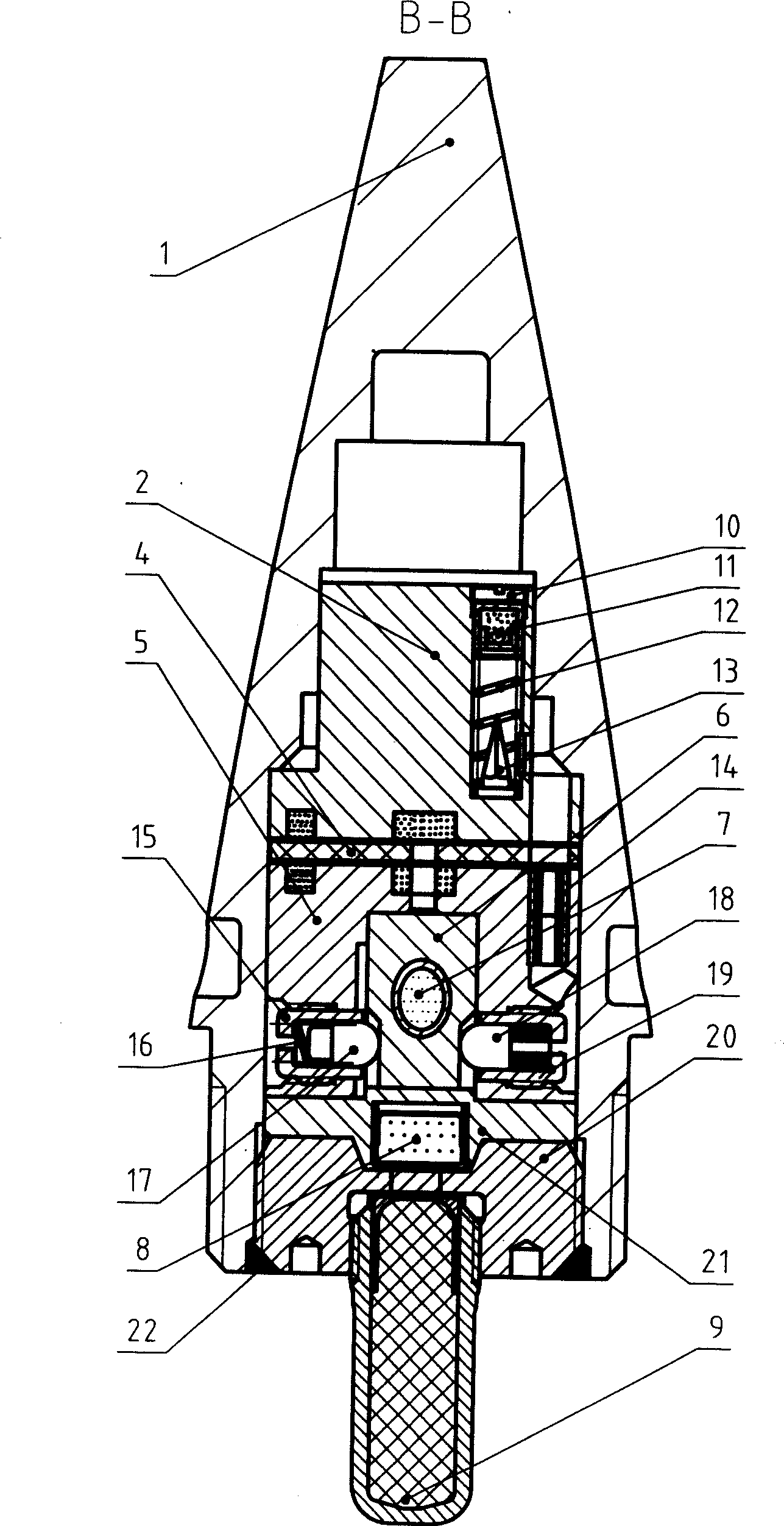

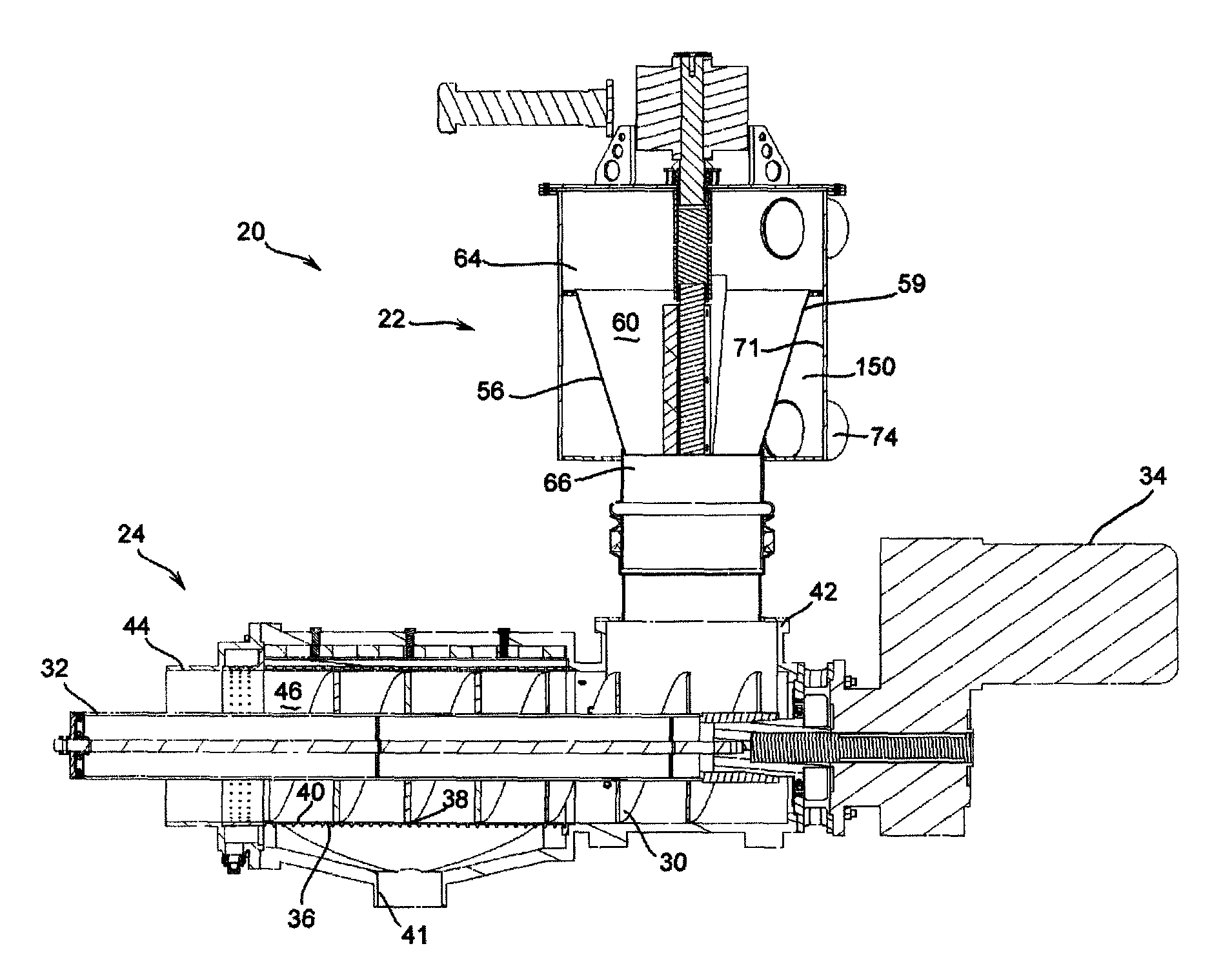

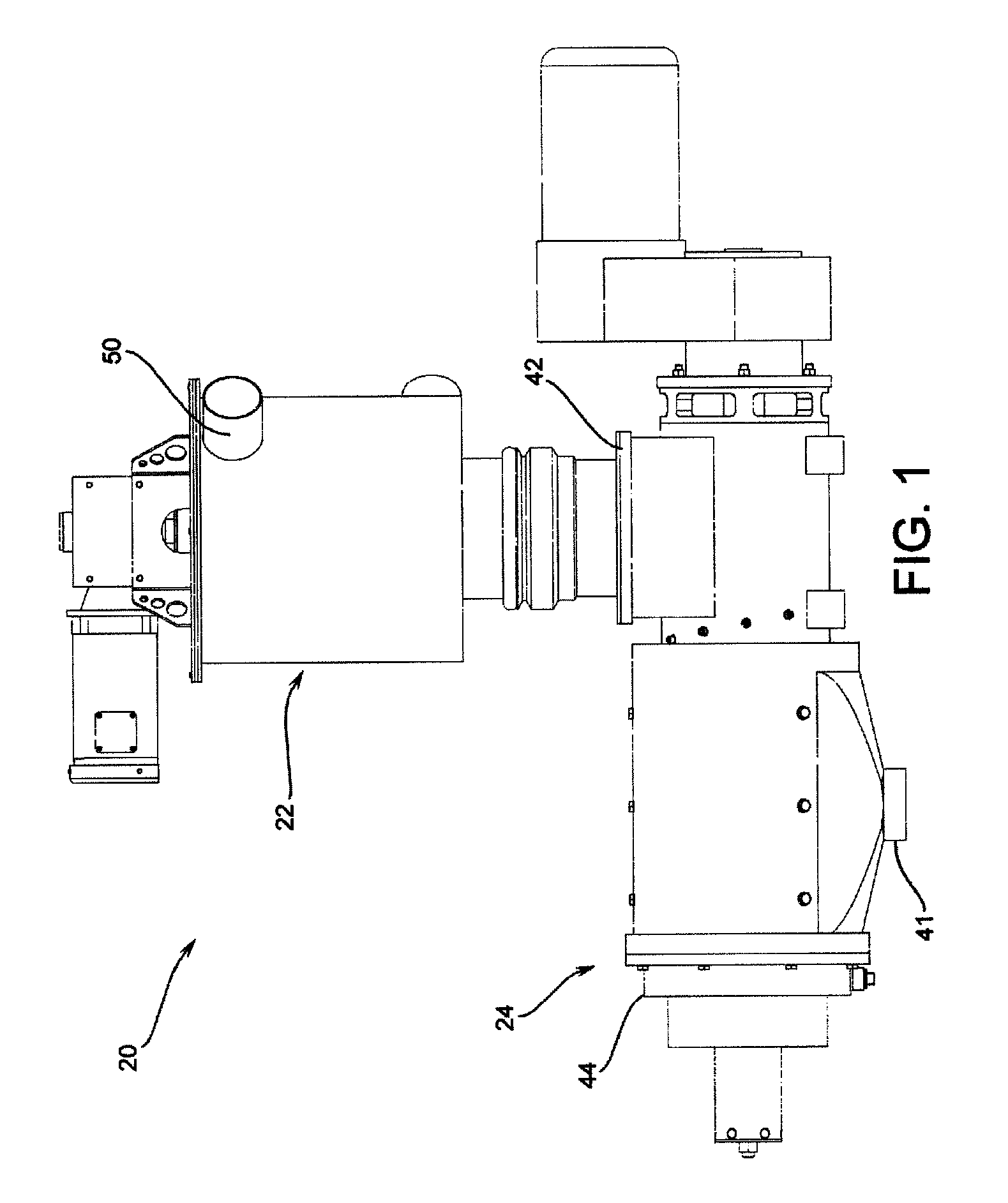

Pre-separator for a screen separator

ActiveUS7987778B1Effective expansionMaintaining engagementSedimentation settling tanksPressesEngineeringScrew press

A pre-separator for a screw press separator wherein the pre-separator increases the concentration of solid material in a water solid material mixture. The pre-separator is configured to have a frustoconical screen surface where a plurality of wiper blades engage the interior portion of the surface to provide de-watering action, and the plurality of blades are configured to reposition with respect to the center axis of the frustoconical surface to allow for engagement between the interior surface of the frustoconical screen, and the wiper blades.

Owner:DARITECH

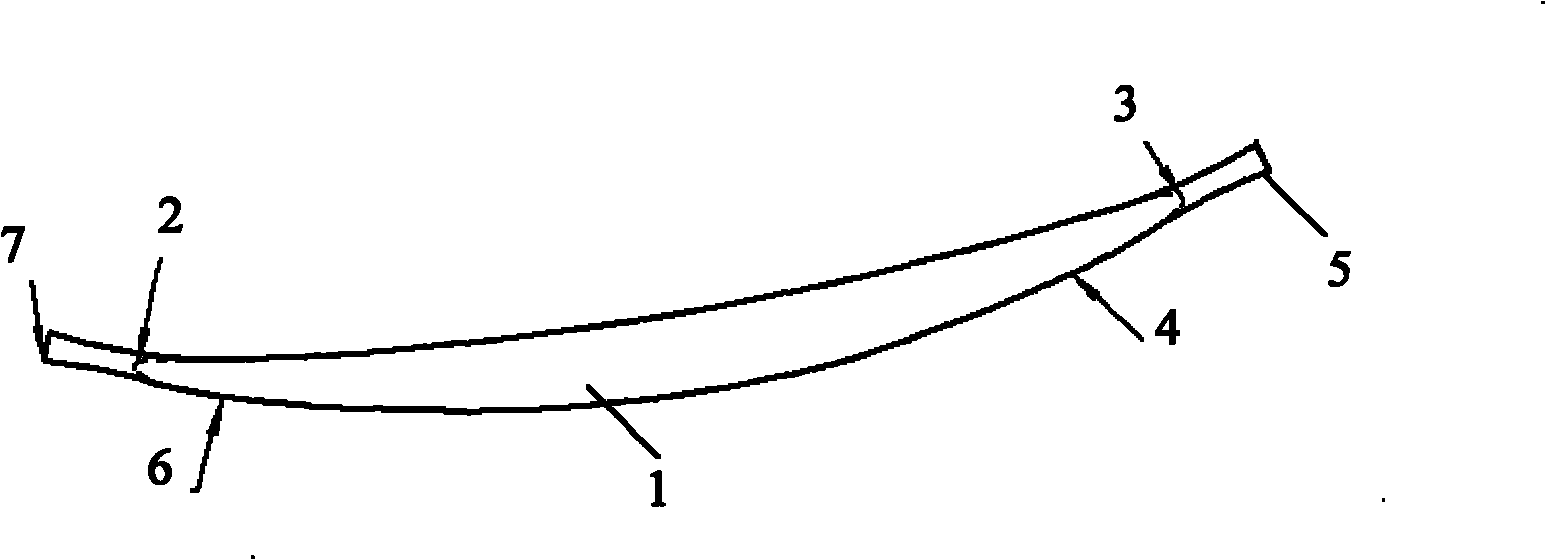

Screw press for separation of liquid from solid-liquid mixtures especially pulp suspensions

Screw press for separation of liquid from solid liquid mixtures, especially pulp suspensions, with a casing with perforations for liquid and a screw shaft provided in it between which a circular gap is formed through which the solid liquid mixture is pressed. Furthermore, a counter pressure device in the area of the discharge end of the circular gap is provided. To reduce the space requirement in the discharge area at the discharge end of the circular gap, which makes it possible to reduce the size of the discharge casing and cut costs due to a less complicated design, the counter pressure device has a counter pressure surface, the radius of which is decreasing in the conveying direction of the solid liquid mixture. In this way the solid liquid mixture with the liquid largely extracted will be redirected radially inwards and outside of the counter pressure device no additional space is needed to discharge the solid liquid mixture with the liquid largely extracted, so that the discharge casing may be reduced in size correspondingly.

Owner:ANDRITZ AG

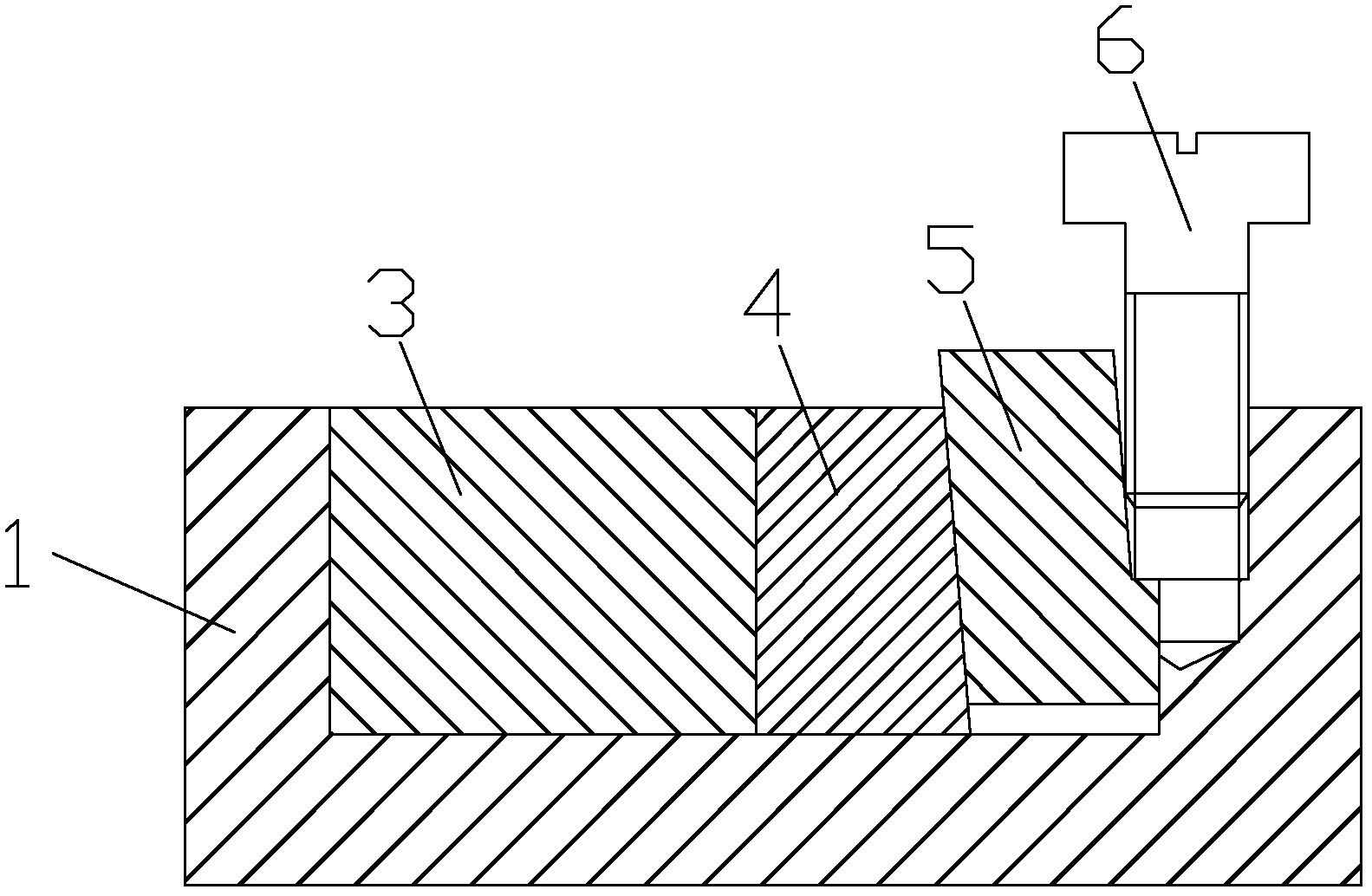

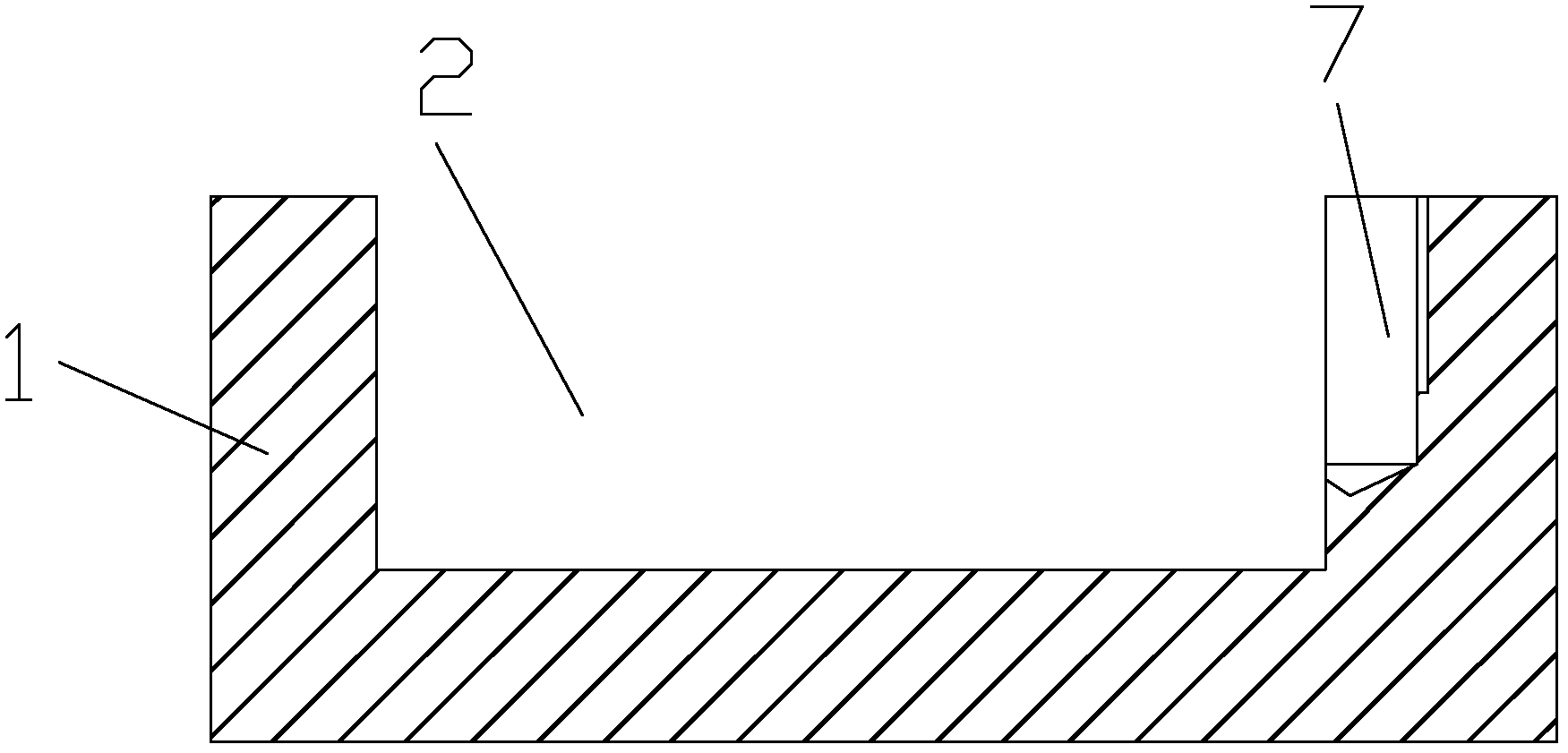

Pre-tightening device

InactiveCN102619821ASimple structureGood preload effectFriction grip releasable fasteningsMountingsEngineeringScrew press

The invention discloses a pre-tightening device, which comprises a machine body, piezoelectric ceramics, a fixed wedge, a moving wedge, a screw, a screw hole and a conical hole. A groove is arranged on the machine body. The piezoelectric ceramics is arranged on one side of the groove. One side of the piezoelectric ceramics is adjacent to a side of the groove, and the other side of the piezoelectric ceramics is adjacent to a vertical face of the fixed wedge. The other end portion of the groove is provided with the screw hole. The moving wedge is inserted into a space between the fixed wedge and the other end of the groove. An inclined face of the moving wedge is adjacent to an inclined face of the fixed wedge. The conical hole is arranged at the end portion of the vertical face of the moving wedge. The screw is screwed into the screw hole, and one part of the screw is inserted into the conical hole too. When the screw is screwed downwards, the screw presses the moving wedge downwards to pre-tighten the piezoelectric ceramics. In the technical scheme, the screw is screwed into the screw hole, and one part of the screw is inserted into the conical hole too; and when the screw is screwed downwards, the screw presses the moving wedge downwards to pre-tighten the piezoelectric ceramics. The pre-tightening device is simple in structure and good in pre-tightening effect.

Owner:SUZHOU TANGFENG ELECTRICAL APPLIANCE

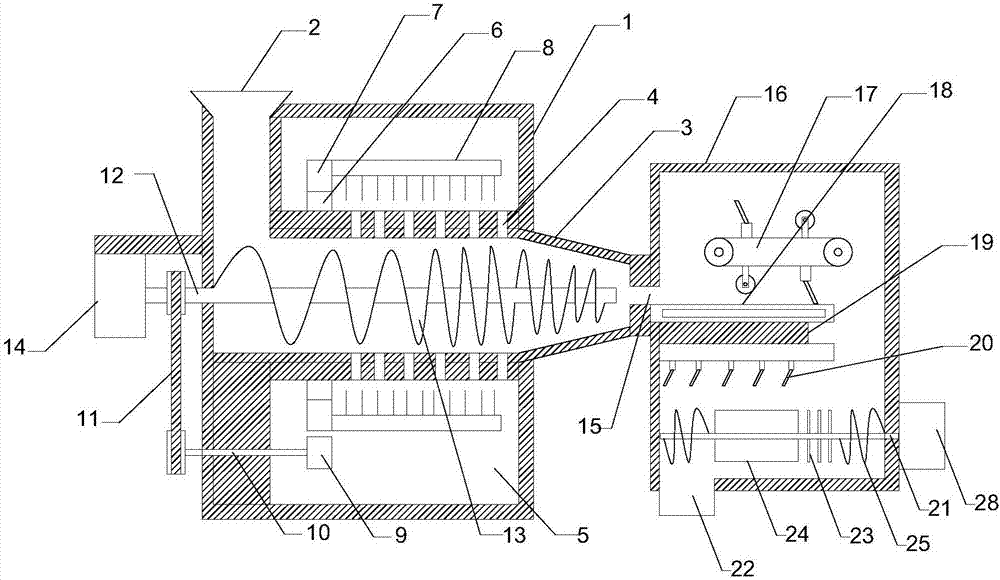

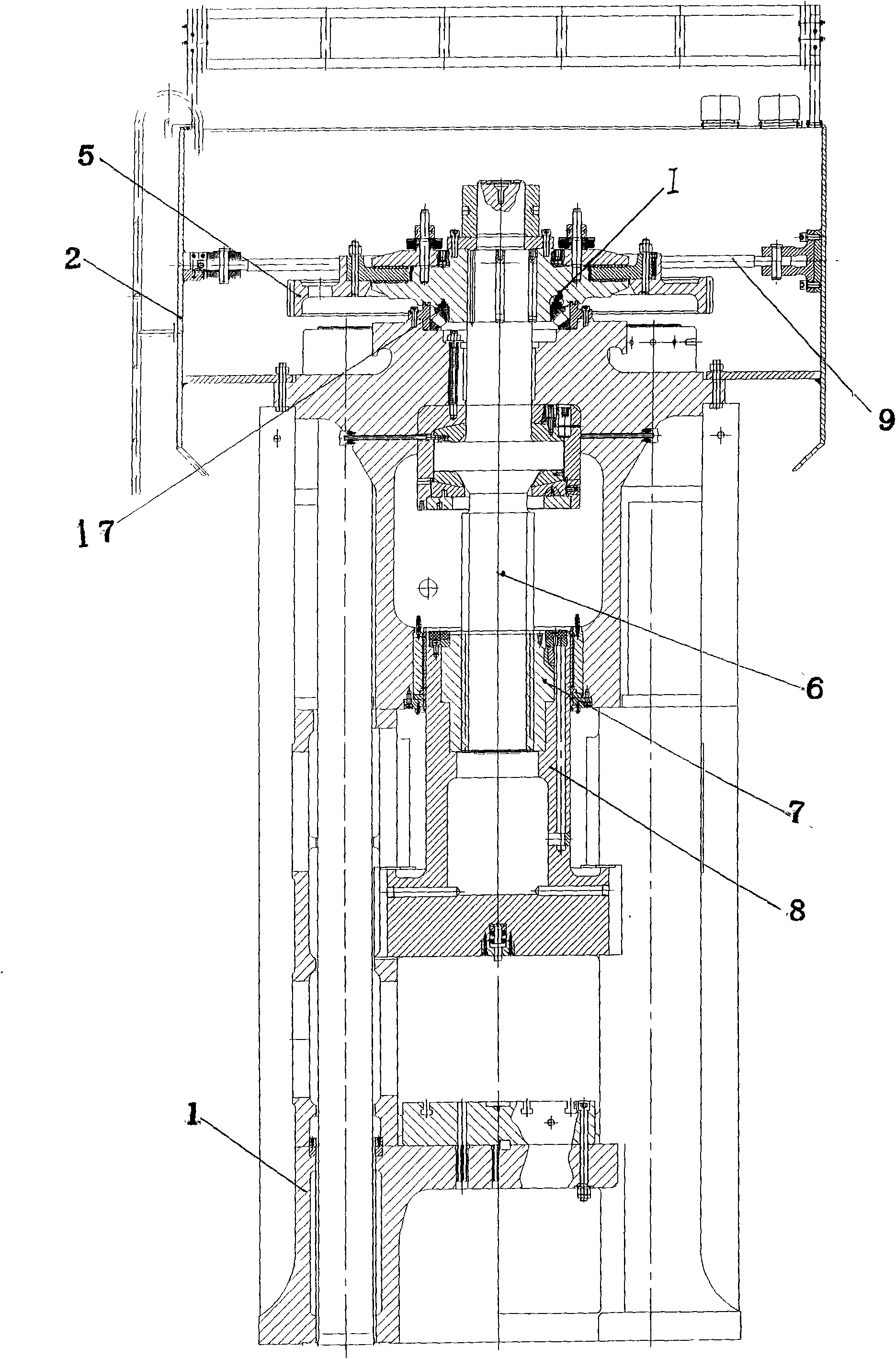

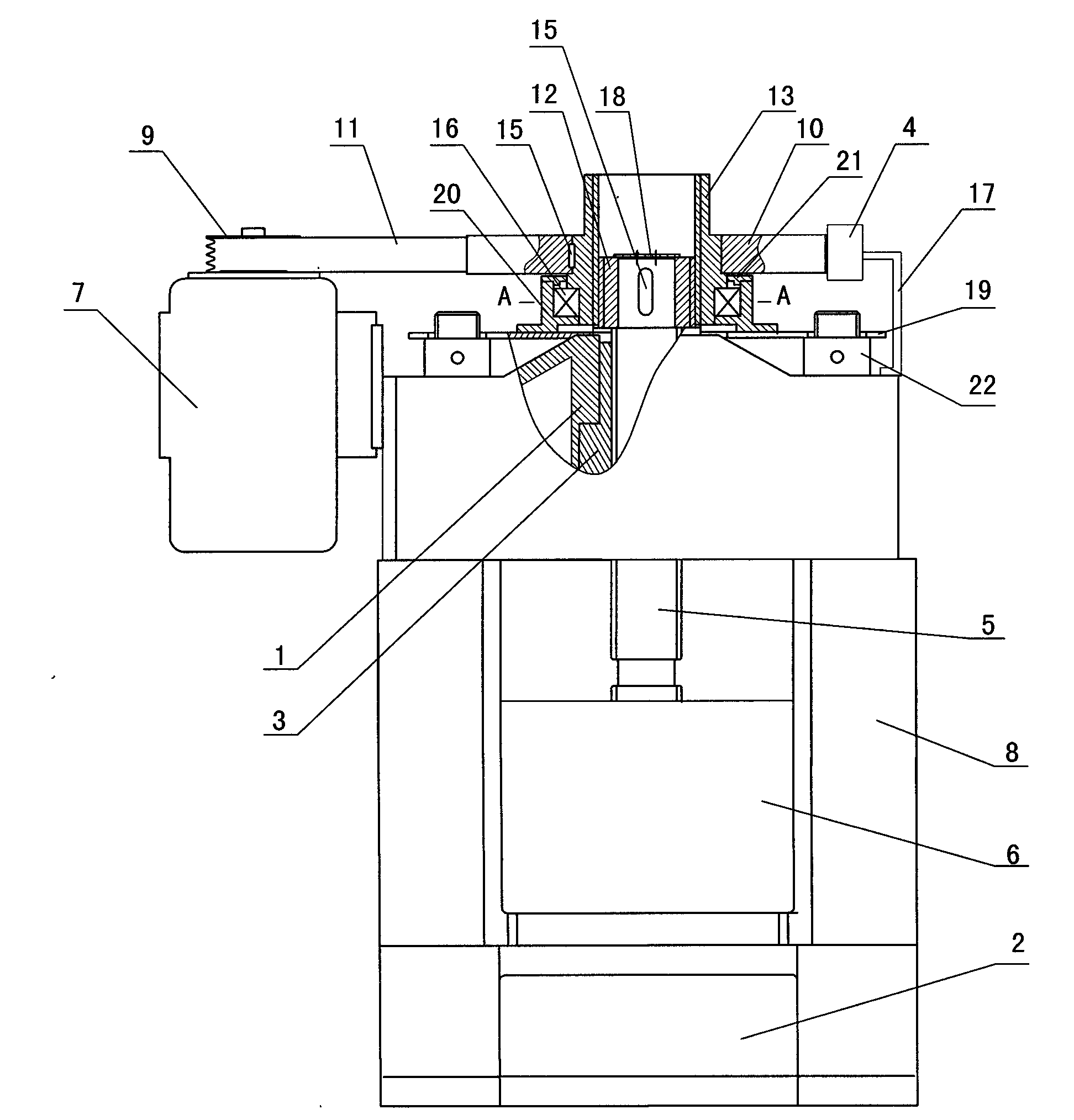

Overload protecting electric screw press

InactiveCN101554640ABig hit energyEliminate energyForging/hammering/pressing machinesForging press drivesLoad resistanceEngineering

An overload protecting electric screw press comprises a body, a platform arranged above the body, a special driving motor vertically disposed and installed at the cross beam of the body, a small driving gear directly mounted on the output shaft of the special driving motor, a friction slipping big flywheel driven by the small driving gear through the joggled transmission, a screw fixed at the flywheel through a pin, a nut driven by the screw, a slide block fixed together with the nut, and an external brake shoe brake installed at the platform for braking the flywheel. The invention has simple structure, a few components, short transmission chain, high mechanical strength, easy manufacturing, convenient maintenance, low cost, simple operation, low loss of components, anti-waving by buffering, good coaxiality, stable running, high beating force and deformation energy, high forming accuracy, strong unbalance loading resistance ability, overload protecting property, safety and reliability, long service life, energy saving and wide application range. The electric screw press can be widely used in forging forming industry.

Owner:青岛宏达锻压机械有限公司

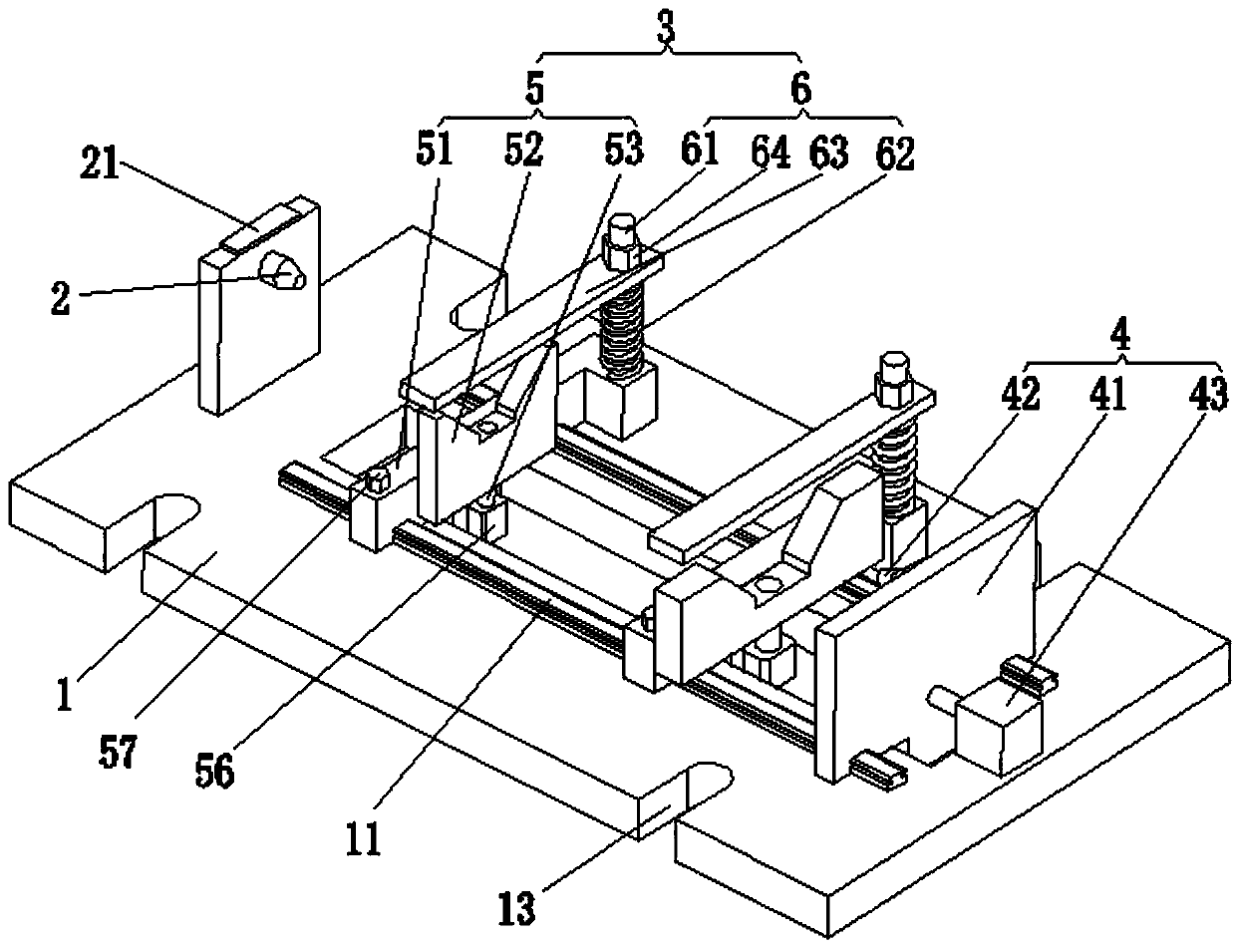

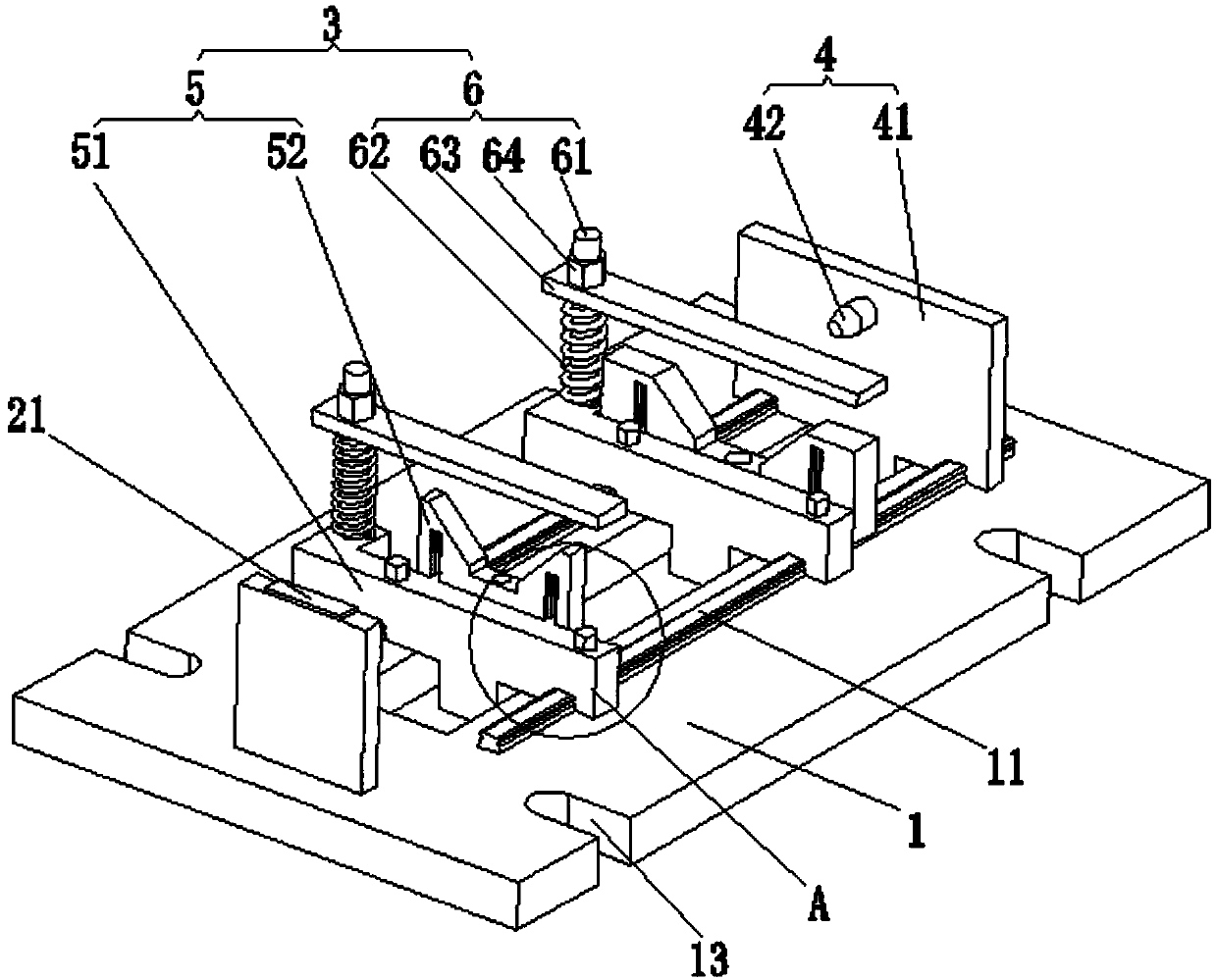

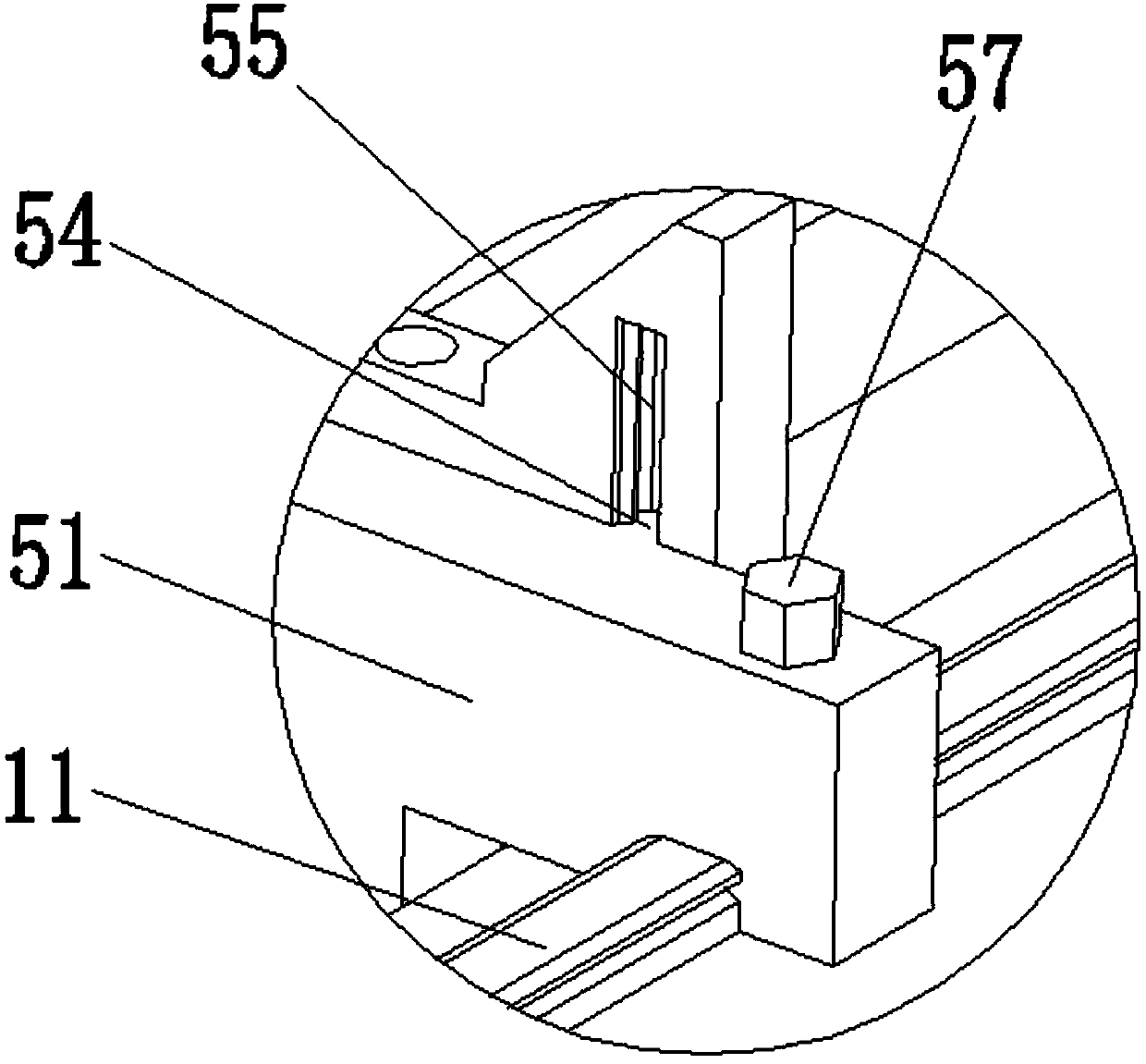

Shaft milling key slot fixture

InactiveCN107931686AEnsure machining symmetryImprove clamping stabilityMilling equipment detailsPositioning apparatusEngineeringScrew press

The invention discloses a shaft milling keyway fixture, which comprises a bottom plate, static thimbles arranged on the bottom plate in sequence along the axial direction, two V-shaped positioning mechanisms and a moving thimble assembly; the static thimble is fixedly connected to the bottom plate; the moving thimble assembly It includes a support seat, a moving thimble and a driving device. The driving device controls the support seat to drive the thimble to move axially; the axis lines of the static thimble and the moving thimble are located on the same straight line, and the directions are opposite; the V-shaped positioning mechanism includes an adjustable V-shaped The positioning assembly and the pressing mechanism, the adjustable V-shaped positioning assembly includes a traversing bracket, a V-shaped block and a fine-tuning screw, the pressing mechanism includes a threaded column, a spring sleeved outside the threaded column, and a pressure threaded on the threaded column. Tightening plate and compression nuts for compressing the compression plate. This fixture has high clamping stability and high positioning accuracy. It can adapt to step-shaped rotating shafts of various sizes by adjusting the position of the V-shaped position. It can reliably ensure the accurate positioning of the shaft and ensure the machining symmetry of the key groove of the shaft.

Owner:SUZHOU ZHENJIACHEN PRECISION MACHINERY CO LTD

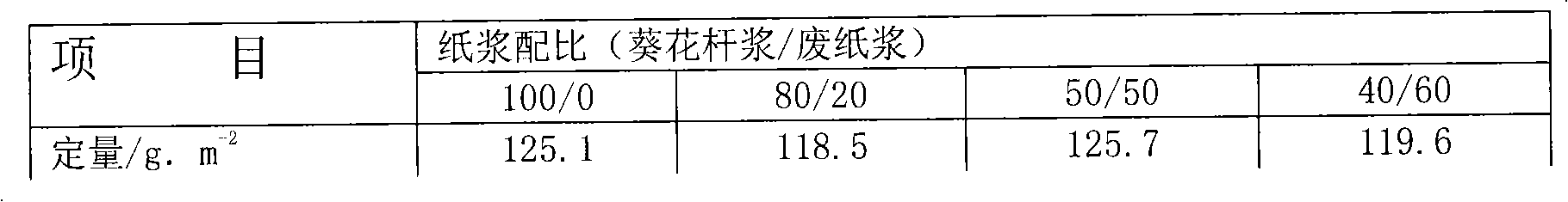

Mechanical method for making pulp by extruding sunflower stems

InactiveCN101586314AReduce the degree of beatingRemove light and heavy impuritiesPretreatment with water/steamPulp beating methodsHigh concentrationSlag

The invention relates to a mechanical method for making pulp by extruding sunflower stems, belonging to the field of paper making and aiming to provide a method for preparing paper making pulp by taking the sunflower stems as raw materials. Severed sunflower stems are firstly delivered into a vertical type depithing machine to carry out depithing by a half wet method and then washed to carry out depithing by a wet method, then the severed sunflower stems are steamed and then enter a twin-screw extrusion impregnating machine, slag charge sheets are extruded and grinded into mass-shaped rough pulp and also impregnated and absorbed by NaOH inside the twin-screw extrusion impregnating machine, the mixed rough pulp enters a reaction chamber to be continuously reacted and then enters a high-concentration attrition mill to mill the rough pulp into highly-concentrated pulp, and the milled pulp is delivered into a latency chest to be diluted, stayed and stirred and finally enters a screw press dewaterer to carry out screw type press and dewatering and extrude finished pulp. The invention has the advantages of low-energy consumption, no pollution, low water consumption (ton paper / 10 tons of water), high intensity, high yielding rate and high benefit.

Owner:杨宏

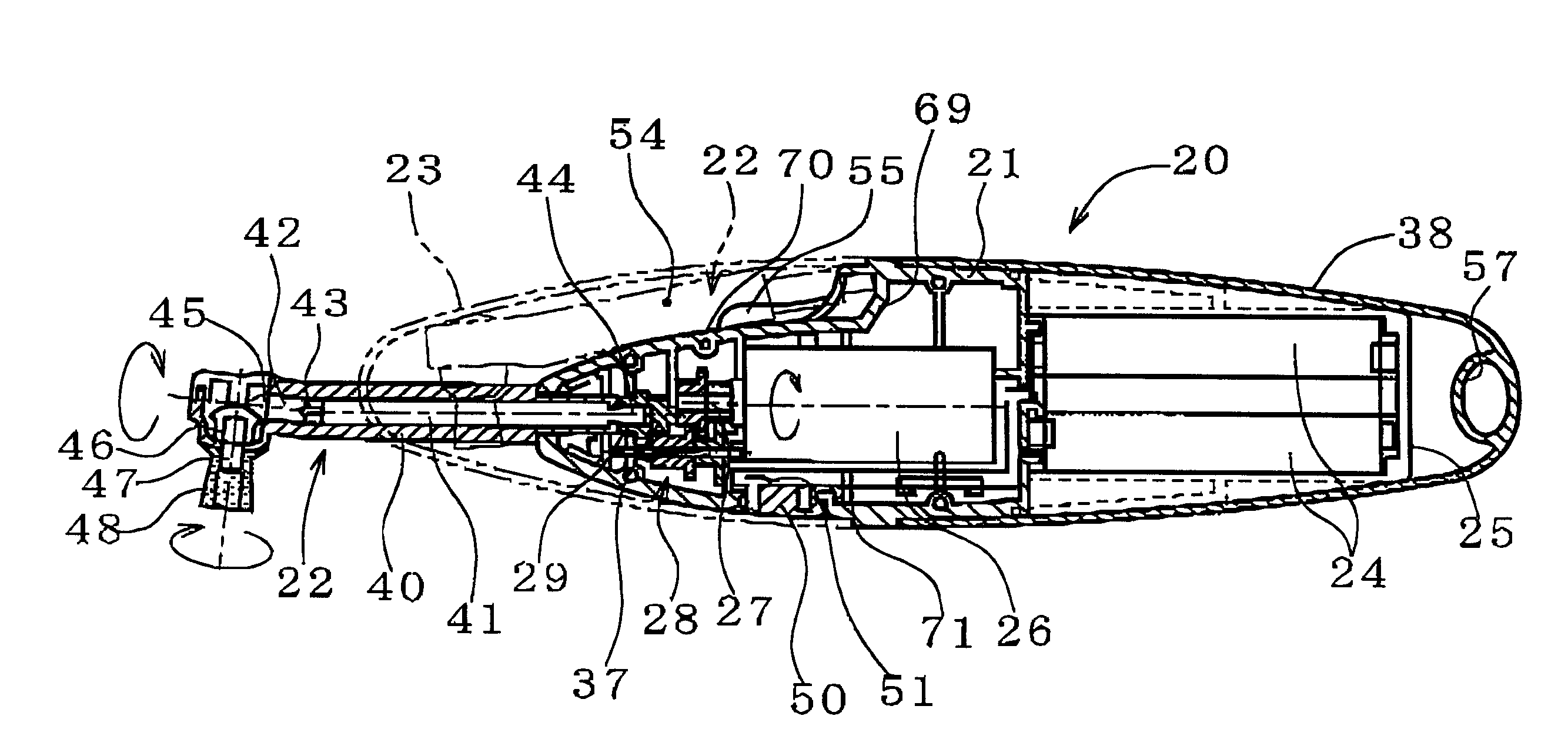

Portable tooth/nail surface cleaning polisher

A portable tooth or nail polisher has a motor connected to a coupler formed in a body. A head member is mounted on the coupler during use. An accommodating space is formed in the body for holding the head when not in use. A head holder for fixing the head member in the accommodating space presses in a direction perpendicular to a longitudinal direction and is constructed of a pair of protrusions extending from the body defining the accommodating space. The distance between the protrusions is smaller than the width of the head member.

Owner:TAKAHASHI ATSUSHI

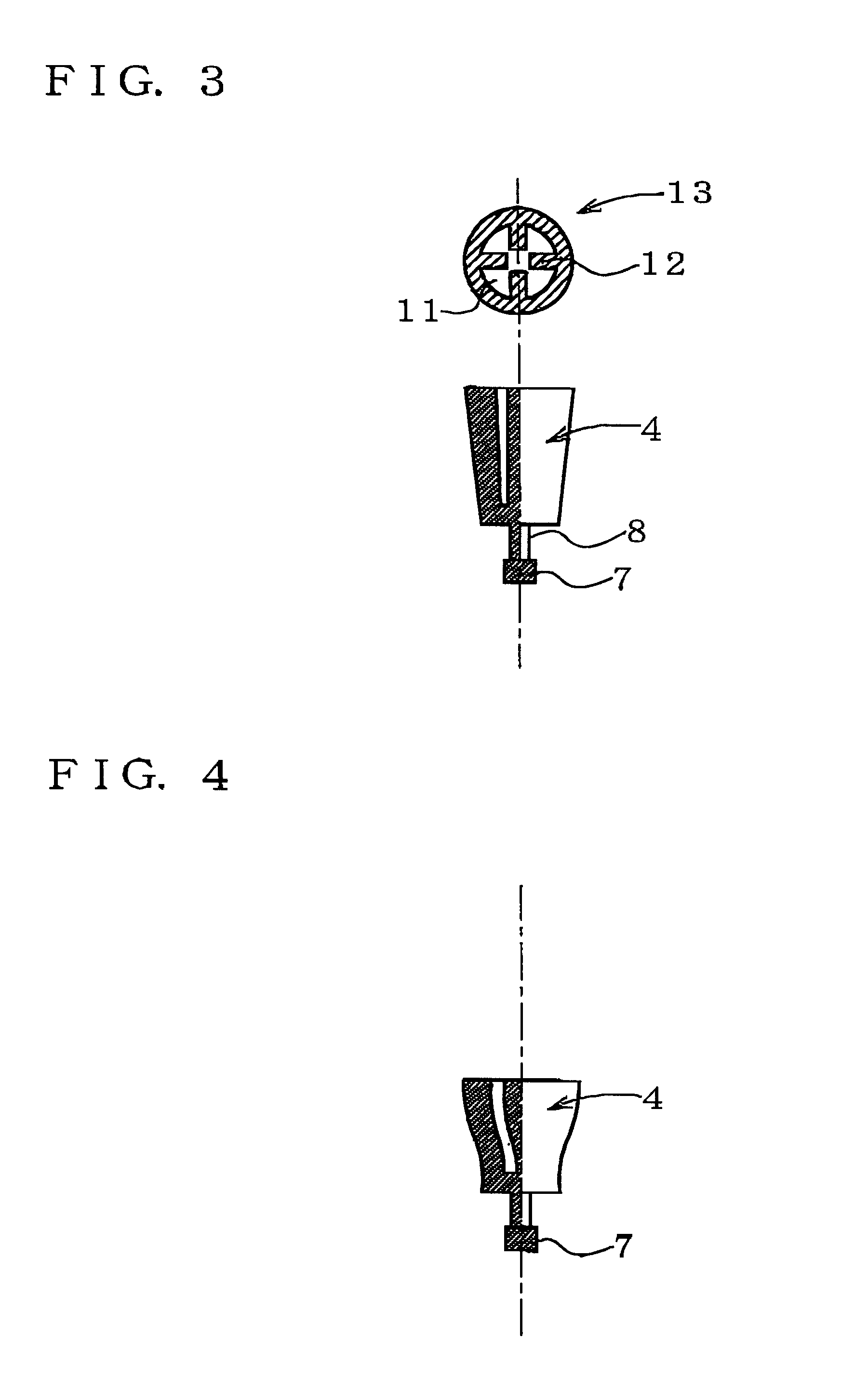

Recycling treatment method of organic waste

InactiveCN102794289AEasy to handleAvoid pollutionSolid waste disposalPulp and paper industryOrganic fertilizer

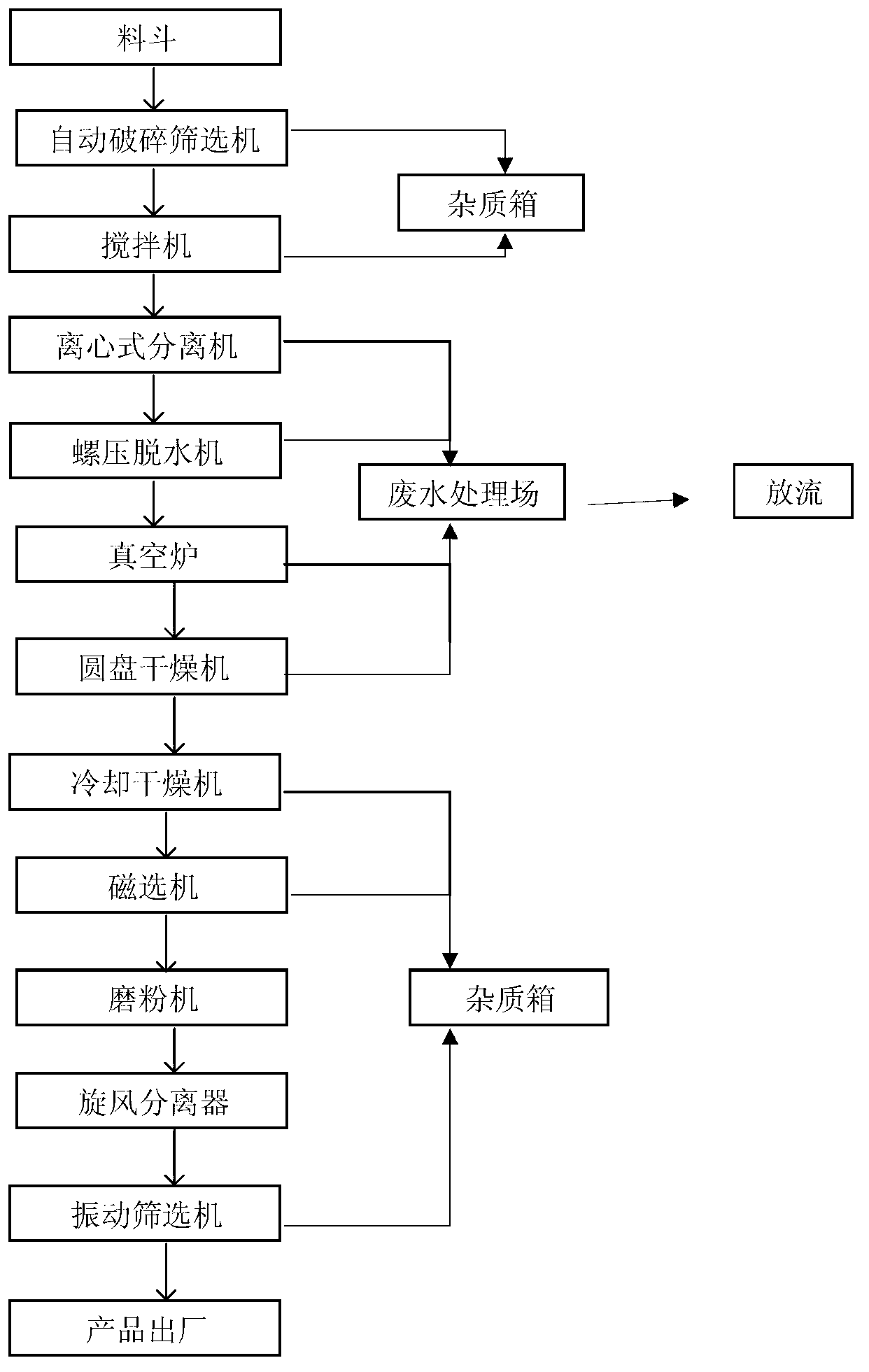

The invention relates to a recycling treatment method of organic waste. The method comprises the following steps: feeding organic waste; automatically crushing and screening; stirring the organic waste; centrifugally separating and dehydrating for the first time; dehydrating with a screw press dehydrator for the second time; boiling at a high temperature; drying at a high temperature; cooling and drying; carrying out magnetic separation; processing into fine powder; collecting powder; performing vibratory screening; and packing the product, and packing the powder which is subjected to vibratory screening with package paper hermetically to obtain the finished product. The organic waste treated by the method can be used for producing high-quality feed and organic fertilizer raw materials.

Owner:(株)新海ECOTECH

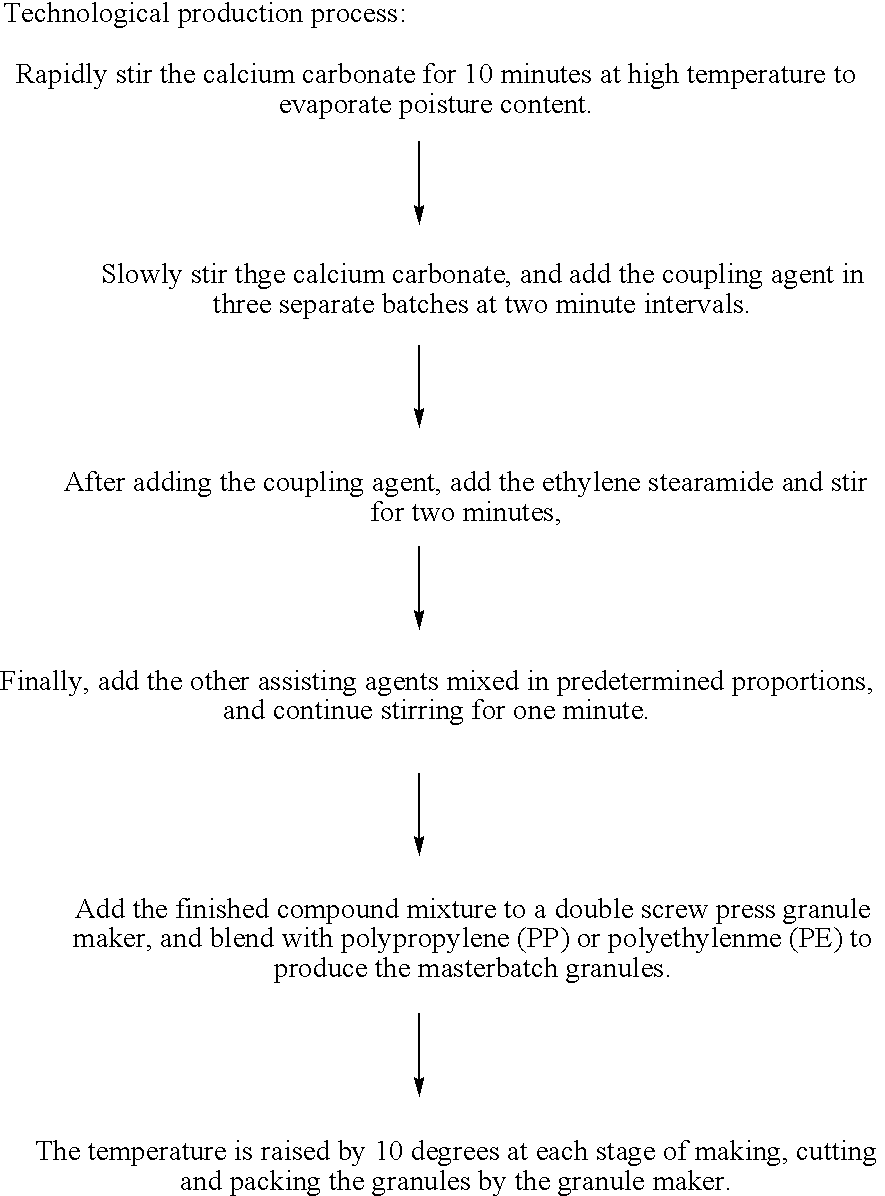

GIM environmental protection brightstone granules masterbatch

A GIM environmental protection brightstone granules masterbatch, compounded from over 85% calcium carbonate (CaCO3), with the addition of 13% polypropylene (PP) or polyethylene (PE), and further addition of 2% composite assisting agents, including an aluminate coupling agent (OLAT), stearic acid (HST), ethylene stearamide macromolecular wax (NE3) containing free radical iron ions (PDC), high melting point wax (NE3), vegetable oil and edible ethanol, which are mixed according to set proportions, whereafter they are uniformly blended by means of a high speed mixer, and white granules are extruded at high temperature through a double screw press, which can be used as a plastic-use degradation agent and as a filler.

Owner:WANG SHIH CHIEH

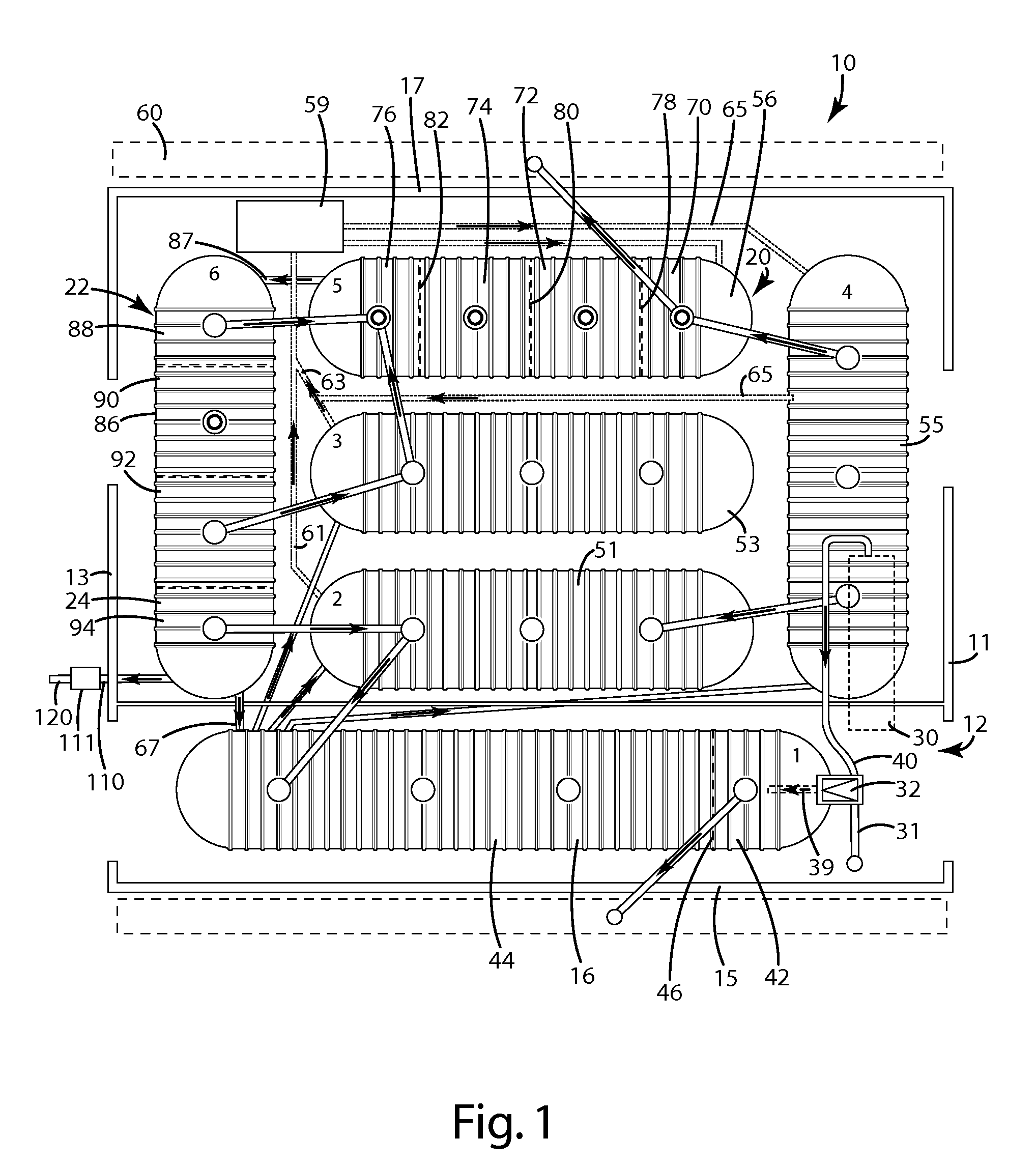

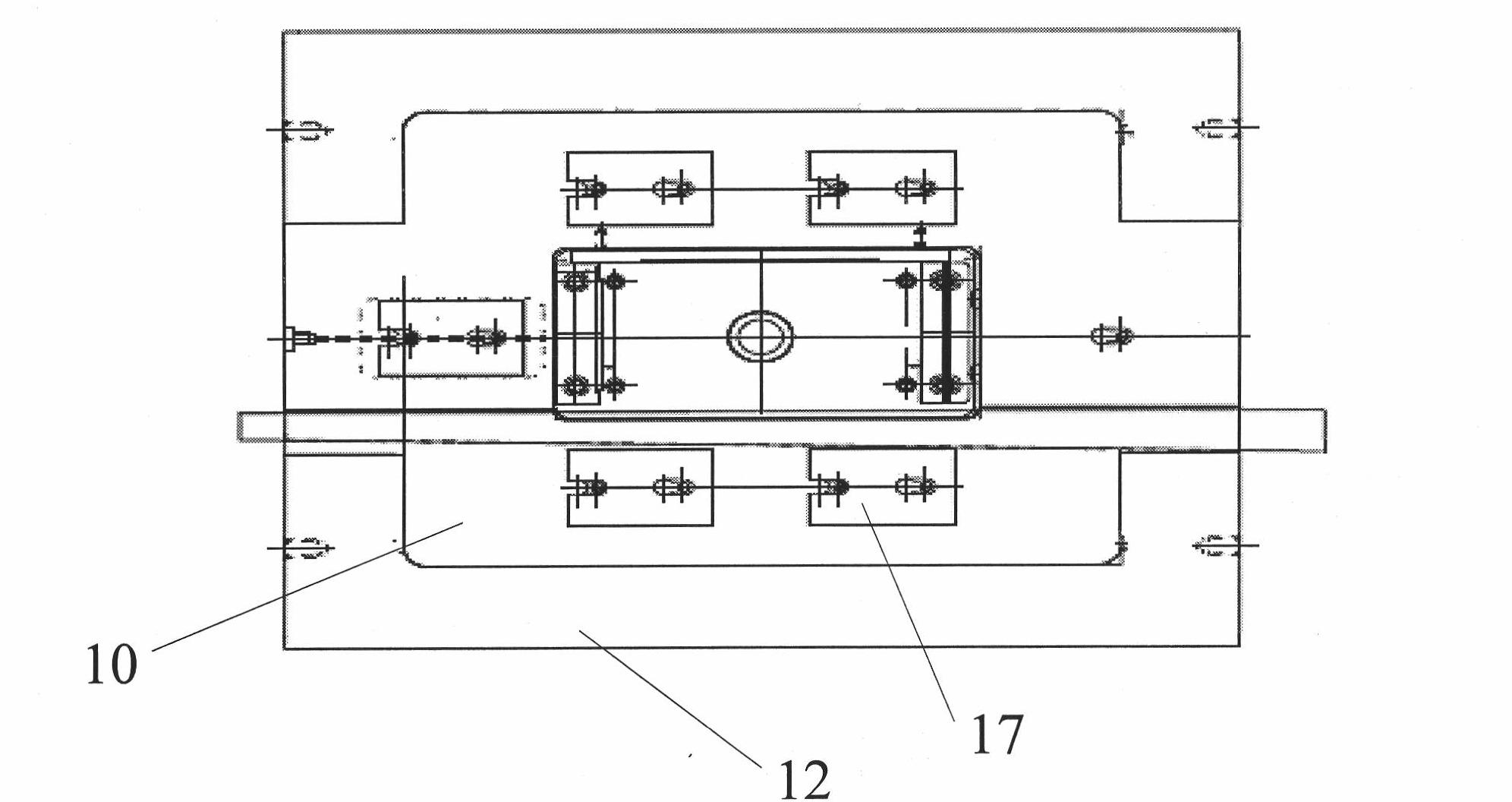

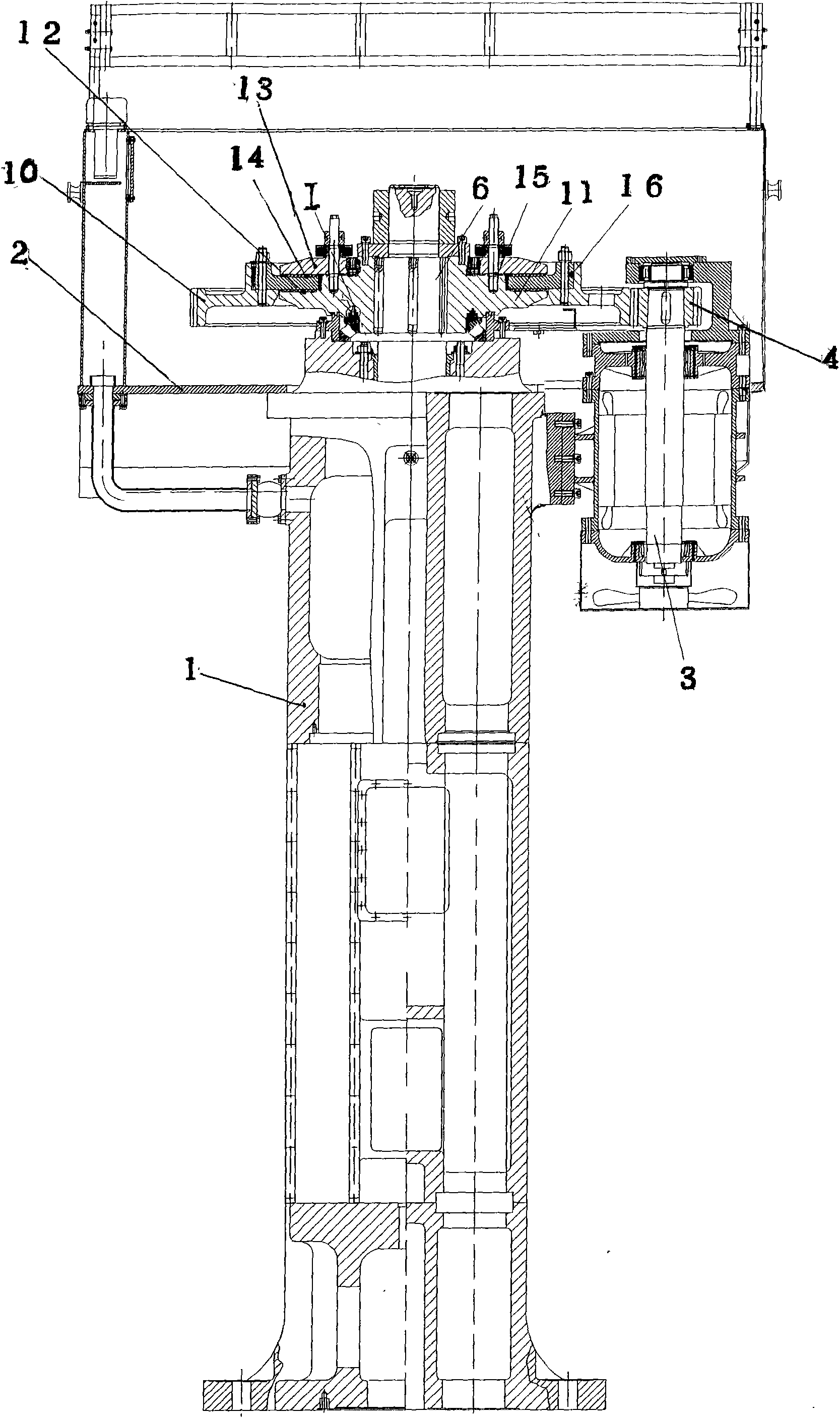

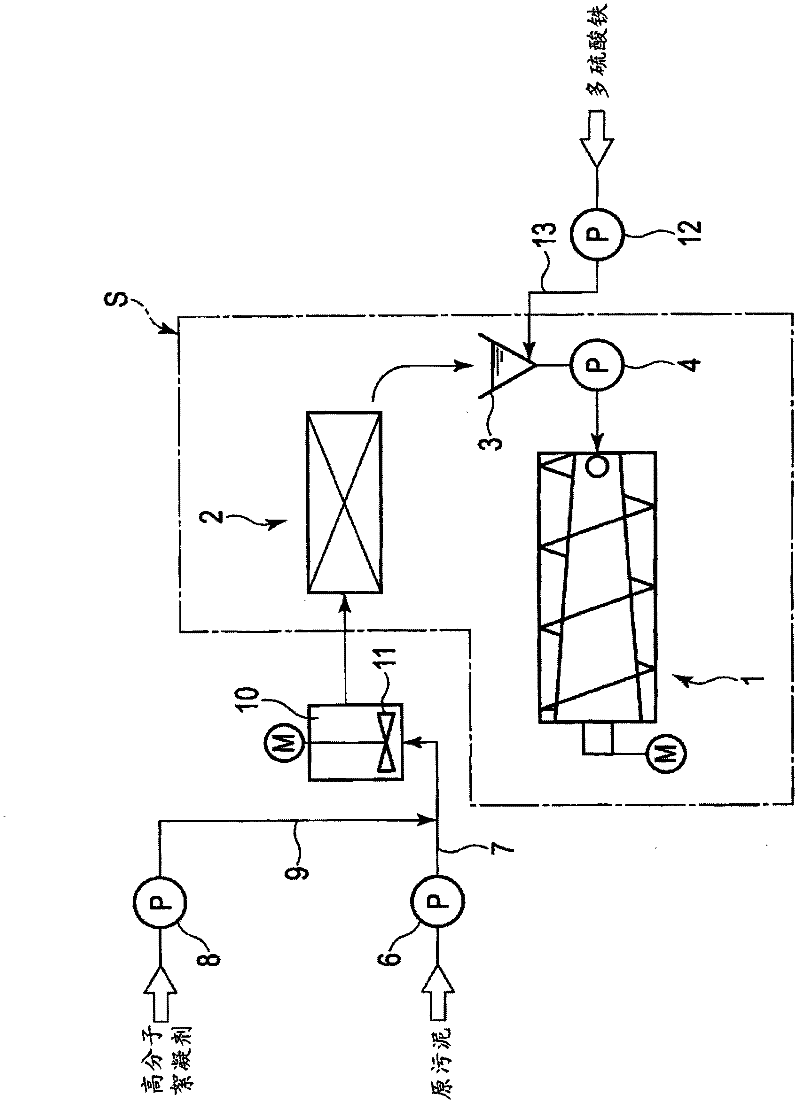

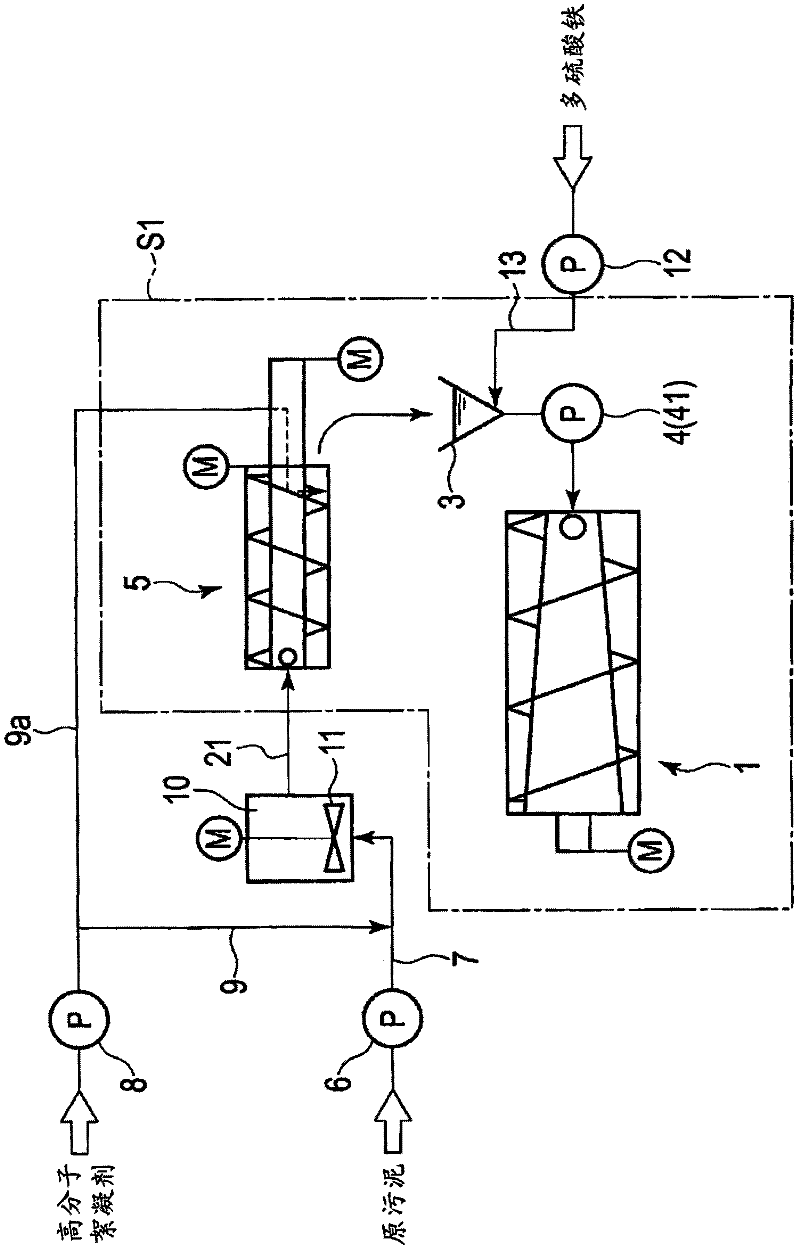

Concentrator-integrated screw press

ActiveCN102348650ASludge treatment by de-watering/drying/thickeningSludge processingSludgeScrew press

A concentrator-integrated screw press which is equipped with: a continuous type concentrator that concentrates sludge continuously and discharges the resulting concentrated sludge and that is equipped with a discharge-leveling unit for leveling the discharge of concentrated sludge per unit time; a positive displacement pump that is connected to the concentrator and that transfers continuously the concentrated sludge discharged from the concentrator; and a screw press that is connected to the discharge side of the positive displacement pump and that presses and squeezes and thus dehydrates the concentrated sludge.

Owner:ISHIGAKI CO LTD

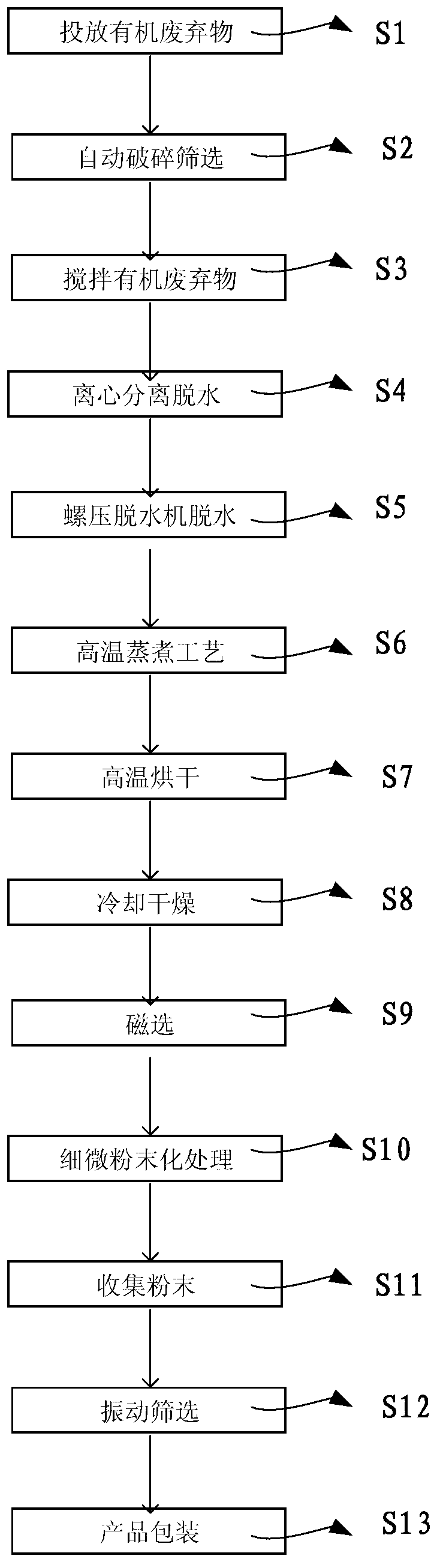

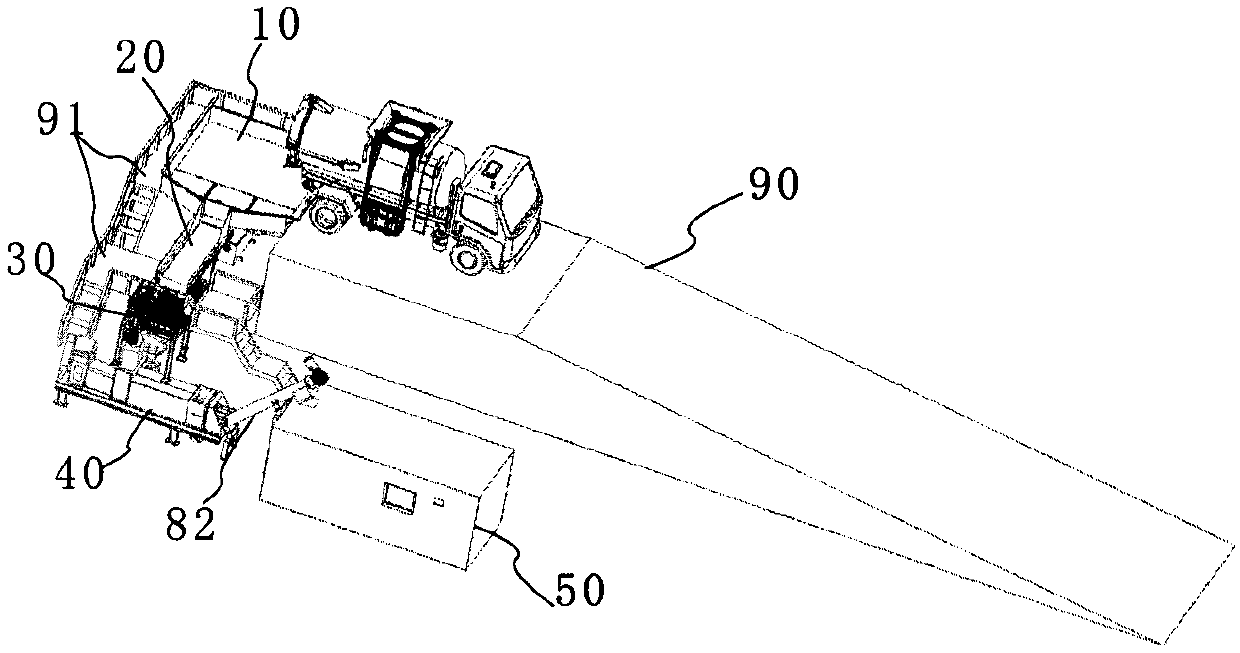

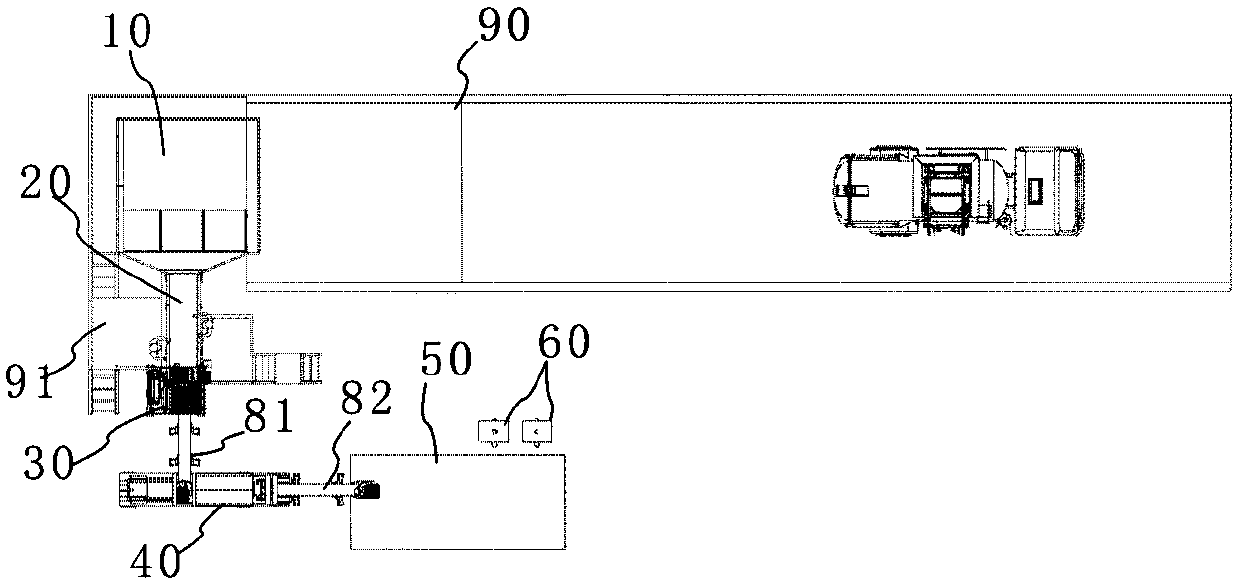

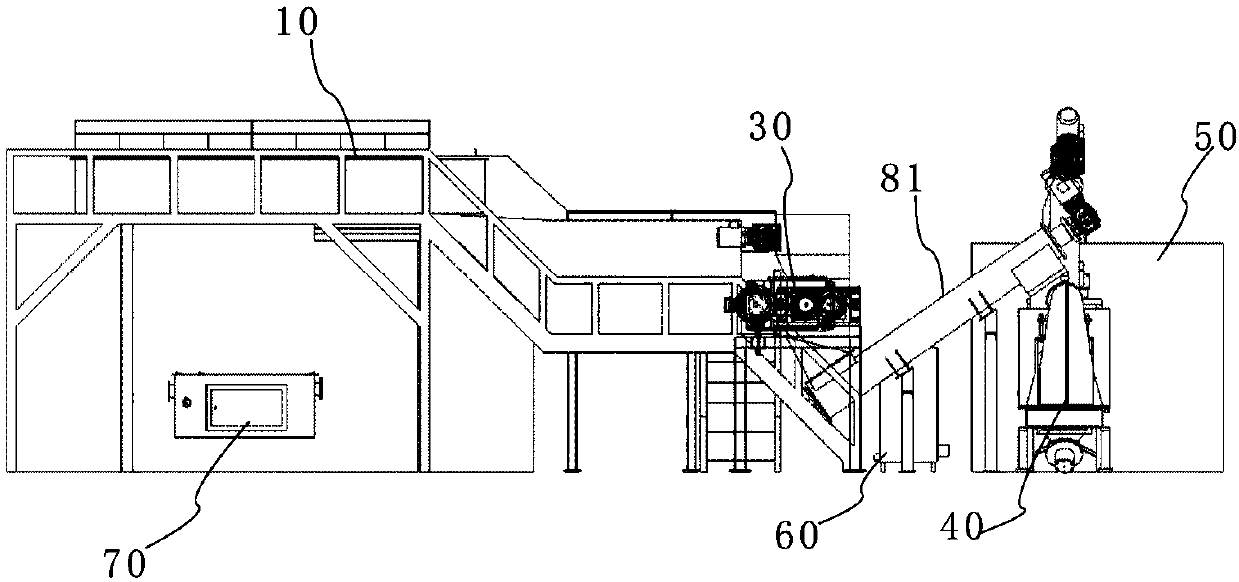

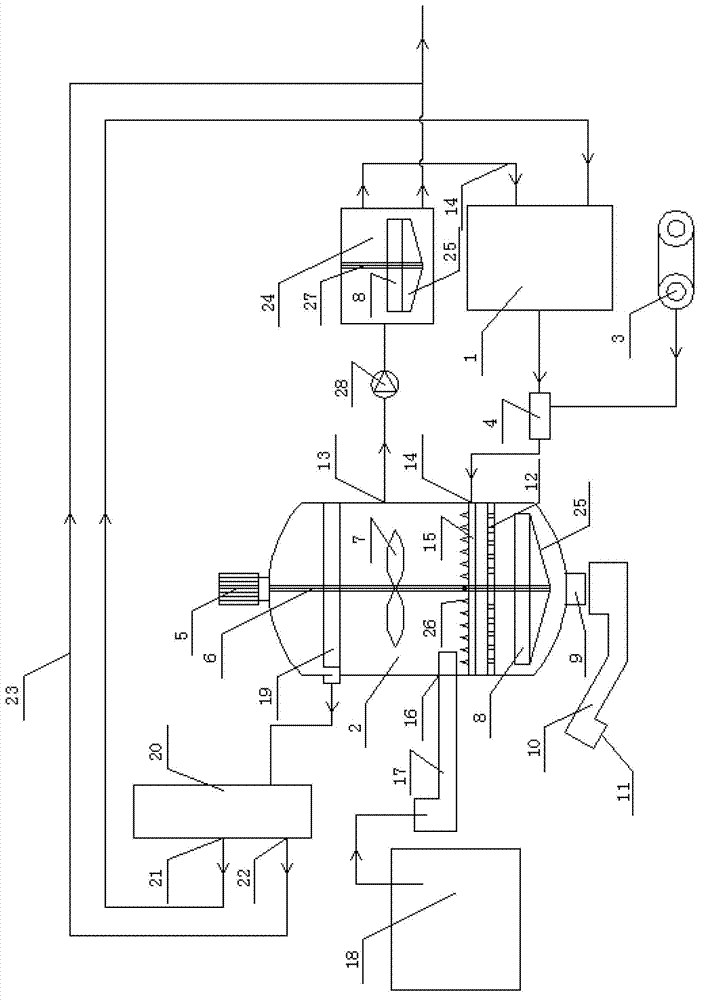

Kitchen waste treatment system and technology

PendingCN107755412AEasy to operateSimple processSolid waste disposalTransportation and packagingAfter treatmentButt joint

The invention discloses a kitchen waste treatment system and technology. The treatment system comprises a collecting hopper, a sorting machine, a crushing machine, a screw pressing machine, a degradation box, an odor treatment machine and an oil-water separator; the collecting hopper is provided with a discharging door and filter net holes; the input end of the sorting machine is connected with the discharging door; the output end of the sorting machine extends obliquely upwards to the feeding opening of the crushing machine; a first screw conveyor is butt-jointed between the feeding opening of the screw pressing machine and the discharging opening of the crushing machine; a second screw conveyor is butt-jointed between the discharging opening of the screw pressing machine and the conveying opening of the degradation box; the oil-water separator is connected with the filter net holes and a water receiving disk of the screw pressing machine through pipelines; and an odor inlet of the odor treatment machine communicates with an air outlet of the degradation box through an exhaust pipe. By the aid of the system and the technology, harmless, reducing and recycling treatment purposes ofkitchen waste treatment can be achieved, the weight loss ratio is high and is 85% or above after treatment of 24 h, and degradation products produced through micro-biological degradation of kitchen waste can be recycled completely.

Owner:福建省劲牛重工发展有限公司

A screw press type filter for wastewater treatment

InactiveCN101244349AGuaranteed functionImprove processing efficiencySludge treatmentFatty/oily/floating substances removal devicesRotational axisWater entry

The invention relates to a screw pressure evaporator used for the waste water treatment, which is used in the process for removing the liquid matter from the waste water in the food industry. A porous cylinder in the cylindrical shape is arranged inside the outer tube, and the cylindrical metal filter is arranged inside the porous cylinder. The screw wiper blade of the rotary worm scrapes the solid matter filtered by the metal filter, and a movable regulating stop piece is inserted in the rotation axis for adjusting the size of the lumpy object export. The liquid matter in the waste water led from the waste water entry flows through the metal filter, thereby discharging singly through the liquid matter export. The solid matter in the waste water is compressed by the crew wiper blade of the rotary worm thereby forming the lumpy object which is then discharged singly from the lumpy object export.

Owner:KIM UN SHOP

Manufacturing method of new-energy automobile drive motor shaft

The invention discloses a manufacturing method of a new-energy automobile drive motor shaft. A blank is heated at a temperature of 1050 DEG C to 1150 DEG C, die forging and forming are conducted on the blank on an electric screw press, and a pre-forging blank is obtained; a ball normalizing method is adopted; phosphorizing and saponifying are conducted; an inner spline is manufactured through cold extruding; machining and thermal processing are conducted, and a motor shaft meeting technological requirements is obtained. Tooth-shaped backward-extrusion forming is adopted in the key spline cold extruding procedure, and a backward-extrusion process replaces a traditional tooth insertion process; due to the metal plastic forming process, a metal assembly line is complete and is not cut off, and product strength is high; meanwhile, due to the fact that a tooth-shaped extrusion male die is integrally machined, imported high-precision line cutting and electric discharge machining devices are adopted for machining, it is ensured that the tooth shape accuracy of the male die is smaller than or equal to the fifth-stage spline accuracy (GB3478.1-2008), and the Fr value and the FP value are greatly optimized. Thus, the extruded inner spline accuracy can reach the sixth-stage spline accuracy, and the tooth shape accuracy is much better than that of the tooth insertion process.

Owner:重庆升科精锻科技有限公司

Recycling processing equipment and processing method for oil-contained silt

ActiveCN103204612AThe separation effect is thoroughSmall effective stressWaste water treatment from quariesSludge treatmentEngineeringOil sludge

Owner:天津清华德人环境工程有限公司

Screw press

The invention provides a screw press which comprises an upper cross beam, a lower cross beam, nuts, a brake, a screw rod, a slide block, a driving mechanism, a motor and upright posts vertically connected between the upper cross beam and the lower cross beam; the nuts are fixed on the upper cross beam and are in threaded connection with the screw rod; the slide block is arranged at the bottom of the screw rod; and the motor is connected with the screw rod through the driving mechanism. The screw press is characterized in that a support mechanism is additionally arranged on the upper cross beam; the driving mechanism comprises a small belt pulley, a large belt pulley, a belt, and an inner sleeve and an outer sleeve which are in spline connection; external convex straight teeth are respectively and uniformly arranged on the outer wall of the inner sleeve and the inner wall of the outer sleeve, wherein the shape and the quantity of the external convex straight teeth on the outer wall of the inner sleeve and the shape and the quantity of the external convex straight teeth on the inner wall of the outer sleeve are completely the same; the inner sleeve is sleeved at the upper end of the screw rod through a key; the motor is arranged on the upper cross beam; the output end of the motor is fixedly connected with the small belt pulley; the large belt pulley is connected with the outer sleeve through a key; and the lower end of the outer sleeve is arranged on the support mechanism through a bearing. The inner sleeve and the outer sleeve are linearly contacted through the outer convex straight teeth, thus the screw press has small friction force, long service life and excellent work performance.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com