Recycling processing equipment and processing method for oil-contained silt

A technology of treatment device and treatment method, which is applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of not considering the effective utilization of oil sludge and sand, and eliminate the use and addition of chemicals. The effect of large turbulence and low operation and management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

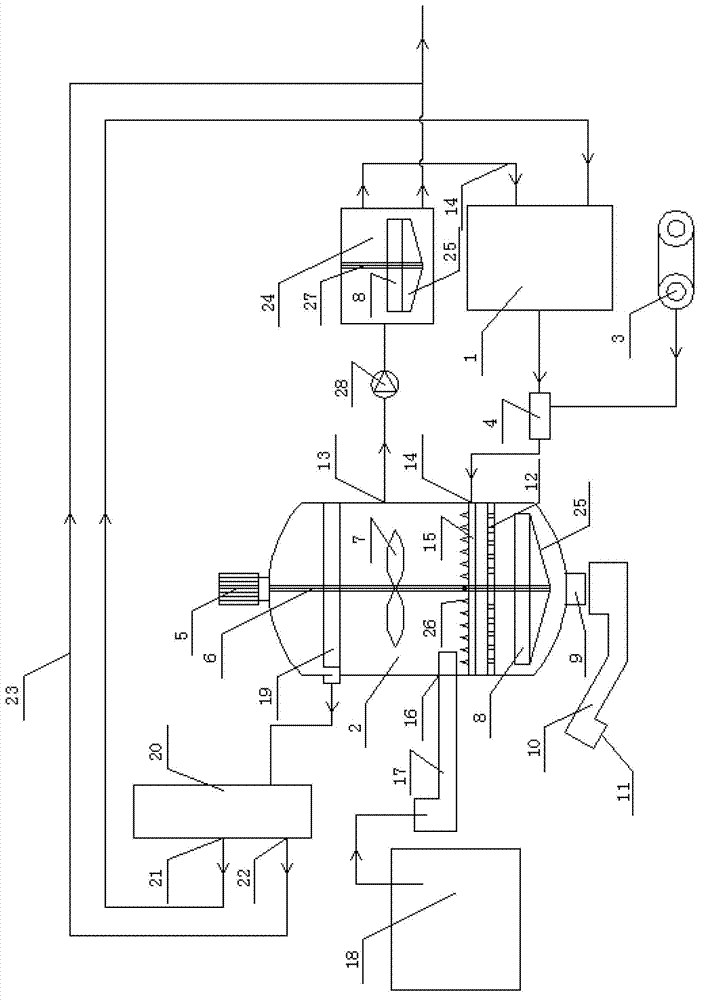

[0035] Embodiment: As shown in the figure, use briquette as fuel to heat the water to 80-90°C through the heater 1, start the stirring tank 2, and set the selection rate to 10 r / min; then start the Roots blower 3, set Send 4 cubic meters of compressed air per minute, the air and water are evenly mixed in the air-water mixer 4, and sent to the mixing tank 2 at a pressure of 0.5 kg / cm2;

[0036] The stirring shaft 6 connected to the motor 5 is inserted in the stirring tank 2 from the top to the bottom, the stirring blade 7 is fixed in the middle of the stirring shaft 6, and the rake frame 8 perpendicular to the stirring shaft 6 is installed on the bottom of the stirring shaft 6. On the rake frame 8 A plurality of scrapers 25 are installed, the bottom of the mixing tank 2 is provided with a discharge port 9, and the discharge port 9 is connected to the screw press conveyor 10 through a pipeline. There is an oil collecting device annular overflow weir 19, an anti-blocking screen 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com