Patents

Literature

1662results about How to "Zero emission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

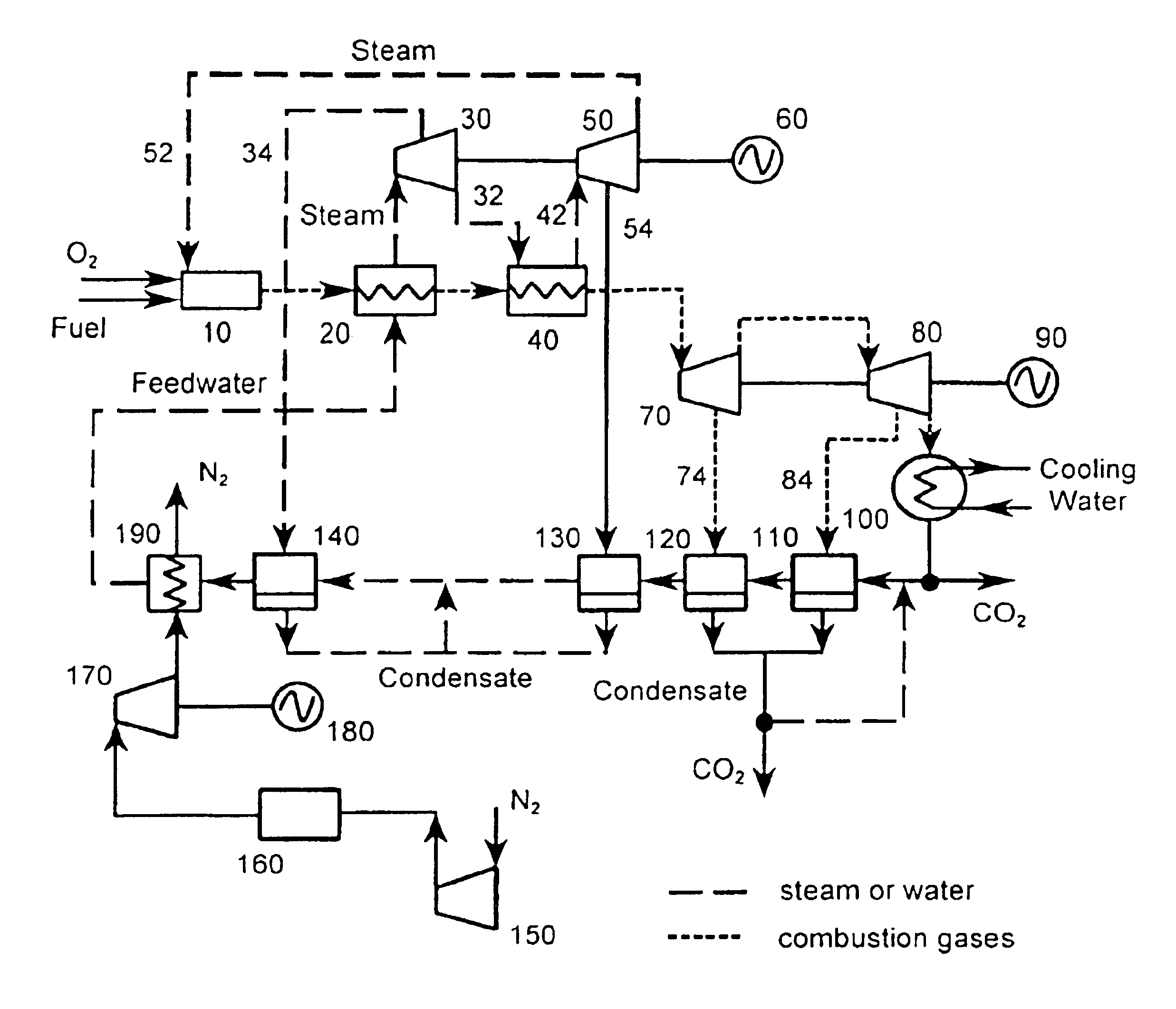

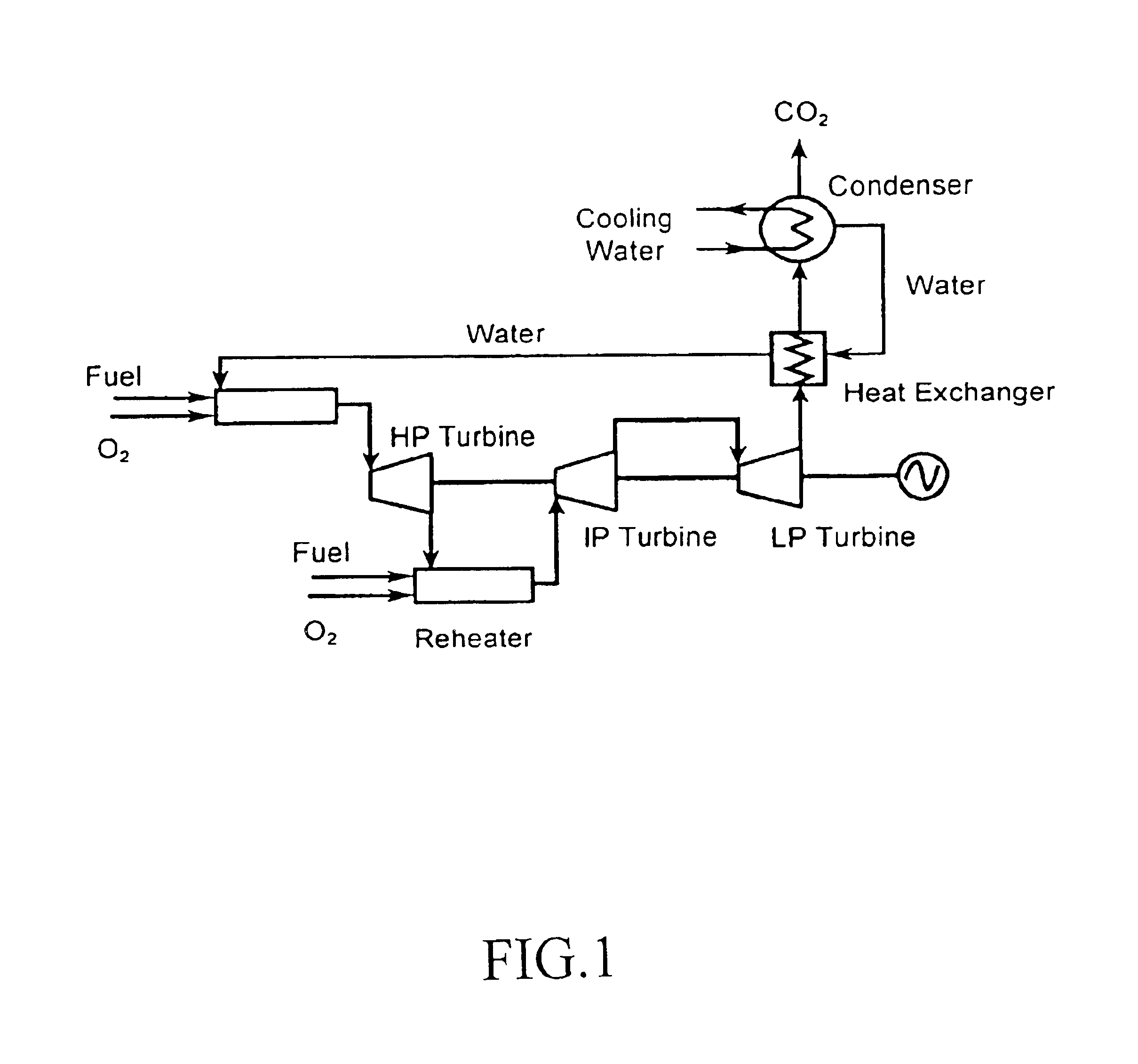

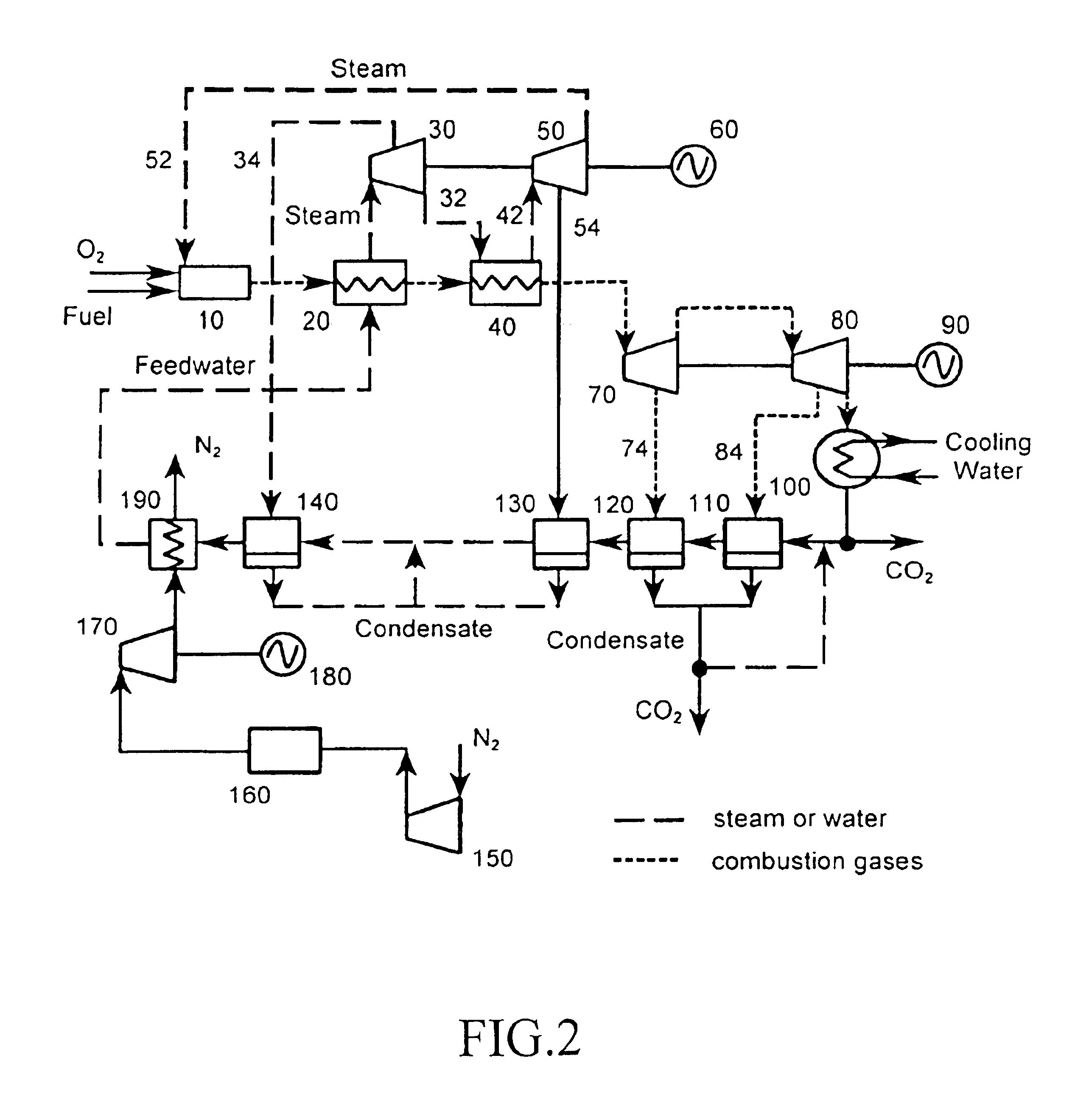

Optimized power generation system comprising an oxygen-fired combustor integrated with an air separation unit

InactiveUS6871502B2Maximize efficiencyImprove efficiencySolidificationLiquefactionHigh pressureCycle efficiency

A novel power generation system, more specifically an integrated power generation and air separation system and an integrated power generation and air separation process is provided. A key component of the system and process is an oxygen-fired combustor designed for gas turbine operating pressures. The combustor produces a high-temperature gas stream that enters one or more heat exchangers to generate / heat steam, and then enters one or more turbines to generate power. The steam from the heat exchanger drives one or more steam turbines to generate power, and the discharged steam is admitted to the combustor. To maximize cycle efficiency, steam extraction and reheat is incorporated in the process. Additional power is generated from a high-pressure nitrogen stream produced by an air separation unit (ASU). This process has the potential to attain high cycle efficiencies with zero emissions, while utilizing existing or near-term steam turbines, and moderate-pressure combustion systems.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

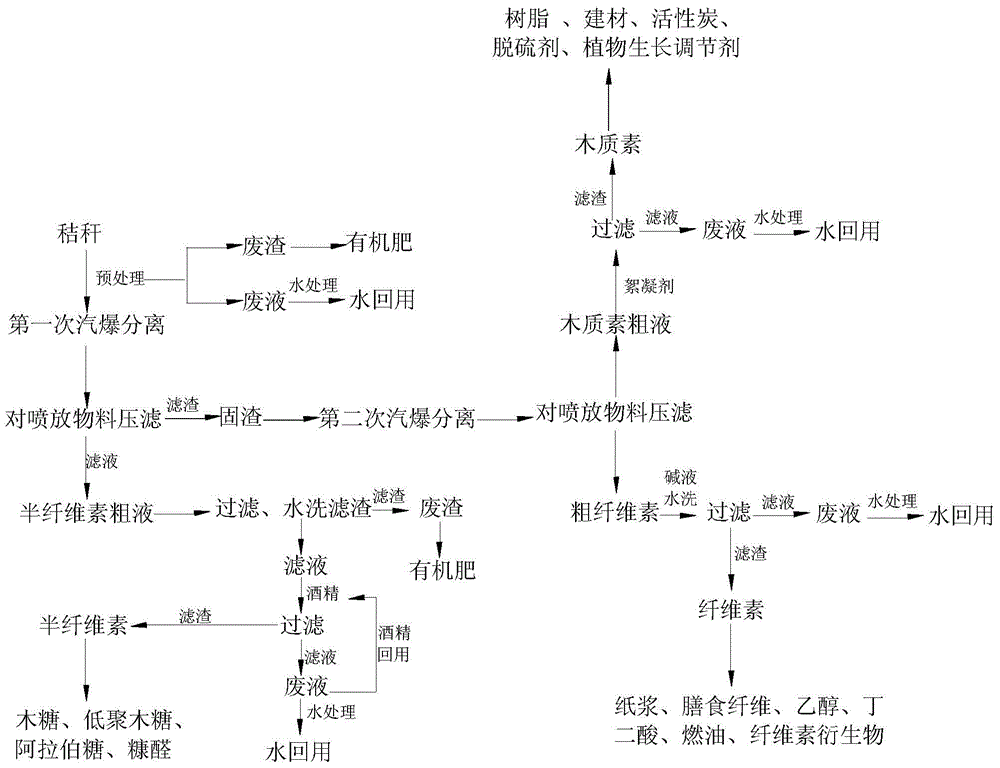

Straw component separation and straw component full utilization method

ActiveCN104404803AAchieve separationEasy to separateRaw material divisionSeparation technologyWastewater

The invention discloses a straw component separation and straw component full utilization method, and relates to the technical field of straw comprehensive utilization. According to the method, straws are subjected to a steam explosion treatment, such that hemicellulose is first separated; and the rest of the material after hemicellulose extraction is subjected to steam explosion treatment again, such that the separation of cellulose and lignin is realized. The method has the advantages of simple process, environment-friendliness, low cost, and thorough separation of hemicellulose, cellulose and lignin. With the method provided by the invention, an environment-friendly separation technology of cellulose and lignin is realized for the first time internationally, and a basis is provided for full-element, high-added-value and comprehensive utilization of straws. On the basis, products with higher added values can be derived or generated. With the production process provided by the invention, all wastewater is treated and is completely recycled, and all waste residue is used for producing organic fertilizers, such that straws are thoroughly utilized, and straw component full utilization is realized. Also, zero emission and zero pollution are realized, such that the difficulty of straw comprehensive utilization is solved.

Owner:JINAN MIDUOTAN NEW ENERGY TECH

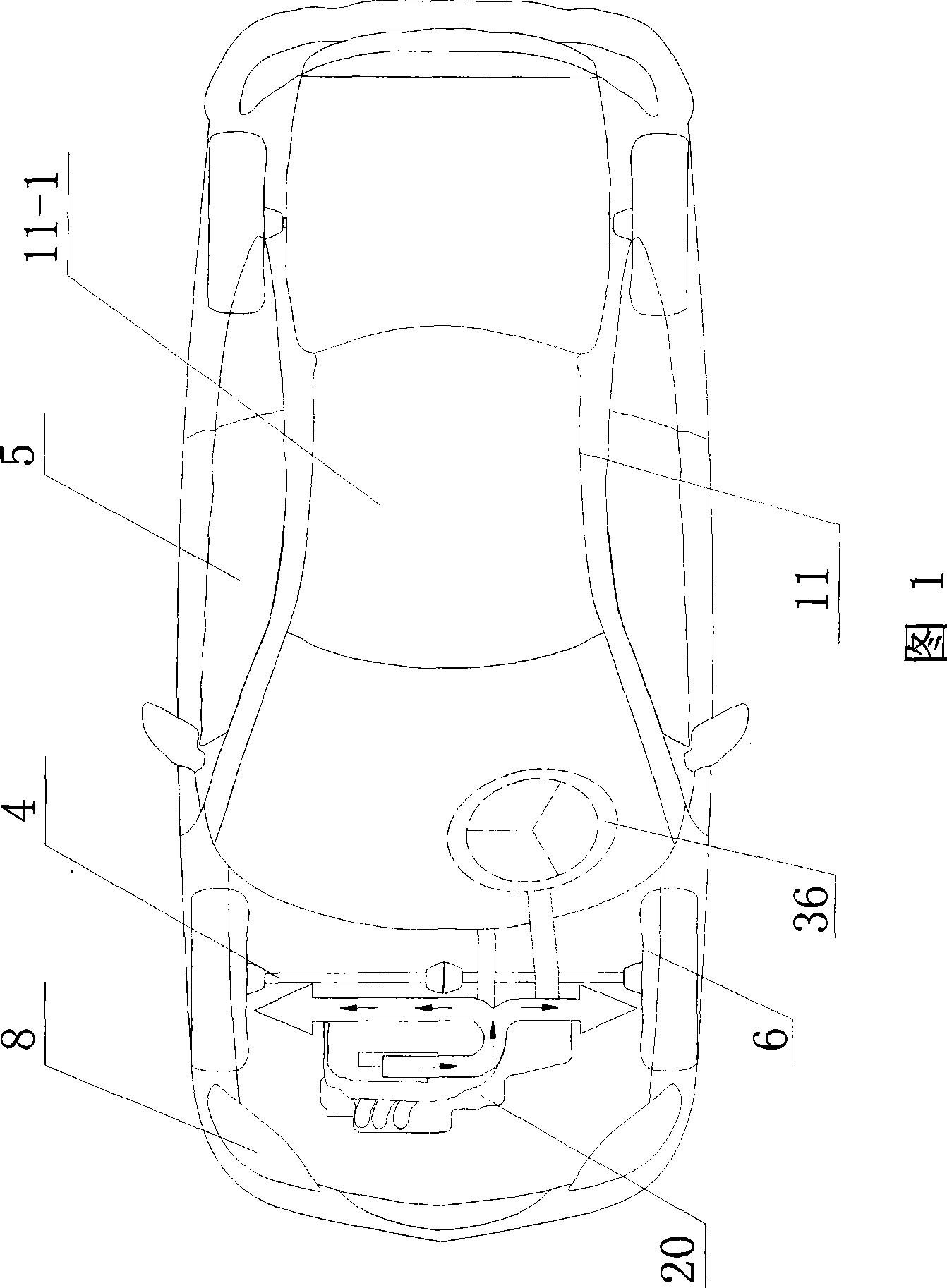

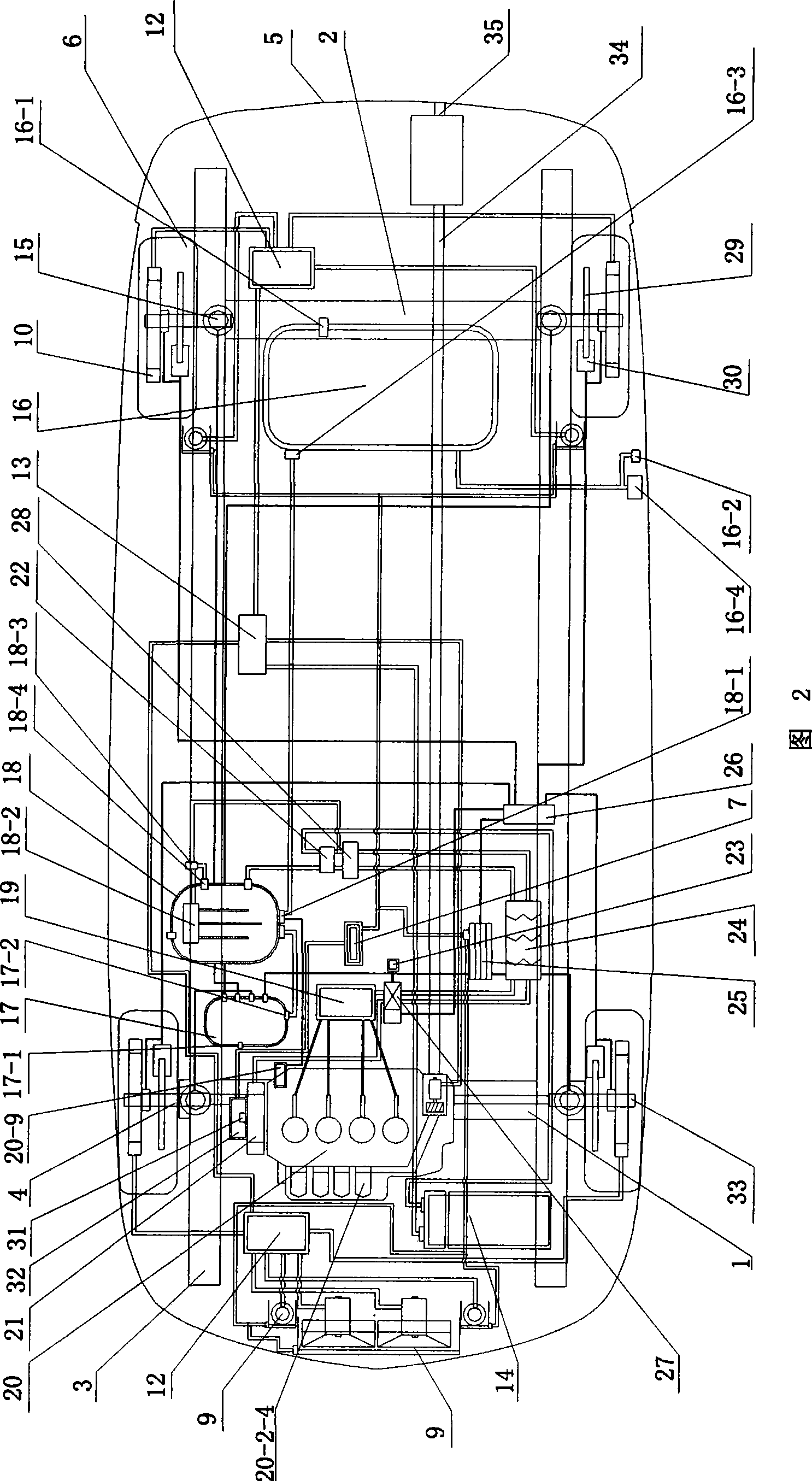

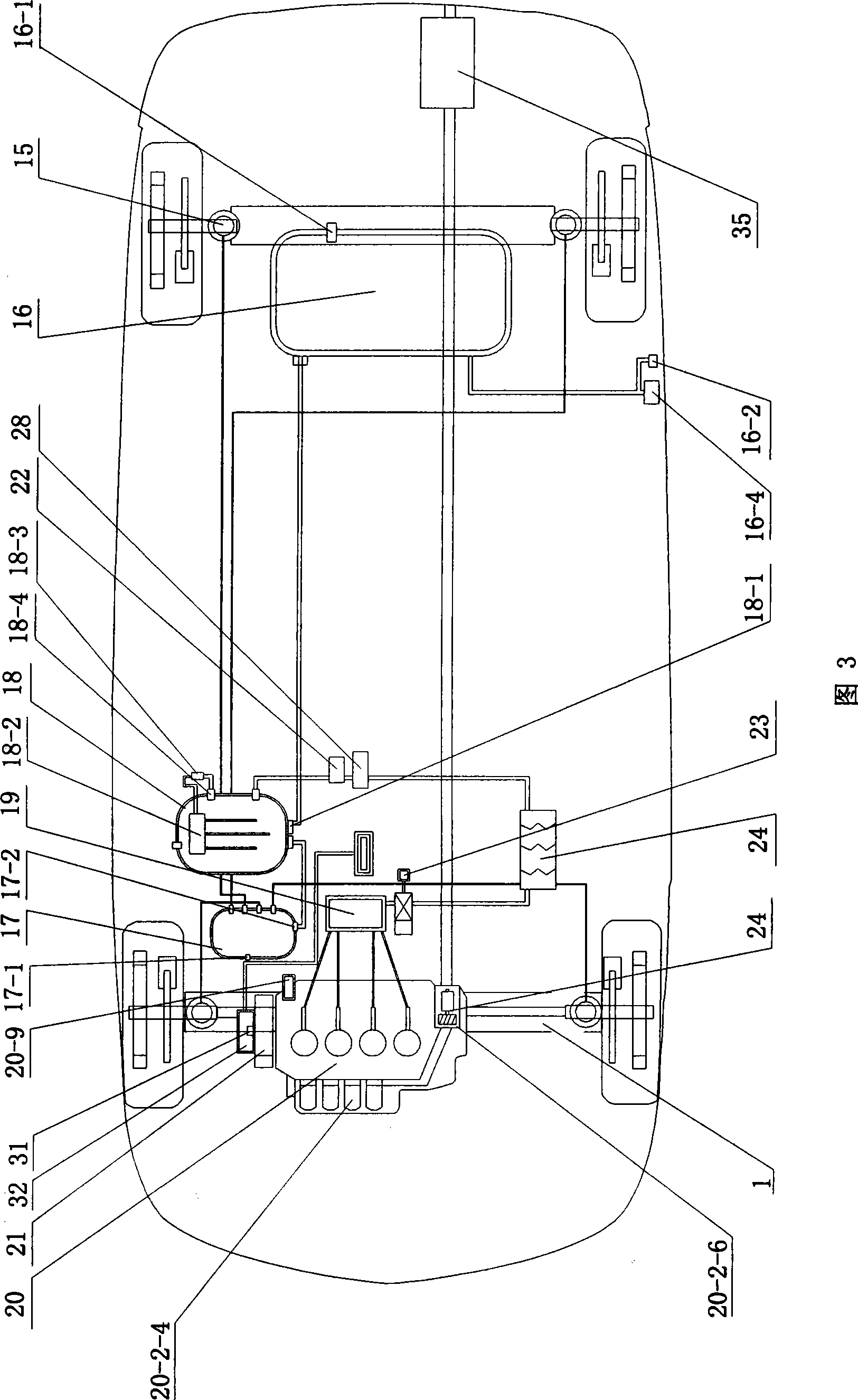

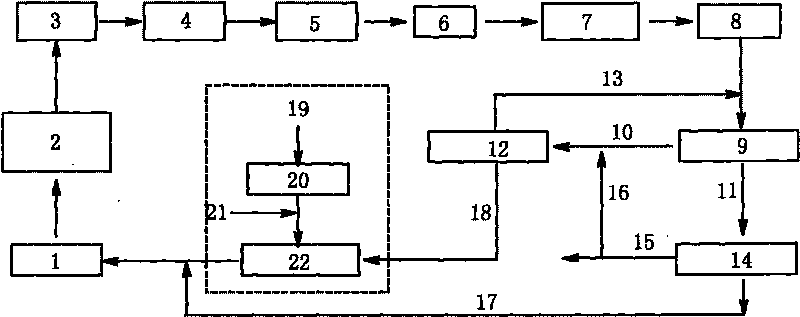

Air hybrid power motor vehicle

ActiveCN101428555AImprove conversion efficiencyConvenient supplementAuxillary drivesWind motor with solar radiationEnergy recoveryEngineering

The invention relates to an air incorporation power machine motor car, which comprises a steering-wheel, a front aperture axle bracket, a rear axle stand, a girder for connecting the front aperture axle bracket and the rear axle stand and a vehicle body. The motor car further comprises a hub, an energy recovery device, an energy storage device, a power drive device, a control device, a shift device and an auxiliary device which are connected to the front aperture axle bracket and the rear axle stand through transmission shafts. The energy recovery device is connected with the energy storage device; the energy storage device is connected with the power drive device; and the control device controls the energy recovery device, the power drive device and the auxiliary device. When a motor vehicle is in normal running, an air power engine supplies power; and when the motor vehicle is needed to decelerate when conducting brake, turning and downhill, the hub and impellers are started to generate electricity and collect the power and use. The power recycled by the manner is rather considerable, so that the energy of the invention can be better made up. In sum, the invention utilizes air power as main power, and the power can be recycled and utilized through multi ways. In addition, the air source collection is convenient, the energy transformation rate is high and the exhaust emission is nearly zero, thereby achieving the aims of the invention.

Owner:周登荣 +1

Method for producing propylene oxide

ActiveCN101735177AReduce investmentAchieve recyclingOrganic chemistryDispersed particle separationProcess designSodium hydroxide

The invention discloses a chemical production method, in particular a novel green production process for propylene oxide. In the method, the process design is carried out by using bipolar membrane, electrodialysis, antiosmosis, air flotation, heat exchange, oxidation, and other technology. In the production process, sodium hydroxide replaces the conventional calcium hydroxide and generates sodium chloride through reaction; the sodium chloride generates hydrochloric acid and sodium hydroxide by the bipolar membrane technology; and the hydrochloric acid is recovered, and the sodium hydroxide and water can be recycled. Therefore, no new sodium hydroxide is needed and no wastewater is discharged in the production of the propylene oxide. The sodium hydroxide is added at the preliminary stage of the production of the propylene oxide, and the input amount of the sodium hydroxide is controlled between 5 and 15 percent. The novel green production process for the propylene oxide has the advantages that: the recycling of the water, sodium chloride and sodium hydroxide is realized, the effects of zero discharge and input reduction of production materials are substantially achieved, and finally better social and economic benefits are achieved. The novel green production process for the propylene oxide can be widely applied to the chlorohydrin production in China.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

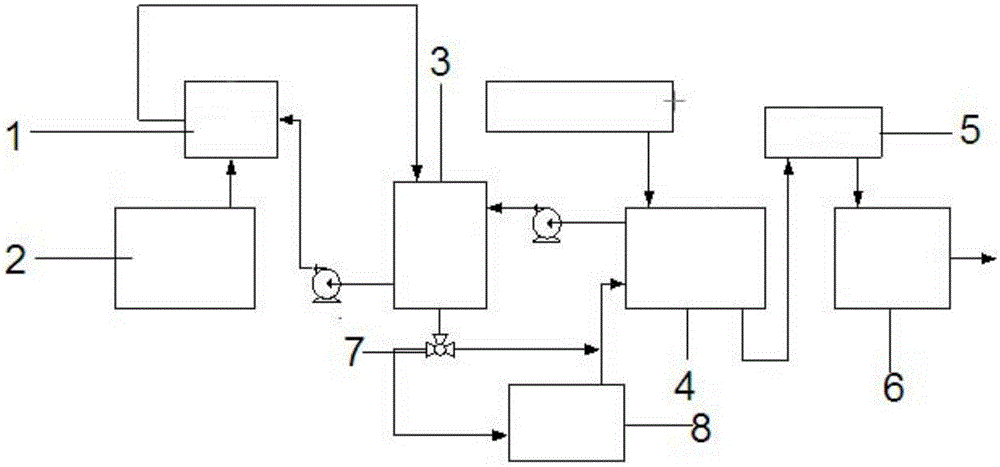

Sintering smoke treatment system and sintering smoke treatment method

InactiveCN102580455AComprehensive management benefit maximizationHigh adsorptionDispersed particle separationMetallurgyMaterials science

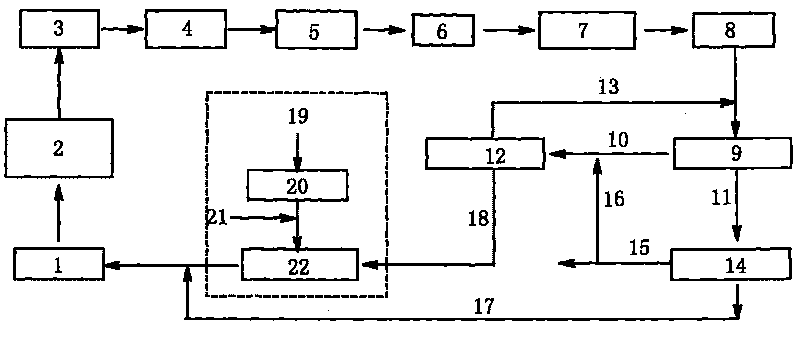

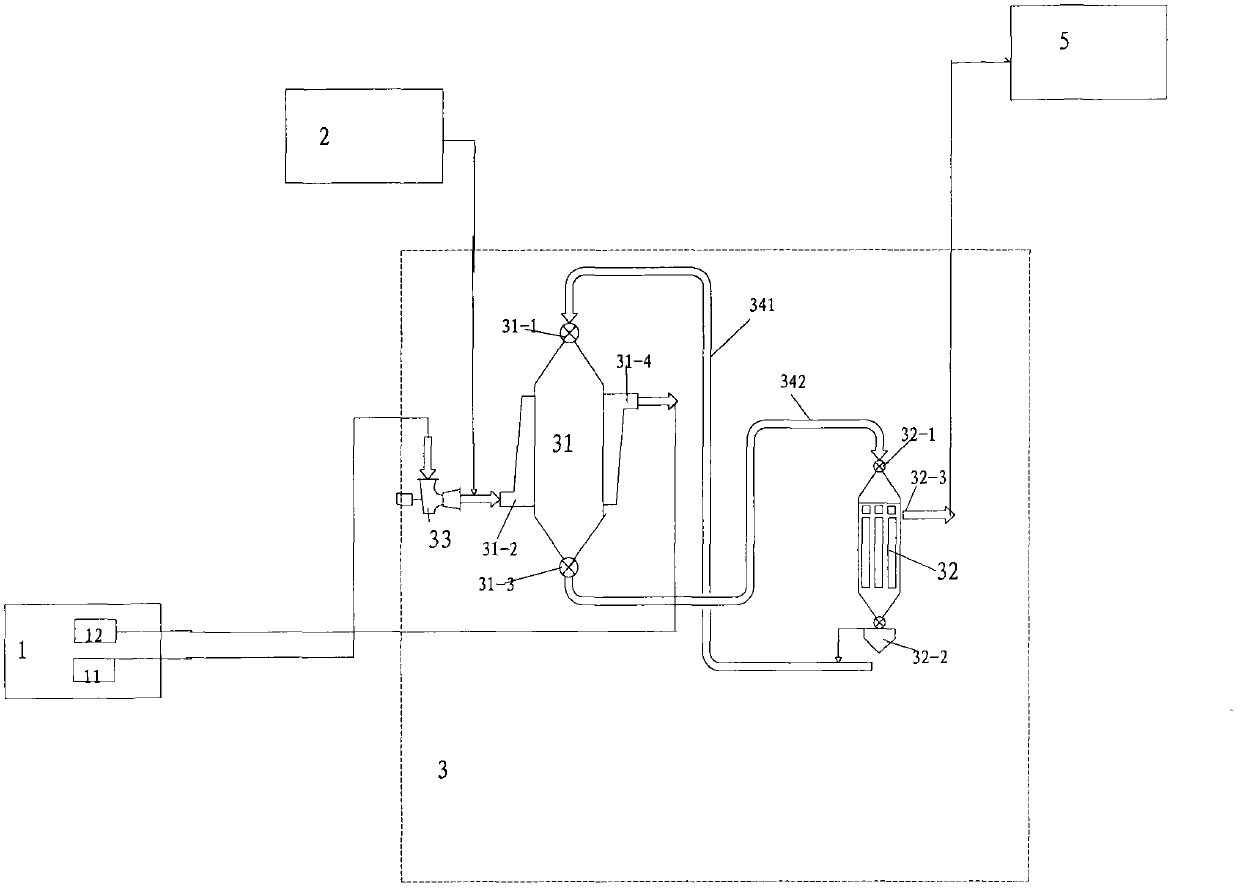

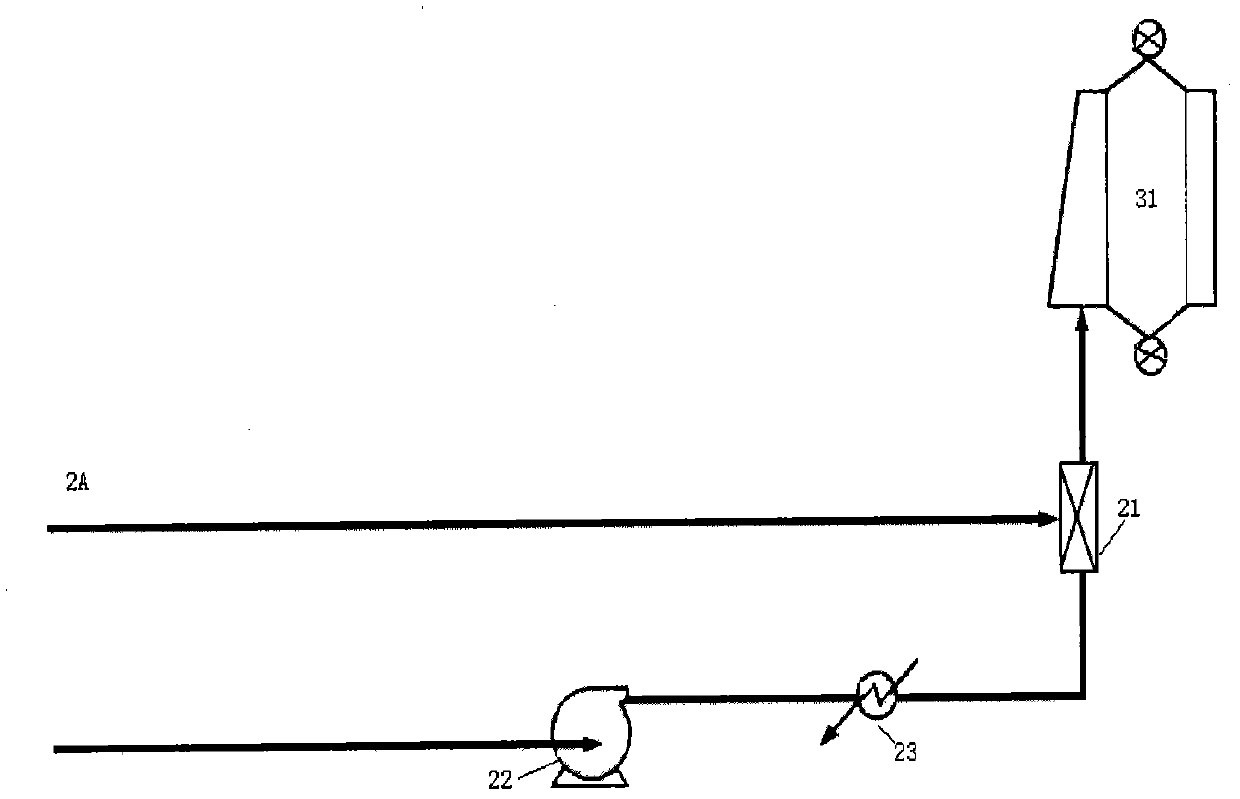

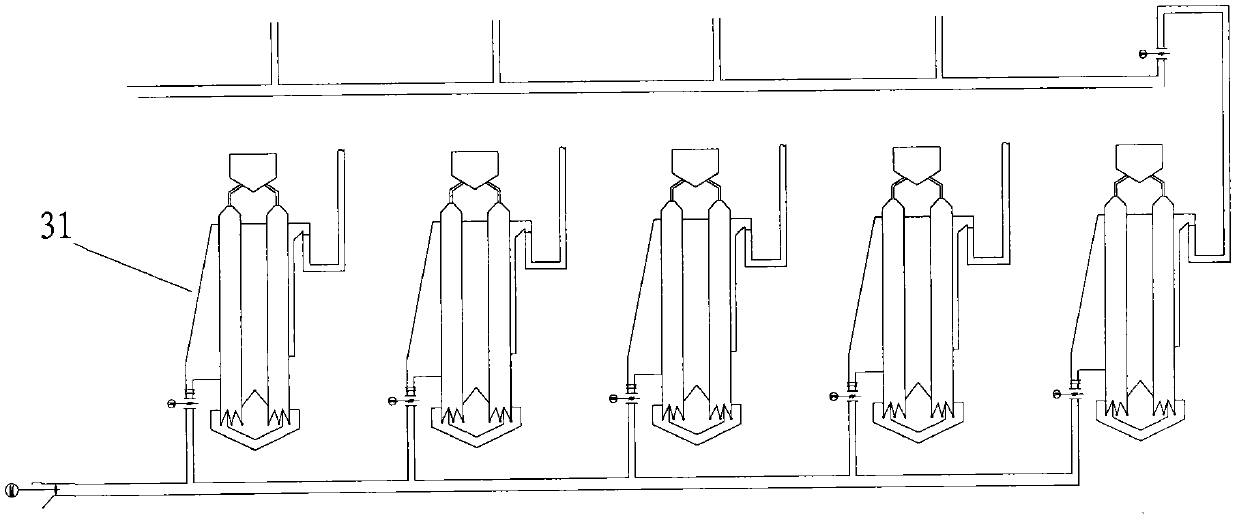

The invention provides a sintering smoke treatment system and a sintering smoke treatment mode, which are used in synchronized desulfuration, denitration, purification and acid making. The sintering smoke treatment system comprises a smoke system (1), an ammonia filling system (2), a smoke treatment system (3) and an acid making system (5), wherein the smoke system (1) comprises a main exhaust fan (11) and a chimney (12), the smoke treatment system (3) comprises an adsorption tower (31) and an analyzing tower (32), and the adsorption tower (31) and the analyzing tower (32) are connected with each other. The main exhaust fan (11) of the smoke system (1) and the chimney (12) are respectively connected with the adsorption tower (31), the analysis tower (32) of the smoke treatment system (3) is connected with the acid making system (5), and the adsorption tower (31) of the smoke treatment system (3) is connected with the chimney (12) of the smoke system (1).

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

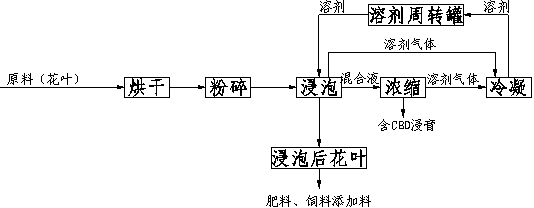

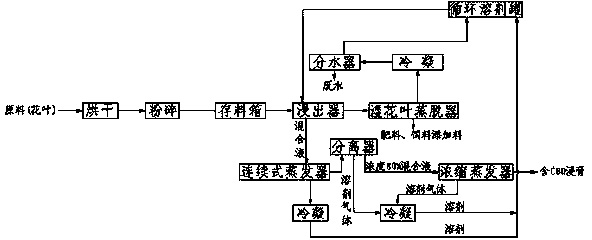

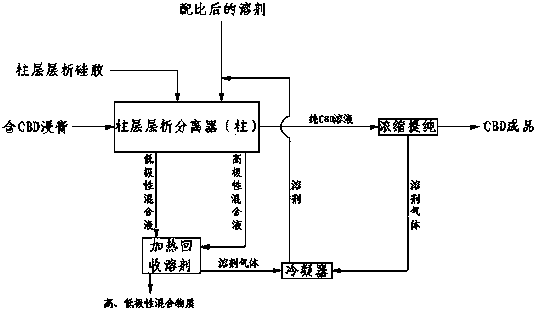

Technology of extracting dihydrogen cannabinol (CBD) from industrial cannabis sativa

The invention discloses a technology of extracting dihydrogen cannabinol from industrial cannabis sativa, and belongs to the technical field of biology. The technology comprises procedures of picking flowers and leaves, drying, crushing, soaking, extracting, concentrating and separating. The technology can implement complete recycle of media, and zero release and zero pollution for raw material classified extraction and waste comprehensive utilization. The technical processes from concrete extraction to separation of various substances as well as CBD purification all adopt international advanced technologies and meet international advanced standards.

Owner:辛荣昆

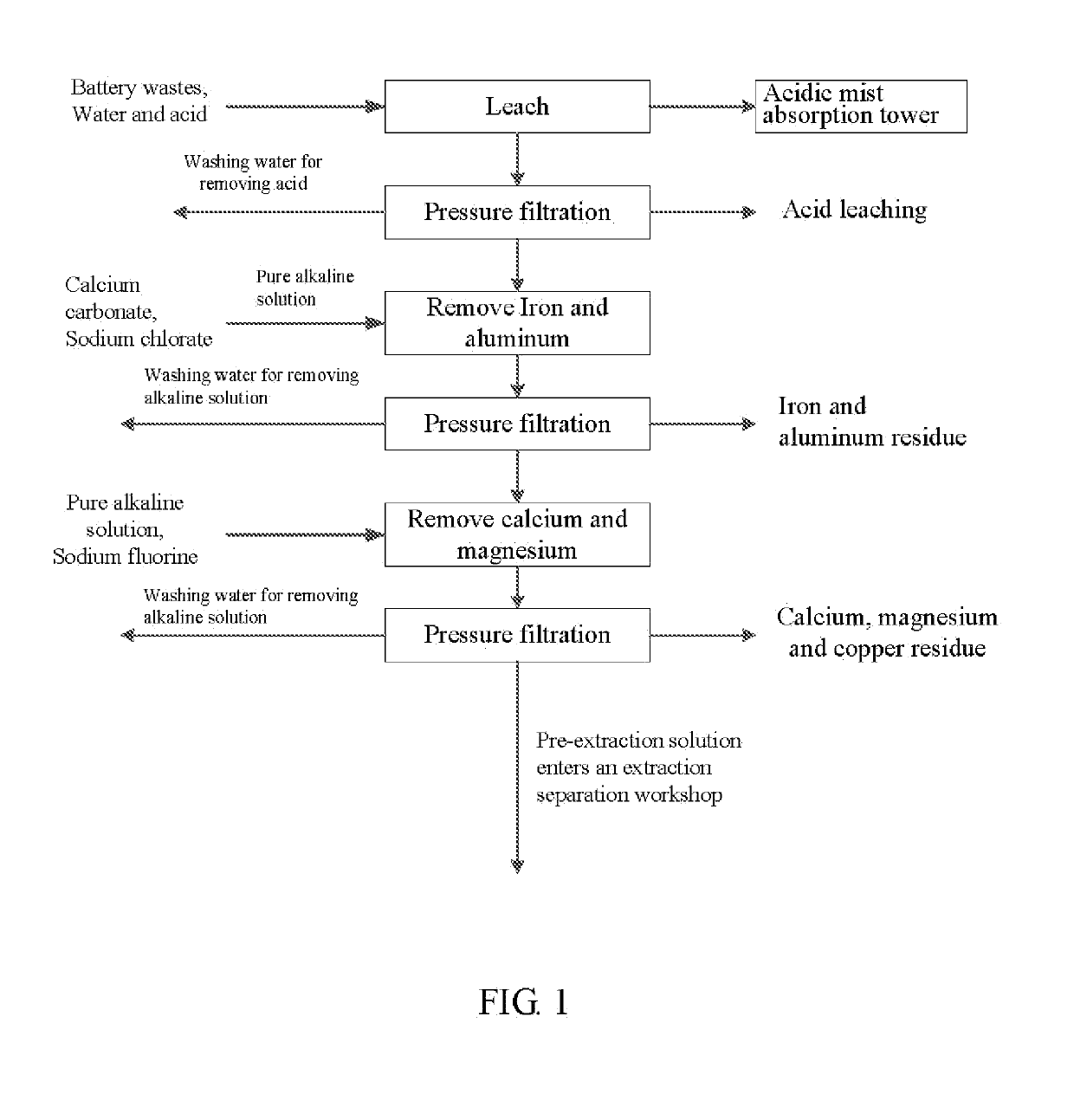

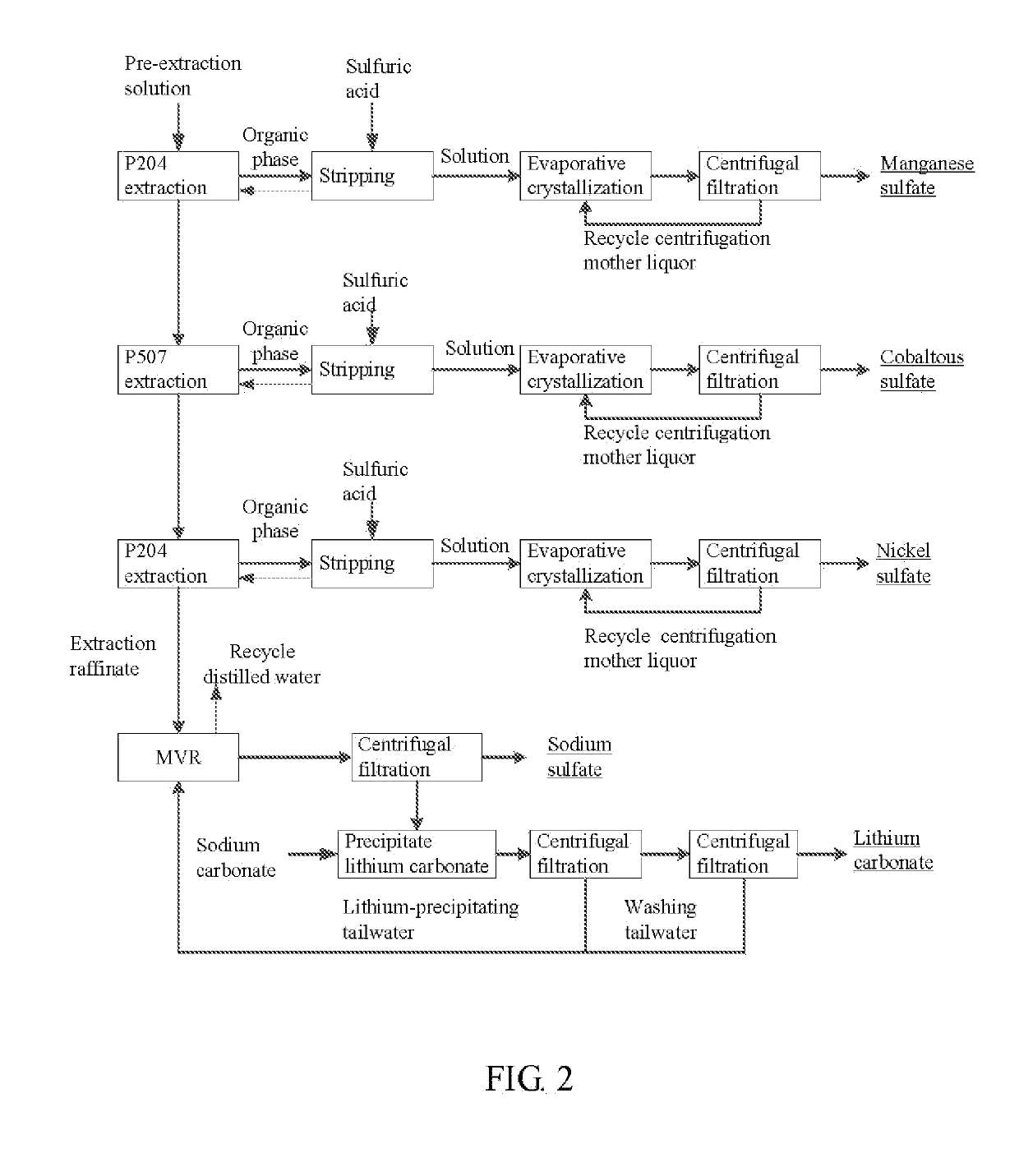

Method for preparing nickel/manganese/lithium/cobalt sulfate and tricobalt tetraoxide from battery wastes

ActiveUS20190152797A1Reduce productionHigh puritySolvent extractionCobalt sulfatesManganeseCobalt Sulfate

A method for preparing nickel / manganese / lithium / cobalt sulfate and tricobalt tetraoxide from battery wastes adopts the following process: dissolving battery wastes with acid, removing iron and aluminum, removing calcium, magnesium and copper, carrying extraction separation, and carrying out evaporative crystallization to prepare nickel sulfate, manganese sulfate, lithium sulfate, cobalt sulfate or / and tricobalt tetraoxide. By using the method, multiple metal elements, such as nickel, manganese, lithium and cobalt, can be simultaneously recovered from the battery wastes, the recovered products are high in purity and can reach battery grade, battery-grade tricobalt tetraoxide can also be directly produced. The method is simple in process, low in, energy consumption and free in exhaust gas pollution, and can realize zero release of wastewater.

Owner:HUNAN JINYUAN NEW MATERIALS CO LTD

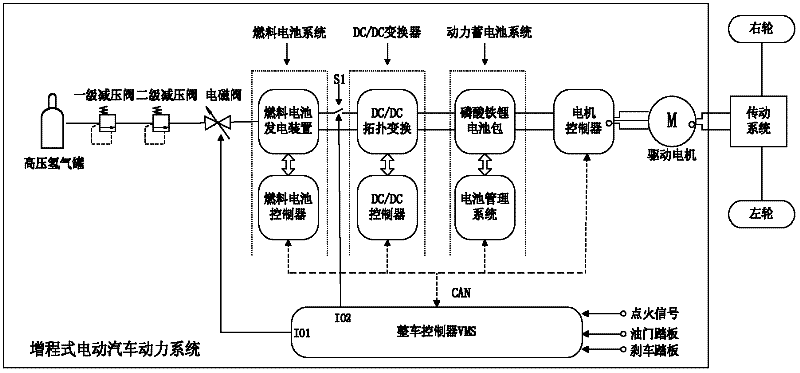

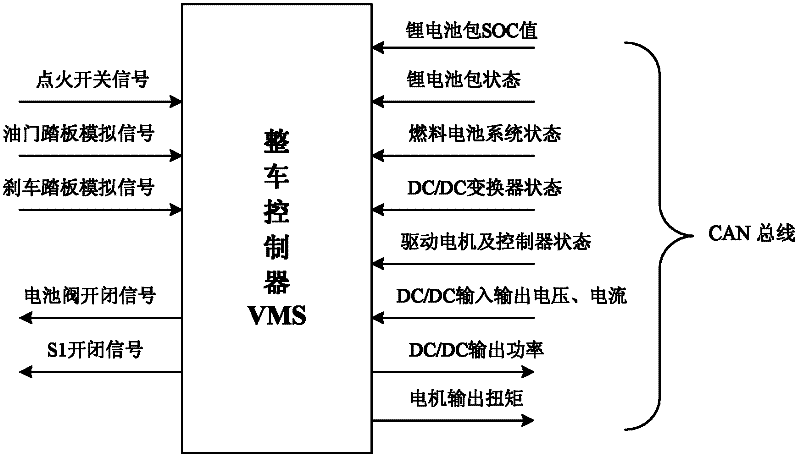

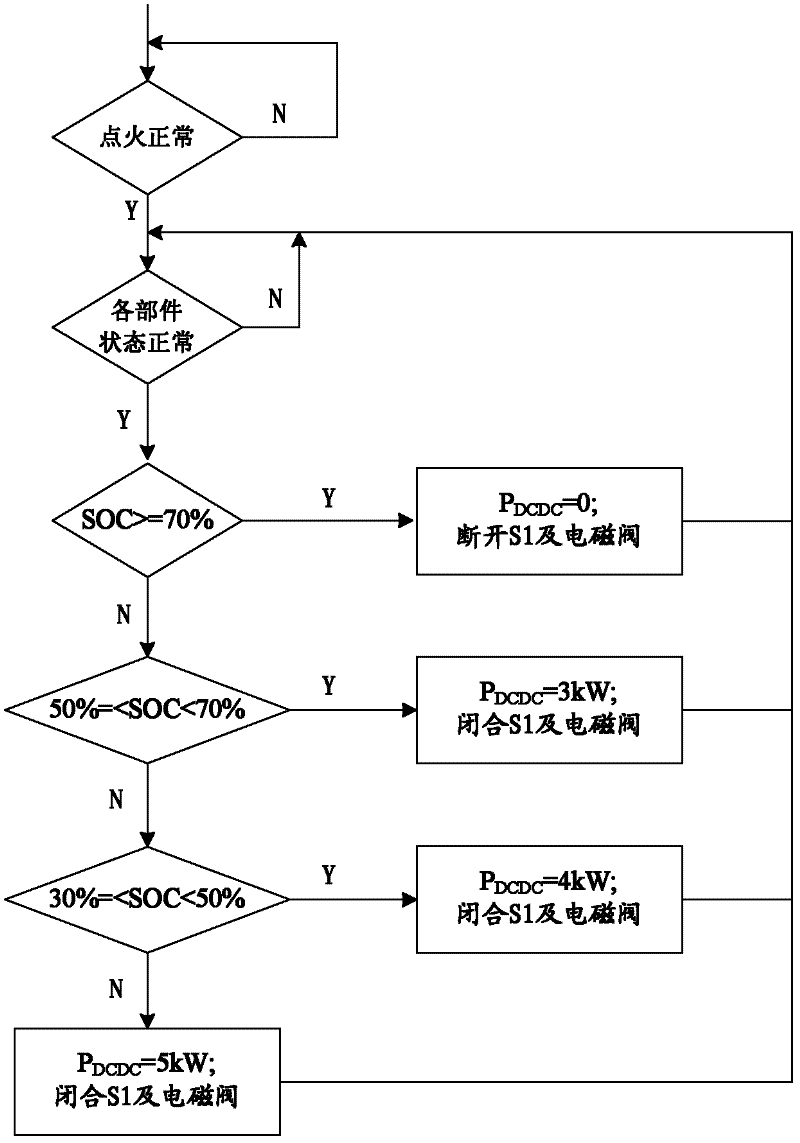

Extended range type electric vehicle power system based on fuel battery and control method for extended range type electric vehicle power system

ActiveCN102358201AIncrease mileageSolve the lack of energy storageVehicular energy storageElectric propulsionDrive motorInternal combustion engine

The invention discloses an extended range type electric vehicle power system based on a fuel battery and a control method for the extended range type electric vehicle power system. The output end of a fuel battery system with a hydrogen pot is connected with an input of a direct current / direct current (DC / DC) transformer through a controllable relay S1; an output of the DC / DC transformer is connected with a lithium iron phosphate power battery pack; the lithium iron phosphate power battery pack is connected with the high voltage input end of a motor controller; the three-phase output end of the motor controller is connected with a driving motor; a whole vehicle controller VMS directly controls an electromagnetic valve for managing hydrogen output and the relay S1 through an input / output (I / O) port, and communicates with the fuel battery system, the DC / DC transformer, a battery management system and the motor controller through controller area network (CAN) buses so as to control a motor to drive the whole vehicle to run and manage the whole power system. The fuel battery system with the hydrogen pot is used as a vehicle-mounted charger for the lithium iron phosphate power battery pack; and a scheme of a vehicle-mounted range extender of an electric vehicle can be provided. The efficiency of the fuel battery system serving as the vehicle-mounted range extender is higher than that of an internal combustion engine; furthermore, the noise is low, and zero emission and zero pollution are realized.

Owner:武汉海亿新能源科技有限公司

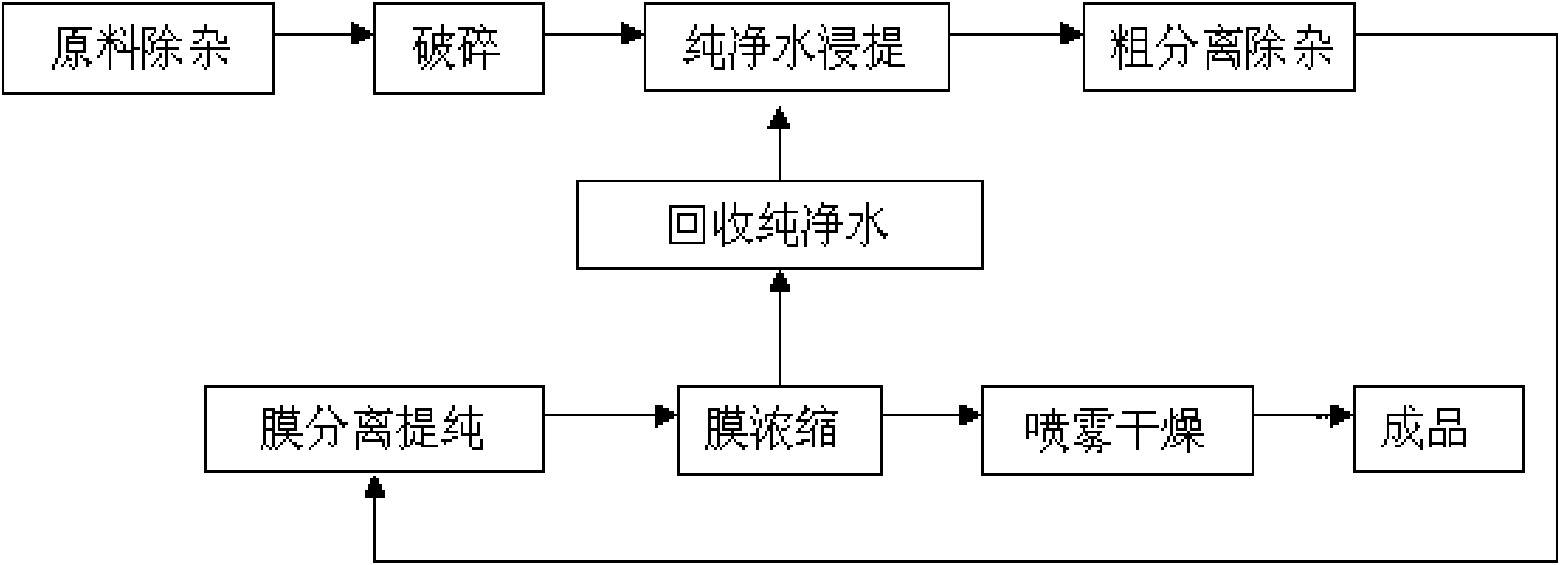

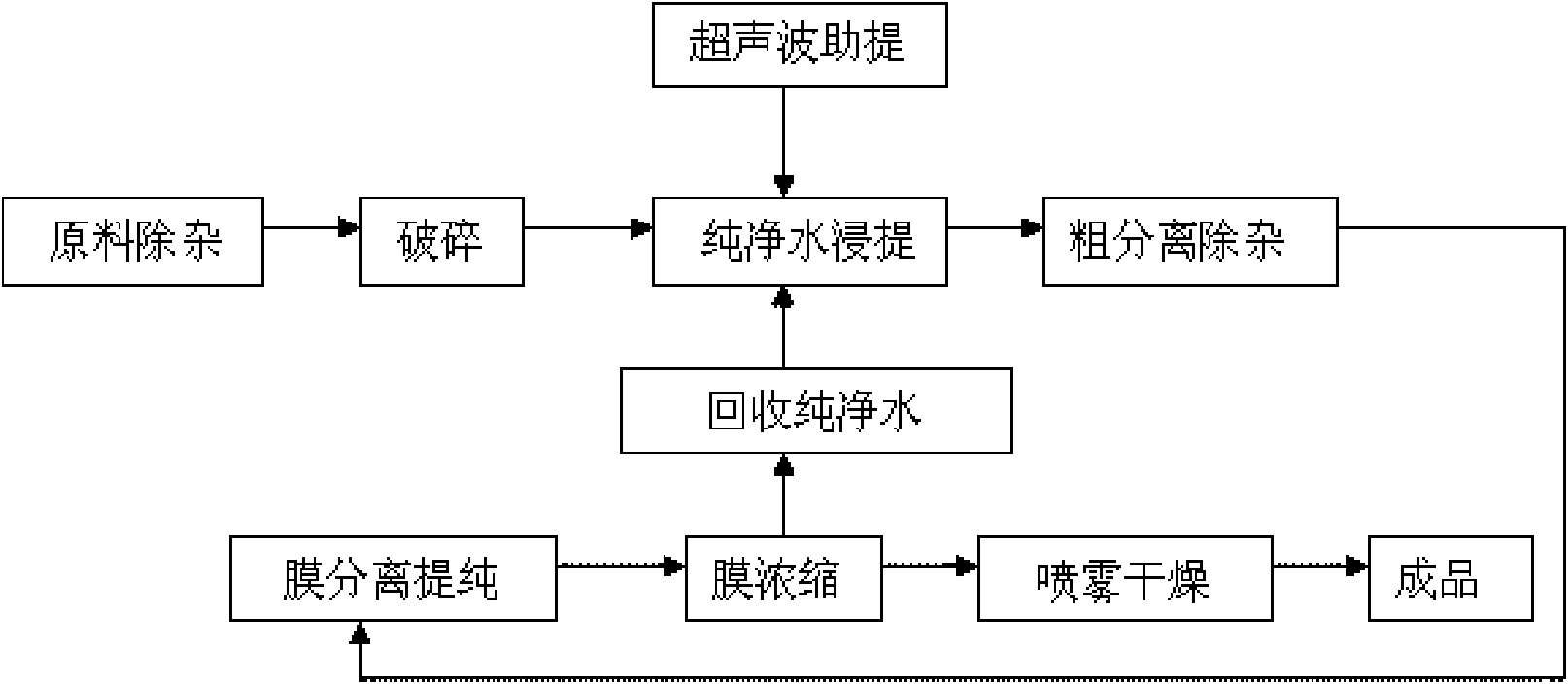

New process for extracting high-purity gardenia yellow pigment by membrane separation and purification technology

InactiveCN101659794AImprove environmental performanceImprove extraction efficiencySemi-permeable membranesNatural dyesFiltration membraneUltrafiltration

The invention relates to a new process for extracting high-purity gardenia yellow pigment by a membrane separation and purification technology. The new process comprises processes of purified water leaching, crude separation and impurity removal, membrane separation and purification, and membrane concentration. After purified water extraction and ultrasonic assisted extraction, raw gardenia is separated by three centrifuges with different specifications and then obtained leaching liquor enters a membrane separation, purification and concentration system which consists of a microfiltration membrane (MF), an ultrafiltration membrane (UF), a nano-filtration membrane (NF) and a reverse osmosis membrane (RO), thus an OD value of the obtained gardenia yellow pigment can be controlled below 0.4 and color number can be increased to be more than 400. The finished product obtained by the process has no residual organic solvent and completely meets technical requirements for exporting to developed countries, including Europe and America, etc. as well as developed areas. The process is safe and clean in the whole production process, capable of realizing zero pollution and zero emission, has high environmental protection performance, and has advantages of greatly reducing energy consumption and lowering production cost due to the membrane concentration technology. The process further has advantages of simple process, stable product quality, high purity, etc.

Owner:广西山云生化科技股份有限公司

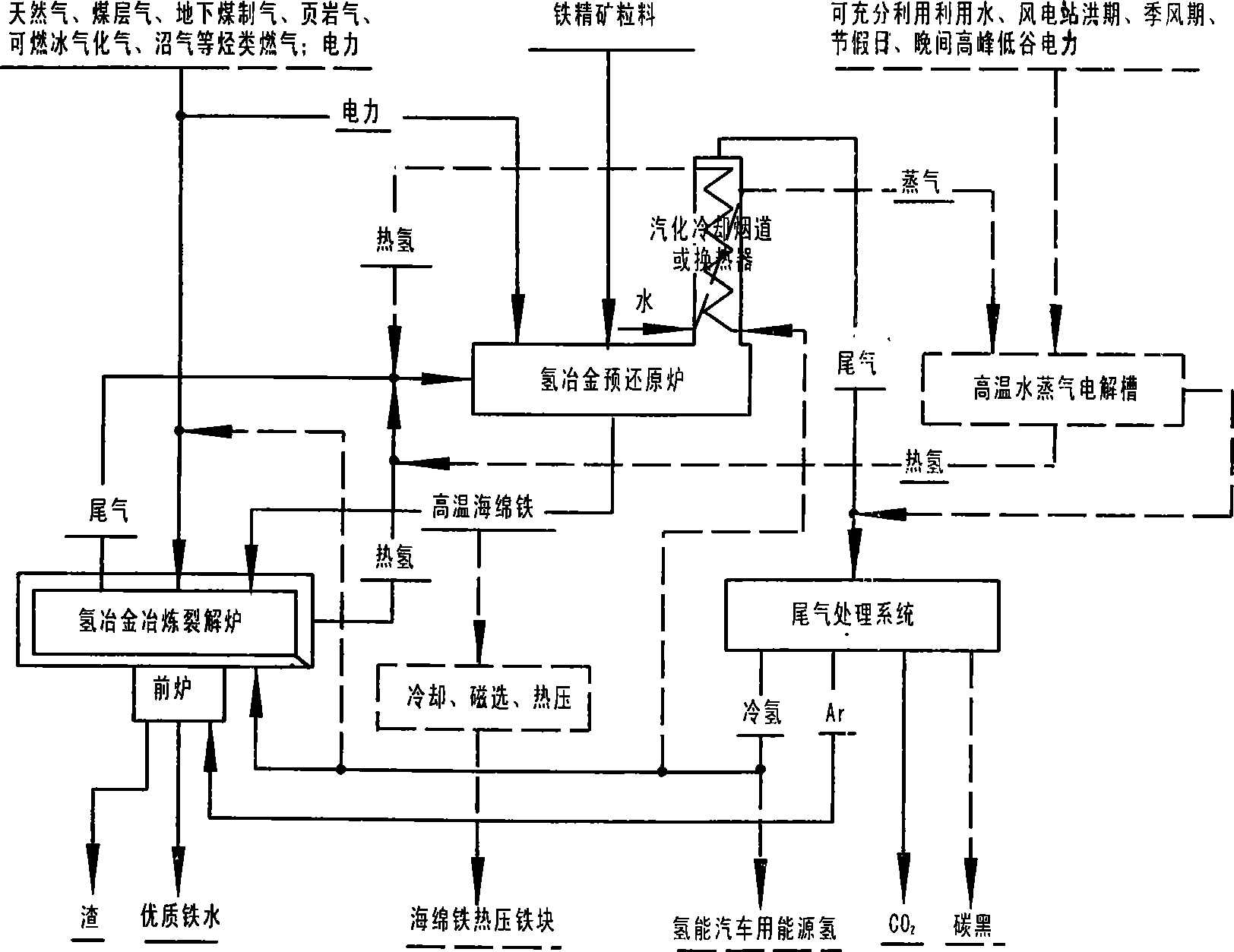

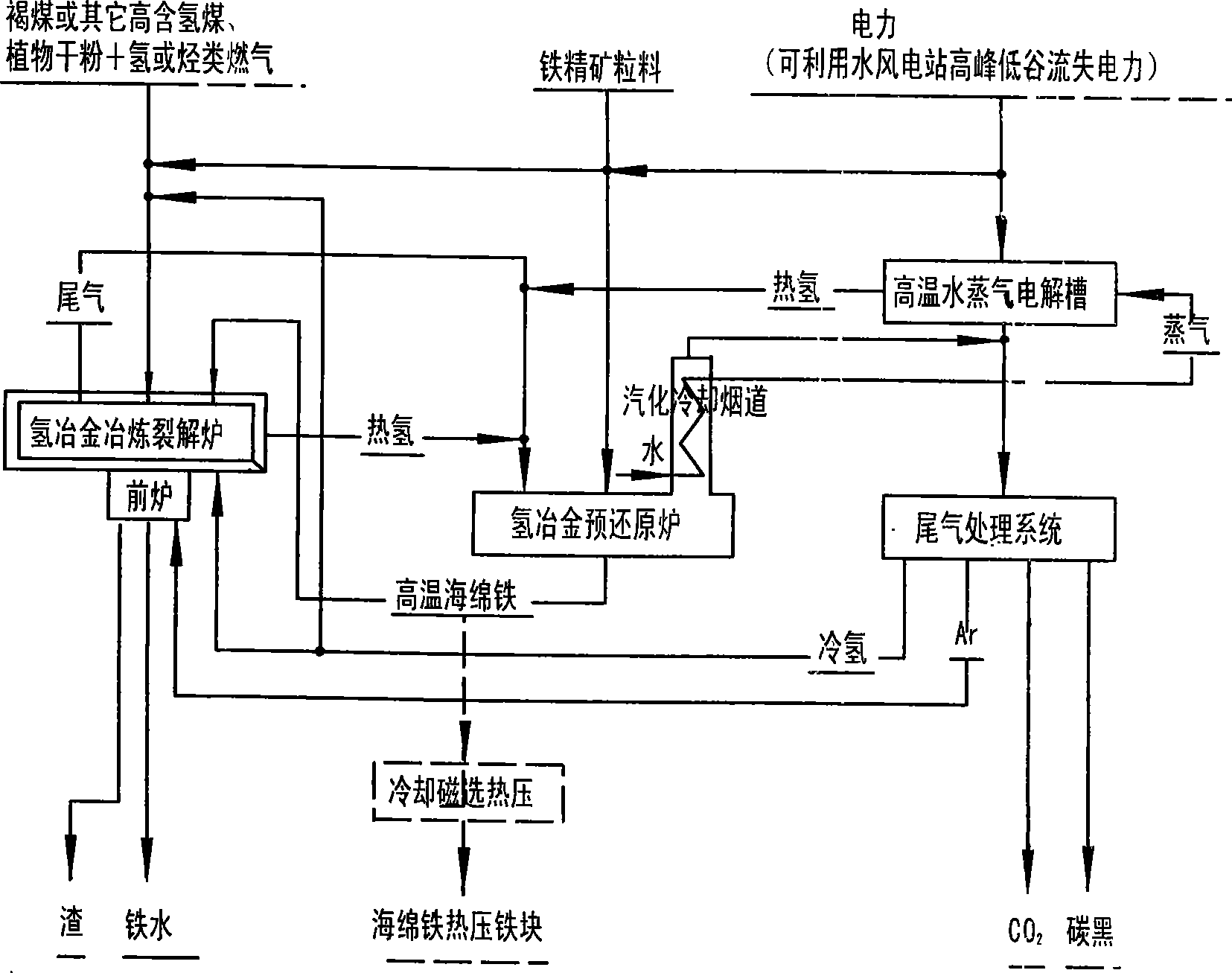

Hydrogen metallurgy method

InactiveCN101768651AAdaptablePowerfulElectrolysis componentsHydrogen separationElectric arcEnergy source

A hydrogen metallurgy method and a relevant device relate to the technical field of hydrogen metallurgy and hydrogen energy source. A pre-reduction furnace is used for rapidly pre-reducing iron ore concentrate granules in a hydrogen-rich, high temperature and high pressure condition to produce sponge iron with a reduction degree of more than or equal to 75 percent and the sponge iron is delivered to a cracking furnace in a heat-preserving enclosed mode; the cracking furnace cracks @ type fuel gas into high-temperature hydrogen and nano @@ through direct current plasma electric arc in a high-temperature oxygen-poor condition, most of the high-temperature hydrogen is delivered to the pre-reduction furnace and the sponge iron is rapidly molten and reduced to smelt molten iron or semi-steel; simultaneously, the residual heat of tail gas from the pre-reduction furnace is used for producing high-temperature steam which is electrolyzed by a water steam electrolytic cell to prepare high-temperature pure hydrogen; and after water in the high-temperature pure hydrogen is separated by heat exchange, the high-temperature pure hydrogen is returned to the pre-reduction furnace and partial high-temperature pure hydrogen is directly delivered as the hydrogen energy source. High efficiency, energy conservation, the best product quality and the optimal emission reduction effect of hydrogen metallurgy are fully shown.

Owner:樊显理

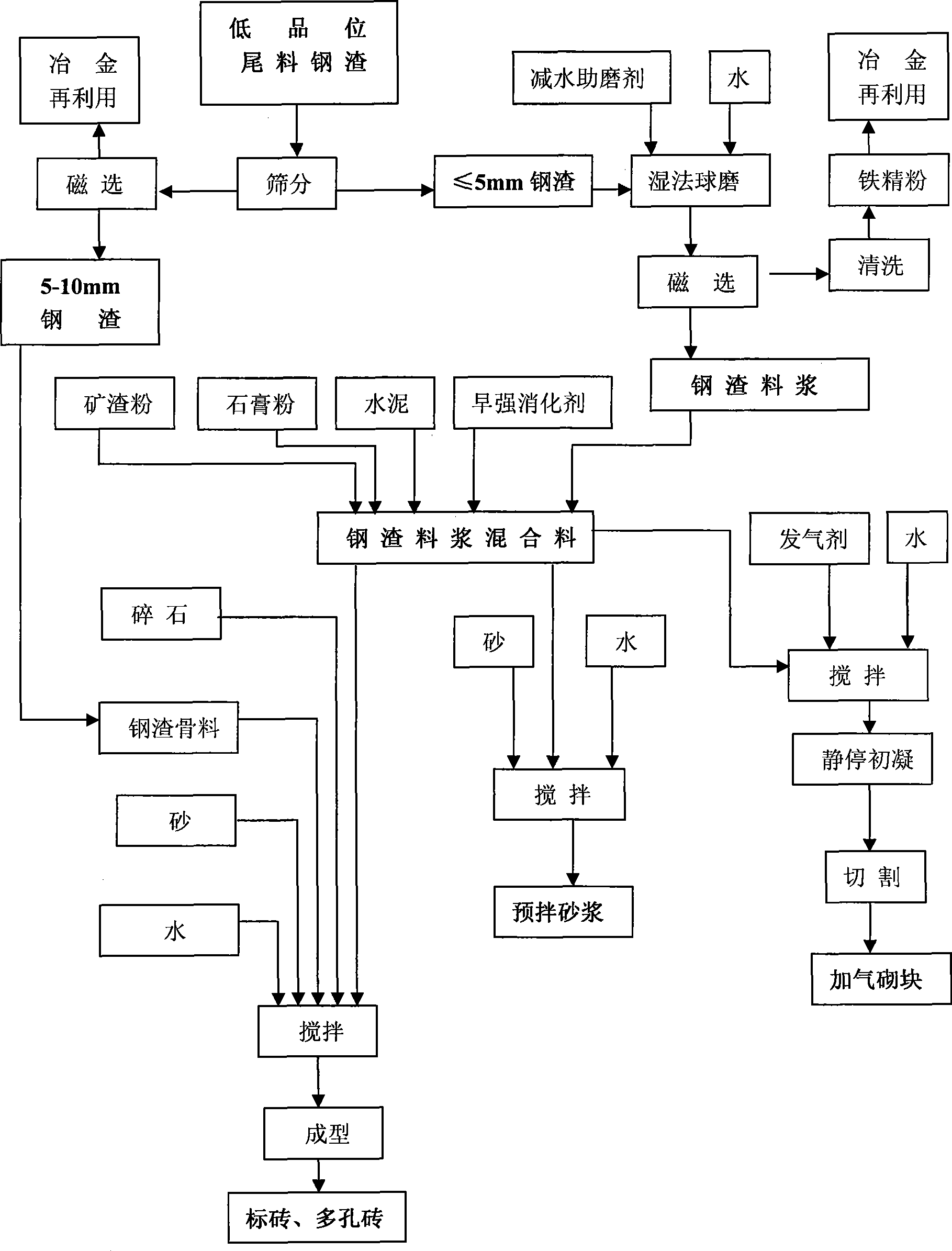

Low grade tailing steel slag re-use method and slurry magnetic separation equipment

InactiveCN101391457AGood economic and social benefitsAchieve diversificationClay processing apparatusMagnetic separationSlagGypsum

The invention discloses a method for reutilization of low-grade after-product steel slag and a magnetic plant thereof, relating to a method for comprehensively utilizing the steel slag. The method comprises the sequential steps as follows: the low-grade after-product steel slag is screened, magnetically selected and ball-grinded by wet-method; the magnetically selected steel slag slurry is mixed with blast-furnace slag powder, plaster powder, cement and precocious digester as steel slag slurry mixture; the steel slag slurry mixture is mixed by compounding with one or more matters out of steel slag aggregate, crushed stone, sand, water and gas former aluminium powder so as to prepare porous bricks or standard bricks or pre-mixing mortar or aerated concrete block. The method can use a plurality of low-grade after-product steel slag, realizes the diversification of product, has large usage quantity and zero exhaust of the steel slag and is a good method for comprehensive utilization.

Owner:中冶武汉冶金建筑研究院有限公司

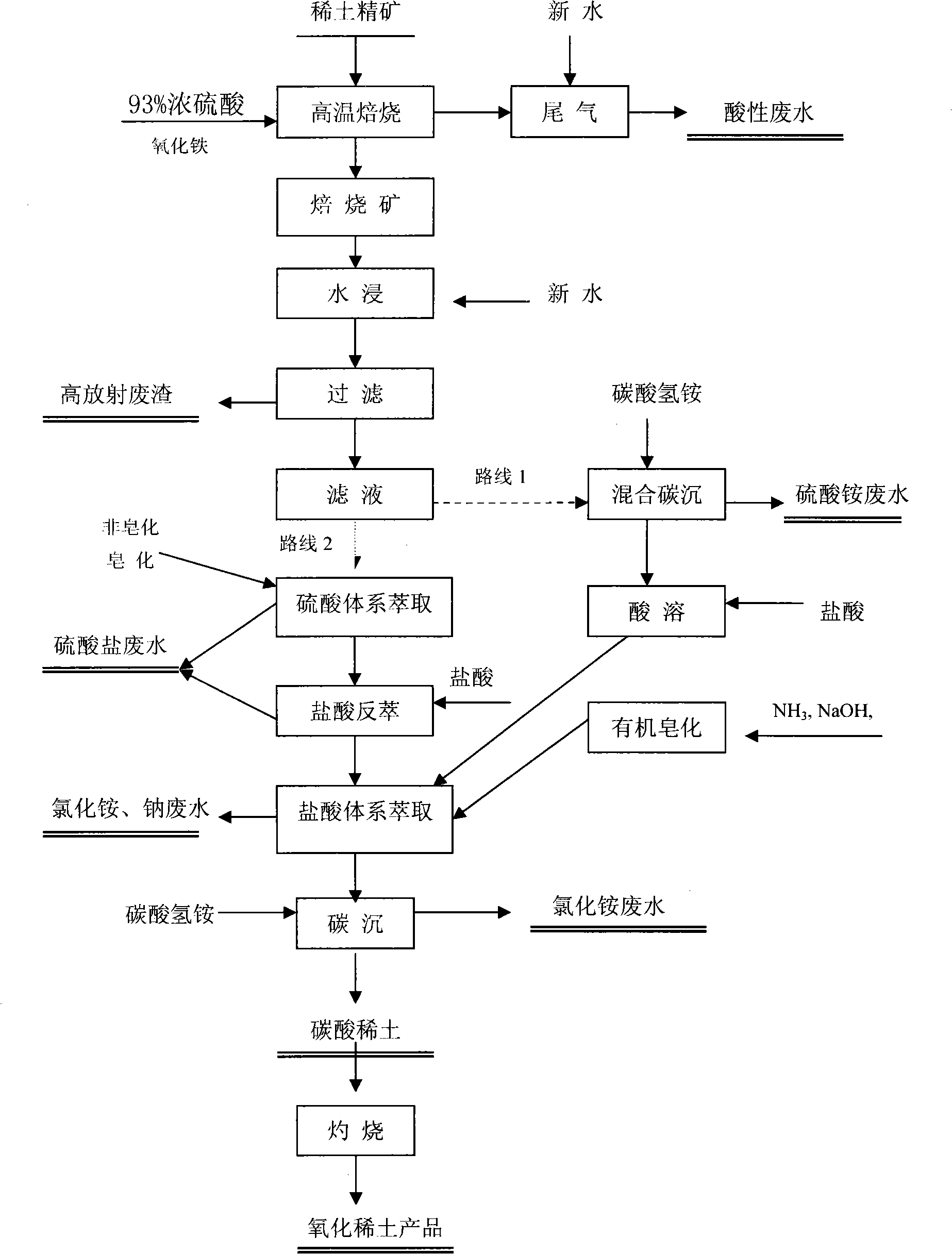

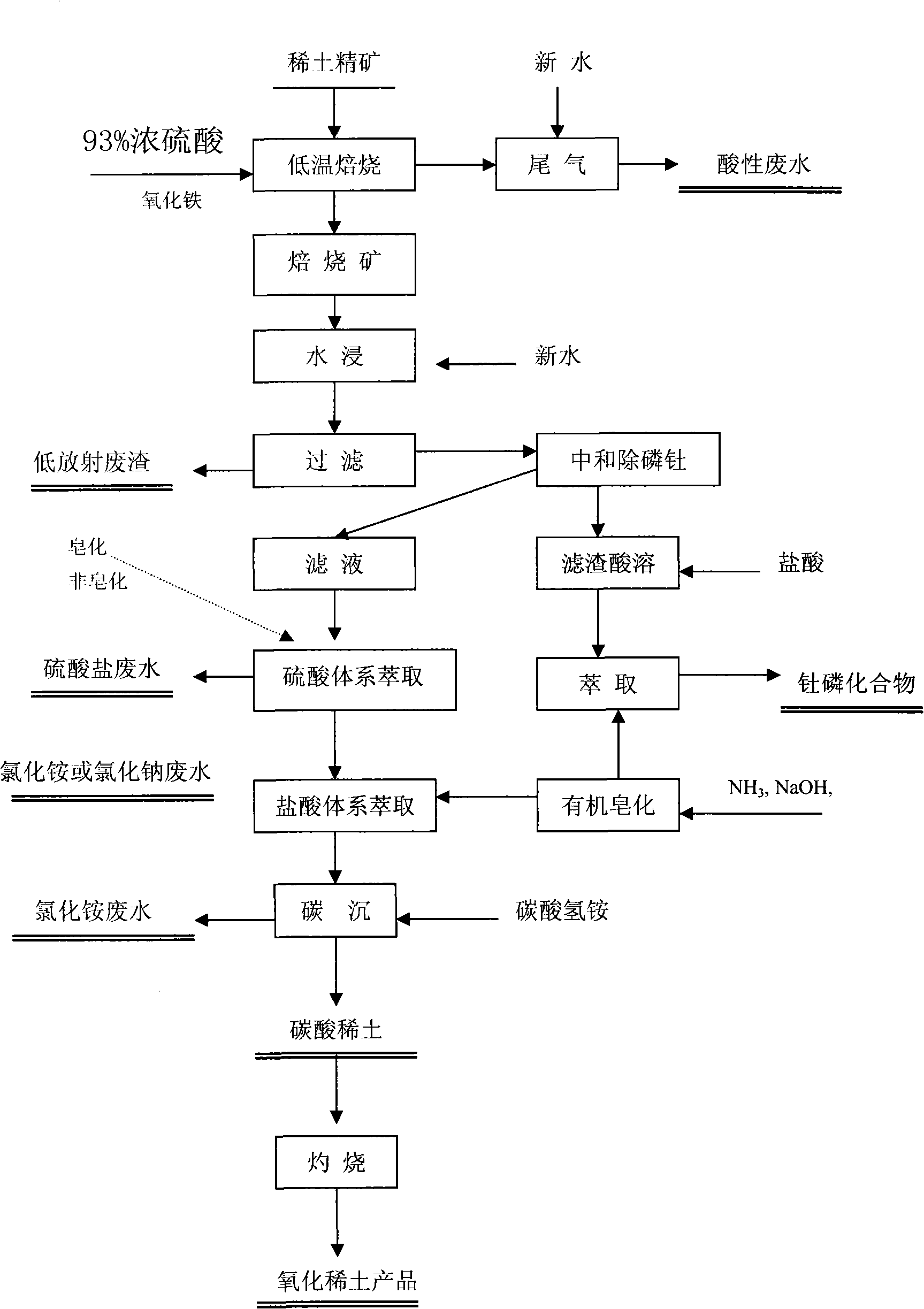

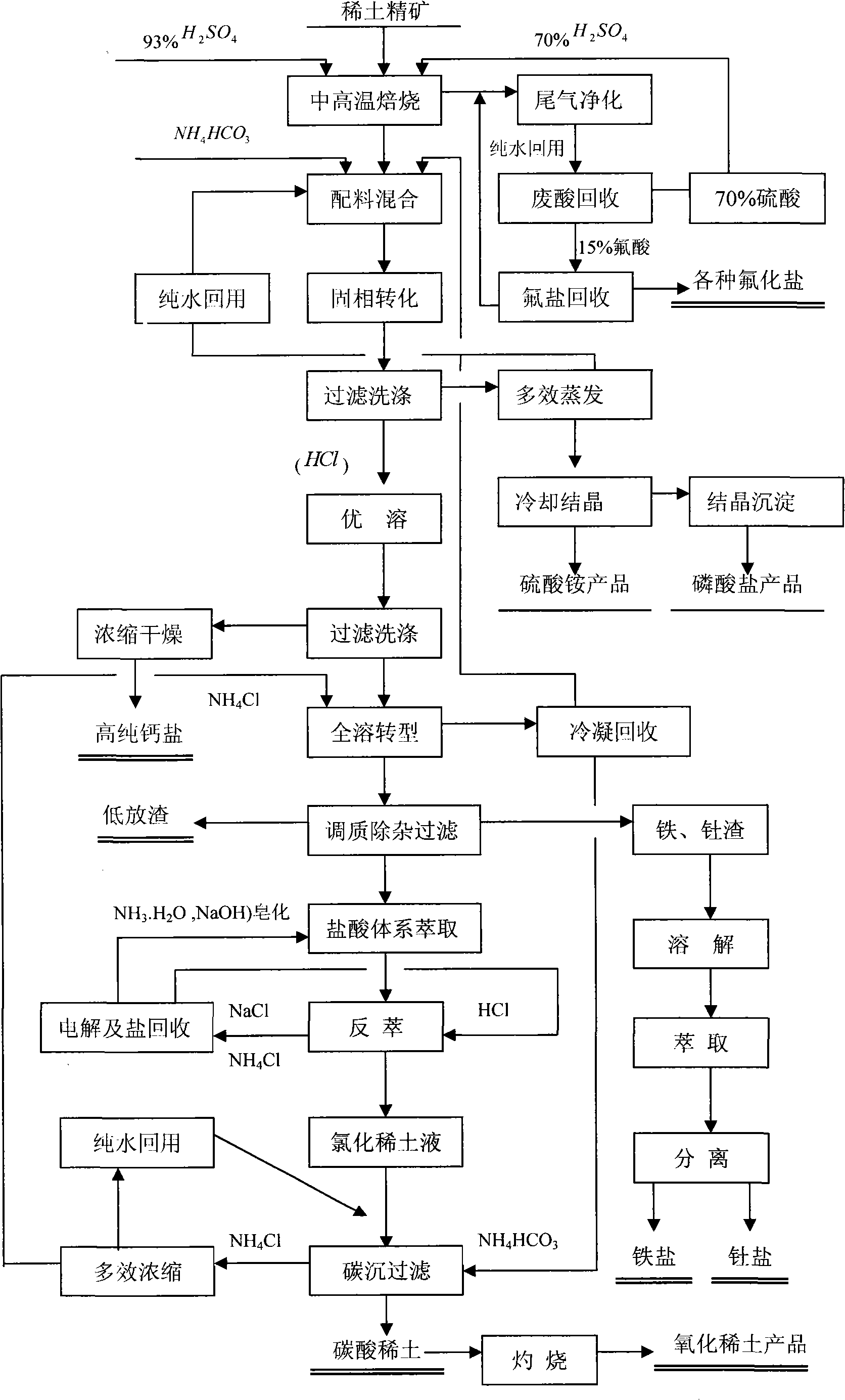

Process for rare-earth smelting resource reclamation and cyclic production

InactiveCN101880782AAchieve governanceAchieve recyclingProcess efficiency improvementIndustrial waste waterSmelting process

The invention relates to a process for rare-earth smelting resource reclamation and cyclic production. The process has the main characteristic of comprehensively and systematically solving the problems of environmental protection and industrial promotion of the whole rare-earth industrial chain by adopting innovative integrated technical means. The process mainly comprises administration and comprehensive utilization of waste gas, waste water and waste slag, revolution of a rare-earth smelting process, and reclamation and repeated utilization of various important resources such as sulfur, fluorine, ammonium, thorium, phosphorus, calcium and the like so as to achieve smokeless and harmless treatment of the waste gas, full utilization of the resources and zero discharge of industrial waste water and fulfill the final goal of cyclic production. The process radically solves the maximum environment-friendly bottleneck problem in a sustainable development process of the Baotou rare-earth industry from resource advantage to industrial advantage, in particular the historical key environment-friendly technical problem, reduces energy consumption of a large amount of resources and pollutiondischarge, greatly reduces the production cost, upgrades the rare-earth industry, and extends the larger industrial chain at the same time.

Owner:马克印 +1

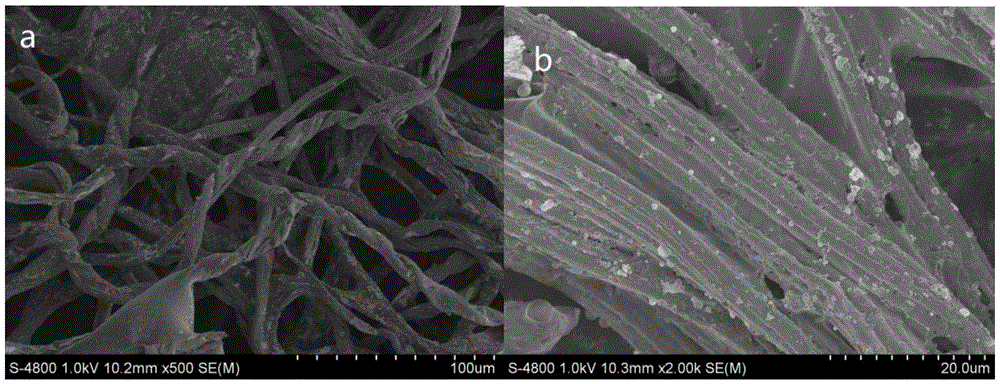

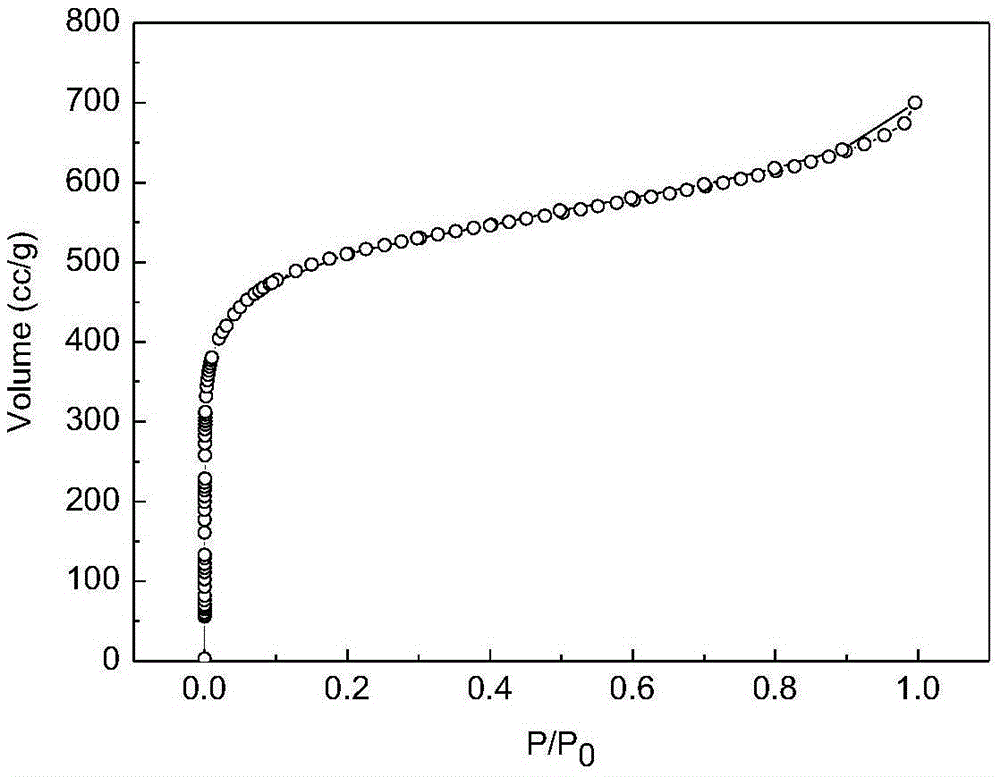

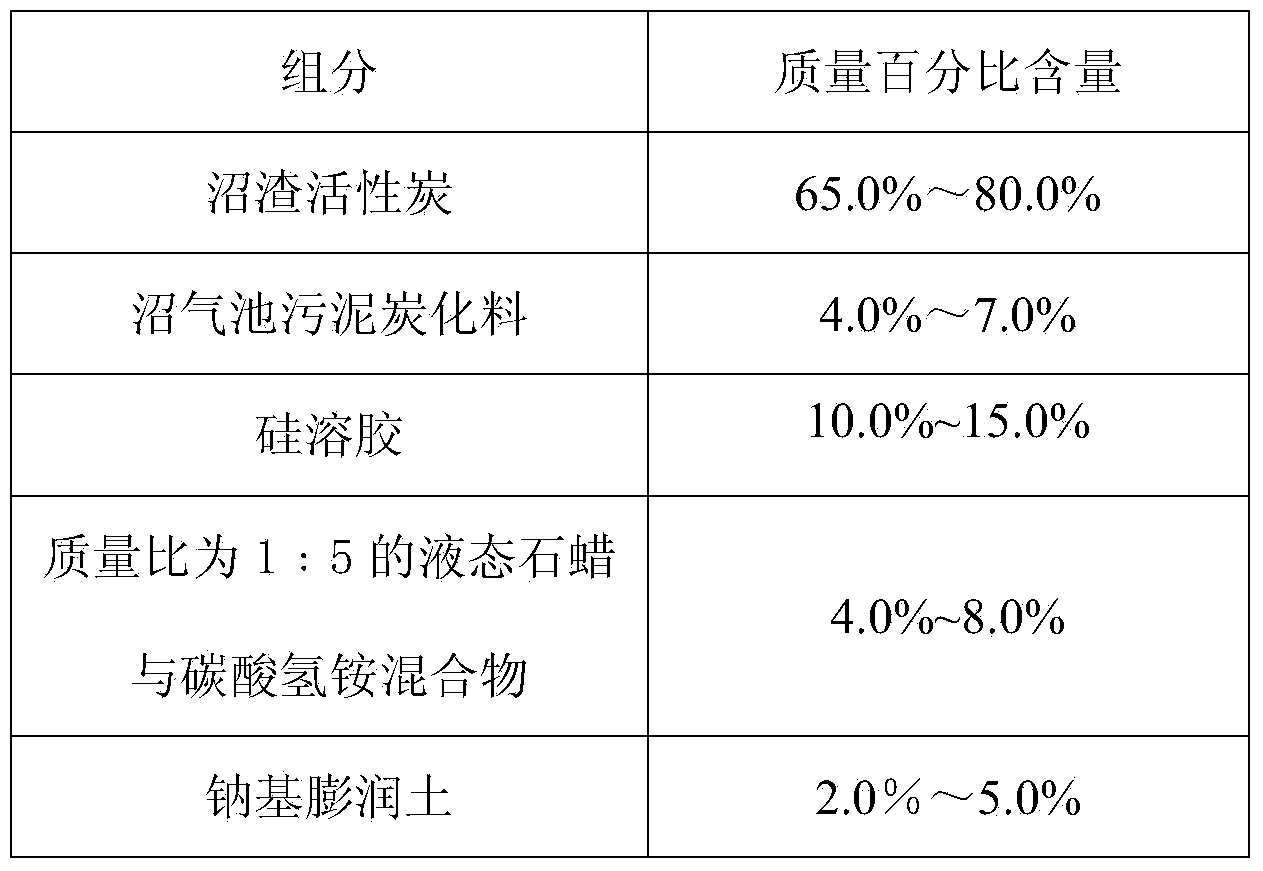

Method for efficiently preparing cotton based mesoporous activated carbon fiber

InactiveCN105480973AWide range of sourcesLow priceFibre chemical featuresChemistryHydrothermal carbonization

The invention relates to a method for efficiently preparing cotton based mesoporous activated carbon fiber. The method comprises a step (1) of washing cotton, placing the cotton in a hydrothermal reaction kettle, performing heating to 150-200 DEG C at the heating rate of 5-30 DEG C / min, performing hydrothermal carbonization, performing heat preservation for 1-3 hours and then performing cooling to room temperature; a step (2) of dipping carbonization materials obtained from the step (1) into activator solution, performing microwave-ultrasonic joint dipping for 5-30 minutes and then performing filtration, sending filtration materials to a microwave heating device, performing activation for 5-15 minutes at 250-350 DEG C and then stopping microwave output, and a step (3) of washing the activated materials to be neutral and performing drying to obtain the activated carbon fiber. According to the method, the characteristics of microwave inner heating and selective heating are fully utilized, the technological process is simple, the activation temperature is only 250-350 DEG C, the activation time is only 5-15 minutes, the mesoporous proportion of the activated carbon fiber of the product reaches 50-90%, and the adsorptive property is good.

Owner:HEBEI UNIV OF TECH

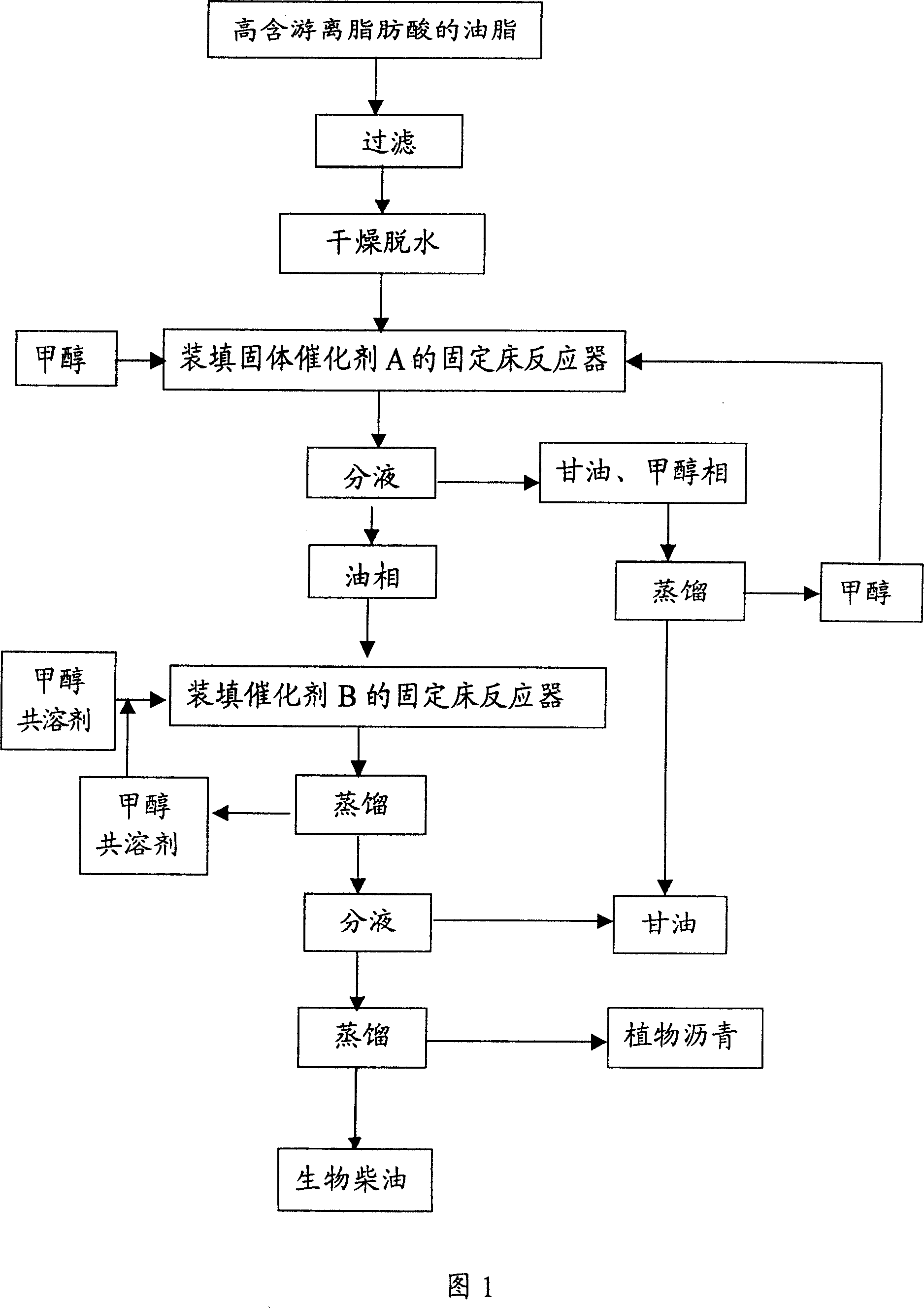

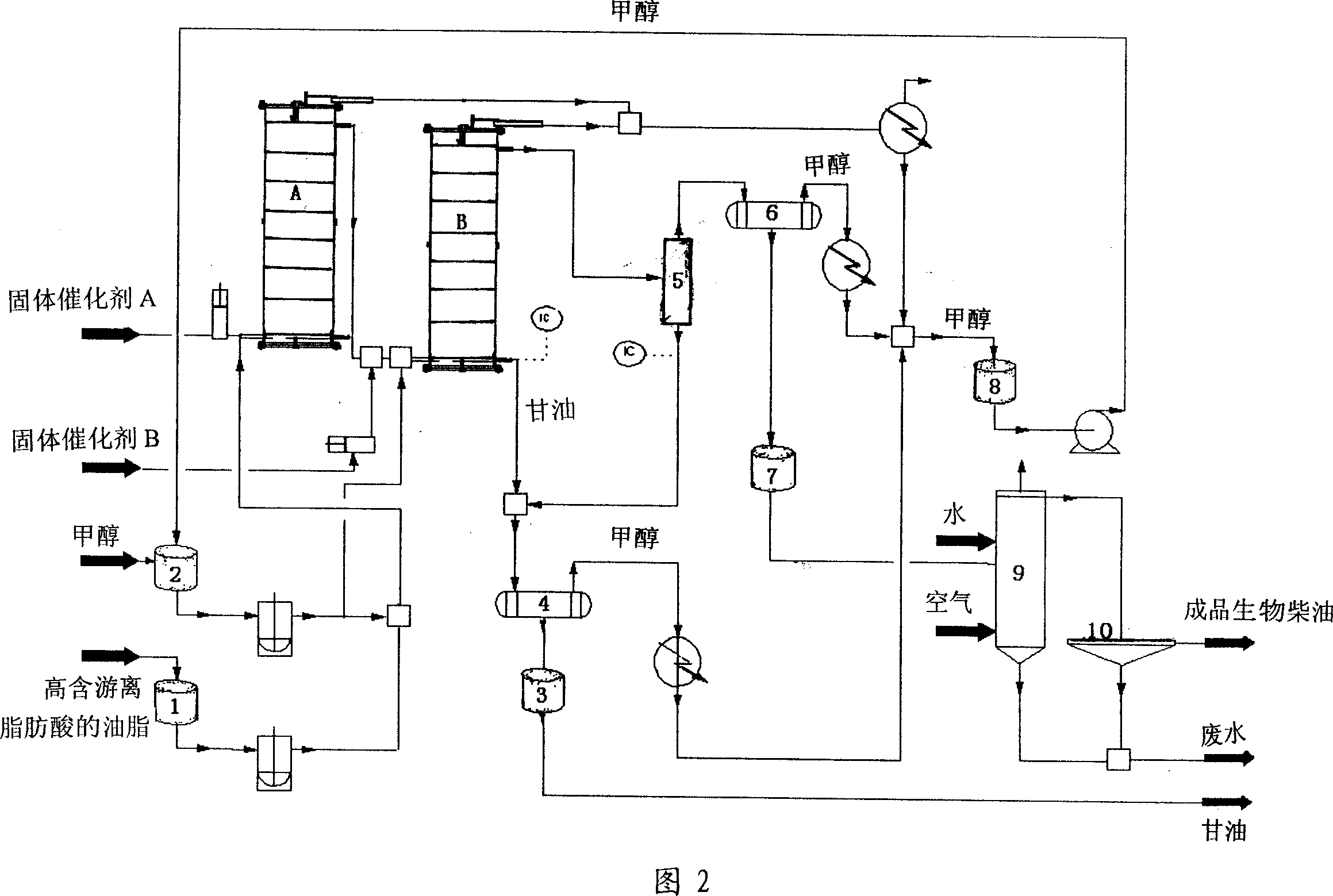

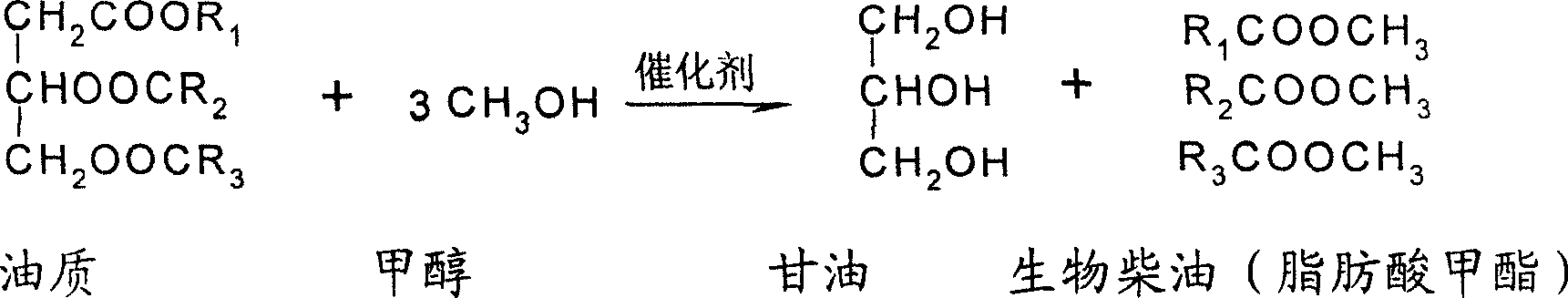

Preparation method of biological diesel oil

InactiveCN1928016AHigh catalytic activityLower activation energyBiofuelsLiquid hydrocarbon mixture productionSolventGlycerol

The present invention relates to biodiesel oil preparing process, and provides one biodiesel oil preparing process with solid acid and solid alkali as catalyst to lower the activating energy and raise the reaction speed. The biodiesel oil preparing process includes the following steps: reacting dried grease with high free fatty acid content, methanol or ethanol, and cosolvent in the molar ratio of 1 to 6-1 to 6.05 in the first fixed bed reactor with solid catalyst A at 60-65 deg.c for about 3 hr; separating the oil phase from others; reacting the oil phase in the second fixed bed reactor with solid catalyst B with methanol or ethanol and cosolvent at 60-65 deg.c for about 3 hr; distilling out methanol or ethanol and cosolvent; separating the biodiesel oil from glycerin phase; and distilling the biodiesel oil phase to obtain biodiesel oil product. The catalyst of the present invention has high catalytic activity and can lower the activating energy and raise the reaction speed.

Owner:张海军

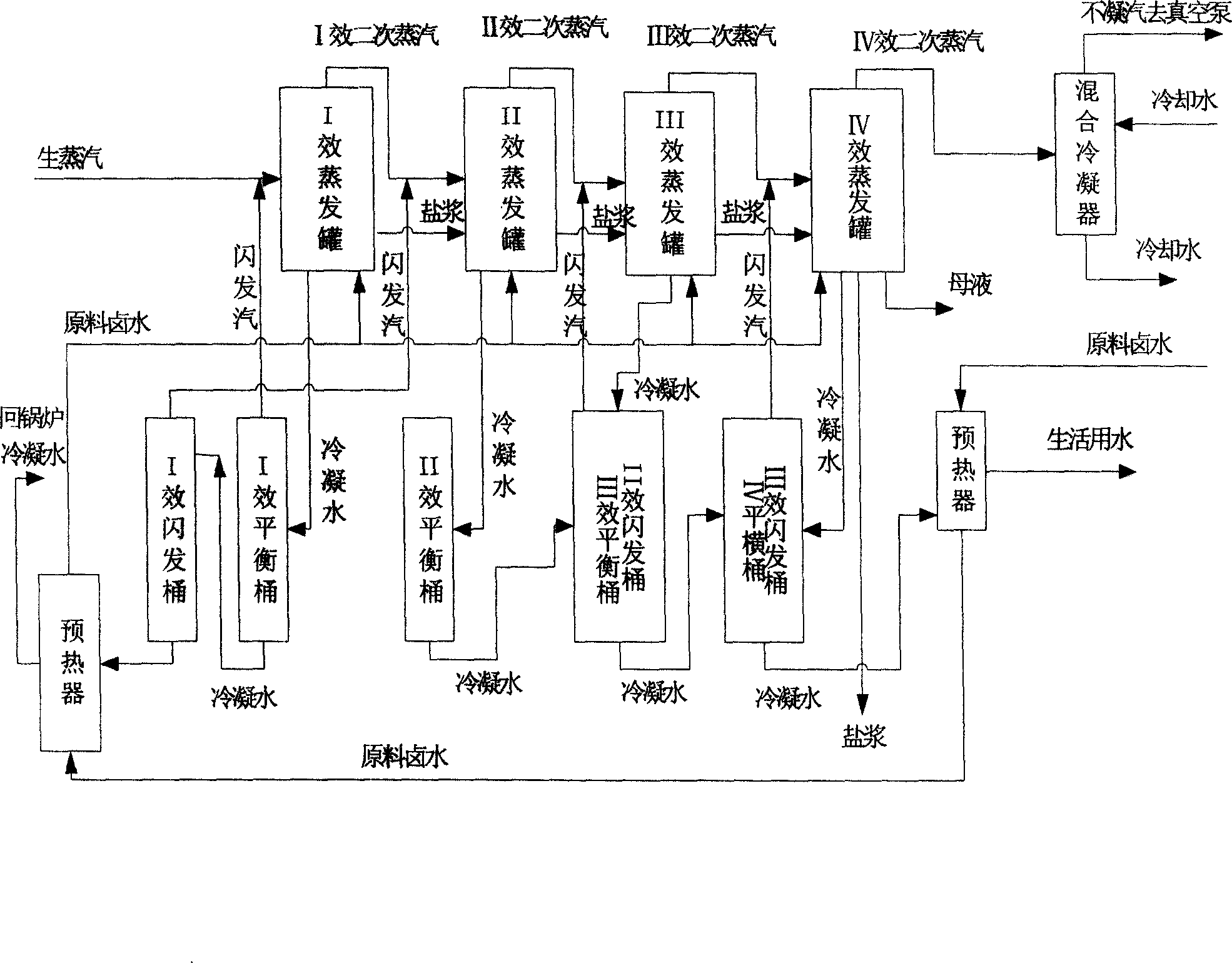

Vacuum salt producing technique of salt-field saturated bittern direct ingress into evaporation tank

InactiveCN101041443ASave crystallization areaZero emissionChemical industryAlkali metal chloridesSea saltEngineering

The invention discloses a vacuum preparing salt craft through leading salt-field saturated brine into evaporation tank in the sea-salt area, which comprises the following steps: pumping saturated brine into calorifier through brine pump; preheating; leading into evaporation tank; leading the vapor into heating room through separate cylinder; setting steam pressure at 0.3-0.4MPa; adopting green steam to heat in the heating room of effect evaporation tank; making the indirect steam through evaporating feed liquid as heat source of the next effect evaporation tank; making the indirect steam of II effect, III effect evaporation tank as the same; leading indirect steam of IV effect evaporation tank into mixing condenser; making salt grout generated by evaporating feed liquid through third washing; drying anticentripetally; drying; packing; getting product.

Owner:ENG TECH INST CO LTD OF CNSIC +1

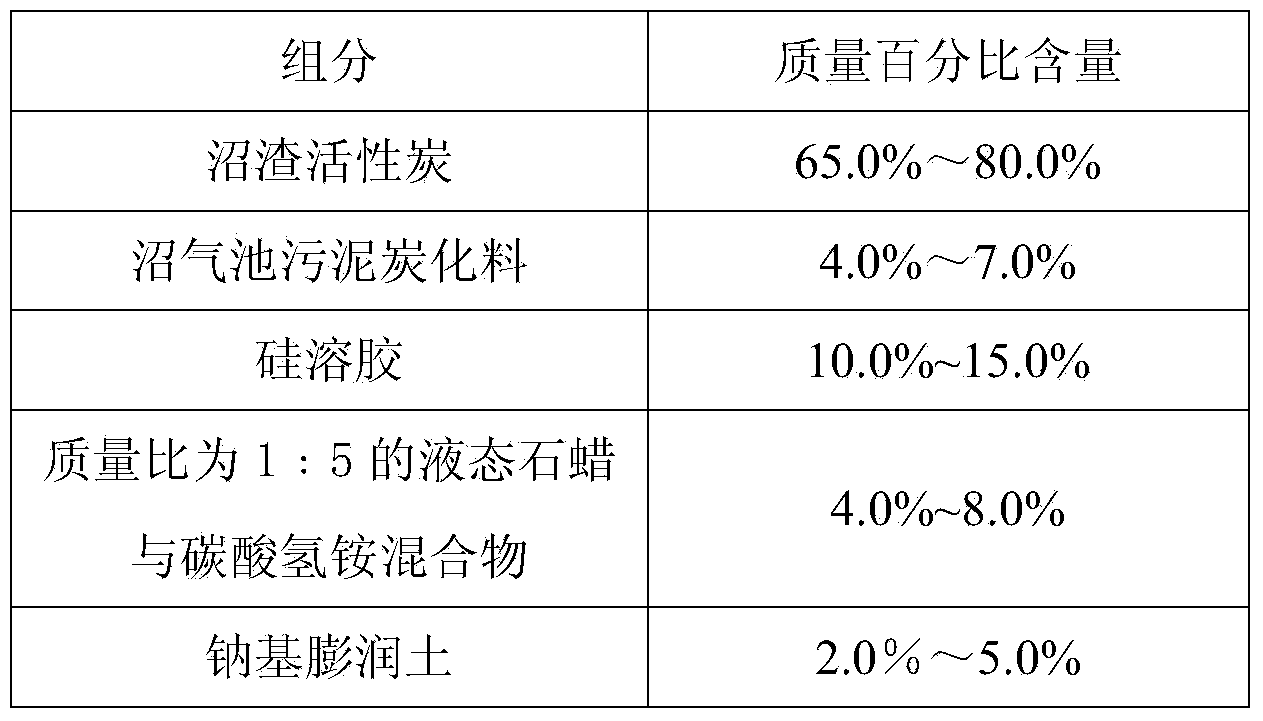

Fermenting bed padding and preparation method and applications thereof

The invention discloses fermenting bed padding and a preparation method and applications thereof. The fermenting bed padding is prepared by materials with the following parts by weight: (1) 35-40 parts of wood chips or wheat bran; (2) 55-60 parts of any one or the mixture of more than one of seed shells, straw, spent mushroom compost or leaves, wherein the mixture is composed by any weight proportion; and (3) 3-6 parts of rice bran or plant cakes and 0.1-0.2 part of anaerobic fermenting agent. The fermenting bed padding mainly has the following advantages of: (1) long using time; (2) no emission, no odour and no pollution; (3) saving feed, reducing cost and improving benefits; and (4) effectively reducing incidence rate of pigs, reducing medication and improving pork quality.

Owner:王颖

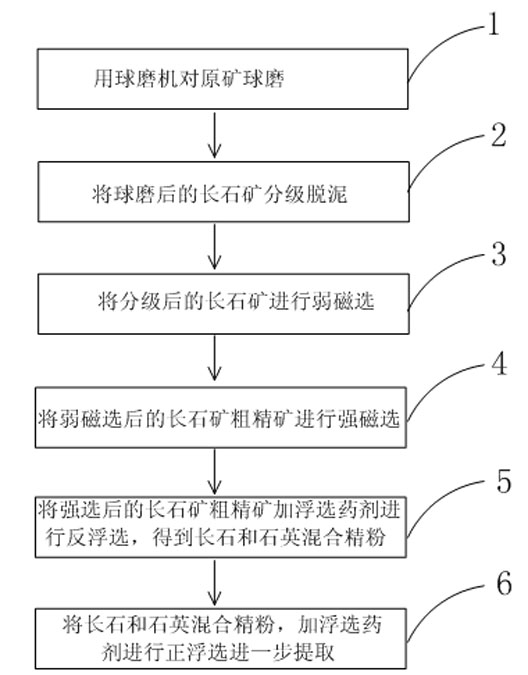

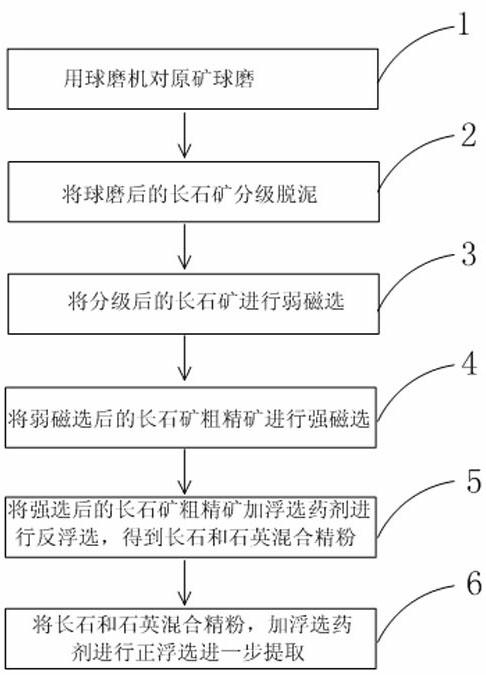

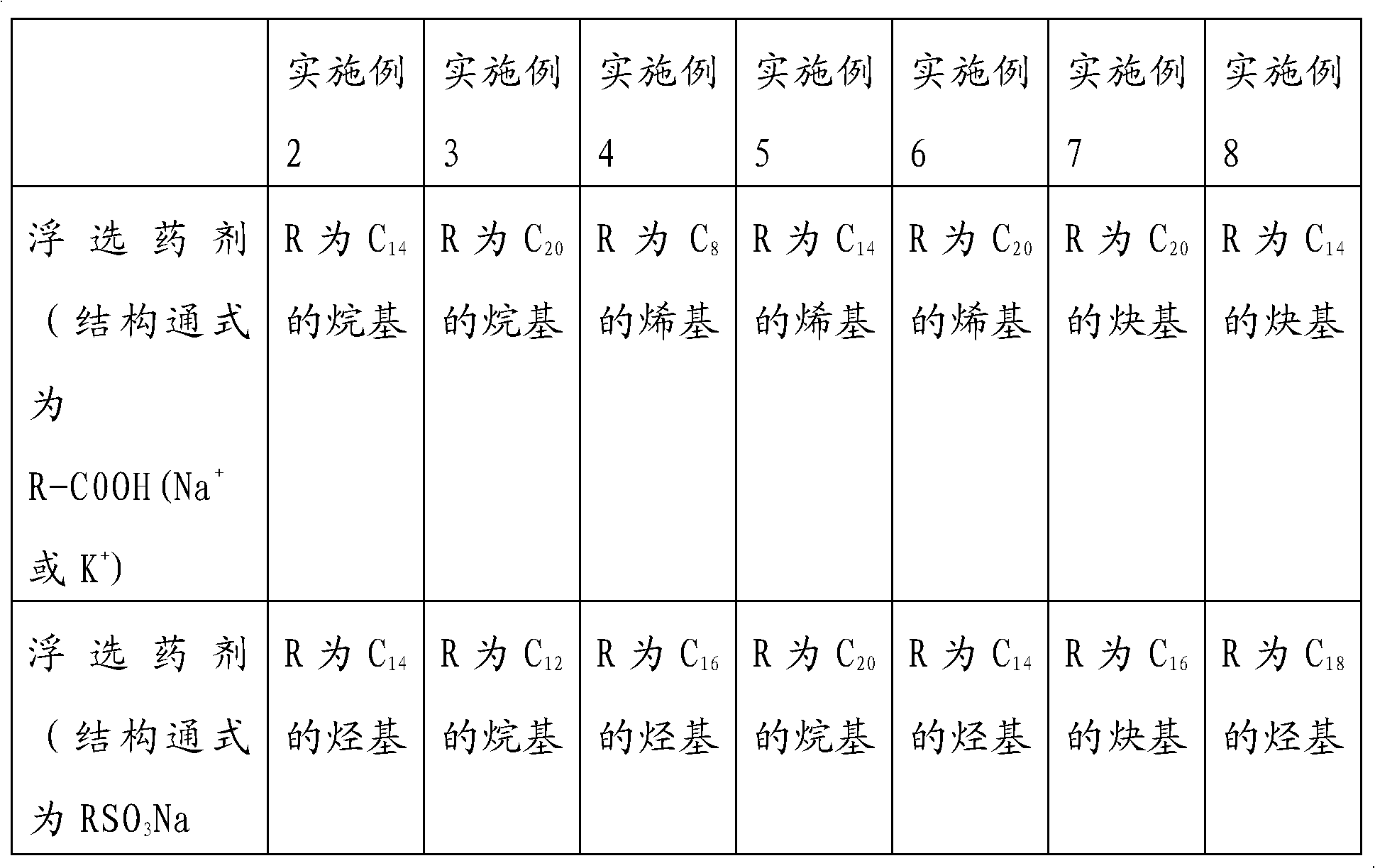

Method for separating and extracting feldspar ore with complex impurity components

InactiveCN102069033AEfficient removalImprove burnt board whitenessWet separationHigh intensityReverse flotation

The invention relates to a method for separating and extracting feldspar ore with complex impurity components, which comprises the following steps of: 1) performing ball milling on the feldspar ore with complex impurity components through a ball mill; 2) performing classification and de-sliming on the milled feldspar ore by using an improved hydraulic classifier; 3) performing low-intensity magnetic separation on the classified feldspar ore through a low-intensity magnetic separator to obtain high-intensity magnetic substances and rough feldspar concentrate for high-intensity magnetic separation; 4) performing high-intensity magnetic separation on the rough feldspar concentrate obtained by the low-intensity magnetic separation through a high-intensity magnetic separator to obtain low-intensity magnetic substances and rough feldspar concentrate for flotation; and 5) performing size mixing and segmentation on the rough feldspar concentrate obtained by the high-intensity magnetic separation, adding a flotation agent, and performing reverse flotation, impurity removal and dehydration through a flotation machine to remove impurities and obtain fine feldspar and quartz mixed powder and flotation water.

Owner:烟台宜陶矿业有限公司

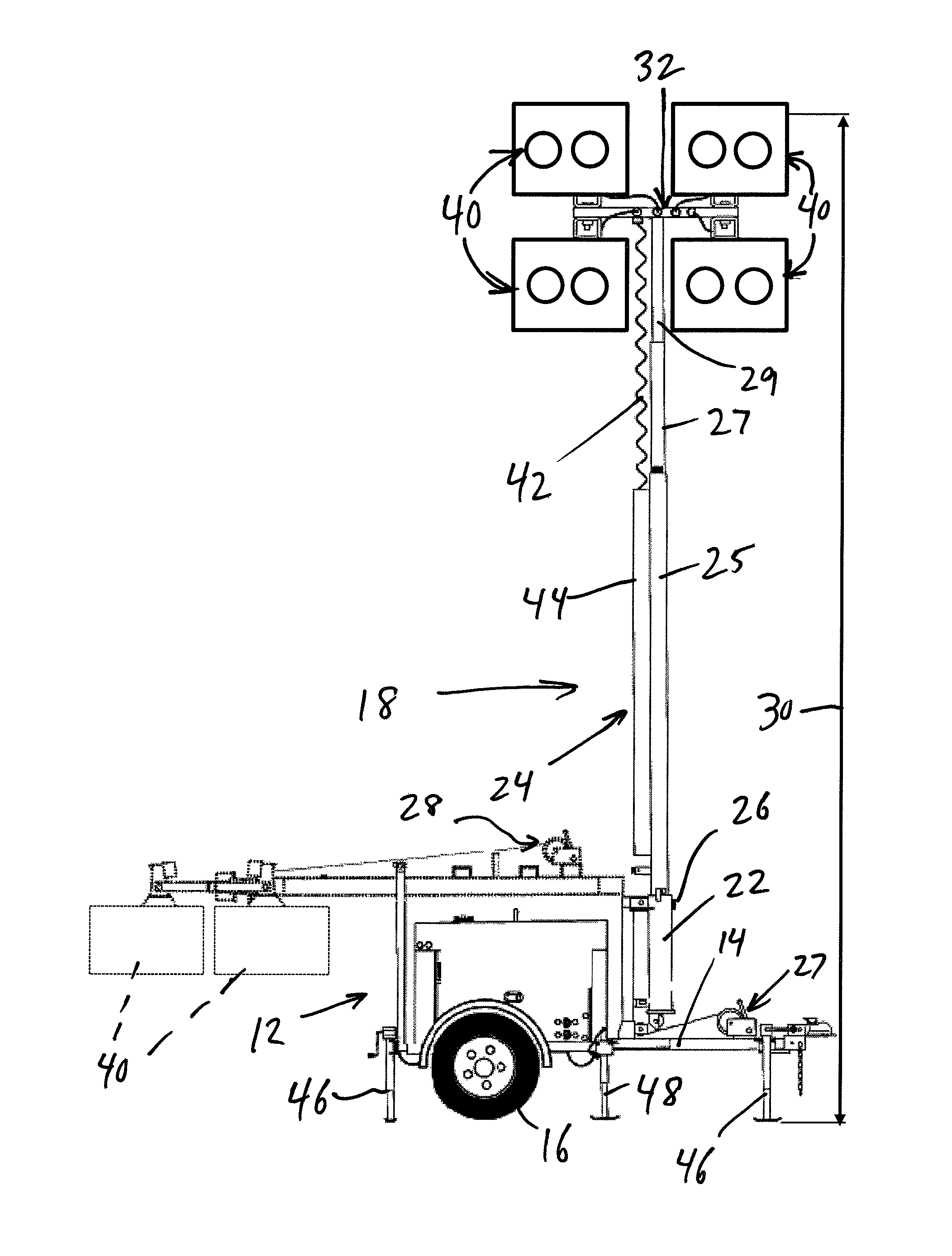

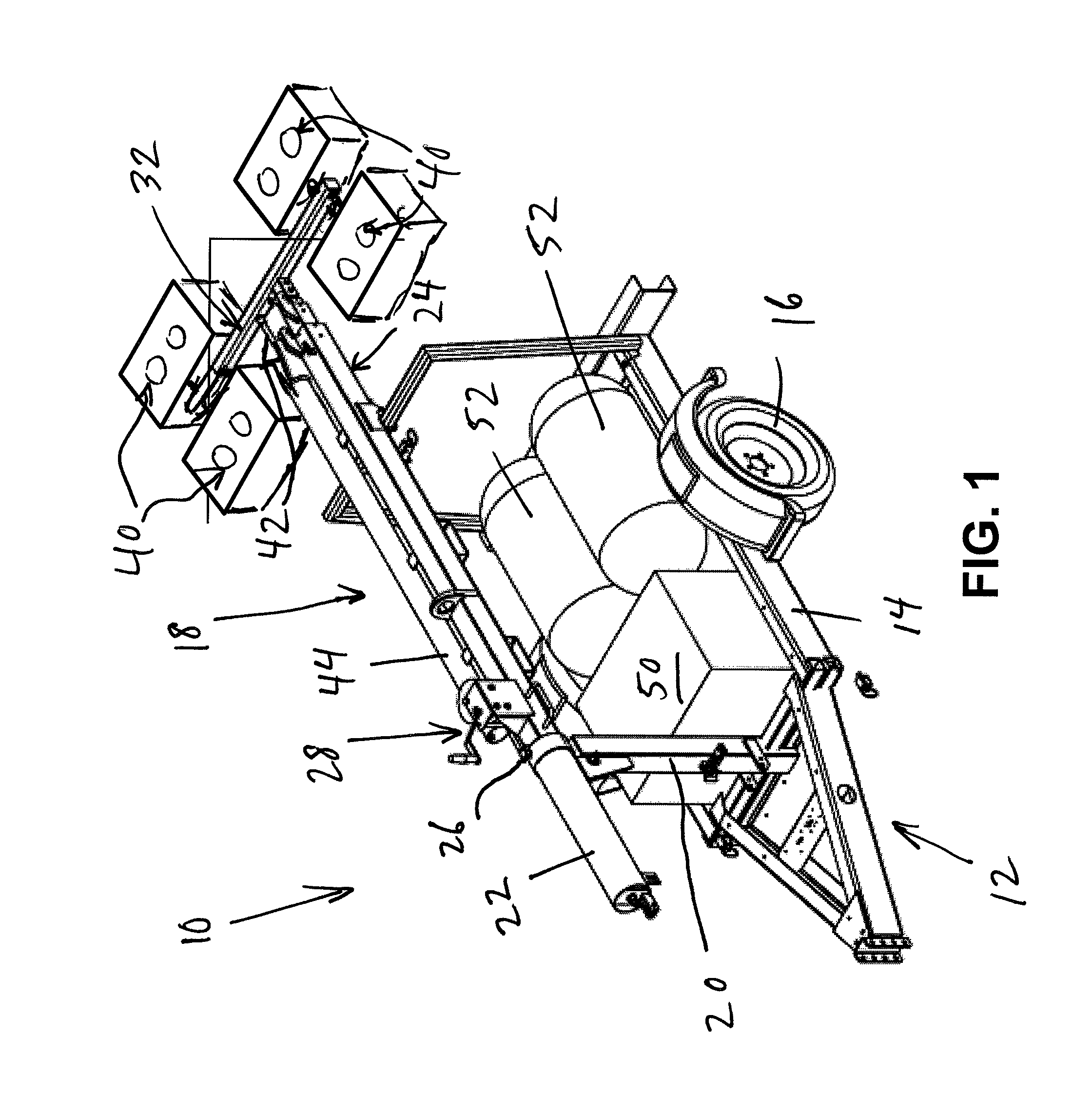

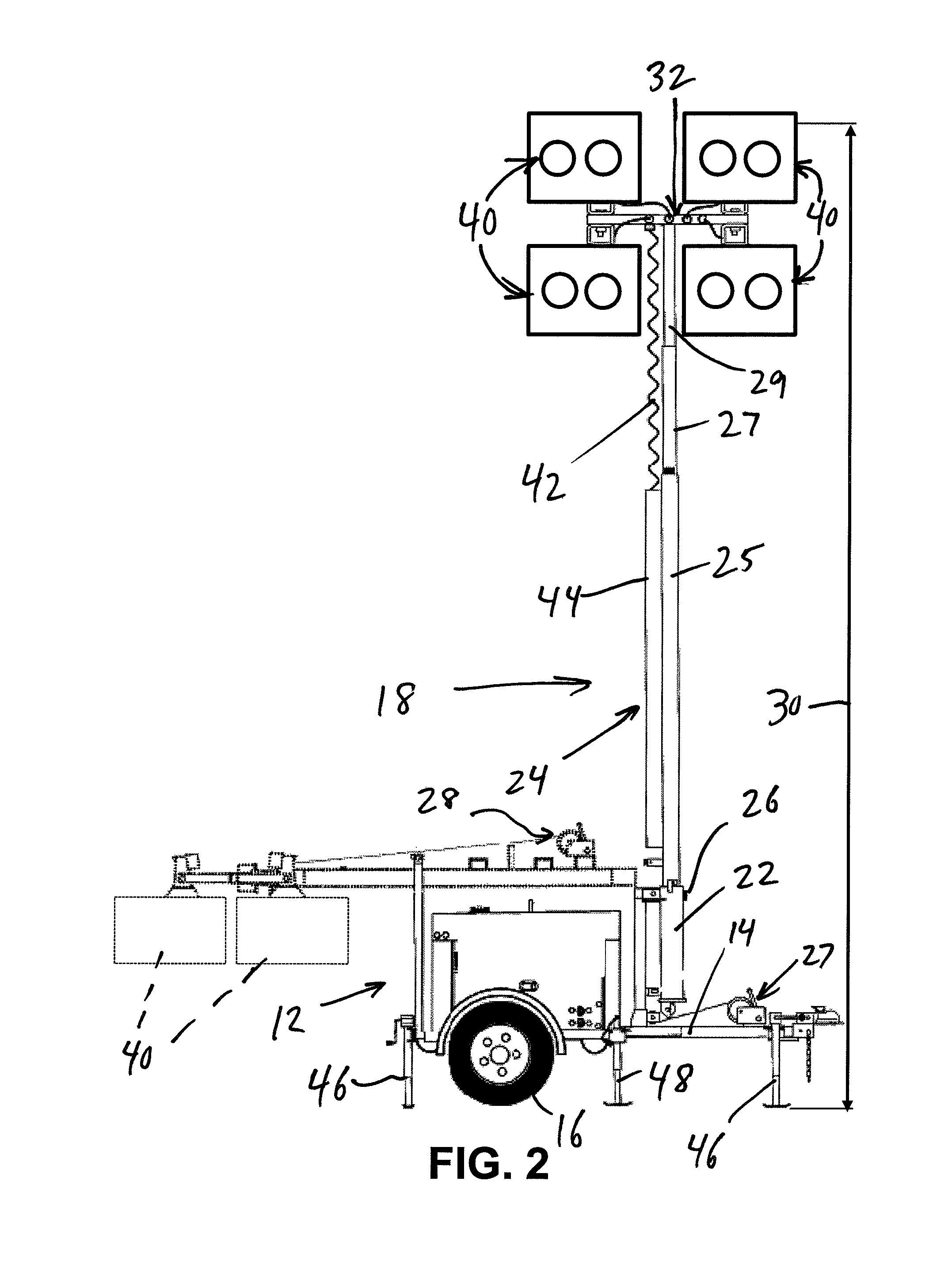

Mobile lighting apparatus

ActiveUS8439534B1Reduces noise and harmful emissionPrecise positioningMechanical apparatusLighting support devicesEngineeringLight equipment

Owner:STRAY LIGHT OPTICAL TECH

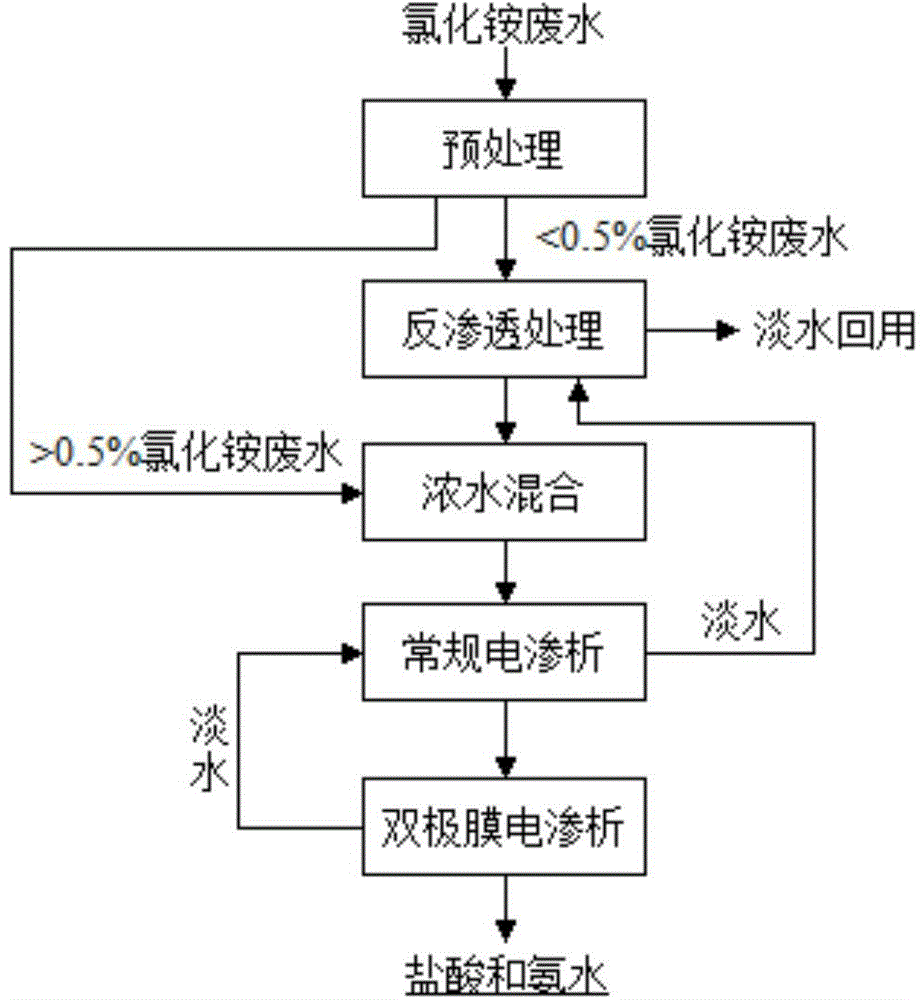

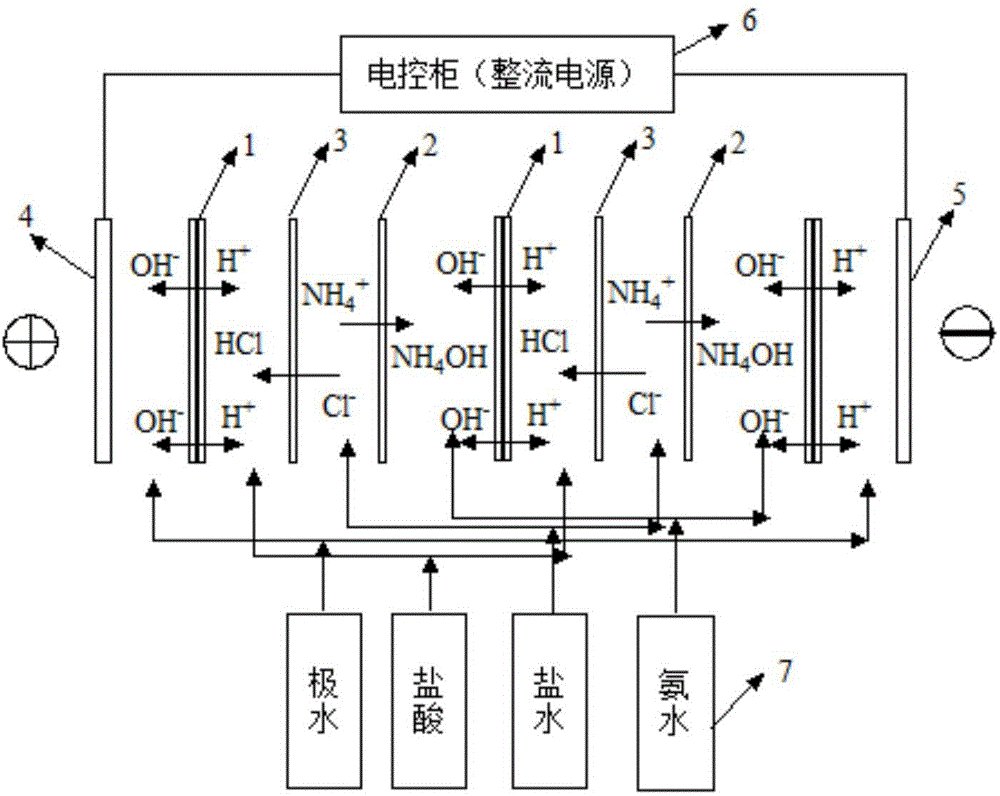

Method for resourceful treatment of ammonia chloride wastewaters

ActiveCN104445755ARealize resource processingAchieving processing powerGeneral water supply conservationWater contaminantsReverse osmosisImpurity

The invention relates to a method for resourceful treatment of ammonia chloride wastewaters. The method comprises the following steps: (1) respectively carrying out pretreatment on ammonia chloride wastewater with different concentrations for removing impurities; (2) carrying out reverse osmosis treatment on a clear liquor of the ammonia chloride wastewater, which is obtained in the step (1), with the concentration being lower than 0.5%; (3) mixing obtained reverse osmosis concentrated water with a clear liquid of the ammonia chloride wastewater, which is obtained in the step (2), with the concentration being higher than 0.5% so as to obtain ammonia chloride mixed wastewater; (4) carrying out conventional electrodialysis treatment on the obtained ammonia chloride mixed wastewater so as to obtain electrodialysis fresh water; (5) returning the obtained electrodialysis fresh water, carrying out reverse osmosis treatment the obtained electrodialysis fresh water to obtain electrodialysis concentrated water, and carrying out acid-alkali regeneration on the electrodialysis concentrated water by adopting bipolar membrane electrodialysis; and (6) converting ammonia chloride in the wastewater into hydrochloric acid and ammonium hydroxide by adopting the bipolar membrane electrodialysis to obtain low-concentration ammonia chloride wastewater, simultaneously returning the obtained low-concentration ammonia chloride wastewater and carrying out the conventional electrodialysis treatment on the obtained low-concentration ammonia chloride wastewater. According to the method, the resourceful treatment and the zero emission of the ammonia chloride wastewater can be really achieved.

Owner:JIANGXI INST OF RARE EARTHS CHINESE ACAD OF SCI

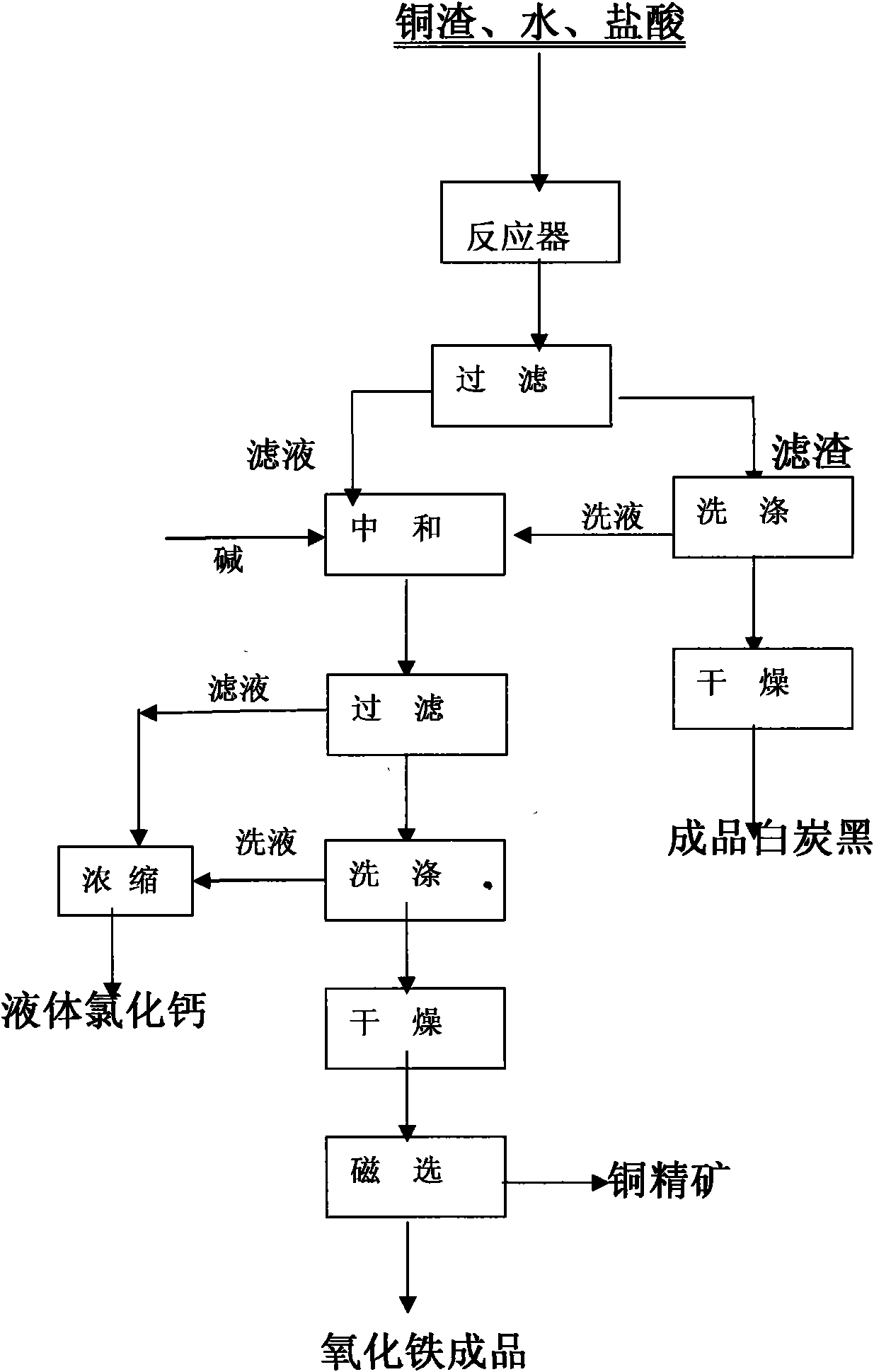

Method for comprehensively recovering Fe, Cu and Si from copper smelting slag

InactiveCN101555551AImprove resource utilizationImprove product added valueSilicaCalcium/strontium/barium chloridesSilicon dioxideMaterials science

The invention discloses a method for comprehensively recovering iron, copper and silicon dioxide from copper smelting slag. The method takes copper smelting slag as a raw material, and comprehensively recovers Fe, Cu and Si in copper slag by adopting wet chemistry metallurgical technology. A muriatic acid and an inorganic acid are mainly adopted for leaching the copper smelting slag, the leaching acid concentration, the solid to liquid ratio, the leaching temperature and the leaching time are selected according to the quality requirement of silicon dioxide products under certain conditions, and silicon dioxide is firstly separated through filtering and drying to prepare silica pigment; the leaching filtered liquid is counteracted, settled, filtered, dried and ground, and ferric oxide phase and copper-bearing phase are selectively separated by adopting a conventional mineral processing method.

Owner:KUNMING UNIV OF SCI & TECH

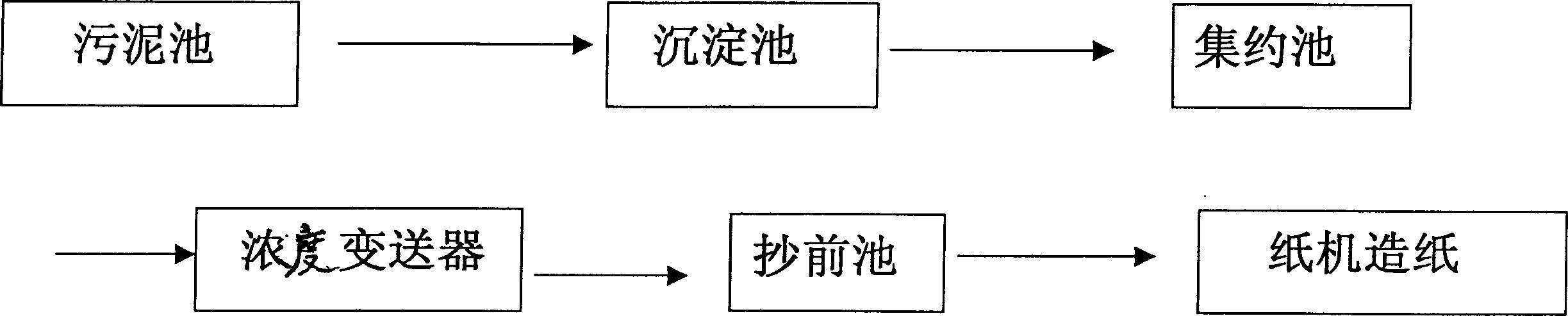

Recovering and reutilizing process for papermaking sludge

InactiveCN1614142AReduce consumptionZero emissionSecondary cellulose fibresCellulose material pulpingSludgeSewage

A process for reclaiming the paper-making sludge includes such steps as directly pumping the sludge from sewage treating pool into depositing pool, depositing, filling clean water to become usable pulp, pumping it into intensity pool, regulating its concentration, mixing it with normal pulp, and making paper.

Owner:喻宏雪

Making method of biological fermentation bed for pig farming

InactiveCN102783424AHarmlessThe purpose of harmlessness is a pollution-freeAnimal feeding stuffAnimal housingMicroorganismAnimal science

The invention relates to livestock feeding technology, in particular to a making method of a biological fermentation bed for pig farming. Using the biological fermentation bed to farm pigs strictly sticks to the scientific process flow. Raw materials (such as sawdust and rice hull) and strain are mixed from top to bottom for three times and are picked for fermentation for about a week. Core temperature of padding reaches 60DEG C-85 DEG C and is kept for 3-5 days. Even pathogenic microbes included in the raw materials can be killed. As strongest pathogenic microbes survive tens of hours at most at 60 DEG C, healthy pigs entering the fermentation bed can grow more healthily.

Owner:张庆云

Energy-saving resourceful treatment technology for drilling mud

InactiveCN106517718ASave on energy billsReduce processing costsSludge treatment by de-watering/drying/thickeningEvaporationSewage

The invention relates to the technical field of drilling pollution treatment, especially to an energy-saving resourceful treatment technology for drilling mud. The treatment technology includes: high temperature tail gas waste heat recovery, mud drying treatment and high temperature ceramic solidification treatment of mud. The waste heat recovery operation is carried out in a waste heat recovery system, the mud drying treatment is carried out in a mud drying system, and the high temperature ceramic solidification treatment of mud adopts a dry mud high temperature ceramic solidification system. The waste heat recovery system, the mud drying system and the dry mud high temperature ceramic solidification system are three independent systems. The technology is simple, the traditional solid-liquid separation process is no longer used, treatment of complex sewage is no longer needed, an evaporation process is employed directly, and the core equipment is simple. The technology has the characteristics of zero emission and thorough harmlessness, and completely achieves zero emission of pollutants and harmless steam. Dry mud is sintered at high temperature into ceramic, and heavy metals are completely solidified and not dissolved. The technology realizes recycling, the ceramic obtained by high temperature sintering of dry mud is an available industrial raw material or a directly usable product.

Owner:JIANGSU QINGQUAN ENVIRONMENTAL PROTECTION EQUIP

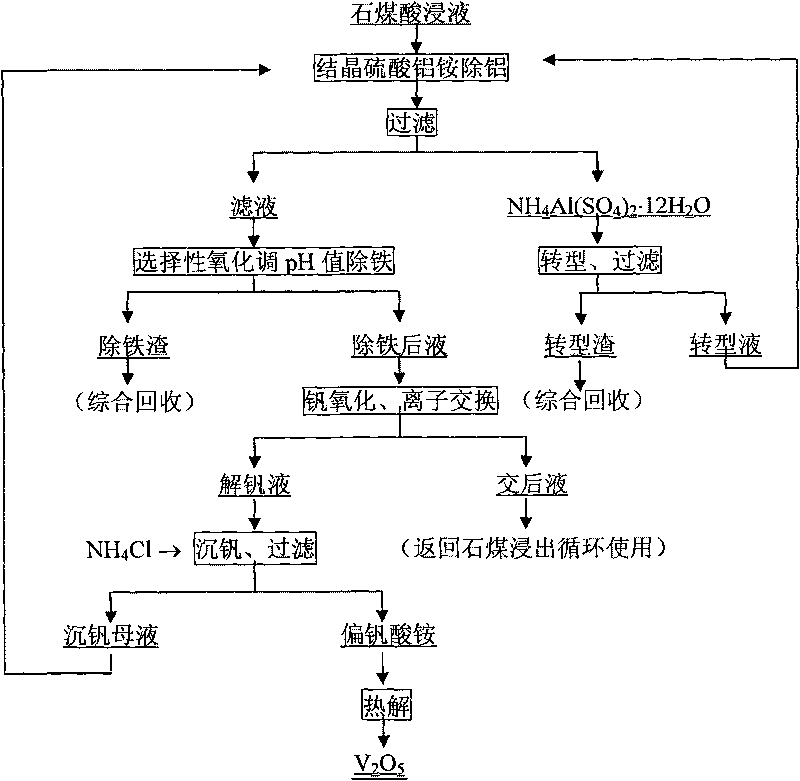

Process for extracting vanadium by acid leaching of stone coal

InactiveCN101760651AShort processLess reagent consumptionProcess efficiency improvementAluminium saltsCoal

The invention provides a process for extracting vanadium by acid leaching of stone coal. The process mainly comprises the following steps of: removing aluminum from crystal aluminum sulfate ammonium vanadium obtained from acid leaching solution of stone coal, performing selective oxidation and adjustment of a pH value of the solution obtained after the aluminum removal to remove iron, performing oxidizing transformation of vanadium in the solution obtained after the iron removal, adsorbing the vanadium in the transformed solution by anion exchange resin, desorbing and regenerating the vanadium-loaded resin, performing ammonium salt precipitation of the vanadium-desorbing solution, performing pyrolysis of ammonium metavanadate, transforming the aluminum sulfate ammonium vanadium and the like. The process has the advantages of short flow, little consumption of reagent, high vanadium recovery rate, low production cost, good product quality and the like.

Owner:CENT SOUTH UNIV

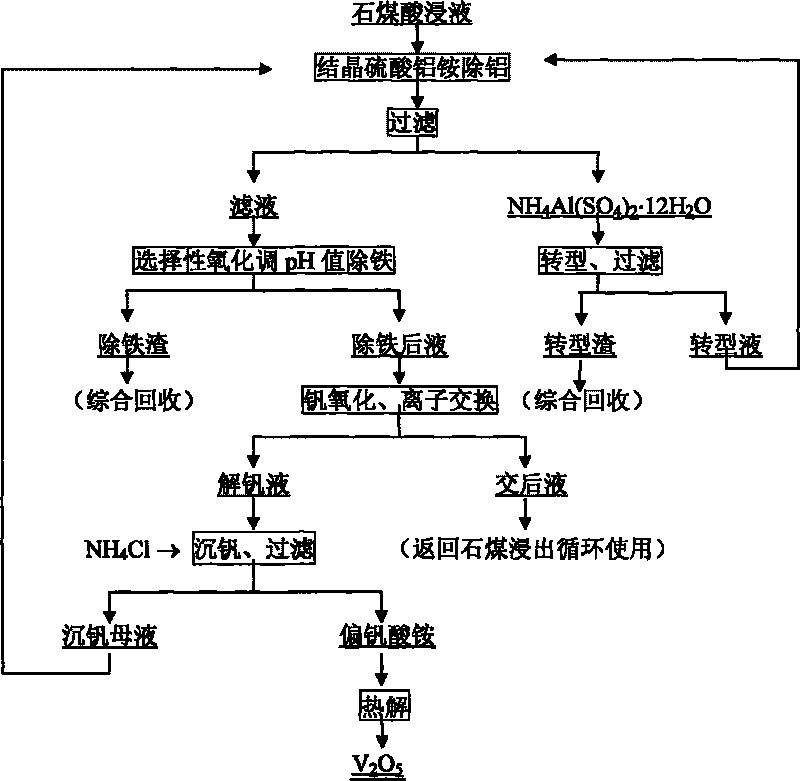

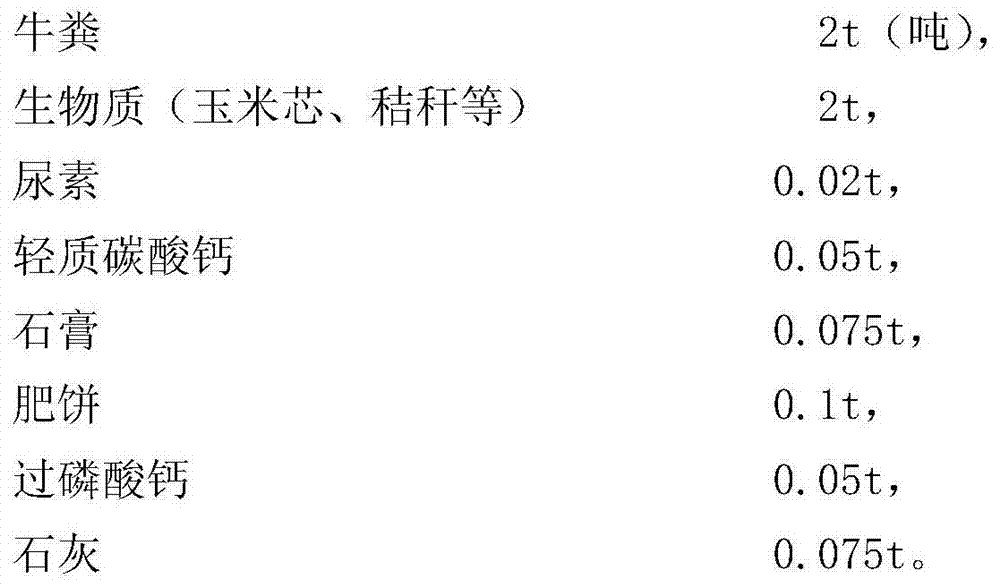

Waste comprehensive utilization process of large-scale beef cattle farms

ActiveCN103918479ASolve the pollution problemRealize rational utilizationBio-organic fraction processingFood processingSlurryBeef cattle

The invention belongs to the technical field of waste comprehensive utilization of beef cattle farms, and discloses a waste comprehensive utilization process of the large-scale beef cattle farms. The process is characterized by comprising the following steps that (1), cattle feed crop raw materials from farmland are used for preparing organic feed for cattle, and the organic feed is used for cattle farming; (2), cattle dung, urine and flushing water are generated during cattle farming and are collected; 10-90% of cattle dung is used for planting agaricus bisporus, and mushroom dregs generated in the planting process of the agaricus bisporus are used for producing organic fertilizers; the rest of cattle dung, the urine and the flushing water are used for producing biogas and biogas slurry at a biogas station, biogas residues are used for producing organic fertilizers, the biogas slurry is used for farmland irrigation, and the organic fertilizers are used for farmland fertilization. The process not only solves the environmental pollution problem, but also improves the rural energy structure, the mushroom dregs generated in the planting process of the agaricus bisporus and the biogas residues generated by a biogas digester are used for manufacturing the organic fertilizers, the yield of crops is improved obviously, the use number of the fertilizers is reduced, and auxiliary non-point source pollution is relieved.

Owner:JINGMEN HUAZHONG AGRI DEV

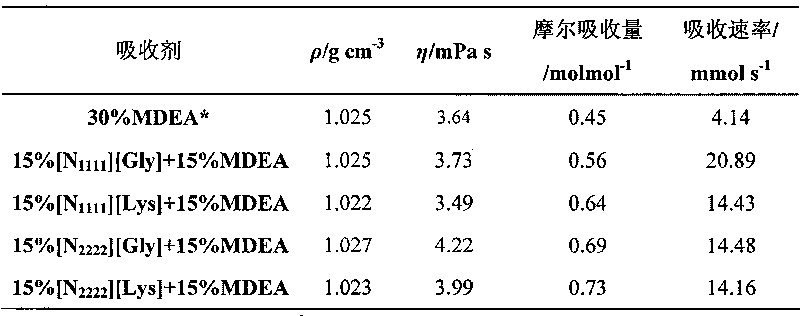

Green carbon dioxide absorbent

InactiveCN101700454APromote absorptionReduce energy consumptionProductsCarbon compoundsSolventAqueous solution

The invention relates to green carbon dioxide absorbent which is aqueous solution compounded from alkaline ionic liquid and organic amine, wherein the mass ratio of the alkaline ionic liquid to the organic amine is 0.2-1:1. The total mass concentration of the solute of the aqueous solution is 20-40 percent. The alkaline ionic liquid which is the functional ionic liquid is used as the additive and is compounded with the organic amine which is the traditional removing solvent to obtain the compound absorbent which can improve the acid gas absorption performance, reduce the process energy consumption and ensure the zero emission of the energy and has the characteristics of reutilization and economical efficiency.

Owner:NANJING UNIV

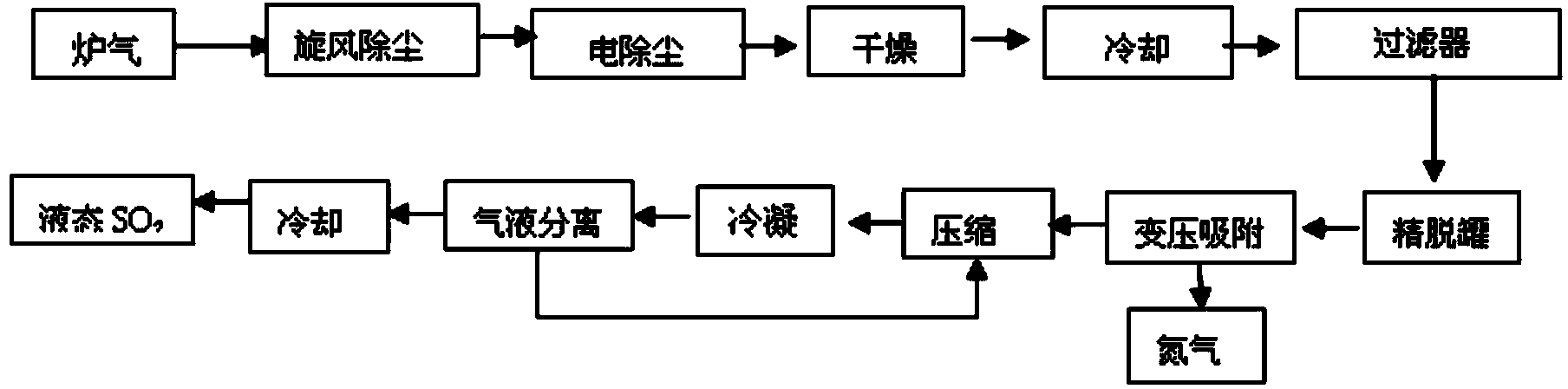

Method for recycling nitrogen gas and sulfur dioxide from calcining iron pyrite burner gas through variable-voltage variable-frequency adsorption

ActiveCN103920365ARealize comprehensive utilizationLow costNitrogen purification/separationCombination devicesCyclic processNitrogen gas

The invention discloses a method for recycling nitrogen gas and sulfur dioxide from calcining iron pyrite burner gas through variable-voltage variable-frequency adsorption. The method comprises the following steps: dedusting, purifying, drying and cooling the calcining iron pyrite burner gas, and removing dust particles and rust by a refining sulfuric acid burner gas filter made of a 200-mesh polytetrafluoroethylene material; deeply dehydrating by a refining dehydrating tank in a refining manner, deoxidizing and removing carbon dioxide, separating N2 and SO2 through variable-voltage variable-frequency adsorption, compressing or cooling and performing gas-liquid separation to obtain liquid SO2, bottling the separated nitrogen gas and the liquid SO2 for industrial use, and enabling SO2 which is not liquefied and separated to enter a circulating process of compression or cooling and gas-liquid separation, so as to enable SO2 to be separated continuously. The method realizes comprehensive utilization and zero emission of mixed burner gas containing a great amount of nitrogen gas and sulfur dioxide caused by calcining of iron pyrite, the obtained liquid SO2 has high purity, the process is green, safe and energy-saving, and realizes zero emission and low cost.

Owner:GUANGXI UNIV

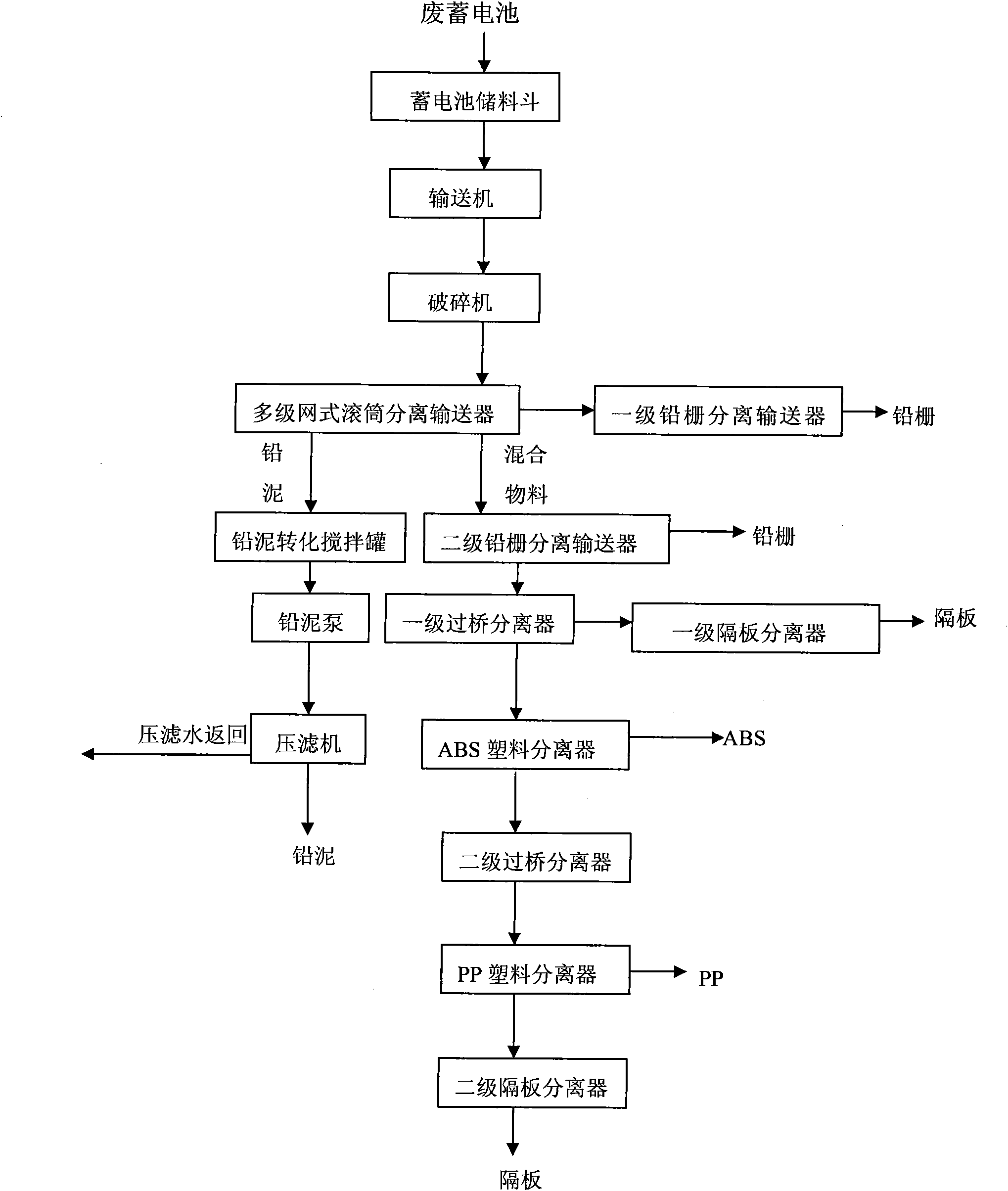

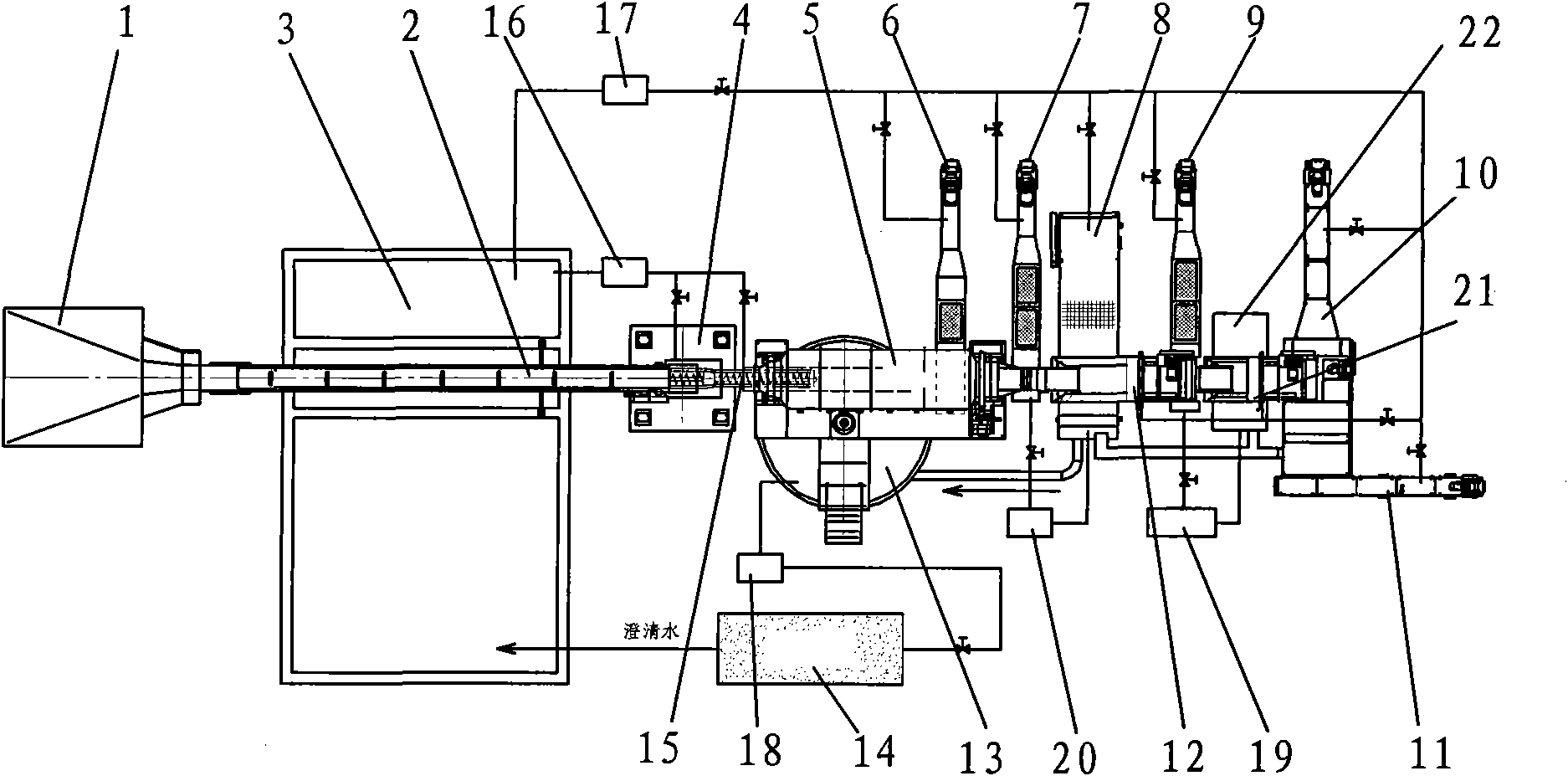

Waste lead-acid accumulator breaking separation machine and method

ActiveCN101979165AEfficient separationEffective and thorough separationSolid waste disposalSolid separationFilter pressPolypropylene

The invention discloses a waste lead-acid accumulator breaking separation machine and a waste lead-acid accumulator breaking separation method. The waste lead-acid accumulator breaking separation machine belongs to waste lead-acid accumulator breaking separation equipment. A lead-acid accumulator storage hopper is connected with a breaker through a belt conveyor, a water circulating pool is positioned below the belt conveyor, a primary conveyor is positioned below the breaker, and a lead slime conversion stirring tank is arranged below a multi-grade net type roller separation conveyor; the lead slime conversion stirring tank is connected with a filter press through a third water pump; a primary lead grid separator and a secondary lead grid separating conveyor are arranged on the rear partof the multi-grade net type roller separation conveyor, and a primary bridge separator is positioned on the rear end of a secondary grid lead separating conveyor; and an acrylonitrile butadiene styrene (ABS) plastic separator is arranged on the rear part of the first bridge separator, a polypropylene (PP) plastic separator is arranged on one end of a secondary baffle separator, and an appliance controller is connected with a motor and a water pump. The machine and the method have the advantages that: blending, breaking and separation can be performed; the separator is low in noise; environment pollution is reduced; energy sources are saved; emission is avoided; a service life is long; automatic level is high; and processing capability is as high as 8 to 30 T / H.

Owner:JIANGSU NEW CHUNXING RESOURCE RECYCLING CO LTD

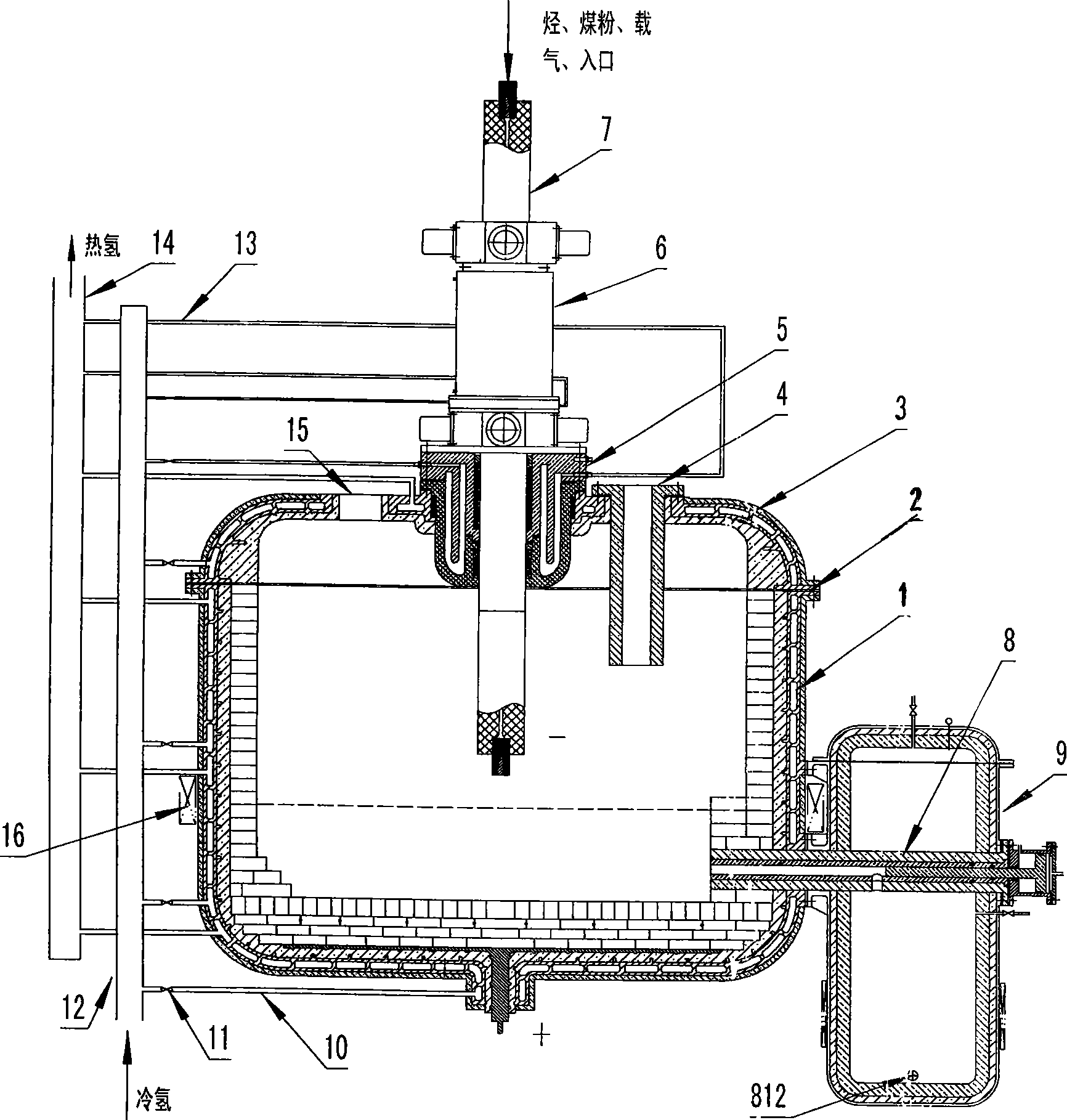

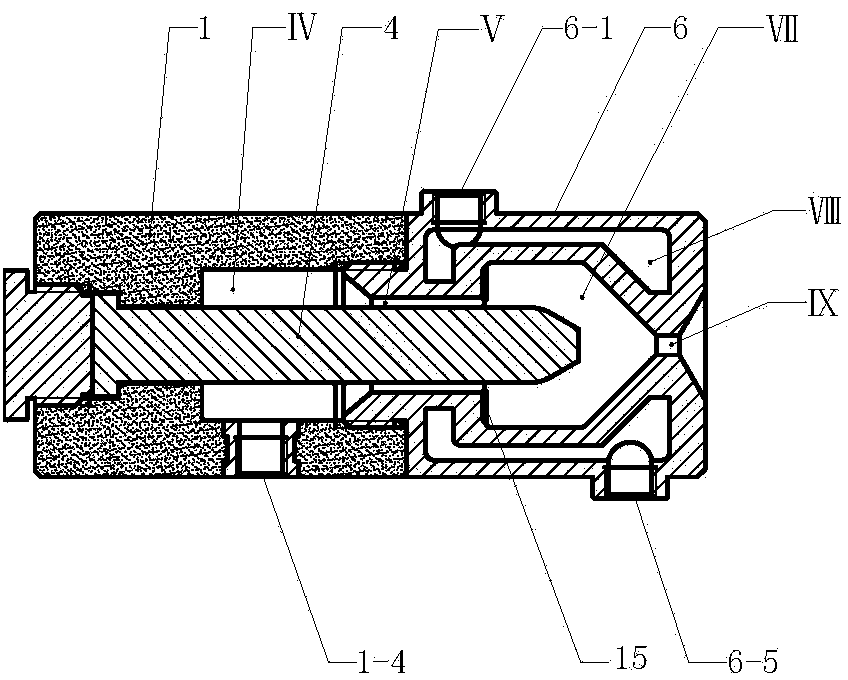

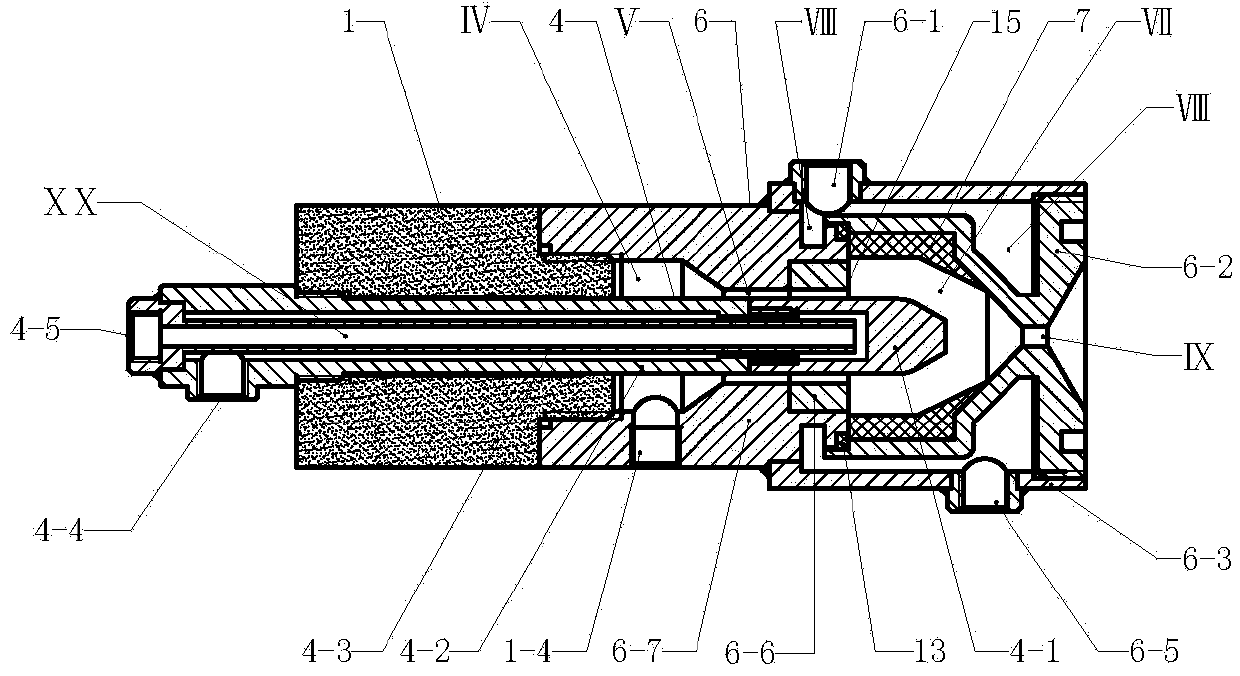

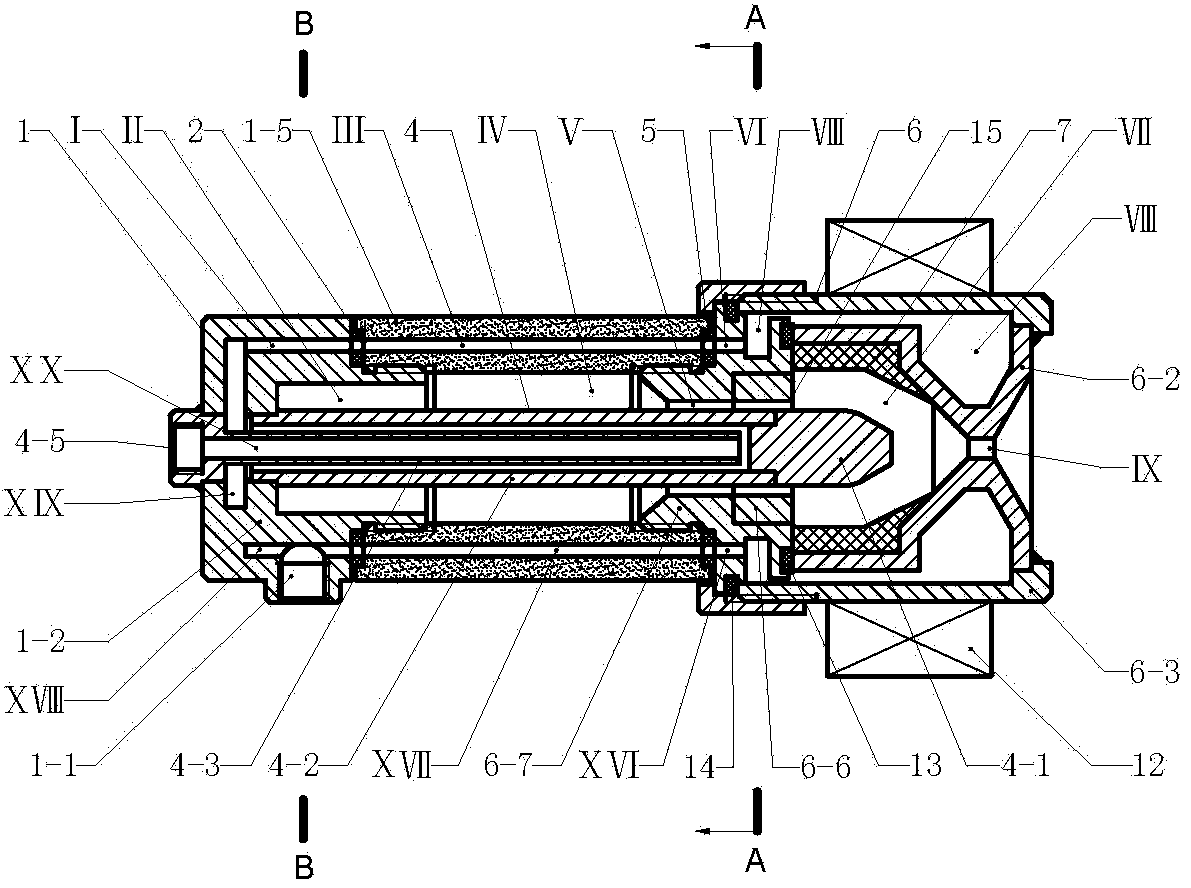

Inner-electric-arc plasma torch for gasifiers

The invention discloses an inner-electric-arc plasma torch for gasifiers and relates to plasma heating equipment. The inner-electric-arc plasma torch is mainly composed of a front torch body, a rear seat, a first electrode and a fourth electrode, an arc cavity and a cooling water jacket are structured in the front torch body, an inlet and a compression nozzle are respectively arranged in two ends of the arc cavity, the cooling water jacket is arranged on the outer side of the arc cavity, and the head of the first electrode is arranged out of the arc cavity of the front torch body and is close to the inlet; the head of the fourth electrode (8) extends to the compression nozzle side in the arc cavity through the compression nozzle, a metal component at the position of the compression nozzle forms a third electrode, a second annular discharging surface is arranged on the third electrode, a metal component at the position of the inlet forms a second electrode, and a first annular discharging surface is arranged on the second electrode; or the head of the fourth electrode further extends to the arc cavity from the compression nozzle and is close to the inlet, and the metal component at the position of the inlet forms an auxiliary electrode. By the inner-electric-arc plasma torch, water vapor can be heated and decomposed in the arc cavity, energy is concentrated on water molecules, and the water molecules are easier to decompose.

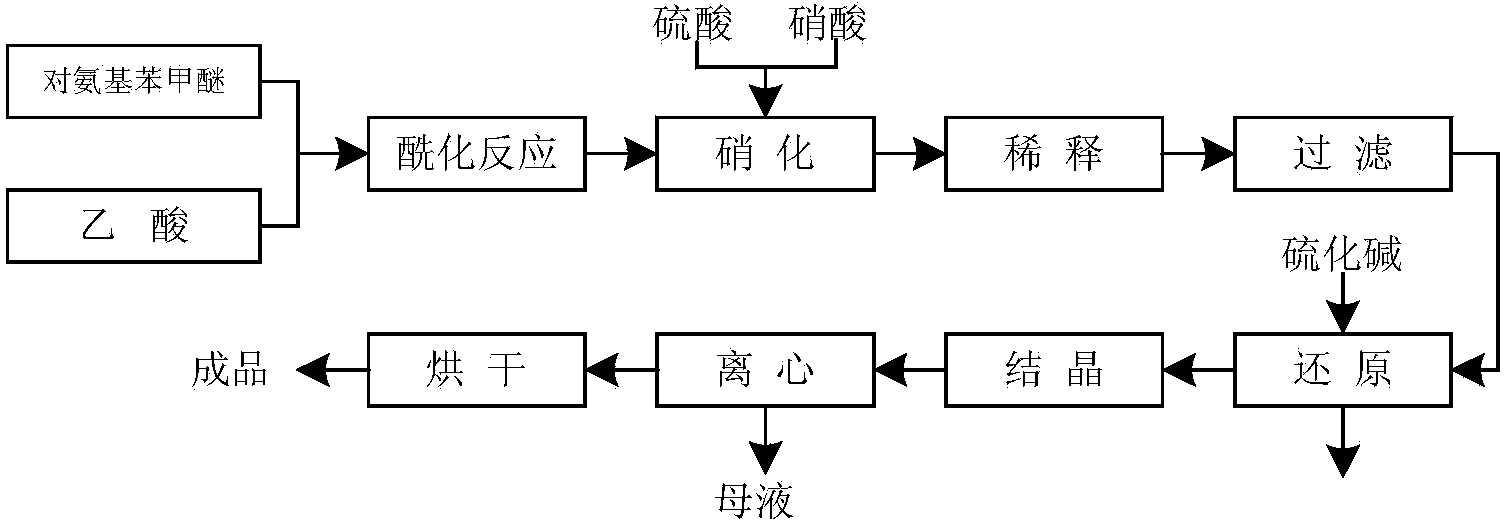

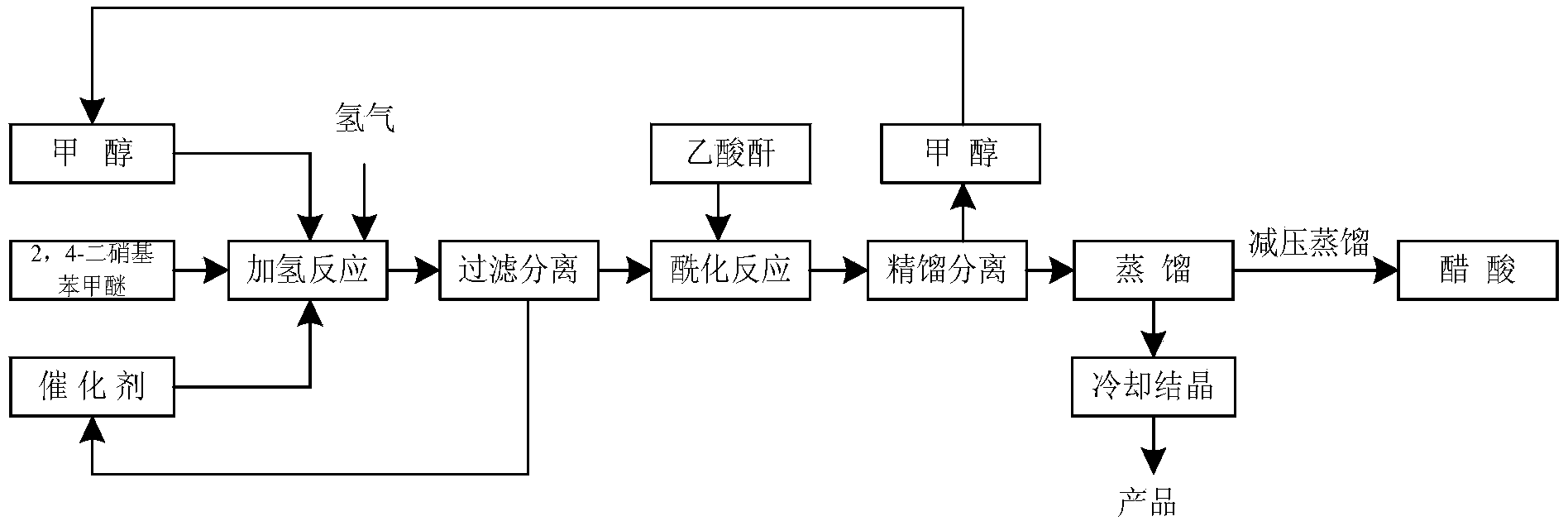

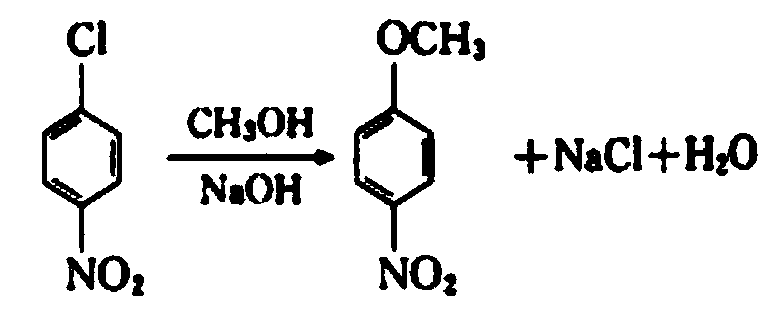

Preparation process of 2-amino-4-acetyl aminoanisole

ActiveCN103524371AHigh purityProcess safetyOrganic compound preparationCarboxylic acid amides preparationSolventAcetic anhydride

The invention discloses a preparation process of 2-amino-4-acetyl aminoanisole. The preparation process comprises the following steps of (1) taking methanol as a solvent and 2,4-dimitroanisole as a raw material, introducing hydrogen to perform catalytic hydrogenation reduction reaction in the presence of a catalyst; (2) performing solid-liquid separation, and recovering the catalyst; (3) adding acetic anhydride to perform acetylation reaction; (4) recovering methanol which is recycled as a solvent for follow-up hydrogenation reduction; (5) performing reduced pressure distillation to recover acetic acid; (6) performing cooling crystallization to obtain a 2-amino-4-acetyl aminoanisole product.

Owner:SHANGHAI ZONGXING CHEM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com